Shaking arc narrow gap melting electrode gas shielded vertical welding method

A technology of molten electrode gas and welding method, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult narrow gap multi-layer vertical welding and low efficiency, so as to improve welding efficiency and reduce production cost , The effect of small groove gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

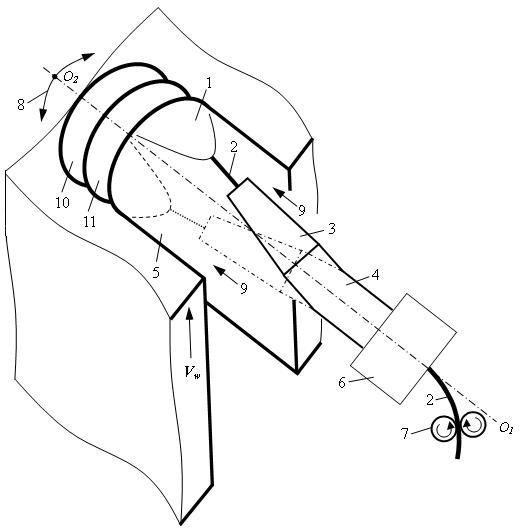

Method used

Image

Examples

Embodiment 1

[0030] The vertical groove 5 to be welded is an I-type welded groove with a gap of 12 mm. During welding, the vertical groove 5 to be welded is in a vertical position. Other welding parameters are: the bending angle of the slightly curved conductive rod 4 is 3°, the arc shaking frequency is 2.0 Hz, the arc shaking angle is 60°, the residence time of the arc 1 on the two side walls of the vertical groove 5 to be welded is respectively The average welding current is 200A, the average arc voltage is 26V, and the welding speed is 15cm / min. The obtained macroscopic photograph of the cross-section of the weld is shown in Figure 3(a). The middle part of the formed weld surface is slightly convex, and the two side walls vertically to the groove 5 to be welded are evenly and symmetrically penetrated.

Embodiment 2

[0032] The vertical groove 5 to be welded is an I-type welded groove with a gap of 14 mm, and the vertical groove 5 to be welded is in a vertical position during welding. Other welding parameters are: the bending angle of the slightly curved conductive rod 4 is 8°, the arc shaking frequency is 0.8 Hz, the arc shaking angle is 84°, the residence time of the arc 1 on the two side walls of the vertical groove 5 to be welded is respectively The average welding current is 155A, the average arc voltage is 22V, and the welding speed is 9.1cm / min. The obtained macroscopic photograph of the cross-section of the weld is shown in Figure 3(b). The surface of the formed weld is flat, and the penetration of the two side walls of the vertical groove 5 to be welded is uniform and symmetrical.

Embodiment 3

[0034] The vertical groove 5 to be welded is an I-type welded groove with a gap of 16 mm, and the vertical groove 5 to be welded is in a vertical position during welding. Other welding parameters are: the bending angle of the slightly curved conductive rod 4 is 15°, the shaking frequency of the arc is 0.4 Hz, the shaking angle is 180°, and the residence time of the arc 1 on the two side walls of the vertical groove 5 to be welded is respectively 600ms, the average welding current is 140A, the average arc voltage is 18V, and the welding speed is 7cm / min. The penetration of both side walls of the welding groove 5 is uniform and symmetrical.

[0035] It can be seen from the above three embodiments and Fig. 3 that the shaking arc narrow-gap gas-shielded vertical weld is well formed, which shows that this method has strong practicability. In addition, for this free-formed well-formed weld, at the bottom of each layer of weld along the plate thickness direction, a penetration with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com