Linear-chain C5/C6 alkane catalyst prepared by sorbitol aqueous phase hydrogenation and preparation method thereof

A catalyst and a technology for sorbitol, which are applied to the production of straight-chain C5/C6 alkane catalysts by aqueous hydrogenation of sorbitol and the field of preparation thereof, can solve the problems of unstable catalyst performance and life, catalyst deactivation, and difficulty in industrial amplification, and the like, To achieve the effect of improving selectivity and activation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

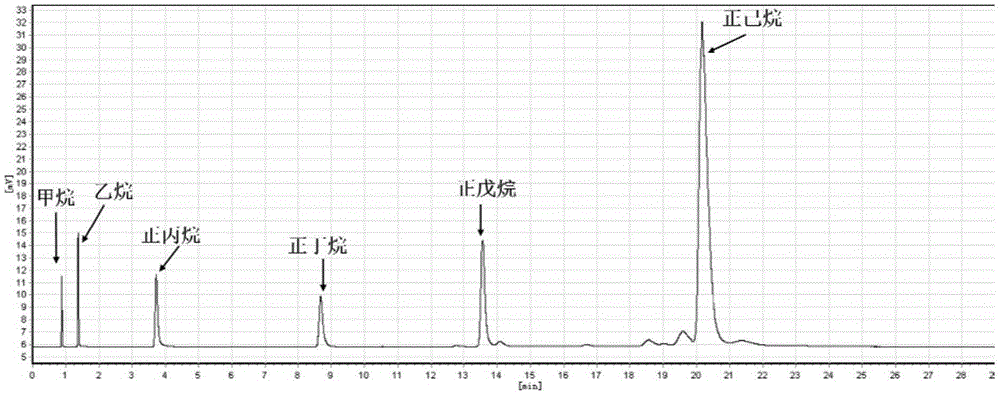

Image

Examples

Embodiment 1

[0031] Weigh 100 grams of granular 40-60 mesh commercial activated carbon carrier and dry it at 200° C. for 12 hours, and set aside. Take 30 grams of dried activated carbon and put it into 60ml of 4.40% ammonium paramolybdate solution, soak it for 10 hours, and dry it at 100°C for 12 hours. The amount is 5%, that is, the catalyst carrier 5Mo / C containing a single metal molybdenum; then take out 15g of the catalyst carrier 5Mo / C, put it into 30ml of a 1.32% ruthenium trichloride solution, soak it for 12 hours, and dry it at 120°C for 10 hours After drying, the sample was placed in a muffle furnace and calcined at 400°C for 4 hours to obtain a 1Ru5Mo / C catalyst with 1% loaded ruthenium and 5% loaded molybdenum, and the resulting catalyst was designated as Cat1.

[0032] Weigh 4 grams of Cat1 and fill it into a continuous high-pressure fixed-bed reactor, reduce it online with hydrogen at 300°C for 6 hours, and react at a hydrogen pressure of 4.0MPa and a reaction temperature of 2...

Embodiment 2

[0034]Weigh 100 grams of granular 40-60 mesh commercial activated carbon carrier and dry it at 200° C. for 12 hours, and set aside. Get 30 grams of dried activated carbon and put it into 60ml of 4.40% ammonium paramolybdate and 1.32% ruthenium trichloride solution, impregnate for 10 hours, dry at 100°C for 12 hours, and place the dried sample in a muffle furnace for 400 ℃ roasting for 4 hours to obtain a 1Ru5Mo / C catalyst with 1% loaded ruthenium and 5% loaded molybdenum, and the obtained catalyst is designated as Cat2.

[0035] Weigh 4 grams of Cat2 and fill it into a continuous high-pressure fixed-bed reactor, reduce it online with hydrogen at 300°C for 6 hours, react at a hydrogen pressure of 4.0MPa and a reaction temperature of 280°C, a hydrogen flow rate of 150ml / min, and a sorbitol solution of 20wt%. The solution injection flow rate was 0.05ml / min.

Embodiment 3

[0037] Weigh 100 grams of granular 40-60 mesh commercial activated carbon carrier and dry it at 200° C. for 12 hours, and set aside. Take 30 grams of dried activated carbon and put it into 60ml of 1.32% ruthenium trichloride solution, soak it for 10 hours, and dry it at 100°C for 12 hours. The amount is 1%, that is, the catalyst carrier 1Ru / C containing a single metal ruthenium; then take out 15g of the catalyst carrier 1Ru / C, put it into 30ml of 4.40% ammonium paramolybdate solution, soak for 12 hours, and dry at 120°C for 10 hours After drying, the sample was placed in a muffle furnace and calcined at 400° C. for 4 hours to obtain a 1Ru5Mo / C catalyst with 1% loaded ruthenium and 5% loaded molybdenum, and the resulting catalyst was designated as Cat3.

[0038] Weigh 4 grams of Cat3 and fill it into a continuous high-pressure fixed-bed reactor, reduce it online with hydrogen at 300°C for 6 hours, and react at a hydrogen pressure of 4.0MPa and a reaction temperature of 280°C, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com