Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

573results about "Hydrogen separation using liquid contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

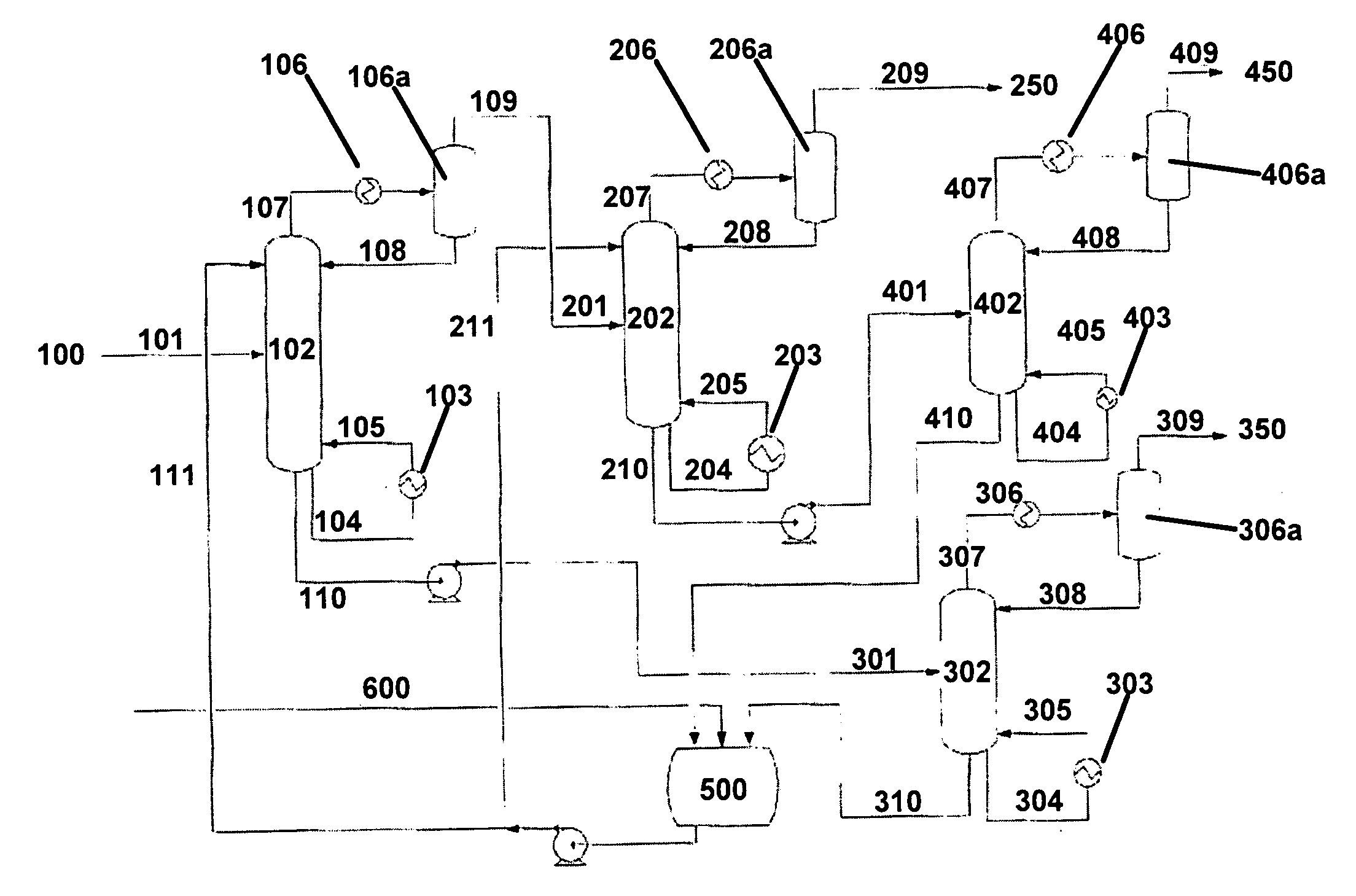

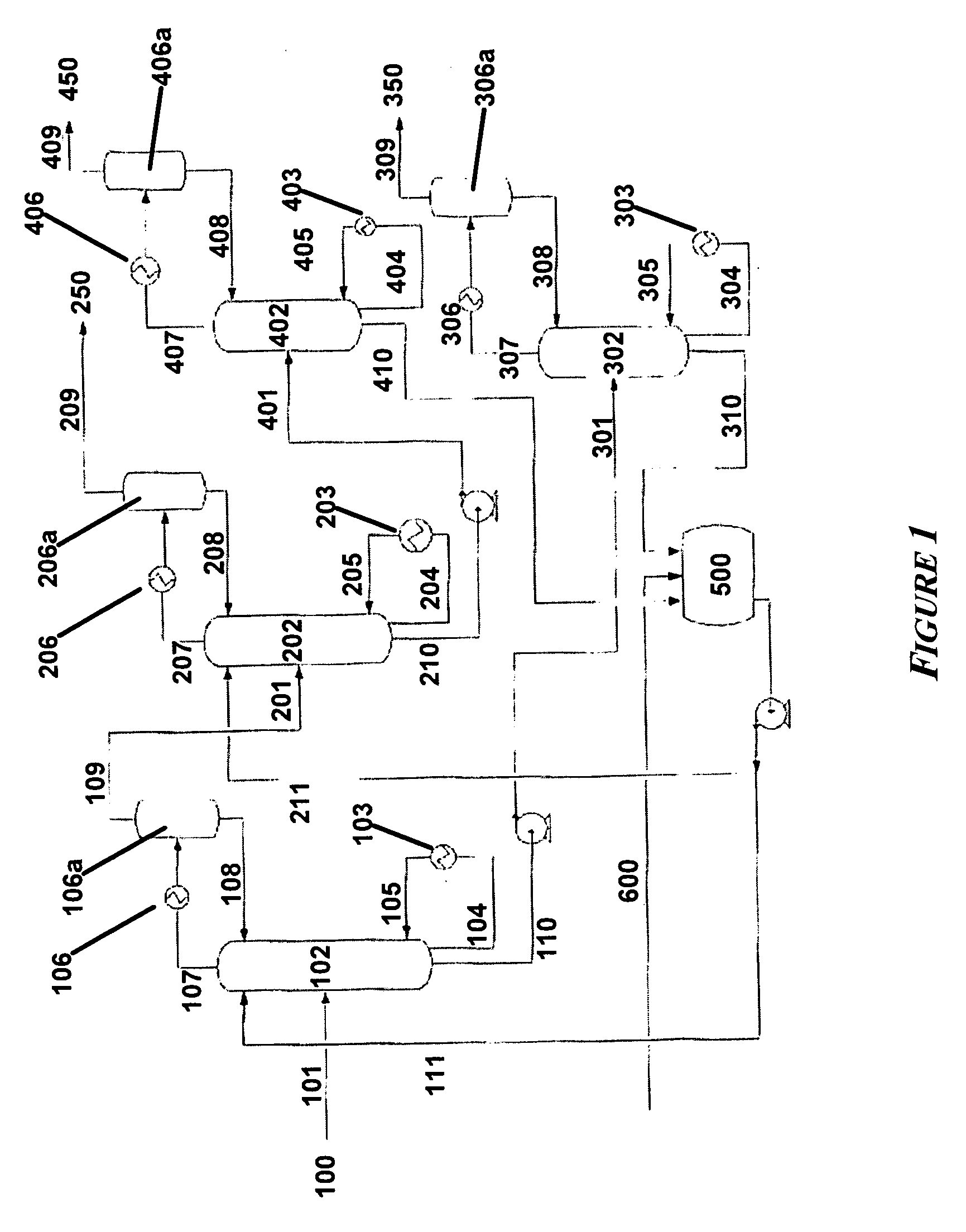

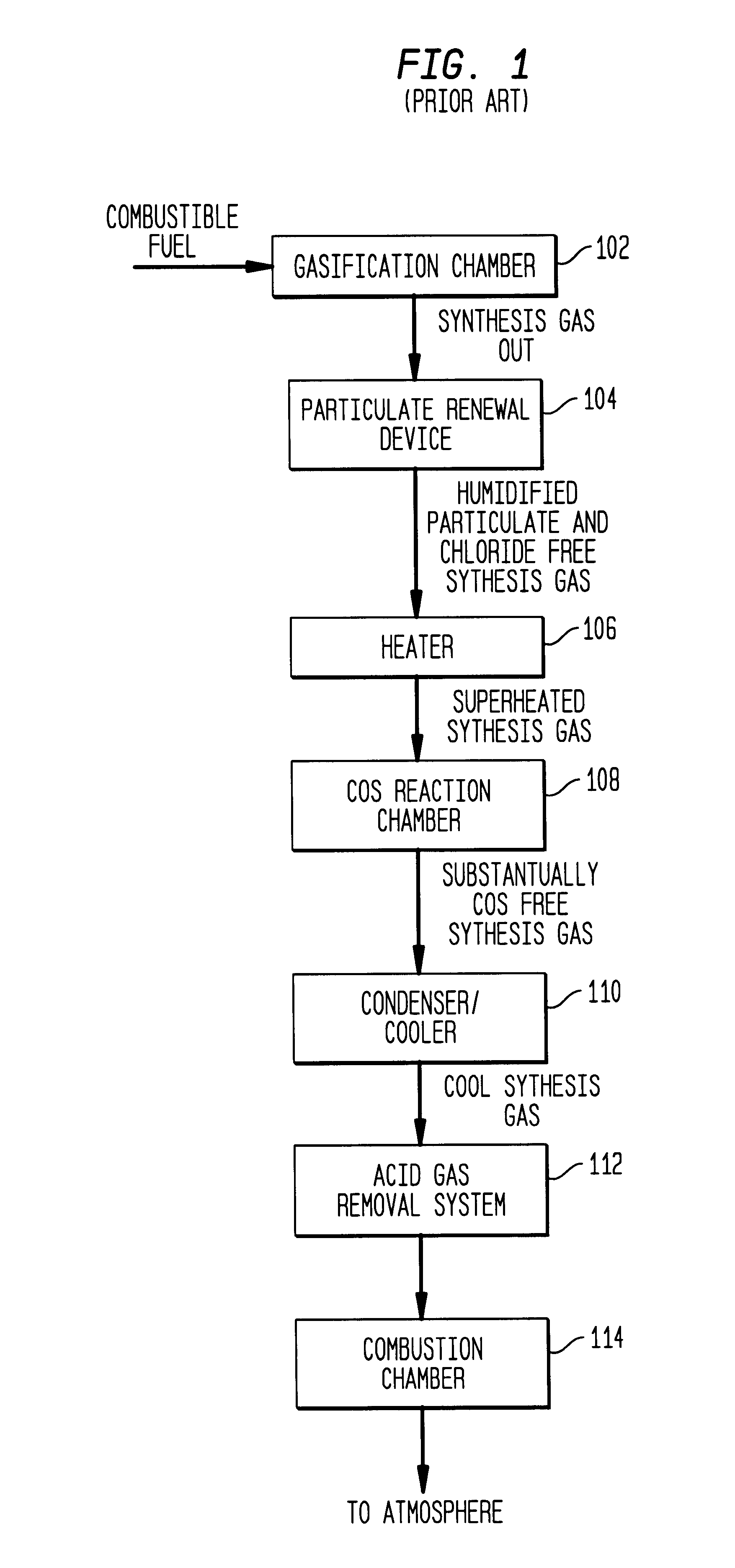

Selective Removal and Recovery of Acid Gases from Gasification Products

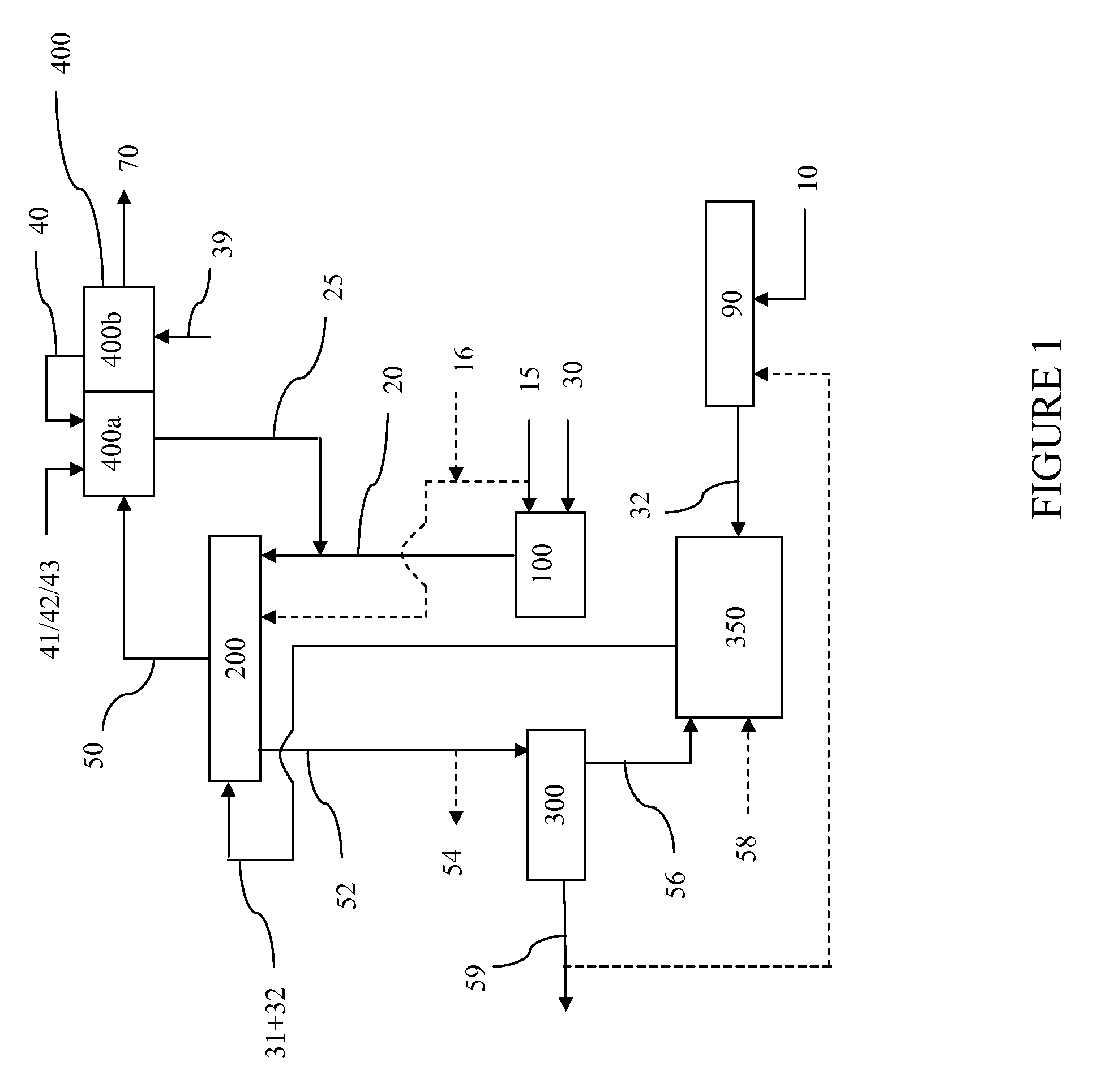

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

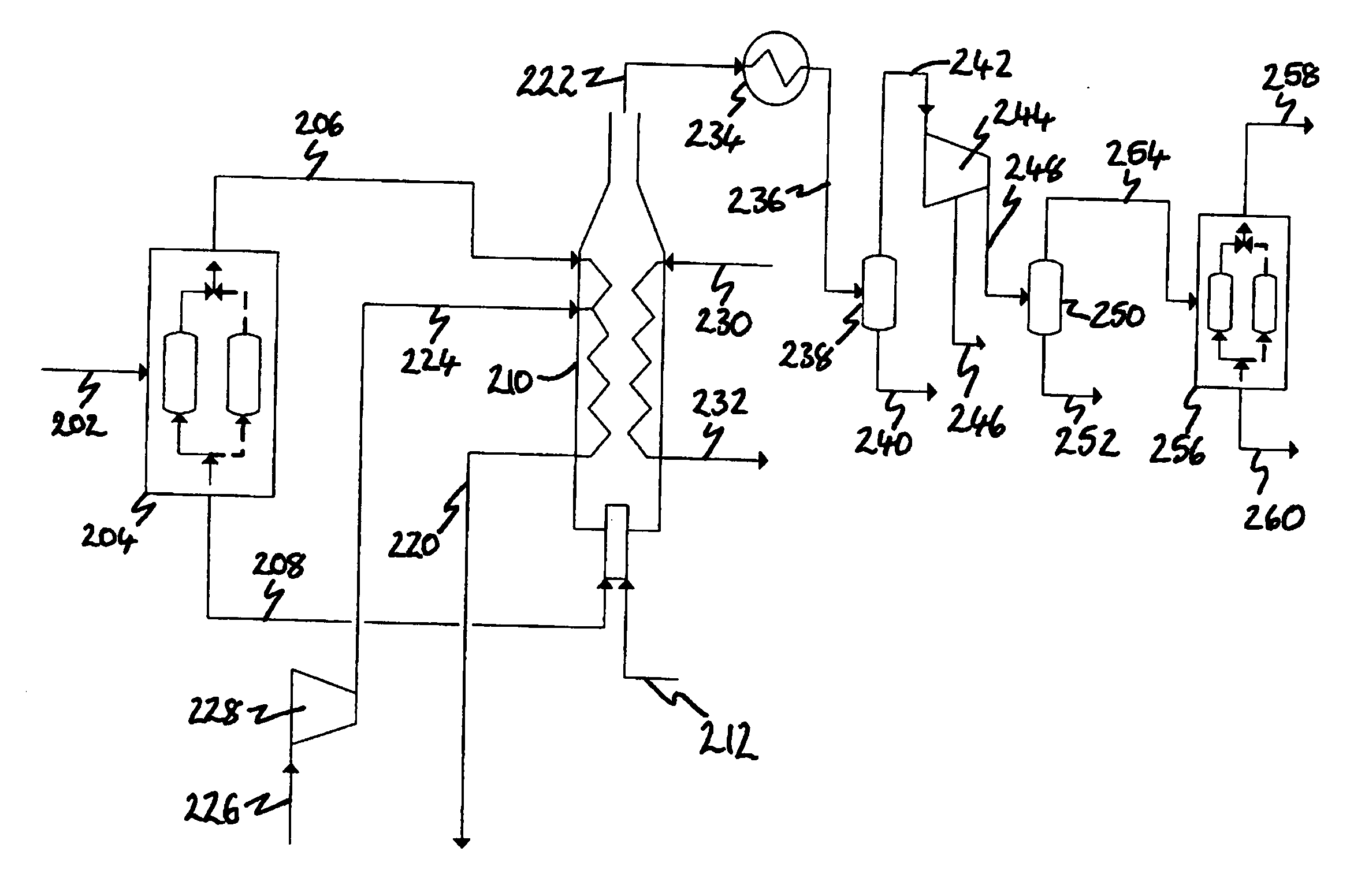

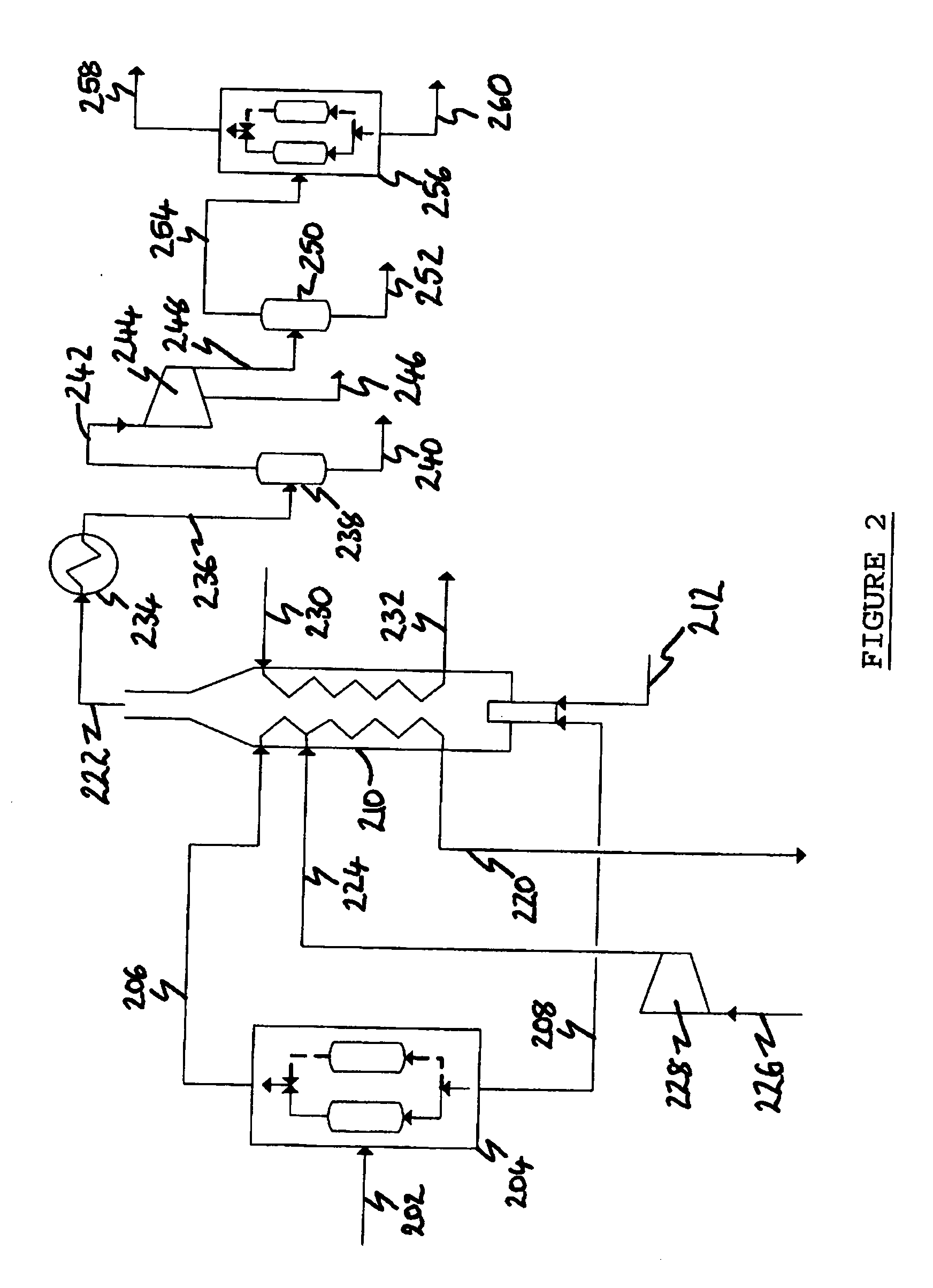

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

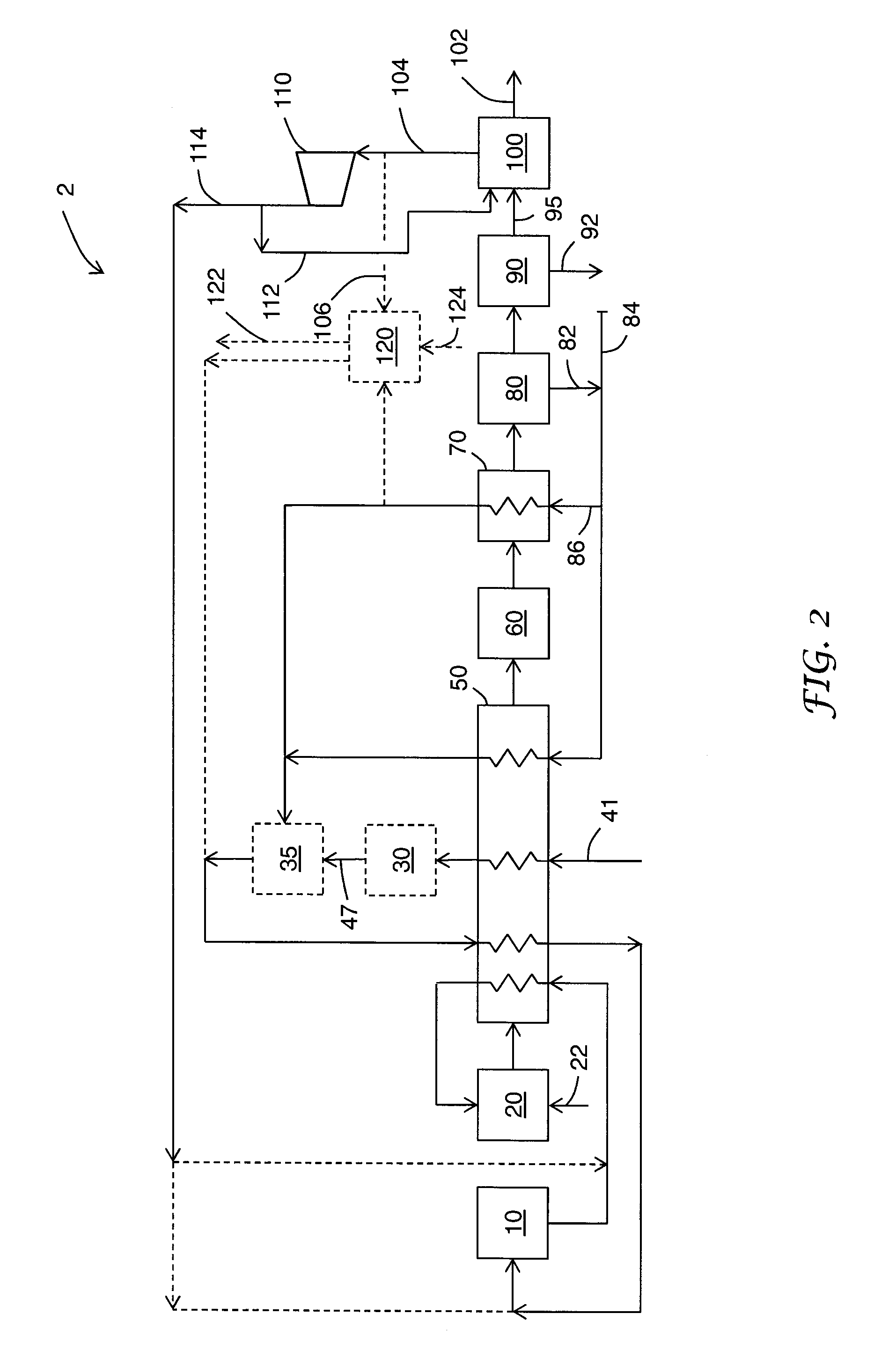

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

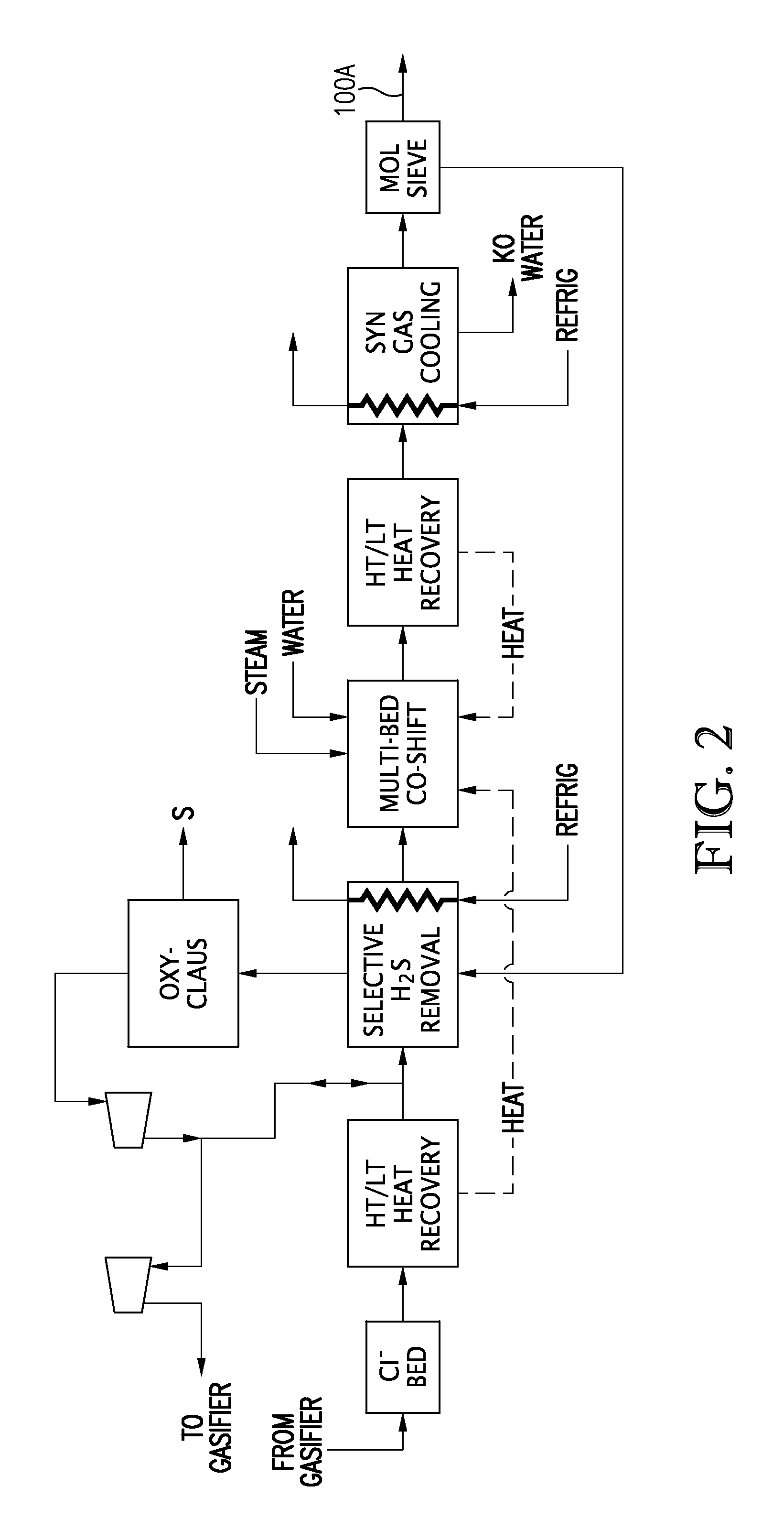

Sour Shift Process for the Removal of Carbon Monoxide from a Gas Stream

ActiveUS20090246120A1Hydrogen separation using liquid contactCombustible gas catalytic treatmentChemistryAirflow

Processes for the catalytic conversion of a carbonaceous composition into a gas stream comprising methane are provided, where a sour shift reaction is used to remove carbon monoxide gas stream produced by the gasification process. The incorporation of the sour shift reaction provides an efficient and cost-effective means of eliminating carbon monoxide from the gas stream. In addition, the sour shift reaction also generates additional hydrogen, thus increasing the amount of hydrogen produced from the gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Process and Apparatus for the Separation of Methane from a Gas Stream

InactiveUS20090260287A1Combustible gas chemical modificationHydrogen separation using liquid contactHydrogenWater vapor

Processes for conversion of a carbonaceous composition into a gas stream comprising methane are provided, where an energy-efficient process and / or apparatus is used to separate methane out of a gas stream comprising methane, carbon monoxide, and hydrogen. Particularly, methane can be separated from hydrogen and carbon monoxide using novel processes and / or apparatuses that generate methane hydrates. Because hydrogen and carbon monoxide do not readily form hydrates, the methane is separated from a gas stream. The methane can be captured as a substantially pure stream of methane gas by dissociating the methane from the hydrate and separating out any residual water vapor.

Owner:SURE CHAMPION INVESTMENT LTD

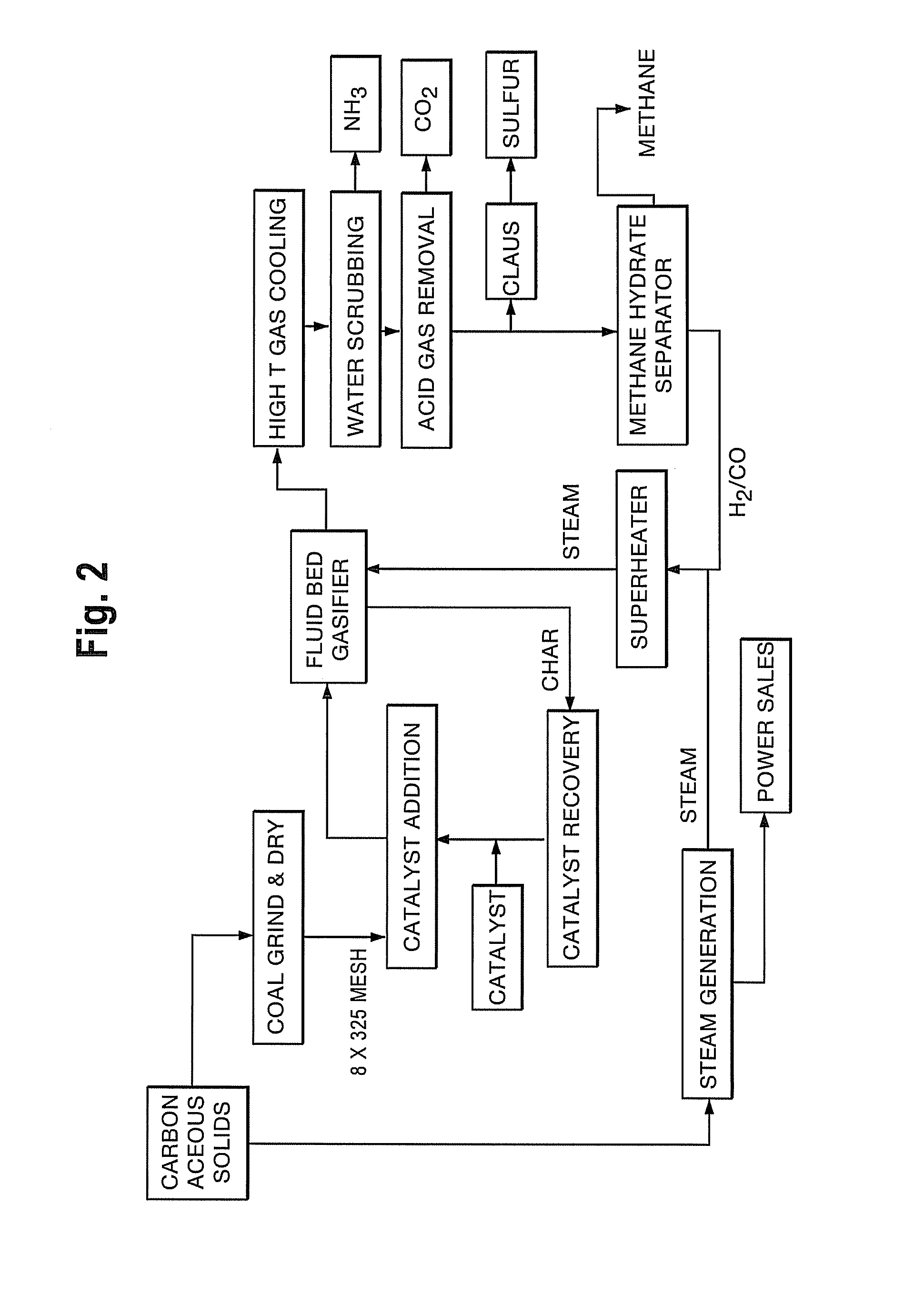

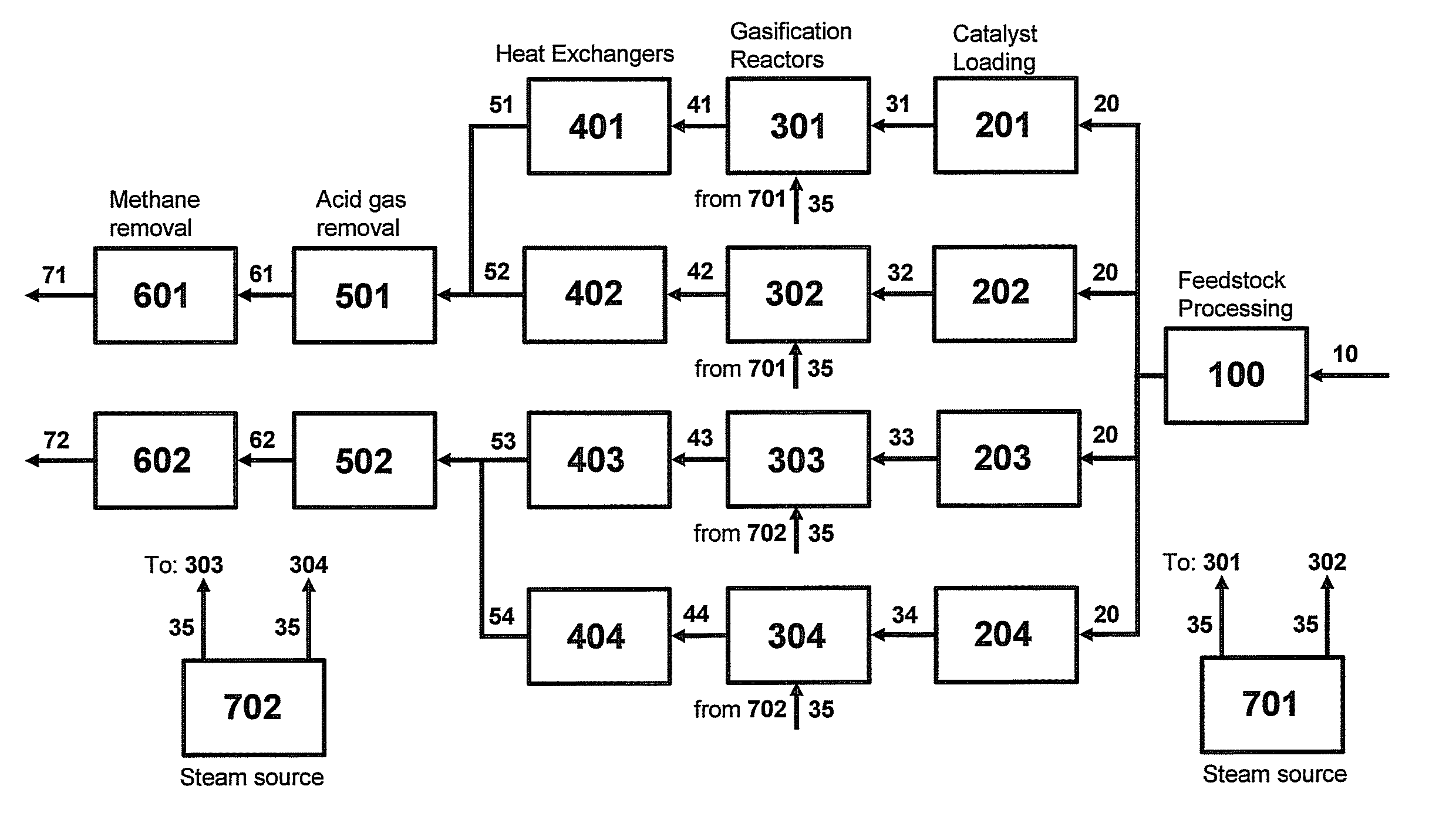

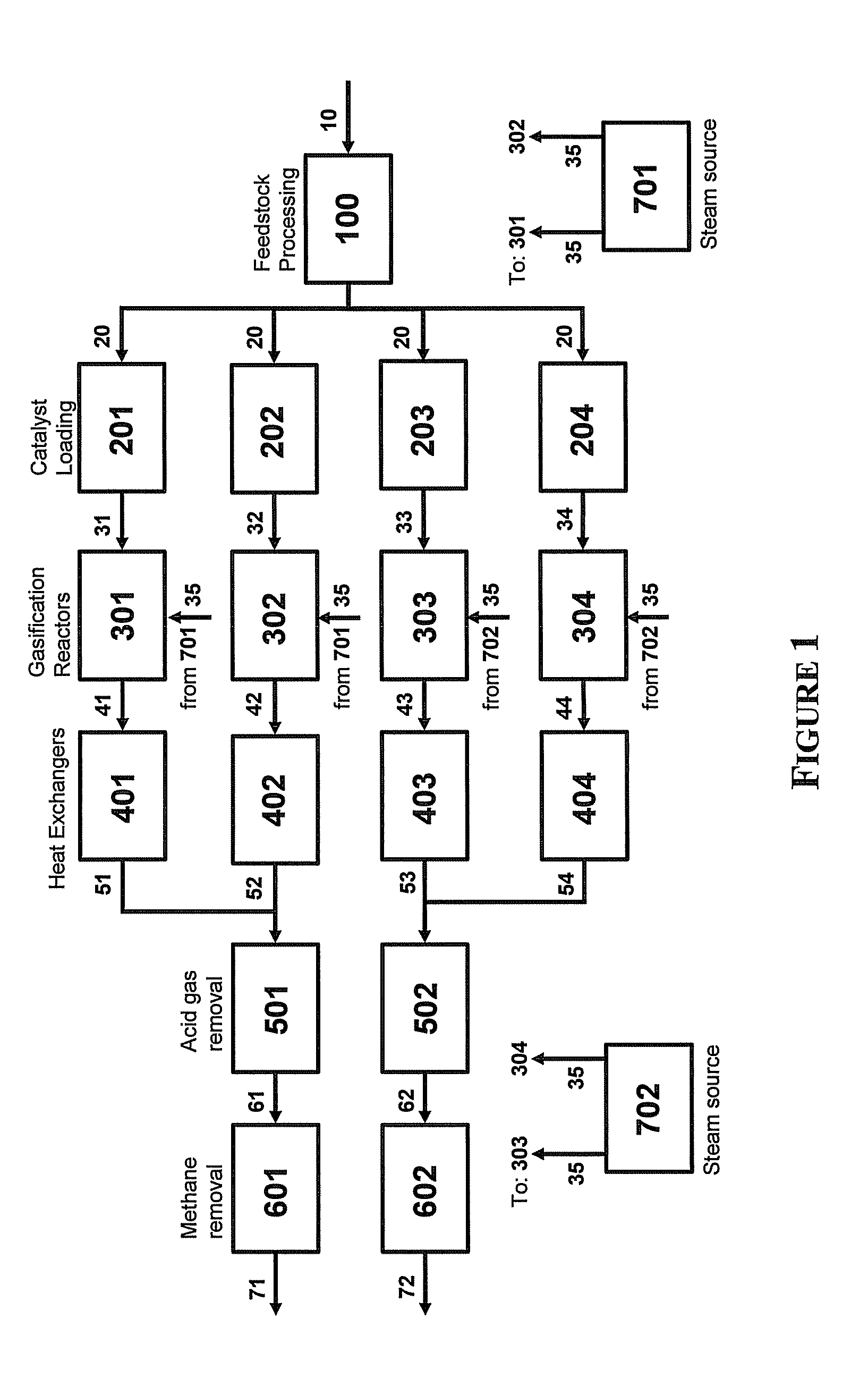

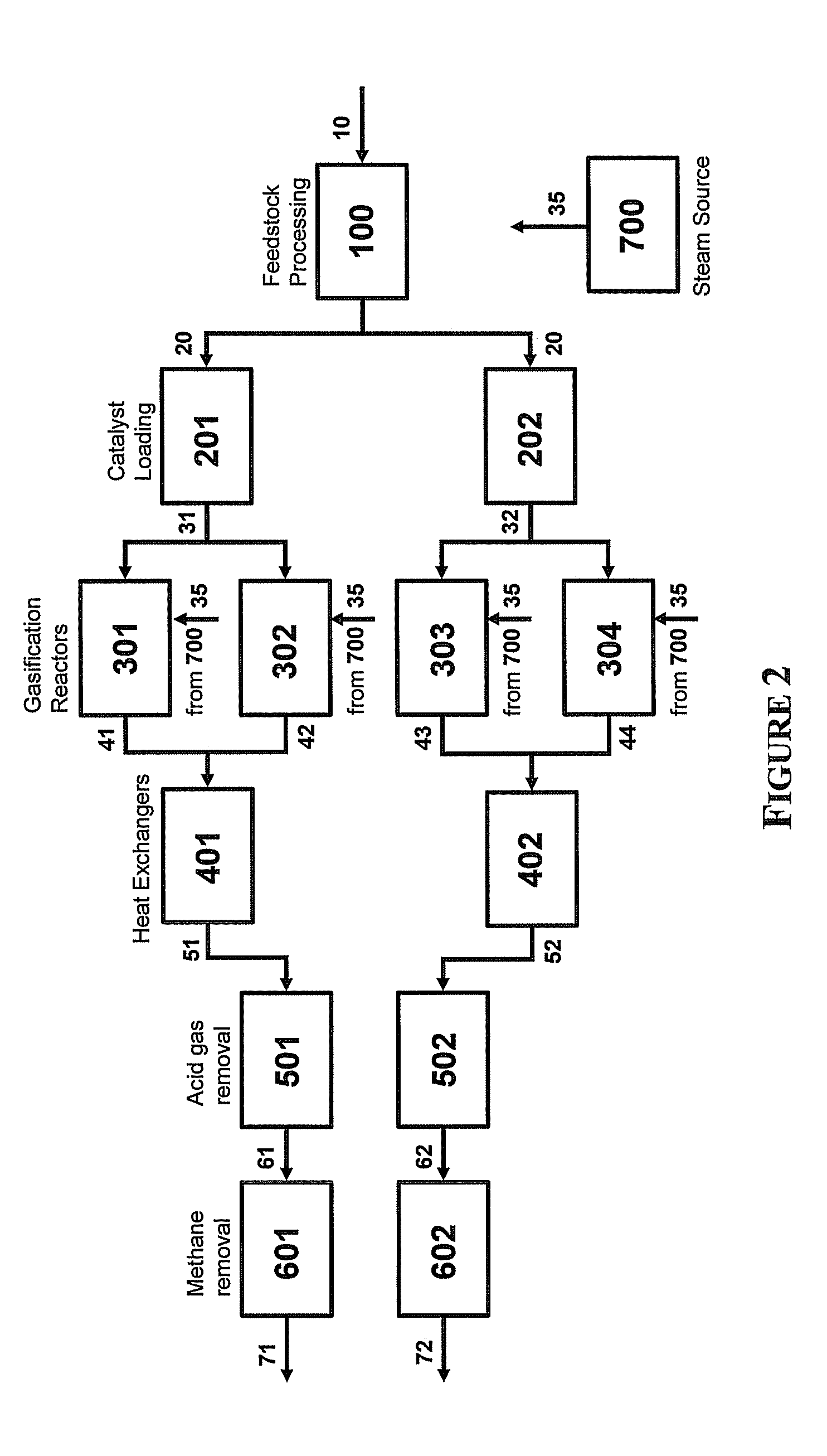

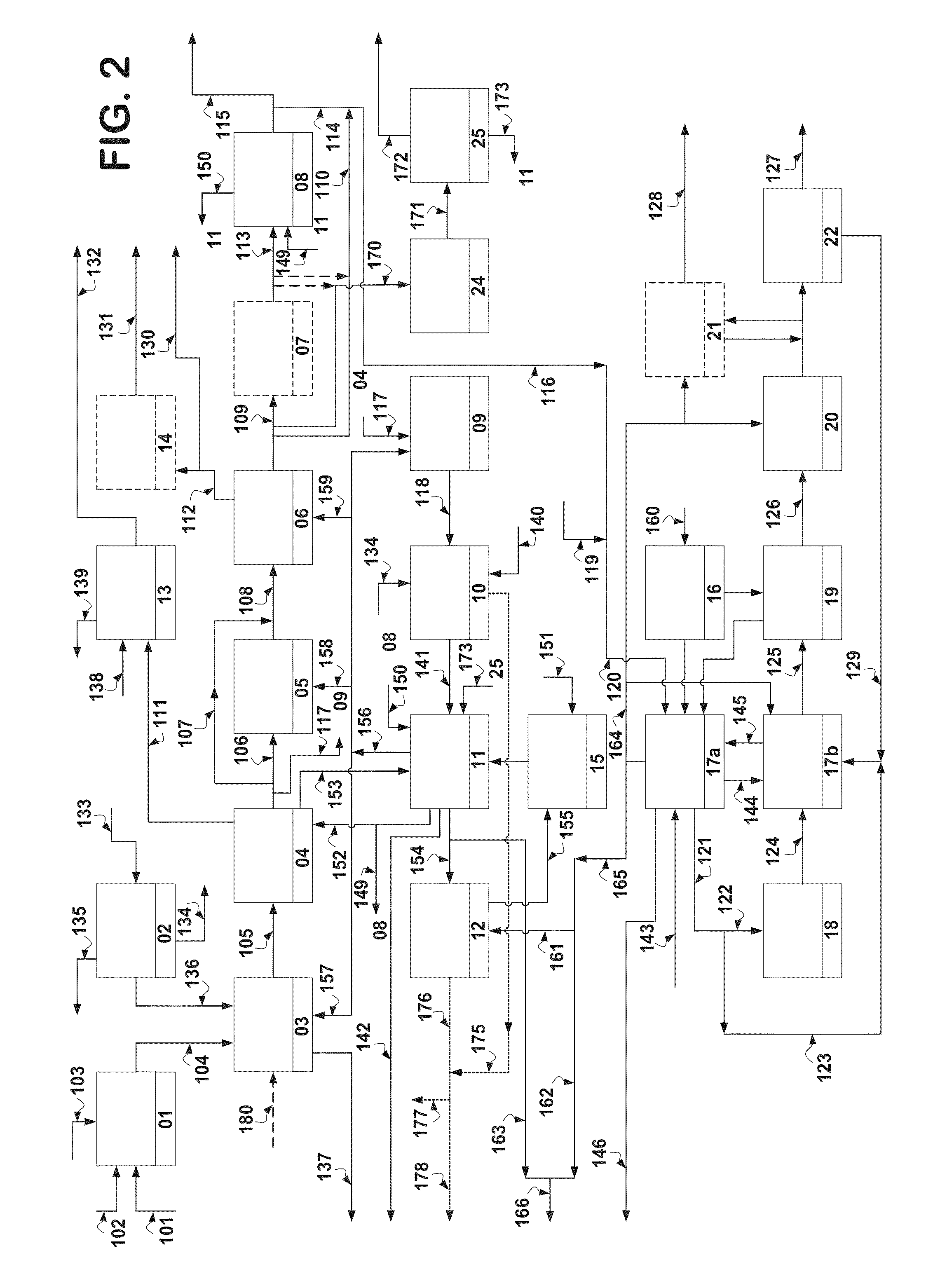

Four-Train Catalytic Gasification Systems

InactiveUS20090324460A1Reduce moisture contentHydrogen separation at low temperatureHydrogen separation using liquid contactUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

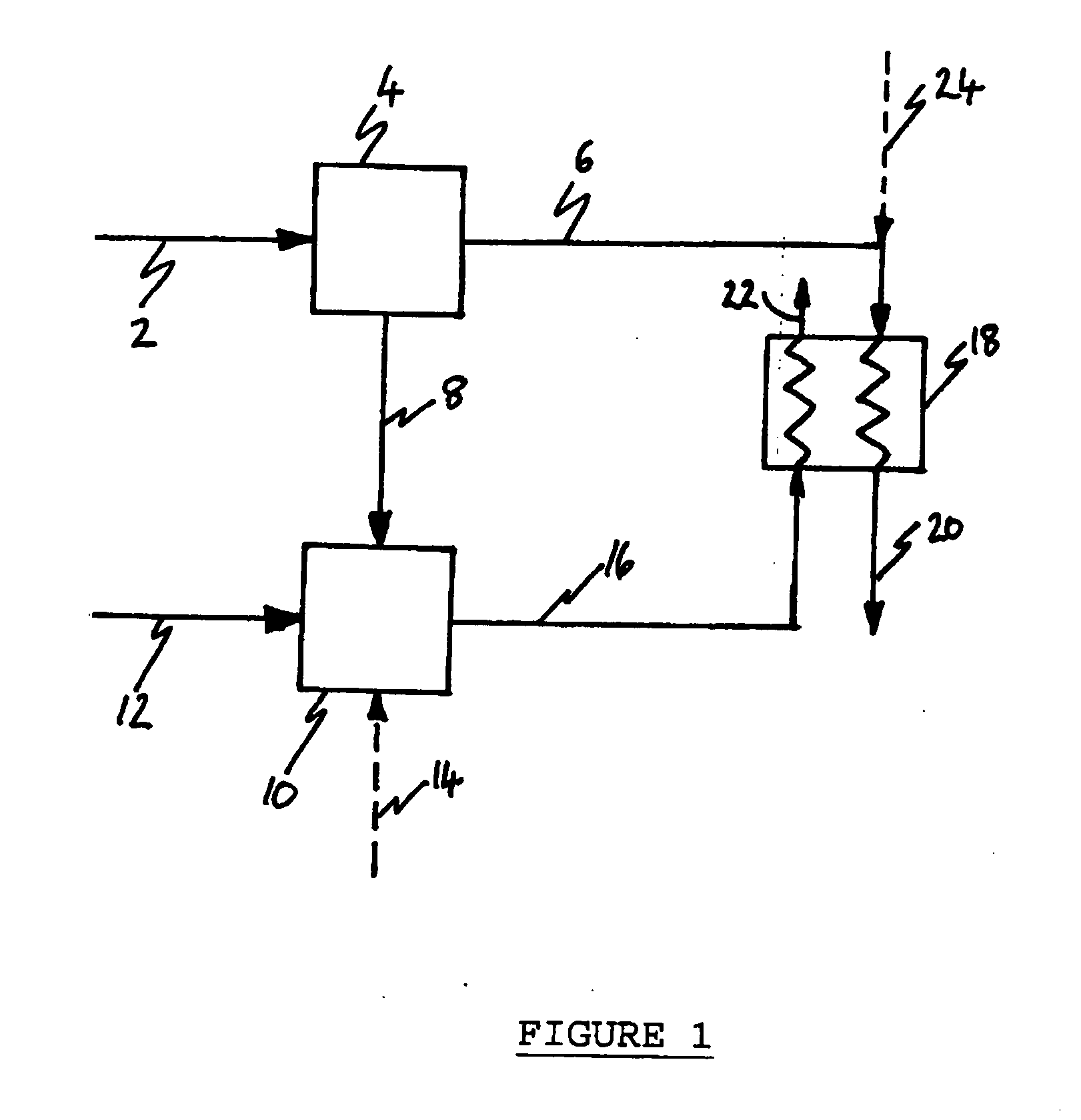

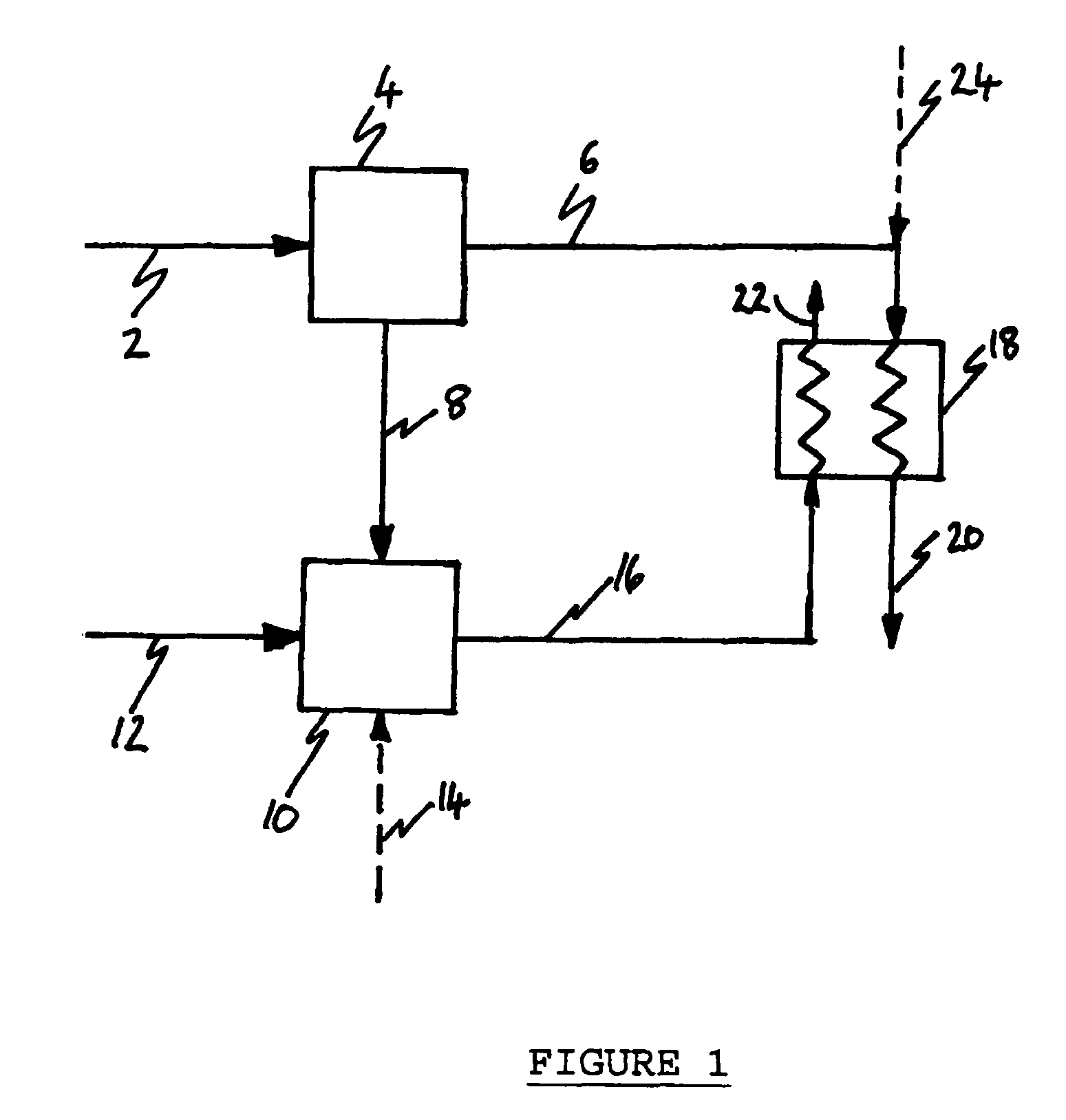

Method of treating a gaseous mixture comprising hydrogen and carbon dioxide

Hydrogen (H2) gas and crude carbon dioxide (CO2) gas are separated from a gaseous mixture thereof. Combustible gas(es) in the crude CO2 gas are combusted to produce heat, at least a portion of which is recovered by indirect heat exchange with at least a portion of the separated H2 gas or a gas derived therefrom. The invention may be integrated with coal-fired power stations to reduce or eliminate emission of harmful components into the atmosphere.

Owner:AIR PROD & CHEM INC

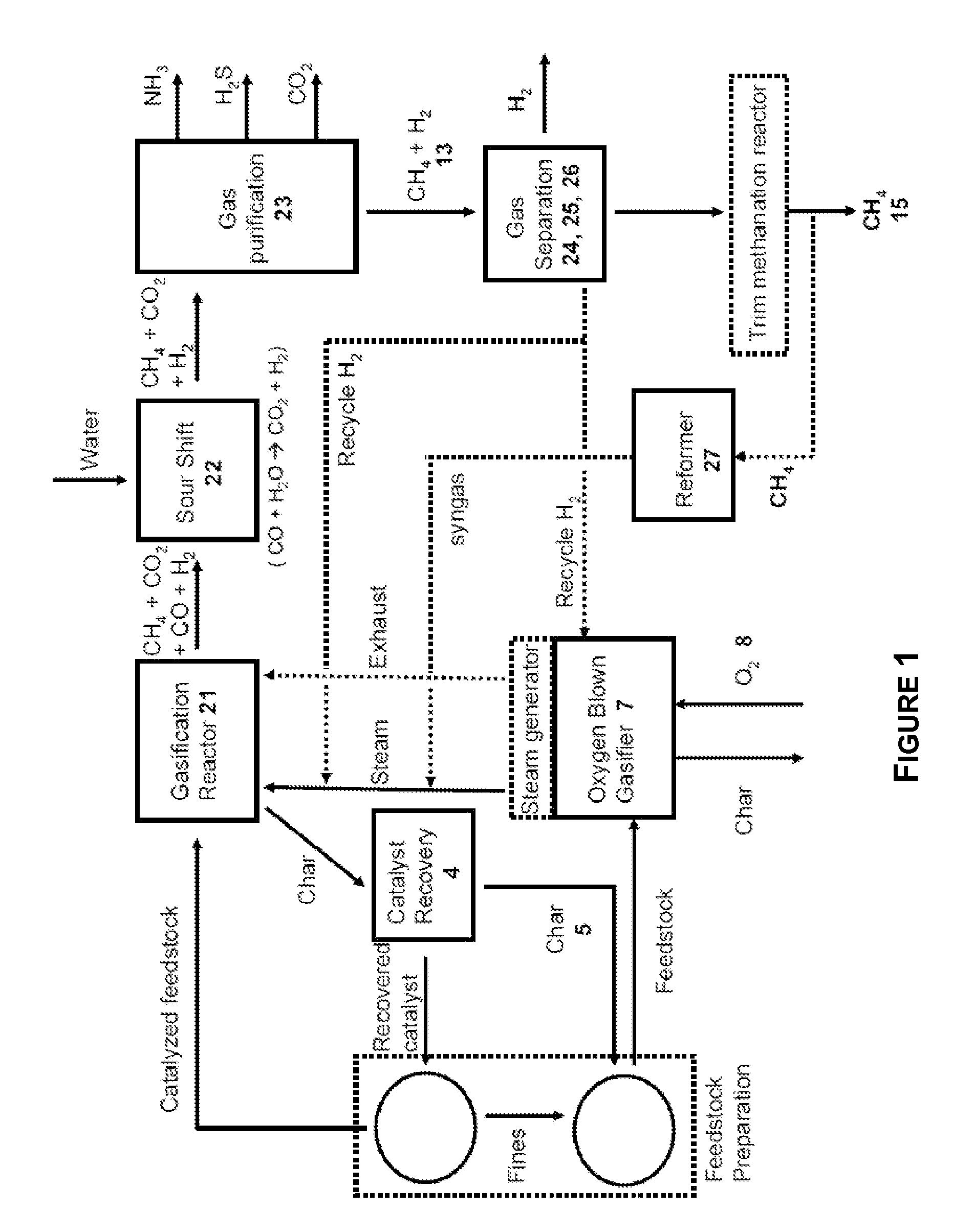

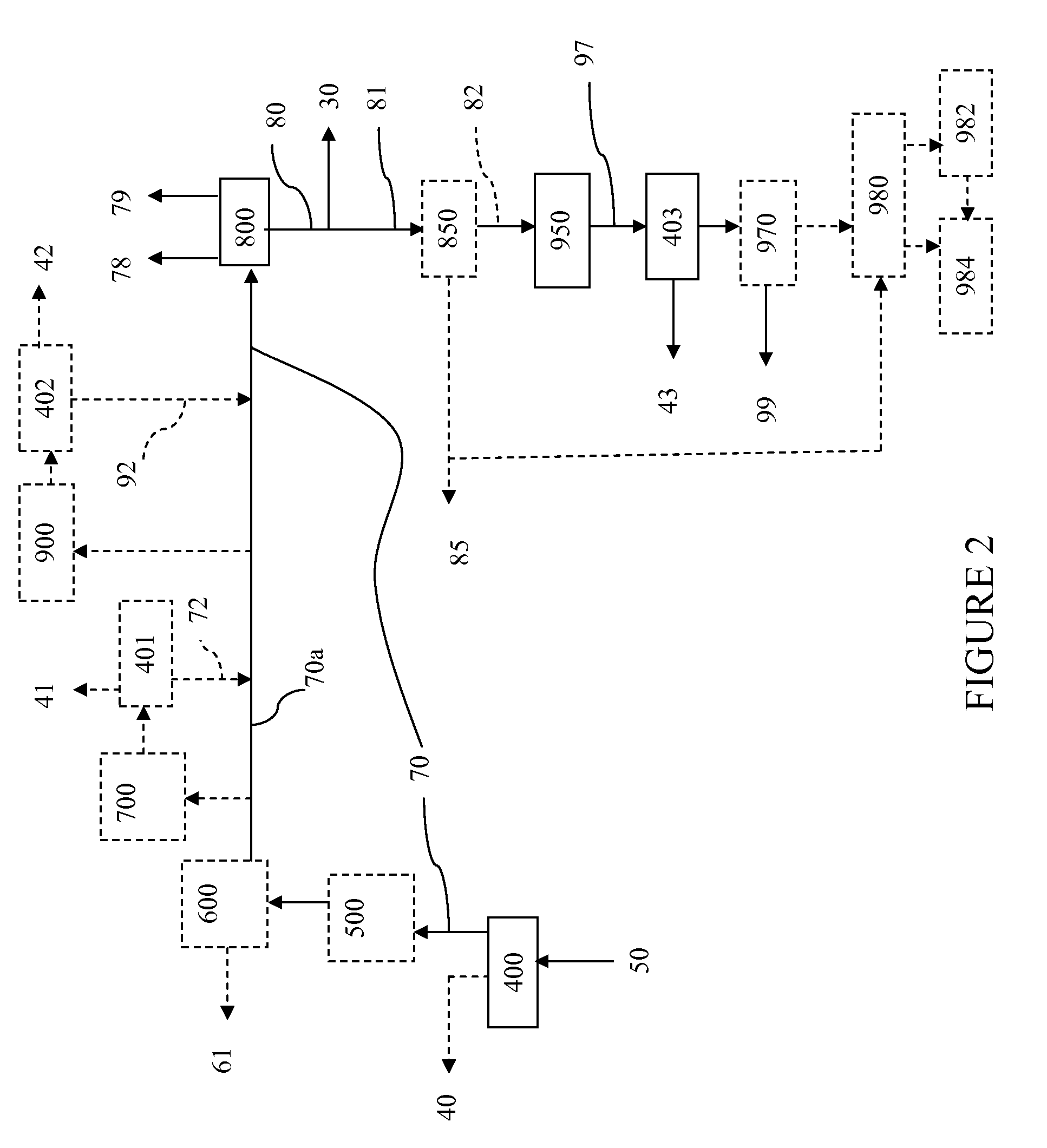

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287836A1Hydrogen separation at low temperatureCarbon compoundsMethanationHydromethanation

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

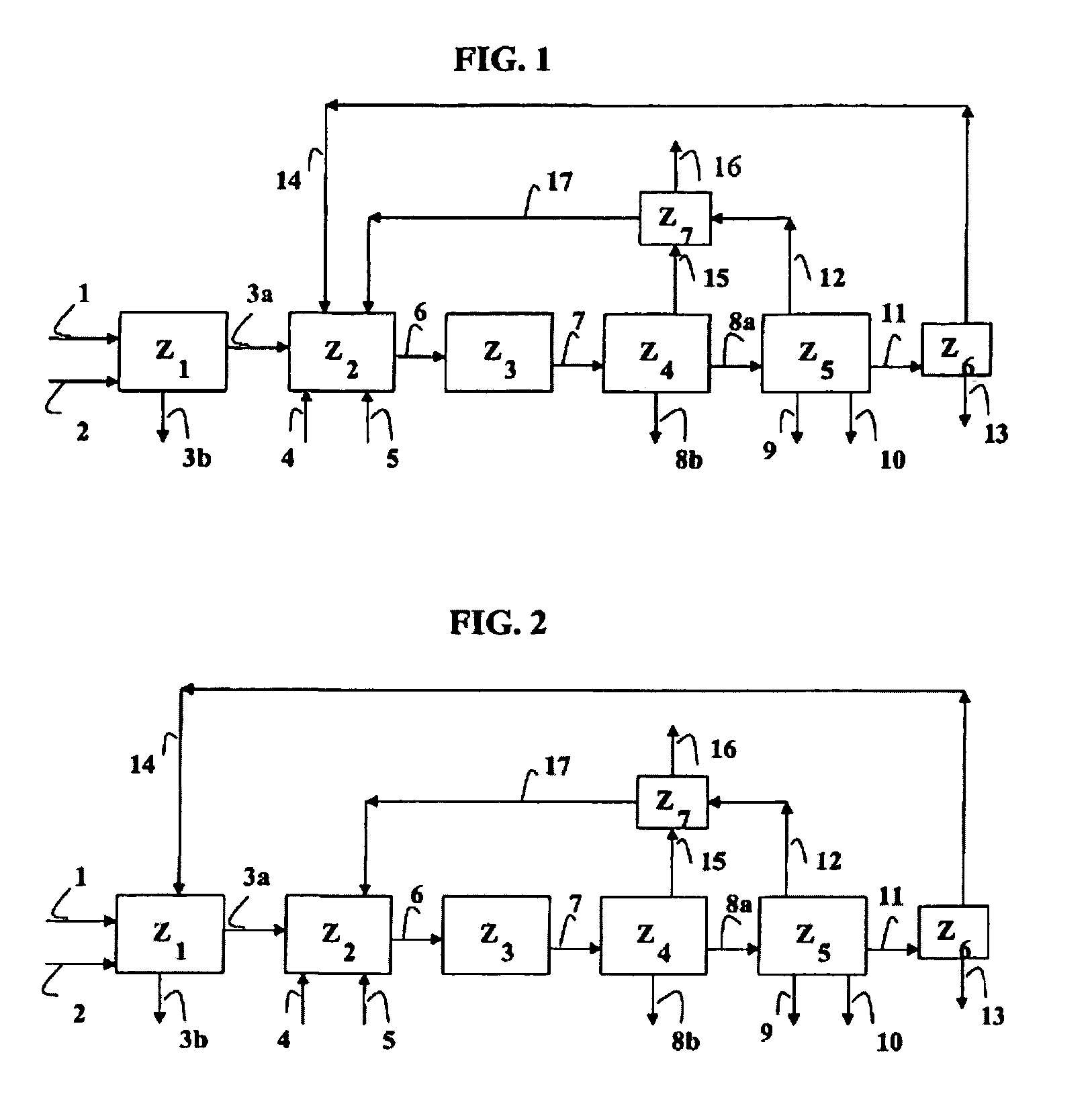

Production of liquid fuels by a concatenation of processes for treatment of a hydrocarbon feedstock

ActiveUS7214720B2Maximize conversion of carbonReduce and to upgrade naphthaThermal non-catalytic crackingCatalytic crackingNaphthaKerosene

The invention relates to an installation and a process for the production of liquid fuels starting from a solid feedstock that contains the organic material in which:a) the solid feedstock is subjected to a gasification stage so as to convert said feedstock into synthesis gas,b) the synthesis gas is subjected to a purification treatment,c) the purified synthesis gas is subjected to a conversion stage that comprises the implementation of a Fischer-Tropsch-type synthesis so as to convert said synthesis gas into a liquid effluent and a gaseous effluent,d) the liquid effluent is fractionated so as to obtain a gaseous fraction, a naphtha fraction, a kerosene fraction and a gas oil fraction, ande) at least a portion of the naphtha fraction is recycled in gasification stage a).

Owner:INST FR DU PETROLE +1

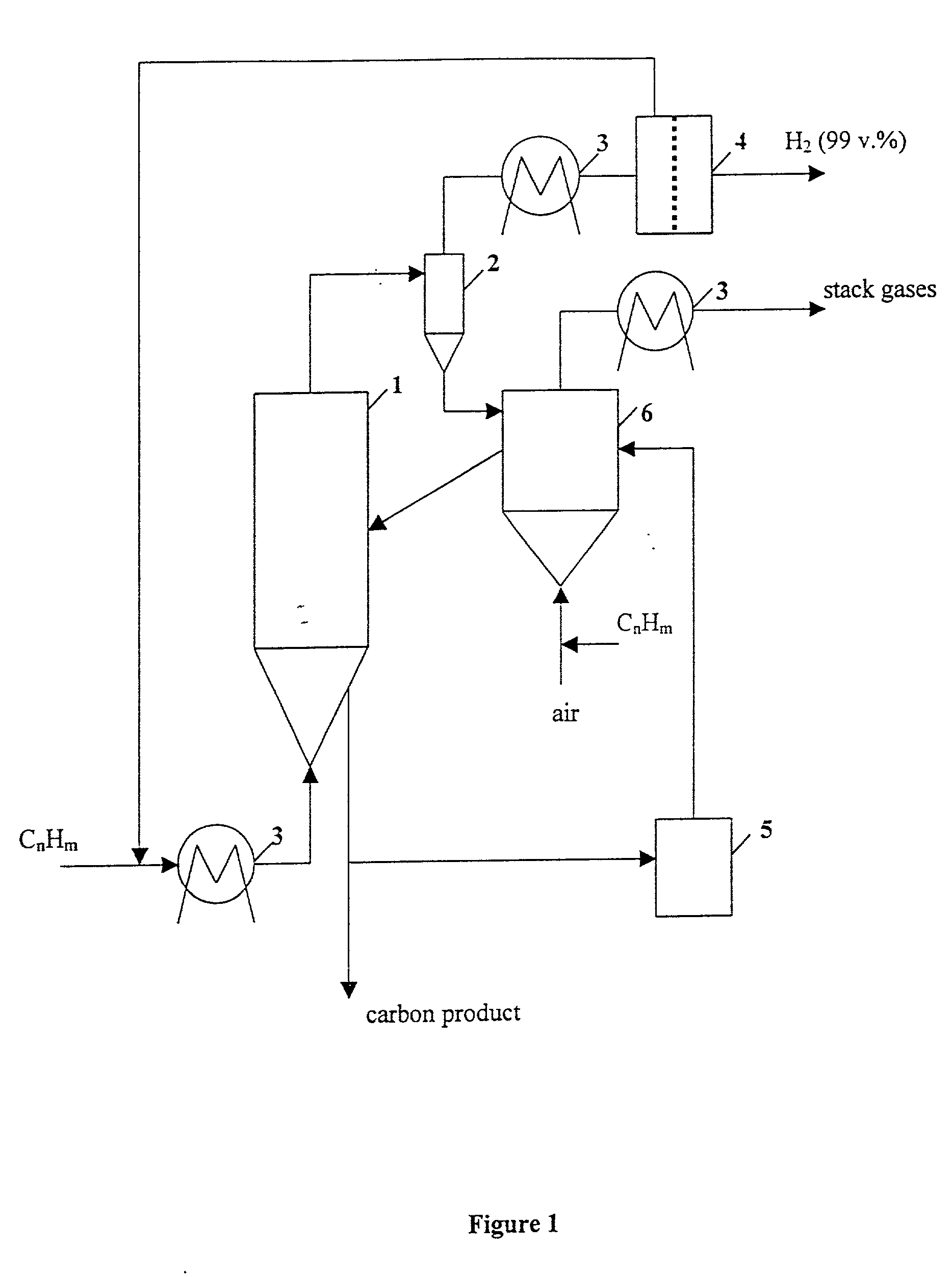

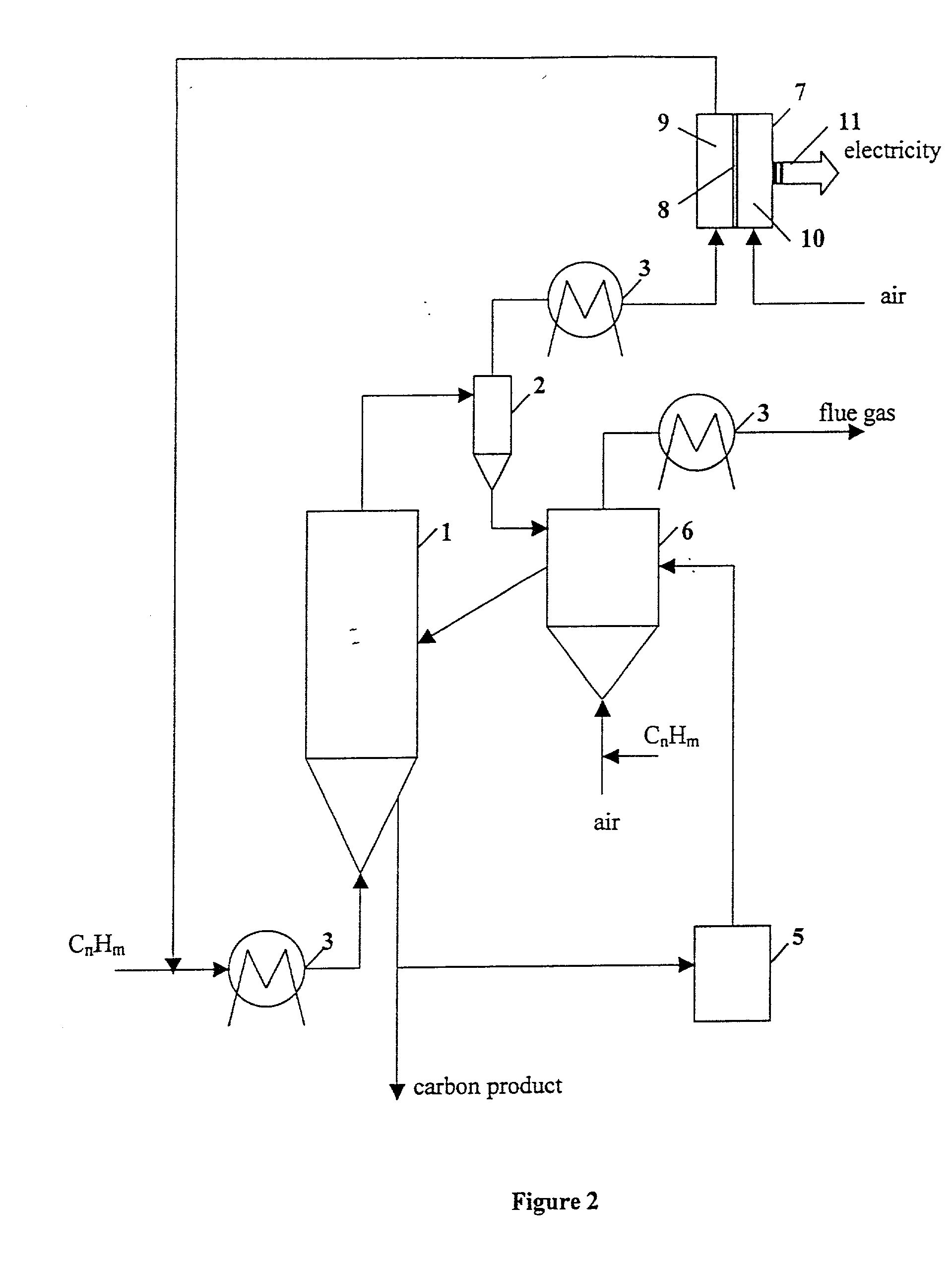

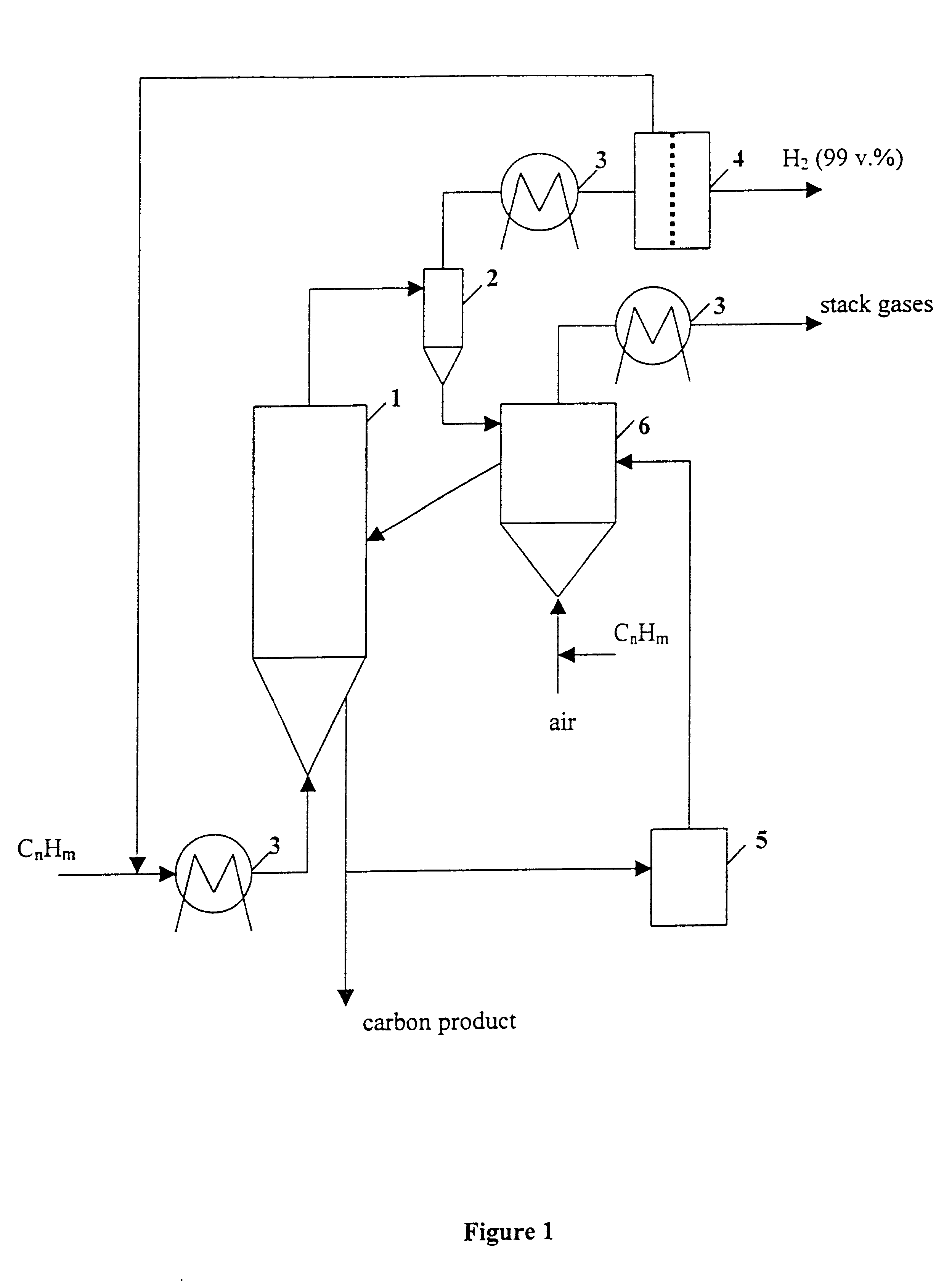

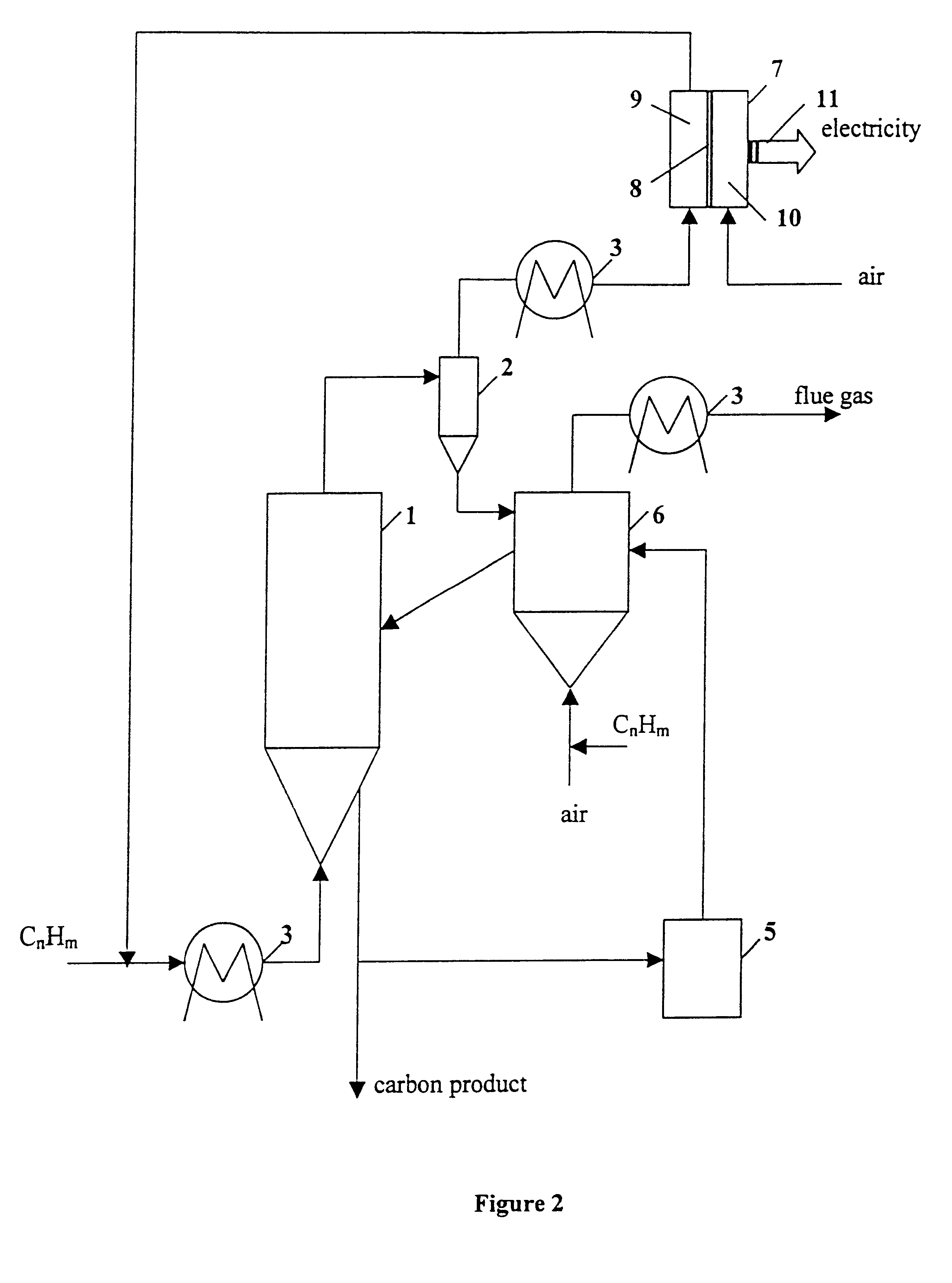

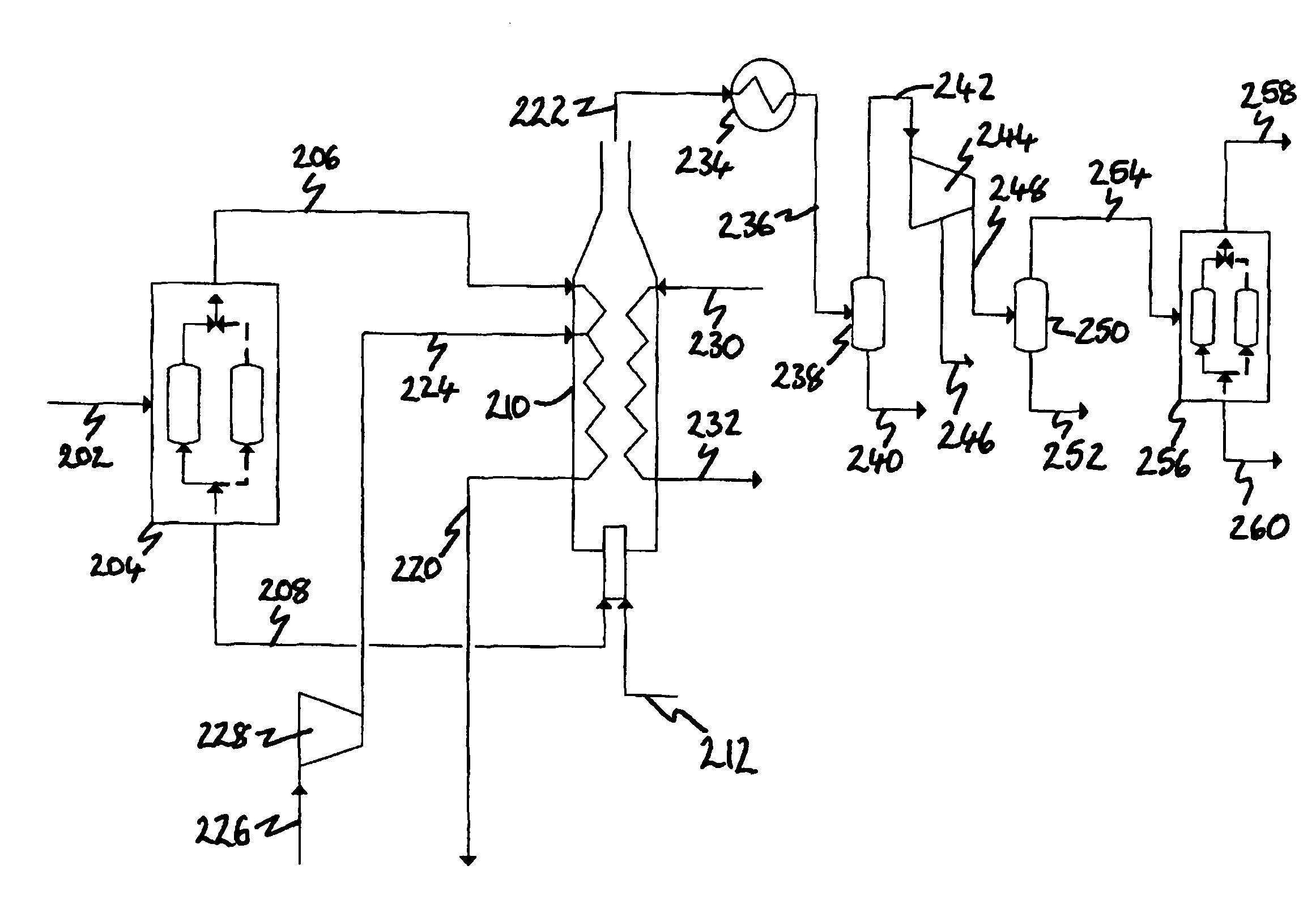

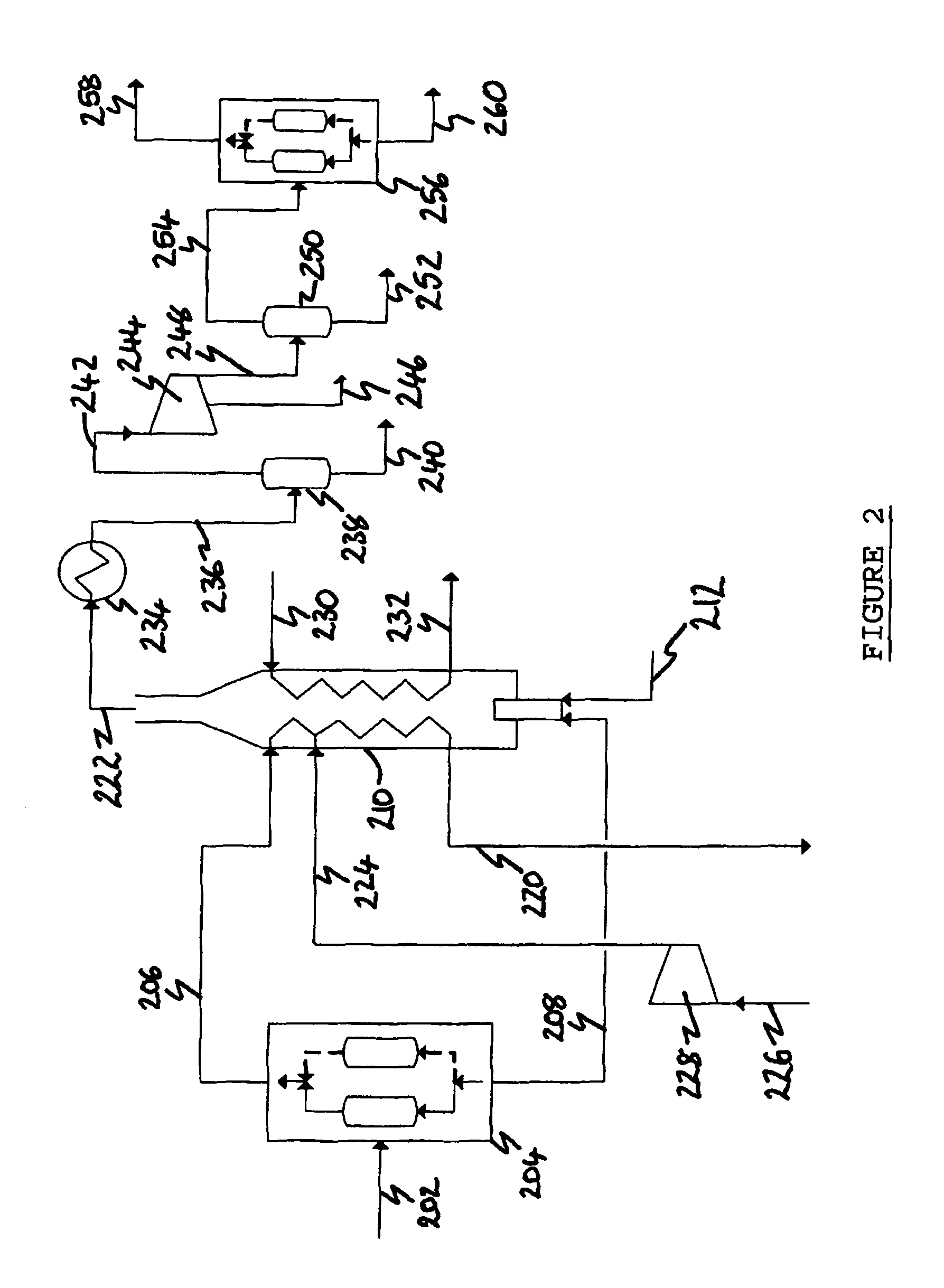

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

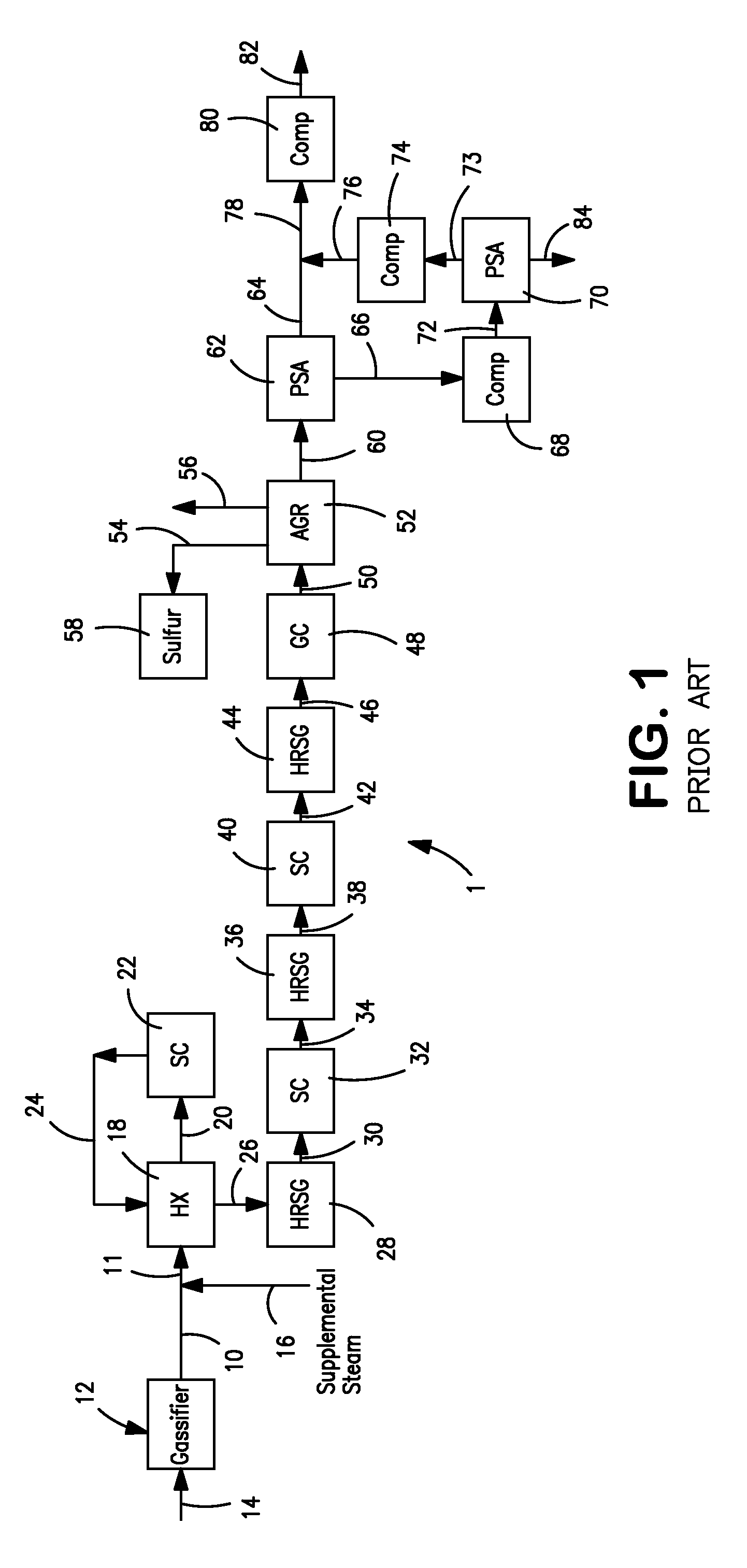

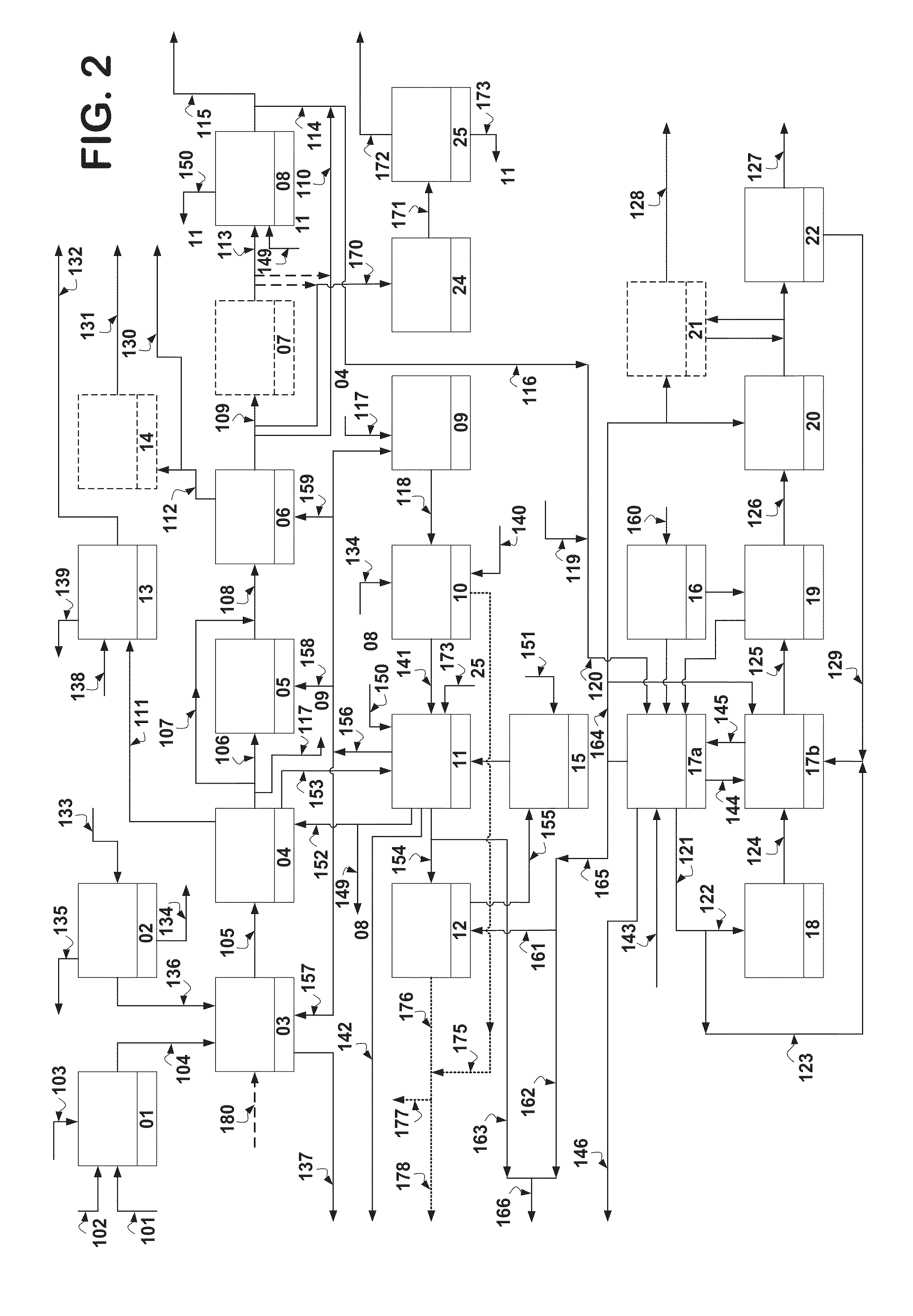

Hydrogen production method and facility

ActiveUS7985399B2High trafficHydrogen separation using solid contactHydrogen separation using liquid contactSyngasHydrocarbon

A hydrogen production method and facility in which a synthesis gas stream produced by the gasification of a carbonaceous substance is processed within a synthesis gas processing unit in which the carbon monoxide content is reacted with steam to produce additional hydrogen that is removed by a pressure swing adsorption unit. The tail gas from the pressure swing adsorption unit is further reformed with the addition of a hydrocarbon containing stream in a steam methane reforming system, further shifted to produce further additional hydrogen. The further hydrogen is then separated in another pressure swing adsorption unit.

Owner:PRAXAIR TECH INC

Methods and apparatus for hydrogen gas production

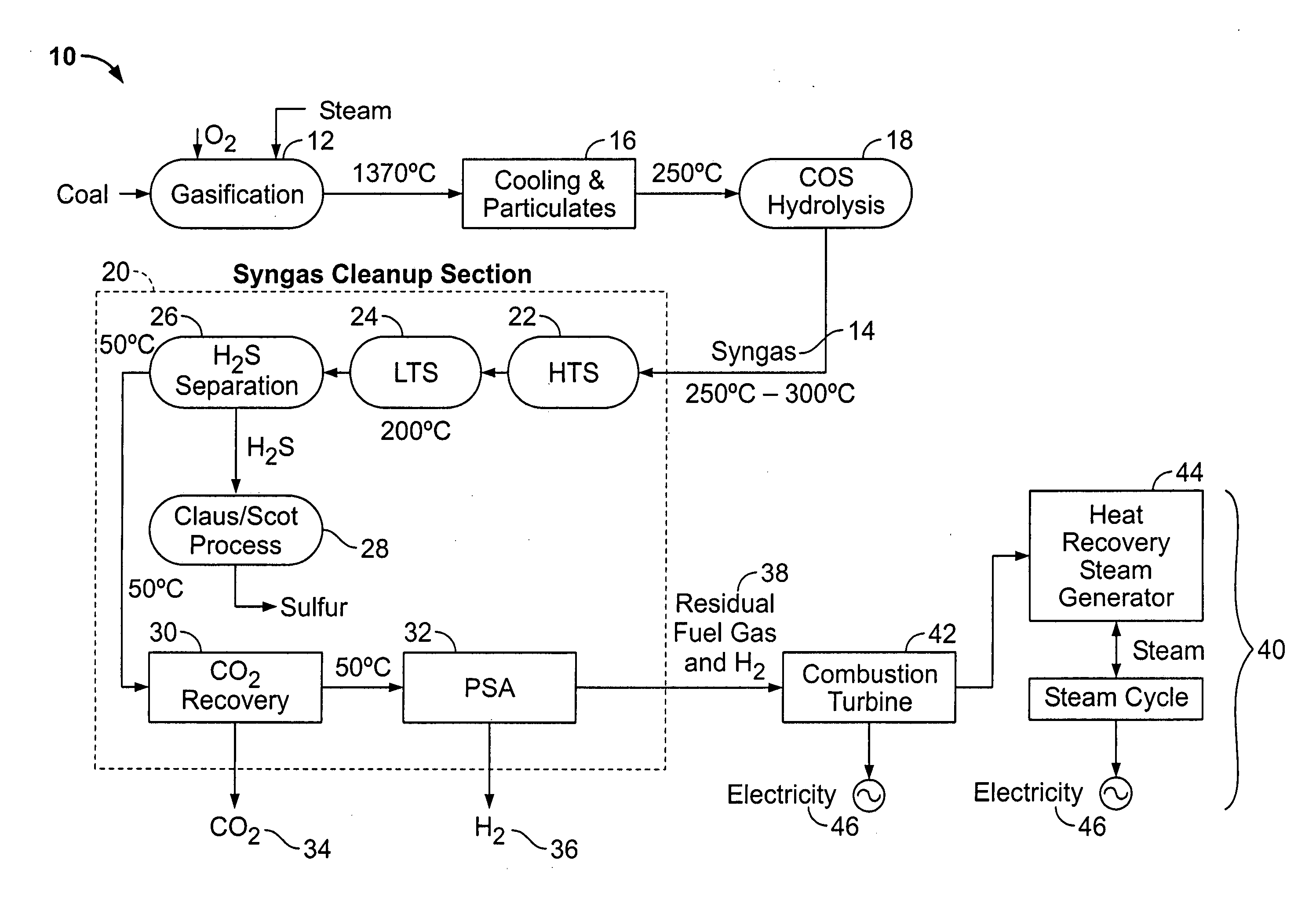

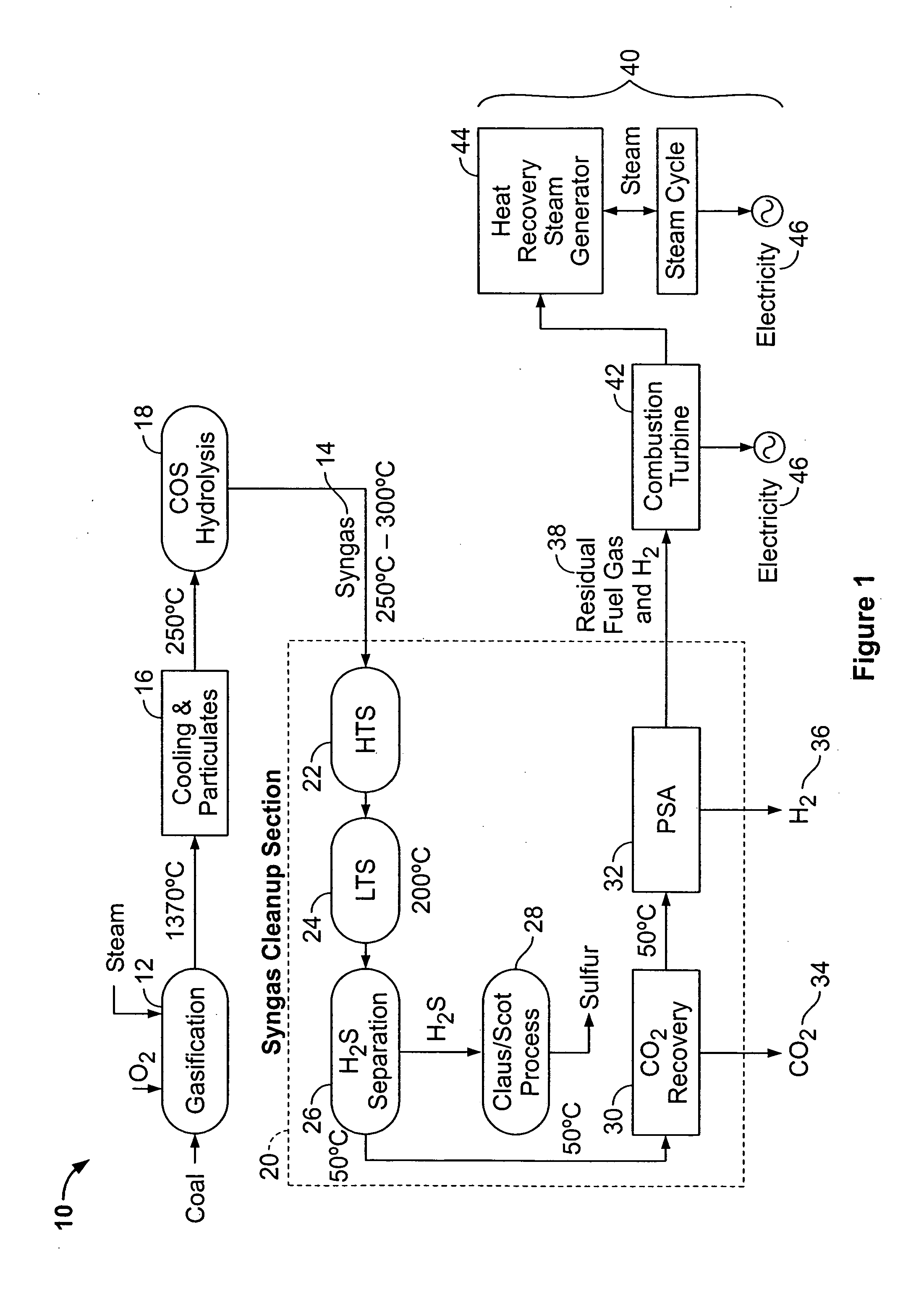

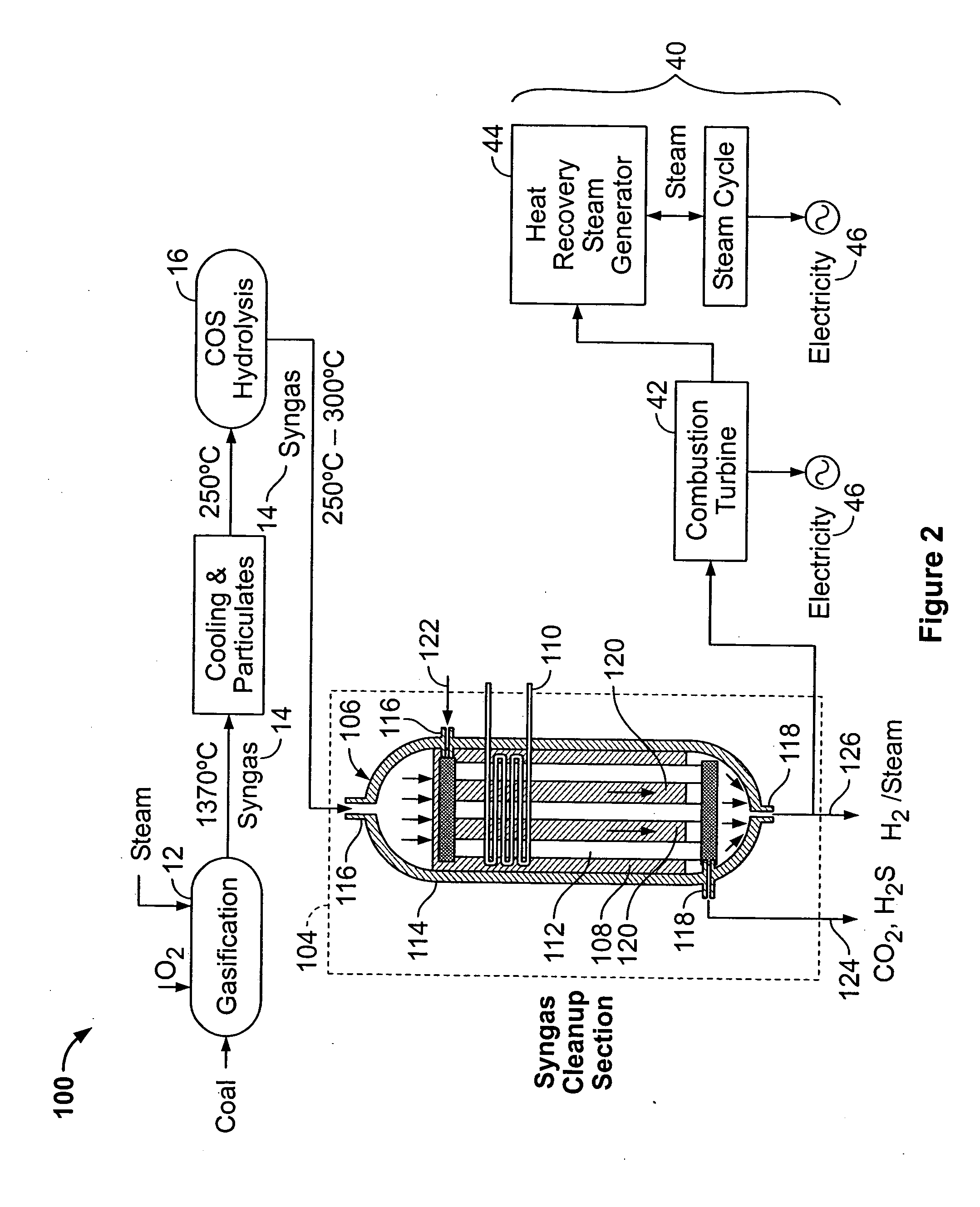

InactiveUS20070072949A1Gas turbine plantsHydrogen/synthetic gas productionHydrogenMembrane configuration

An apparatus for producing hydrogen gas, wherein the apparatus includes a reactor. The reactor includes a catalyst, a membrane in flow communication with the catalyst, and a heat exchanger integrated with the reactor.

Owner:GENERAL ELECTRIC CO

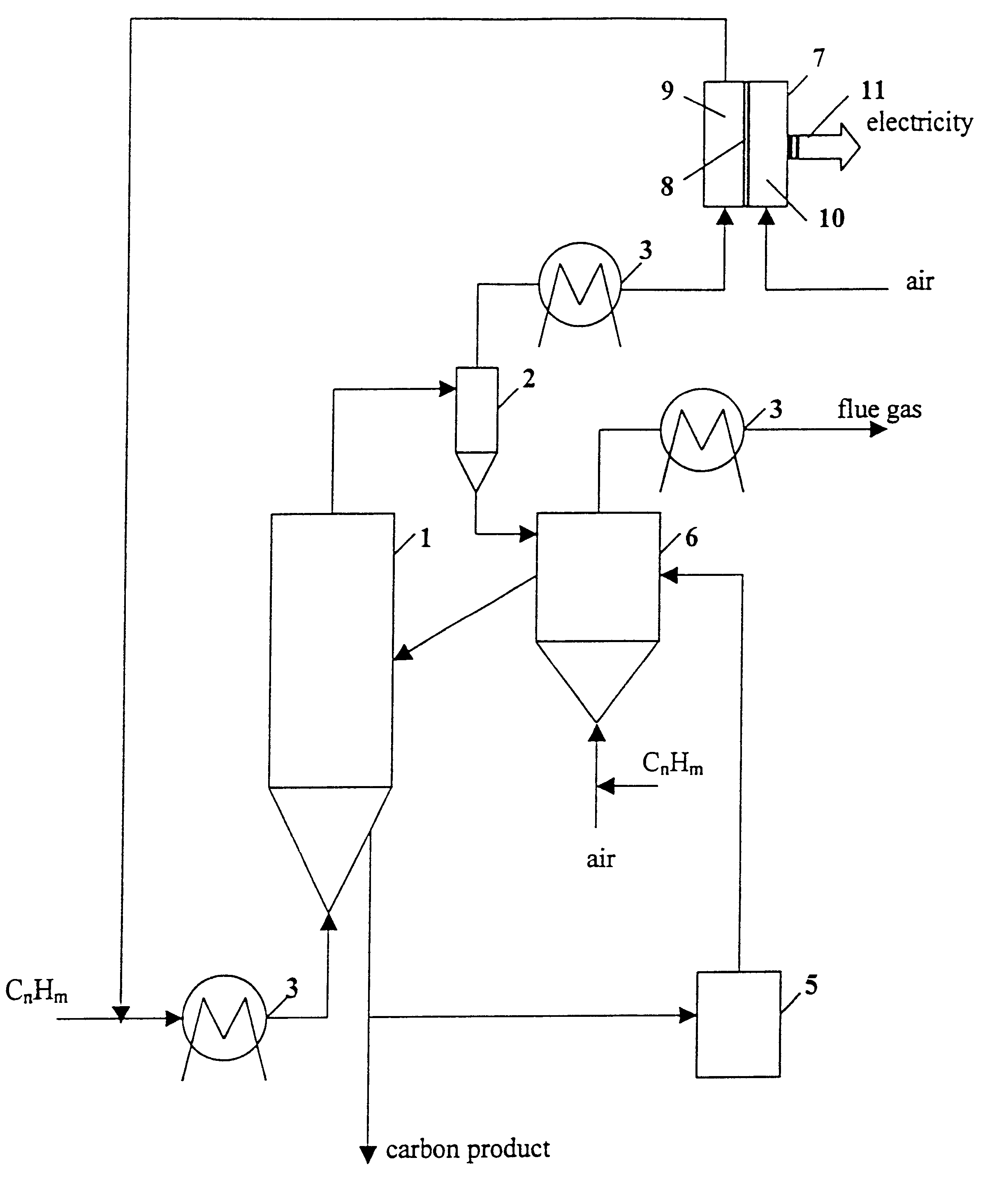

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

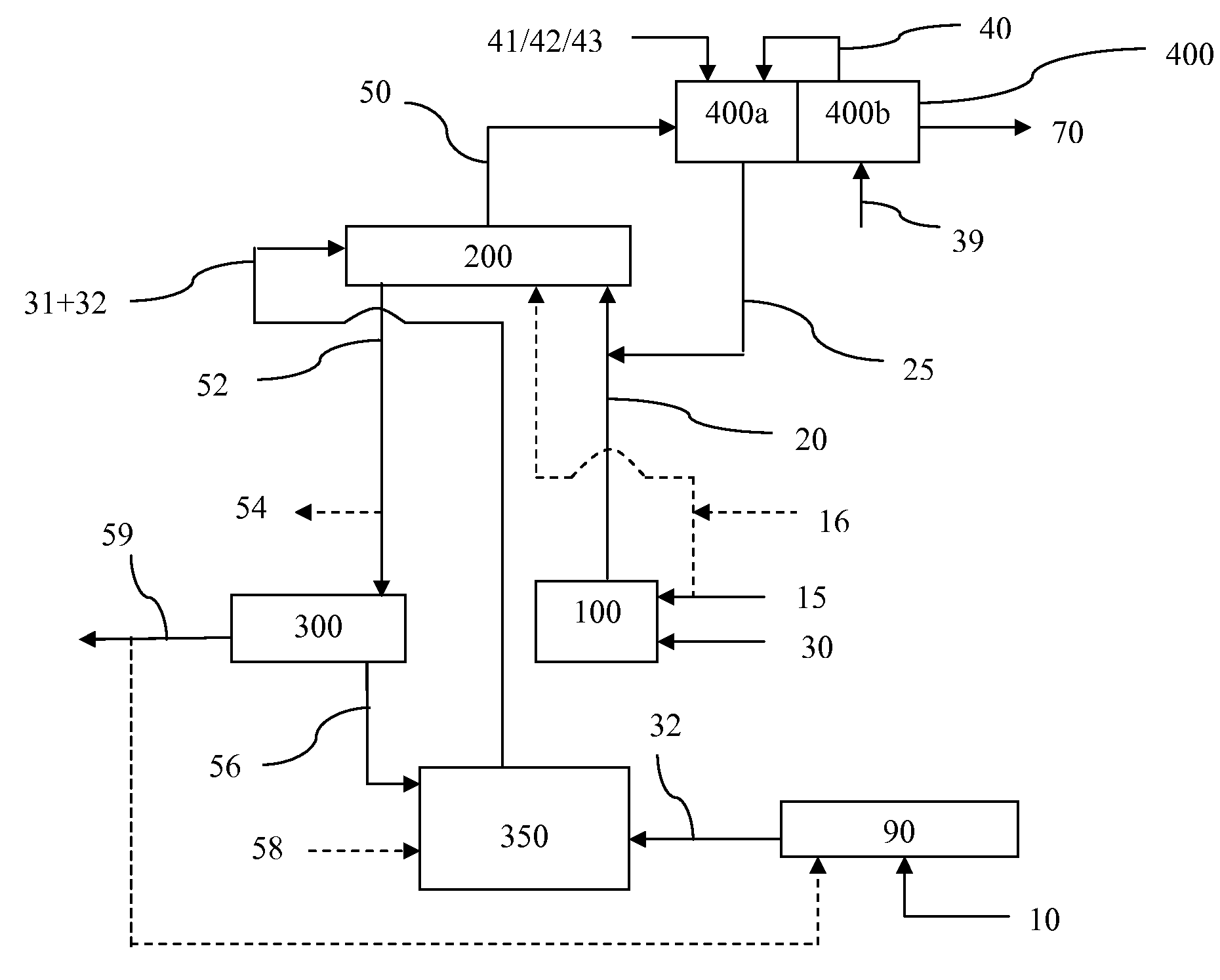

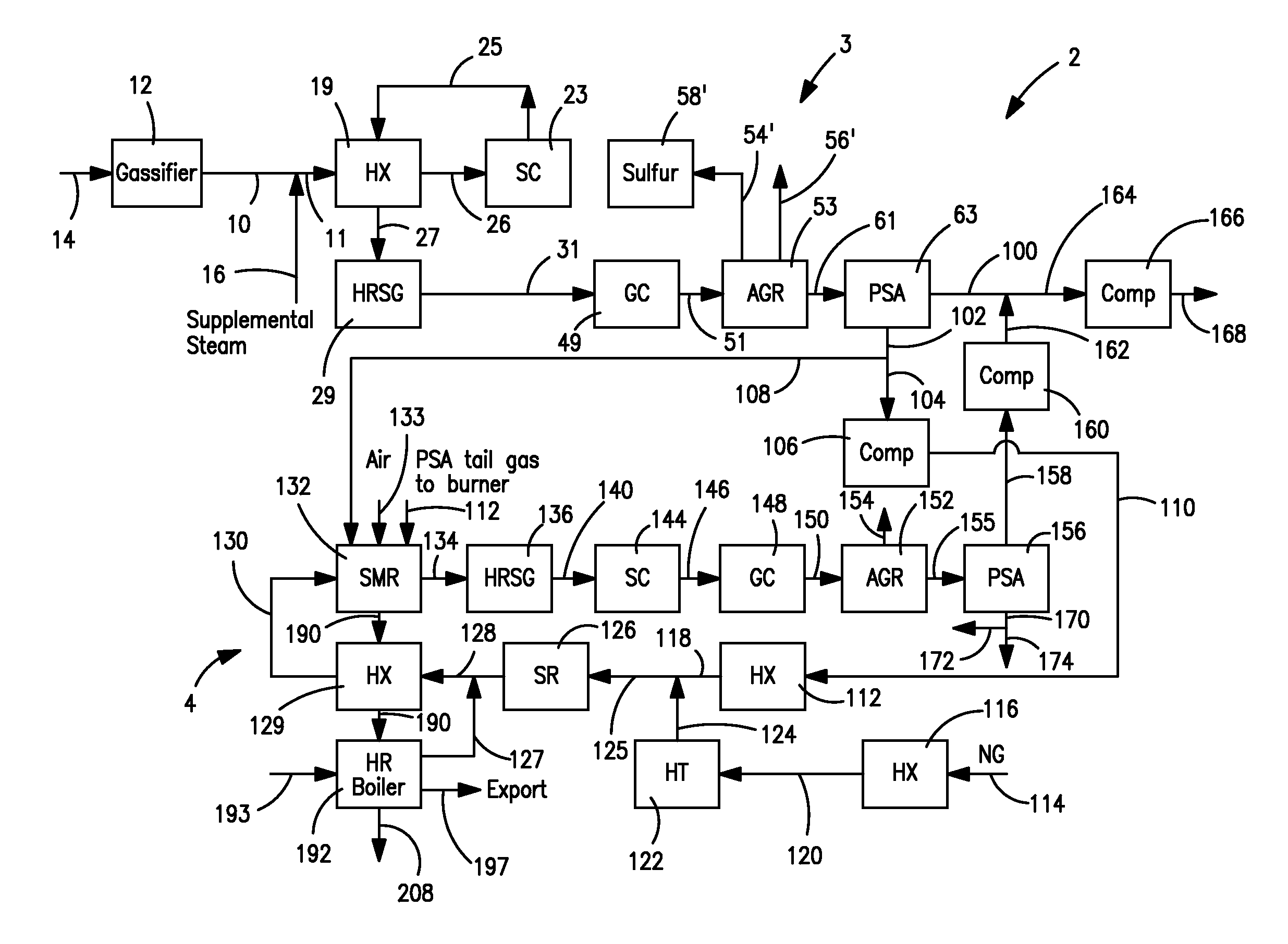

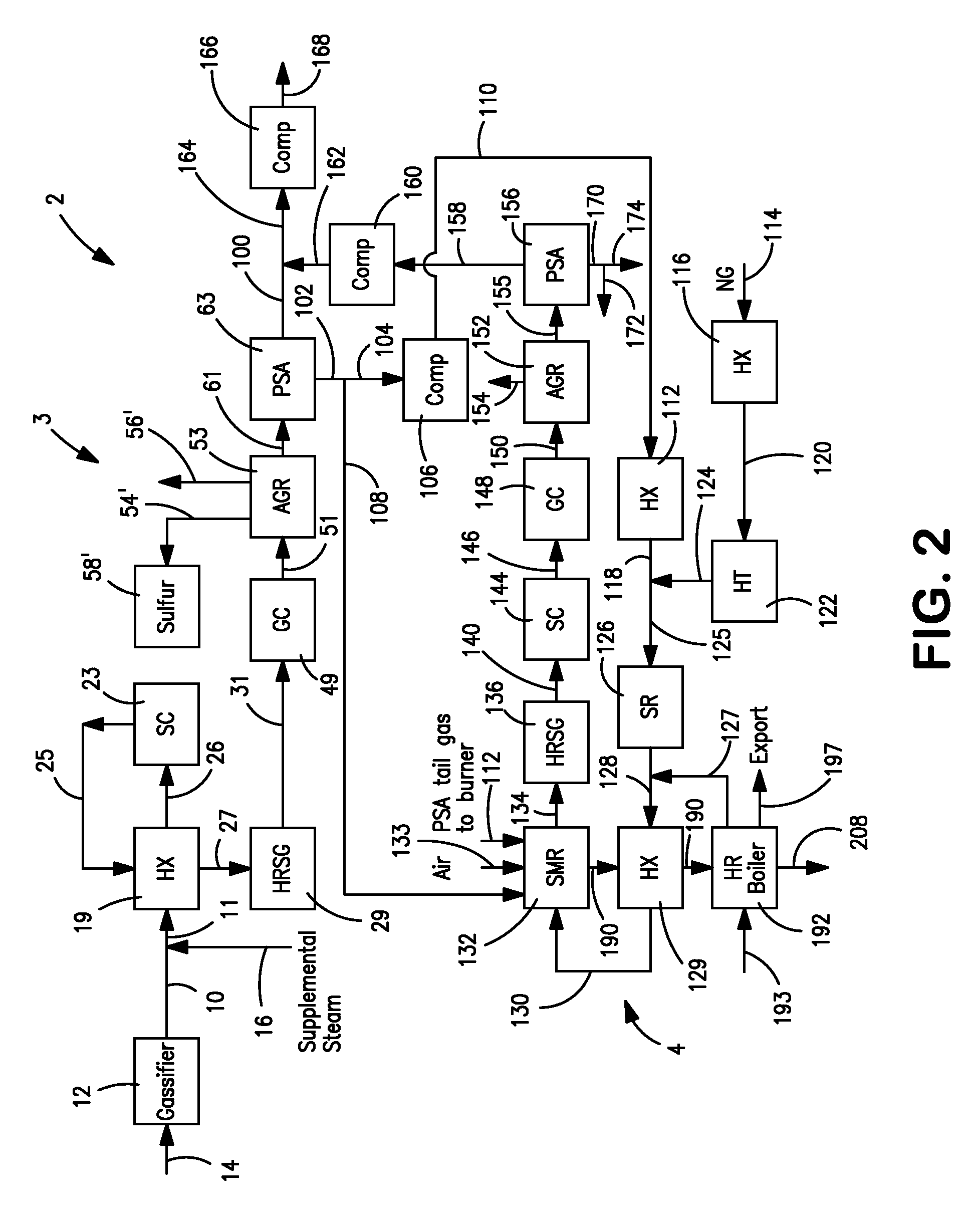

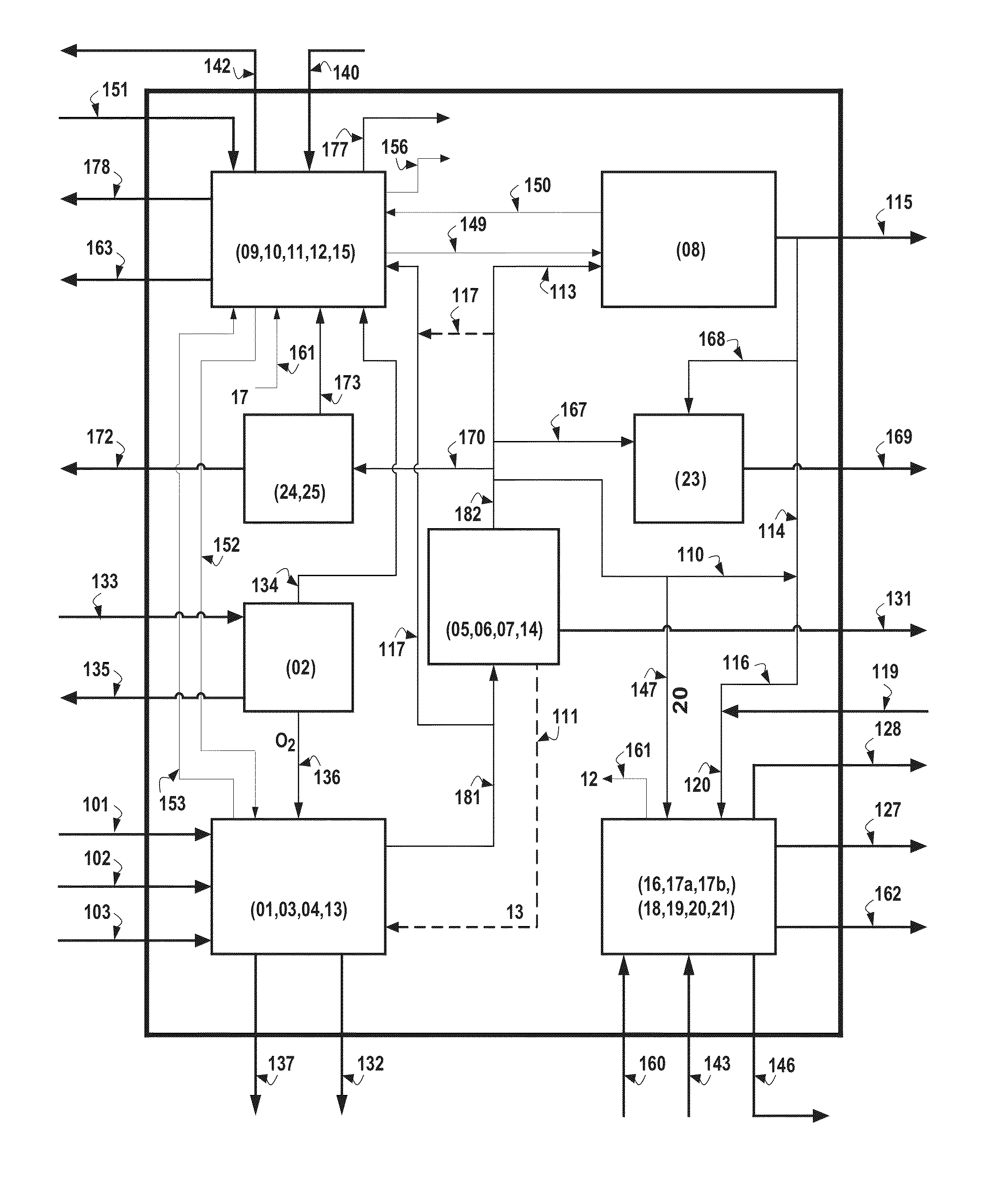

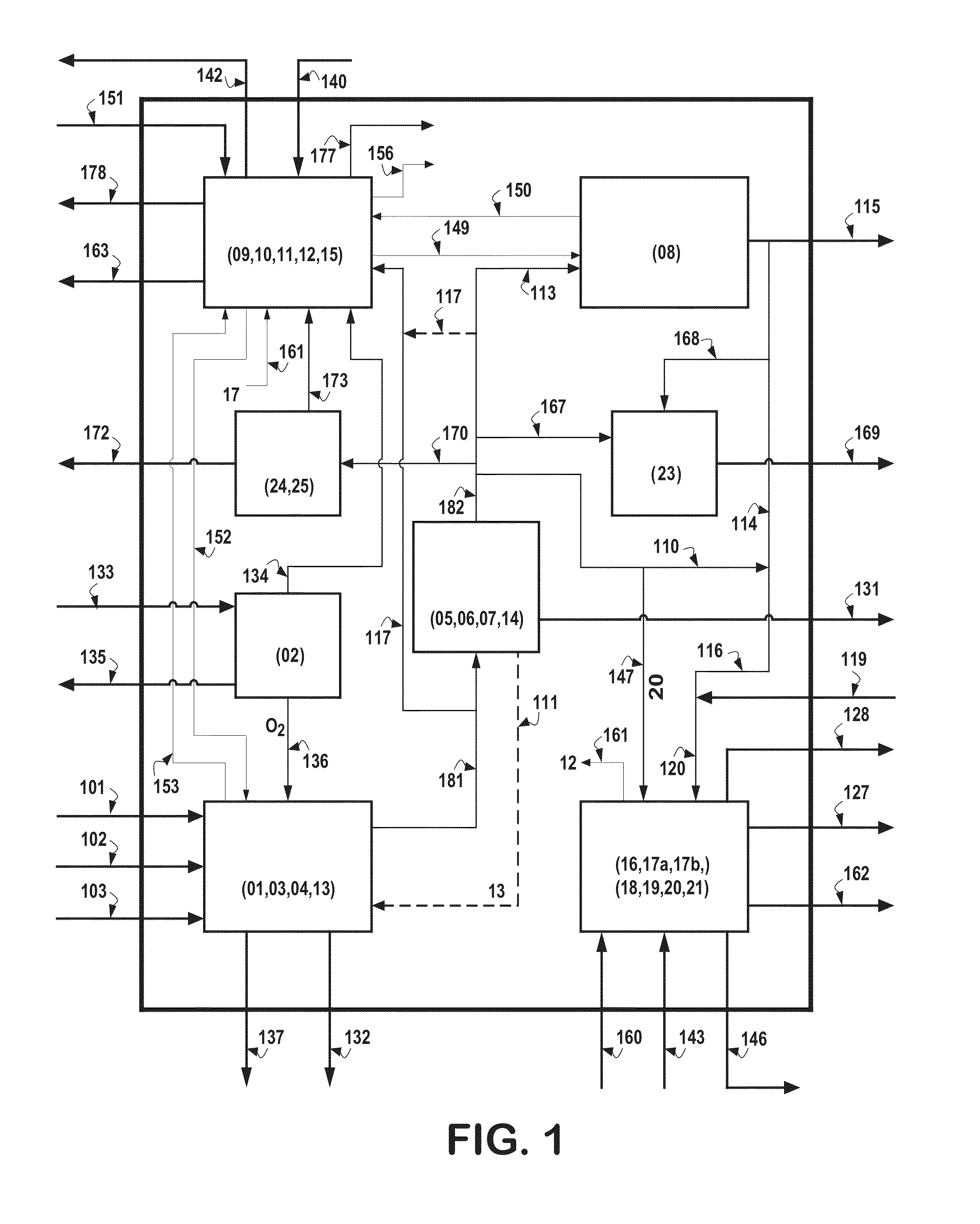

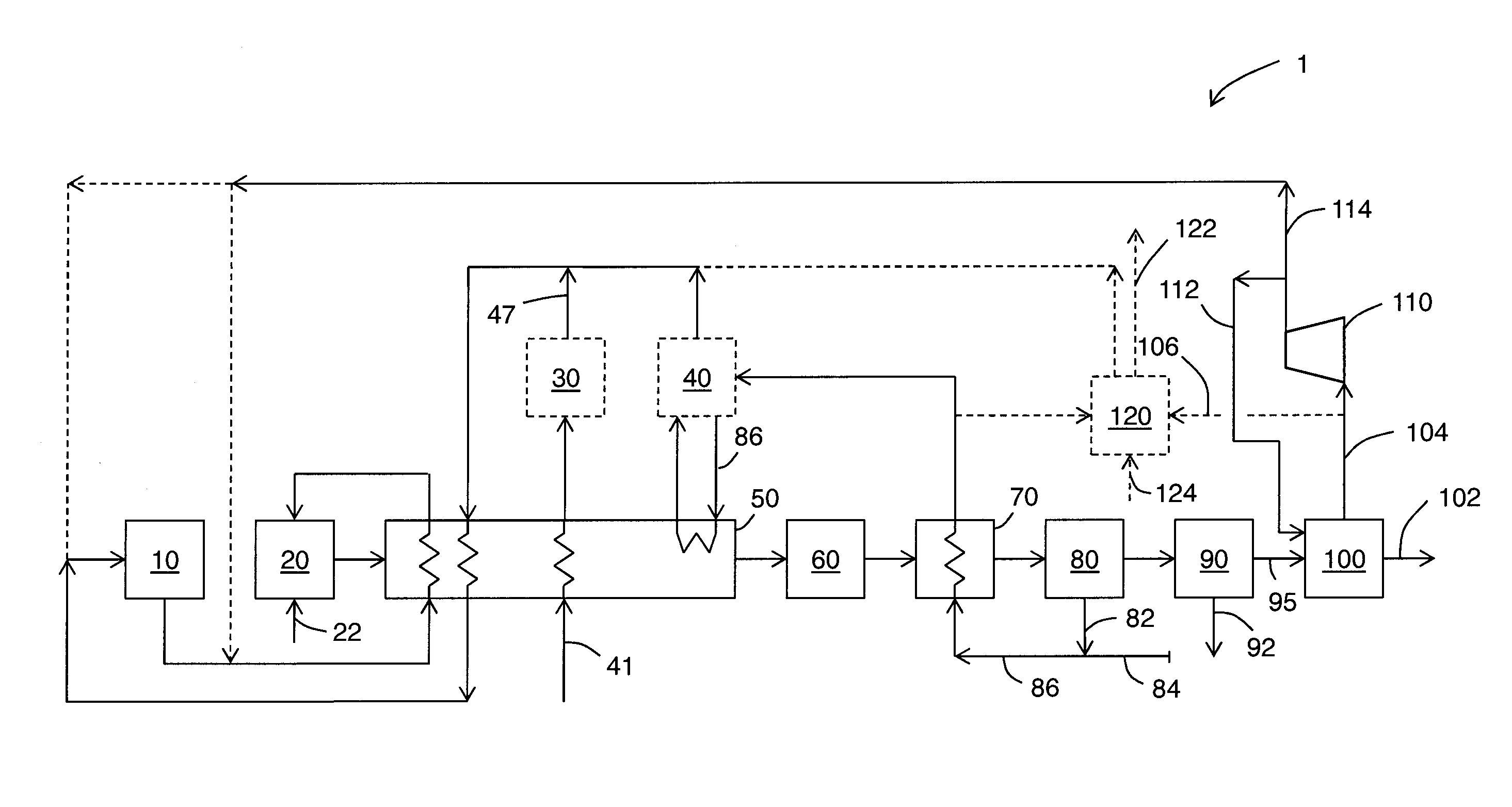

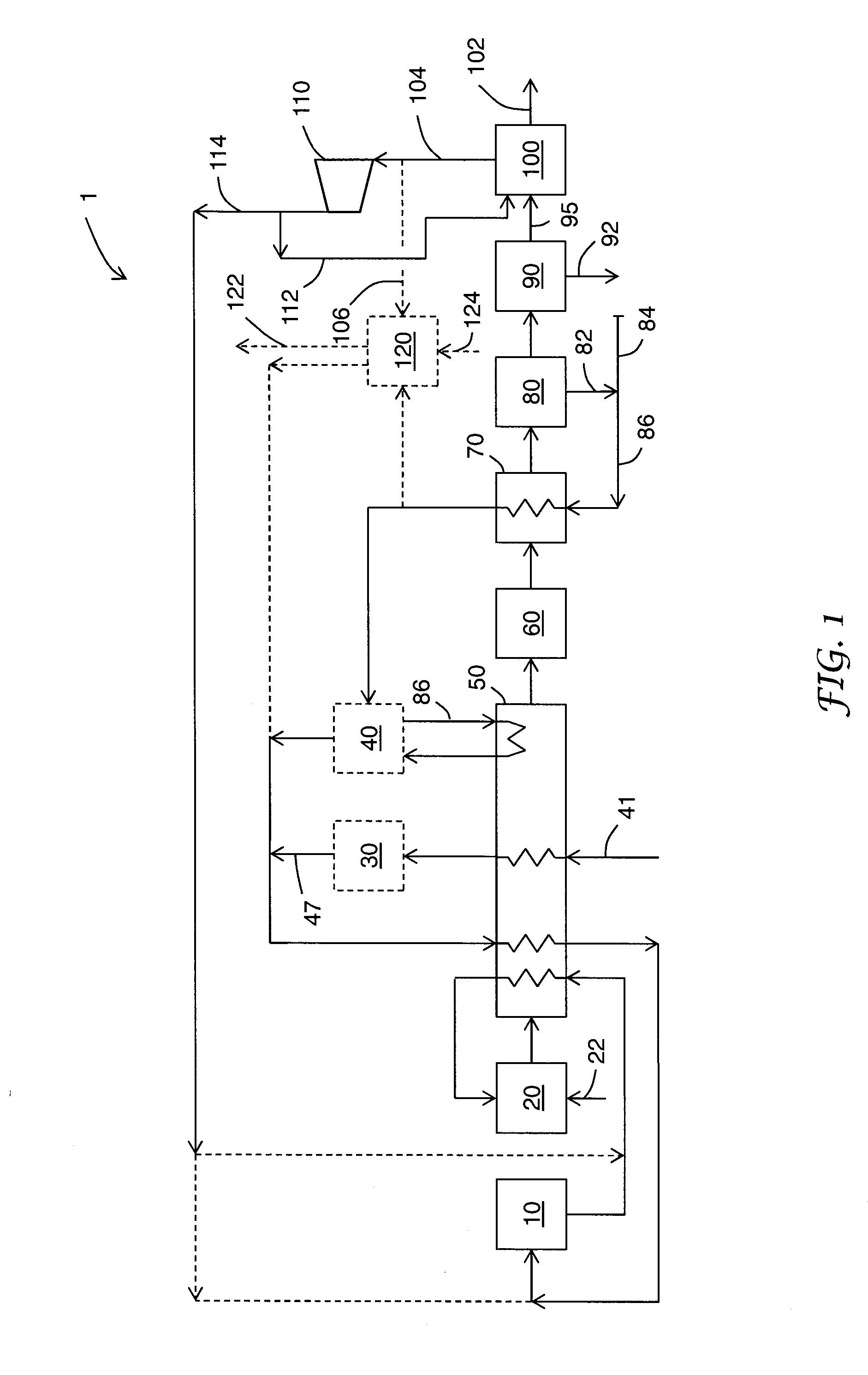

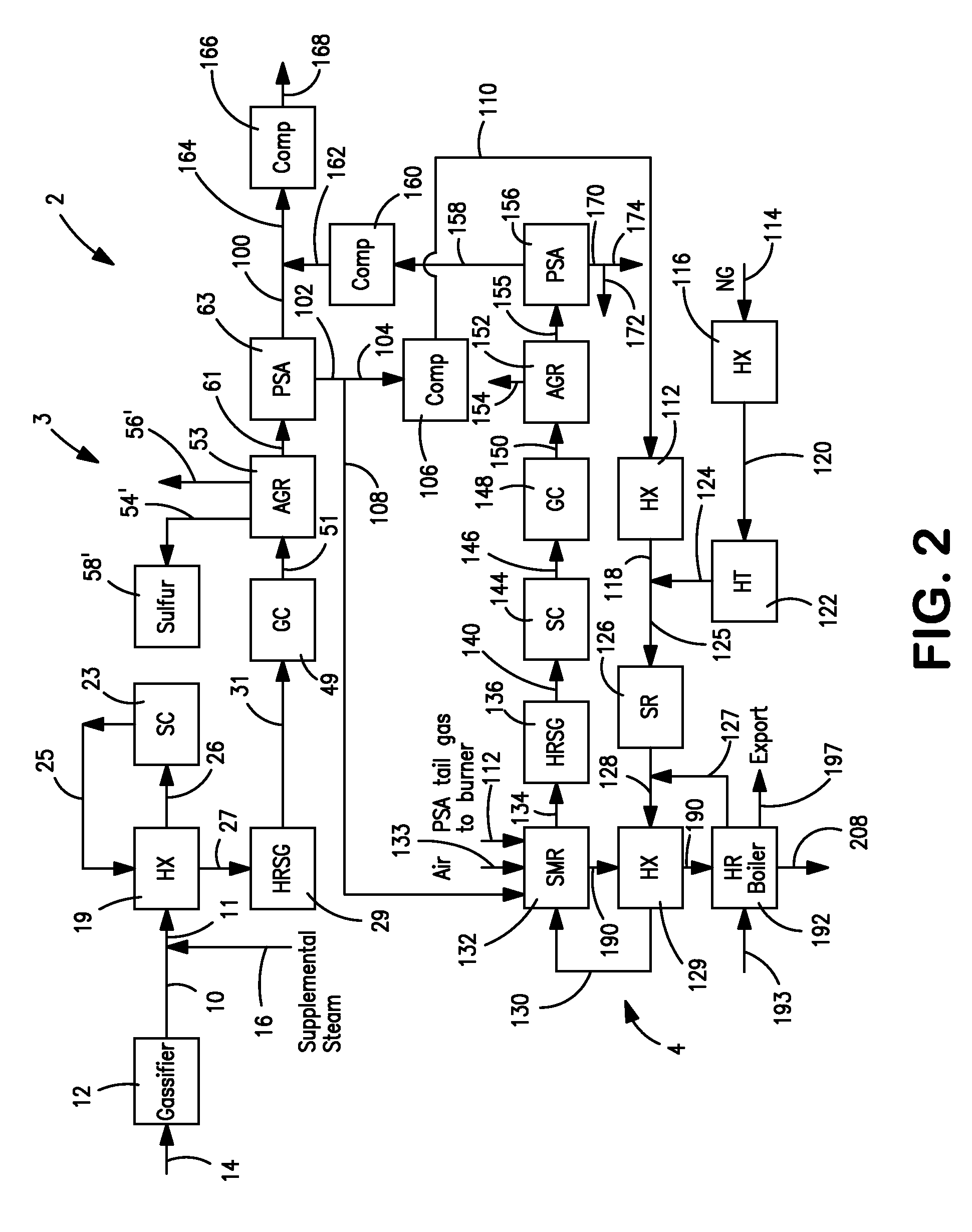

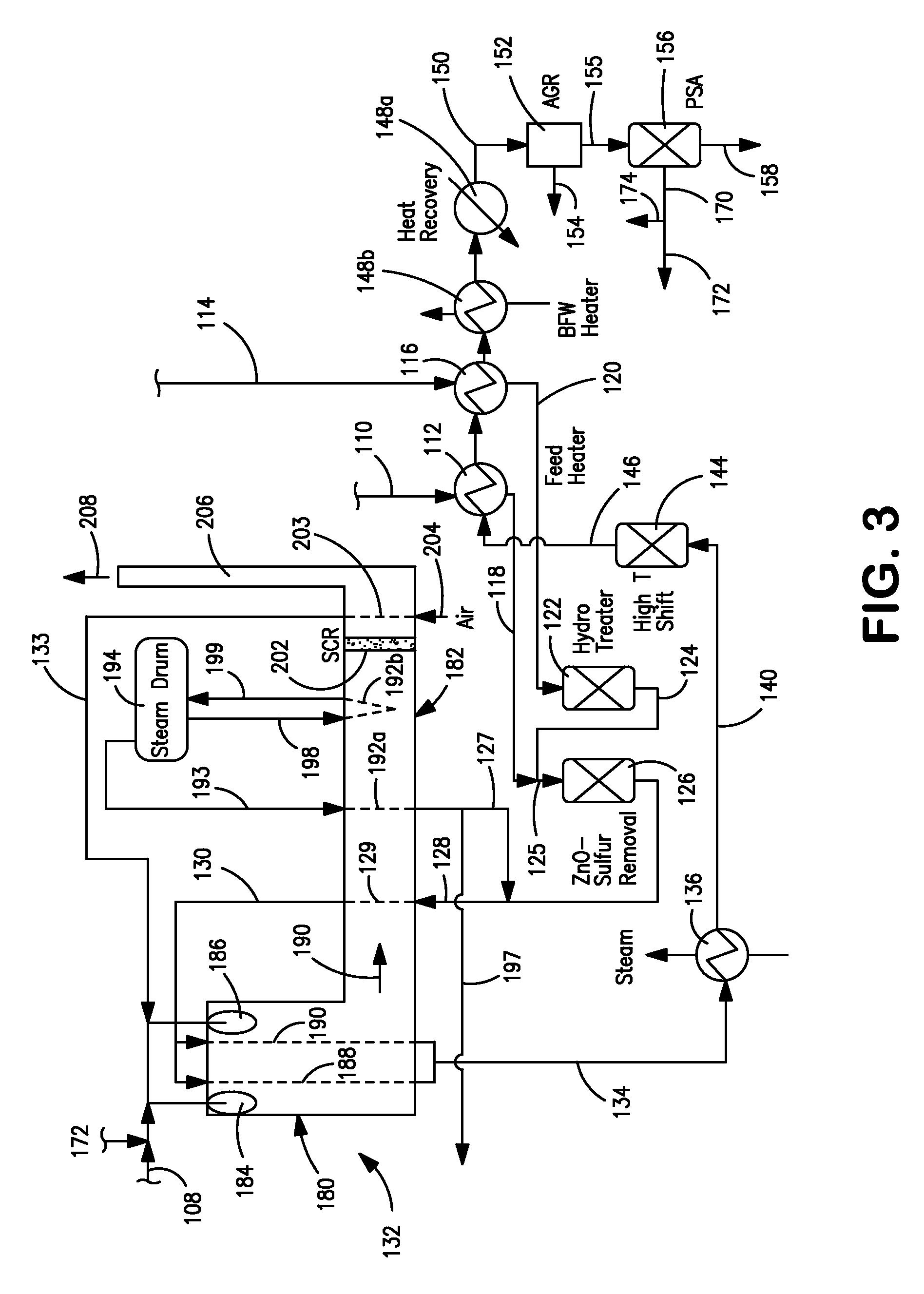

Gasification and steam methane reforming integrated polygeneration method and system

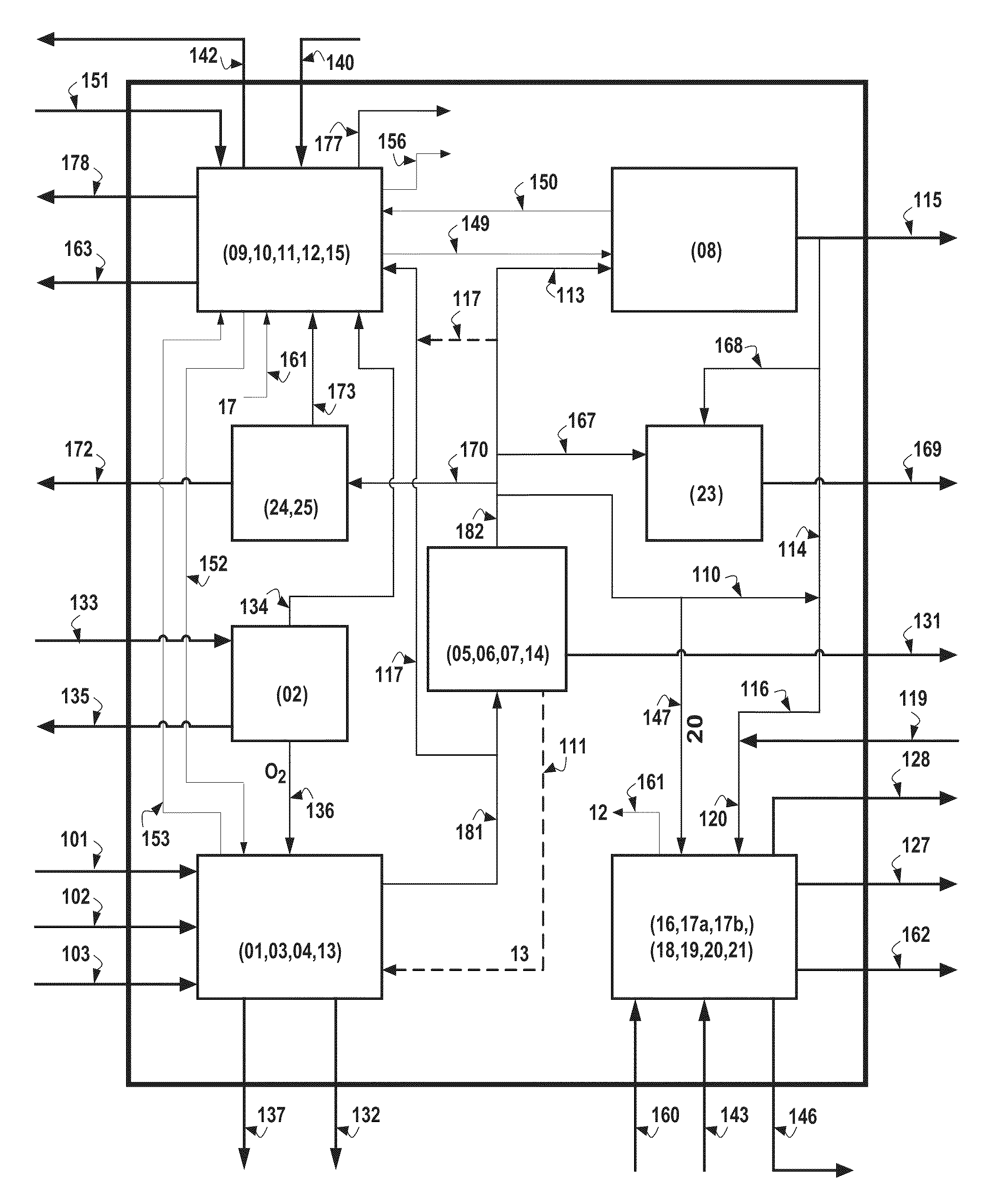

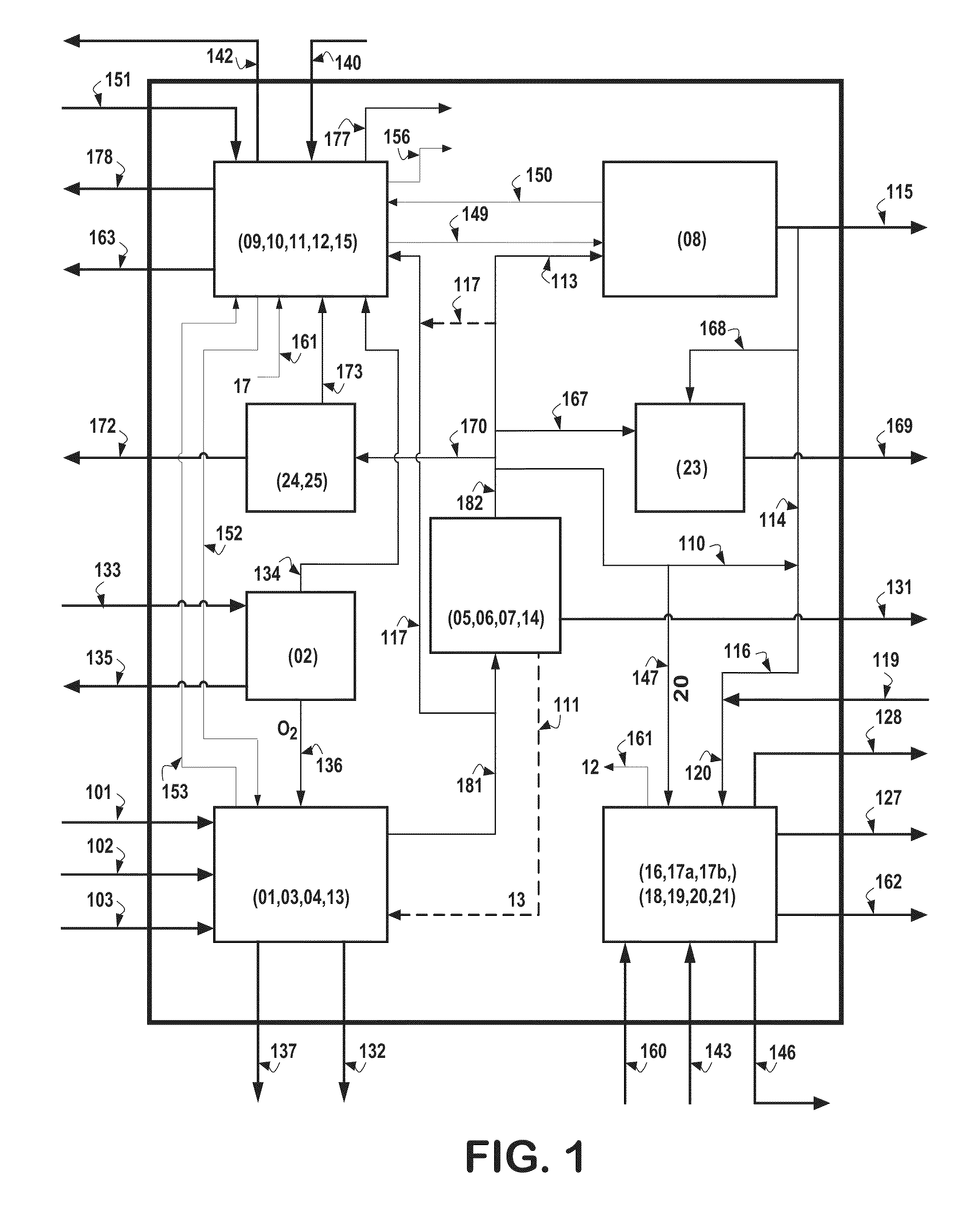

InactiveUS8409307B2Improve reliabilityMaximize reliabilityCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

Method of treating a gaseous mixture comprising hydrogen and carbon dioxide

Hydrogen (H2) gas and crude carbon dioxide (CO2) gas are separated from a gaseous mixture thereof. Combustible gas(es) in the crude CO2 gas are combusted to produce heat, at least a portion of which is recovered by indirect heat exchange with at least a portion of the separated H2 gas or a gas derived therefrom. The invention may be integrated with coal-fired power stations to reduce or eliminate emission of harmful components into the atmosphere.

Owner:AIR PROD & CHEM INC

Method for production and upgrading of oil

An integrated process for production and upgrading of heavy and extra-heavy crude oil, comprising (a) reforming of hydrocarbons such as natural gas to produce hydrogen, CO2 and steam (b) separating the produced hydrogen from the CO2, steam and any other gases to give a hydrogen rich fraction and a CO2 rich fraction and steam, (c) injecting the steam alone or in combination with the CO2 rich fraction into a reservoir containing heavy or extra heavy oil to increase the oil recovery, and (d) upgrading / refining of the heavy or extra heavy oil to finished products by extensive hydroprocessing, comprising several steps of hydrocracking and hydrotreating (sulfur, nitrogen and metals removal as well as hydrogenation of olefins and aromatics), using the hydrogen rich fraction.

Owner:STATOIL ASA PETRO SA (NO)

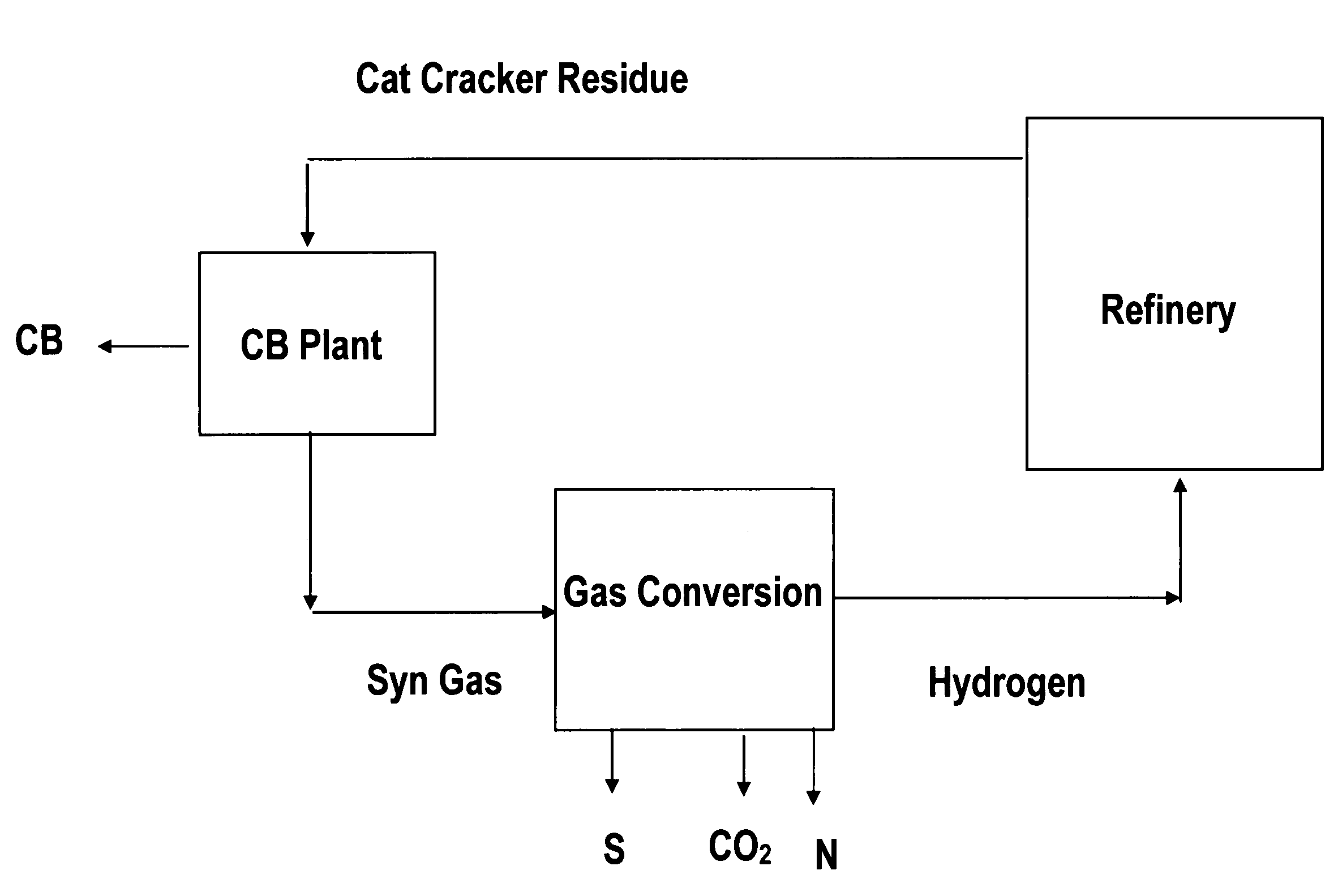

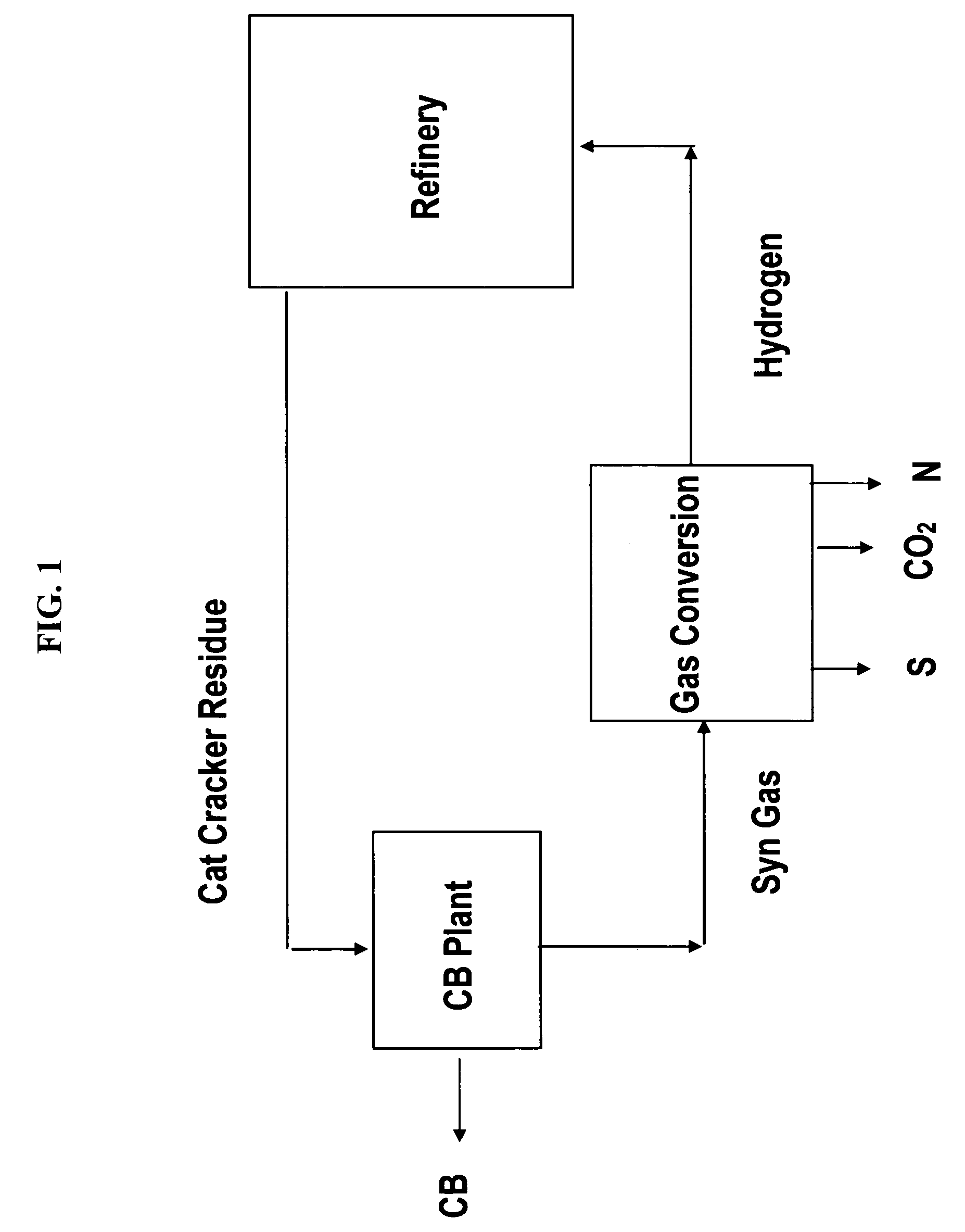

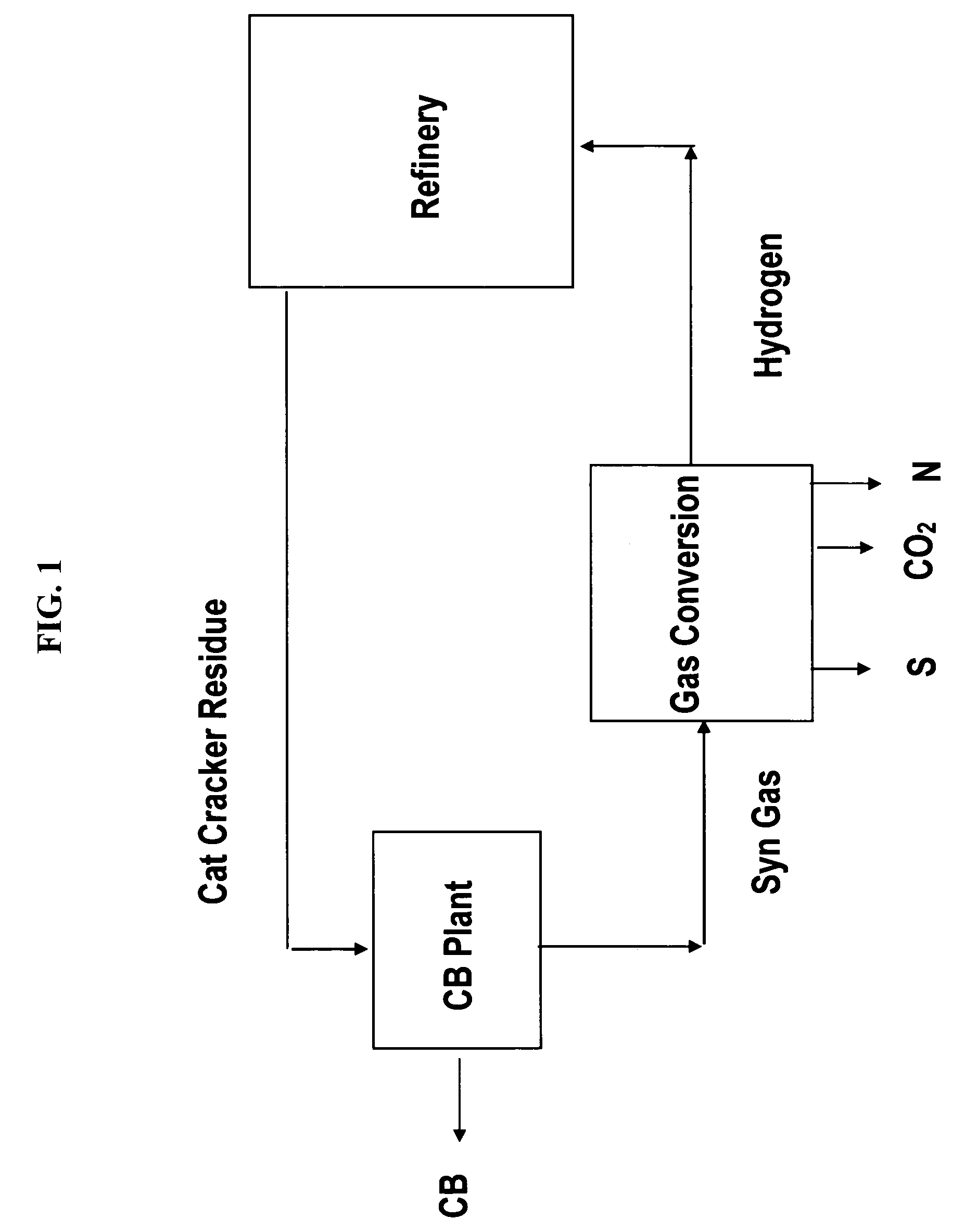

Method to produce hydrogen or synthesis gas and carbon black

InactiveUS7666383B2Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenOil refinery

Owner:CABOT CORP

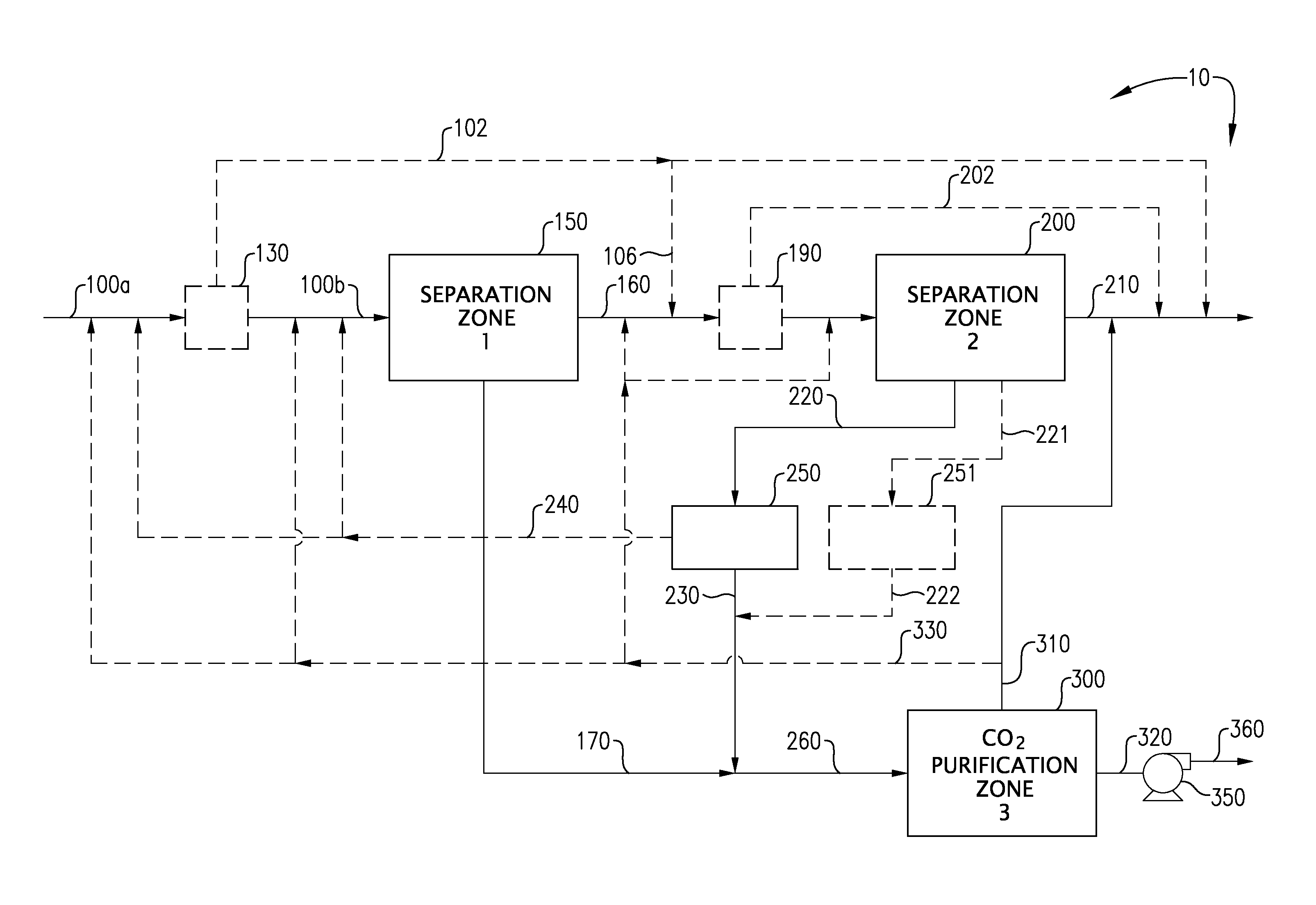

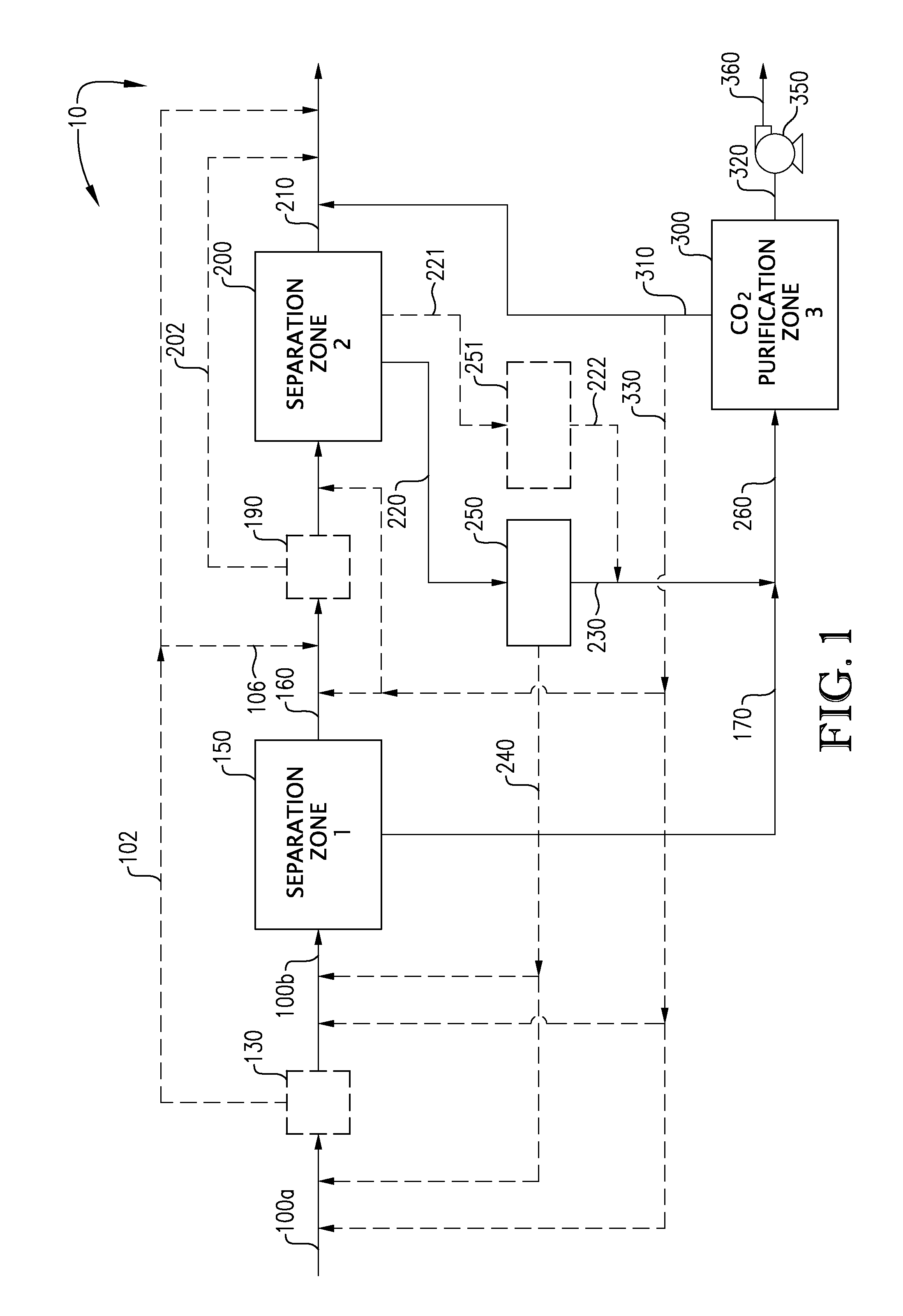

Carbon dioxide capture and liquefaction

ActiveUS20120006054A1Big advantageMinimize energy consumptionSolidificationLiquefactionLiquid stateHigh pressure

An energy-efficient method of recovering carbon dioxide (CO2) in a high-pressure liquid state from a high-pressure gas stream. The method includes cooling, condensing, and / or separating CO2 from a high-pressure gas stream in two or more separation zones and further purifying the resulting sub-critical pressure liquid CO2 streams in a third purification zone to thereby provide purified CO2. The purified liquid CO2 may be pumped to above the critical pressure for further utilization and / or sequestration for industrial or environmental purposes.

Owner:KELLER ARNOLD

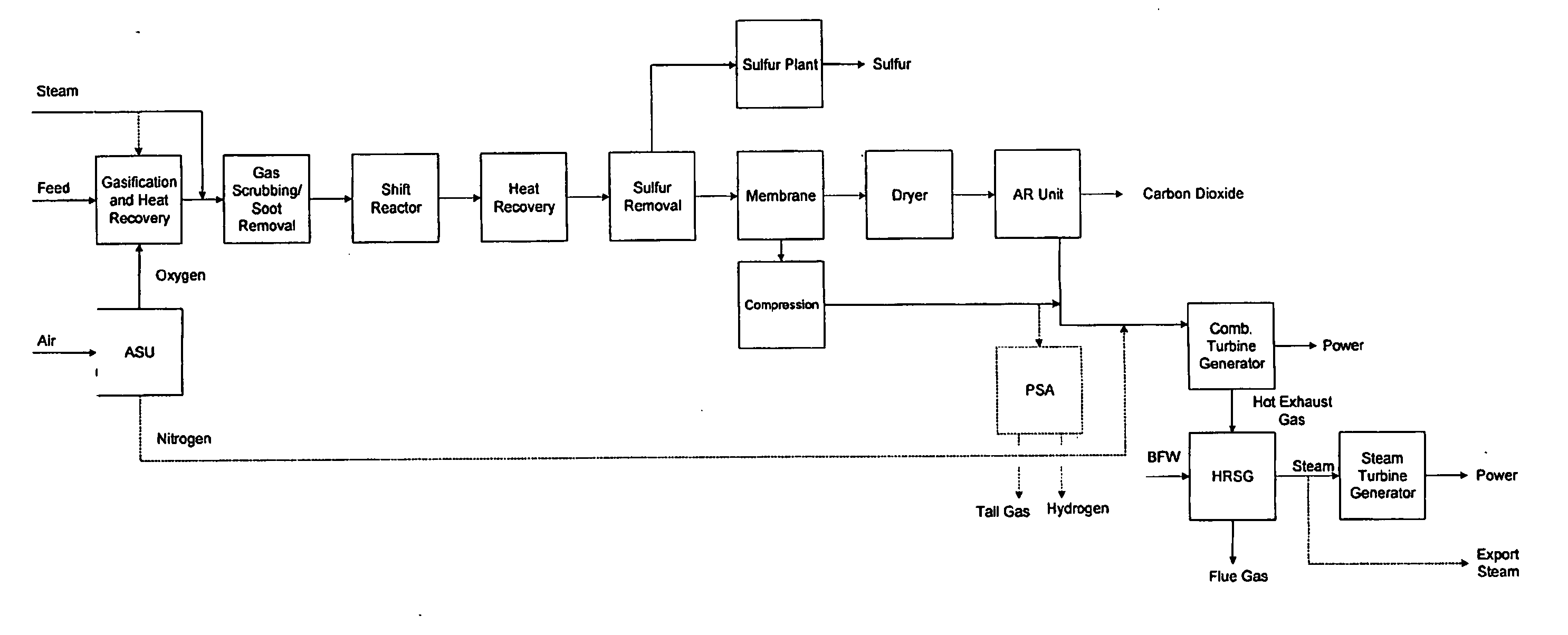

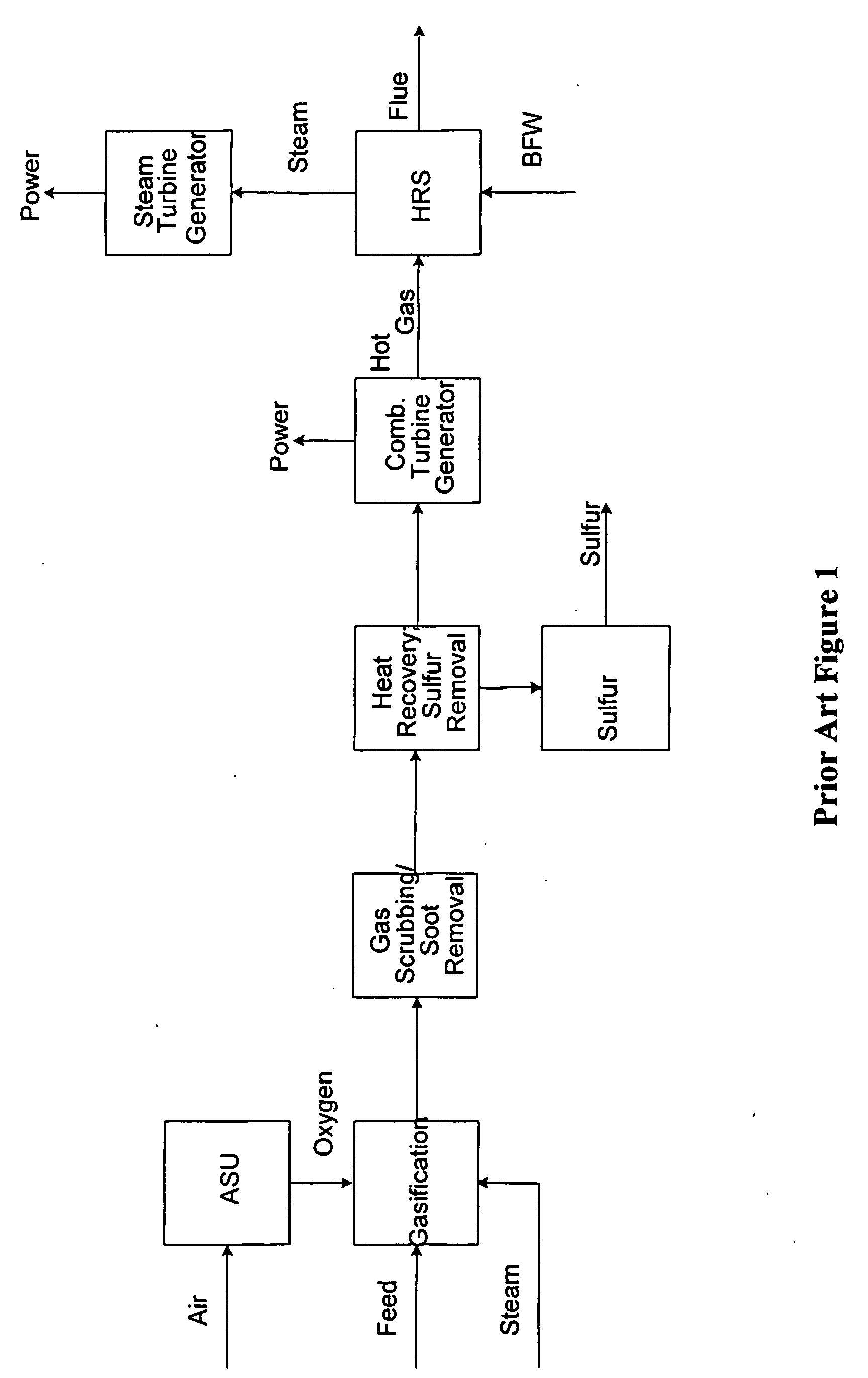

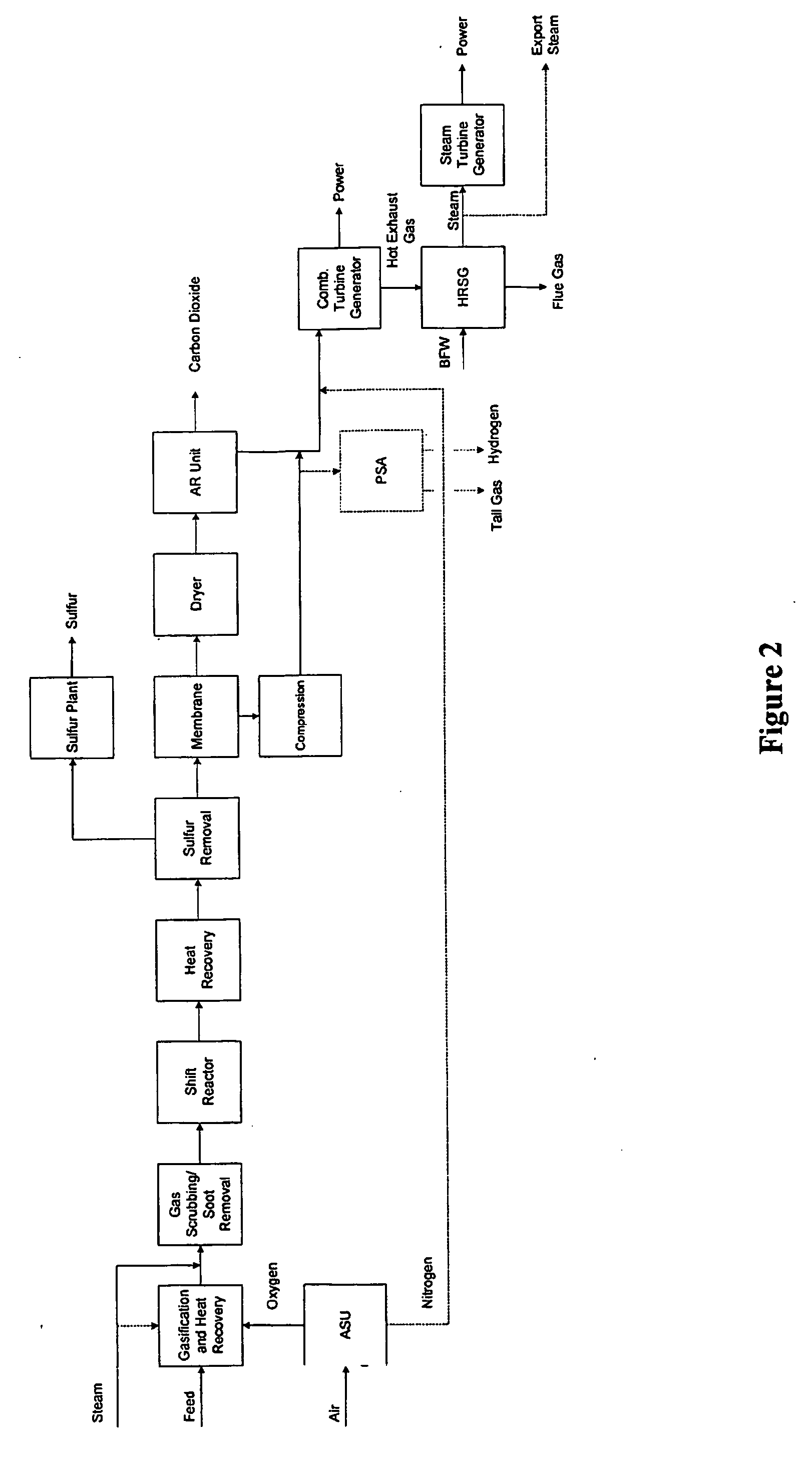

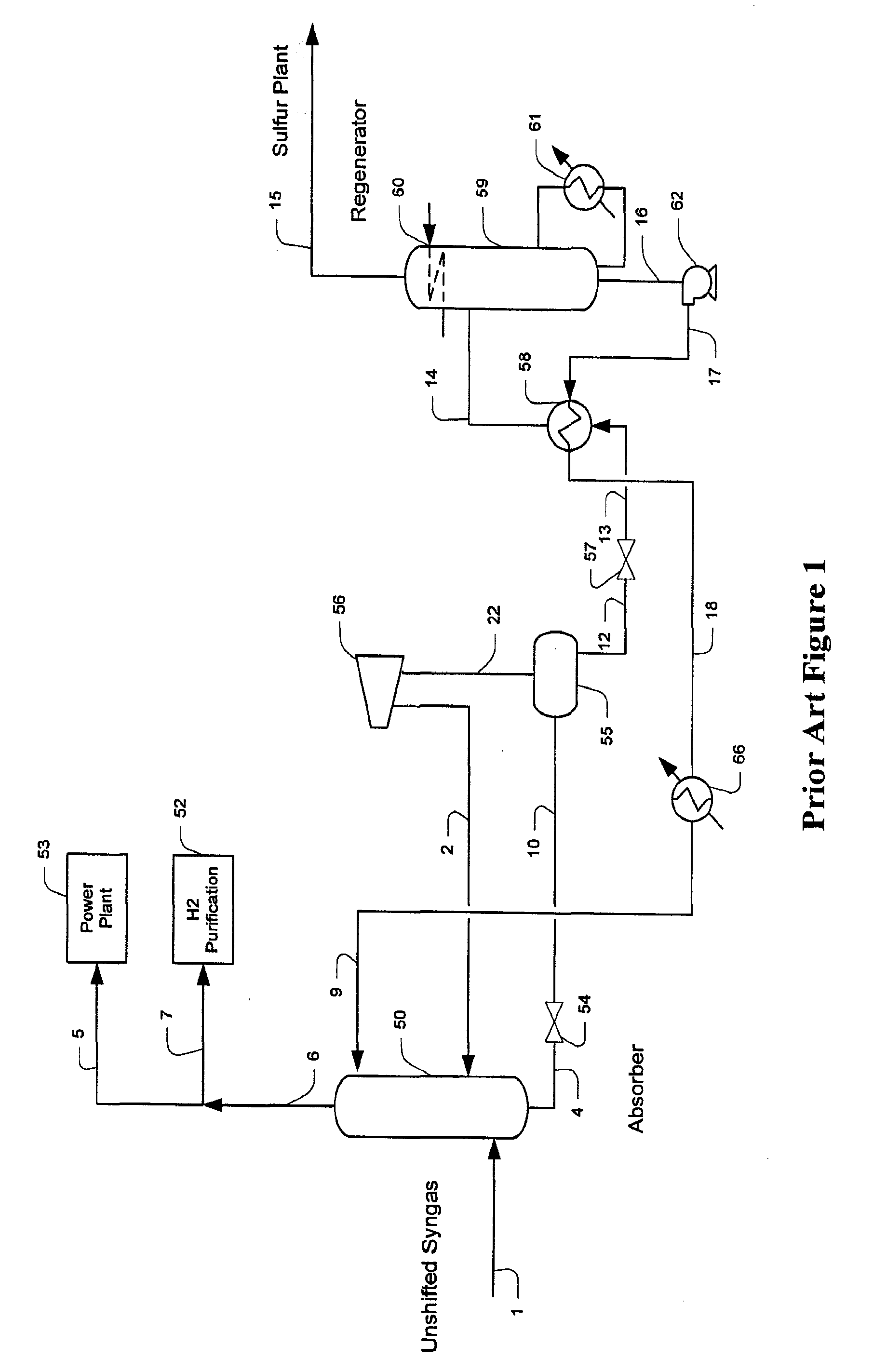

Configurations and methods of carbon capture

An IGCC plant has a precombustion decarbonization unit in which acid gas is removed from a combustion gas before the combustion gas enters a combustion turbine. In one preferred configuration, a sulfur removal unit removes hydrogen sulfide from a feed gas before the desulfurized feed gas enters an autorefrigeration unit in which carbon dioxide is removed. In another preferred configuration, hydrogen sulfide is converted to carbonyl sulfide in a dryer, and the carbonyl sulfide is absorbed in the liquid carbon dioxide that is prepared from the feed gas using autorefrigeration.

Owner:FLUOR TECHSE CORP

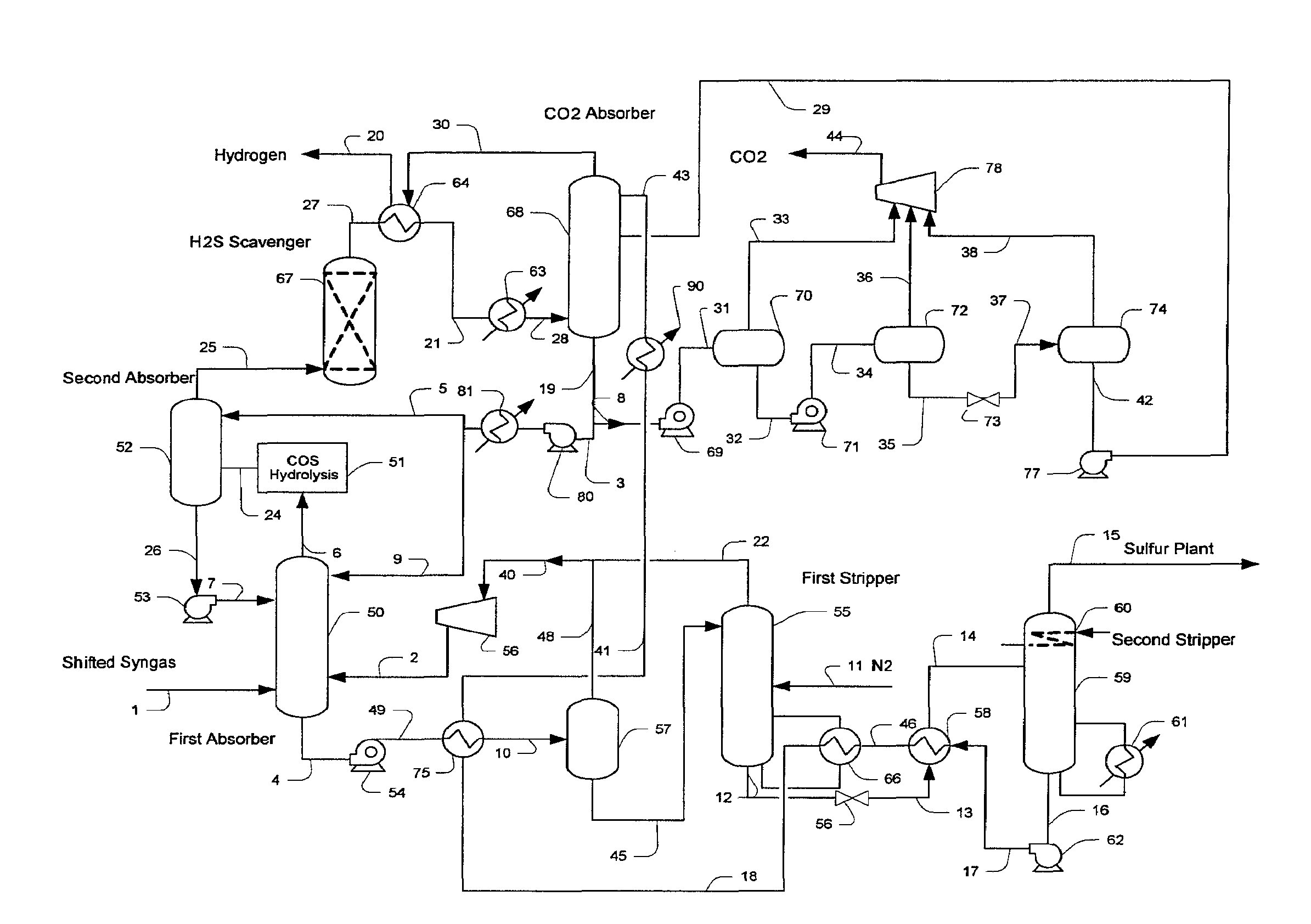

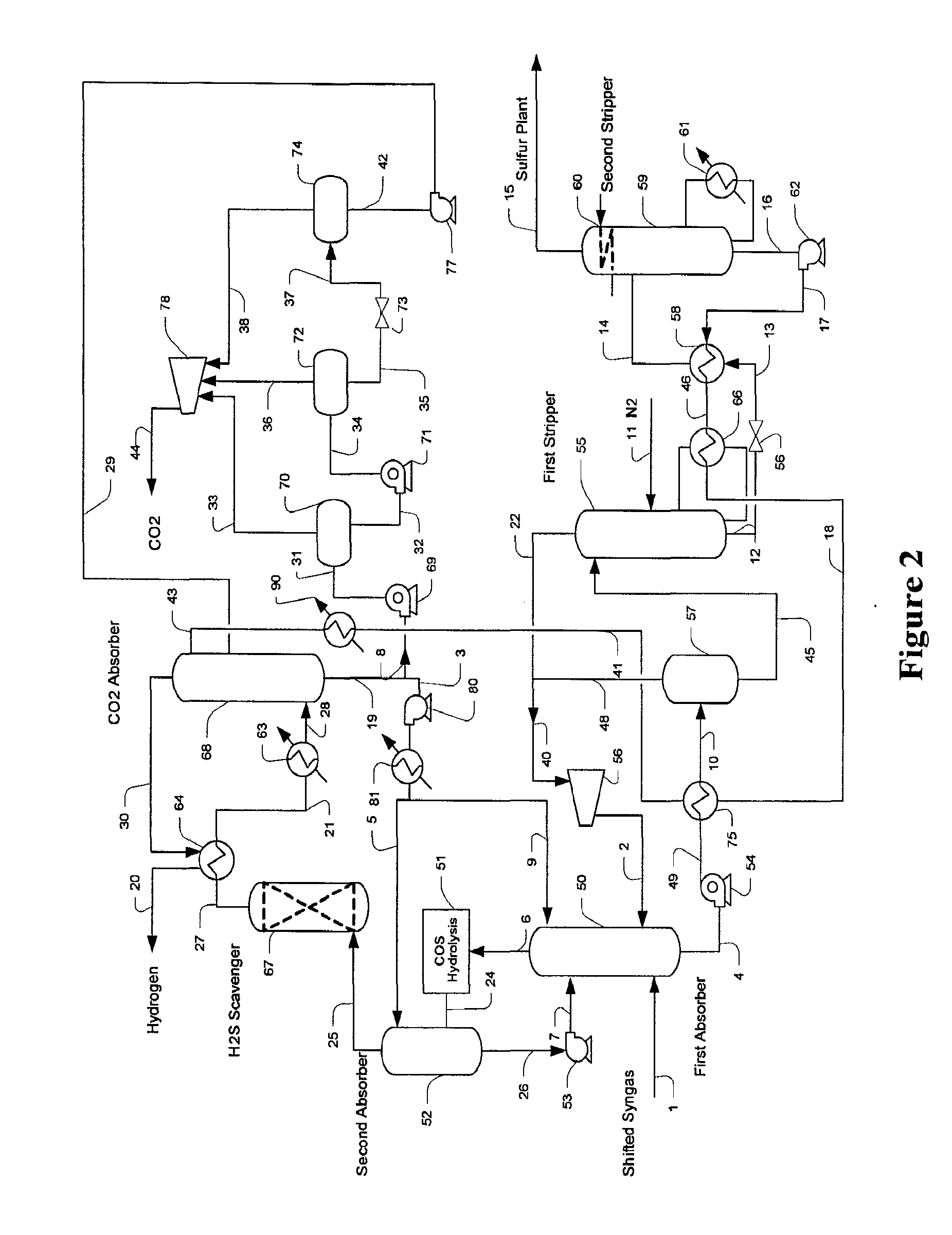

Configurations And Methods For Carbon Dioxide And Hydrogen Production From Gasification Streams

InactiveUS20100111784A1Significant energy savingSave energyCarbon compoundsHydrogen production carbon captureSyngasSolvent

A syngas treatment plant is configured to remove sulfurous compounds and carbon dioxide from shifted or un-shifted syngas in a configuration having a decarbonization section and a desulfurization section. Most preferably, the solvent in the decarbonization section is regenerated and cooled by flashing, while the solvent is regenerated in the desulfurization section via stripping using external heat, and it is still further preferred that carbonylsulfide is removed in the desulfurization section via hydrolysis, and that the so produced hydrogen sulfide is removed in a downstream absorber.

Owner:FLUOR TECH CORP

Hydrogen production process with low CO2 emissions

A hydrogen production process wherein steam and a hydrocarbon feed is reacted in a prereformer, the prereformed intermediate is further reacted in an oxygen-based reformer, the reformate is shifted and then separated by a pressure swing adsorber to form a H2 product stream and a tail gas, a first portion of the tail gas is recycled to the prereformer and / or the oxygen-based reformer, and a second portion of the tail gas is recycled to the pressure swing adsorber.

Owner:AIR PROD & CHEM INC

Gasification and steam methane reforming integrated polygeneration method and system

InactiveUS20100158792A1Improve reliabilityMaximizes reliability of productionCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum coke

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

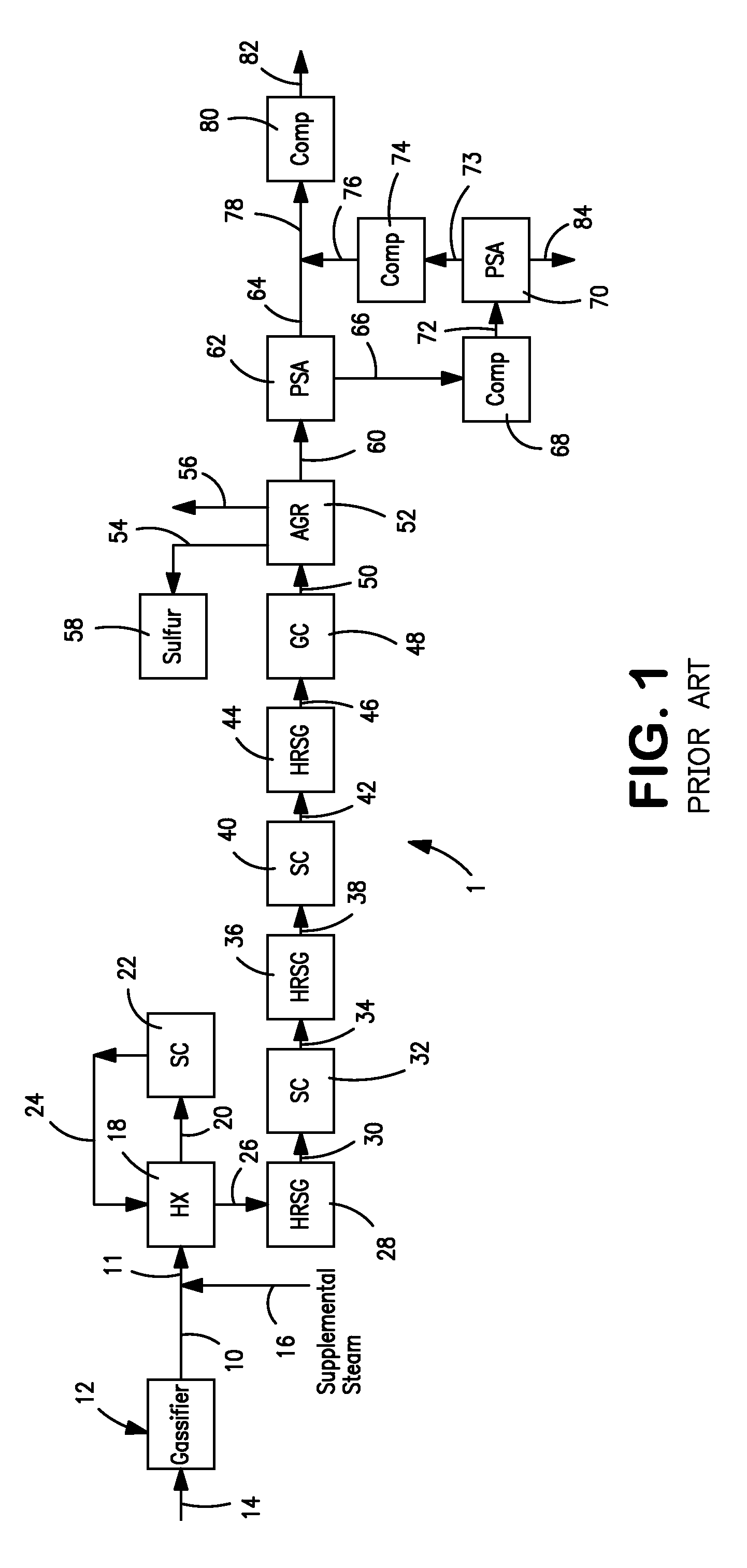

Hydrogen production method and facility

ActiveUS20090246118A1Produce hydrogenHigh trafficHydrogen separation using solid contactHydrogen separation using liquid contactSyngasHydrocarbon

A hydrogen production method and facility in which a synthesis gas stream produced by the gasification of a carbonaceous substance is processed within a synthesis gas processing unit in which the carbon monoxide content is reacted with steam to produce additional hydrogen that is removed by a pressure swing adsorption unit. The tail gas from the pressure swing adsorption unit is further reformed with the addition of a hydrocarbon containing stream in a steam methane reforming system, further shifted to produce further additional hydrogen. The further hydrogen is then separated in another pressure swing adsorption unit.

Owner:PRAXAIR TECH INC

Process for the production of hydrogen with very high purity from alcohols that comprise at least two carbon atoms

InactiveUS20050244329A1High purityLow calorific valueHydrogen separation using liquid contactEnergy inputSteam reformingHydrogen

Process for the production of high-purity hydrogen from an ethanol or higher-alcohol feedstock, employing a vapor reforming unit, a carbon monoxide conversion unit and a membrane separation unit and comprising intense thermal integration that is obtained by combustion under the control of an effluent of the process so as to provide the calories that are necessary to the vapor reforming reaction.

Owner:INST FR DU PETROLE

Method to produce hydrogen or synthesis gas

InactiveUS20060228290A1Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenChemistry

A method to produce hydrogen gas or synthesis gas is described and involves the use of a staged reactor. The present invention further relates to effectively running a process such that efficient quantities of hydrogen gas are produced, along with economically useful amounts of carbon black. A combined facility utilizing a carbon black manufacturing plant and a refinery plant are further described, as well as products made by the various methods of the present invention.

Owner:CABOT CORP

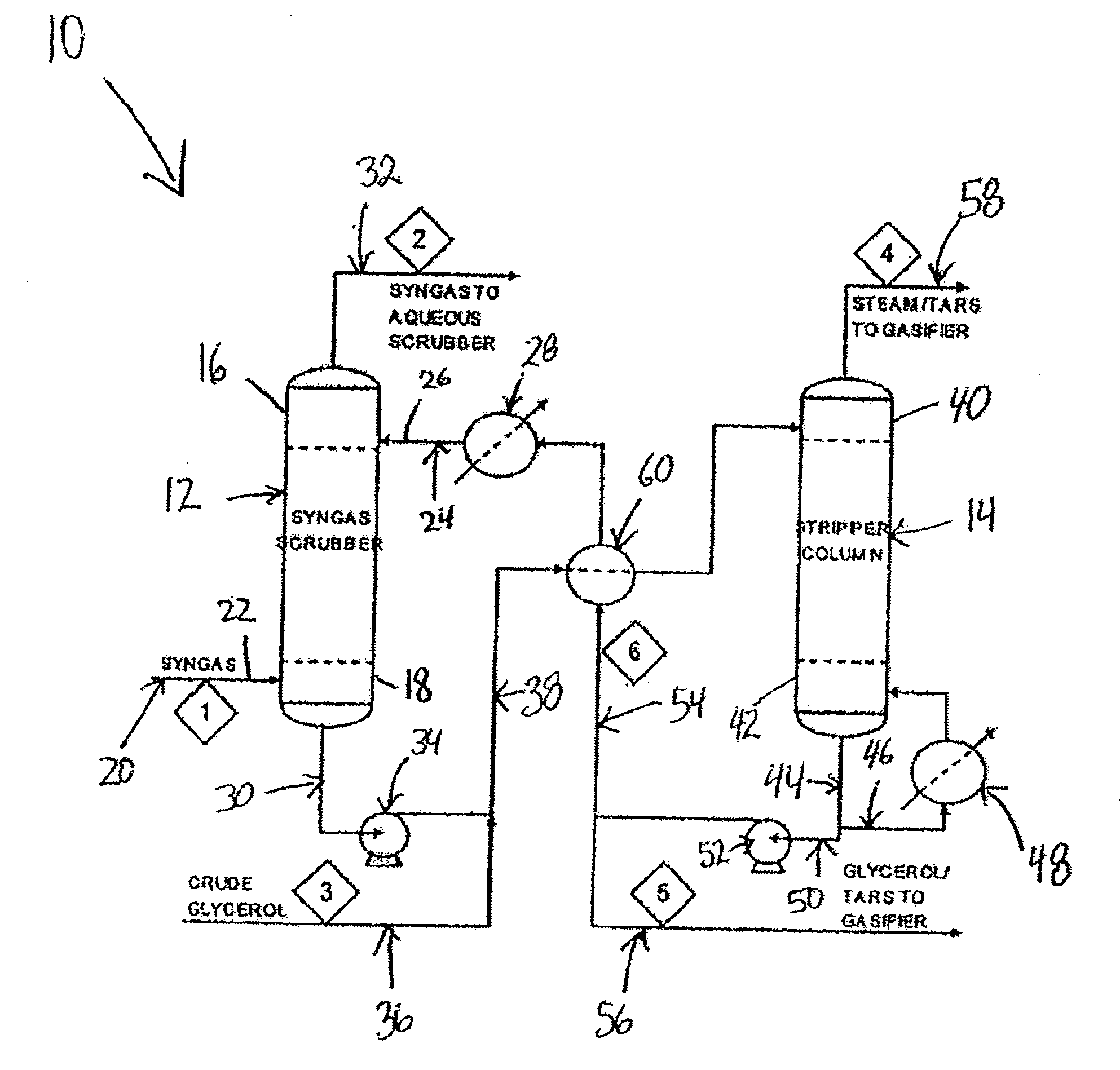

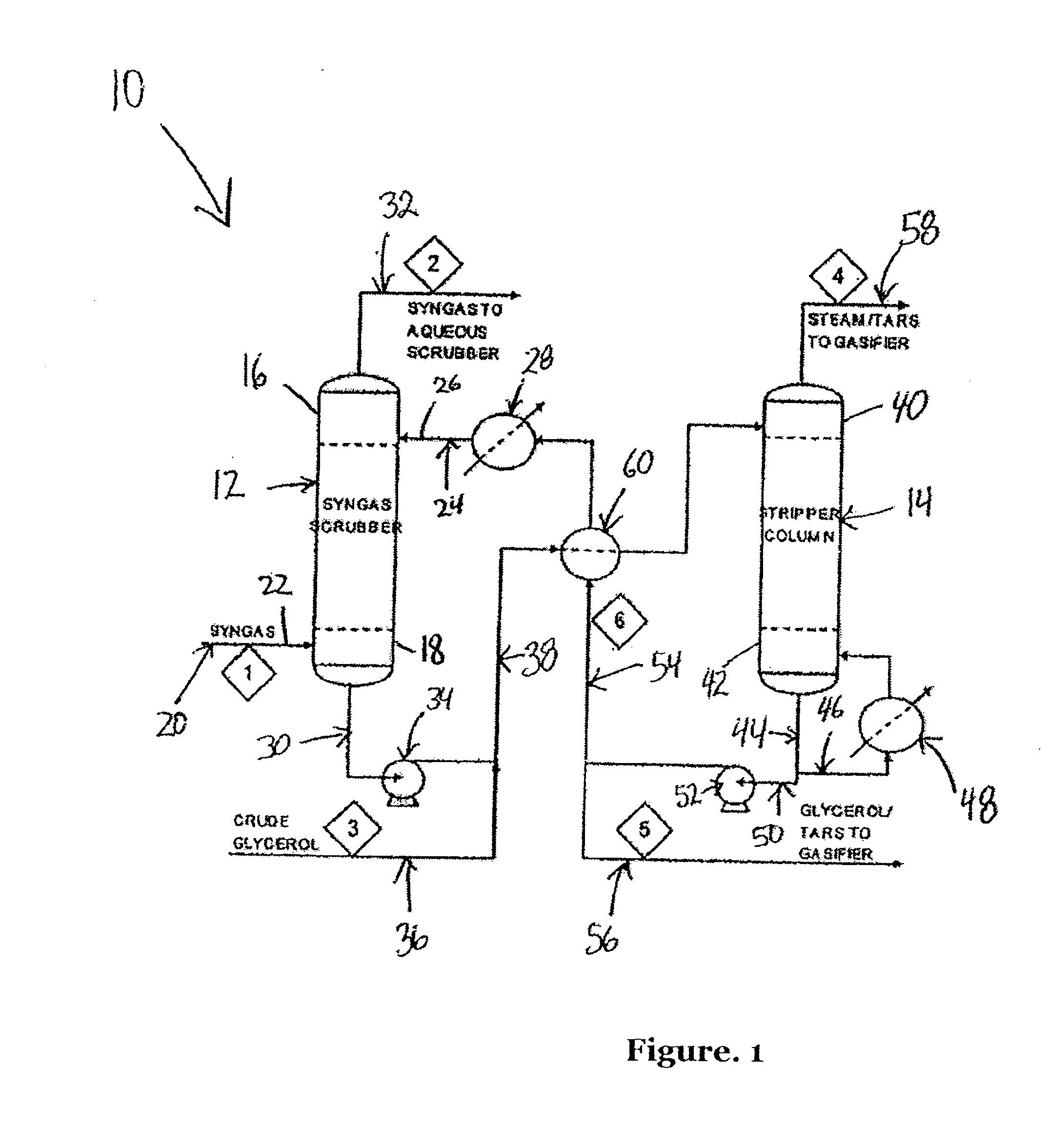

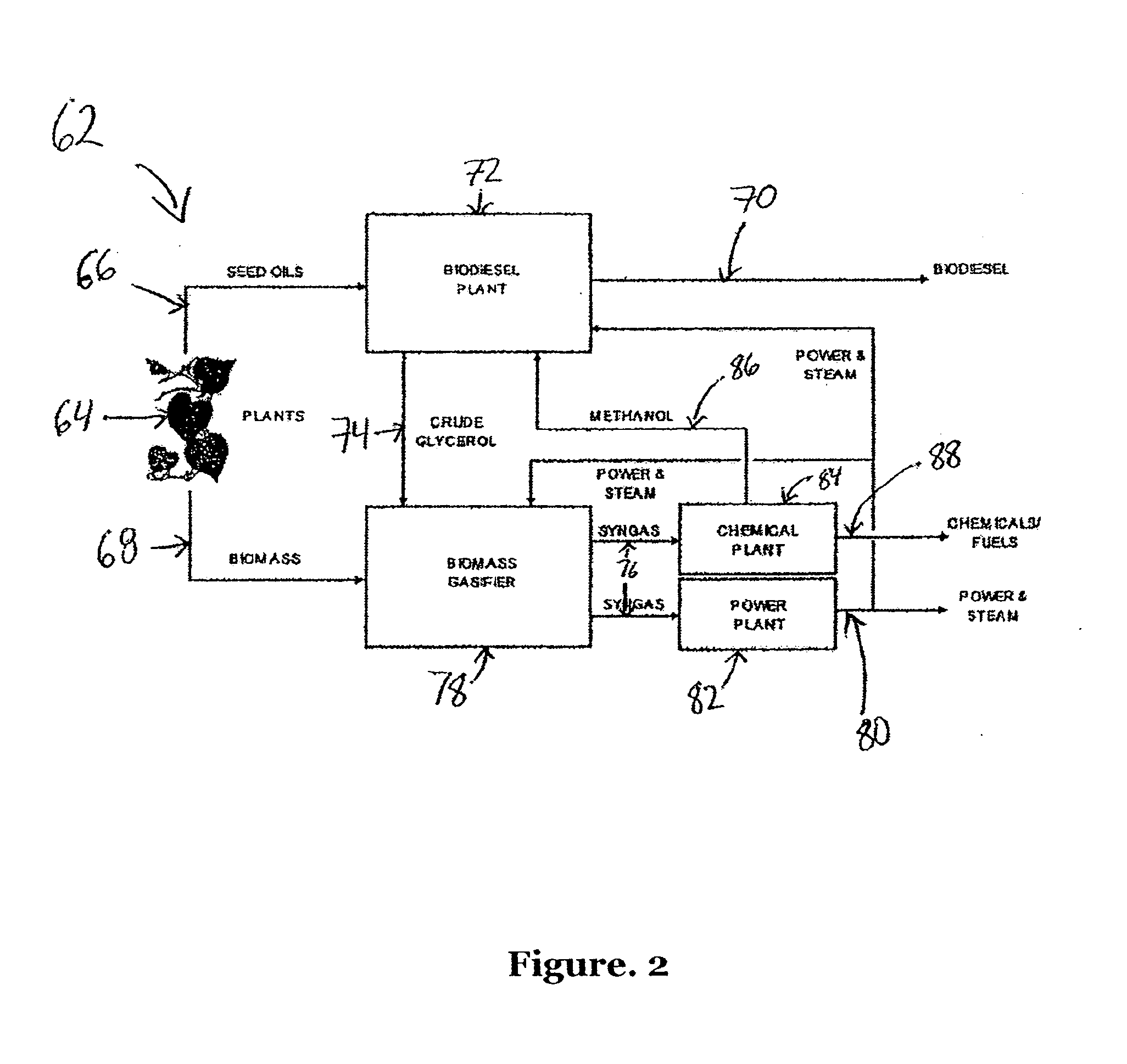

Process for removing tar from synthesis gas

A process and system for removing tars from synthesis gas uses glycerol produced as a byproduct of biodiesel manufacture. The biodiesel may be made from various oil feedstocks such as canola, rapeseed, or soybean oils. Associated with the harvesting of these crops may be the ready availability of byproduct biomass useful as feedstock for gasification. In addition, methanol may be sourced from the gasification of biomass to exploit a potential synergy between biodiesel manufacture and biomass gasification. The present invention develops those synergies further by making use of a byproduct stream from the manufacture of biodiesel to remove tars from the gasifier synthesis gas and to provide a useful end use for the byproduct.

Owner:IHI E&C INT

Method for low-severity gasification of heavy petroleum residues

A method for co-producing a sulfur-containing raw synthetic gas and an essentially desulfurized solid residue from a sulfur-containing heavy petroleum residue feedstock, comprising feeding a bubbling fluidized-bed gasification reactor with the feedstock, and converting the feedstock to a raw synthetic gas by a partial oxidation reaction in the presence of water at a temperature at or below about 1000° C. and a pressure at or below about 10 atm, thereby also producing an essentially desulfurized solid residue, while the sulfur components are essentially comprised in the raw synthetic gas; and separately recovering the essentially desulfurized solid residue and the sulfur-containing raw synthetic gas.

Owner:ENERKEM INC

Thermochemical hydrogen produced from a vanadium decomposition cycle

InactiveUS20050013771A1Improve reliabilityHydrogen separation using liquid contactEnergy inputHydrogenDecomposition

A thermochemical water-splitting process all reactions of which operate at relatively low temperatures and high efficiencies, and in which relatively inexpensive materials and processing methods are made possible. This invention involves the decomposition of a metal halide compound, i.e., one which is capable of being reduced from a higher oxidation state to lower oxidation state, e.g. vanadium chloride III→vanadium dichloride. The process is cyclic and regenerative, and the only net inputs are water and heat; and the only net outputs are hydrogen and oxygen. The process makes it possible to utilize a wide variety of available heat, including solar, sources for the energy input.

Owner:AMENDOLA STEVEN

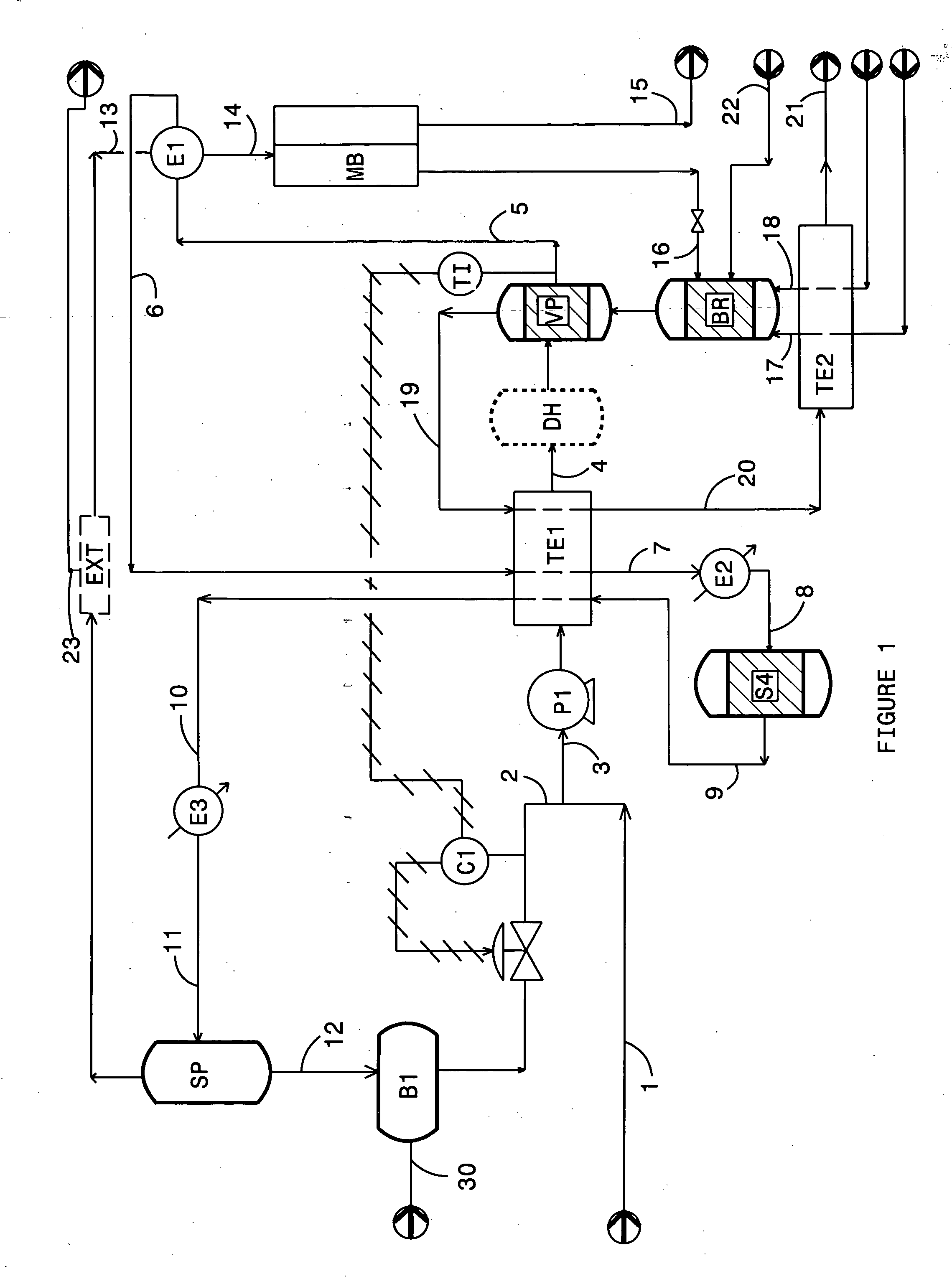

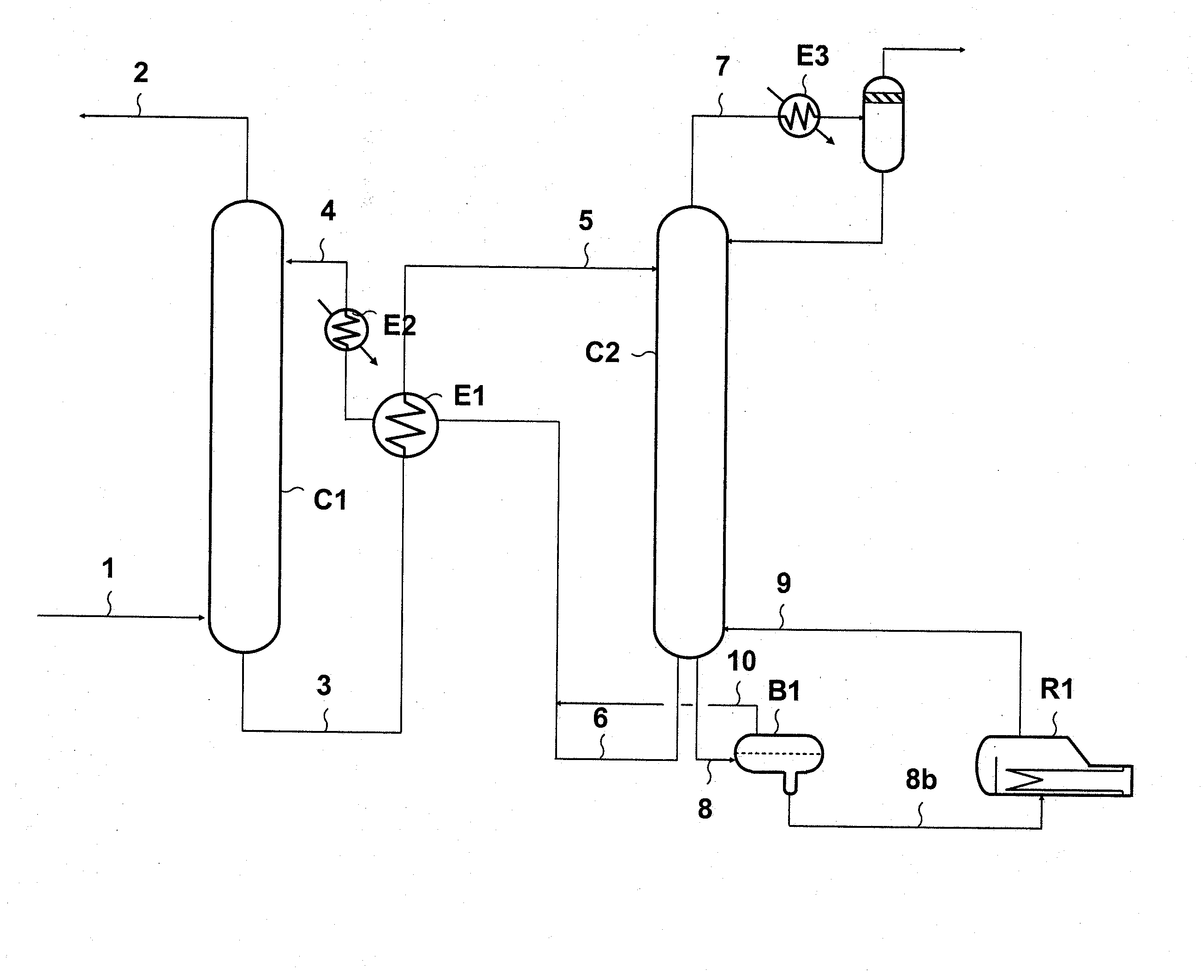

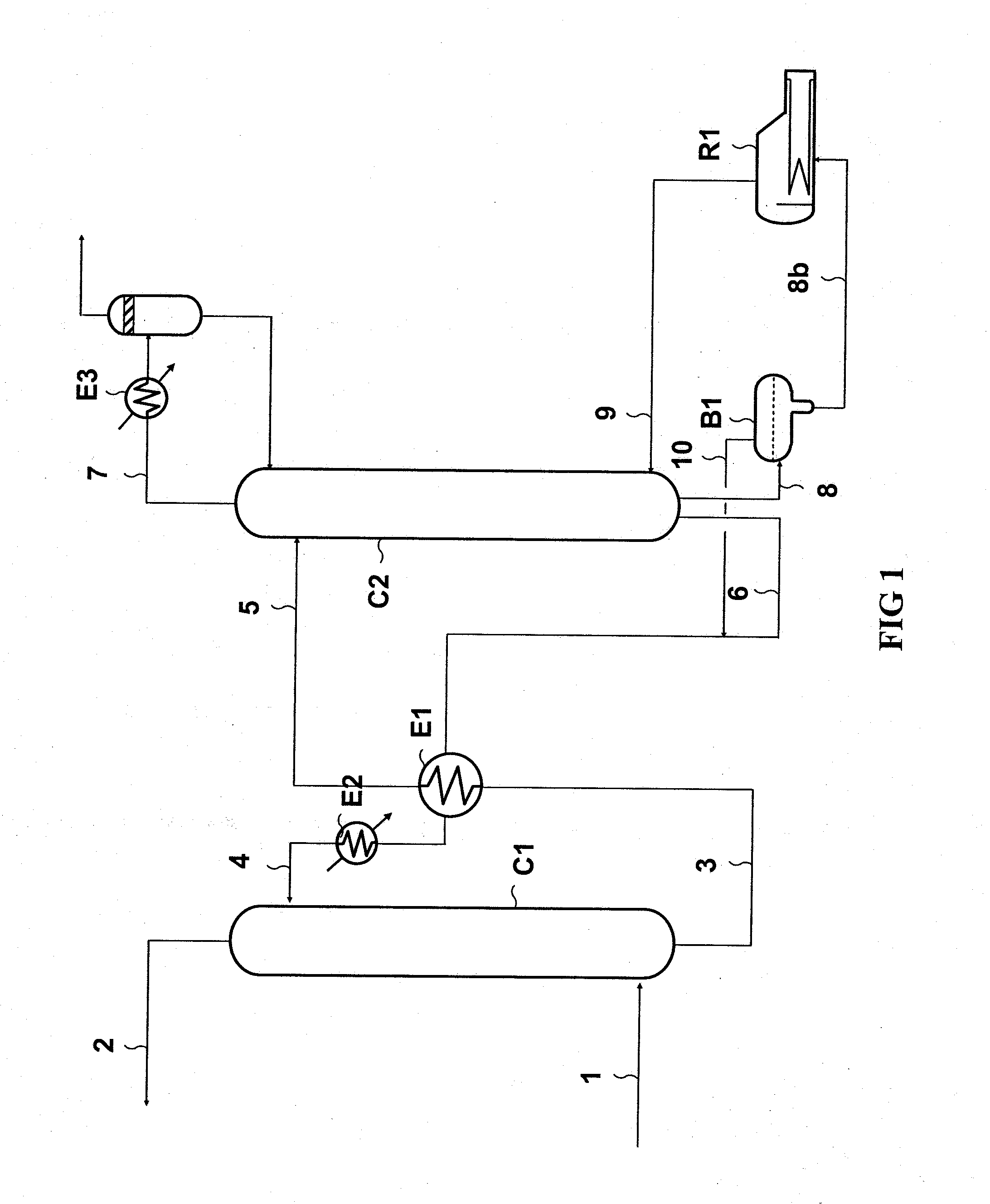

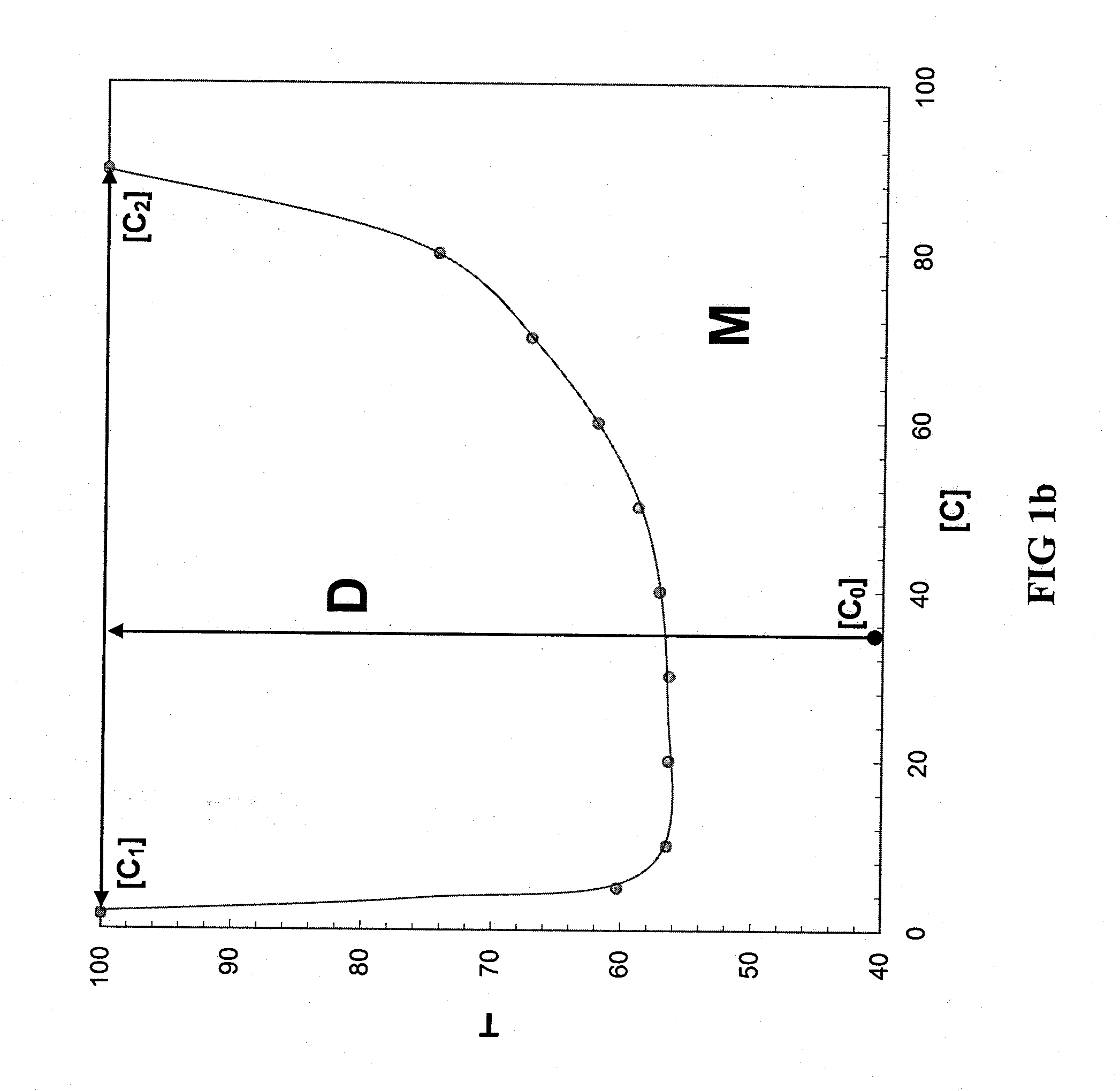

Gas deacidizing method using an absorbent solution with vaporization and/or purification of a fraction of the regenerated absorbent solution

ActiveUS20110081287A1Prevent degradationReduce the amount of solutionUrea derivatives preparationPhosphatesChemical compoundPhysical chemistry

The gaseous effluent to be treated is contacted in column C1 with an absorbent solution selected for its property of forming two separable phases when it is heated. The regenerated absorbent solution is separated into two phases in drum B1; a fraction rich in water and a fraction rich in reactive compounds.Separation allows to optimize the operations performed on the regenerated absorbent solution. On the one hand, separation allows to carry out vaporization, through reboiler R1, of a fraction of the absorbent solution, preferably containing a limited reactive compound concentration in relation to the absorbent solution, thus limiting their degradation. On the other hand, separation of the phases allows to reduce the amount of solution to be treated in order to remove the non-regeneratable salts and thus to reduce the costs linked with their elimination. Finally, separation allows to eliminate the degradation products by carrying out a specific and suitable purification for each phase.The method can be applied to combustion fumes decarbonation and to natural gas or synthesis gas deacidizing.

Owner:INST FR DU PETROLE

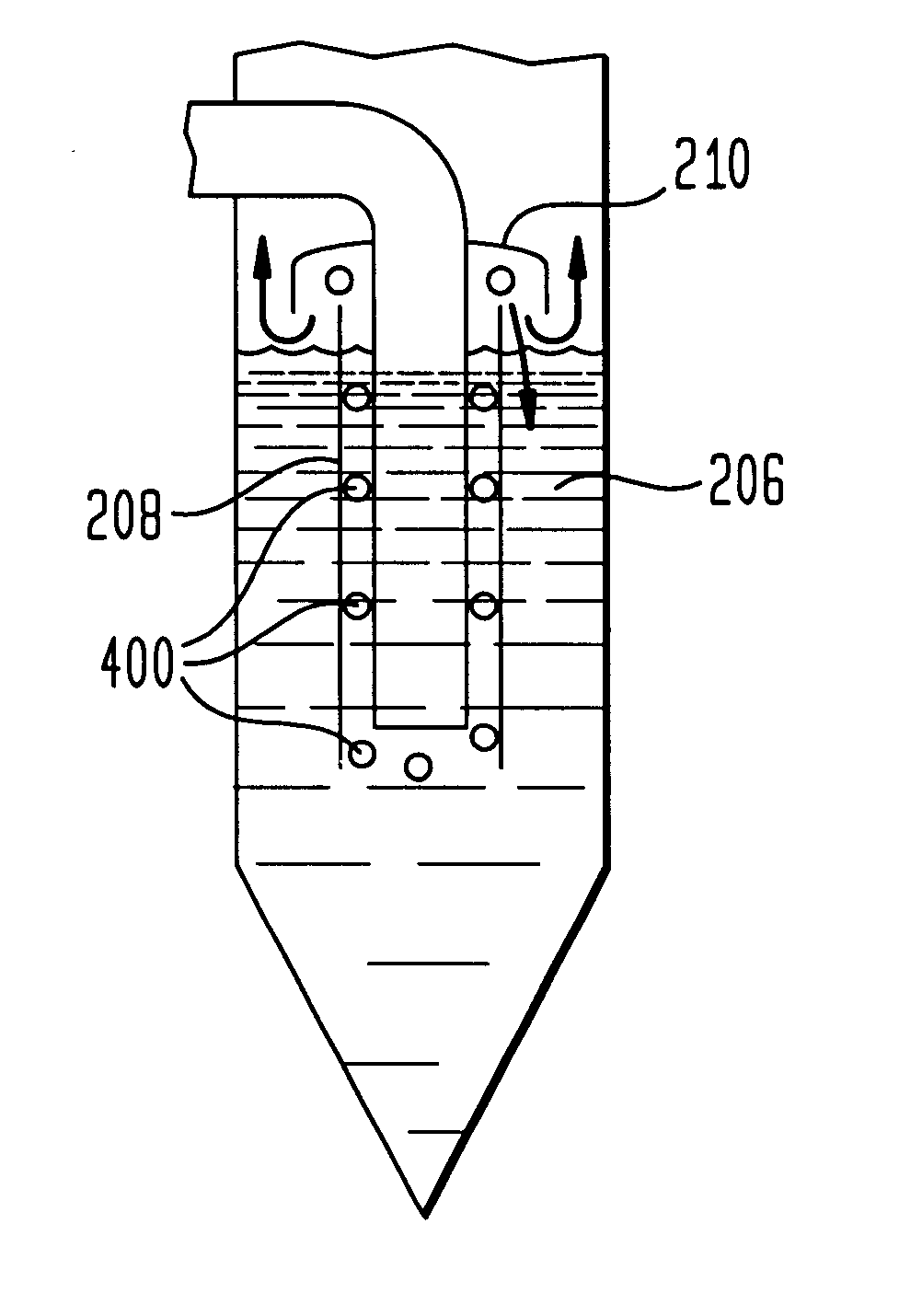

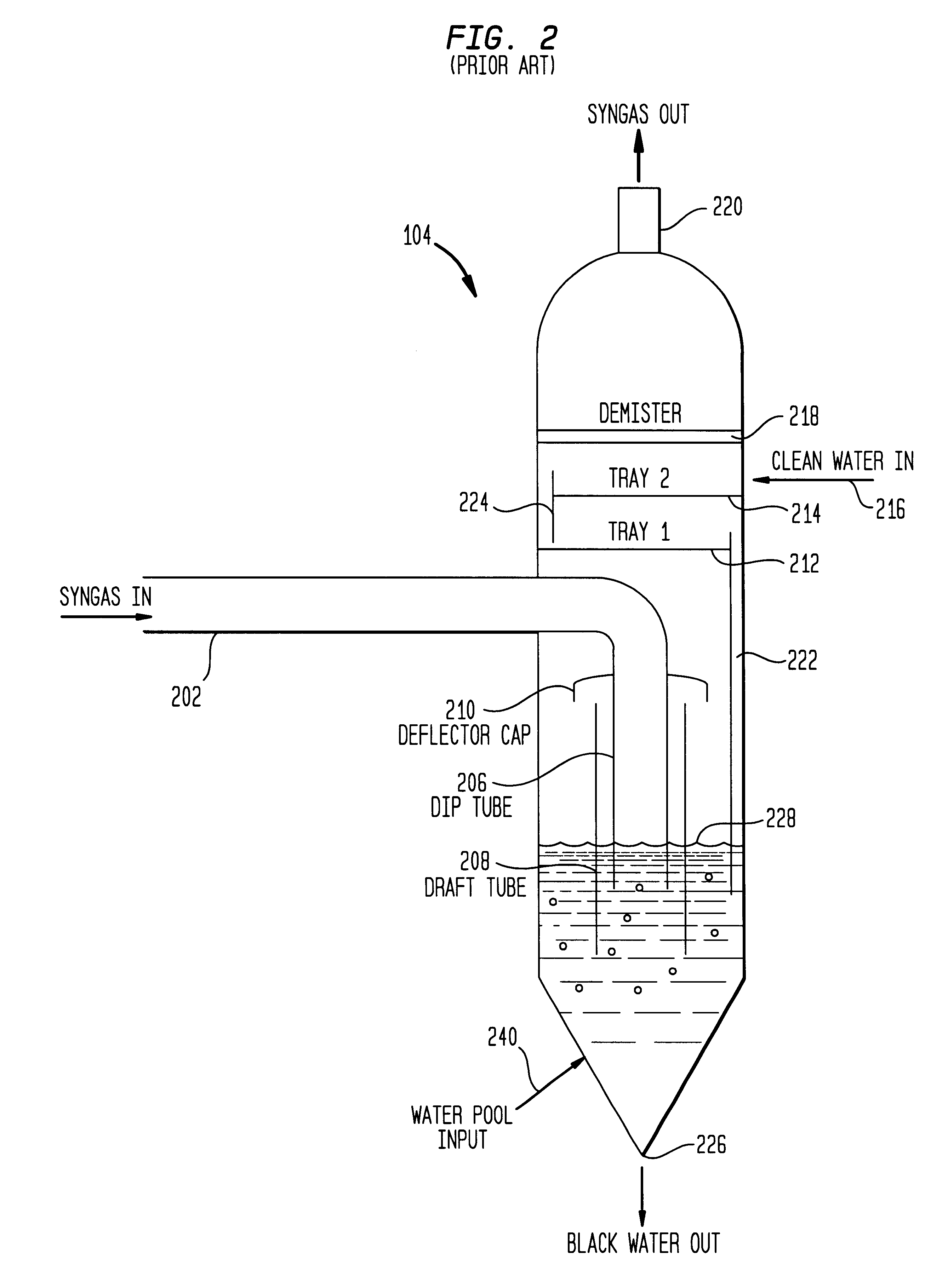

Method and apparatus for removing carbonyl sulfide from a gas stream via wet scrubbing

InactiveUS6322763B1Weaken energyLower Level RequirementsGas treatmentUsing liquid separation agentCarbonyl sulfideWater flow

Methods for removing carbonyl sulfide (COS) from a synthesis gas stream are disclosed. The method entails raising the water level of a wet scrubber so that hydrolysis of the COS may occur in the scrubber itself instead of a COS reduction chamber and no additional catalysts other than those naturally occurring in the production of the synthesis gas need be introduced into the scrubber. The water is raised, in one example, to a level such that water within an inner tube of the wet scrubber flows over an upper end of the inner tube. Raising the water level in the scrubber ensures intimate and vigorous interaction between the water, the COS, and the naturally occurring catalyst, and promotes the hydrolysis of the COS. In one example, the naturally occurring catalyst (e.g., alumina oxide) is present in the coal ash produced when coal is the fuel gasified that creates the synthesis gas stream.

Owner:MTI INSULATED PROD

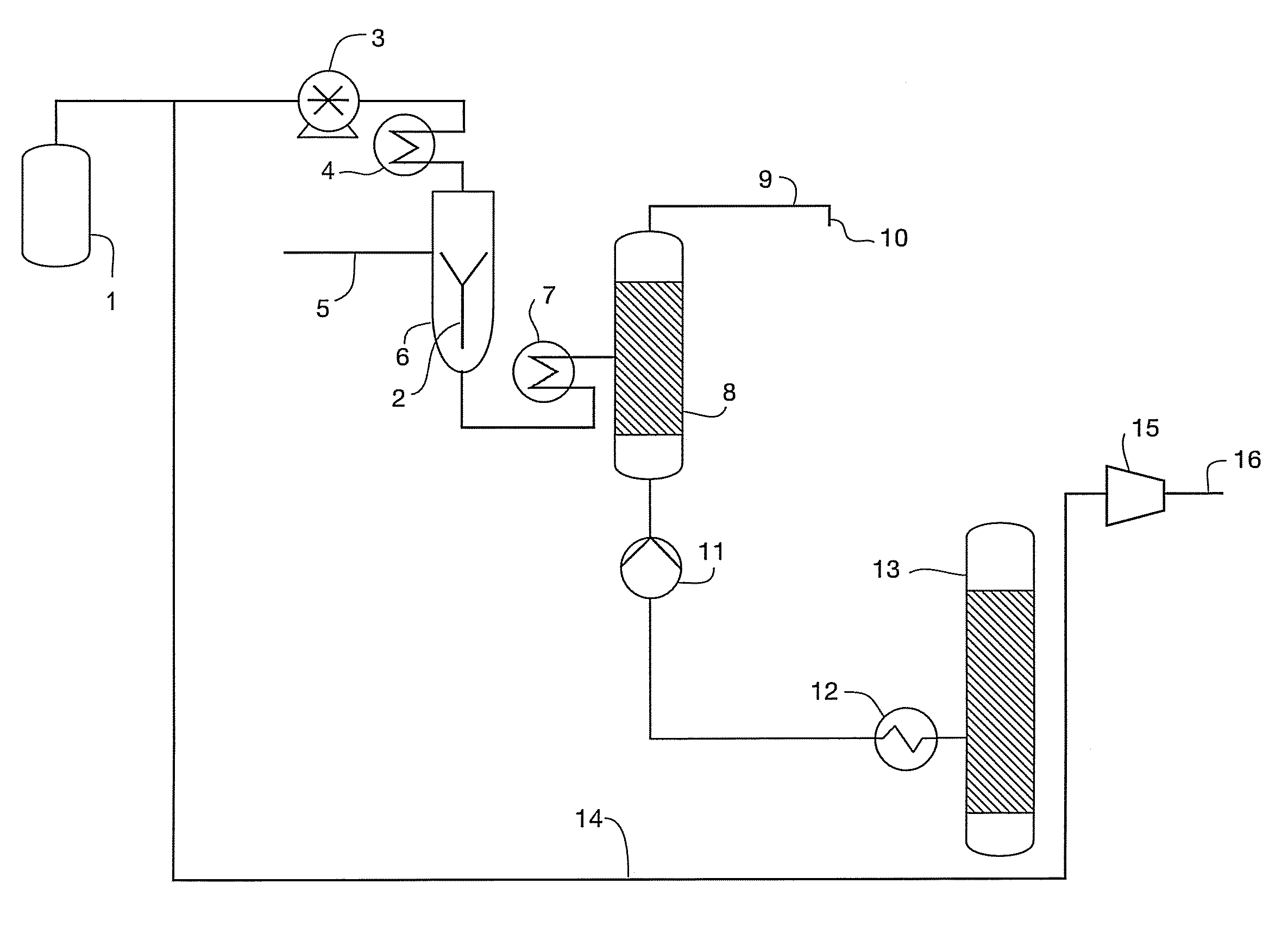

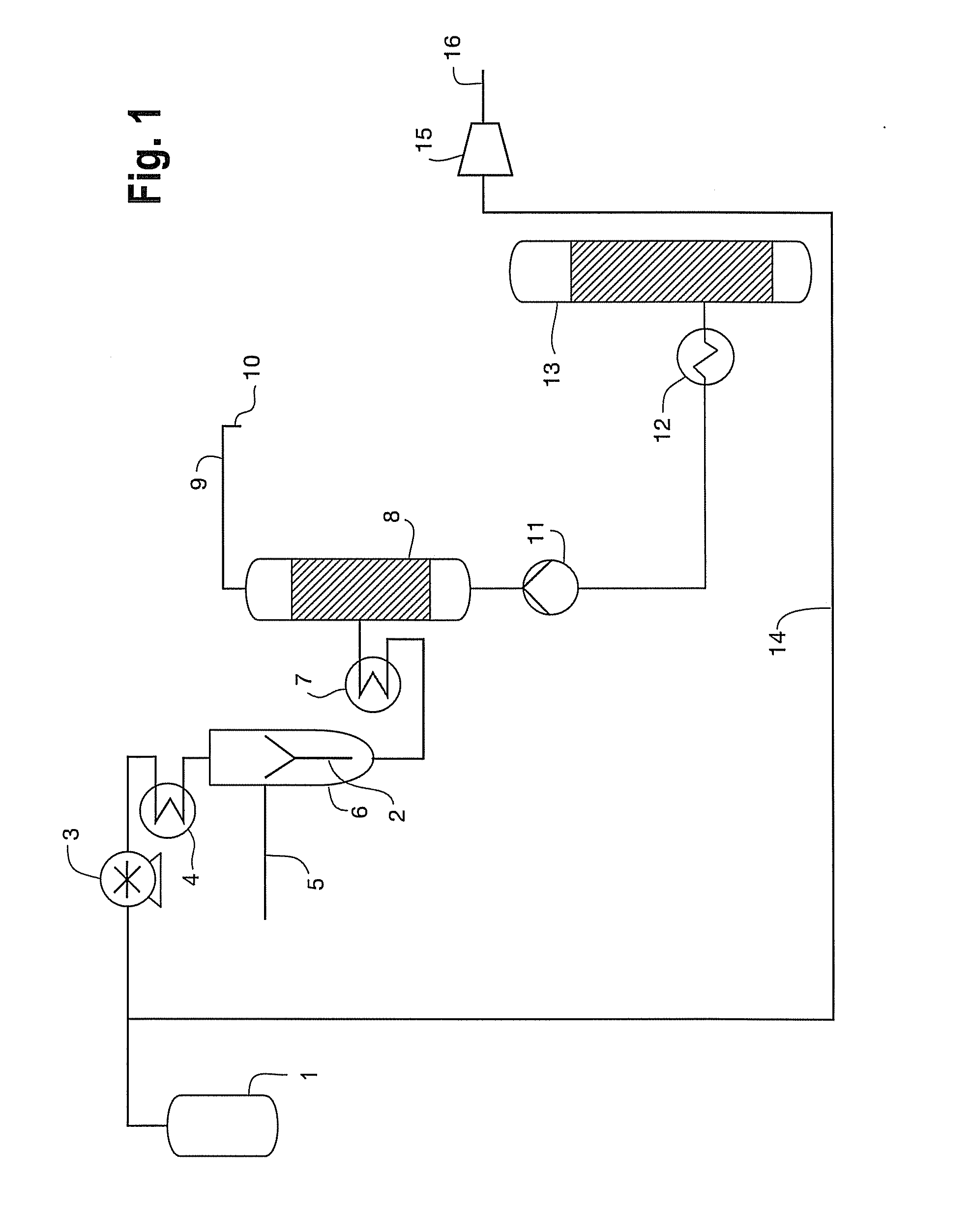

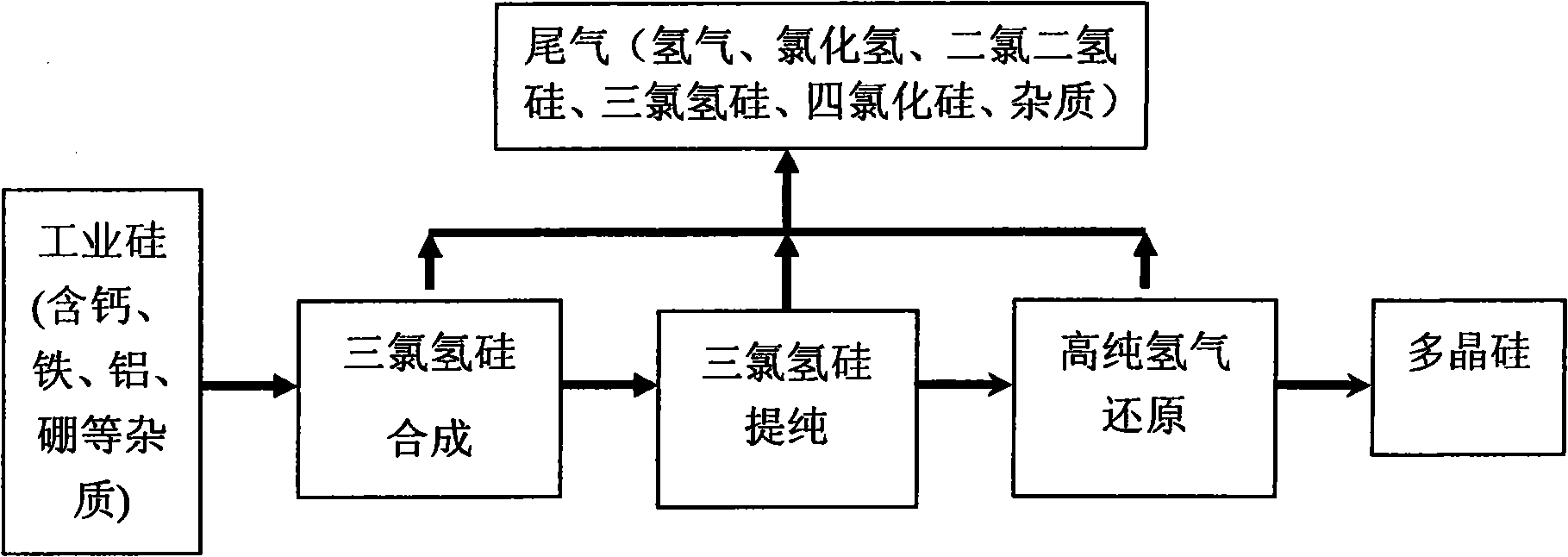

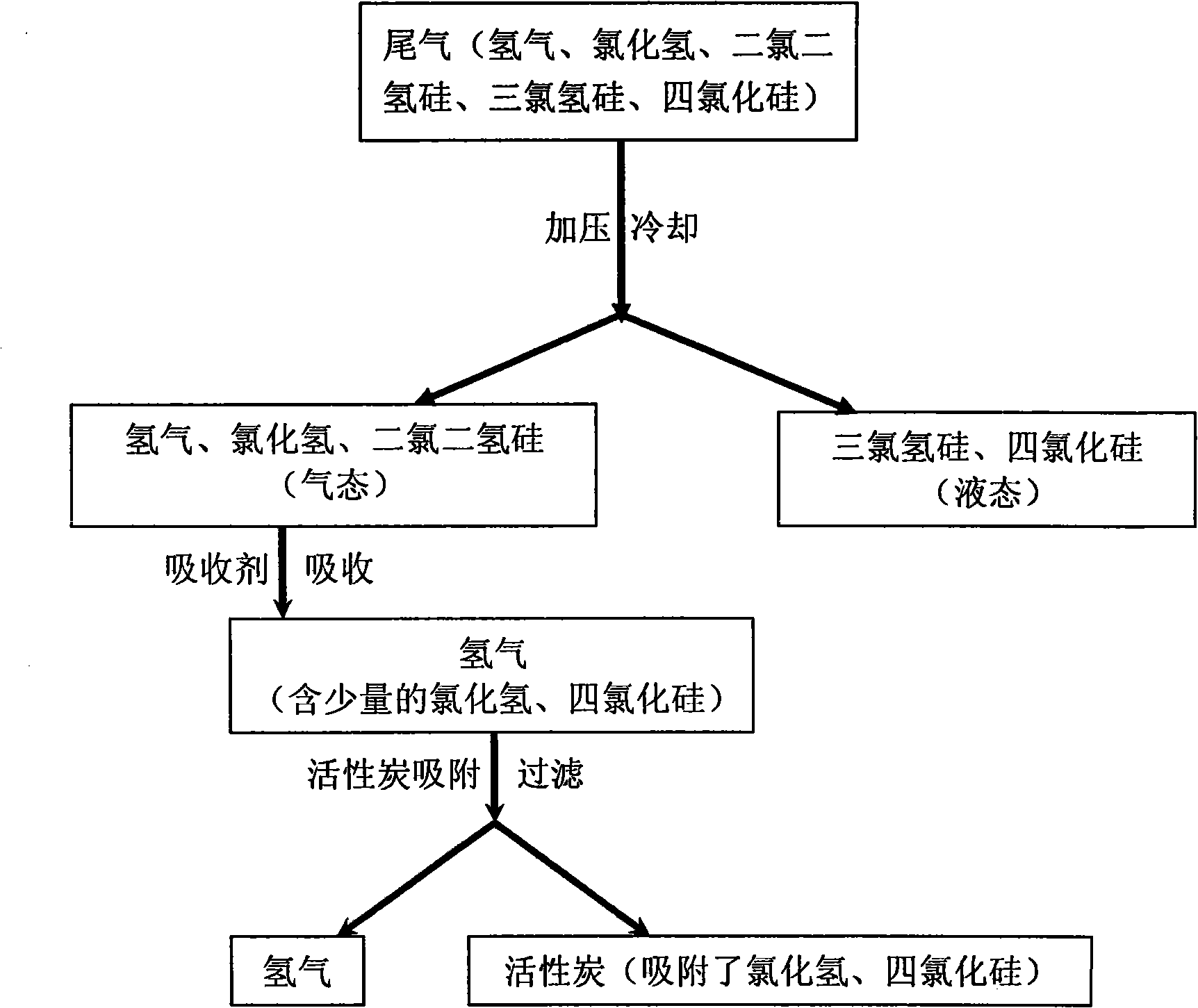

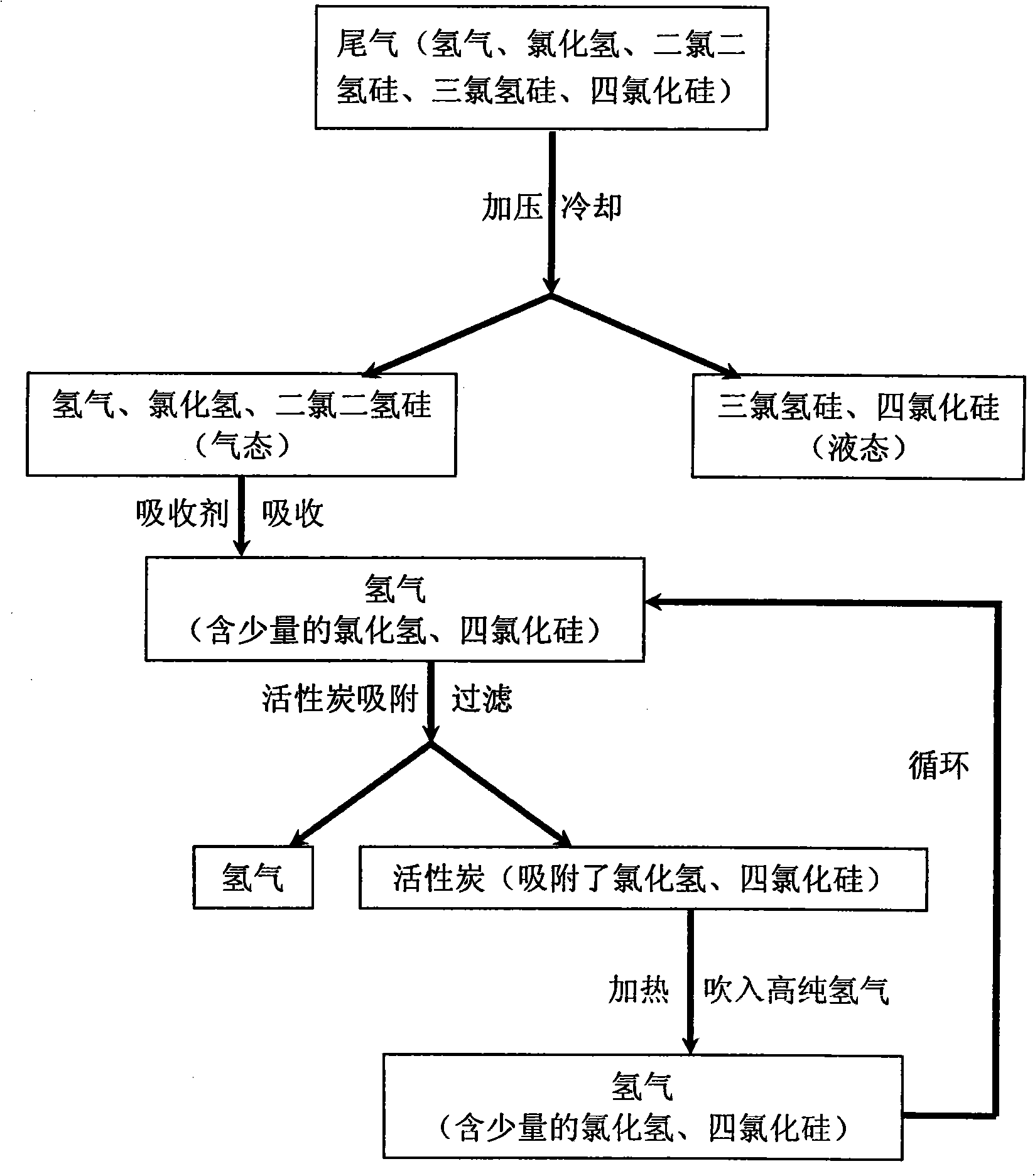

Method for reclaiming hydrogen from tail gas from polysilicon production

ActiveCN101327912AOvercome and eliminate the disadvantages of recycling technologyOvercome and eliminate shortcomingsHydrogen separation using liquid contactDispersed particle separationRecovery methodLiquid state

The invention relates to a hydrogen recovery method in the exhaust generated by producing polysilicon. The exhaust mainly comprises hydrogen, chlorine hydride, dichlorosilane, trichlorosilane and tetrachlorosilane. The method comprises the following steps: pressurizing and cooling the exhaust in order to turn trichlorosilane and tetrachlorosilane to liquid state while hydrogen, chlorine hydride and dichlorosilane still being gas state, so that the gas hydrogen, chlorine hydride and dichlorosilane can be separated from the liquid trichlorosilane and tetrachlorosilane by gas liquid separation; dissolving the gas chlorine hydride and dichlorosilane into the liquid tetrachlorosilane by passing gas hydrogen, chlorine hydride and dichlorosilane through the liquid tetrachlorosilane, so that separating the hydrogen from chlorine hydride and dichlorosilane. The invention recovers the hydrogen in the exhaust by dry treatment and the hydrogen can be reused in the polysilicon production, which makes good use of the material, reduces pollutants, settles the problem of environmental pollution, improves the product quality and reduces the cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com