Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201 results about "High value products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In United States agricultural policy, high value products (HVP) refers to agricultural products that are high in value, often but not necessarily due to processing.

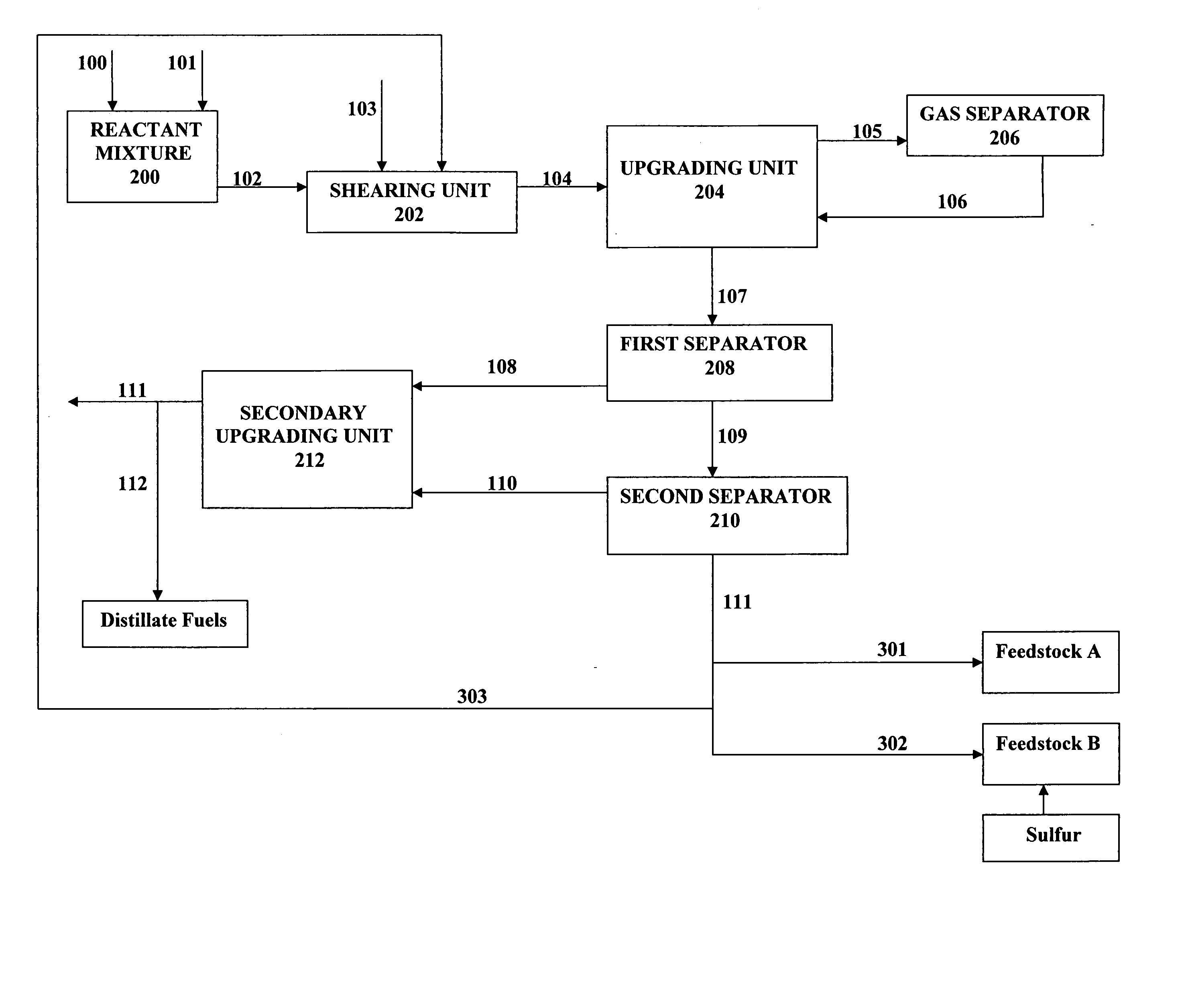

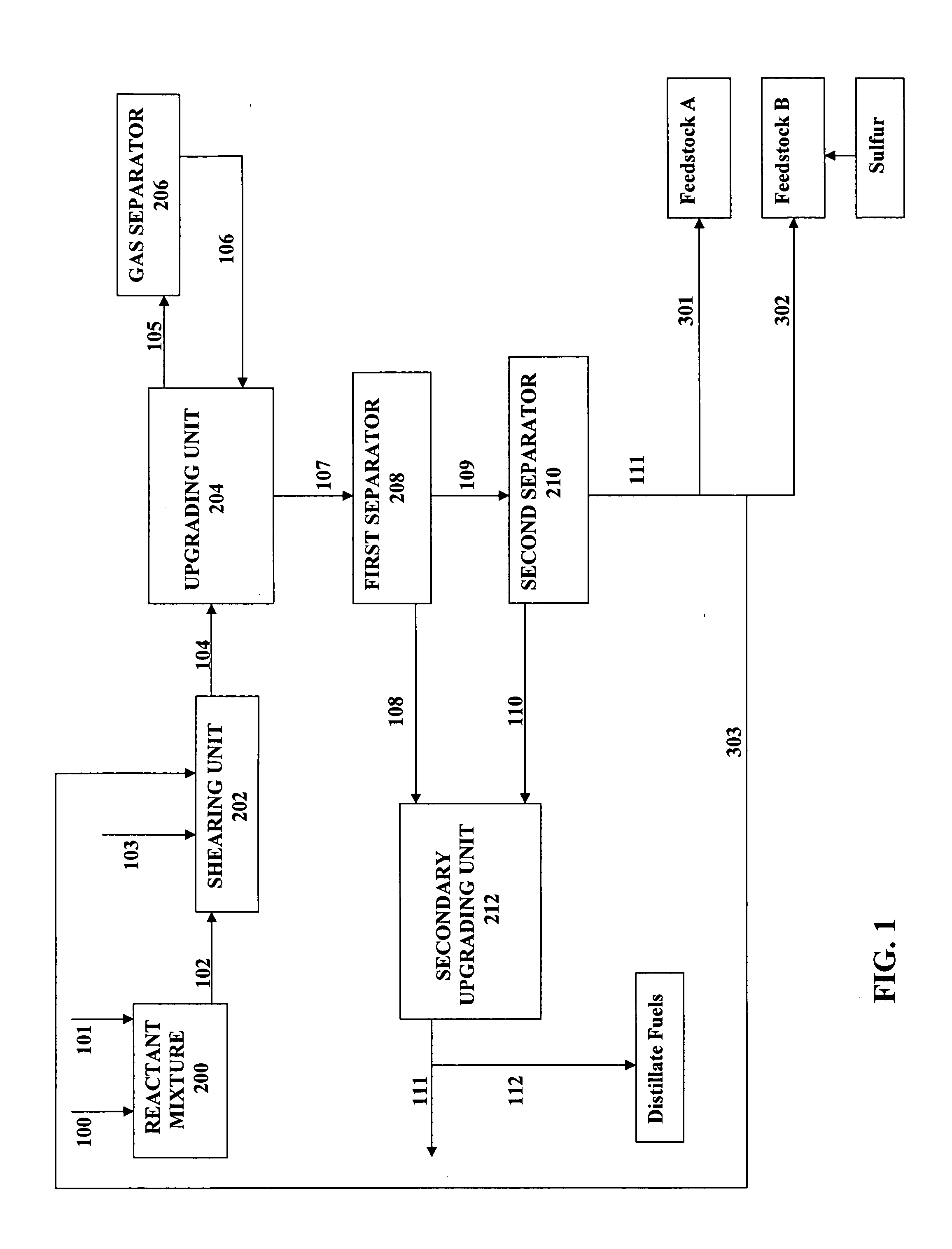

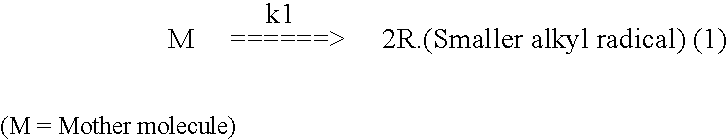

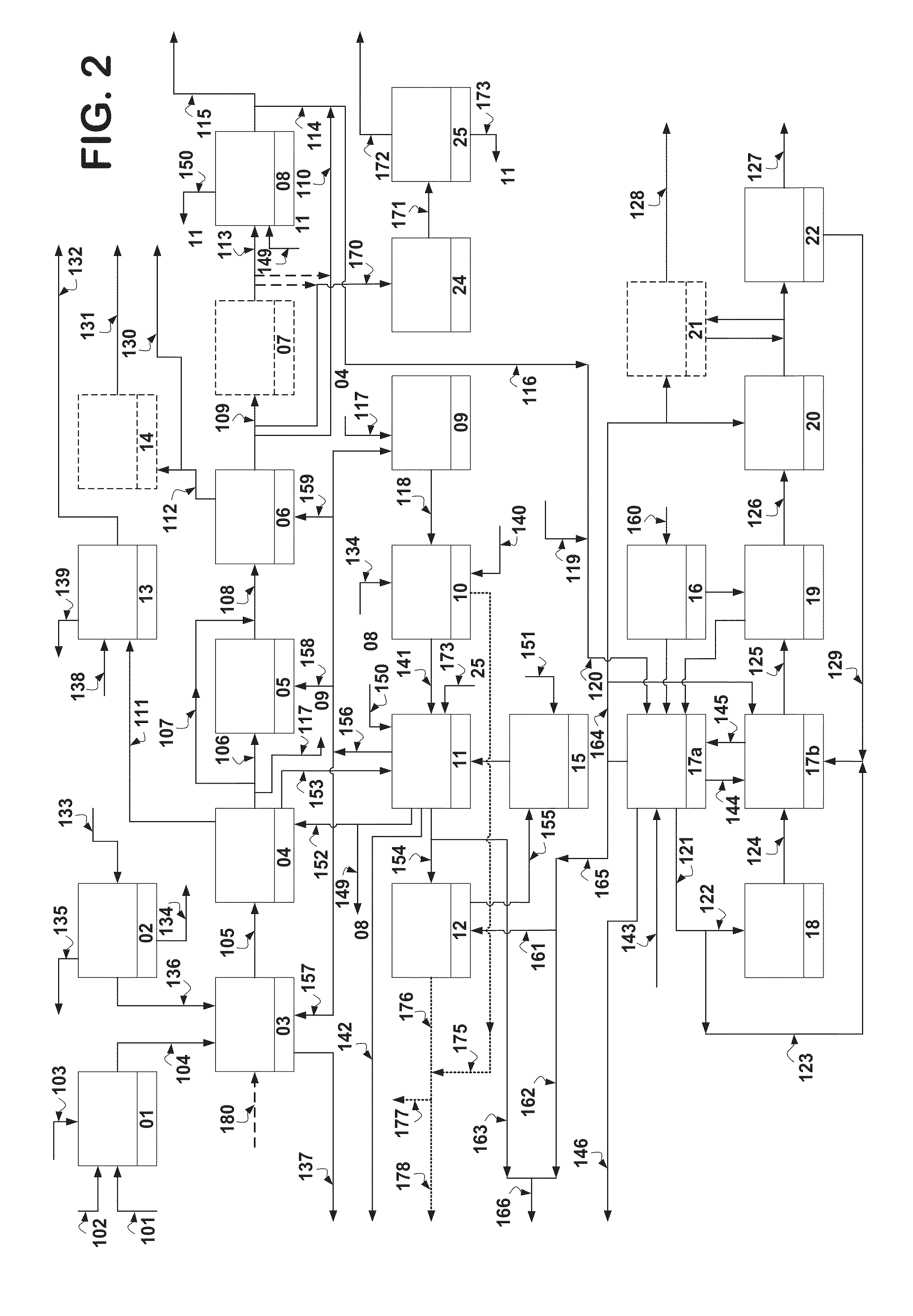

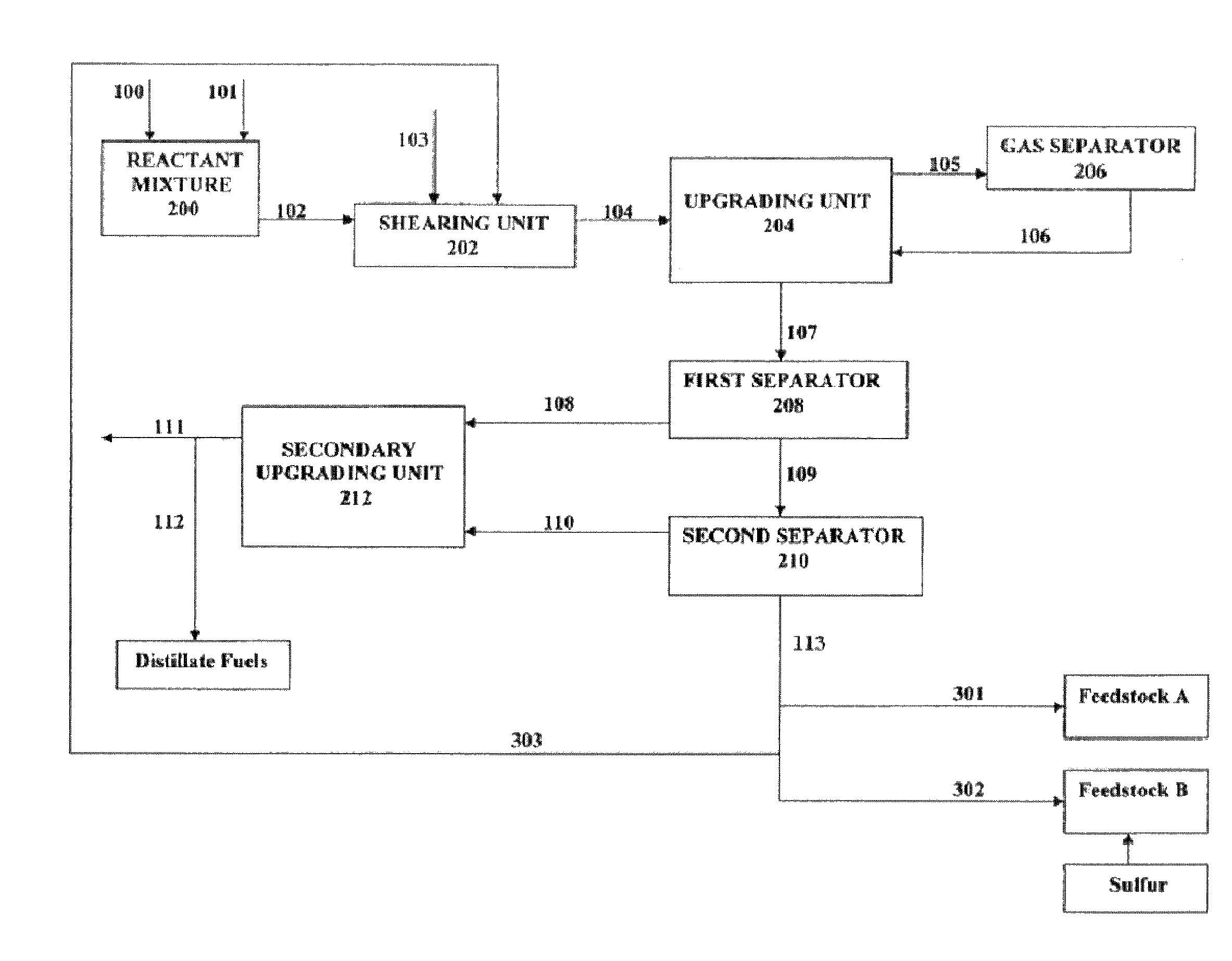

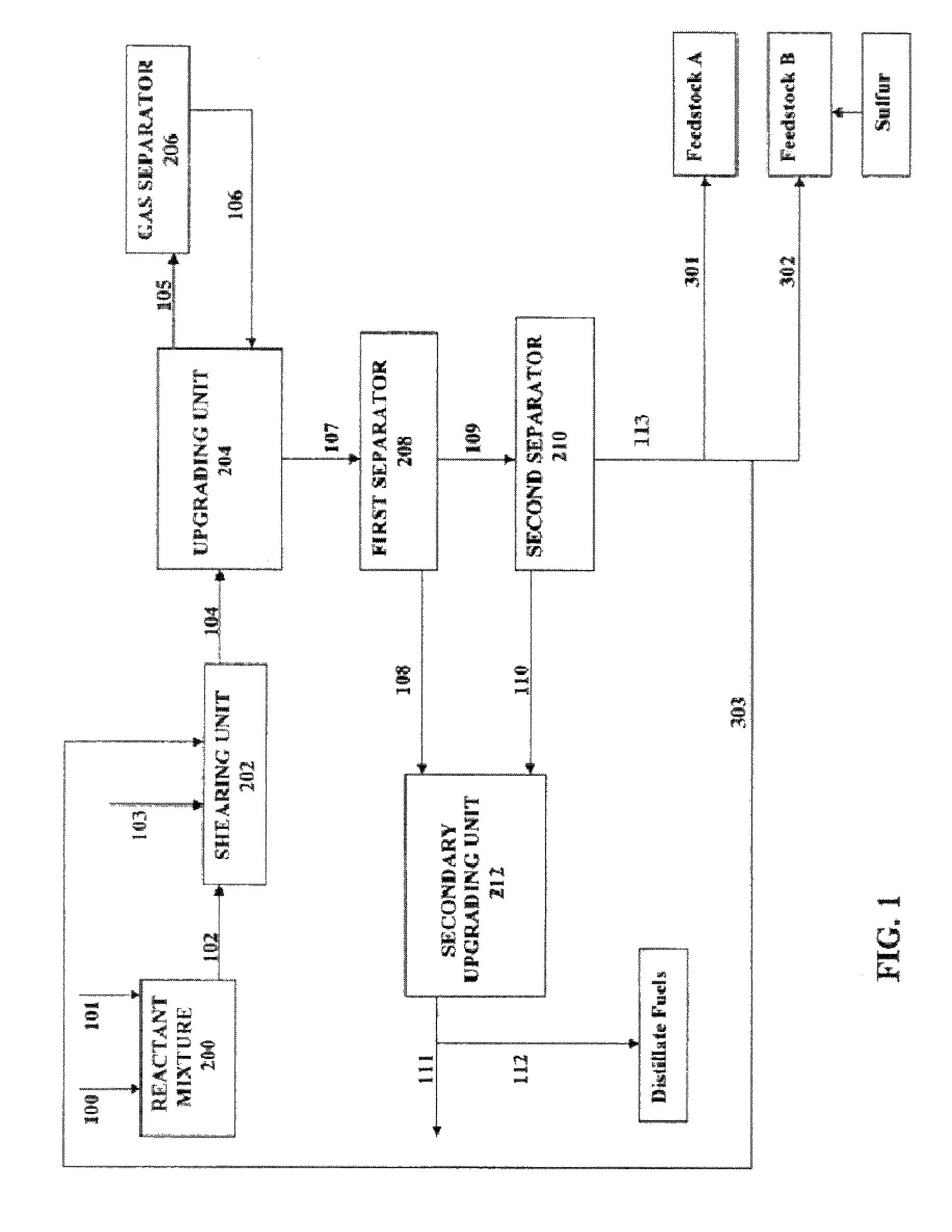

Methods for making higher value products from sulfur containing crude oil

ActiveUS20060254956A1High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

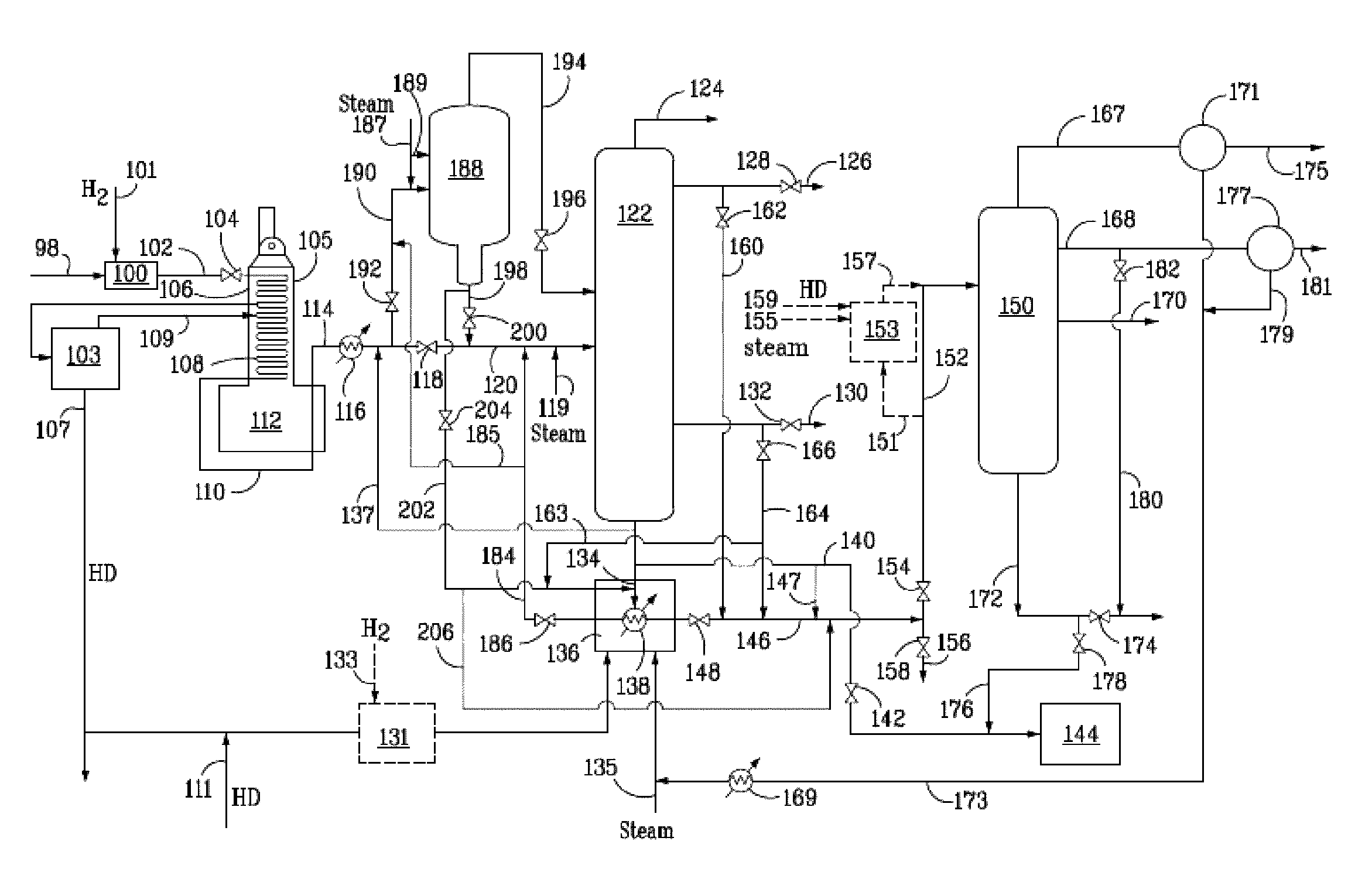

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

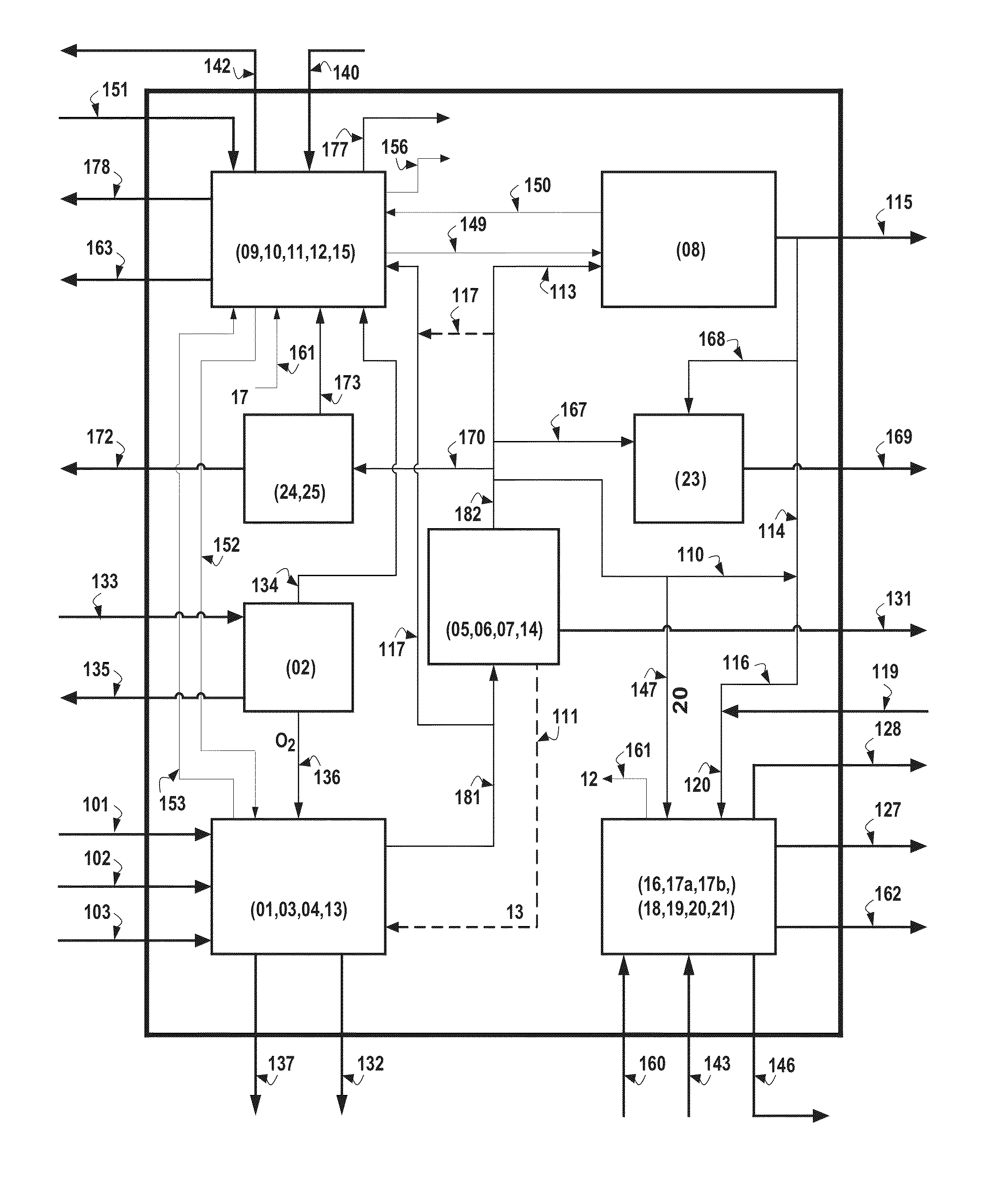

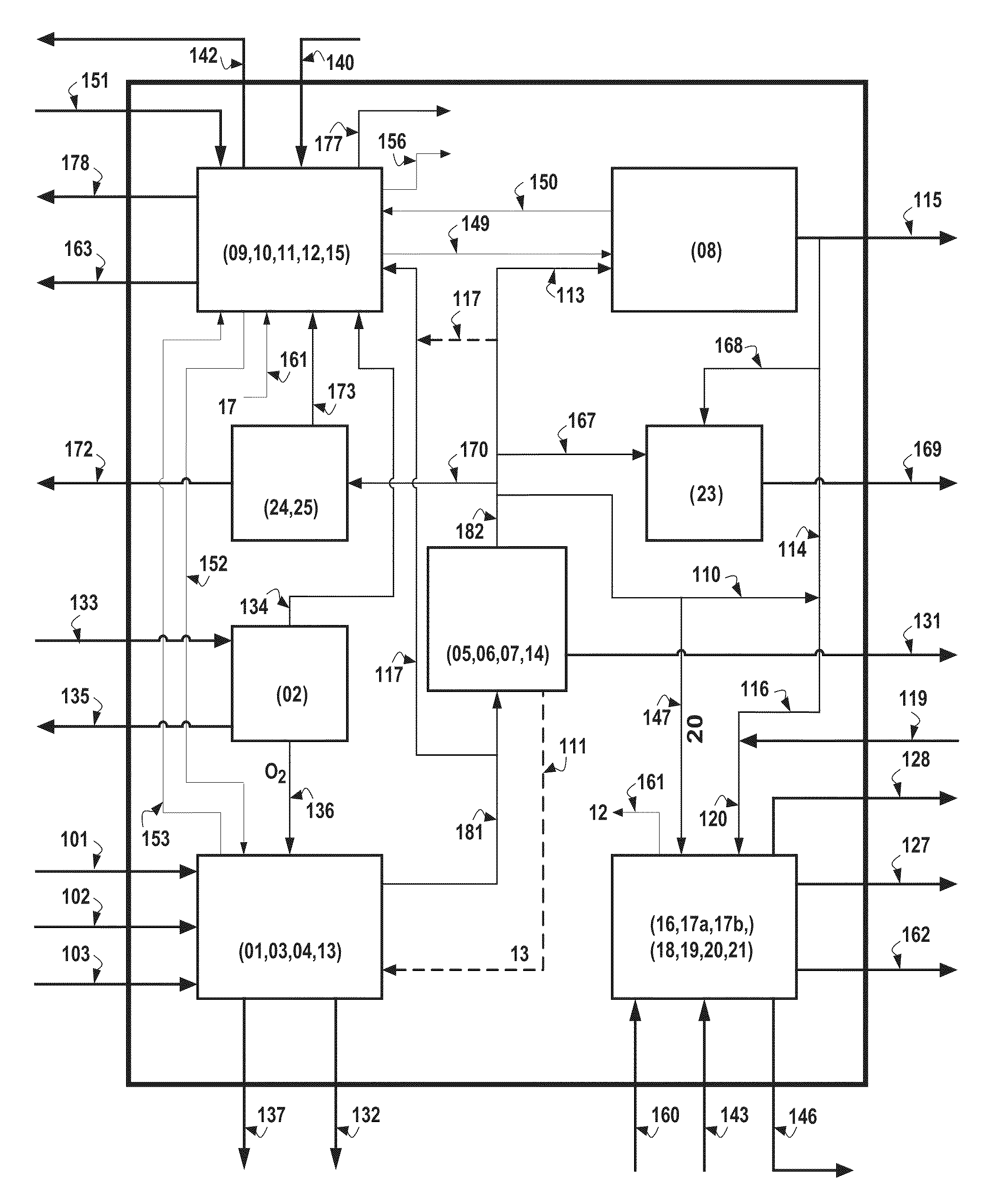

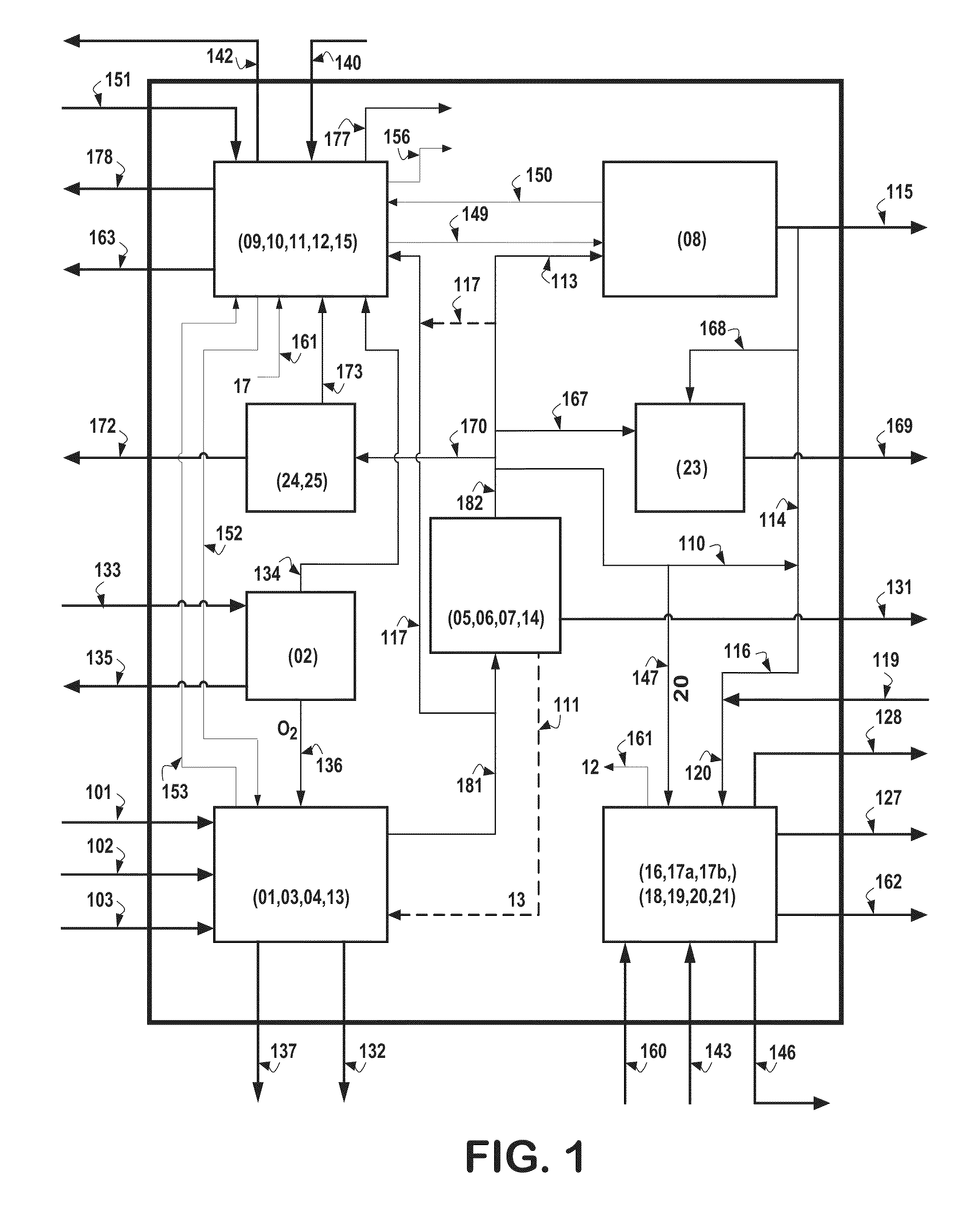

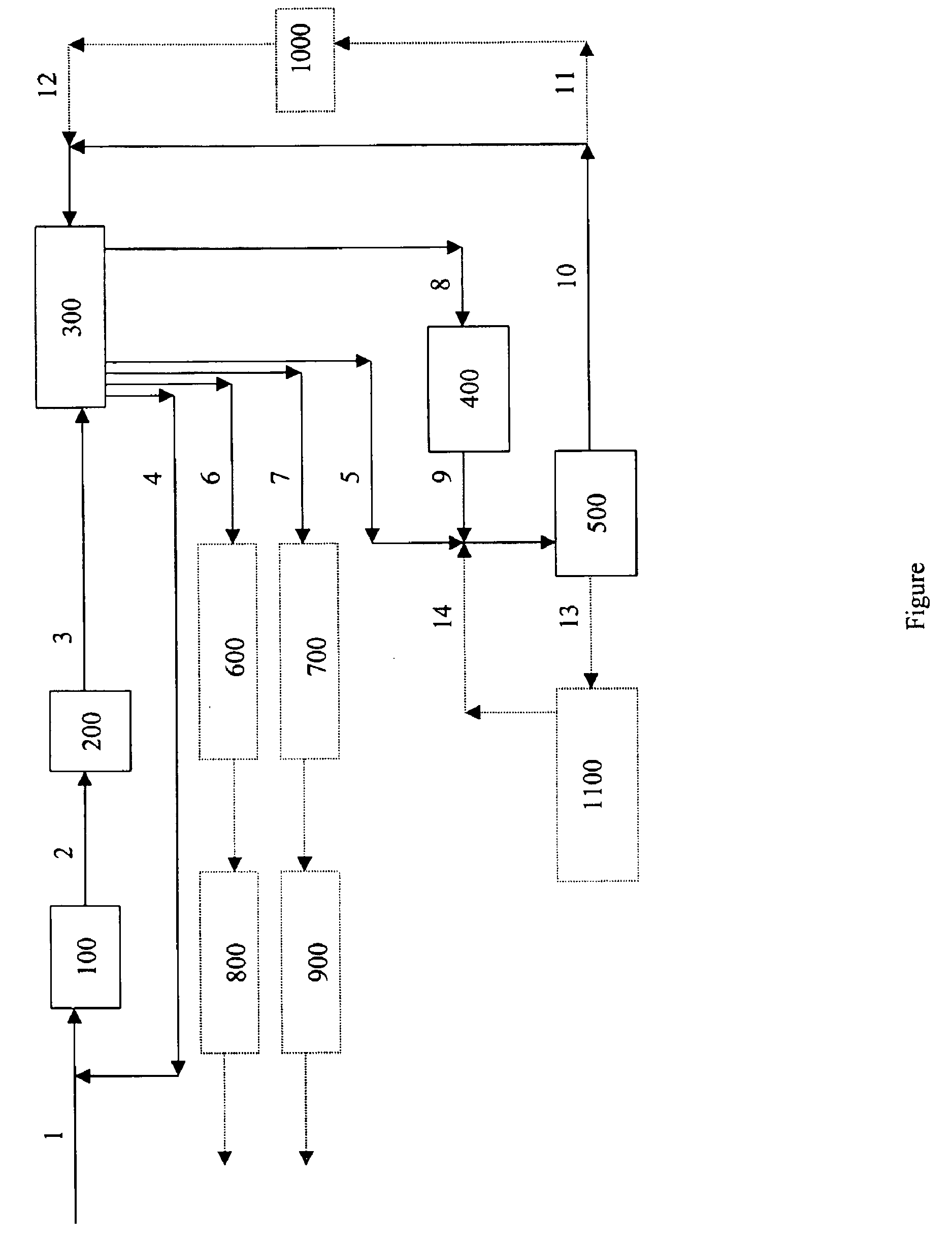

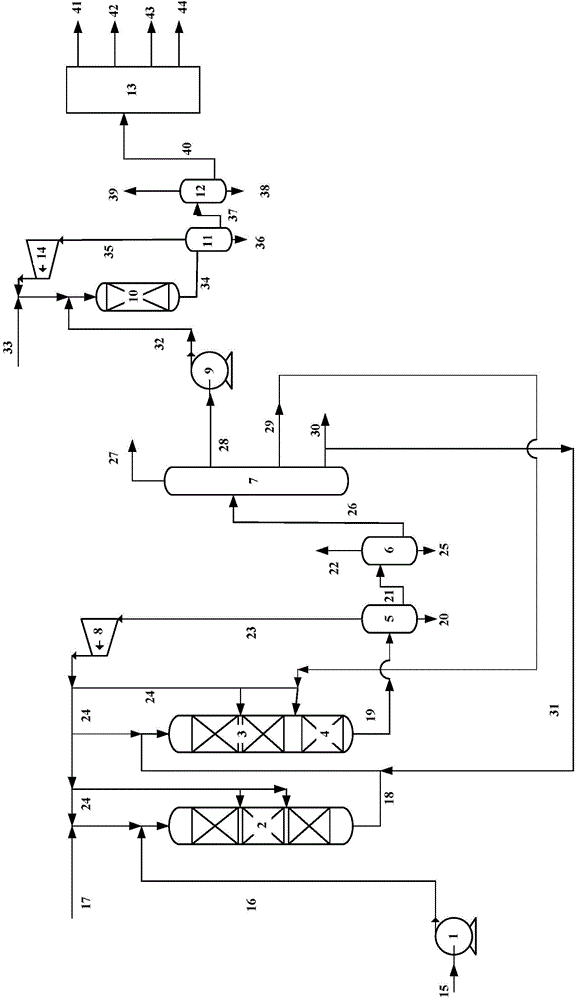

Gasification and steam methane reforming integrated polygeneration method and system

InactiveUS8409307B2Improve reliabilityMaximize reliabilityCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

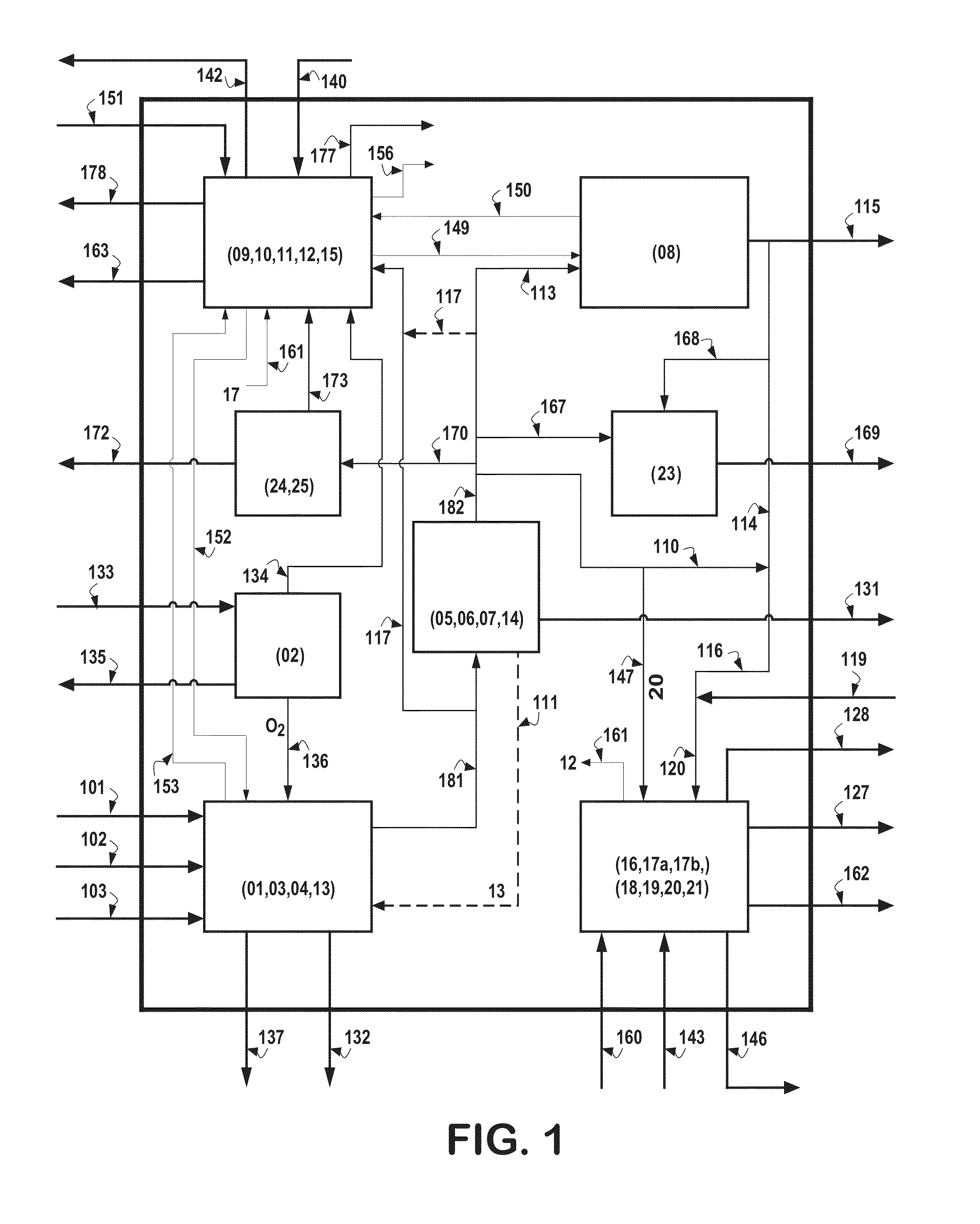

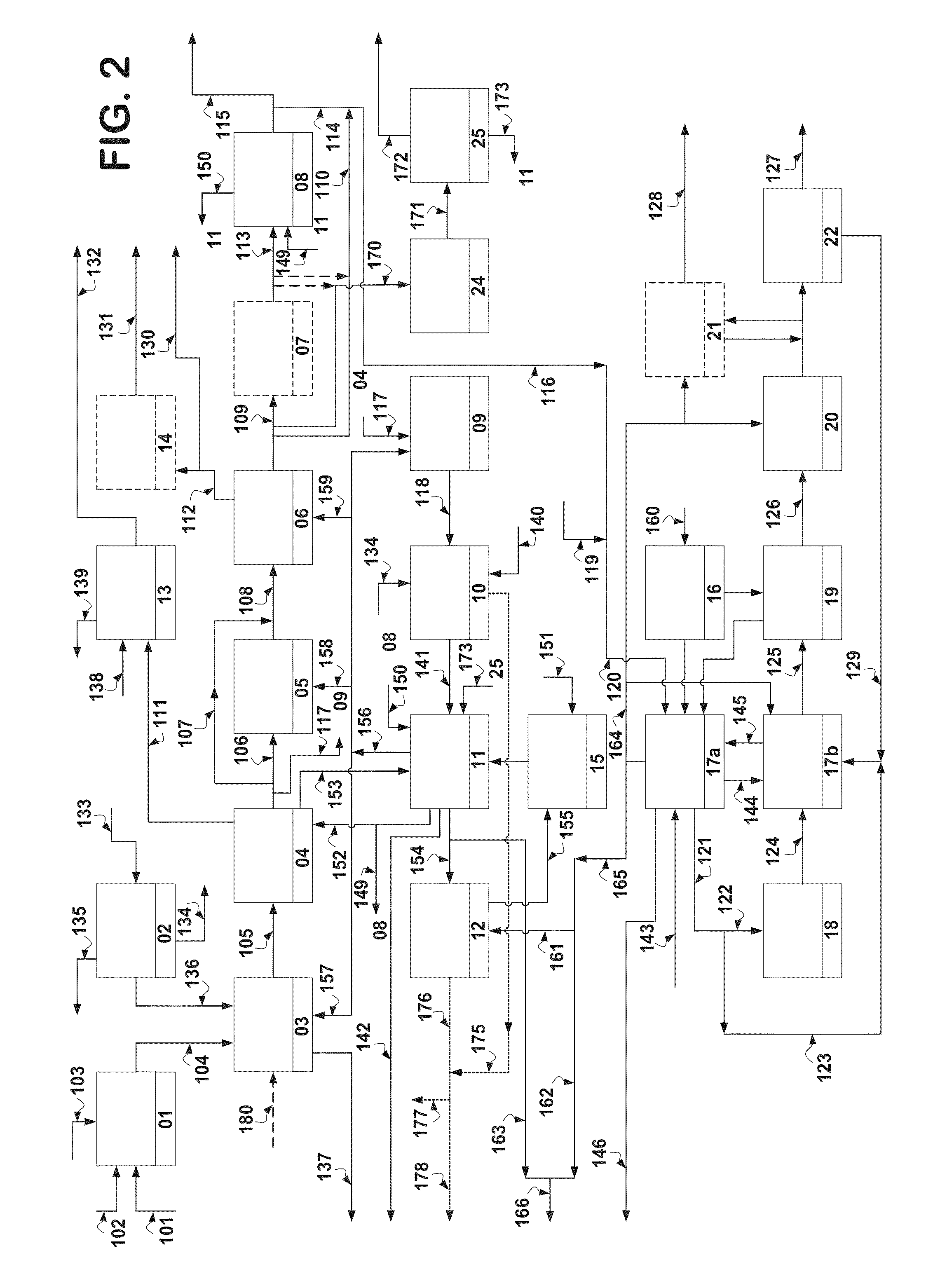

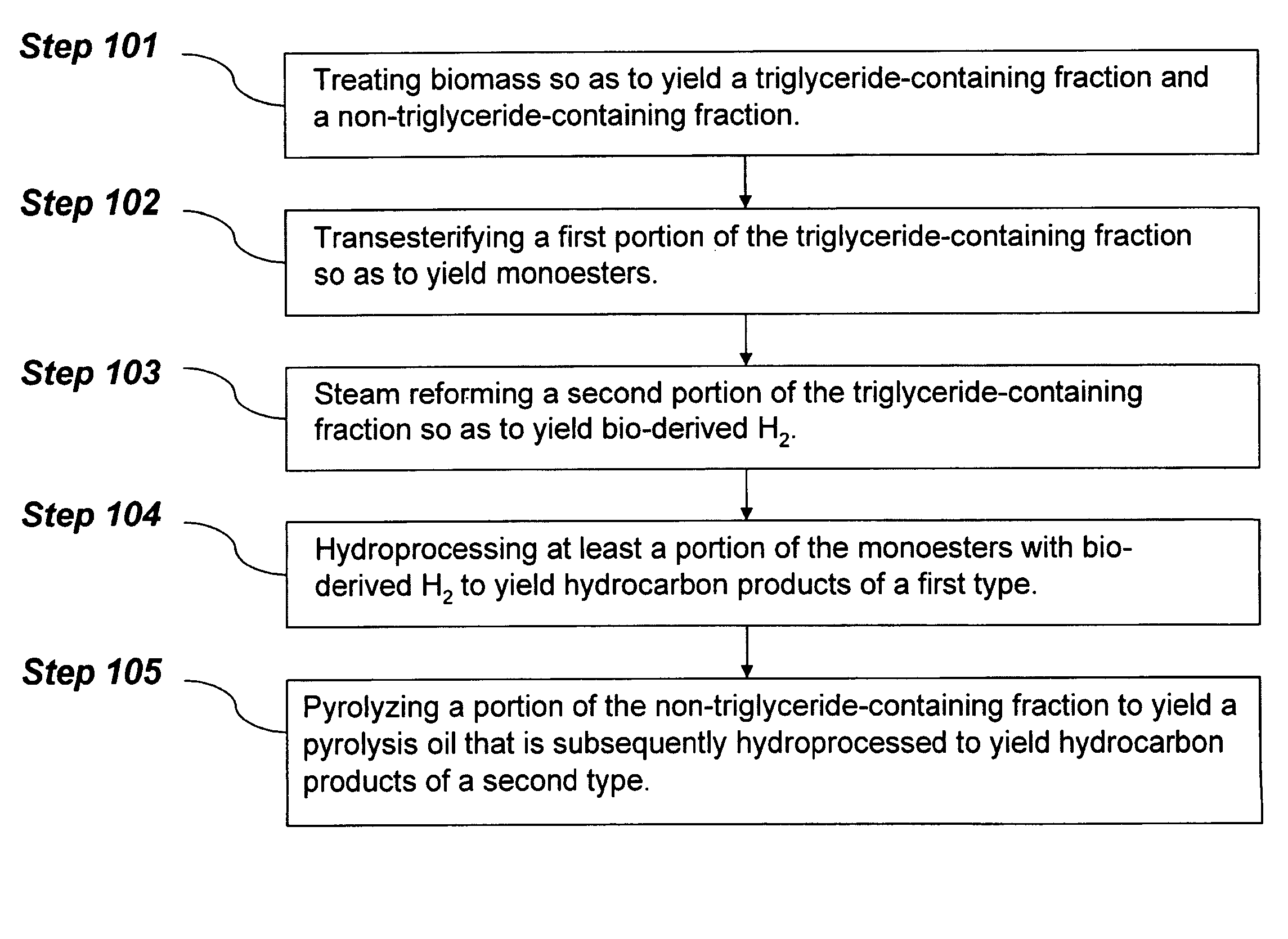

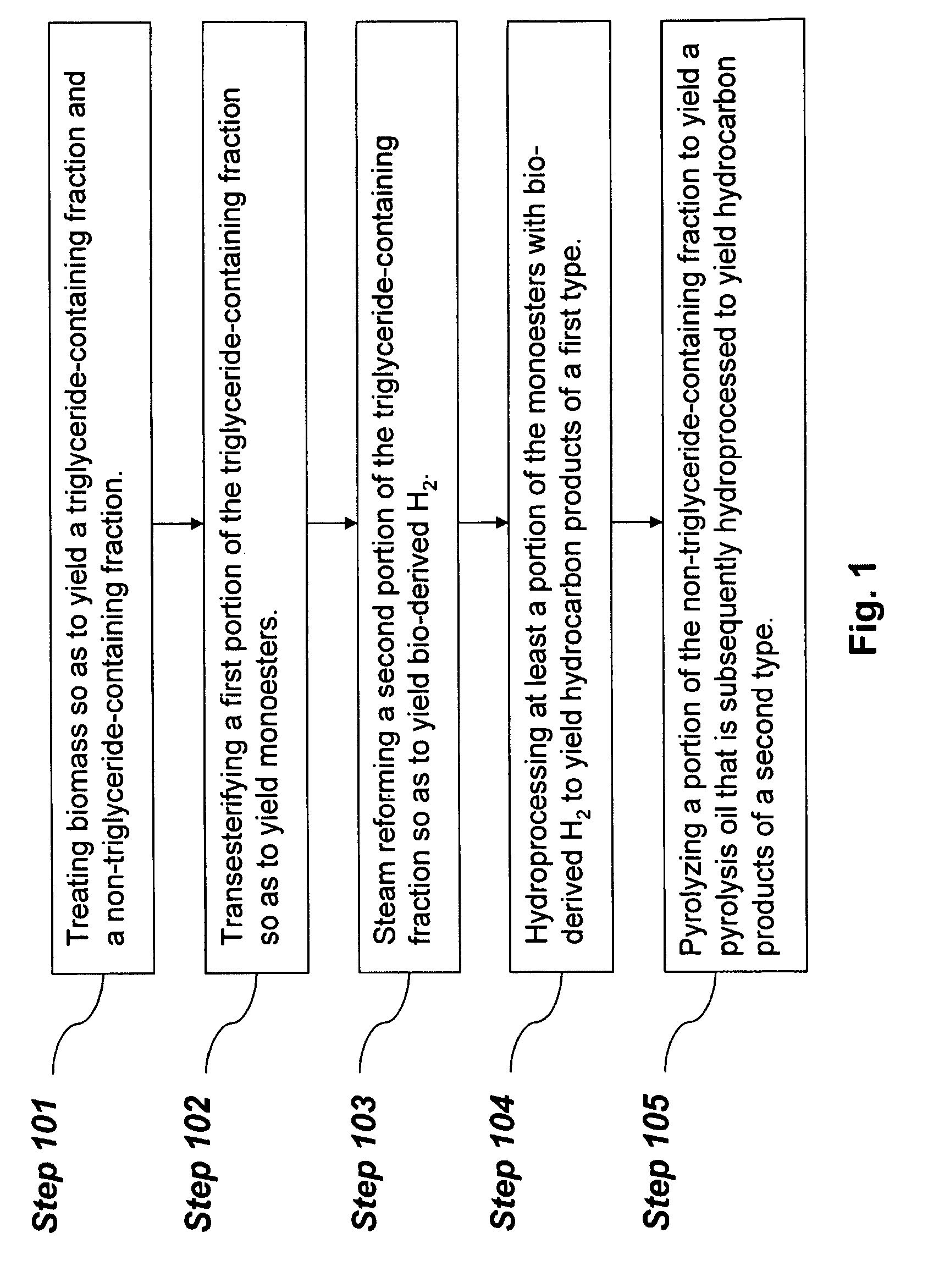

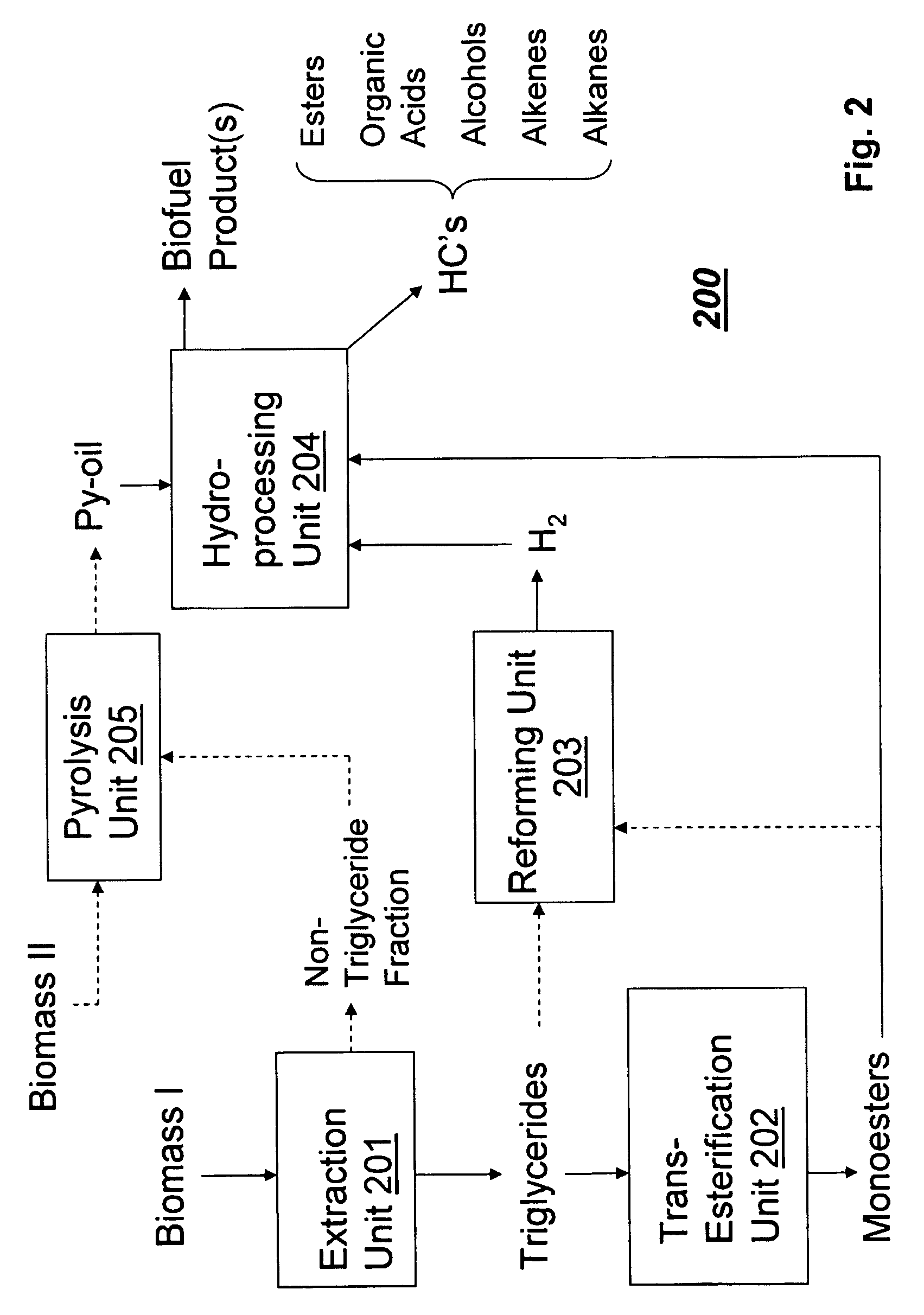

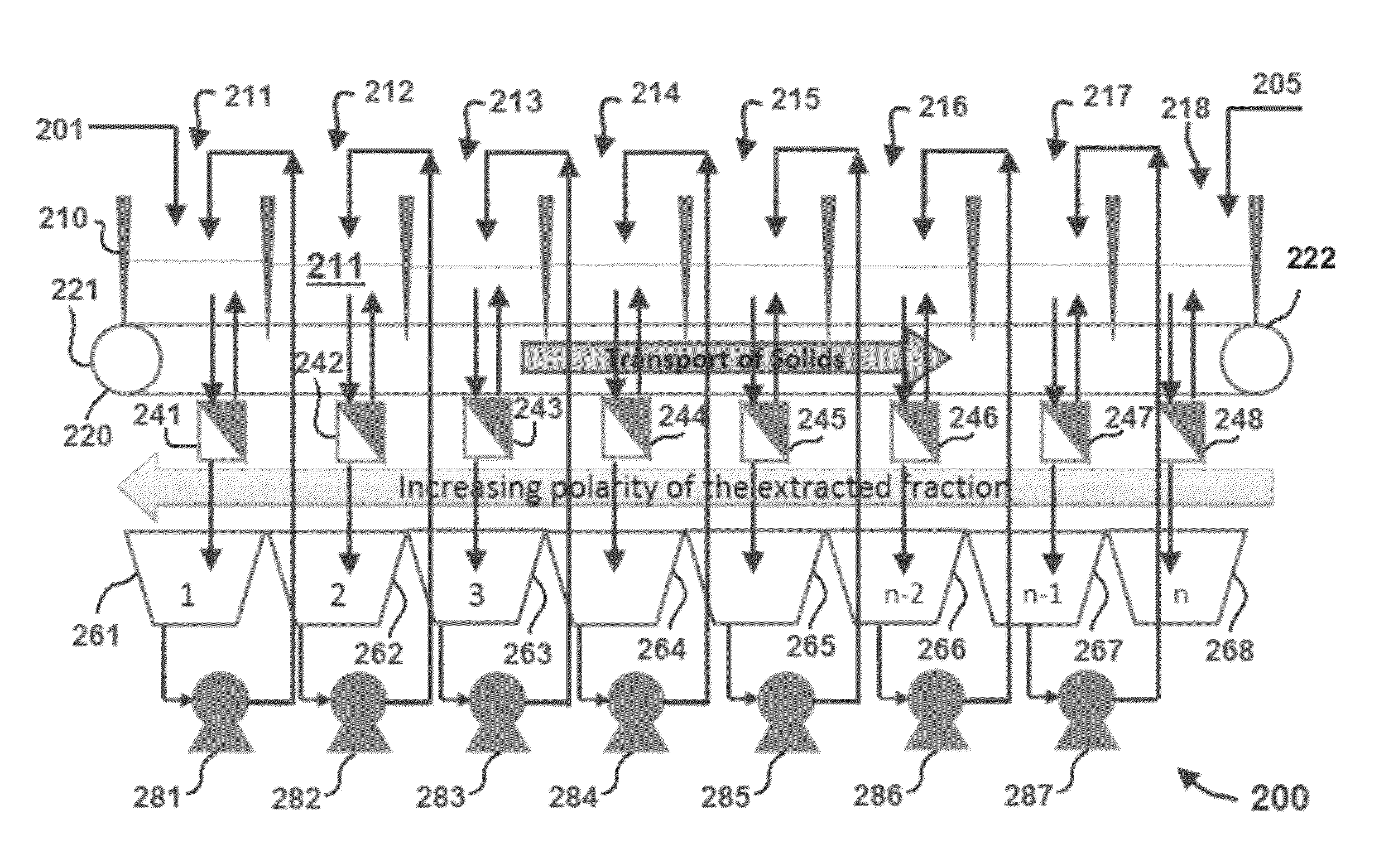

Selective, integrated processing of bio-derived ester species to yield low molecular weight hydrocarbons and hydrogen for the production of biofuels

The present invention relates to methods for processing biomass to selectively yield a variety of hydrocarbon molecules and hydrogen as products, wherein some or all of these products can be further utilized for other biomass processing sub-processes, particularly wherein they lead to the generation of biofuels and / or other high-value products.

Owner:CHEVROU USA INC

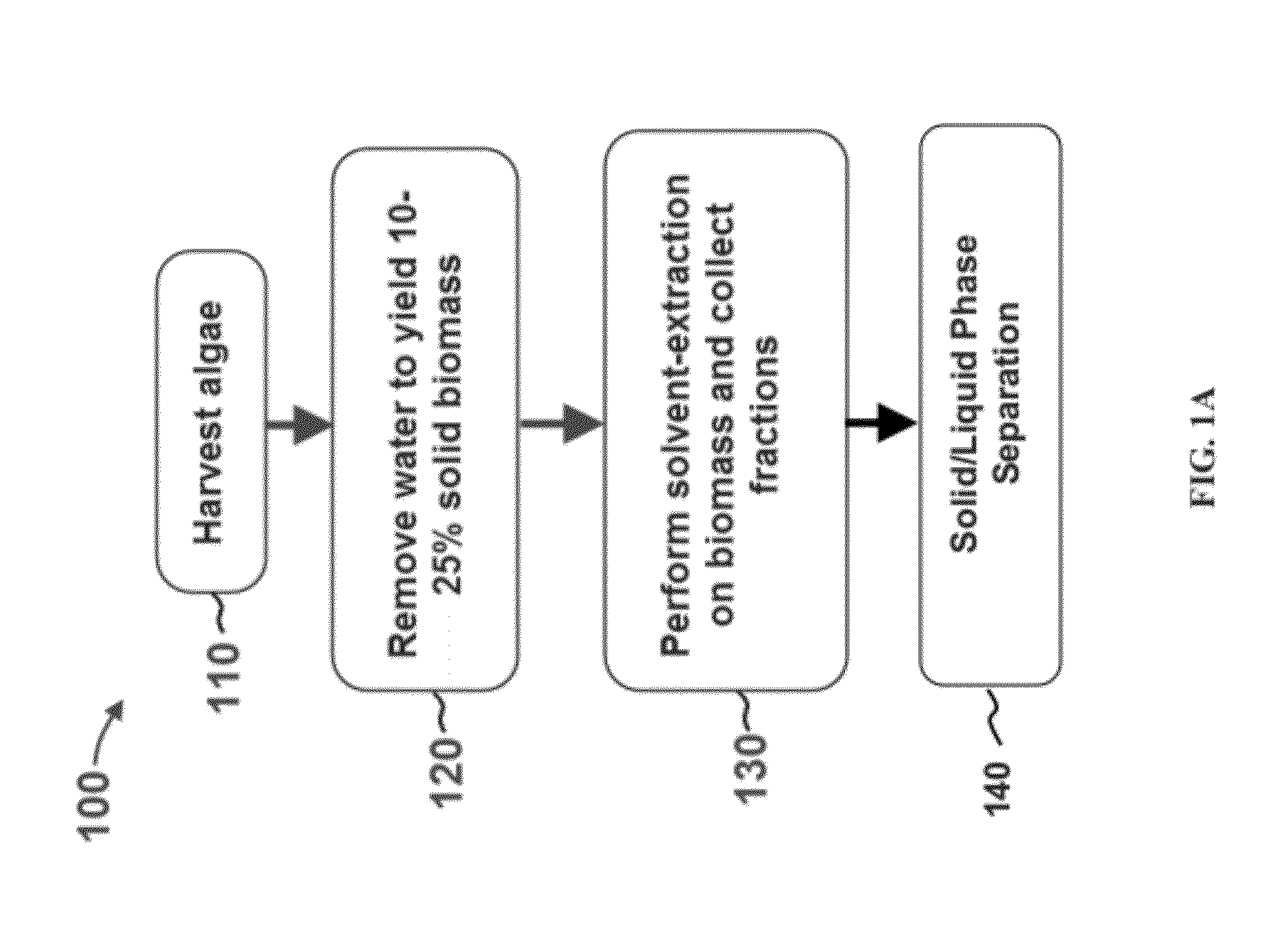

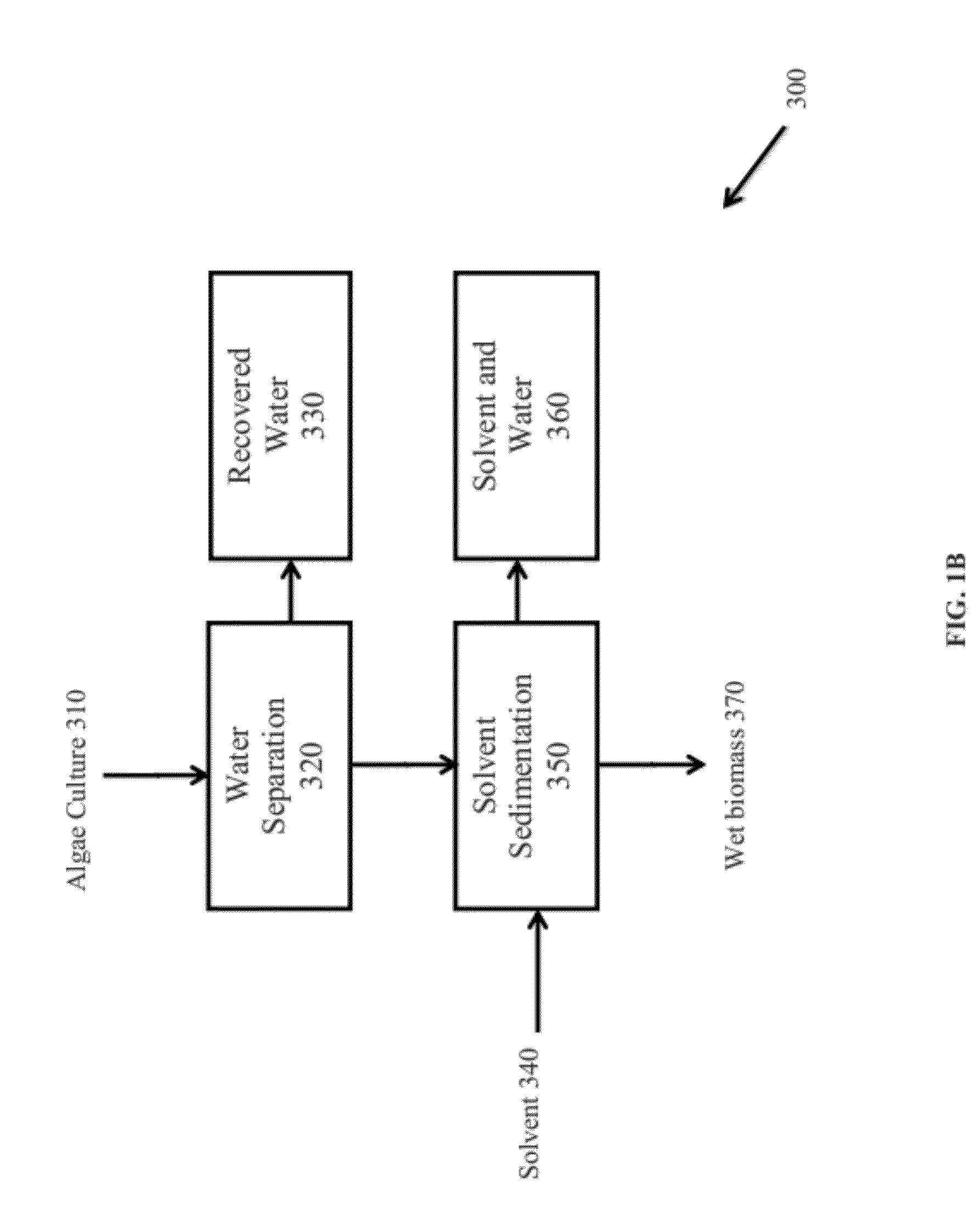

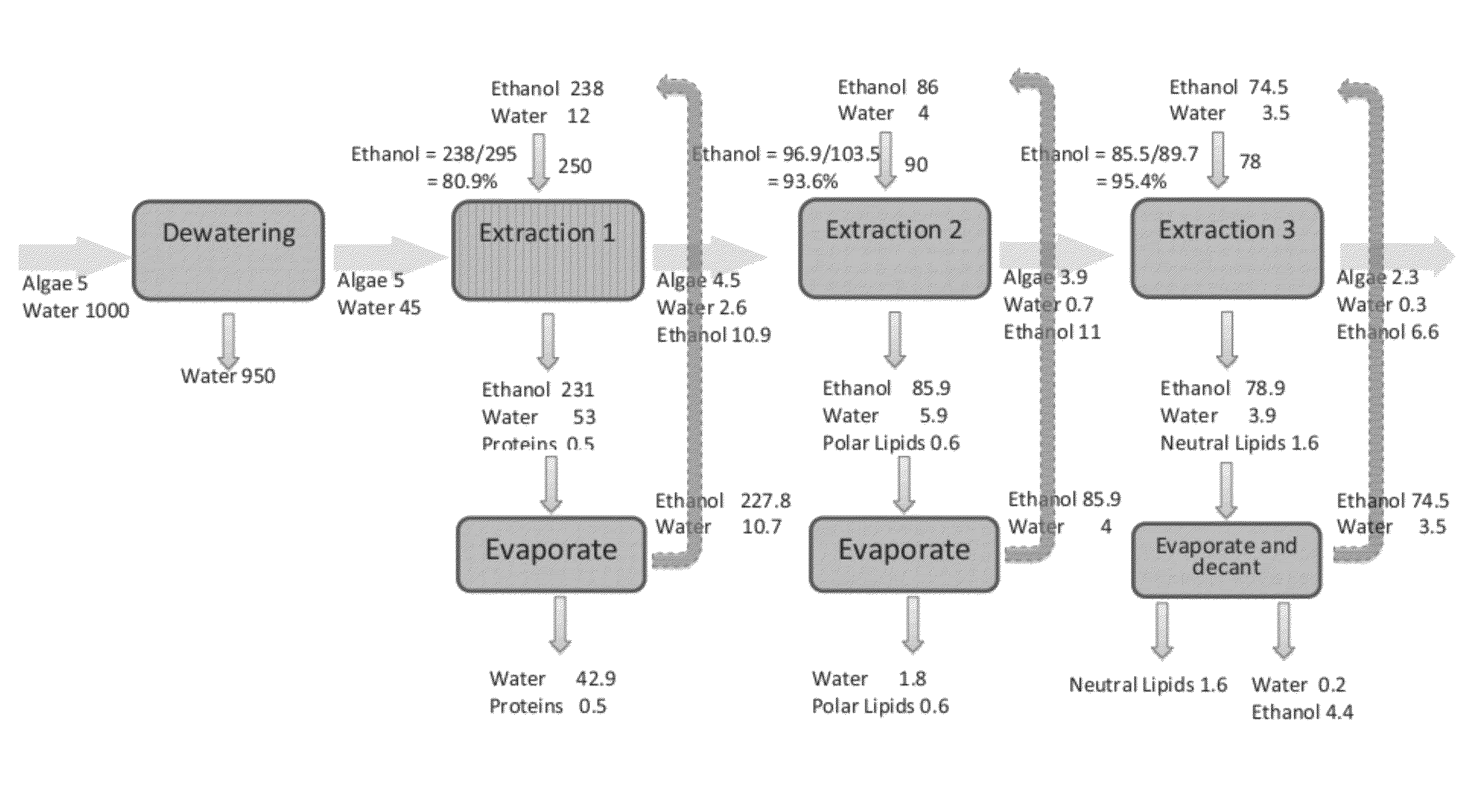

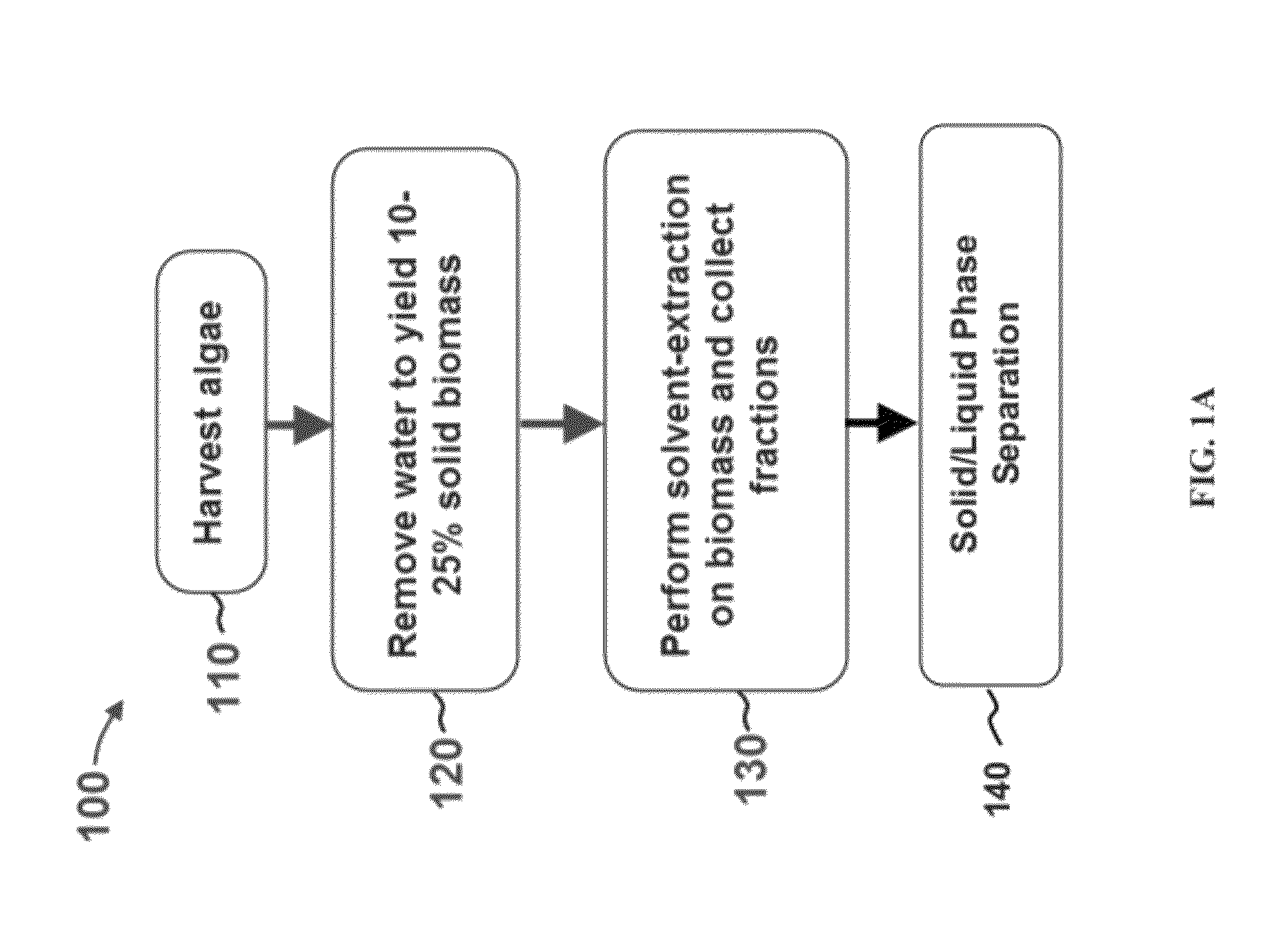

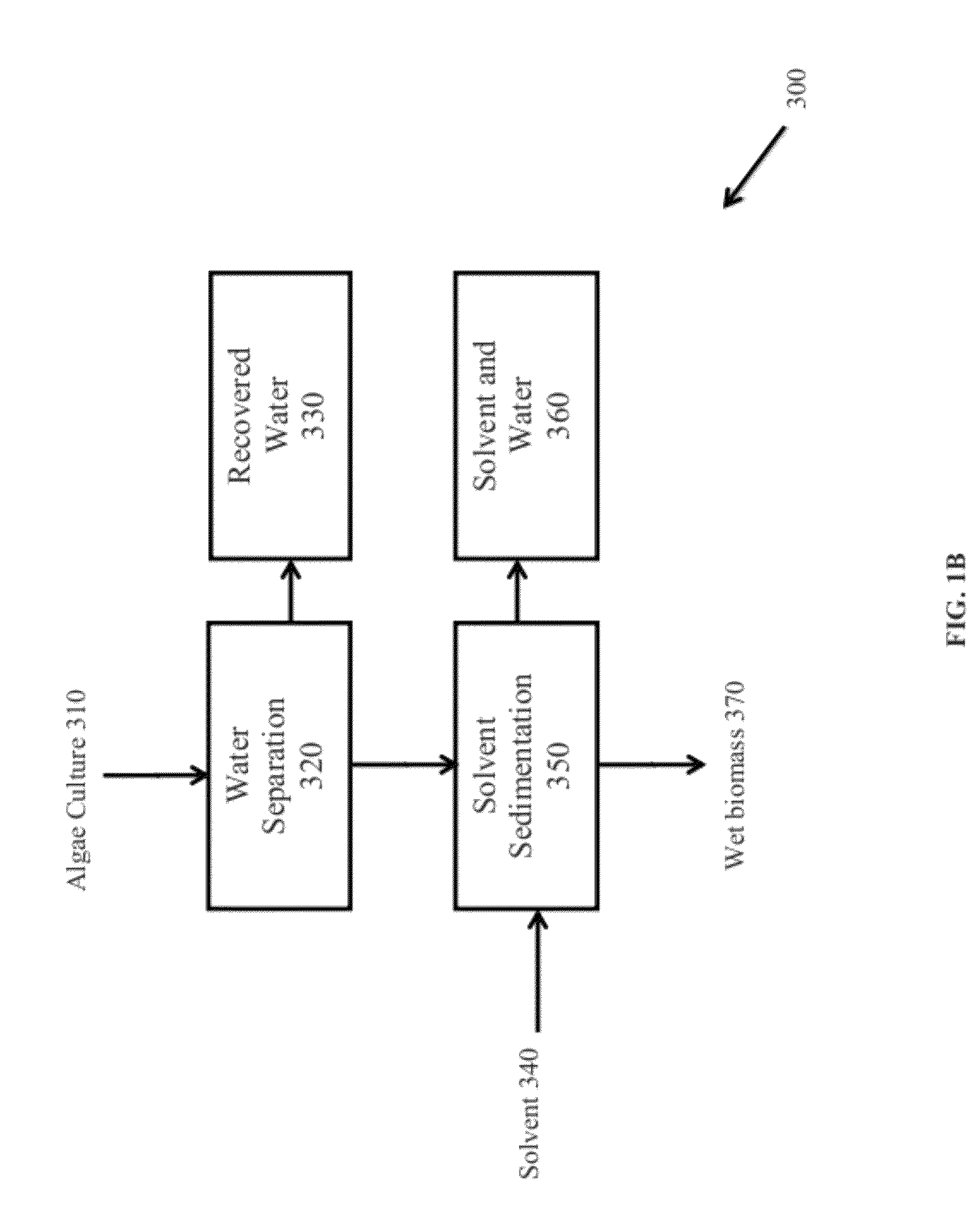

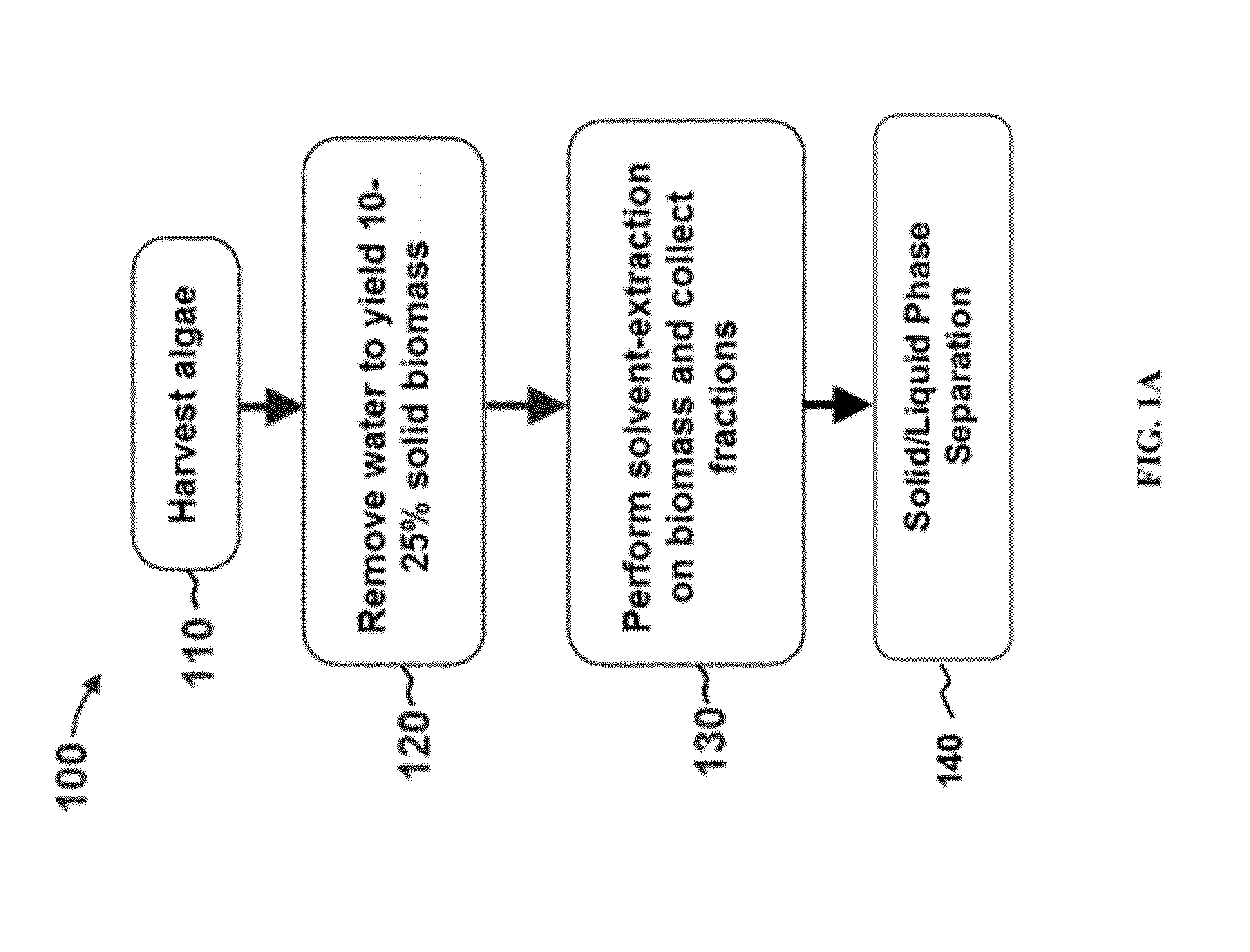

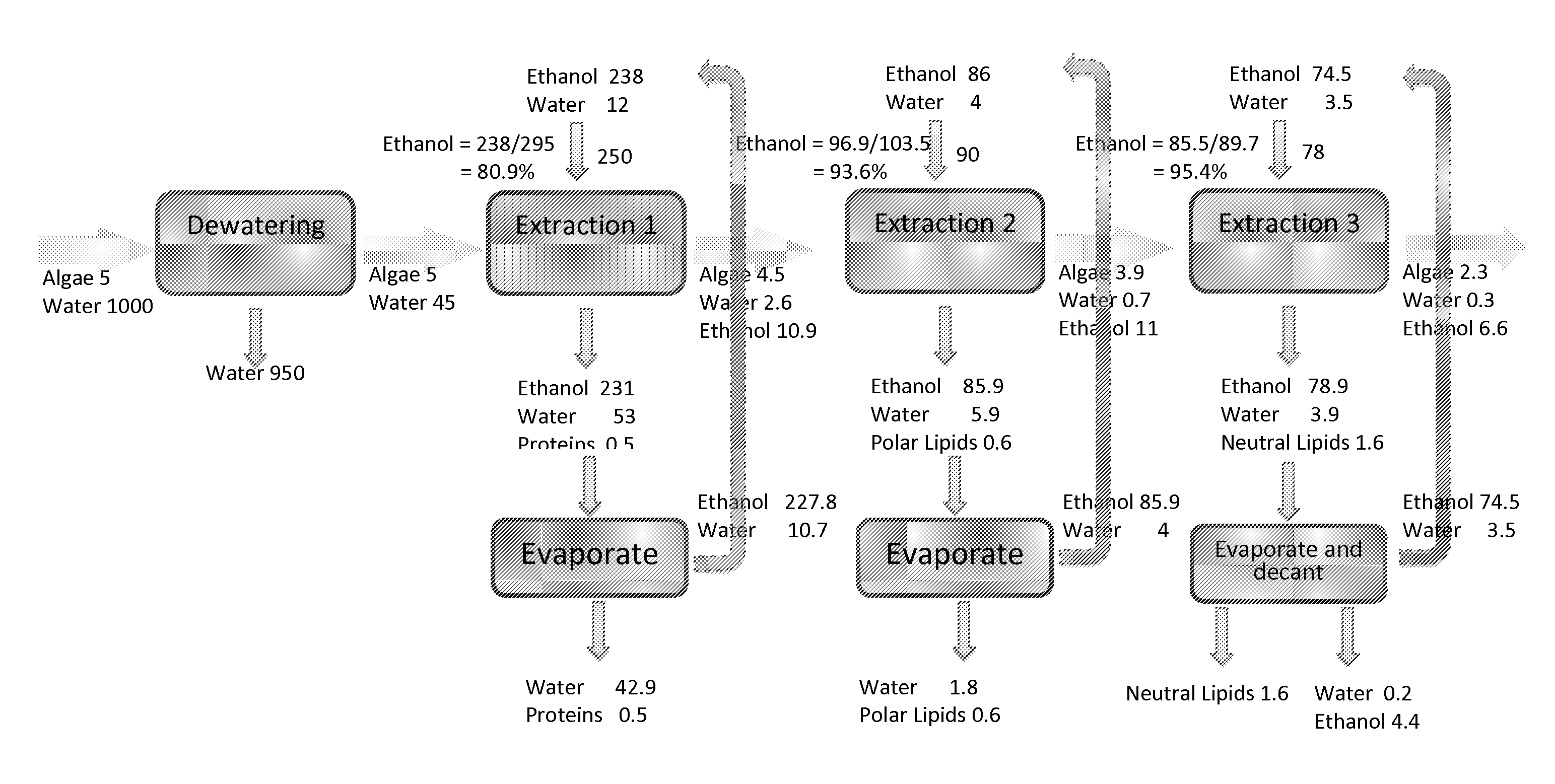

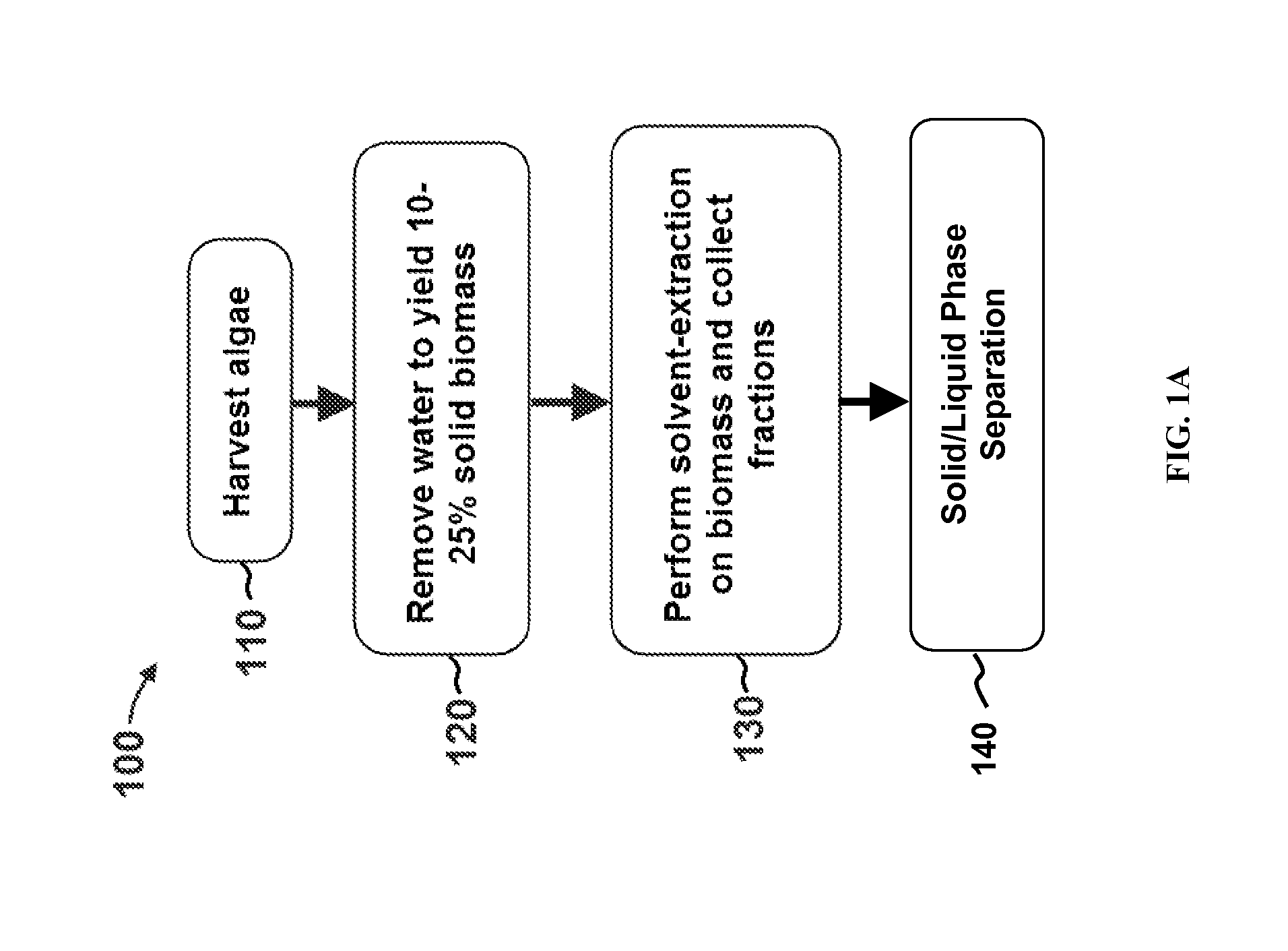

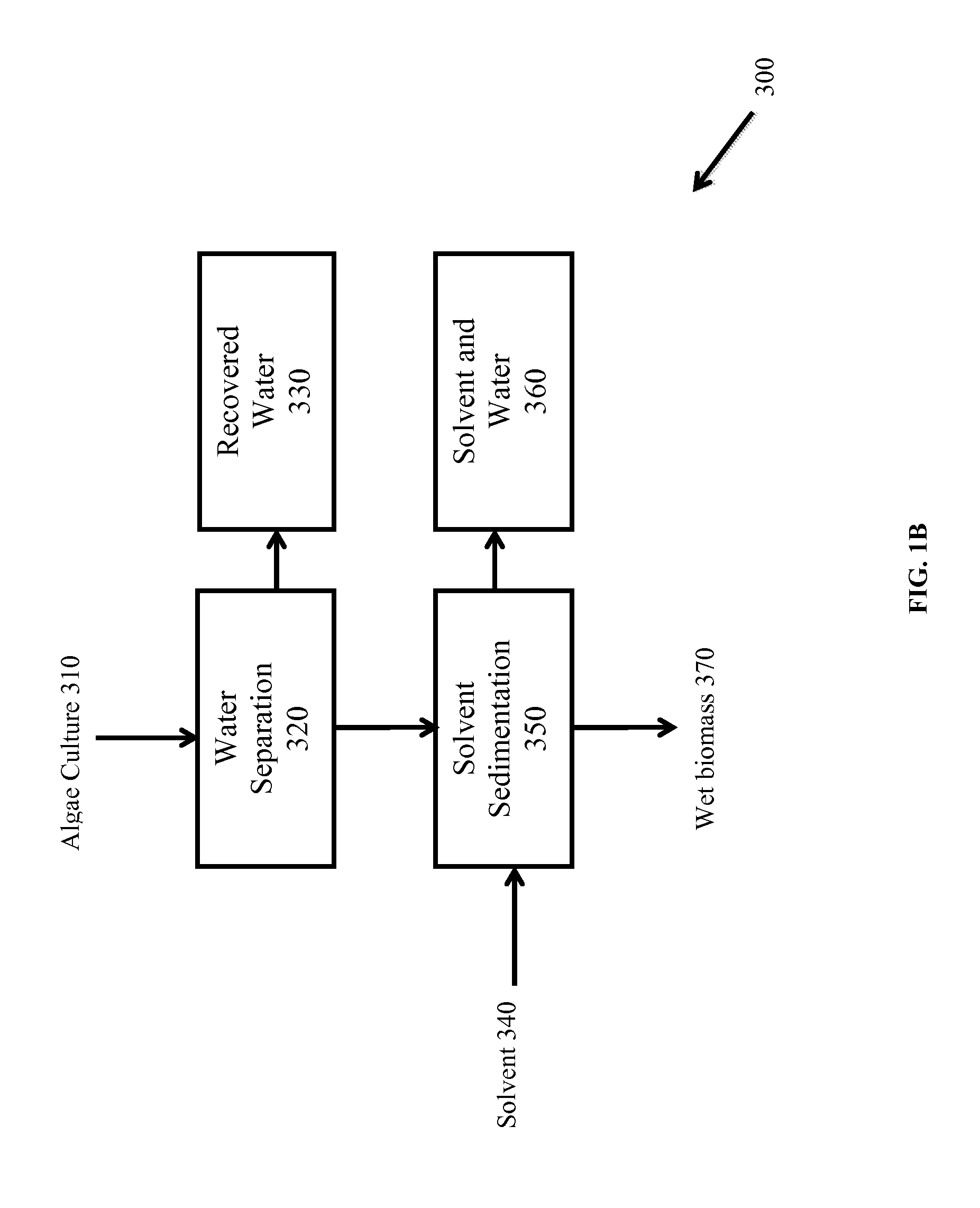

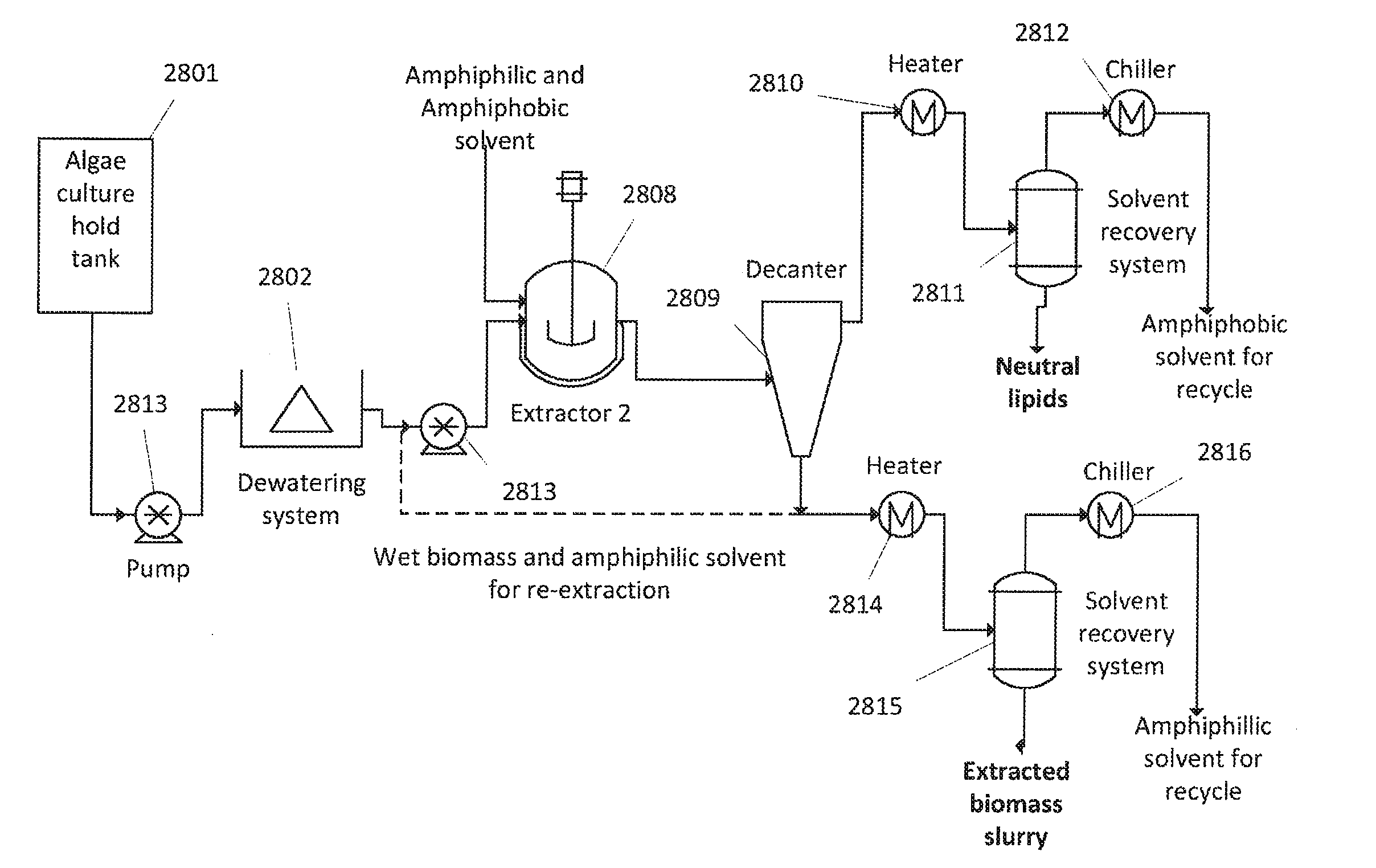

Extraction of polar lipids by a two solvent method

InactiveUS20120053357A1Reduce processing latencyQuantity minimizationWater/sewage treatment by centrifugal separationSemi-permeable membranesFood additiveSolvent

Owner:HELIAE DEVMENT

Gasification and steam methane reforming integrated polygeneration method and system

InactiveUS20100158792A1Improve reliabilityMaximizes reliability of productionCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum coke

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

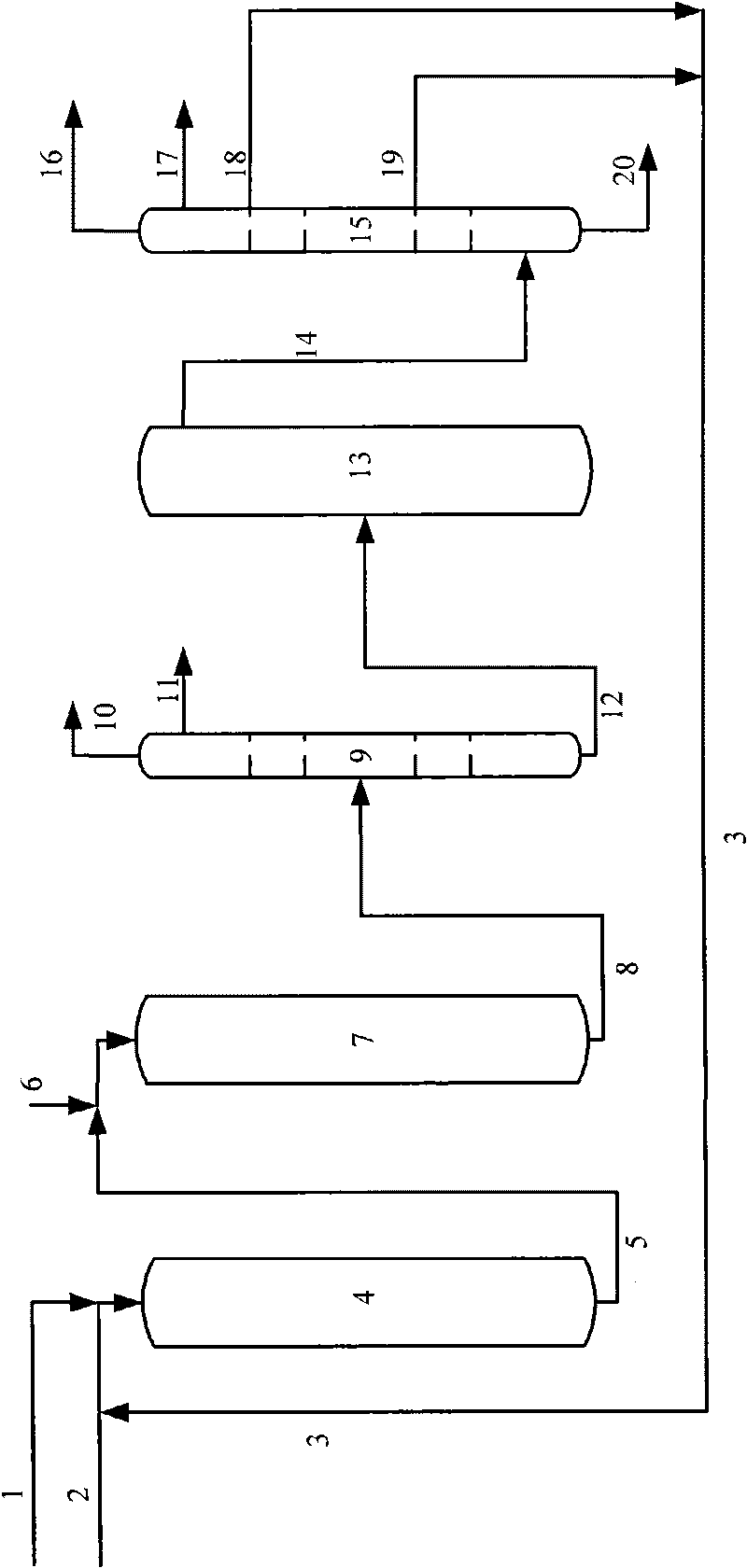

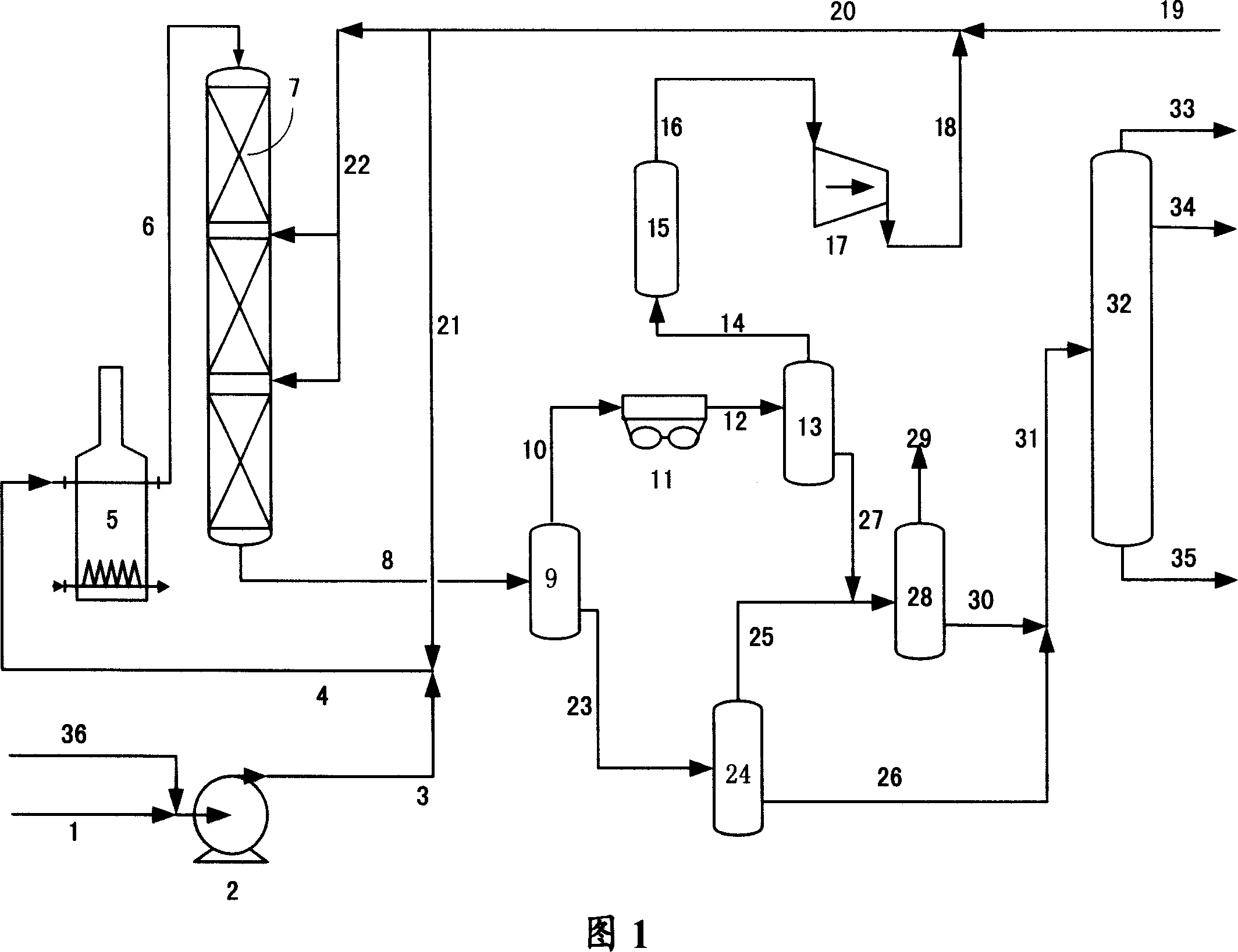

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

ActiveCN101747935AImprove propertiesDoes not affect activityTreatment with hydrotreatment processesWaxResidual oil

The invention provides a method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons. The method produces qualified catalytic cracking raw materials through hydrogenation by taking wax oil and residual oil as raw materials, returns light cycle oil and heavy cycle oil which are catalytic cracking by-products to a hydrogenation unit for the catalytic cracking rawmaterials at the same time, hydrogenates the catalytic cracking by-products together with the catalytic cracking raw materials, and then takes the obtained product as the catalytic cracking raw materials to produce light olefins and monocyclic aromatic hydrocarbons. By introducing the residual oil before a second reaction zone of hydrogenation, the method widens the sources of the catalytic cracking raw materials, increases the processing amount of low-value residual oil, and solves the problem of the heat balance of catalytic cracking units. The light and heavy cycle oil of catalytic cracking is introduced into the hydrogenation unit, hydrogenated and then taken as the catalytic cracking raw materials, so that the yield of high-value products of the catalytic cracking units can be increased, and the deactivation of hydrogenation catalysts is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

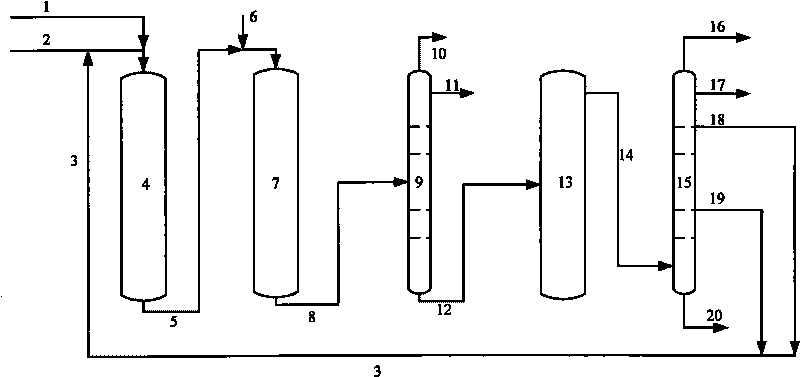

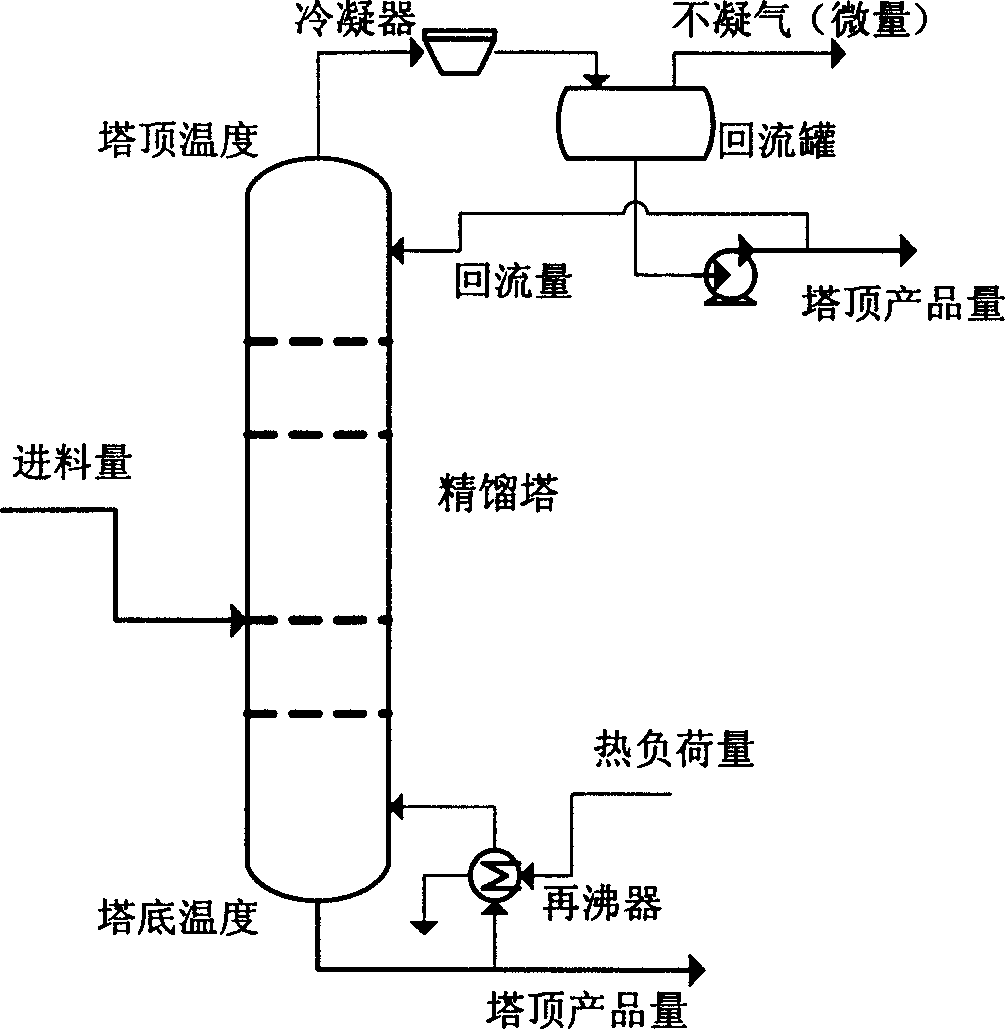

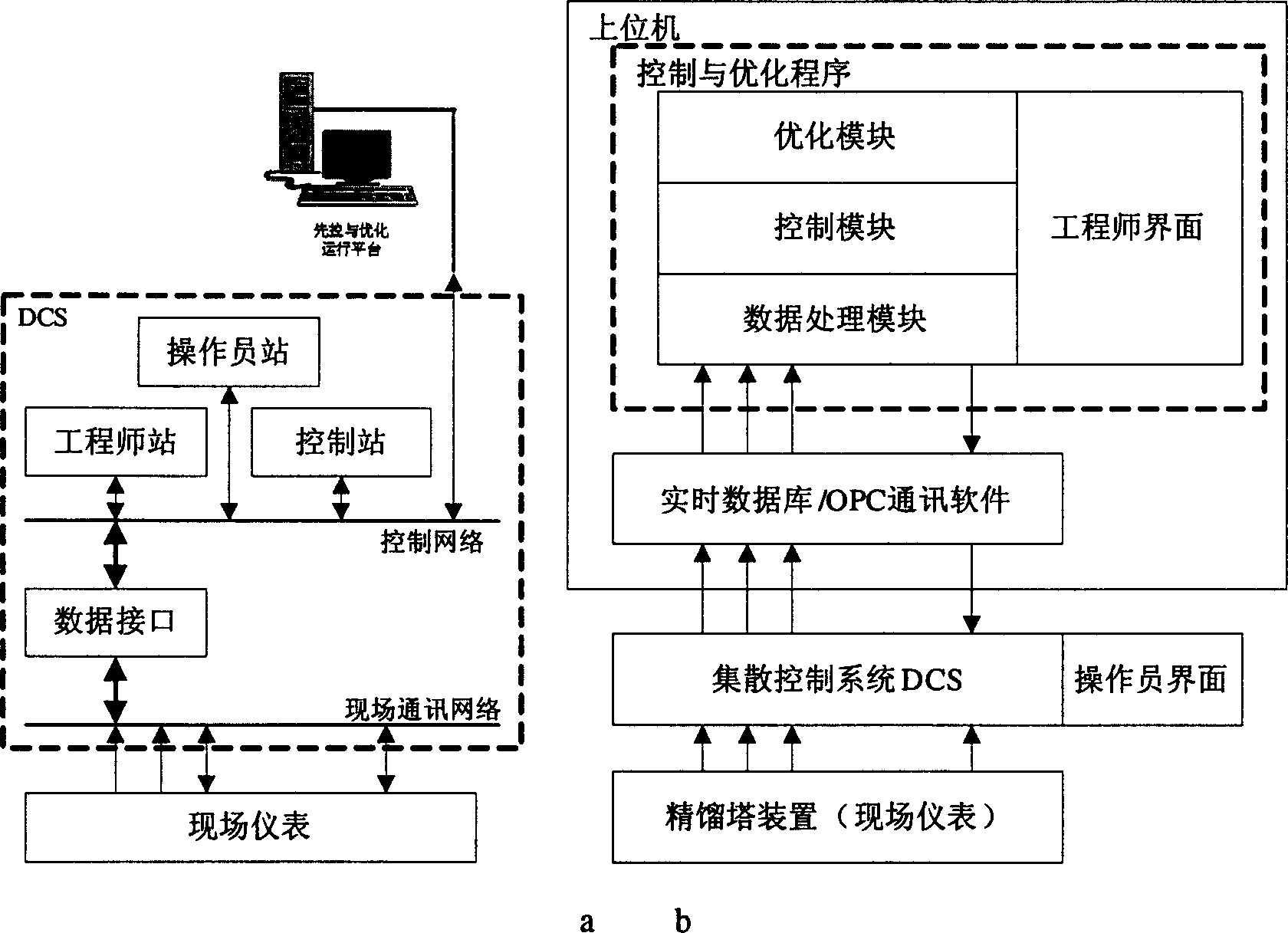

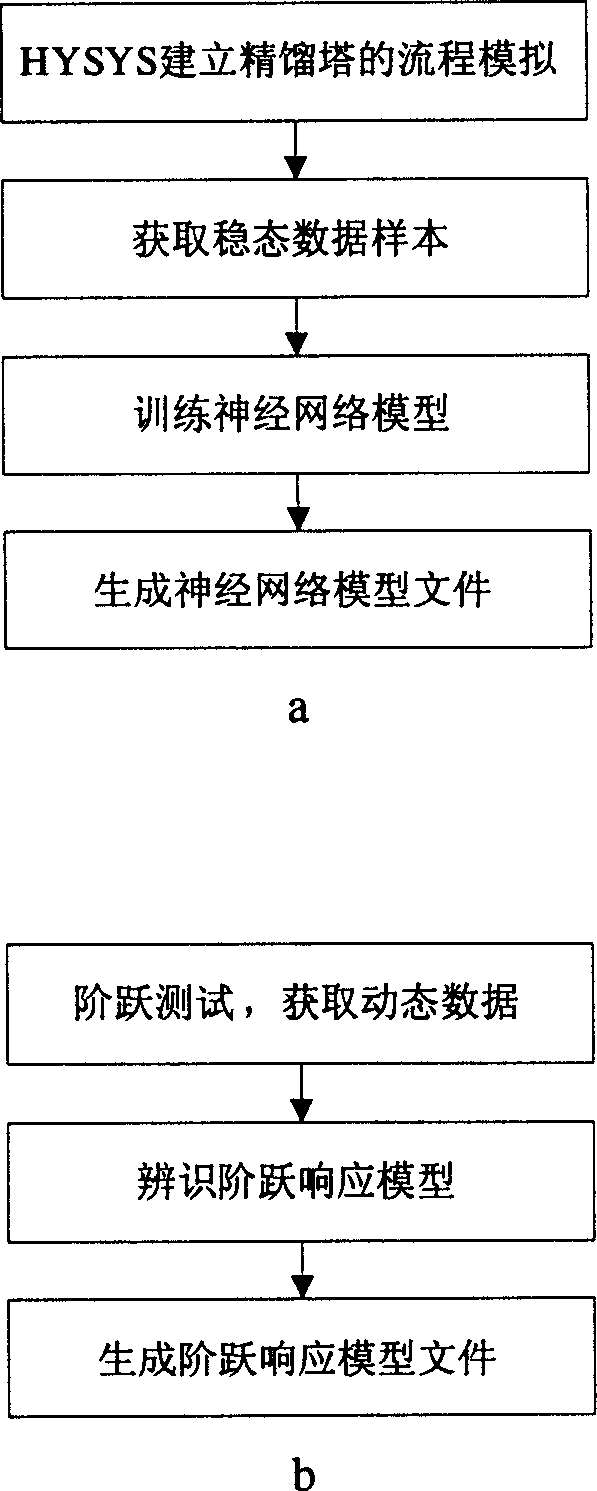

Rectification tower automatic control and optimization method

InactiveCN1762525AEasy to operateLess impuritiesDistillation regulation/controlAutomatic controlMaterial balance

The invention relates to a method for controlling and optimizing the distillation tower. It controls the distillation tower in dependence on the material balance relation and component balance relation, optimizes the distillation tower by using representative model. Employing the abstraction proportion between the light product on the top of the tower and heavy product in the bottom of the tower (in following, taking the proportion between light and heavy product for abbreviation) as main controlled variable depending on the distillation principle, the material balance and component balance in the distillation tower, controlling the proportion between the light and heavy product, temperature, reflux ratio to realize stable operation by regulating the quantity of reflux and heat load of re-boiler. Simulating the practical course through the technological process simulation software, and training the nerve net model to become the representative model for the course optimization. Optimizing the operation with the representative model by using the analytical data for the raw material and product to realize the product Ka bian optimization, increasing the productivity of product with high value on the condition of guaranteeing the product quality and realizing the device energy saving and consumption reduction.

Owner:TSINGHUA UNIV

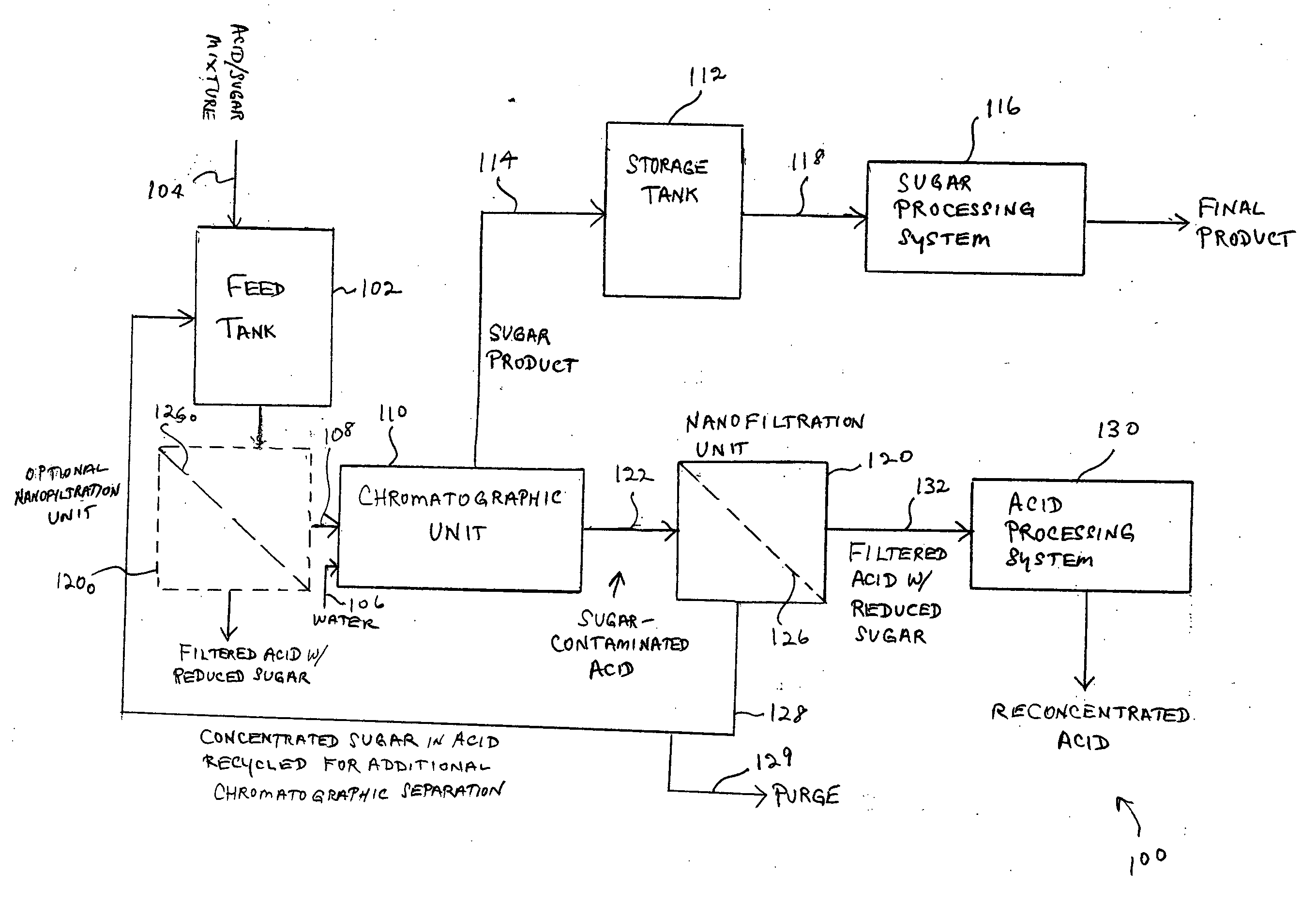

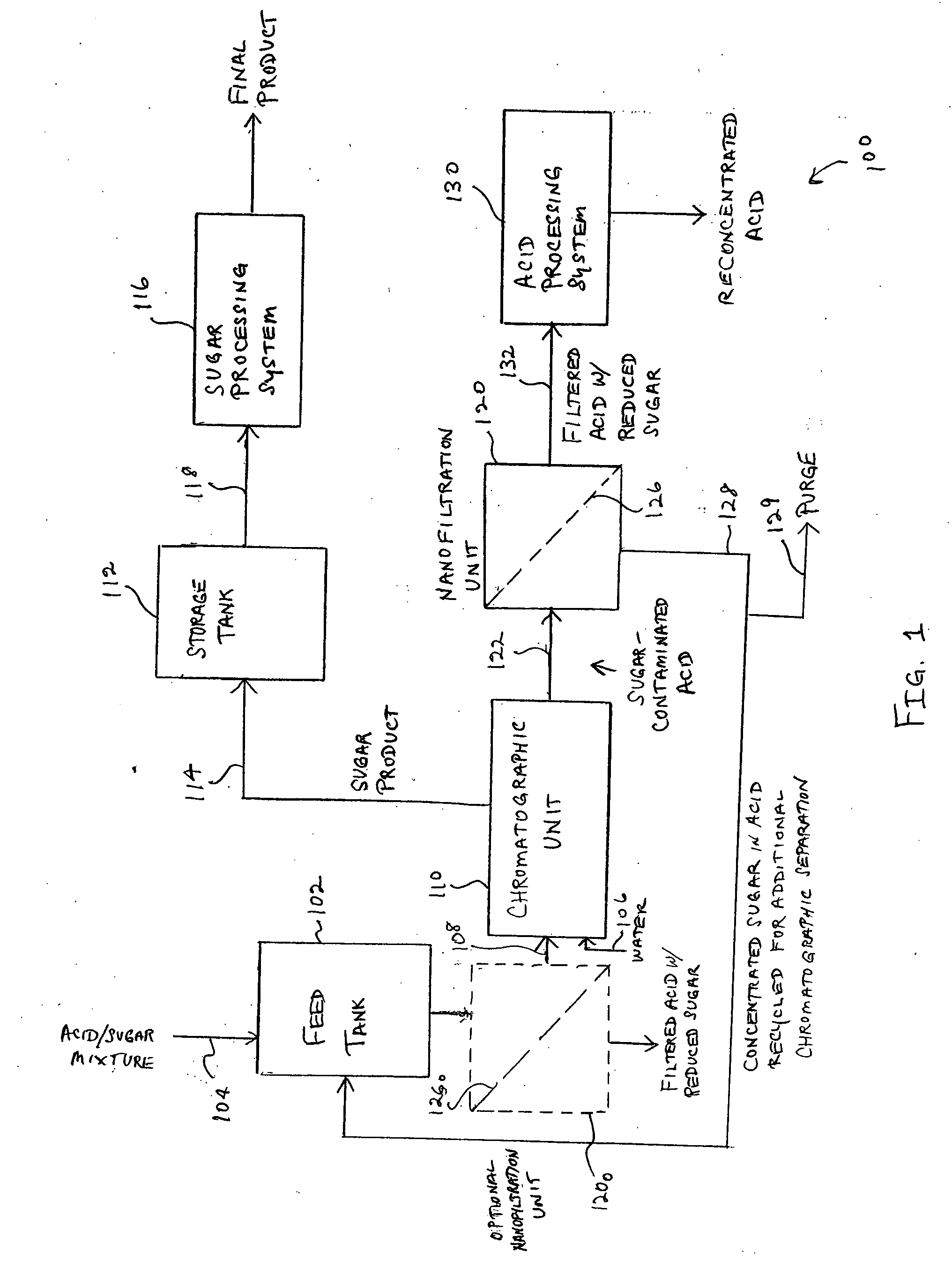

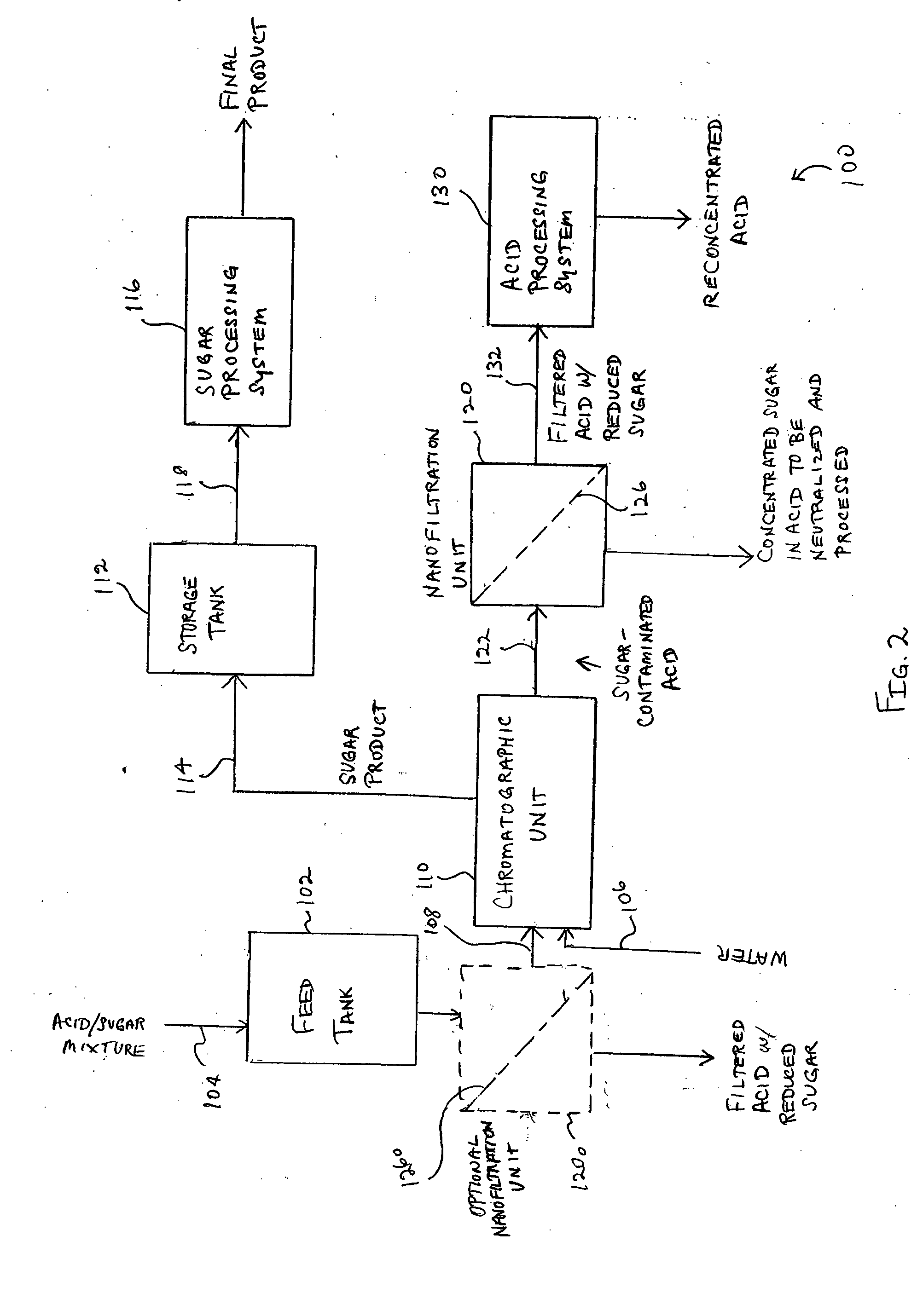

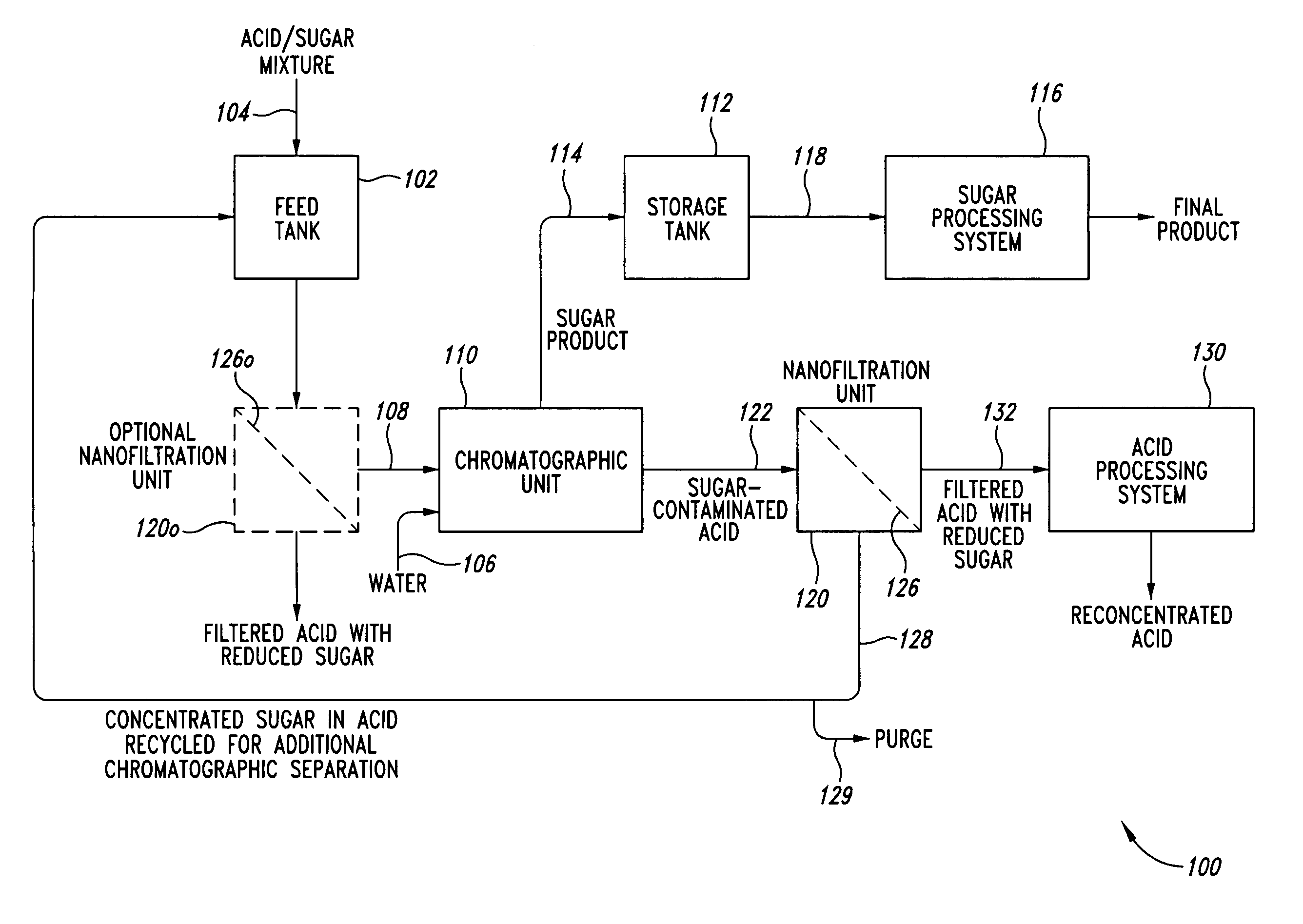

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

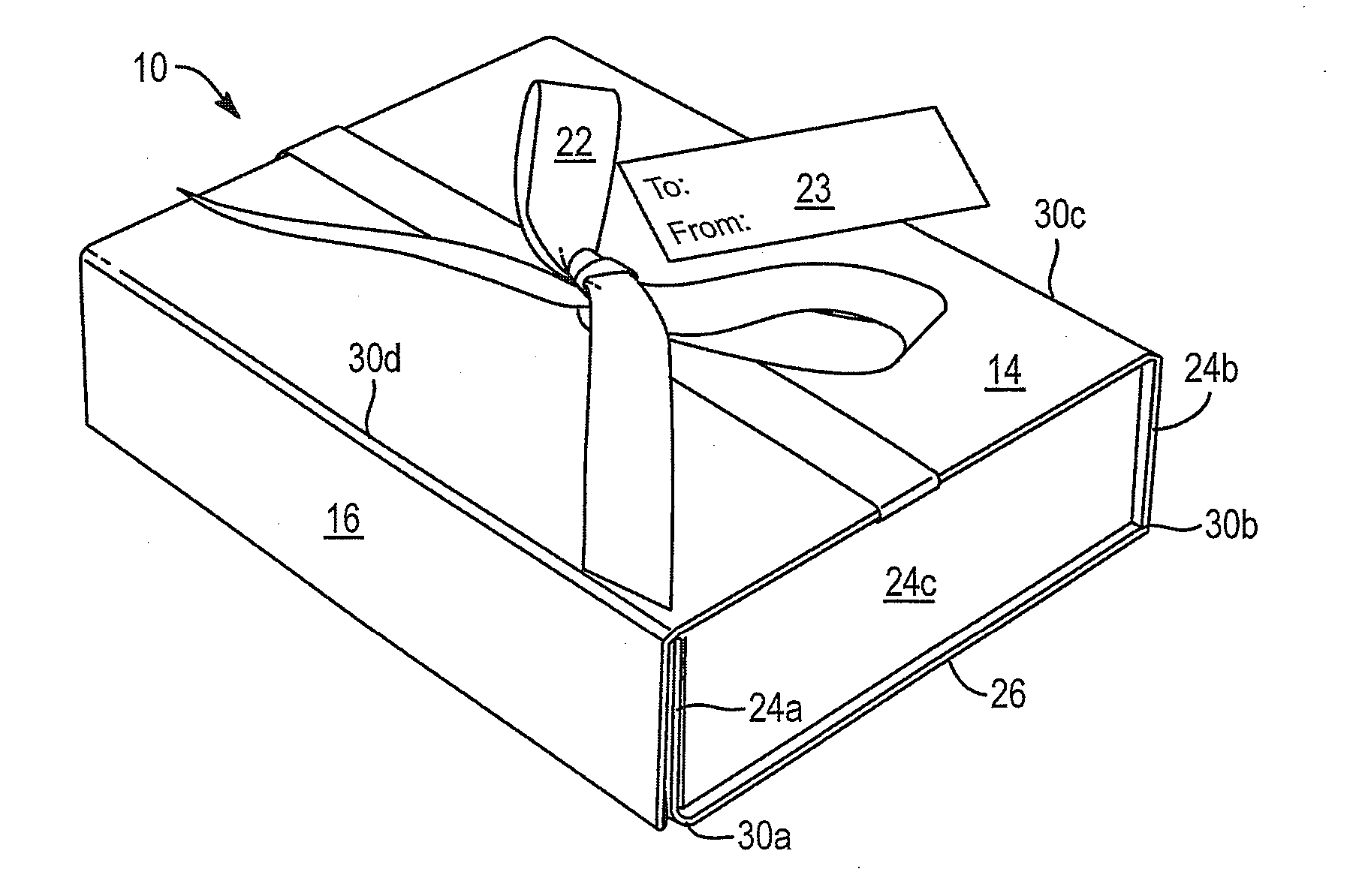

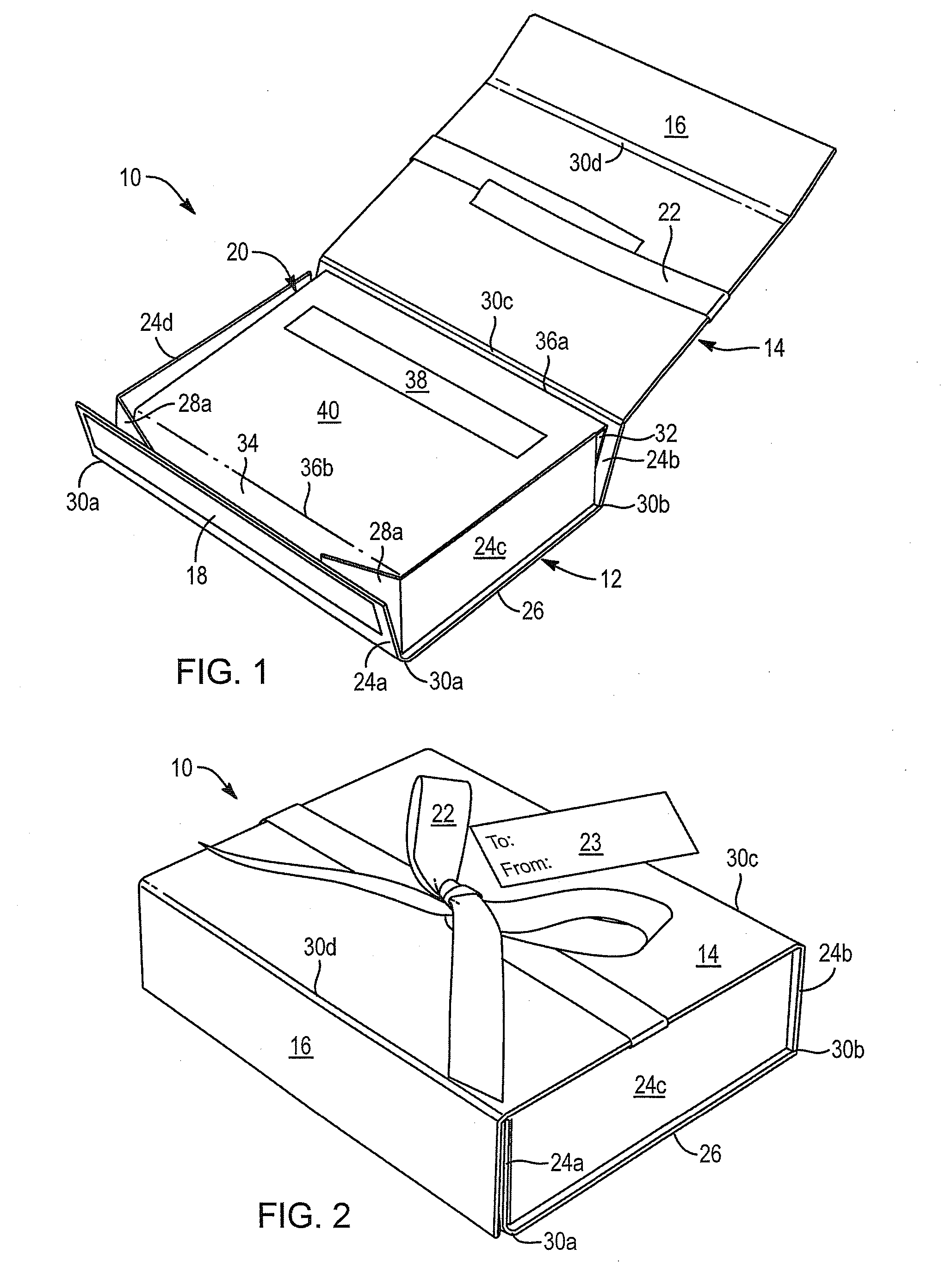

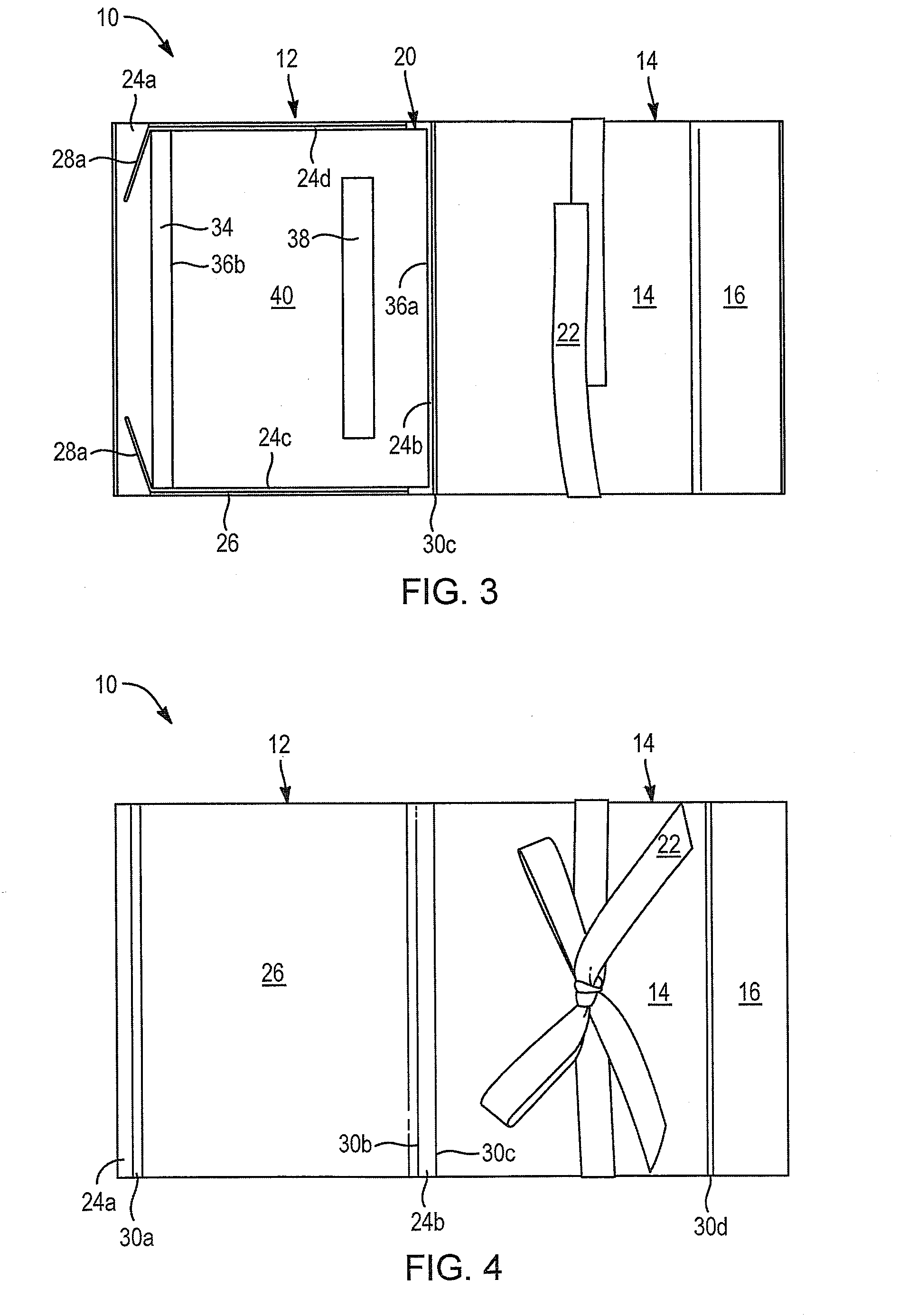

Tuck-and-retain, presentation panel apparatus and method

A gift box for gift cards provides a presentation appearing like gift boxes for other high value products, such as jewelry. With strength, durability, three full dimensions, colors, quality, and design options, it can receive decorations, ribbons, and bows, a to / from card, and the like. Requiring no assembly of components, a single, integrated box includes all parts and configures simply. An interior panel presents a gift card, a debit card pre-loaded with a purchased value. A front flap of the interior panel may tuck down into the box. Alternatively, the panel may be pushed down at the front, leaving the front flap extending straight up, holding the front of the panel downward in place while also serving as an interior, front, wall liner for the box.

Owner:NEBEKER MICHAEL S +3

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

Extraction of polar lipids by a two solvent method

InactiveUS8211308B2Quantity minimizationReduce processing latencyWater/sewage treatment by centrifugal separationSemi-permeable membranesFood additiveSolvent

A method for separating polar lipids from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting polar lipids from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal polar lipids from a wet algal biomass while avoiding emulsification of extraction mixtures. These polar lipids are high value products which can be used as surfactants, detergents, and food additives. Neutral lipids remaining in the algal biomass after extraction of polar lipids can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

Methods for making higher value products from sulfur containing crude oil

ActiveUS7790018B2High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

Extraction of polar lipids by a two solvent method

InactiveUS20120277450A1Reduce processing latencyQuantity minimizationFatty-oils/fats productionFood additiveSolvent

A method for separating polar lipids from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting polar lipids from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal polar lipids from a wet algal biomass while avoiding emulsification of extraction mixtures. These polar lipids are high value products which can be used as surfactants, detergents, and food additives. Neutral lipids remaining in the algal biomass after extraction of polar lipids can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

Method of dense raw material hydrotreatment-catalytic cracking for improving propylene productivity

ActiveCN101063047AHigh yieldTreatment with hydrotreatment processesHydrogenation reactionCutting oil

The invention discloses a heavy raw material hydrotreating-catalytic cracking method to increase propone productivity, which comprises the following steps: choosing light circling oil and or weight circling oil from catalytic cracking unit; adding into hydrogenation reaction zone with heavy cut oil; or adding into two hydrogenation reaction zone with different hydrogenation catalyst to react; getting effluent; cooling; separating; fractionating; getting heavy liquid phase fraction; moving catalytic cracking unit; separating the catalytic cracking reacting product; getting the final product. This invention can dispose cycloalkyl heavy raw material, which propone receiving ratio can increase by 5-7 percent dot.

Owner:CHINA PETROLEUM & CHEM CORP +1

Conversion of syngas to distillate fuels

An integrated process for producing high value products, including for example distillate fuel, from syngas is disclosed. The integrated process of the present invention produces high value products from a Fischer Tropsch with minimal production of low value products, including methane. In a process of the present invention, syngas is reacted under low temperature Fischer-Tropsch reaction conditions to provide a hydrcarbon product stream comprising substantially waxy products. The waxy products are subjected to an olefin-selective paraffin cracking process, preferably in a Paragon reactor to form olefins. The resulting olefins are then subjected to oligomerization conditions to form iso-olefins. In the processes of the present invention, the hydrocarbon product stream from the Fischer Tropsch reaction comprises desirable low levels of methane, preferably below 10%.

Owner:CHEVROU USA INC

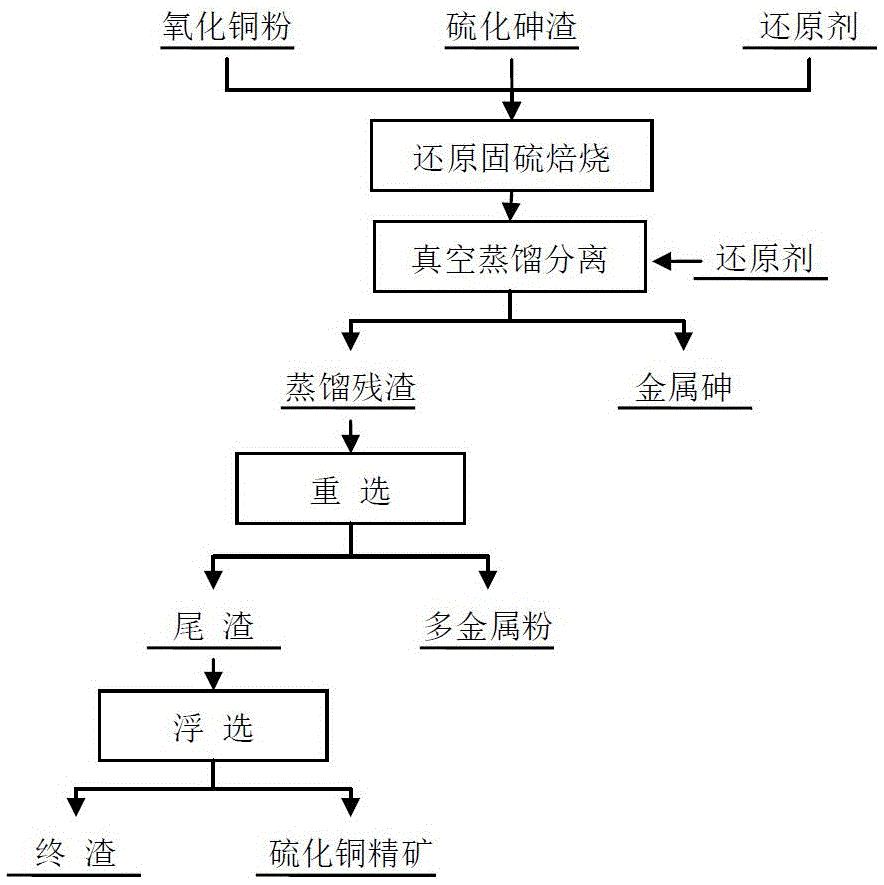

Method for metallic arsenic production directly through reducing sulfur-fixed roasting of arsenic sulfide residues

ActiveCN106756113AEfficient arsenic removalShort processProcess efficiency improvementDistillationCopper sulfide

The invention discloses a method for metallic arsenic production directly through reducing sulfur-fixed roasting of arsenic sulfide residues. The arsenic sulfide residues produced in the acidic wastewater purifying working procedure of a copper smelting plant serve as a raw material, meanwhile cupric oxide powder and a reducing agent are added, low-temperature reducing sulfur-fixed roasting is conducted after metallurgy calculation and ingredient mixing are conducted, and volatility of arsenic is utilized to enable roasted products to be subjected to vacuum separation in the reducing atmosphere so that the crude metal arsenic and distillation residues can be obtained; and distillation residues are subjected to a reselection technique for separation to obtain multi-metal powder and tailings, and the tailings are subjected to a flotation technique to obtain final residues and copper sulfide concentrates. According to the method for metallic arsenic production directly through reducing sulfur-fixed roasting of the arsenic sulfide residues, efficient arsenic removal of the arsenic sulfide residues can be achieved, harmless high-value products of the arsenic are directly produced, the process is short, energy consumption is low, the process is clean, and the direct recovery rate of the metal arsenic reaches up to 96.45%; and meanwhile, recovery of valuable metal existing in the arsenic sulfide residues is completed, and the cupric oxide powder is recovered in a high-quality copper sulfide concentrate mode finally.

Owner:广西河池鑫银环保科技有限公司

Technique for coproducing methanol from coke oven gas and fuel products by hydrogenating coal tar prepared from tail gas of methanol preparation

InactiveCN101239887ATo achieve the effect of energy saving and emission reductionOrganic compound preparationHydroxy compound preparationNitrogen gasHeat energy

The invention relates to a hydrogenation process for preparing oil products from coal tar which is generated together with exhaust gas synthesized during preparation of methanol from a coke oven and coal gas. Methanol is prepared from coal gas which is the by-product of the coke oven, large amount of relief gas and nitrogen gas during the methanol preparation process, hydrogen is extracted from the relief gas and used as one of the materials for hydrogenation preparing light fule oil from tar, nitrogen is extracted as the material of a coke dry quenching unit, the heat energy generated during the coke dry quenching process is used for generating electric power. With the recycling of coke oven coal gas, the prior exhaust gas which is directly exhausted or burnt is changed into a high-value product, such as electricity, methanol, light fuel oil, advanced charcoal material, etc., at the same time, the object of energy conservation can be realized.

Owner:QITAIHE BAOTAILONG COAL CHEM IND

Extraction of proteins by a two solvent method

InactiveUS8308951B1Quantity minimizationReduce processing latencyFatty acid esterificationMicroorganism lysisFood additiveSolvent

A method for separating proteins from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting proteins from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal proteins from a wet algal biomass. These proteins are high value products which can be used as renewable sources of food and food additives. Neutral lipids remaining in the algal biomass after extraction of proteins can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

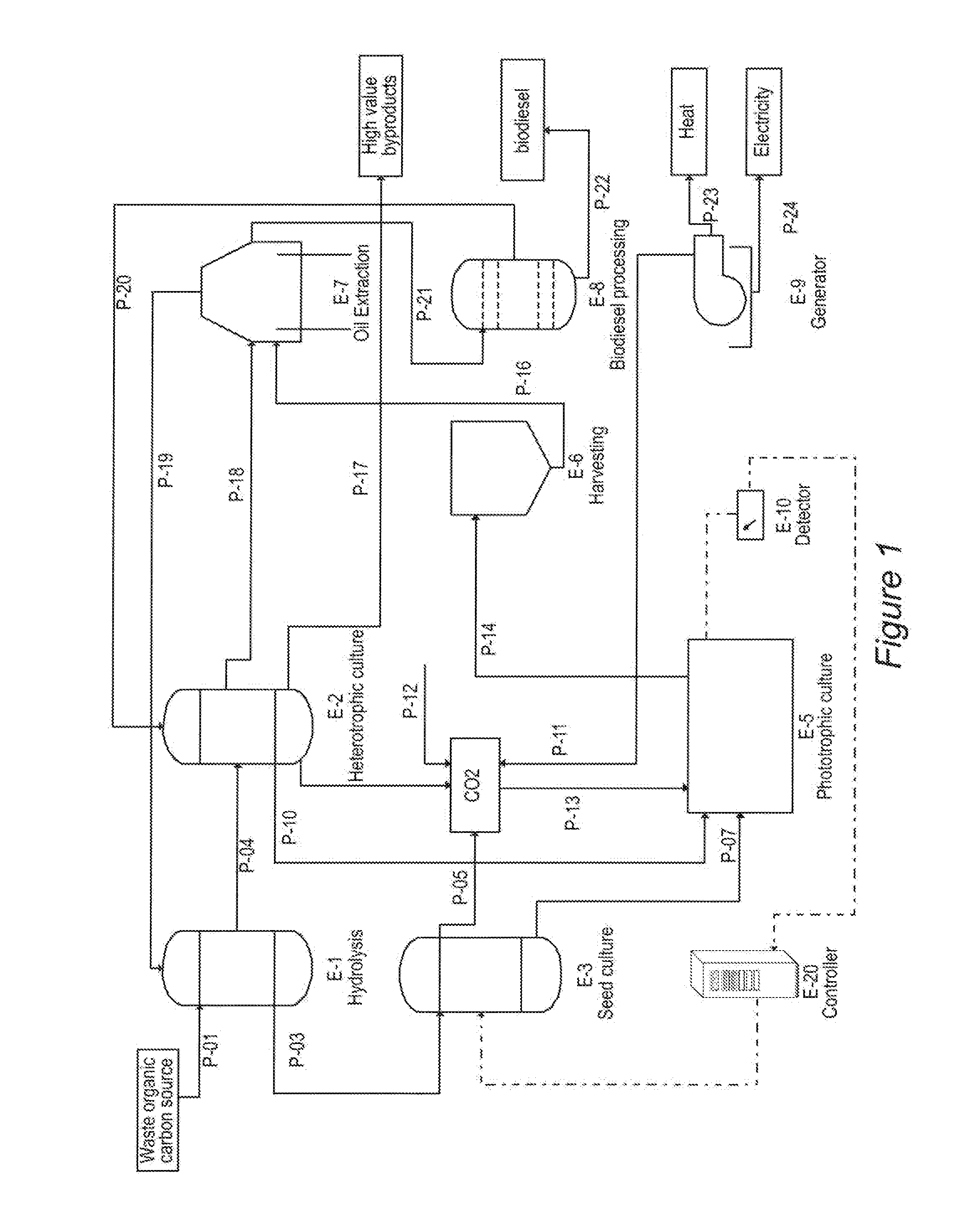

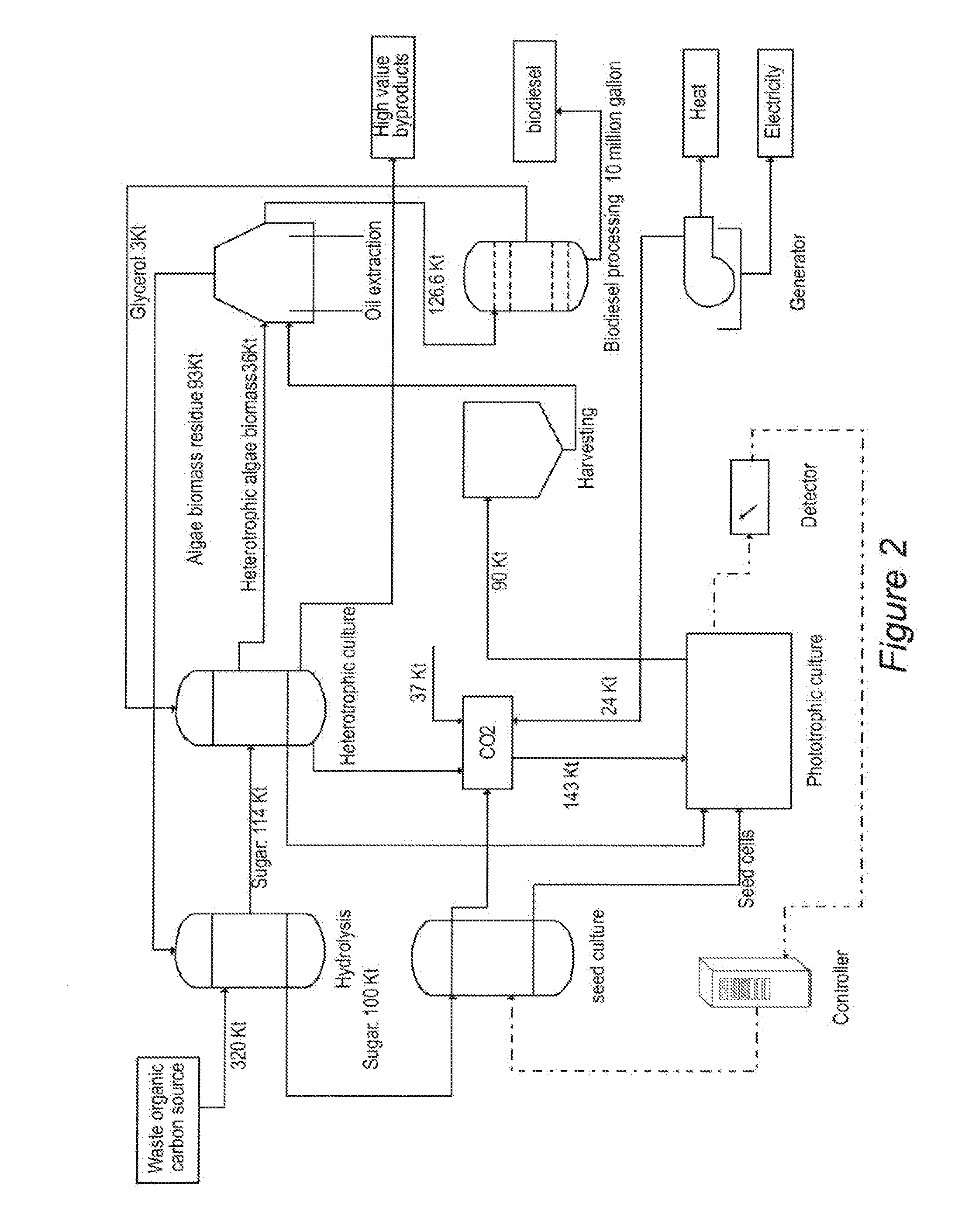

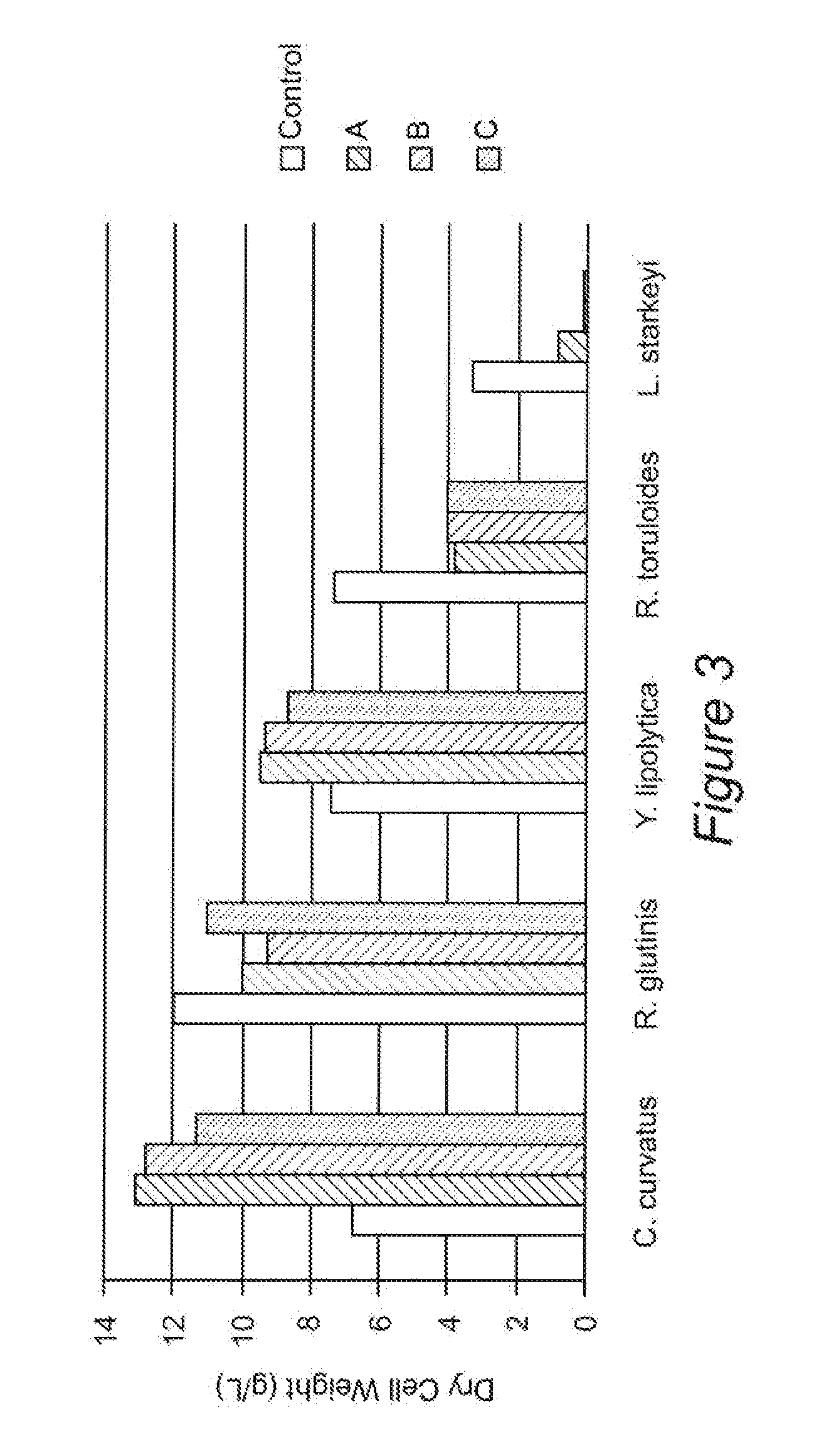

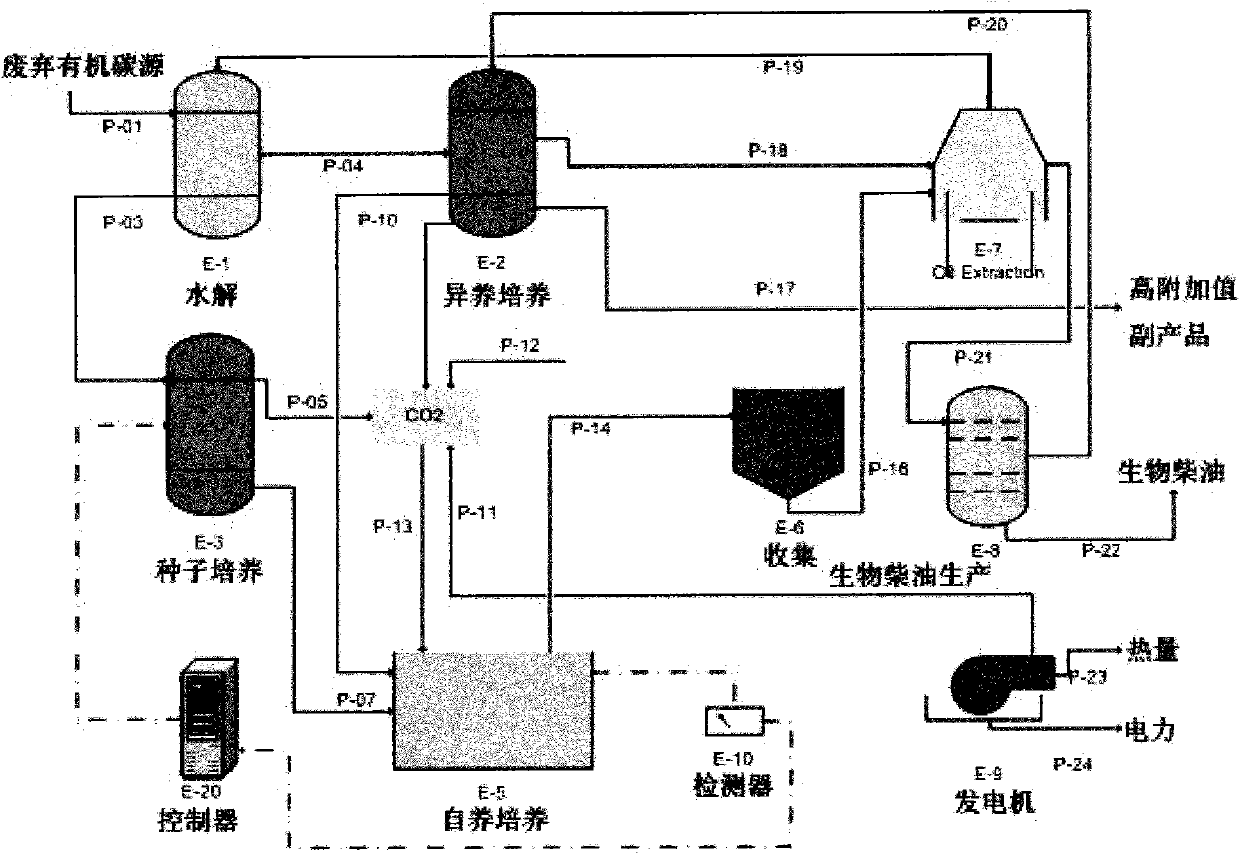

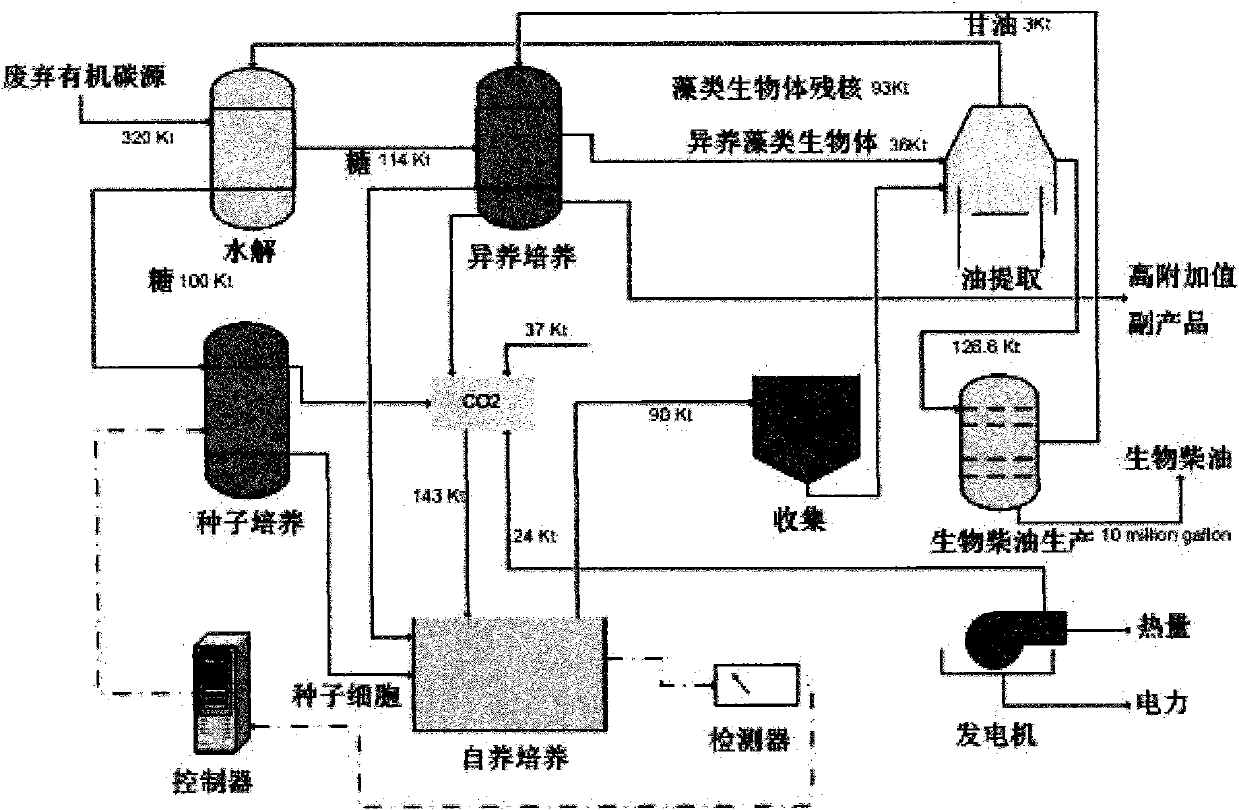

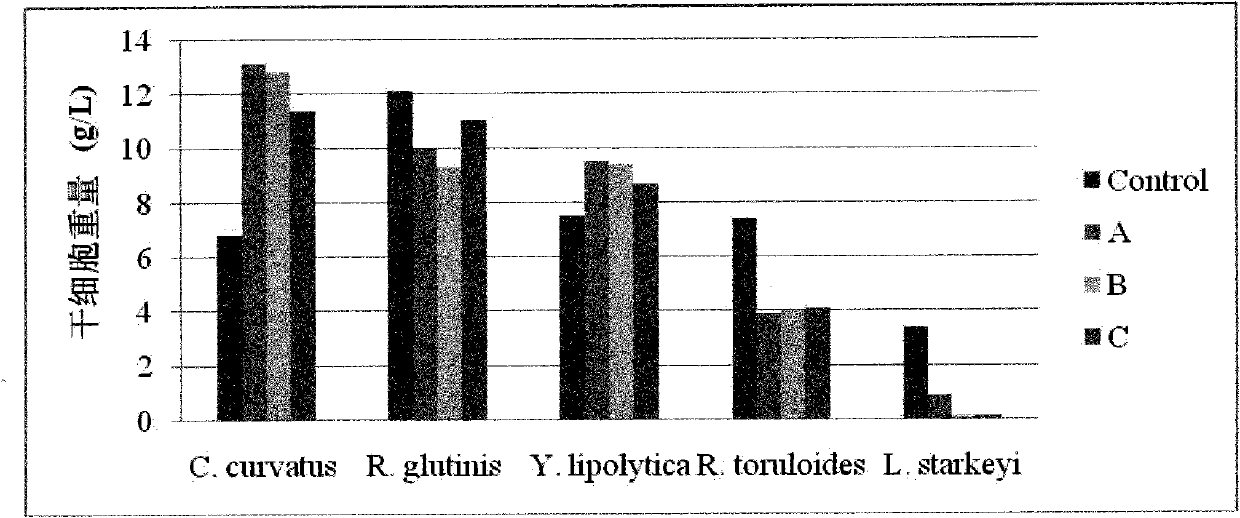

Integrated system for production of biofuel feedstock

InactiveUS20110027827A1Increase flexibilityReduces concern regarding contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsWaste streamBiofuel feedstock

Disclosed is a culture system for the production of algae biomass to obtain lipid, protein and carbohydrate. By integrating heterotrophic processes with a phototrophic process in parallel, this system provides year around production in colder climates. By integrating heterotrophic processes with a phototrophic process in series, this system creates a two-stage, separated mixed-trophic algal process that uses organic carbon and nutrients for the production of seed in the heterotrophic process, followed by release of cultured seed in large-scale phototrophic culture for cell biomass accumulation. Organic carbon source including waste materials can be used to feed the heterotrophic process. The production capacity ratio between the heterotrophic and the phototrophic processes can be adjusted according to season and according to the availability of related resources. The systems are used for producing and harvesting an algal biofuel feedstock as well as other potential high-value products. The sequence and approach enhances utilization of carbon and nutrient waste-streams, provides an effective method for controlling contamination, adds flexibility in regard to production and type of available products, and supplies greater economic viability due to maximized use of available growth surface areas.

Owner:WASHINGTON STATE UNIVERSITY

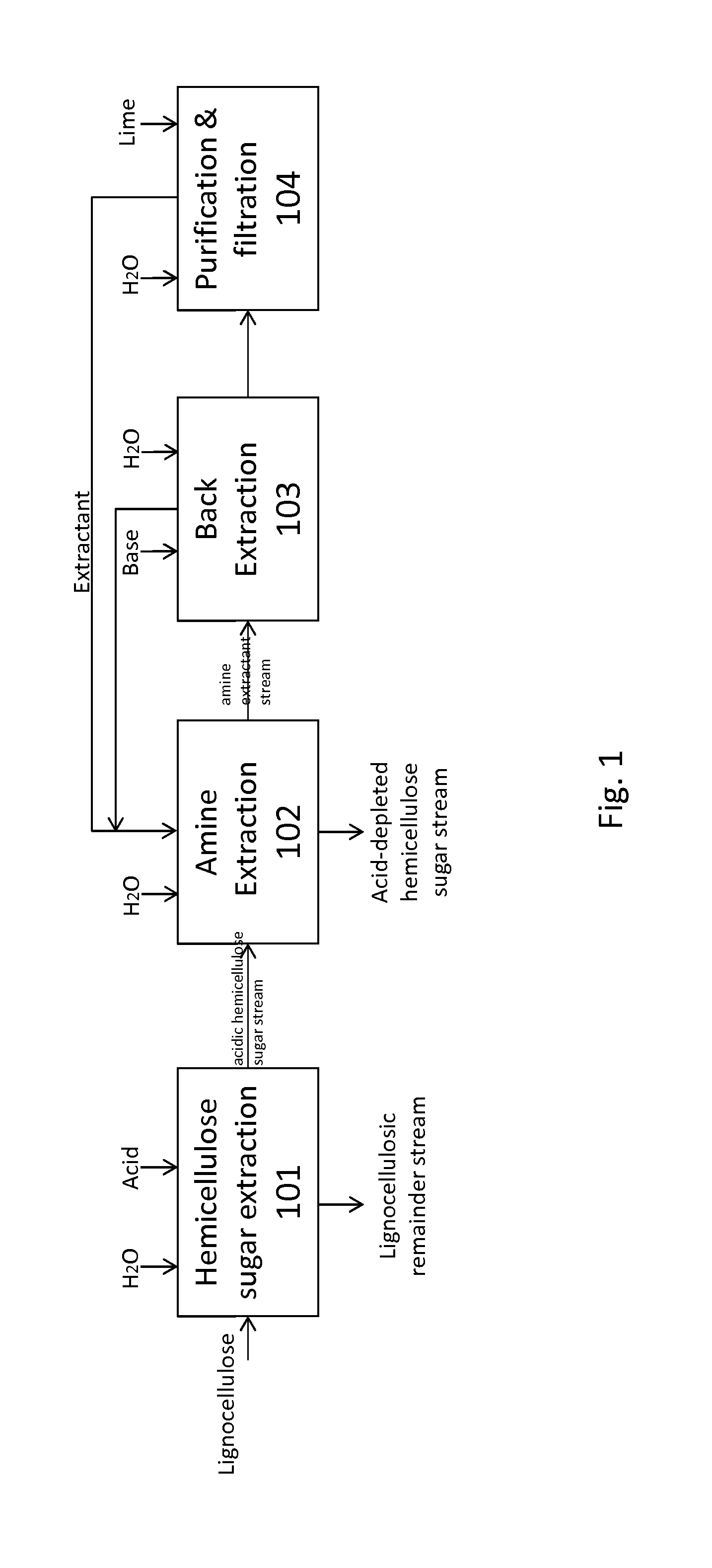

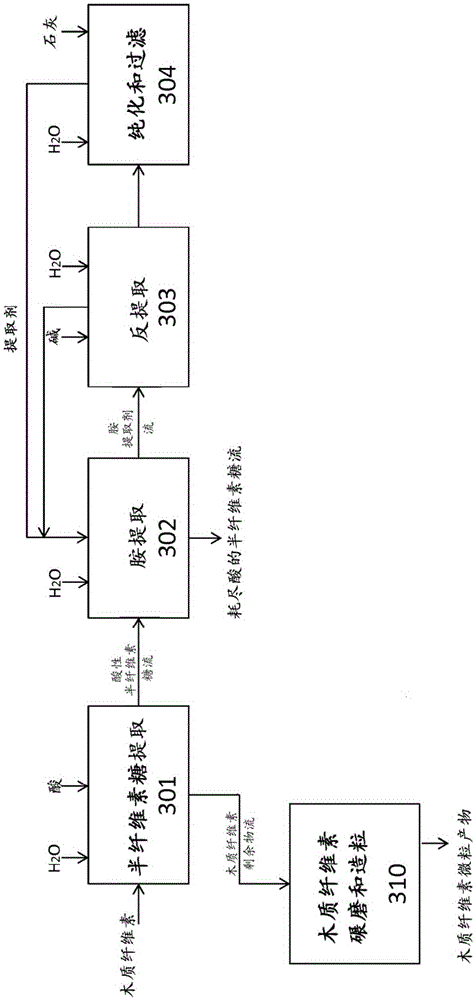

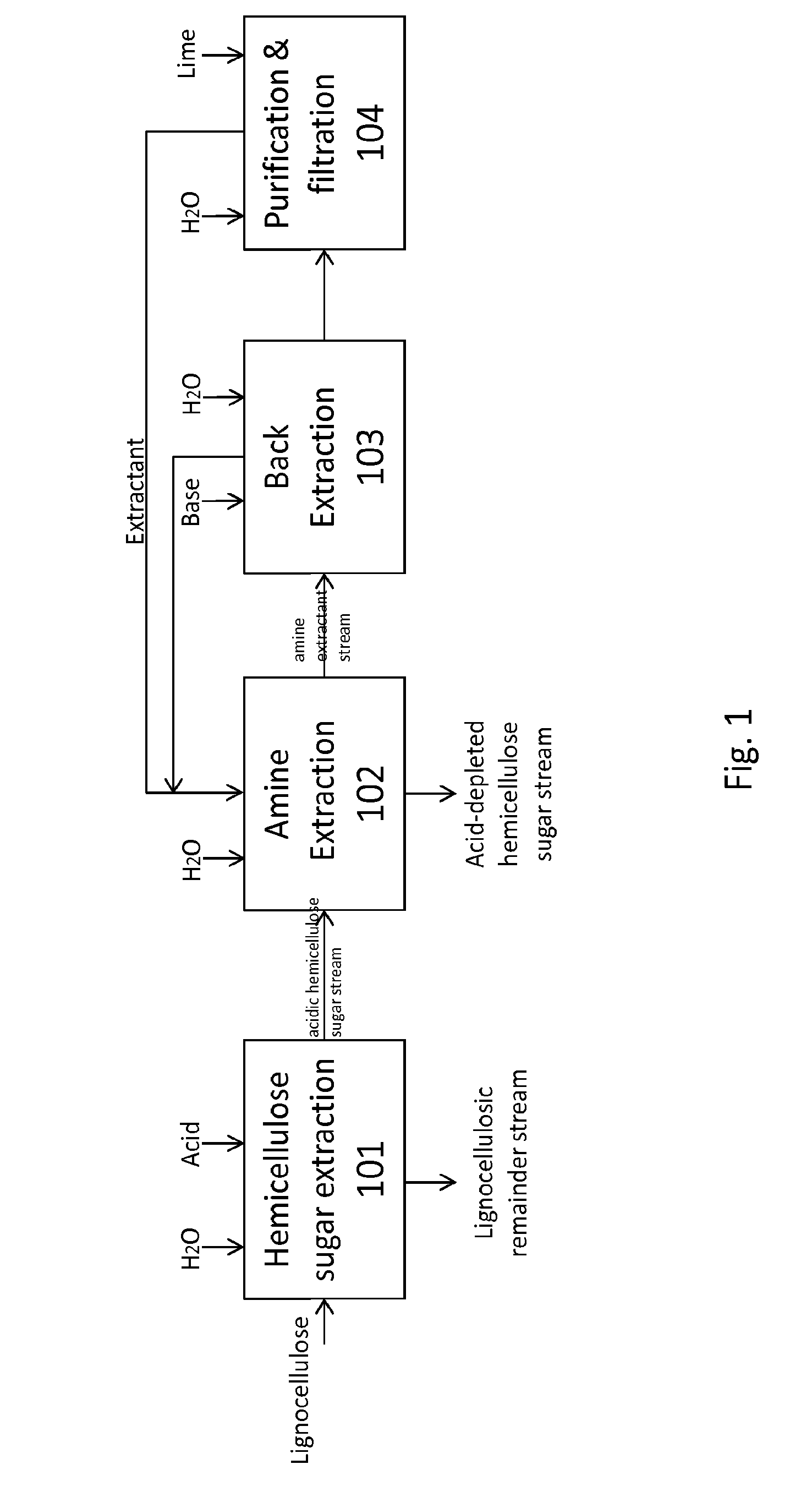

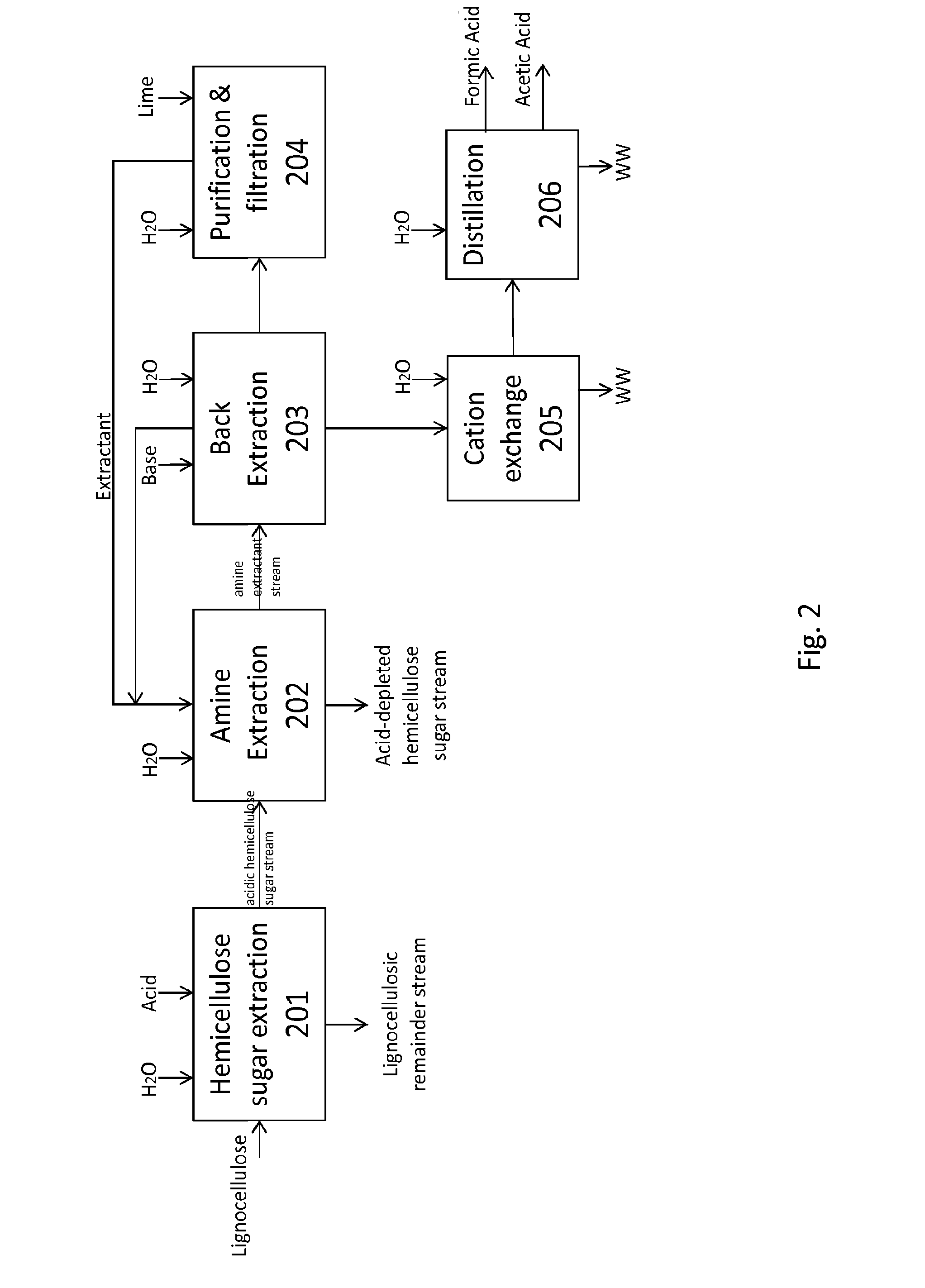

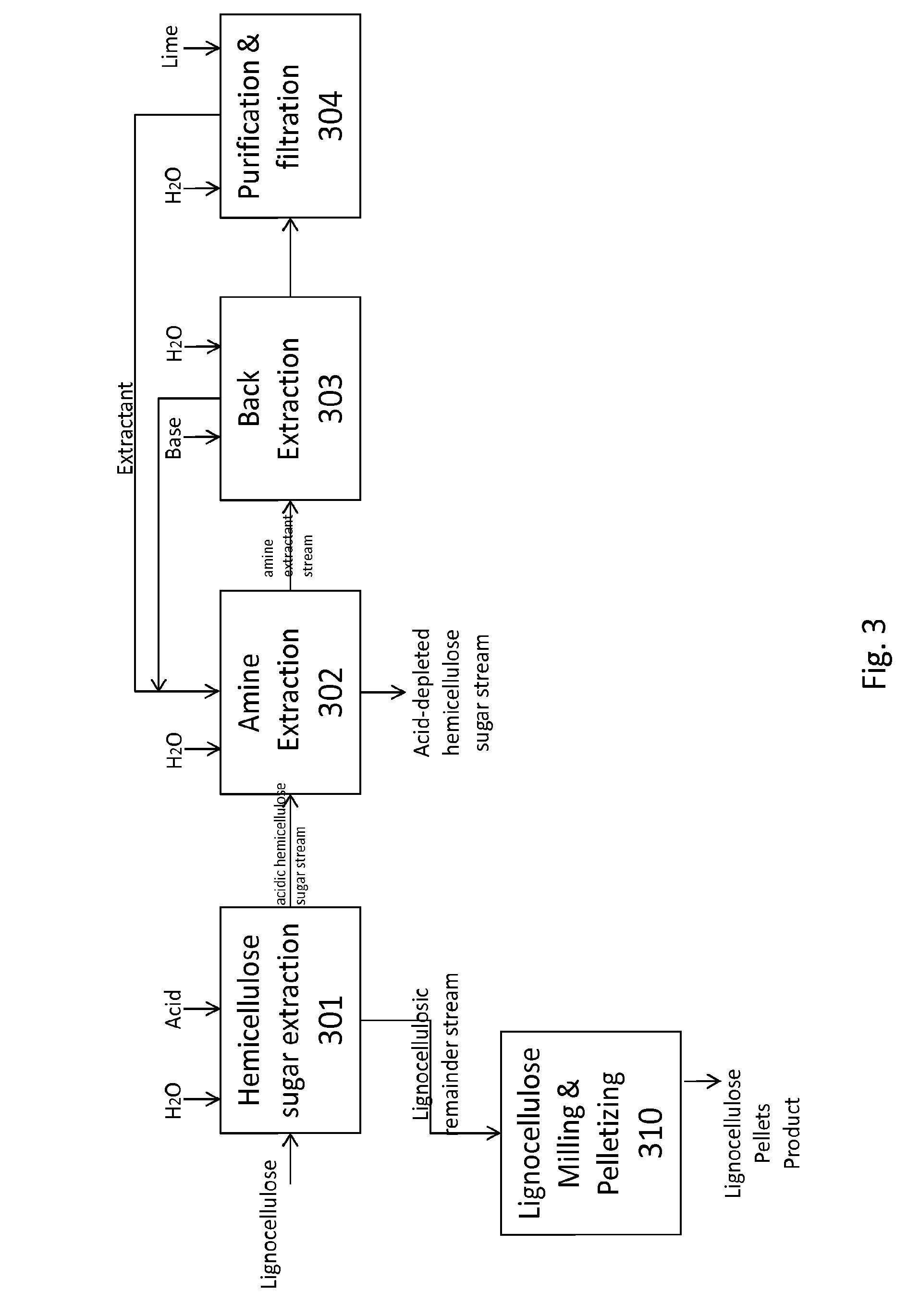

Methods for treating lignocellulosic materials

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRIDA

Pyrolysis Tar Upgrading Process

InactiveUS20150344790A1Hydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystSulfide

A process for upgrading pyrolysis tar to higher value products. More particularly, this invention relates to the upgrading of steam cracker tar using relatively small amounts of a transition metal sulfide-containing particulate catalyst dispersed throughout the tar chargestock and in the presence of hydrogen, at relatively mild hydroconversion conditions.

Owner:EXXONMOBIL CHEM PAT INC

Integrated system for productioin of biofuel feedstock

InactiveCN102089434AIncrease flexibilityReduce sizeUnicellular algaeBiofuelsBiotechnologyBiofuel feedstock

Disclosed is a culture system for the production of algae biomass to obtain lipid, protein and carbohydrate. By integrating heterotrophic processes with a phototrophic process in parallel, this system provides year around production in colder climates. By integrating heterotrophic processes with a phototrophic process in series, this system creates a two-stage, separated mixed- trophic algal process that uses organic carbon and nutrients for the production of seed in the heterotrophic process, followed by release of cultured seed in large-scale phototrophic culture for cell biomass accumulation. Organic carbon source including waste materials can be used to feed the heterotrophic process. The production capacity ratio between the heterotrophic and the phototrophic processes can be adjusted according to season and according to the availability of related resources. The systems are used for producing and harvesting an algal biofuel feedstock as well as other potential high-value products. The sequence and approach enhances utilization of carbon and nutrient waste-streams, provides an effective method for controlling contamination, adds flexibility in regard to production and type of available products, and supplies greater economic viability due to maximized use of available growth surface areas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

Method of extracting neutral lipids with two solvents

InactiveUS20140005422A1Reduce processing latencyQuantity minimizationFatty acid esterificationSolvent extractionSolventNeutral lipid

A method for separating neutral lipids from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting neutral lipids from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal neutral lipids from a wet algal biomass while avoiding emulsification of extraction mixtures. These neutral lipids are high value products which can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

Method for manufacturing carbon molecular sieve with plant nutshell

InactiveCN102328924ASolve the pollution of the environmentReduce manufacturing costMolecular sieveKneader reactor

The invention discloses a method for manufacturing a carbon molecular sieve with a plant nutshell, which sequentially comprises the following steps: a, crushing the plant nutshell into powdery material; b, drying and grinding the powdery material to obtain micro-powdery material; c, mixing and kneading the micro-powdery material with adhesives in a kneader; d, placing the kneaded material into a bar extruding machine for formation; e, placing the formed material into a converter for carbonization; and f, depositing the carbonized material with carbon to obtain a finished carbon molecular sieve. By adopting the method, the problem of environment pollution caused by the carbon molecular sieve process can be solved effectively, and the environment protection can be facilitated. Meanwhile, the finished carbon molecular sieve is manufactured with the plant nutshell sequentially via crushing, drying, grinding to produce the micro powder, placing of the micro powder along with the adhesives into the kneader, formation, carbonization and surface carbon deposition to obtain the finished carbon molecular sieve. Waste is fully utilized to manufacture high-value products, the manufacturing cost of the carbon molecular sieve is reduced, the process is simple, and industrialization can be realized easily.

Owner:胡耀明

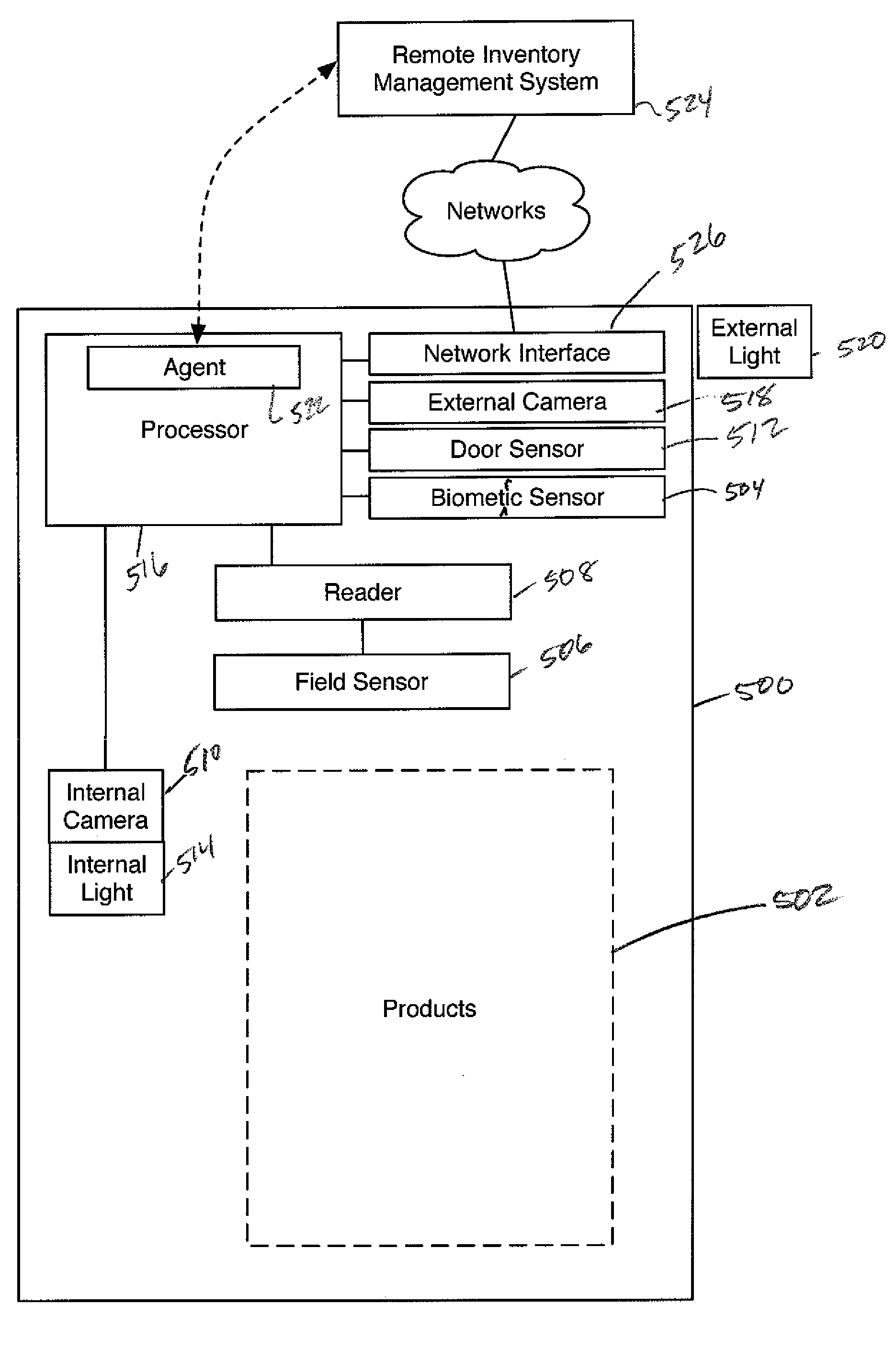

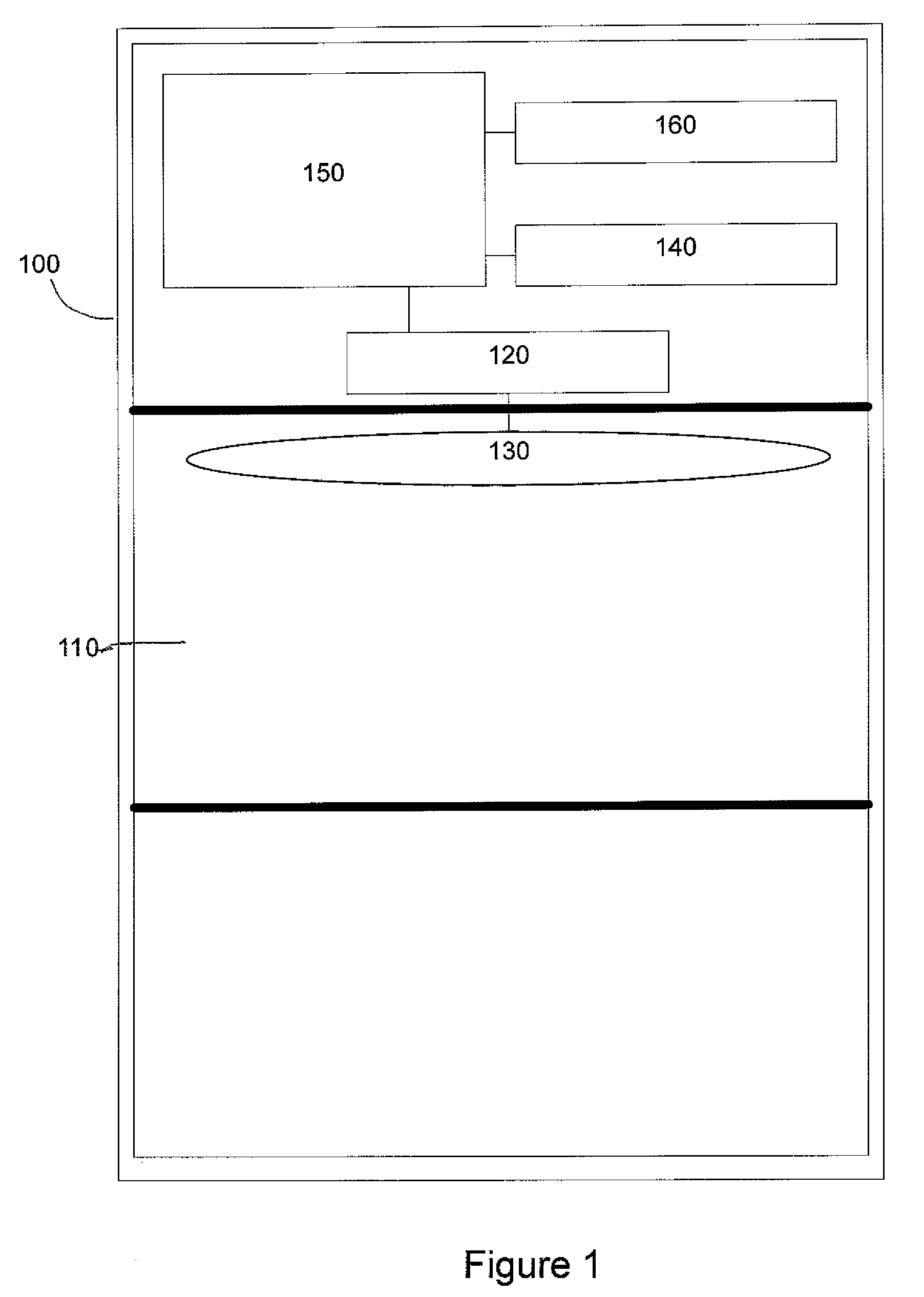

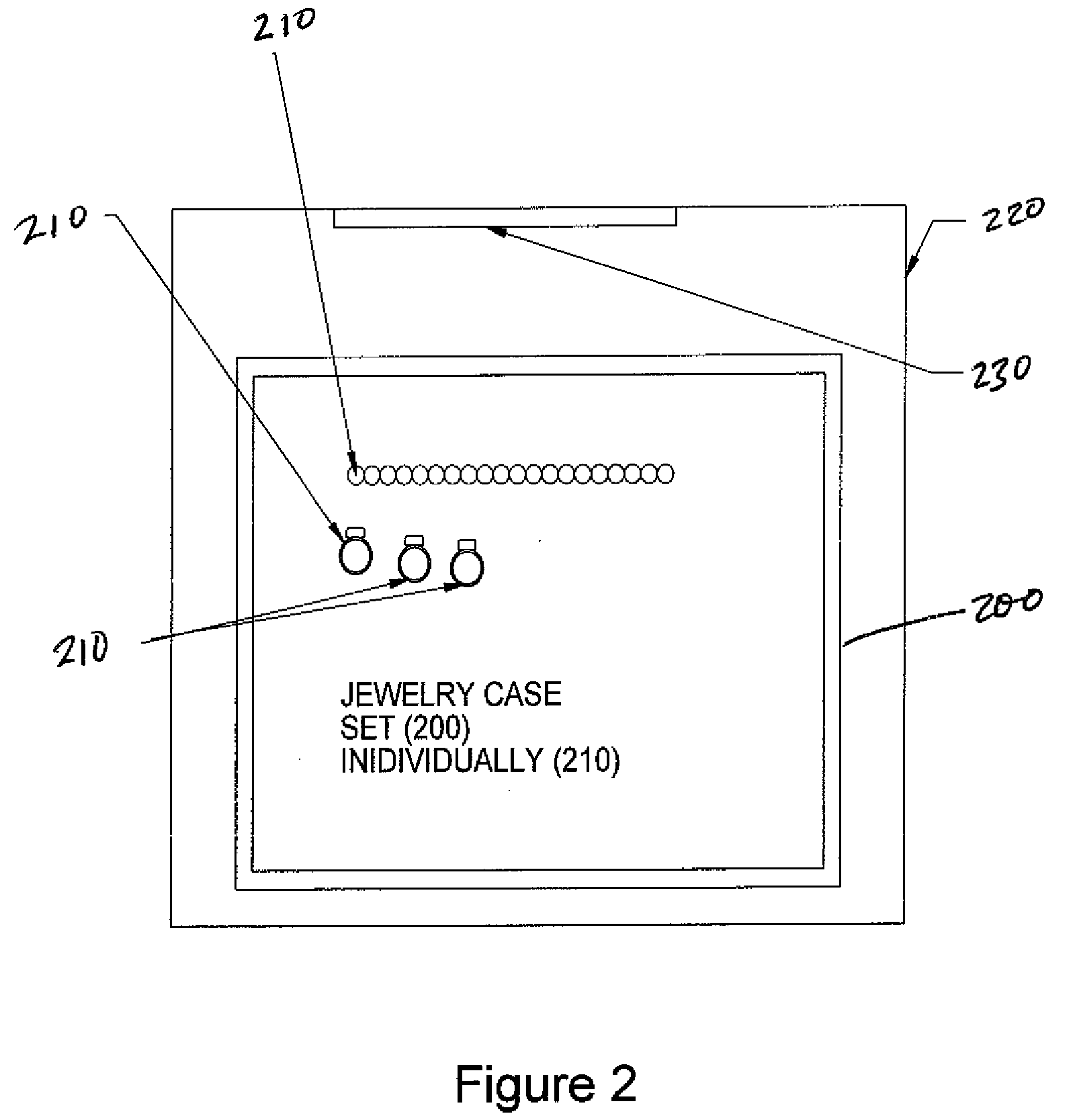

System, method, and apparatus for high value product management and tracking

Systems, methods, and computer program products for managing product inventory, and particularly for managing inventories.

Owner:FAUSAK ANDREW T +1

Process and apparatus for upgrading steam cracker tar using hydrogen donor compounds

ActiveUS8197668B2Efficiently managing introductionIncrease percentageThermal non-catalytic crackingTreatment with plural serial cracking stages onlyThermodynamicsTetralin

A process and apparatus are provided for upgrading steam cracker tars from steam crackers. The invention also relates to a steam cracking process and apparatus for reducing yields of tars produced from steam cracking while increasing yields of higher value products by heating steam cracker tar, in the presence of hydrogen donor compounds, e.g., tetralin. The hydrogen donor compounds can be provided in a hydrogen donor-rich hydrocarbon stream, e.g., light cycle oils, or low sulfur vacuum tower bottoms. The treated tar can be separated into gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

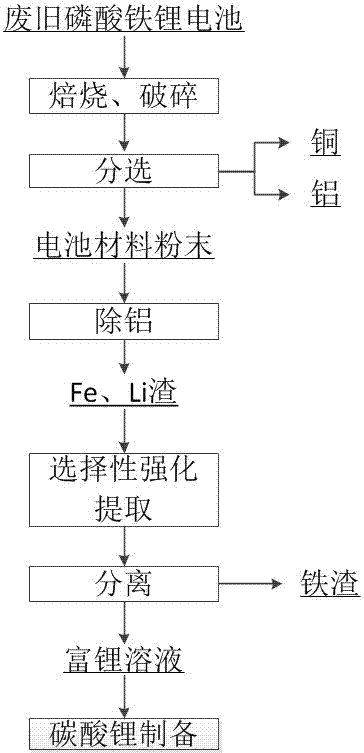

Method for recycling metal in waste lithium iron phosphate batteries

InactiveCN107017444AAvoid it happening againSolve problems such as secondary pollutionWaste accumulators reclaimingProcess efficiency improvementLithium hydroxideChemical agent

The invention provides a method for recycling metal in waste lithium iron phosphate batteries. The method comprises the following steps: roasting and sorting the waste lithium iron phosphate batteries to obtain lithium-containing positive electrode powder; carrying out enhanced leaching on the lithium-containing powder in a mixed solution of ammonium salt and / or ammonia; converting divalent iron into trivalent iron in an oxidative environment and forming sediment, so as to obtain a lithium-containing solution; and filtering the lithium-containing solution and preparing a high-purity lithium product, so as to obtain high-value products including lithium hydroxide or lithium carbonate and the like. Compared with a traditional wet-process acid leaching process, an acidic leaching agent is not used any more so that a condition that a lot of high-salt wastewater is generated is avoided; the lithium element is selectively leached in an enhanced leaching manner; the leaching efficiency is high and the consumption amount of a leaching solution is small; a high-purity lithium-containing solution can be obtained; finally, the purity of the obtained lithium products is high and a flow is short; chemical agents have a wide source and technological conditions are simple; the lithium element can be selectively leached in the enhanced leaching manner and the high-purity lithium products are harvested; and the recycling benefits of the waste lithium iron phosphate batteries are improved and the method has a good industrial application prospect.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Method for producing benzene, toluene and xylene from poor-quality diesel oil raw material

ActiveCN105316040AGood choiceWeakened hydrogenationHydrocarbonsTreatment with hydrotreatment processesThiolSulfur

The invention relates to a method for producing benzene, toluene and xylene from a poor-quality diesel oil raw material. According to the method, a poor-quality diesel oil raw material reacts in a hydrorefining zone, a hydrocracking reaction zone I and a hydrocracking reaction zone II to generate a stream being rich in benzene, toluene and xylene, the reaction products of the hydrocracking reaction zone I are subjected to fractionation to separate so as to obtain the light gasoline distillate, the heavy gasoline distillate, the middle distillate and the tail gasoline distillate, thiophene, mercaptan and the like are removed from the heavy gasoline through a desulfurization reaction zone, and separation is performed to obtain the high added value products such as benzene, toluene and xylene, raffinate oil, and the like. With the method of the present invention, the poor-quality diesel oil raw material can be effectively converted into the high added value products such as benzene, toluene, xylene and the like while the partial light gasoline and the low sulfur diesel oil blending component can be concurrently produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production methodology of hydrolyzed collagen using swiftlet nest as raw material

ActiveCN105377958AIncrease energy densityLower scoreNon-fibrous pulp additionBiofuelsCelluloseCooking methods

Health benefits manifested by consuming collagen / hydrolyzed collagen and swiftlet nest exhibit resemblance of each other. Logical instinct should have linked the duos. However, due to age-old assumptions and cultural misplacement, this relationship have been undergrounded. Swiftlet nest has been consumed by Chinese community as a premium delicacy and effective medicine as well as beauty enhancer. So much so that it has become the food of status and command very high price. Due to this reason, the culture of "if it ain't broken, dont fix it" permeated. Double steaming, sometimes called double boiling, is the only widely used cooking method till today, under the belief that over heating above 100 DEG C will destroy the nutrion value of swiftlet nest. This invention is a breakthrough from tradition. Swiftlet nest is cooked above 100 DEG C, using steam sterilization method. Amino acids analysis has been carried out on the sample of the swiftlet nest cooked using this invention. It shows the amino acids profile does fit the amino acids profile of collagen and hydrolyzed collagen. Hence, with this invention, swiftlet nest proved to be a source rich in amino acids and can be used as the raw material to produce collagen and hydrolyzed collagen.

Owner:VIRDIA

Methods for treating lignocellulosic materials

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRDIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com