Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

373 results about "Cutting oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cutting Oil is a light oil used in Pistol-Grip Cutters to prolong the life of the scoring wheel when cutting stained glass for mosaic art. Keep in mind that any stained glass exposed to cutting oil needs to be washed with detergent to ensure that the glues and mortars used in mosaic work can bond securely.

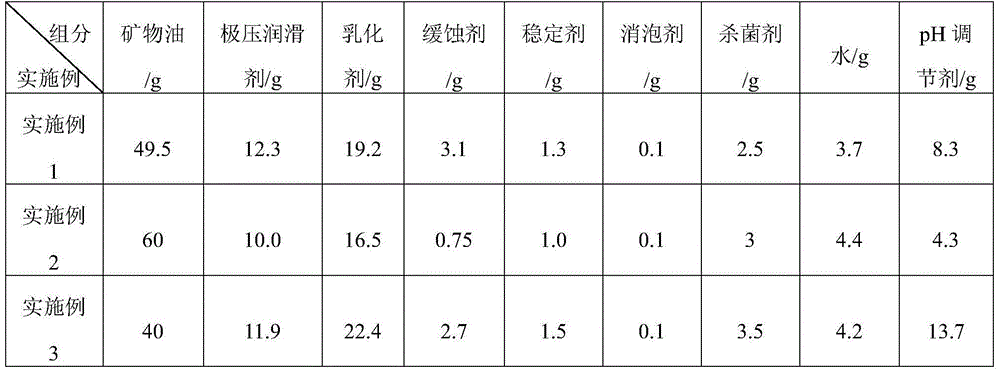

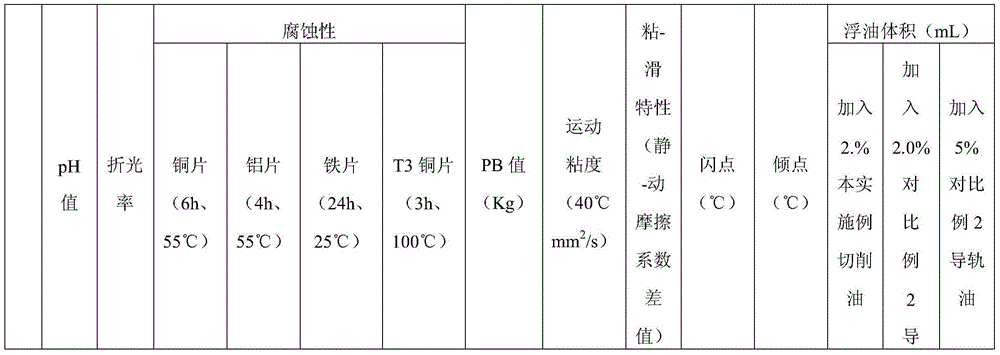

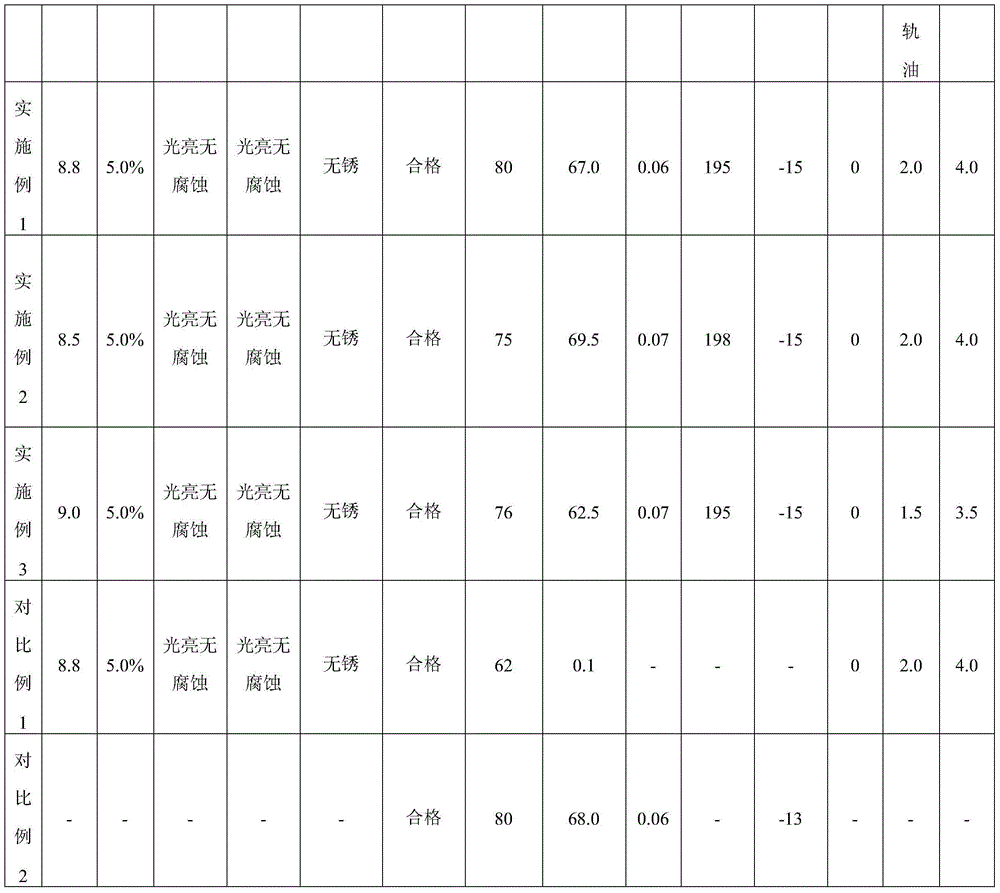

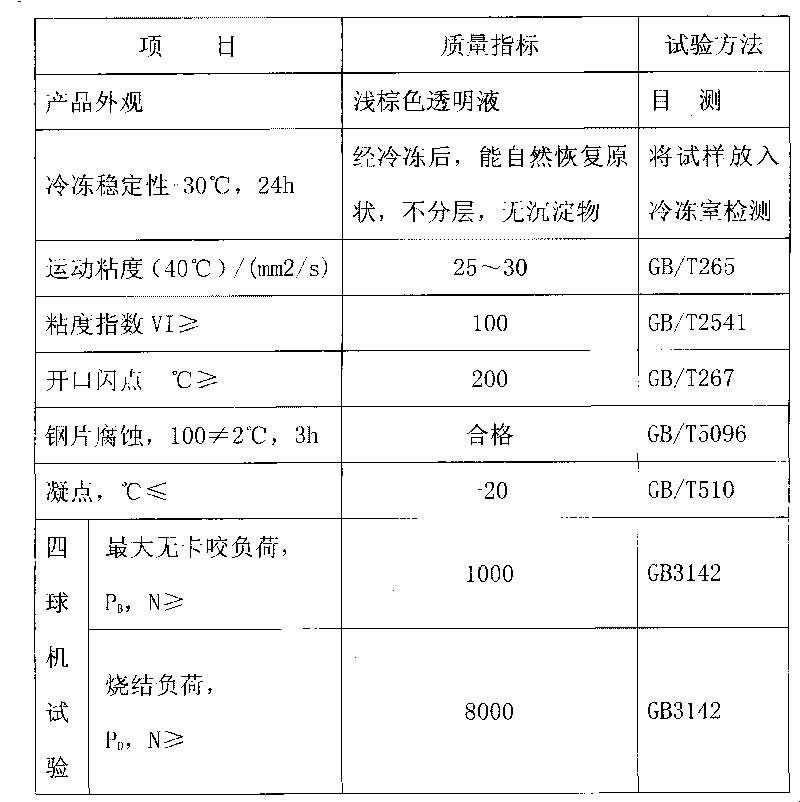

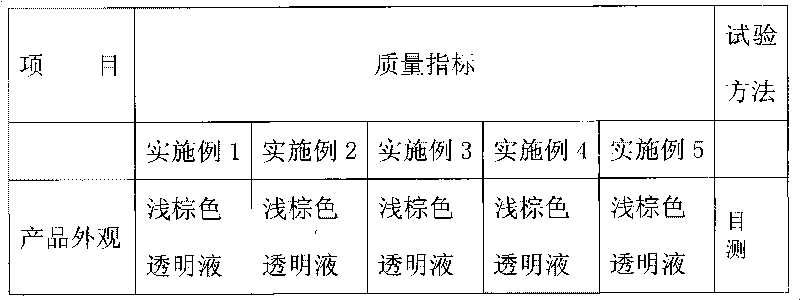

Water-soluble cutting oil applied to cutting work and guide rail lubrication

InactiveCN104130839AImprove wear resistanceImprove adhesionLubricant compositionEngineeringWater soluble

Owner:KAIFENG AOKEBAO SPEICAL OIL AGENT CO LTD

Cutting oil composition

InactiveUS6383991B1Good dispersionEasy to cleanWork treatment devicesAdditivesHydrogen atomChemical composition

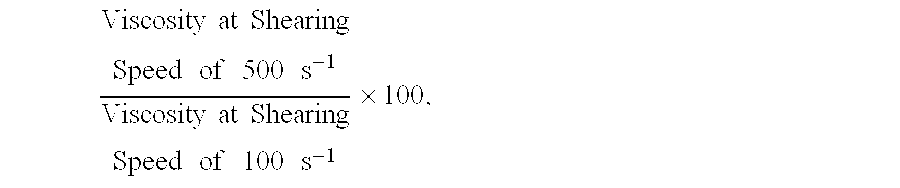

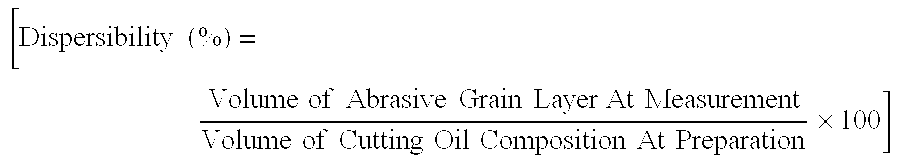

The present invention relates to a cutting oil comprising (a) a polyether compound represented by the formula (I):wherein each of R1 and R2, which may be identical or different, is hydrogen atom or a hydrocarbon group having 1 to 24 carbon atoms, at least one of which is a hydrocarbon group; EO is oxyethylene group; AO is an oxyalkylene group having 3 or 4 carbon atoms; and each of m and n is 1 to 50, wherein a sum of m and n is from 4 to 100; a cutting oil composition comprising the above cutting oil and an abrasive; a cutting method using the above cutting oil composition; and a process of cleaning a wafer, comprising the steps of cleaning a wafer obtainable by cutting an ingot with a wire saw using the above cutting oil composition; heating the resulting waste water to a temperature equal to or higher than a cloud point of a polyether compound represented by the formula (I) contained in the waste water, to allow separation into an oil phase and an aqueous phase; and removing the oil phase comprising the polyether compound from the waste water. According to the present invention, there can be obtained excellent dispersibility of the abrasive, and excellent re-dispersibility, cutting performance and workability when sedimented, and the object to be cut obtained after cutting can be easily cleaned.

Owner:KAO CORP

Twist drill

InactiveUS20060269372A1Minimize wearMinimize chippingWood turning toolsTransportation and packagingLeading edgeEngineering

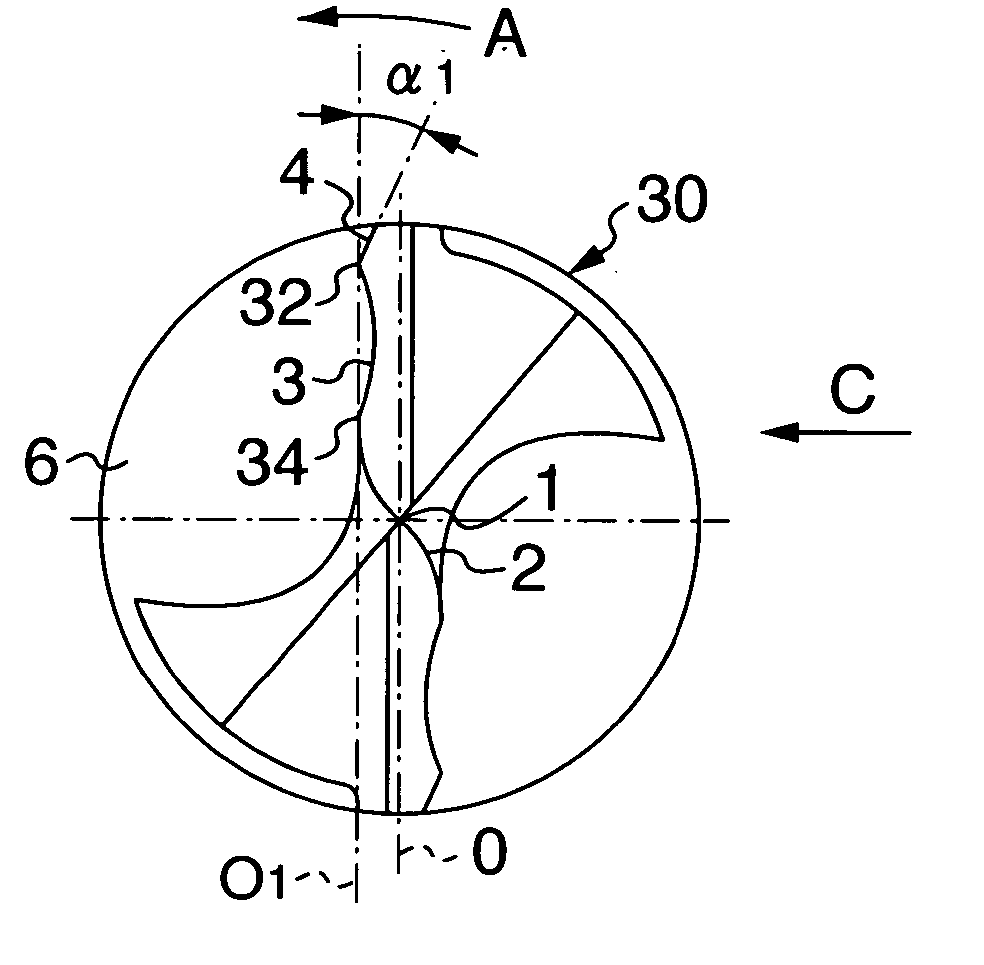

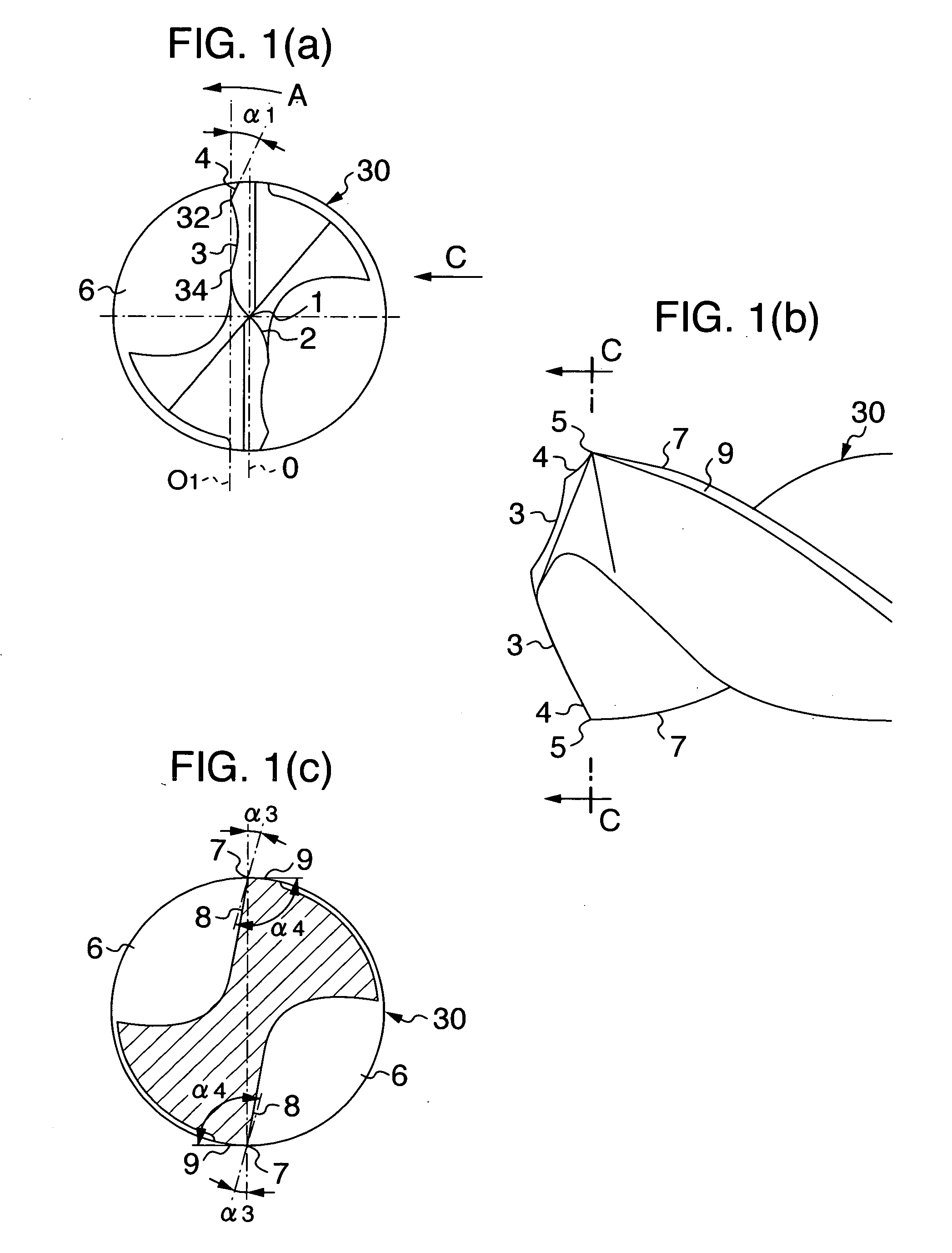

A twist drill has a pair of concave-shaped main cutting edges continuous outwardly to respective center cutting edges, and a pair of corner cutting edges receding at an angle from the outer ends of the respective main cutting edges with respect to a drill rotation direction. Respective ends of the concave-shaped main cutting edges are situated on a straight line almost parallel to a plane passing through a drill axis. These cutting edges have a function of minimizing wear and chipping of corner portions and damage to leading edges in a drilling operation using no cutting oil, or a drilling operation wherein a very small amount of cutting oil is sprayed to the drill, or in a drilling operation on relatively hard steel. They also have a function of facilitating breaking of cut chips into pieces during a drilling operation using cutting oil and during a drilling operation on steel of relatively low hardness such as general structural rolled steels and low carbon steels.

Owner:NACHI-FUJIKOSHI

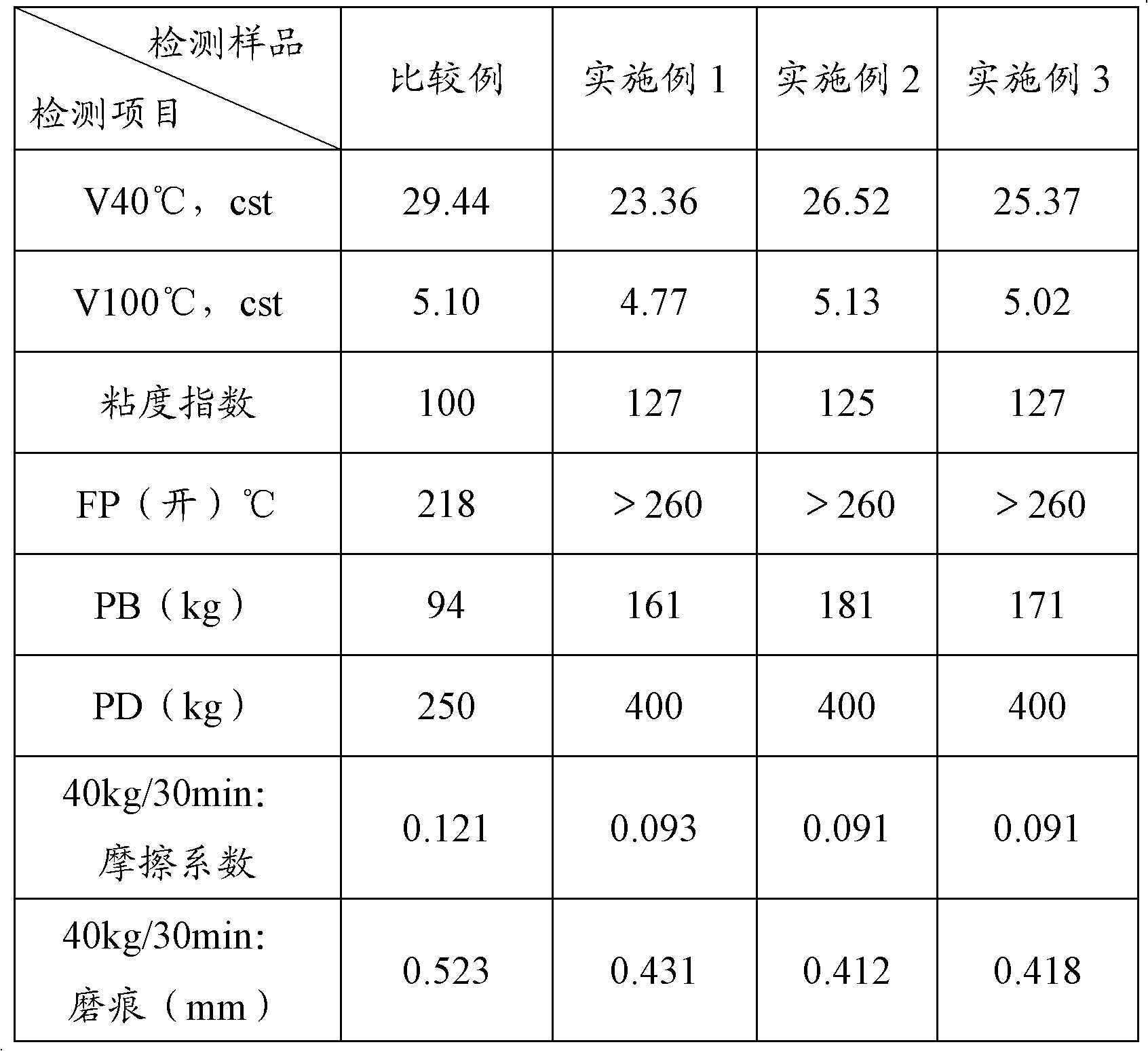

Cutting oil and preparation method thereof

InactiveCN102031190AImprove low temperature performanceImprove filtering effectBase-materialsEcological environmentEnvironmental index

The invention provides environmentally-friendly efficient atomization cutting oil, which comprises the following components in percentage by weight: 20 to 40 percent of synthetic ester, 60 to 80 percent of vegetable oil, 0 to 3 percent of antioxidant, 0 to 2 percent of anti-rusting agent, 0 to 5 percent of extreme pressure abrasion-resistant agent and 0 to 1 percent of metal passivator. The synthetic ester and the vegetable oil are matched and used base oil, so the cutting oil has the advantages of good lubricating property and biodegradability, resource recycle, no toxicity and the like, has low toxin and low harm to the human body and the ecological environment, meets the requirements of related environmental indexes, has good low-temperature performance and oxidation stability and strong universality, is suitable for metal cutting and processing of most materials, is particularly special cutting oil for modern advanced semi-dry and trace lubrication processing and development, and is mainly used for oil mist lubrication; and the gas and liquid two-phase oil mist can play a role in lubricating, take away a large amount of heat, reduce the consumption of cutting fluid, lower the cost and reduce the discharge of waste solution, and is favorable for environmental protection.

Owner:东莞太平洋博高润滑油有限公司

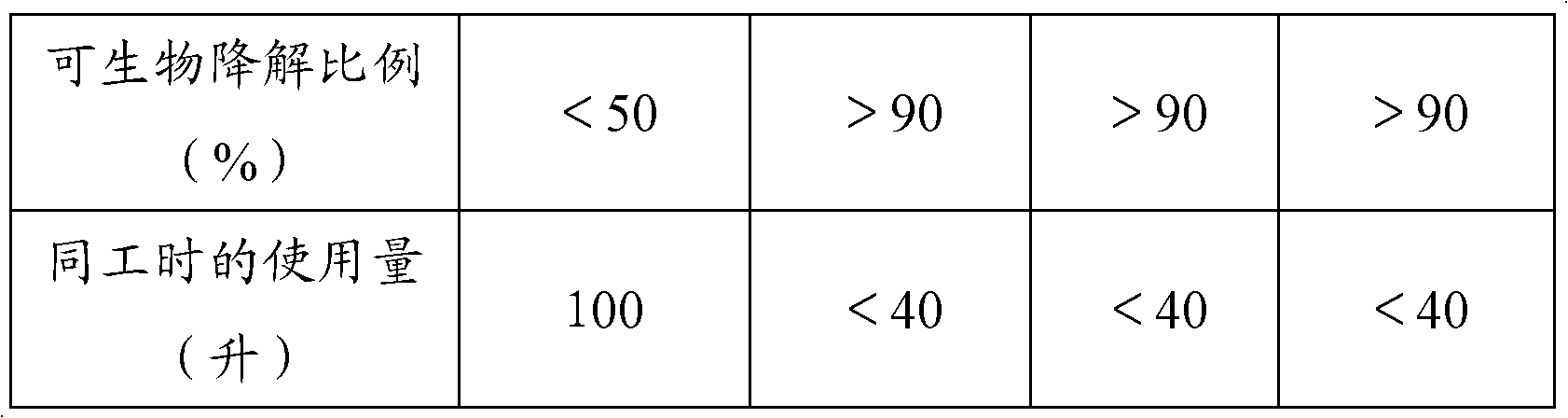

Lighted cutting tools

InactiveUS6918331B2Efficient illuminationReduce the amount requiredShearing machinesPortable power driven sawsEngineeringKnife blades

A cutting tool includes a saw blade and a blade case adapted to cover the saw blade. A light may have a light for illuminating a portion of a workpiece that will be cut by the saw blade during a cutting operation. The light may be mounted within the blade case, so that the light is laterally displaced from the saw blade. A mounting device may be utilized to receive the light and the mounting device may be disposed within the blade case.

Owner:MAKITA CORP

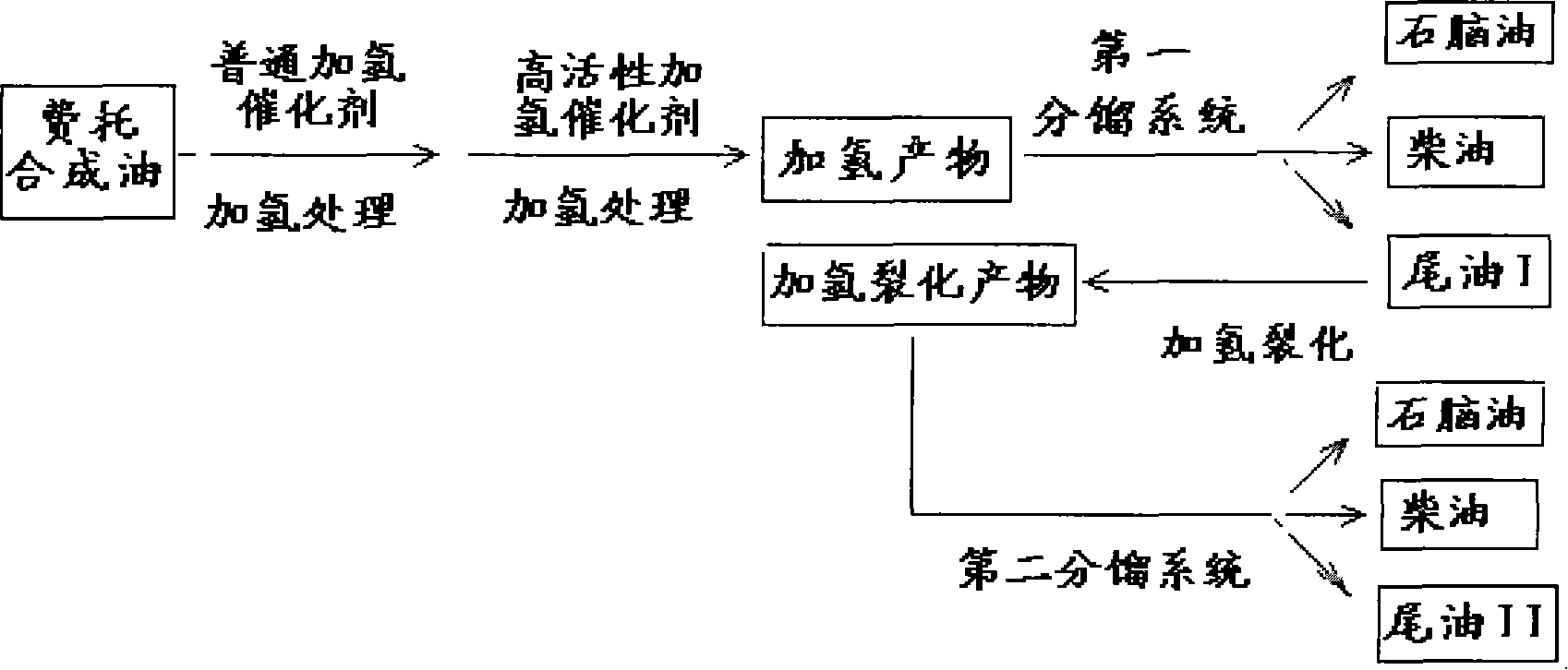

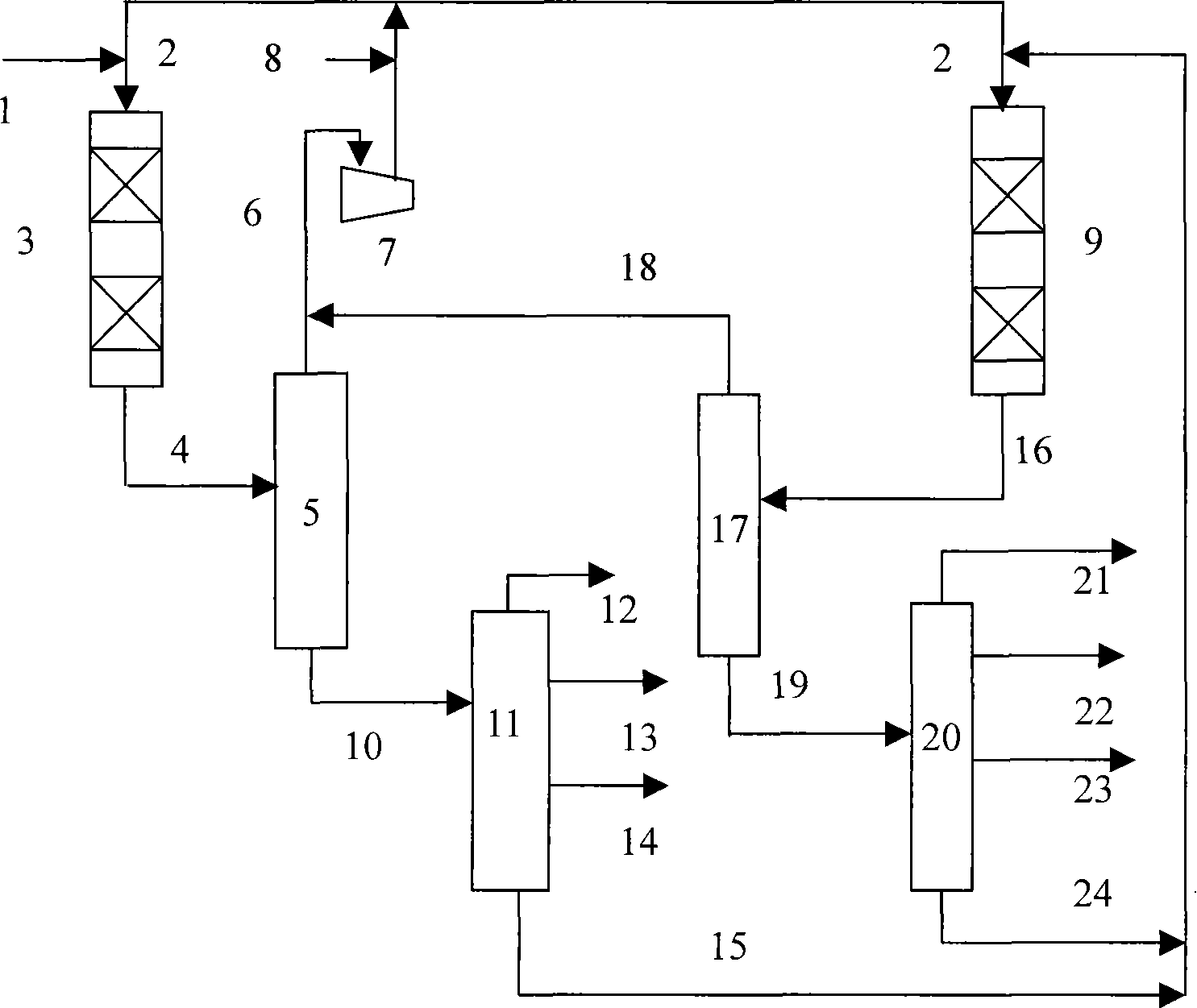

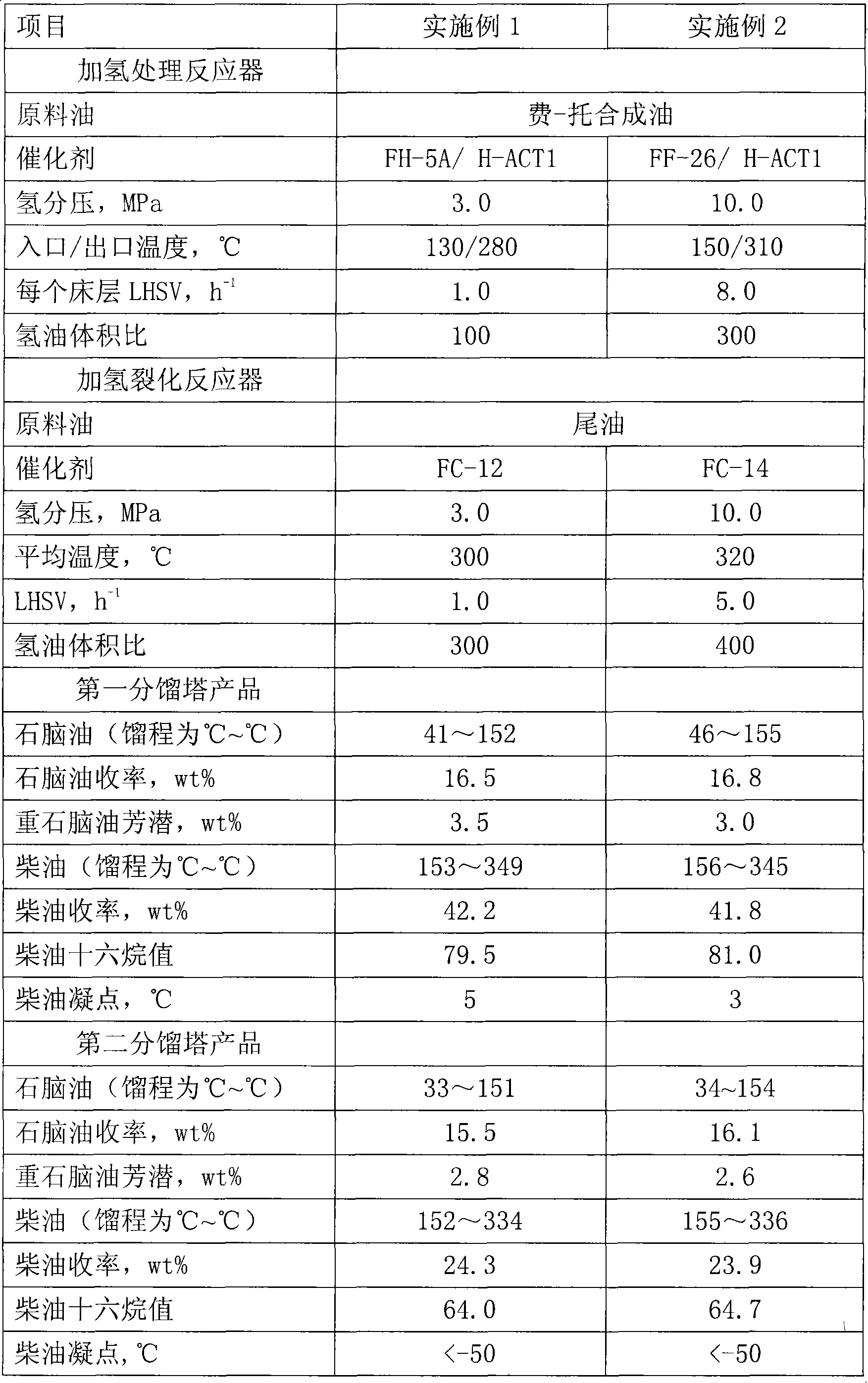

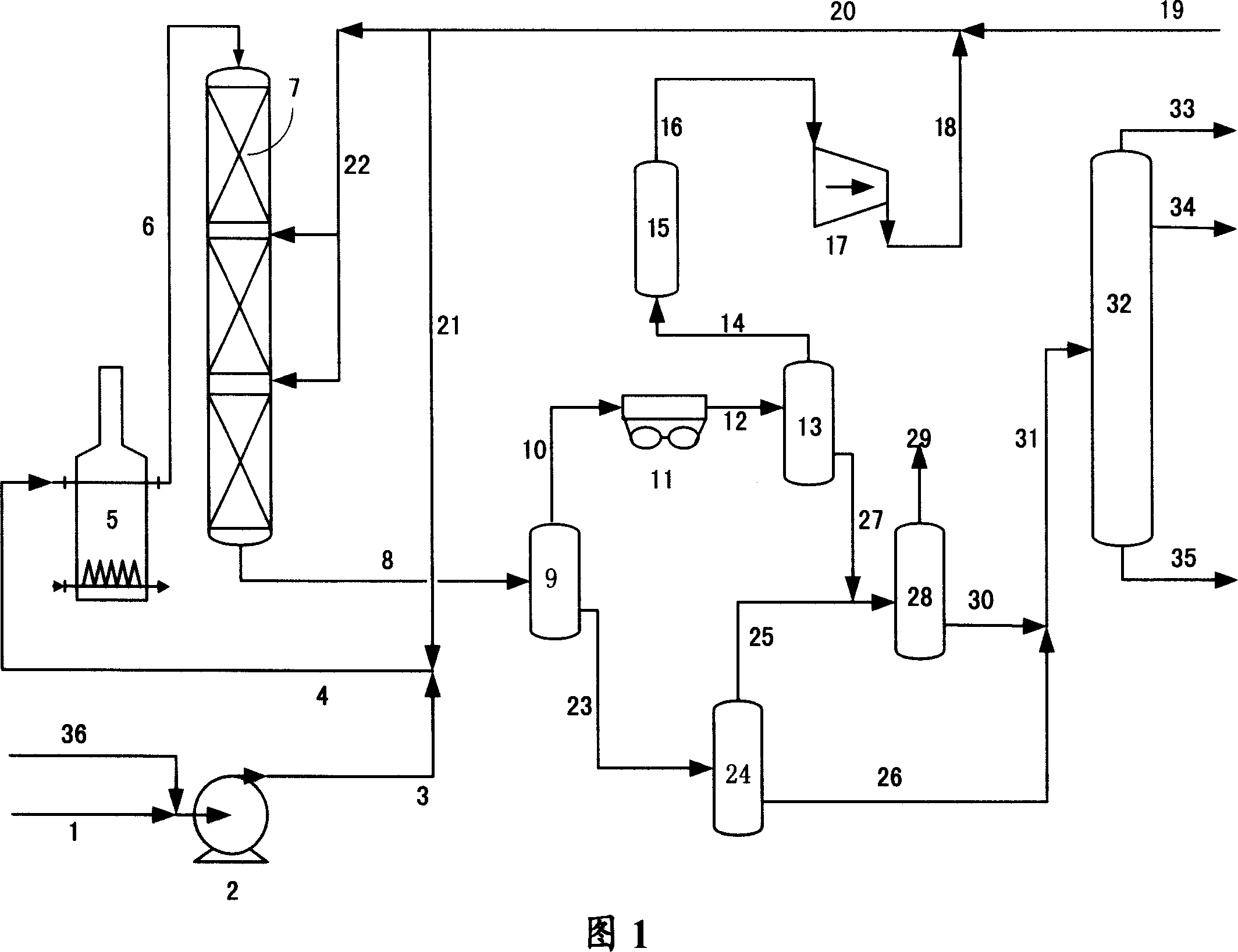

Hydrogenation processing method for f-t synthetic oil

ActiveCN101177625AEffective hydrotreatingReduce the impactTreatment with hydrotreatment processesHydrogenNaphtha

The invention discloses a hydrogenation processing method of Fischer-Tropsch synthetic oil, particularly, the method of the invention is that raw naphtha cut, raw diesel oil cut, mixed cut of raw naphtha and raw diesel oil or Fischer-Tropsch synthetic full cut oil in liquid-phase products acquired from Fischer-Tropsch synthetic process are treated by hydrogenation processing. The method comprises steps that raw material of the Fischer-Tropsch synthetic oil goes through at least two sections of hydrogenation processing catalyst bed layers with different activation for hydrogenation processing and then tail oil acquired from separation after hydrogenation processing is subjected to hydrogen cracking and then hydrogenation processing products and hydrogen cracking products are sent into different fractionating systems for separating. The method of the invention can acquire high-quality clean diesel oil with cetane value higher than 75 and excessively low-freezing clean oil with solidifying point lower than 50 DEG C below zero, meanwhile, the naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Volatile stamping cutting oil composite for machining for machining of moderate-thickness aluminum plate and preparation method thereof

InactiveCN102199476AImprove the lubrication effectImprove rust resistanceLubricant compositionIrritationPhosphate

The invention relates to volatile stamping cutting oil composite for machining of a moderate-thickness aluminum plate and a preparation method thereof. The stamping cutting oil composite comprises the following raw materials in percentage by weight: 90-95 percent of solvent oil, 1-4 percent of antiwear additive, 1-4 percent of oiliness additive, 0.5-2 percent of antirust additive and 0.2-1 percent of antioxidant; the solvent oil has low sulphur content, low aromatic hydrocarbon content, no toxicity and smell and has the kinematic viscosity of 1.5-3.5mm<2> / s at 20 DEG C; the antiwear additive is selected from phosphates; the oiliness additive contains more than one of fatty alcohol and fatty acid methyl ester; the antirust additive is sodium alkylsulfonate; and the antioxidant is an antioxidant BHT (butylated hydroxytoluene). The preparation method of the volatile stamping cutting oil composite for the machining of the moderate-thickness aluminum plate, provided by the invention, is simple and convenient; and the composite provided by the invention does not contain a chlorine extreme pressure agent, is a biological environment-friendly product and has the advantages of excellent extreme pressure lubrication performance and favorable demoulding performance, volatilization completeness, no trace leaving, no clean, extremely low smell, no irritation to skin, time and labor saving and capability of greatly prolonging the service life of a mould.

Owner:上海德润宝特种润滑剂有限公司

Method of dense raw material hydrotreatment-catalytic cracking for improving propylene productivity

ActiveCN101063047AHigh yieldTreatment with hydrotreatment processesHydrogenation reactionCutting oil

The invention discloses a heavy raw material hydrotreating-catalytic cracking method to increase propone productivity, which comprises the following steps: choosing light circling oil and or weight circling oil from catalytic cracking unit; adding into hydrogenation reaction zone with heavy cut oil; or adding into two hydrogenation reaction zone with different hydrogenation catalyst to react; getting effluent; cooling; separating; fractionating; getting heavy liquid phase fraction; moving catalytic cracking unit; separating the catalytic cracking reacting product; getting the final product. This invention can dispose cycloalkyl heavy raw material, which propone receiving ratio can increase by 5-7 percent dot.

Owner:CHINA PETROLEUM & CHEM CORP +1

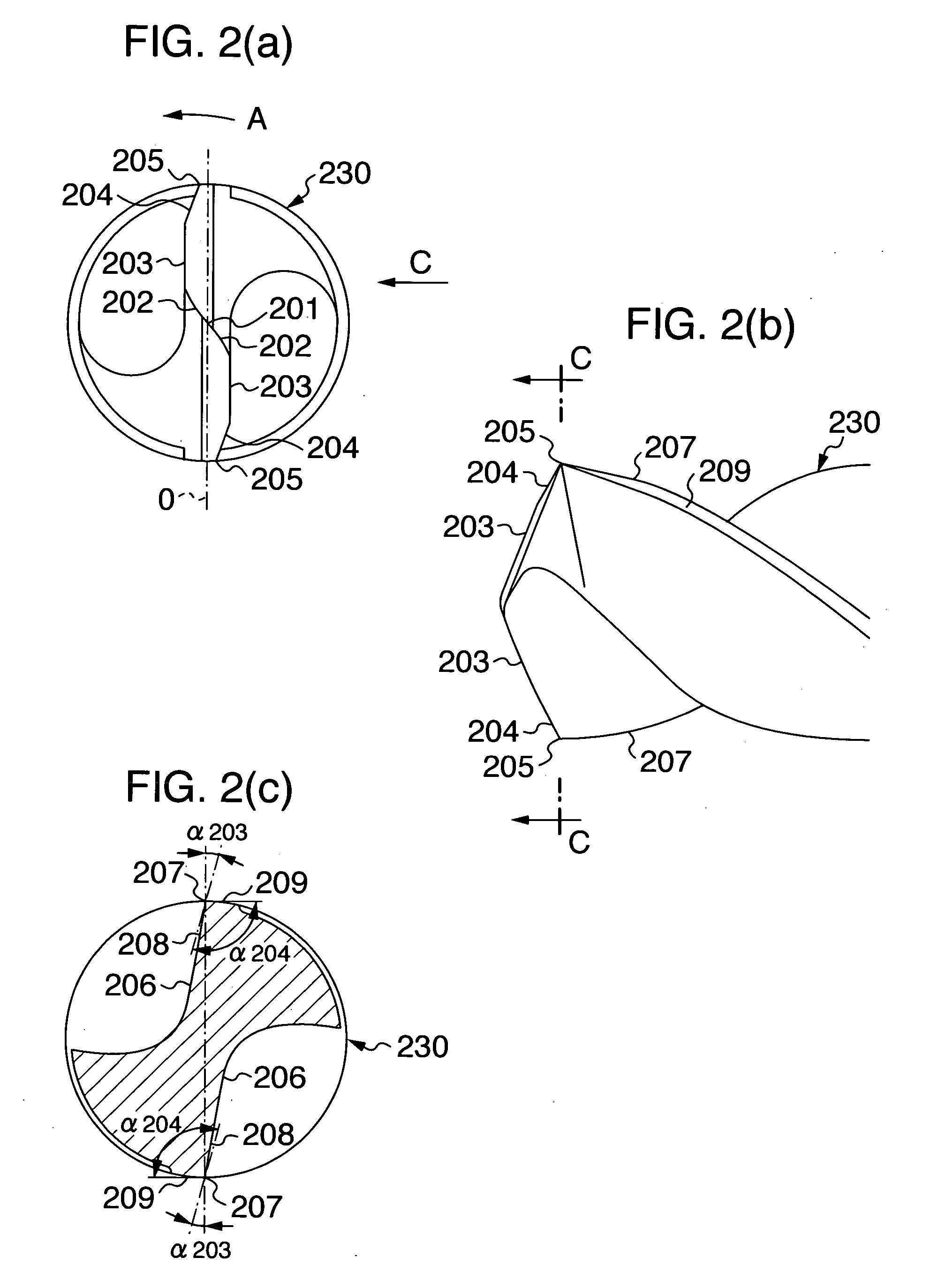

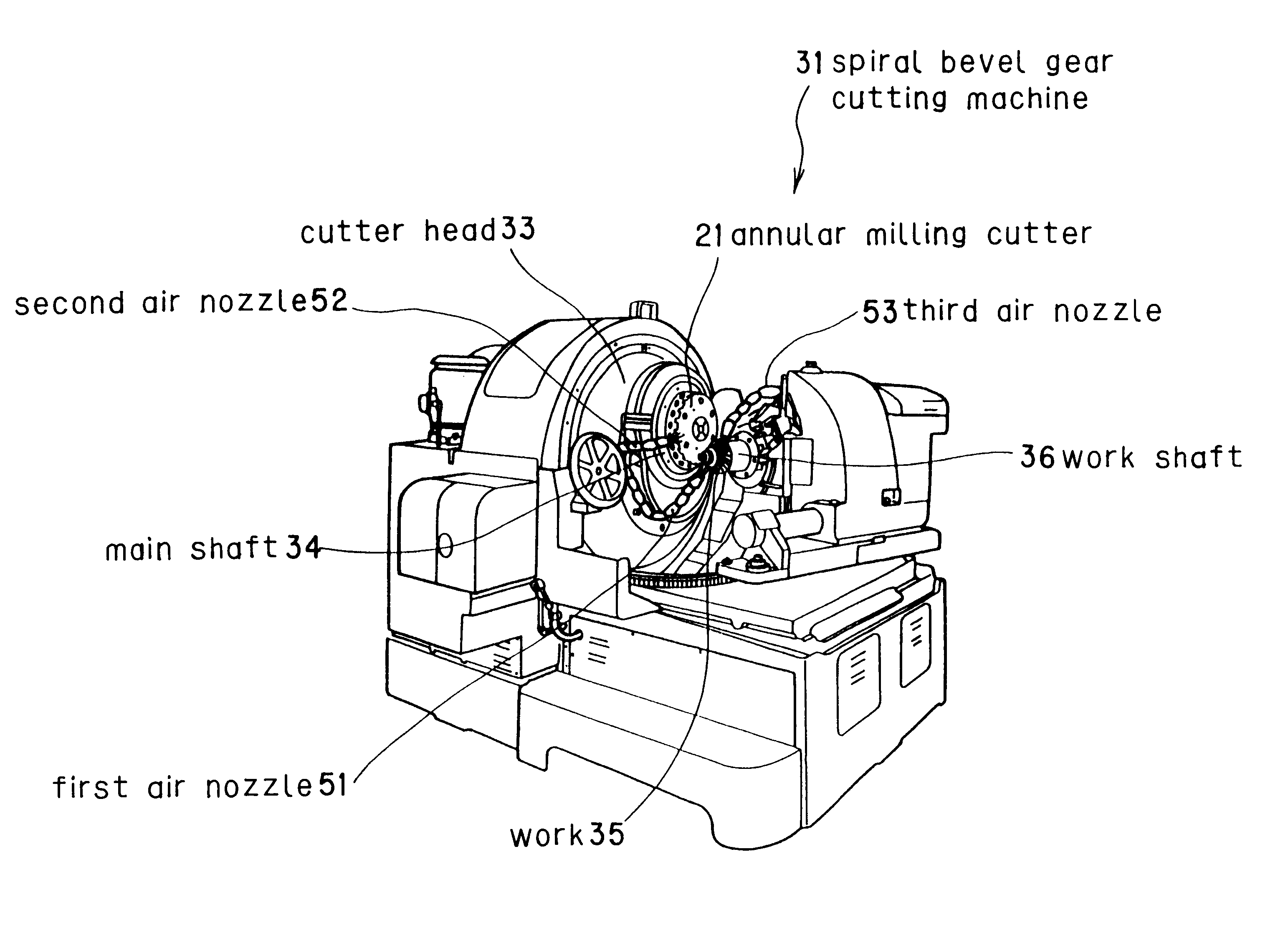

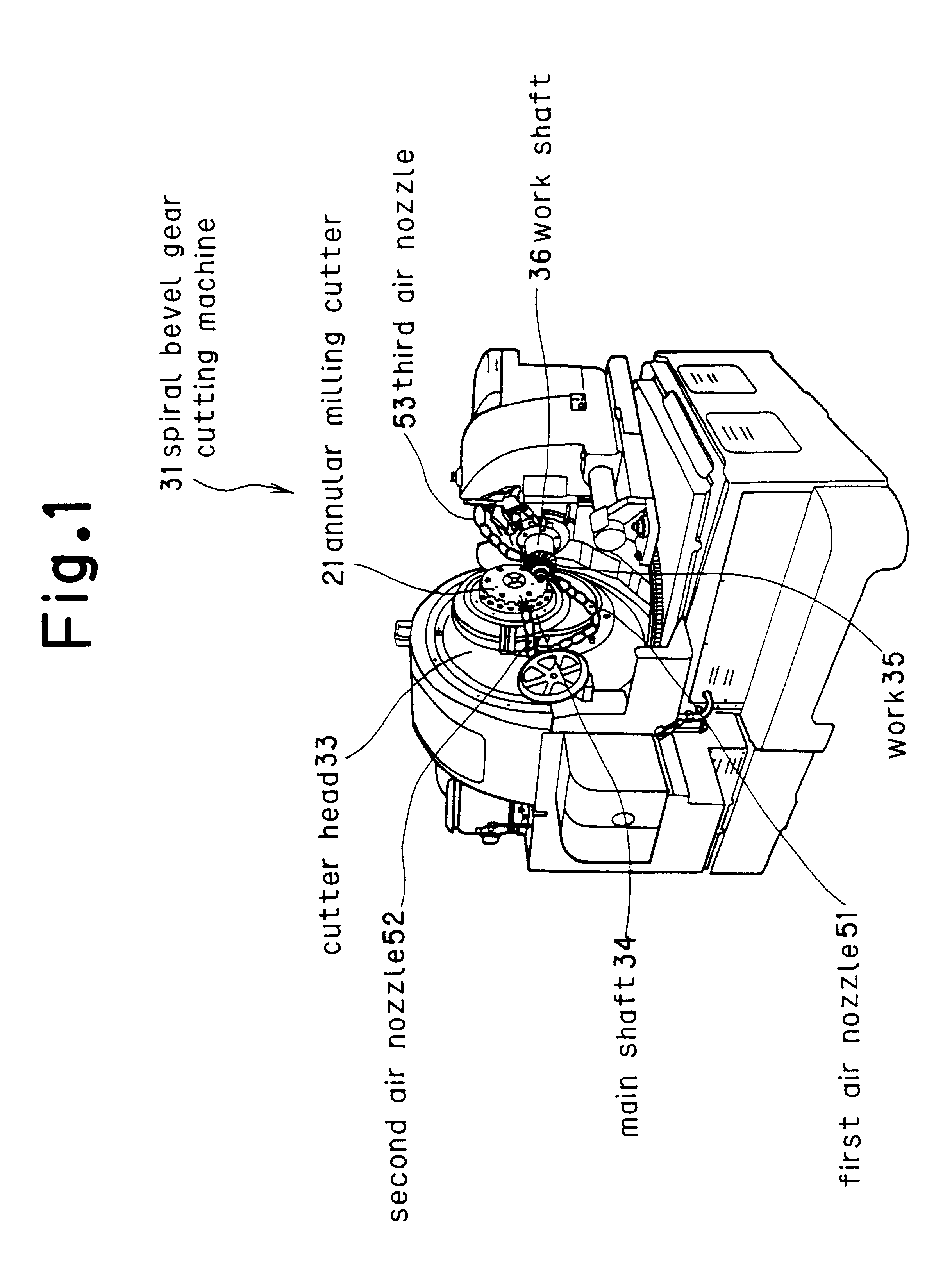

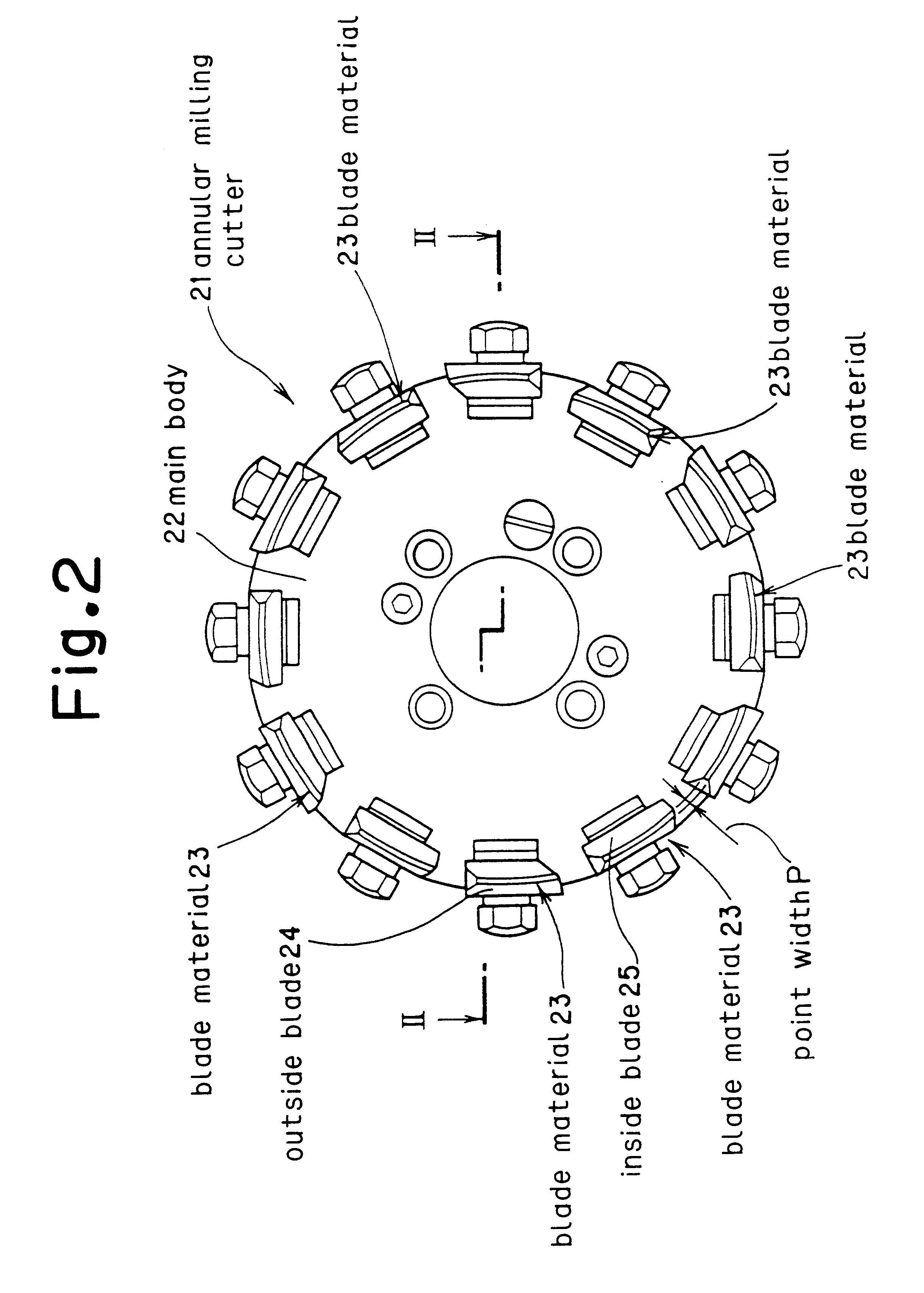

Gear shaping method and device and spiral bevel gear cutter

InactiveUS6416262B1Fast cutting speedNatural mineral layered productsGear teeth manufacturing toolsMilling cutterGear wheel

A bevel gear is generated using an annular milling cutter having a blade material made of a high-speed tool steel mounted to a main body, the blade material being coated with at least one layer of a film of a composition substantially comprising (Ti(1-x)Alx)(NyC(1-y)) (where, 0.2<=x<=0.85, 0.2<=y<=1.0), and dry cutting is performed at a cutting speed in the range from 20 to 400m / min without using a cutting oil. With this method, teeth can be generated at a greatly improved cutting speed without using any expensive tool such as cemented carbide, thereby realizing efficient production of a bevel gear at a reduced cost.

Owner:MITSUBISHI HEAVY IND LTD

Spray supply mode cutting oil for metal material cutting processing

ActiveCN101717684AEasy to useImprove extreme pressure lubrication performanceAdditivesPhosphoric Acid EstersVegetable oil

The invention relates to spray supply mode cutting oil for metal material cutting processing, which is prepared from the following raw materials in parts by weight: 40-60 parts of base oil, 30-40 parts of vulcanized fat and 10-20 parts of phosphoric acid ester, wherein the base oil is vegetable oil or synthetic ester or a mixture of the vegetable oil and the synthetic ester; since the consumptionof the vulcanized fat and the phosphoric acid ester used as extreme pressure additives of the cutting oil is large, the cutting oil has good extreme pressure lubricating performance, thereby ensuringthat process requirements are satisfied by consuming a minute quantity of cutting oil when the cutting oil is used for the cutting processing and spray oil supply of difficultly processed materials; and the adopted raw materials are biodegradable and have no toxicity to human bodies, small damage to ecological environment and low pollution.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Gear cutting oil

Metalworking fluids contain active sulfur, a certain kind of inactive sulfur called “available sulfur”, and fat in a base oil of a lubricating viscosity. The metalworking fluids are chlorine free and phosphorous free. Boundary lubrication is provided by the fat, while extreme pressure lubrication is provided by the sulfur. Available sulfur is inactive sulfur minus any contribution of inactive sulfur from sulfurized saturated fats. Active sulfur and available sulfur are present in balanced proportions, while fat is present at an amount effective to provide boundary lubrication. Use of the fluids reduces tool wear over a long period of action and over a variety of boundary and extreme pressure conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

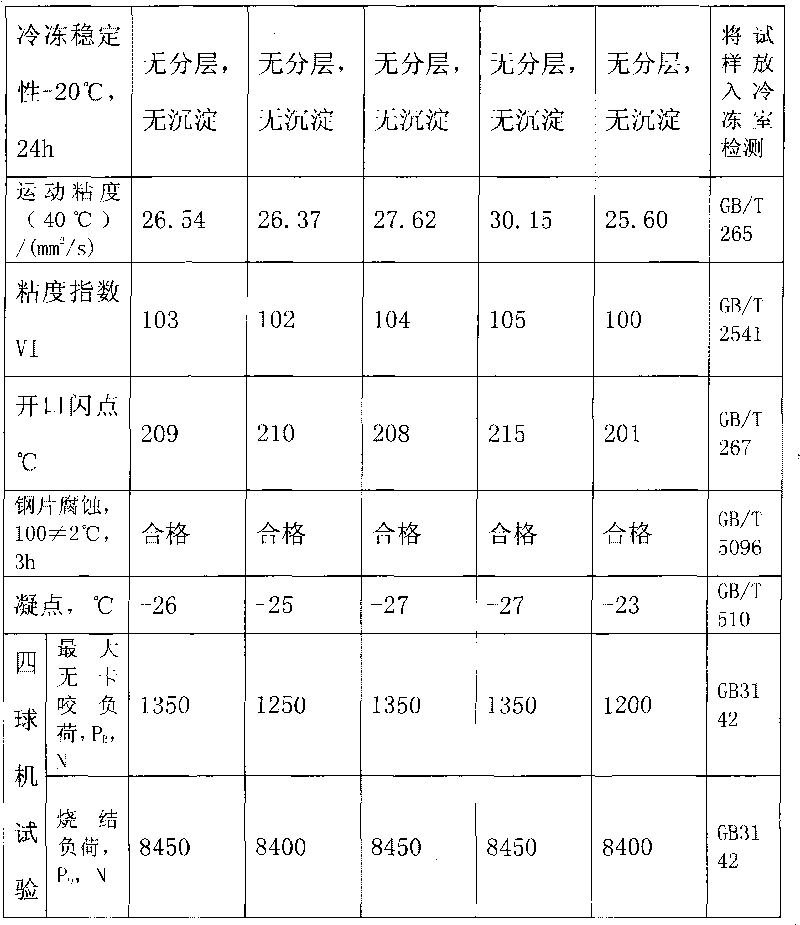

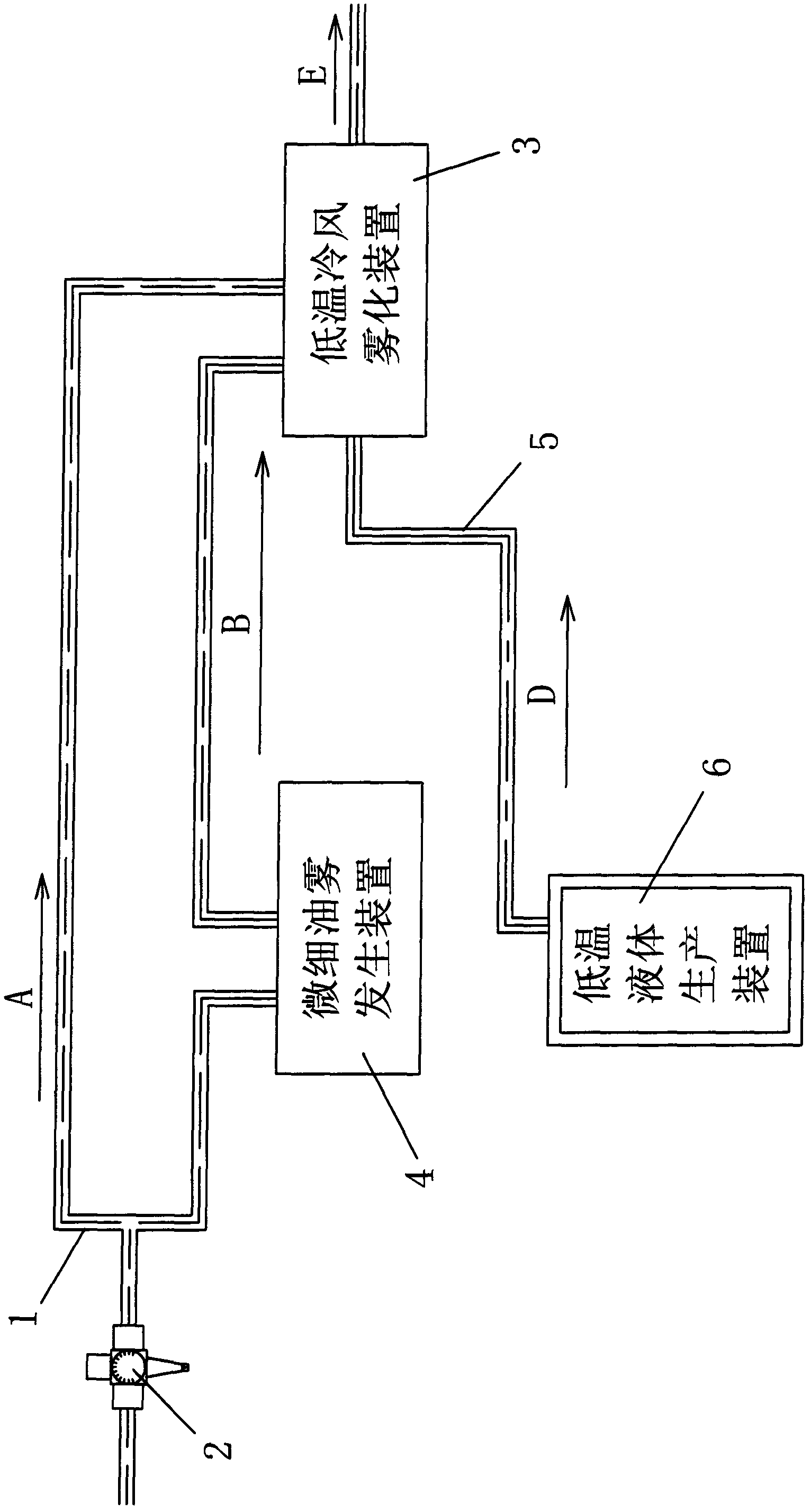

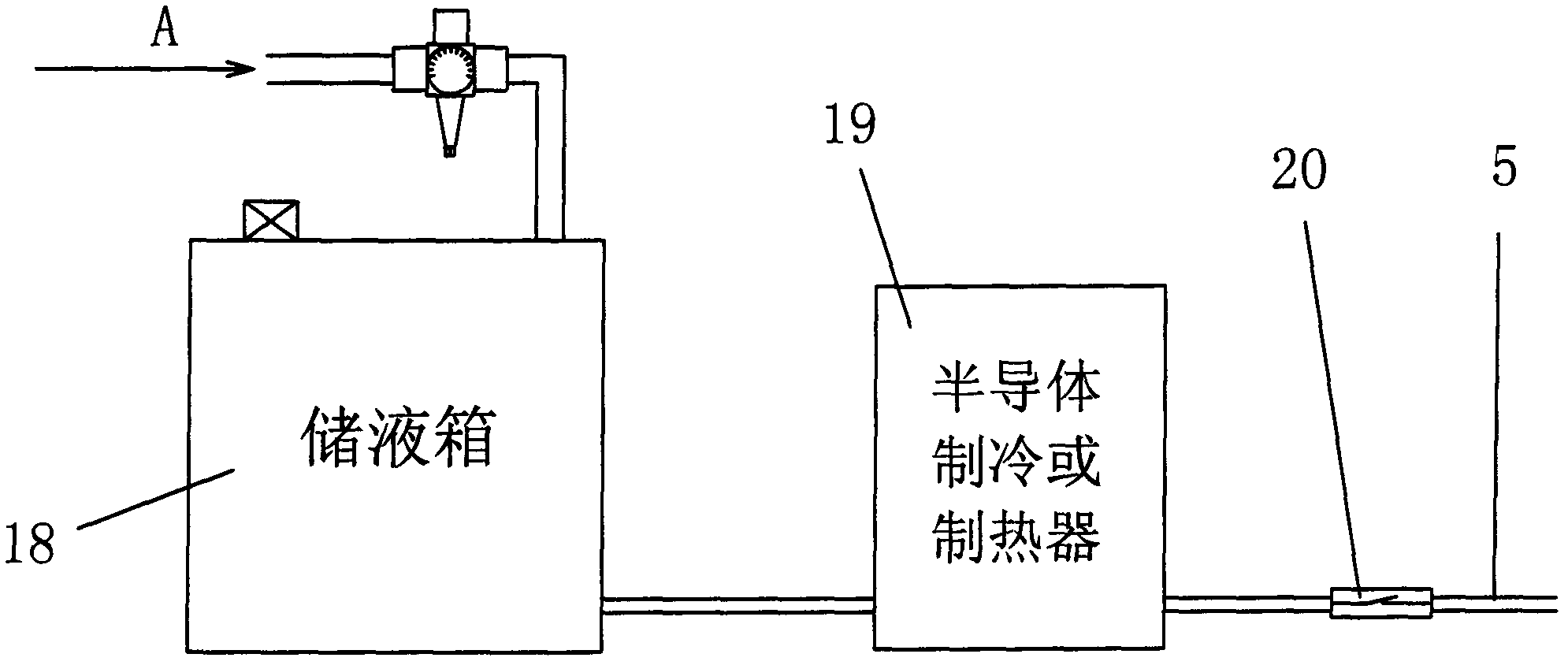

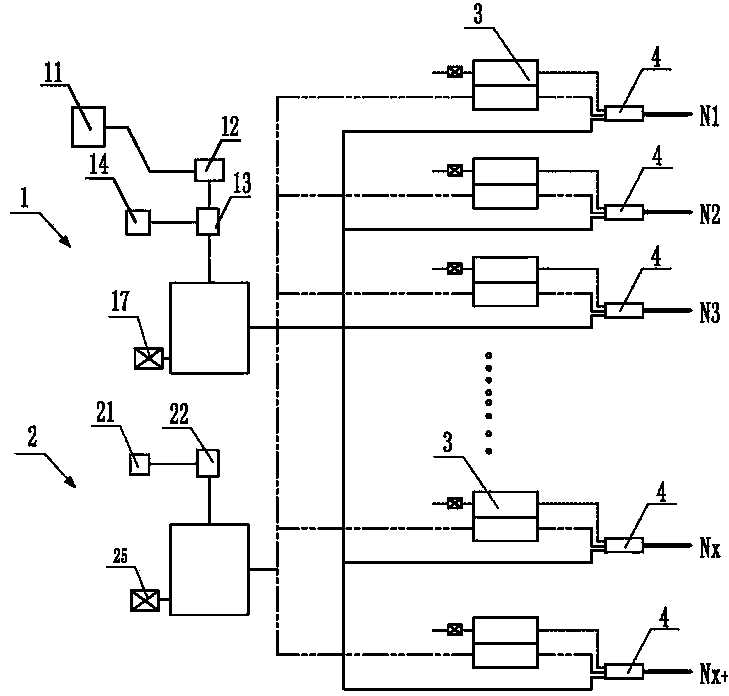

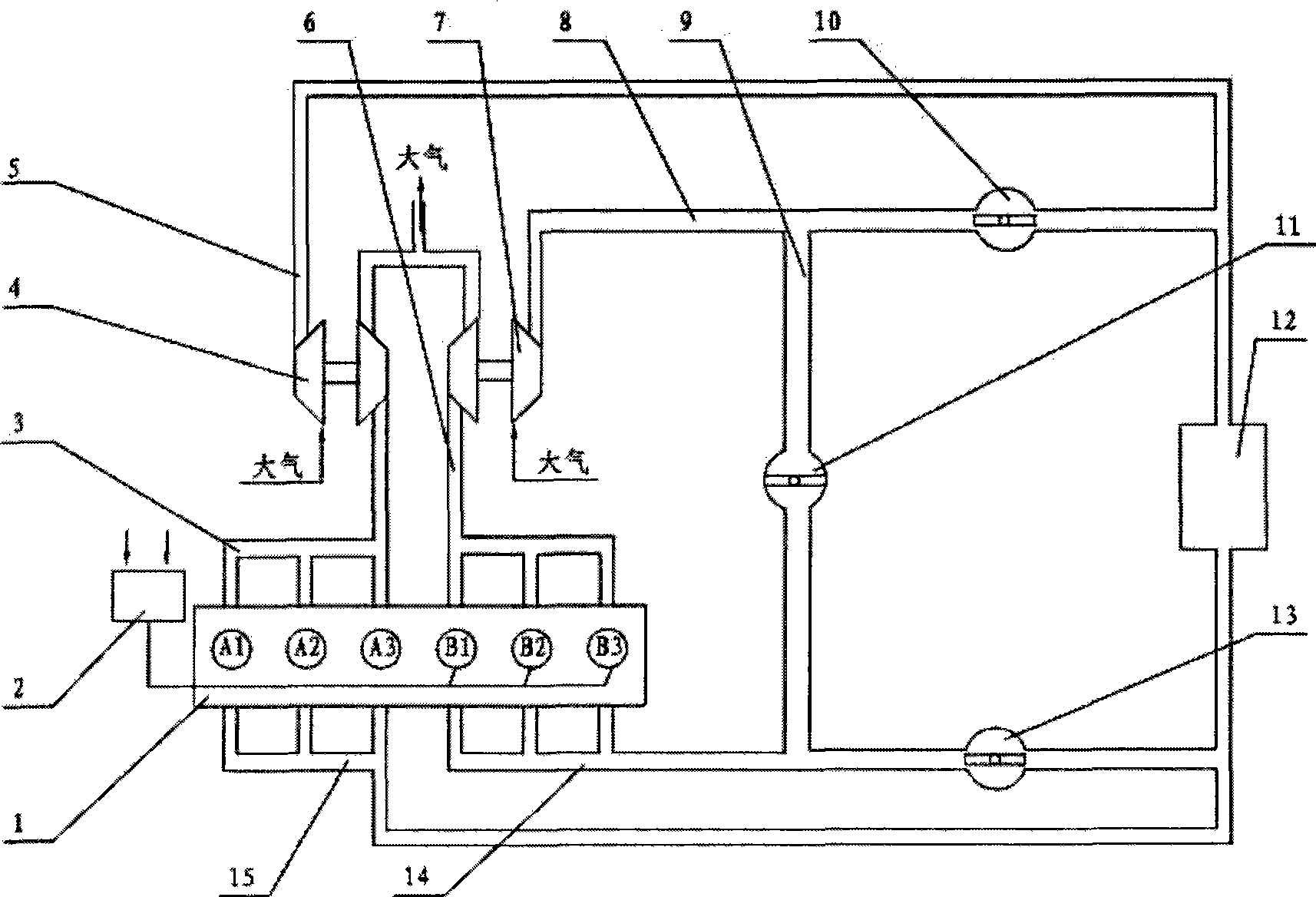

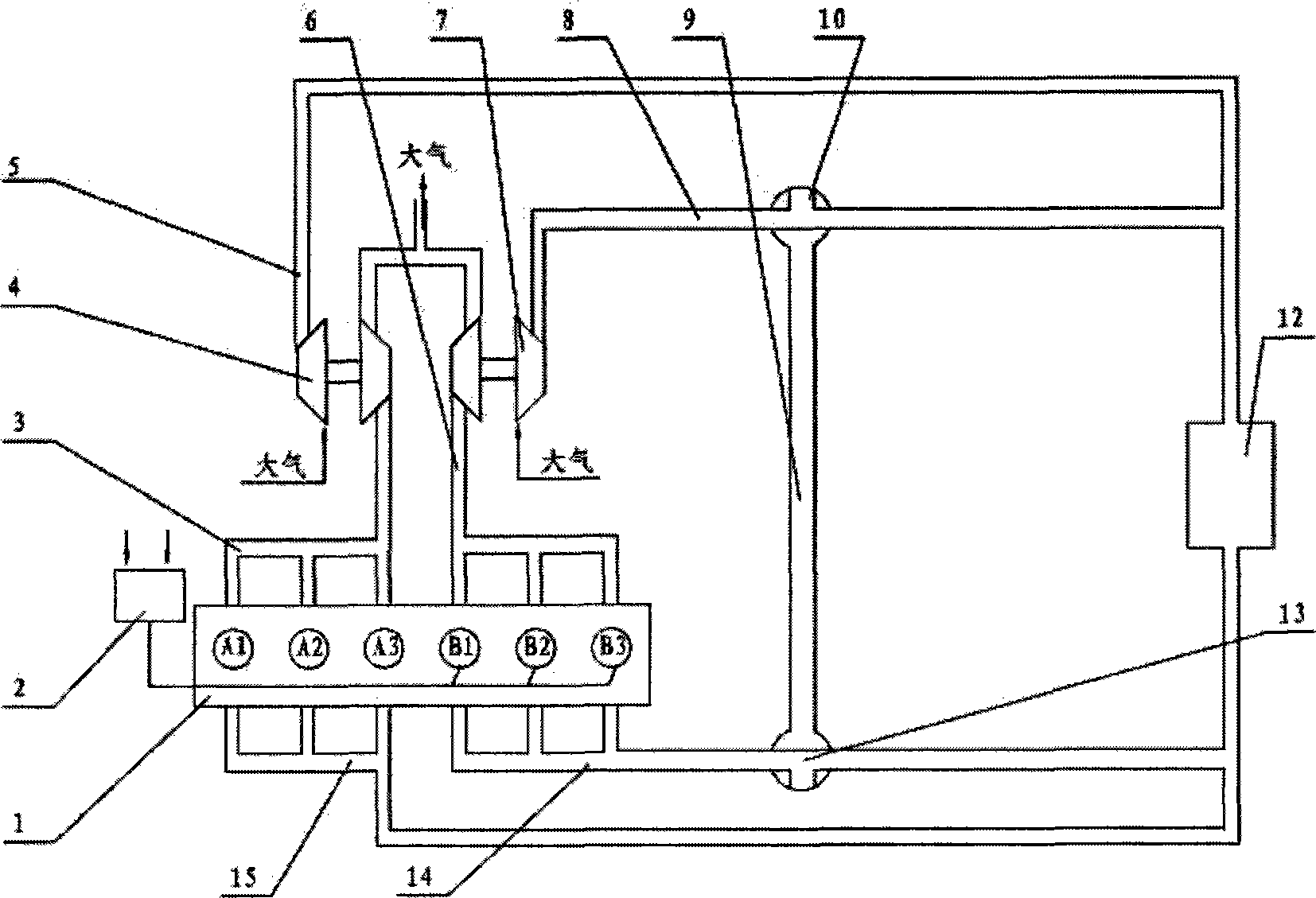

Low-energy-consumption low-temperature composite spray cutting system

ActiveCN102501132AEnsure adequate lubricationSufficient wear reductionMaintainance and safety accessoriesLiquid storage tankCutting oil

The invention discloses a low-energy-consumption low-temperature composite spray cutting system and belongs to the technical field of machining and clean production. The low-energy-consumption low-temperature composite spray cutting system mainly comprises a filter pressure reducing valve, a fine oil spray generation device, a low-temperature liquid production device, a low-temperature cold air atomization device, a common conveying pipe and an insulation conveying pipe. The fine oil spray generation device comprises a partition plate, an atomization chamber, a precipitation chamber, a micro oil pump and an oil capacity control valve. The low-temperature liquid production device comprises a liquid storage tank, a semiconductor refrigerating or heating device, a liquid level control valve and an insulation conveying pipe; the low-temperature cold air atomization device comprises a vortex refrigeration device which produces cold air and a nozzle; and the nozzle comprises a fixed sheet, an oil spray thin pipe outlet, a water thin pipe outlet, a mixing cavity and a spray outlet channel. The system forms low-temperature composite oil spray in which a layer of thin oil film is covered on water drops by using purely oily plant oil based cutting oil with good performance, frozen low-temperature purified water and low-temperature cold air, accurately sprays the low-temperature composite oil spray onto a metal cutting area at high speed, and fulfills the aims of effective cooling and lubrication.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

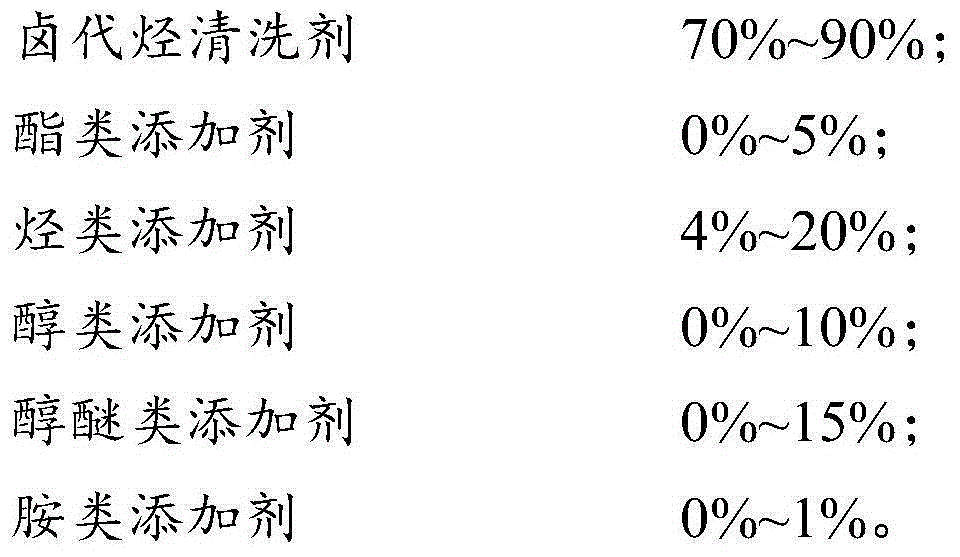

Metal cleaner

The invention discloses a metal cleaner. The metal cleaner is prepared from, by weight, 50%-90% of halohydrocarbon cleaners, 0%-10% of ester additives, 2%-30% of hydrocarbon additives, 0%-20% of alcohol additives, 0%-25% of alcohol ether additives and 0%-5% of amine additives, wherein the halohydrocarbon cleaners are chlorohydrocarbon and / or chloro-fluoro-hydrocarbon, chlorohydrocarbon is tetrachloroethylene and / or dichloromethane, and chloro-fluoro-hydrocarbon is 1-fluoro-1,1-dichloroethane. The metal cleaner is large in cleaning force, high in permeability and dispersity, capable of cleaning wax, ink, punching oil, cutting oil and lubricating oil, small in smell and free of toxicity.

Owner:SHENZHEN XINJUNXIANG TECHCAL

Water-soluble lubricating oil

InactiveCN1575330AImprove machinabilityGood stamping performanceDischarging arrangementOther chemical processesOil and greaseMetalworking

The water-soluble lubricating oil composition of this invention contains animal fats and oils and / or plant fats and oils, and the nonionic surfactant of polyoxyethylene sorbitol fatty acid ester. The water-soluble lubricating oil composition of this invention is excellent in emulsion stability, and it can reduce environmental pollution. It is suitably as metal processing oils such as cutting oil and plastic working oils, and release agent such as asphalt mixture adhesion prevention agent and concrete release agent.

Owner:THE NISSHIN OILLIO GRP LTD

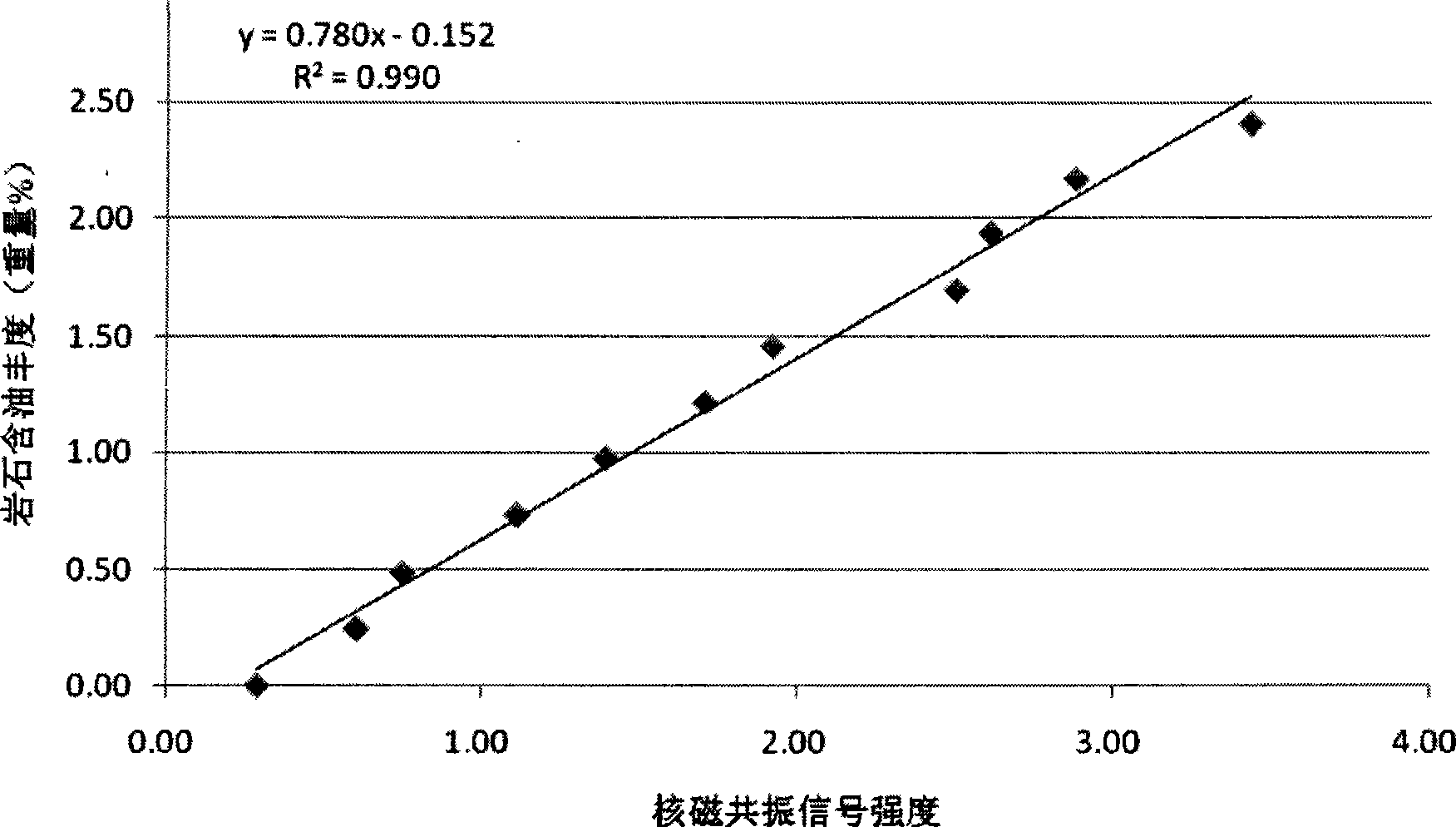

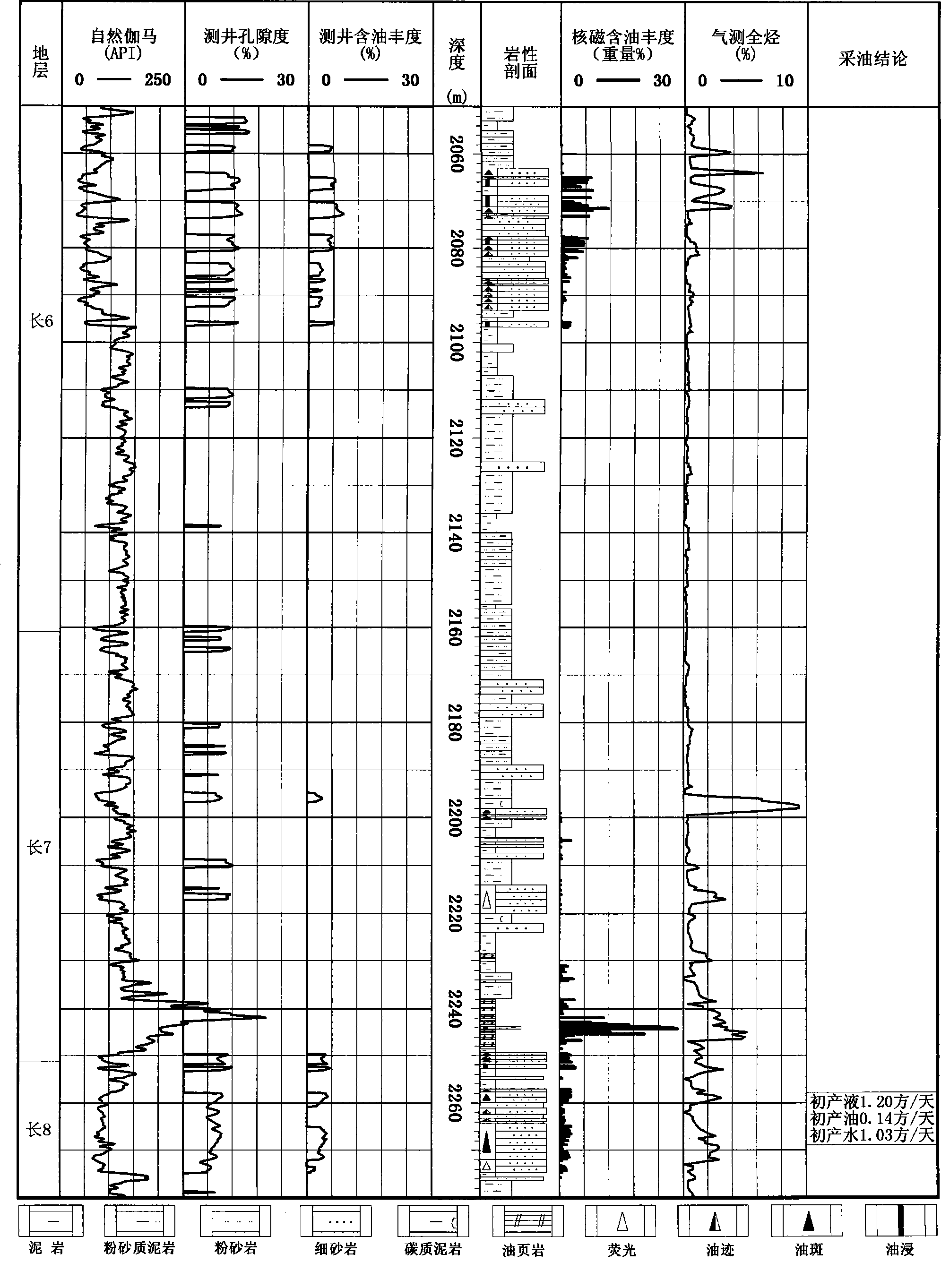

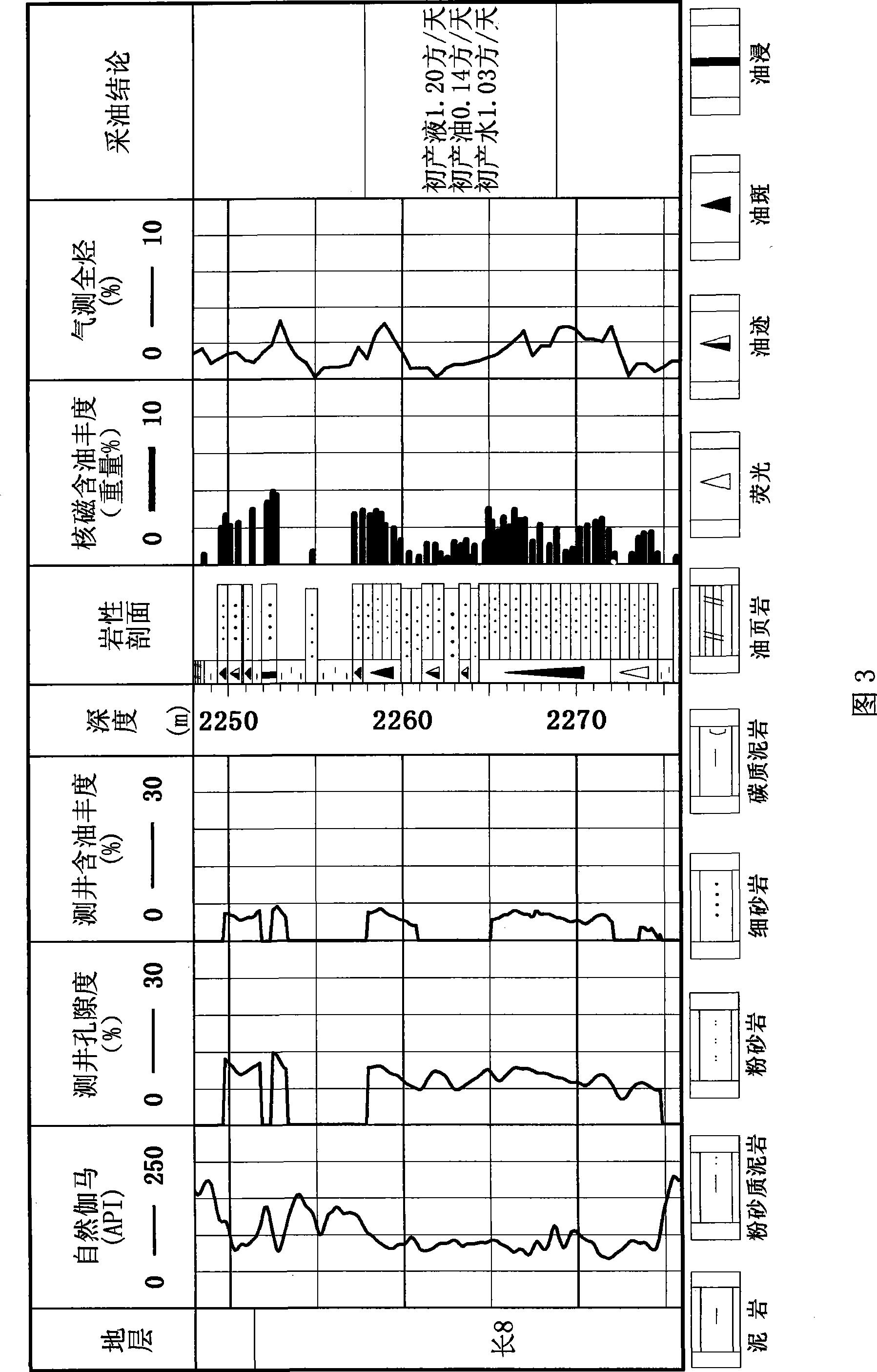

Quantitative analysis method for oil-containing abundance of nuclear magnetic resonance rock in petroleum well drilling

ActiveCN101368481AReal-time analysisObtain oil abundance data in real timeAnalysis using nuclear magnetic resonanceBorehole/well accessoriesHorizonRock cutting

The invention relates to a fine well-drilling cuttings oil-abundance analysis method based on nuclear magnetic resonance technology. The method includes the following steps: debugging and calibrating a nuclear magnetic resonance analytical apparatus; making up a rock oil-abundance working curve at target horizon, getting rock cuttings at a reservoir layer without oil gas at the target horizon within the work area and preparing the rock cuttings into a sample mixture of crude oil and cuttings; soaking the sample mixture in water-soluble paramagnetic ion solution; conducting nuclear magnetic resonance analysis; with the intensity of nuclear magnetic resonance signals as the abscissa and the content of crude oil in the sample as the ordinate, drawing a rock oil-abundance working curve of the target horizon; and then calculating the rock oil-abundance data. The method can analyze well-drilling cuttings real-timely, work out the rock oil-abundance data real-timely and carry out quantitative evaluation to the oil-abundance of the reservoir layer, providing real-time technical support to oil exploration, development and production.

Owner:中石化石油工程技术服务有限公司 +3

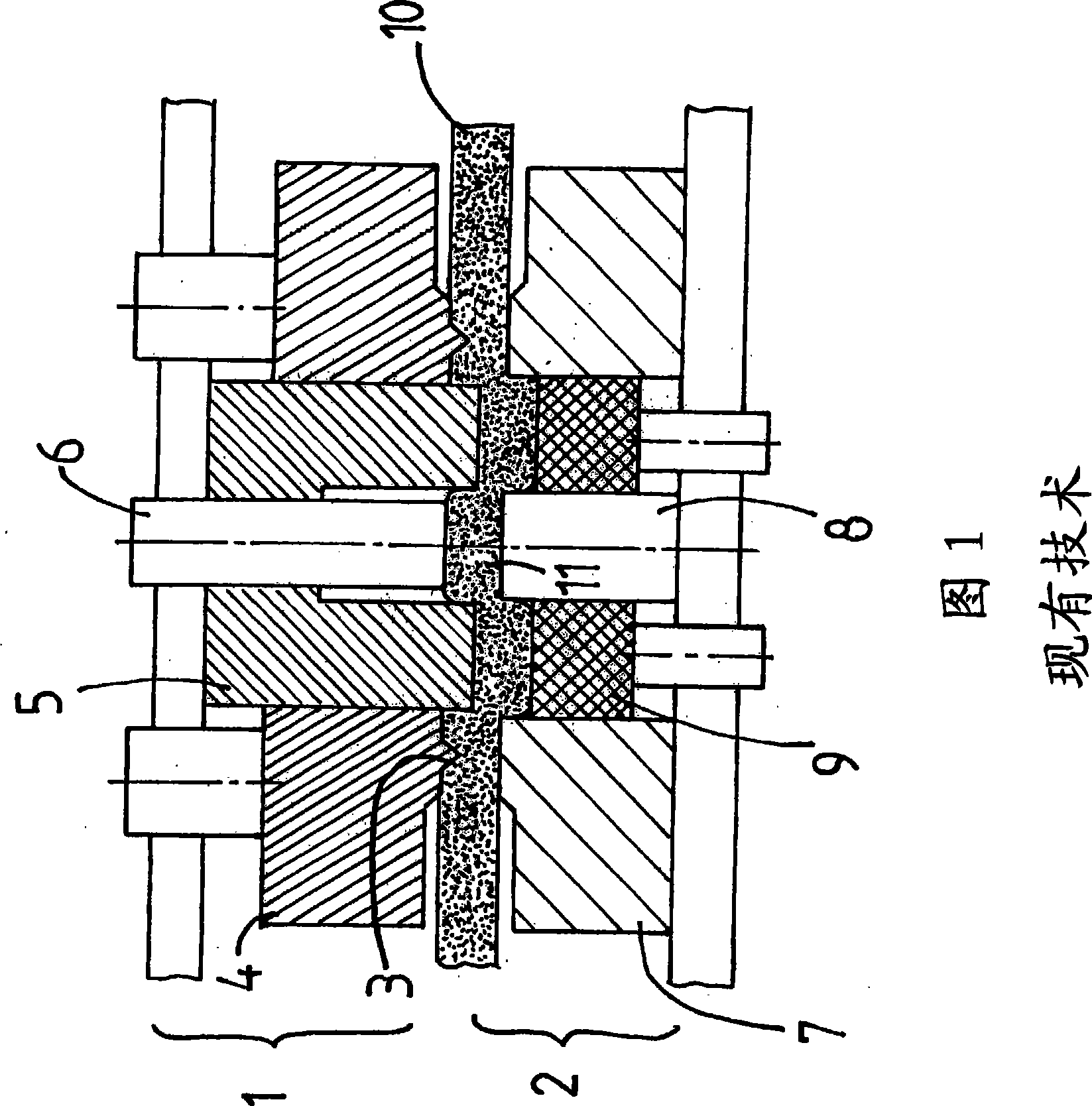

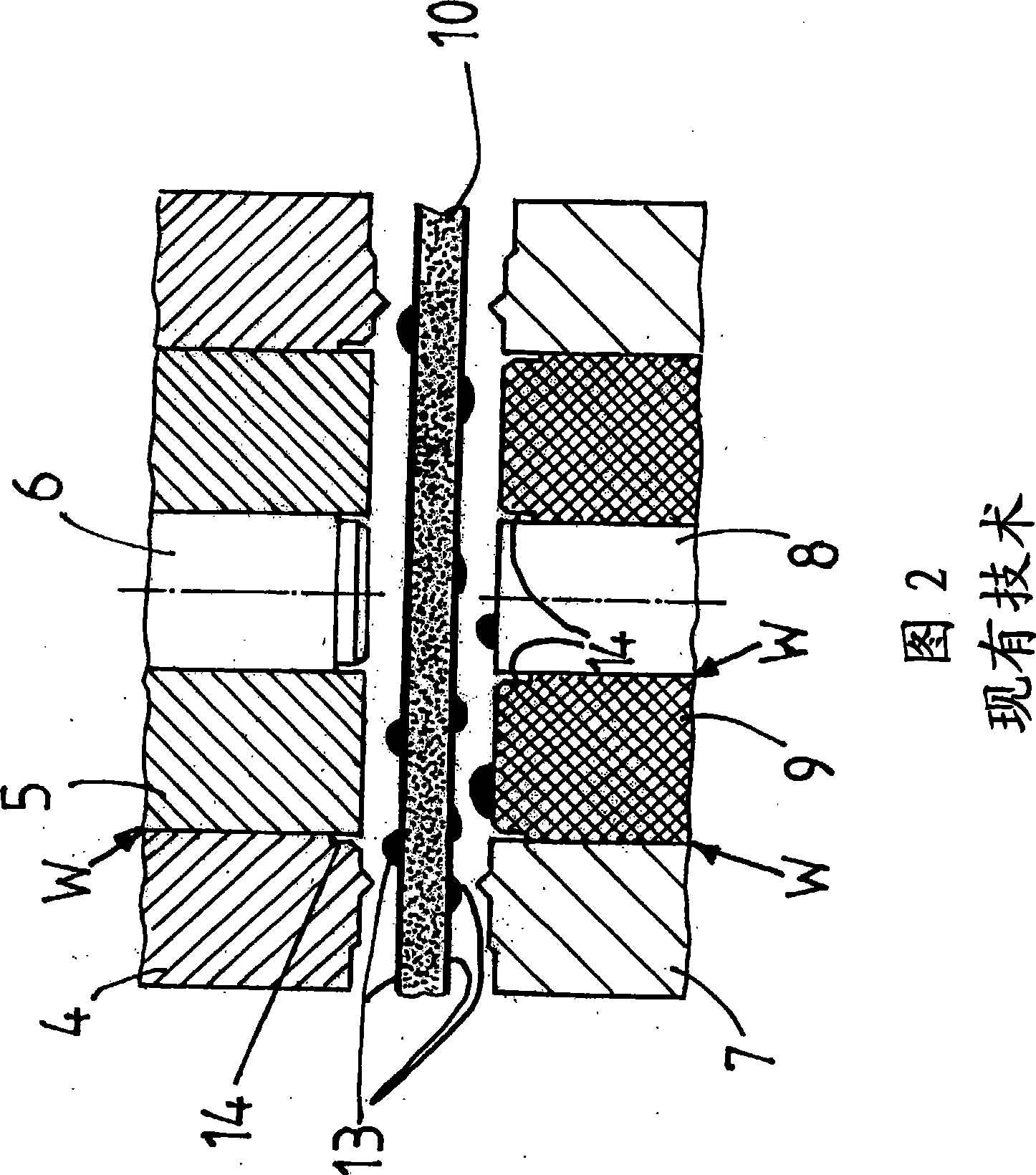

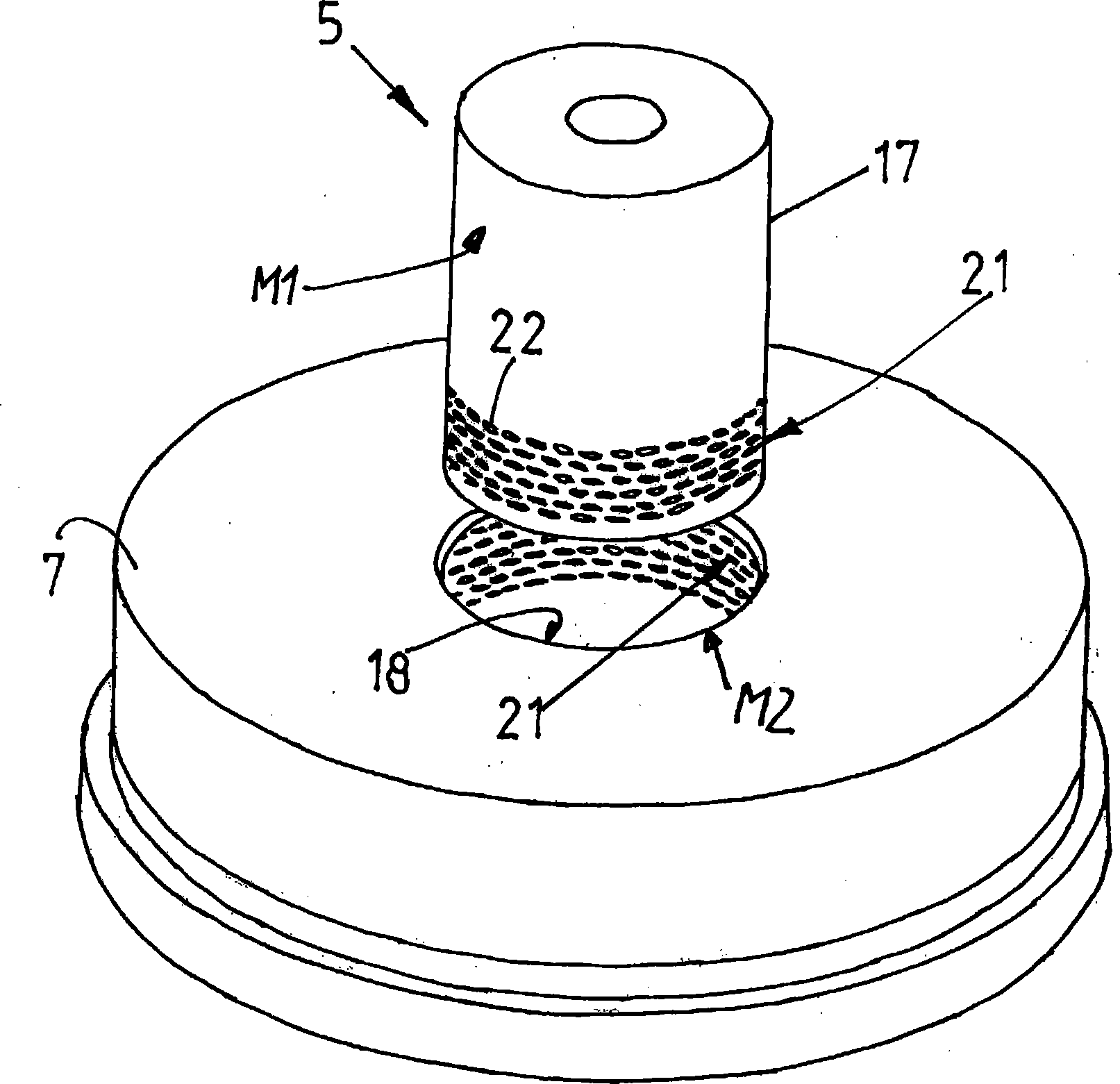

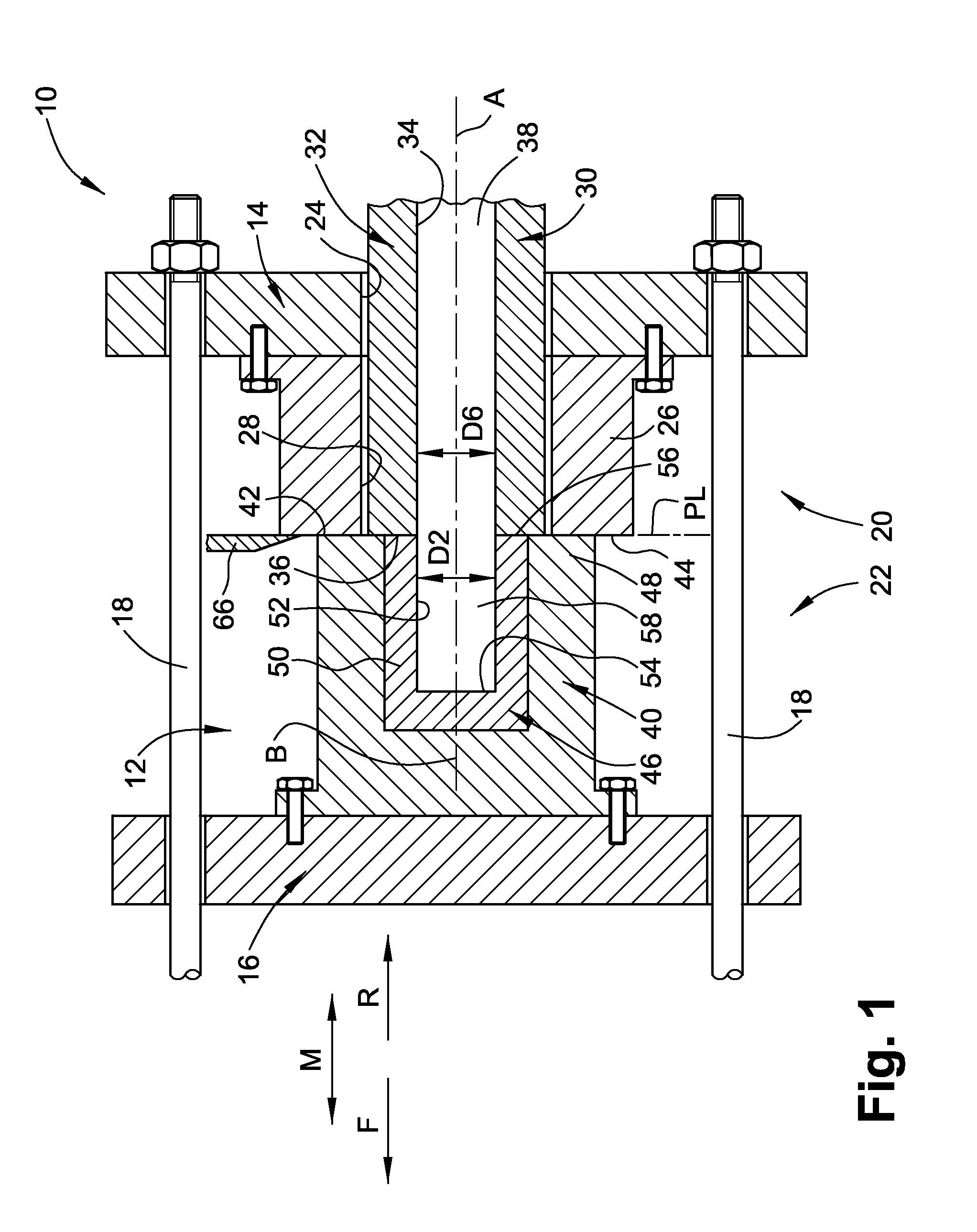

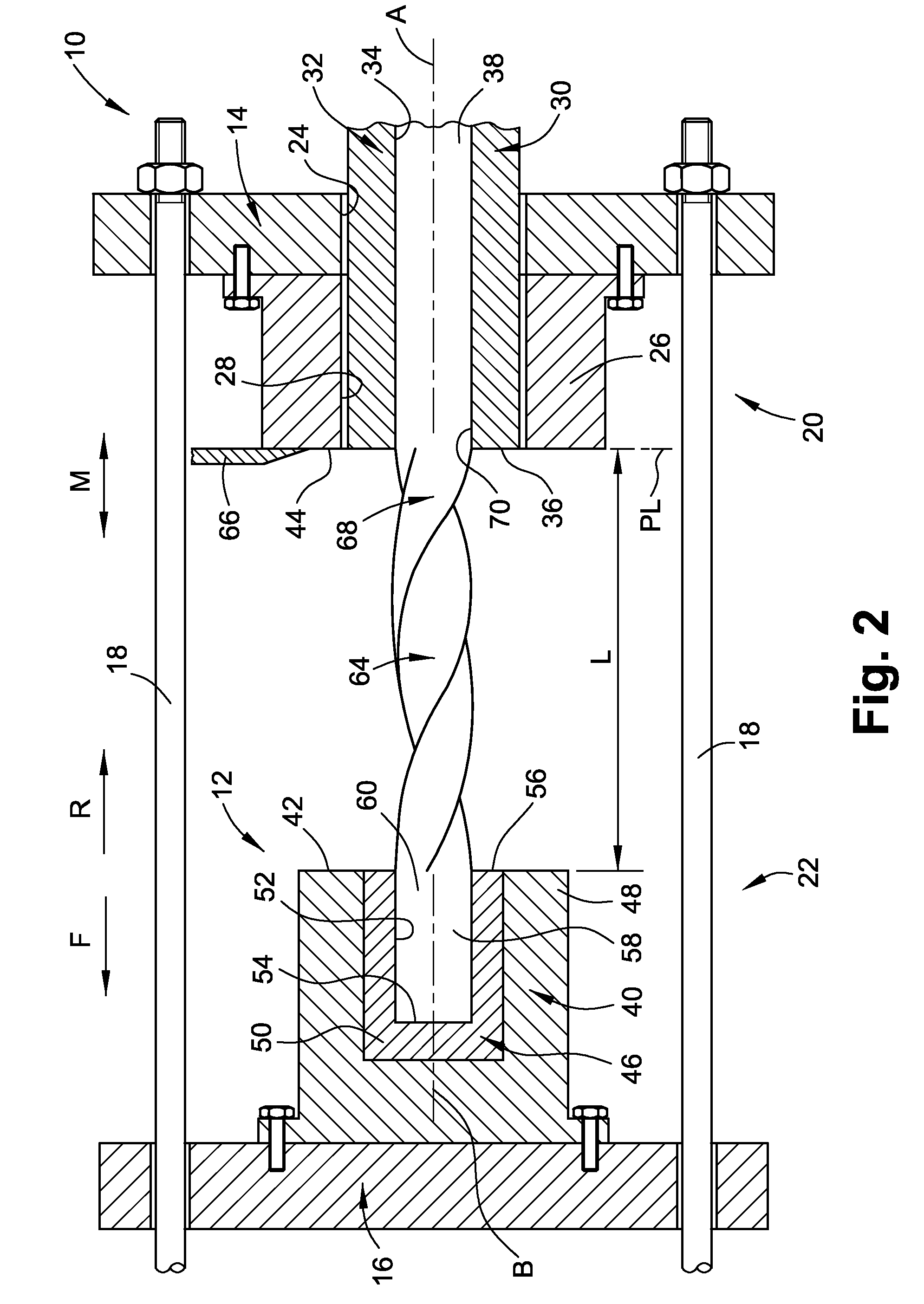

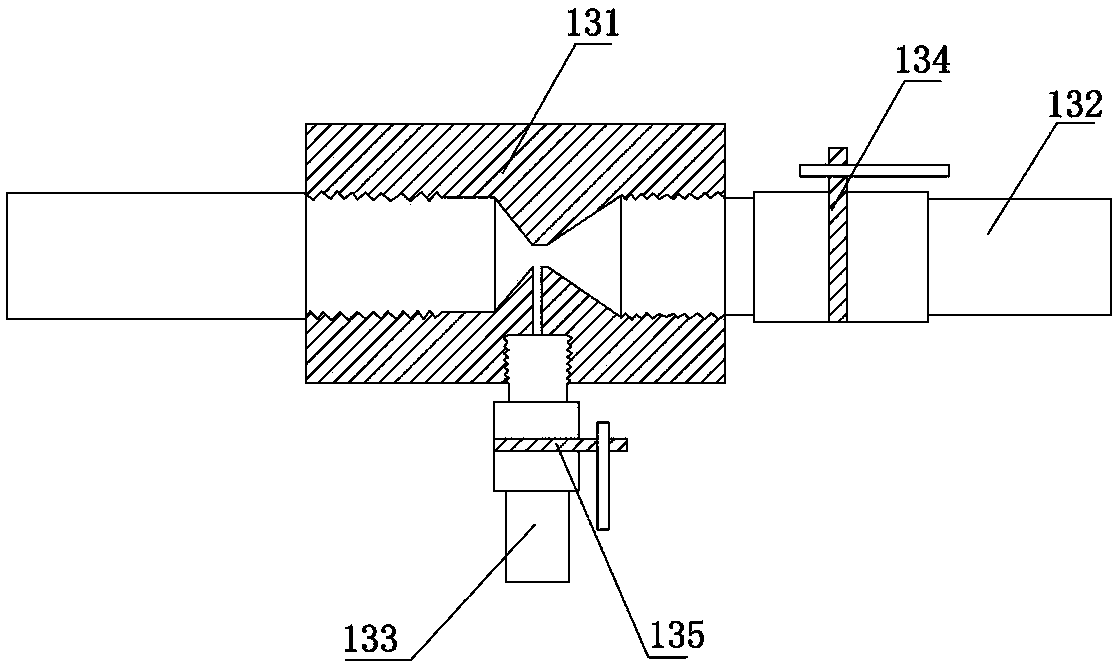

Method and device for lubricating a tool and workpiece when cutting

InactiveCN101386047AHigh process reliability/safetyHigh precisionShaping toolsMaintainance and safety accessoriesEngineeringCutting oil

The invention relates to a method and a device for lubricating tool and workpiece at cutting and forming, especially fine blanking of a workpiece with a thickness of 5 mm or more and with complex part geometry from a flat strip. The invention has the task to further develop a method and a device for lubricating a tool and a workpiece at cutting and forming, especially at fine blanking of workpieces, so that fine blanking of thicker parts is reproducible controlled process secure with high quality and at the same time extended edge life of the tools by lubricating the active surfaces up to the forming zone without the provided lubricating film breaking off. This task is solved in the manner that from the stocked up cutting oil one quantity is accumulated in a micro-surface structure of a functional surface of shearing punch and cutting die and evenly distributed on the functional surfaces as quasi-stationary cutting oil film by cooperation of moving past each other functional surfaces, when the tool is closed, and that one quantity of accumulated cutting oil via the respective effective gaps is provided to the active surfaces of shearing punch and workpiece in the forming zone.

Owner:FEINTOOL INTPROP

Cutting method

InactiveUS20090000441A1Weaken energyEasy to removeThread cutting feeding devicesTransportation and packagingSuction stressEngineering

An object is to provide a cutting method capable of efficiently removing cutting chips around a cutting point with a little electric power, and cutting a work with high accuracy.A ball end mill having a slit shaped-opening part at a portion adjacent to a rake face of a cutting edge and internally having a suction passage is used, and a work in which a cutting liquid is previously coated on an inclined face is cut while the cutting liquid is sucked in the area around the cutting edge from the opening part through the suction passage. As a result of this, in case of using non water-miscible cutting oil, when the cutting liquid in the area around the cutting edge is sucked from the opening part, a cutting power decreasing rate is higher than a case where the suction is not carried out.

Owner:OKUMA CORP

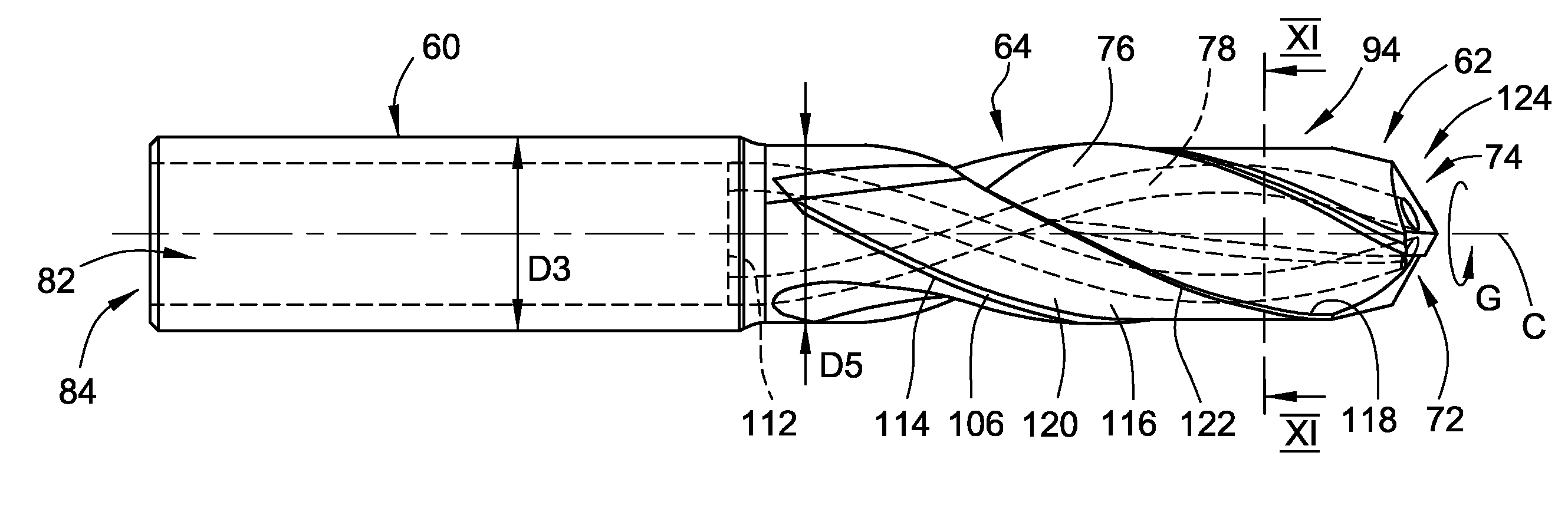

Cutting Tool and a Process for making Such a Cutting Tool

ActiveUS20100272531A1Saving substantial amountFirmly connectedMetal-working drilling toolsTransportation and packagingEngineeringCutting oil

A cutting tool having a monolithic construction includes an injection molded shank, and an extruded fluted portion extending forwardly from the shank, the shank and the fluted portion having a monolithic construction. The process for making the cutting tool includes forming a cutting tool green body by injection molding a shank of the green body and extruding a fluted portion of the green body such that the shank and the fluted portion have a monolithic construction; and then sintering the cutting tool green body.

Owner:ISCAR LTD

Environment-friendly emulsion cutting oil with high lubricity and high permeability for metal working

ActiveCN102250673ANo stimulationLittle mechanical pollutionLubricant compositionEmulsionMetal working fluid

The invention discloses an environment-friendly emulsion cutting oil with high lubricity and high permeability for metal working. The emulsion cutting oil is composed of a polymer carboxylic acid, an amine, a surfactant, mineral oil, a synthetic lubricant, a defoamer and an anti-corrosive agent. The emulsion cutting oil disclosed by the invention causes small pollution during processing, has excellent lubricity and permeability, and is safe to human and environment.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

Water insoluble cutting oil

InactiveCN1548507AExtended service lifeExcellent extreme pressure lubricityAdditivesLow speedWater insoluble

The water insoluble cutting oil consists of base oil, grease, sulfide extreme pressure additive, lubricant agent, antioxidant and mist inhibitor mixed together. The product of the present invention excellent extreme pressure lubricating performance, and is suitable for low speed high load cutting to raise service life of cutting tool and ensure excellent machining surface. It is used as common cutting oil for broaching and forming gear, has excellent use effect, no uncomfortable smell and no harmful matter, and is good for environment protection.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD

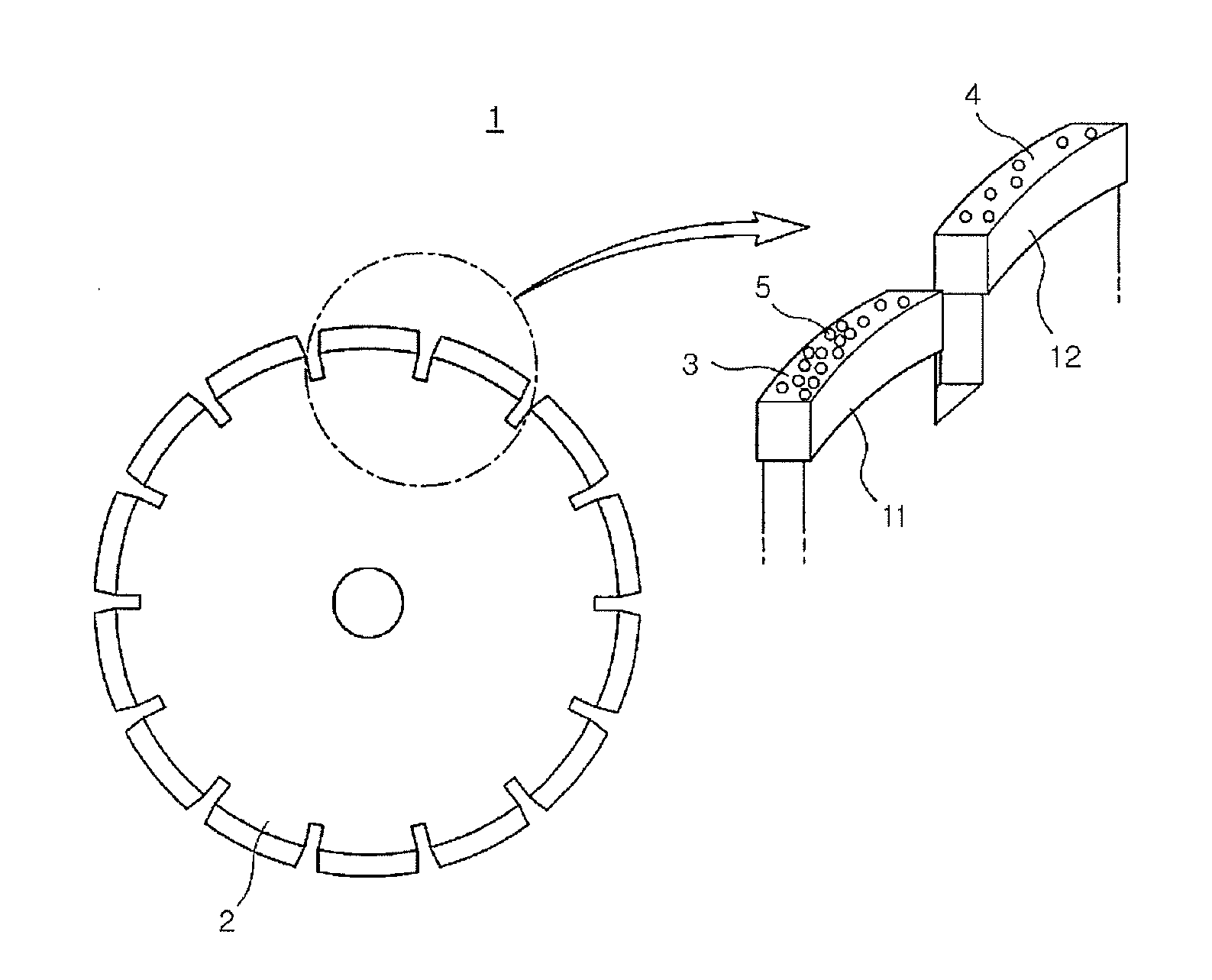

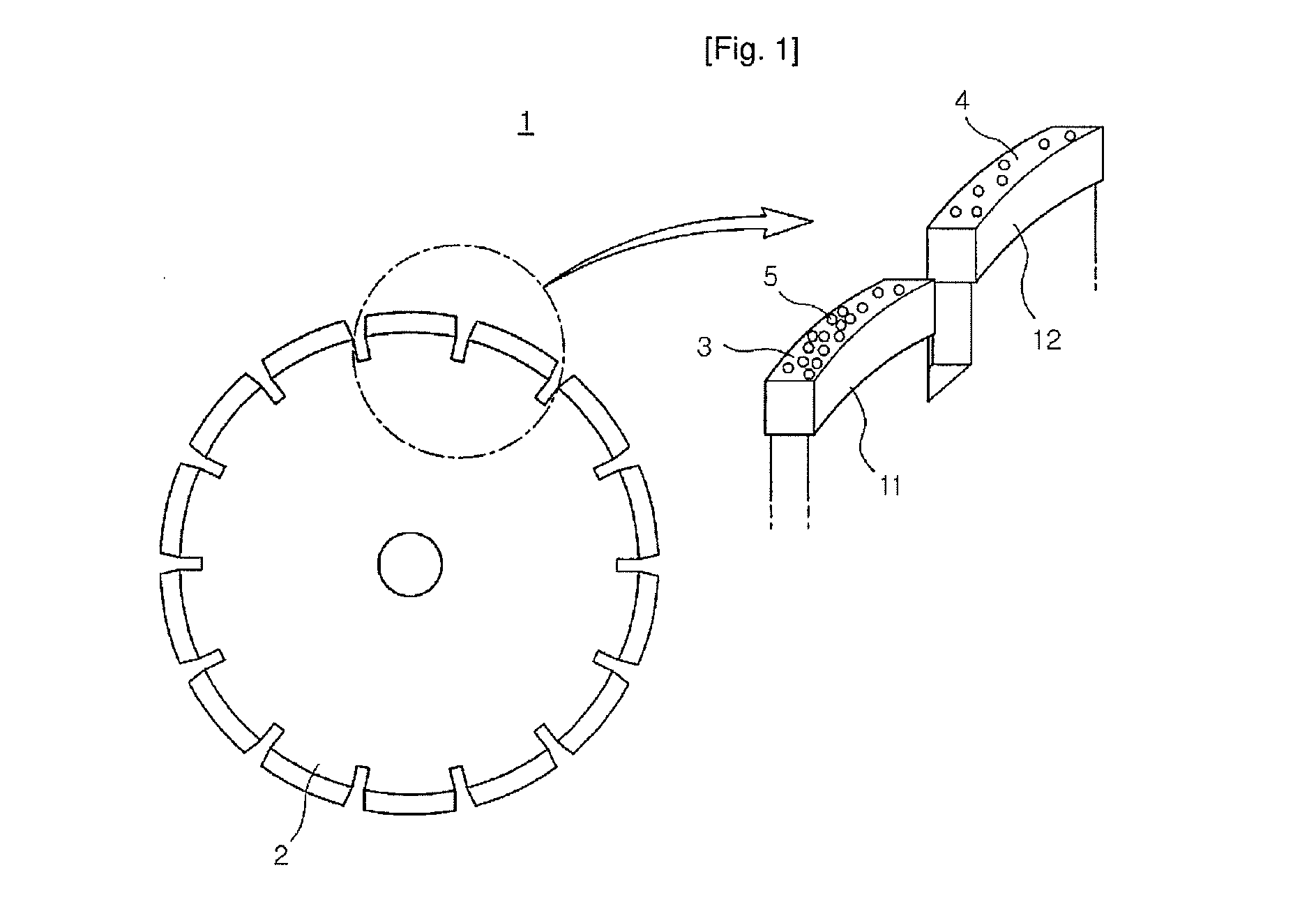

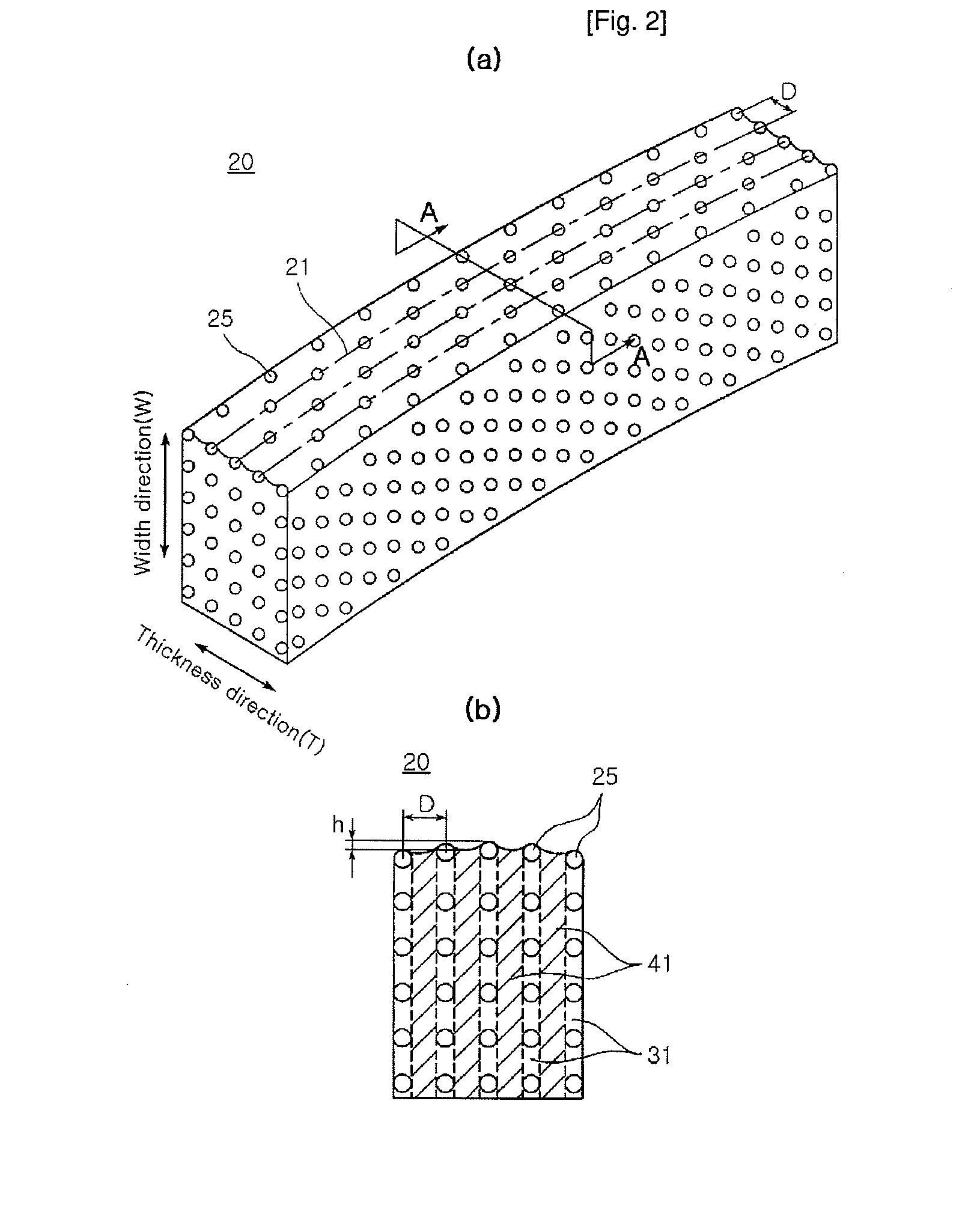

Cutting Segment for Cutting Tool and Cutting Tools

ActiveUS20080202488A1Increase cutting rateExtended useful lifeBonded abrasive wheelsSaw bladesBrickCutting oil

The invention provides a cutting segment for a cutting tool for cutting or drilling a brittle work piece such as stone, bricks, concrete and asphalt, and a cutting tool having the cutting segment. The cutting segment includes a cutting surface for cutting a work piece and a plurality of abrasive particle layers. The abrasive particle layers are disposed perpendicular to a cutting direction. Each of the abrasive layers has a plurality of abrasive particle rows in a width direction of the cutting segment. Each of the abrasive rows has a plurality of abrasive particles arranged in a line. Further, the abrasive layers have a plurality of blank sections therebetween. In the blanks sections, abrasive particles are absent or have a concentration of 70% or less with respect to those in the abrasive rows. In addition, the blank sections include relatively thick blank sections and relatively thin blank sections.

Owner:NIWA DAIYAMONDO INDS +1

Lubrication cutting agent and preparation method thereof

ActiveCN103865617AImprove the finishReduce wearLubricant compositionTriethylamine phosphateSuccinic acid

The invention provides a lubrication cutting agent and a preparation method thereof. The lubrication cutting agent comprises: 10-40 parts of sulfurized cutting oil, 5-10 parts of naphthenic oil, 2-6 parts of triethyl phosphate, 1-4 parts of dinonyl naphthalene barium sulfonate, 0.2-1.5 parts of 1,2,6-butylated hydroxytoluene, 0.5-2.8 parts of dodecyl phenyl succinic acid, 1-5 parts of stearic acid, 0.1-1.2 parts of triethanolamine boric acid ester, 0.5-3.2 parts of sodium citrate, 0.3-1.2 parts of polyacrylamide, 12-18 parts of sodium dodecyl benzene sulfonate, 0.01-0.1 part of dodecenylsuccinic acid, 1-7 parts of oleamide, 5-13 parts of ethylenediamine tetraacetic acid tetrasodium, 0.2-0.8 part of chlorinated paraffin and 10-20 parts of hydrophilia polyhydric alcohols. The preparation method comprises steps of firstly, uniformly mixing a part of the components, and secondly, adding the rest components. The lubrication cutting agent provided by the invention has remarkable effects on improving the surface smoothness of a workpiece and alleviating abrasion of a cutter.

Owner:上海德润宝特种润滑剂有限公司

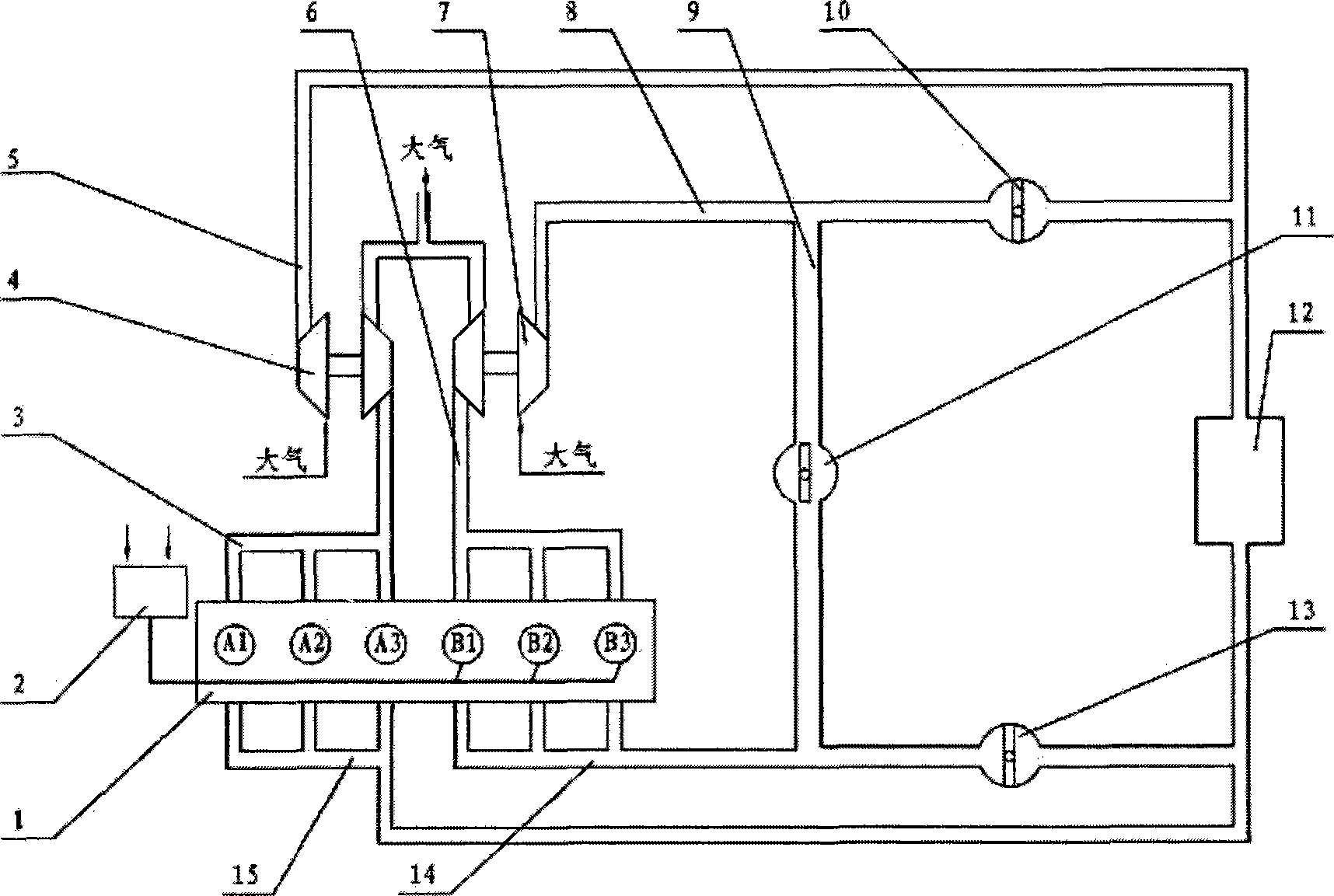

Automatic supply system of composite spray cooling oil for machining

ActiveCN104227494AImprove anti-corrosion performanceGuaranteed cleanlinessMaintainance and safety accessoriesAssistive device/technologySpray nozzle

The invention relates to the technical field of auxiliary equipment for machining, in particular to an automatic supply system of a composite spray cooling oil for machining. The automatic supply system comprises an automatic water supply system, an automatic oil supply system, a minimal quantity lubricating and cooling system and a composite atomizing spray nozzle, wherein a water outlet of the automatic water supply system is connected with a liquid inlet of the composite atomizing spray nozzle through a conveying pipe; an oil outlet of the automatic oil supply system is connected with a liquid inlet of the minimal quantity lubricating and cooling system through the conveying pipe; a liquid outlet of the minimal quantity lubricating and cooling system is connected with the liquid inlet of the composite atomizing spray nozzle. According to the automatic supply system disclosed by the invention, cutting oil can be automatically replenished, the problems that a manual mode of replenishing the cutting oil is miscellaneous and a long time is consumed are solved, the production efficiency is improved, and the application range of a minimal quantity lubricating technology is effectively widened.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Long-service-life environment-friendly energy-saving plant-based cutting oil

InactiveCN102925264AImprove working environmentReduce the risk of inhaling harmful substancesLubricant compositionAntioxidantSulfur

The invention discloses long-service-life environment-friendly energy-saving plant-based cutting oil which comprises the following raw materials by weight: 70-90 parts of base oil, 3-5 parts of anti-wear and anti-friction agent, 5-10 parts of extreme pressure anti-wear agent, 0.1-0.3 parts of antioxidant and 0.5-1 part of oil mist inhibitor. The long-service-life environment-friendly energy-saving plant-based cutting oil has the advantages that the long-service-life environment-friendly energy-saving plant-based cutting oil has good lubricating, anti-wear and rustproof performance and most importantly, belongs to the plant-based cutting oil; modified plant oil can serve as oiliness agent simultaneously to be matched with the novel anti-attrition and anti-wear agent; and the long-service-life environment-friendly energy-saving plant-based cutting oil does not contain environment-friendly components such as sulfur and chlorine, easily achieves biological degradation, is low in oil mist, can reduce risks of inhalation of harmful substances of operators, and can create a good operation environment for staff.

Owner:何国锐

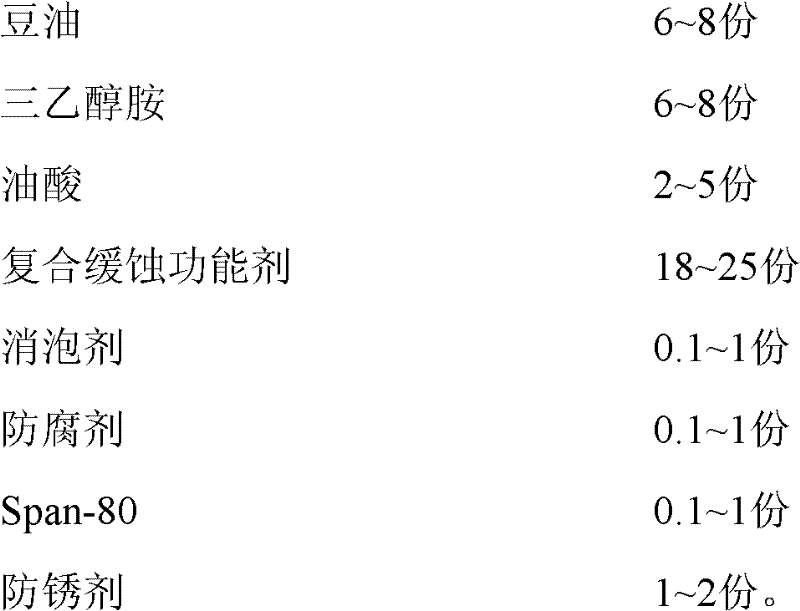

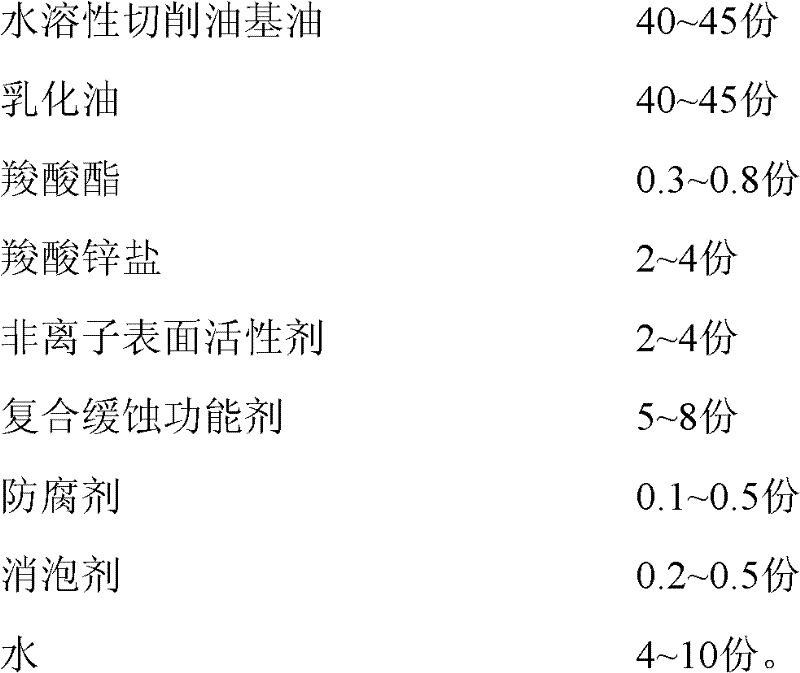

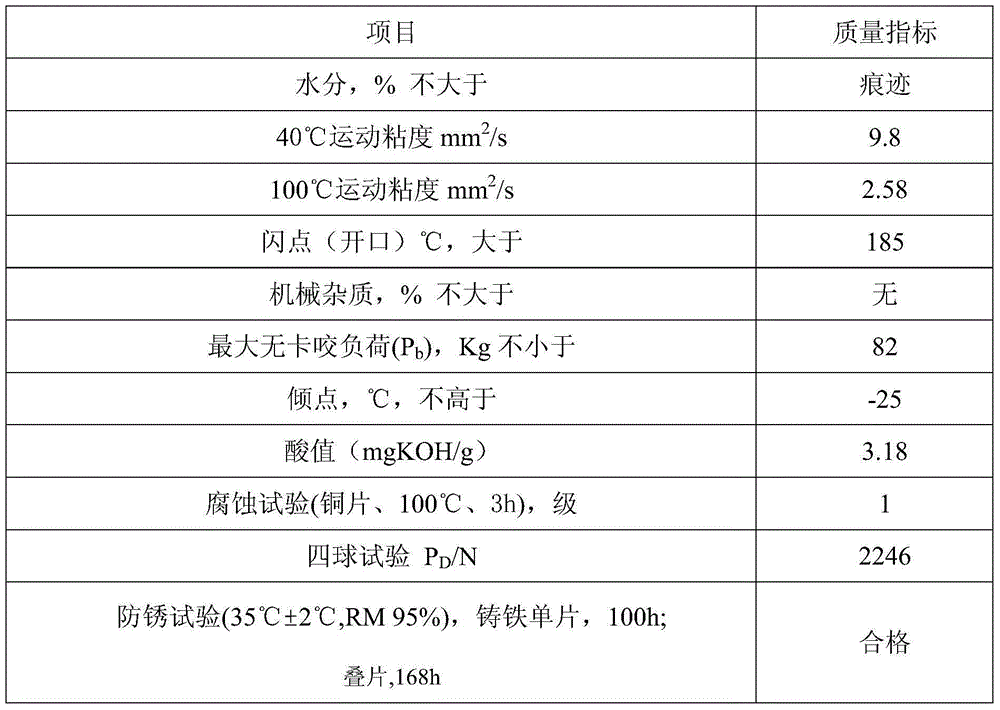

A kind of water-soluble cutting oil and preparation method thereof

InactiveCN102295975AImprove cooling effectImprove the lubrication effectAdditivesOrganic synthesisCarboxylic salt

The invention relates to water-soluble cutting oil which comprises the following raw material components in parts by weight: 40-45 parts of water-soluble cutting oil base oil, 40-45 parts of emulsified oil, 0.3-0.8 part of carboxylic ester, 2-4 parts of zinc carboxylate, 2-4 parts of non-ionic surface active agent, 5-8 parts of compound corrosion inhibition functional agent, 0.1-0.5 part of corrosion inhibitor, 0.2-0.5 part of defoamer and 4-10 parts of water. In the invention, a safe and environmentally-friendly organic synthesis grease process is adopted; and the prepared cutting oil has strong cooling property, lubricity and antirust property, and is easy to wash and is not easy to deteriorate, thereby remedying the defects of a heavy-load water-soluble cutting liquid in the aspects ofantirust property, odor and the like in the use process.

Owner:TIANJIN DONGFANG SPECIAL LUBRICANT

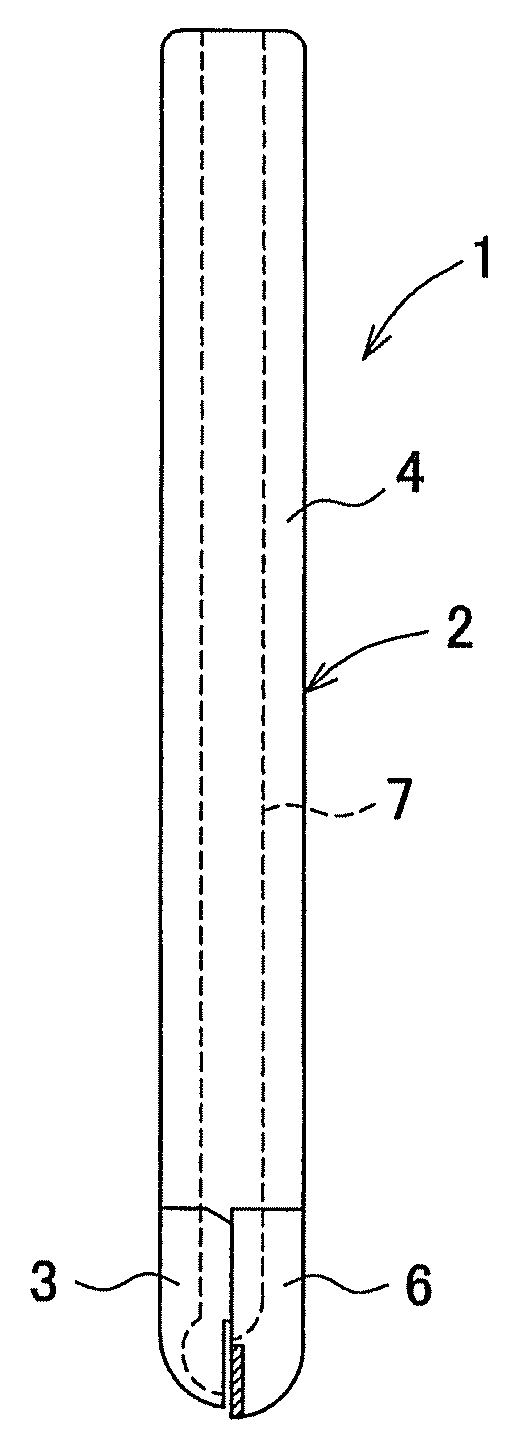

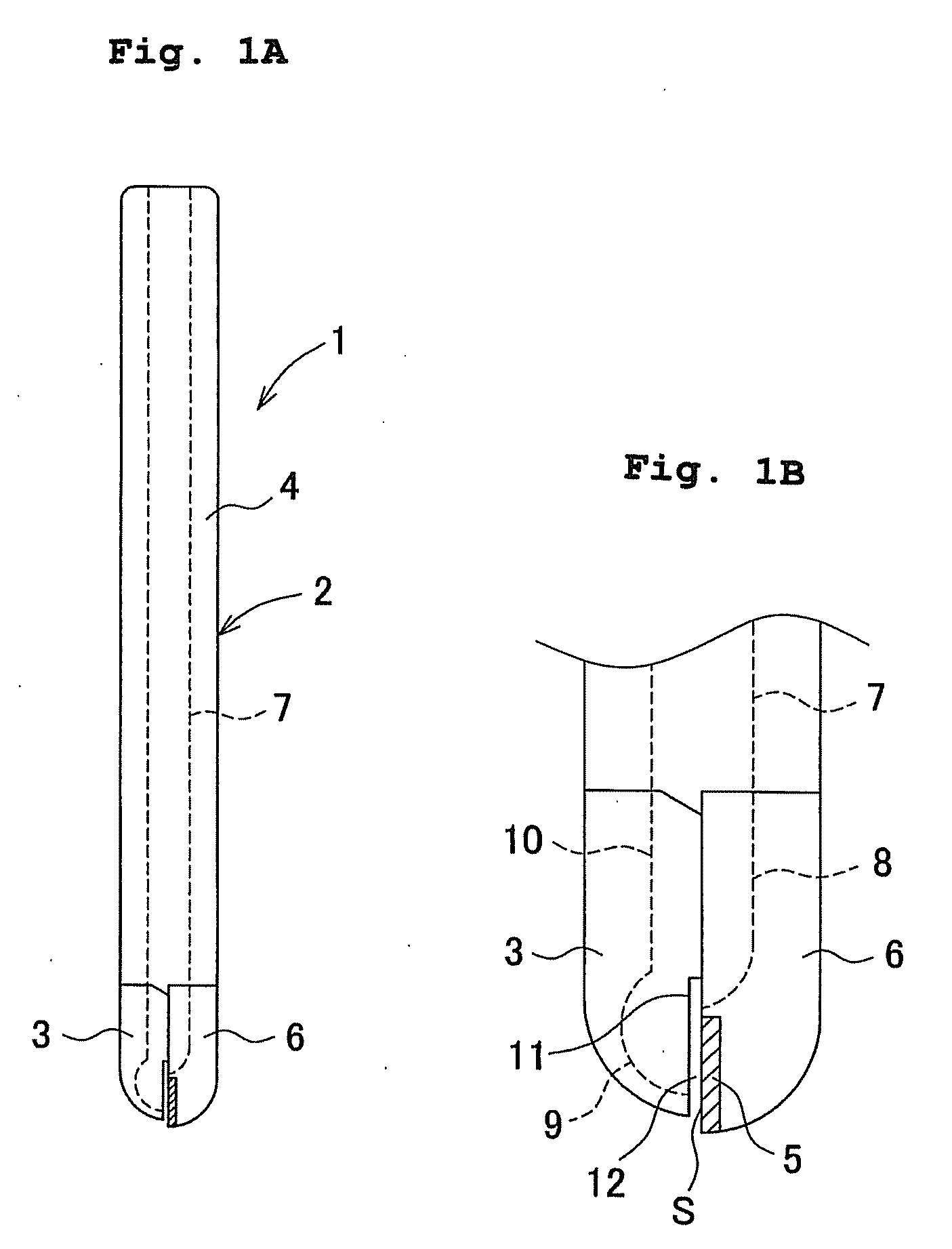

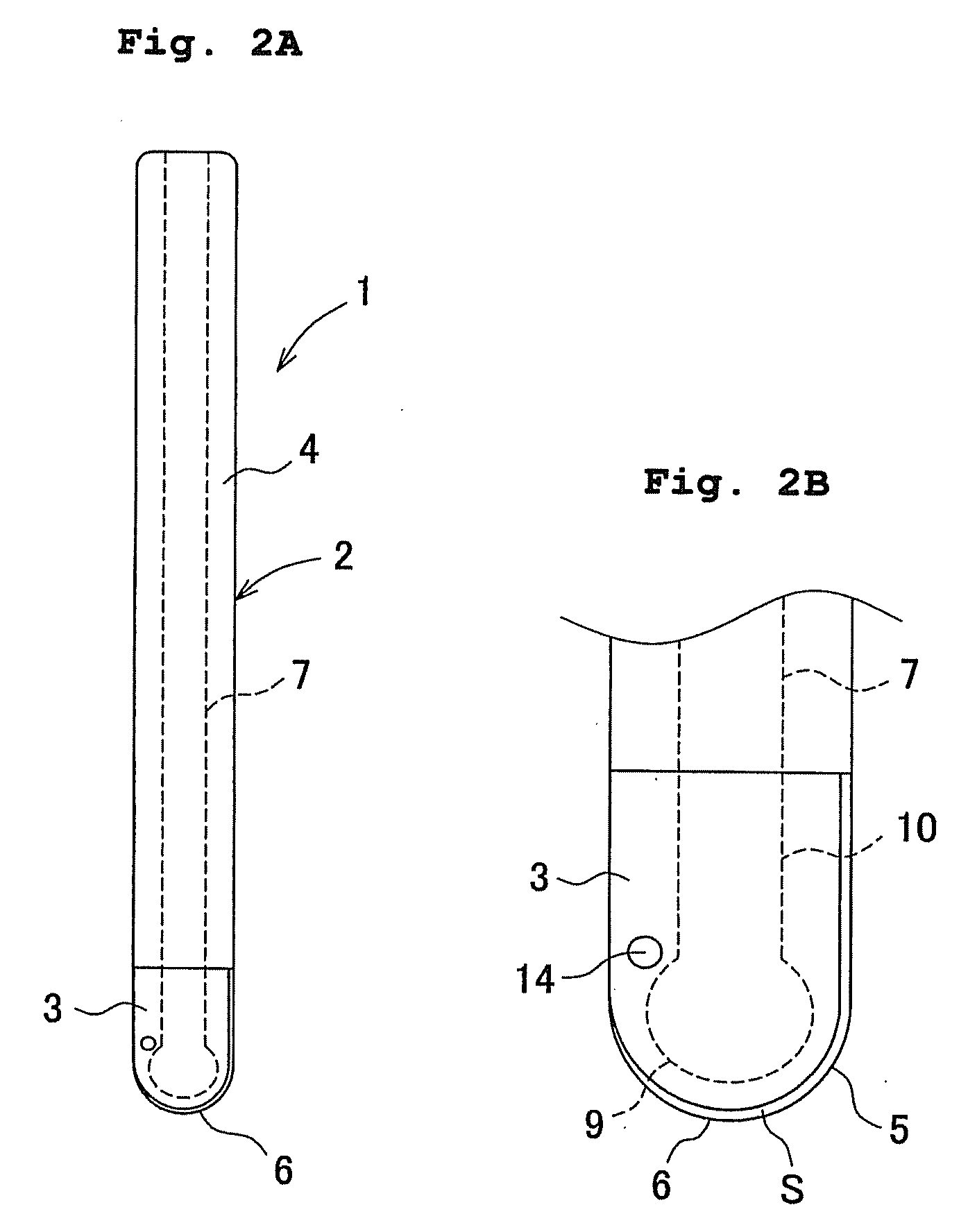

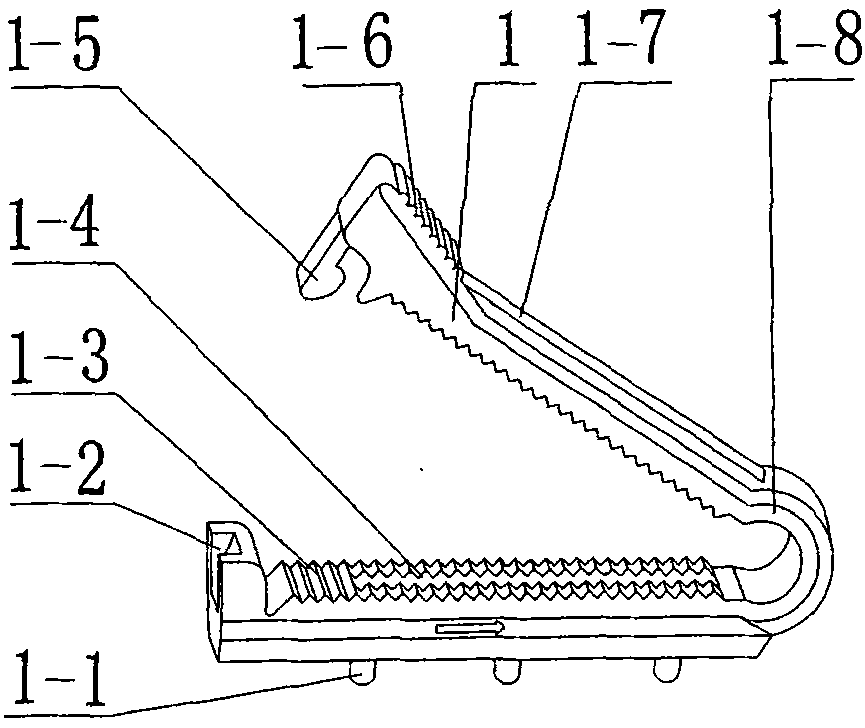

Umbilic clamping cutter

The invention provides an umbilic clamping cutter, comprising a pushing and cutting rod, a mother clamp, an infant clamp and a clamp holder, wherein one end of the pushing and cutting rod is provided with a blade while the other end is a cartoon; one surface of the pushing and cutting rod is fixed with a pick matched with the infant clamp; and one end of the clamp holder is connected with the mother clamp and the infant clamp while an inwall chute at the other end thereof is matched with the pushing and cutting rod. As one end of the clamp holder is manufactured into a big opening, only one end of the clamp holder operates by fingers, the whole operation process can be seen clearly from the big opening; the umbilical cord is clamped by two clamps in advance so as to facilitate the blade to cut; when in operation, the pushing and cutting rod is driven by hands to cut the umbilical cord actively like an injector, thus having easy cut-off and good cutting effect, saving labor, and avoiding blood from sputtering, thereby ensuring physical and psychological health of medical care personnel. The umbilical cord is clamped at first and then the blade is moved to cut, so the length of the reserved umbilical head can be short so as to shorten the drying time thereof, accelerate drop of umbilical head and avoid infection risk induced by the overlong reserved umbilical head.

Owner:宁波菲特医疗器械有限公司

Composition of castor-based EC-2 hardened gear face cutting oil

The invention discloses a composition of castor-based EC-2 hardened gear face cutting oil. The composition of the castor-based EC-2 hardened gear face cutting oil is prepared by compounding isomerised polyolefin and castor-based dioctyl sebacate as a base oil and matching with a variety of composite additives, and comprises an oily agent, an anti-wear agent, an anti-foaming agent, a catalytic refrigerant, a demulsifier, a penetrating agent, a friction modifier, a reinforcing agent, an antioxidant and a rust inhibitor. The composition of the castor-based EC-2 hardened gear face cutting oil has good flowability, permeability, cooling performance, lubricity, wear resistance, rust resistance, anti-foaming performance and emulsification resistance, can form a good lubricant film on the surface of a workpiece in a gear machining process to play a boundary lubricating role, can reduce friction in the machining process to reduce wear, can weaken a crumb sticking phenomenon, can take away cutting heat in time, can reduce thermal shock of cutter teeth and collapse of a cutter, and can prolong the service life of the cutter.

Owner:GUANGXI UNIV

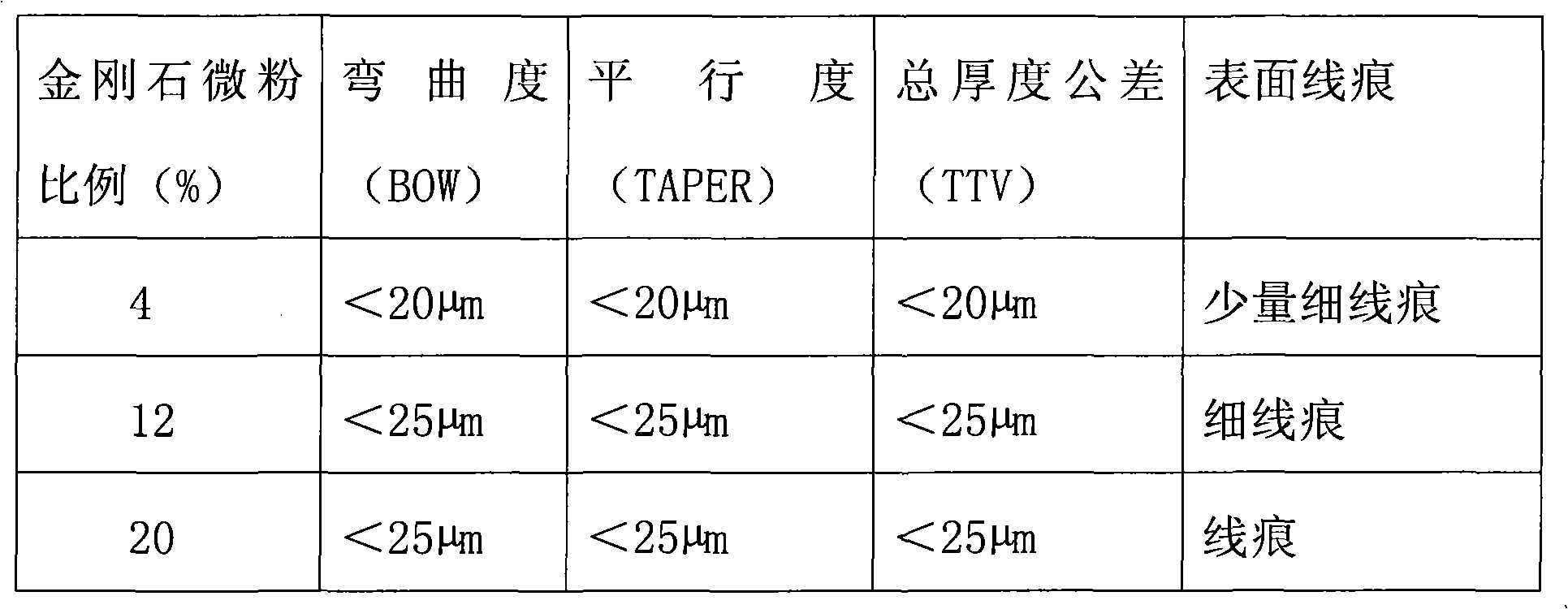

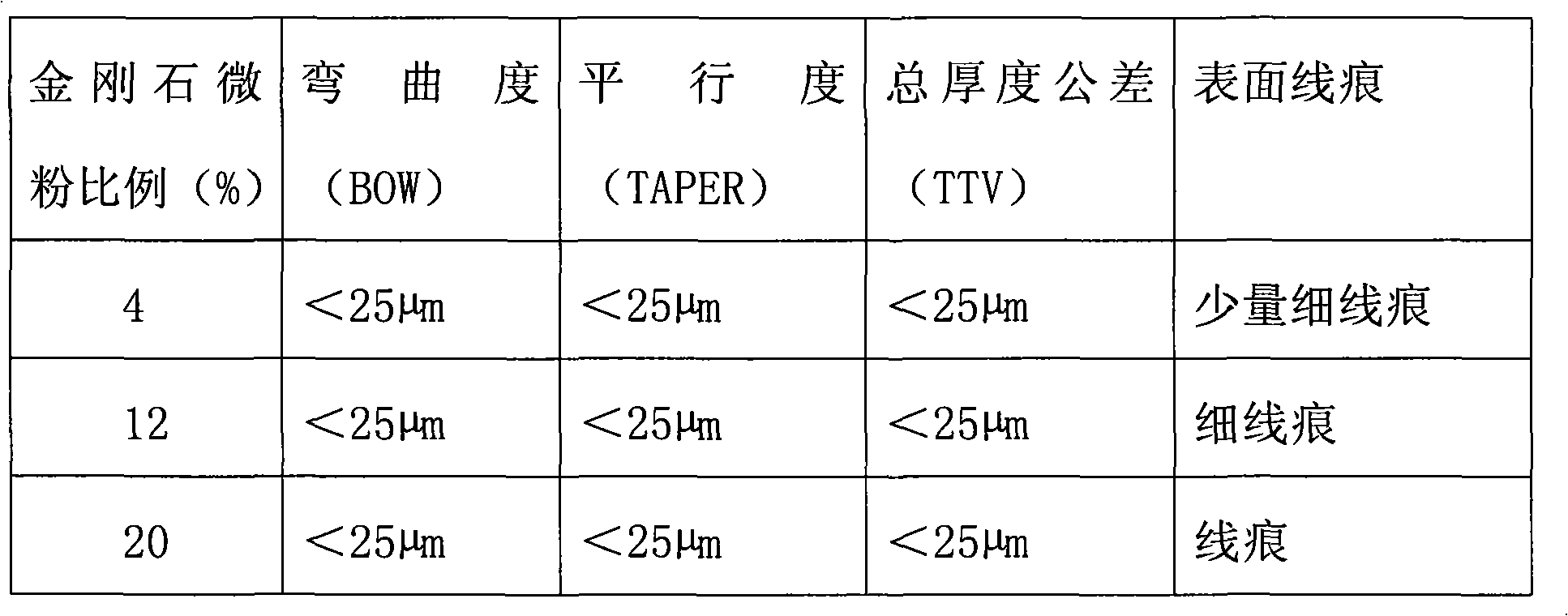

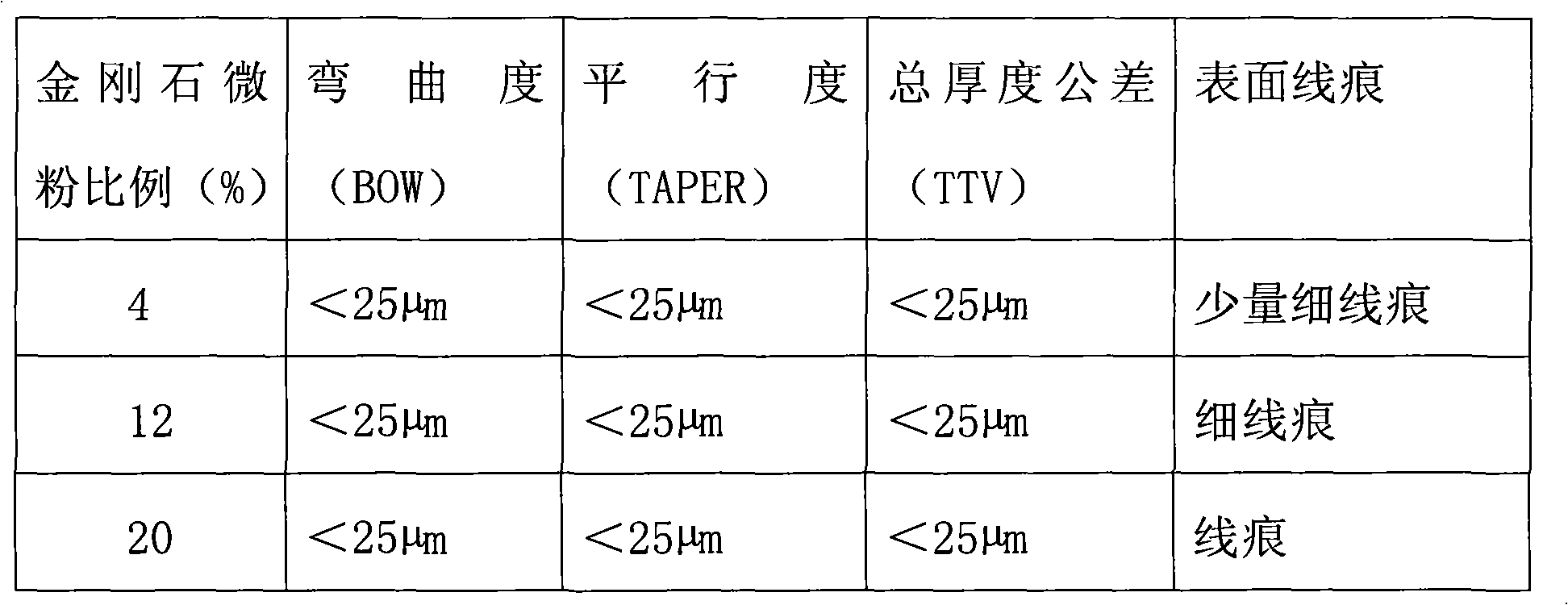

Sapphire wafer cutting method

InactiveCN101870084AImprove liquidityPrevent agglomeration and adhesionOther chemical processesGrinding machinesWaferingSapphire wafer

The invention discloses a sapphire wafer cutting method, which is characterized in that a free grinding material multi-line cutting method is adopted, cutting lines adopt metal lines, and grinding materials adopt diamond micro powder. The viscocity of cutting oil used by mortar preparation is between 20 and 50 mpa*s at the normal temperature, and the grain diameter of the diamond micro powder is between 4 and 12 mum. The invention provides the technical method for cutting the sapphire in a free grinding material mode. When the method is adopted, a multi-line cutting machine for cutting crystals can be used for processing sapphire wafers, and the invention has the advantages of high cutting efficiency, high precision, low equipment investment, small cutting loss and low cutting cost.

Owner:铜陵市琨鹏光电科技有限公司

Diesel engine cylinder fuel-cut oil-saving system with twin-pressure charging system and pressure relief device

InactiveCN101532436AImprove spray qualityImprove combustion efficiencyOutput powerMachines/enginesCutting oilDiesel engine

The invention relates to a diesel engine cylinder fuel-cut oil-saving system with a twin-pressure charging system and a pressure relief device. The diesel engine cylinder fuel-cut oil-saving system comprises a multi-cylinder diesel engine, a first pressure charging systems, a second pressure charging system, a charge air cooler and a set of cylinder pressure relief device, wherein cylinders in the multi-cylinder diesel engine are divided into two groups according to the sequence of ignition: the first group of cylinders are connected with the first pressure charging system, while the second group of the cylinders are connected with the second pressure charging system; the cylinder pressure relief device is connected with the second group of the cylinders; and the charge air cooler is connected with the two groups of the cylinders through the first pressure charging system and the second pressure charging system respectively. The diesel engine cylinder fuel-cut oil-saving system can increase fuel injection capacity of one group of the cylinders by cylinder fuel-cut, thereby improving the quality of injection and atomization of the system, and improving thermal efficiency; two independent superchargers are adopted, so that interference on non-working cylinders on the superchargers when a supercharged diesel is in fuel cut can be overcome, thereby ensuring normal work of the working cylinders; and friction work of the non-working cylinders are greatly reduced by the cylinder pressure relief cylinder, thereby further reducing fuel consumption.

Owner:SHANGHAI JIAO TONG UNIV

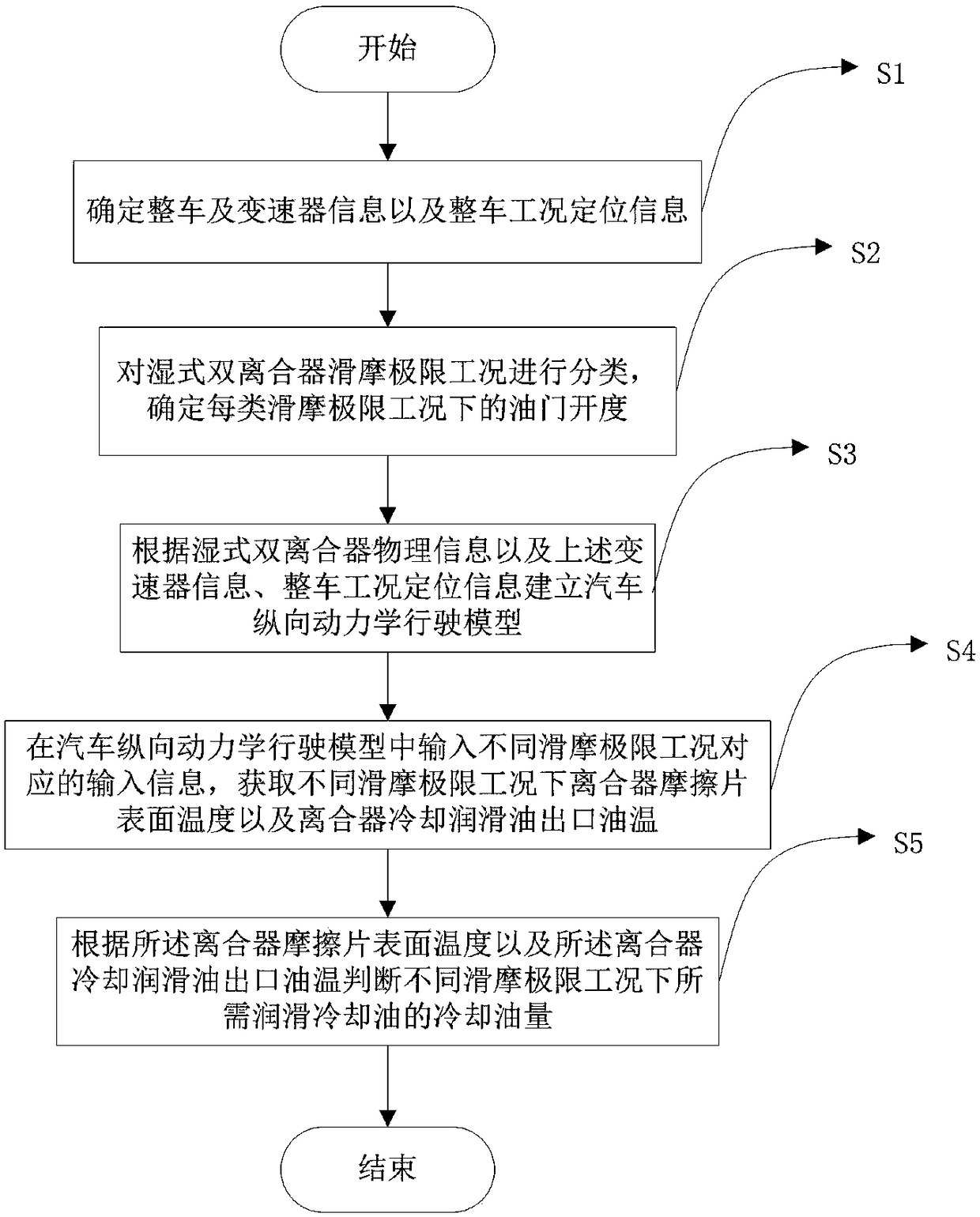

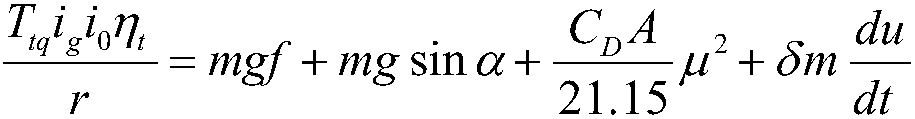

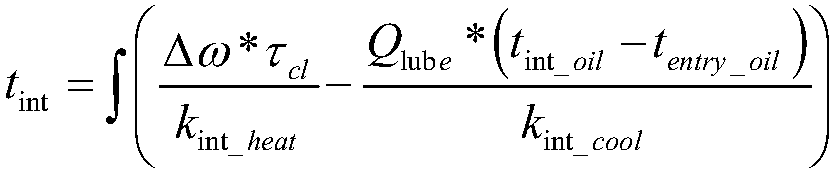

Wet-type double-clutch slipping friction limiting condition and cooling flow demand analysis method

ActiveCN108363826AAvoid burnsEfficient and Accurate SimulationGeometric CADClutchesDemand analysisOil temperature

The invention provides a wet-type double-clutch slipping friction limiting condition and cooling flow demand analysis method. The method comprises steps: determining vehicle and speed changer information and vehicle working condition positioning information; classifying wet-type double-clutch slipping friction limiting conditions, determining throttle opening under each kind of slipping friction limiting condition; according to wet-type double-clutch physical information and speed changer information, and vehicle working condition positioning information, establishing a vehicle longitudinal dynamics travel model; inputting input information corresponding to different slipping friction limiting conditions in the vehicle longitudinal dynamics travel model, to obtain clutch friction plate surface temperature and clutch cutting oil outlet oil temperature under different slipping friction limiting conditions; according to the clutch friction plate surface temperature and the clutch cuttingoil outlet oil temperature, determining coolant oil amount of lubricating cooling oil required under different slipping friction limiting conditions. The method is low in simulation cost, and fast inspeed.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com