Method and device for lubricating a tool and workpiece when cutting

A blanking, workpiece technology, used in maintenance and safety accessories, metal processing machinery parts, forming tools, etc., can solve problems such as the inability to ensure that lubricants can enter the forming area, and achieve high process reliability/safety and service life. Long, highly repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

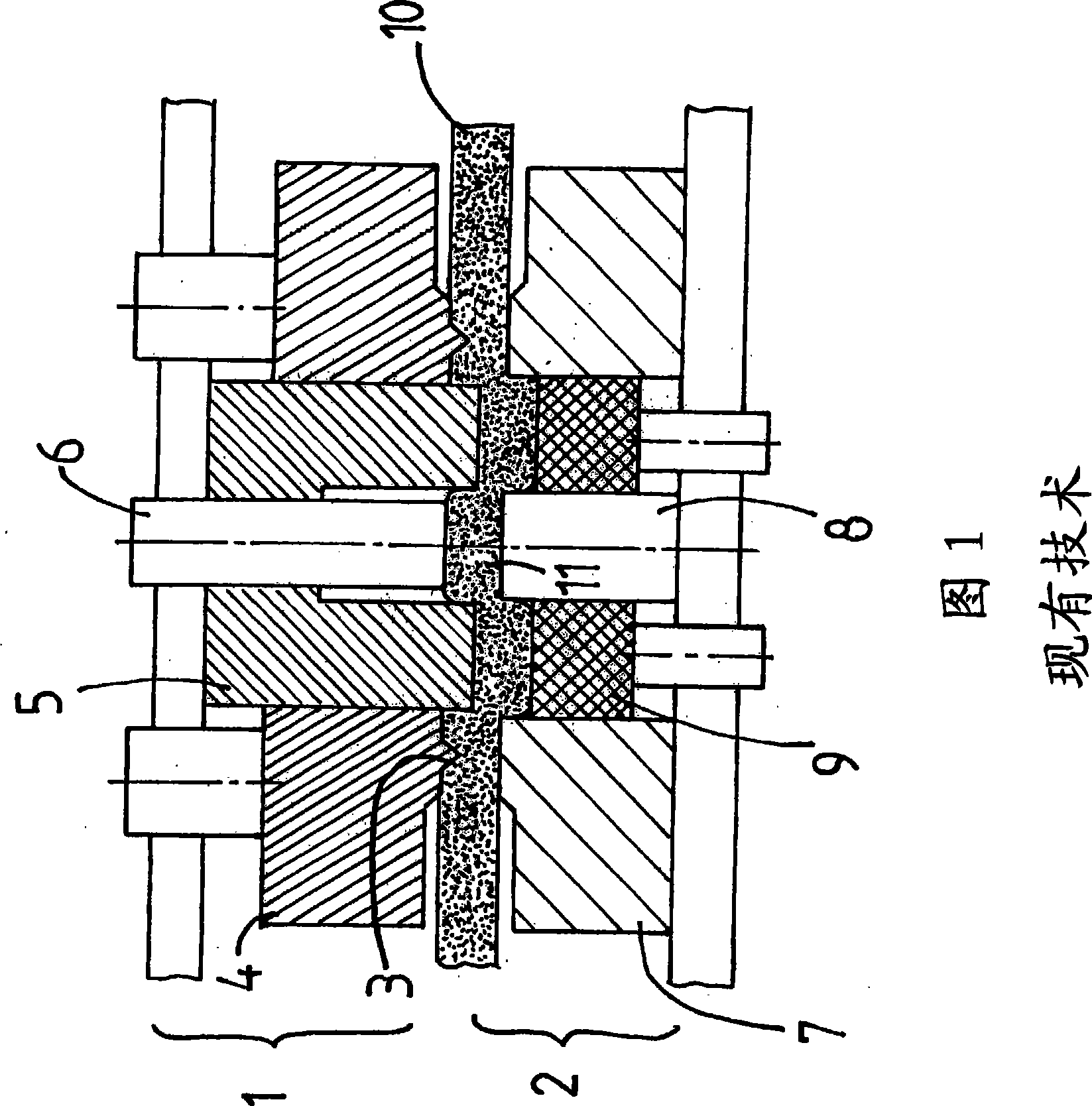

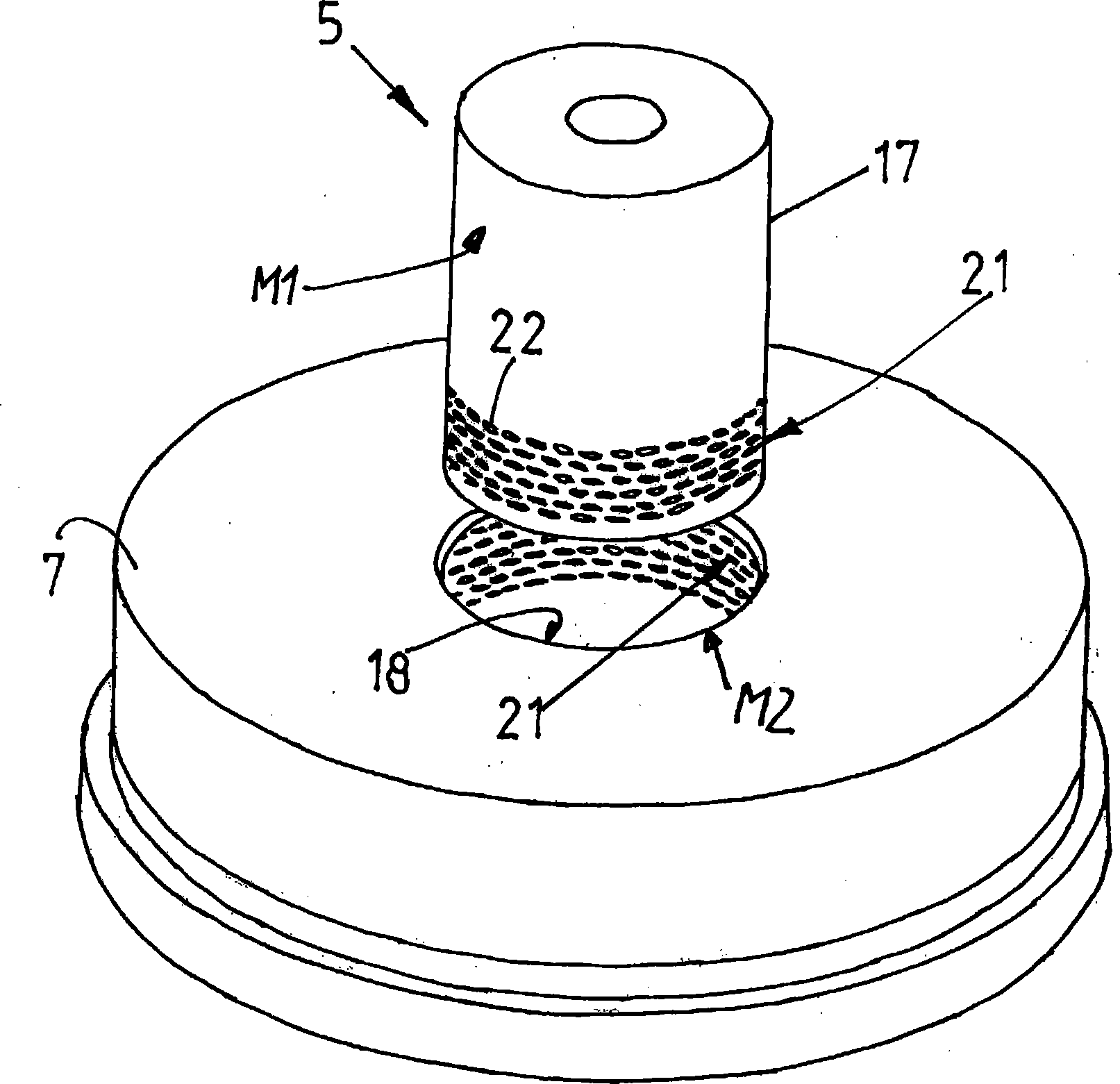

[0044] The device according to the invention in Example 1 has essentially the same structure as the device described with reference to FIG. 1 . image 3 The microsurface structure 21 according to the invention is shown on the example of the functional surfaces 17 and 18 of the punch punch 5 and the punch die 7 . The outer surface M1 of the punch punch 5 and the outer surface M2 of the punch die 7 are polished and coated with, for example, titanium carbonitride (Titankarbonitrid). A plurality of recesses 22 formed by laser machining or other suitable machining methods (such as grinding, milling, etc.) cover the outer surfaces M1 and M2. The average depth of the depressions 22 is about 0.05mm. The depressions 22 are distributed in regular, mutually spaced horizontal rows which are arranged perpendicular to the punching direction SR. The depressions cover the functional surfaces 17 and 18 evenly.

[0045] The depressions 22 can have different geometries (sizes) and shapes. Thu...

Embodiment 2

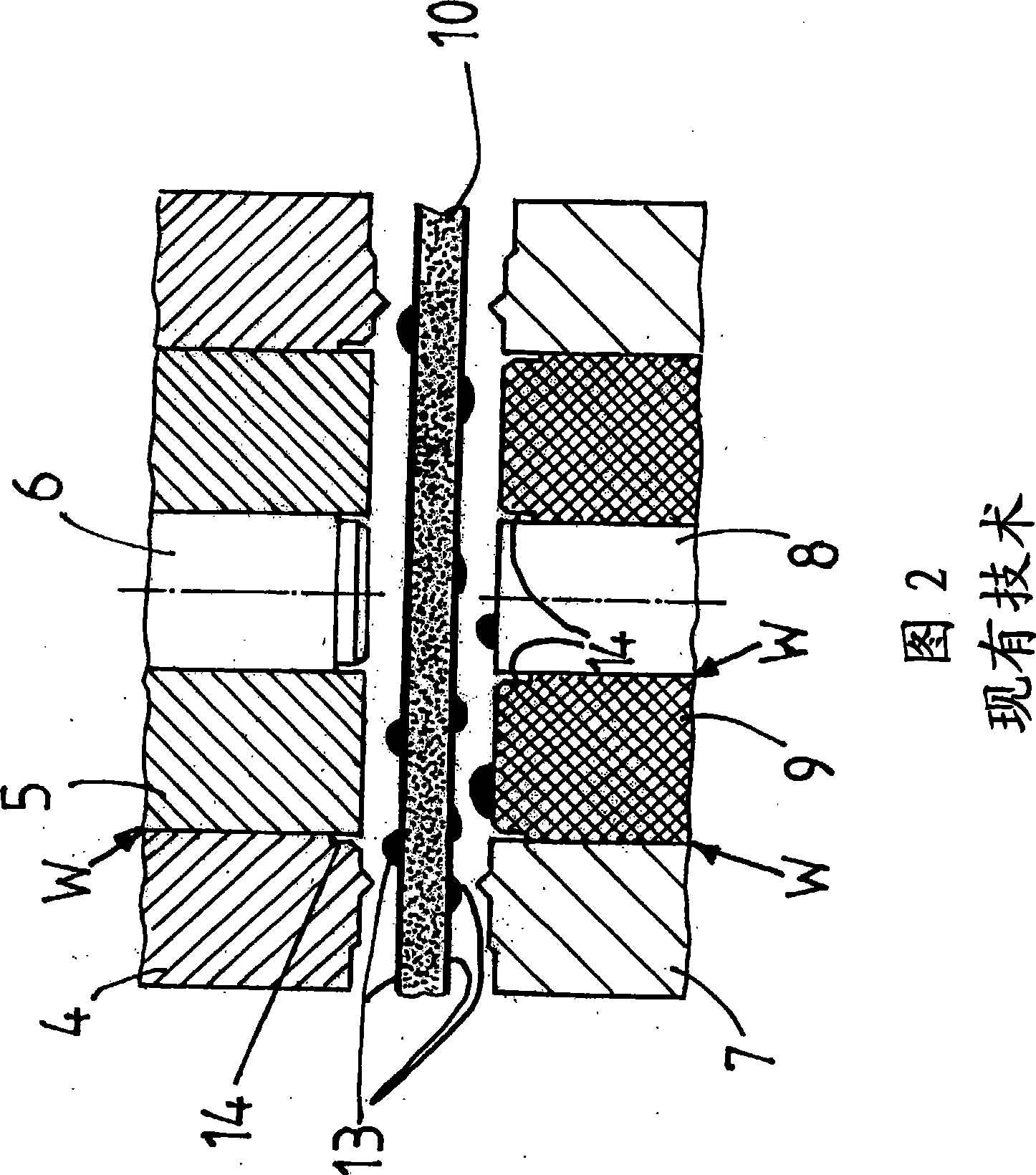

[0056] FIGS. 6-8 show another variant of the device according to the invention, which is identical in basic structure to that of the mold shown in FIG. 1 . In addition to the oil chamber 14 on the guide plate 4 and the ejector 9, the guide plate 4, the ejector 9 and the pusher 6 also have channels 23 for passing between the guide plate 4 and the blanking punch 5. , punching punch 5 and pusher 6 and between punching die 7 and ejector 9 are used to feed additional punching oil 13 into the corresponding microstructure. The channel 23 is connected to a supply line (not shown) for connection to a pressure pump for setting the pressure of the punching oil 13 to be supplied. The channel 23 extending in the punching direction SR in the guide plate 4, the ejector 9 and the pusher 6 transitions into a region 24 extending perpendicularly to the punching direction with an opening 25 widening towards the active seam, which is maintained continuously. The punching oil 13 under pressure can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com