Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

879results about How to "Improve spray quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

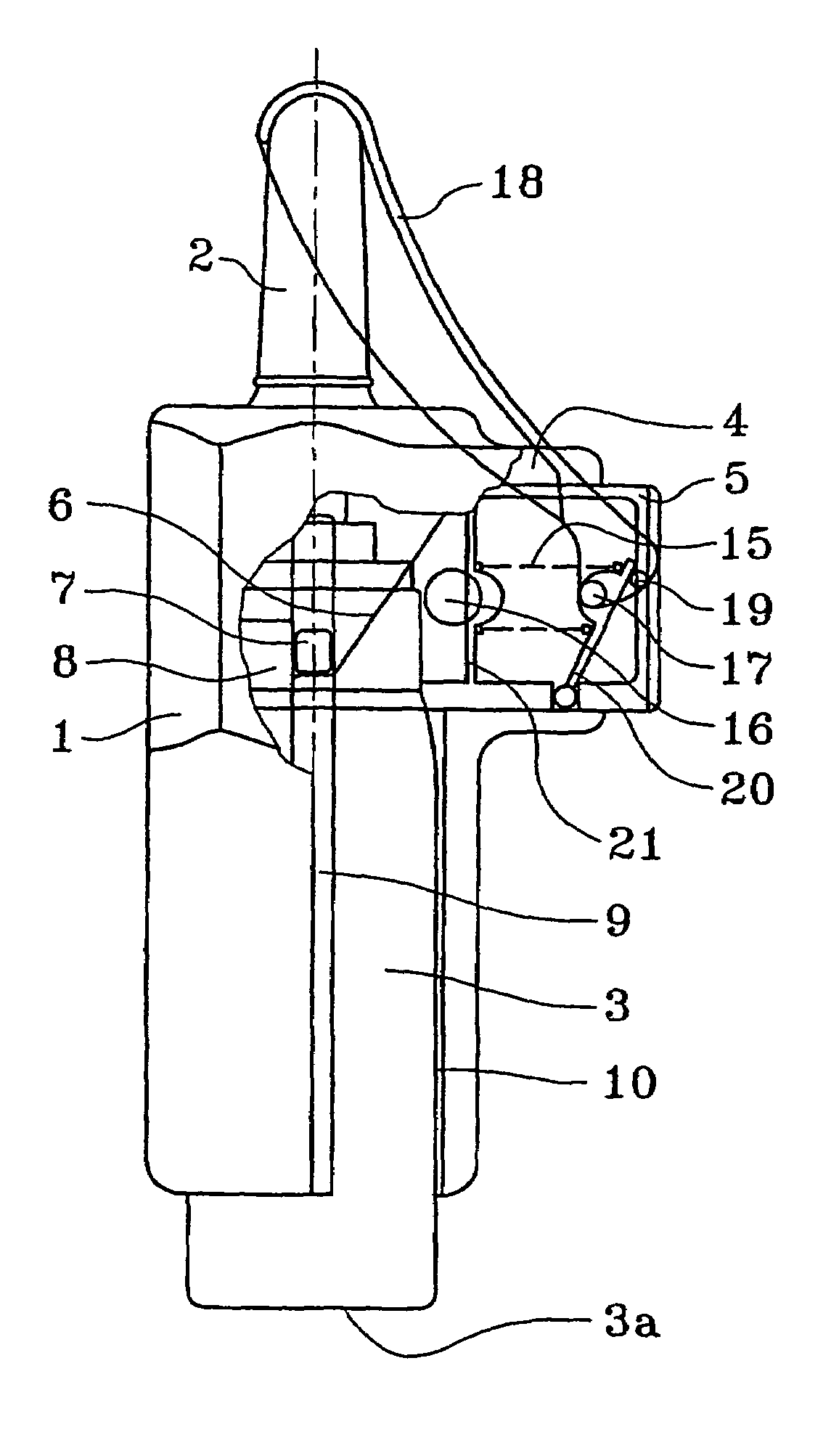

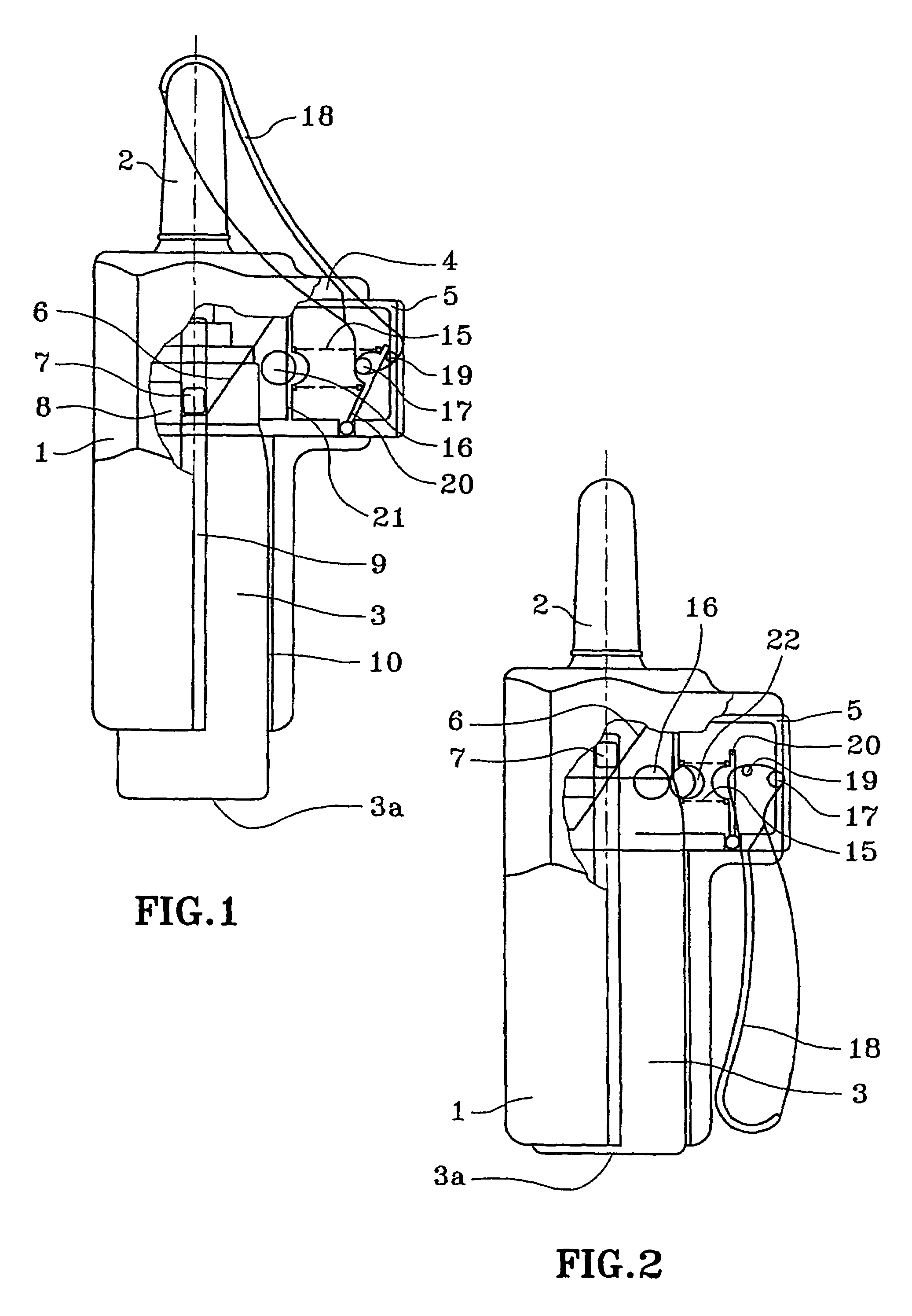

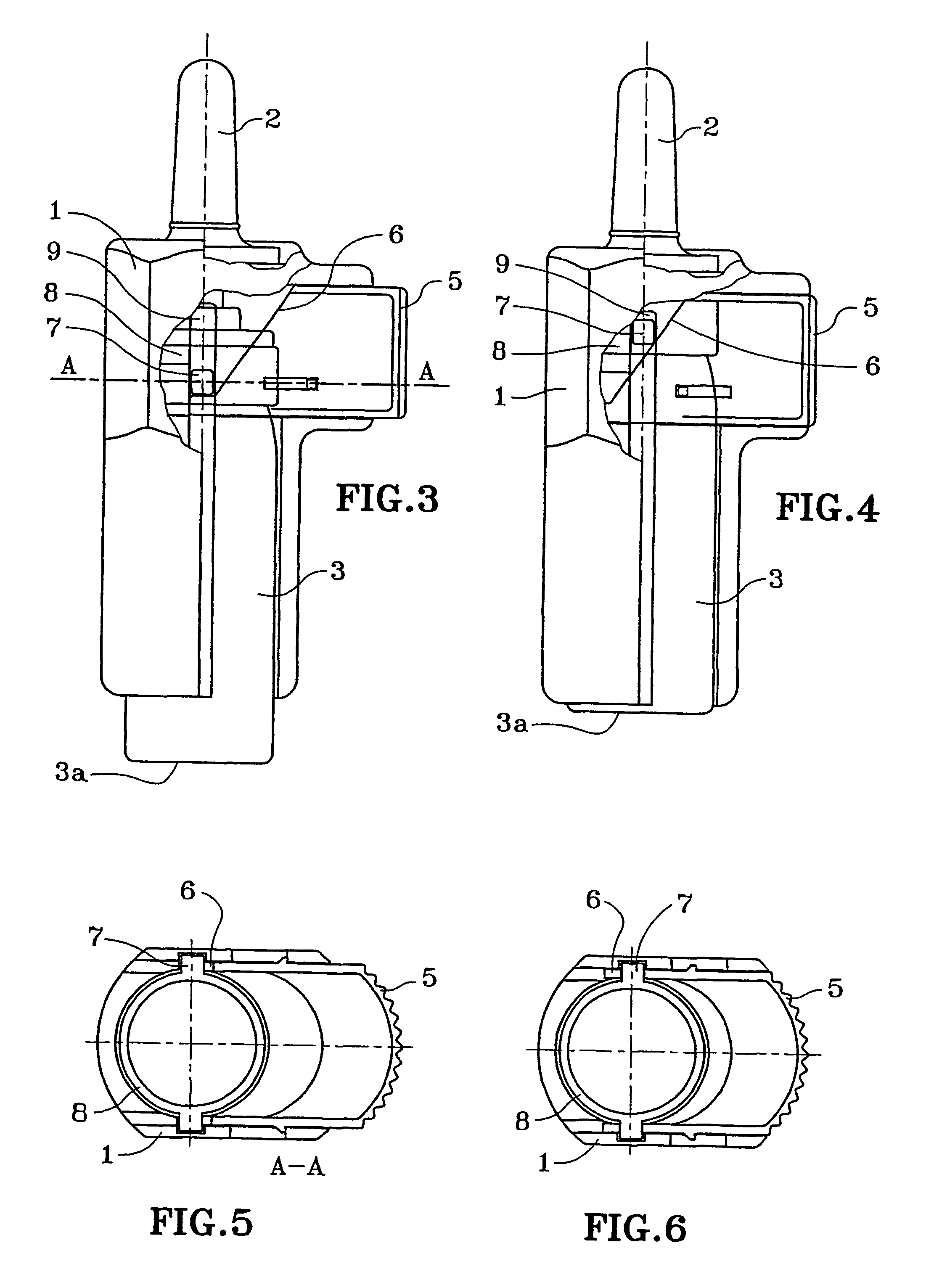

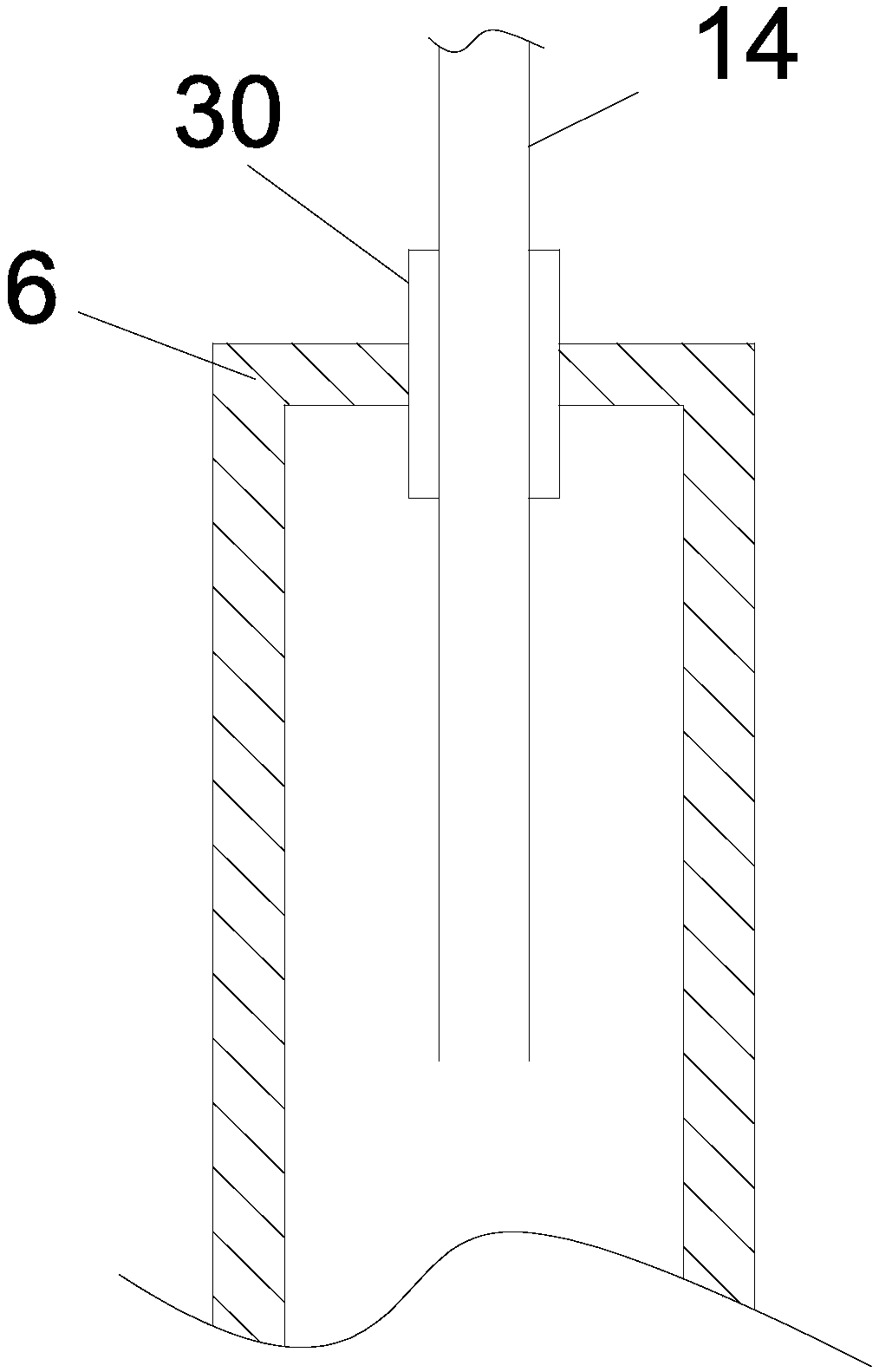

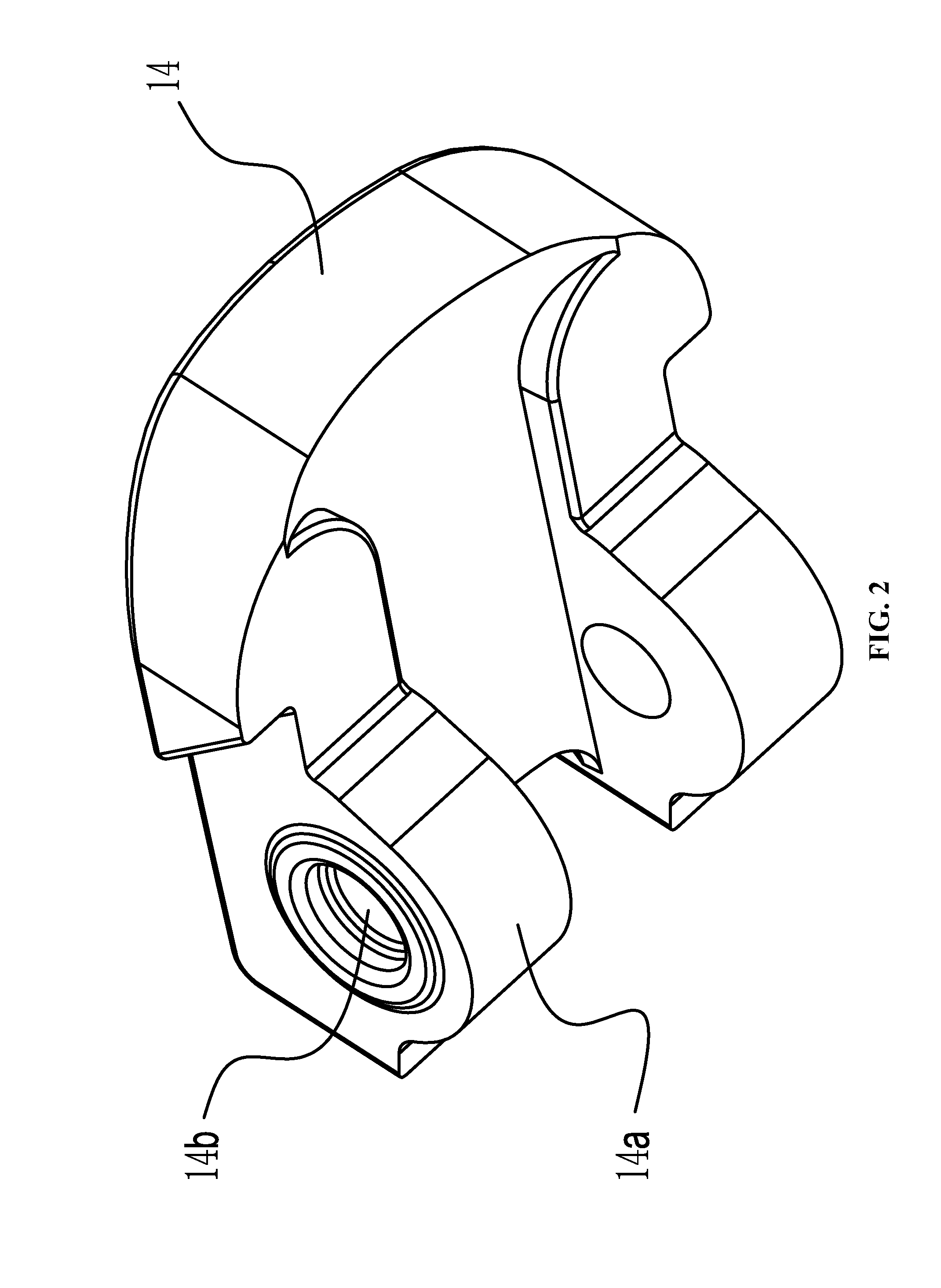

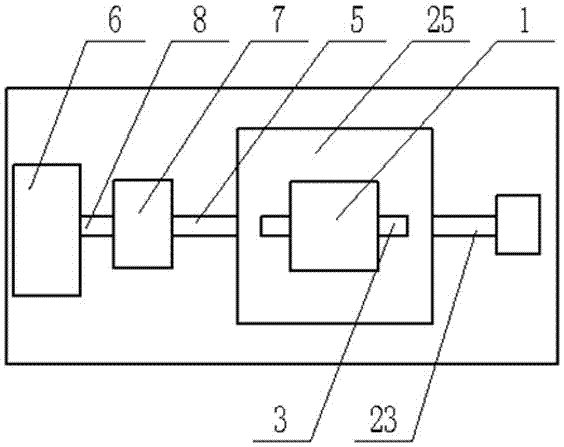

Fluid dispenser device of the multi-dose type

InactiveUS7108159B2Simple and inexpensive to and to assembleSimple and inexpensive to manufactureLarge containersLiquid transferring devicesRest positionEngineering

A fluid dispenser device a body (1), a fluid reservoir (3), a dispensing member, such as a pump or a metering valve having a piston or a valve member that is mounted to move axially, which dispensing member is fitted to the reservoir (3), and an actuating element (5) mounted to move between a rest position and an actuating position, for actuating the dispensing member and thus for selectively dispensing the fluid contained in the reservoir (3), fluid dispenser device being characterized in that the direction in which actuating element (5) moves is different from, and in particular perpendicular to, the axial direction in which the piston or the valve member of the dispensing member moves, the actuating element (5) having an end portion provided with the cam surface (6) which co-operates with the reservoir (3) or a fixing ring (8) adapted to fix the dispensing member to the reservoir (3) so that the actuating member (5) being moved substantially radially into its actuating position causes the reservoir (3) to be moved axially relative to the piston or to the valve member of the dispensing member so as to dispense a dose of fluid.

Owner:APTAR FRANCE SAS

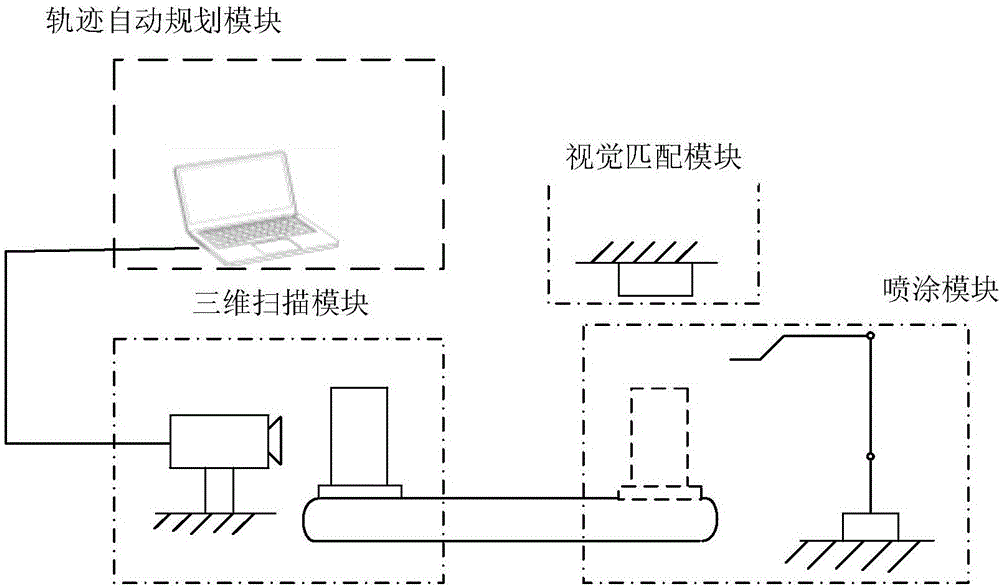

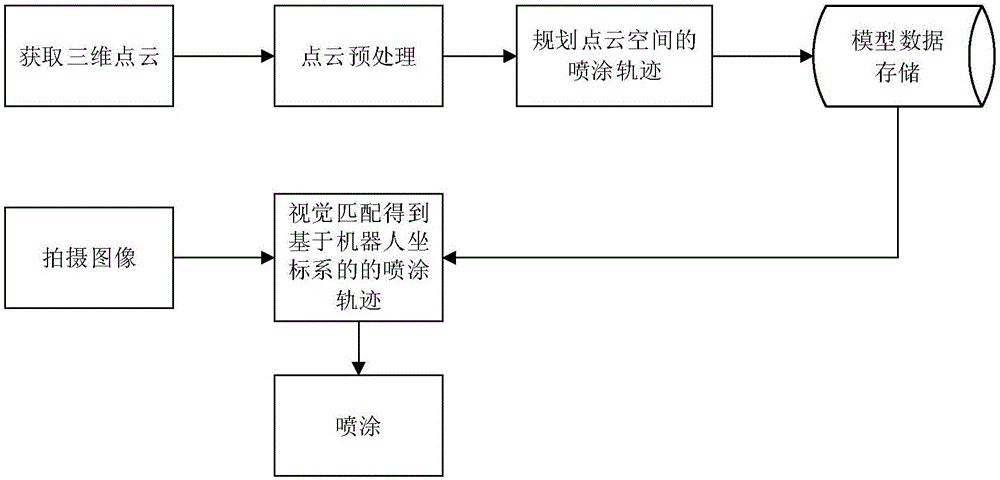

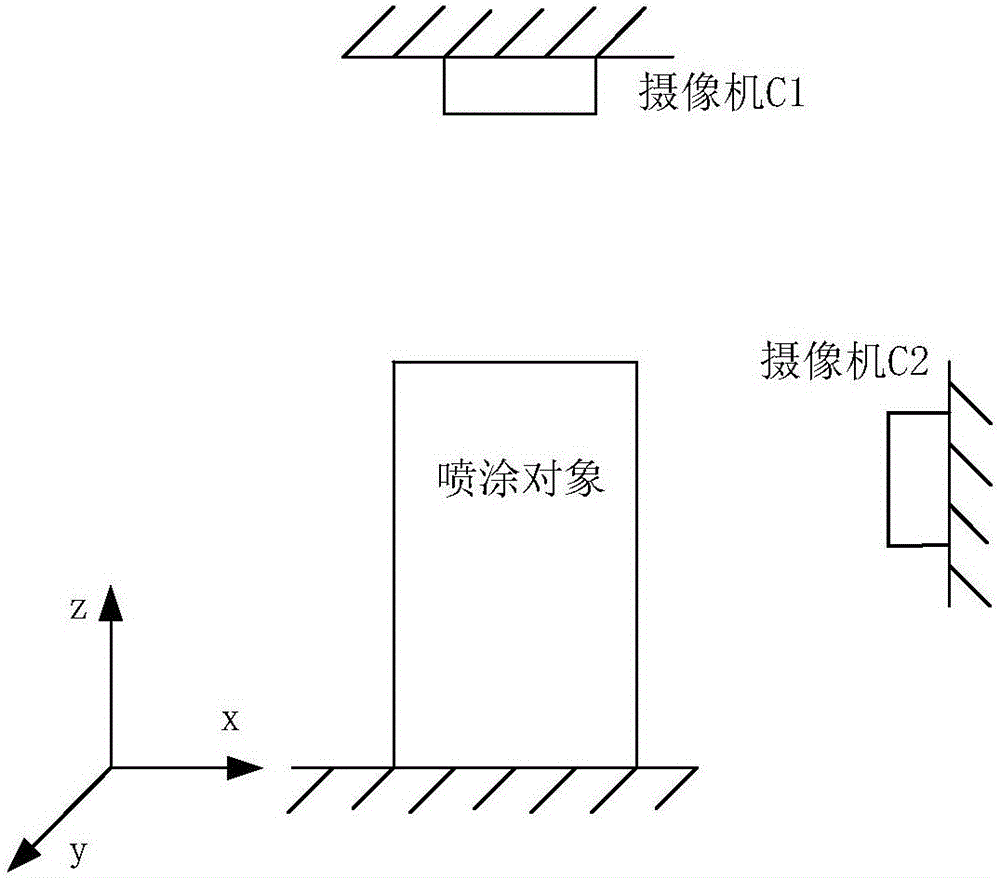

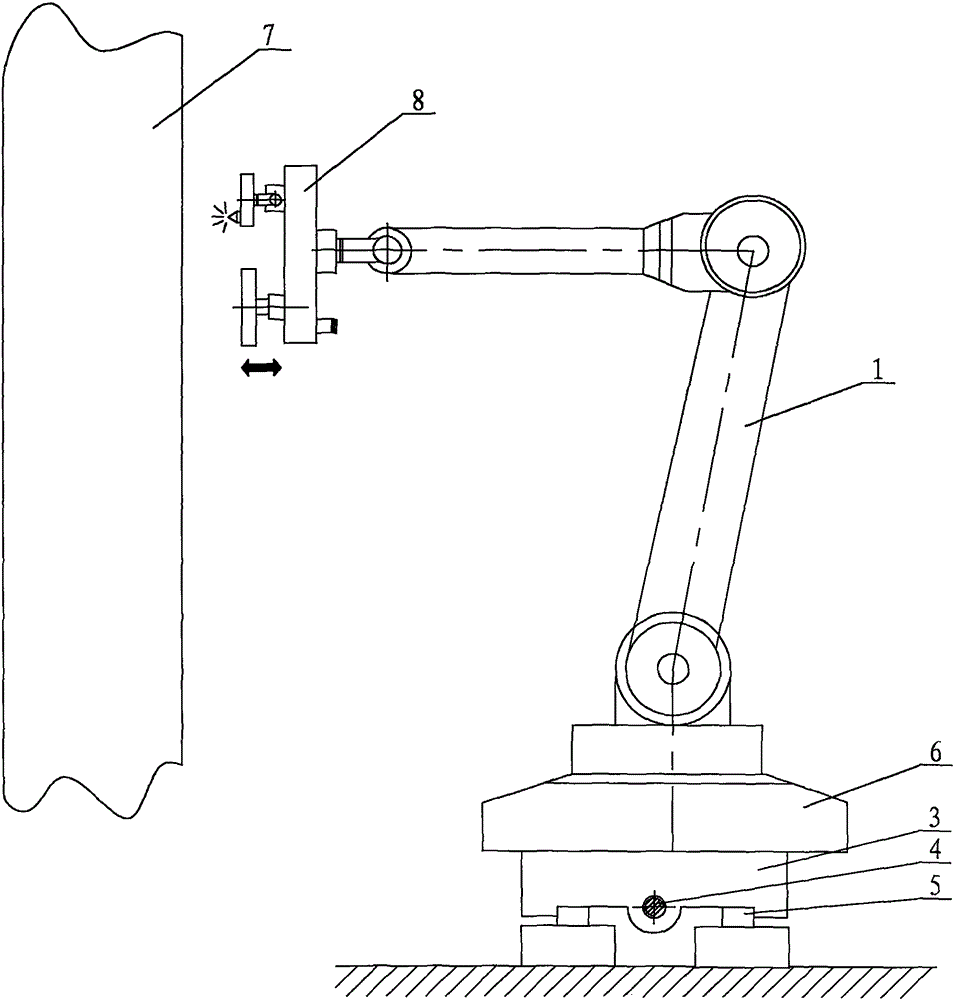

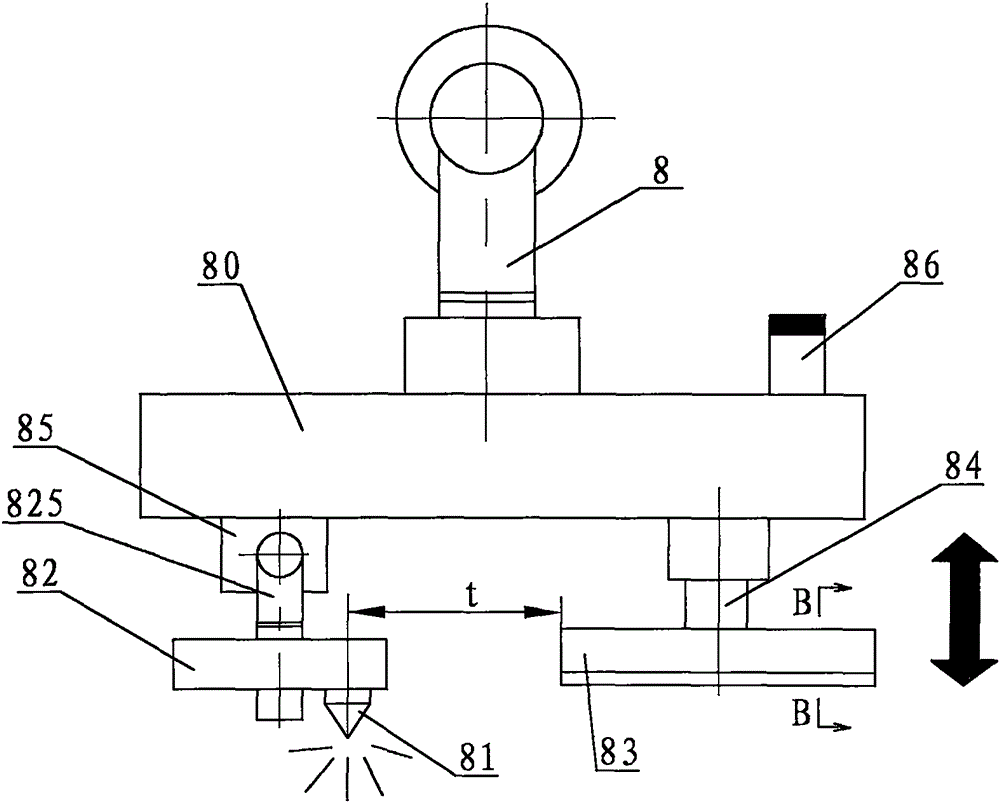

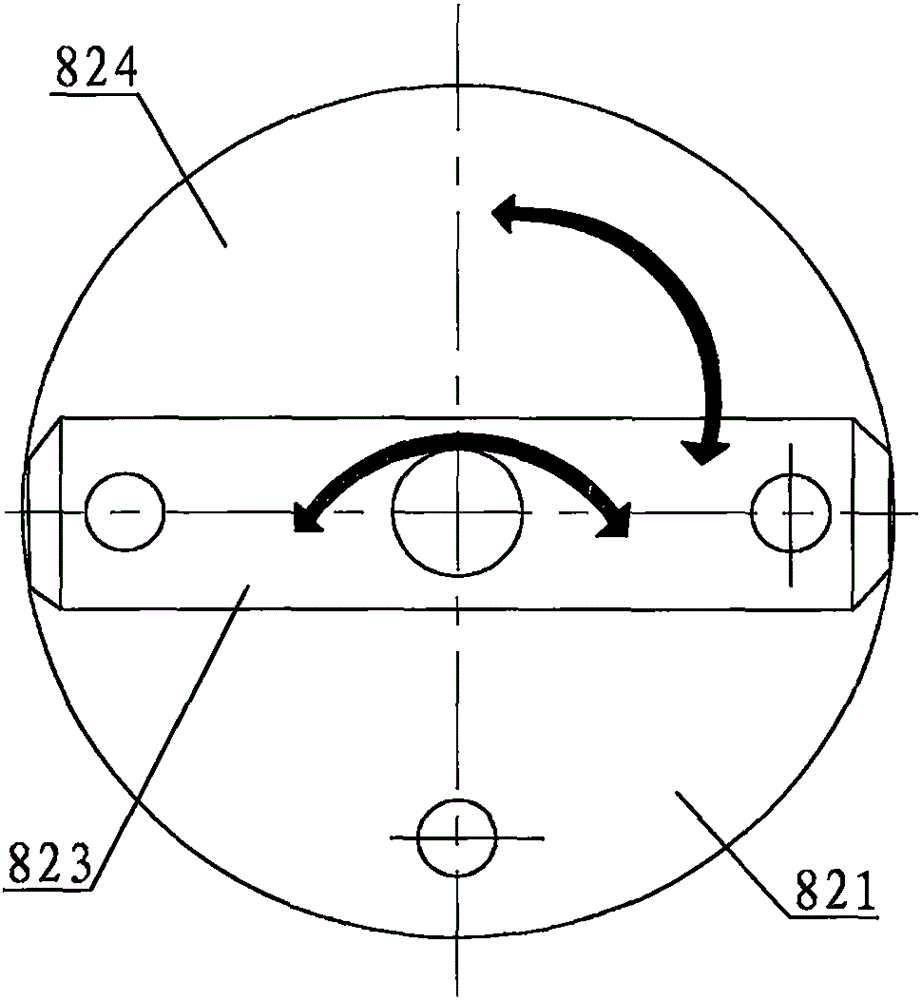

Automatic spraying system and automatic spraying method based on point cloud and image matching

ActiveCN106423656AReduce difficulty of useRealization of automatic sprayingSpraying apparatusVisual matchingPoint cloud

The invention provides an automatic spraying system based on point cloud and image matching. The automatic spraying system comprises a three-dimensional scanning module, an automatic trajectory planning module, a visual matching module and a spraying module. The three-dimensional scanning module is used for scanning a spraying object and acquiring a point cloud model according to scanned three-dimensional point cloud data; the automatic trajectory planning module is used for planning spraying trajectories in a point cloud space; the visual matching module is used for acquiring a transformational relation between a point cloud coordinate system and a spraying robot coordinate system; the spraying module is used for automatically spraying the spraying object. The automatic spraying system has the advantages that an algorithm is planned automatically according to a robot spraying path of the point cloud coordinate system, the point cloud coordinate system is correlated with the robot coordinate system according to the cloud point and image matching algorithm, and accordingly, automatic spraying of the spraying object is realized; on the basis of guaranteeing spraying efficiency, the spraying quality is improved greatly, calculation quantity for trajectory planning is reduced, and trajectory planning quality is improved.

Owner:CHONGQING UNIV

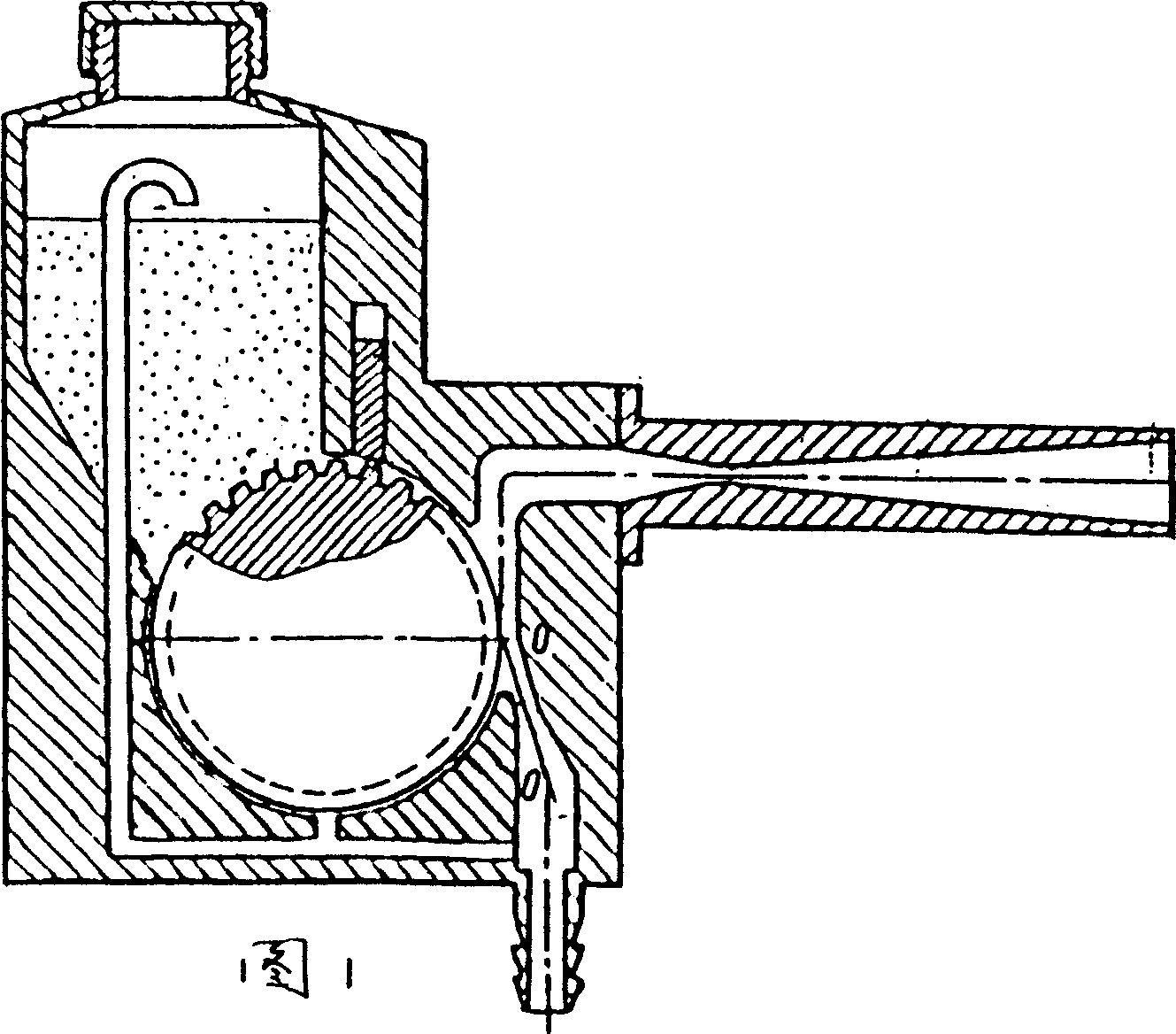

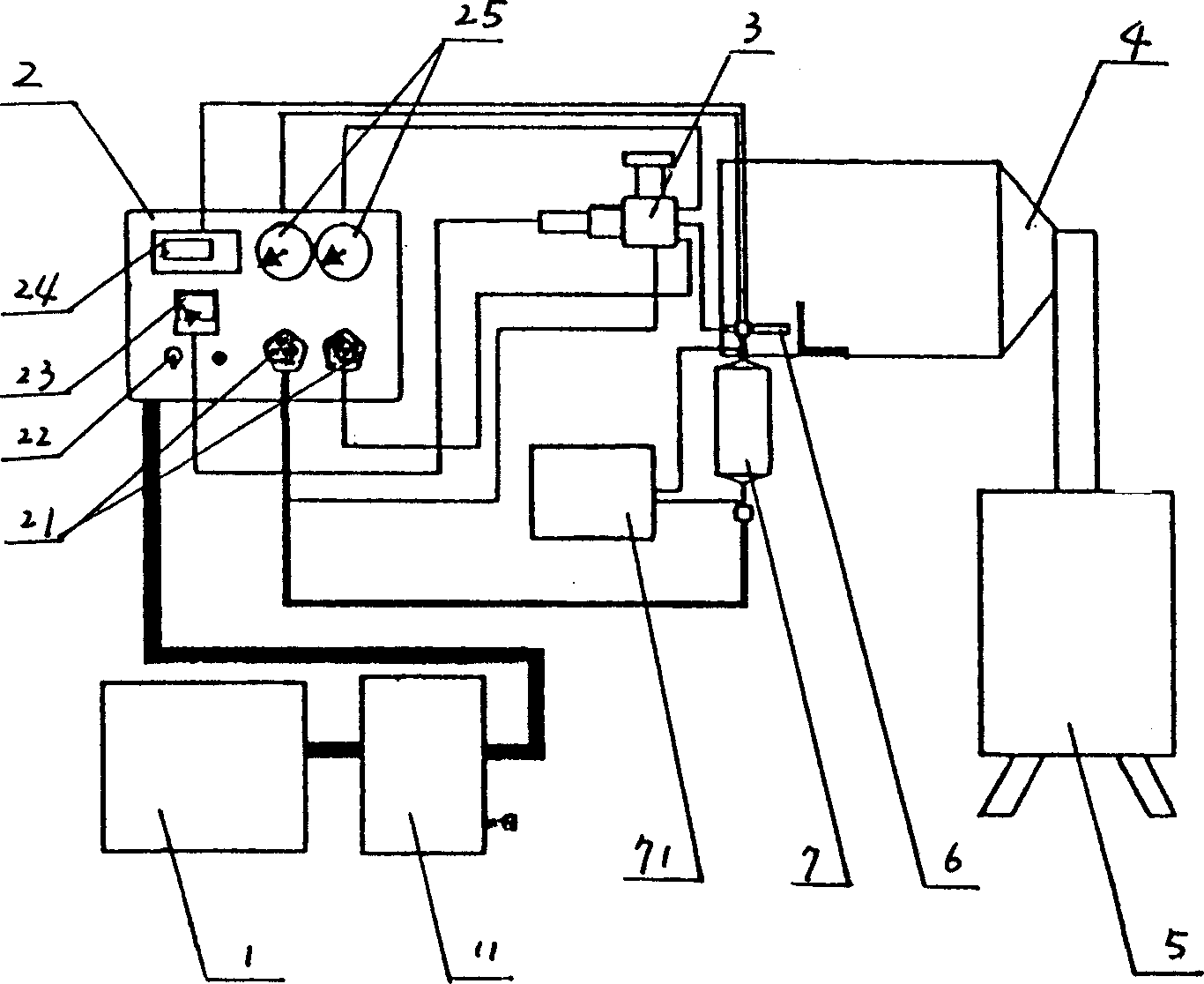

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Spray gun track planning method for free-form surface spraying robot

ActiveCN102527554AReduce planning timeSimple calculationSpraying apparatusSpecial data processing applicationsNumerical controlFree form

The invention discloses a spray gun track planning method for a free-form surface spraying robot. According to the spray gun track planning method disclosed by the invention, the characteristic that a numerical control processing process is very similar to the spaying process is utilized, so that the motion track of a spray gun can be obtained by little calculation on the basis of the tool path. The method comprises the following steps of: firstly, dividing the sprayed surface in three-dimensional modeling software into a plurality of areas with regular shape, generating m equidistant tool paths and deriving the equidistant tool paths into standard APT (Automatic Programming Tools) files by using a five-axis numerical control machining method; extracting tool motion information contained in the APT files, extending the obtained tool points, processing the corner parts into circular arc transition to generate a spray gun path point sequence and then solving a spray gun posture sequence on the path point sequence; and interpolating the spray gun posture sequence to generate a complete motion track of the spray gun. According to the spray gun track planning method disclosed by the invention, accurate control over the track of the spray gun can be realized and the high praying quality is ensured; and the spray gun track planning method is simple in calculation process and calculation amount.

Owner:清研同创机器人(天津)有限公司

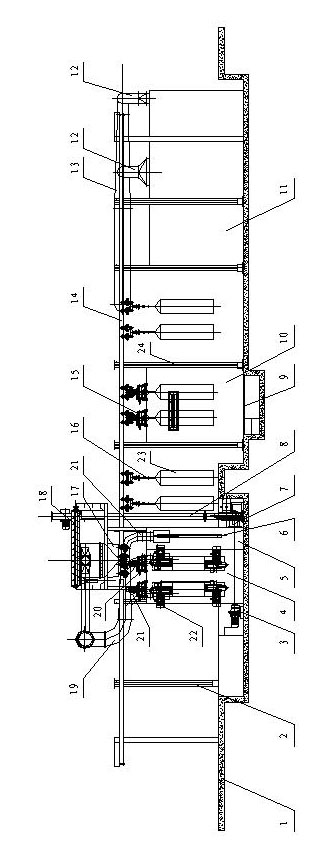

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

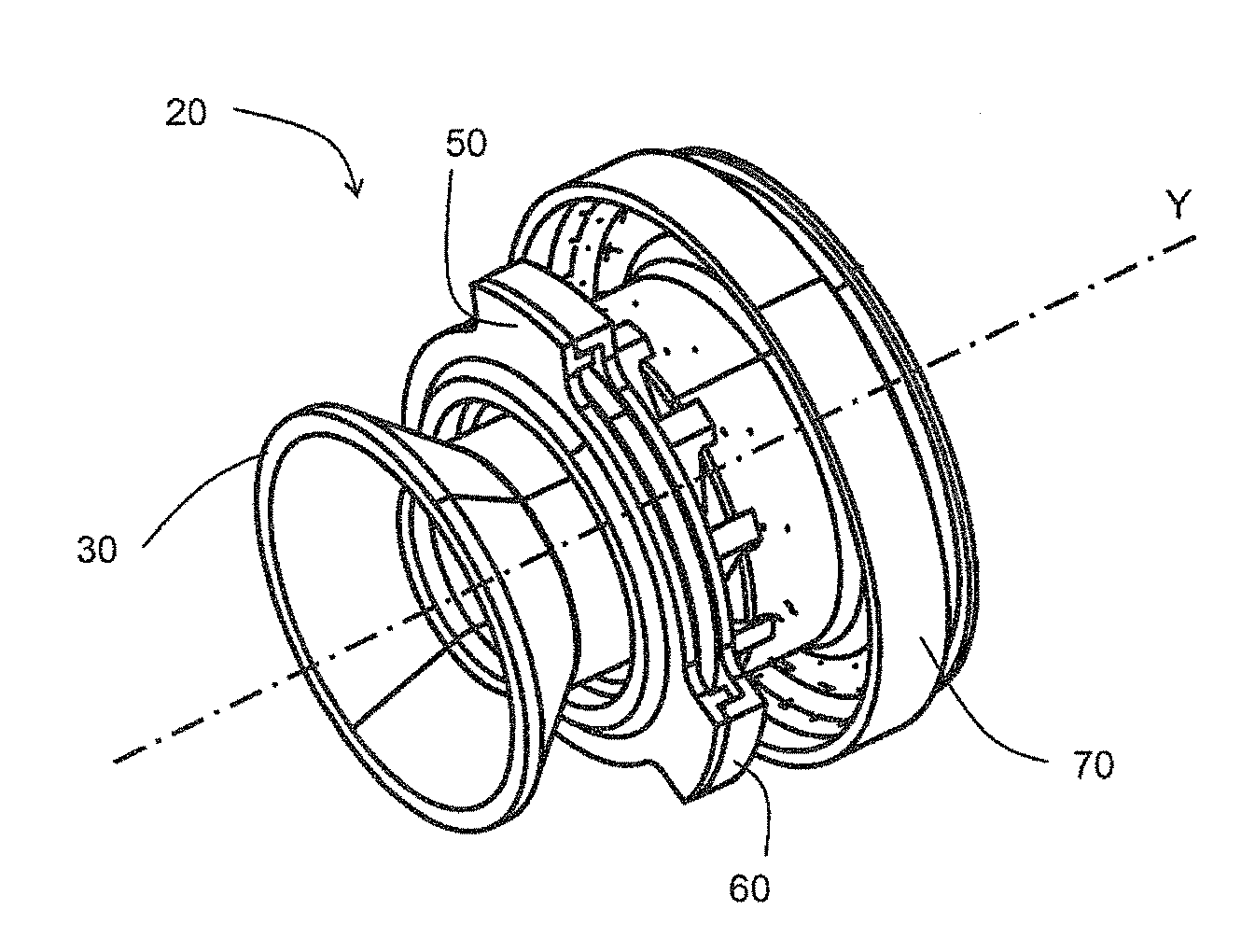

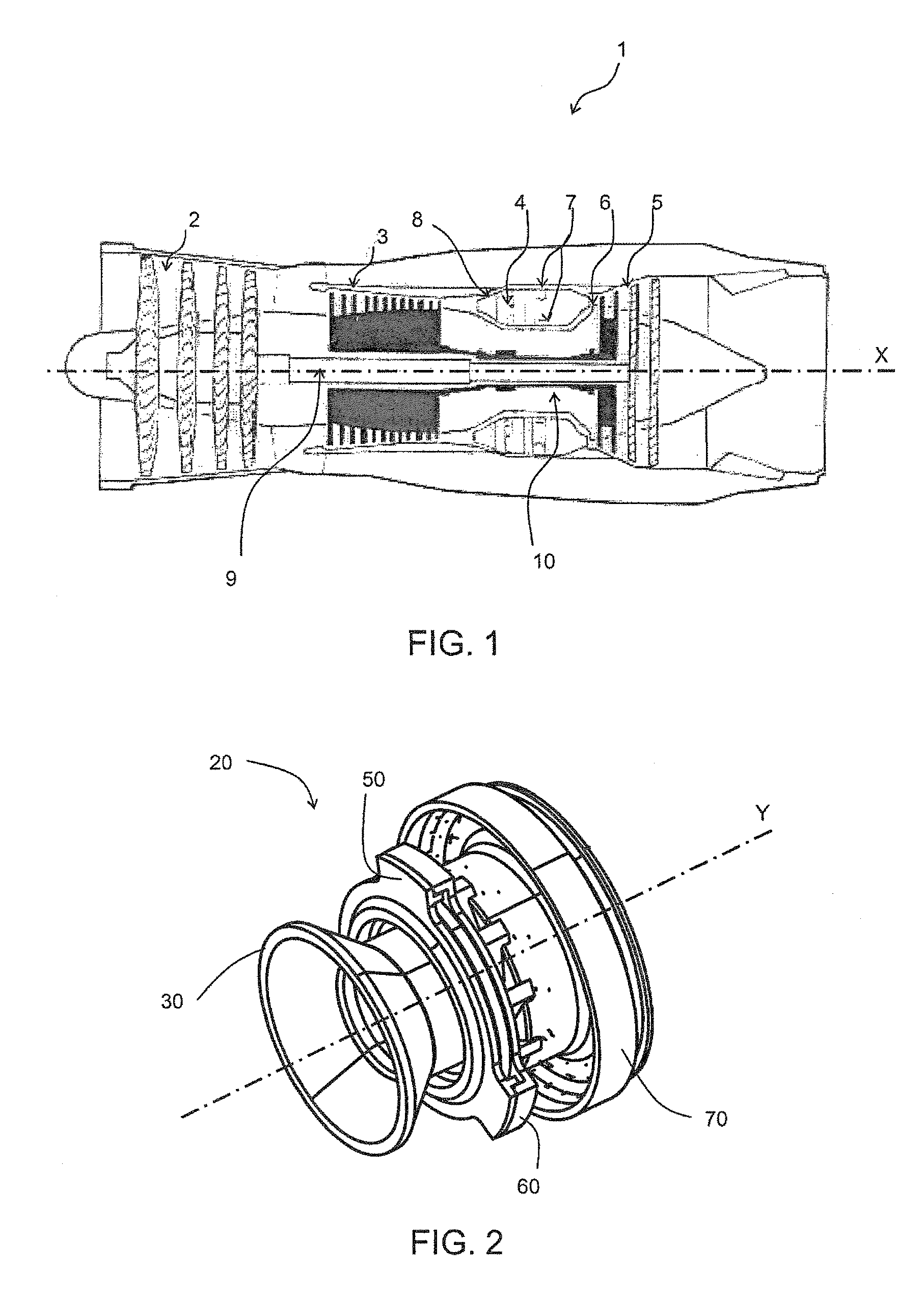

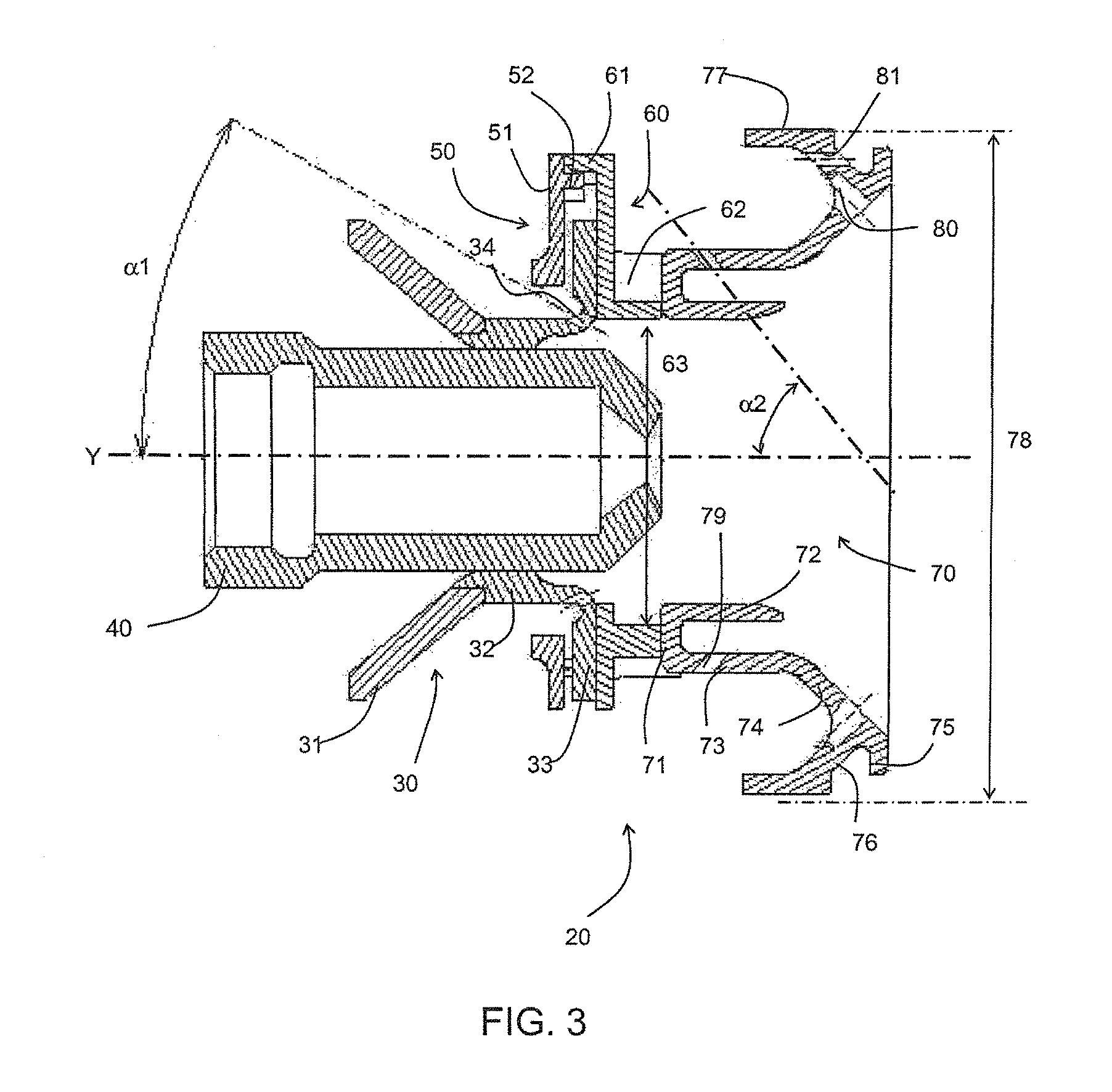

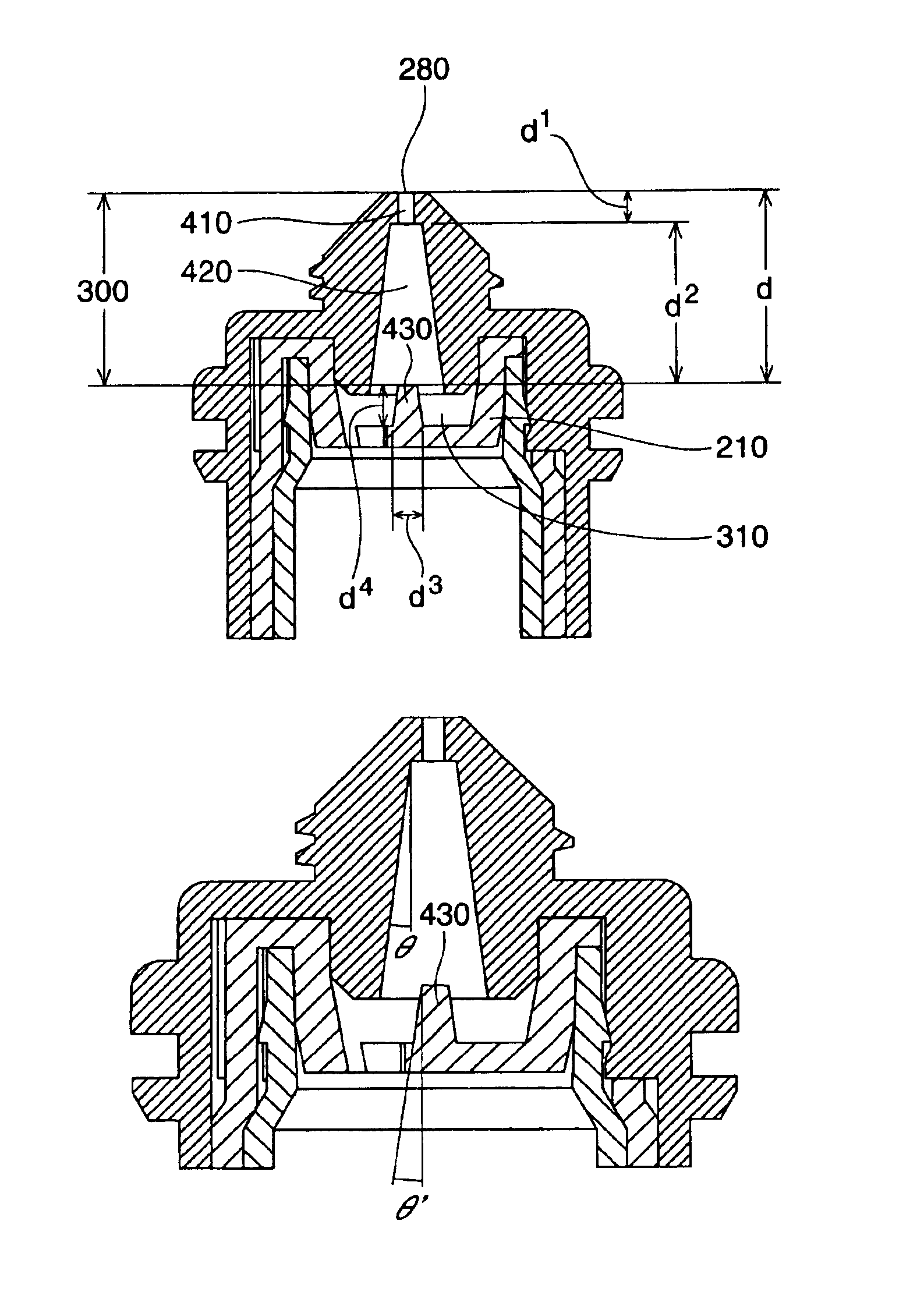

Device for injecting a mixture of air and fuel, and combustion chamber and turbomachine provided with such a device

ActiveUS20080000234A1Effective cross sectionImprove spray qualityContinuous combustion chamberBurner coolingCombustion chamberEngineering

The invention relates to a device for injecting an air / fuel mixture into a combustion chamber, which is to be mounted within a restricted space. This injection device (20) comprises a bowl (70) having an external cylindrical wall (73) continued at its downstream end by a divergent section (74) provided, downstream, with a collar (75) having the form of a ring extending radially outward, the divergent section of the bowl being connected, immediately upstream of the flange, by a connecting wall (76) to a cylindrical ring (77), the cylindrical ring and the connecting wall forming a connection rim oriented in the upstream direction. At least one row of vortex holes (79) is formed in the external cylindrical wall, close to its upstream end, and the connecting wall of the connection rim of the bowl is provided with a row of cooling orifices (81) inclined axially at an angle y to the axis of symmetry of the injection device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

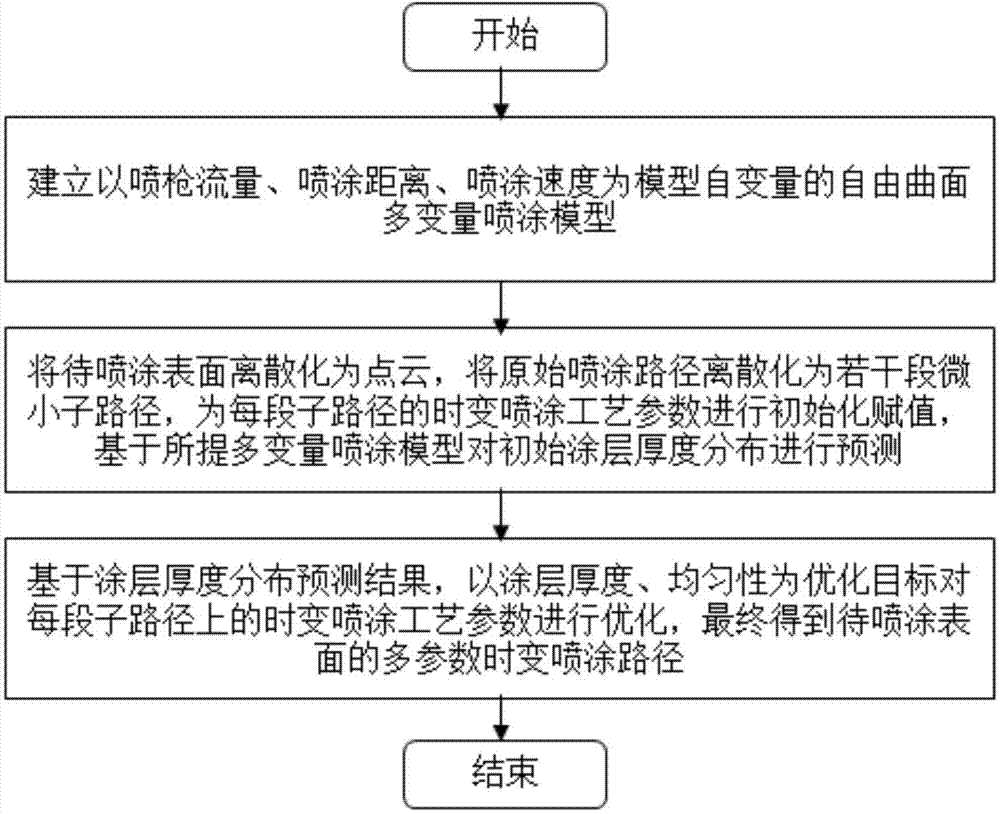

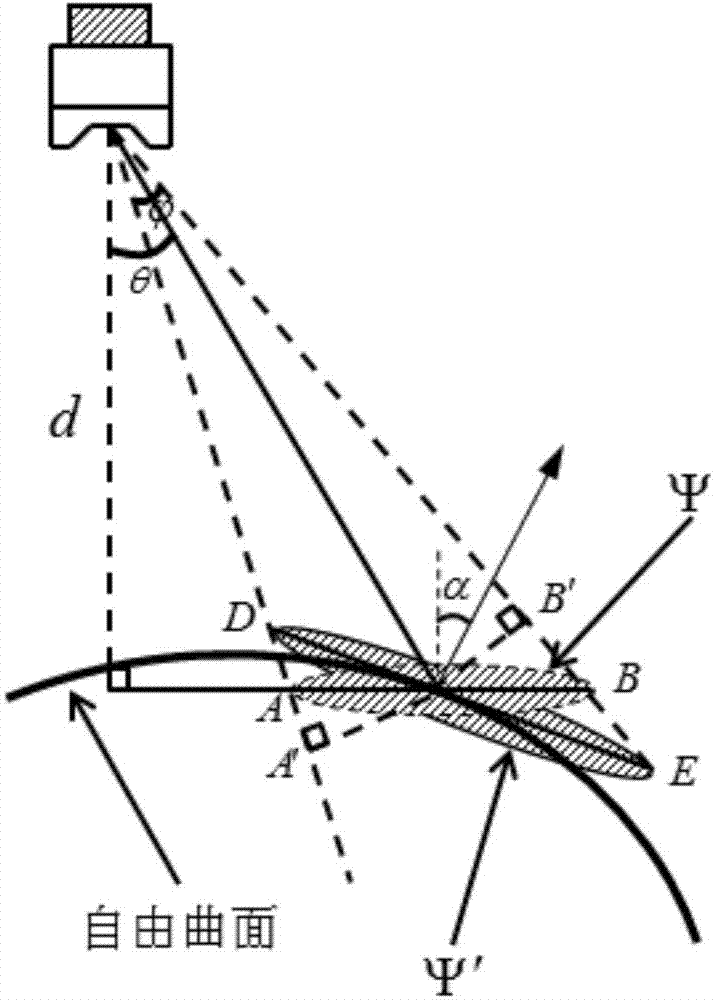

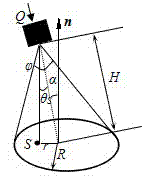

Multi-parameter time-varying robot spraying method

ActiveCN104324861AImprove efficiencyImprove spray qualityLiquid surface applicatorsSpraying apparatusFree formEngineering

The invention relates to a multi-parameter time-varying robot spraying method which comprises the following steps: firstly, establishing a free-form surface multivariable spraying model which uses flow of a spraying gun, a spraying distance and a spraying speed as model independent variables; then discretizing an original spraying path into a plurality of sections of minute sub paths, distributing initial values of time-varying spraying process parameters to each sub path and on the basis of the established multivariable spraying model, predicting distribution of an initial coating thickness; next, on the basis of a prediction result on distribution of the coating thickness, carrying out combined optimization on the time-varying process parameters to obtain the optimal process parameters on each section of sub path and finally, obtaining a multi-parameter time-varying spraying path of a surface to be sprayed. According to the method disclosed by the invention, various process parameters are used as variables; by the multivariable spraying model and a free-form surface coating thickness predicting method, the optimal process parameters on the sub paths of the discretized spraying path are obtained; dynamic optimization of the process parameters is implemented; the multi-parameter time-varying robot spraying method has the important effect of improving spraying operation efficiency, quality and safety of a robot.

Owner:清研同创机器人(天津)有限公司

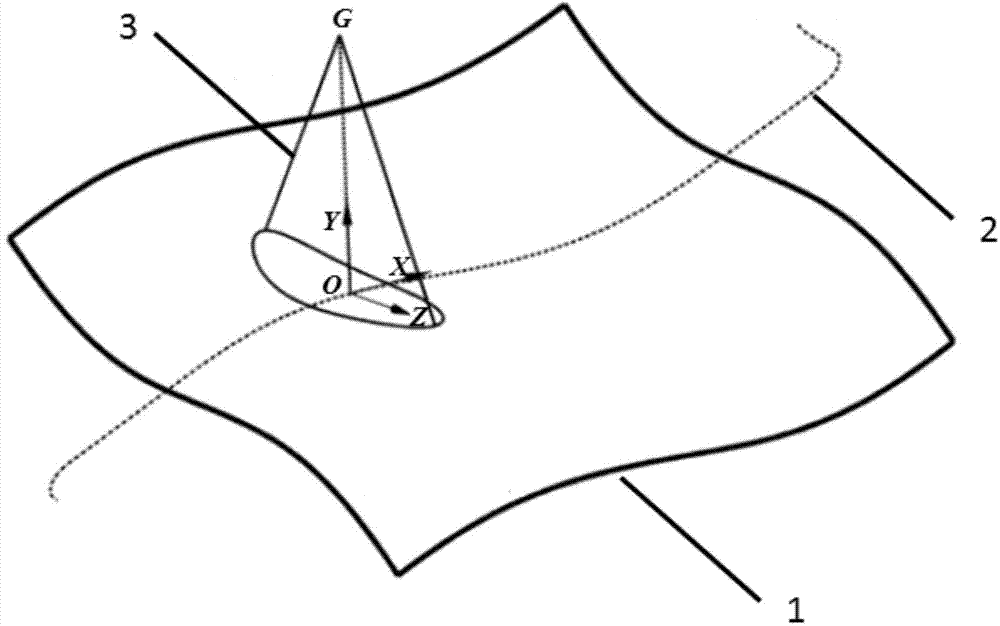

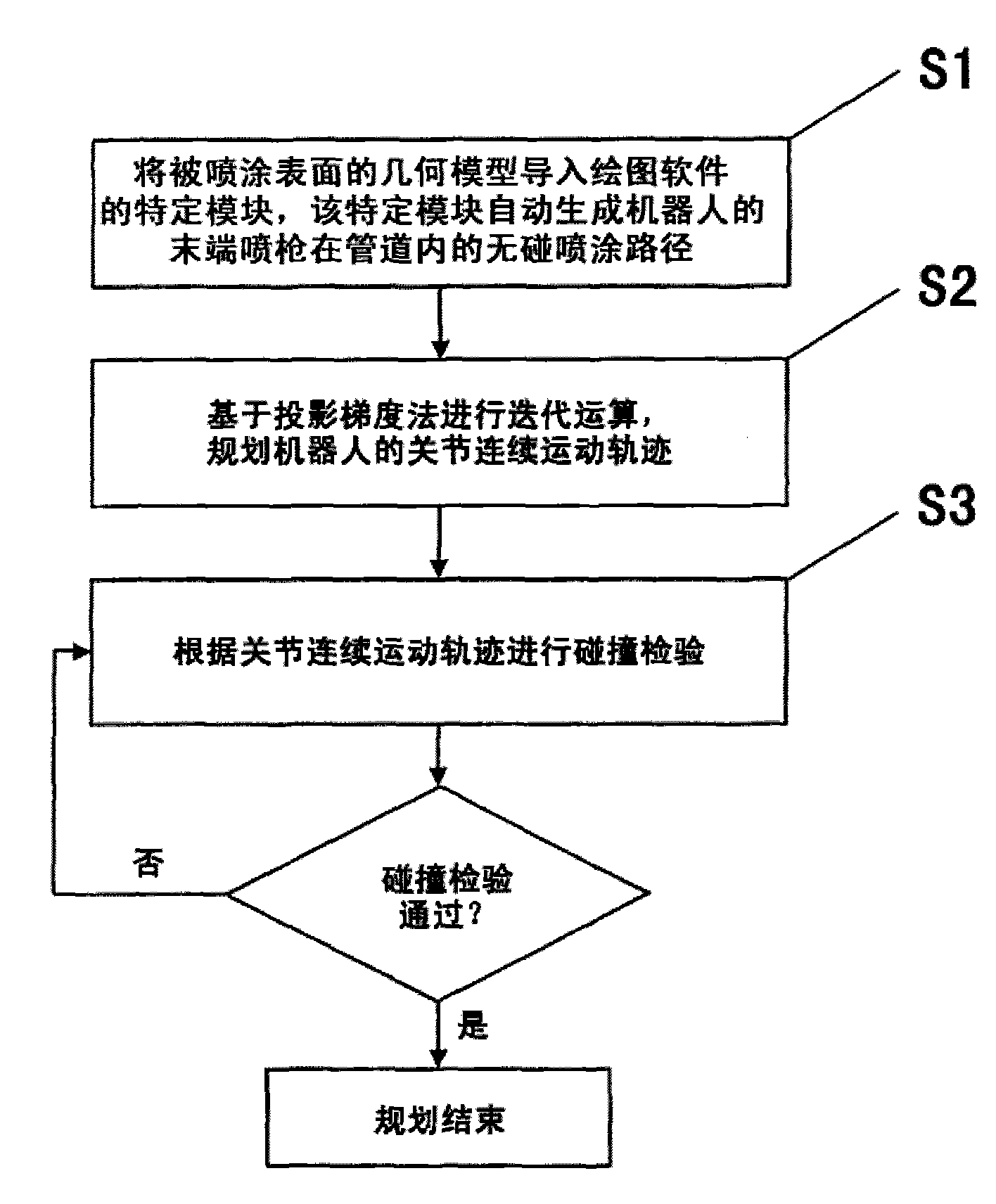

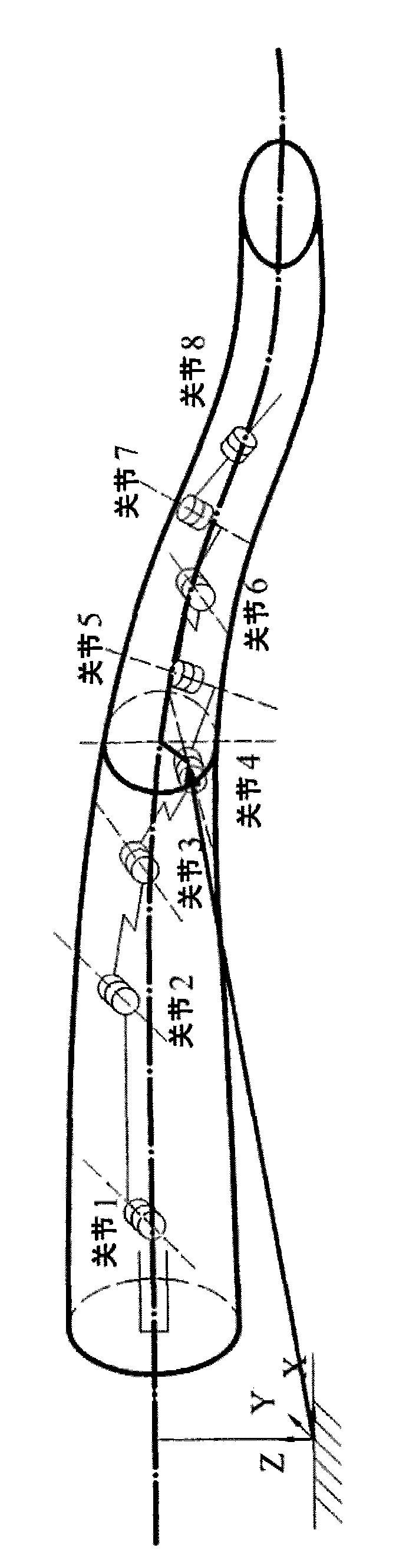

Pipeline spraying robot and operation track planning method thereof

InactiveCN101612734ASmall amount of calculationImprove spray qualityProgramme-controlled manipulatorSpraying apparatusAbnormal shapedEngineering

The invention discloses a pipeline spraying robot with multiple-redundant degree of freedom and an operation track planning method thereof. The method comprises the following steps: S1, a geometric mode of a sprayed surface is led into a specified module of a drawing software, the specified module automatically generates a no-touching spraying path of the spraying workpiece of the robot in the pipeline; S2, iterative operation is carried out based on a projection gradient method, and the continuous movement track of the joints of the robot is planned; S3, collision detection is carried out according to the continuous movement track of the joints, if colliding, the weighting coefficient of an optimization function is revised, and S2 is restarted to re-plan the continuous movement track of the joint; otherwise, planning ends. The method of the invention has small calculation amount, can ensure no wall collision occurs when the method is used for spraying the inner wall of a special-shaped long path after planning tracks, and has high spraying quality.

Owner:TSINGHUA UNIV +1

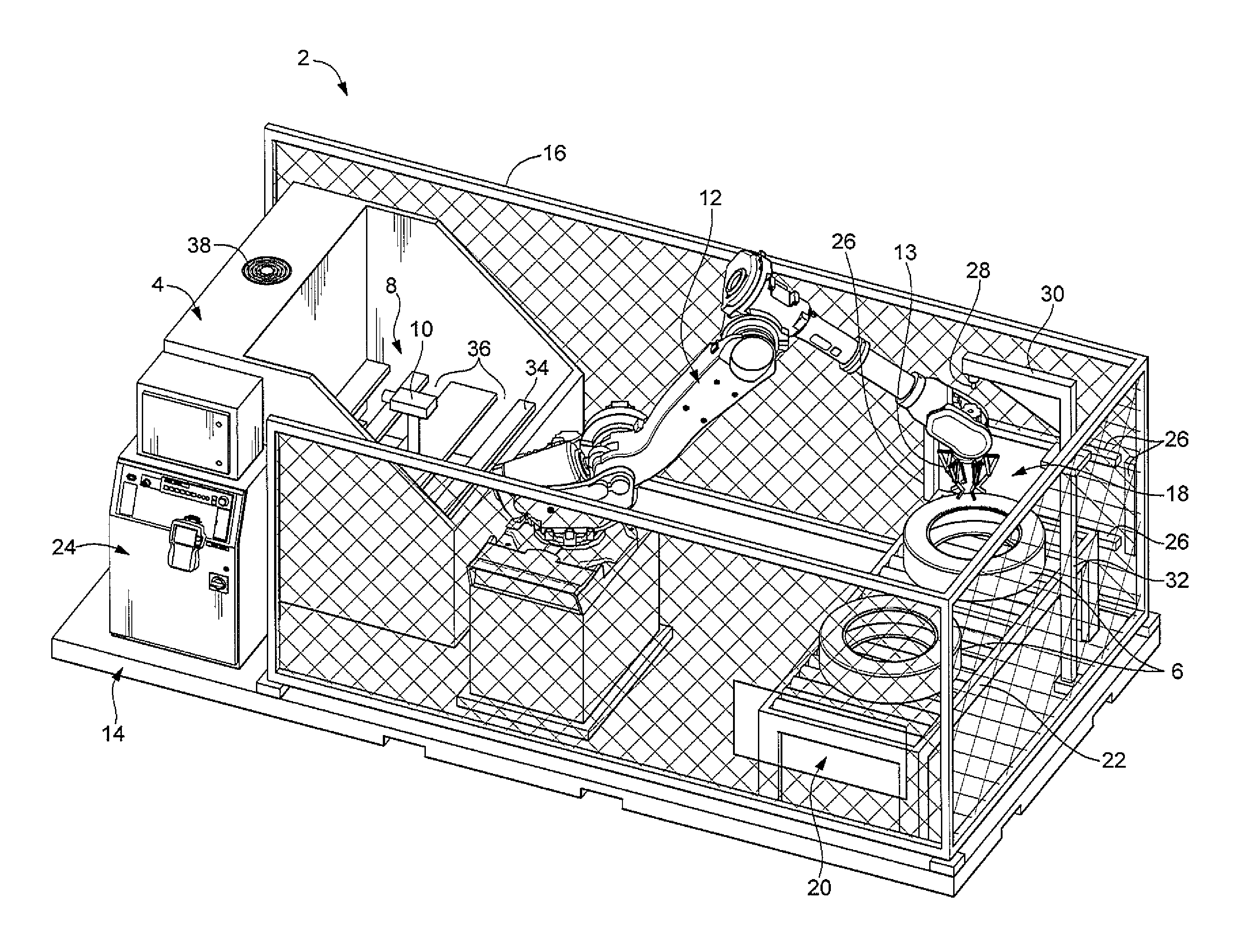

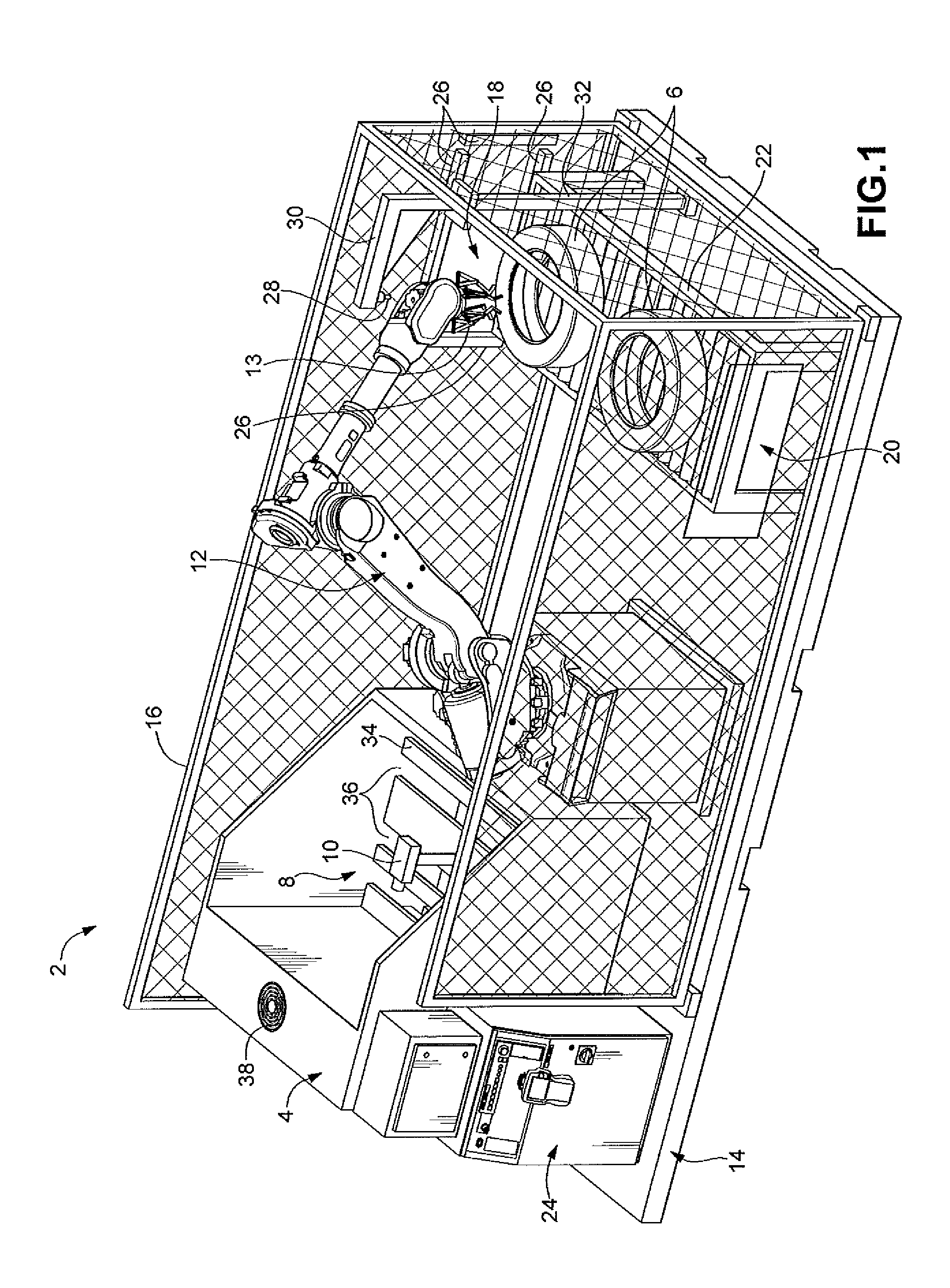

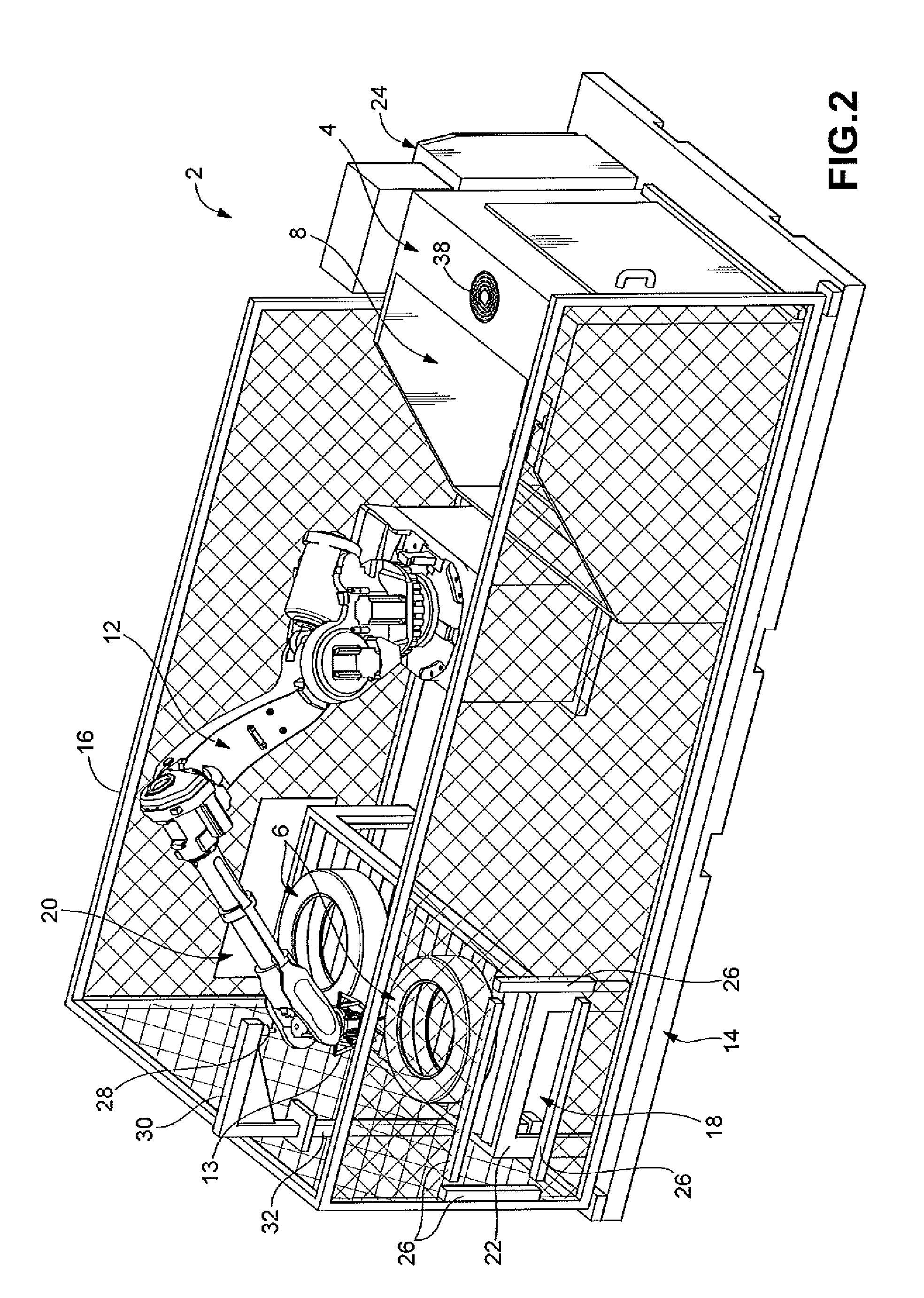

Modular tire spraying system

ActiveUS20130078385A1Use minimizedUniform coverageLiquid surface applicatorsTyresAgricultural engineeringDelivery system

A modular tire spraying system includes a downdraft spray booth for receiving a tire, a fluid delivery system disposed in the spray booth, a robot for transporting the tire to the spray booth, and a platform on which each of the spray booth, the fluid delivery system, and the robot is disposed. The fluid delivery system includes at least one spray gun for delivering a coating to the tire.

Owner:PIONEER IND SYST

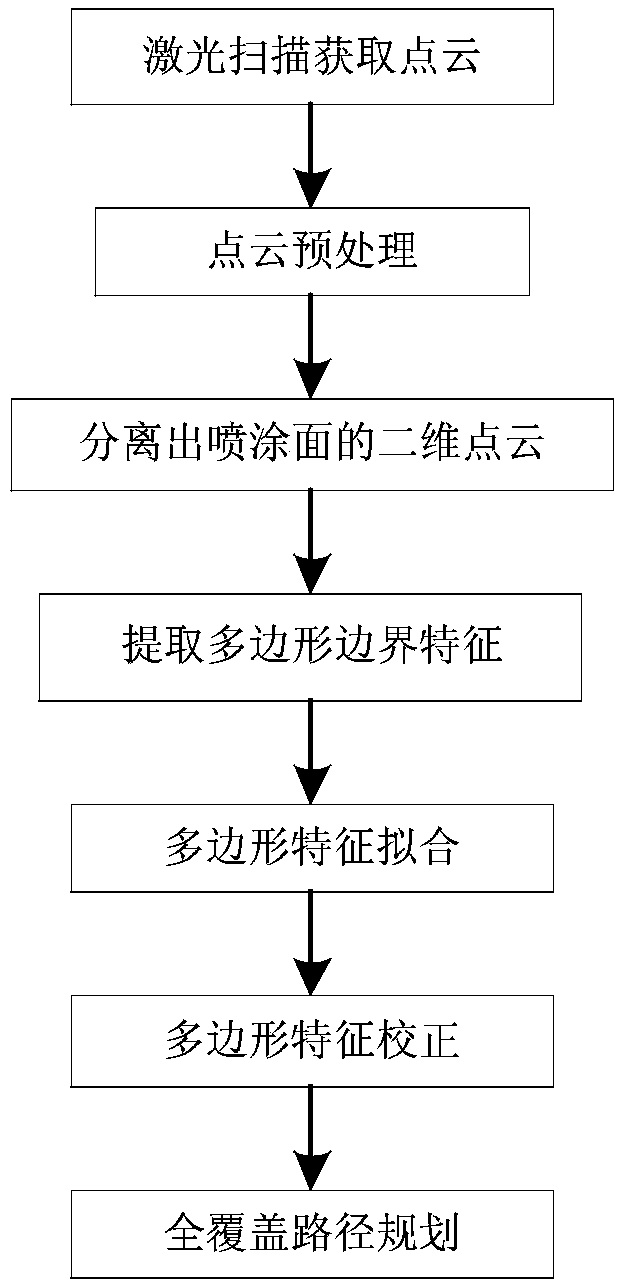

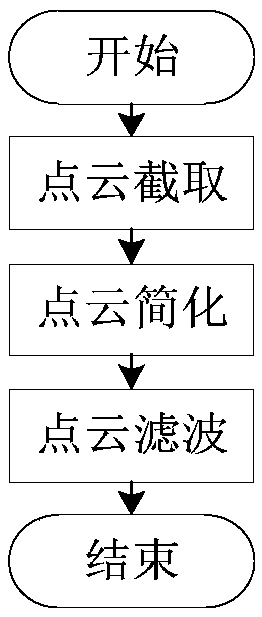

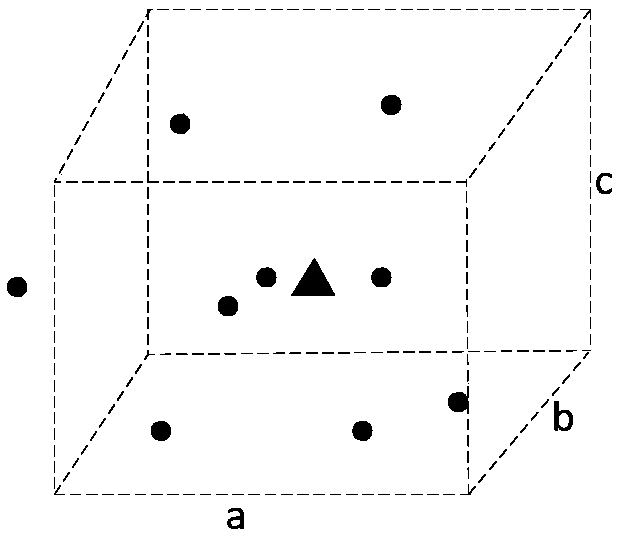

Fast intelligent programming method for spraying robot for planar/approximate planar workpieces

ActiveCN109541997AImprove spraying efficiencyImprove spray qualityProgramme controlComputer controlPoint cloudLaser scanning

The invention discloses a fast intelligent programming method for a spraying robot for planar / approximate planar workpieces. Firstly, laser is adopted to scan the surface of a workpiece to acquire a set of original point clouds, the point cloud of the workpiece is then intercepted, the point clouds are simplified and noise points are filtered; secondly, a two-dimensional plane point cloud representing the spraying surface is separated from a three-dimensional point cloud, the polygonal boundary features of the point cloud are further extracted, and straight line fitting is carried out; thirdly, the boundary polygonal features of the spraying surface are extracted through operations such as polygon fitting, correction and vertex sorting; and finally, the full-coverage path on the surface ofthe workpiece is planned. According to the fast, intelligent and de-teaching programming method for the planar / approximate planar workpieces, a tedious manual teaching process is not needed, the workpiece surface features are extracted through automatic scanning of low-cost 2D line laser, the full-coverage path of the robot is automatically optimized and generated, and the spraying efficiency andthe spraying operation quality of a specific workpiece surface can be effectively improved.

Owner:SOUTHEAST UNIV

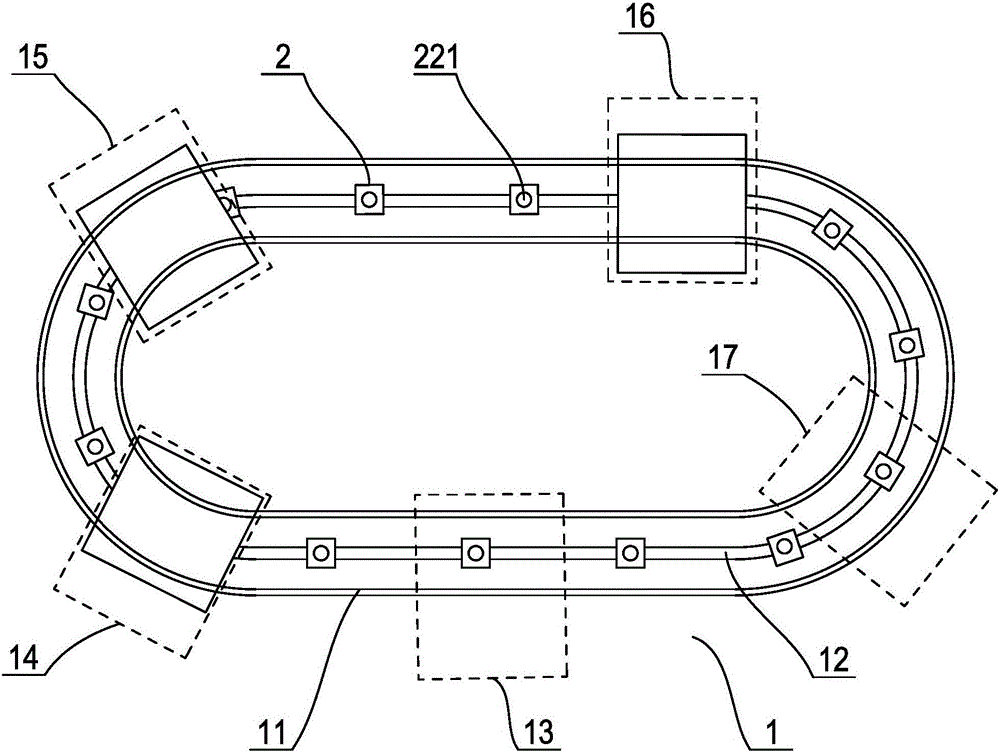

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

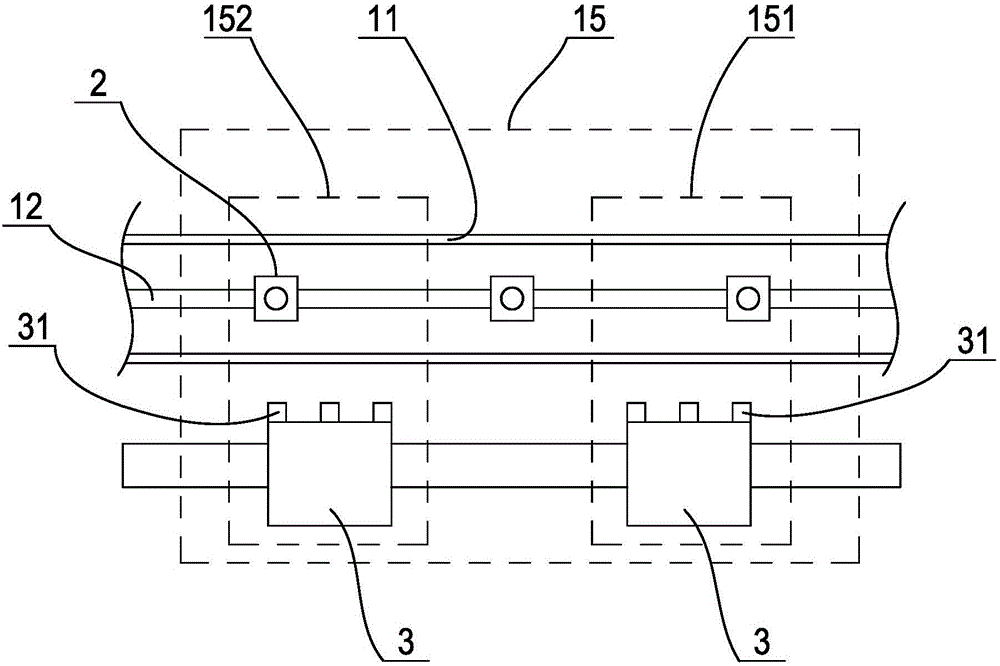

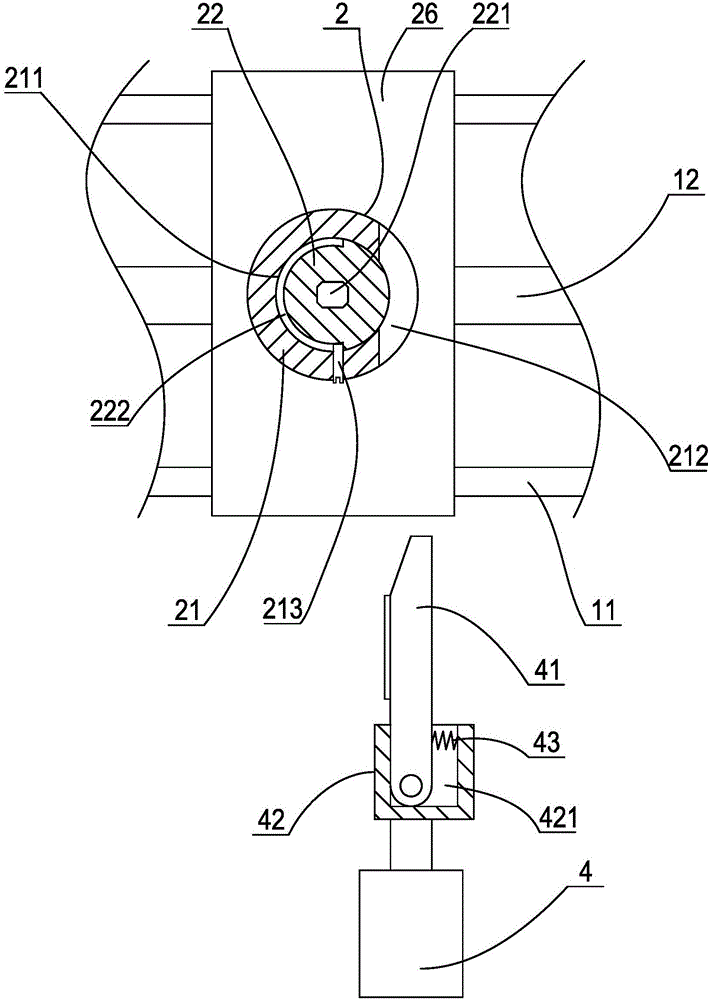

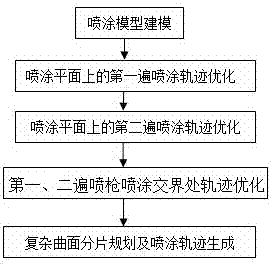

Two-pass automatic-spraying track optimization method of complex curved surfaces

ActiveCN103495516AHigh coating uniformityImprove spray qualitySpraying apparatusSpecial data processing applicationsEngineeringMechanical engineering

The invention relates to a two-pass automatic-spraying track optimization method of complex curved surfaces. On the basis that first-pass spaying track parameters are obtained, to guarantee second-pass spraying uniformity, changes of the spraying height of a spraying gun are considered, and three second-pass spraying-gun spraying models are built on this account. Variance minimality of an ideal coating thickness and an actual coating thickness is made as an optimization objective, second-pass spraying-gun spraying track parameters are solved and obtained, and finally a spraying-gun spraying track is generated according to a spraying pane obtained through fragmentation of the complex curved surfaces. Therefore, coating uniformity of the complex curved surfaces in the two-pass spraying process is promoted further, and spraying quality of the surfaces of products is improved.

Owner:江苏三旗流体设备有限公司

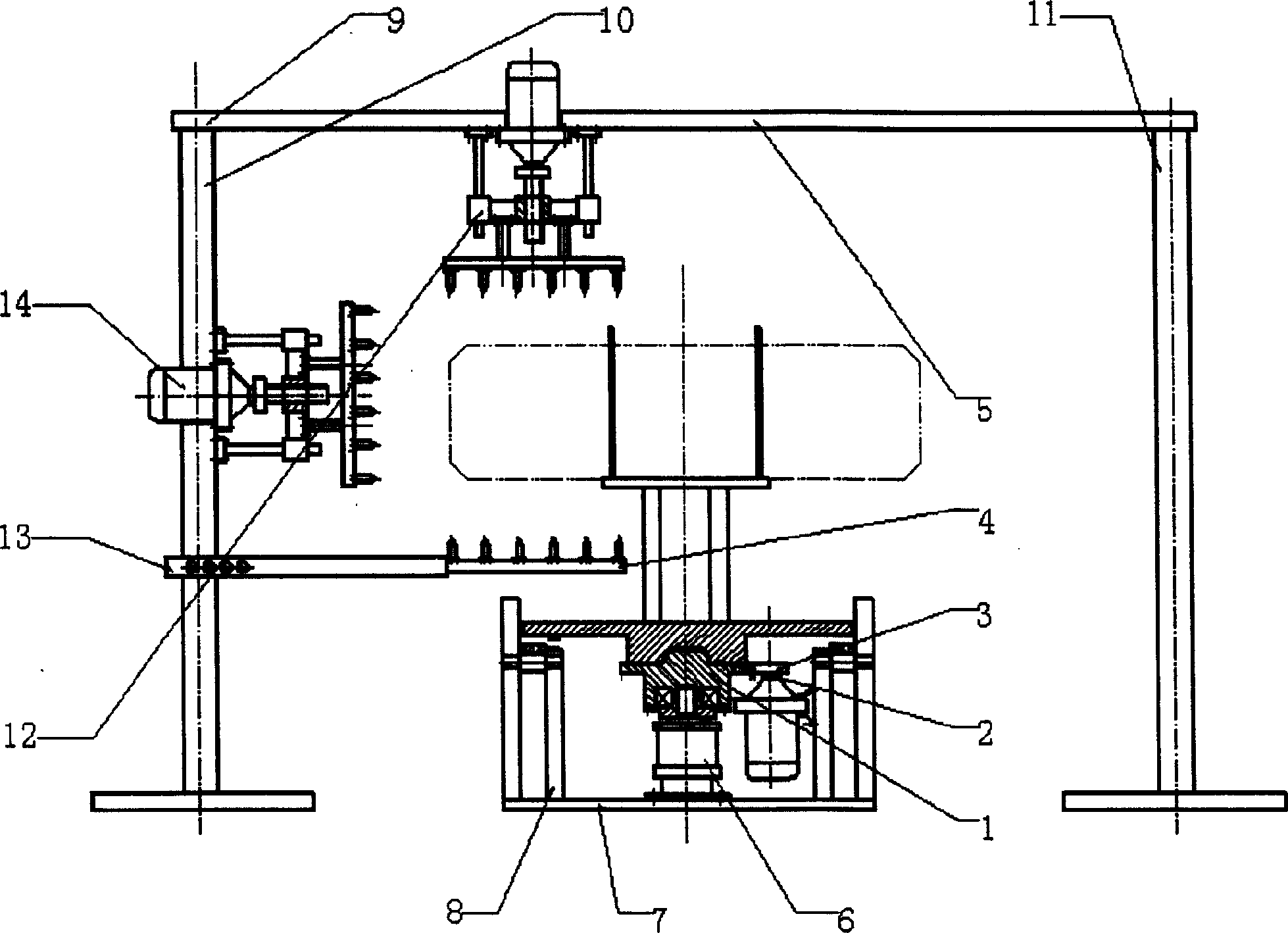

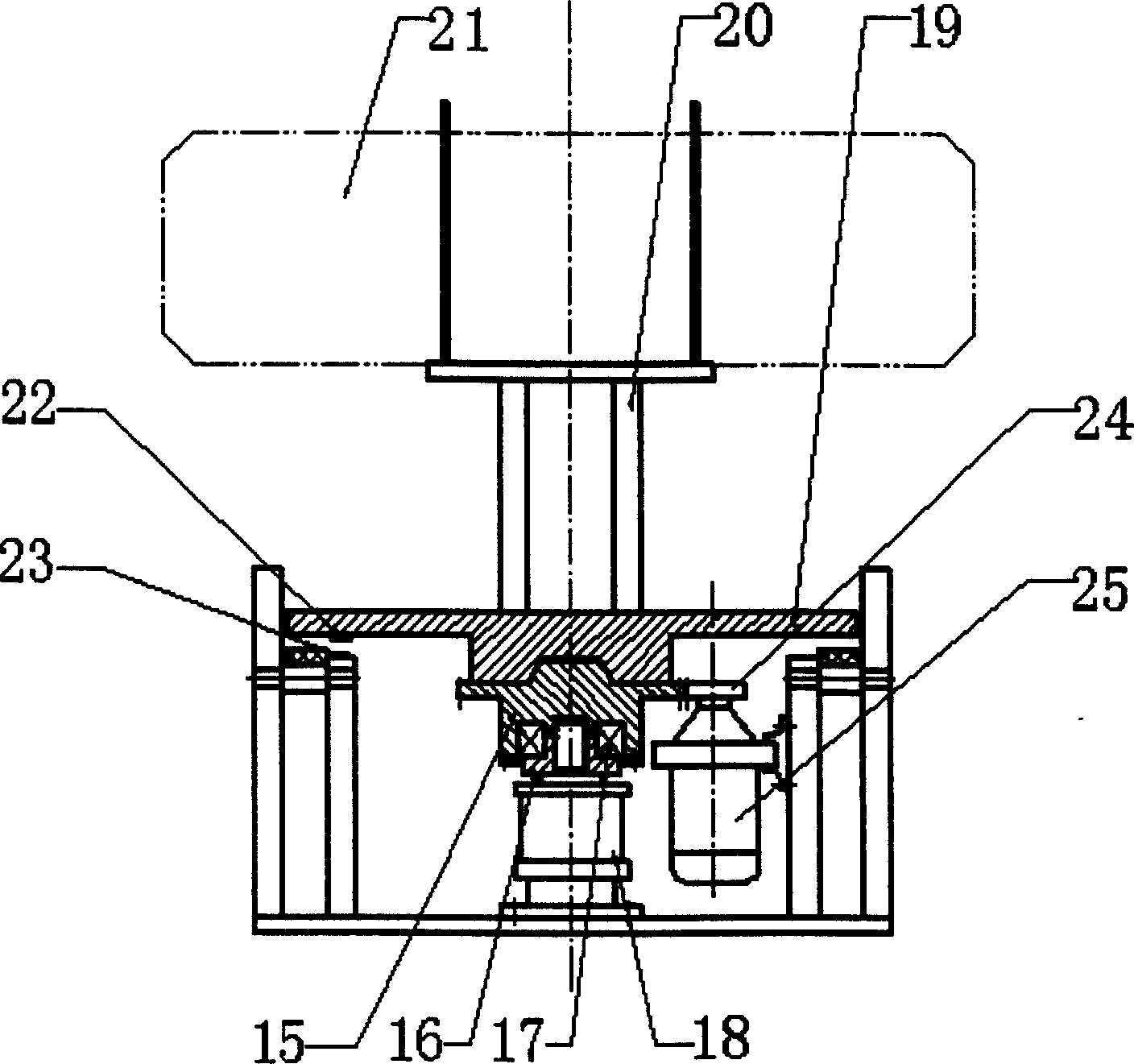

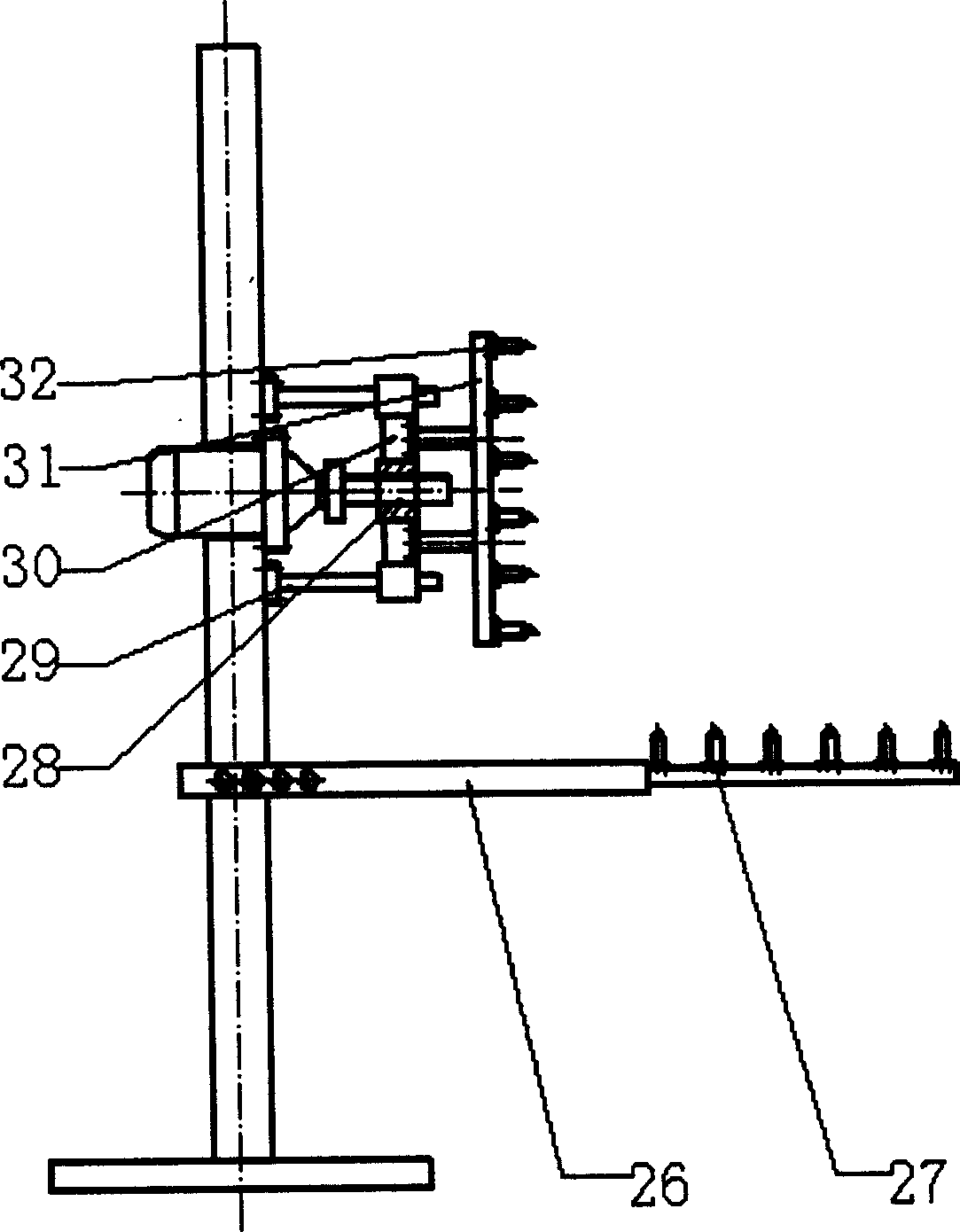

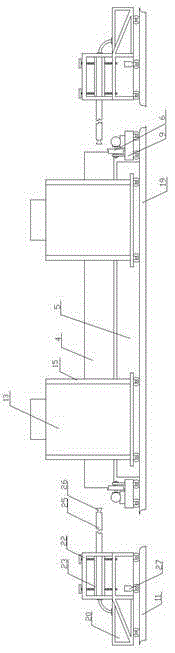

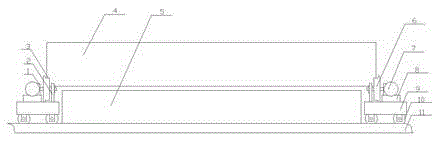

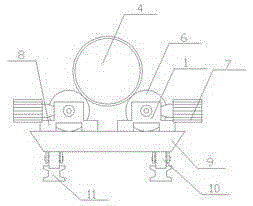

Spray-coating machine for external surface of tire

The tyre surface spray-coating machine mainly includes tyre lifting device, tyre conveyer device, tyre-turning device, tyre nozzle group and supporting frame. Its connection mode; the lifting cylinder of tyre lifting device is mounted on the base plate of supporting frame, when the tyre conveyer device is lifted up, the tyre lifting device and tyre conveyer device are matched and positioned by means of oblique surface embossed structure, the tyre turning device is fixed on the side face supporting frame, and the side face supporting frame is mounted on the base plate of supporting frame, the tyre turning device is connected with tyre conveyer device by means of gear transmission, and the tyre nozzle group is mounted on the supporting frame.

Owner:SHANGHAI JIAO TONG UNIV

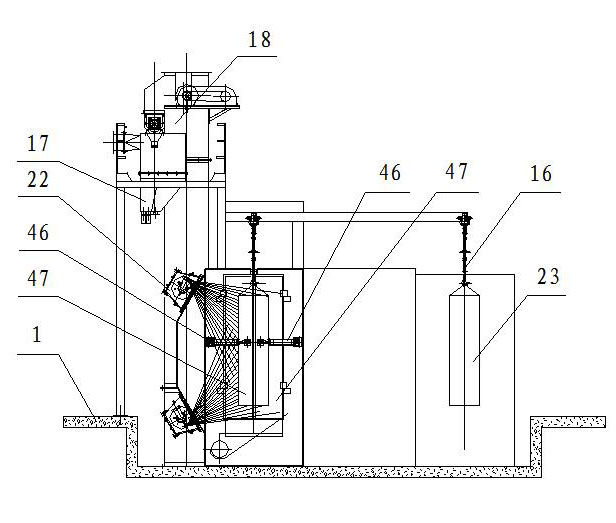

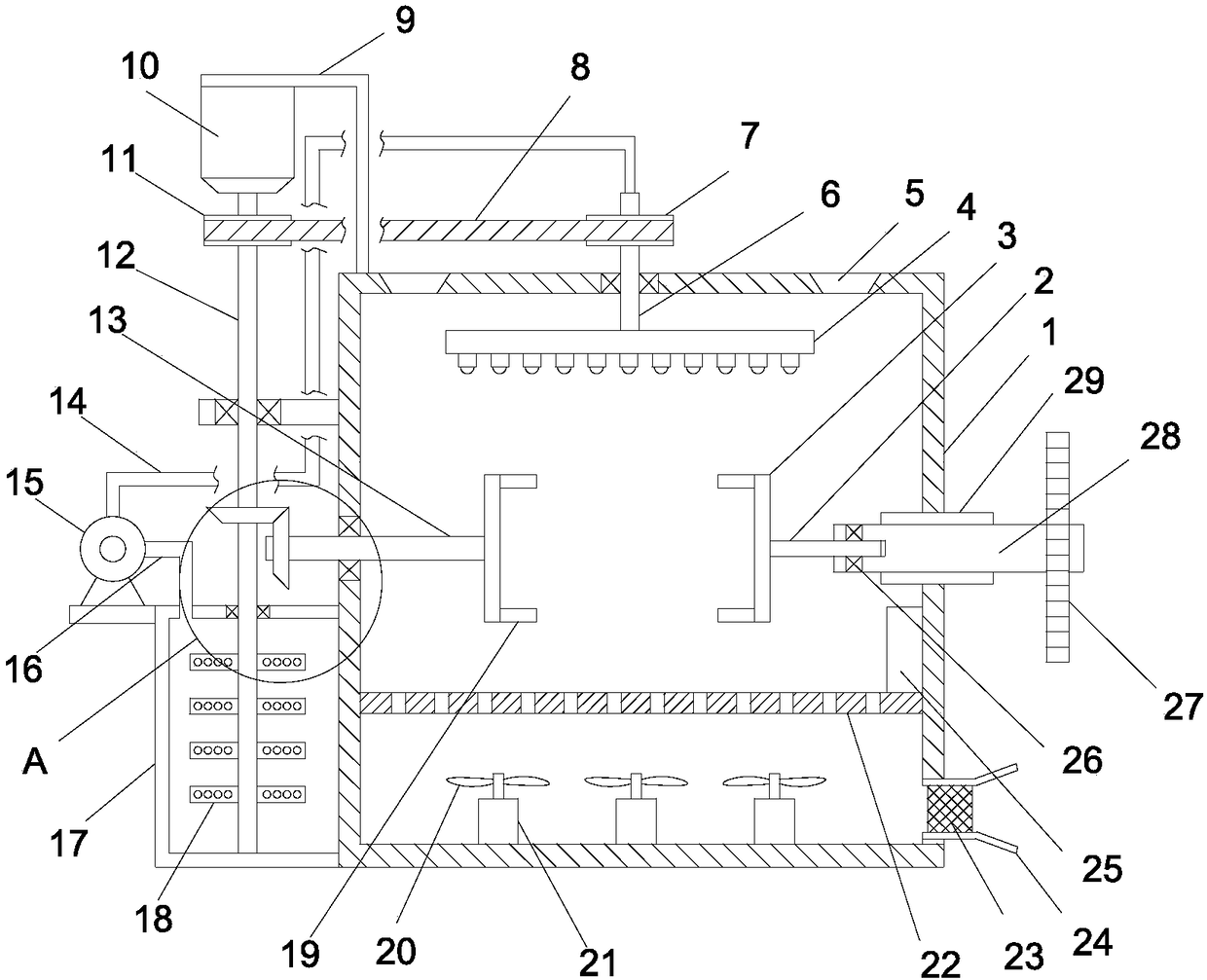

Robot continuous and automatic paint spraying apparatus for large work piece

ActiveCN105107654APrecise control of paint thicknessQuality improvementLiquid surface applicatorsCoatingsEngineeringDistance sensors

The invention discloses a robot continuous and automatic paint spraying apparatus for a large work piece, and aims to solve problems in large work piece spraying that the automation degree is low, continuous work is difficult to carry out, a cleaning nozzle is difficult to replace and the work piece cannot be rapidly dried. The tail portion of an industrial robot is fixedly mounted on a movable platform through a pedestal. The movable platform is in threaded connection with a screw and in sliding connection with a rail. A spraying device is mounted at the tail end of the industrial robot. A driving main shaft on a cleaning device is connected to a driving part which is fixedly mounted on an installation seat. A main nozzle is mounted in a nozzle installation hole. The top end of a drying shell is connected to a piston rod of a cylinder. The tail end of the cylinder is connected to the installation seat. A distance sensor is arranged above the drying shell and on the installation seat. The paint spraying apparatus is used for automatically spraying the surface of the large work piece.

Owner:HARBIN UNIV OF COMMERCE

Motor shell paint spraying device with drying function

InactiveCN108339702AImprove spraying effectImprove spraying efficiencySpray boothsDrive shaftEngineering

The invention discloses a motor shell paint spraying device with a drying function. The device comprises an operating box, wherein an oil pant box is fixedly mounted on the left side wall of the operating box; a motor supporting rack is fixedly mounted on the top of the operating box; a reducing motor is fixedly mounted on the motor supporting rack; a plurality of rotating motors are fixedly mounted in the bottom of the operating box; and a plurality of fan blades are fixedly mounted on an output shaft of each rotating motor. The device disclosed by the invention sprays the oil paint uniformlyby means of rotary paint spray of a paint spray disc and attaches the oil paint uniformly to the surface of the motor shell by clamping and rotating the motor shell by means of a first clamp and a second clamp, so that the oil paint spraying effect and efficiency are improved; the oil paint in the oil paint box is uniformly stirred as the stirring blades rotate along with a driving shaft, so thatthe uniform degree of the oil paint is improved effectively, agglomeration of the oil paint is avoided, and the oil paint spraying quality is improved. The device also has a very good oil paint drying function, accelerates quick drying of the oil paint on the surface of the motor shell, and improves the work efficiency.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

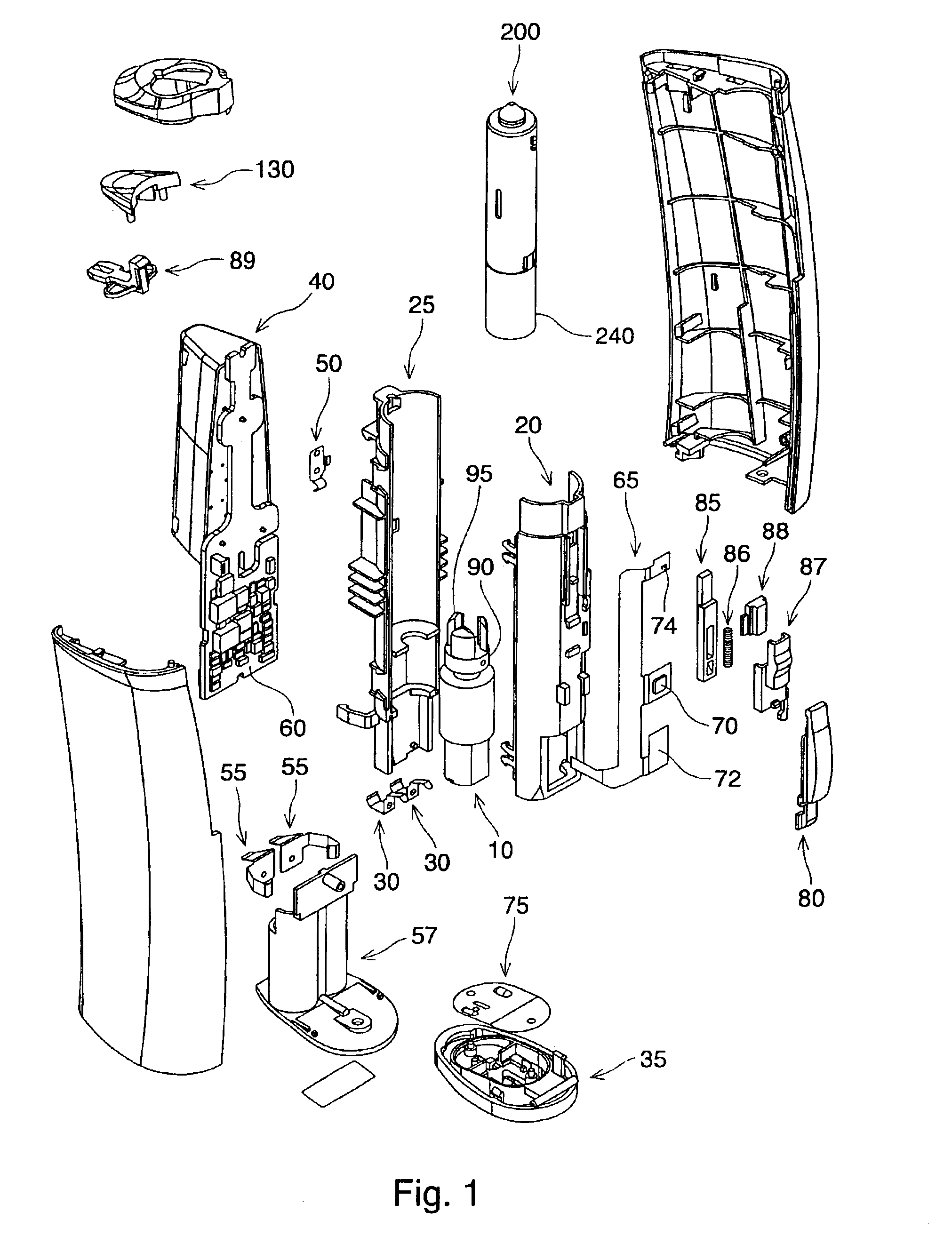

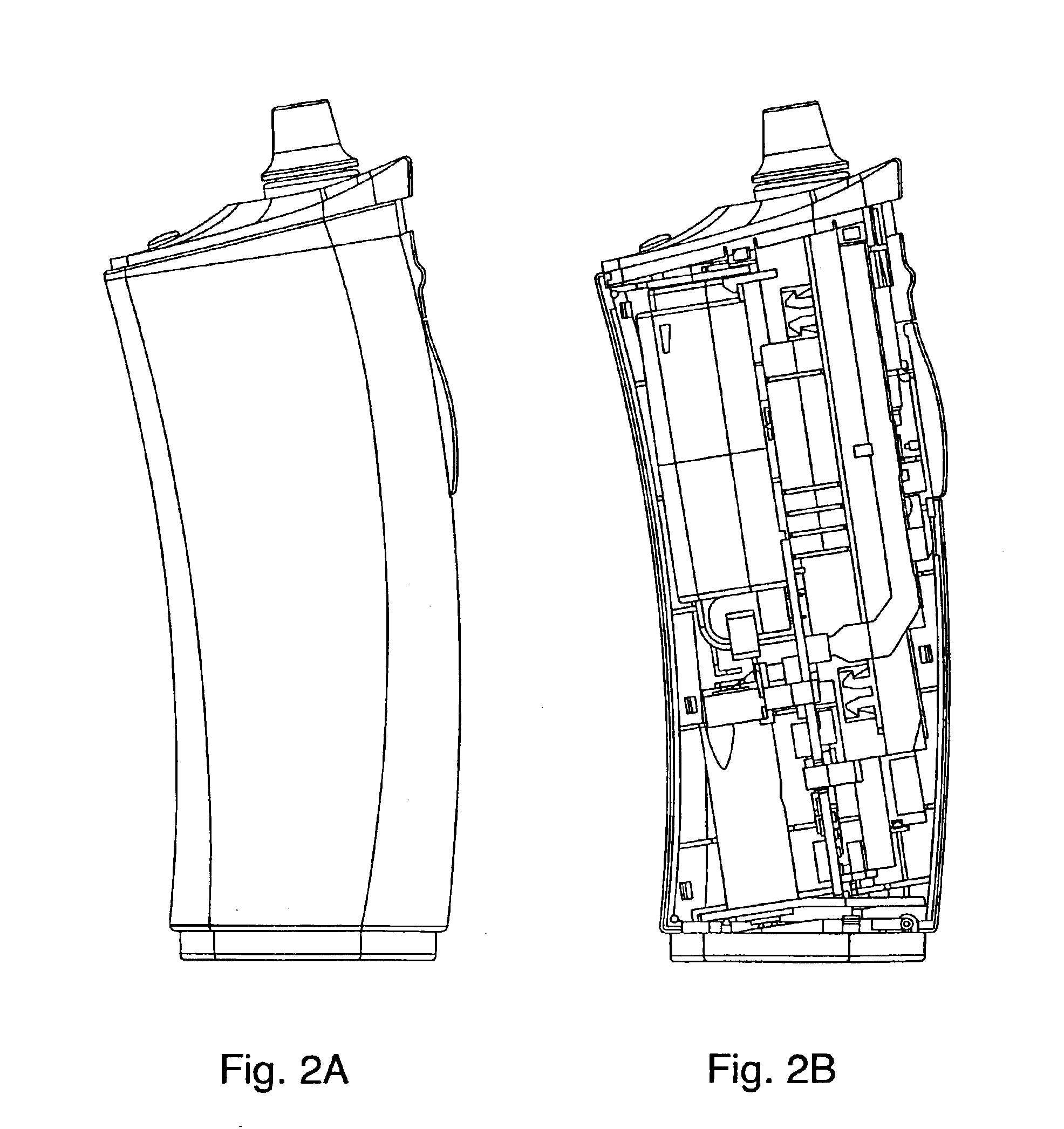

Electrostatic spray device

InactiveUS6866212B2Easy to moveImprove spray qualityBurnersLiquid supply arrangementsElectricityEngineering

An electrostatic spraying device being configured and disposed to electrostatically charge and dispense a liquid composition from a supply to a point of dispersal, wherein the device comprises:[0002]a reservoir configured to contain the supply of liquid composition;[0003]a nozzle to disperse the liquid composition, the nozzle being disposed at the point of dispersal;[0004]a channel disposed between the reservoir and the nozzle, wherein the channel permits the electrostatic charging of the liquid composition upon the liquid composition moving within the channel;[0005]a high voltage power supply electrically connected to the power source; and[0006]a high voltage electrode electrically connected to the high voltage power supply, wherein a portion of the high voltage electrode is disposed between the reservoir and the nozzle, and wherein the high voltage electrode electrostatically charges the liquid composition within the channel at a charging location,[0007]wherein the nozzle pathway comprises an outlet path disposed adjacent to the nozzle, the outlet path having a diameter of from about 0.1 mm to about 1 mm and being a point or having a length of from about 0 mm to about 5 mm, and a main path disposed between the outlet path and the charging location, the main path having a diameter greater than the outlet path to about 5 mm and being straight or outwardly tapered towards the charging location at an angle of from about 0 to about 10 degrees.

Owner:THE PROCTER & GAMBLE COMPANY

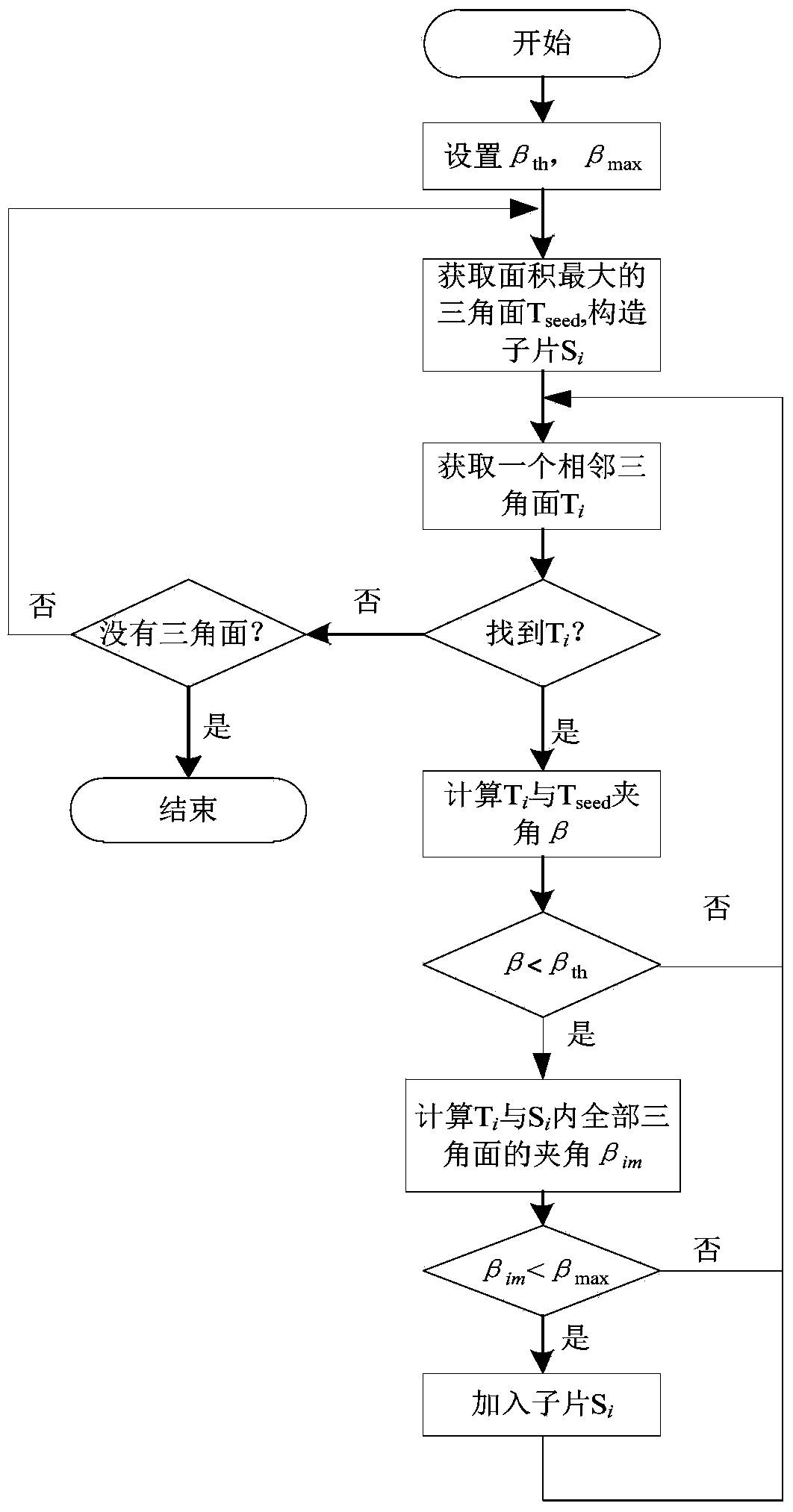

Inter-sheet dead area optimization process based uniform-spraying manufacturing method for complex curved surface

InactiveCN103394430AImprove spray uniformityImprove spray qualitySpraying apparatusNumerical modelsGenetic algorithm

The invention discloses an inter-sheet dead area optimization process based uniform-spraying manufacturing method for a complex curved surface. The inter-sheet dead area optimization process based uniform-spraying manufacturing method comprises the steps as follows: firstly, performing sheet division on an STL model via geometrical and topological characteristics of a workpiece, dividing the curved surface of the original workpiece into a plurality of simple sub-sheets approximate to planes and treating the sub-sheets respectively, then performing optimization solution on key spraying parameters such as the moving speed and the stroke pitch of a spray gun according to a spray forming model of the spray gun and corresponding process production indexes, so as to generate a spraying path inside each sub-sheet, extracting the position relation between edges of every two adjacent sub-sheets and the heading direction of the spray gun, and adopting a segmented sampling method to establish a numerical model for uniform spraying aiming at several common typical dead area conditions, and finally adopting a genetic algorithm to perform optimization solution on spraying paths in dead areas in an unified way. According to the invention, coating and manpower cost are saved, so that improvement on spraying production benefits is facilitated, and favorable application value and economic prospect are achieved.

Owner:SOUTHEAST UNIV

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

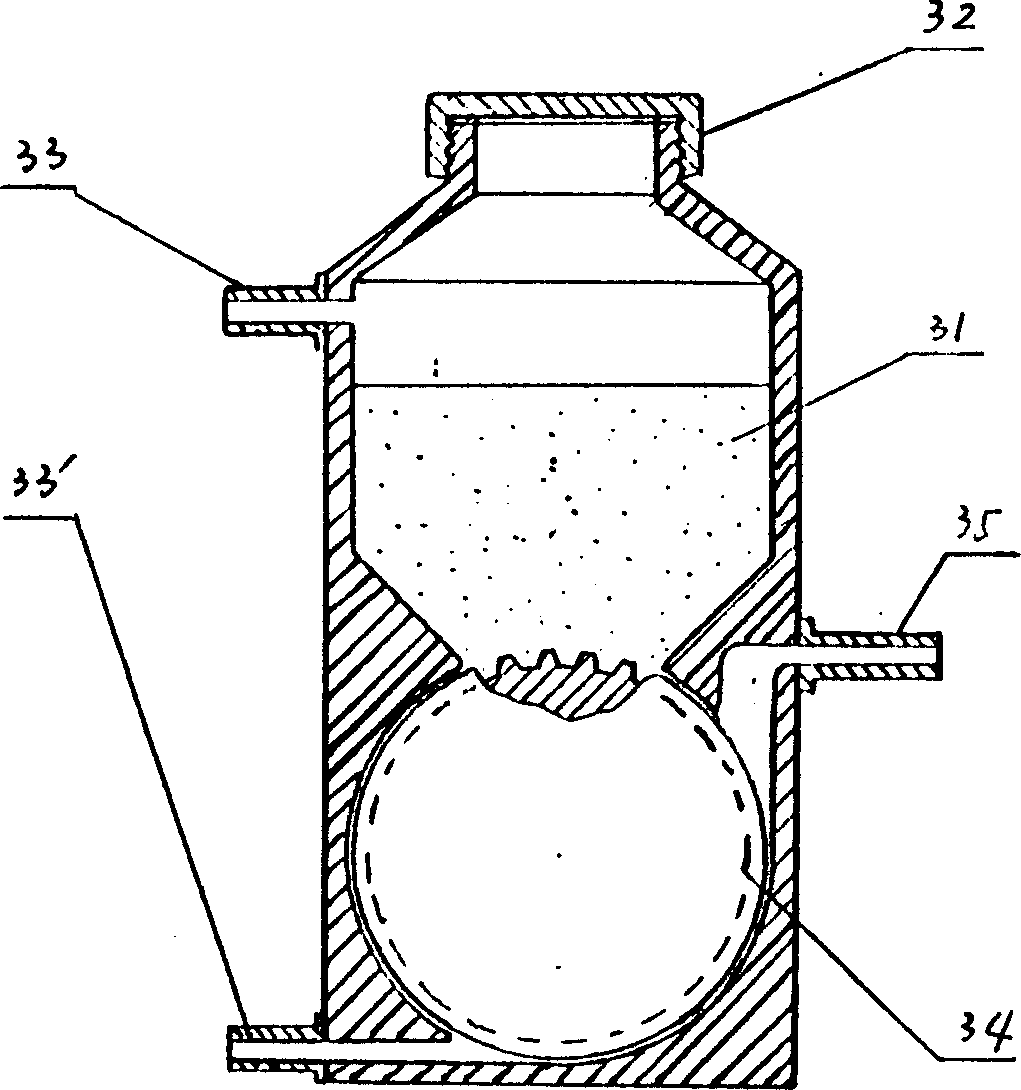

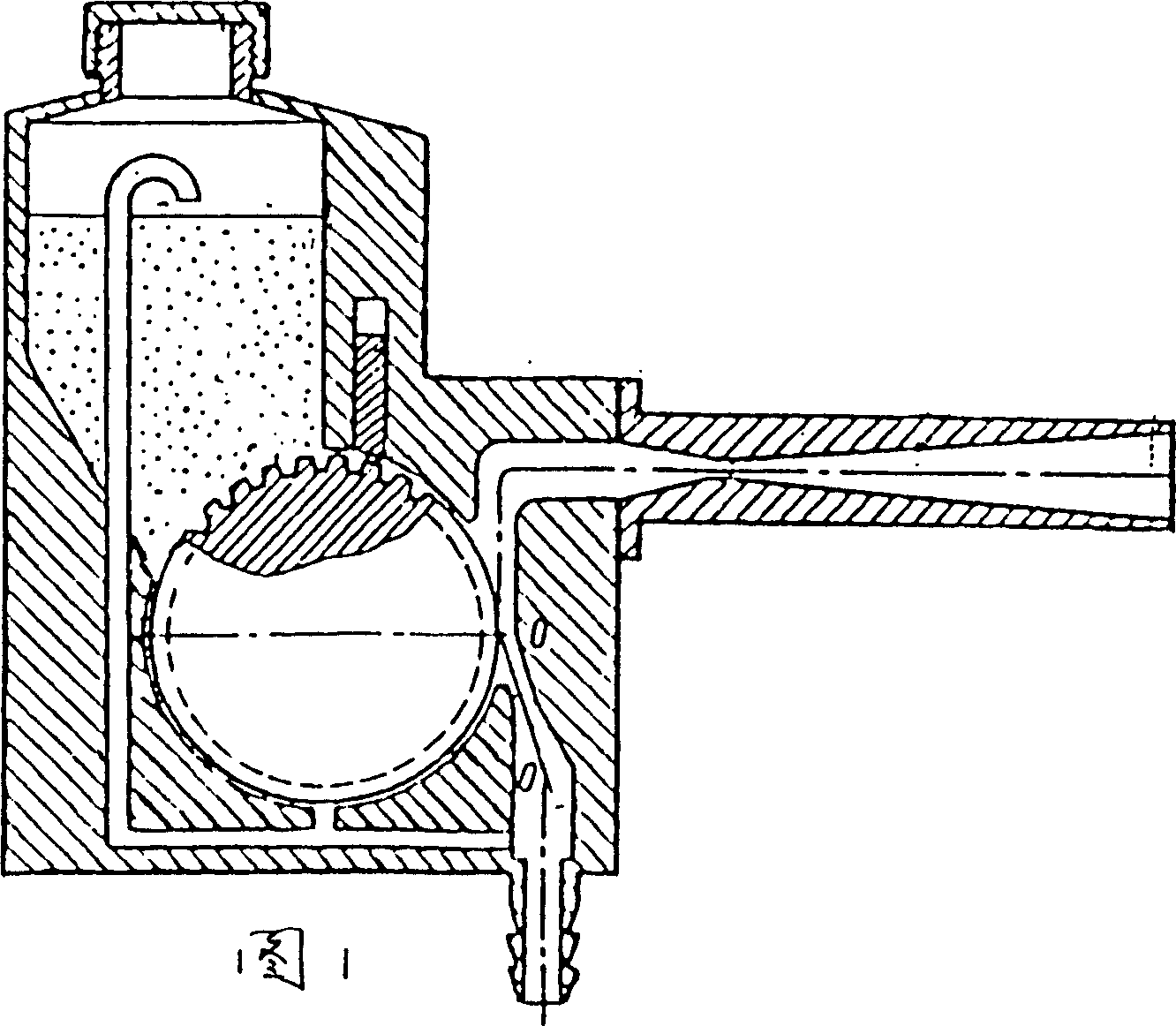

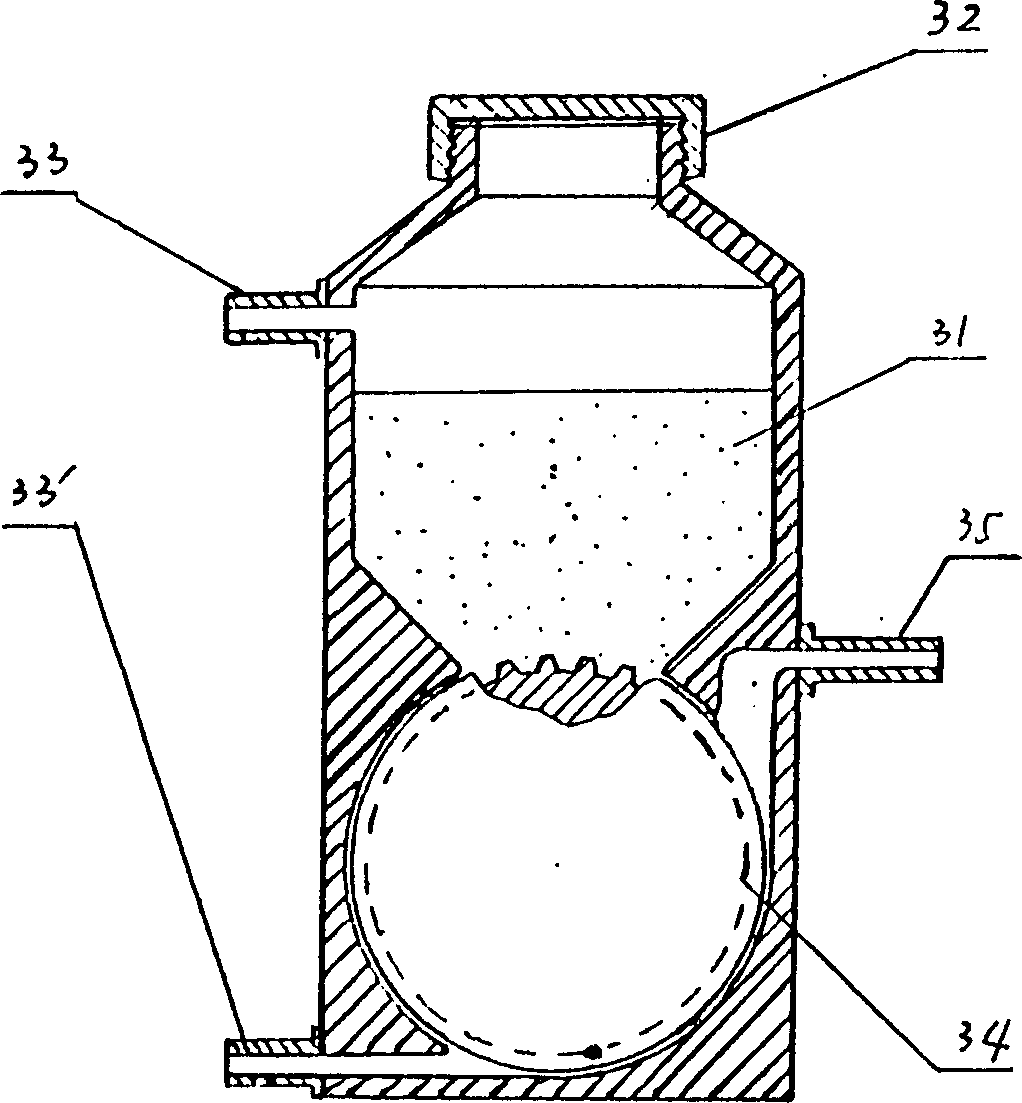

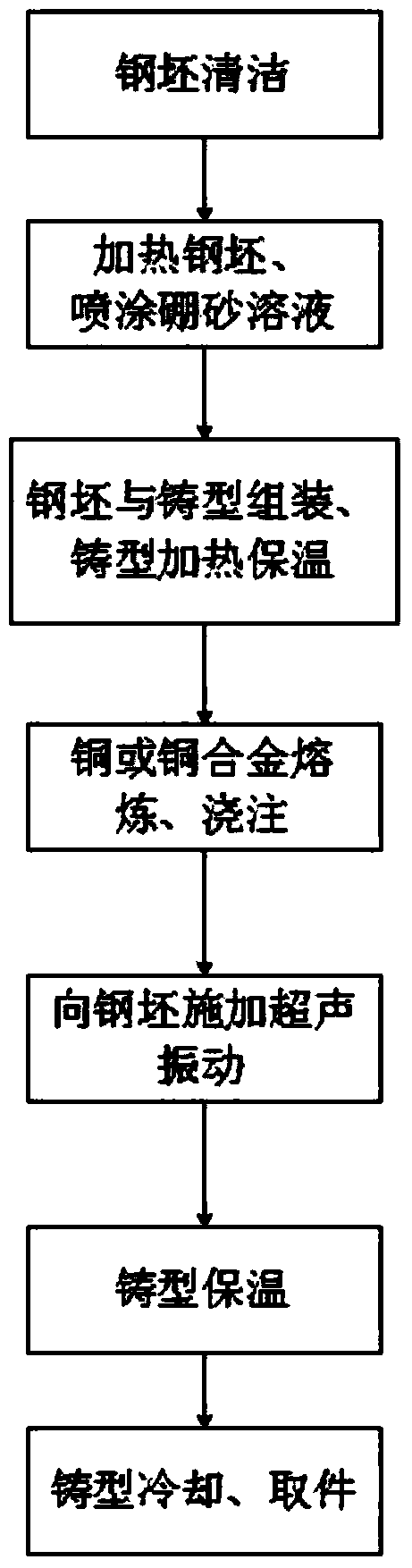

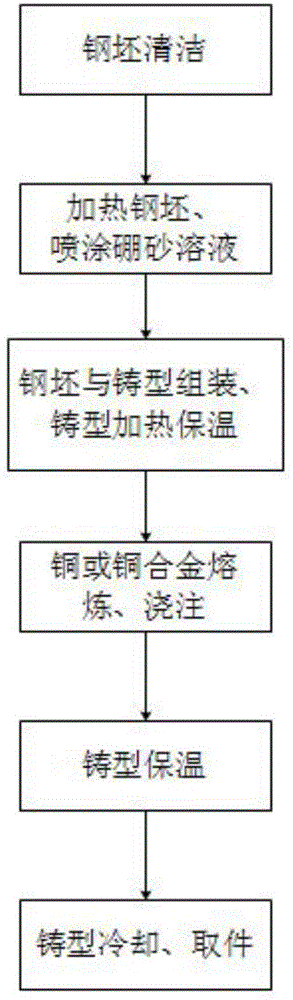

Copper-steel bimetal casting improved technology

The invention provides a copper-steel bimetal casting improved technology. Copper or copper alloy in a certain thickness is directly cast on a steel base body through a static cast type casting method, and the main technical process comprises the steps of: cleaning a steel billet, heating the steel billet and spraying a borax solution on the heated steel billet, combining the cast, heating and keeping the heat, melting and pouring the copper or copper alloy, performing ultrasonic vibration on the steel billet, and keeping the high temperature of the cast. Through the copper-steel bimetal casting improved technology provided by the invention, the ultrasonic vibration and stirring step is added on the basis of the static embedding process technology, a copper or copper alloy layer in a certain thickness and without segregation can be obtained by casting on steel billets in various types and various sizes, and good metallurgical bonding can be realized between the copper or copper alloy layer of the obtained cast and the steel billet.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Spraying device for building material machining

ActiveCN110653110AAvoid occlusionPlay a limiting effectPretreated surfacesCleaning using toolsConstruction engineeringStructural engineering

The invention discloses a spraying device for building material machining. The spraying device for building material machining comprises a device body, material supplying boxes and treating boxes; connecting plates are arranged at the inner ends of first hydraulic telescopic rods; cleaning rolls are rotatably connected to the inner side walls of first U-shaped frames, second rotation shafts penetrate through the back side walls of the first U-shaped frames, and the second rotation shafts on the left sides are connected with second motors; the treating boxes are arranged on the front side faceand the back side face of the device body and arranged on the left sides of first motors; first fans are arranged on the right sides of the treating boxes and connected with suction pipes; and secondhydraulic telescopic rods are arranged on the upper side wall and the lower side wall of the device body, second U-shaped frames are arranged at the inner ends of the second hydraulic telescopic rods,and flattening rolls are rotatably connected to the inner side walls of the second U-shaped frames. According to the spraying device for building material machining, a coating in the material supplying boxes is sprayed to building plates through spraying pipes at the upper end and the lower end, and the two faces of the building plates can be simultaneously sprayed.

Owner:徐州思达新技术开发有限公司

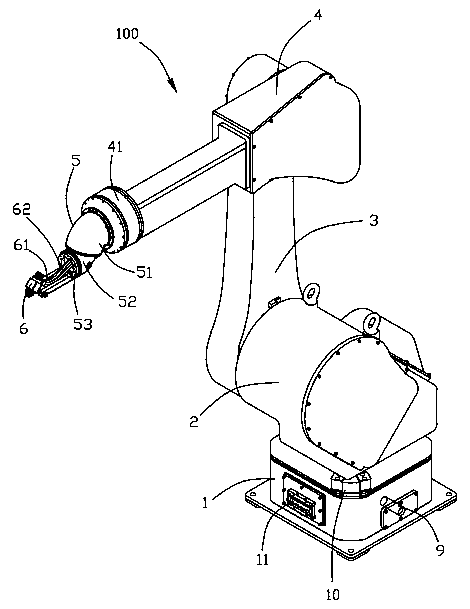

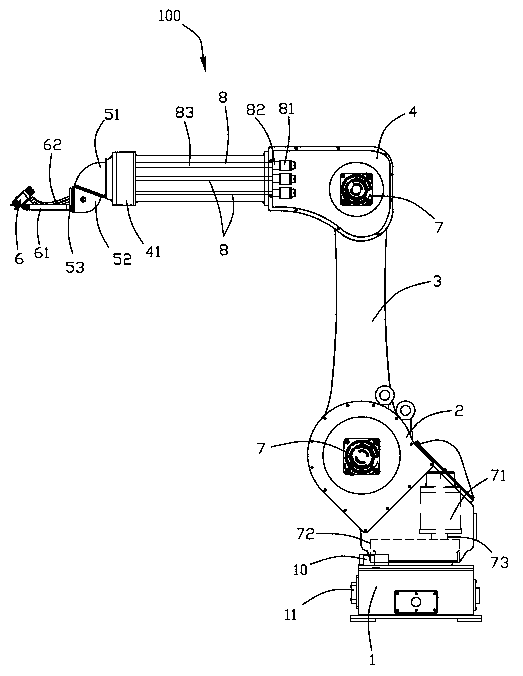

Six-freedom-degree spray coating robot

InactiveCN103538053AHigh transmission precisionImprove precision controlProgramme-controlled manipulatorJointsDrive shaftSpray coating

The invention provides a six-freedom-degree spray coating robot which comprises a base, a waist joint, a big arm joint, a small arm joint, a three-freedom-degree obliquely crossed wrist, a spray gun support, flanges, bearings, a plurality of first drive mechanisms and second drive mechanisms, wherein the waist joint is movably fixed to the base, the big arm joint is movably fixed to the waist joint, the small arm joint is movably fixed to the big arm joint, the three-freedom-degree obliquely crossed base is movably fixed to the small arm joint, the spray gun support is connected to the tail end of the three-freedom-degree obliquely crossed wrist, and the flanges and the bearings are movably connected among all the joints or between the joints and the wrist. The first drive mechanisms are used for driving the waist joint, the big arm joint and the small arm joint to work, and the second drive mechanisms are used for driving the three-freedom-degree obliquely crossed wrist to work. Each first drive mechanism comprises a first servo motor and an RV speed reducer. Each second drive mechanism comprises a second servo motor, a planetary reducer, a hollow transmission shaft and a gear pair, wherein the planetary reducer is connected with the second servo motor, the hollow transmission shaft is connected with the planetary reducer in a matched mode, and the gear pair is arranged in the three-freedom-degree obliquely crossed wrist and connected with the hollow transmission shaft.

Owner:HUAHENG WELDING

Copper and steel bimetallic casting application technology

The invention provides a copper and steel bimetallic casting application technology. Copper or copper alloy with certain thickness is directly cast on a steel base body by a static casting mold casting method. The technology mainly comprises the following steps of cleaning a steel billet, heating the steel billet, spraying a borax solution, combining a casting mold, heating and insulating heat, melting and casting the copper or the copper alloy, and insulating the heat of the casting mold at high temperature. The copper and steel bimetallic casting application technology has the advantages that a copper or copper alloy layer with certain thickness and without segregation can be cast on various shapes and various sizes of steel billets, and the good metallurgical combination between the copper or copper alloy layer of a casting and the steel billets is realized.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

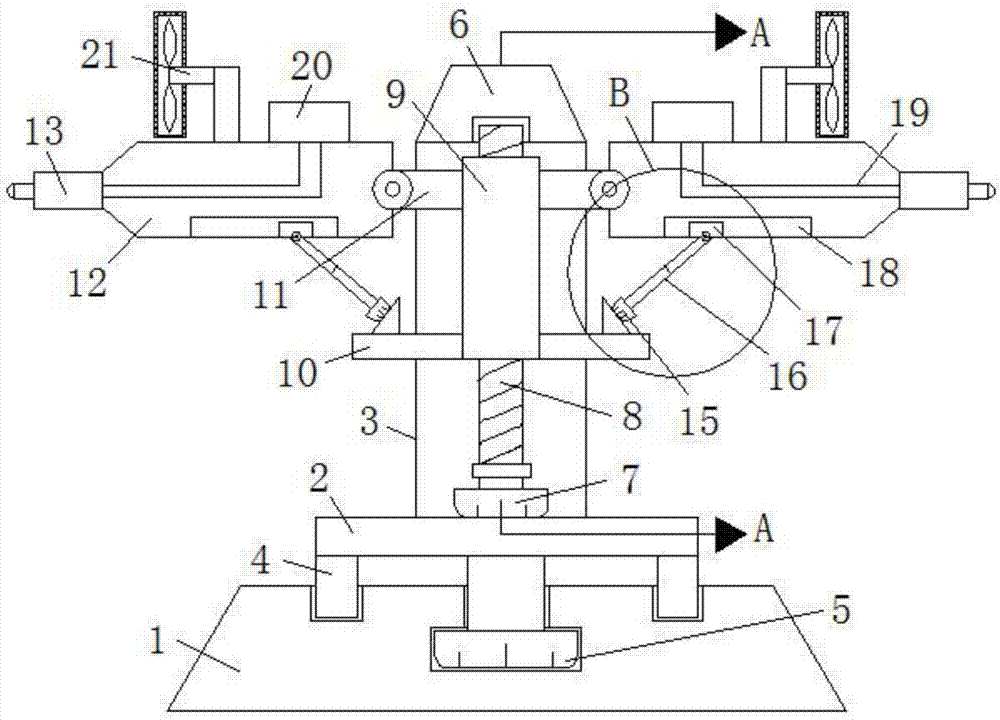

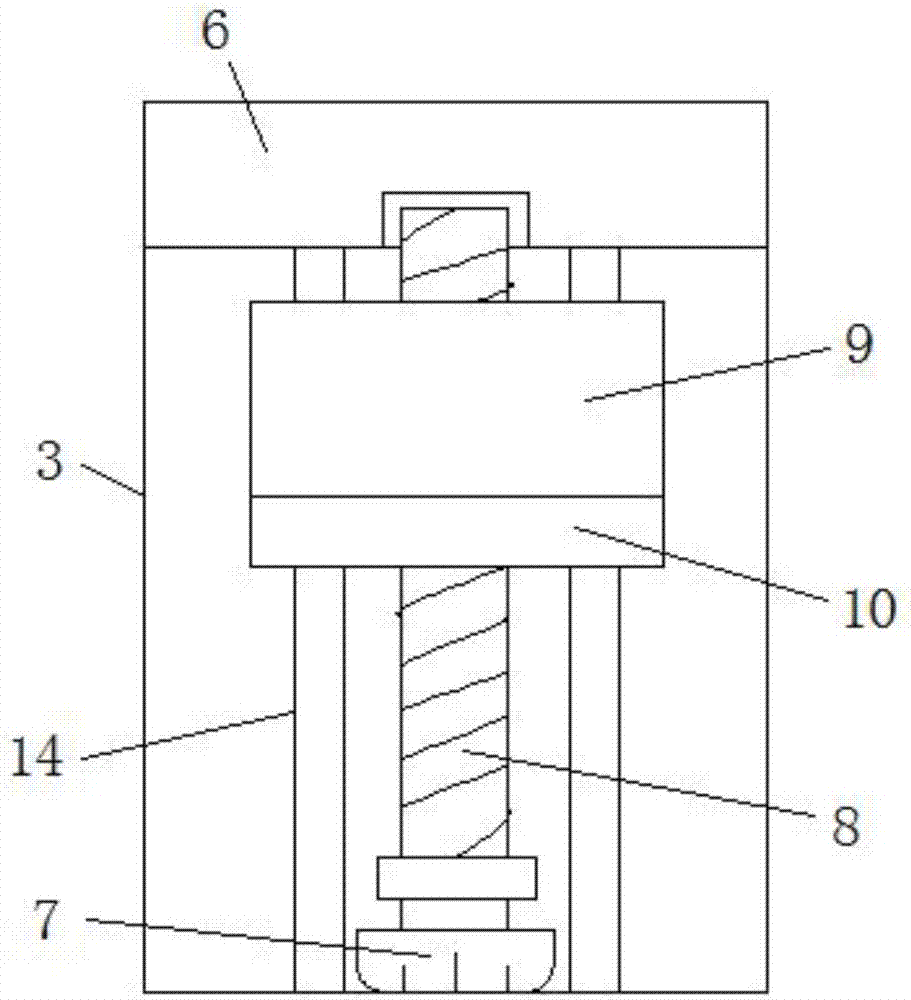

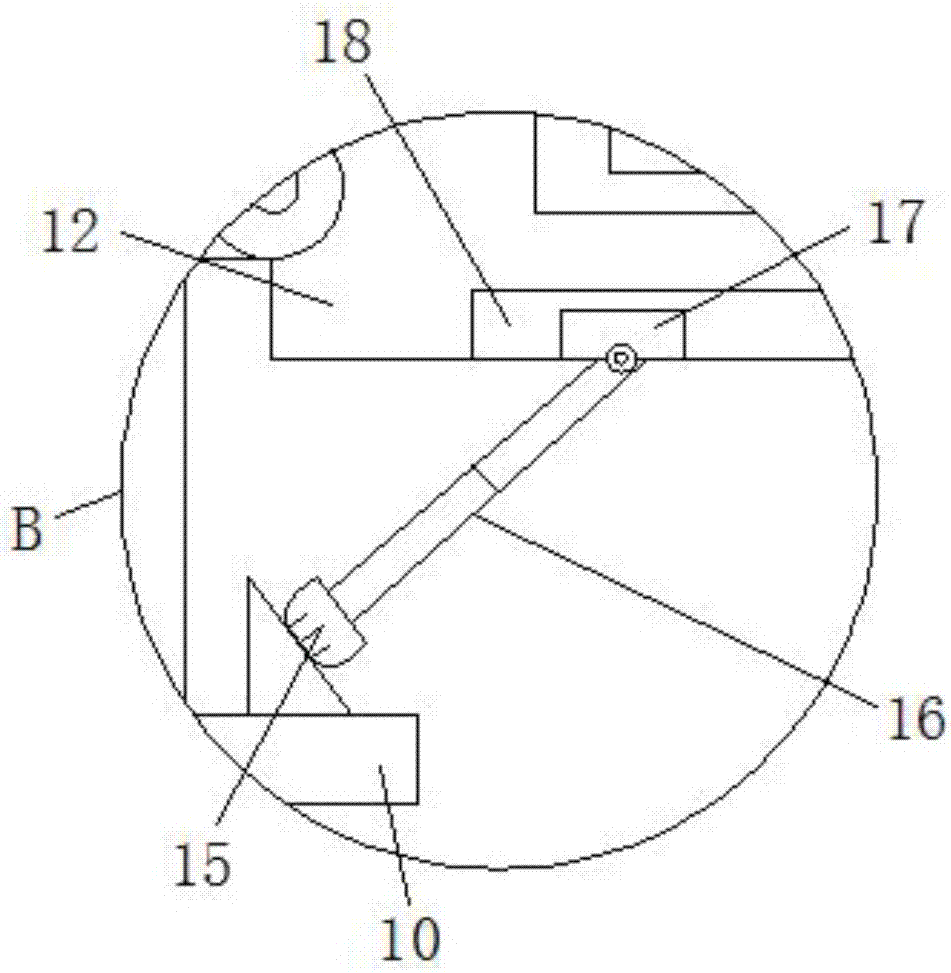

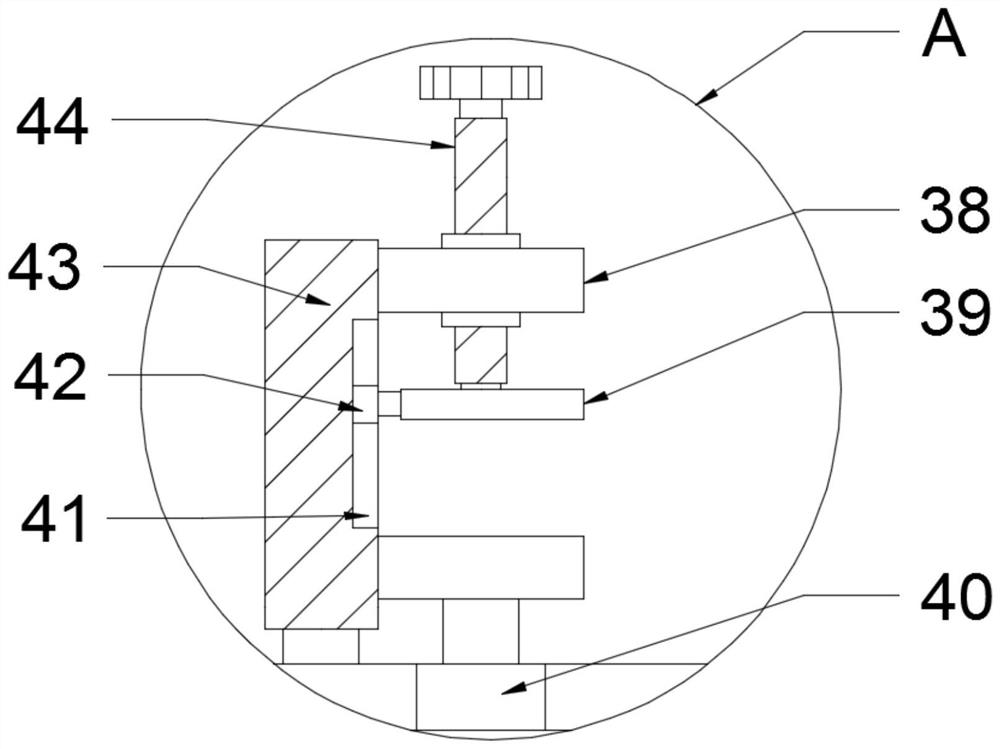

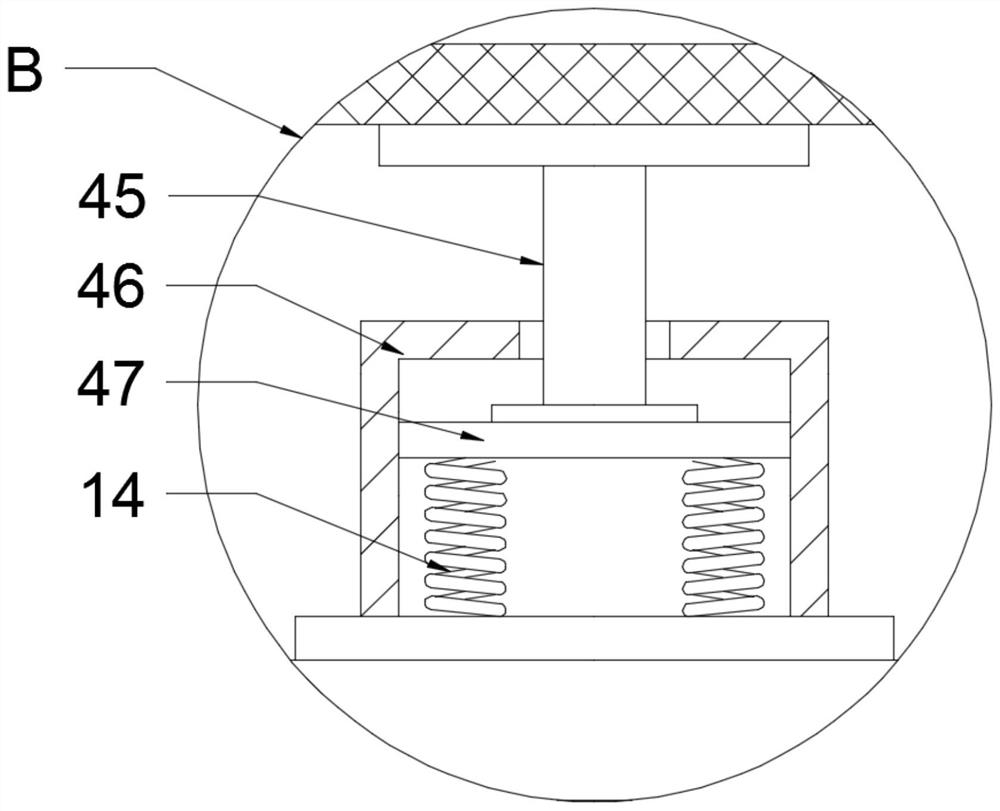

Pulse electrostatic spraying machine

InactiveCN107930878AImprove spray qualityMake sure it's not flatLiquid spraying plantsLiquid supply arrangementsRotary stageEngineering

The invention discloses a pulse electrostatic spraying machine. The pulse electrostatic spraying machine comprises a base, a closed box body and a workpiece rotating table, wherein the closed box bodyand the base are fixedly connected to form a closed space, the workpiece rotating table contained in the closed box body is fixedly connected with the base, and a workpiece thimble device is arrangedright above the workpiece rotating table; a transverse driving mechanism and a longitudinal driving mechanism are arranged in the closed box body, and the longitudinal driving mechanism moves along with the transverse driving mechanism; a spray gun is arranged on the longitudinal driving mechanism, the spray gun communicates with a powder supply device outside the closed box body through a powderpipe, and the spray gun further communicates with a pulse electrostatic generator outside the closed box body through an electrostatic pipe; a rubber pipe collecting wheel is further arranged on theouter wall of the closed box body, and the powder pipe and the electrostatic pipe are wound around the rubber pipe collecting wheel; and the top of the closed box body is also provided with a dust recovery device. The spraying machine is high in workpiece spraying quality, environment-friendly and safe.

Owner:TIANCHANG JINLING ELECTRONICS

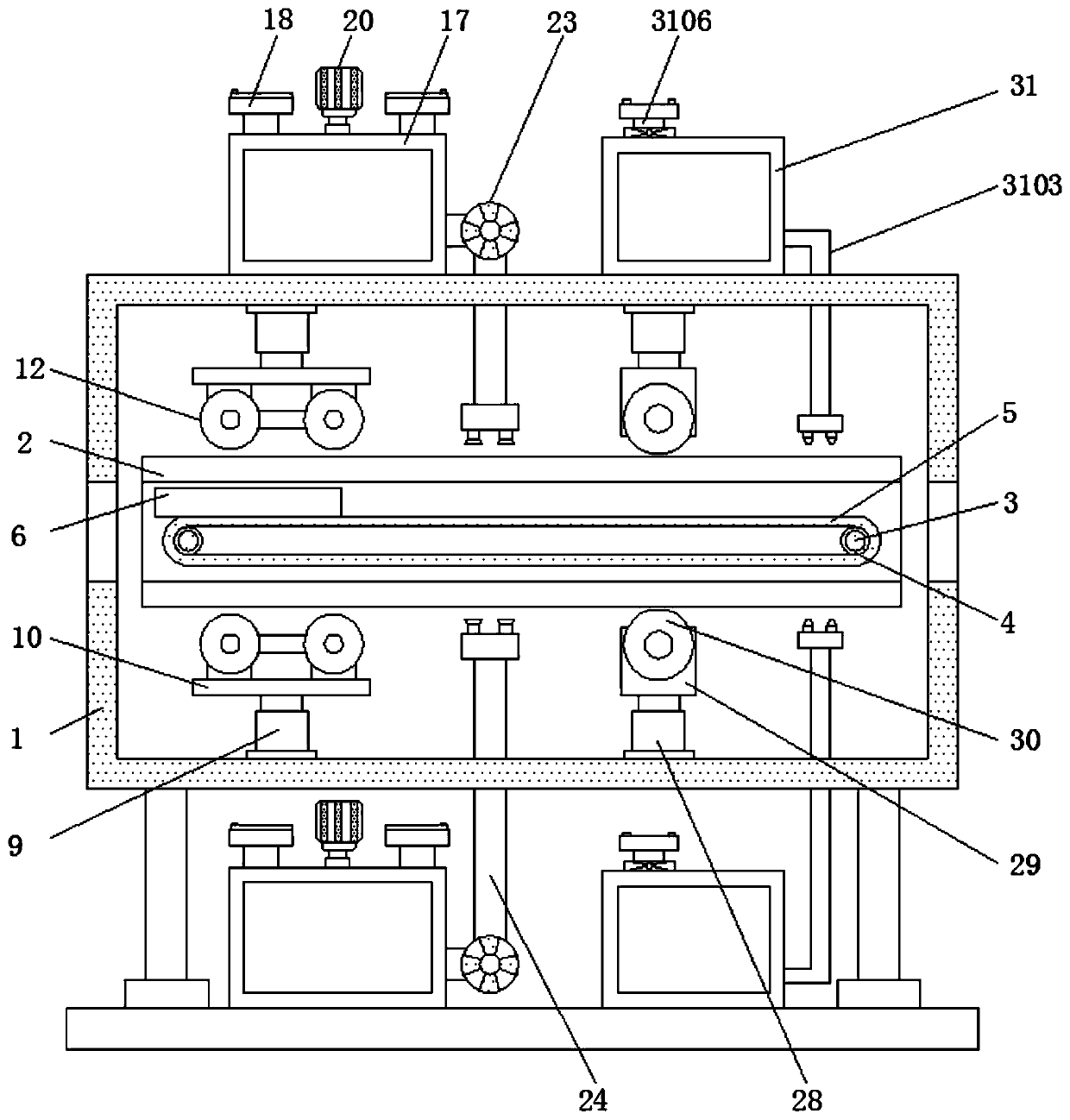

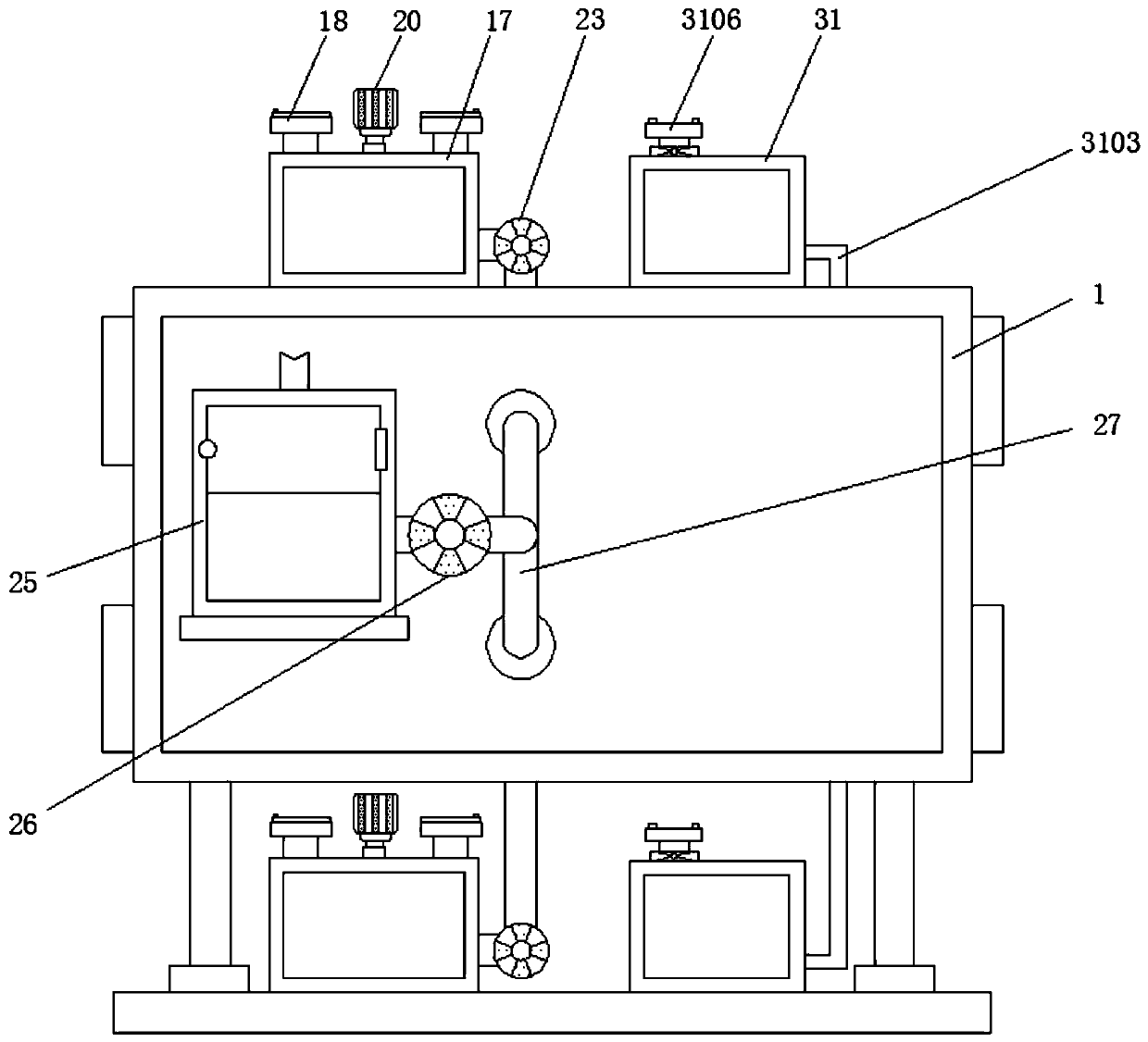

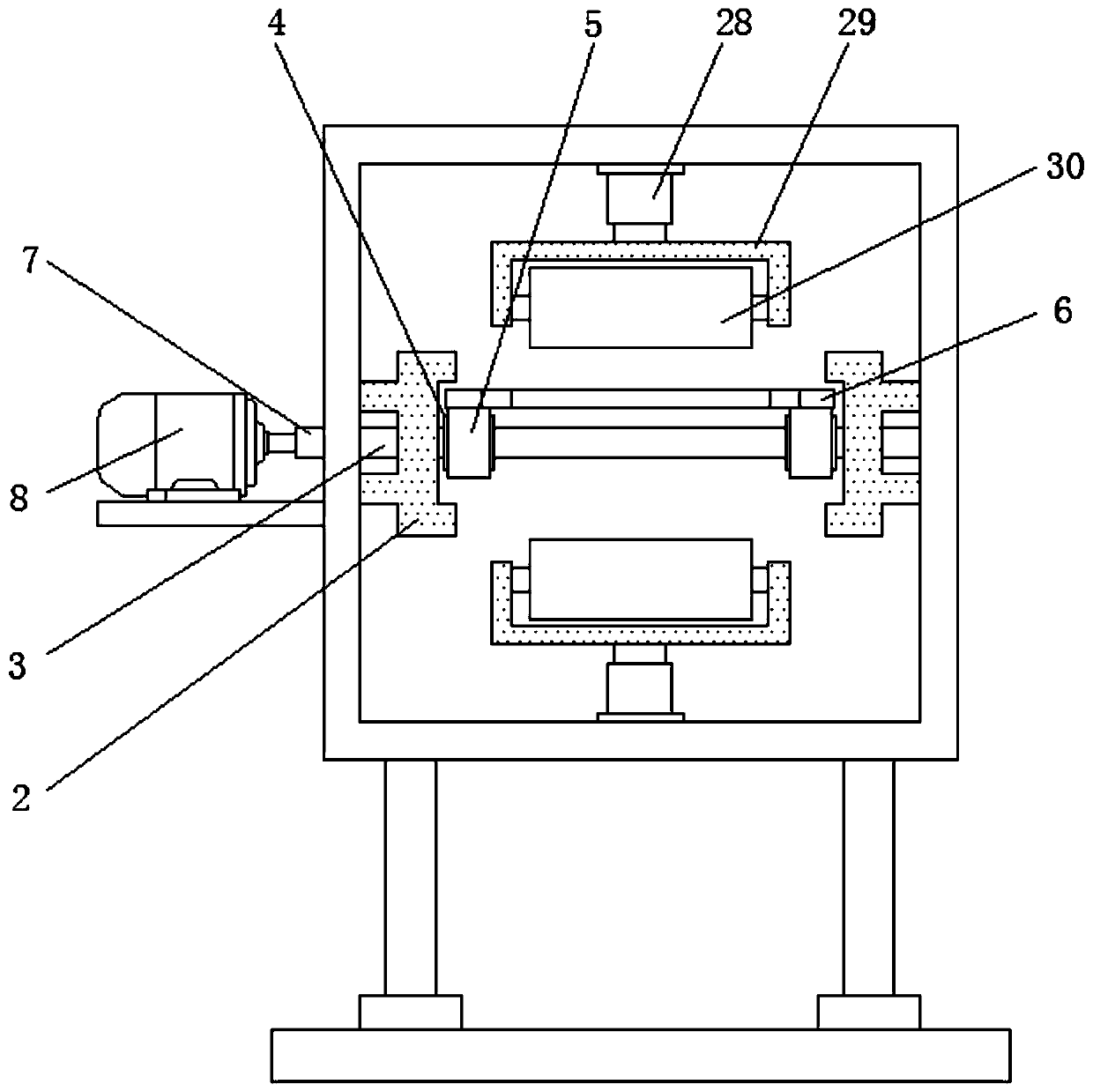

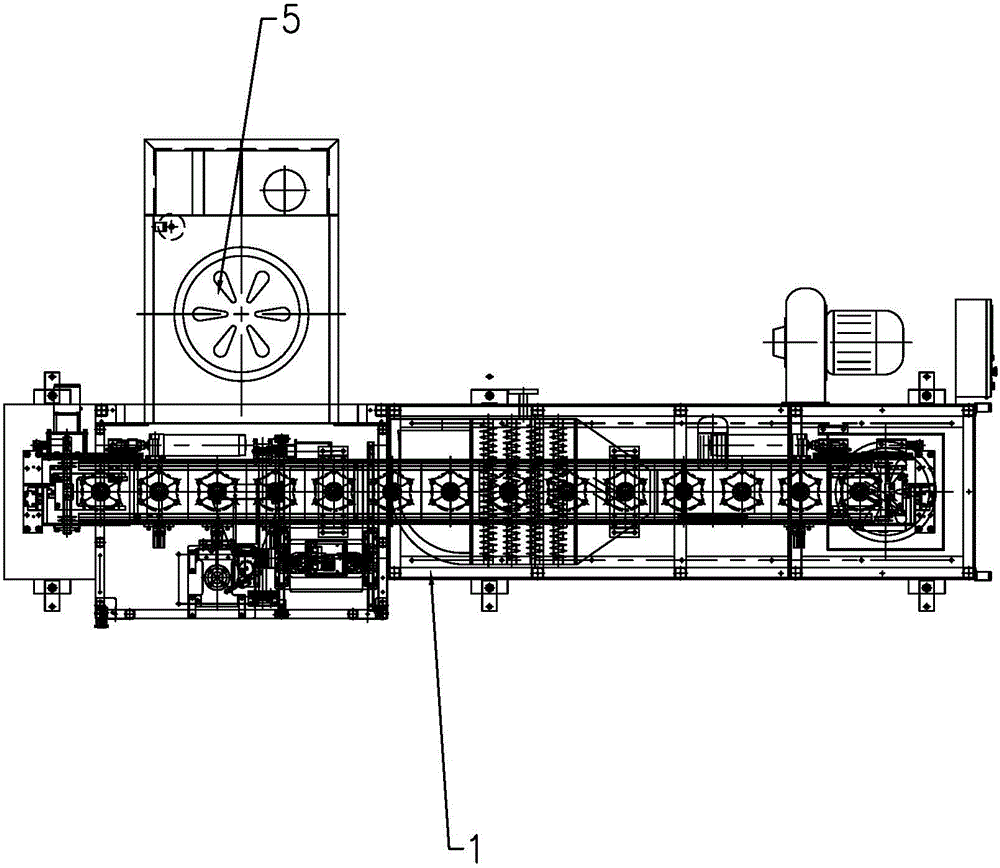

Double-layer conveying coating machine

ActiveCN104588236AImprove spray qualityImprove absorption rateLiquid surface applicatorsCoatingsVertical motionAbsorption rate

The invention relates to a coating machine, in particular to a double-layer conveying coating machine, and belongs to the technical field of coating equipment. The double-layer conveying coating machine comprises a machine frame, wherein a pneumatic material pushing component is arranged at the upper part of the machine frame; a preheating baking channel is arranged at the right part of a sliding rail, and a spraying station is arranged at the left part of the sliding rail; a movable spraying component, a fixed spraying component and a self-rotating mechanism are arranged on the sliding rail in sequence from top to bottom; the fixed spraying component is used for spraying a workpiece, the movably spraying component simultaneously drives a spray gun to realize horizontal movement, vertical movement and swinging, and the self-rotating mechanism drives the workpiece to carry out self-rotation when the workpiece is sprayed. The sprayed workpiece can realize self-rotation so as to realize uniform coating everywhere, and the fixed spraying component and the movable spraying component are used for spraying the workpiece simultaneously, so that the workpiece can receive spray when rotating at the center and the outer edge of a circle, and the spraying quality is improved. The sprayed workpiece is transferred to a lower layer by a lifting component, and is dried by a drying device, so that the absorption rate of the spray is improved, the drying speed is quickened, and the production efficiency is improved.

Owner:WUXI HUANENG SURFACE TREATMENT

Spraying type industrial robot

InactiveCN107321534AEasy to sprayThe turntable turns smoothlySpraying apparatusPretreated surfacesCouplingEngineering

The invention discloses a spraying type industrial robot. The spraying type industrial robot comprises a base; annular clamping blocks are arranged on the base through annular clamping grooves, a rotary table is fixedly connected to the annular clamping blocks, the center of the bottom of the rotary table is connected with a first driving motor through a first rotary shaft, the first driving motor is fixed in an inner cavity of the base, a fixing frame is fixedly connected to the rotary table, a second driving motor is arranged at the bottom of the fixing frame, the second driving motor is connected with a coupler through a second rotary shaft, a threaded rod is arranged at the end, far away from the second rotary shaft, of the couple, the external of the threaded rod is screwed with a movable part, and connecting rods are symmetrically and fixedly connected to the two sides of the outer wall of the movable part; a mechanical arm is rotationally connected with the end, far away from the movable part, of each connecting rod; a spraying gun is arranged on the end, away from the corresponding connecting rod, of each mechanical arm, the end portion of each spraying gun communicates with a spraying pipeline, each spraying pipeline penetrates through the inner wall of the corresponding mechanical arm and extends outwards to communicate with a spraying box, fixing plates are symmetrically arranged on the two sides of the outer wall at the lower end of the movable part, an inclined block is fixedly connected to each fixing plate, a third driving motor is arranged on the outer side of each inclined block, each third driving motor is rotationally connected with a sliding block through a telescopic rod, and the lower side of the outer wall of each mechanical arm is provided with a sliding groove corresponding to the corresponding sliding block.

Owner:SUZHOU INST OF INDAL TECH

Advertising board fixing plate spraying device

InactiveCN112275490AExpand the spraying rangeAvoid damageDirt cleaningLiquid spraying apparatusReciprocating motionElectric machine

The invention discloses an advertising board fixing plate spraying device, and relates to the technical field of advertising equipment. The advertising board fixing plate spraying device comprises a spraying box and an adjusting box, a screw rod is arranged in the adjusting box, a nut is arranged on the surface of the screw rod, a driving motor is arranged on the left side wall of the spraying boxand connected with a rotating shaft through a belt, and the rotating shaft is connected with a crankshaft; a spraying liquid box is arranged on the upper surface of the top wall of the spraying box,a piston cylinder is arranged at the left side of the spraying liquid box, an air blower is arranged in the spraying box, a dust collector is installed at the right side wall of the spraying box, a filter box is arranged below the dust collector, the piston cylinder conveys spraying liquid to a spray head through a liquid inlet pipe and a liquid conveying pipe to spray a metal plate, and the air blower blows away dust on the surface of the metal plate; and the dust collector sucks the dust into the filter box through a dust suction hood and a dust suction pipe to be filtered, and a movable base drives the spray head below to reciprocate in the horizontal direction, so that the spraying range of the metal plate is widened, the spraying efficiency is improved, the spraying quality is higher,and damage to the human body during manual spraying is effectively avoided.

Owner:李桂英

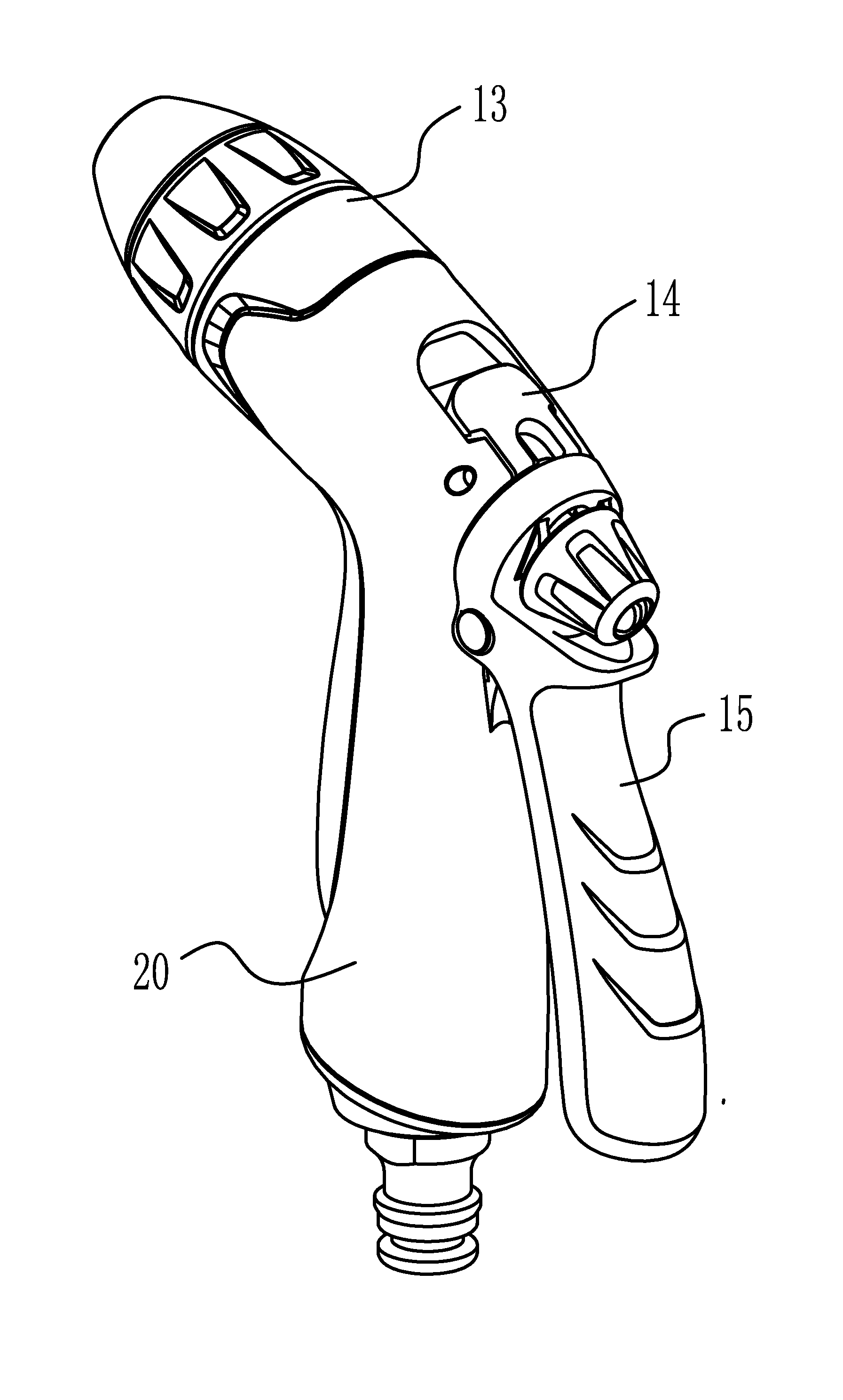

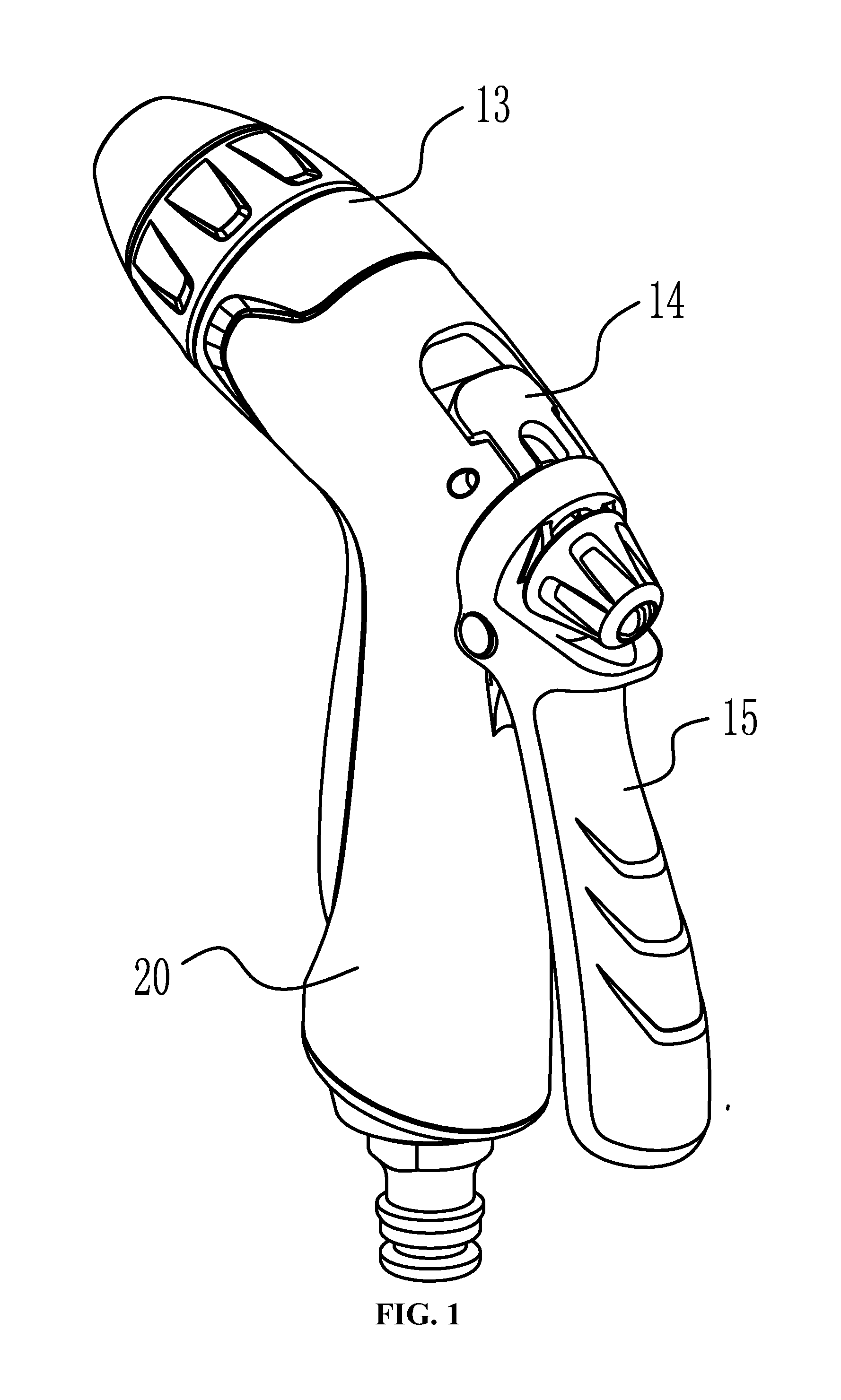

Spray gun

ActiveUS20130193236A1Low costImprove convenienceLiquid spraying apparatusLocking mechanismEngineering

A spray gun, including a gun body, a handle attached to the gun body, a fluid passageway, a handle switch, and a buckle. The fluid passageway is disposed in the gun body and the handle. The handle switch is movably disposed on the handle by a rivet for opening and shutting the fluid passageway. The buckle is movably disposed on the handle via a switch shaft. The spray gun employs the buckle as a locking mechanism that has fewer parts, and therefore costs are reduced and convenience, reliability, and durability improved. The spray gun can be operated with one hand only by swinging it once to open and swinging it again to close. As a result, the performance and quality of the spray gun are improved.

Owner:NINGBO DAYE GARDEN IND

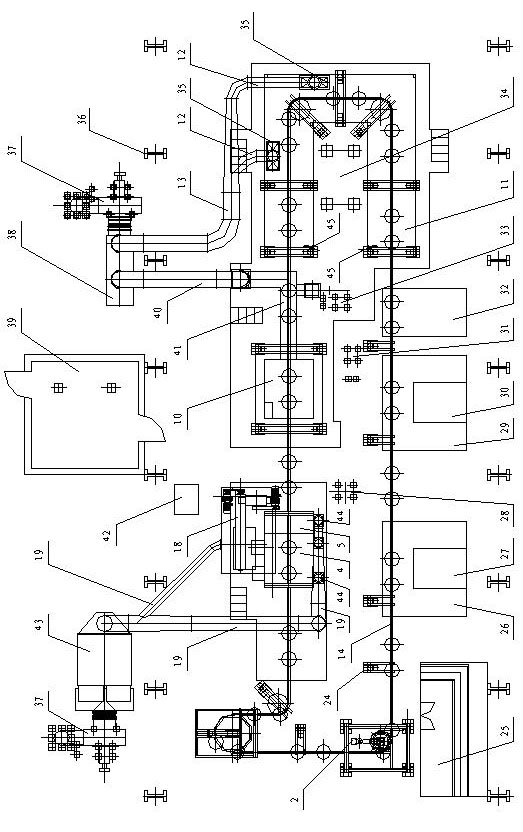

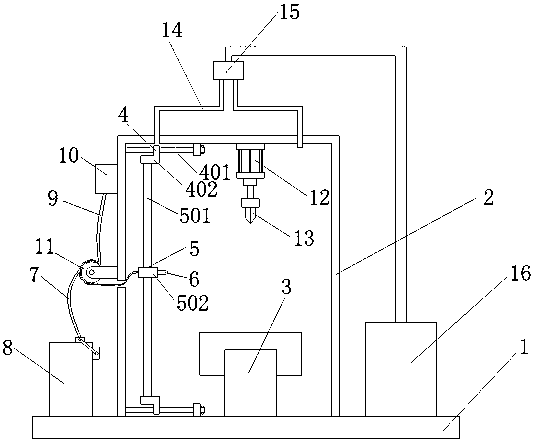

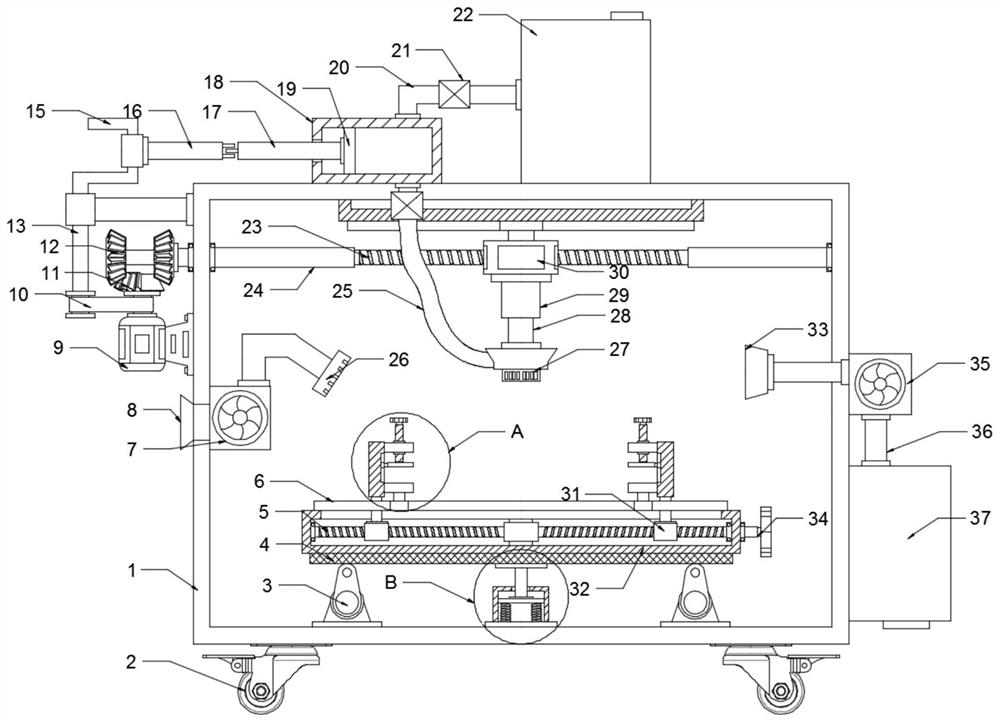

Synchronous spraying and curing processing method for pipelines arranged in parallel

ActiveCN105413978AIncrease profitAvoid vibrationSpraying apparatusPretreated surfacesMedium frequencyMaterials science

The invention discloses a synchronous spraying and curing processing method for pipelines arranged in parallel. The method includes the following steps that A, steel pipes are thrown into an acid pickling pond to be subjected to acid pickling for removing rust; B, the steel pipes subjected to acid pickling are cleanly flushed through clear water and then are dried for standby application; C, the steel pipes obtained in the step B are subjected to medium frequency heating; D, the interiors and the exteriors of the steel pipes are subjected to synchronous plastic coating through an electrostatic spraying method; E, heating and curing are carried out, and the pipelines are moved side by side before being cured; and F, natural cooling is conducted. In the step D, the plastic coating operation is carried out through an electrostatic spraying line, and the electrostatic spraying line comprises a steel pipe conveying device, an external spraying device, an internal spraying device, a powder recovery device and a pipeline side-by-side moving device. The method is simple, using is convenient, and production efficiency can be improved; a spray gun can be prevented from vibrating, powder is uniformly sprayed, and the powder utilization rate is high; the pipelines do not need to be lifted repeatedly and can be moved side by side.

Owner:青岛豪德博尔实业有限公司

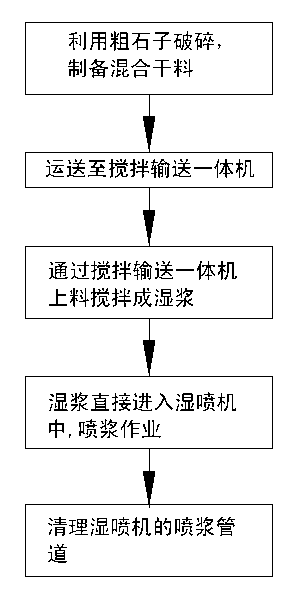

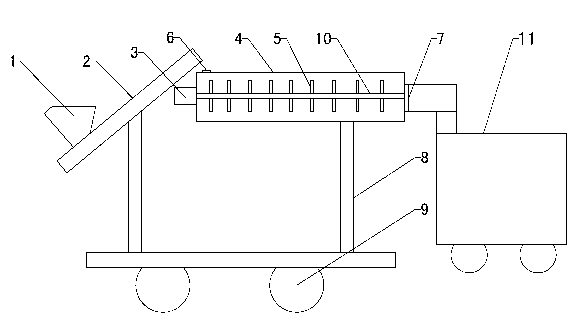

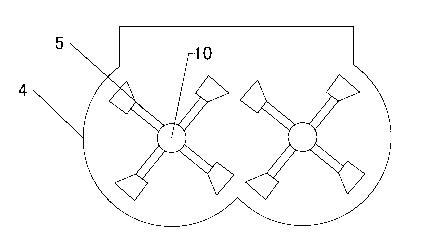

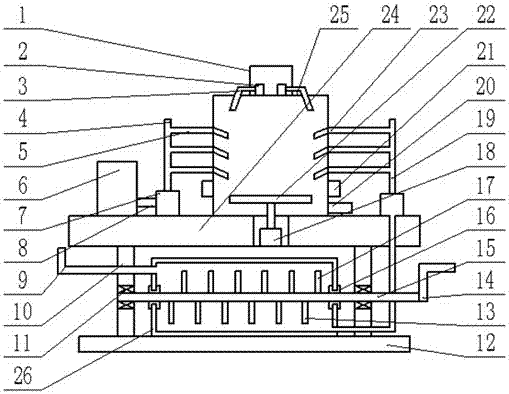

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

Coating equipment capable of heating and drying

InactiveCN106984484AEasy to cleanInstant dryingLiquid surface applicatorsCoatingsAgricultural engineeringCoating

The invention discloses a coating equipment capable of heating and drying, comprising an upper base, a lower base and a spraying box. The lower end of the upper base is provided with a lower base, and a stirring box is arranged between the upper base and the lower base. A stirring shaft is arranged horizontally inside, a plurality of stirring rods are welded on the stirring shaft, a discharge pipe is connected to the right side of the lower end of the stirring box, a spraying box is fixed in the middle of the upper end of the upper base, and a rotating disc is arranged near the bottom end of the spraying box. A plurality of paint nozzles are arranged on the inner side of the left end of the spraying box, and the paint nozzles are connected with the discharge pipe. The inner side of the upper end of the spraying box is provided with a cleaning liquid nozzle. The invention has simple structure and reasonable design, can stir the paint and coating before spraying, ensures uniform spraying, improves spraying quality, and at the same time, the workpiece can be dried during the spraying process, and the subsequent operation is reduced.

Owner:盐城三强线缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com