Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

559results about How to "Increase air velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

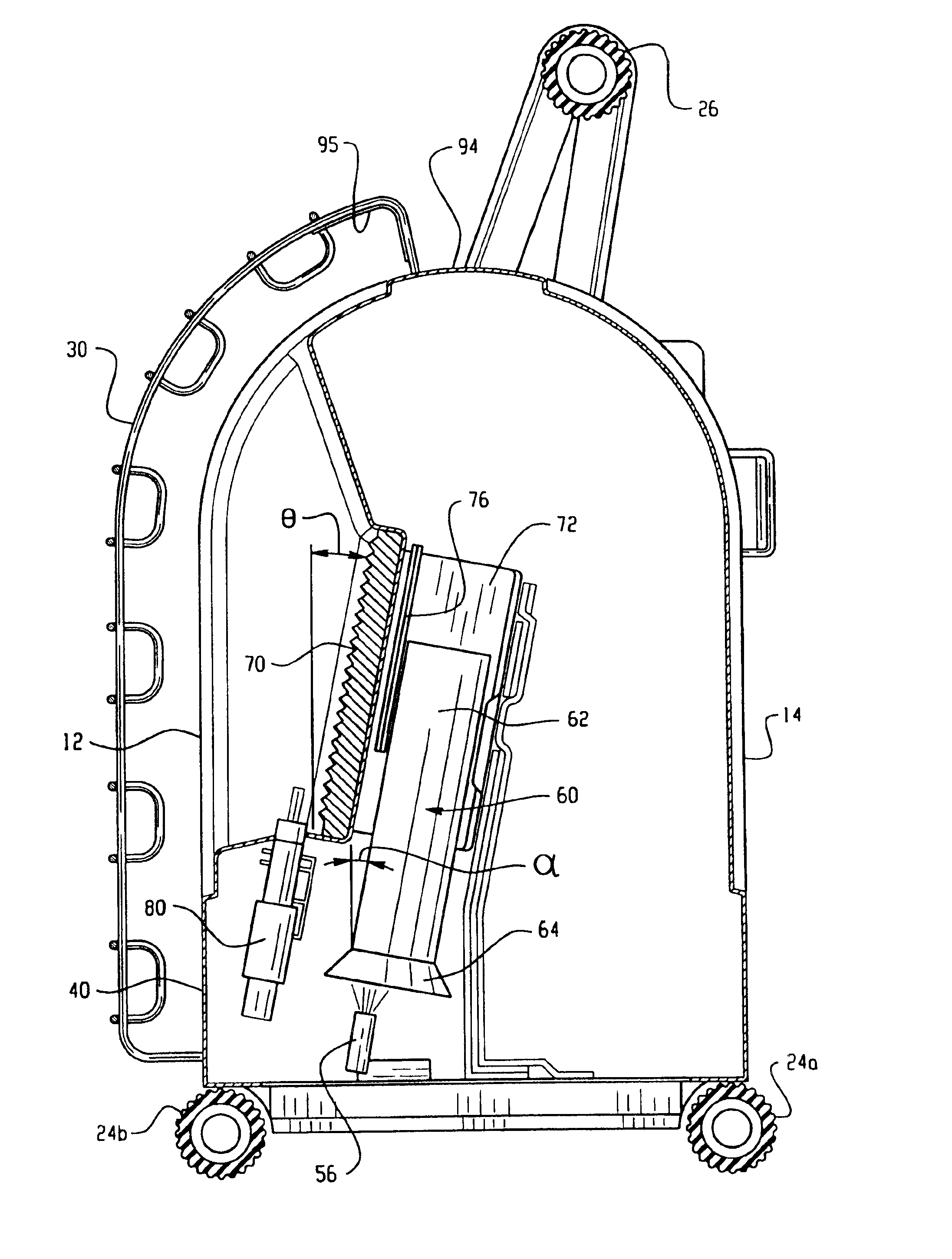

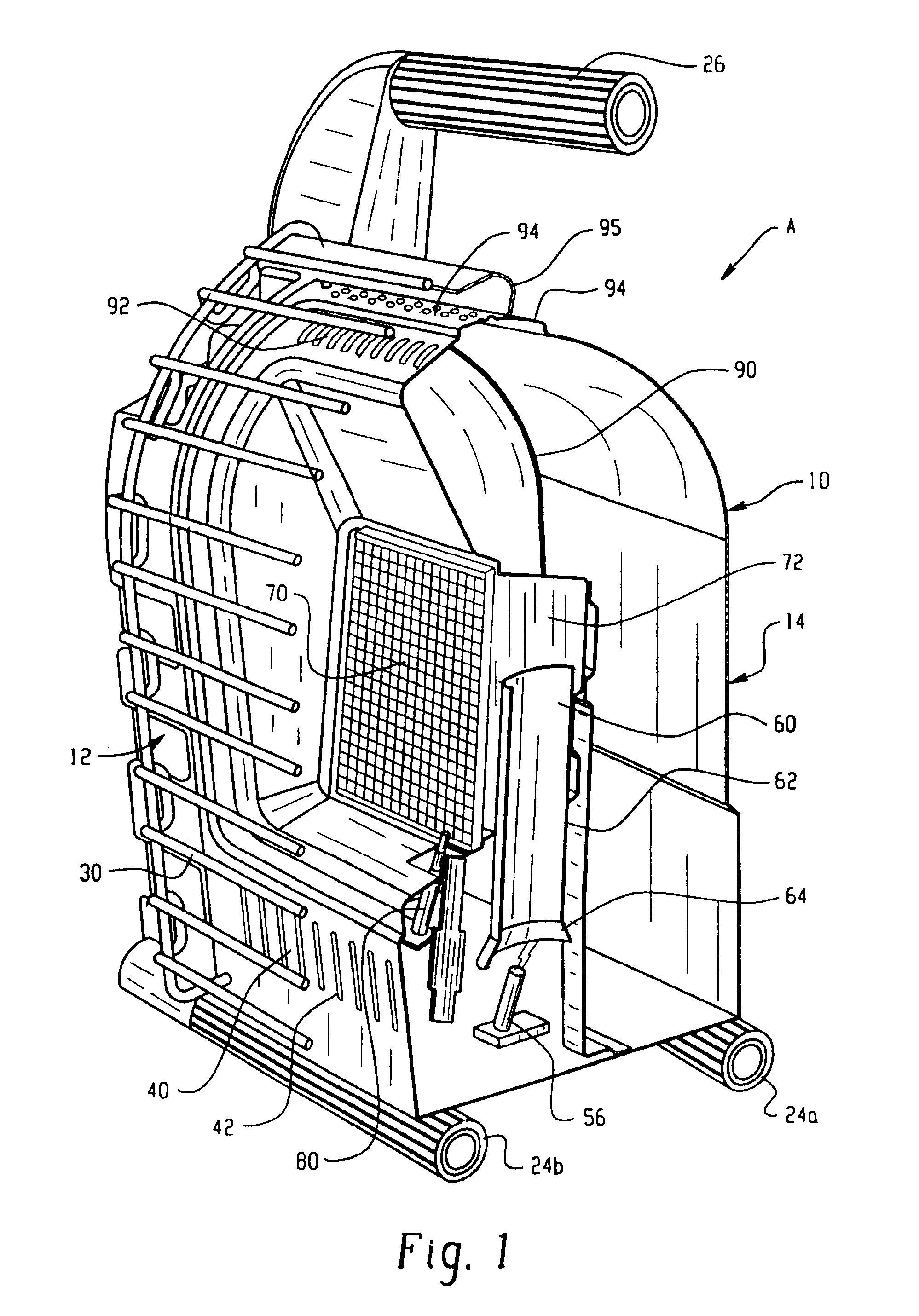

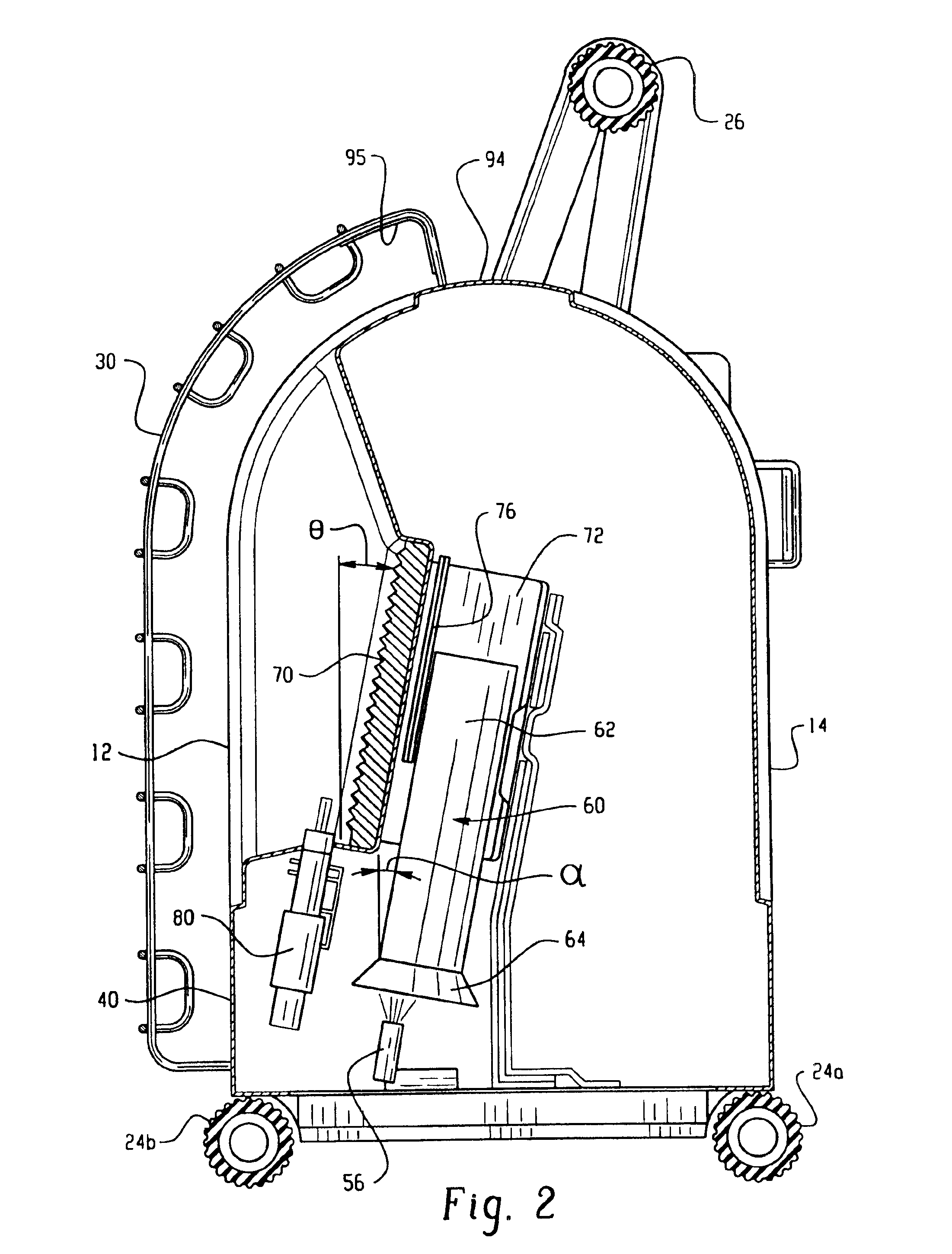

Gas fired portable unvented infrared heater

InactiveUS6884065B2Reduce the temperatureIncrease air velocityMechanical apparatusDomestic stoves or rangesFresh airEngineering

A portable heater adapted for use in a recreational enclosure or temporary work enclosure includes a housing having an air inlet on the lower front face. A gas supply is partially enclosed by the housing which provides propane to the mouth of a burner venturi located within the housing. Air is drawn through the air inlet and also enters the mouth of the burner venturi. The air and gas are mixed thoroughly as they travel upwardly through the burner venturi. A chimney effect increases fresh air flow velocity into the burner venturi and allows the heater to operate at a reduced fuel gas pressure. Upon exiting the burner venturi, the air / gas mixture is to a plenum and radiant surface where combustion takes place. Any conventional means may be provided to ignite the air / gas mixture in order to cause combustion. The combustion products deflect off a deflector, which is cooled on a rear face by air flow through the housing, which decreases the temperature of the combustion products before exiting an outlet. An oxygen depletion system (ODS) shuts off the portable heater when oxygen levels begin to drop and consequently carbon monoxide levels begin to rise.

Owner:ENERCO GROUP

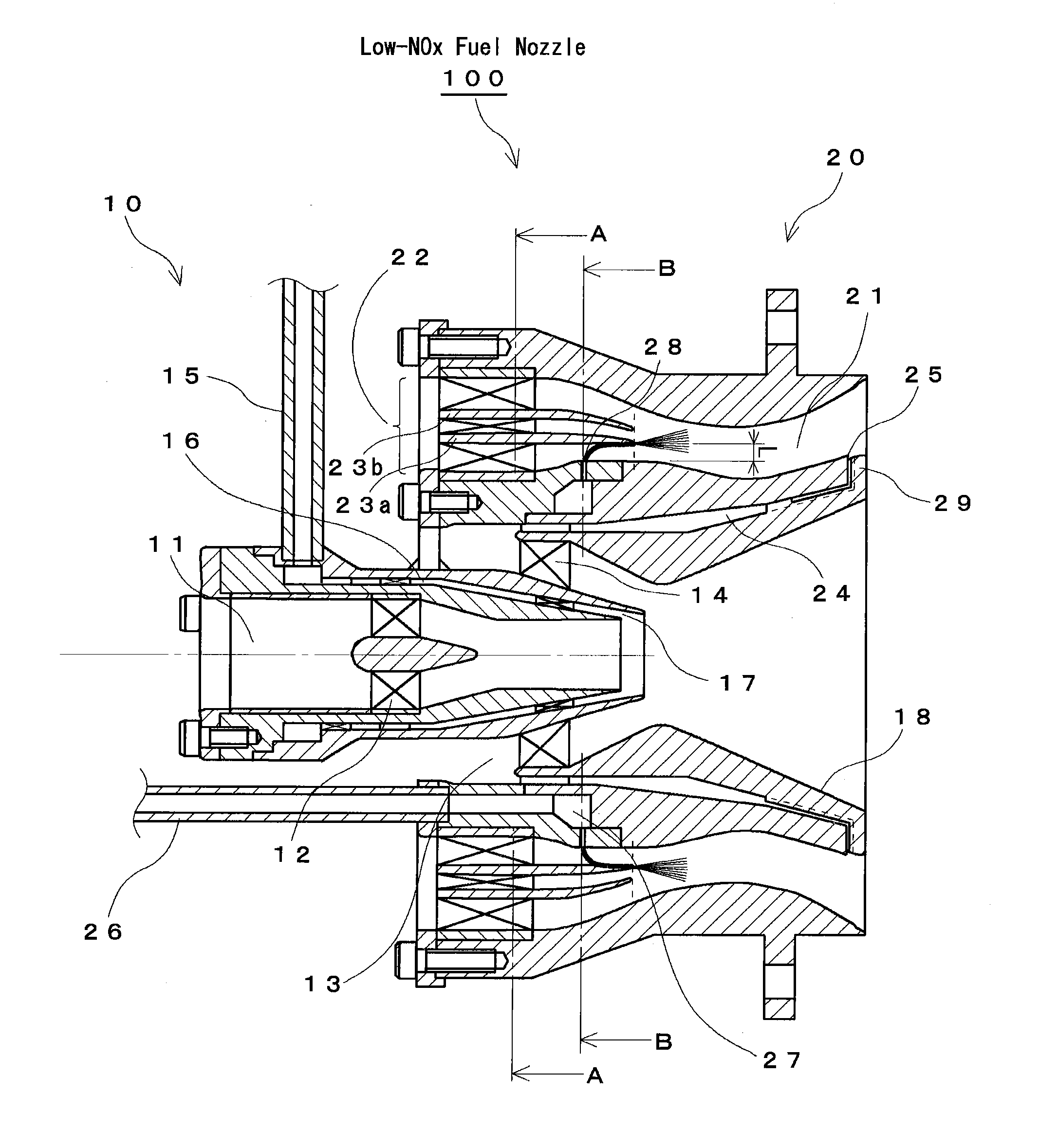

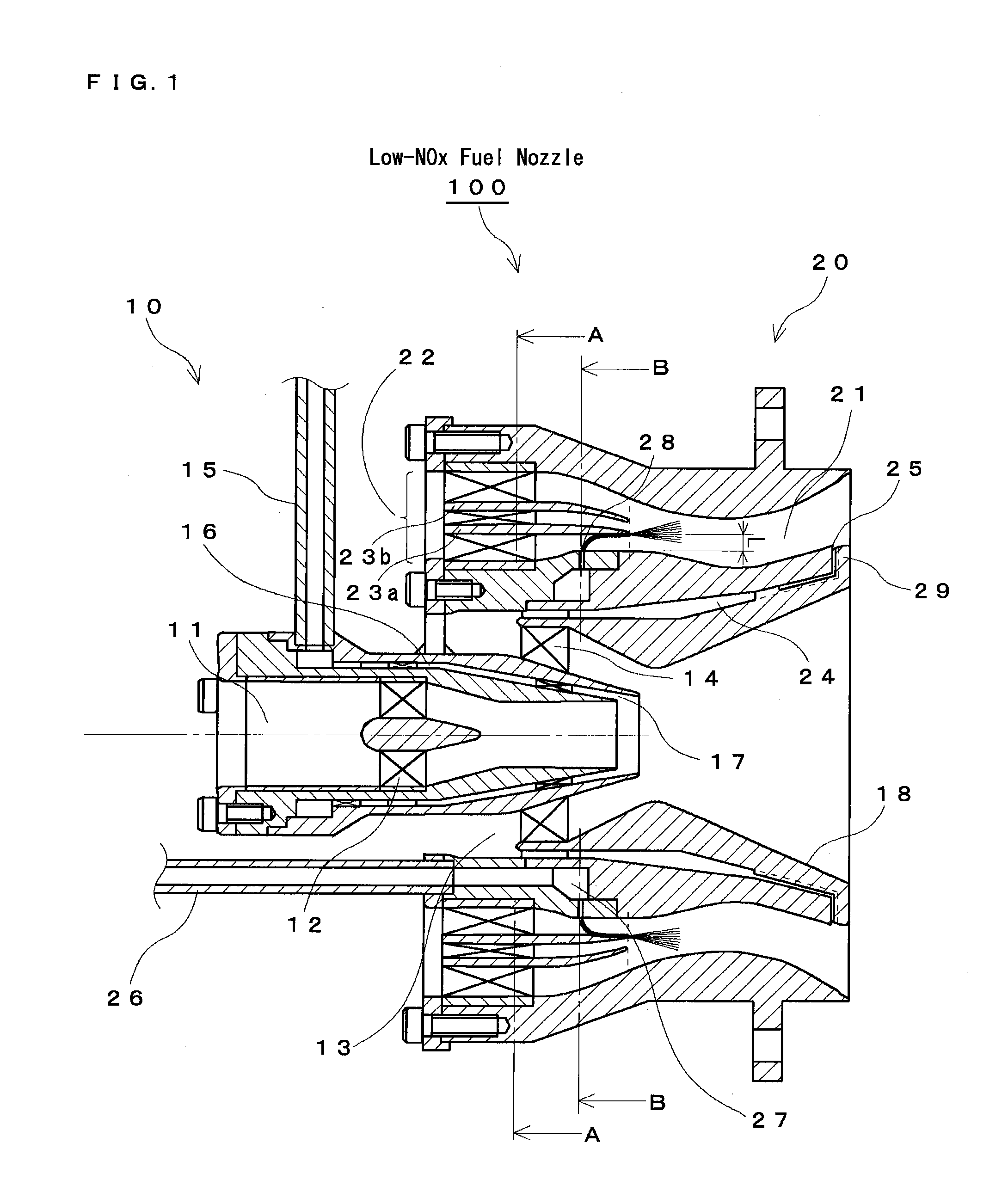

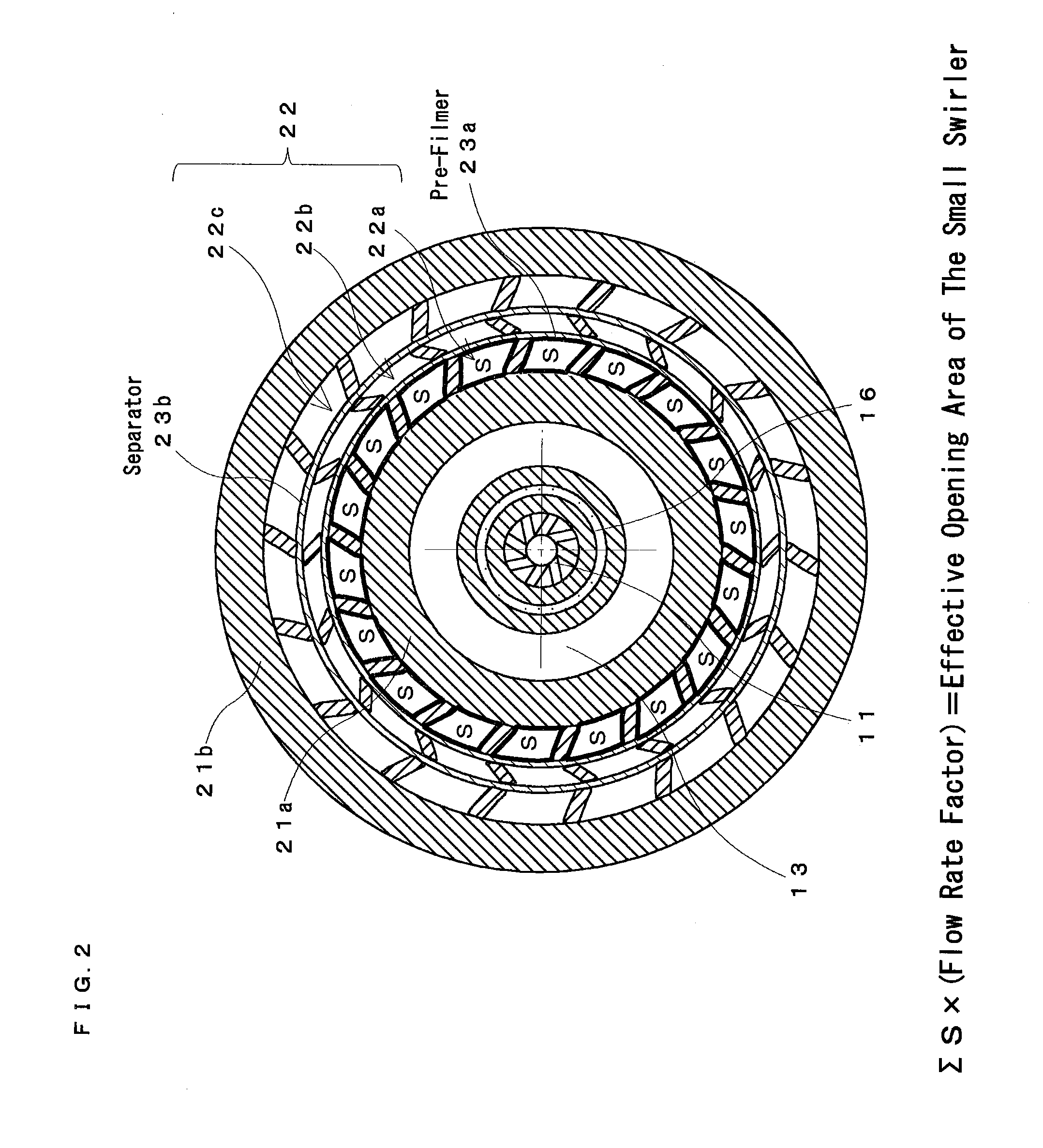

Staging fuel nozzle

ActiveUS20100308135A1Reduce amount of NOx generateHigh degree of atomizationBurnersTurbine/propulsion fuel supply systemsEngineeringFuel injection

A main swirler of a triple annular configuration that is partitioned by a pre-filmer and a separator is installed in an inlet port of a main air flow channel. The vicinity of the inner wall of the main air flow channel provided with a main fuel injection port is bulged radially outward from the innermost surface (innermost surface of a small swirler) of a main swirler. Further, a distance from the main fuel injection port and the pre-filmer is set such that an effective opening area between the pre-filmer and “the inner wall of the main air flow channel provided with the main fuel injection port” is equal to an effective opening area of the small swirler. The swirling directions of the swirlers of the main swirler are “clockwise”-“counter-clockwise”-“clockwise” respectively along the radial outward direction when the swirling direction of the innermost swirler is taken as “clockwise”.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

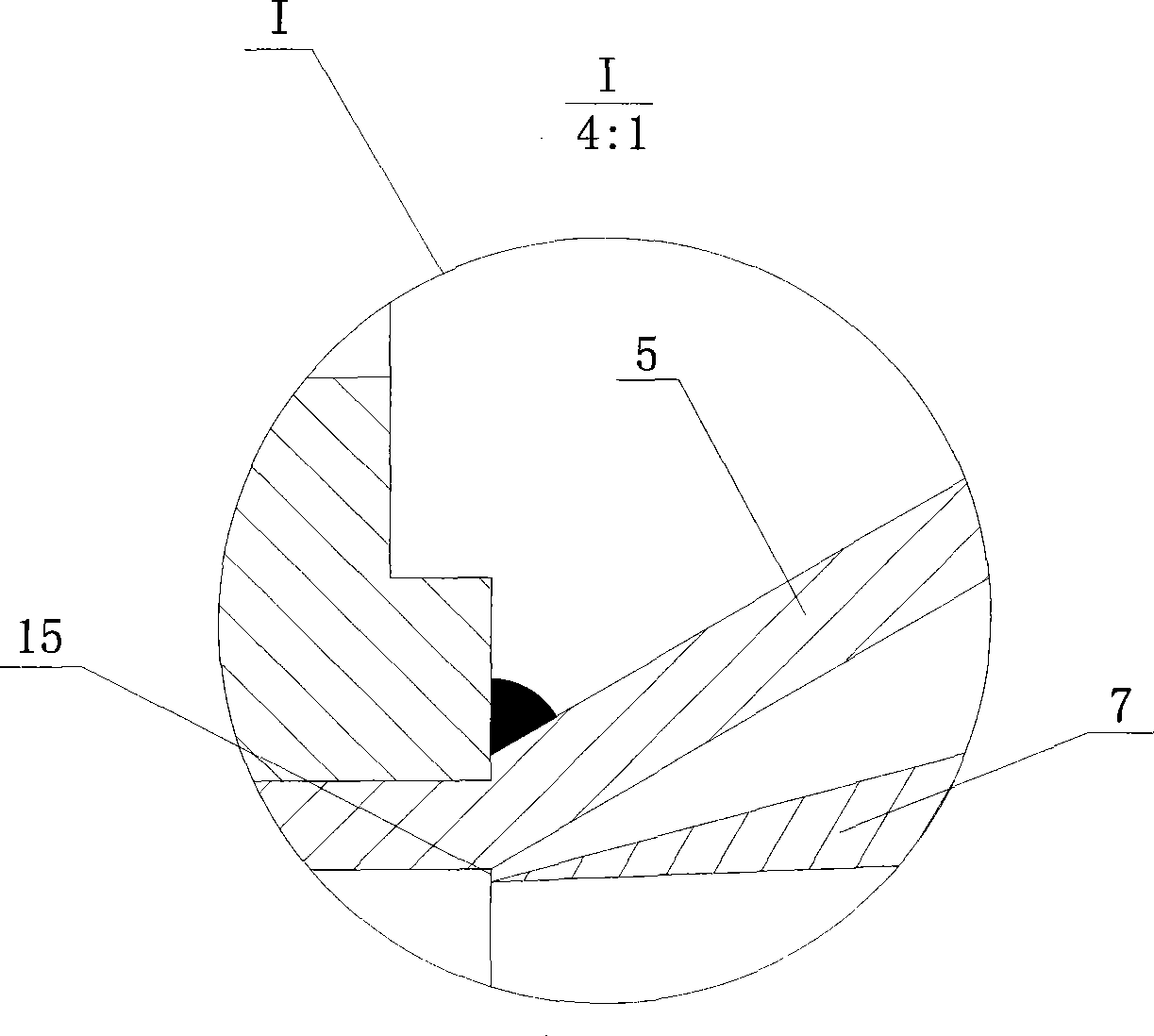

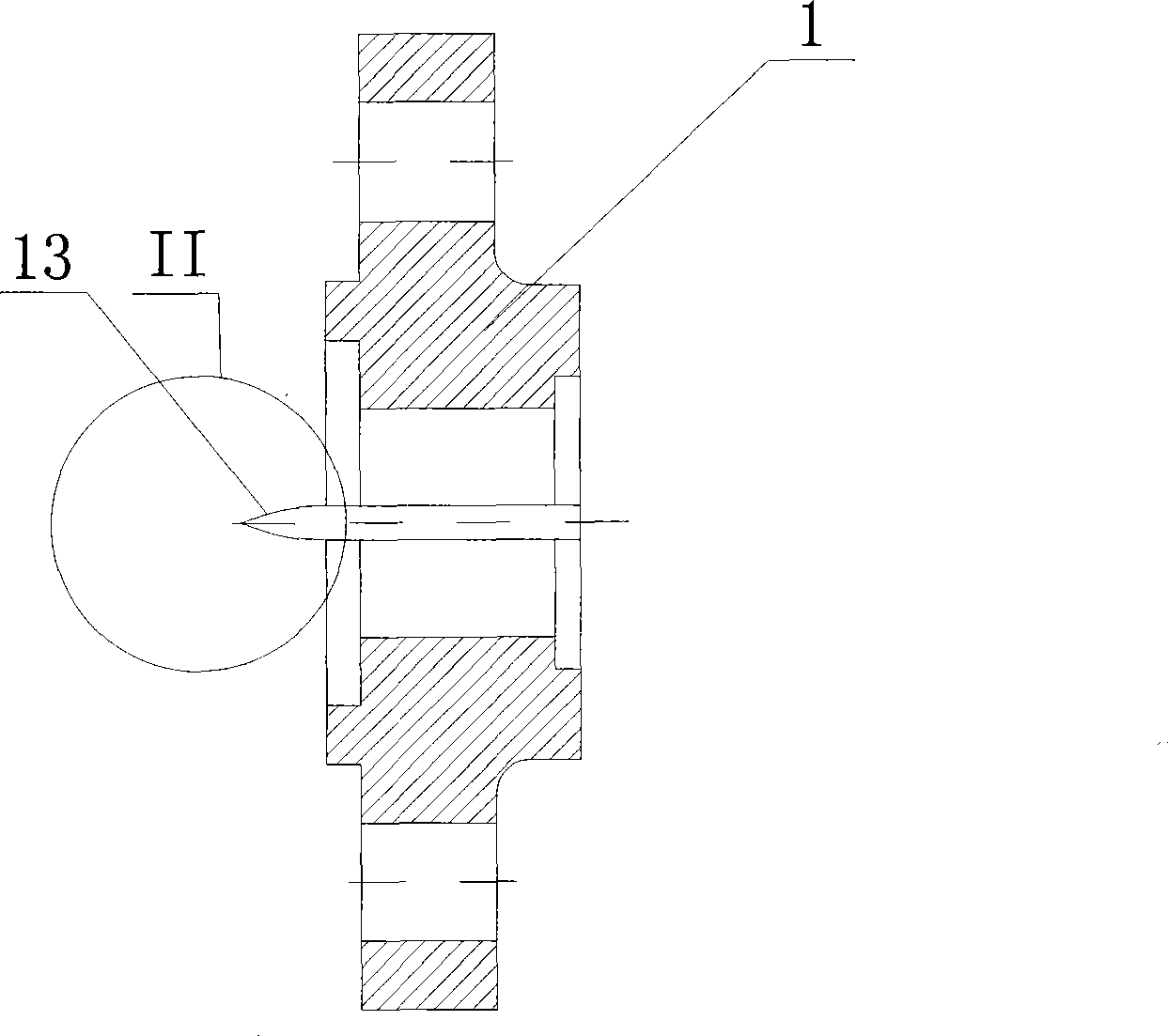

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

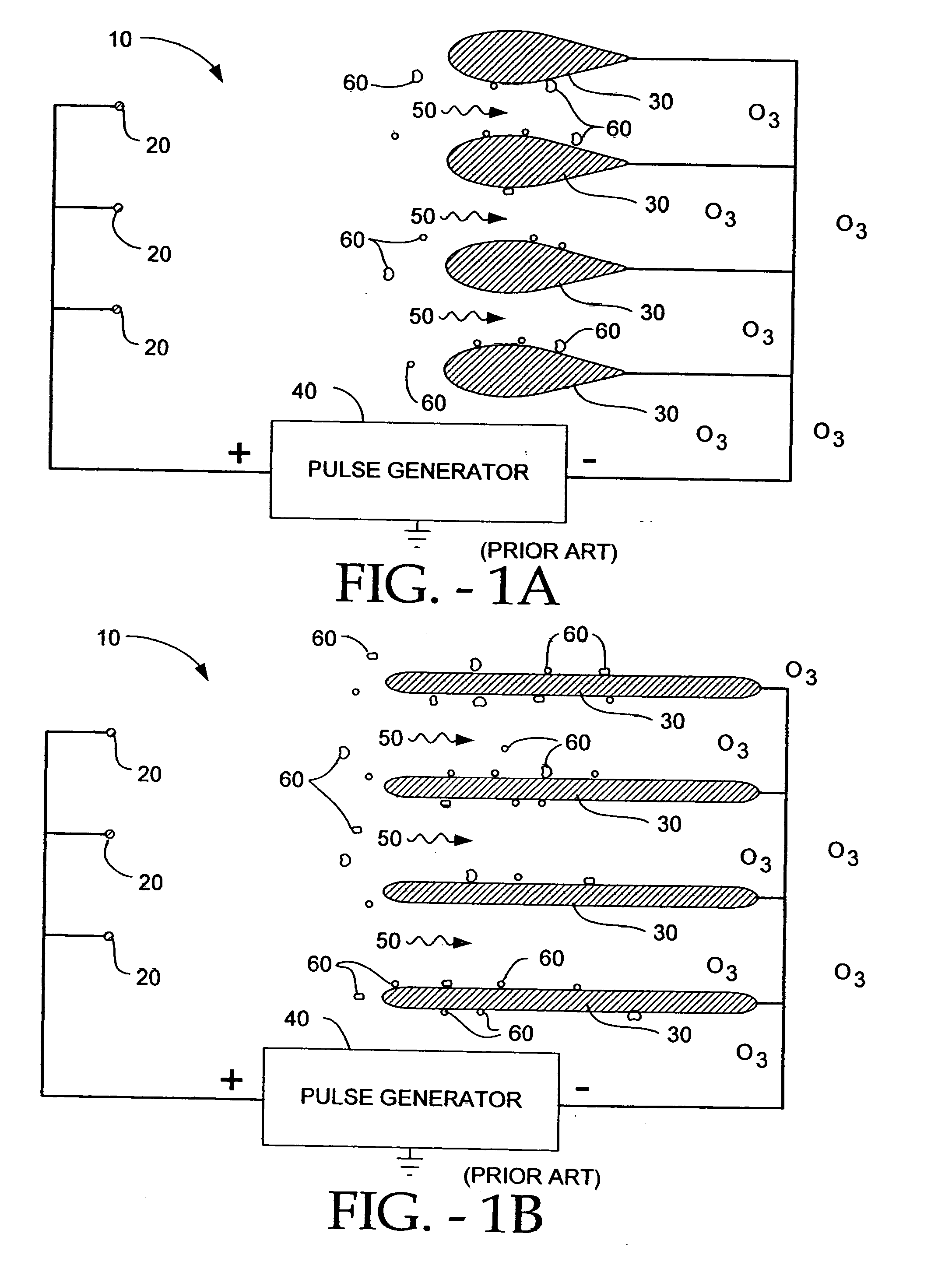

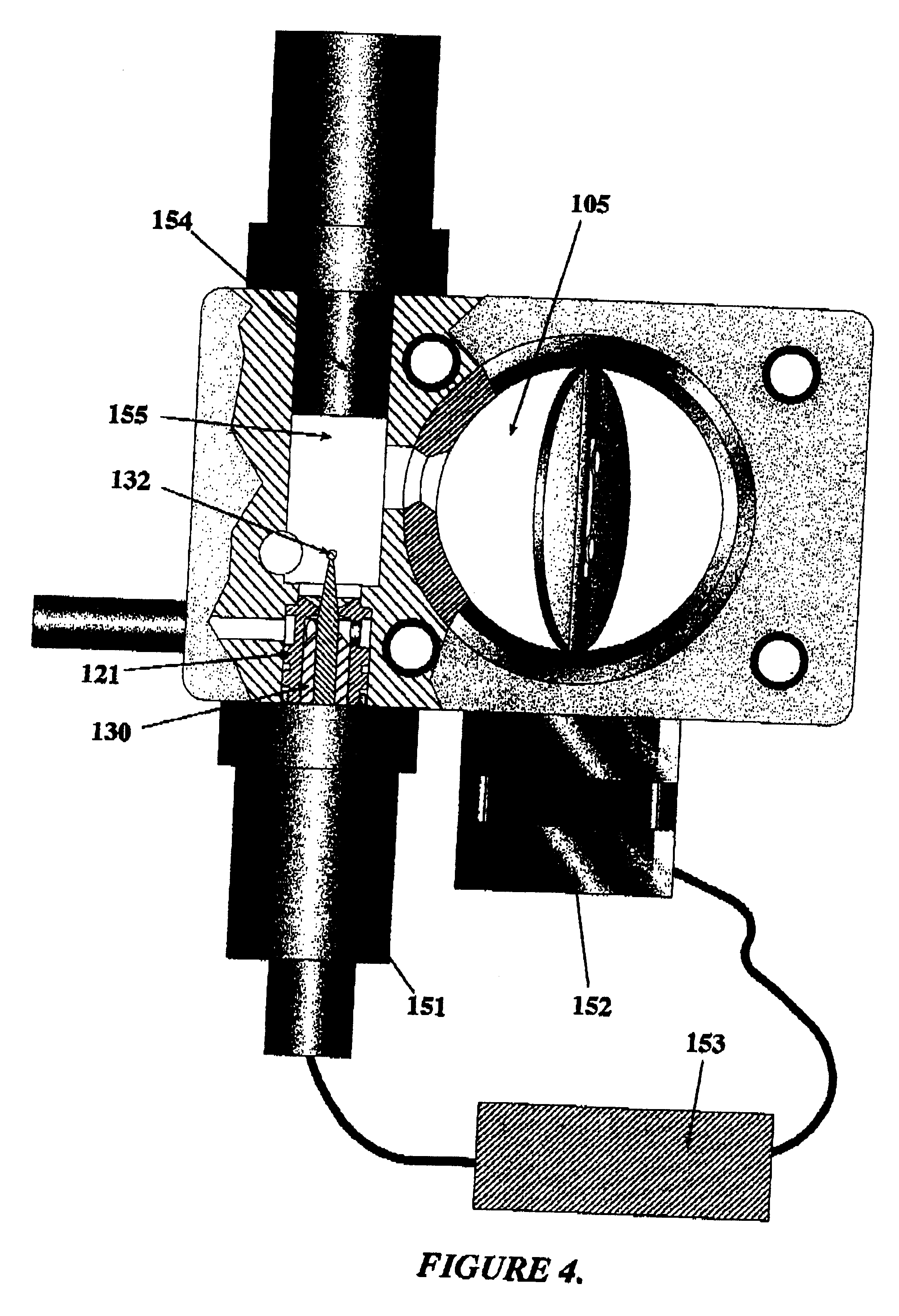

Air conditioner device with trailing electrode

InactiveUS20050000793A1Increase air velocityEasy to collectMechanical apparatusLighting and heating apparatusParticulatesEmissivity

An electro-kinetic air conditioner for removing particulates from the air creates an airflow using no moving parts. The conditioner includes an ion generator that has an electrode assembly including a first array of emitter electrodes, a second array of collector electrodes, and a high voltage generator. Preferably, a third or leading or focus electrode is located upstream of the first array of emitter electrodes, and / or a trailing electrode is located downstream of the second array of collector electrodes. The device can also include an interstitial electrode located between collector electrodes, an enhanced collector electrode with an integrally formed trailing end, and an enhanced emitter electrode with an enhanced length in order to increase emissitivity.

Owner:THE SHARPER IMAGE

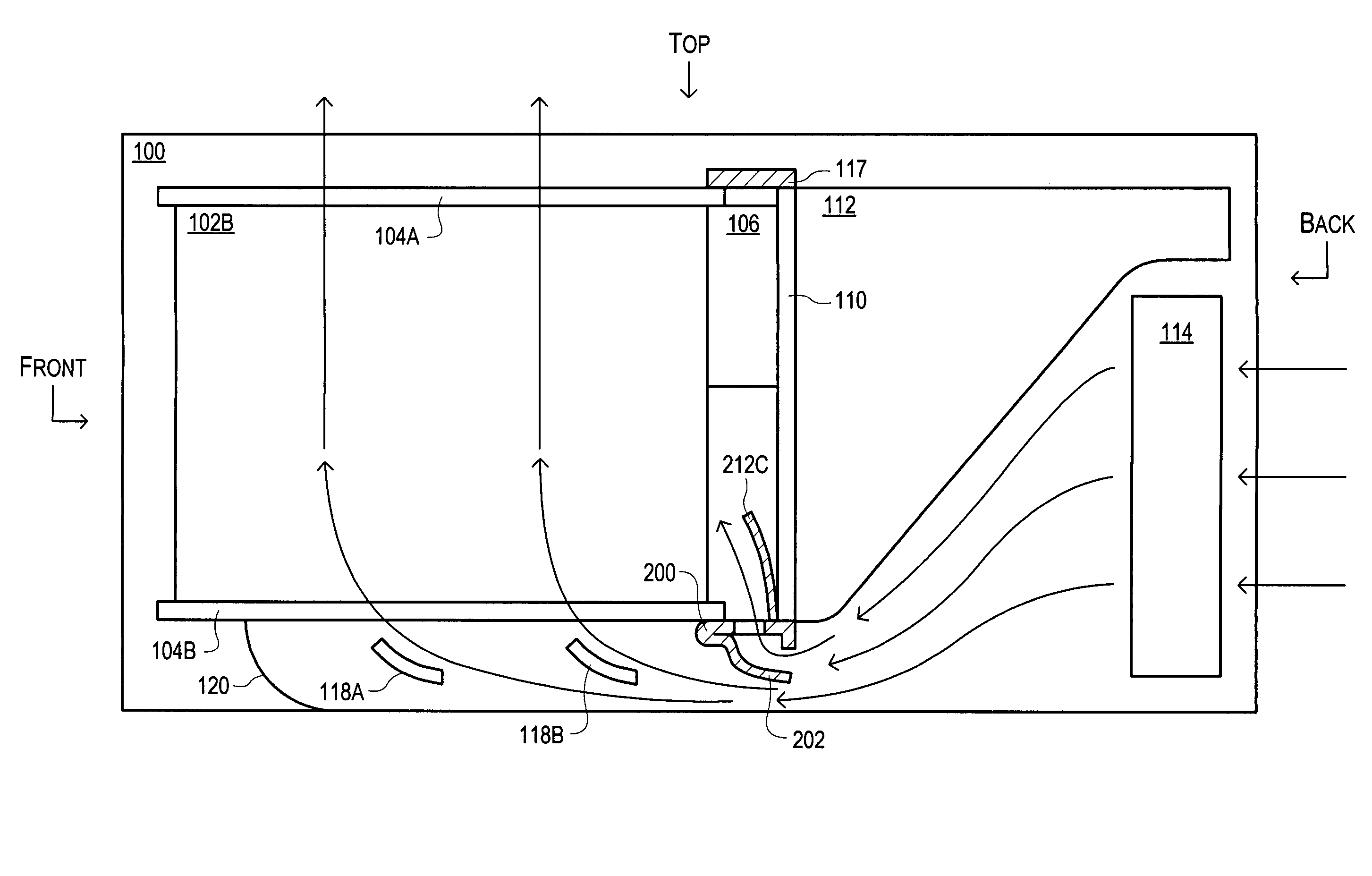

Vented and ducted sub-rack support member

ActiveUS7355850B2Increase airflowReduce ambient temperatureCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringBackplane

A chassis for plug-in modules may be provided with a vented and ducted sub-rack support member. The vented and ducted sub-rack support member may deflect a portion of the air flowing within the chassis through vents in the top surface of the vented and ducted sub-rack support member in order to increase the air flow to heat producing components mounted on the backplane above the support member. The increased air flow may increase air flow velocity and decrease the ambient temperature of the air around these components and improve the dissipation of heat from each component into the air. Air flow above the vented and ducted sub-rack support member may also be redirected by upper deflectors mounted on the support member to portions of plug-in cards adjacent to the upper deflectors and may provide additional cooling to components on the plug-in cards near the backplane.

Owner:NATIONAL INSTRUMENTS

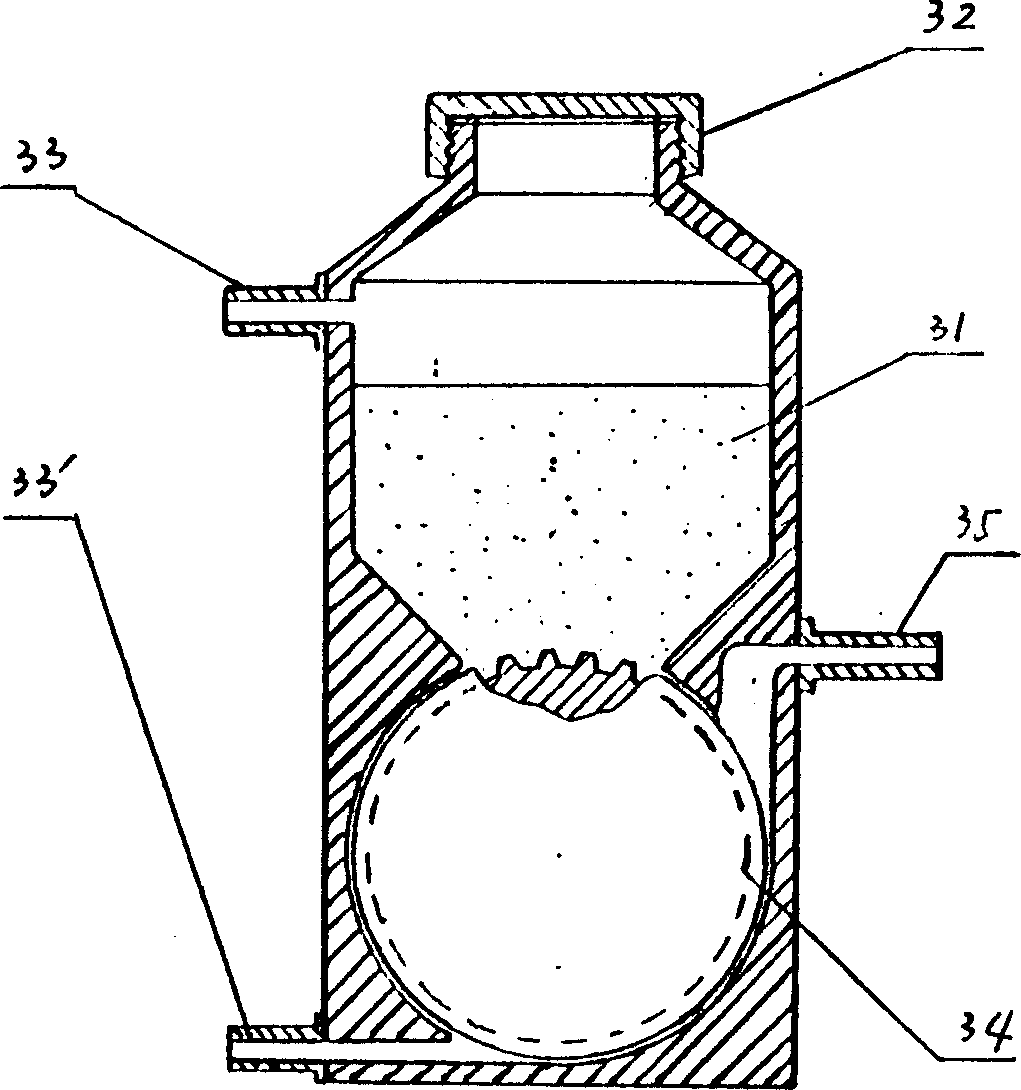

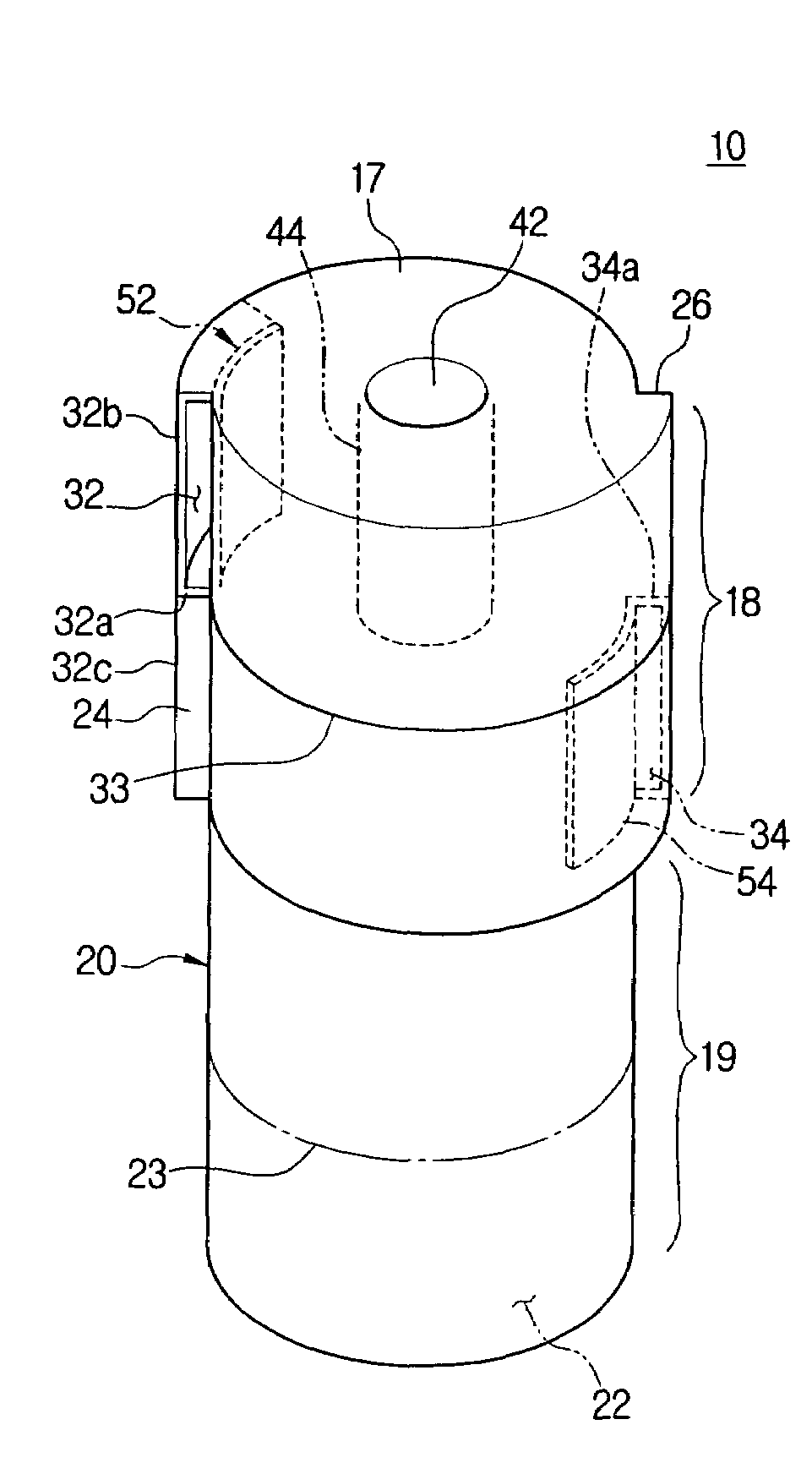

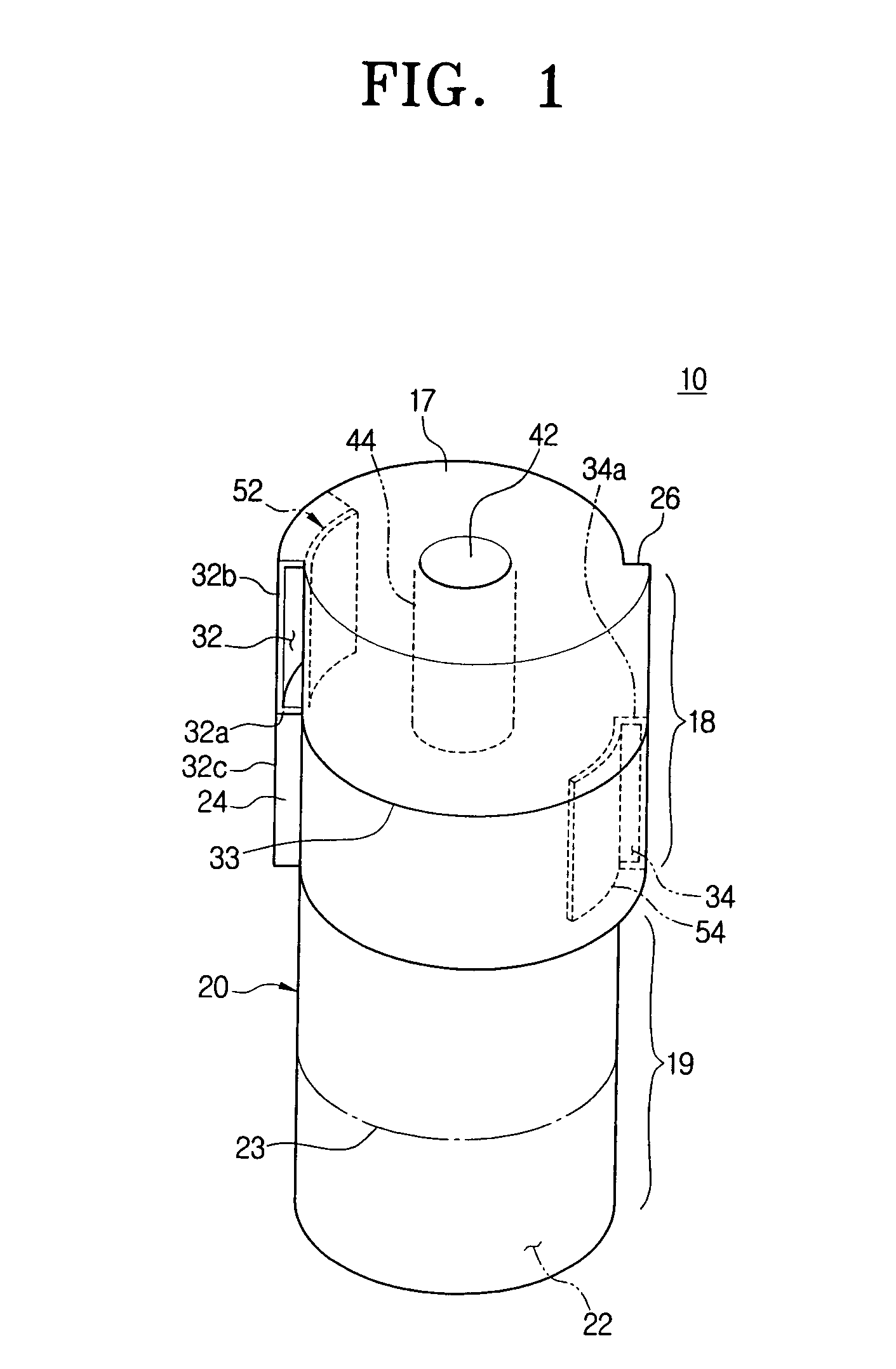

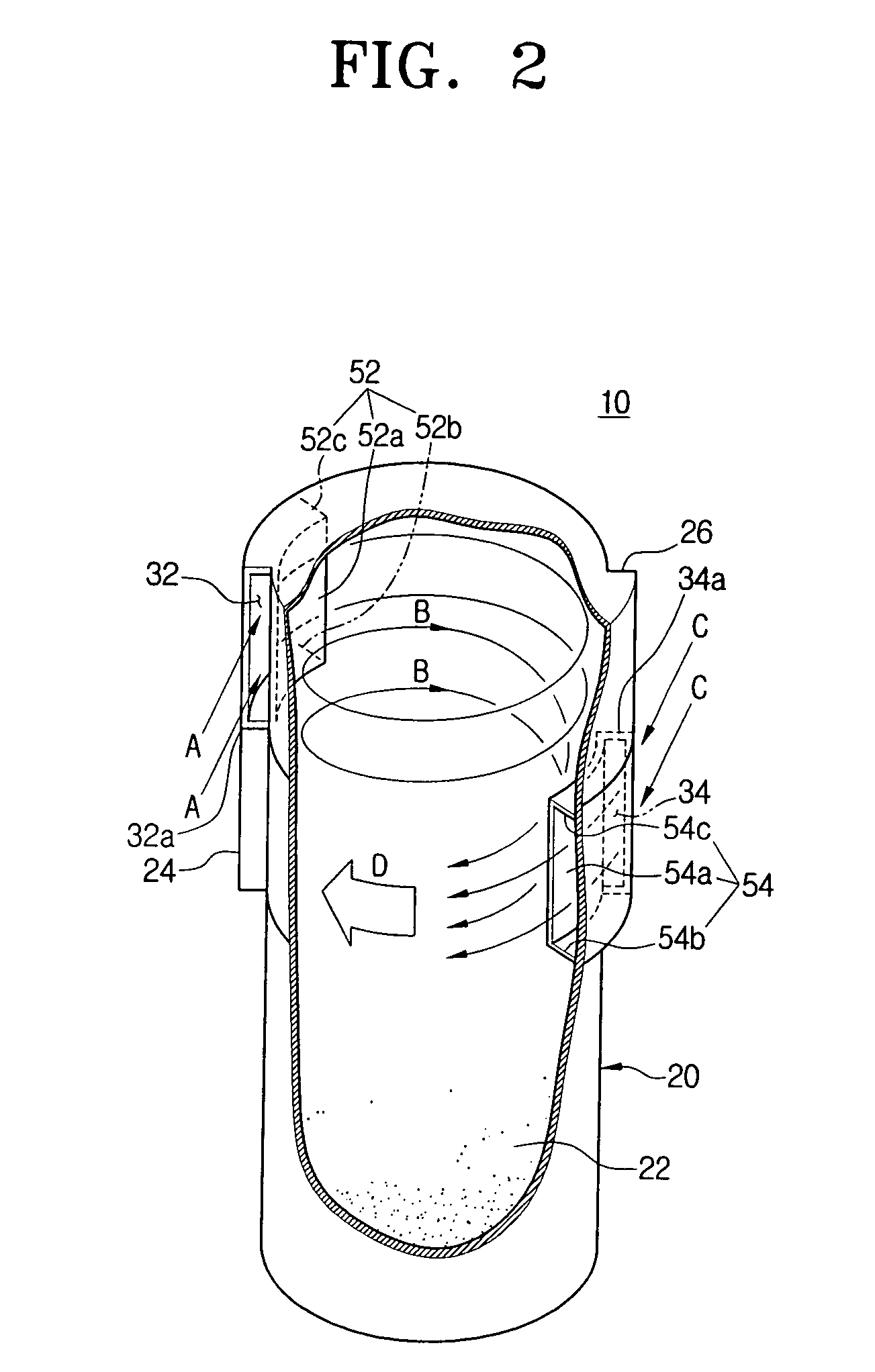

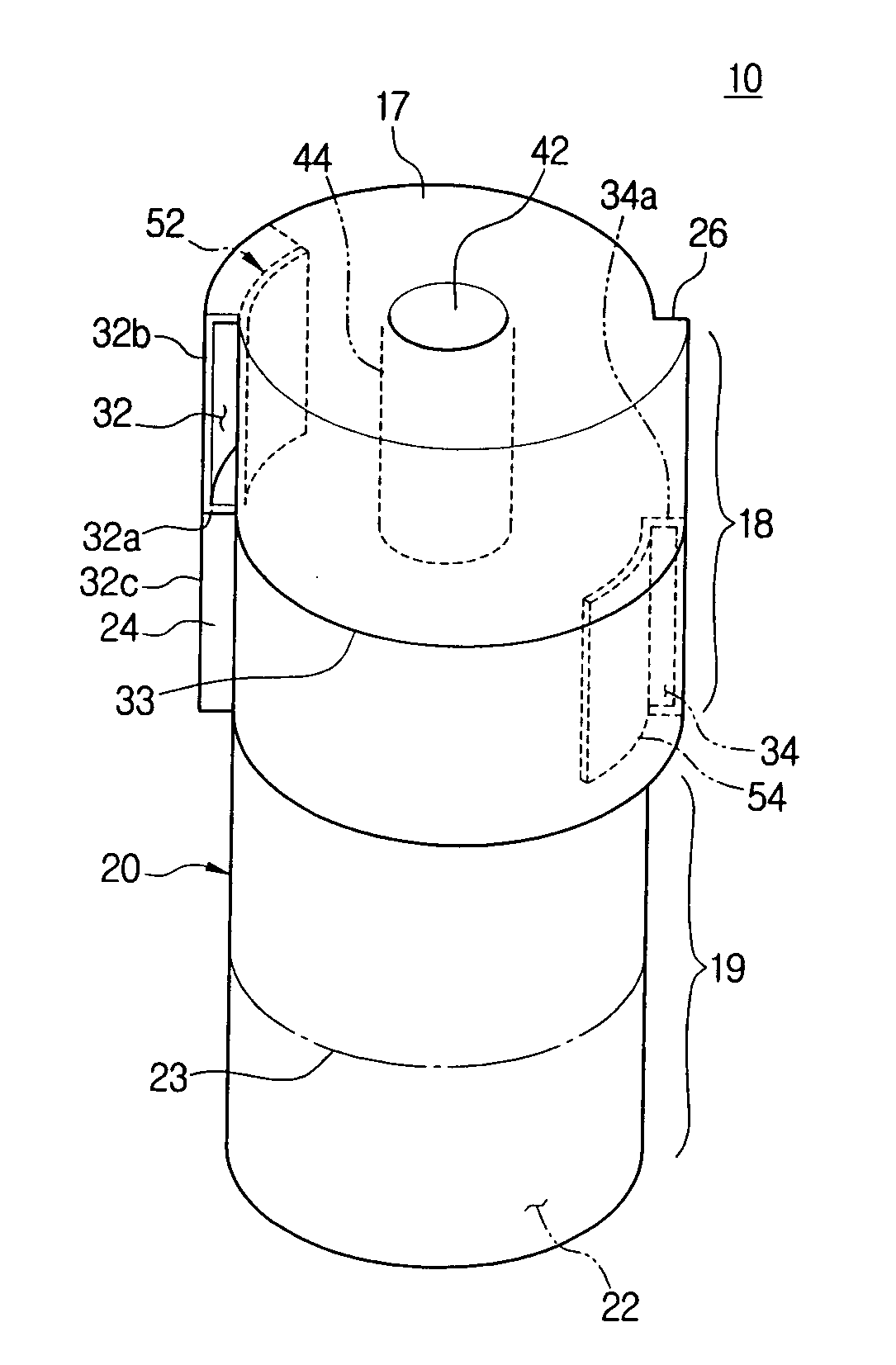

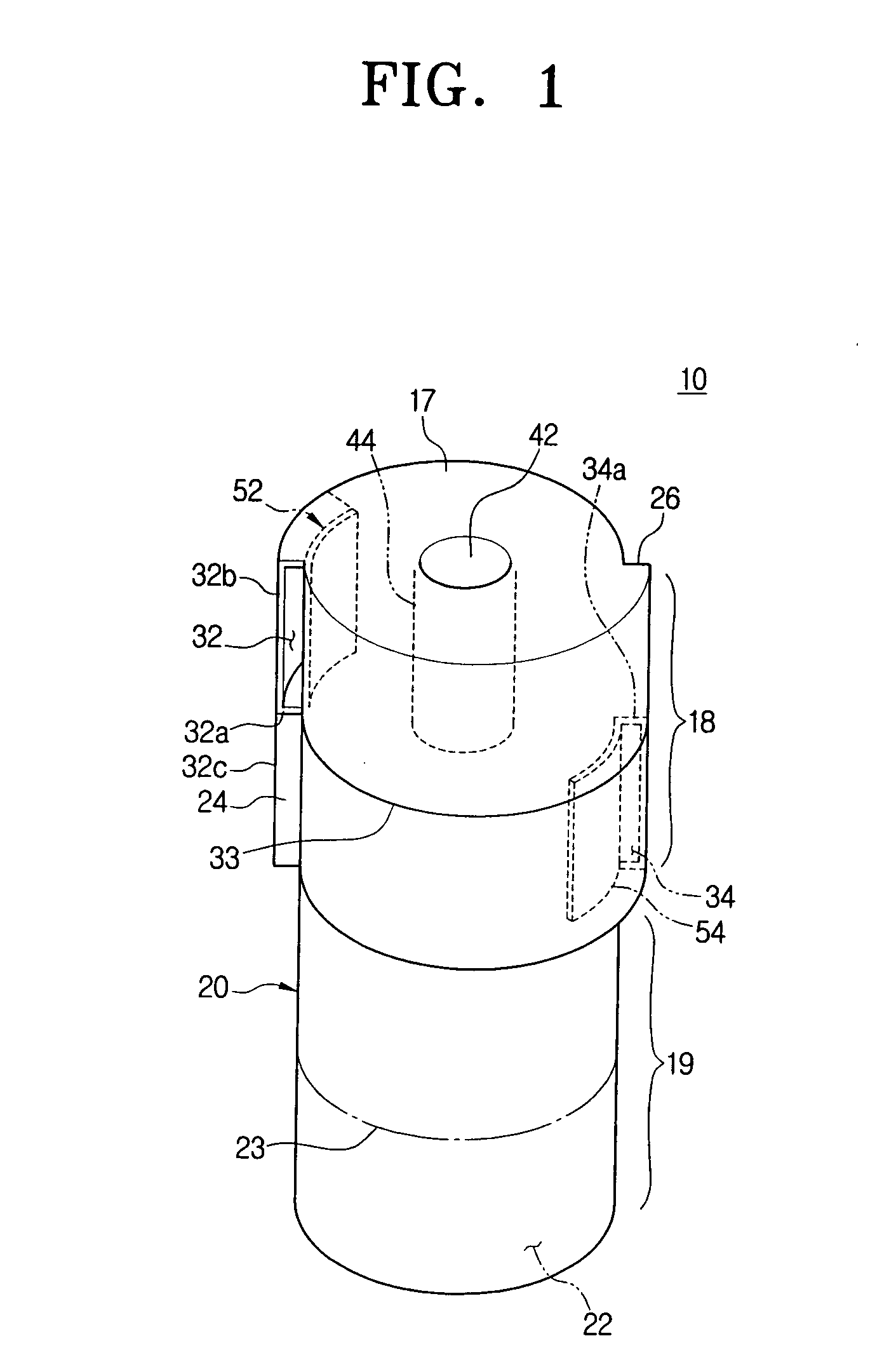

Dust collecting apparatus with a plurality of inlets

InactiveUS7662201B2Simple structureIncrease rotational forceCleaning filter meansSuction filtersMechanical engineering

The present disclosure relates to a dust collecting apparatus. The dust collecting apparatus includes a cyclone body forming a cyclone chamber; a plurality of inlets formed at the cyclone body, and causing air to enter through; and a discharging port formed at the cyclone body, and discharging the air from the cyclone chamber, wherein each inlet of the plurality of inlets is formed at a different height at a side of the cyclone body so that the air is divided to enter the cyclone chamber at a different height.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

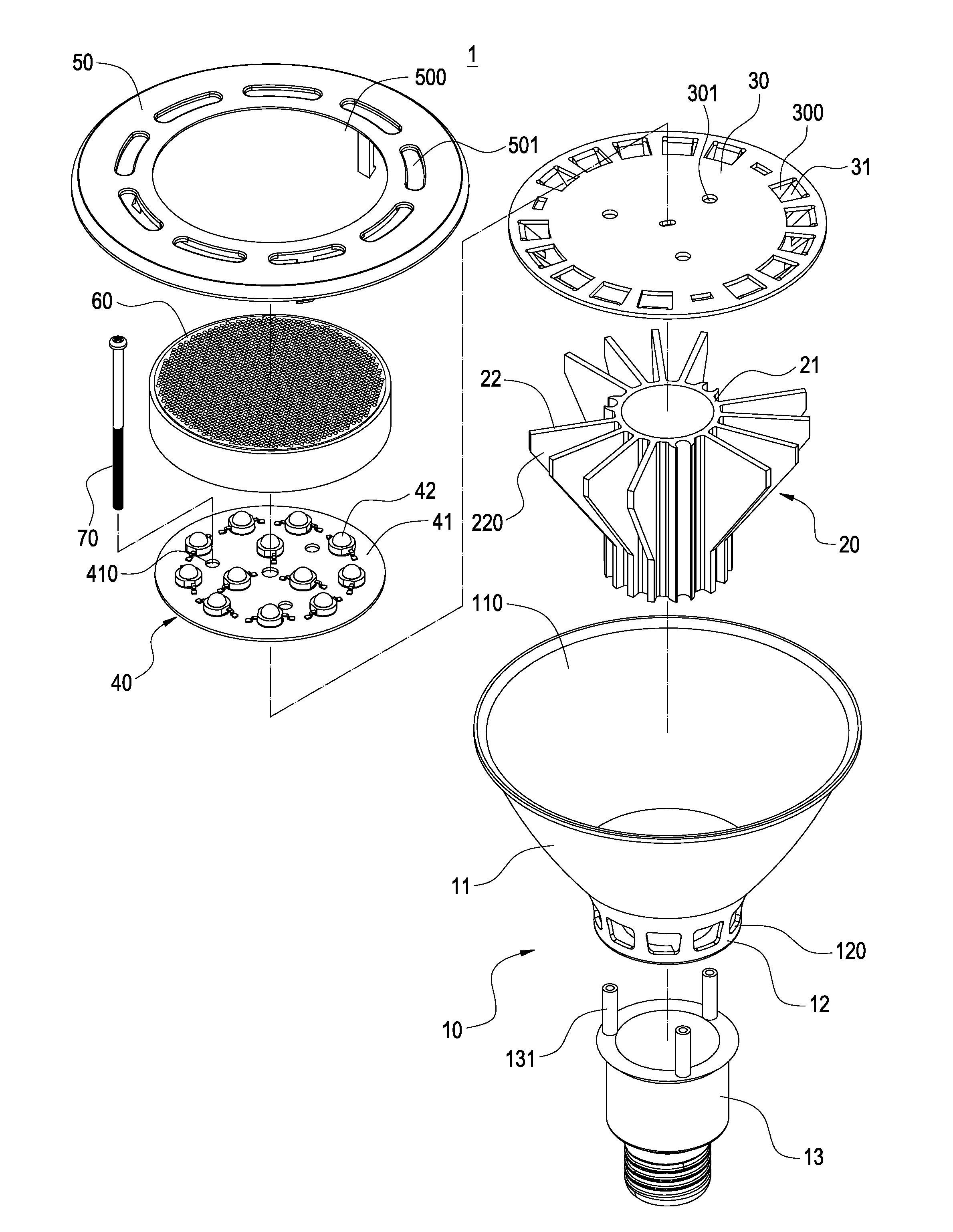

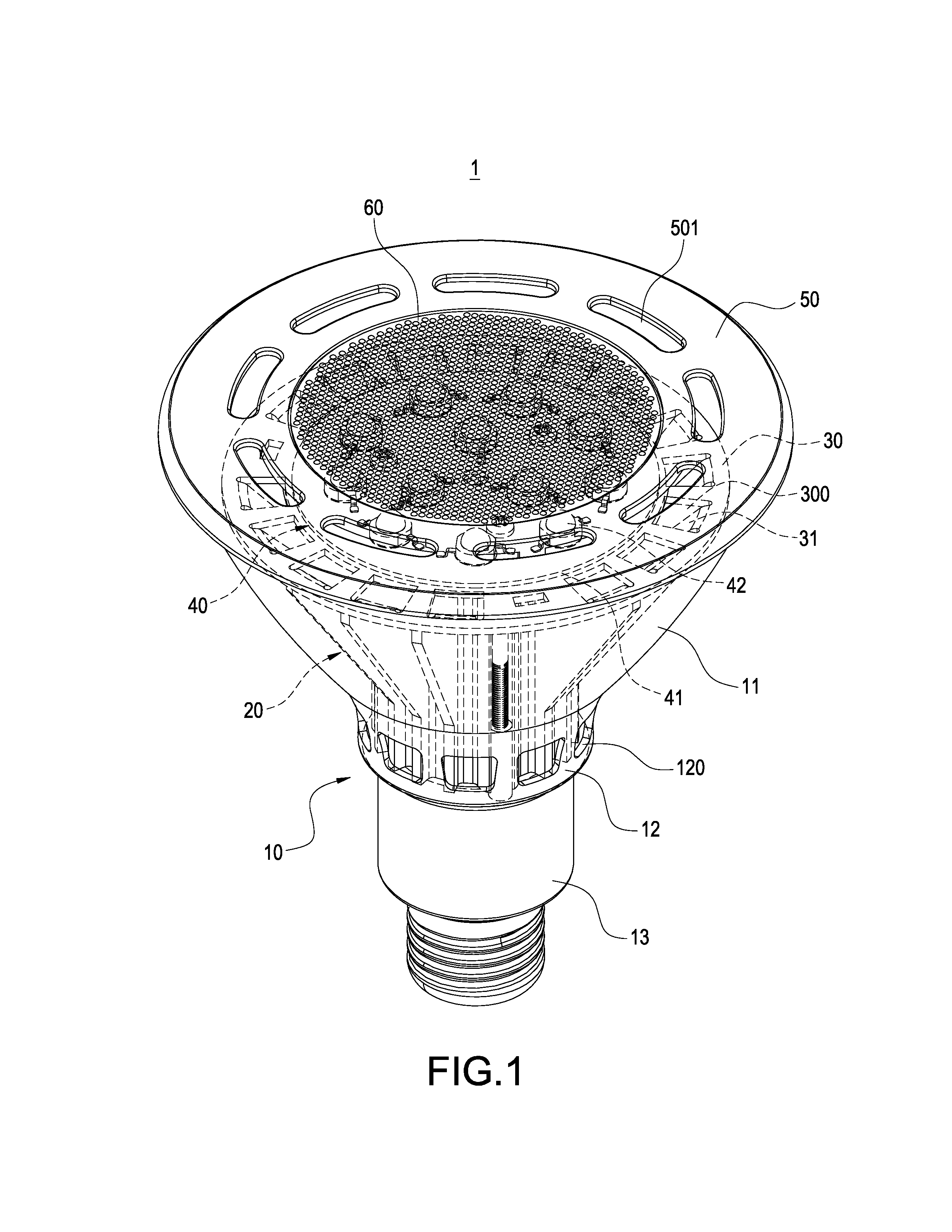

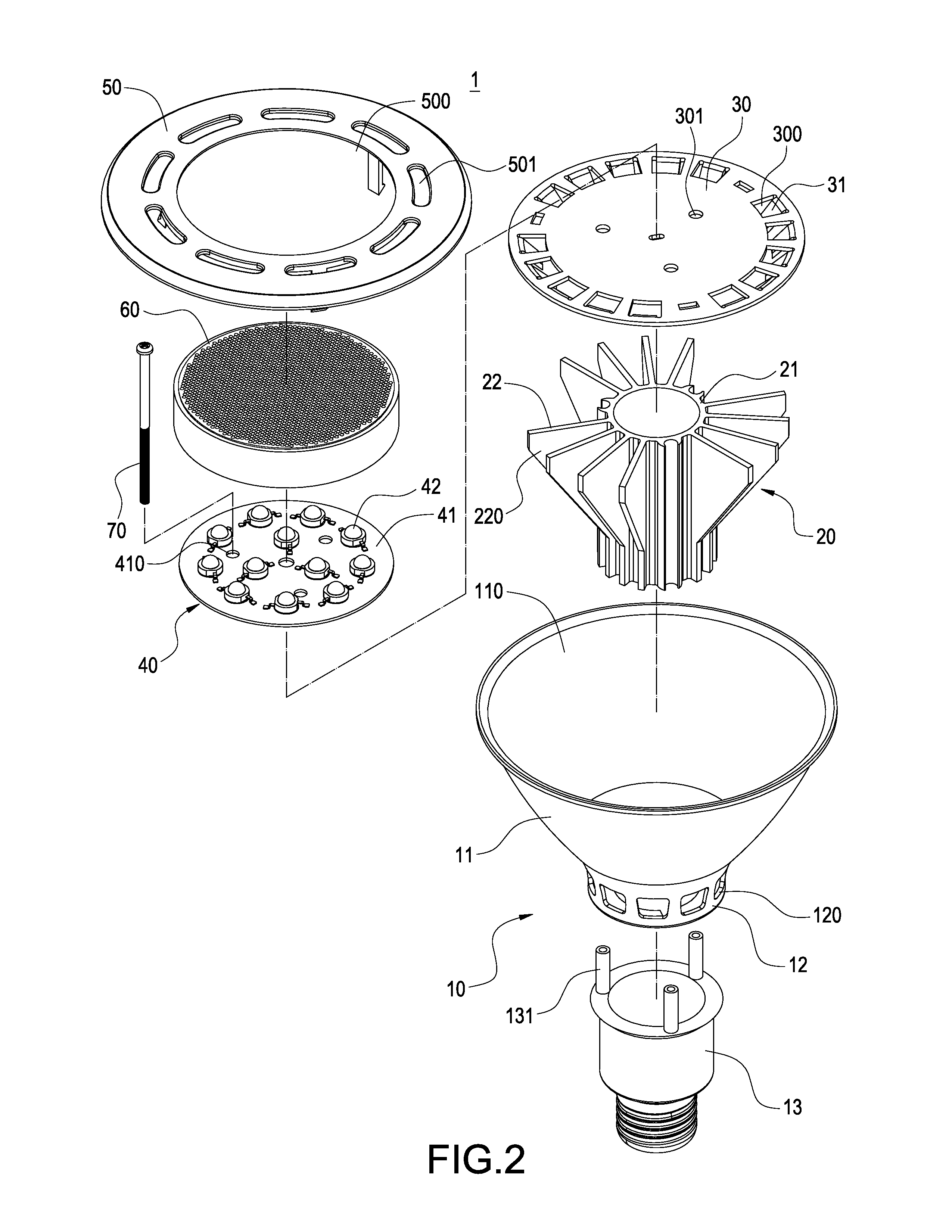

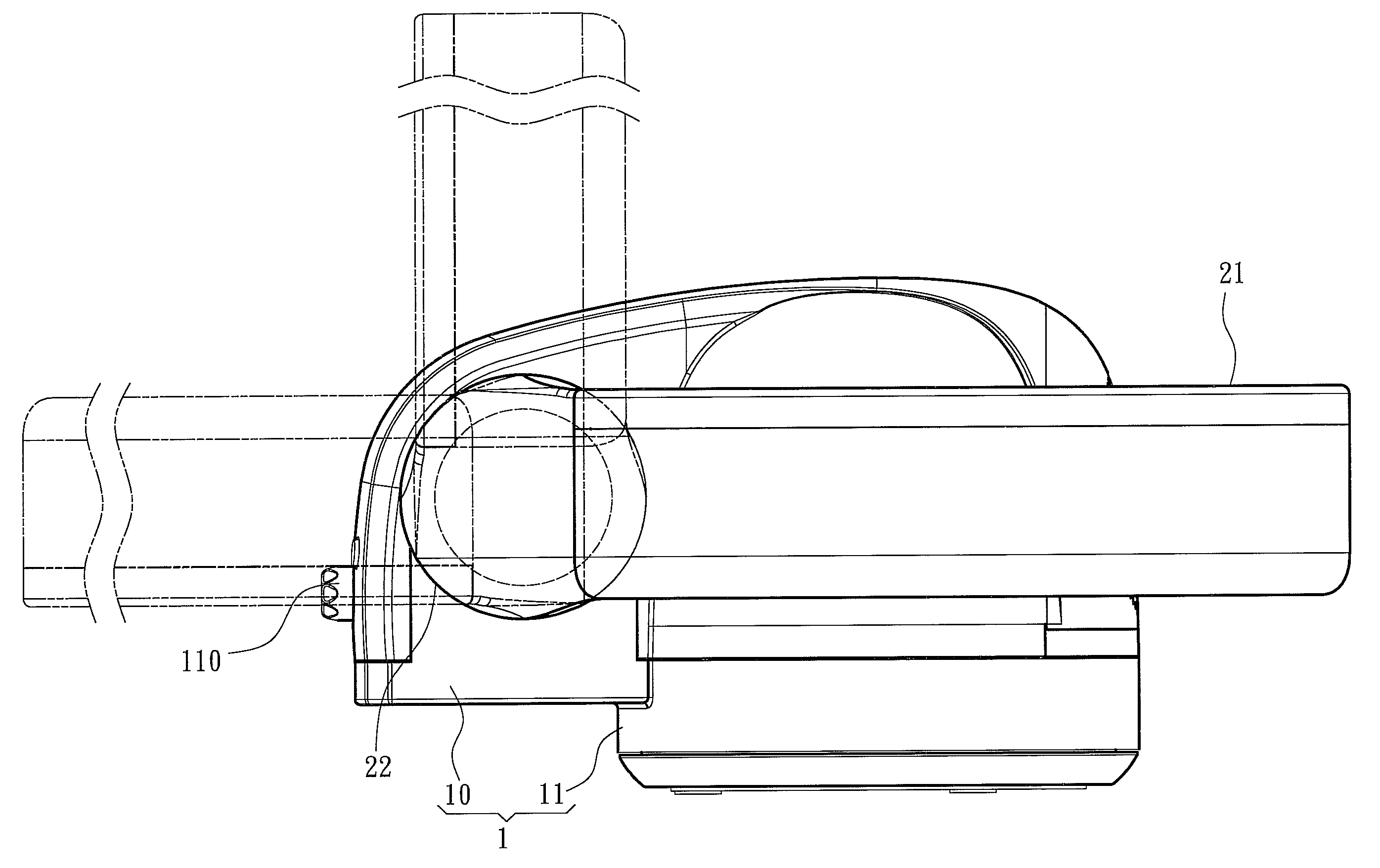

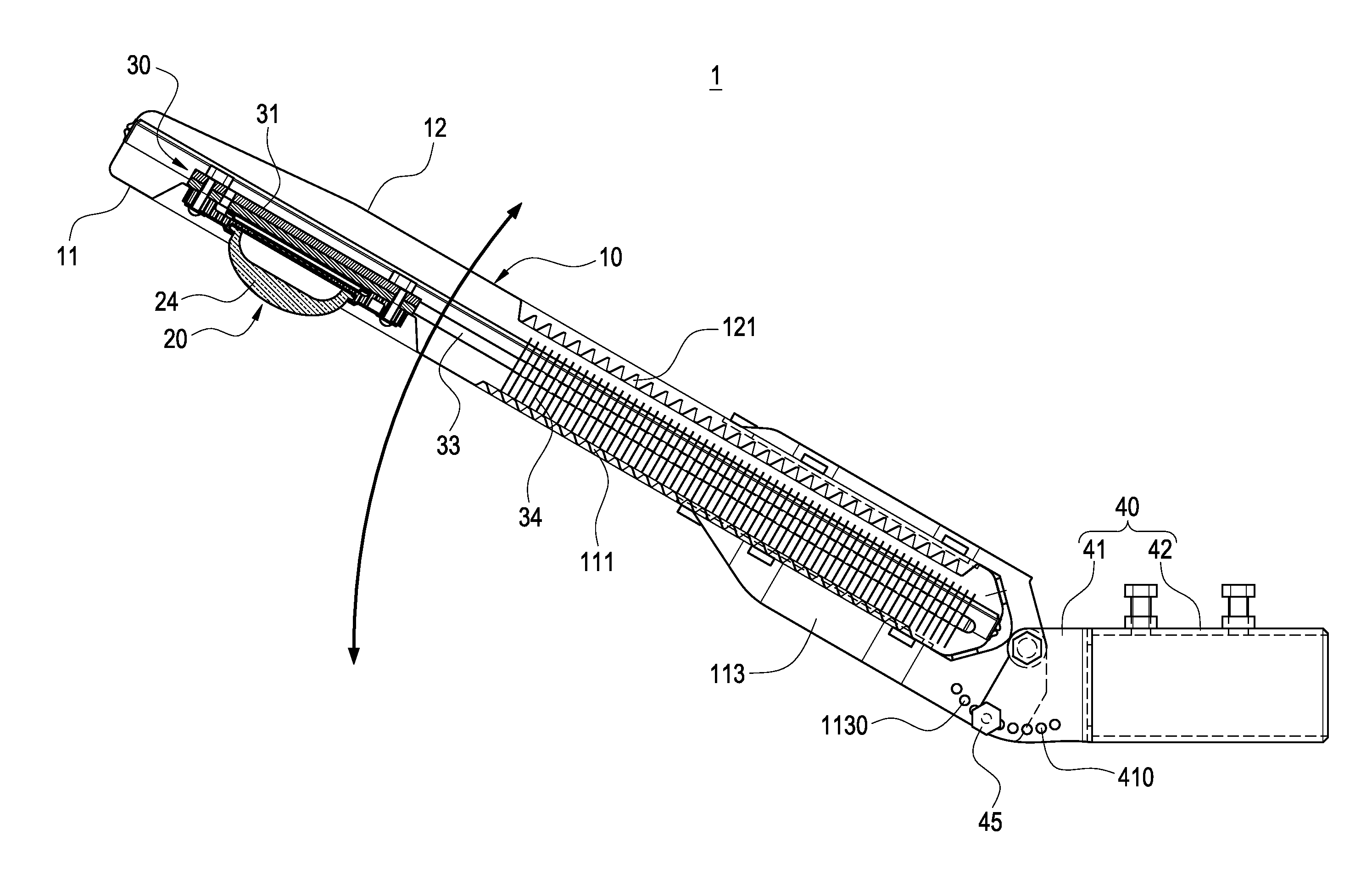

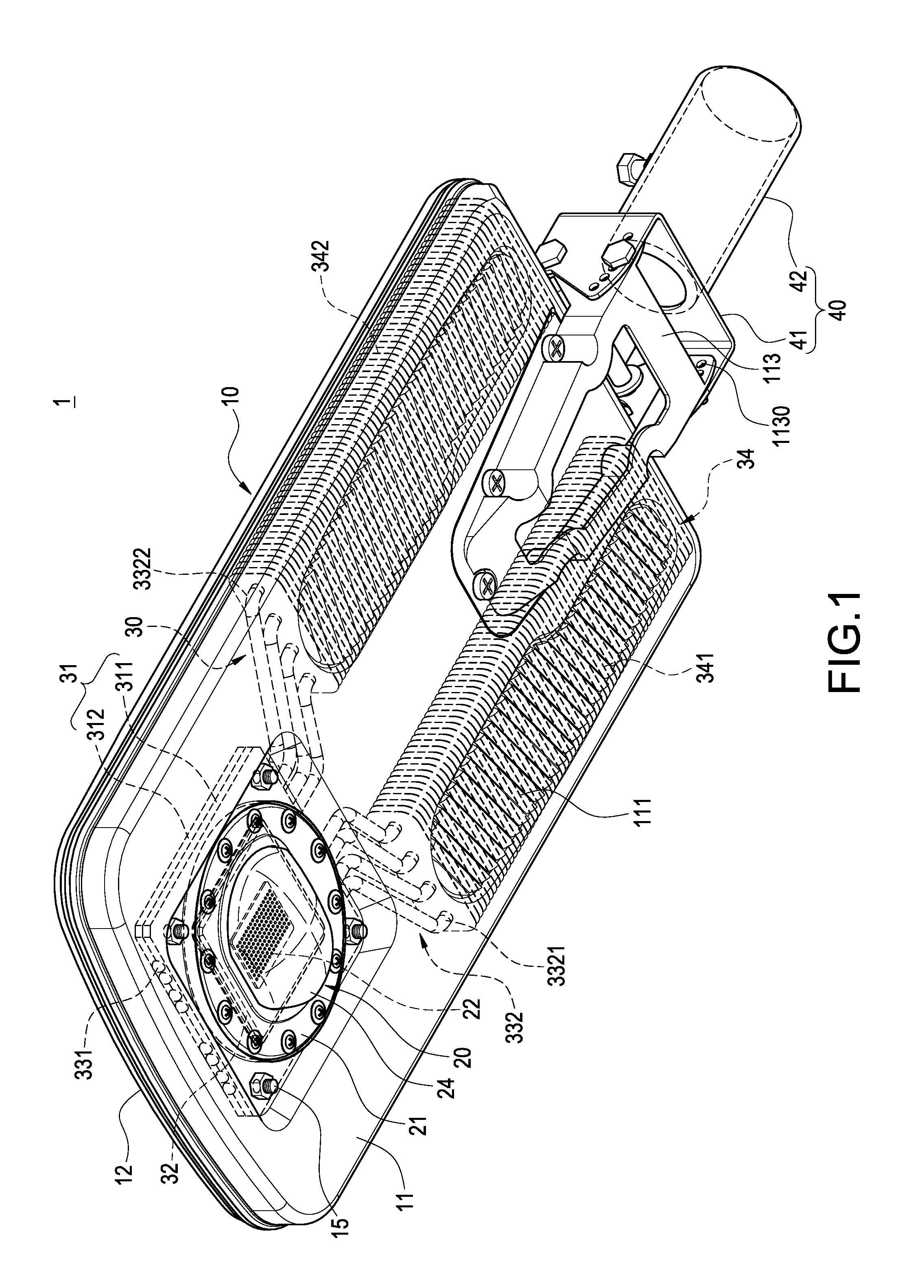

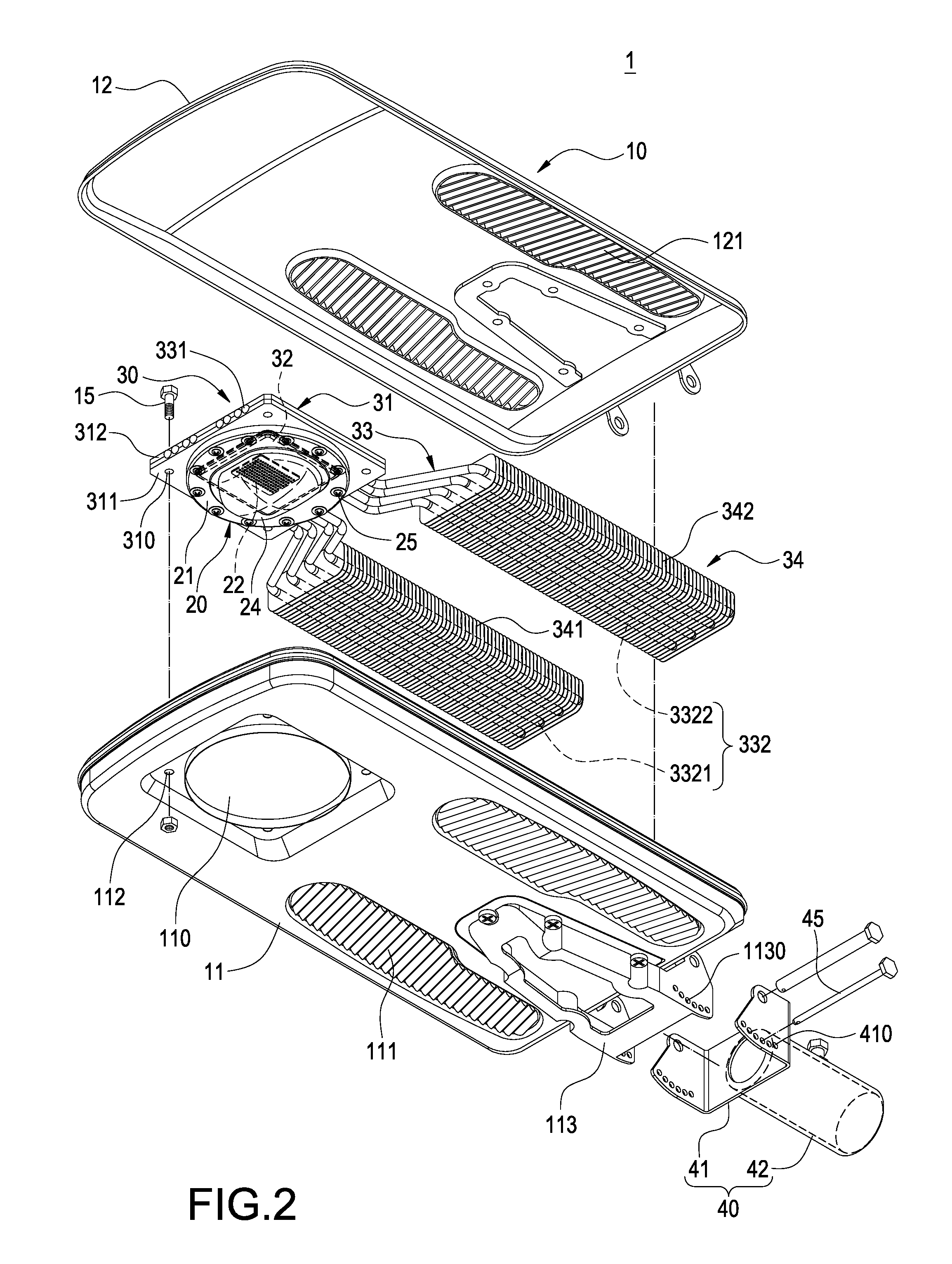

LED lamp with flow guide function

InactiveUS8164237B2Avoid heatEnhanced natural convectionPlanar light sourcesElectric discharge tubesNatural convectionEngineering

An LED lamp with a flow guide structure guides external air to dissipate heat from the LED lamp includes a lamp base, a heat dissipating body, a heat dissipating plate and an LED module installed in the lamp base, and heat dissipating holes formed on the lamp base. The heat dissipating body includes heat dissipating fins, and a heat dissipating passage defined between any two fins and disposed corresponding to the heat dissipating hole. The LED module is in a thermal contact with the heat dissipating plate. The heat dissipating plate is attached onto the heat dissipating fins and includes openings. A flow guide plate is formed at a lateral edge of each opening and extended from the heat dissipating plate for guiding external air into the heat dissipating passage and out from the heat dissipating hole to expedite a natural convection in the lamp and prevent a thermal aggregation.

Owner:GEM SUN TECH

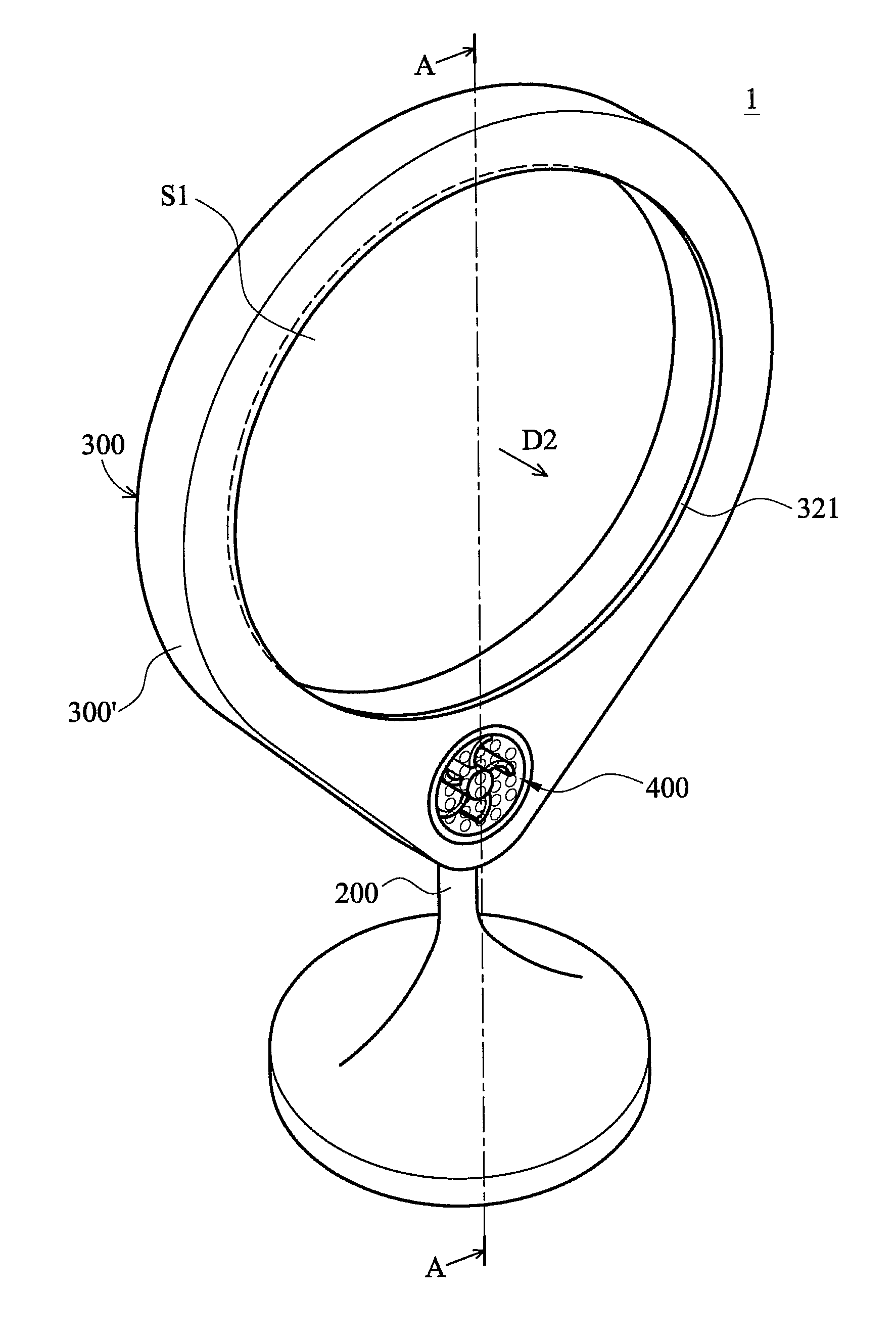

Bladeless air fan

InactiveUS8529226B2Increase rangeIncrease air velocityCircuit elementsSpray nozzlesAirflowAerospace engineering

A bladeless air fan includes a host and an airflow guiding frame. The host divides into a housing section to hold an airflow generator and a pivoting section to include two first pivoting portions. The airflow generator is connected to an airflow guiding manifold extended from the housing section to the pivoting section. The airflow guiding frame includes an air discharging portion and an airflow guiding passage and two second pivoting portions being annular to form two air intake ports communicating with the airflow guiding passage. The second pivoting portions are rotatably coupled with the first pivoting portions such that the airflow guiding passage communicates with the airflow guiding manifold. The air discharging portion encircles an airflow passage being formed at an inner diameter allowing the housing section to pass through to enlarge the range of the second pivoting portions rotating against the first pivoting portions.

Owner:KABLE ENTERPRISE

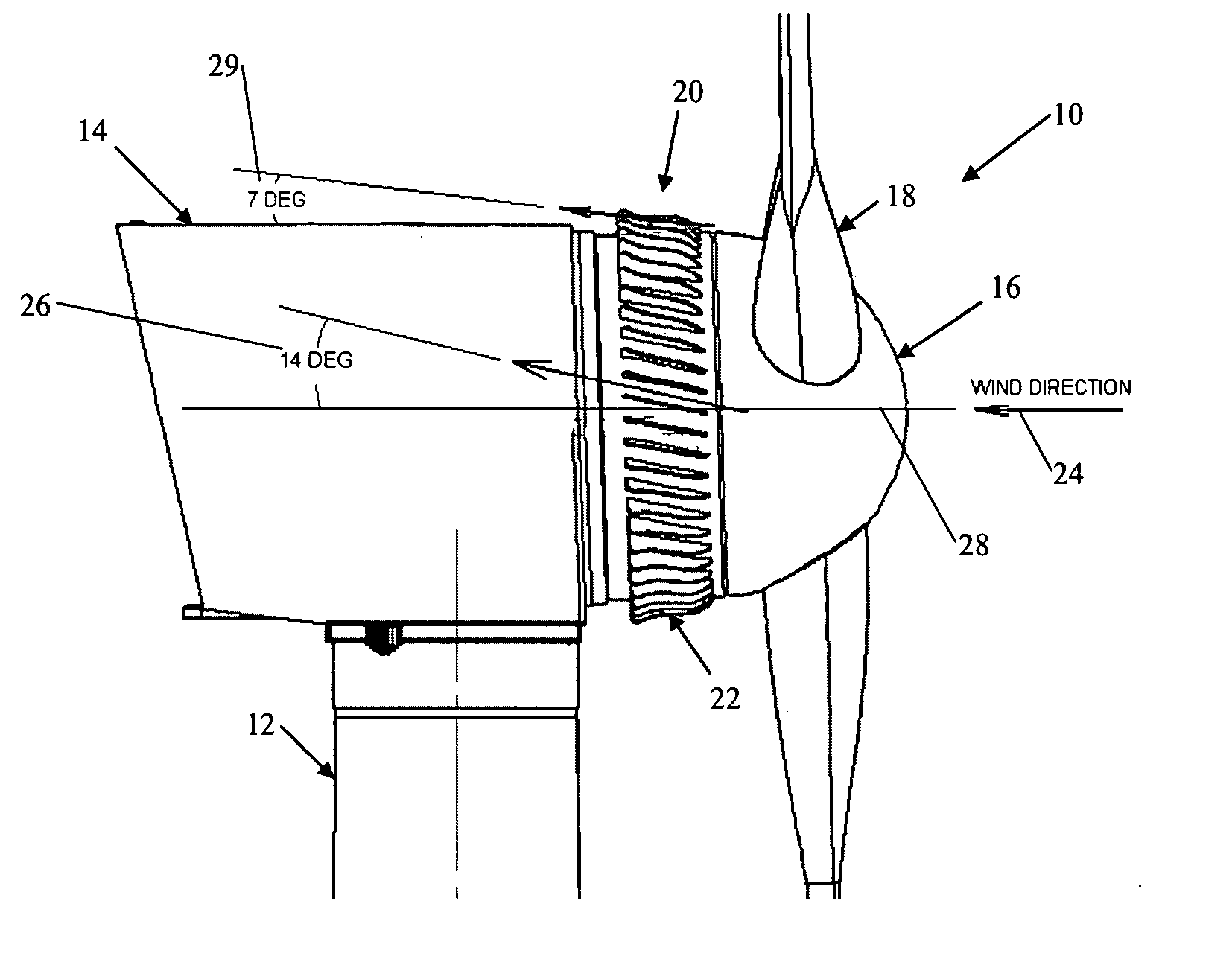

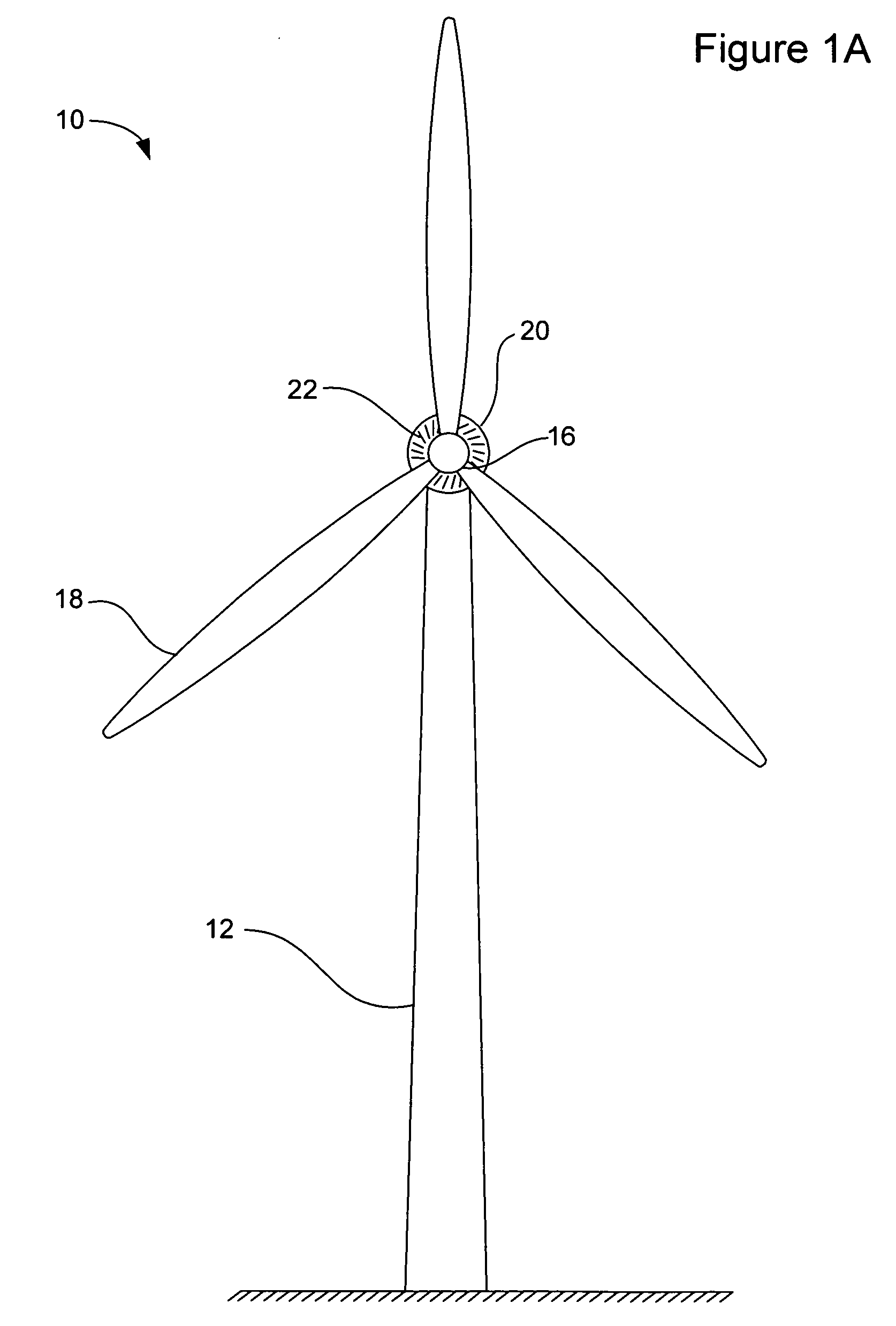

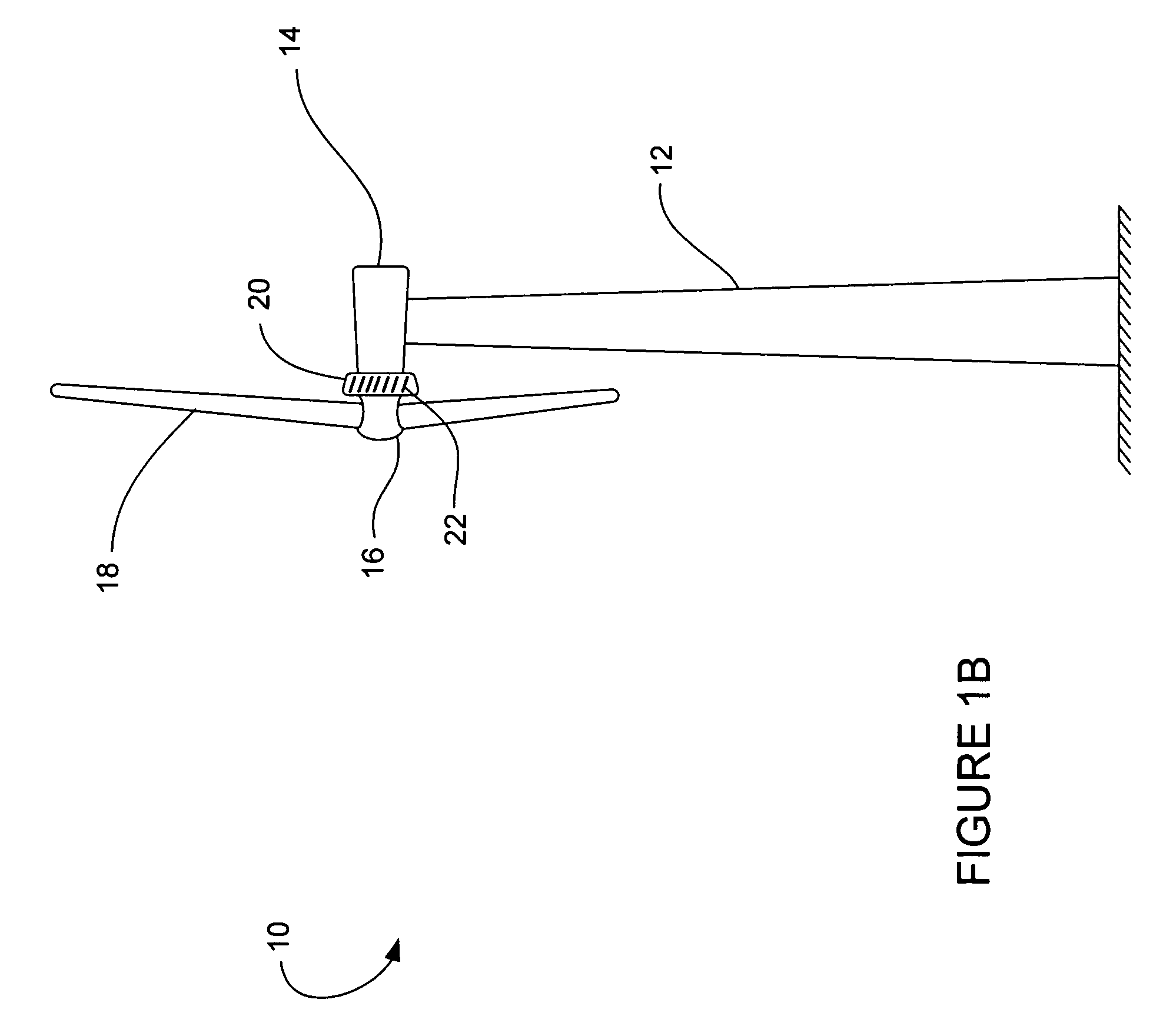

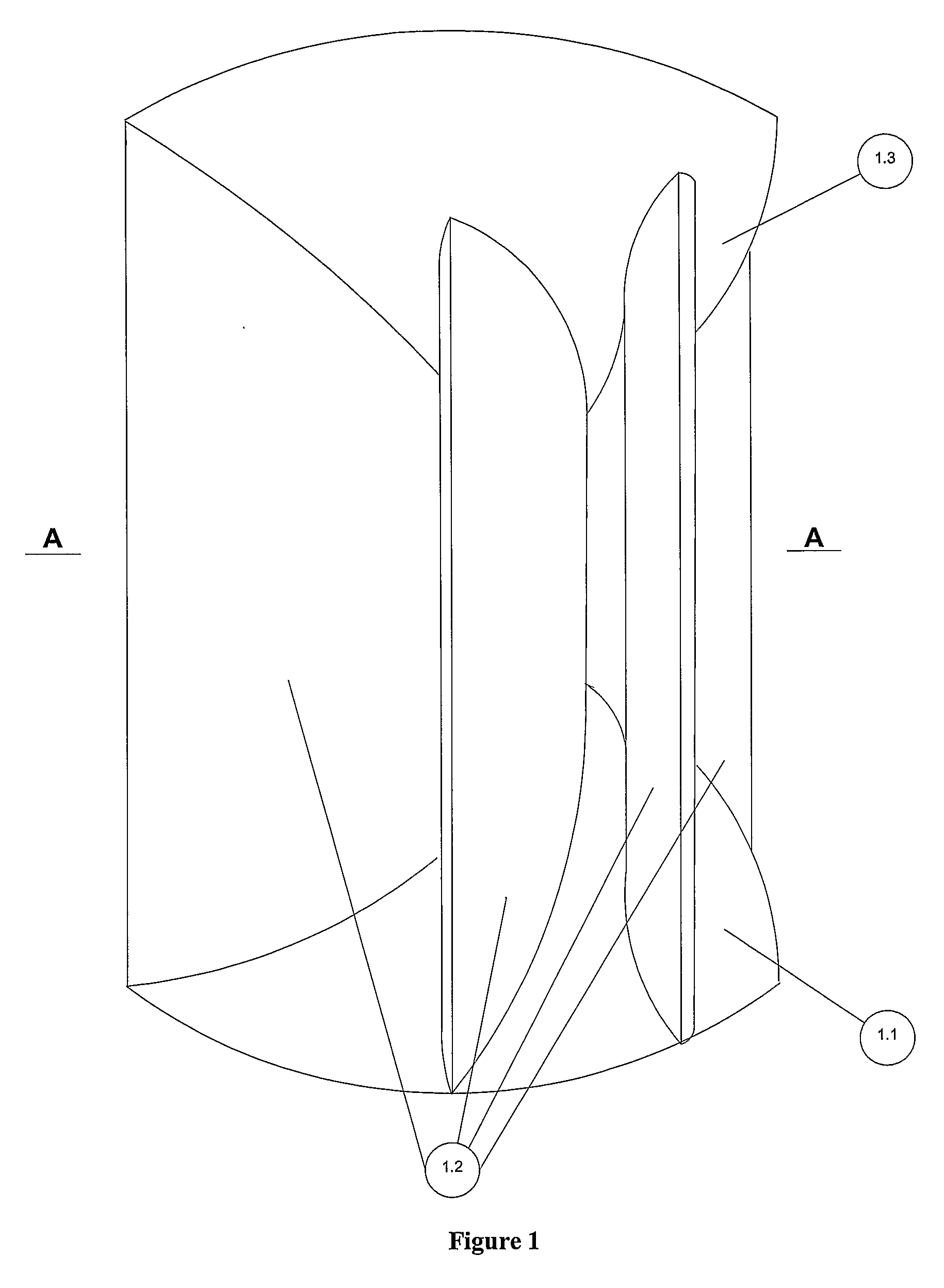

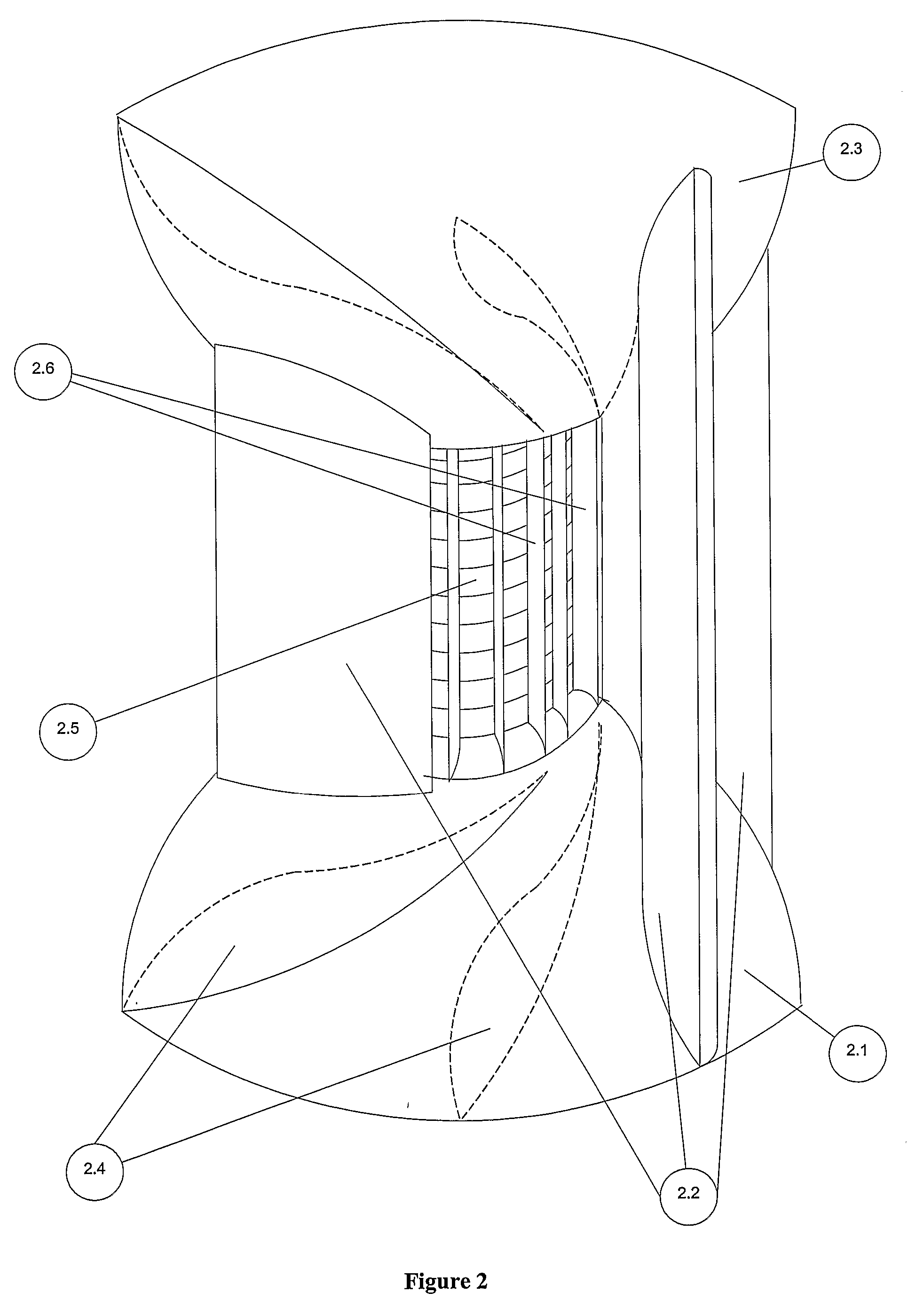

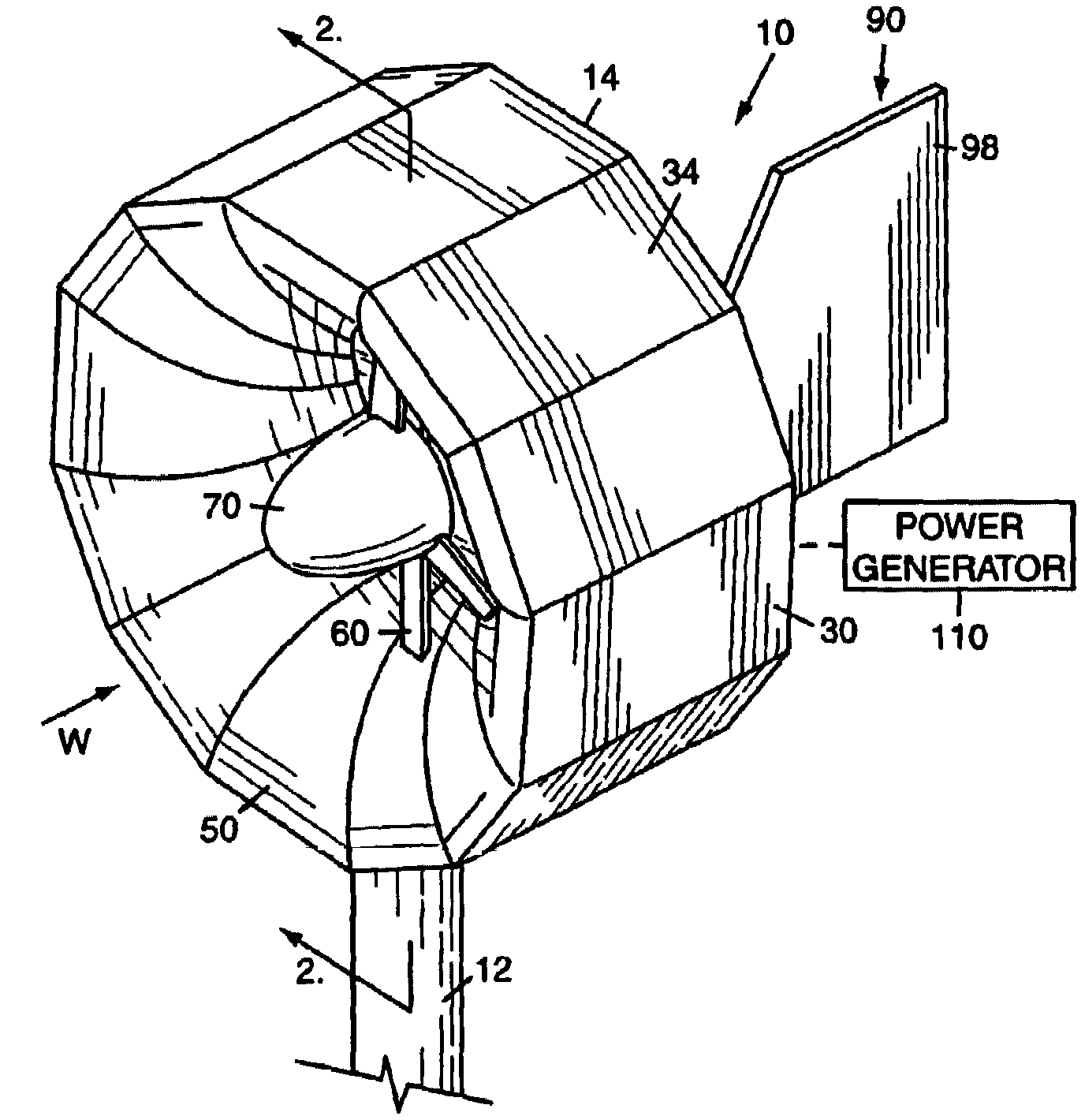

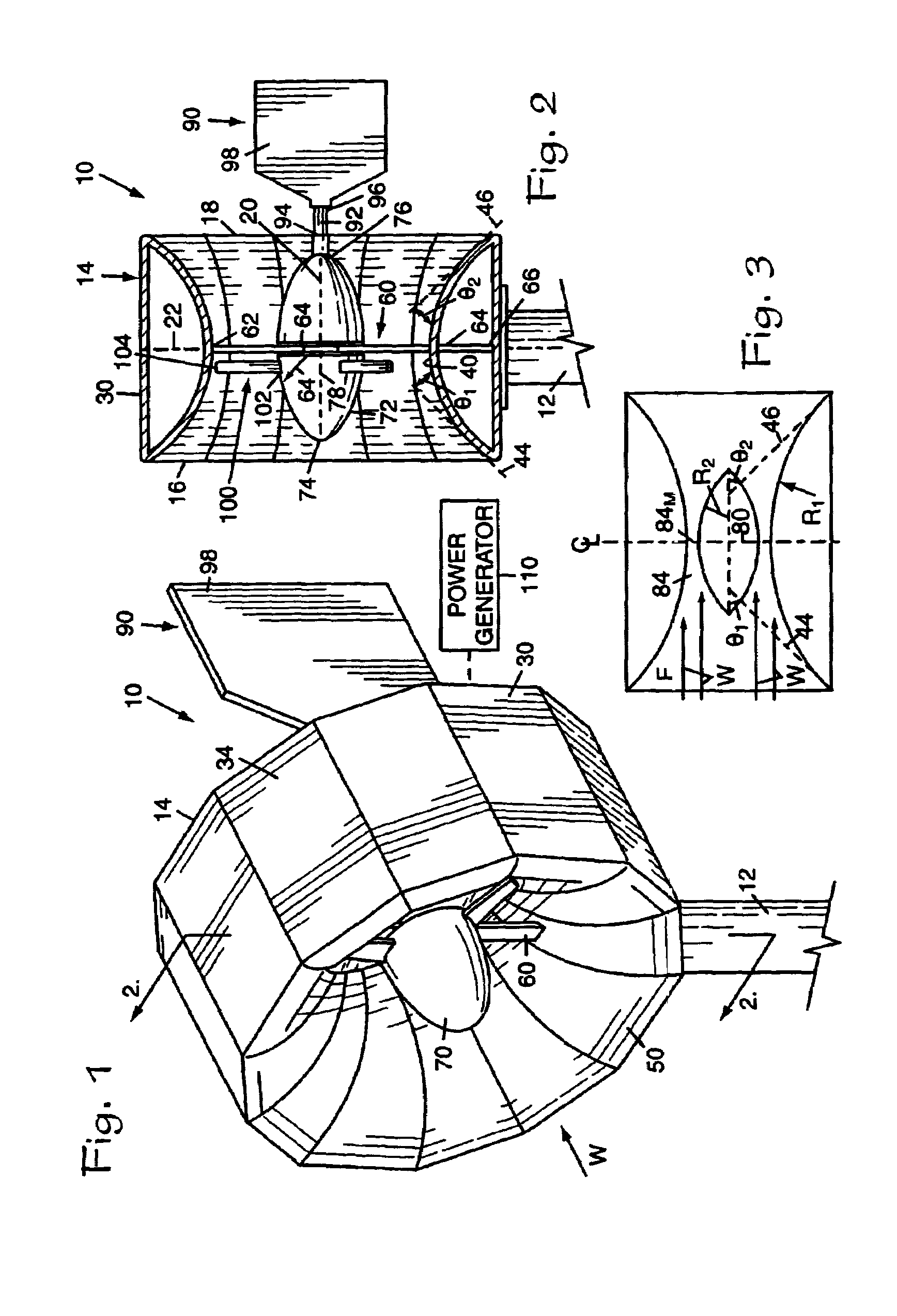

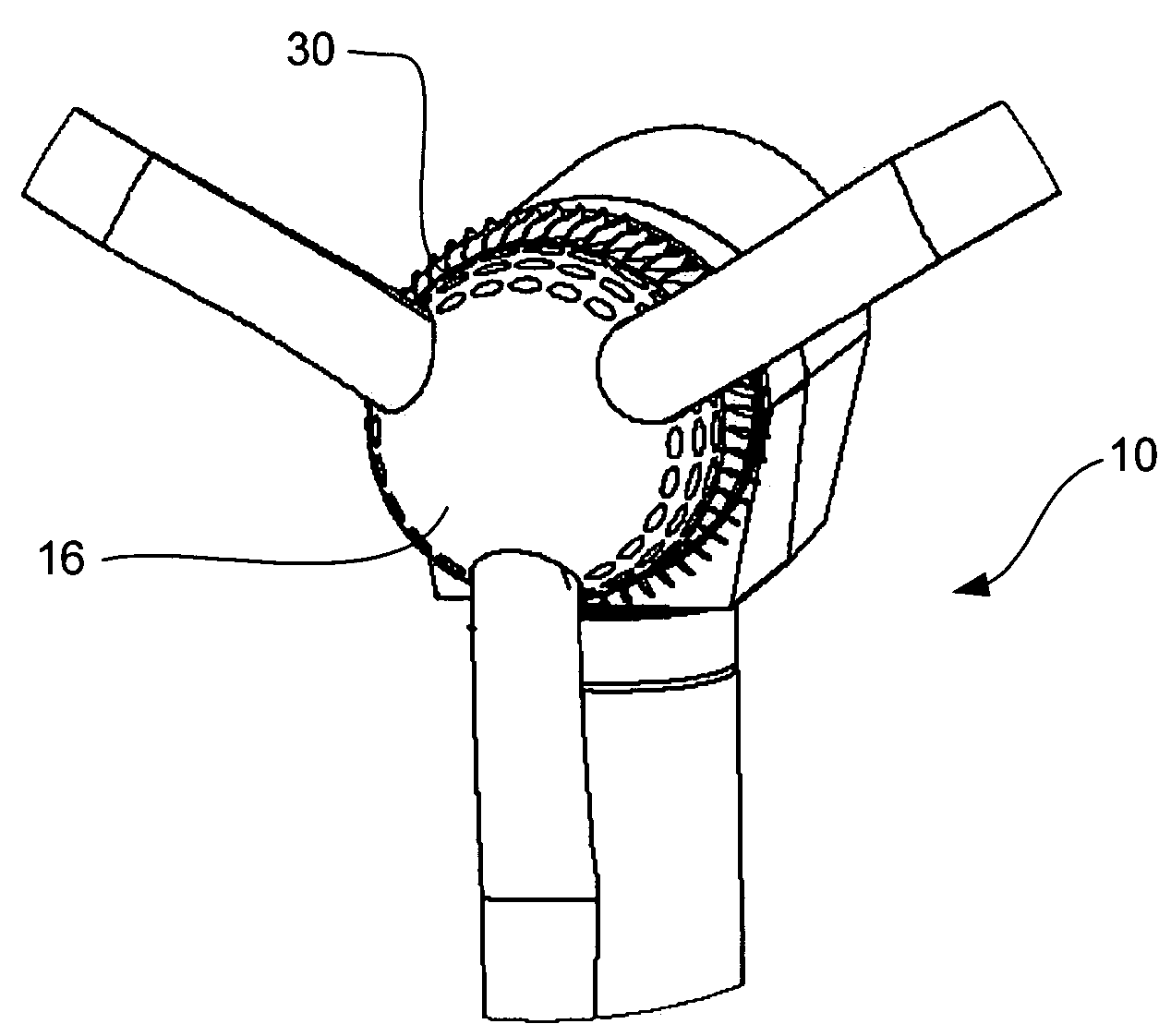

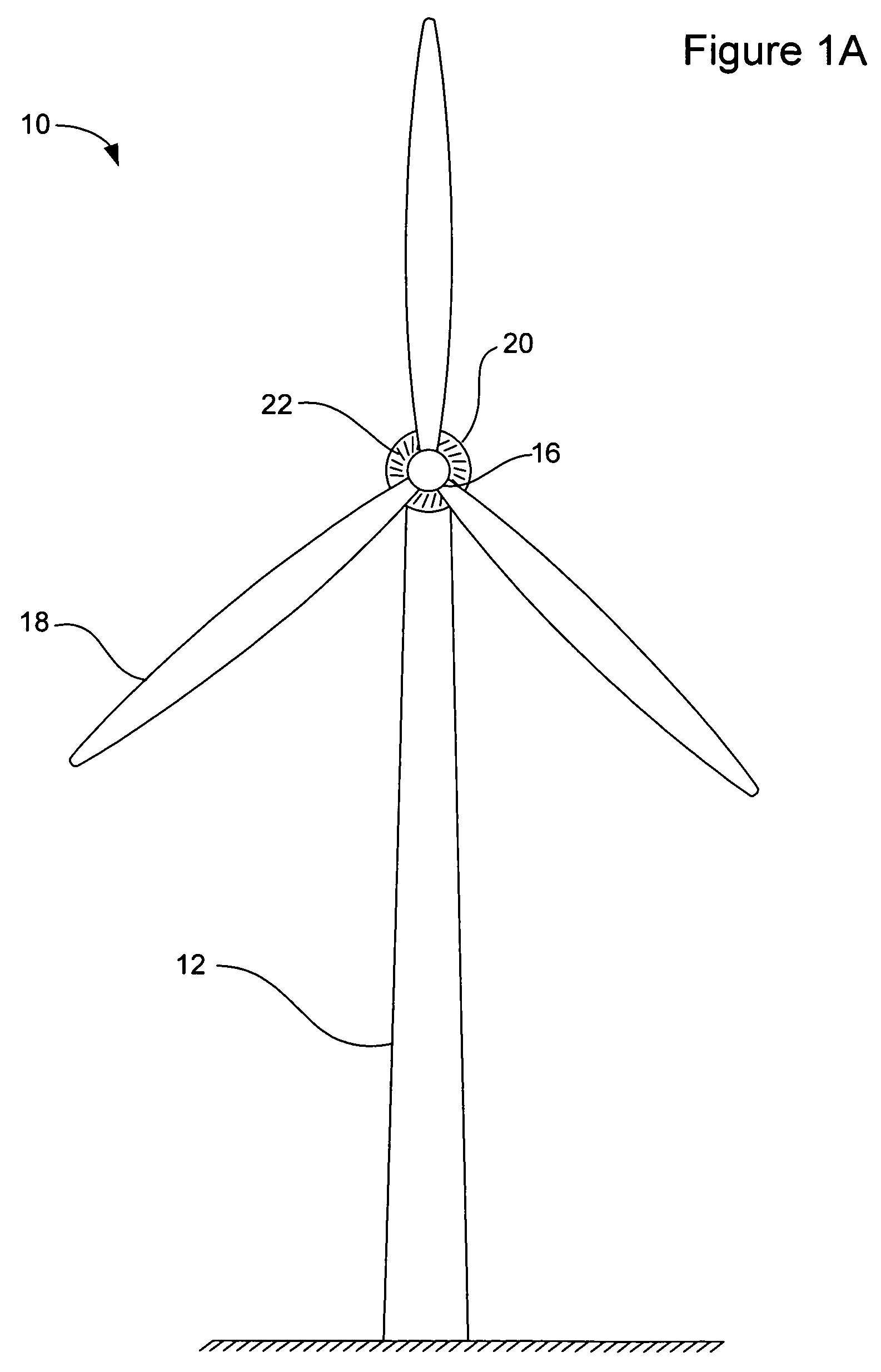

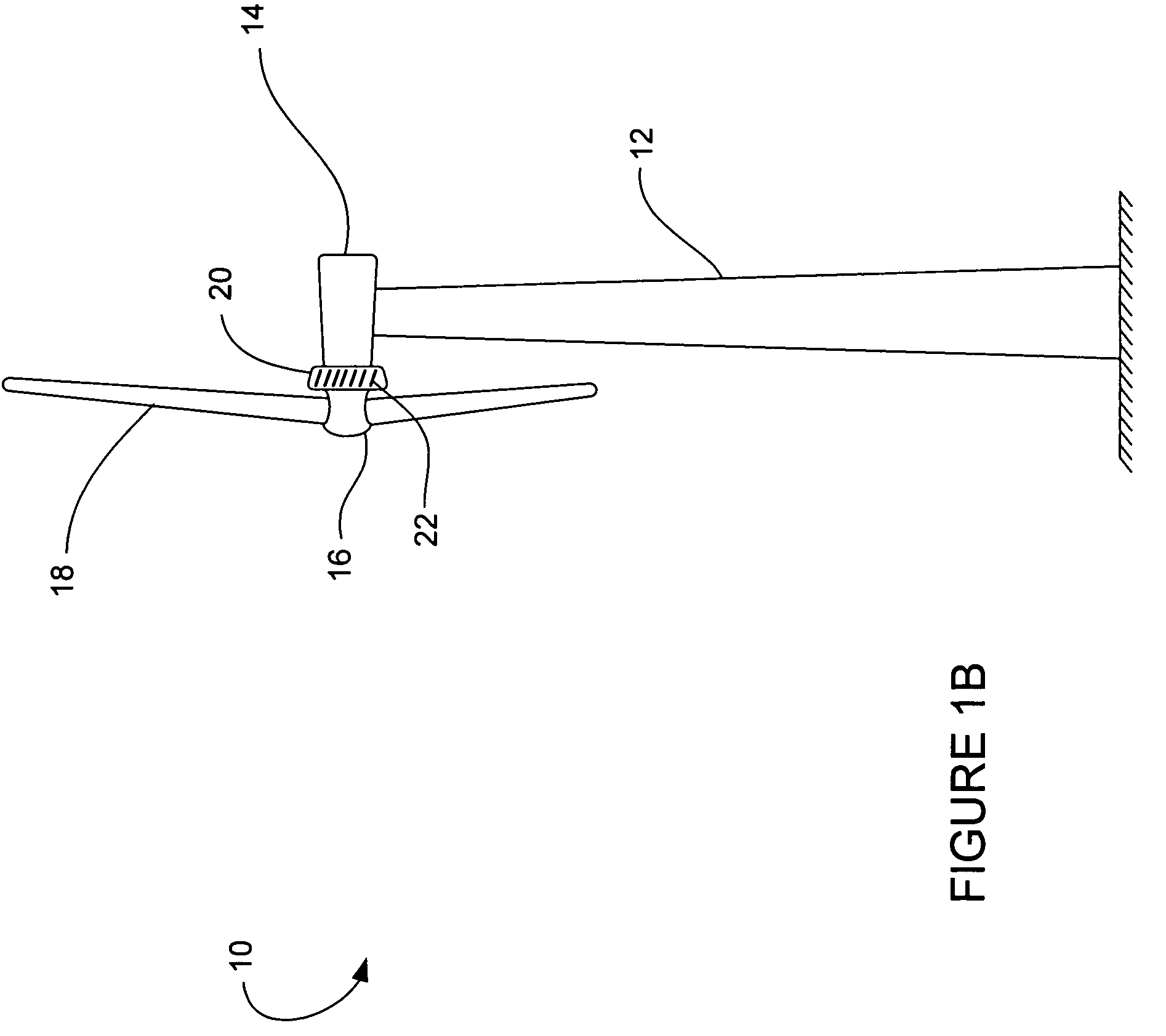

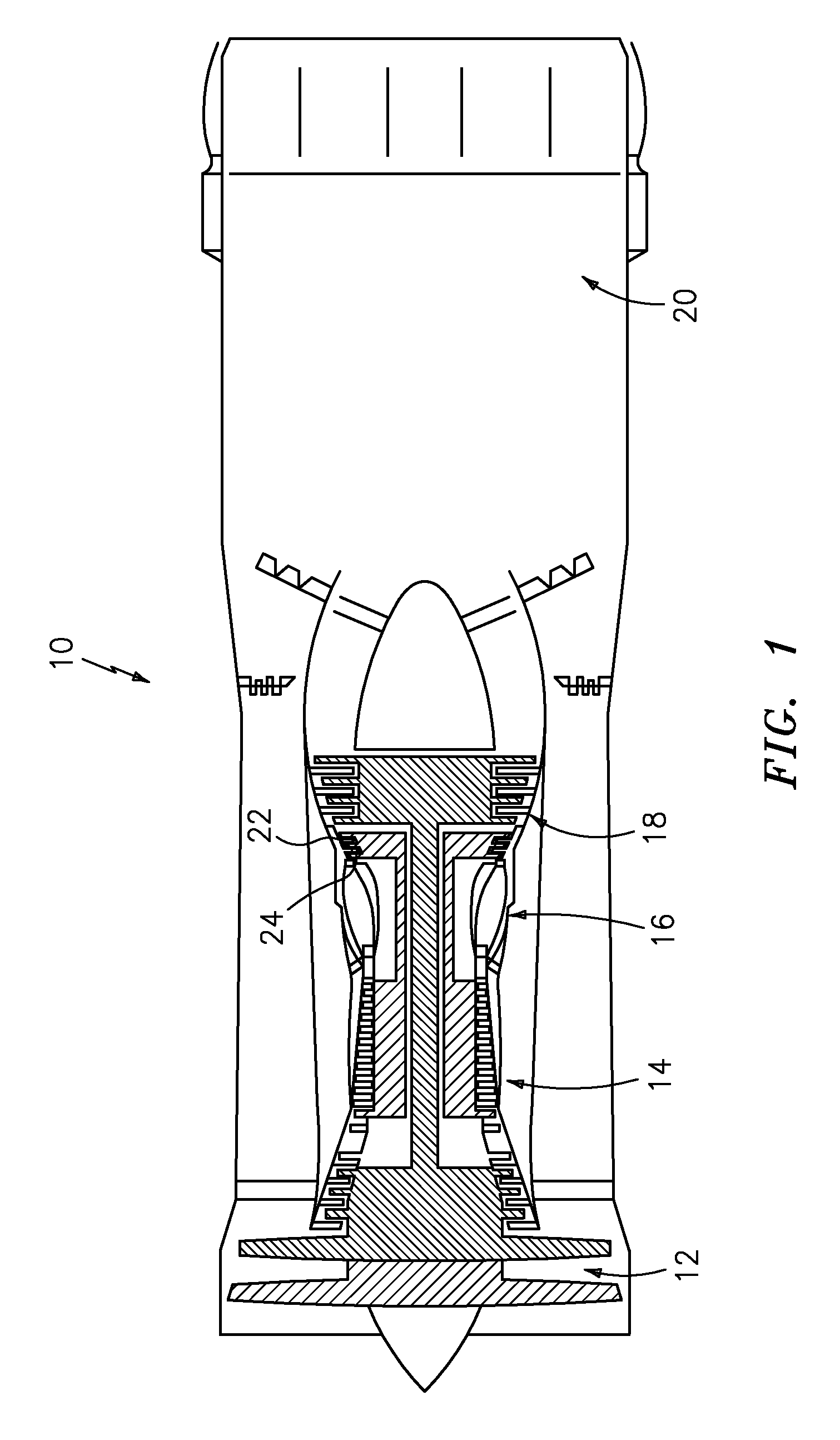

Passively cooled direct drive wind turbine

ActiveUS20060113804A1Improve heat transfer performanceIncrease air velocityEngine fuctionsMachines/enginesTurbineWind force

A wind turbine is provided that passively cools an electrical generator. The wind turbine includes a plurality of fins arranged peripherally around a generator house. Each of the fins being oriented at an angle greater than zero degrees to allow parallel flow of air over the fin. The fin is further tapered to allow a constant portion of the fin to extend beyond the air stream boundary layer. Turbulence initiators on the nose cone further enhance heat transfer at the fins.

Owner:WEG ELECTRIC CORP +1

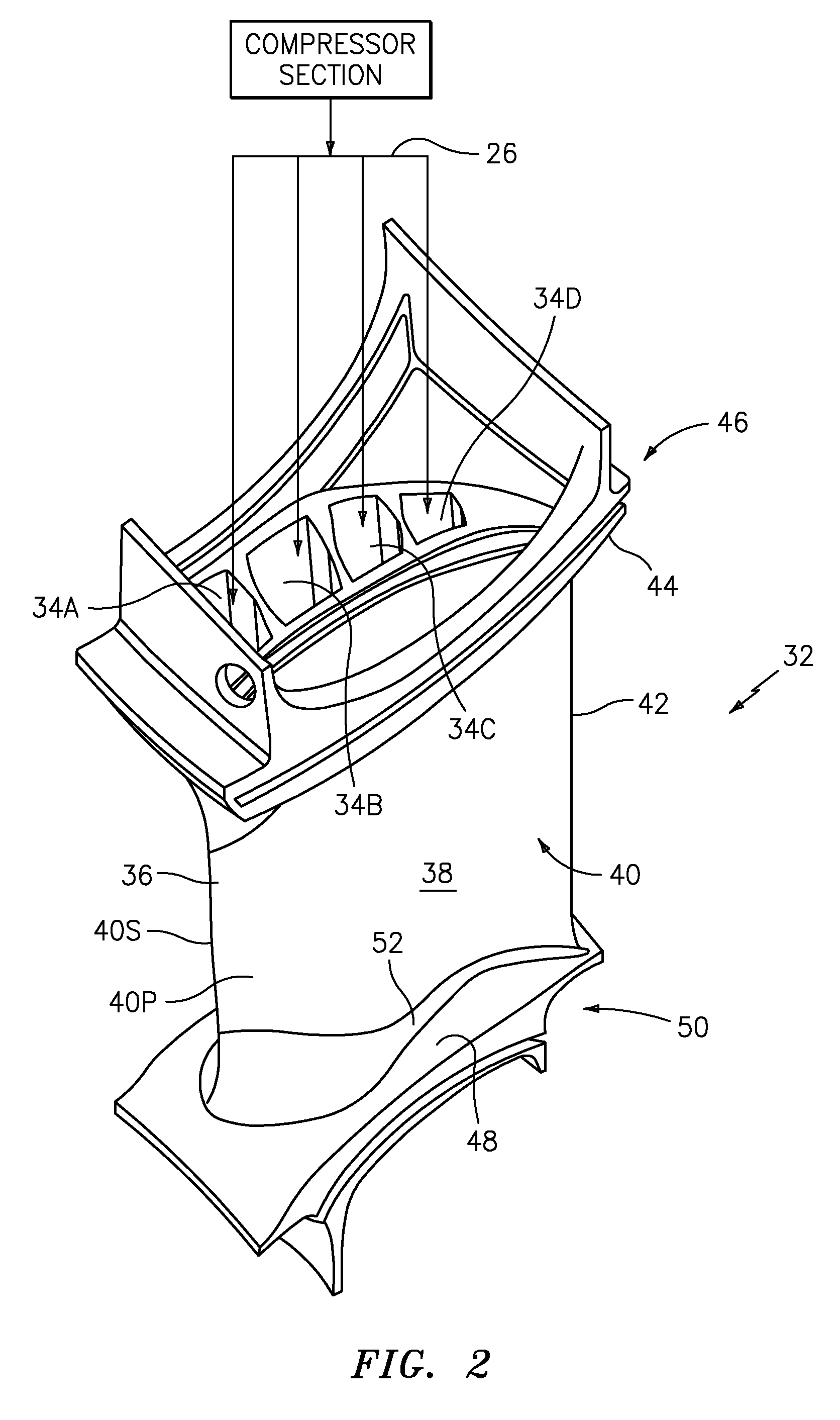

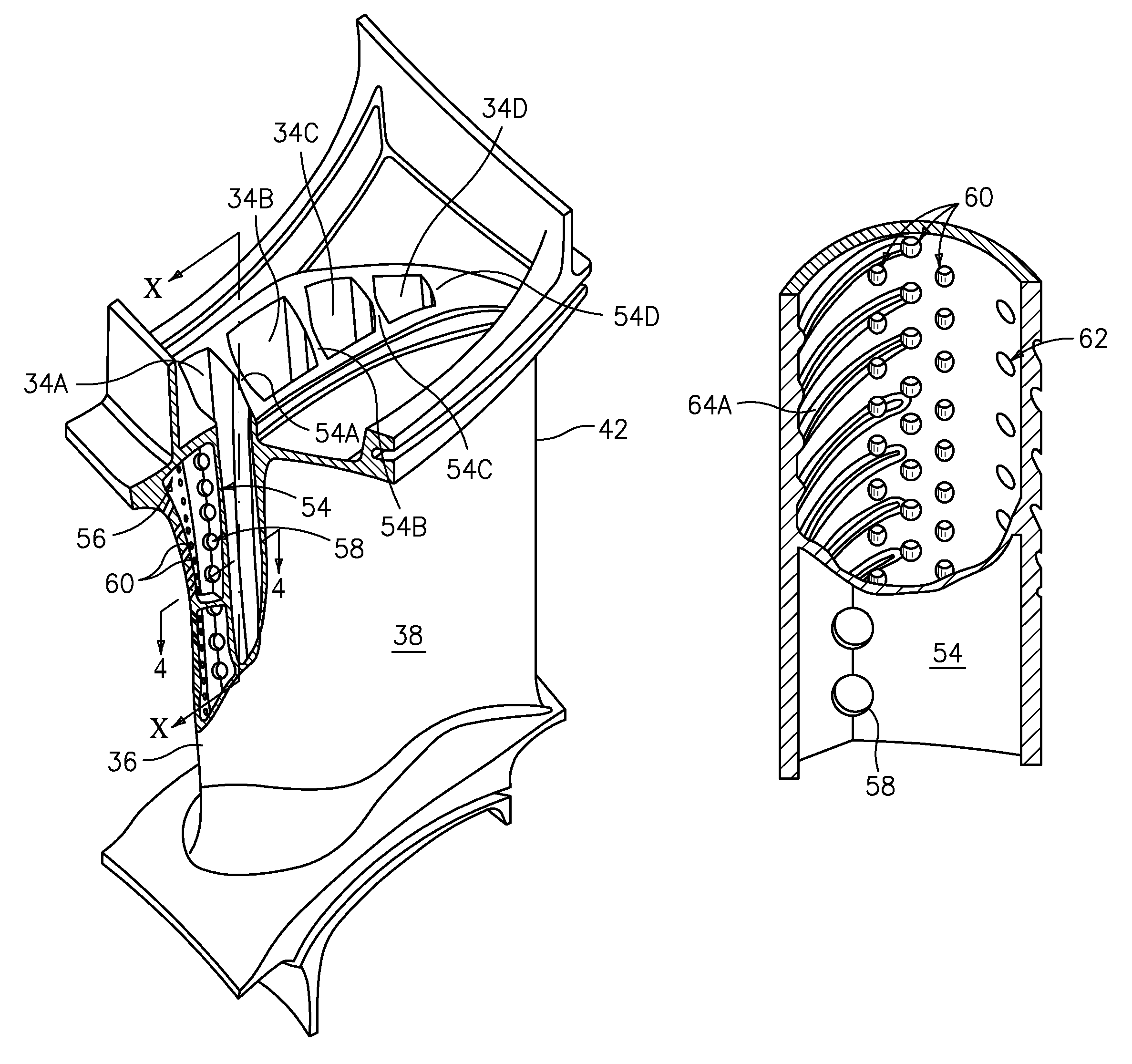

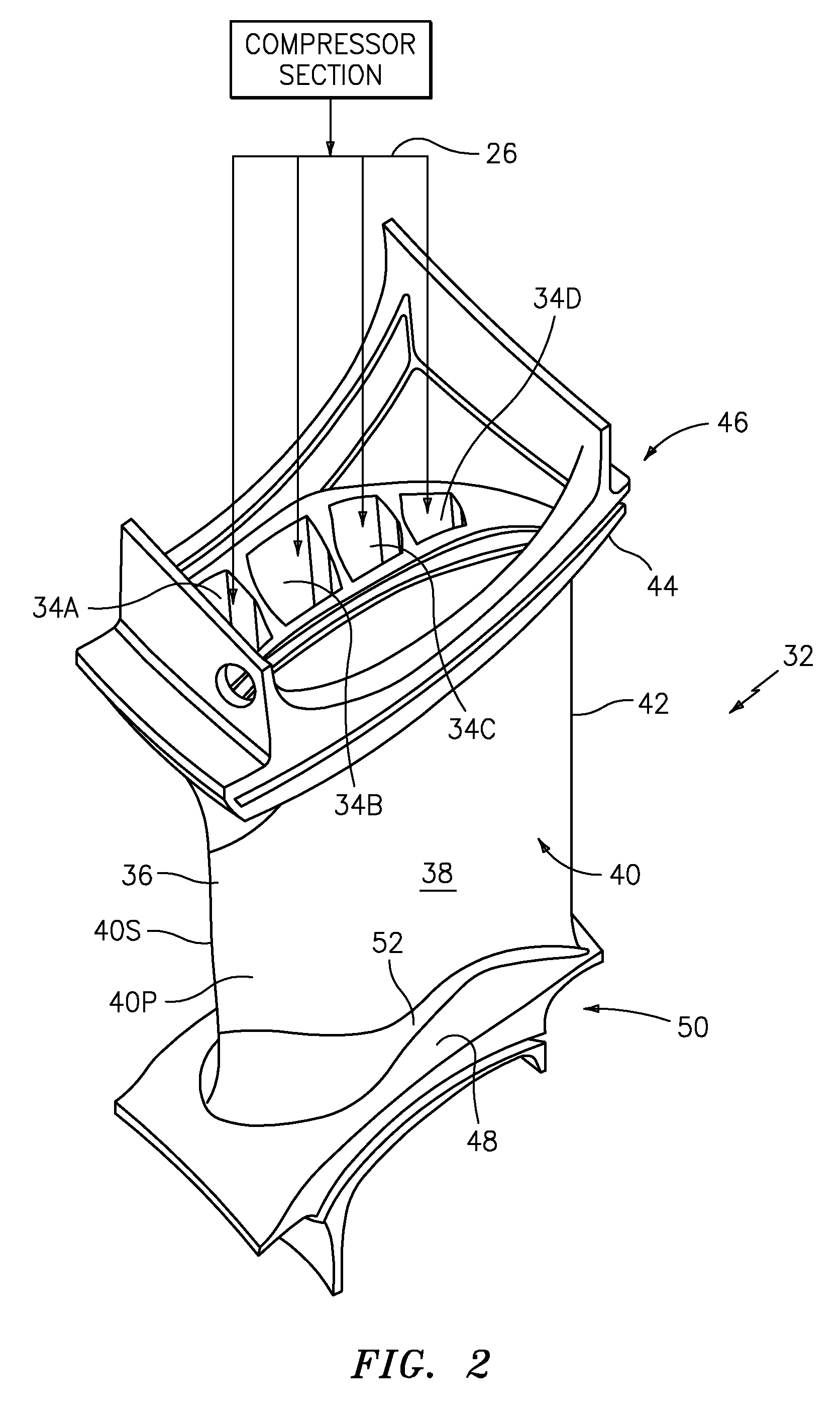

Cooling circuit flow path for a turbine section airfoil

ActiveUS20090074575A1Increase air velocityImprove transfer qualityPropellersPump componentsLeading edgeTurbine

A cooled airfoil includes an impingement rib having a multiple of openings which supply a cooling airflow from a cooling circuit flow path toward an airfoil leading edge. The multiple of openings are offset in the impingement rib opposite an outer airfoil wall which includes gill holes. Offsetting the multiple of openings opposite an outer airfoil wall which includes the gill holes focuses the cooling airflow across turbulators to increase the cooling airflow dwell time to increase the thermal transfer therefrom in higher temperature airfoil areas.

Owner:RTX CORP

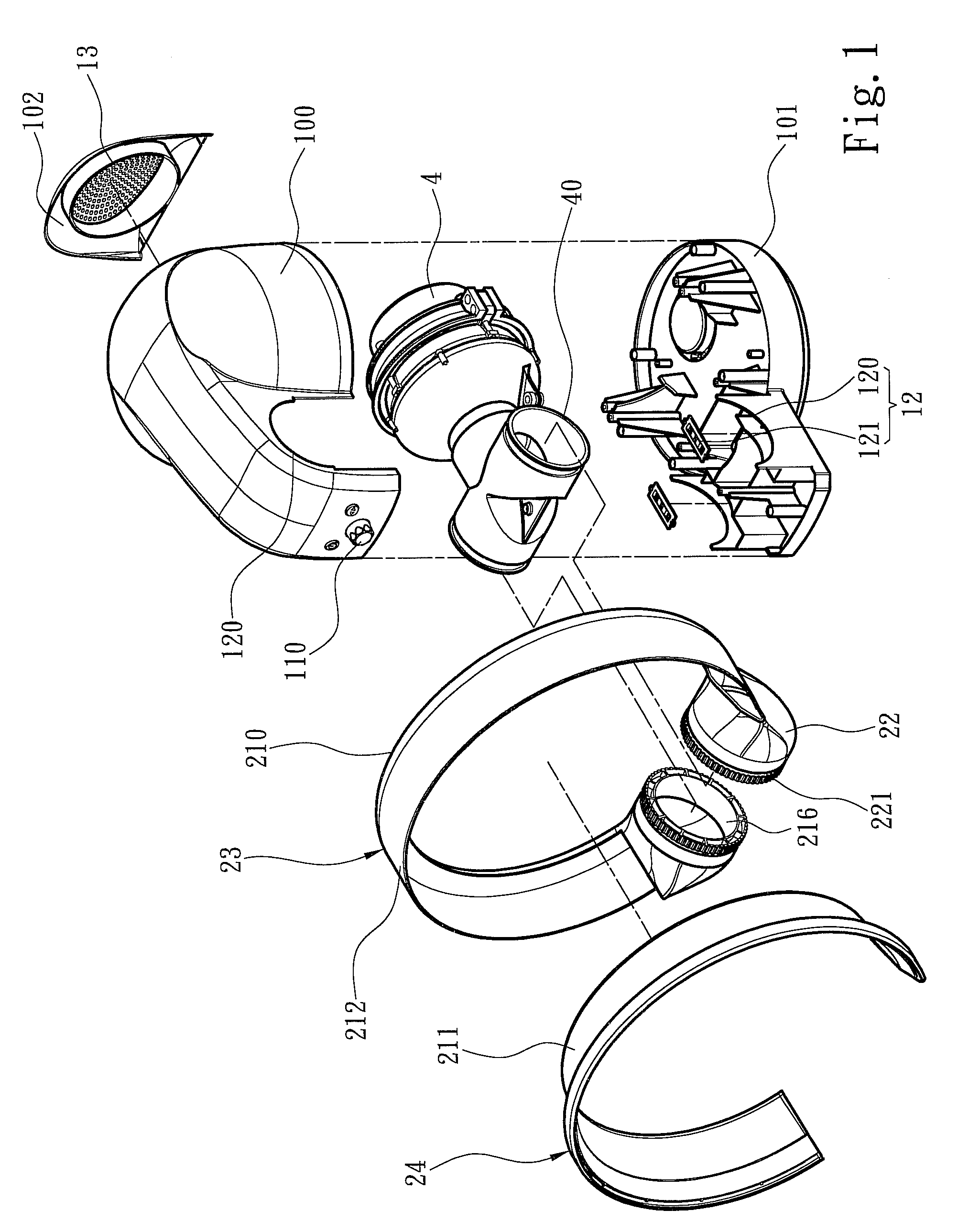

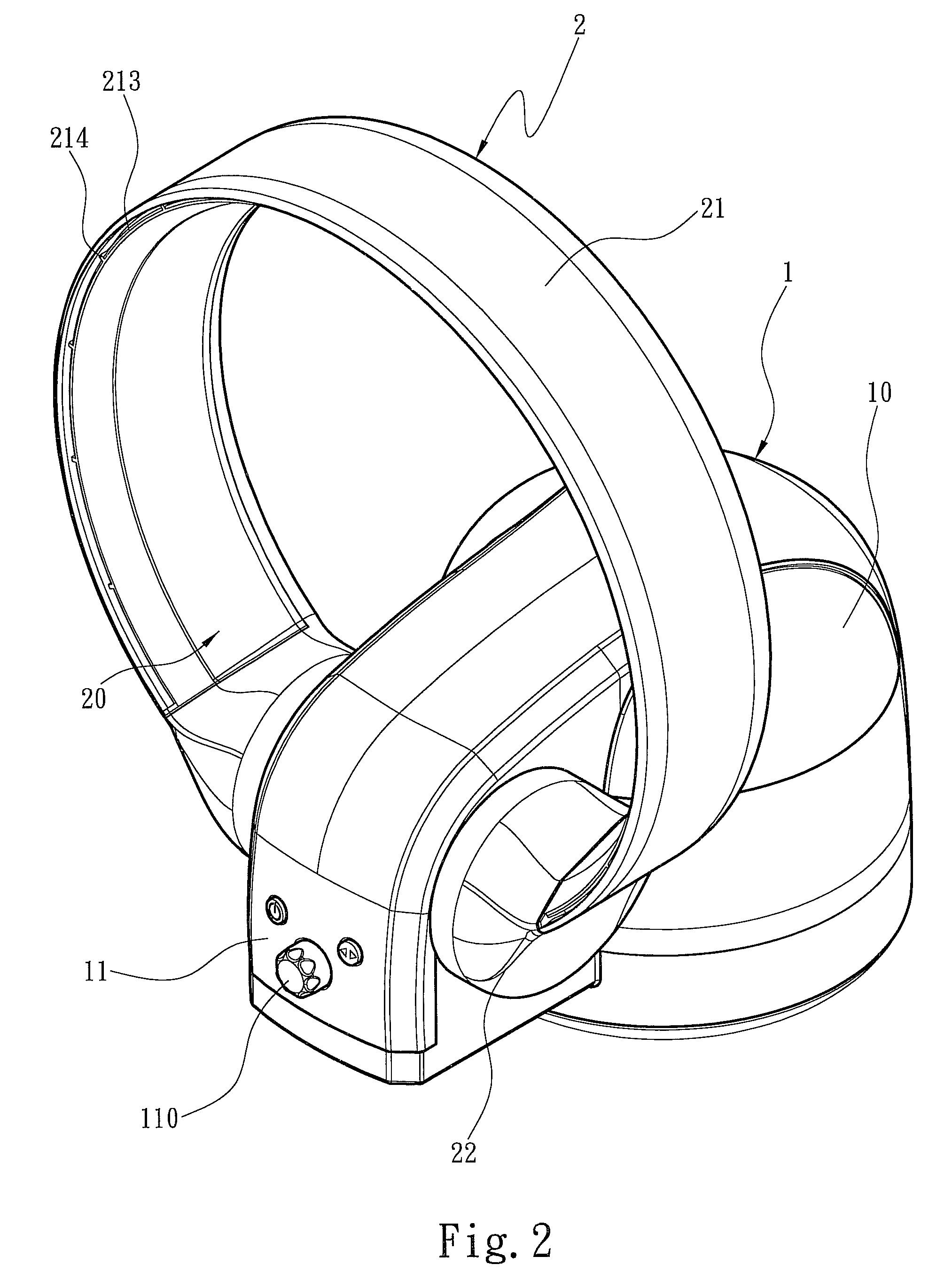

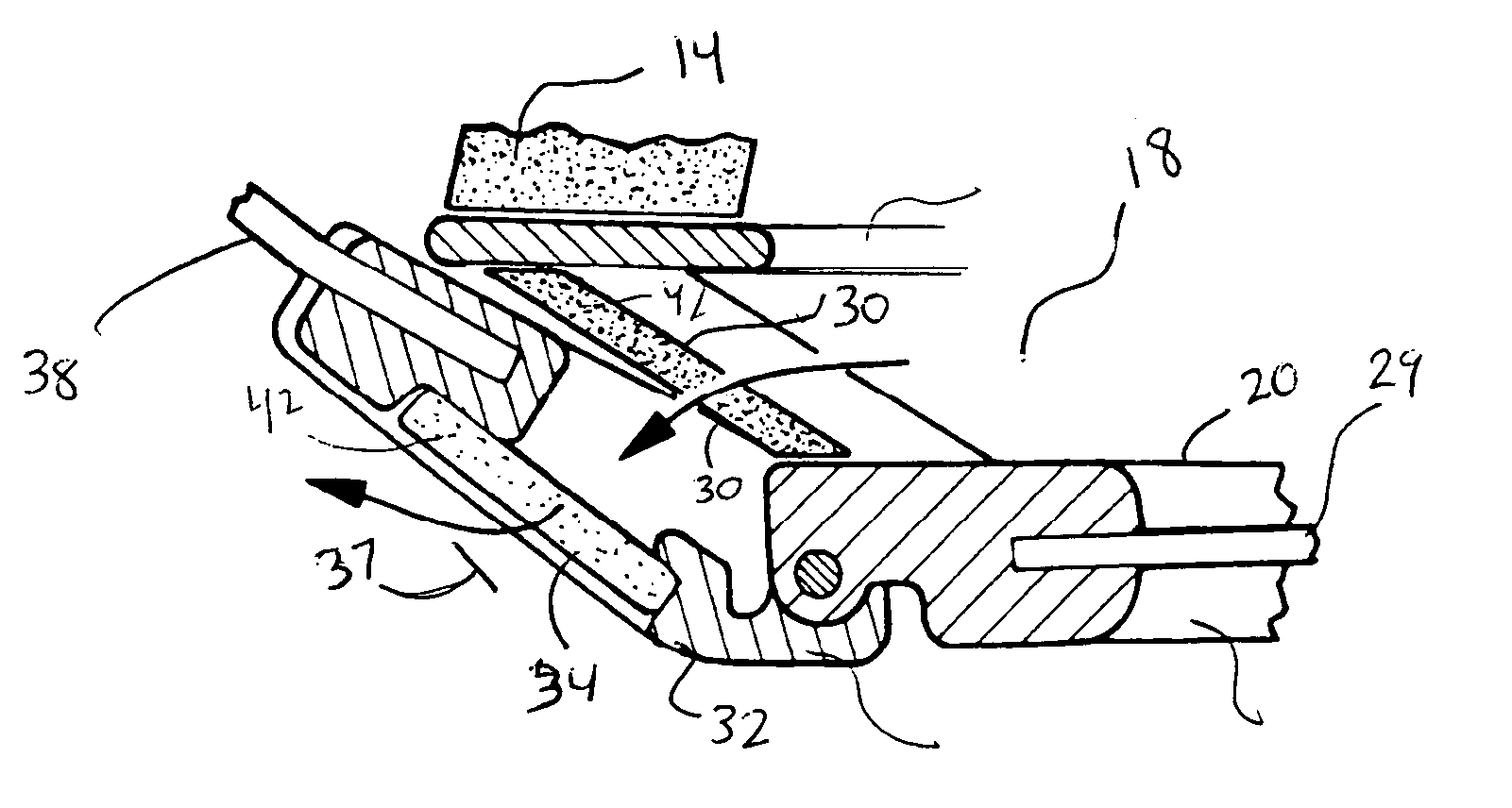

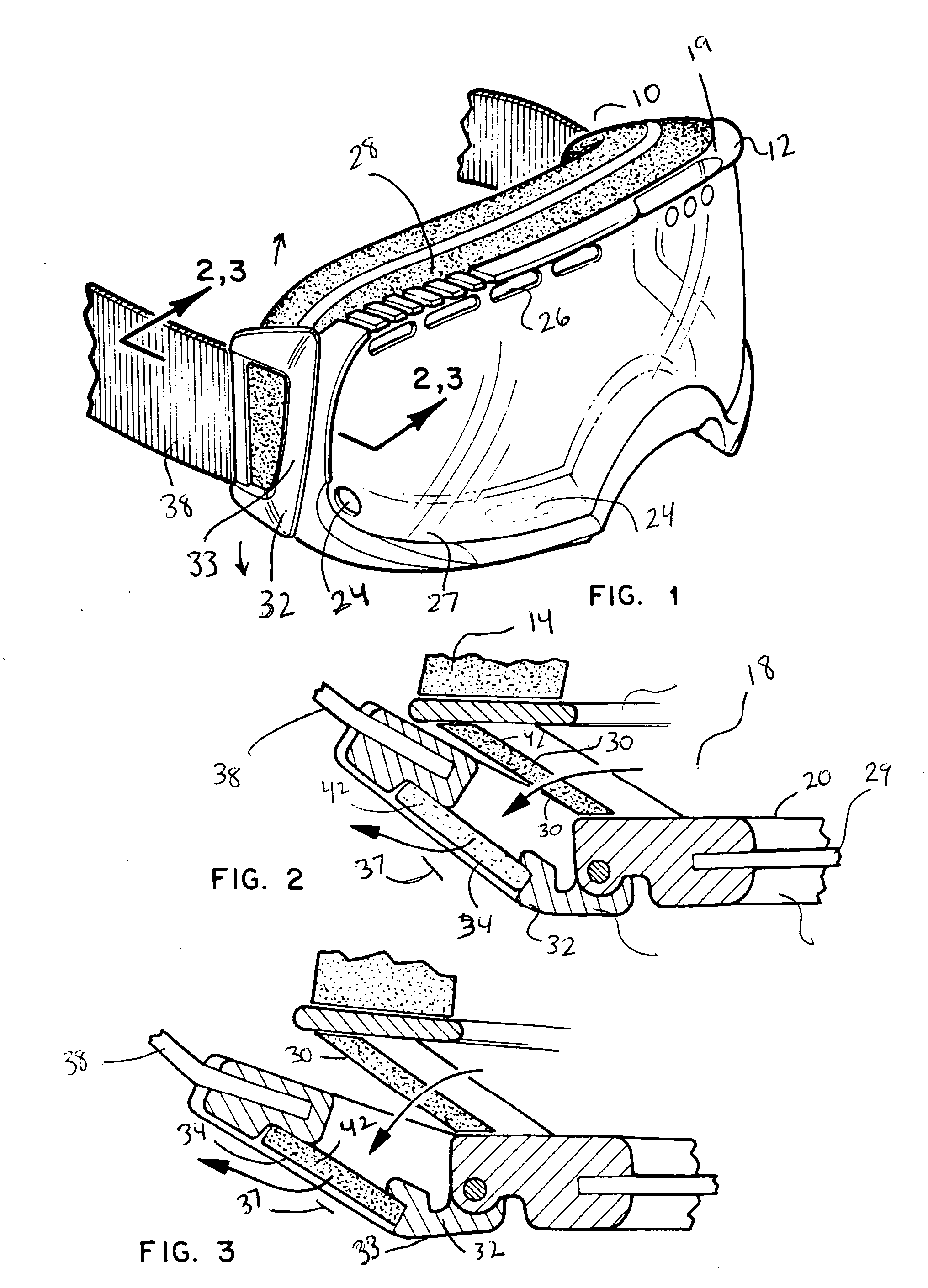

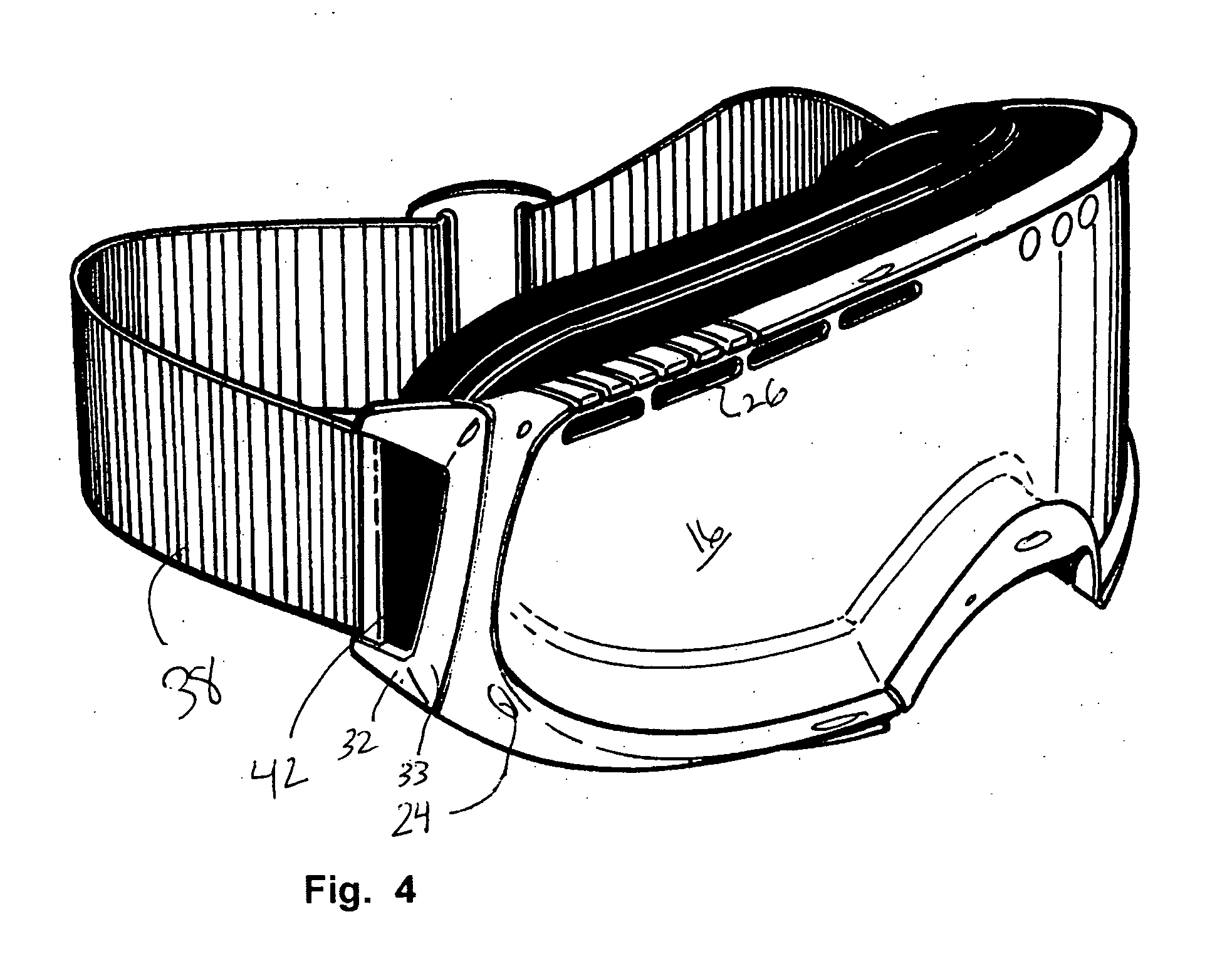

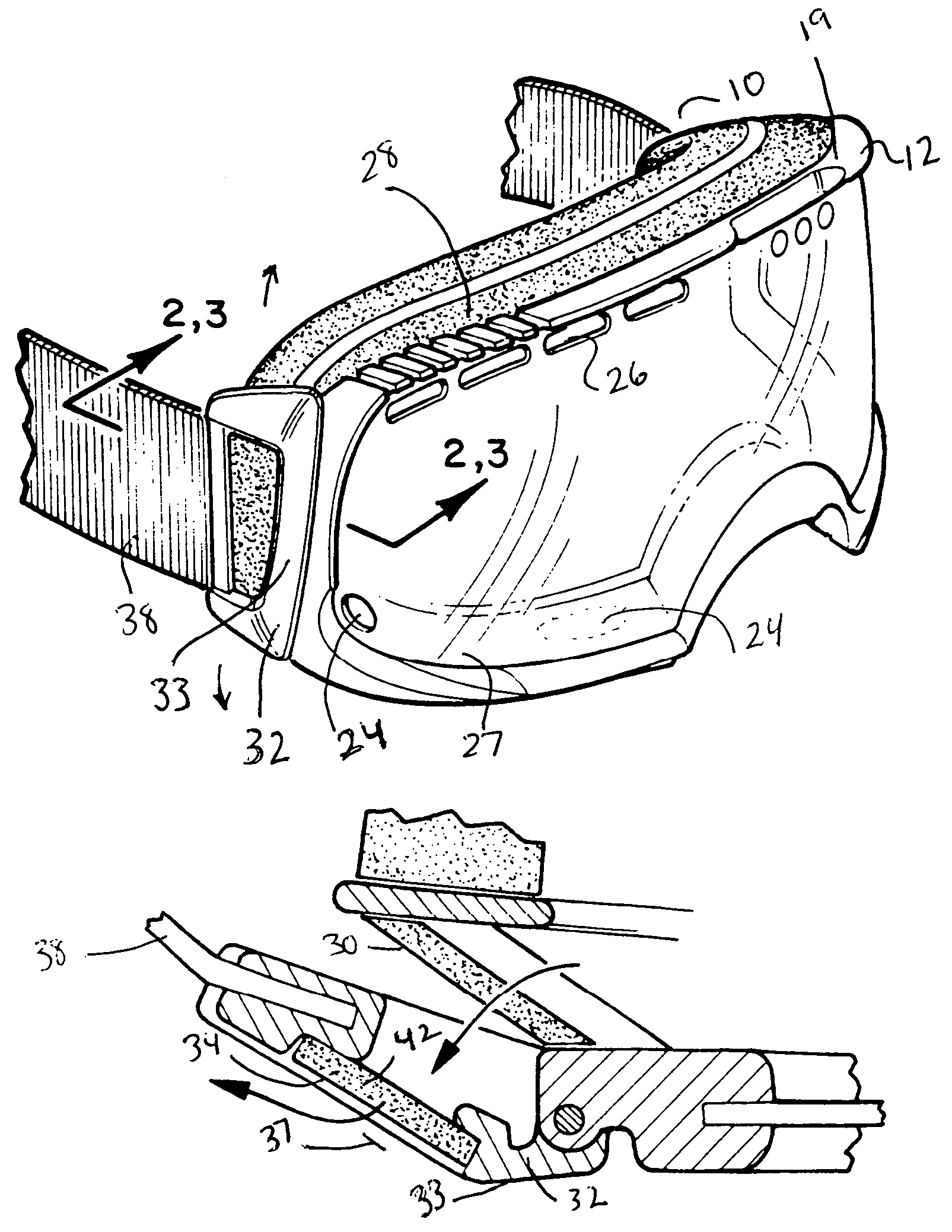

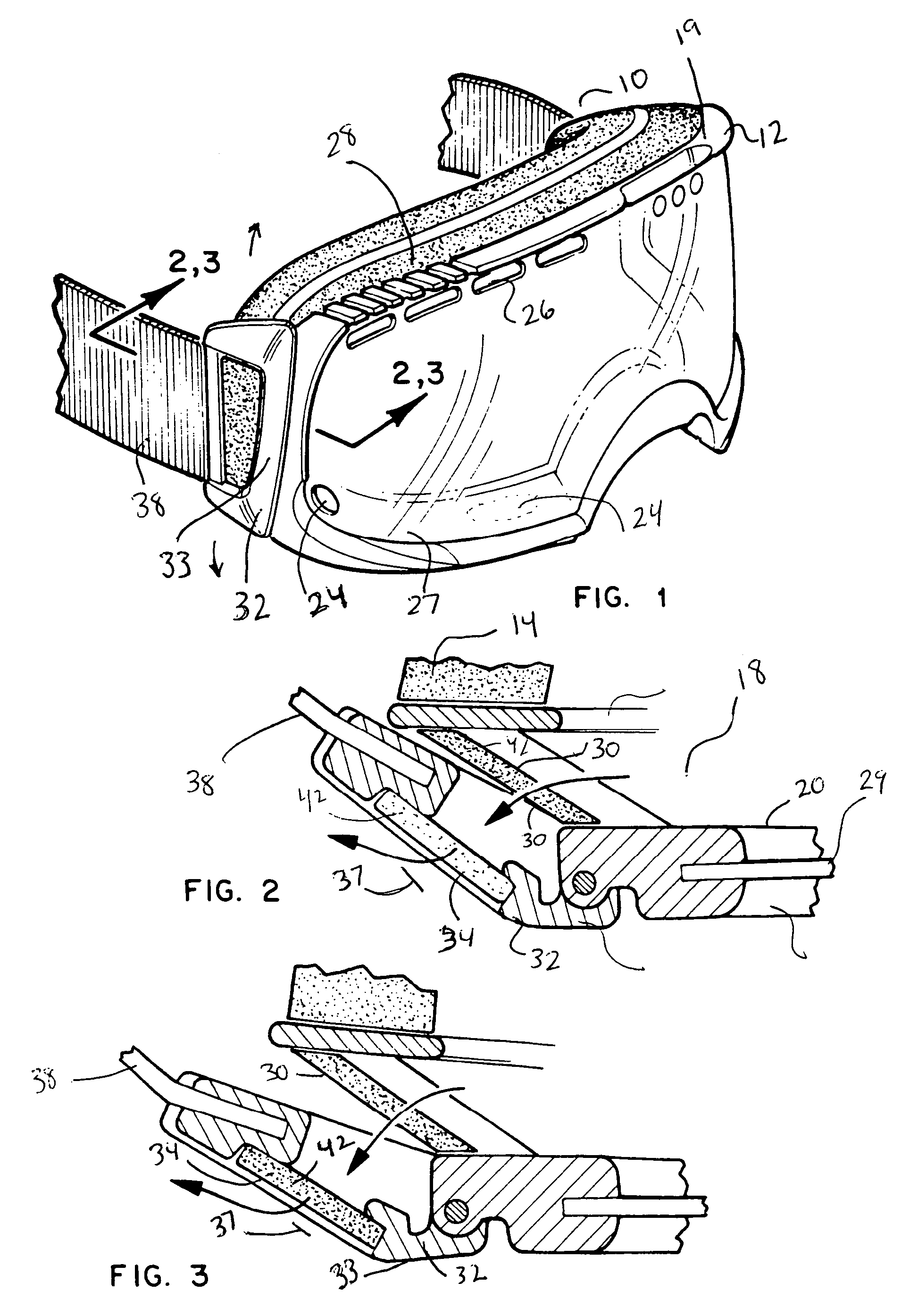

Sport goggle with side vent for improved ventilation

InactiveUS20050160521A1Avoid communicationEasy to cleanGogglesProtective garmentEngineeringHead parts

An improved sport goggle for skiing, motorcycling, paintball, racing, and other sports featuring clip-mounted side apertures communicating with the eye cavity of the goggle through adjacent venting apertures. Venting of the eye cavity of the sport goggle is aided by forming of the clip shape to create low pressure zones adjacent to the side venting apertures. The clips are rotationally attached to the goggle to provide an adjustable mount for the strap around heads or helmets while still forming the negative air pressure zone in all rotated positions. The clips may also be provided in a kit of differently dimensioned clips to adjust the negative air pressure venting characteristics of the clips and goggle to the intended sport or task.

Owner:K 2 CORP

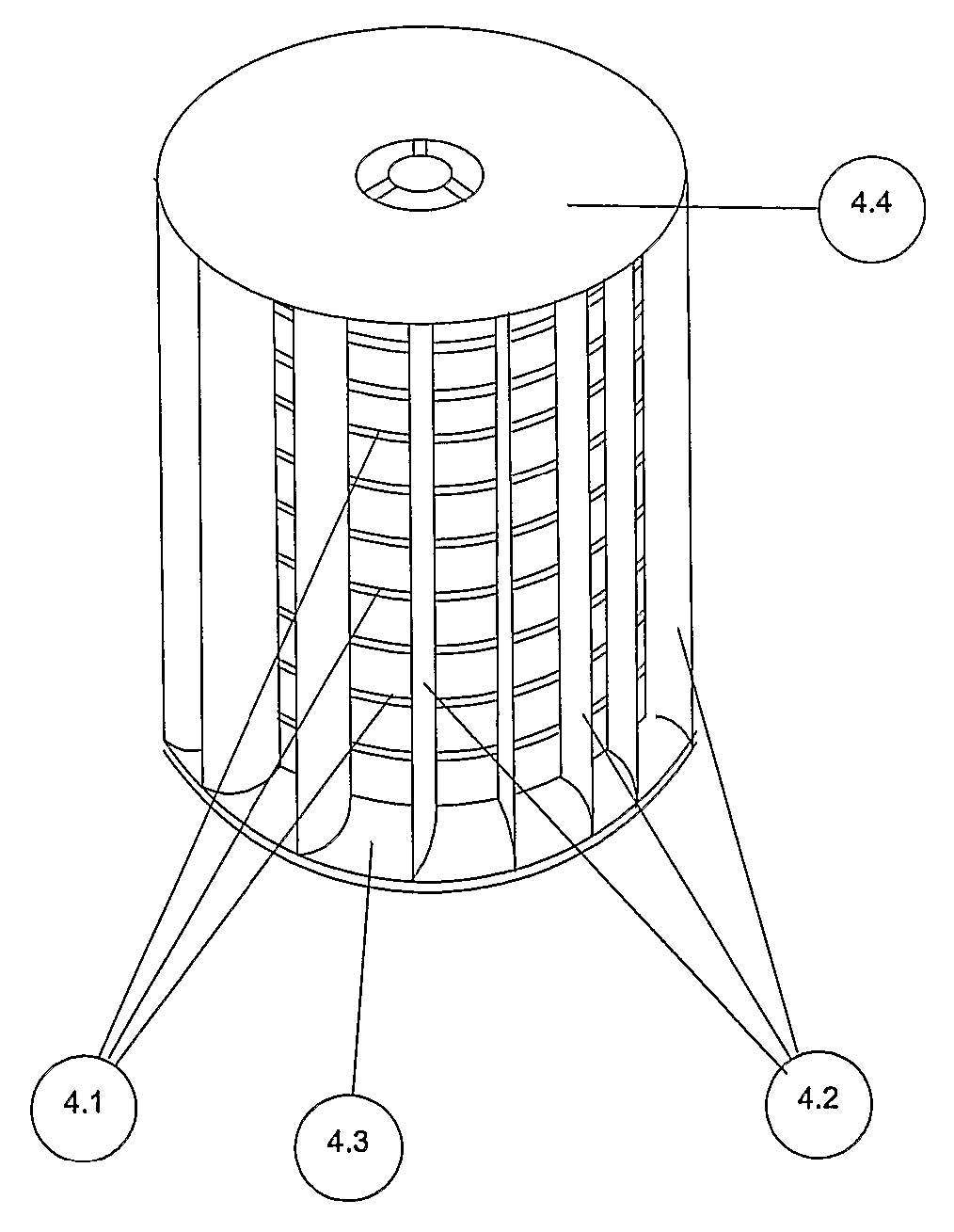

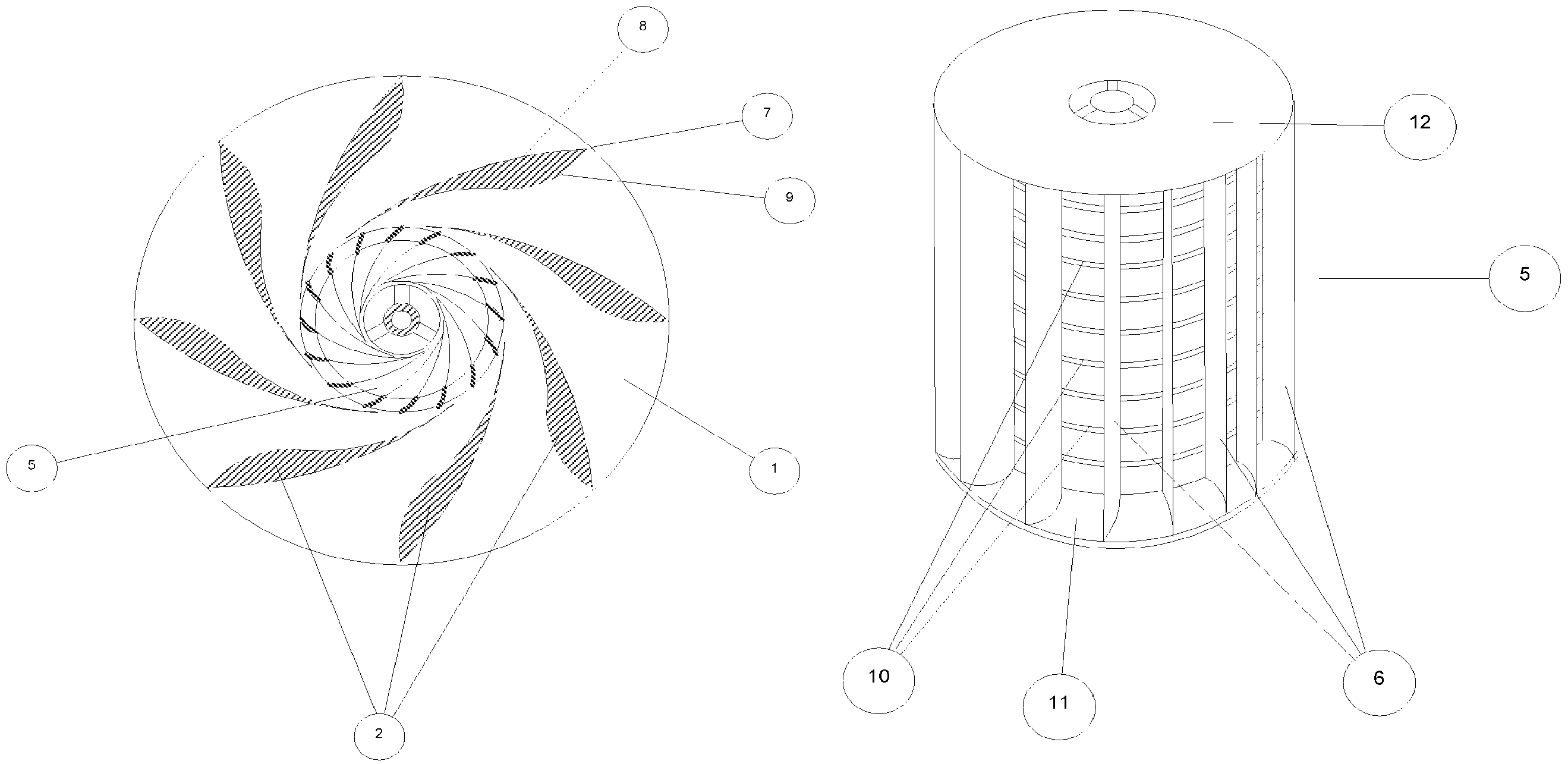

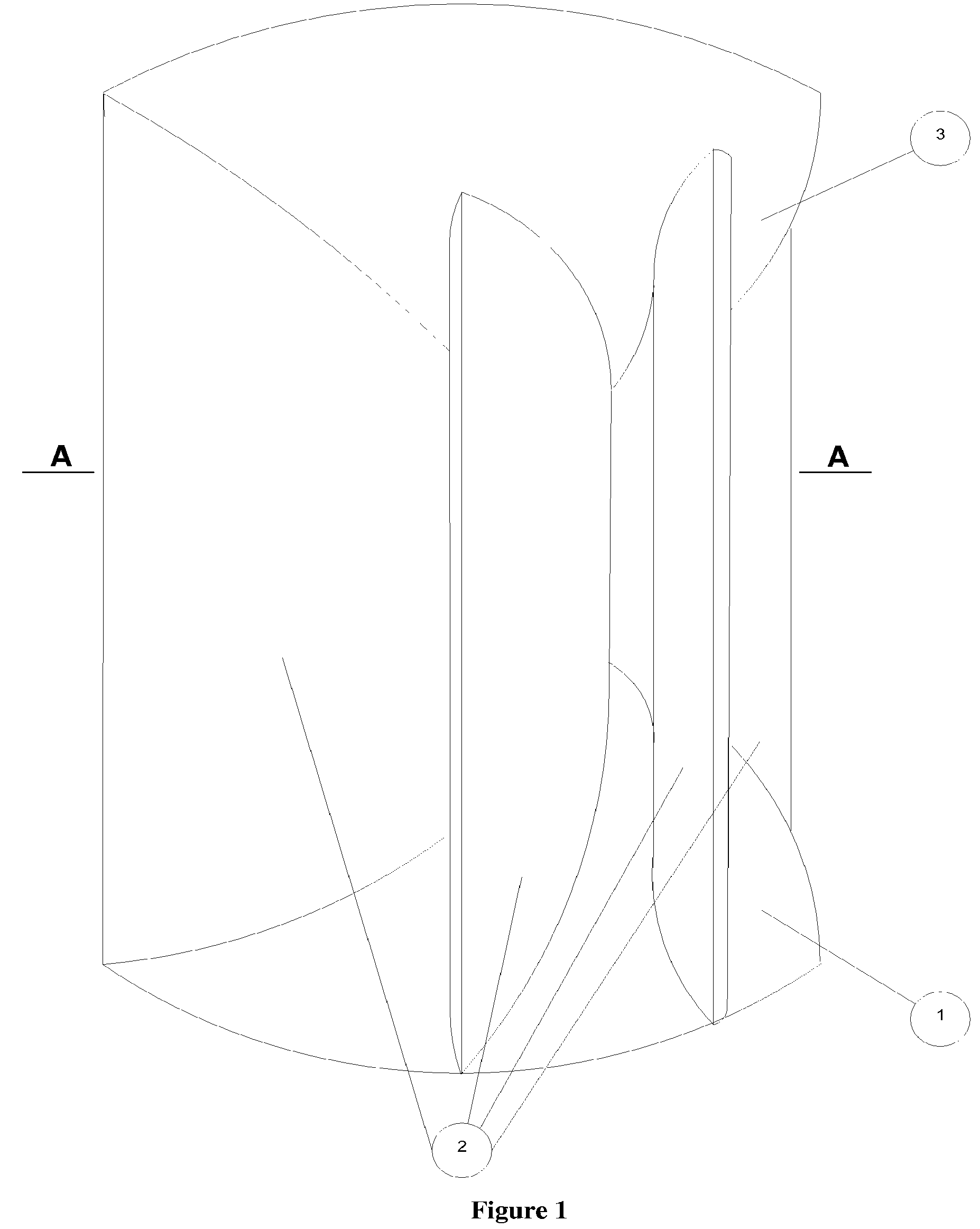

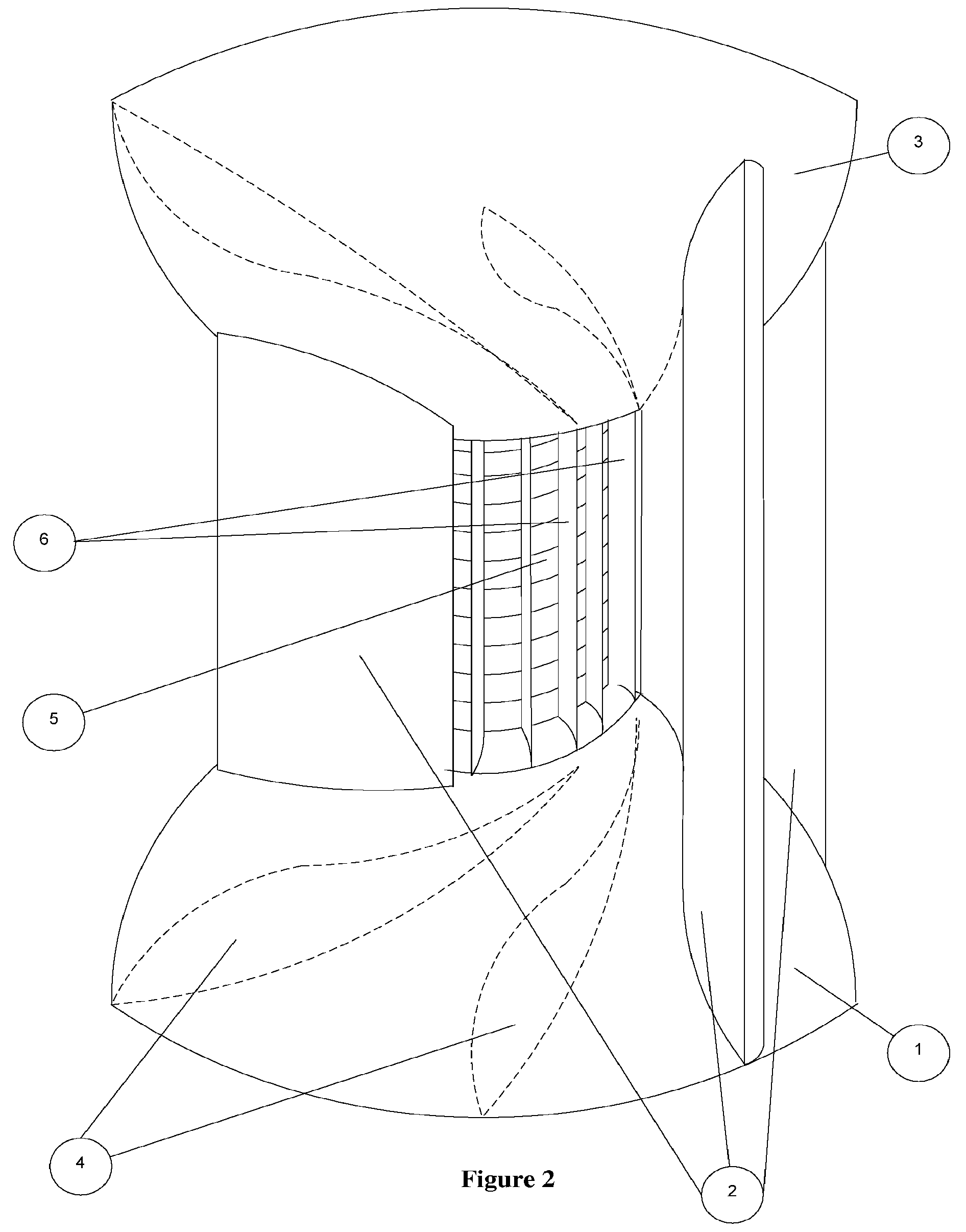

Boundary Layer Wind Turbine

InactiveUS20070296219A1Reliable and effective meanIncrease speedPropellersWind motor controlTurbineWind force

A wind turbine including a stator assembly having a plurality of stator blades for tangentially redirecting wind into a rotor assembly having a plurality of vertical rotor blades disposed circumferentially on a plurality of disks stacked one on top of each other. Each disk defines at least one opening thereon for redirecting the wind axially through each of the disks.

Owner:NICA HORIA

Wind power generator

InactiveUS7094018B2Speed up the air flowOverall efficiency of the wind power generator is maximizedPump componentsWind motor controlEngineeringWind force

Owner:GRUBB KELLY W

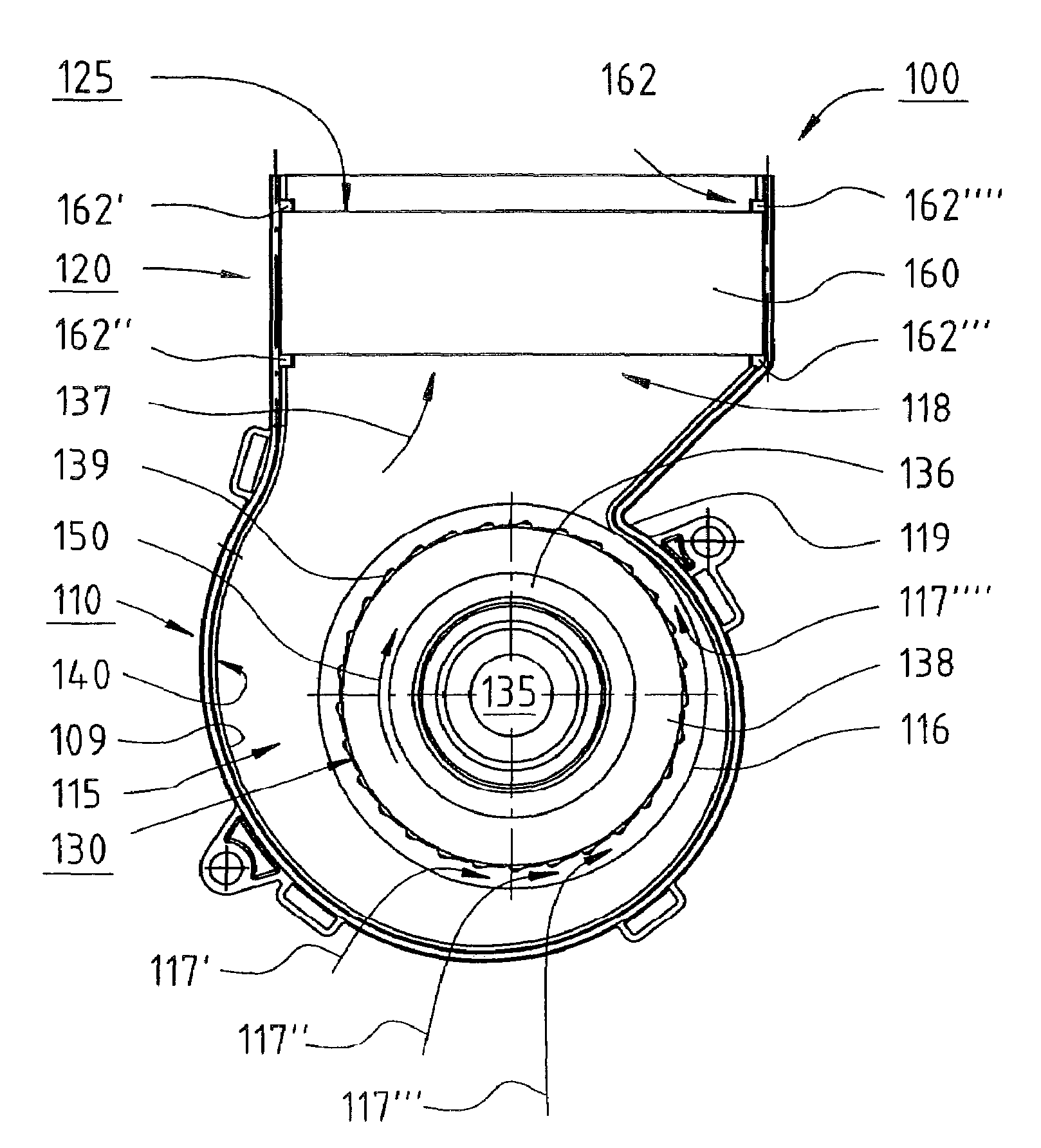

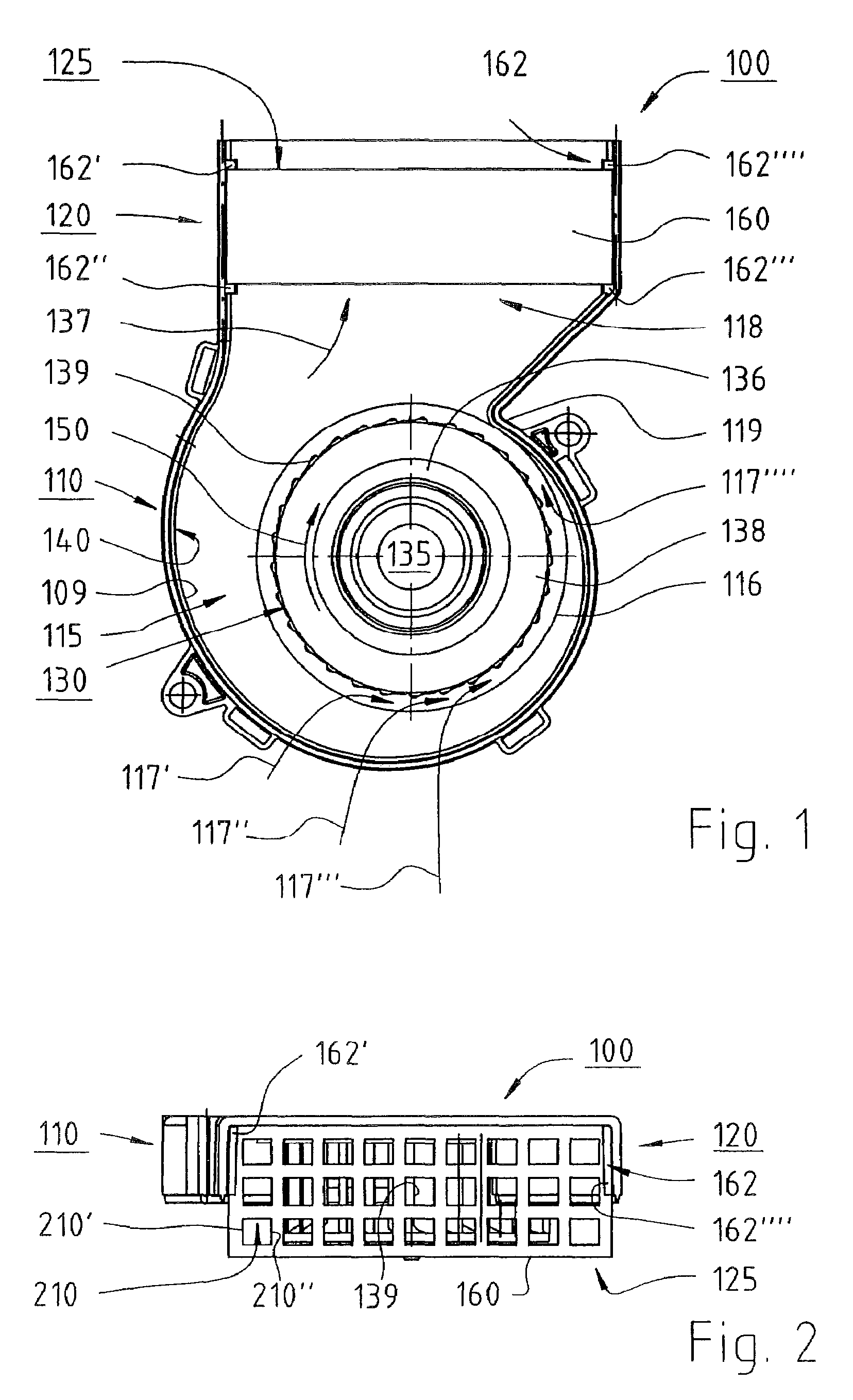

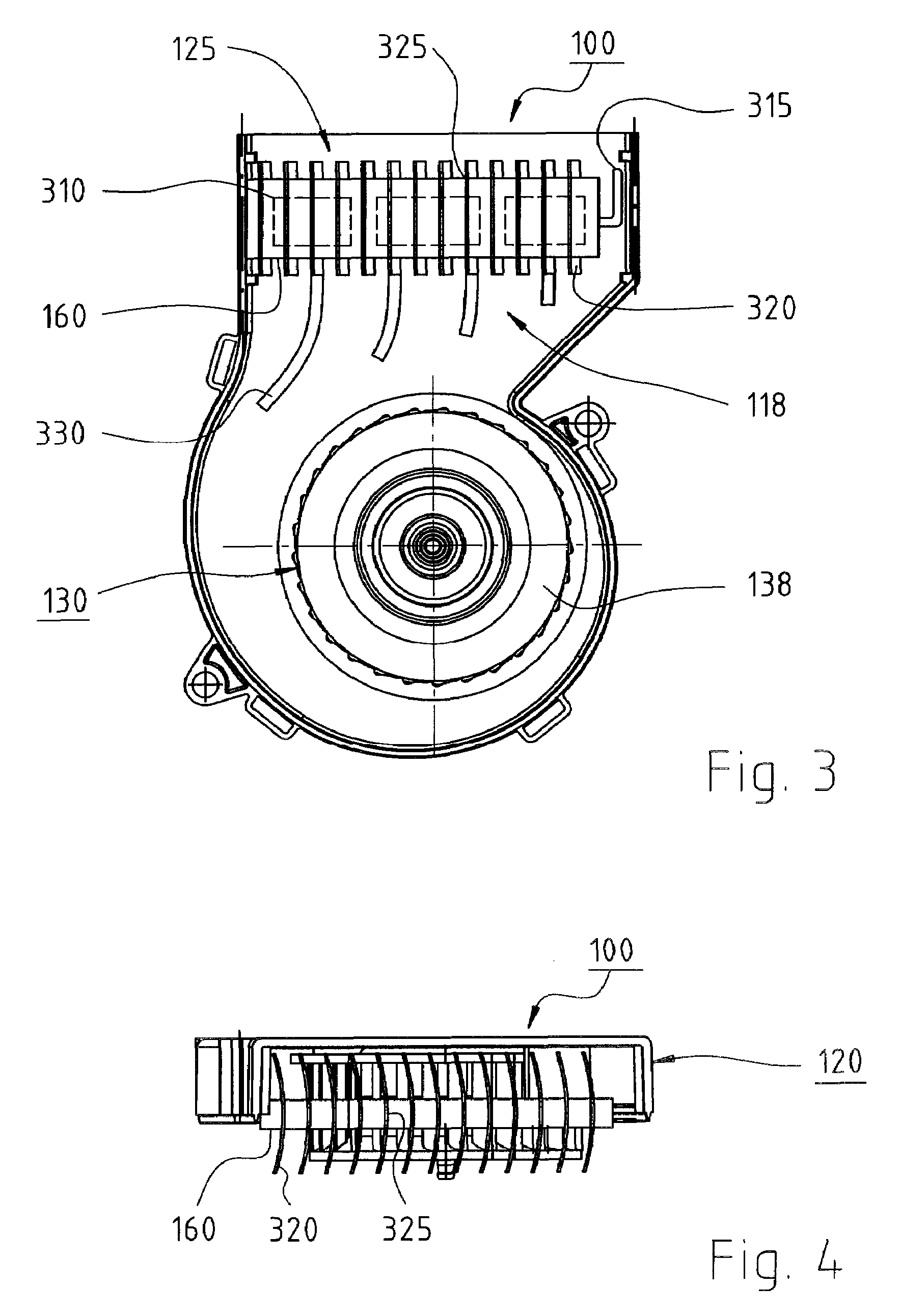

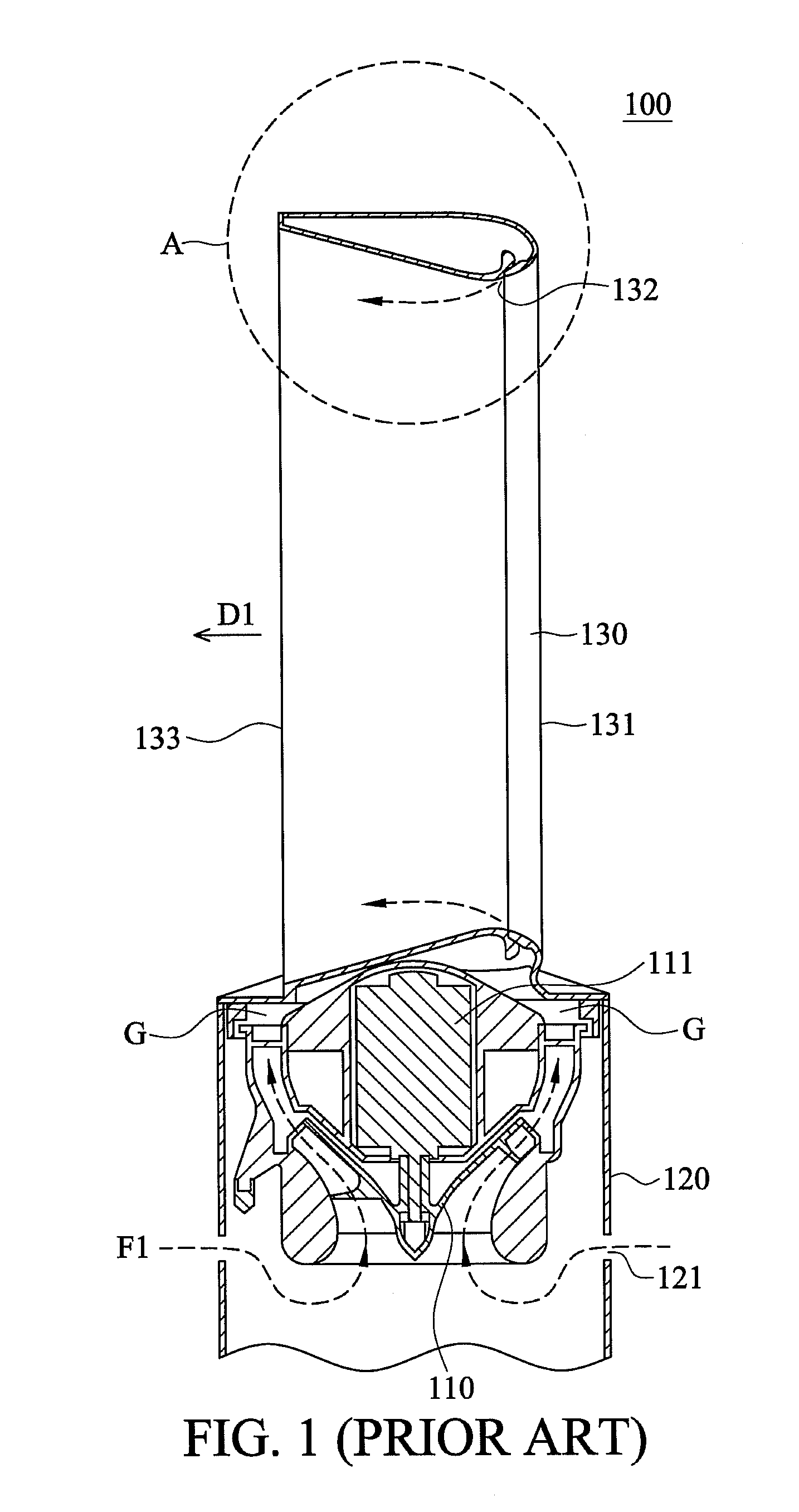

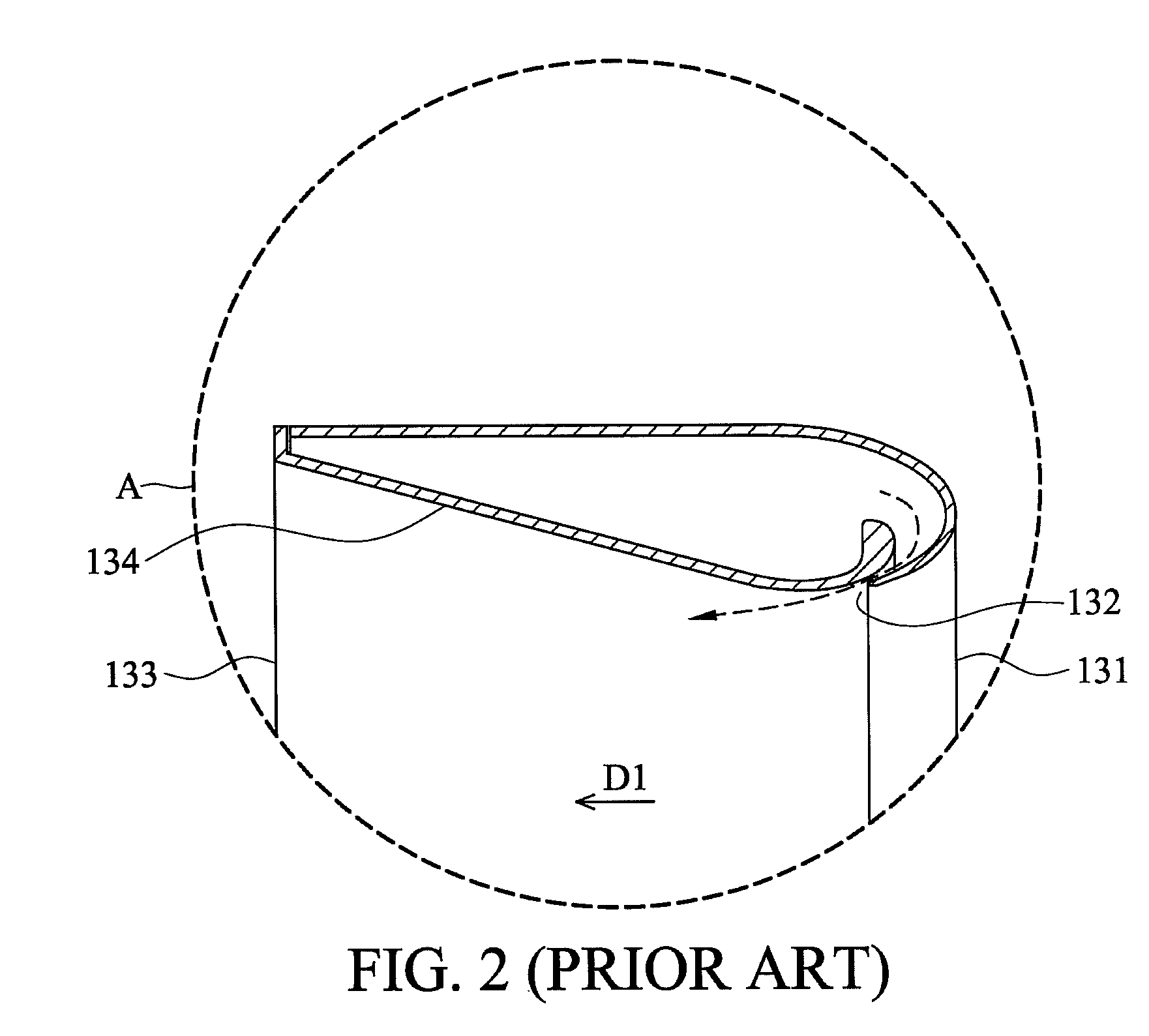

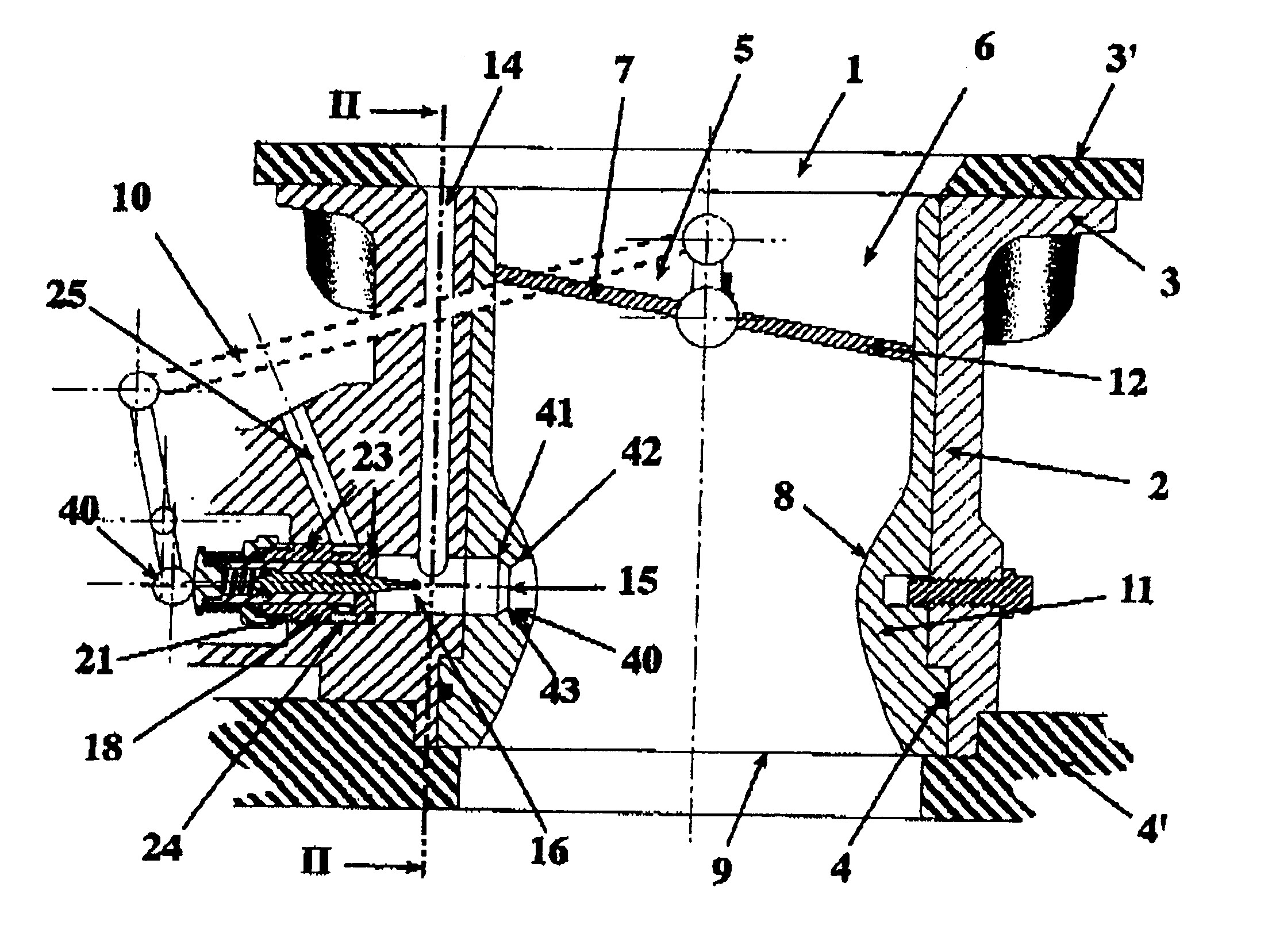

Heating unit

ActiveUS7355146B2Improve uniformityPhysically compactAir-treating devicesRailway heating/coolingImpellerEngineering

A heating unit for a vehicle features a radial fan (100) having a housing (110), which housing has an air inlet (116) and an air exit opening (118). The heating unit has an air-directing device (140) that guides an air flow in a pressure chamber (115) of the housing (110) to the exit opening (118). Arranged in the housing (110) is a radial fan wheel (130) that serves to generate a flow from the air inlet (116) via the pressure chamber (115) to the air exit opening (118). Also provided is an electrical heating element, e.g. a PTC (Positive Temperature Coefficient) heating element (125), that serves to transfer heat to the air flow generated by the fan. Air-directing elements (632, 634, 636, 638) are provided between the exit opening (118) and the heating element (125), in order to generate an air flow having a more uniform (680) velocity distribution.

Owner:EBM PAPST ST GEORGEN & -

Fan assembly

ActiveUS8992174B2Increase air velocityIncrease speedPump componentsJet pumpsEngineeringCentrifugal force

A fan assembly includes a channel structure and a centrifugal fan. The channel structure includes a housing and at least a slit. The housing has an accommodating space and a flow channel adjacent to each other. The slit is extended along the flow channel. The flow channel is communicated with the outside of the housing via the slit. The centrifugal fan is disposed in the accommodating space. The centrifugal fan draws air along an axial direction and generates an airflow. The airflow flows into the flow channel along a radial direction, and flows out to the outside of the housing via the slit.

Owner:DELTA ELECTRONICS INC

Passively cooled direct drive wind turbine

ActiveUS7345376B2Improve heat transfer performanceIncrease air velocityEngine fuctionsMachines/enginesTurbineWind force

A wind turbine is provided that passively cools an electrical generator. The wind turbine includes a plurality of fins arranged peripherally around a generator house. Each of the fins being oriented at an angle greater than zero degrees to allow parallel flow of air over the fin. The fin is further tapered to allow a constant portion of the fin to extend beyond the air stream boundary layer. Turbulence initiators on the nose cone further enhance heat transfer at the fins.

Owner:WEG ELECTRIC CORP +1

Boundary layer wind turbine

A wind turbine including a stator assembly having a plurality of stator blades for tangentially redirecting wind into a rotor assembly having a plurality of vertical rotor blades disposed circumferentially on a plurality of disks stacked one on top of each other. Each disk defines at least one opening thereon for redirecting the wind axially through each of the disks.

Owner:NICA HORIA

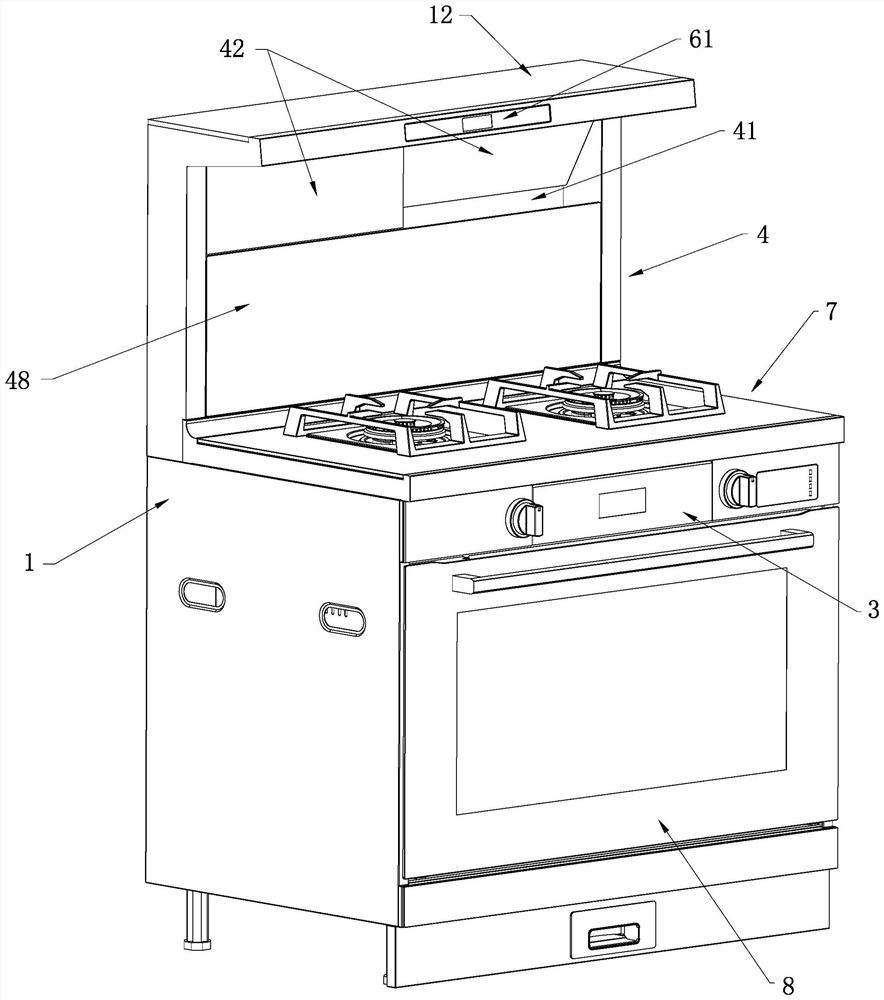

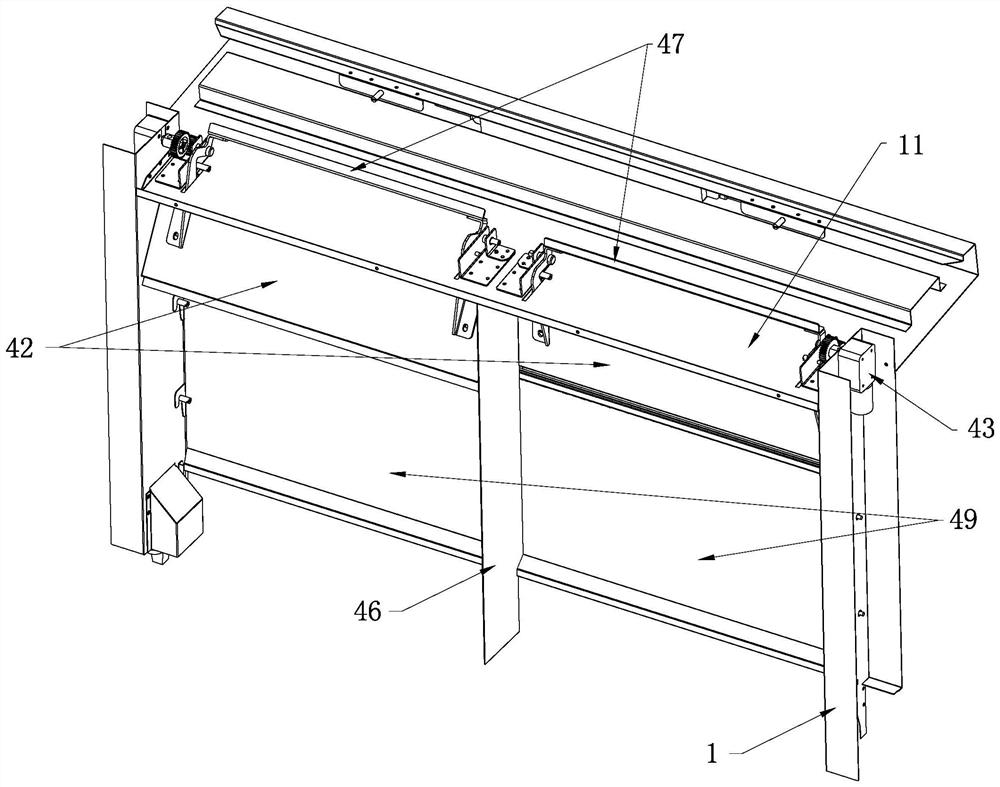

Integrated cooker

PendingCN112555906AOutstanding and Beneficial Technical EffectsGuaranteed tightnessDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention belongs to the technical field of kitchen appliances, and particularly relates to an integrated cooker. The integrated cooker comprises a machine body and a range hood body; the range hood body comprises an air inlet, an air collecting box and a fan assembly; the air collecting box communicates with the air inlet; the fan assembly is arranged in the air collecting box; a volute air duct of the fan assembly extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with an air outlet base; and an air outlet is formed in one side of the air outlet base. According to the integrated cooker, the volute air duct extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with the air outlet base; the air outlet base is directly located on the outer side of the air collecting box, and the situation that a channel is located inside and occupies too much space is avoided; a through hole does not need to be additionally formed in the side edge of the machine body, and leakproofnessof the side face of the machine body is guaranteed; and meanwhile, the air outlet base is rotatably arranged, so that a user can conveniently adjust the air outlet direction according to actual needs,and humanization is achieved.

Owner:浙江安德电器有限公司

Dust collecting apparatus with a plurality of inlets

InactiveUS20070214756A1Improved structureIncrease rotational forceCleaning filter meansAuxillary pretreatmentEngineeringMechanical engineering

The present disclosure relates to a dust collecting apparatus. The dust collecting apparatus includes a cyclone body forming a cyclone chamber; a plurality of inlets formed at the cyclone body, and causing air to enter through; and a discharging port formed at the cyclone body, and discharging the air from the cyclone chamber, wherein each inlet of the plurality of inlets is formed at a different height at a side of the cyclone body so that the air is divided to enter the cyclone chamber at a different height.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Sport goggle with side vent for improved ventilation

InactiveUS7181779B2Increase airflowIncrease air velocityGogglesProtective garmentCollateral ventilationEngineering

An improved sport goggle for skiing, motorcycling, paintball, racing, and other sports featuring clip-mounted side apertures communicating with the eye cavity of the goggle through adjacent venting apertures. Venting of the eye cavity of the sport goggle is aided by forming of the clip shape to create low pressure zones adjacent to the side venting apertures. The clips are rotationally attached to the goggle to provide an adjustable mount for the strap around heads or helmets while still forming the negative air pressure zone in all rotated positions. The clips may also be provided in a kit of differently dimensioned clips to adjust the negative air pressure venting characteristics of the clips and goggle to the intended sport or task.

Owner:K 2 CORP

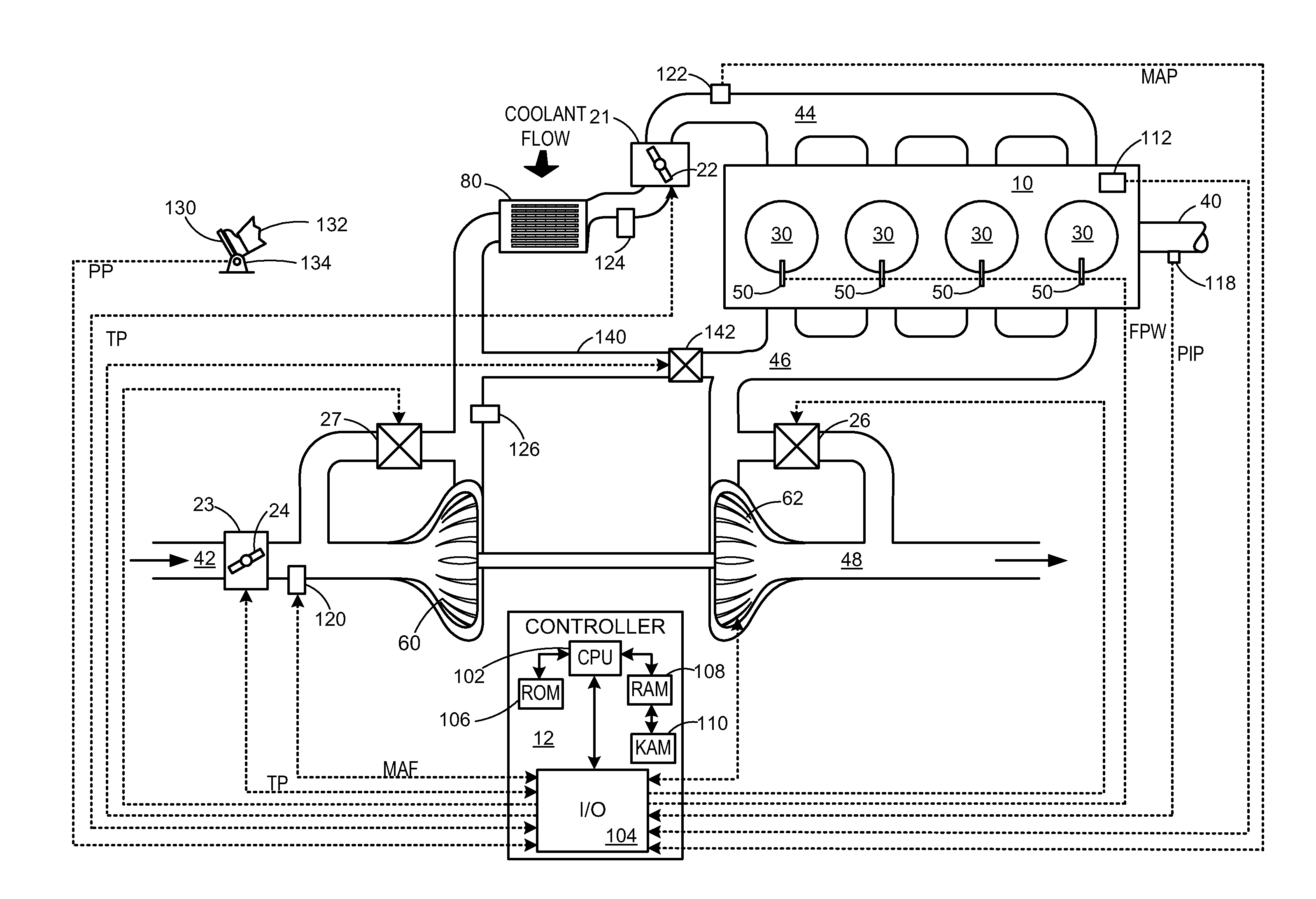

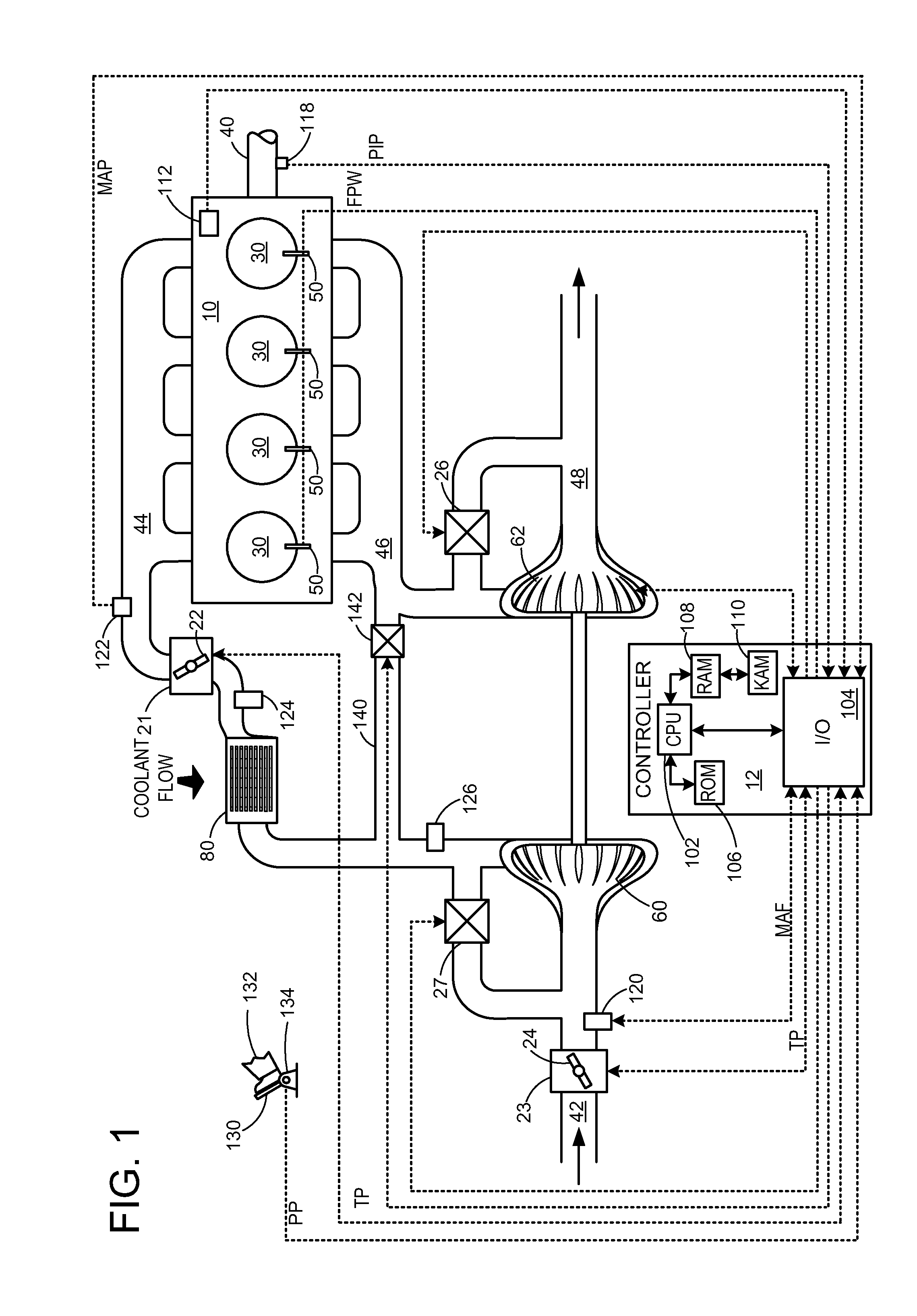

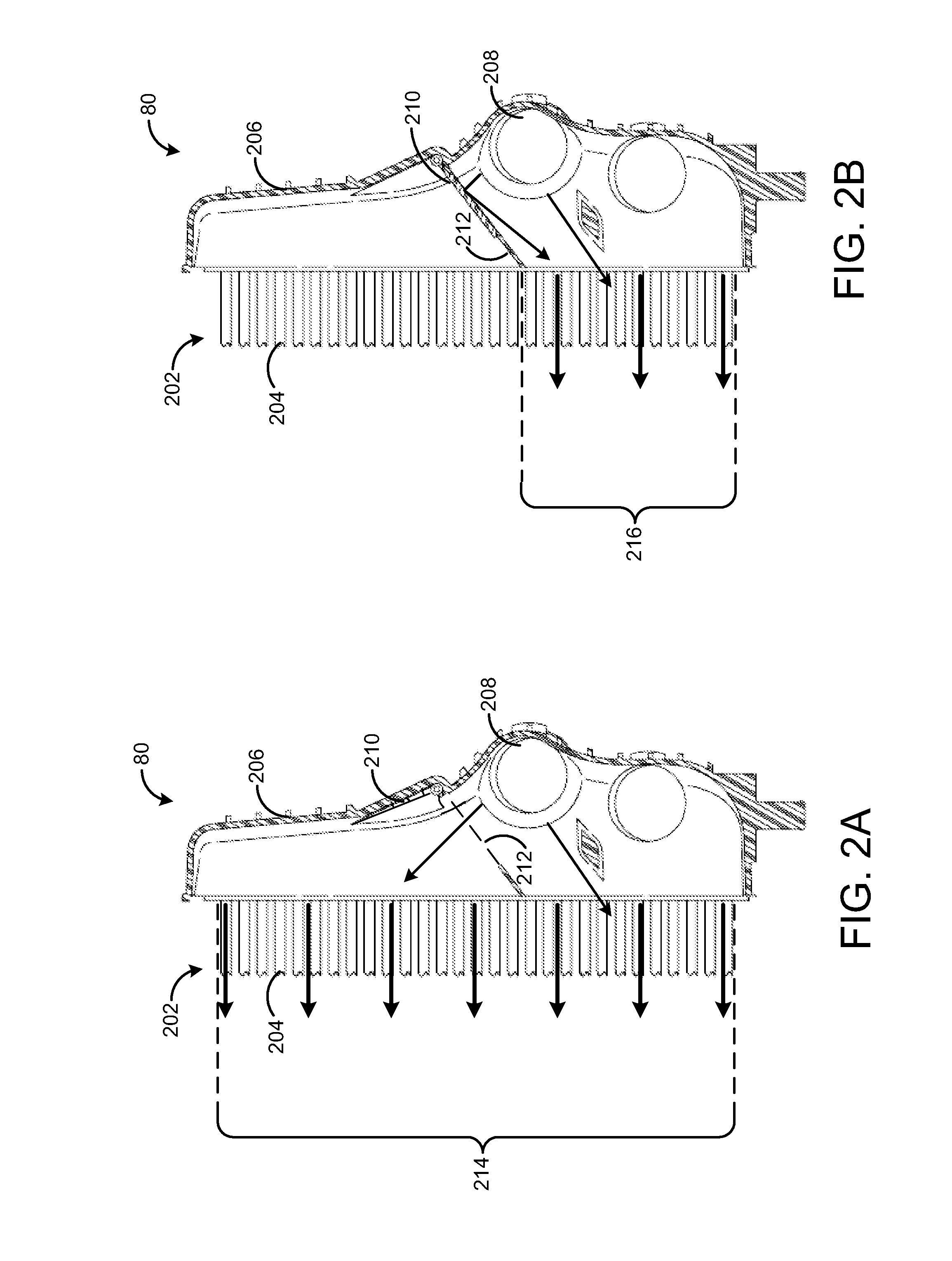

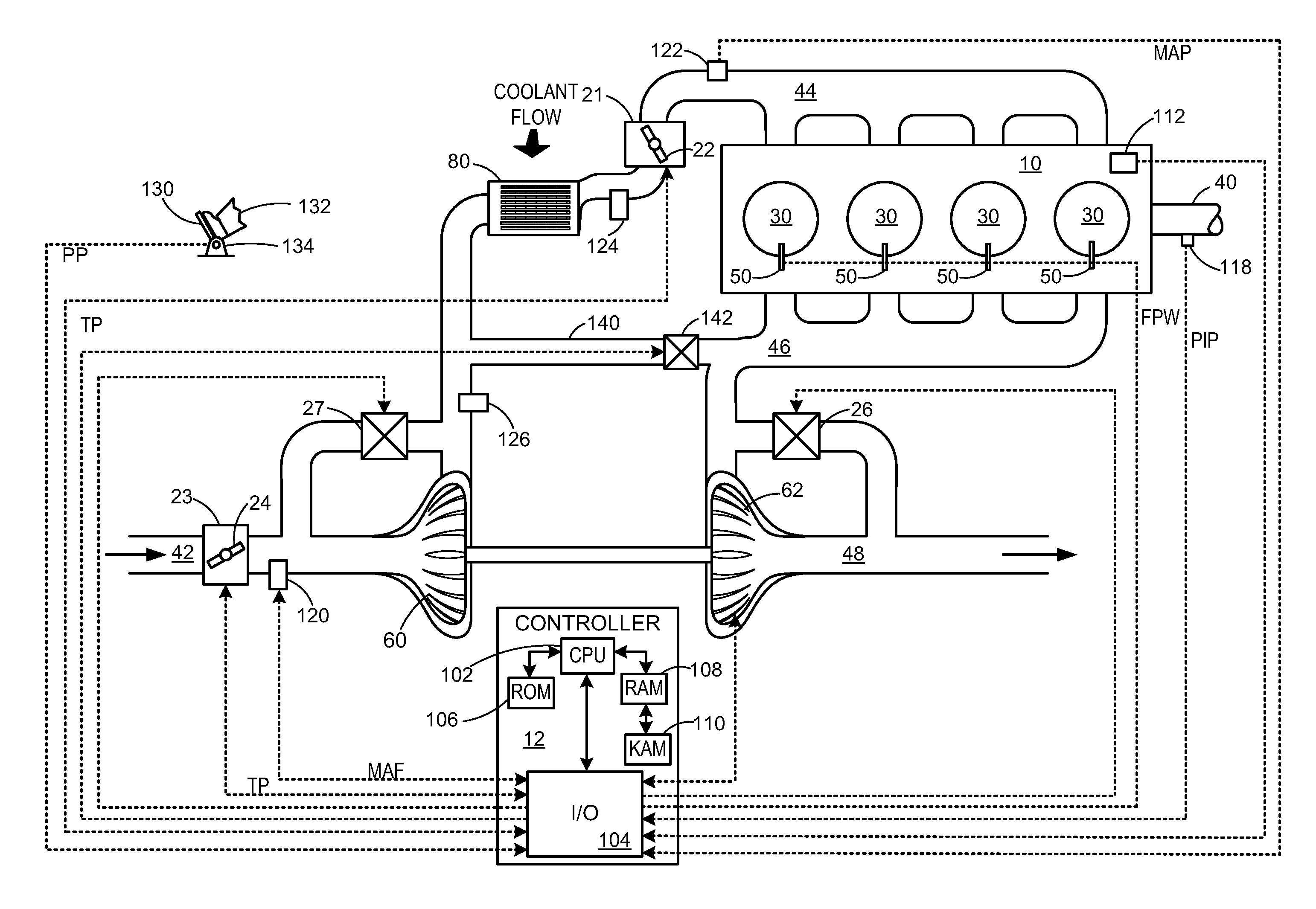

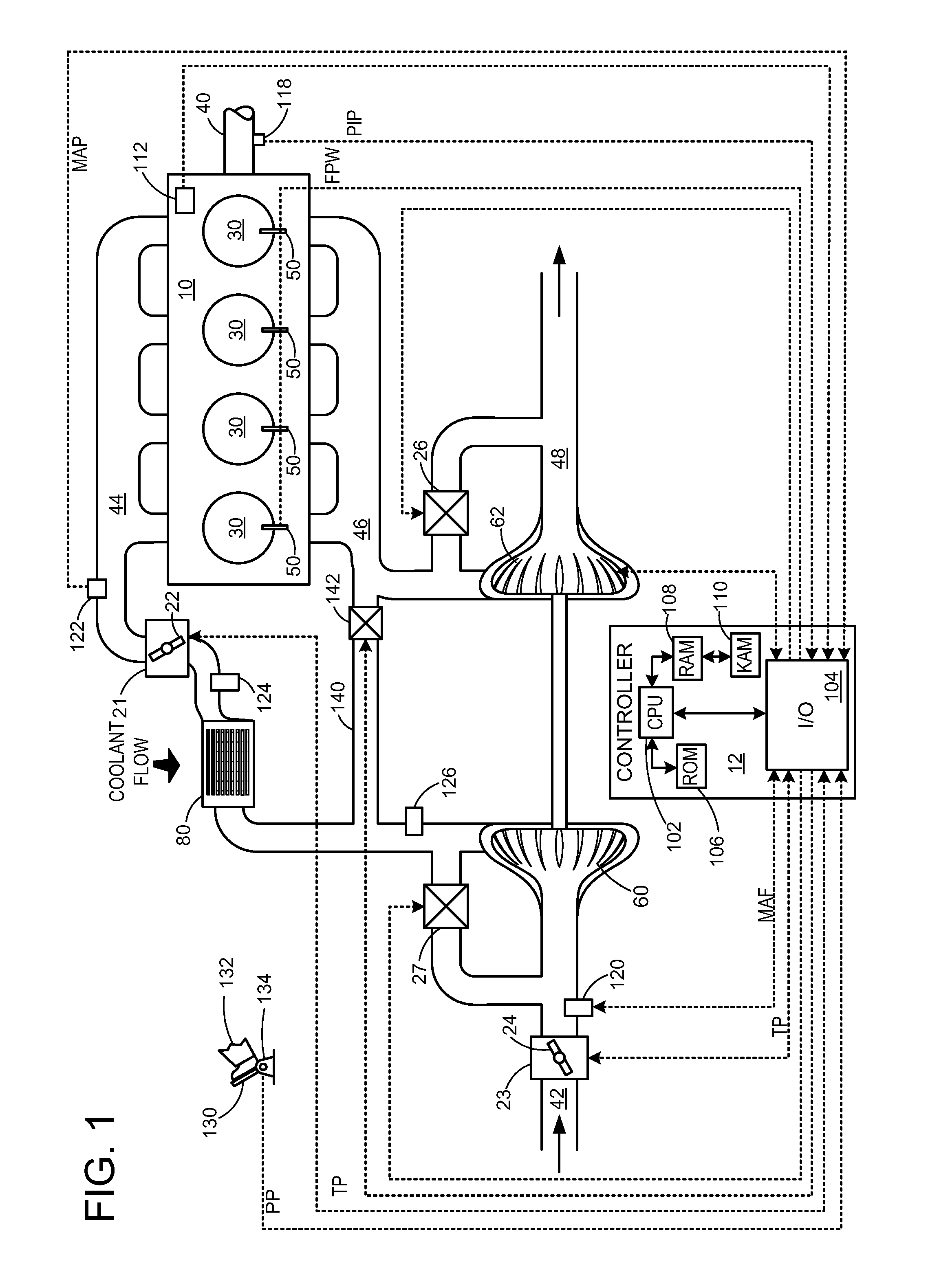

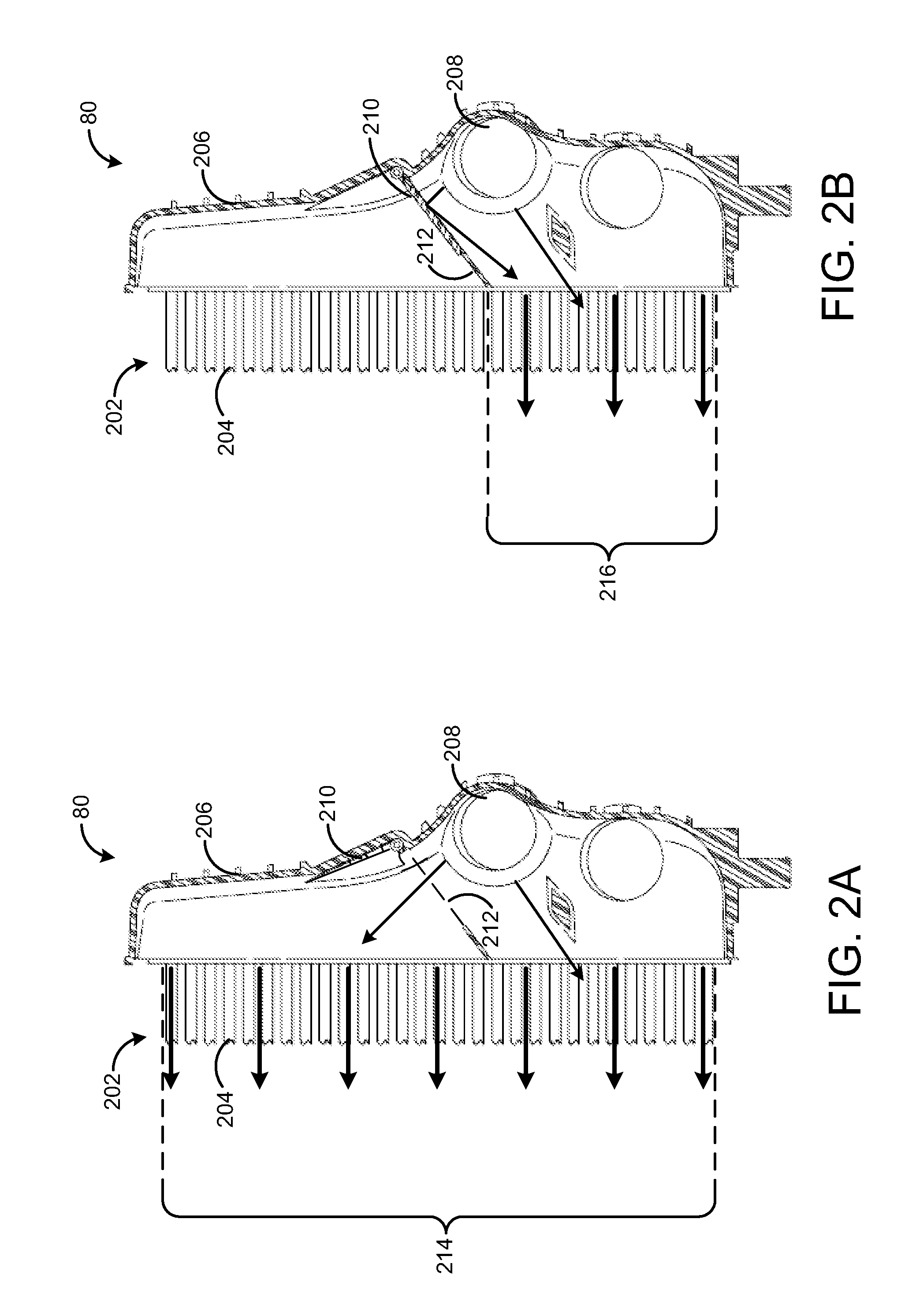

Method for controlling a variable charge air cooler

ActiveUS20140047833A1Reduce chargeIncrease air velocityLiquid coolingElectrical controlChillerAerospace engineering

Owner:FORD GLOBAL TECH LLC

LED street lamp

InactiveUS20120008329A1Reduce thicknessAvoid obstructing airflowMechanical apparatusPoint-like light sourceEffect lightEngineering

A LED street lamp including a housing, a lighting module, a metal base, and a heat dissipating module. The housing includes a bottom shell and a top shell both with openings. The lighting module is arranged in the housing. The heat dissipating module includes a metal base, a plurality of heat pipes, and a plurality of heat dissipating fins. The metal base includes a first plate and a second plate attached together. The first plate is thermally contacted with the lighting module. The heat pipes each have a heat absorbing section and a heat dissipating section. The heat absorbing section is arranged between the first plate and the second plate. The heat dissipating section is extending away from a side of the metal base. The heat dissipating fins are arranged on the heat dissipating sections. Air in the housing can naturally flow upwardly to effectively dissipate operating heat.

Owner:WANG CHIN WEN +1

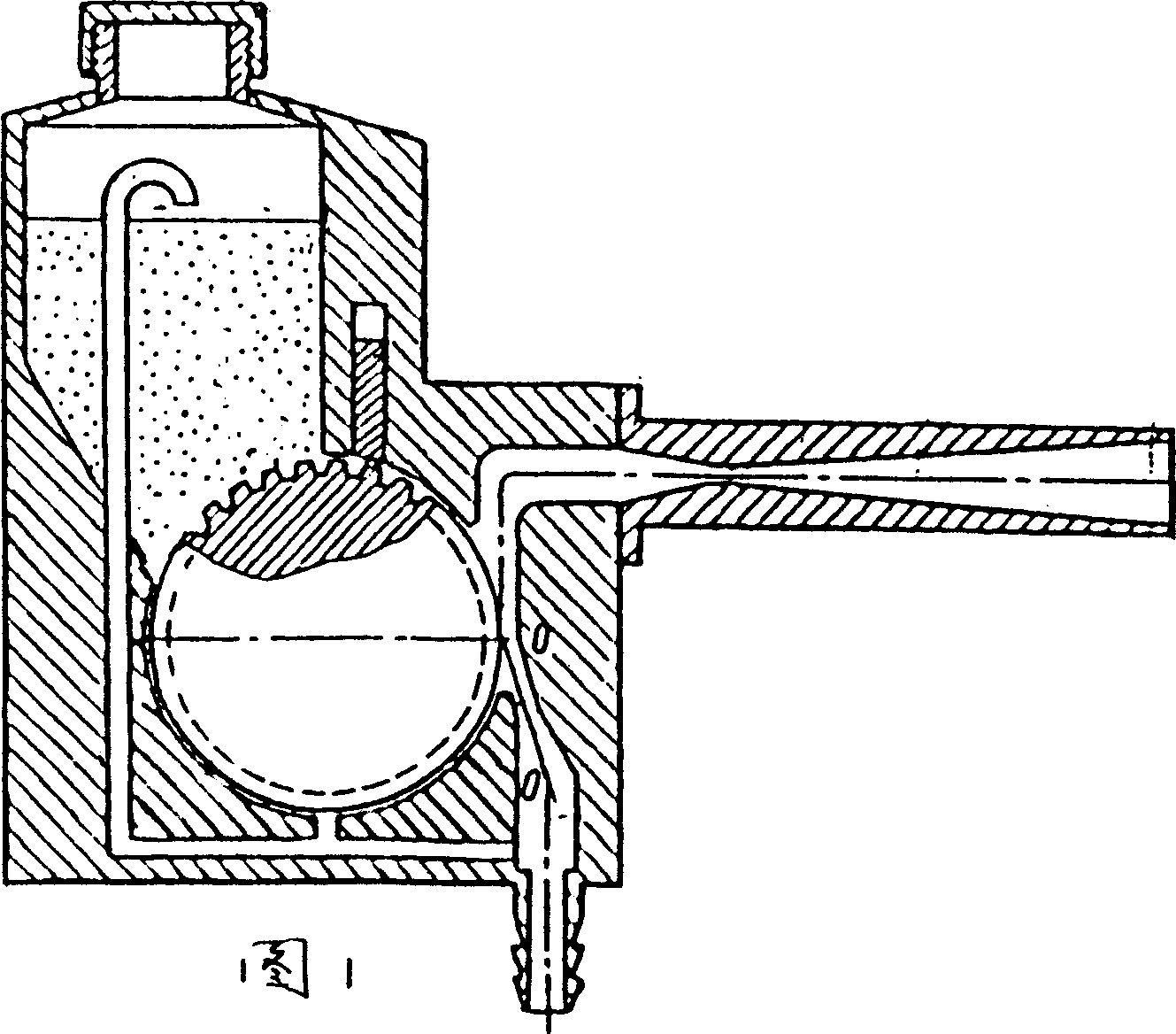

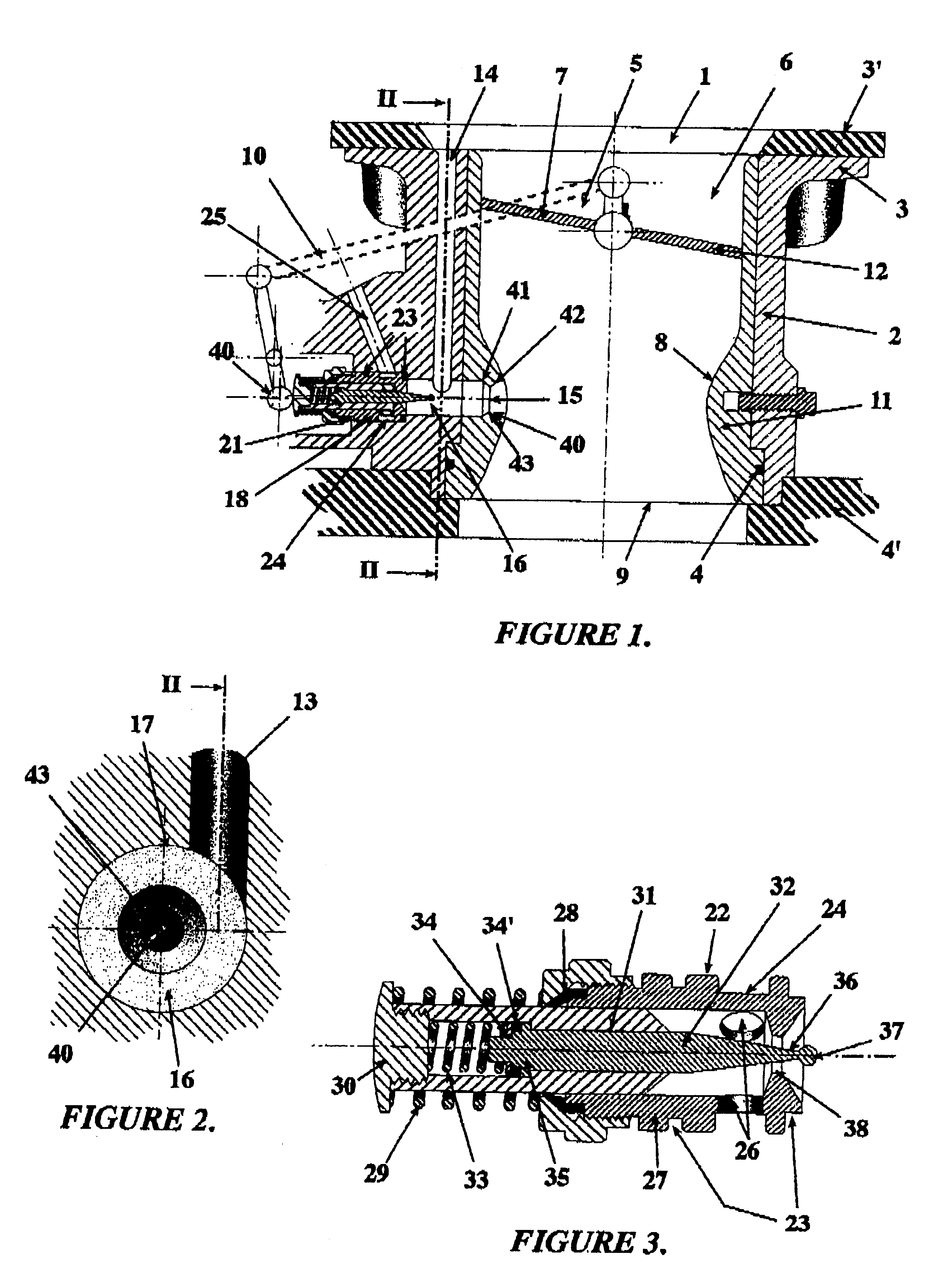

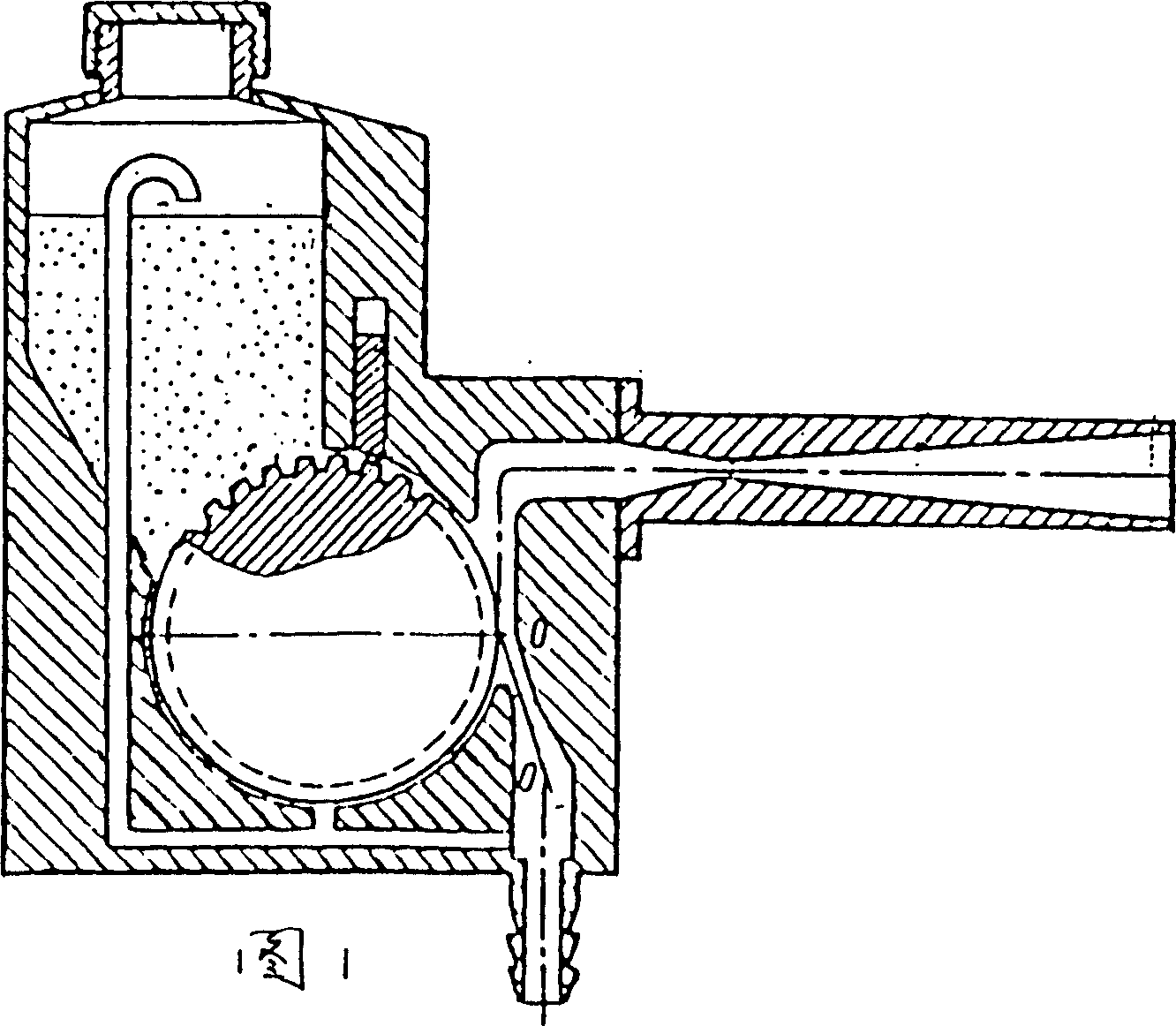

Fuel-air mixture apparatus

InactiveUS6283460B1Low quantity requiredIncrease airflowLighting and heating apparatusUsing liquid separation agentEngineeringStreamflow

An improved fuel air mixture apparatus which enhances the degree of mixing of fuel with air. The fuel-air mixture device includes a primary air passage having an inlet, an adjustable throttle and an outlet; a secondary air passage having an inlet and an outlet to the primary air passage between its adjustable throttle and its outlet; a nozzle having an orifice opening into the secondary air passage for introducing a flow of fuel therein; a needle arranged co-axially of the nozzle with its small diameter at least normally extending from the orifice into the secondary air passage, the needle being axially moveable to provide variability of the orifice and control of the fuel flow; a control device for directly linking or controlling the position of the needle to the position of the adjustable throttle in the primary air passage for adjustment of the orifice of the nozzle. The arrangement is such that the fuel flow from the nozzle is matched to the position of the adjustable throttle and the fuel flowing from the orifice towards the small diameter end of the needle mixes with air flowing through the secondary passage prior to mixing with the air flowing through the primary air passage.

Owner:OMARSSON KRISTJAN BJORN

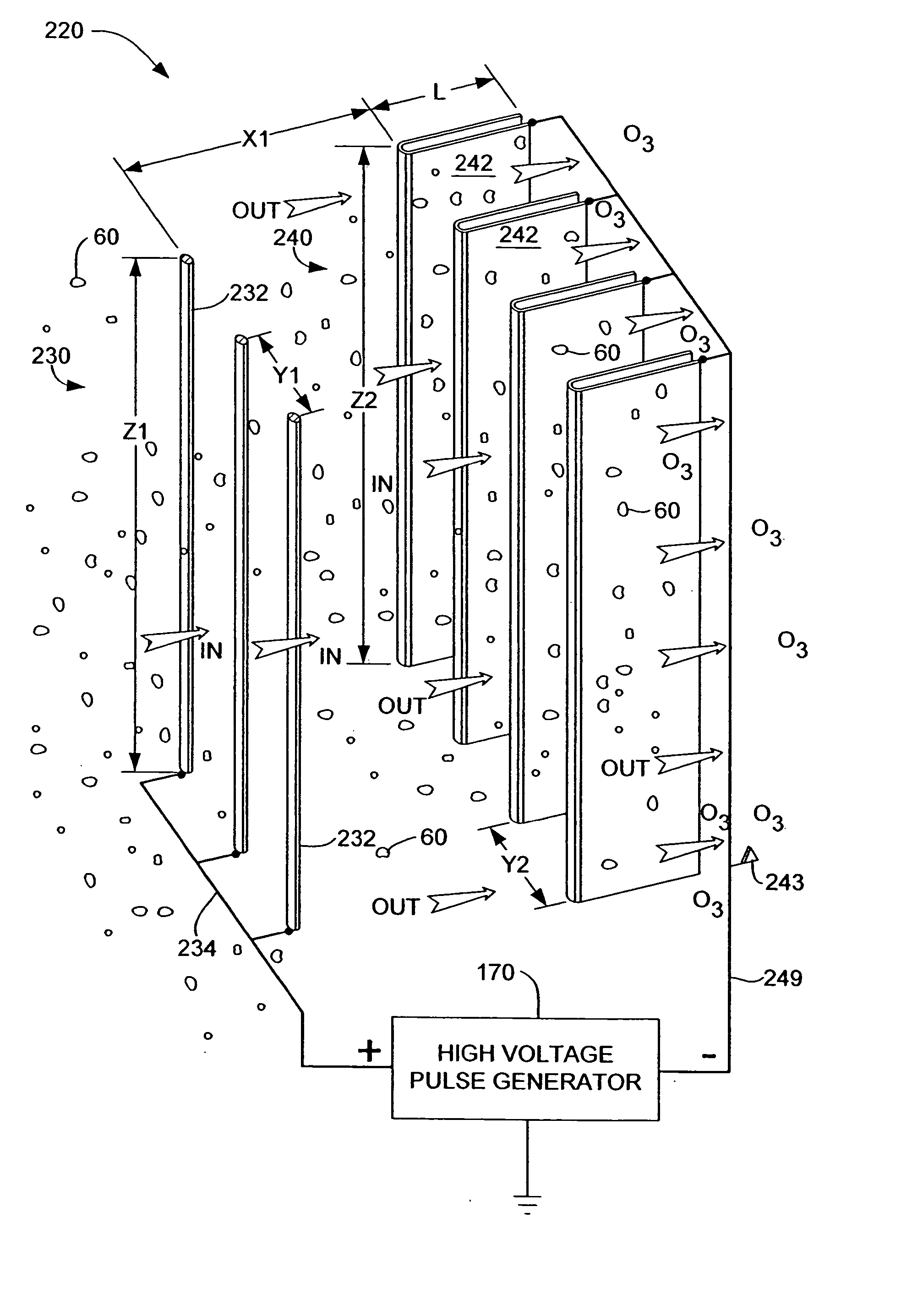

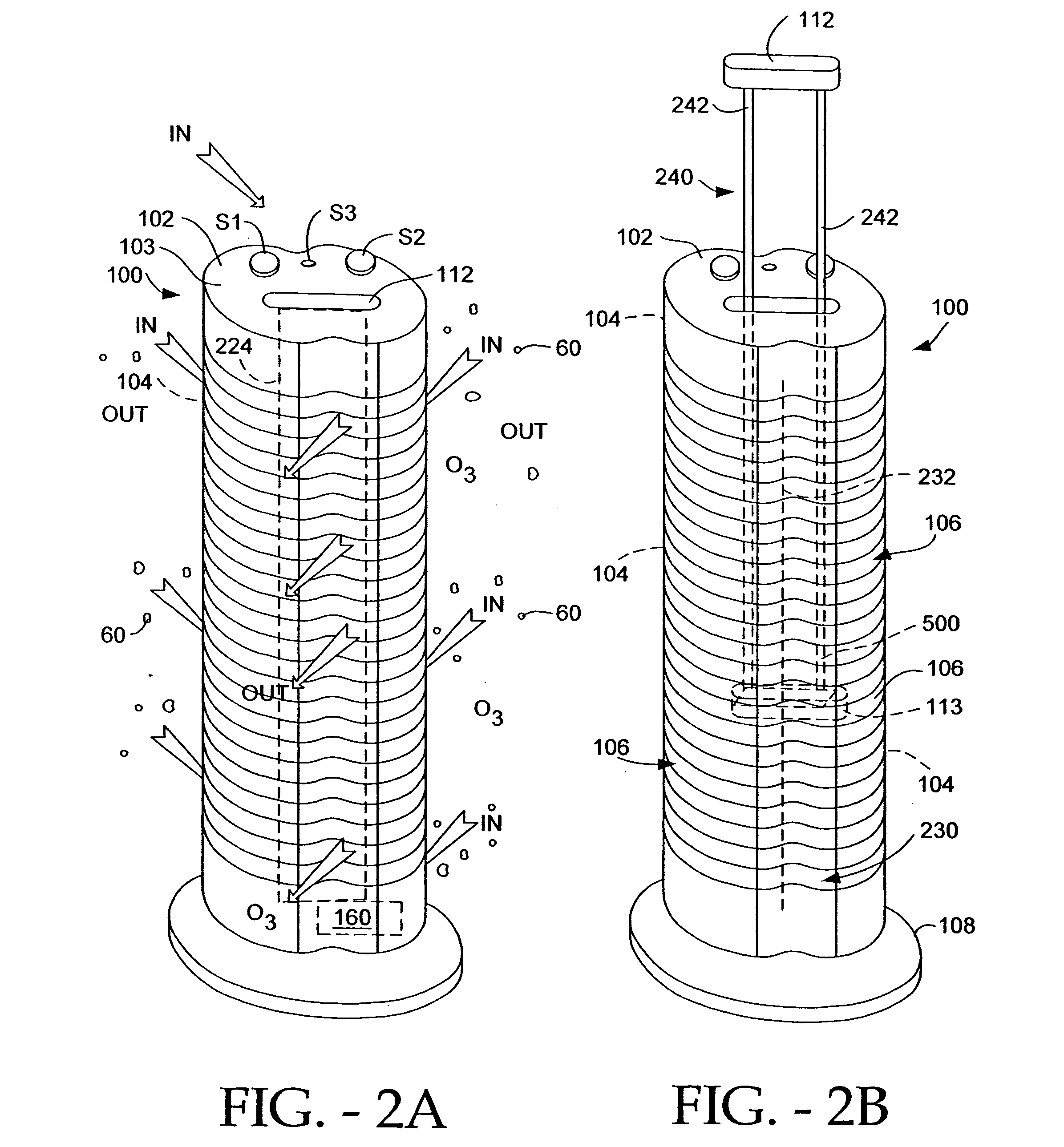

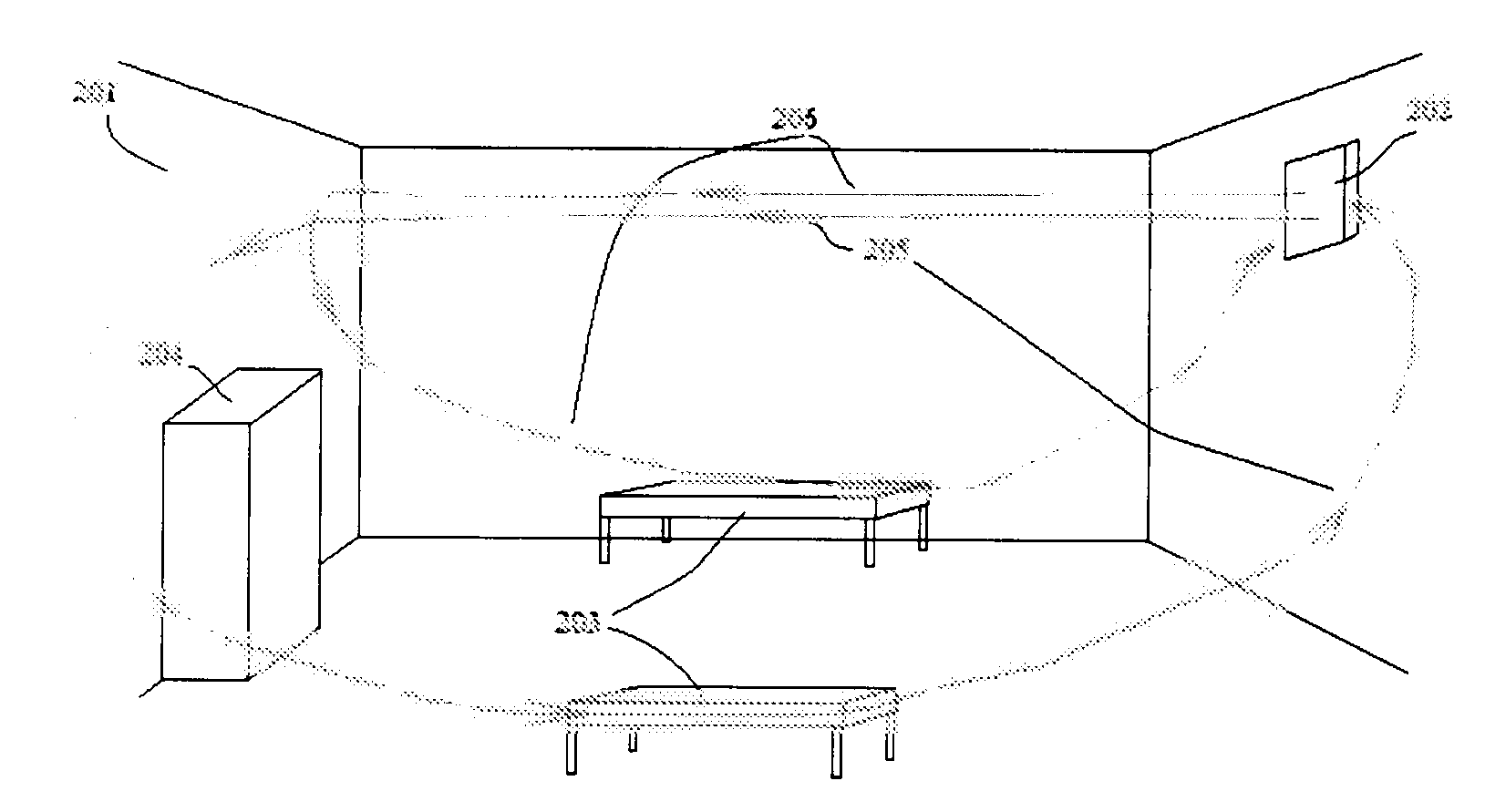

Method of and apparatus for cleaning and disinfection of air

InactiveUS20100047115A1Minimizing and eliminating “ dead spot ”Rapid DisinfectionCombination devicesDispersed particle filtrationAir movementAir cleaning

The methods and apparatus according to embodiments of the present invention provide substantially complete and rapid air cleaning and / or disinfection in the rooms that are substantially closed to outside air and have the typical complement and arrangement of furniture and people present, i.e. a “normal”environment. A study of air flow patterns in a variety of room configurations and arrangements demonstrates that EFA location within the room as well as furniture and people play a crucial role in air movement and airflow throughout the room, in minimizing or eliminating “dead spots” of stagnant air, and in achieving a goal of cleaning and disinfecting substantially all of the air.

Owner:KRONOS ADVANCED TECH

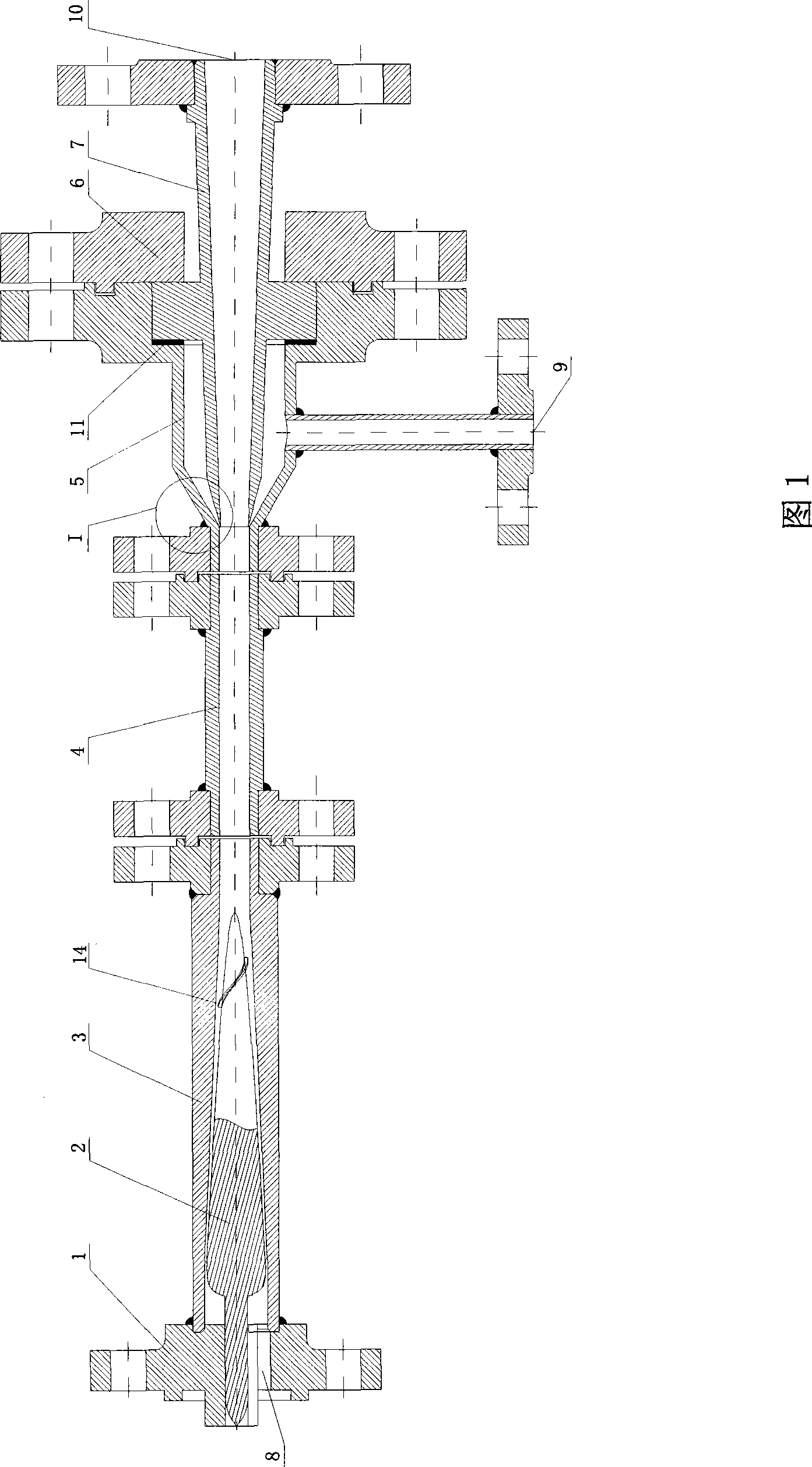

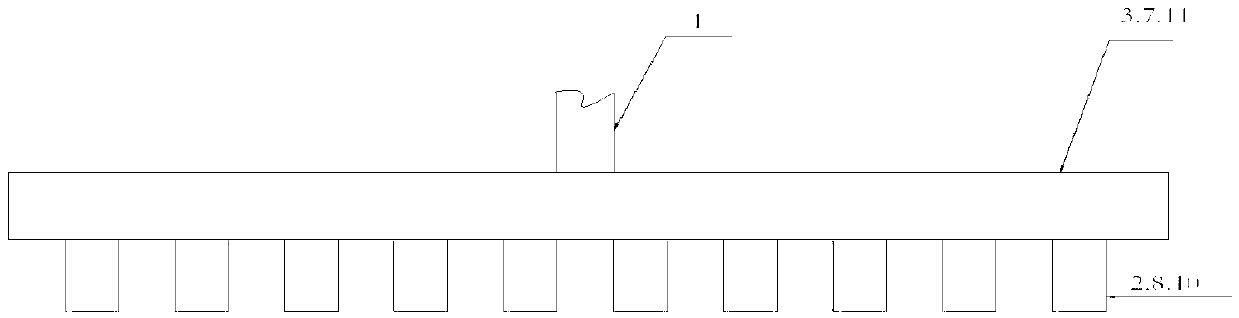

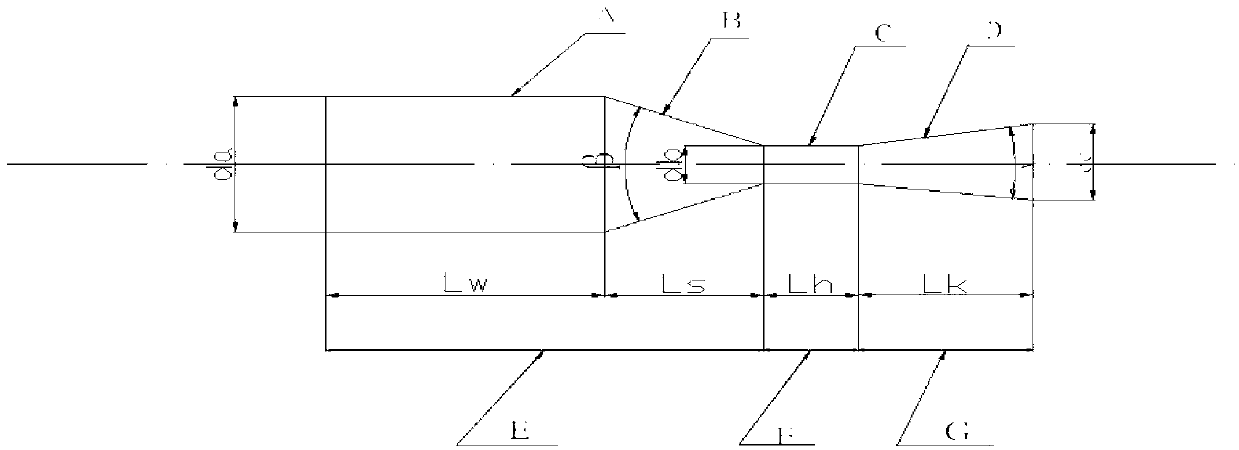

Low flow resistance supersonic speed gas purification and separation device

InactiveCN101380537ASimple structureUnmanned operationGaseous fuelsDispersed particle separationEngineeringSupersonic speed

The invention relates to a low flow resistance supersonic device for purifying and separating gas and is applied to the field of gas separation and purification such as natural gas dehydration, etc. Natural gas enters a laval nozzle by a gas inlet, the temperature and pressure thereof lowers, the speed is increased, then the gas mixture floating at high speed flows through a whirl vane, the swirl with high speed is produced, the swirl with high speed enters a separation pipe, for the temperature becomes low, when the gas is below ground pressure and saturation temperature, the water or partial dew points in the gas are condensed into liquid, for the centrifugal forces born are different, the liquid from the gas by condensation is 'flung' to the wall of the pipe and forms a very thin layer of liquor film, the liquid flows out of the separation pipe through the ring-shaped groove between the separation pipe and a diffuser pipe and flows out from the liquor outlet. Then the dry gas in which water is removed enters the diffuser pipe, and the gas flows out of the separation device by the gas outlet. The device does not comprise motion components and structure is simple; and the circulation transversal area of the laval nozzle in the device is ring-shaped and can be processed easily.

Owner:BEIJING UNIV OF TECH

Cooling circuit flow path for a turbine section airfoil

ActiveUS8757974B2Increase air velocityImprove transfer qualityEngine fuctionsBlade accessoriesLeading edgeTurbine

A cooled airfoil includes an impingement rib having a multiple of openings which supply a cooling airflow from a cooling circuit flow path toward an airfoil leading edge. The multiple of openings are offset in the impingement rib opposite an outer airfoil wall which includes gill holes. Offsetting the multiple of openings opposite an outer airfoil wall which includes the gill holes focuses the cooling airflow across turbulators to increase the cooling airflow dwell time to increase the thermal transfer therefrom in higher temperature airfoil areas.

Owner:RTX CORP

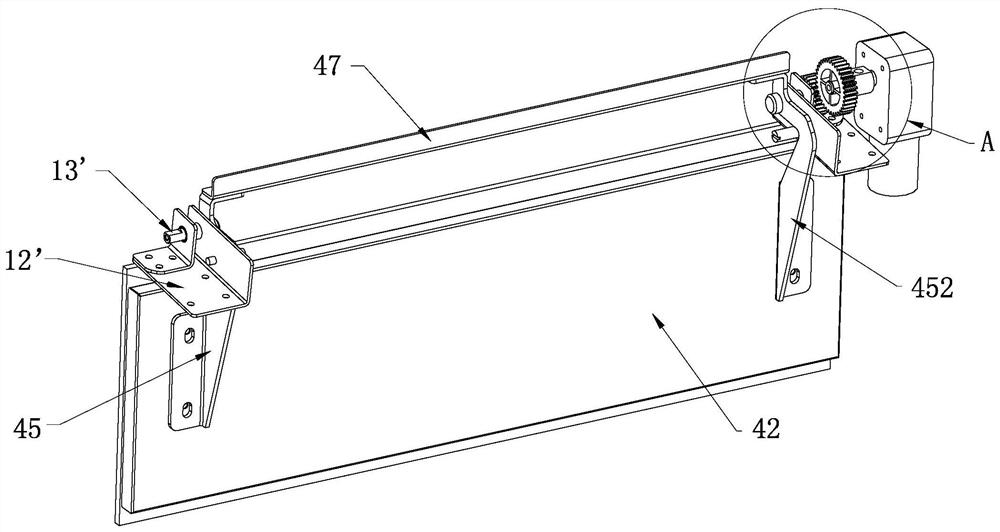

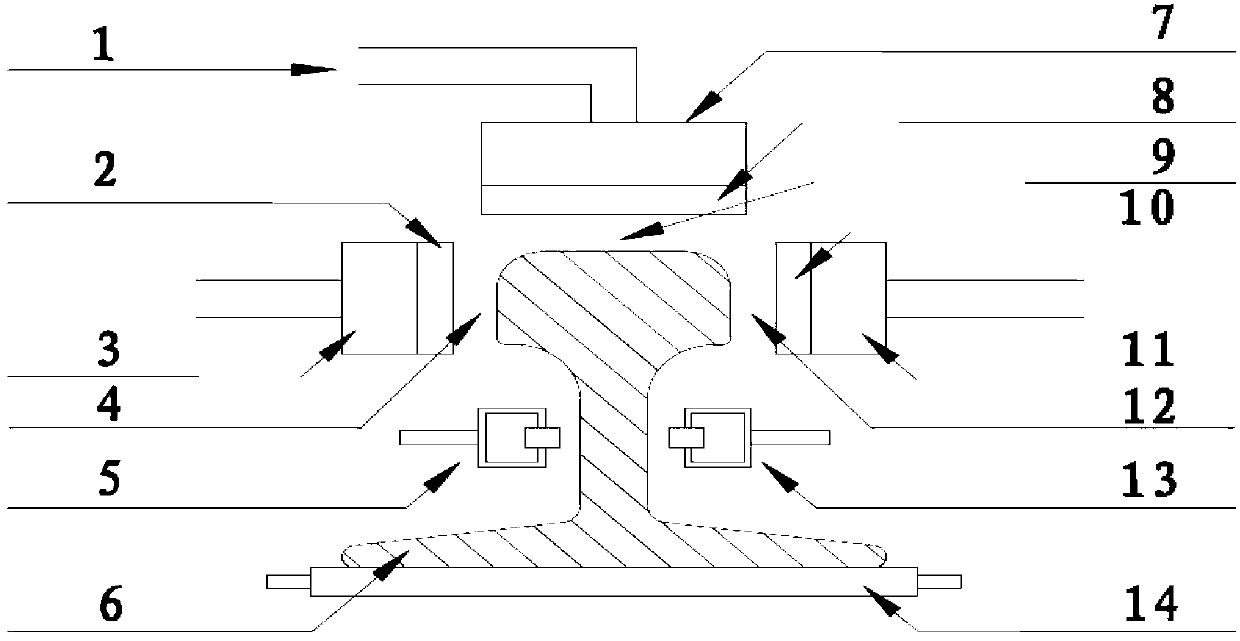

Steel rail on-line wind-jet quenching heat treatment simulation experiment device

InactiveCN103131826AEvenly distributedThe distribution is flat and stableFurnace typesQuenching agentsProduction lineExperimental research

The invention relates to a steel rail on-line wind-jet quenching heat treatment simulation experiment device, and belongs to the technical field of steel metallurgy. The experiment device is composed of the structures of: a Laval-type flat-slot nozzle system, a steel rail guiding system, a frame system, a valve system, a compressed air pipe system, a roller way system, a detection instrument system, a steel rail heating furnace system, and the like. With wind, water, heating furnace, and roller way conditions in an experimental innovation platform in metallurgical rolling, a steel rail on-line wind-jet quenching heat treatment simulation experiment device is designed and manufactured, and a steel rail on-line wind-jet quenching heat treatment simulation experiment method is developed. The method and the device are used for carrying out heavy rail full-length on-line quenching simulation experimental researches. The experiment method is simple and reliable. With the method, heavy rail full-length on-line quenching process research period can be greatly shortened, and process research cost can be reduced. The method is a feasible method of laboratory simulation research currently. With the device and he method, technical support can be provided for a heavy rail full-length on-line quenching production line.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for controlling a variable charge air cooler

ActiveUS20140048048A1Increase air flow velocityDecrease in chargeElectrical controlNon-fuel substance addition to fuelChillerAerospace engineering

Owner:FORD GLOBAL TECH LLC

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

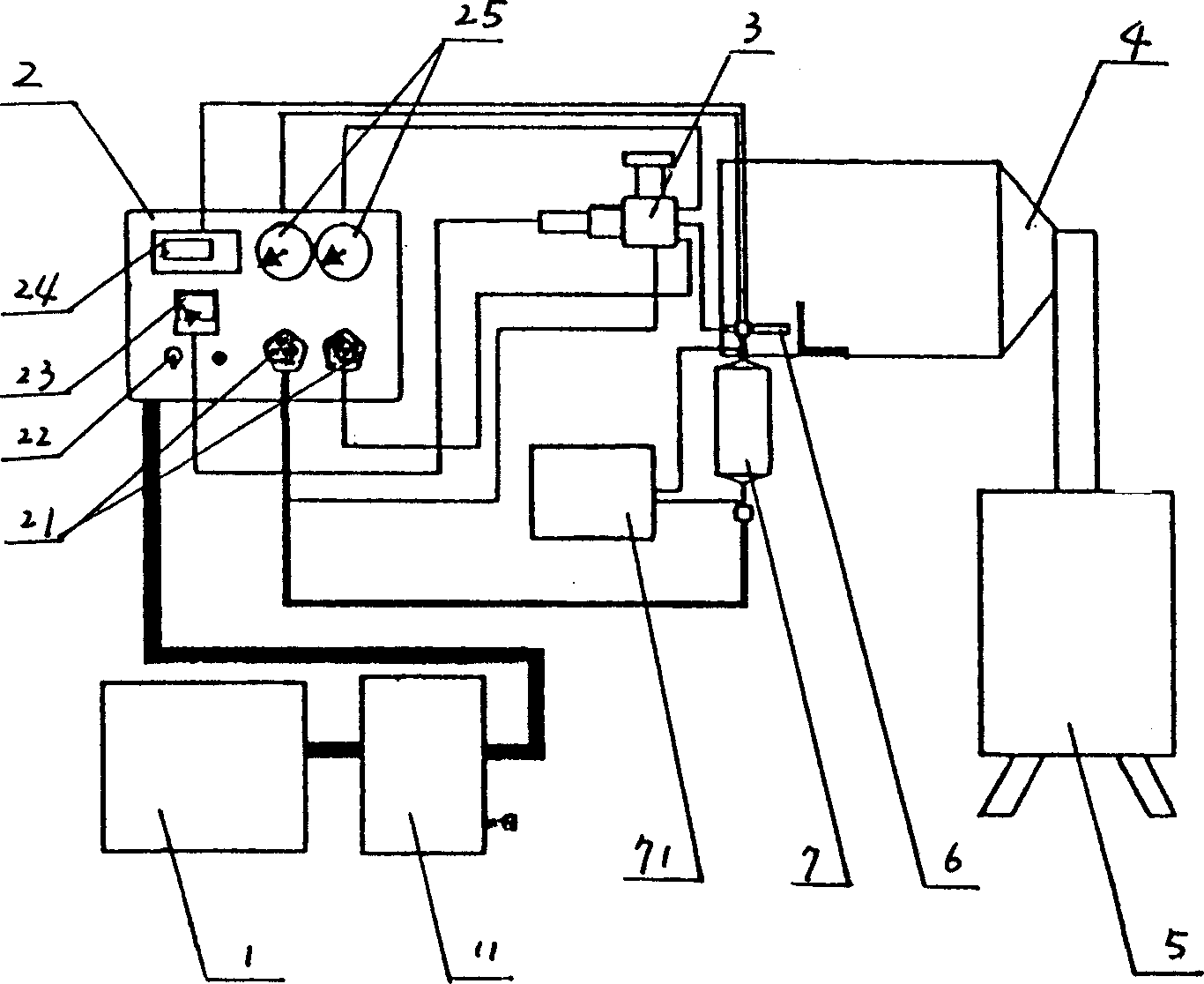

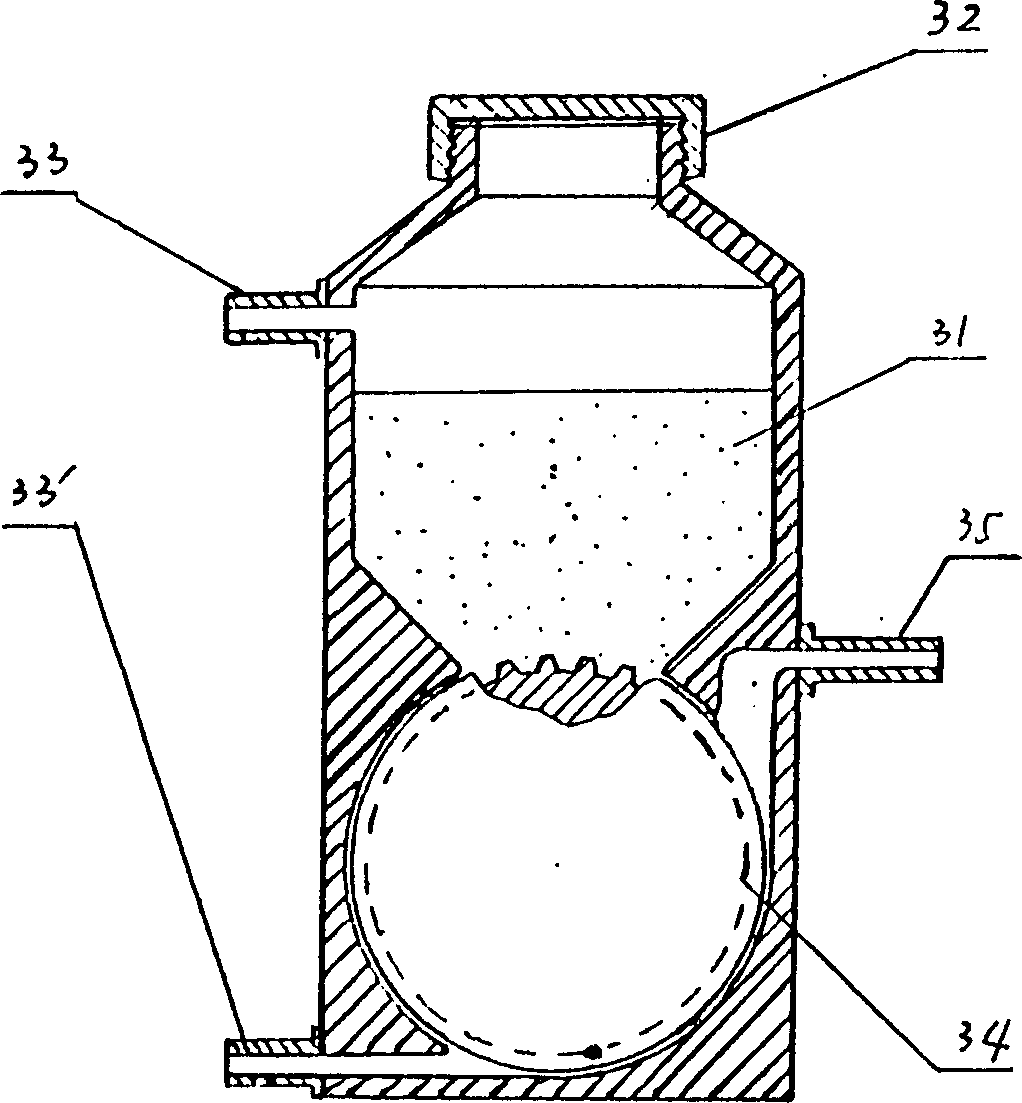

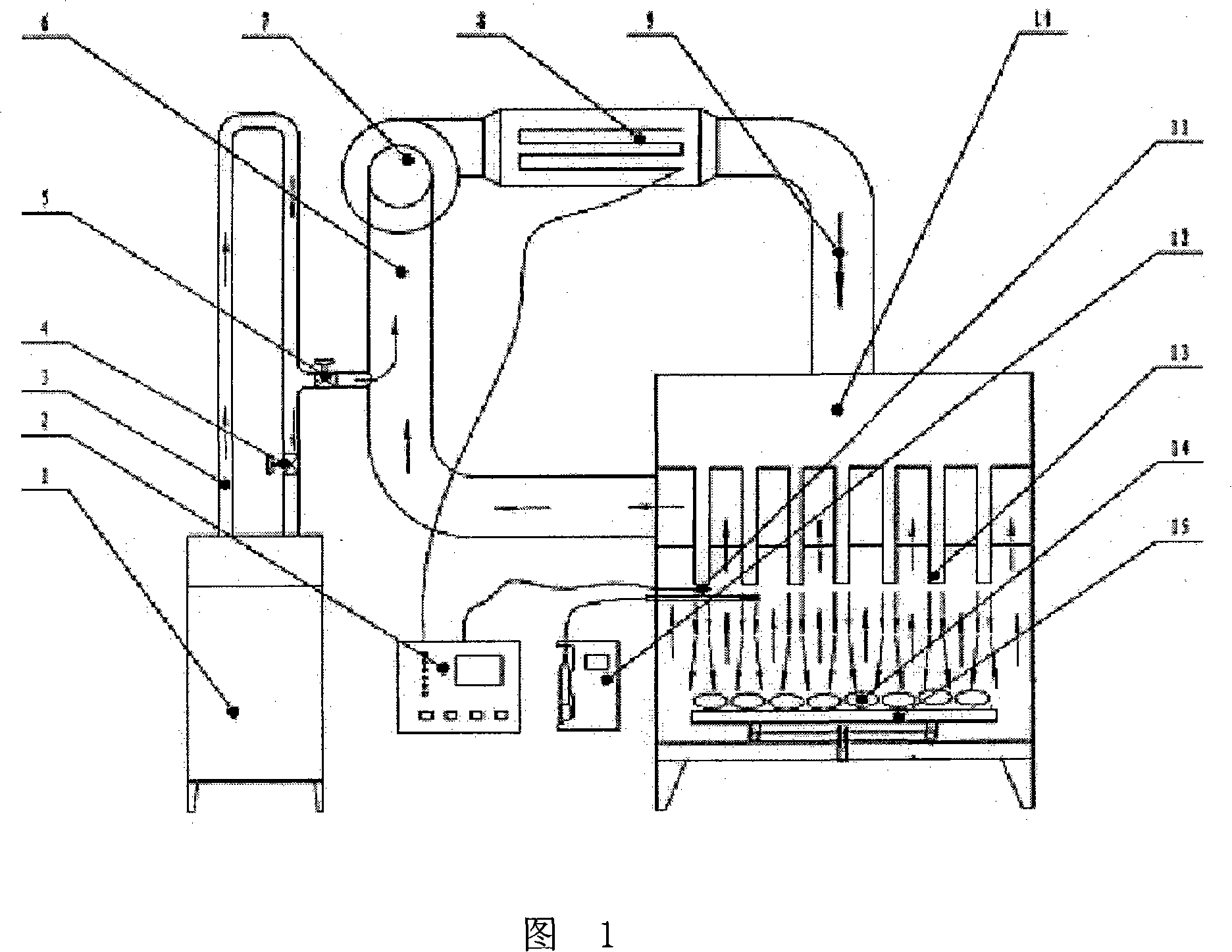

Gas jet impaction sea cucumber drying method and apparatus thereof

InactiveCN101138354APreserve nutritional valueAvoid churnMeat/fish preservation by heatingFood processingElectricityCelsius Degree

The present invention discloses a cucumber drying method and device with air spray impact belonging to the technical field of food processing. The technical proposal comprises that the viscera of cucumber is removed and the cucumber is put in a steam environment of the relative humidity of 10 to 50 percent, temperature of 90 to 200 Celsius degrees, air speed of 3 to 20m / s for 5 to 40 minutes to thoroughly destroy the autoenzyme; and then the cucumber is dried under an environment of the temperature of 40 to 80 Celsius degrees and air speed of 5 to 20 m / s for 5 to 16 hours. The device comprises a steam generator (1), an automatically controlled box (2), a steam duct (3), an air circulation duct (6), a fan (7), an electric heater (8), an air duct (9), an air distribution chamber (10), a temperature and air speed sensor (11), a humidity sensor (12), a nozzle (13) and a cucumber tray (15). The cucumber dried with the present invention is characterized by no nutrition loss and the properties of saving water, energy and environmental protection and the automatic control is realized in the process.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com