Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Good fuel atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

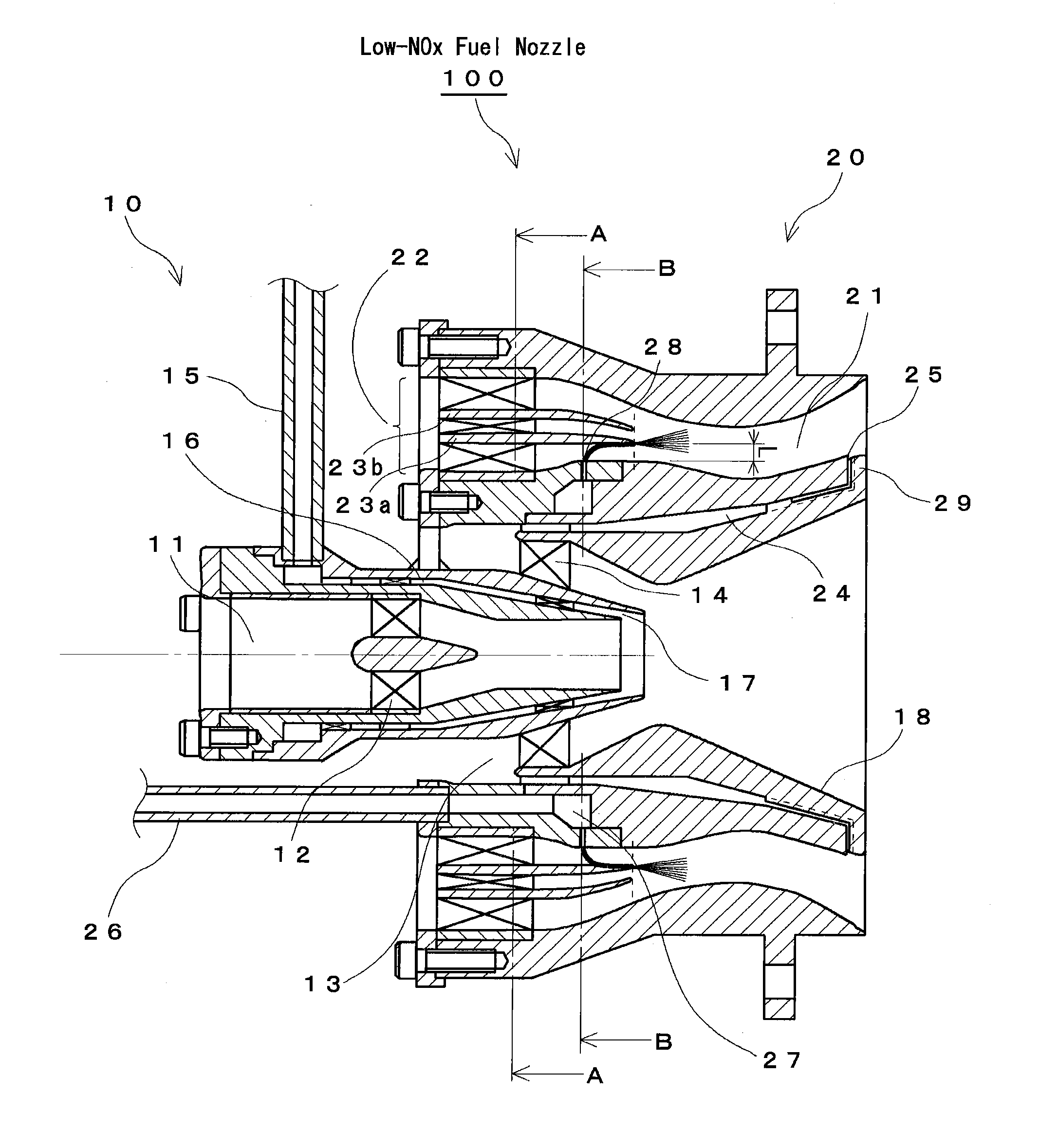

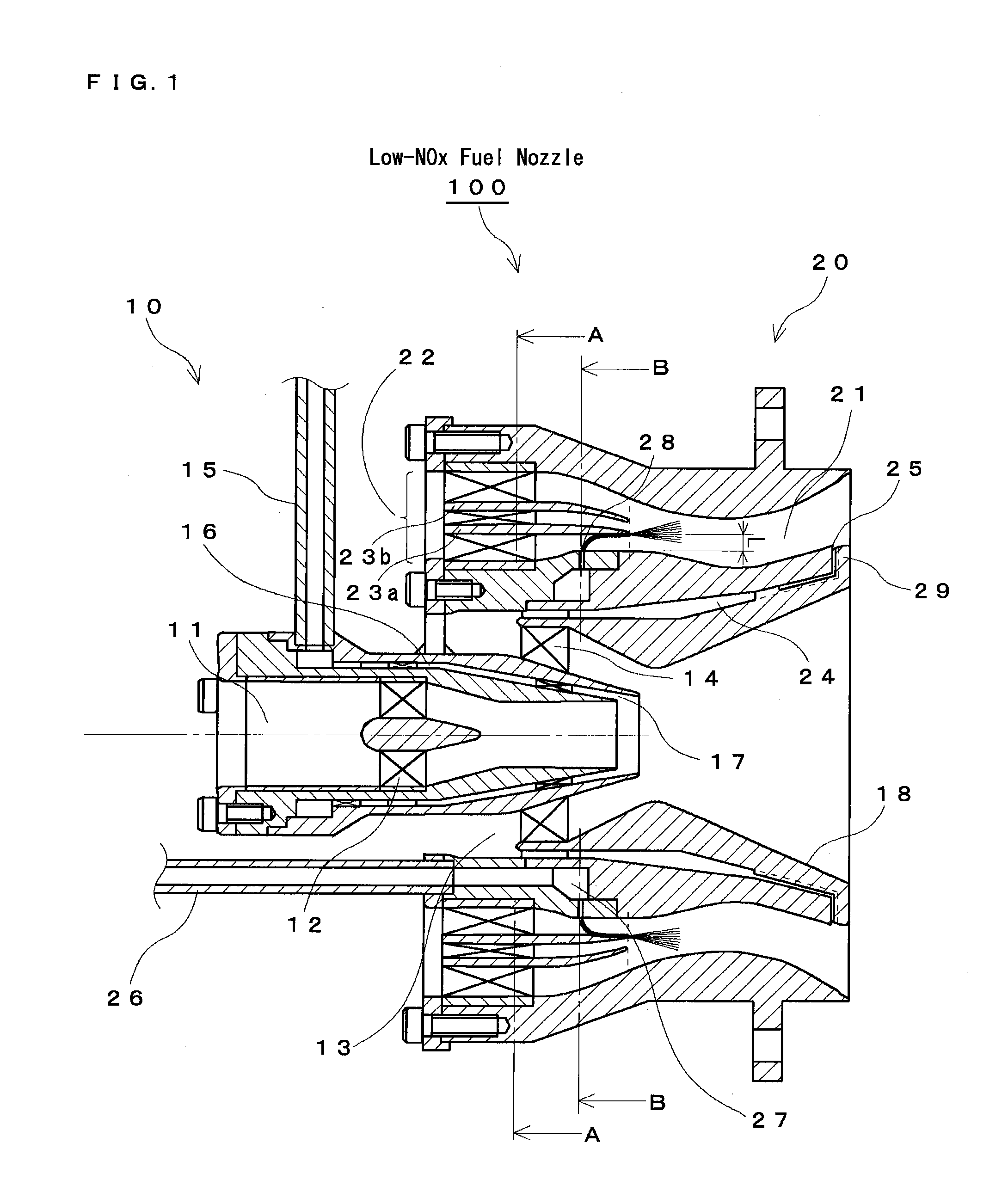

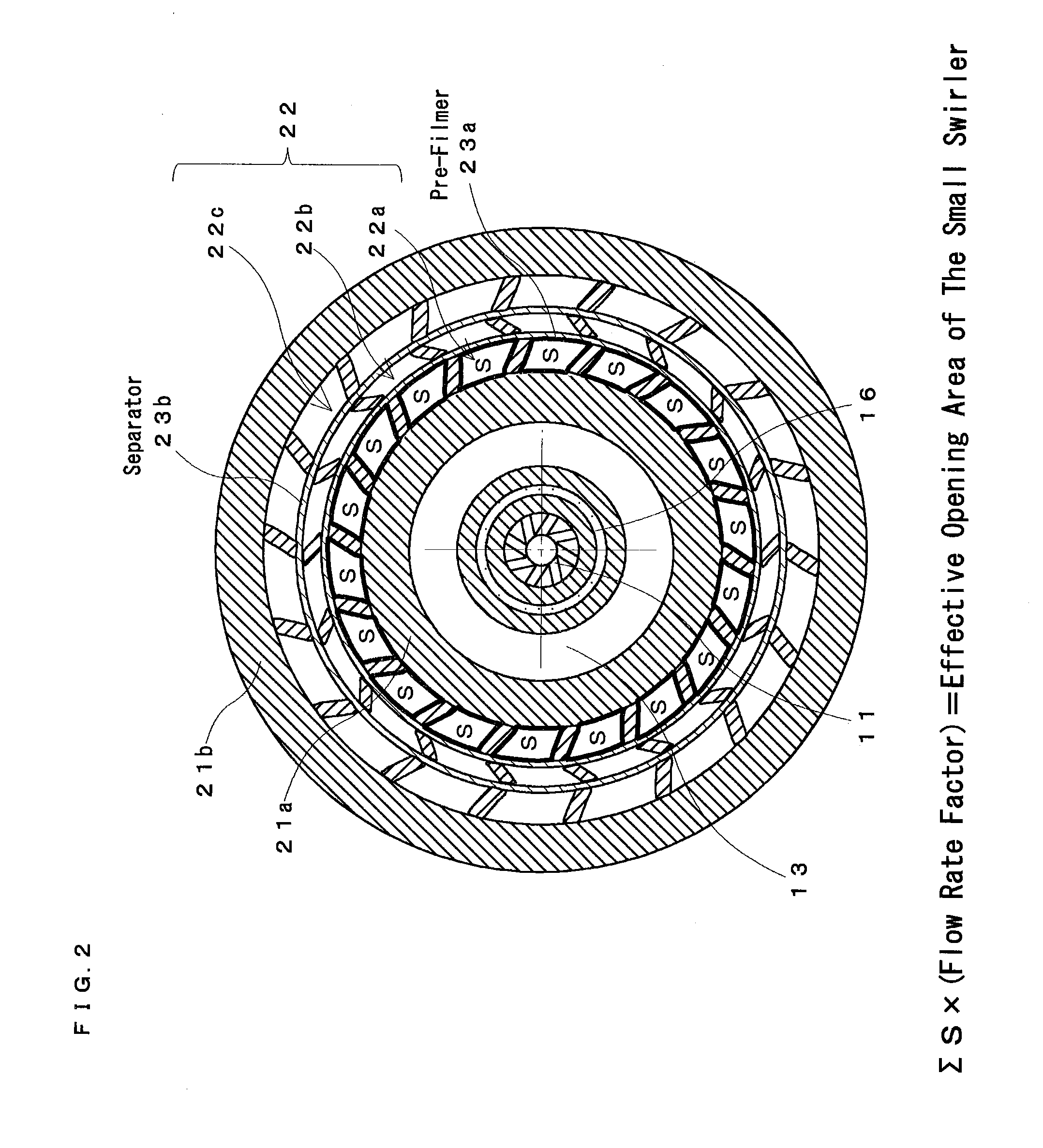

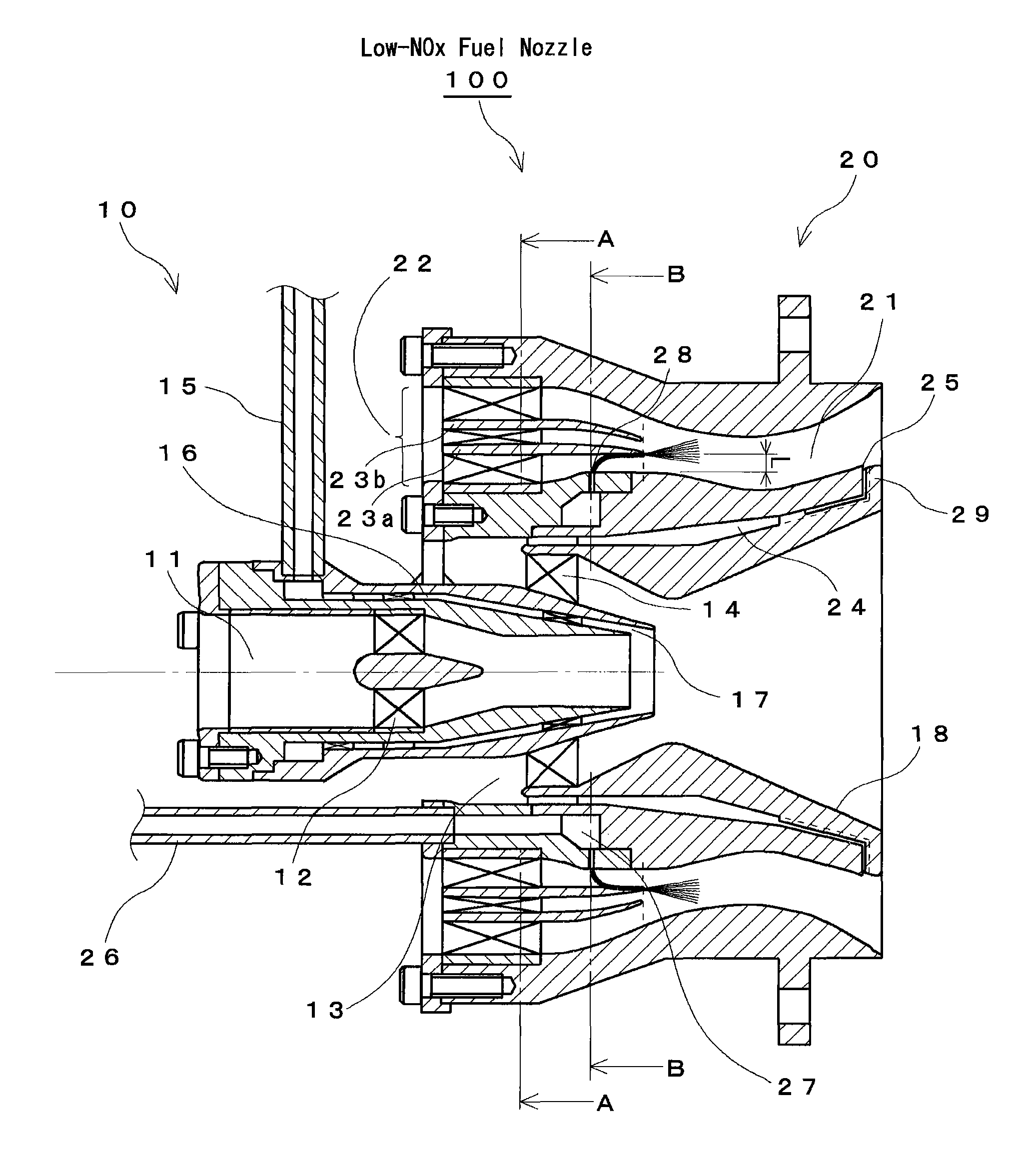

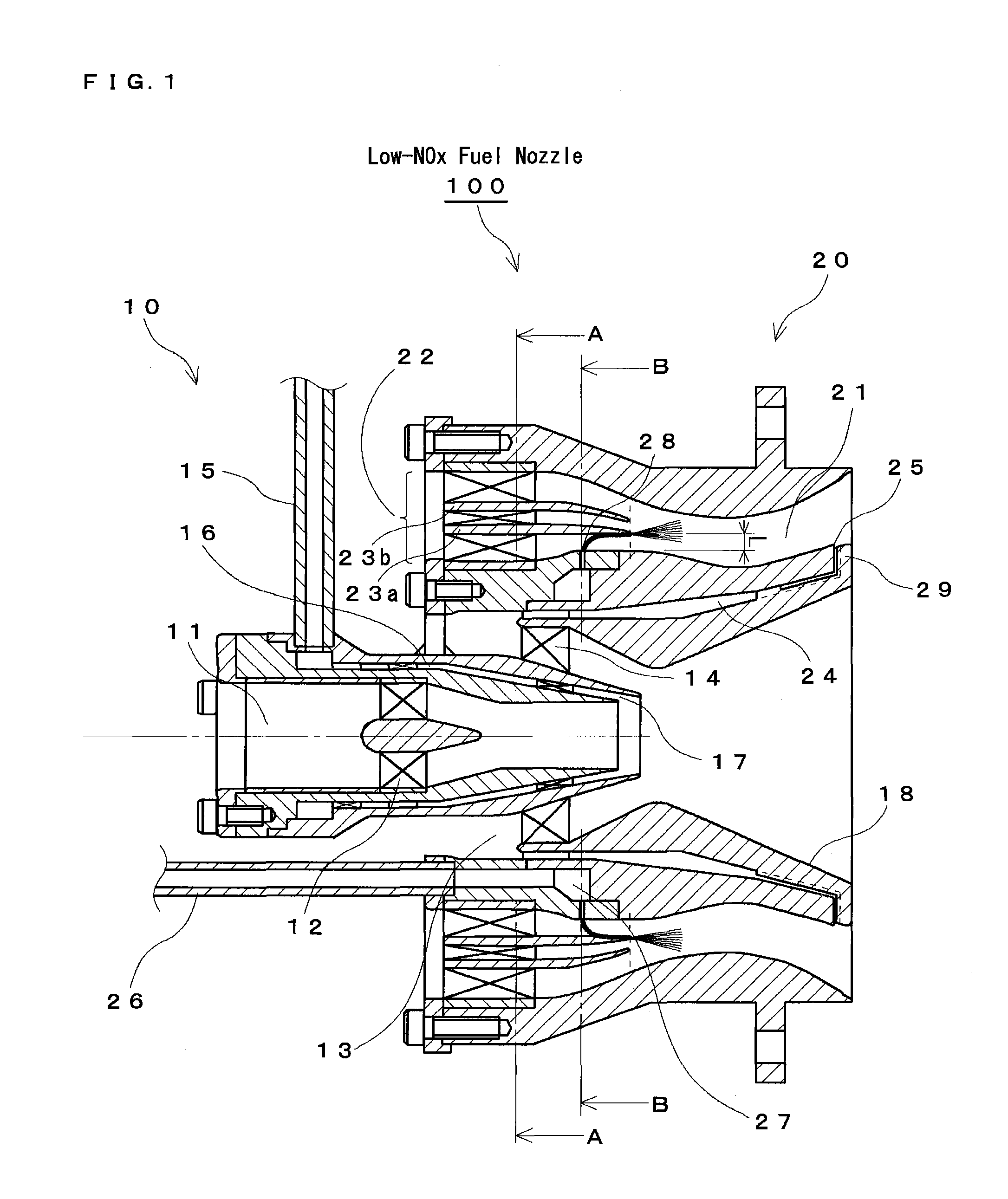

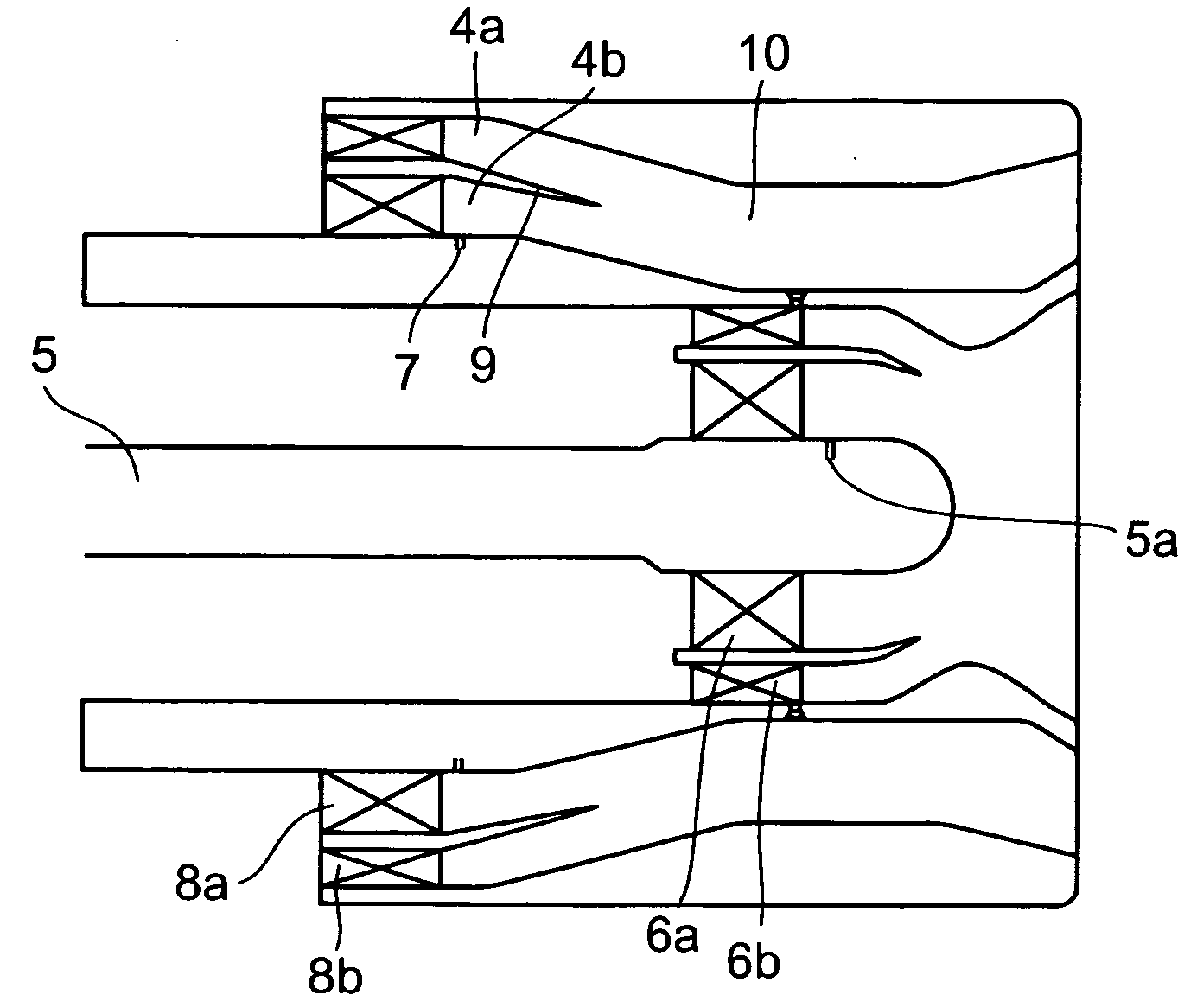

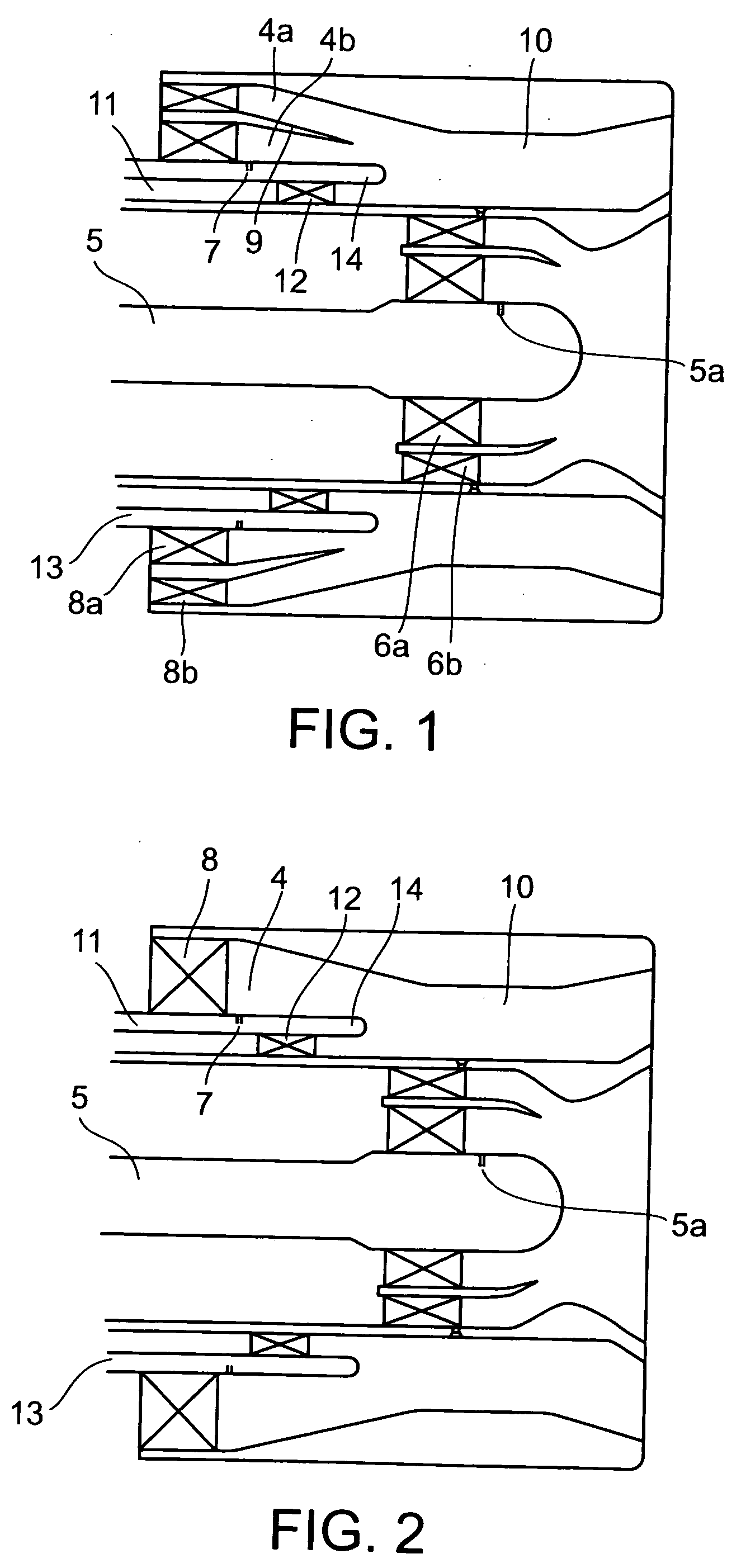

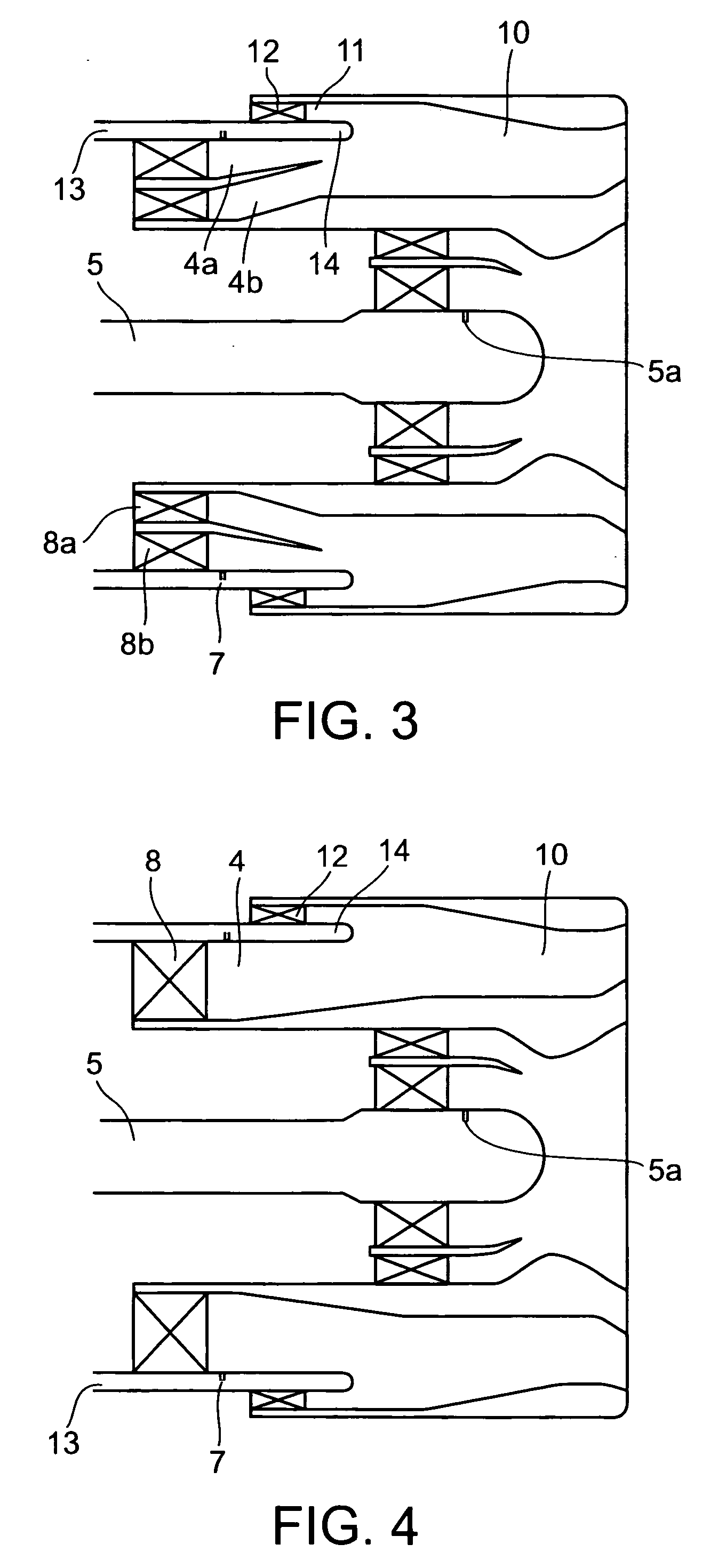

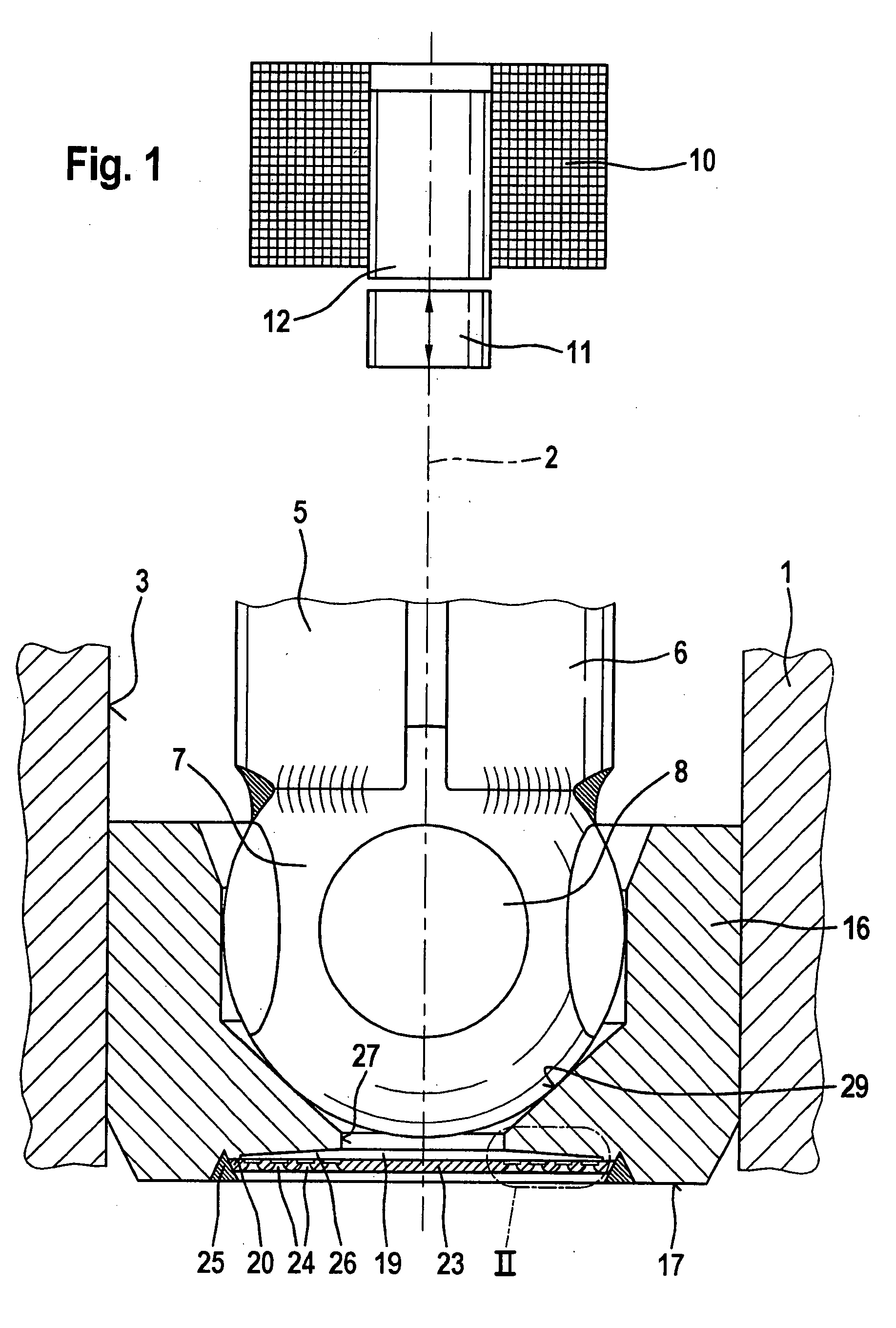

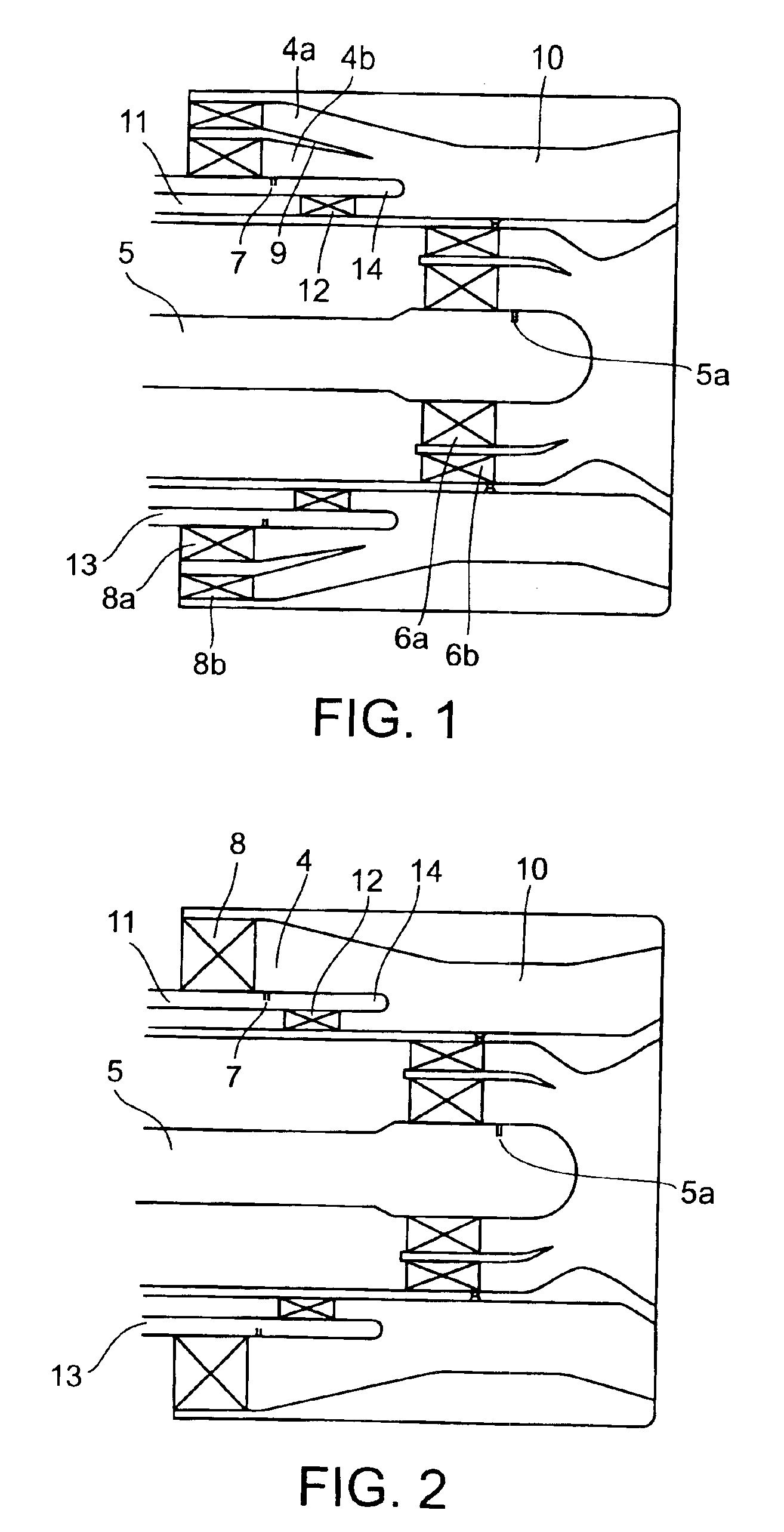

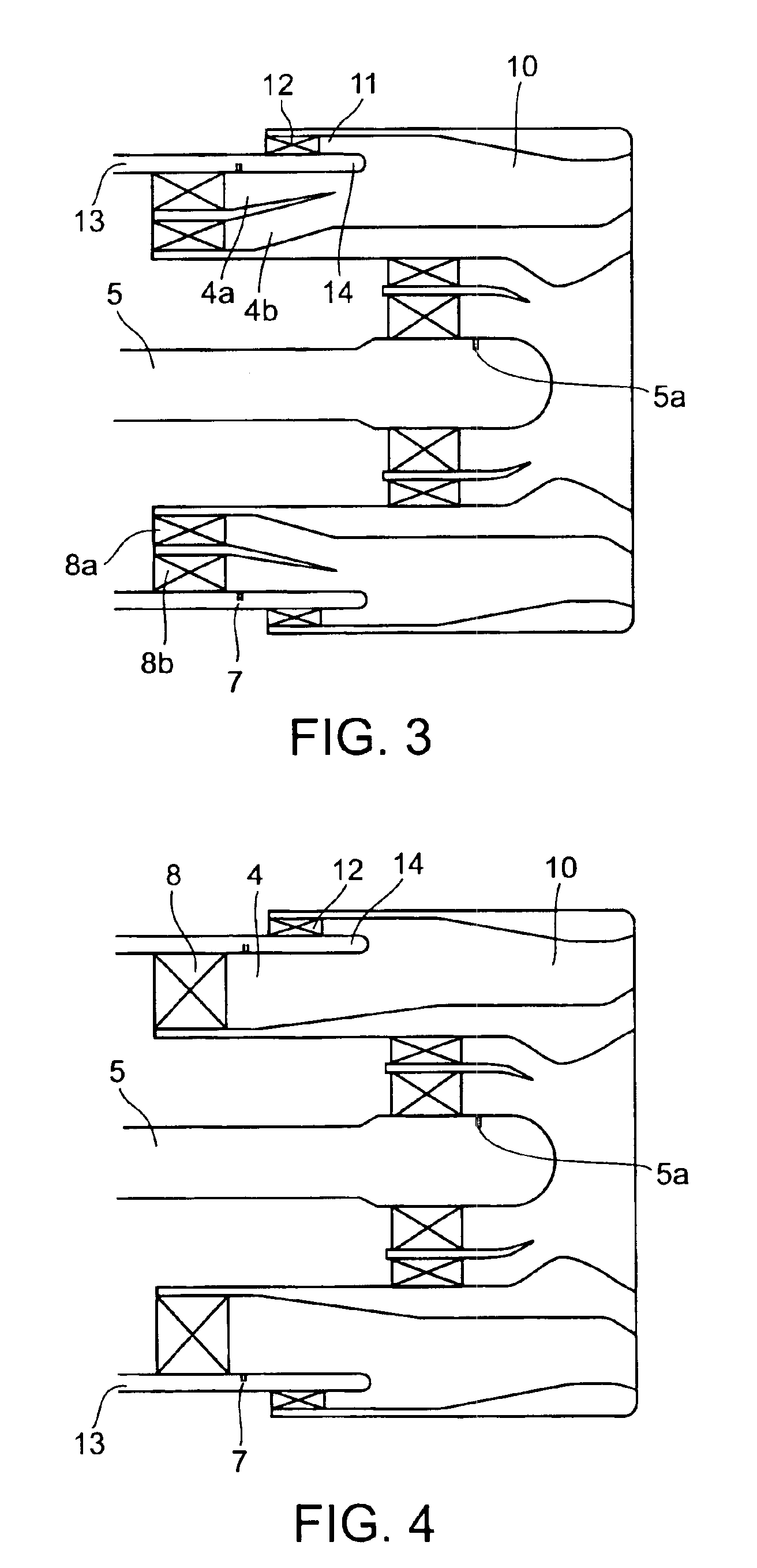

Staging fuel nozzle

ActiveUS20100308135A1Reduce amount of NOx generateHigh degree of atomizationBurnersTurbine/propulsion fuel supply systemsEngineeringFuel injection

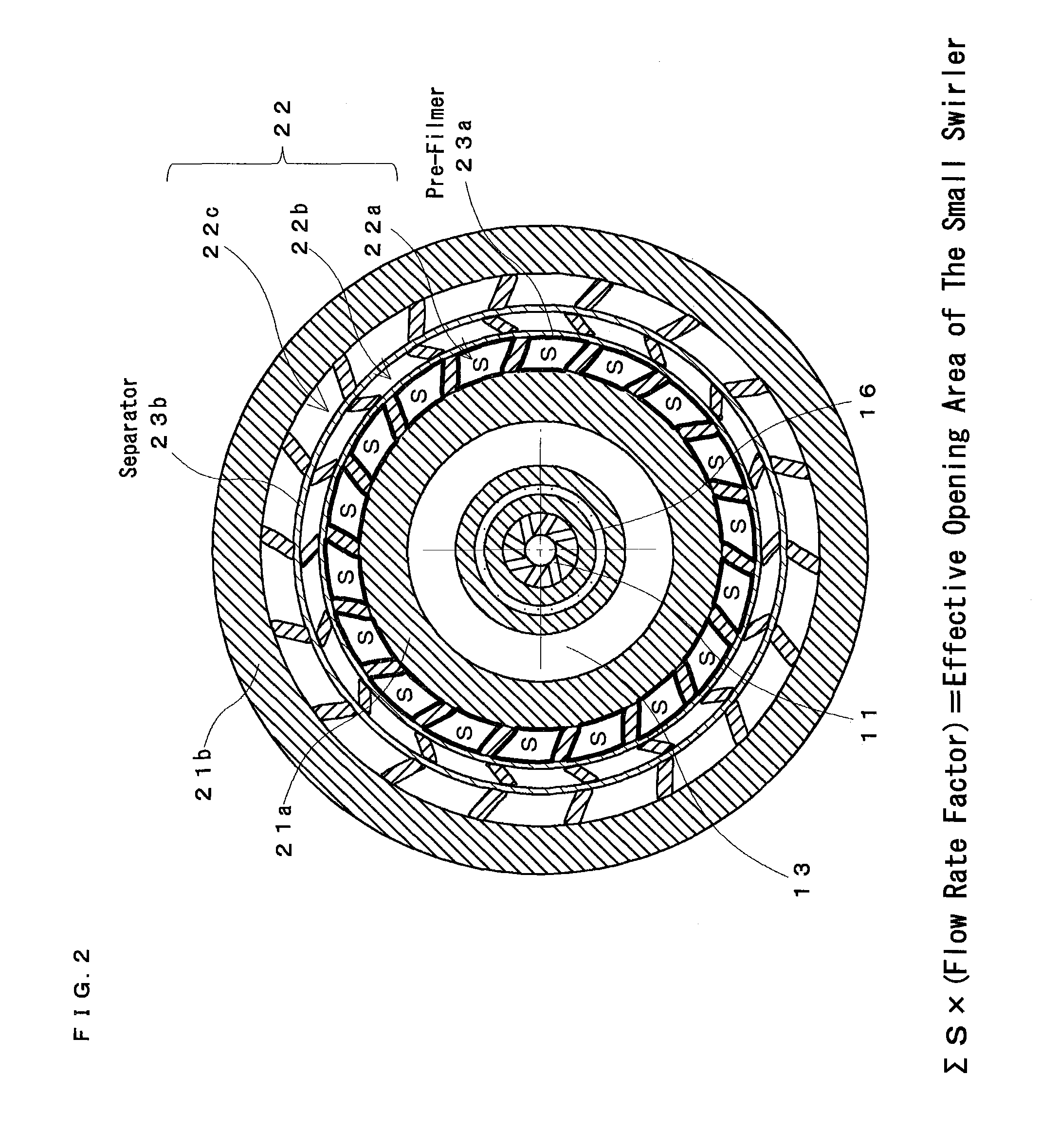

A main swirler of a triple annular configuration that is partitioned by a pre-filmer and a separator is installed in an inlet port of a main air flow channel. The vicinity of the inner wall of the main air flow channel provided with a main fuel injection port is bulged radially outward from the innermost surface (innermost surface of a small swirler) of a main swirler. Further, a distance from the main fuel injection port and the pre-filmer is set such that an effective opening area between the pre-filmer and “the inner wall of the main air flow channel provided with the main fuel injection port” is equal to an effective opening area of the small swirler. The swirling directions of the swirlers of the main swirler are “clockwise”-“counter-clockwise”-“clockwise” respectively along the radial outward direction when the swirling direction of the innermost swirler is taken as “clockwise”.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

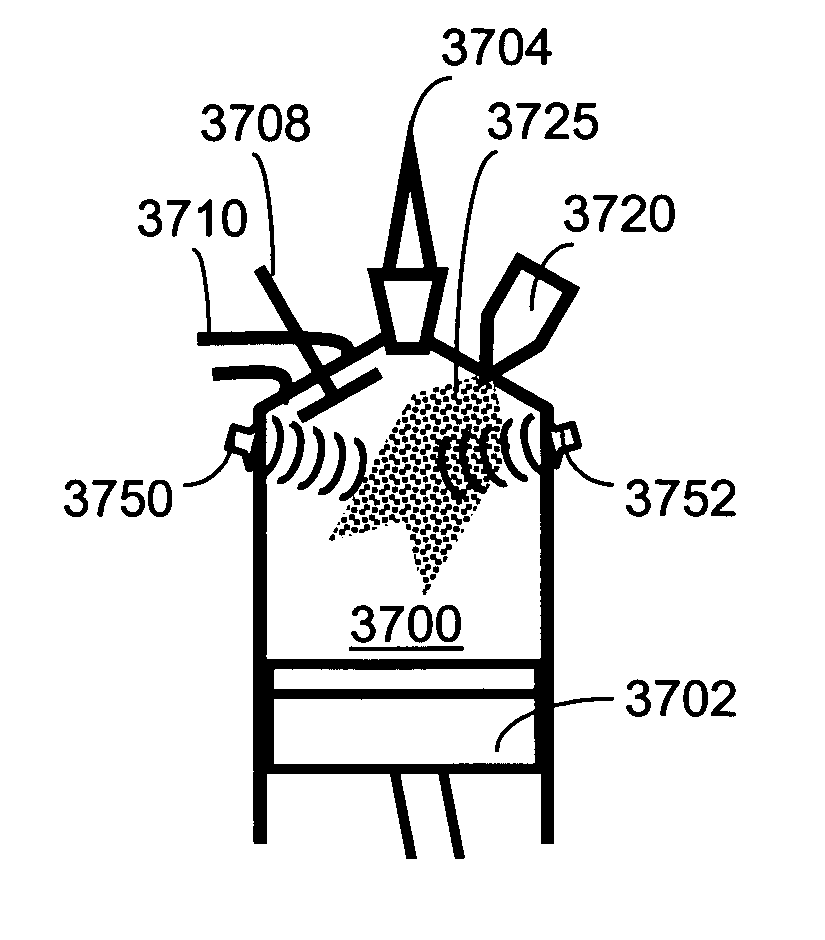

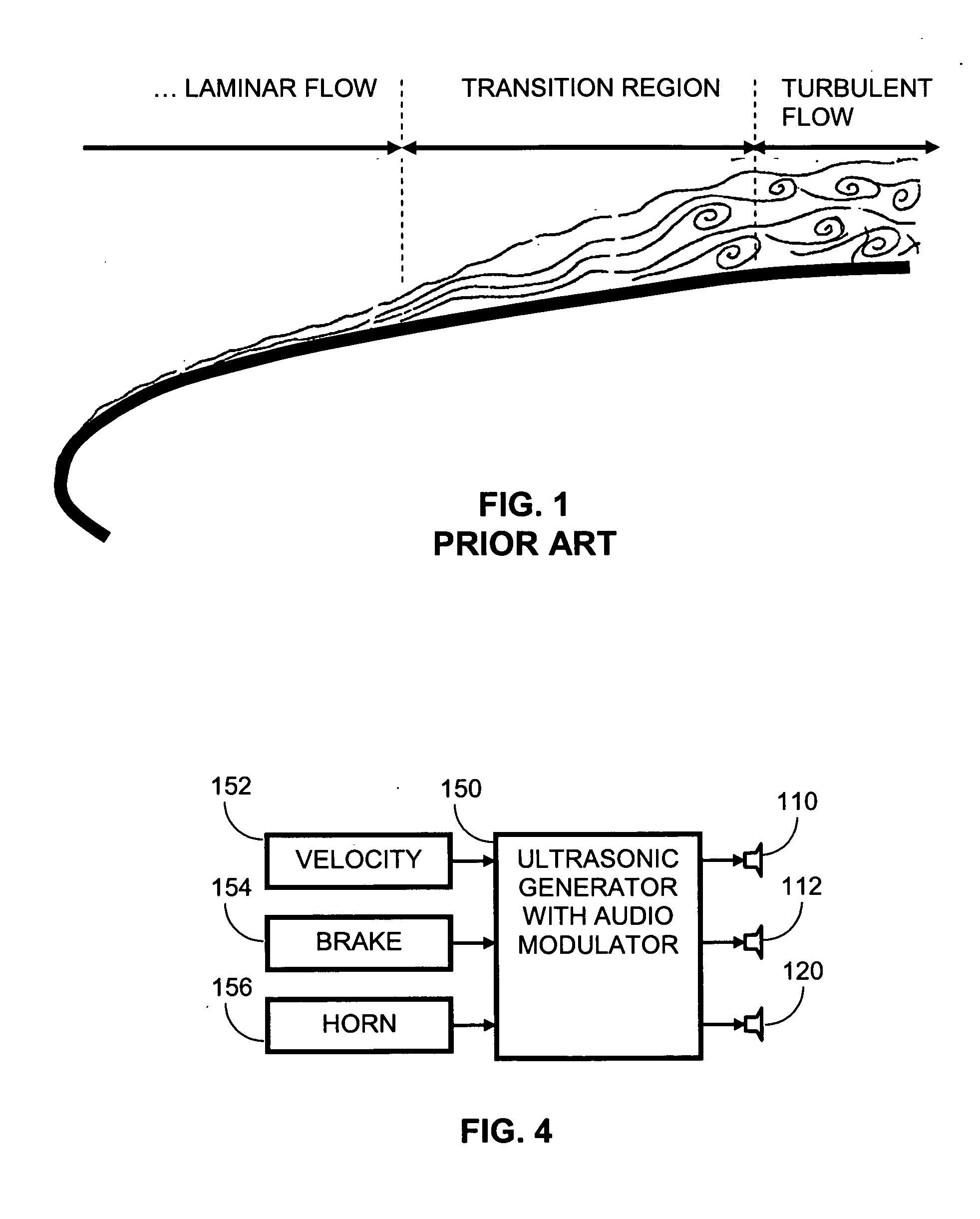

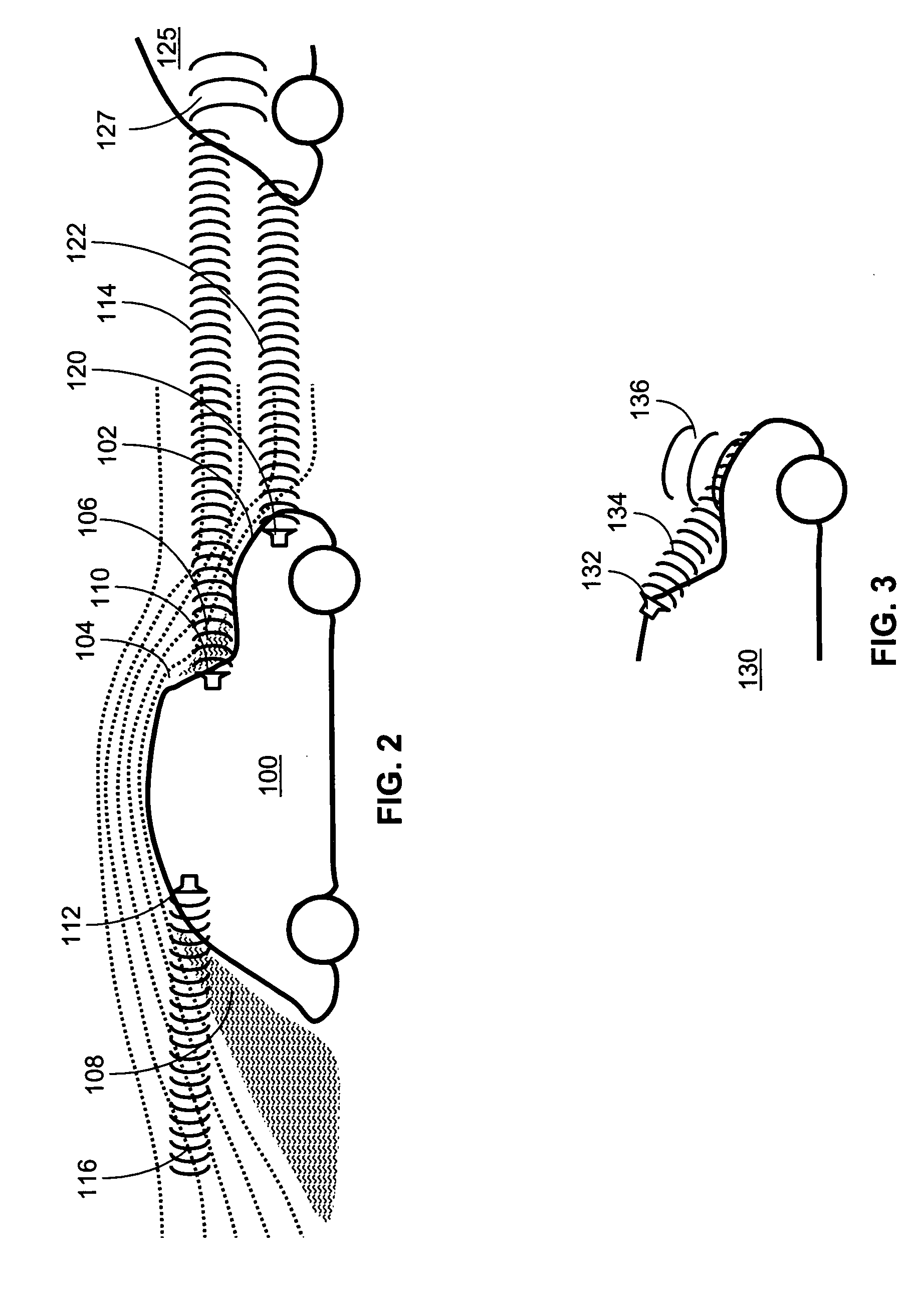

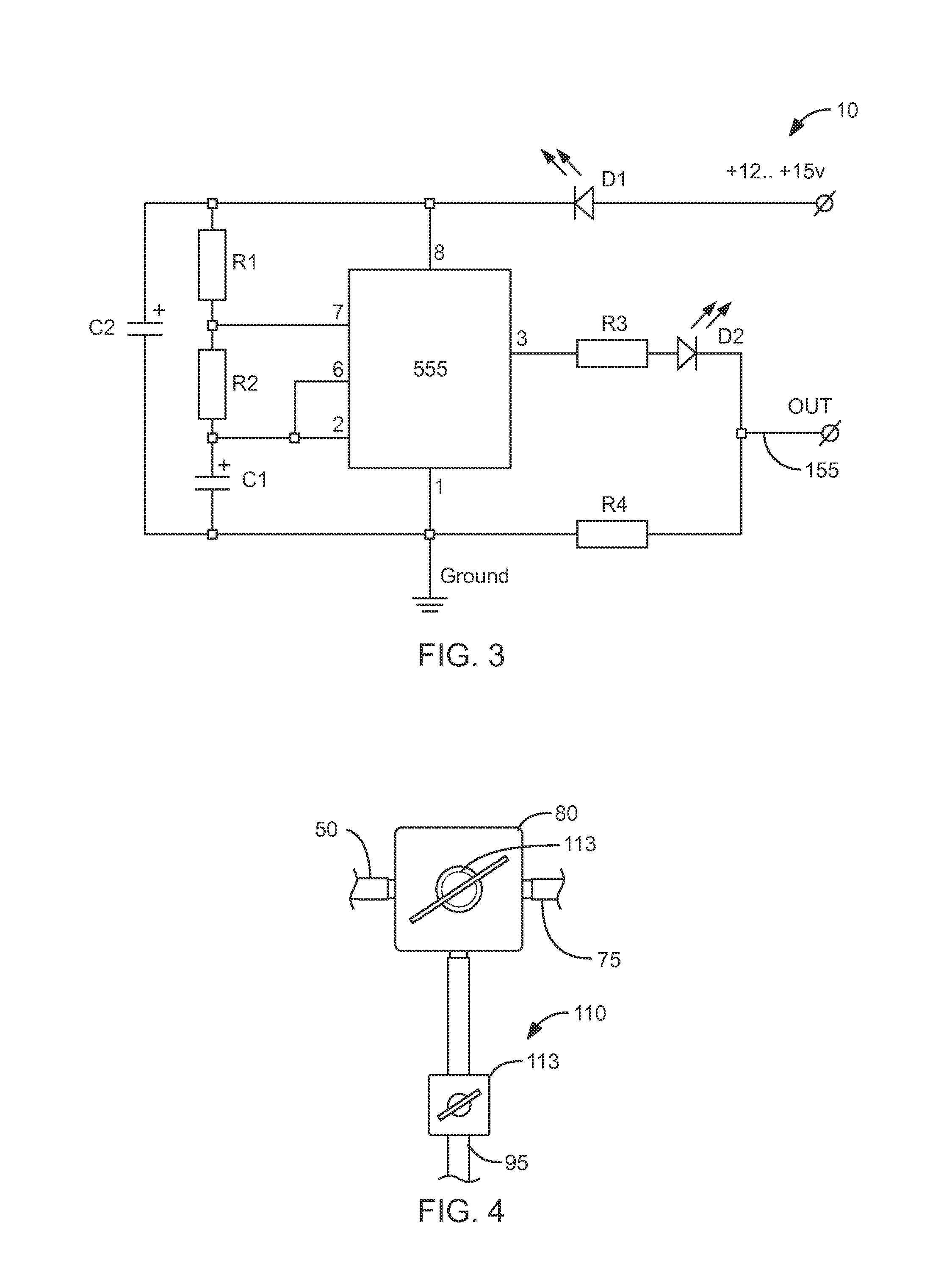

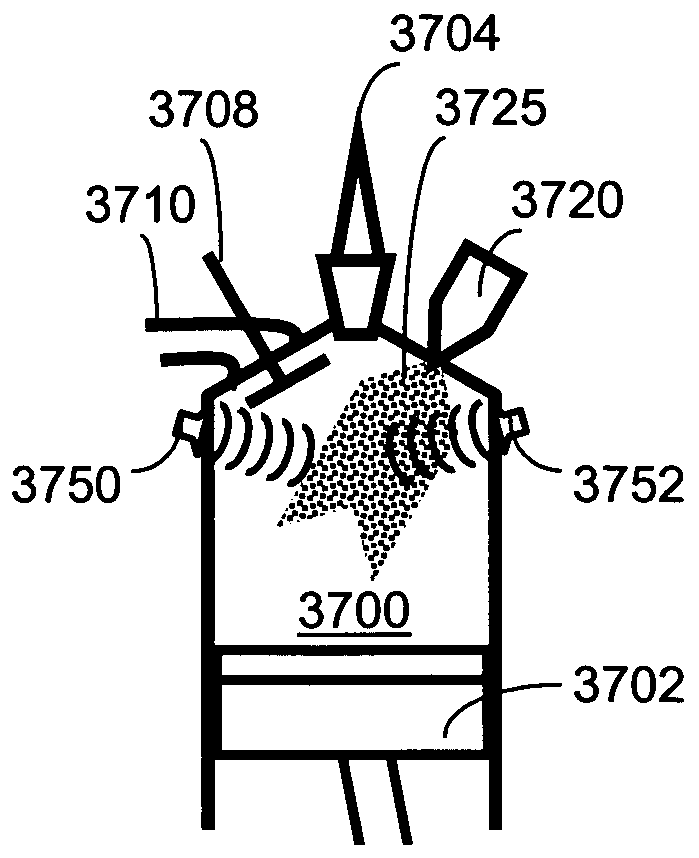

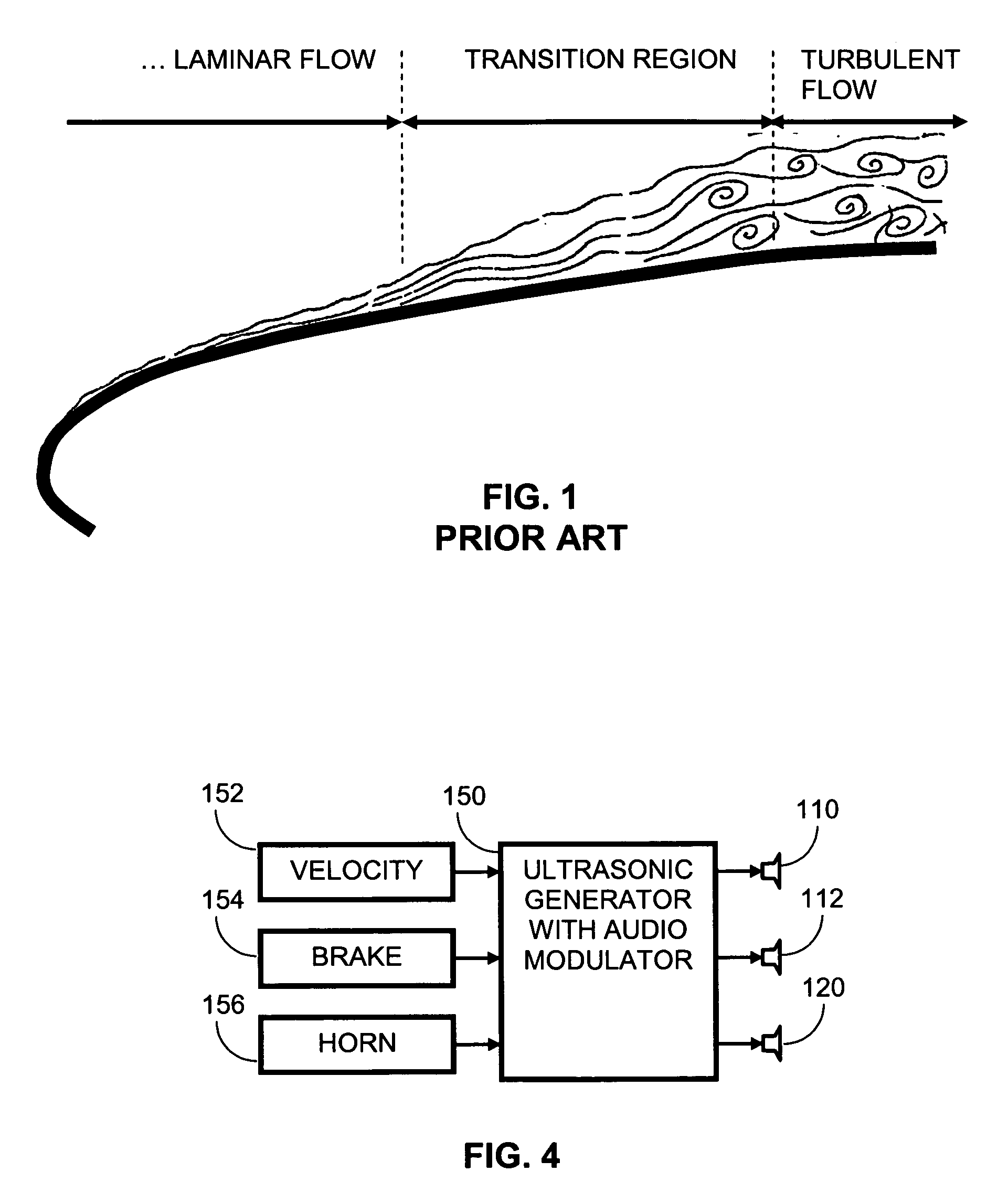

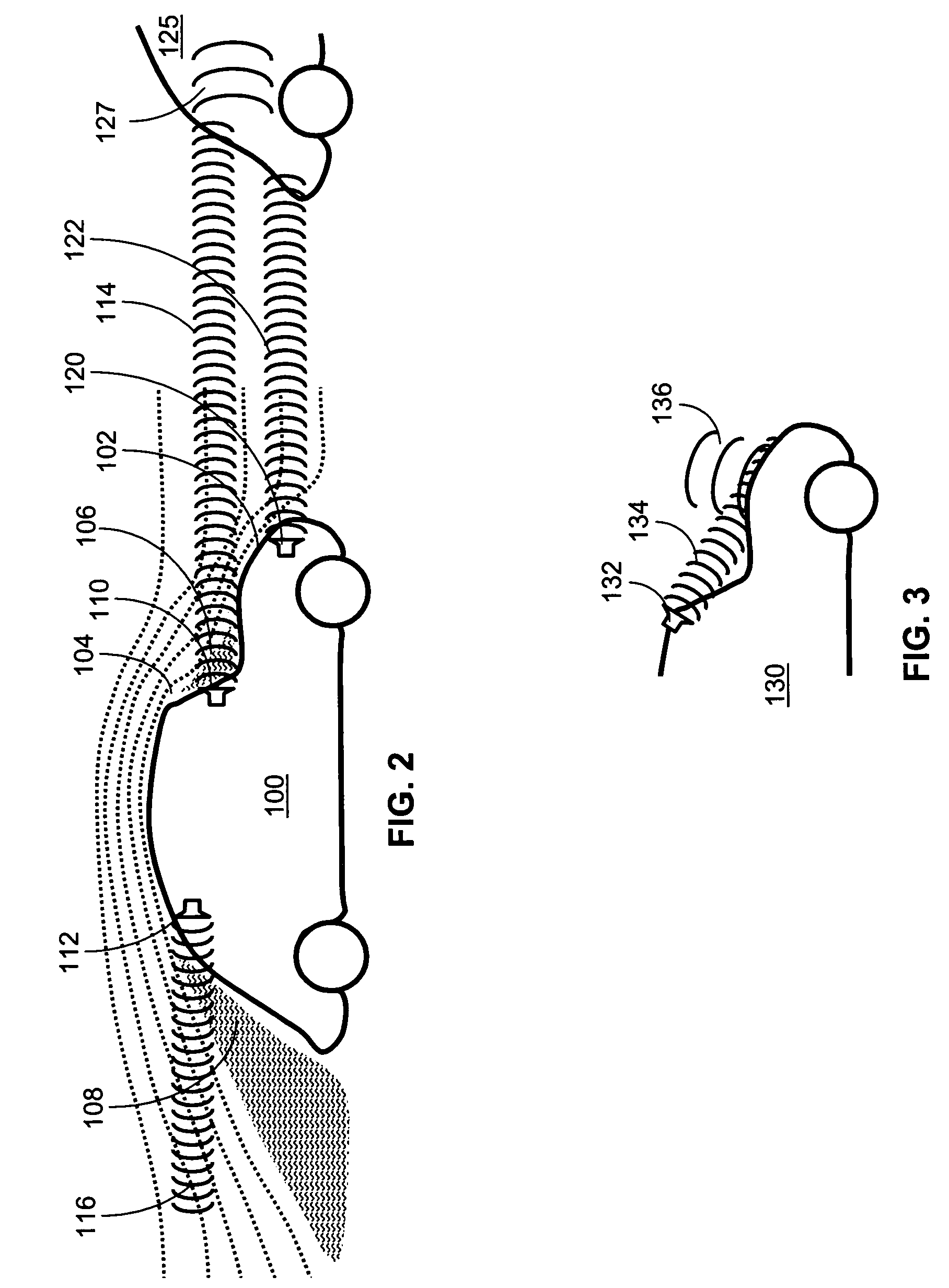

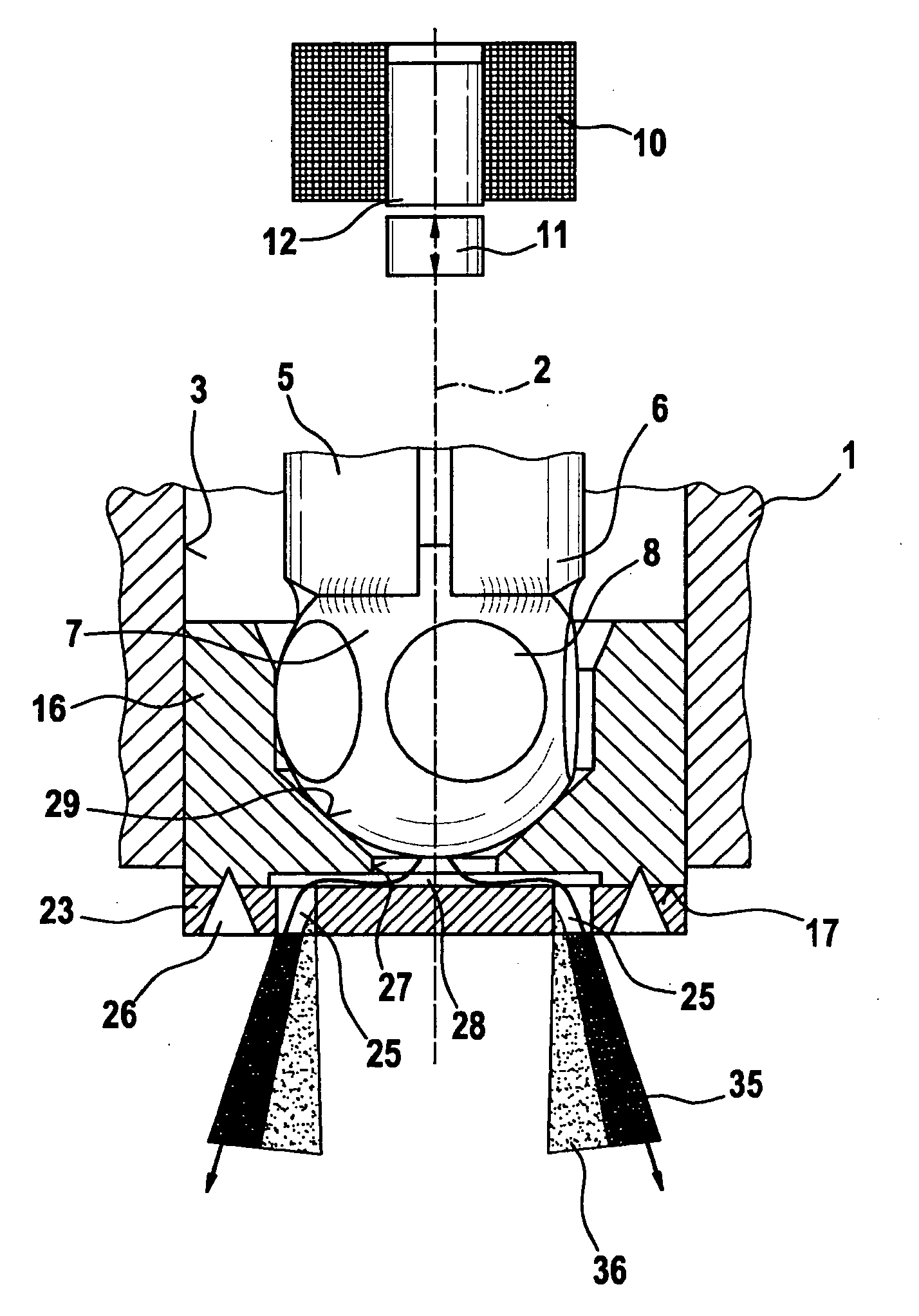

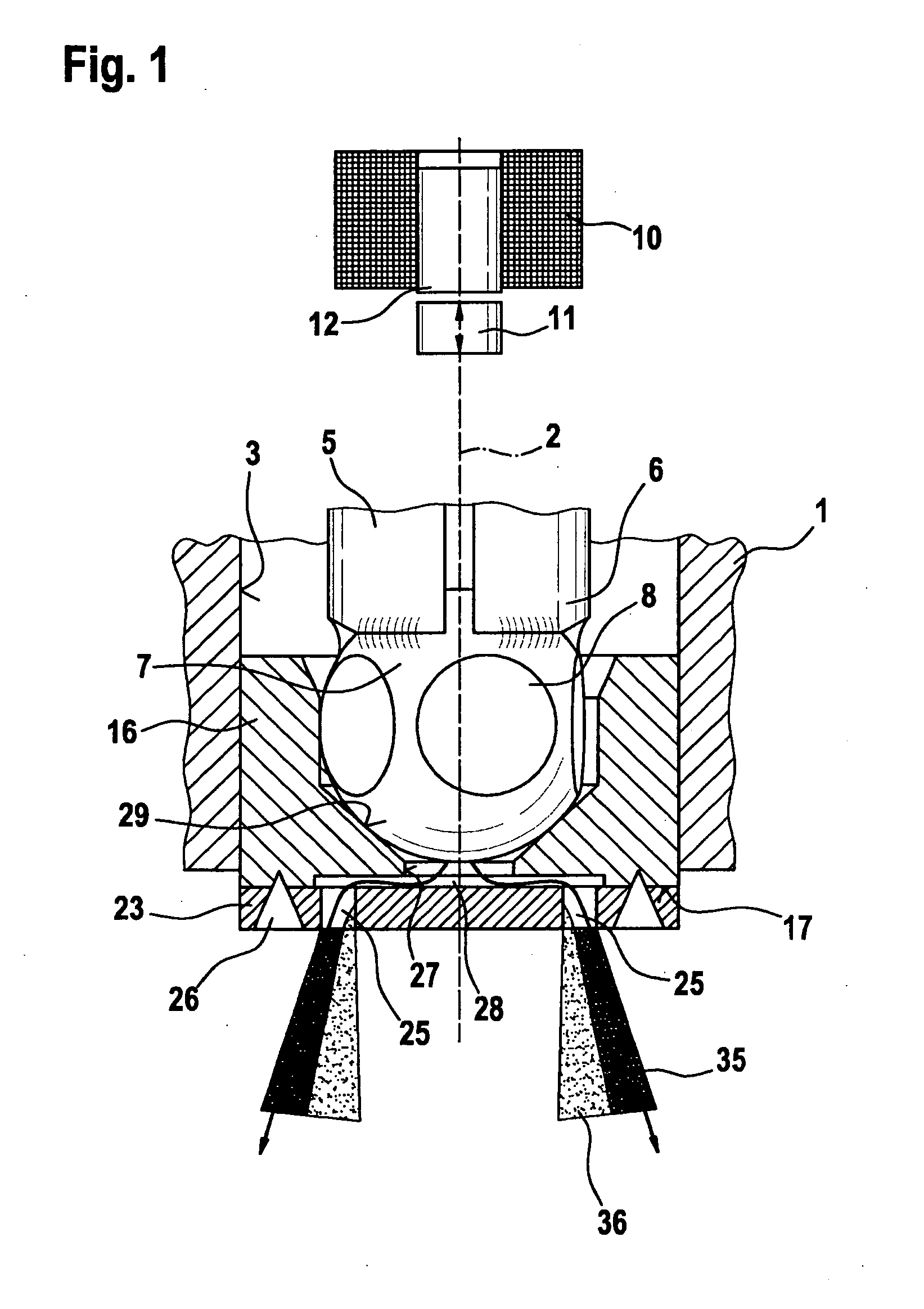

Active drag and thrust modulation system and methods

InactiveUS20050257776A1Good fuel atomizationPromote atomizationTyre partsInternal combustion piston enginesLeading edgeCombustion

A vehicle traveling through an environmental media such as air experiences drag. The drag is actively modulated by energy beams which may either increase or decrease the drag. The energy beams may provide either a chemical, acoustic or electromagnetic energy at a transition region between turbulent and laminar flows or at the leading edge of a laminar flow or in the direction of a crosswind in order to facilitate the respective increase or decrease in drag. If the vehicle is a sailing ship, areas of the sails are selectively roughened or widened to enhance the thrust derived from the wind. Furthermore, the keel or hull of the sailing ship may be modified to improve the hydrodynamic characteristics of the sailing ship. If the vehicle is an automobile, the tires or road surface may be selectively heated to improve the traction of the automobile. Furthermore, the energy beams may be used to facilitate atomization of the air / fuel mixture prior to combustion in an internal combustion engine thereby improving the thrust of provided to the vehicle. Energy beams may be used to generate virtual extensions of a vehicle to enhance traveling efficiency.

Owner:P TECH

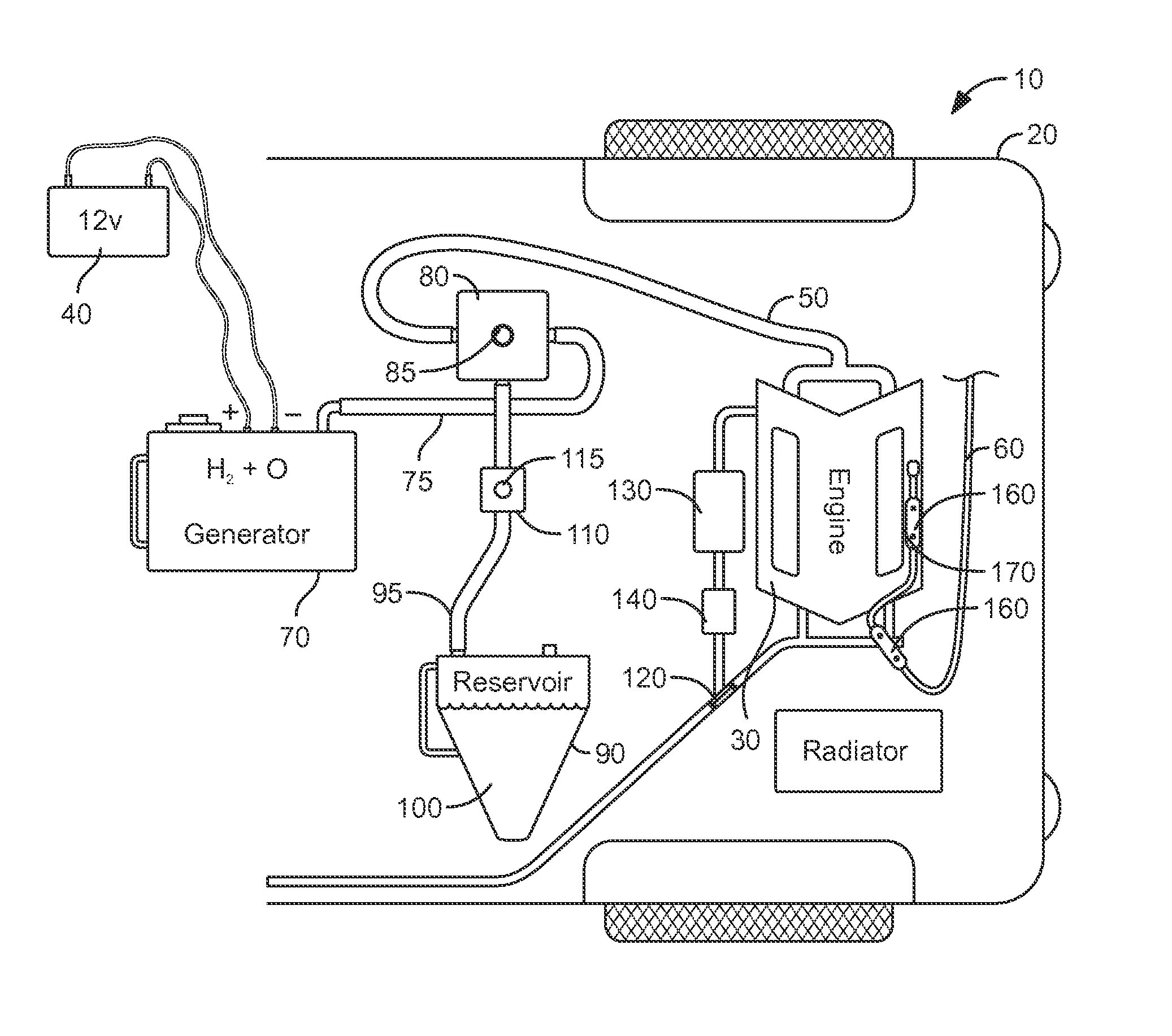

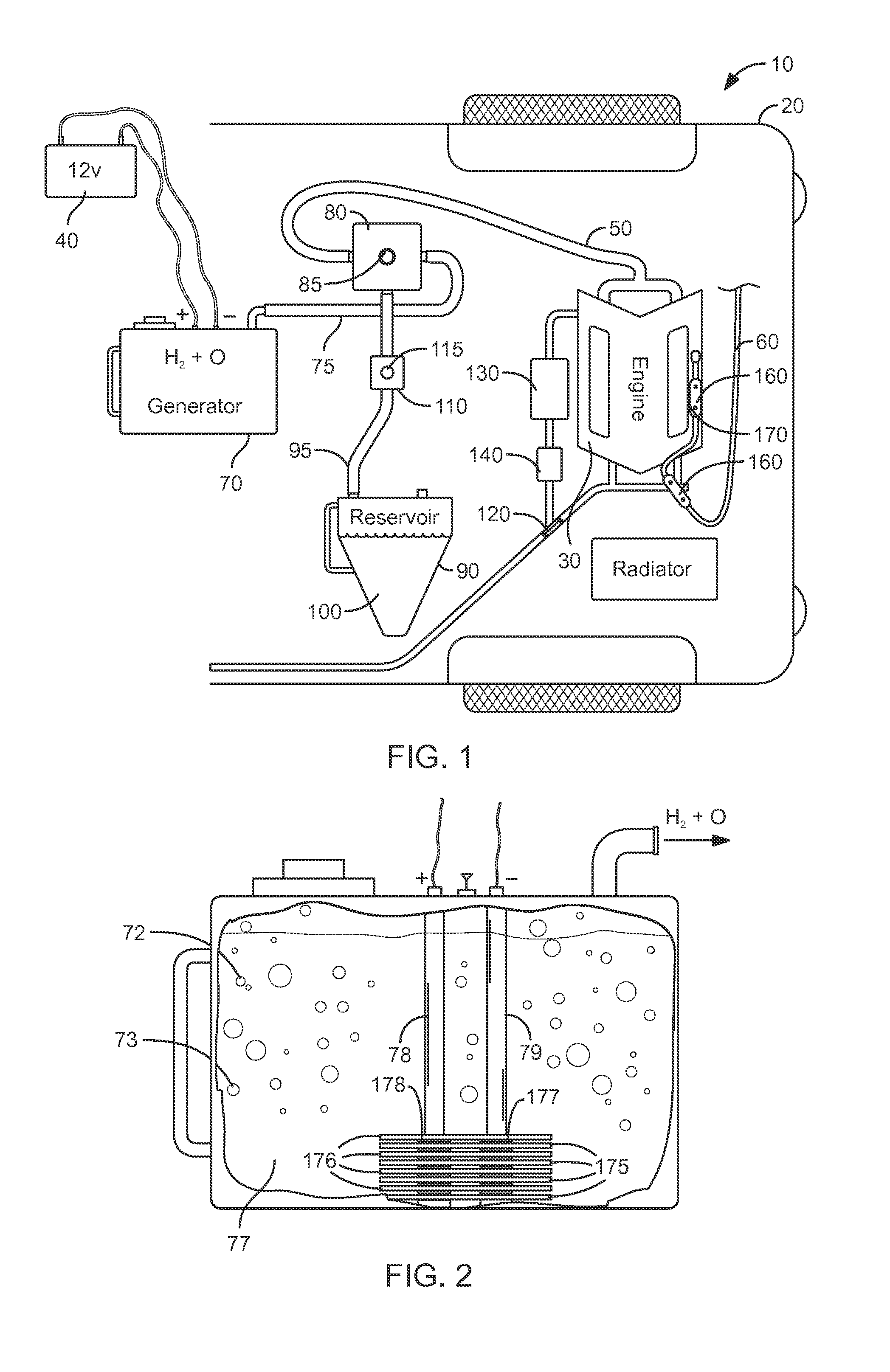

Engine fuel efficiency improvements

InactiveUS7458368B1Good fuel atomizationEfficient combustionPhotography auxillary processesNon-fuel substance addition to fuelFuel efficiencyInternal combustion engine

The present invention is a system for increasing the fuel efficiency of a vehicle of the type having an internal combustion engine, a battery, a vacuum line, and a fuel line that feeds fuel to the engine. The system comprises a hydrogen gas generator and a vacuum regulator. A vacuum regulator is in fluid communication with the vacuum line of the vehicle and an output line of the gas generator. The vacuum regulator includes a vacuum pressure adjustment means for controlling the amount of hydrogen gas that is introduced into the vacuum line of the vehicle. In use, hydrogen gas is introduced into the vehicle vacuum line and then into the engine where it is mixed with the fuel from the fuel line and ambient air. The hydrogen gas increases the atomization of the fuel for more efficient burning thereof in the engine. A fuel additive including an acetone-based compound, a xylene-based compound, and an upper cylinder lubricant may be mixed with the hydrogen gas to further atomize the fuel. An oxygen sensor signal generator that generates a bypass signal replicates the output of a vehicle oxygen sensor under normal operating conductions to keep the air mixture of the engine unaffected. The system may additional include at least one fuel heating means fixed to a high-temperature portion of the engine, such that the fuel is heated before being introduced into the engine so as to further increase atomization of the fuel for more efficient burning thereof in the engine.

Owner:HUFFMAN DANIEL

Active drag and thrust modulation system and methods

InactiveUS6978767B2Good fuel atomizationPromote atomizationTyre partsInternal combustion piston enginesLeading edgeCombustion

A vehicle traveling through an environmental media such as air experiences drag. The drag is actively modulated by energy beams which may either increase or decrease the drag. The energy beams may provide either a chemical, acoustic or electromagnetic energy at a transition region between turbulent and laminar flows or at the leading edge of a laminar flow or in the direction of a crosswind in order to facilitate the respective increase or decrease in drag. If the vehicle is a sailing ship, areas of the sails are selectively roughened or widened to enhance the thrust derived from the wind. Furthermore, the keel or hull of the sailing ship may be modified to improve the hydrodynamic characteristics of the sailing ship. If the vehicle is an automobile, the tires or road surface may be selectively heated to improve the traction of the automobile. Furthermore, the energy beams may be used to facilitate atomization of the air / fuel mixture prior to combustion in an internal combustion engine thereby improving the thrust of provided to the vehicle. Energy beams may be used to generate virtual extensions of a vehicle to enhance traveling efficiency.

Owner:P TECH

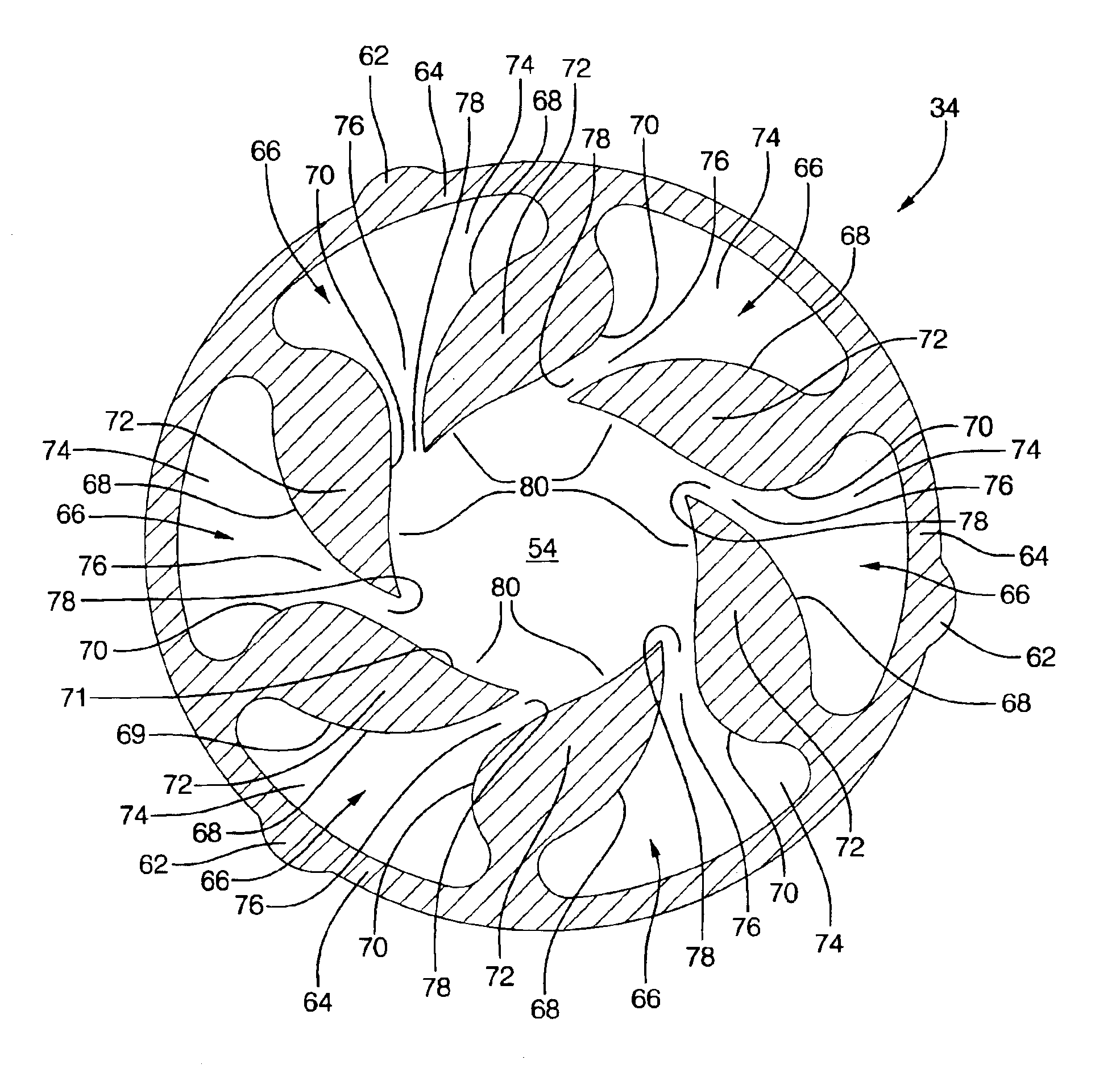

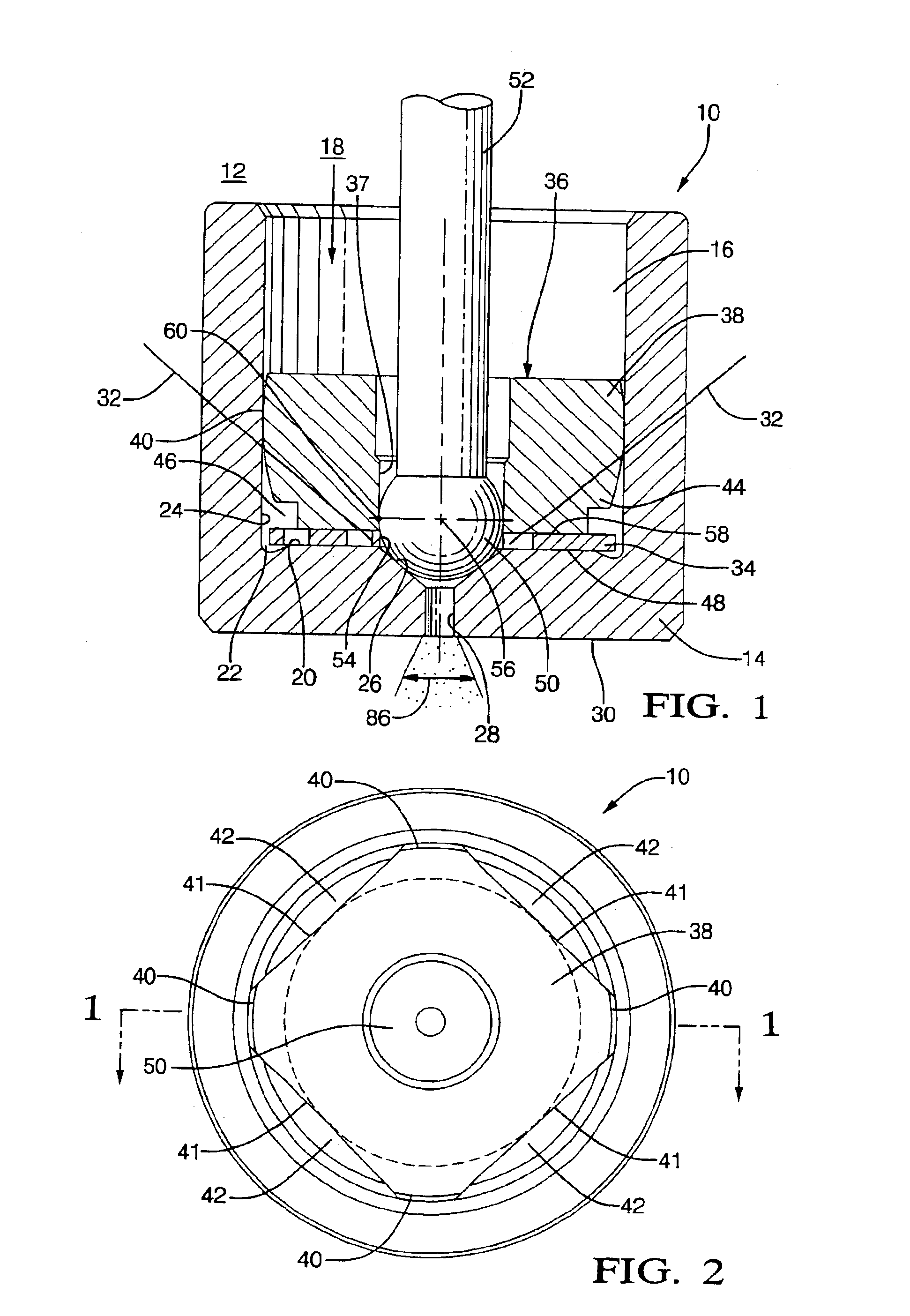

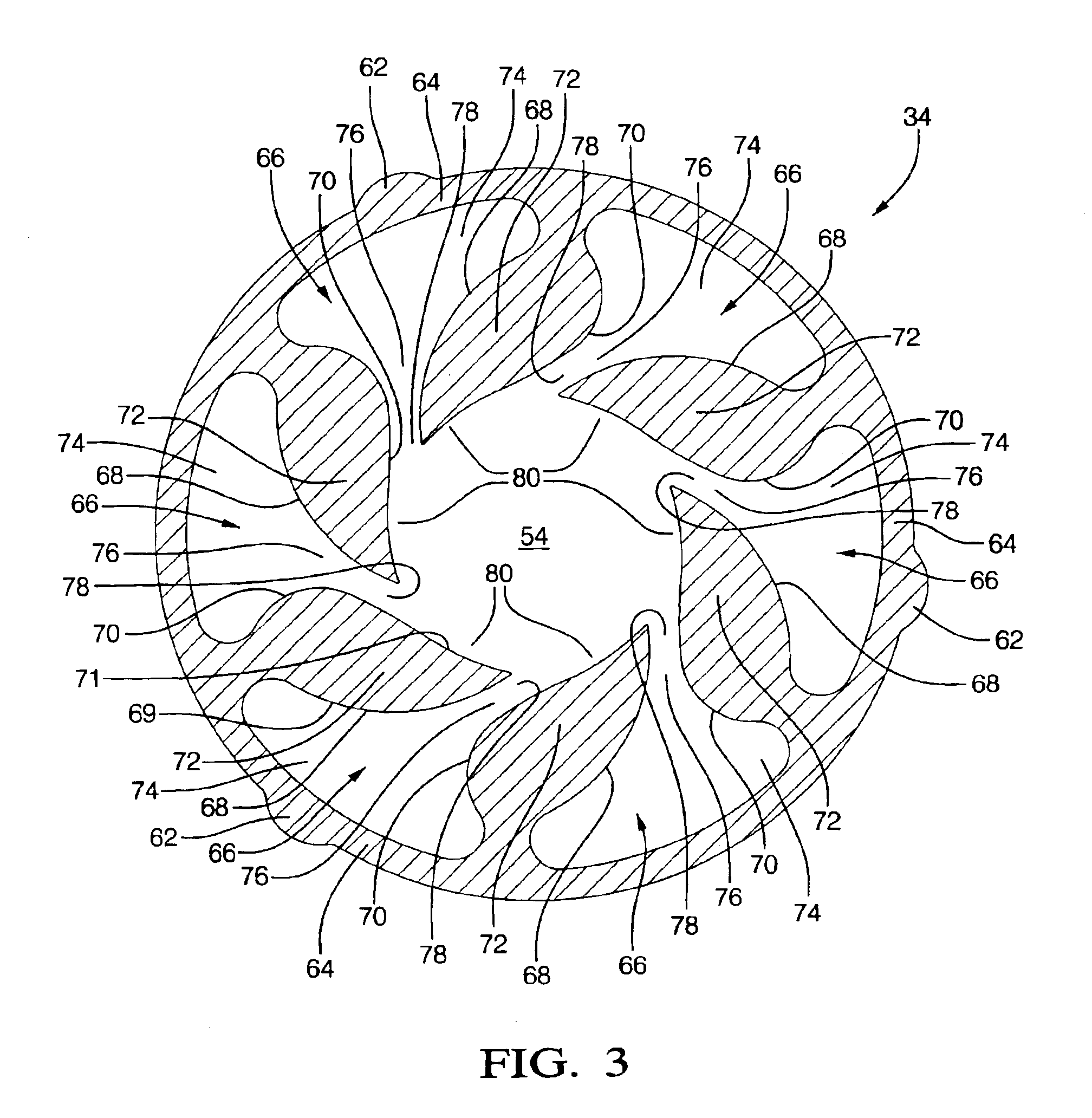

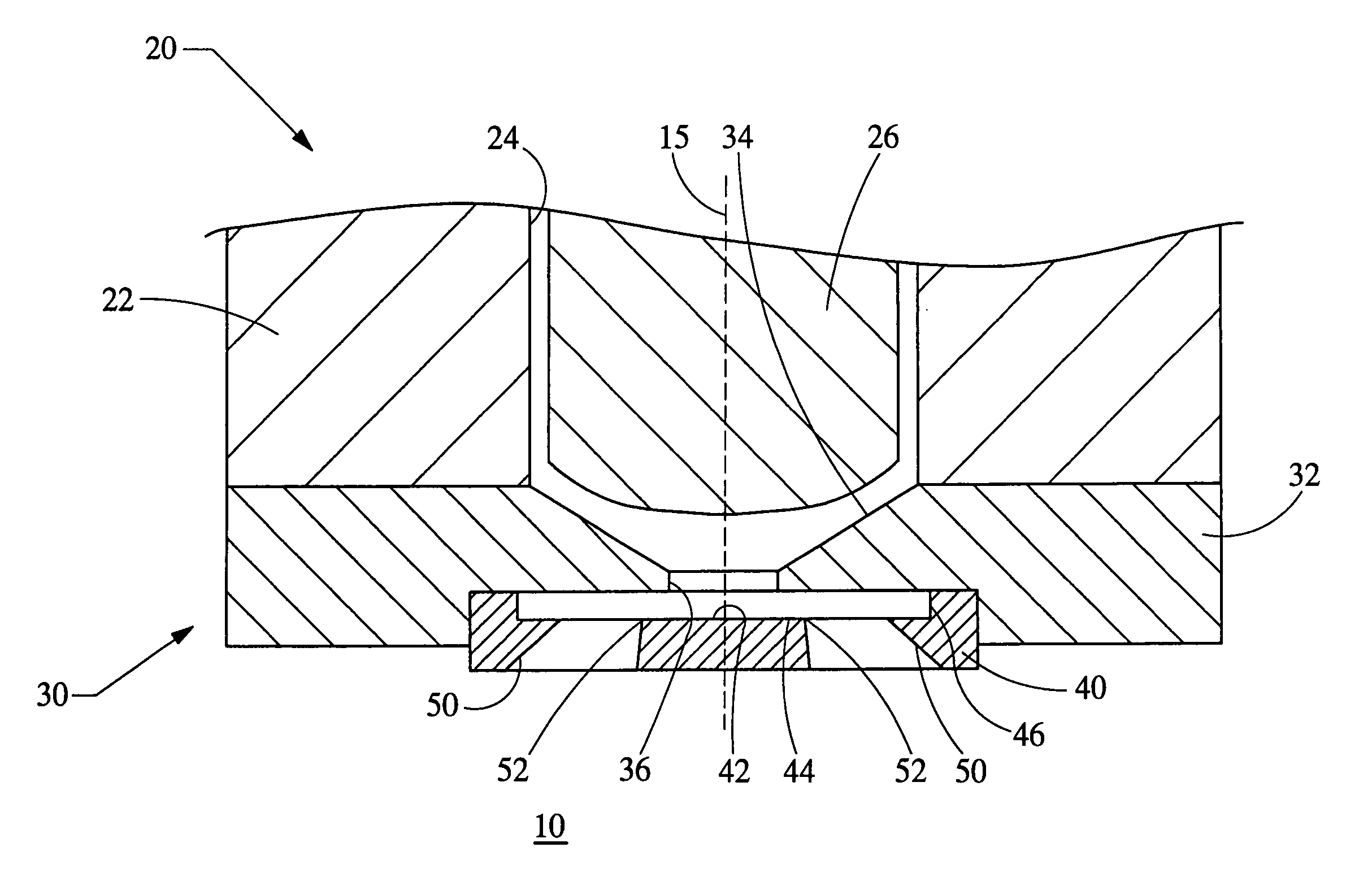

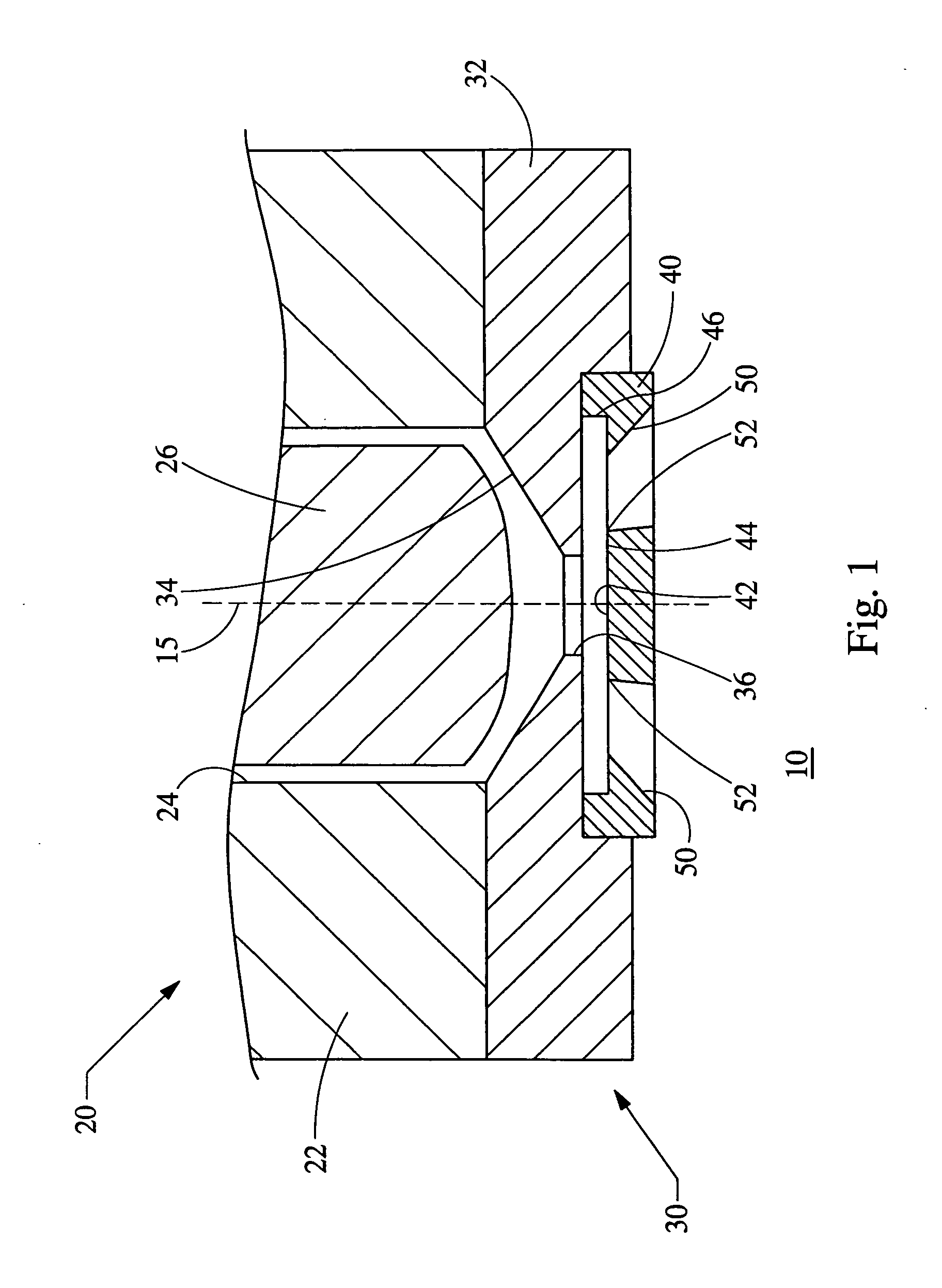

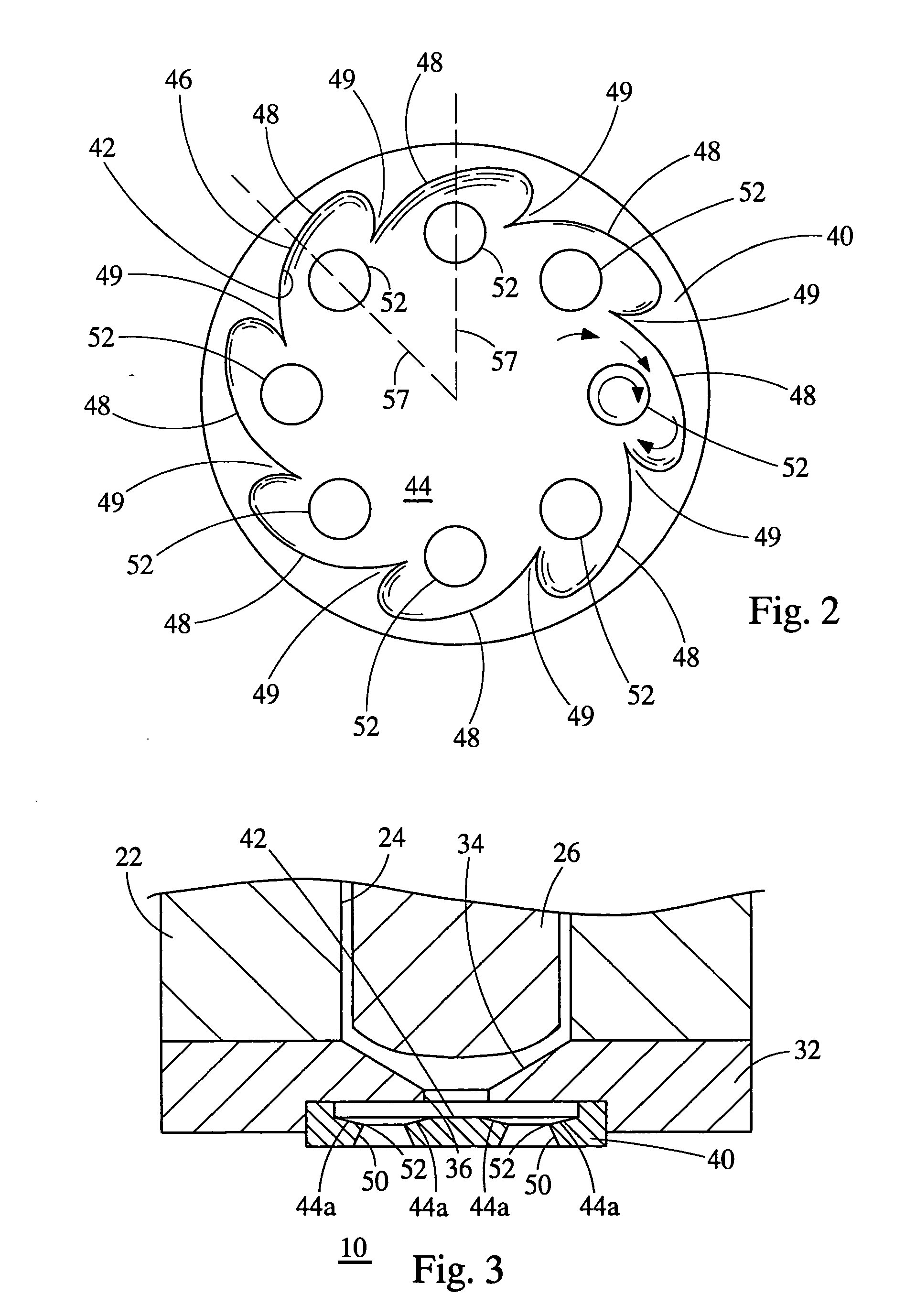

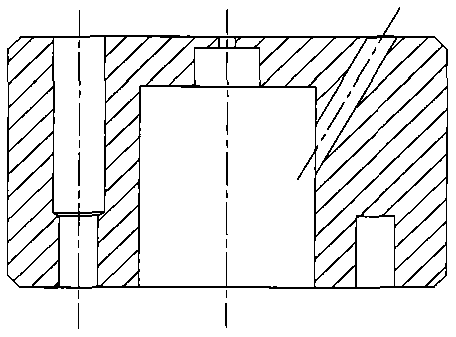

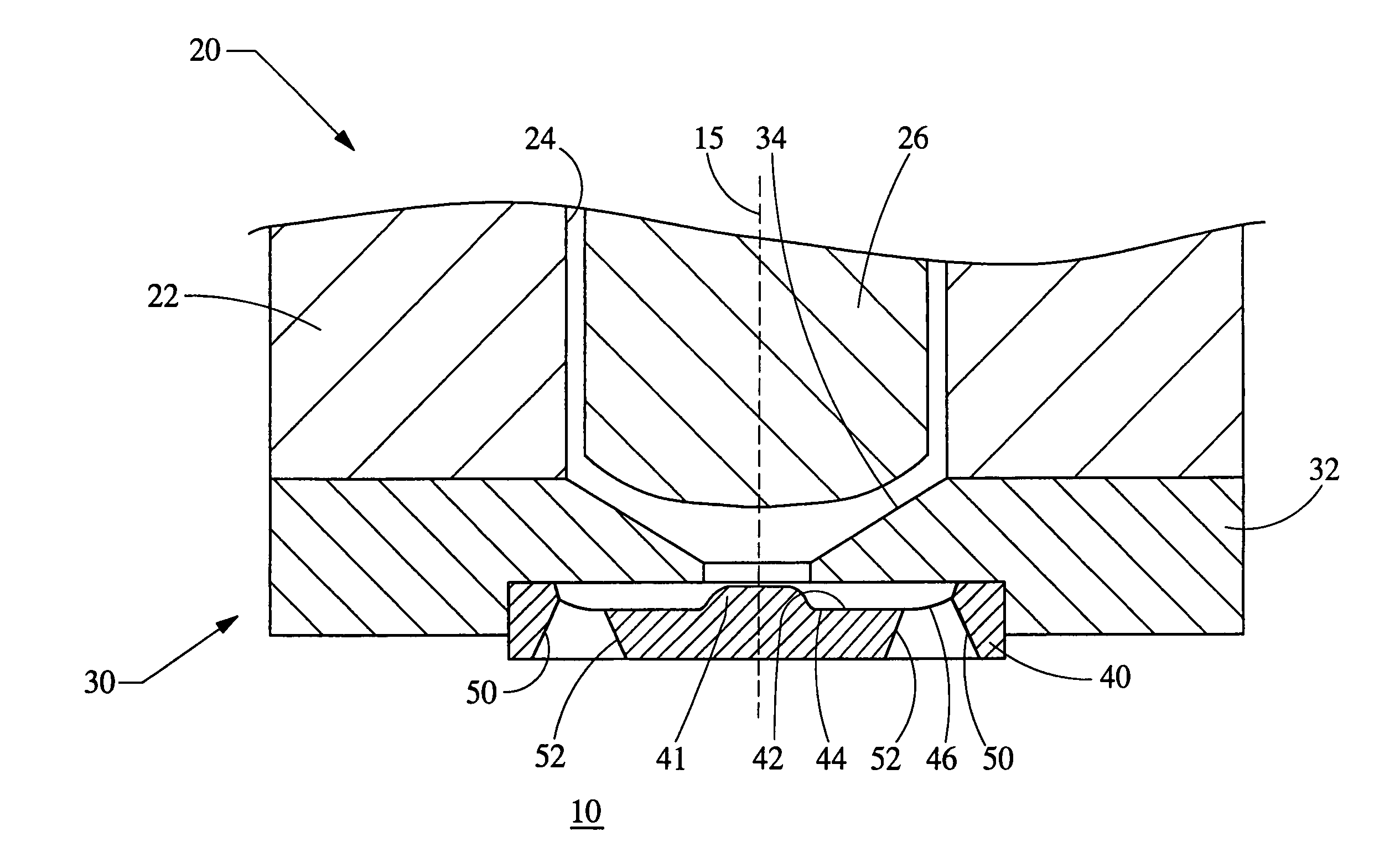

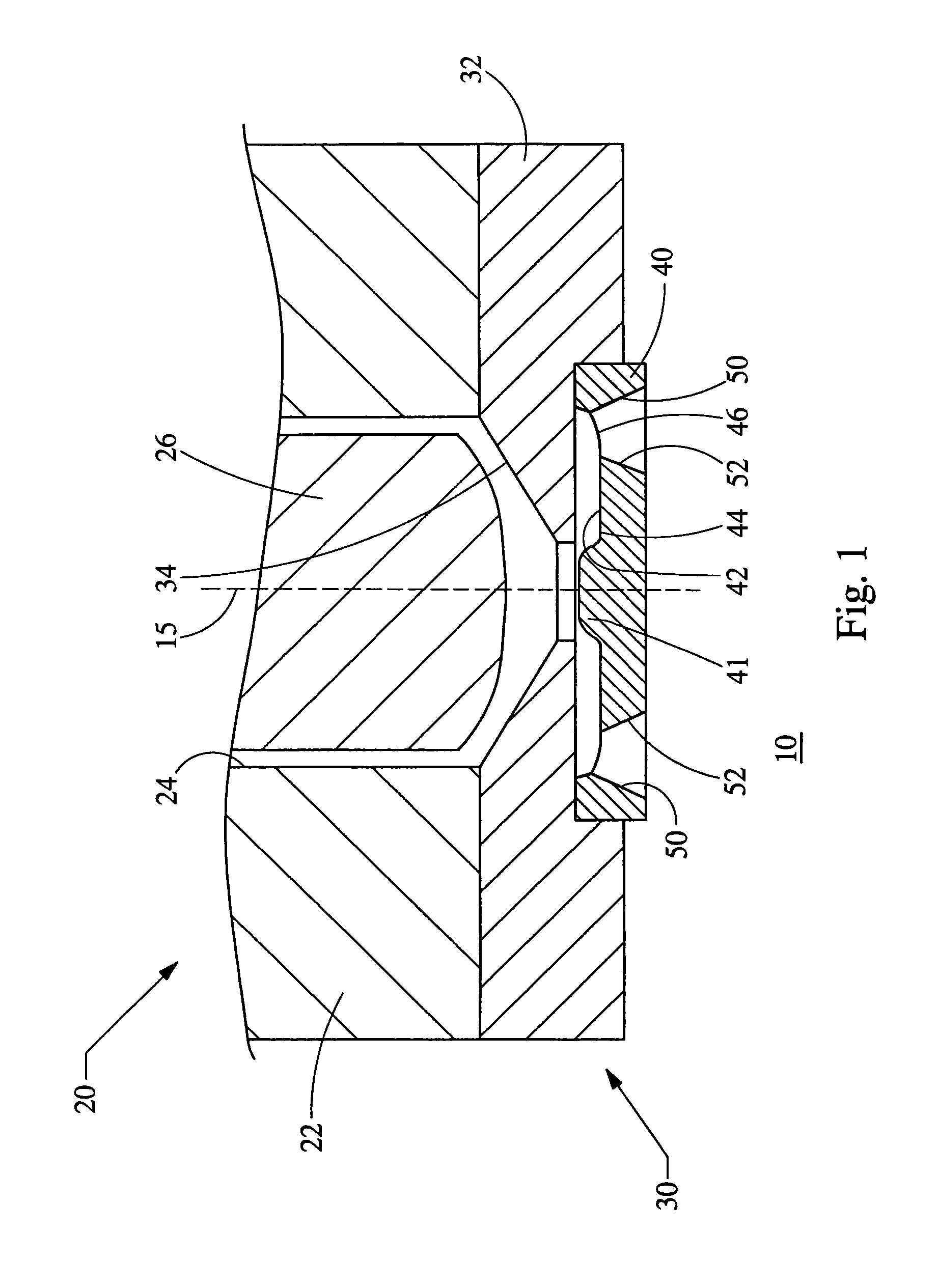

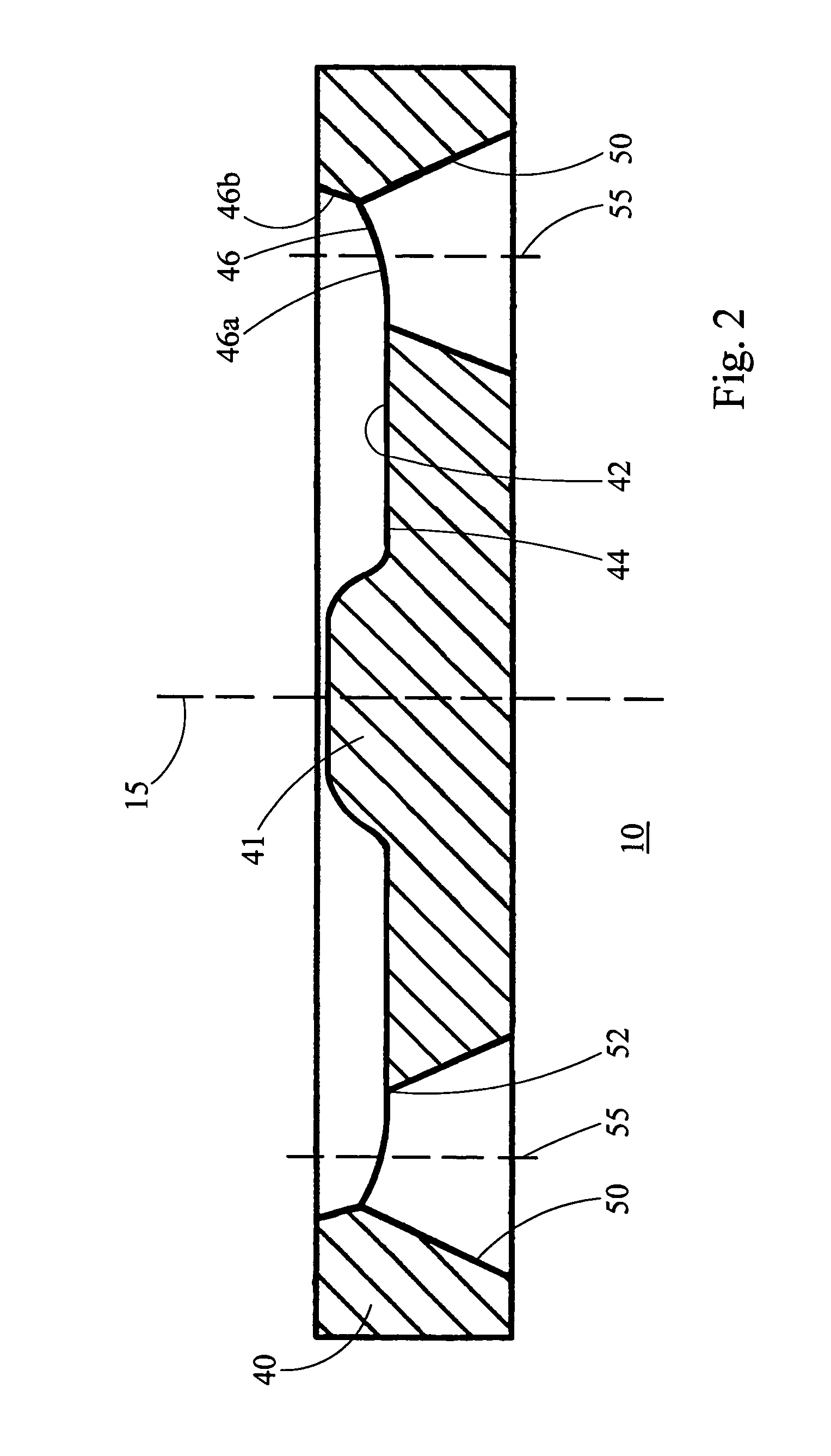

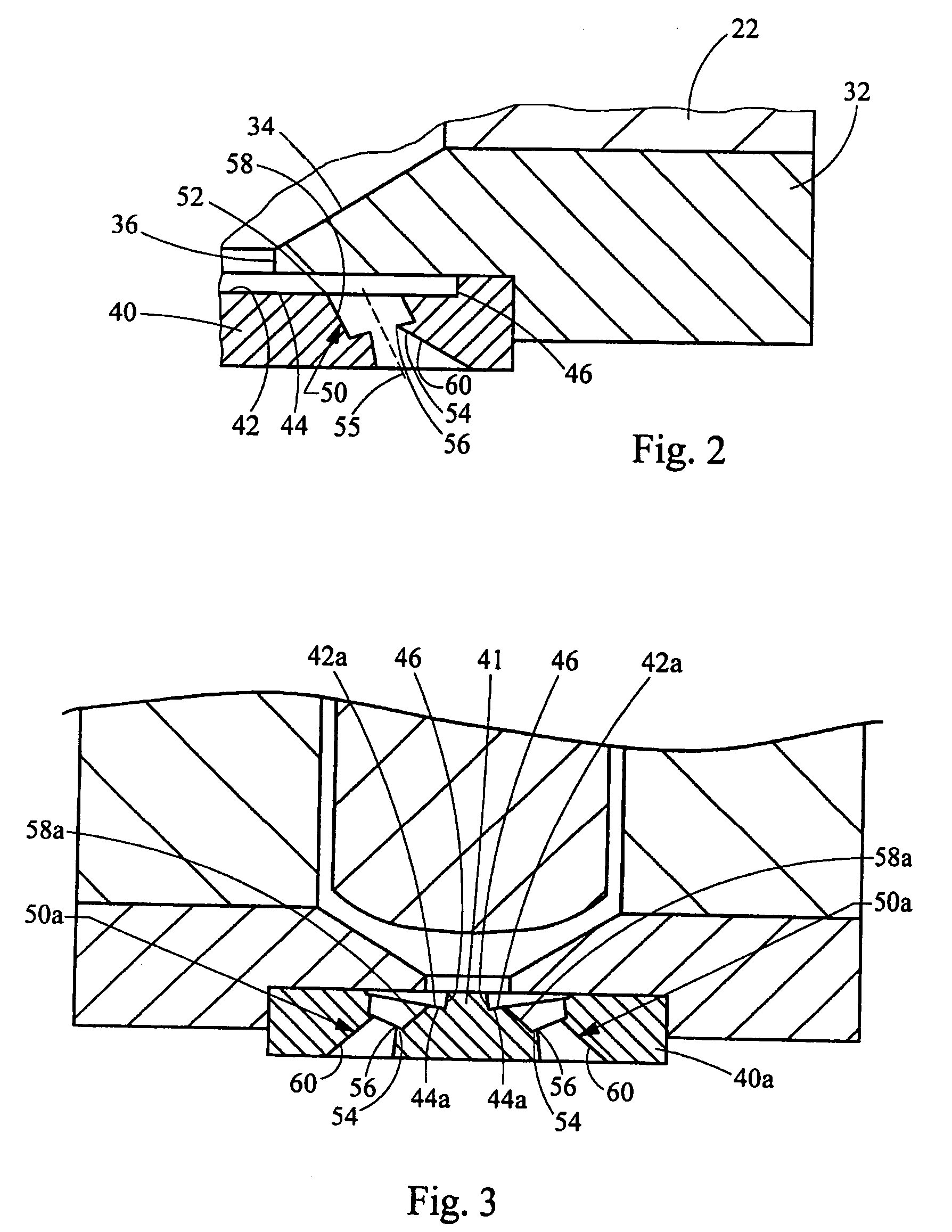

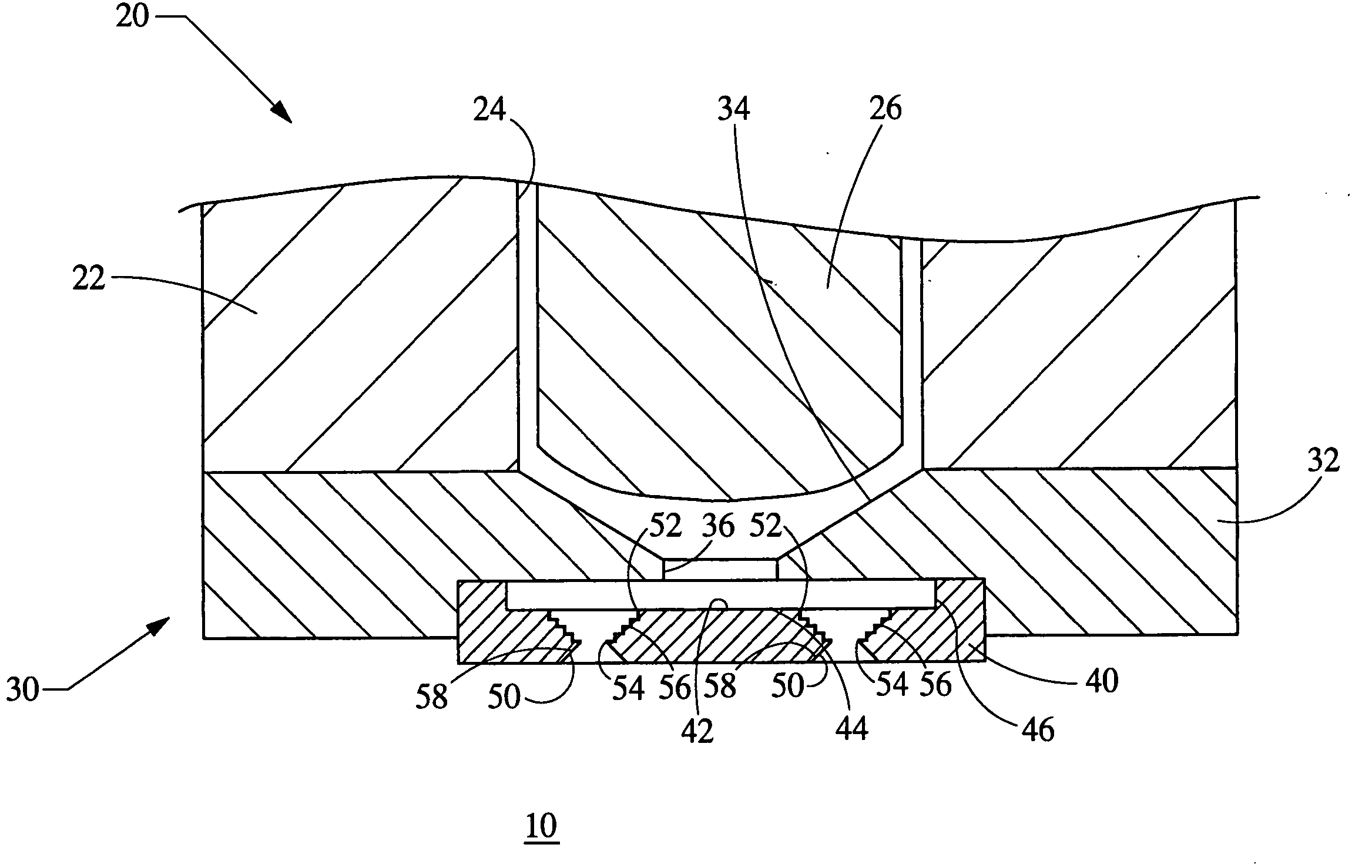

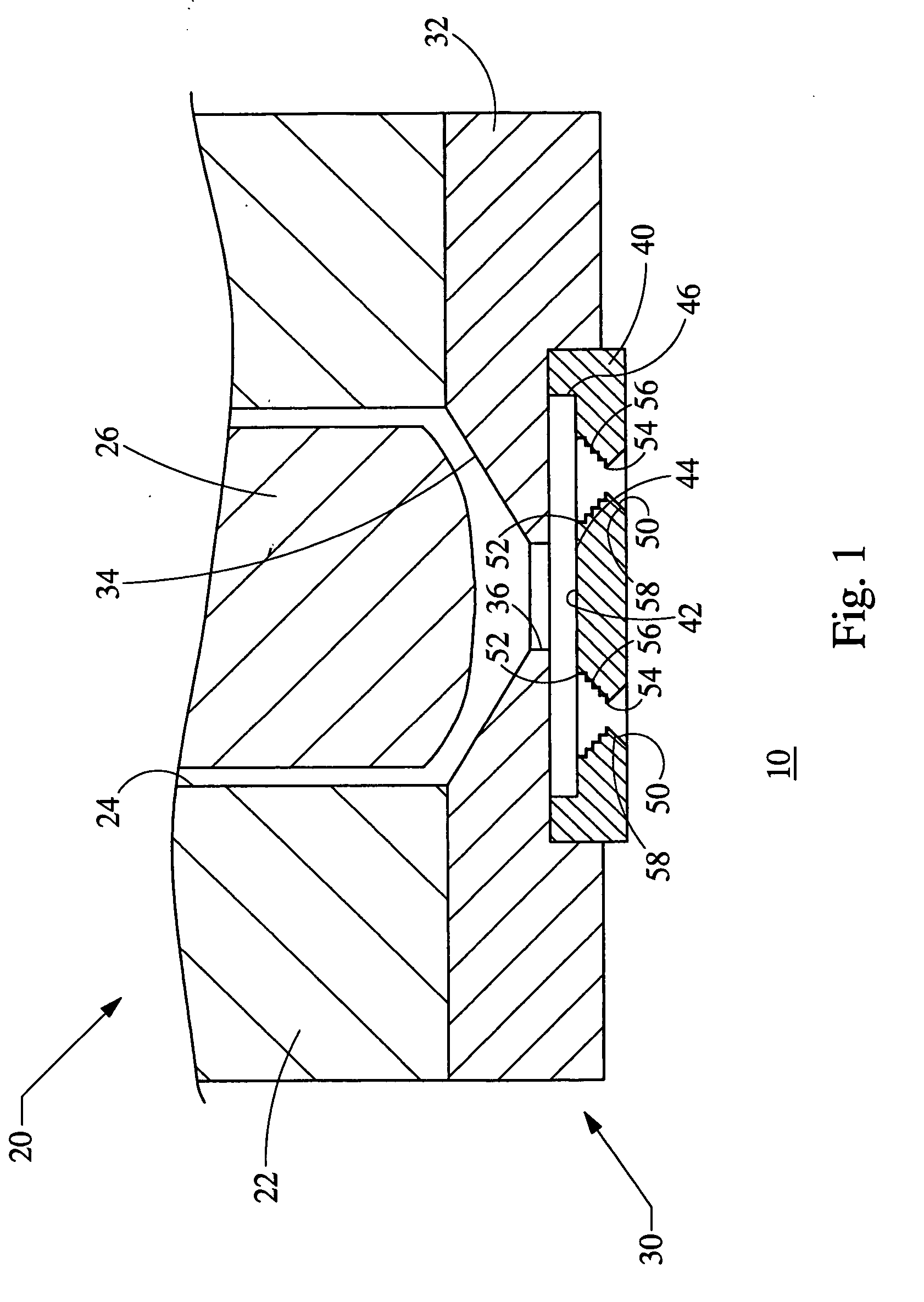

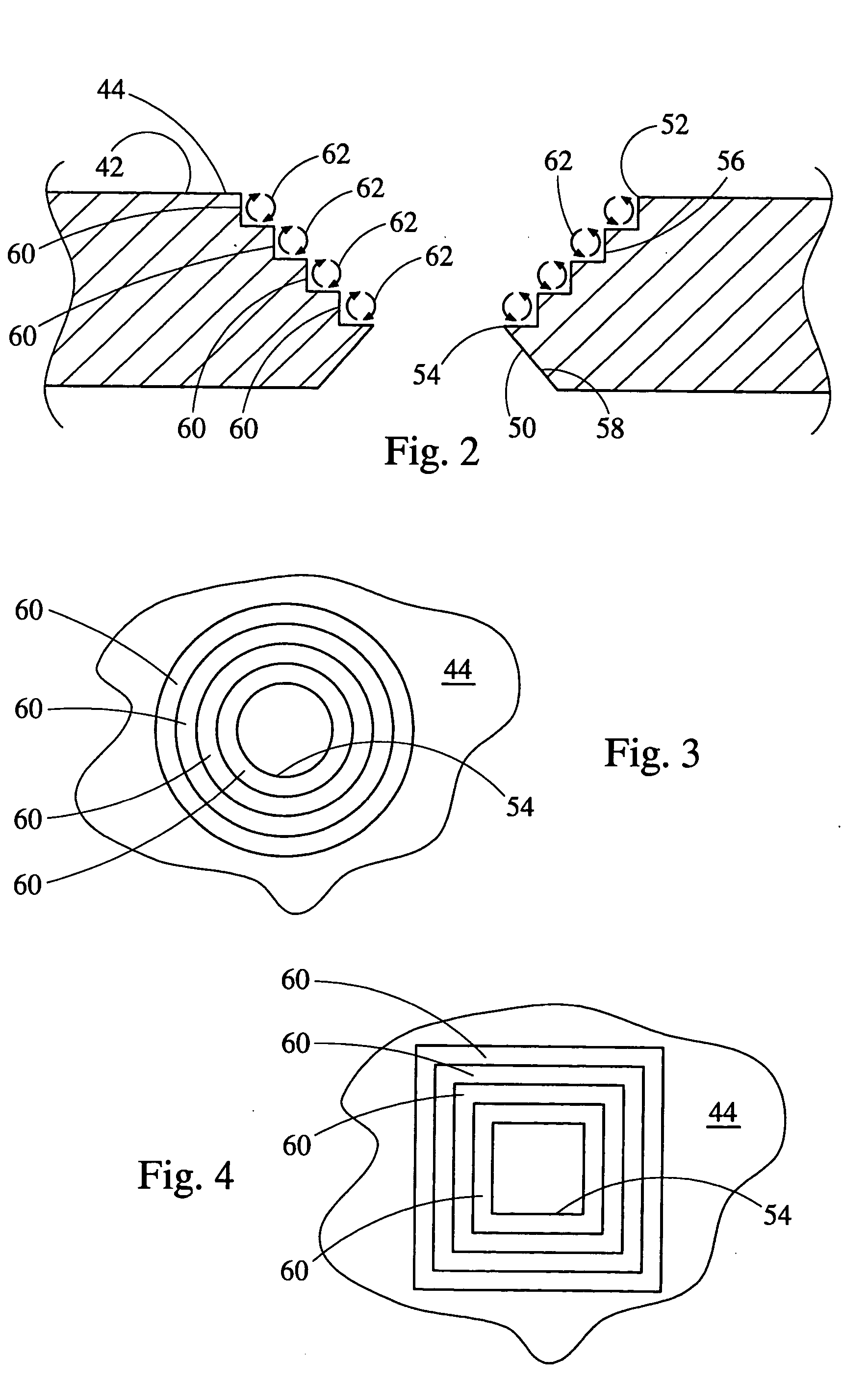

Fuel swirler plate for a fuel injector

InactiveUS6899290B2Good fuel atomizationIncrease speedSpray nozzlesFuel injection apparatusState of artLeading edge

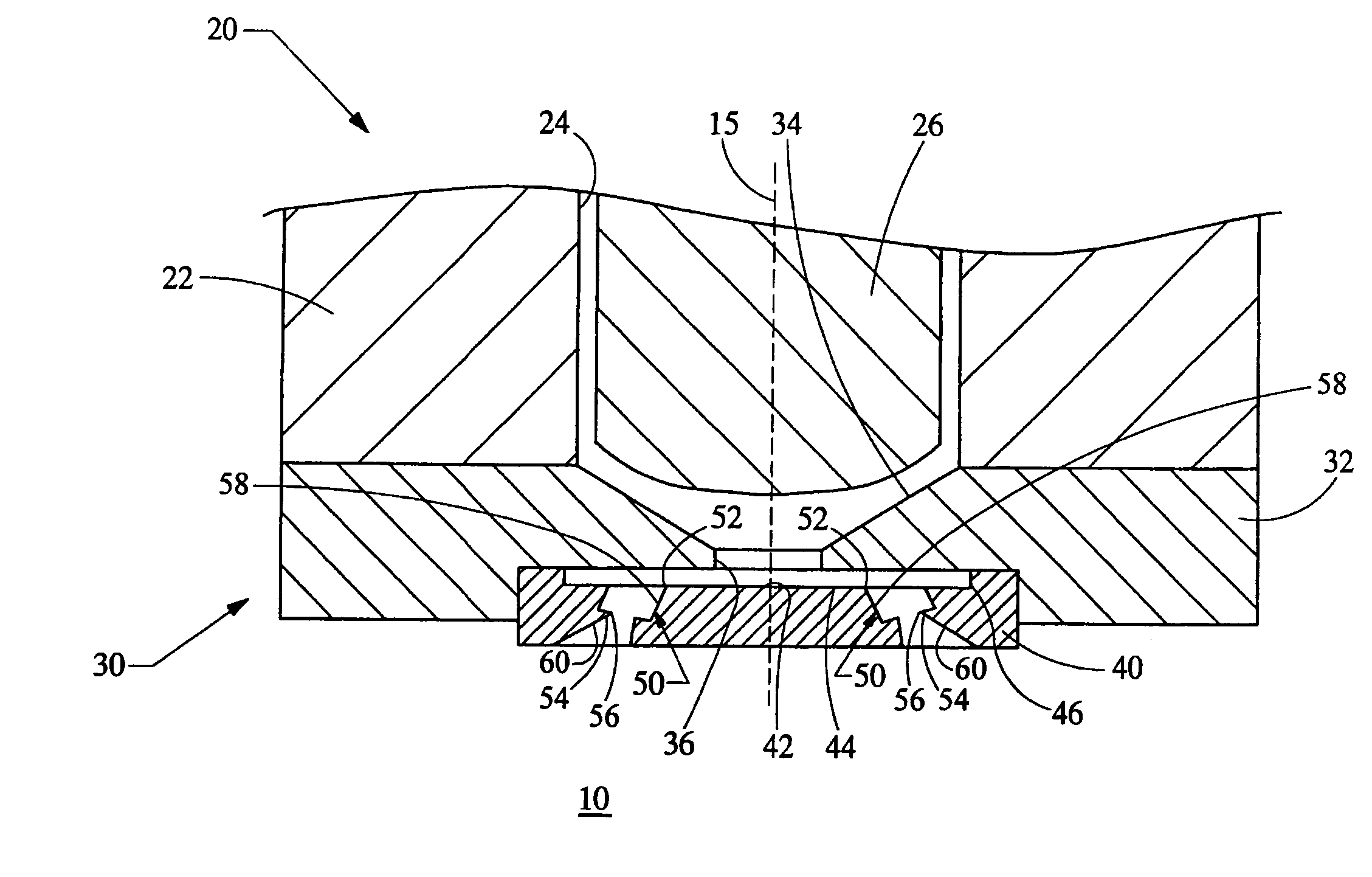

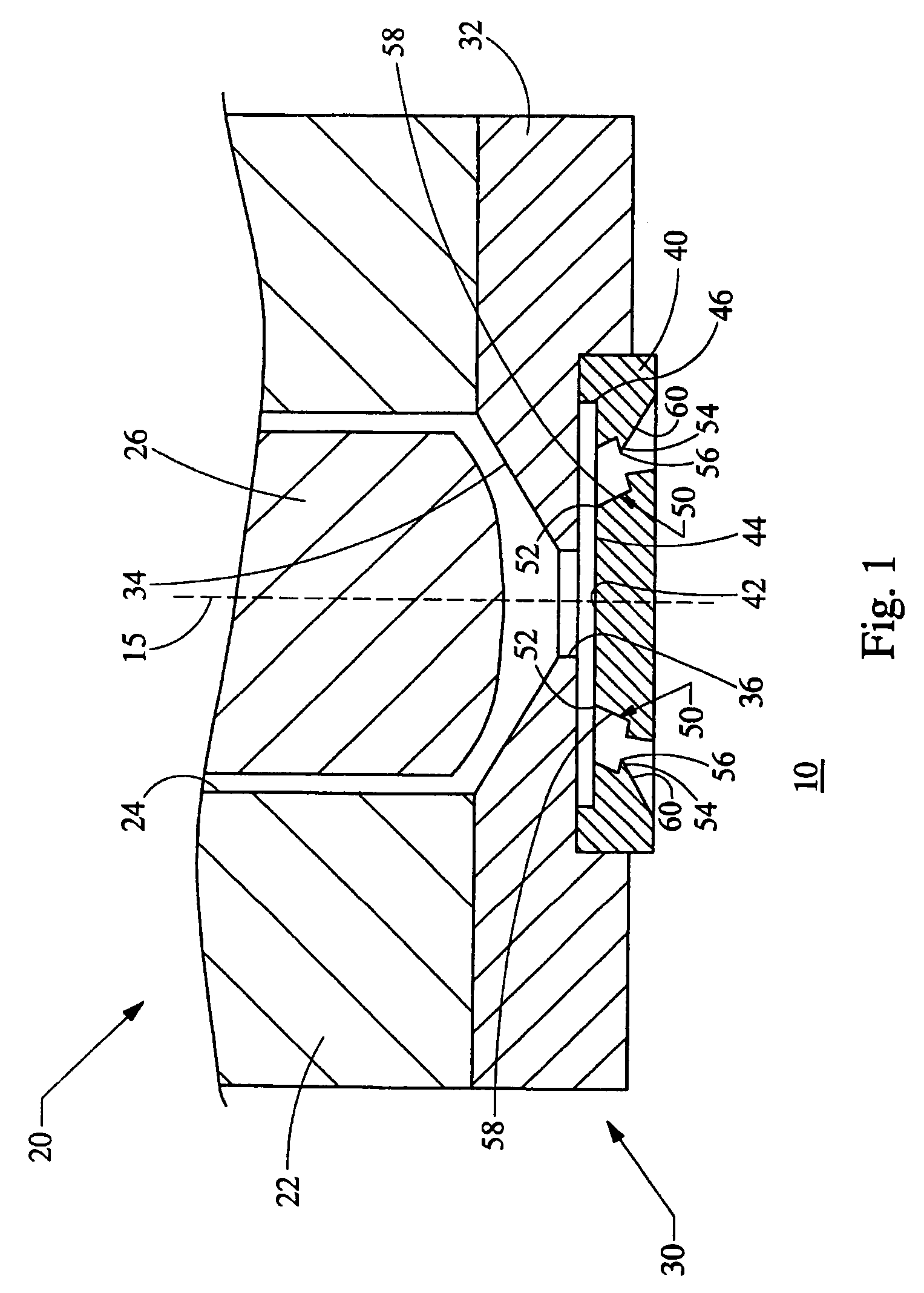

A fuel swirler plate for improving atomization of fuel in a fuel injector. A plurality of identical fuel supply passages is formed in the plate, each passage including an outer fuel reservoir region; a region having converging walls wherein fuel is accelerated and turned partially tangential to the axis of the plate and fuel injector; a metering region wherein flow is regulated; and an exit region wherein the fuel is combined with similar fuel flows from the other passages to form a high velocity swirl annulus between the swirler plate and a pintle ball of the fuel injector. An advantage of the novel swirl plate over prior art plates is that, when the injector valve is closed, only a very small volume of fuel resides in the swirl annulus between the pintle ball and the exit region of the plate, and such residual fuel is urged rotationally and becomes the leading edge of a new vortex the next time the valve is opened, thus minimizing SAC spray formation. The present invention is useful in fuel cells, burners, and in both direct injection and port injection fuel injectors of internal combustion engines.

Owner:DELPHI TECH INC

Low pressure fuel injector nozzle

InactiveUS20060097081A1Good fuel atomizationSpray nozzlesFuel injection apparatusInjector nozzleEngineering

Owner:MICHIGAN MOTOR TECH LLC

Staging fuel nozzle

ActiveUS8327643B2Promote generationReduce the amount requiredBurnersContinuous combustion chamberEngineeringFuel injection

A main swirler of a triple annular configuration that is partitioned by a pre-filmer and a separator is installed in an inlet port of a main air flow channel. The vicinity of the inner wall of the main air flow channel provided with a main fuel injection port is bulged radially outward from the innermost surface (innermost surface of a small swirler) of a main swirler. Further, a distance from the main fuel injection port and the pre-filmer is set such that an effective opening area between the pre-filmer and “the inner wall of the main air flow channel provided with the main fuel injection port” is equal to an effective opening area of the small swirler. The swirling directions of the swirlers of the main swirler are “clockwise”-“counter-clockwise”-“clockwise” respectively along the radial outward direction when the swirling direction of the innermost swirler is taken as “clockwise”.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

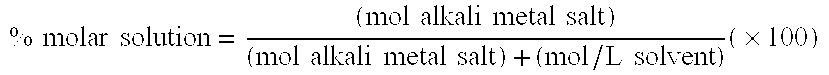

Fuel additive containing lithium alkylaromatic sulfonate and peroxides

InactiveUS6858047B1Increase in fuel mileageSmoother runningLiquid carbonaceous fuelsFuel additivesLithiumSulfonate

A fuel additive, especially for gasoline and diesel engines, has a major portion of lithium aromatic sulfonate and an organic peroxide; for example, lithium bezene sulfonate and as the peroxide methyl ethyl ketone peroxide and / or tert-butyl perbenzoate. The additives provides better mileage and better operation for internal combustion engines.

Owner:NORMAN FR L

Low pressure fuel injector nozzle

InactiveUS7104475B2Good fuel atomizationIncreases the spray angleSpray nozzlesMachines/enginesInjector nozzleEngineering

Owner:VISTEON GLOBAL TECH INC

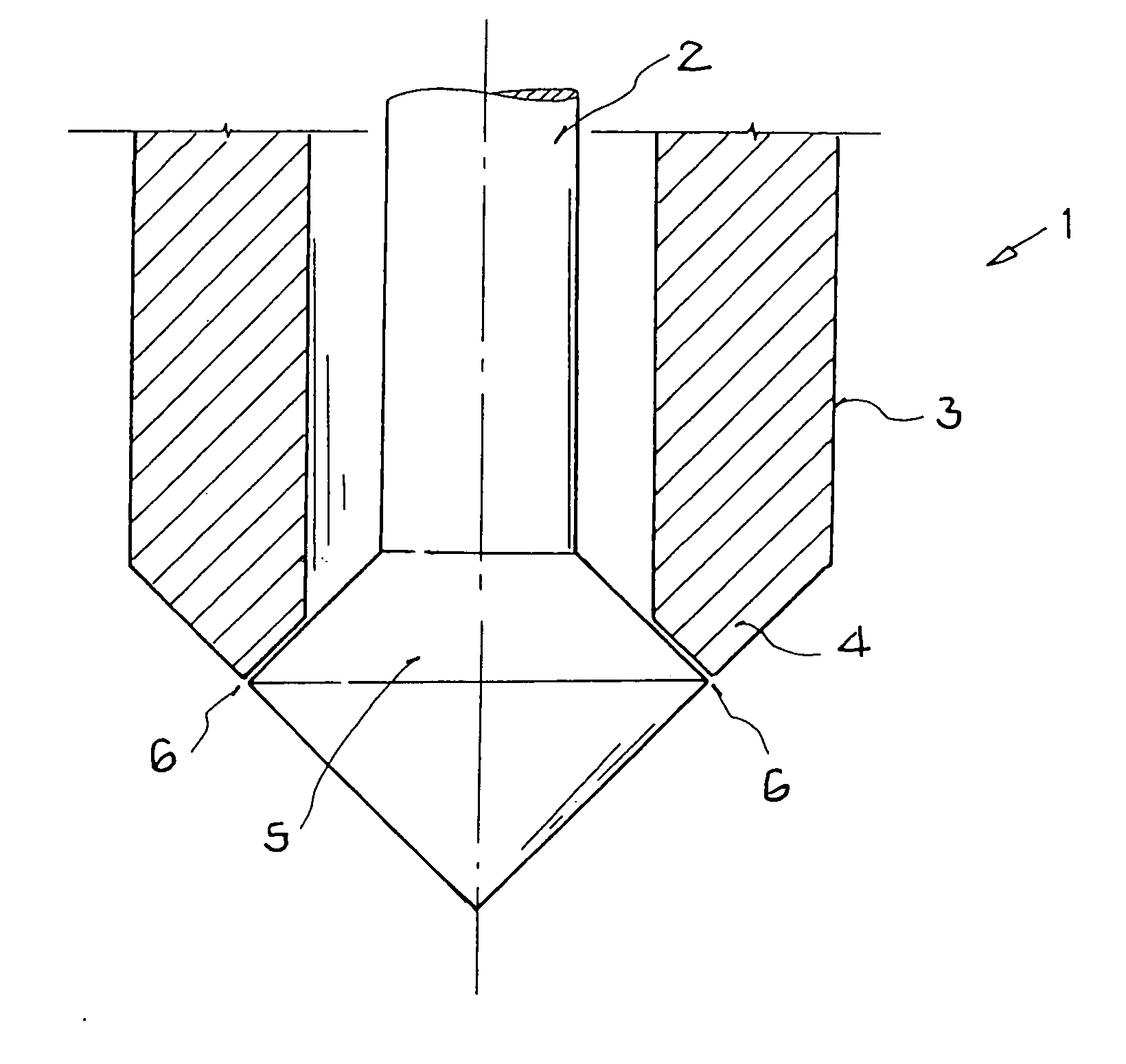

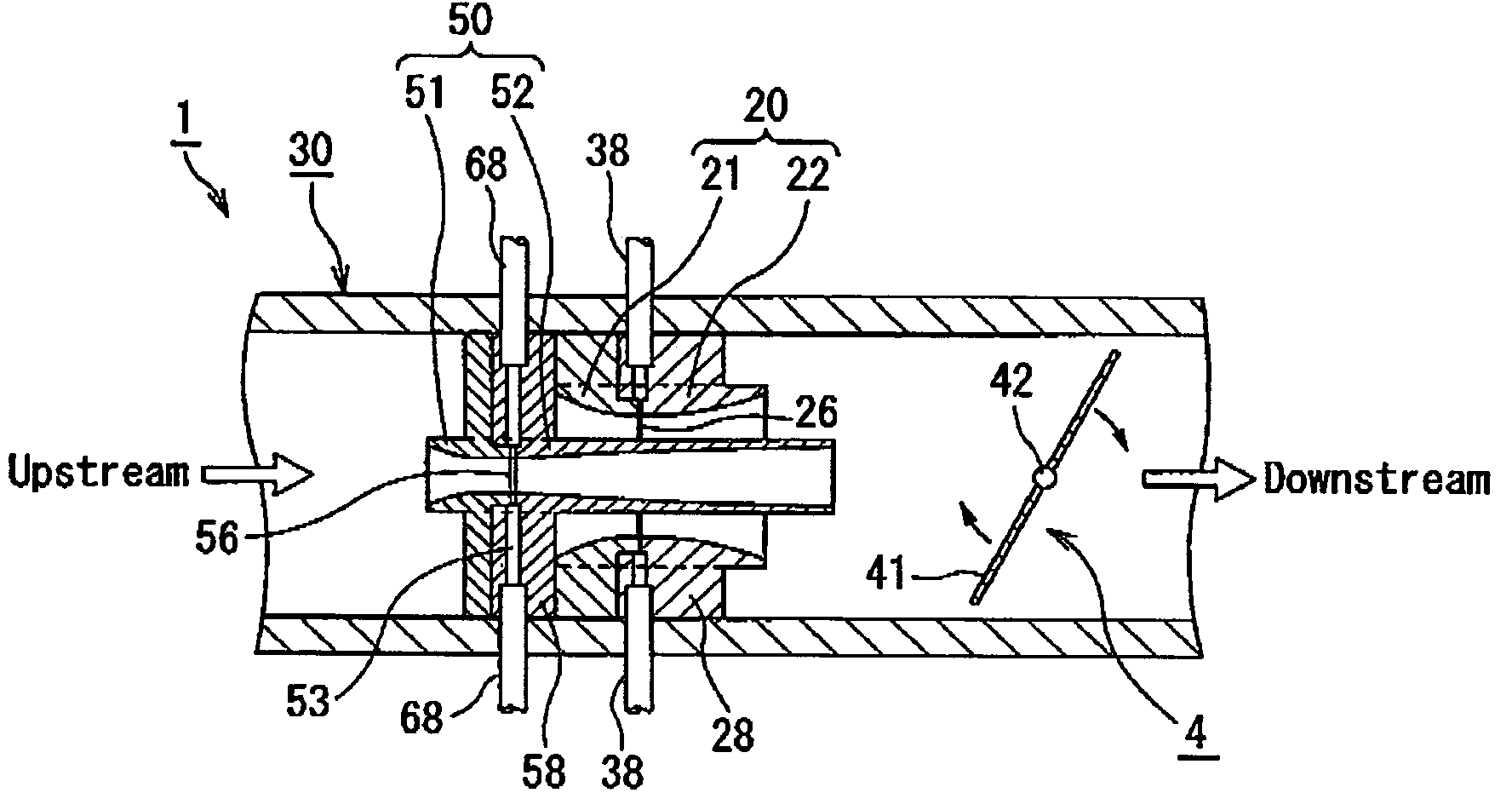

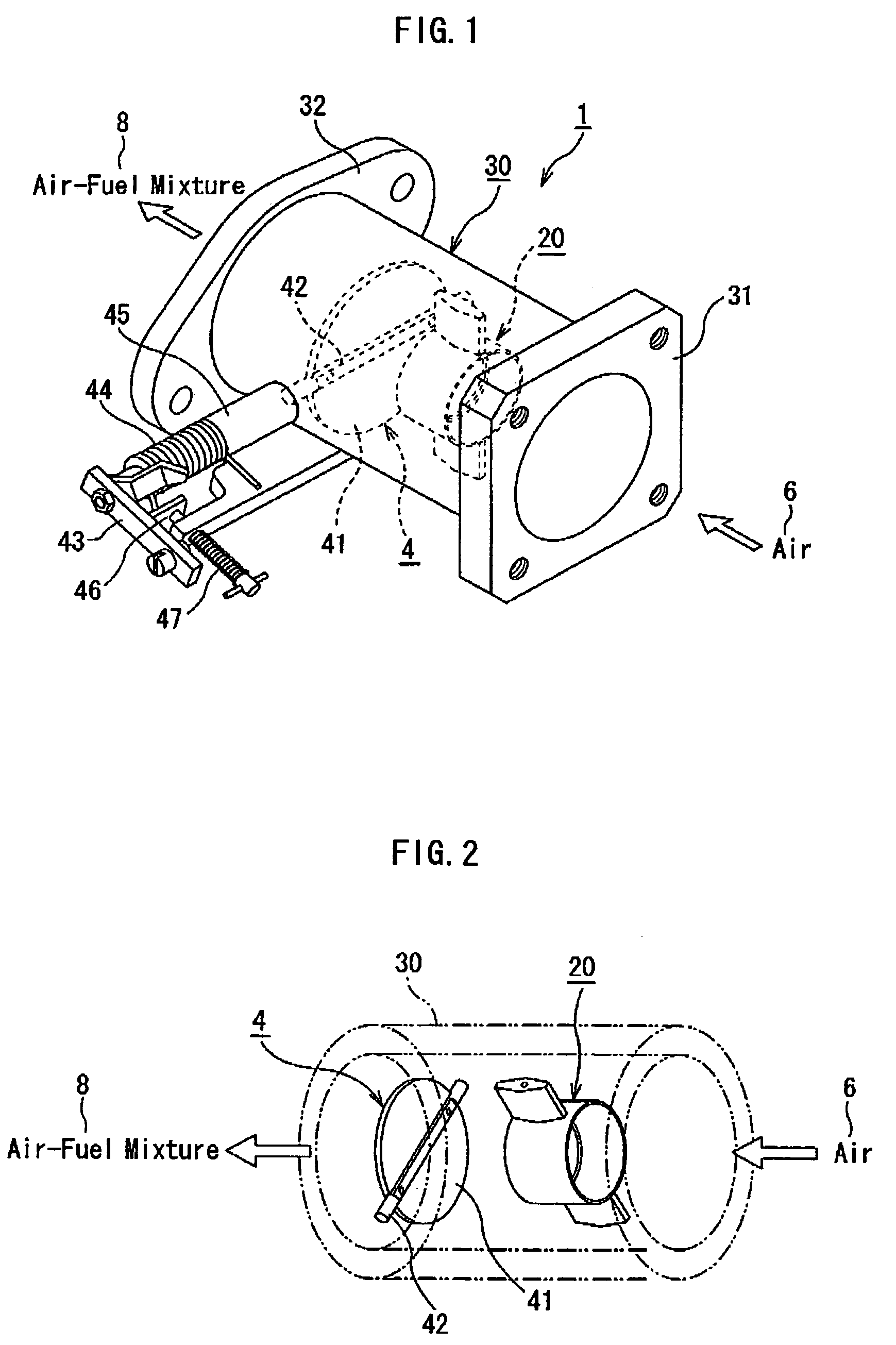

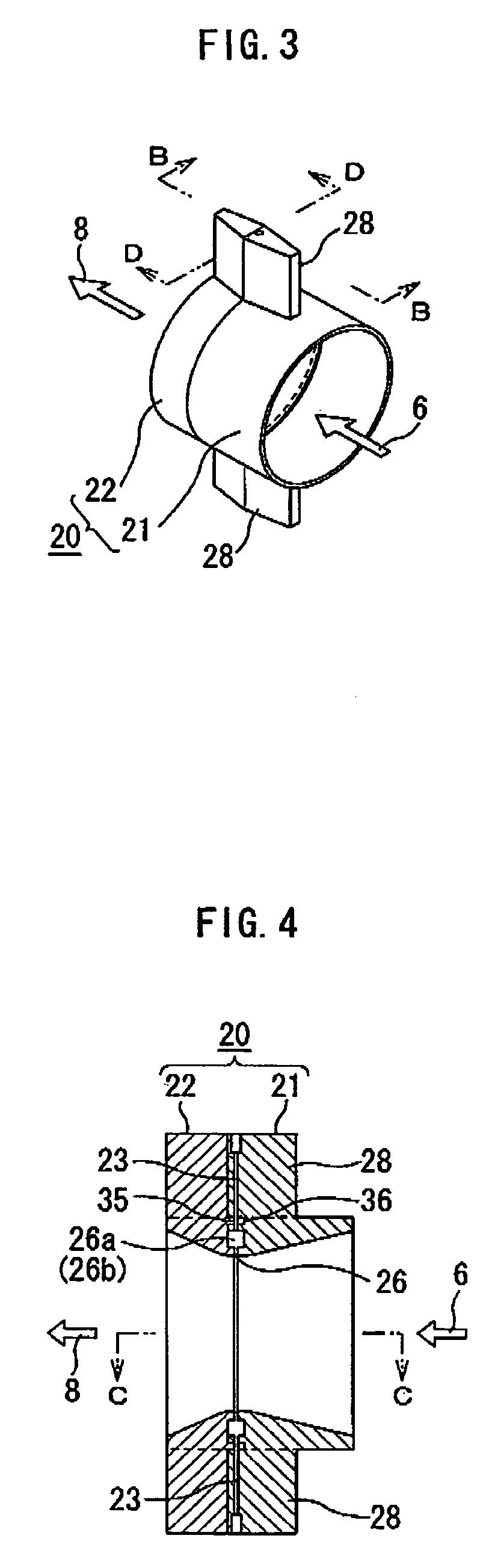

Premixed air-fuel mixture supply device

ActiveUS20050130089A1High injection rateHigh injection velocityCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorGas turbines

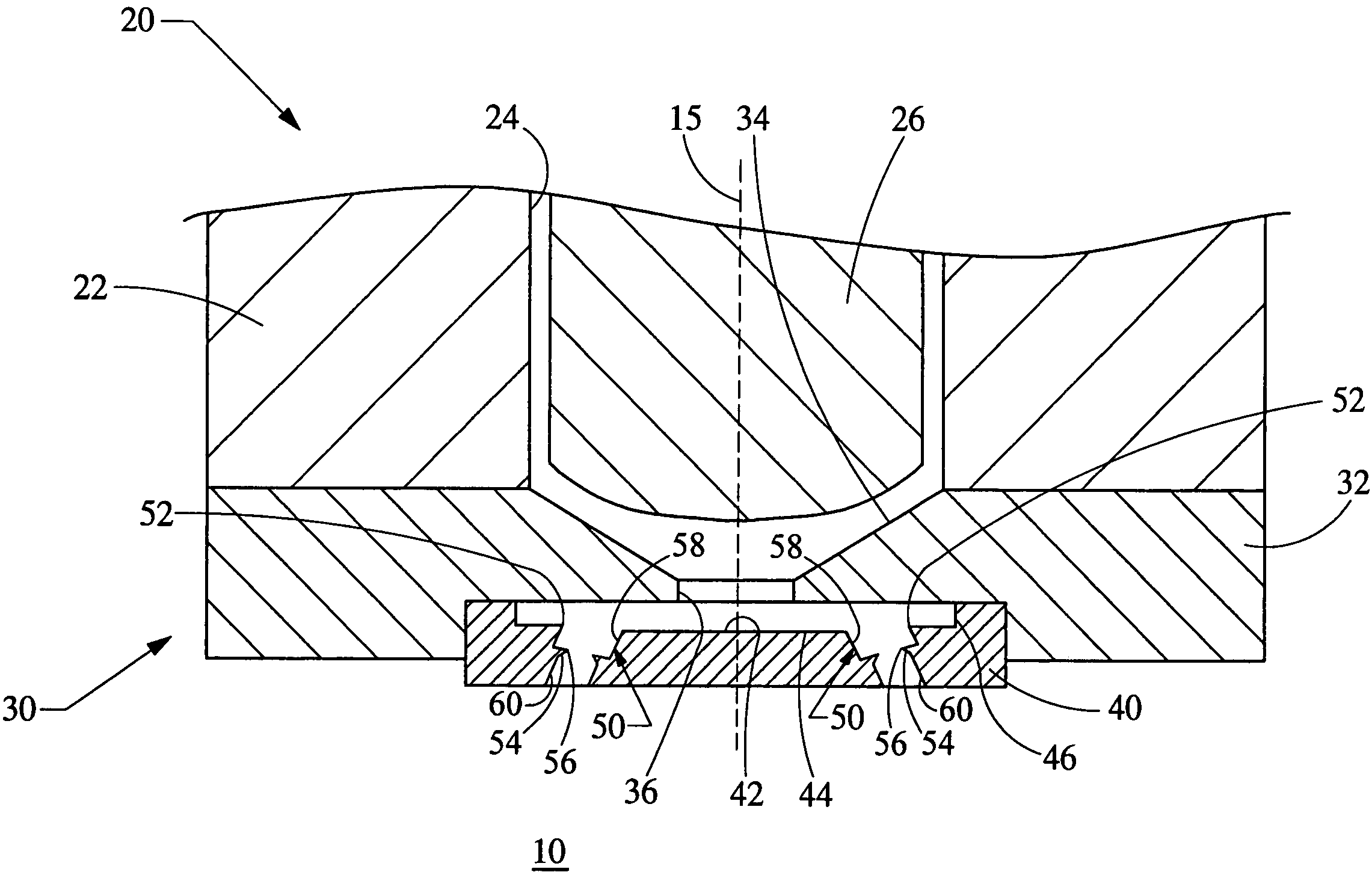

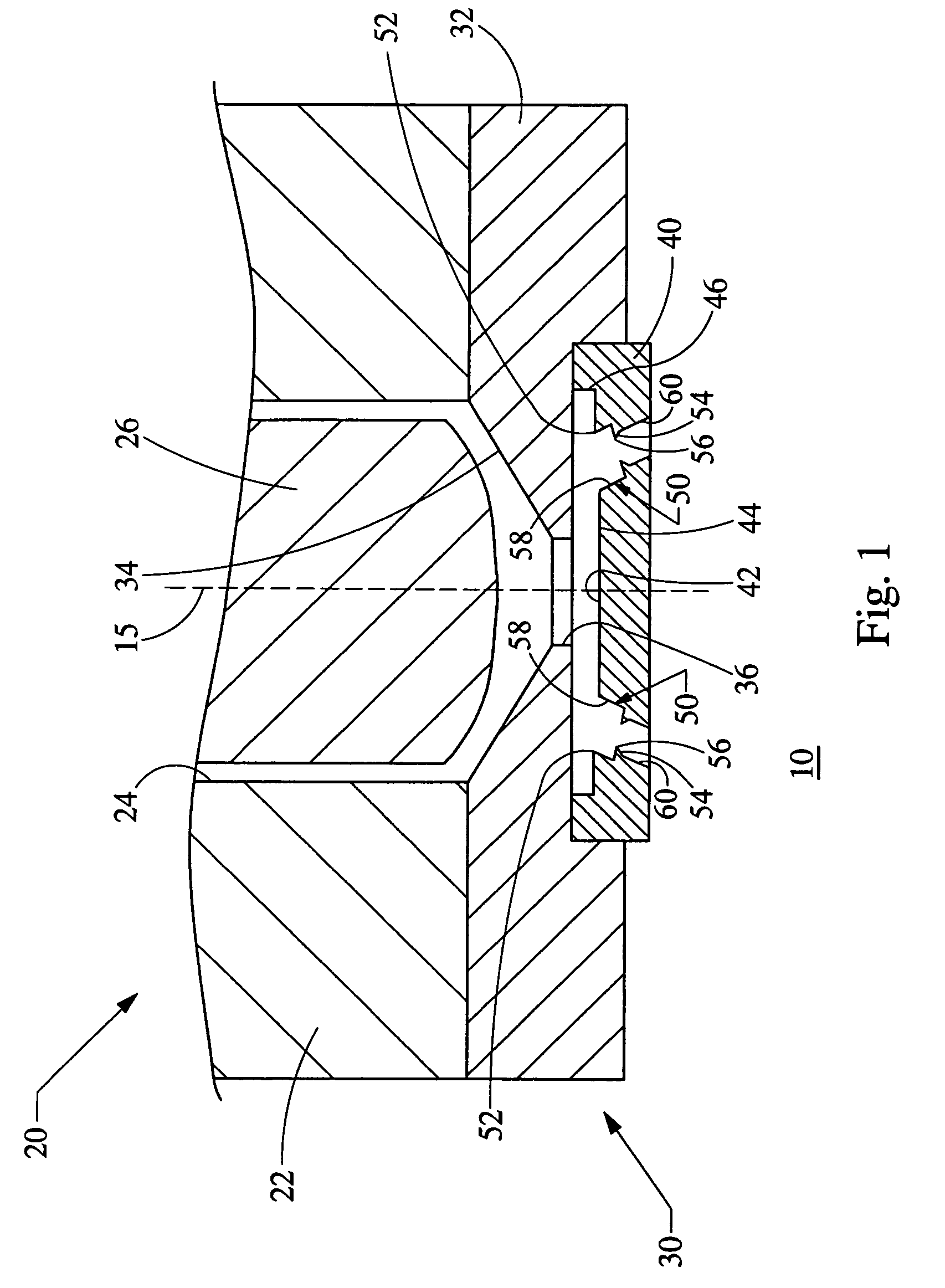

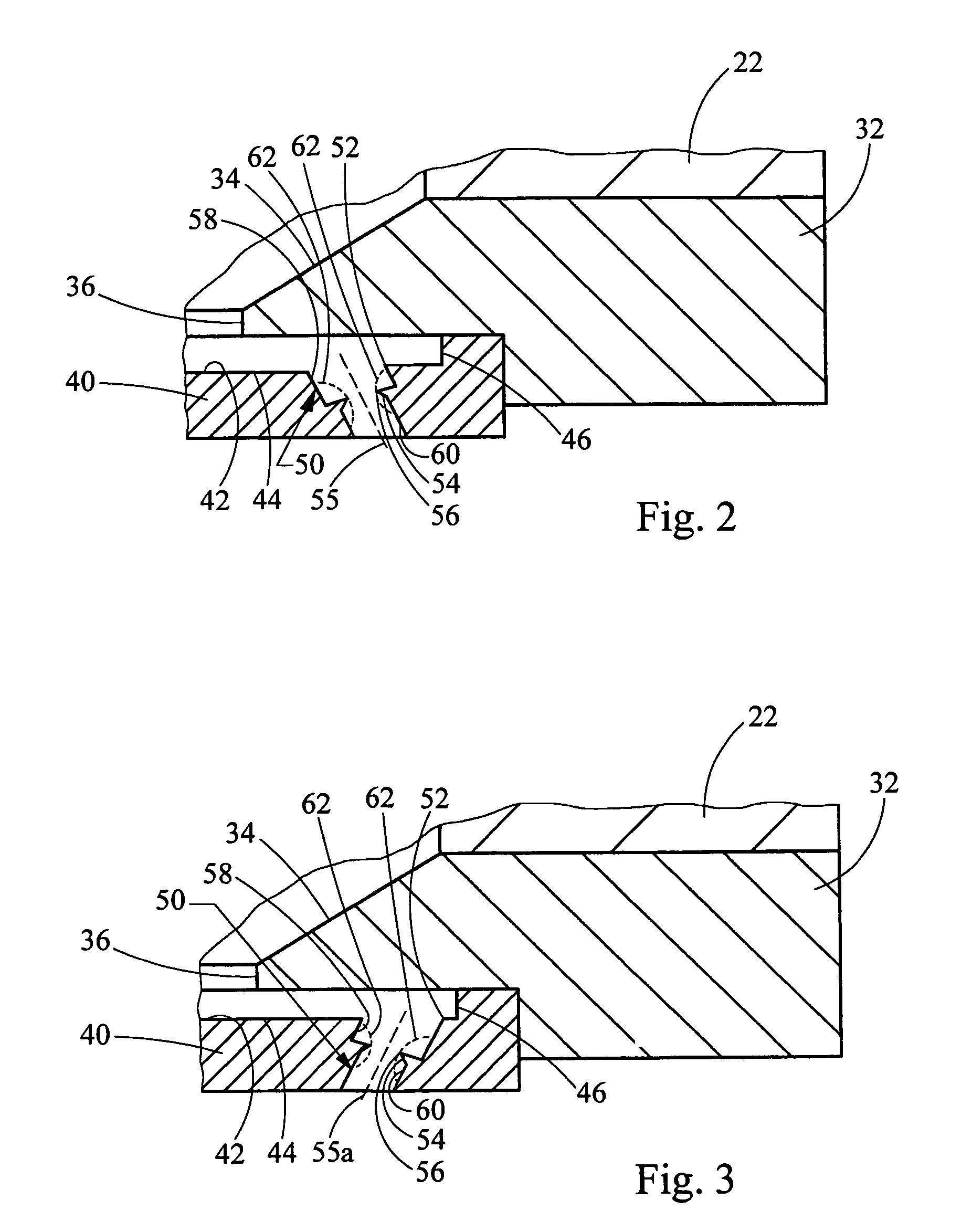

A premixed air-fuel mixture supply device is joined to a combustor liner included in a combustor for a gas turbine or an aircraft engine. The premixed air-fuel mixture supply device has a pilot fuel injection unit having an inner wall, and a prevaporizing, premixing main fuel injection unit having an outer wall surrounding the inner wall. A combustion air passage is defined by the inner and the outer wall. An intermediate wall is disposed in the combustion air passage so as to divide an upstream part of the combustion air passage into a secondary combustion air passage surrounding the inner wall, and an outer combustion air passage surrounding the intermediate wall. Fuel inject holes are formed in the intermediate wall to inject fuel radially outward into the outer combustion air passage. A swirling device is disposed in the secondary combustion air passage to swirl combustion air flowing through the secondary combustion air passage. An atomization lip is formed in a tail part of the intermediate wall.

Owner:KAWASAKI HEAVY IND LTD

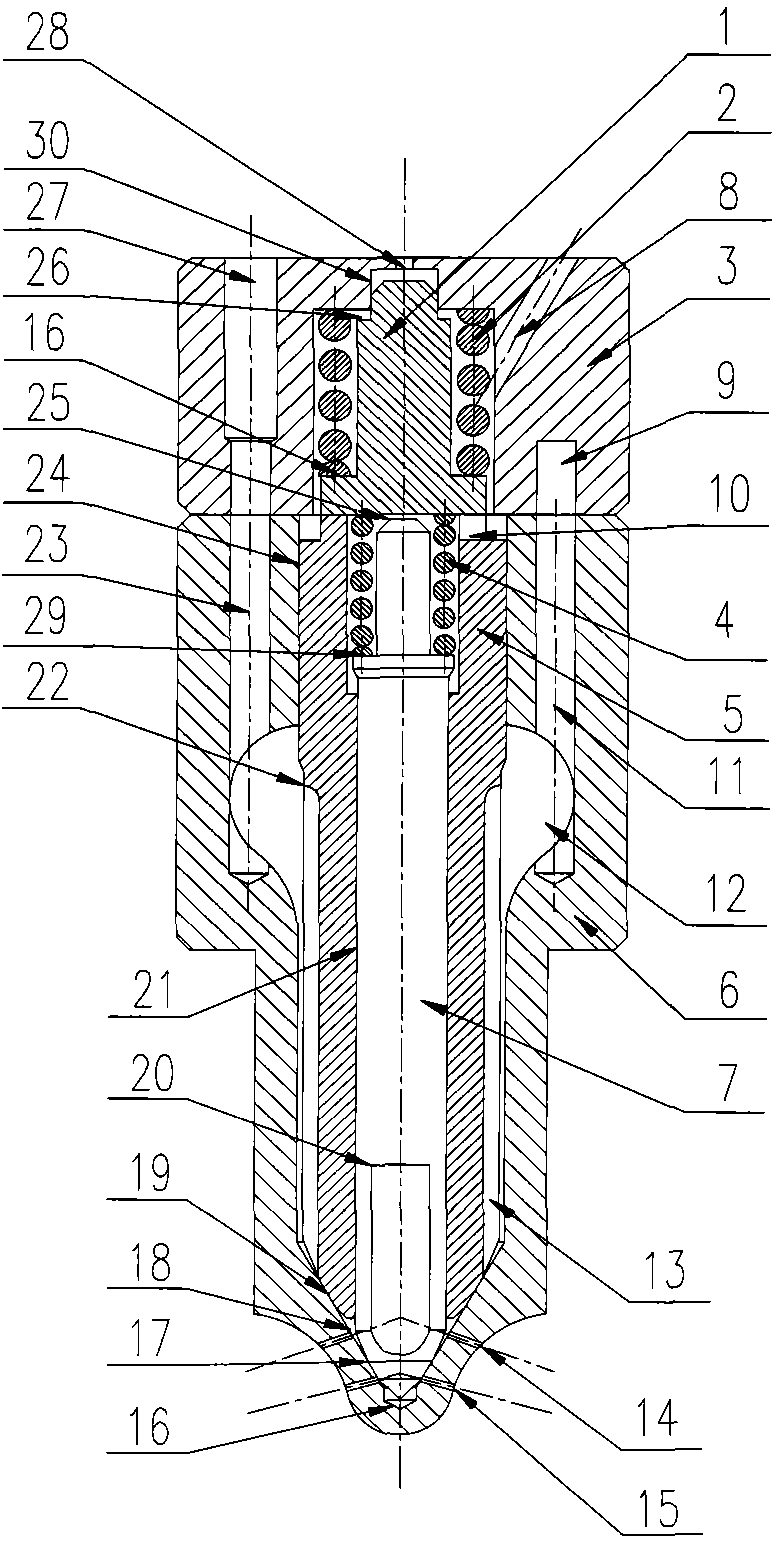

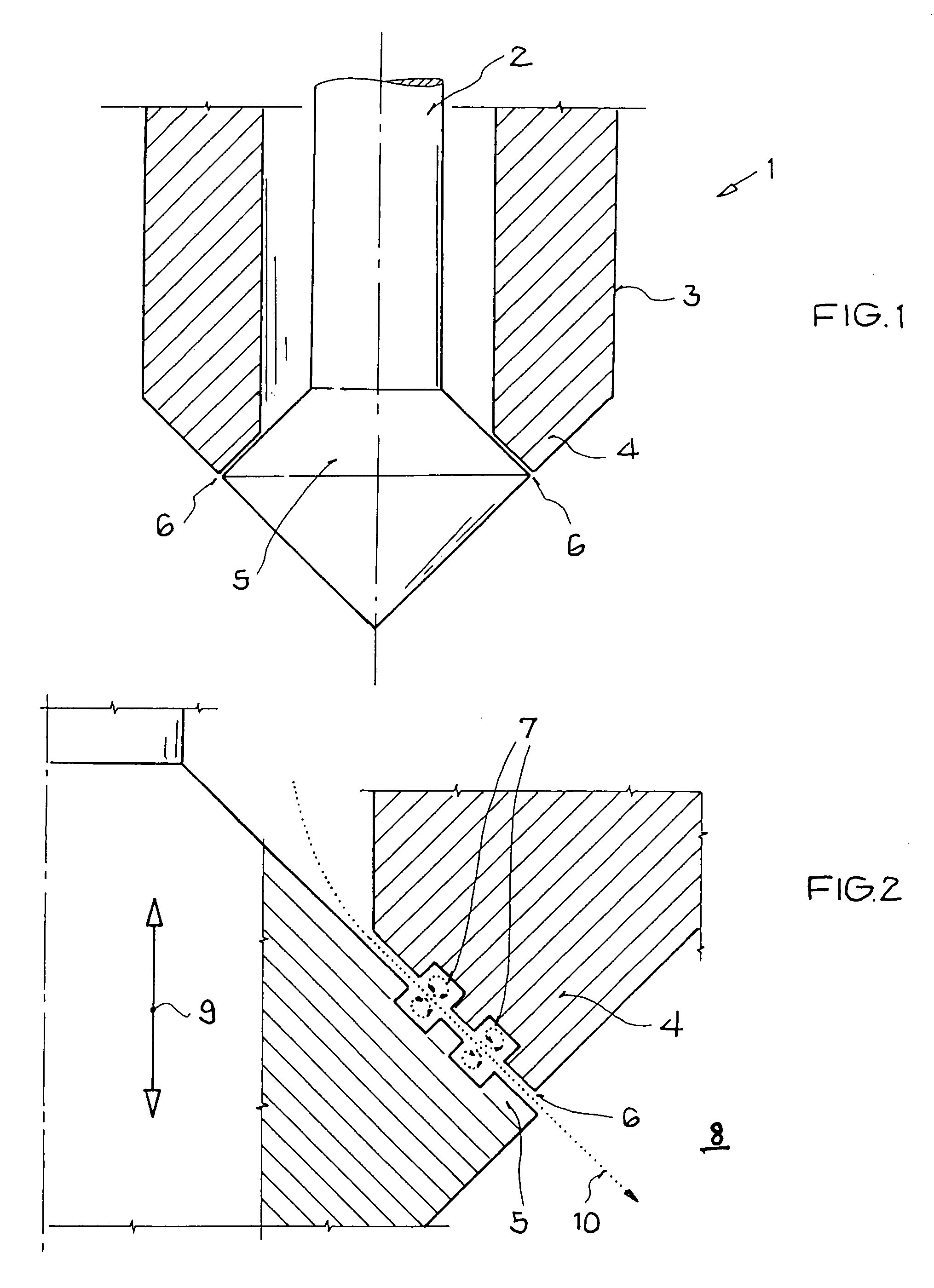

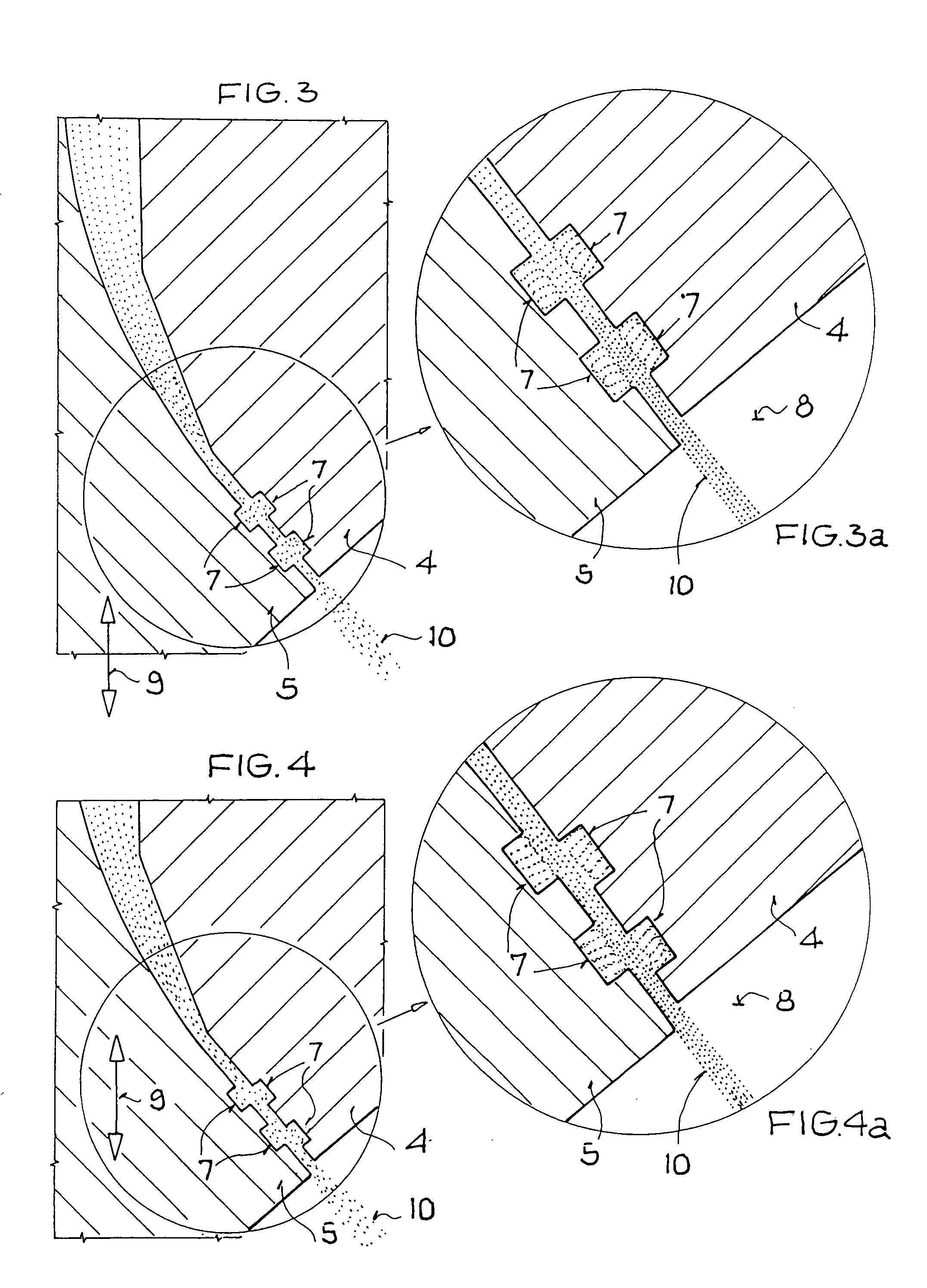

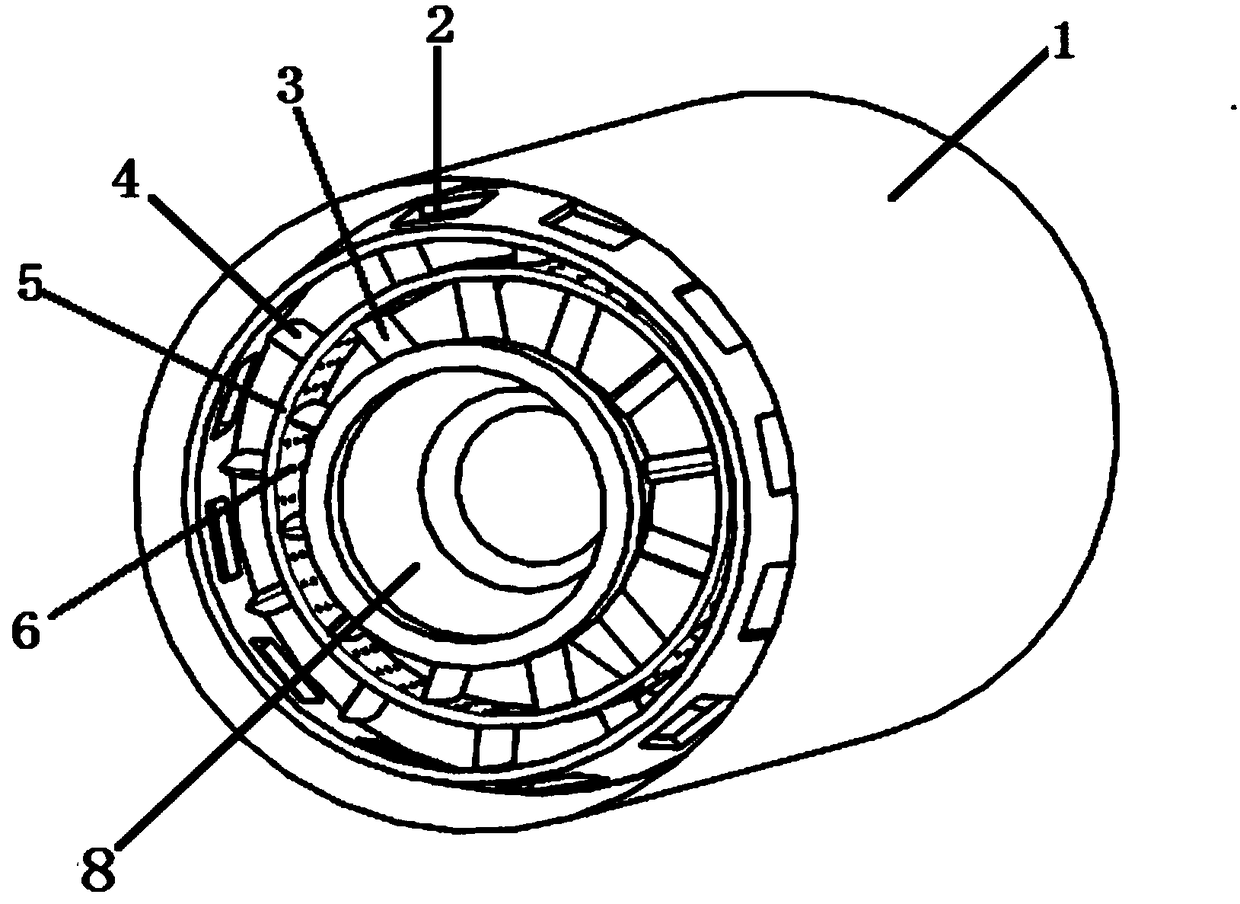

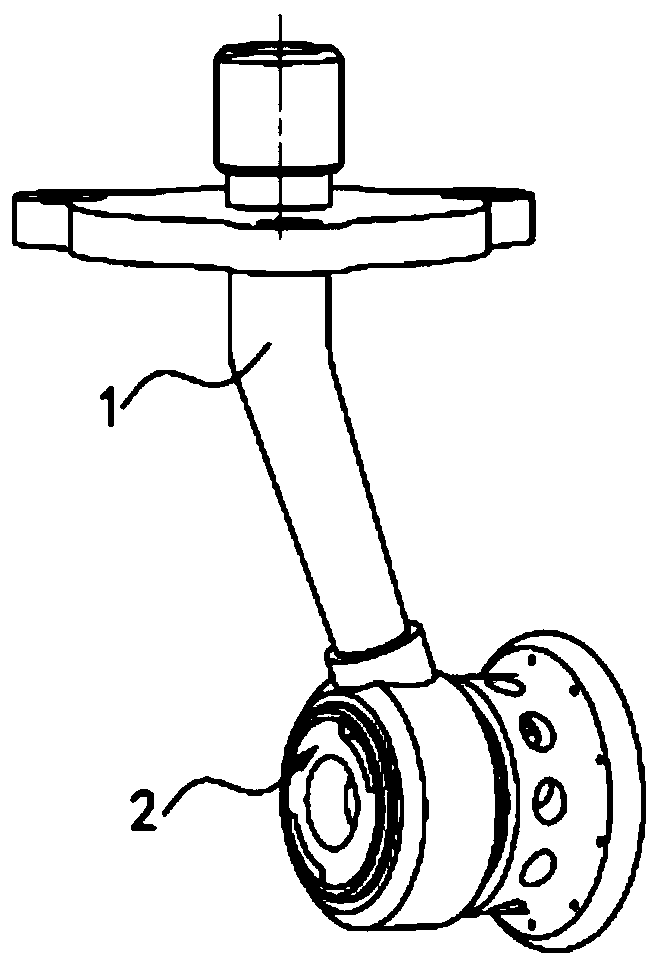

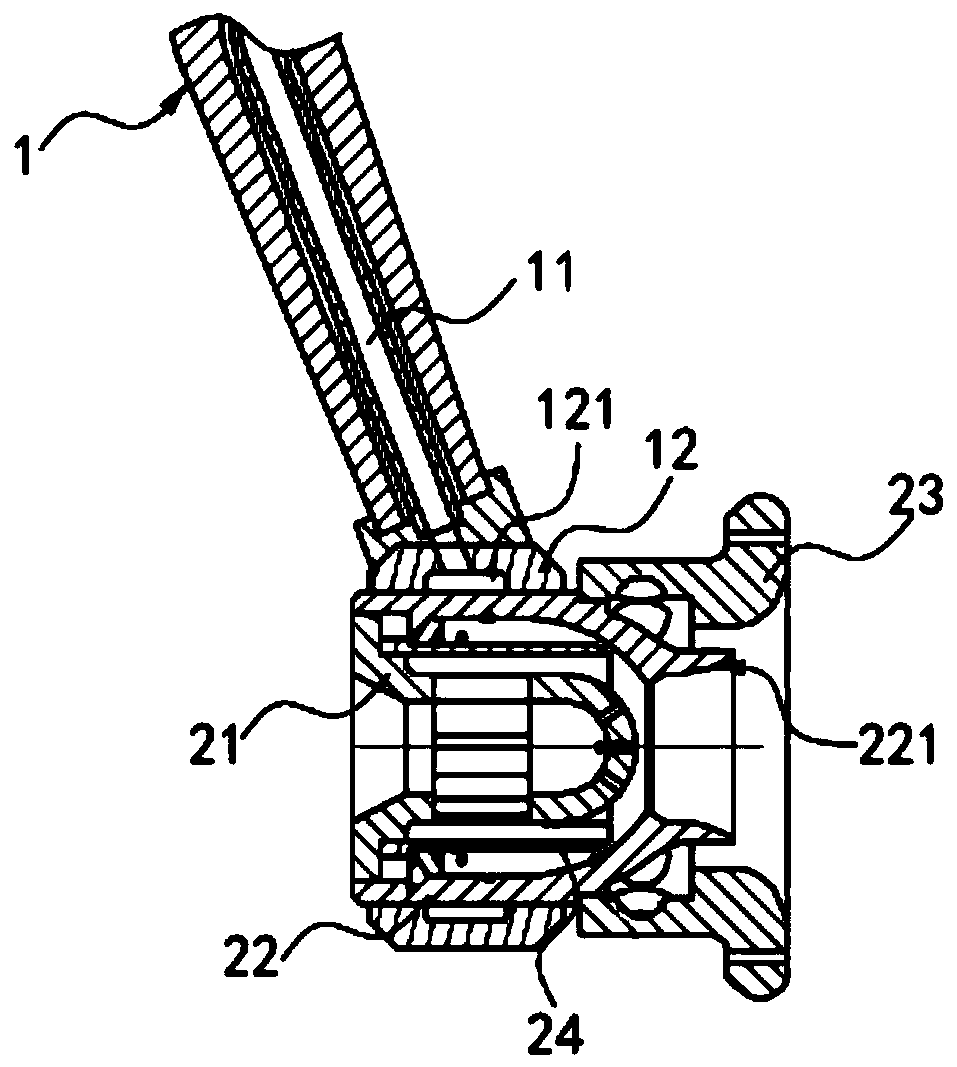

Dual-valve orifice-area-variable fuel nozzle

InactiveCN103967671AImproved fuel atomizationImprove adjustment flexibilityFuel injection apparatusMachines/enginesFuel supplyNeedle valve

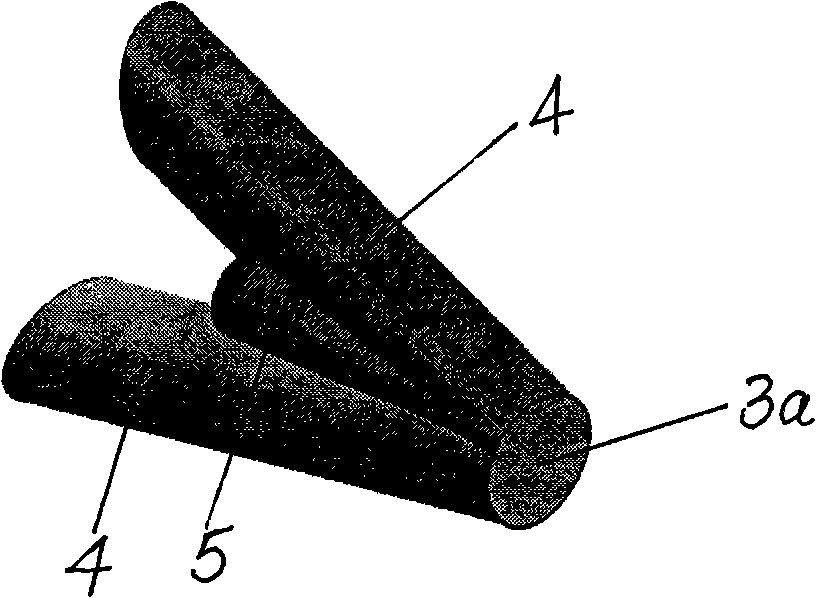

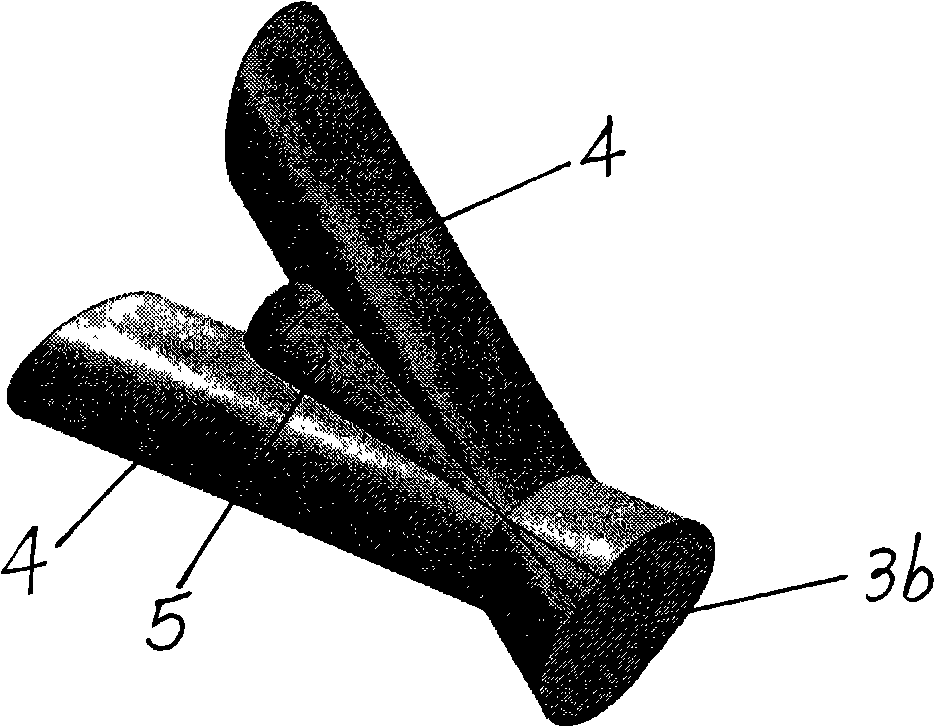

The invention relates to a dual-valve orifice-area-variable fuel nozzle which comprises an ejector rod (1), a sleeve valve spring (2), a switching base (3), a needle valve spring (4), a sleeve valve (5), a nozzle body (6) and a needle valve (7). The sleeve valve (5) and the needle valve (7) which control opening of orifices are arranged in the nozzle body (6). The sleeve valve (5) is arranged in the nozzle body (6) and the needle valve (7) is arranged in the sleeve valve (5). The auxiliary orifice (14) and the main orifice (15) are formed in the nozzle body (6). The sleeve valve (5) controls opening and closing of the auxiliary orifice (14) and the needle valve (7) controls opening and closing of the main orifice (15). The dual-valve orifice-area-variable fuel nozzle can be applied to a fuel supply system composed of inline type fuel injection pumps or monoblock pumps, the orifice area is controlled through fuel supply pressure of the pumps, so that the law that fuel is injected slowly and then injected rapidly or the fuel is injected in a stepped mode is finally achieved, the fuel atomizing effect under low injection pressure is improved, the orifice area can be changed through fuel pressure change.

Owner:CHINA NORTH ENGINE INST TIANJIN

Fuel injector

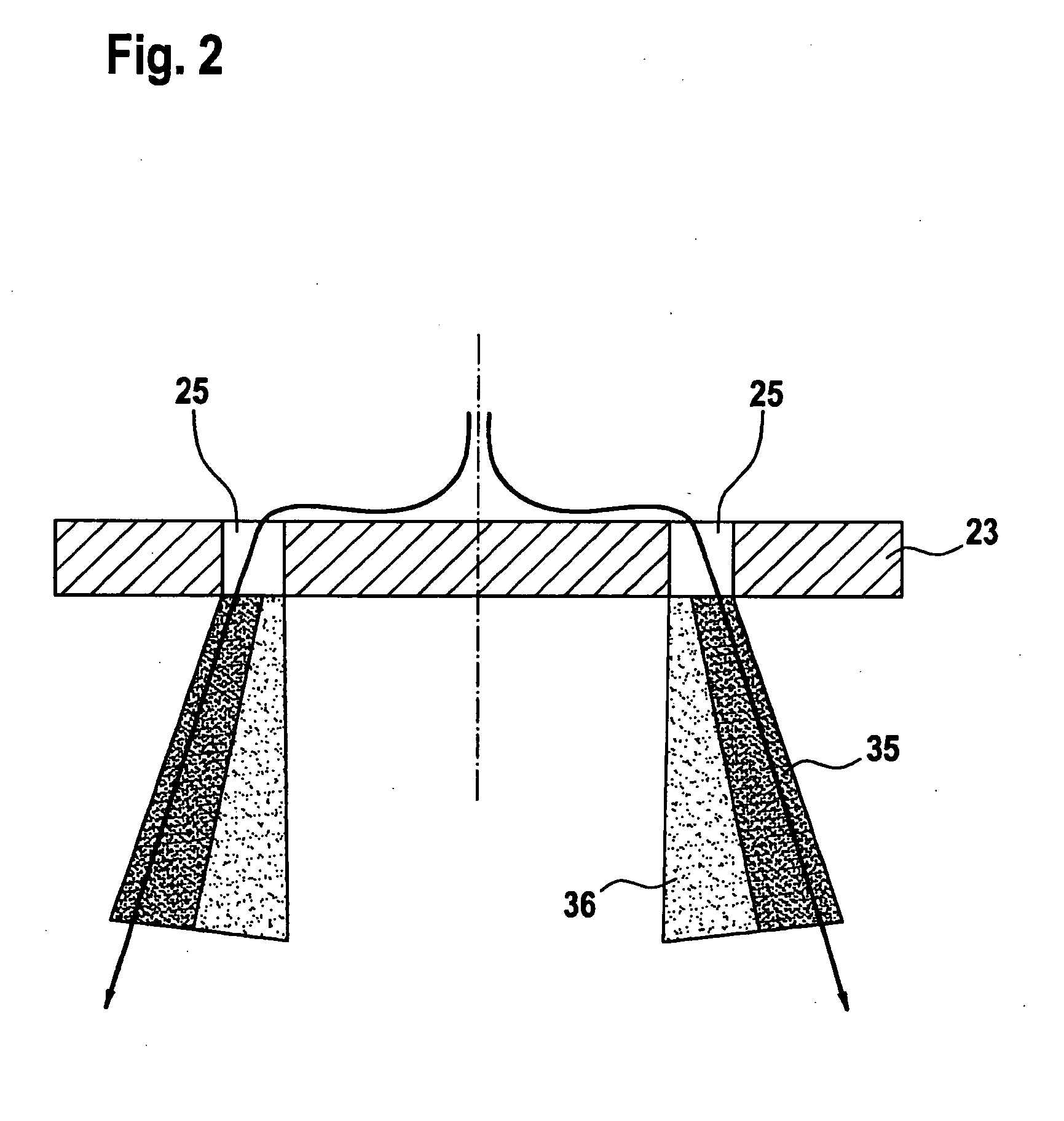

InactiveUS20090200402A1Uniform and very fine atomization of fuelSimple wayMachines/enginesFuel injecting pumpsVena contracta diameterSharp angle

The fuel injector including an orifice plate which is provided with a multitude of outlet openings and situated downstream from a valve-seat body having a fixed valve seat. Directly upstream from the outlet openings is an inflow opening having an annular inflow cavity. The valve-seat body covers the inflow cavity in such a way that the downstream outlet openings of the orifice plate are covered. The outlet openings each have an inflow region whose diameter D1 is considerably larger than the diameter D2 of a region that abuts at a sharp angle directly downstream therefrom, which forms the narrowest cross section of the outlet opening and from where the outlet opening widens in the flow direction to a diameter D3 in a trumpet-shaped manner. The fuel injector may be particularly suitable for use in fuel injection systems of mixture-compressing ignition engines having externally supplied ignition.

Owner:ROBERT BOSCH GMBH

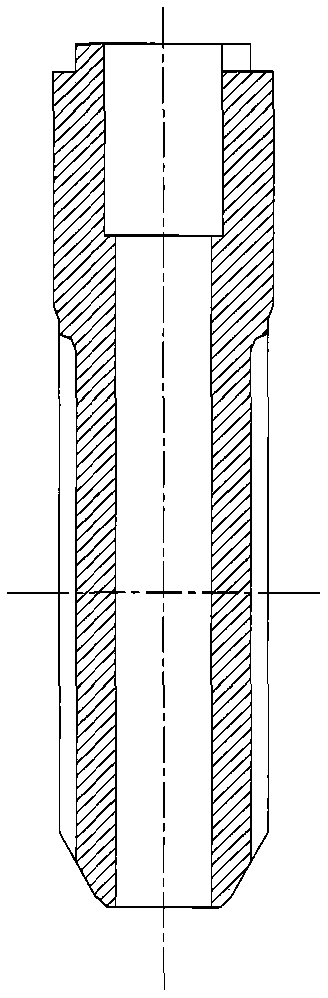

Fuel injection nozzle for an internal combustion engine with direct fuel injection

InactiveUS20050150978A1Good fuel atomizationPromote combustionSpray nozzlesFuel injection apparatusCombustion chamberEngineering

In an injection nozzle for an internal combustion engine including a nozzle housing, a closure member disposed in a nozzle opening and connected to a nozzle needle for axially moving the closure member outwardly off its seat in the nozzle opening to open the nozzle by providing a gap to permit fuel to be discharged into a combustion chamber of an internal combustion engine so as to form a fuel injection cone, the nozzle seal and the closure member have seal surface areas provided with turbulence chambers for imparting turbulence to the fuel flowing through the gap in order to more finely atomize the fuel forming the fuel cone in the combustion chamber.

Owner:DAIMLER AG

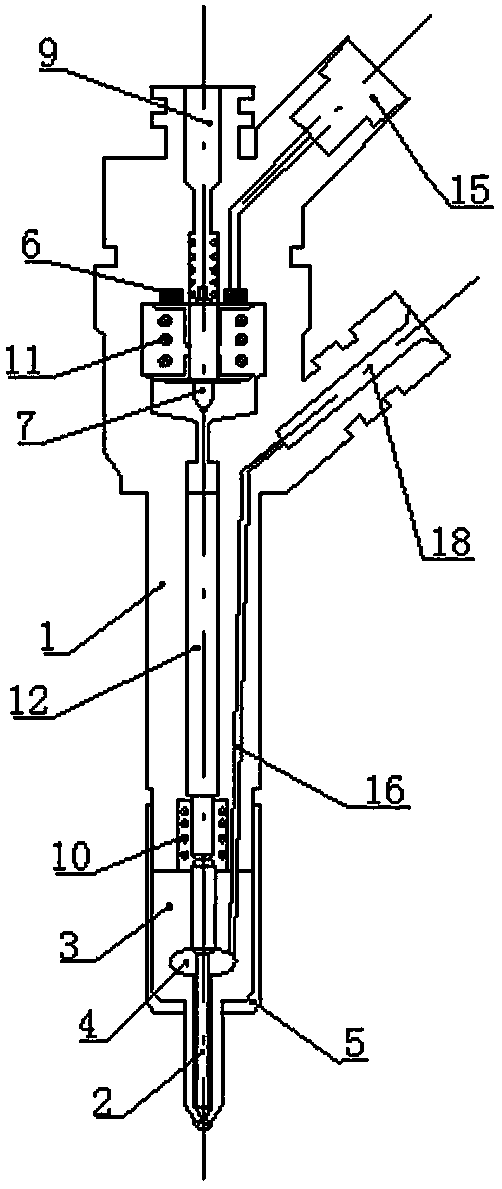

Double-oil-duct oil atomizer with controllable fuel oil temperature

InactiveCN103590947AEasy to controlGood fuel atomizationFuel injection apparatusMachines/enginesCombustionEconomic benefits

The invention relates to a double-oil-duct oil atomizer with a controllable fuel oil temperature. A main oil duct and a controlled oil duct are formed inside an oil atomizer body. Meanwhile, a fuel oil heating plug is arranged in front of an oil inlet of the controlled oil duct and used for heating fuel oil injected into the controlled oil duct, the main oil duct can continuously provide low-temperature fuel oil, the controlled oil duct provides set high-temperature fuel oil, and the high-temperature fuel oil and the low-temperature fuel oil are proportionally mixed in a fuel mixing cavity, so that the fuel oil is ejected according to different temperatures. Meanwhile, after the fuel oil heating plug is removed from the oil atomizer, the main fuel is distributed in the main oil duct, the auxiliary fuel is distributed in the controlled oil duct, so that mixing of the double fuel is achieved, and the double-oil-duct oil atomizer can be well adapted to the combustion mode of double fuel ejecting at the current stage. The fuel oil atomizing effect of a direction injection engine in a cylinder is optimized, combustion and emission quality of the engine is greatly promoted, and meanwhile quantitative mixing and ejecting combustion of the double fuel are achieved. The double-oil-duct oil atomizer is scientific and reasonable in design and has high social and economic benefits.

Owner:ZHONGBEI UNIV

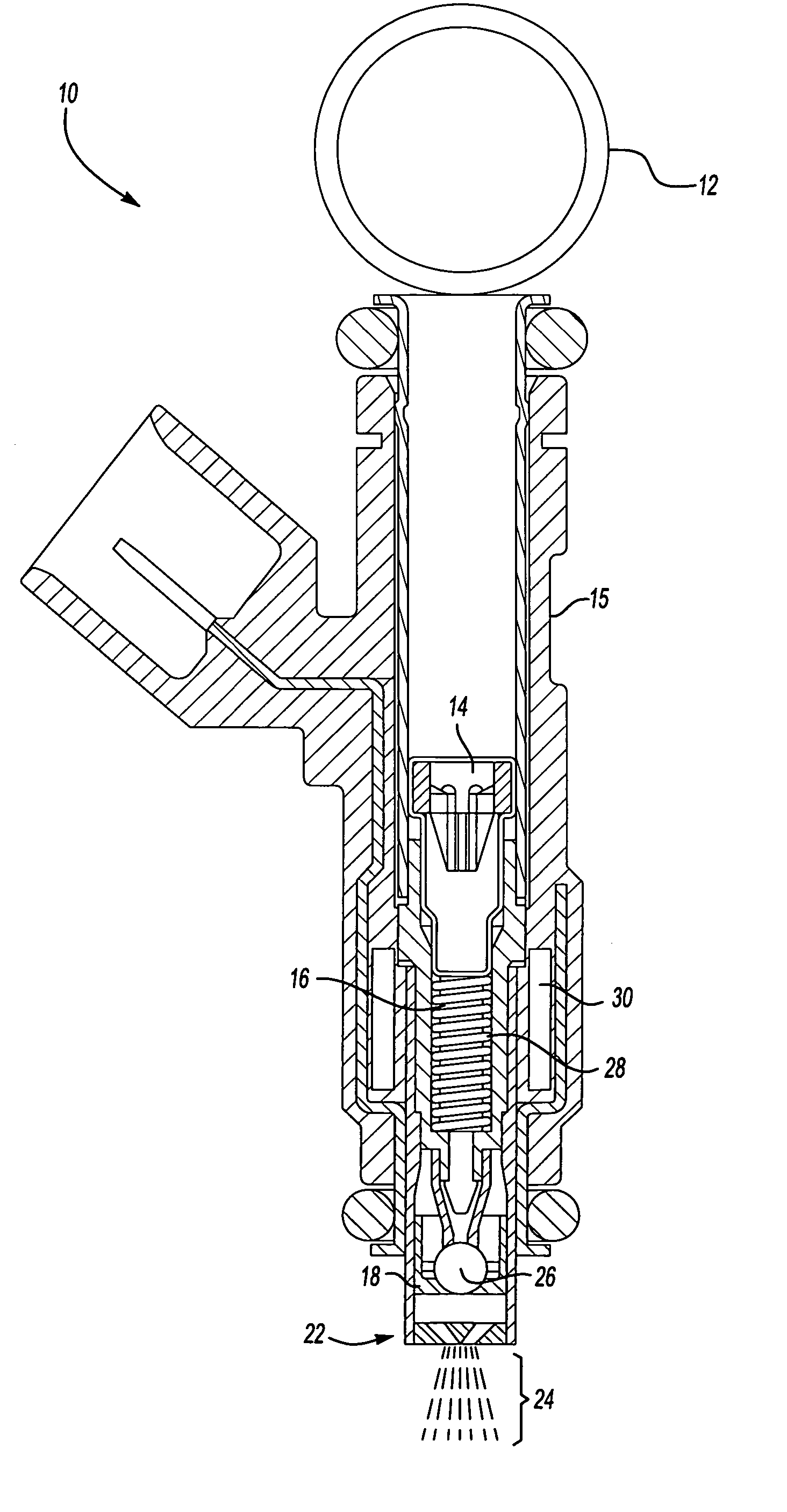

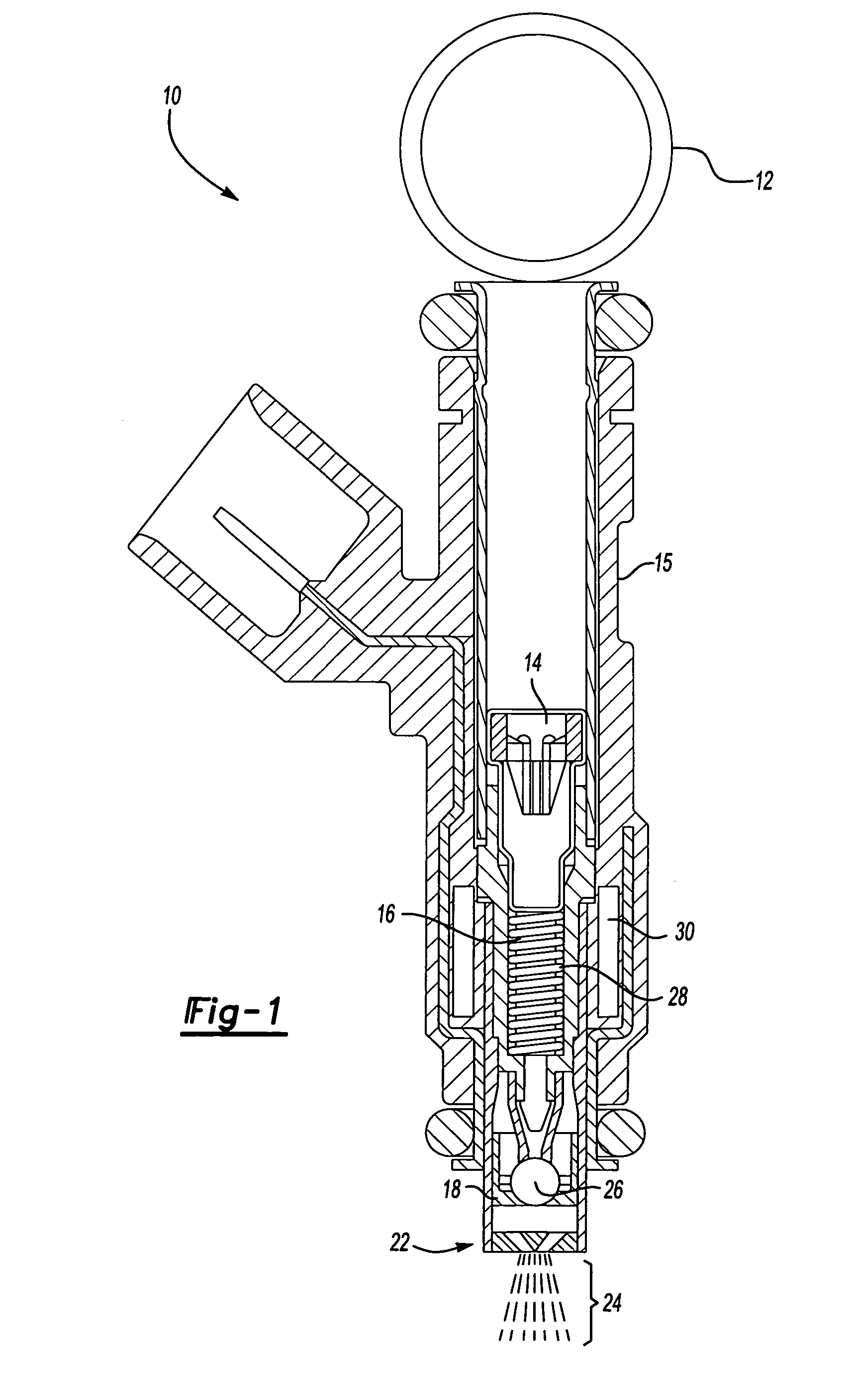

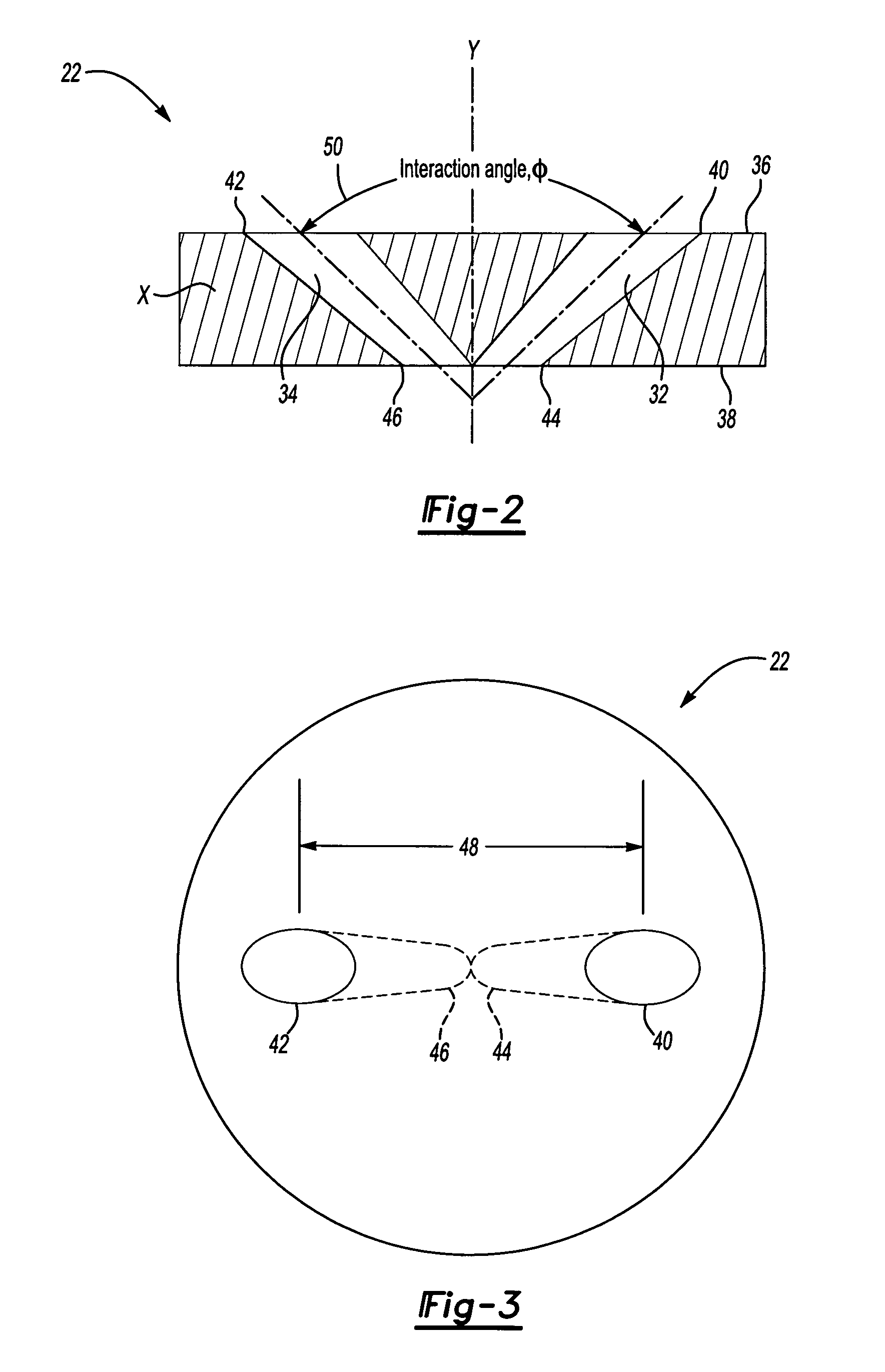

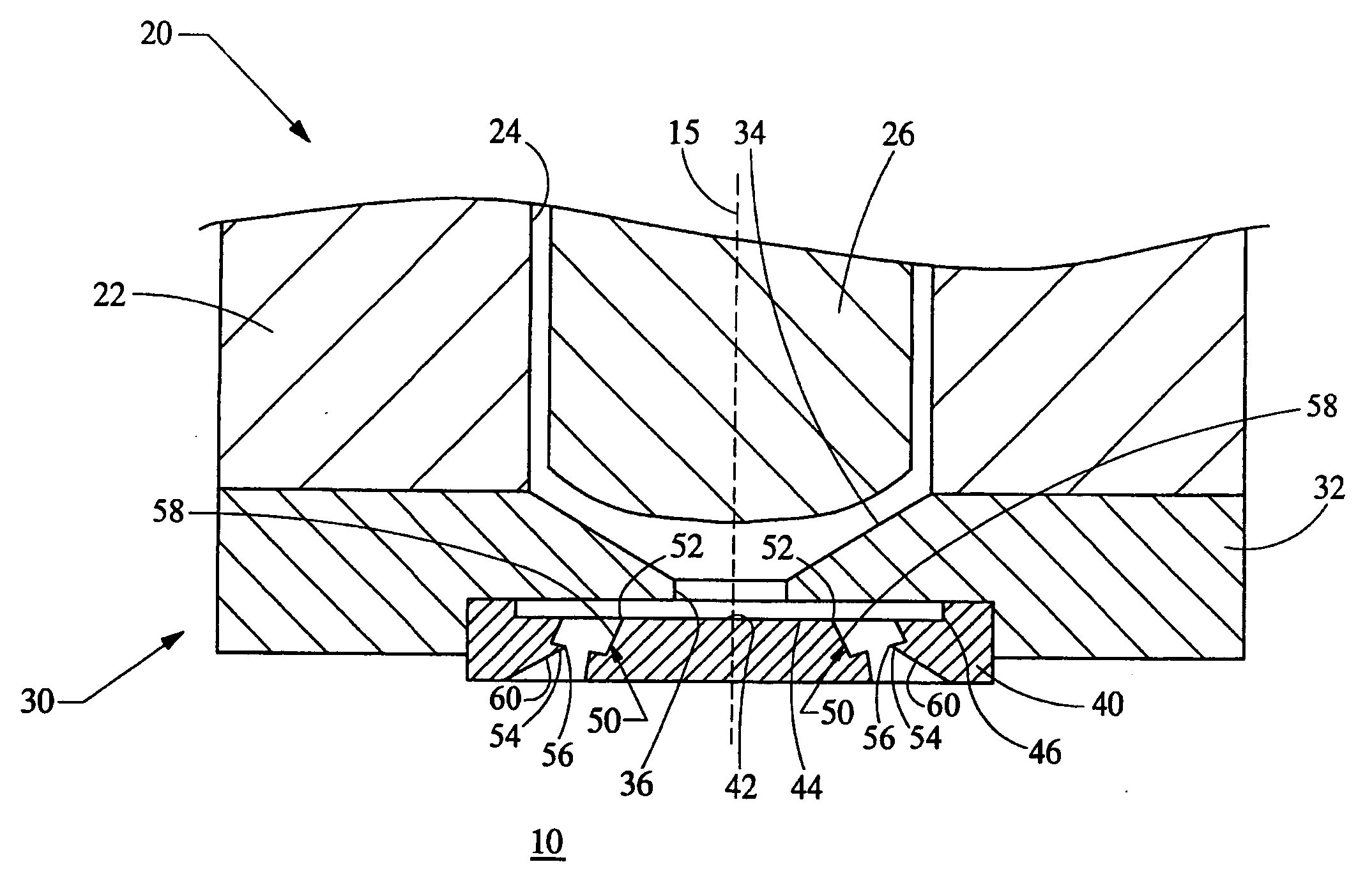

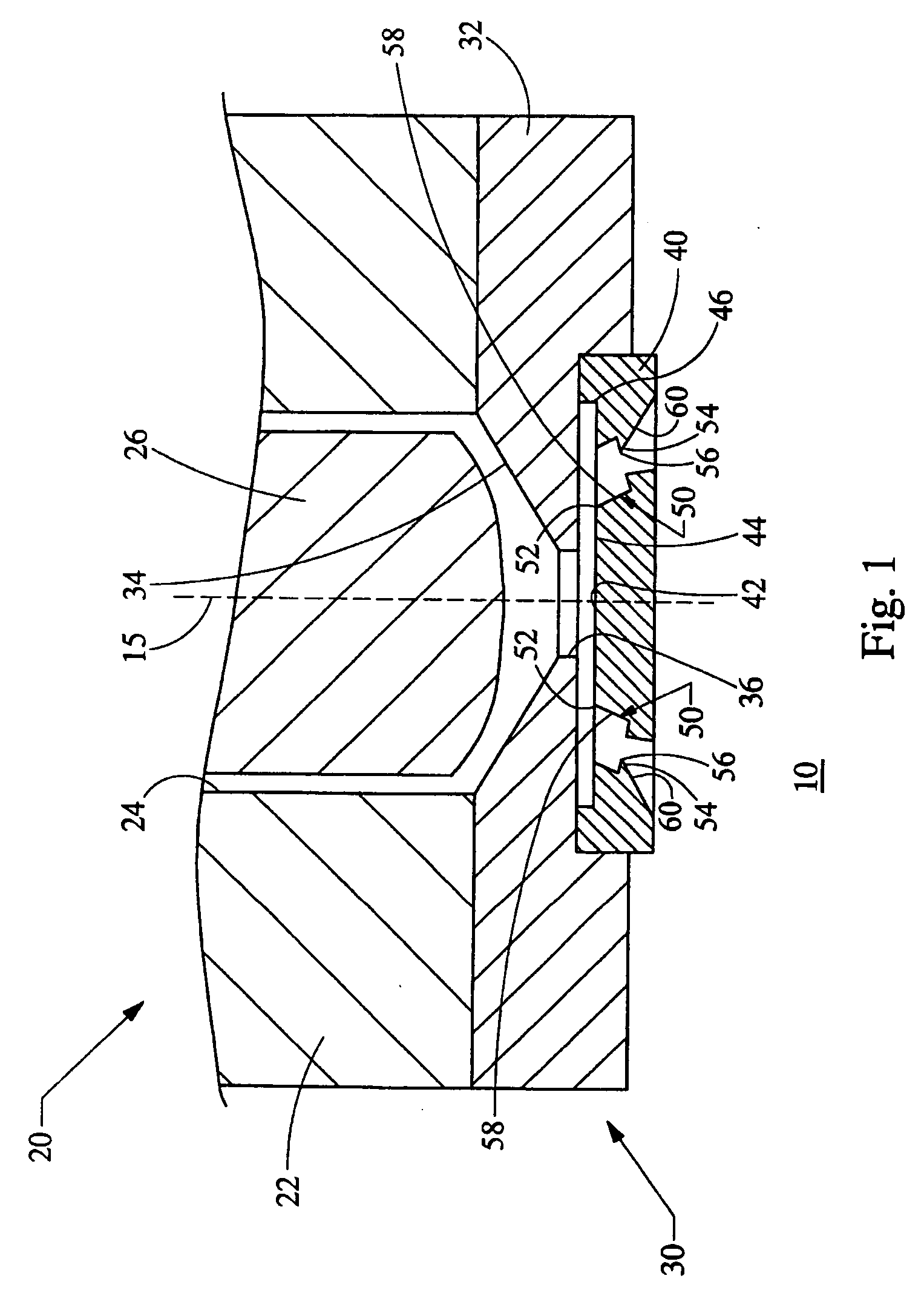

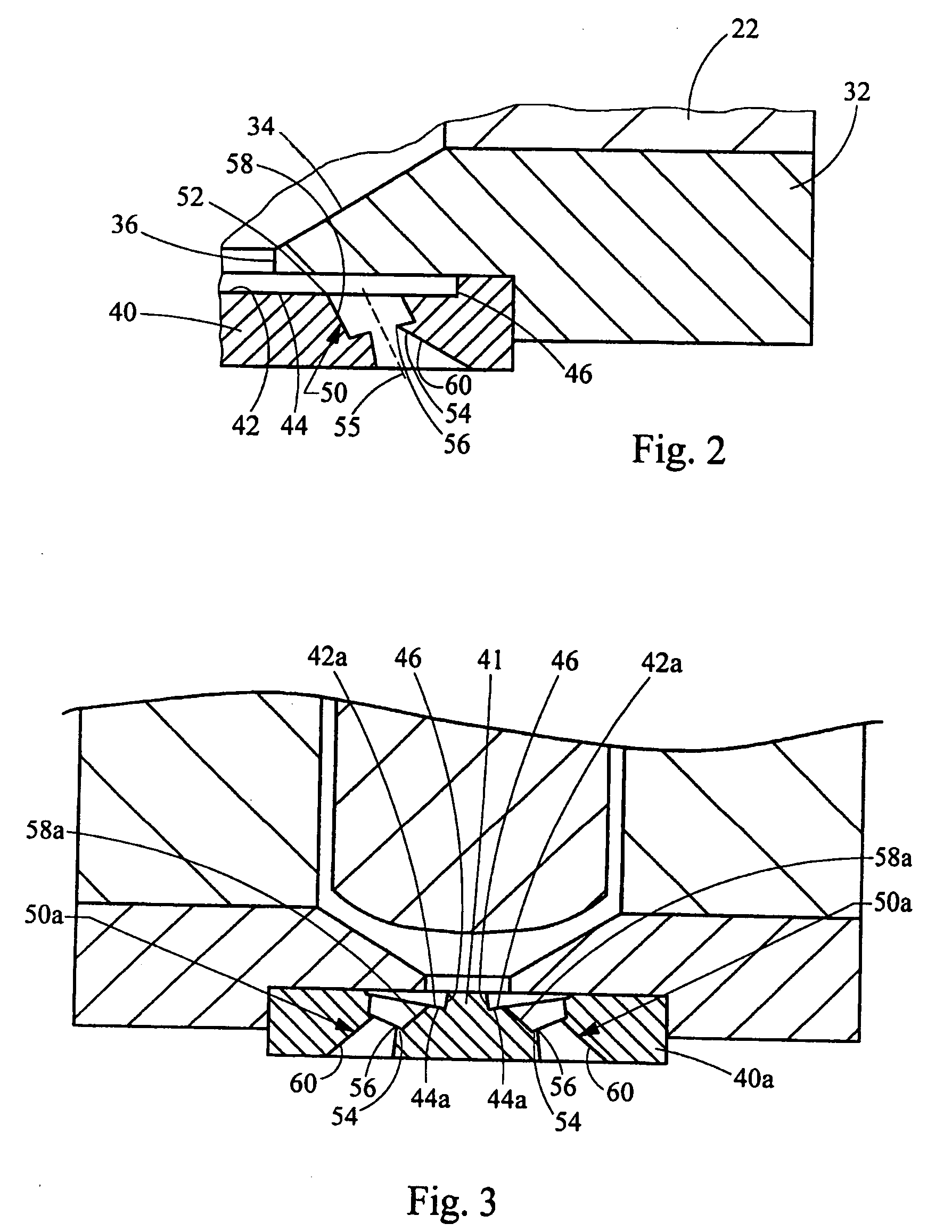

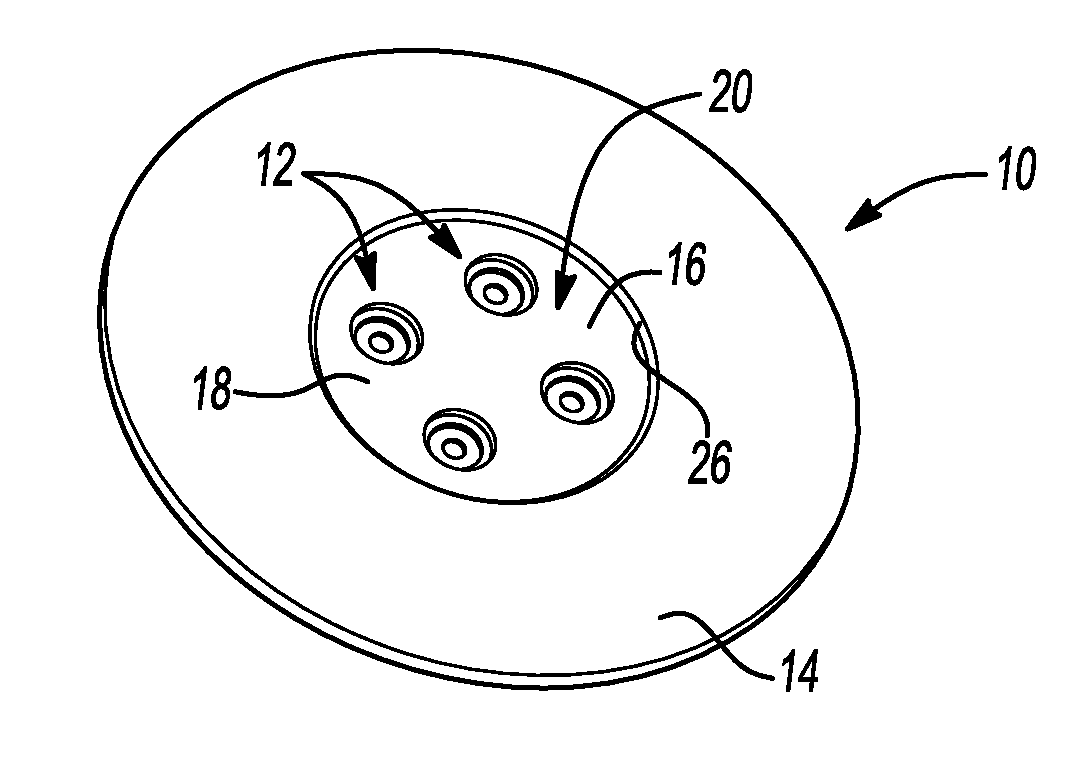

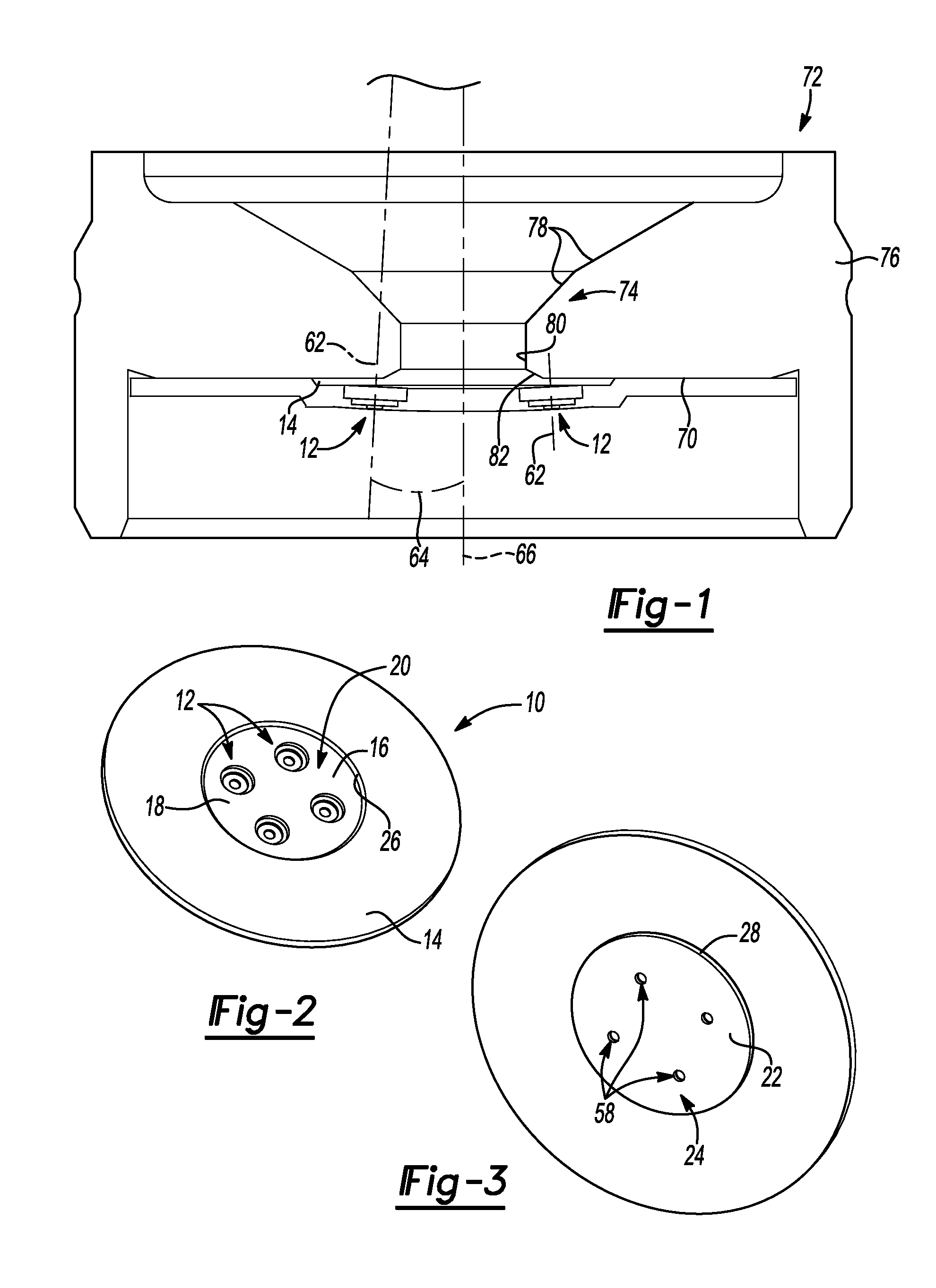

Orifice disc for fuel injector

InactiveUS20060202062A1Atomization of fuel be increaseImprove combustion performanceBurnersSpray nozzlesInjectorEngineering

An orifice disc for a fuel injector includes two orifices that provide a desired interaction between two fuel flows to increase fuel atomization and improve combustion performance. The orifice disc includes a first orifice and a second orifice that are disposed at an interaction angle relative to each other. The orifices are orientated relative to each other such that fuel flow exiting the outlets impinges on each other to further reduce the size of fuel droplets. Large dramatic changes in momentum caused by the impingement of fuel flows disintegrates fuel droplets into much smaller finer fuel droplets that provided enhanced atomization.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Annular oil supply type integrated afterburner

ActiveCN108131684AStable jobIncrease mixing intensityContinuous combustion chamberCombustion chamberEngineering

The invention provides an annular oil supply type integrated afterburner. A worm gear rear rectification supporting plate and a flame stabilizer are integrated, two stages of rectification supportingplates and the flame stabilizer are subjected to radially misplaced structure design, and in this way, a stable low speed backflow area large in size range and high in swirl flowing is more easily formed at the downstream of the annular oil supply type integrated afterburner. A whole-ring groove stabilizer is arranged between the two stages of rectification supporting plates. An oil cavity is formed inside a force-adding inner cone and is connected with a fuel channel inside the first-stage rectification supporting plate, and after absorbing heat of the force-adding inner cone, fuel finally reaches the inside of the whole-ring groove stabilizer. Main fuel is sprayed out longitudinally from the two sides of the whole-ring groove stabilizer, on-duty fuel is sprayed out from a groove of the whole-ring groove stabilizer to form on-duty flame, and soft ignition is achieved. By reasonably forming nozzle small holes, the atomization effect of the fuel can be effectively improved, and thus thestability and combustion efficiency are improved. The annular oil supply type integrated afterburner has the advantages that the two stages of rectification supporting plates which are radially misplaced are adopted, and a better backflow area is formed; meanwhile, through longitudinal oil spray of the whole-ring groove stabilizer, the fuel-gas mixing effect is improved, the on-duty flame is formed, the soft ignition is achieved, and thus the combustion stability is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low pressure fuel injector nozzle

ActiveUS20060096569A1Increase spray angleGood fuel atomizationInternal combustion piston enginesSpray nozzlesInjector nozzleEngineering

Owner:FORD GLOBAL TECH LLC

Carburetor for internal combustion engine

InactiveUS7090203B2Simple structureIncrease consumptionFlow mixersUsing liquid separation agentExhaust fumesExhaust gas emissions

A carburetor for an internal combustion engine has an intake pipe having a throttle valve plate therein. An annular venturi tube is disposed upstream or downstream of the throttle valve plate inside the intake pipe. The annular venturi tube is located at a predetermined interval with the throttle valve plate. The annular venturi tube has a fine continuous annular slit or four or more annularly arranged fuel discharging pores so as to atomize the fuel thereat. Atomization is always carried out near a position where a fastest air moves so as to improve the atomization and a uniform air-fuel mixture, thereby improving an output, fuel consumption and exhaust gas emission of the internal combustion engine.

Owner:GOTO SHINJI

Fuel Additives

InactiveUS20070256355A1Increase powerSmoother runningLiquid carbonaceous fuelsFuel additivesBiodieselGasoline

Owner:PETROCRYSTAL

Low pressure fuel injector nozzle

InactiveUS7051957B1Good fuel atomizationSpray nozzlesFuel injection apparatusInjector nozzleEngineering

Owner:VISTEON GLOBAL TECH INC

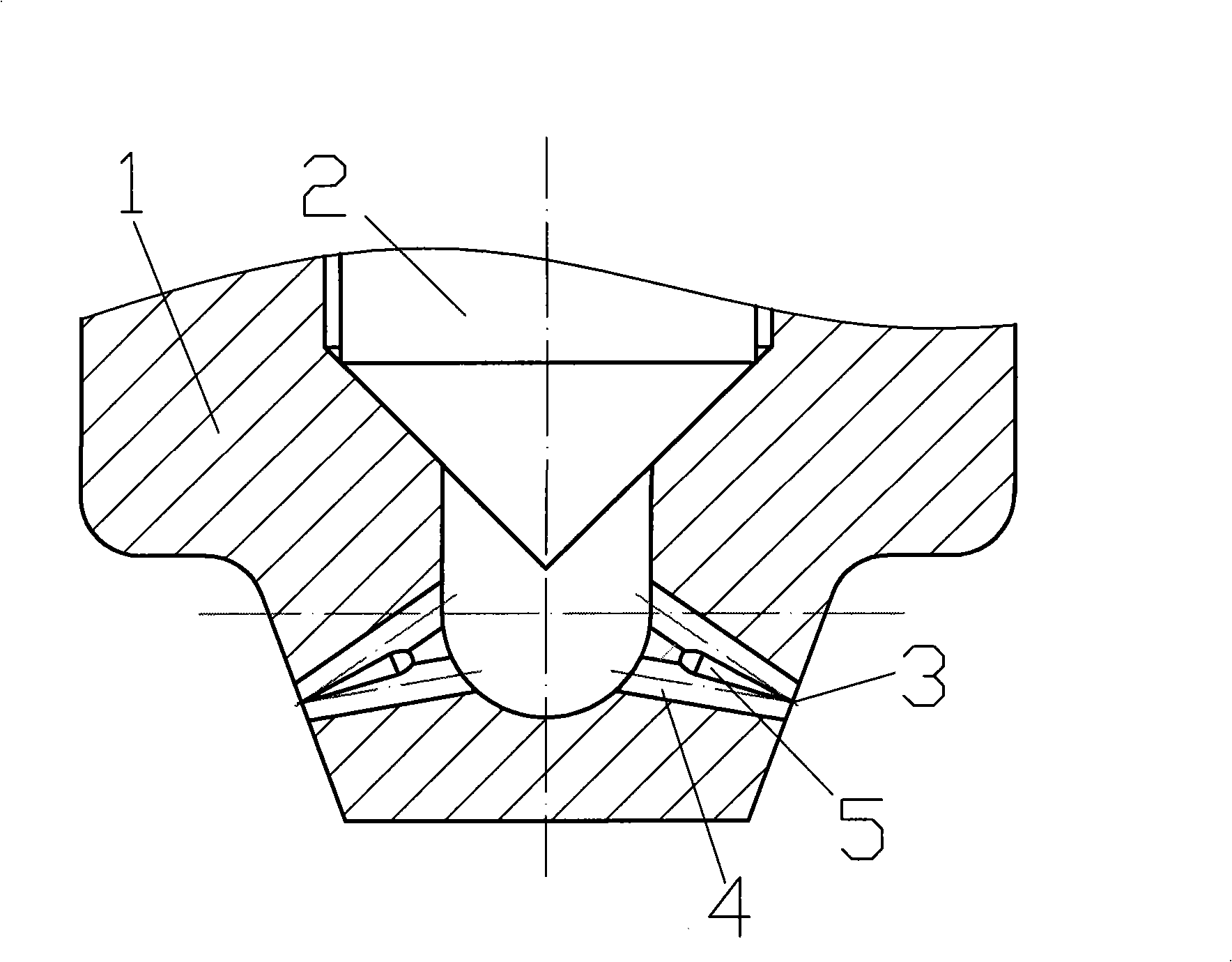

Internal-combustion engine alternating spray hole type nozzle with perturbing zone

ActiveCN101333993APromotes fuel atomizationEnhanced mixing processFuel injection apparatusMachines/enginesPower performanceNeedle valve

Disclosed is a cross jet-hole injection nozzle with a disturbance area of an internal combustion engine, which belongs to the oil injection device of the internal-combustion fuel-oil system. The cross jet-hole injection nozzle with the disturbance area of the internal combustion comprises a precise matching part composed of a needle valve body and a needle valve; at least a cross jet-hole injection hole with the disturbance area is arranged on the head part of the needle valve body. The turbulence flow of the internal fuel oil intensity of the injection nozzle, based on the turbulence flow disturbance generated on the cross position of the sub nozzle is further improved; thereby, the fuel-oil pulverization of the injection nozzle outlet is improved; the quality of the mixed gas is improved; the combustion is enabled to be more rapid, sufficient and complete; the engine is ensured to obtain better economy, exhaust and power performance under the same injection pressure.

Owner:DALIAN UNIV OF TECH

Low pressure fuel injector nozzle

ActiveUS7185831B2Easy to controlGood fuel atomizationInternal combustion piston enginesSpray nozzlesInjector nozzleEngineering

Owner:FORD GLOBAL TECH LLC

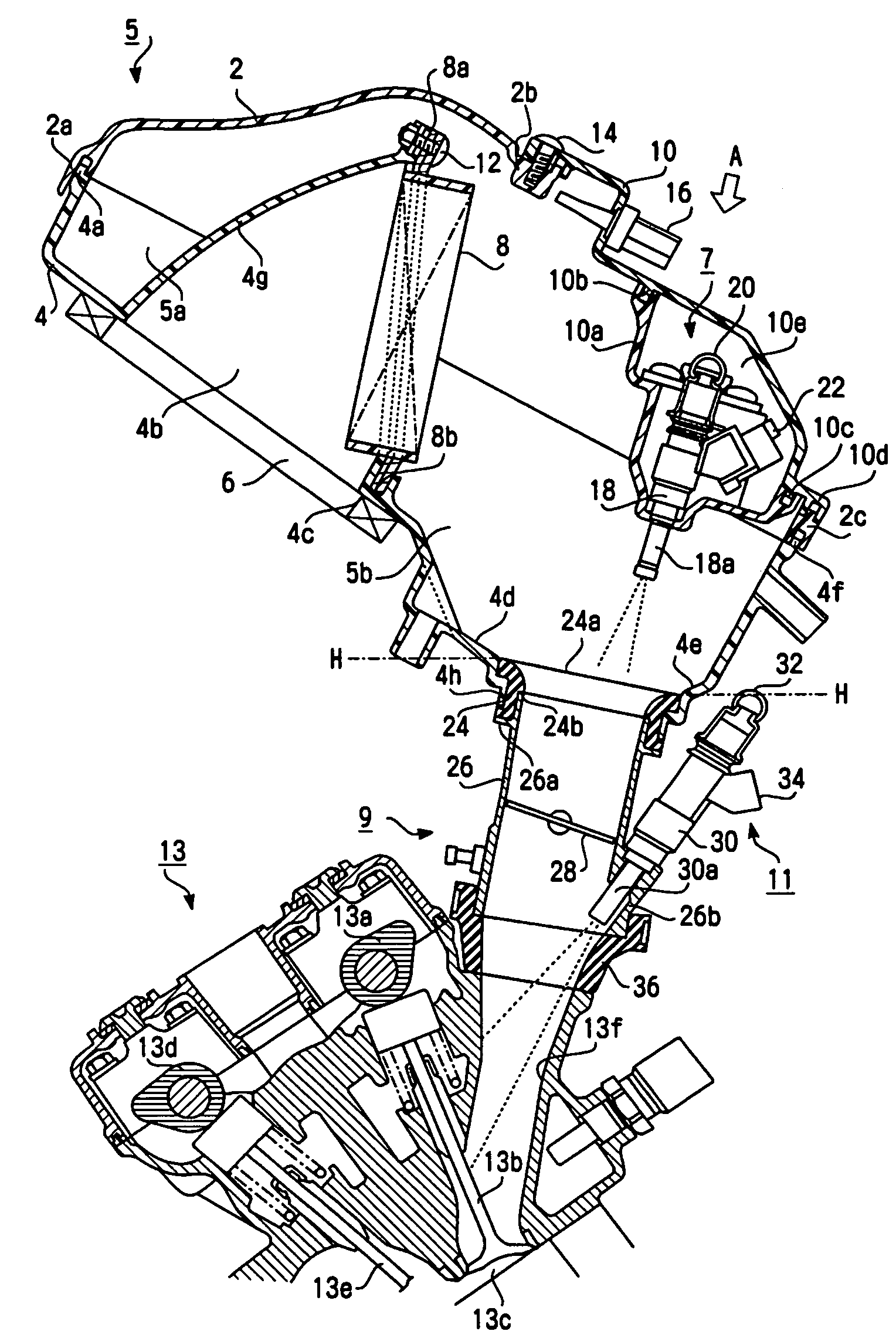

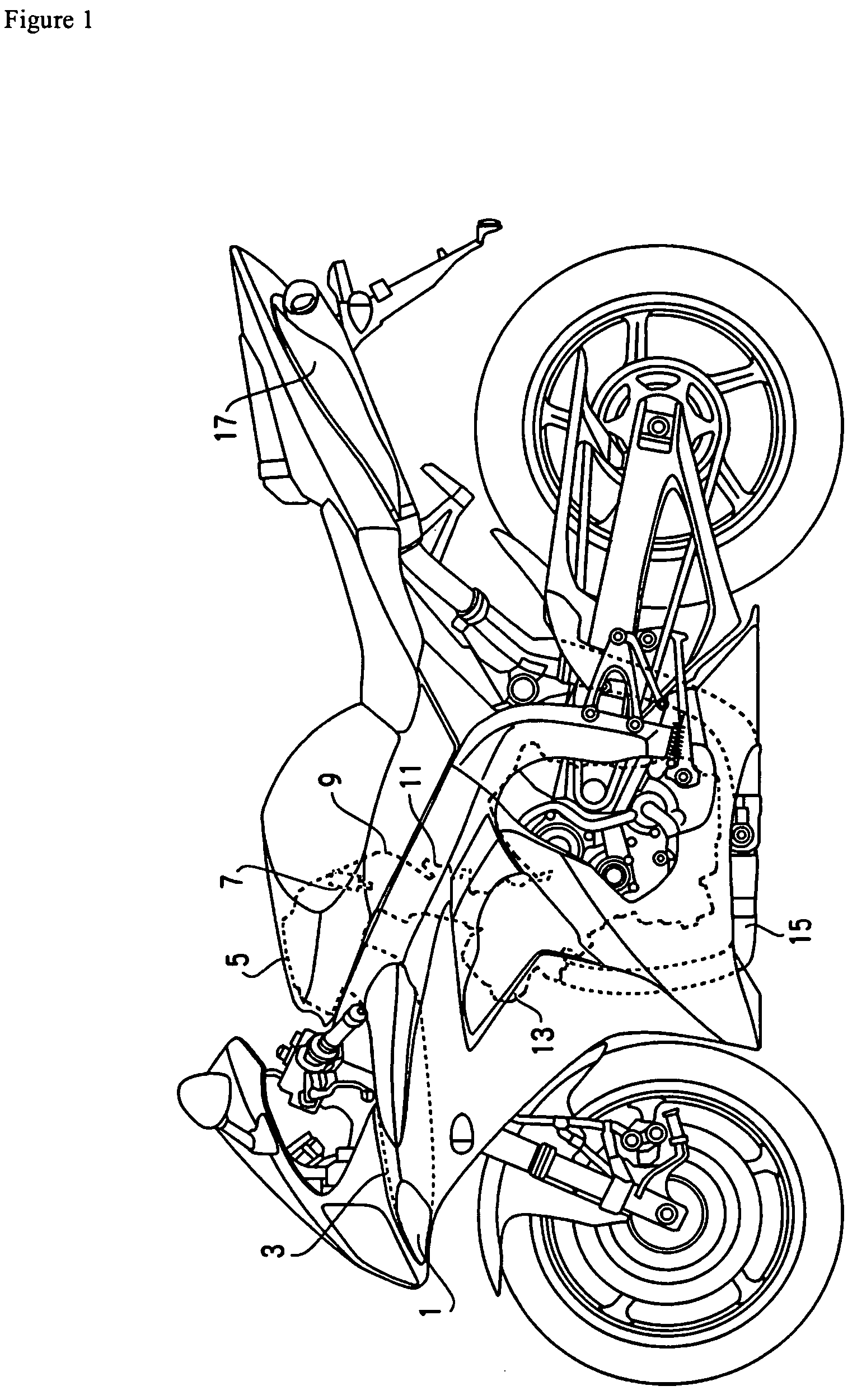

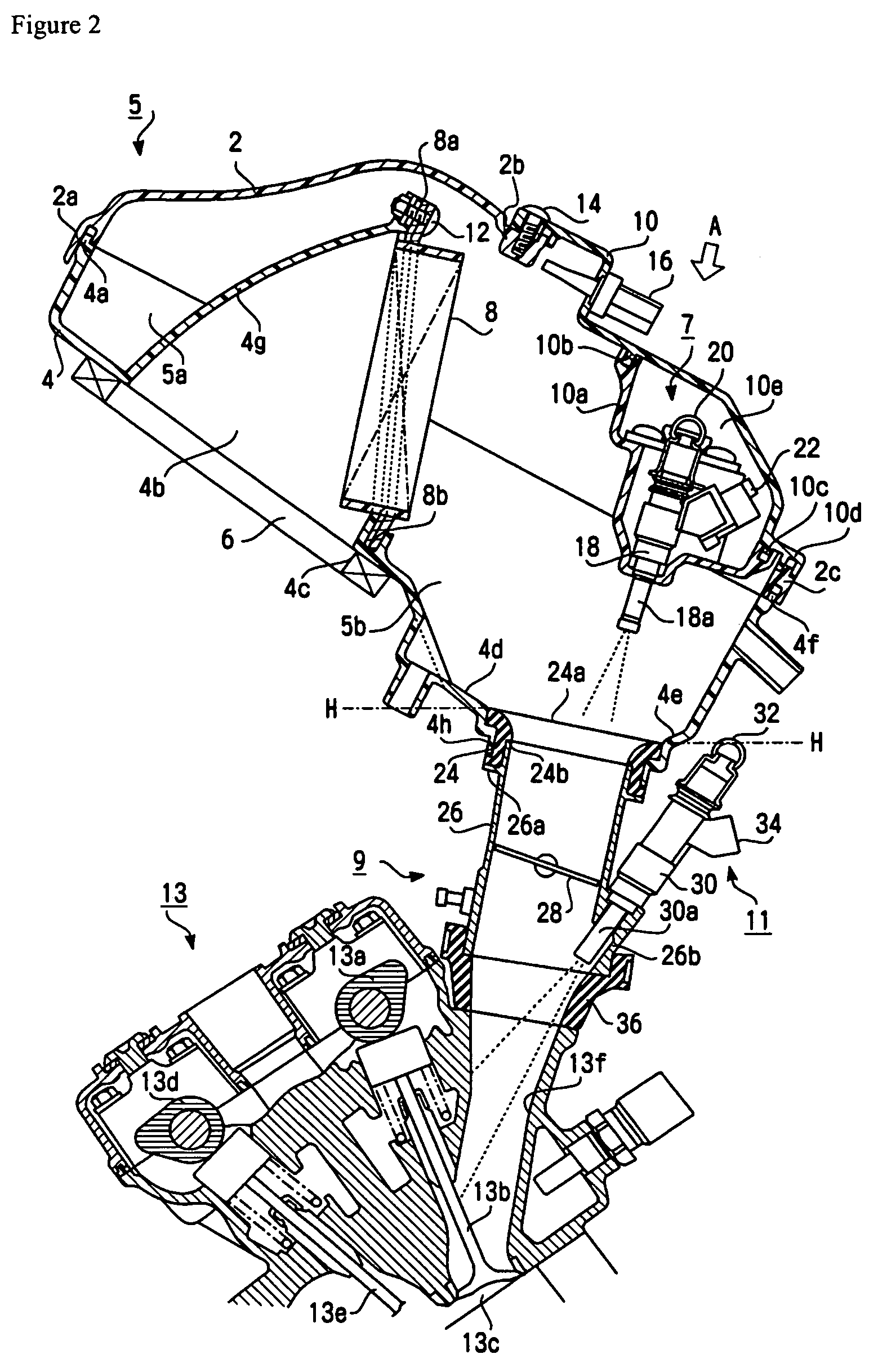

Fuel supply system and vehicle

ActiveUS7637242B2Good fuel atomizationImprove engine performanceNon-fuel substance addition to fuelCombustion enginesFuel supplyInjector

A fuel supply system has an air chamber that contains a fuel injector. At least one aperture is formed in a substantially lowermost portion of a lower surface of the air chamber. The aperture and the lower surface have a generally uninterrupted or smooth transition or interface.

Owner:YAMAHA MOTOR CO LTD

Low pressure fuel injector nozzle

InactiveUS20060097087A1Increases spray angleGood fuel atomizationDust removalFire preventionInjector nozzleEngineering

Owner:VISTEON GLOBAL TECH INC

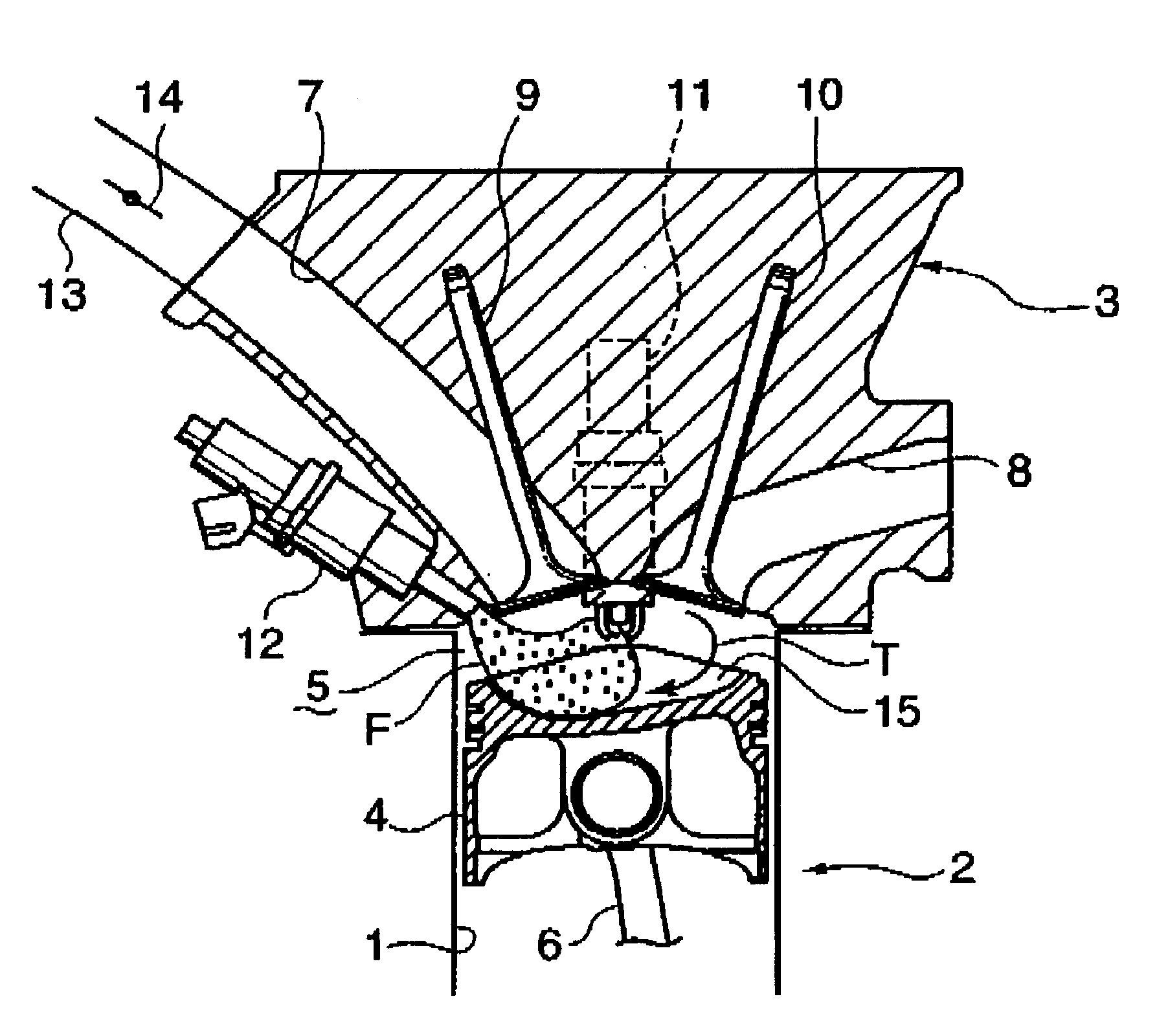

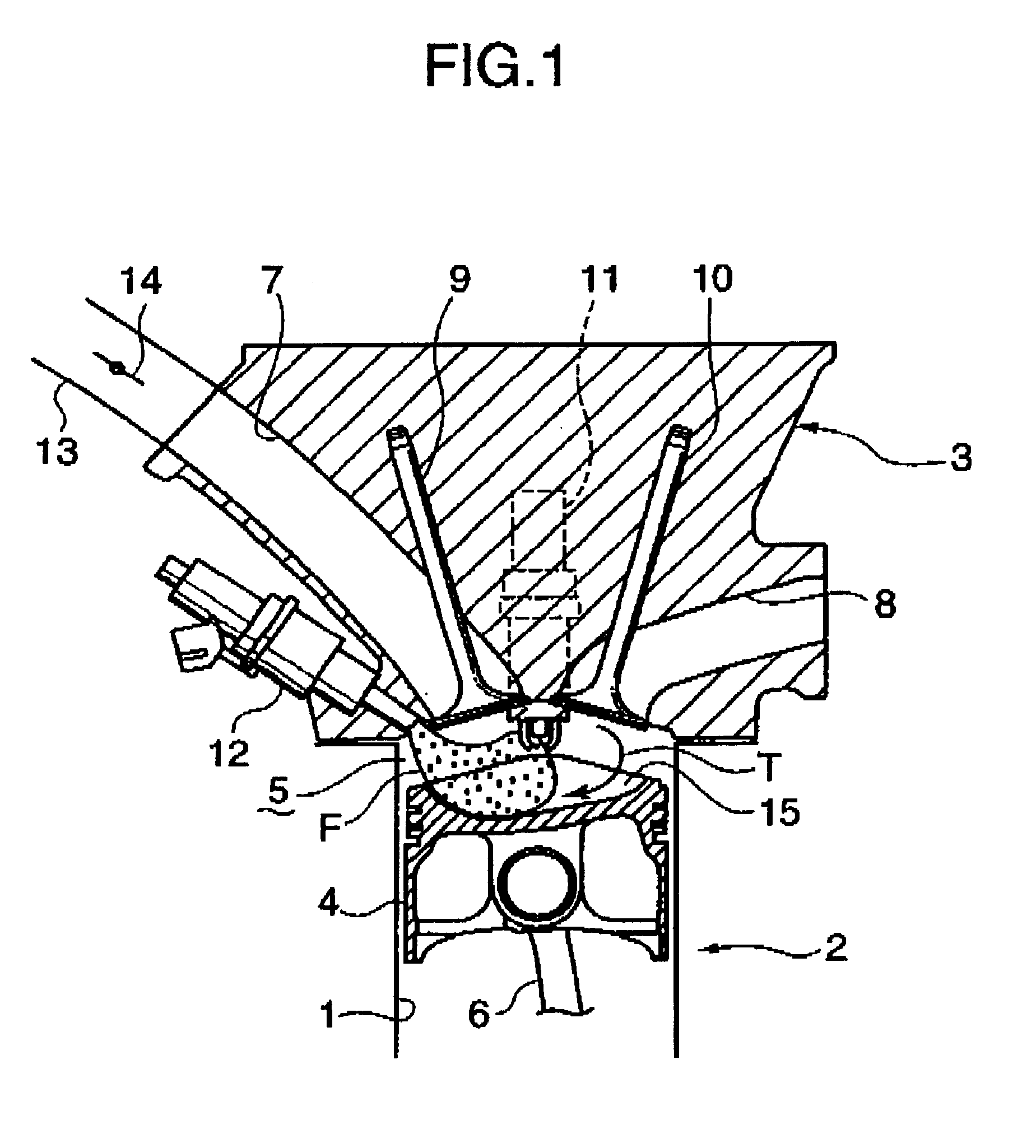

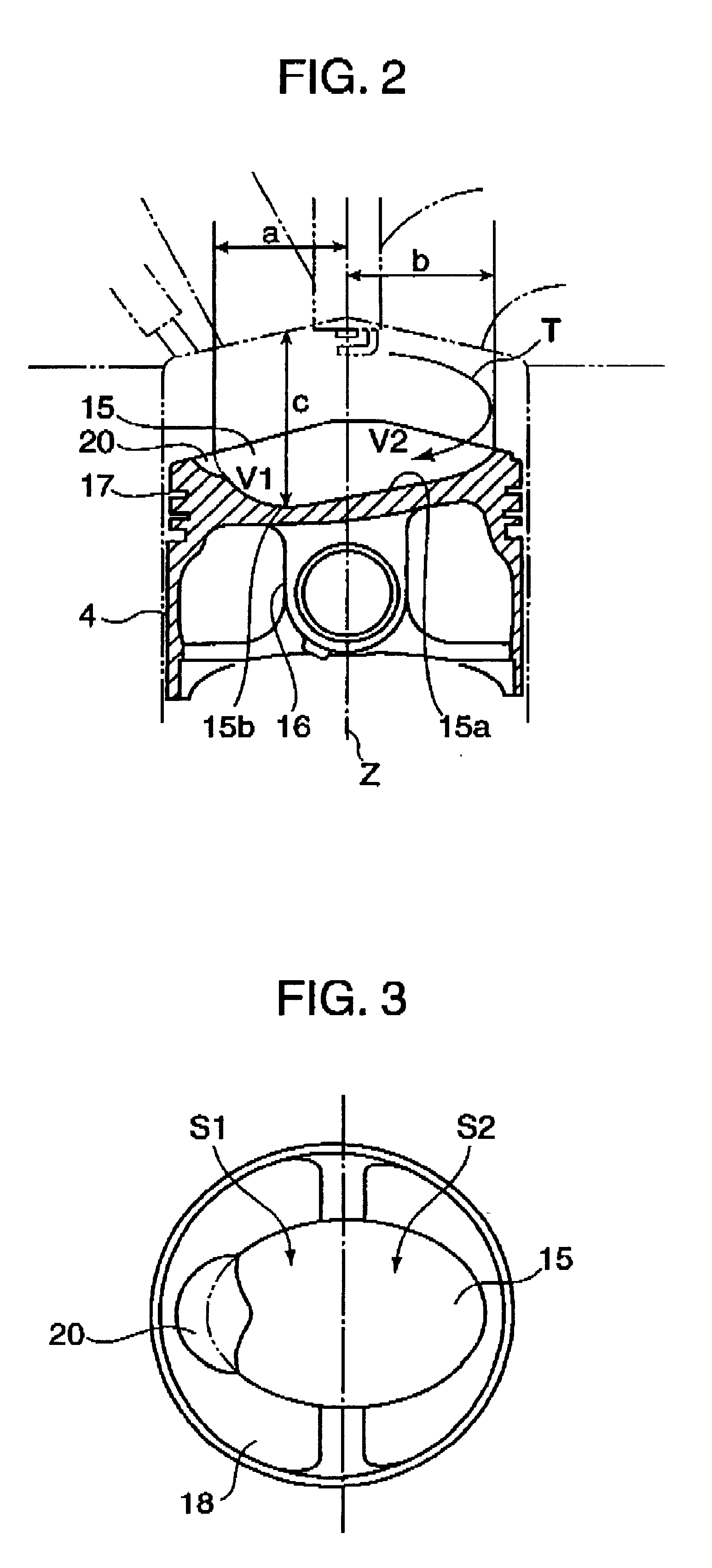

Direct-injection spark-ignition engine

InactiveUS6684848B2Good fuel atomizationIncrease freedomInternal combustion piston enginesCylinder headsPistonFuel injection

Owner:MAZDA MOTOR CORP

Fuel Injector

InactiveUS20090321540A1Lower emission valueShorten the overall cycleDust removalFire preventionVena contracta diameterEngineering

A fuel injector has an orifice plate including a plurality of spray-discharge orifices, which orifice plate is situated downstream from a valve seat member having a fixed valve seat. An inflow opening, which is provided directly upstream from the spray-discharge orifices as incident-flow cavity, is designed in such a way that an incident flow to the spray-discharge orifices takes place largely at a right angle to the longitudinal extension of the spray-discharge orifices. The spray-discharge orifices are placed and oriented in such a way that at least one fuel spray in the form of a hollow cone lamella or full cone lamella is able to be spray-discharged, in which a radially outer region is made up of larger droplets than a radially inner region of the spray.

Owner:ROBERT BOSCH GMBH

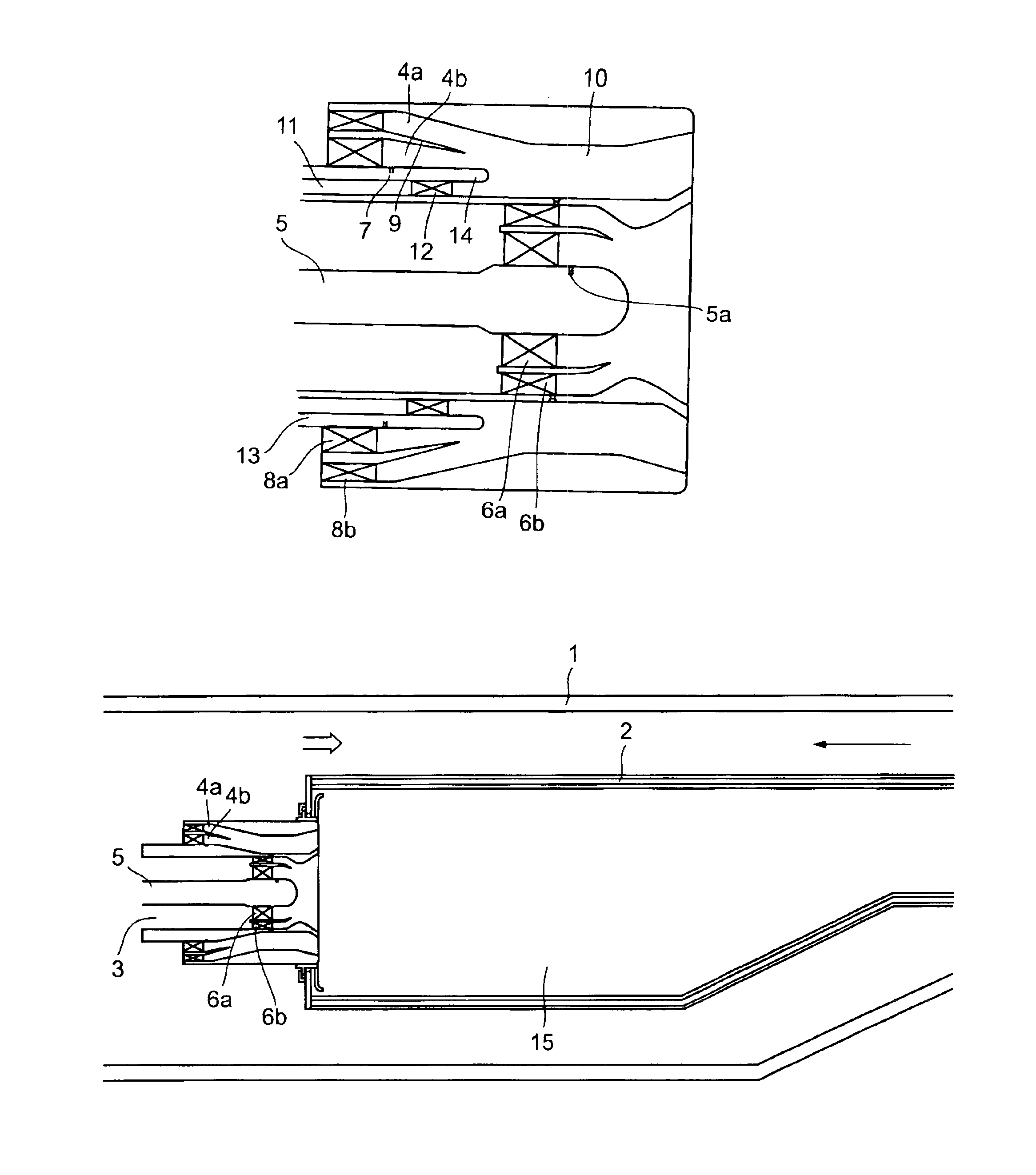

Premixed air-fuel mixture supply device

ActiveUS6908303B1Good fuel atomizationEasy to optimizeCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorGas turbines

A premixed air-fuel mixture supply device is joined to a combustor liner included in a combustor for a gas turbine or an aircraft engine. The premixed air-fuel mixture supply device has a pilot fuel injection unit having an inner wall, and a prevaporizing, premixing main fuel injection unit having an outer wall surrounding the inner wall. A combustion air passage is defined by the inner and the outer wall. An intermediate wall is disposed in the combustion air passage so as to divide an upstream part of the combustion air passage into a secondary combustion air passage surrounding the inner wall, and an outer combustion air passage surrounding the intermediate wall. Fuel inject holes are formed in the intermediate wall to inject fuel radially outward into the outer combustion air passage. A swirling device is disposed in the secondary combustion air passage to swirl combustion air flowing through the secondary combustion air passage. An atomization lip is formed in a tail part of the intermediate wall.

Owner:KAWASAKI HEAVY IND LTD

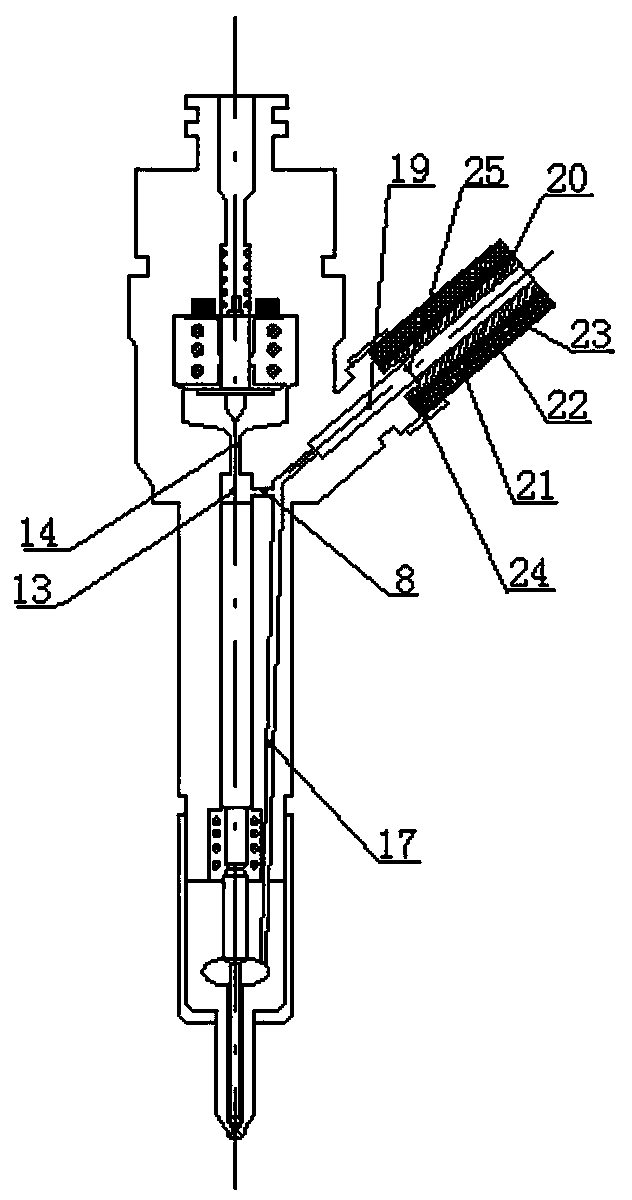

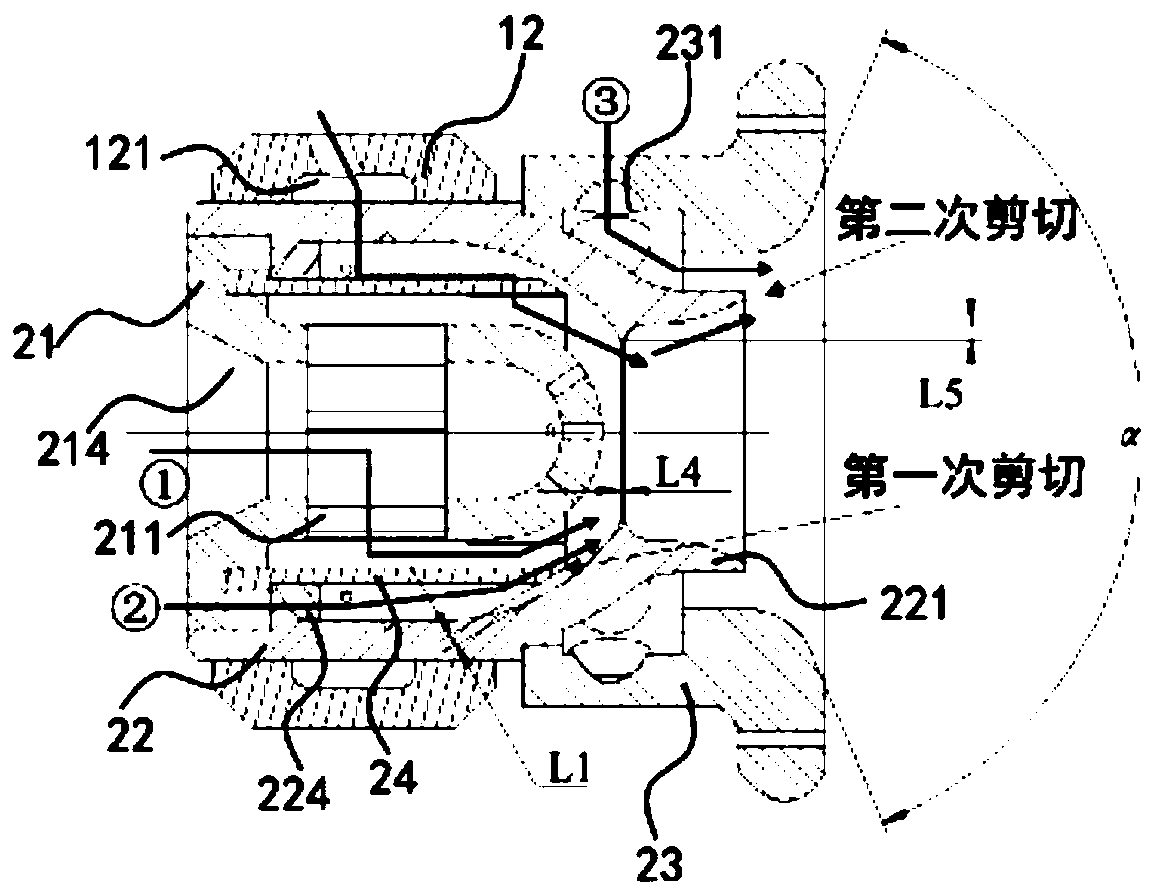

Fuel nozzle, combustion chamber and aircraft engine

ActiveCN109945235AImprove stabilityGood fuel atomizationContinuous combustion chamberAviationCombustion chamber

The invention provides a fuel nozzle, a combustion chamber and an aircraft engine. The fuel nozzle comprises a nozzle body and a nozzle rod, wherein the nozzle rod is used for conveying fuel to the nozzle body; the nozzle body comprises a first swirl component with a first swirl structure, second swirl components with second swirl structures and third swirl components with third swirl structures;the second swirl components surround the first swirl component in an interval mode, and the first swirl component has a Venturi structure; the third swirl components surround the Venturi structure inan interval mode; a first airflow, a second airflow and a third airflow respectively pass through the first swirl structure, the second swirl structures and the third swirl structures to form a firstswirl flow, a second swirl flow and a third swirl flow; the first swirl flow is opposite to the second swirl flow; and the second swirl flow is opposite to the third swirl flow. The first shearing ofthe fuel oil is completed under the combined action of the first swirl flow and the second swirl flow, and the second shearing of the fuel oil is completed under the combined action of the second swirl flow and the third swirl flow.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

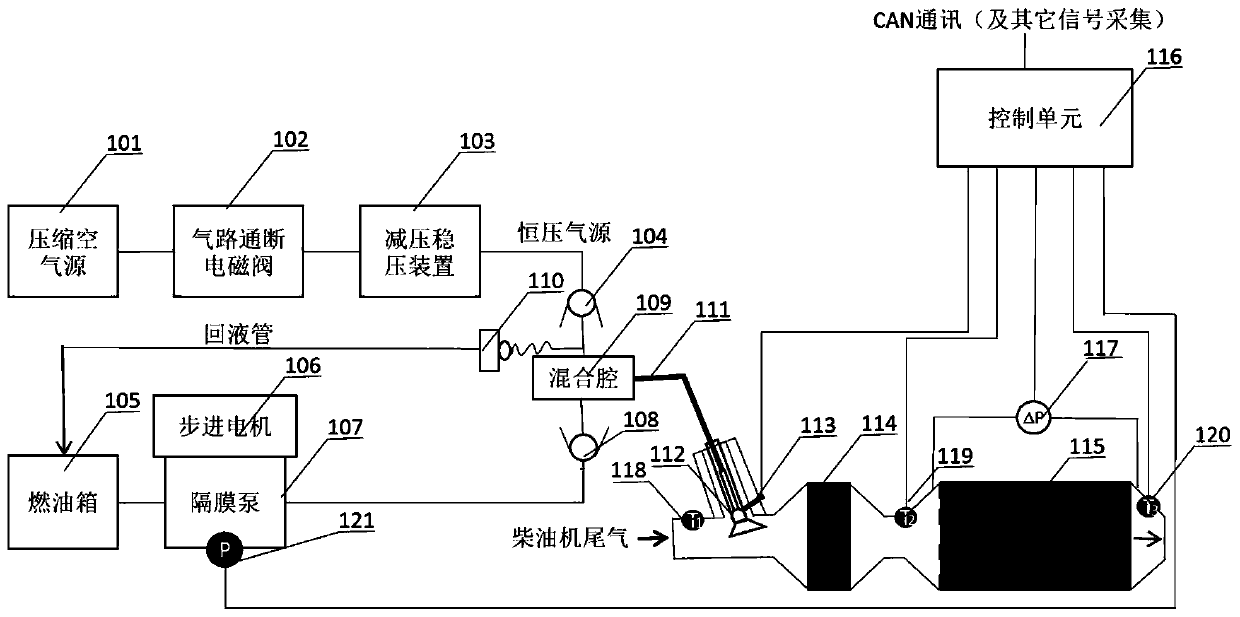

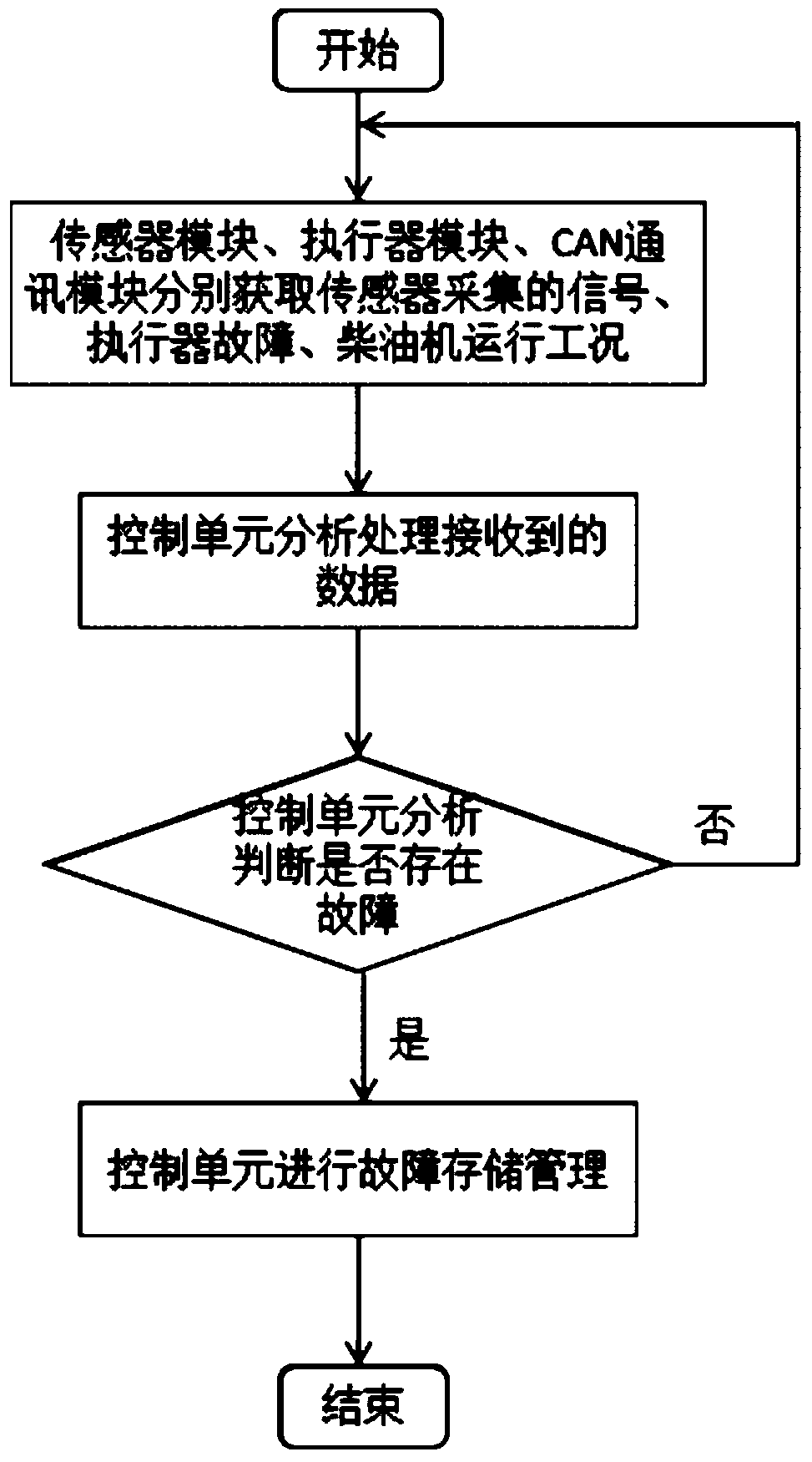

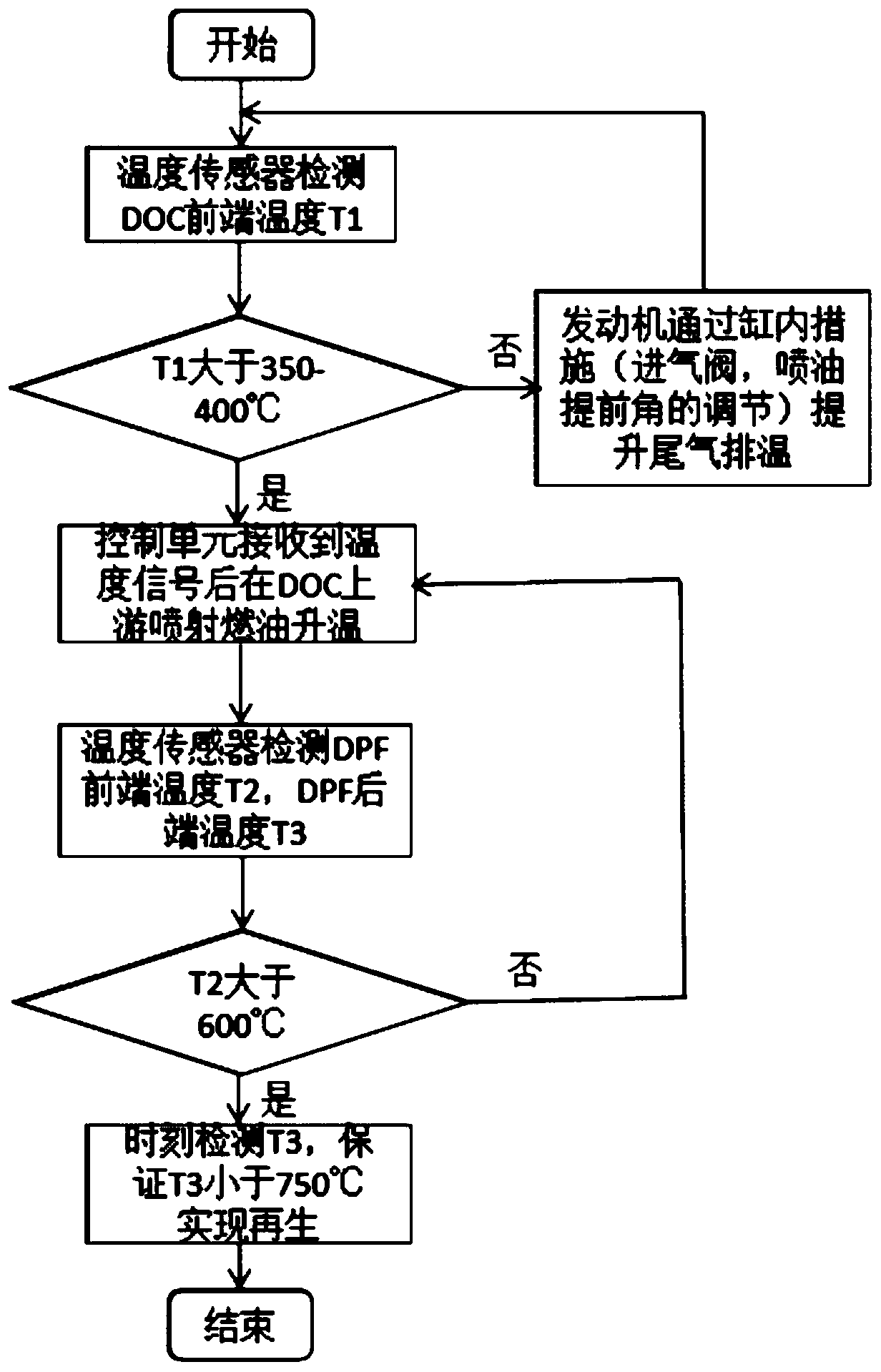

DPF regeneration device for mixing two-phase flow mediums and exhaust air temperature increment strategy of DPF regeneration device

ActiveCN110067618AProduce secondary pollutionSimple structureInternal combustion piston enginesExhaust apparatusParticulatesControl system

The invention provides a DPF regeneration device for mixing two-phase flow mediums and an exhaust air temperature increment strategy of the DPF regeneration device. The inlet of an exhaust pipe is provided with a nozzle; a diesel oxidation catalyst (DOC) and a particulate filter (DPF) are arranged inside the exhaust pipe; the DPF regeneration device comprises a two-phase flow medium mixing deviceand a control system; the two-phase flow medium mixing device is used for providing the two-phase flow mediums which are mixed in the nozzle; the control system comprises a control unit, a DPF temperature sensor, a DOC front exhaust air temperature sensor and a DPF pressure difference sensor; the DPF temperature sensor is used for measuring the temperature of the inlet and the outlet of the DPF; the DOC front exhaust air temperature sensor is used for measuring the temperature of the inlet of the DOC; and the pressure difference sensor of the DPF is used for measuring the pressure difference of the inlet and the outlet of the DPF. According to the DPF regeneration device provided by the invention, the two-phase flow mediums are sprayed into the exhaust pipe via the nozzle; oil gas is ignited by virtue of an ignition plug; and the control system implements state monitoring and state control of the overall regeneration process.

Owner:JIANGSU UNIV

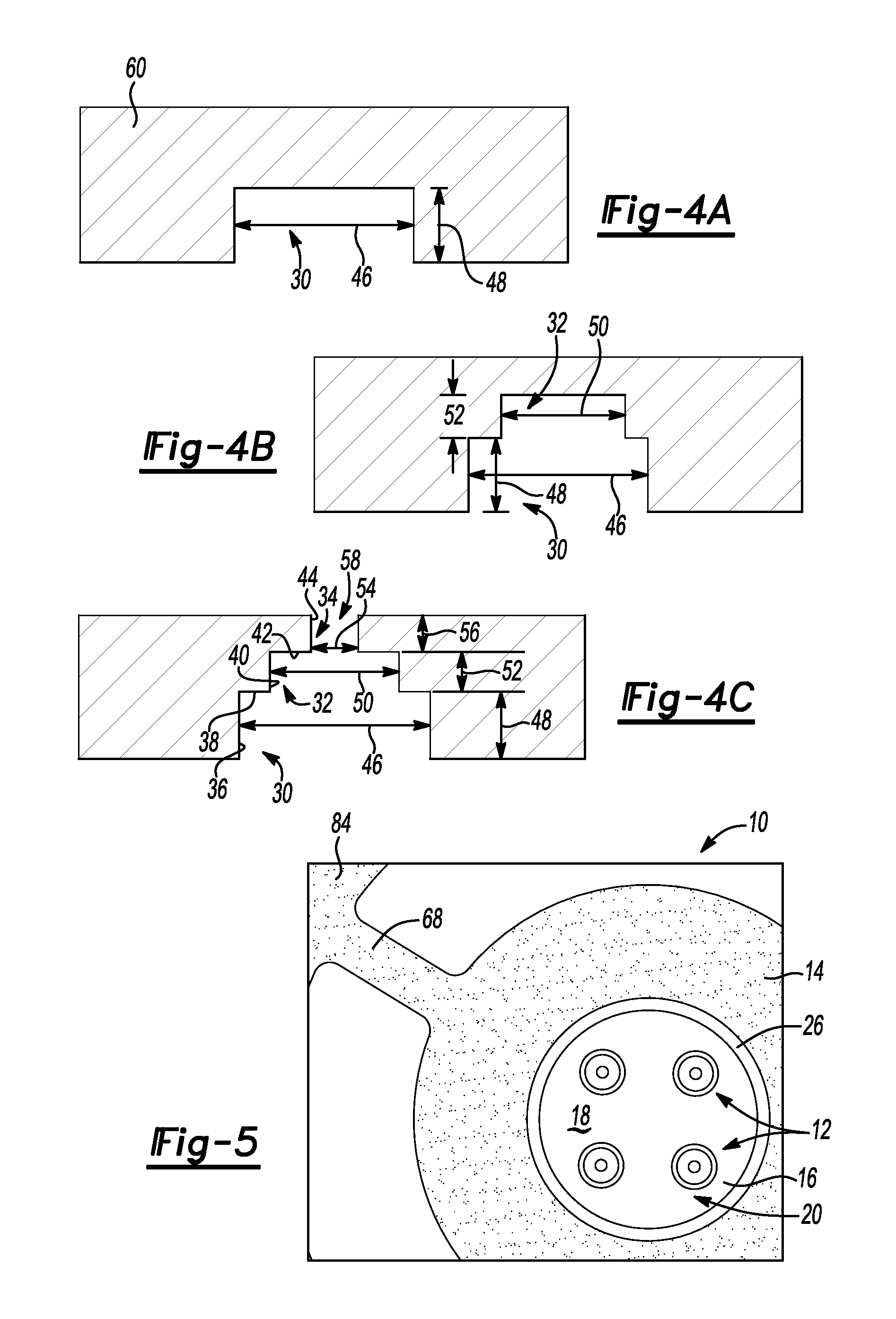

Stepped Orifice Hole

ActiveUS20130327855A1Improve breakupReduce material thicknessSpray nozzlesFire rescueVena contracta diameterEngineering

An orifice plate used as part of a fuel injector. The orifice plate has a base portion, an offset portion integrally formed with the base portion, a flow entry side and a flow exit side, where the base portion and the offset portion are part of the flow entry side and the flow exit side. A plurality of exit apertures is integrally formed with the offset portion. Each of the plurality of exit apertures includes a plurality of stepped portions, and at least one inner diameter, and each exit aperture is disposed at an angle relative to a central axis extending through the orifice plate. Each exit aperture is of a depth that is about twice the size of the inner diameter, providing optimal atomization of the fluid as the fluid flows through the exit apertures.

Owner:VITESCO TECH USA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com