Double-oil-duct oil atomizer with controllable fuel oil temperature

A fuel injector and oil passage technology, which is applied in the field of engine fuel injectors, can solve the problems of increasing the difficulty of structural arrangement, increasing costs, etc., to optimize fuel atomization effect, improve combustion and emission quality, and realize quantitative mixing and injection. burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

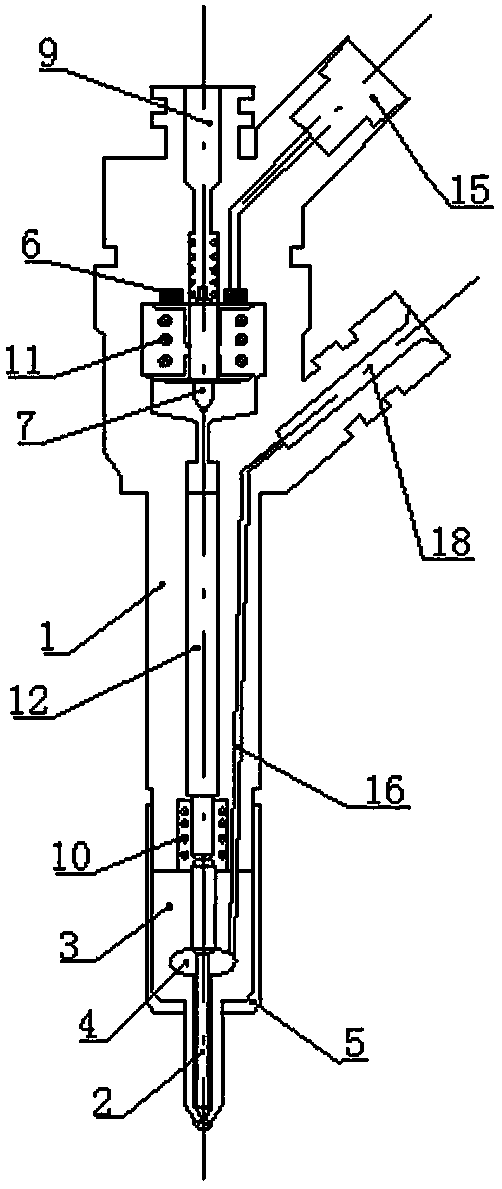

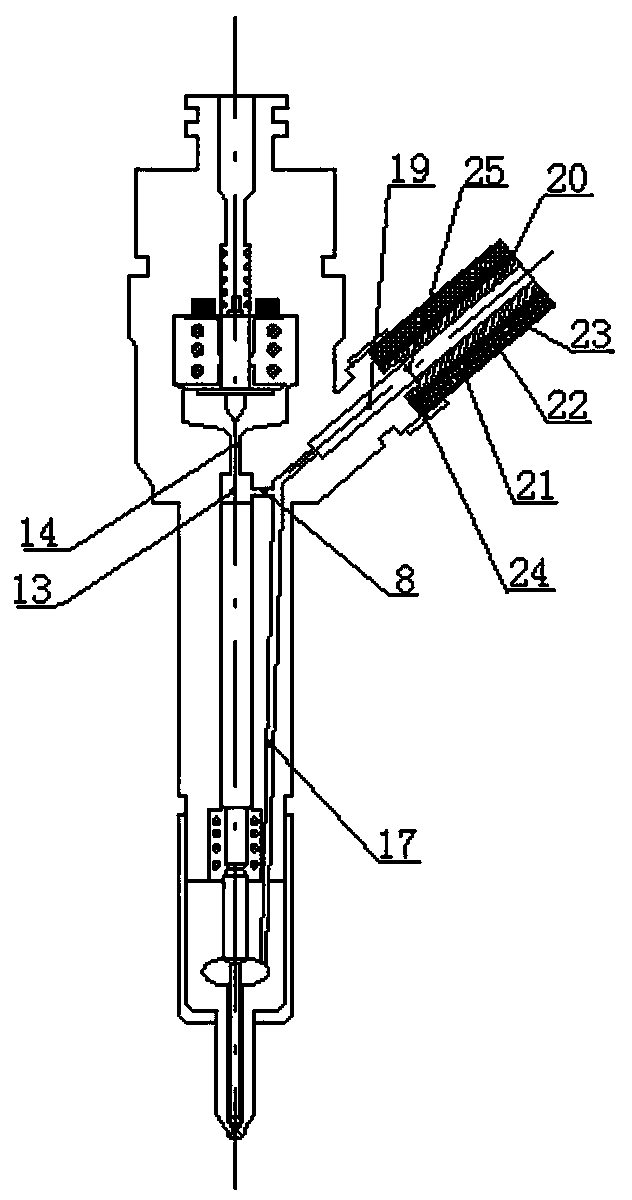

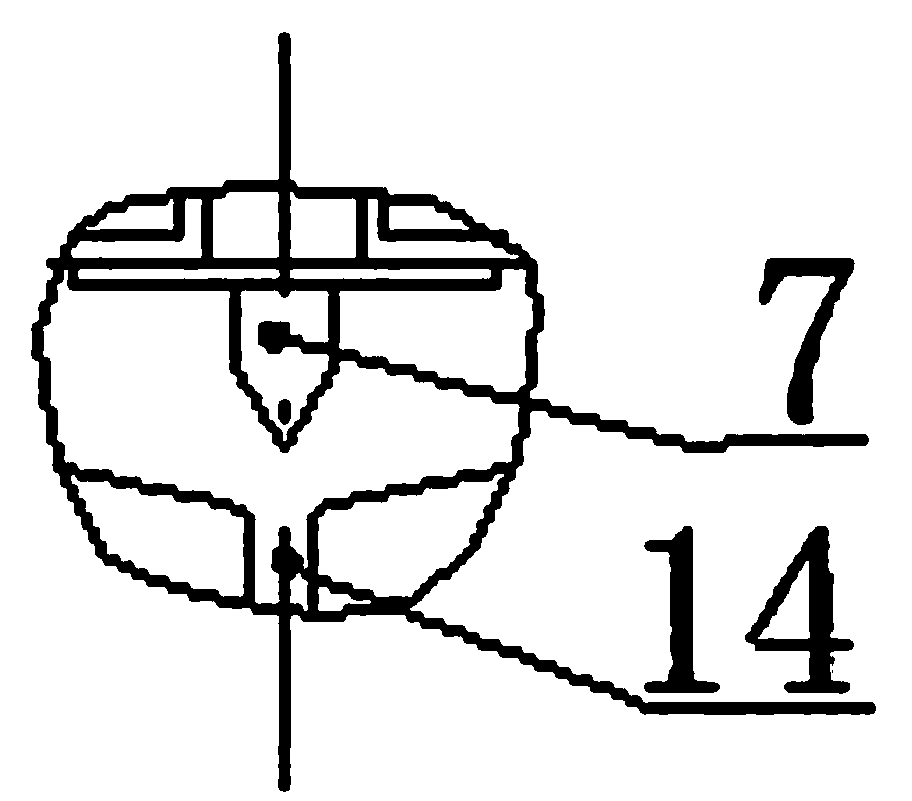

[0014] like figure 1 and 2 As shown, a dual-channel injector with controllable fuel temperature includes injector body 1, main needle valve 2, needle valve body 3, fuel mixing chamber 4, compression nut 5, injector solenoid valve 6. Drain needle valve 7, throttle hole 8, oil return hole 9, main needle valve spring 10, auxiliary needle valve spring 11, plunger 12, plunger chamber 13, overflow hole 14, electrical interface 15, main oil Road 16, controlled oil passage 17, main oil passage oil inlet hole 18, controlled oil passage oil inlet hole 19, fuel heating plug 20; wherein the main oil passage oil inlet hole 18 is connected with the main oil passage 16, and the fuel heating plug 20 is connected with the controlled oil passage The oil inlet hole 19 of the controlled oil passage is connected with the lock nut 24 through the interference fit of the positioning boss 25, and the oil inlet hole 19 of the controlled oil passage is connected with the controlled oil passage 17, at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com