Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

730results about "Meat/fish preservation by heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

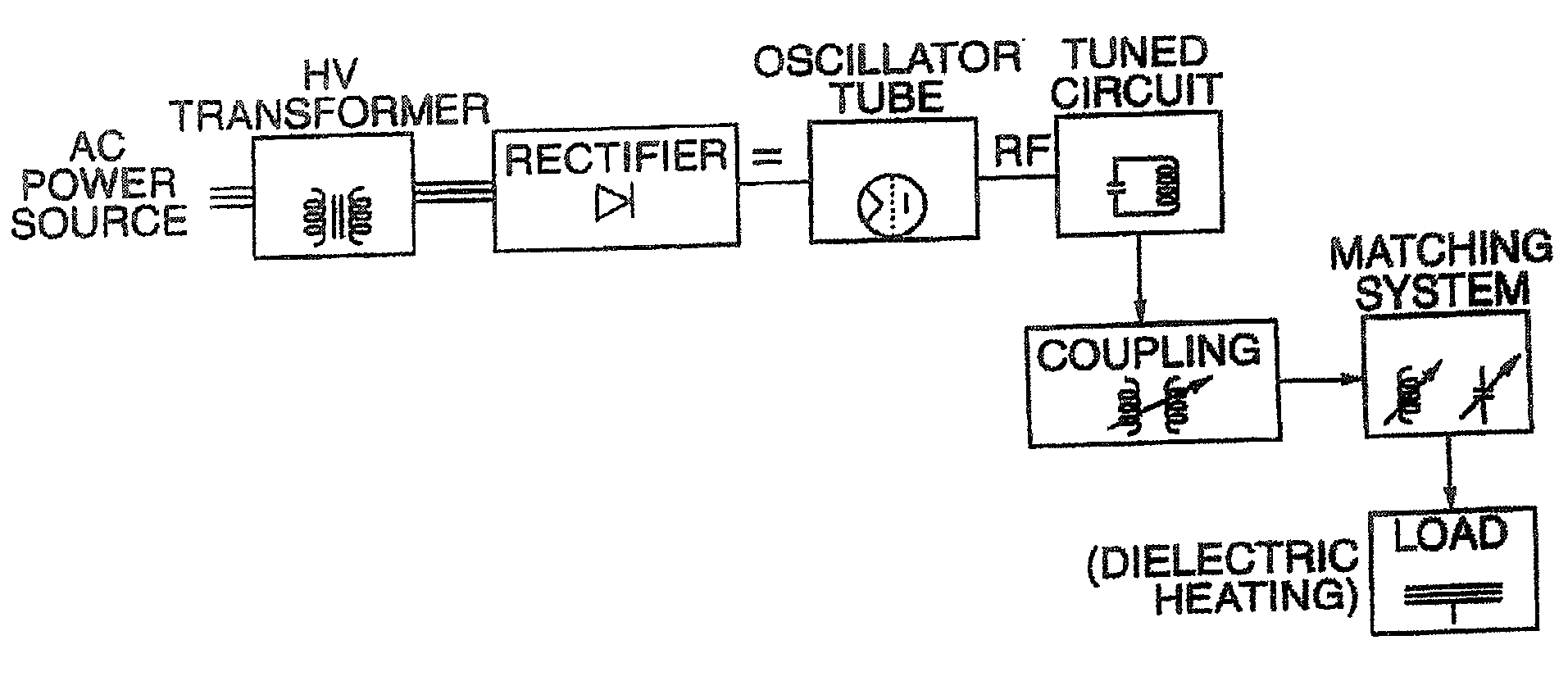

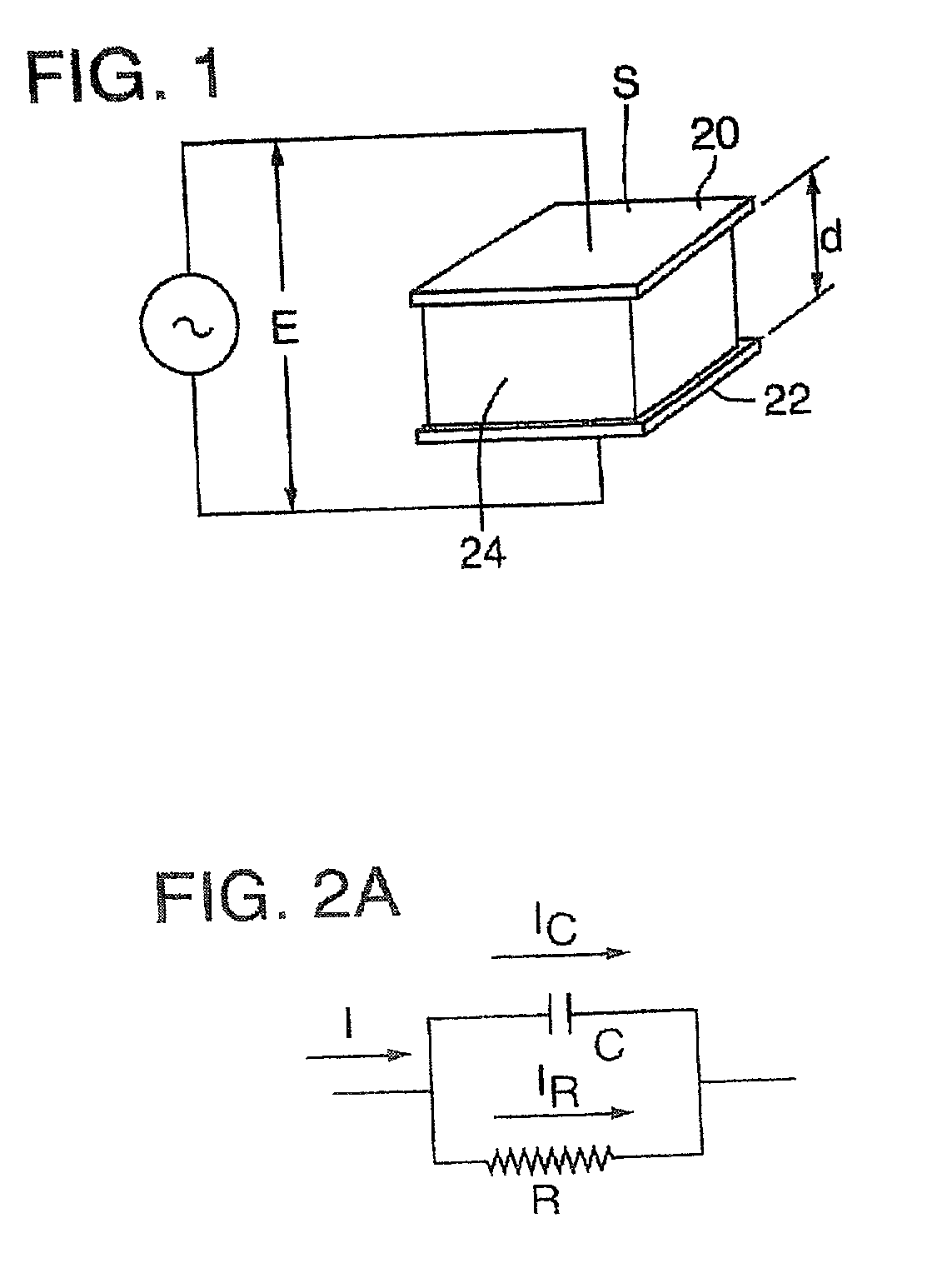

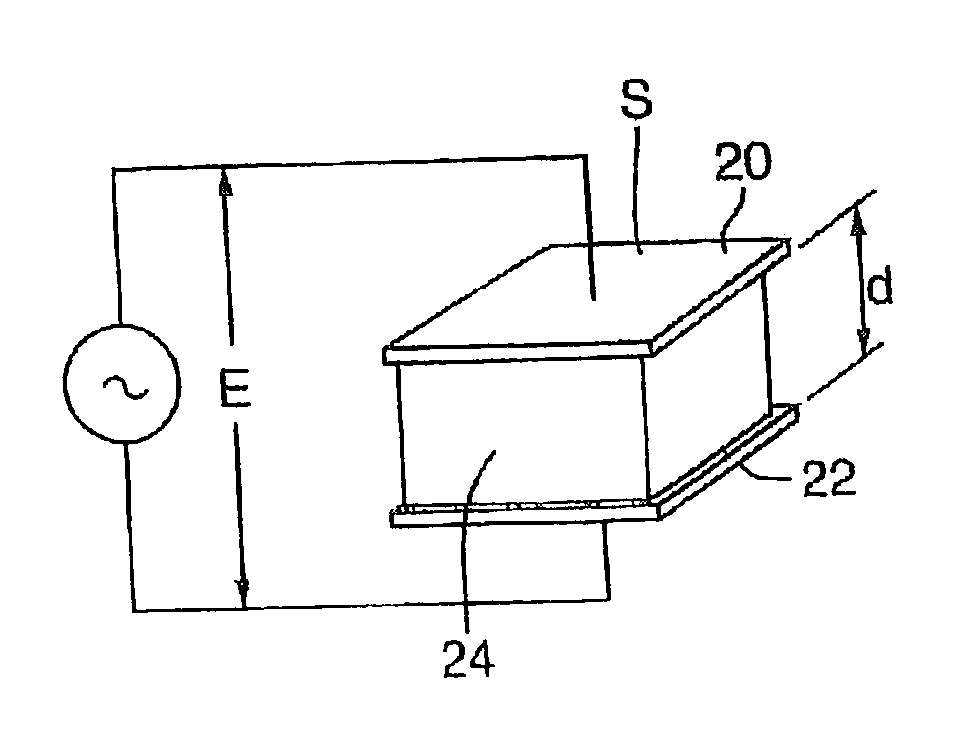

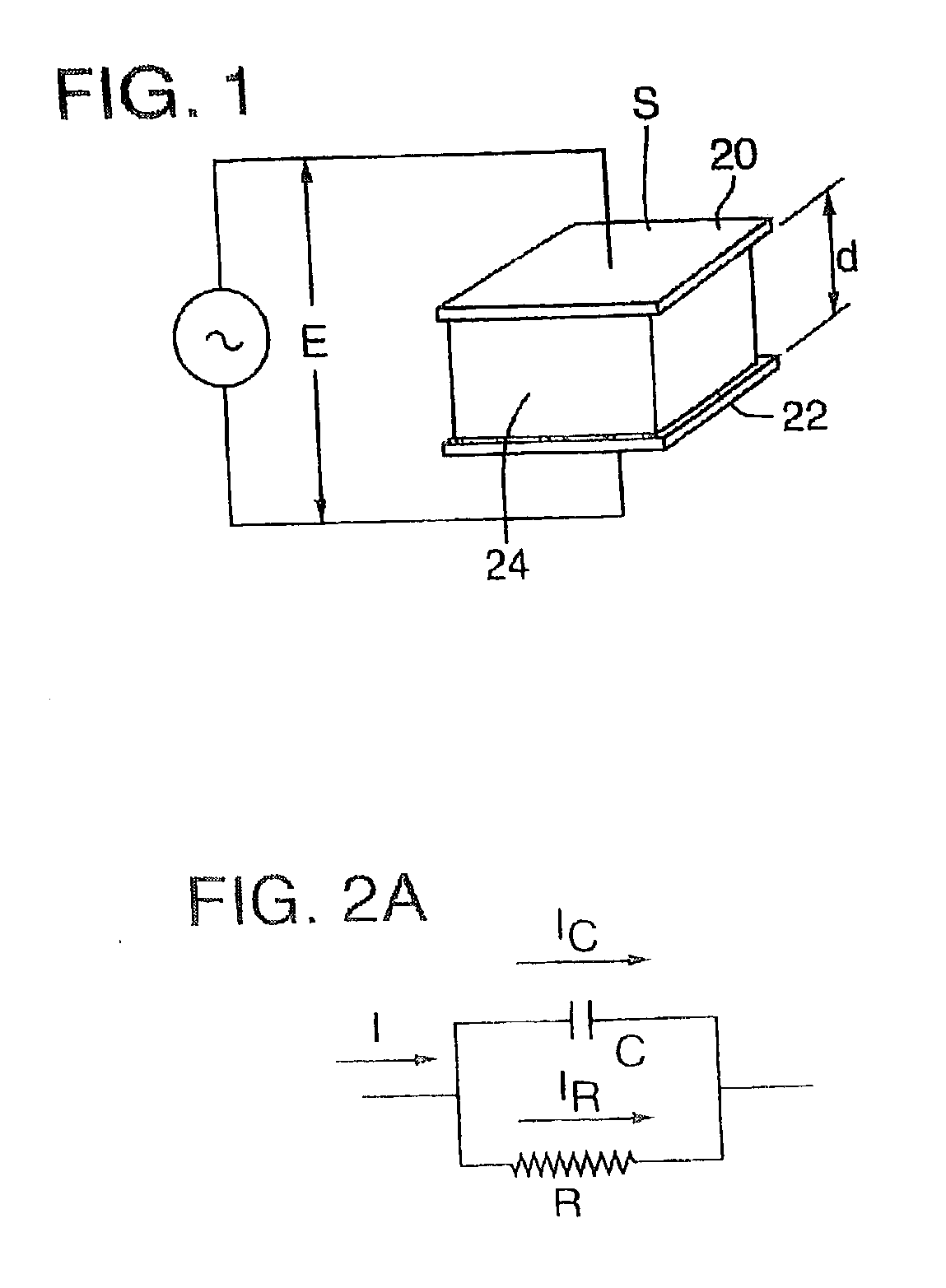

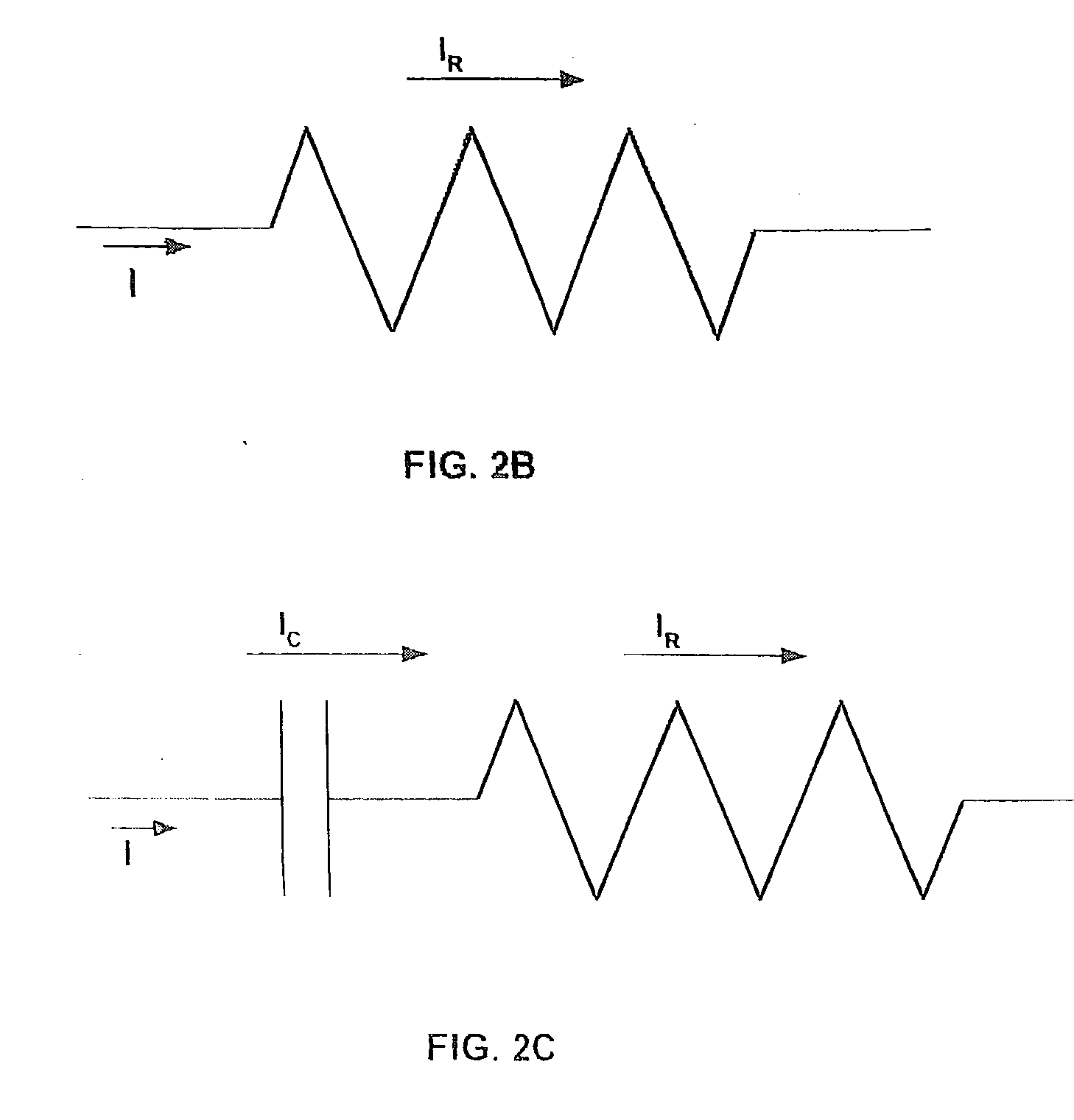

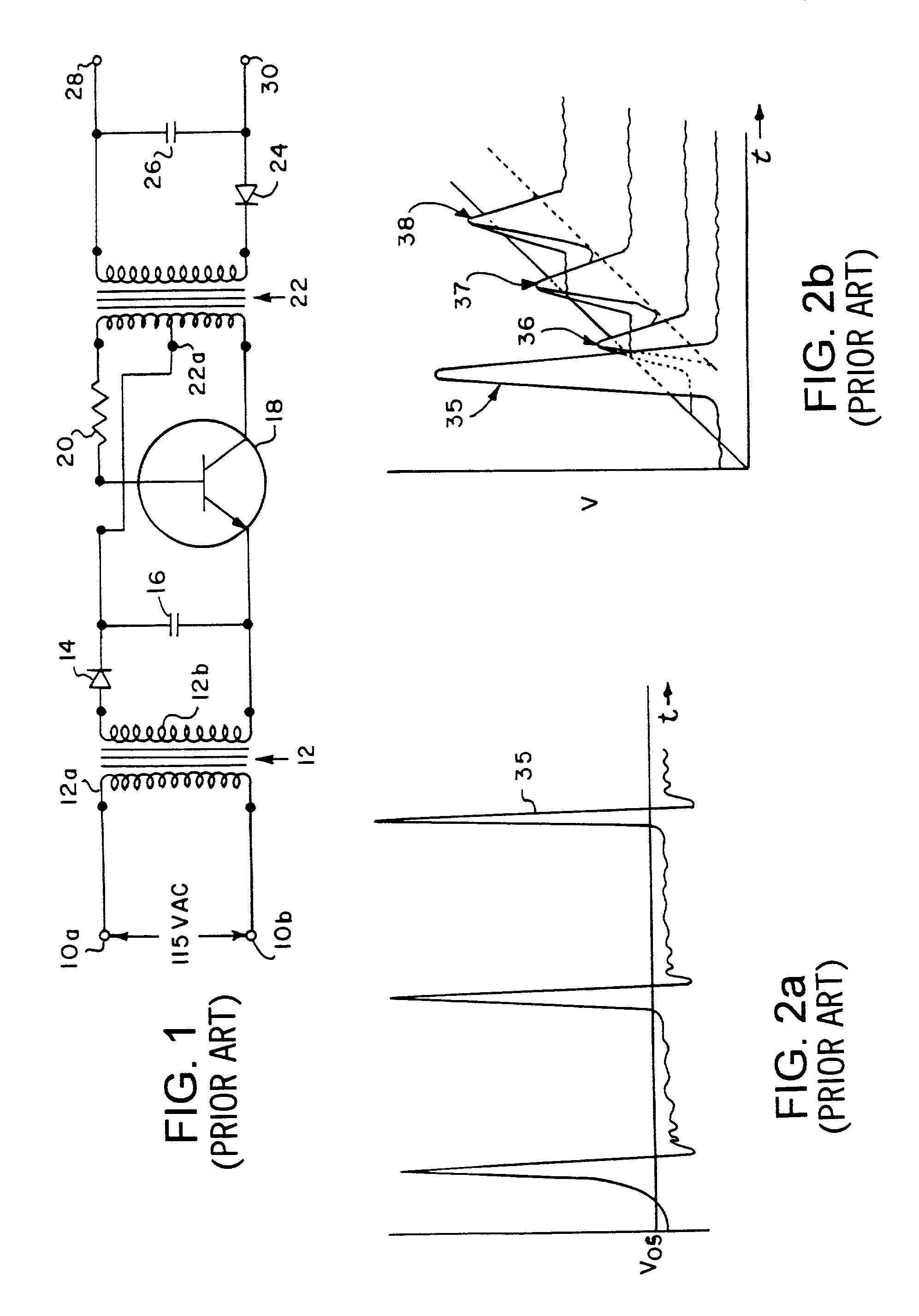

Variable frequency automated capacitive radio frequency (RF) dielectric heating system

InactiveUS20020047009A1Improve sealingLowering gap impedanceMeat/fish preservation by heatingDielectric heating circuitsRadio frequencyHeating system

A food product is heated by maintaining the food product in an AC electrical field generated by an RF signal. As the heating takes place, maximum energy is delivered to the food product using automatic impedance matching to adjust the rate of the process.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV +1

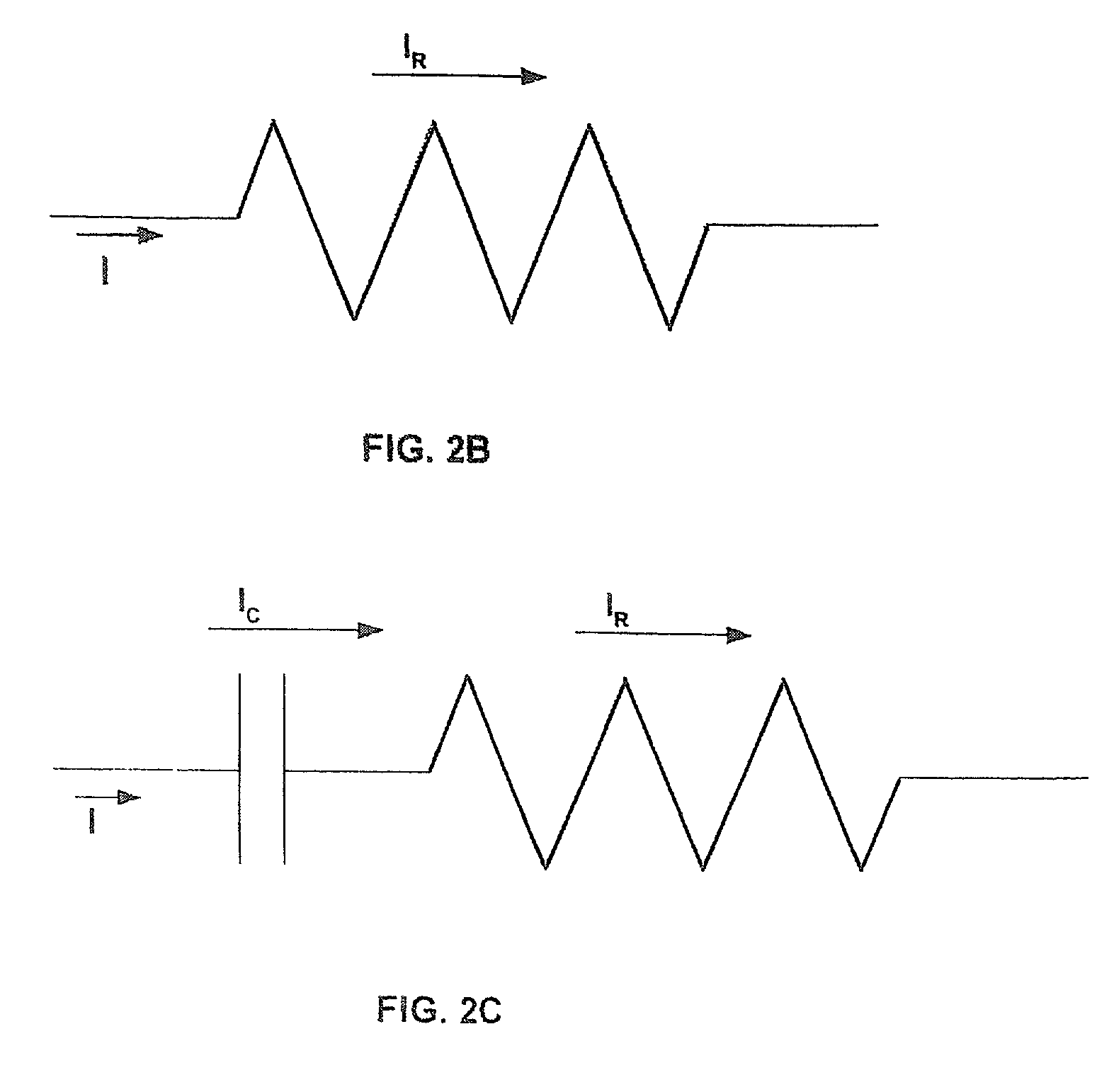

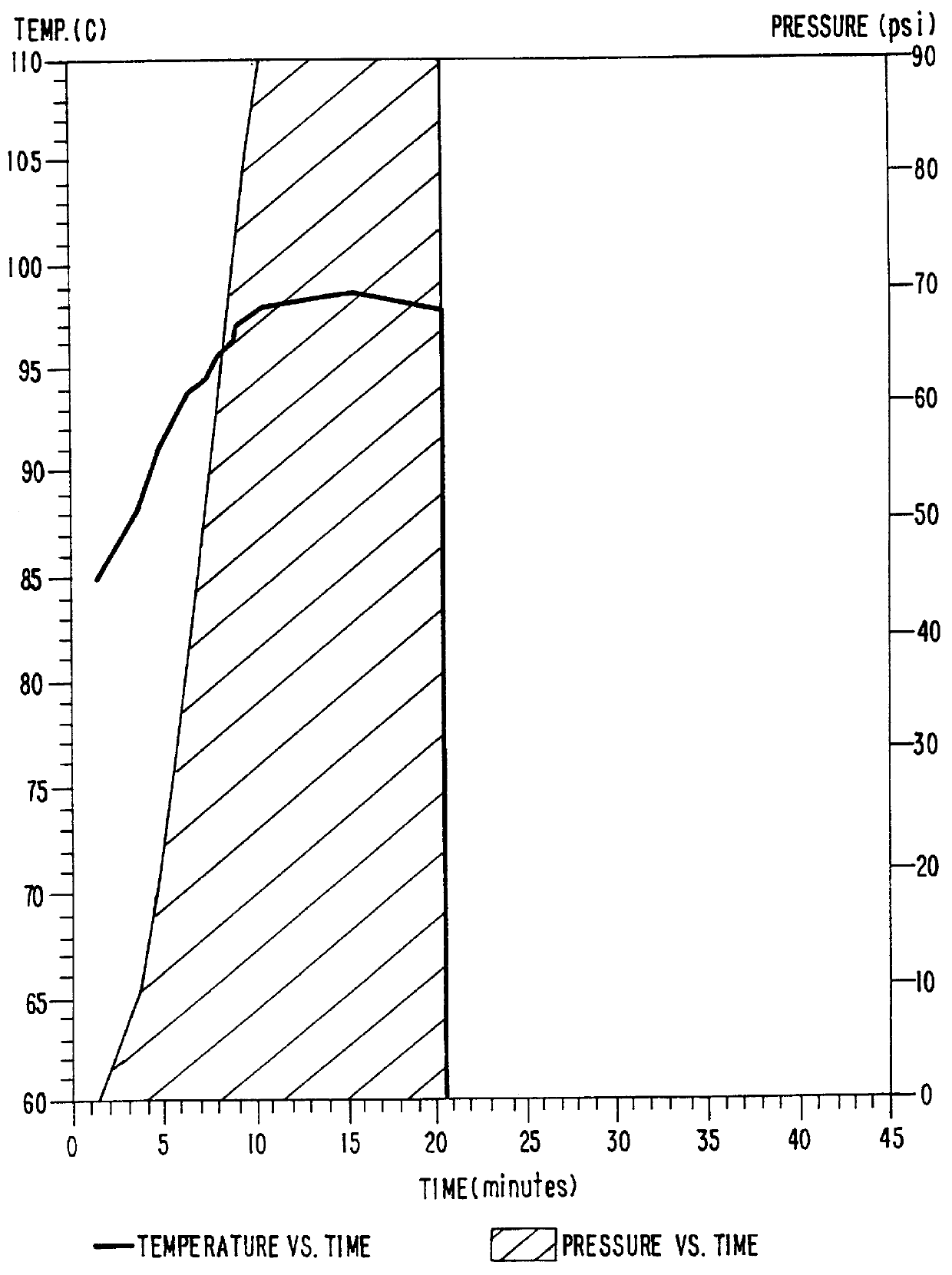

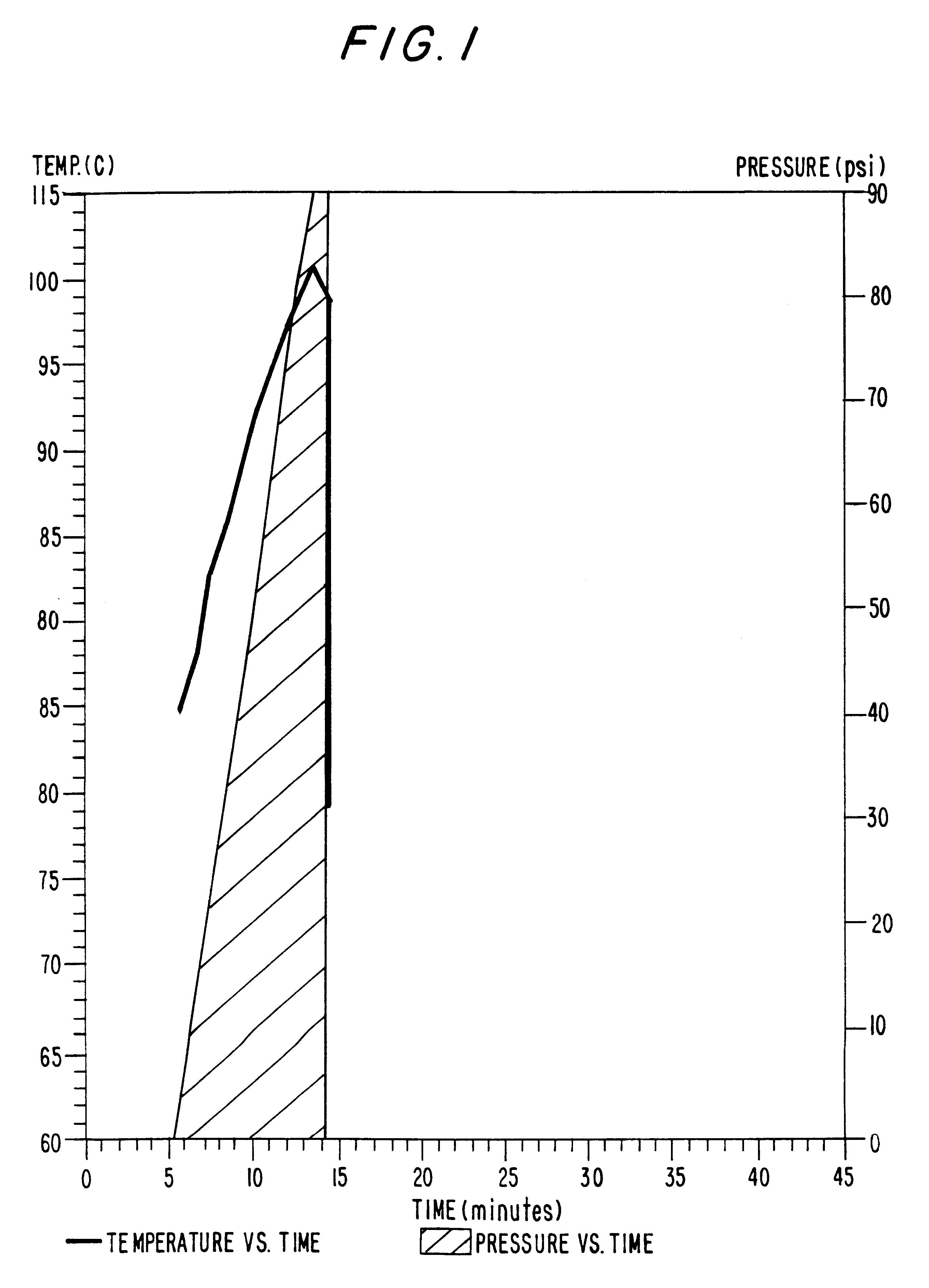

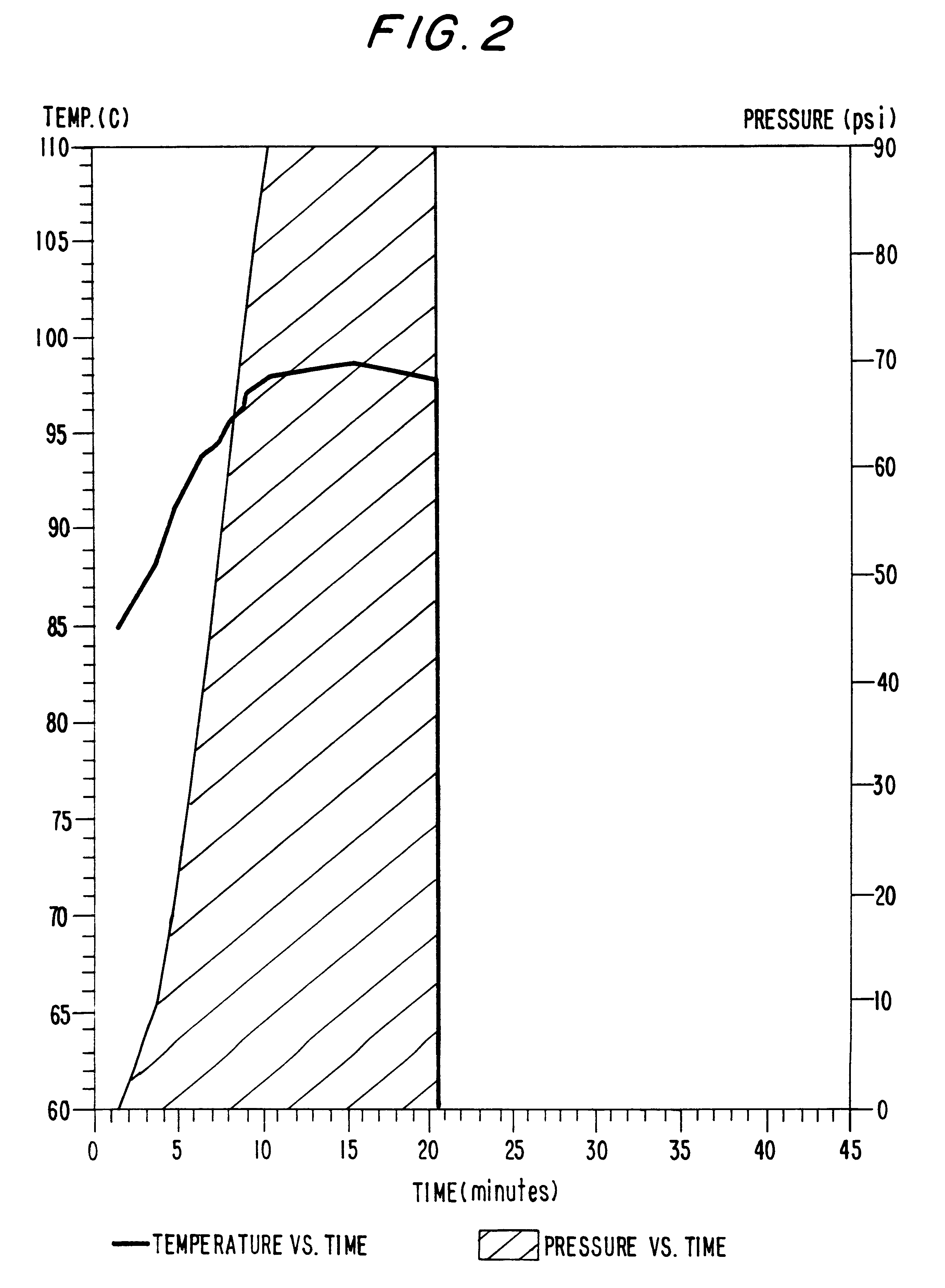

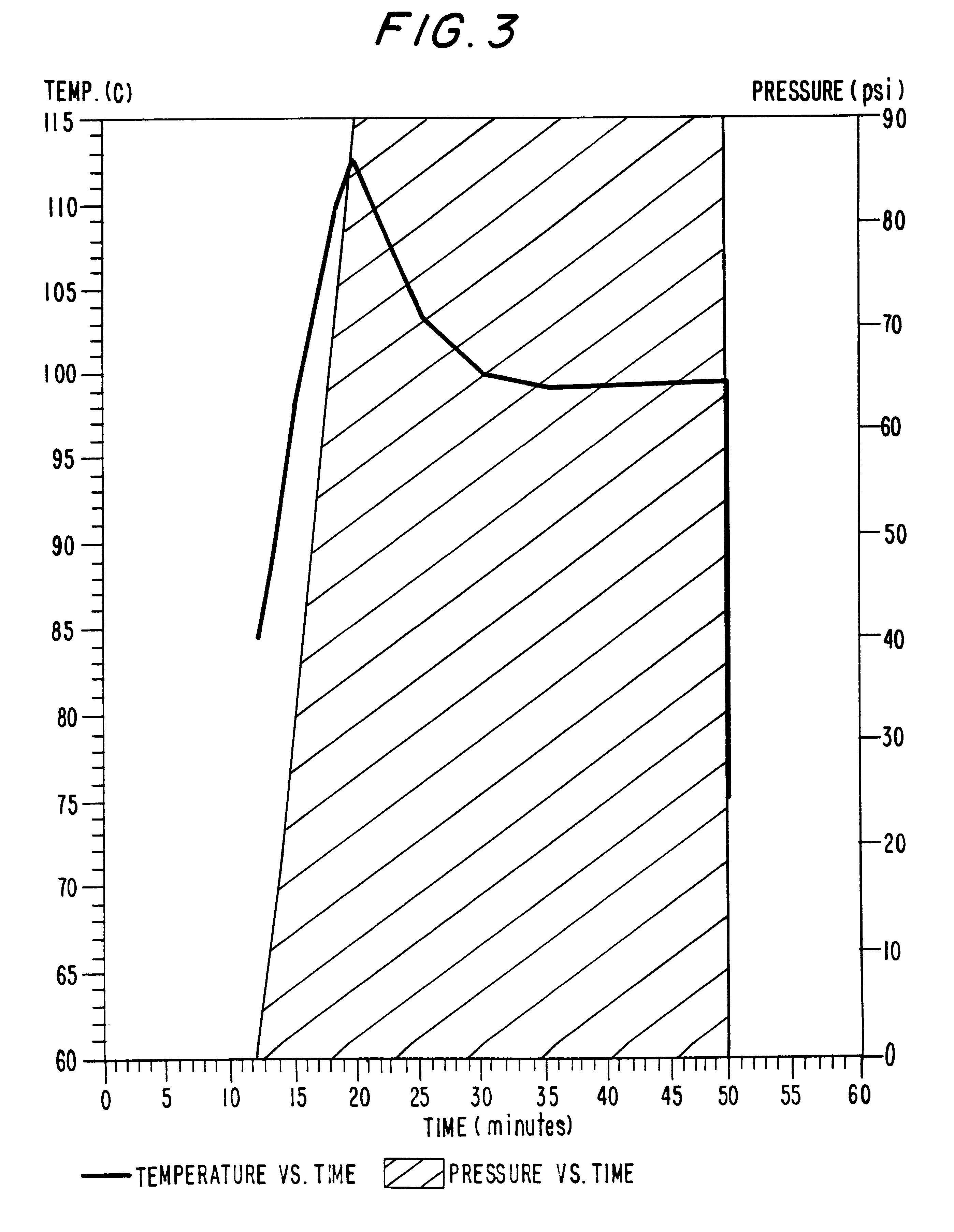

High temperature/ultra-high pressure sterilization of foods

InactiveUS6086936AImprove efficiencyFaster and more energy efficientMilk preservationMeat/fish preservation by heatingUltra high pressureProcess engineering

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions.

Owner:KAL KAN FOODS

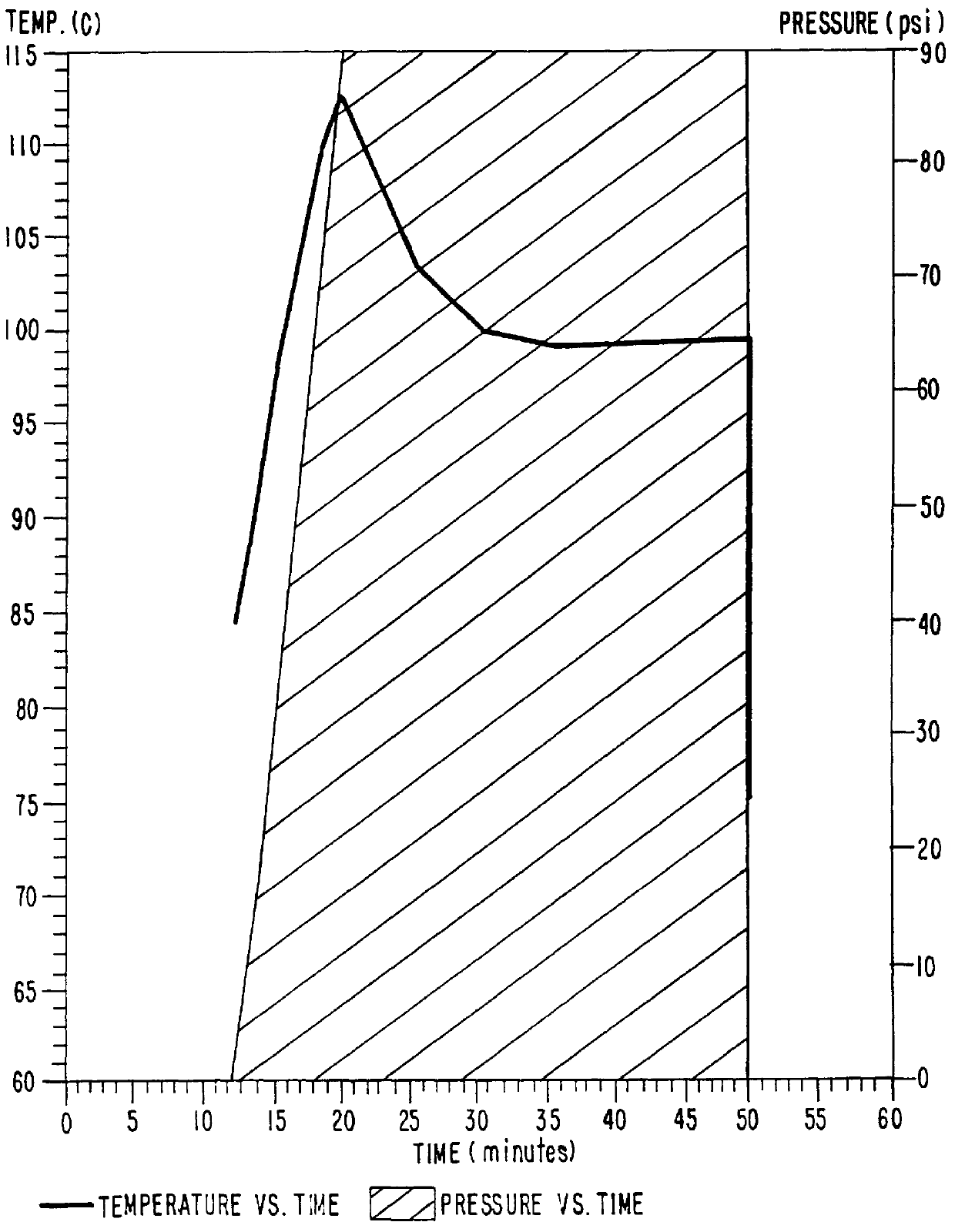

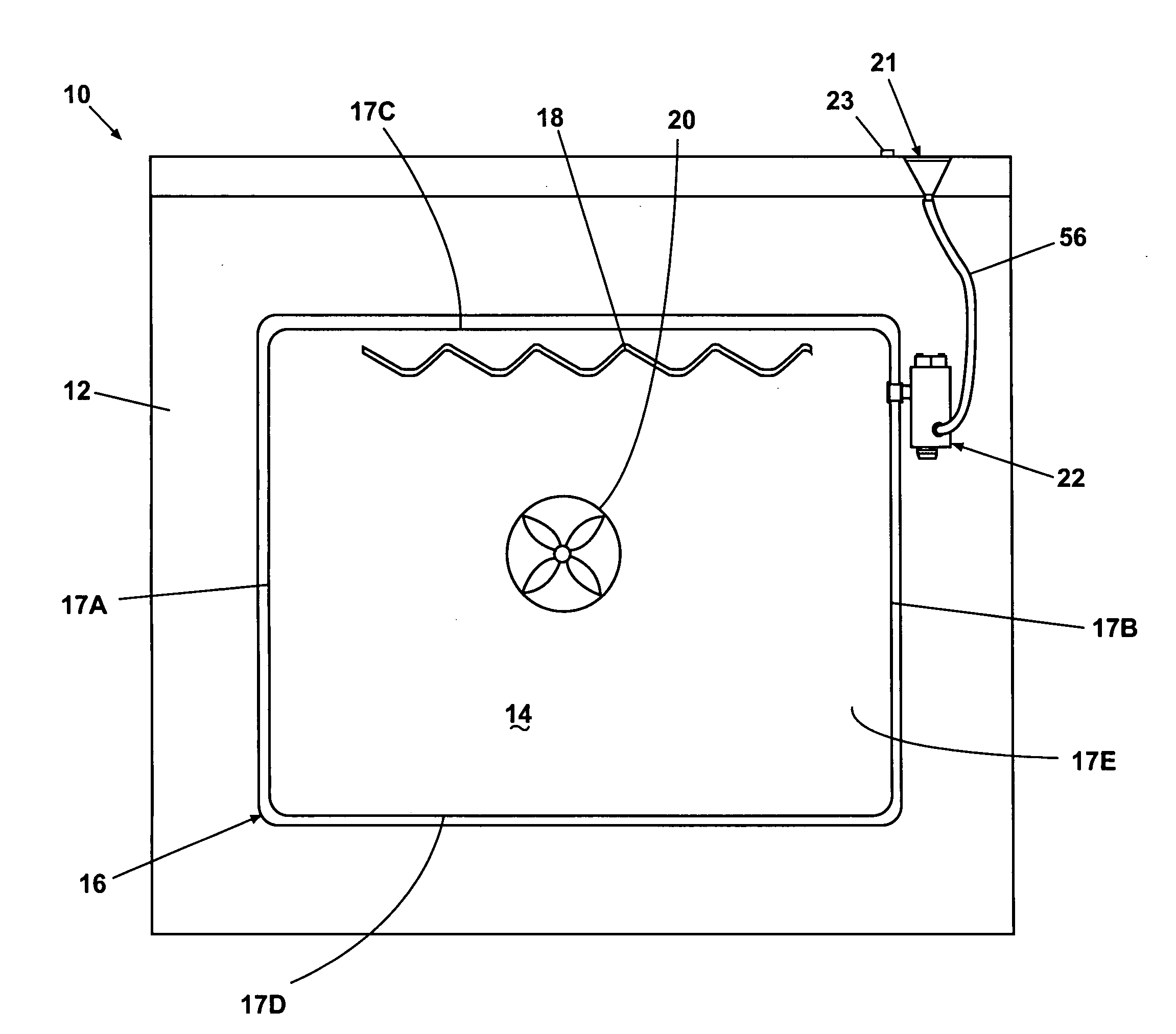

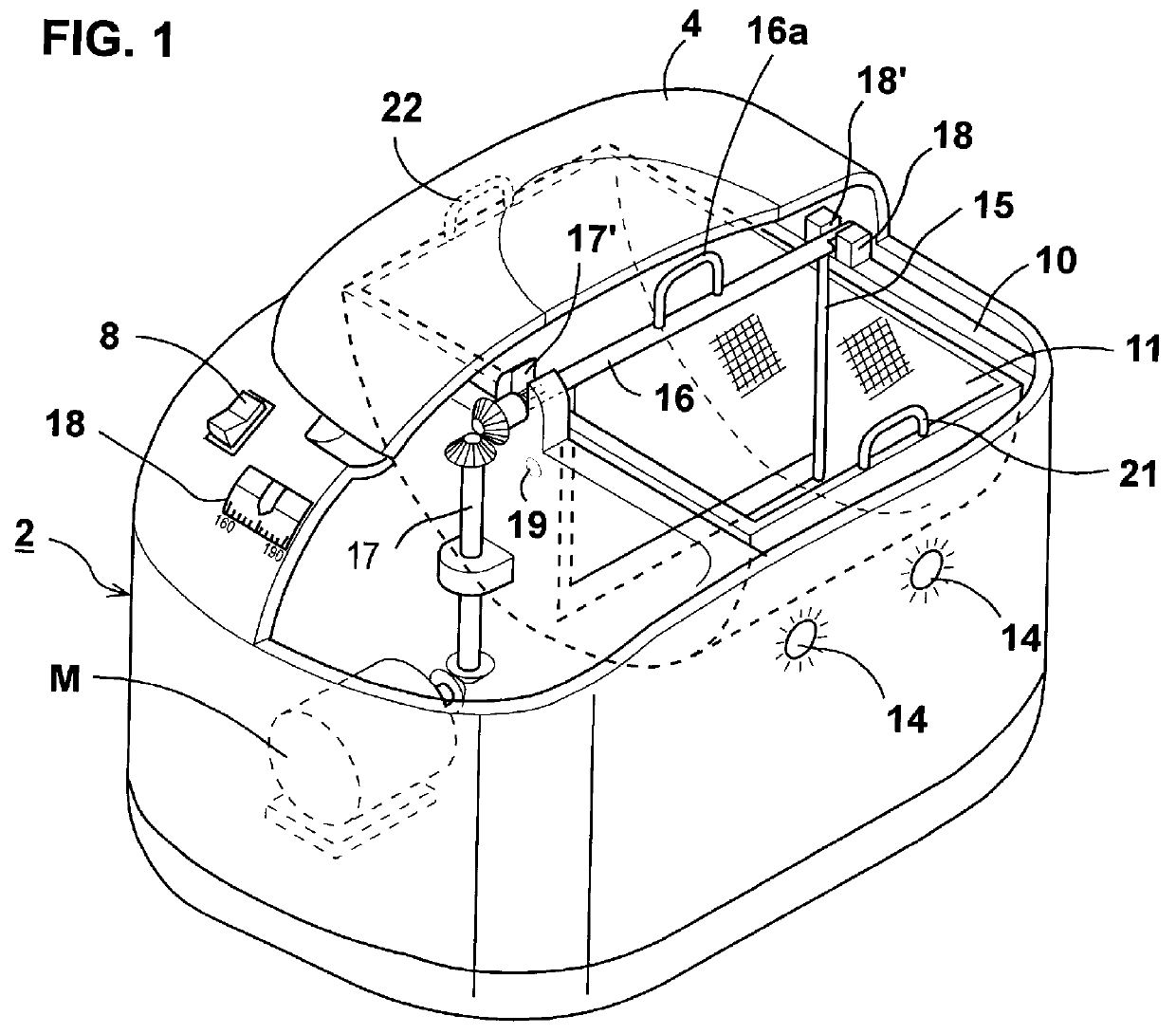

Cooking appliance with steam generator

InactiveUS20080095905A1More energy efficientEnergy efficiencyMilk preservationDough treatmentPulp and paper industryEngineering

Owner:WHIRLPOOL CORP

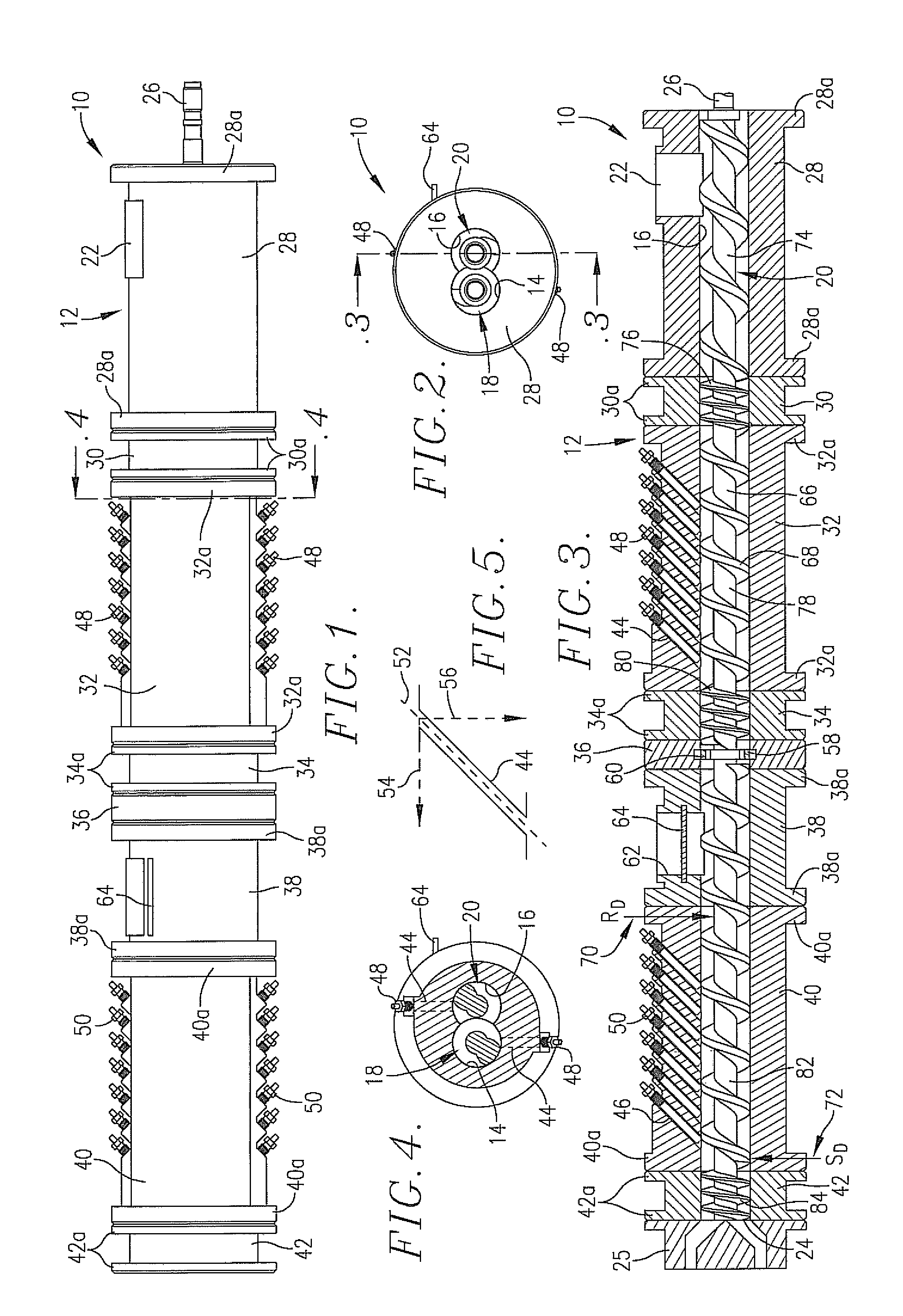

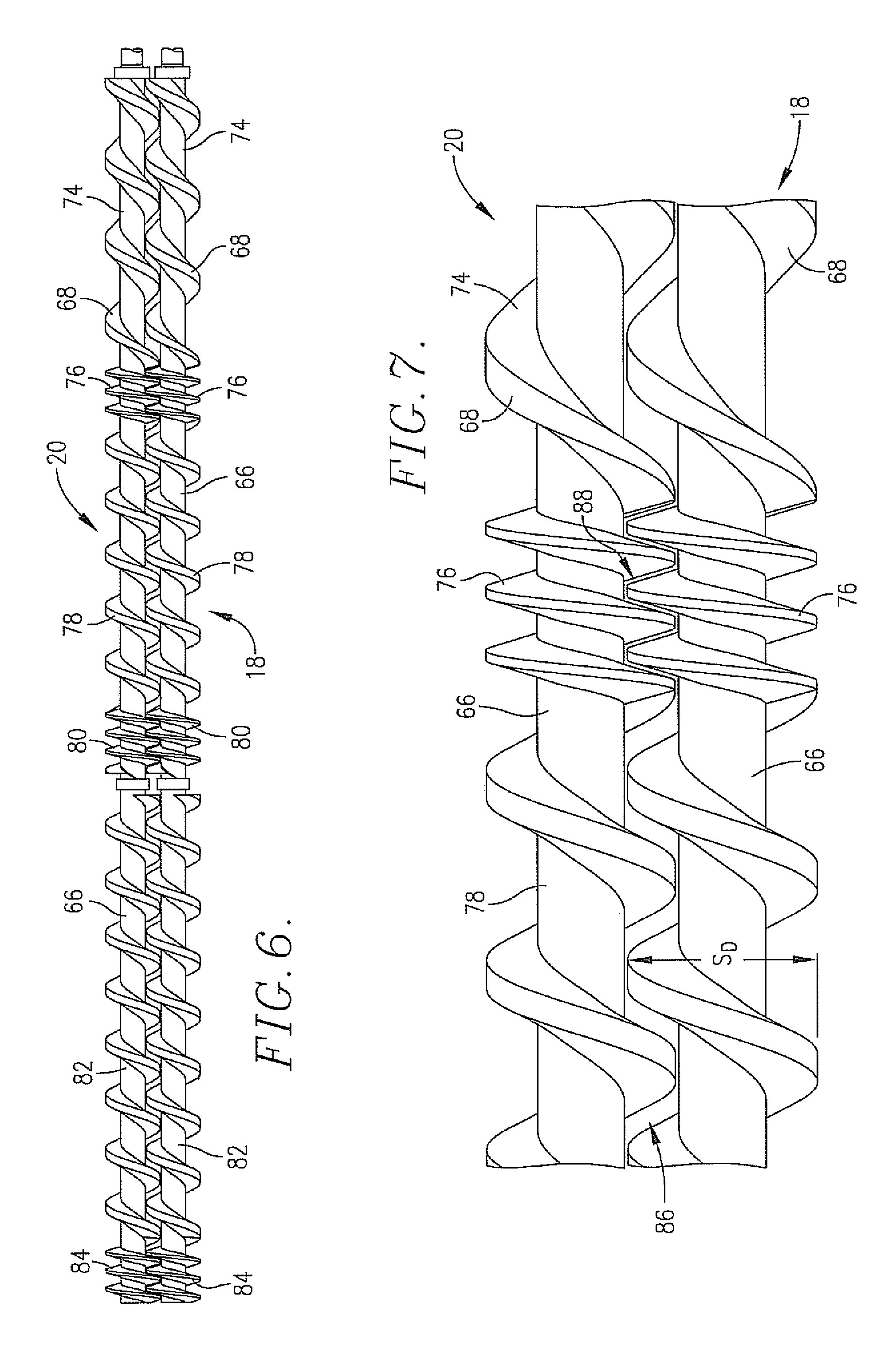

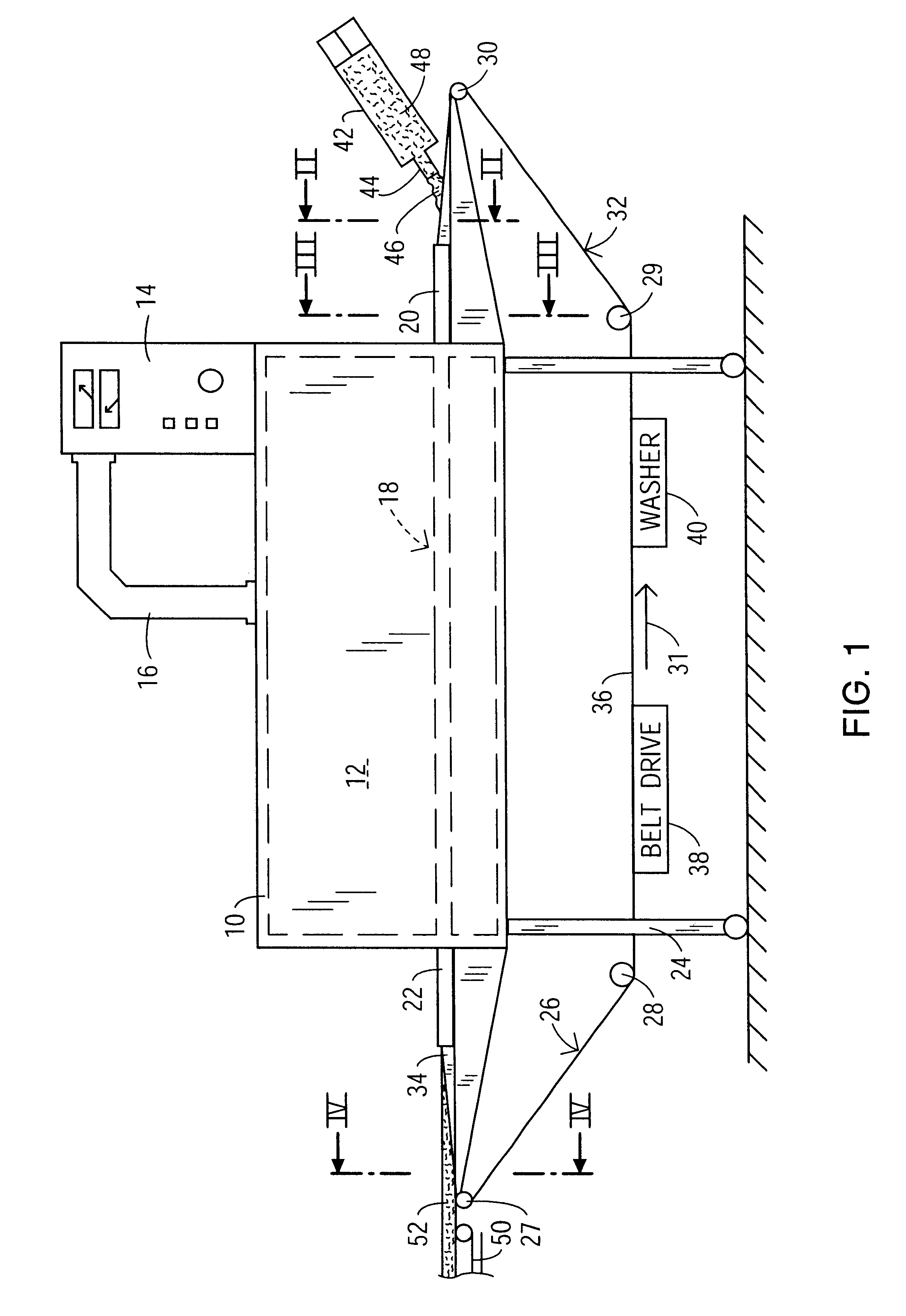

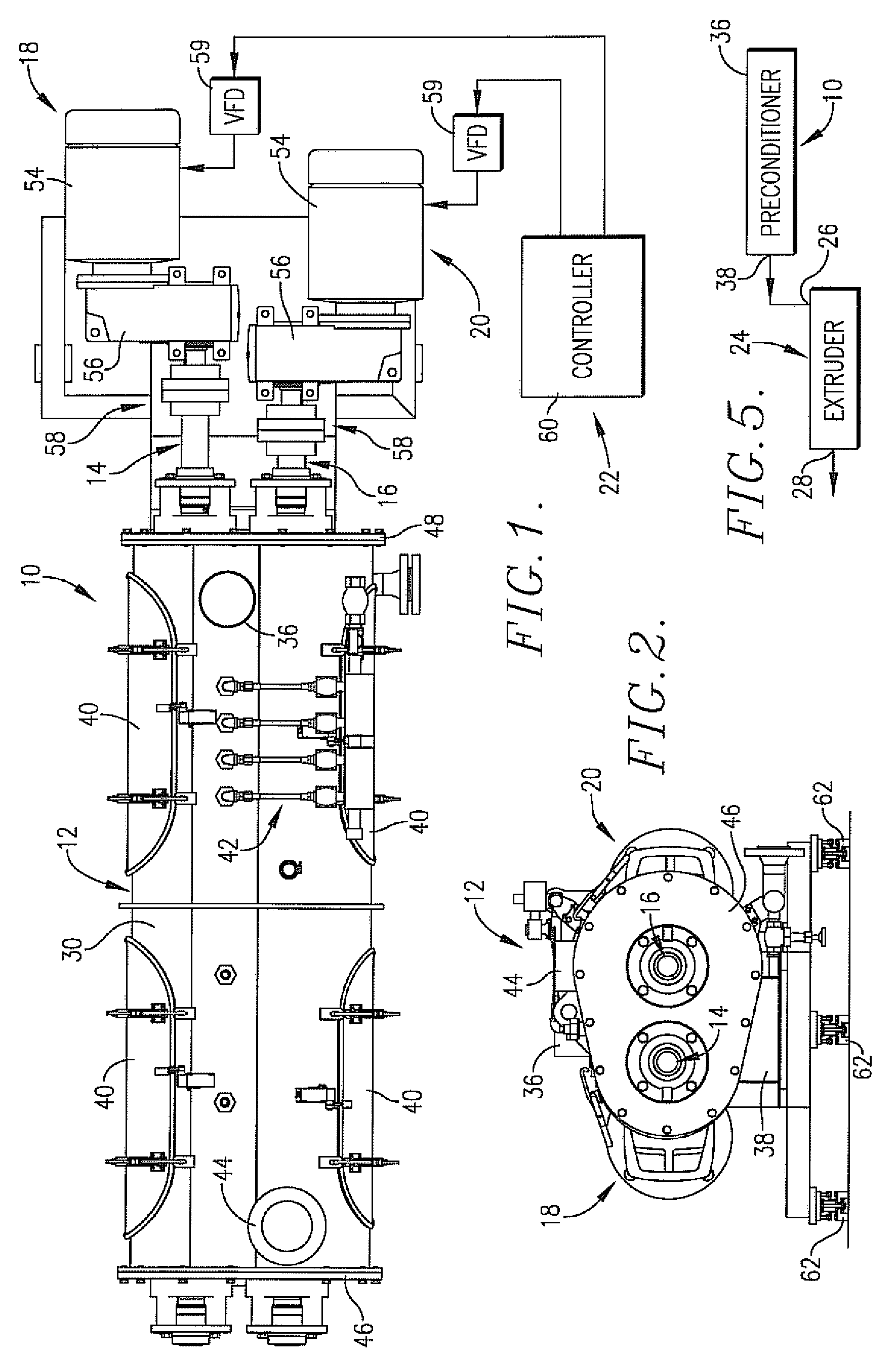

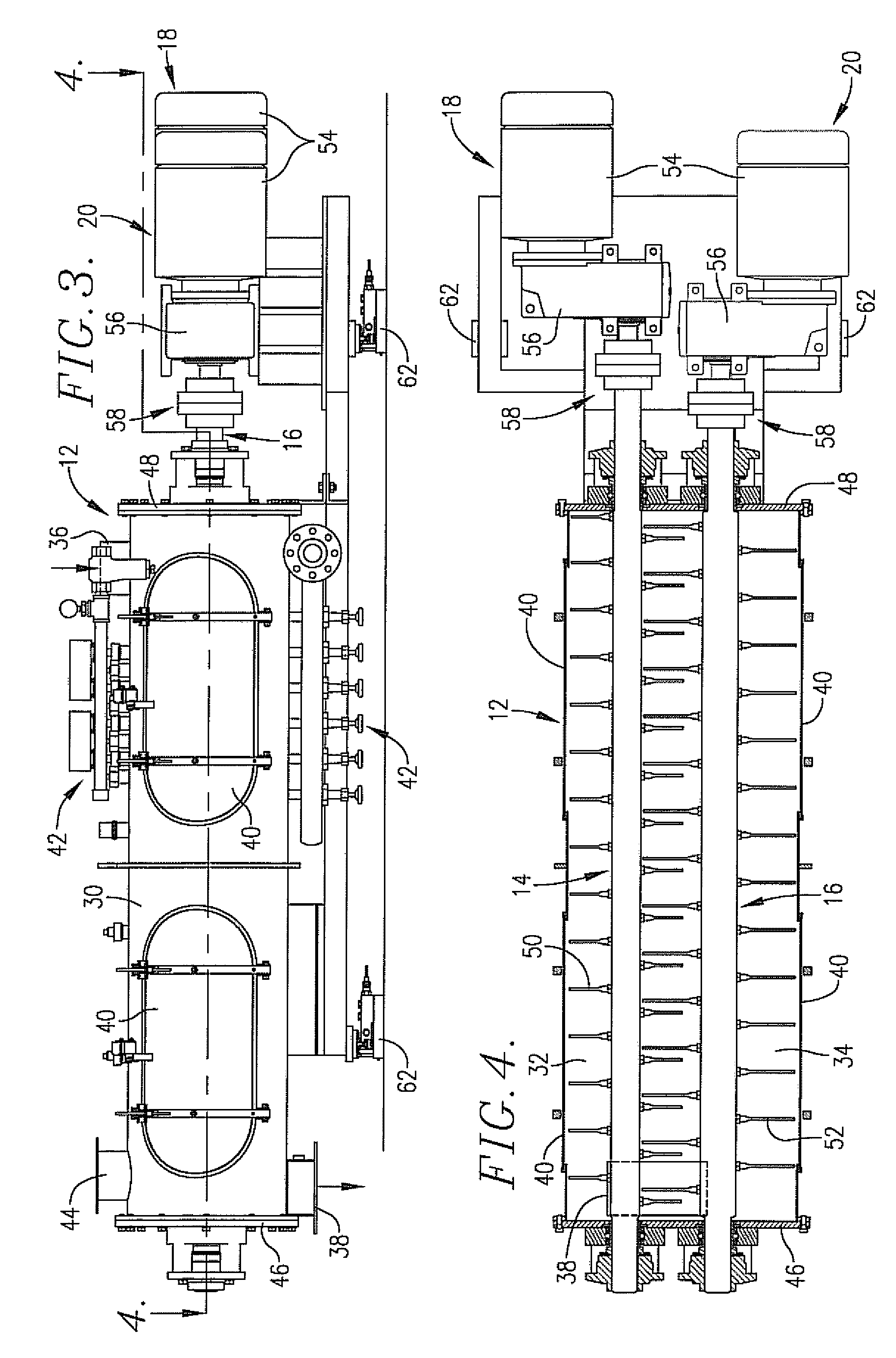

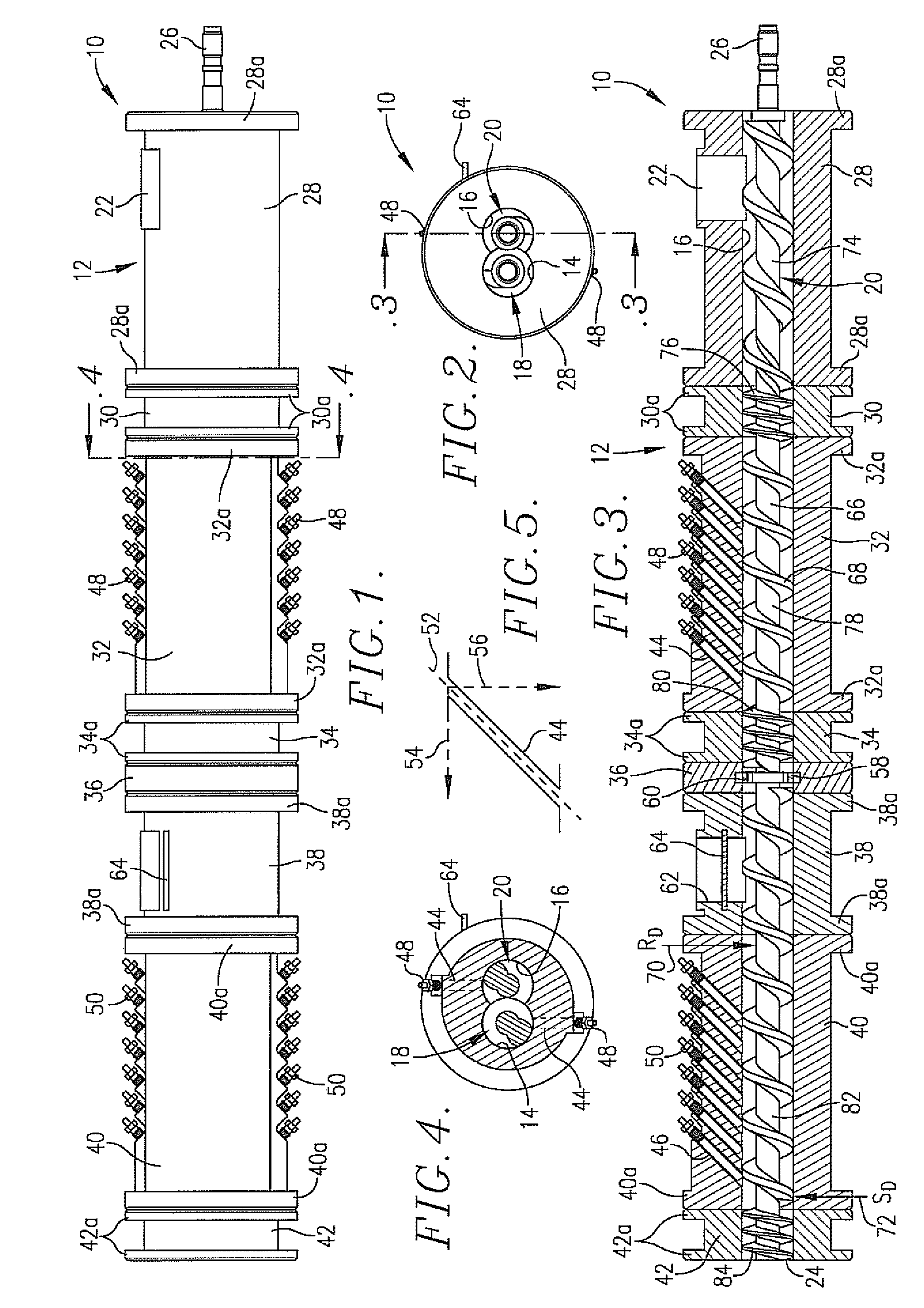

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

ActiveUS7521076B1The implementation process is simpleLow costMilk preservationFeeding-stuffEngineeringPreconditioner

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MFG LLC

Variable frequency automated capacitive radio frequency (RF) dielectric heating system

InactiveUS20030205571A1Near independence of thermal conductivityEasy to adaptMeat/fish preservation by heatingDielectric heating circuitsEngineeringImpedance matching

A food product is heated by maintaining the food product in an AC electrical field generated by an RF signal. As the heating takes place, maximum energy is delivered to the food product using automatic impedance matching to adjust the rate of the process.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV +1

High temperature/ultra high pressure sterilization of foods

InactiveUS6207215B1Fresh lookAchieves commercial sterility of low acid food productsMilk preservationMeat/fish preservation by heatingUltra high pressureEngineering

Method for sterilizing foods using both ultra-high pressures and high temperatures. The instantaneous temperature change that occurs when pressure is applied combines a high-temperature short-time process with ultra-high pressure to deliver a fast and therefore gentle thermal process to a pre-packaged product. The process involves heating a food to a pre-pressurized temperature, subjecting the food to ultra-high pressure, which instantaneously raises the temperature of the food, and then releasing the pressure so that the temperature returns to the original pre-pressurized temperature. The method leverages the adiabatic temperature rise which occurs when the food is hydrostatically pressurized, coupled with the lethality of the pressure, to achieve appropriate sterilization conditions. The disclosure also includes foods which have been sterilized using both ultra-high pressures and high temperatures.

Owner:KAL KAN FOODS

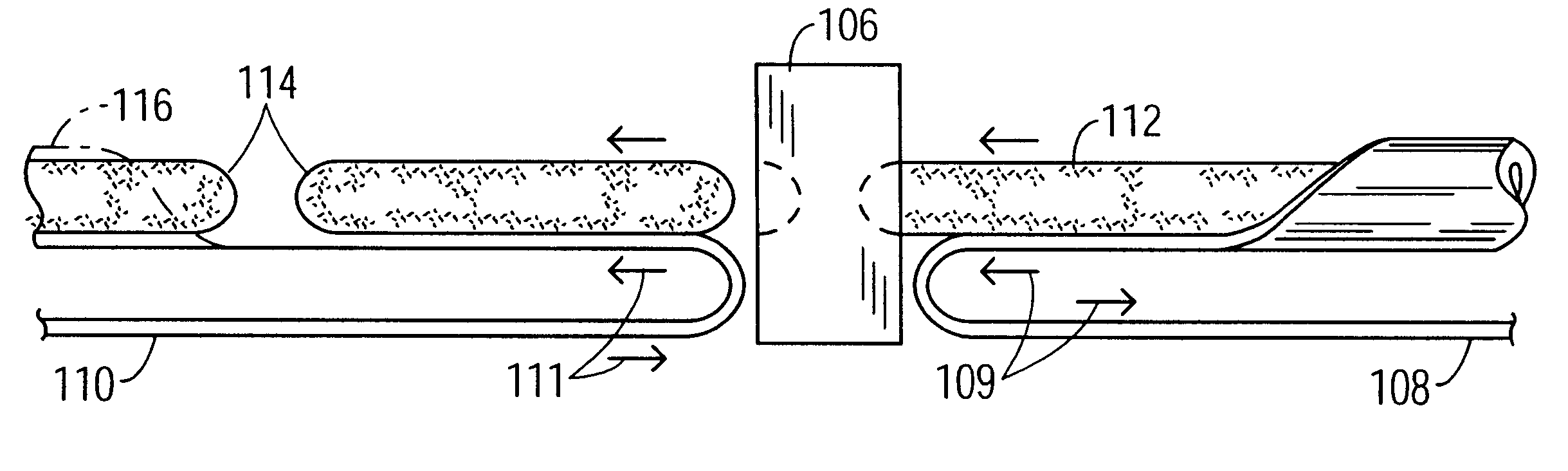

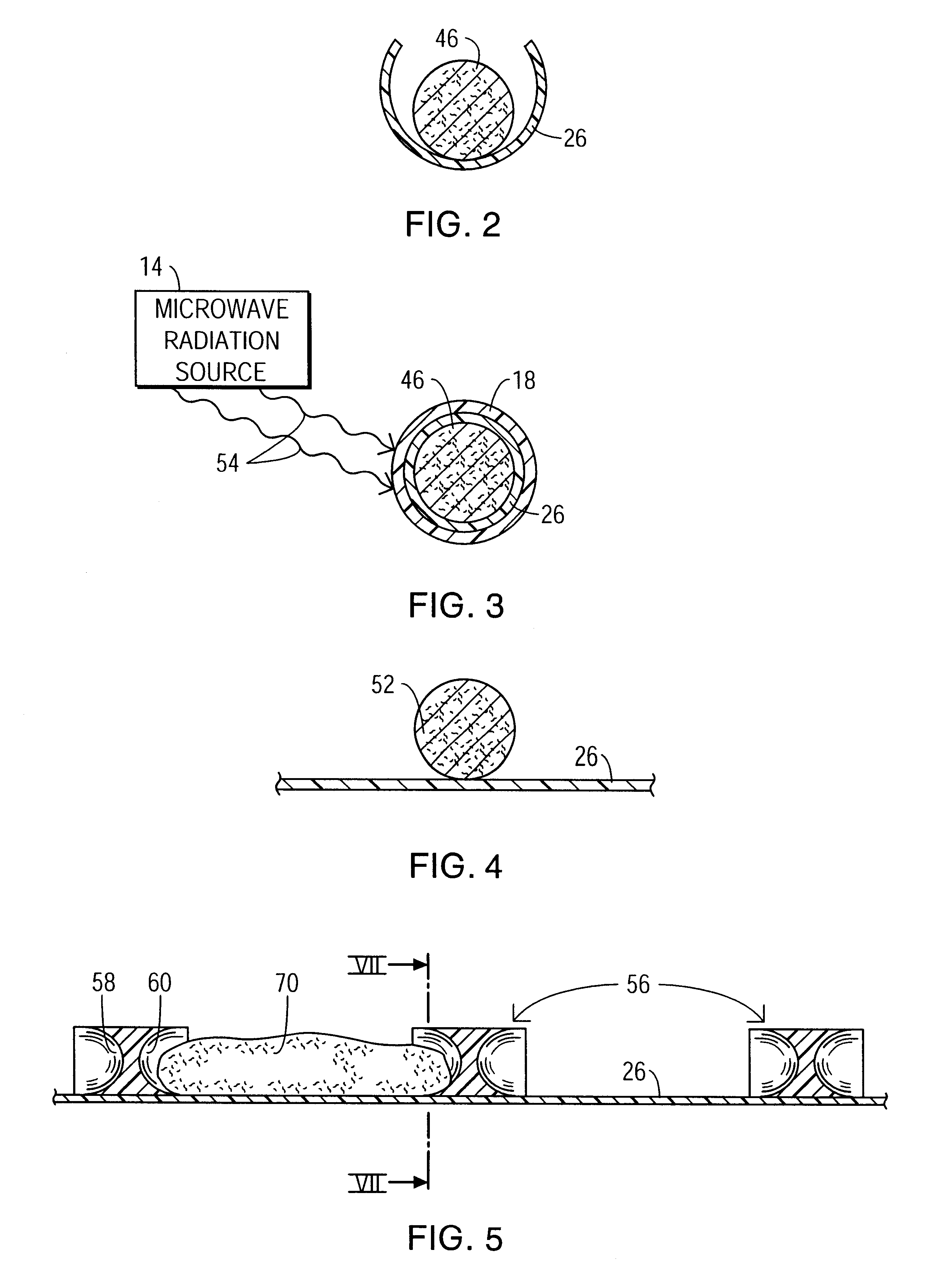

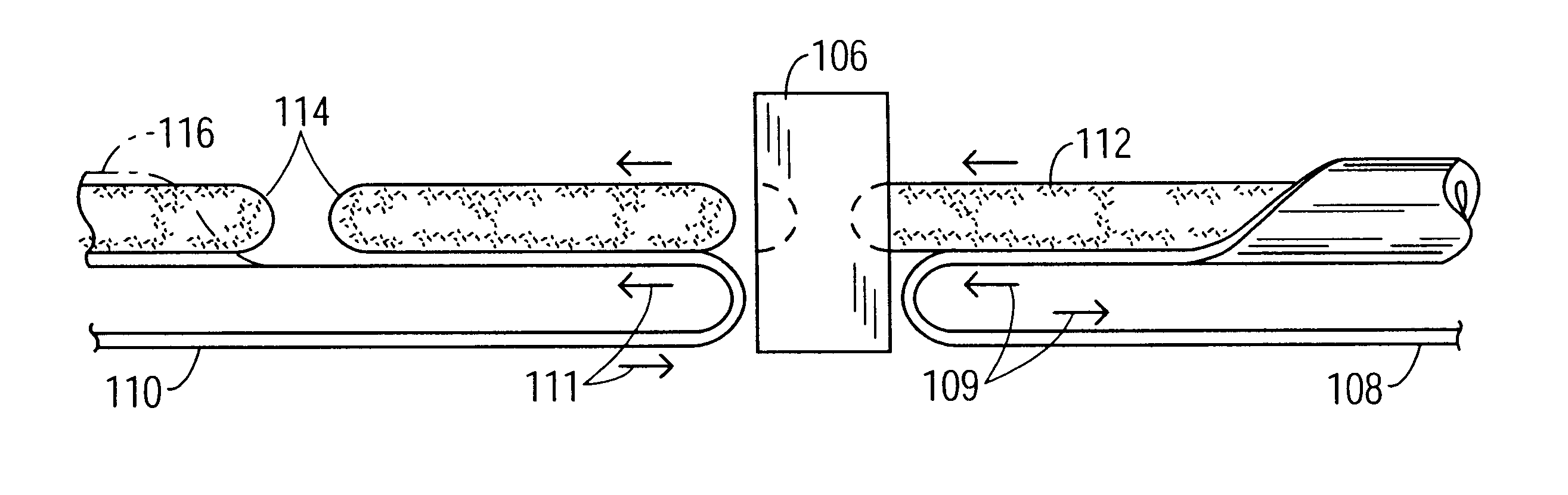

Skinless sausage or frankfurter manufacturing method and apparatus utilizing reusable deformable support

InactiveUS6326039B1Reduce manufacturing costLow costDough treatmentConfectioneryEngineeringConveyor belt

In a method for the manufacture of frankfurters, hot dogs and other skinless sausage products, a meat emulsion is extruded onto a flexible conveyor belt which is then conveyed through a tube whose internal diameter is equal to the desired diameter of the sausage product plus twice the thickness of the conveyor belt. In a camming type process, the conveyor belt is caused, upon its entry into the tube, to temporarily form a cylinder containing the meat emulsion. The temporary belt cylinder together with the surrounded meat emulsion extrudate is then conveyed through an ultrasonic waveform generator to cook an outer layer of the meat emulsion. The outer layer may be part of the meat emulsion or a thermoset gelling material deposited on the extruded meat emulsion. At the exit end of the tube, the conveyor belt naturally opens under internal stresses from its cylindrical shape to a flattened belt. The at least partially cooked sausage is then removed from the belt for further processing or packaging. The conveyor belt acts as a temporary skin to hold the meat emulsion during its ultrasonic processing.

Owner:MISONIX INC

Conveyorized oven with moisture laden air impingement and method

A conveyor oven having a heating chamber and an oven chamber. A conveyor is disposed in the oven chamber to convey food products between an entry port and an exit port. An air impingement assembly is disposed to provide jets of impingement air toward the food product. A fan blower, a heater and a moisture delivery device are arranged to provide heat and moisture to an airflow to the air impingement assembly so that the jets of air are heated and laden with moisture and provide as a blanket-like mixture of air and moisture at the surface of the food product.

Owner:ENODIS

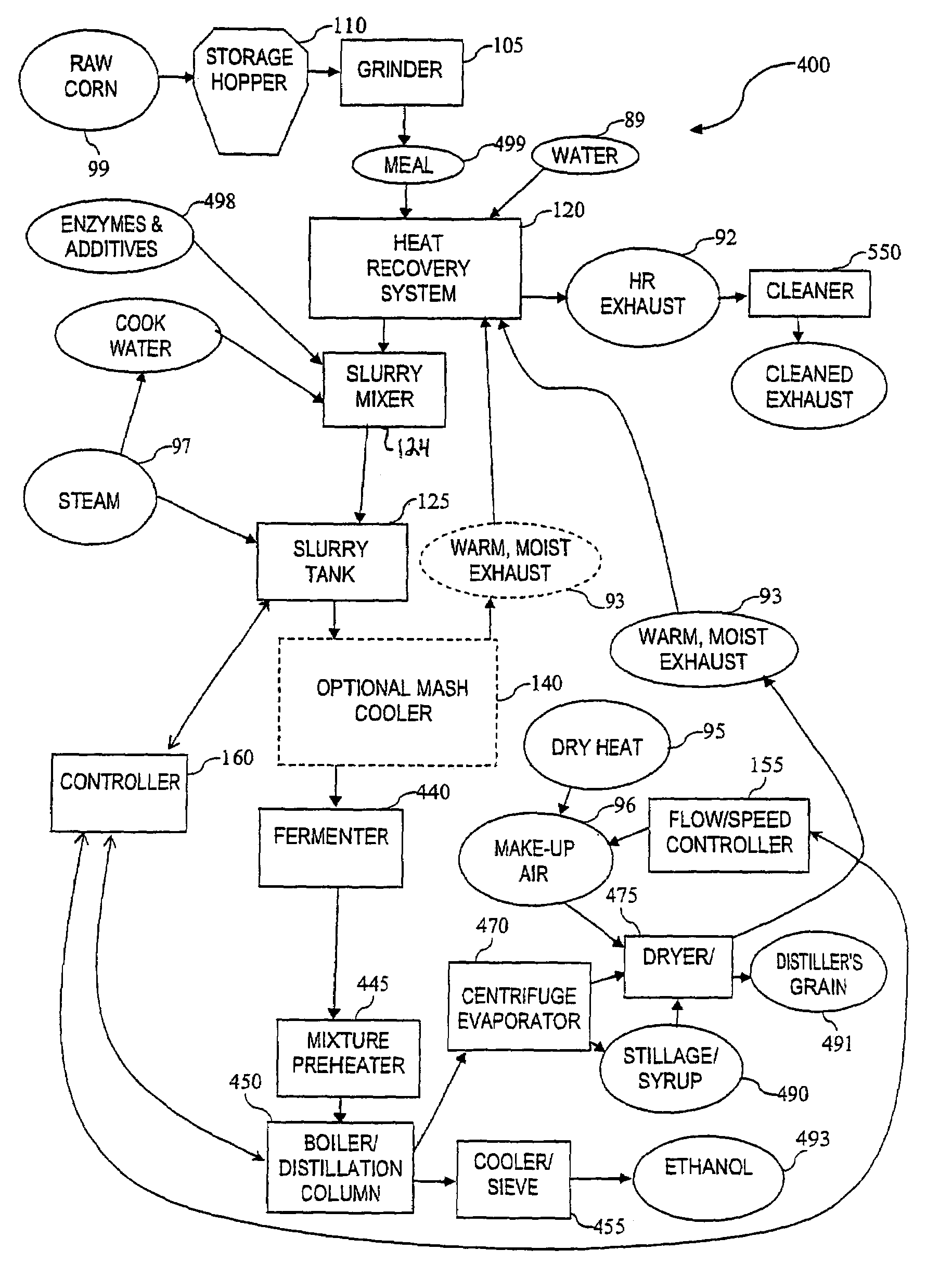

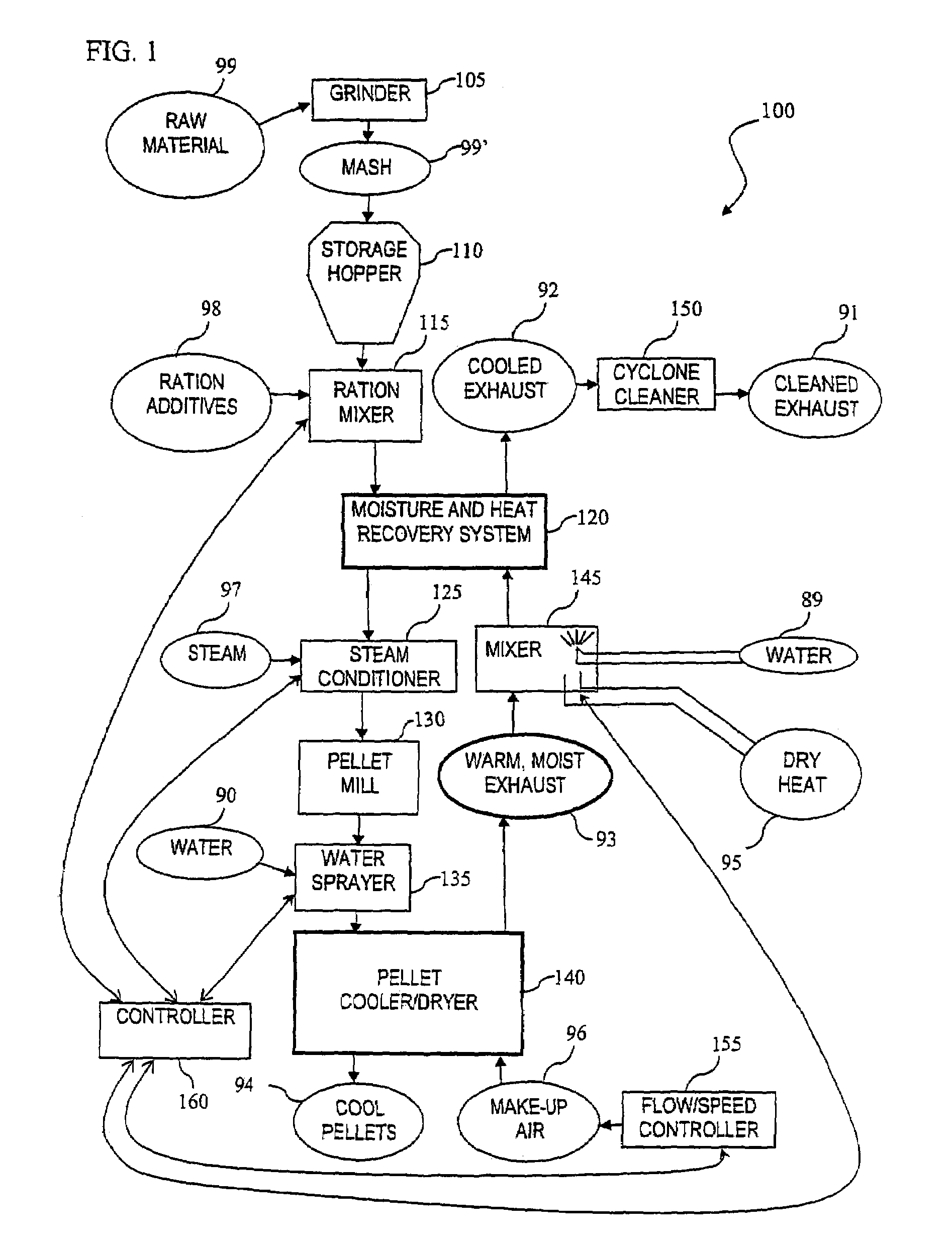

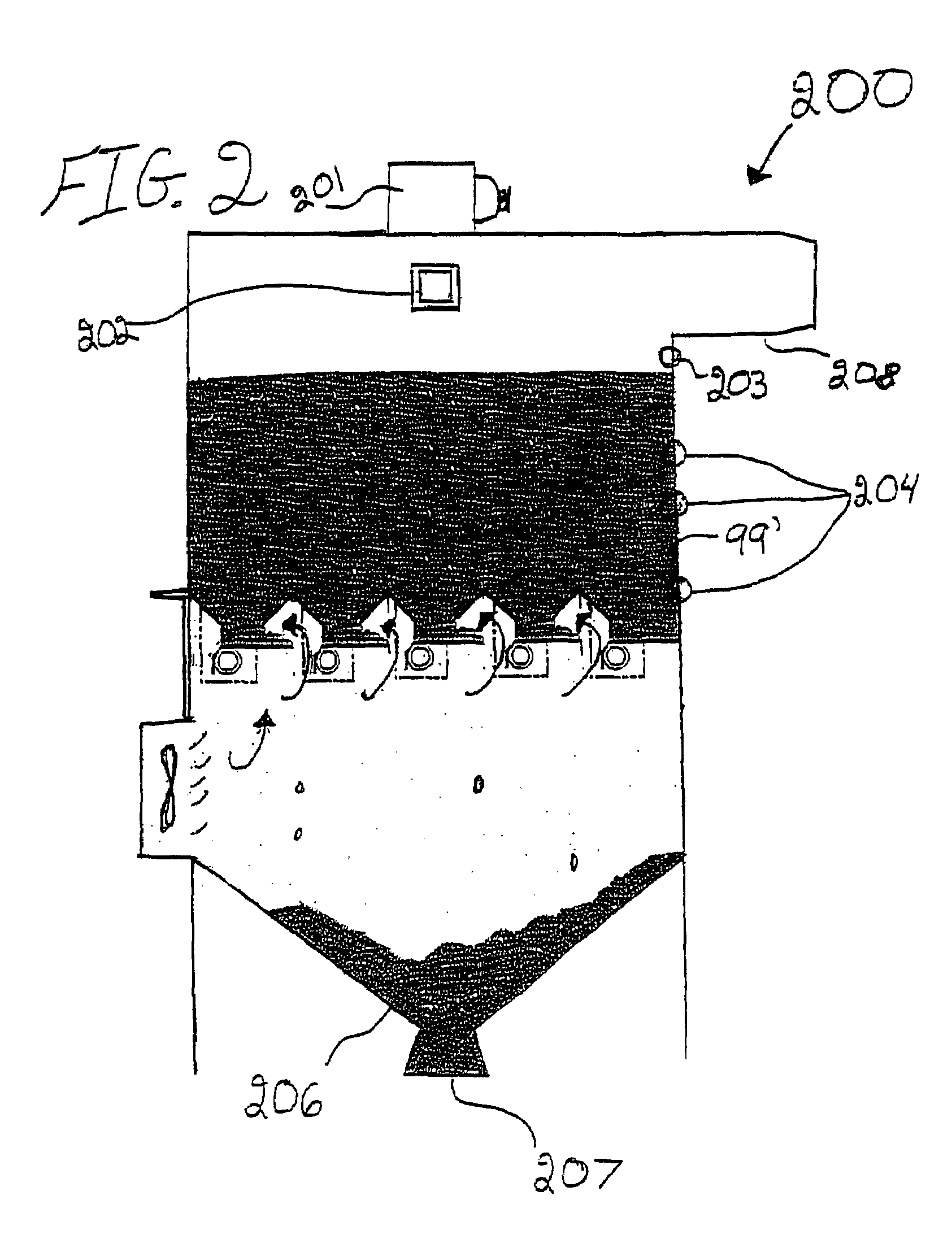

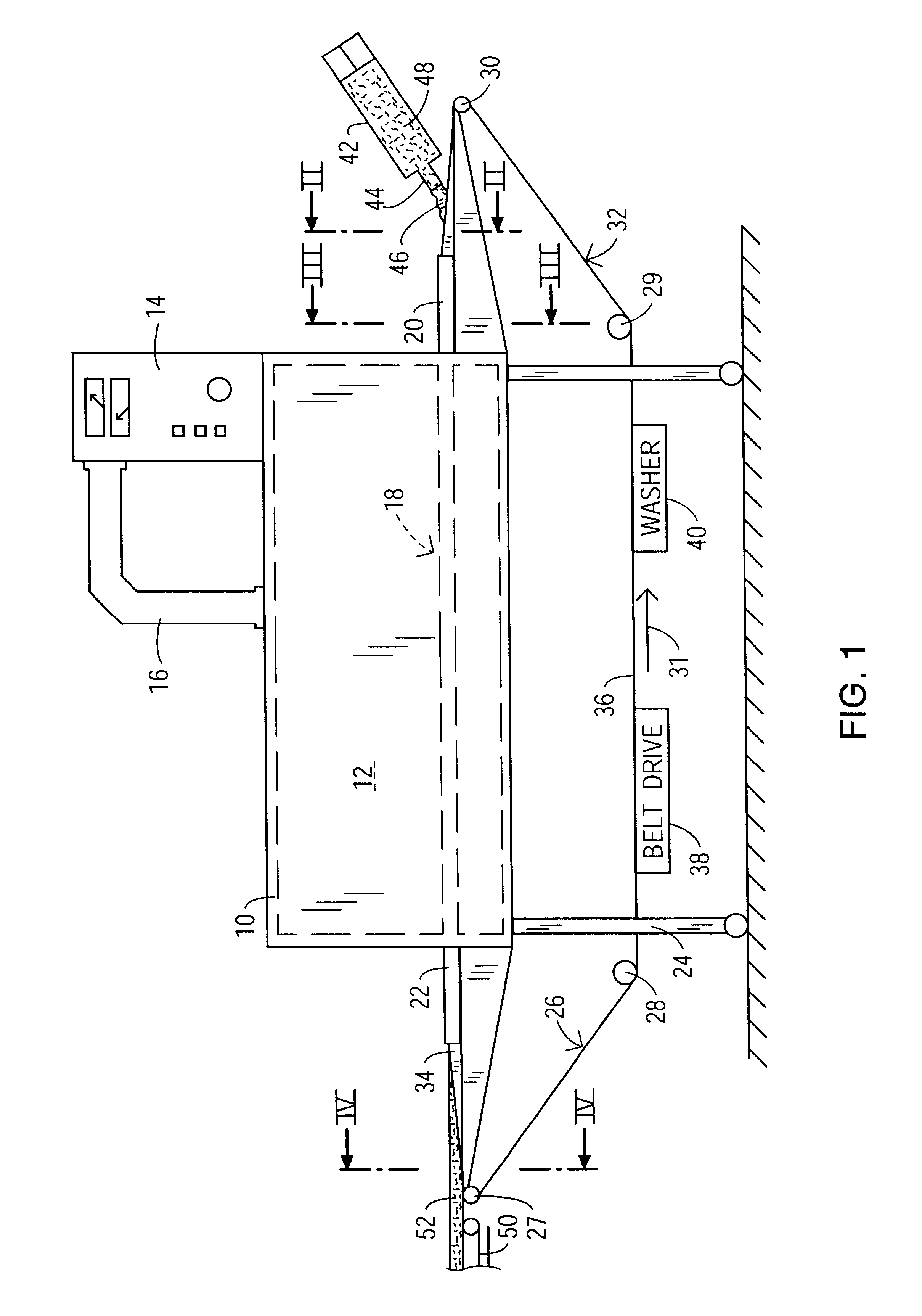

Heat-moisture control in agricultural-product production using moisture from water vapor extraction

InactiveUS7404262B2Reduce the amount requiredHigh production costDrying using combination processesMeat/fish preservation by heatingWater vaporSprayer

A method and apparatus for agricultural product production with heat and moisture control with optional heat and moisture recovery. Some embodiments transfer heat and moisture from a warm, moist exhaust air stream to incoming agricultural material, steam condition the material, pelletize the material into warm pellets, cool the warm pellets with make-up air to produce the warm, moist exhaust air used to transfer heat to the incoming material and to produce cooled pellets, wherein the cooled pellets are at a temperature lower than the warm moist air. In some embodiments, the system includes counter-flow devices to transfer heat and moisture. In some embodiments, a controller is used to adjust system devices and overall system flow. In some embodiments a water sprayer, to moisten agricultural product when the product is over dry, and an air flow controller, to slow air flow through the pellet dryer / cooler when ambient temperatures are dryer / cooler, are provided.

Owner:PESCO +1

Method for preventing off-flavor development and preserving seasoning flavor in irradiated meat and meat products

InactiveUS6099879ASlow onsetReduce developmentMilk preparationDough treatmentAdditive ingredientFood flavor

A method comprising the step of treating meat and meat products, including fish, poultry, fish products, and poultry products, with a stabilizing amount of rosemary extract or rosemary extract in combination singly or collectively with tocopherols, ascorbic acid, citric acid, or sodium tripolyphosphate, prior to exposure of the meat or meat products to ionizing radiation, enhances the flavor and shelf life thereof. In addition, the active antioxidant ingredients of rosemary extract may be used individually or collectively as a replacement for rosemary extract, these being carnosic acid, carnosol, and rosmarinic acid, which have been found equivalent to or superior to rosemary extract itself for purposes of the present invention when used in the concentrations set forth herein.

Owner:KALAMAZOO HLDG INC

Ultra-high temperature pasteurized milk concentrate, package, dispenser and method of producing same

An ultra-high temperature pasteurized liquid (UHT) milk concentrate provides a reconstituted milk beverage that tastes like fresh milk. A direct steam injection process is used to form the UHT milk concentrate having at least about 30% by weight, preferably 35% to 45% by weight, nonfat milk solids having a shelf stability of at least 30 days. The UHT milk concentrate is homogenized and aseptically packaged for subsequent mixing in conventional beverage dispensers with water at volume ratios of about 3:1 to 4:1 of water to concentrate to make a beverage that tastes like fresh milk.

Owner:MOO TECH

Compositions for improving flavor and safety of marinated meat products

A composition for improving the flavor and juiciness of marinated meats and inhibiting growth of pathogenic and spoilage microorganisms and a process for making the composition are described. Lemon juice and vinegar are neutralized, concentrated and blended with non-neutralized lemon juice and non-neutralized vinegar in appropriate proportions to achieve the desired water binding and antimicrobial effects.

Owner:KERRY GRP SERVICES INT

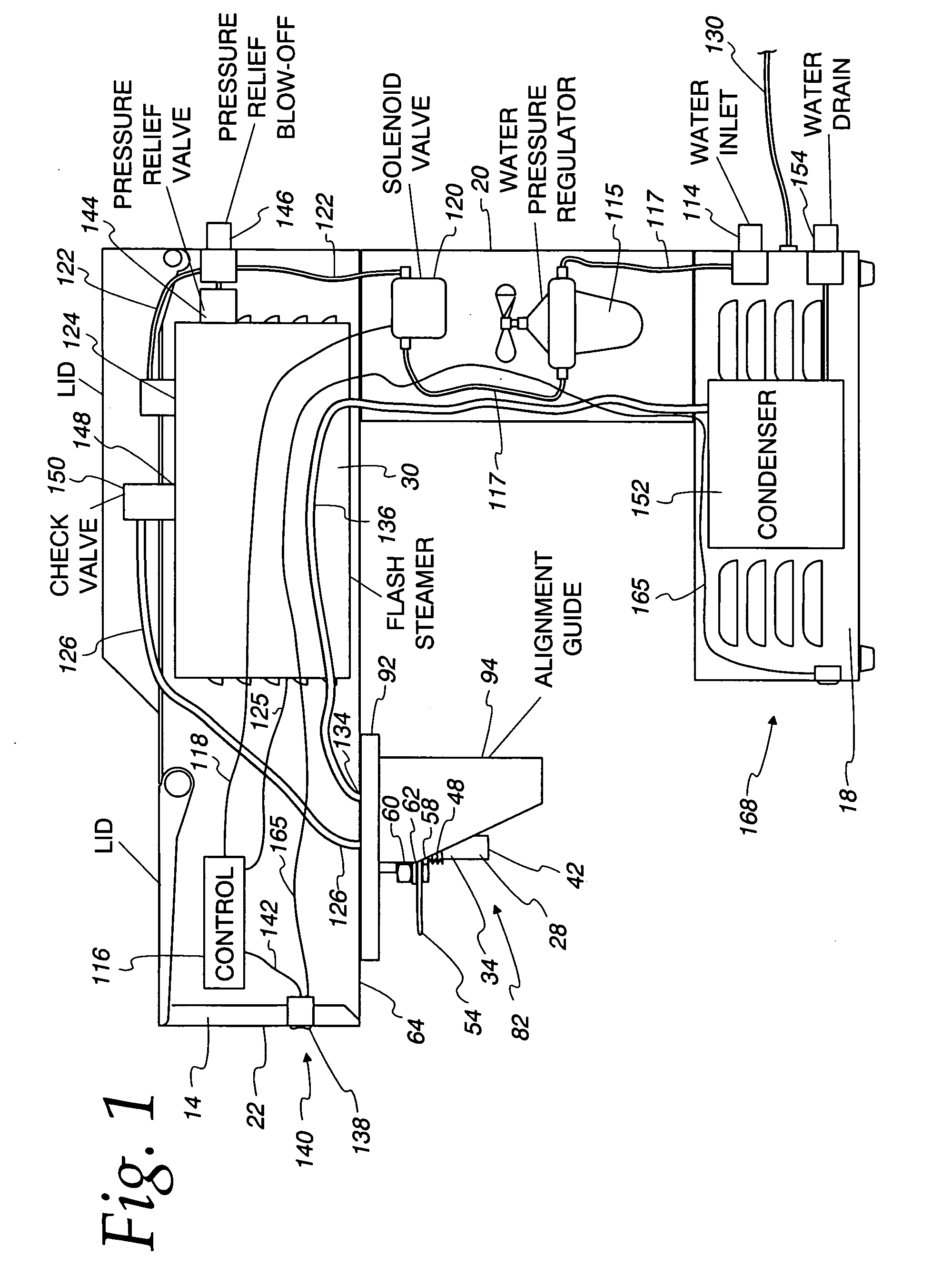

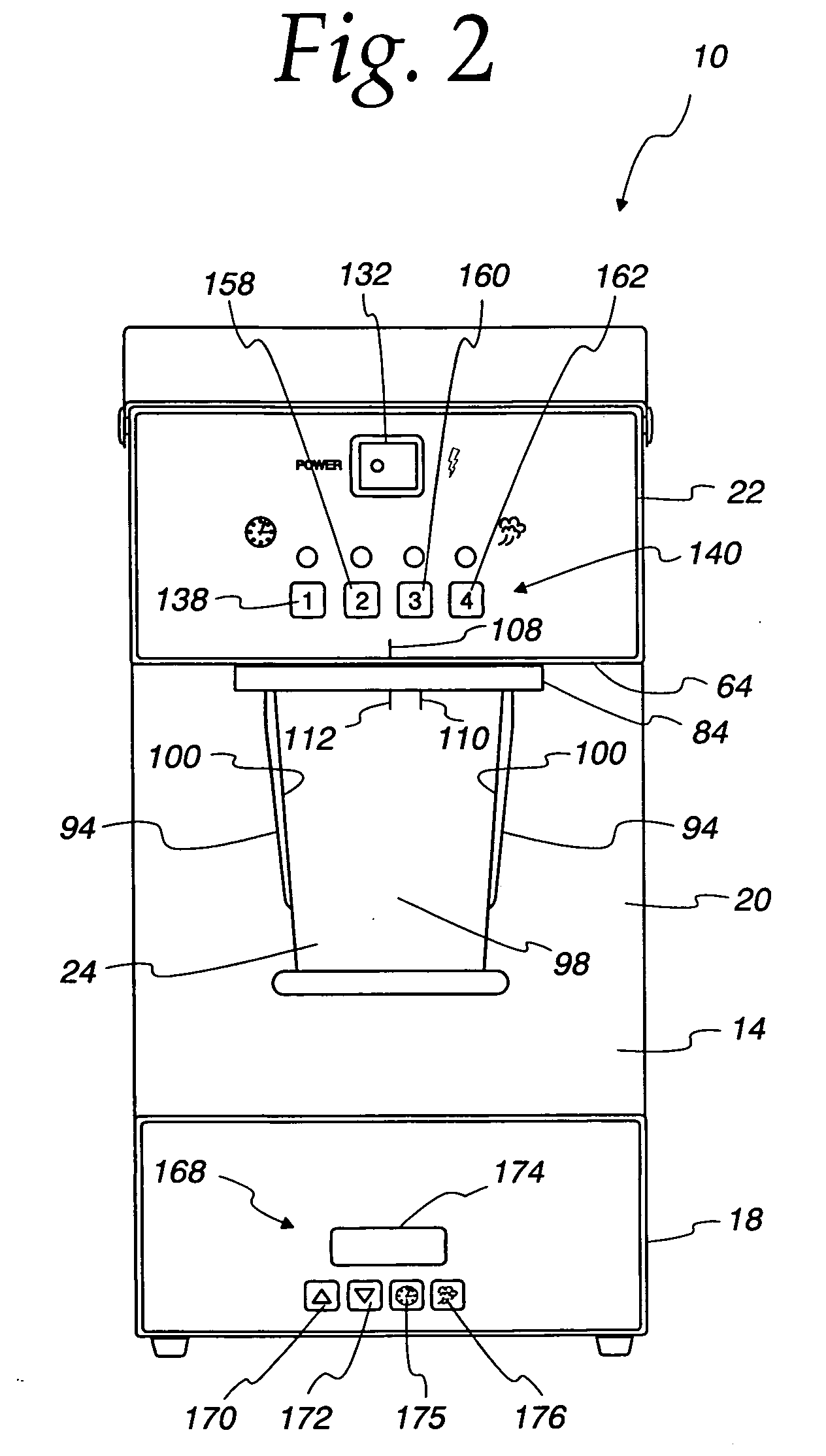

Method and apparatus for generating and applying steam for food cooking and finishing

InactiveUS6171630B1Heating fastAir-treating devicesMeat/fish preservation by heatingTransport mediumEngineering

Food cooking apparatus for melting cheese disposed on a food product. The cheese topped food product, for example a bun half, burger patty and cheese stack, is transferred in and out of a cooking chamber by a trolley. Entry of the trolley to the cooking chamber starts a cooking cycle. A steam generator provides pressurized steam from a location just above the cheese by a distance of up to about 2.0 inches for a short time until the cheese is melted. The trolley carries a transport medium upon which the food product is placed. A plurality of holes is disposed in the medium to remove from it any water formed by condensation. The steam generator includes a heated platen and a lid that form a steam generating chamber. Water is injected into the chamber onto the heated platen in a small enough quantity that substantially all of the water is converted to steam substantially instantaneously. The steam quickly pressurizes the chamber and is forced through passageways disposed in bosses that extend from the platen into the chamber. The steam exits the passageways on the outside surface of the platen.

Owner:LINCOLN FOODSERVICE PRODS

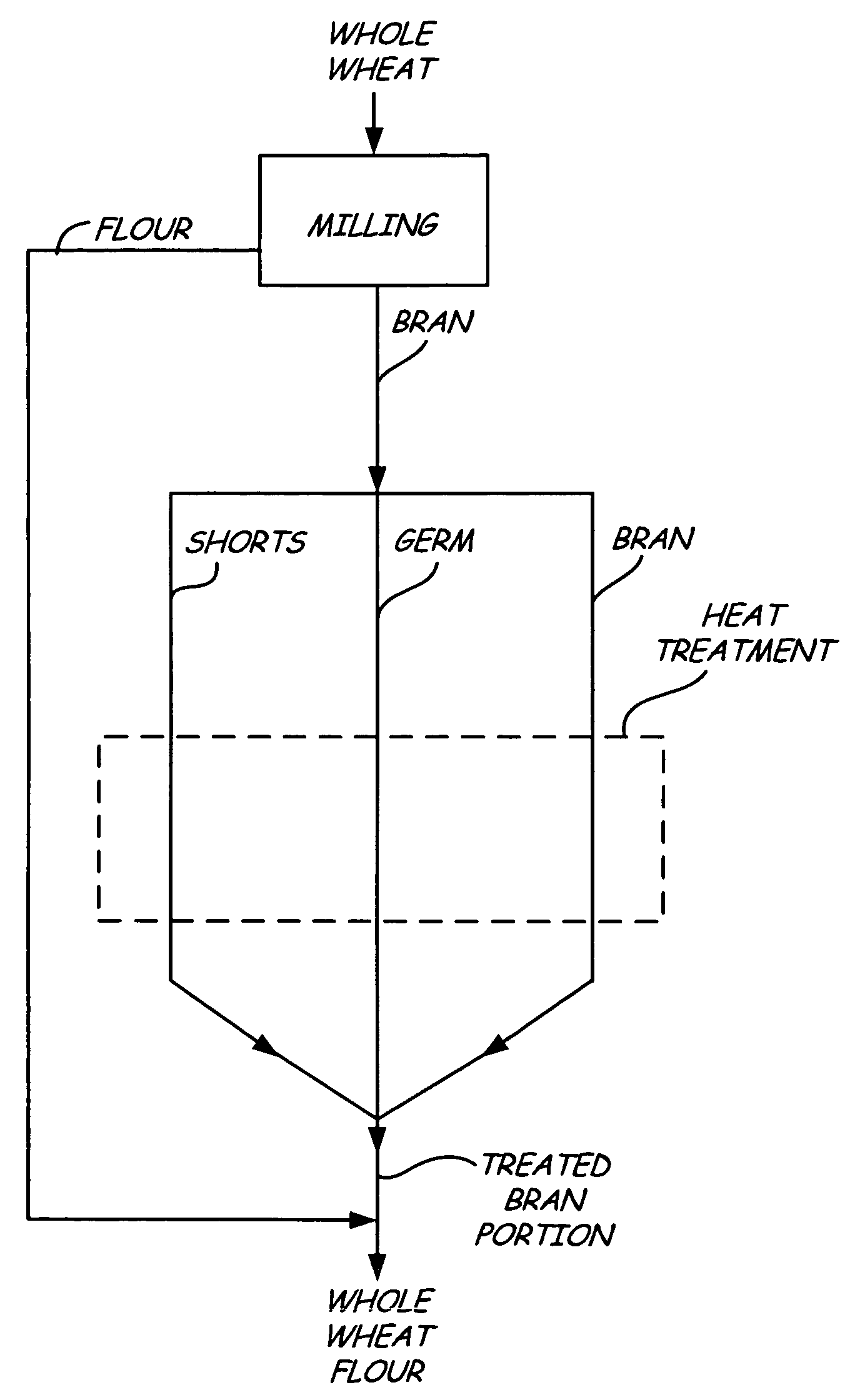

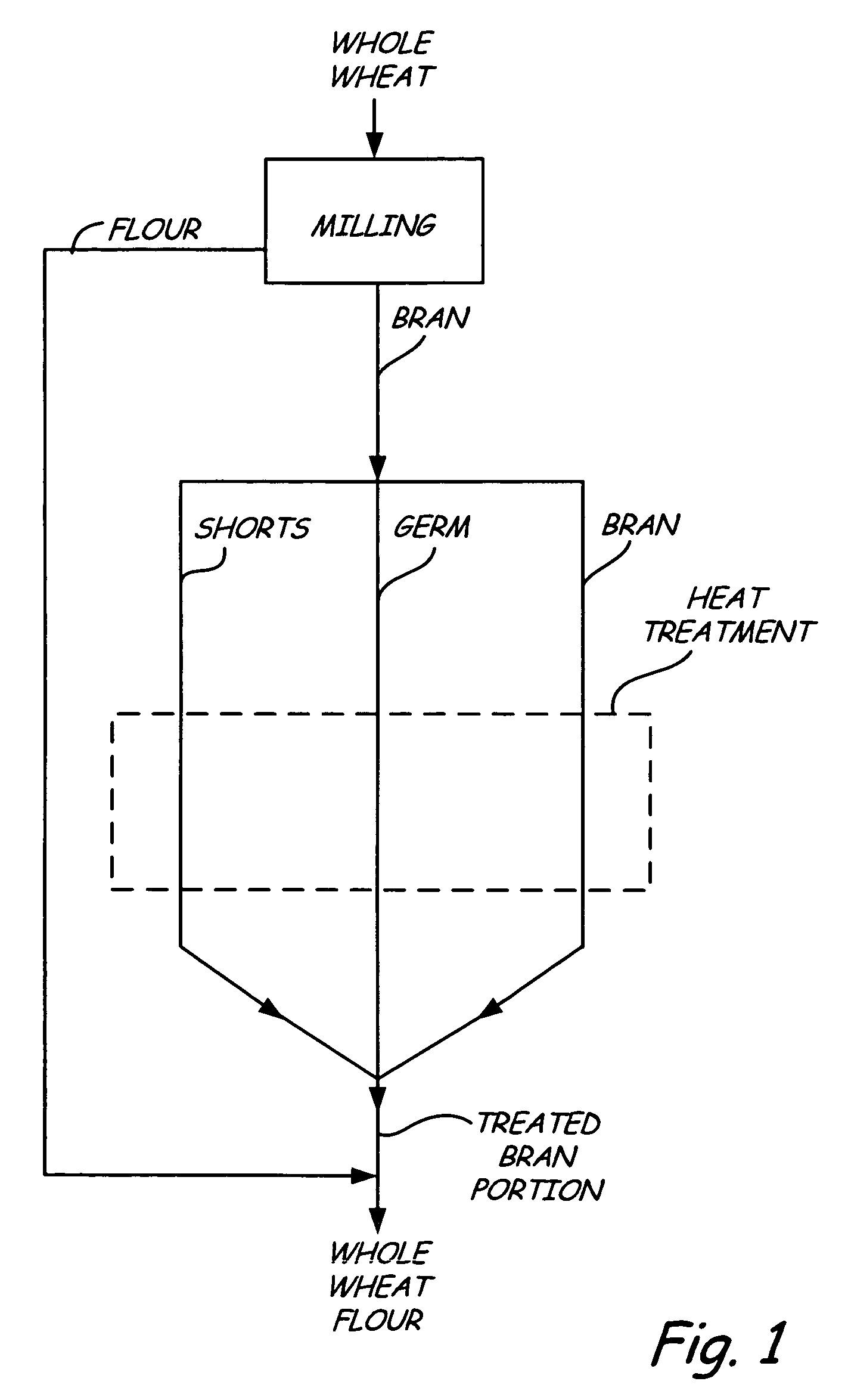

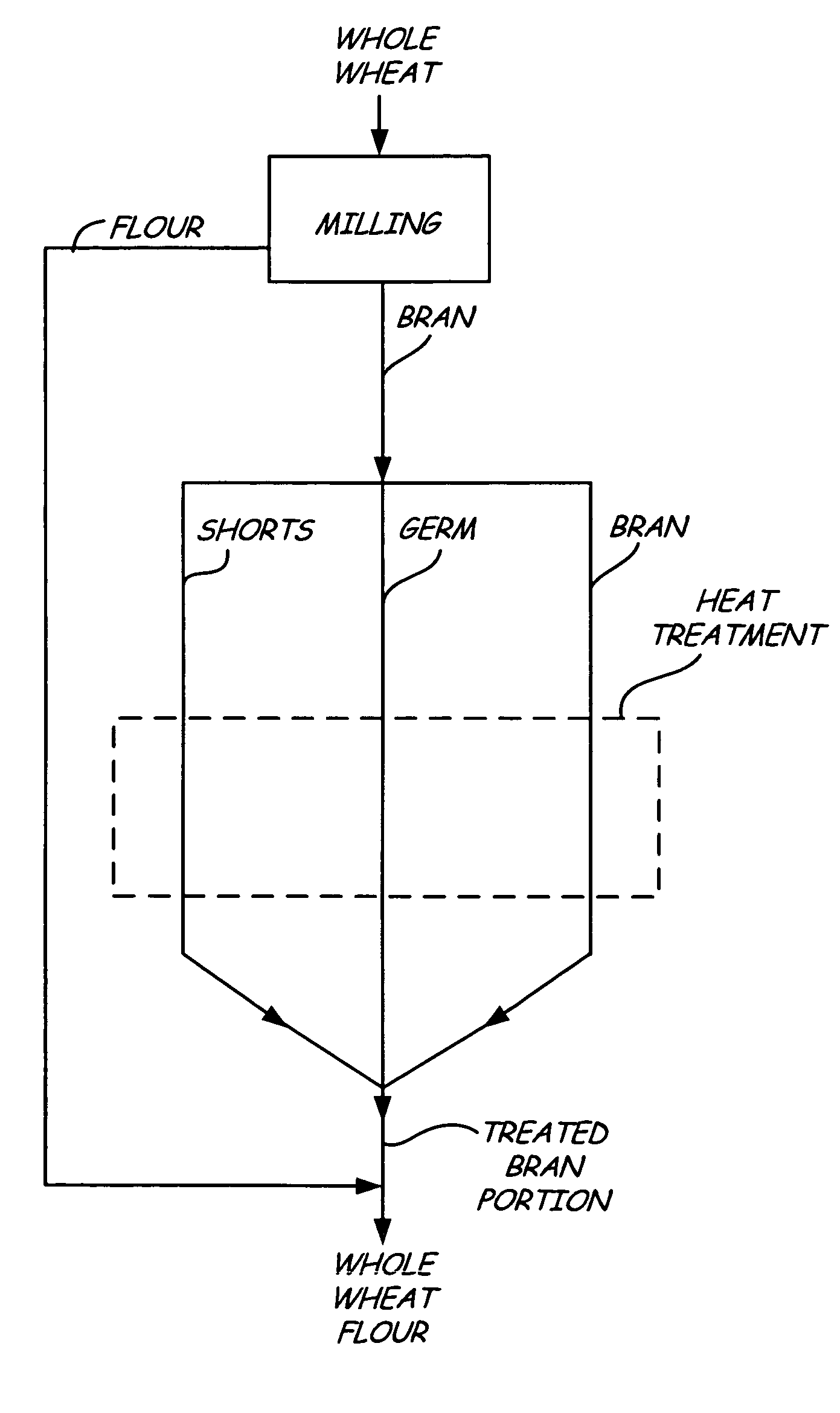

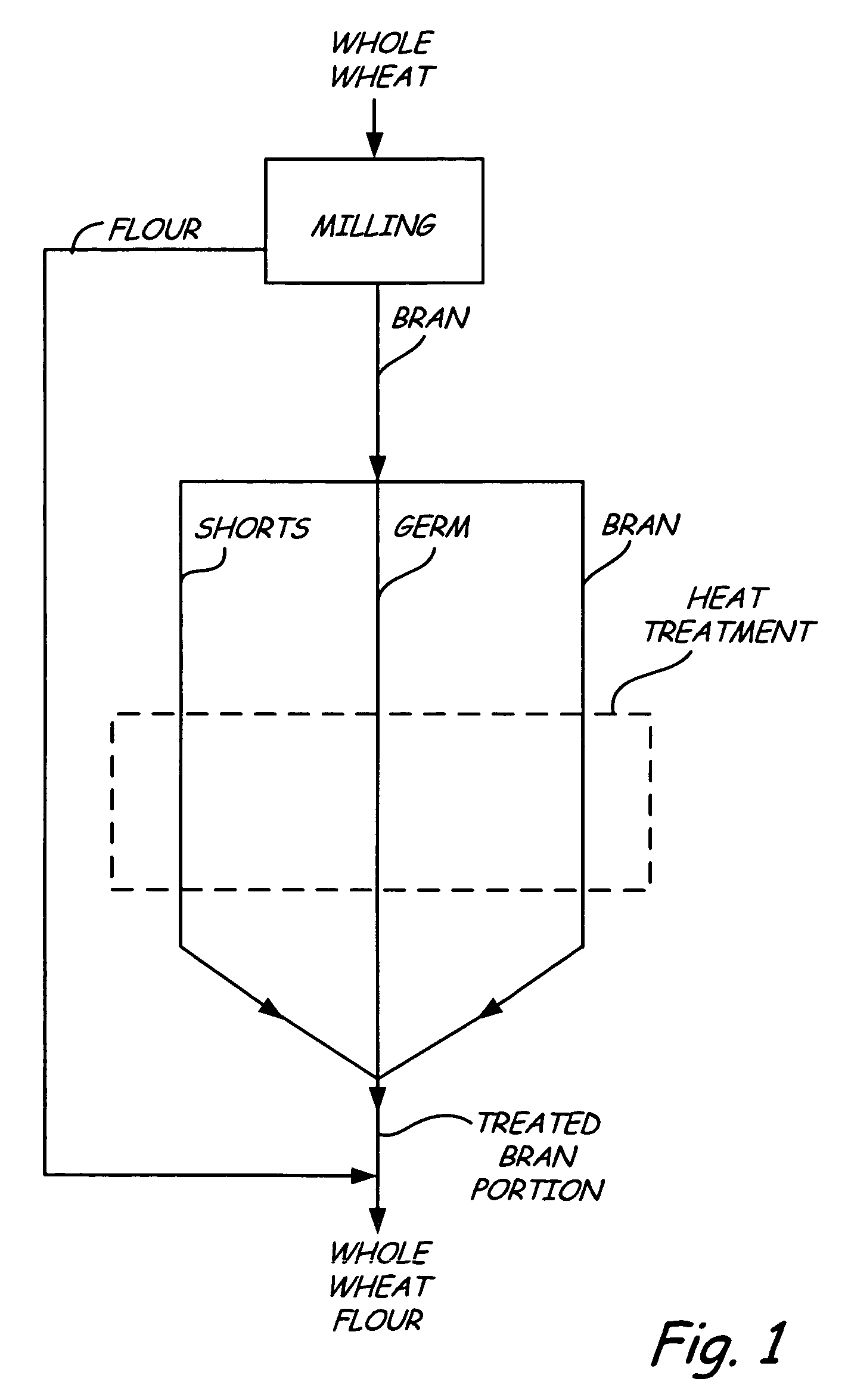

Flour and dough compositions and related methods

ActiveUS20050255219A1Increase concentrationReduced active-enzyme contentReady-for-oven doughsMeat/fish preservation by heatingWheat germWheat grain

Described are methods of treating wheat grain, including reducing the amount of active enzymes in a milled wheat grain by treating a portion of the wheat grain that includes one or more of wheat bran or wheat germ to deactivate enzymes; as well as flour and dough compositions prepared from the treated portion of wheat grain.

Owner:GENERAL MILLS INC

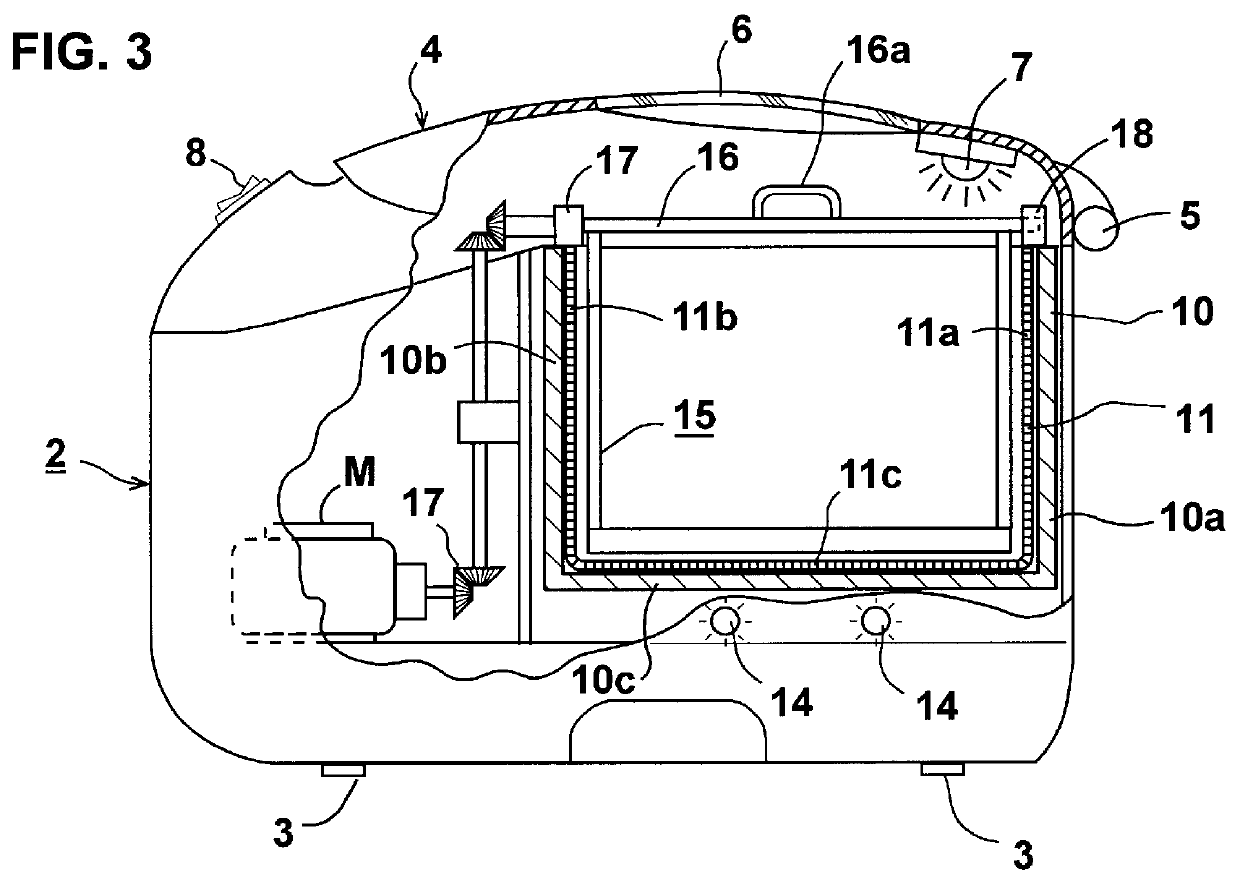

Cooking appliance and method particularly useful for frying or steaming food

InactiveUS6077555AMinimal spaceGreat tasteMilk preservationMeat/fish preservation by heatingEngineeringFood products

An appliance for cooking food articles includes a receptacle for receiving a quantity of food articles to be cooked, and a sufficient quantity of cooking liquid to only partially immerse the food articles therein; a heater for heating the cooking liquid and the food articles when received therein; a paddle movably mounted with respect to the receptacle so as to be movable therein; and a periodically-reversing drive for driving the paddle back and forth in the receptacle to move the food articles therein back and forth through the cooking liquid. The appliance is particularly useful for frying as it causes all the surfaces of the food article to be crisply fried without absorbing undue quantities of the frying oil. The appliance is also useful for other applications including steaming food, cooking rice, and popping corn.

Owner:DIME GROUP

Processing method of instant squid

InactiveCN101396137AImprove convenienceSimple methodMeat/fish preservation by heatingFood preparationSquidHigh heat

The invention relates to a processing method of an instant squid. The method comprises the following steps: live or frozen whole squids which are not polluted, have no abnormality and even size are adopted, cleaned, treated to remove internal organs, cleared and cleaned, cut up, scalded, rinsed, pickled and roasted at high temperature for sterilization, and the instant squid is obtained after mild secondary sterilization. The instant squid comprises various parts such as squid rings, squid tentacles, squid mouths, squid wings and the like, and the nutrients of fresh squids are well kept; besides, the squids have beautiful appearance, and can be eaten after being opened; and the instant squid is characterized by delicious taste, convenient eating and rich nutrition. The method adopts small package, and high-temperature short-time sterilization technology is adopted before vacuum packaging to effectively kill microbes, and measures such as a mild secondary sterilization and the like are taken after packaging, therefore, the shelf life of the squid can reach half a year to one year. The method is simple in preparation, and the procedures are reasonable, simple and feasible, the squid product processed has no nutrition loss and natural color, thus improving the edible convenience of the squid product.

Owner:SHANDONG HOMEY AQUATIC DEV +1

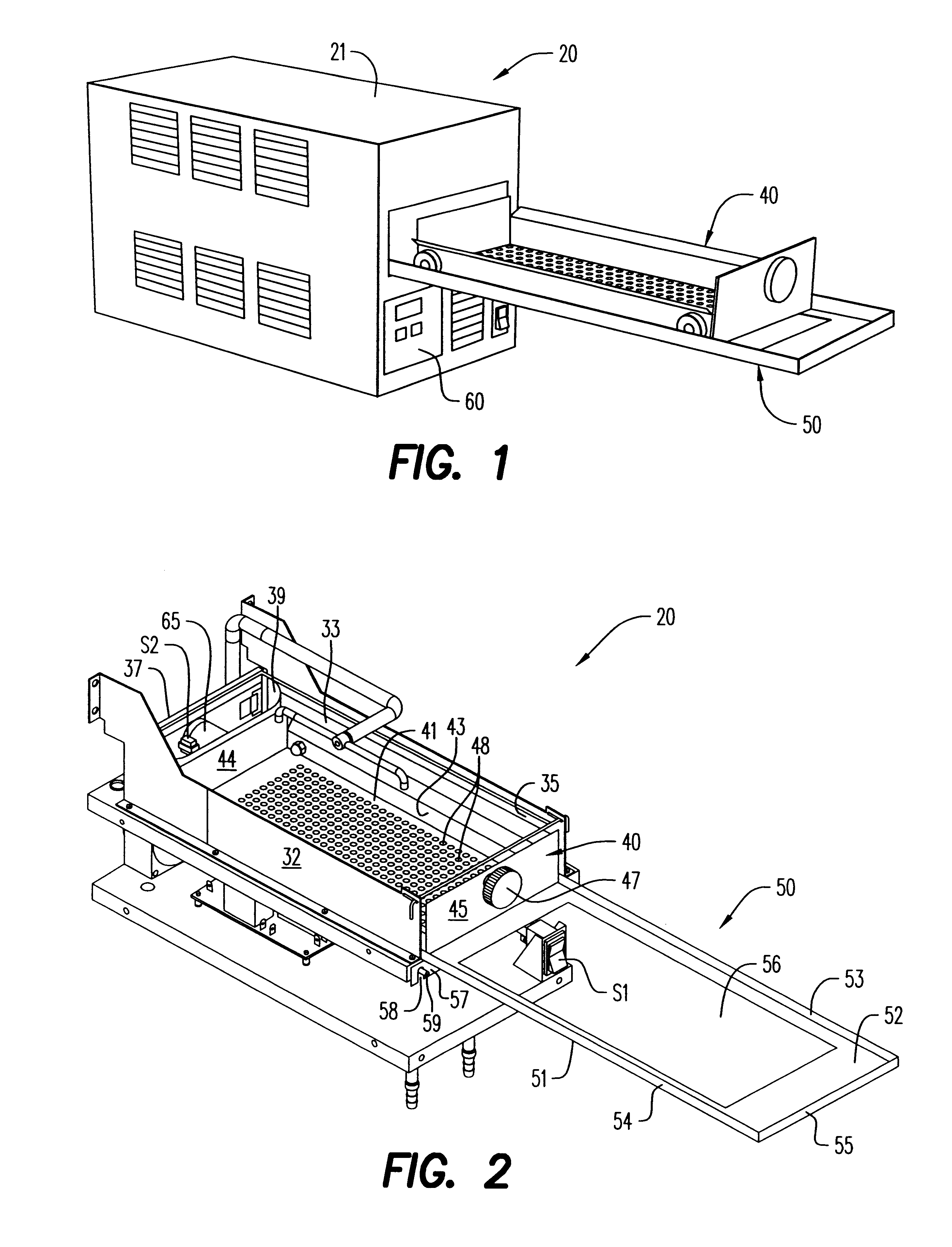

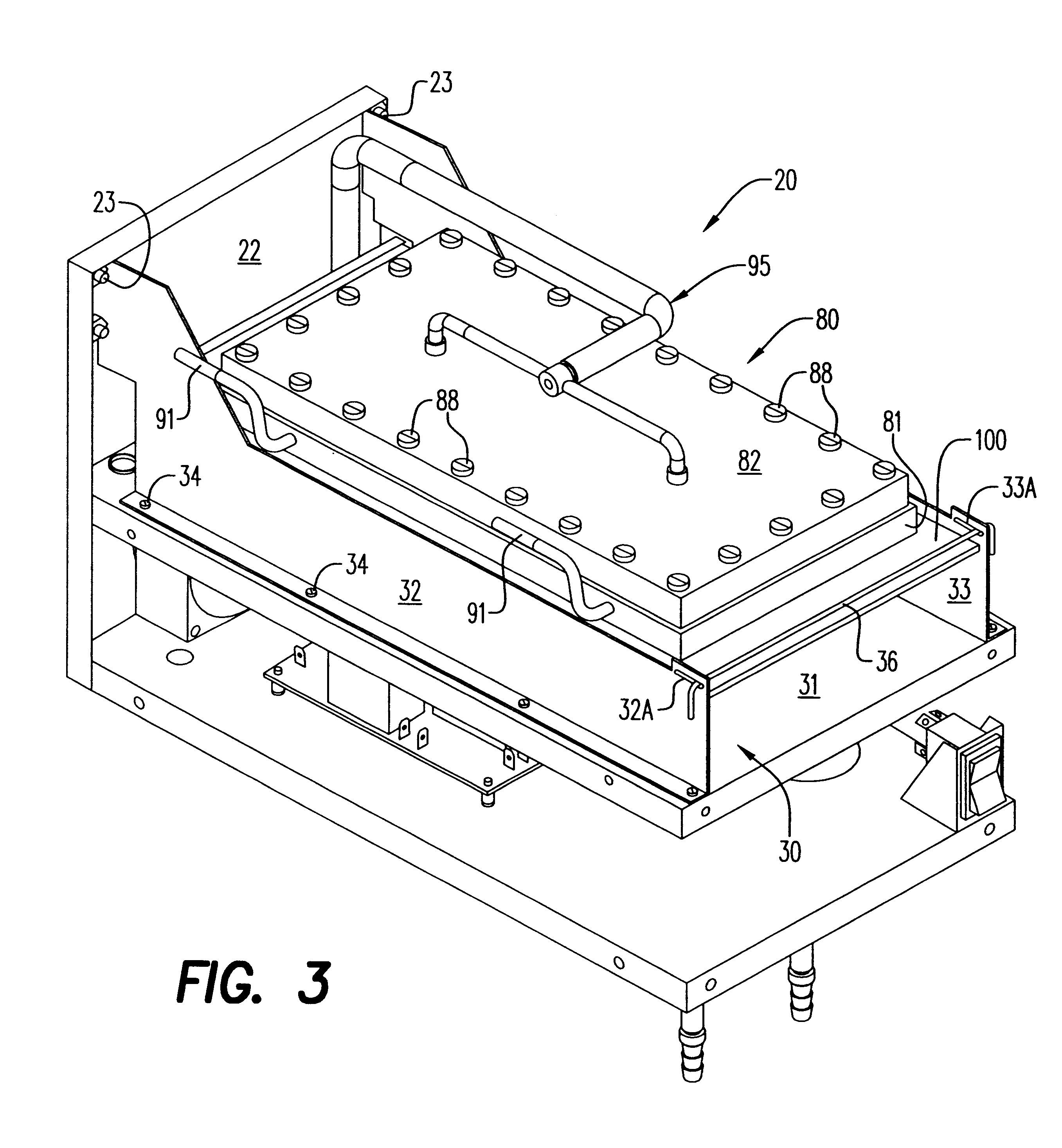

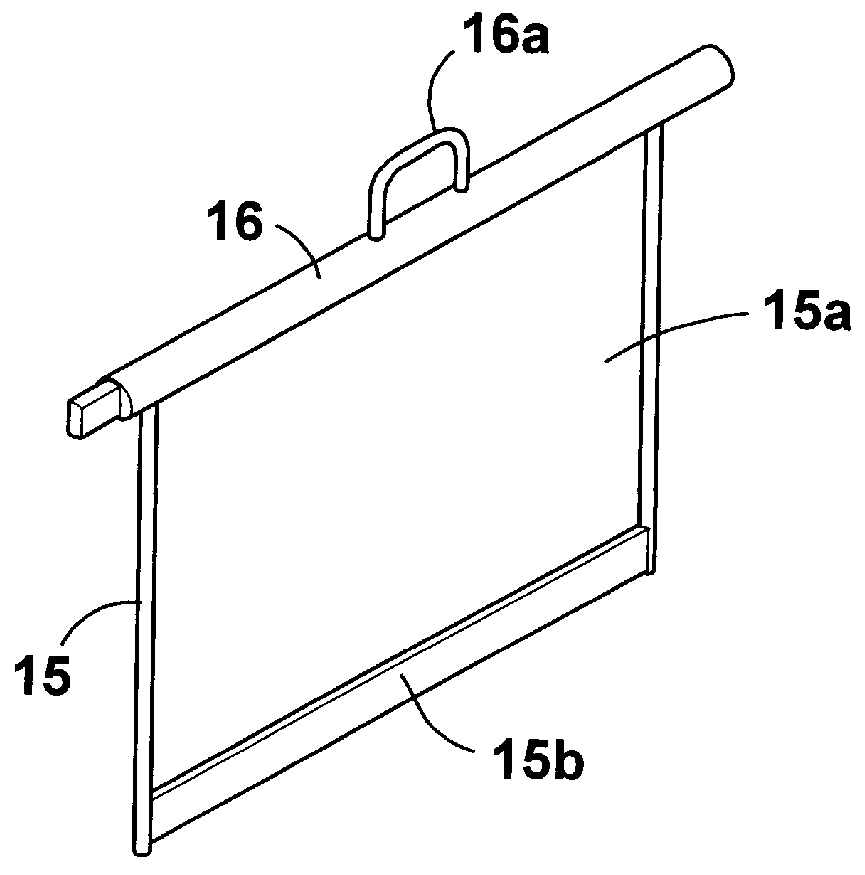

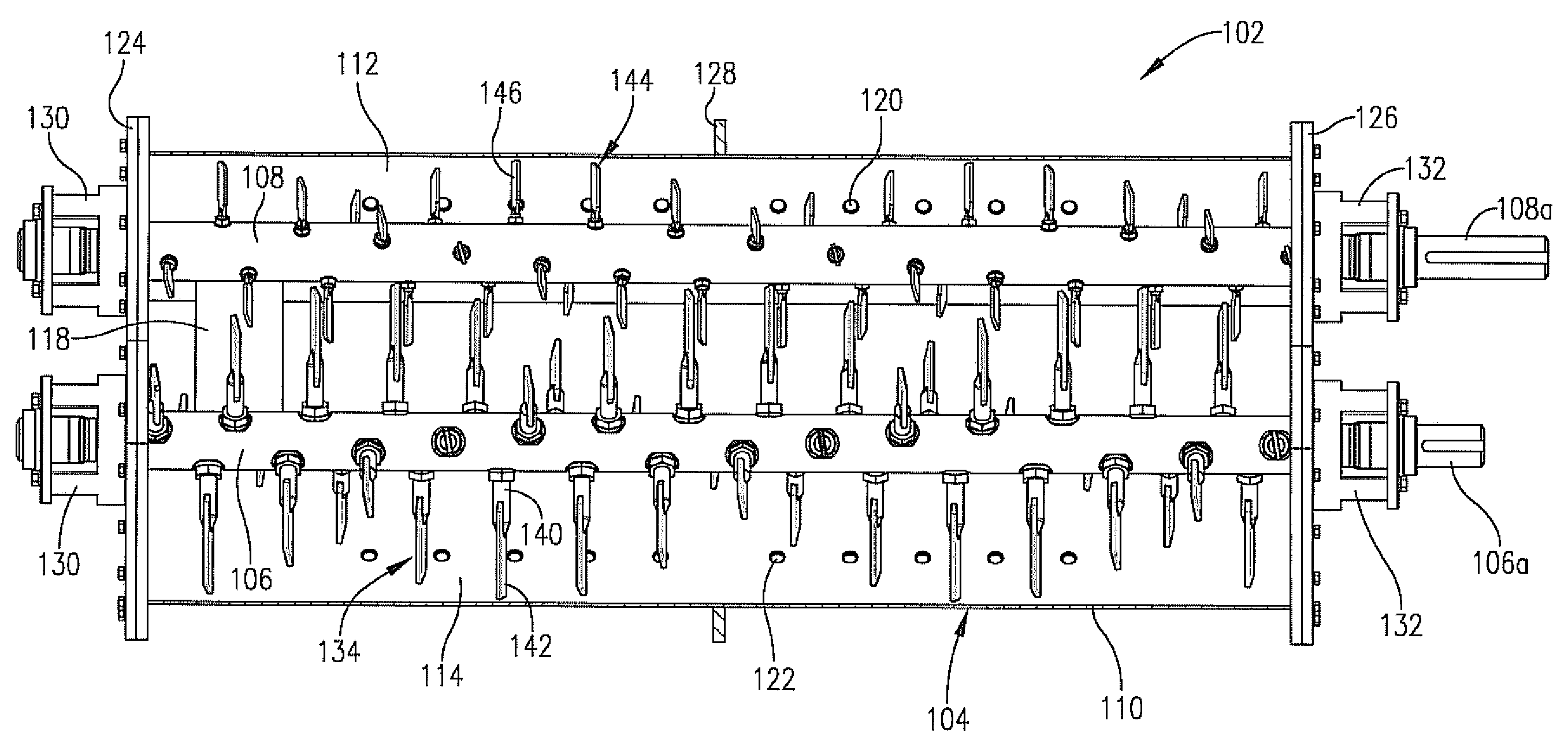

Preconditioner having independently driven high-speed mixer shafts

InactiveUS20080095910A1Facilitate easy changeFeeding-stuffRotary stirring mixersRetention timeEngineering

An improved, dual-shaft preconditioner (10, 70, 102) is provided having independent drive mechanism (18, 20, 78, 80) operatively coupled with a corresponding preconditioner shaft (14, 16, 74, 76, 106, 108) and permitting selective rotation of the shafts (14, 16, 74, 76, 106, 108) at rotational speeds and directions independent of each other. Preferably, the speed differential between the shafts (14, 16, 74, 76, 106, 108) is at least about 5:1. The mechanisms (18, 20, 78, 80) are operatively coupled with a digital control device (60) to allow rotational speed and direction control. Preferably, the preconditioner (10, 70, 102) is supported on load cells (62, 100) also coupled with control device (60) to permit on-the-go changes in material retention time within the preconditioner (10, 70, 102). The preconditioner (10, 70, 102) is particularly useful for the preconditioning and partial gelatinization of starch-bearing feed or food materials, to an extent to achieve at least about 50% cook in the preconditioned feed or food materials.

Owner:WENGER MANUFACTURING INC

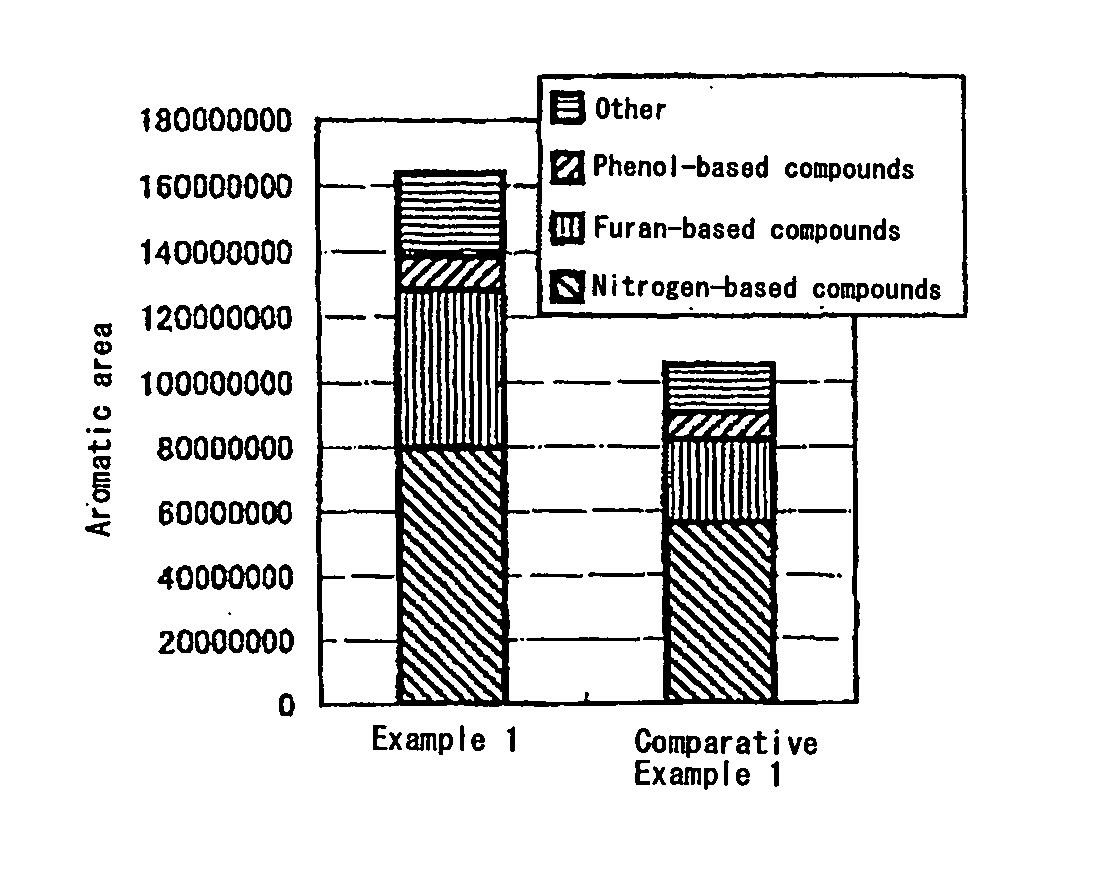

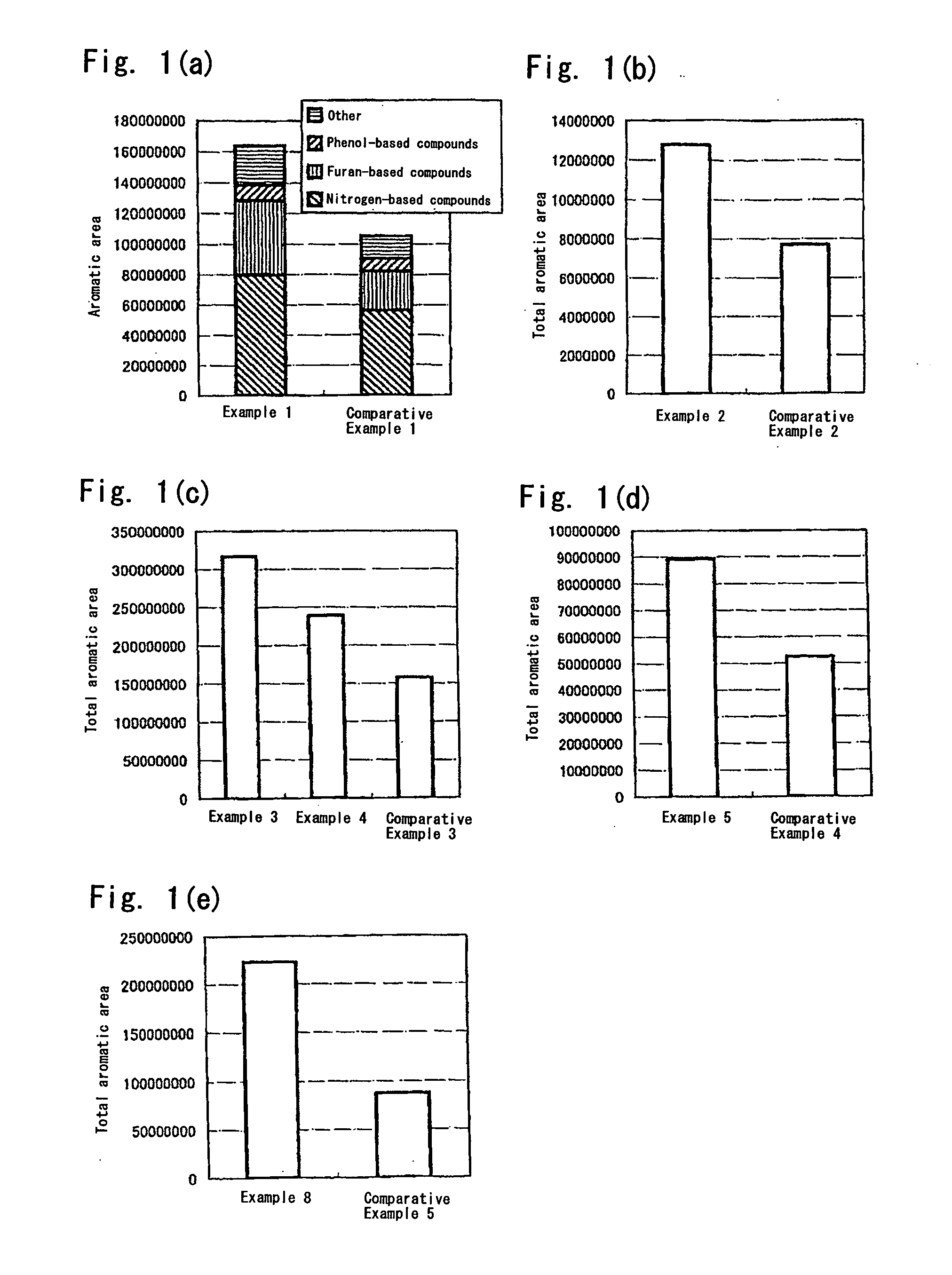

Method of extracting volatile component from tasty material, the volatile component and foods and drinks containing the volatile component

InactiveUS20070003683A1Meat/fish preservation by heatingTea extractionSaturated water vaporSuperheated steam

Volatile components are obtained by steam extraction of tasty materials. Coffee beans following roasting or tea leaves following tea manufacturing are used as tasty materials. Steam extraction includes of processing in which steam is contacted with a tasty material followed by recovery of the steam after that contact. Saturated water vapor or super heated steam is used for the steam, while super heated steam is used preferably. The coffee beans are preferably those that have been obtained by roasting raw coffee beans using super heated steam. The food or drink contains the aromatic components, and preferably contains the volatile components as well as an aqueous extract of the tasty material.

Owner:POKKA SAPPORO FOOD & BEVERAGE

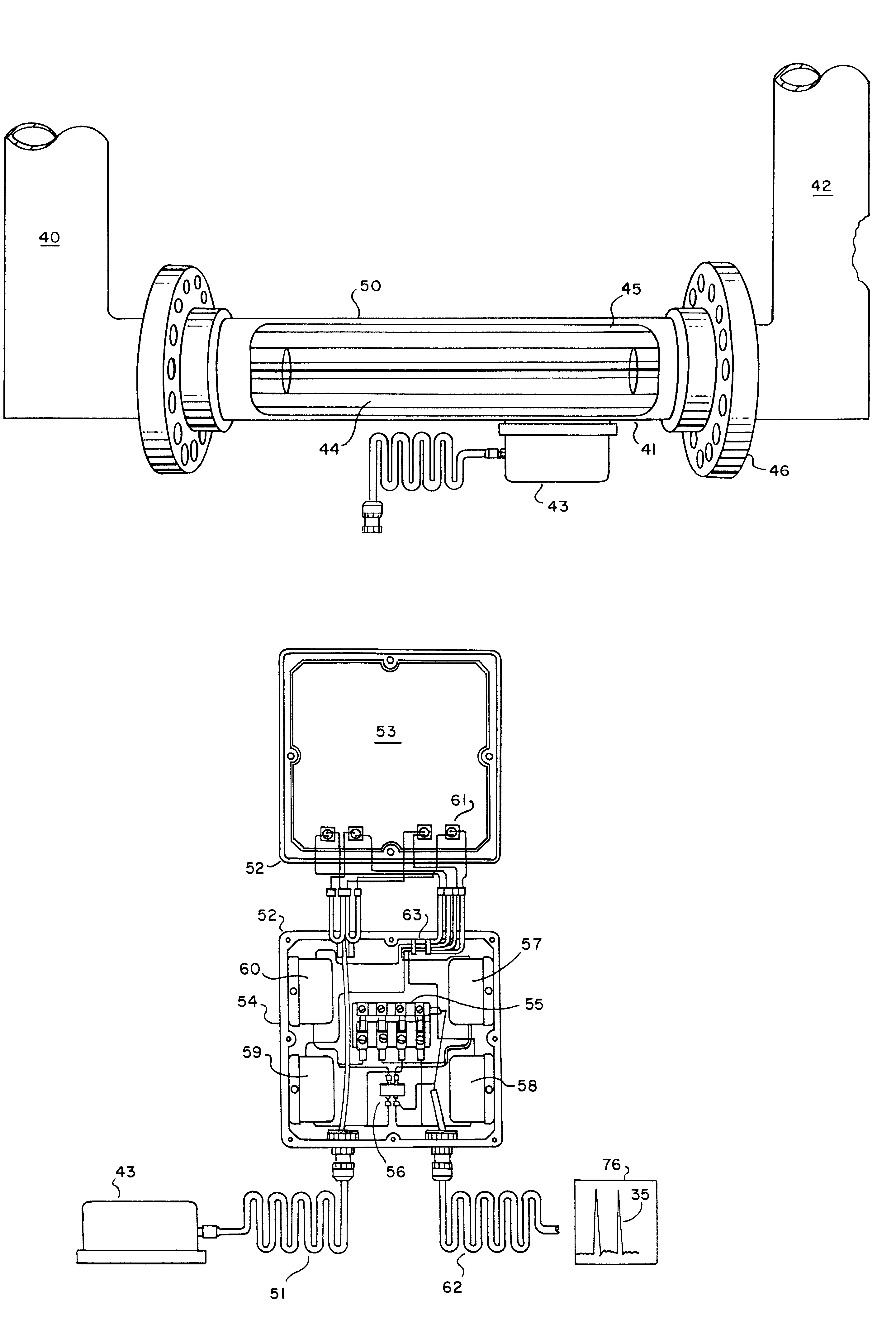

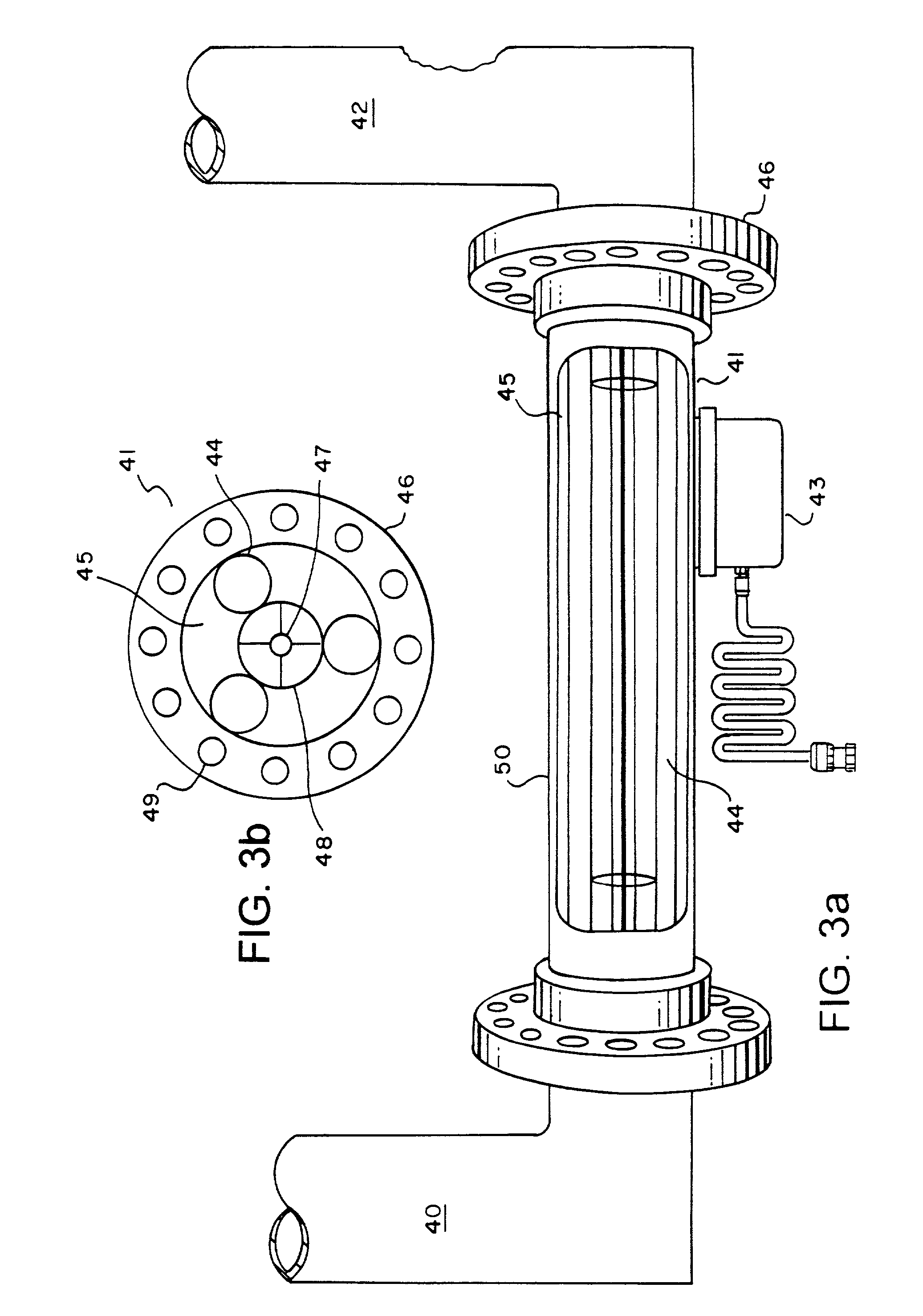

Methods of preparing and using electrostatically treated fluids

InactiveUS6974561B1Measurably betterIncrease crop yieldElectrolysis componentsLiquid separation by electricityWater basedVoltage spike

The present invention includes an improved electrostatic device for energizing fluids, in particular water based fluids, which will be used to provide a benefit to living organisms, machinery, processes and substances. The improved device of the invention will include an electrostatic voltage spike signal generator, two or more radio frequency signal generators, one or more antennas, optional one or more signal boosters and a fluid conduit. When fluid is treated with the improved device of the invention, the fluid will become energized and can be used to provide significant benefits in applications such as milk production, flower production, fruit production, crop production, vegetable production, shrimp production, egg production, meat production, gasoline combustion, waste fluid combustion, scale removal, water purification, fluid tracking, fluid sterilization and more.

Owner:COMPLETE WATER SYST L L C

Cooking appliance with steam generator

Owner:WHIRLPOOL CORP

Flour and dough compositions and related methods

ActiveUS7258888B2Increase concentrationReduced active-enzyme contentReady-for-oven doughsMeat/fish preservation by heatingWheat germWheat grain

Described are methods of treating wheat grain, including reducing the amount of active enzymes in a milled wheat grain by treating a portion of the wheat grain that includes one or more of wheat bran or wheat germ to deactivate enzymes; as well as flour and dough compositions prepared from the treated portion of wheat grain.

Owner:GENERAL MILLS INC

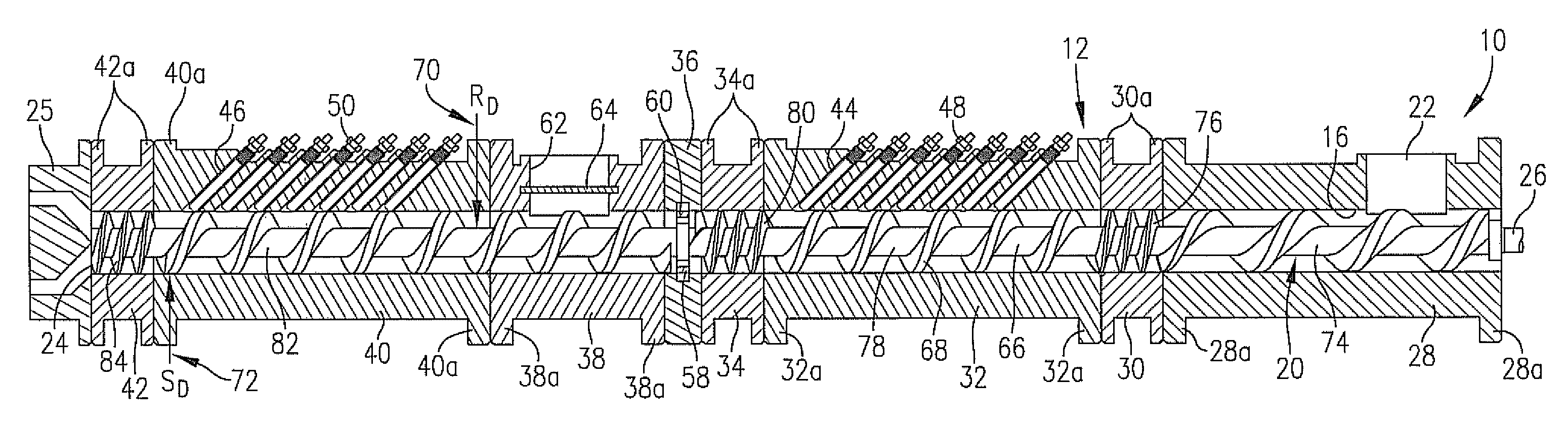

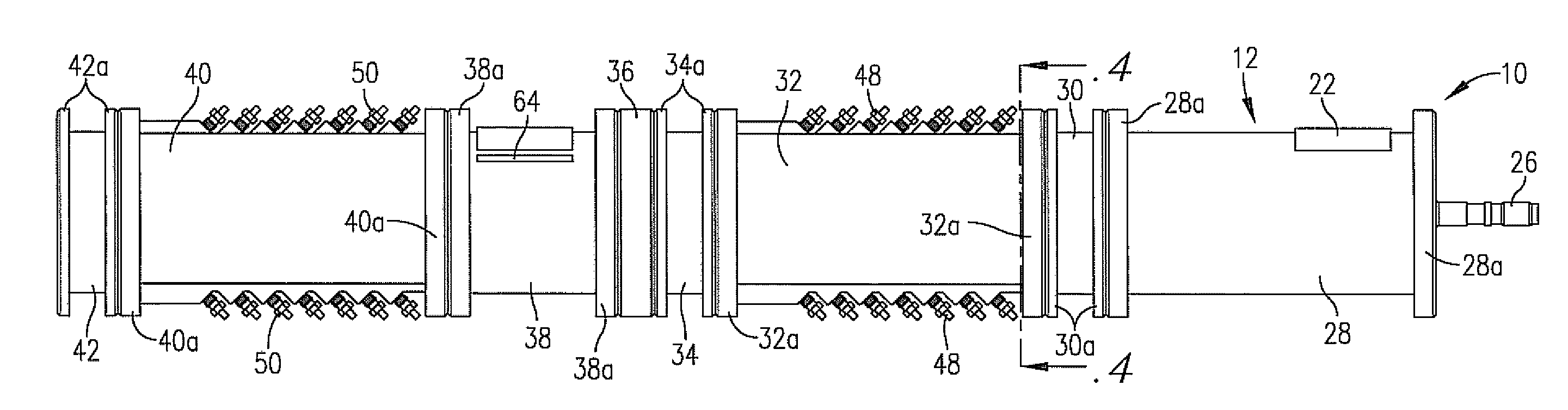

Cooking extruder with enhanced steam injection properties

ActiveUS20080223223A1Overcome problemsAvoid flowFeeding-stuffWorking-up animal fodderEngineeringPitch length

An improved extruder (10) is provided which permits successful introduction of very high quantities of injected steam into material being processed, on the order of 6-8% or more by weight steam. The extruder (10) includes an elongated extruder barrel (12) having at least one elongated, axially rotatable, helically flighted extrusion screw (16,18) therein. The barrel (12) is equipped with obliquely oriented steam injection ports (44, 46) along the length thereof, housing steam injectors (48, 50). The barrel (12) includes relatively high free volume steam injection heads (32 and 38, 40) having therein screw sections (78, 82) of relatively long pitch length, together with steam restriction heads (30, 34, and 42) on opposite sides of the injection heads (32, and 38, 40) having therein relatively short pitch length screw sections (76, 80, 84).

Owner:WENGER MFG LLC

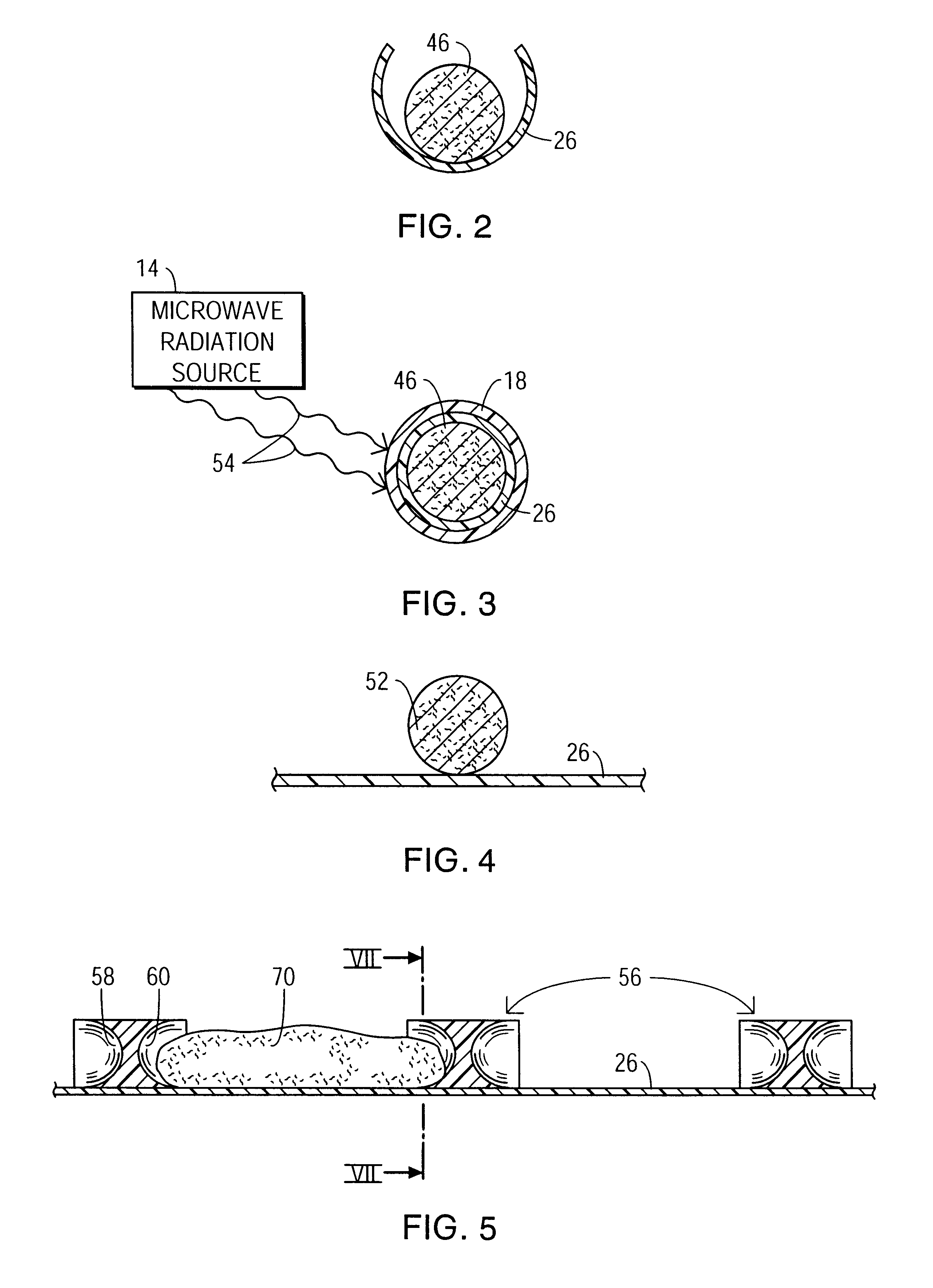

Manufacturing method and apparatus utilizing reusable deformable support

InactiveUS6322832B1Reduce manufacturing costLow costDough treatmentConfectioneryCanis lupus familiarisConveyor belt

In a method for the manufacture of frankfurters, hot dogs and other skinless sausage products, a meat emulsion is extruded onto a flexible conveyor belt which is then conveyed through an at least partially microwave-transparent tube whose internal diameter is equal to the desired diameter of the sausage product plus twice the thickness of the conveyor belt. In a camming type process, the conveyor belt is caused, upon its entry into the tube, to temporarily form a cylinder containing the meat emulsion. The temporary belt cylinder together with the surrounded meat emulsion extrudate is then conveyed through a microwave applicator to partially or thoroughly cook the meat emulsion. At the exit end of the tube, the conveyor belt naturally opens under internal stresses from its cylindrical shape to a flattened belt. The at least partially cooked sausage is then removed from the belt for further processing or packaging. The conveyor belt acts as a temporary skin to hold the meat emulsion during its microwave cooking.

Owner:MISONIX INC

Steam injection cooking device and method

InactiveUS20090252855A1Boiling over preventionMeat/fish preservation by heatingPortion sizeLiquid water

An apparatus and method are provided for steam injection heating of a bulk food product. When cooking scrambled eggs, the method includes providing a predetermined amount of liquid uncooked egg. A predetermined amount of water is injected into a heated cavity to form a quantity of steam that is sufficient to cook the predetermined quantity of liquid uncooked egg when injected therein. The liquid egg may be liquid pasteurized whole egg. The predetermined amount of the food product may be a single serving, or integer multiples thereof. When heating a serving amount that is an integer multiple of at least two times the amount of a single serving, the predetermined quantity of water is injected in pulses. The number of pulses is the same as the integer multiple of servings being heated, and each pulse contains substantially equal amounts of liquid water.

Owner:RESTAURANT TECH

Curable resin composition for sealing LED element

InactiveUS20060229408A1Improve adhesionExcellent level of heatDrying solid materials with heatMeat/fish preservation by heatingOptical transparencyHeat resistance

A curable resin composition for sealing an LED element is provided. The composition includes (i) an organopolysiloxane with a polystyrene equivalent weight average molecular weight of at least 5×103, (ii) a condensation catalyst, (iii) a solvent, and (iv) a finely powdered inorganic filler. It is suited to formation of a coating film or the like with excellent heat resistance, ultraviolet light resistance, optical transparency, toughness and adhesion, and is ideal for applications such as the sealing of LED elements.

Owner:SHIN ETSU CHEM IND CO LTD

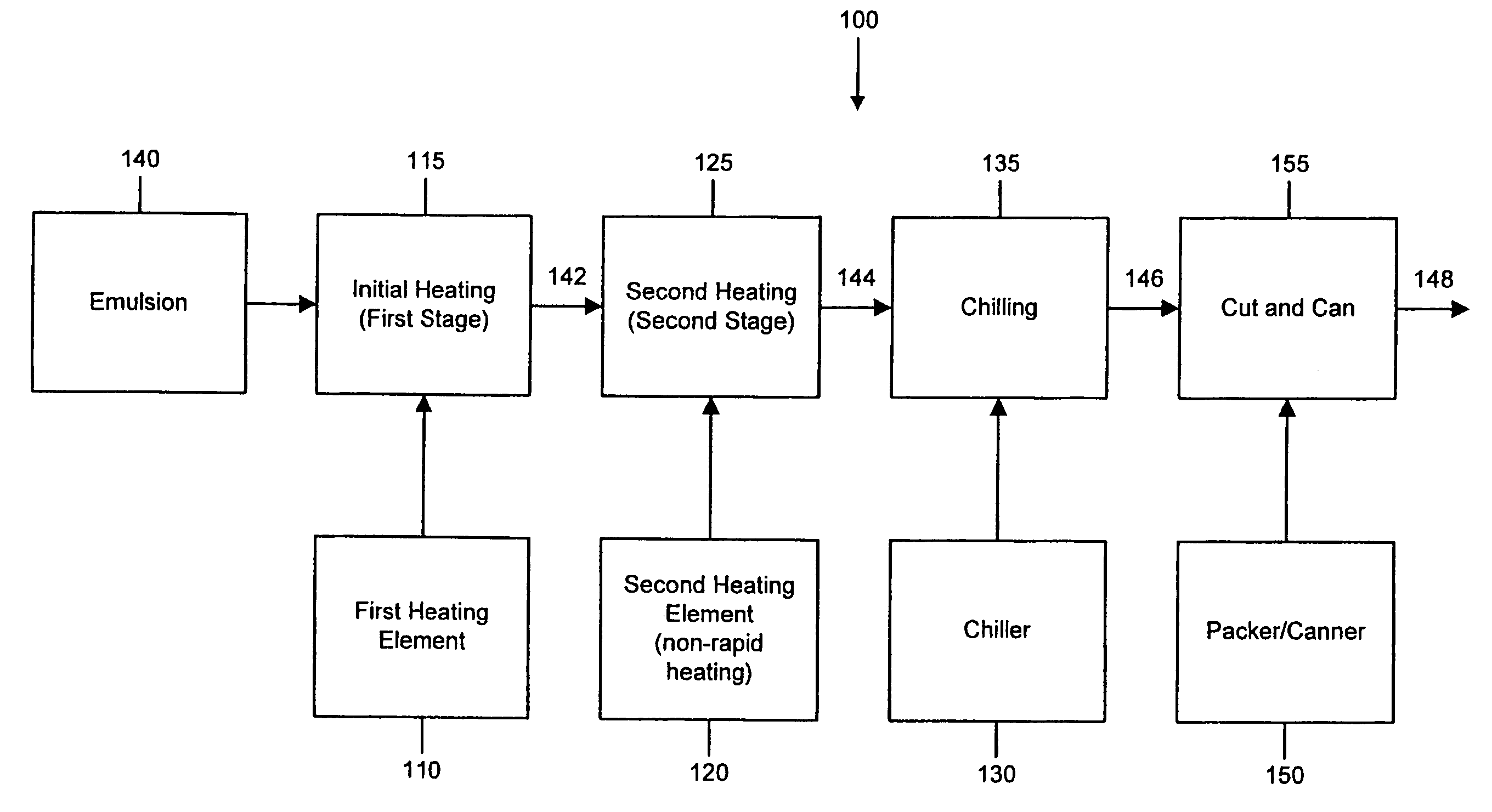

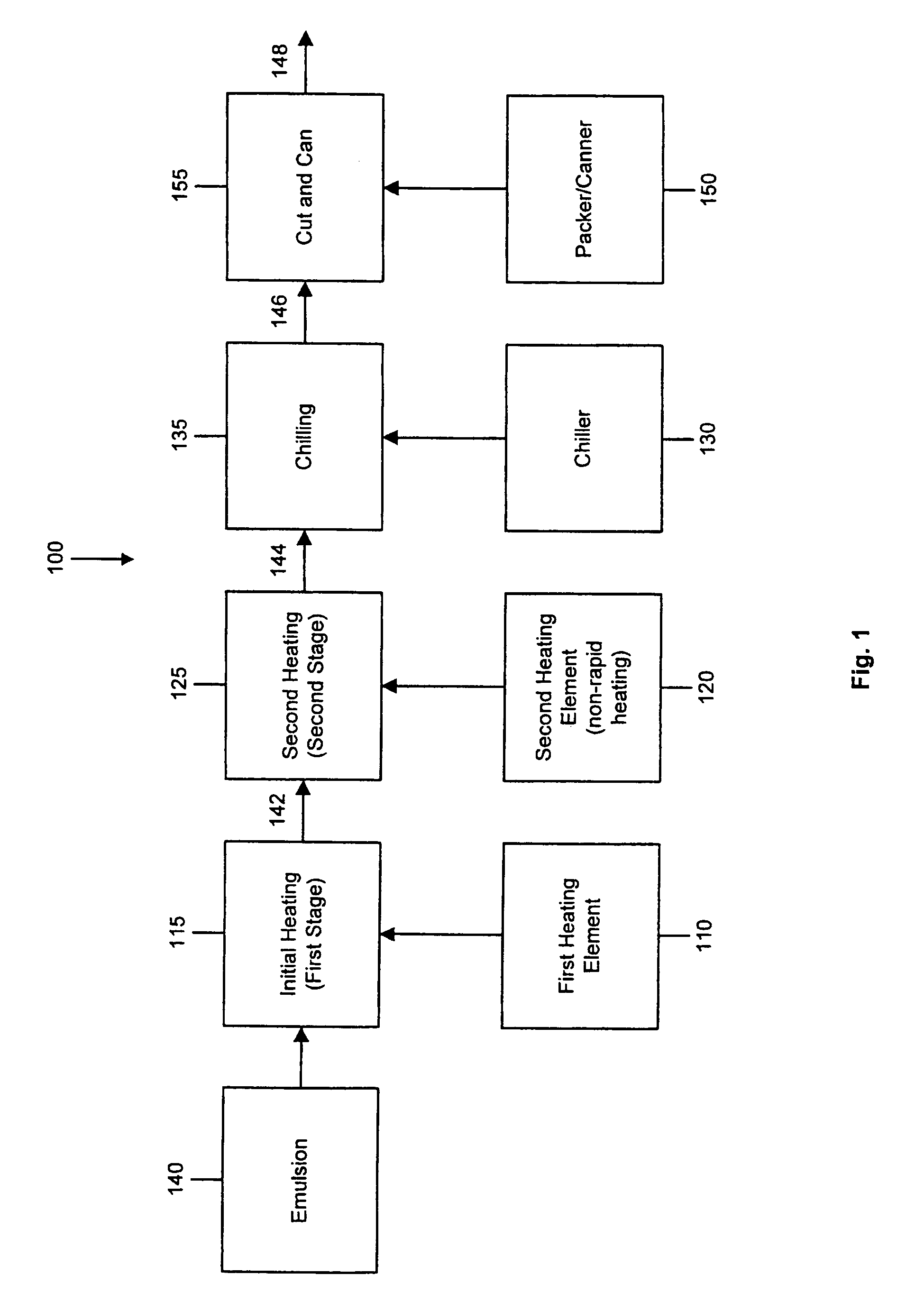

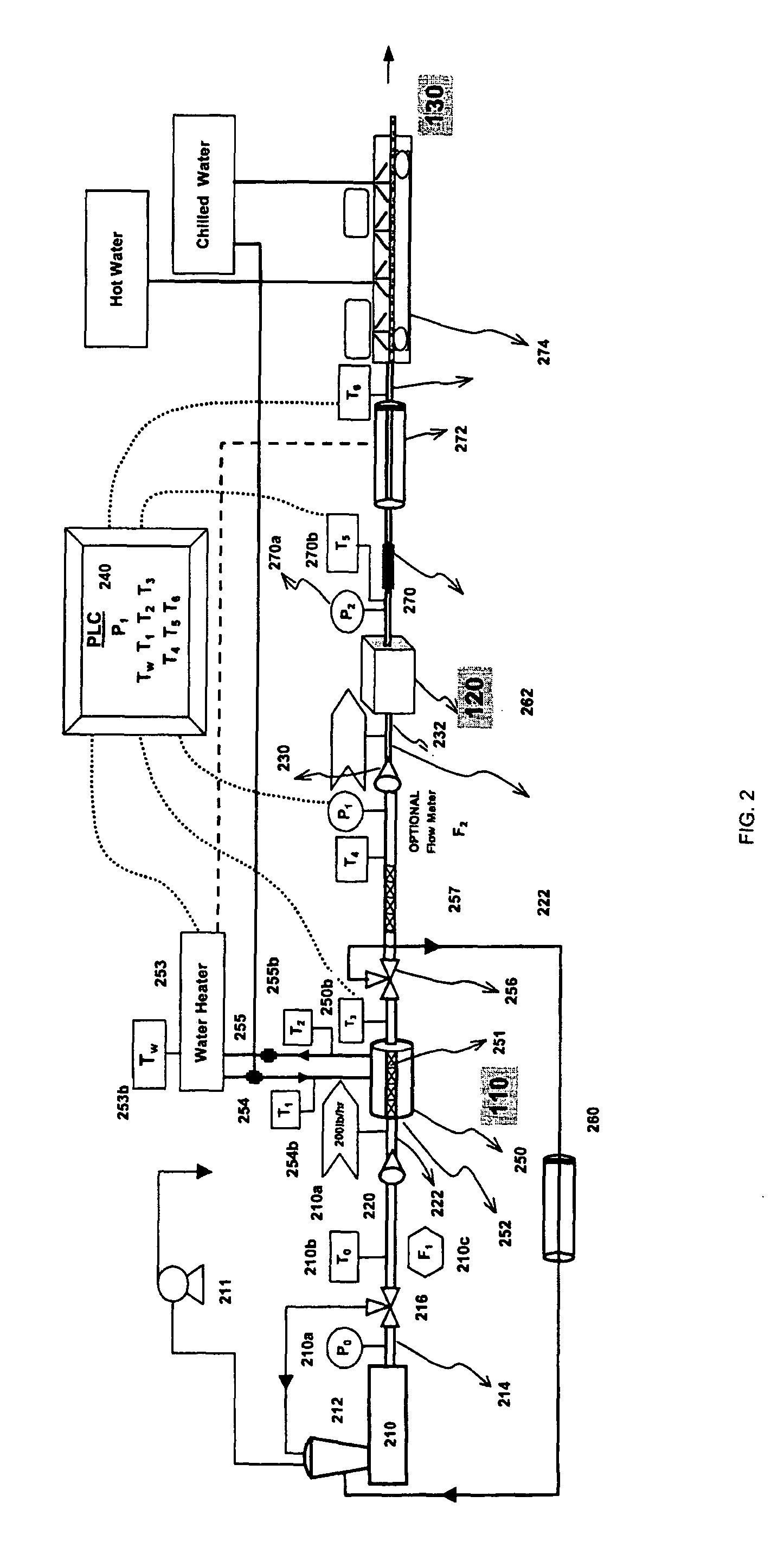

System and method for making casingless sausage

A method and system for producing a casingless sausage product. An emulsion, such as a meat emulsion, is heated by a first heating element, such as conductive element, such as a heat exchanger or a direct heating element, from a first temperature to an initial heating temperature. The initial heating forms a warm emulsion. After the first heating stage, the warmed emulsion is heated again during a second stage with a second heating element from the initial heating temperature to a higher, second heating temperature. Other numbers of heating elements can be utilized as necessary. The second heating element can be a rapid heating element, such as a microwave or radio frequency (RF). The second heating produces a casingless sausage. The casingless sausage is subsequently cooled or chilled to produce the casingless sausage product. The product can be cut to a length and packaged in a container or can.

Owner:CONAGRA FOODS

Heat and moisture control in agricultural-product production

InactiveUS20060093713A1Easy to controlReduce operating costsDrying using combination processesFeeding-stuffCounter flowSprayer

A method and apparatus for agricultural product production with heat and moisture control with optional heat and moisture recovery. Some embodiments transfer heat and moisture from a warm, moist exhaust air stream to incoming agricultural material, steam condition the material, pelletize the material into warm pellets, cool the warm pellets with make-up air to produce the warm, moist exhaust air used to transfer heat to the incoming material and to produce cooled pellets, wherein the cooled pellets are at a temperature lower than the warm moist air. In some embodiments, the system includes counter-flow devices to transfer heat and moisture. In some embodiments, a controller is used to adjust system devices and overall system flow. In some embodiments a water sprayer, to moisten agricultural product when the product is over dry, and an air flow controller, to slow air flow through the pellet dryer / cooler when ambient temperatures are dryer / cooler, are provided.

Owner:PESCO +1

Method for processing corn grit and product

Corn grit is continuously processed to corn collects, or corn flour, by first treating the corn grit in a conditioner at a basic pH and a temperature in the range of about 180° F. to about 200° F. in the presence of steam and at a relatively low moisture content, i.e., no more than about 15 weight percent, preferably about 14 weight percent for a time period sufficient to effect partial gelatinization. Thereafter the obtained, partially gelatinized corn grit is passed through an extruder to produce corn collets that can be comminuted to corn flour. The corn grit moisture content in the extruder is about 20 to about 25 weight percent, and the corn collets are extruded at an exit temperature in the range of about 200 to 215° F. and a moisture content of about 9 to about 12 weight percent. The extruded corn collets have a dextrin value of about 8 to about 10.

Owner:BETHEL GRAIN

Method for processing instant clam

InactiveCN101411515AImprove convenienceNo churnMeat/fish preservation by heatingFood preparationChemistryNutrient content

The invention relates to a method for processing ready-to-eat clams, which comprises the following steps: firstly, selecting pollution-free alive clams, temporarily breeding the clams, then washing the clams, and removing shells through steaming to obtain integral clam meat; and using the clam meat as a raw material, performing high temperature baking for sterilization after washing, draining away the water, salting, and dehydrating; then vacuumizing and sealing the clam meat; and performing secondary sterilization on the clam meat to obtain the ready-to-eat clams. The method better keeps the completeness and the nutrient content of the clam meat and the clam meat can be eaten after opening the package. The method is simple and easy to perform, the processed clam product has no nutrient loss, and the color and luster of the product is natural, thus the convenience for eating the clam is improved. The ready-to-eat production clam can be stored for six months to one year at normal temperature, the cost can be saved, and the product is easy to store and circulate.

Owner:SHANDONG HOMEY AQUATIC DEV +1

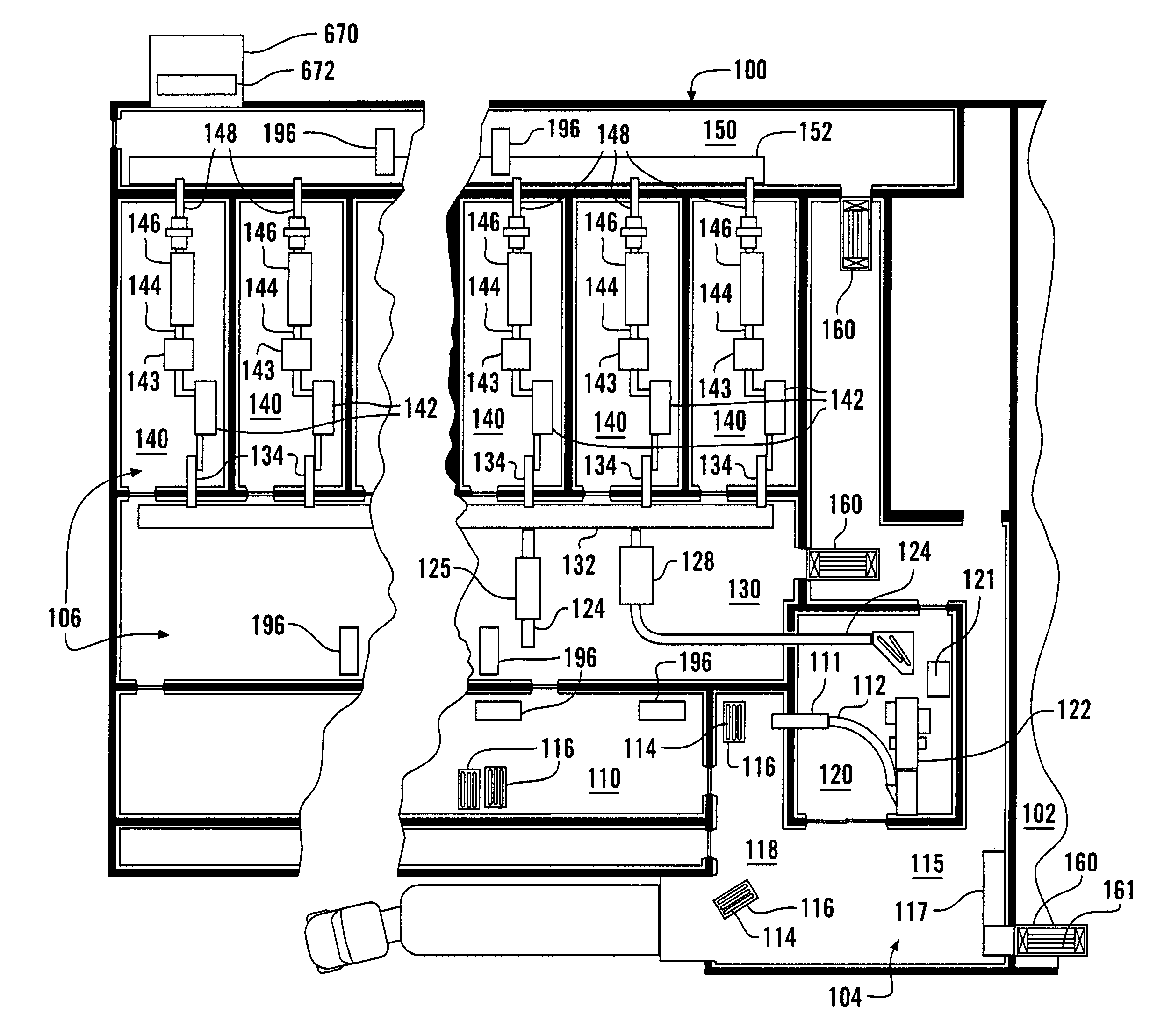

Clean room food processing systems, methods and structures

Owner:WEST LIBERTY FOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com