Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

282results about How to "Satisfies requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

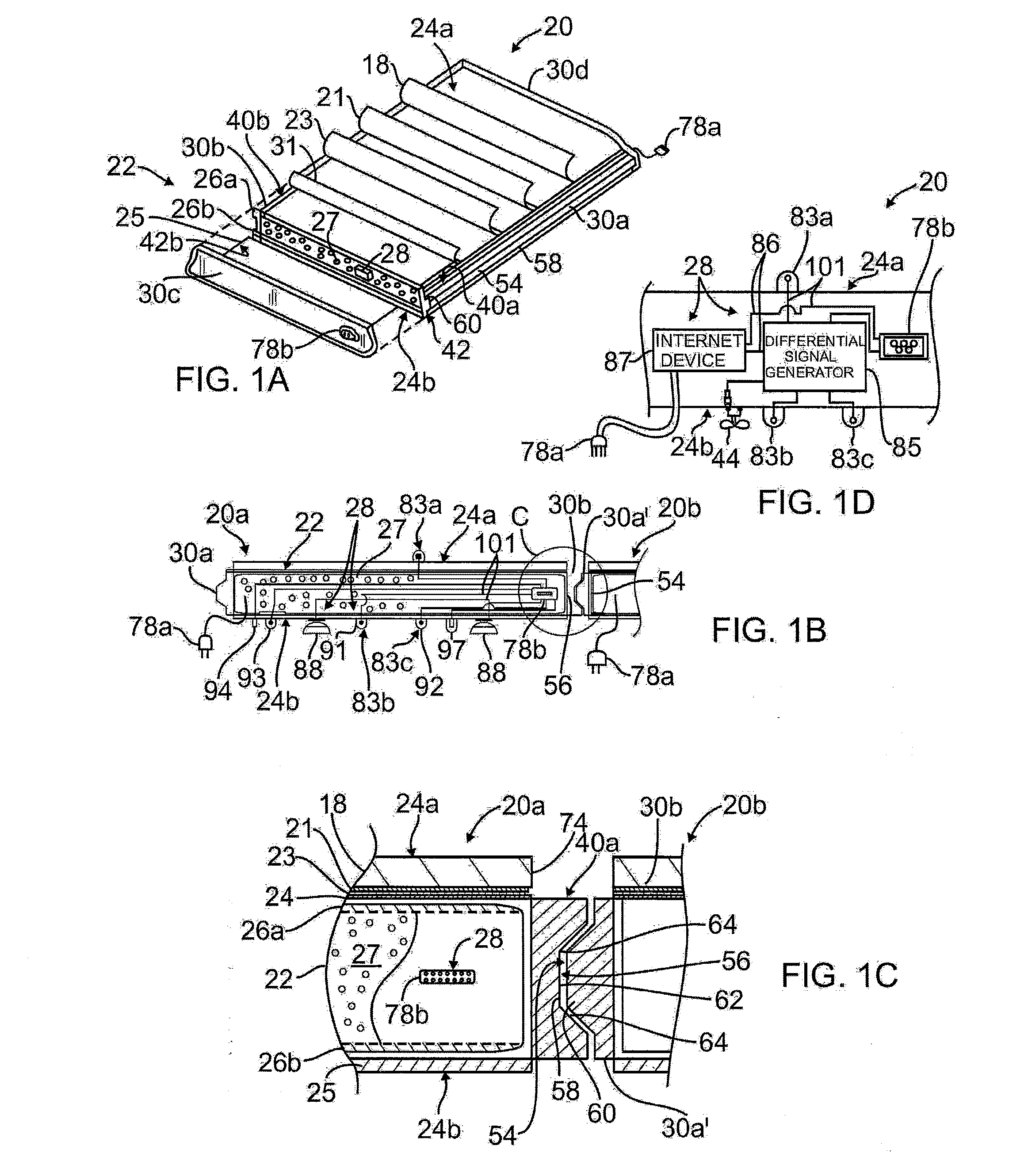

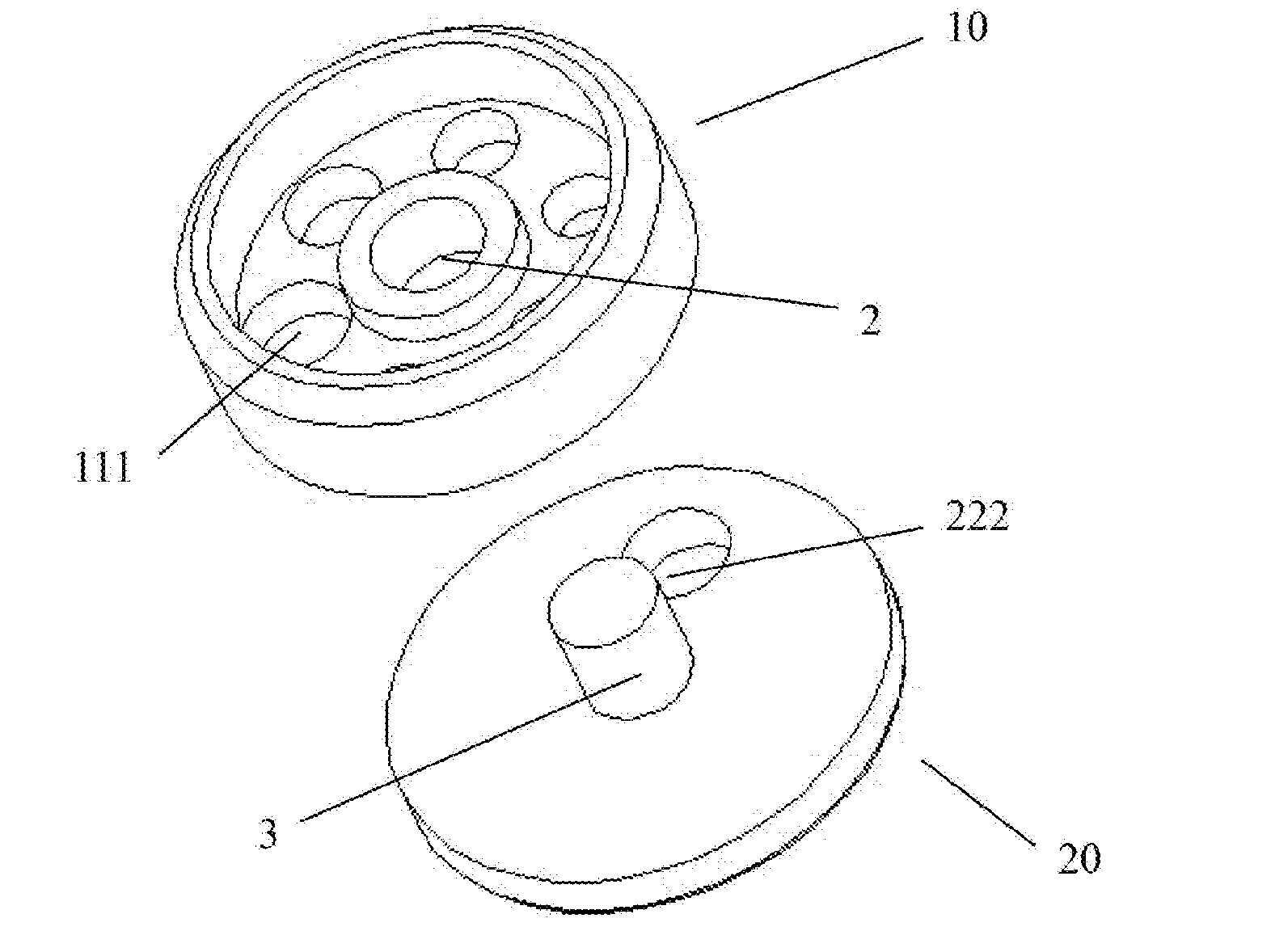

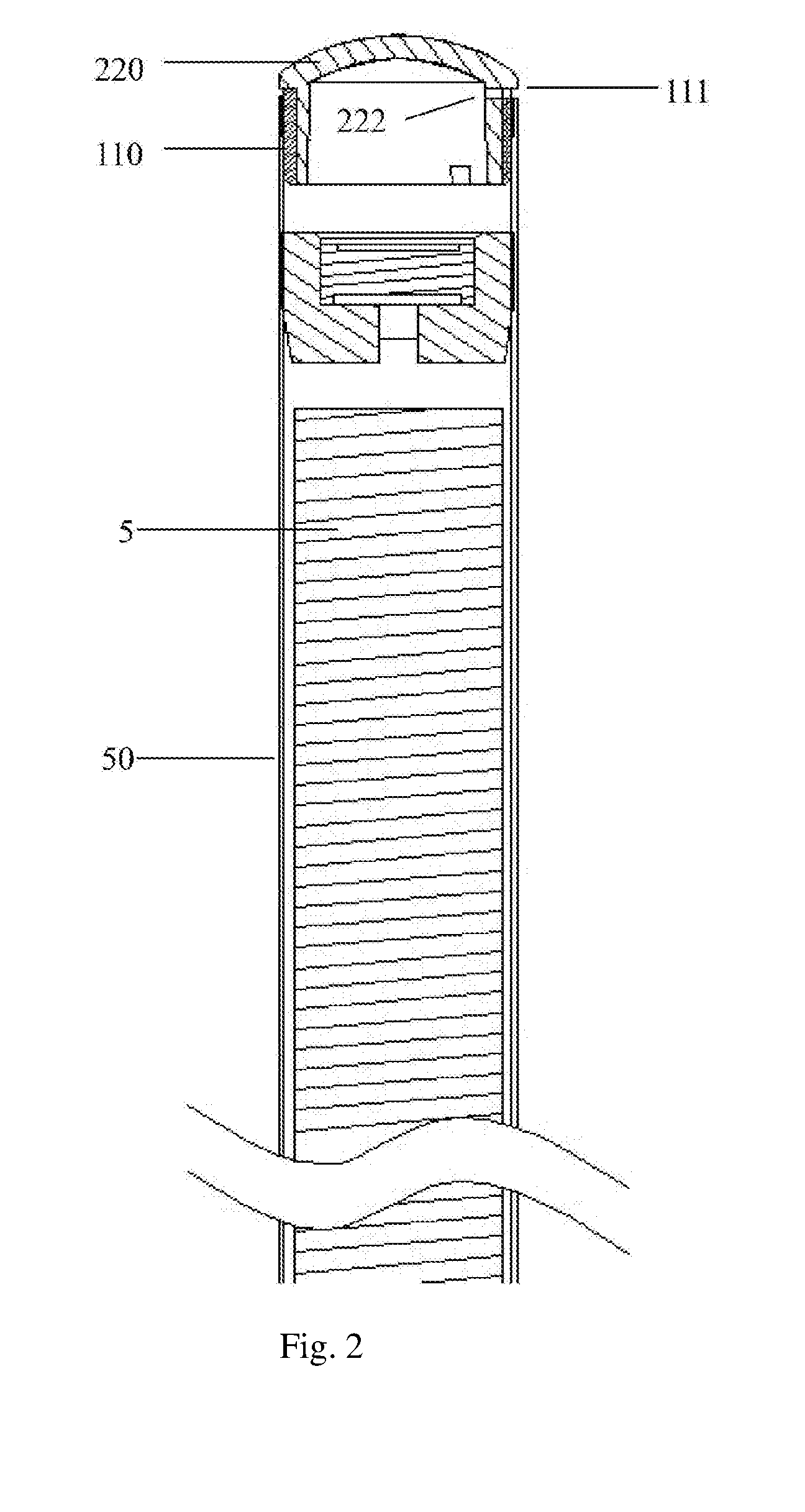

Method and apparatus for wireless power transmission

ActiveUS20080067874A1Sufficient powerSimple and low-cost receivingBatteries circuit arrangementsTransformersElectric power transmissionTransmitted power

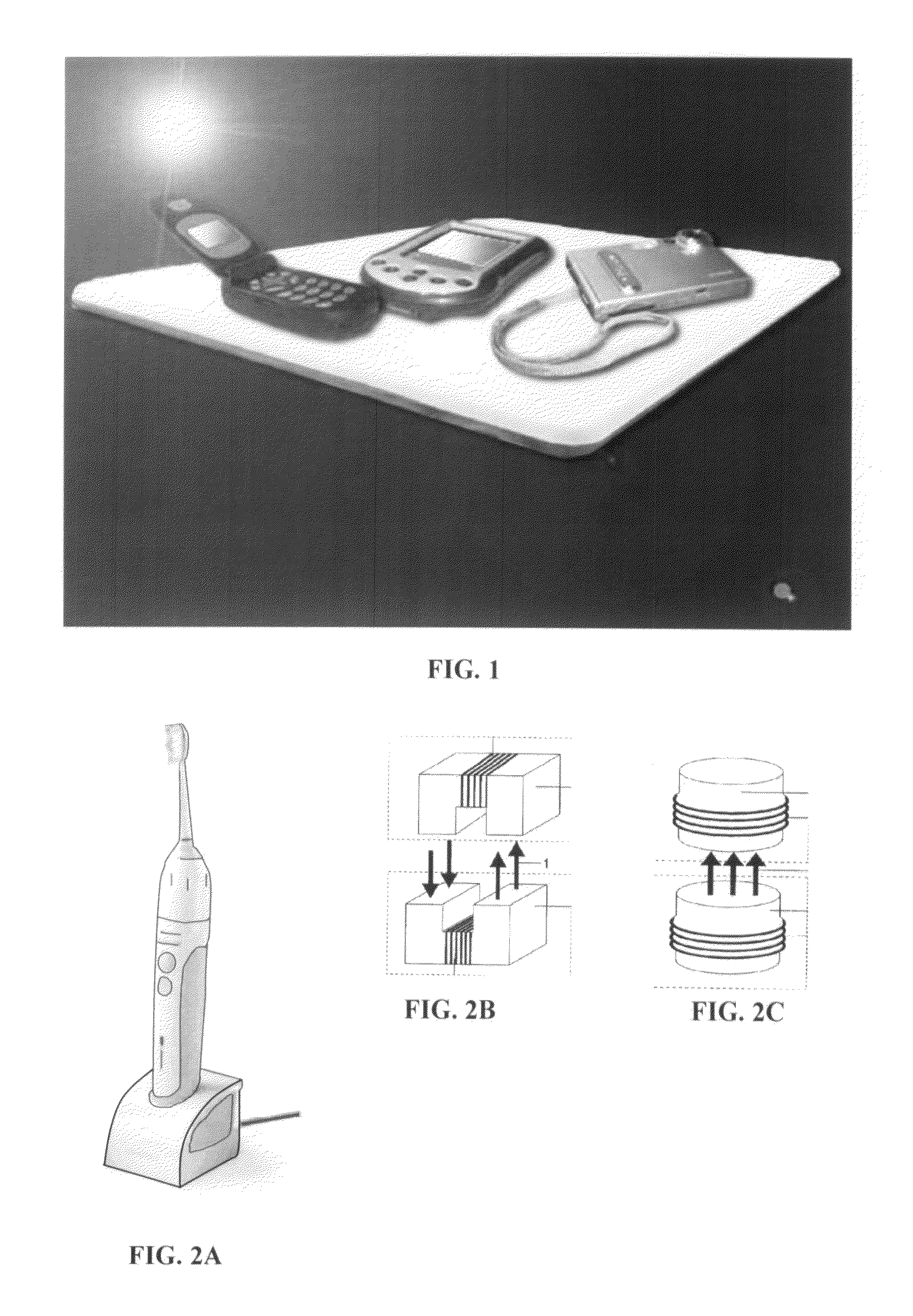

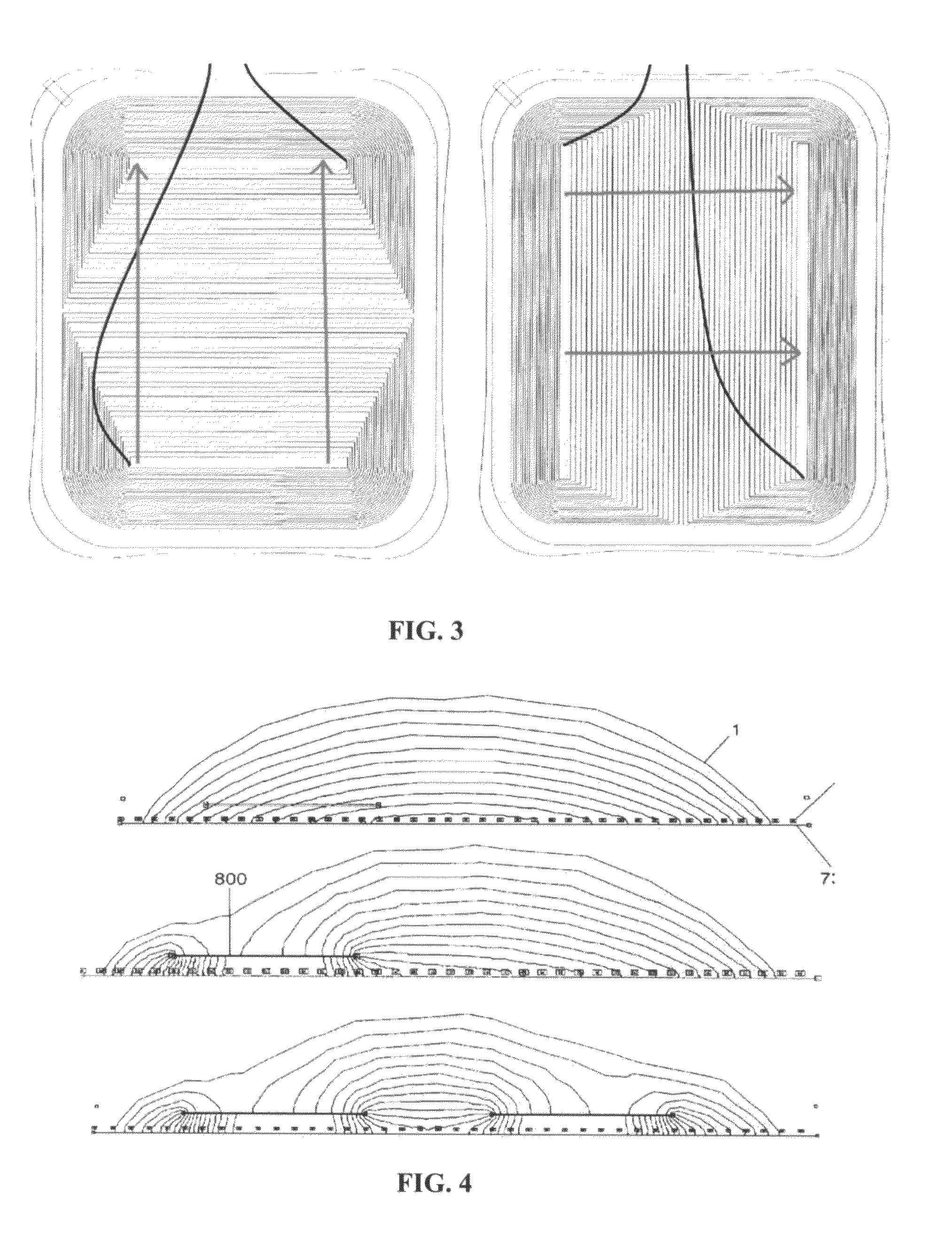

Embodiments of the invention relate to a method and system for transferring power wirelessly to electronic devices. The system can utilize magnetic coupling between two coils at close proximity to transfer sufficient power to charge an electronic device. Embodiments of the invention pertain to an array of spiral coils that can be used to transmit power for transfer to receiver coils. Potential applications of this technology include charging consumer electronic devices (cell phones, laptops, PDAs, etc), developing hermetically sealed devices for extreme environments, and less invasive transcutaneous energy transfer (TET) systems. Various embodiments of the subject system can be referred to as PowerPad system. Embodiments can incorporate one or more of the following: planar inductors, PCB transformers, and very high frequency power supplies. Embodiments of the invention also pertain to planar inductors having characteristics that allow the production of even magnetic field, as well as systems that incorporate such planar inductors.

Owner:QUALCOMM INC

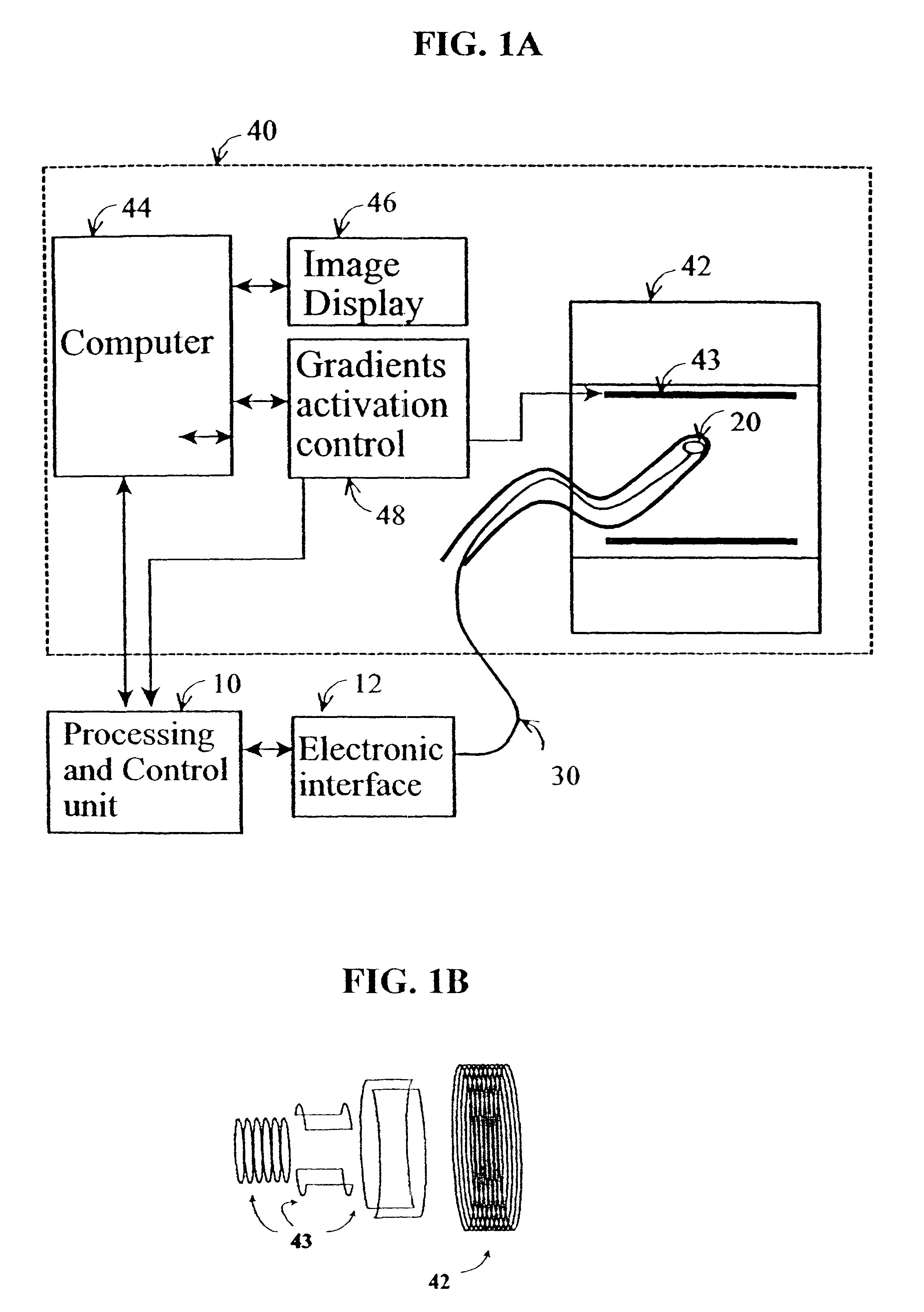

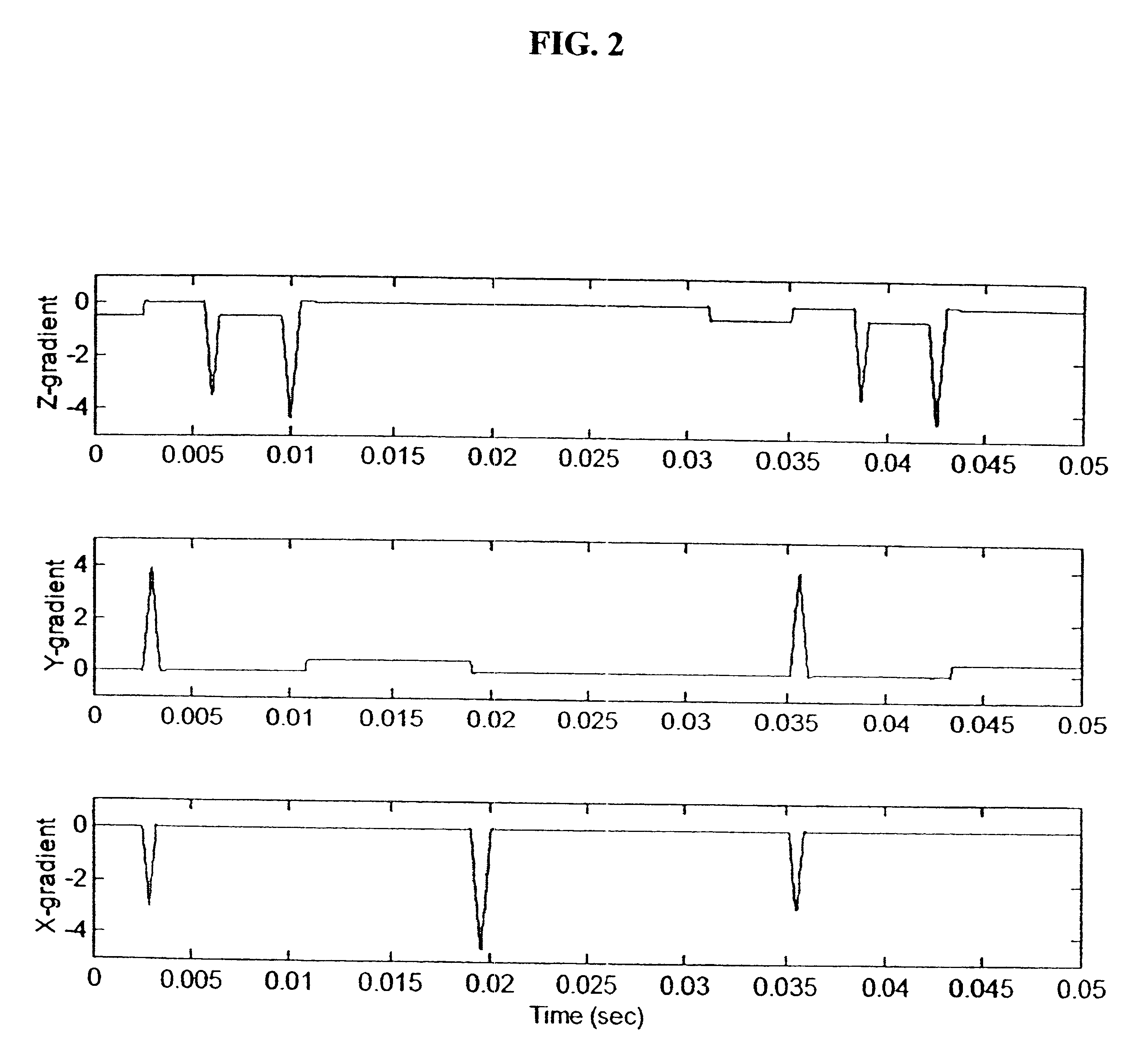

Method and apparatus to estimate location and orientation of objects during magnetic resonance imaging

InactiveUS6516213B1Limited accuracy of orientationSatisfies requirementDiagnostic recording/measuringSensorsMagnetic field gradientThree-dimensional space

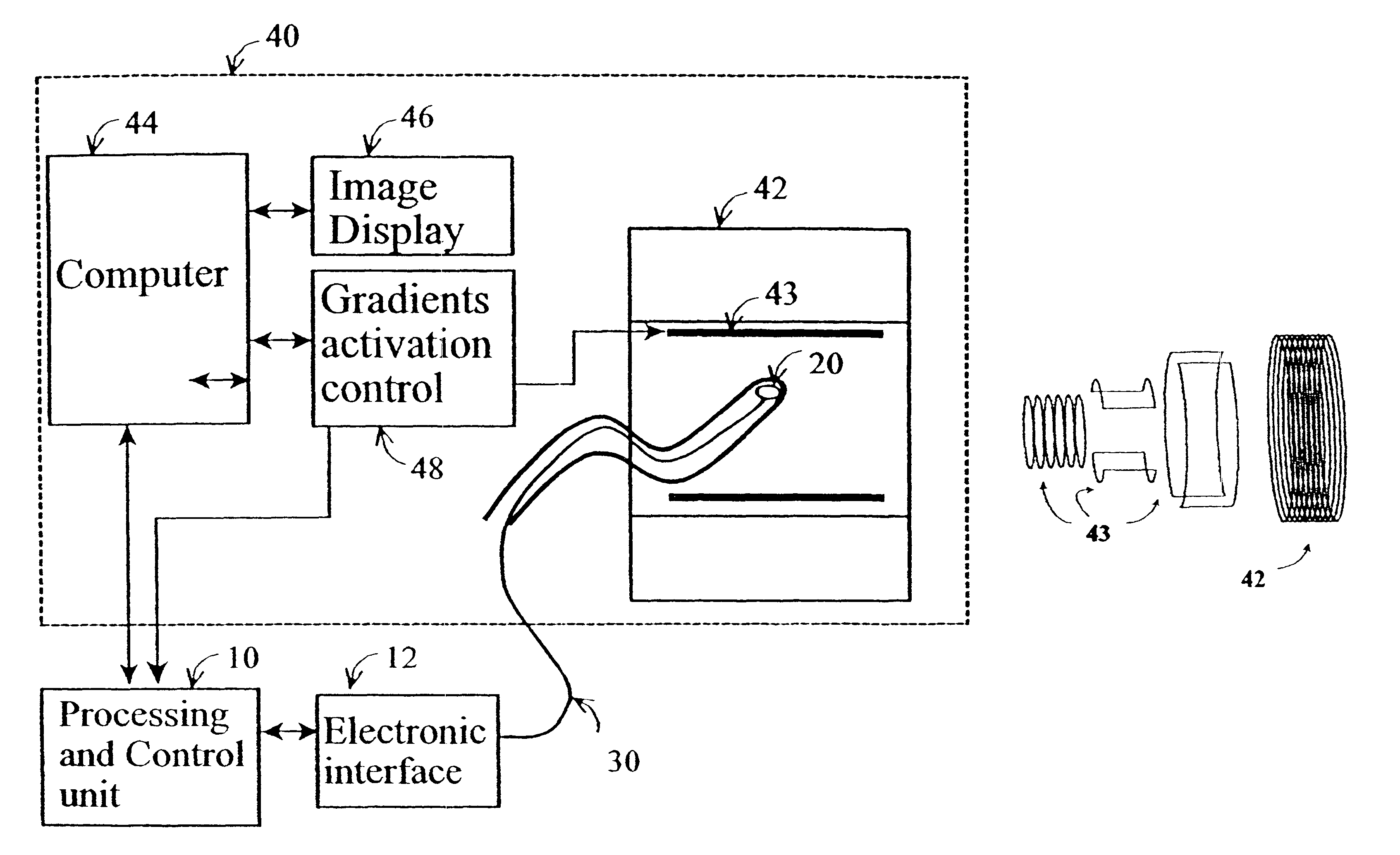

Method and apparatus for determining the instantaneous location, the orientation of an object moving through a three-dimensional space by applying to the object a coil assembly including a plurality of sensor coils (20) having axes of known orientation with respect to each other including components in the three orthogonal planes; generating a time-varying, three-dimensional magnetic field gradient having known instantaneous values of magnitude and direction; applying the magnetic field gradient to the space, and object moving therethrough to induce electrical potentials in the sensor coils; measuring the instantaneous values of the induced electrical potentials generated in the sensor coils; processing the measured instantaneous values generated in the sensor coils together with the known magnitude, direction of the generated magnetic field gradient, the known relative orientation of the sensor coils in the coil assembly to compute the instantaneous location, orientation of the object within the space.

Owner:ROBIN MEDICAL

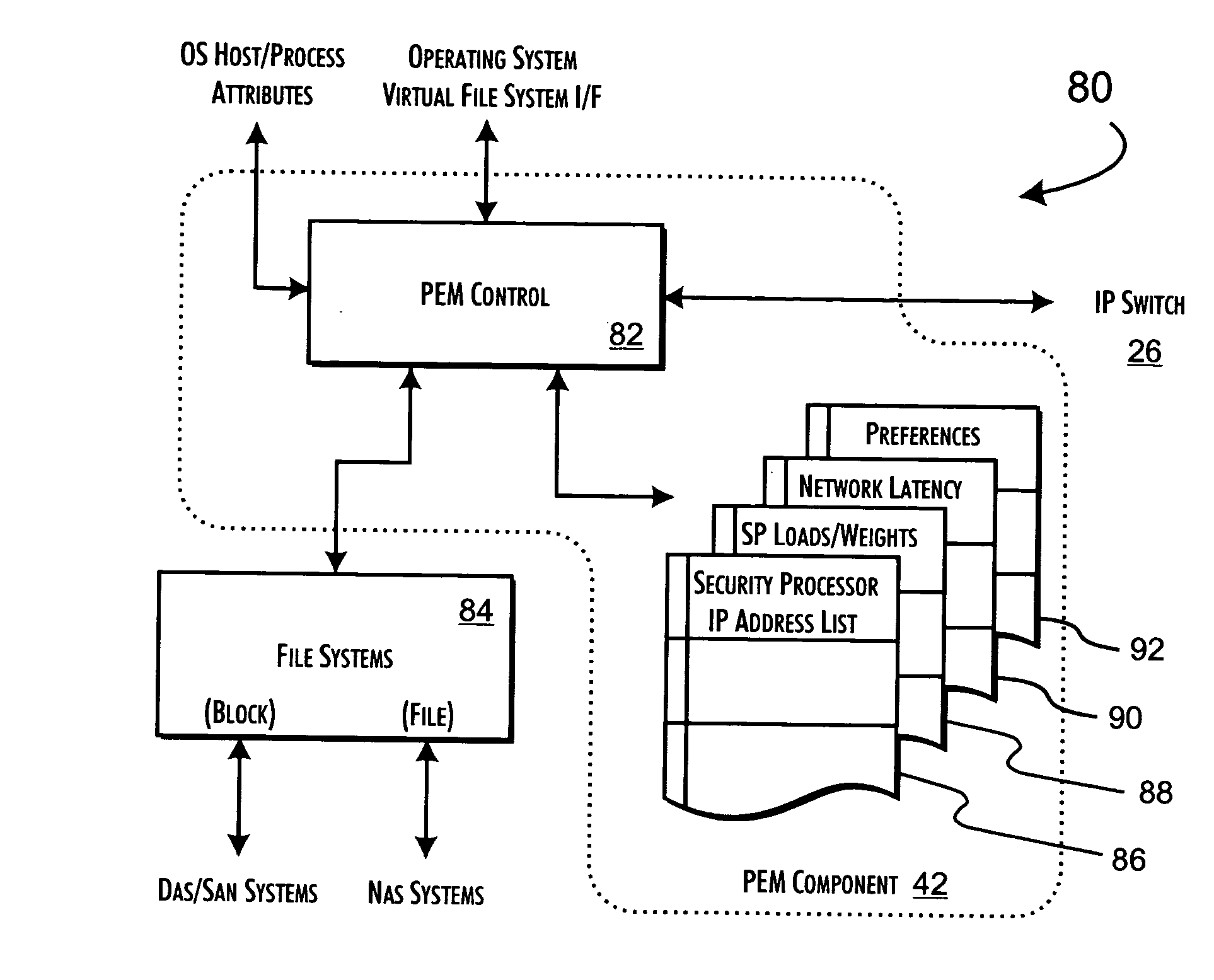

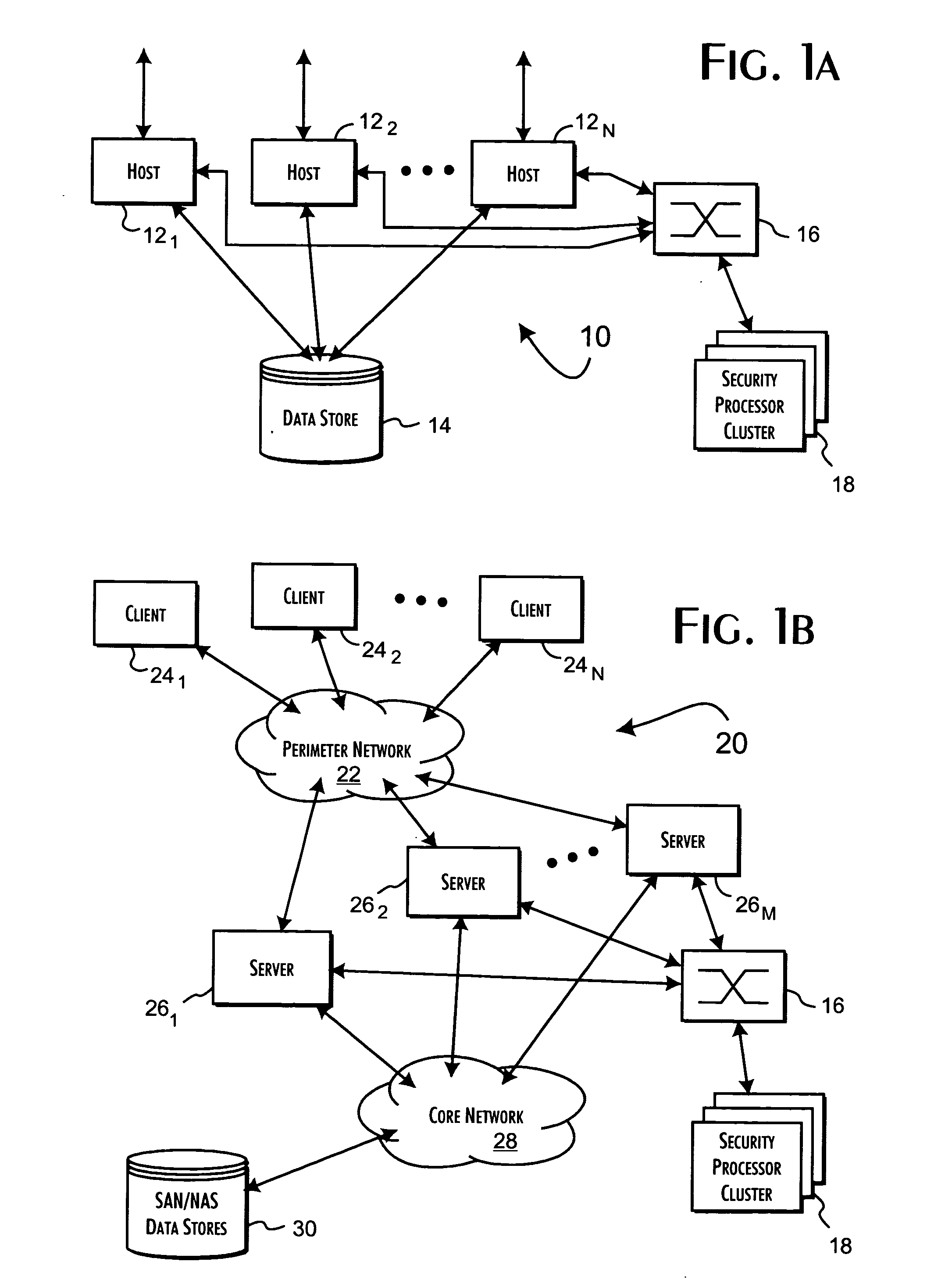

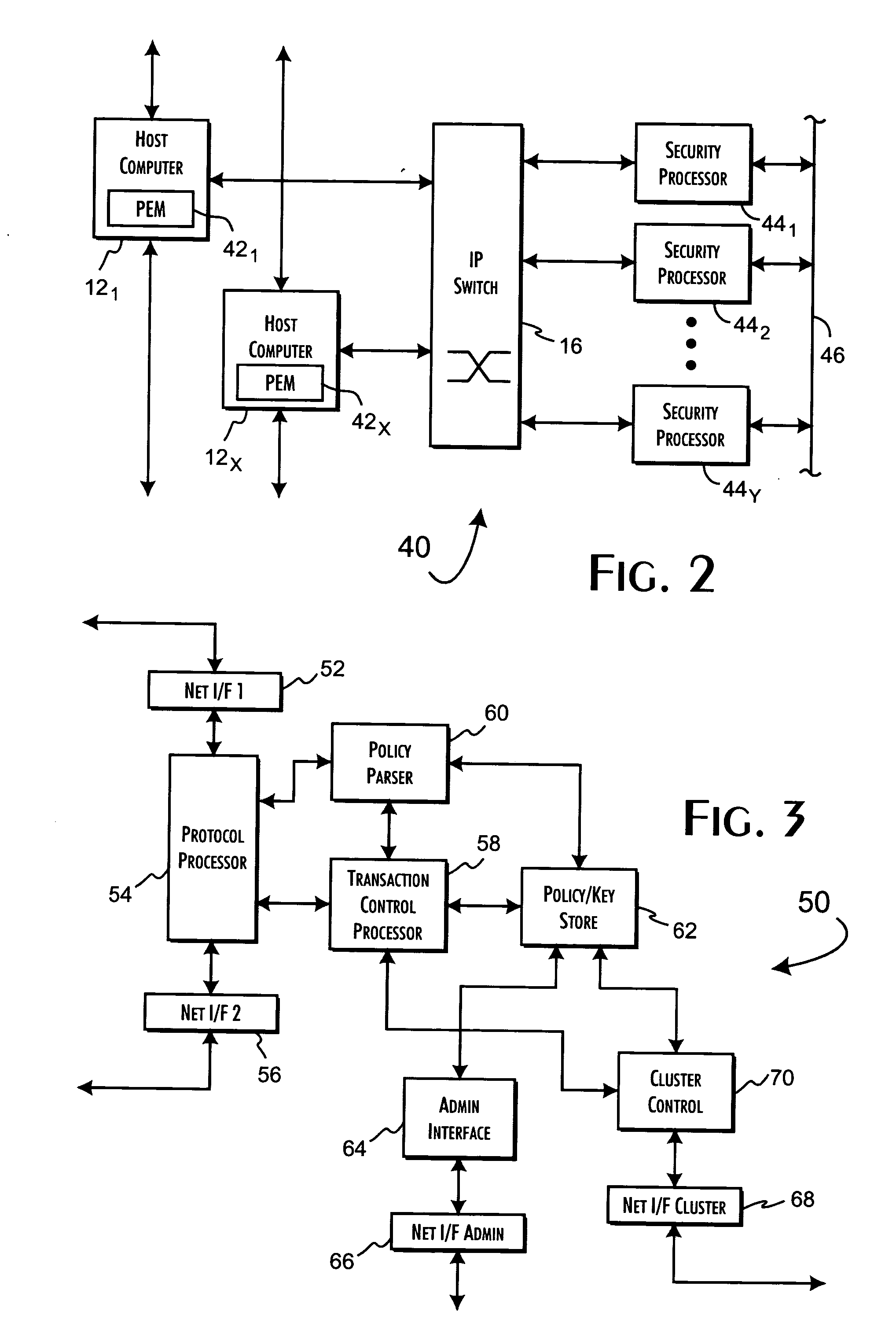

System and methods of cooperatively load-balancing clustered servers

InactiveUS20050027862A1No lost performanceEfficient load balancingDigital computer detailsMultiprogramming arrangementsComputerized systemNetwork service

Host computer systems dynamically engage in independent transactions with servers of a server cluster to request performance of a network service, preferably a policy-based transfer processing of data. The host computer systems operate from an identification of the servers in the cluster to autonomously select servers for transactions qualified on server performance information gathered in prior transactions. Server performance information may include load and weight values that reflect the performance status of the selected server and a server localized policy evaluation of service request attribute information provided in conjunction with the service request. The load selection of specific servers for individual transactions is balanced implicitly through the cooperation of the host computer systems and servers of the server cluster.

Owner:VORMETRIC INC

Methods and Systems for Modular Buildings

InactiveUS20100235206A1Modify designSatisfies requirementRoof covering using slabs/sheetsPublic buildingsModular constructionEngineering

The present invention provides a multifunctional building panel which may comprise a sensor to measure an interior condition and an exterior condition and generate a signal in response, along with systems and methods for designing, optimizing and constructing modular buildings, including buildings constructed at least in part of multifunctional building panels, by utilizing a priority distribution ranking as an optimization constraint.

Owner:PROJECT FROG INC

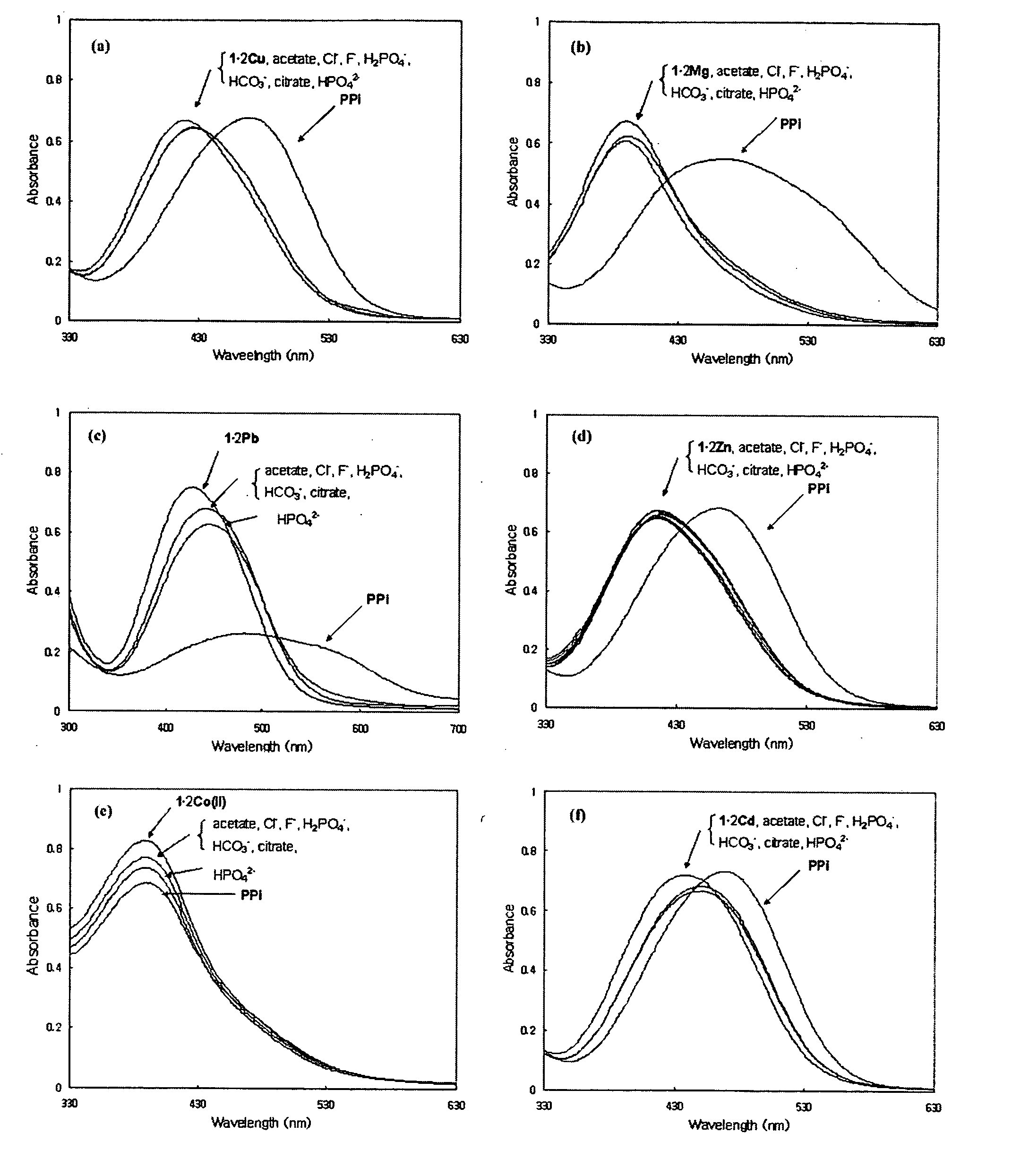

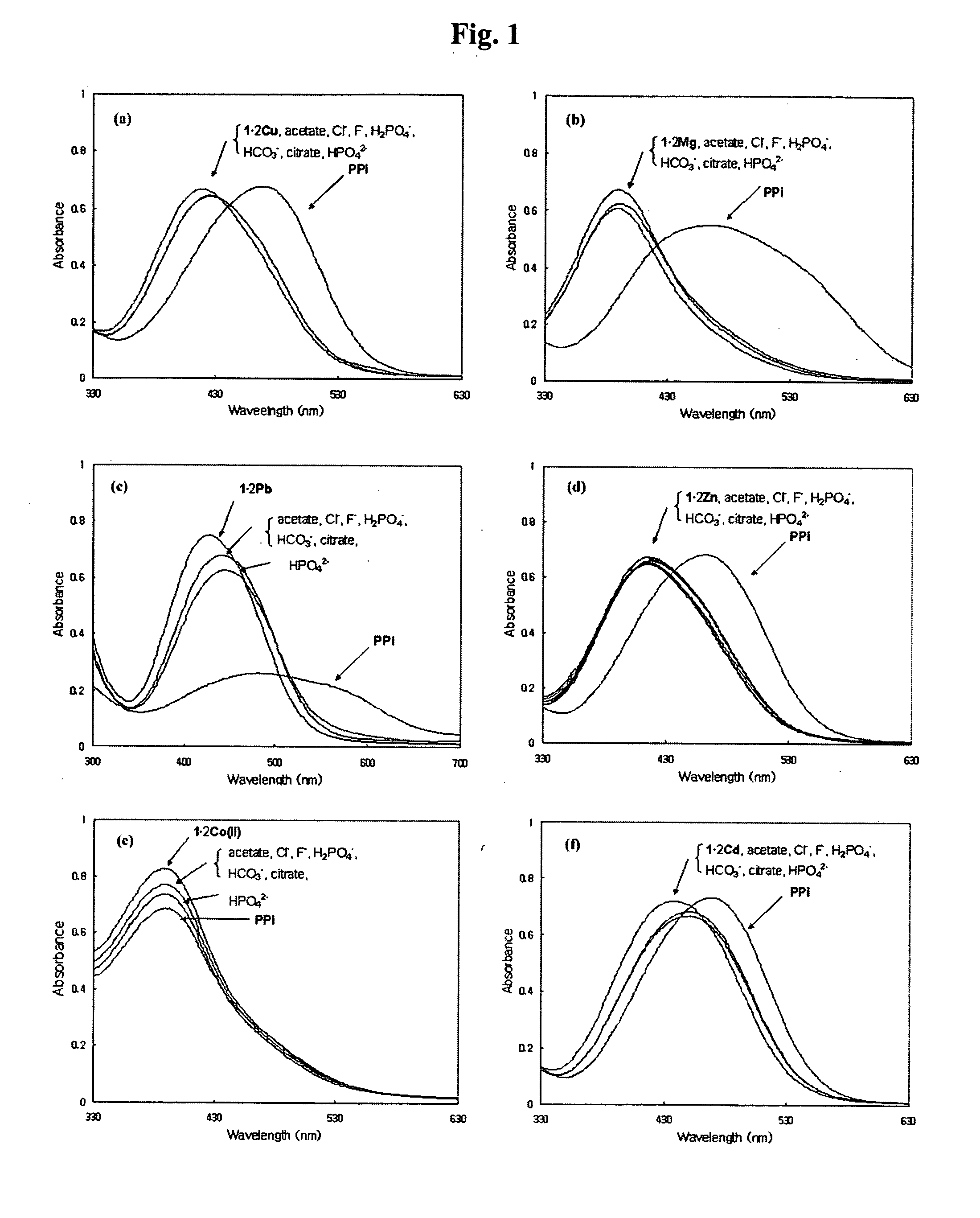

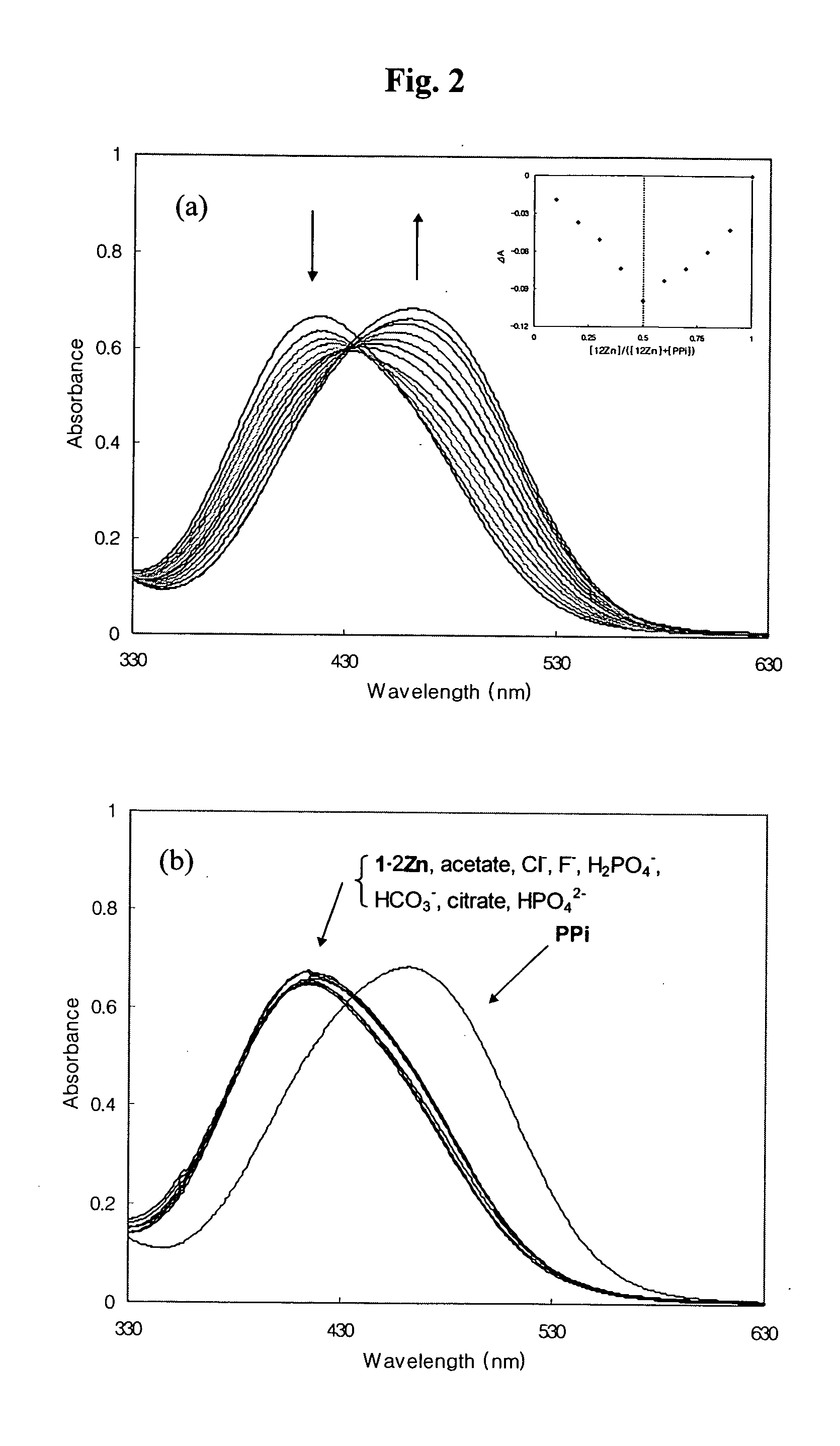

Novel dinuclear metal complex and pyrophosphate assay using the same

InactiveUS20050119497A1Increase electron densityEnhanced electron donationUltrasonic/sonic/infrasonic diagnosticsGroup 8/9/10/18 element organic compoundsElectronic densityPyrophosphate

A novel coordination complex formed by dinuclear metal complexation is provided. The complex is a dinuclear metal complex of a compound, wherein the compound comprises a conjugation ring system substituted with: a) an electron donating group selected from —OH, —SH and —NH2; b) an indicating group selected from a chromogenic group, a fluorescent group and an electrochemical group; and c) two binding auxiliary groups, in combination with the electron donating group each of which being coordinated with the metal to provide an anion bonding site, wherein as the complex binds to a anion, the coordination of the electron donating group with the metal is weakened and electron donation of the electron donating group to the conjugation ring system is reinforced such that the reinforced electron donation by the electron donating group is transferred through the conjugation ring system to the indicating group to produce an indicating signal concomitant with the change of its electronic density. The coordination complex shows high sensitivity and high selectivity for pyrophosphate over other anions in an aqueous solvent over a wide pH range. Therefore, the complex is useful for pyrophosphate assay as a pyrophosphate sensor.

Owner:SEOUL NAT UNIV FOUND

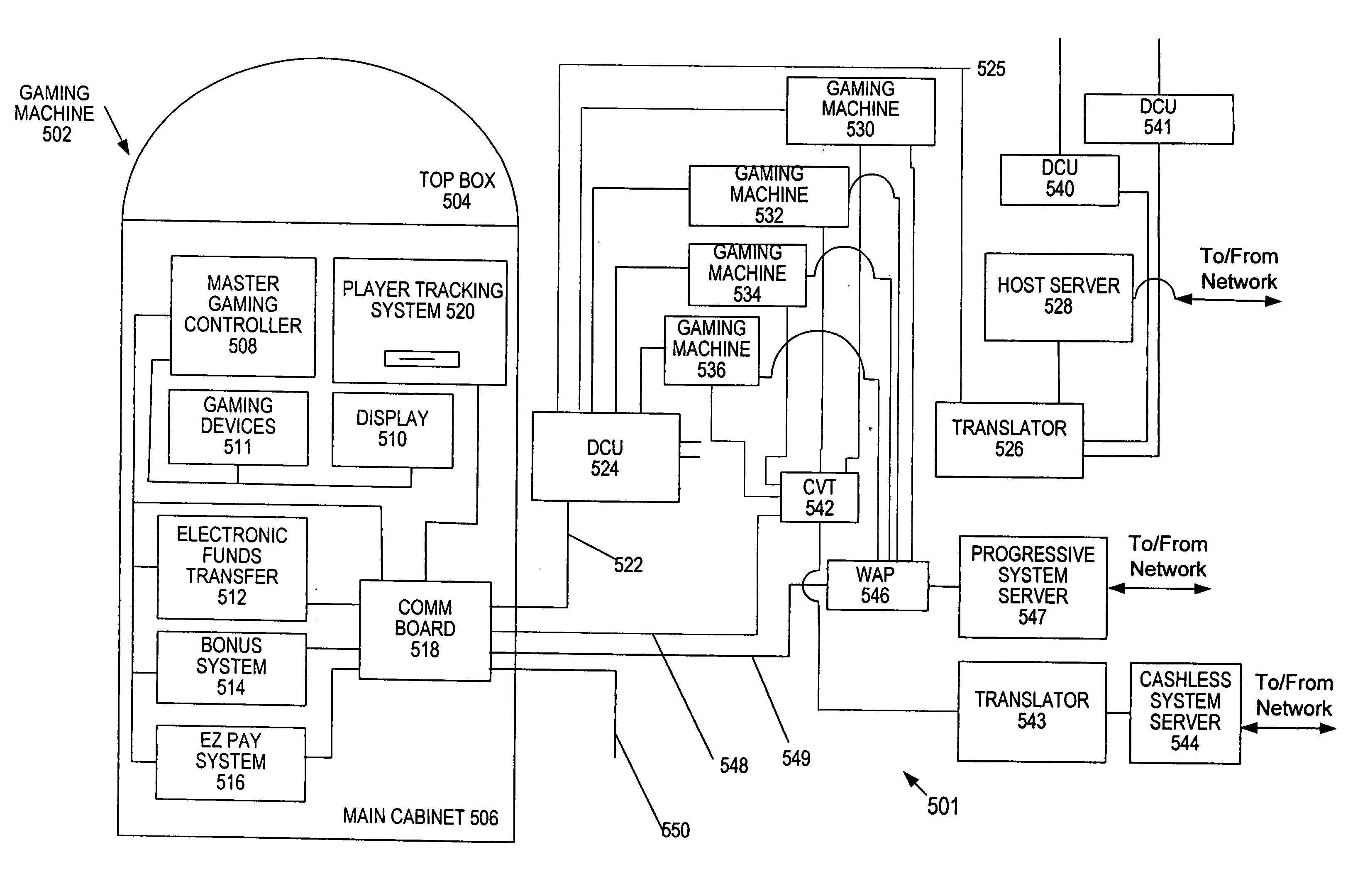

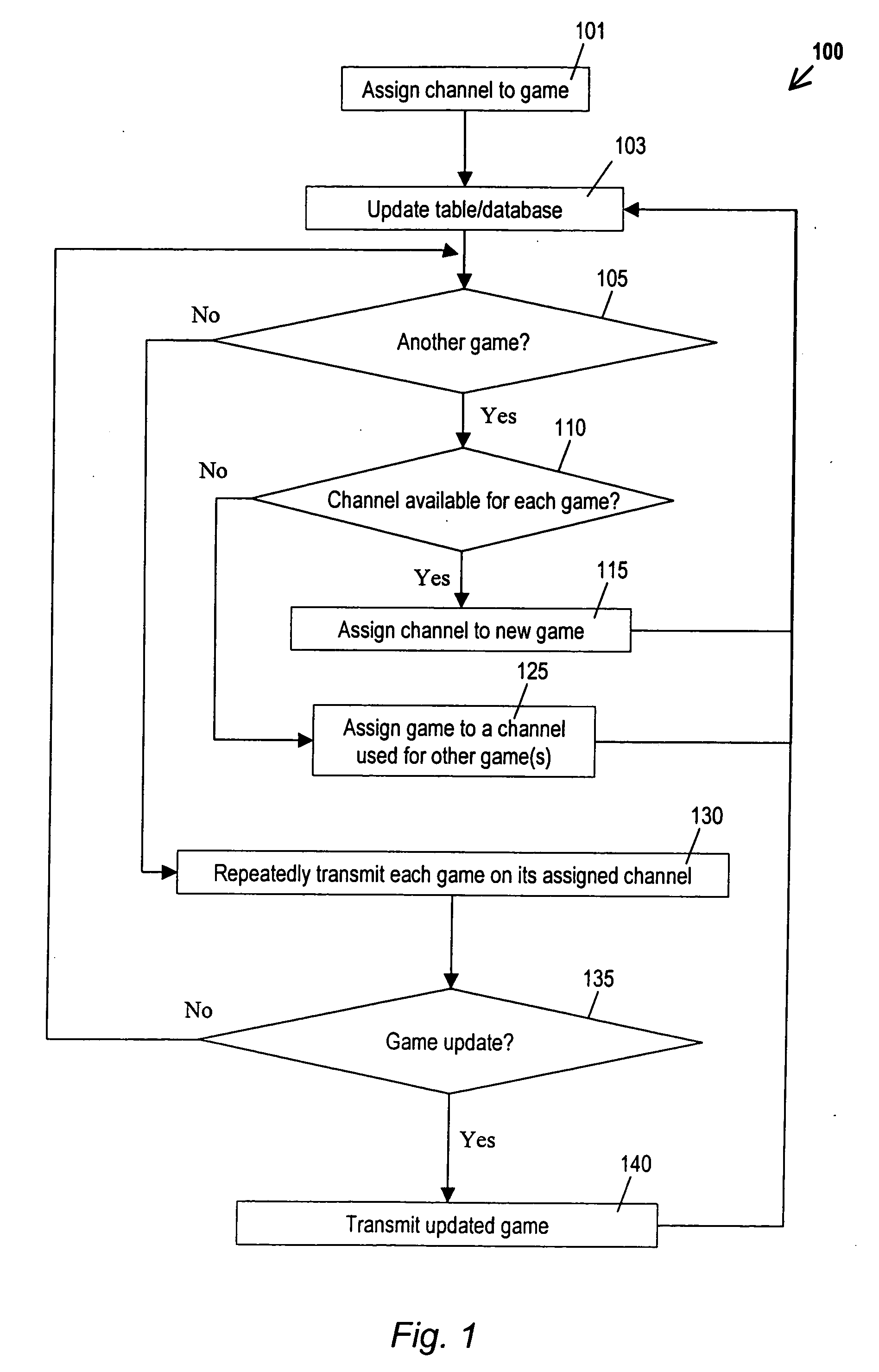

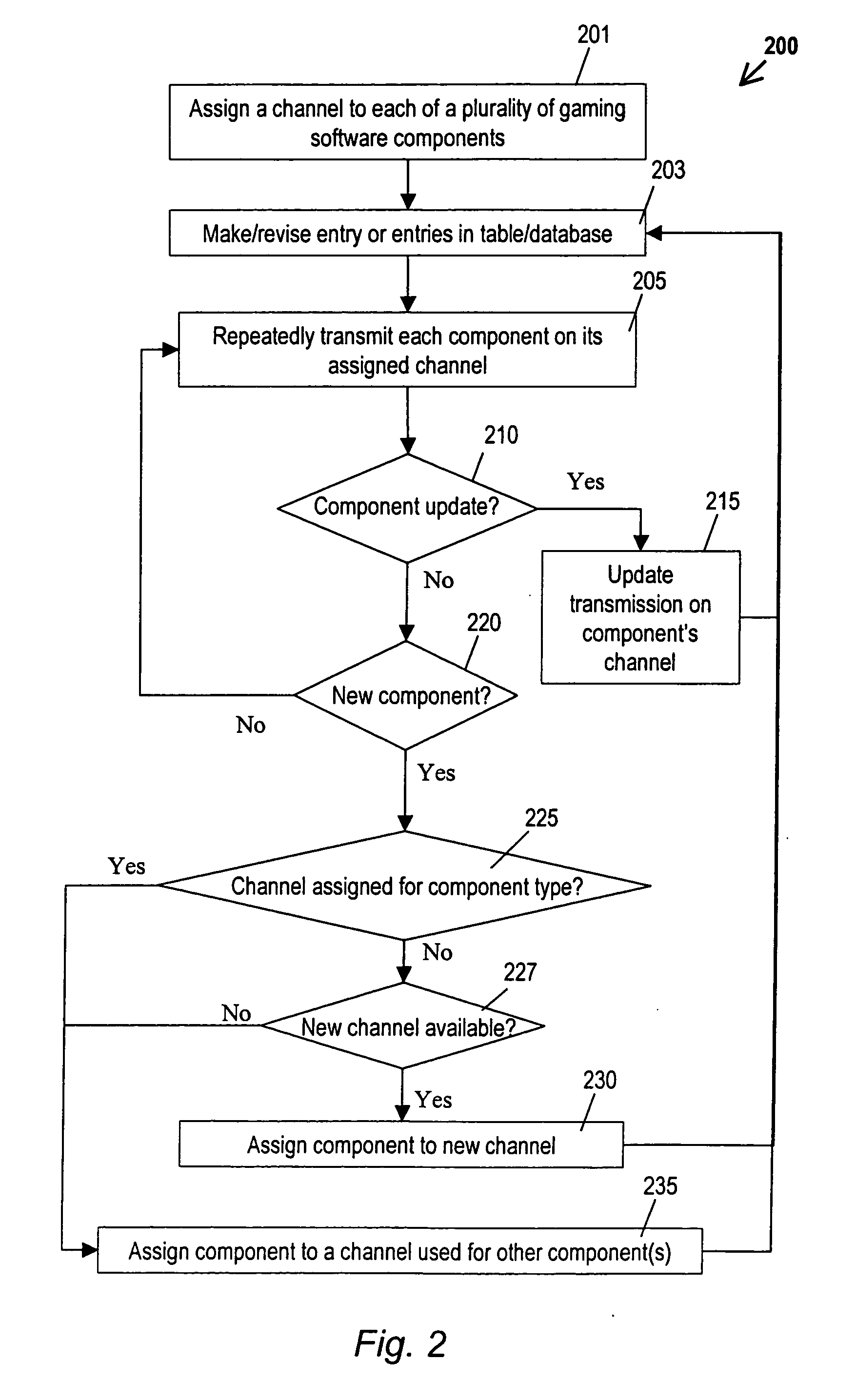

Methods and devices for downloading games of chance

InactiveUS20070004506A1Satisfies requirementData resettingApparatus for meter-controlled dispensingNetwork onPublic network

The present invention provides methods, devices and systems for downloading gaming software. According to some implementations of the invention, gaming software is continuously transmitted on a plurality of channels, e.g., by one or more servers. In some such implementations, each channel is dedicated to software for a different wagering game. In other implementations, gaming software components are transmitted on a plurality of channels, with each channel dedicated to a particular gaming software component. Some implementations provide gaming software in response to a request from a gaming machine. Implementations over dedicated and / or public networks are provided. Preferred implementations of the invention allow gaming software to be downloaded to gaming machines in a secure manner that automatically ensures that licensing and regulatory requirements are satisfied. Some such implementations determine whether payment is required for gaming software and provide for automated payment, if so required.

Owner:IGT

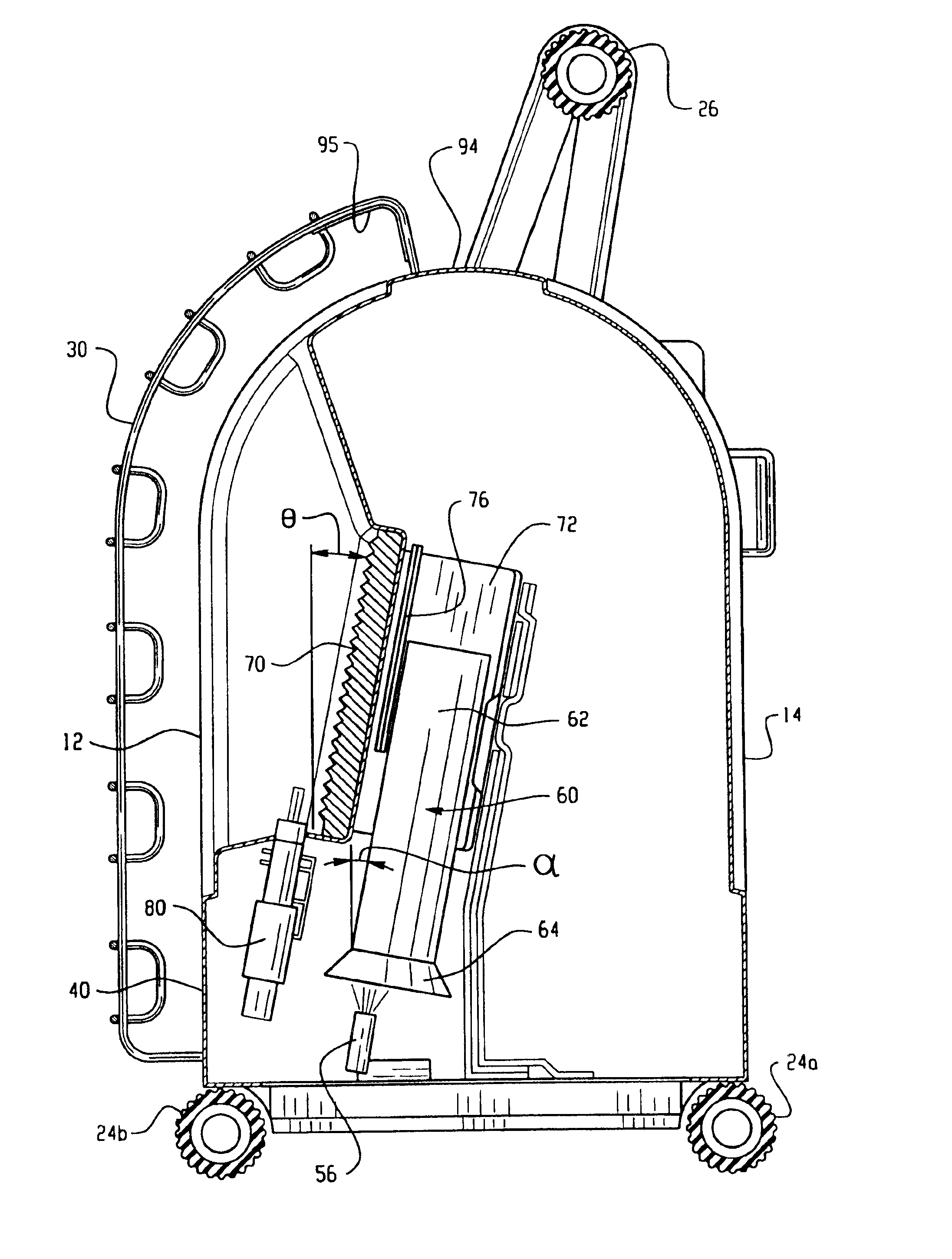

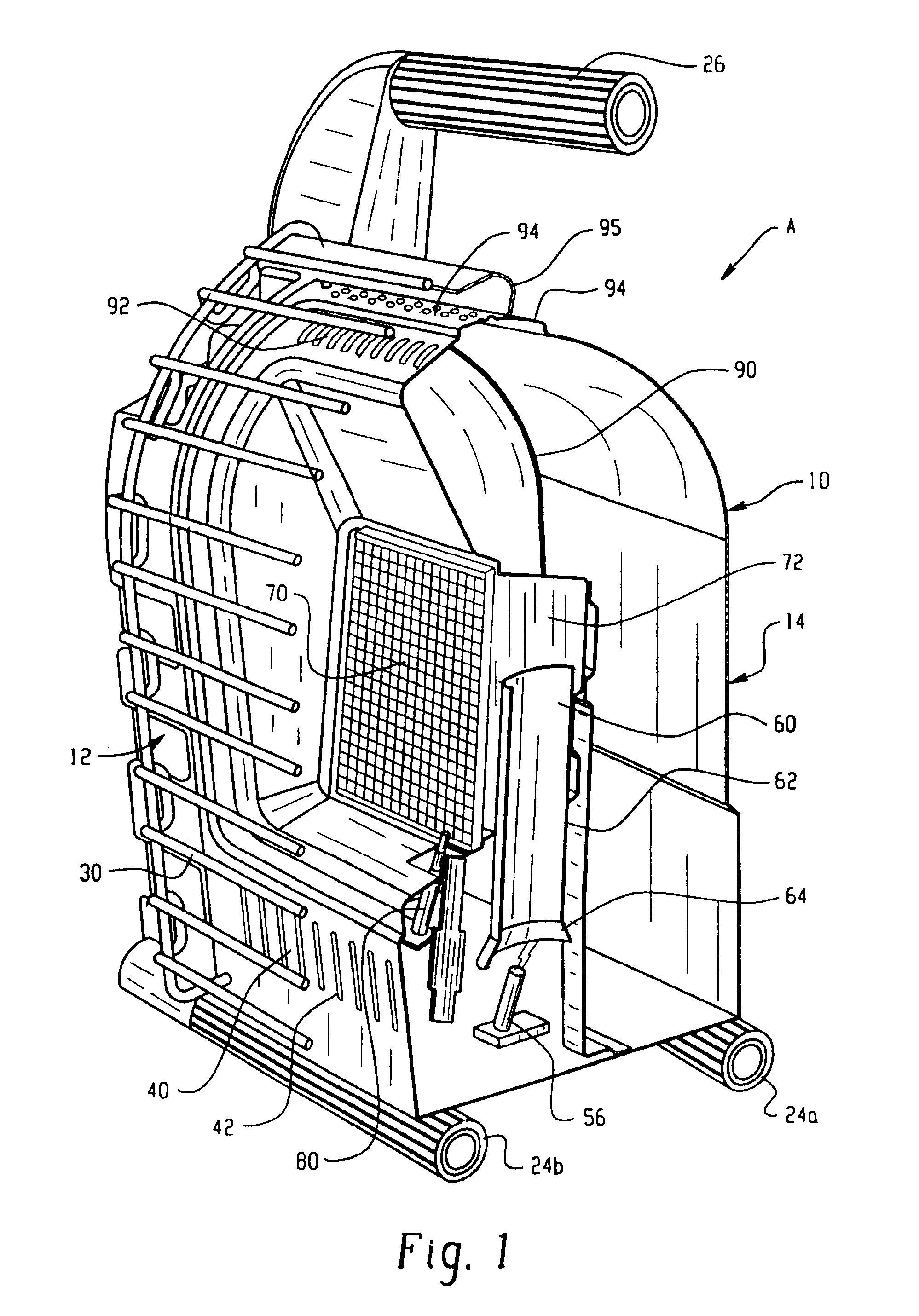

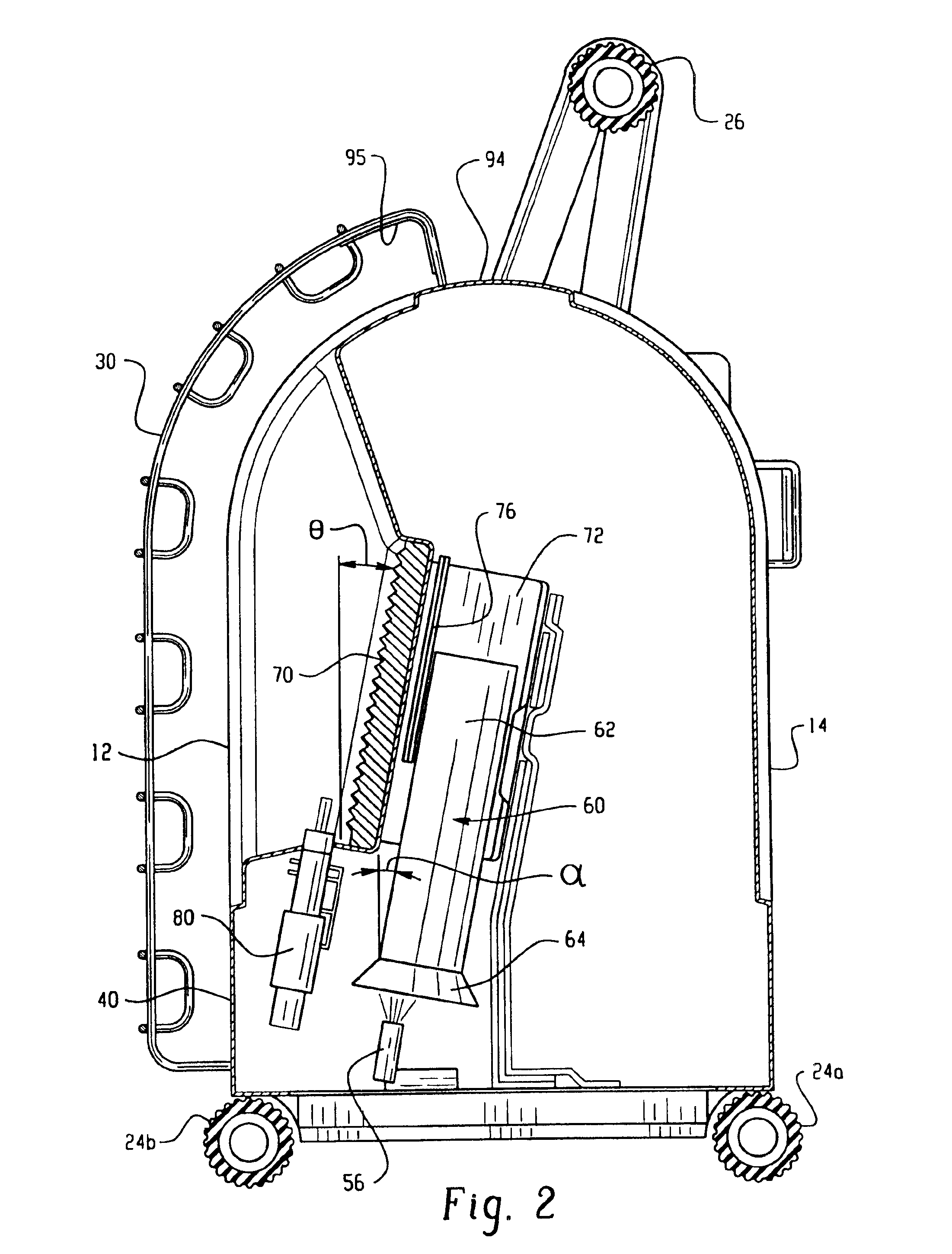

Gas fired portable unvented infrared heater

InactiveUS6884065B2Reduce the temperatureIncrease air velocityMechanical apparatusDomestic stoves or rangesFresh airEngineering

A portable heater adapted for use in a recreational enclosure or temporary work enclosure includes a housing having an air inlet on the lower front face. A gas supply is partially enclosed by the housing which provides propane to the mouth of a burner venturi located within the housing. Air is drawn through the air inlet and also enters the mouth of the burner venturi. The air and gas are mixed thoroughly as they travel upwardly through the burner venturi. A chimney effect increases fresh air flow velocity into the burner venturi and allows the heater to operate at a reduced fuel gas pressure. Upon exiting the burner venturi, the air / gas mixture is to a plenum and radiant surface where combustion takes place. Any conventional means may be provided to ignite the air / gas mixture in order to cause combustion. The combustion products deflect off a deflector, which is cooled on a rear face by air flow through the housing, which decreases the temperature of the combustion products before exiting an outlet. An oxygen depletion system (ODS) shuts off the portable heater when oxygen levels begin to drop and consequently carbon monoxide levels begin to rise.

Owner:ENERCO GROUP

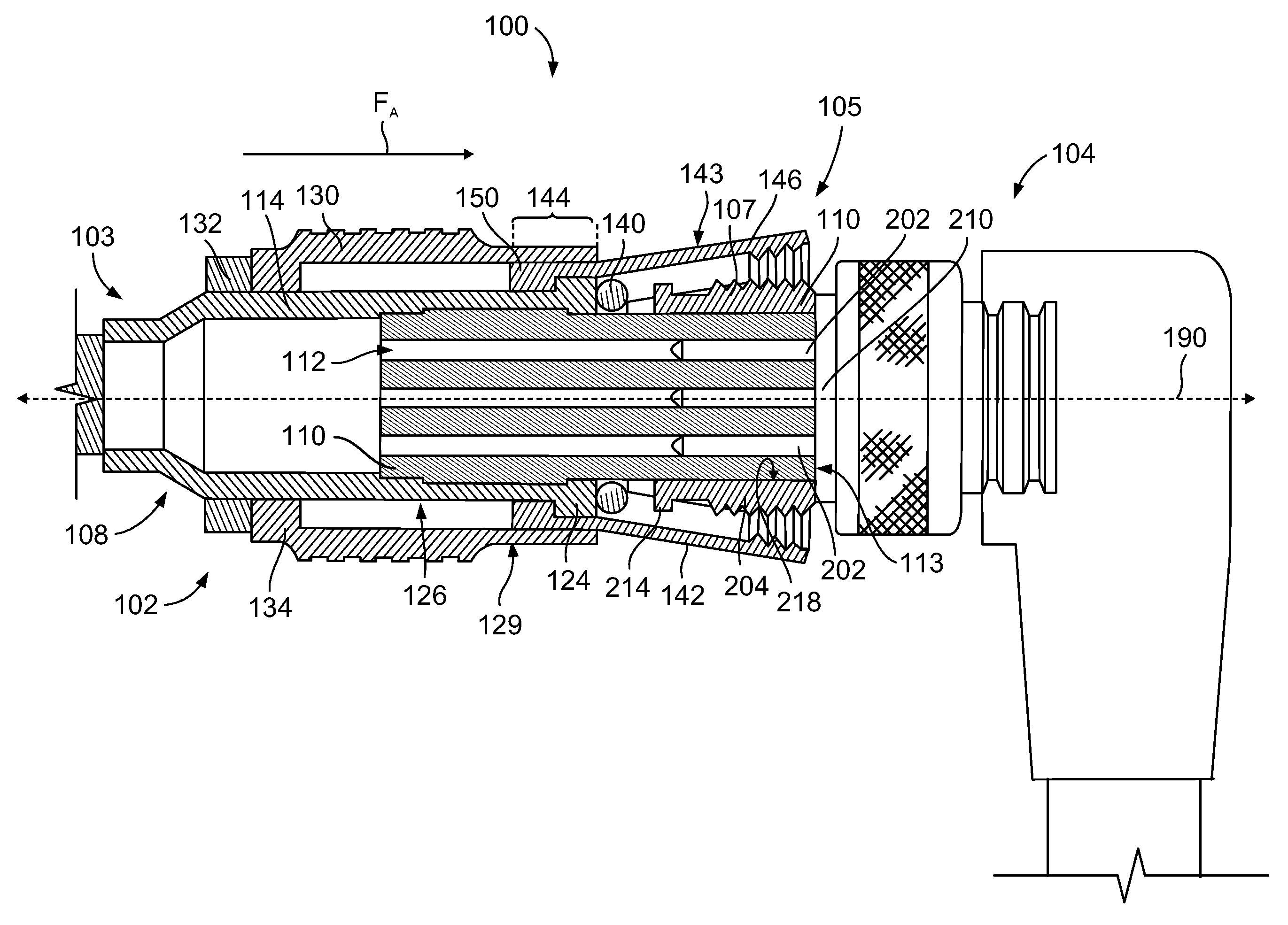

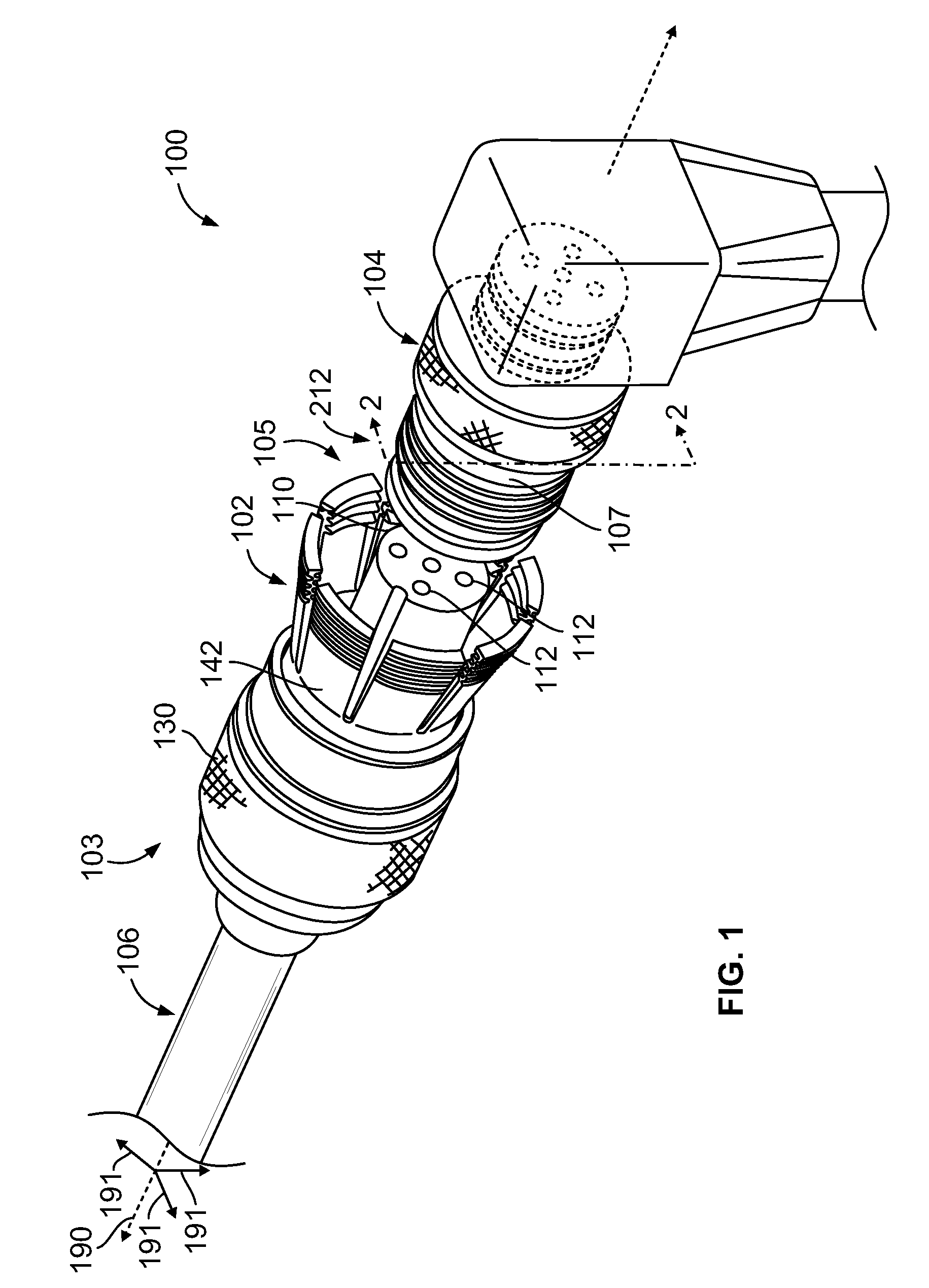

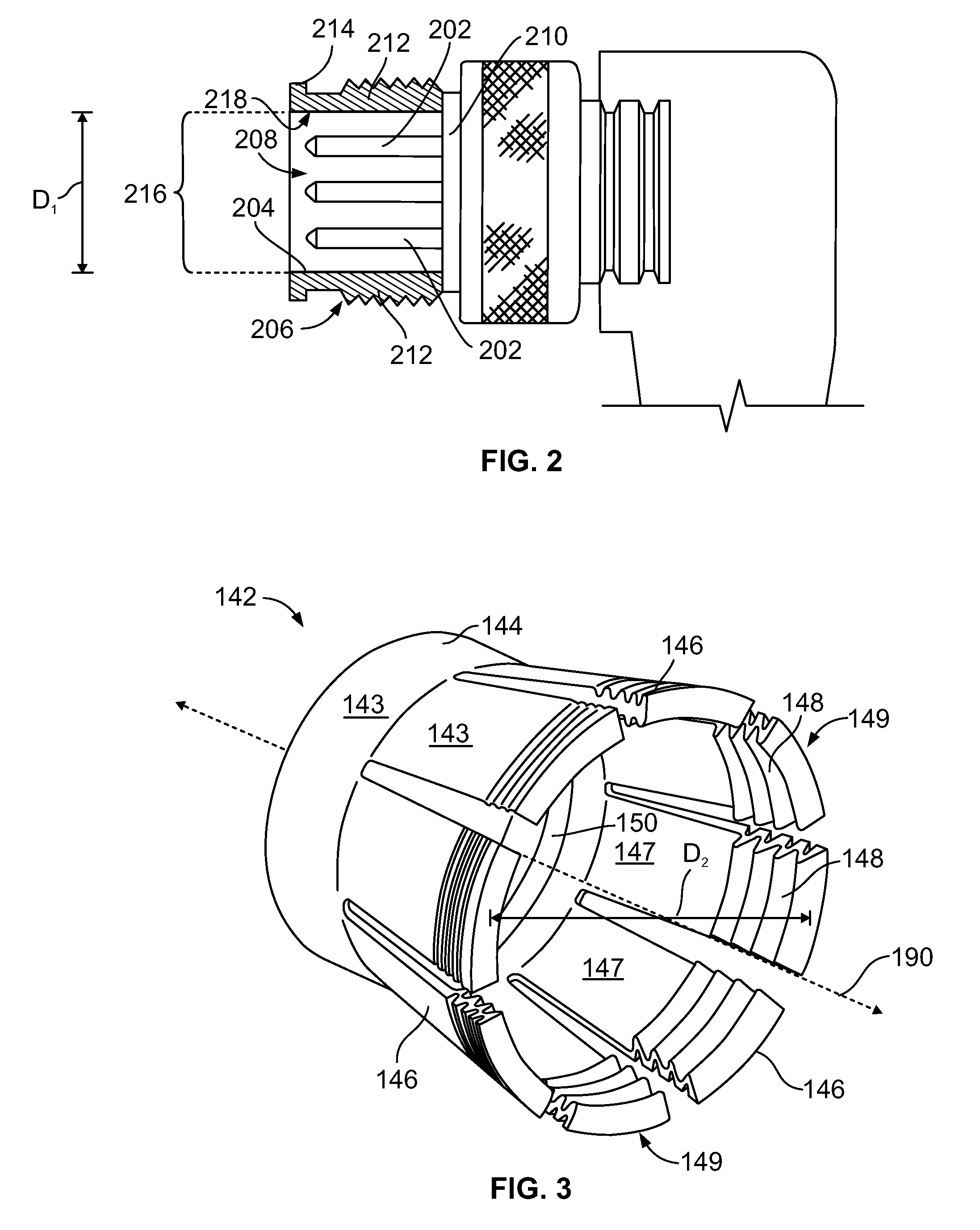

Connector having a sleeve member

ActiveUS20090264003A1Satisfies requirementEngagement/disengagement of coupling partsElectrically conductive connectionsMating connectionEngineering

A connector assembly configured to sealably engage with a mating connector. The connector assembly includes a plug assembly that has a mating end configured to be inserted into the cavity of the mating connector. The connector assembly also includes a collar that surrounds the plug assembly. The connector assembly also includes a sleeve member that is positioned between the collar and the plug assembly. The sleeve member surrounds the plug assembly about the central axis and includes a plurality of fingers that extend toward the mating end. The sleeve member is stamped and formed from a common piece of sheet material. The fingers are biased away from the central axis in a flared arrangement when the collar is in the withdrawn position. The lingers press against the wall surface of the mating connector when the collar is moved from the withdrawn position to the locked position.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

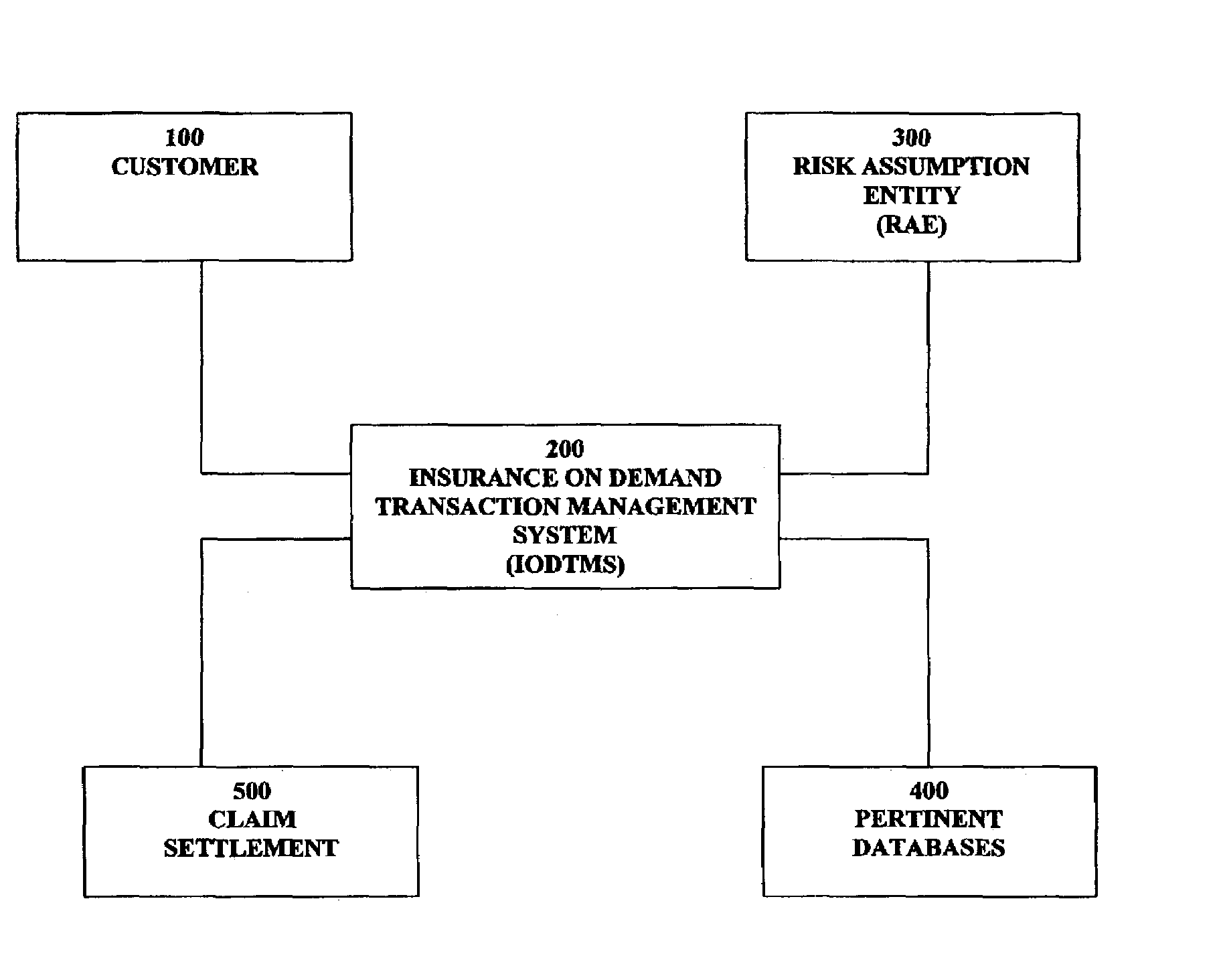

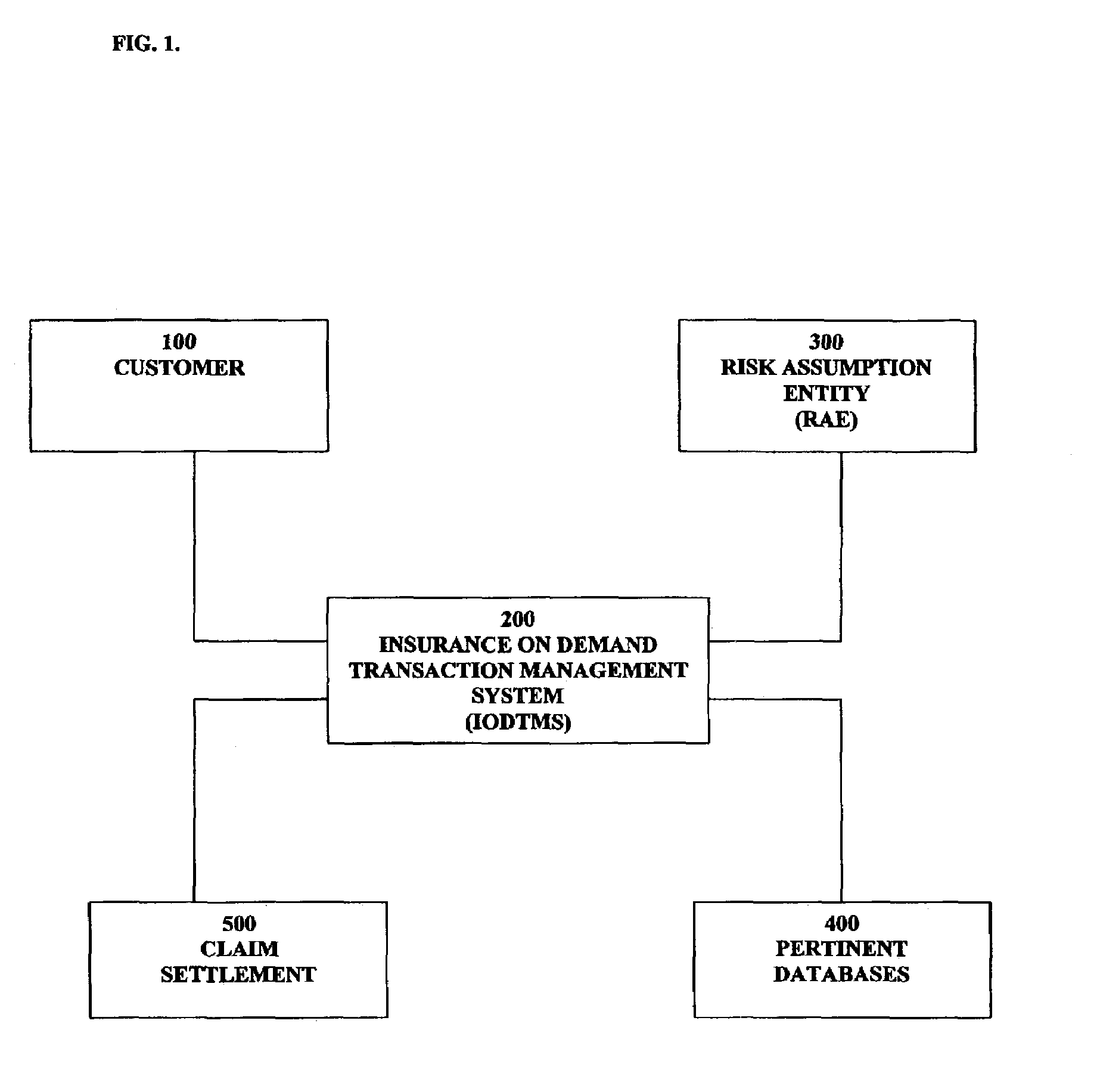

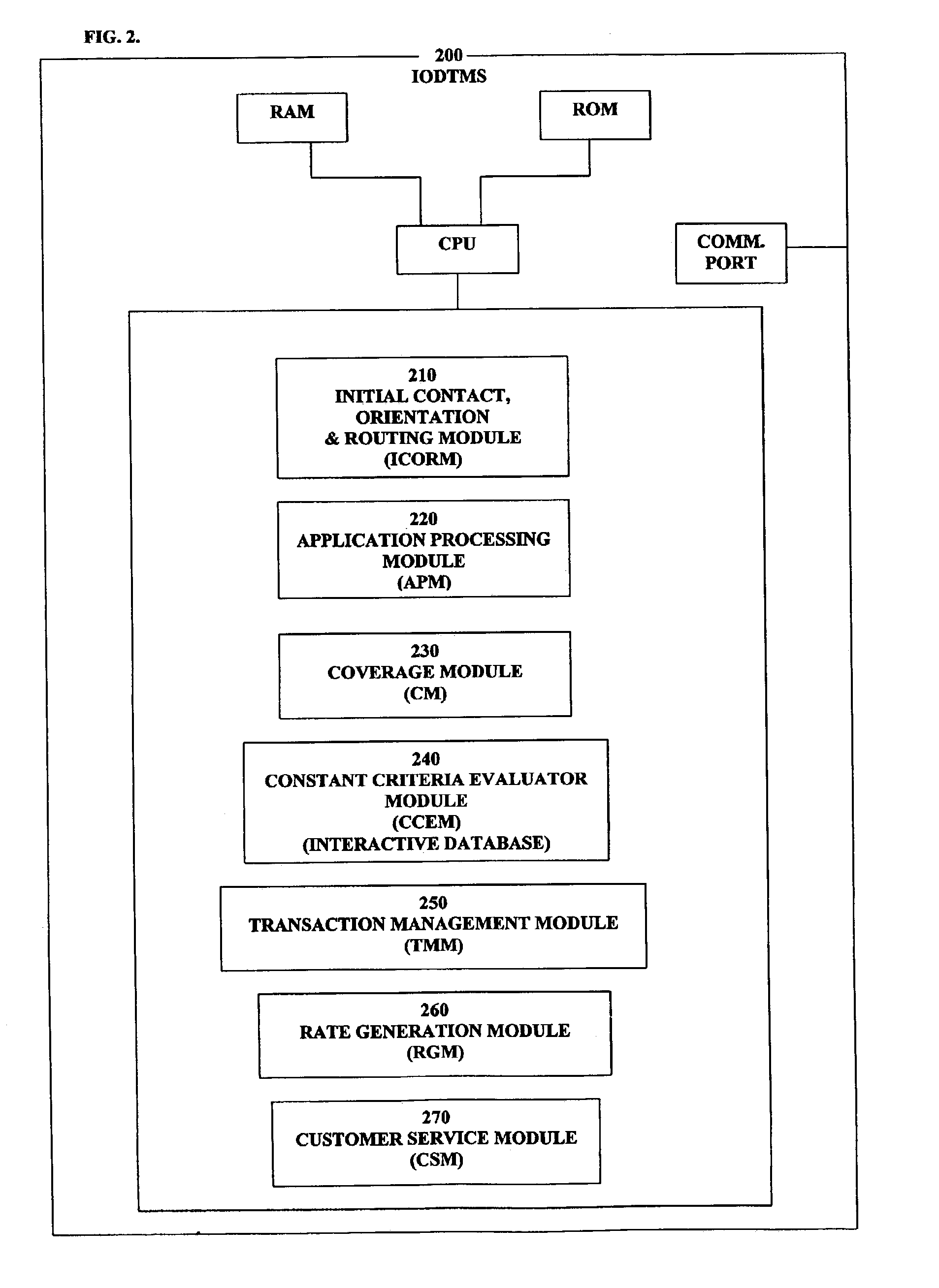

Insurance on demand transaction management system

An intermittent risk exposure liability insurance method comprising the steps of: establishing an Internet business site enabled for communication with insurers and insureds through Internet service providers; enrolling the insureds in intermittent risk exposure liability insurance policies, the policies providing for a variable insurance premium rate depending upon an intermittent use of an insured article; logging start and completion times of each intermittent use of the insured article on the Internet business site by the insured; verifying start and completion times of use of the insured article in accordance with the logged start and completion times; and applying and billing premium insurance rates in accordance with the verified and logged start and completion times of use.

Owner:STRECH KENNETH RAY

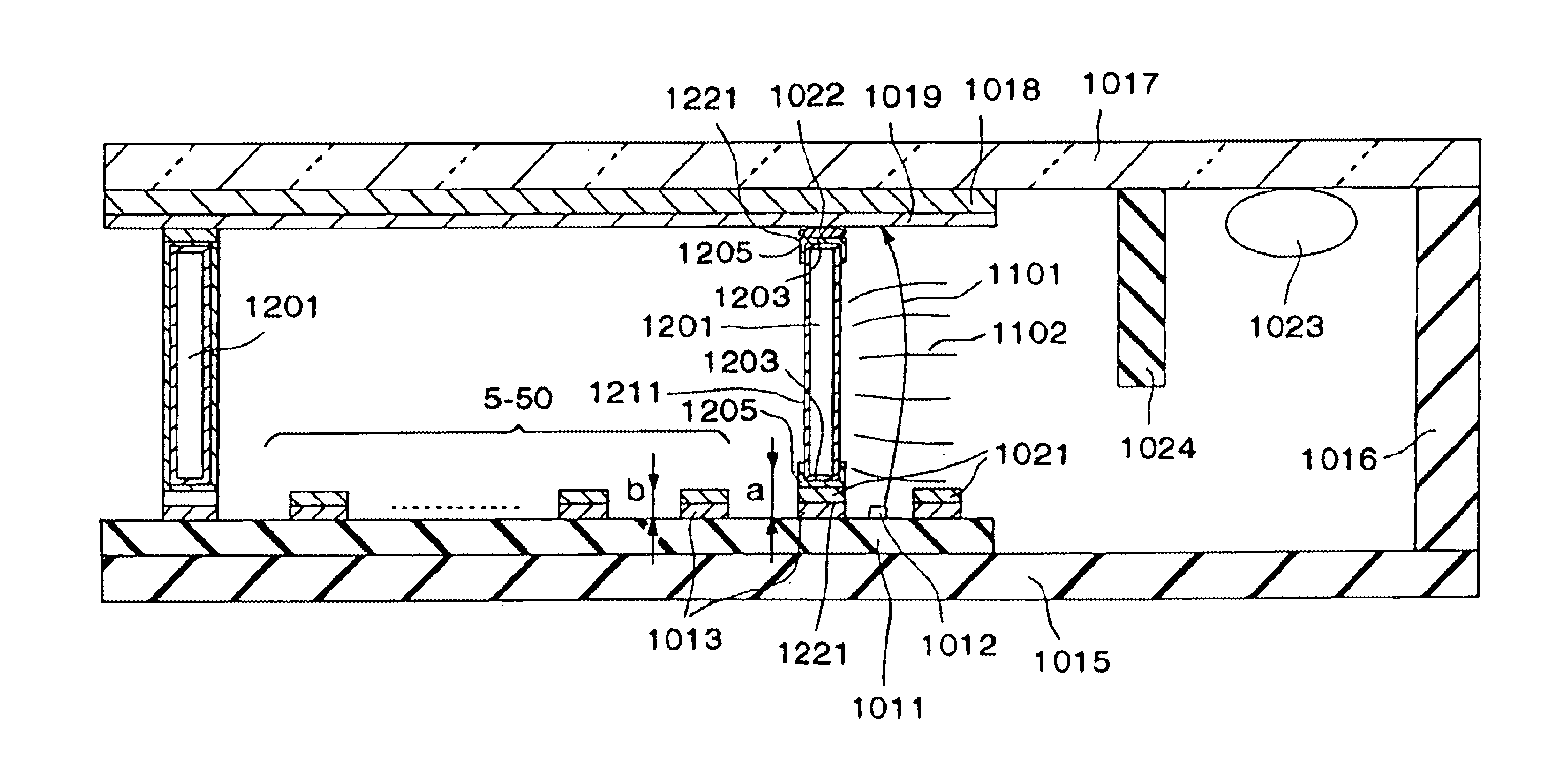

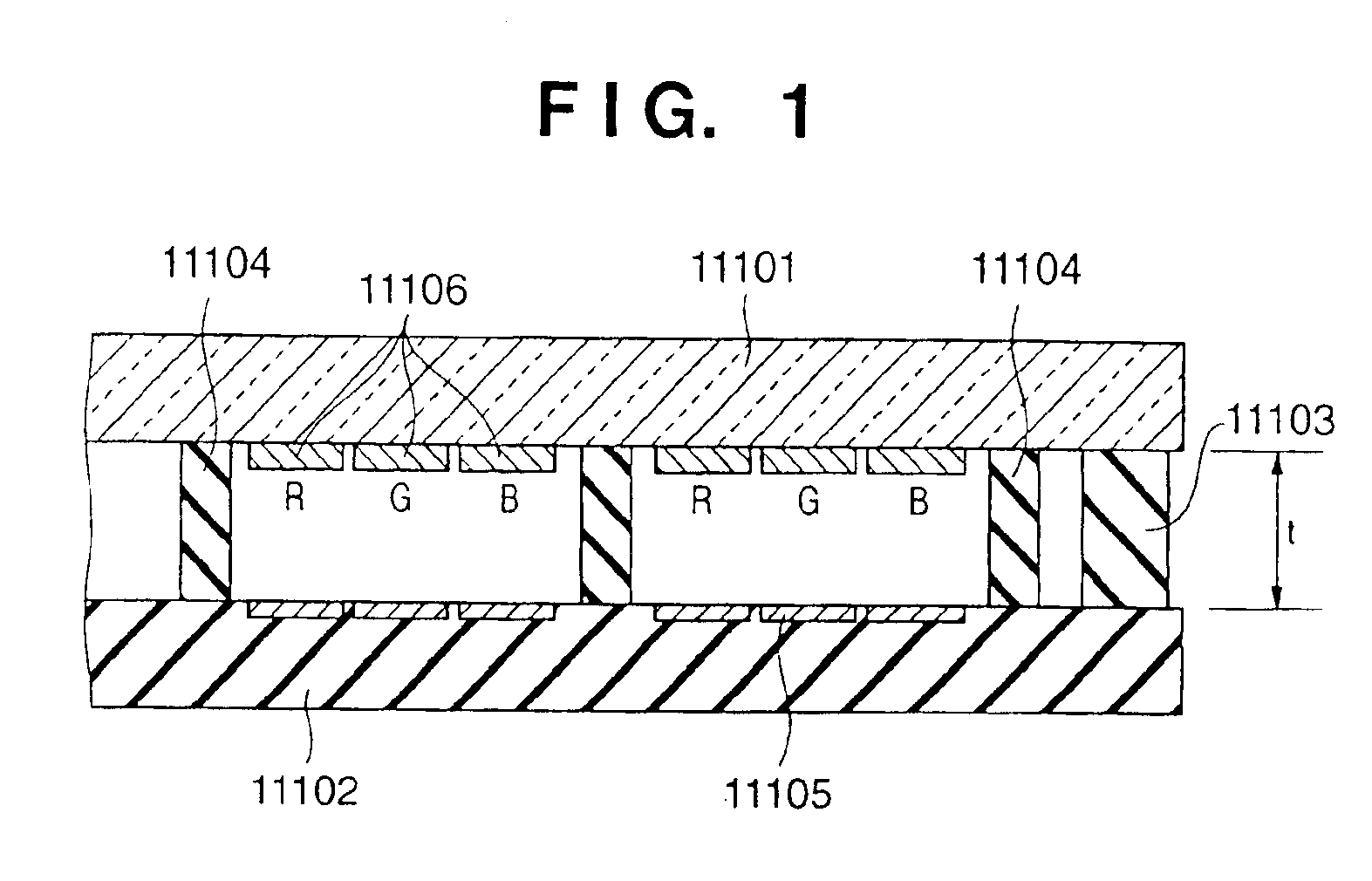

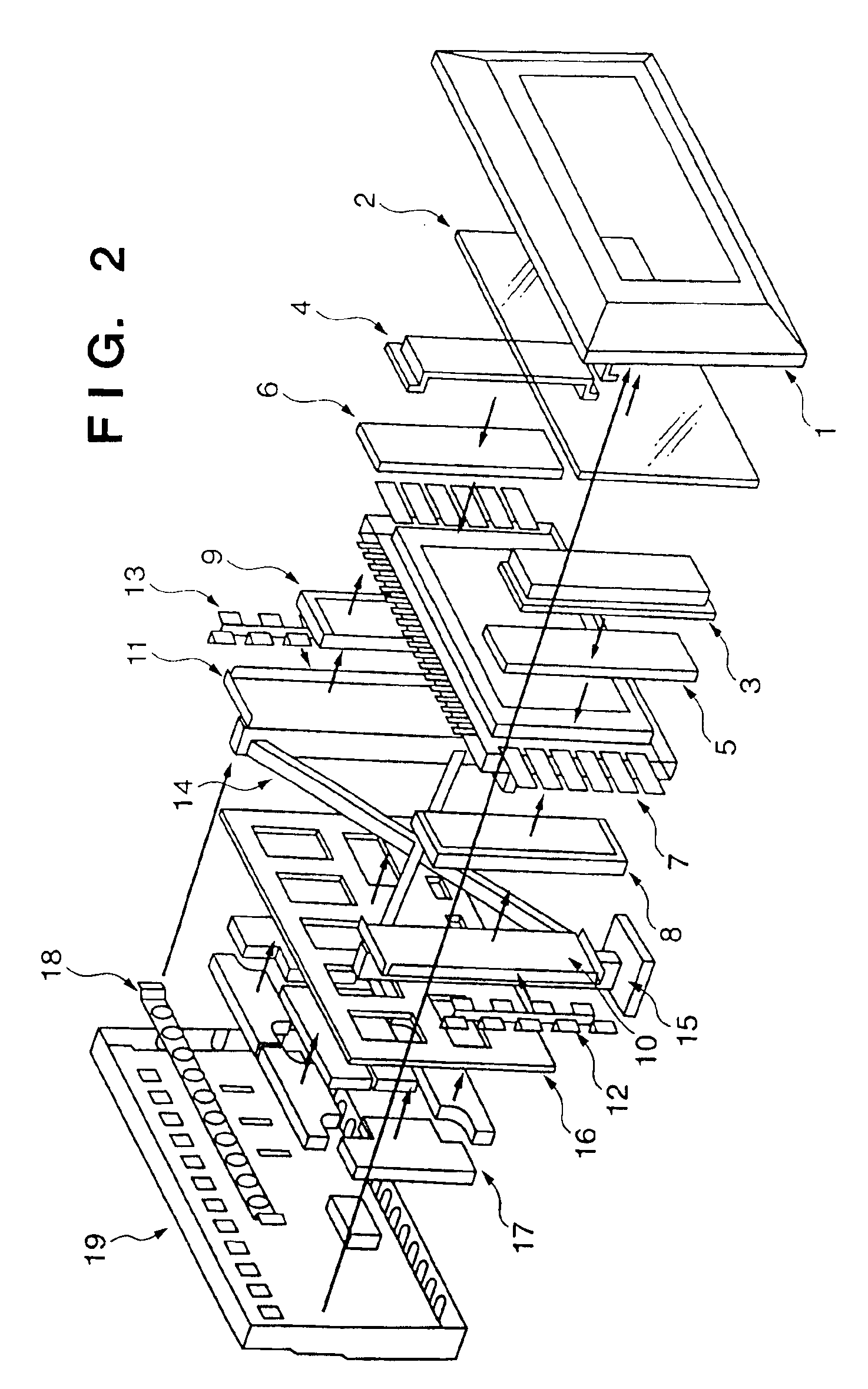

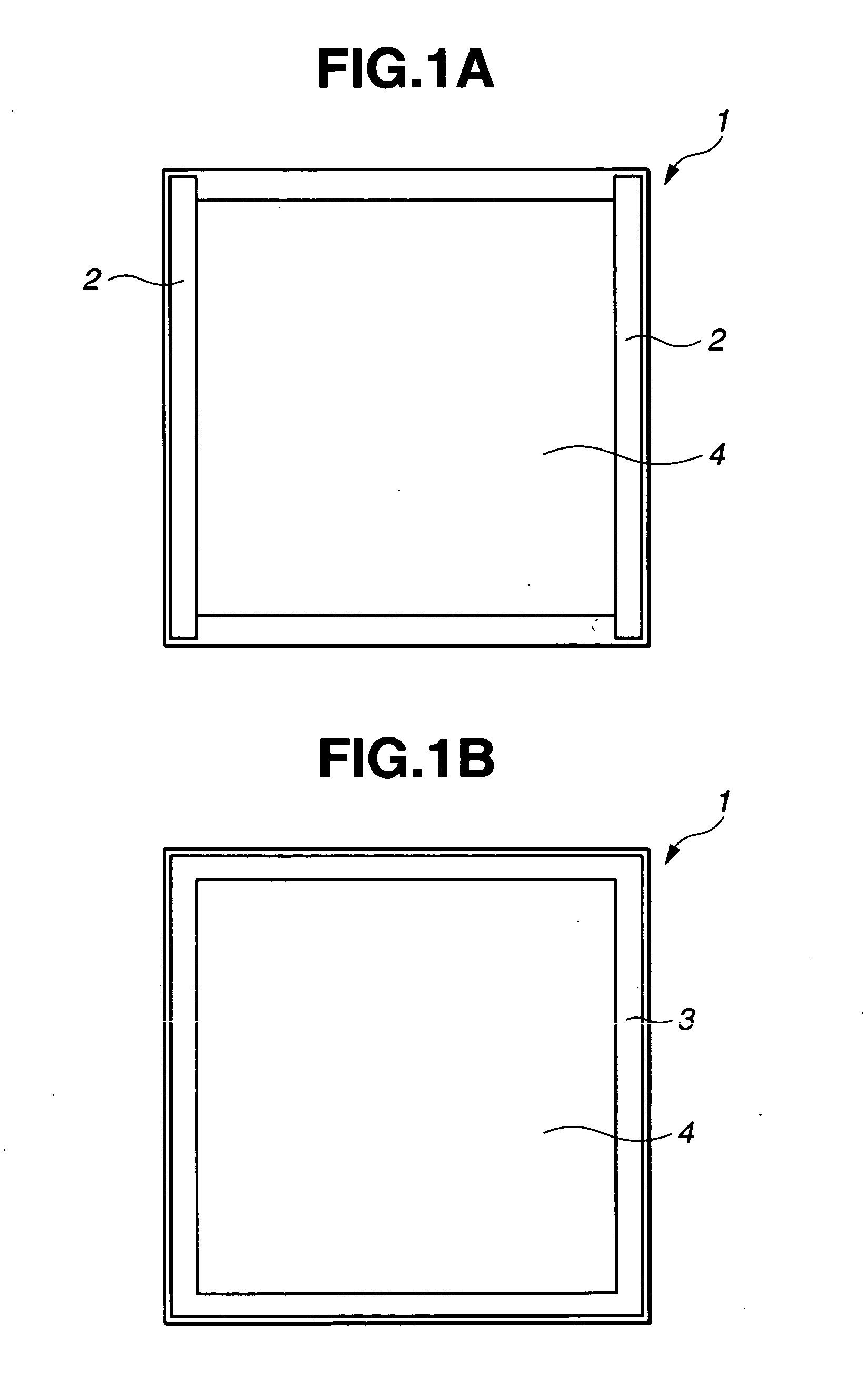

Image formation apparatus

InactiveUS6879096B1High display-quality configurationSatisfies requirementTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

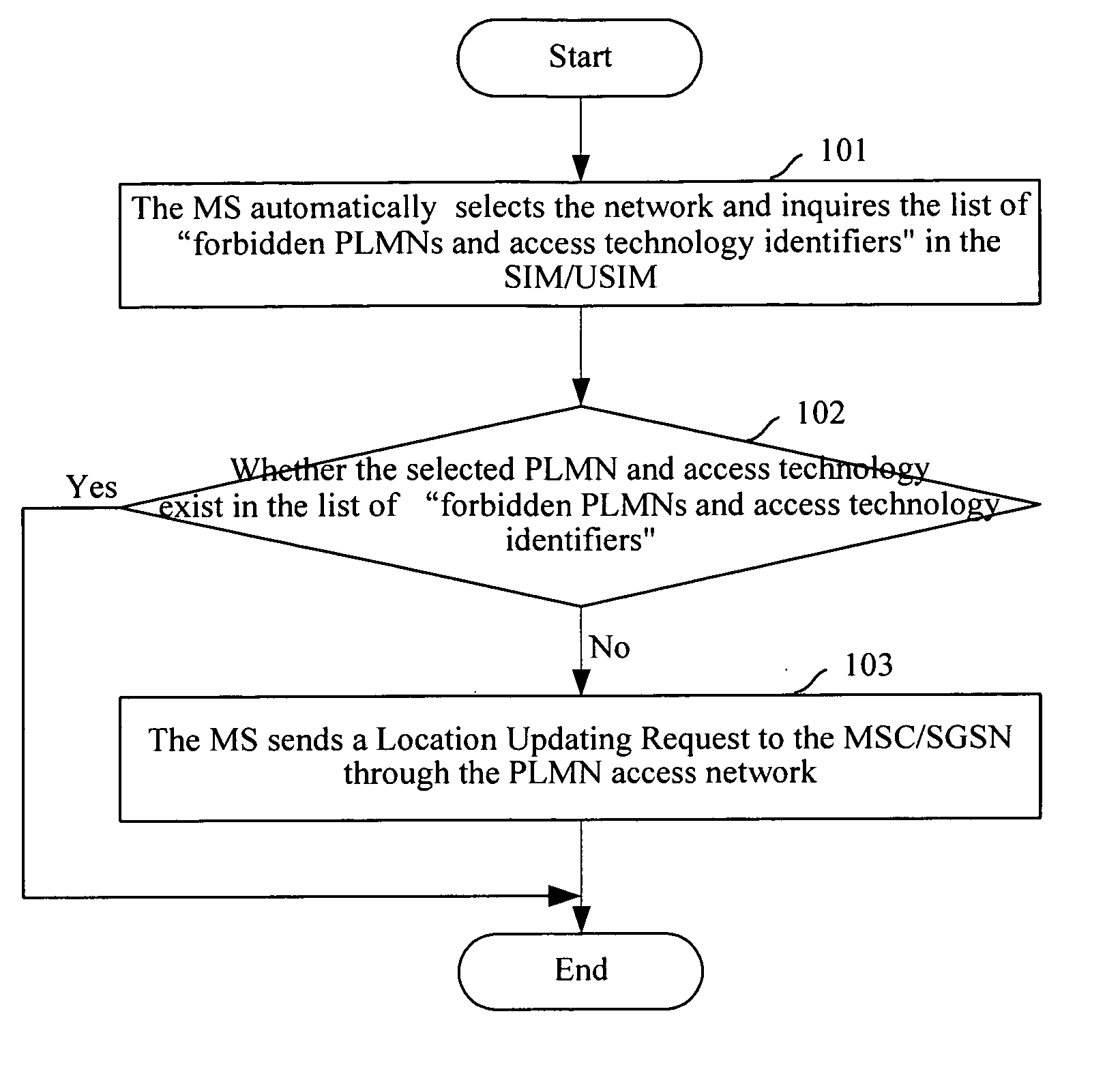

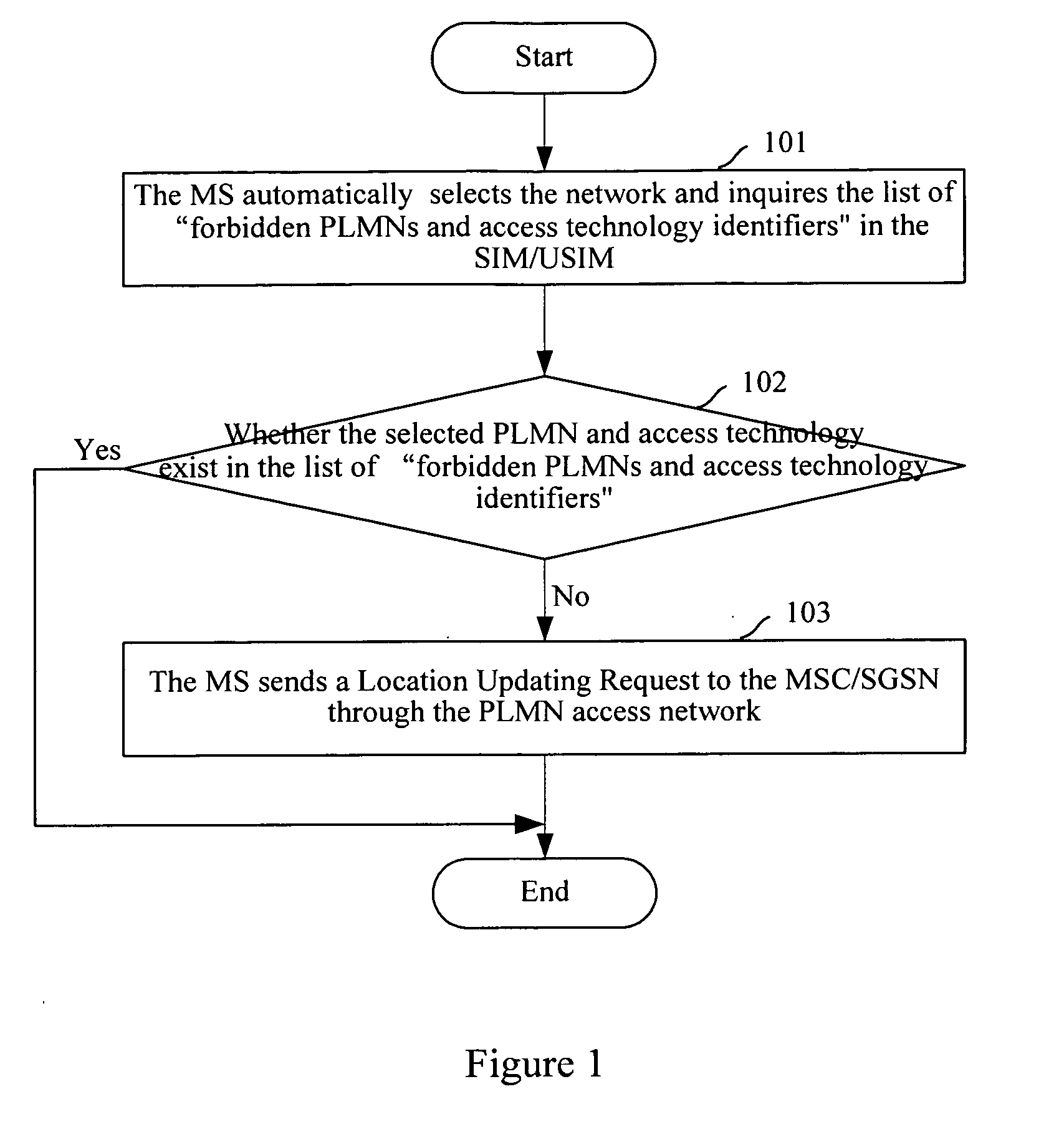

Method for Implementing Access Restriction of Mobile Networks

InactiveUS20070287419A1Easy to implementSatisfies requirementUnauthorised/fraudulent call preventionAssess restrictionAccess networkPublic land mobile network

The present invention discloses a method for implementing access restriction of mobile networks. The method includes the following steps: a Mobile Station (MS) inquiring a list of forbidden Public Land Mobile Networks (PLMNs) and access technology identifiers, which is saved by itself, when selecting a PLMN network; the MS determining whether the selected PLMN network and the access technology exist in the list of forbidden PLMNs and access technology identifiers, if they exist, the MS will not send a Location Updating Request to a Mobile Switching Center / Serving GPRS Support Node (MSC / SGSN); otherwise, the MS will send the Location Updating Request to the MSC / SGSN in order to access to the network. The present invention makes it possible to implement the access restrictions upon different types of access networks using different restriction rules. Furthermore, during the process of implementing the access restriction, the modification to the existing networks and user terminals is very small, the method is easy to implement and can well satisfy demands on the access restriction of operators.

Owner:HUAWEI TECH CO LTD

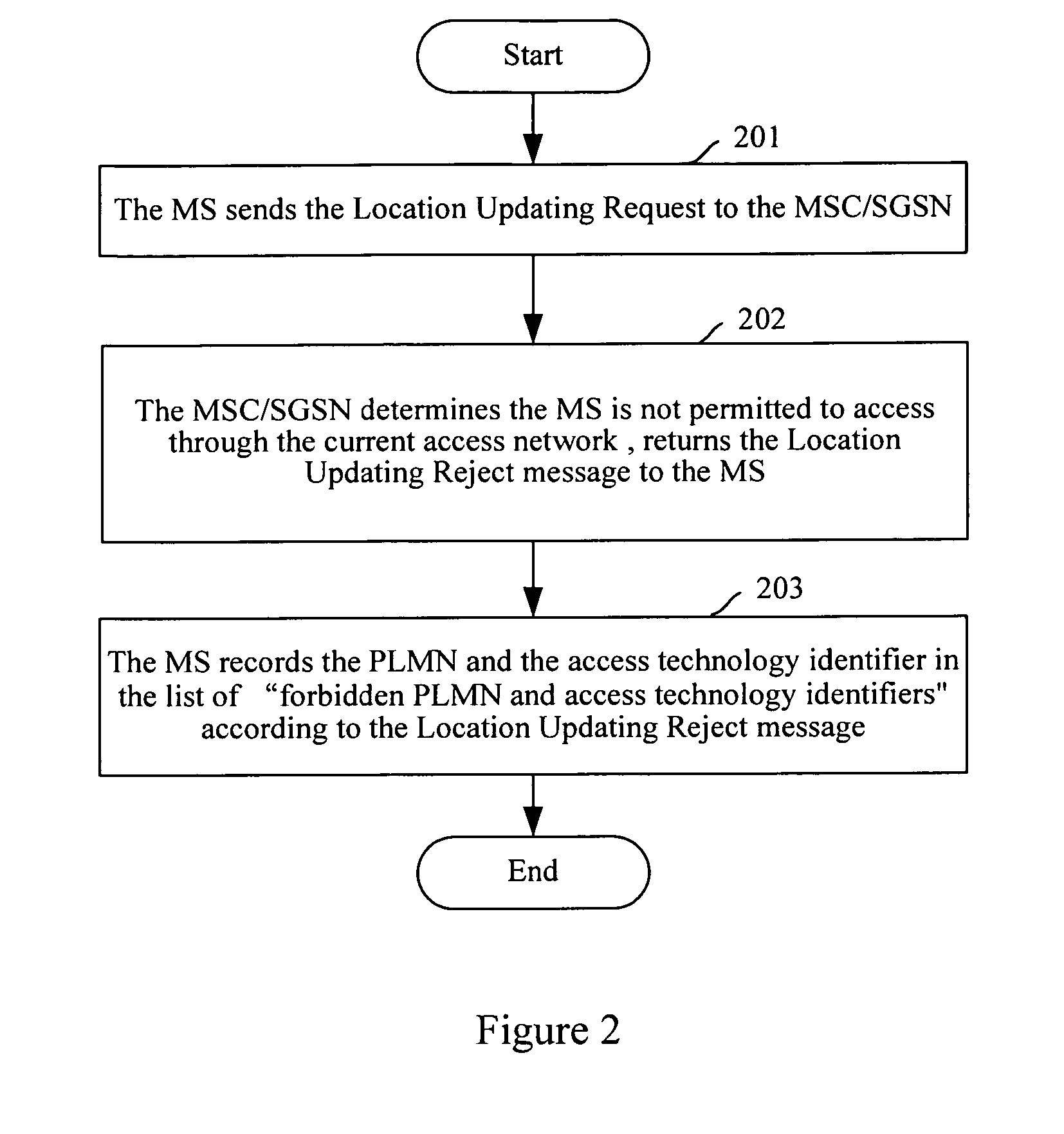

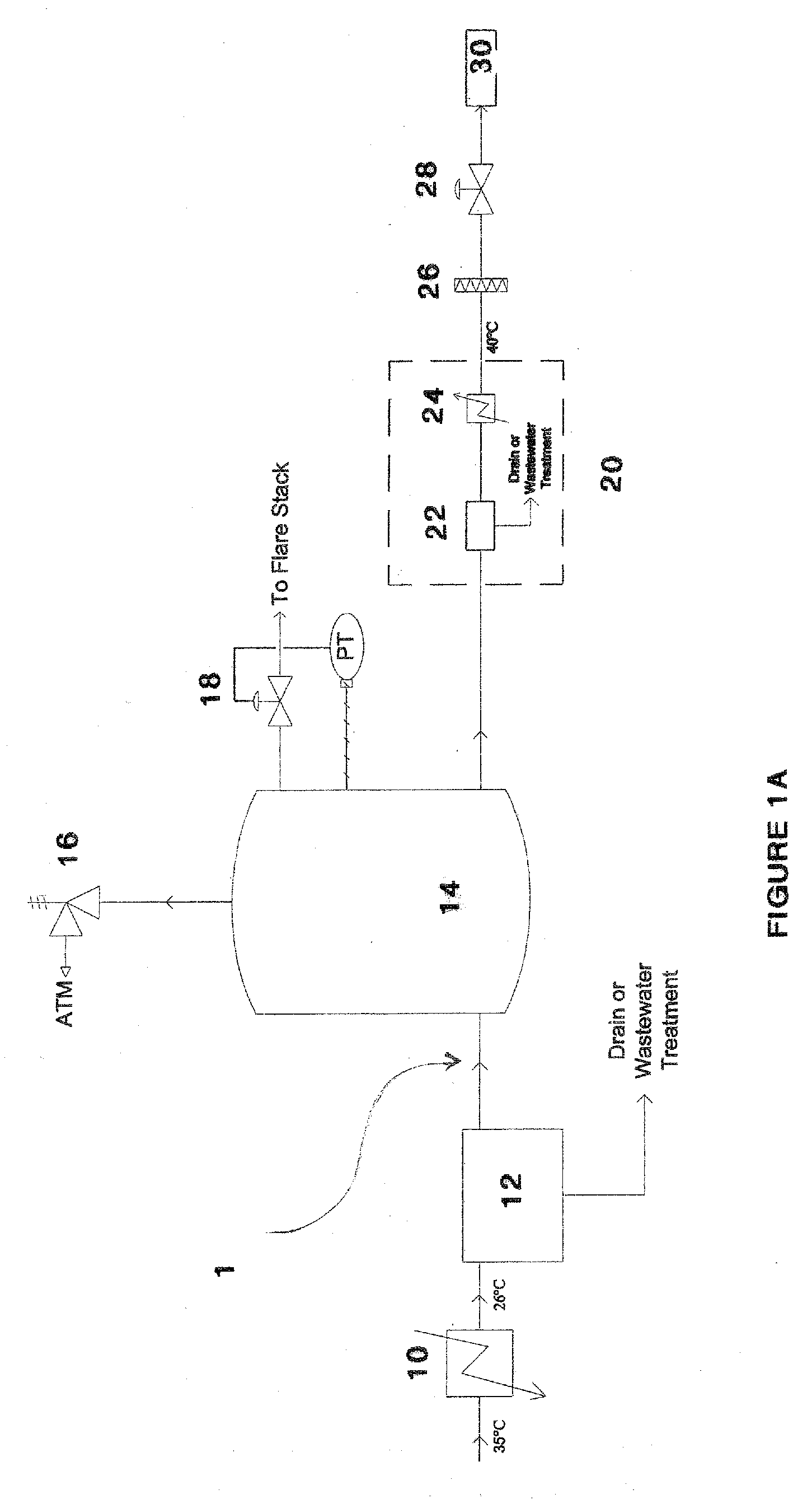

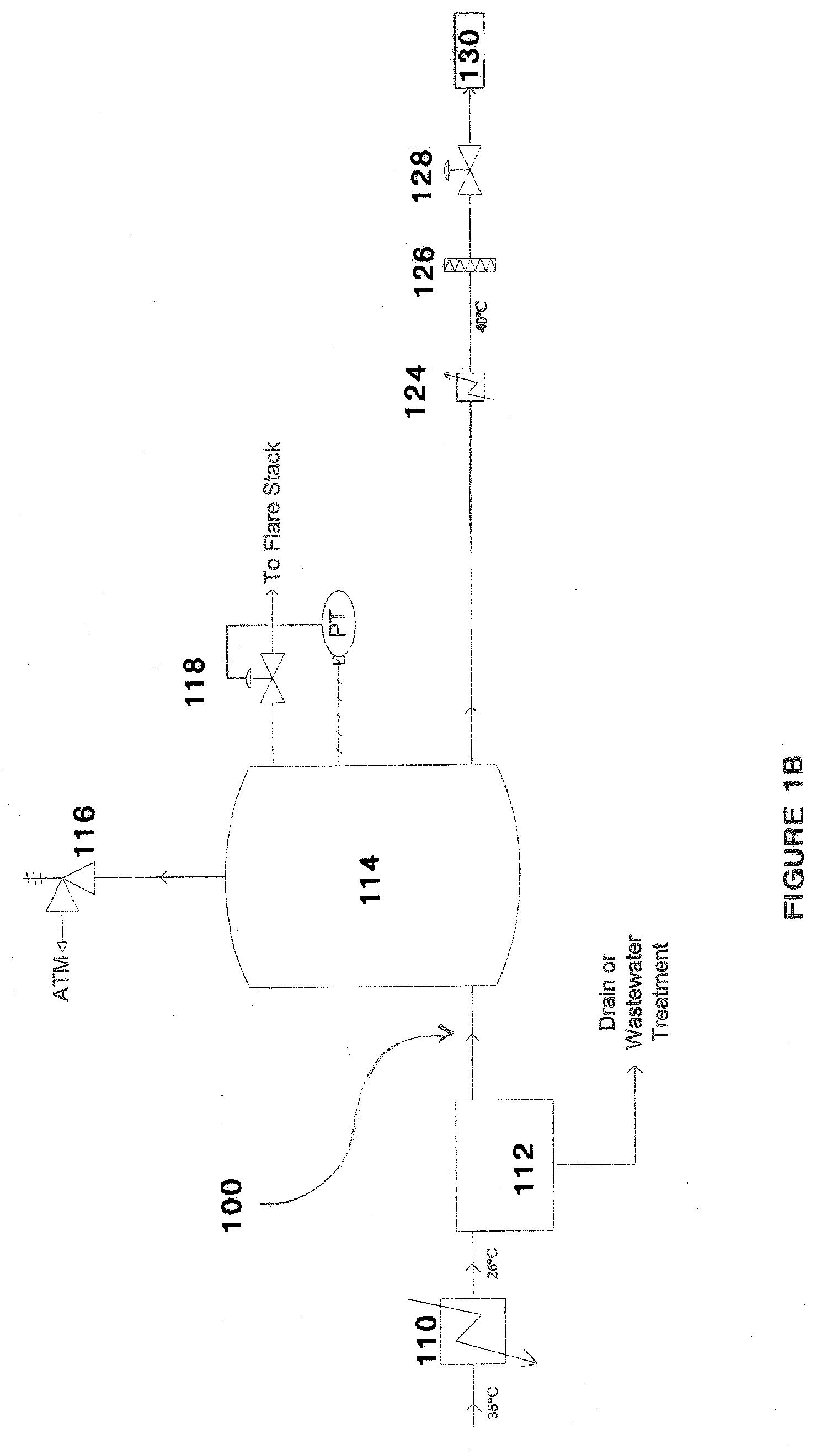

Gas Homogenization System

InactiveUS20070266632A1Satisfies requirementCombination devicesAuxillary pretreatmentChemical synthesisStream flow

A system and process for gas homogenization is disclosed. This has application in the areas of generation of gas and its conversion to electricity in downstream applications. The homogenization system minimizes variance in the gas characteristics (composition, flow, pressure, temperature), thereby rendering a steady stream of gas of consistent quality to the downstream machinery. This homogenization system can be adjusted to optimize the output gas stream for specific end-applications, or to optimize the output gas stream for different input feedstocks. This ensures that overall conversion efficiencies are maximised while keeping the process cost-effective. Such a uniform, steady output gas stream has a wide range of applications in the broad areas of generation of electricity (e.g. using internal combustion engines and combustion turbine engines), chemical synthesis (e.g. of compounds such as ethanol, methanol, hydrogen, methane, carbon monoxide, hydrocarbons), fuel-cell technologies and in polygeneration processes (processes that result in co-production of electricity and synthetic fuels).

Owner:PLASCO ENERGY GROUP INC

Vent hole-adjustable electronic cigarette

InactiveUS20160143354A1Satisfies requirementTobacco pipesTobacco devicesEngineeringElectronic cigarette

A vent hole-adjustable electronic cigarette is provided which comprises an airflow channel used for airflow circulation to facilitate smoke inhalation. The electronic cigarette also comprises a smoke volume adjustment mechanism used for adjusting the size of the airflow channel. The smoke volume adjustment mechanism is provided to adjust the volume of the airflow in the airflow channel, thus satisfying requirements of a smoker for different mouthfeel.

Owner:KIMREE HI TECH

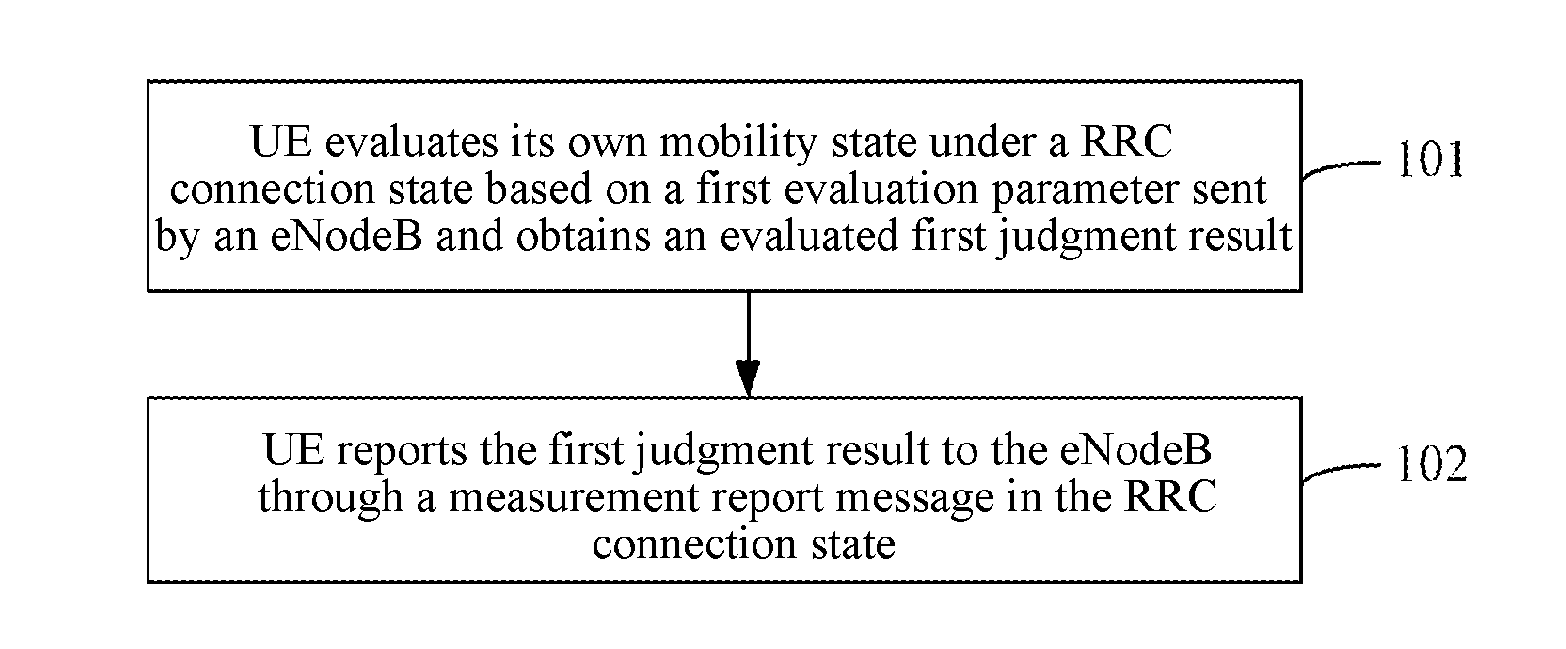

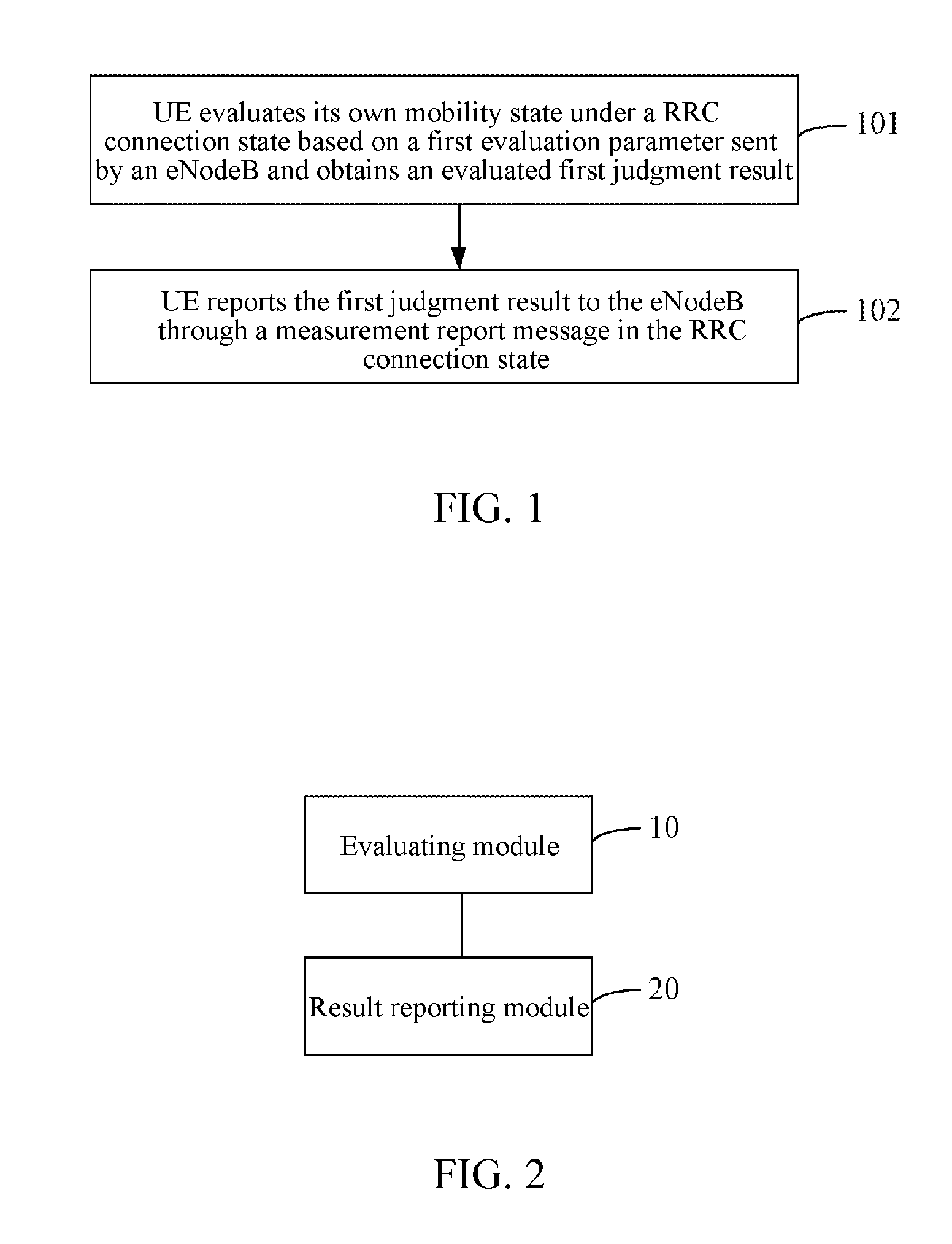

Mobile terminal and mobile state reporting method thereof

ActiveUS20120088509A1Satisfies requirementMethod is differentConnection managementTelecommunicationsRadio Resource Control

The present invention discloses a method for reporting a mobility state of a mobile terminal comprising: a User Equipment (UE) evaluating its own mobility state under a Radio Resource Control (RRC) connection state based on a first evaluation parameter sent by an evolved Node B (eNodeB), and obtaining an evaluated first determination result; and the UE reporting the first determination result to the eNodeB through a measurement report message in the RRC connection state. The present invention also discloses a mobile terminal configured to report determination result of its own mobility state to an eNodeB such that the eNodeB can adopt different pertinent processing strategies for UEs in different mobility states, thereby bringing convenience to practical application.

Owner:K MIZRA LLC

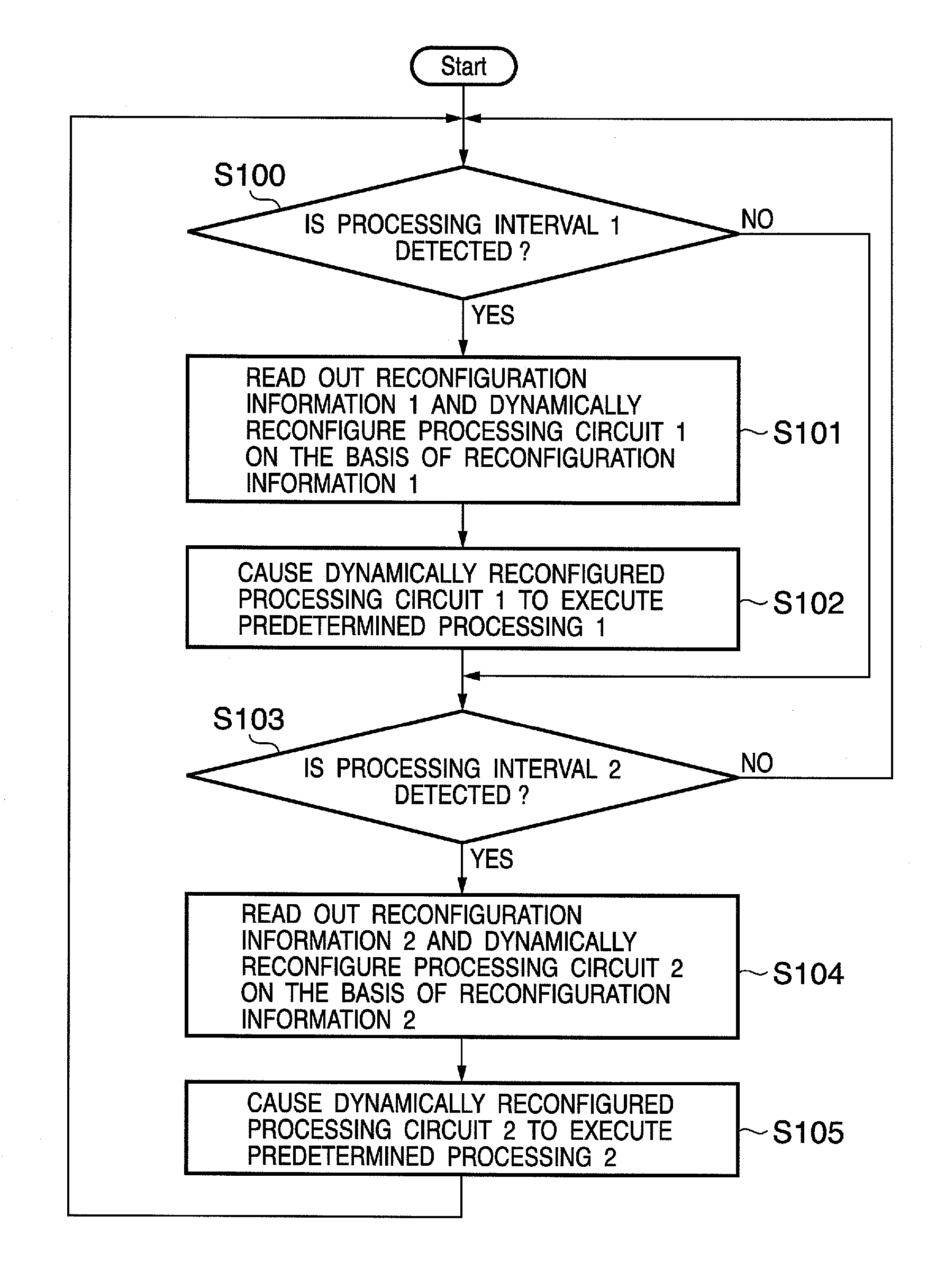

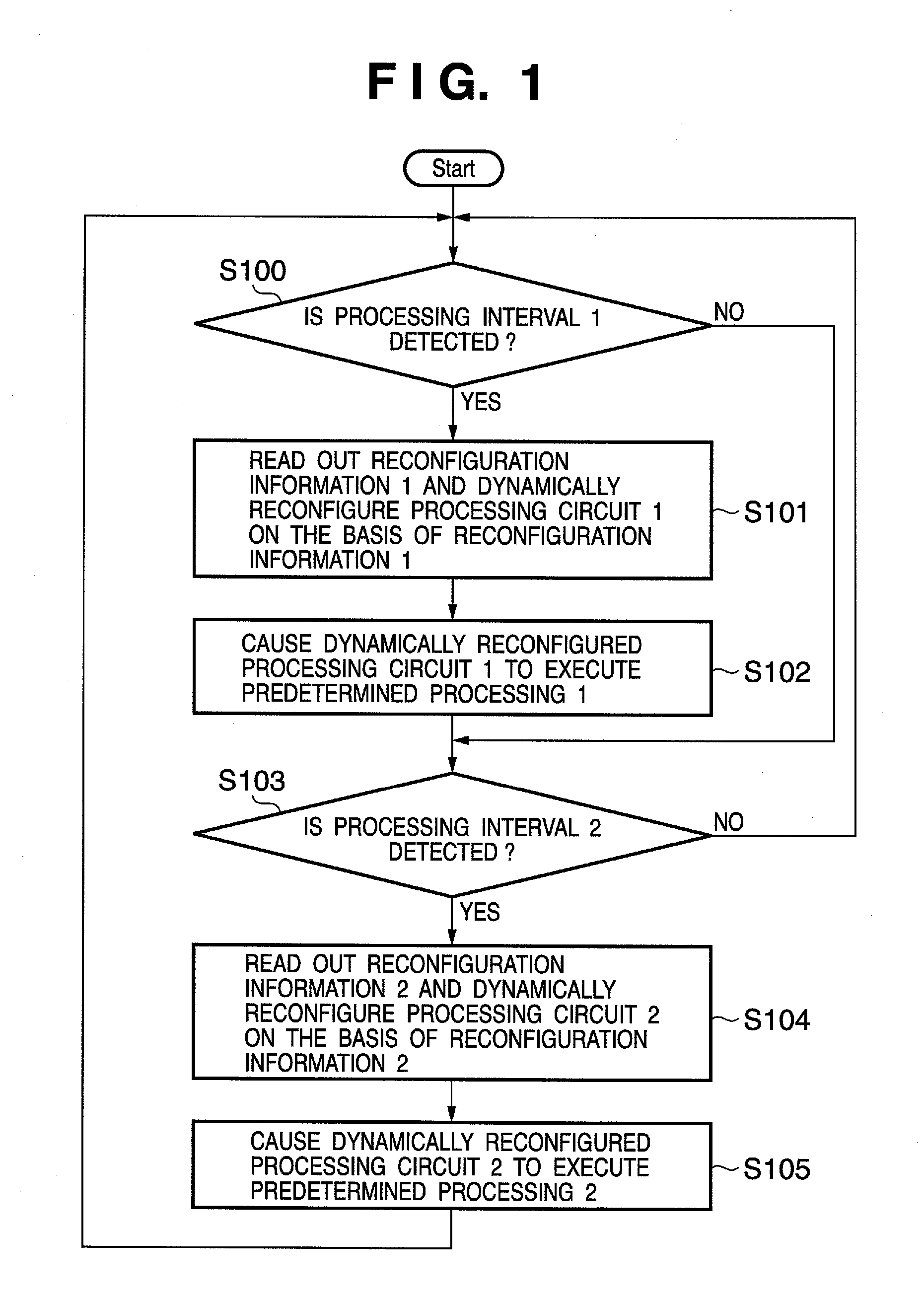

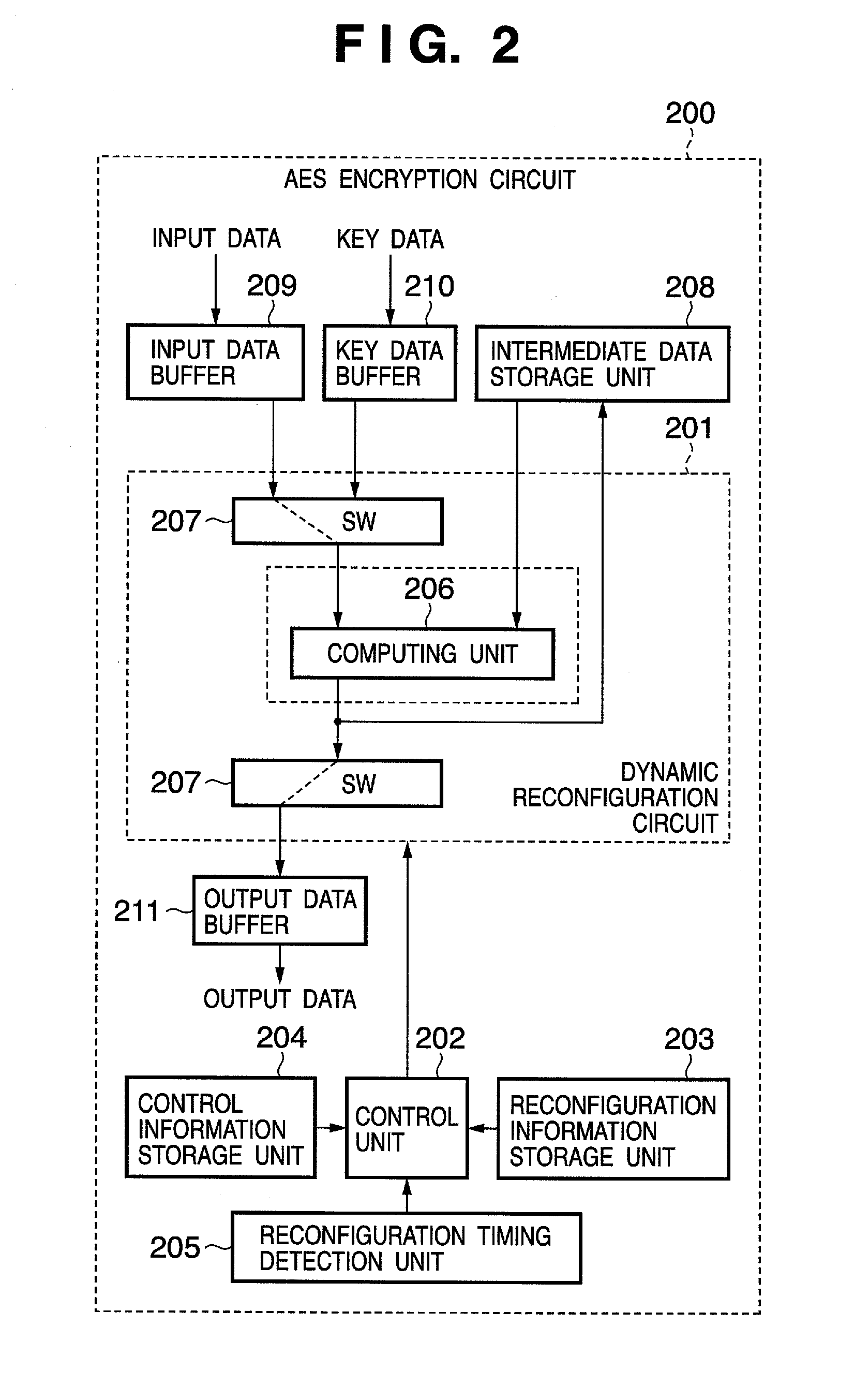

Cryptographic processing apparatus

InactiveUS20070098153A1Reduce power consumptionReduce gate sizePublic key for secure communicationSecret communicationComputer hardwareControl unit

A cryptographic processing apparatus includes a holding unit adapted to hold data of a processing target, an intermediate data holding unit adapted to hold information generated during the cryptographic processing as intermediate data, a circuit reconfiguration processor which reconfigures a first circuit which generates round key information on the basis of the intermediate data and / or the key information, in accordance with input of first control information, and reconfigures a second circuit which performs operation processing on the basis of the data and / or the intermediate data and the round key information, in accordance with input of second control information, and a control unit adapted to output the first control information to the circuit reconfiguration processor at a first timing, and output the second control information to the circuit reconfiguration processor at a second timing.

Owner:CANON KK

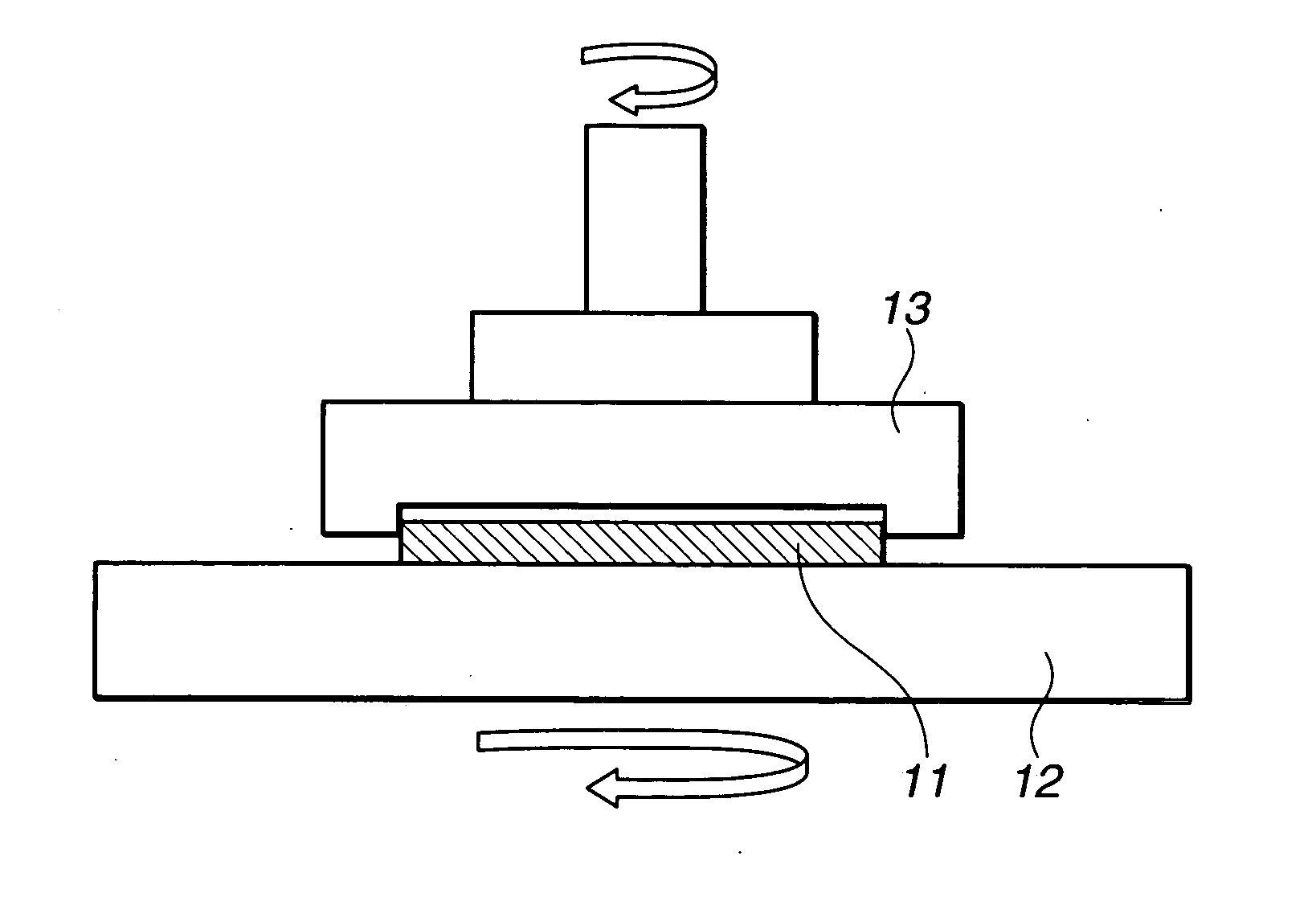

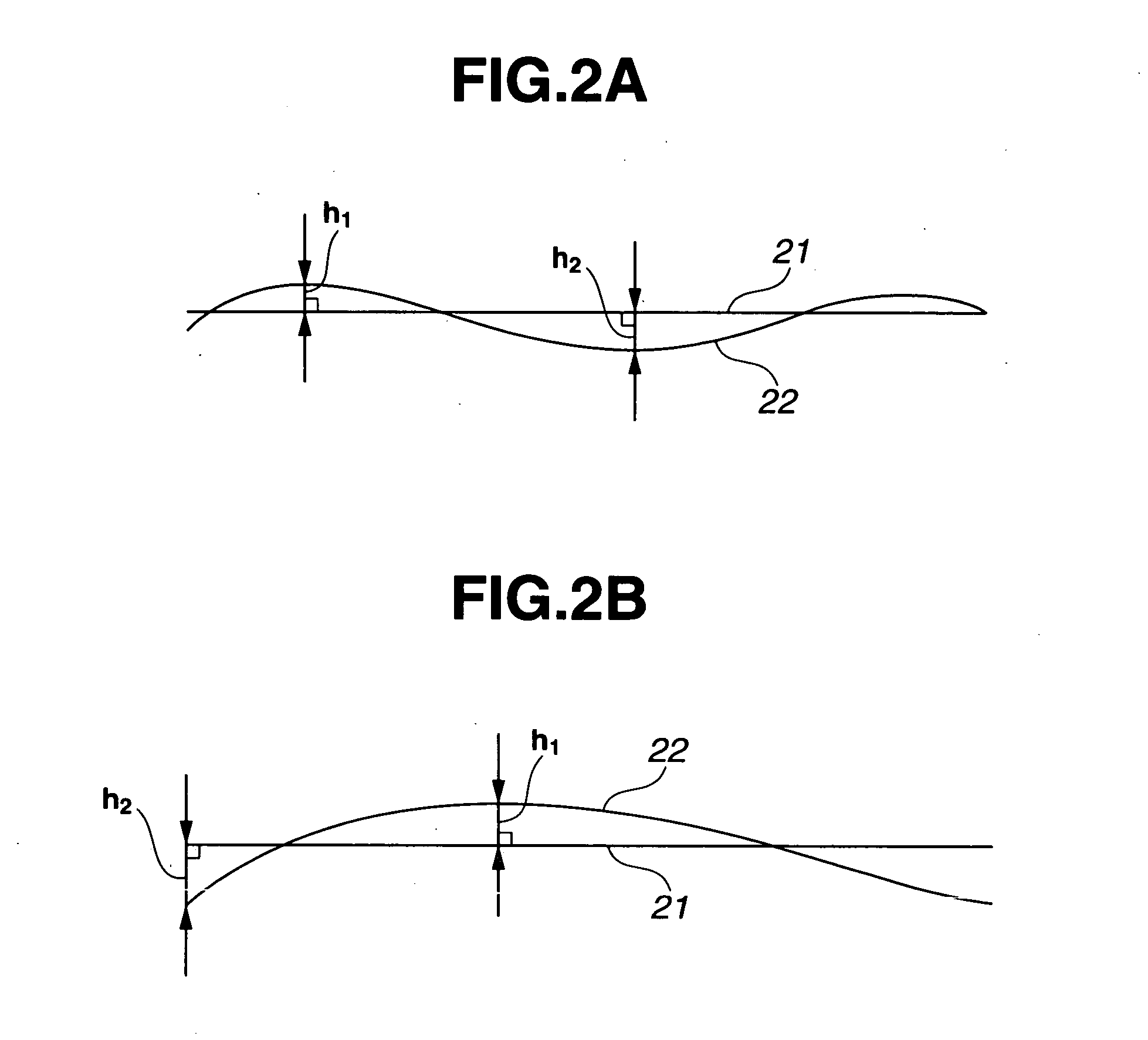

Photomask blank substrate, photomask blank and photomask

ActiveUS20050019677A1Good surface smoothnessImprove flatnessGlass/slag layered productsOriginals for photomechanical treatmentLeast squaresPhotomask

In a quadrangular photomask blank substrate with a length on each side of at least 6 inches, which has a pair of strip-like regions that extend from 2 to 10 mm inside each of a pair of opposing sides along an outer periphery of a substrate top surface, with a 2 mm edge portion excluded at each end, each strip-like region is inclined downward toward the outer periphery of the substrate, and a difference between maximum and minimum values for height from a least squares plane for the strip-like region to the strip-like region is at most 0.5 μm. The substrate exhibits a good surface flatness at the time of wafer exposure.

Owner:SHIN ETSU CHEM IND CO LTD +2

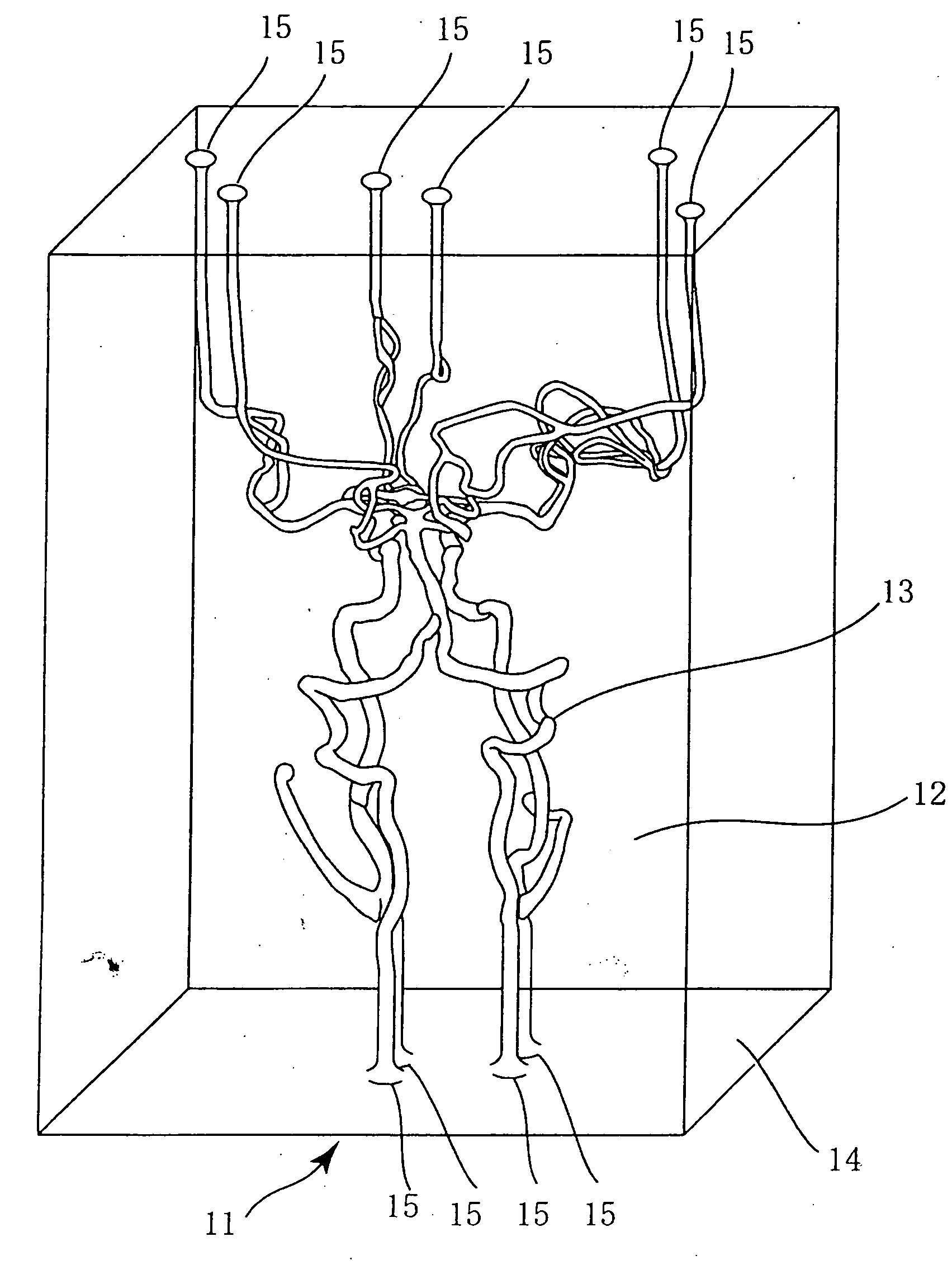

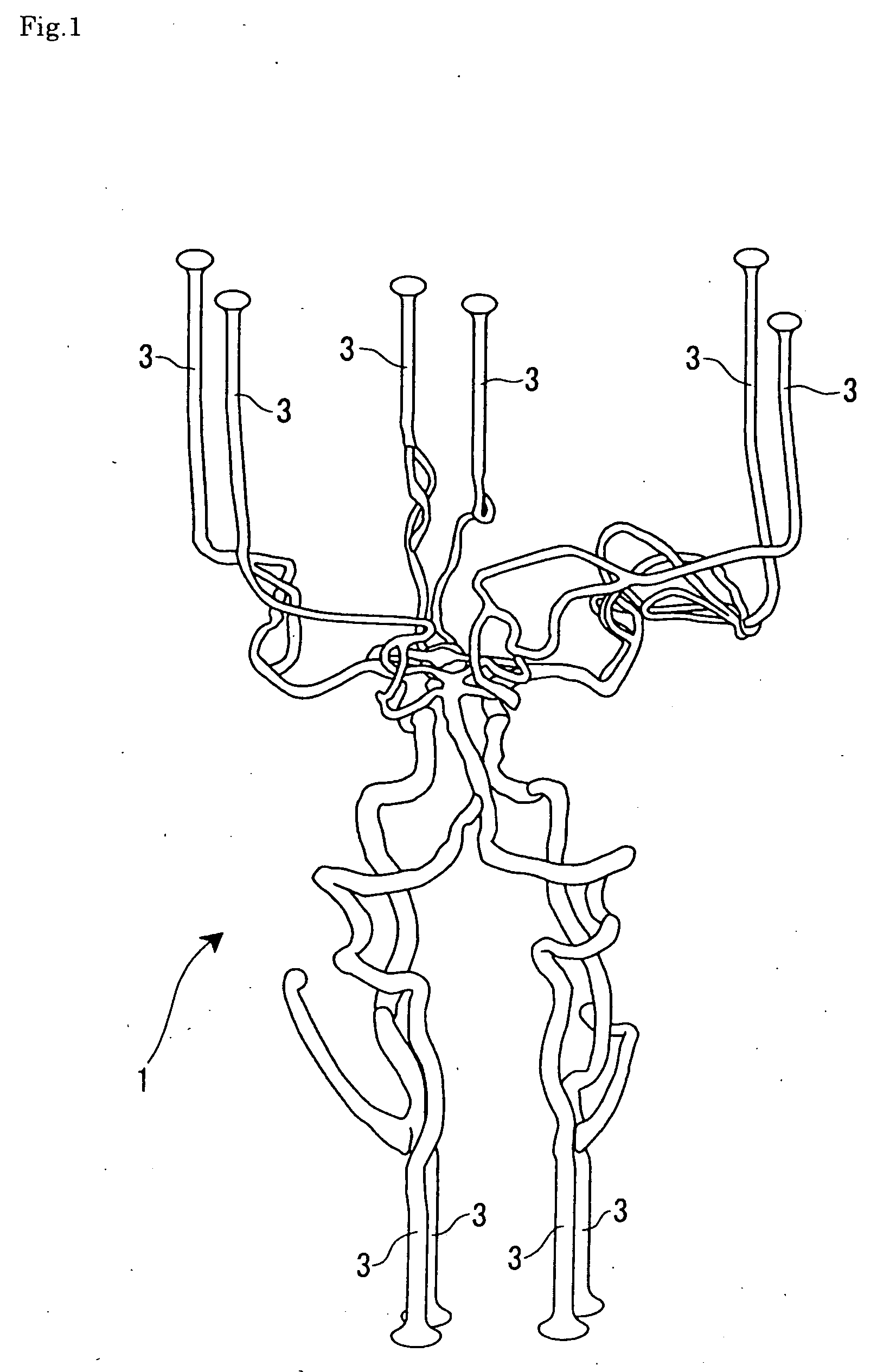

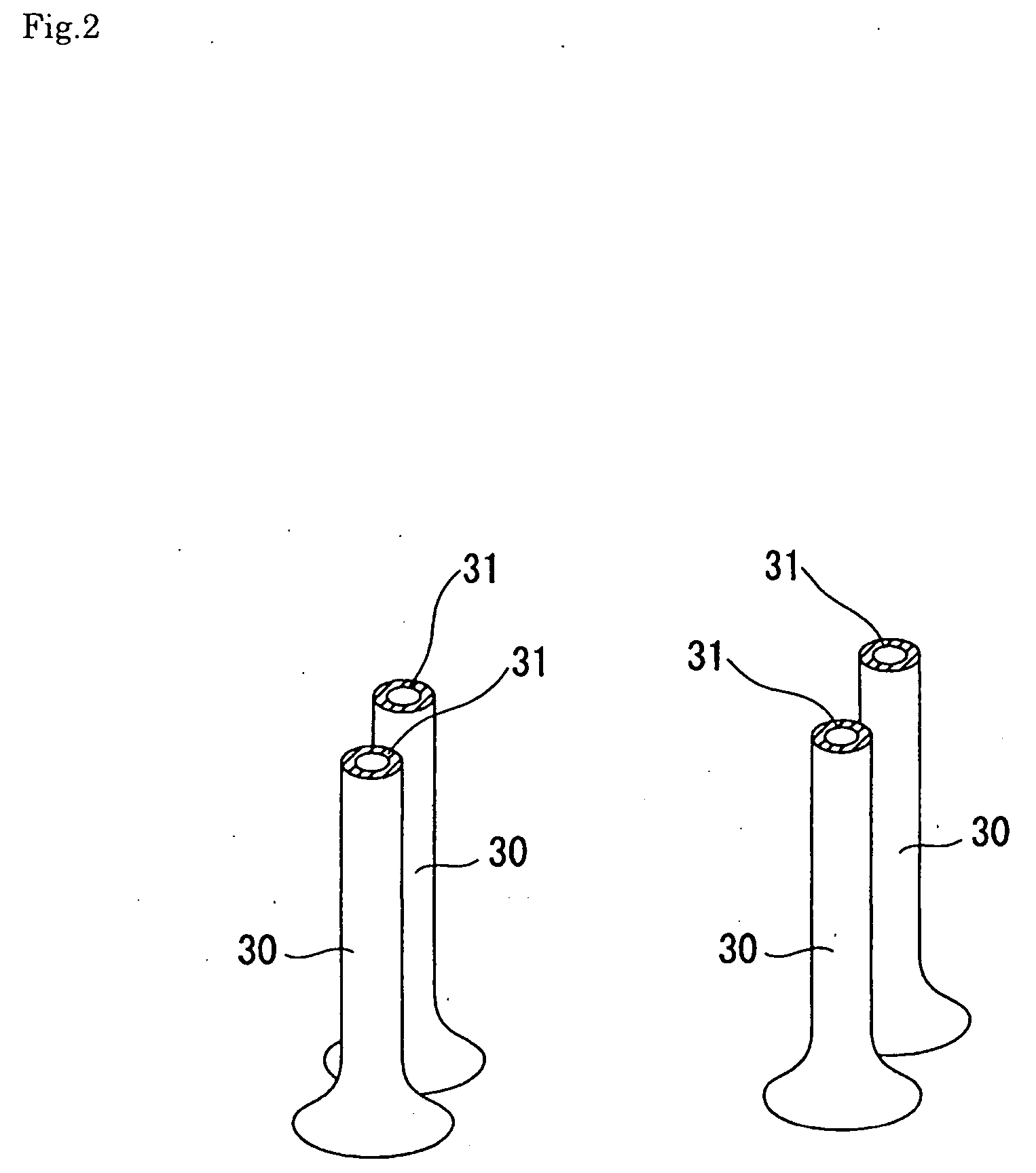

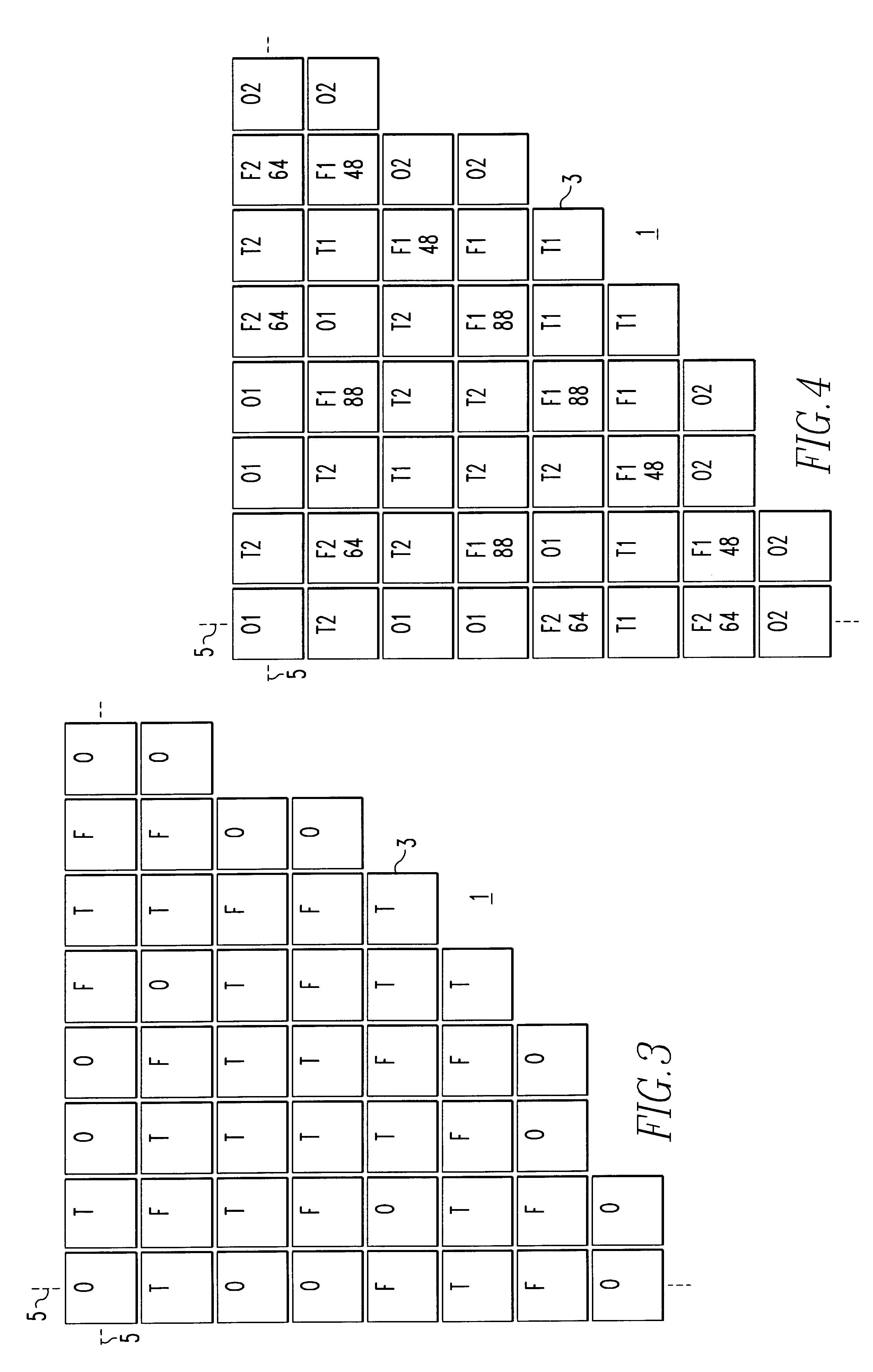

Three-dimensional model

A three-dimensional model, wherein coelom models such as blood vessels are stackingly molded based on tomogram data on a subject, the peripheries of the coelom models are surrounded by a three-dimensional model forming material, the three-dimensional model forming material is hardened, and the coelom models are fused or molten and removed, whereby a specified three-dimensional model can be formed.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

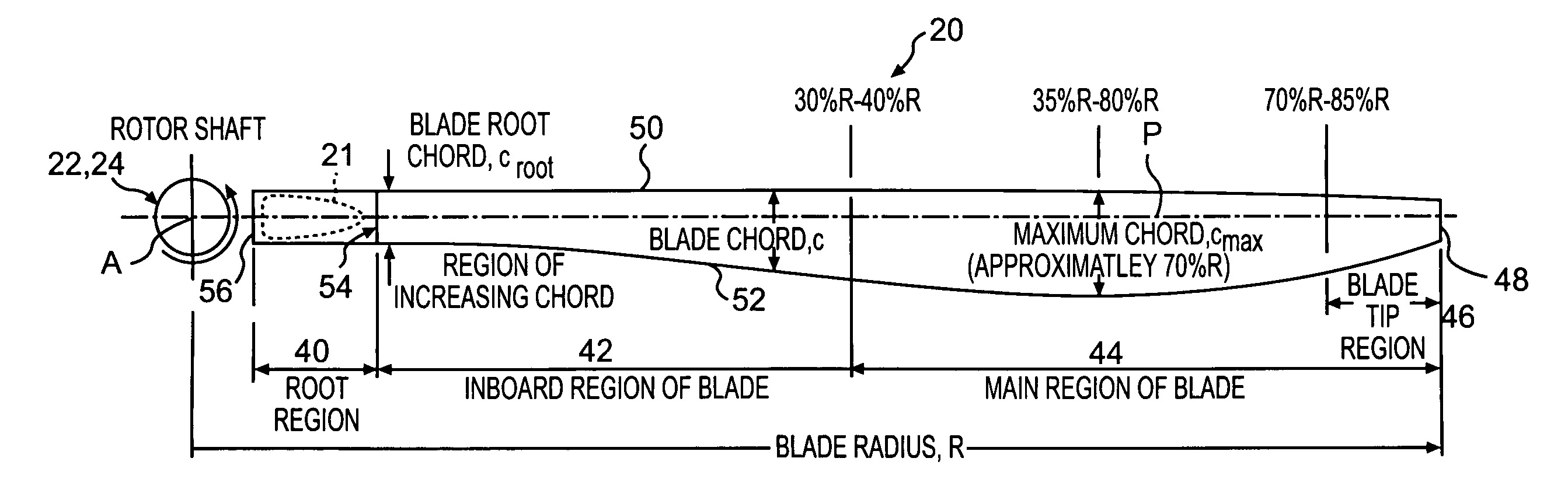

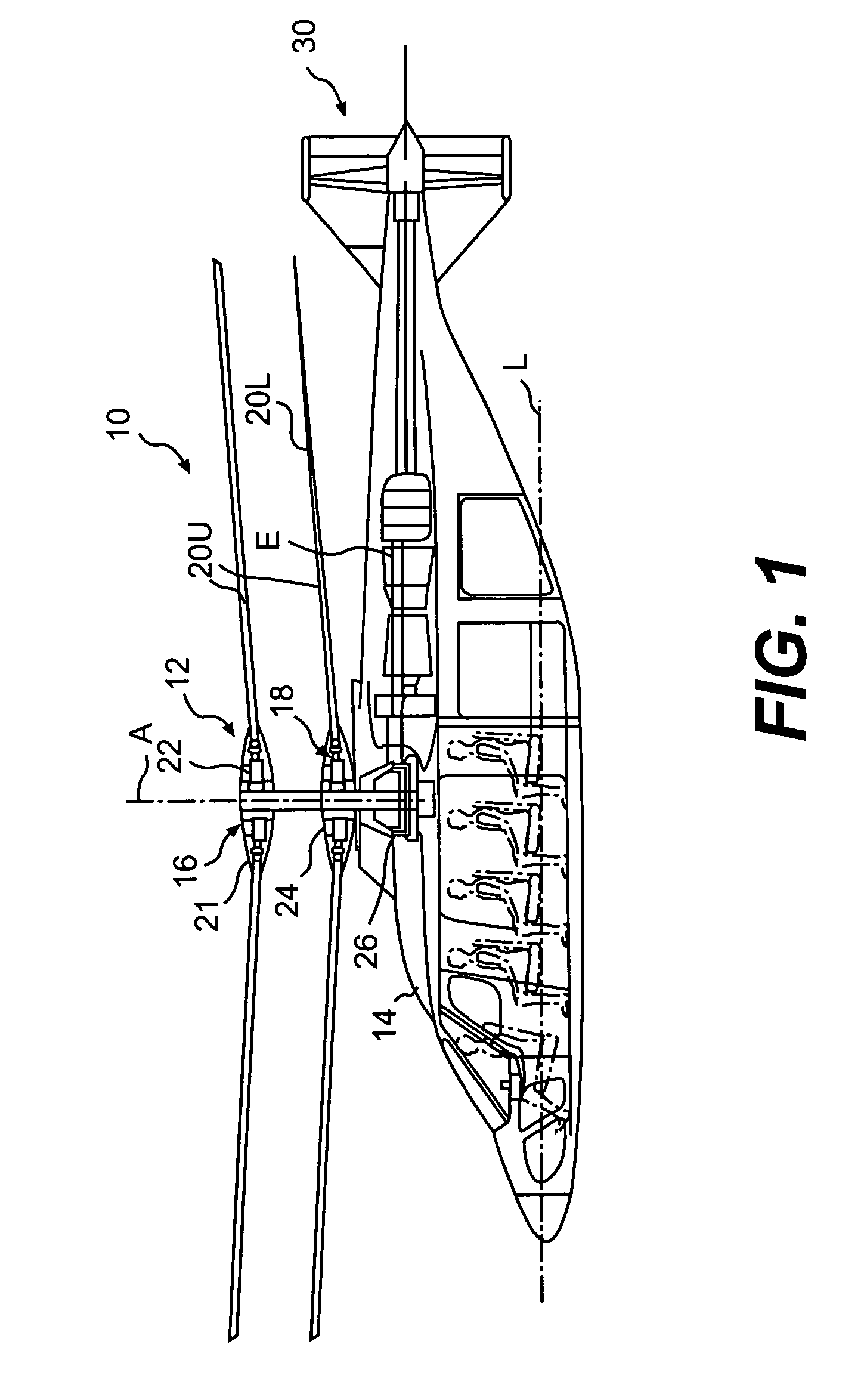

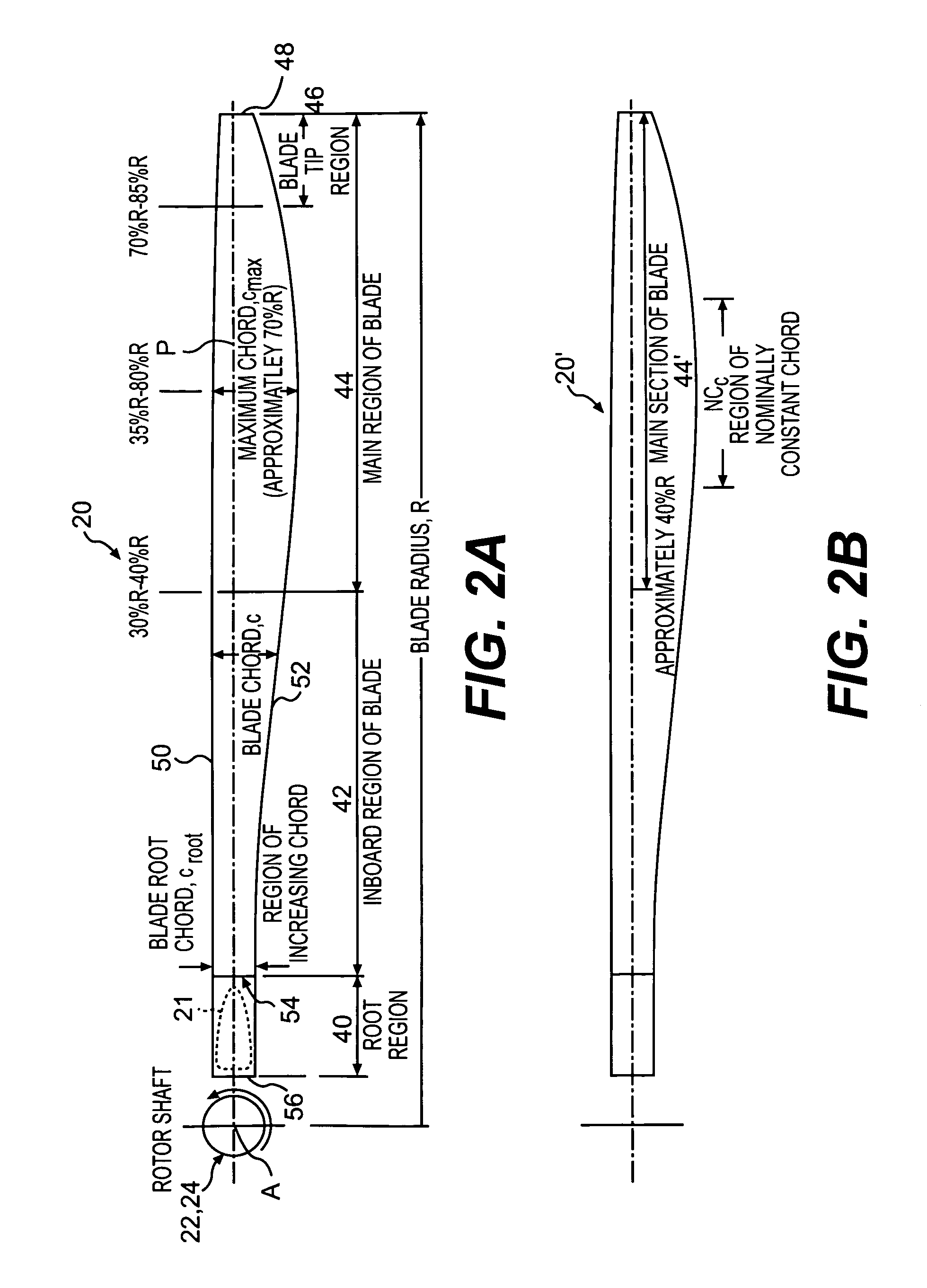

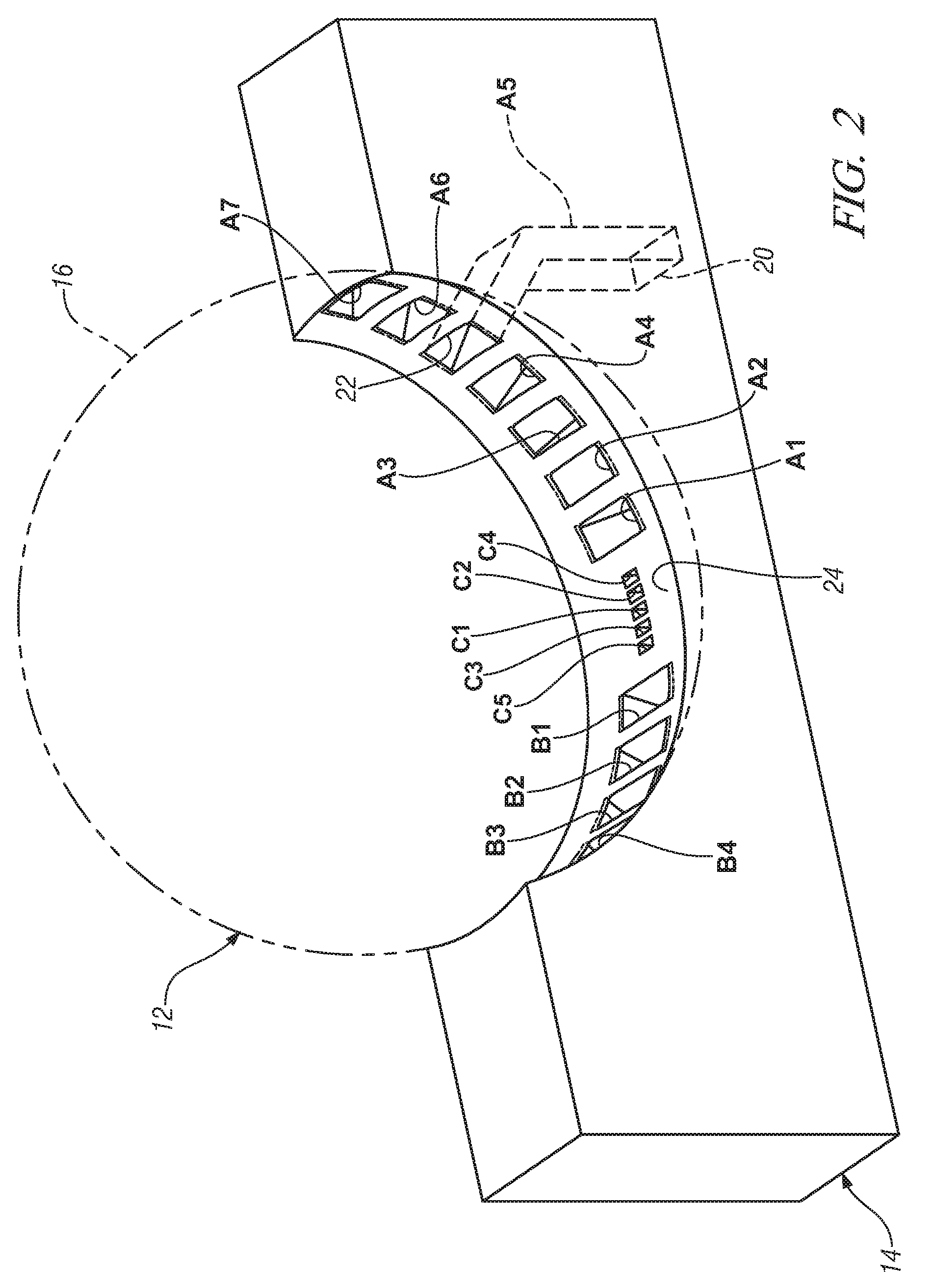

Rotor blade twist distribution for a high speed rotary-wing aircraft

ActiveUS20070110582A1Optimizing rotor performanceImprove flight efficiencyPropellersPump componentsFigure of meritRotary wing

Main rotor blades of the dual, counter-rotating, rigid coaxial rotor system exhibit a unique unconventional combination of positive and negative twist gradients in which the rotor system rotor Figure of Merit (hover efficiency) is improved by providing a dissimilar twist distribution between the lower rotor blade and the upper rotor blades. This improvement is specifically a result of reduced profile drag of the lower rotor system, achieved by driving the effective operating condition of the lower rotor blades to be similar to the upper rotor blade such that the tip drag losses of the lower main rotor have been reduced considerably using a mathematically vigorous approach. While minimal induced power consumption resulted due to the dissimilar lower main rotor twist, a significant profile power benefit is realized, resulting in the improved hover efficiency with essentially no reduction in rotor forward flight performance.

Owner:SIKORSKY AIRCRAFT CORP

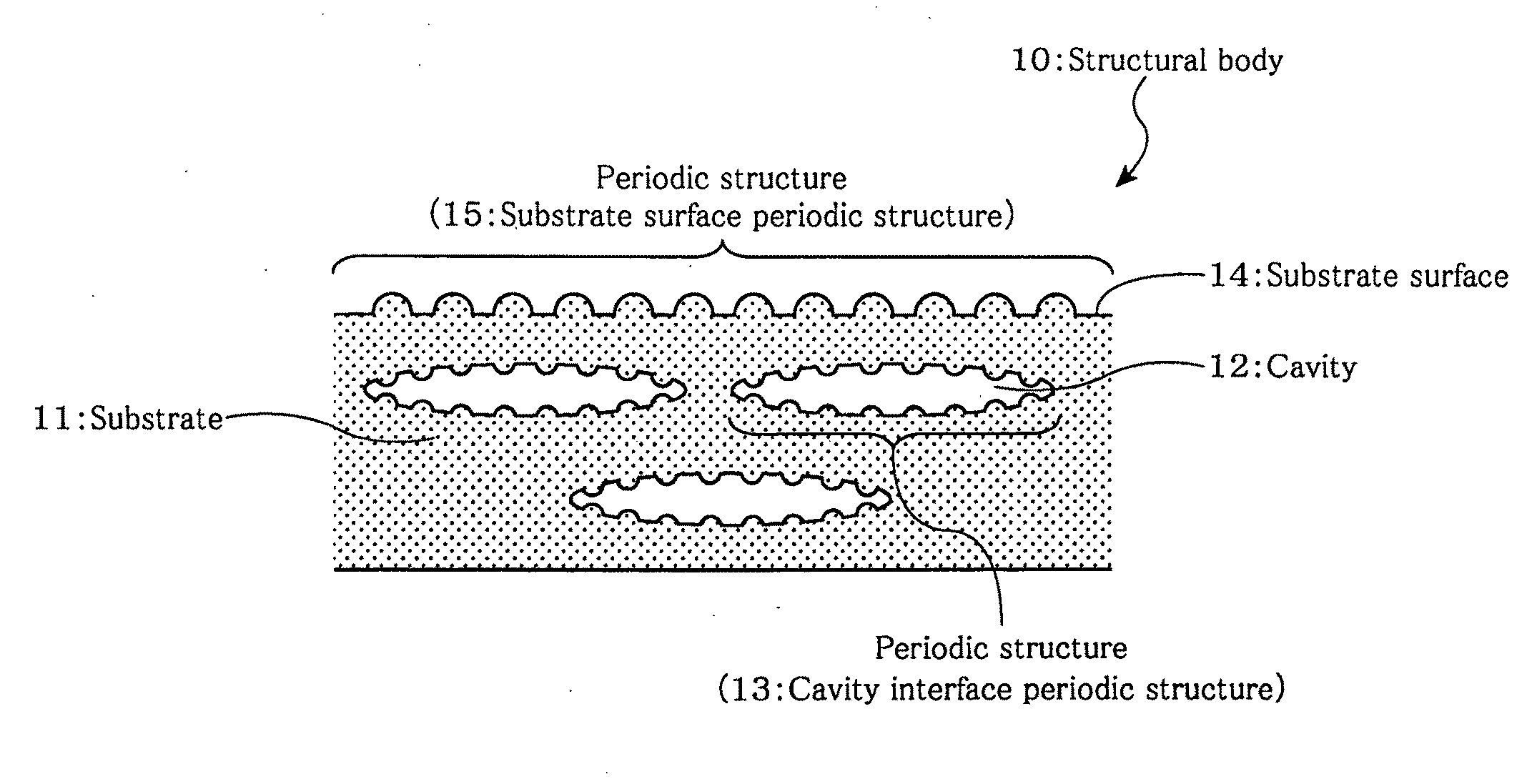

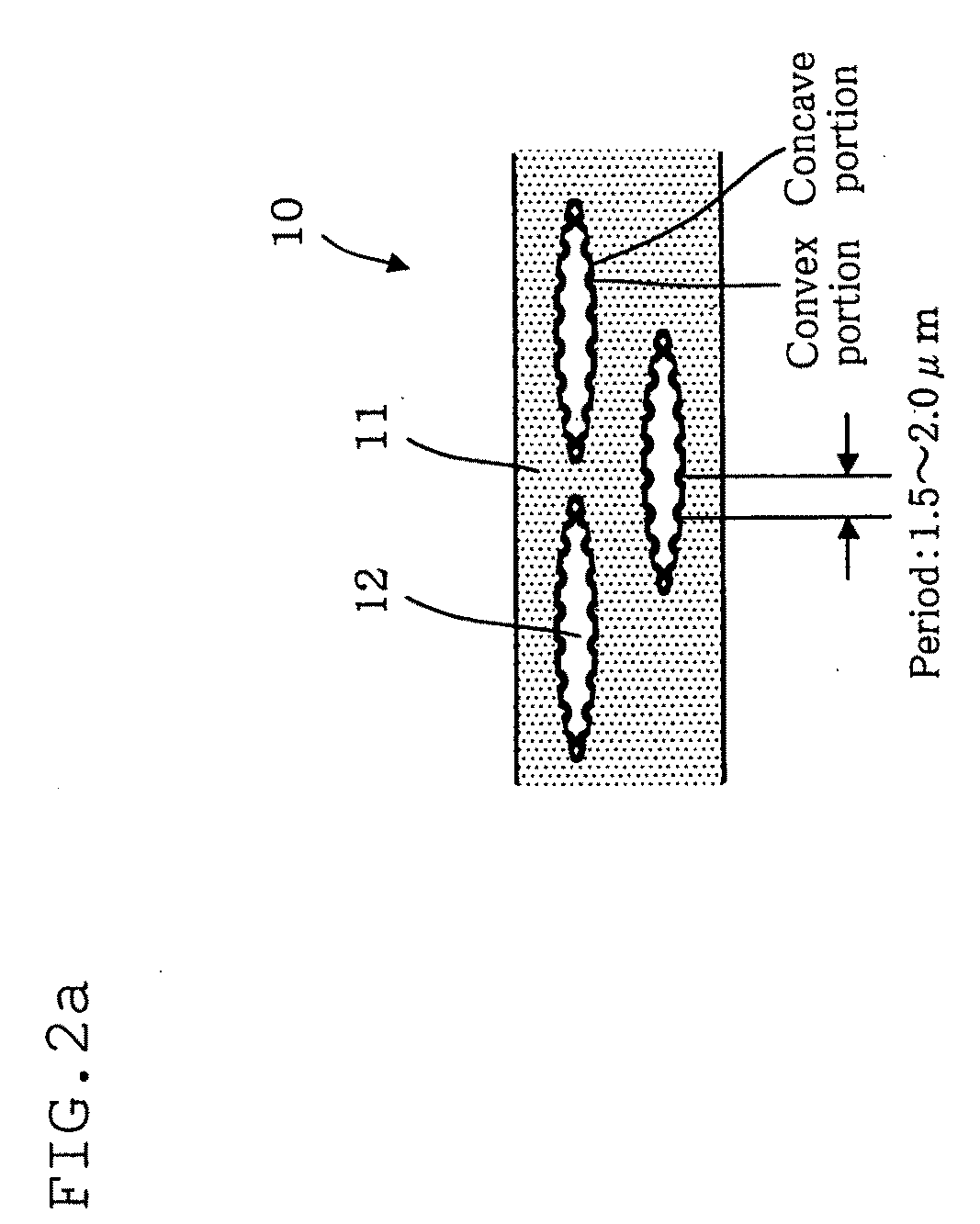

A Structural Body, a Method for Forming a Structural Body, an Apparatus for Forming a Structural Body, a Method for Reading a Structural Color and/or Diffraction Light, and a Truth/False Discriminating Method

InactiveUS20090174944A1Satisfies requirementImprove recycling effectPaper-money testing devicesAuxillary shaping apparatusOptical diffractionOptoelectronics

Decoration of a material is enabled with a high degree of recycling properties while satisfying the requirements for putting a structural color into practical use on the industrial scale. Furthermore, whether an object is genuine or not can be verified easily, and reusing by peeling as in the case of a hologram seal is prevented.A cavity 12 having a periodic structure 13 causing optical diffraction is formed in the inside of a substrate 11, and a periodic structure 15 causing optical diffraction is formed on part or the whole of the substrate 11. These cavity interface periodic structure 13 and the substrate surface periodic structure 15 have a regular arrangement developing a structural color. In addition, by bringing a functional material to be in contact with the substrate surface periodic structure 15, development of a structural color by the substrate surface periodic structure 15 is suppressed, thereby enabling a structural color developed by the cavity interface periodic structure 13 to be read.

Owner:TOYO SEIKAN KAISHA LTD

Hybrid power supply unit

ActiveUS20070166574A1Satisfies requirementFulfil requirementsPrimary cell to battery groupingLarge-sized flat cells/batteriesEngineeringElectrolyte

A hybrid power supply unit, comprises a high-capacity nonaqueous electrolyte battery group and a high-power nonaqueous electrolyte battery group different in discharge characteristics connected to each other in parallel. The high-capacity nonaqueous electrolyte battery group has a 0.2 C discharge capacity per cell greater than that of the high-power nonaqueous electrolyte battery group, and the high-power nonaqueous electrolyte battery group has a rate of 5 C discharge capacity per cell to 0.2 C discharge capacity per cell (5 C discharge capacity / 0.2 C discharge capacity) greater than that of the high-capacity nonaqueous electrolyte battery group.

Owner:PANASONIC CORP

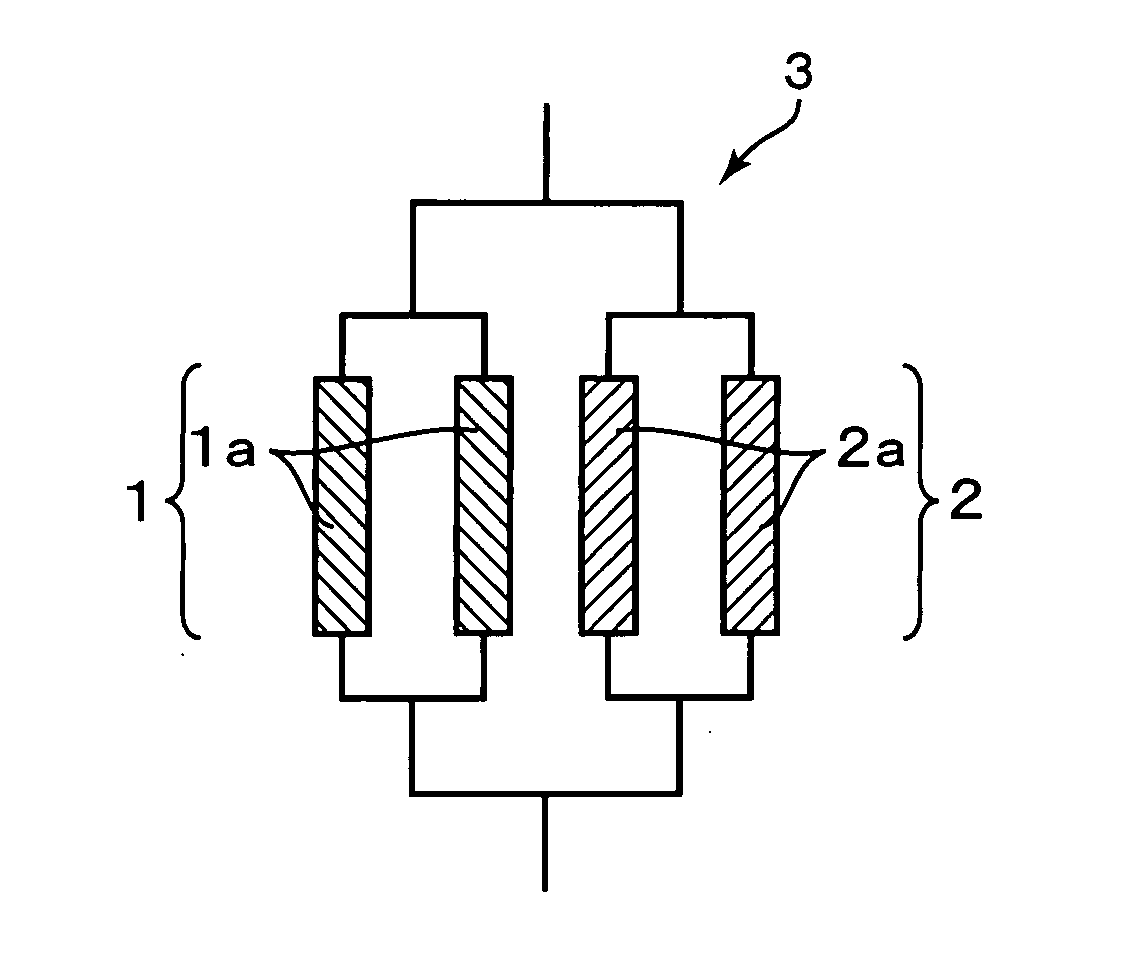

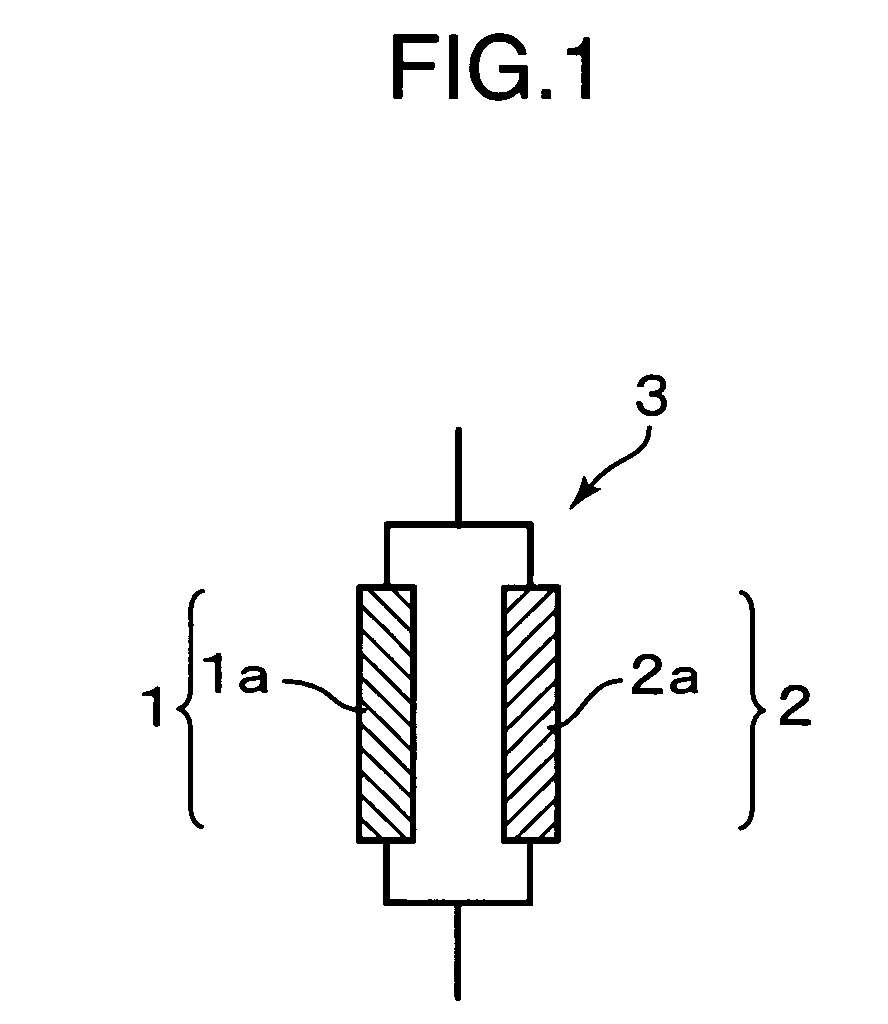

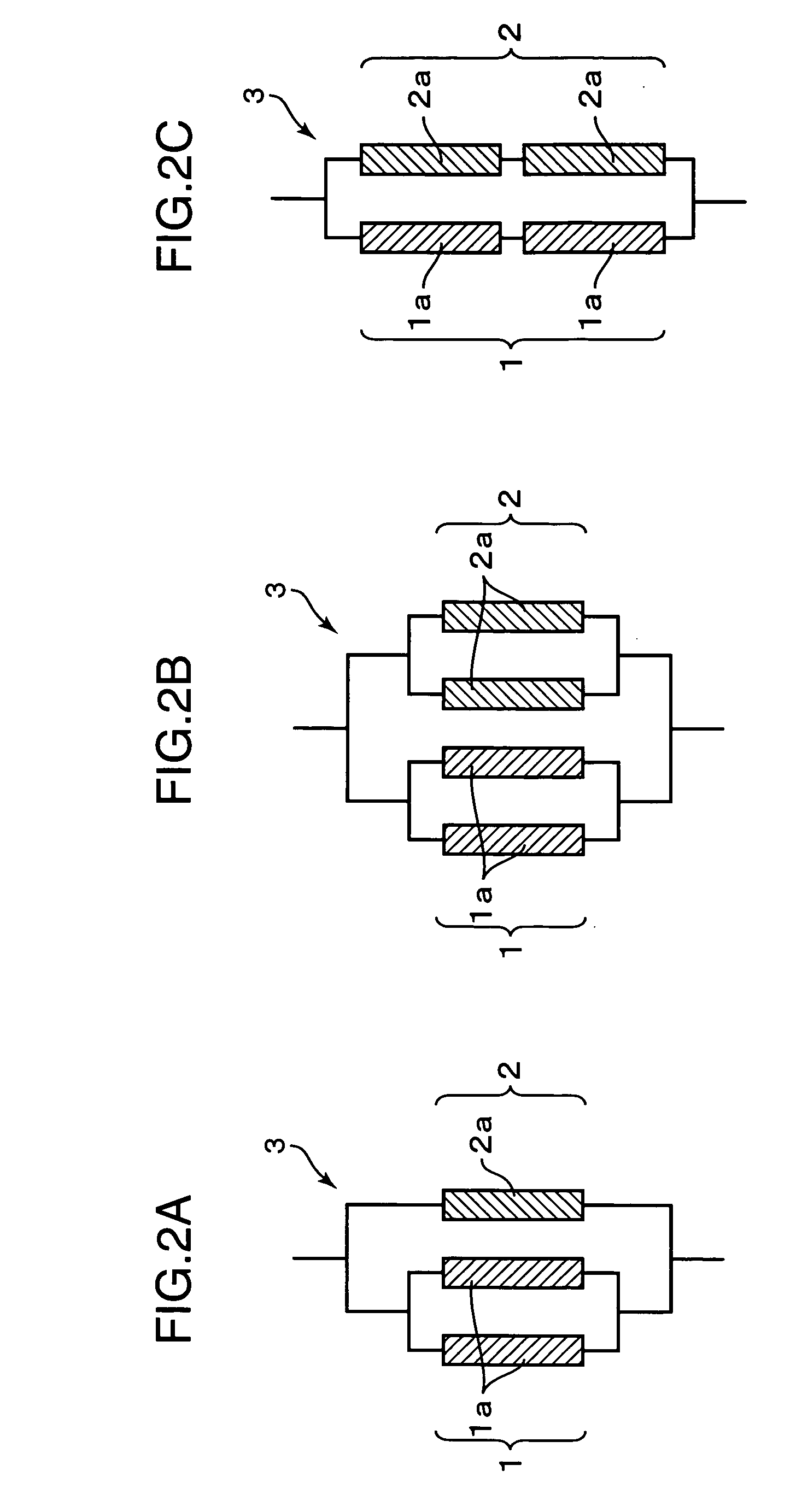

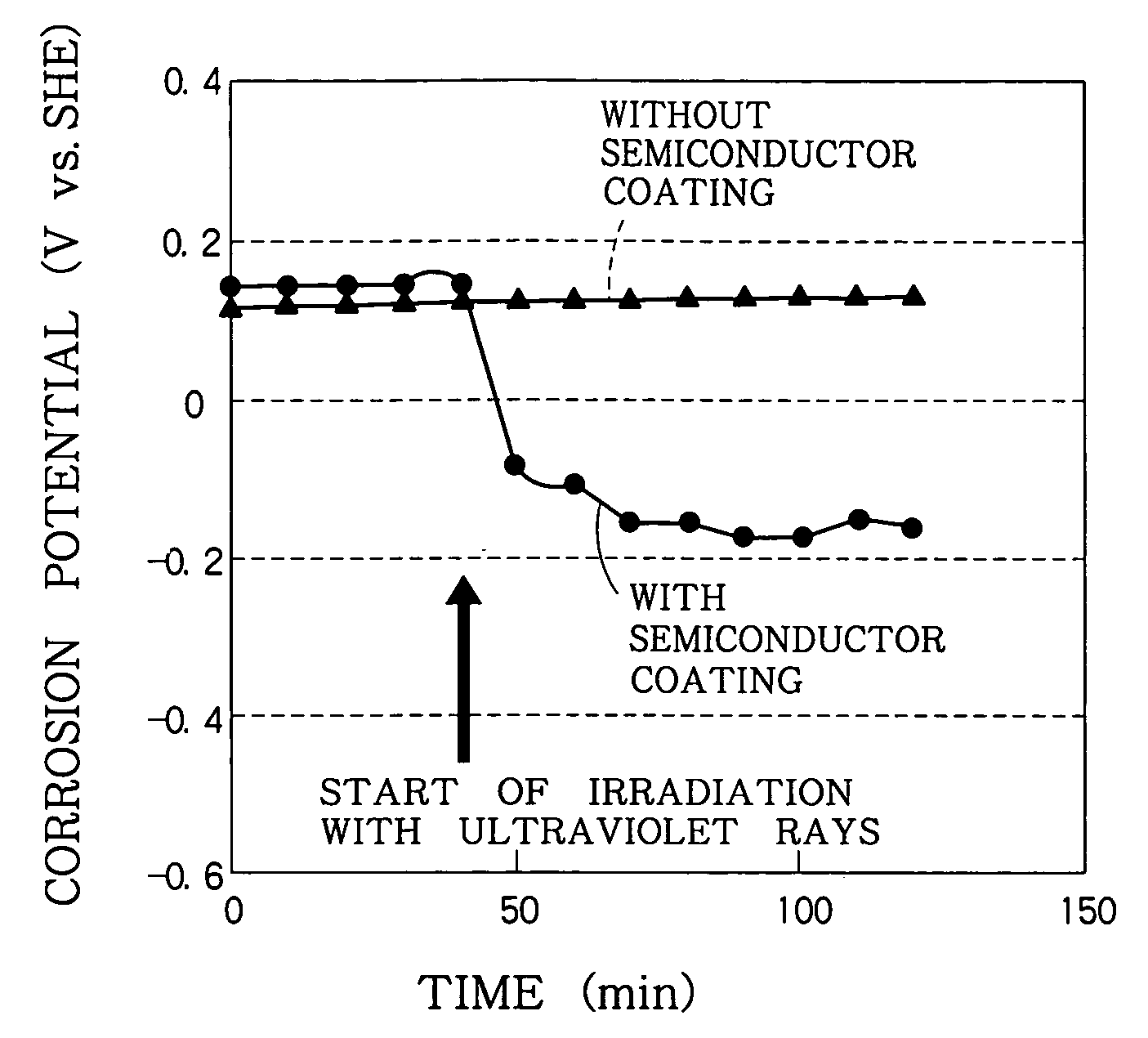

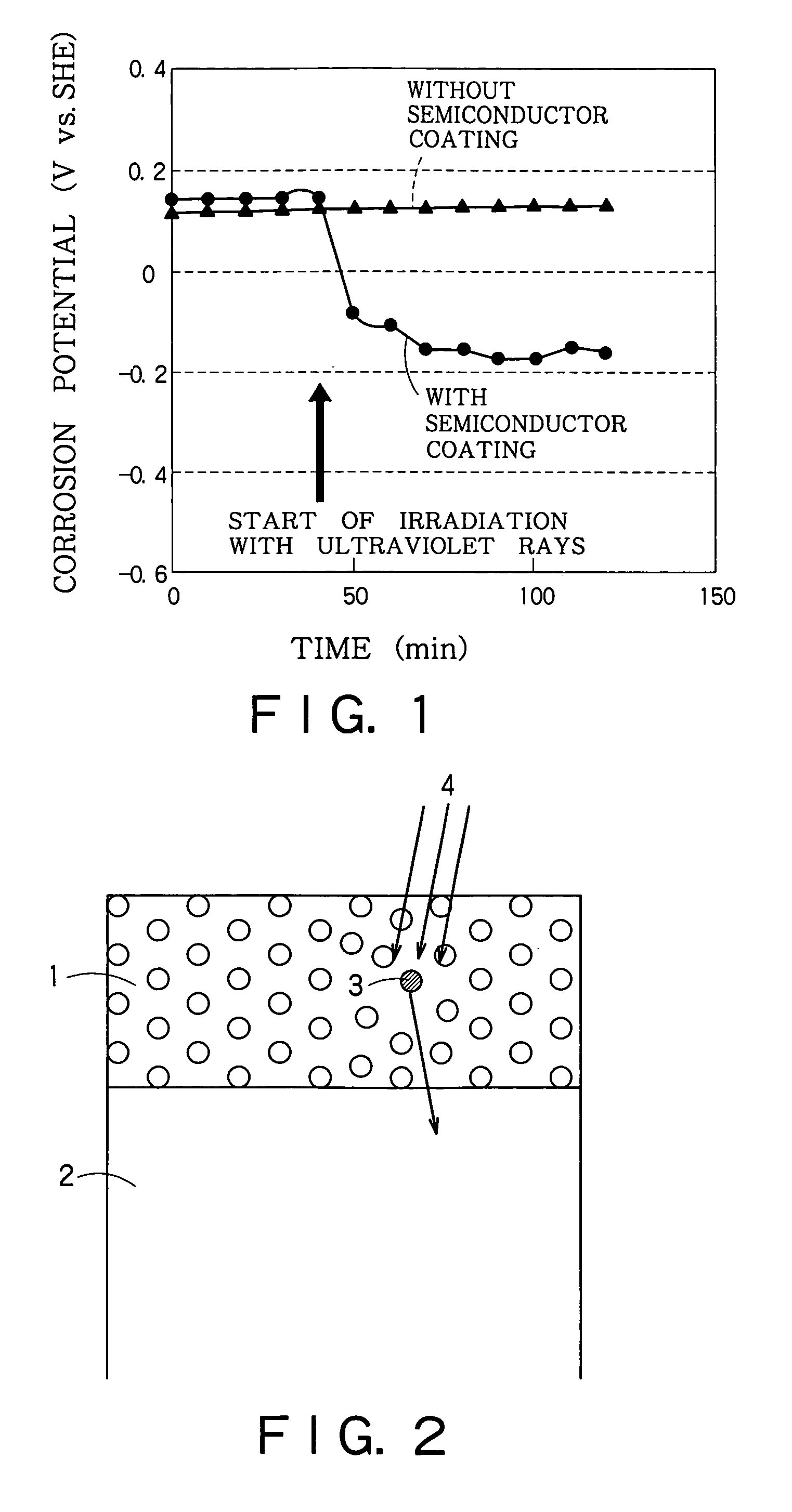

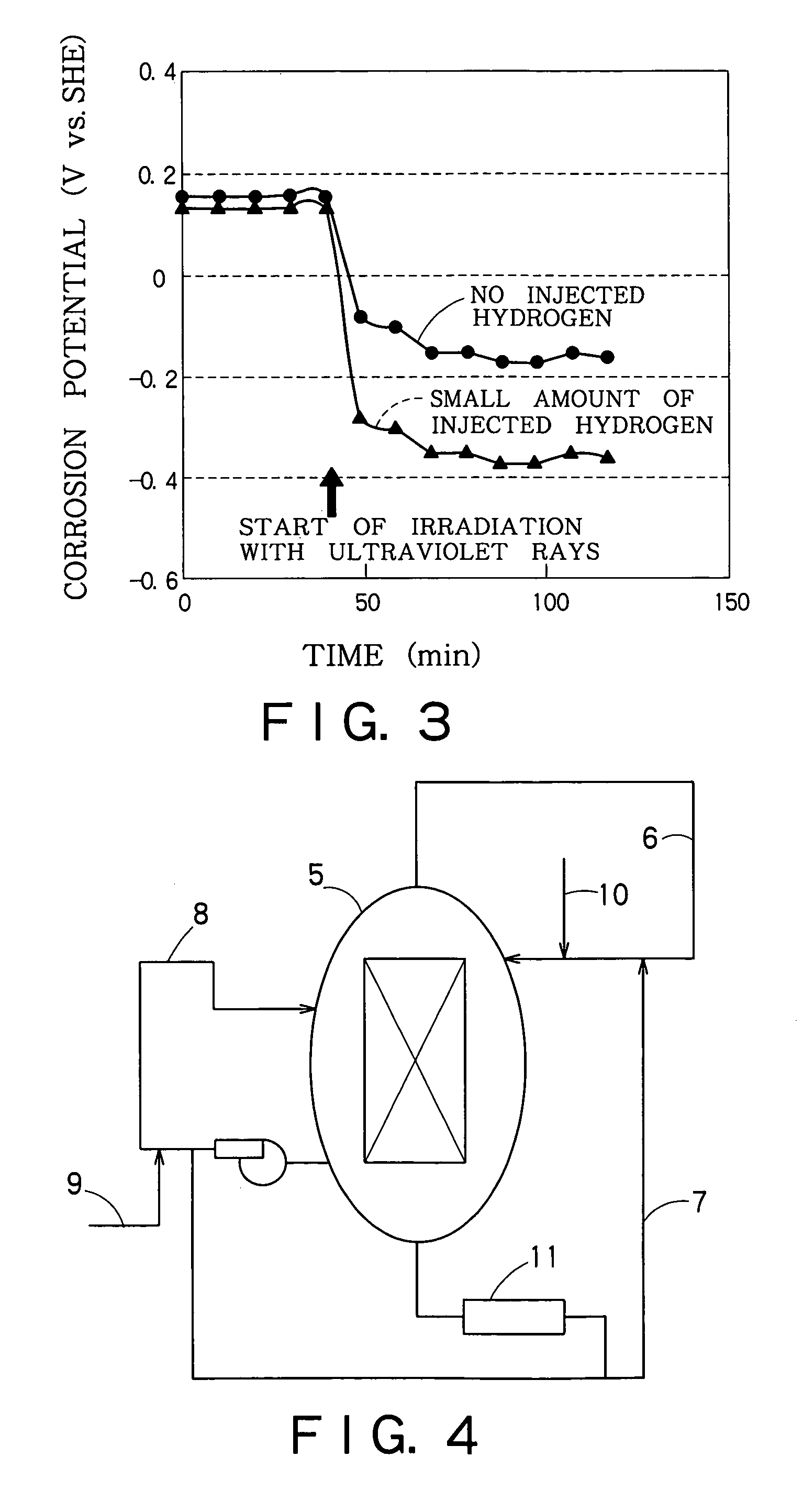

Reactor structural member and method of suppressing corrosion of the same

InactiveUS6940939B1Increase the concentration of hydrogenEffective preventionNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

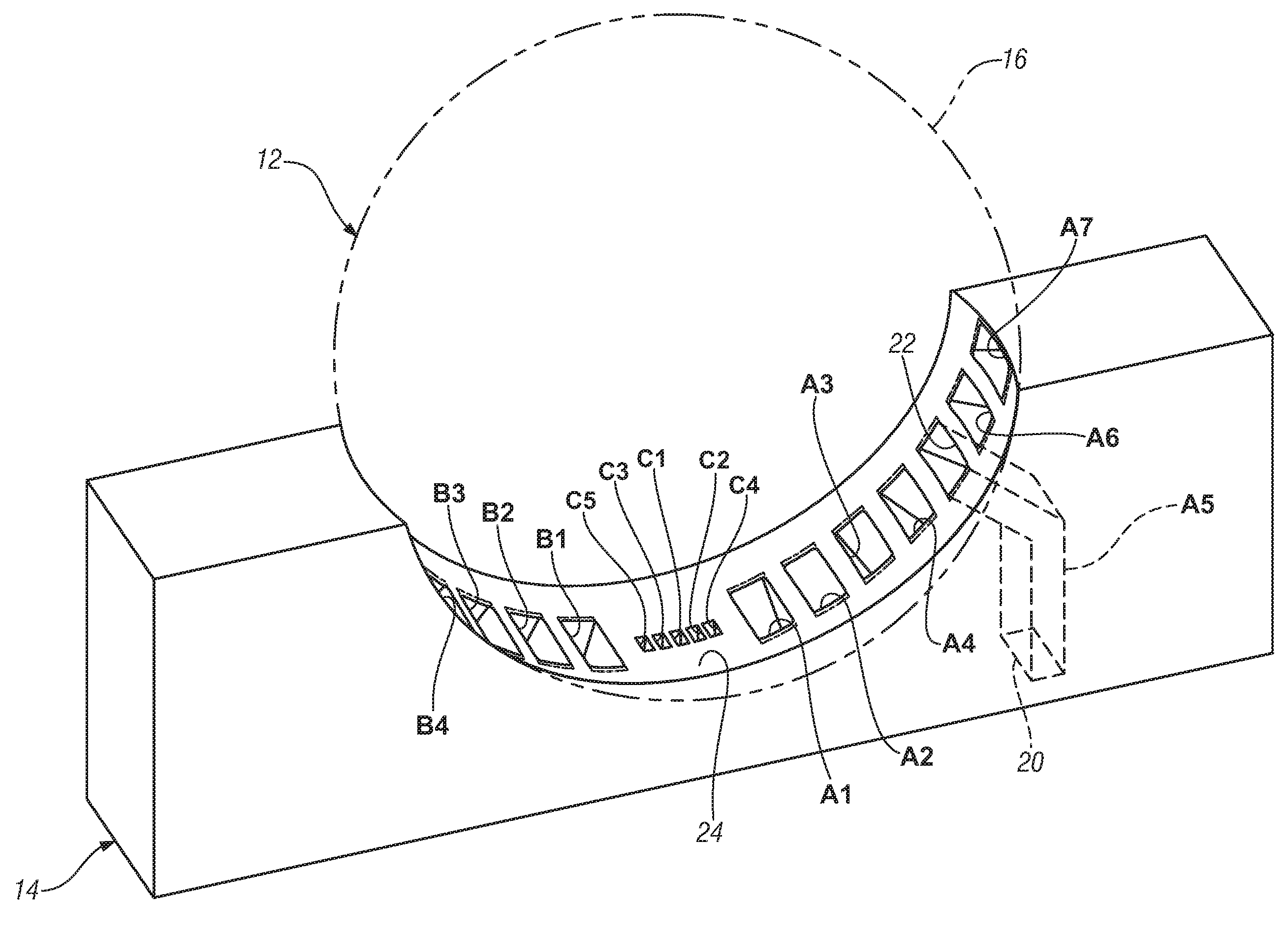

Multi-beam antenna with shared dielectric lens

An integrated multi-beam antenna with a shared dielectric lens is disclosed. The antenna is formed by positioning the feed apertures of a plurality of waveguide feeds at positions located on the surface of the shared dielectric lens. The angular direction and shape of radiation beams produced by the waveguide feeds are determined by the physical and dielectric characteristics of the lens, the location of feed apertures of the waveguide feeds on the surface of the lens, and the frequency of electromagnetic energy propagating in the waveguide feeds. The principles of the invention are applied to realize an inexpensive, integrated multi-feed antenna adapted to provide desired angular areas of coverage for both a long range and short range radar in an automotive radar safety system.

Owner:GM GLOBAL TECH OPERATIONS LLC

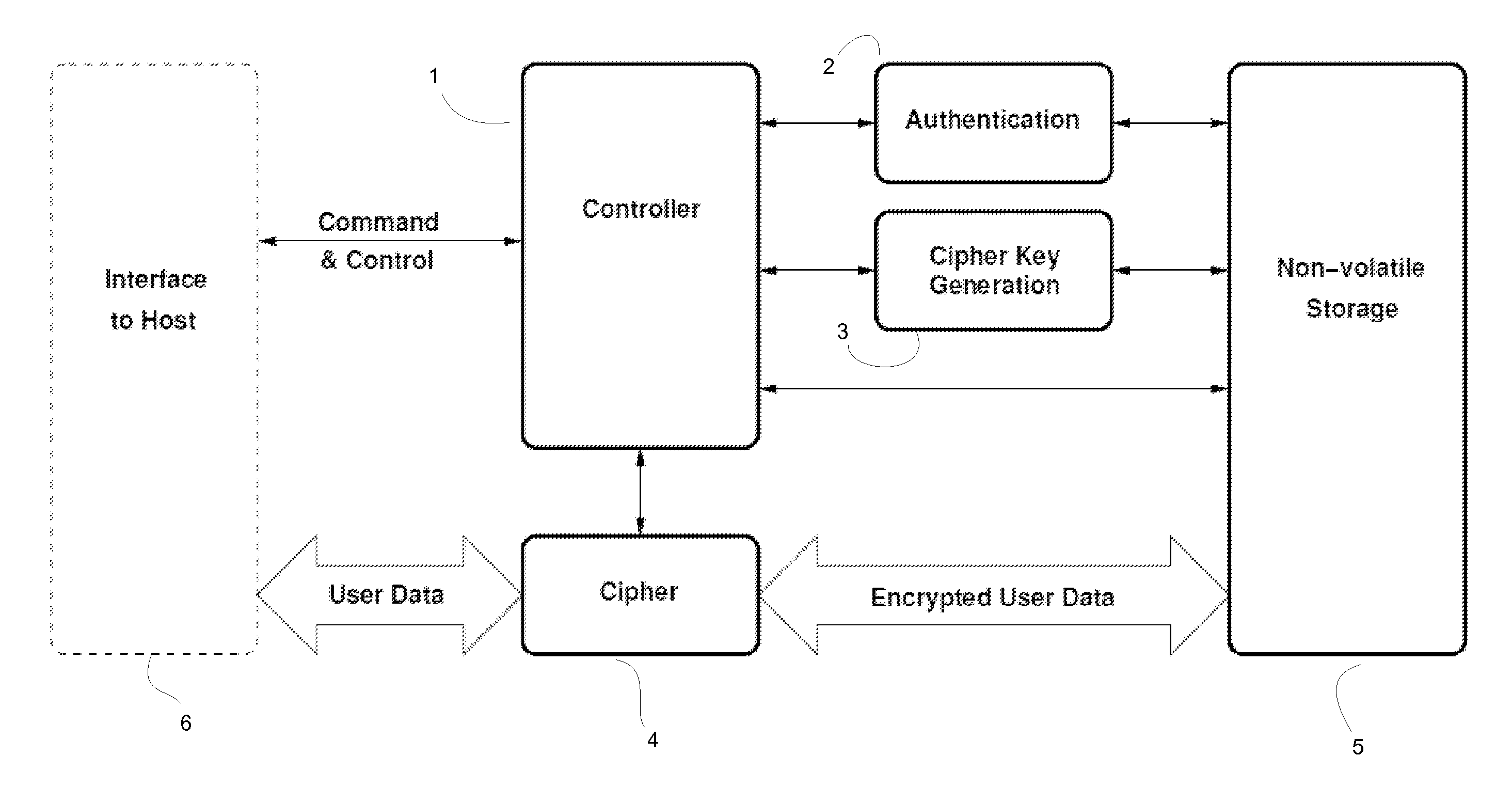

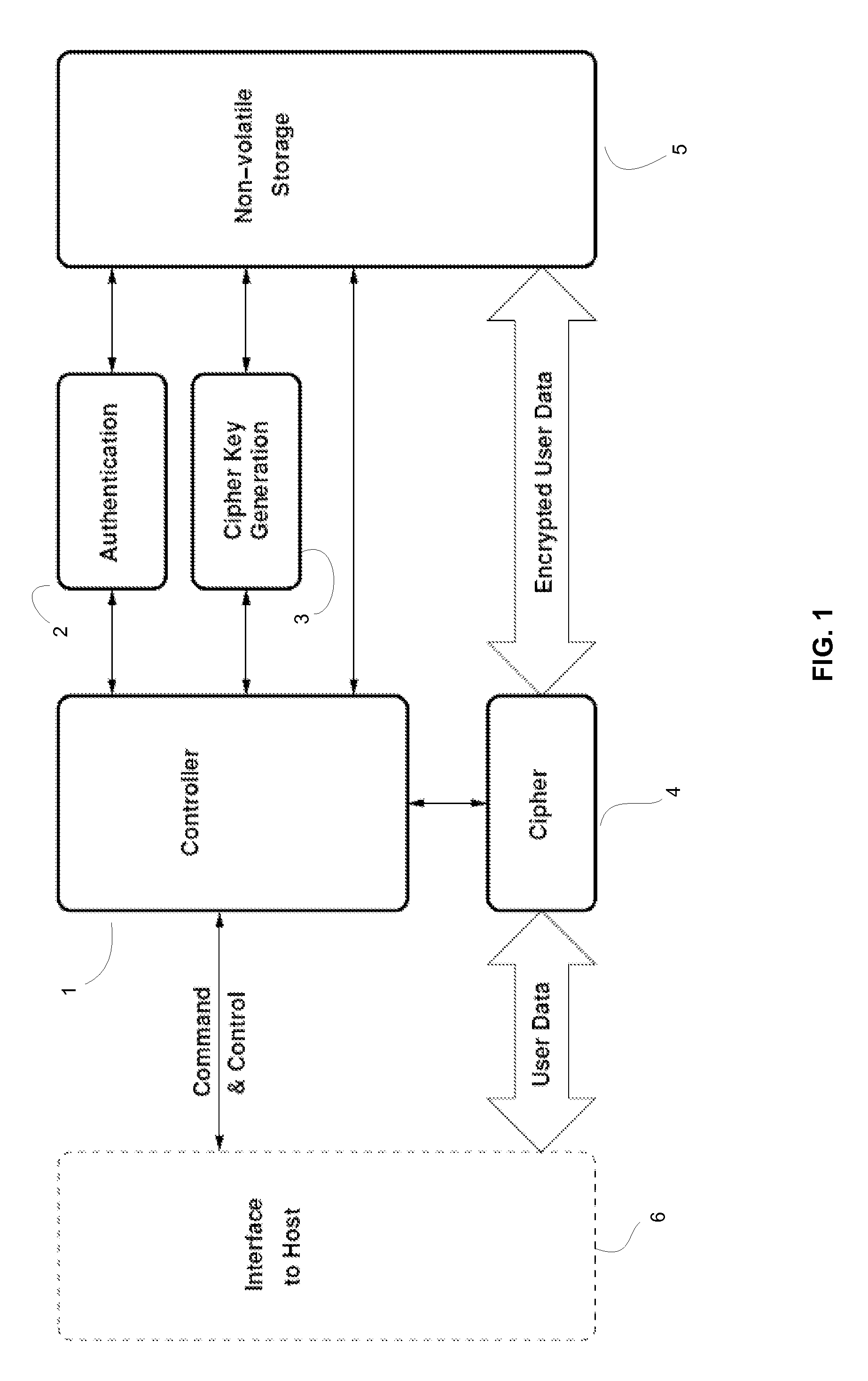

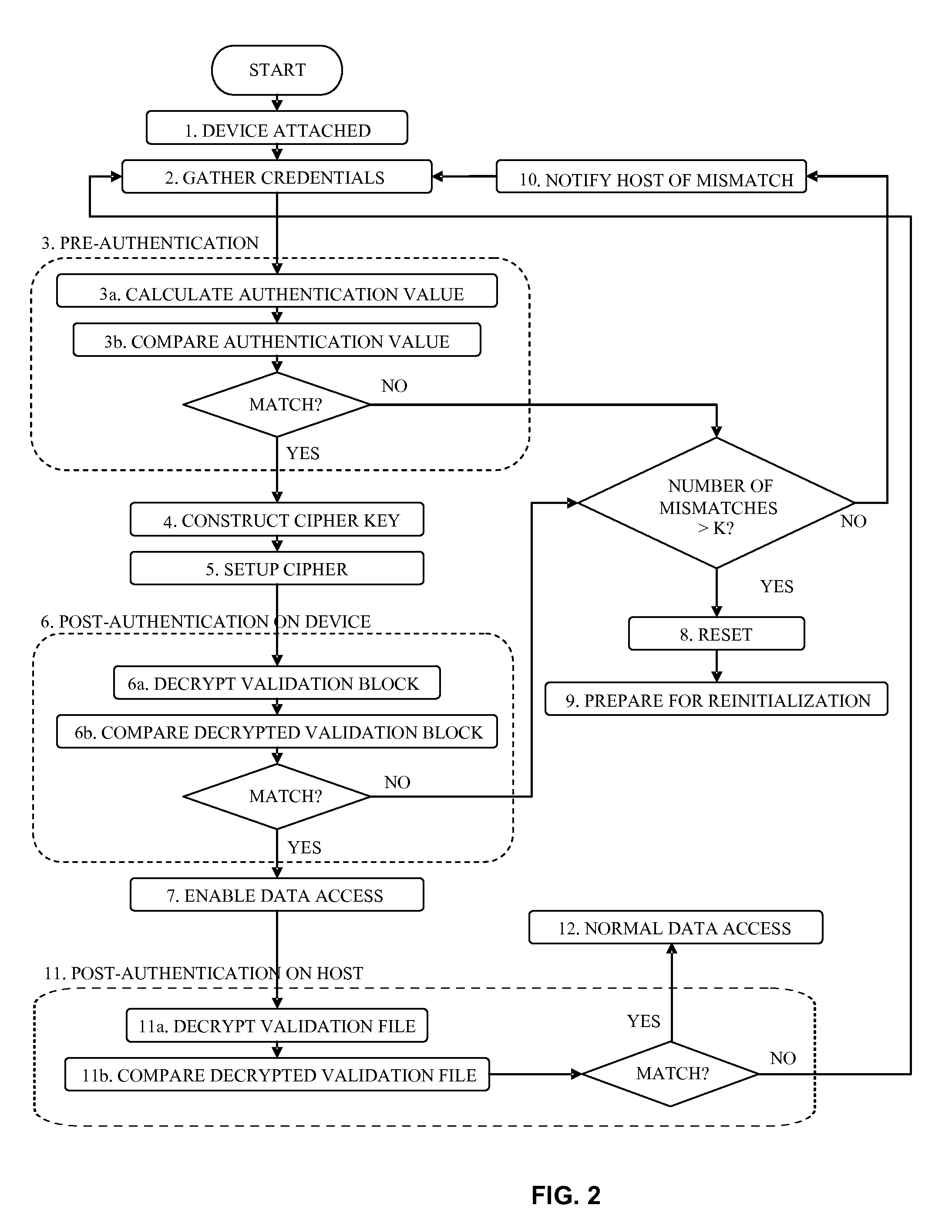

Secure User/Host Authentication

ActiveUS20120297205A1Improve performanceLow costUnauthorized memory use protectionHardware monitoringEngineeringData store

A portable storage device has a storage peripheral interface connecting to a computer. An encrypted data storage is available to the computer connected to the interface. The encrypted data storage includes a first part accessible after an authentication. A controller has a first operation mode performing encryption and decryption of data of the first part after the authentication of a first combined credential. The encryption and the decryption rely on a cipher key derived from a second combined credential. The first combined credential and the second combined credential are derived from at least a computer signature of the computer connected to the interface and a user credential of a user of the computer connected to the portable storage device.

Owner:CPO TECH

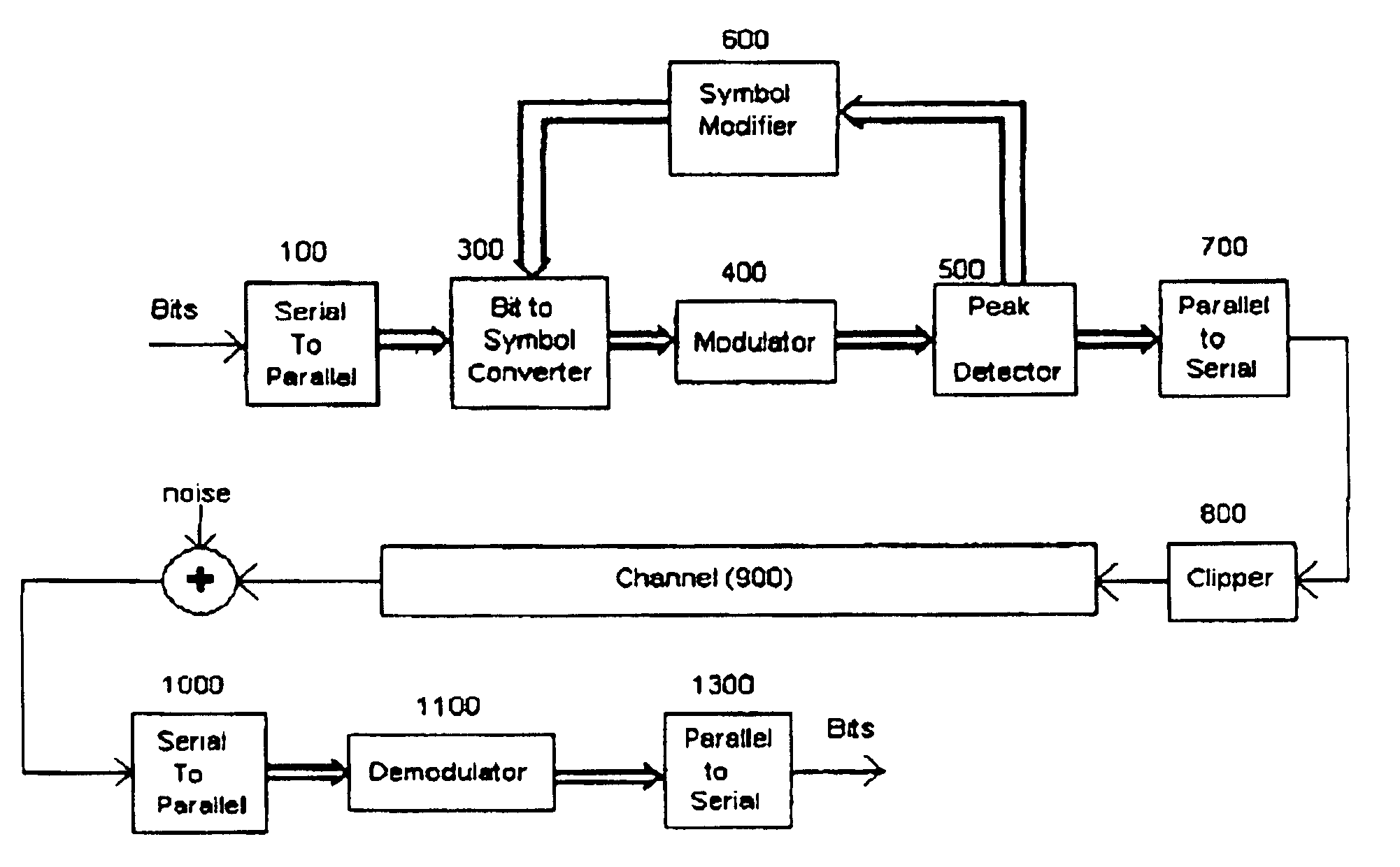

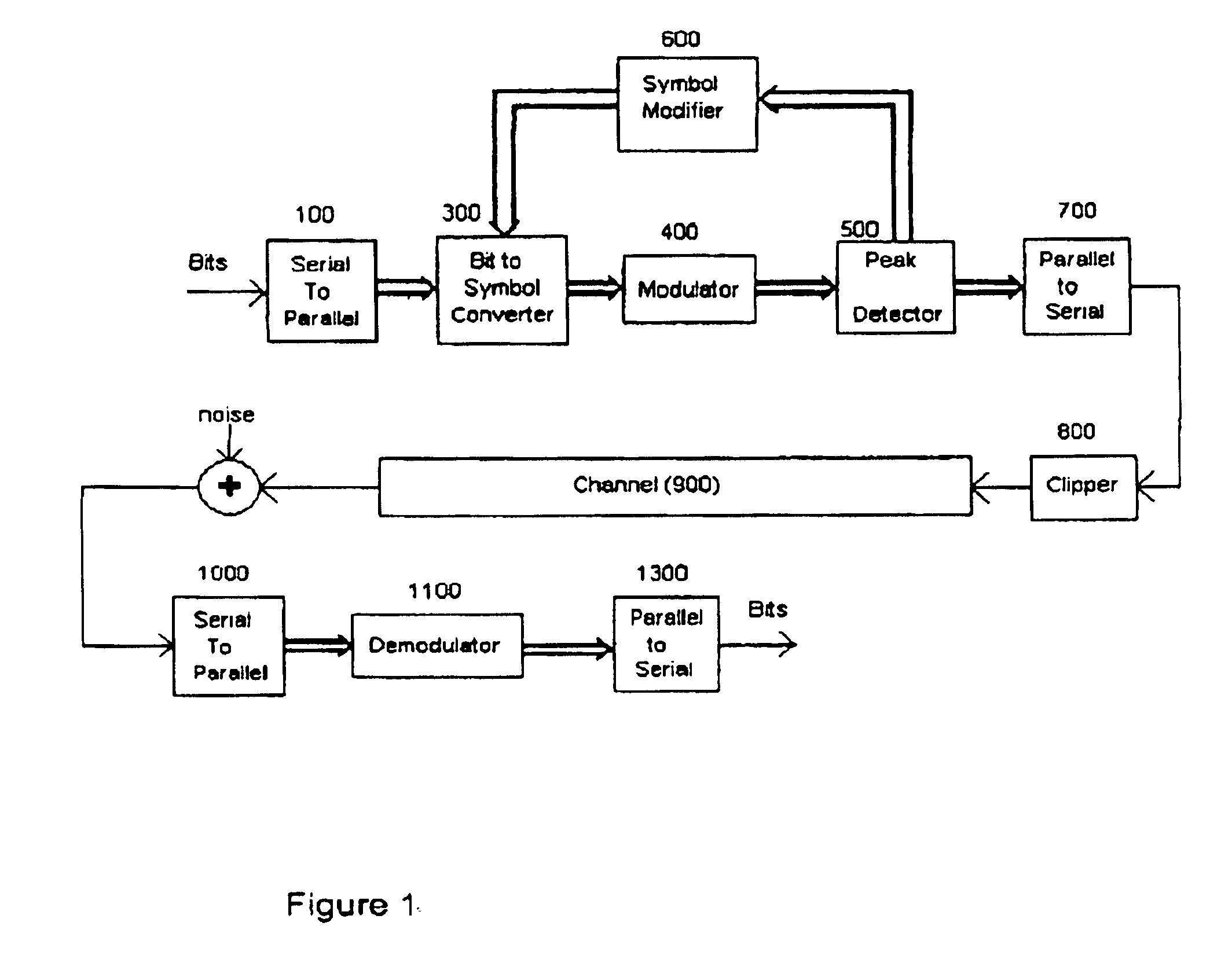

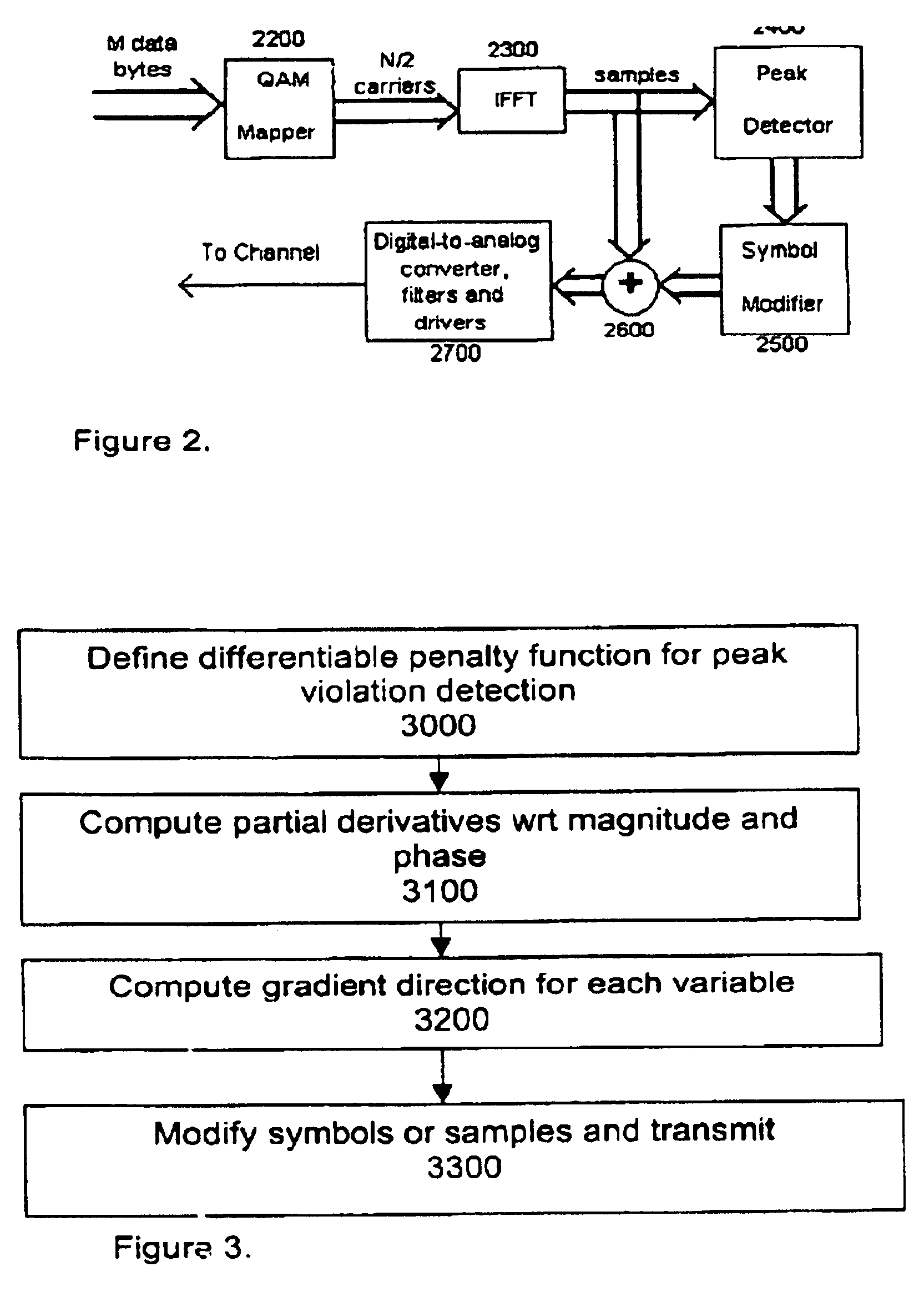

Technique for peak power to average power ratio reduction in multicarrier communication systems

InactiveUS6853632B1Providing some amountReduce PARFrequency-division multiplexMulti-frequency code systemsCommunications systemPeak value

A gradient sensitivity based method is described for reducing Peak to Average Power Ratio in multicarrier communication systems. The method involves definition of a differentiable penalty function which has non-zero values whenever there is a peak violation. The gradient of the function with respect to the symbol magnitudes and phases is evaluated at the given symbol vector. Symbol perturbations are computed in the opposite direction of the gradient in such a way that the peaks are reduced and the amount of errors introduced in the symbols is not large enough to affect the decoding process. In order to reduce computation, a variant of the method is proposed where a peak reduction kernel is precomputed and stored. The kernel is rotated to the location of the peak and added with proper sign to reduce PAR.

Owner:SILICON AUTOMATION SYST LIMITED AN INDIAN

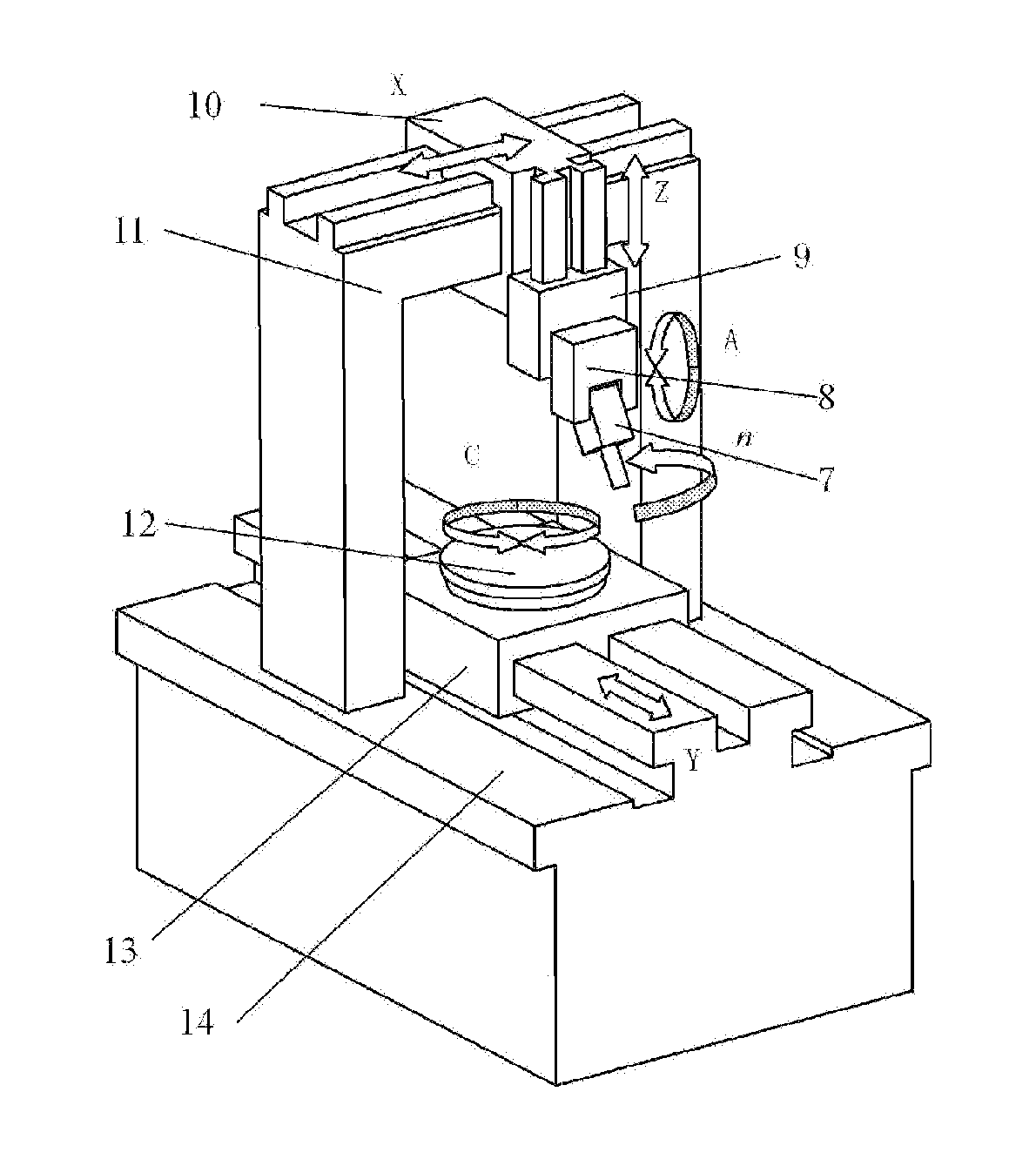

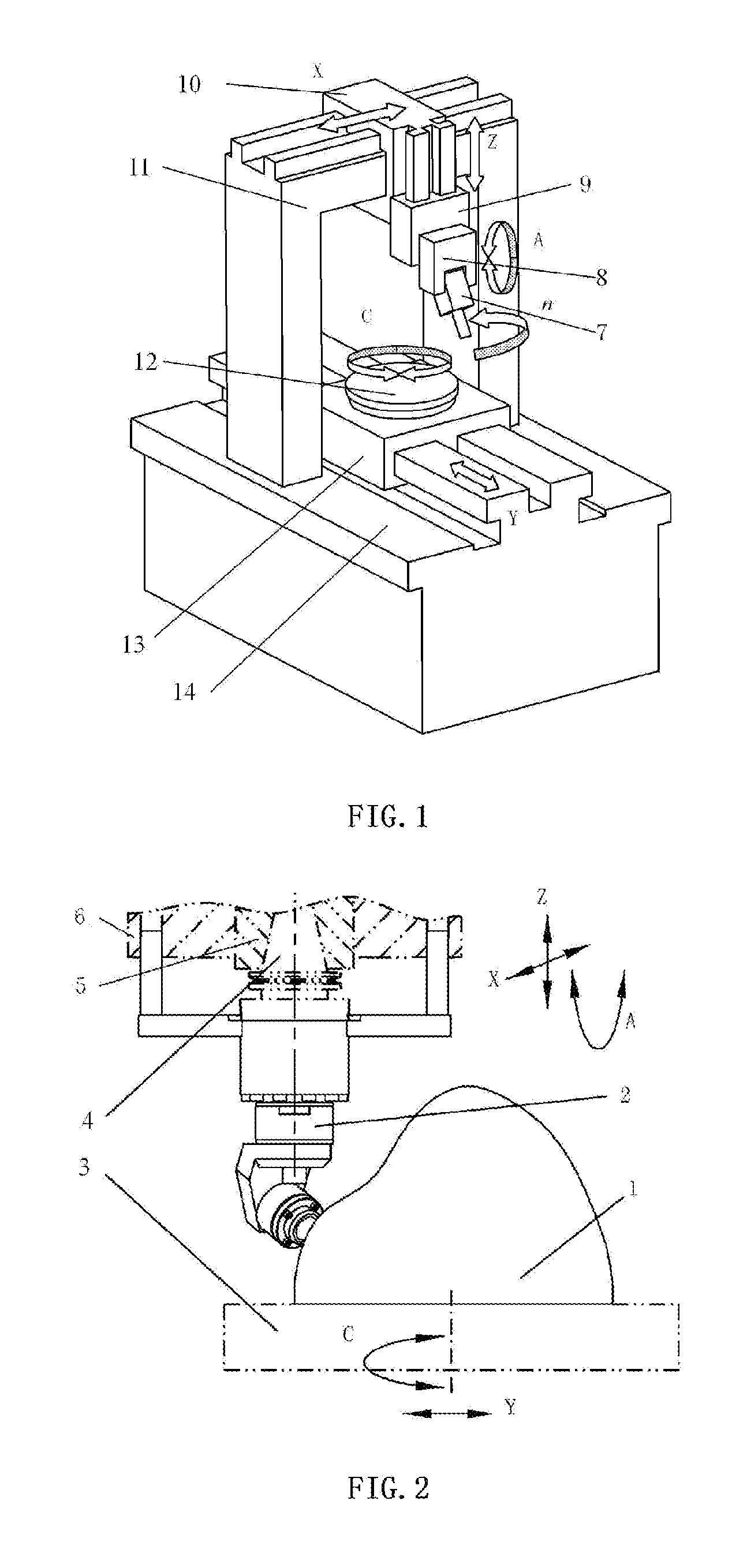

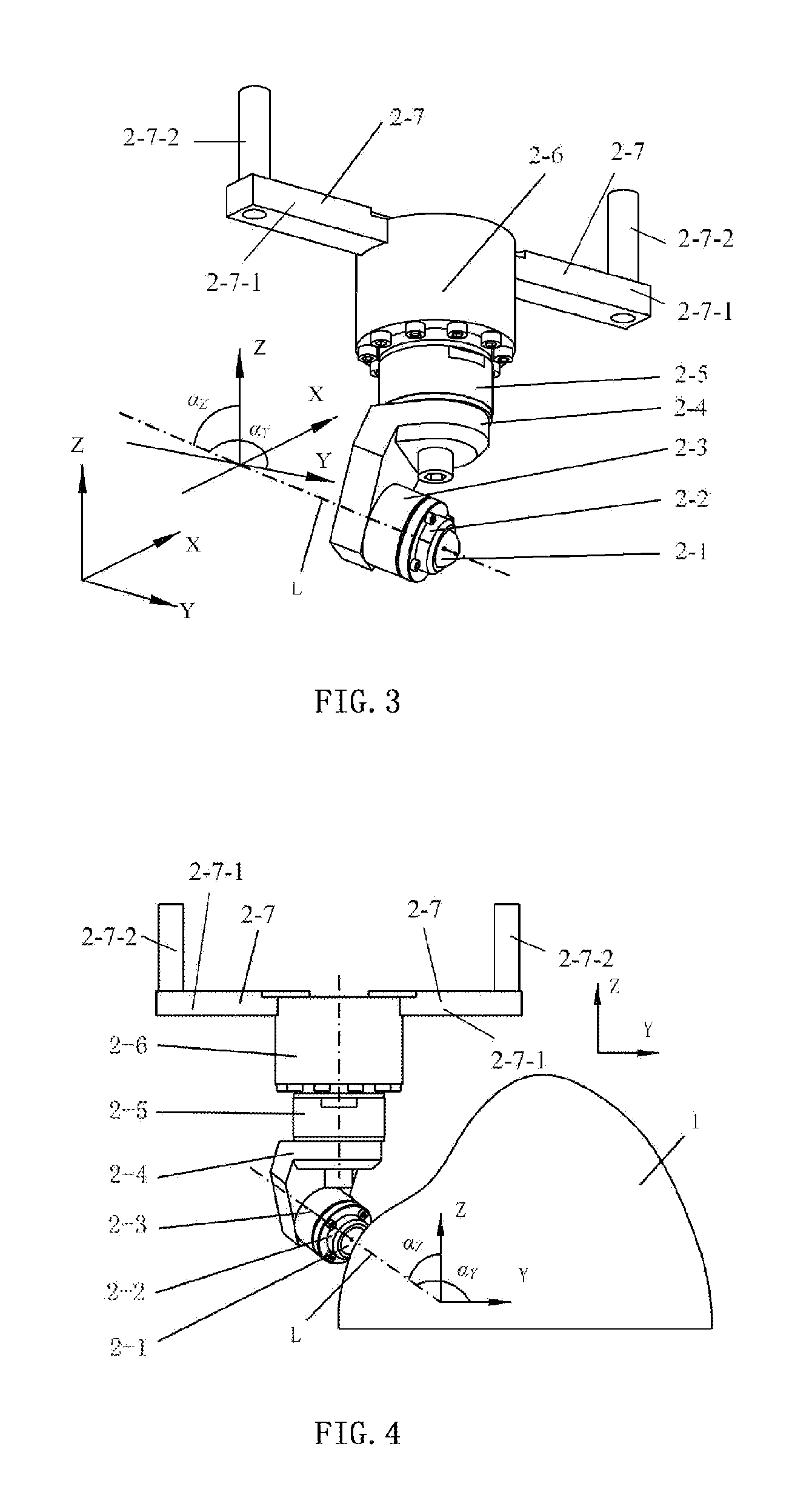

Multi-axle joint shifting loading apparatus for processing center and detection method for static stiffness distribution

ActiveUS20130111981A1Satisfies requirementMachine tool componentsMeasurement/indication equipmentsMultiaxial jointSteel ball

Disclosed is a processing center multi-axis joint deflection loading apparatus comprising a load-receiving test piece and a load-exerting component. The load-exerting component is constituted by a steel ball, a cap, a ball socket, a bent board, a force sensor, a connection component A, and a connection component B. The connection component A is fixedly connected to a blade handle of the processing center; the blade handle is pulled tight within a bored hole on a main axle; and the connection component A is connected to a main housing via the connection component B. In a method using the apparatus for an inspection of static stiffness distribution, by means of a multi-axle joint movement, moving the load-exerting component and the load-receiving test piece to a preset loading position, allowing the normal at a load-receiving point on a load-receiving face of the load-receiving piece to be aligned with the axis of the ball socket; with the amount of shift measured by position-shift sensors fitted on the main axle, the main axle housing, and a working platform, and the amount of simulated load measured by the force sensor of the loaded-exerting component, deriving a stiffness measurement of the load-exertion position under a simulated load; changing the load-exertion position by means of a multi-axle joint movement, repeating in sequence the previous steps, thus deriving a stiffness distribution under the simulated load.

Owner:XIAN UNIV OF TECH

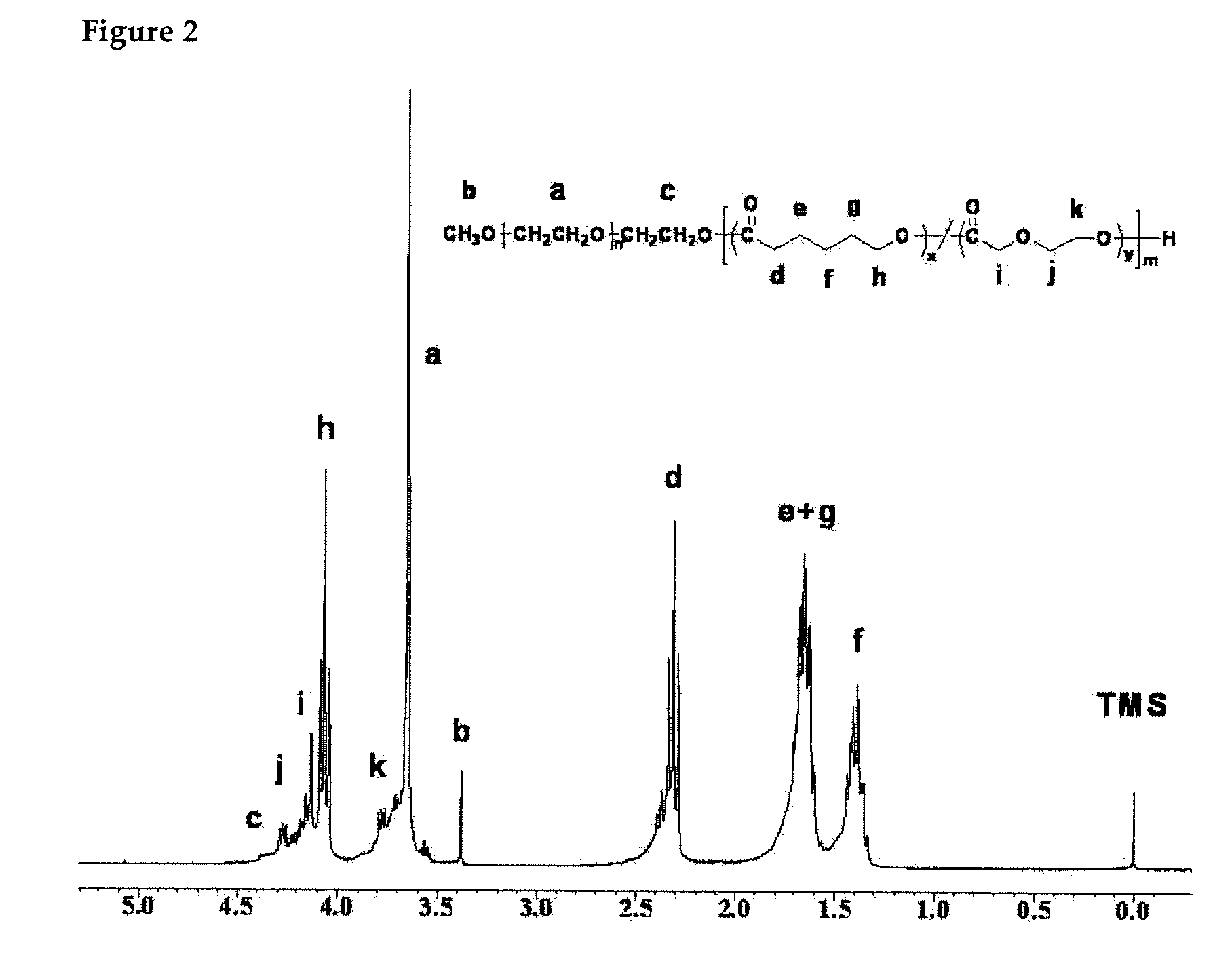

Preparation and characterization of polyethyleneglycol/polyesters as biocompatible thermo-sensitive materials

InactiveUS20070218099A1Reduce molecular weightWell formedPharmaceutical non-active ingredientsProsthesisPolyesterPolymer science

The present invention relates to a biocompatible and thermosensitive poly(ethylene glycol) / polyester block copolymer and a method of its preparation thereof, and particularly to a multi-functional intelligent hydrogel polymer comprising a hydrophilic part of a poly(ethylene glycol) (PEG) having a low molecular weight and a hydrophobic part comprising an ester-based caprolactone (CL) segment as an essential ingredient and further comprising a para-dioxanone (PDO) segment, a trimethylene carbonate (TMC) segment or a PDO / TMC copolymer containing the PDO and the TMC segments in a predetermined ratio, which easily forms a desired-shaped gel and decomposes or disperses without necessitating the operation process for removing the gel due to the temperature-dependent phase transition caused by the coagulation and the expansion of polymer micelles comprising a hydrophilic part and a hydrophobic part, thus being applicable to a drug delivery system or a porous support for tissue engineering purpose.

Owner:KOREA RES INST OF CHEM TECH

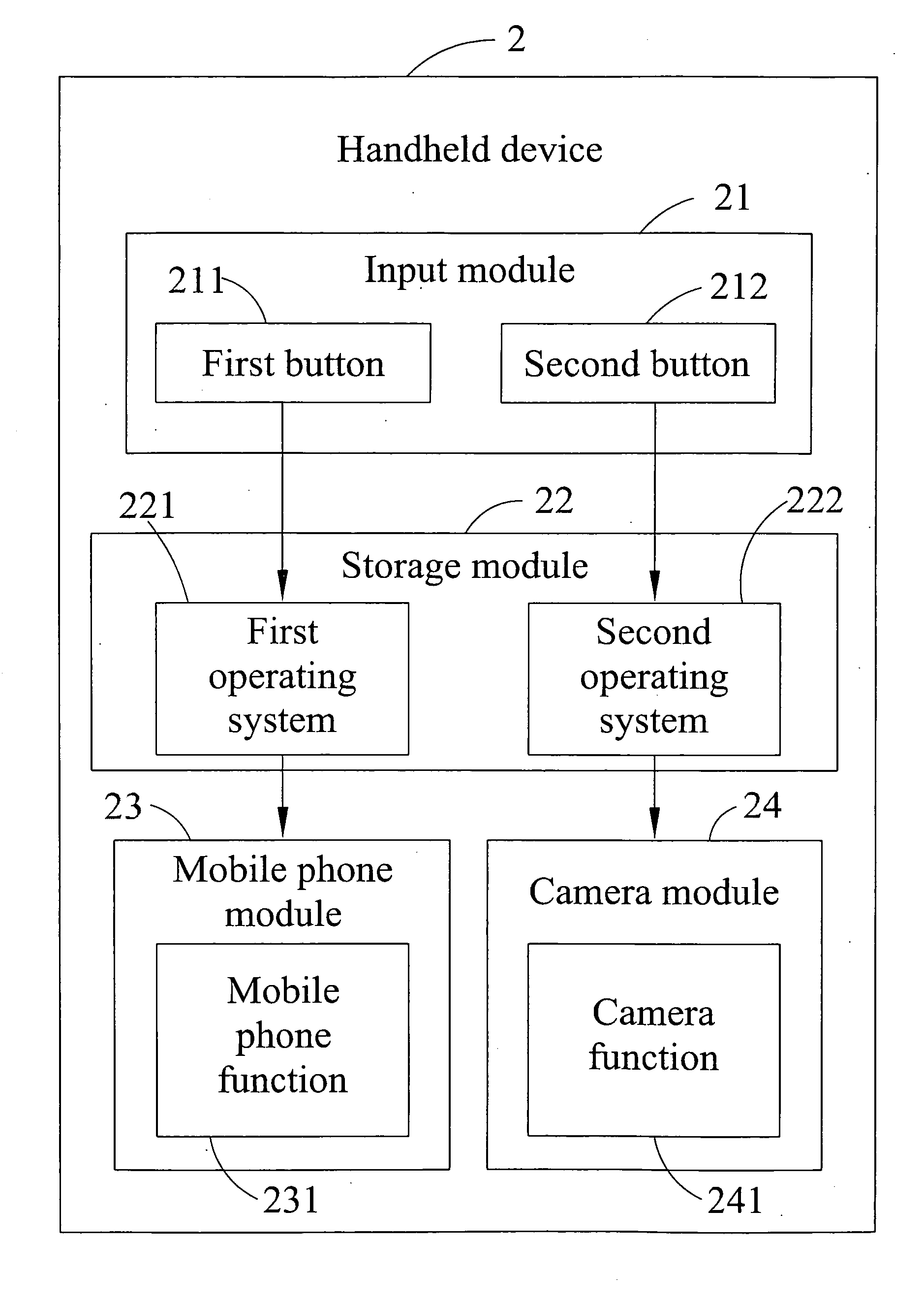

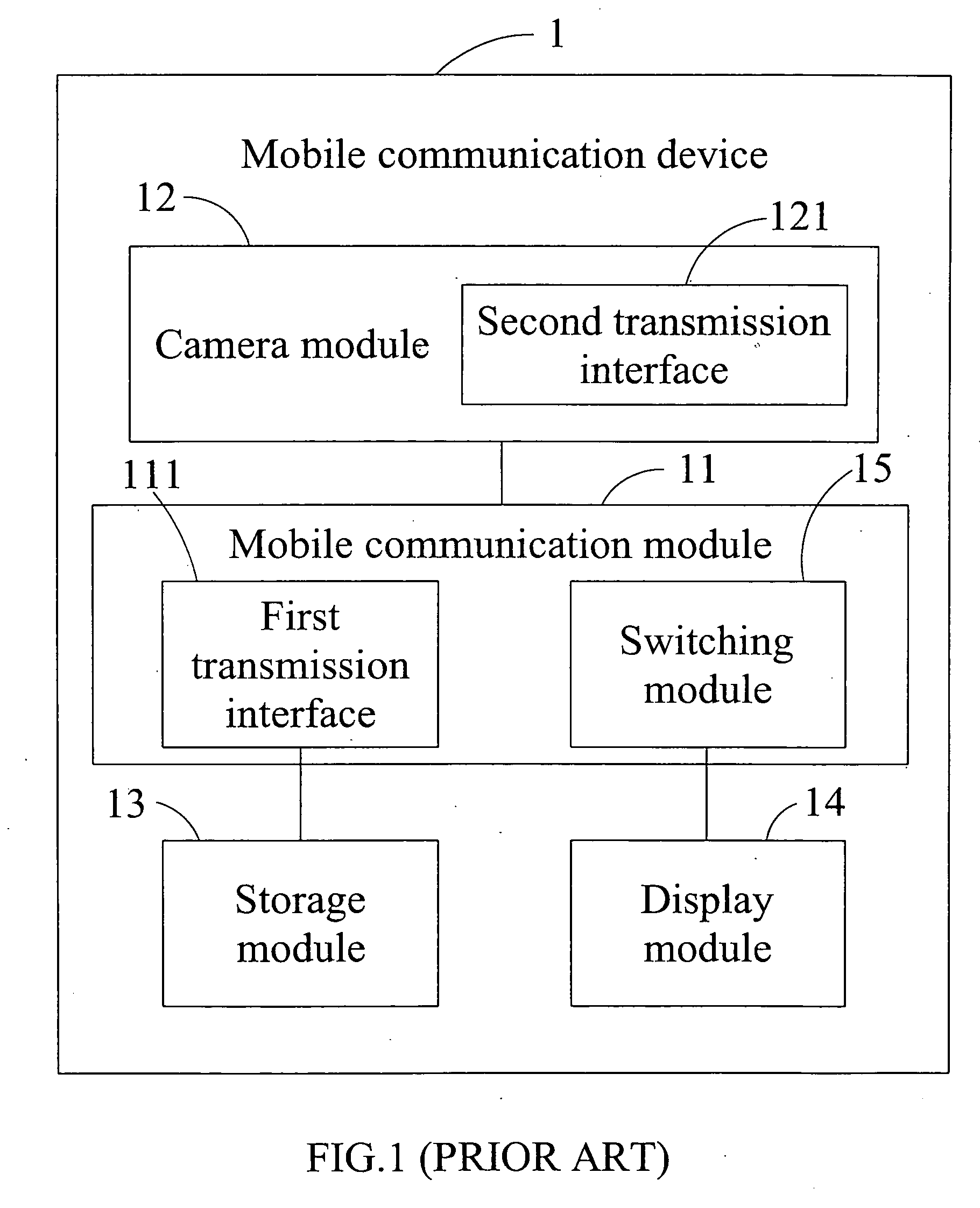

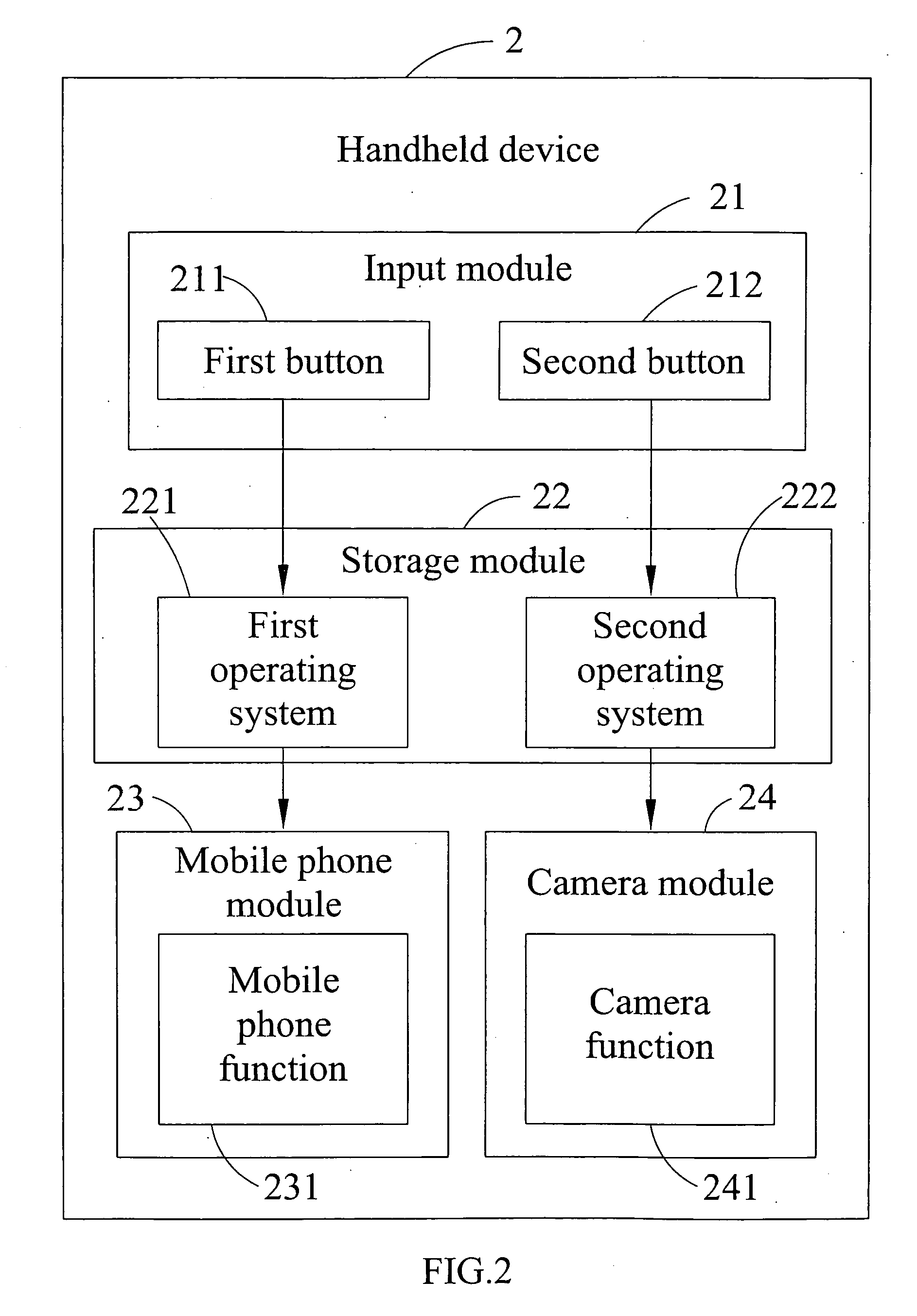

Handheld device capable of independently actuating camera and method thereof

InactiveUS20090111517A1Camera function can be quicklyReduce power consumptionSubstation equipmentDevices with fuctional cameraCamera moduleHand held devices

The present invention discloses a handheld device capable of independently actuating camera and method thereof. The handheld device comprises an input module, a storage module, a mobile phone module and a camera module. The input module has a first button and a second button. The storage module is connected to the input module and stores a first operating system and a second operating system. The mobile phone module is connected to the storage module and provides a mobile phone function. The camera module is connected to the storage module and provides a camera function. When the first button is pressed, the first operating system is activated for enabling the mobile phone module to provide the mobile phone function. When the second button is pressed, the second operating system is activated for enabling the camera module to provide the camera function.

Owner:MITAC INT CORP

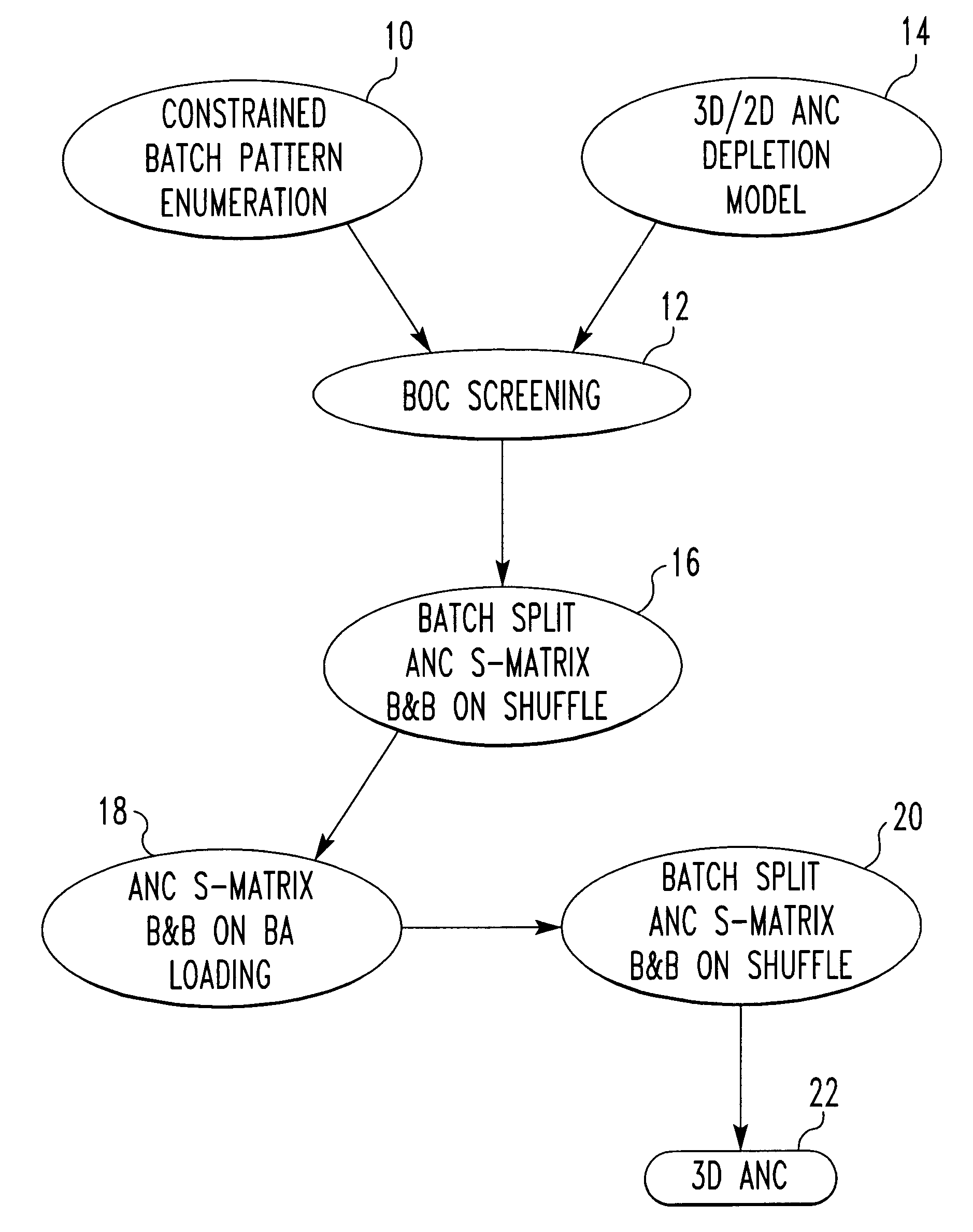

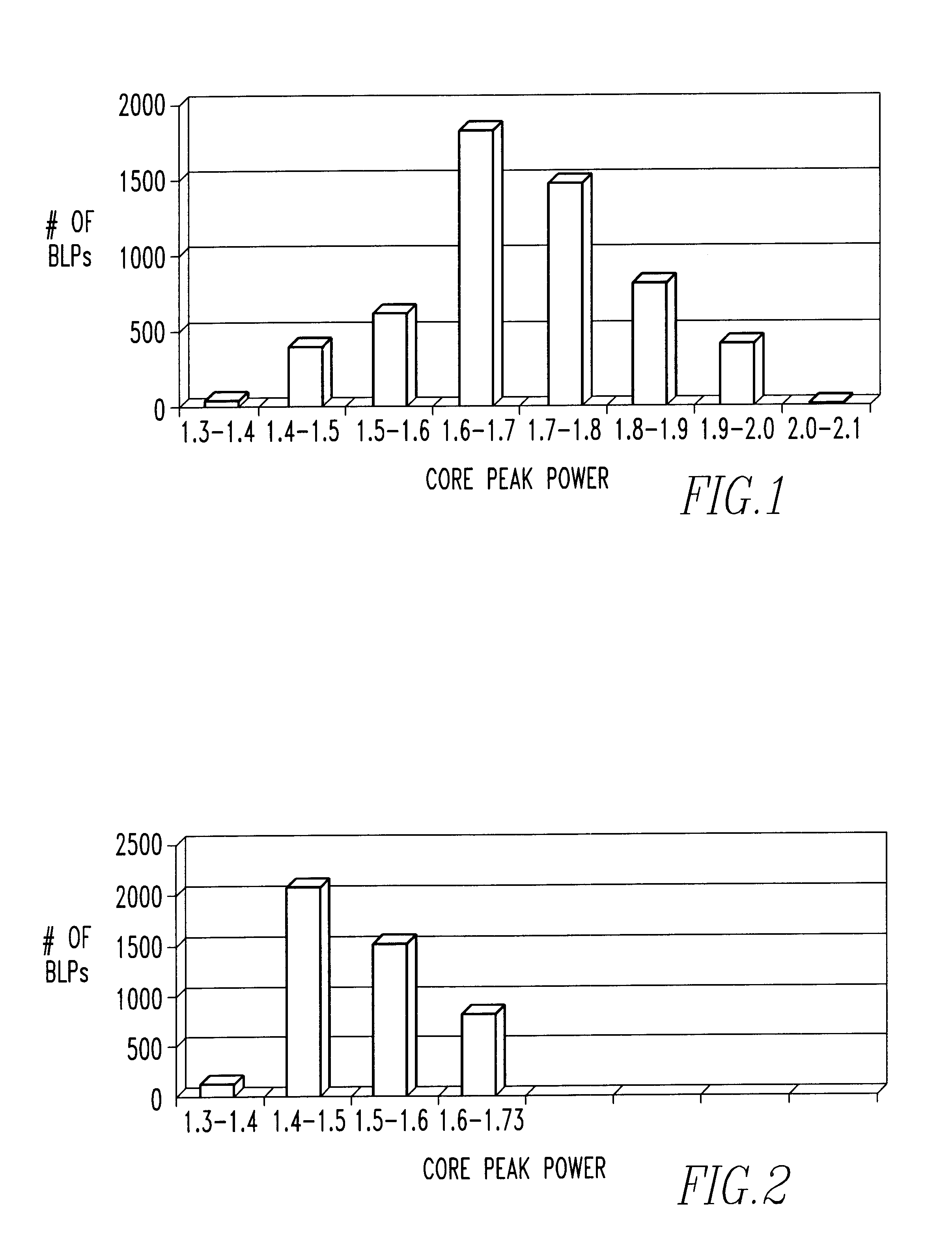

Method of establishing a nuclear reactor core fuel assembly loading pattern

ActiveUS6931090B2Satisfies requirementBetter meetingCosmonautic condition simulationsAnimal housingNuclear reactor coreNuclear reactor

All possible loading patterns for a nuclear reactor core are searched and optimized for compliance with design constraints. The fuel inventory is divided into a few batches according to coarse levels of reactivity. A recursive enumeration process identifies patterns meeting selected core position constraints, which can be user modified to adjust the search space size. For the batch loading patterns satisfying the constraints, the batches are divided into several smaller batches. A sensitivity matrix linearizing the relationship between fuel assembly position and the depletion model is processed through mixed integer linear programming with branching and bounding to identify an optimal daughter loading pattern. The process is repeated through several levels of batch refinement and selection of optimal daughter patterns, including a level where burnable absorbers are assigned to feed assemblies, until the individual fuel assembly level is reached. The multiple optimal patterns remaining provide a range of solutions.

Owner:WESTINGHOUSE ELECTRIC CORP

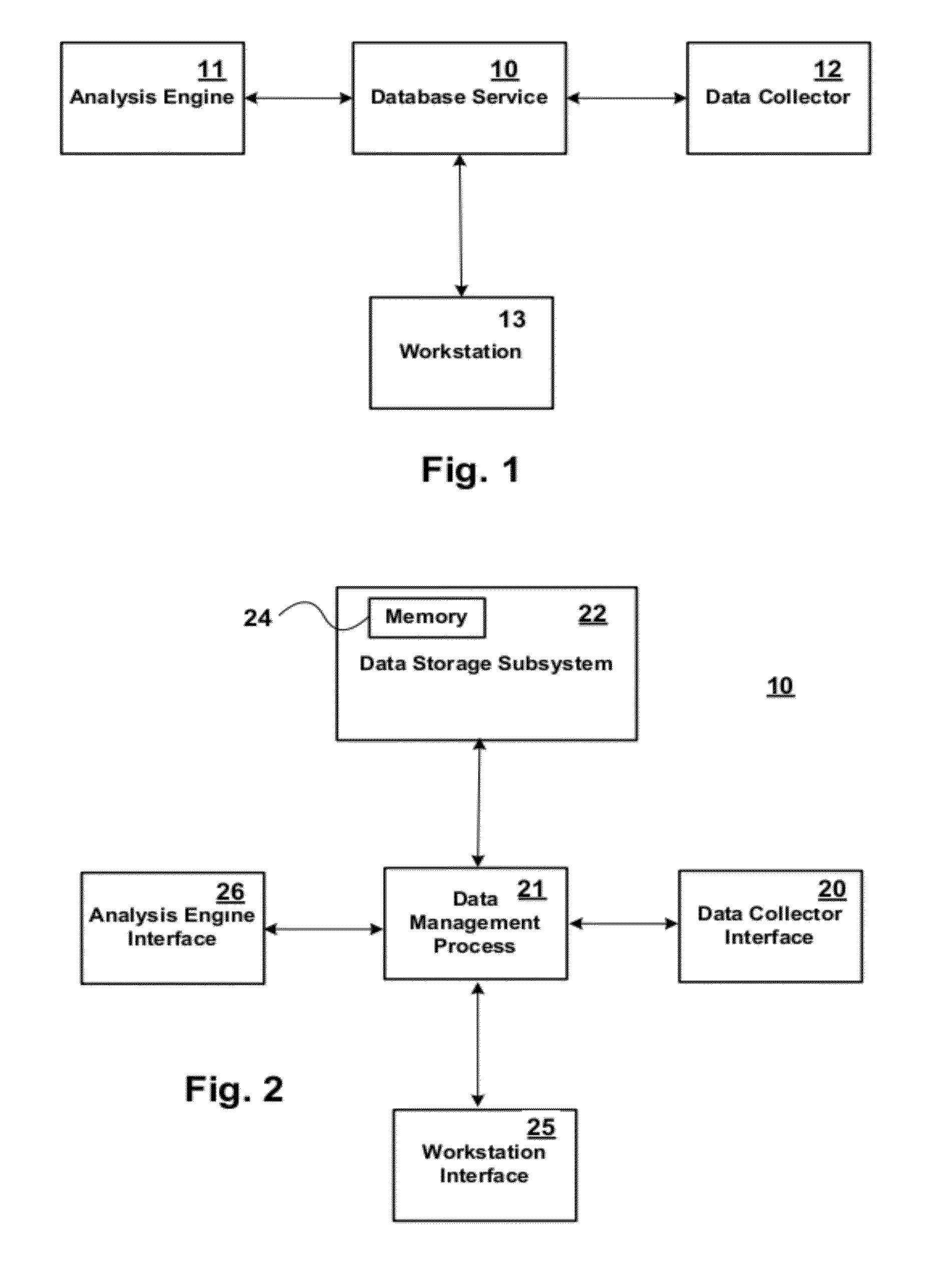

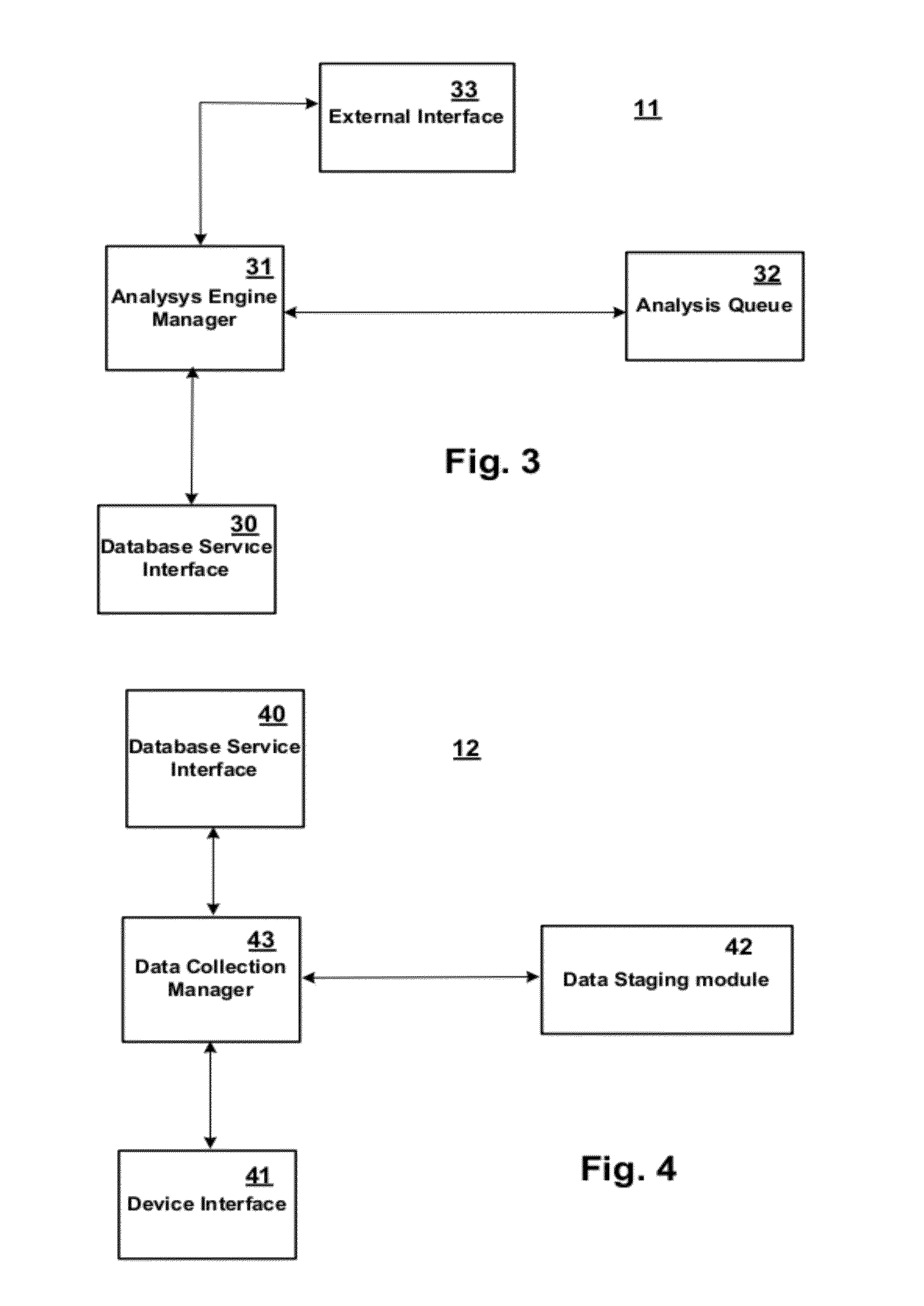

Data Analysis System

ActiveUS20120290576A1Satisfies requirementEliminate requirementsDigital data processing detailsComputer security arrangementsAnalysis dataStructure of Management Information

A data analysis system for analyzing data from multiple devices has a database service module including a data storage subsystem storing data from collected from different devices. The data is stored in a meta-structure using primitives to classify the data. An analysis engine analyzes the data to determine whether the data defined by the meta- structure meets certain criteria in accordance with a stored set of rules. The system is useful, for example, in the detection of faults in railway infrastructure.

Owner:GROUND TRANSPORTATION SYST CANADA INC

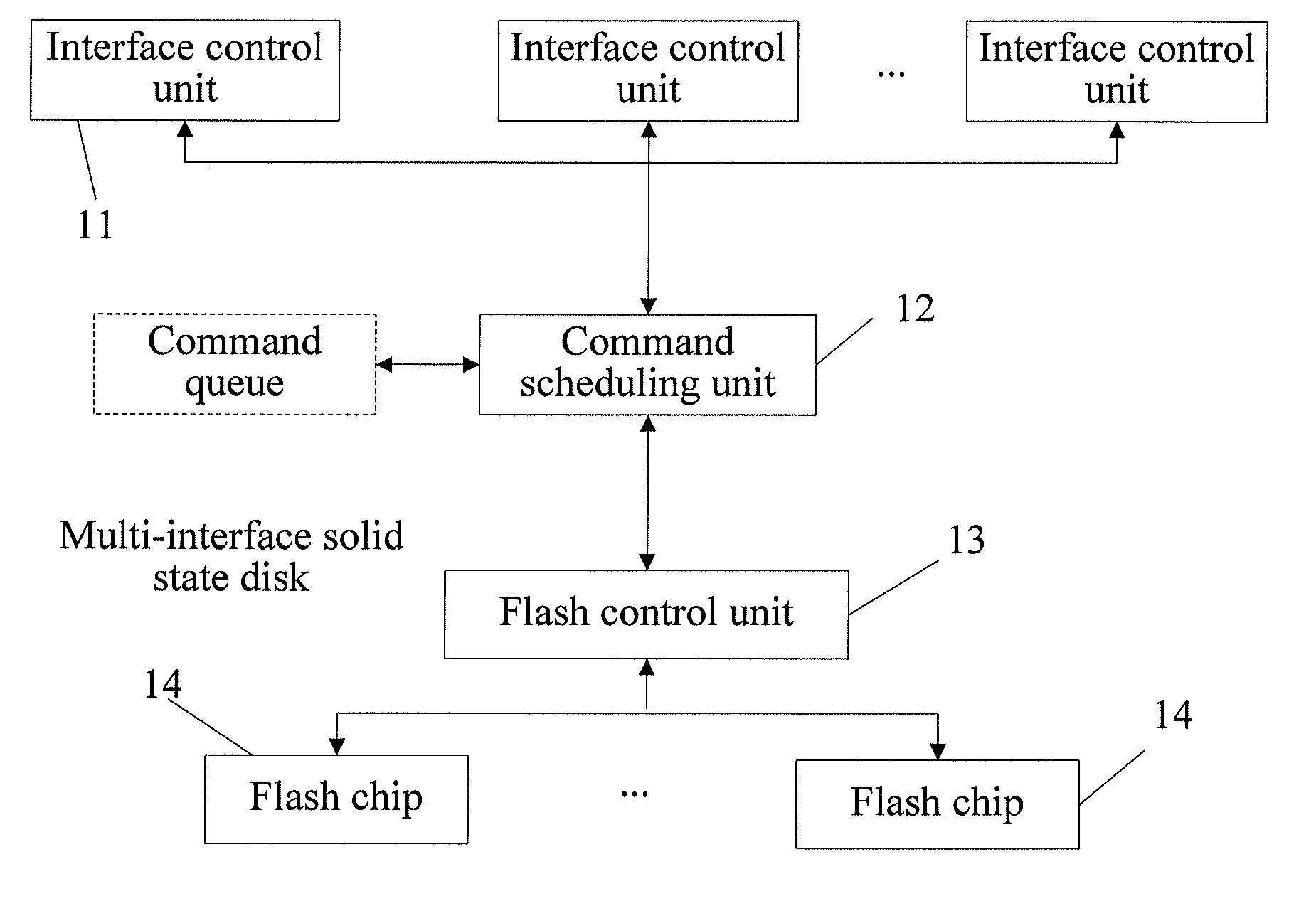

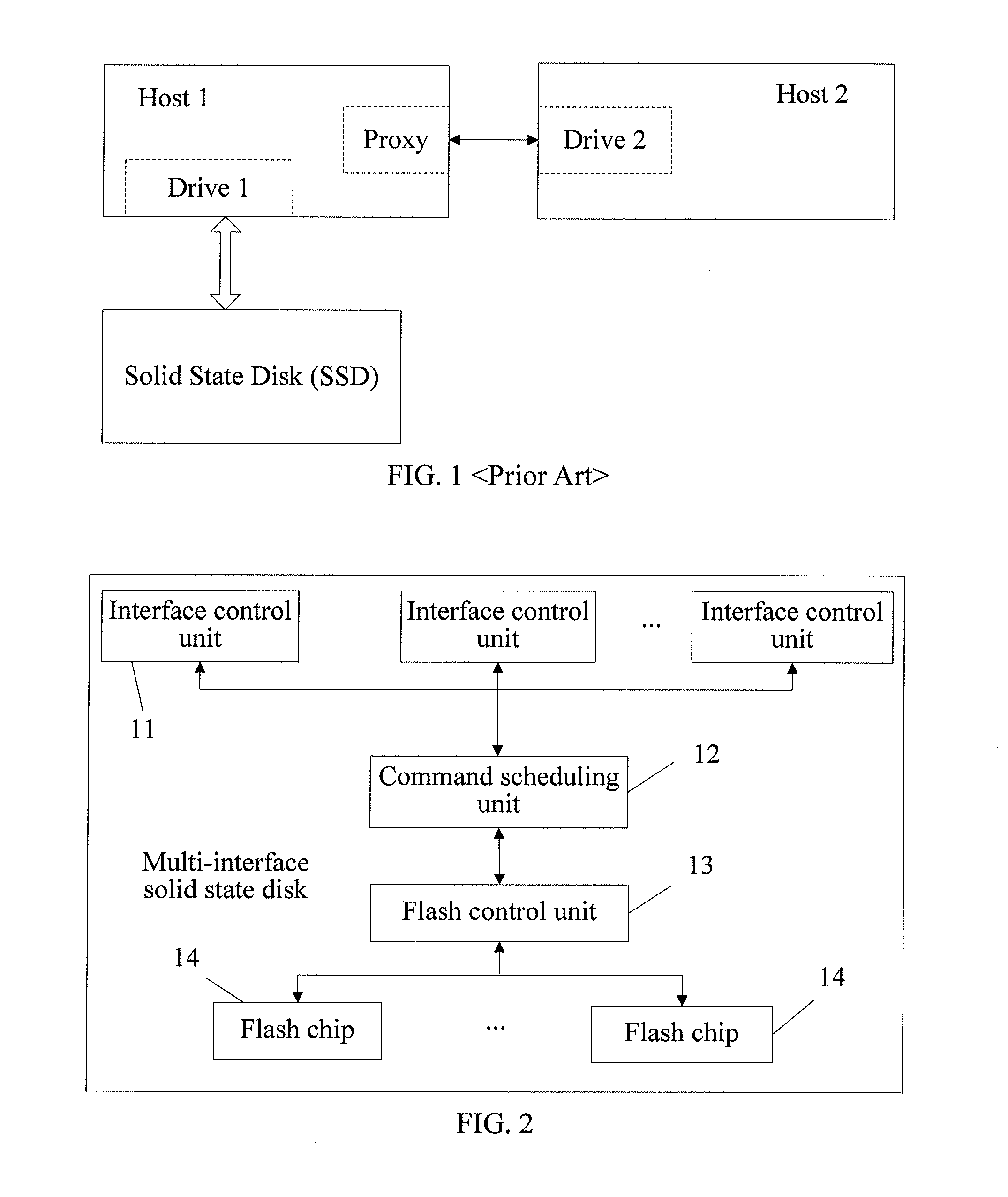

Multi-interface solid state disk, processing method and system of multi-interface solid state disk

InactiveUS20120233386A1Improve access bandwidthImprove performanceMemory adressing/allocation/relocationDigital storageCommunication interfaceSolid-state drive

Embodiments of the present disclosure disclose a multi-interface solid state disk, and a processing method and system of the multi-interface solid state disk. The multi-interface solid state disk according to the present disclosure includes: plurality of interface control units, a command scheduling unit, a flash control unit and a flash chip. Each interface control unit corresponds to a communication interface respectively. The interface control unit receives an operating command through the communication interface. The command scheduling unit obtains, according to a scheduling rule, operating commands from the plurality of interface control units, puts the operating commands in a command queue, takes an operating command from the command queue, and sends the operating command to the flash control unit. The flash control unit converts the operating command into a flash operating command to operate the flash chip.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com