Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3647results about "Auxillary pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

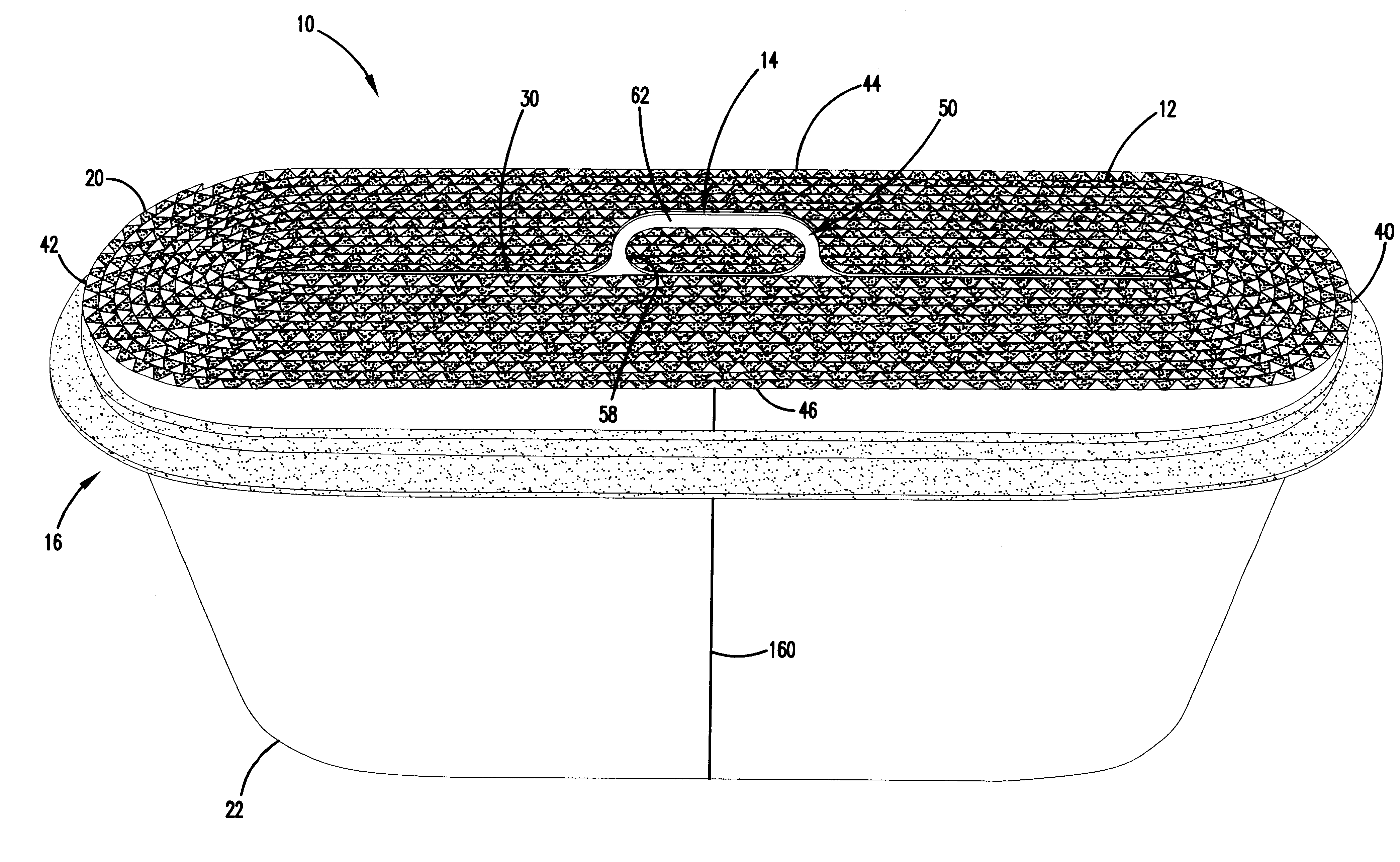

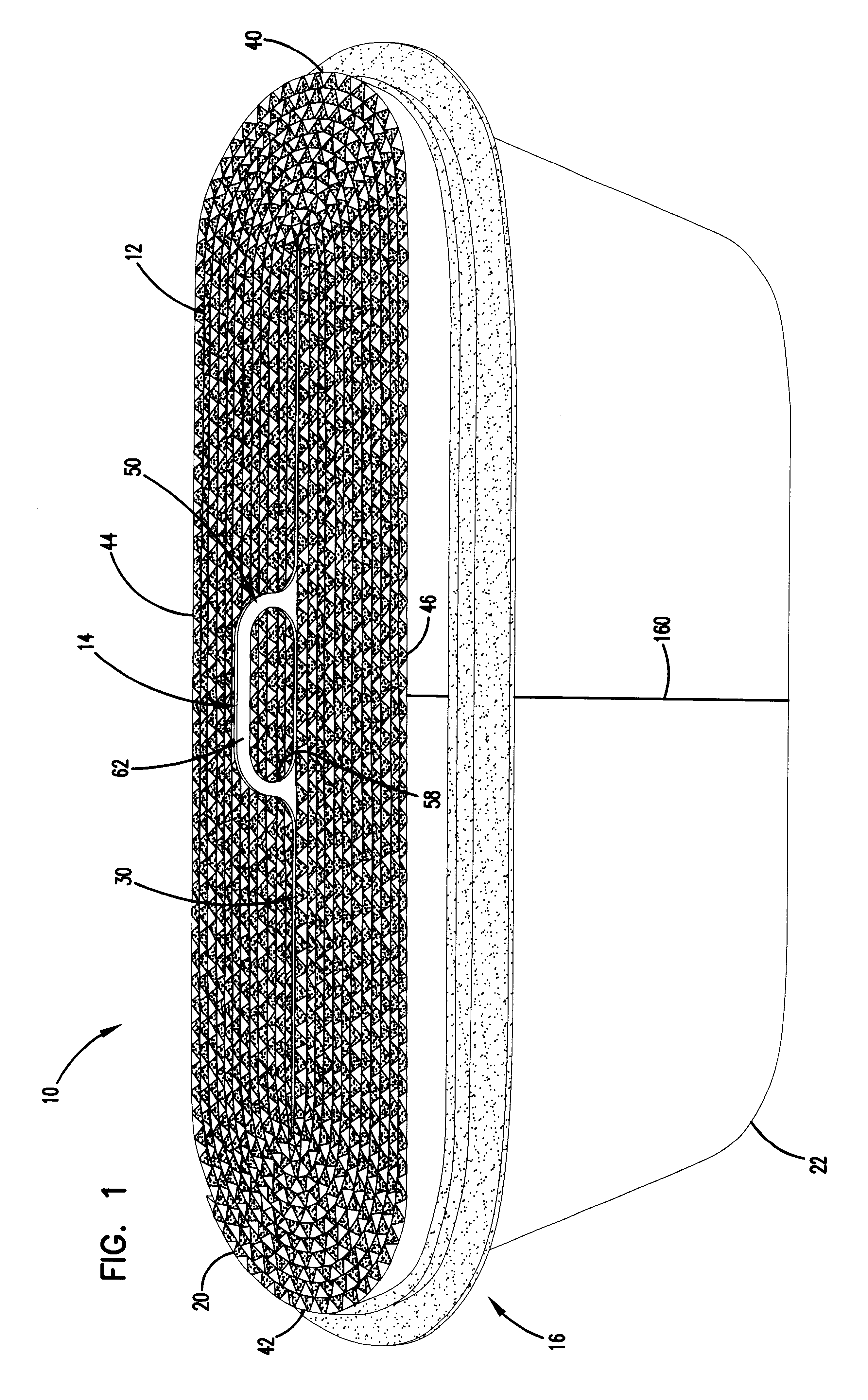

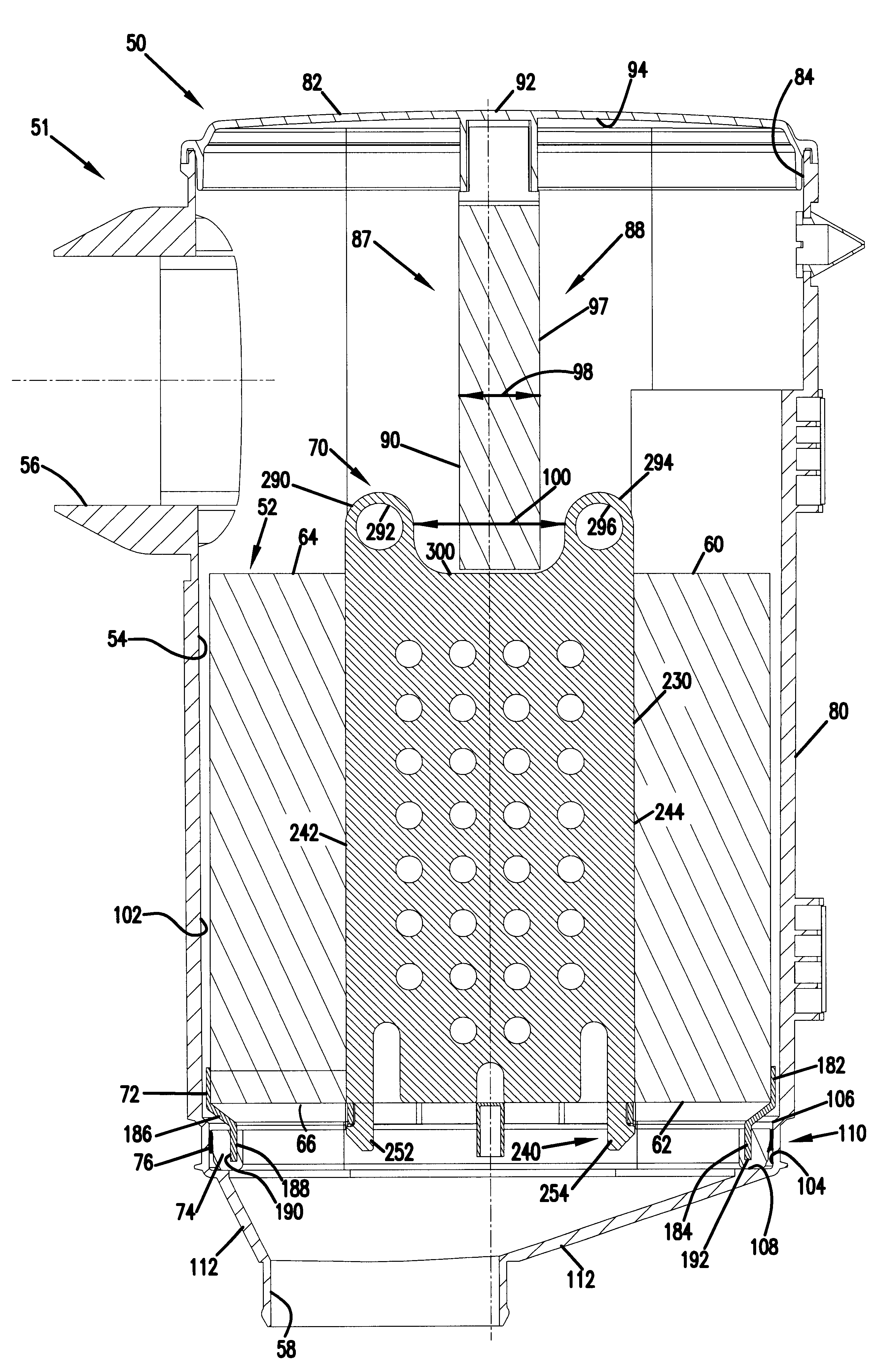

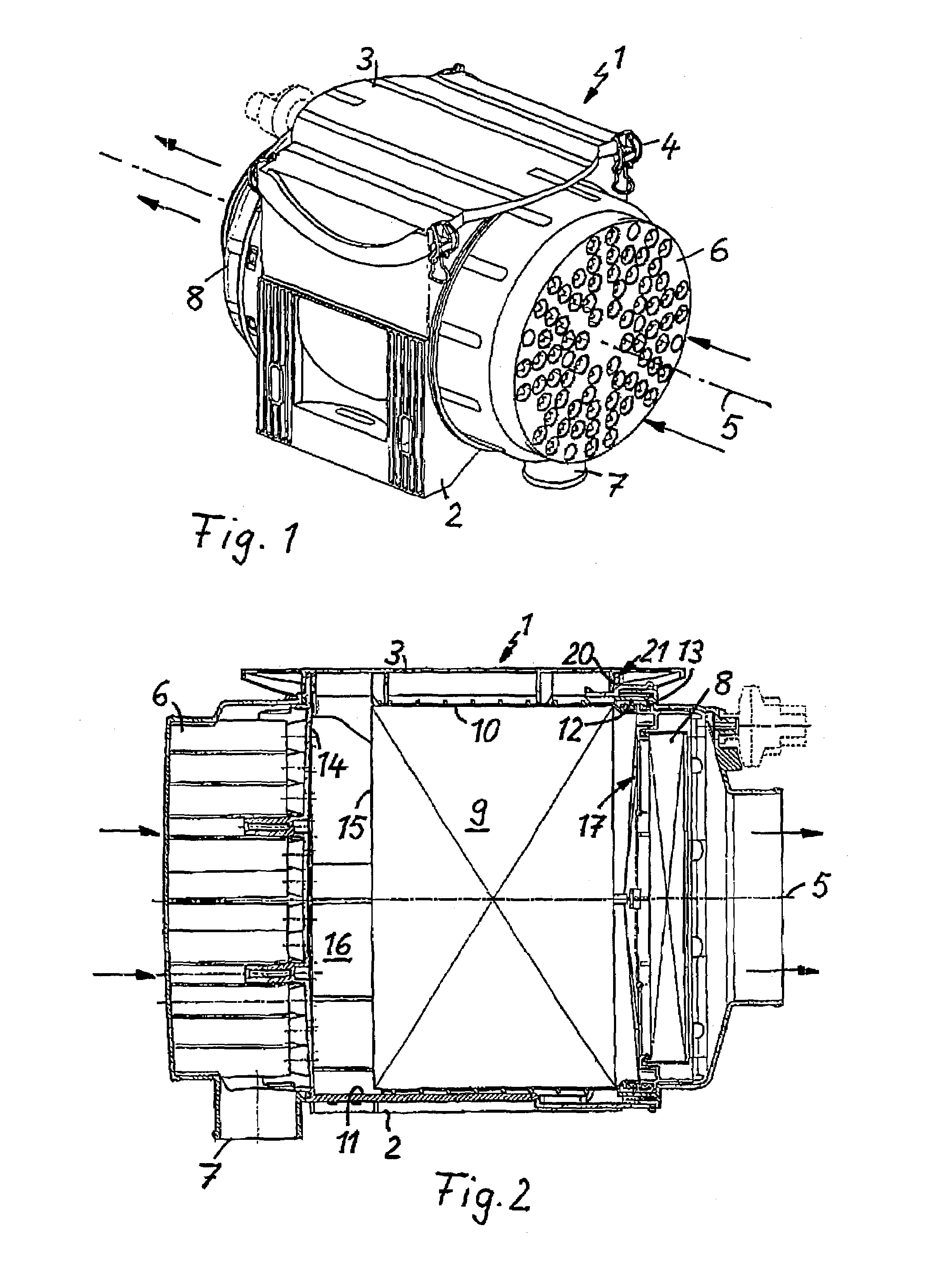

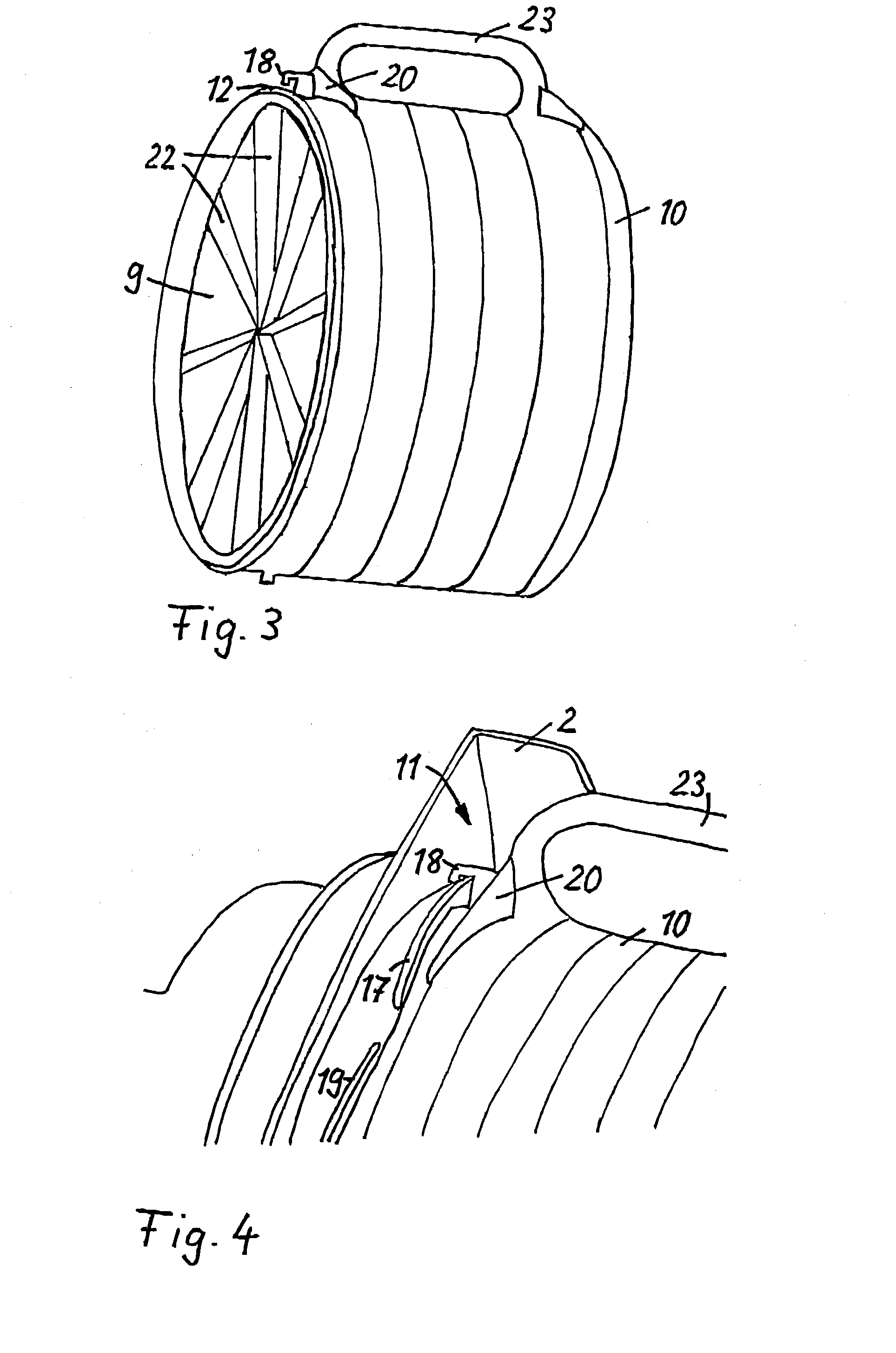

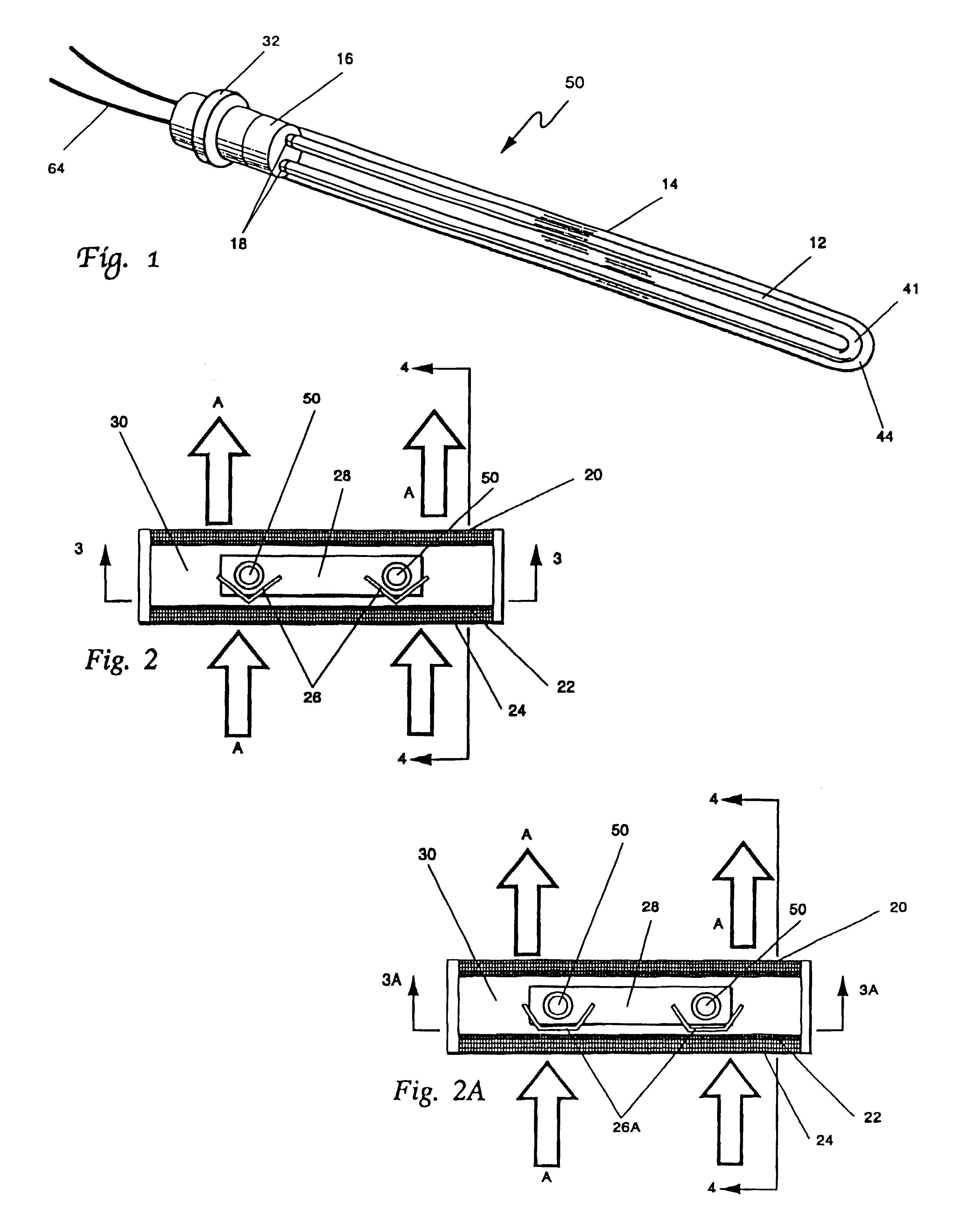

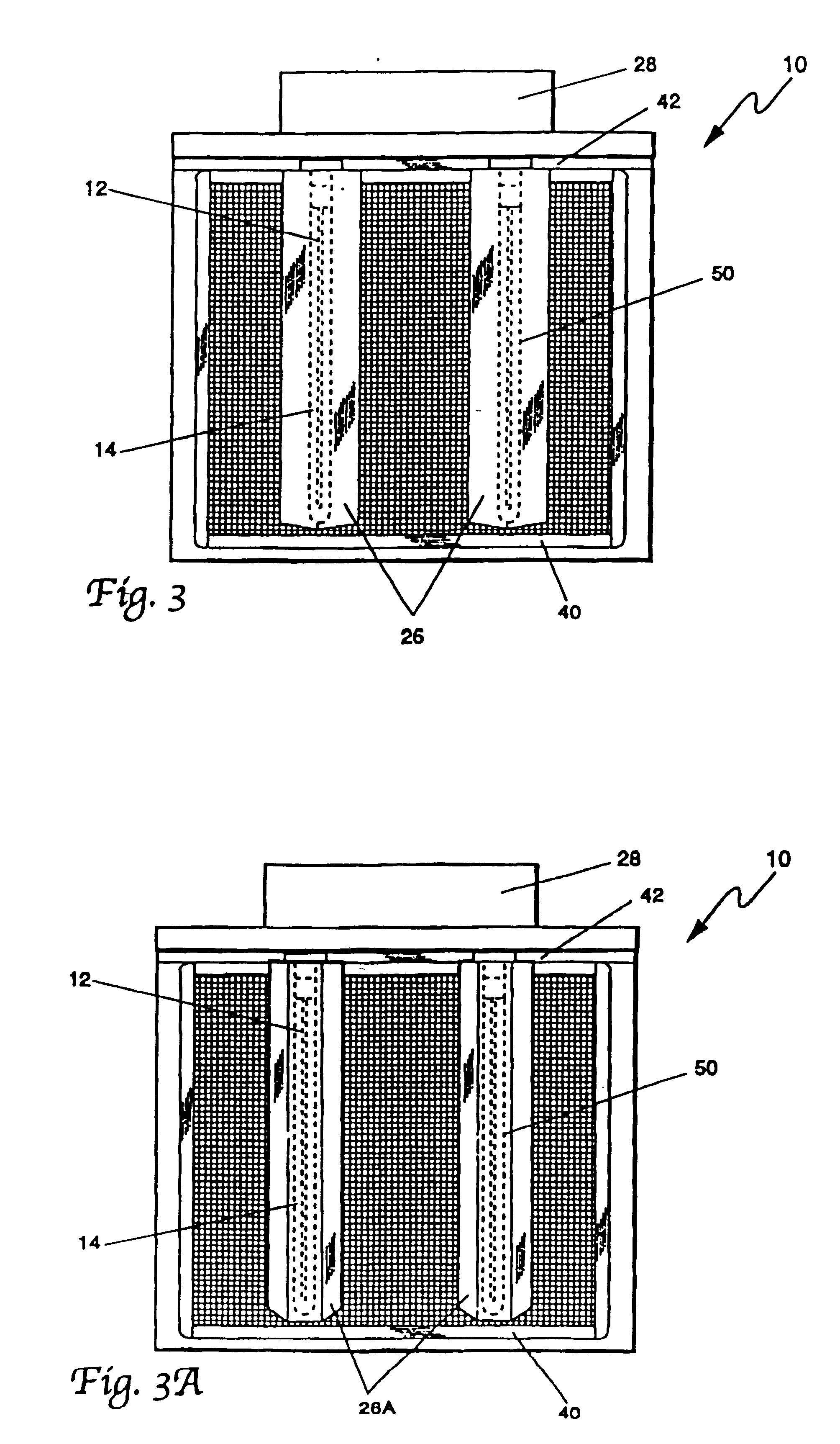

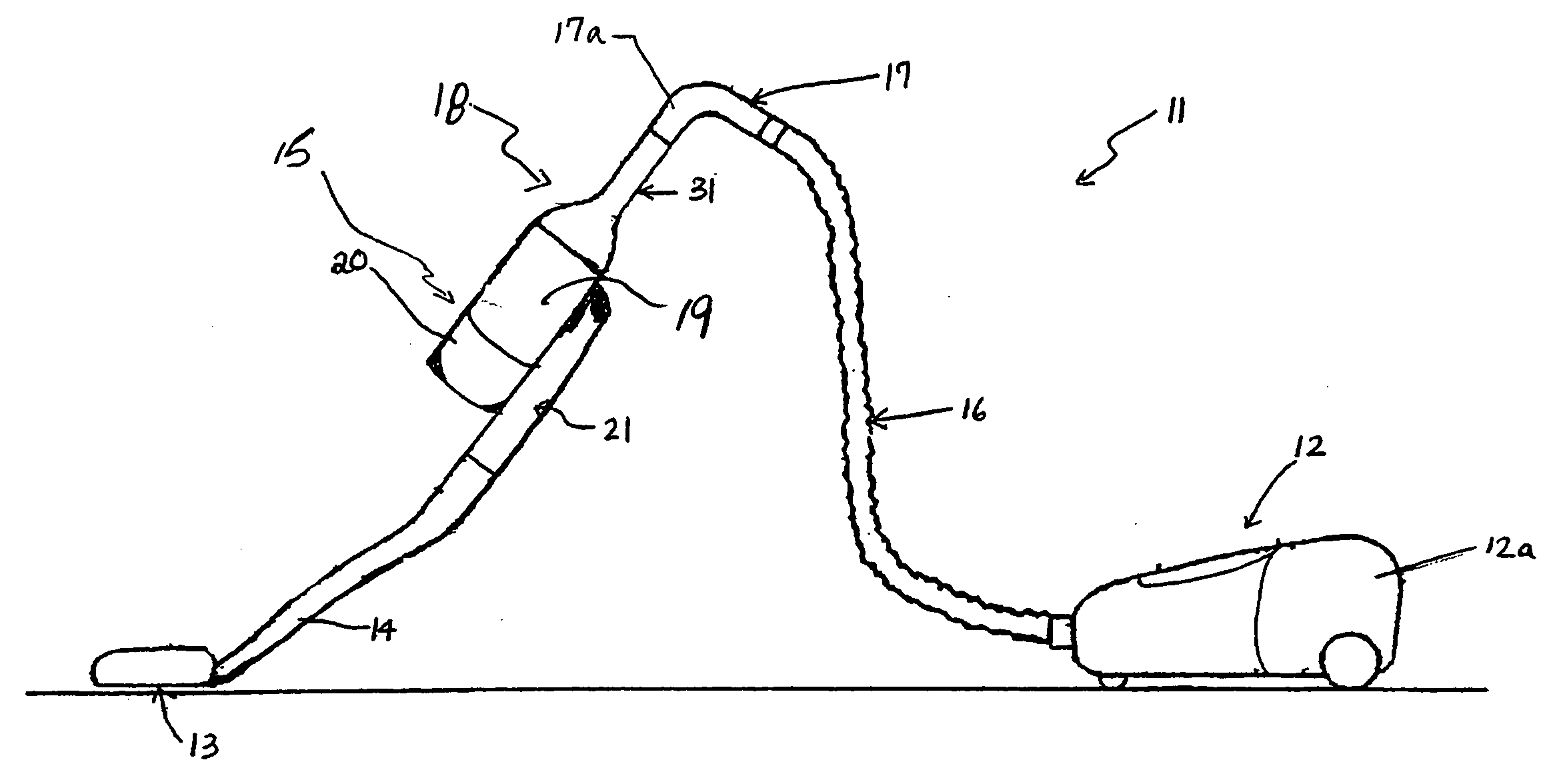

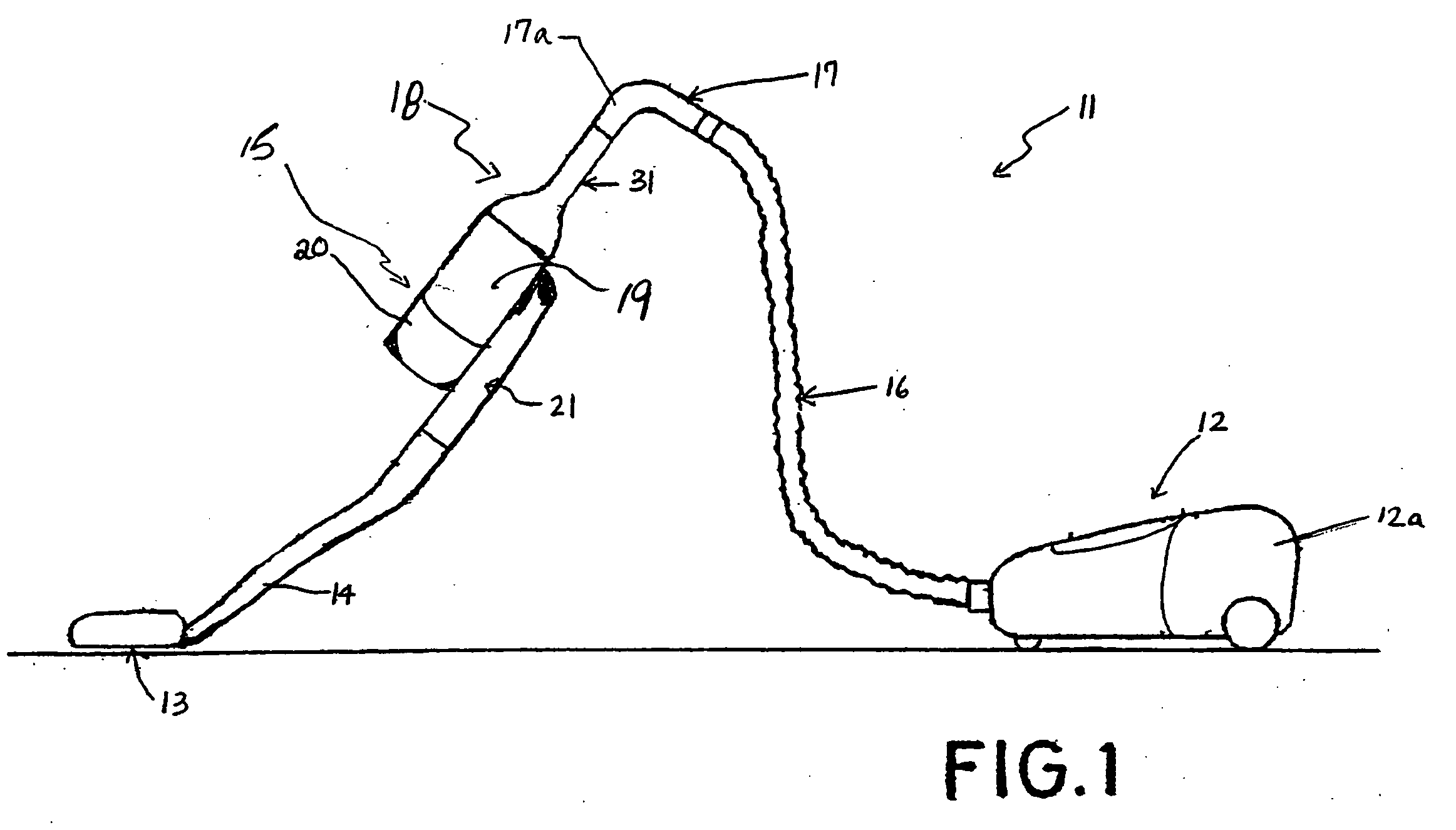

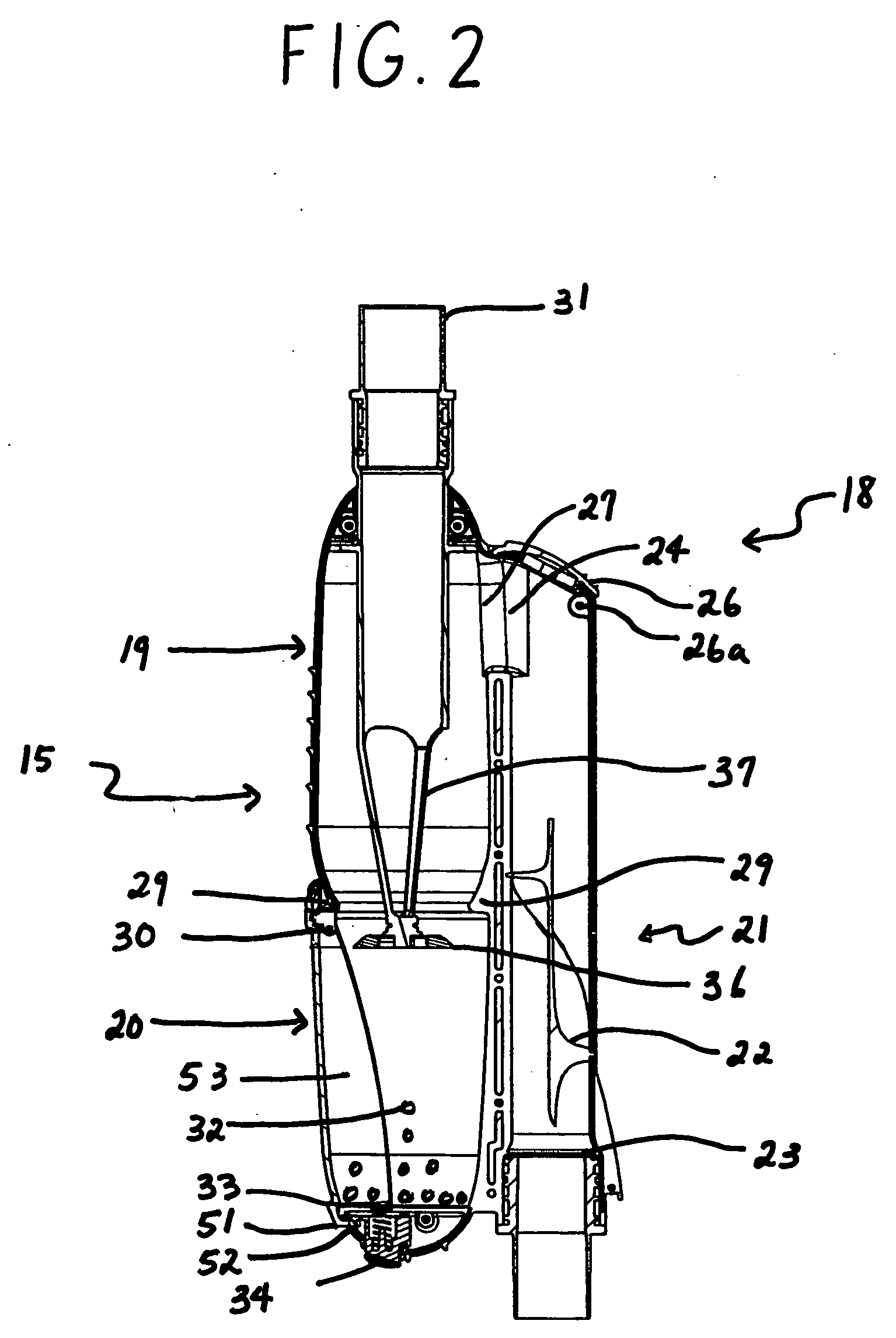

Filter element incorporating a handle member

InactiveUS6235195B1Convenient manipulationEasy to handleCombination devicesAuxillary pretreatmentEngineeringMechanical engineering

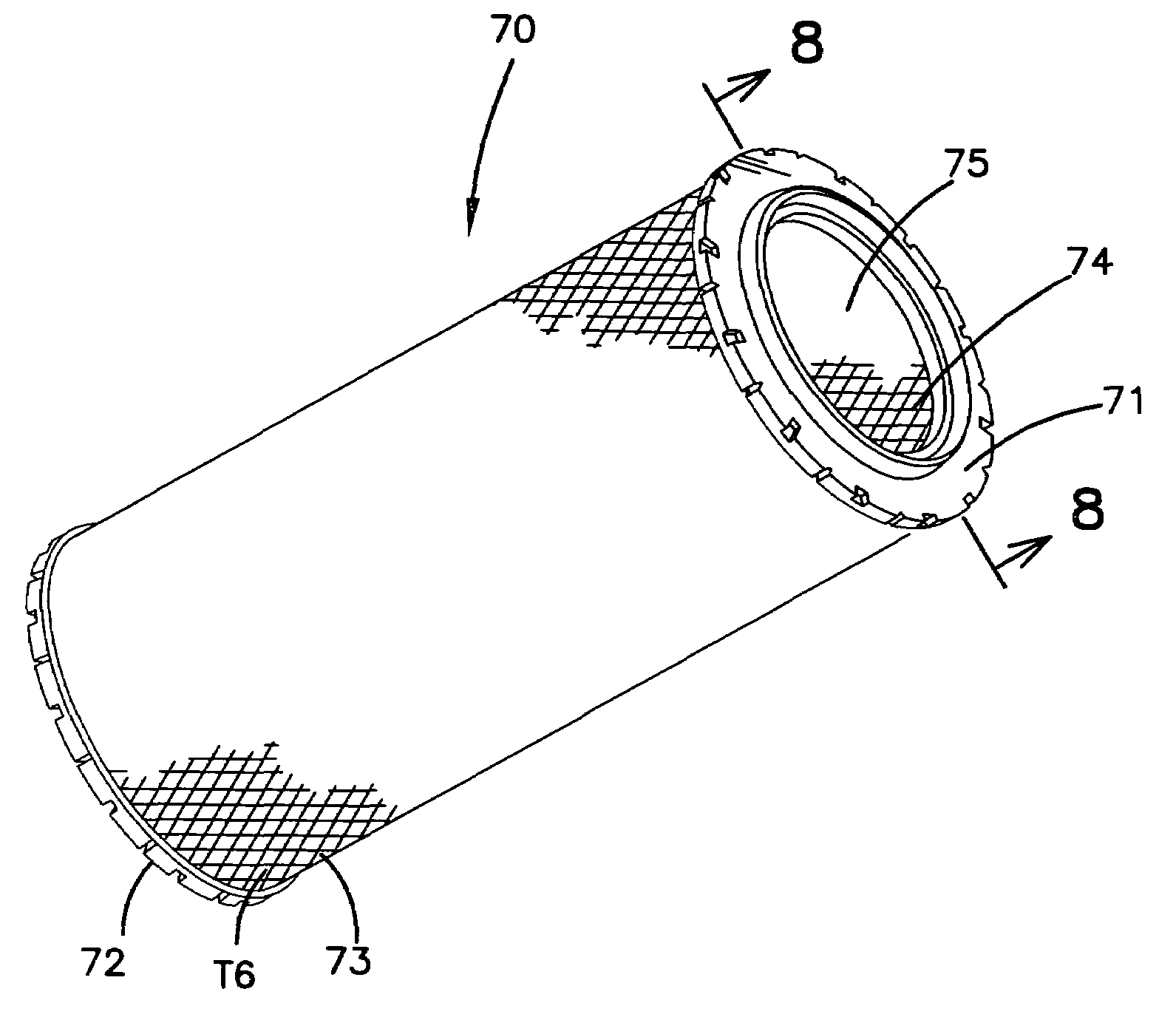

A filter arrangement includes a filter element configured for straight through flow and a handle member secured to the filter element. The filter element may typically have a plurality of flutes where selected ones of the flutes are open at upstream portions and closed at downstream portions, and where selected ones of the flutes are closed at the upstream portions and open at the downstream portions. In one embodiment, the handle member is secured to the central core member. In some embodiments, the handle member and the central core member are a single molded construction. The handle member can include a single aperture, such as an elongated slot, or a plurality of apertures. A method for servicing a system having a straight through flow filter element includes grasping a handle secured to the filter element, and pulling the handle to remove the filter element from the system.

Owner:DONALDSON CO INC

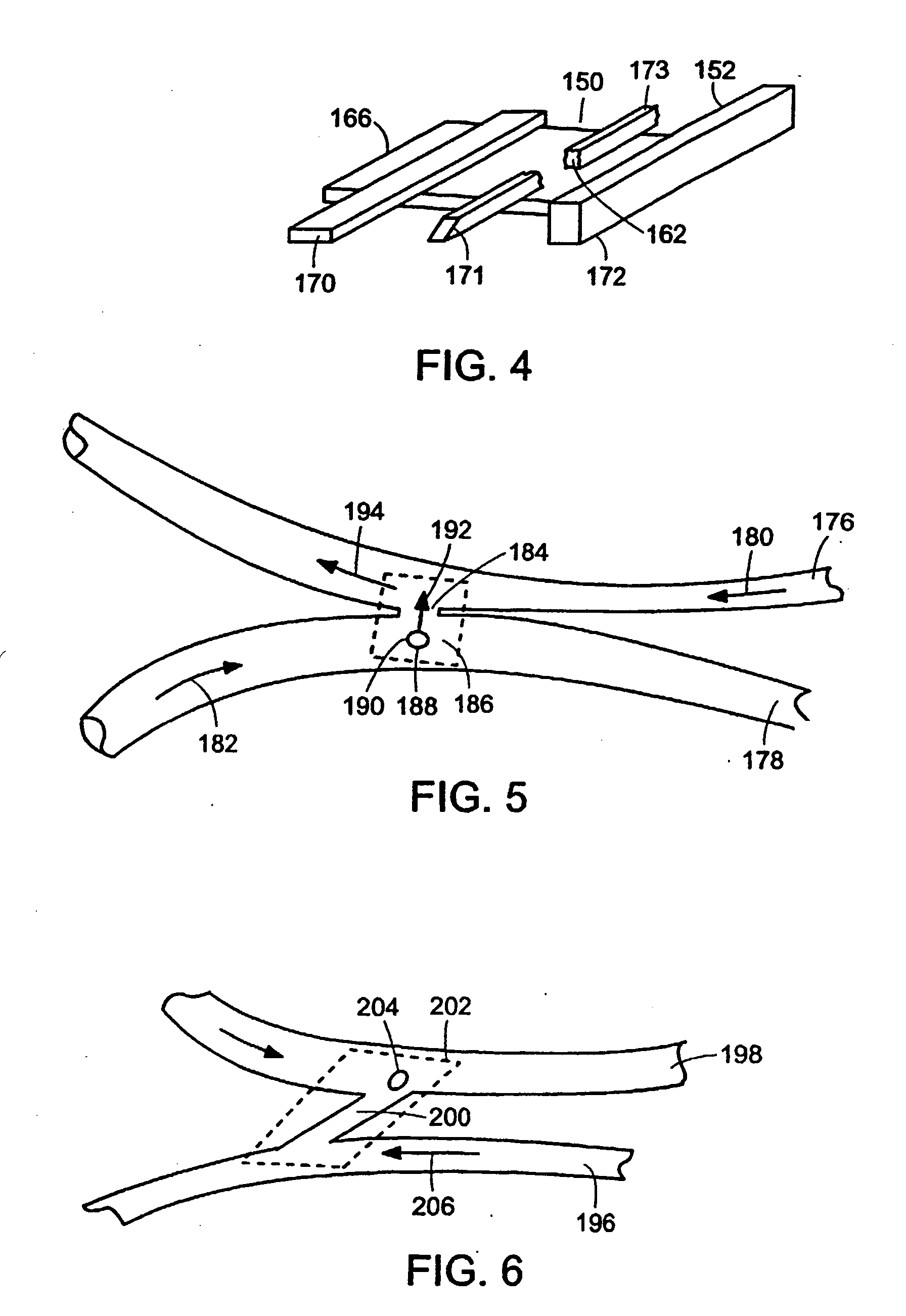

Filter element, air cleaner, and methods

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

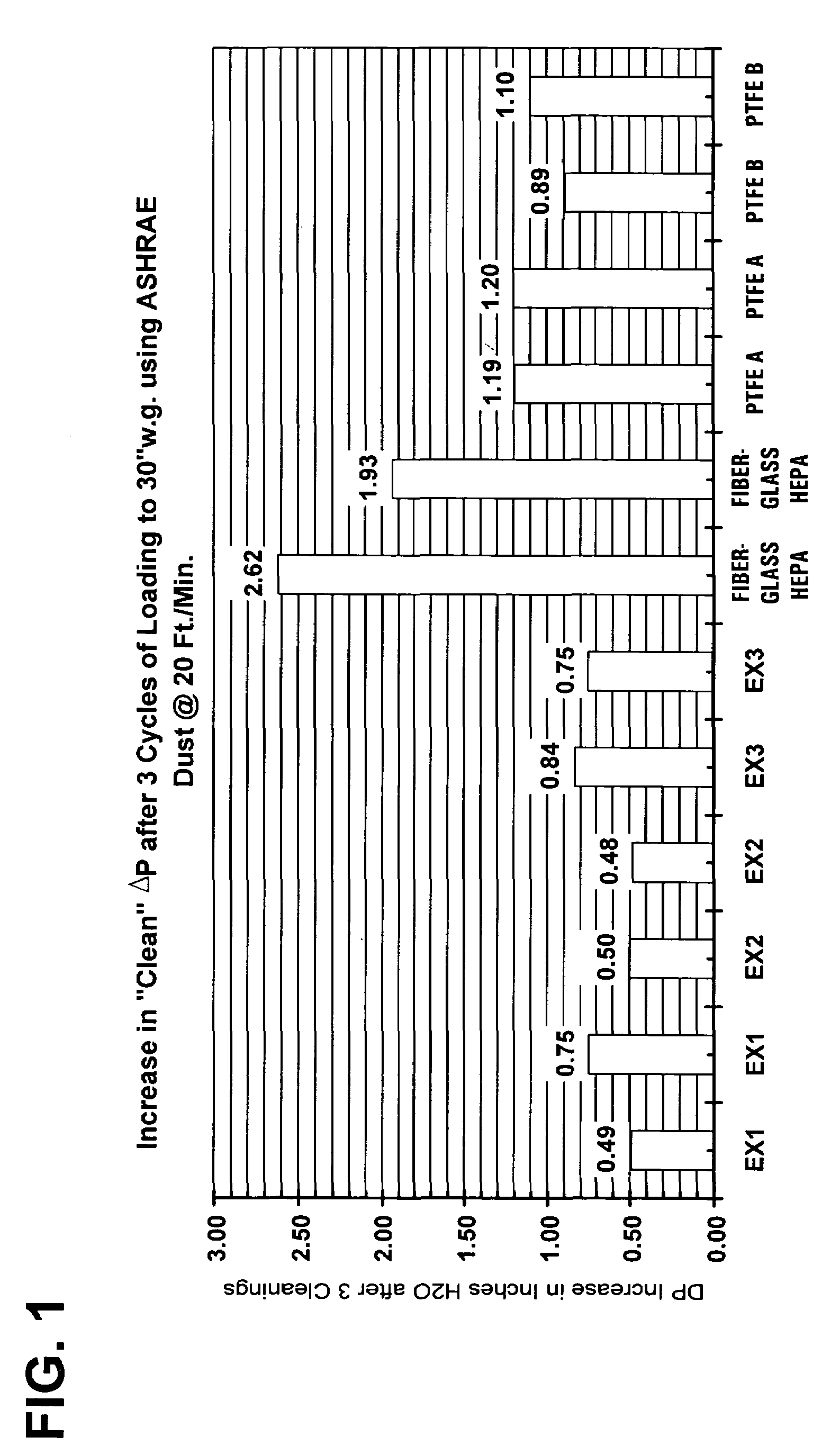

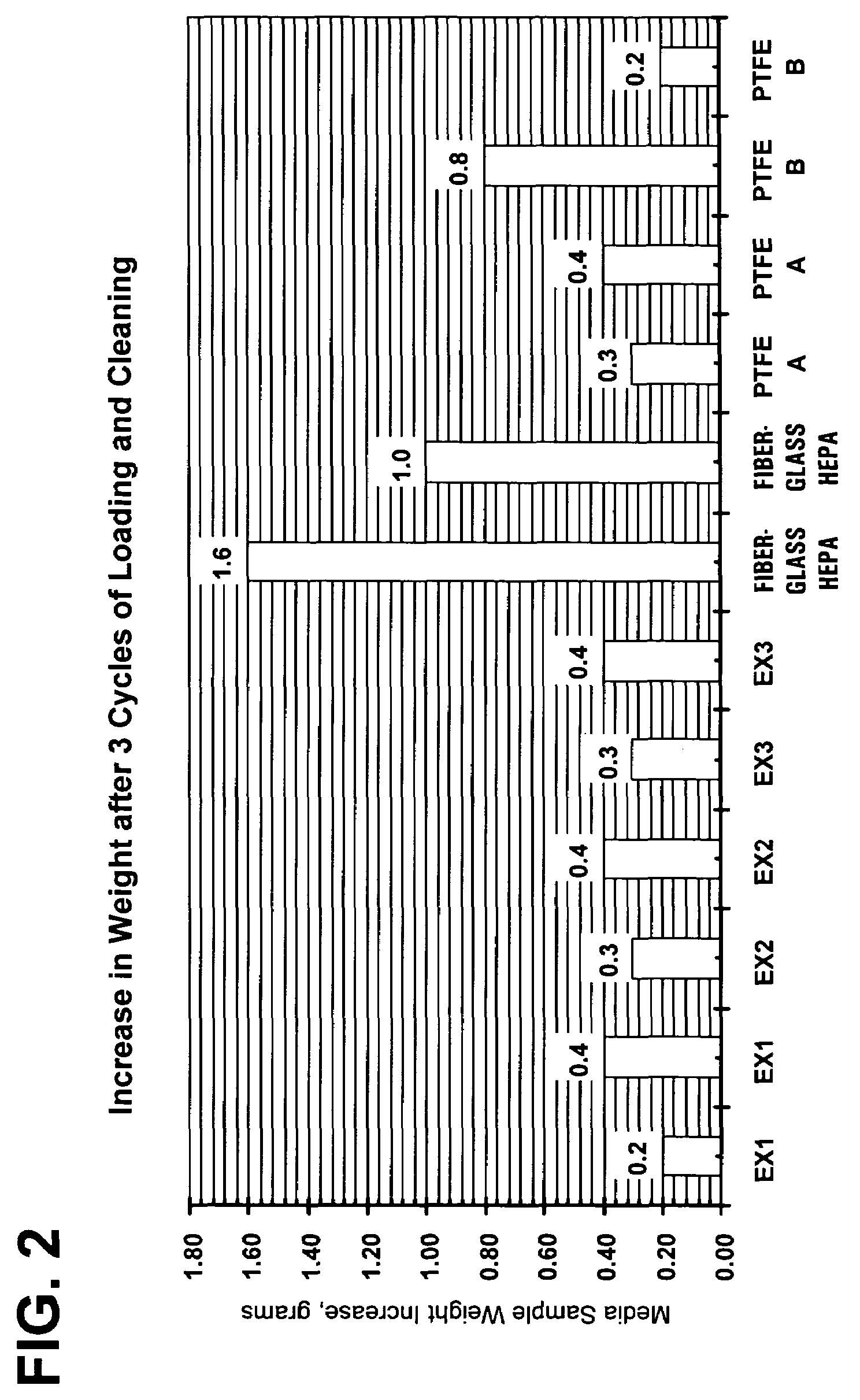

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

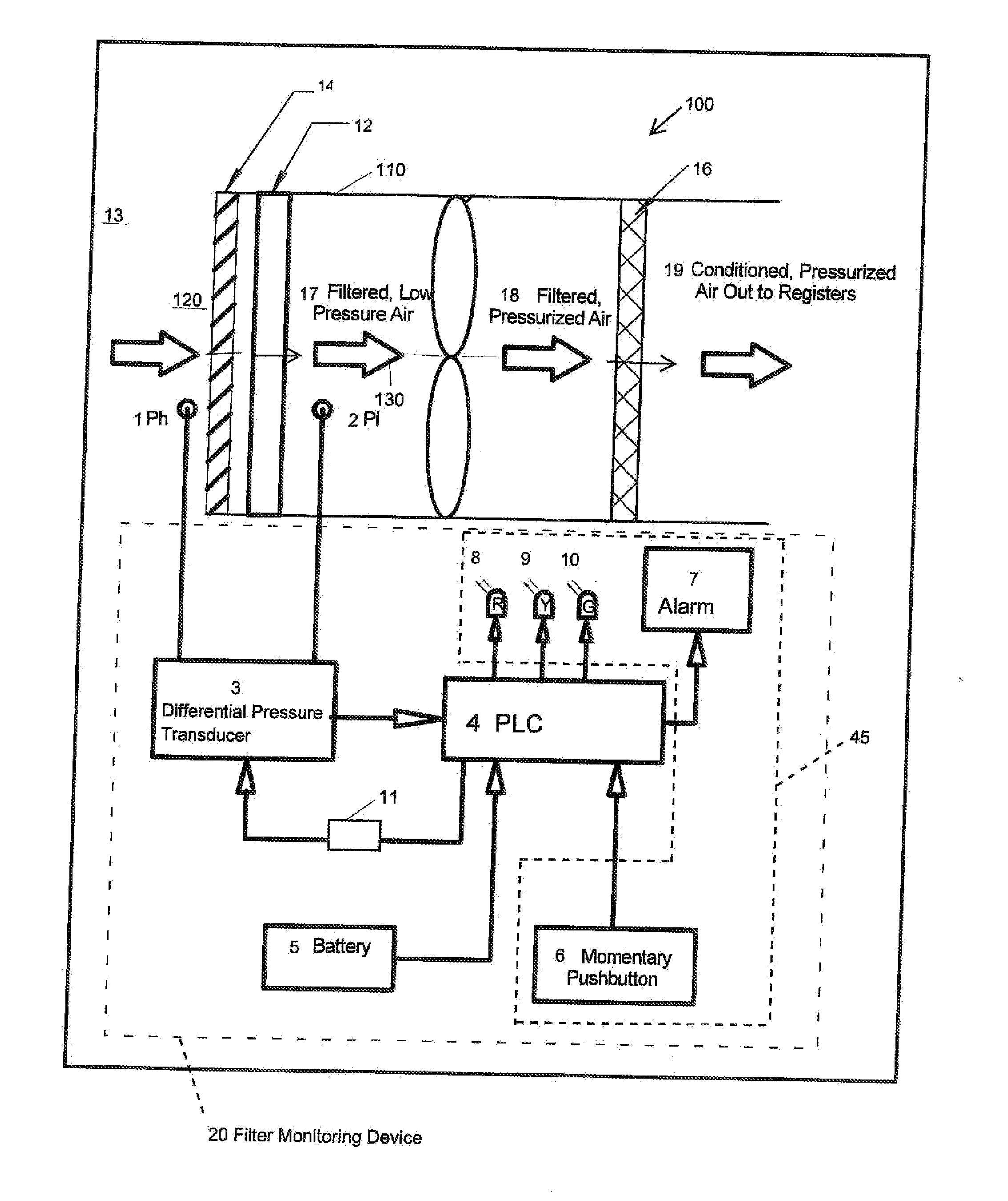

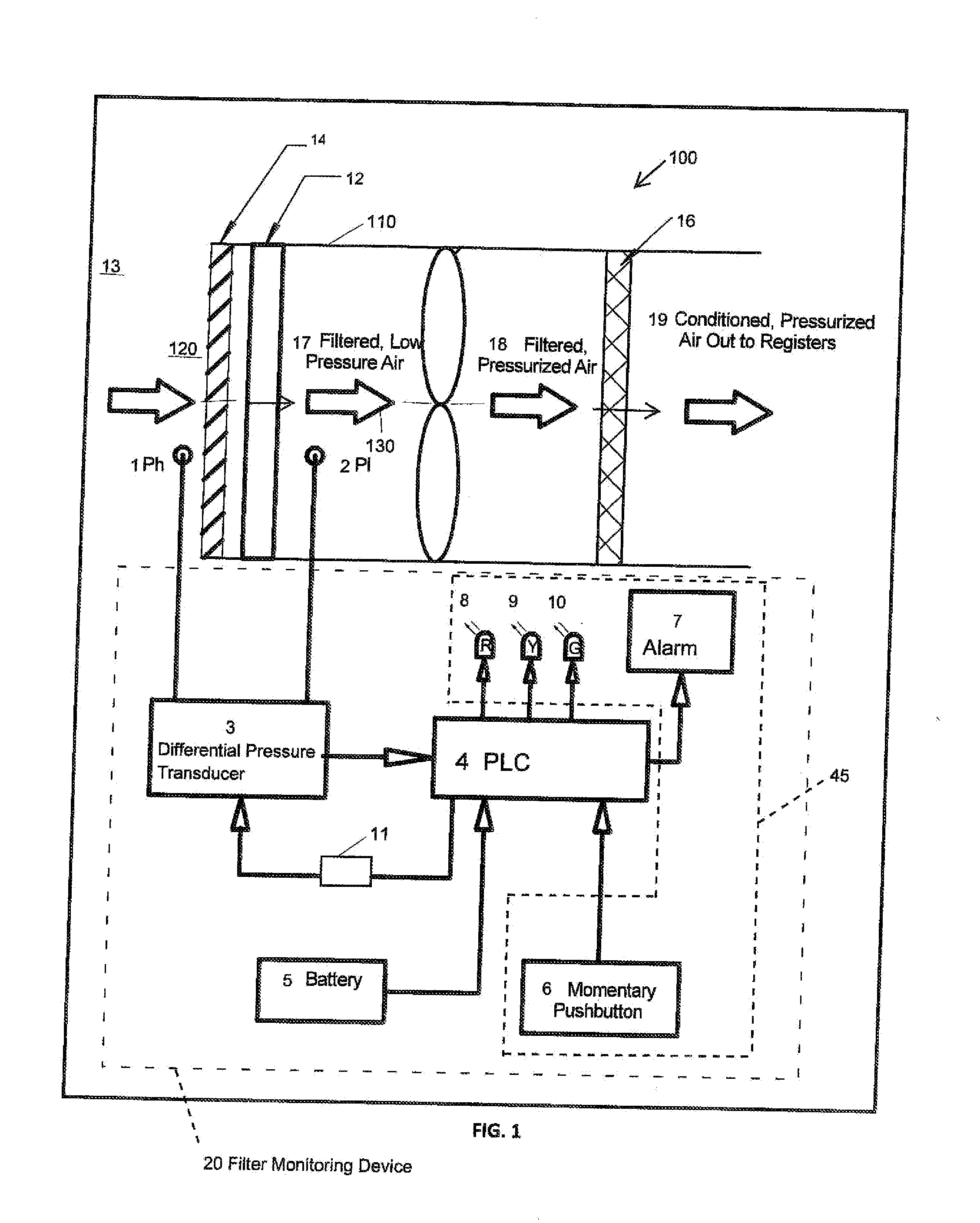

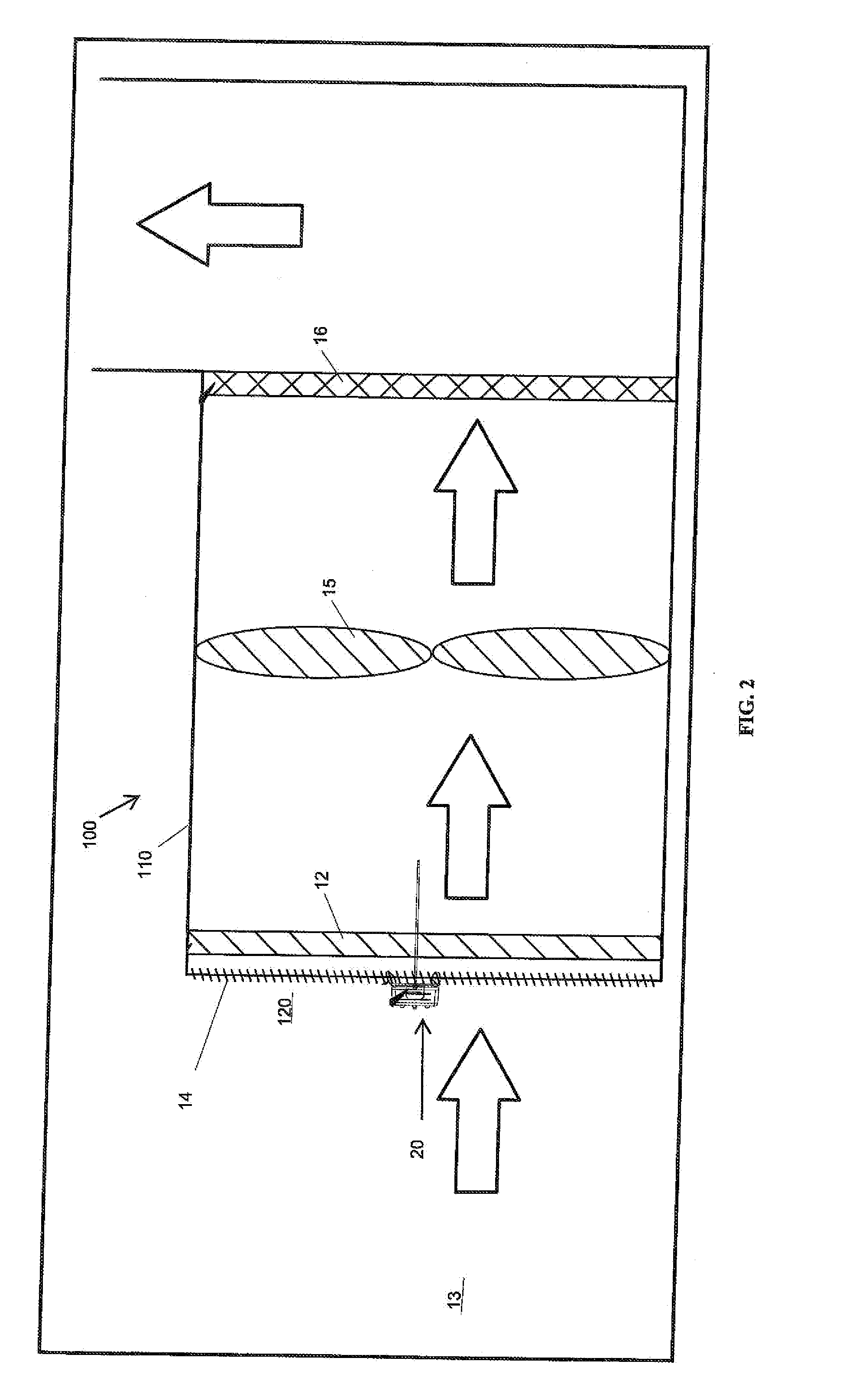

Filter apparatus and method of monitoring filter apparatus

Methods, systems, and products for monitoring an air filter. Methods involve determining a difference between a baseline pressure differential and a current pressure differential, the differential pressure between pressure at an upstream side of the filter and pressure at a downstream side of the filter. The baseline pressure differential may be set automatically or by a user. Reaching or exceeding a predetermined threshold triggers an indication of a clogged condition. The method also includes monitoring the air filter condition intermittently. The filter monitor may operate for extended periods in a sleep state and intermittently power up to a wake state to measure the current pressure differential and compare the current pressure differential with a baseline pressure differential.

Owner:FREEN PAUL

Method and apparatus for removing substances from gases

InactiveUS7799300B2Simple and reliable technicalEliminate the problemAuxillary pretreatmentEnergy based chemical/physical/physico-chemical processesSurface reactionGas phase

The present invention concerns a method and an apparatus for removing substances from gases discharged from gas phase reactors. In particular, the invention provides a method for removing substances contained in gases discharged from an ALD reaction process, comprising contacting the gases with a “sacrificial” material having a high surface area kept at essentially the same conditions as those prevailing during the gas phase reaction process. The sacrificial material is thus subjected to surface reactions with the substances contained in the gases to form a reaction product on the surface of the sacrificial material and to remove the substances from the gases. The present invention diminishes the amount of waste produced in the gas phase process and reduces wear on the equipment.

Owner:ASM INTERNATIONAL

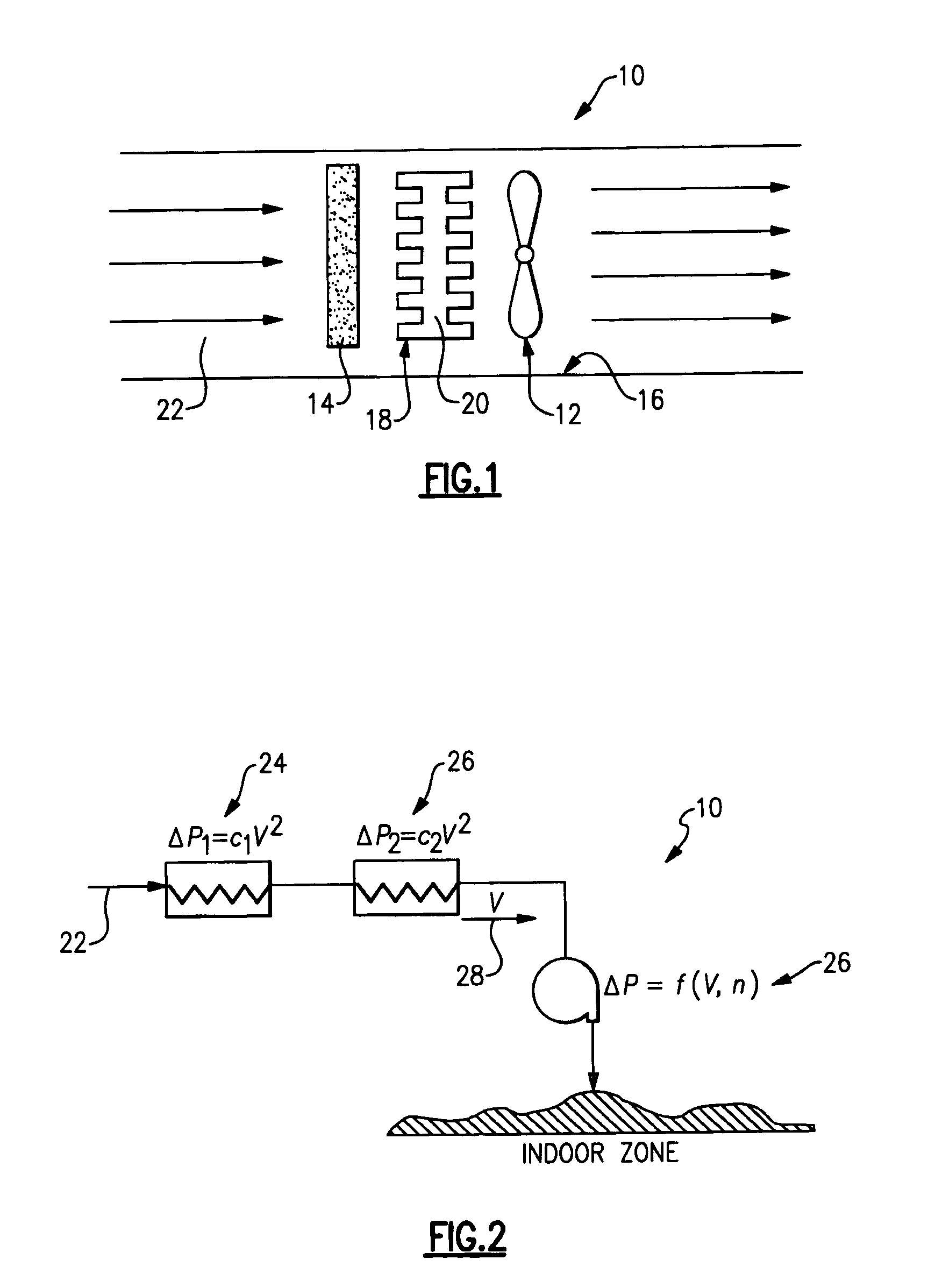

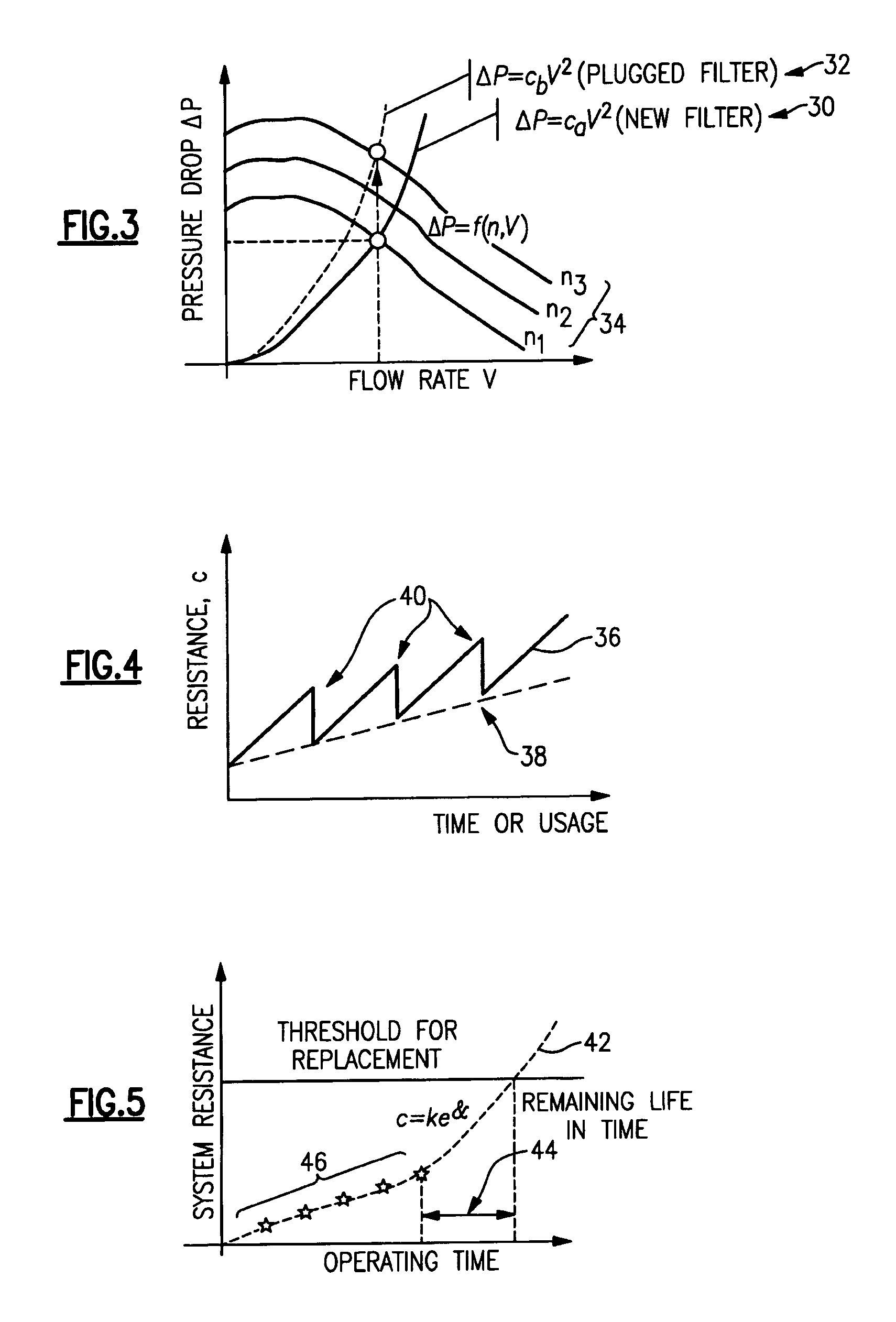

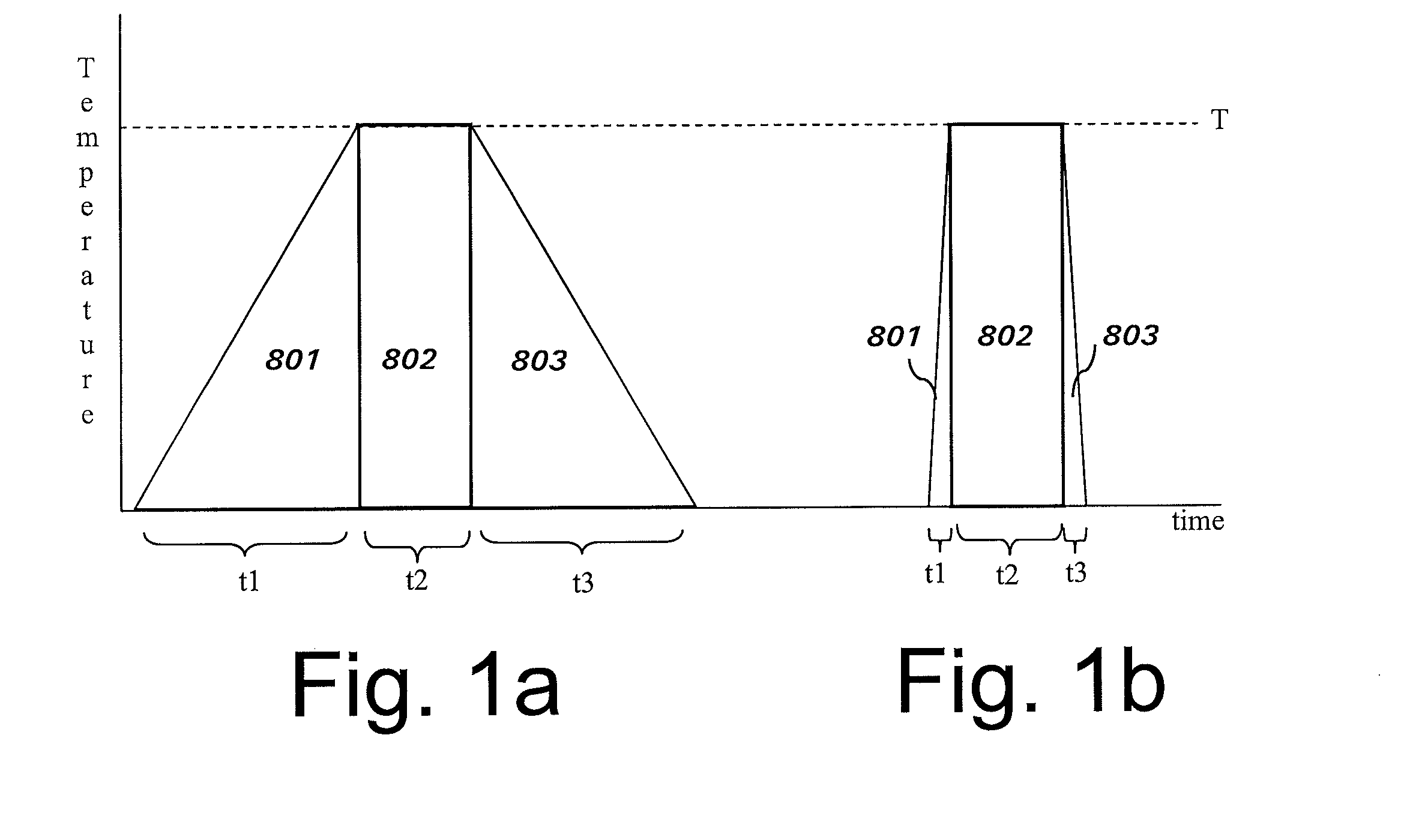

Technique for detecting and predicting air filter condition

InactiveUS7261762B2Combination devicesAuxillary pretreatmentElectrical resistance and conductanceAir filter

Owner:CARRIER CORP

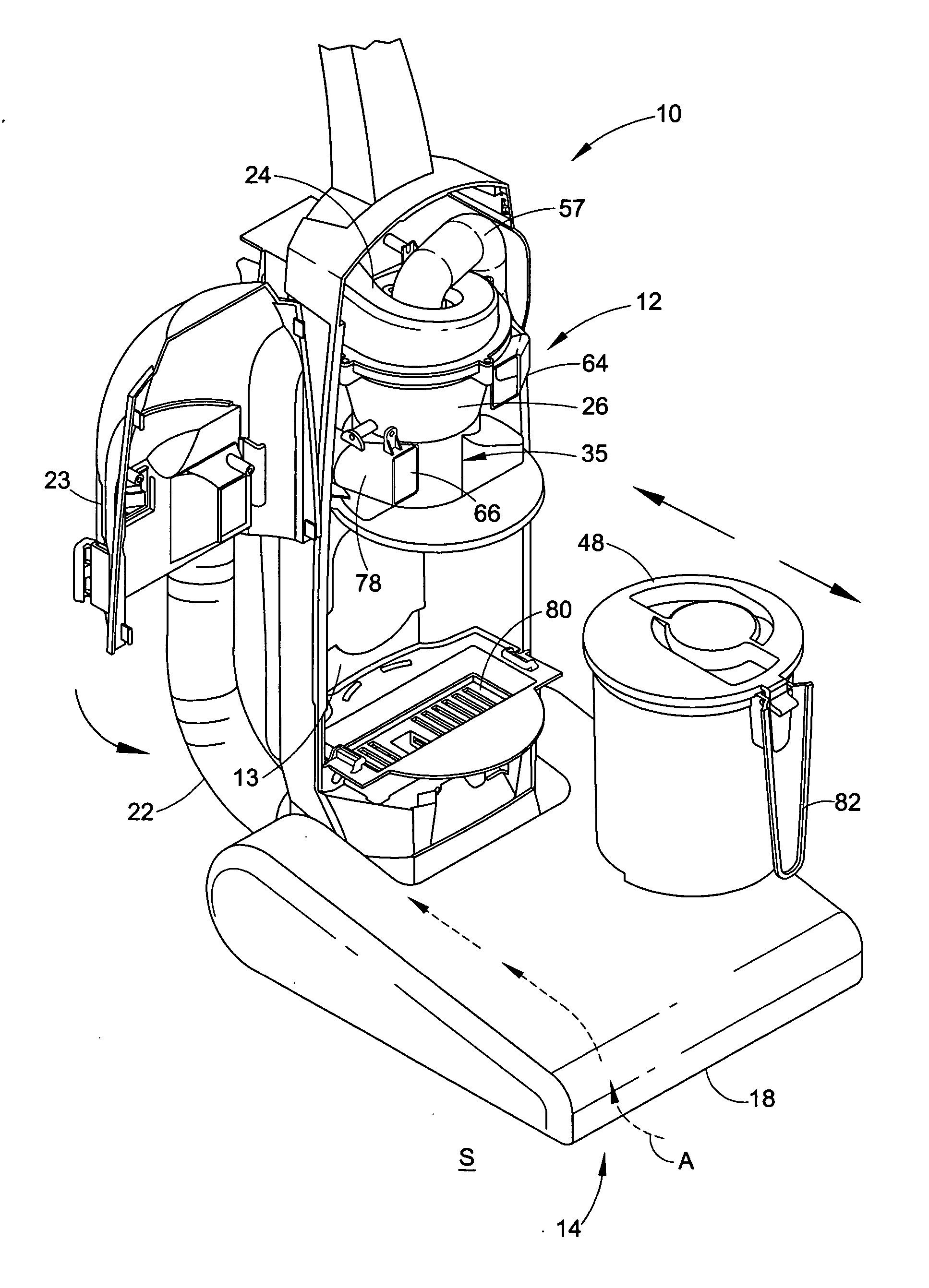

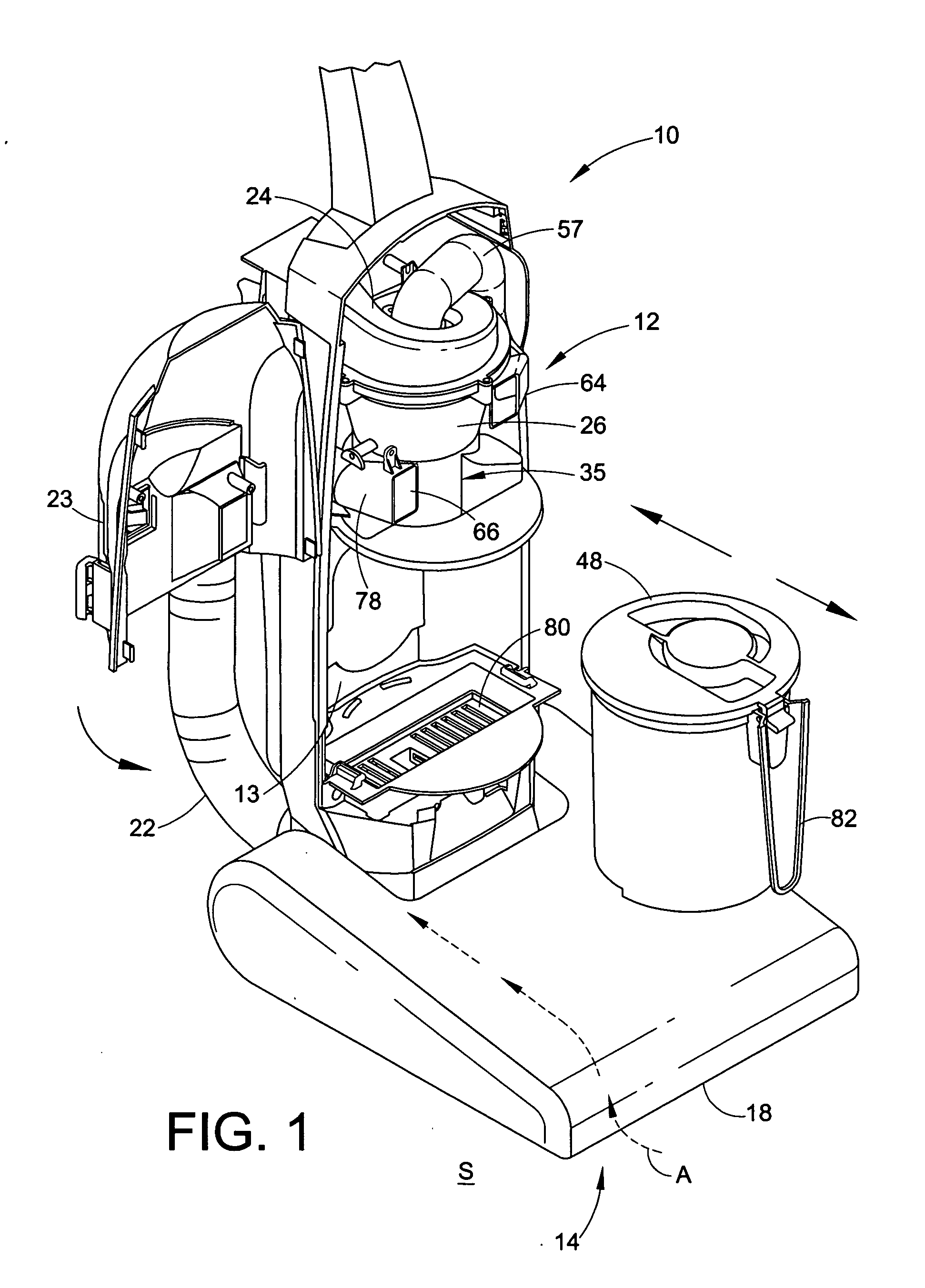

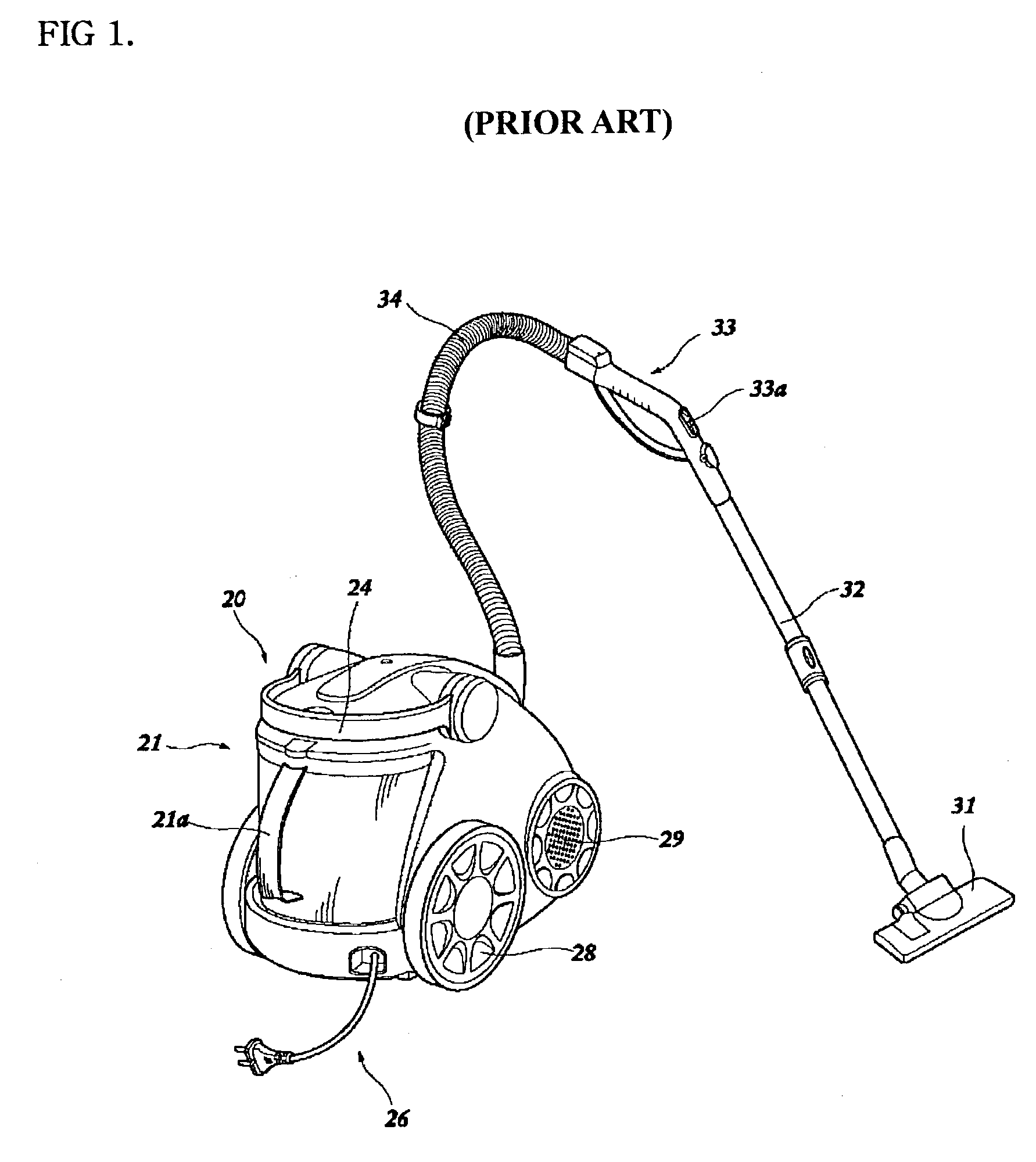

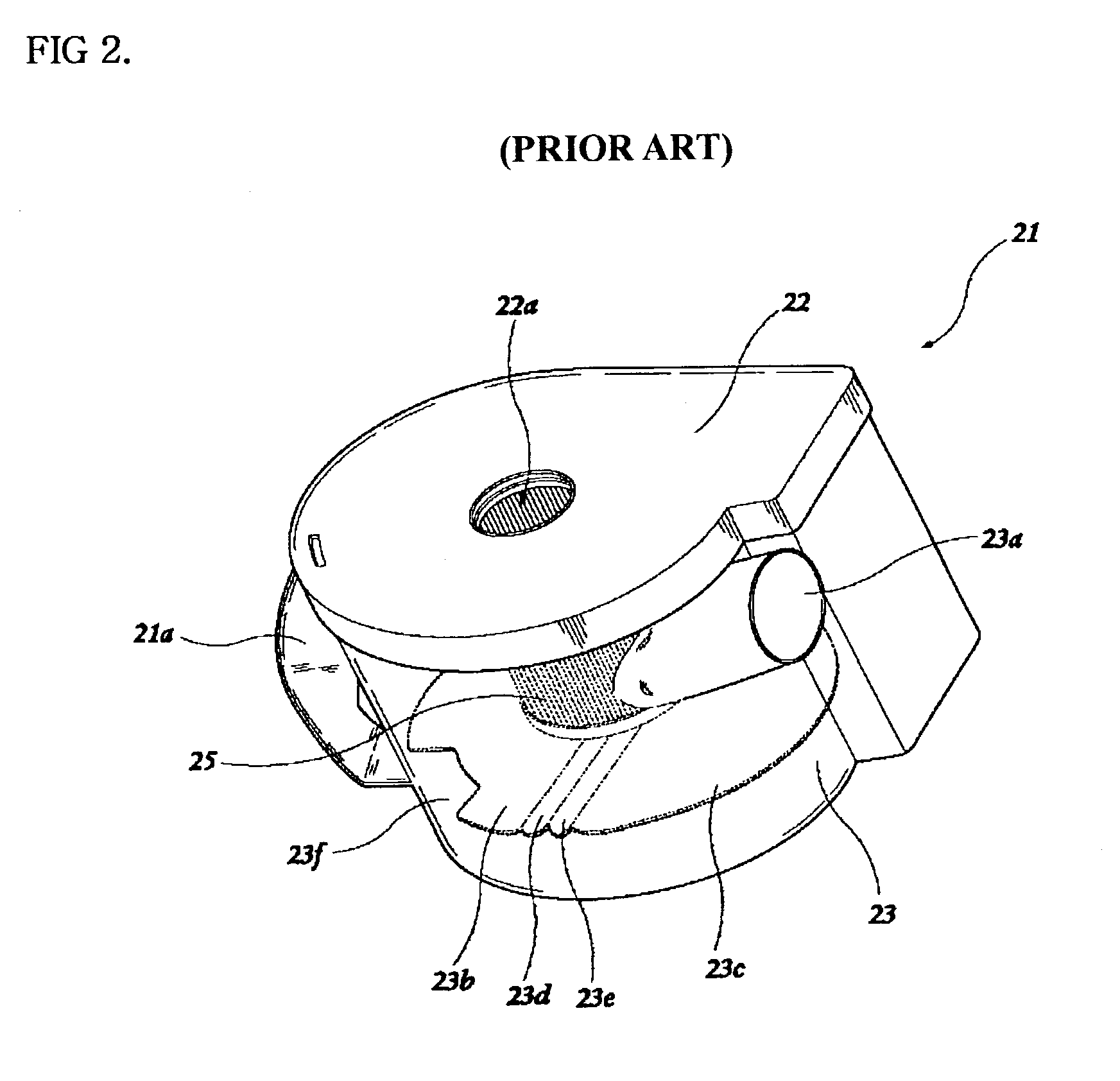

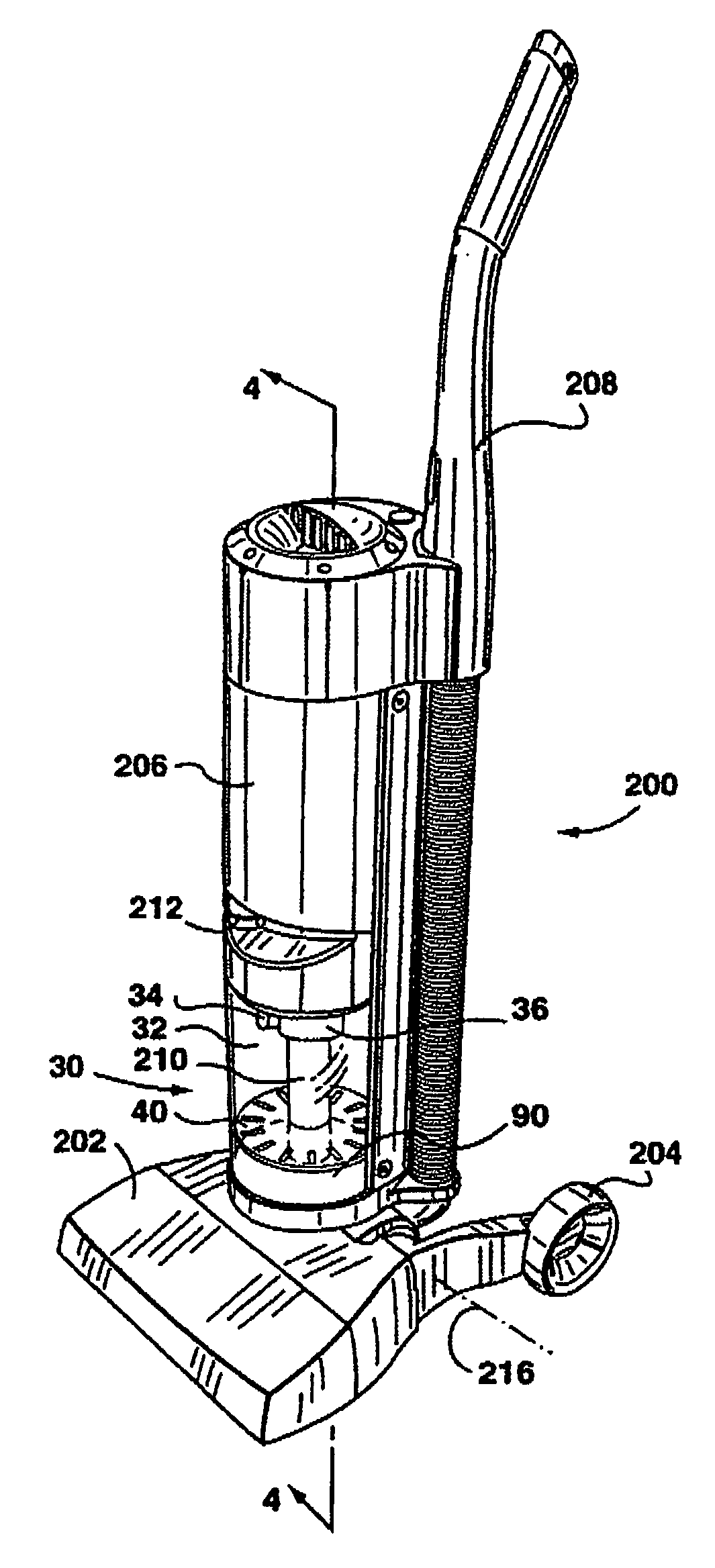

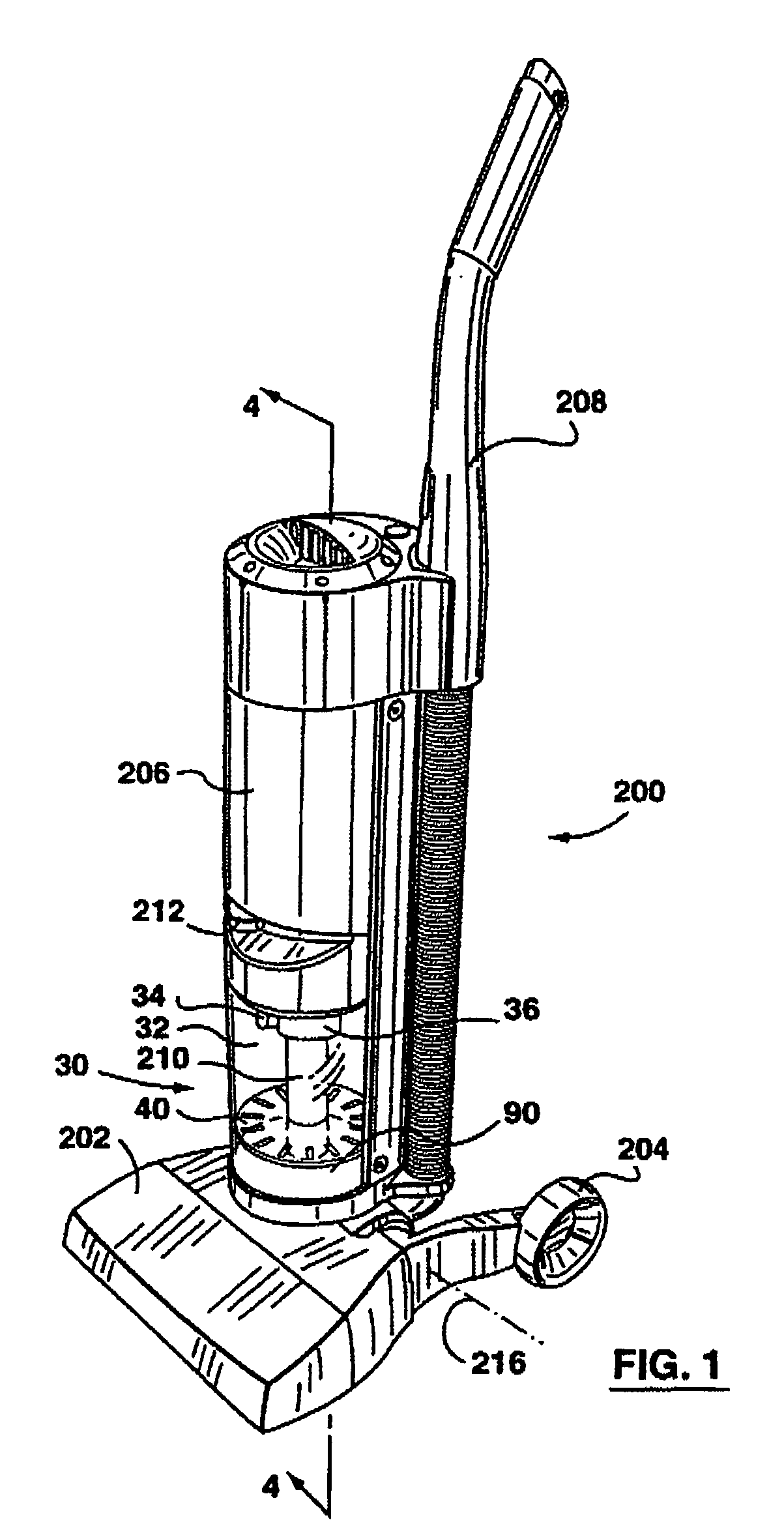

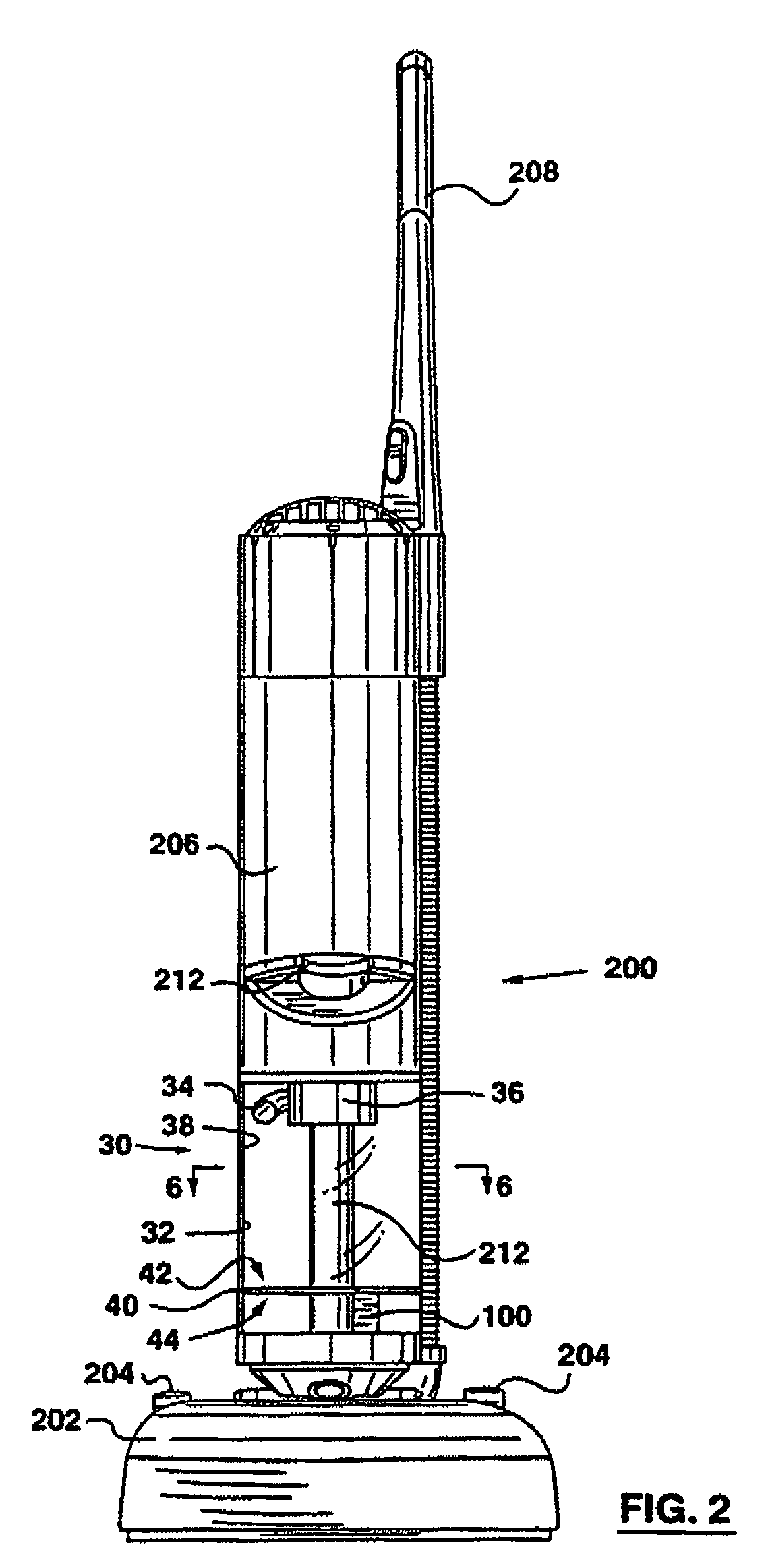

Cyclonic vacuum cleaner

InactiveUS20050138763A1Improve efficiencyEasy to emptyCleaning filter meansCombination devicesCycloneVacuum cleaner

A cyclonic vacuum cleaner includes a body portion, a nozzle portion and a dirt cup which is removable from the body portion. The dirt cup collects dirt and other debris separated by a cyclone and a cyclone slinger portion in the body portion. A main filter may be housed in a transparent filter door downstream of the cyclone. The dirt cup may be inserted into and sealingly held within the body portion by using a rotational camming structure.

Owner:MIDEA AMERICA CORP

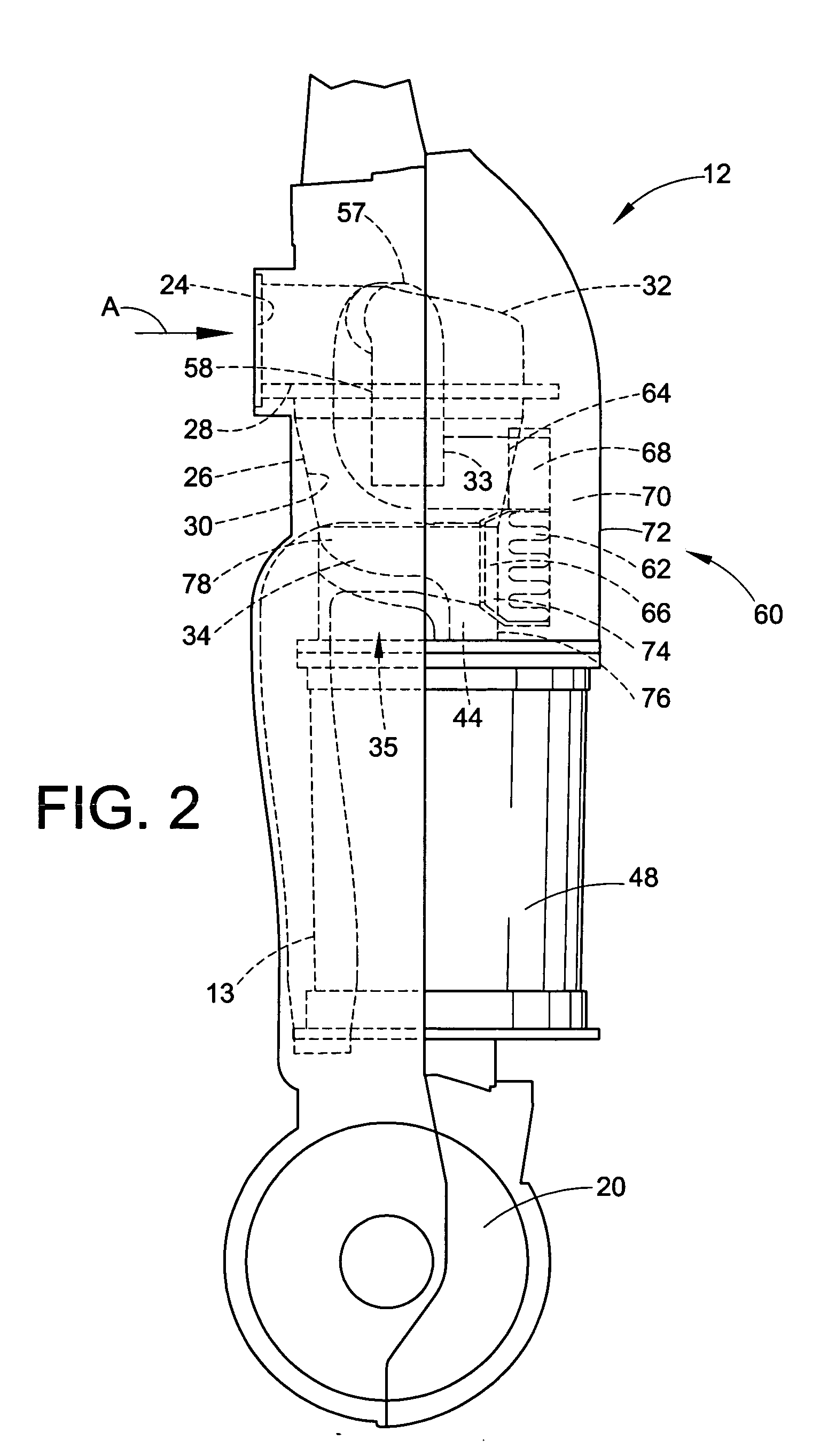

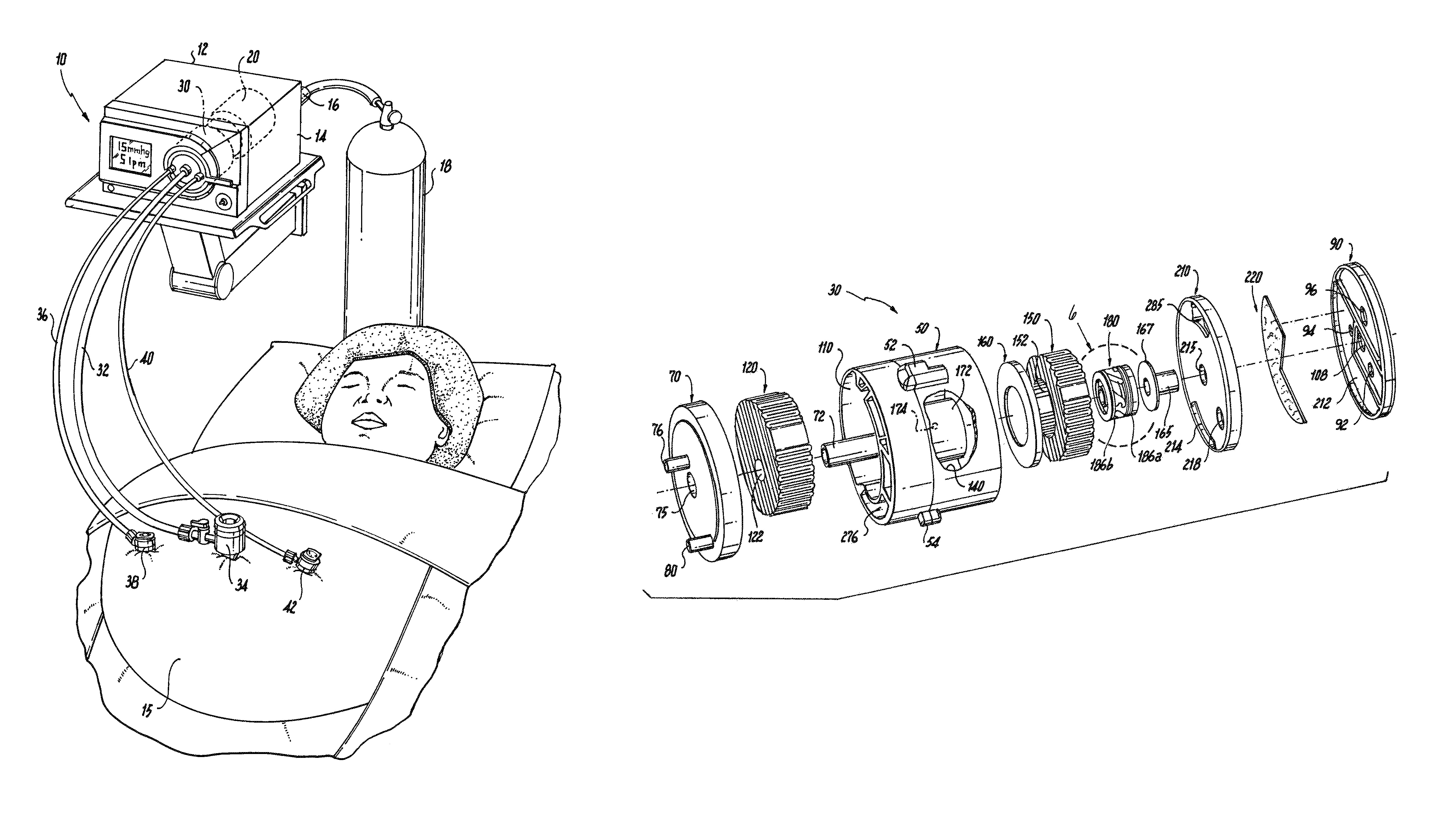

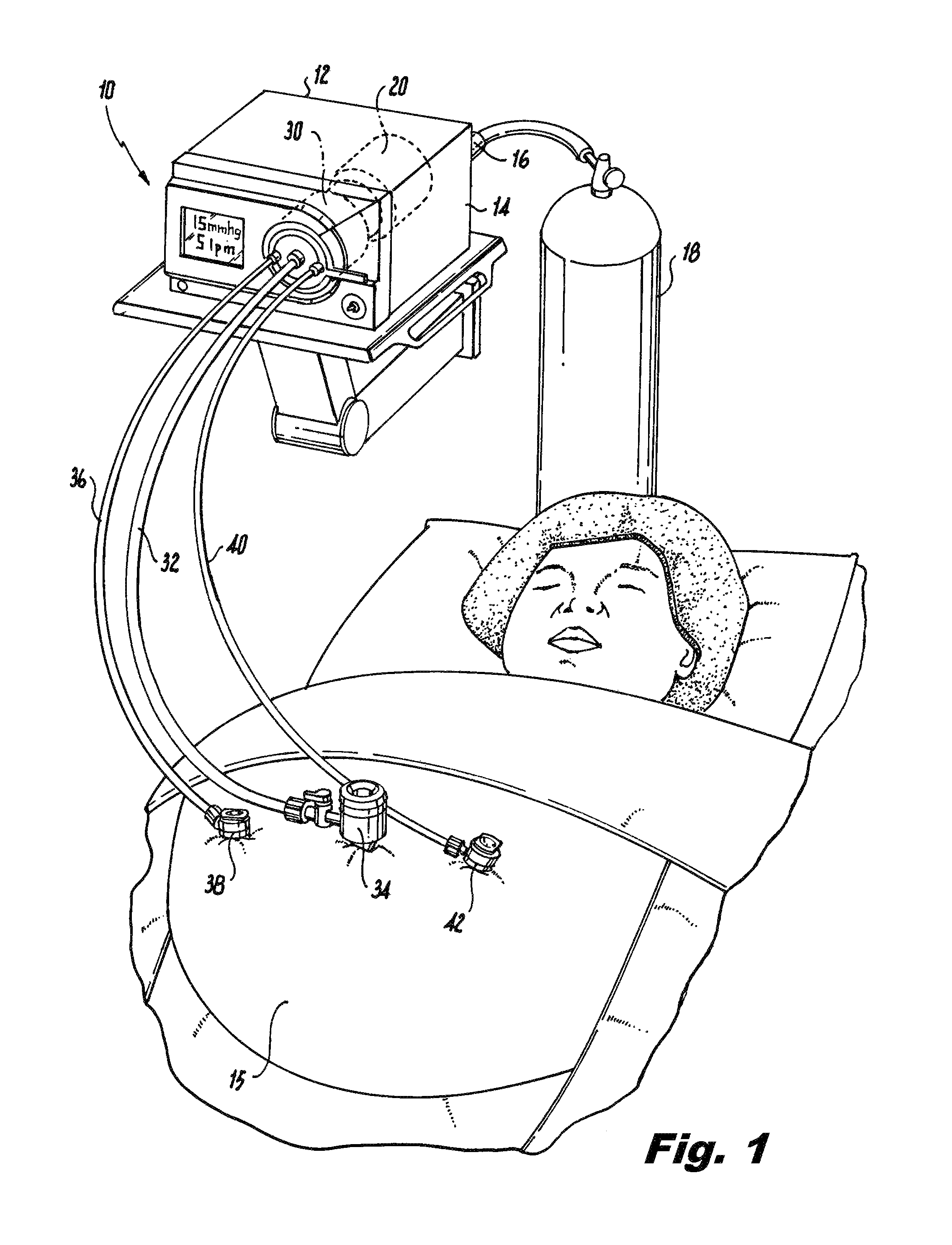

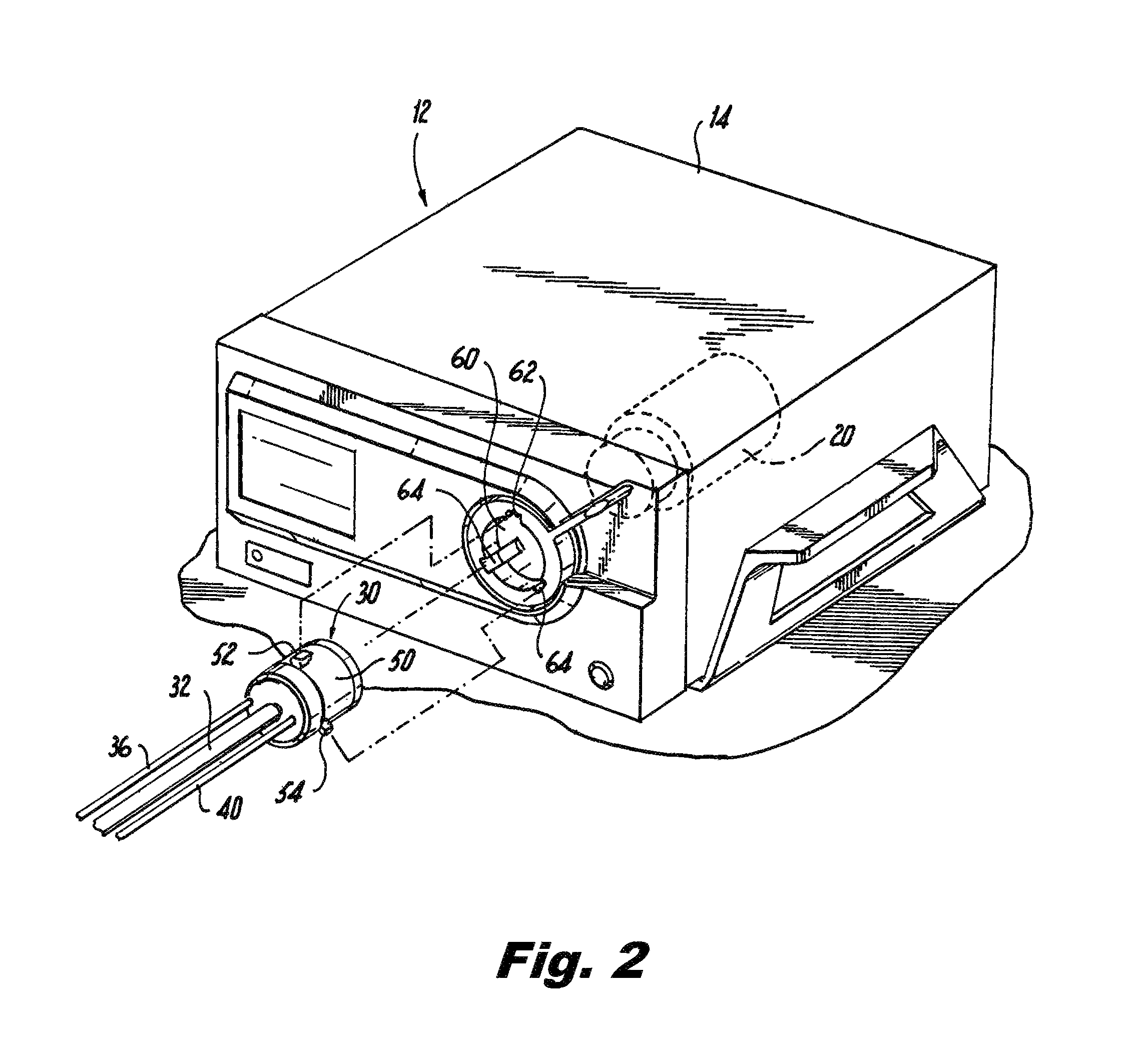

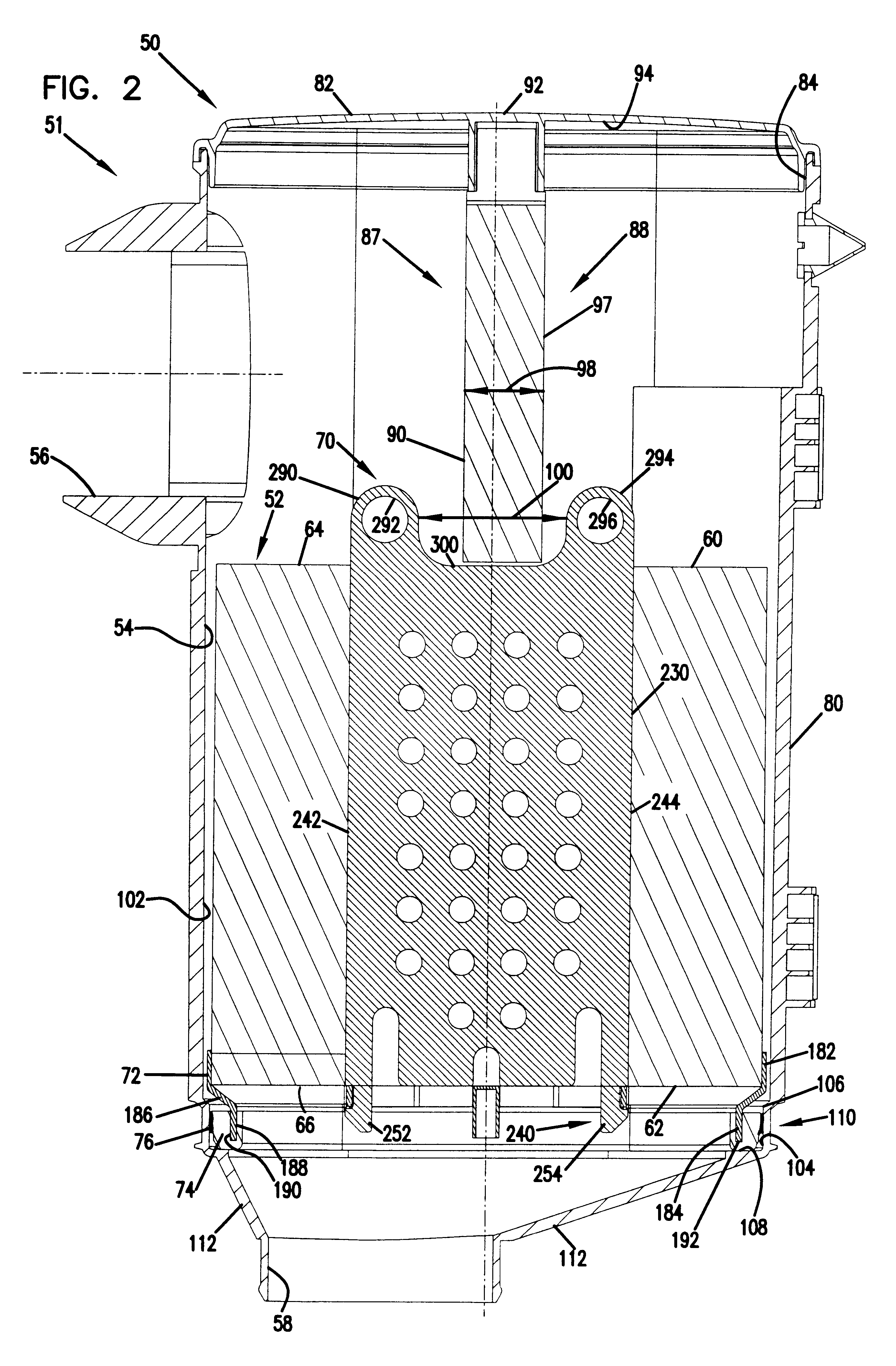

Filter cartridge with internal gaseous seal for multimodal surgical gas delivery system having a smoke evacuation mode

A system is disclosed for delivering gas during a laparoscopic surgical procedure performed within a patient's abdominal cavity requiring smoke evacuation which includes a gas delivery device having a housing with a port for receiving pressurized insufflating gas from a gas source, a pump assembly for circulating gas throughout the system, and a disposable gas conditioning unit or filter cartridge configured for operative association with the gas delivery device.

Owner:SURGIQUEST

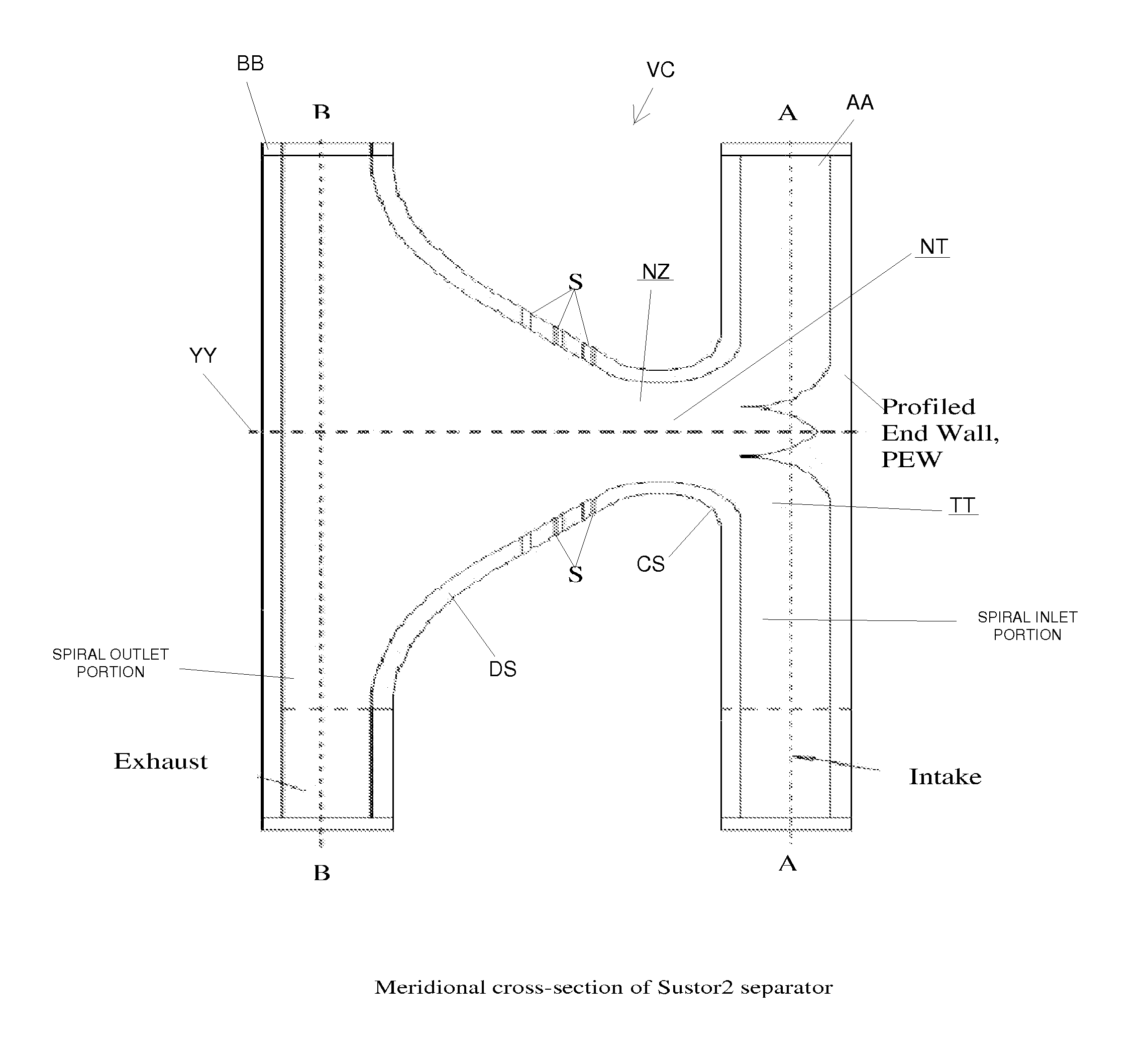

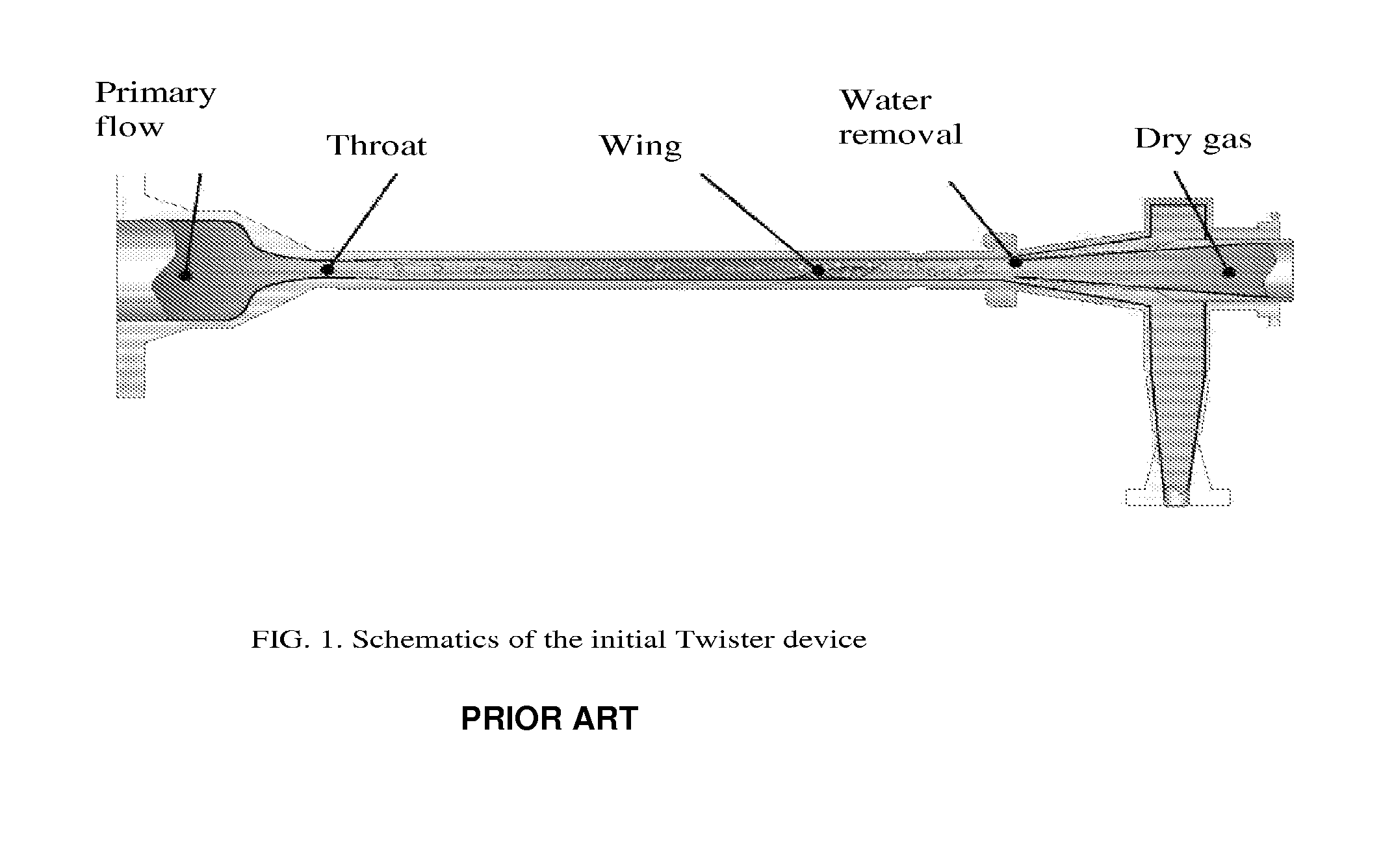

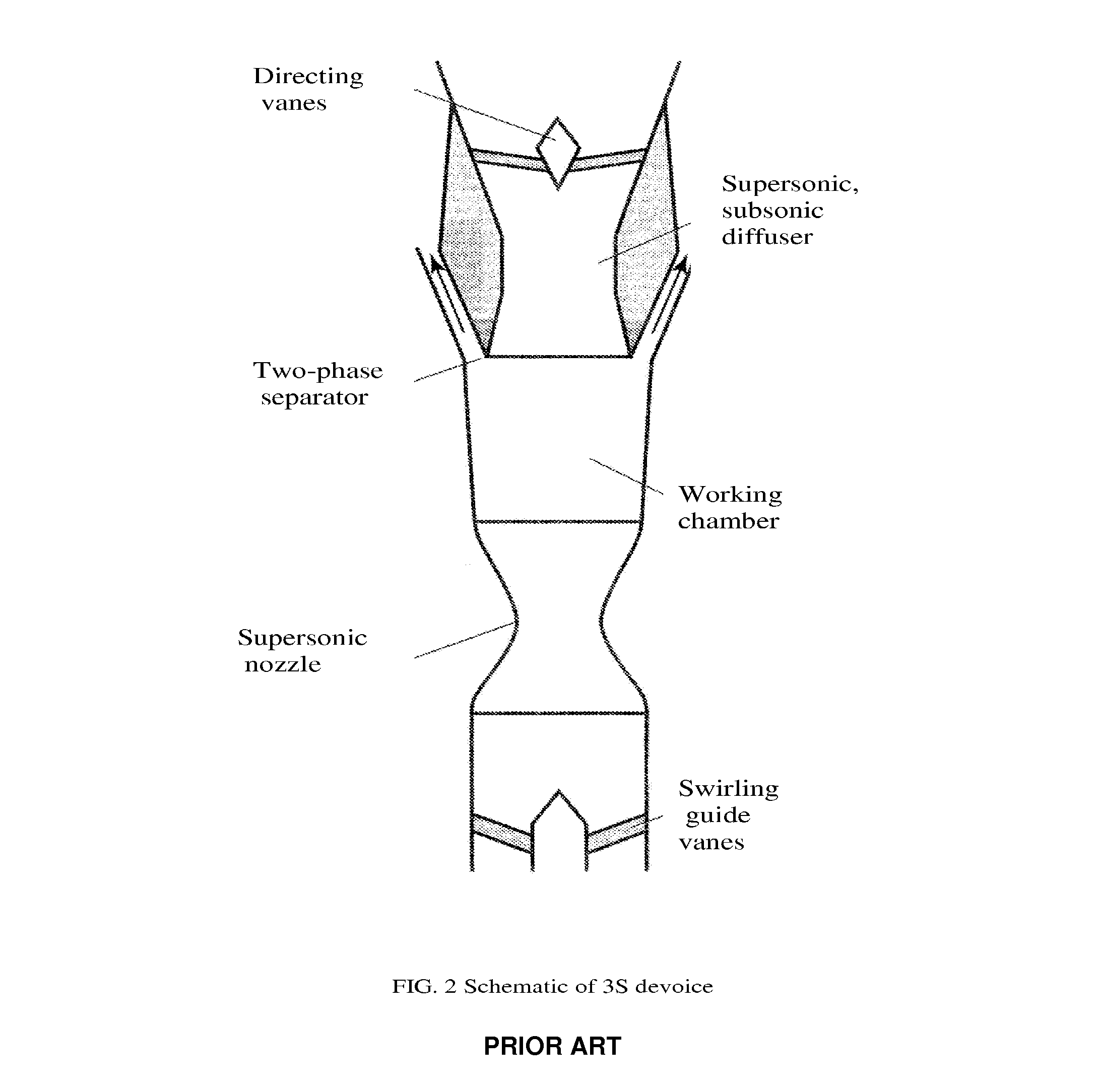

Supersonic swirling separator 2 (Sustor2)

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

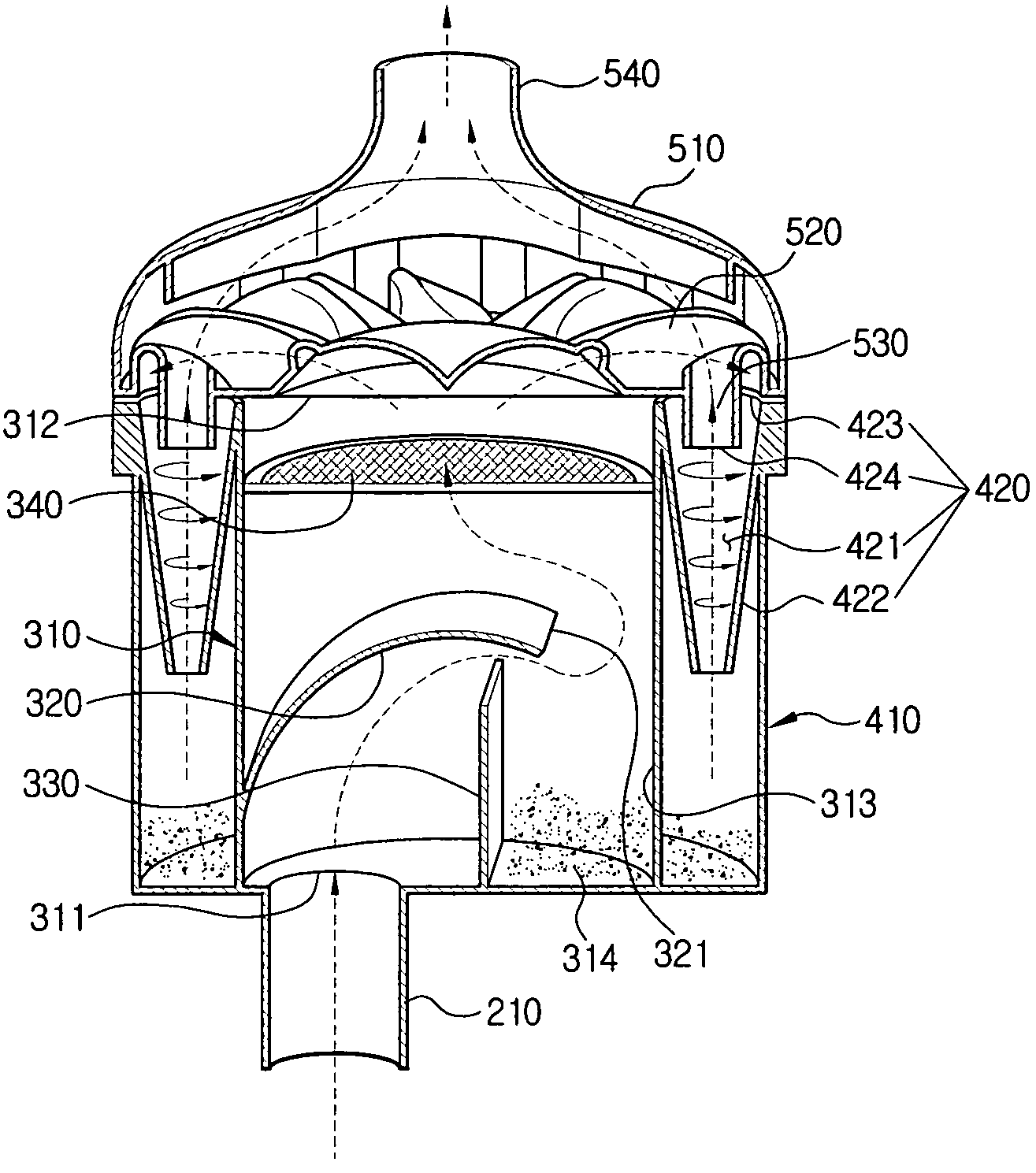

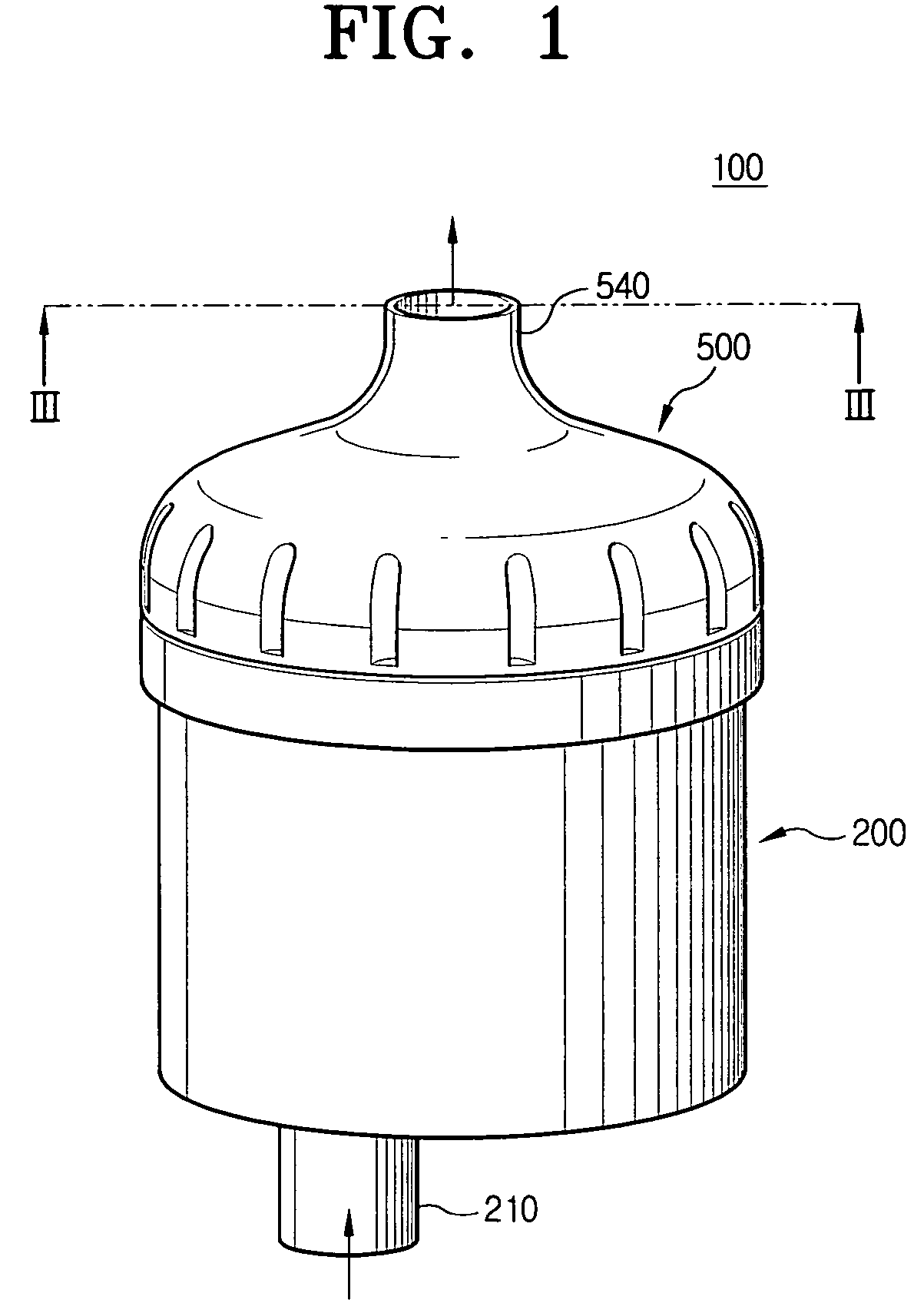

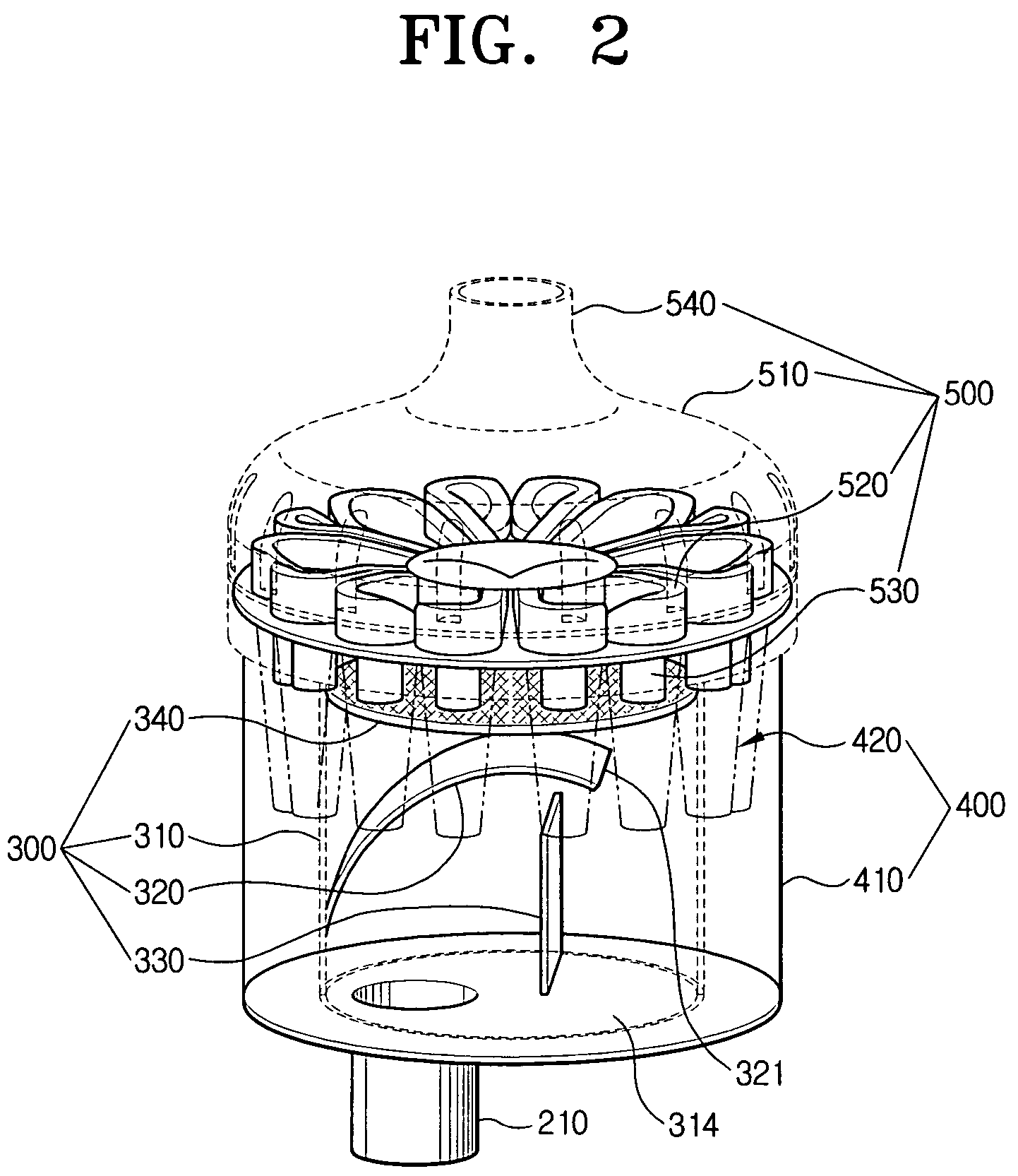

Cyclone separating apparatus for vacuum cleaner

InactiveUS20080190080A1High contaminant separating efficiencyProblem and drawbackCleaning filter meansCombination devicesCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone with an air entrance disposed on a lower portion of the first cyclone and an air exit disposed at an upper portion of the first cyclone; a first contaminants chamber substantially enclosing the first cyclone to collect contaminants discharged from the first cyclone; a plurality of second cyclones above the first cyclone, the plurality of second cyclones being substantially perpendicular to a center axis of the first cyclone; and a second contaminants chamber disposed outside the first contaminants chamber to collect contaminants discharged from the plurality of second cyclones.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

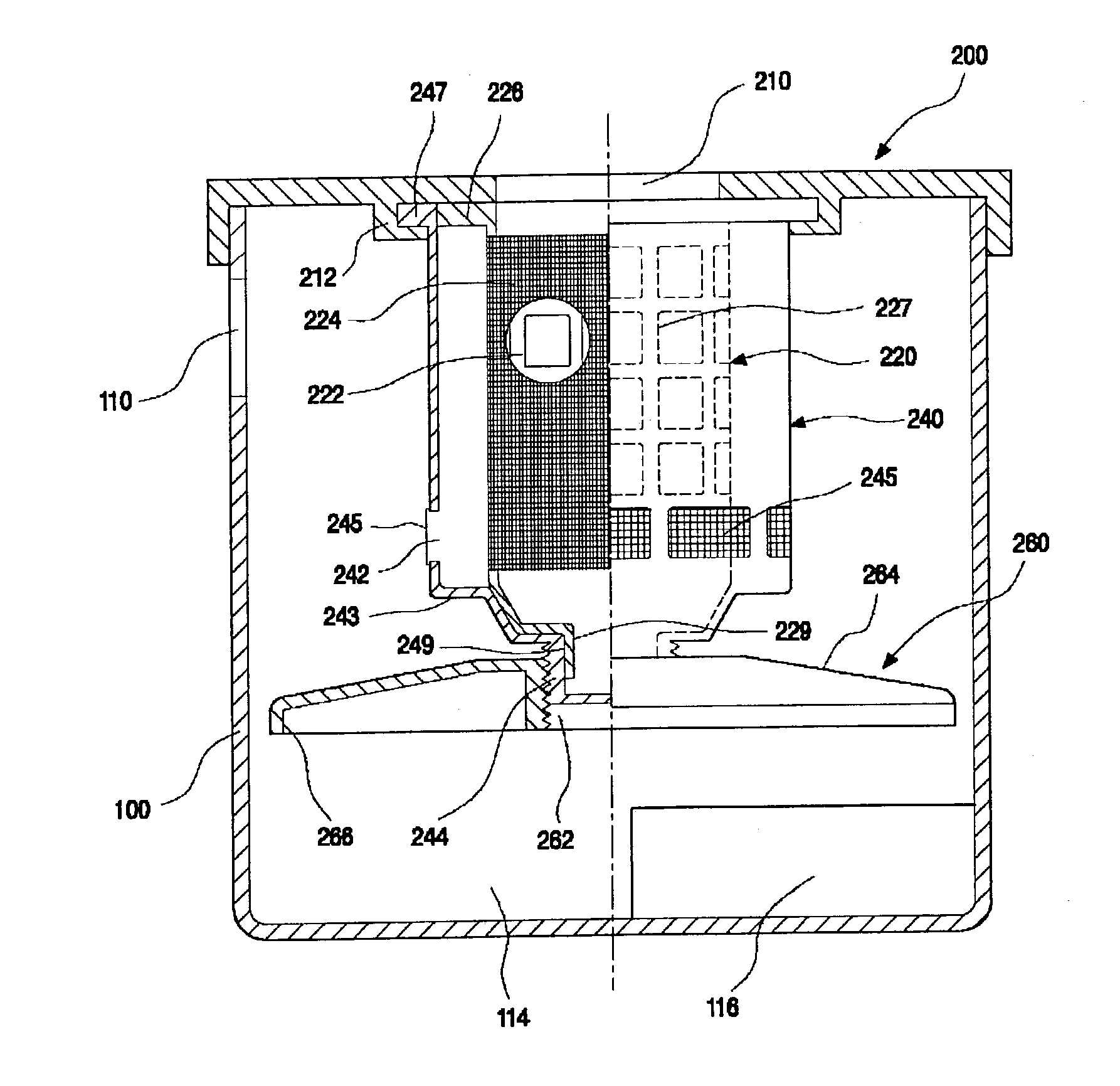

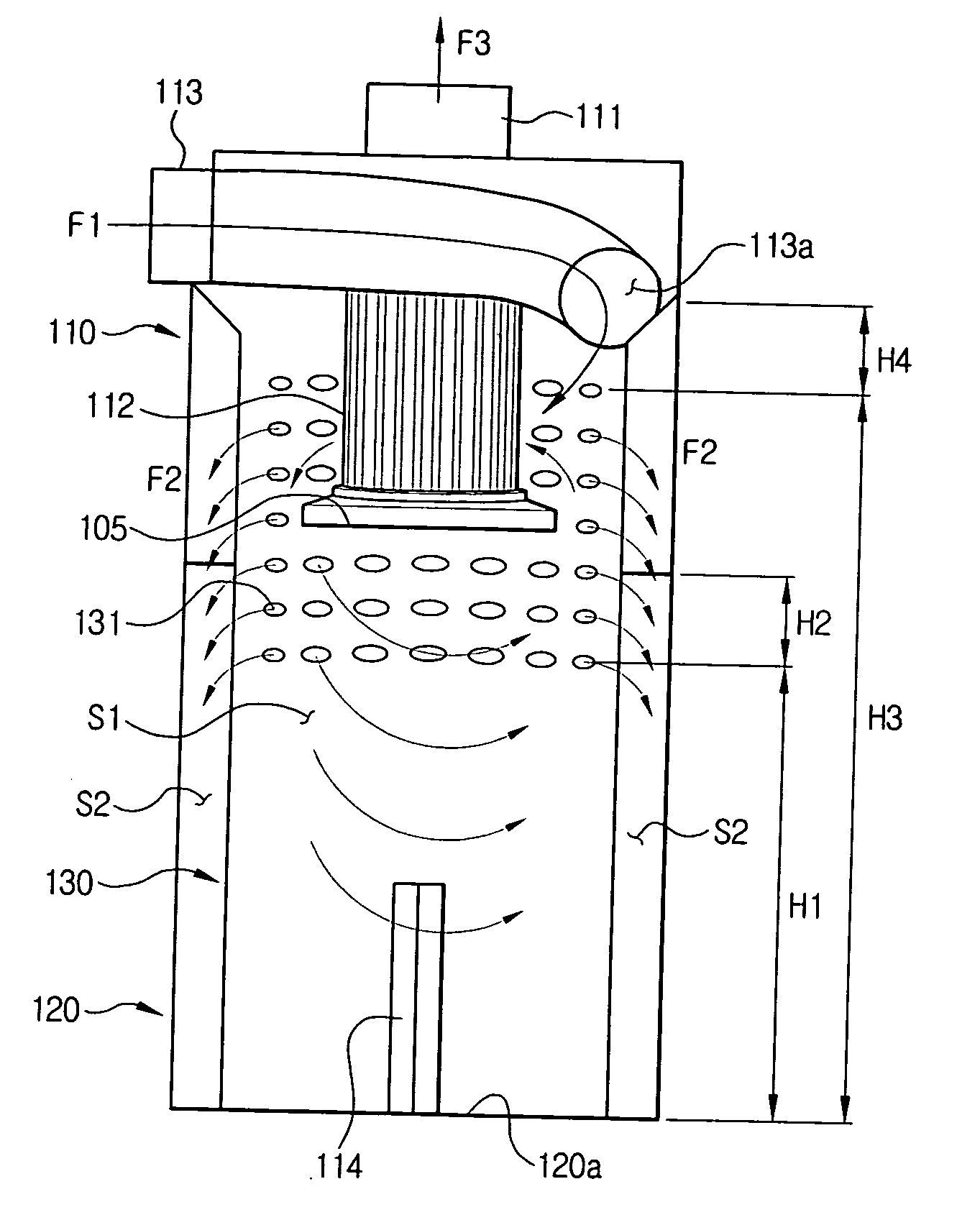

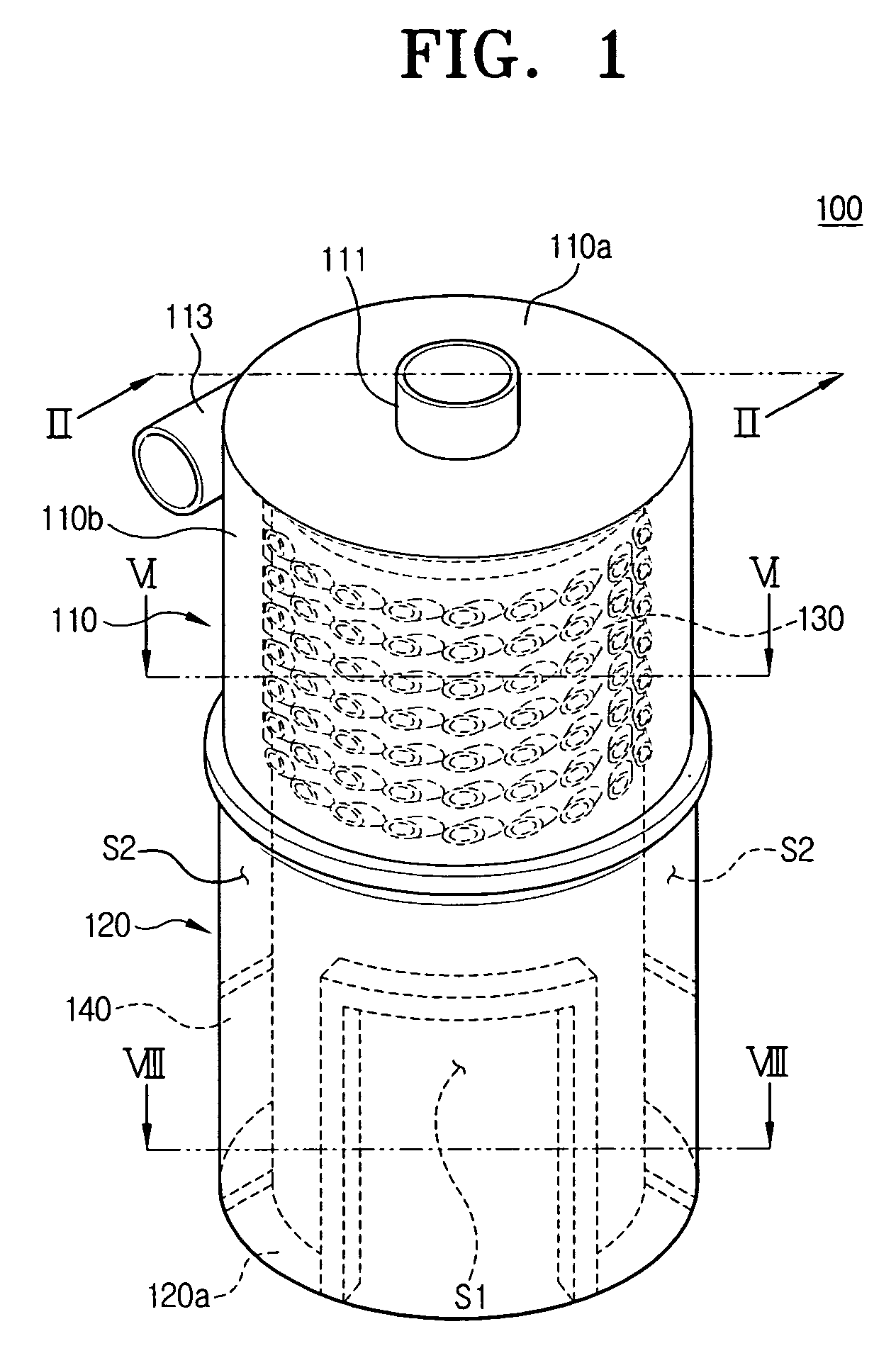

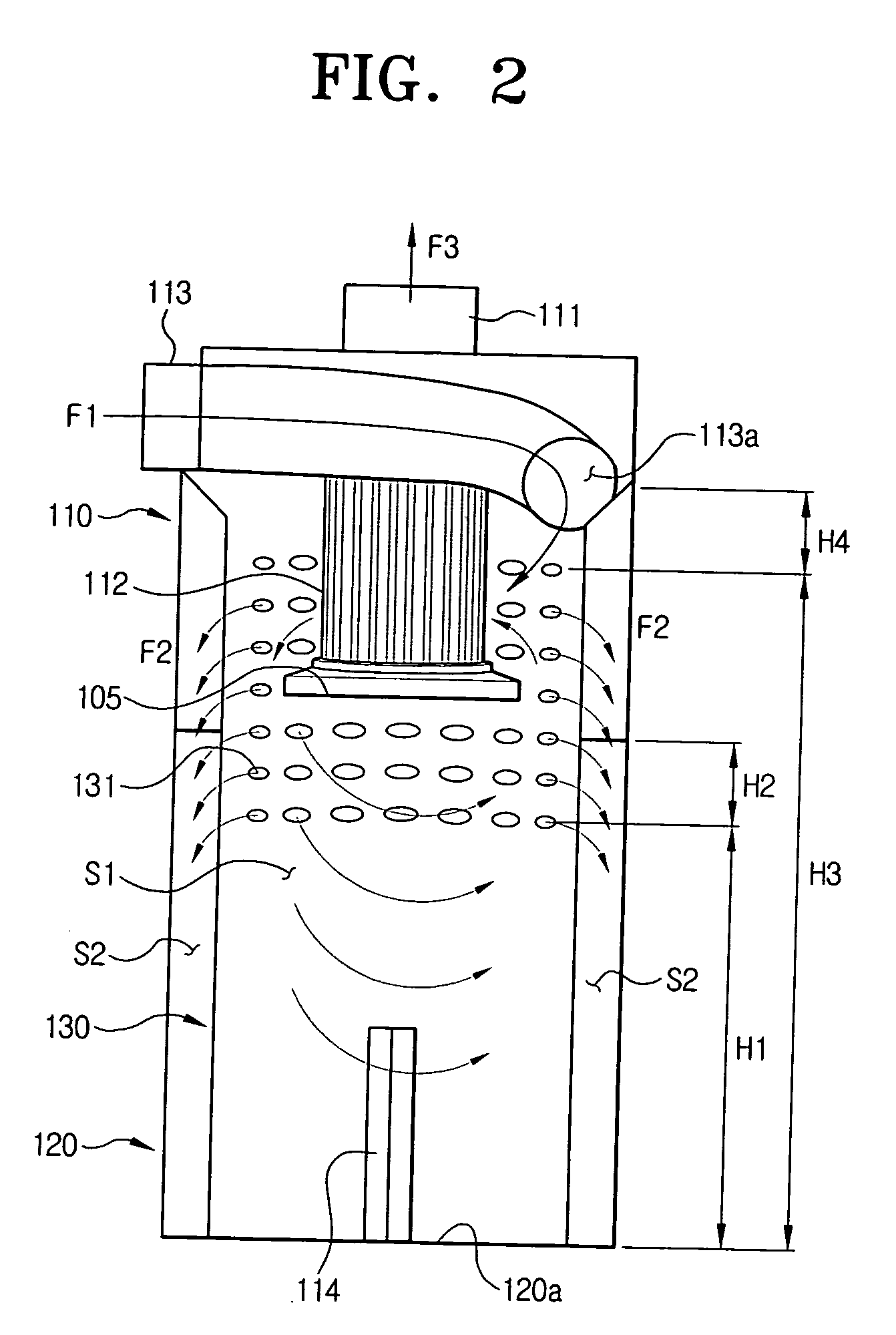

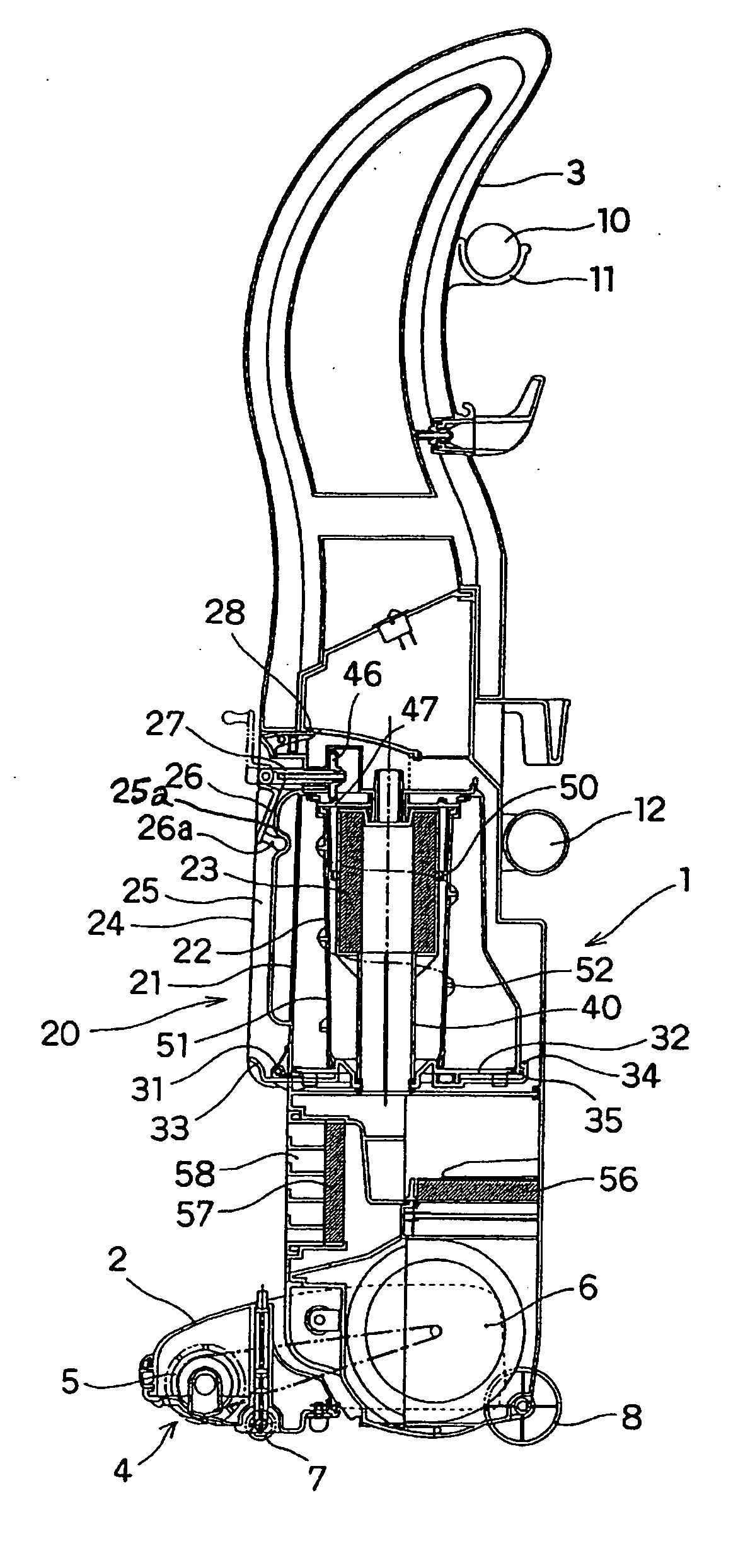

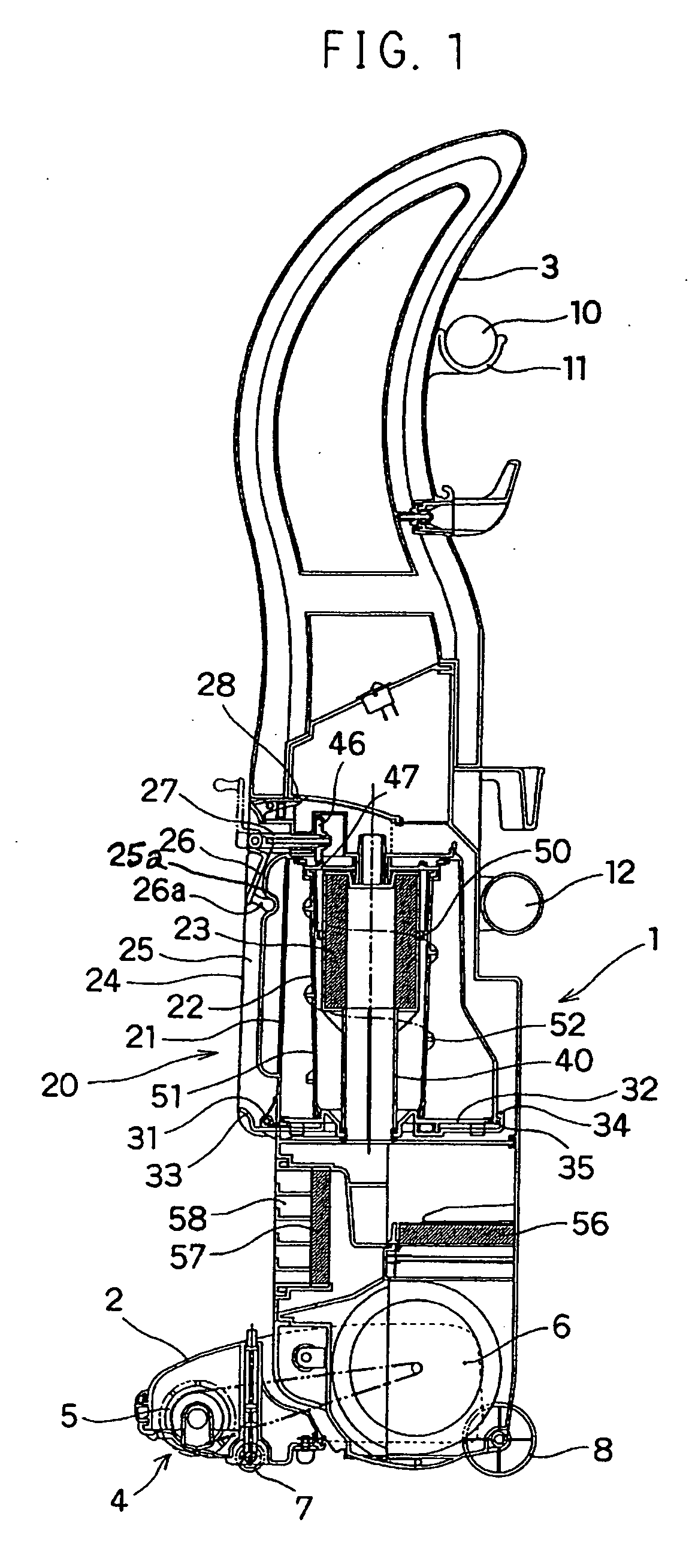

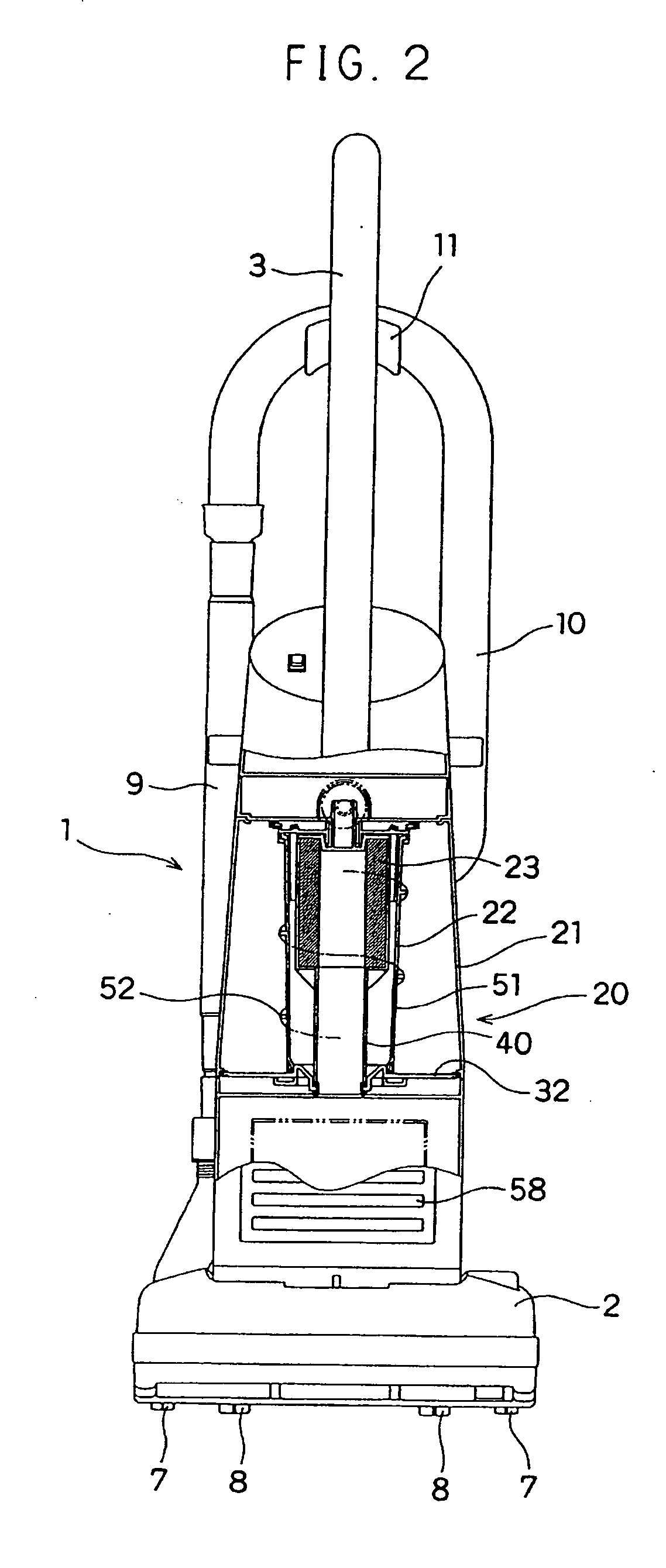

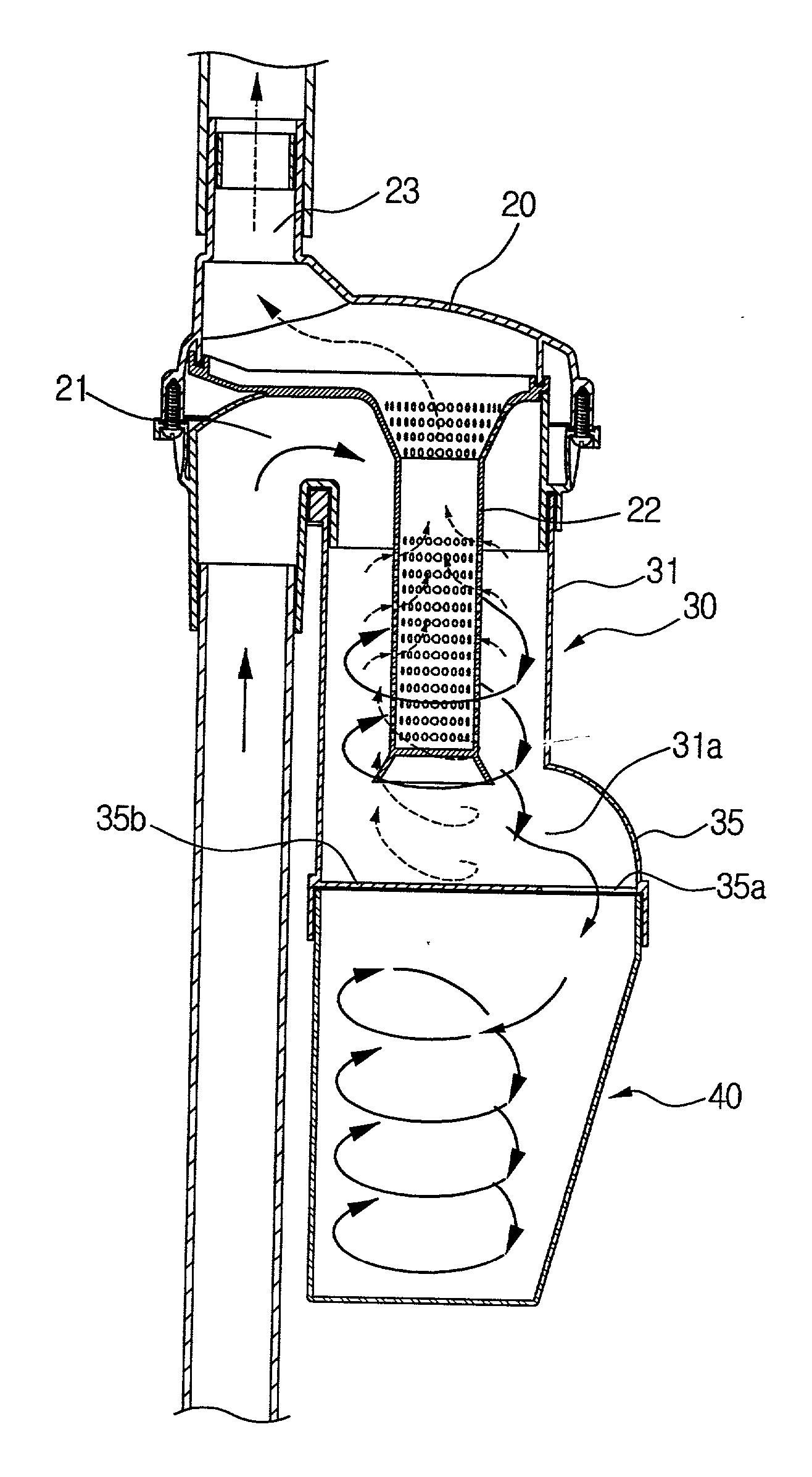

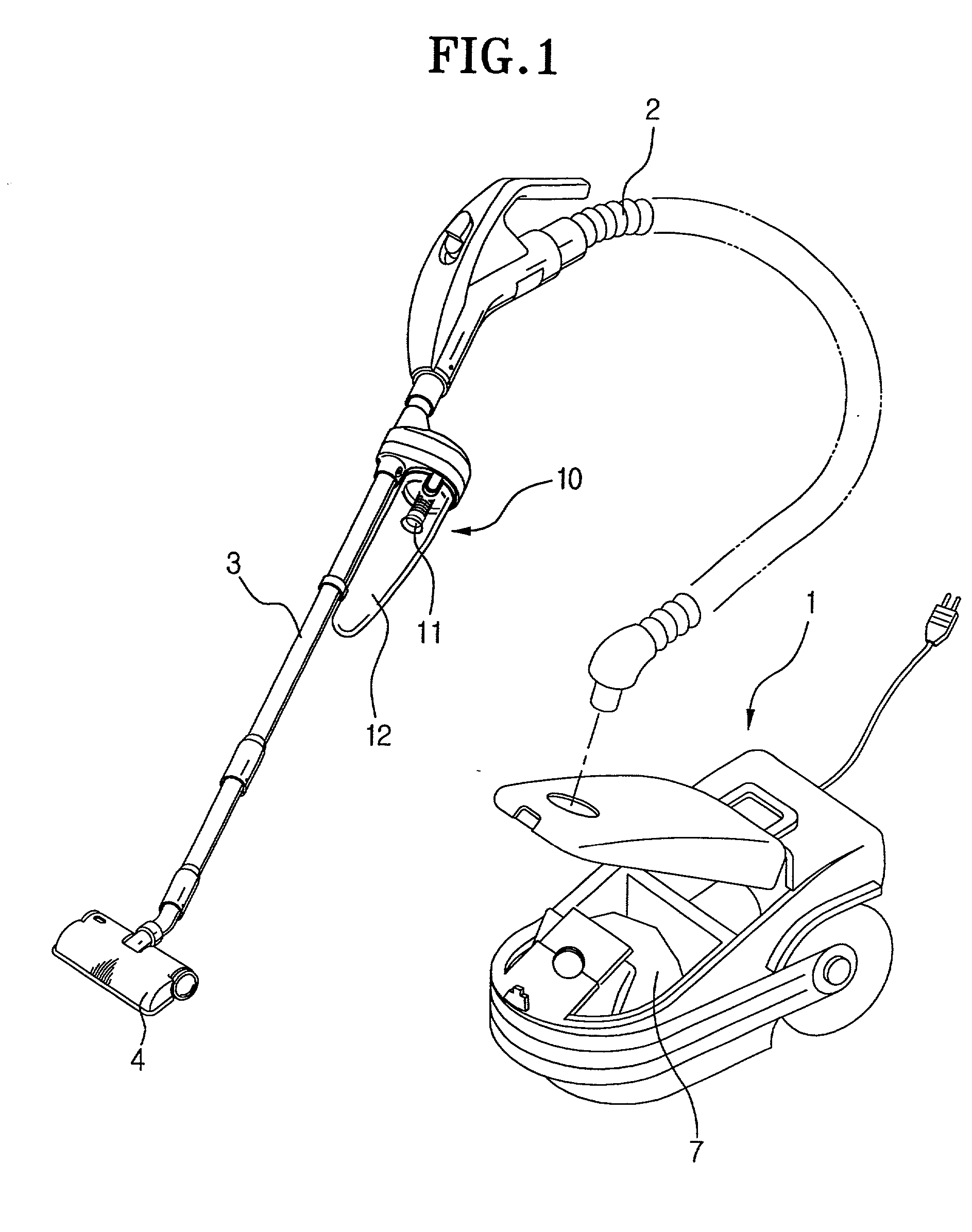

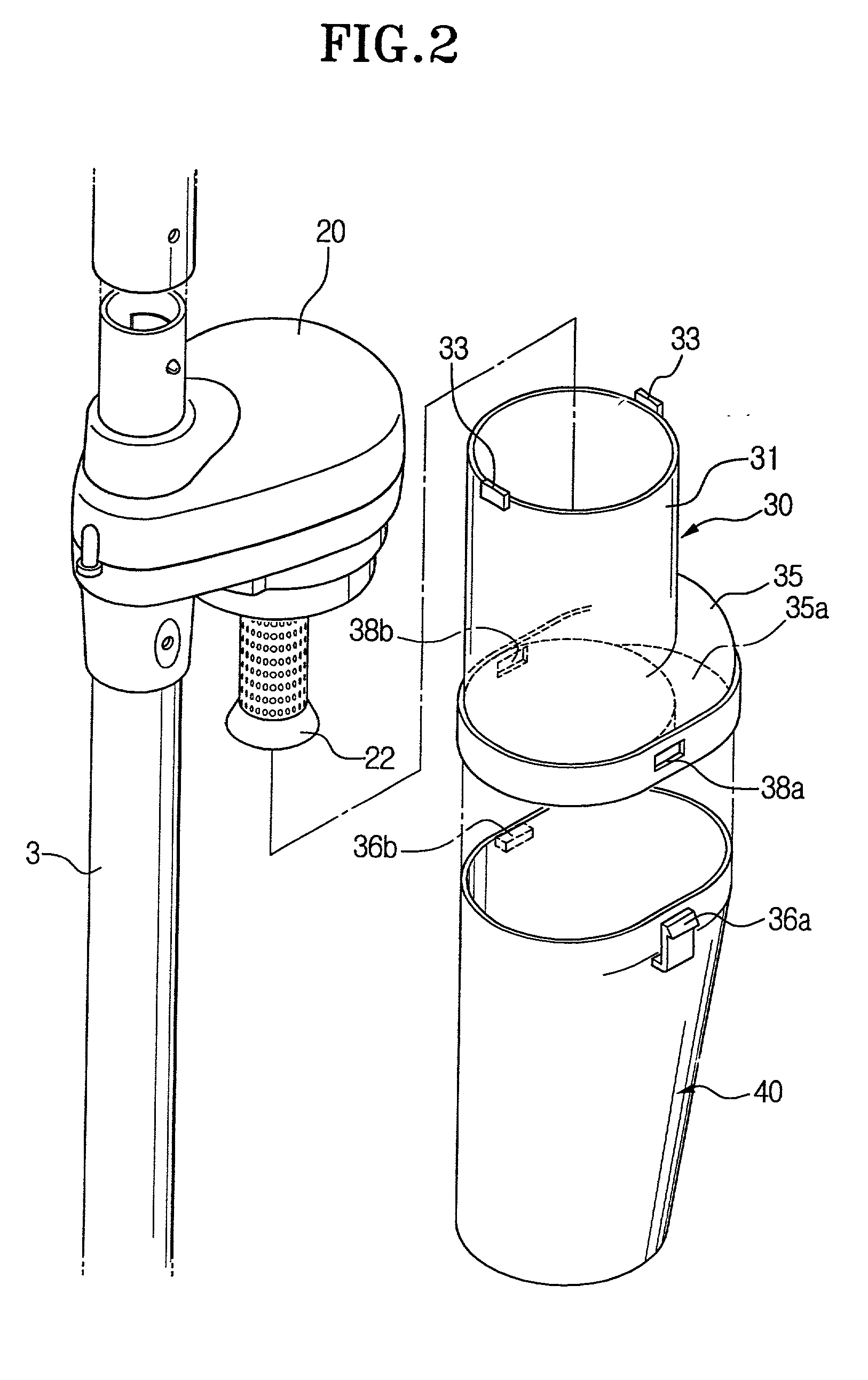

Dust and dirt collecting unit for vacuum cleaner

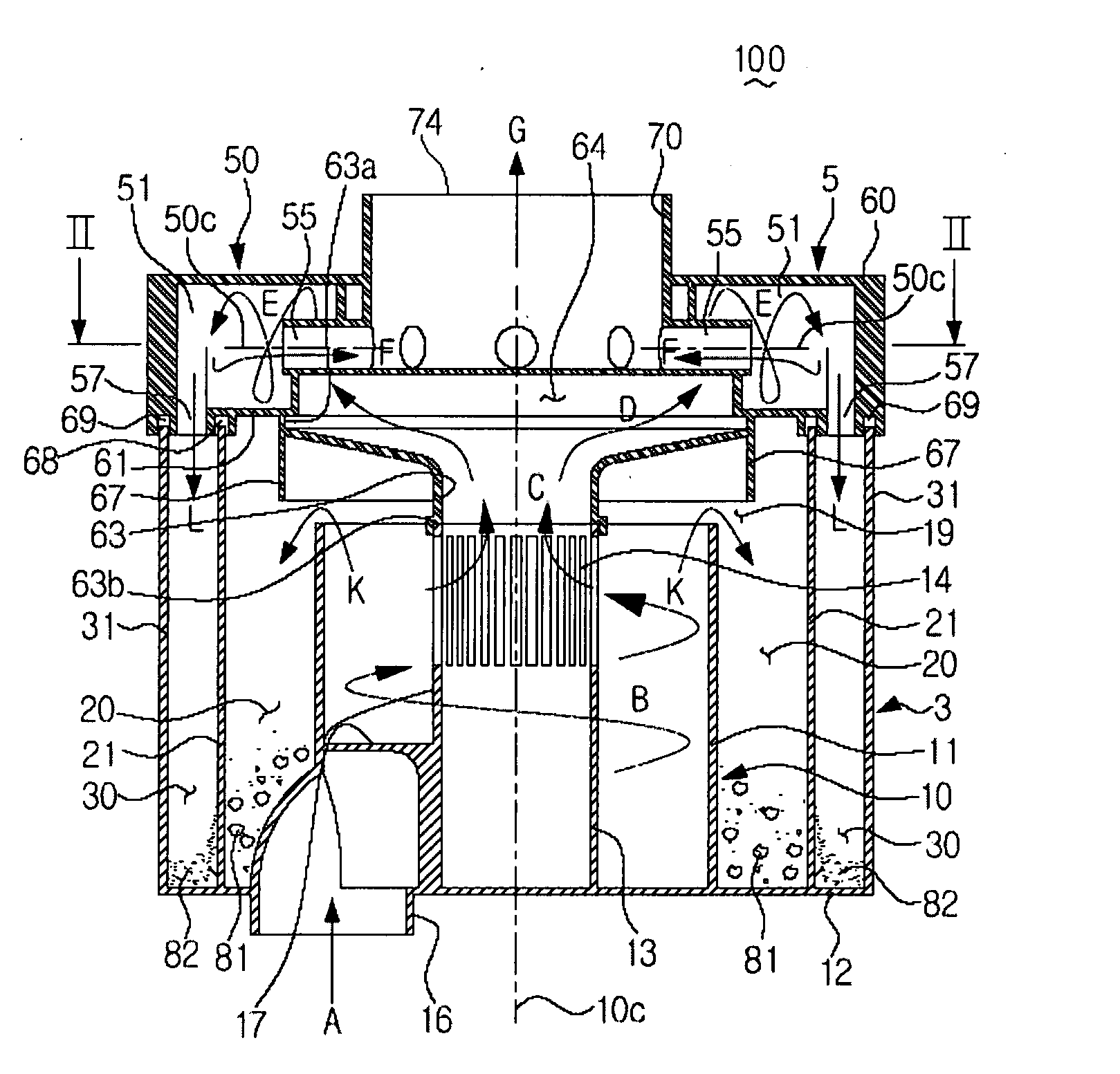

InactiveUS7160346B2Preventing mesh clogging of filterCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust and dirt collecting unit for a vacuum cleaner capable of simultaneously performing a primary cyclonic dust collection and a secondary filter dust collection. According to the present invention, there is provided a dust and dirt collecting unit for a vacuum cleaner, which is mounted to one side of a main body of the vacuum cleaner to filter sucked air containing foreign substances. The dust and dirt collecting unit of the present invention comprises a dust casing which has an inlet formed in a direction tangential thereto for introducing the air containing the foreign substances thereinto and of which a top portion is open; a cover which is used to open and close the top portion of the dust casing and is provided at the center thereof with an outlet for discharging air from which the foreign substances have been filtered out; a filter assembly which is installed at a bottom surface of the cover corresponding to the outlet and includes a cylindrical filter of which the interior communicates with the outlet; a protective cylindrical body which is formed to wrap around an outer periphery of the filter assembly and installed below the cover so that the interior thereof can communicate with the exterior thereof through a plurality of vent holes formed at a lower portion thereof; and a separating plate which is coupled with the bottom of the filter assembly and extends radially to be spaced apart from an inner circumferential surface of the dust casing by a predetermined gap.

Owner:LG ELECTRONICS INC

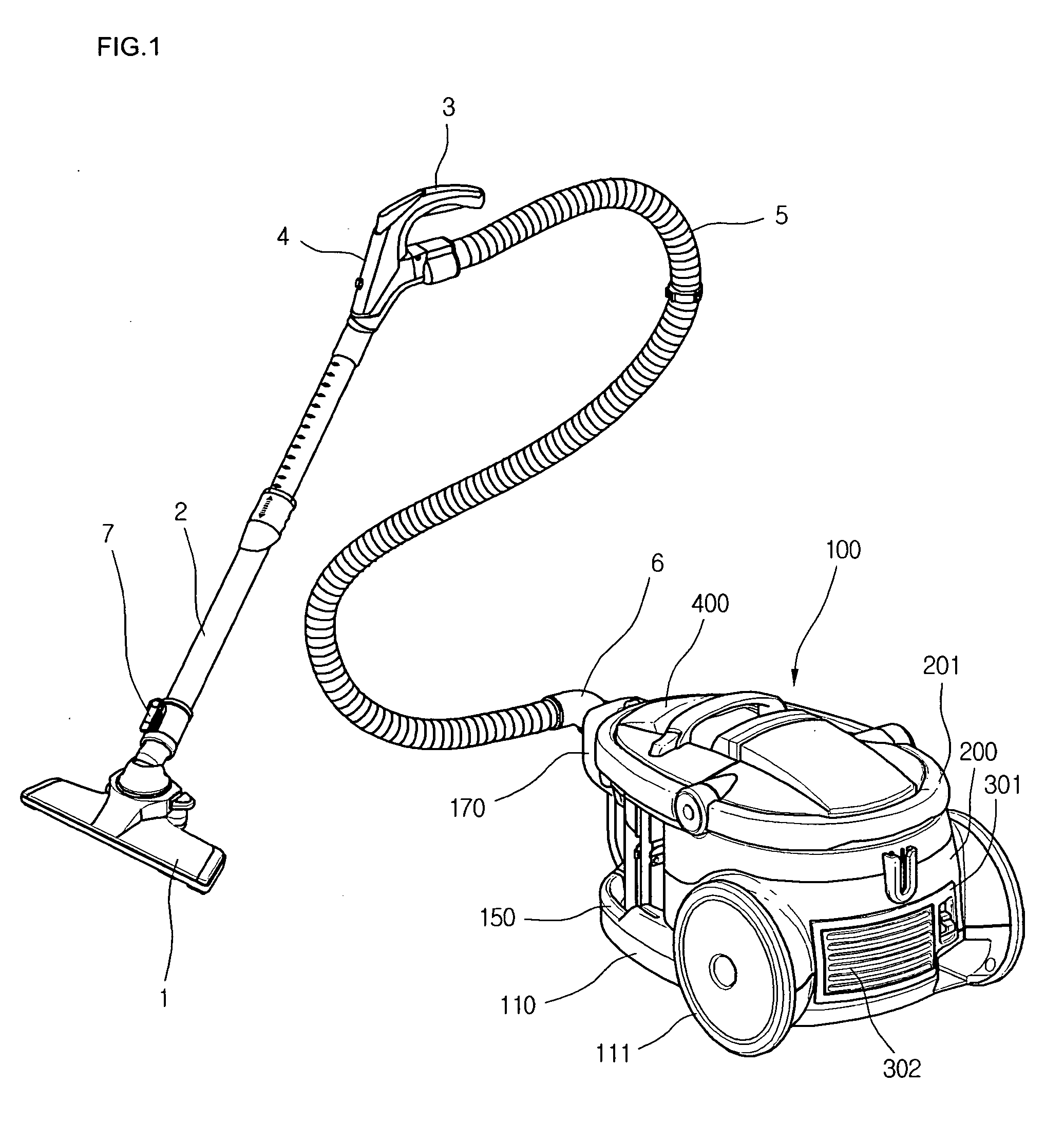

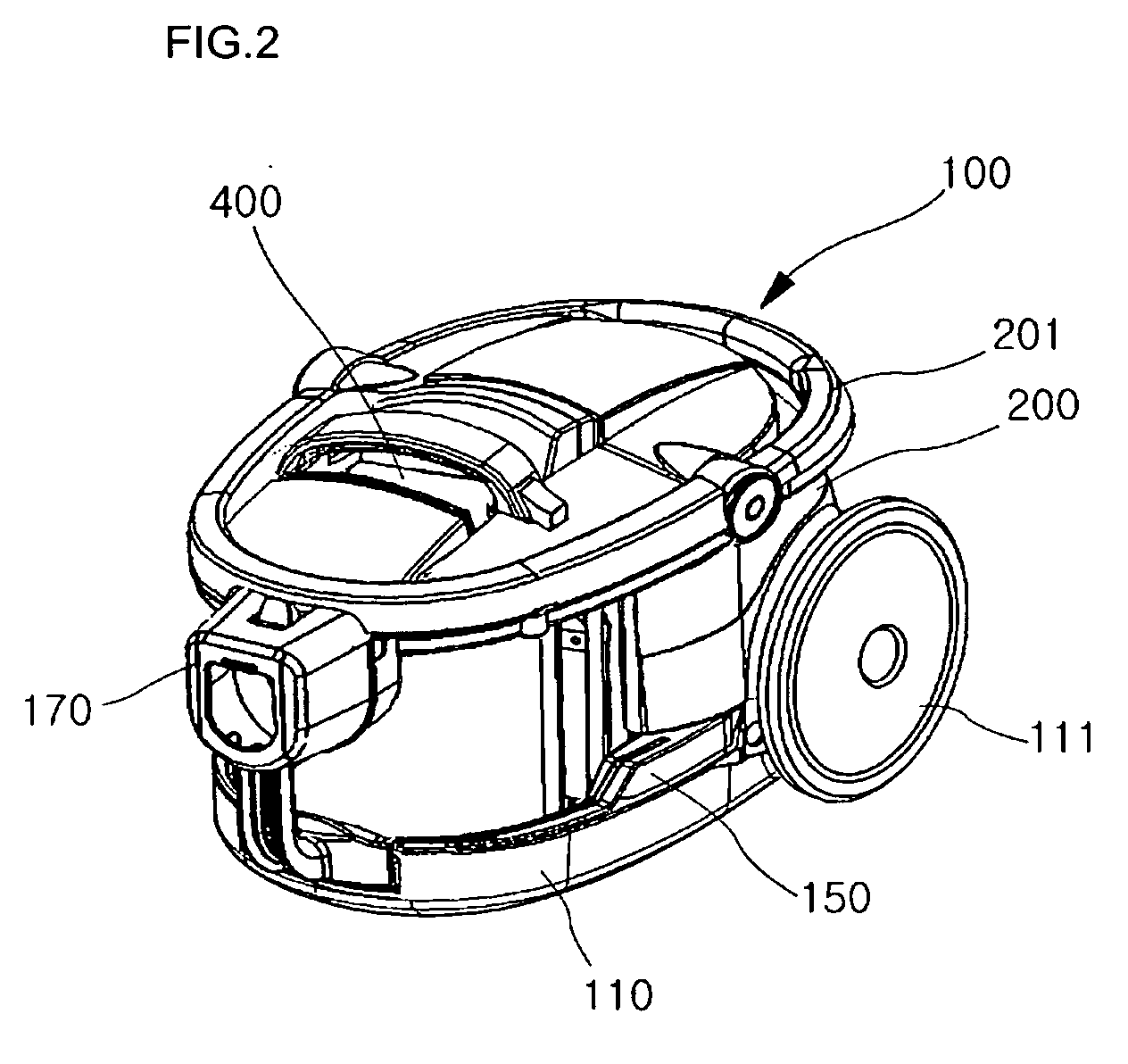

Dust collection unit and vacuum cleaner with the same

ActiveUS20060137309A1Improve foreign object removal efficiencyEasy to disassembleCombination devicesAuxillary pretreatmentForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

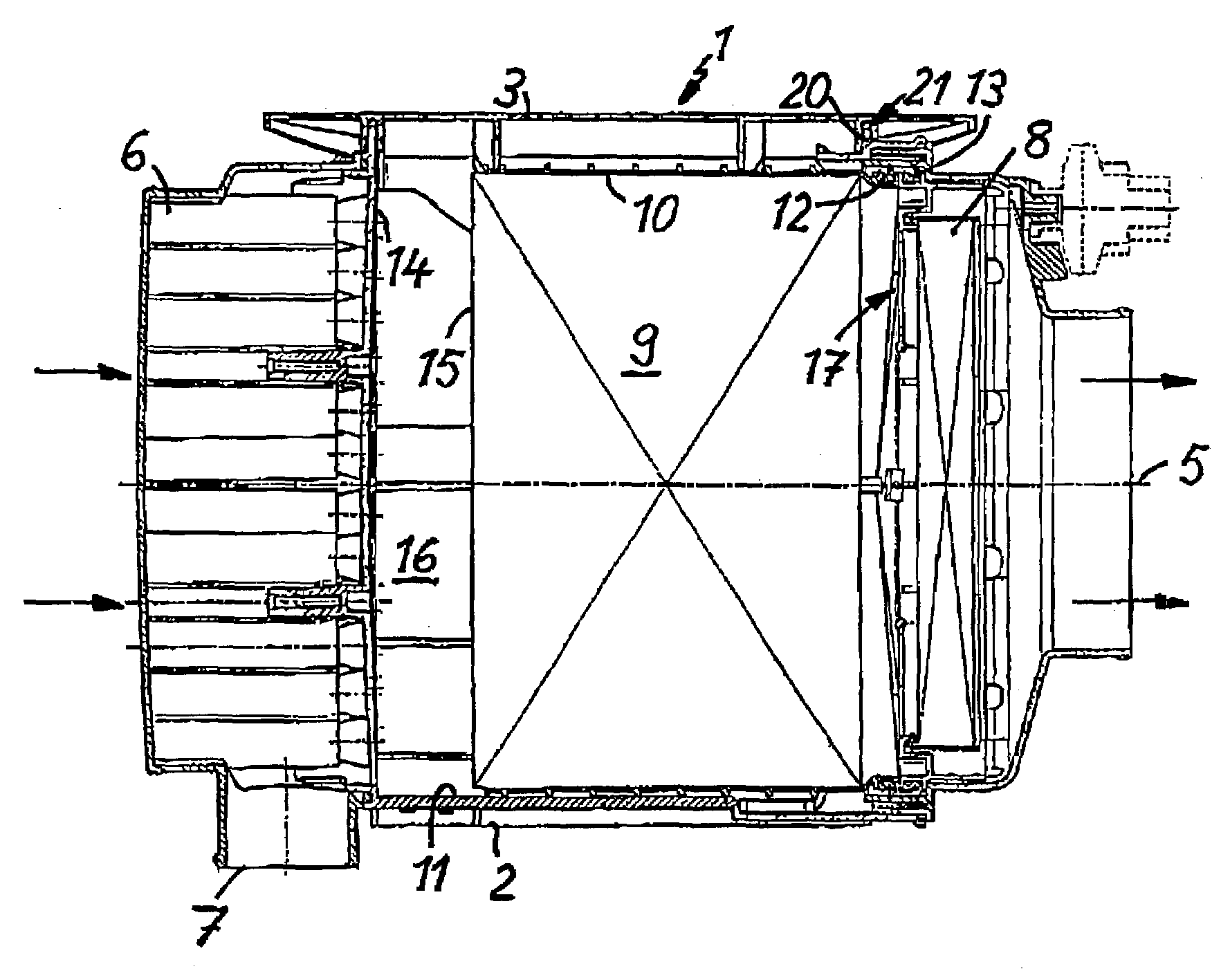

Filter in a filter housing

InactiveUS7004986B2Avoid spaceSimple designCombination devicesAuxillary pretreatmentFilter elementWaste management

A filter has a filter housing and a receptacle chamber in the filter housing into which a filter element is insertable. The filter housing has a housing cover for opening and closing an opening of the receptacle chamber. The housing cover is situated in an area of the filter housing between the oncoming flow side and the outgoing flow side of the filter element.

Owner:MANN HUMMEL GMBH

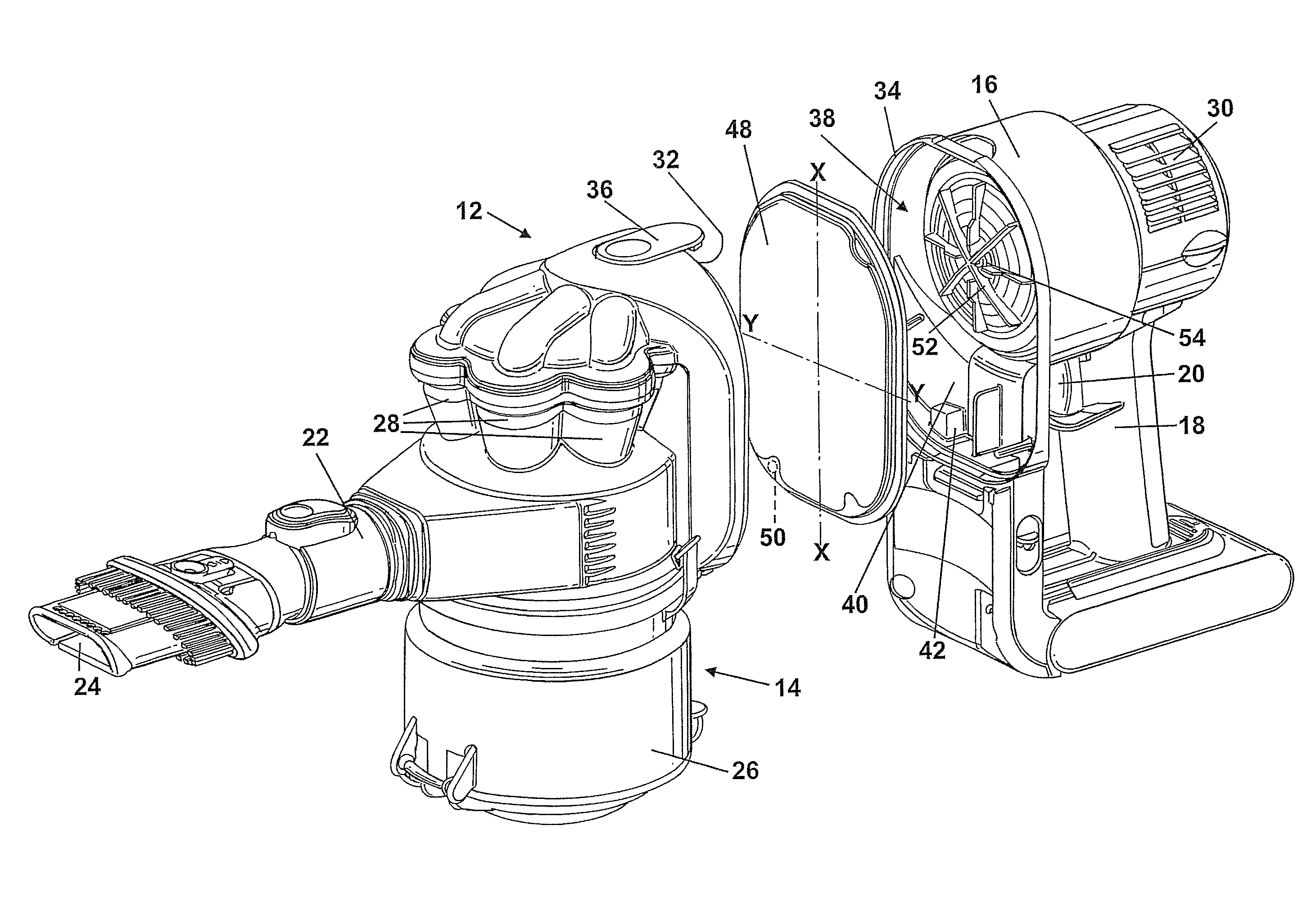

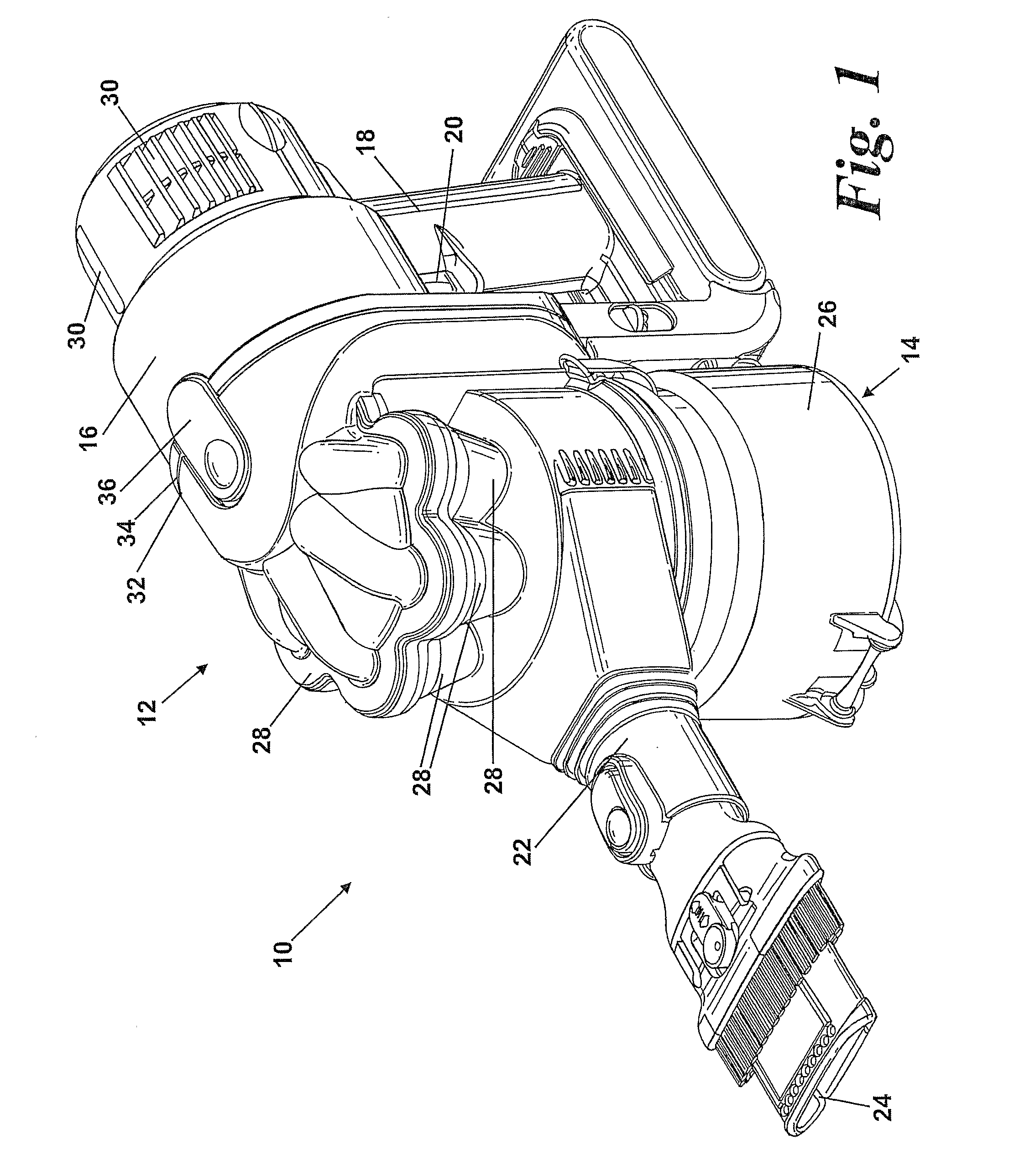

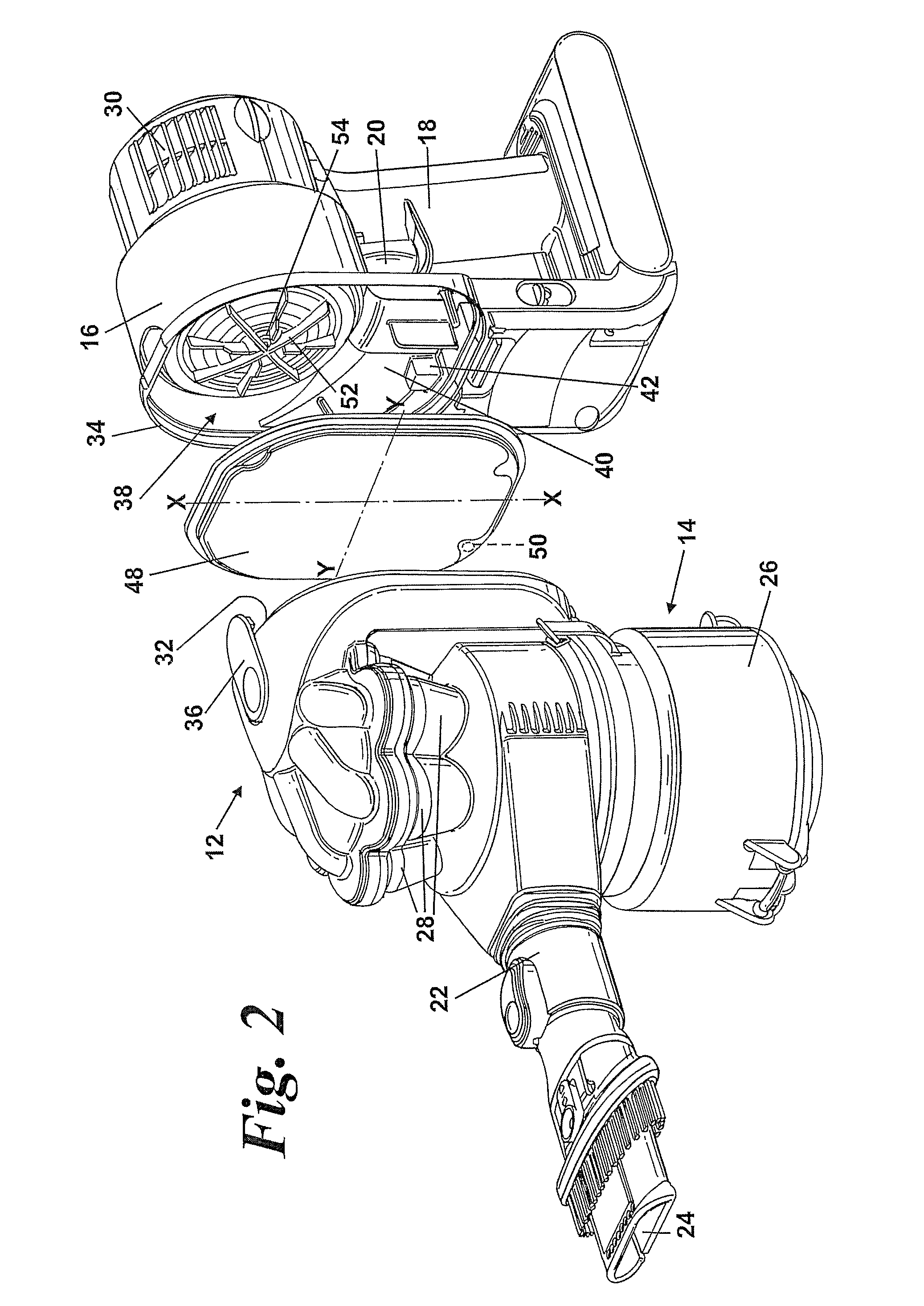

Handheld cleaning appliance

InactiveUS7931716B2Reduce cloggingLess prone to failureCombination devicesAuxillary pretreatmentHand heldWaste management

A cleaning appliance includes a main body, a filter and an interlock. The main body includes an airflow generator, a separating apparatus separating dirt and dust from an airflow, and a flowpath between the separating apparatus and the airflow generator delimited by a wall. The interlock has a first part located on the filter and a second part located on the main body outside the flowpath, arranged to communicate remotely when the filter is correctly located in the pre-determined position. The interlock is arranged selectively to allow or prevent operation of the airflow generator depending upon the relative separation between the first and second parts. By providing an interlock which has first and second parts which communicate remotely, the second part located on the main body can be isolated from the airflow path so that the second part is not subject to dirt and dust carried by the airflow.

Owner:DYSON TECH LTD

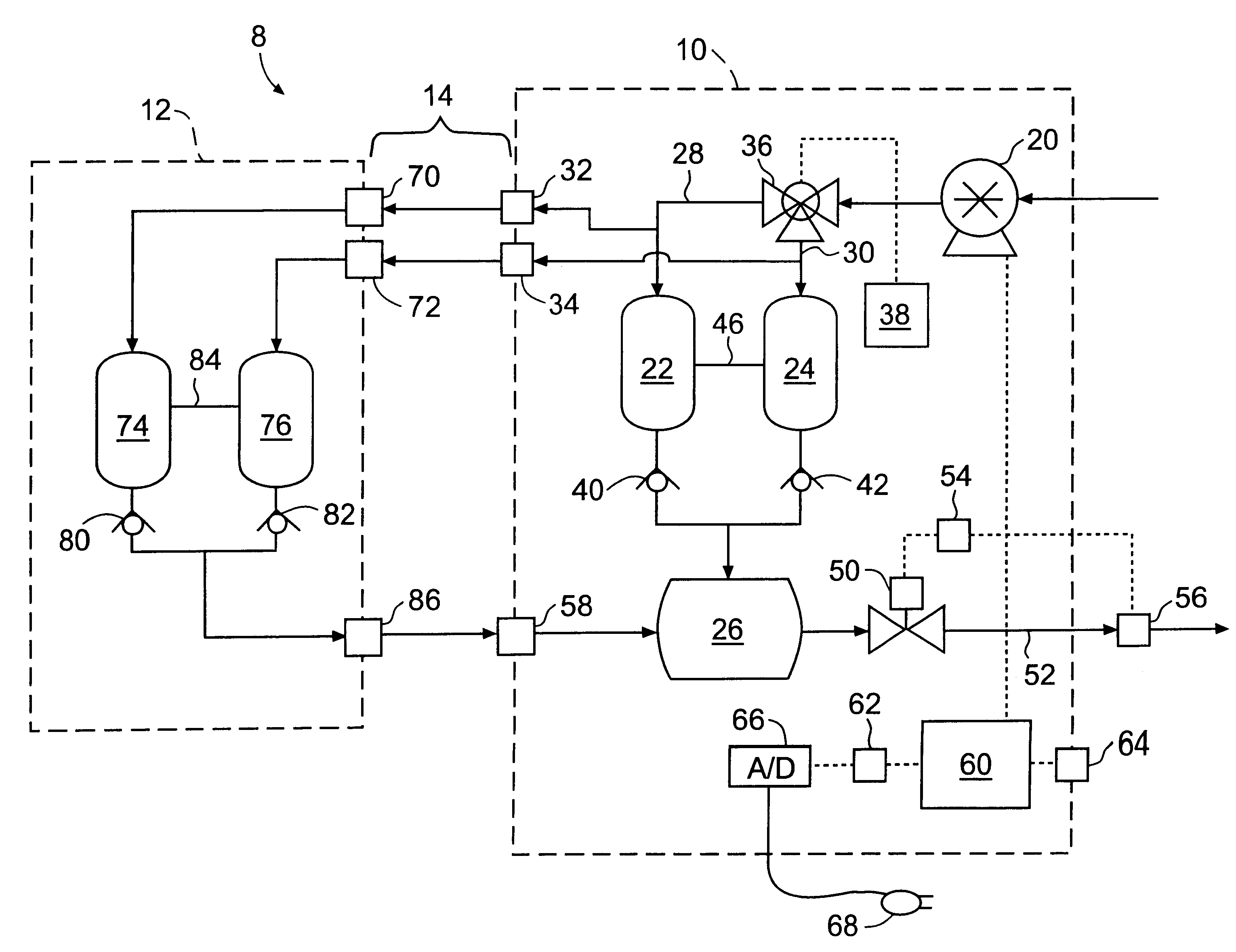

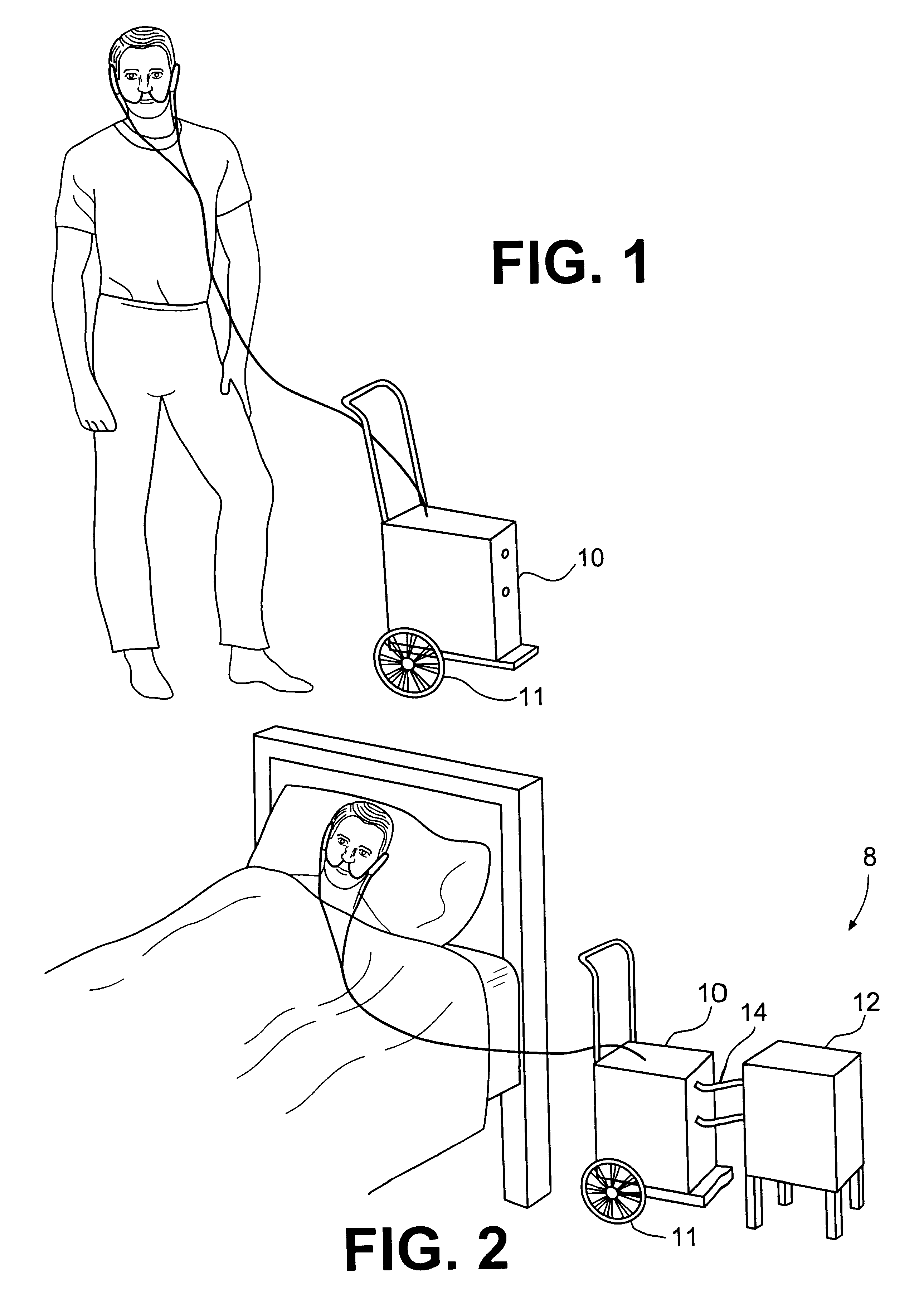

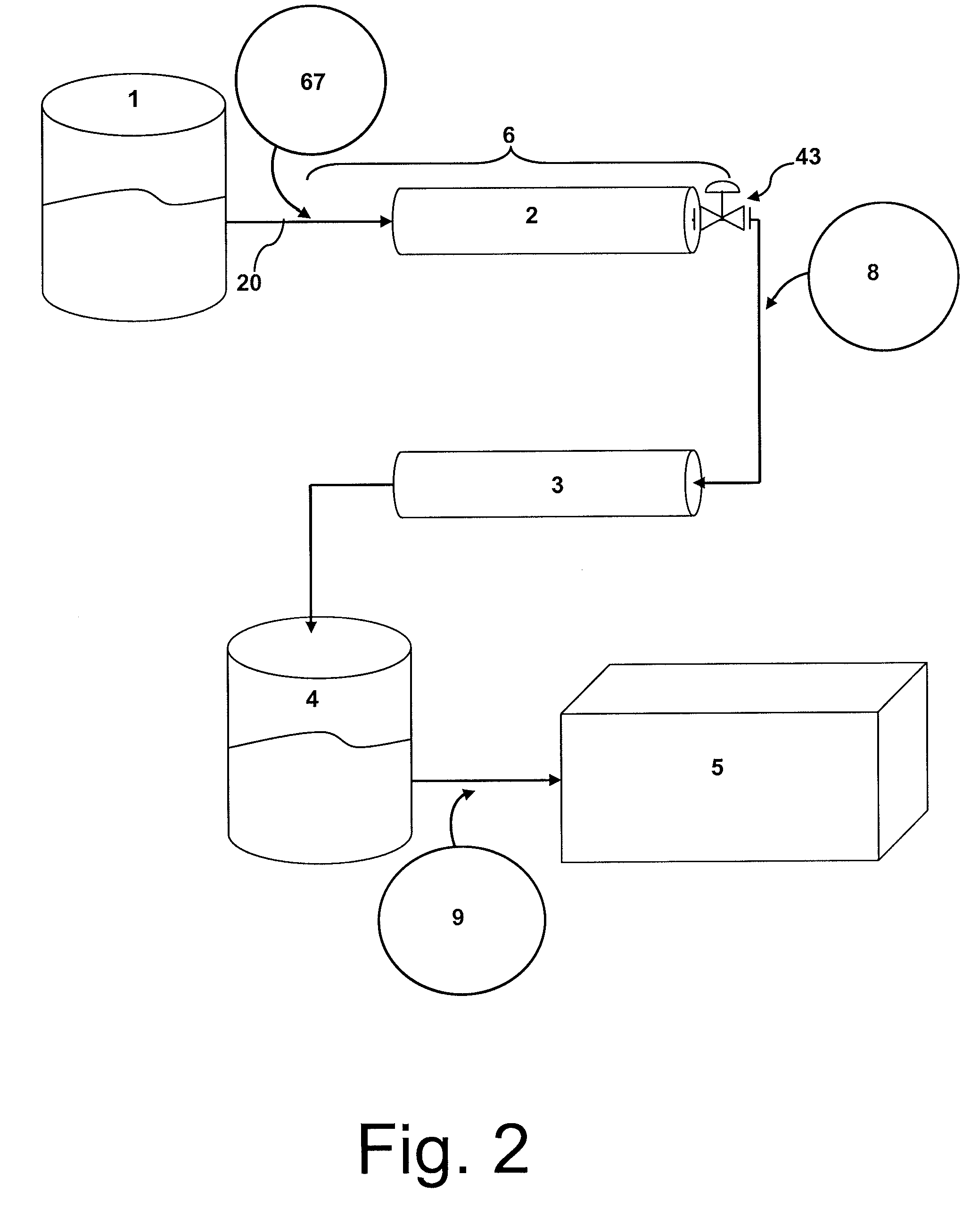

Total delivery oxygen concentration system

InactiveUS6346139B1Quickly and easily be dockedRespiratorsCombination devicesDelivery oxygenChemistry

A total delivery oxygen concentration system is provided to supply concentrated oxygen to end users having a variety of oxygen capacity requirements. The system includes a first oxygen concentrating device that may be operated either singularly to produce a first flow of concentrated oxygen or in conjunction with a supplemental oxygen concentrating device. When operating in conjunction with the supplemental oxygen concentrating device, the first oxygen concentrating device serves as a source of compressed air for the supplemental oxygen concentrating device and receives a second flow of concentrated oxygen from the supplemental oxygen concentrating device to provide a combined concentrated oxygen flow to the end user.

Owner:RIC INVESTMENTS LLC

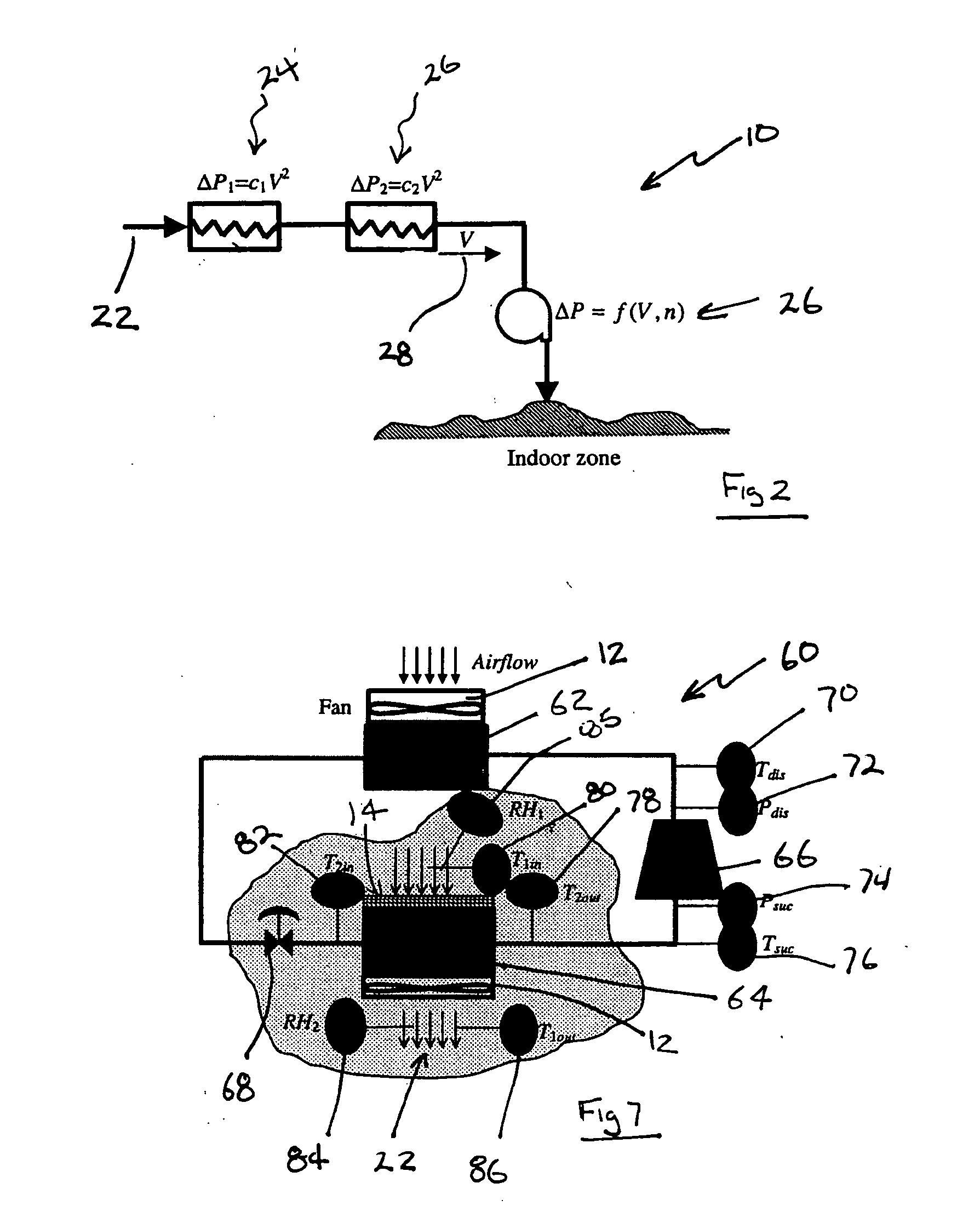

Air filter monitoring system

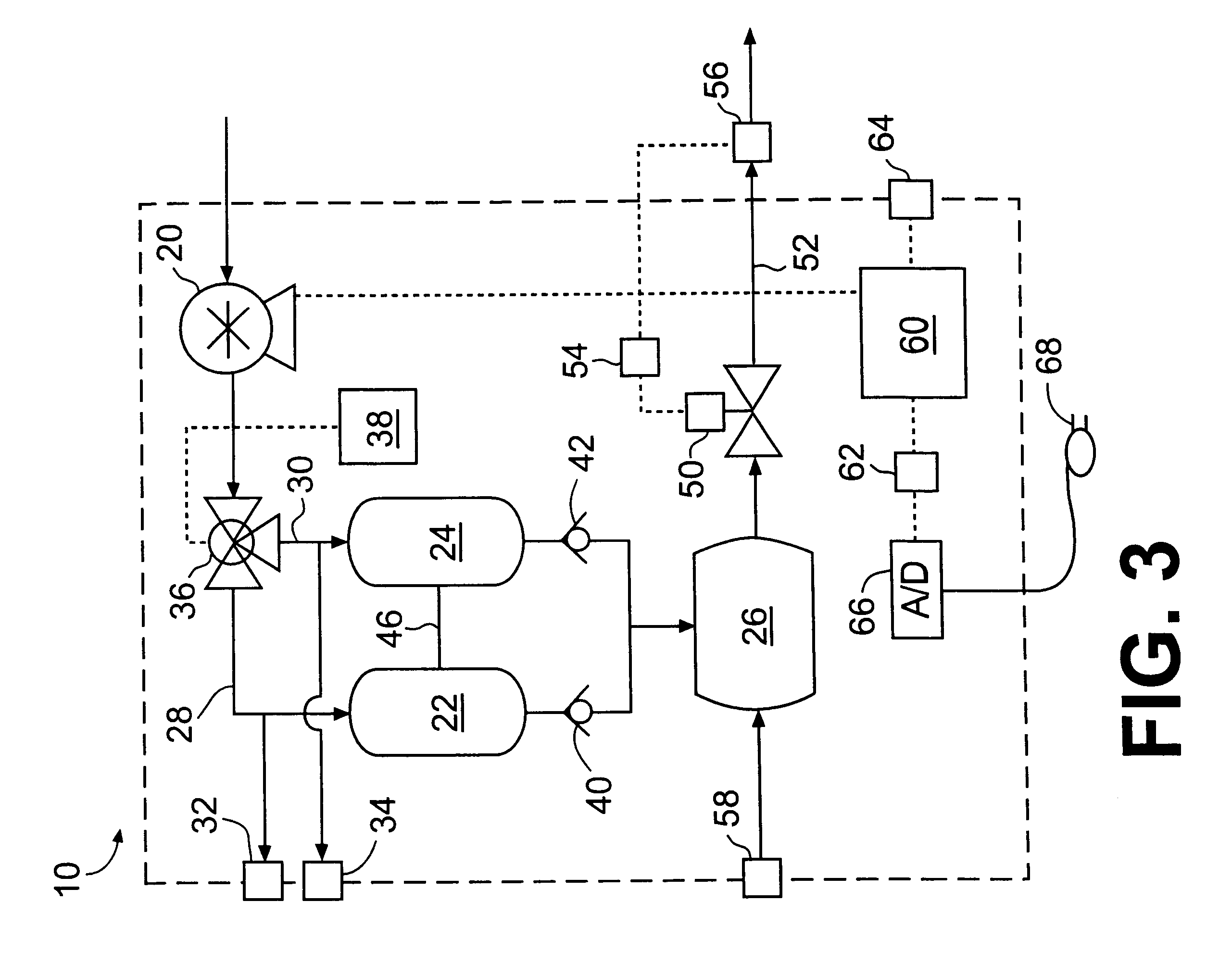

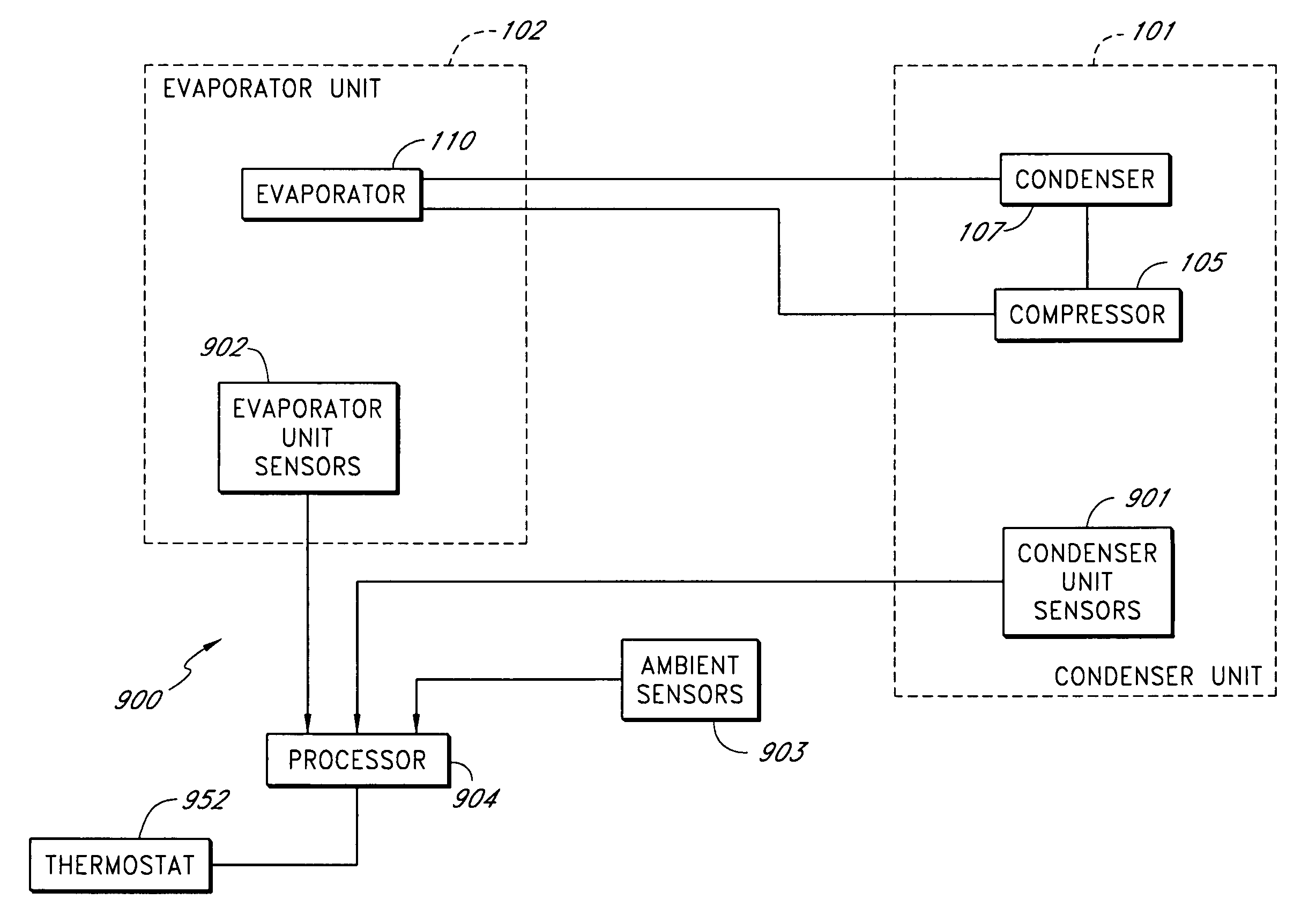

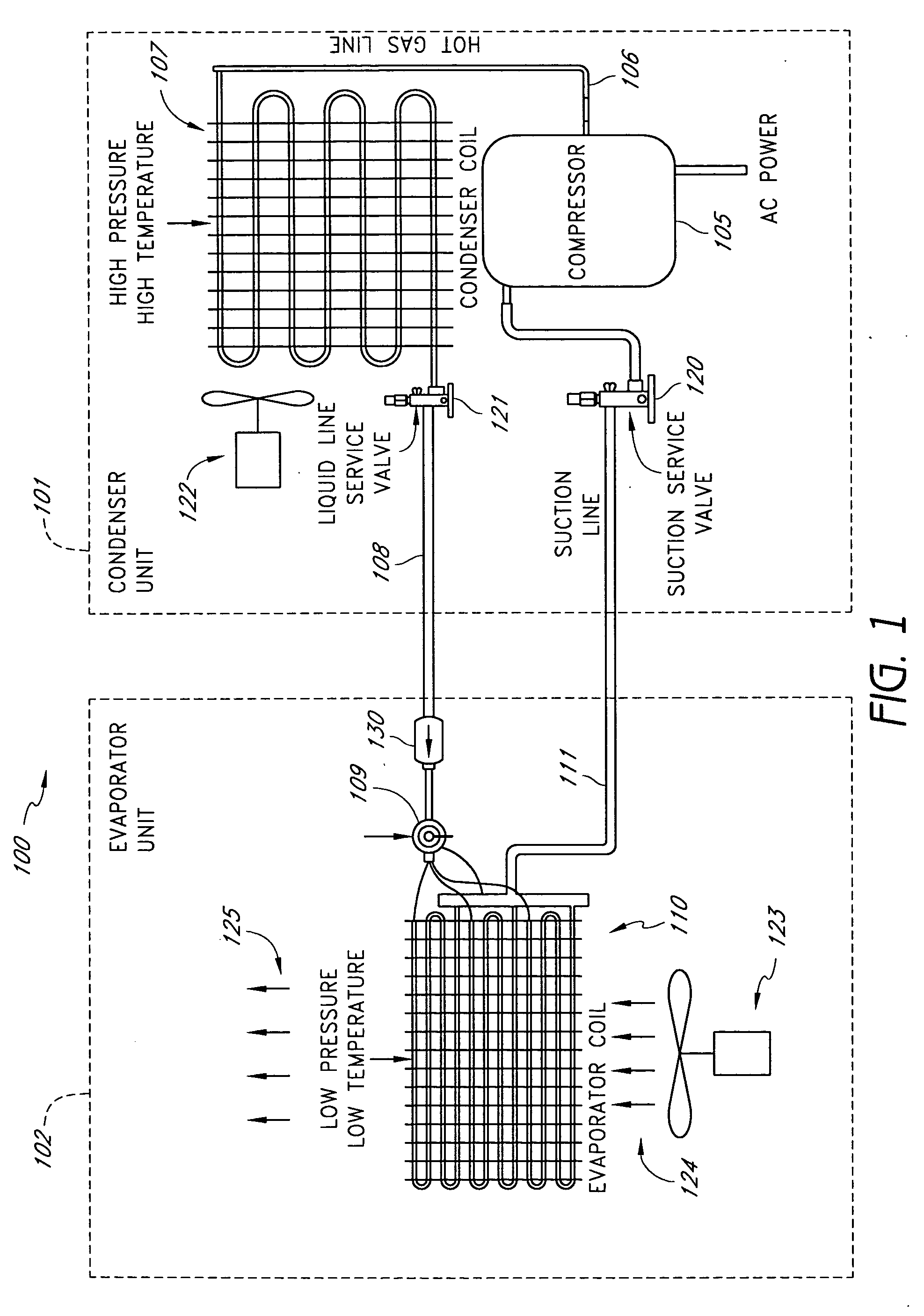

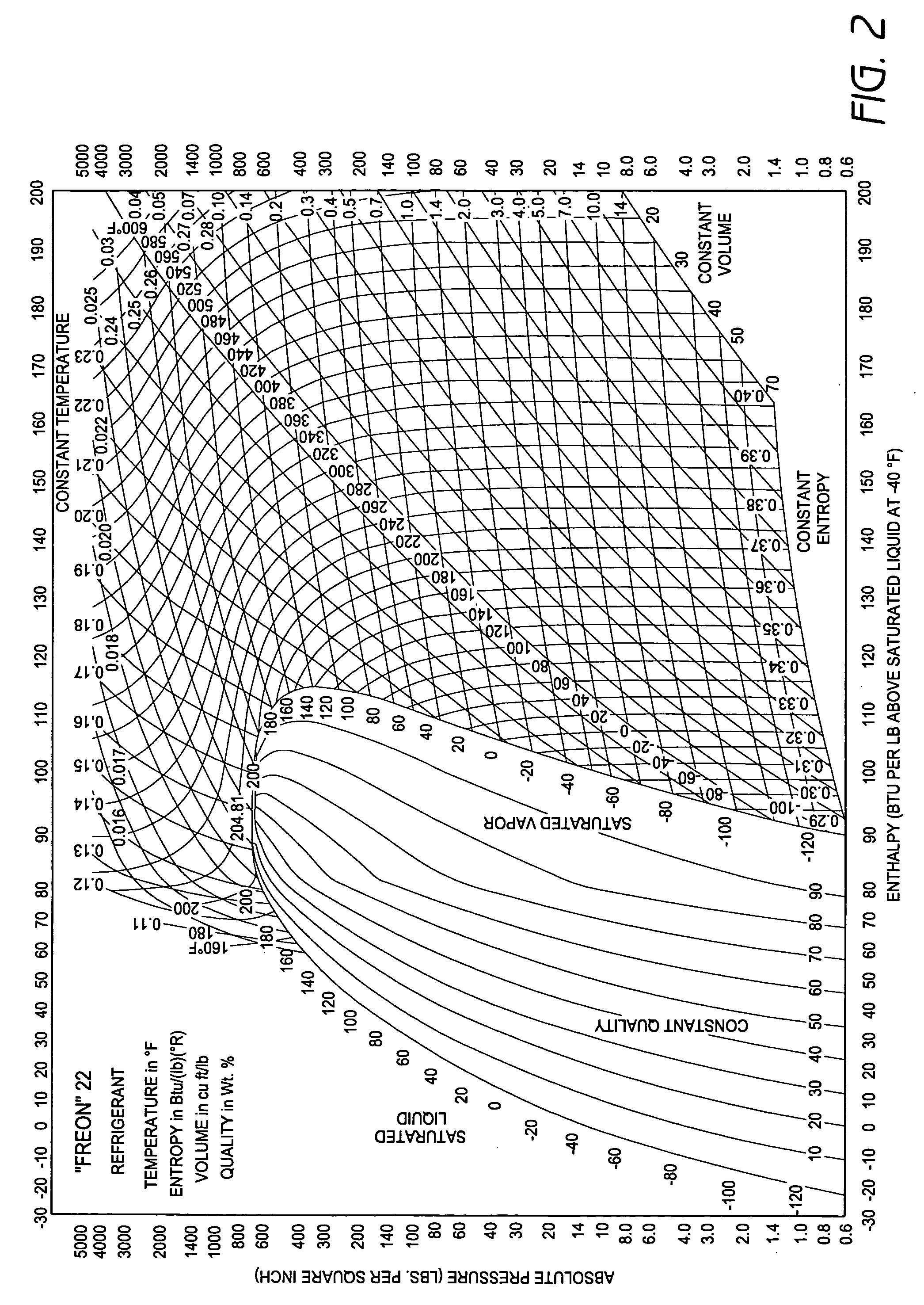

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:EMERSON CLIMATE TECH INC

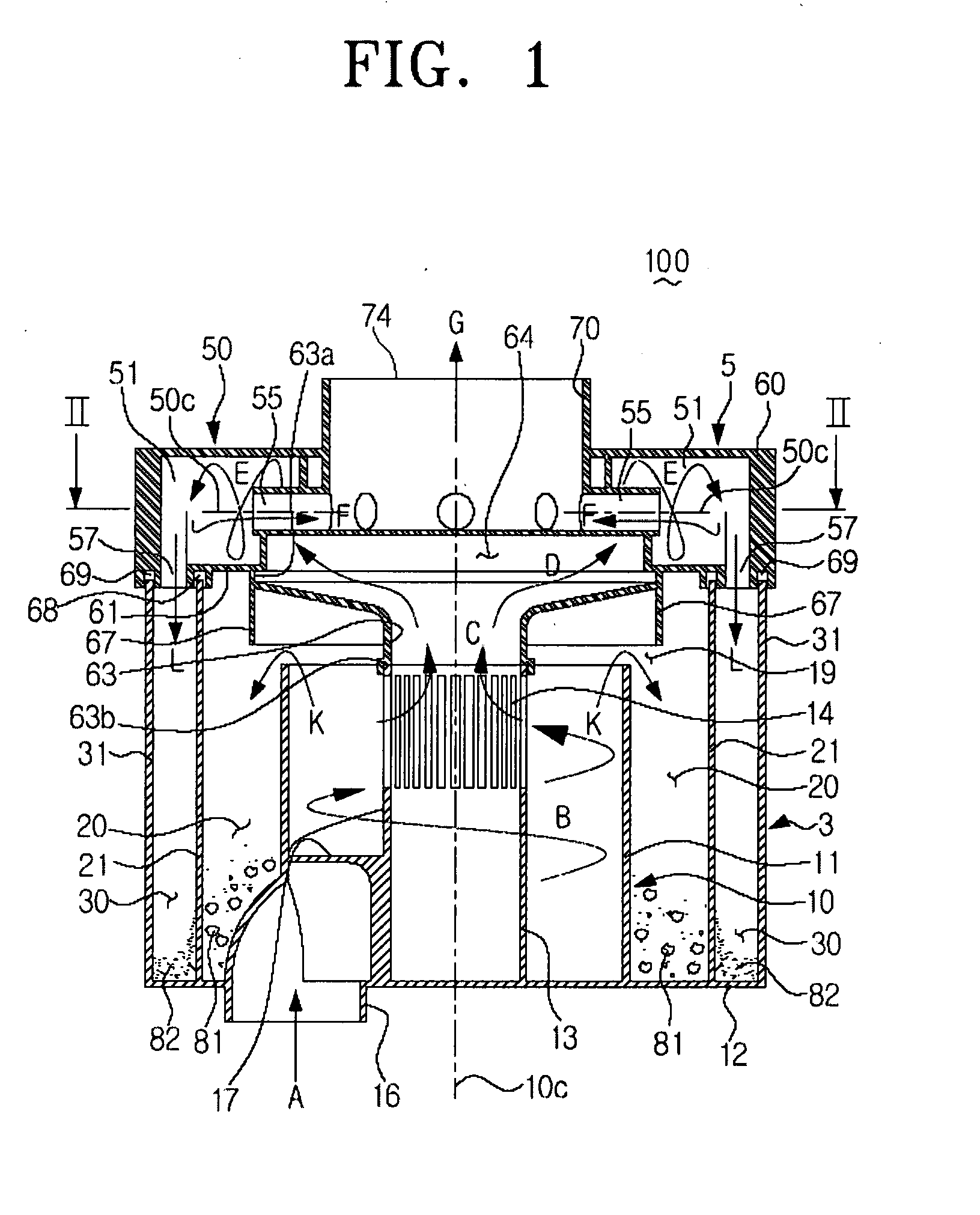

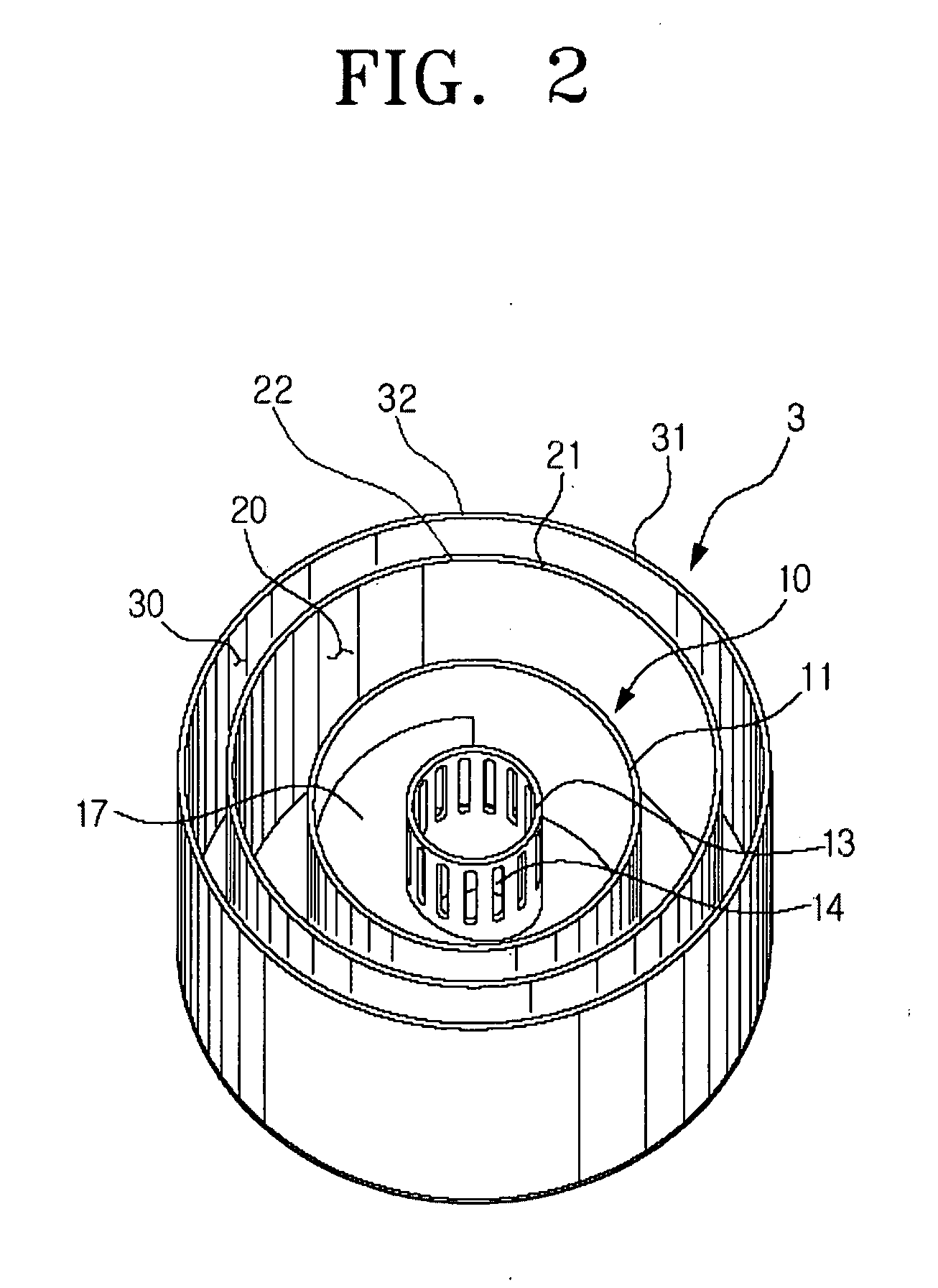

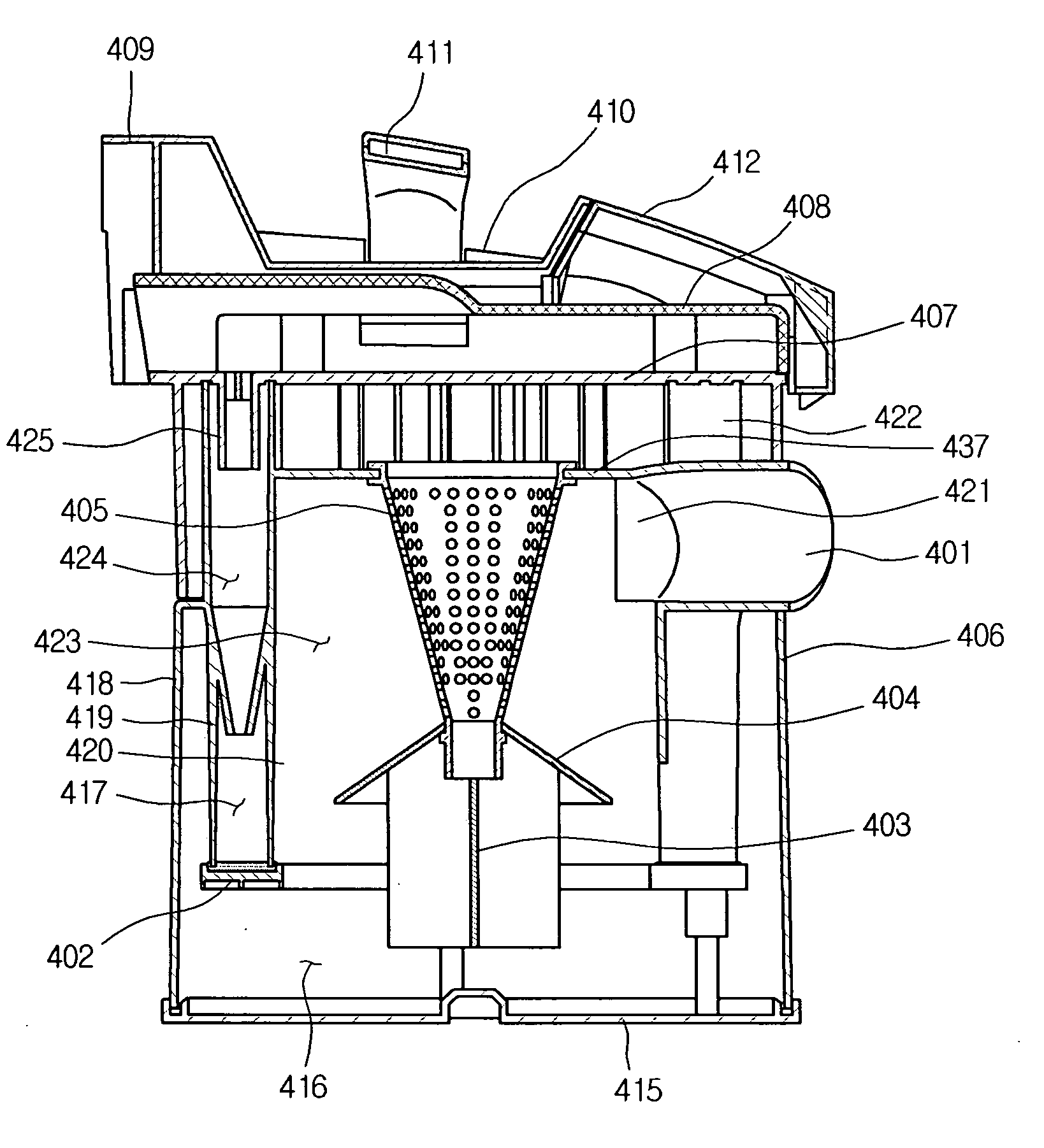

Multi dust-collecting apparatus

InactiveUS7547338B2Improve efficiencyConstant forceCombination devicesAuxillary pretreatmentCycloneEngineering

A multi dust-collecting apparatus for a vacuum cleaner is provided. The apparatus includes a dust-collecting unit having an air guide member to separate dirt particles from drawn-in air by using a gravity and an inertia and a filter member to remove dirt particles from the discharged air. The apparatus also includes a plurality of cyclones to swirl the air discharged from the dust-collecting unit and separate minute dirt particles from the air by using a centrifugal force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

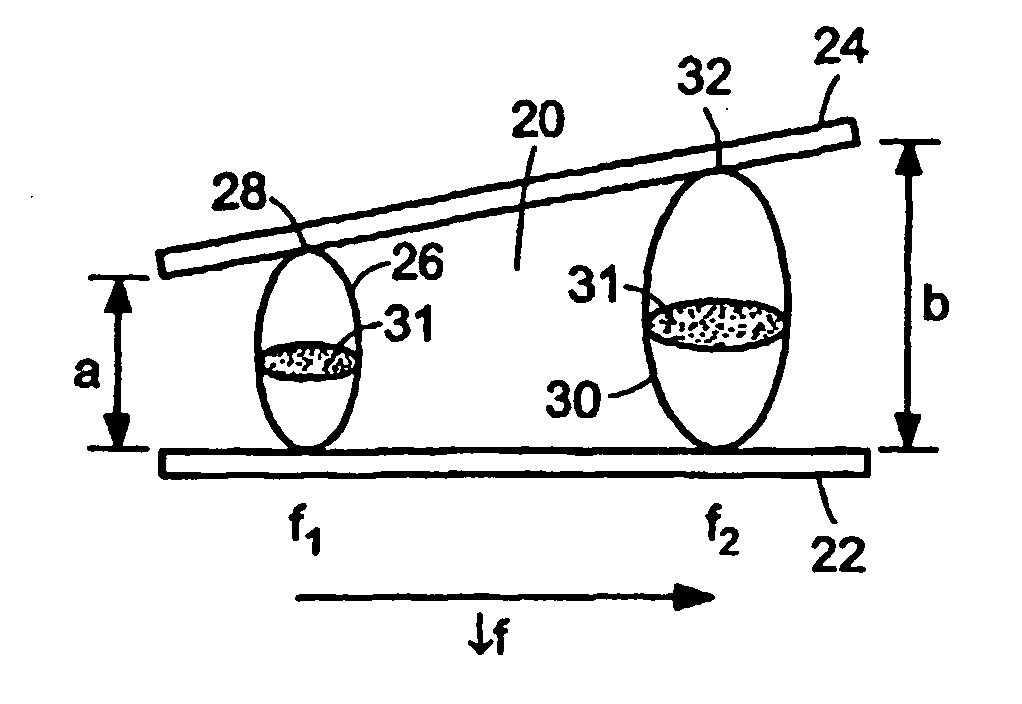

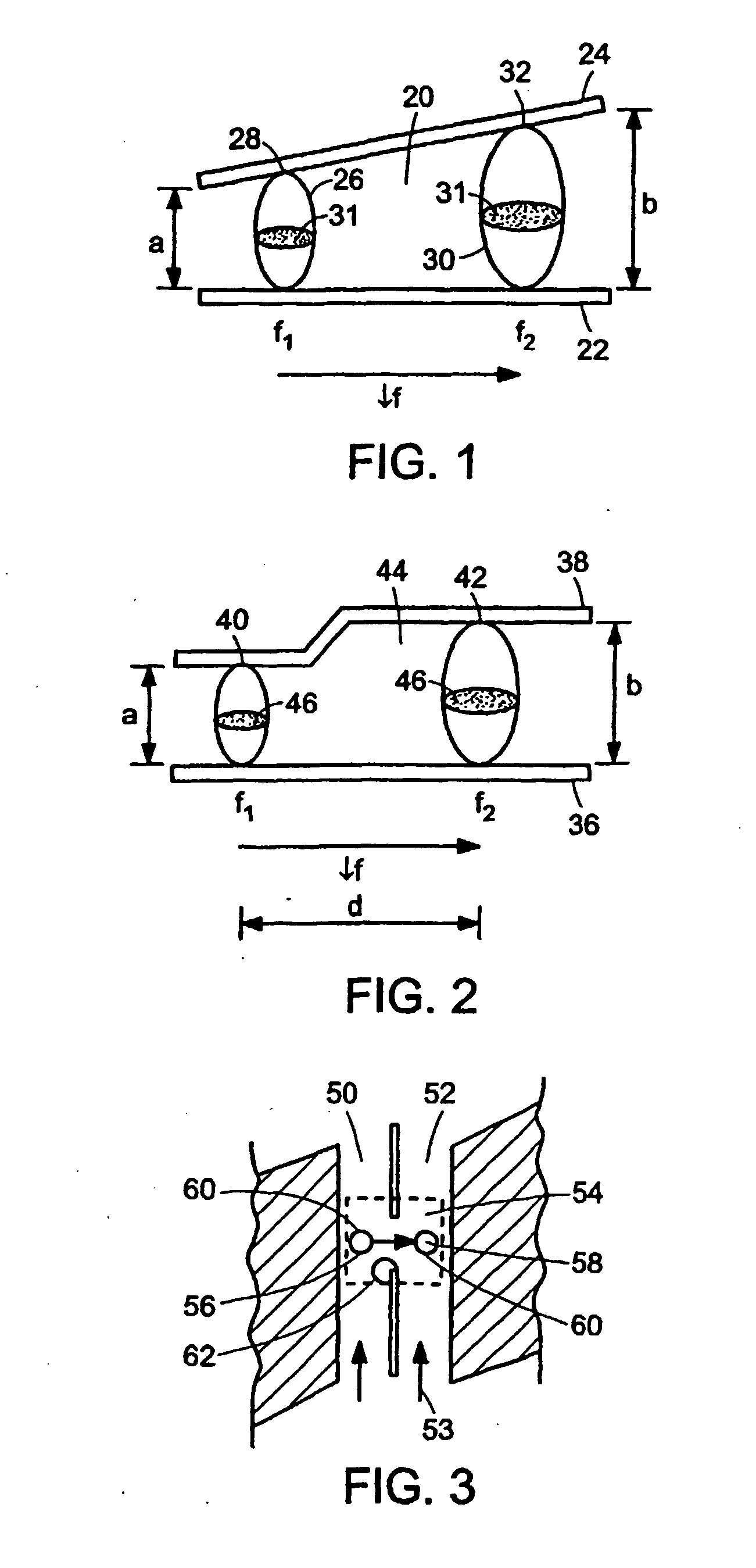

Method and device for ultrasonically manipulating particles within a fluid

InactiveUS20060037915A1Easy to operateAuxillary pretreatmentShaking/oscillating/vibrating mixersSolid phase extractionBiological particles

Fluid-handling methods and devices for ultrasonic manipulation of fluid-borne particles comprise a fluid-handling manifold and an ultrasonic particle manipulator defining an ultrasonic cavity within the manifold. Fluid-borne particles introduced into the manifold are manipulated by controlling ultrasonic standing waves at the ultrasonic cavity. Cavities having non-uniform configurations, asymmetric standing waves and / or multiple ultrasonic cavities within the manifold are operative to control the movement of the fluid-borne particles, optionally including collecting and holding such particles, transferring particles through an intersection from one channel to another, etc. Solid phase extraction (SPE) particles, biological particles and other fluid-borne particles can be manipulated within the fluid-handling manifold.

Owner:PROTASIS CORP

Filter element, air cleaner, and methods

InactiveUS6547857B2High strengthCombination devicesAuxillary pretreatmentClassical mechanicsFilter media

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

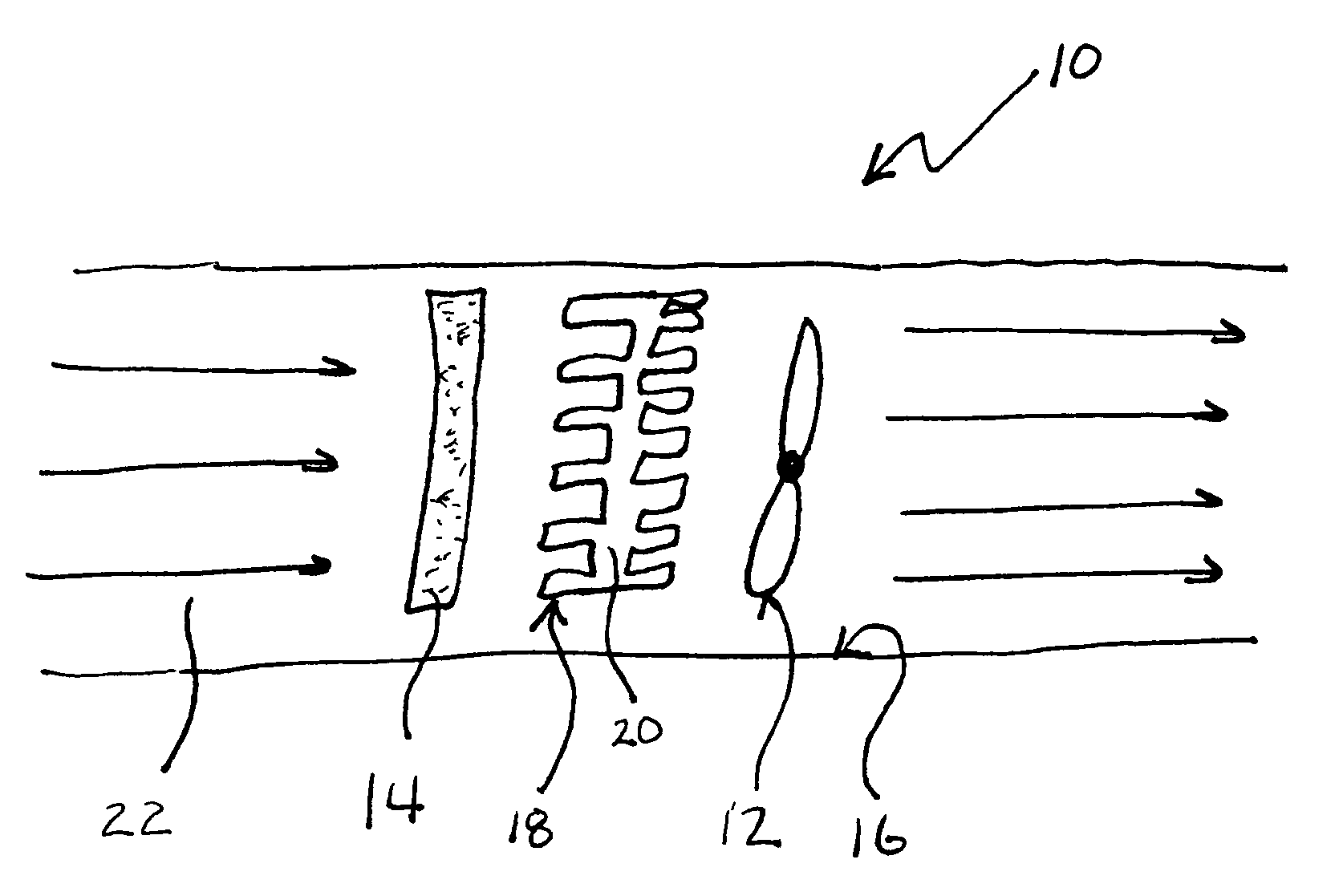

Air actinism chamber apparatus and method

An apparatus and method for ultraviolet irradiation of air for the purpose of removing contaminants from that air is disclosed. A U-shaped ultraviolet bulb enshrouded within a quartz tube provides enhanced contaminant destruction characteristics. By combining a plurality of those bulbs in a chamber that is of polished aluminum, and further combining aluminum filters therewith, added irradiation enhancement is achieved. Further provided are baffles or baffling proximate the ultraviolet bulbs that cause the air to go turbulent thus drawing the air closer to the ultraviolet bulb and further enhancing the contaminant destruction characteristics. Moreover disclosed is treatment of substrates with a chemical agent that facilitates the arrest of contaminants from the air onto the substrate for further irradiation of the contaminants from the bulbs. This further irradiation breaks down the arrested contaminants thus providing the substrate with a self-cleansing effect.

Owner:PHASYC

Cyclonic separating apparatus for vacuum cleaner which is capable of separately collecting water from dust

InactiveUS20060162298A1Easy to separatePreventing dispersion and subsequent backflowCombination devicesAuxillary pretreatmentInterior spaceCyclonic separation

A cyclonic separating apparatus for a vacuum cleaner that can separately collect dust and water. The cyclonic separating apparatus includes: a cyclone body having an air inlet passage and an air discharge passage; a dust receptacle connected to a lower end of the cyclone body; and a screen dividing the cyclone body and interior space of the dust receptacle into a first chamber and a second chamber, the screen having a plurality of passing holes, wherein drawn air rotates in the first chamber and water separated from the air moves to the second chamber through the passing holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

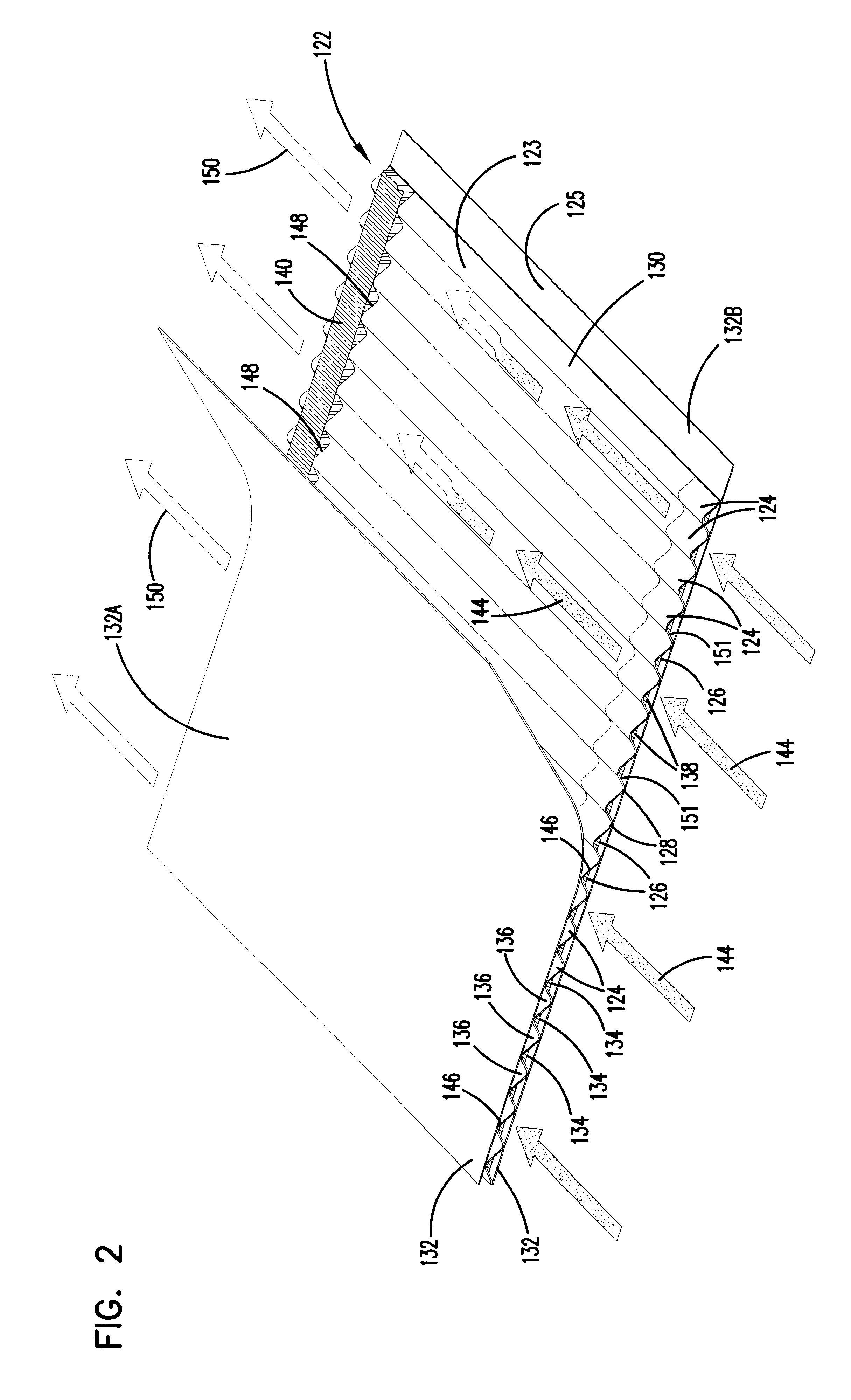

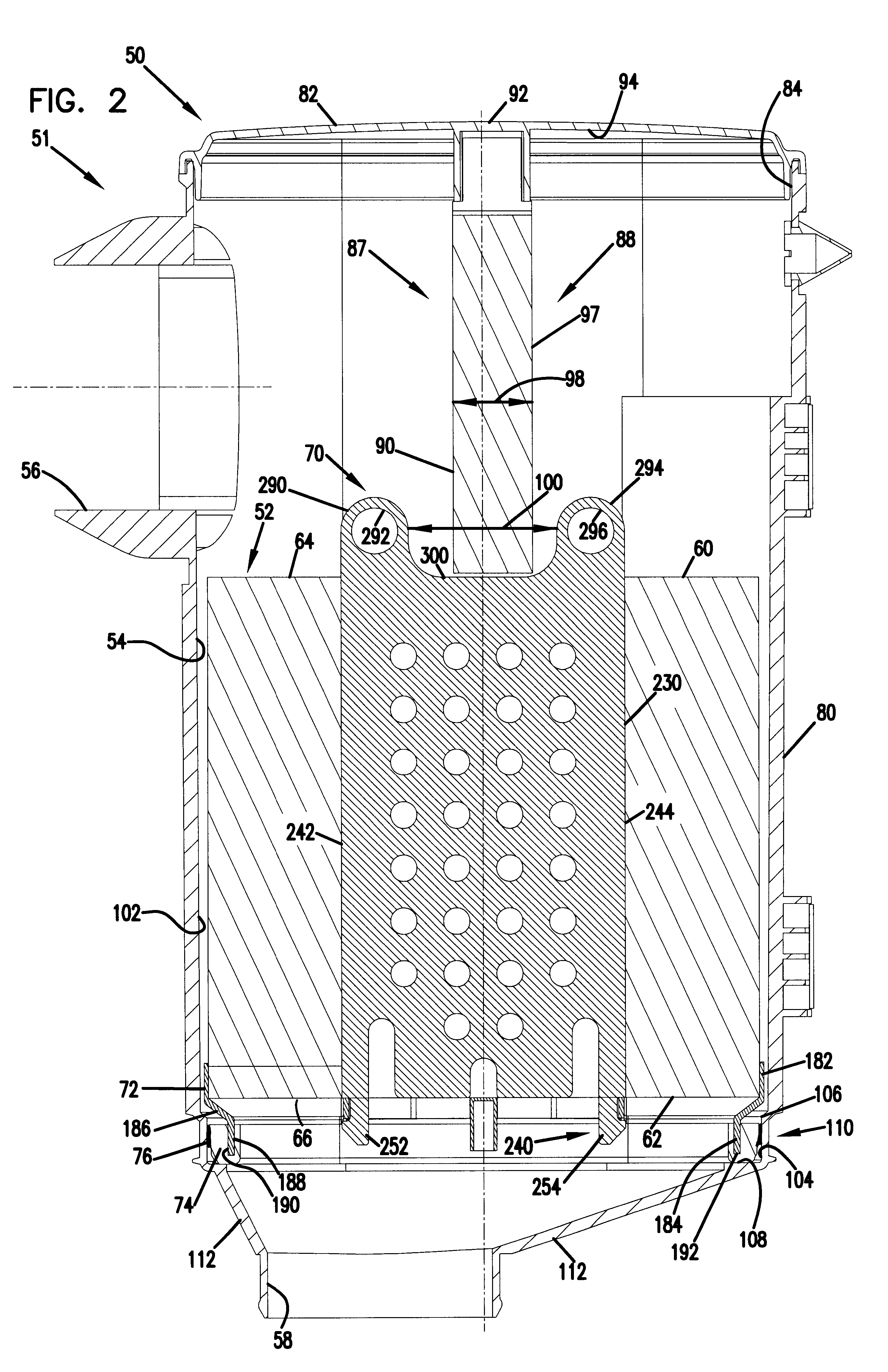

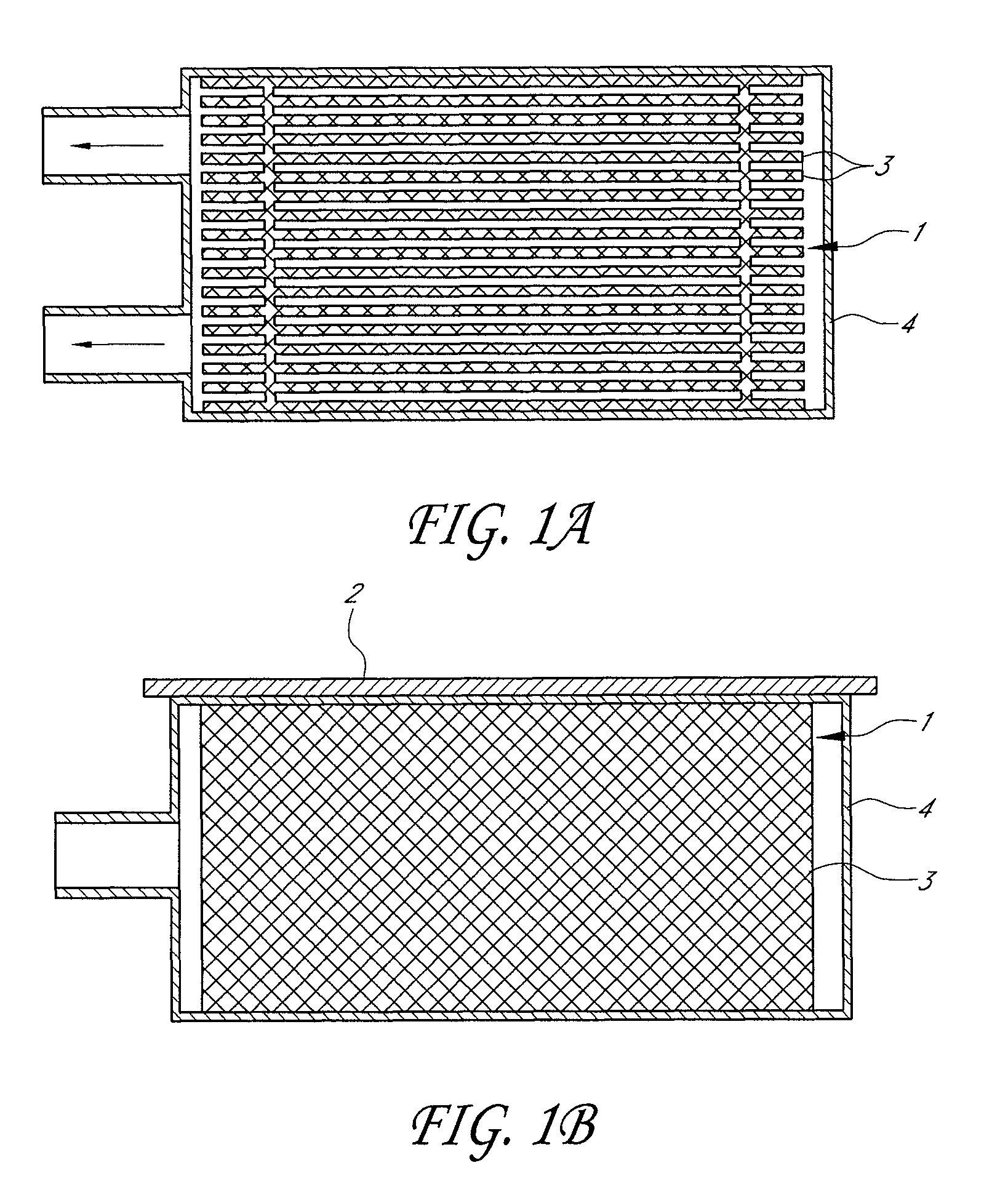

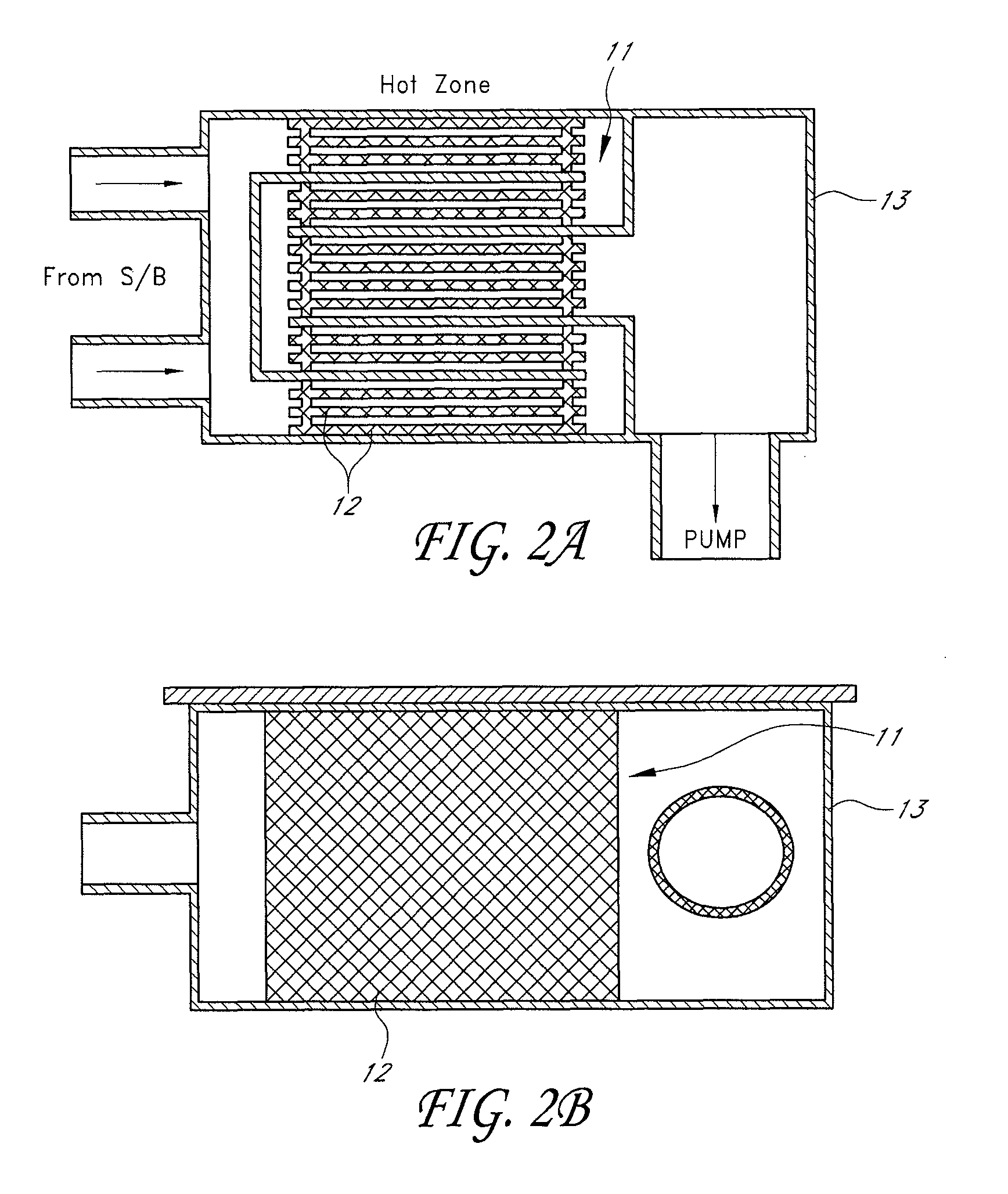

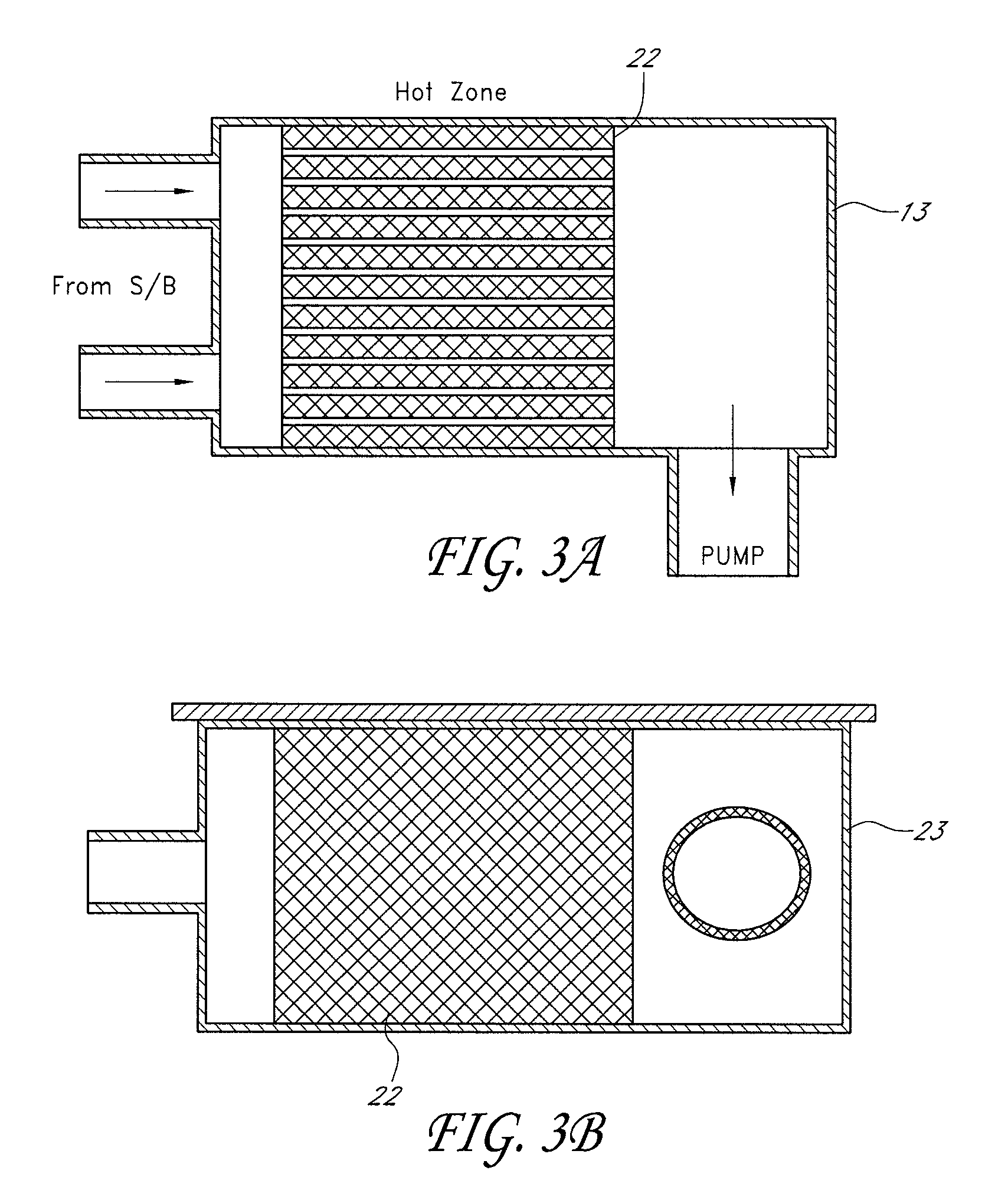

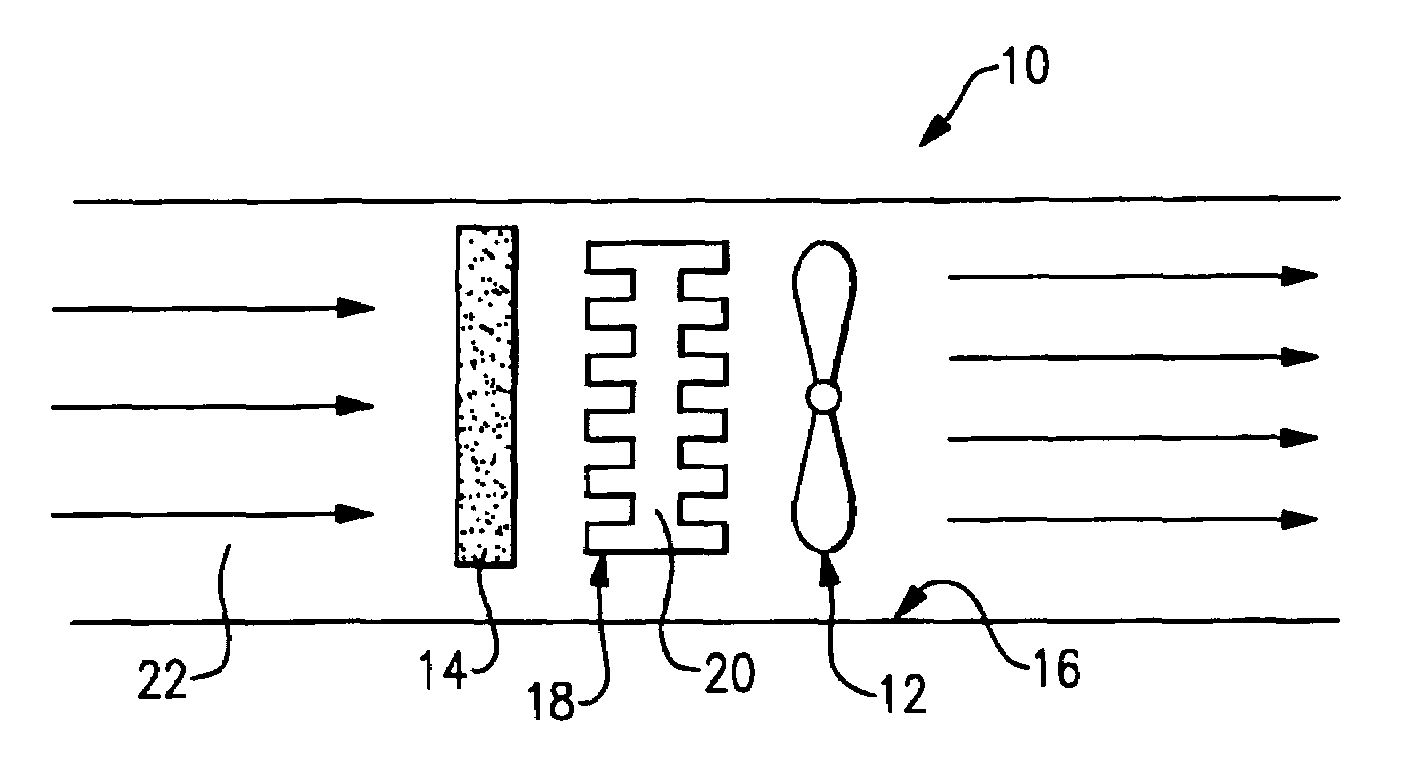

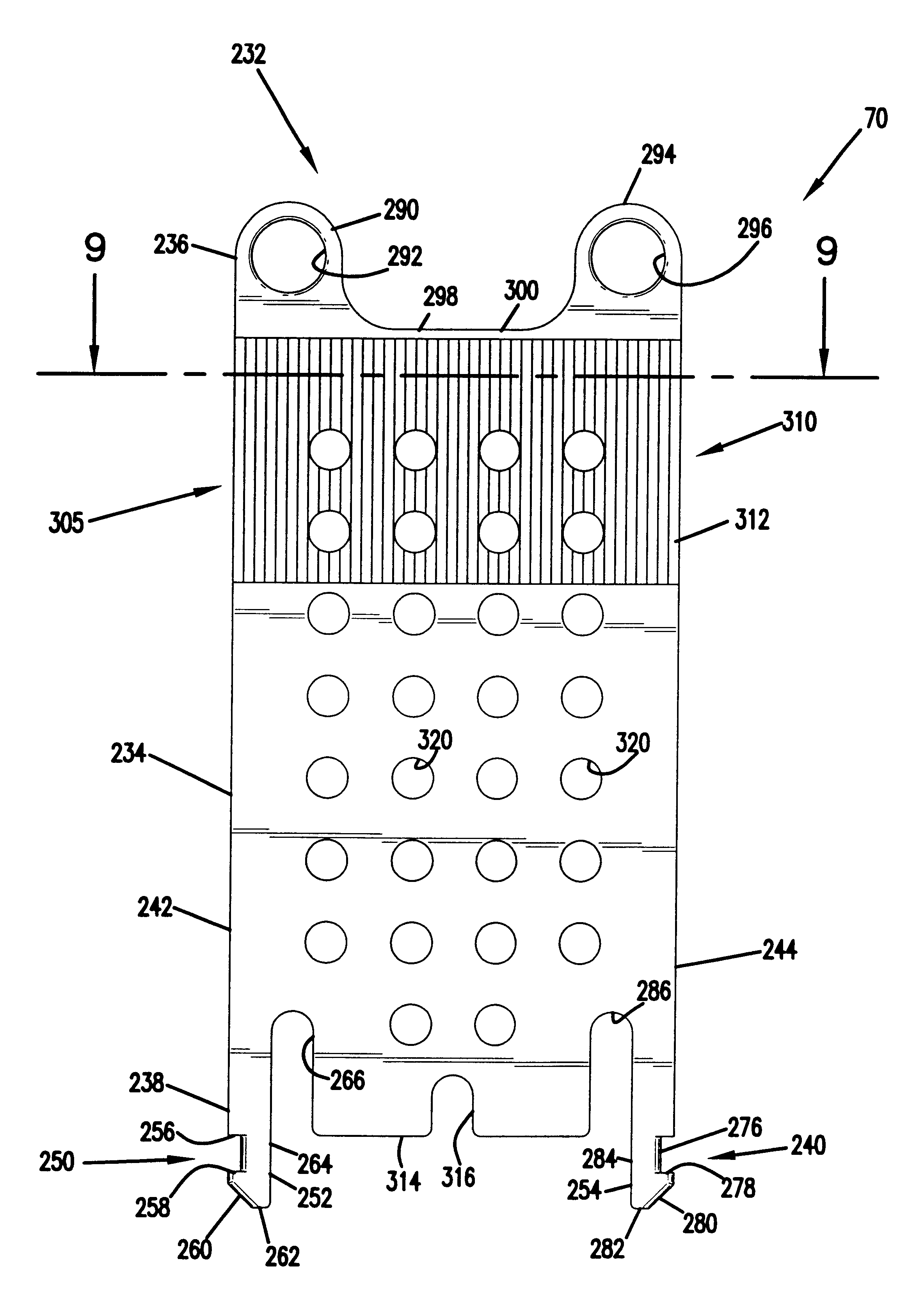

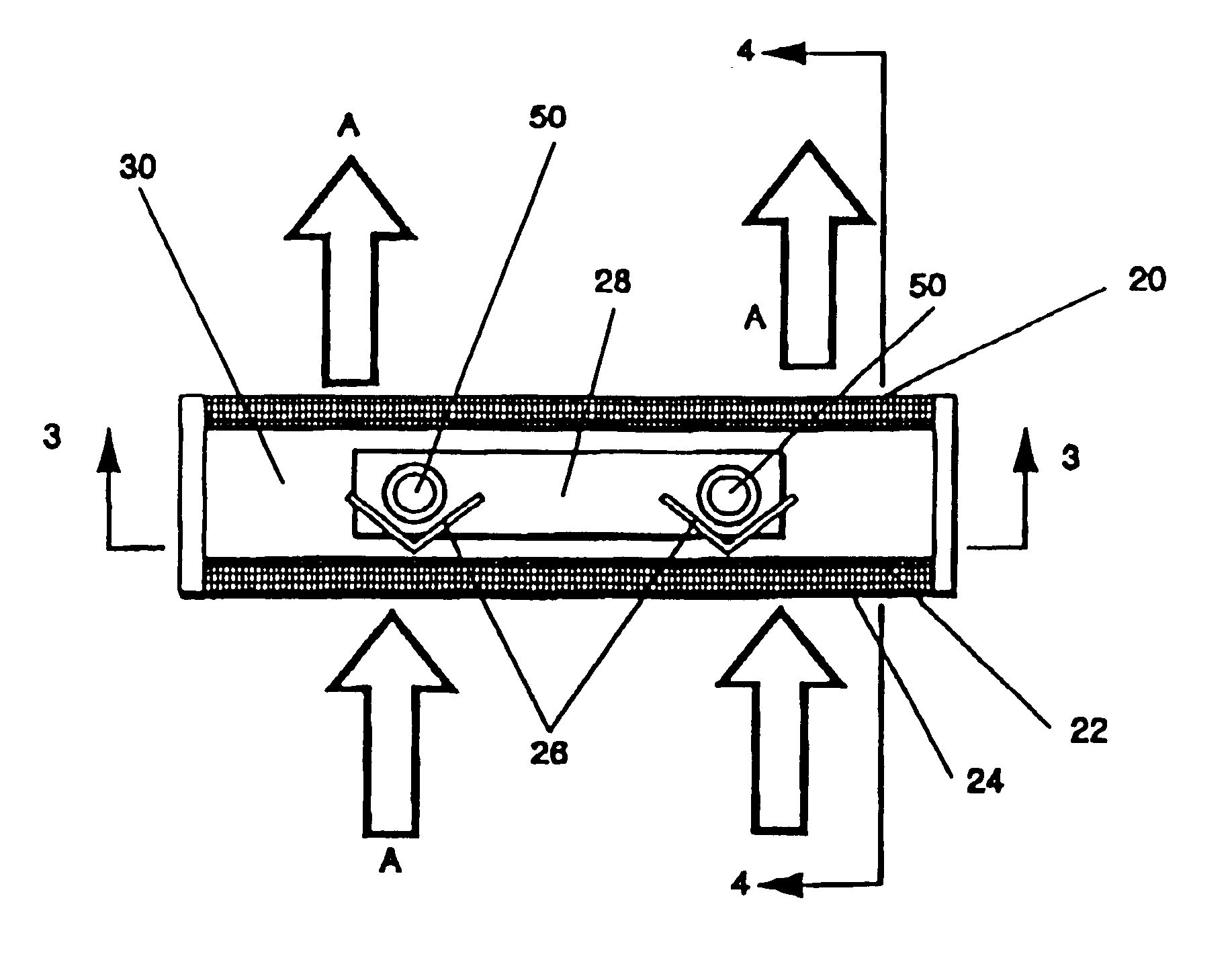

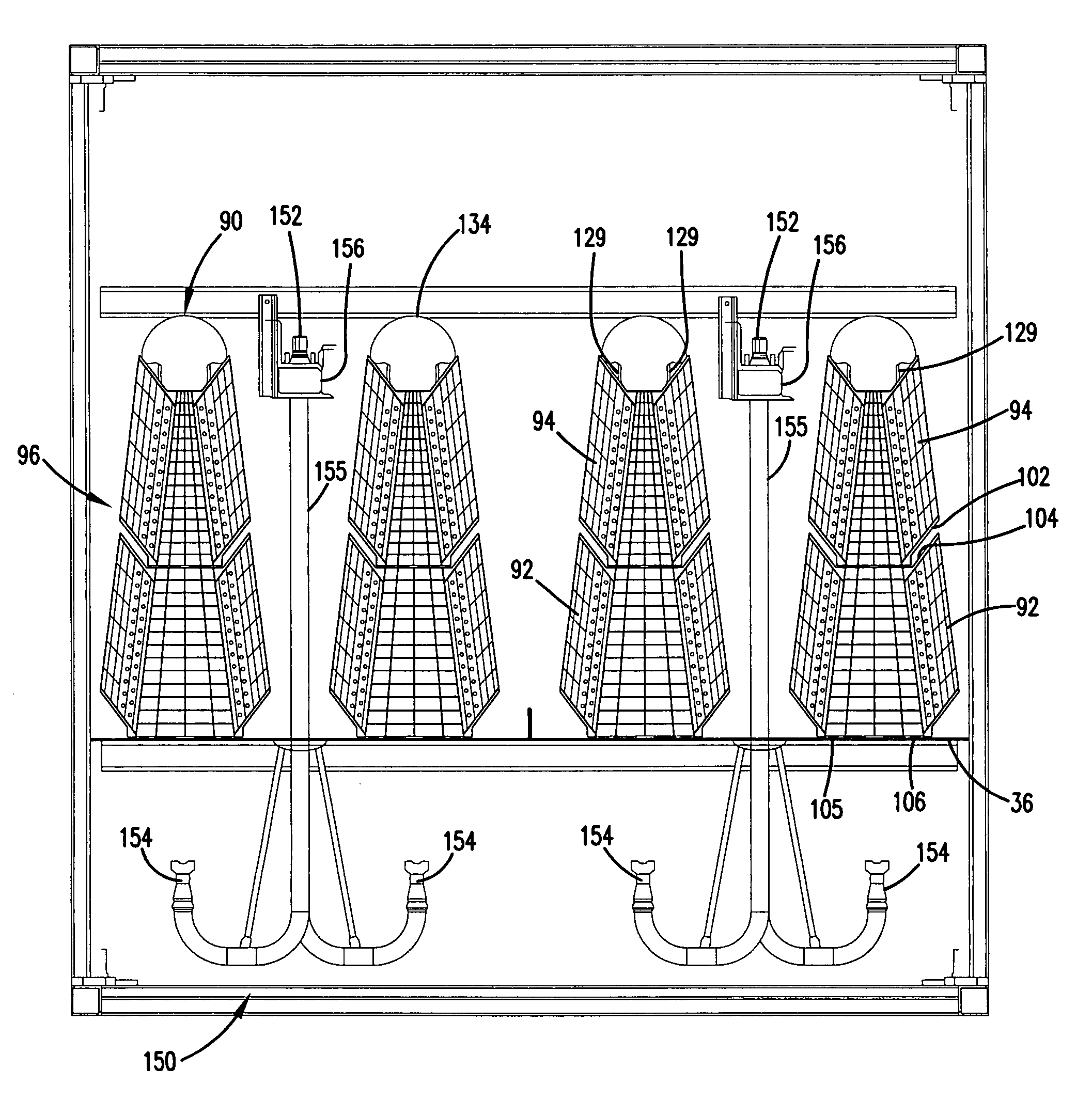

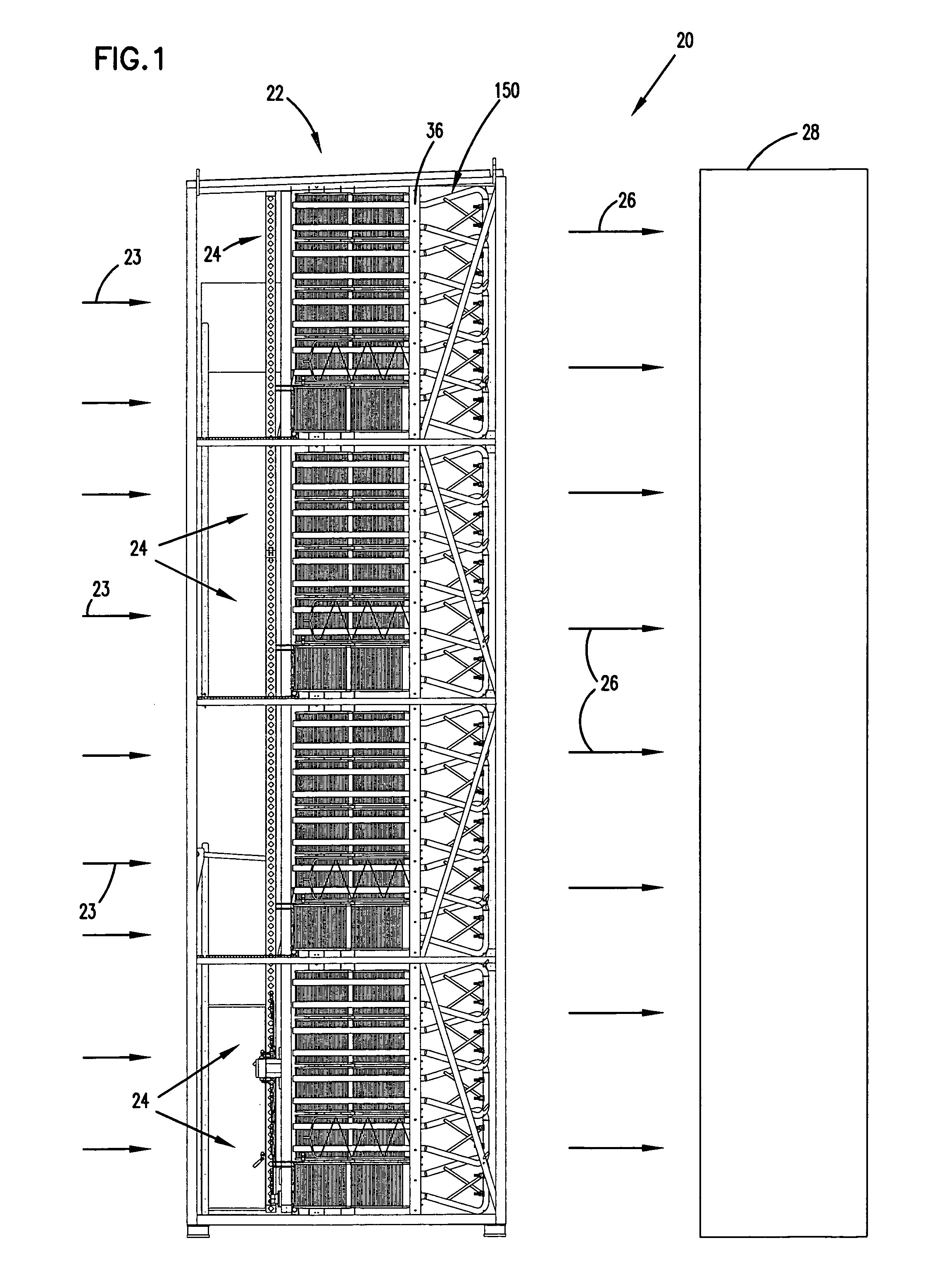

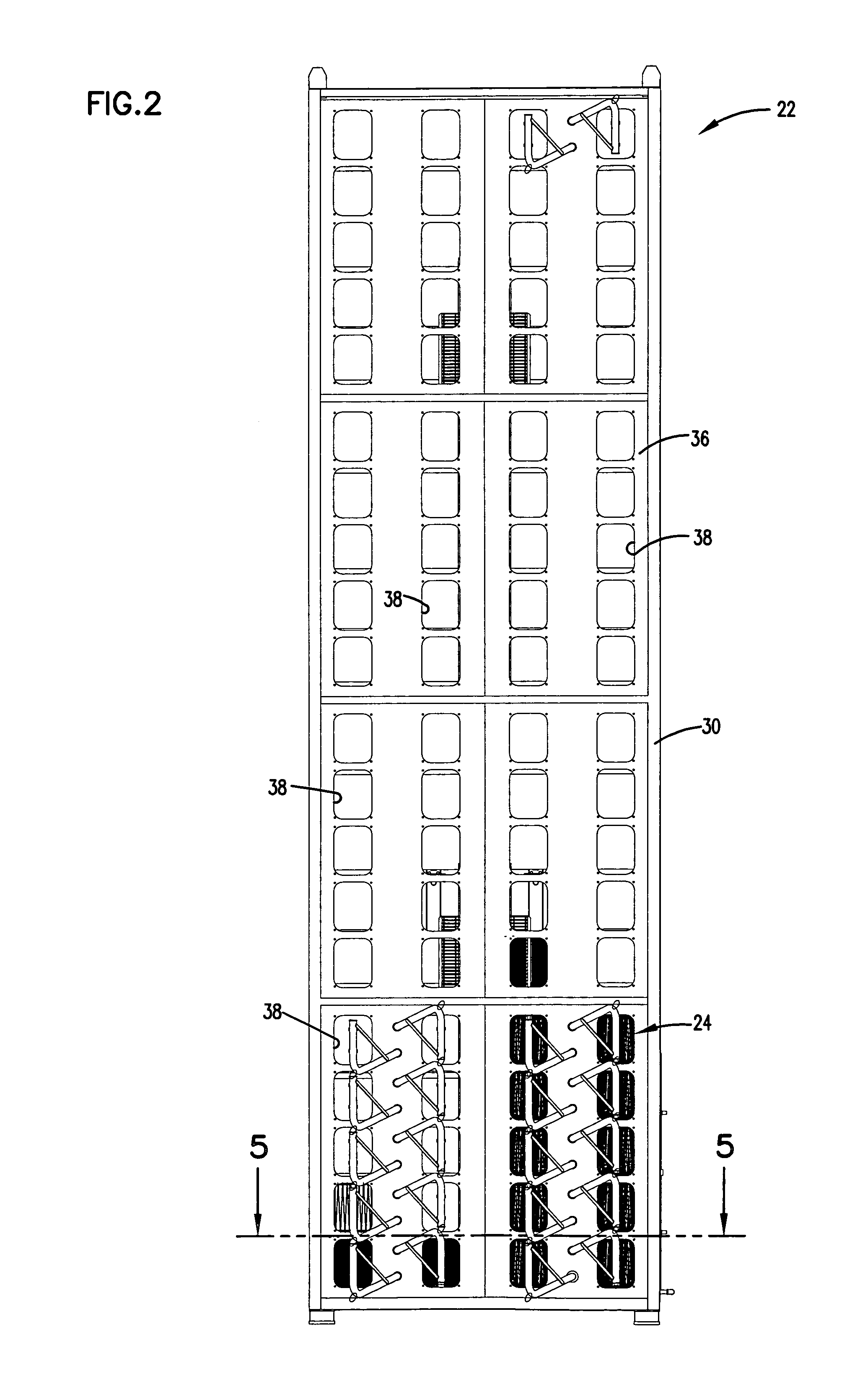

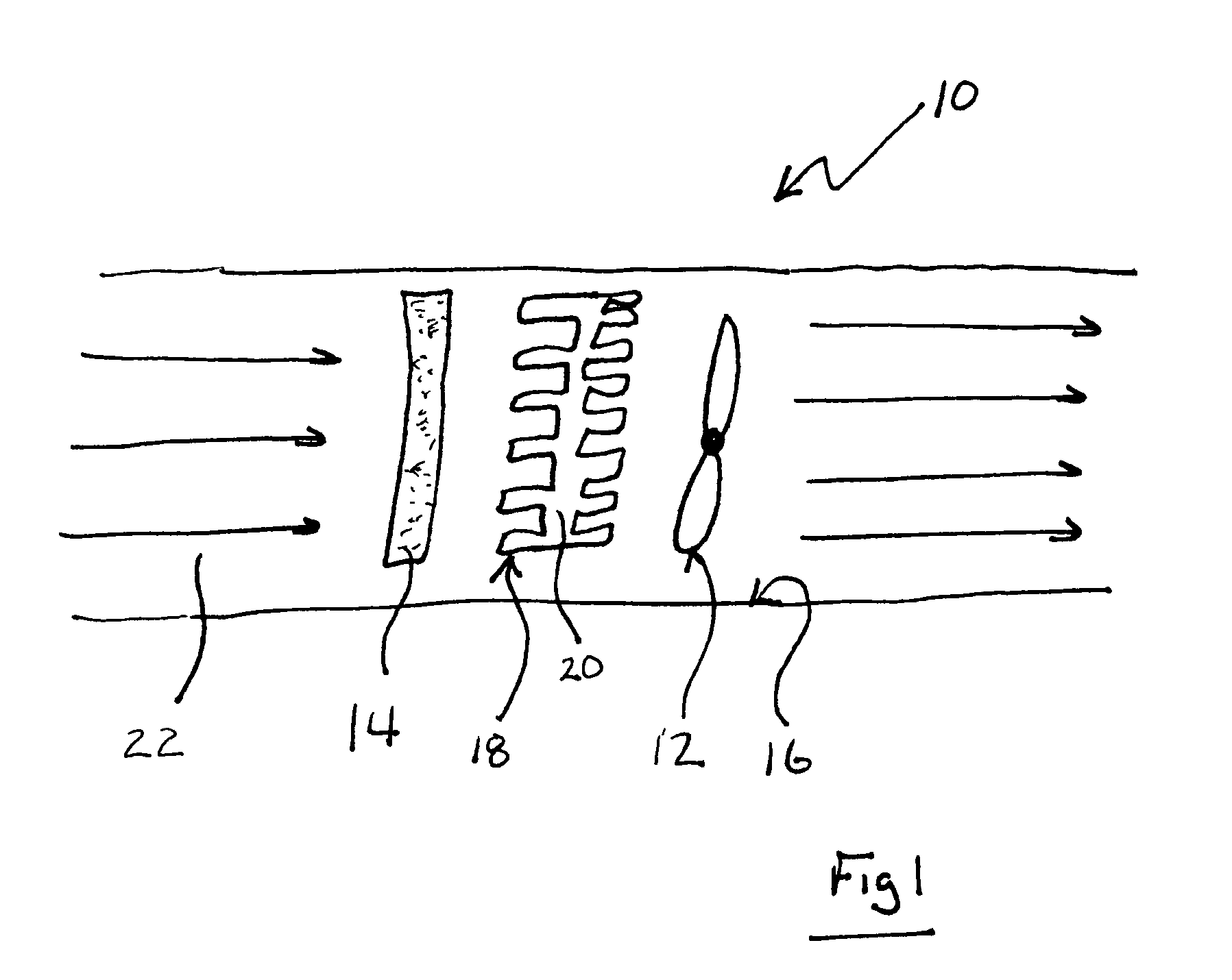

Z-filter media with reverse-flow cleaning systems and methods

A method for cleaning a filter having Z-media includes providing a filter having Z-media and cleaning the media construction by directing a pulse of compressed gas into the media construction through the downstream flow face. Filter elements useable with such methods include elements made of Z-media. An example system utilizing the method includes a gas turbine air intake system.

Owner:DONALDSON CO INC

Compact cyclonic separation device

ActiveUS20060042206A1Easy to disassemblePrevent re-entrainmentCleaning filter meansCombination devicesCyclonic separationVacuum cleaner

A cyclonic separation device for a vacuum cleaner including a cylindrical housing, an inlet tube parallel to the axis of the housing having a vortex vane disposed axially in the inlet tube. Air rotates in one direction in the inlet tube, and preferably in the opposite direction in the housing. The housing includes a cylindrical sidewall with an upper central outlet tube and a closed bottom for collecting separated dirt. A disrupter ring located on the inside wall of the middle portion of the housing includes a curved surface and sharp edge for lifting air flow off the housing wall. An outlet tube disc spaced from the inlet of the outlet tube is located in the housing below the disrupter ring.

Owner:SHARKNINJA OPERATING LLC

Dirt separation and collection assembly for vacuum cleaner

A dirt separation and collection assembly suitable for use in a bagless vacuum cleaner including two dirt separation and collection zones is provided. Dirty air enters the upper portion of a container and enters a first stage dirt separation zone including a disruptor ring extending inwardly from the outer wall to allow coarse dirt particles and fibers to pass through and collect at the base of the outer wall of the device. The spinning air is then drawn through a conical shroud and fed into a second stage conical separator for separating fine dirt particles and collecting them in an inner substantially cylindrical collection chamber. Air exits the conical separator at the opposite cone opening before being drawn to the suction source. Elements may be oriented upwardly or downwardly depending upon the configuration of the housing for receiving the dirt separation and collection assembly.

Owner:SHARKNINJA OPERATING LLC

Cyclone dust- collecting apparatus for vacuum cleaner

A cyclone dust-collecting apparatus of a vacuum cleaner includes a cyclone body installed at an extension hose for generating air current of vortex from incoming air, a grill for filtering back drafting current of the air current of vortex, and a cyclone cover including a partly blocked plate, which is placed to correspond to the grill, a filth passage for guiding filth to a filth-collecting container, and a first connection member for connecting the cyclone body with the filth-collecting container. The filth-collecting container has second connection member for connecting with the cyclone cover. Accordingly, it can be prevented a grill from being blocked by back drafting of piled filth in the filth-collecting container regardless of the position of a user. When the user eliminates collected filth, breakage of a grill or falling down of the filth clung to the grill, can also be prevented.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Technique for detecting and predicting air filter condition

InactiveUS20050247194A1Life predictionCombination devicesAuxillary pretreatmentOperational systemAir filter

Owner:CARRIER CORP

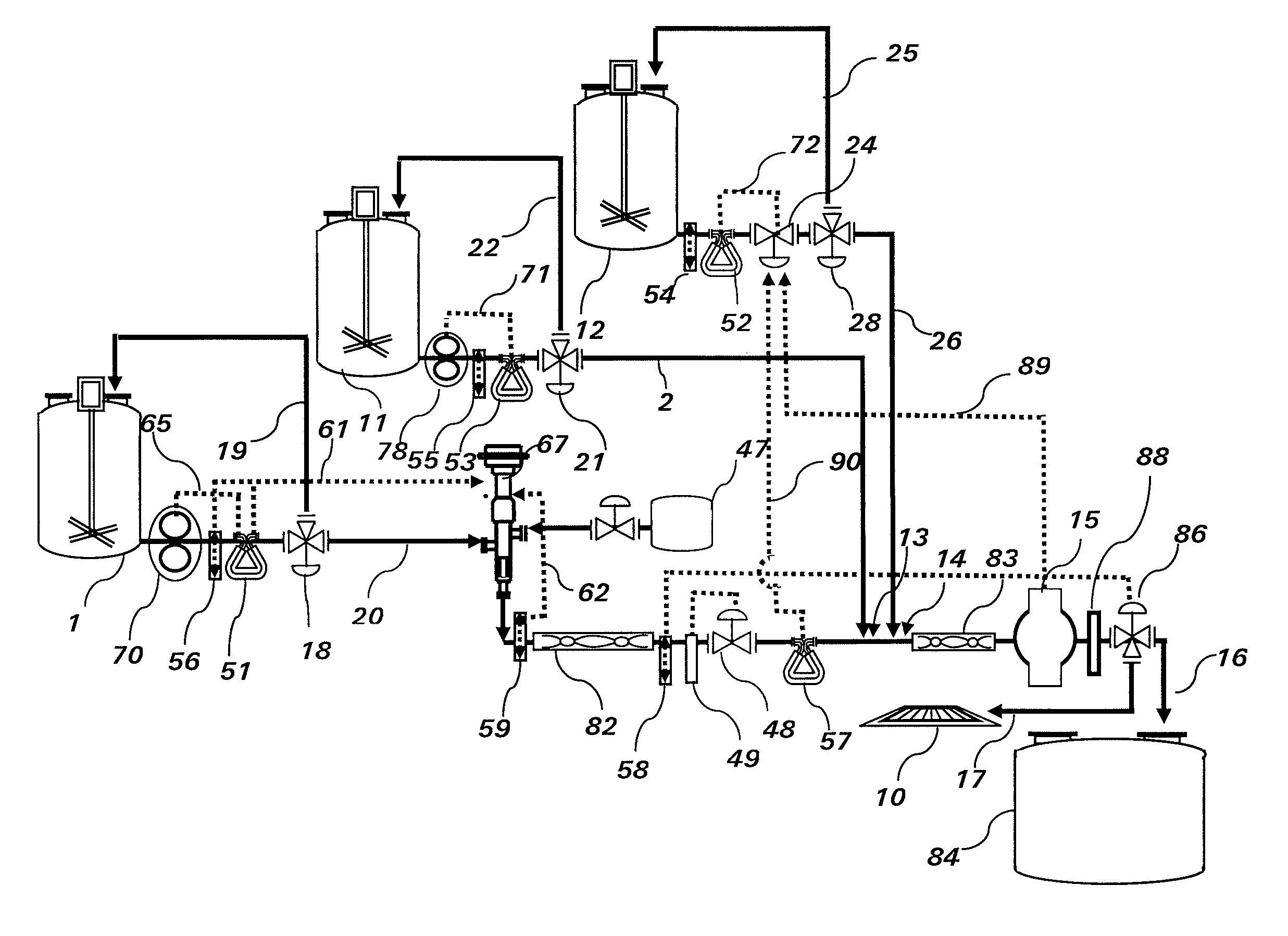

Sterilization of Flowable Food Products

InactiveUS20080160149A1Prevent degradationExtend heating timeCombination devicesAuxillary pretreatmentSporeAlicyclobacillus acidoterrestris

Methods of beverage and flowable food product production using steam injection are provided to efficiently destroy microorganisms able to withstand normal pasteurization temperatures. Microorganisms such as Alicyclobacillus acidoterrestris and its spores may be eliminated from fruit juices and the like while minimizing organoleptic degradation due to heating. The apparatus is capable of pasteurizing, blending and controlling the product specifications of a finished beverage in a continuous matter.

Owner:KRAFT FOODS GLOBAL BRANDS LLC

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS20060137314A1Prevent reentrainmentEfficient separationCleaning filter meansCombination devicesParticle separationPhysics

A particle separation member is provided for use with a cyclone separator. The particle separation member divides the separator into a cyclone chamber and a particle receiving chamber. The cyclone chamber and the particle receiving chamber communicating via a plurality of apertures in the particle separation member.

Owner:OMACHRON INTPROP

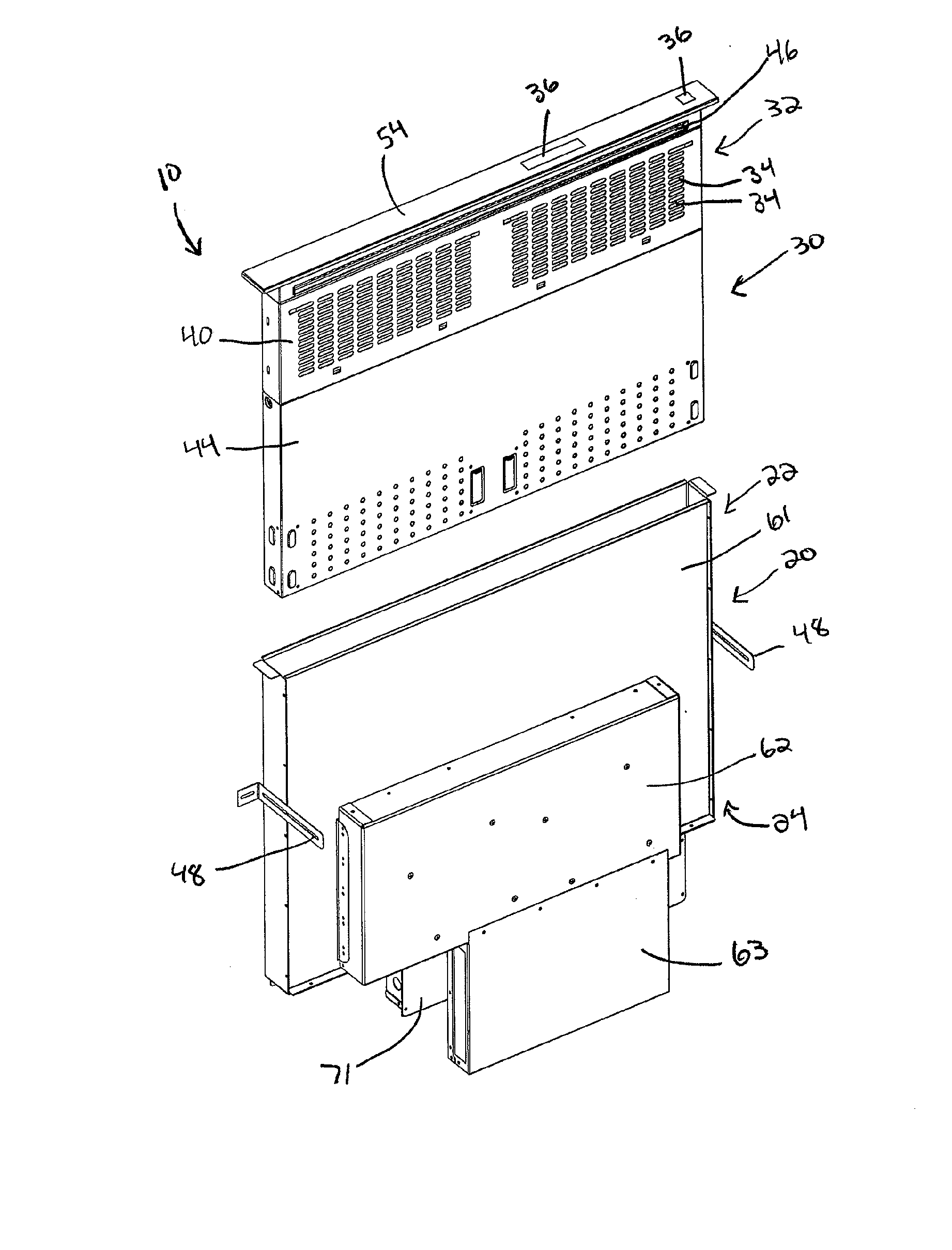

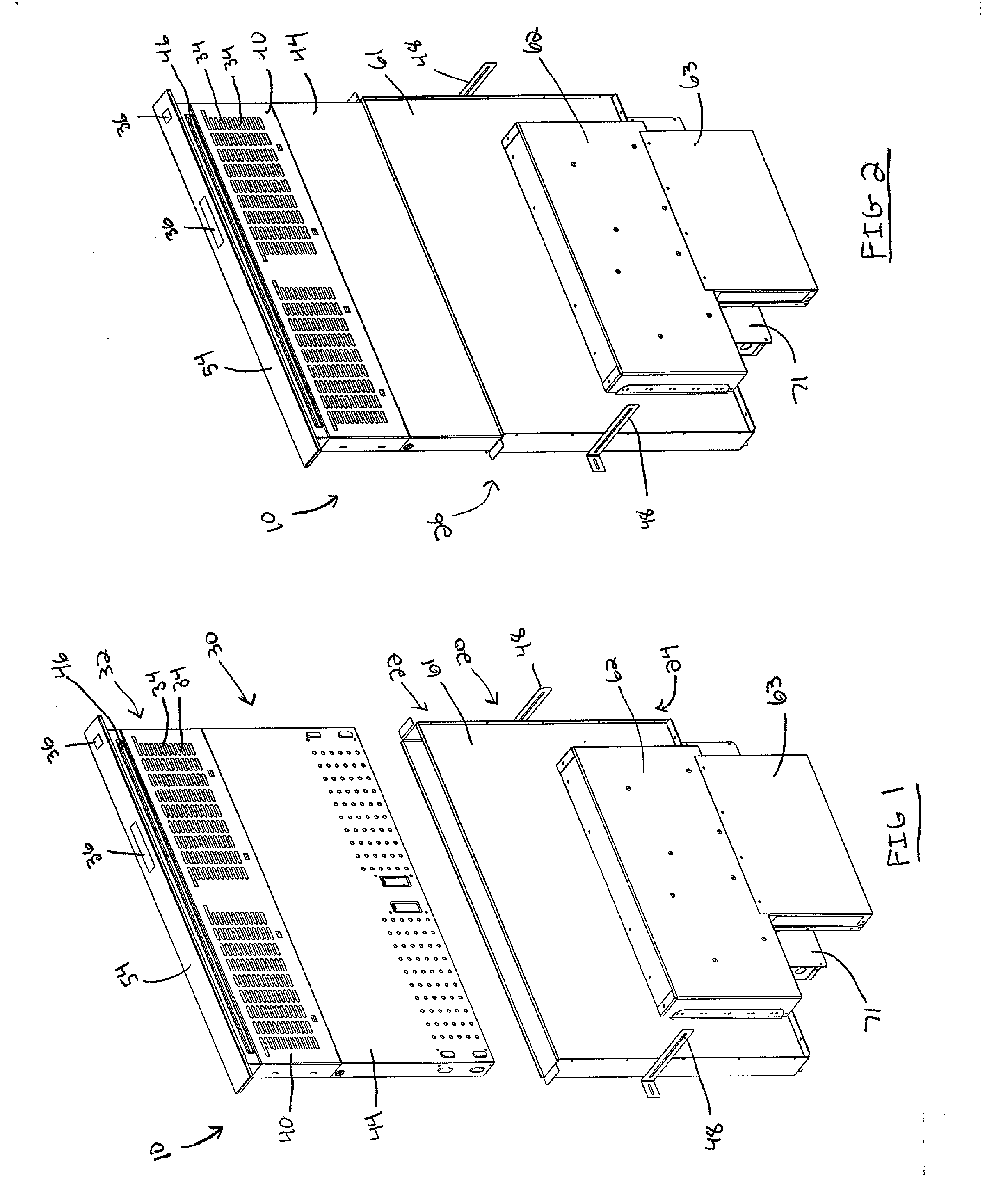

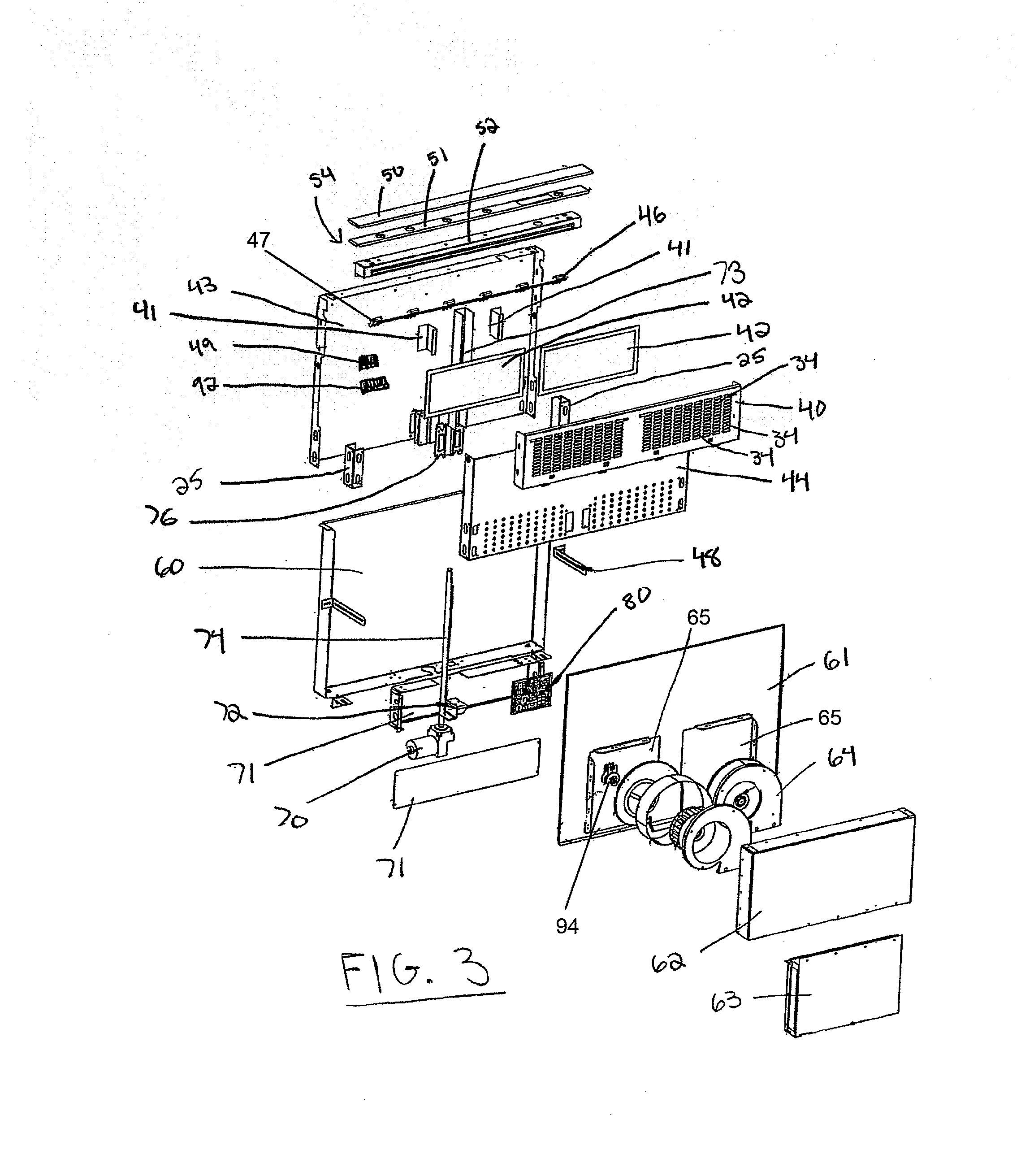

Low Depth Telescoping Downdraft Ventilator

ActiveUS20080029081A1Accuracy in removalEasy to controlCombination devicesLiquid degasificationElectrical resistance and conductanceElectronic controller

A low depth telescoping downdraft ventilator controlled by an electronic controller providing a precisely controlled and efficient way of removing gases and fumes is disclosed. The low depth telescoping downdraft ventilator has the ability to fit behind a built-in oven placed below a cook top unit. The telescoping downdraft ventilator has an almost infinitely selectable range of heights above a cook top with a built in oven. The ventilator collects and draws in exhaust fumes and smoke, filters it and re-circulates or expels it either outdoors or indoors. The inner member of the telescoping ventilator may house the exhaust fans and may move up or down without the use of mechanical switches for elevation detection and stopping. The ventilator may have sensors to detect temperatures, filter change need, fan speeds, telescoping stop points, energy consumption, resistance and voltage, enabling programmable set point operation.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

Coalescing filters

A filter is provided for coalescing droplets of oil in a stream of gas, comprising an oil coalescing layer of a microfibrous material and a second layer of an oil drainage material located downstream of and in face to face contact with the first layer. The drainage layer is for receiving oil from the coalescing layer and providing a path for oil to flow by gravity from the filter. Oil carry-over is reduced by providing a drainage layer which is a non-woven felt or wadding thermally bonded by bi-component polyester fibers.

Owner:PSI GLOBAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com