Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1659 results about "Spiral flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

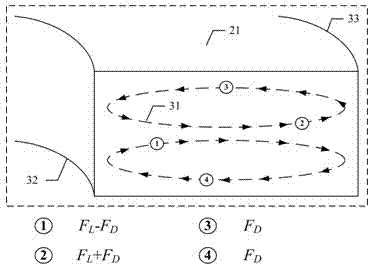

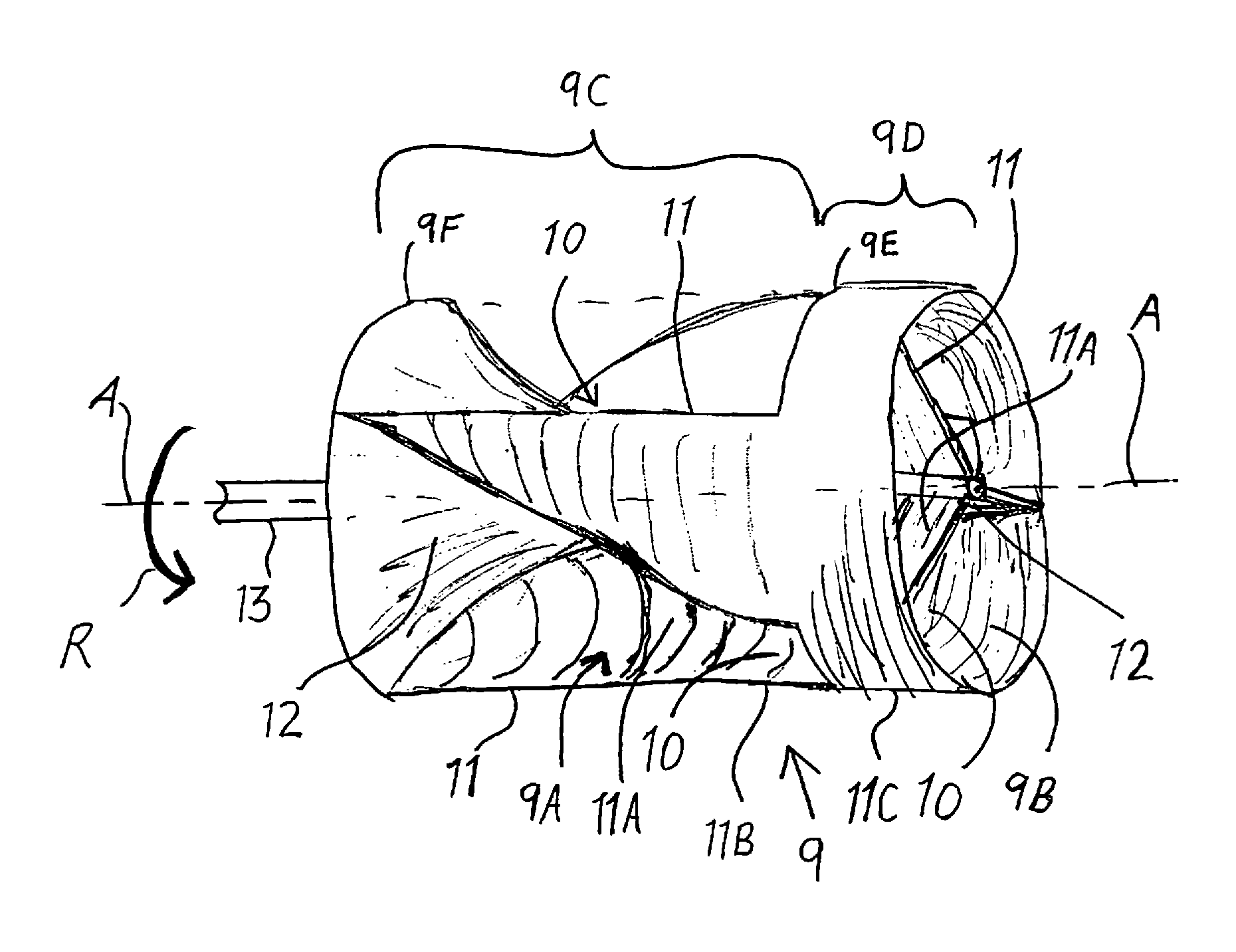

Supersonic swirling separator 2 (Sustor2)

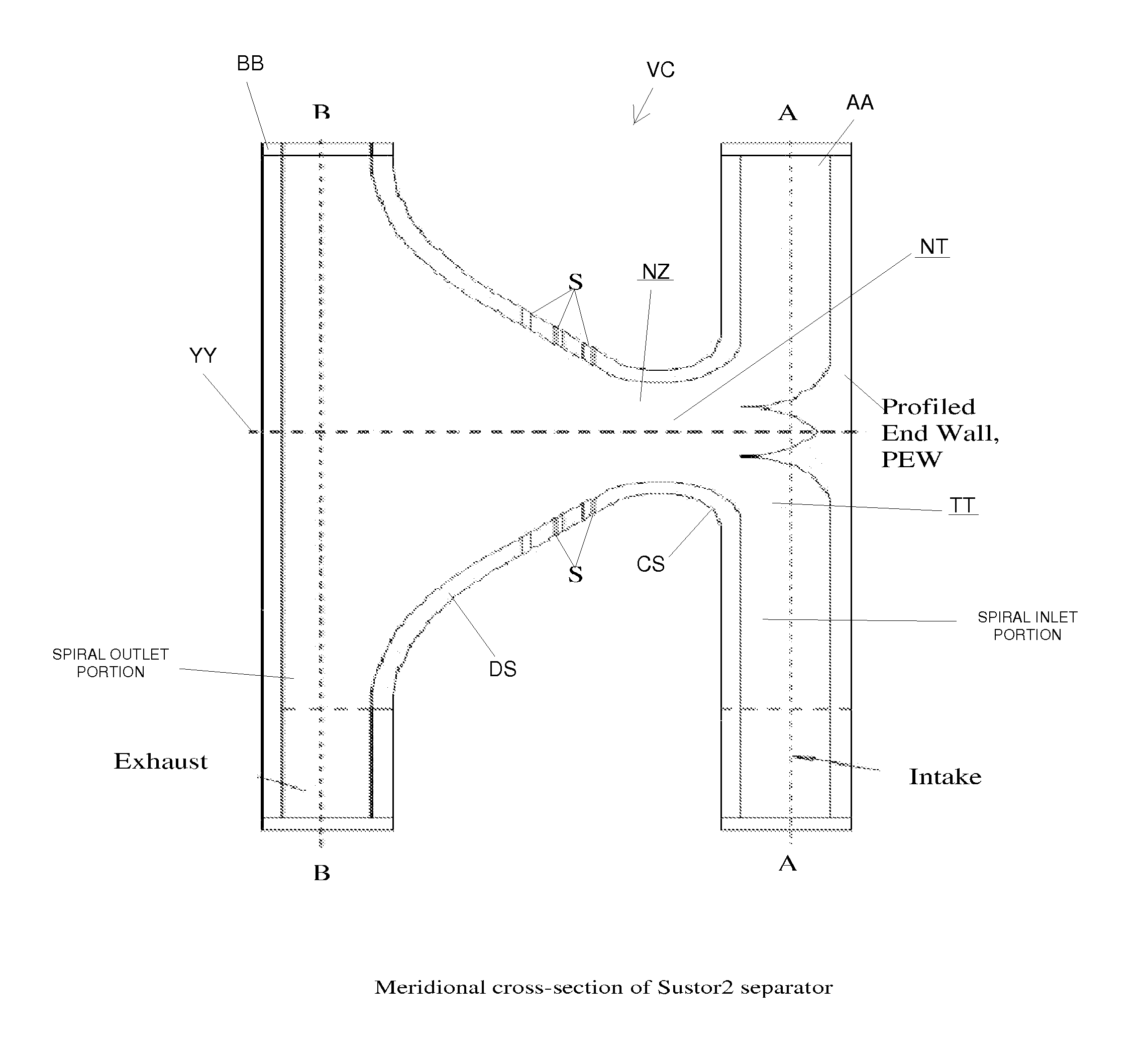

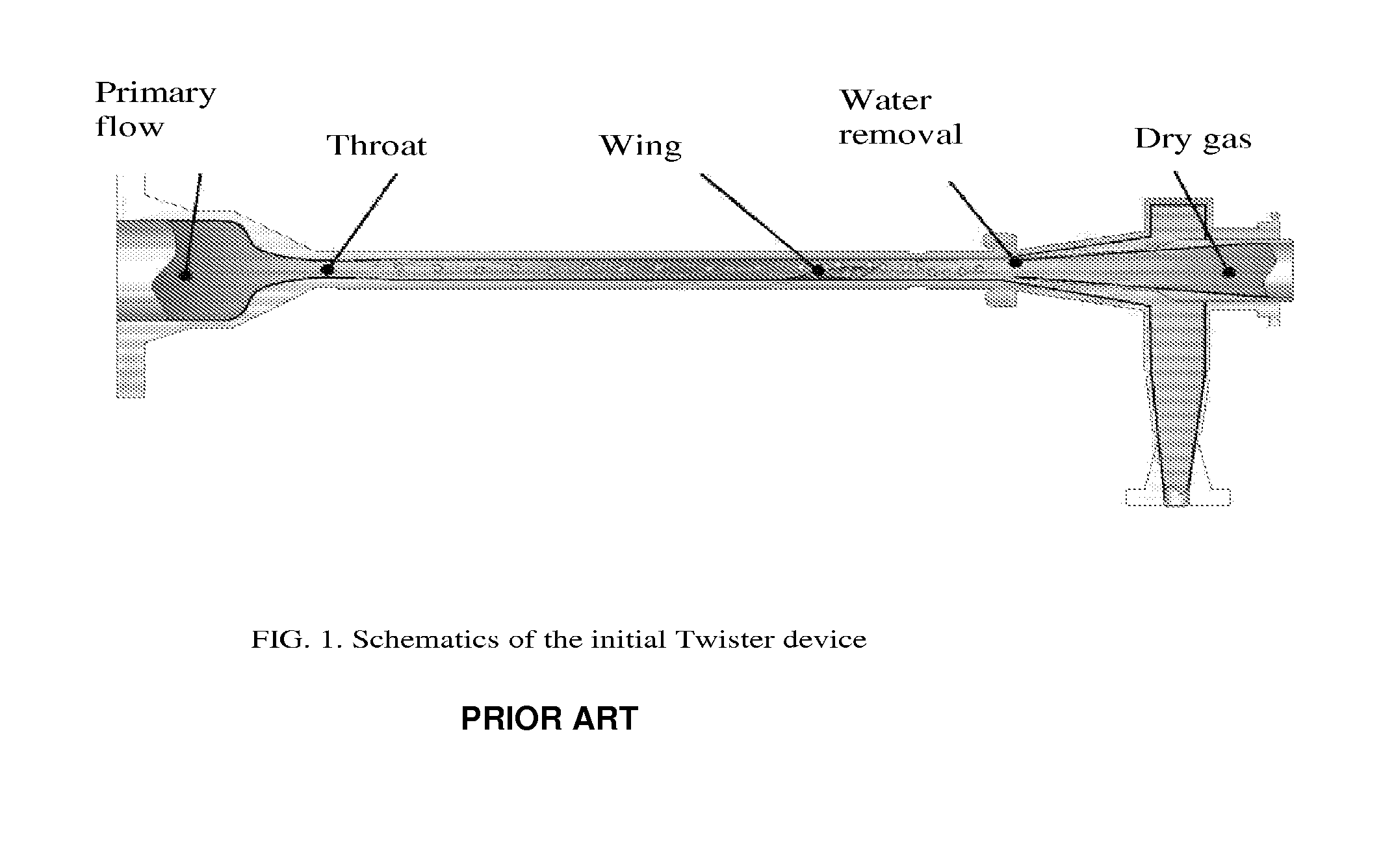

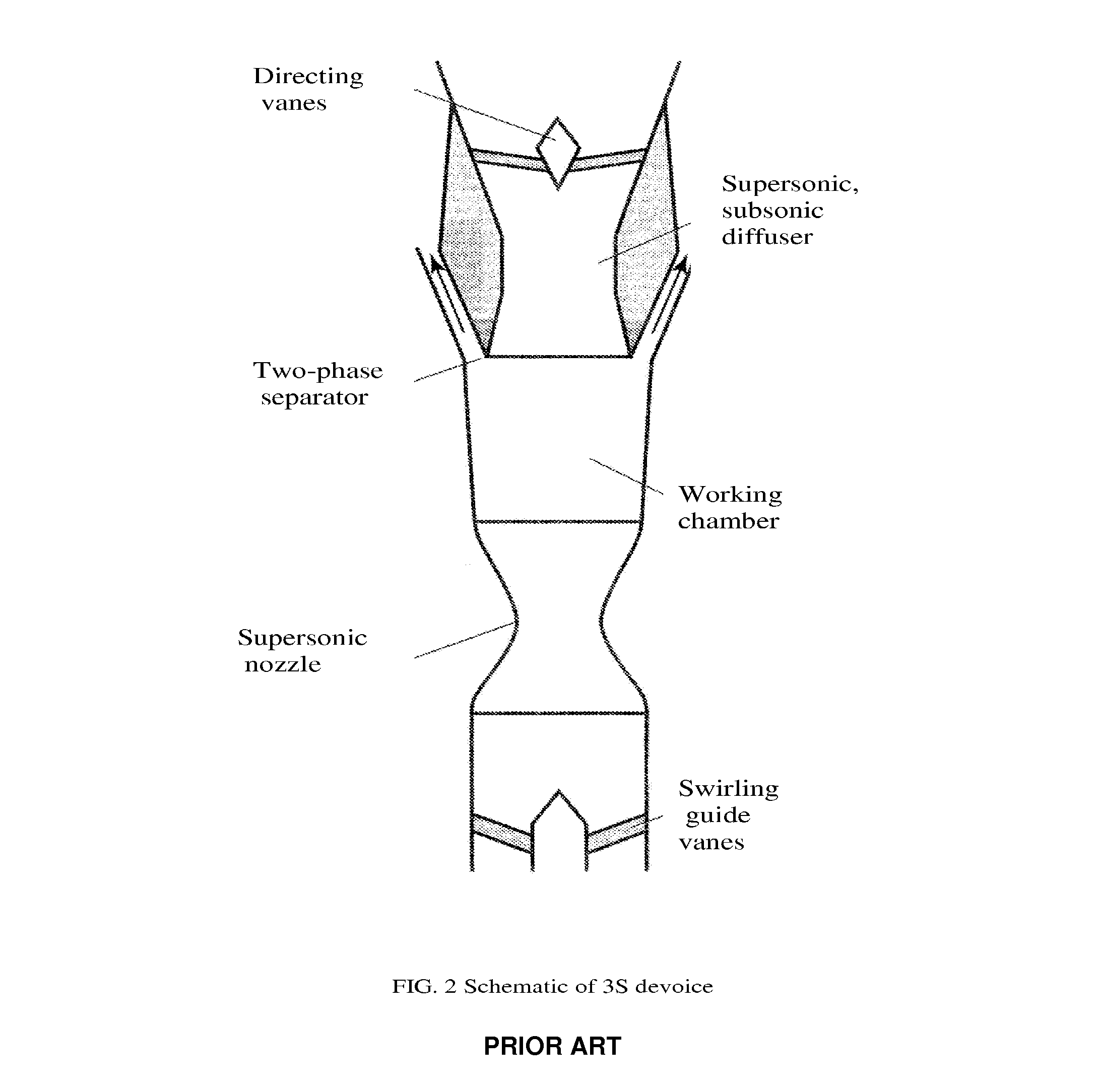

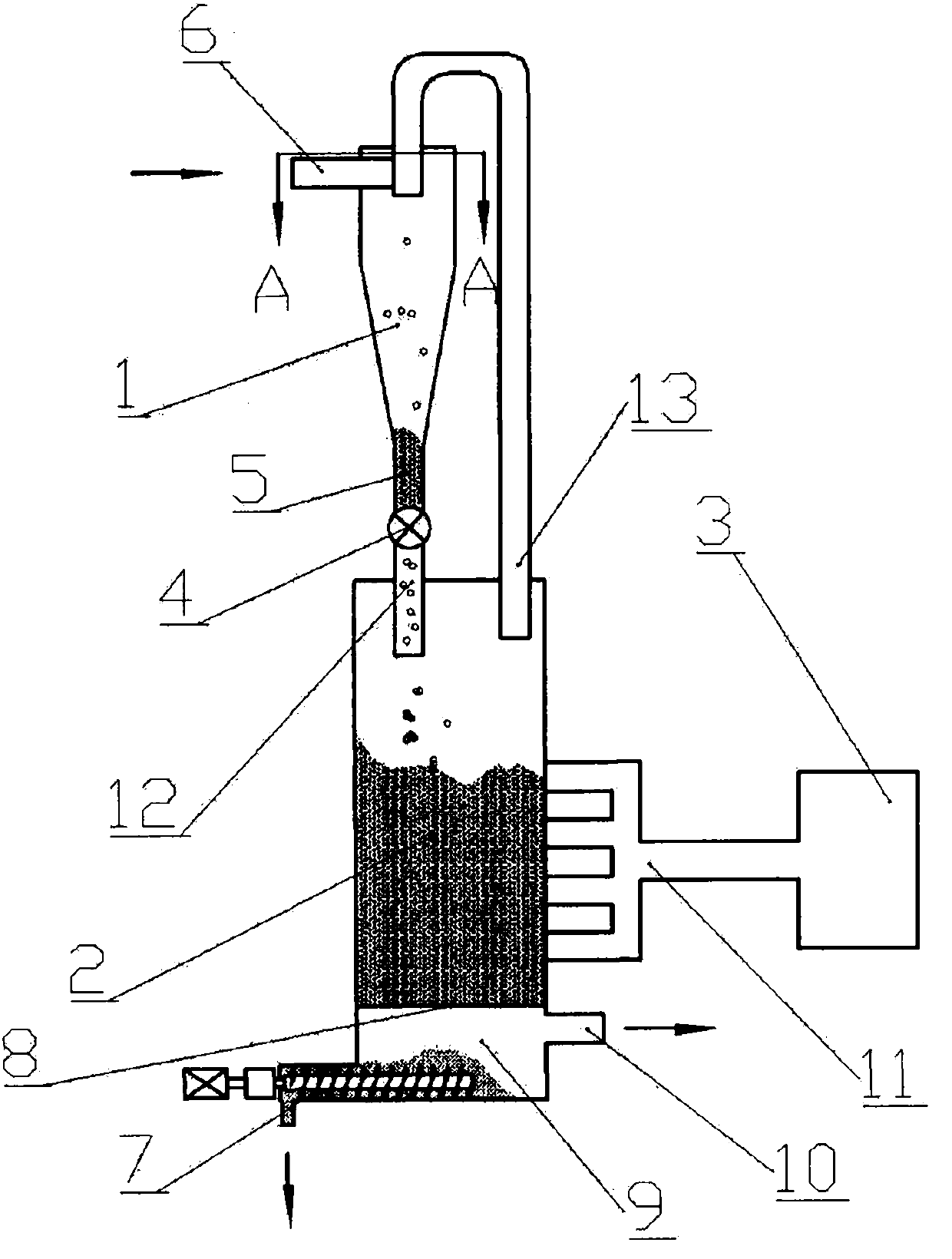

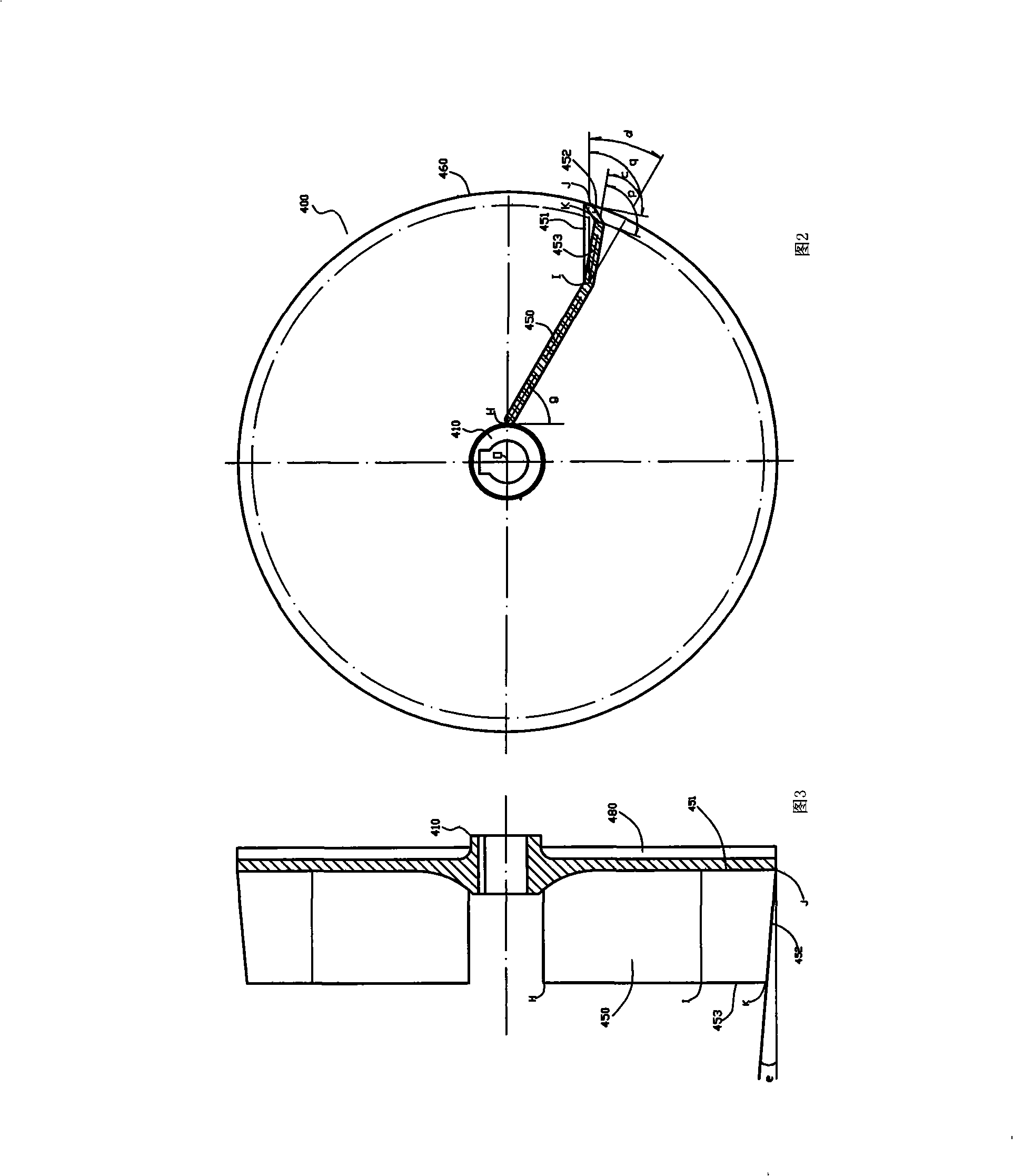

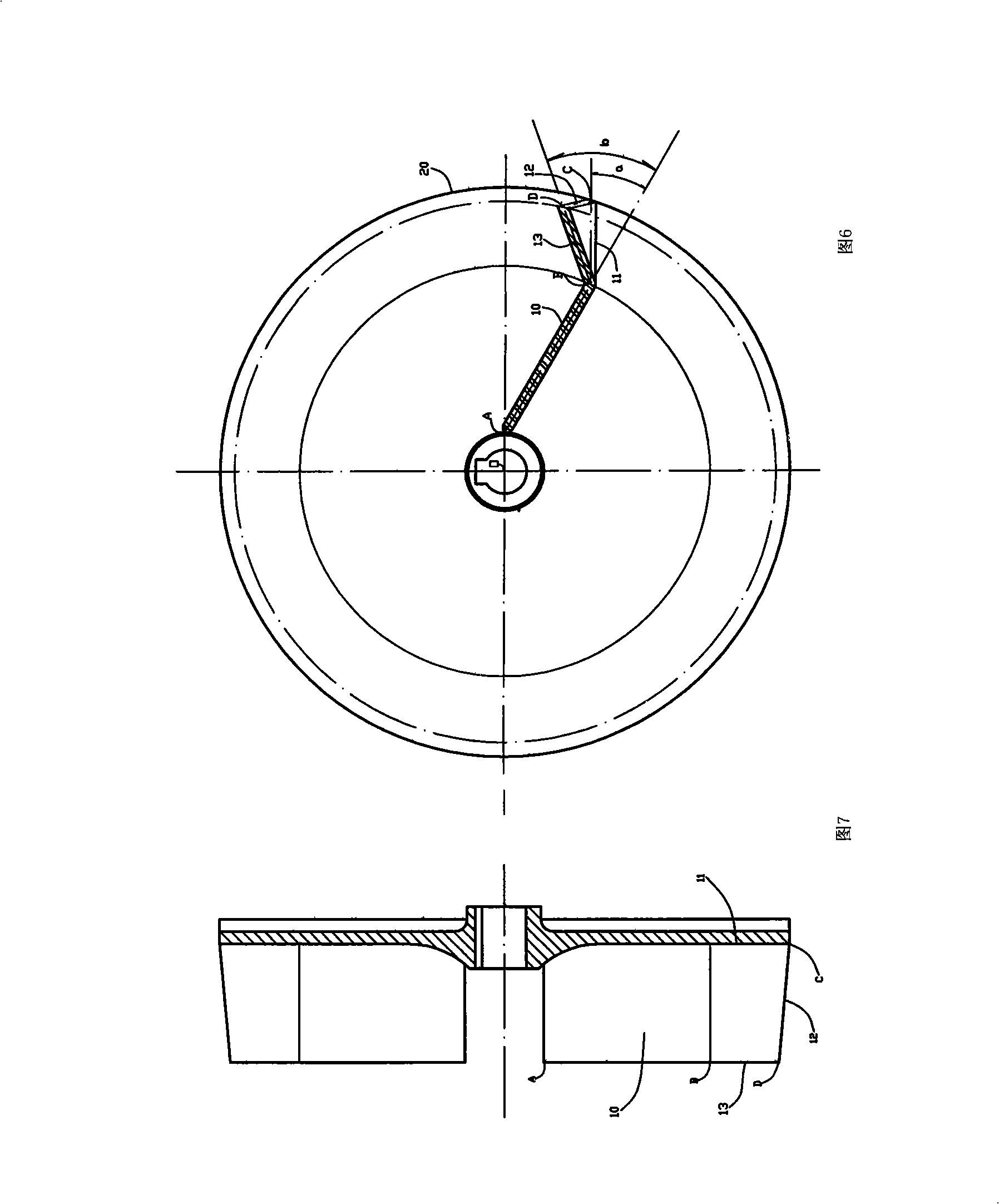

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

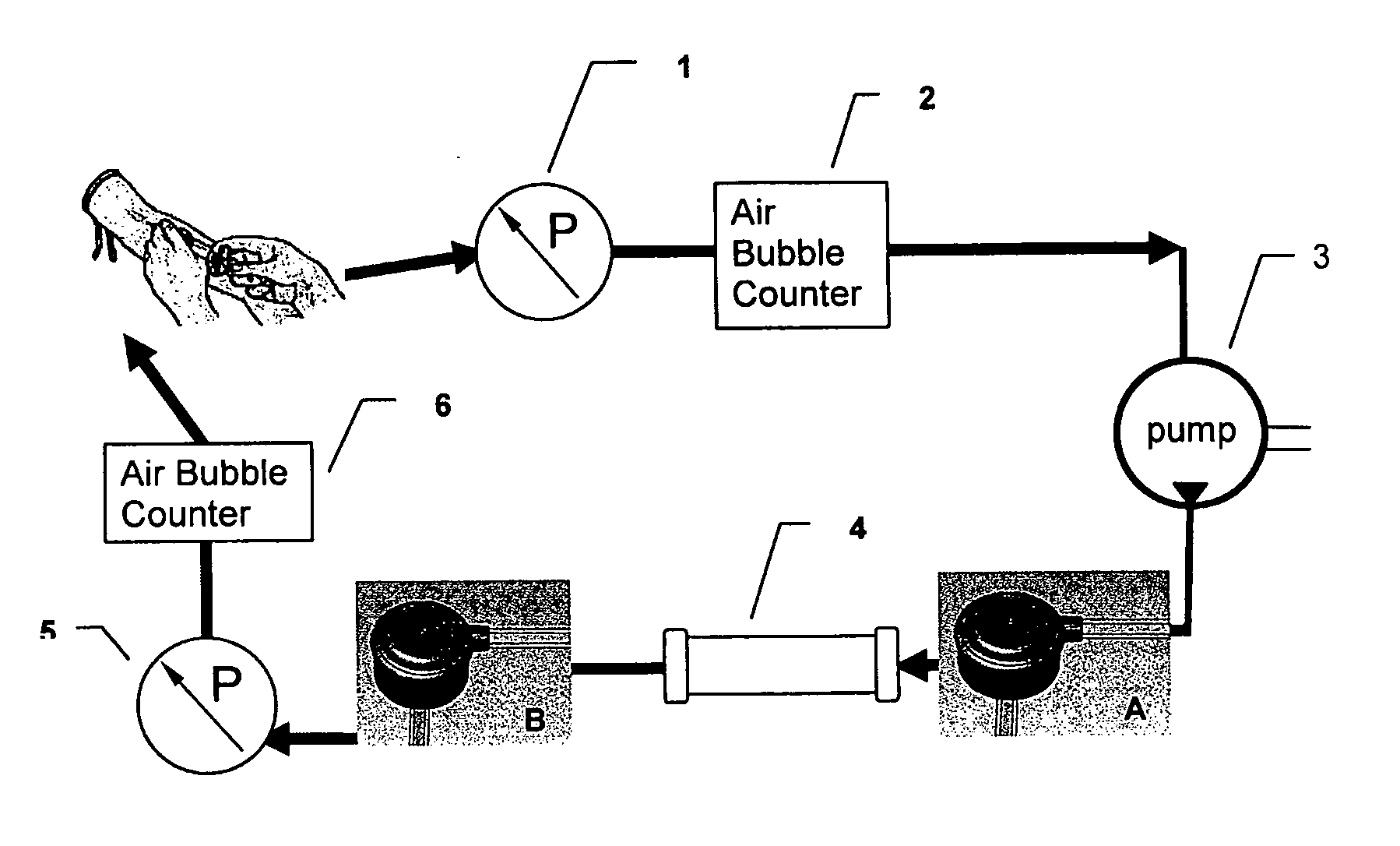

Degassing device

ActiveUS20110092875A1Maximize advantageReduced effectivenessDialysis systemsMedical devicesHaemodialysis machineEngineering

Owner:GAMBRO LUNDIA AB

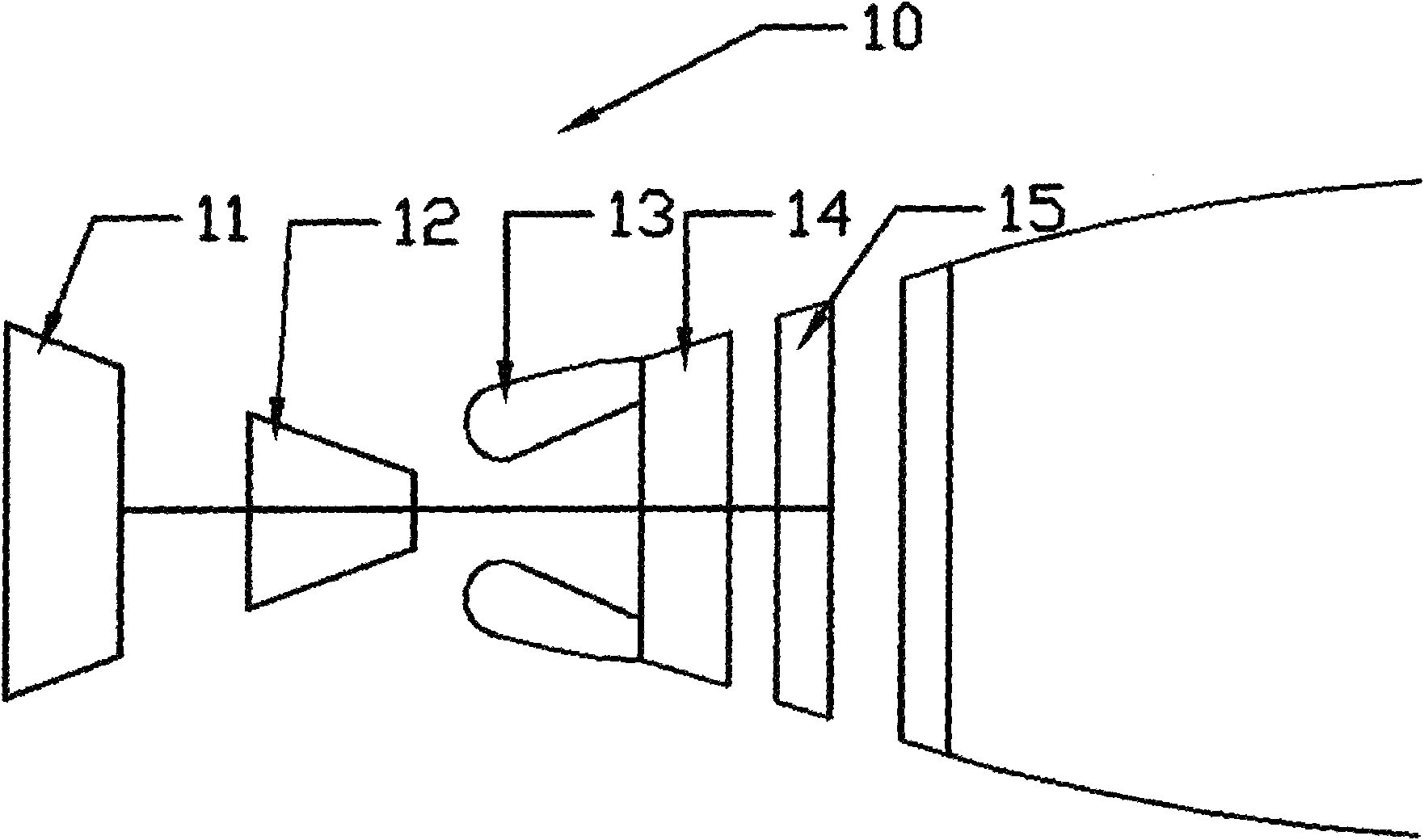

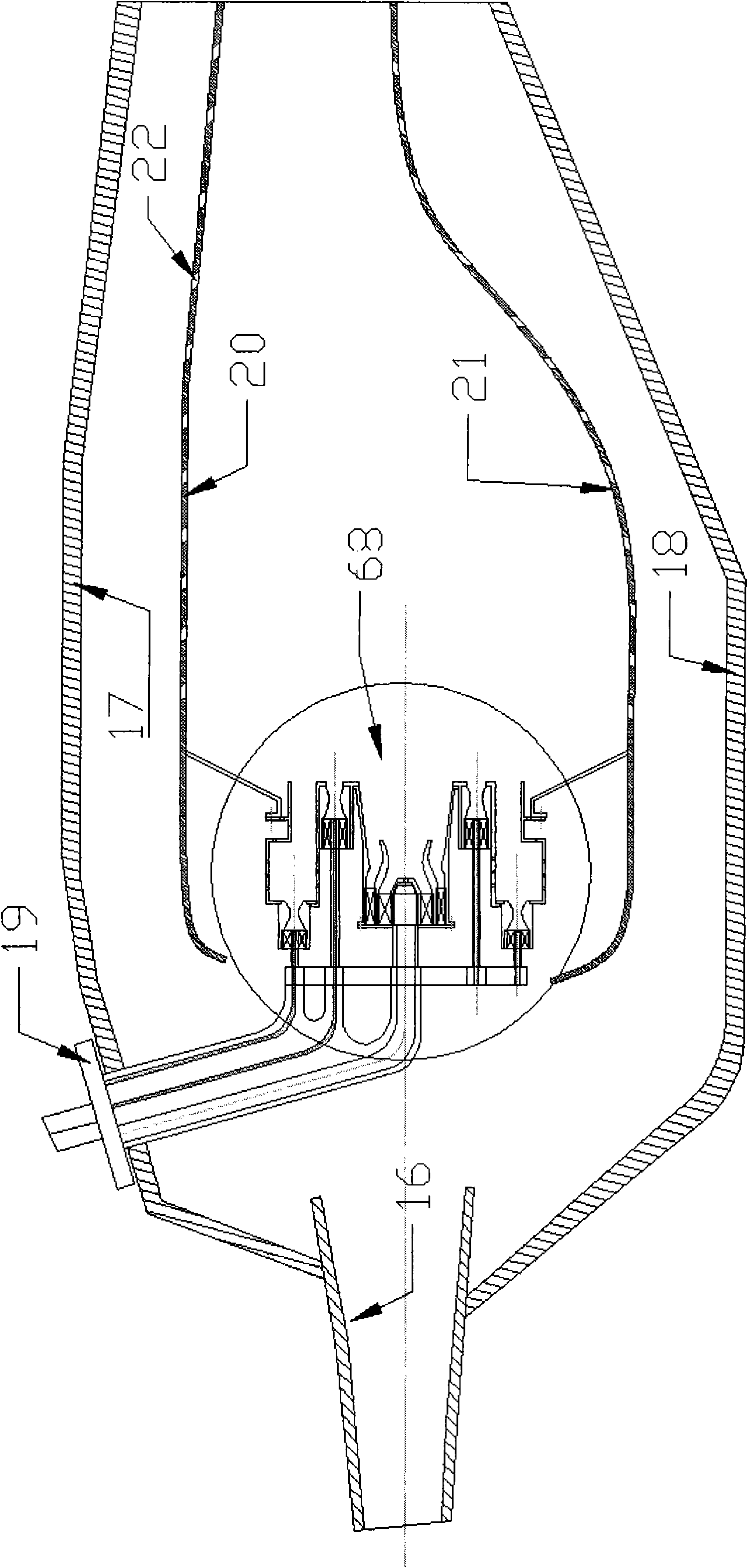

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

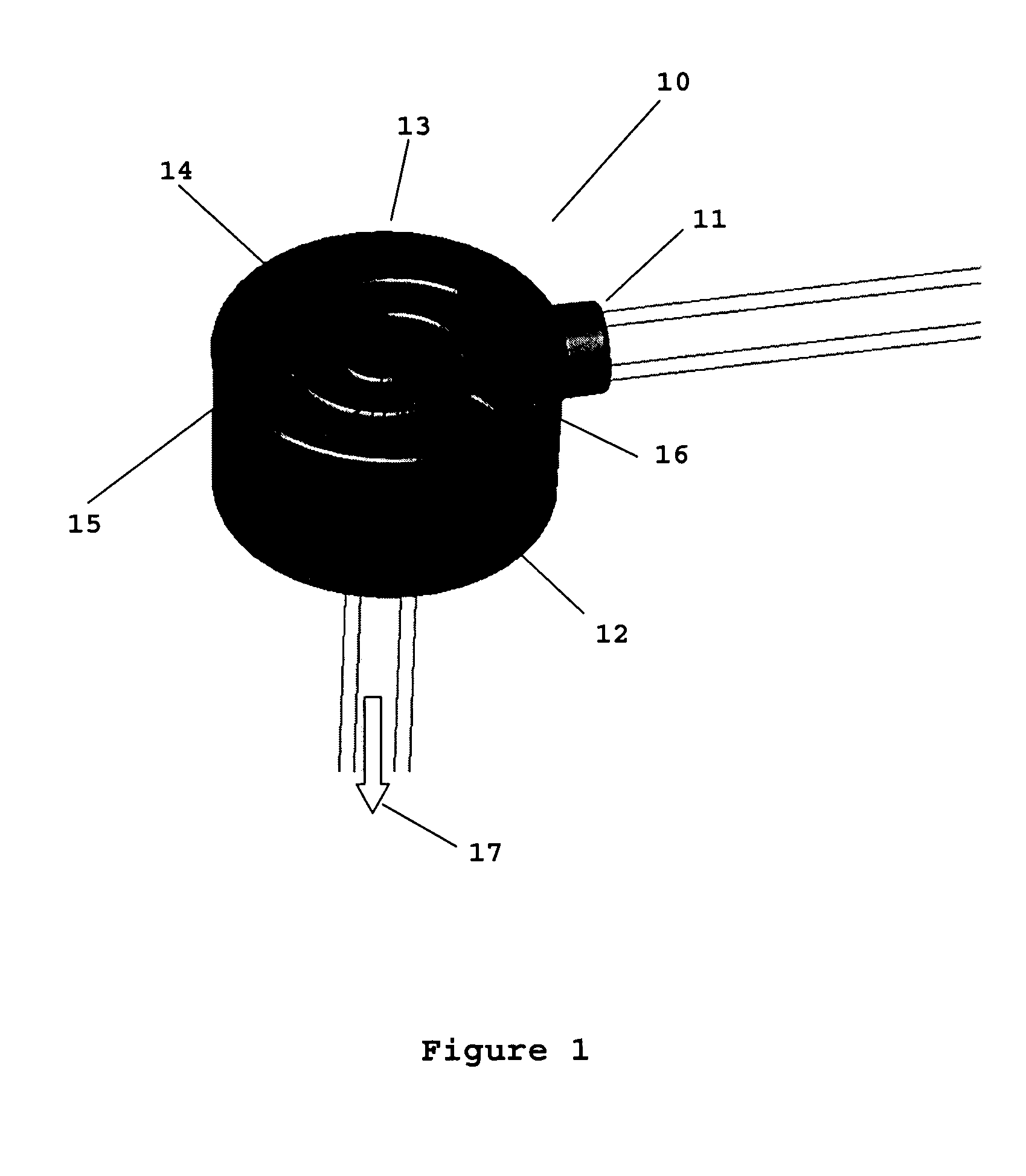

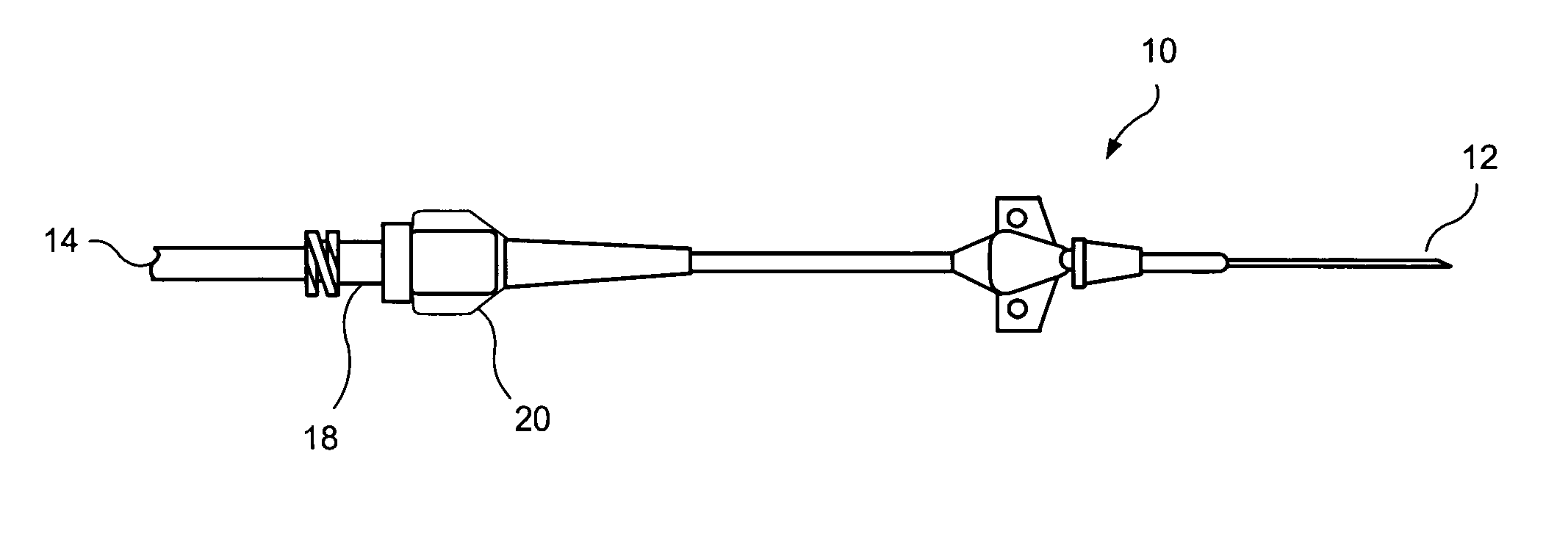

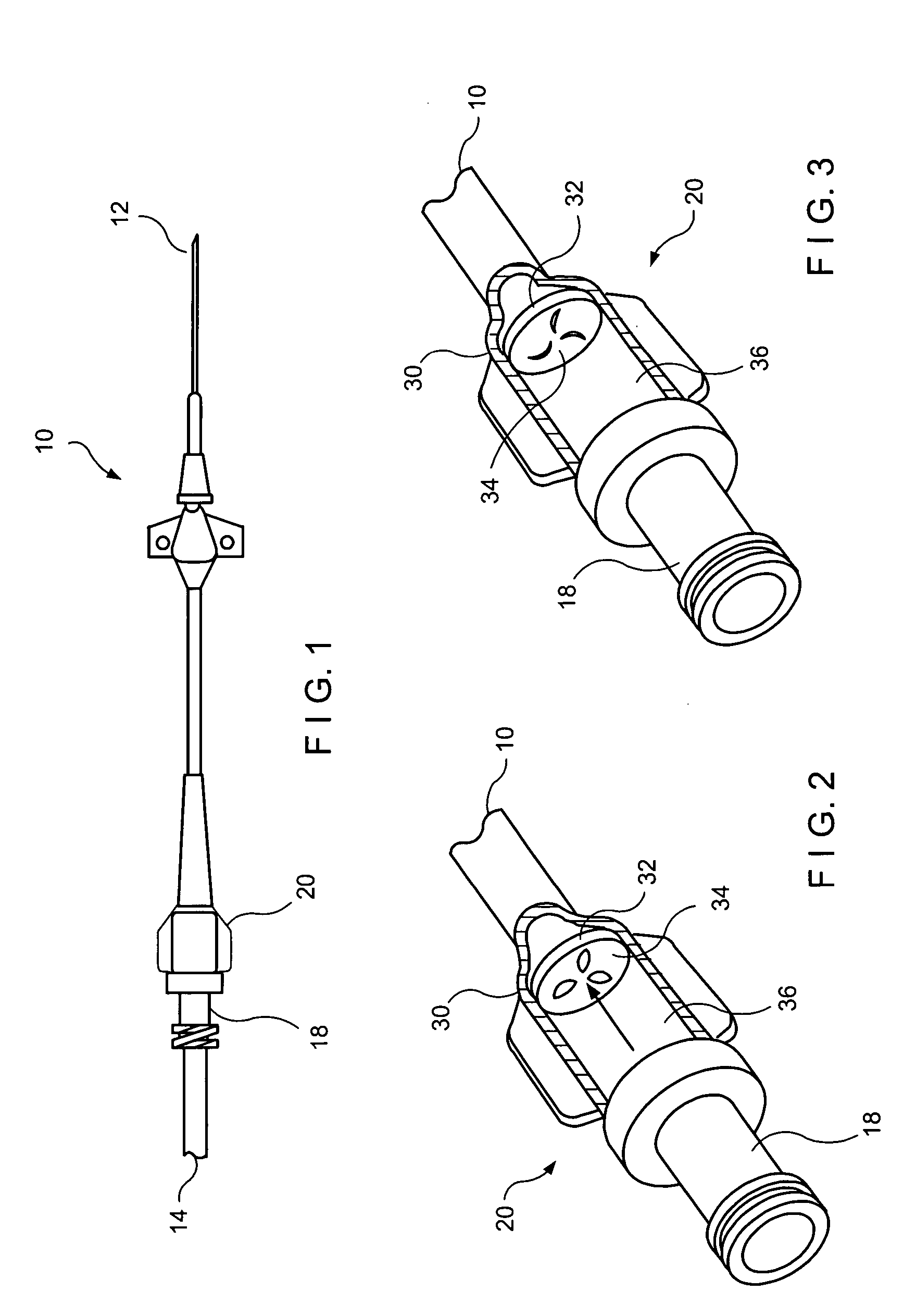

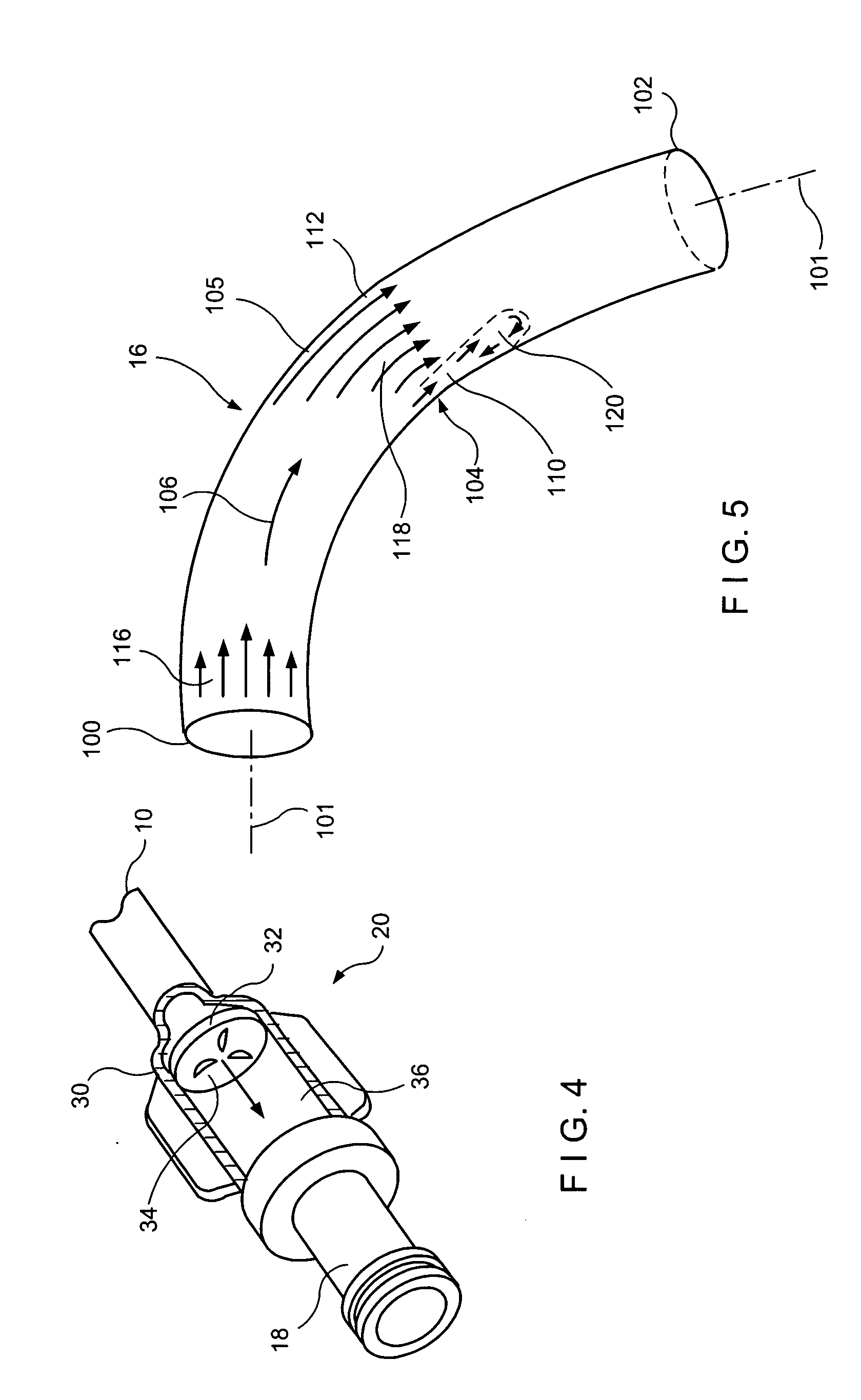

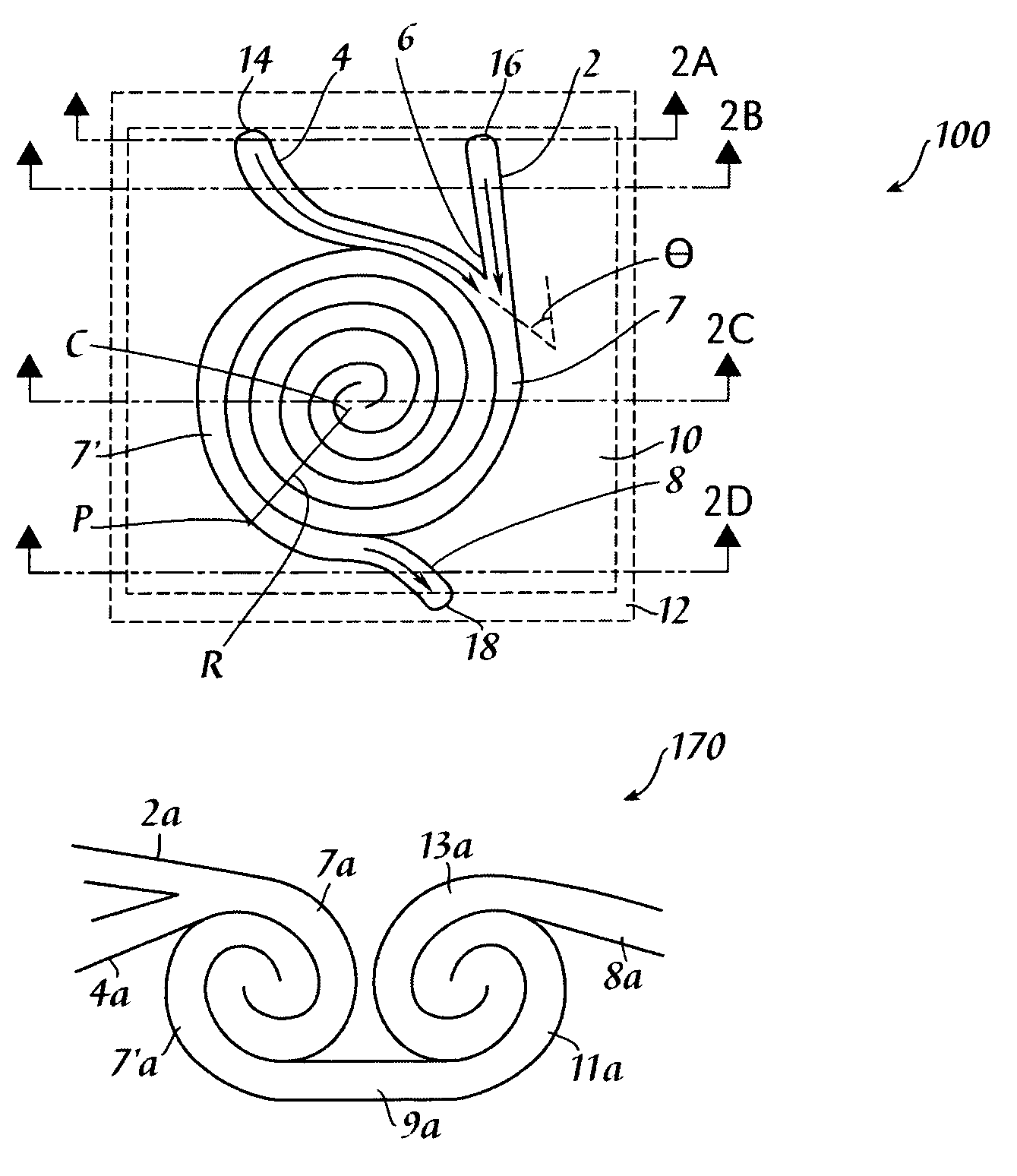

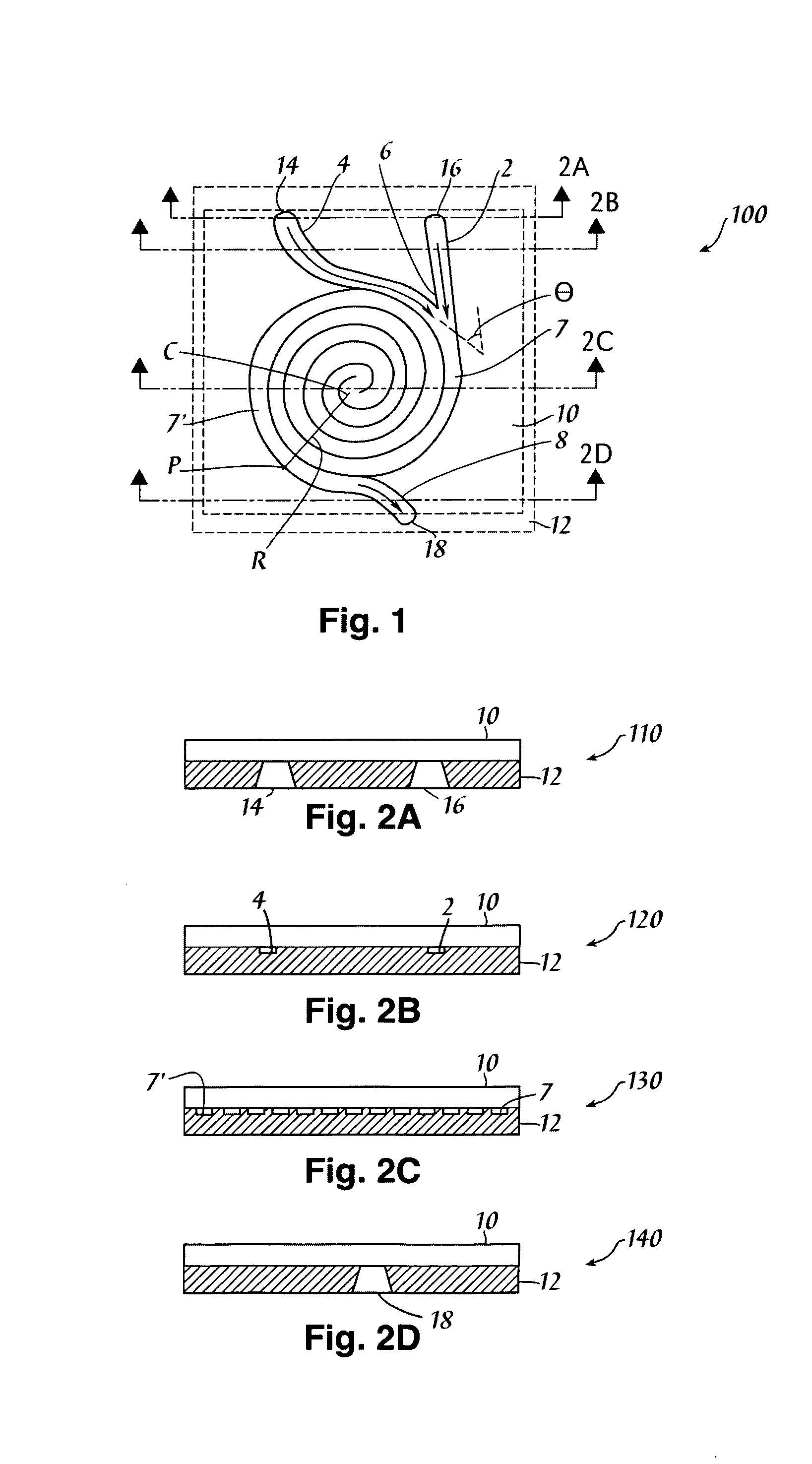

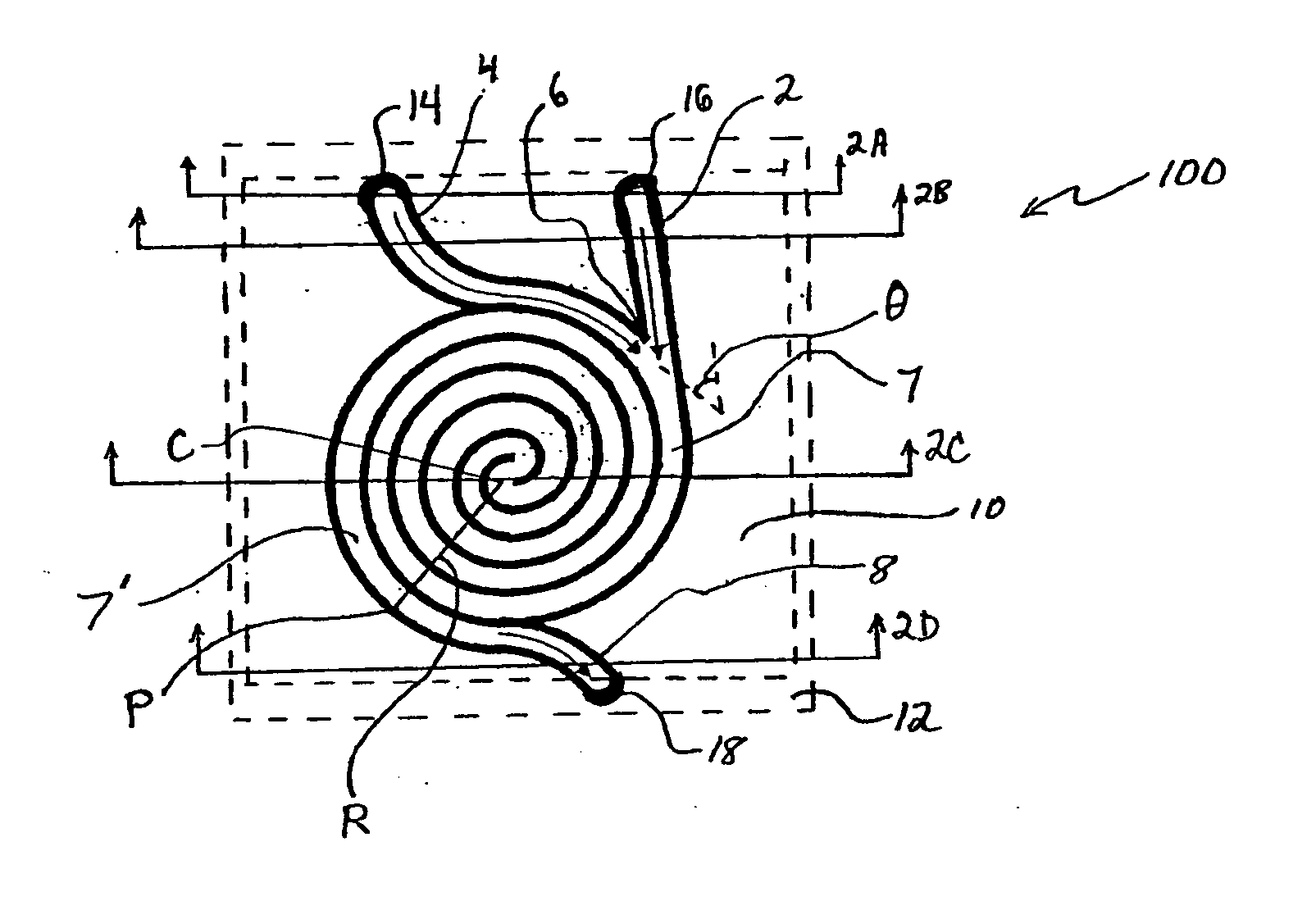

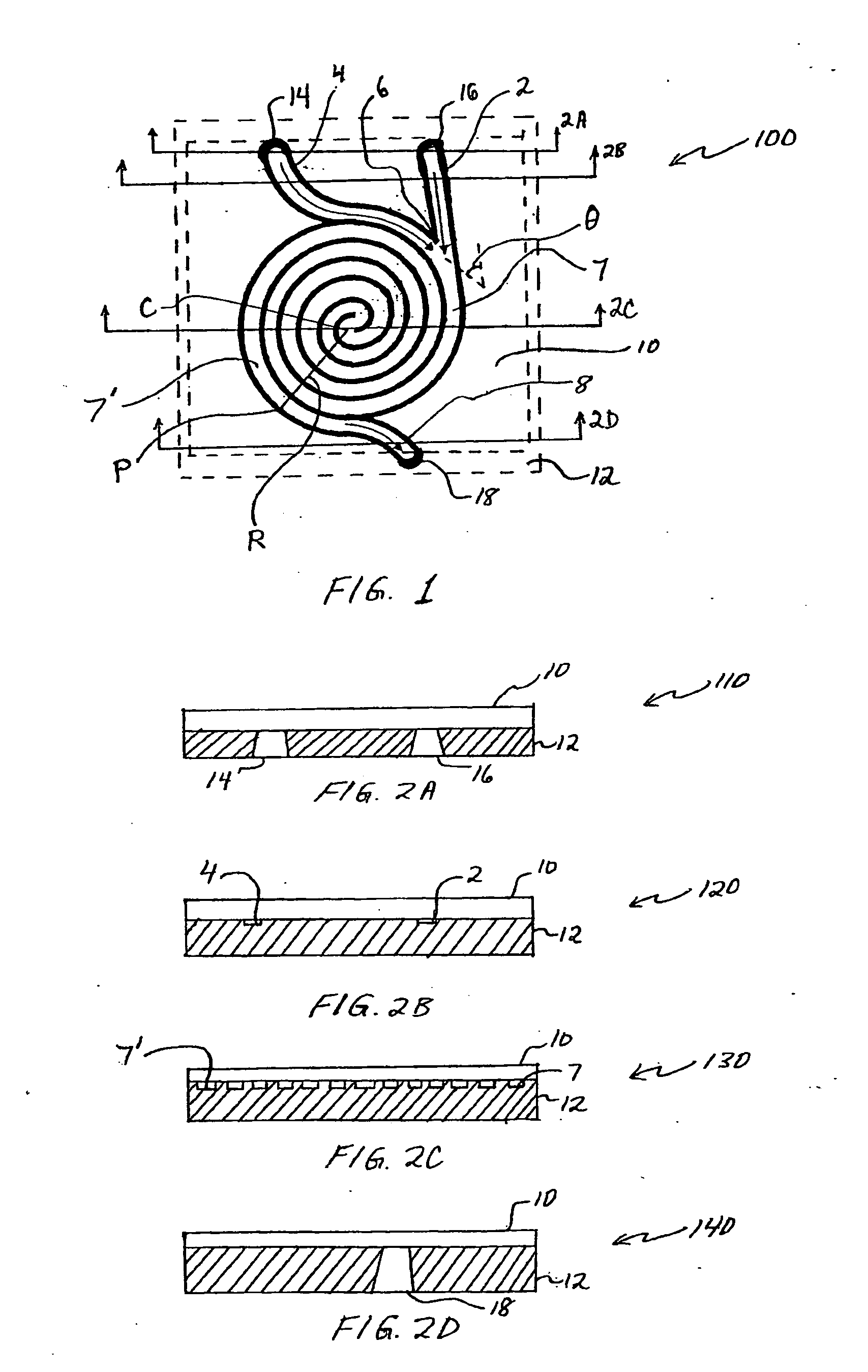

Pressure actuated safety valve with spiral flow membrane

A pressure actuated valve, comprises a flow chamber having an inlet and an outlet and a resilient membrane extending across the flow chamber to selectively impede passage of a fluid between the inlet and the outlet. The membrane includes at least one slit formed therein so that, when a fluid pressure to which the membrane is subjected is at least a predetermined threshold level, edges of the at least one slit separate to permit fluid flow therethrough. The at least one slit has a first curvature in a surface plane of the membrane and a second curvature along a thickness of the membrane to impart a rotational velocity component to a flow of fluid therethrough relative to a centerline of the flow chamber.

Owner:NAVILYST MEDICAL

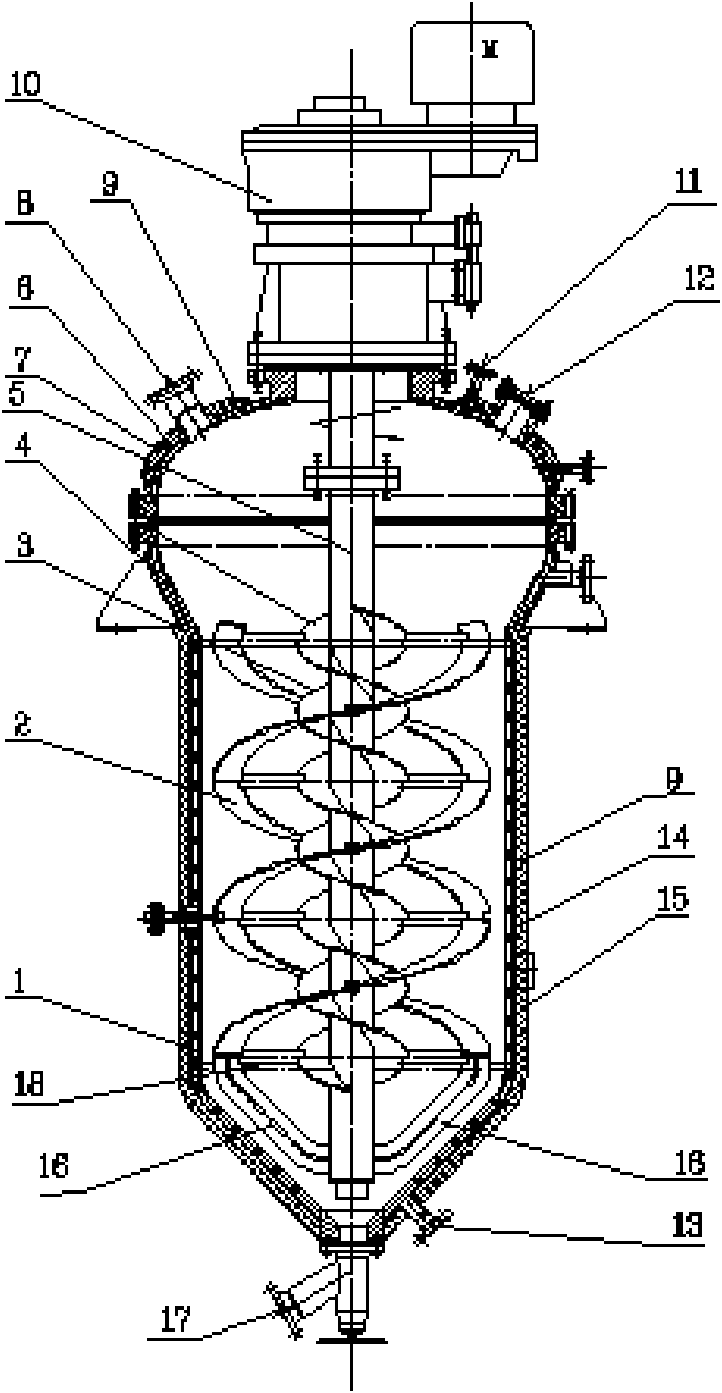

Macromolecular material polymerization reaction kettle

ActiveCN101596440AImprove the output effectReduce inventoryRotary stirring mixersChemical/physical/physico-chemical stationary reactorsInsulation layerElectric machinery

The invention discloses a macromolecular material polymerization reaction kettle. The kettle comprises a kettle body, an upper closed cover, a drive sealing device, a stirring device, a feed and discharge port, wherein the upper part of the kettle body is an inverted cone-shaped wide mouth; the middle part of the kettle body is of a bucket shape; the lower part of the kettle body is cone; the kettle body is provided with a heating jacket 14 with a spiral flow channel and a heat insulation layer 9; the upper closed cover 6 is provided with a heating jacket 7, a heat insulation layer 9, a vacuum port 8 and a feed port 12; the stirring device consists of a stirring shaft 5, an inner strip-shaped spiral stirring paddle 3, an outer strip-shaped spiral stirring paddle 2, a scraping blade 16 and a supporting oar 18; the drive sealing device consists of a motor, a retarder and a sealing machine; and the upper part of the stirring shaft is connected with the drive sealing device. The macromolecular material polymerization reaction kettle has good stirring effect and high heat and mass transferring efficiency, can solve the difficult problems of pole climbing and devolatilization of high-viscosity fusant and is in particular suitable for the polymerization reaction of a high-viscosity macromolecular material.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

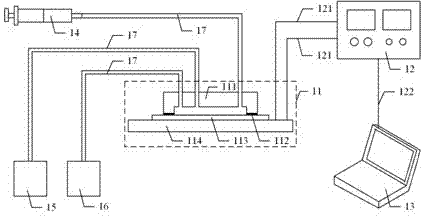

Microfluidic chip system integrating cell sorting and detection

ActiveCN103923825AOvercoming integratioOvercoming frequencyBioreactor/fermenter combinationsBiological substance pretreatmentsRare cellBiological studies

The invention discloses a microfluidic chip system integrating cell sorting and detection. The system comprises a microfluidic chip, a high-frequency lock-in amplifier and a processor, wherein the microfluidic chip is formed by aligning and packaging a flow channel layer, an electrode layer, a substrate layer and a PCB (printed circuit board) in sequence; a cell sorting spiral flow channel, a detection main flow channel and a retraction flow channel are formed in the flow channel layer; the retraction flow channel is aligned to a planar metal electrode of the electrode layer; liquid electrode structures are formed on two sides of the main flow channel; an electrode of the electrode layer forms a differential high-frequency impedance measurement circuit together with the high-frequency lock-in amplifier through a power amplification circuit and an I / V conversion circuit of the PCB to realize differential detection of cell alternating-current impedance. The system can realize the integration of rare cell sorting and representation function, improves the integrity and accuracy of a cell detection technology, and can be widely used in the fields of rare cell biological study, early disease diagnosis and treatment and the like.

Owner:SOUTHEAST UNIV

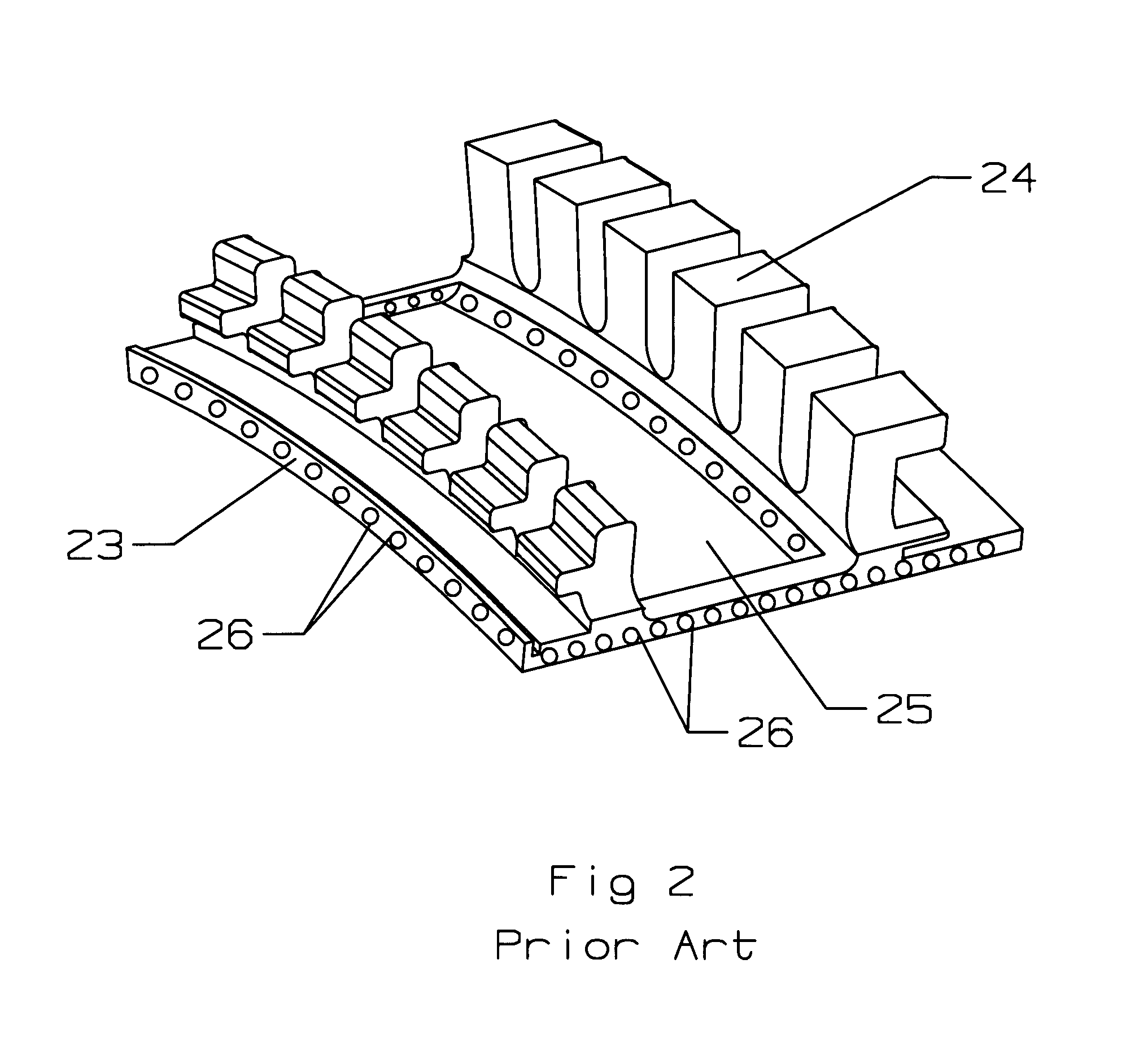

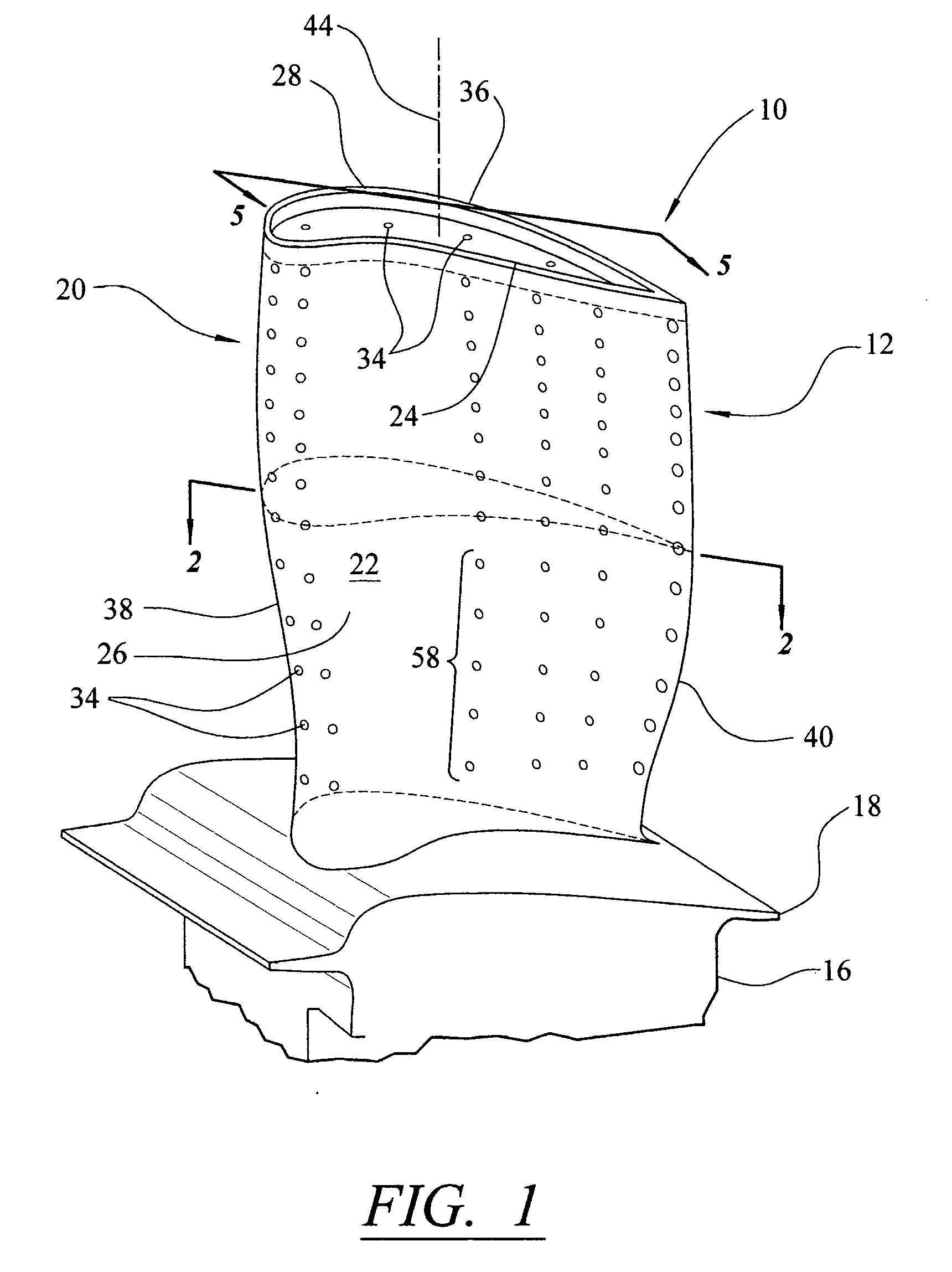

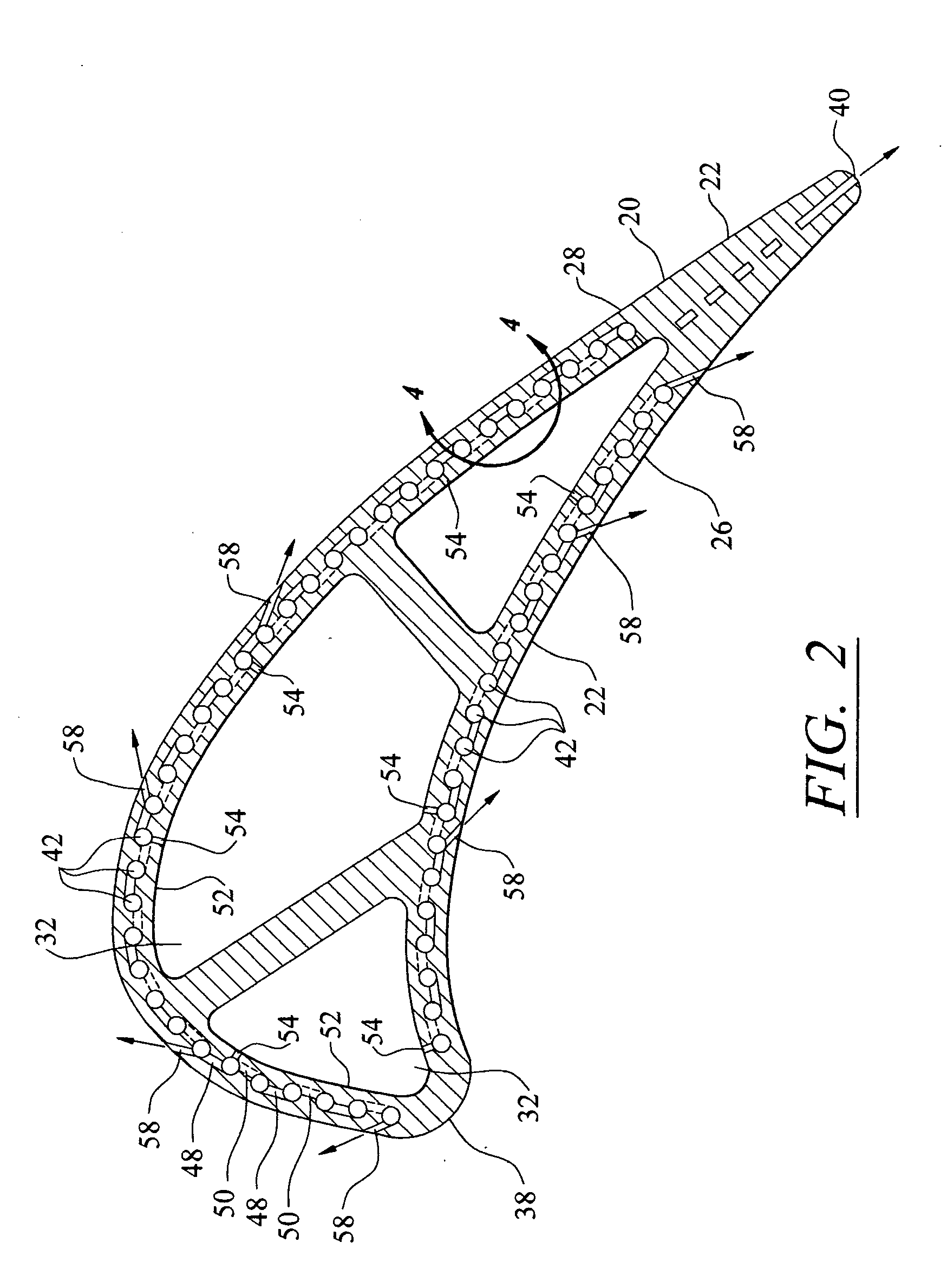

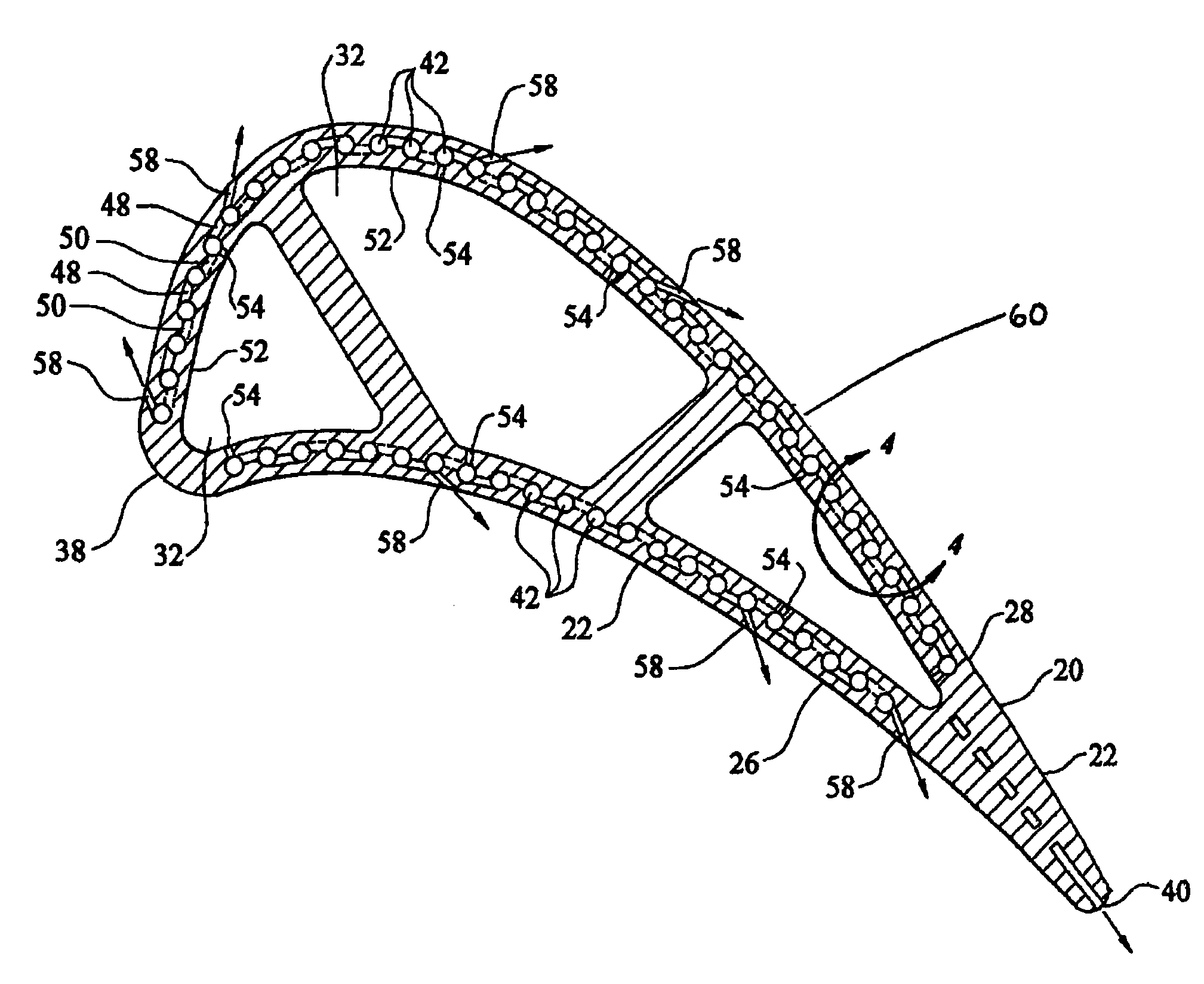

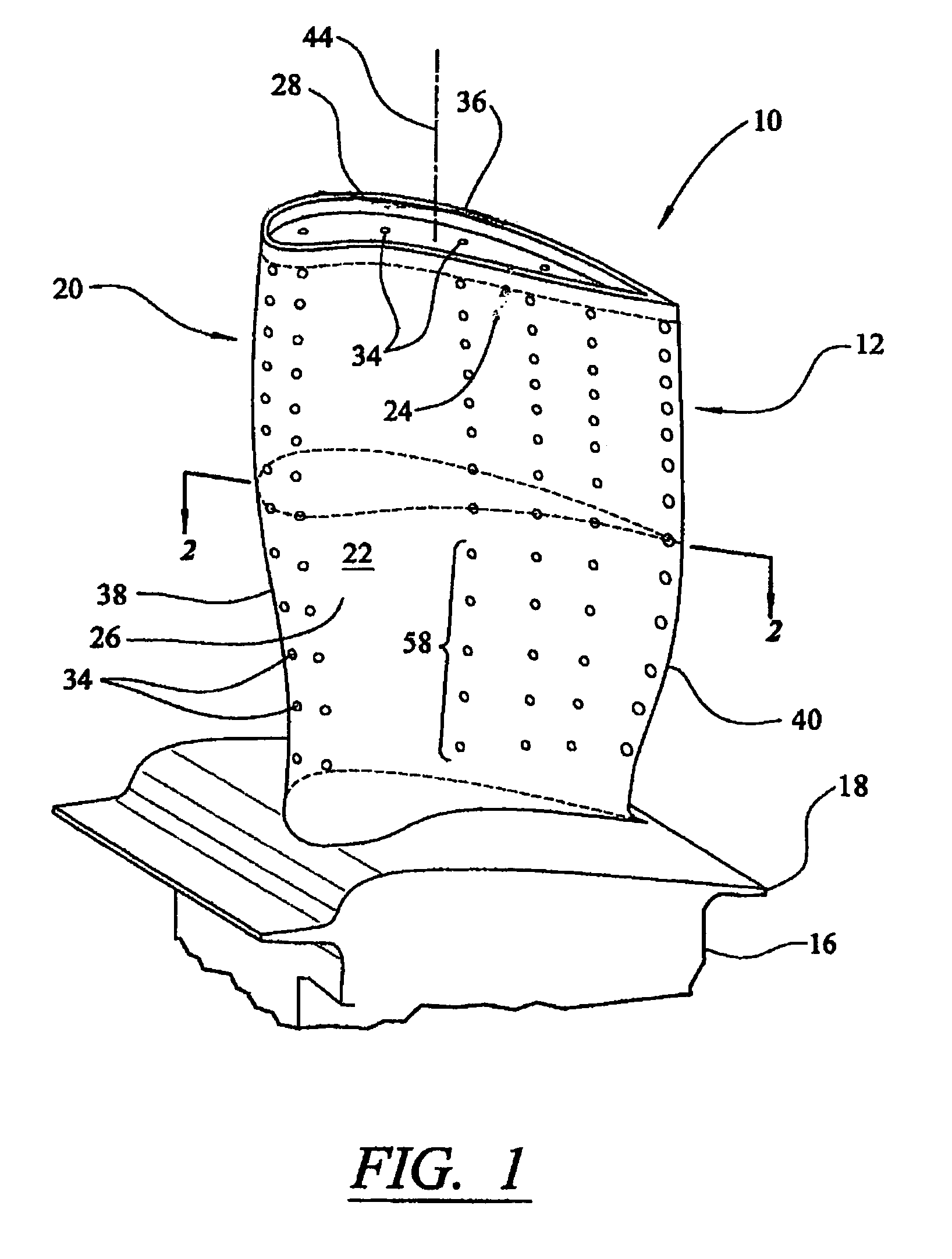

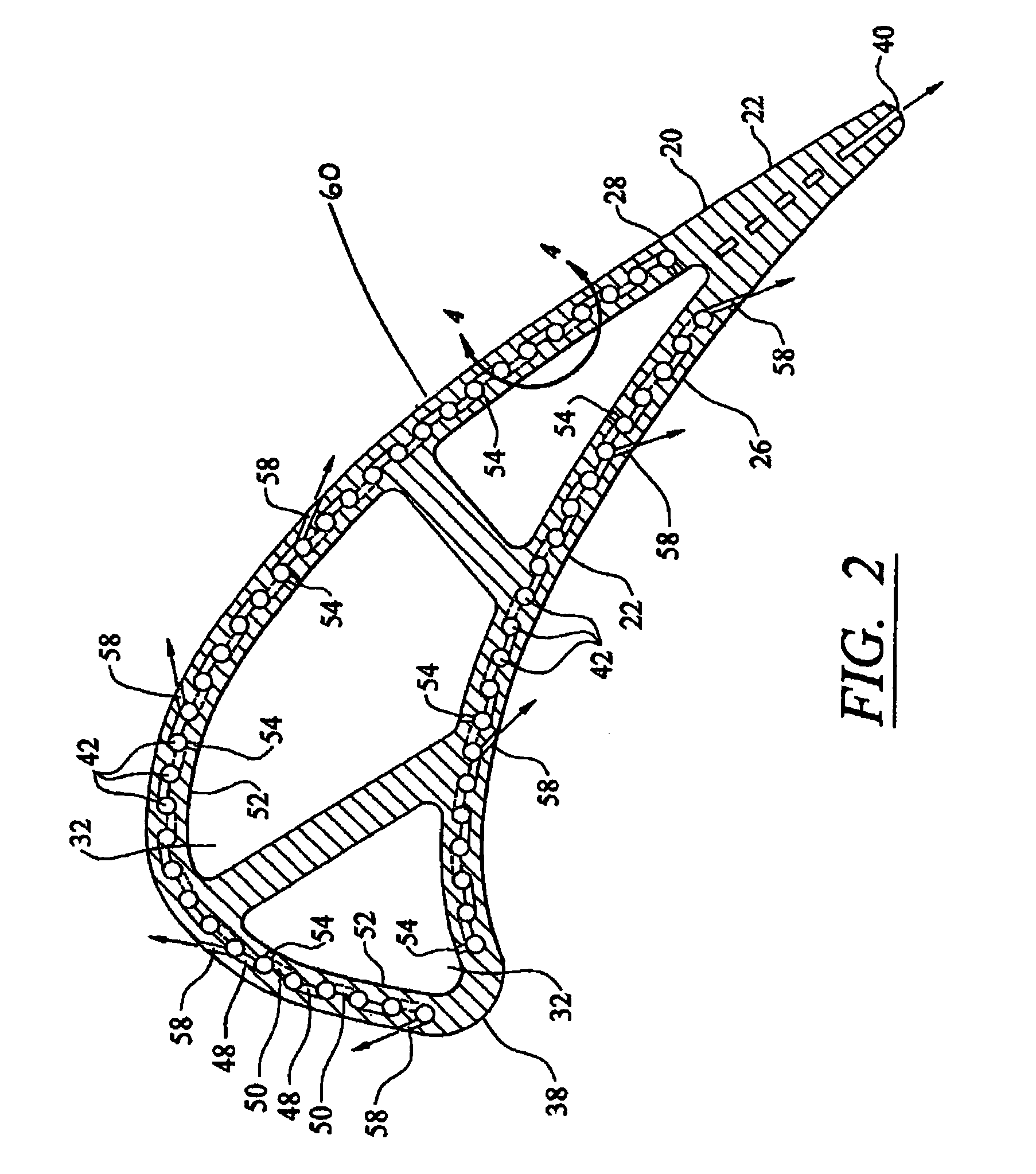

Turbine BOAS with edge cooling

A cooling hole having an inlet passage forming an inward spiral flow path and an outlet passage forming an outward spiral flow path in which the two paths are counter flowing in order to improve the heat transfer coefficient. The spiral cooling hole is used in a blade outer air seal (BOAS) for a turbine in which the edges of the shroud segments include a counter flowing micro serpentine flow cooling circuit with thin diffusion discharge cooling slots for the BOAS edges. The total BOAS cooling air is impingement from the BOAS cooling air manifold and metered through the impingement cooling holes to produce impingement cooling onto the backside of the BOAS. The spent cooling air is then channels into the multiple micro serpentine cooling flow circuits located around the four edges of the shroud segments. This cooling air then flows in a serpentine path through the horizontal serpentine flow channels and then discharged through the thin diffusion cooling slots as peripheral purge air for the mate faces as well as the spacing around the BOAS or shroud segments. Trip strips are used in the serpentine flow channels for the augmentation of internal heat transfer cooling capability. The micro serpentine flow cooling air circuits spaced around the four edges of the shroud segments are formed into the shroud segments during the casting process of the shroud segments.

Owner:FLORIDA TURBINE TECH

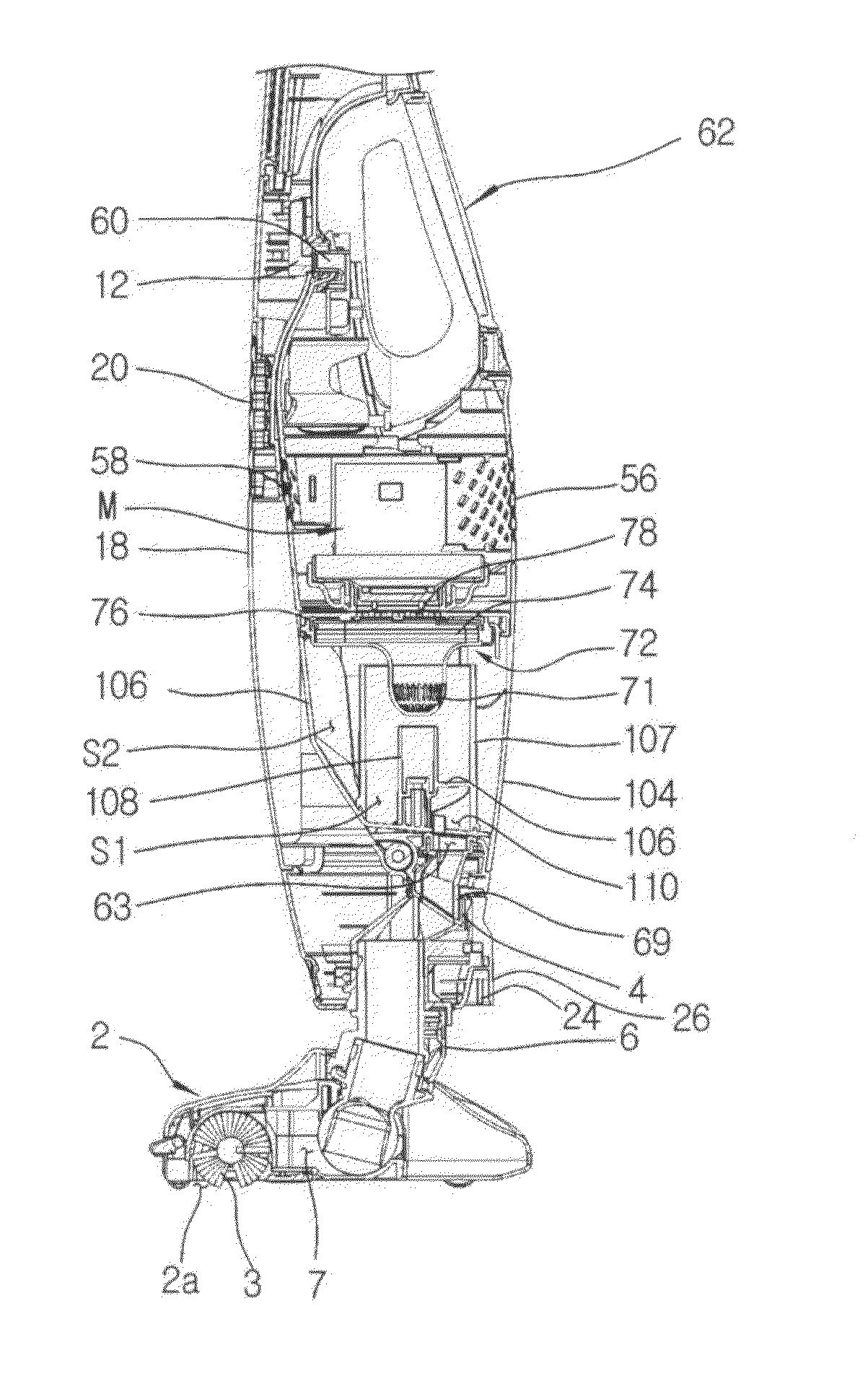

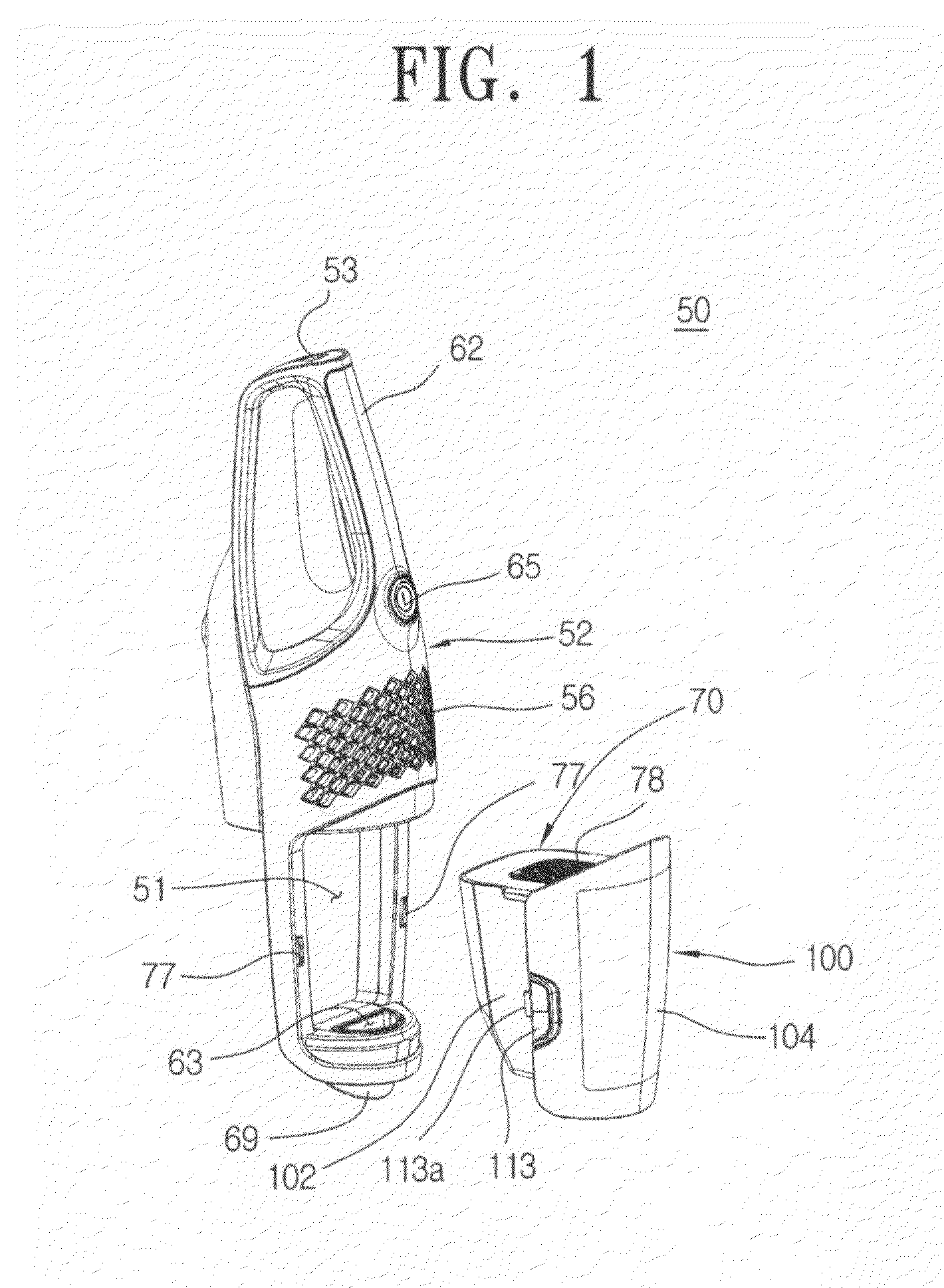

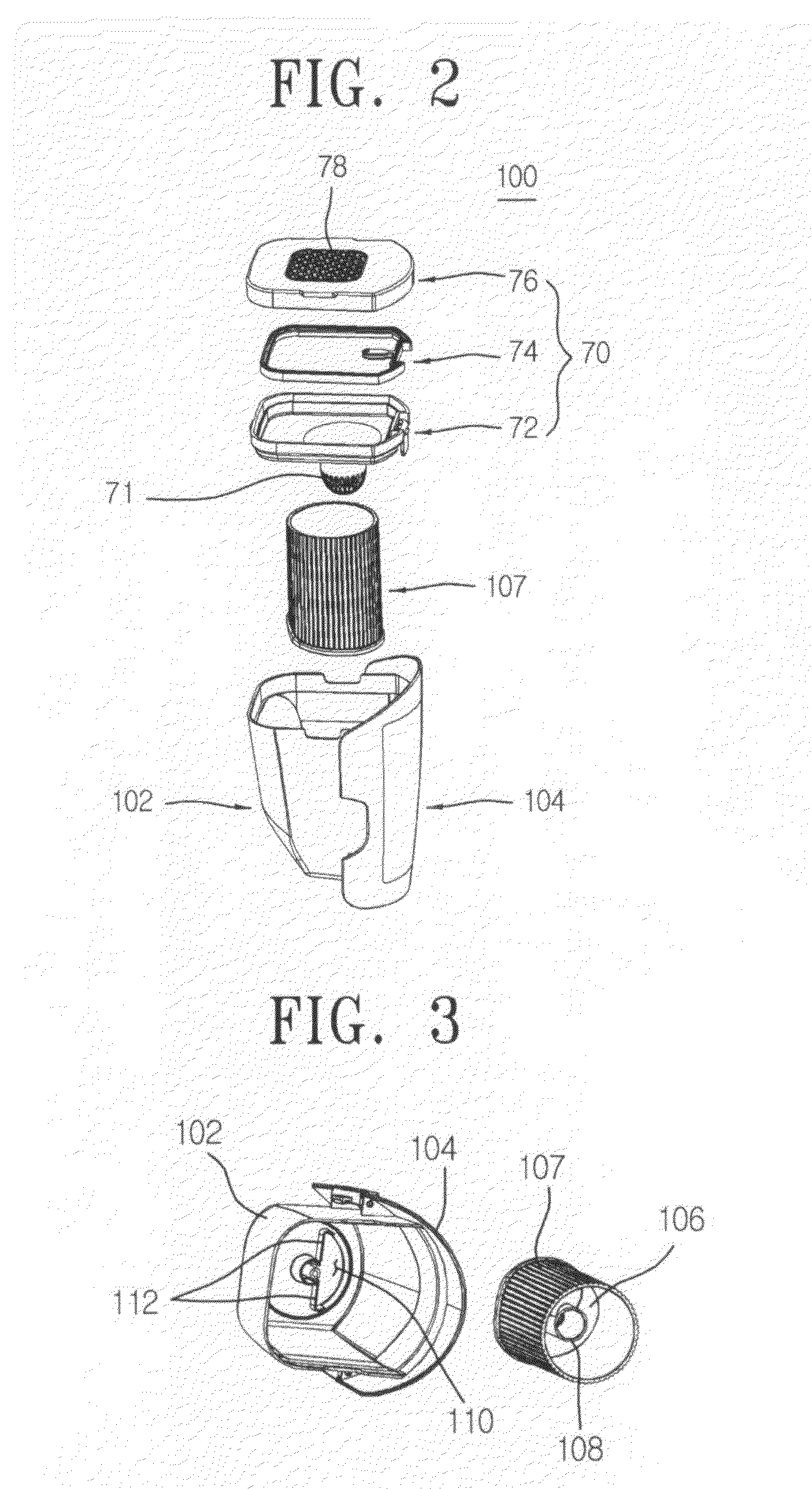

Cyclone dust collecting apparatus and hand-held cleaner having the same

ActiveUS20110289720A1Reduce total pressure lossImprove efficiencyCombination devicesVortex flow apparatusCycloneSpiral flow

The hand-held cleaner includes a body, and a cyclone dust collecting apparatus detachably mounted in the body. The cyclone dust collecting apparatus includes a pre-motor filter unit having a filter grill and a filter member, a dust collecting bin having one end to which the pre-motor filter unit is coupled and the other end opposite to the one end in which an cyclone inlet is formed, and a cyclone bin disposed in the dust collecting bin and having a spiral flow path-guide member integrally formed therein. A moving path of air drawn into the cyclone inlet is maintained in the same direction until the air is discharged through the pre-motor filter unit via the cyclone bin.

Owner:SAMSUNG ELECTRONICS CO LTD

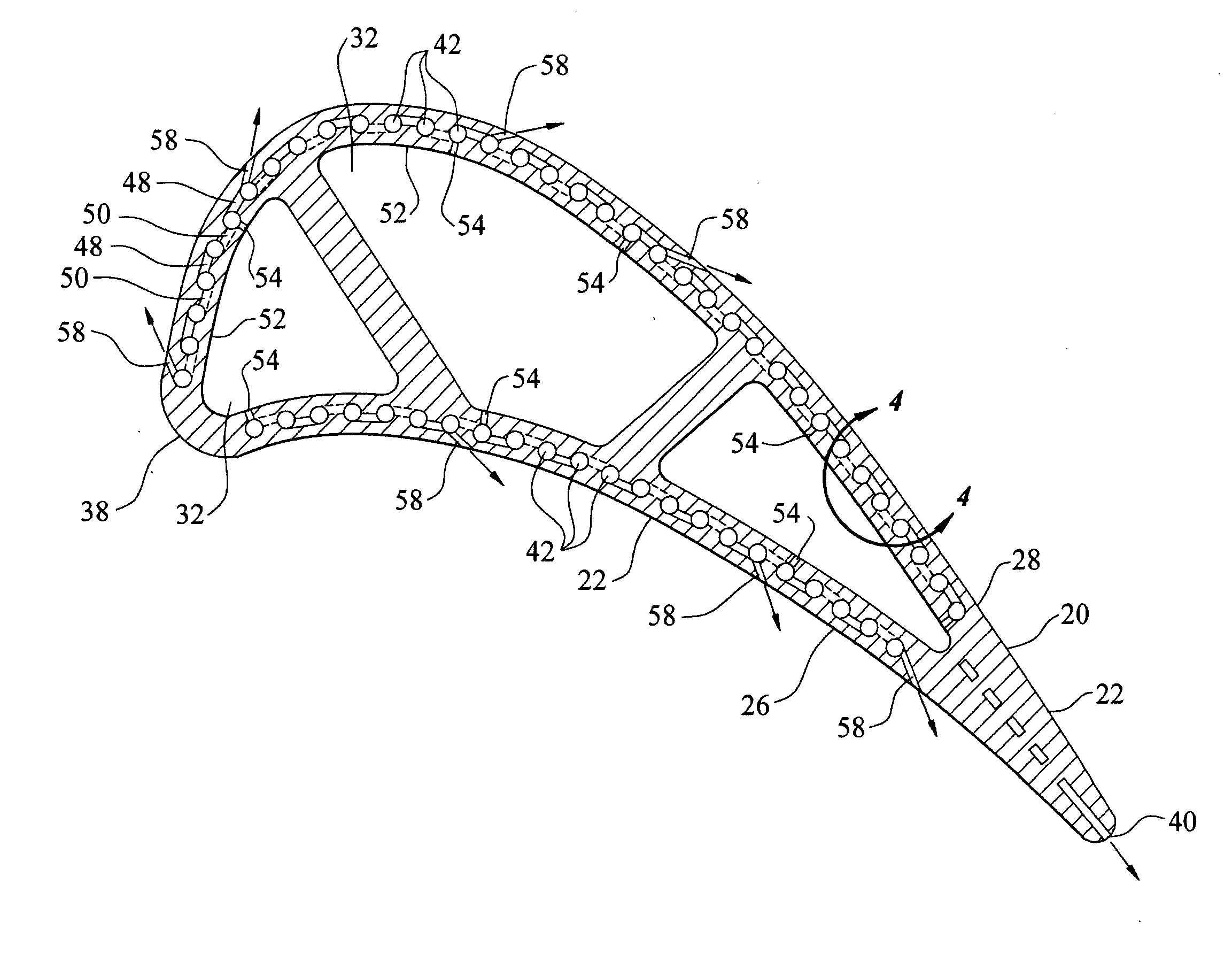

Cooling system for an outer wall of a turbine blade

InactiveUS20050031452A1Increase rate increaseLimit aerodynamic lossEngine manufactureBlade accessoriesTurbine bladeSpiral flow

A turbine blade for a turbine engine having a cooling system in at least an outer wall. The cooling system in at least the outer wall formed from at least a first plurality of parallel cavities intersected by a second plurality of parallel cavities positioned in a nonparallel position relative to the first plurality of parallel cavities. In at least one embodiment, the second plurality of parallel cavities may include an alternating configuration of cavities, such that a first cavity may be positioned proximate to an inner surface of the outer wall and a second cavity adjacent to the first cavity is positioned proximate to the outer surface of the outer wall. The first cavity may also be offset from the second cavity to form a spiral gas flow path. The cooling system in the outer wall of the turbine blade may form a spiral flow path.

Owner:SIEMENS ENERGY INC

Micromixer apparatus and methods of using same

Owner:AGENCY FOR SCI TECH & RES +1

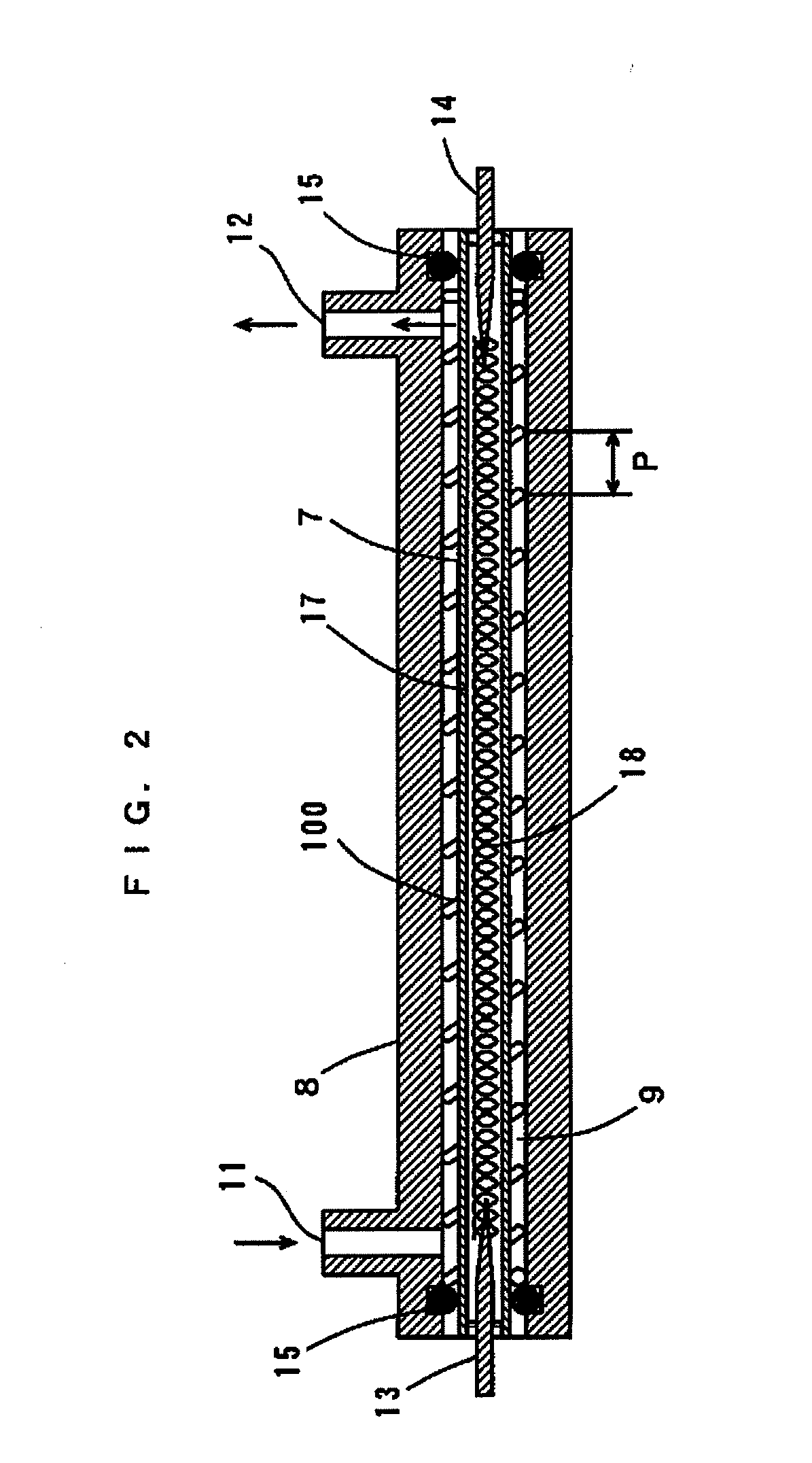

Heat exchanger

InactiveUS20110036544A1Reduce and prevent adhesionSolution to short lifeOther washing machinesLavatory sanitoryPlate heat exchangerCoil spring

A heat exchanger comprises a substantially pillar sheathed heater, a substantially cylindrical case, and a spiral spring. The sheathed heater is accommodated in the case. The spring is provided so as to be wound around an outer peripheral surface of the sheathed heater. Thus, a spiral flow path is formed among an outer peripheral surface of the sheathed heater, an inner peripheral surface of the case, and the spring. The spring functions as a flow velocity conversion mechanism, a turbulent flow generation mechanism, a flow direction conversion mechanism, and an impurity removal mechanism. A water inlet and a water outlet are respectively arranged at positions eccentric from a central axis of the case on a side surface of the case.

Owner:PANASONIC CORP

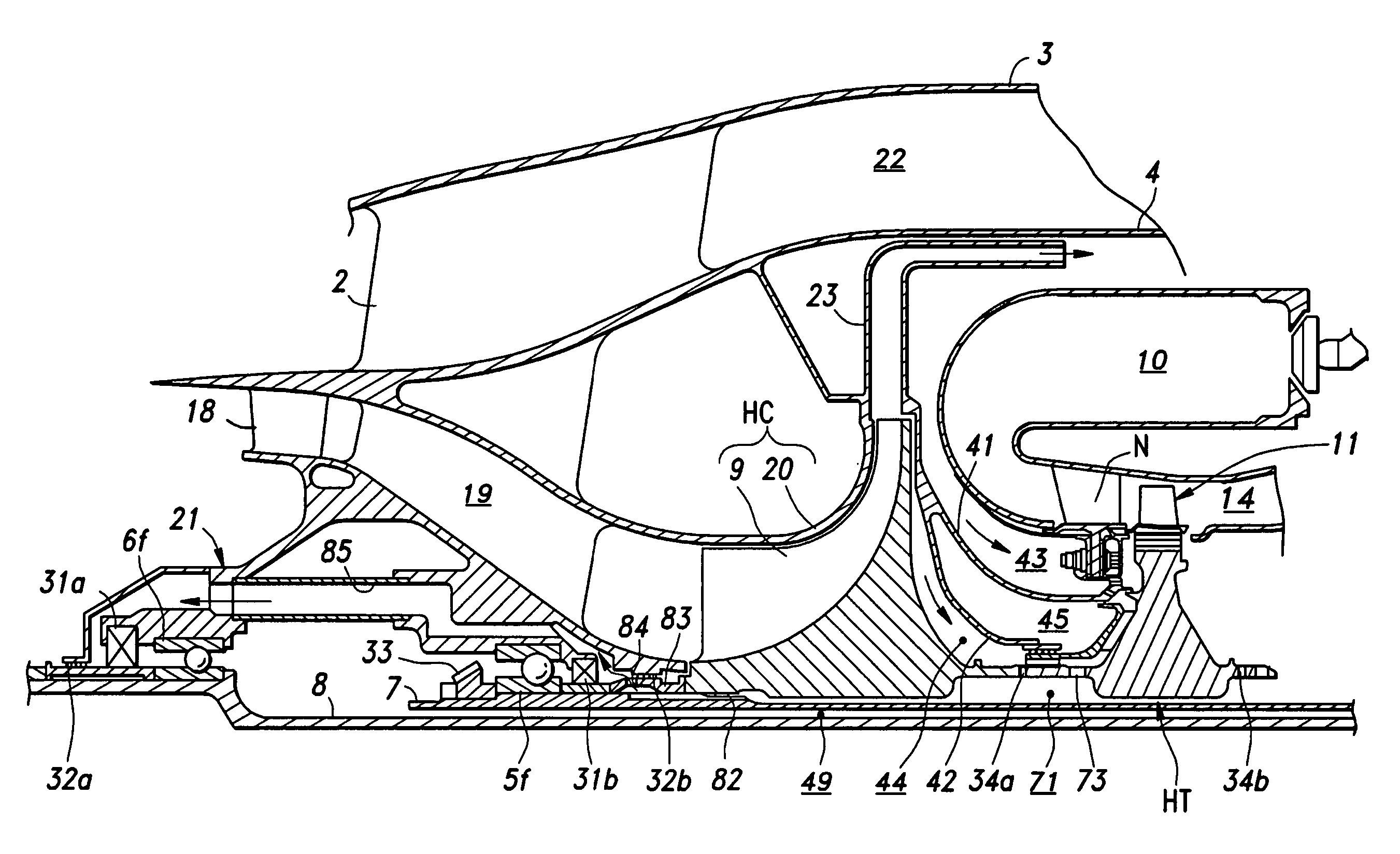

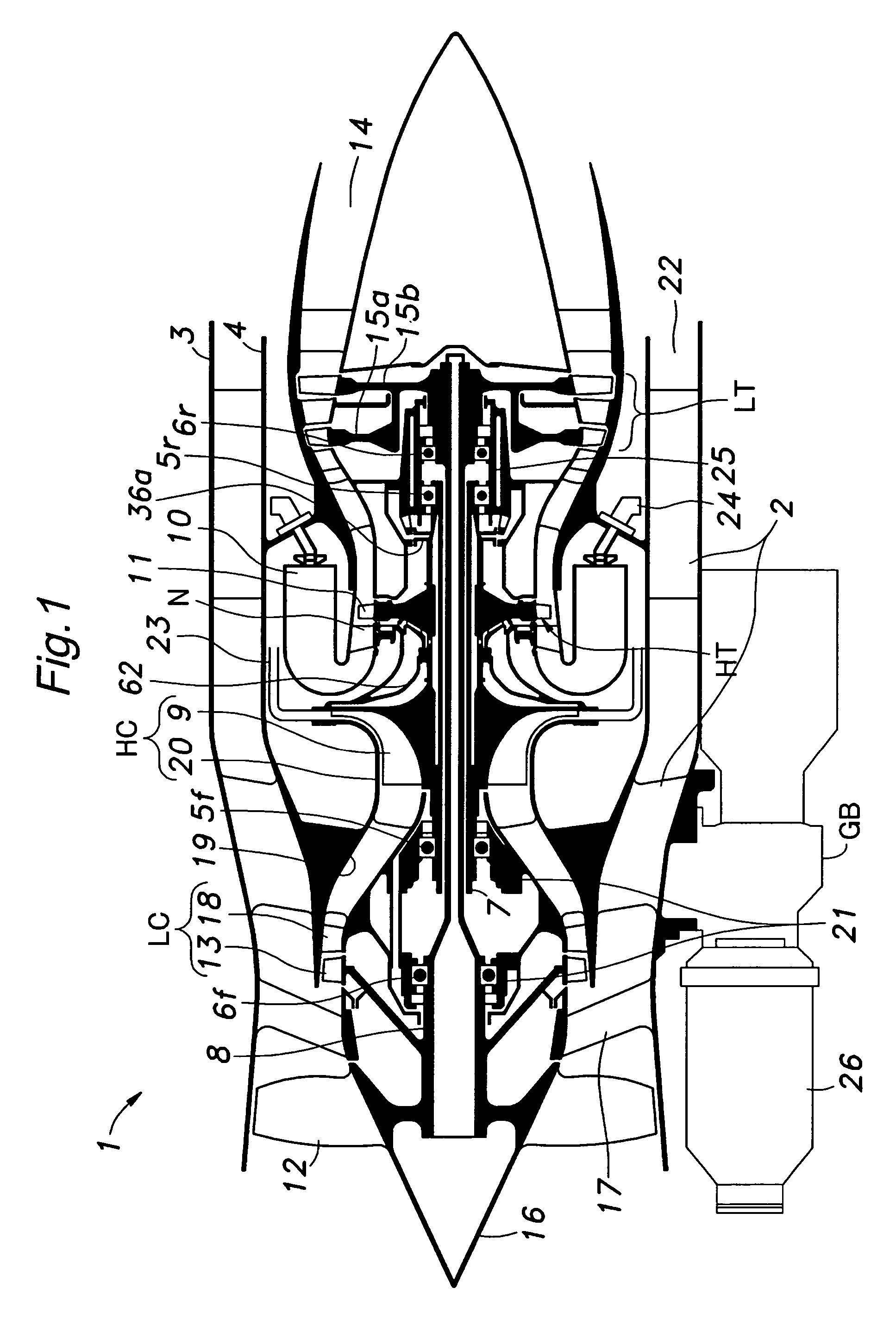

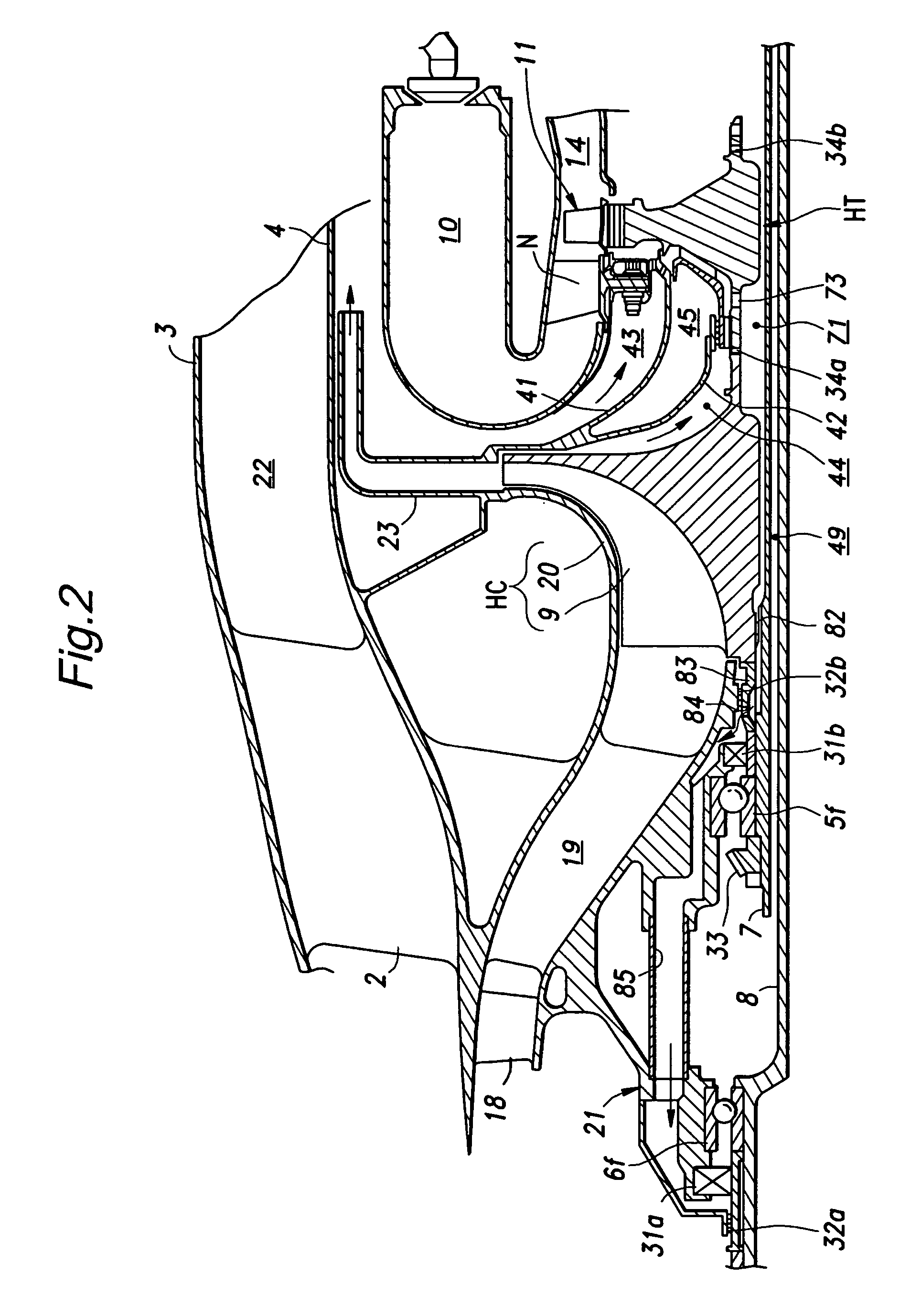

Device for supplying secondary air in a gas turbine engine

InactiveUS20060213202A1Without complicating structureGood energy dissipationBlade accessoriesGas turbine plantsImpellerHigh pressure

In a device for supplying secondary air in a gas turbine engine provided with an inner shaft (8) and a hollow outer shaft (7) coaxially nested with each other, a seal air introduction passage (71, 85, 88) is defined inside the engine for introducing a part of high pressure air drawn from a high pressure compressor into a seal section provided in each of the bearing boxes for supporting the inner and outer shafts; and a swirl air cooling turbine (59) is provided in the seal air introduction passage and attached to a part attached to the outer shaft in a rotationally fast manner. The swirl air cooling turbine (59) is formed around a section of the outer shaft intermediate between the high pressure compressor and the high pressure turbine, the swirl air cooling turbine including a spiral flow path extending in a substantially cylindrical plane coaxial with the outer shaft. Because the high pressure swirl air is cooled by the swirl air cooling turbine provided in a radially central part, the energy of the swirl air is effectively expended, and this prevents the generation of a stagnation zone. Thereby, the secondary air can be favorably cooled before it is forwarded to the user such as the bearing boxes without causing an undue rise in the pressure of the impeller back chamber.

Owner:HONDA MOTOR CO LTD

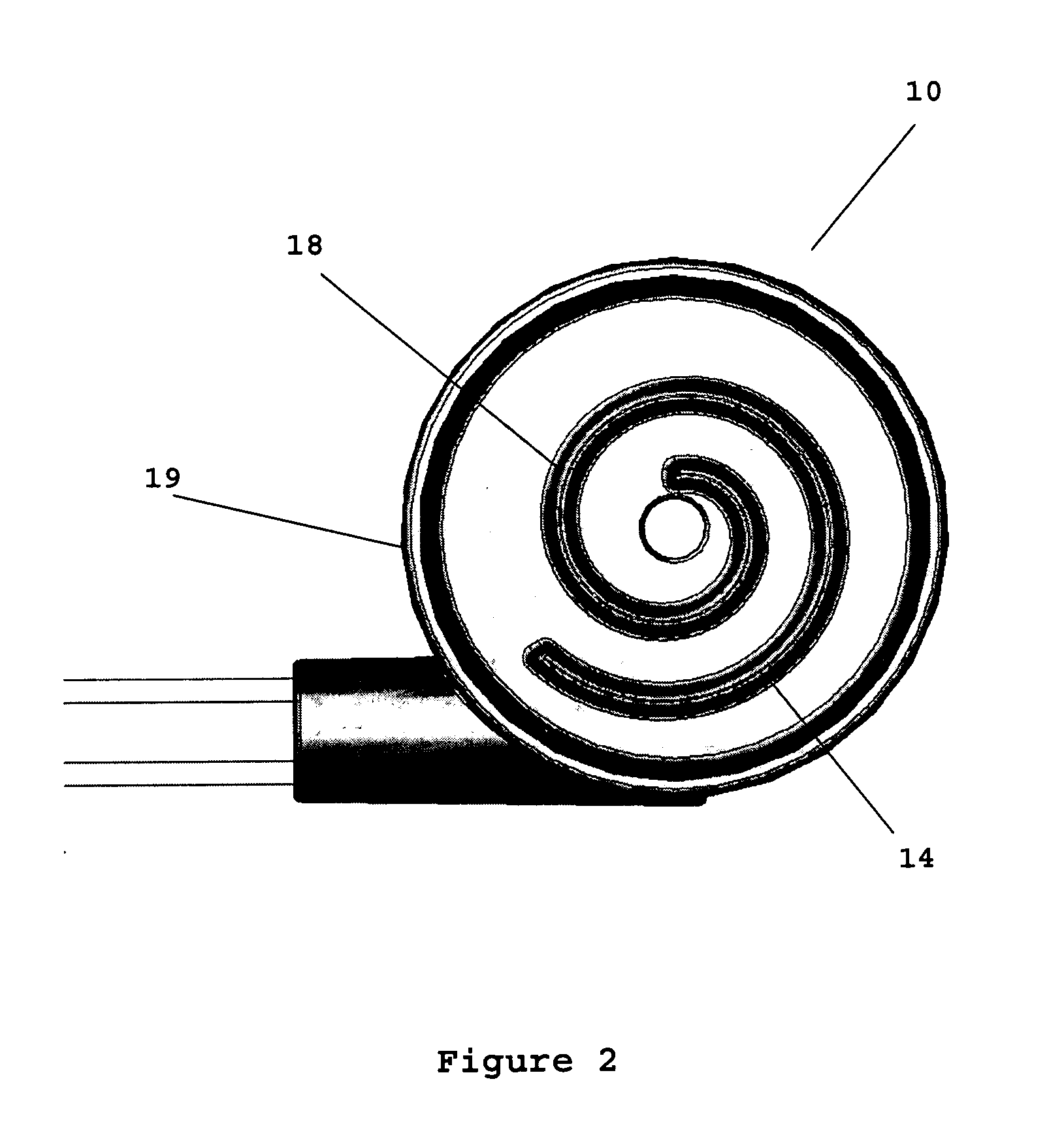

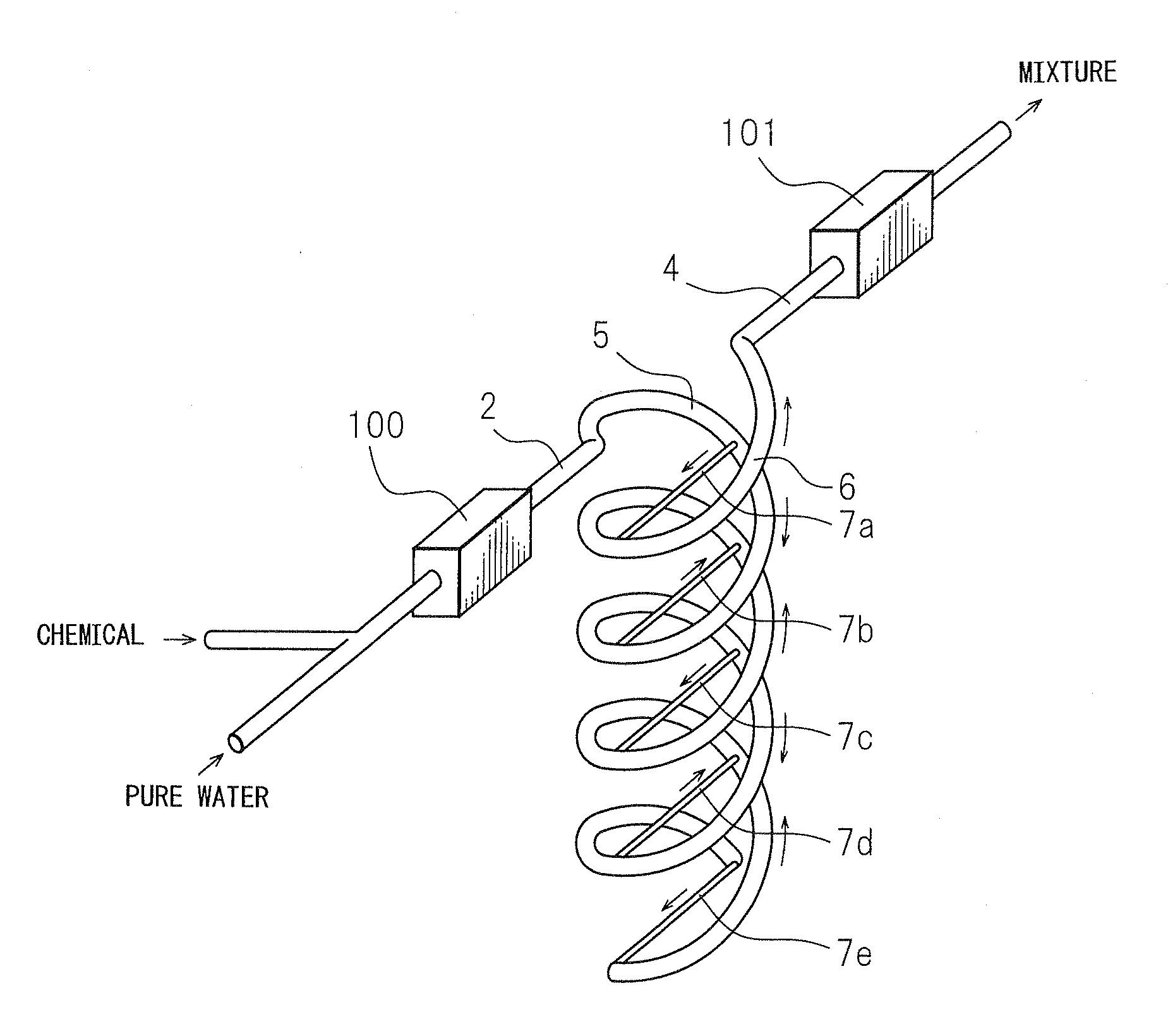

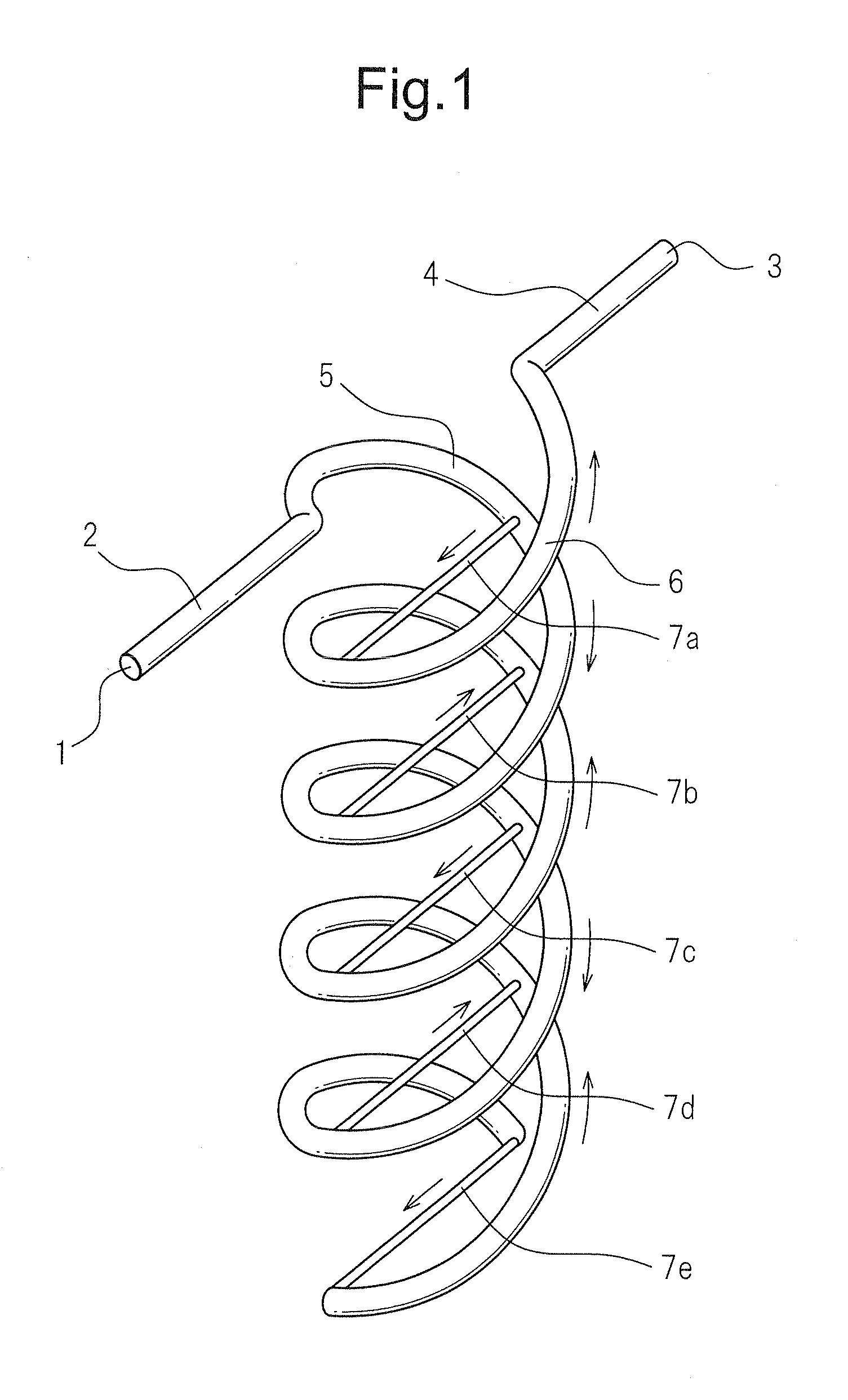

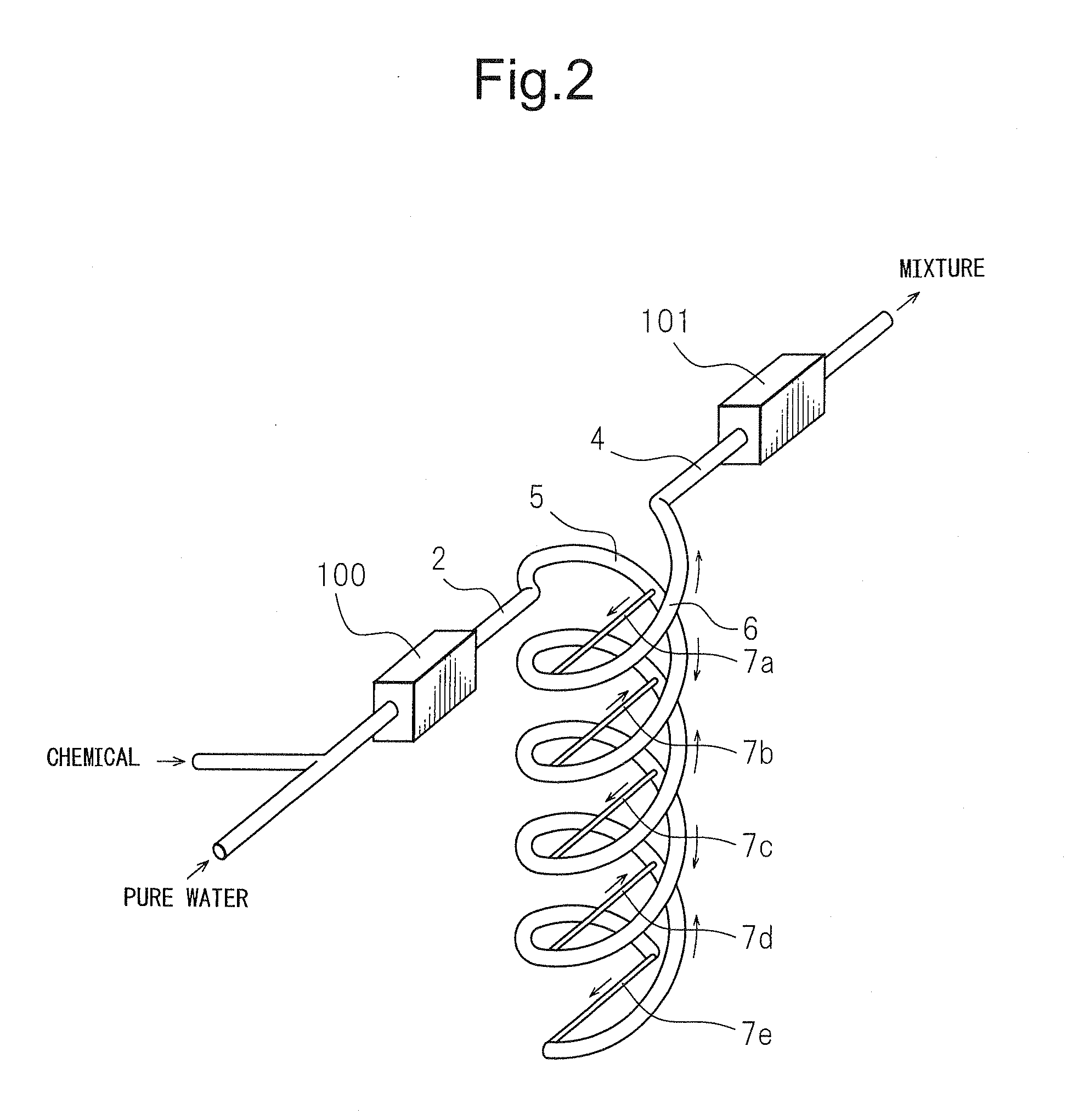

Fluid mixer and apparatus using fluid mixer

ActiveUS20110128814A1Avoid defectsEvenly distributedFlow mixersTransportation and packagingEngineeringSpiral flow

A fluid mixer which can mix fluid while making the distribution of concentration or distribution of temperature of the fluid in the direction of flow uniform without any unevenness and which is both compact and easy to install piping for is provided. This fluid mixer has a fluid inlet, a first flow path connected to the fluid inlet, a spiral flow path connected to the first flow path, a plurality of branch flow paths branched from the spiral flow path, a second flow path to which the plurality of branch flow paths are connected, and a fluid outlet connected to the second flow path, the plurality of branch flow paths branching from different positions of the spiral flow path and being connected with the second flow path at different positions of the second flow path.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Bladeless conical radial turbine and method

ActiveUS7192244B2Improve efficiencyIncrease speedEngine manufacturePump componentsEngineeringRadial turbine

Turbo-machinery and methods are disclosed for a bladeless conical radial turbine wherein fluid is directed axially within the pump body to produce an axial output. The rotor comprises a plurality of spaced apart conical elements. A plurality of spiraling flow paths may be provided to receive fluid to which fluid has been imparted by acceleration of the fluid through the spaces between the conical elements using boundary layer adhesion techniques. The fluid is smoothly directed to any number of subsequent boundary layer pumping stages which are axially positioned with respect to each other.

Owner:GRANDE III SALVATORE F +1

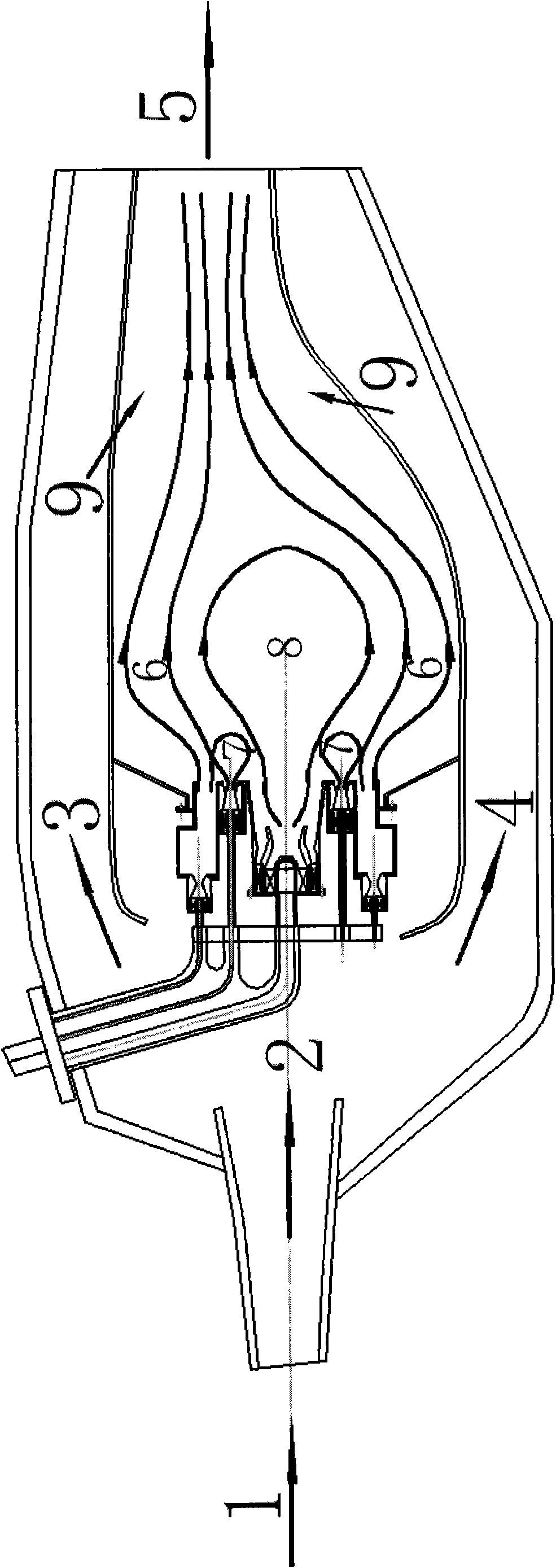

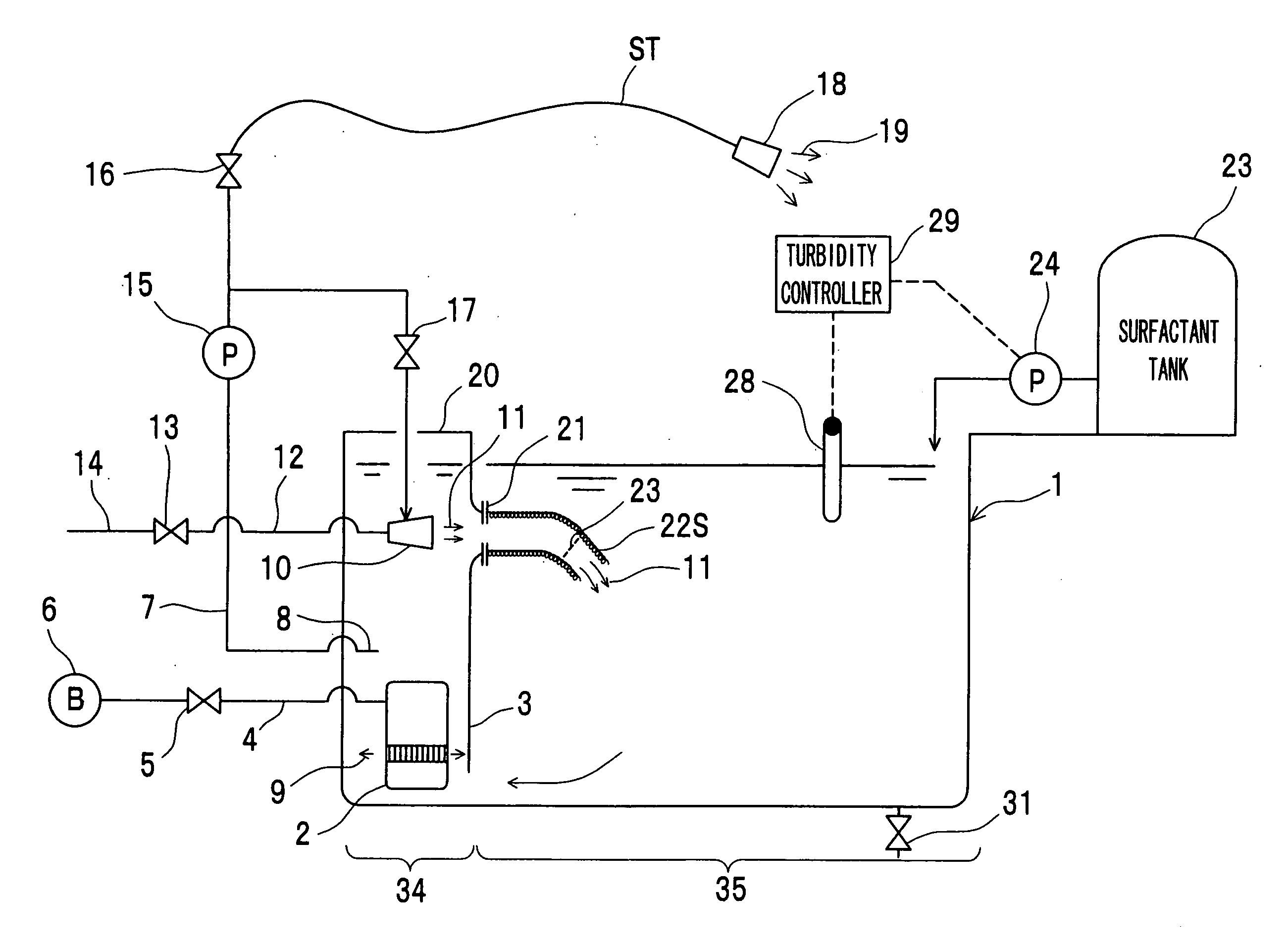

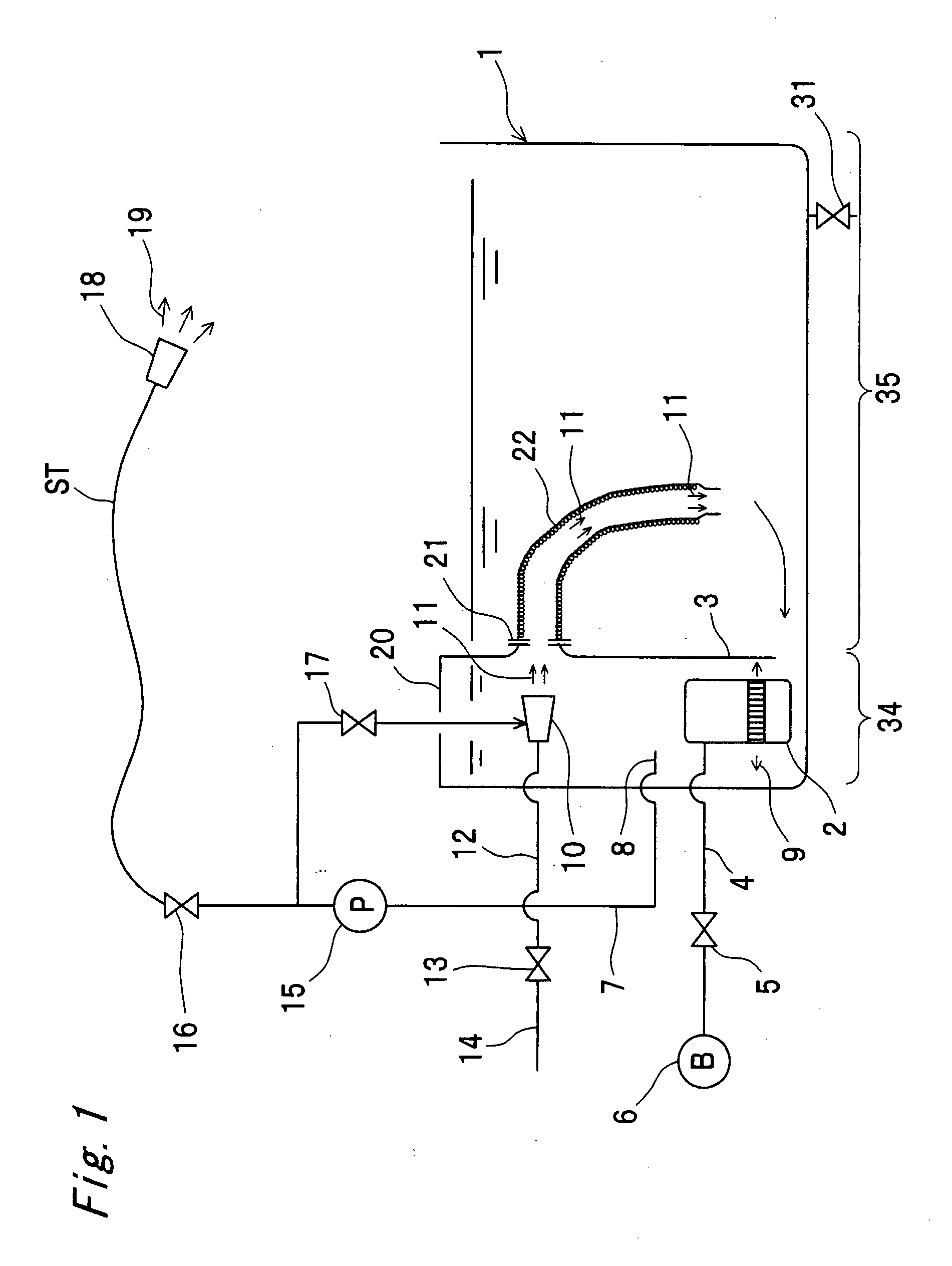

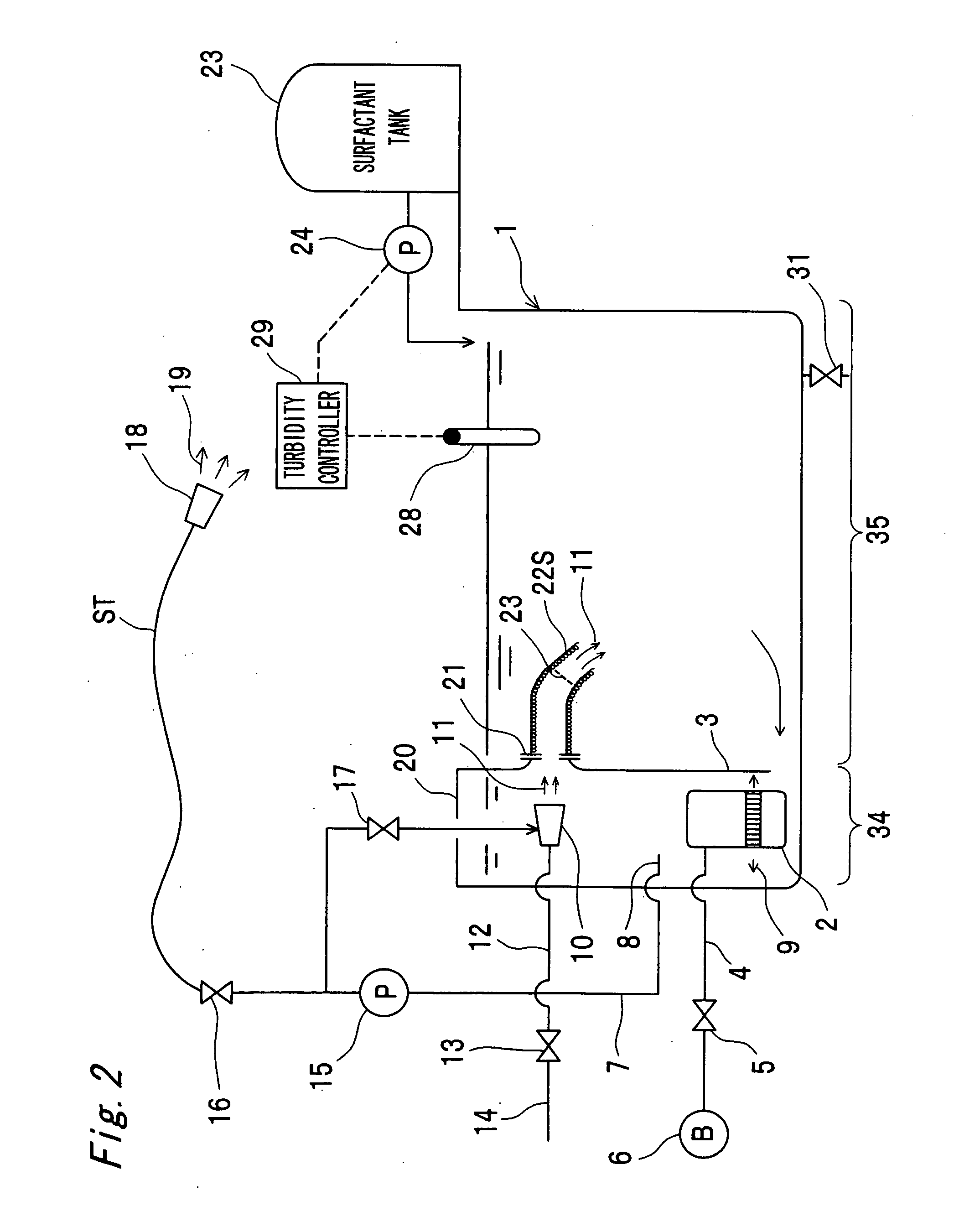

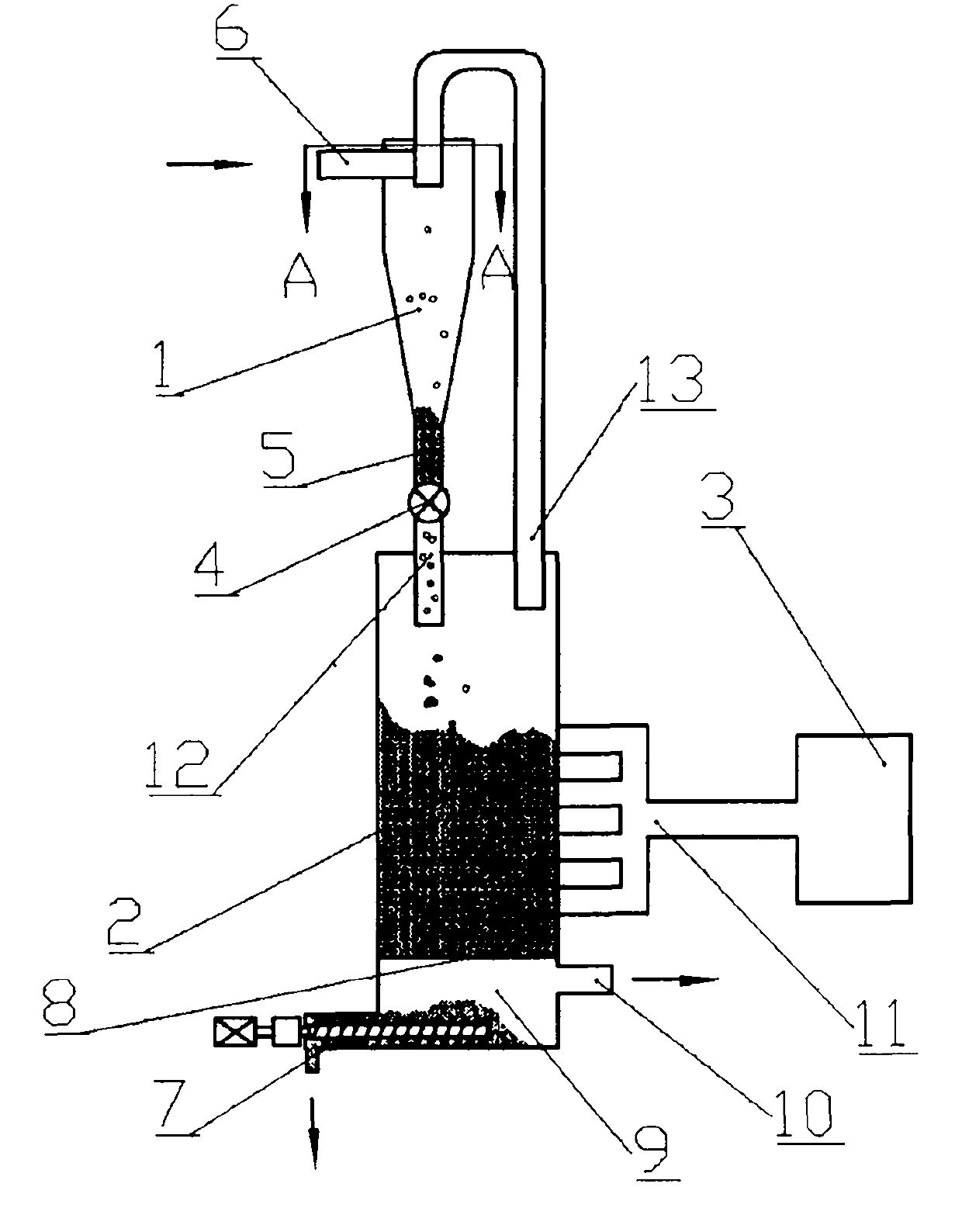

Manufacturing method for micro-nano bubble bathtub water and micro-nano bubble bathtub

In the upper part and the lower part of a micro-nano bubble generation section 34 in a micro-nano bubble bathtub 1, two kinds of micro-nano bubbles different in a size distribution are generated by first and second micro-nano bubble generators (submerged pump-type micro-nano bubble generator 2 and spiral flow-type micro-nano bubble generator 10) of two kinds, so that bathtub water containing micro-nano bubbles in a wide size distribution can be produced in a large amount. Some of the water containing micro-nano bubbles generated in the lower part is thrown into the first micro-nano bubble generator (spiral flow-type micro-nano bubble generator 10) in the upper part, so that the spiral flow-type micro-nano bubble generator 10 can generate micro-nano bubbles in a smaller size. Therefore, in this bathtub, micro-nano bubbles abundant in size and large in amount can be produced economically.

Owner:SHARP KK

Method and device for preparing low-tar combustible gas through biomass gasification

ActiveCN101906323AHigh cracking rateMake up for the problem of low conduction rateGranular/pulverulent flues gasificationFixed bedCombustible gas

The invention discloses a method and a device for preparing a low-tar combustible gas through biomass gasification. The method comprises the followings steps of: pulverizing and gasifying biomass, and rapidly separating obtained gasification gas products and biomass char; heating and activating the biomass char in a microwave field; catalytically cracking tar in the gasification gas products by introducing the gasification gas products to pass through a treated biomass char layer, and carrying out secondary reaction on the gasification gas and the biomass char to produce the combustible gas. The device comprises a spiral-flow gasifier 1, a fixed bed reactor 2 and a microwave generator 3 which are connected through ducts, and the middle part of the fixed bed reactor is connected with the microwave generator 3 through a microwave duct 11. The microwave technology is applied to tar cracking, so that the problem of low heat transfer speed due to porous and loose biomass char is solved. Meanwhile, the cracking rate of tar and the secondary reaction activity between the char and the gasification gas are increased by using the 'hot spot effect' of microwaves. The device has the advantages of strong adaptability, simple and compact structure and easy enlargement.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

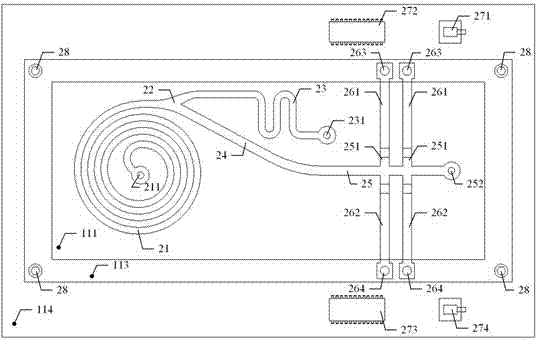

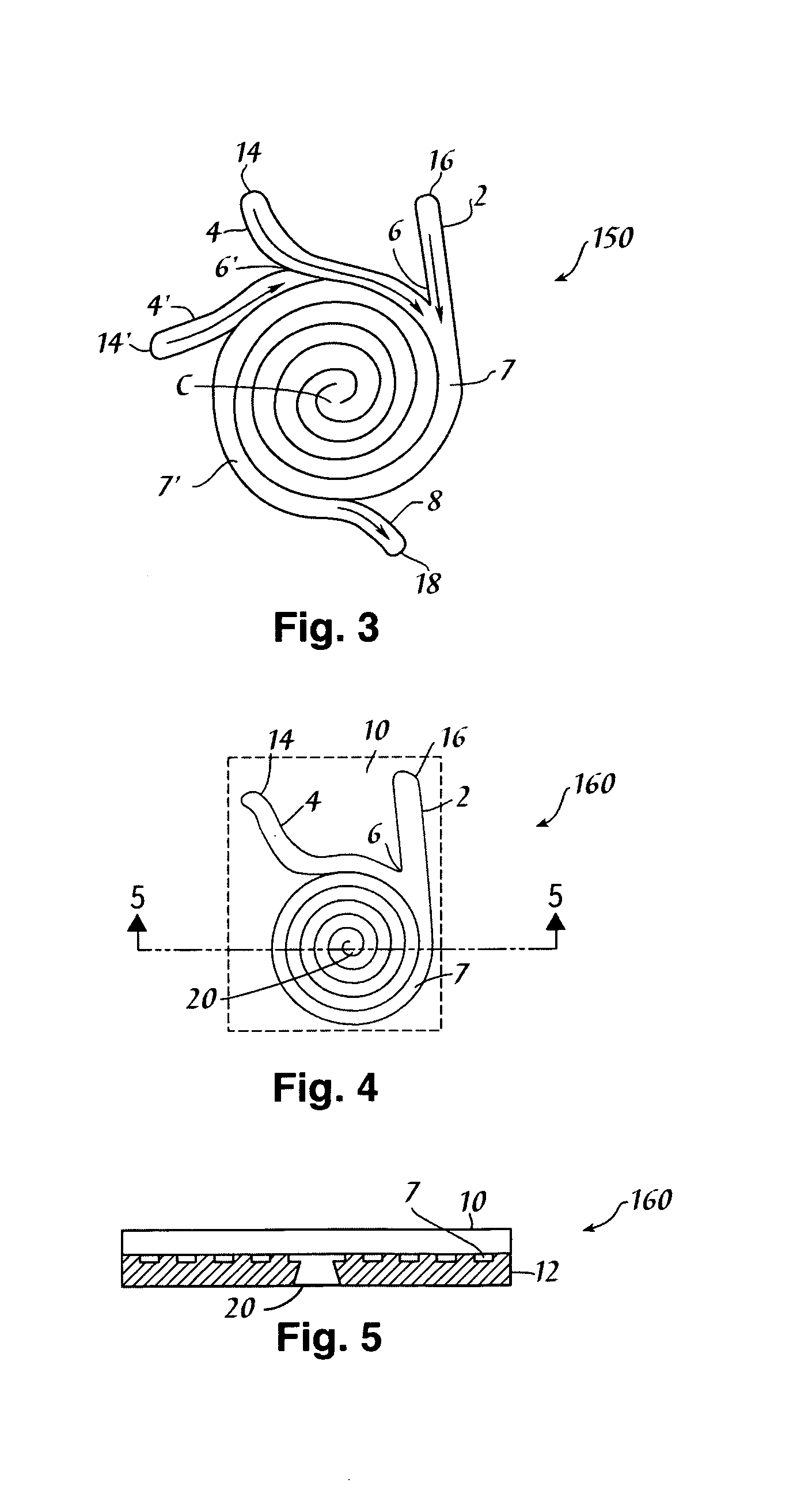

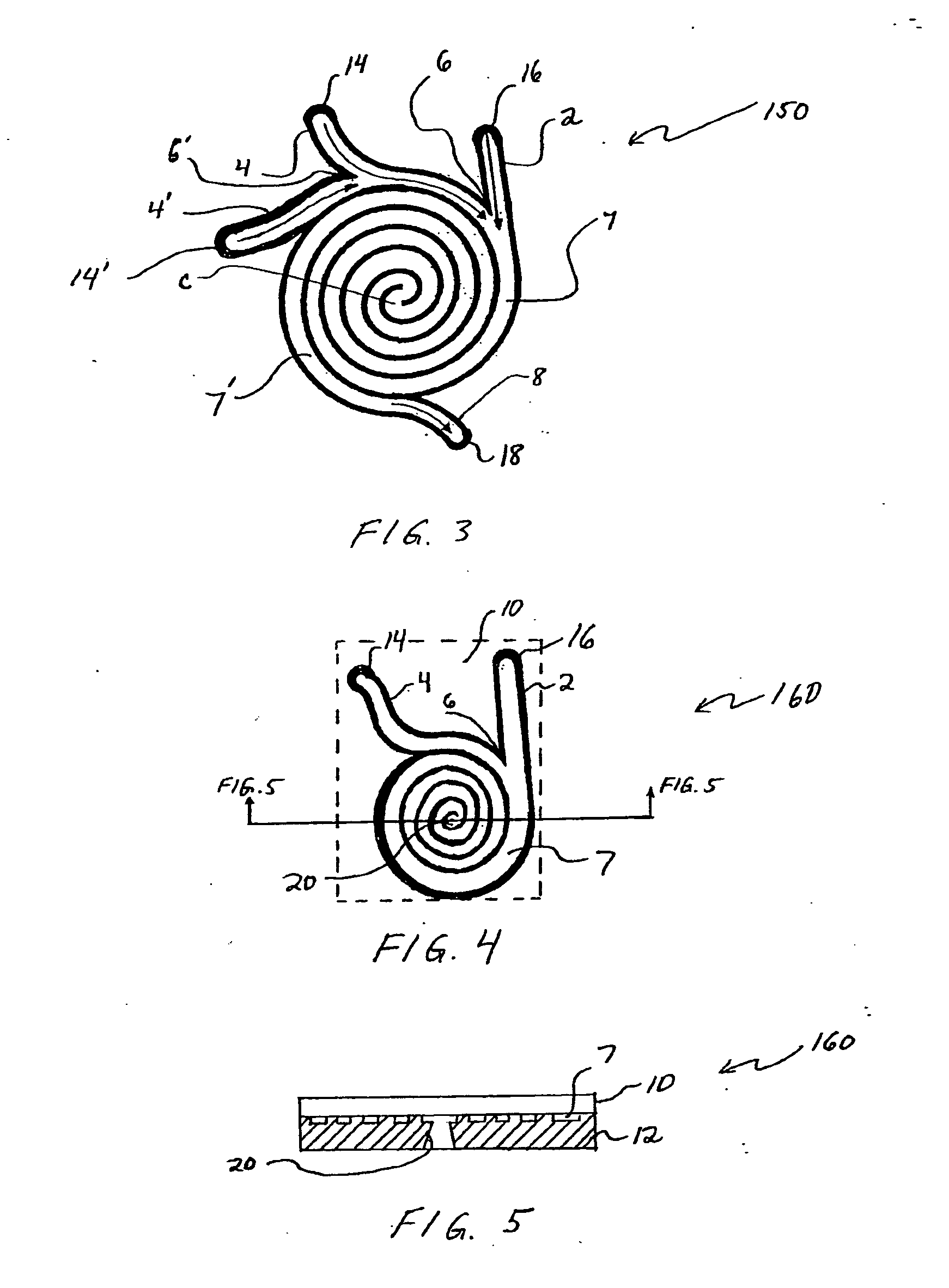

Micromixer apparatus and methods of using same

Microfluidics mixing apparatus and methods of using same are disclosed for mixing fluids using increasing centrifugal force as the fluids being mixed traverse a mixing channel. One inventive apparatus comprises a generally planar substrate having a top major surface and a bottom major surface generally parallel to the top major surface, and a cover plate over the top major surface. The substrate has at least one inlet port that routes fluid to the top major surface, and at least one outlet port for mixed fluid. The substrate comprises a mixing channel having a depth measured from the top surface and a width, the mixing channel adapted to route fluids to be mixed therein in laminar flow and in a substantially spiral flow pattern that is parallel to the top surface. Apparatus of the invention can mix fluids flowing serially, or two or more fluids entering the device from different feed channels.

Owner:AGENCY FOR SCI TECH & RES

Bladeless conical radial turbine and method

ActiveUS20050214109A1Improve efficiencyIncrease speedEngine manufacturePump componentsEngineeringRadial turbine

Turbo-machinery and methods are disclosed for a bladeless conical radial turbine wherein fluid is directed axially within the pump body to produce an axial output. The rotor comprises a plurality of spaced apart conical elements. A plurality of spiraling flow paths may be provided to receive fluid to which fluid has been imparted by acceleration of the fluid through the spaces between the conical elements using boundary layer adhesion techniques. The fluid is smoothly directed to any number of subsequent boundary layer pumping stages which are axially positioned with respect to each other.

Owner:GRANDE III SALVATORE F +1

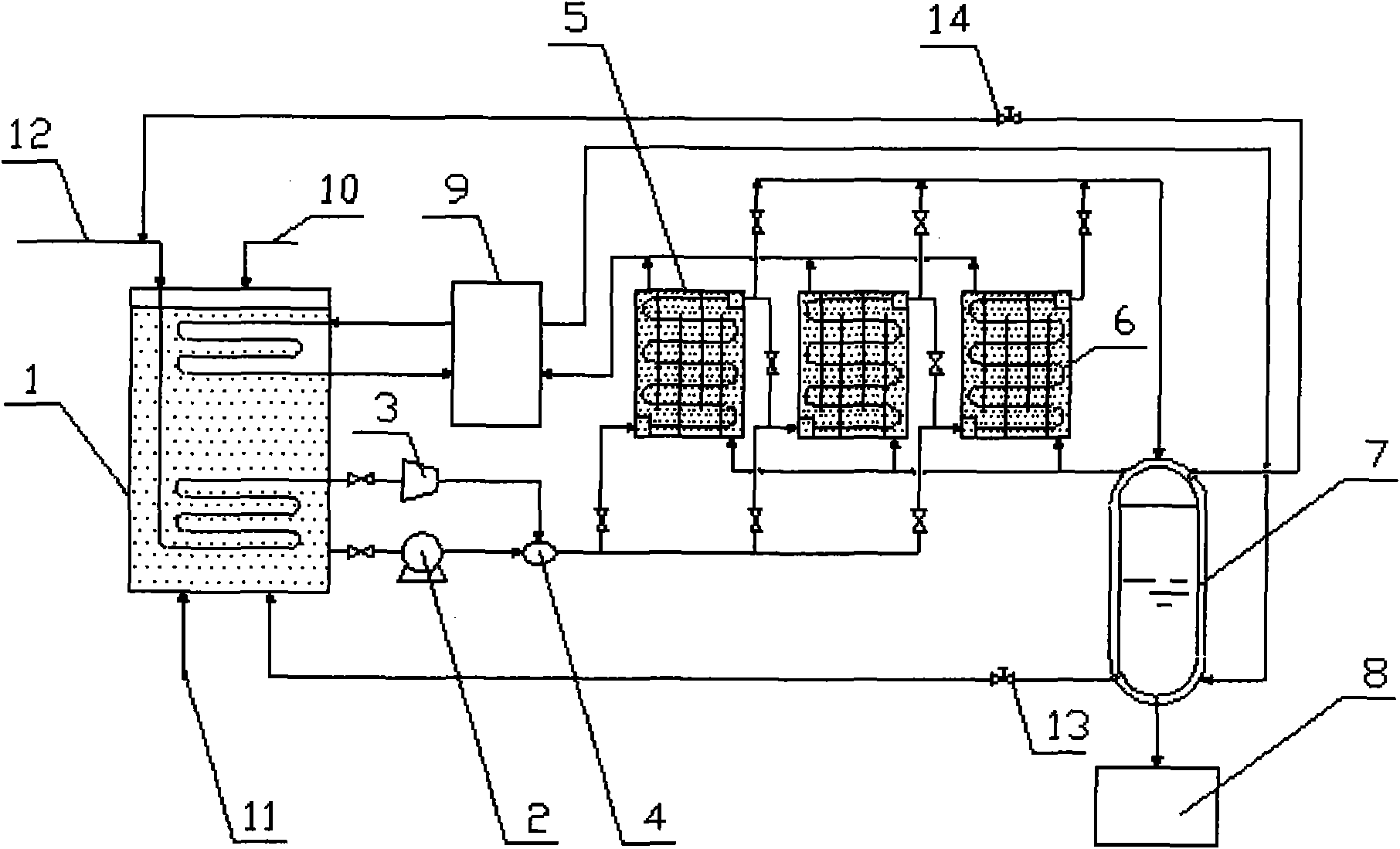

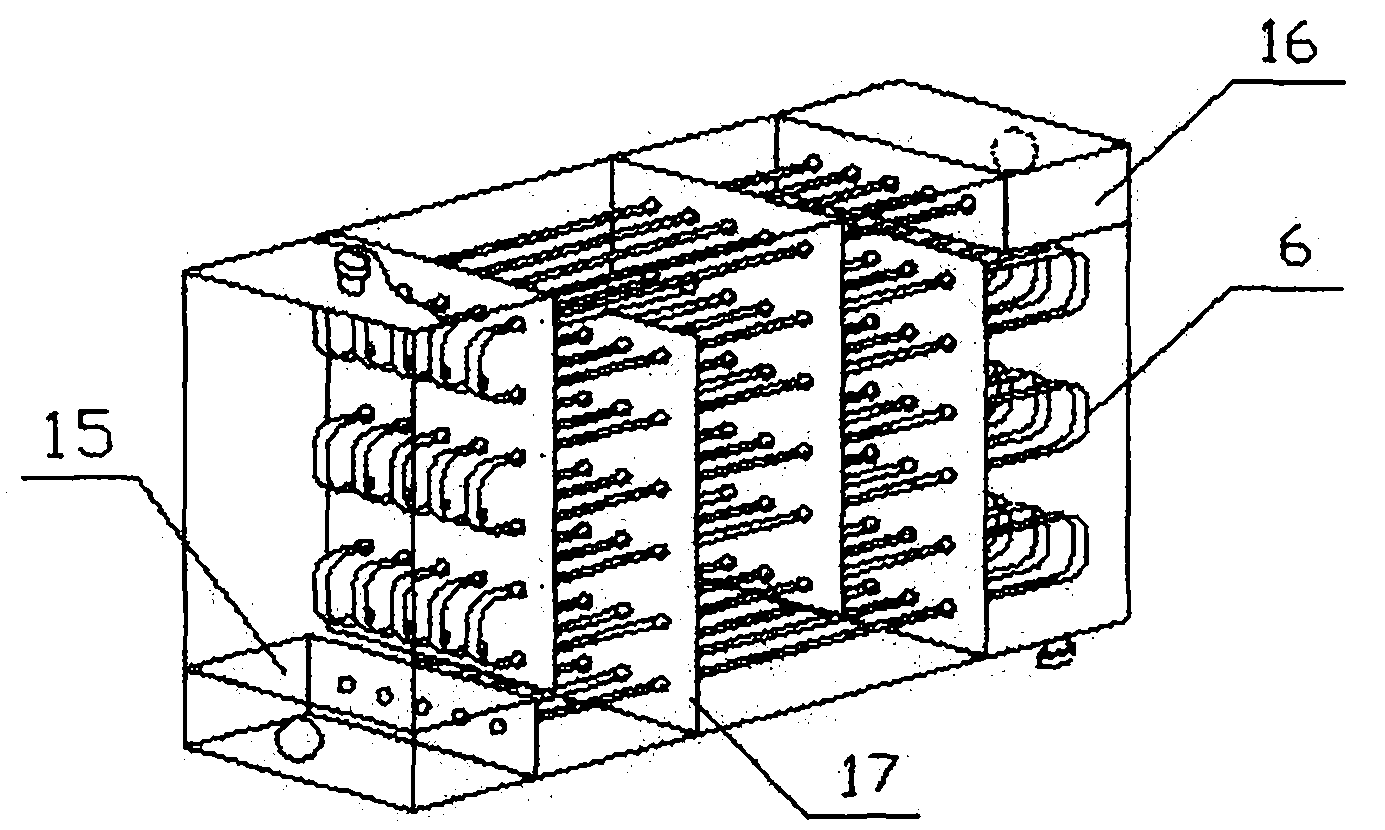

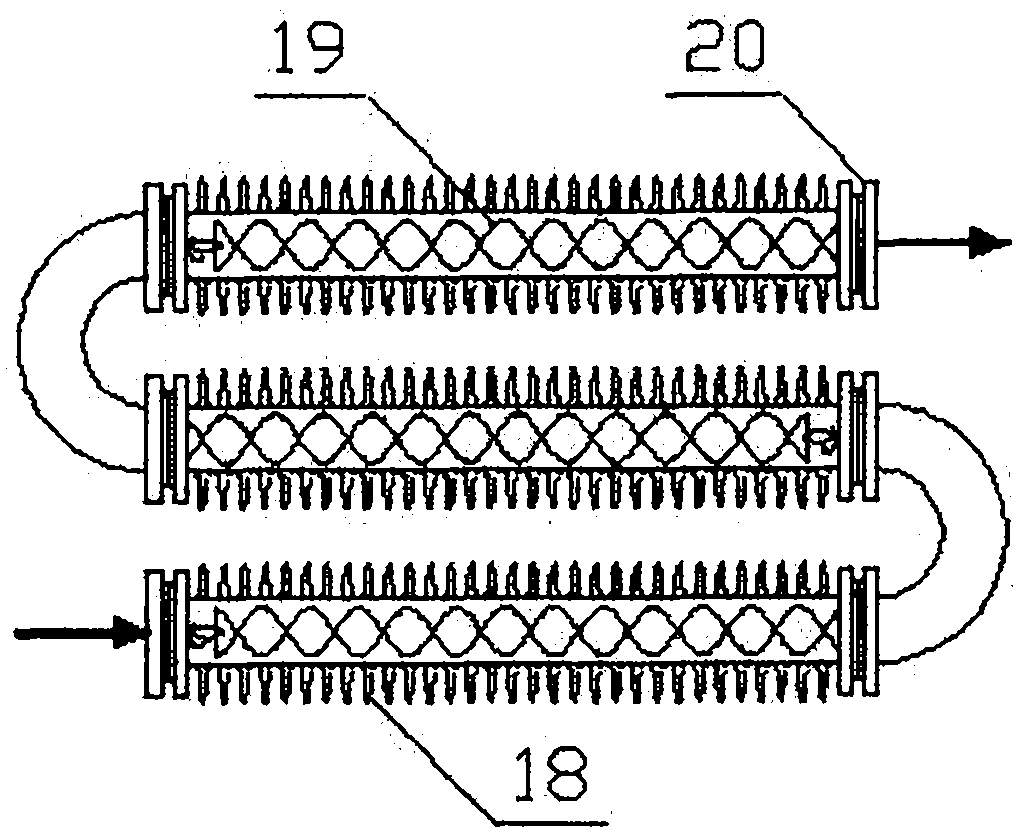

Efficient continuous preparation method and device for natural gas hydrate

The invention relates to an efficient continuous preparation method and an efficient continuous preparation device for a natural gas hydrate. The method comprises the following steps of: feeding water from a water supply pipe and a hydrate promoter from a medicating pipe into a low-temperature water tank together, cooling the mixture to a hydrate forming temperature through low-temperature water bath, and driving the mixture into a pipeline through a booster water pump; cooling natural gas from a gas inlet pipe through the low-temperature water tank, then charging the natural gas into a gas compressor, and mixing the water boosted by the booster water pump and carrying the promoter and the natural gas boosted by the gas compressor in a gas-liquid mixer together; feeding the gas-liquid mixture into a folding tubular reactor to perform spiral flow, fully mixing the gas and the liquid and exchanging heat, efficiently and continuously obtaining generated hydrate slurry, cooling the hydrate slurry in a hydrate separator to further generate a hydrate, then separating the hydrate, and feeding the separated hydrate into a hydrate storage tank. The method and the device have the advantagesof increasing the gas-water contact area, quickly removing hydrate generating heat and realizing efficient and continuous preparation of the natural gas hydrate under dynamic conditions, with the yield of 500kg / h.

Owner:溧阳常大技术转移中心有限公司

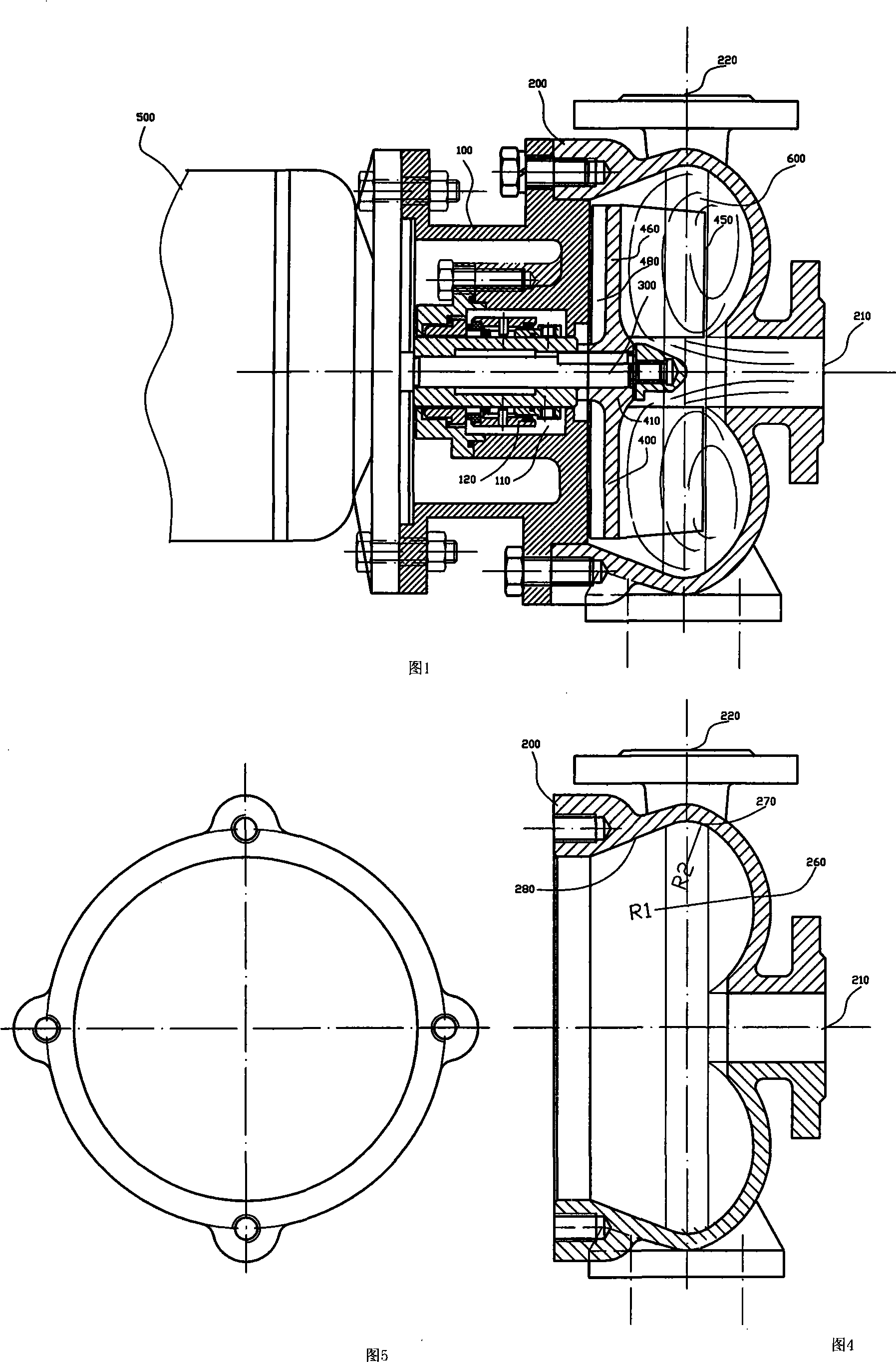

Spiral flow constant-pressure pump

Owner:李世煌

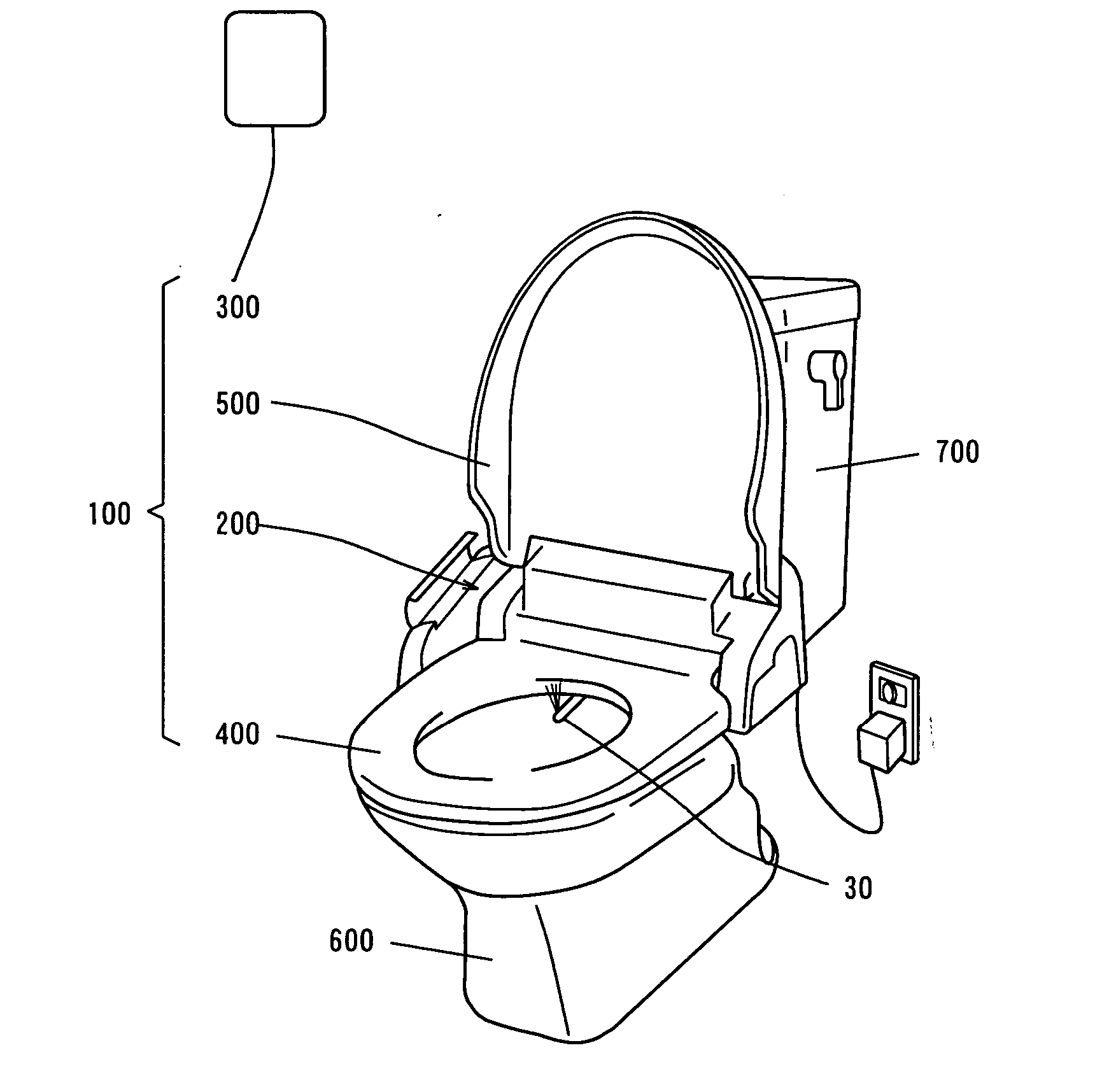

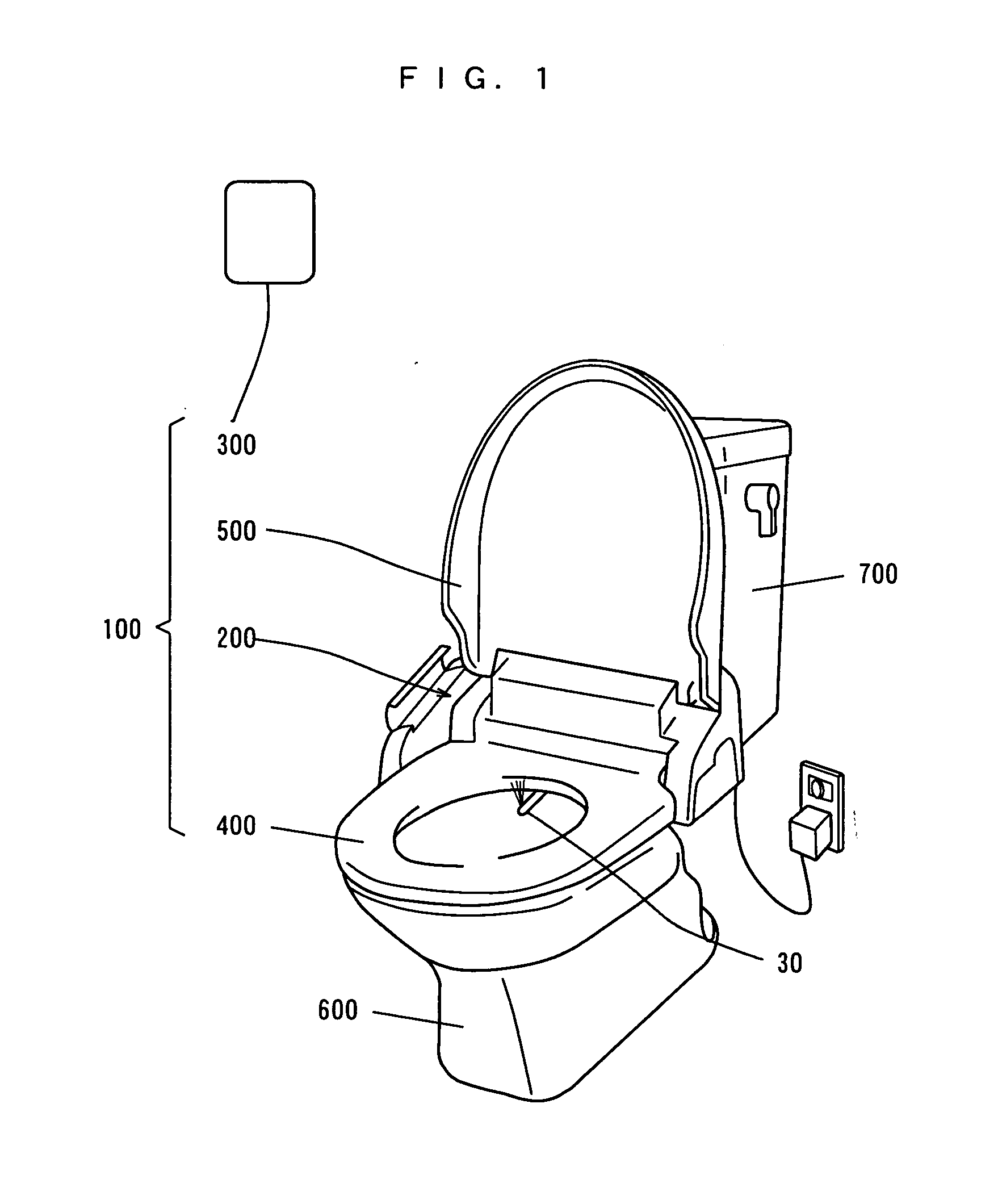

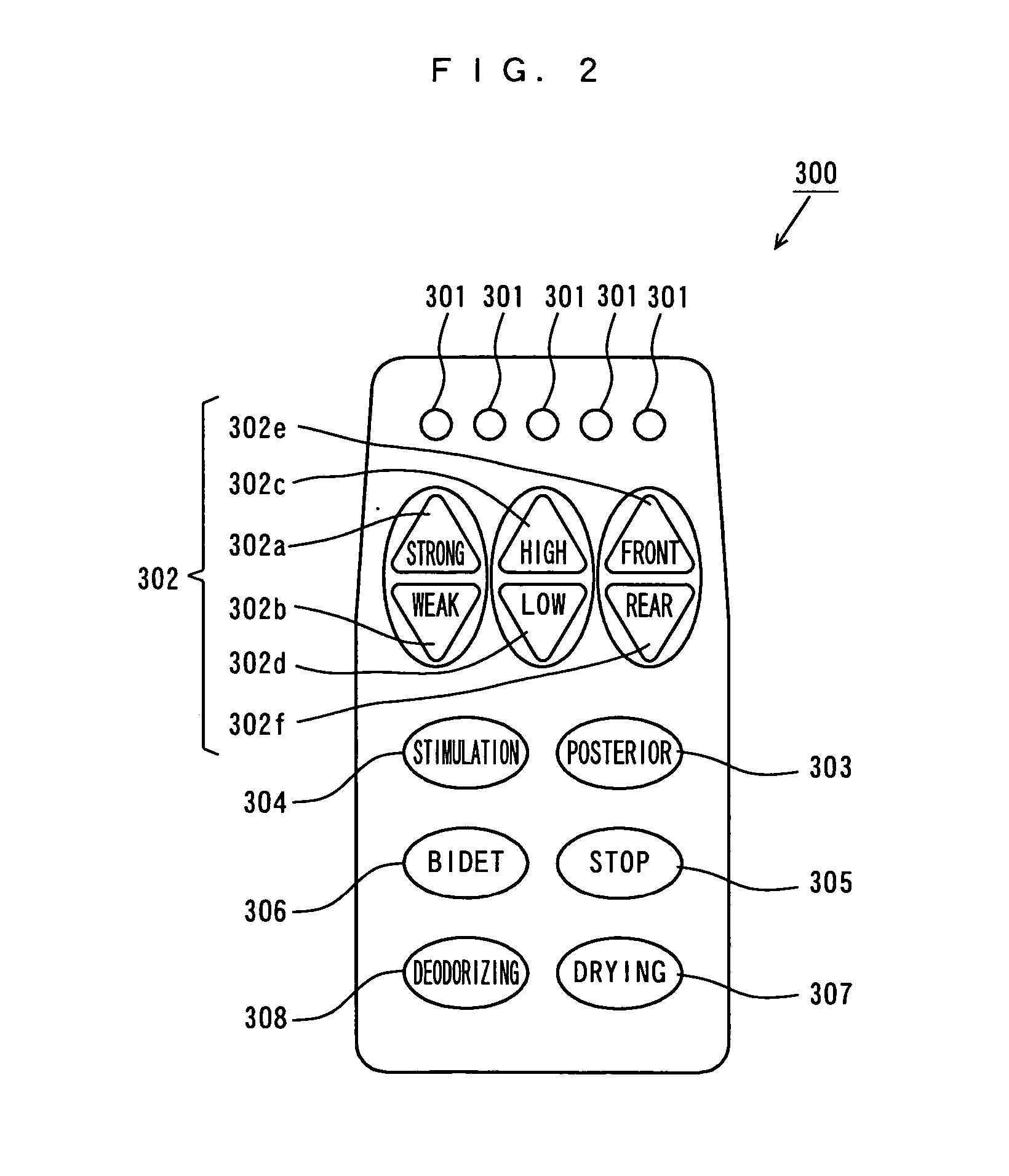

Nozzle device and hygienic washing device

Since the inner diameter of a flow-contracting portion continuously decreases toward a cylindrical swirl chamber, the velocity of flow of washing water flowing in the flow-contracting portion continuously rises. Since the inner diameter of the flow-contracting portion continuously decreases toward a spray hole, the velocity of flow of the washing water flowing in the flow-contracting portion continuously rises. Washing water supplied to one of flow paths in a two-flow path pipe is supplied to a flow path merger through a one-flow path pipe. The washing water supplied to the other flow path in the two-flow path pipe is supplied to the flow path merger after passing through a space between the one-flow path pipe and a nozzle cover. Washing water sprayed from a nozzle cleaning hole flows out of an opening at a front end of a nozzle cleaning cylinder along an outer peripheral surface of a piston while being spirally swirled in a space between an inner wall of the nozzle cleaning cylinder and the outer peripheral surface of the piston. A position fixing member having a curved shape along an inner surface at a front end of the nozzle cover is formed at a front end of the flow path merger. While a posterior nozzle moves from a forward position to a backward position, dispersed spiral flow and linear flow are alternately sprayed.

Owner:PANASONIC CORP

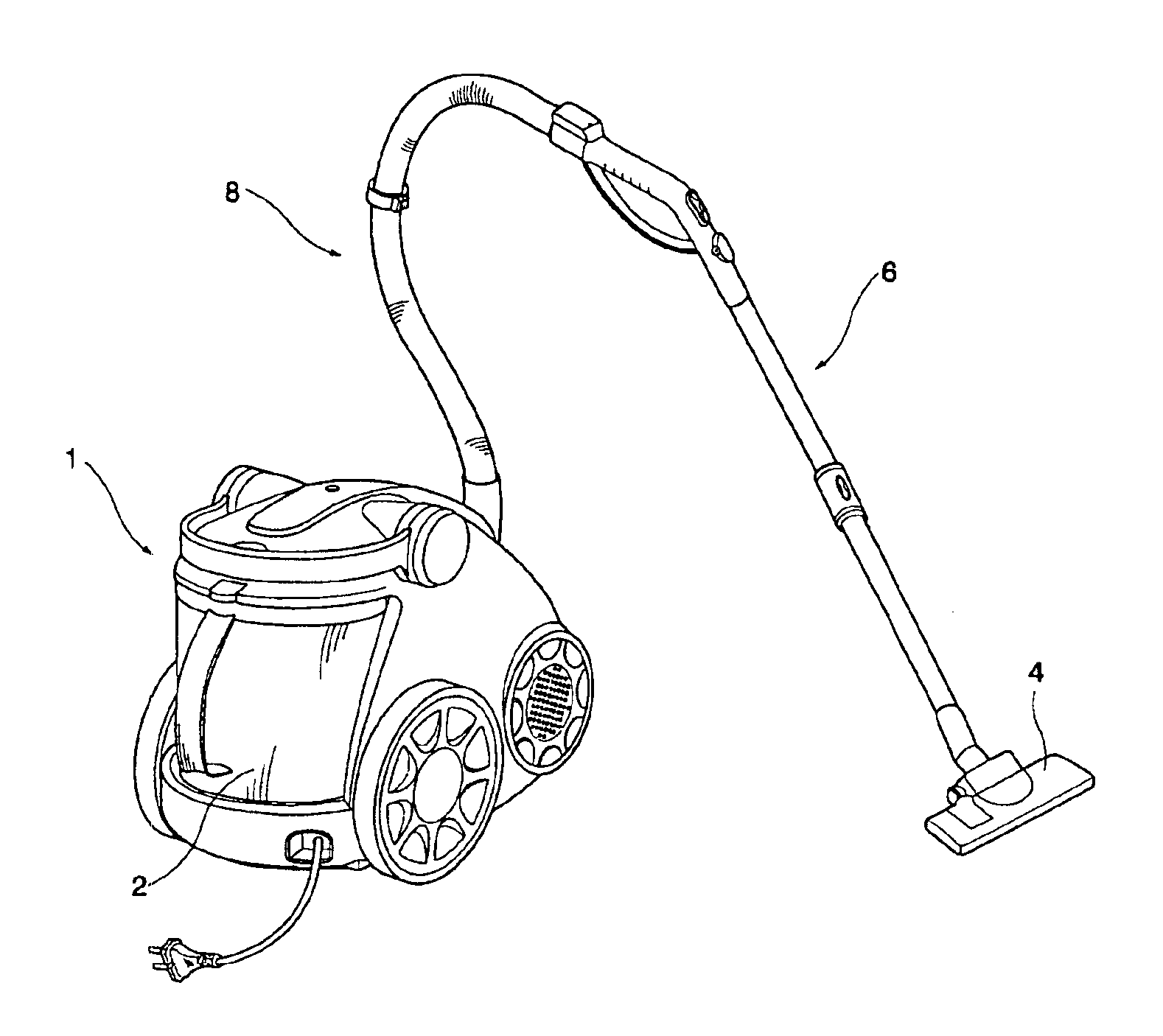

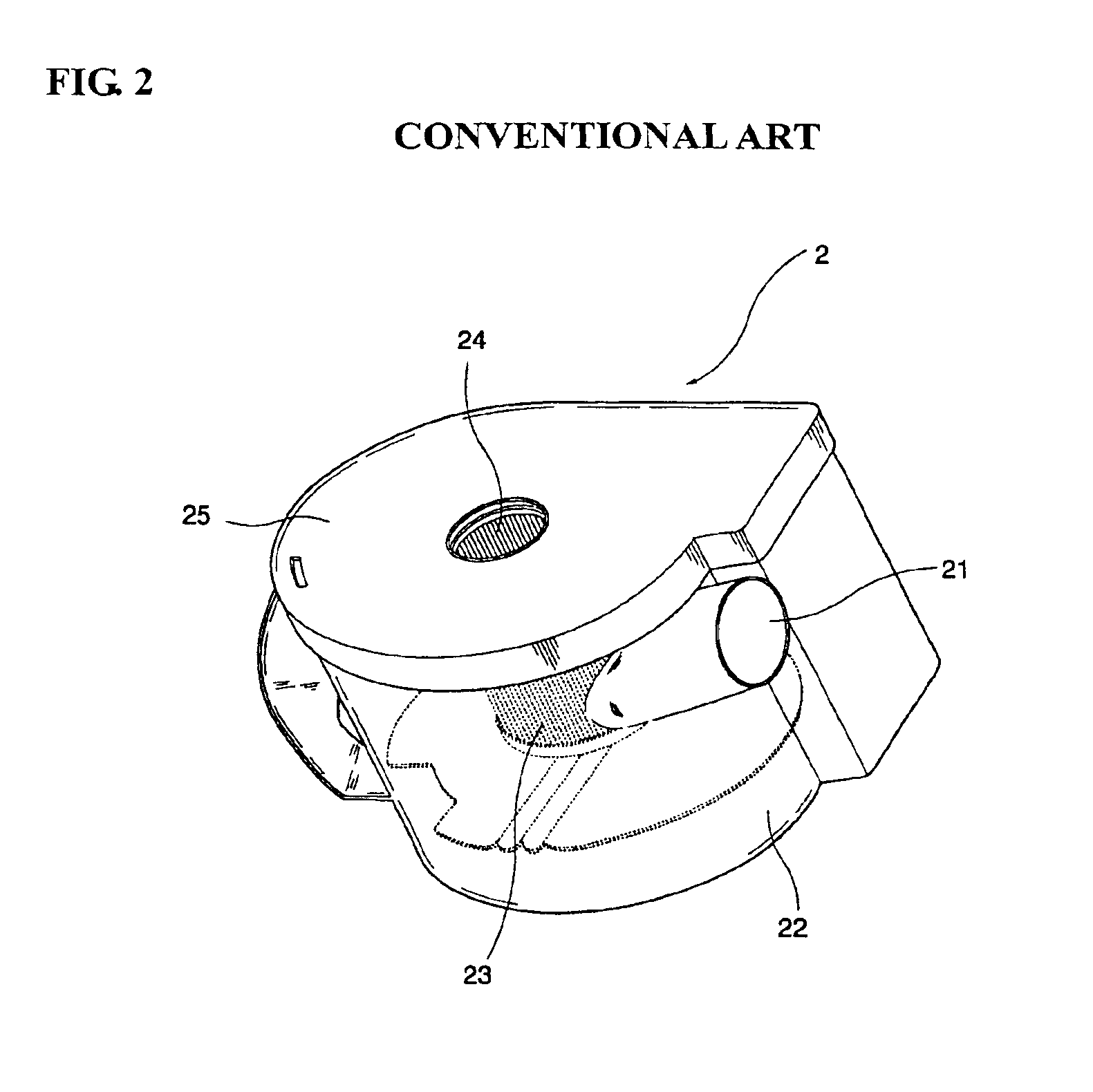

Dust collection unit for use in vacuum cleaner and main body of vacuum cleaner having the same

InactiveUS6901625B2Simple internal structureCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust collection unit for use in a vacuum cleaner. According to the present invention, there is provided a dust collection unit for use in a vacuum cleaner which comprises a cylindrical casing in which air introduced through an inlet port is formed into spiral flow and of which an upper end is open; a cover for opening and closing the upper end of the casing; a filter which is installed on a bottom surface of the cover and formed in the shape of a cylinder having a predetermined length and by which fine foreign substances can be filtered out when the air is introduced from the exterior thereof, and through which the air is discharged downwardly; and an exhaust duct which comes into close contact with a bottom surface of the filter and including an exhaust port on a side surface of the casing to discharge the air from the filter to the exterior of the casing. It is preferred that the exhaust port of the casing be formed at a lower portion of the side surface of the casing.

Owner:LG ELECTRONICS INC

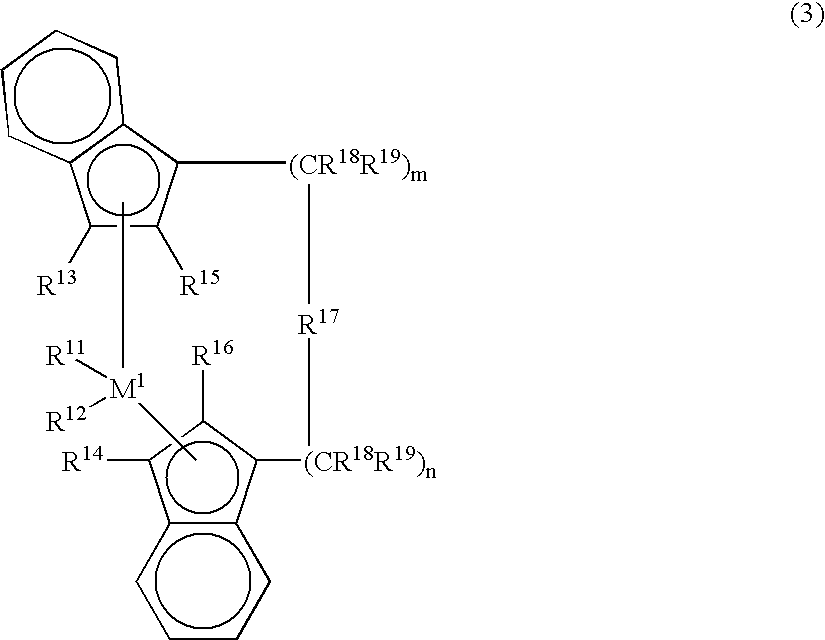

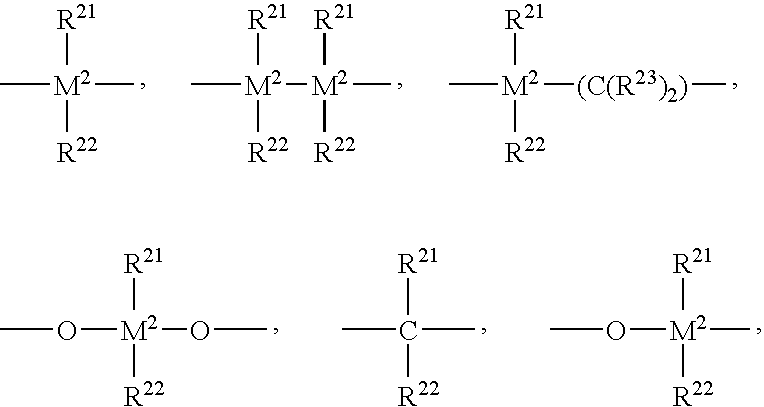

Process for producing injection molded product

InactiveUS20080064805A1Thin moldingImprove productivityCeramic shaping apparatusCoatingsWaxPolymer science

The present invention provides a process for producing an injection molded product comprising injection molding a mixture containing a thermoplastic resin (A) and a polyolefin wax (B), wherein the mixture has L / L0≧1.05, the L being a flow length in the case where the mixture contains the polyolefin wax and the L0 being a flow length in the case where the mixture contains no polyolefin wax, the L and L0 being measured under the conditions of a mold temperature of 40° C. and a resin temperature, Tr, as determined by the following expression: Tr=3 / 4×Tm+100 (wherein Tm represents a melting temperature (° C.) of the thermoplastic resin), using a spiral flow mold having a thickness of 1 mm and a width of 10 mm. According to the invention, by adding the polyolefin wax, a flow length of a thermoplastic resin can be lengthened, and releasability can be improved, and thus the thermoplastic resin can be thin molded or precision molded by injection molded without deteriorating the characteristics of the molded product to be obtained.

Owner:MITSUI CHEM INC

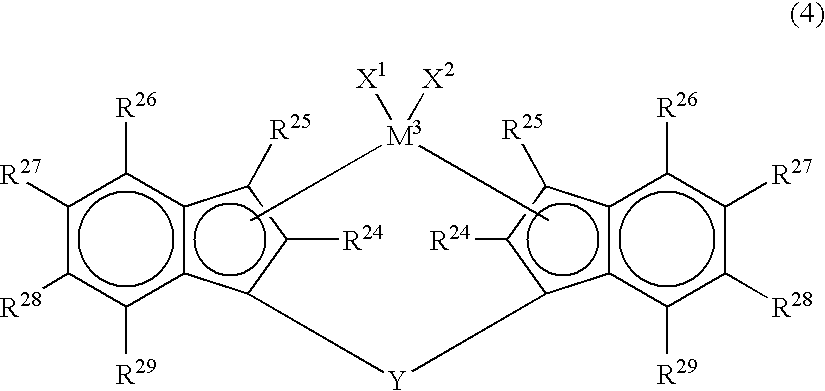

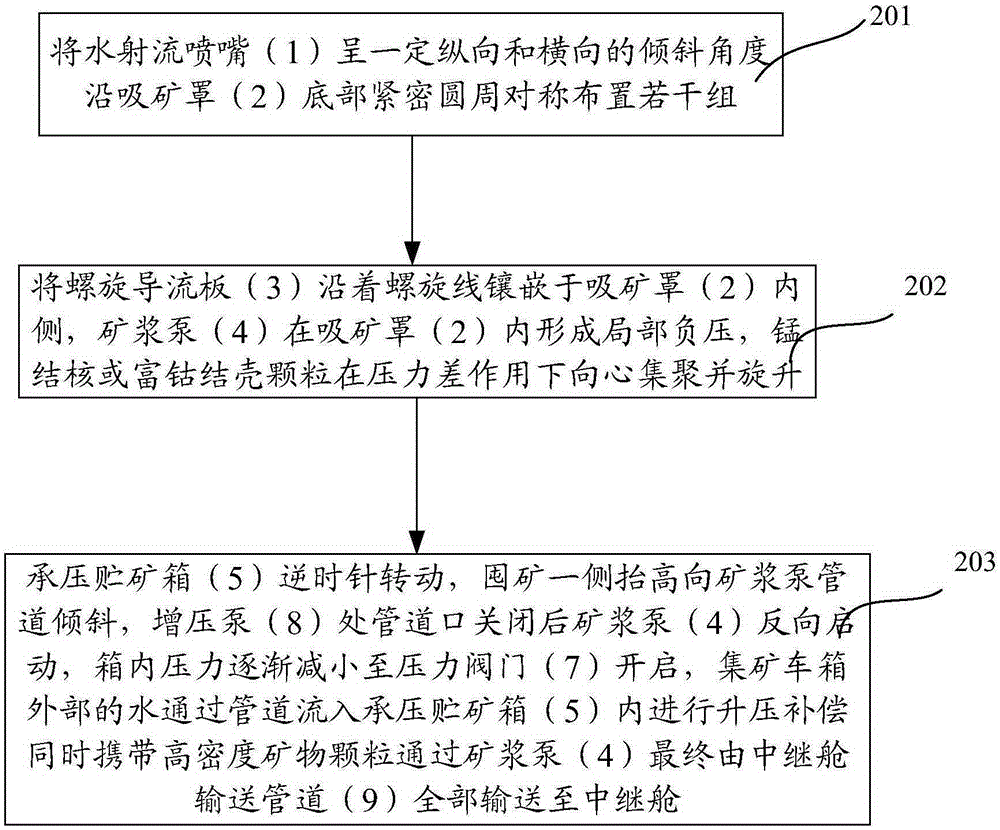

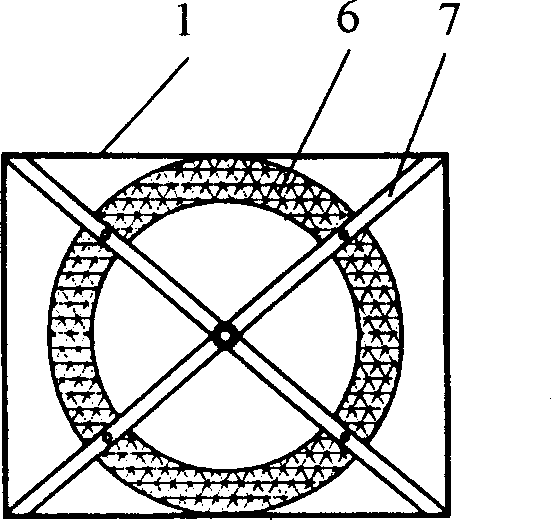

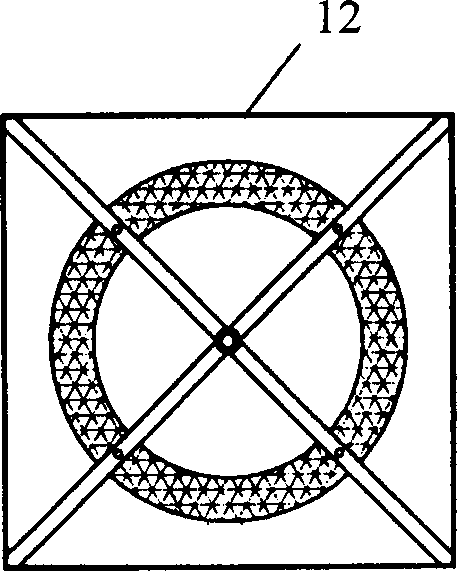

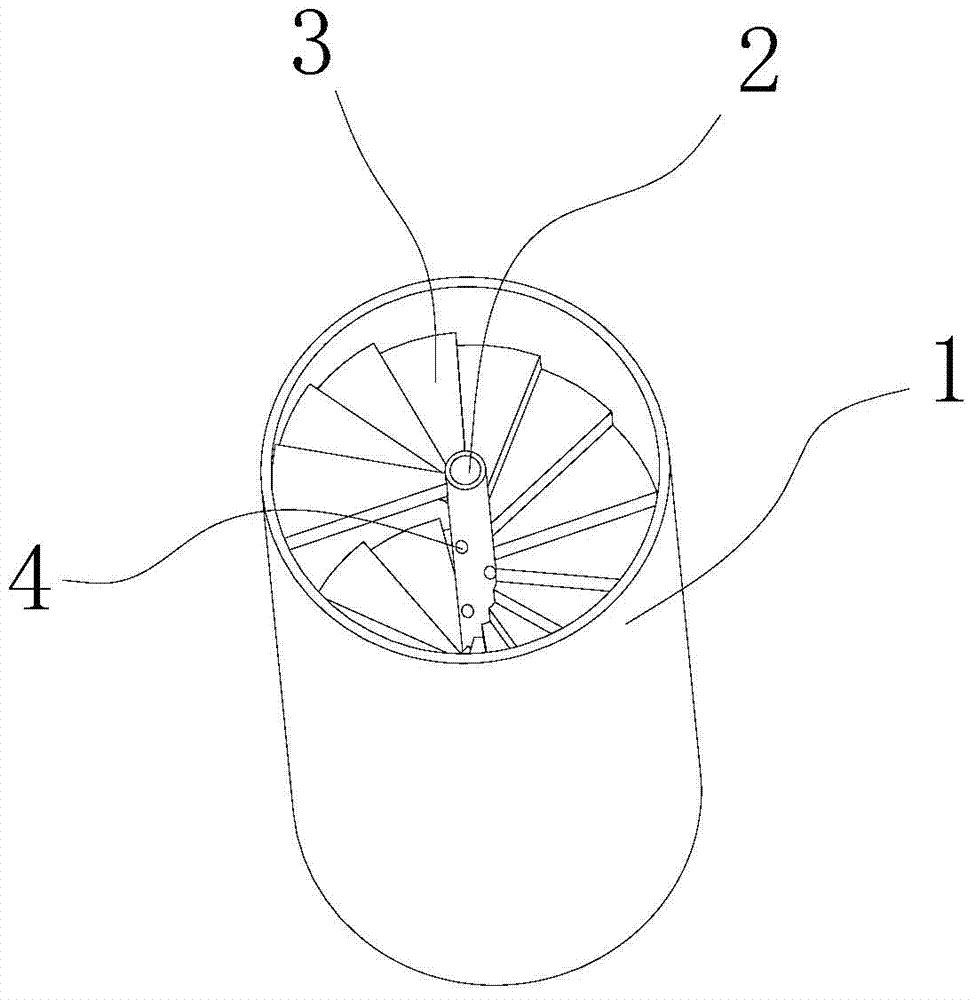

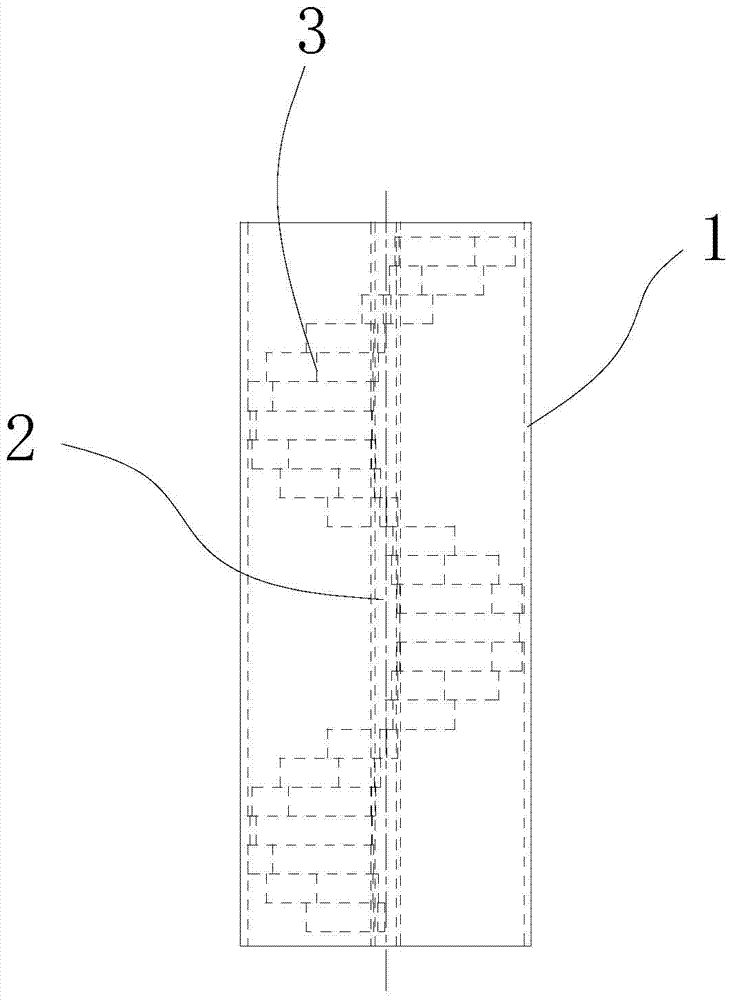

Submarine ore collecting vehicle and ore collecting method thereof

The invention discloses a submarine ore collecting vehicle and an ore collecting method thereof. The submarine ore collecting vehicle comprises water jet nozzles (1), an ore sucking hood (2), a spiral flow guiding plate (3), an ore slurry pump (4), a pressure-bearing ore storage tank (5), a relay cabin conveying pipeline (9) and an ore collecting vehicle cabin body (10), wherein the water jet nozzles (1) are closely arranged into a plurality of groups along the bottom of ore sucking hood (2) at certain vertically and transversely inclined angles; the spiral flow guiding plate (3) is embedded into the inner side of the ore sucking hood (2) along a spiral line; the ore slurry pump (4) is connected to the ore sucking hood (2) through an ore slurry pump pipeline, so that local negative pressure is formed in the ore sucking hood (2), and a vertical-axis whirlpool which flows upwards is formed under the flow guiding action of the spiral flow guiding plate (3); the ore slurry pump (4) conveys collected ores to a relay cabin through the relay cabin conveying pipeline (9), and is further connected with the pressure-bearing ore storage tank (5). The submarine ore collecting vehicle and the ore collecting method have the advantages of being environmentally friendly, efficient, lower in energy consumption, and reliable.

Owner:SHANGHAI JIAO TONG UNIV

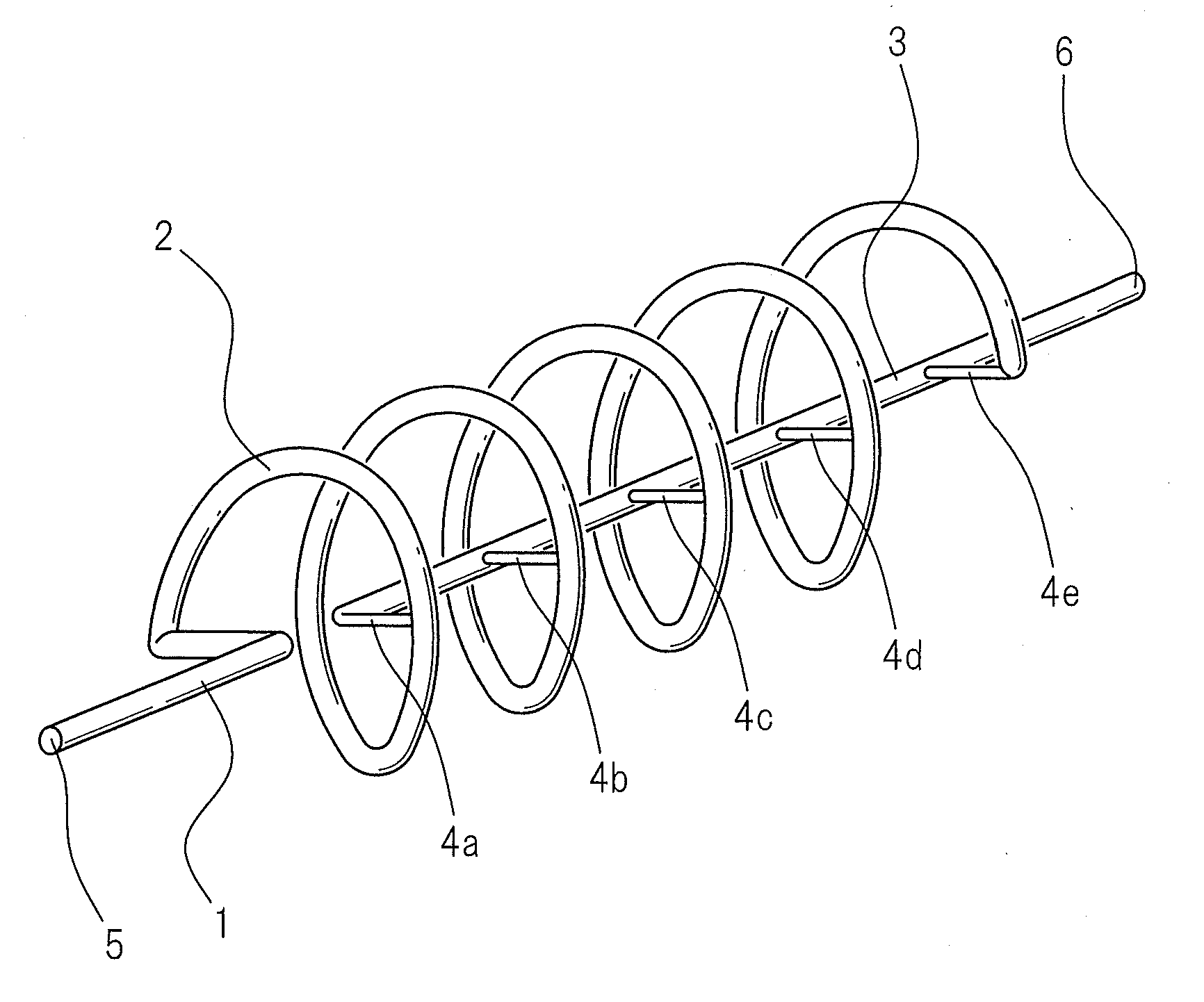

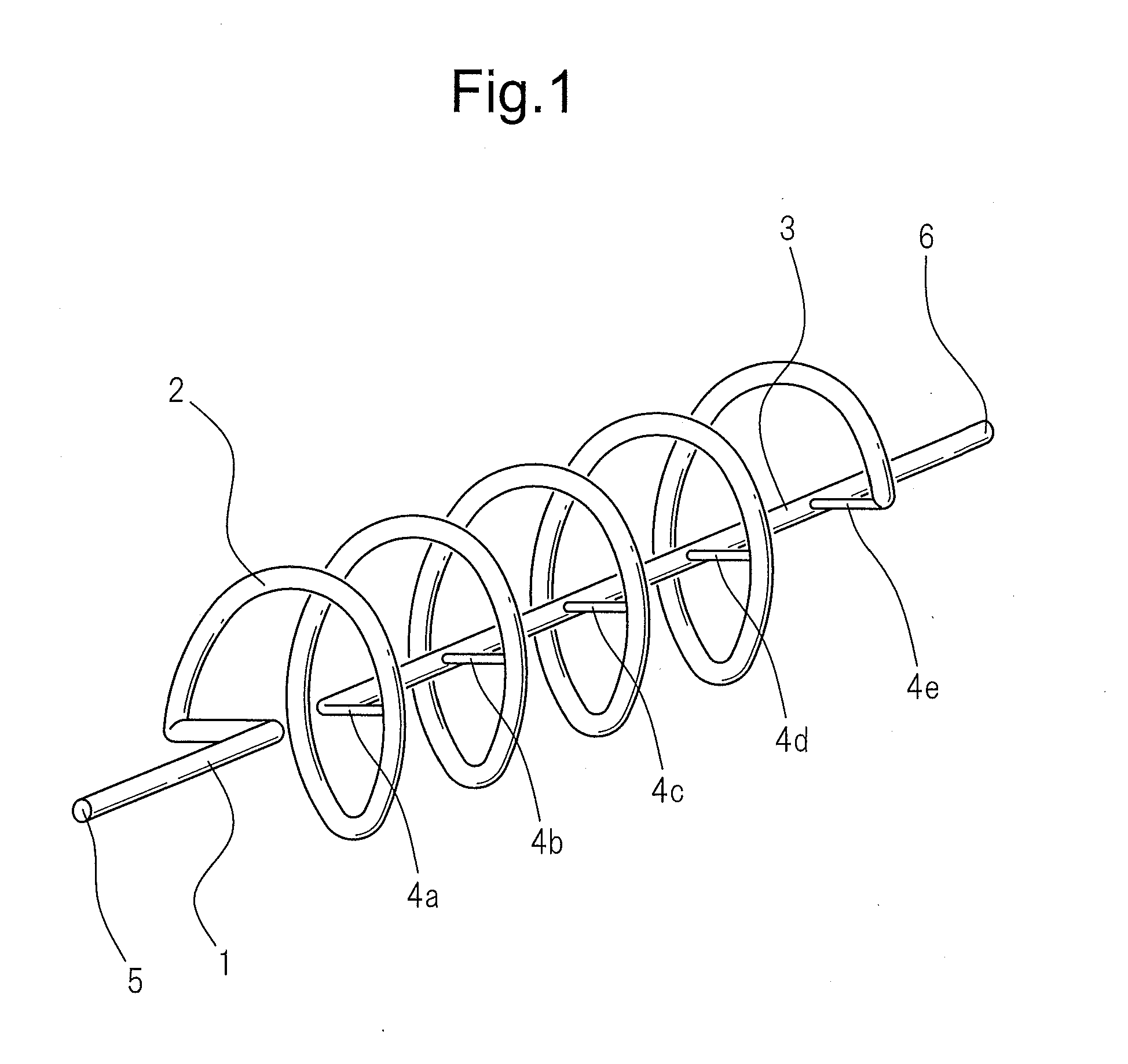

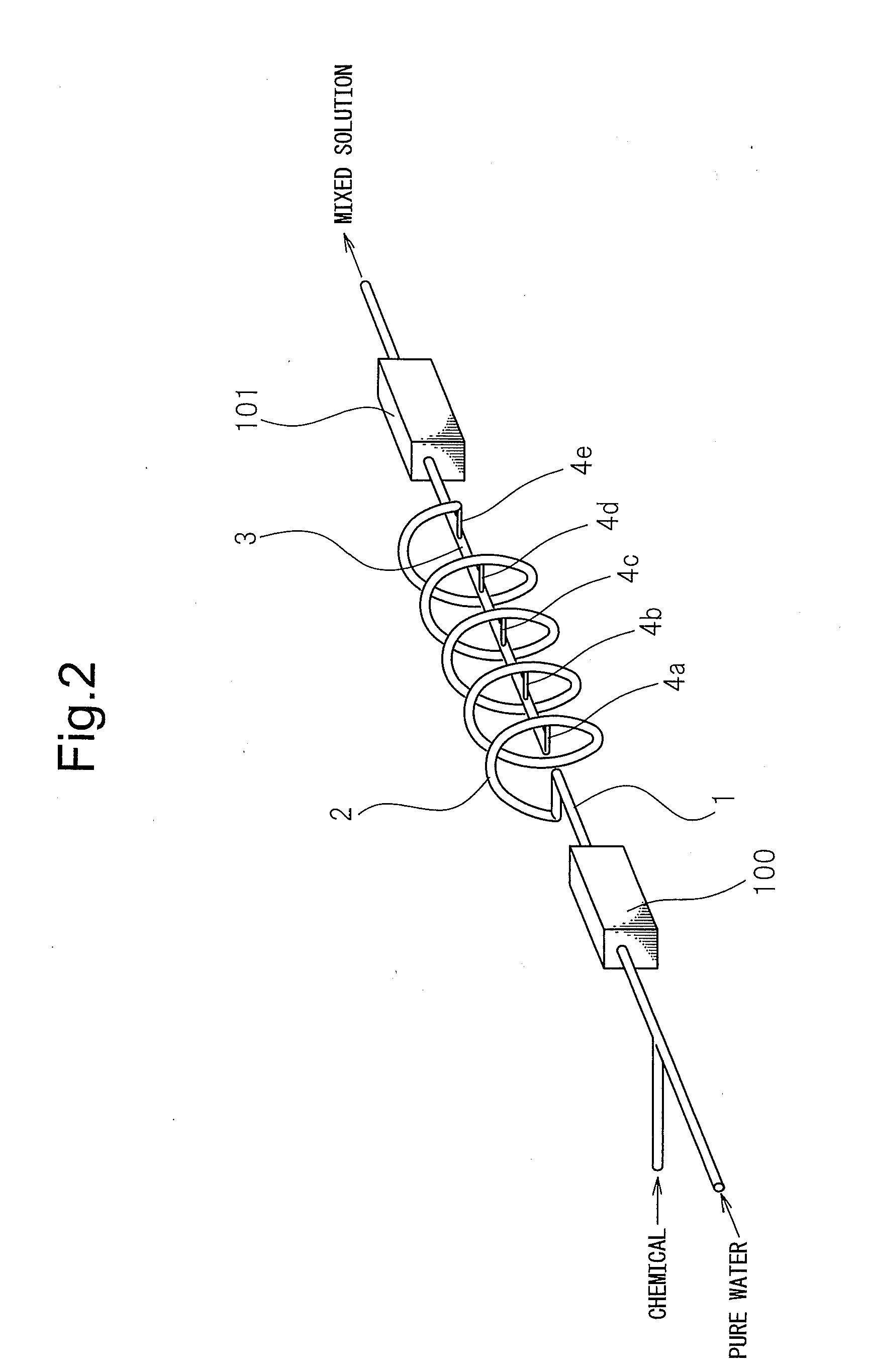

Spiral type fluid mixer and apparatus using spiral type fluid mixer

InactiveUS20110199855A1Avoid defectsStable temperatureFlow mixersTransportation and packagingEngineeringSpiral flow

A spiral type fluid mixer which enables mixing by a distribution of concentration or distribution of temperature in a flow direction of the fluid made uniform without unevenness and which is compact and enables easy piping work is provided. This spiral type fluid mixer is provided with a fluid inlet, a first flow path which is connected to the fluid inlet, a first spiral flow path which is connected to the first flow path, a plurality of branch flow paths which are branched from the first spiral flow path, a second spiral flow path to which the plurality of branch flow paths are connected, a second flow path which is connected to the second spiral flow path, and a fluid outlet which is connected to the second flow path, the plurality of branch flow path being branched from different positions of the first spiral flow path and being connected with the second spiral flow path at different positions of the second spiral flow path.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Cooling system for an outer wall of a turbine blade

InactiveUS6955525B2Increase rate increaseImprove cooling effectEngine manufactureBlade accessoriesTurbine bladeEngineering

A turbine blade for a turbine engine having a cooling system in at least an outer wall. The cooling system in at least the outer wall formed from at least a first plurality of parallel cavities intersected by a second plurality of parallel cavities positioned in a nonparallel position relative to the first plurality of parallel cavities. In at least one embodiment, the second plurality of parallel cavities may include an alternating configuration of cavities, such that a first cavity may be positioned proximate to an inner surface of the outer wall and a second cavity adjacent to the first cavity is positioned proximate to the outer surface of the outer wall. The first cavity may also be offset from the second cavity to form a spiral gas flow path. The cooling system in the outer wall of the turbine blade may form a spiral flow path.

Owner:SIEMENS ENERGY INC

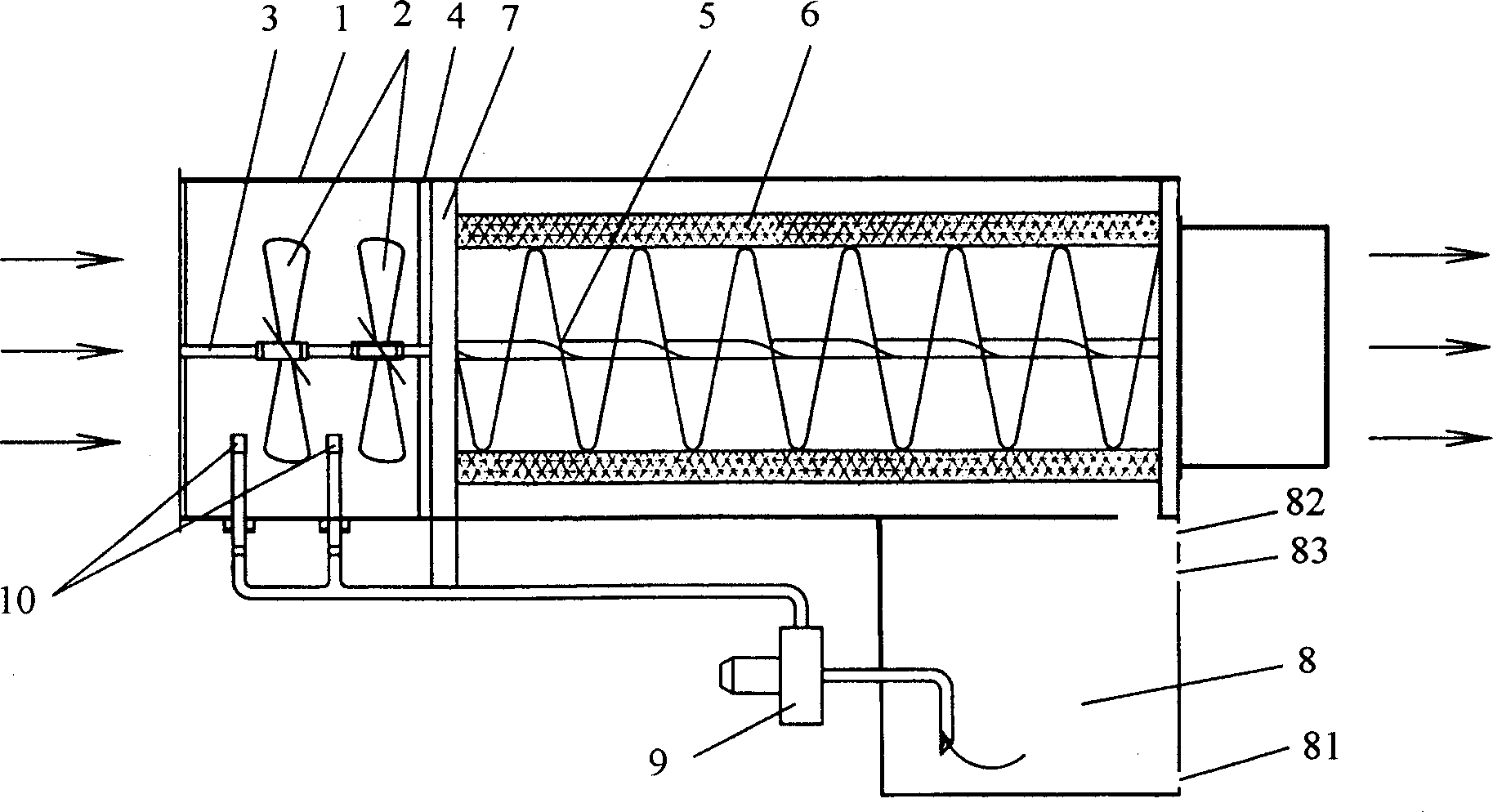

Industrial waste-gas purifier

InactiveCN1895736AAvoid easy cloggingLess investmentCombination devicesDispersed particle filtrationImpellerSprayer

An industrial waste gas cleaning apparatus with simple structure is composed of casing, at least one blade wheel, rotary shaft, spiral flow guider, cylindrical filter and its supporter, water tank with water inlet and blow-off outlet, water pump and at least one liquid sprayer.

Owner:白金龙

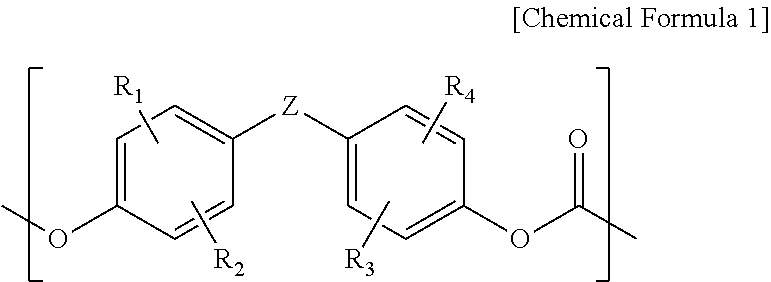

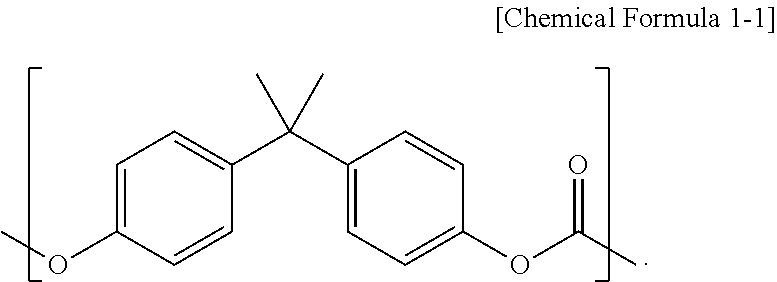

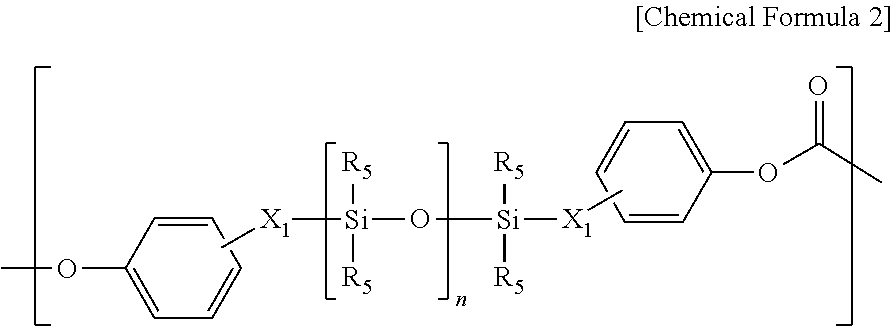

Copolycarbonate and composition containing the same

The present invention relates to a copolycarbonate and a composition comprising the same. The copolycarbonate according to the present invention has a structure in which a specific siloxane compound is introduced in a main chain of the polycarbonate, and thus exhibits an excellent transparency and a high spiral flow while having a high impact strength at room temperature and a low melt index.

Owner:LG CHEM LTD

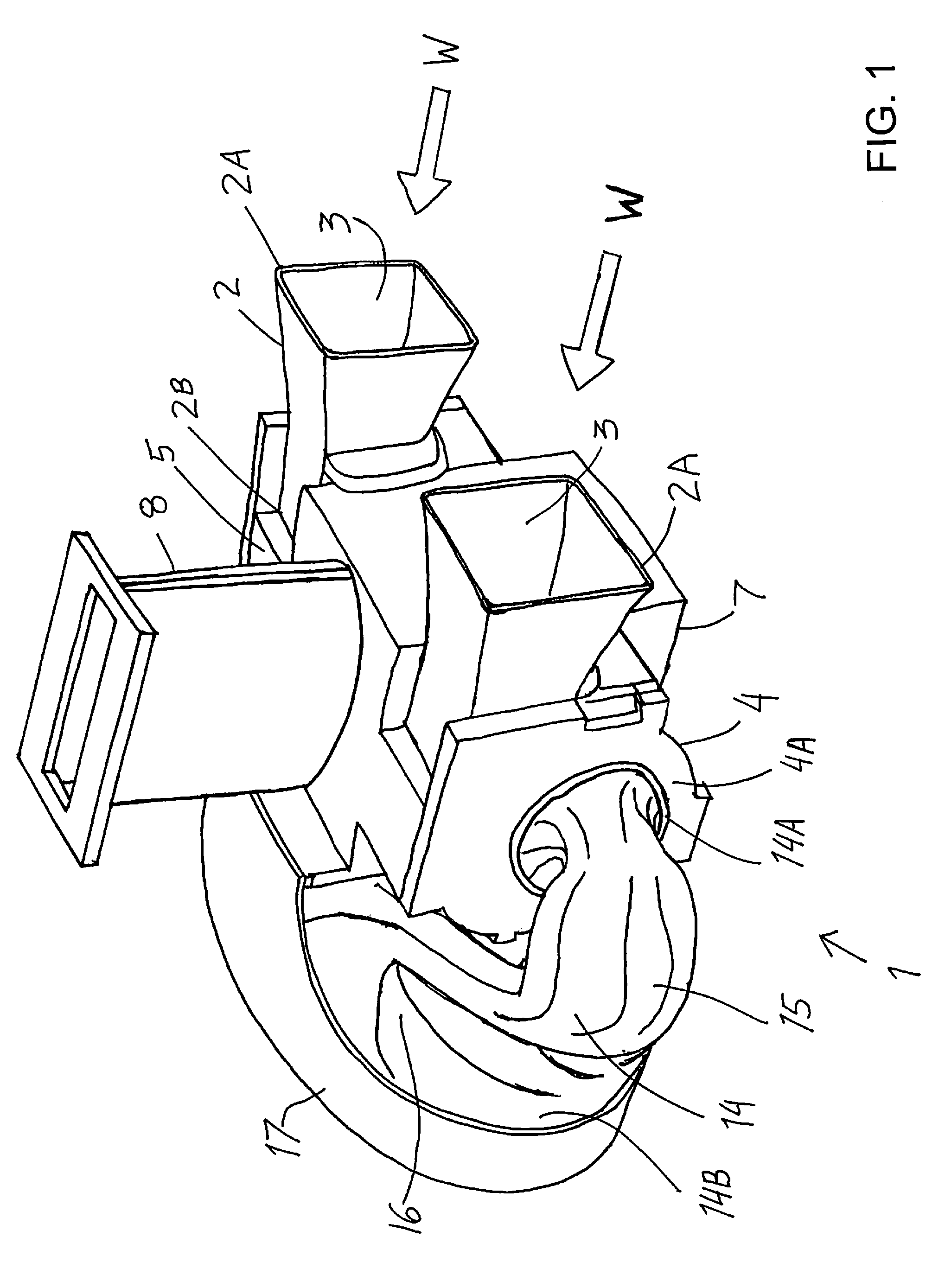

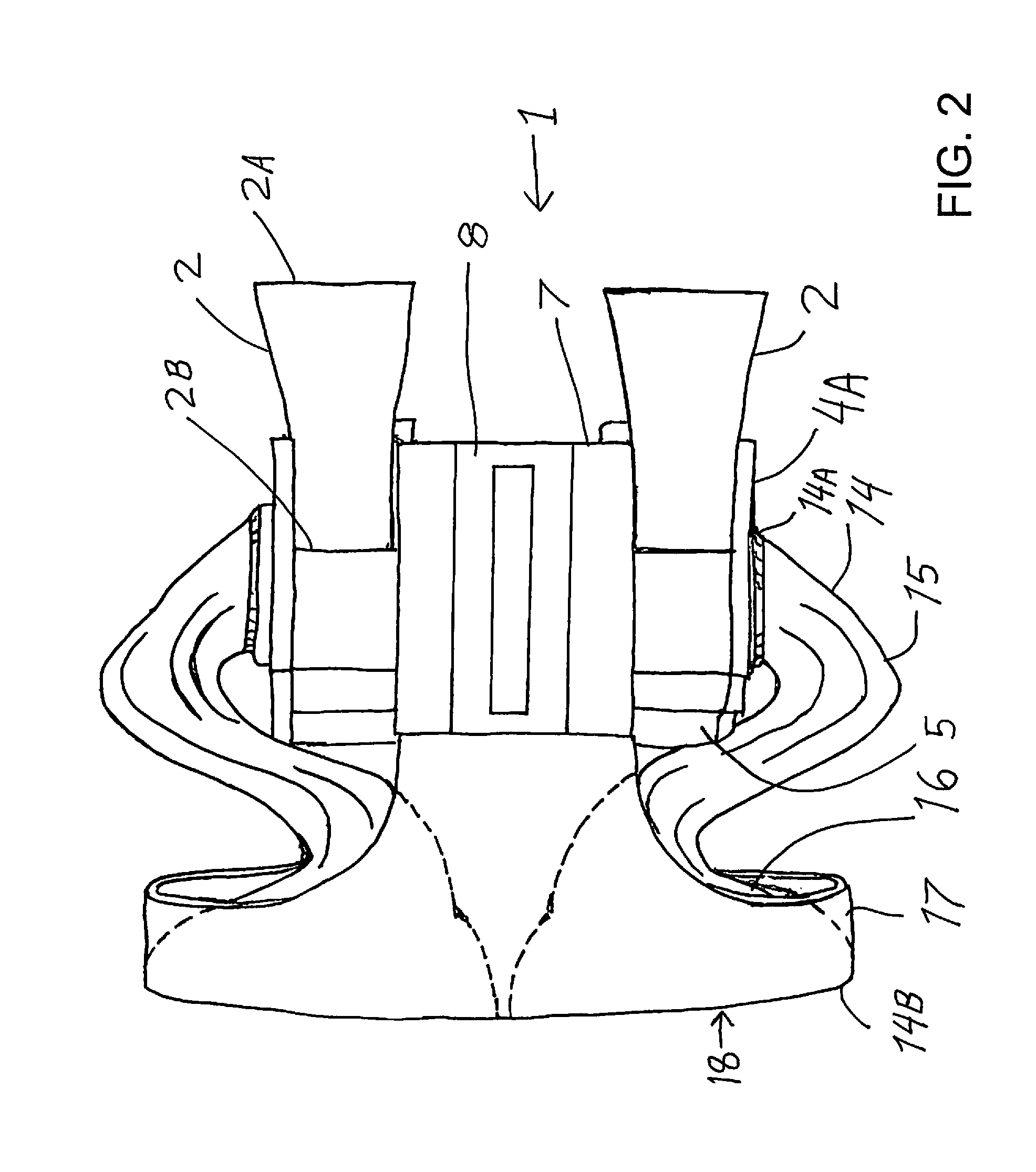

Instream hydro power generator

ActiveUS8506244B2Smoothly accelerate and redirect and decelerateReduces and minimizesPropellersRotary propellersCavitationWater flow

A turbine apparatus is immersed in an ambient stream of a flowing fluid, such as water, so as to encapture a portion of the flowing fluid and extract power therefrom, before returning it back into the ambient stream, which may be a tidal flow of ocean water, or a relative flow of water behind a boat. The apparatus includes a converging intake duct with an inlet opening that faces forward into the ambient stream flow, a spiral volute casing that redirects the fluid into a spiral flow, a rotor arranged coaxially on the spiral axis, and an exhaust duct that diverges and curves from an exhaust inlet coaxial with the spiral axis to an exhaust outlet that opens rearwardly into the ambient flow. The rotor has a peripheral rotor inlet around the circumference of a first stage thereof and an axial rotor outlet at one axial end thereof, and is arranged with its rotor axis coinciding with the spiral axis oriented transverse to the ambient stream flow. The rotor redirects the fluid from the spiral tangential and radial direction at the rotor inlet to the axial direction at the rotor outlet, while extracting power therefrom. Fluid flow channels are designed to achieve smooth acceleration, redirection, power transfer, and deceleration of the fluid preferably without turbulence and cavitation, and preferably using streamlines to develop the surface contours of complex channel components.

Owner:MCBRIDE GEORGE F

Energy dissipation flood discharging device

The invention relates to the field of water conservancy and hydropower, in particular an energy dissipation flood discharging device. The energy dissipation flood discharging device is gentler in the energy dissipation process. The energy dissipation flood discharging device comprises a flood discharging hole and further comprises a central shaft and a spiral flow channel. The central shaft is arranged at the axis position of the flood discharging hole, the spiral flow channel is arranged with the central shaft as the axis, an inlet of the spiral flow channel is communicated with an inlet of the flood discharging hole, and an outlet of the spiral flow channel is communicated with an outlet of the flood discharging hole. When water flow enters the structure, the water flow moves spirally along the spiral flow channel and finally arrives at the bottom of the structure. The spiral flow channel is long and many curves exist, so that the water flow is acted by friction force for a long time, and since the water flow collides with the spiral flow channel, a large amount of gravitational potential energy is transferred into heat energy. Thus, the purpose of energy dissipation is achieved.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com