Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "High cracking rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

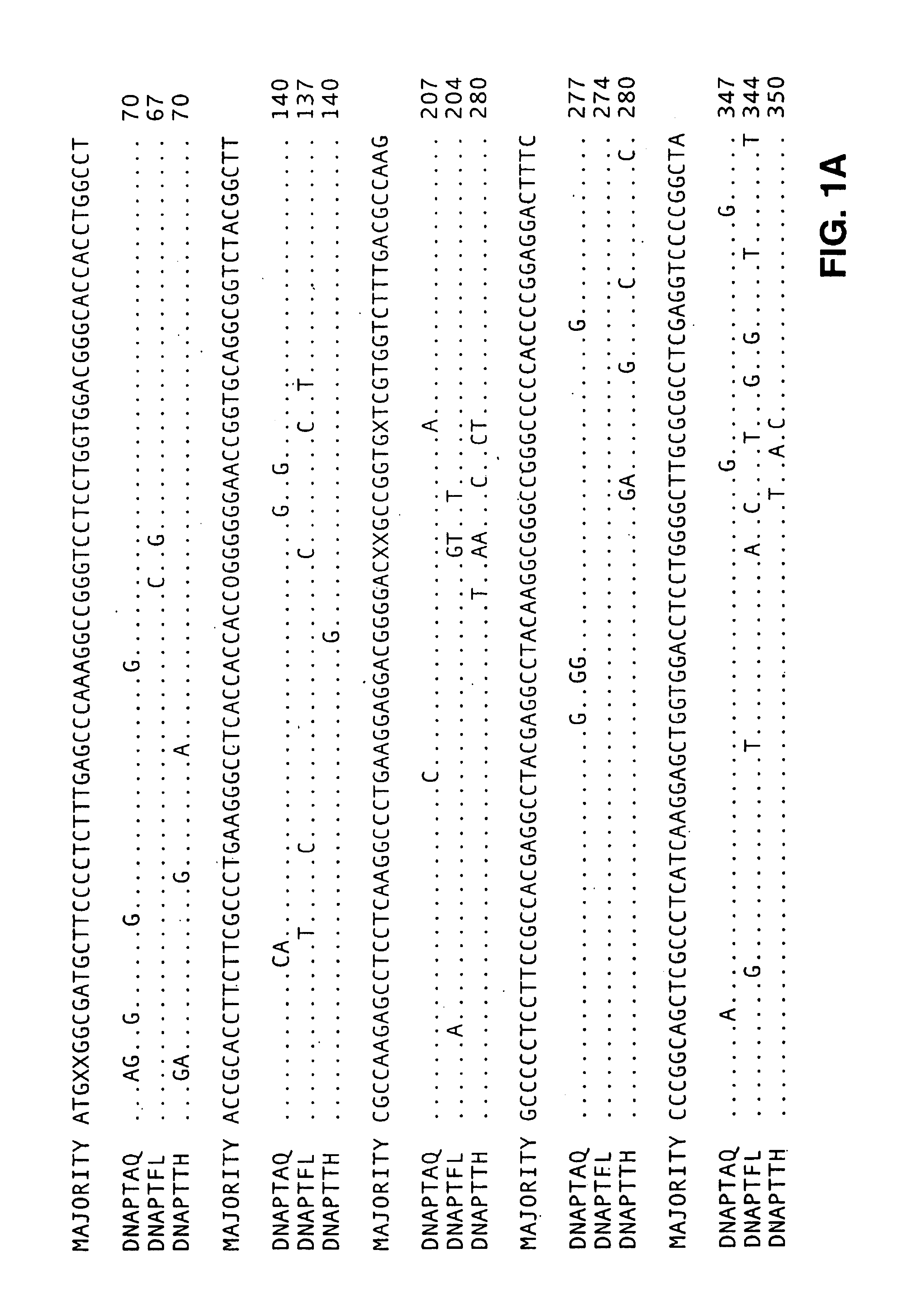

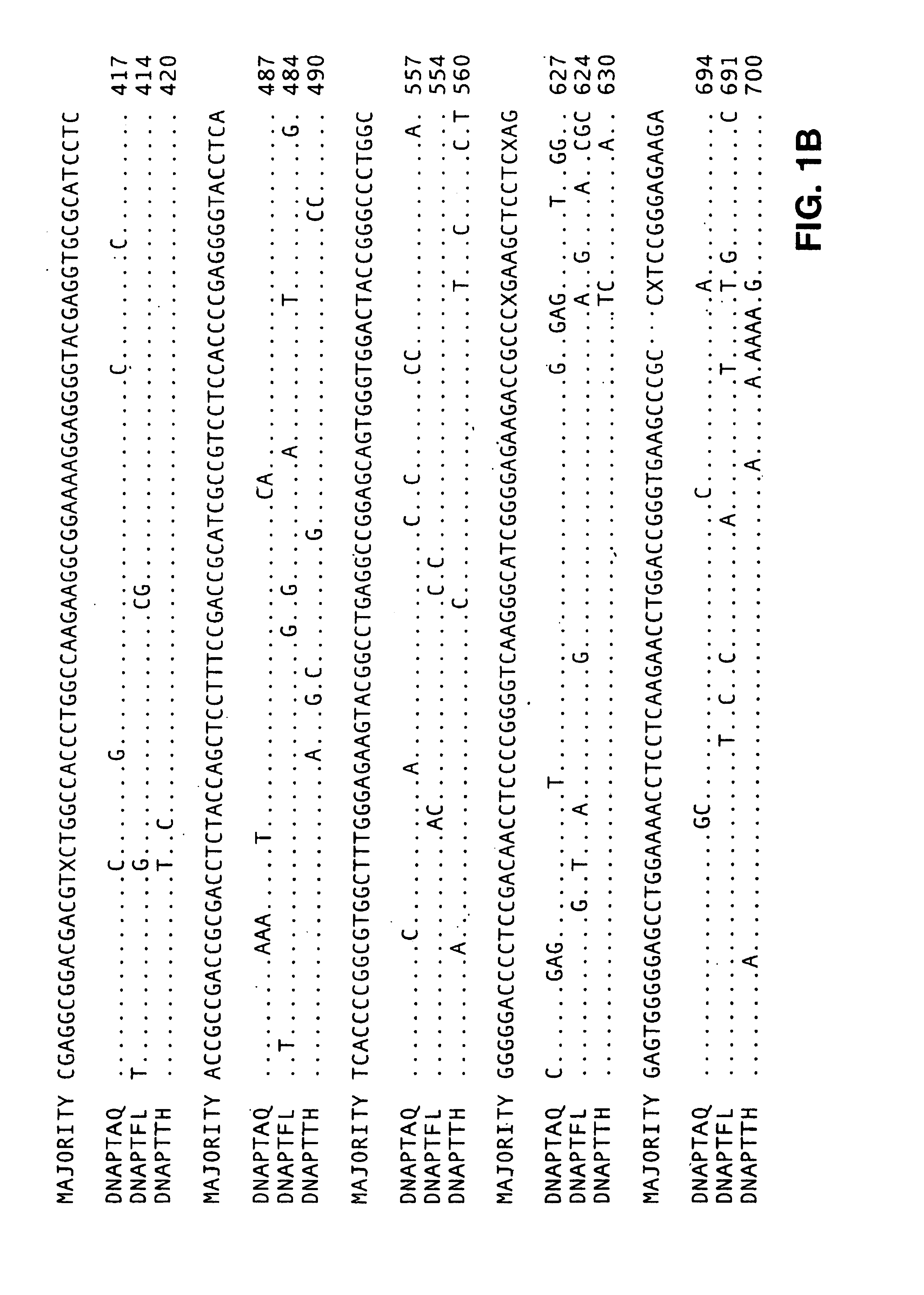

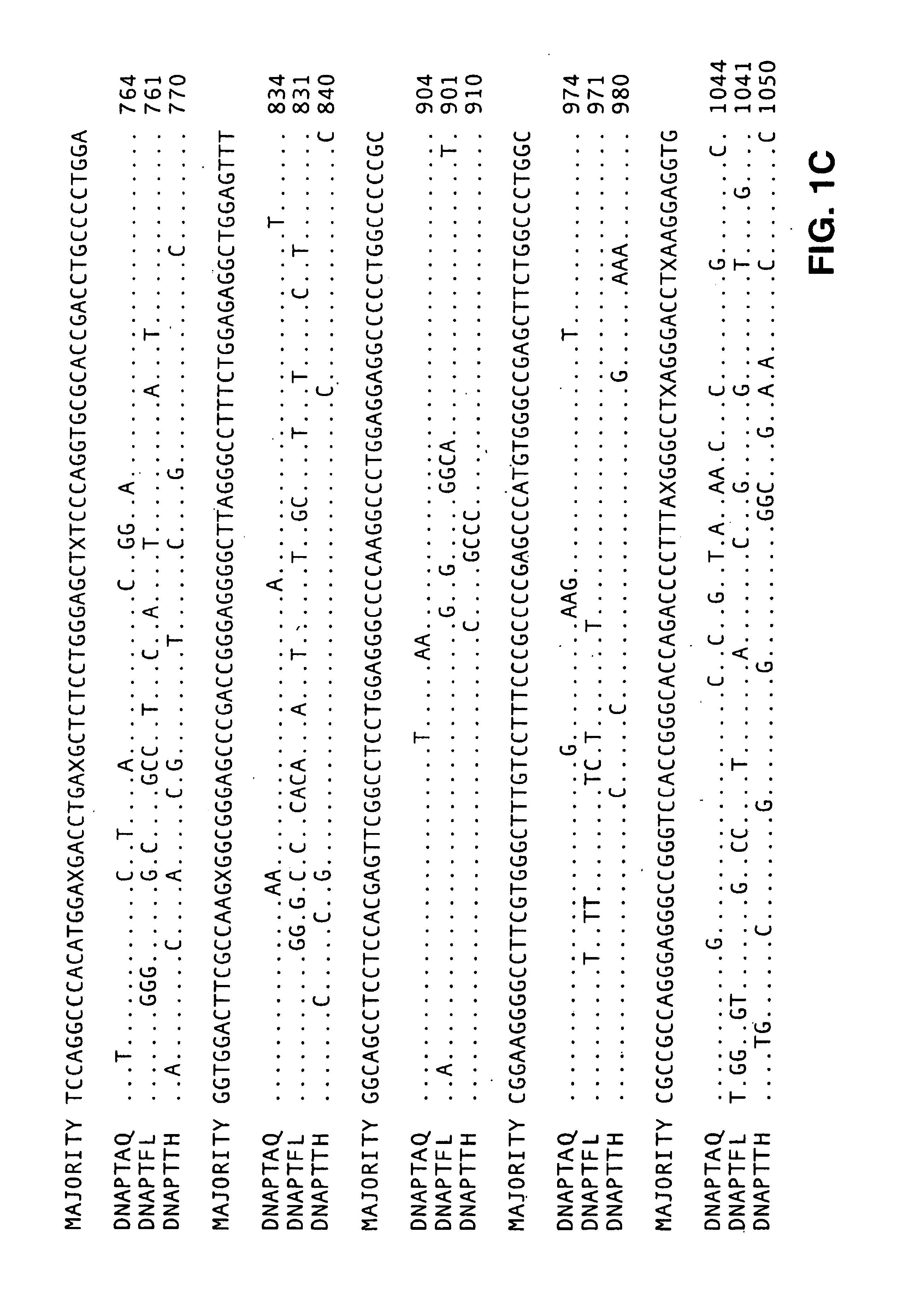

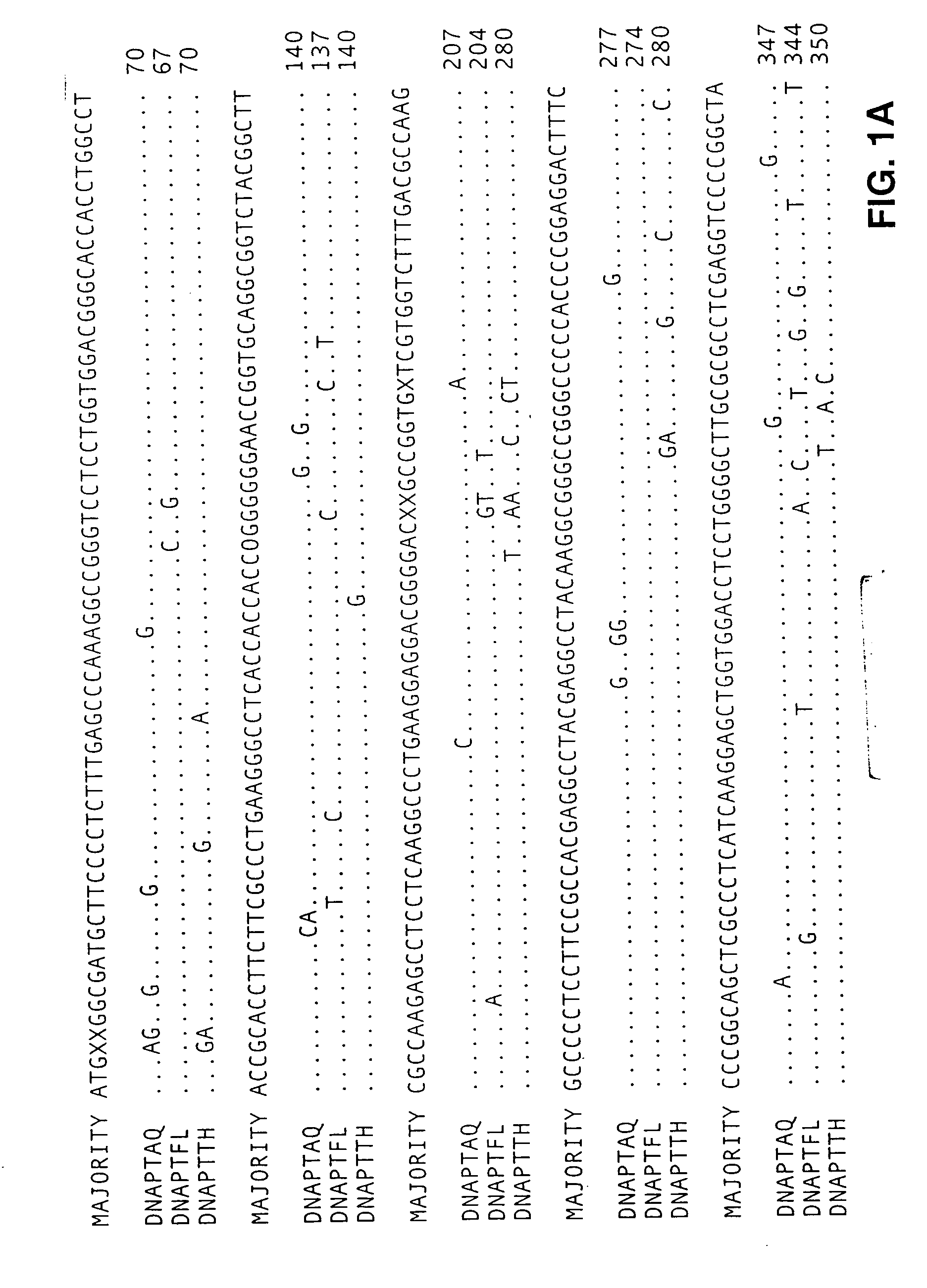

FEN endonucleases

InactiveUS7122364B1Improve performanceA large amountHydrolasesMicrobiological testing/measurementPolymerase LNucleic acid sequencing

The present invention provides novel cleavage agents and polymerases for the cleavage and modification of nucleic acid. The cleavage agents and polymerases find use, for example, for the detection and characterization of nucleic acid sequences and variations in nucleic acid sequences. In some embodiments, the 5′ nuclease activity of a variety of enzymes is used to cleave a target-dependent cleavage structure, thereby indicating the presence of specific nucleic acid sequences or specific variations thereof.

Owner:GEN PROBE INC

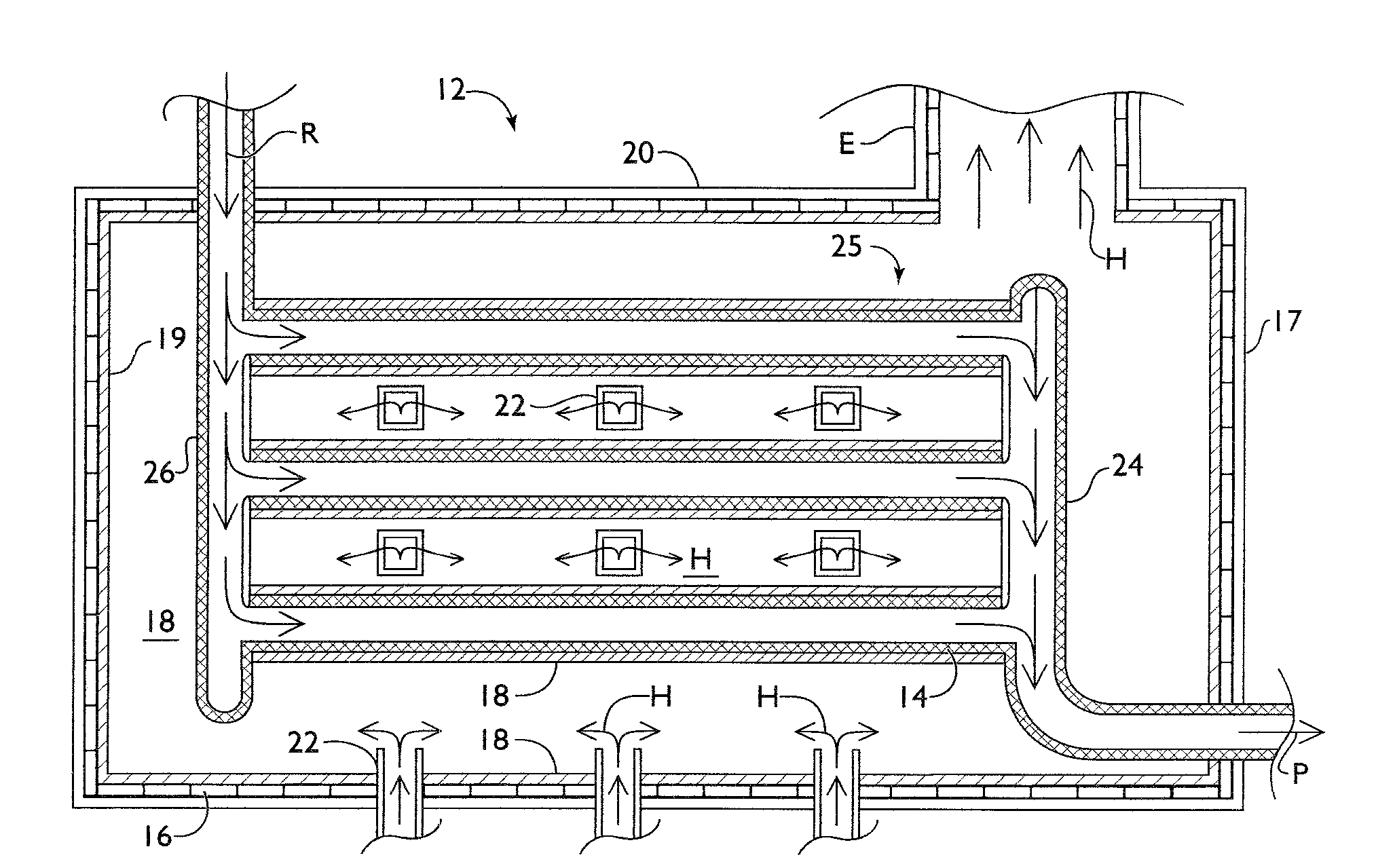

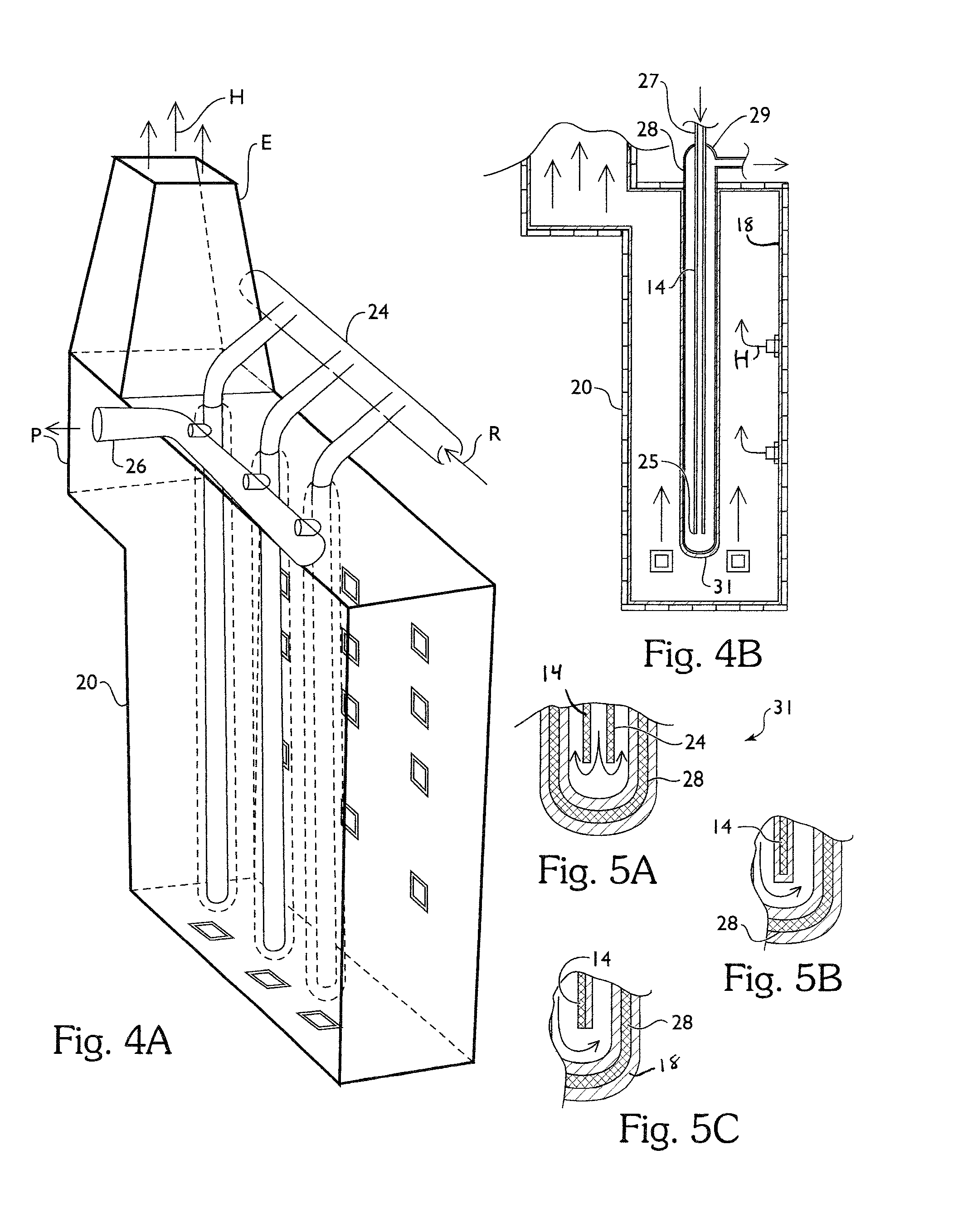

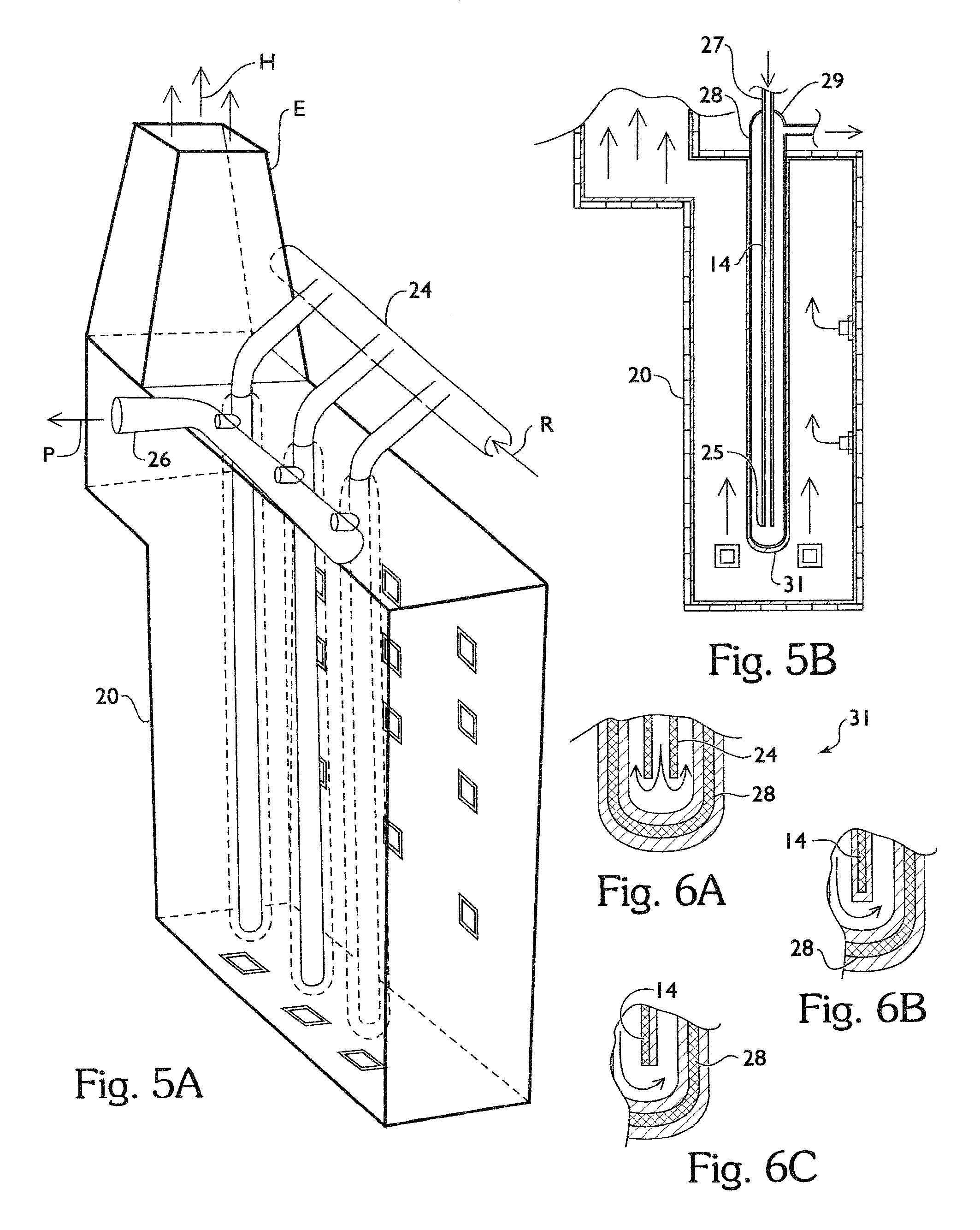

Pyrolysis furnace and process tubes

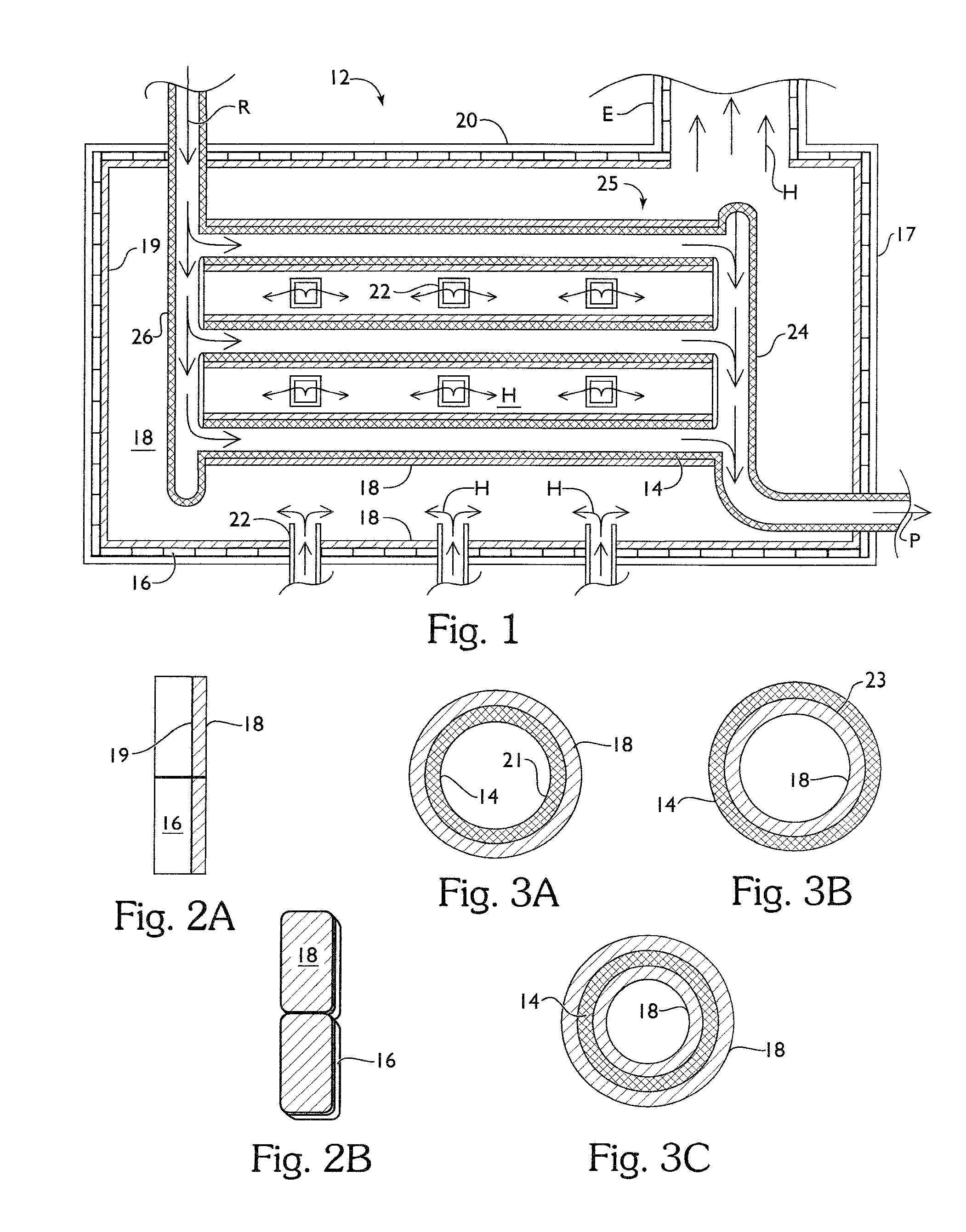

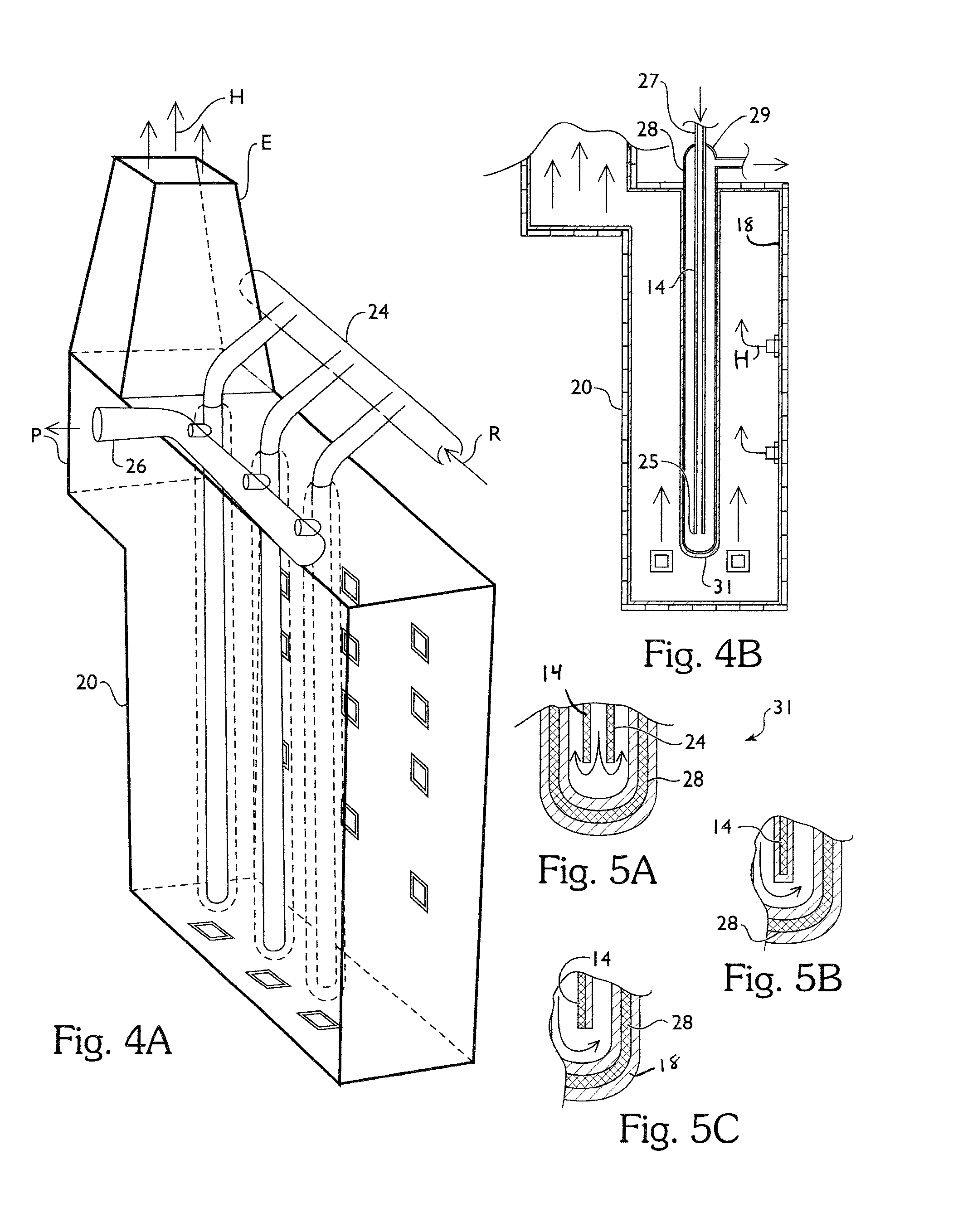

ActiveUS20090252660A1Increase volumeReduce maintenanceThermal non-catalytic crackingLiquid surface applicatorsColloidal silicaCombustion chamber

A cracking furnace construction includes a firebox defining a chamber having a high emissivity thermal protective coating disposed on at least part of the refractory walls and / or on process tubes disposed within the chamber. The coating contains an inorganic adhesive for metal / alloy tubes or colloidal silica and / or colloidal alumina for refractory walls or ceramic tubes, a filler, and one or more emissivity agents. A method of coating the firebox chamber includes preparing the surface of the tubes / refractory walls, preparing the coating, and applying the coating to the surface.

Owner:EMISSHIELD

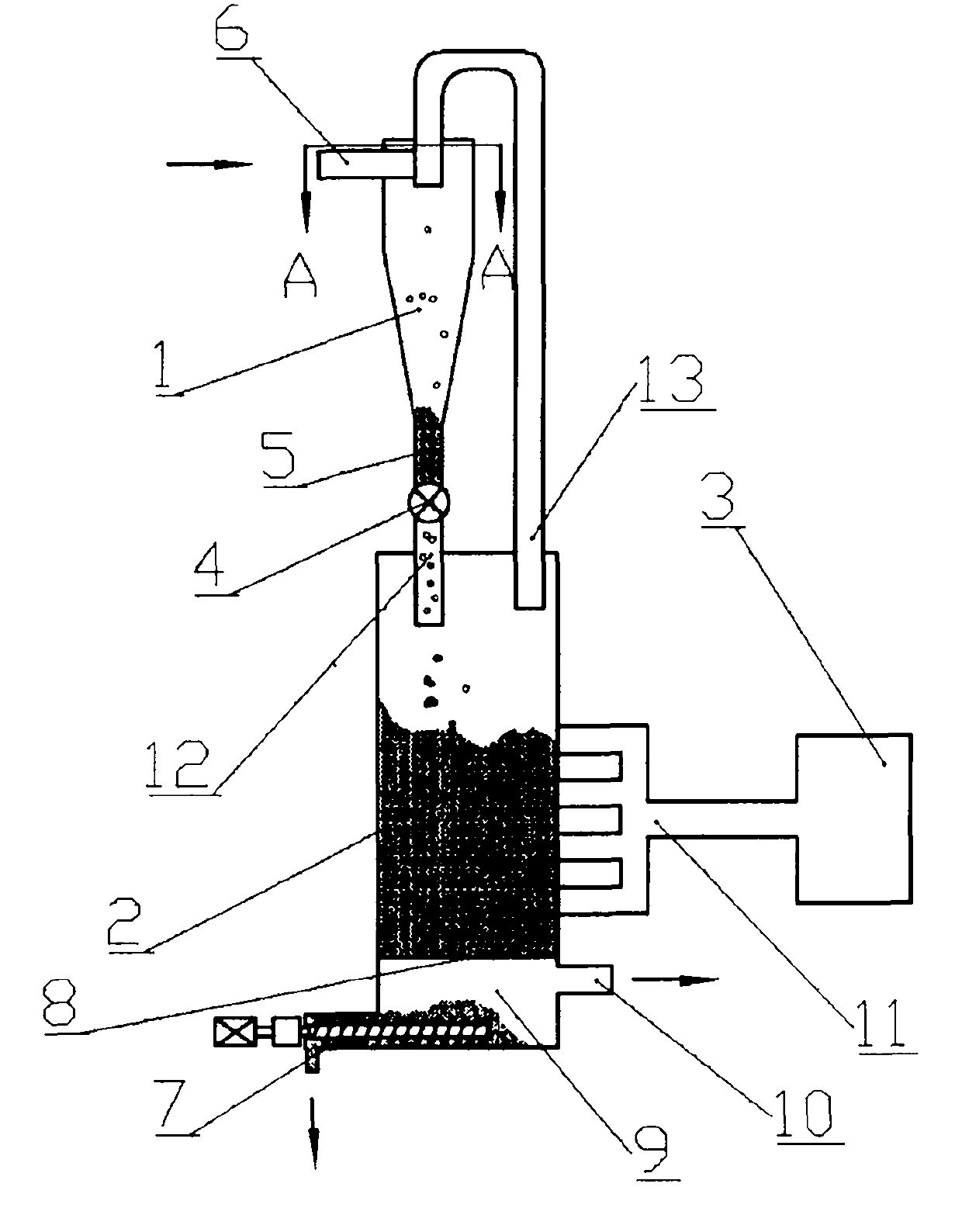

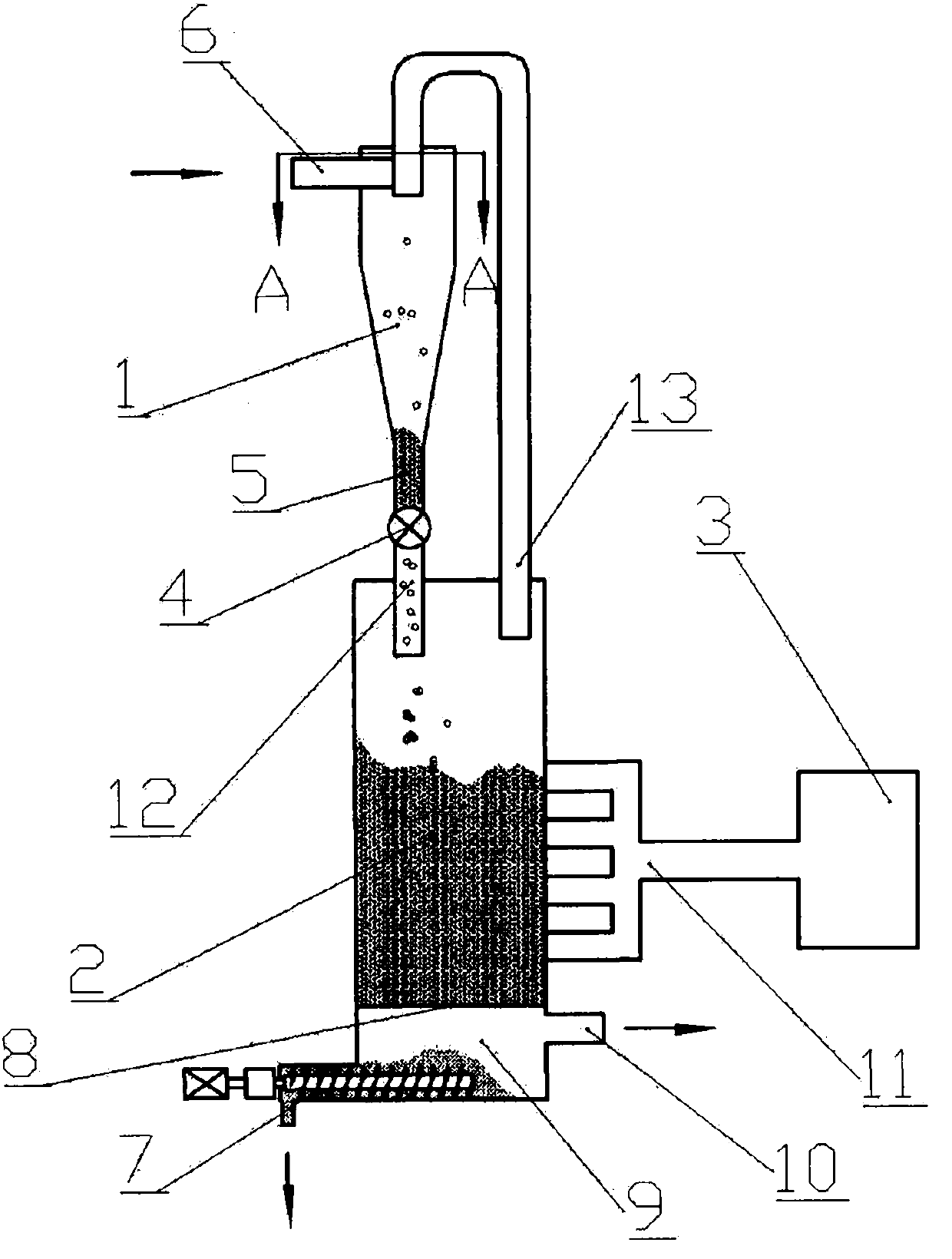

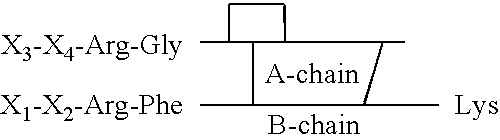

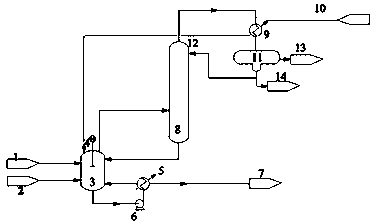

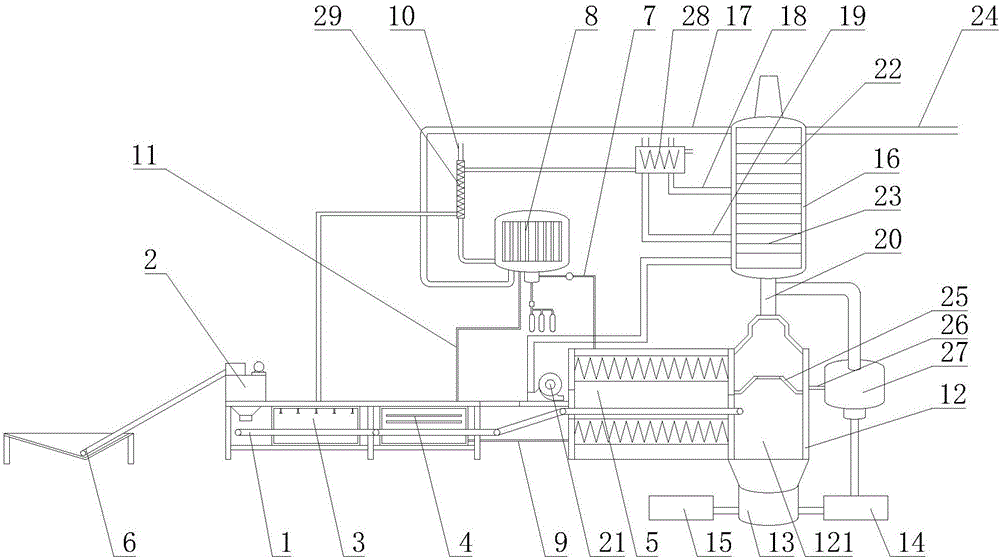

Method and device for preparing low-tar combustible gas through biomass gasification

ActiveCN101906323AHigh cracking rateMake up for the problem of low conduction rateGranular/pulverulent flues gasificationFixed bedCombustible gas

The invention discloses a method and a device for preparing a low-tar combustible gas through biomass gasification. The method comprises the followings steps of: pulverizing and gasifying biomass, and rapidly separating obtained gasification gas products and biomass char; heating and activating the biomass char in a microwave field; catalytically cracking tar in the gasification gas products by introducing the gasification gas products to pass through a treated biomass char layer, and carrying out secondary reaction on the gasification gas and the biomass char to produce the combustible gas. The device comprises a spiral-flow gasifier 1, a fixed bed reactor 2 and a microwave generator 3 which are connected through ducts, and the middle part of the fixed bed reactor is connected with the microwave generator 3 through a microwave duct 11. The microwave technology is applied to tar cracking, so that the problem of low heat transfer speed due to porous and loose biomass char is solved. Meanwhile, the cracking rate of tar and the secondary reaction activity between the char and the gasification gas are increased by using the 'hot spot effect' of microwaves. The device has the advantages of strong adaptability, simple and compact structure and easy enlargement.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Reactions on a solid surface

InactiveUS20050164177A1Improve performanceA large amountBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid sequencingNucleic acid cleavage

The present invention relates to compositions and methods for the detection and characterization of nucleic acid sequences and variations in nucleic acid sequences. The present invention relates to methods for forming a nucleic acid cleavage structure on a solid support and cleaving the nucleic acid cleavage structure in a site-specific manner. For example, in some embodiments, a 5′ nuclease activity from any of a variety of enzymes is used to cleave the target-dependent cleavage structure, thereby indicating the presence of specific nucleic acid sequences or specific variations thereof.

Owner:GEN PROBE INC

Purifying system for biomass gasifying oven

InactiveCN1667086ASimple structureLow production costSpecial form destructive distillationWater bathsCombustor

This invention discloses a biomass gasification furnace purification system. the main points of its technical proposal is that the system is consisted by catalysis ware, catalyst, labyrinth type gasometer, adsorption filter, adsorption filtering agent, waste tar and waste water collecting pit. Fuel gas current of biomass gasification furnace is transferred to labyrinth type gasometer through catalyst in the catalyst ware, then it istrasferred to adsorption filtering agent in the adsorption filter, the fuel gas current after three times purification is transferred to burner, and the whole purification course is finished. This invention is used to biomass gasification furnace purification system, its structure is simple, cost is low, and operation is simple. Water bath is not used in the system, the waste tar and water is few, and can be value things after proposed. The tar cracking ratio and gas current heating value is high, and the rate of gasification of the furnace can be improved. There is no environmental pollution.

Owner:许庆华

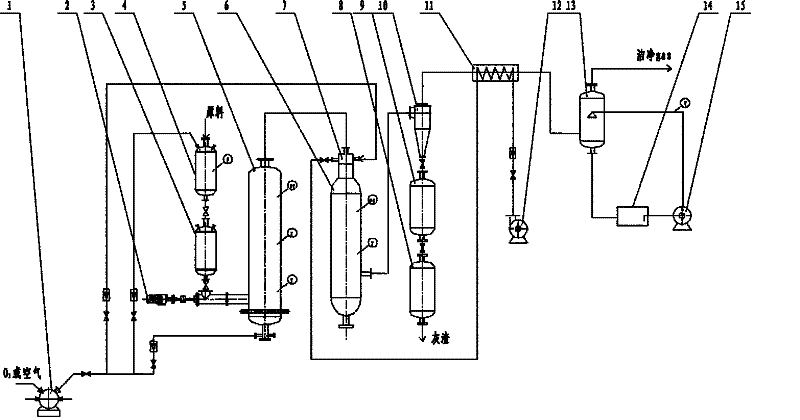

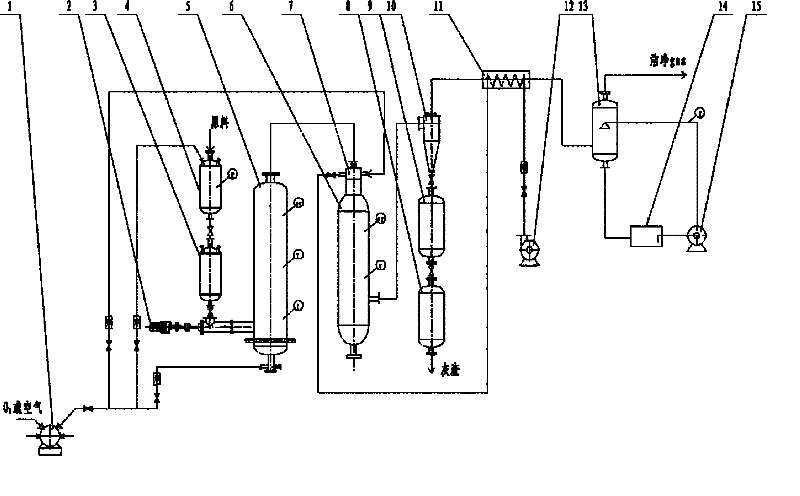

Technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification

InactiveCN102226107AImprove equipment production capacityHigh calorific valueProductsReagentsTarCoal tar

The invention relates to a technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification. Gasification in the technology is carried out in two stages, namely, primary gasification and high temperature gasification; biomass combustion gas, unreacted solids, tar and the like obtained in the primary gasification are directly delivered into a high temperature vapourizing furnace at high temperature and steam and air are also delivered into the vapourizing furnace so as to carry out high temperature gasification, thereby enhancing thermal efficiency, conversion rate of carbon and cracking rate of tar. In the process of the preparation, heat energy is self supplied, and heat is recovered to improve thermal efficiency; a thermal value of prepared synthetic gas can reach 7 to 8 MJ / m<3>. Equipment for realizing the technology comprises a biomass feed unit, gasification reactors, a dust collector, a heat reclaim unit, a washing unit, an air compressor, etc. The technology and equipment provided in the invention can be used to convert biomass raw materials like agricultural waste into synthetic gas with a high thermal value and low content of tar and are applicable to heat supply by biomass combustion gas, power generation by combustion gas or synthesis of liquid fuels.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Biomass gasification catalyst and its production method

InactiveCN1686606AIncrease gas calorific valueHigh cracking rateOther chemical processesGas purification with selectively adsorptive solidsTarBiomass gasifier

A catalyst used in biomass gasifier or gas furnace for cracking tar and removing uncracked tar and alkali metal is prepared from attapulgite-type clay, high-A alumina, iron oxide, magnesium oxide, calcium oxide and anthracite through proportionally mixing, stirring, grinding, granulating and baking.

Owner:许庆华

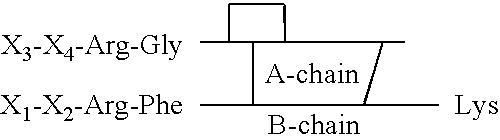

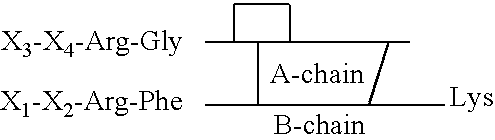

Processes for making acylated insulin

InactiveUS7402565B2High cracking ratePeptide/protein ingredientsPeptide sourcesYeastProteinase activity

Owner:NOVO NORDISK AS

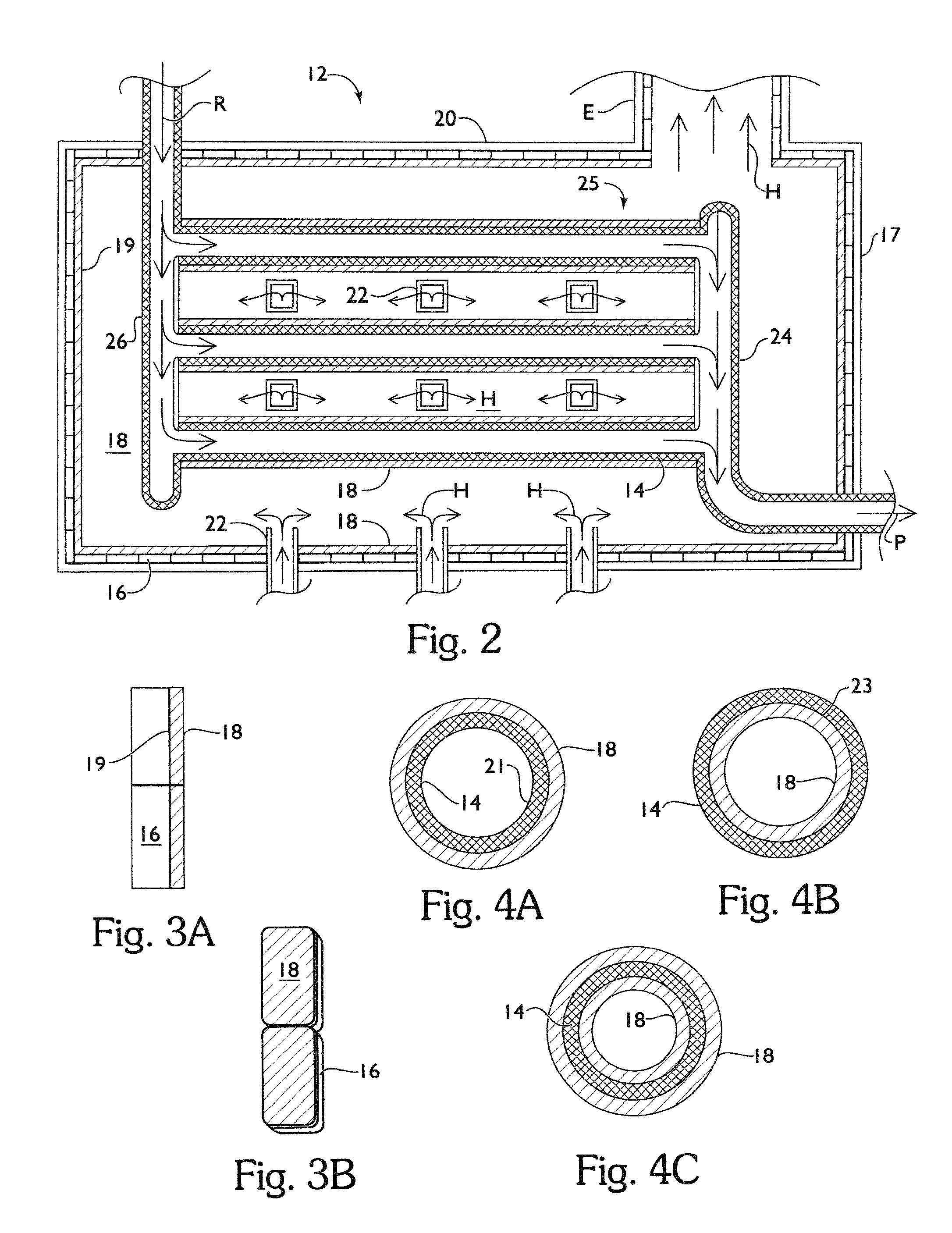

Process and apparatus for production of vinyl chloride monomer

ActiveUS20100041927A1Increase volumeReduce maintenancePreparation by hydrogen halide split-offChemical/physical/physico-chemical processesColloidal silicaCombustion chamber

Process and apparatus to form vinyl chloride monomer from ethylene dichloride in a cracking furnace, including a firebox chamber having a thermal protective layer disposed on refractory walls and / or process tubes disposed within the chamber, a quencher to form vinyl chloride monomer, and fractionator separate products. The thermal protective layer which contains an inorganic adhesive for metal / alloy tubes or colloidal silica and / or colloidal alumina for refractory walls or ceramic tubes, a filler, and one or more emissivity agents.

Owner:WESSEX

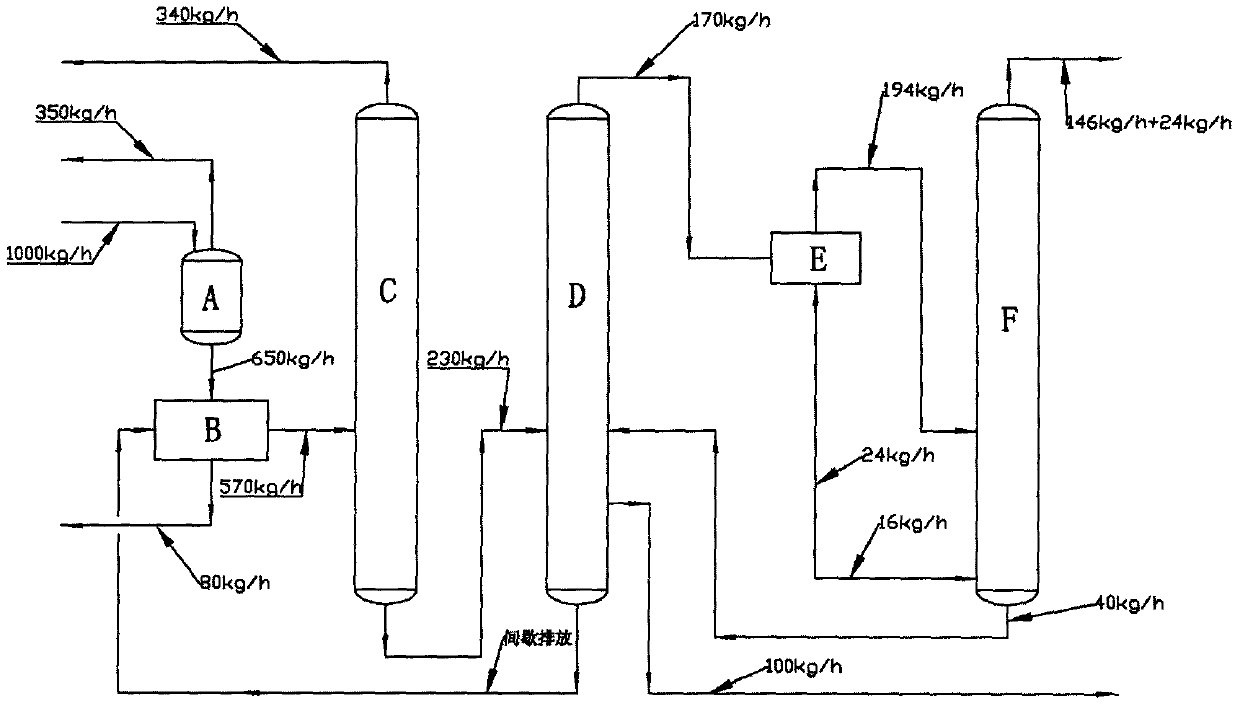

Method and device for recovering efficient high-boiling substance from organic silicon residue slurry

The invention provides a method and a device for recovering efficient high-boiling substance from organic silicon residue slurry. The method mainly comprises the following steps: discharging residue slurry from a reboiler of an organic silicon monomer synthesis washing tower into a distillation still; utilizing waste heat to evaporate high-boiling residues in the residue slurry; carrying out rectification in a packing tower; collecting the recificated product; conveying the collected product into a high-boiling lysis device; cooling down residual slug; discharging the cooled residual slug. The invention has the advantages that the waste heat of the monomer synthesis system is sufficiently utilized, and the temperature of the distillation still and the evaporation rate of the high-boiling residue are controlled, part of high-boiling residue of high lysis value is selectively recovered. Practices show that the lysis rate of the high-boiling residue treated according to the method reaches 80 percent or higher in lysis rate, the solid content of discharged residue is improved by 15 to 25 percent, the utilization value of the high-boiling residue is greatly improved, and the residue slug treatment cost is reduced.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Process for preparing granular type threonine product

ActiveCN104757273AReduce pollutionAvoid pollutionAnimal feeding stuffFertilizer mixturesEnvironmental resistanceMycoprotein

The invention belongs to the technical field of production of amino acids and in particular relates to a process for preparing a granular type threonine product. The process comprises the following steps: (1) preparing threonine fermentation liquor; (2) preparing powdery threonine; (3) preparing threonine granules; (4) refining a mycoprotein; (5) preparing the feed; and (6) preparing an organic fertilizer. According to the process disclosed by the invention, the threonine granules are prepared, moisture absorption and agglomeration can be avoided, the components of the waste mother solution are effectively utilized, wastes are not produced in the whole process, the process is environmentally friendly and pollution-free, and energy conservation and emission reduction are realized.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Environment-friendly technology for treating threonine fermentation mother liquid

ActiveCN104844468AReduce processingIncrease profitFungiOrganic compound preparationLiquid wasteThreonine

Belonging to the bio-fermentation industry fermentation waste liquid treatment field, the invention discloses an environment-friendly technology for treating threonine fermentation mother liquid. The technology includes the steps of: 1) preparing threonine crystals and a mother liquid, 2) preparing granule protein, 3) preparing chicken feed, and 4) preparing a fertilizer. The technology provided by the invention prepares the granule protein, feed and fertilizer simultaneously, and makes full use of the fermentation mother liquid components. The whole process generates no waste, is environment-friendly and pollution-free, and truly realizes turning waste into wealth.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

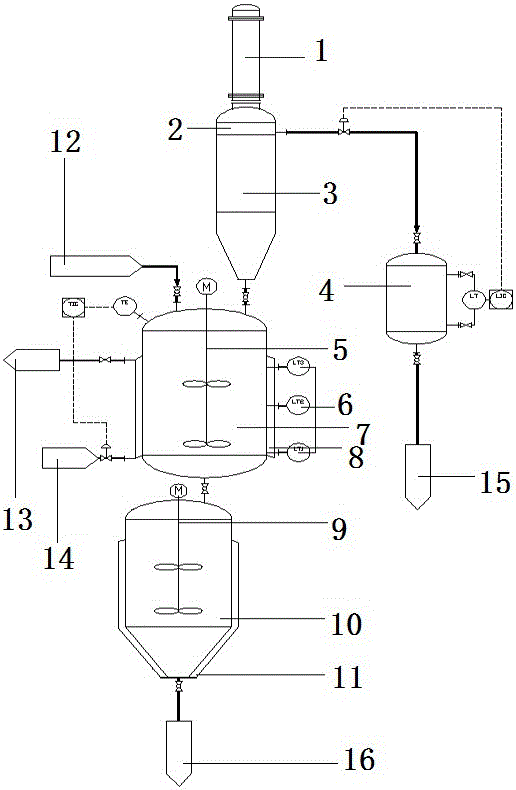

Pulse detonation pushing device based on regenerative cooling structure

InactiveCN109209678ABlending fastLow critical ignition energyIntermittent jet plantsRocket engine plantsRegenerative coolingFuel oil

The invention provides a pulse detonation pushing device based on a regenerative cooling structure. Based on the regenerative cooling structure, a convection / impact composite type heat exchange methodis adopted, liquid fuel oil is heated, catalyzed and cracked through heat radiation of detonation combustion, micromolecule gas fuel excellent in detonation performance is generated, the time and distance of deflagration to detonation transition (DDT) of a pulse detonation engine can be effectively shortened, and meanwhile efficient cooling of the wall face of a detonation pipe can be achieved. The catalytic and cracking fuel oil pretreatment method is adopted, the detonation performance of fuel is effectively improved, and meanwhile the pushing performance and safety of the engine are improved. The regenerative cooling structure provides a heat source for a catalytic and cracking reaction, and meanwhile airborne fuel oil is adopted as cooling media to cool the wall face of the detonationpipe. Temperature distribution of the wall face of the detonation pipe is considered, the convection / impact composite type cooling manner is adopted on the DDT segment of the detonation pipe, and a microchannel inner convection heat exchange manner is adopted in the detonation spread segment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Processes for making acylated insulin

InactiveUS20060264606A1High cracking rateIncrease cleavage ratePeptide/protein ingredientsPeptide sourcesInsulin PrecursorPancreatic hormone

A method is provided which allows high yields of acylated insulin. The method comprises expressing a singe-chain insulin precursor, preferably in yeast, cleaving the single-chain insulin precursor with a suitable protease which will open the peptide bond between the C-terminal amino group in the B-chain and a connecting peptide connecting the B chain with the A-chain, acylating the two-chain insulin intermediate in the ε-amino group in LysB29 and subjecting the acylated two-chain insulin intermediate to a proteolytic enzyme which will cleave of the N-terminal extension on the B- and A-chains on the precursor molecule.

Owner:NOVO NORDISK AS

Pyrolysis furnace and process tubes

ActiveUS9011791B2Increase volumeReduce maintenanceThermal non-catalytic crackingLiquid surface applicatorsColloidal silicaEmissivity

A cracking furnace construction includes a firebox defining a chamber having a high emissivity thermal protective coating disposed on at least part of the refractory walls and / or on process tubes disposed within the chamber. The coating contains an inorganic adhesive for metal / alloy tubes or colloidal silica and / or colloidal alumina for refractory walls or ceramic tubes, a filler, and one or more emissivity agents. A method of coating the firebox chamber includes preparing the surface of the tubes / refractory walls, preparing the coating, and applying the coating to the surface.

Owner:EMISSHIELD

Cracking recovery process of n-butyl acrylate heavy components

InactiveCN110372509AImprove cracking rate and recoveryReduce equipment maintenance rate and maintenance costOrganic compound preparationCarboxylic acid esters preparationMaterial consumptionChemistry

The invention discloses a cracking recovery process of n-butyl acrylate heavy components. The cracking recovery process of the n-butyl acrylate heavy components comprises the following steps that in asynthesis process of n-butyl acrylate produced from acrylic acid and n-butanol, the bottom components of a n-butyl acrylate refining tower are injected into the bottom of a cracking reactor, meanwhile, acrylic acid, a catalyst, a polymerization inhibitor and water are added into the cracking reactor, and after cracking is carried out, the n-butyl acrylate is recovered from the top of the crackingreactor and is discharged into a recovery tower, and the top of the recovery tower communicates with the n-butyl acrylate reactor to realize the cracking of the n-butyl acrylate heavy components, then the n-butyl acrylate enters an esterification section to participate in the reaction, and the recovery is realized. The cracking recovery process of the n-butyl acrylate heavy components has the characteristics of high cracking efficiency of the n-butyl acrylate heavy components, high recovery of n-butanol and n-butyl acrylate and low material consumption and energy consumption cost.

Owner:谦信化工集团有限公司

Catalyst for pyrolysis of oil shale as well as preparation method and use method of catalyst

InactiveCN103878031AIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisMetallic sulfide

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

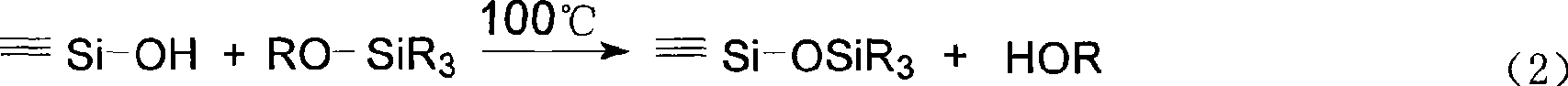

Modified nano molecular sieve catalyst for cracking endothermic hydrocarbon fuels and preparation method

InactiveCN101502807AHigh cracking rateReduce heat transfer resistanceCatalytic crackingMolecular sieve catalystsMolecular sieveGrignard reagent

The invention relates to a nano molecular sieve catalyst for cracking of endothermic hydrocarbon fuel and a preparation method. The preparation method uses nano-scale Na type molecular sieve raw powder as a raw material, firstly prepares an H-shaped molecular sieve, and then carries out modification preparation by a grafting method; and a proportion of the nano molecular sieve to a grafting reagent is 0.016-1.560 mmol / g (grafting reagent / molecular sieve). The method uses the nano molecular sieve with the advantages of large specific surface area, short pore canal, more surface active sites and the like as a modification precursor of the catalyst, uses organic chlorosilane, organic siloxane or Grignard reagent and the like as a modified reagent, and adopts the grafting method to carry out organic functional modification for the surface of the nano molecular sieve so as to obtain the nano molecular sieve catalyst. The catalyst used for catalytic cracking reaction can make up the defects of easy carbon deposit, easy inactivation of the catalyst and the like in the prior thermal cracking and catalytic cracking process of the endothermic hydrocarbon fuel, reduces the heat transmission resistance of a pipeline, and improves the cracking rate of the fuel.

Owner:TIANJIN UNIV

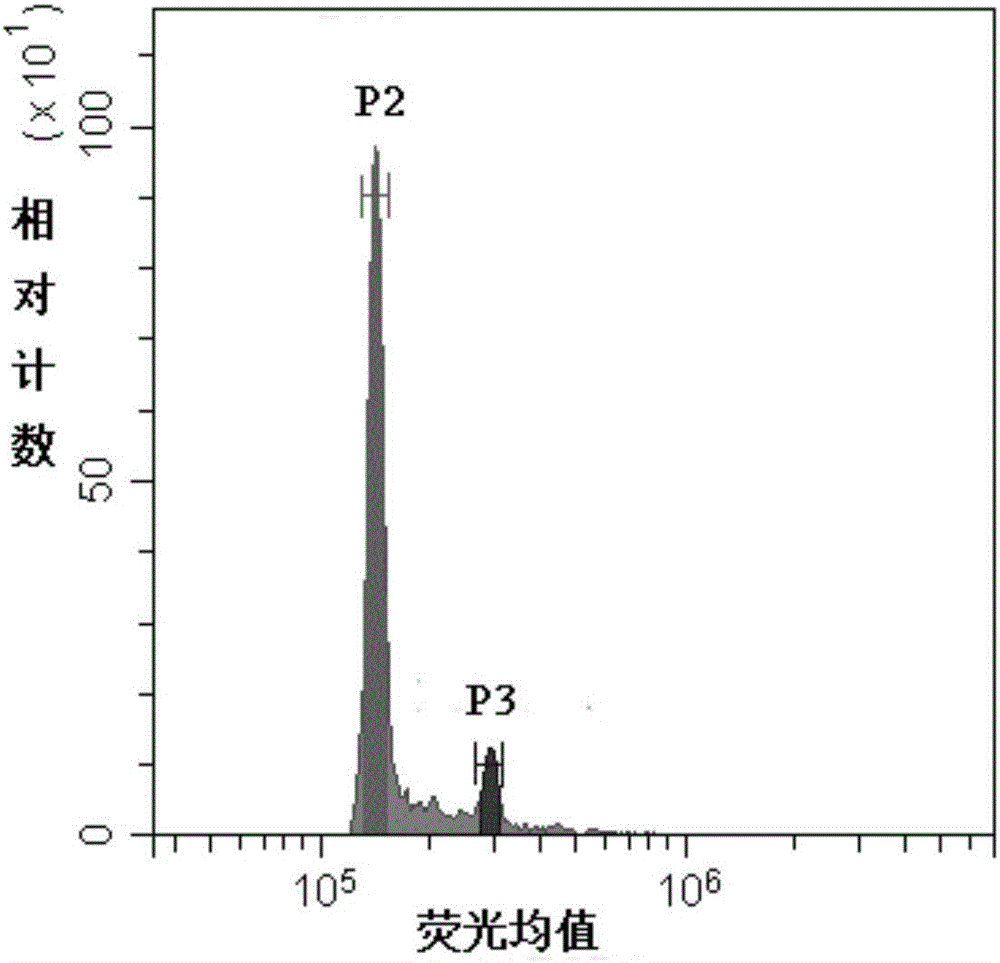

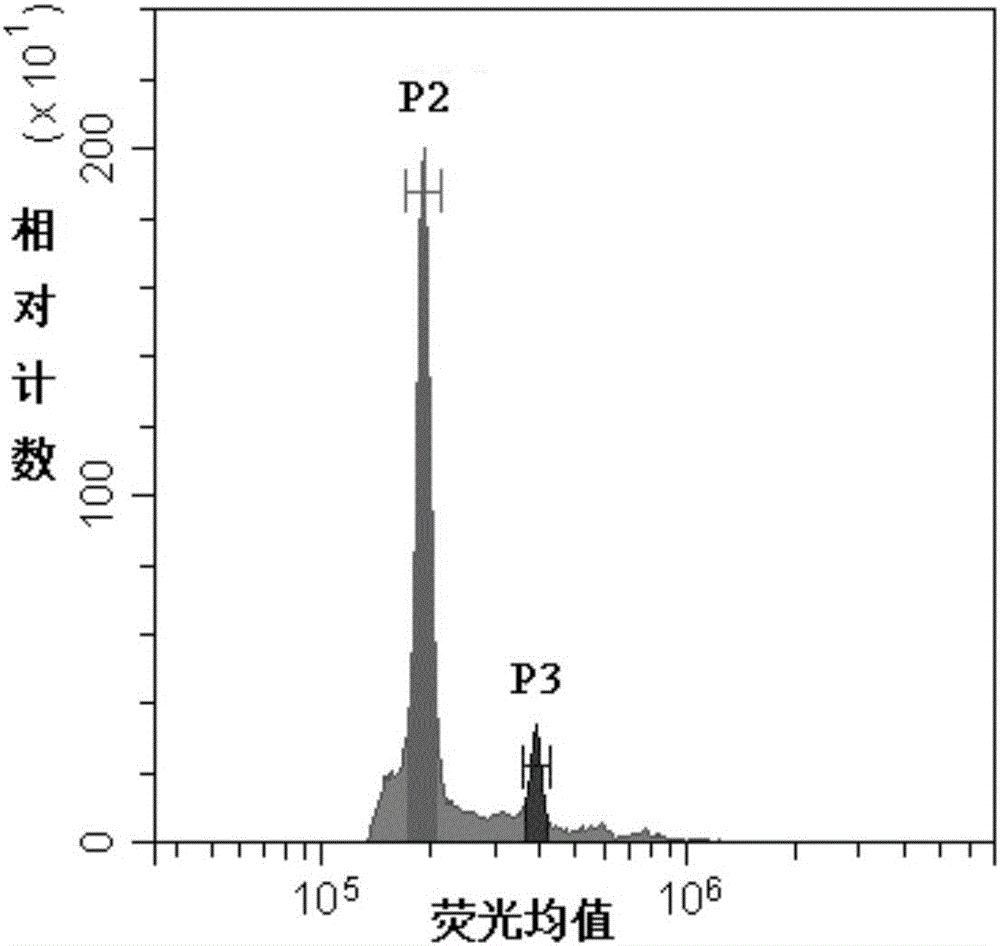

Eucalyptusurophylla*E. grandis flow-type detection method

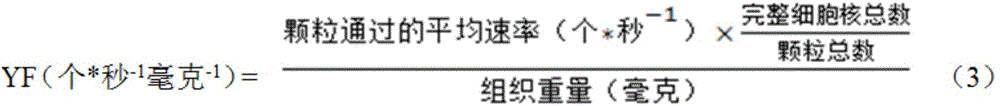

InactiveCN106092864AReduced dye resistanceHigh cracking rateIndividual particle analysisHydrolysateBiology

The invention belongs to the field of plant ploidy detection and discloses a Eucalyptusurophylla*E. grandis flow-type detection method. The method comprises 1, taking tender leaves of Eucalyptusurophylla*E. grandis DH32-29, adding the tender leaves into a lysate, cutting the tender leaves through a blade and carrying out cracking to obtain a cell cracking fluid suspension, 2, filtering the cell cracking fluid suspension, centrifuging the filtrate, removing the supernatant, adding a lysate into the filter residues so that cell nucleuses in the precipitates are re-suspended and filtering the suspension to obtain a filtrate, 3, adding a RNase enzyme solution into the filtrate obtained by the step 2 and carrying out enzymolysis to obtain an enzymatic hydrolysate, 4, adding a PI dye solution into the enzymatic hydrolysate obtained by the step 3 and carrying out dying to obtain a dyed solution, and 5, detecting the dyed solution through a flow cytometer. The method realizes instant sample preparation after material collection in the field. After preparation for 2 days (48h), the cell nucleus dyed solution is subjected to flow-type detection and analysis so that detection effect stability is ensured and the problem that the existing flow-type detection method needs immediate detection after collection is solved.

Owner:RES INST OF TROPICAL FORESTRY CHINESE ACAD OF FORESTRY

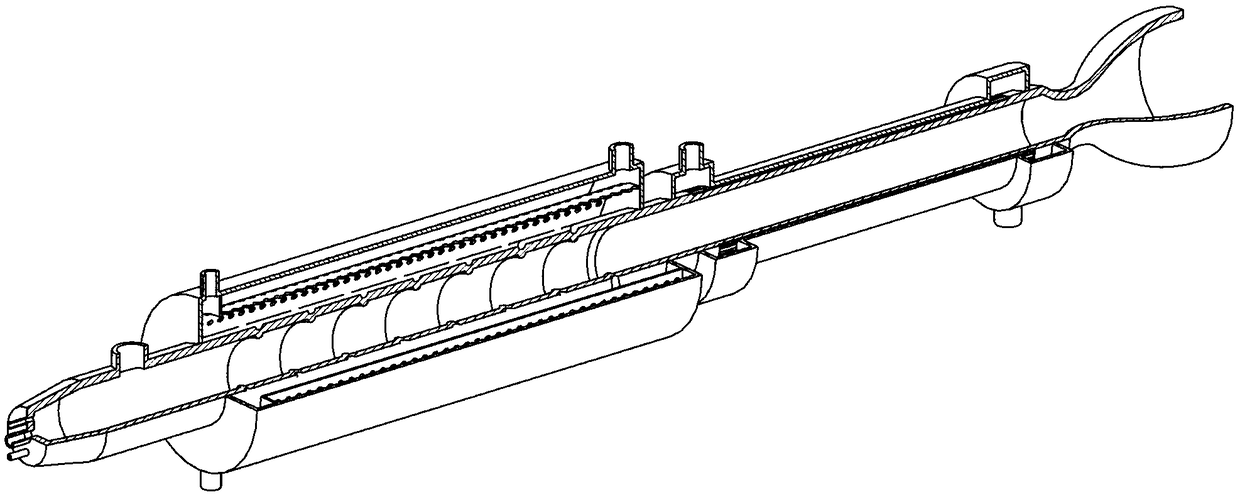

Chlorosilane high-boiling residue recovery technology combining slurry treatment with pyrolysis reaction

ActiveCN110078080AHigh cracking rateExtended service lifeChemical recyclingHalogenated silanesChemistryPyrolysis

The invention relates to a chlorosilane high-boiling residue recovery technology combining slurry treatment with pyrolysis reaction. The technology comprises the following steps: pre-treating chlorosilane high-boiling residue slurry through a slurry treatment device, separating recycled materials, feeding a chlorosilane low polymer into a pyrolysis reactor loaded with a catalyst to react with hydrogen chloride to obtain a pyrolysis product, and performing subsequent separation to obtain a monosilane product. The chlorosilane high-boiling residue recovery technology combining the slurry treatment with the pyrolysis reaction has the advantages that the slurry treatment device can effectively remove solid impurities, such as metal chloride and the like, contained in the materials, and inactivation and coking phenomena of a pyrolysis catalyst are avoided; a high-boiling residue separation tower has a function of beside collection, and can separate liquid-phase high polymers, so that accumulation is avoided; a pyrolysis reaction rectifying tower performs pyrolysis reaction and separation process at the same time, so that the pyrolysis ratio can be improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

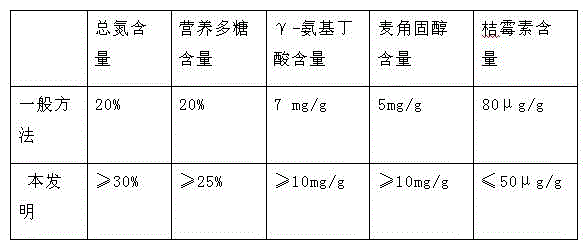

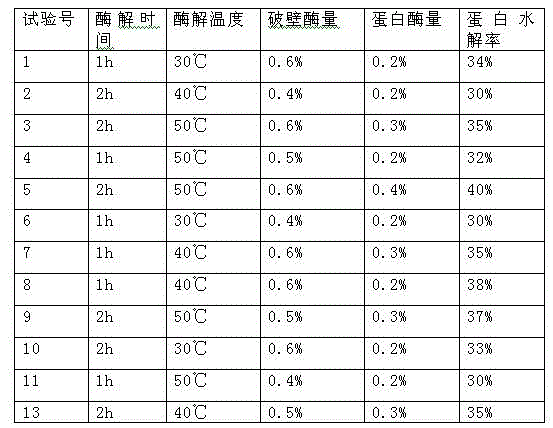

Method for treating monascus residue

ActiveCN104432019ALower cholesterol levelsLower total cholesterolMetabolism disorderSkeletal disorderMedicineBlood pressure

The invention belongs to the technical field of monascus residue waste utilization, and specifically discloses a method for treating monascus residue, namely a method for preparing health-care food for reducing blood fat, reducing blood pressure and preventing osteoporosis by enzymolysis of monascus residue. The monascus residue left after monascus pigment is produced is treated by ultrasonic wave and composite enzymolysis, mycelia are crushed to release protein and polysaccharides therein, then the monascus residue is degraded into protein polypeptide or amino acid, residual active substances such as ergosterol and gamma-aminobutyric acid are enriched, and the monascus residue can be prepared into a microcapsule preparation for reducing blood fat, reducing blood pressure and preventing osteoporosis, so that secondary pollution in the traditional acid-alkali treatment process is avoided.

Owner:山东中惠生物科技股份有限公司

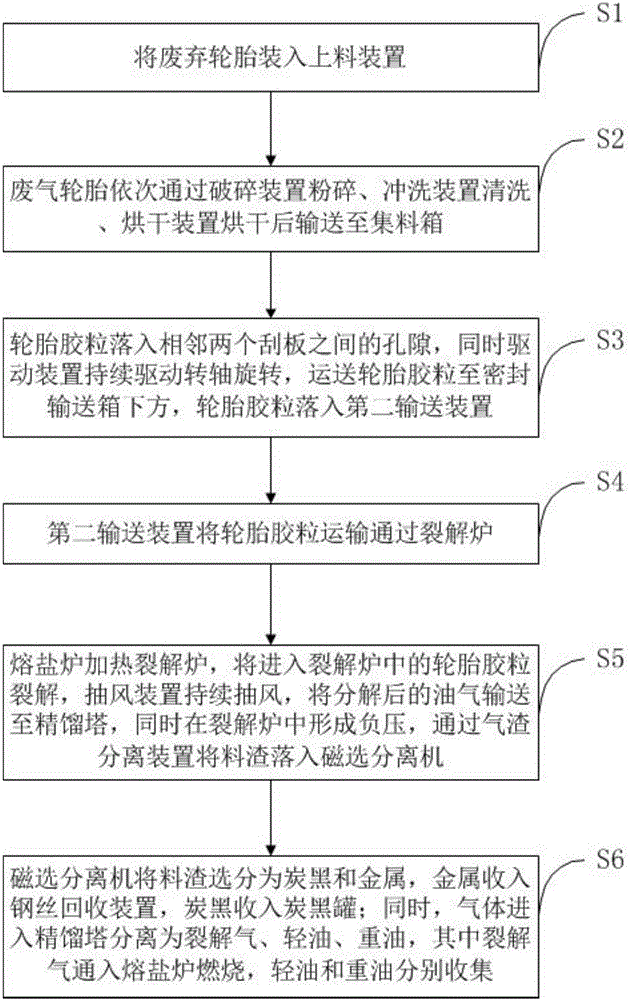

Waste and old tire colloidal particle cracking system and method

ActiveCN106513419AImprove combustion effectImprove efficiencyProductsReagentsGas collecting tubeSlag

The invention discloses a waste and old tire colloidal particle cracking system and method. The system comprises a conveying device, a breaking device, a washing device, a drying device and a cracking furnace are sequentially connected to the conveying device, the cracking furnace is further connected with a molten salt furnace, the molten salt furnace is connected with the drying device through a transition salt pipe, the drying device is connected with the molten salt furnace through a salt returning pipe, the cracking furnace is further connected with a gas and slag separation device, the gas and slag separation device is connected with a carbon black tank and a steel wire recycling device through a magnetic separator, and the gas and slag separation device is further connected with a rectifying tower; a gas pipe is further communicated with the cracking furnace, the cracking furnace and the gas and slag separation device are arranged side by side, the conveying device penetrates the cracking furnace to stretch into the gas and slag separation device, a slag cavity is formed in the lower portion of the gas and slag separation device, the upper portion of the gas and slag separation device is communicated with a gas collecting pipe communicated with the rectifying tower, and the bottom of the slag cavity is communicated with the magnetic separator. The waste and old tire colloidal particle cracking system and method are high in tire colloidal particle cracking rate, high in cracking object recycling rate, capable of achieving continuous production and low in energy consumption.

Owner:国宏中晶集团有限公司

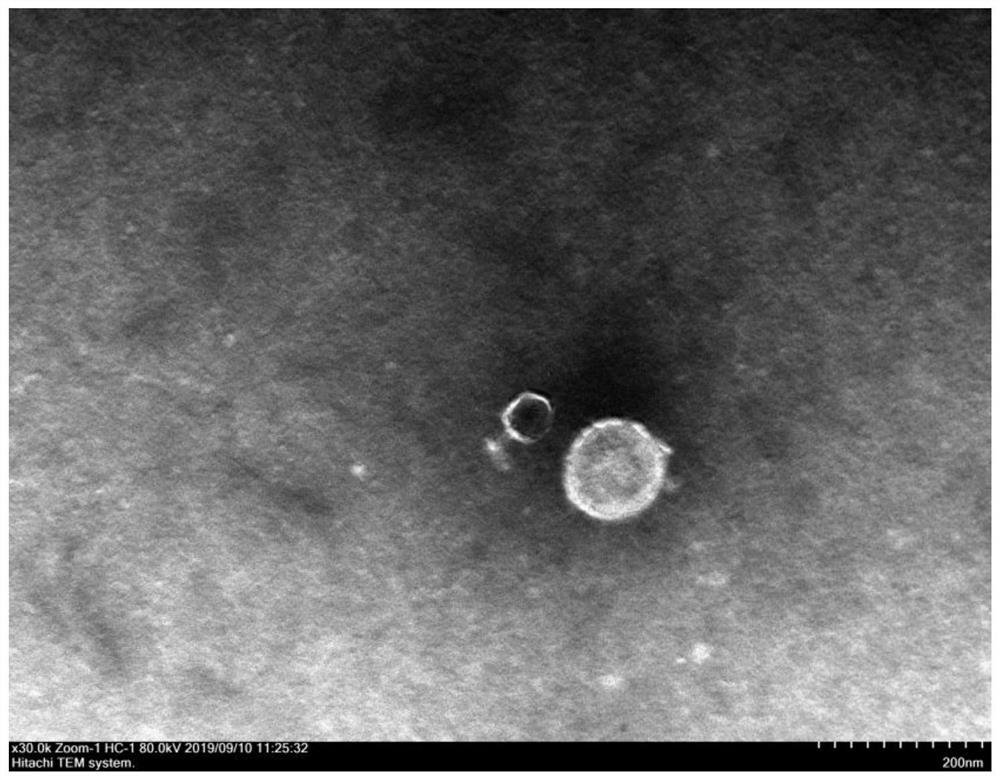

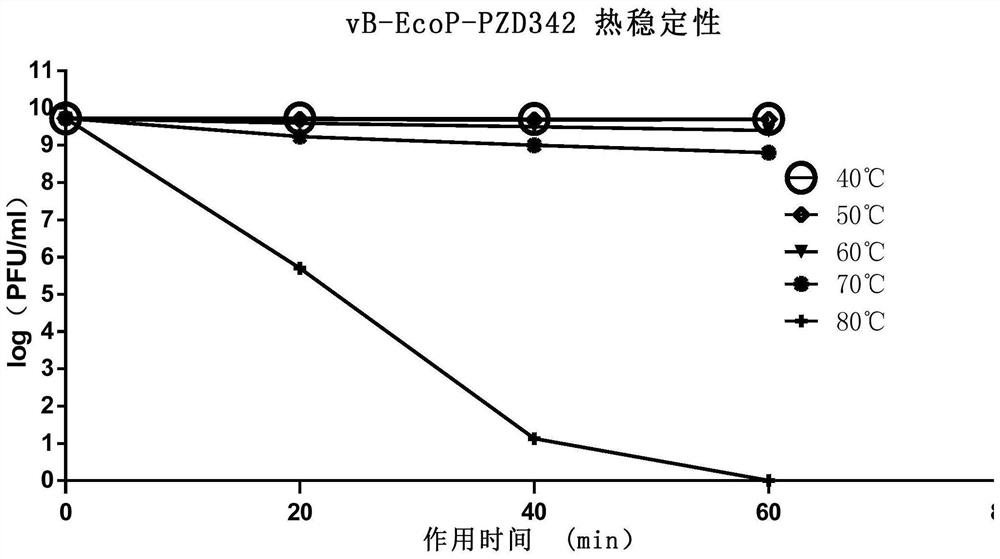

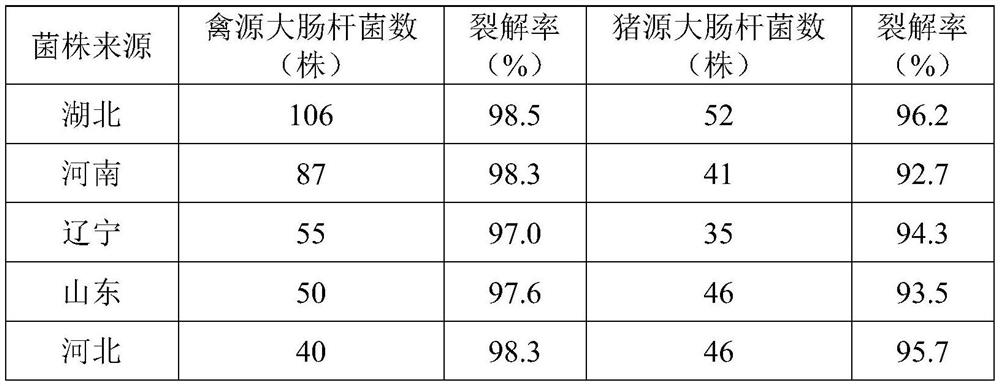

Piglet diarrhea coliphage and application thereof

ActiveCN113201502AHigh cracking rateGood pH and temperature toleranceAntibacterial agentsBiocideColiphageDiarrhea

The invention discloses and relates to a piglet diarrhea coliphage and application thereof, the piglet diarrhea coliphage is named as vB-EcoP-ZPD342, and the preservation number is CGMCC NO.18863. The coliphage preparation can effectively prevent and treat piglet diarrhea caused by escherichia coli, can be used for disinfecting escherichia coli in a farm environment and breeding equipment, and can also be used as a preservative of meat products. The coliphage preparation provided by the invention is colorless, non-toxic and odorless, does not pollute the environment when being sprayed in the environment, and has broad-spectrum bactericidal performance. The coliphage preparation disclosed by the invention provides a new idea for preventing and treating piglet diarrhea, killing escherichia coli in a farm environment and preventing and treating meat products.

Owner:QINGDAO PHAGEPHARM BIO TECH CO LTD

Process and apparatus for production of vinyl chloride monomer

ActiveUS7968756B2Increase volumeReduce maintenancePreparation by hydrogen halide split-offChemical/physical/physico-chemical processesColloidal silicaAdhesive

Process and apparatus to form vinyl chloride monomer from ethylene dichloride in a cracking furnace, including a firebox chamber having a thermal protective layer disposed on refractory walls and / or process tubes disposed within the chamber, a quencher to form vinyl chloride monomer, and fractionator separate products. The thermal protective layer which contains an inorganic adhesive for metal / alloy tubes or colloidal silica and / or colloidal alumina for refractory walls or ceramic tubes, a filler, and one or more emissivity agents.

Owner:WESSEX

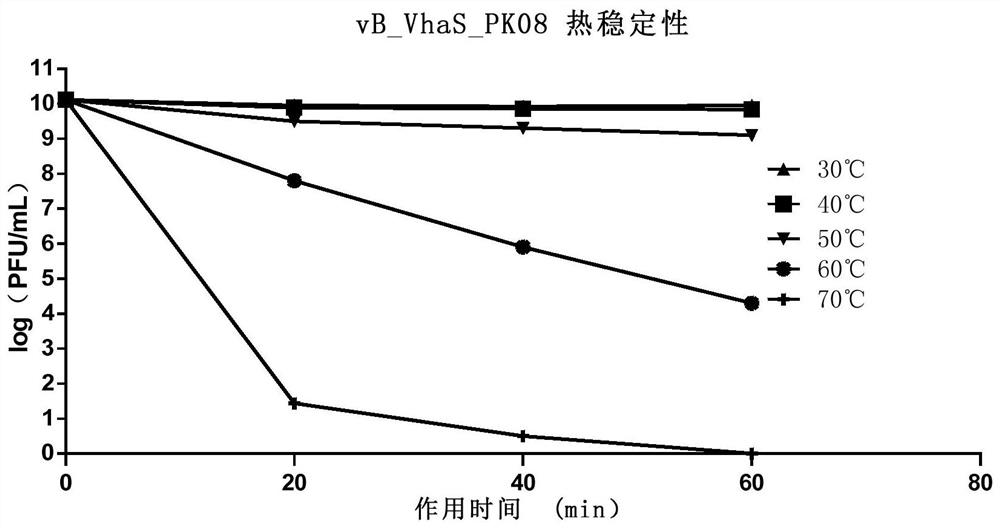

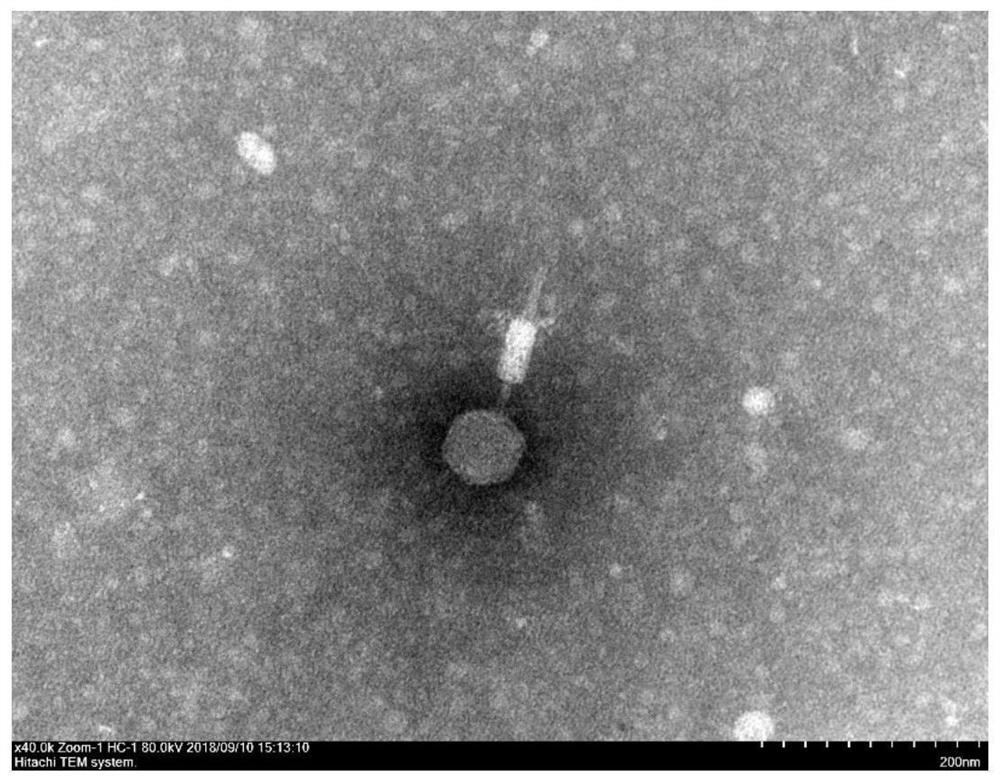

Vibrioharveyi bacteriophage, and bacteriophage composition and application thereof

ActiveCN111676197AStrong cracking abilityComprehensive disinfectionAntibacterial agentsBiocideBiotechnologyAquaculture industry

The invention discloses a vibrioharveyi bacteriophage, and a bacteriophage composition and application thereof. The bacteriophage is named as vB_KaS_PK08, and is preserved in China General Microbiological Culture Collection Center on 15th May, 2020, and the preservation No. is CGMCC No.19973. The bacteriophage not only has wide lysis spectrum, is high in specificity, and can effectively prevent and control vibrioharveyi diseases of in-home aquatic farms, and invasion probability of various diseases caused by the vibrioharveyi can be greatly reduced. The vibrioharveyi bacteriophage can also bewidely applied to respects of daily disinfection for links and breeding environment, to which loss is easy to cause due to infection with the vibrioharveyi in the aquaculture process, bacteriostasis of aquatic products and fresh foods, and the like, and is beneficial for healthy development of aquaculture trade.

Owner:QINGDAO PHAGEPHARM BIO TECH CO LTD

Serial L-shaped non-phase change superconducting heat pipe heat recovery type volatile organic chemicals (VOCs) incinerator

InactiveCN102865584AReduce consumptionReduce volumeIncinerator apparatusCombustion chambersOrganic chemicalsHearth

The invention discloses a serial L-shaped non-phase change superconducting heat pipe heat recovery type volatile organic chemicals (VOCs) incinerator which is suitable for all VOCs removing systems. The VOCs incinerator comprises an internal spiral type incinerator body, a ceramic Archimedes spiral line hearth, a burner, a processing fan, a non-phase change superconducting heat pipe heat exchanger, a programmable logic controller (PLC) control box and the like. After being subjected to adsorption, concentration, desorption and preheating of a rotary wheel of the removing system, VOCs enter the ceramic Archimedes spiral line hearth to form spiral gas flow, are completely cracked into CO2 and O2 through two-sectional burning, and are discharged into the atmosphere through a chimney. The non-phase change superconducting heat pipe heat exchanger performs heat recovery. Compared with the traditional two-tower type or three-tower type VOCs incinerator, by means of the rotary gas flow burning mode and waste heat recovery mode, the serial L-shaped VOCs incinerator improves burning and cracking rate by 0.5-1%, reduces fuel consumption by 25-30%, and reduces construction cost by 35-40%.

Owner:深圳市华懋环保节能设备有限公司 +2

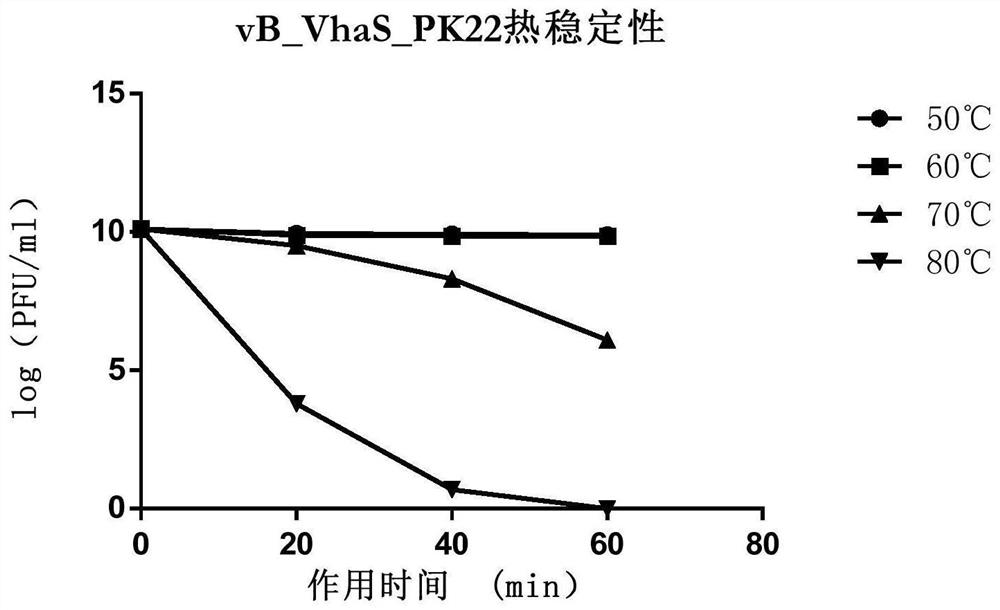

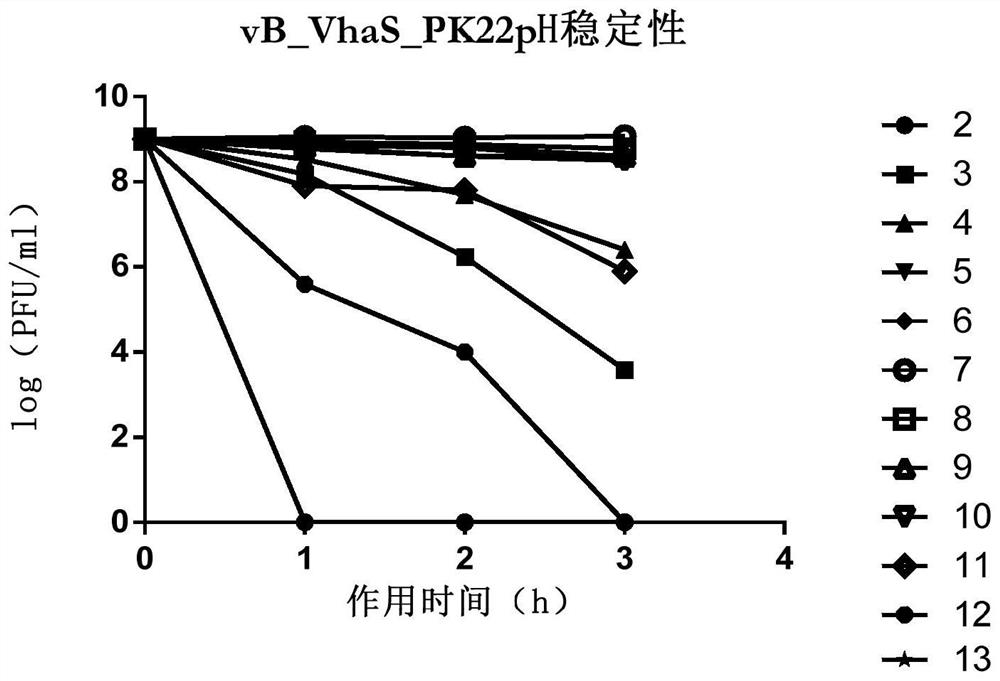

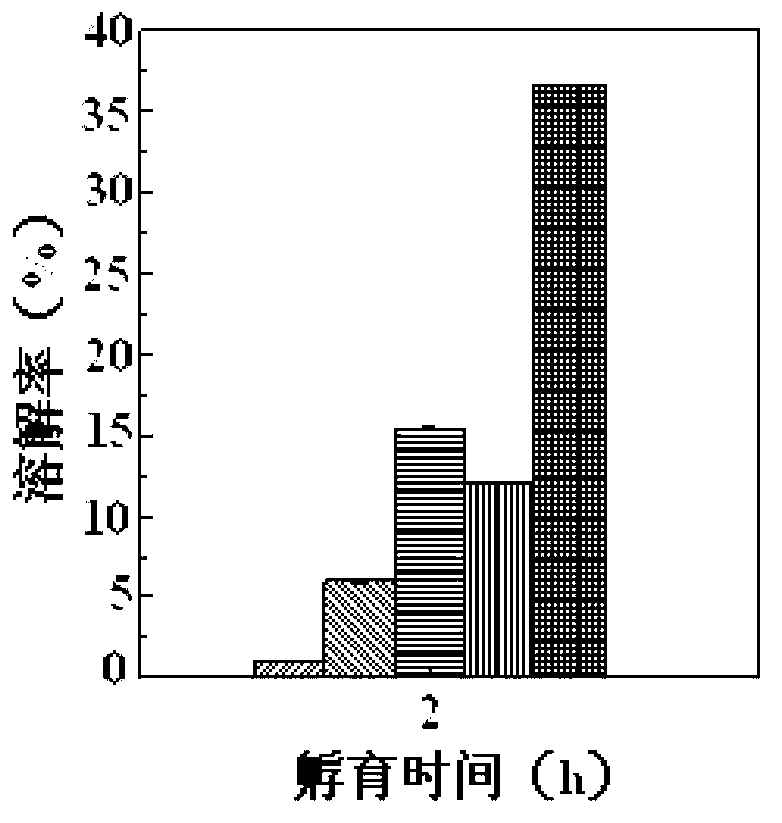

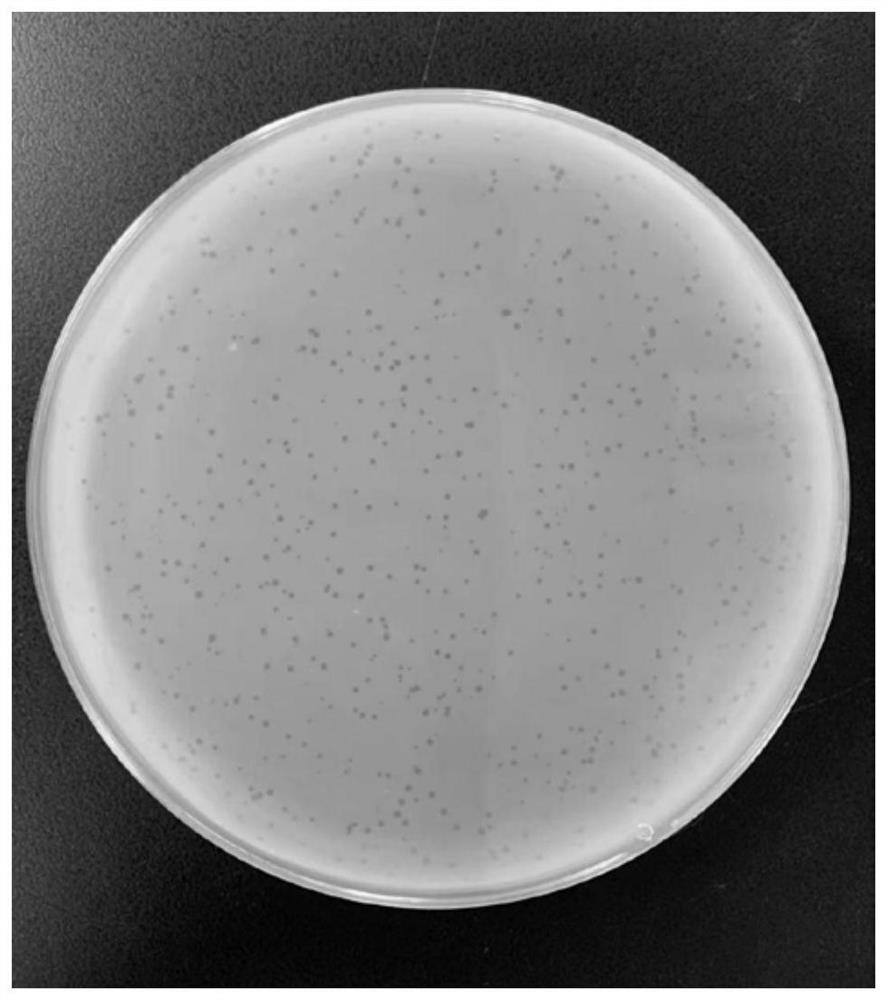

Vibrio harveyi phage vB_KaS_PK22, Vibrio harveyi phage-containing phage composition and application of Vibrio harveyi phage

ActiveCN111705041AReduce morbidityReduce mortalityAntibacterial agentsBiocideBiotechnologyAquaculture industry

The invention discloses a Vibrio harveyi phage vB_KaS_PK22, a Vibrio harveyi phage-containing phage composition and application of the Vibrio harveyi phage. The phage vB_KaS_PK22 is deposited in the China General Microbiological Culture Collection Center on May 15, 2020, and has a collection number of CGMCC No. 19974. The phage composition includes the Vibrio harveyi phage vB_KaS_PK22 and other matched phage. The phage has a wide lysis spectrum and high specificity, and is capable of effectively preventing and controlling Vibrio harveyi in aquaculture farms and greatly reducing the incidence of multiple diseases which are caused by Vibrio harveyi; and the Vibrio harveyi phage can also be applied widely to steps with easy losses which are caused by infection of Vibrio harveyi, daily disinfection of breeding environments and bacteriostasis of fresh aquatic products in the process of aquaculture, so that healthy development of the aquaculture industry is facilitated.

Owner:QINGDAO PHAGEPHARM BIO TECH CO LTD

Method for promoting excess sludge microorganisms to hydrolyze by using thermophilic geobacillus sp

InactiveCN103193368AIncrease the rate of hydrolysisPromote water machineSludge processingBiological sludge treatmentMicroorganismSludge

The invention relates to a method for promoting excess sludge microorganisms to hydrolyze by using thermophilic geobacillus sp, and relates to a method for promoting excess sludge microorganisms to hydrolyze. The invention aims to solve the technical problems of being low in biological hydrolysis rate of excess sludge microorganisms and high in cost. The method disclosed by the invention comprises the following steps of: 1, obtaining activated thermophilic geobacillus sp; 2, inoculating activated thermophilic geobacillus sp into a fermented culture medium to culture, and obtaining fermentation liquid of thermophilic geobacillus sp; and 3, adding supernate of fermentation liquid of thermophilic geobacillus sp into excess sludge to react, so that hydrolysis promotion of excess sludge microorganisms by using thermophilic geobacillus sp is completed. The method disclosed by the invention is capable of promoting the cracking rate of microorganisms and increasing the hydrolysis rate of sludge and is applicable in the technical field of hydrolysis of microorganisms.

Owner:HARBIN INST OF TECH

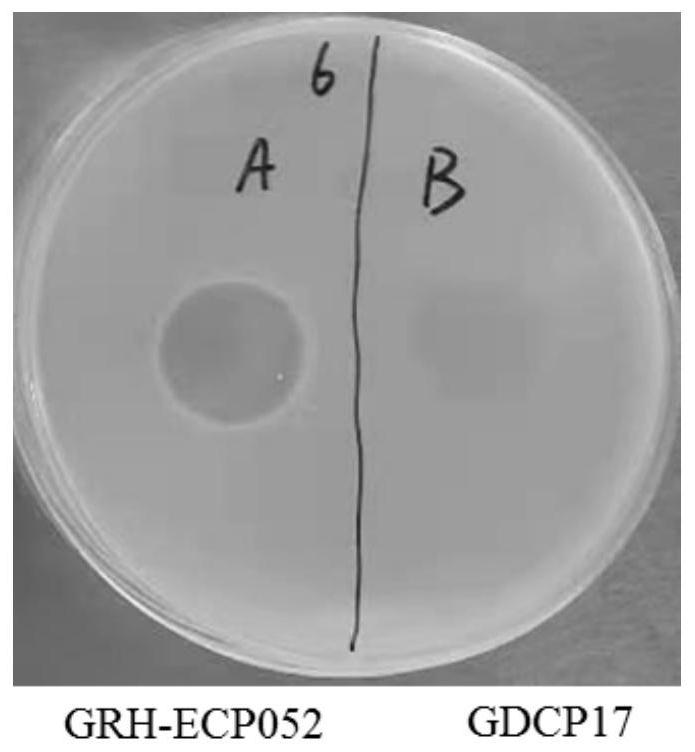

Broad-spectrum phage for rapidly cracking livestock and poultry escherichia coli and application

PendingCN113604441ABroad cracking spectrumImprove fermentation efficiencyAntibacterial agentsDigestive systemColiphageLivestock

The invention belongs to the technical field of agricultural microorganism application, and particularly relates to a broad-spectrum phage for rapidly cracking livestock and poultry pathogenic escherichia coli and application. The escherichia coli phage GRH-ECP052 which is rapid in cracking and wide in cracking spectrum is obtained through screening, the phage is preserved in the China center for type culture Collection, and the preservation number is CCTCC NO: M20211009. The phage has a good prevention and treatment effect on poultry colibacillosis and piglet yellow-white dysentery.

Owner:武汉观海生物科技有限公司

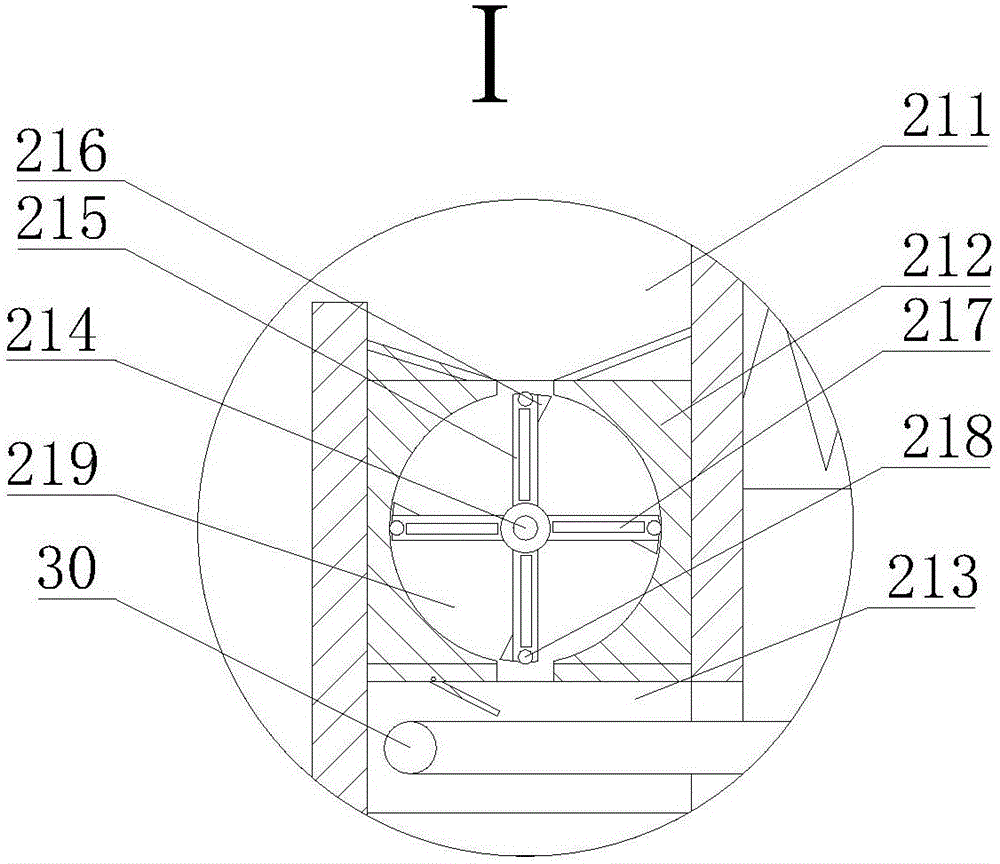

Negative-pressure cracking system and cracking method

The invention discloses a negative-pressure cracking system and a cracking method. The system comprises a conveying device, wherein the conveying device is sequentially connected with a crushing device, a washing device, a drying device, a feeding device and a cracking furnace; a gas-dreg separation device is further connected with a rectifying tower; a dreg material chamber is arranged below the gas-dreg separation device, and an upper part of the gas-dreg separation device is communicated with a gas collection pipe communicated with the rectifying tower; the bottom of the dreg material chamber is communicated with a magnetic separation machine; the feeding device comprises a vertical box body; the vertical box body is composed of a material collection box, a sealed conveying box and a blanking transferring box, which are communicated in sequence from top to bottom; the sealed conveying box is internally provided with a round cavity; a rotary shaft is arranged in the round cavity; a plurality of scraping plates are uniformly mounted on the rotary shaft; the rotary shaft is further connected with a driving device; one end of a second conveying device is arranged in the blanking transferring box and the other end of the second conveying device is arranged in the gas-dreg separation device. In the negative-pressure cracking system and the cracking method, the cracking rate of tire rubber grains is high and the recovery rate of cracked products is high; continuous production can be realized and the energy consumption is low.

Owner:中科钢研节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com