Chlorosilane high-boiling residue recovery technology combining slurry treatment with pyrolysis reaction

A technology of cracking reaction and chlorosilane, which is applied in the direction of silicon compound, halosilane, chemical recovery, etc., can solve the problems of increased production cost, catalyst deactivation, high boiling material cracking rate cannot be improved, etc., to avoid accumulation and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

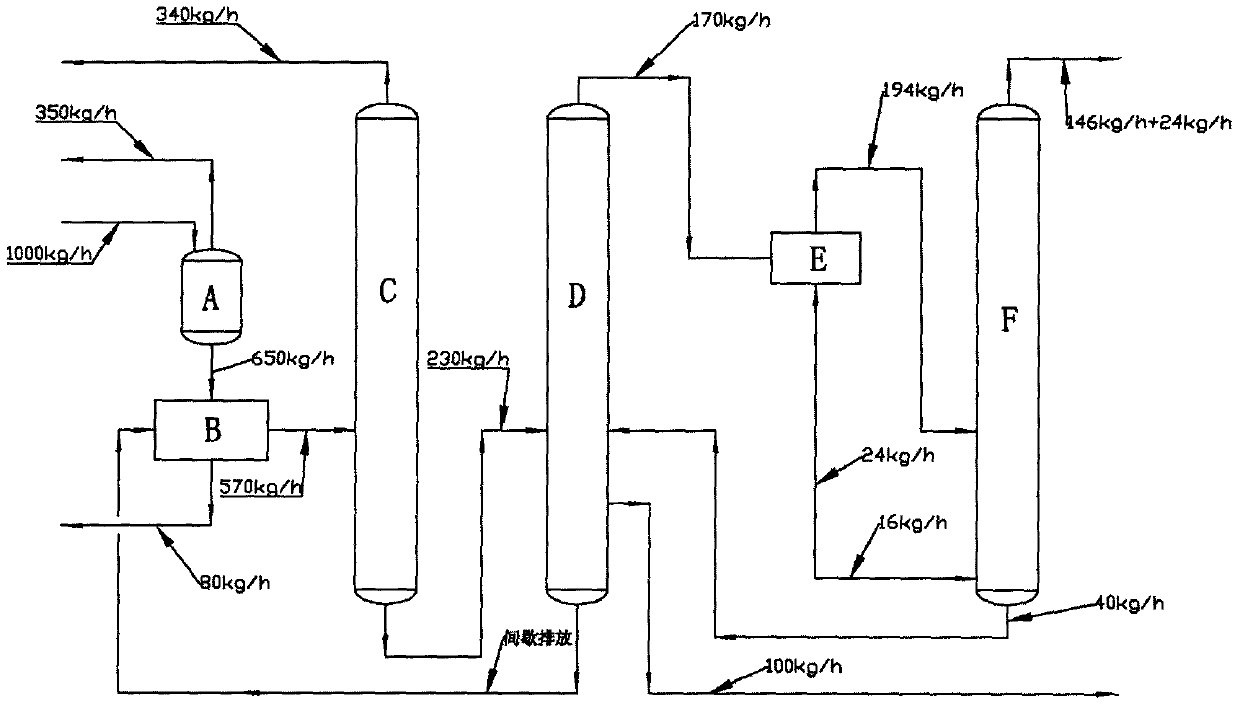

[0052] The processing capacity of chlorosilane high-boiler slurry is 1000kg / h, and the content of silicon tetrachloride is 70%. 2 Cl 6 The representative chlorosilane oligomer content is 12%, the chlorosilane high polymer content is 10%, and the solid impurity content is 8% as an example, and the calculation is explained. The specific process flow and material balance are as attached figure 2 Shown.

[0053] The 1000kg / h chlorosilane high-boiler slurry enters the silicon tetrachloride recovery equipment (A), and the amount of silicon tetrachloride recovered is 350kg / h, and the remaining 650kg / h material enters the deslagging drying equipment (B). Through the equipment (B), 80kg of solid impurities are removed per hour, and 570kg of liquid phase high boilers are obtained and sent to the silicon tetrachloride recovery tower (C) of the high boiling cracking device. The operating pressure of the tower (C) is 0.1MPa(G). Through the separation of the tower (C), the amount of silicon t...

example 2

[0055] The processing capacity of chlorosilane high-boiler slurry is 2000kg / h, and the content of silicon tetrachloride is 65%. 2 Cl 6 The representative chlorosilane oligomer content is 15%, the chlorosilane high polymer content is 10%, and the solid impurity content is 10% as an example, and the calculation is explained. The specific process flow and material balance are as attached image 3 Shown.

[0056] The 2000kg / h chlorosilane high-boiler slurry enters the silicon tetrachloride recovery equipment (A) to recover 650kg / h of silicon tetrachloride, and the remaining 1350kg / h material enters the deslagging and drying equipment (B). Through equipment (B), 200kg of solid impurities are removed per hour, and 1150kg of liquid phase high boiler is sent to the silicon tetrachloride recovery tower (C) of the high boiling cracking device. The operating pressure of the tower (C) is 0.1MPa(G). Through the separation of the tower (C), the amount of silicon tetrachloride recovered from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com