Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1398results about "Halogenated silanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

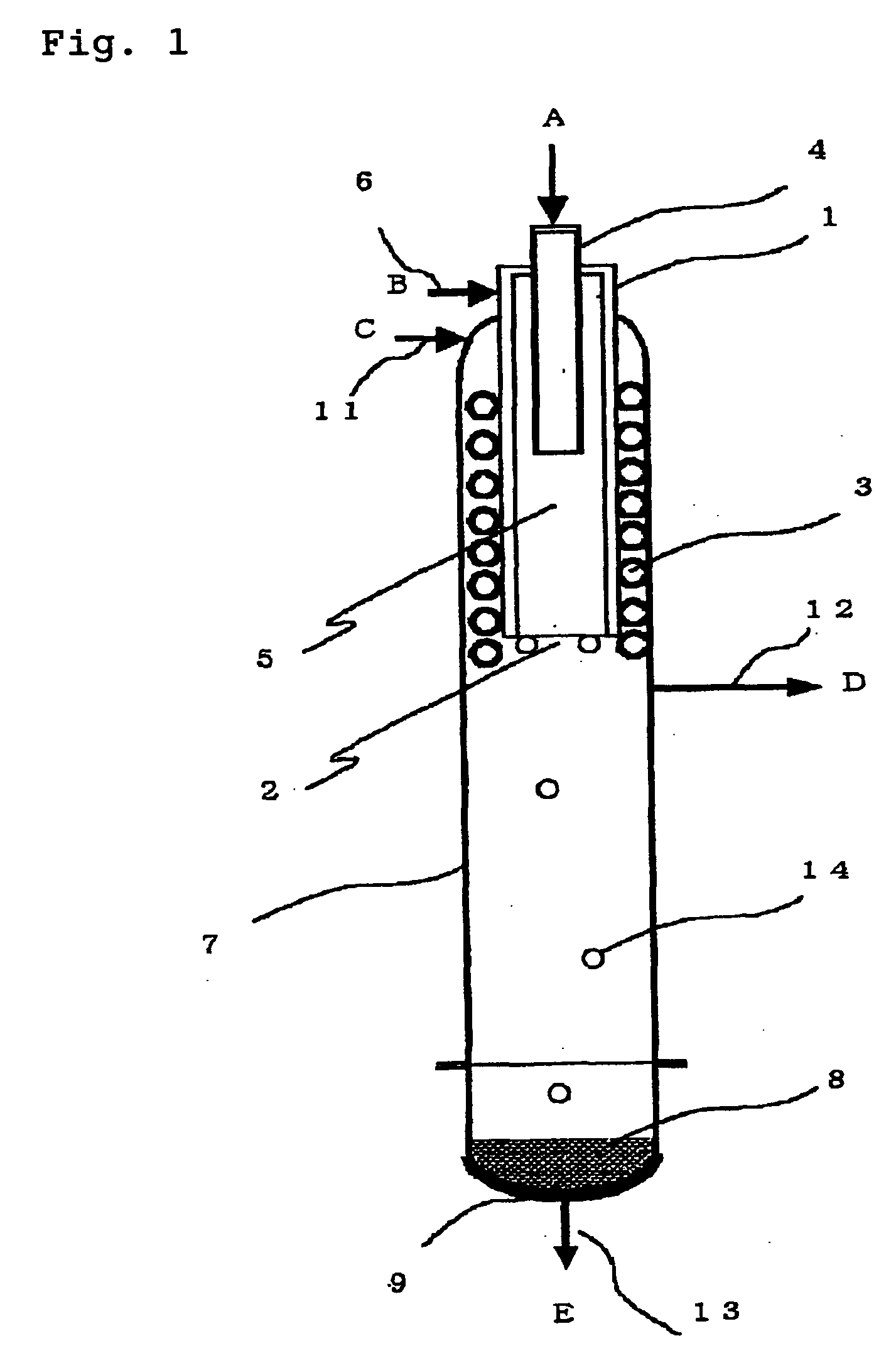

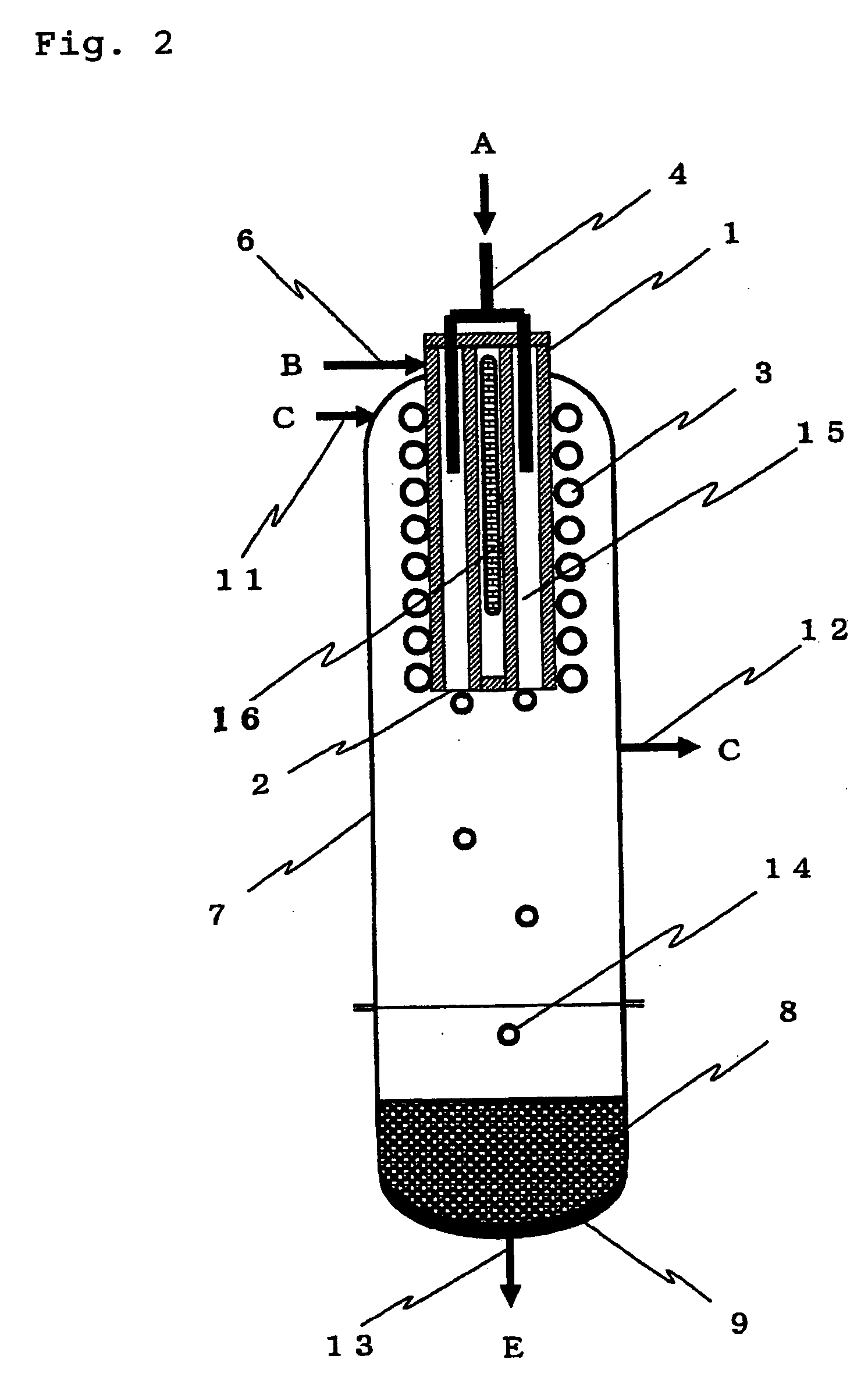

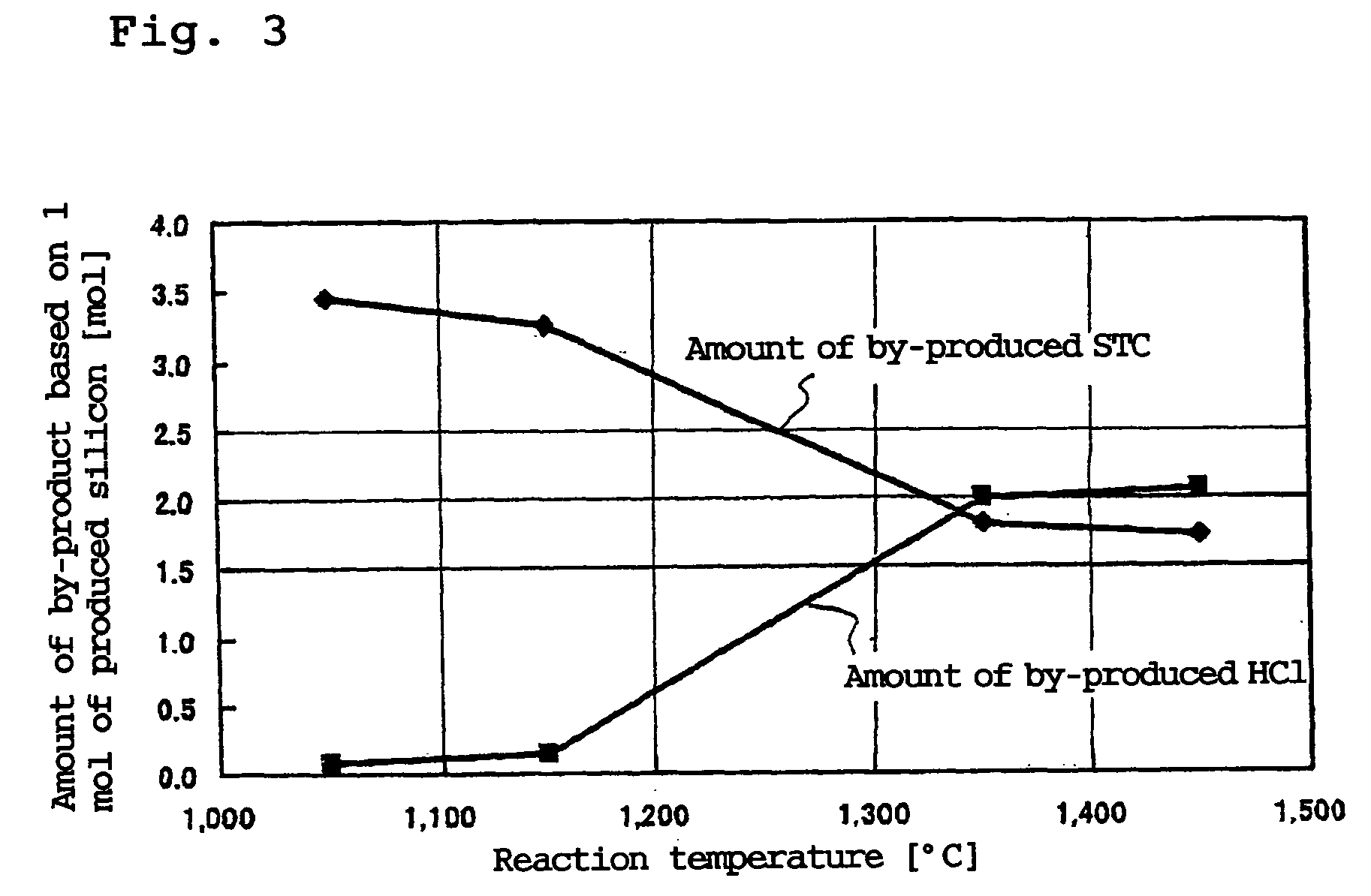

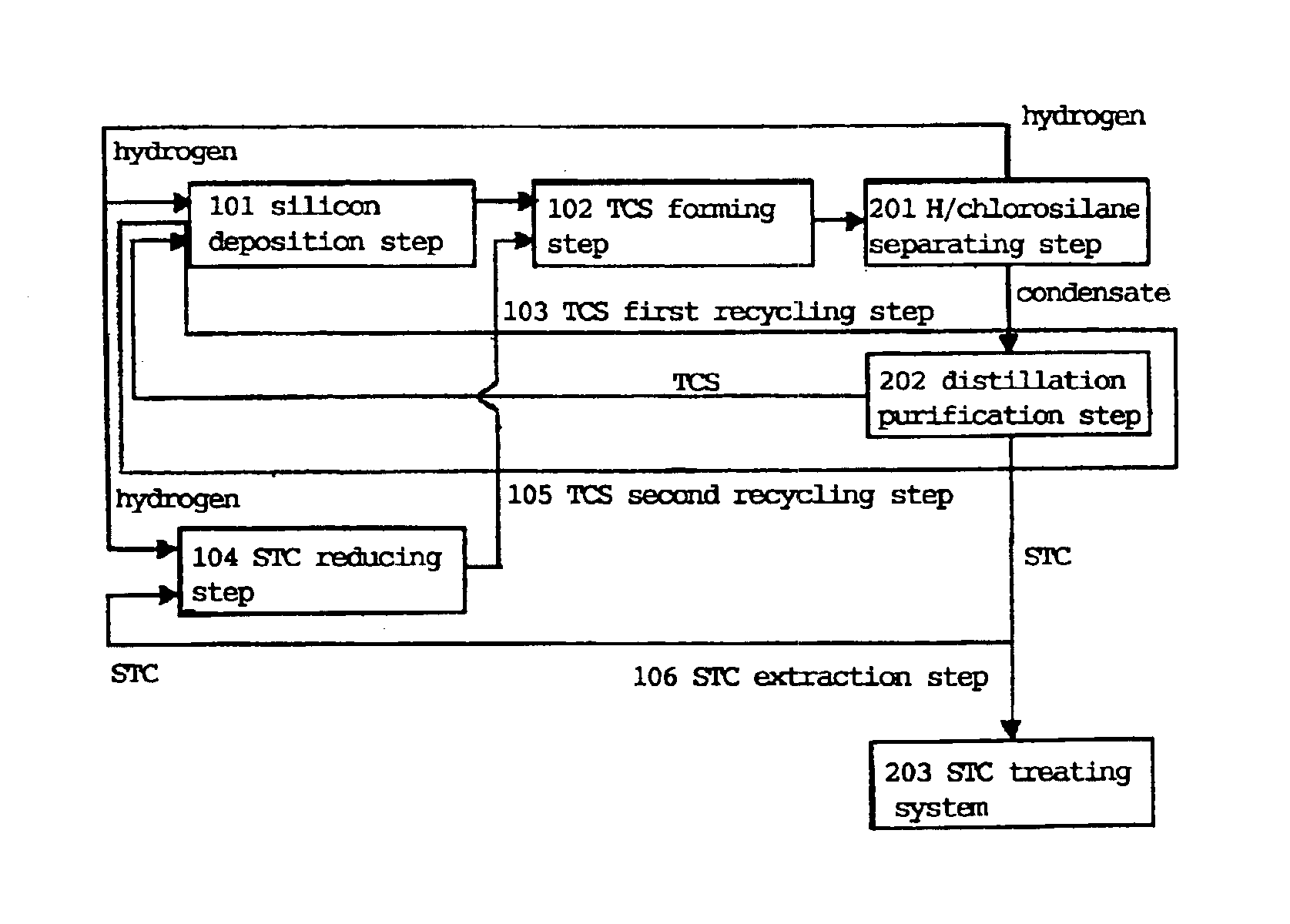

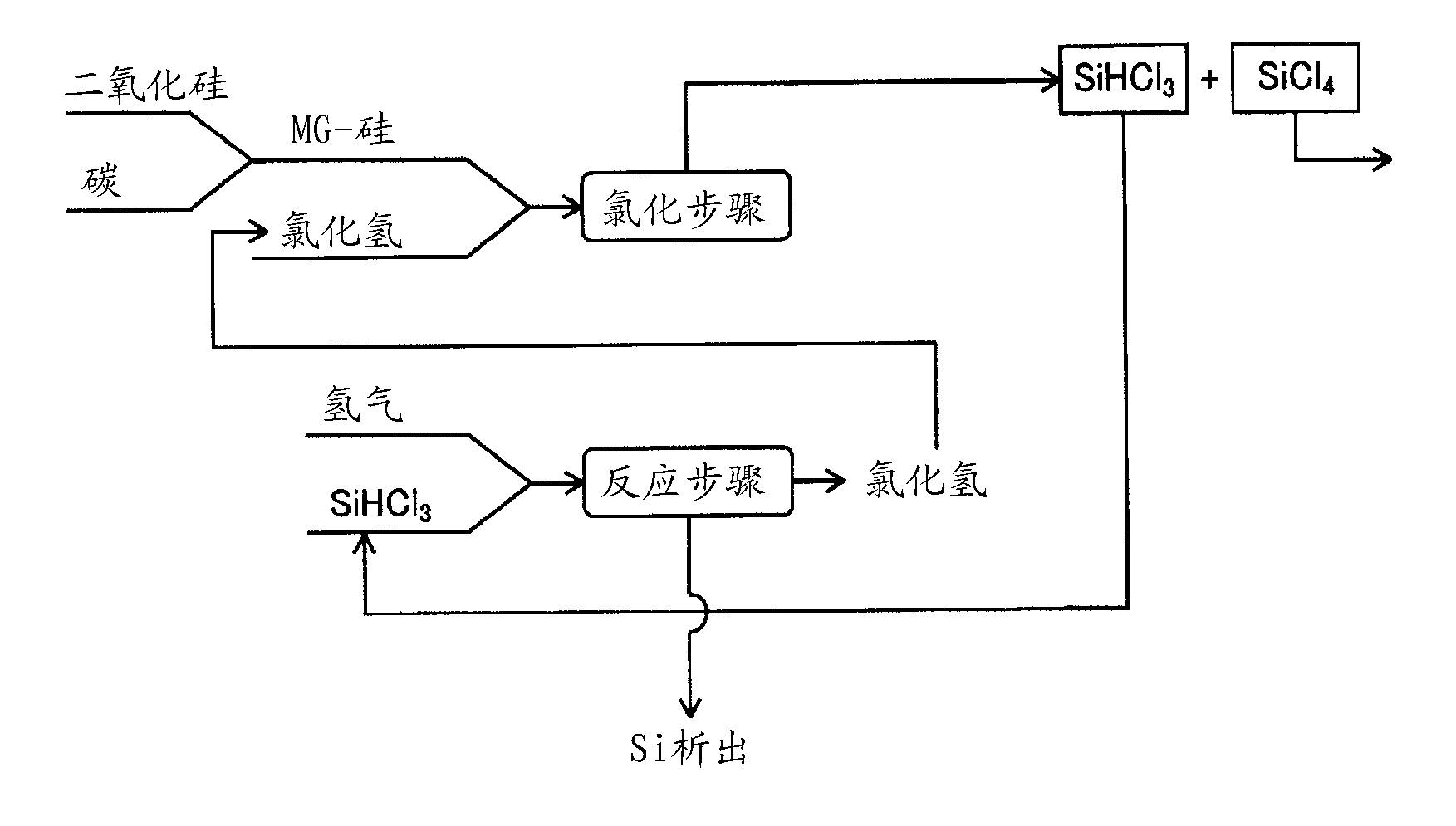

Method for producing silicon

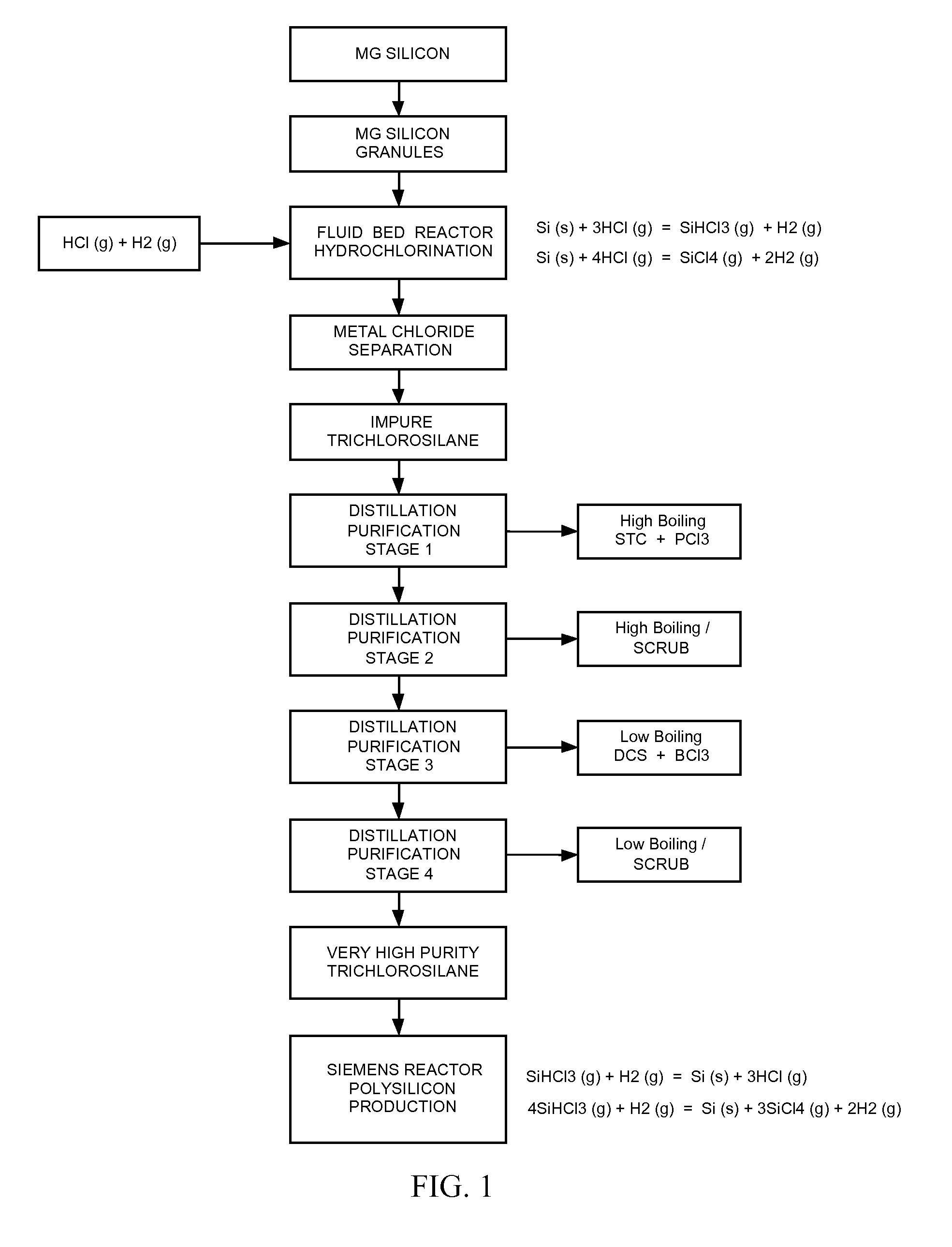

A silicon production process which improves the production efficiency of trichlorosilane while an industrially advantageous output is ensured and the amount of the by-produced tetrachlorosilane is suppressed. This process does not require a bulky reduction apparatus for the by-produced tetrachlorosilane, can construct a closed system, which is a self-supporting silicon production process, can easily control the amount of the by-produced tetrachlorosilane and therefore can adjust the amount of tetrachlorosilane to be supplied to a tetrachlorosilane treating system when the tetrachlorosilane treating system is used. This process comprises a silicon deposition step for forming silicon by reacting trichlorosilane with hydrogen at a temperature of 1,300° C. or higher, a trichlorosilane forming step for forming trichlorosilane by contacting the exhausted gas in the above silicon deposition step to raw material silicon to react hydrogen chloride contained in the exhausted gas with silicon, and a trichlorosilane first recycling step for separating trichlorosilane from the exhausted gas in the trichlorosilane forming step and recycling it to the silicon deposition step.

Owner:TOKUYAMA CORP

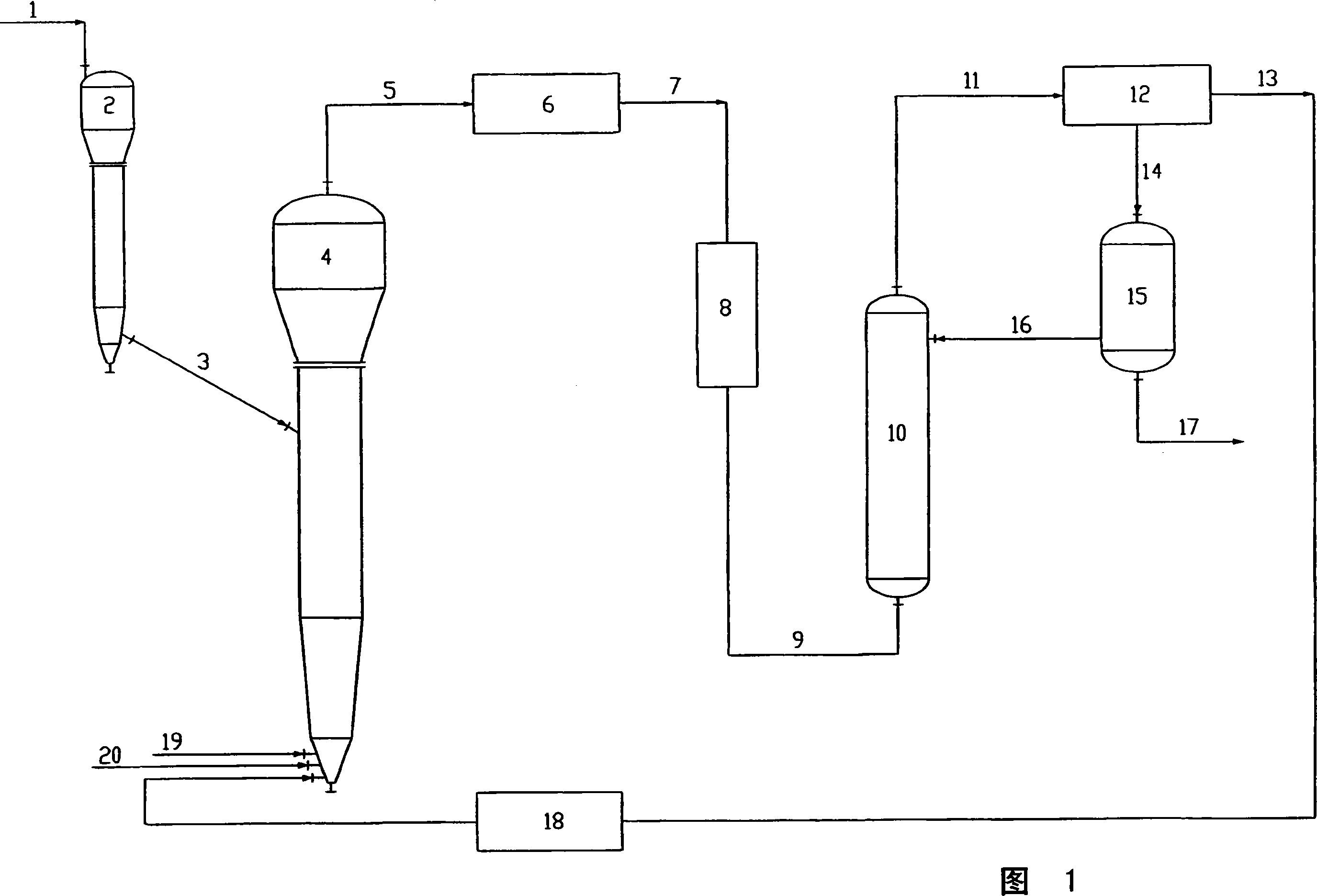

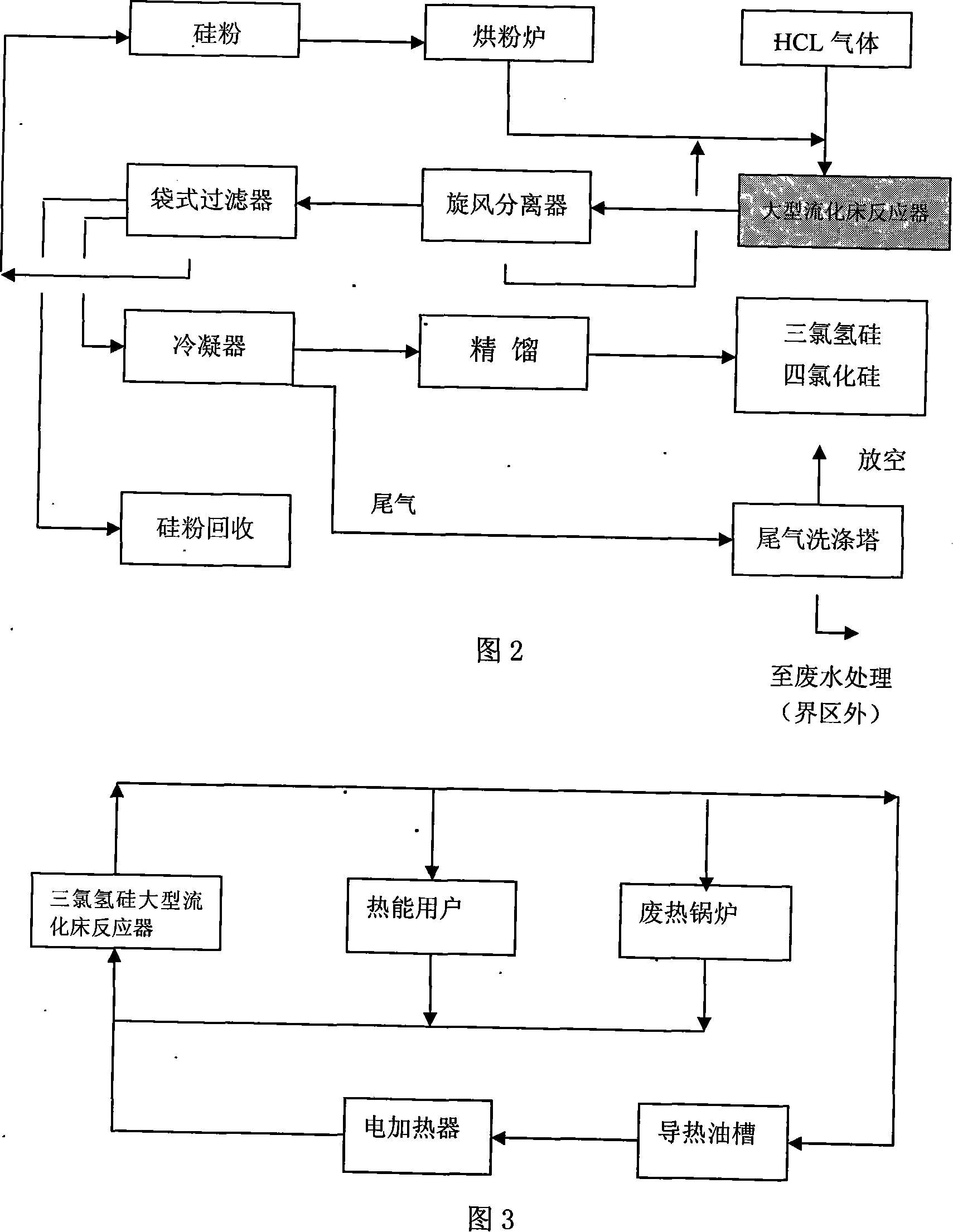

Production method and apparatus for trichlorosilane

InactiveCN101279735AReduce consumptionReduce automatic controlEnergy inputHalogenated silanesReaction temperatureEnergy recovery

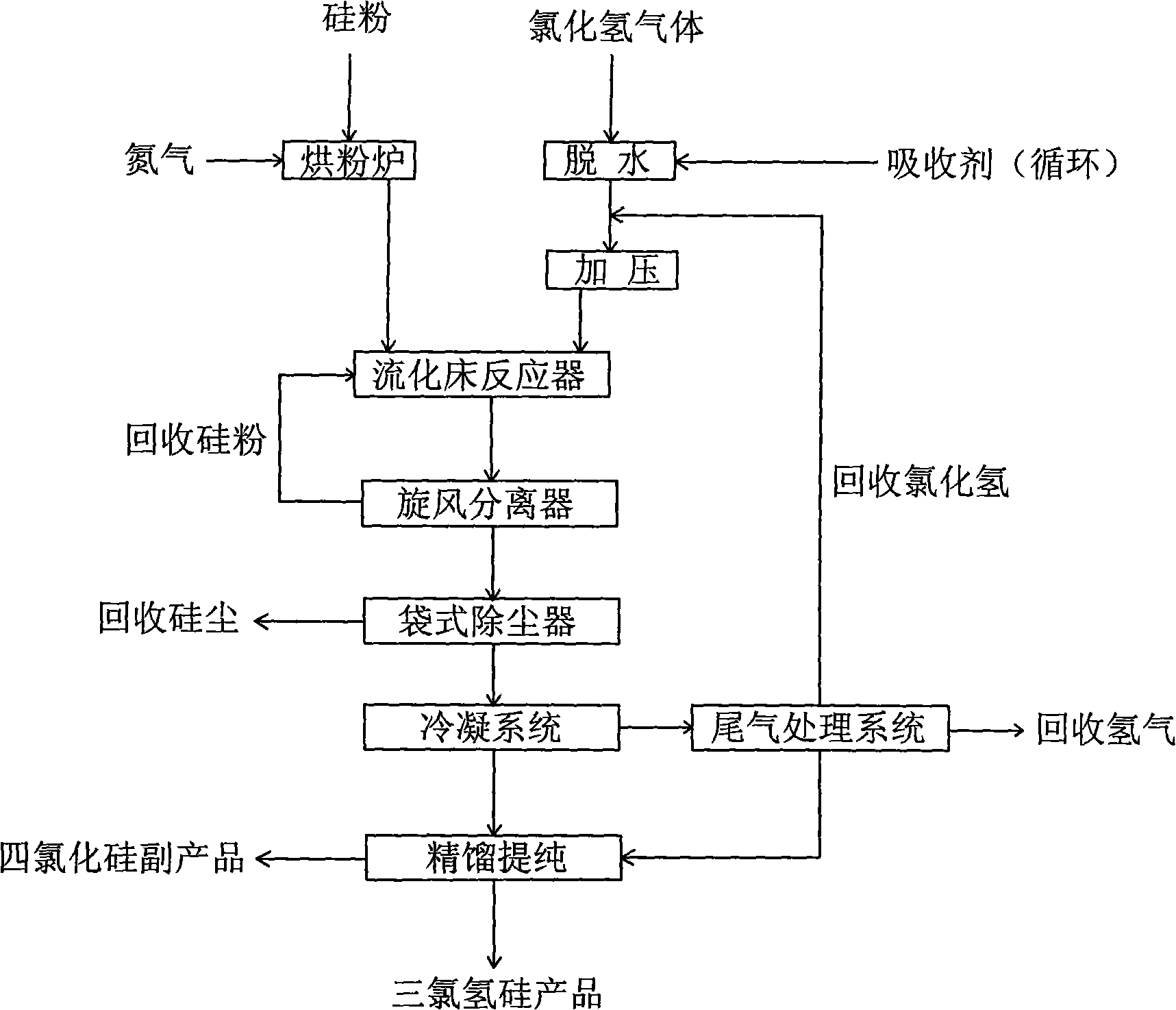

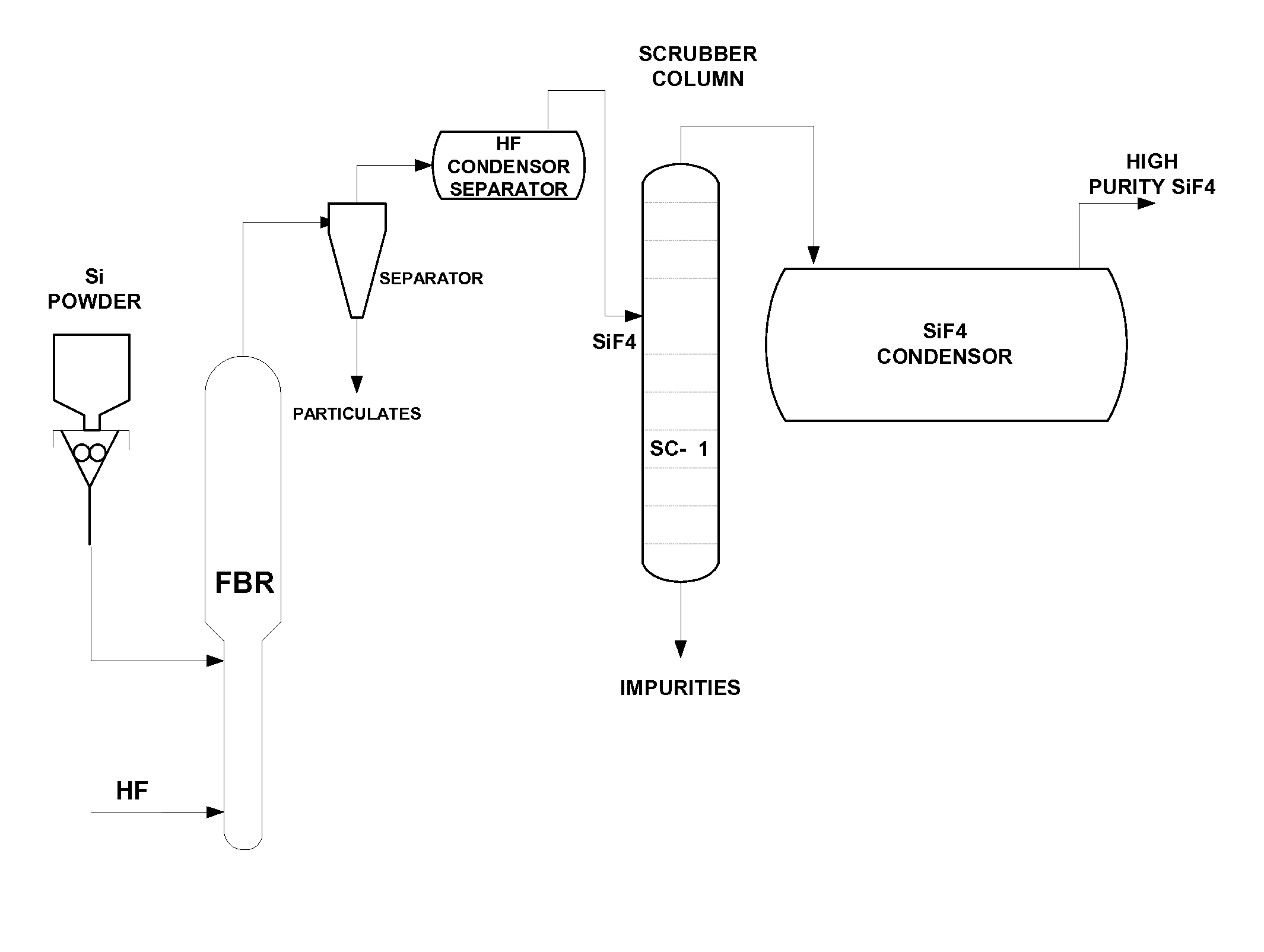

The invention relates to a method for producing chlorosilane, in particular to a method for producing trichlorosilane and a device thereof and pertains to the chemical field. The method comprises six steps, namely, hydrogenchloride treatment, silica powder drying and pushing material, synthesis reaction, dust removal and condensation, rectification separation and tail gas recovery, and the device relates to a special equipment large fluidized bed reactor. The invention reduces corrosion on the system equipment by hydrogenchloride gas and the fluidization quality of the reactor is high. The tail gas contains chlorosilane and is easy to be condensed, and the consumption of low temperature refrigerant is greatly reduced. The synthesis tail gas is recovered fully, no temperature runaway phenomenon happens at the expansion section of the reactor, reaction heat is removed by heat transfer oil and sent in a waste heat boiler to produce by product steam which is merged into a steam pipe network or directly applied in part heating equipment; the whole technique system is a closed system with self materials cycling and energy recycling. The technique of the invention is advanced and reliable, the reaction temperature can be adjusted accurately and the fluidized bed reactor has long service life and low production cost and is applicable to popularization and application.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Silicon tetrachloride hydrogenating process of producing trichloro hydrosilicon

InactiveCN1436725ANo pollution in the processEasy to controlSilicon hydridesHalogenated silanesNickel catalystHydrogen atmosphere

The silicon tetrachloride hydrogenating process of producing trichloro-hydrosilicon includes: mixing powdered nickel catalyst and silicon powder in the mass ratio of 1-10 and activating the mixture in hydrogen atmosphere and at the temperature of continuously change from 20 deg.C to 420 deg.c; and making mixed gas of hydrogen and SiCl4 in the molar ratio of 1-10 pass through the activated catalyst and silicon powder layer for hydrogenating SiCl4 continuously at 400-500 deg.c temperature and 1.2-1.5 MPa pressure. The equipment, system and operation of the present invention has high once SiCl4 converting rate and low power consumption and may be used in large-scale production.

Owner:CHINA ENFI ENG CO LTD

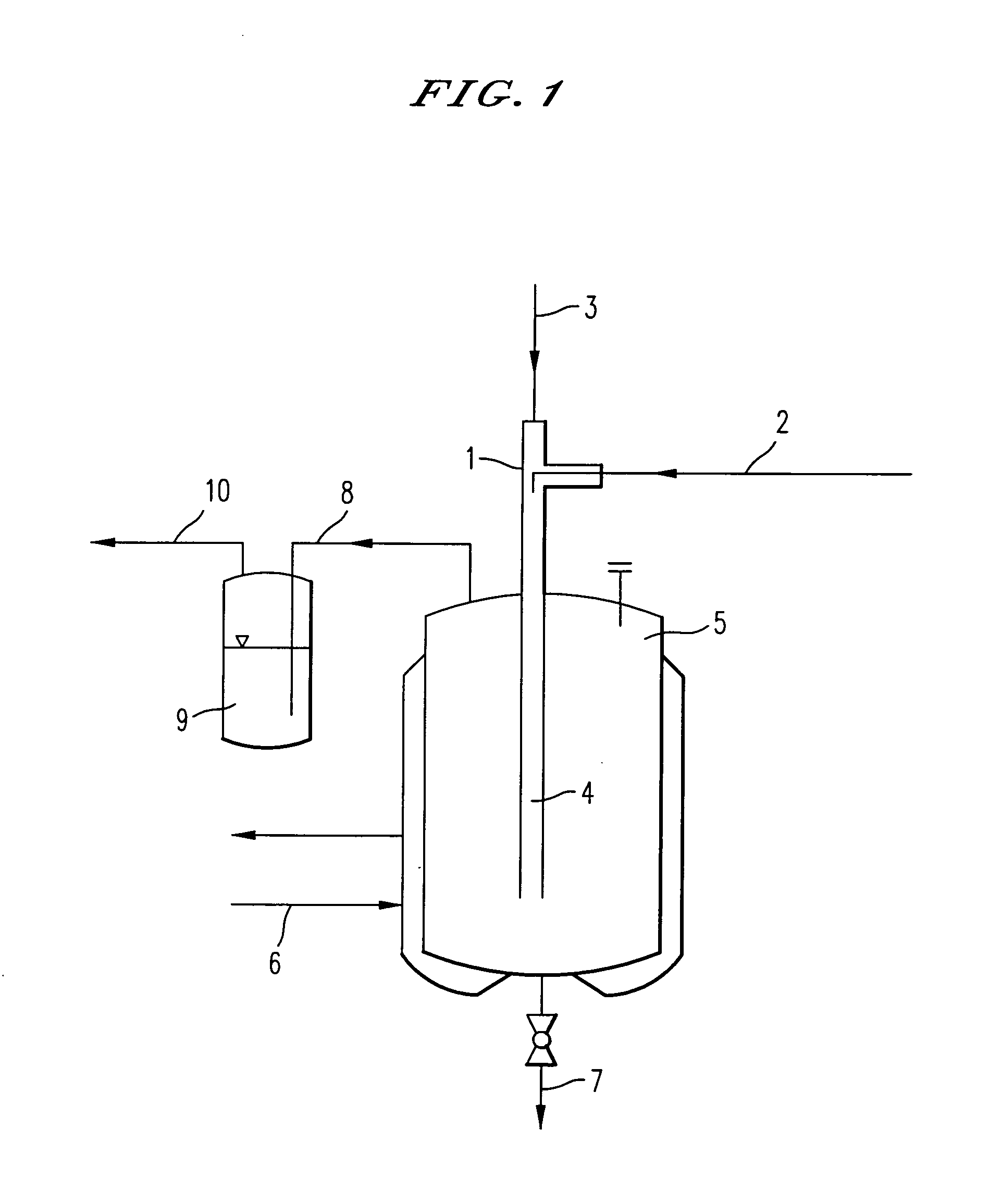

Purification of silicon-containing materials

InactiveUS20050054211A1Impurities increaseSilicon organic compoundsSemiconductor/solid-state device manufacturingSilanesLiquid state

Systems and methods of purifying a silicon-containing material include the step of directing the silicon-containing material in a liquid state through an adsorption unit including an adsorbent material to facilitate adsorption of at least one component from the silicon-containing material. Alternatively, the silicon-containing material is directed, in liquid state and / or gaseous state, through two or more purification units, including an adsorption unit, a vaporization unit, a filter unit and a condenser. The silicon-containing material can be a low-k silicon-containing material such as trimethylsilane, tetramethylsilane, dimethyldimethoxysilane, tetramethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, dimethylphenyl silane, and dimethyldivinyl silane.

Owner:XU MINDI +2

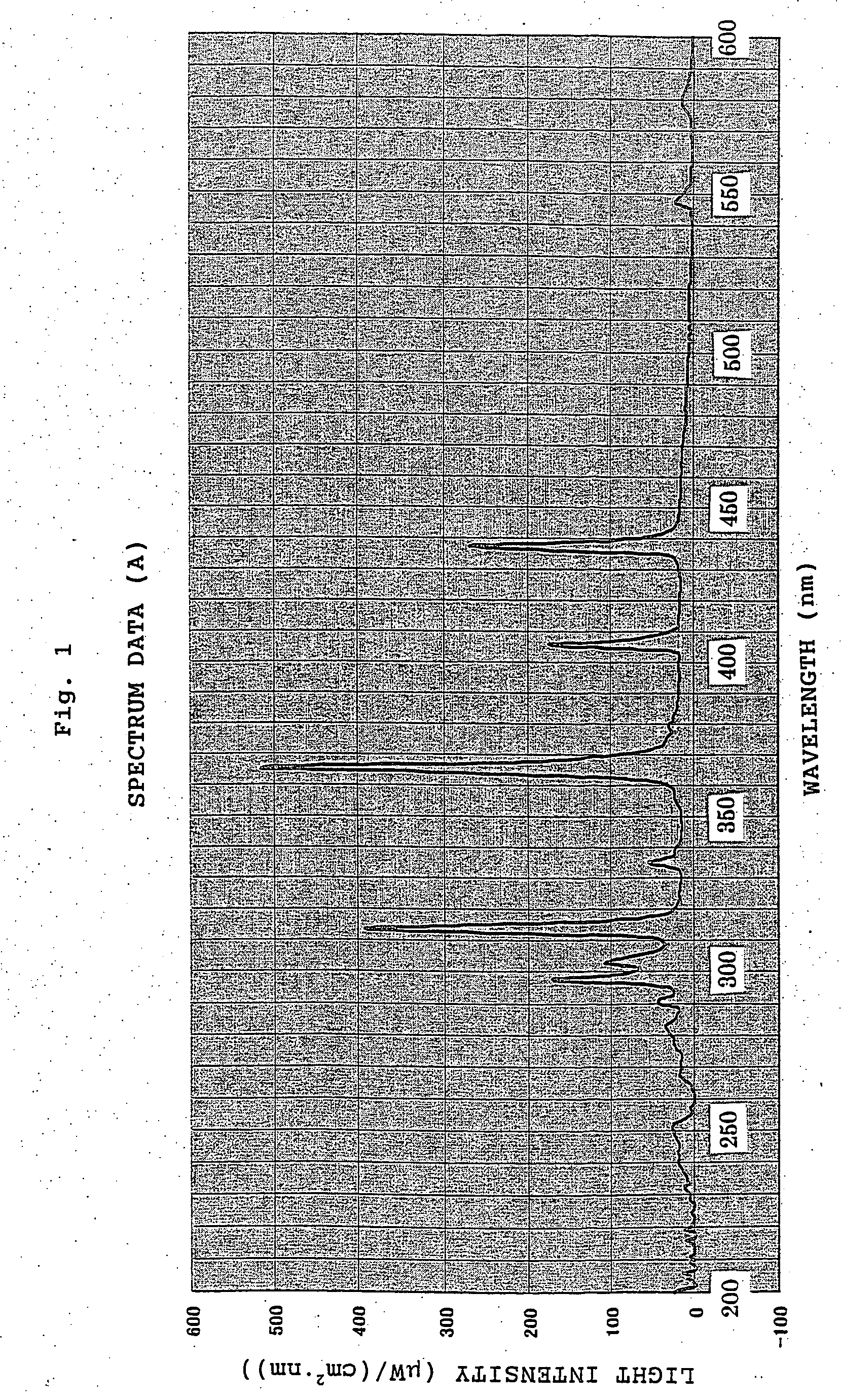

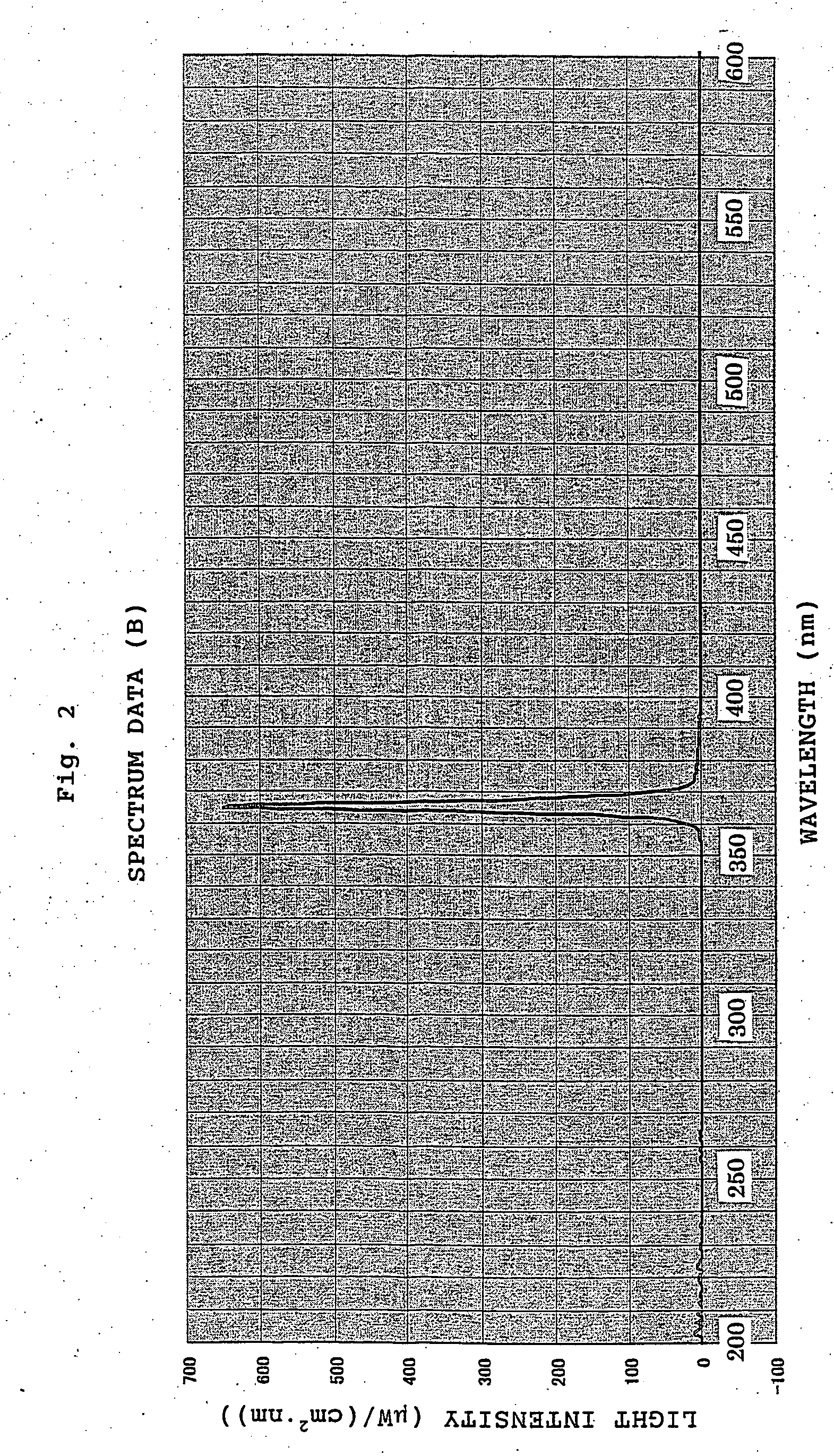

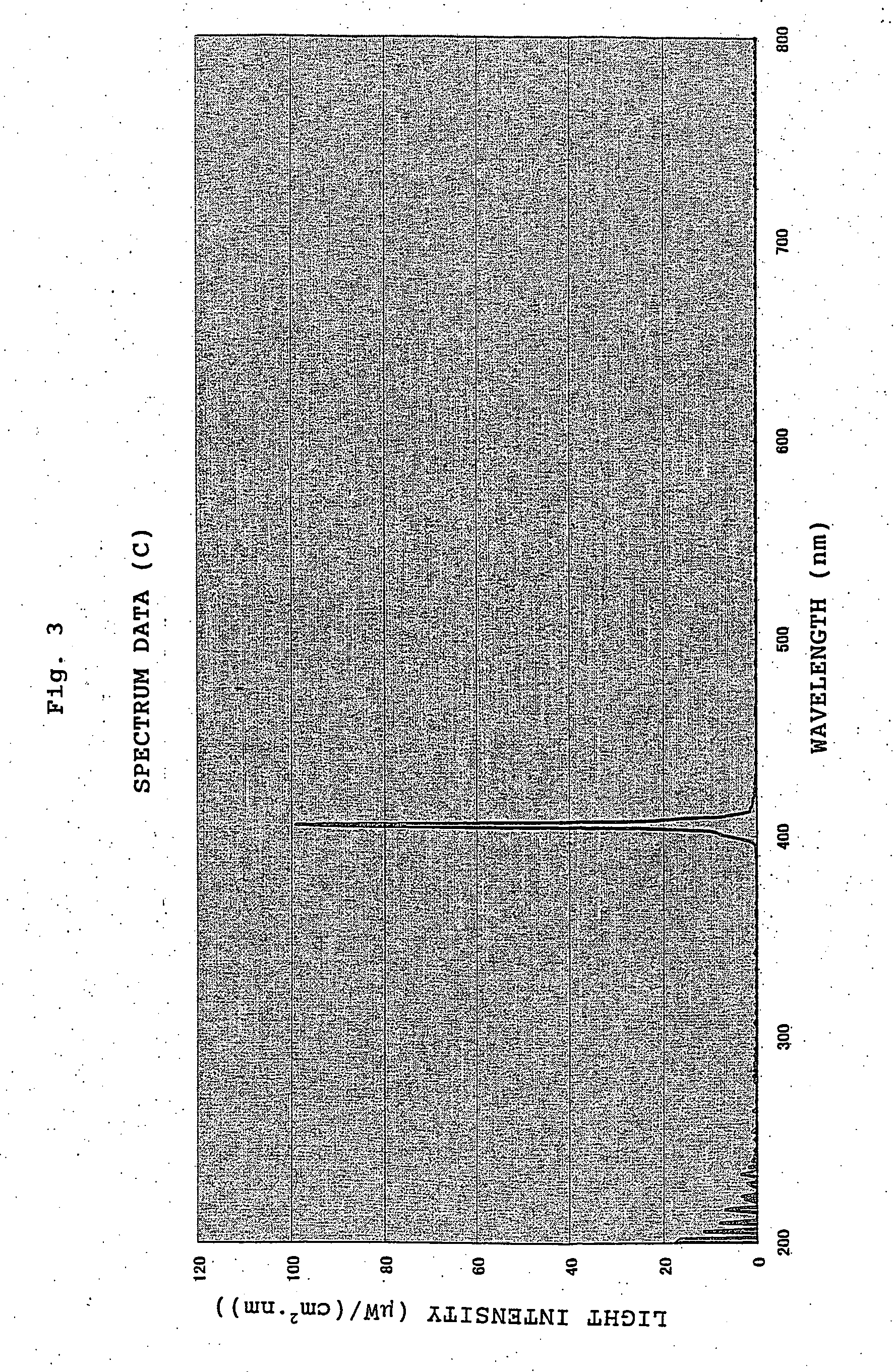

Silane polymer and method for forming silicon film

InactiveUS20060159859A1High molecular weightSilicon organic compoundsSiliconSilane compoundsBoiling point

There are provided a silane polymer having a higher molecular weight from the viewpoints of wettability when applied to a substrate, a boiling point and safety, a composition which can form a high-quality silicon film easily, a silicon film forming composition which comprises a silane polymer obtained by irradiating a photopolymerizable silane compound with light of specific wavelength range to photopolymerize it, and a method for forming a silicon film which comprises applying the composition to a substrate and subjecting the coating film to a heat treatment and / or a light treatment.

Owner:JSR CORPORATIOON

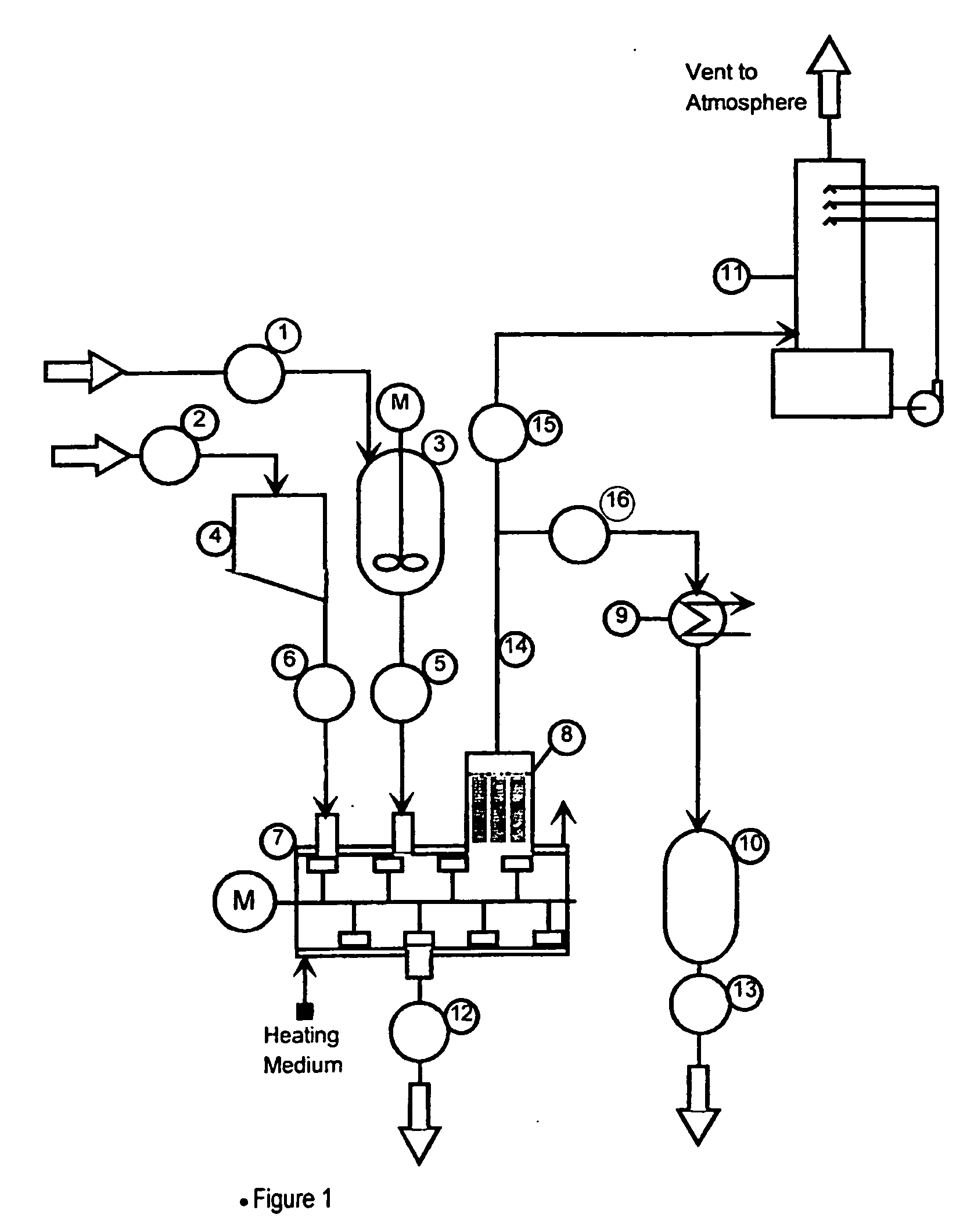

Modified method and device for preparing trichlorosilane and multicrystal silicon

The invention relates to an improved method and equipment for the preparation of trichlorosilane and polysilicon. The trichlorosilane is prepared by a chlorine hydrogenation method during the preparation process of polysilicon. The process is as follows: a) the metallurgical silicon is put into a reactor after being heated to 300-500DGE C in a powder baker; b) the silicon tetrachloride is vaporized and heated through an external heating device, which generates the silicon tetrachloride gas at the temperature of 160-600DGE C; c) the hydrogen chloride gas is preheated to 150-300DGE C through the external heating device; d) the hydrogen gas is preheated to 300-600DGE C through a heater; and e) the gases of step b), c) and d) are added into the reactor; wherein, the molar ratio between the hydrogen gas and the silicon tetrachloride is 1-5:1, the molar ratio between the hydrogen chloride gas and the silicon tetrachloride is 1: 1-20; and the temperature in the reactor is maintained at 400-600DGE C and the pressure in the reactor is kept at 1.0-3.0MPa. The method of the invention can effectively prepare the polysilicon at a low cost, which suits for semiconductor industry and solar battery.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV +1

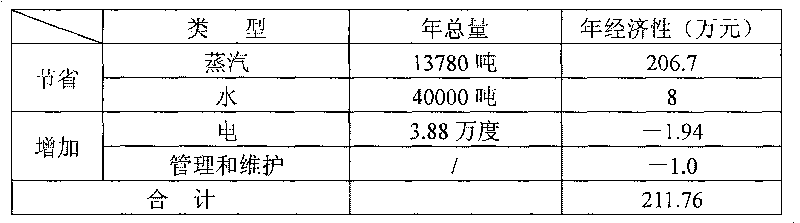

Production device and method of high purity trichlorosilane by using heat pump distillation

ActiveCN101704524AIncrease pressureIncrease temperatureEnergy inputHalogenated silanesReboilerEconomic benefits

The invention relates to a production device and a method of high purity trichlorosilane by using heat pump distillation. Trichlorosilane raw materials enter a de-heavy fractionator to eliminate heavy components after light component elimination through a light component eliminating tower, thereby obtaining high purity trichlorosilane. On the basis, the light component eliminating tower and the de-heavy fractionator both adopt a heat pump distillation process. Cooling medium in a condenser absorbs heat after exchanging the heat with materials on the top of the tower and is evaporated into gas, the gas enters a reboiler as tower reactor heat source reactor liquid after pressure and temperature enhancement through compression, and the gas is condensed into liquid. The liquid returns to the condenser after reduction of expenditure and pressure so as to finish a cycle. Therefore, the heat at the low temperature part of the tower top is transferred to the high temperature part of a tower reactor through the cooling medium. The invention has the advantages that by adopting the heat pump distillation process, the energy consumption can be greatly lowered, and the annual economic benefit is greatly enhanced.

Owner:TIANJIN UNIV

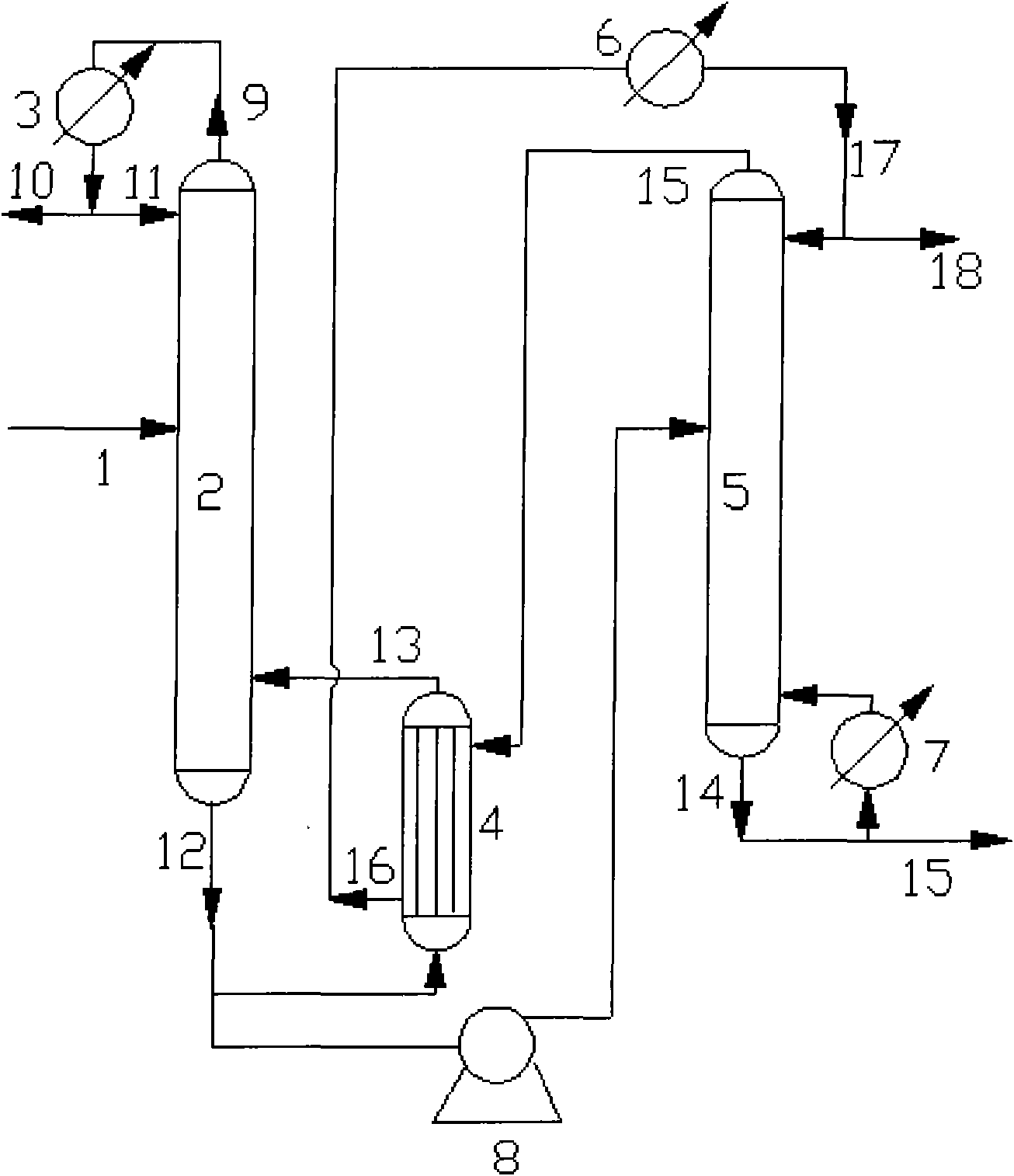

Method and apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction

ActiveCN101955187AResolve enrichmentIncrease profitChemical industryHalogenated silanesDichlorosilaneTower

The invention relates to a method and an apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction. The method comprises the following steps of: reacting dichlorosilane with silicon tetrachloride in the upper middle part of a reaction rectification tower, obtaining incompletely reacted dichlorosilane at the top of the reaction rectification tower; reflowing at the top of the tower and in the middle of the tower, obtaining a mixture of dichlorosilane, trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a light-end removal tower to remove a light component, obtaining the dichlorosilane at the top of the light-end removal tower; reflowing to the reaction rectification tower for recycling, obtaining a mixture of trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a heavy-end removal tower to separate the trichlorosilane from the silicon tetrachloride, wherein the trichlorosilane at the top of the heavy-end removal tower is a product; and taking out the silicon tetrachloride at the side line of the lower part of the tower, entering the reaction rectification tower for recycling, and obtaining excessive silicon tetrachloride at the bottom of the tower. In the invention, by utilizing the proportionate reaction, the utilization ratio of the raw materials is enhanced; the problem of dichlorosilane and silicon tetrachloride enrichment is solved; and the final conversion ratio of the dichlorosilane is ensured to reach 100 percent theoretically.

Owner:TIANJIN UNIV

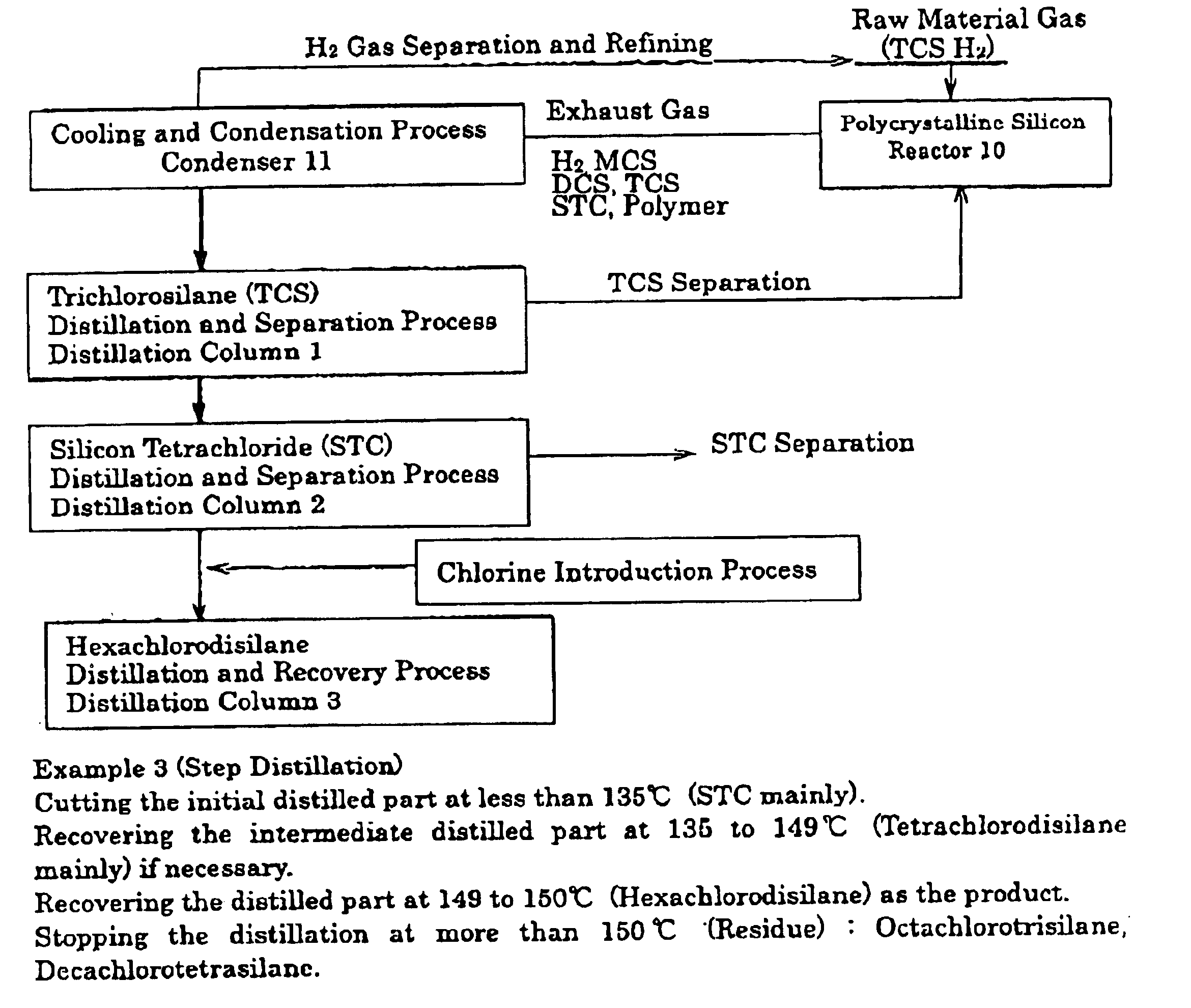

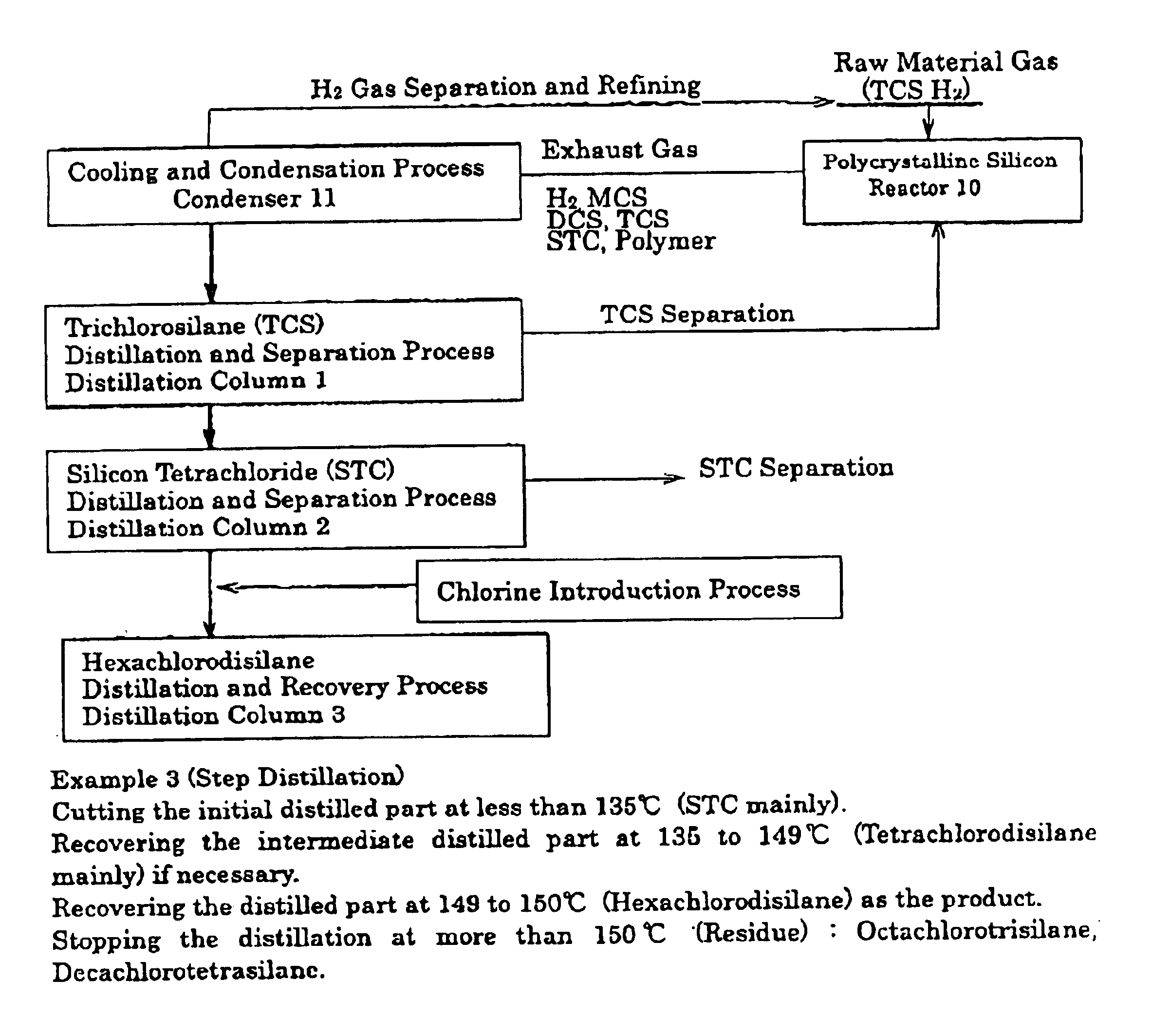

Process for producing hexachlorodisilane

InactiveUS6846473B2High purityEffective recoverySiliconDistillation separationHydrogenSilicon tetrachloride

A process for producing hexachlorodisilane comprising, condensing an exhaust gas discharged from a reactor for producing polycrystalline silicon from a chlorosilane and hydrogen to separate the hydrogen, distilling the resultant condensate to separate the unreacted chlorosilane and by-product silicon tetrachloride, and then further distilling to recover hexachlorodisilane, wherein tetrachlorodisilane can be recovered together with the hexachlorodisilane, and the hexachlorodisilane and tetrachlorodisilane recovered have a far higher purity than the conventional ones produced from metallic silicon.

Owner:MITSUBISHI MATERIALS CORP

Compositions and methods for the selective removal of silicon nitride

ActiveUS20100176082A1Increase etch rateHigh selectivitySolid-state devicesPhotomechanical apparatusSilicic acidSilicon oxide

Compositions useful for the selective removal of silicon nitride materials relative to poly-silicon, silicon oxide materials and / or silicide materials from a microelectronic device having same thereon. The removal compositions include fluorosilicic acid, silicic acid, and at least one organic solvent. Typical process temperatures are less than about 100° C. and typical selectivity for nitride versus oxide etch is about 200:1 to about 2000:1. Under typical process conditions, nickel-based silicides as well as titanium and tantalum nitrides are largely unaffected, and polysilicon etch rates are less than about 1 Å min−1.

Owner:ENTEGRIS INC

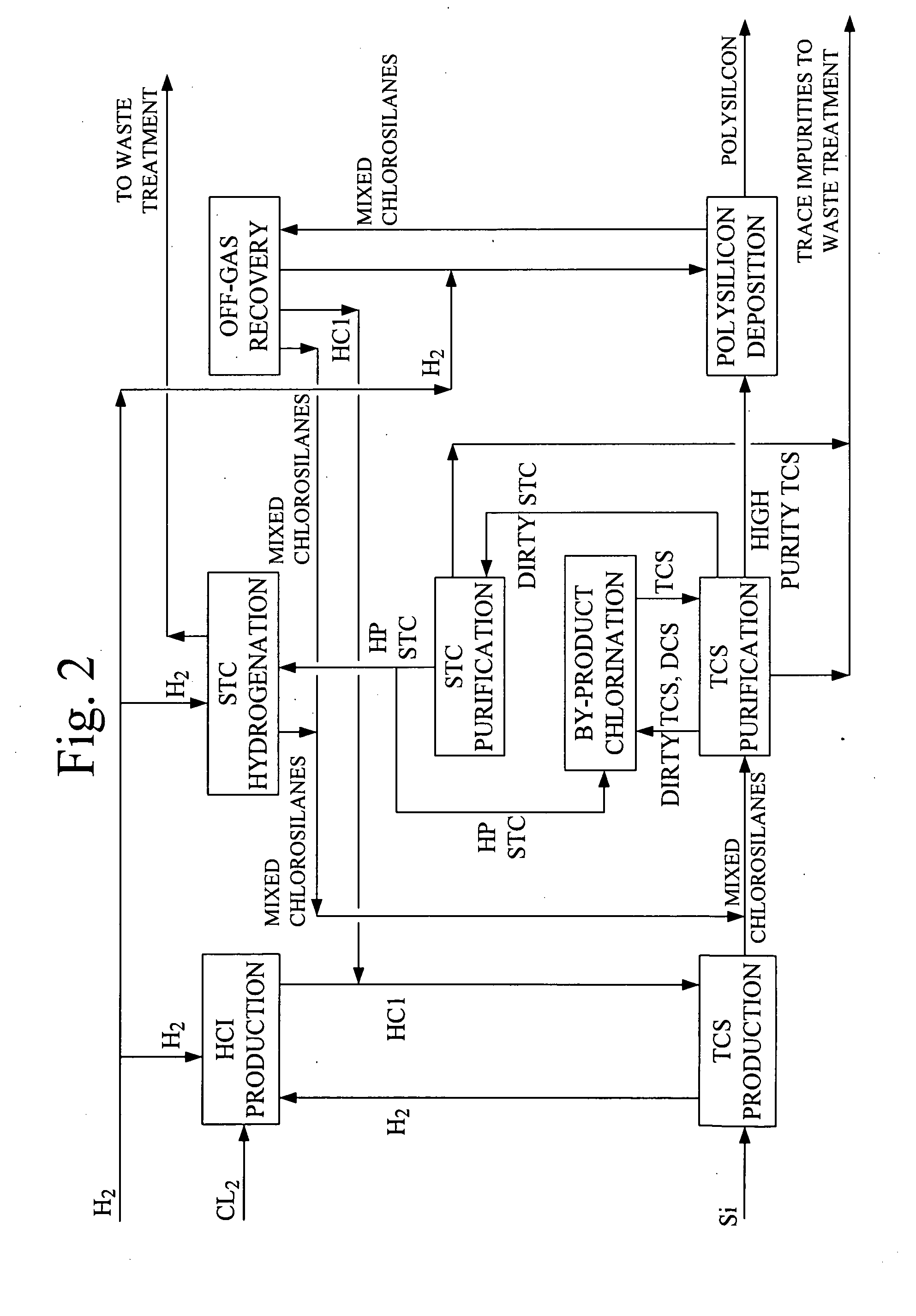

Process for producing trichlorosilane

InactiveUS20090060819A1Reduce kilogramLower requirementChemical/physical/physico-chemical stationary reactorsMetal/metal-oxides/metal-hydroxide catalystsBoiling pointDichlorosilane

A process for preparing high purity trichlorosilane (TCS) utilizing contaminated by-products of primary reaction products hydrogen chloride, metallurgical or chemical grade silicon stock, and / or by-products of the improved Siemens process, including “dirty” TCS containing low boiling impurities such as dichlorosilane (DCS) and “dirty” STC containing high boiling impurities. The “dirty” STC is first purified and a portion is reacted with “dirty” TCS containing DCS to produce additional TCS feedstock for the TCS purification process. Another portion of the purified STC is hydrogenated and converted back to TCS providing another feedstock to the TCS purification process. Overall net yield of high purity TCS produced is increased over established practice.

Owner:DYNAMIC ENG

Method for producing silicon

Owner:TOKUYAMA CORP

Process for the treatment of waste metal chlorides

InactiveUS20060183958A1Low costMaximize recoveryTitanium tetrachlorideSilicon oxidesMetal chlorideOrganic chloride compound

A process is described for treating the residues from metal chlorination processes wherein valuable volatile metal chlorides or metalorgano chlorides are recovered while low volatility metal chlorides and chloride complexes are reacted with a neutralizing humectant. The resulting neutral, dry solid is suitable for land fill disposal or for recovery of valuable metal constituents by extractive metallurgy techniques.

Owner:REC SILICON

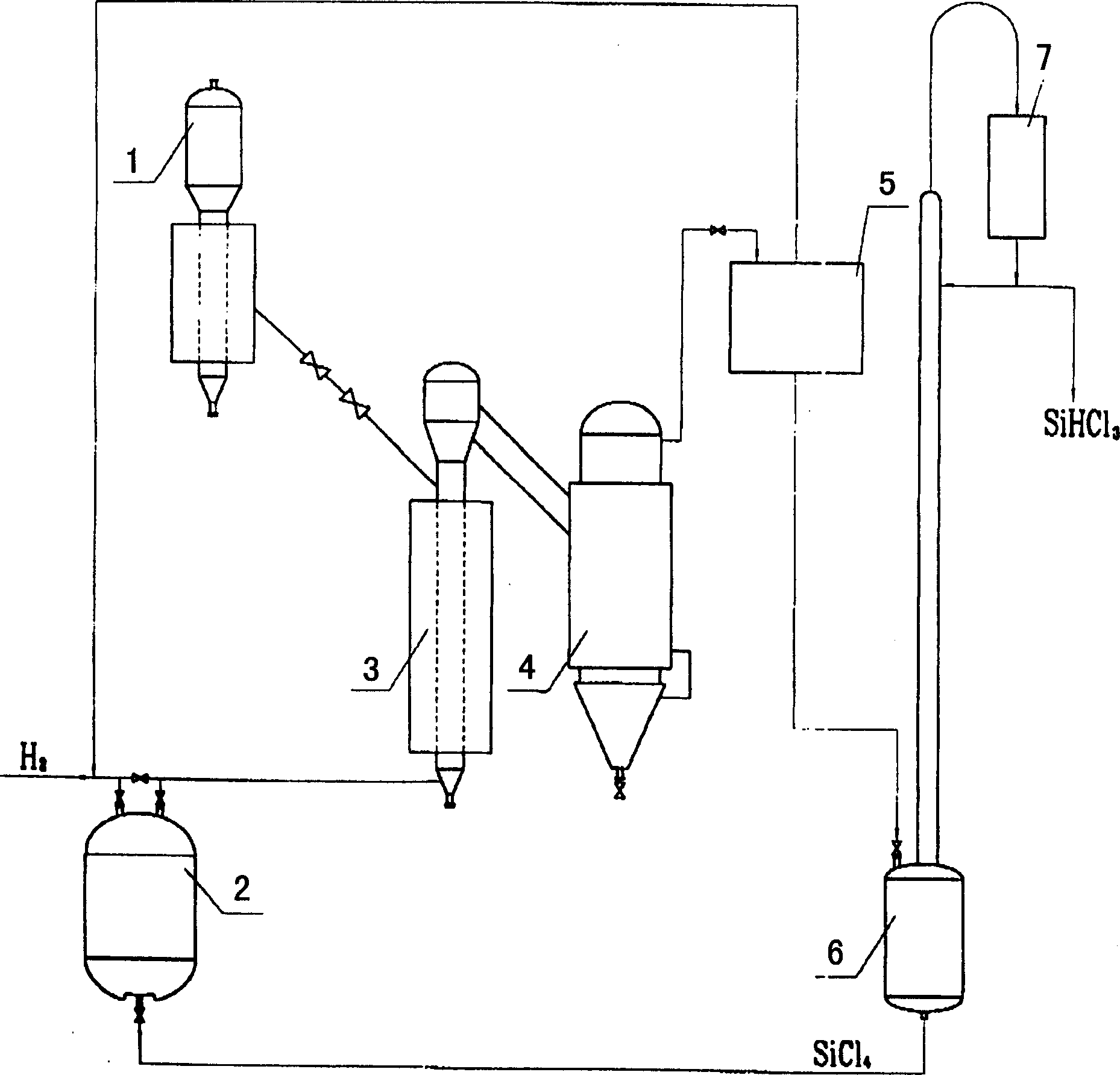

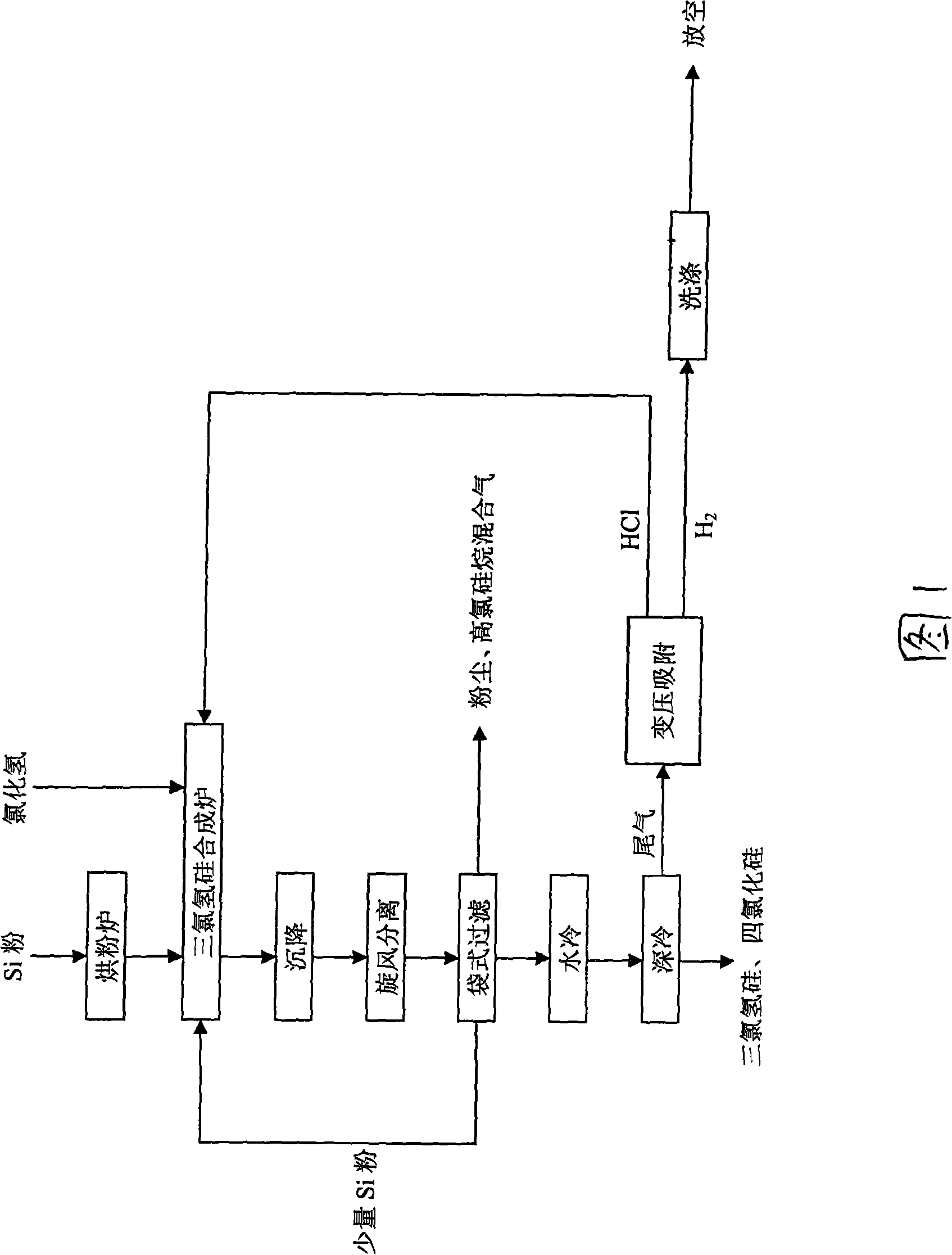

Method for synthesizing polysilicon raw material trichlorosilane

The invention discloses a method for the synthesis of a polysilicon raw material trichlorosilane. The method comprises the following steps: A) silica powder is conveyed to a trichlorosilane synthesis furnace by dried hydrogen chloride gas; B) hydrogen chloride for reaction is input into the synthesis furnace from the bottom of the trichlorosilane synthesis furnace proportionally and proper amount of hydrogen and silicon tetrachloride are added in the synthesis furnace at the same time; C) silica powder and hydrogen chloride react at the temperature of 280-310 DEG C to generate mixing gas containing trichlorosilane and silicon tetrachloride; D) the mixing gas of dust and high chlorosilane is removed, after water cooling and pressuring by a diaphragm compressor, trichlorosilane and silicon tetrachloride are condensed into liquid by a refrigerant with -40 DEG C, wherein, noncondensable gas containing H2 and HCI is separated. The method of the invention can improve the yield of trichlorosilane from 82 percent to more than 88 percent.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

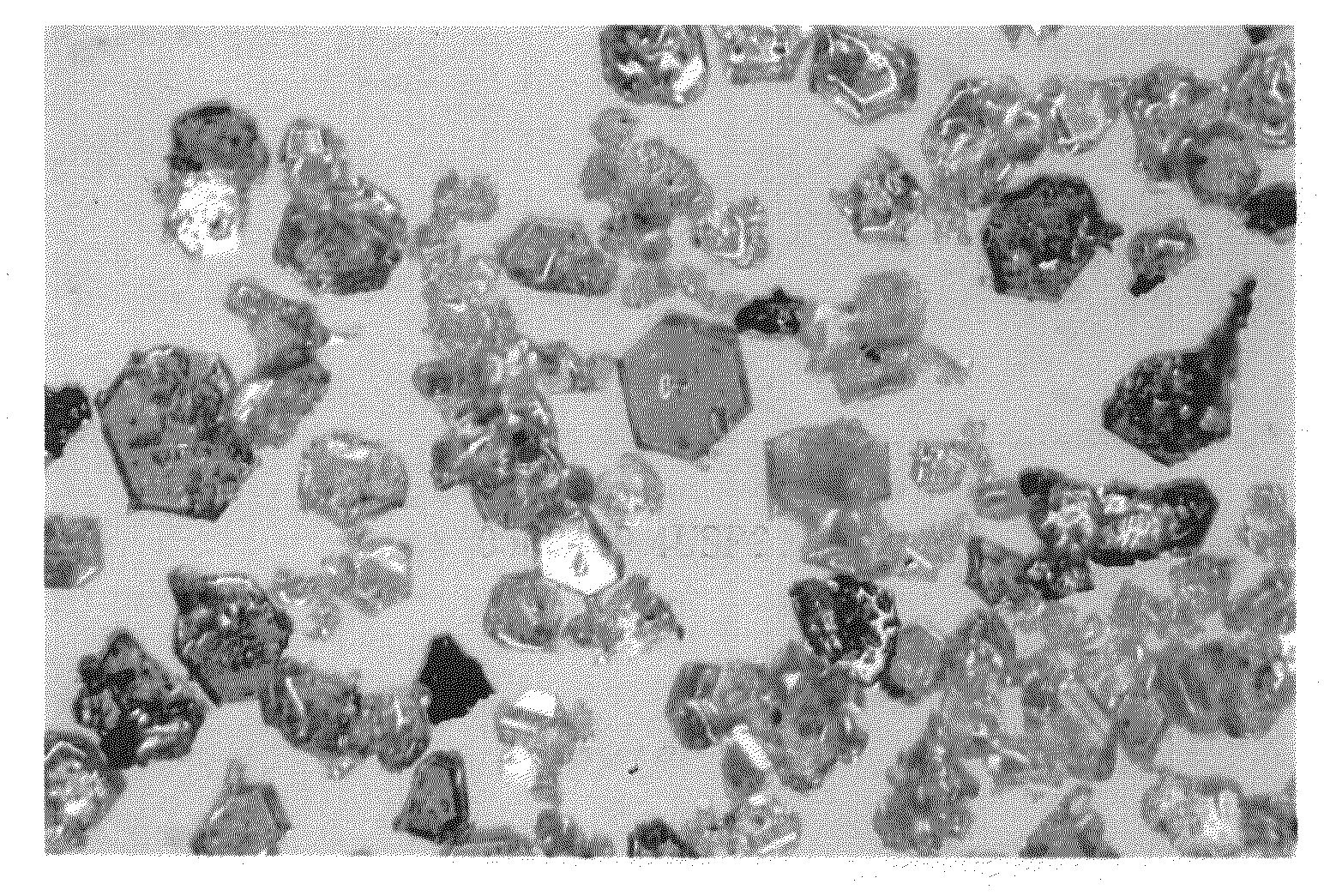

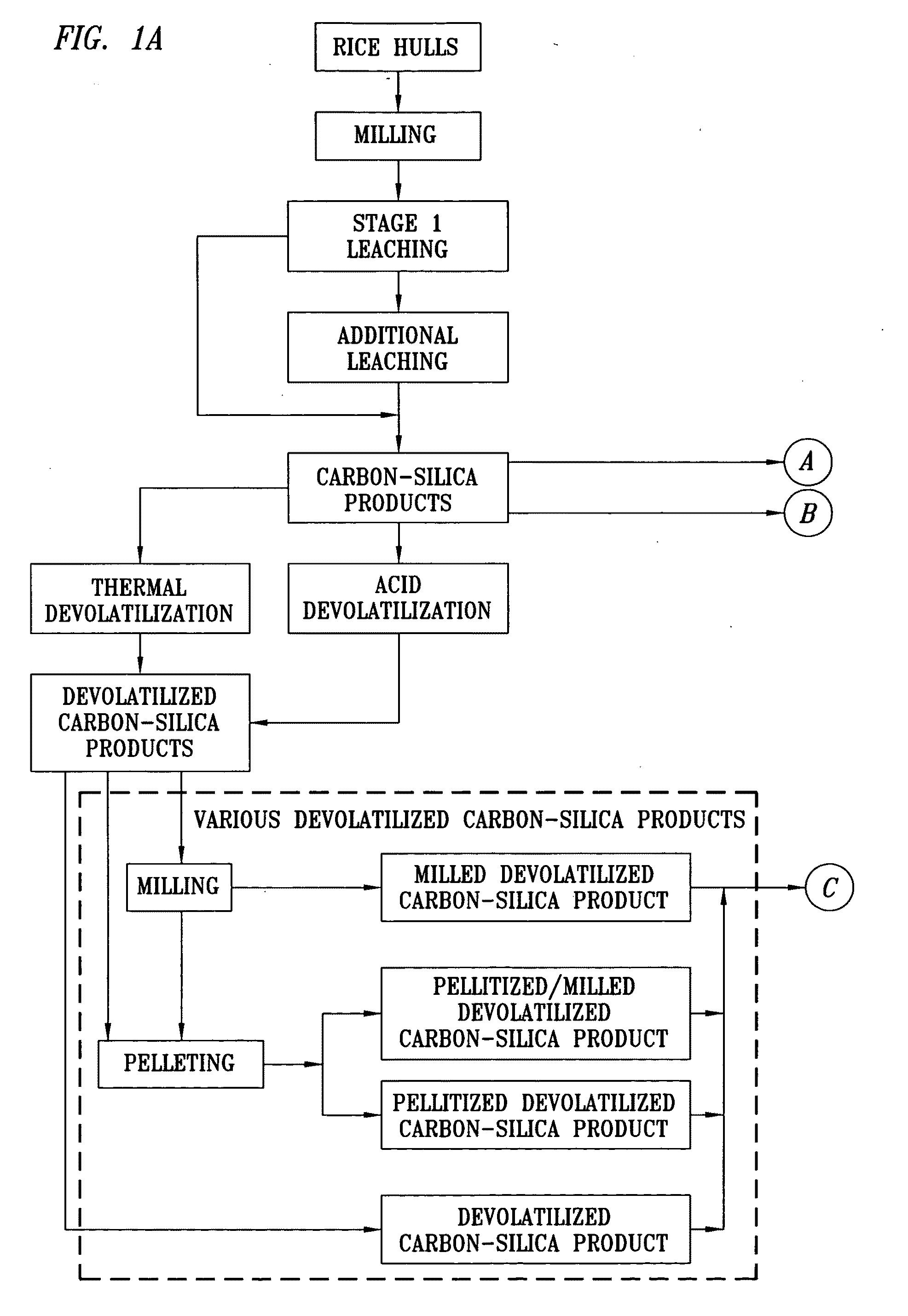

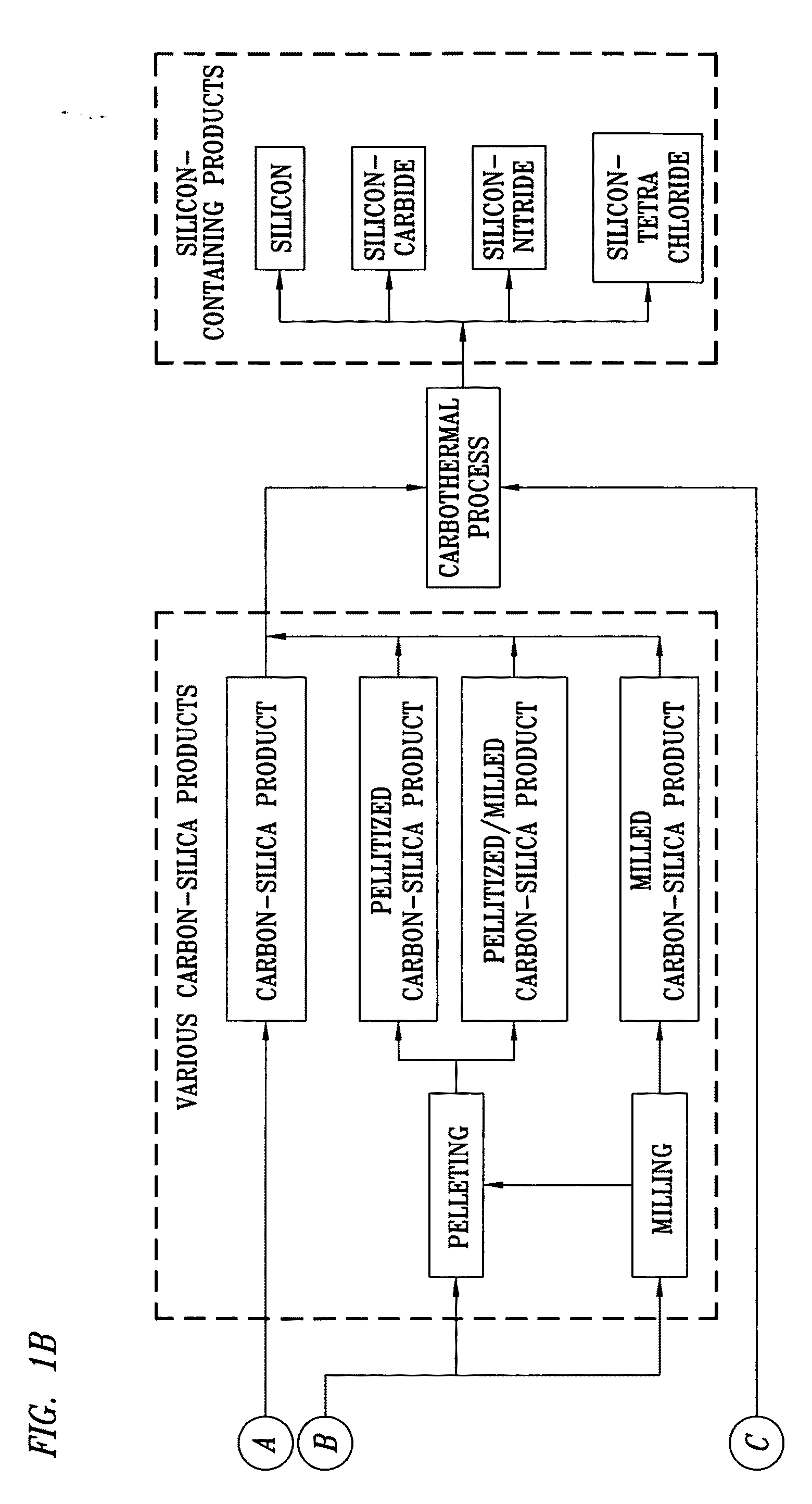

High Purity Silicon-Containing Products and Method of Manufacture

InactiveUS20110008236A1Lower energy requirementsImprove throughputSilicaNitrogen compoundsSilicon dioxideImpurity

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

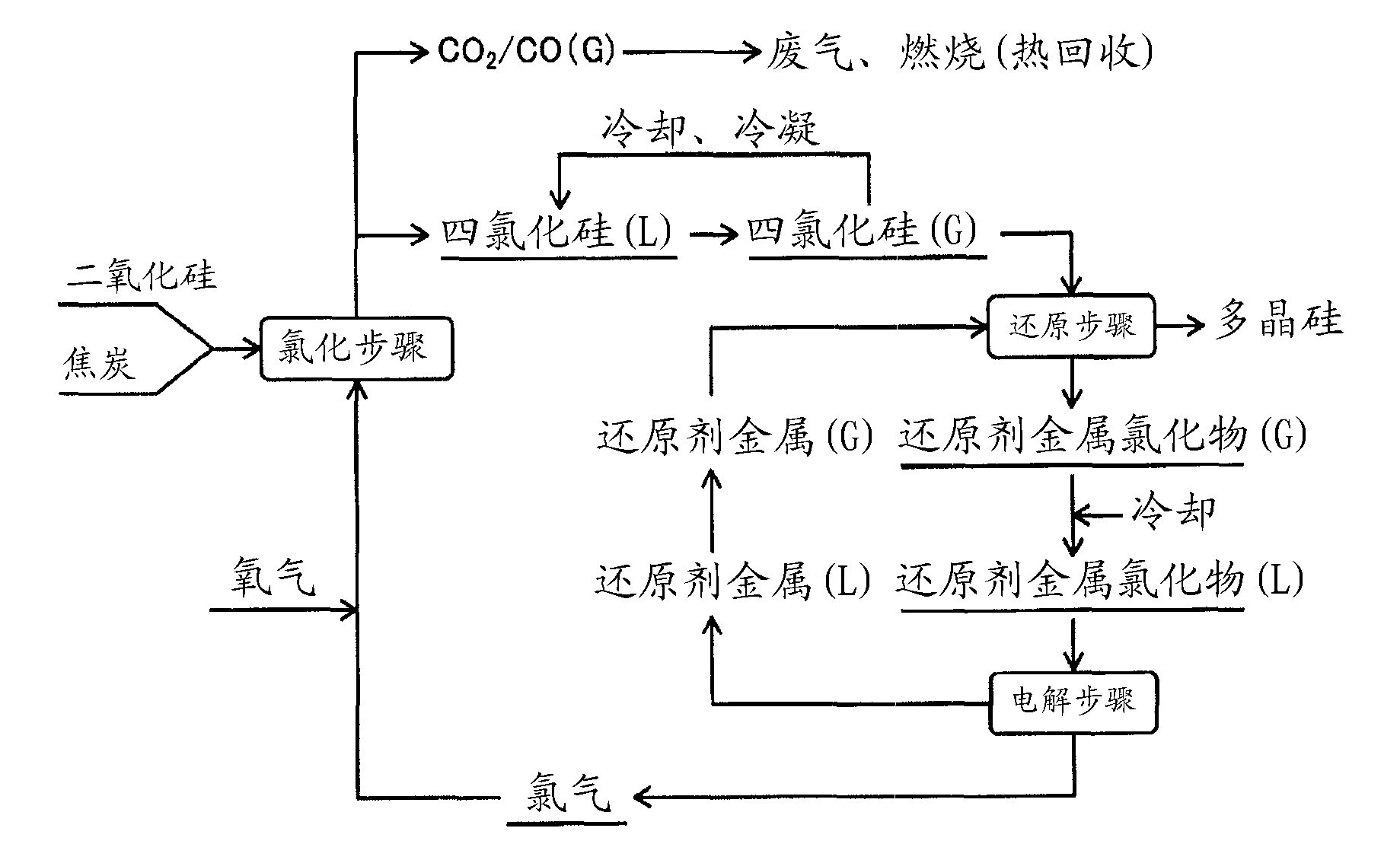

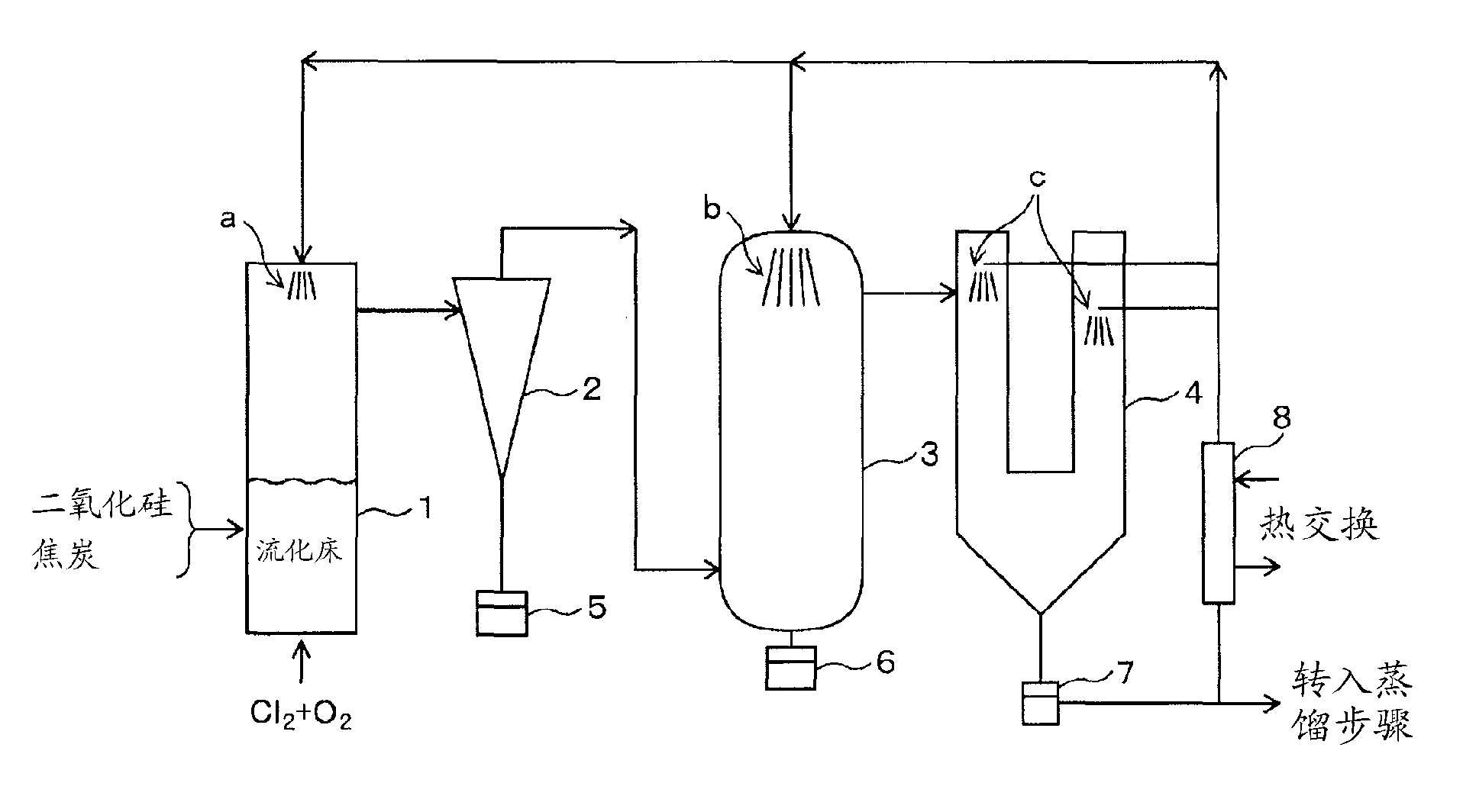

Method for manufacturing polysilicon and method for manufacturing silicon tetrachloride

InactiveCN102686514AEfficient use ofCheap manufacturingSiliconHalogenated silanesElectrolysisSilicon dioxide

Provided is a method for manufacturing polysilicon and silicon tetrachloride. The polysilicon manufacturing process used in said method is energy-efficient and can use an inexpensive raw material, the supply of which is stable. The chlorination reaction in said process proceeds smoothly and post-chlorination impurities are minimized. The provided method comprises: a chlorination step which generates silicon tetrachloride by chlorinating granules comprising silicon dioxide and a carbon-containing substance; a reduction step which generates polysilicon by using a reducing metal to reduce the silicon tetrachloride; and an electrolysis step which generates chlorine gas and a reducing metal by performing molten-salt electrolysis on a reducing metal chloride generated as a by-product from the reduction step. In the chlorination step, chlorine gas is supplied to the silicon dioxide and the carbon-containing substance in the presence of oxygen gas in order to react said substances. The reducing metal generated in the electrolysis step is reused as the reductant for the silicon tetrachloride in the reduction step, and the chlorine gas generated in the electrolysis step is reused in the chlorination step.

Owner:JNC CORP +2

Conversion of direct process high-boiling residue to monosilanes

InactiveUS6013235APromote conversionSilicon organic compoundsPhysical/chemical process catalystsHydrogenBoiling point

A process for the production of monosilanes from the high-boiling residue resulting from the reaction of hydrogen chloride with silicon metalloid in a process typically referred to as the "direct process." The process comprises contacting a high-boiling residue resulting from the reaction of hydrogen chloride and silicon metalloid, with hydrogen gas in the presence of a catalytic amount of aluminum trichloride effective in promoting conversion of the high-boiling residue to monosilanes. The present process results in conversion of the high-boiling residue to monosilanes. At least a portion of the aluminum trichloride catalyst required for conduct of the process may be formed in situ during conduct of the direct process and isolation of the high-boiling residue.

Owner:DOW SILICONES CORP

Method for comprehensively recovering tungsten and fluorine from minerals

InactiveCN102586632AHigh recovery rateImprove solubilitySilicaProcess efficiency improvementDecompositionApatite

The invention provides a method for comprehensively recovering tungsten and fluorine from minerals, namely a mixed acid of phosphoric acid and sulfuric acid is adopted for decomposing complex calcium-containing minerals containing fluorite, scheelite, apatite, and calcite, wherein the fluorite is decomposed to fluorine hydride or silicon tetrafluoride to escape, and absorption treatment is performed for preparing hydrofluoric acid or a fluoride salt; and the scheelite is transformed to phosphotungstic acid to enter into a solution, and filtrate after filtration is supplemented into the consumed sulfuric acid and the phosphoric acid after extraction of the tungsten and returned to the new-round mineral leaching. The method disclosed by the invention has the advantages of comprehensively recovering the fluorine and the tungsten from the minerals, reducing the requirements on the fluorite or the tungsten ore raw material, reducing the pressure on a mineral dressing link, improving the comprehensive recovery rate and simultaneously ensuring the decomposition rate of the fluorite and the scheelite, wherein the decomposition rate of the fluorite is above 98%, and WO3 contained in decomposition slag is reduced to below 0.5%; furthermore, a leaching agent can be recycled, so that leaching cost and wastewater emission are greatly reduced; and the method also has the advantages of simple leaching equipment, convenience in operation and easiness in realization of industrialization.

Owner:CENT SOUTH UNIV

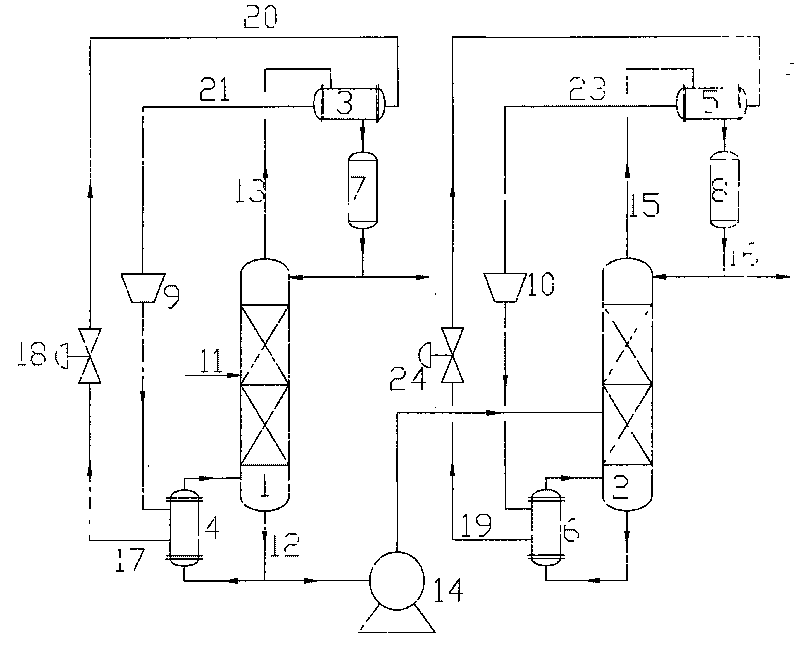

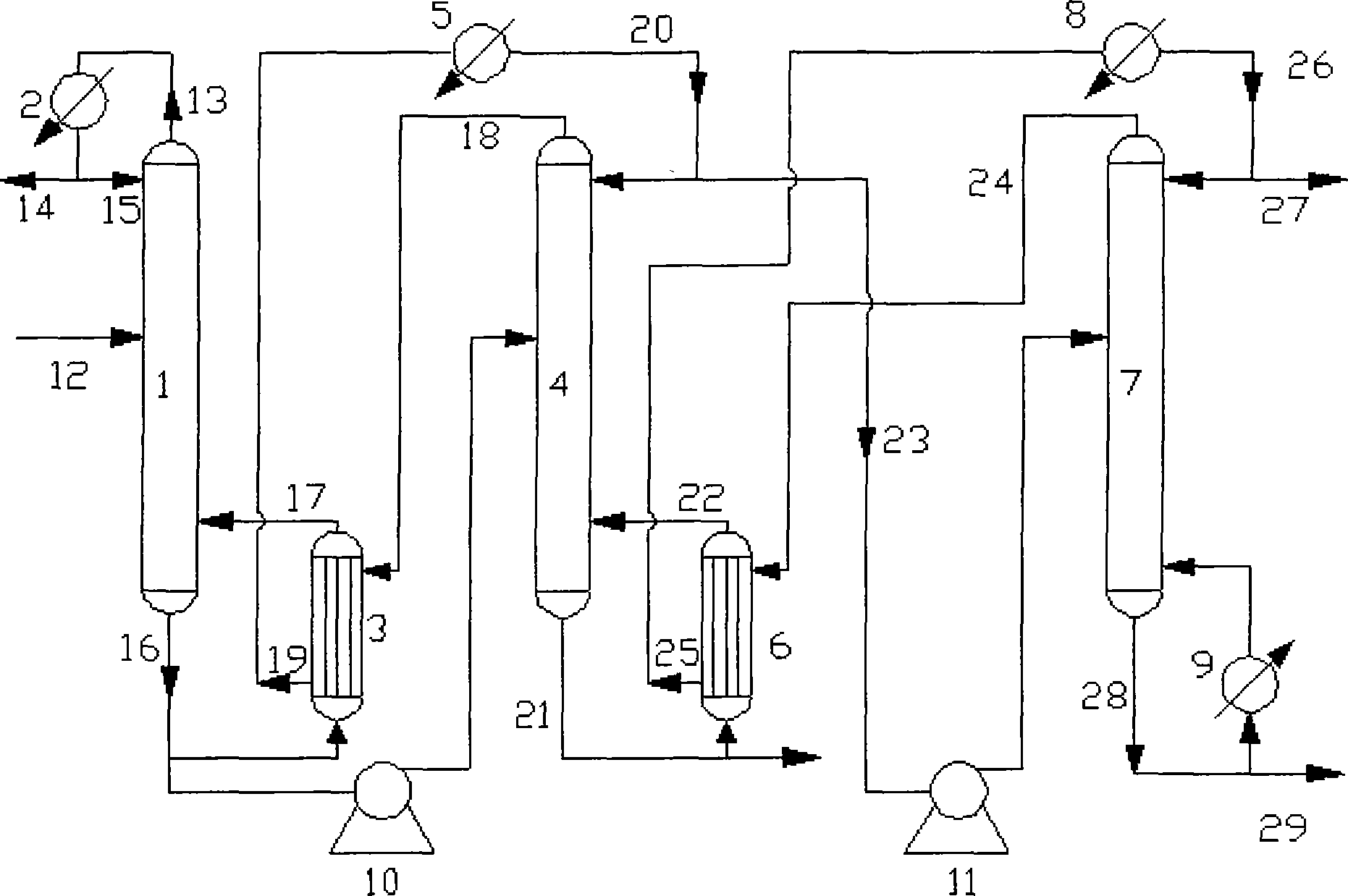

Trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and operating method

ActiveCN101786630ASave heating and energy saving lossReduce cooling loadChemical industryHalogenated silanesDifferential pressureProcess engineering

The invention relates to a trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and an operating method. The trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system comprises a primary tower, a secondary tower and a tertiary tower; the three towers are connected in series from low pressure to highpressure or from high pressure to low pressure, and a condensation re-boiler is arranged between the primary tower and the secondary tower and between the secondary tower and the tertiary tower respectively; and the three towers can be used for light removal, heavy removal and light removal in turn, and also can be used for combining light removal, heavy removal and light removal. According to the characteristics of approach full tower composition and approach temperature in the process of rectifying the trichlorosilane, the invention provides a trichlorosilane differential pressure coupling rectifying process which is expected to greatly reduce the production cost and energy consumption and theoretically rectify and save energy by nearly 70 percent. The technology remarkably improves themarket competitiveness of polycrystal silicon materials and promotes the development of a photovoltaic and information material industry chain.

Owner:TIANJIN UNIV

Process for the separation of chlorosilanes from gas streams

Chlorosilanes are continuously removed from a gas stream in an apparatus in which the gas stream is treated in a first stage with water vapor in the gas phase, and in a second stage with a liquid, aqueous phase.

Owner:EVONIK DEGUSSA GMBH

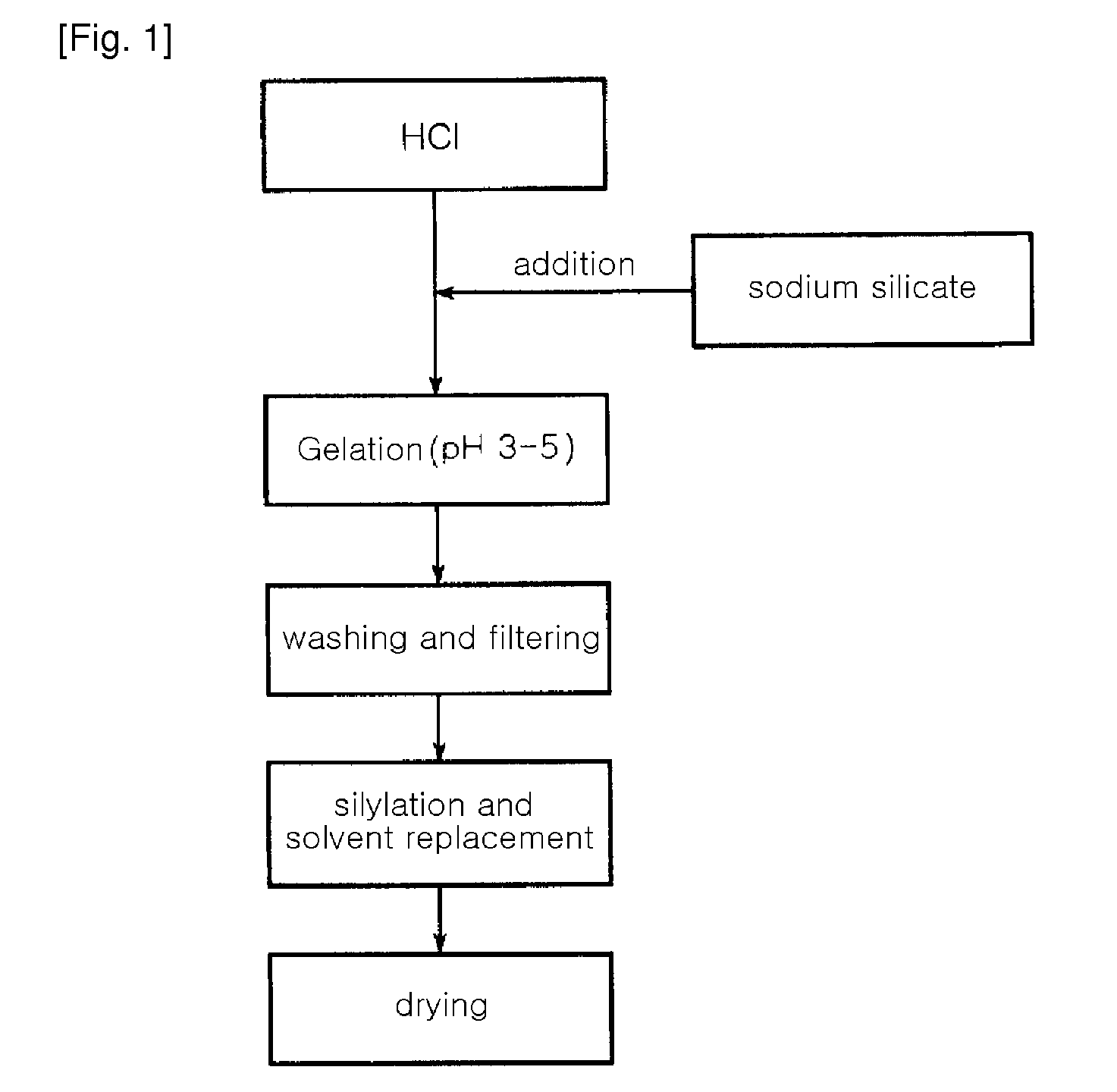

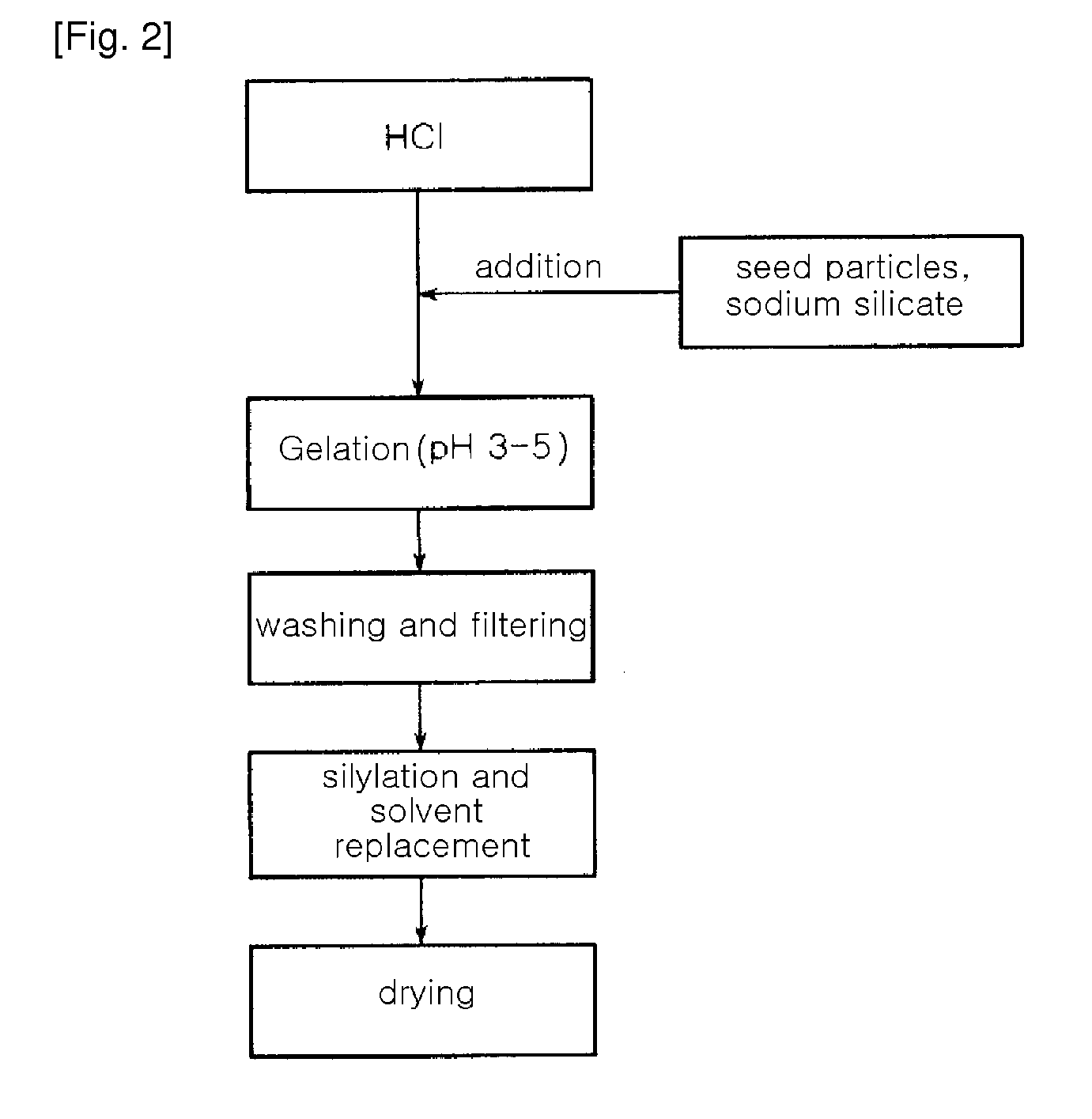

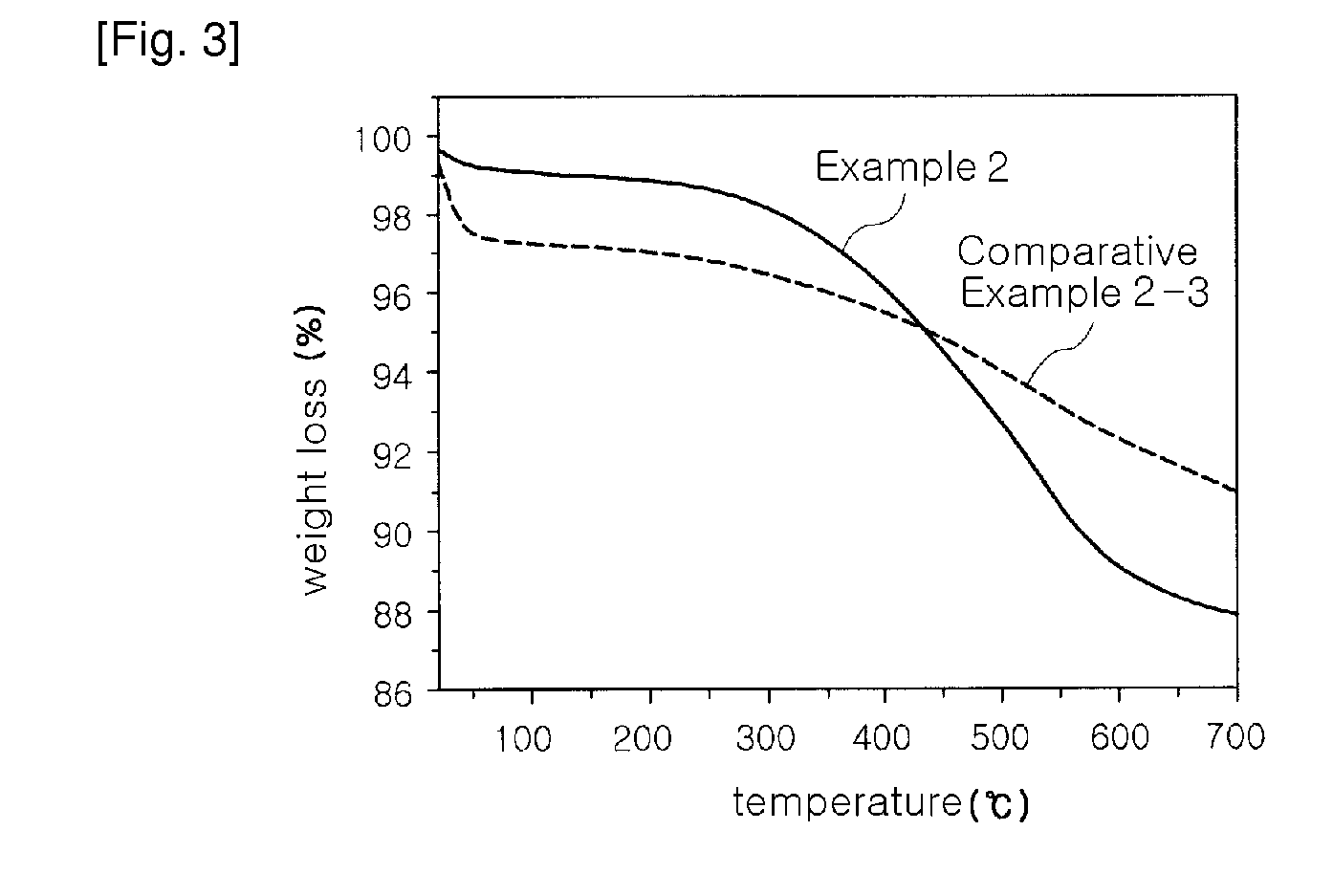

Method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by using the method

A method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by the method. The method comprises adding sodium silicate to HCl at 30 to 90° C. until an acidity reaches pH 3-5, to form silica hydrogel under acidic conditions of pH 3-5, washing the silica hydrogel with distilled water using a mixer, followed by filtering, adding the silica hydrogel to a silylating solution of silylating agent in n-butanol at pH 1-5 using an acid selected from hydrochloric acid, sulfuric acid, phosphoric acid and nitric acid, to simultaneously conduct silylation and solvent replacement, and drying the silica hydrogel; The method has the following advantages; i) silylation and solvent replacement can be simultaneously conducted, ii) n-butanol is used as a reaction solvent instead of methanol upon silylation, thus obtaining a thermal conductivity comparable to conventional aerogel powders, iii) silylation is conducted under improved conditions, i.e., strong acidic conditions of pH 1-5, and as a result, all of the aerogel powders can be reacted with a silylating agent, thereby obtaining permanently hydrophobic aerogel, iv) the washing with a mixer makes the amount of removed sodium ions uniform, thus it is suitable for mass-production, and v) the method provides a relatively simplified procedure and the use of the silylating agent in a small amount enables low costs and mass-production.

Owner:KOREA INST OF IND TECH

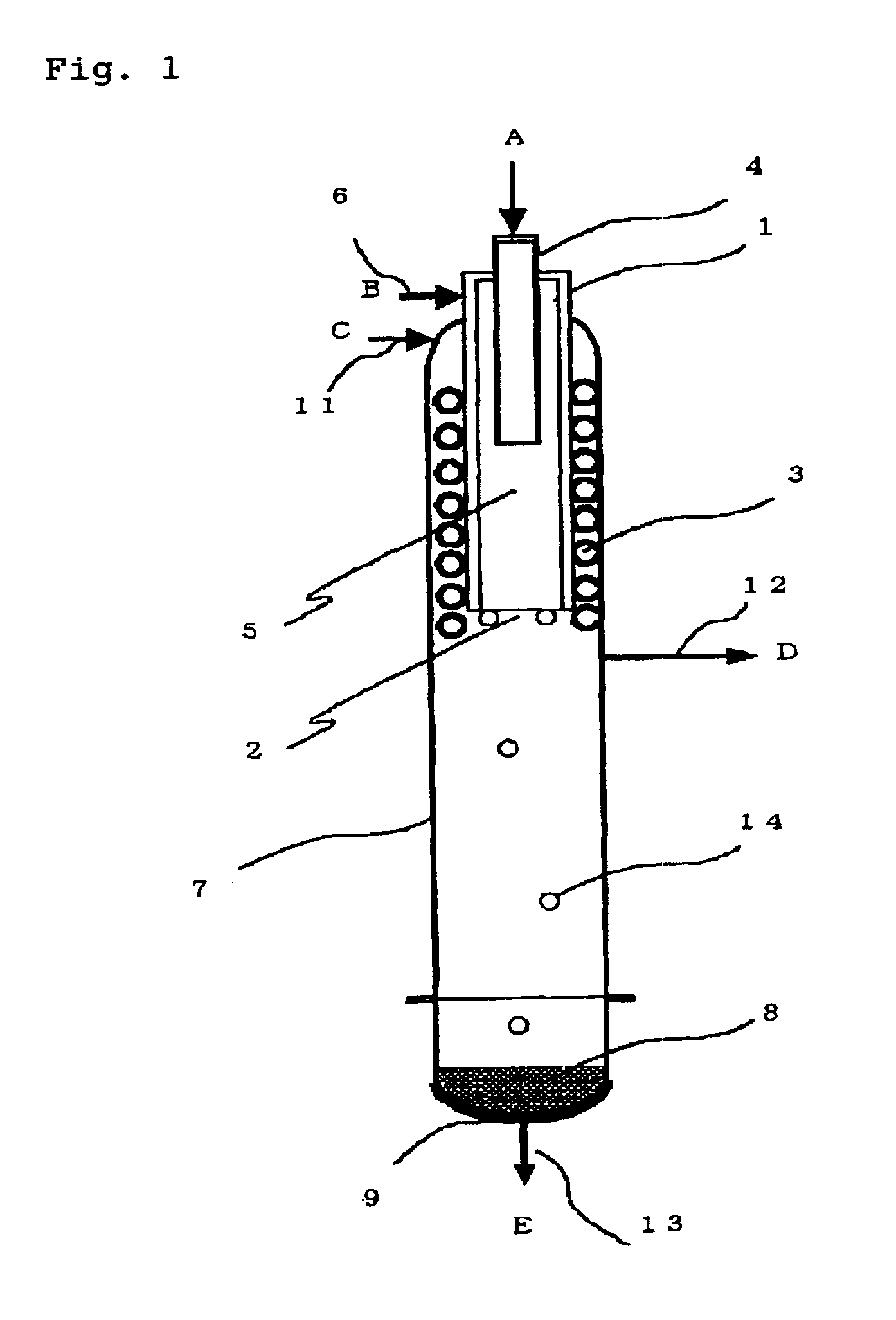

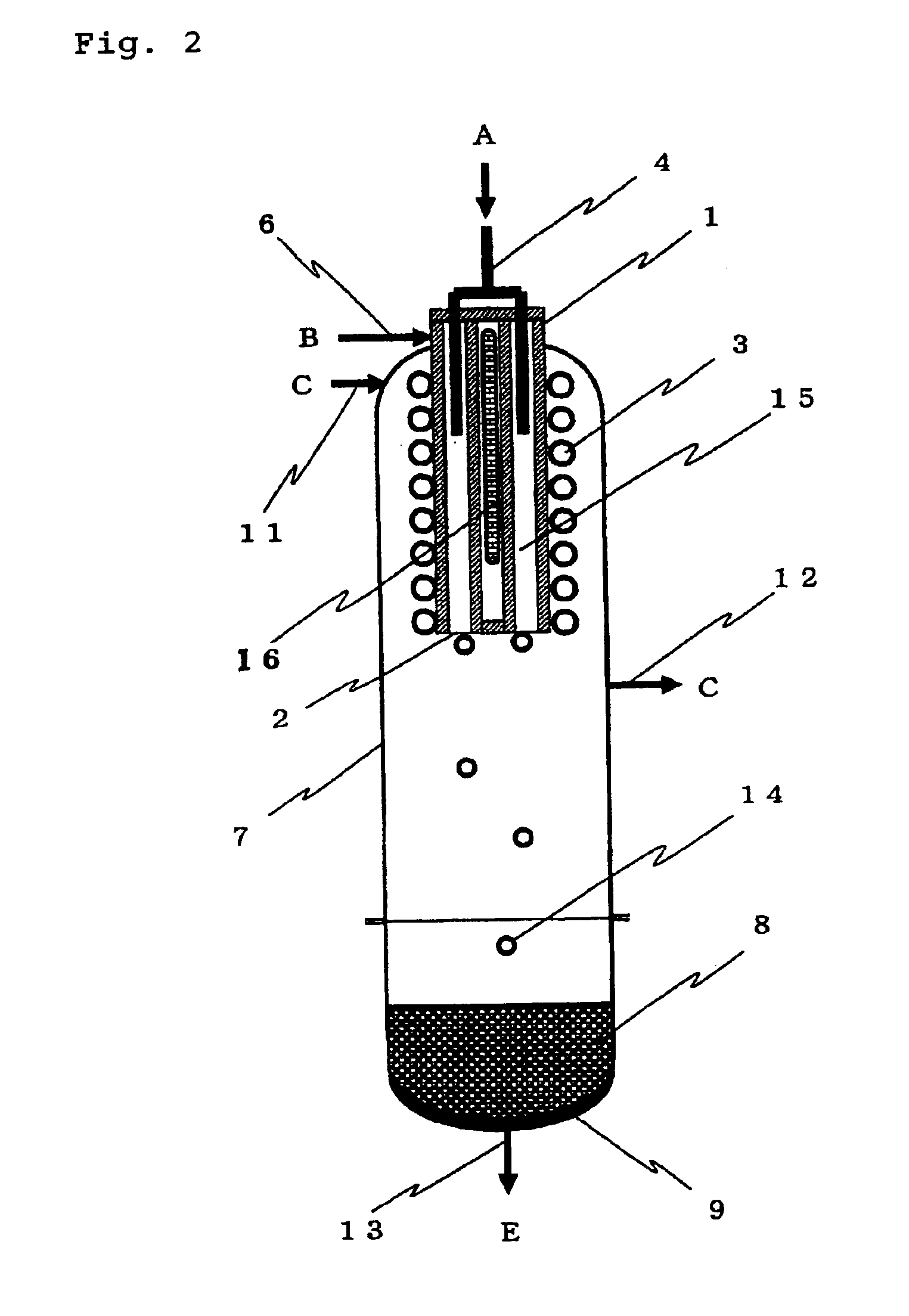

Silicon and catalyst material preparation in a process for producing trichlorosilane

InactiveUS20090060818A1Reduce size requirementsReduce yieldSiliconHalogenated silanesMaterials preparationHydrogen

A process for preparing trichlorosilane by reacting silicon with hydrogen chloride, or silicon tetrachloride with hydrogen in the presence of silicon, and catalysts where the silicon and catalysts are laminated together and reduced in particle size prior to reaction.

Owner:DYNAMIC ENG

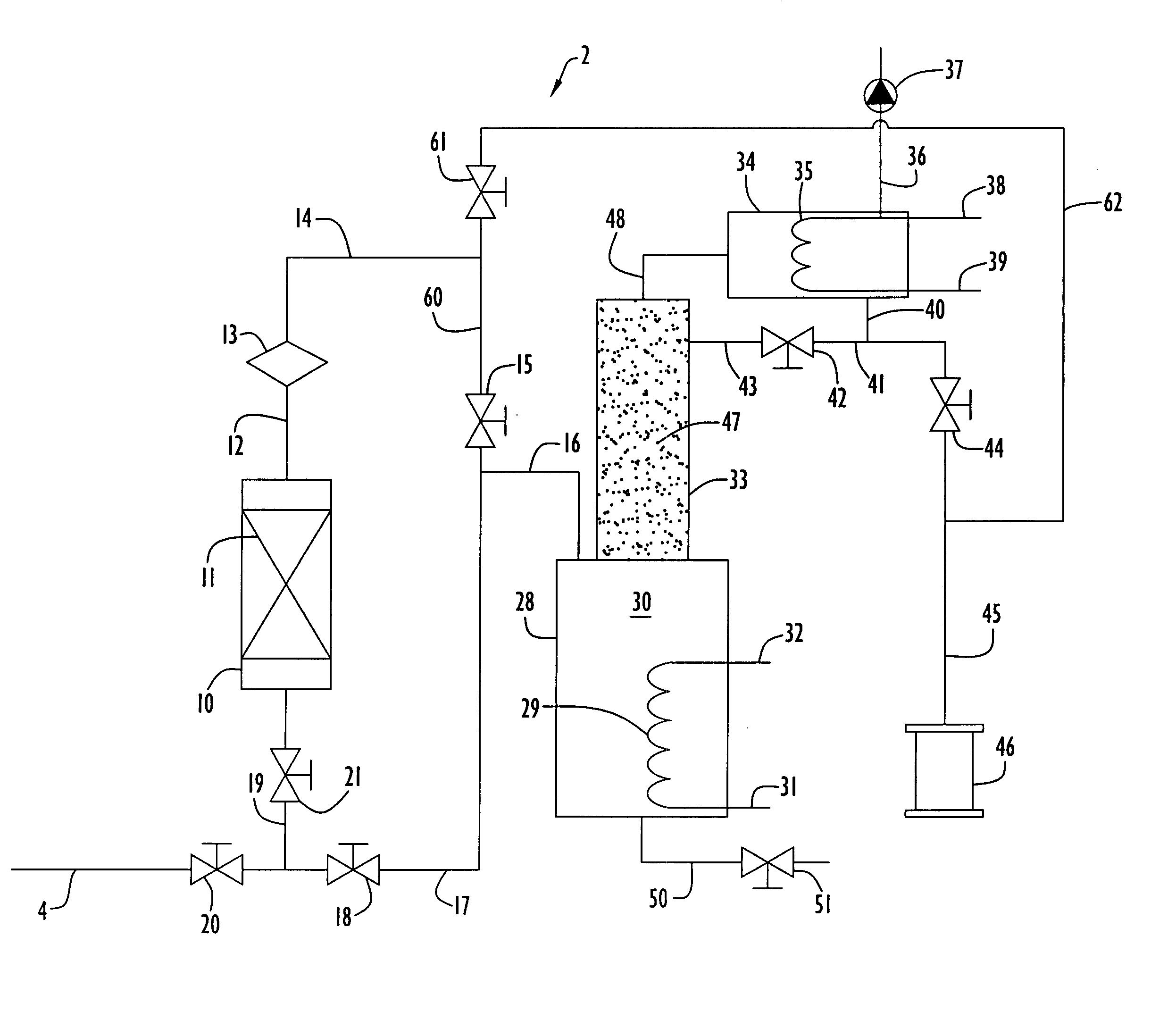

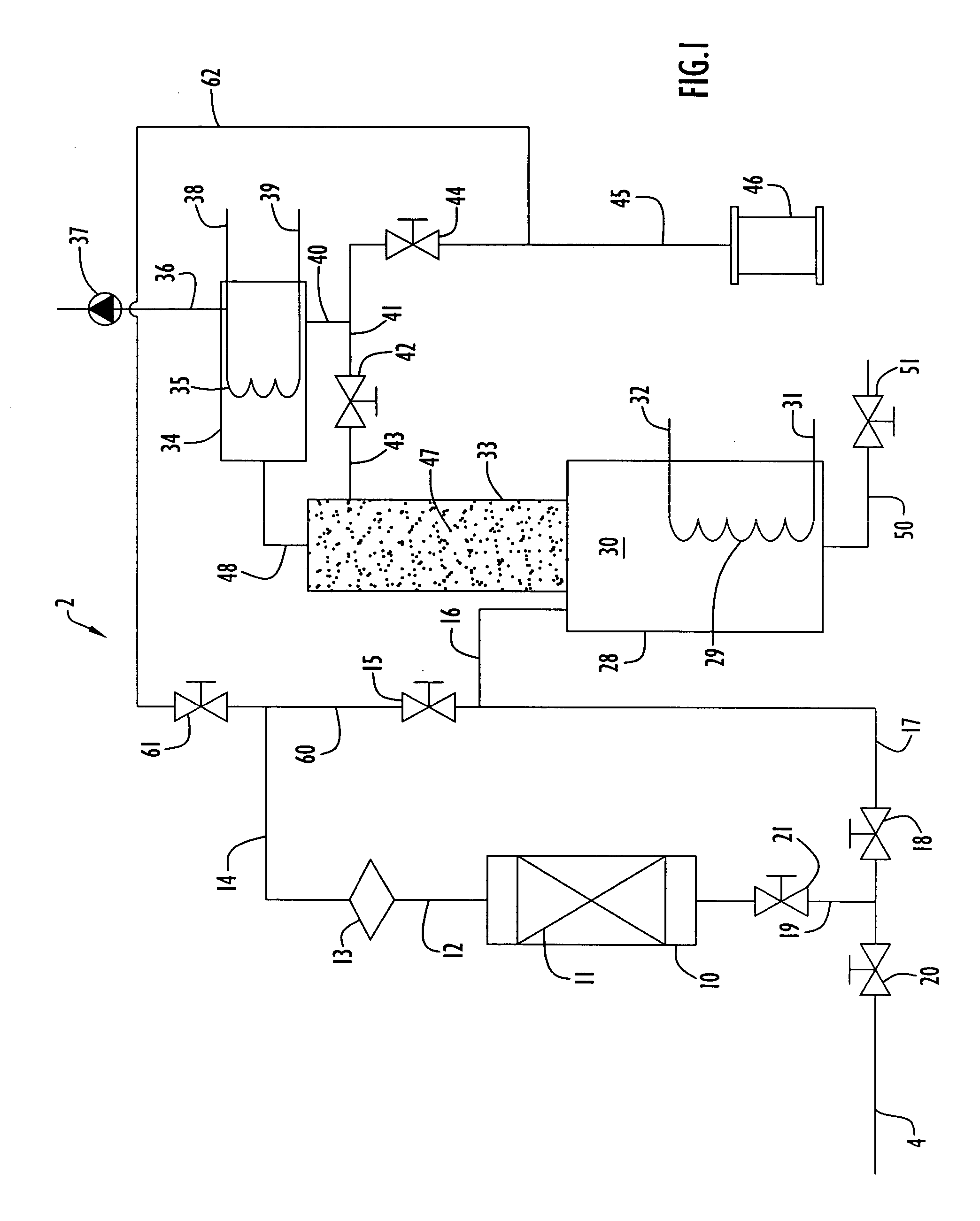

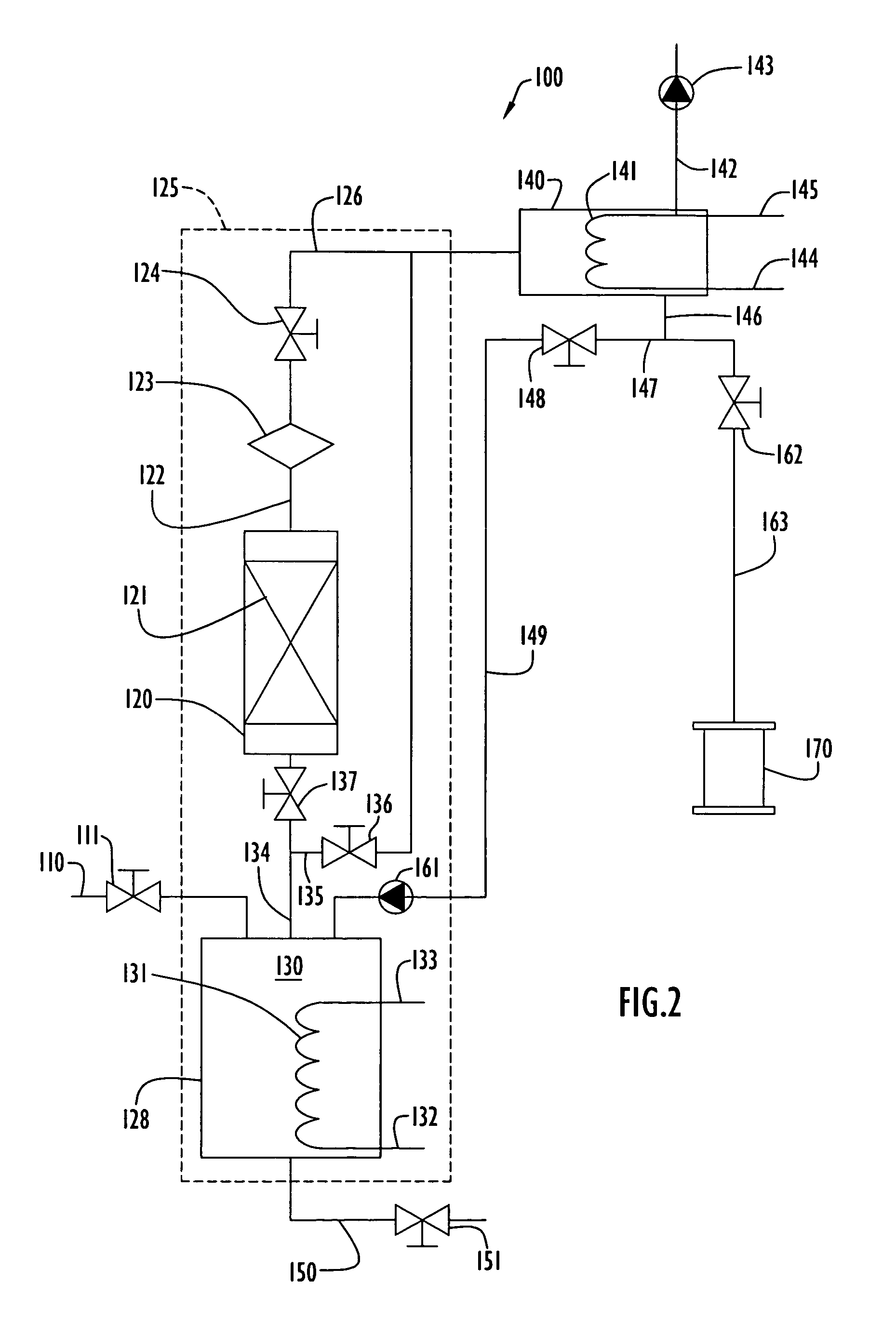

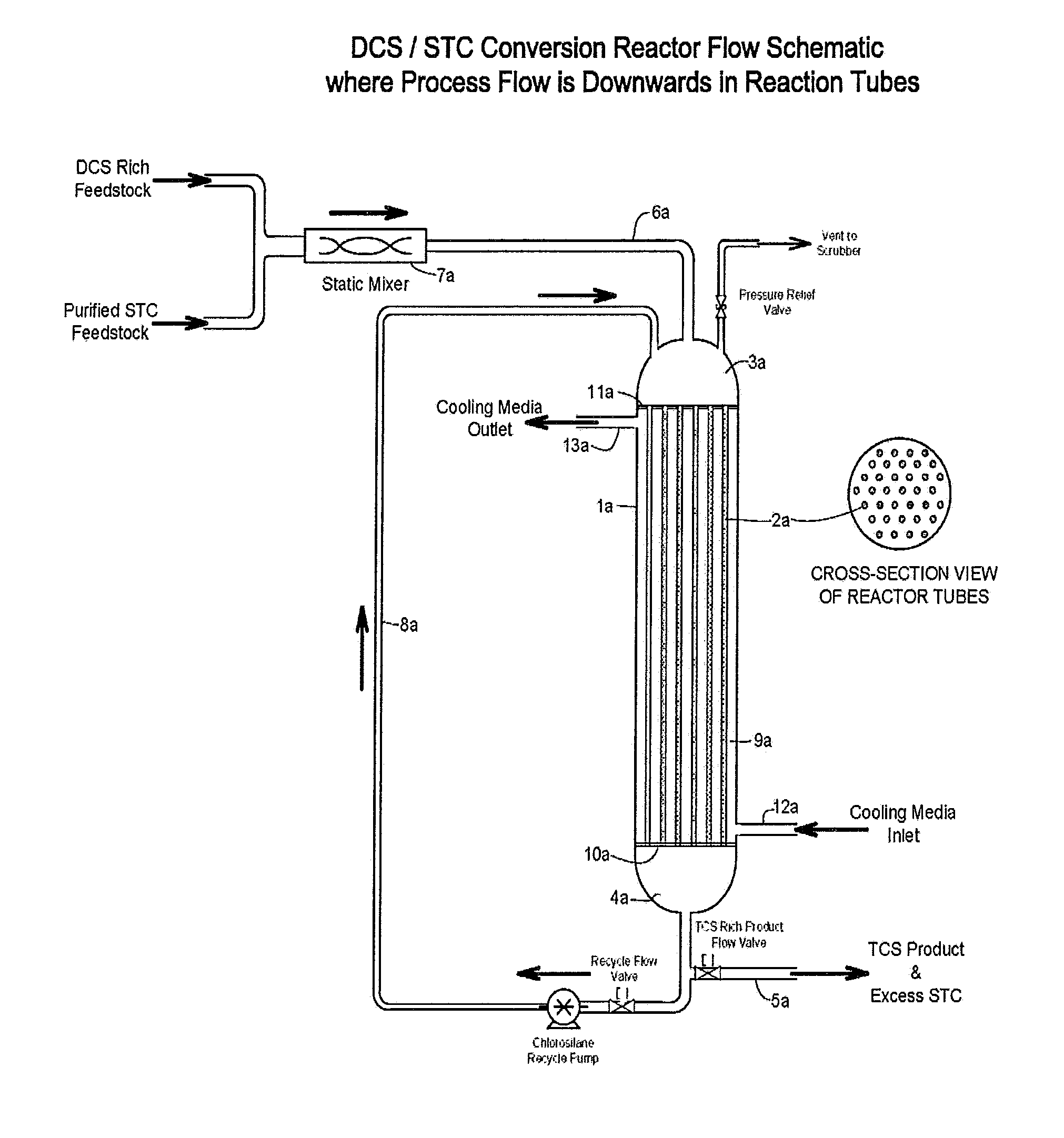

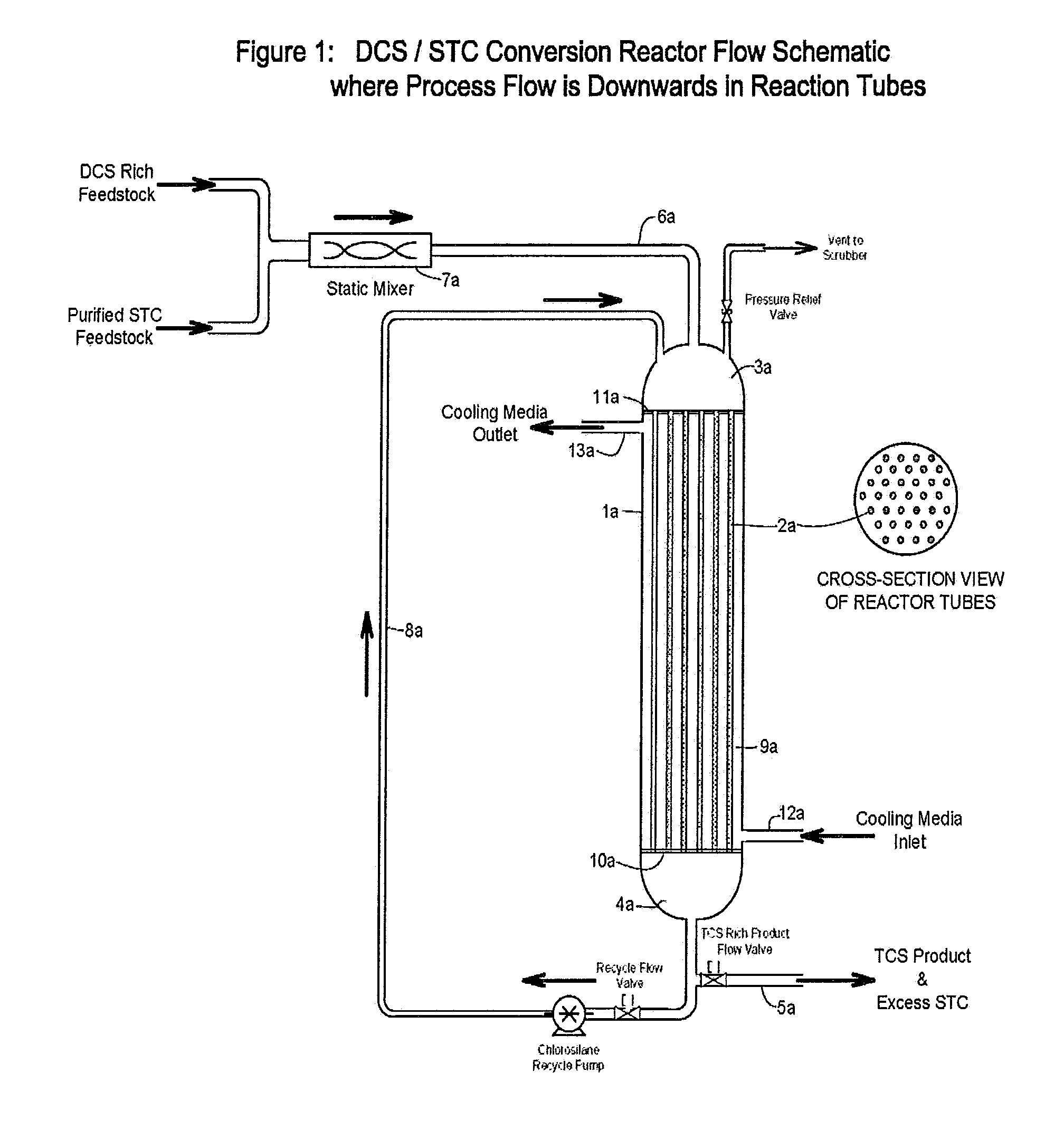

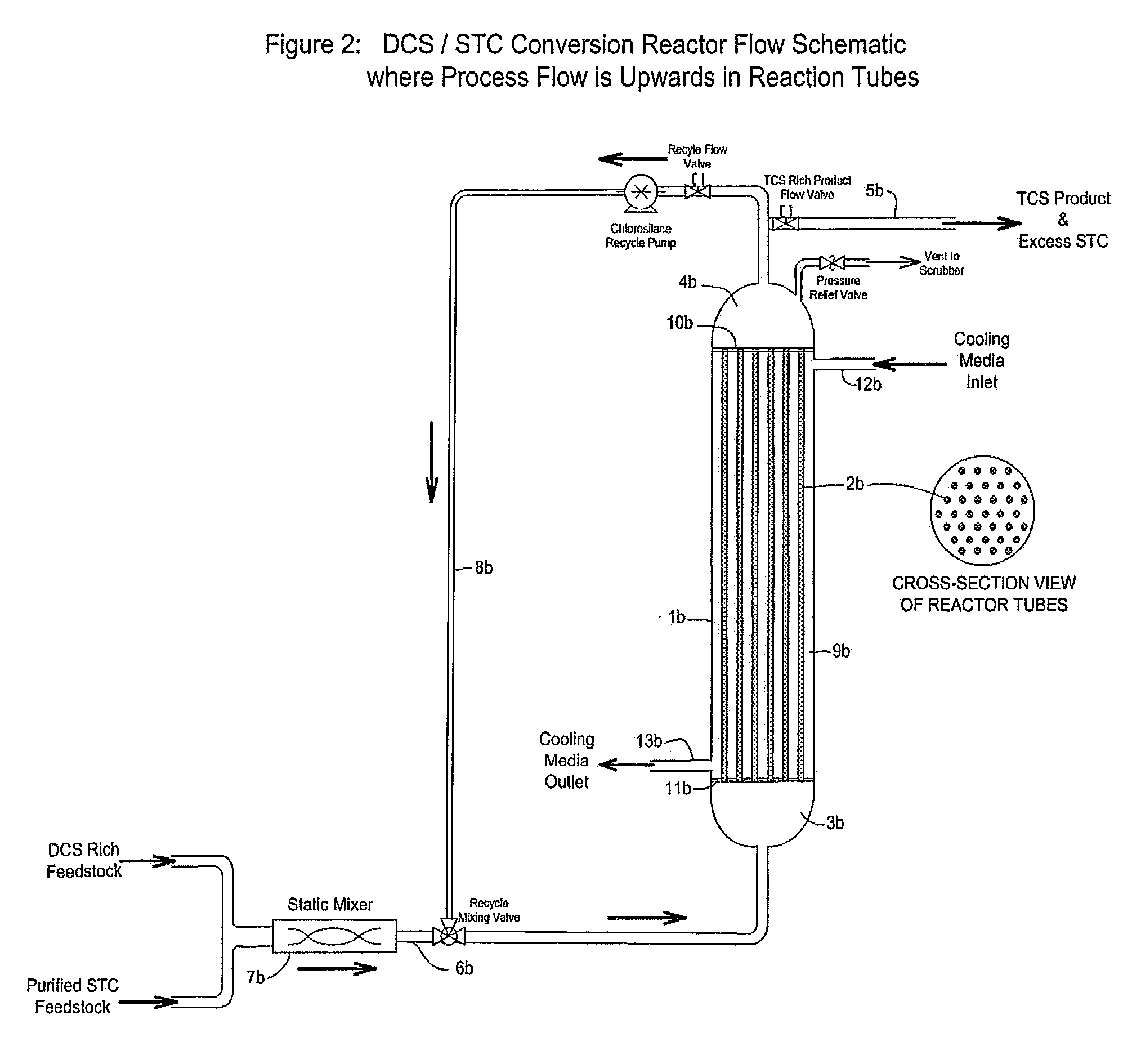

Enhancements for a chlorosilane redistribution reactor

The present invention includes a process and means for using two isolated by-products from the reaction of at least one of metallurgical silicon and silicon tetrachloride with at least one of anhydrous hydrogen chloride and hydrogen to produce trichlorosilane. The two isolated by-products are dichlorosilane and silicon tetrachloride. The present process reduces chlorosilane waste and improves efficiency of overall process for production of trichlorosilane for use in chemical vapor deposition of polysilicon for electronic and solar applications. The present invention further includes a chemical reactor for the reacting dichlorosilane with silicon tetrachloride to produce additional trichlorosilane.

Owner:DYNAMIC ENG

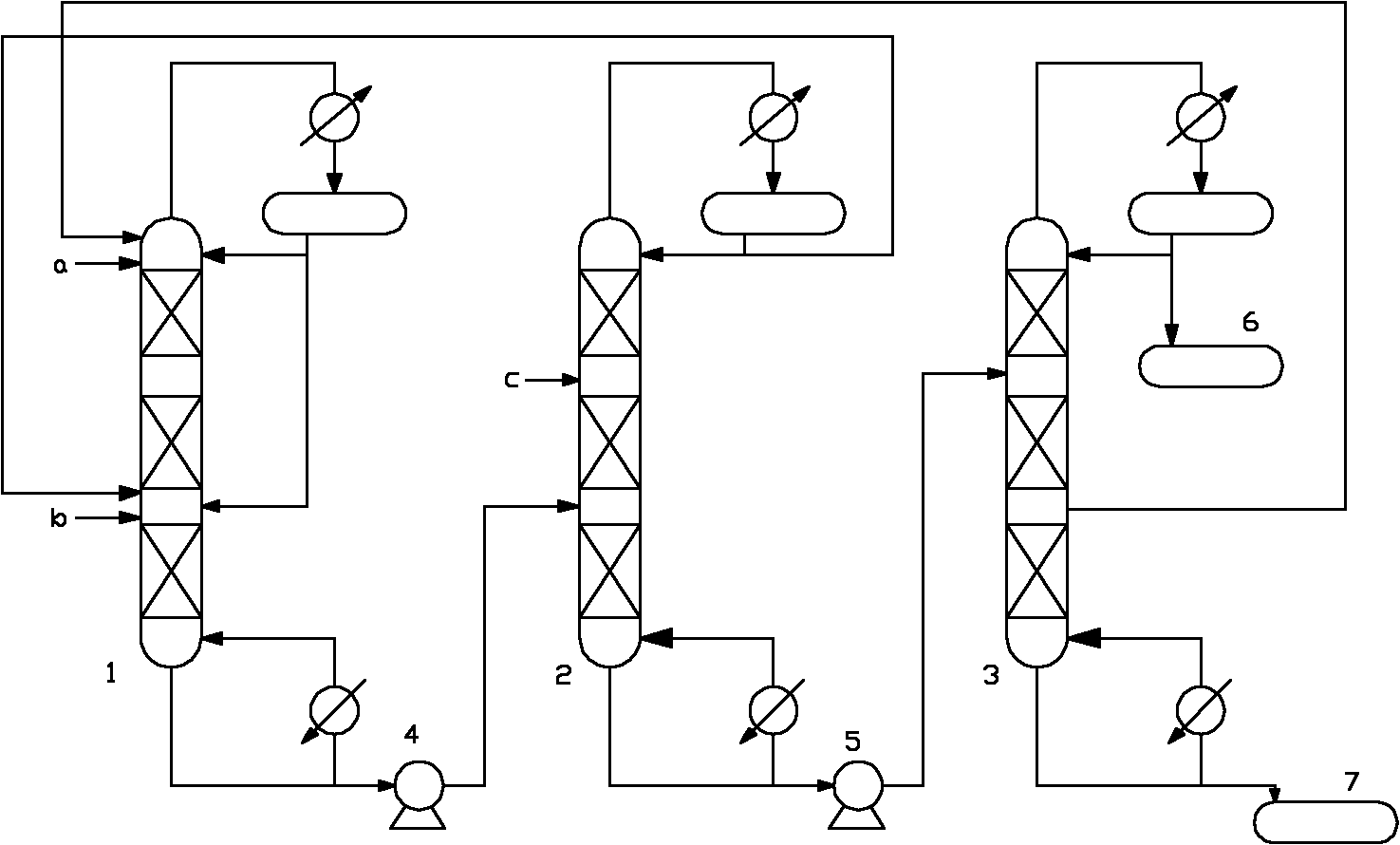

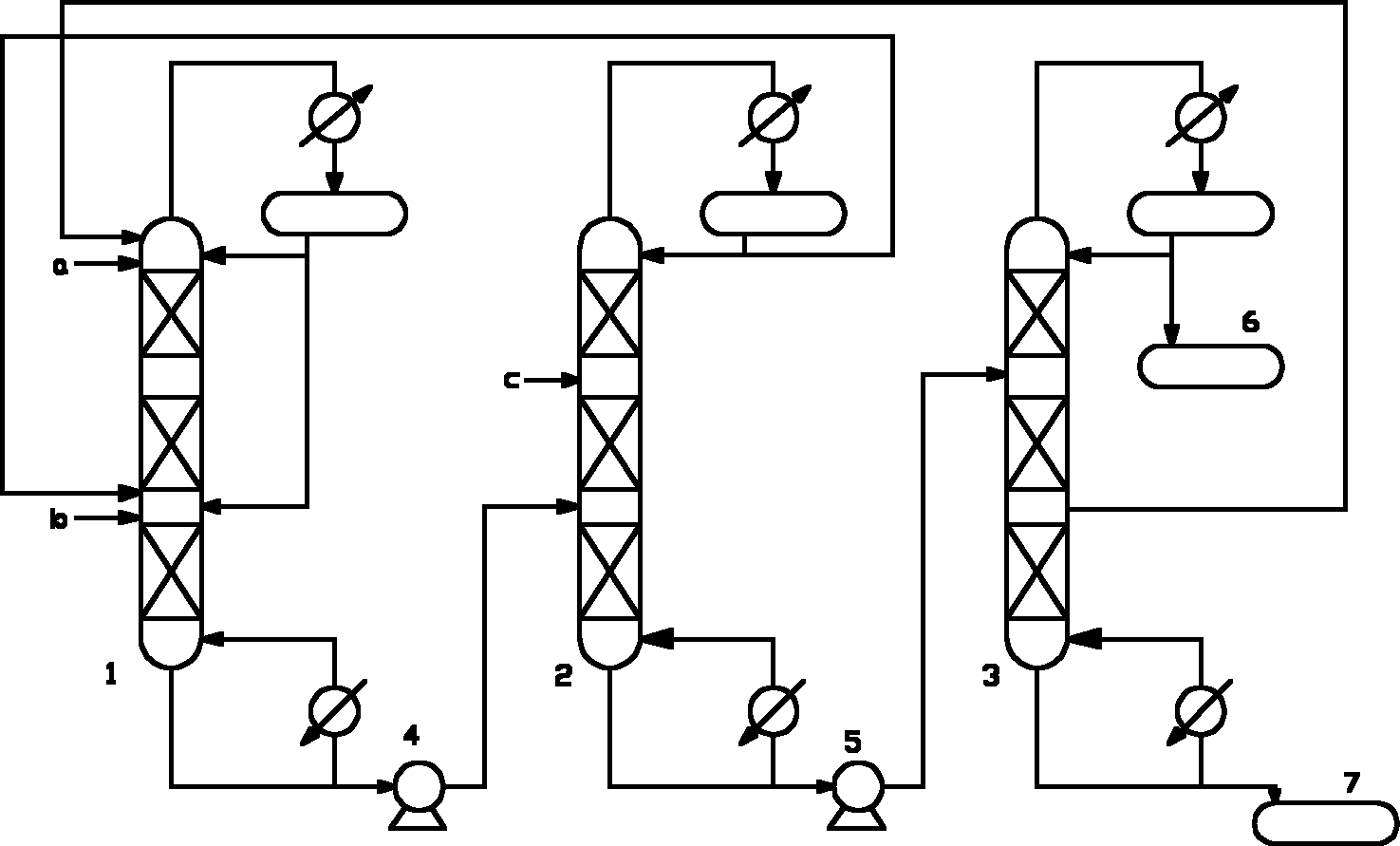

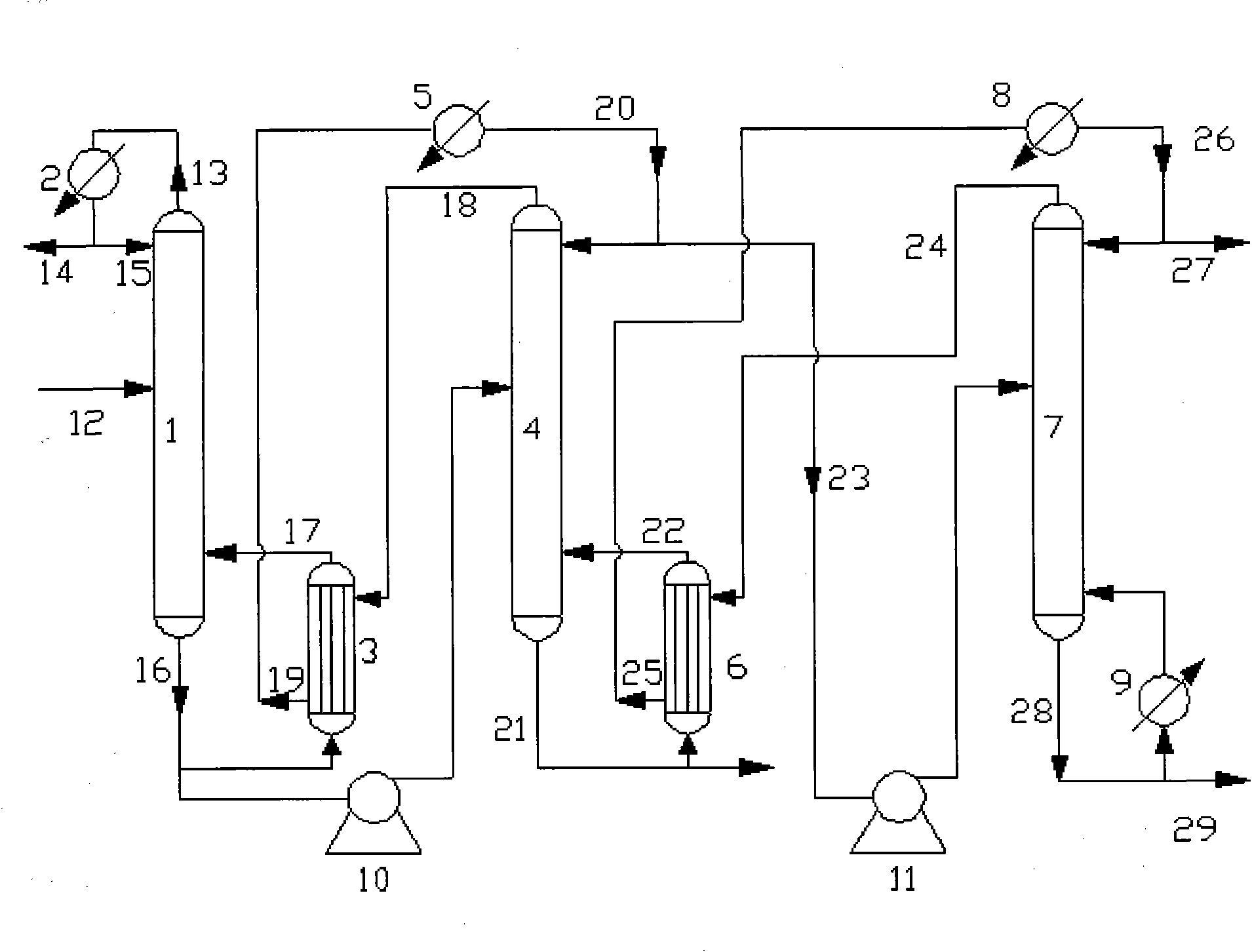

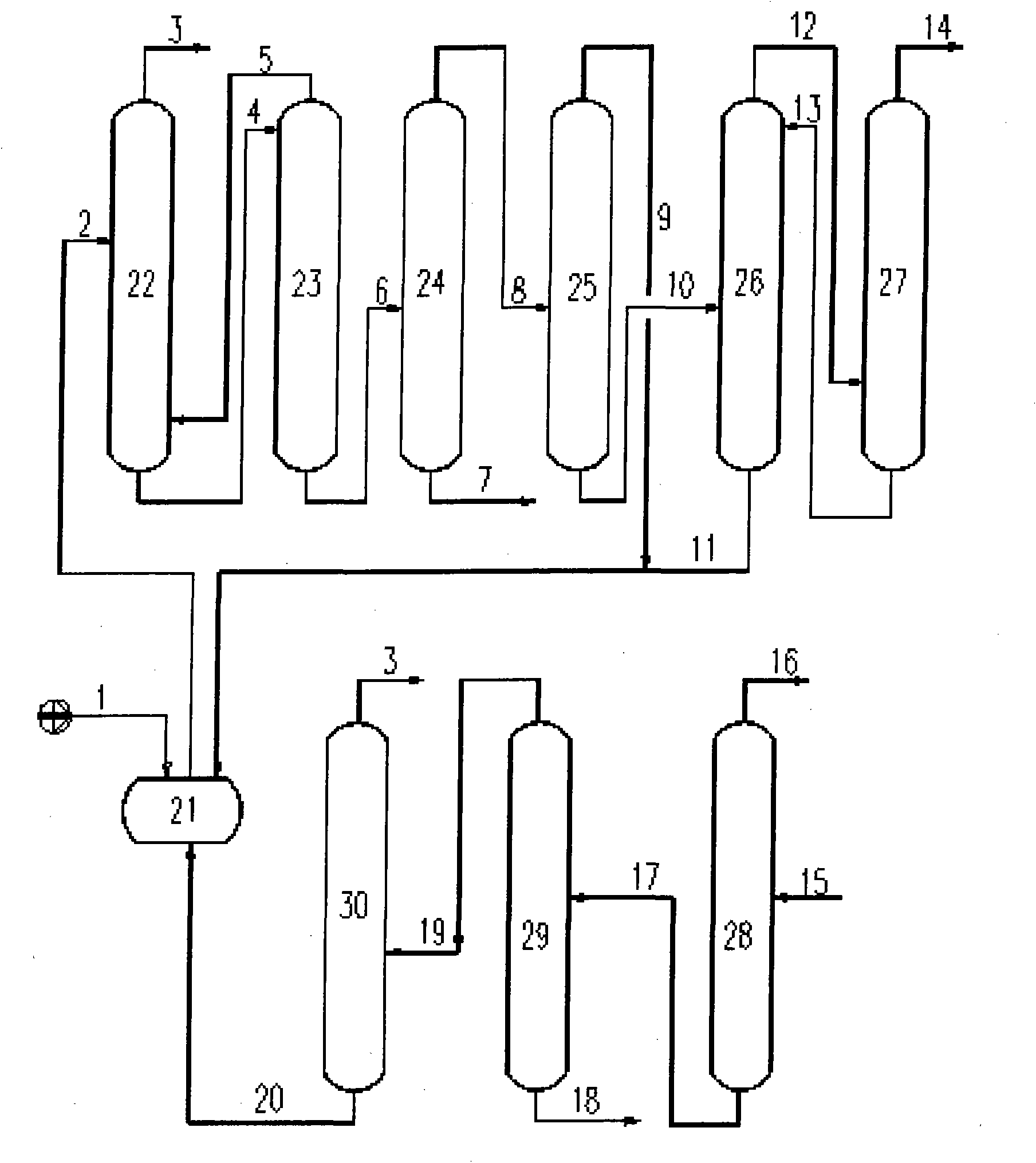

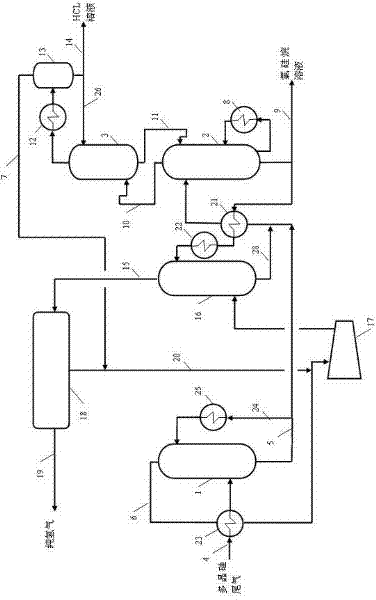

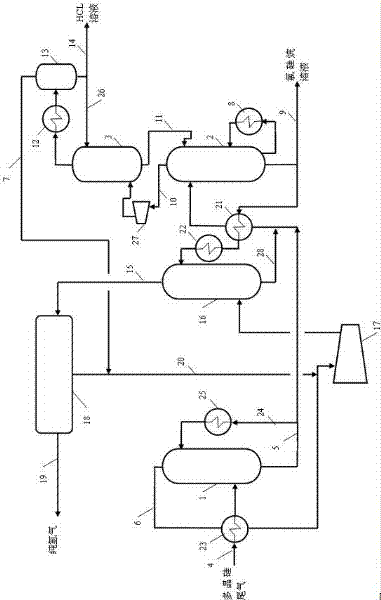

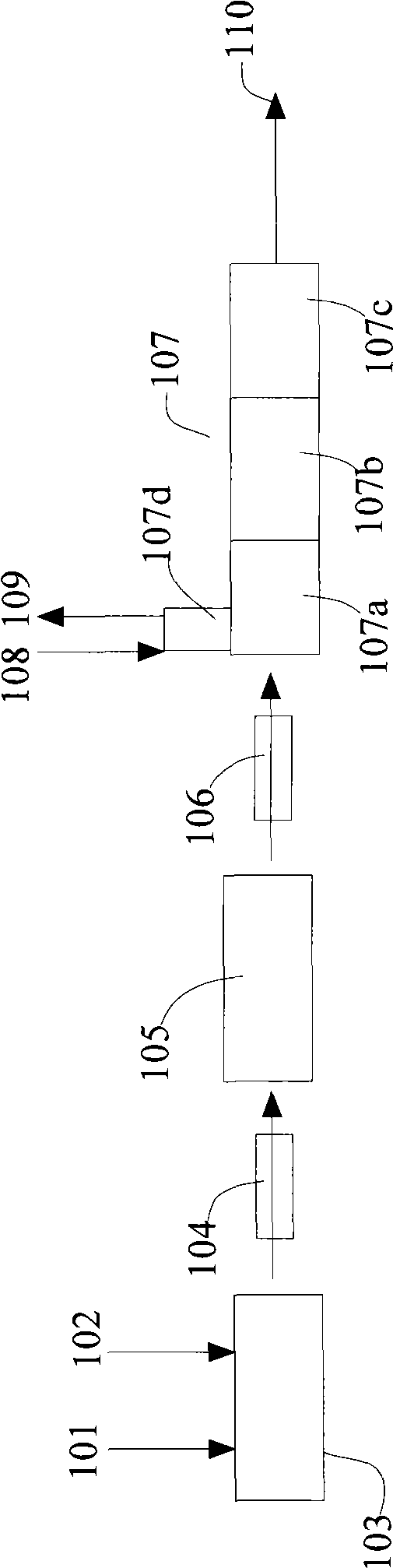

System for separating and purifying trichlorosilane in production process of polysilicon and operation method thereof

ActiveCN101538044ALow impurity contentMeet production requirementsChemical industryHalogenated silanesProcess engineeringTower

The invention provides a system for separating and purifying trichlorosilane in production process of polysilicon and an operation method thereof. The system consists of a rectification working section and a recovery refining working section; wherein, the rectification working section comprises six towers, and the recovery refining working section includes three towers; the connection mode of the six towers of the rectification working section is that a lightness-removing tower I, a lightness-removing tower II, a weight-removing tower, a secondary lightness-removing tower, a secondary weight-removing tower I and a secondary weight-removing tower II are sequentially connected with each other; the connection mode of the three towers of the recovery refining working section is that a lower-removing tower, a higher-removing tower and a product refining tower are sequentially connected with each other. Chlorsilane rectification technical equipment can be one of main technical bottlenecks limiting the production of the high-quality polysilicon material in China. The invention can achieve the separation requirements and energy-saving aim under the condition that the mass flow rate elastic ratio between feeding of the rectification working section and feeding of the recovery working section is 1:1-1:5. The rectification technique is simplified and optimized, the separation efficiency is improved, the energy consumption of rectification products is reduced, the reliability and stability of system operation can be enhanced, and the content of phosphorus, arsenic, boron and metallic contamination in the rectification products can be lowered.

Owner:TIANJIN UNIV

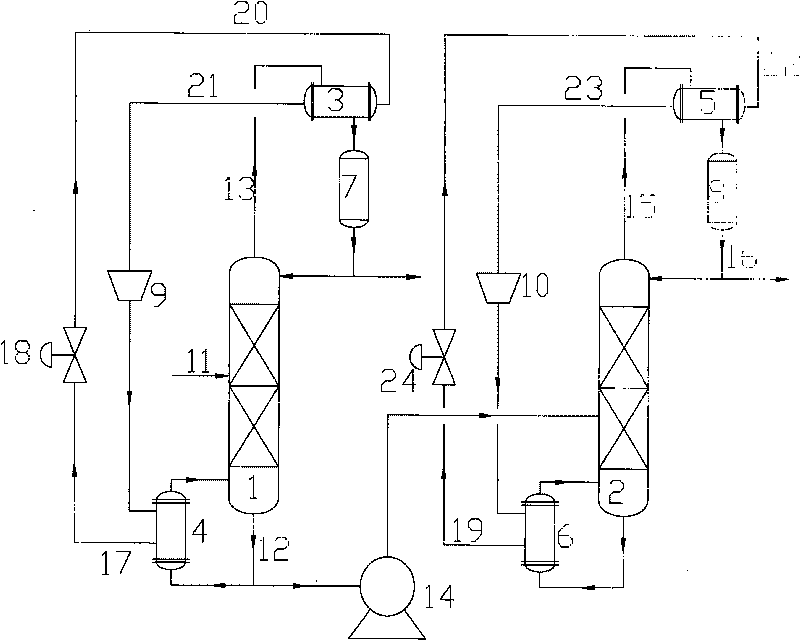

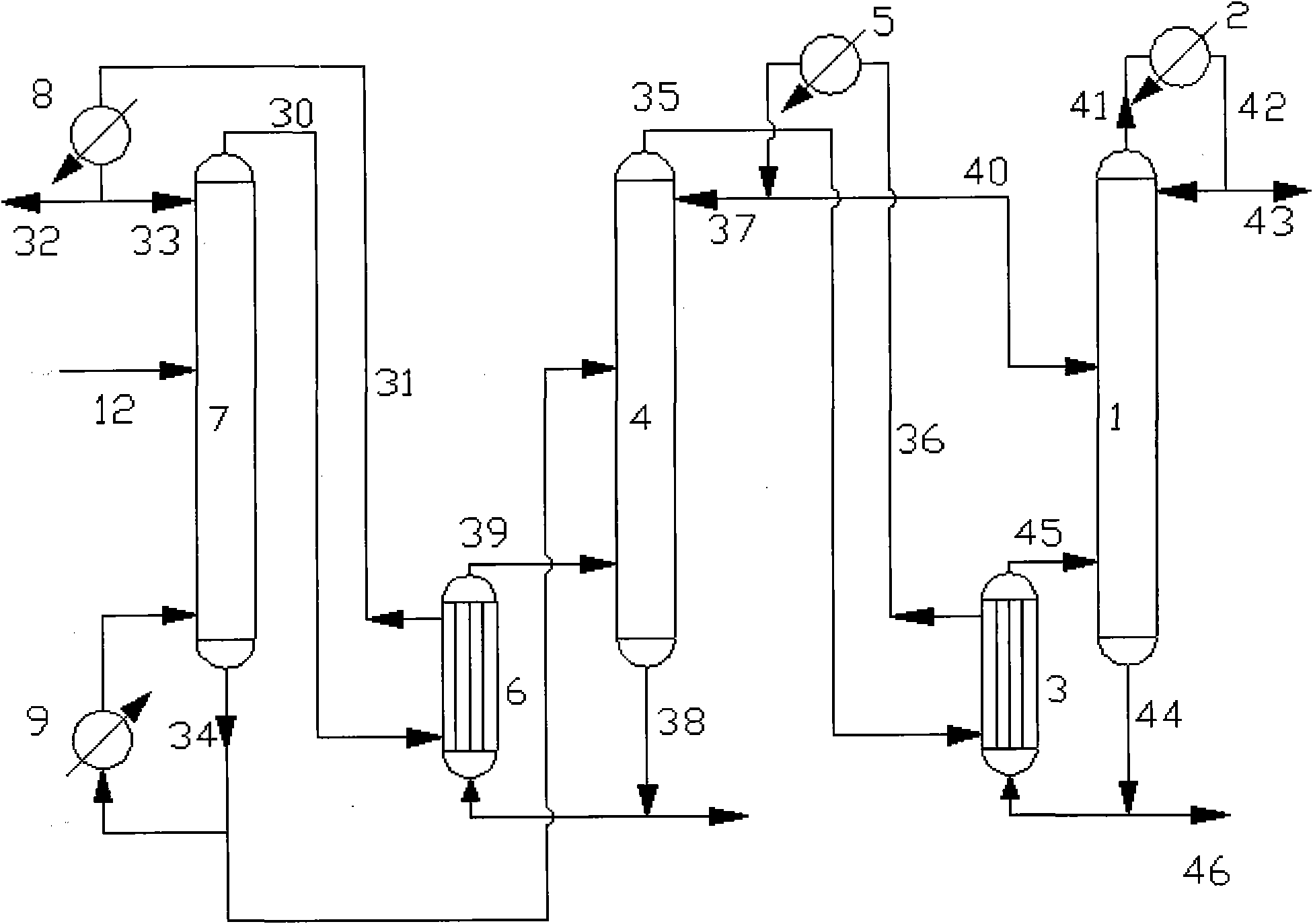

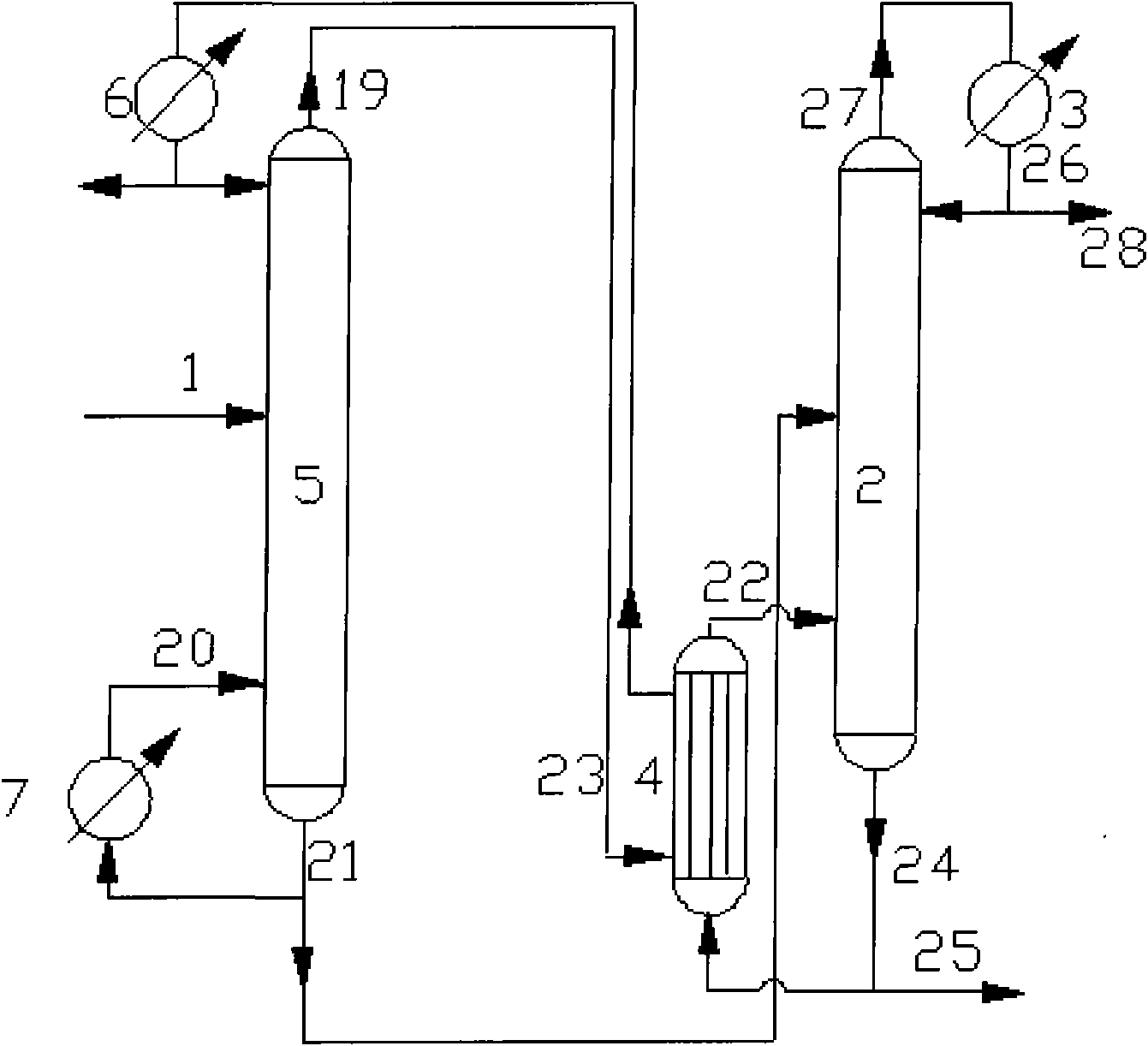

Trichlorosilane differential pressure coupling rectification system and operation method thereof

InactiveCN101538045AReduce energy lossReduce lossSiliconChemical industryDifferential pressureReboiler

The invention relates to a trichlorosilane differential pressure coupling rectification system and an operation method thereof. The system comprises a low pressure rectifying tower, a pressurizing rectifying tower, a tower kettle reboiler, an overhead condenser and an auxiliary condenser; a condensation reboiler is arranged between the low pressure rectifying tower and the pressurizing rectifying tower, a vapor phase material outlet on the top of the pressurizing rectifying tower is connected with a heating medium inlet of the condensation reboiler, and a heating medium outlet returns to the top of the pressurizing rectifying tower; a liquid phase material outlet at the bottom of the low pressure rectifying tower is connected with a heated medium inlet of the condensation reboiler, and a heated medium outlet returns to the bottom of the low pressure rectifying tower. Raw materials are fed through different towers, so that two sets of process flow can be adopted; the process flow A adopts a low pressure tower as a front tower for removing lightness, and a feeding pump is added for feeding a pressurizing tower; the process flow B adopts the pressurizing tower as the front tower for removing lightness, and the feeding pump is not needed to be added for feeding the low pressure tower. The invention greatly reduces the production cost and energy consumption, and saved energy by about 40% in rectification. The technology remarkably improves the market competitiveness of the polysilicon material.

Owner:TIANJIN UNIV

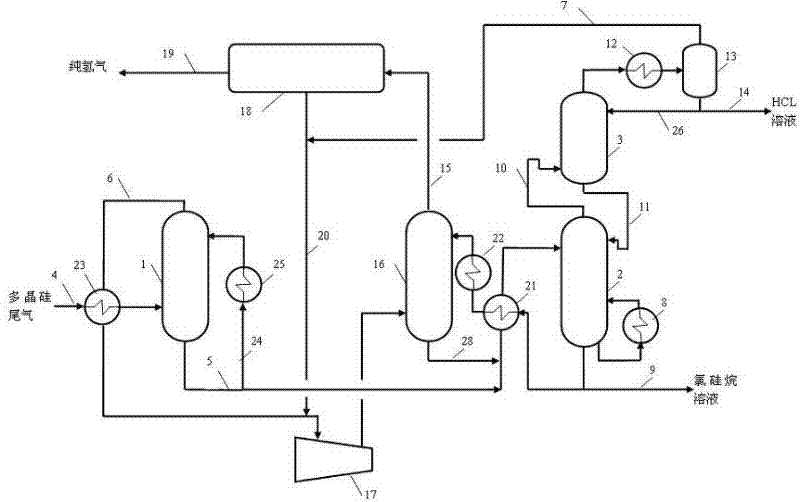

System and process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment

InactiveCN102249187ASolve environmental problemsEfficient recyclingChlorine/hydrogen-chloride purificationHydrogen separation using liquid contactHydrogenReboiler

The invention discloses a system for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment, and the system mainly comprises a tail gas circulated condensing and washing tower, a chlorosilane stripper and a HCl rectifying tower, wherein the tail gas circulated condensing and washing tower is equipped with a polysilicon tail gas inflow pipe, a first chlorosilane solution outflow pipe and a first hydrogen outflow pipe, and the first chlorosilane solution outflow pipe is connected with the chlorosilane stripper; the chlorosilane stripper is equipped with a reboiler, a second chlorosilane solution outflow pipe, a first HCl outflow pipe and a stripping backflow pipe, and the first HCl outflow pipe and the stripping backflow pipe are connected with the HCl rectifying tower; and the HCl rectifying tower is equipped with a condenser, a separator and a second HCl outflow pipe which are connected in turn, and the separator is equipped with a non-condensable gas outflow pipe. The invention also discloses a process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment. Through the system and process disclosed by the invention, the polysilicon tail gas is turned into things of value, the resources are saved, and simultaneously the energy consumption during the treatment process is reduced.

Owner:SICHUAN TECHAIRS

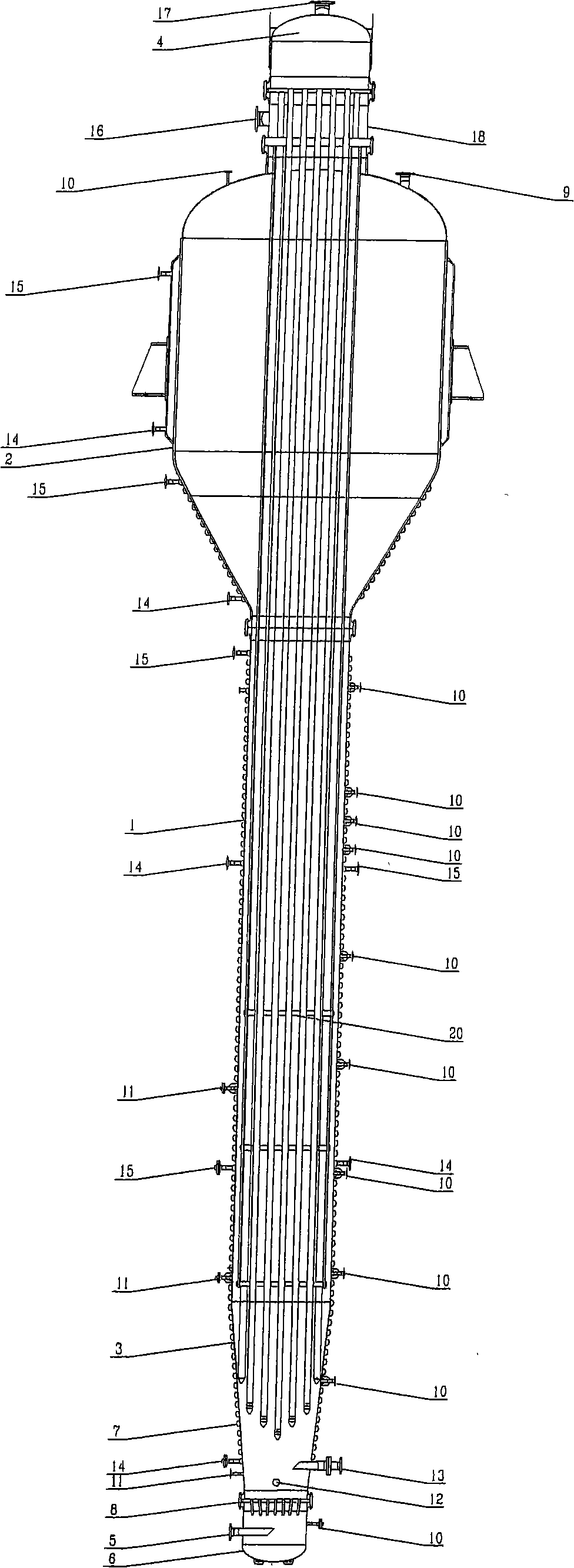

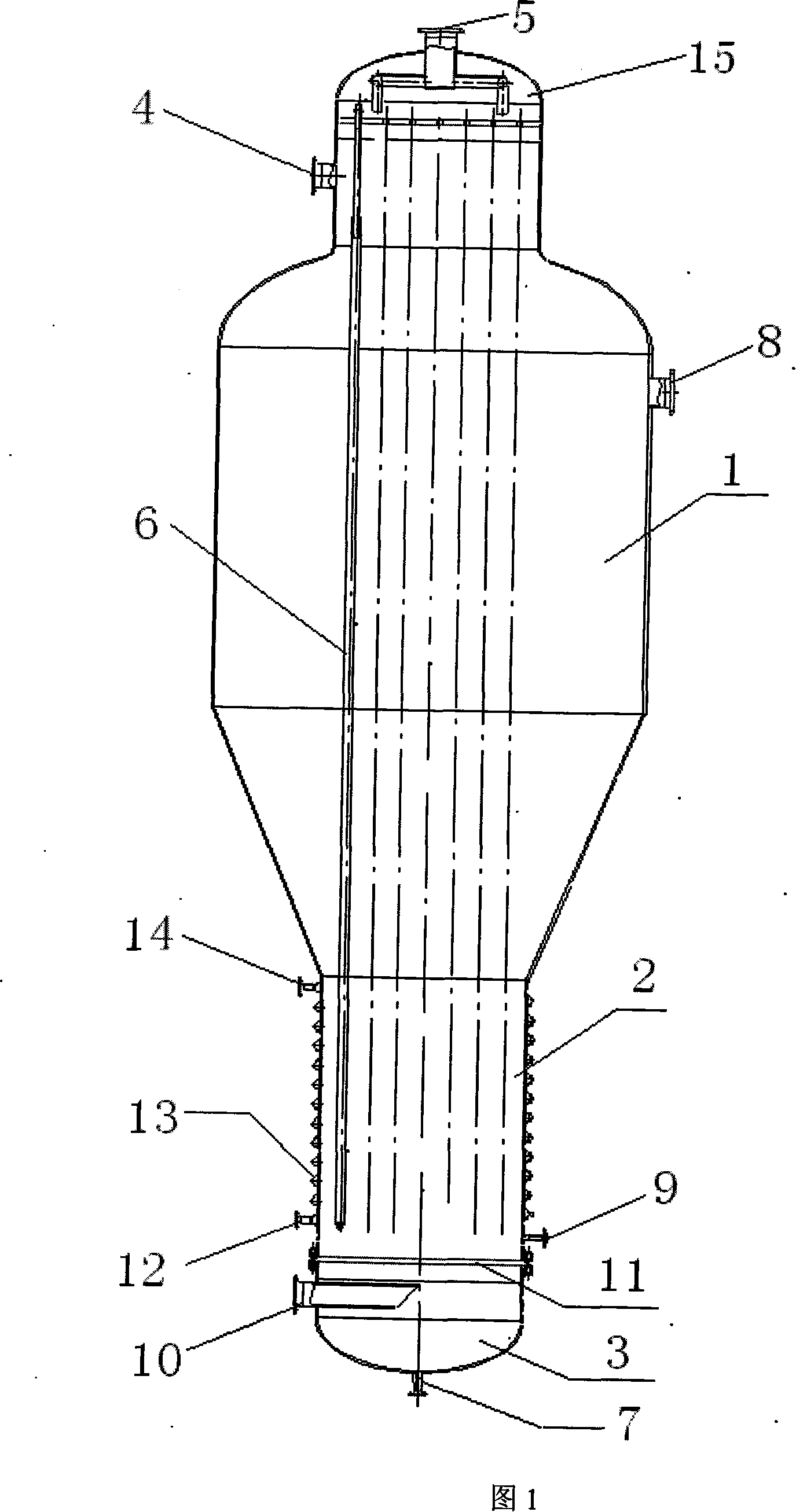

Large-scale fluidized bed reactor used for trichlorosilane production

InactiveCN101125654ASimple structureIncrease the diameterChemical/physical processesHalogenated silanesFluidized bedReaction temperature

The invention discloses a large trichlorosilane fluidized bed reactor, comprising a lower reaction section and an upper extension section; the lower part of the reaction section is provided with a silicon powder inlet, and the lower part of a reactor is provided with an overhaul cap which is provided with a hydrogen chloride inlet and a discharge mouth; the extension section has a synthesized gas outlet, and a hydrogen chloride gas distributor is arranged between the overhaul cap and the reaction section; a heat transfer oil finger-shaped tube is arranged in the reaction section and the extension section and extends from the extension section till the bottom of the reaction section; the top of the extension section is provided with a finger-shaped overhaul flange with a finger-shaped tubular heat transfer oil inlet, and the extension section is provided with a finger-shaped tubular heat transfer oil outlet; the outside of the reaction section is provided with a reactor half-pipe jacket, and both ends of the half-pipe jacket of the reactor are provided with a coiled-pipe heat transfer oil inlet and a coiled-pipe heat transfer oil outlet. The heat transfer oil is adopted to heat the reactor during the temperature rising period and transfer the reaction heat during the reaction, and the reaction temperature can be controlled by regulating the quantity of the heat transfer oil, thus acquiring the stable product yielding.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL +1

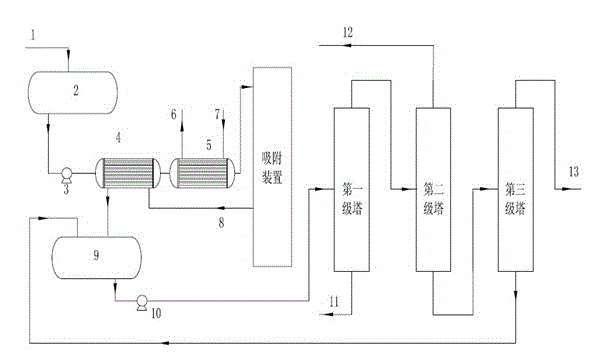

Production process of high-purity refined trichlorosilane

The invention relates to the field of rectification and purification; at present, a conventional multi-stage rectification technology is adopted in existing polycrystalline silicon production to purify trichlorosilane, rectification stages are multiple, reflux ratio is large, energy consumption is large and device investment is high; in order to overcome the problems, a technical scheme in the invention adopts a novel process of combining resin adsorption with multi-stage rectification. Coarse trichlorosilane is pre-cooled and cooled, and pumped into an adsorbing device with special divinylbenzene resin by a pump to remove boron and phosphor impurities; and then, rectification is carried out on the adsorbed trichlorosilane liquor in a three-level rectification tower to obtain the high-purity trichlorosilane. The production process disclosed by the invention not only achieves the purpose in the invention, but also has high trichlorosilane purity, lower rectification separator impurity content and can recycle the trichlorosilane for use in disproportionated reaction, so that energy consumption is further lowered, and material utilization rate is improved.

Owner:XINTE ENERGY

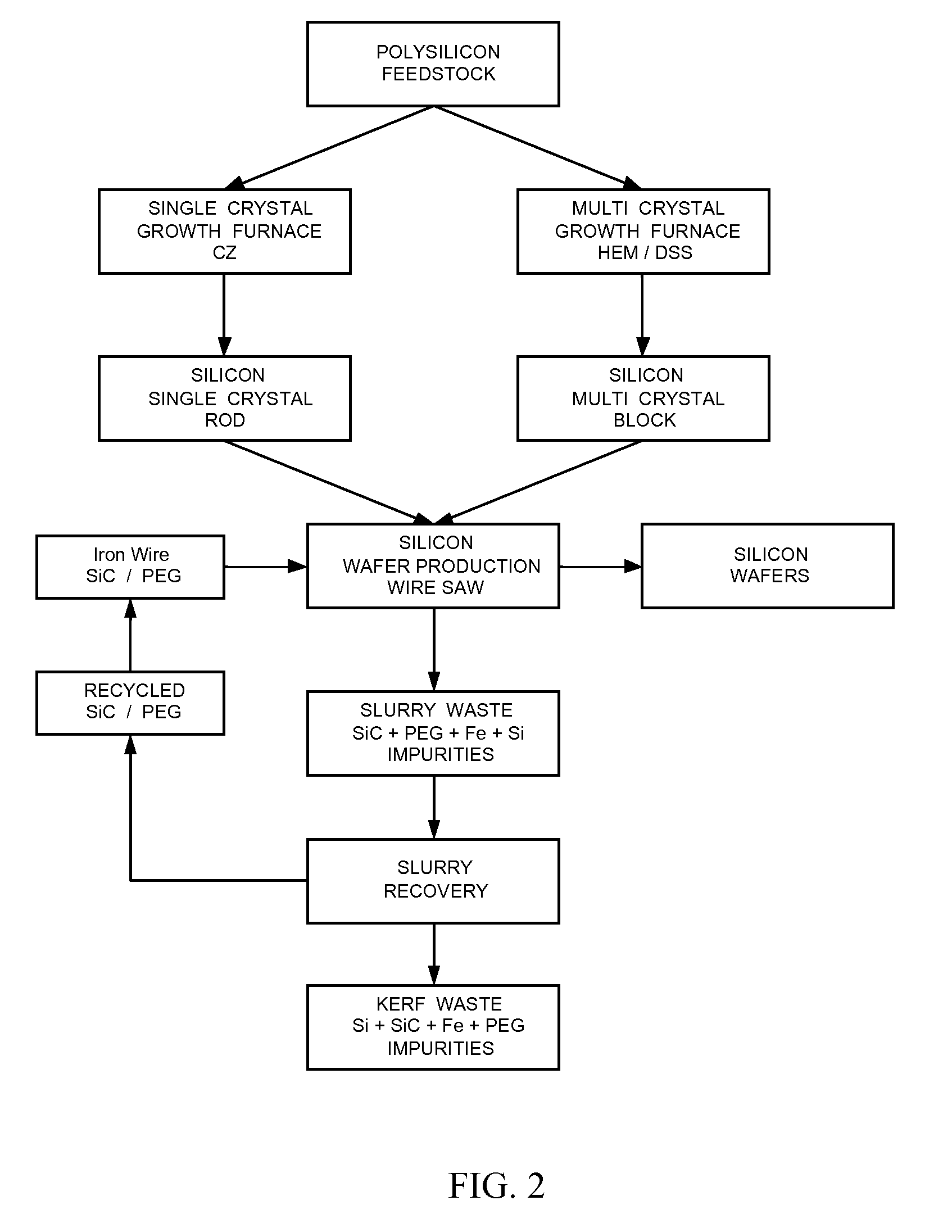

Method to convert waste silicon to high purity silicon

A process for the recovery of silicon includes providing silicon-containing solids recovered from a silicon manufacturing process, said recovered silicon-containing solids being substantially free of semiconductor dopants; converting the recovered silicon-containing solids into gaseous silicon forms; subjecting to purification by minimal distillation; collecting the gaseous silicon forms as a condensed liquid of silicon-containing compounds; and utilizing the silicon-containing compounds for silicon deposition.

Owner:HARIHARAN ALLEPPEY V +1

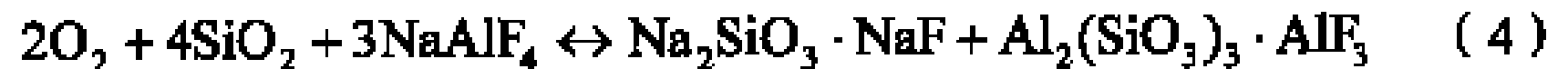

Method for preparing silicon tetrafluoride

ActiveCN101544374AImprove conversion rateTo avoidHalogenated silanesState of artSilicon tetrafluoride

The present invention discloses a method for preparing silicon tetrafluoride, including a) mixing a raw material powder containing NaAlF4 and Si source powder; b) heating the mixture of the step a) with sulfuric acid to 240 DEG C to 350 DEG C to react to obtain silicon tetrafluoride. The silicon tetrafluoride is prepared by a reaction of the raw material containing NaAlF4 powder and Si source and sulfuric acid under a heating condition, comparing with the present technology, it is not only capable of avoiding to use a great amount of fluorite to prepare the silicon tetrafluoride, which reduces cost, it is also capable of using the accessory substances NaAlF4 generated during a process for producing the silicone hydride effectively, and preparing the silicon tetrafluoride with a high percent conversion.

Owner:YINGLI ENERGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com