Trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and operating method

A trichlorosilane three-tower, differential pressure coupling technology, applied in the field of rectification, can solve the problems of many theoretical plates, large reflux ratio, and high energy consumption of polysilicon, so as to reduce production costs and energy consumption, save heating and energy-saving losses, The effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

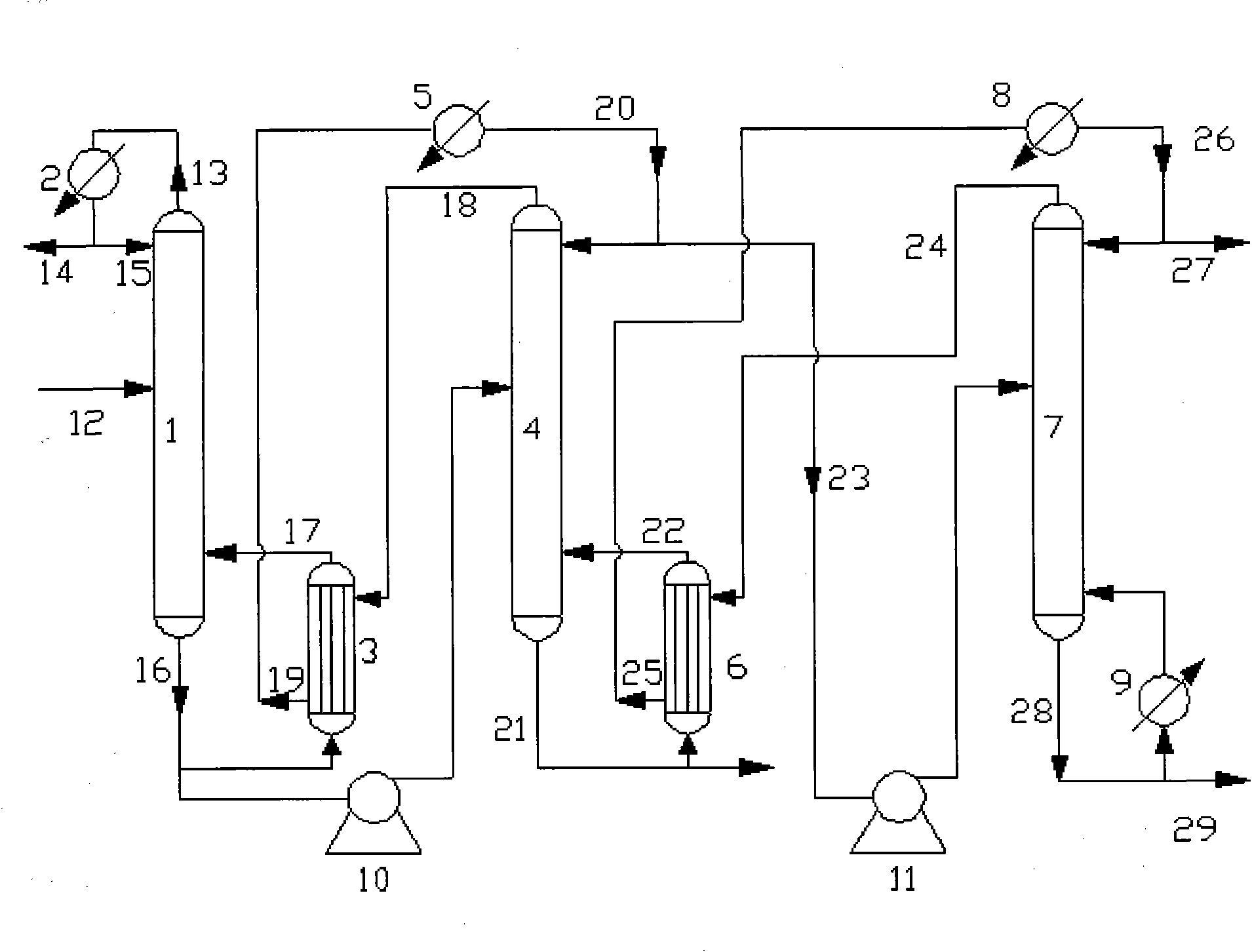

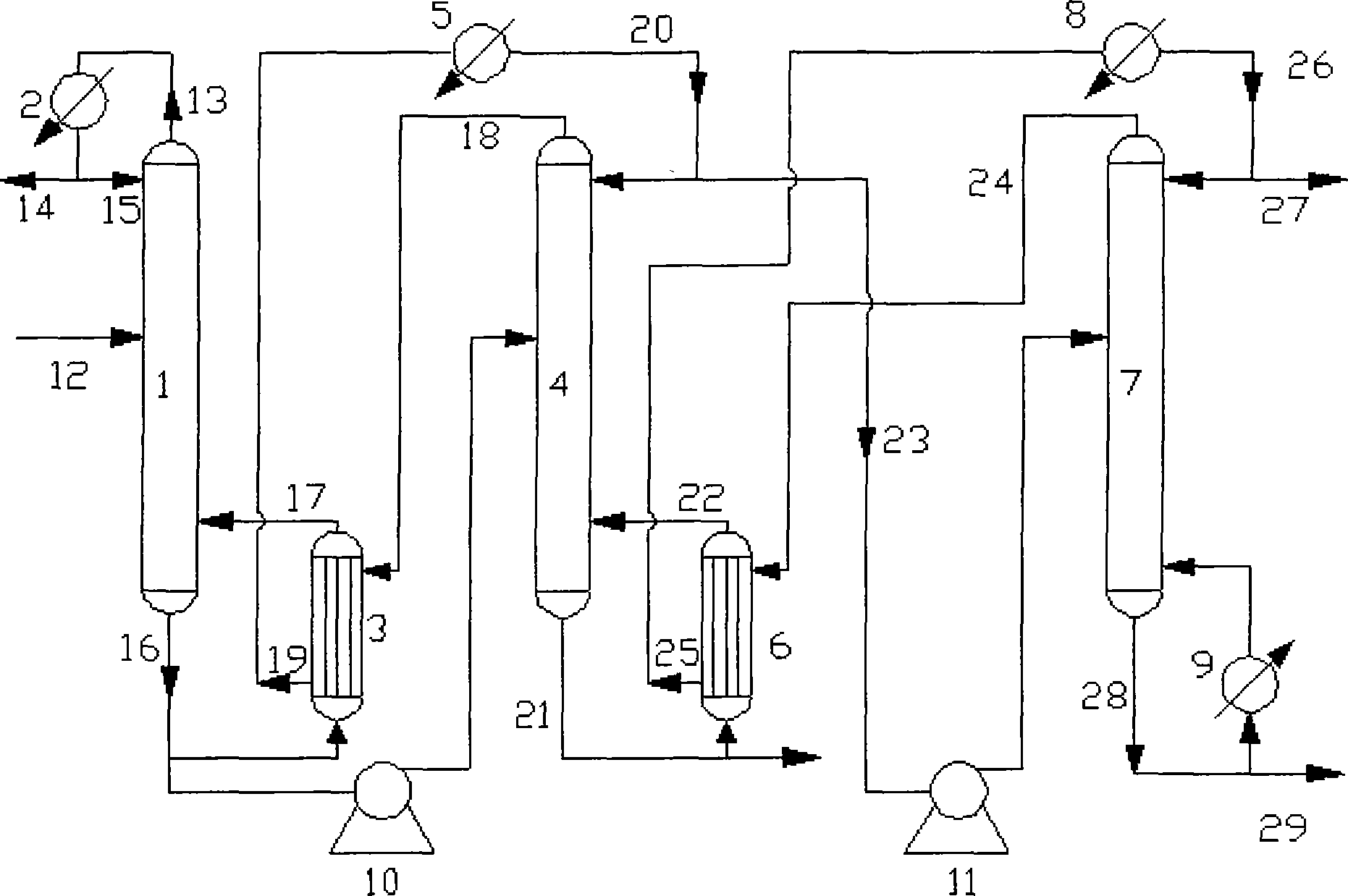

[0031] The operating method of the A process that adopts the primary tower (1) feed is as follows:

[0032] Such as figure 1As shown, after the trichlorosilane raw material (12) is separated through the primary tower (1), the light component A (13) is divided into the reflux material A (15 ) and the extracted material A (14), the delight liquid A (16) at the bottom of the tower is divided into two parts, and a part enters the tower kettle condensation reboiler (3) to form a high boiling liquid A (17) after heating and returns to the first-stage tower ( 1), the other part enters the secondary tower (4) and forms high boiling liquid A (21) in the tower still after rectification, forms trichlorosilane gas phase A (18) at the top of the tower and enters the heating of the condensation reboiler (3) The medium inlet provides the required heat for the condensing reboiler to form the feed liquid A (19) into the auxiliary condenser (5) to become the condensed feed liquid A (20), and p...

example 2

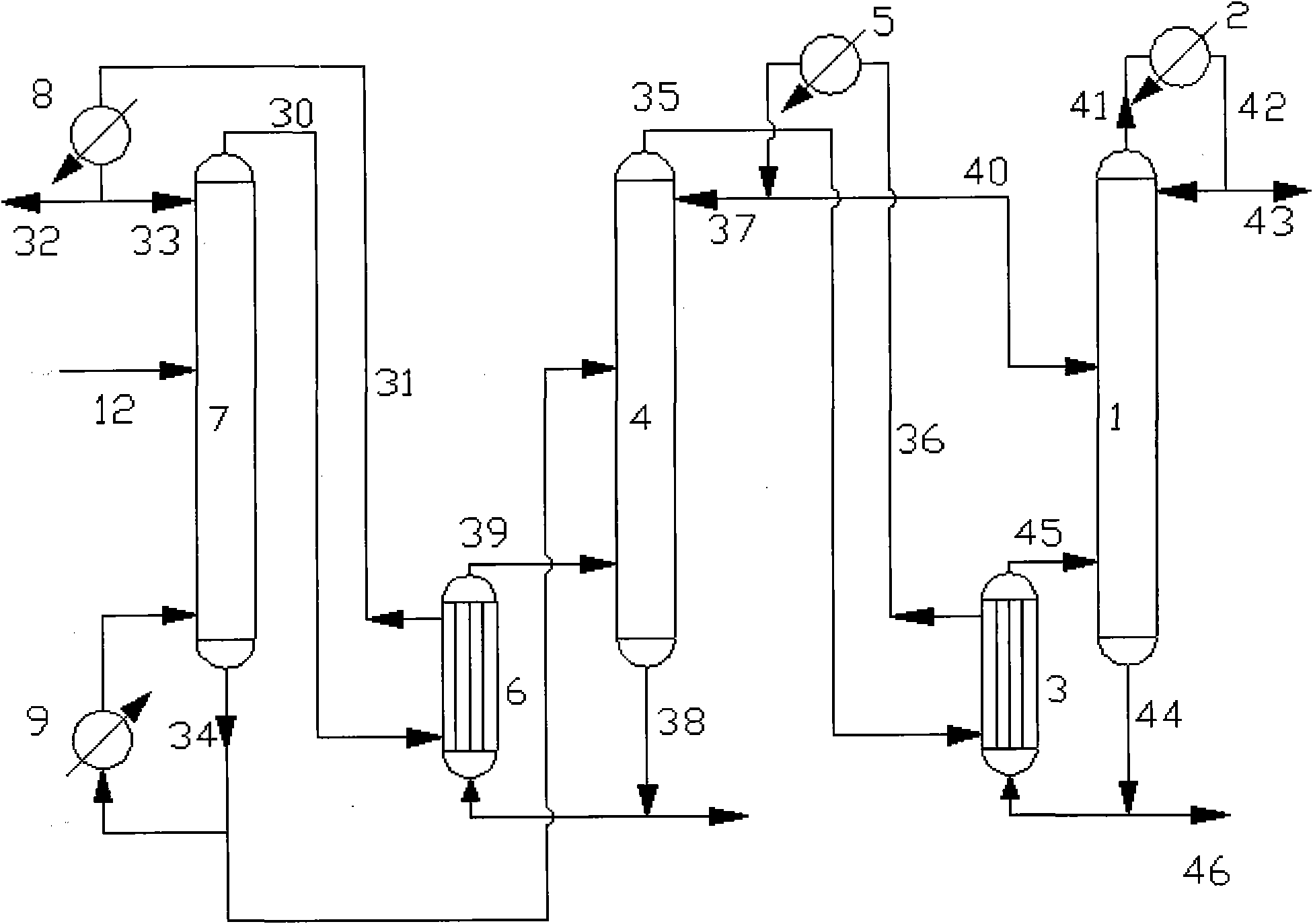

[0043] The operating method of the B process that adopts three-stage tower (7) feeding is as follows:

[0044] Such as figure 2 Shown, the operating method of process flow B is: after trichlorosilane raw material (12) is separated through three-stage tower (7), tower top light component B (30) enters the heating medium inlet of condensing reboiler (6), After providing the required heat for the condensing reboiler, it becomes the condensed feed liquid B (31), and then a part (33) of the auxiliary condenser (8) is returned to the top of the third-stage tower (7) with a certain reflux feed ratio, and a part is collected Out of (32), part of the light liquid B (34) removed from the tower kettle is returned to the third-stage tower (7) after being heated by the tower kettle reboiler (9), and the other part uses the pressure difference between the two towers to directly enter the second-stage tower as a feed. The tower (4) is separated, and the light component B (35) at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com