Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1031results about "Chlorine/hydrogen-chloride purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

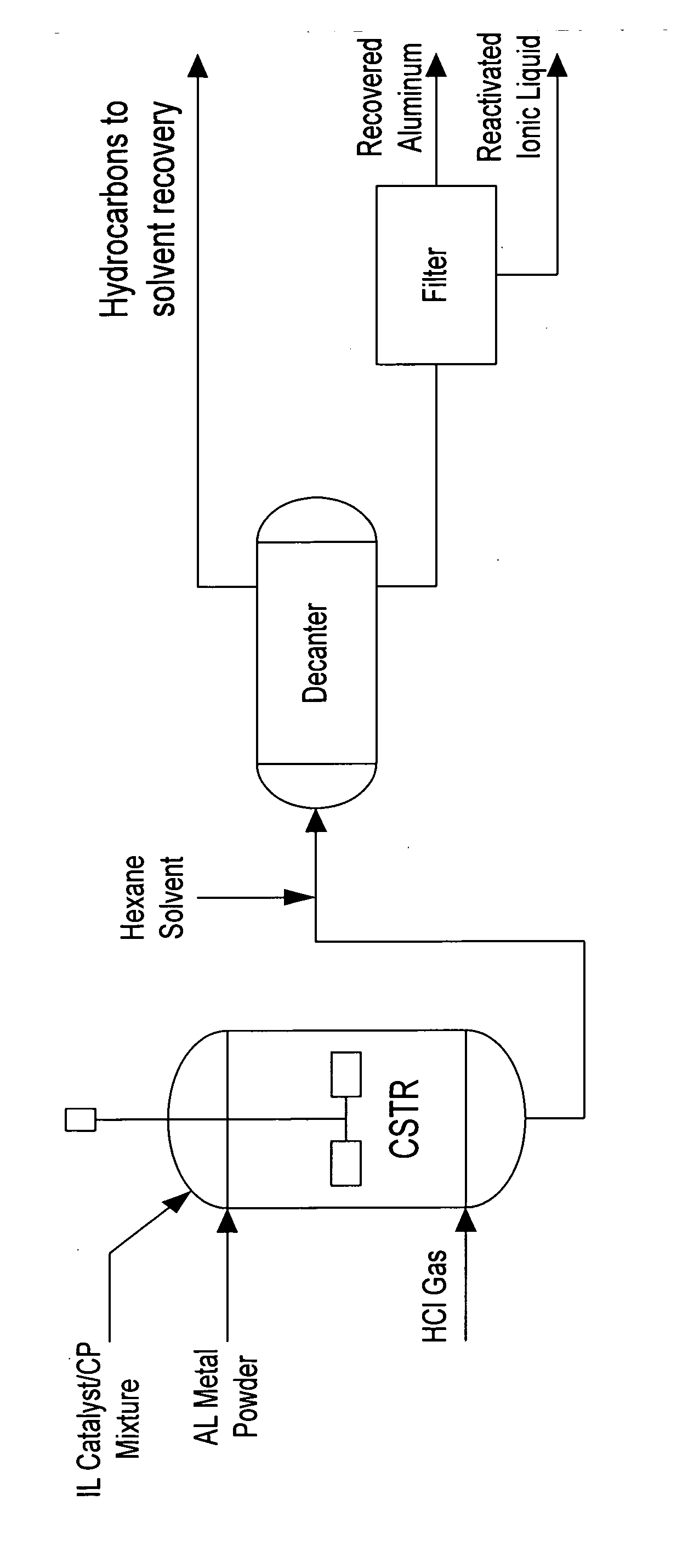

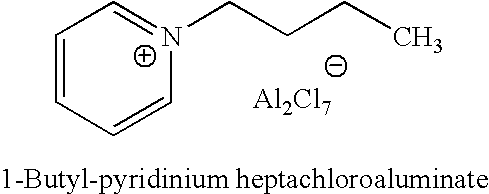

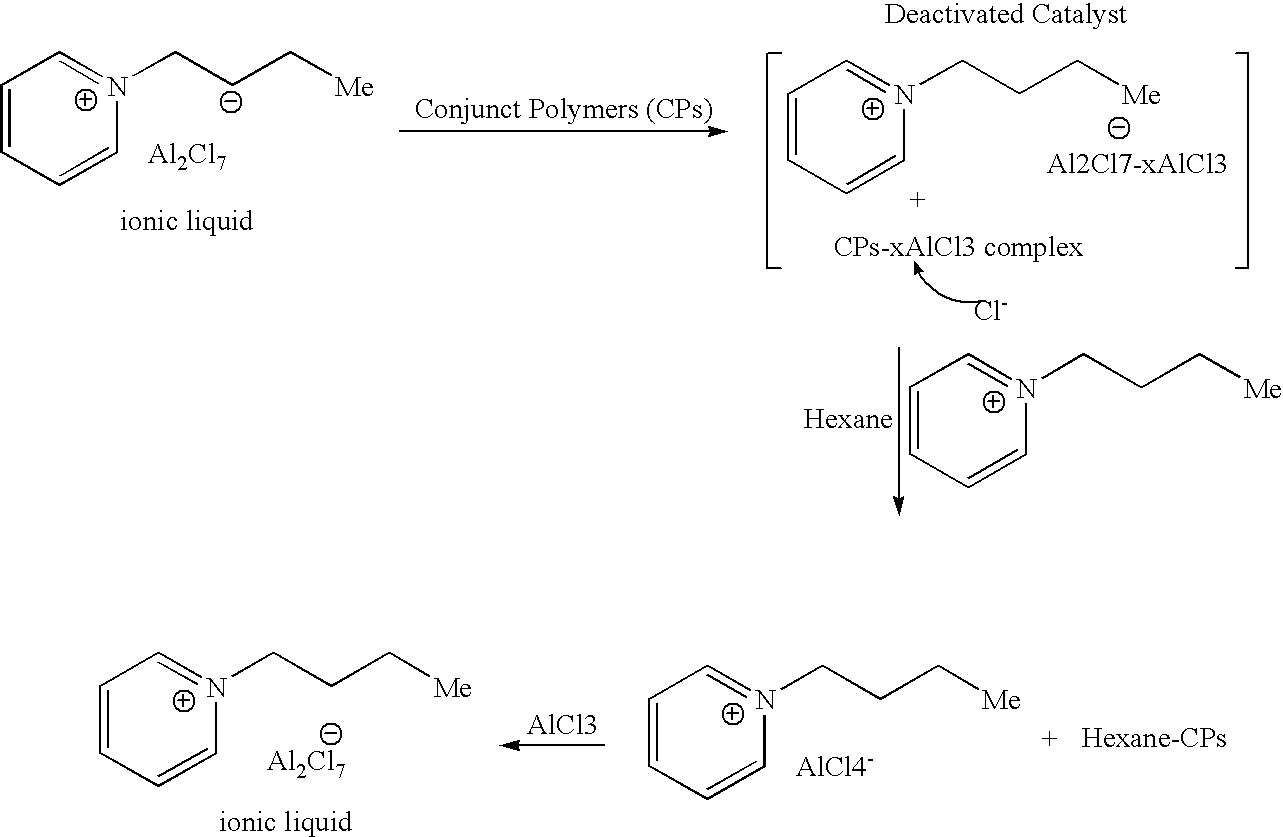

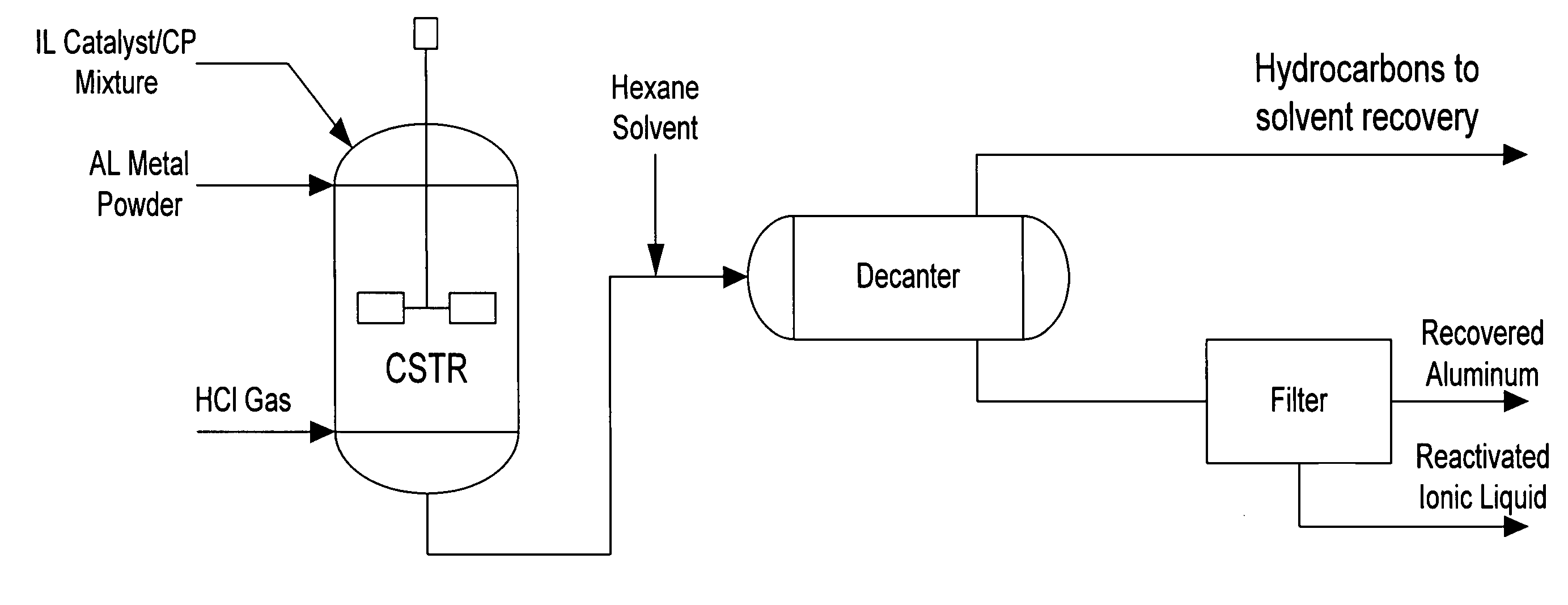

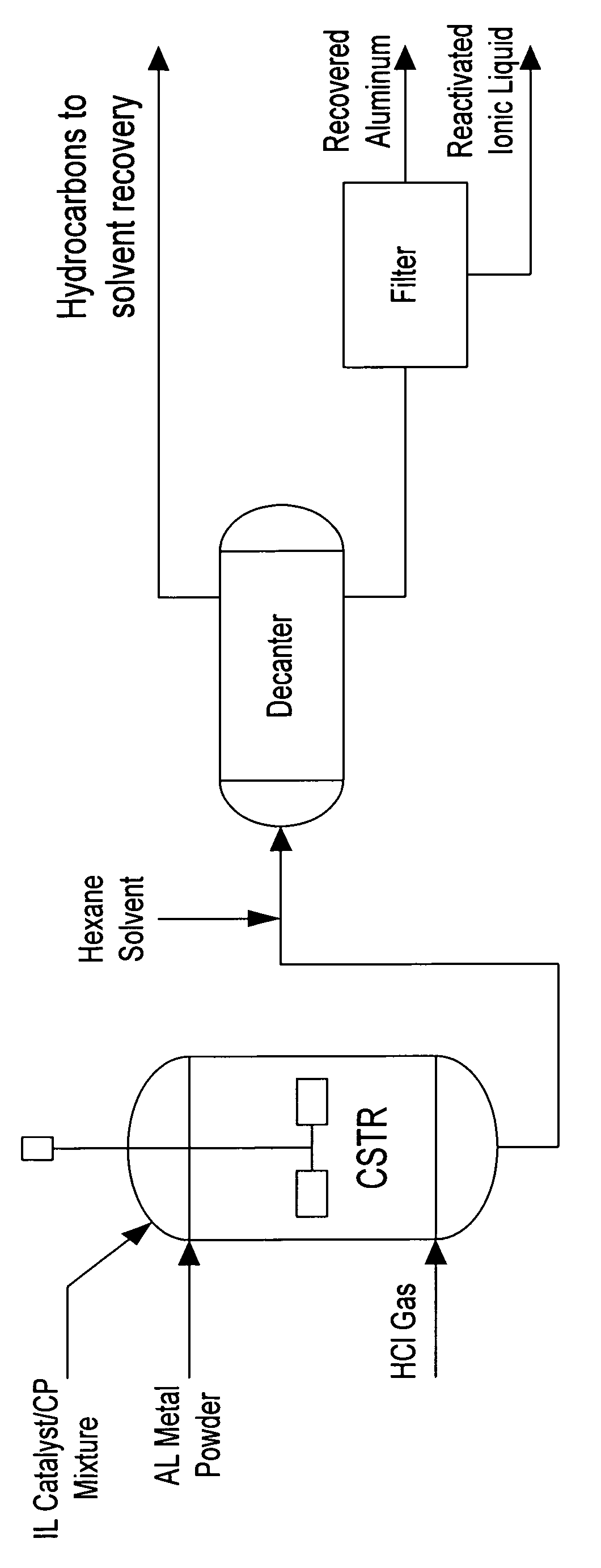

Regeneration of acidic catalysts

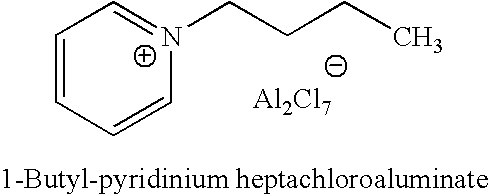

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

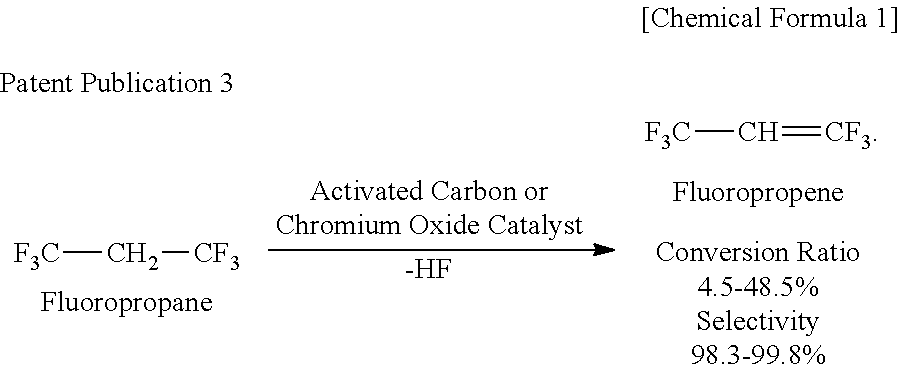

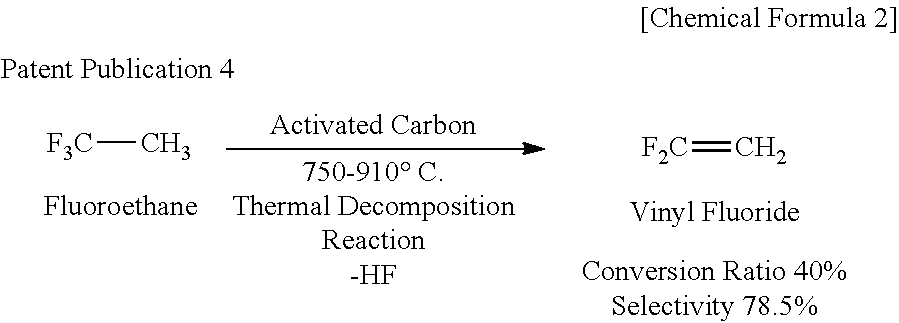

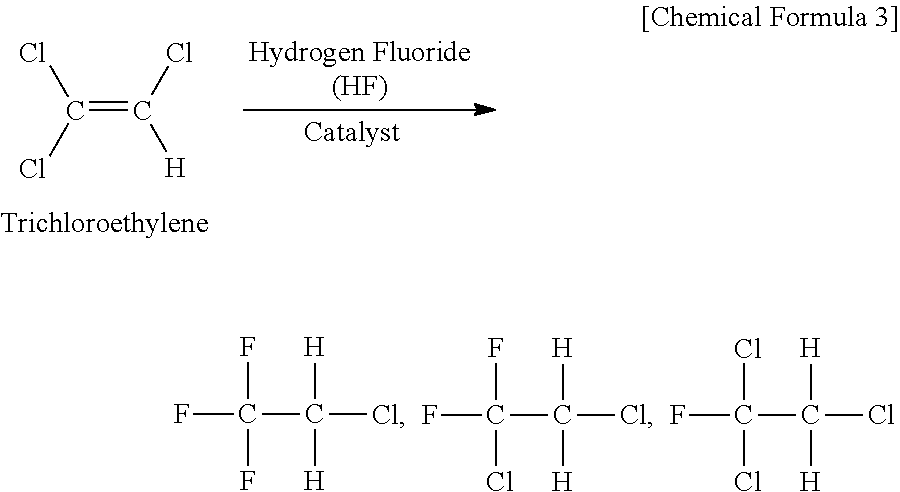

Process for Producing 1,3,3,3-Tetrafluoropropene

InactiveUS20110172472A1High selectivityHigh yieldChlorine/hydrogen-chloride purificationPreparation by hydrogen halide split-offHydrogen fluoride1,3,3,3-Tetrafluoropropene

According to the first characteristic of the present invention, there is provided a production process for 1,3,3,3-tetrafluoropropene including: the first step of reacting 1,1,1,3,3-pentachloropropane with hydrogen fluoride thereby obtaining 1-chloro-3,3,3-trifluoropropene; and the second step of reacting 1-chloro-3,3,3-trifluoropropene obtained in the first step with hydrogen fluoride in a gaseous phase in the presence of a fluorination catalyst. According to the second characteristic of the present invention, there is provided a dehydration process including bringing 1,3,3,3-tetrafluoropropene containing at least water into contact with zeolite.

Owner:CENT GLASS CO LTD

Regeneration of acidic catalysts

ActiveUS7732363B2High activityChlorine/hydrogen-chloride purificationHydrocarbon purification/separationAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

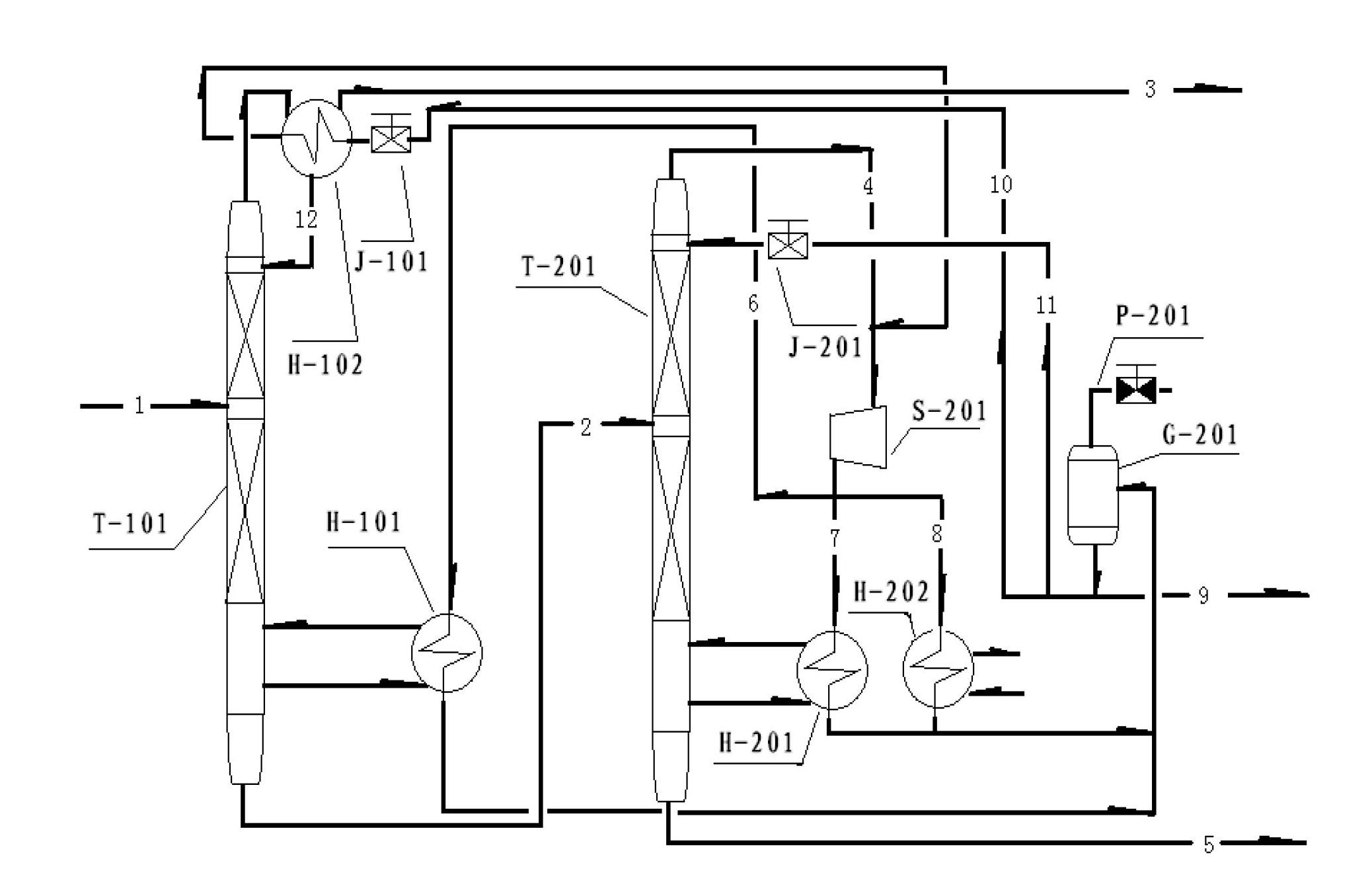

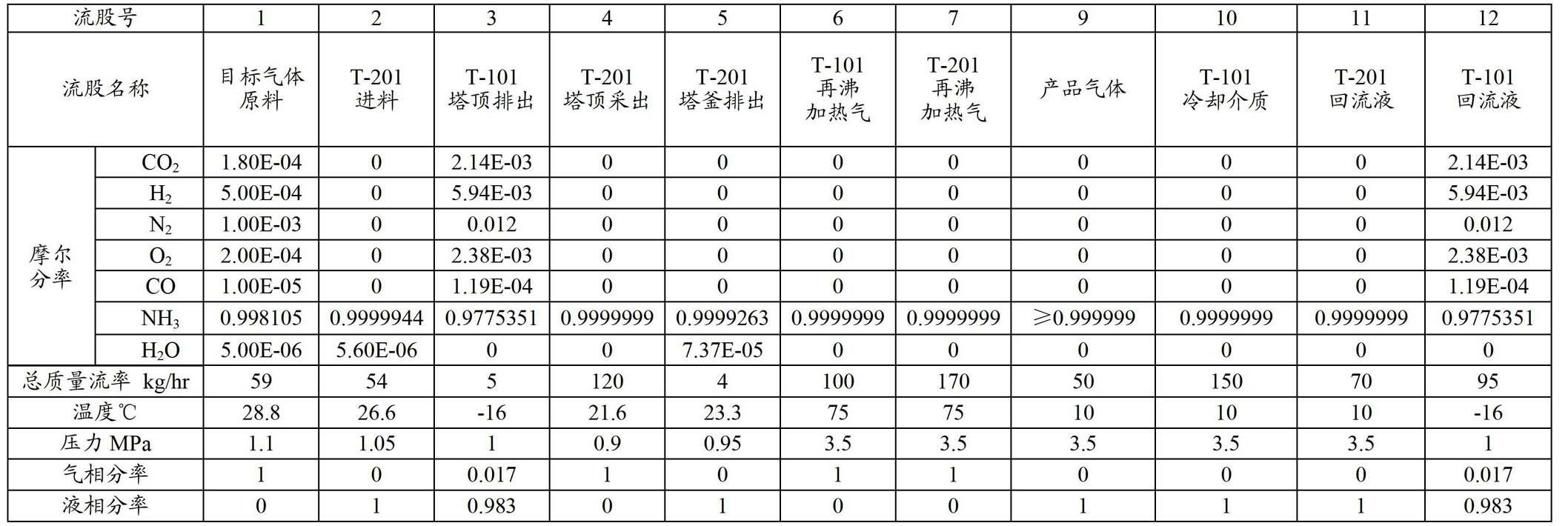

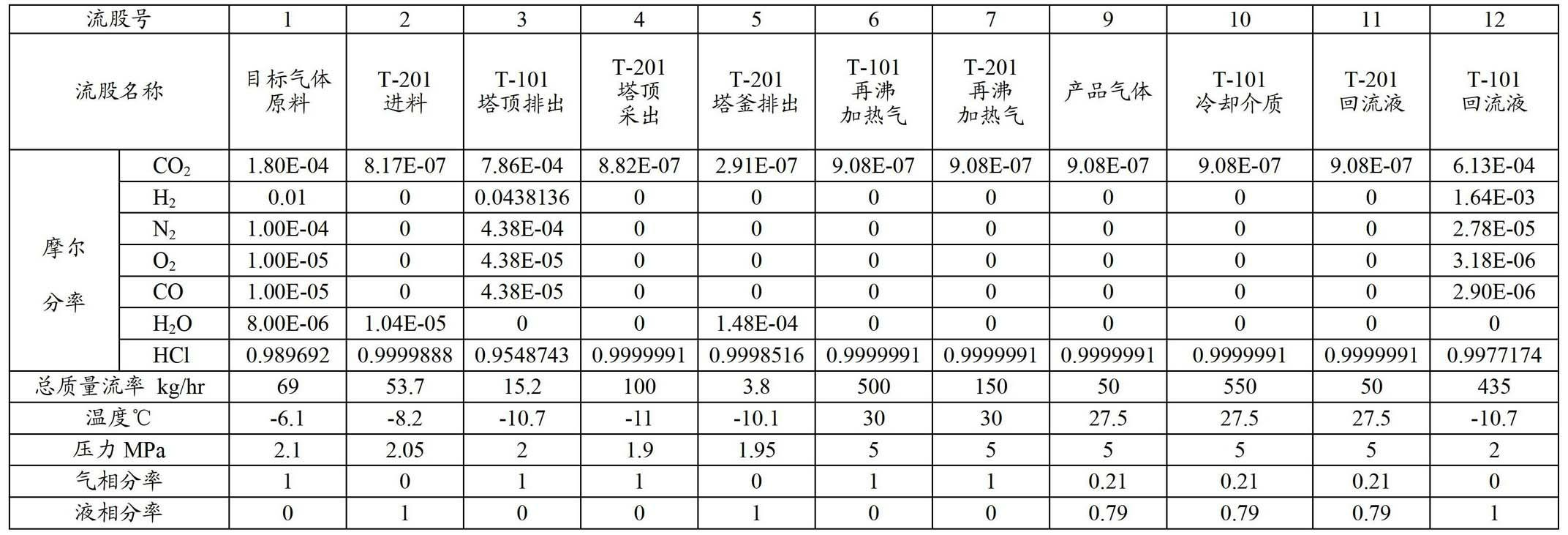

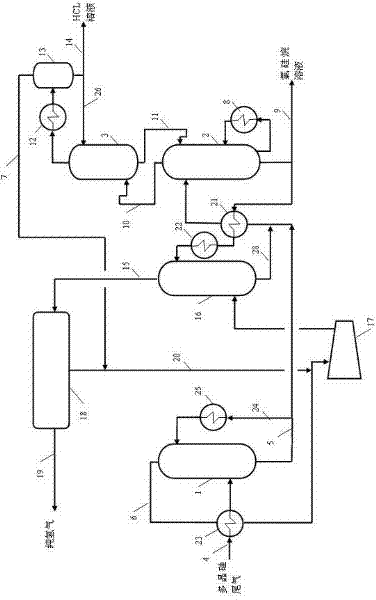

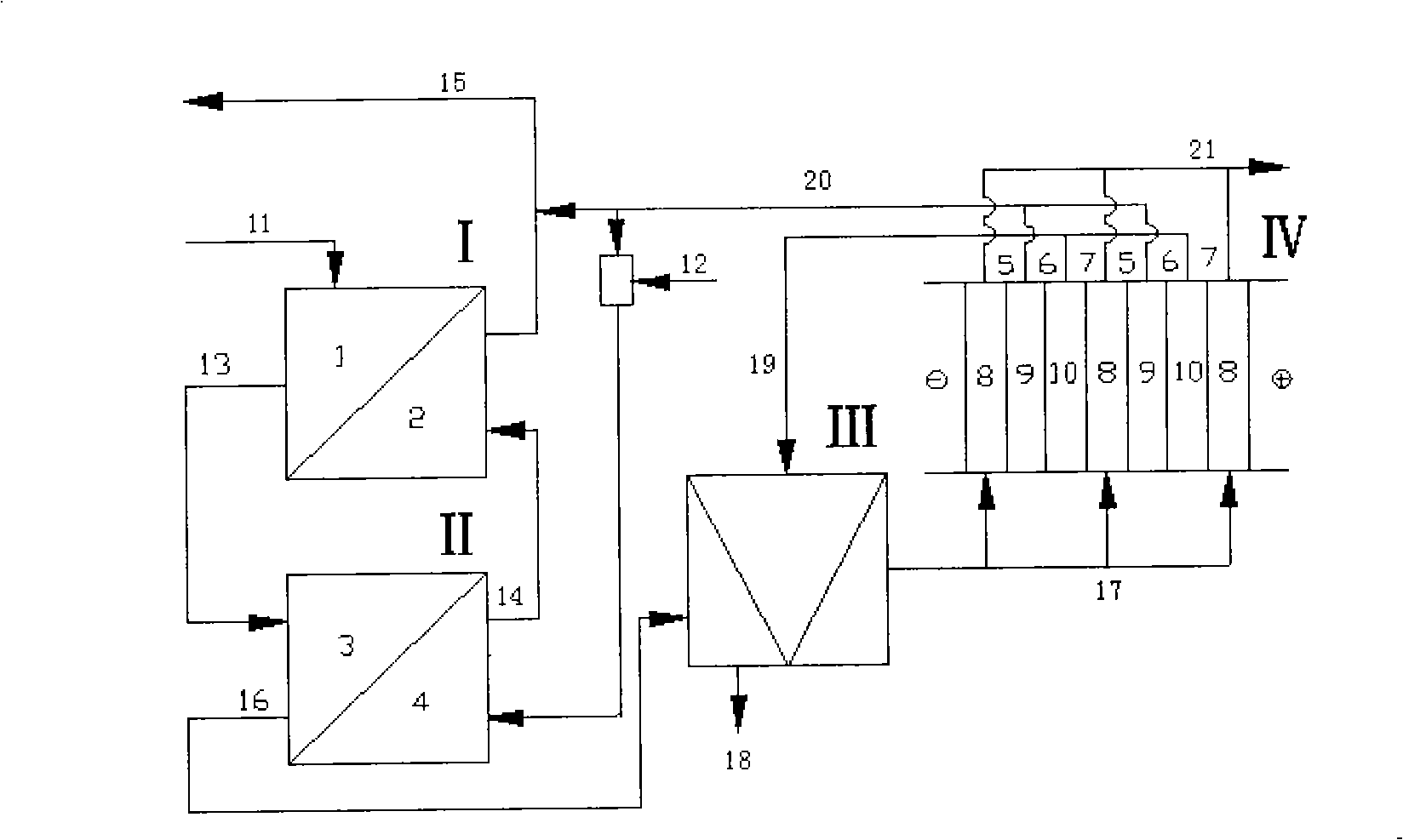

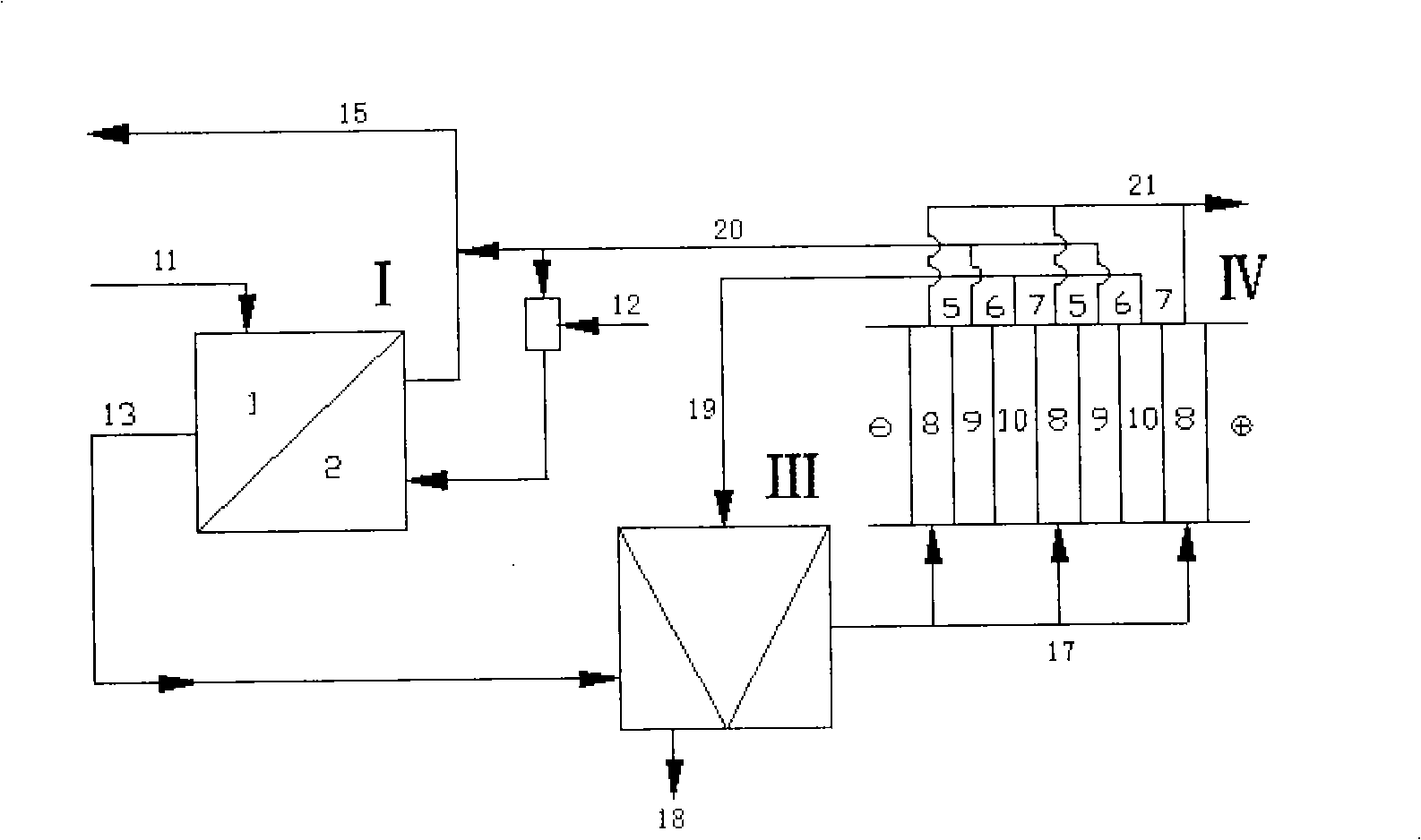

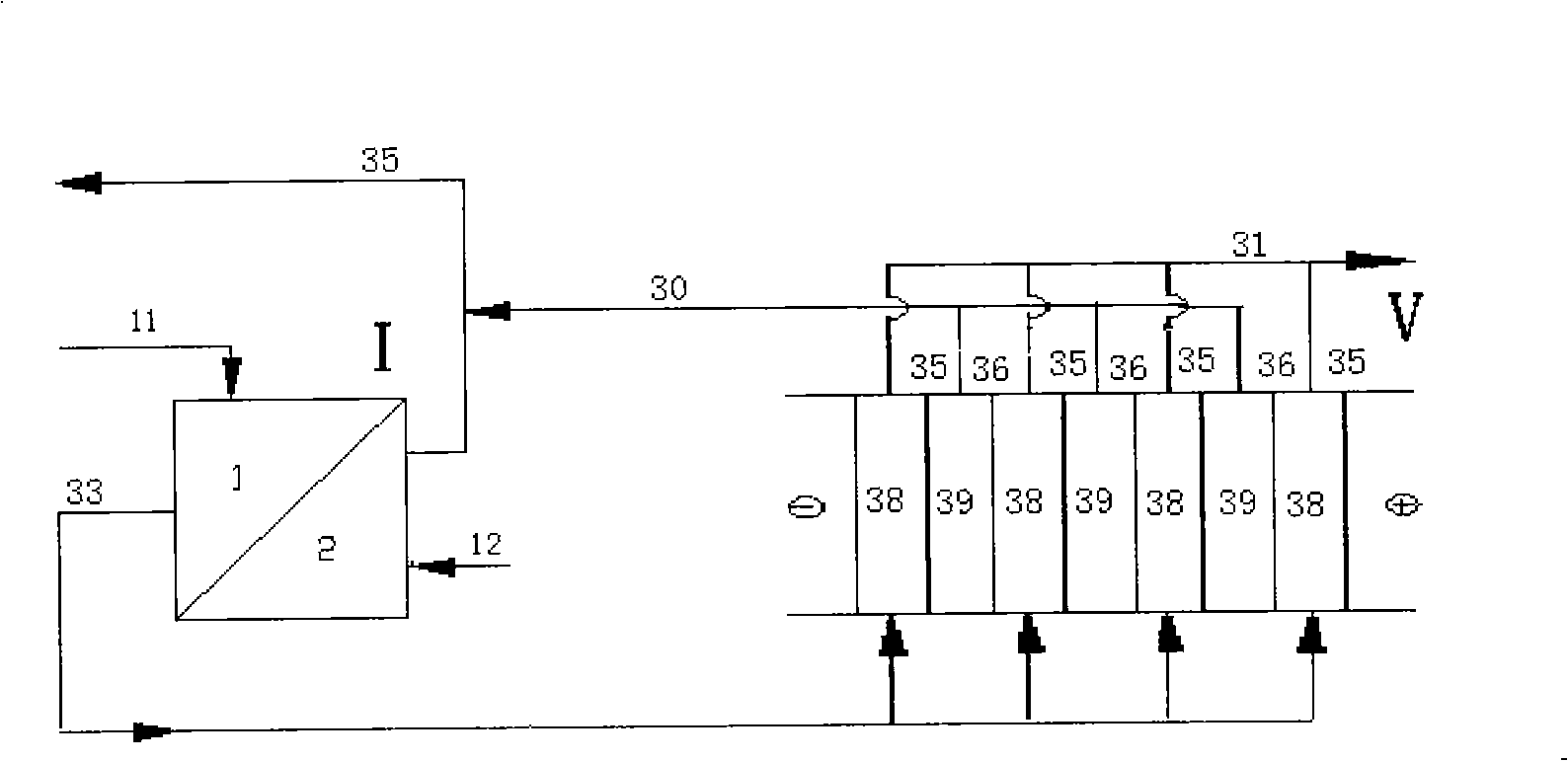

Method and system for preparing high purity gas by rectification method

ActiveCN102661654AImprove utilization efficiencySave energySolidificationChlorine/hydrogen-chloride purificationReboilerLiquid storage tank

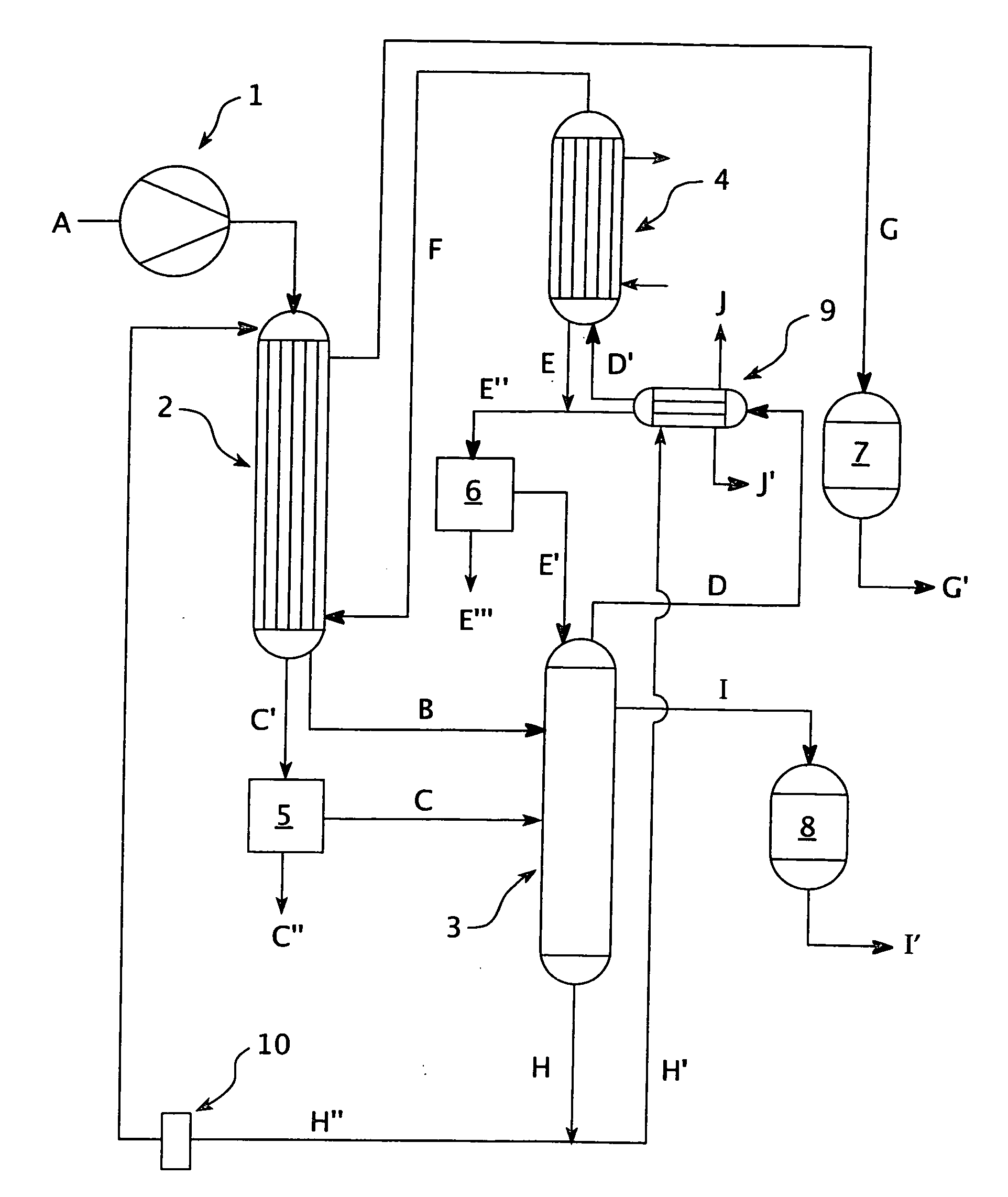

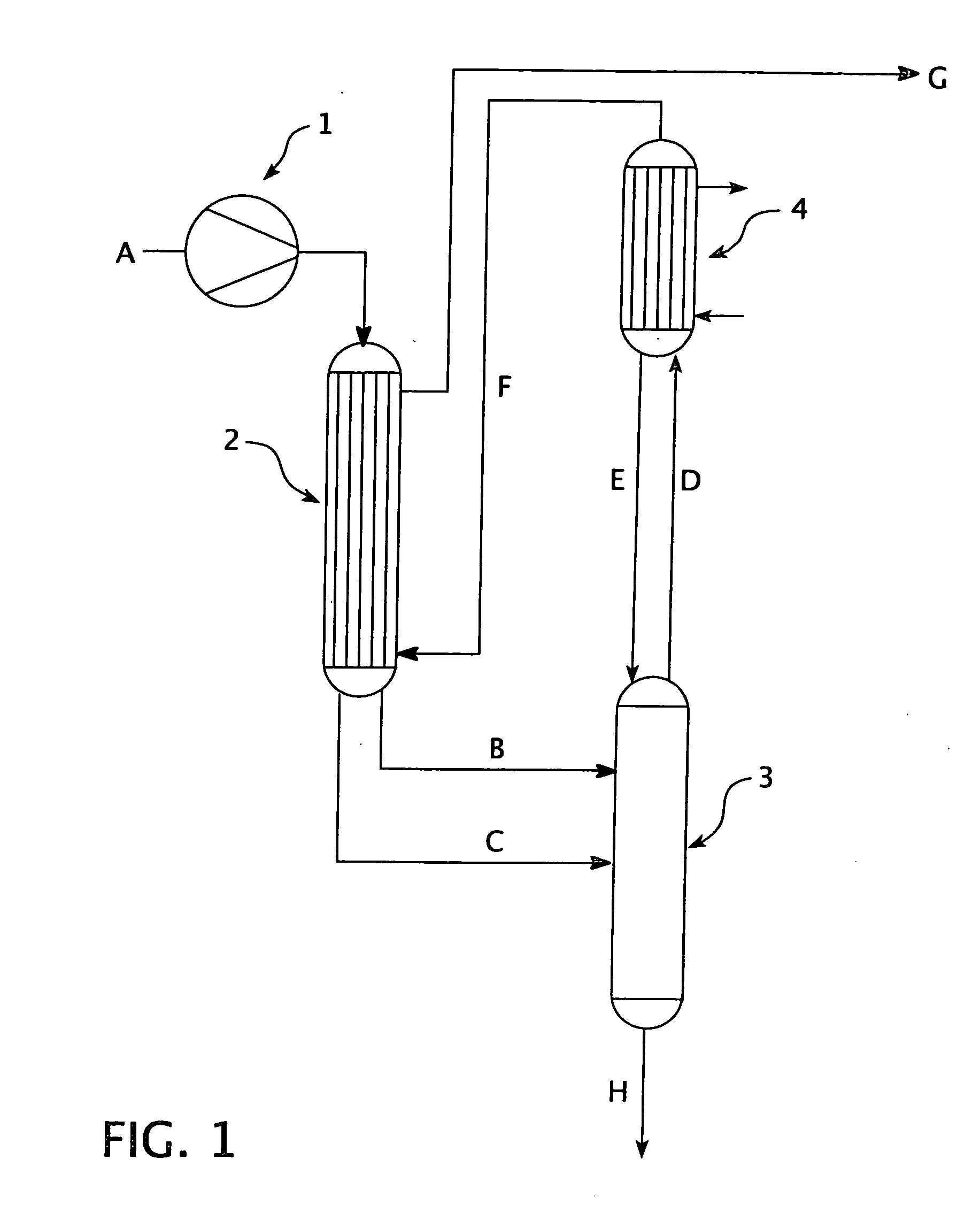

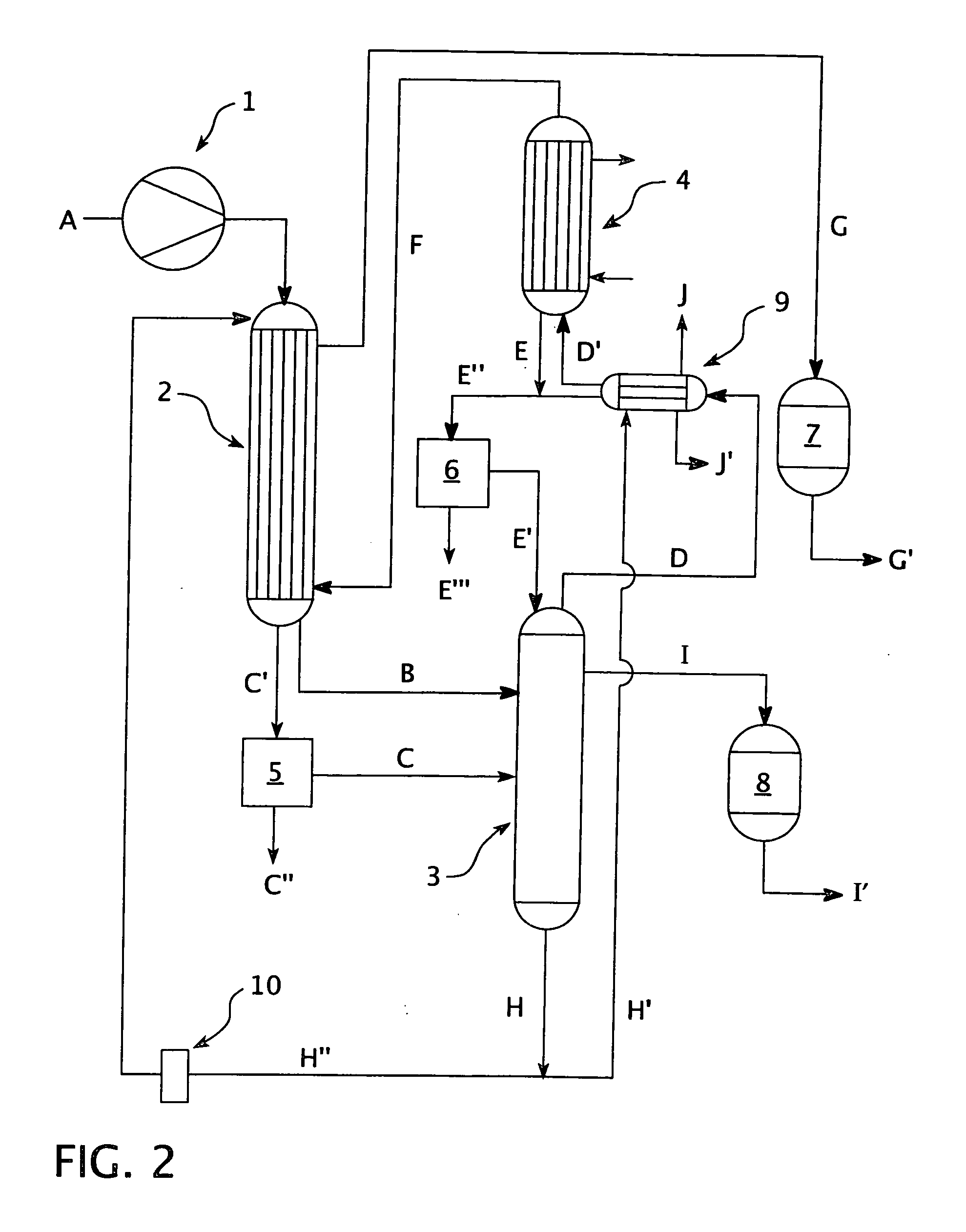

The invention relates to a method and a system for preparing high purity gas by a rectification method. According to the method disclosed by the invention, a target gas raw material is firstly processed by a light component removal tower to remove light component impurities and then is processed by a heavy component removal tower to remove heavy component impurities; obtained purified gas is compressed into compressed gas; the compressed gas is at least divided into two parts which are respectively used as heat sources of a tower kettle reboiler of the light component removal tower and a tower kettle reboiler of the heavy component removal tower; the two parts of compressed gas are condensated into liquid to be converged and stored; the stored liquid is divided into three parts; two parts of the stored liquid are respectively used as a cooling medium of a tower top condenser of the light component removal tower and reflux of the heavy component removal tower after being respectively subjected to throttling expansion; and the third part of the stored liquid is recovered as a product. The system disclosed by the invention comprises the light component removal tower, the tower top condenser of the light component removal tower, the heavy component removal tower, a compressor, the tower kettle reboiler of the light component removal tower, the tower kettle reboiler of the heavy component removal tower, a liquid storage tank and a connecting pipeline. The method and the system which are disclosed by the invention have the advantages that equipment is simple; energy is saved; the method and the system are flexible to operate and have wide application; the system is easy to maintain; and the method and the system have few requirements on public works.

Owner:北京华宇同方化工科技开发有限公司

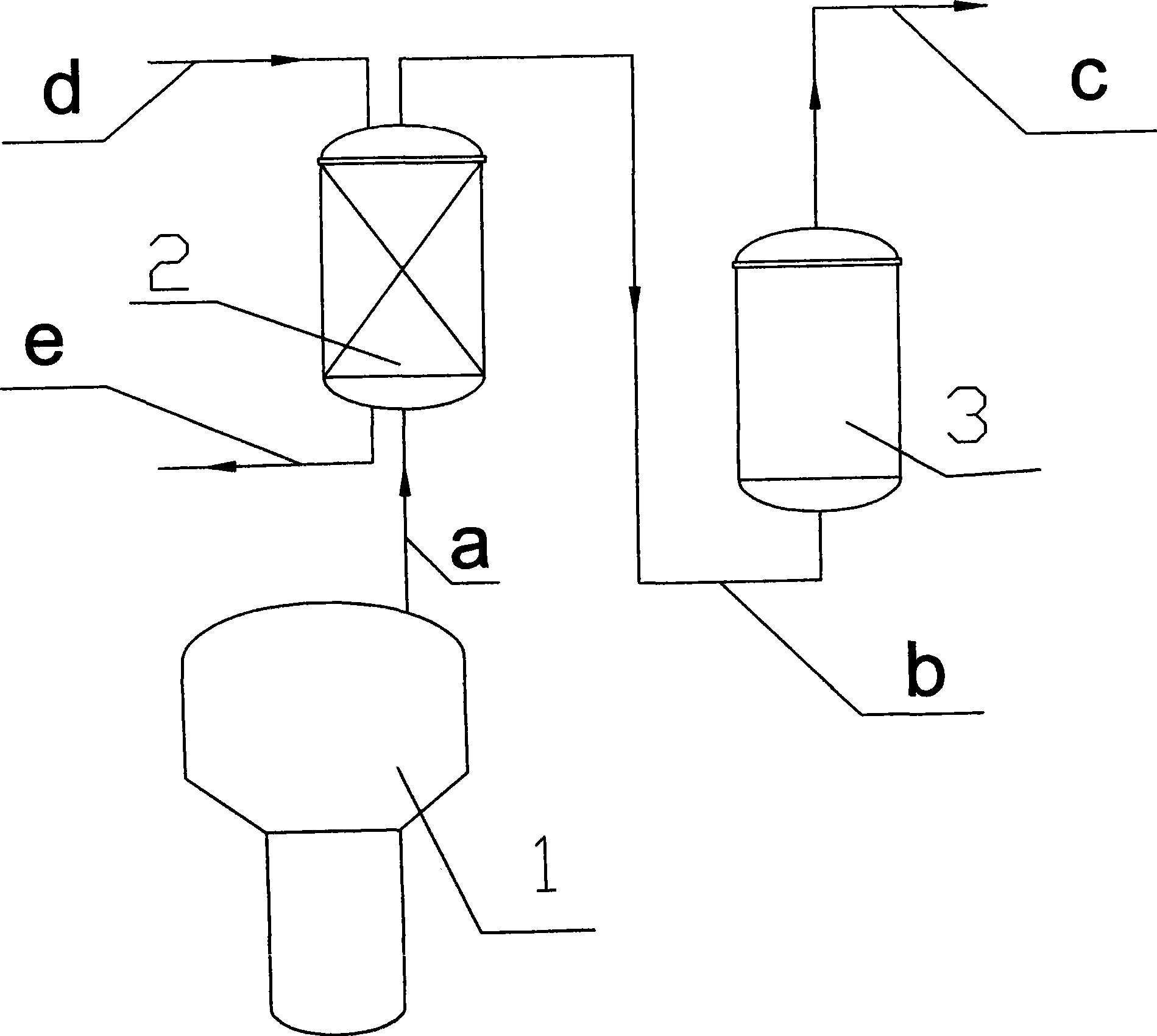

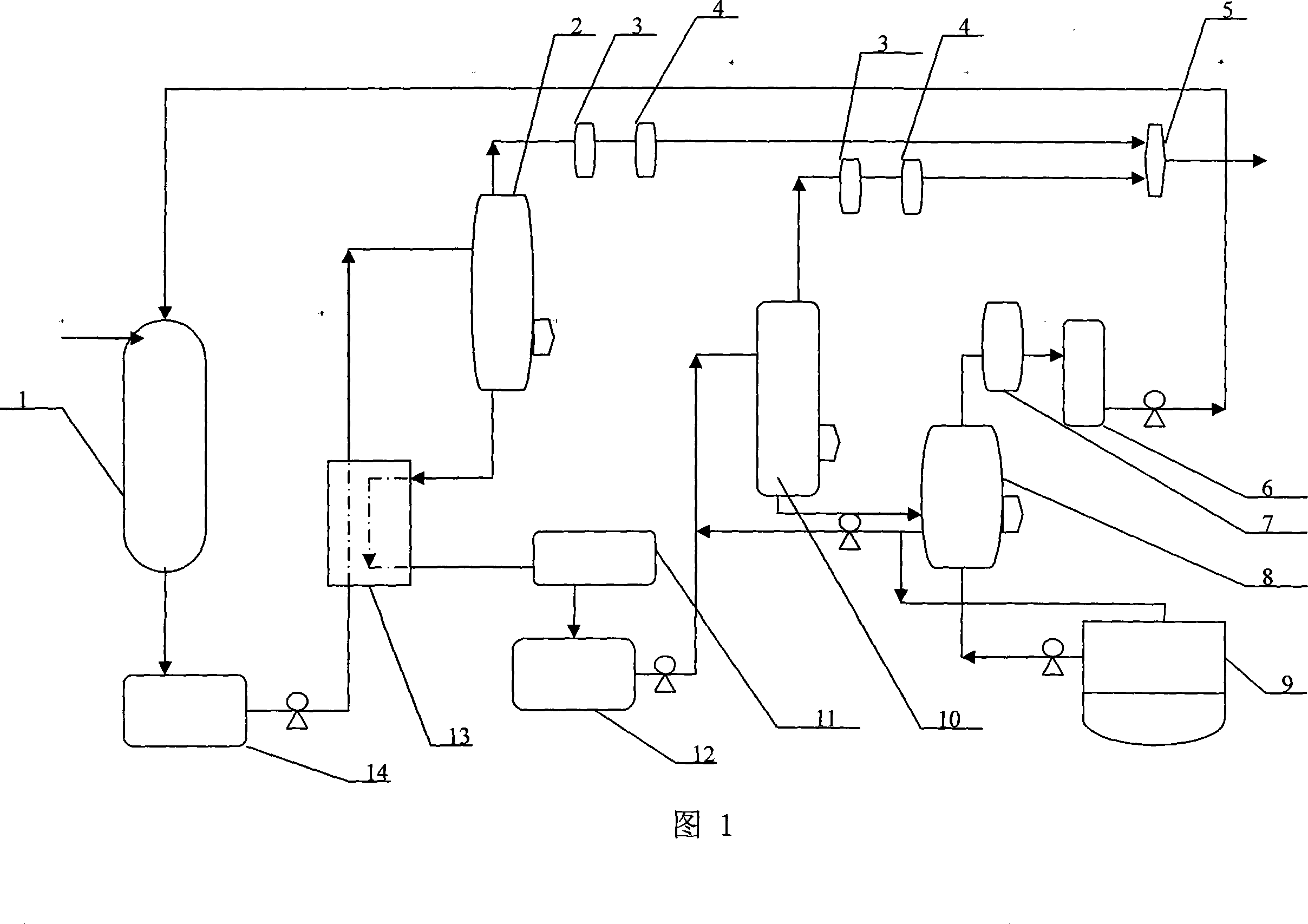

Technique for reducing impurity content in gas phase hydrogenchloride from hydrolysis of dimethyldichlorosilane

InactiveCN101423193ALow impurity contentHigh yieldChlorine/hydrogen-chloride purificationGas phaseHydrolysate

The invention discloses a process method used for reducing the content of impurities in gas-phase hydrogen chloride after hydrolysis of dichlorodimethyl silane, comprising the steps as follows: a two-step device is used for separating the impurities; a vapour liquid separator leads the mixed hydrogen chloride gas generated after the hydrolysis of dichlorodimethyl silane to enter a washing tower of a guide structure so as to remove most of impurities; subsequently, the hydrogen chloride gas with most of impurities removed is arranged into the bottom of a demister; the adsorption medium at the internal layer of the demister is porous fiber which is used to adsorb the siloxane impurity in the hydrogen chloride gas; and the hydrogen chloride gas with the siloxane impurity removed is sent to a methyl chloride device to carry out the subsequent process. The method reduces the content of the impurities in the hydrogen chloride gas, improves the yield of hydrolysate of the dichlorodimethyl silane, keeps the pressure of the hydrogen chloride gas at a high level after purification, does not generate a great deal of waste acid, avoids the disposal of waste acid, and has low energy consumption and low equipment expense.

Owner:浙江恒业成有机硅有限公司

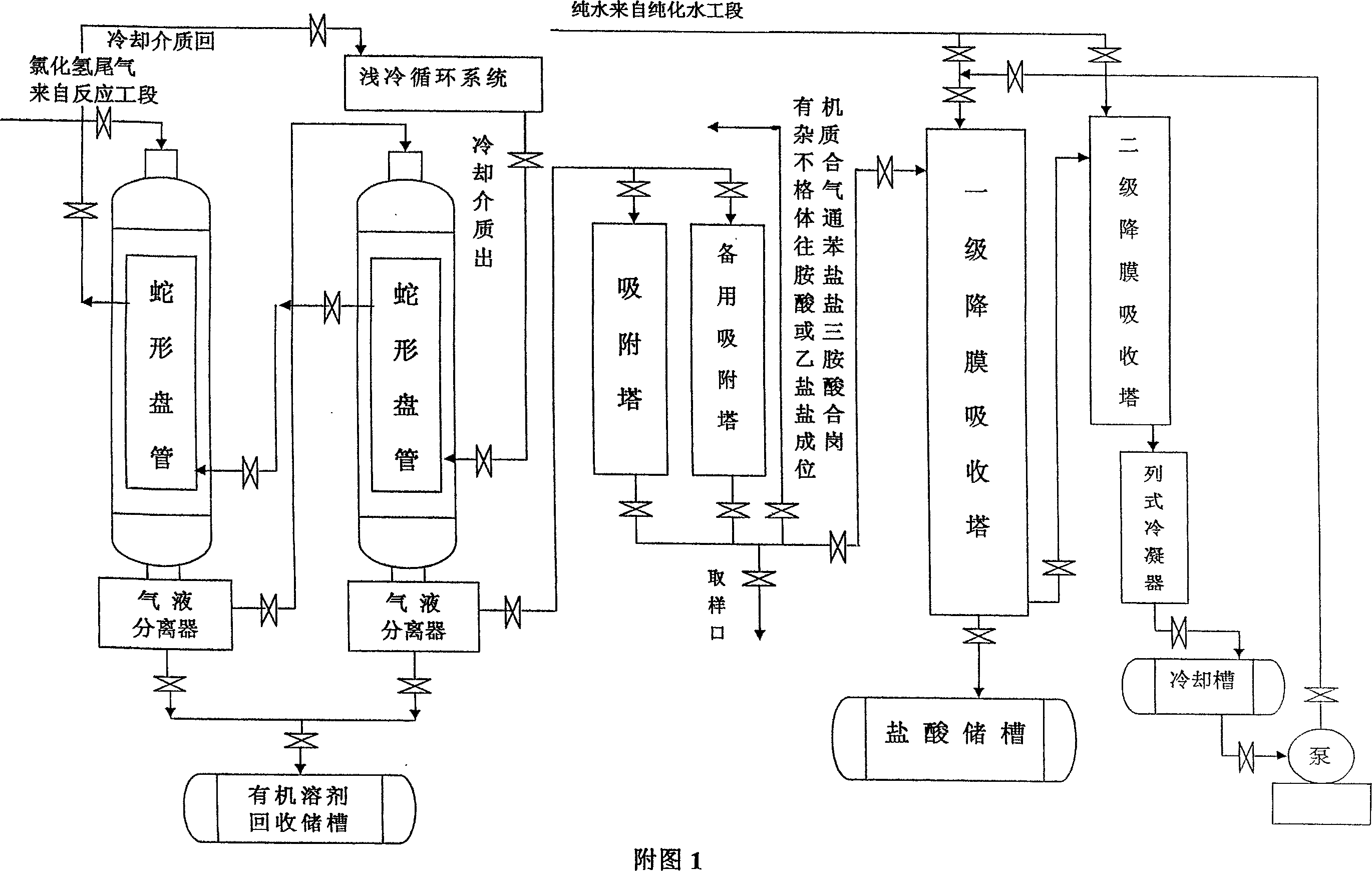

Process for preparing high purity hydrochloric acid by circularly absorbing hydrogen chloride by-product

InactiveCN1951801ASatisfied with the resultExpand the range of industrial applicationsChlorine/hydrogen-chloride purificationActive particlesPolypropylene

The invention discloses a preparing method of high-purity alcaine technology through circulating and adsorbing by-product of hydrogen chloride, which comprises the following steps: aerating hydrogen chloride gas with organic impurity in the condenser at -10- -40 deg.c and gas-liquid separator; adsorbing gas with little impurity through active particle charcoal; aerating adsorbed gas into one-grade and two-grade graphite falling-film; adsorbing through pure water to obtain the high-purity alcaine; adsorbing non-adsorbed hydrogen chloride through cold water; putting hydrogen chloride and diluted acid in the graphite polypropylene falling-film adsorbing tower into cooling groove; utilizing circulating pump to transmit the inlet of one-grade falling-film adsorbing tower; circulating the adsorption.

Owner:ZHEJIANG UNIV OF TECH

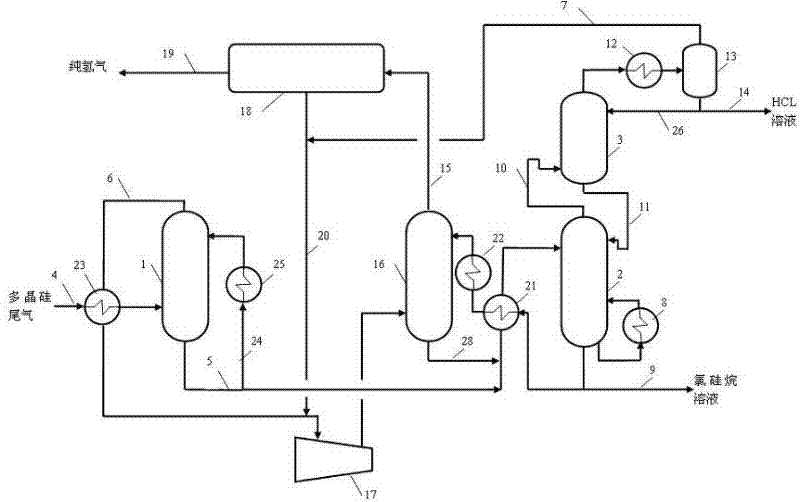

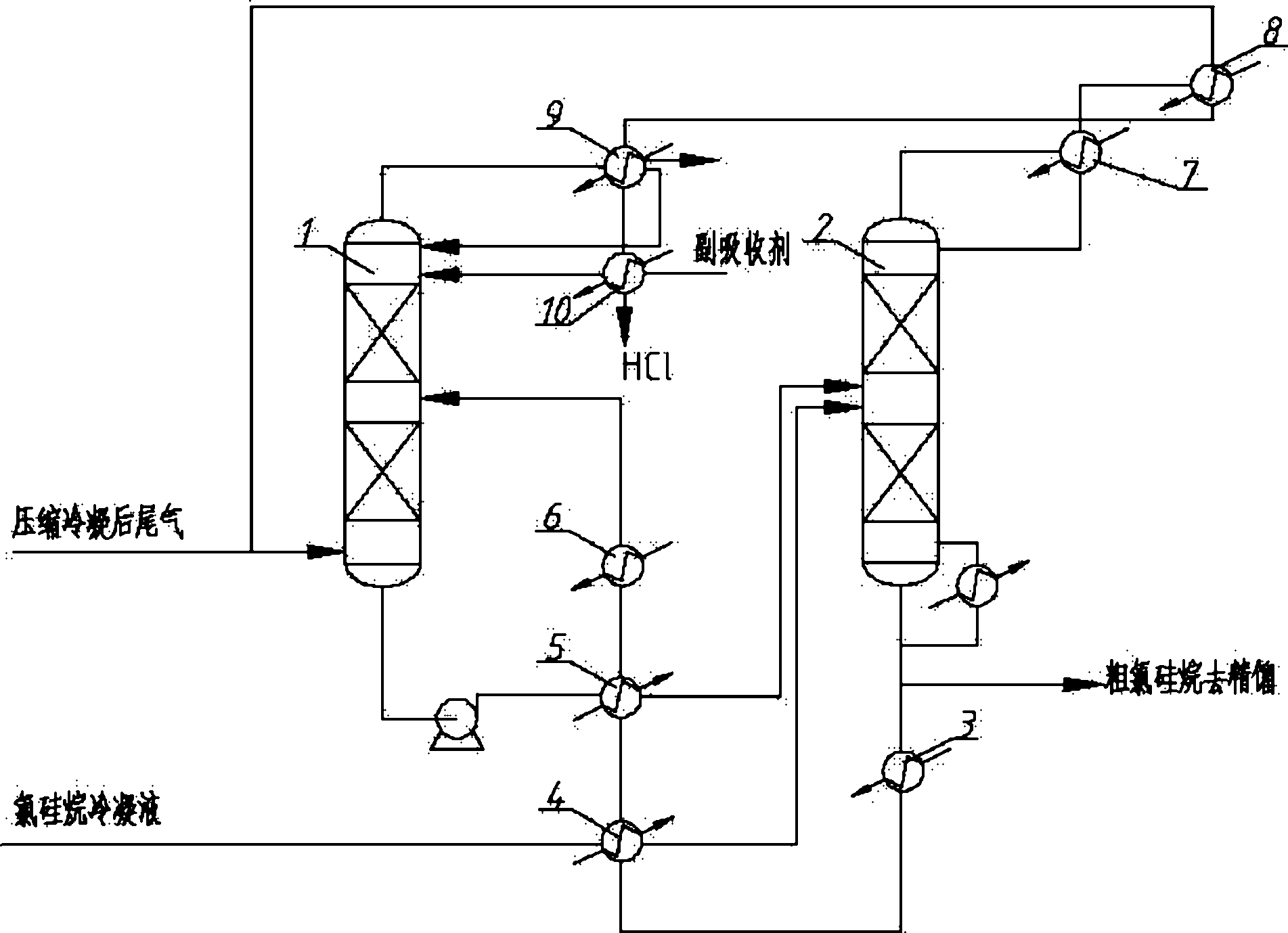

Method for recycling hydrogen chloride in tail gas of polysilicon production

ActiveCN101791487AHigh purityLarge storage capacityChlorine/hydrogen-chloride purificationSiliconDistillationChloride

The invention discloses a method for recycling hydrogen chloride in tail gas of polysilicon production. In the method, tail gas is cooled and condensed, so that most of chlorosilane is liquefied; compressed gas enters a hydrogen chloride absorption tower and absorbed by chlorosilane solution, and hydrogen gas is exhausted from the hydrogen chloride absorption tower and collected; liquid hydrogen-chloride-rich chlorosilane discharged from the bottom of the hydrogen chloride absorption tower is introduced into a hydrogen chloride distillation tower, and chlorosilane solution is discharged form the bottom of the hydrogen chloride distillation tower; and hydrogen chloride containing trace hydrogen gas is exhausted from the top of the hydrogen chloride distillation tower and enters a full condenser on the top of the distillation tower, condensate of the full condenser on the top of the distillation tower enters a return tank of the distillation tower, the trace hydrogen is exhausted from the top of the return tank of the distillation tower and collected, a part of the condensate of the return tank of the distillation tower is introduced into the hydrogen chloride distillation tower and used as return liquid, and the other part of the condensate enters a liquid hydrogen chloride reservoir for storage. The method improves the purity of recycled hydrogen chloride and the storage amount of hydrogen chloride and saves the investment of equipment.

Owner:CHINA TIANCHEN ENG

Method for industrial hydrochloric acid purification by liquid extraction

InactiveCN101041421AReduce pollutionRealize automatic controlChlorine/hydrogen-chloride purificationKeroseneDiluent

The invention discloses a method of extractive purifying industrial alcaine, which comprises the following steps: setting triallylamine as extractant, isooctanol as assisting solvent and coal oil as diluent; forming extract organic phase through kerosene; extracting industrial alcaine in the extract pot; washing through pure water; stripping; getting high-purity alcaine. The invention possesses steady quality and high-purity, which can realize continuous mass production.

Owner:广东省富远稀土有限公司

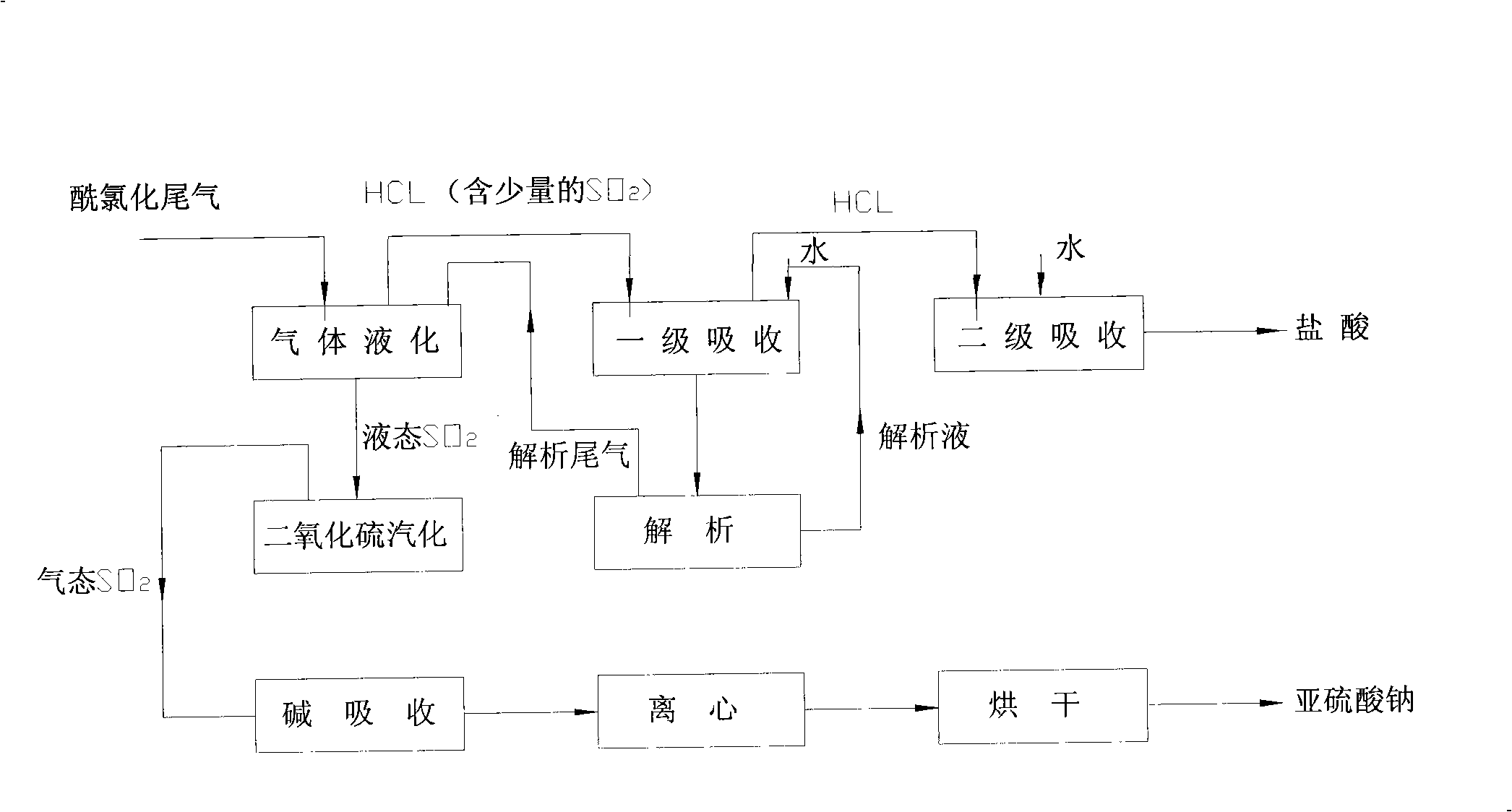

Method for treating tail gas of acyl chlorination

The invention relates to a processing method of thionyl chloride acyl-chlorinated tail gas. Mixed tail gas produced by a acyl chlorinating process contains hydrogen chloride and sulfur dioxide; the sulfur dioxide is liquefied under a certain temperature condition; the incondensable hydrogen chloride and a little sulfur dioxide are absorbed in two stages by water; the absorbed tail gas in a first stage is pure hydrogen chloride gas; after being absorbed in a second stage, the qualified chlorhydric acid is obtained; first-stage falling film absorption liquid is resolved by heating; then the tail gas is sent to a liquefying process again; the liquid sulfur dioxide can be canned as a product; or after being vaporized, the liquid sulfur dioxide is absorbed by 30 percent of sodium hydroxide solution to obtain sodium sulfite aqueous solution which is further dried after low temperature crystallization or distillation to obtain 97 percent of sodium sulfite solid. With the method, the hydrogen chloride, the sulfur dioxide and a little thionyl chloride produced by an acyl chlorination synthetic process can be separated out to obtain the chlorhydric acid and the pure sodium sulfite solid. The processing method of the thionyl chloride acyl-chlorinated tail gas of the invention is capable of effectively recovering the thionyl chloride acyl-chlorinated tail gas, which has the advantages of safety process and easy control.

Owner:JIANGSU YANGNONG CHEM +2

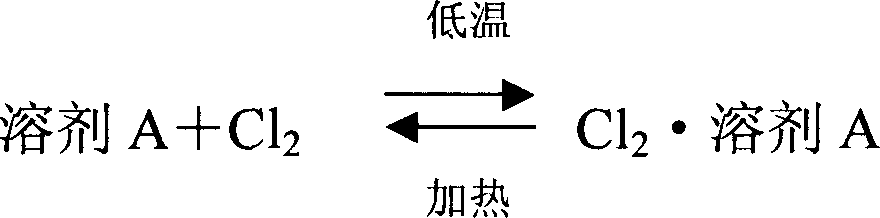

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

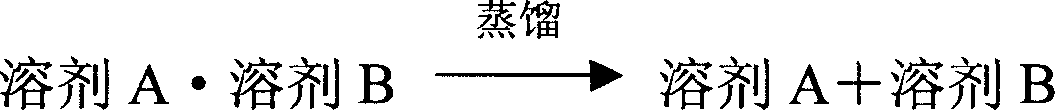

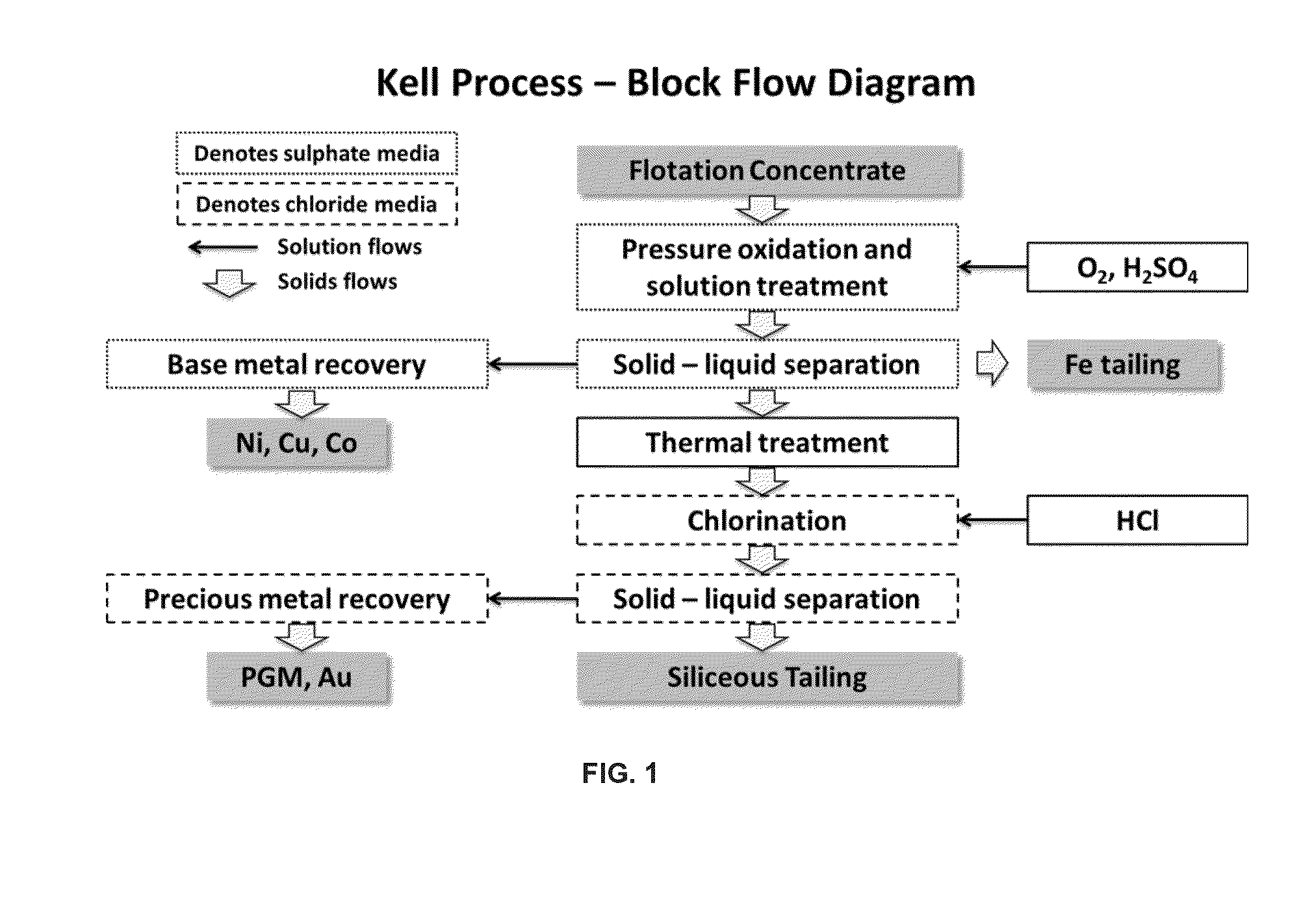

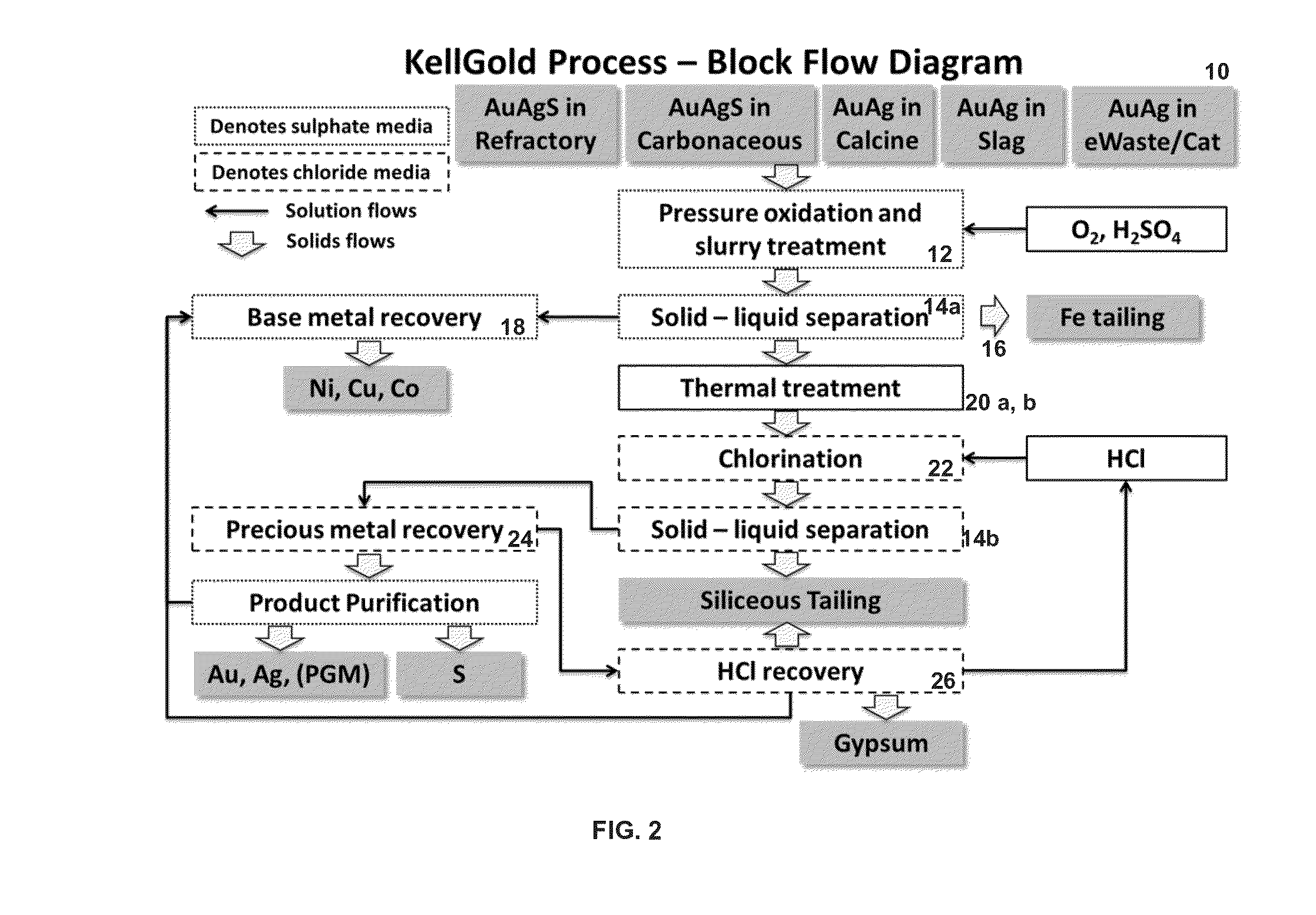

Treatment process for extraction of precious, base and rare elements

ActiveUS20160145714A1Low recovery ratePolycrystalline material growthChlorine/hydrogen-chloride purificationTrace elementRefractory

This invention describes a hydrometallurgical process for the recovery and separation of valuable elements, in particular gold and silver, from a feed material comprising a refractory, intractable or otherwise poorly responding to conventional treatment routes ores, concentrates and other materials. In particular, the process is a process integrated into one or more existing value element extraction processes.

Owner:LIFEZONE

A kind of waste hydrochloric acid recovery process

ActiveCN102285641AAvoid wastingReduce processing costsChlorine/hydrogen-chloride purificationHydrogenReboiler

The invention relates to a recycling process of waste hydrochloric acid. The recycling process of waste hydrochloric acid is characterized in that: after being preheated, the waste hydrochloric acid is fully mixed with a prepared calcium chloride solution which is used as a catalyst; the mixture is fed into a hydrochloric acid desorption tower; the hydrochloric acid is resolved by a reboiler at the bottom of the hydrochloric acid desorption tower; after passing through a cooler and a demister, the separated hydrogen chloride gas is collected; the water with a small number of hydrogen chloridereturns to the hydrochloric acid desorption tower for continuous resolution; and the calcium chloride solution used as the catalyst is fed into a flash distillation stream dividing tank to be prepared and reused. The waste of hydrogen chloride is avoided, and sewage treatment cost is reduced.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

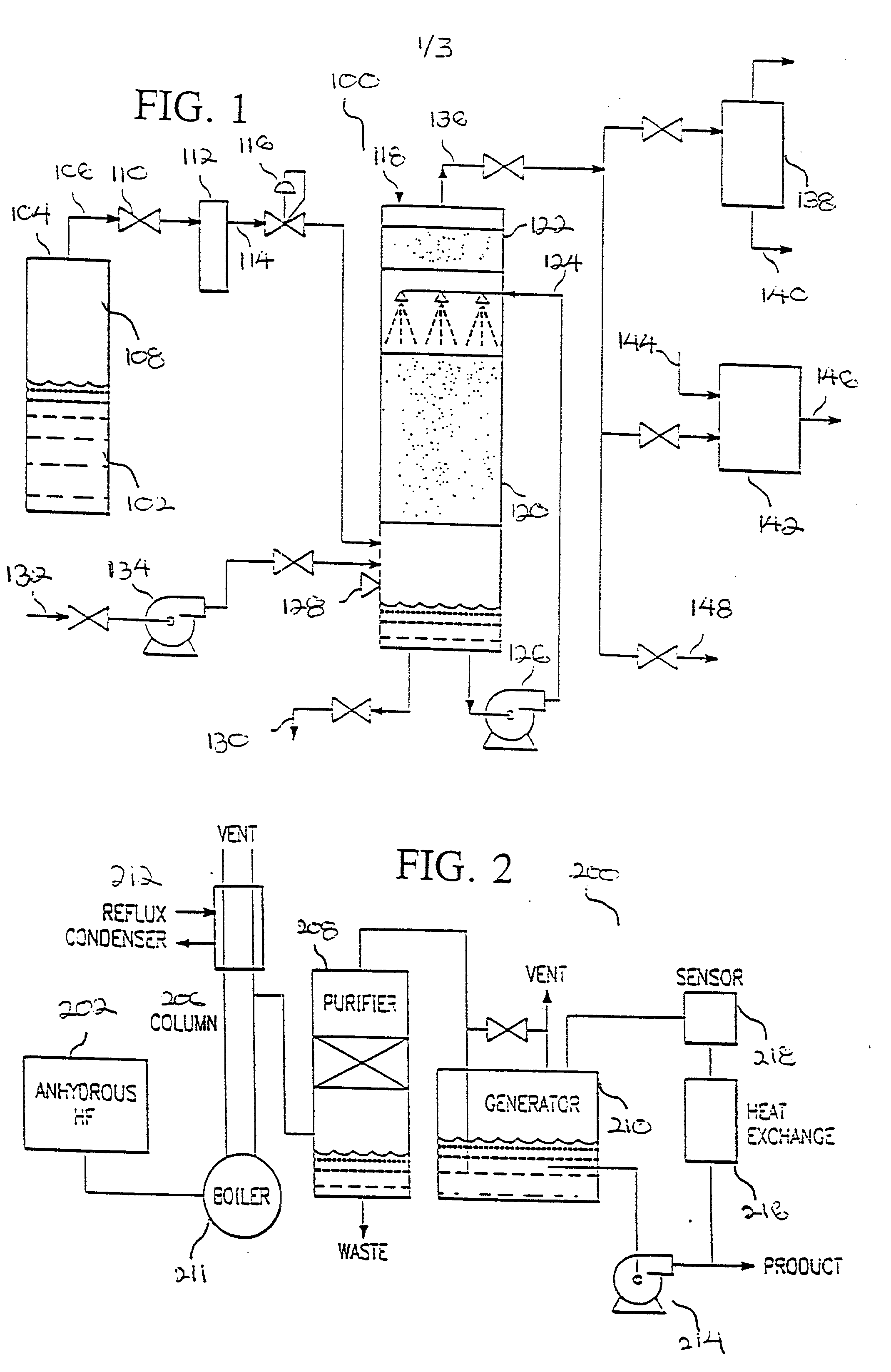

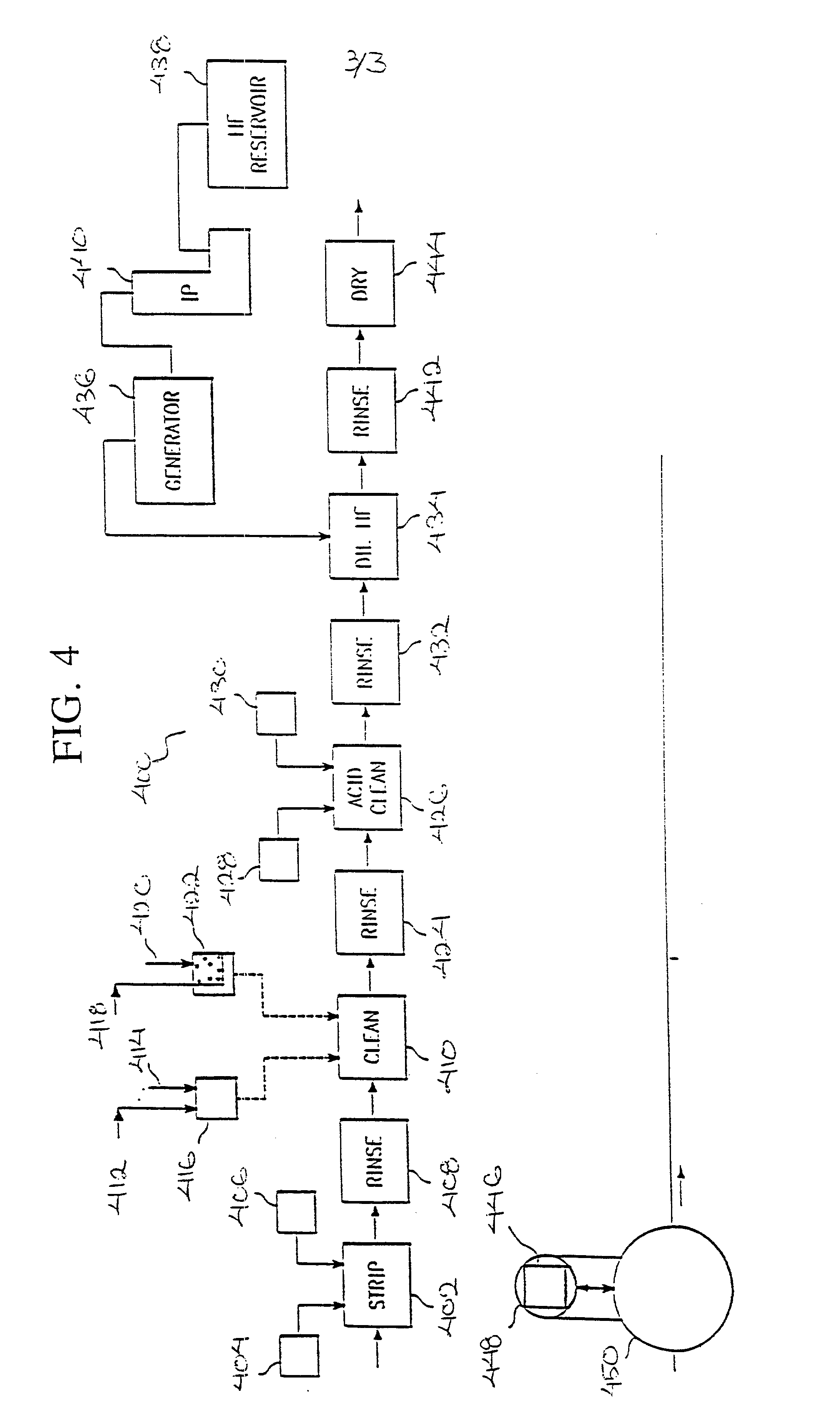

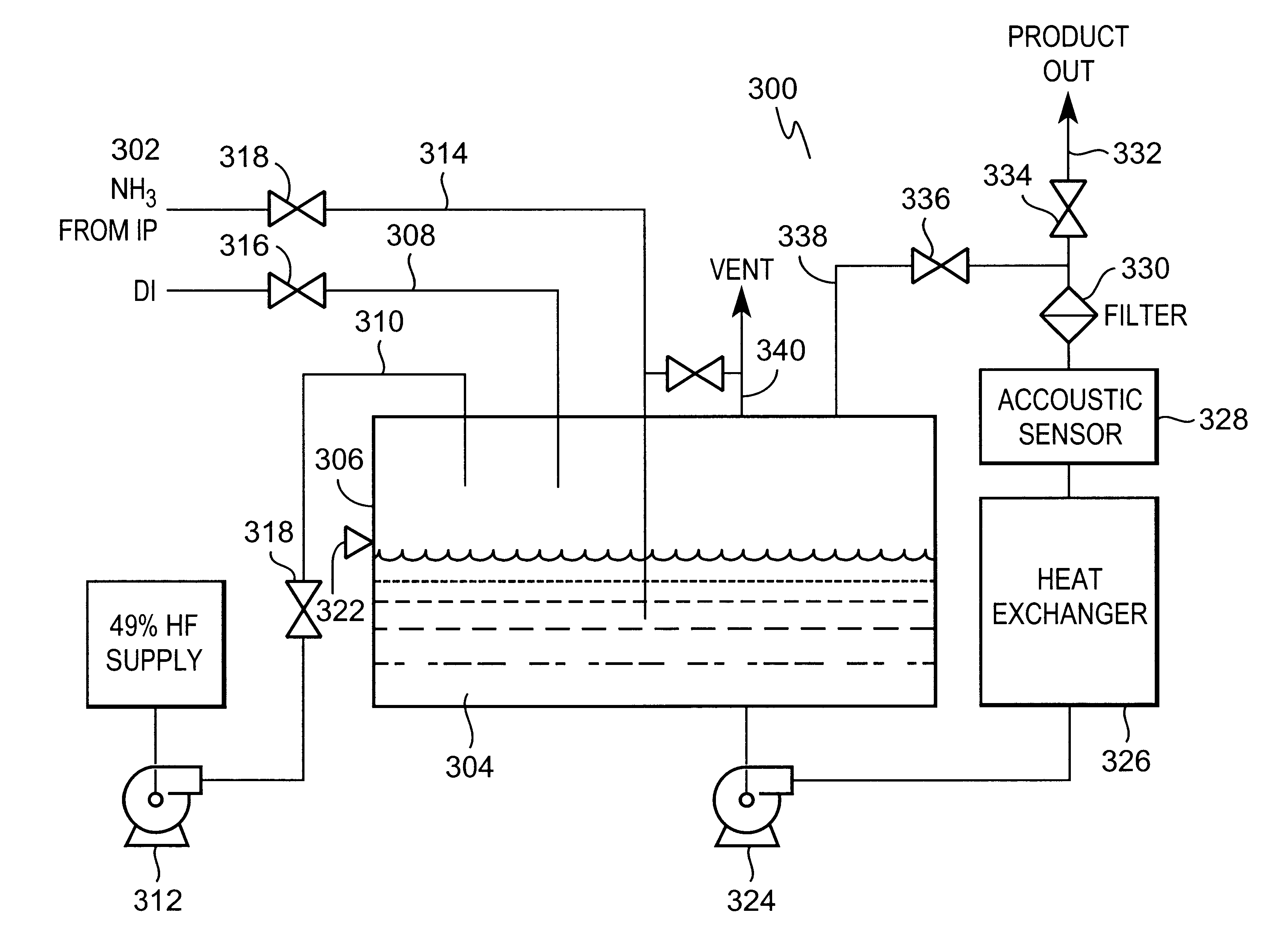

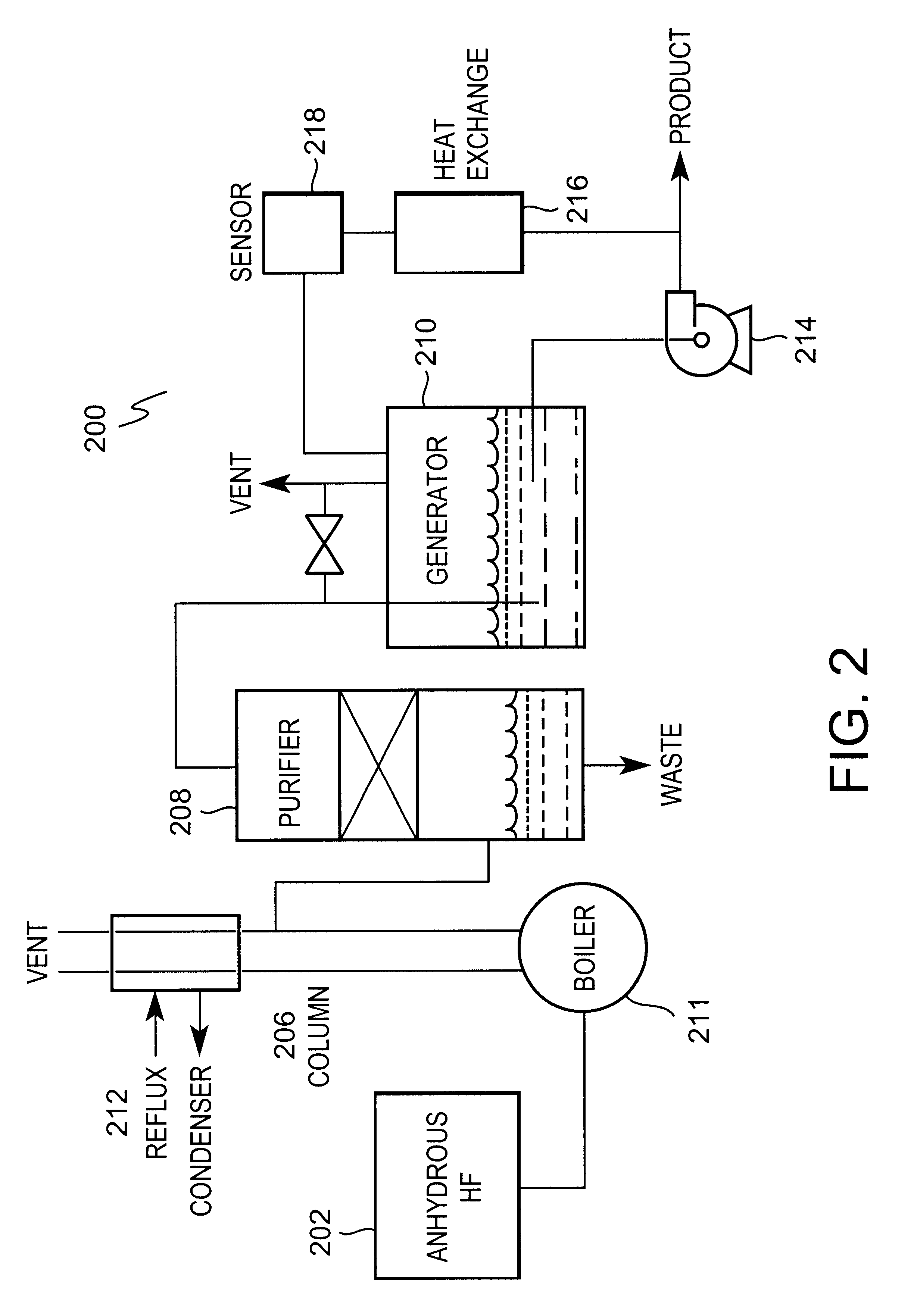

On-site generation of ultra-high-purity buffered-hf and ammonium fluoride

InactiveUS20010051128A1Low impurity contentImprove device characteristicsChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration. The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

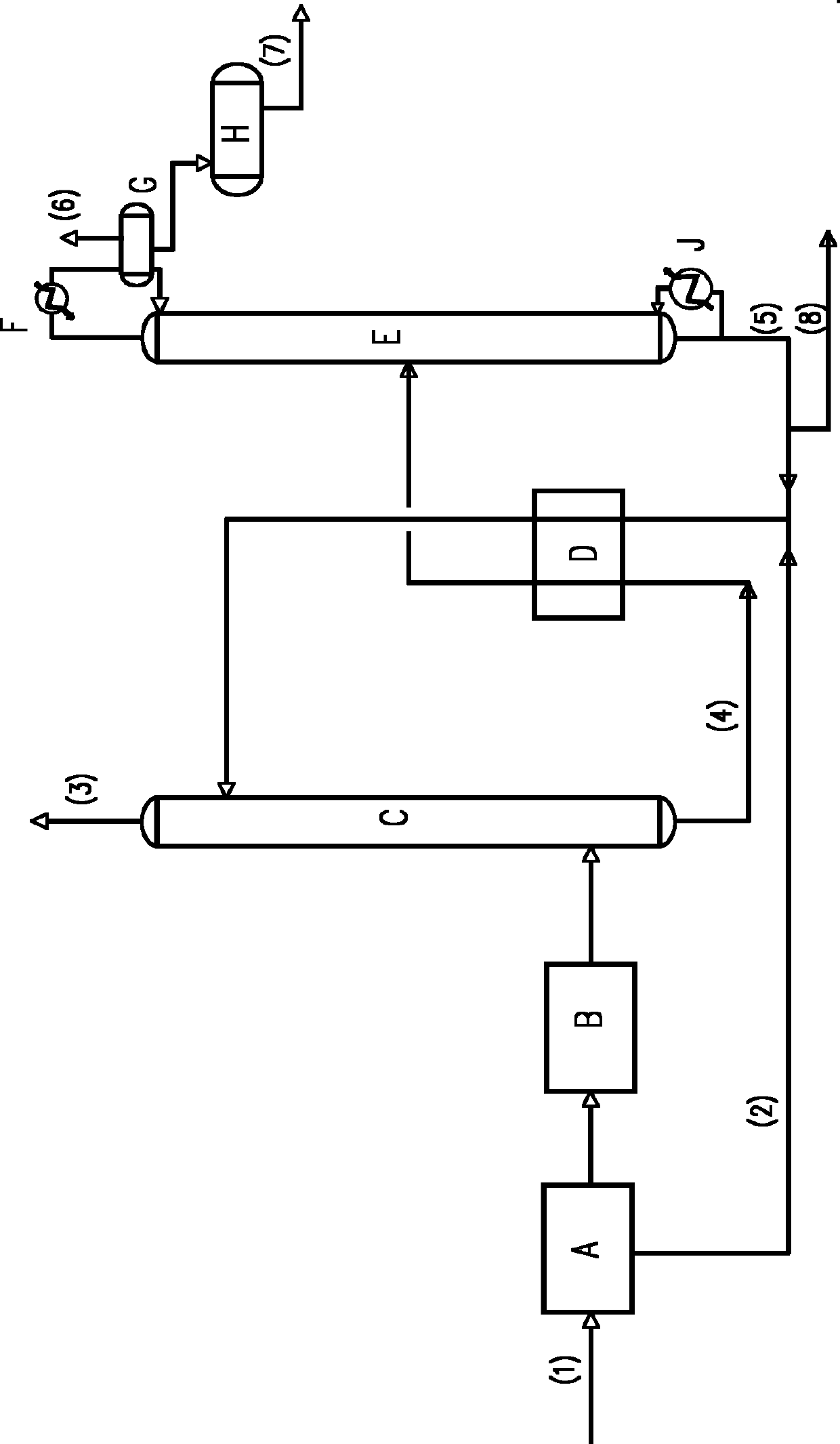

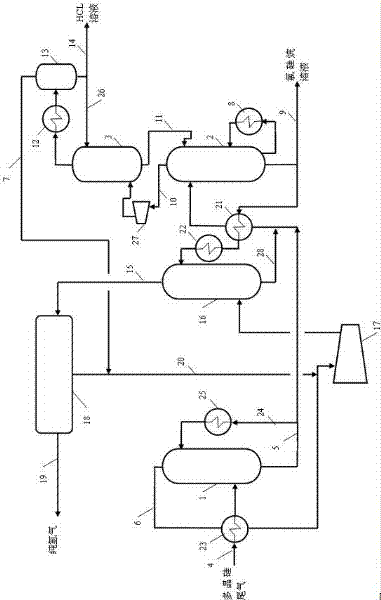

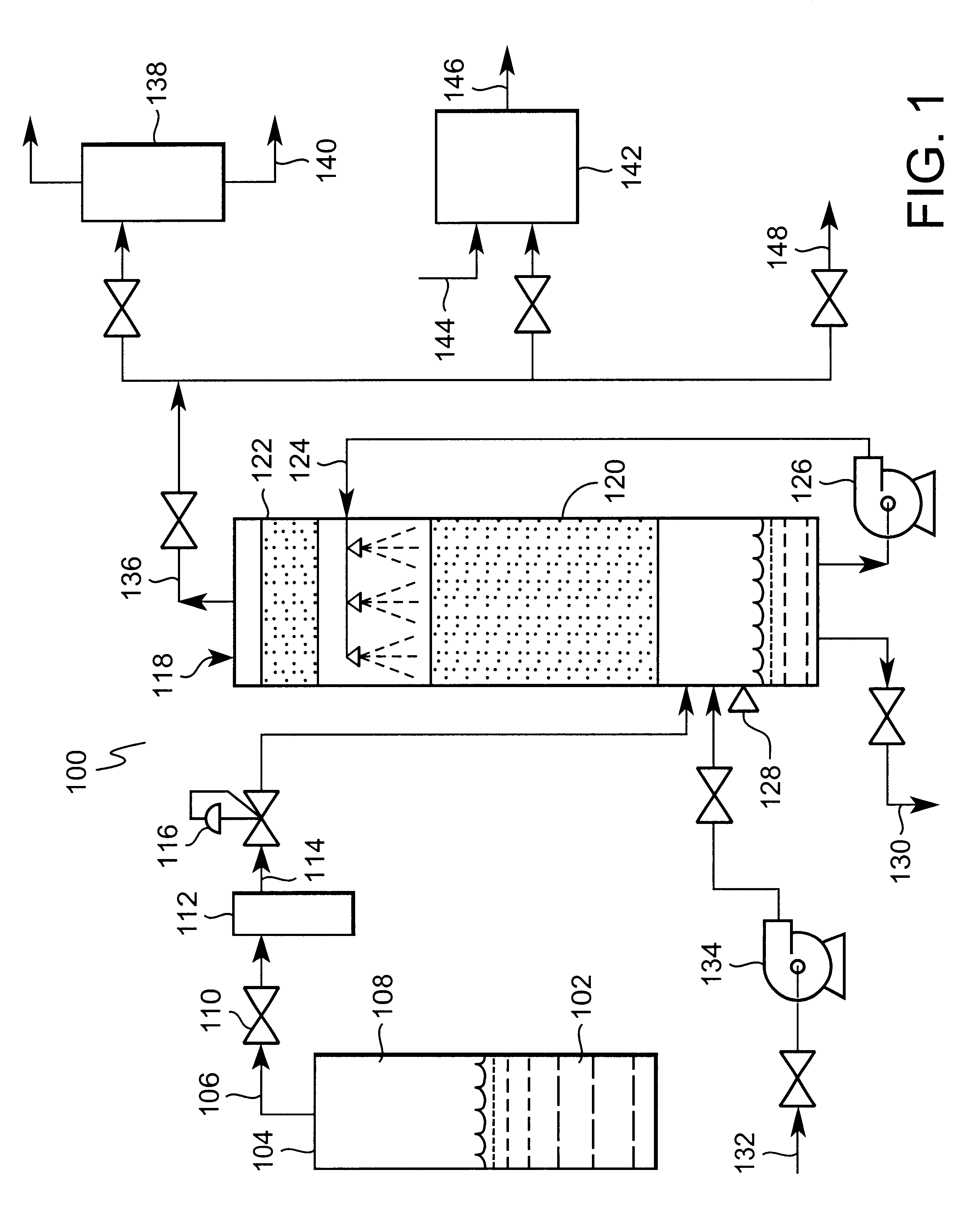

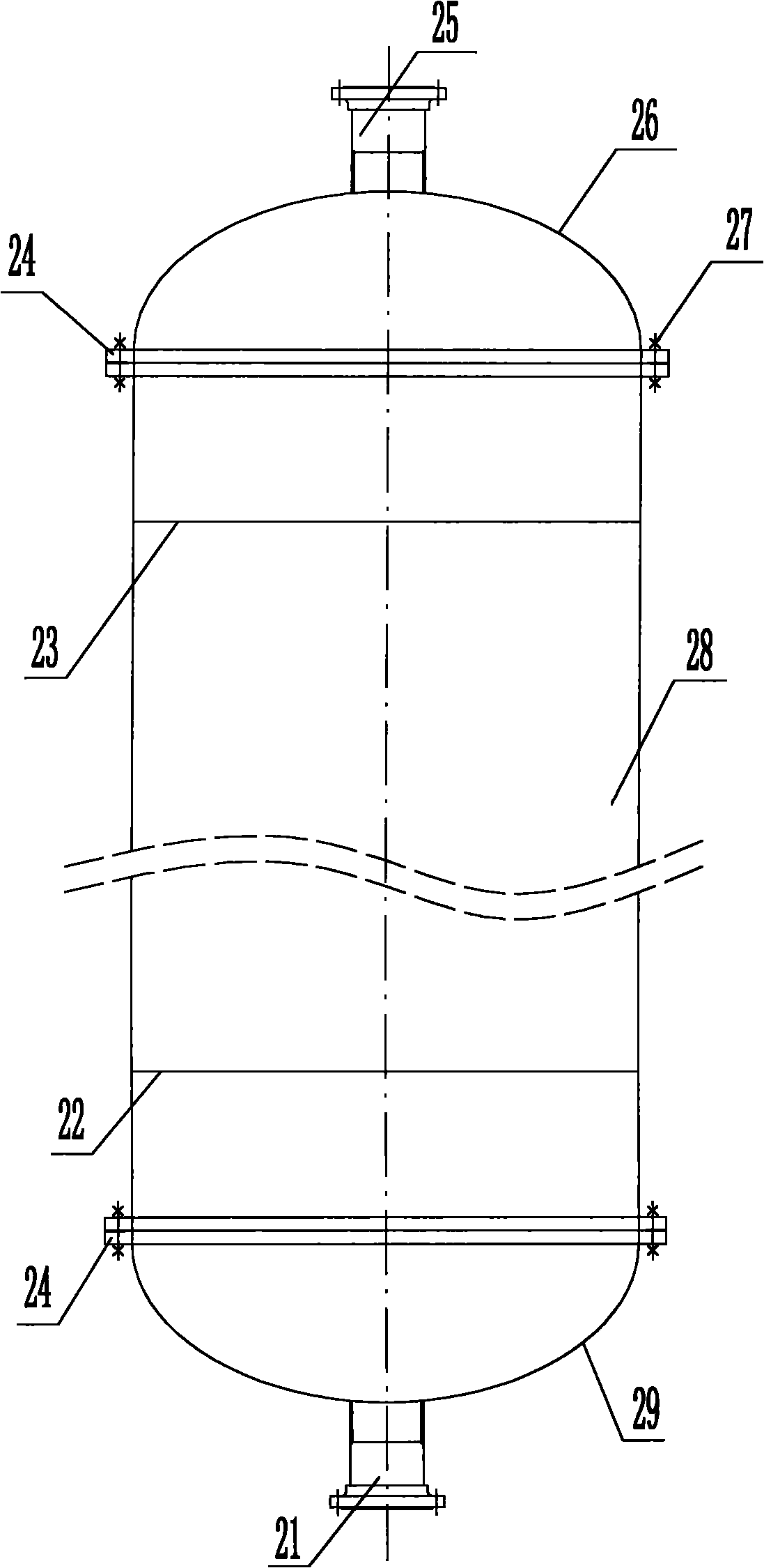

System and process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment

InactiveCN102249187ASolve environmental problemsEfficient recyclingChlorine/hydrogen-chloride purificationHydrogen separation using liquid contactHydrogenReboiler

The invention discloses a system for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment, and the system mainly comprises a tail gas circulated condensing and washing tower, a chlorosilane stripper and a HCl rectifying tower, wherein the tail gas circulated condensing and washing tower is equipped with a polysilicon tail gas inflow pipe, a first chlorosilane solution outflow pipe and a first hydrogen outflow pipe, and the first chlorosilane solution outflow pipe is connected with the chlorosilane stripper; the chlorosilane stripper is equipped with a reboiler, a second chlorosilane solution outflow pipe, a first HCl outflow pipe and a stripping backflow pipe, and the first HCl outflow pipe and the stripping backflow pipe are connected with the HCl rectifying tower; and the HCl rectifying tower is equipped with a condenser, a separator and a second HCl outflow pipe which are connected in turn, and the separator is equipped with a non-condensable gas outflow pipe. The invention also discloses a process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment. Through the system and process disclosed by the invention, the polysilicon tail gas is turned into things of value, the resources are saved, and simultaneously the energy consumption during the treatment process is reduced.

Owner:SICHUAN TECHAIRS

Method for recycling pure acid from metallic ion containing waste acid and regenerating alkali

ActiveCN101343039AHigh recovery rateReduce manufacturing costChlorine/hydrogen-chloride purificationSulfur-trioxide/sulfuric-acidFiltrationAcid concentration

Disclosed is a method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline, and belongs to the environmental protection field. The process steps include that: (a) the waste acid solution with the acid concentration 10%-40% is processed with the first level diffusion dialysis; (b) the residue after the step a is processed with the second level diffusion dialysis; the volume ratio of the first level (or the second level) waste acid (or the first level diffusion residue) in the first level (or the second level) diffusion dialysis groove residue and the acid recovery chamber collected solution is 1:0.5-1:3.0; the flow rate of the waste acid (or the first level diffusion residue) is enabled to be 0.2-0.6L / h; the flow rate of the acid recovery chamber collected solution is 0.1-1.8L / h; (c) the second residue after the step b is processed with neutralization and deposition; (d) the neutralized filtrate after the solid-liquid separation-filtration is fed to the three compartment electrodialysis groove middle chamber, the electrodialysis is processed for 1-3h under the voltage 5-15V to obtain the reproduction acid and reproduction alkaline. The method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline has the advantages of high acid recovery rate, low production cost and energy-consumption, less film pollution, saving water, reducing discharge and no secondary pollution.

Owner:HARBIN COSLIGHT STORAGE BATTERY

Porous solid supported ionic liquid for adsorption of HCl gas

InactiveCN107651651AHigh adsorption rateHigh purityChlorine/hydrogen-chloride purificationGas treatmentPhosphoniumCarbon nanotube

The invention disclosed a porous solid supported ionic liquid and application thereof in adsorption of HCl gas, the porous solid supported ionic liquid comprises a porous solid support and an ionic liquid supported on the support, the porous solid support is activated carbon, mesoporous carbon, carbon nanotubes, silicon oxide, aluminum oxide, titanium oxide, a molecular sieve, a metal organic framework compound or a covalent organic framework compound; the ionic liquids is imidazole, pyridine, quaternary phosphonium and pyrrolidinium ionic liquid, the Ionic liquid loading amount is 1 to 50% based on the mass of the porous solid support. The porous solid supported ionic liquid can be used for adsorbing of the HCl gas, and is used in typical occasions for adsorbing of the HCl gas in industrial exhaust gas of vinyl chloride synthesis by HCl / C2H2 mixed gas and ethyne hydrochlorination for enriching or separating recovering of the HCl. The adsorption rate of the HCl is up to 99.97%, and thepurity of HCl thus obtained is high, up to 99.999%.

Owner:ZHEJIANG UNIV OF TECH

Method for refining byproduct hydrogen chloride during production process of organochlorine products

InactiveCN101200286AHigh economic valueLarge adsorption capacityChlorine/hydrogen-chloride purificationDispersed particle separationBenzeneDesorption

The utility model relates to a refining method of by-product HCl gas in organic chlorine production process, the by-product HCl gas passes by the absorption post filled with absorption resin at flow speed of 0.1-0.5m / s under constant-temperature constant-pressure, the removal ratio of the organic in the HCl gas can reach 99.8 percent, afterwards the absorption resin that absorbs the organic is desorbed by 110-160 DEG C saturation vapor, the desorption ratio can exceed more than 99 percent, the desorption liquid is condensed, oil-gas separated, recycled to obtain the organic mixture containing benzene or chlorobezene, the mixture is furthermore distilled and separated to obtain the benzene or chlorobezene, finally the absorption resin after desorbed by the vapor is dried by 110-140 DEG C hot air, and then cooled to room temperature for next stage absorption. The absorption resin can be reused after desorption and regeneration.

Owner:NANJING UNIV +1

Enhanced process for the purification of anhydrous hydrogen chloride gas

InactiveUS20070261437A1SolidificationChlorine/hydrogen-chloride purificationDeacon processHydrogen chloride

The present invention relates to a process for purifying anhydrous hydrogen chloride gas (“aHCl”), and preferably the anhydrous hydrogen chloride gas recovered from an isocyanate production process. In the process of the present invention, the content of chlorinated organics may be reduced from up to 1000 ppm by volume to below 10 ppb by volume levels. Generally, the process of the invention allows for chlorinated organic levels to be reduced to from 1 to 100 ppb, rendering the treated hydrogen chloride gas usable in a catalytic oxychlorination process or a Deacon process. The treated gas is also suitable for absorption in water or dilute hydrochloric acid.

Owner:BAYER MATERIALSCIENCE AG +2

On-site generation of ultra-high-purity buffered-HF and ammonium fluoride

InactiveUS6350425B2Reduce processingLow impurity contentChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

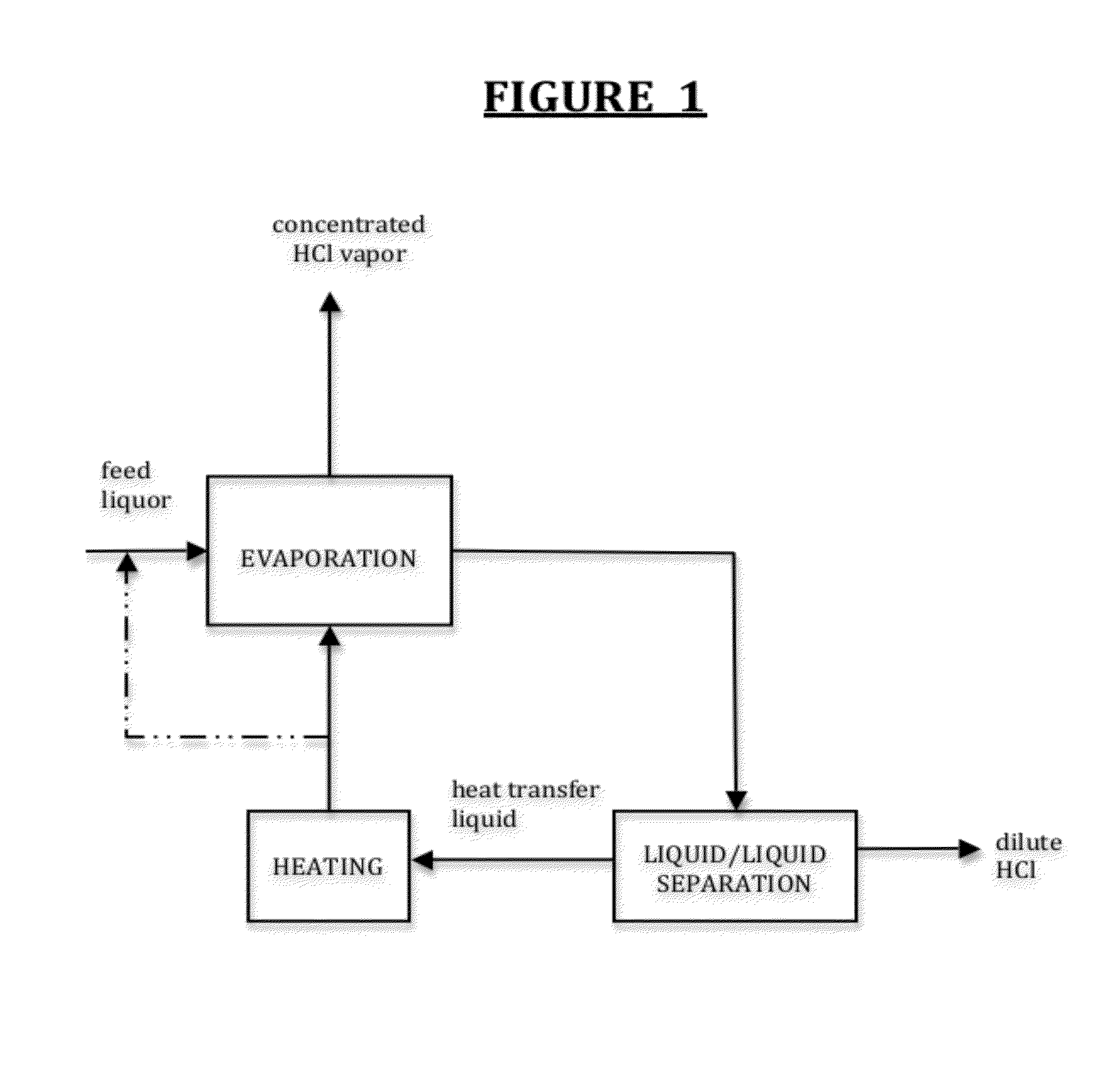

Method of concentrating hydrochloric acid

InactiveUS8163092B2Chlorine/hydrogen-chloride purificationOther chemical processesHeat transfer fluidAqueous solution

A method for producing concentrated HCl vapor from an aqueous solution of HCl, including: (a) introducing an aqueous feed liquor to an evaporation chamber containing a mother liquor, the feed liquor having an initial, super-azeotropic HCl concentration; (b) directly contacting a liquor of these liquors with a heat-laden heat transfer fluid, to transfer heat from the fluid; (c) utilizing the heat to evaporate HCl, within the chamber, to produce the concentrated HCl vapor and to produce the mother liquor, the mother liquor including an aqueous phase having a reduced concentration of HCl, with respect to the initial HCl concentration; (d) subjecting the mother liquor to a liquid-liquid separation to produce a liquid phase containing HCl, and another liquid phase containing the heat transfer fluid in a heat-depleted state, with respect to the heat transfer fluid in step (b); (e) heating the heat transfer fluid in the heat-depleted state, to regenerate the heat-laden heat transfer fluid, and (f) returning this heat transfer fluid to step (b).

Owner:VIRDIA

Electronic grade hydrogen chloride purification method

ActiveCN105502295AAvoid introducingReduce manufacturing costChlorine/hydrogen-chloride purificationComing outPurification methods

The invention provides an electronic grade hydrogen chloride purification method. The method is characterized by comprising the following steps: introducing industrial liquid hydrogen chloride with purity of 99% to the middle position of a first rectifying tower to be rectified so as to remove light components; introducing a liquid coming out from the bottom of a reboiler of the first rectifying tower to the middle position of a second rectifying tower by a pump to be rectified, condensing hydrogen chloride generated through heating by a second reboiler with a second condenser, controlling the reflux ratio, enabling part of hydrogen chloride to flow back to the second rectifying tower and transferring the other part of hydrogen chloride to middle storage tanks to be stored and pumping out residual liquid from the bottom of the second reboiler to a waste liquid storage tank so as to remove heavy components; and obtaining high-purity hydrogen chloride with purity above 99.9999% through adsorption and purification of at least an adsorption tower with a molecular sieve inside. The method has the effect of avoiding introduction of other impurity media, is simple to operate and is low in production cost.

Owner:SHANGHAI ZHENGFAN TECH +1

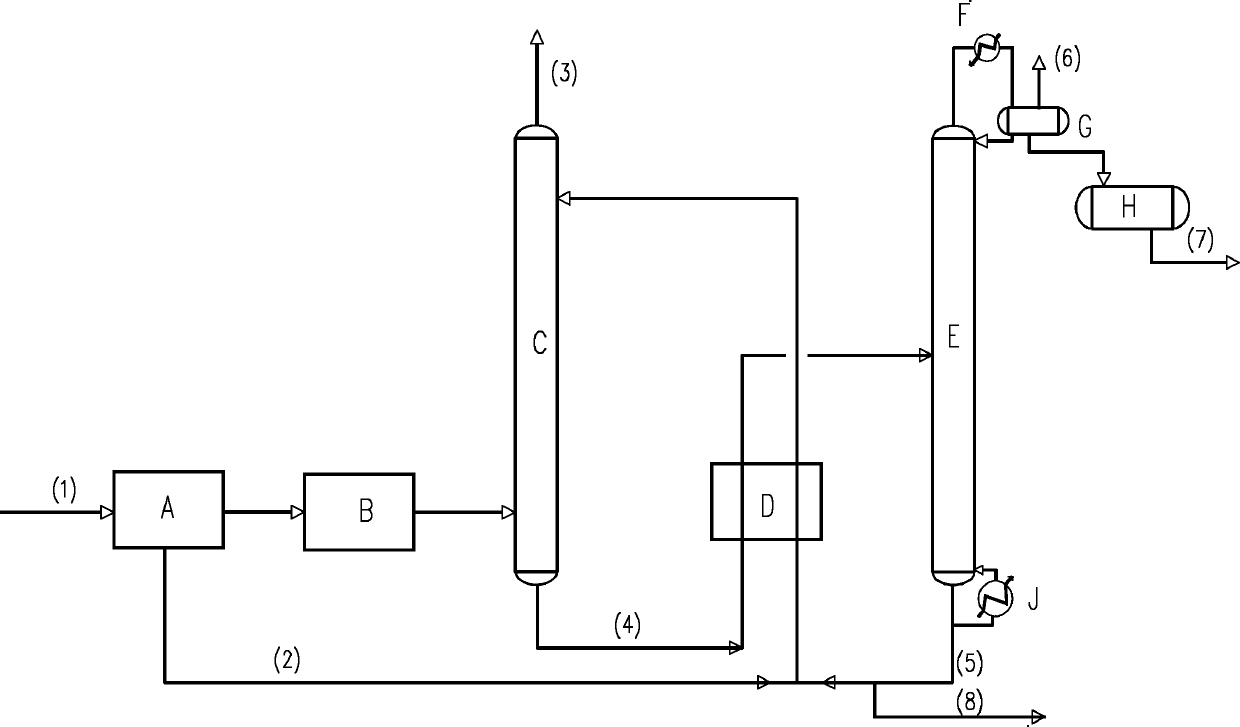

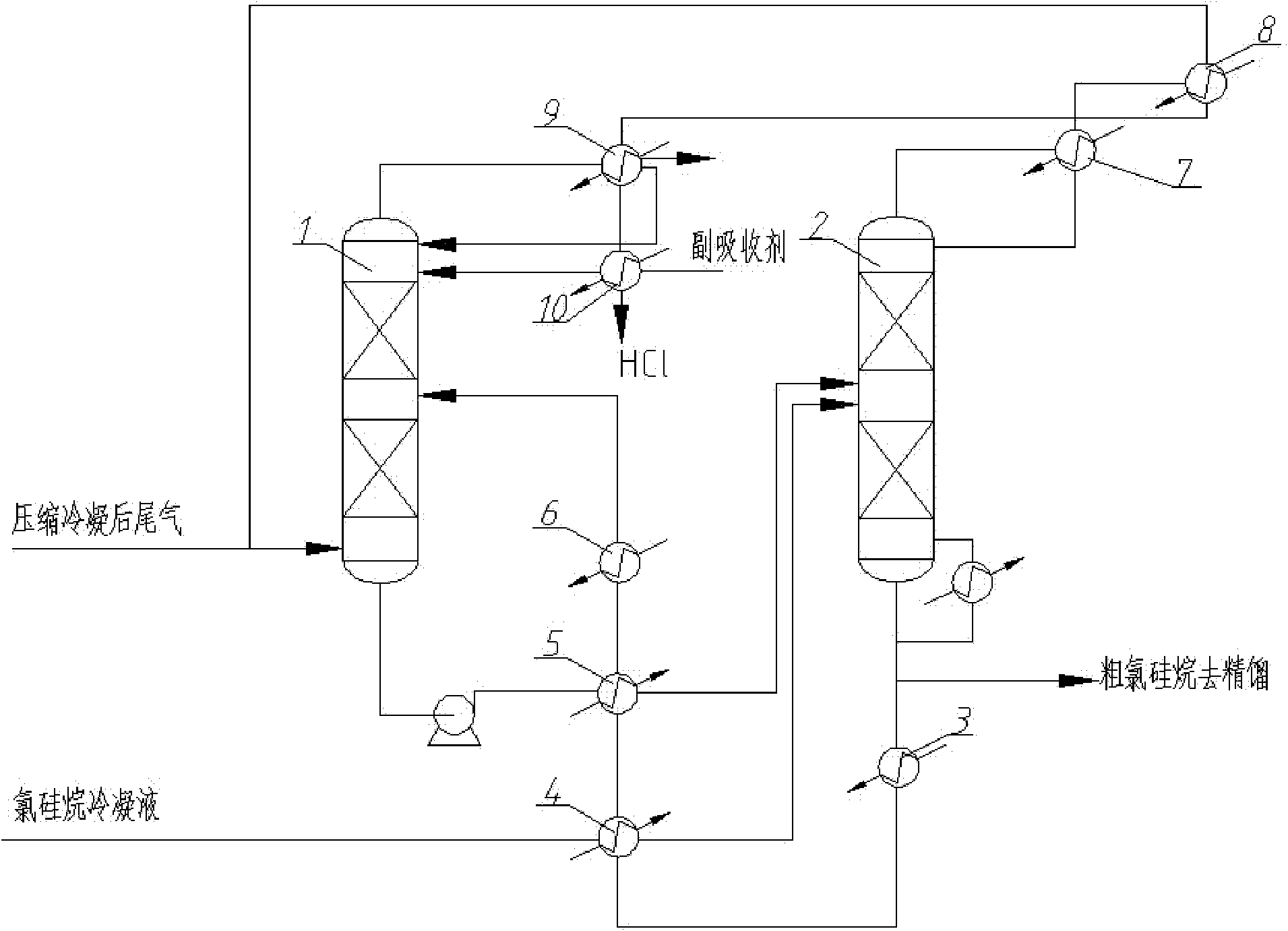

Green and environment-friendly recycling method of trichlorosilane tail gas

ActiveCN101885473AHigh purityEliminate emissionsChlorine/hydrogen-chloride purificationHydrogen separation using liquid contactHydrogenGas phase

The invention discloses a green and environment-friendly recycling method of trichlorosilane tail gas, which comprises the following steps: (1) transmitting the tail gas generated in the process of synthesizing trichlorosilane to an absorption tower, adopting two-stage absorption by an absorption tower, cooling hydrogen exhausted from the tower top of the absorption tower to obtain a liquid phase component, reflowing the liquid phase component to the top of the absorption tower, conducting heat exchange for coarse chlorosilane and hydrogen chloride exhausted from the tower bottom of the absorption tower, and transmitting chlorosilane condensate to a rectifying tower for rectification with the coarse chlorosilane and the hydrogen chloride after heat exchange; (2) completely reflowing overhead fraction in the rectifying tower after passing through the condensed liquid phase, and simultaneously entering into a cryogenic device in a gaseous phase mode for condensation, extracting hydrogen chloride in a liquid phase mode, and returning the gaseous phase mixture extracted from the cryogenic device to the absorption tower as feeds; and (3) enabling one part of tower bottom discharged material to enter into coarse chlorosilane rectification system and the other part thereof after cooling to return the absorption tower as a main absorption liquid in step (1). The invention adopts a recycling system which comprises a single tower for two-stage absorption and rectification so as to obtain hydrogen, hydrogen chloride and chlorosilane with high purity and completely eliminate tail gas emission.

Owner:TIANJIN UNIV

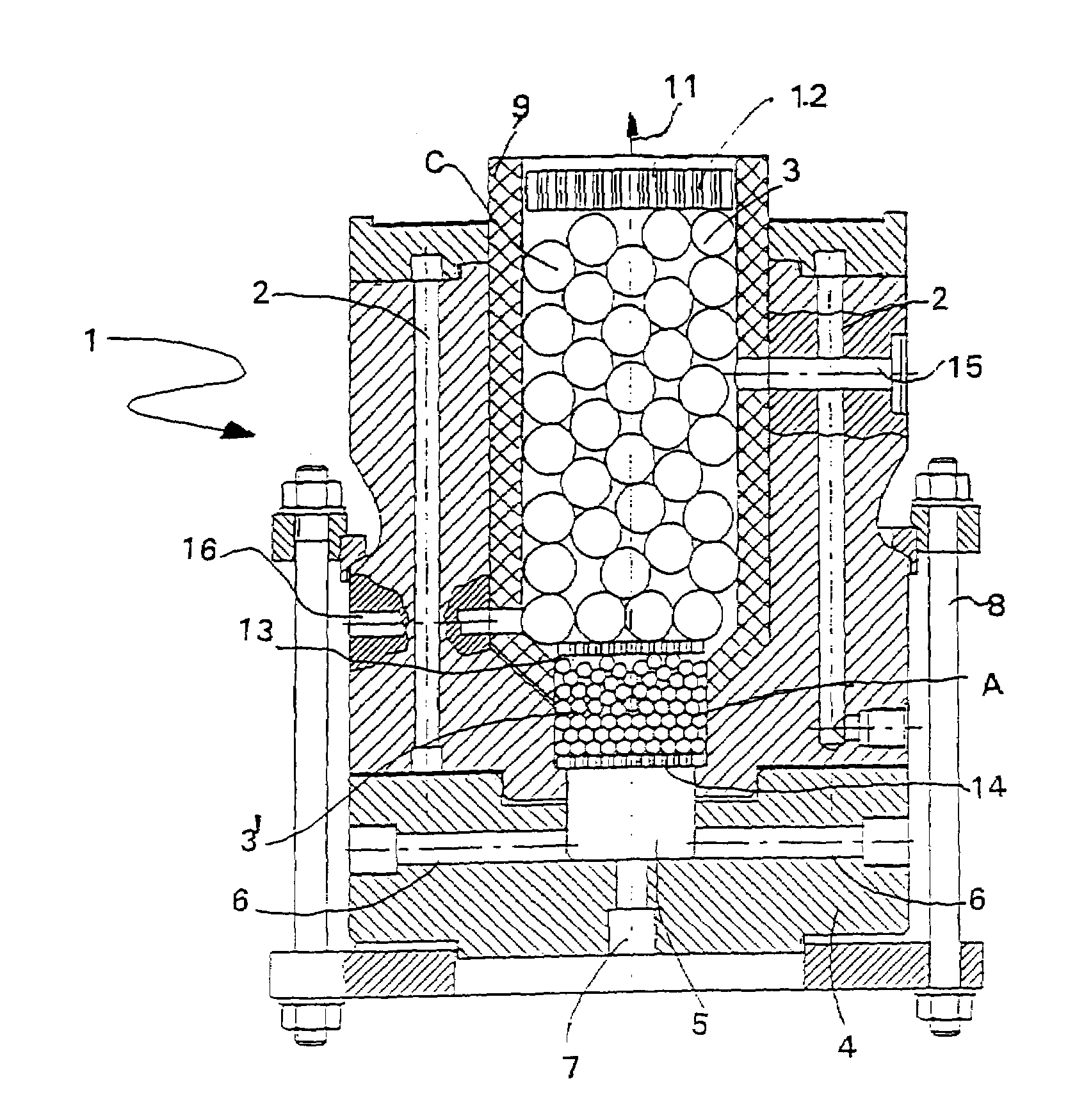

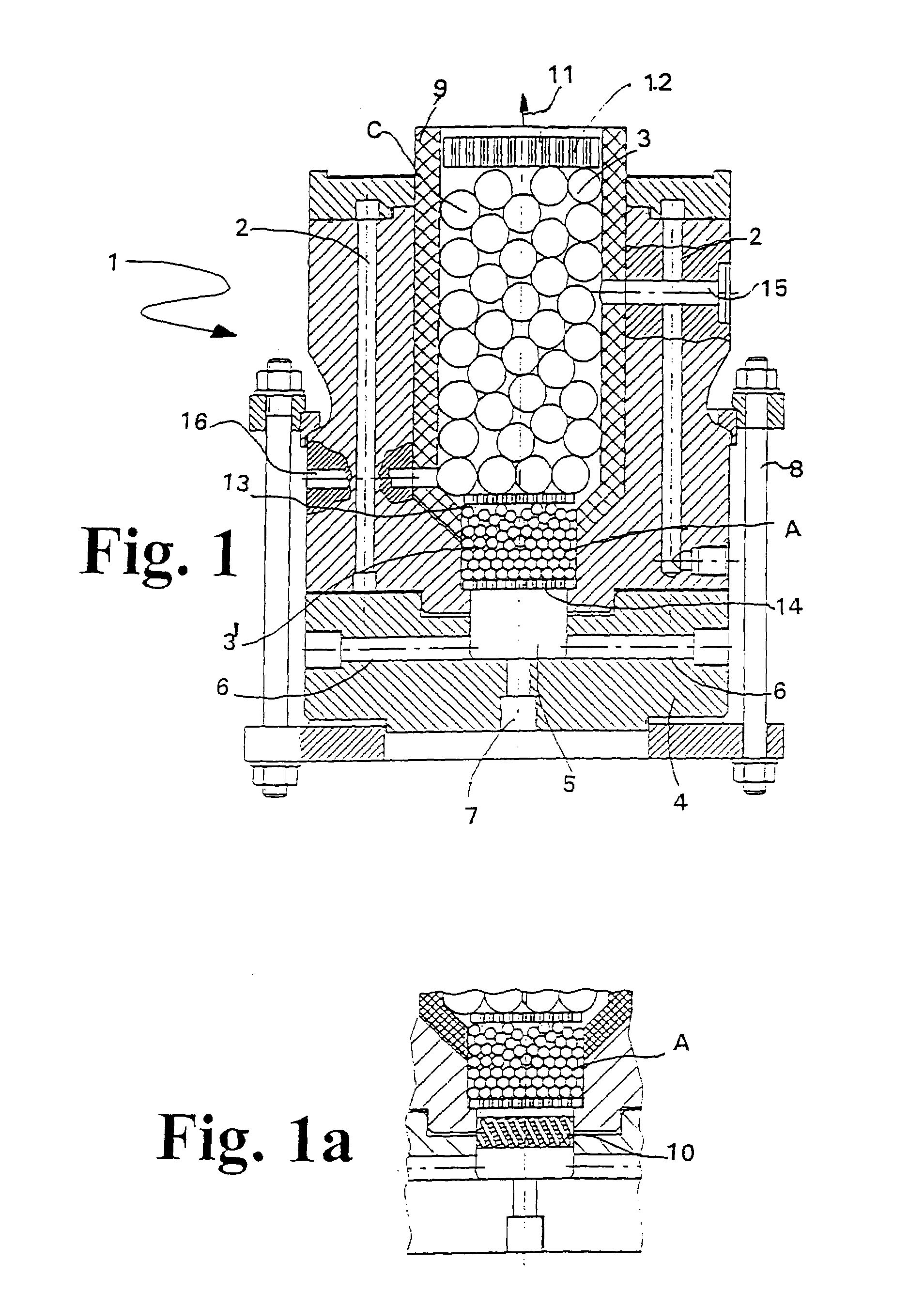

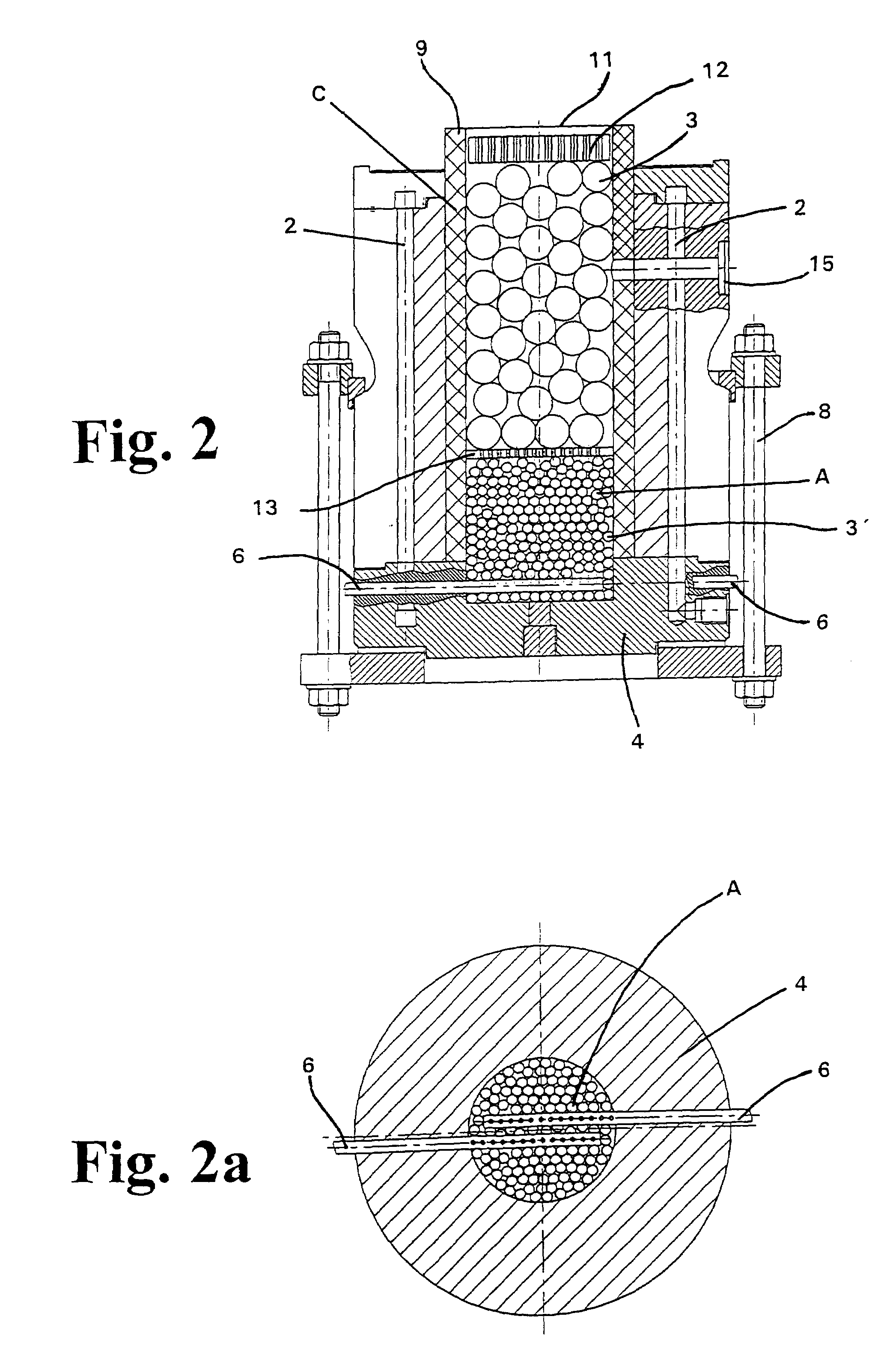

Method for a burner and a corresponding device

InactiveUS7666367B1Less spaceMitigate such drawbackChlorine/hydrogen-chloride purificationPhysical/chemical process catalystsCombustorCombustion chamber

The invention relates to a device equipped with a burner for combusting a fuel / oxidant mixture inside a combustion chamber in which a material (3, 3′, 3″, 3′″) is provided that endures a maximum temperature. The inventive device also comprises one or more supply lines (25, 26) for the fuel as well as for the oxidant which are provided for supplying the same into the combustion chamber. The inventive device is characterized in that it is designed for carrying out a combustion with a combustion temperature of the fuel / oxidant mixture that exceeds the maximum temperature. The device is designed in such a way that at least one additional supply line (30) is provided via which an additional gas having, in particular, a low calorific value can be supplied to the combustion chamber. Said additional gas enables the temperature during combustion to be lowered to a value that is less than the maximum temperature.

Owner:SGL CARBON SE

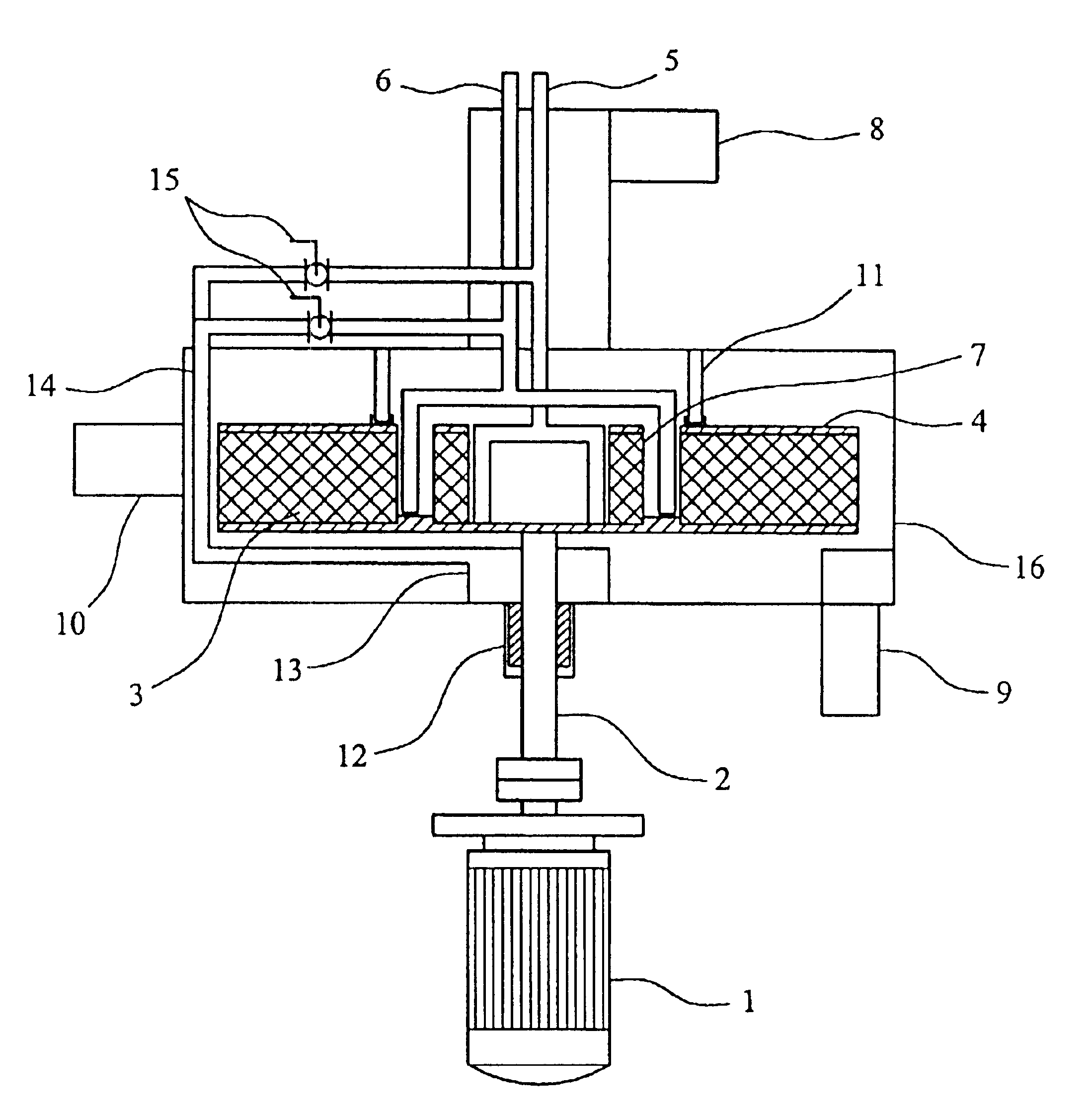

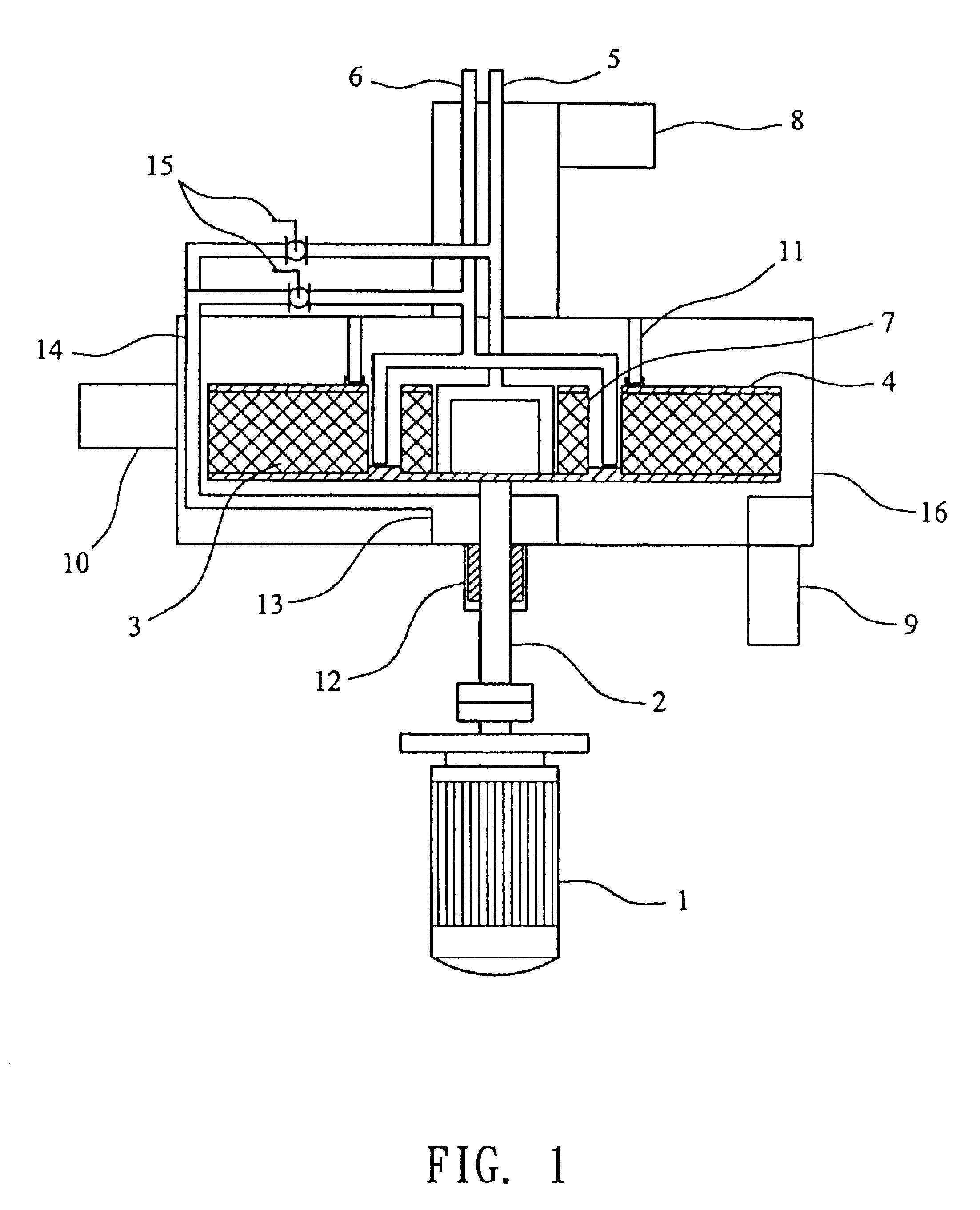

Device and method for preparing hydrogen chloride gas through continuous method full hydrochloric acid analysis

ActiveCN108383085AReduce consumptionLower requirementChlorine/hydrogen-chloride purificationEnergy inputHigh concentrationWater vapor

The invention relates to a device and method for preparing hydrogen chloride gas through continuous method full hydrochloric acid analysis. The device comprises an analysis system and a dilute sulfuric acid vacuum concentration system, wherein the analysis system comprises a hydrochloric acid analysis tower, a first-stage hydrogen chloride cooler, a second-stage hydrogen chloride cooler, a concentrated sulfuric acid drying tower and an acid mist separator; the dilute sulfuric acid vacuum concentration system comprises a dilute sulfuric acid flash tank, an acid-acid heat exchanger, a first-stage sulfuric acid concentration tank, a second-stage sulfuric acid concentration tank, a first-stage washing tower, a first-stage water vapor condenser, a second-stage washing tower, a second-stage water vapor condenser, a wastewater storage tank and a concentrated sulfuric acid intermediate tank. According to the device, high-concentration sulfuric acid serves as an extraction agent, and dilute heat of concentrated sulfuric acid is fully utilized; meanwhile, the concentrated sulfuric acid is continuously added from the top of the hydrochloric acid analysis tower so that the reflux ratio of thetop of the hydrochloric acid analysis tower can be reduced to the minimum, and the energy consumption is reduced to the maximum extent; a segmented vacuum concentration technology is adopted, and waste heat of later-stage acid is fully utilized, so that the heating steam consumption is reduced to the maximum extent, and technical support is provided for long-period continuous work of the device.

Owner:杭州东日节能技术有限公司

Combined absorption analytical method for hydrochloric acid

InactiveCN101214923ANo pollution in the processIncrease relative volatilityChlorine/hydrogen-chloride purificationChemical industryWastewaterEmission standard

The invention relates to a hydrochloride combined absorption and analytic method, which includes the following steps: concentrated hydrochloric acid in a concentrated hydrochloric acid tank enters into a concentrated acid analytic tower through a pump and a double-effect heat exchanger to be analyzed, and partial hydrogen chloride gas is obtained; the no-analyzed dilute hydrochloric acid enters into a dilute acid tank through the double-effect heat exchanger and a cooler; calcium chloride solution in dilute hydrochloric acid and calcium chloride concentration towers goes through a pump, is mixed and enters into a dilute acid tower to be analyzed, the hydrogen chloride gas is obtained; the dilute calcium chloride solution with trace hydrochloride in a dilute hydrochloride analytic tower enters into the calcium chloride concentration tower to be concentrated, waste water within hydrochloride meeting the emission standard is obtained; the concentrated calcium chloride flows back to a calcium chloride preparing tank. The invention improves the recovery rate (99.99 percent) of the hydrogen chloride, reduces the neutralization procedure, resource waste and environmental pollution of the waste water, and can also used together with the processes of the upstream industry.

Owner:XINJIANG TIANYE GRP

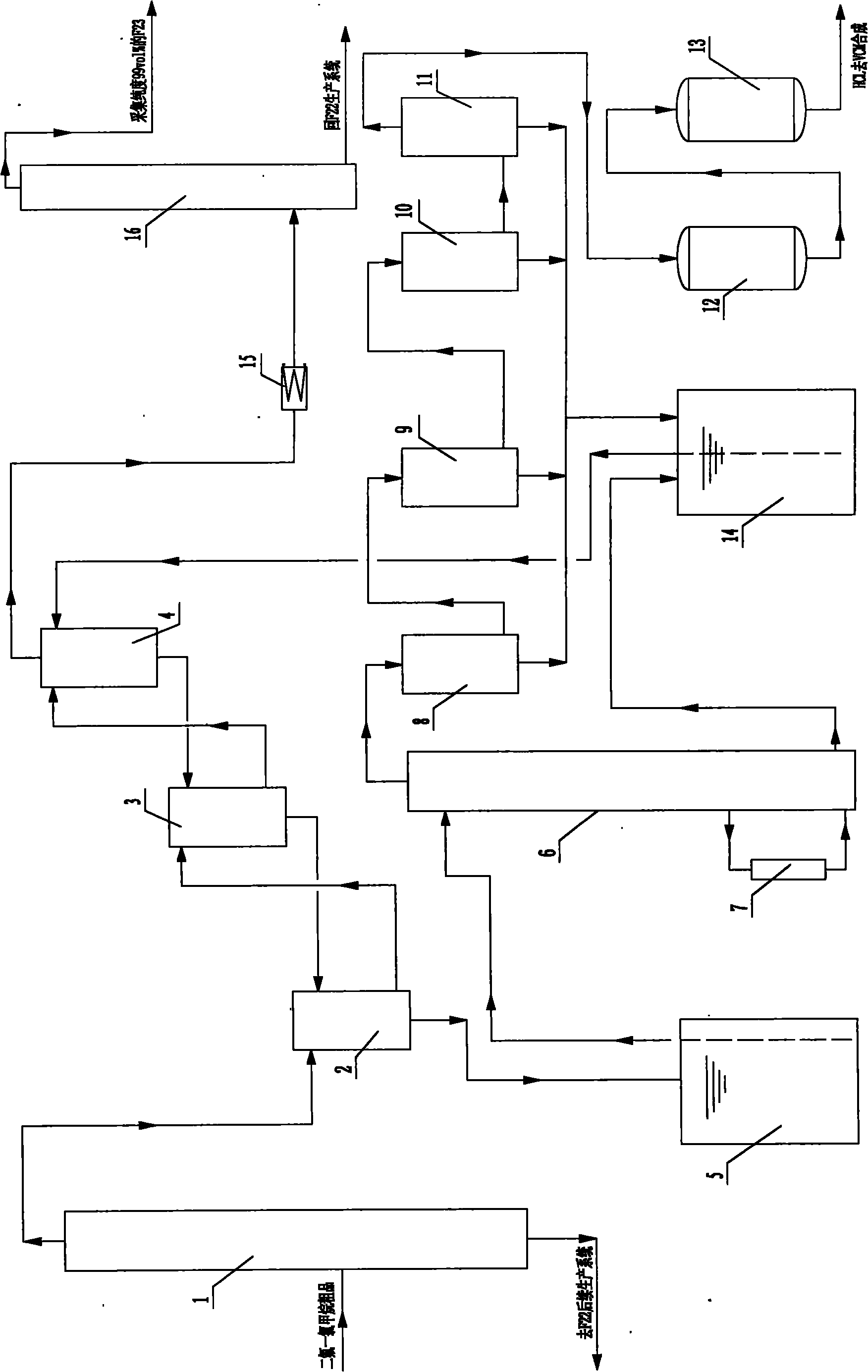

Method and device for refining chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane

ActiveCN102101651AAchieve cycle productionAvoid pollutionChlorine/hydrogen-chloride purificationHalogenated hydrocarbon separation/purificationPolyvinyl chlorideWater resources

The invention relates to a method for refining a chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane. Refined high-purity chlorine hydride can directly serve as a raw material for synthesizing vinyl chloride monomers; and the trifluoromethane byproduct separated in the refining process can be effectively recovered, wherein the refining of the HCl comprises the following steps of: crude separation, absorption, analysis, condensation, capture of acid mist, and adsorption; and after a F23 byproduct in the production of the monochlorodifluoromethane is separated in the absorption process in the refining of the HCl, the F23 byproduct is subjected to lossless compression and rectification to form the trifluoromethane with the purity of over 99 vol percent. By combining the recovery and comprehensive utilization of the HCl and the recovery of the trifluoromethane, the high consumption of water resources and liquid caustic soda is avoided, and the production cost of the monochlorodifluoromethane is reduced; and the effective recovery of the trifluoromethane prevents environmental pollution, and the chloroalkali, the monochlorodifluoromethane and polyvinyl chloride (PVC) can be circularly produced.

Owner:SHANDONG DONGYUE CHEM

Method for removing volatile components from a high viscosity liquid by using rotation pack bed

InactiveUS6884401B2Chlorine/hydrogen-chloride purificationDispersed particle separationSuction forceGas phase

A high viscosity liquid is fed into a rotation pack bed at a position with a distance far enough from a rotation axis, creating a centrifugal force exerted on the high viscosity liquid overwhelming a drag thereof, so that it can flow radially through the rotation pack bed. A high pressure gas is introduced into the rotation pack bed peripherally and / or a suction force source is connected to a position near the rotation axis, so that a volatile component contained in the high viscosity fluid is entrained in the gas counter currently flowing through the rotation pack bed and withdrawn from the position near the rotation axis, or the volatile component exits from the position near the rotation axis in gas phase, and thus the volatile component is removed from the high viscosity liquid. A second fluid can also be fed into the rotation pack bed to react with the high viscosity liquid, so that a reaction product is formed, and a volatile side product is removed at the same time.

Owner:IND TECH RES INST

Method for refining hydrochloric acid as byproduct in procedure for producing chemical products of chlorinated hydrocarbons

ActiveCN1562733AHydrogen chloride concentration has no effectNo smellChlorine/hydrogen-chloride purificationBenzeneChlorobenzene

The method includes following steps, (A) adsorption: to filter industrial by-product hydrochoric acid containing organic substances (benzene, methylbenene, chlorobenzene and triclene etc.) from tens to hundreds, the organic substance in the by-product hydrochoric acid is absorbed on resin by adsorption tower filled with phenylethene and styrene-divinglbenzene large aperture adsorbing resin, the by-product hydrochoric acid being absorbed is colourless and transparent, the content of organic substance can be reduced below 1 mg / L. (B) deadsorption; to do deadsorption and regeneration to the larger aperture adsorbing resin which absorbed organic substances during step A that water vapour is used as absorbent agent, the deadsorption temp. is 110-150 deg.C, the time is 2-16 hrs, (C) recovery: to recover the organic substances by gas and liquid deadsorption, oil and water sepaation, the water phase is returned to hydrogen chloride adsorption process to be used generating by-product hydrochloric acid.

Owner:NANJING UNIV

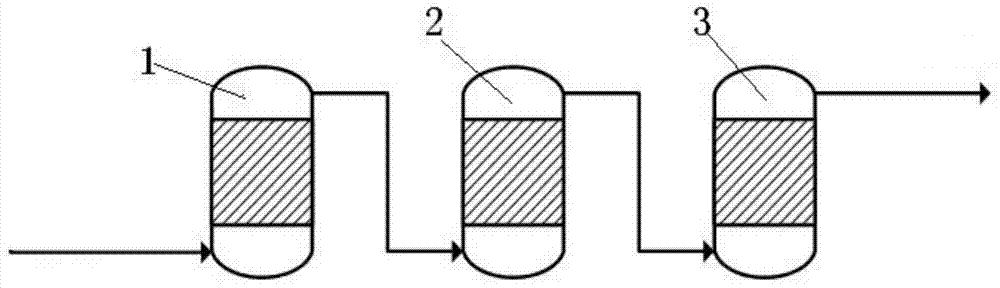

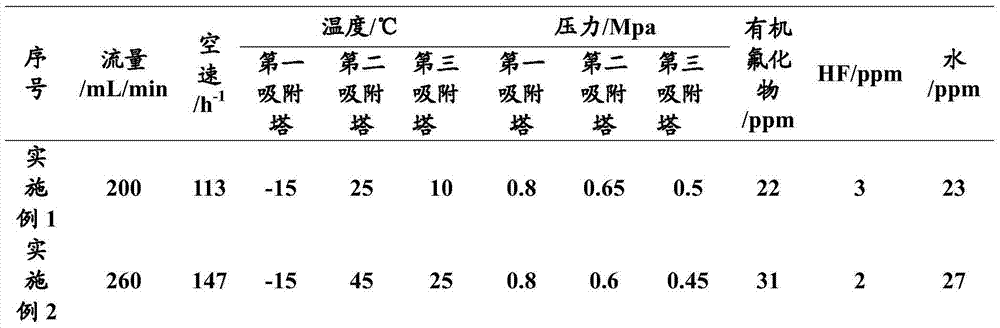

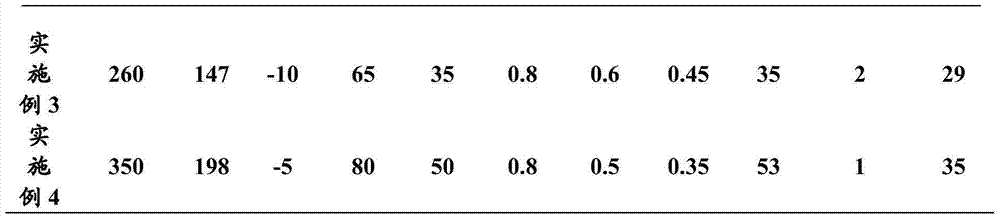

Method for purifying byproduct hydrogen chloride in fluorinated alkane production

ActiveCN103588173AIncrease added valueChlorine/hydrogen-chloride purificationDispersed particle separationSorbentSilica gel

The invention relates to a method for purifying a byproduct hydrogen chloride in fluorinated alkane production. The method comprises the following steps: sequentially passing the byproduct in fluorinated alkane production through a first absorption tower filled with an activated carbon absorbent, a second absorption tower filled with an aluminum oxide absorbent, and a third absorption tower filled with a molecular sieve absorbent and a silica gel absorbent, so as to obtain a hydrogen chloride product, wherein the weight content of the hydrogen chloride in the hydrogen chloride product is less than 5 ppm, the weight content of an organic fluoride is less than 50 ppm, and the weight content of water is less than 50 ppm. The purified hydrogen chloride gas can be used for synthesizing products such as vinyl chloride monomers, metal chloride, chlorocarbon and trichlorosilane, and raw materials for preparing chlorine in a oxychlorination mode, the application range of the byproduct hydrogen chloride gas is widened, the additional value is improved, and compared with the conventional process that the hydrogen chloride gas is converted into a byproduct hydrochloric acid, the method has remarkable economic benefits.

Owner:太仓中化环保化工有限公司

Process for the production of hcl gas from chloride salts and for the production of carbohydrates

InactiveUS20110178290A1Weak acidImprove hydrophilicityChlorine/hydrogen-chloride purificationPhosphatesChloride saltWater insoluble

A process for the co-production of gaseous HCl and a salt product comprising a cation and an anion, which process comprises the steps of a. providing an aqueous solution comprising protons, chloride anions, and cations and anions of the salt product, b. bringing the solution into contact with a substantially immiscible extractant, the extractant comprising: 1) an oil soluble amine, which amine is substantially water insoluble both in free and in salt form; and 2) a carrier solvent for the amine; whereupon HCl selectively transfers to the extractant to form an HCl-carrying extractant and a chloride depleted aqueous solution containing the salt product; c. separating the HCl-carrying extractant from the chloride-depleted aqueous solution; and d. distilling HCl from the separated HCl-carrying extractant to form gaseous HCl and HCl depleted extractant.

Owner:VIRDIA

Popular searches

Hydrocarbon from saturated and unsaturated hydrocarbon addition Chemical recycling Filter regeneration Molecular sieve catalysts Organic-compounds/hydrides/coordination-complexes catalysts Catalyst regeneration/reactivation Combustible gas purification Catalytic reactions Hydrocarbons Fluorine/hydrogen-fluoride

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com