Green and environment-friendly recycling method of trichlorosilane tail gas

A trichlorosilane, green and environmentally friendly technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, hydrogen separation, etc., can solve the problems of absorption liquid consumption, pollution sources, and affecting the rectification process, so as to reduce energy consumption and eliminate tail gas The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

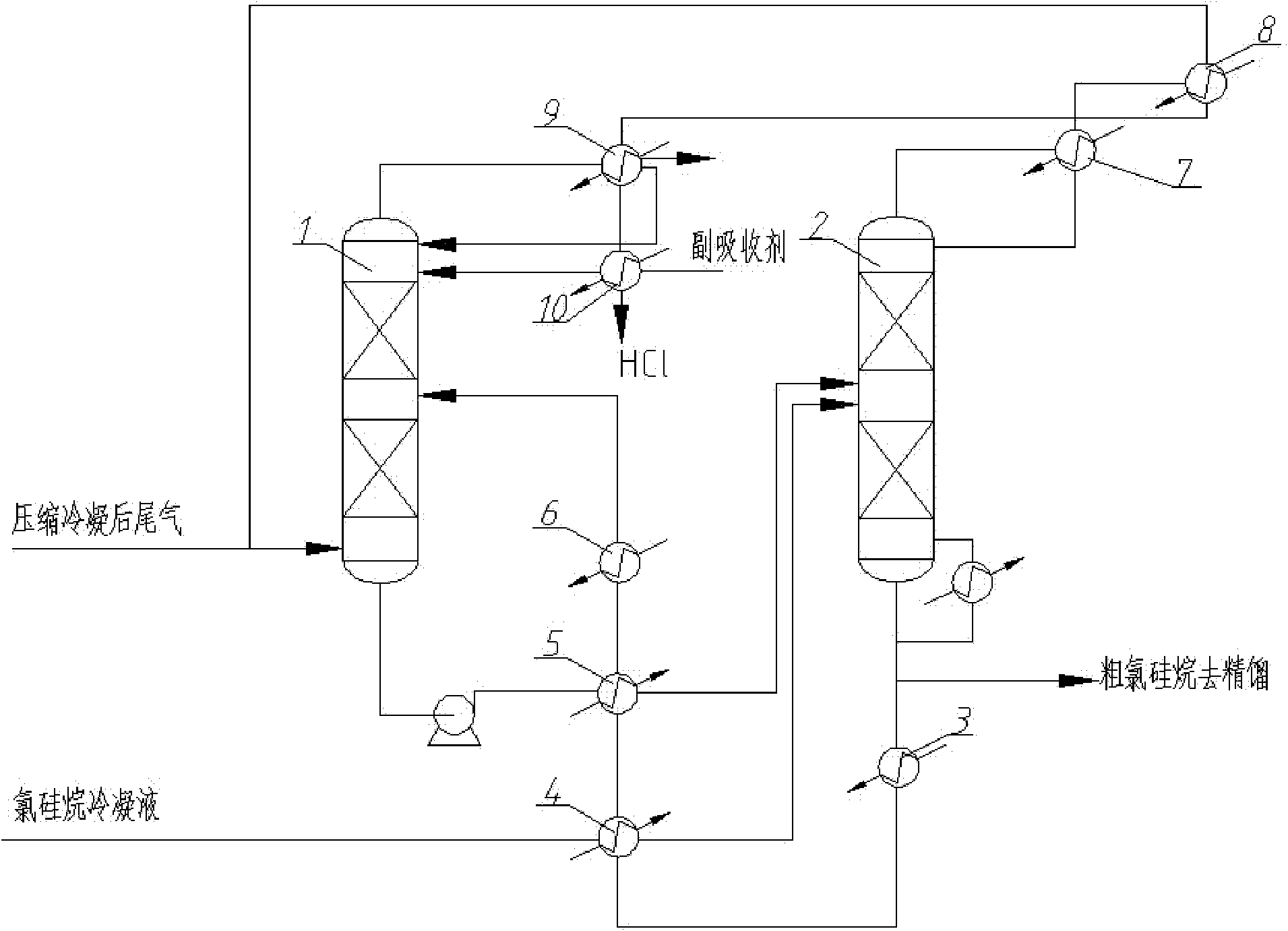

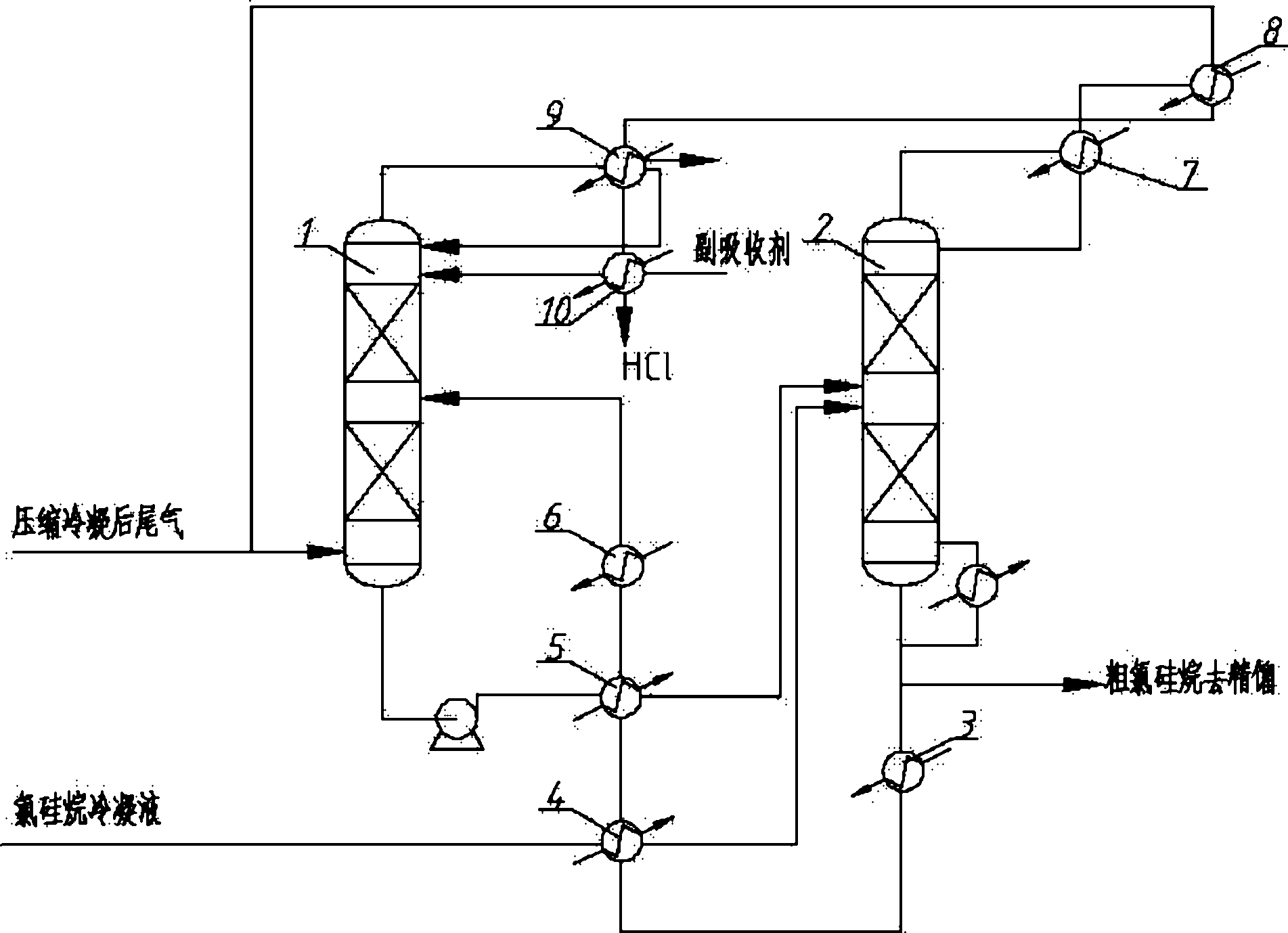

[0029] (1) The tail gas that synthetic trichlorosilane produces is sent into absorption tower 1 with the pressure of 0.4MpaA (absolute pressure) (the composition sees the condensed tail gas composition in Table 2), and the tower top operating pressure of absorption tower is lower than the pressure of tail gas 15kPaA; the absorption tower adopts two-stage absorption, the main absorption liquid is the thick chlorosilane after removing hydrogen and hydrogen chloride, the secondary absorbent is silicon tetrachloride, and the secondary absorbent expands with the second hydrogen chloride before entering the absorption tower. The cooler is cooled to -55°C by heat exchange and then enters the absorption tower. The amount of secondary absorbent accounts for 2.3% of the weight of the main absorbent. The hydrogen gas discharged from the top of the absorption tower is refluxed to the top of the absorption tower through the liquid phase components cooled by the first hydrogen chloride expan...

Embodiment 2

[0035] (1) the tail gas that will synthesize trichlorosilane to produce is sent into absorption tower 1 with the pressure of 0.6MpaA (absolute pressure) (the composition sees the condensed tail gas composition in Table 2), and the tower top operating pressure of absorption tower is lower than tail gas The pressure is 20kPaA; the absorption tower adopts two-stage absorption, the main absorption liquid is crude chlorosilane after removing hydrogen and hydrogen chloride, the secondary absorbent is silicon tetrachloride, and the secondary absorbent expands with the second hydrogen chloride before entering the absorption tower The refrigerator enters the absorption tower after heat exchange and cooling to -60°C, and the amount of secondary absorbent accounts for 2% of the weight of the main absorbent. The hydrogen gas discharged from the top of the absorption tower is refluxed to the top of the absorption tower through the liquid phase components cooled by the first hydrogen chlorid...

Embodiment 3

[0041] (1) The tail gas that synthetic trichlorosilane produces is sent into absorption tower 1 with the pressure of 0.5MpaA (absolute pressure) (the composition sees the condensed tail gas composition in Table 2), and the tower top operating pressure of absorption tower is lower than the pressure of tail gas 10kPaA; the absorption tower adopts two-stage absorption, the main absorption liquid is the thick chlorosilane after removing hydrogen and hydrogen chloride, the secondary absorbent is silicon tetrachloride, and the secondary absorbent expands with the second hydrogen chloride before entering the absorption tower. The cooler is cooled to -50°C by heat exchange and then enters the absorption tower. The amount of secondary absorbent accounts for 3% of the weight of the main absorbent. The hydrogen gas discharged from the top of the absorption tower is refluxed to the top of the absorption tower through the liquid phase components cooled by the first hydrogen chloride expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com