Method and device for refining chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane

A technology of difluorochloromethane and trifluoromethane, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chlorodifluoromethane production, etc., and can solve problems that do not involve effective recovery of trifluoromethane, cooling water, high steam consumption, High infrastructure investment costs and other issues, to achieve the effects of strong production continuity and operability, reduced consumption, and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

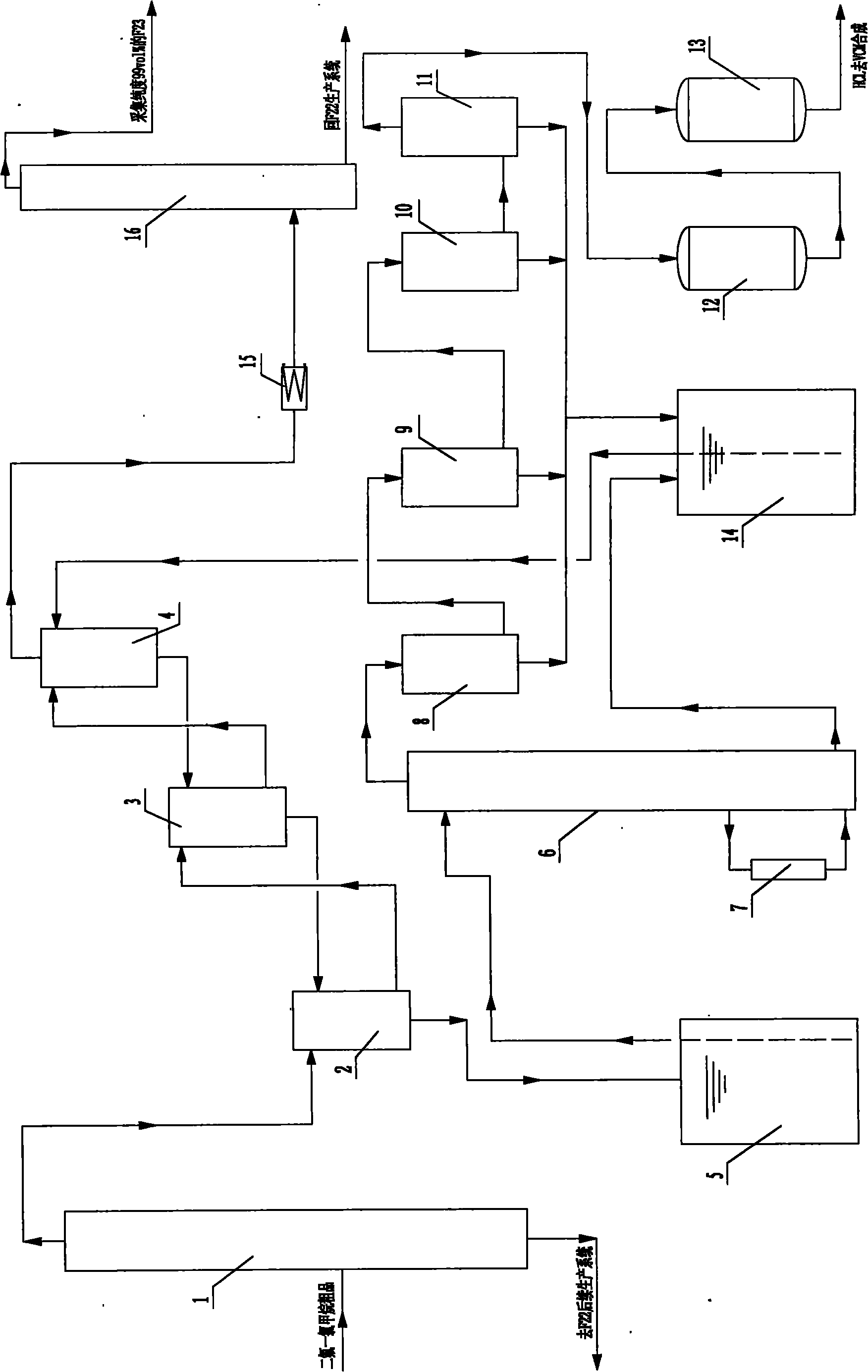

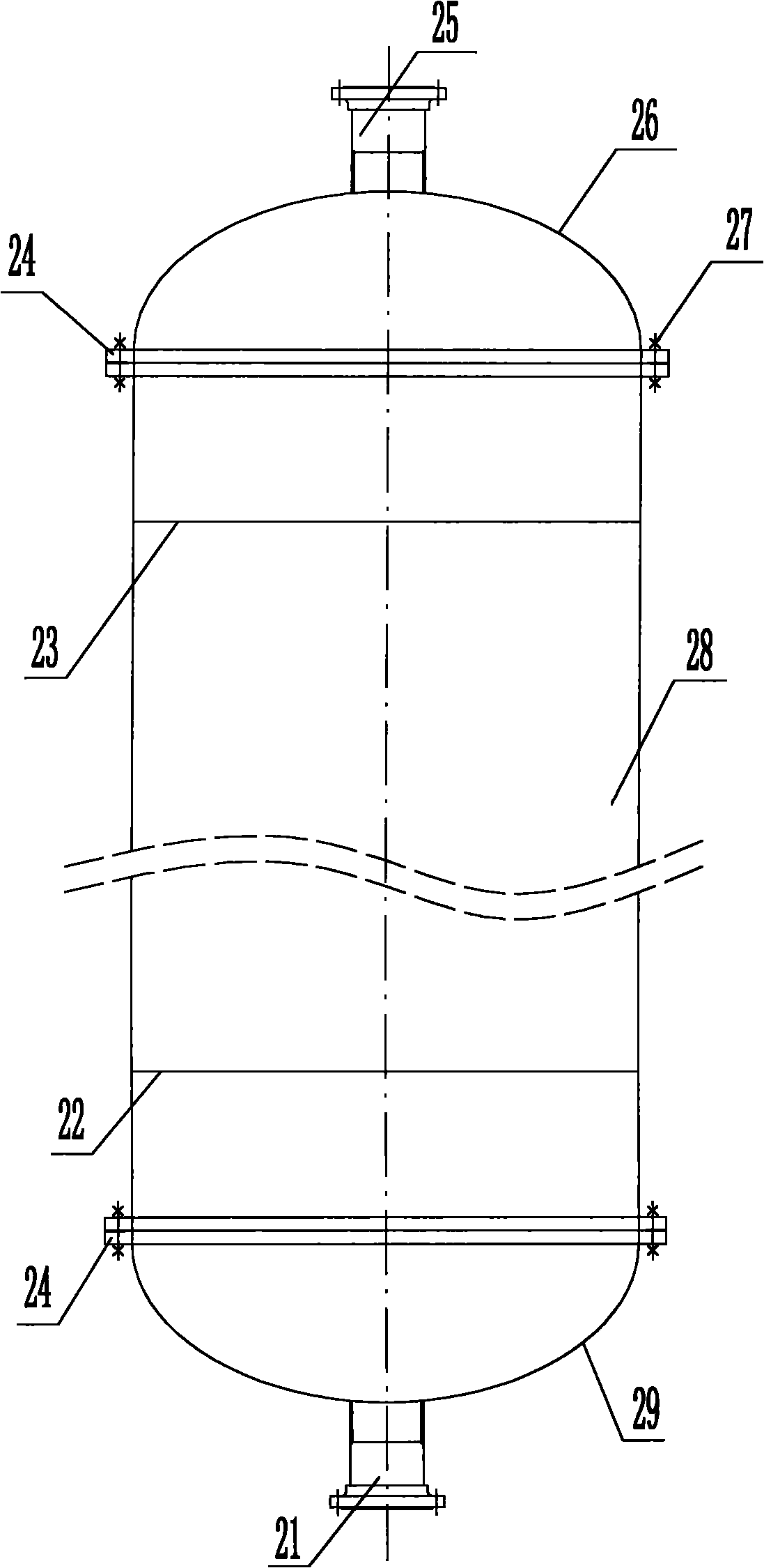

[0047] Process flow chart such as figure 1 As shown, the devices used include hydrogen chloride tower 1, primary, secondary, and tertiary graphite absorbers 2, 3, 4, concentrated hydrochloric acid storage tank 5, desorption tower 6, desorption tower reboiler 7, primary, secondary, Tertiary condensers 8, 9, 10, acid mist trap 11, primary and secondary adsorbers 12, 13, dilute hydrochloric acid storage tank 14, F23 recovery compressor 15, F23 rectification tower 16. Wherein, the hydrogen chloride tower 1 is an internal reflux stainless steel casting packed tower, and the filler is a stainless steel wire mesh corrugated packing or Pall ring; the first-level graphite absorber 2, the second-level graphite absorber 3 and the third-level graphite absorber 4 are connected in series , the bottom of the first-stage graphite absorber 2 is connected to the concentrated hydrochloric acid storage tank 5, the upper part of the third-stage graphite absorber 4 is connected to the dilute hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com