Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129 results about "Chlorodifluoromethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorodifluoromethane or difluoromonochloromethane is a hydrochlorofluorocarbon (HCFC). This colorless gas is better known as HCFC-22, or R-22. It is commonly used as a propellant and refrigerant. These applications are being phased out in developed countries due to the compound's ozone depletion potential (ODP) and high global warming potential (GWP), although global use of R-22 continues to increase because of high demand in developing countries. R-22 is a versatile intermediate in industrial organofluorine chemistry, e.g. as a precursor to tetrafluoroethylene. R-22 cylinders are colored light green.

Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

The invention relates the multicomponent mixed working substance used for preparing dual-temperature by single-machine vapor compression refrigerator. The low temperature is between -60- -40Deg.C and the high temperature is between -25- 10Deg.C. The multicomponent mixed working substance comprises lower boiling working substance and high boiling working substance. The lower boiling working substance comprises tetrafluoromethane, ethylene, ethane, fluoroethylene, trifluoromethane, fluoromethane, hydrofluoeic ether, carbon dioxide, difluoromethane and penfluoroethane; the high boiling working substance comprises trifluoro-thane, hydrofluoeic ether, propylene, propane, perfluoropropylamine, propadiene, cyclopropane, difluo-monochloromethane, penta-monochloroethane, perfluoroethane, difluoroethane, isobutene, butane, butylenes, isobutylene, sevofluoropropane, hexafluoropropane, penfluoropropane and tetrachloromonofluoroethane.

Owner:XI AN JIAOTONG UNIV

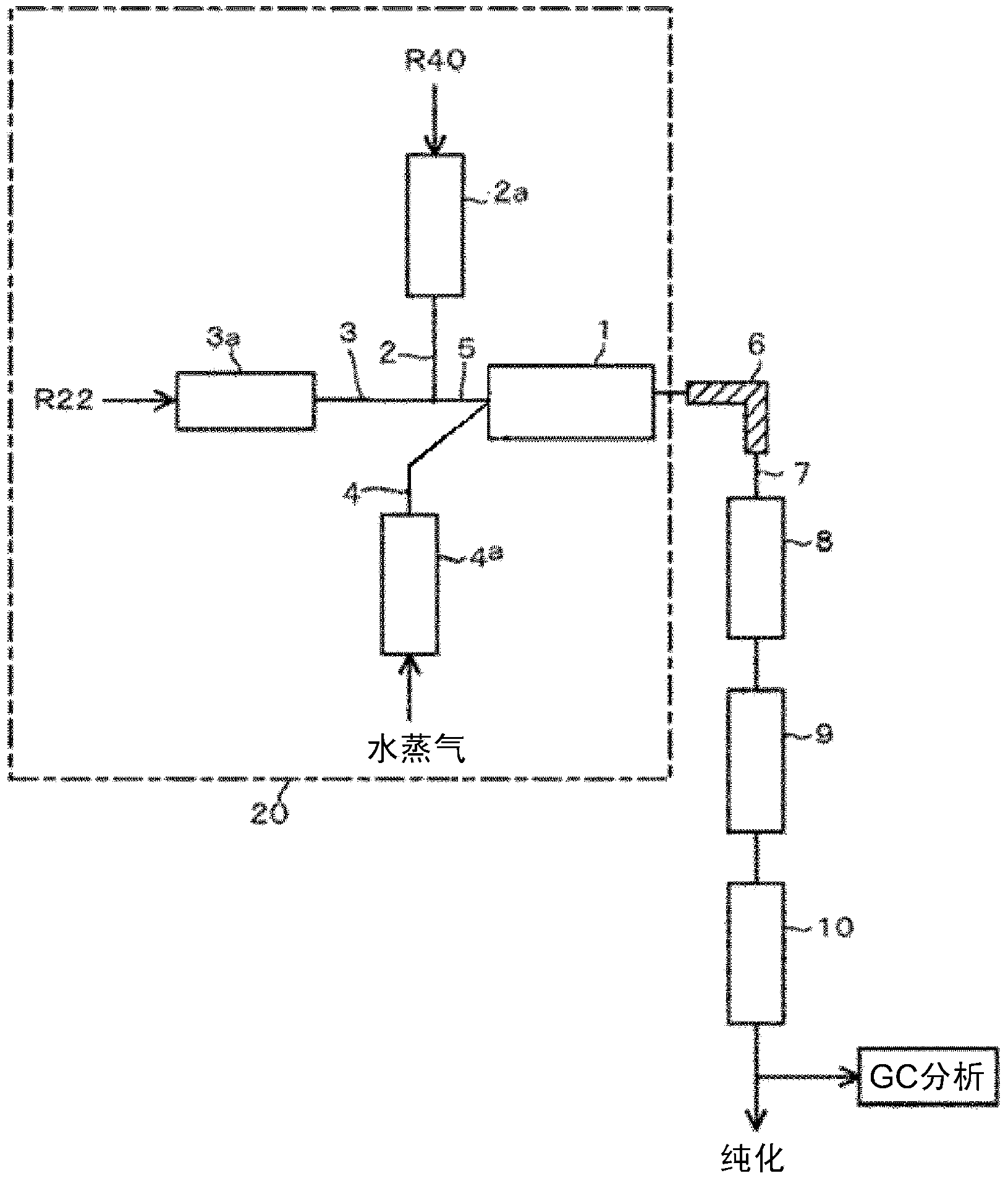

Method for resource utilization of fluoroform

ActiveCN104628513AReduce processing costsReduce equipment investmentPreparation by halogen replacementChemical recyclingHalohydrocarbonResource utilization

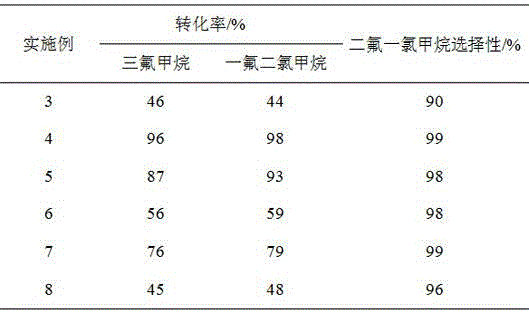

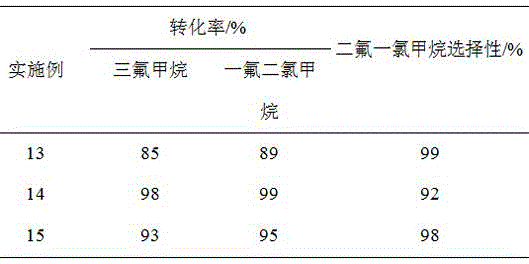

The invention discloses a method for resource utilization of fluoroform. The method is characterized by mixing fluoroform with one or a plurality of halohydrocarbon, converting the mixture into a product containing monochlorodifluoromethane in the presence of a catalyst, and reacting unreacted fluoroform with other reaction products in a reactor. According to the method, chlorofluorocarbon containing chlorine or bromine or chlorofluorocarbon which contains chlorine or bromine and needs to be processed during a production process is utilized as reaction material to perform chlorine / fluorine exchange reaction with fluoroform to prepare monochlorodifluoromethane, better economic benefits and social benefits are provided; and in products, monochlorodifluoromethane can be recycled though separation, remained waste gas does not need to be processed, and can still enter the reactor as gas reacted with fluoroform, the conversion rate of reactants is improved, and zero-discharge is realized.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

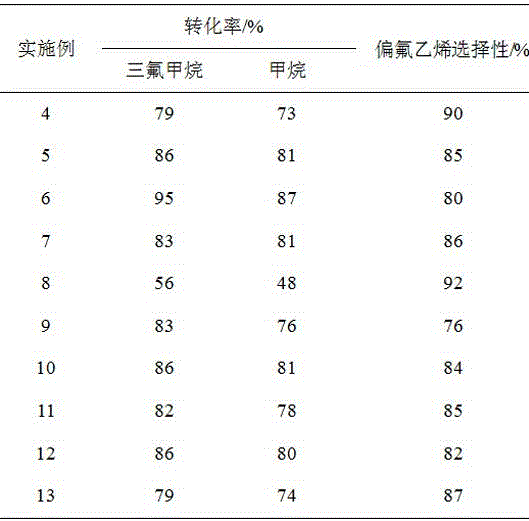

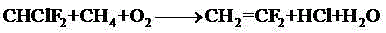

Preparation method of vinylidene fluoride and preparation method of catalyst used by same

ActiveCN104628514AIncrease added valueImprove conversion rateHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsSocial benefitsOxygen

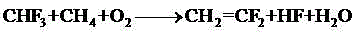

The invention discloses a preparation method of vinylidene fluoride and a preparation method of a catalyst used by the same. The preparation method of vinylidene fluoride comprises the following steps: mixing methane, oxygen and fluoroform or monochlorodifluoromethane or the mixed gas of fluoroform and monochlorodifluoromethane at any ratio or the mixed gas of multiple gases including fluoroform and monochlorodifluoromethane; adding O2 at a certain proportion, and reacting at a temperature of 550-1,050 DEG C under a total pressure of 1-10bar and at an air speed of 50-10,000h<-1>; and reacting in the presence of a catalyst to generate vinylidene fluoride. According to the method disclosed by the invention, the vinylidene fluoride with relatively high added value is generated under a catalytic action from several waste fluoroform raw materials which are cheap or need forced treatment, has relatively high added value, and brings good economic and social benefits.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Refrigerant composition

InactiveUS20030001132A1Domestic cooling apparatusLighting and heating apparatus1,1-DifluoroethaneButane

The present invention relates to a refrigerant composition of four-constituent system, comprising: (a) a first constituent of difluoromethane, (b) a second constituent of 1,1,1,2,3,3,3-heptafluoropropane, (c) a third constituent selected from the group consisting of 1,1,1,2-tetrafluoroethane and 1,1-difluoroethane and (d) a for the constituent selected from the group consisting of isobutane, 1,1,1,2,3,3,-hexafluoropropane and butane, useful as a substitute for chlorodifluoromethane (HCFC-22).

Owner:KOREA INST OF SCI & TECH

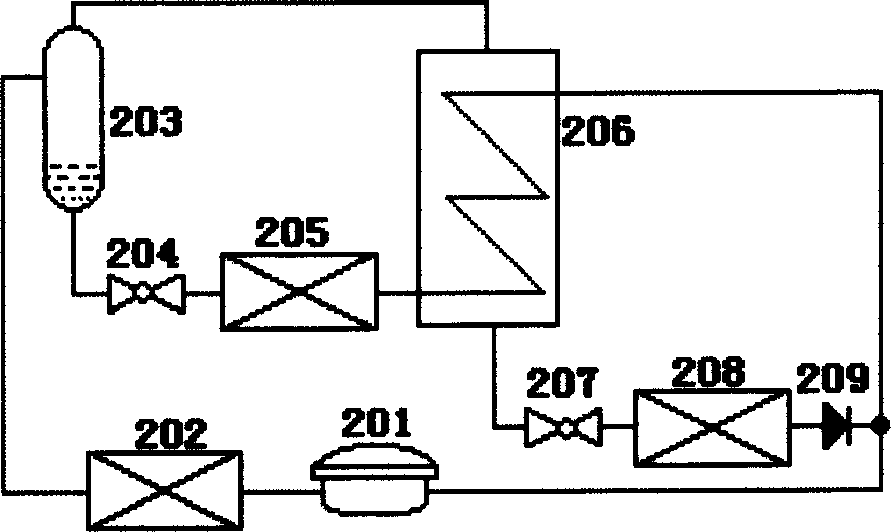

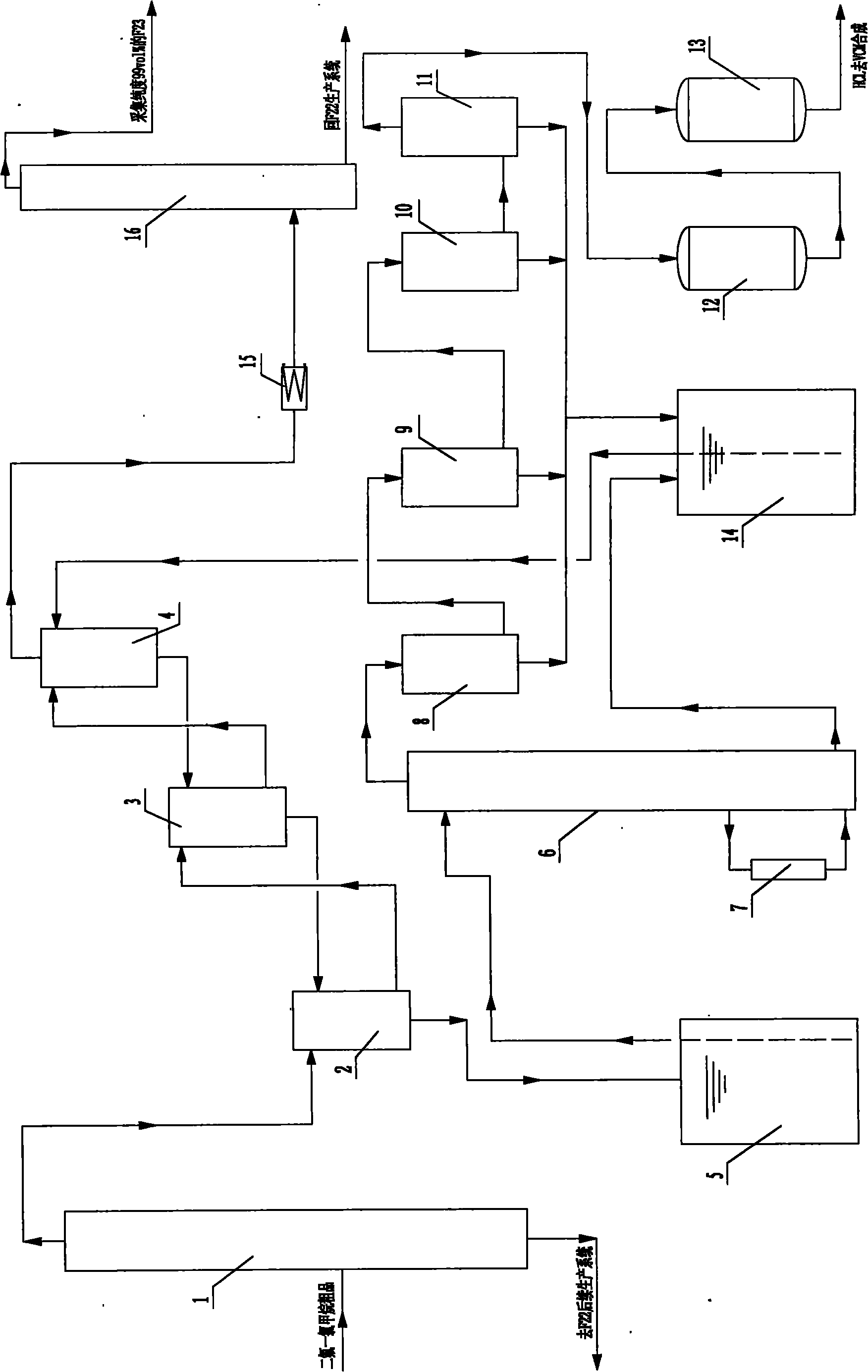

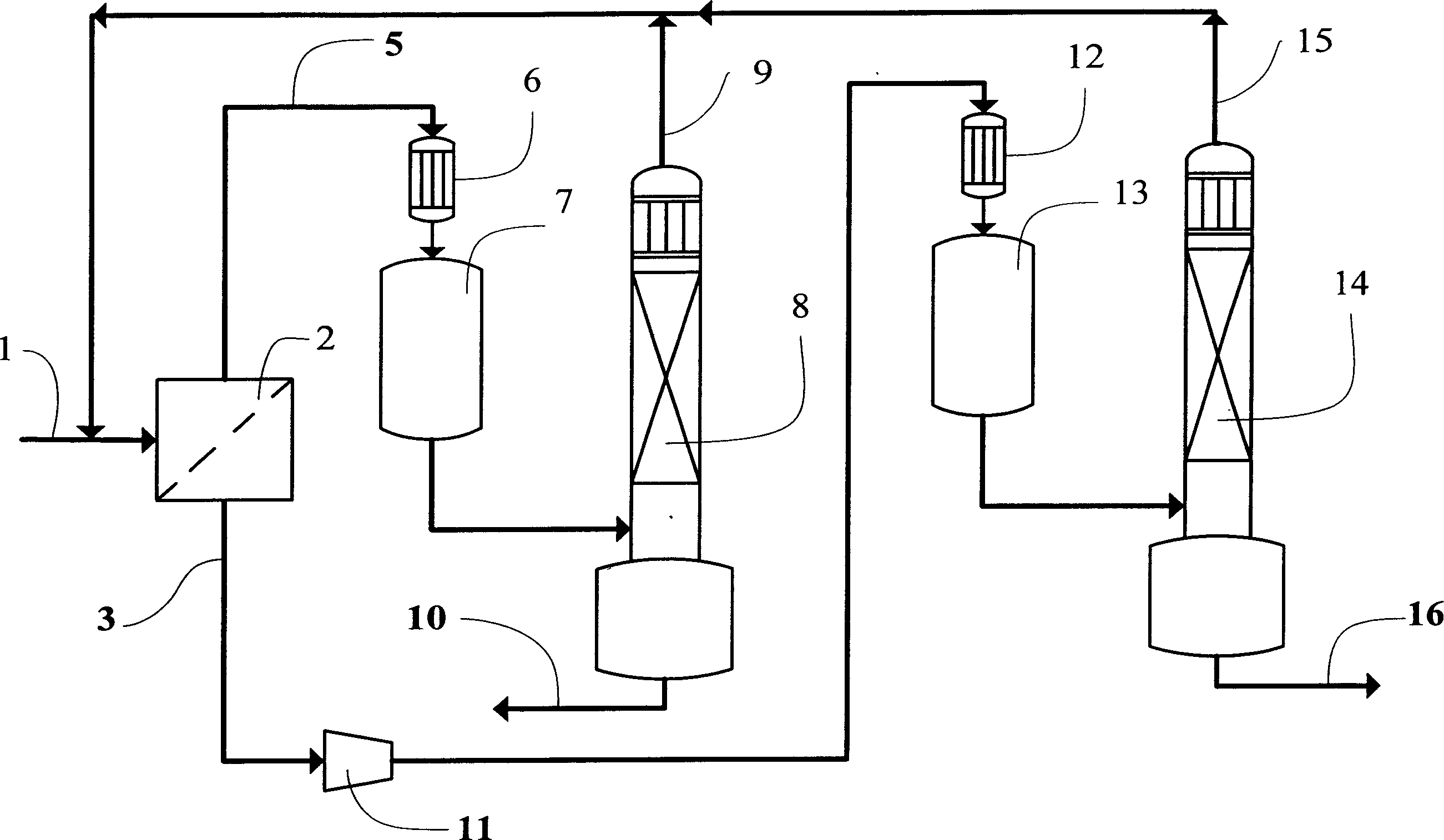

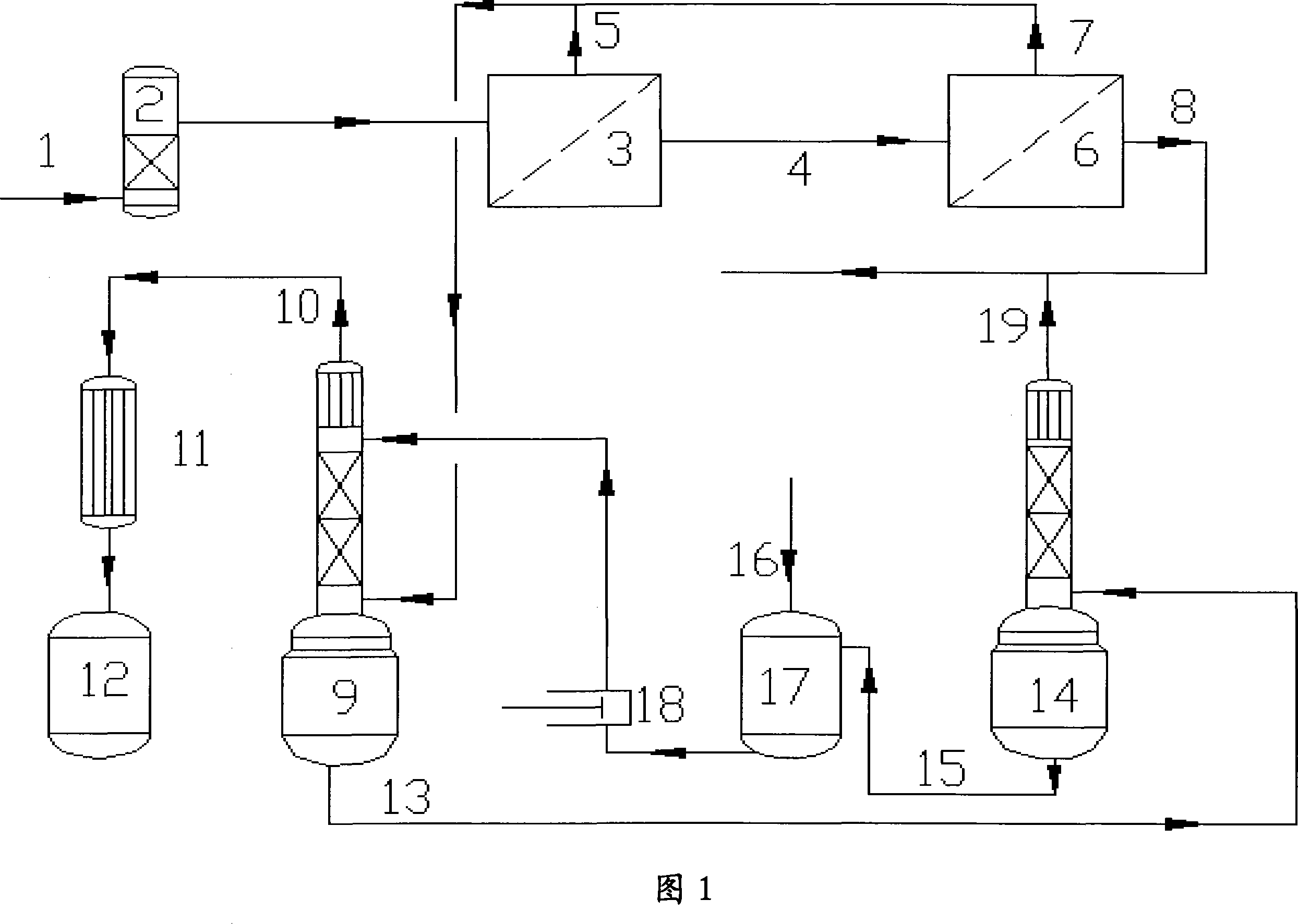

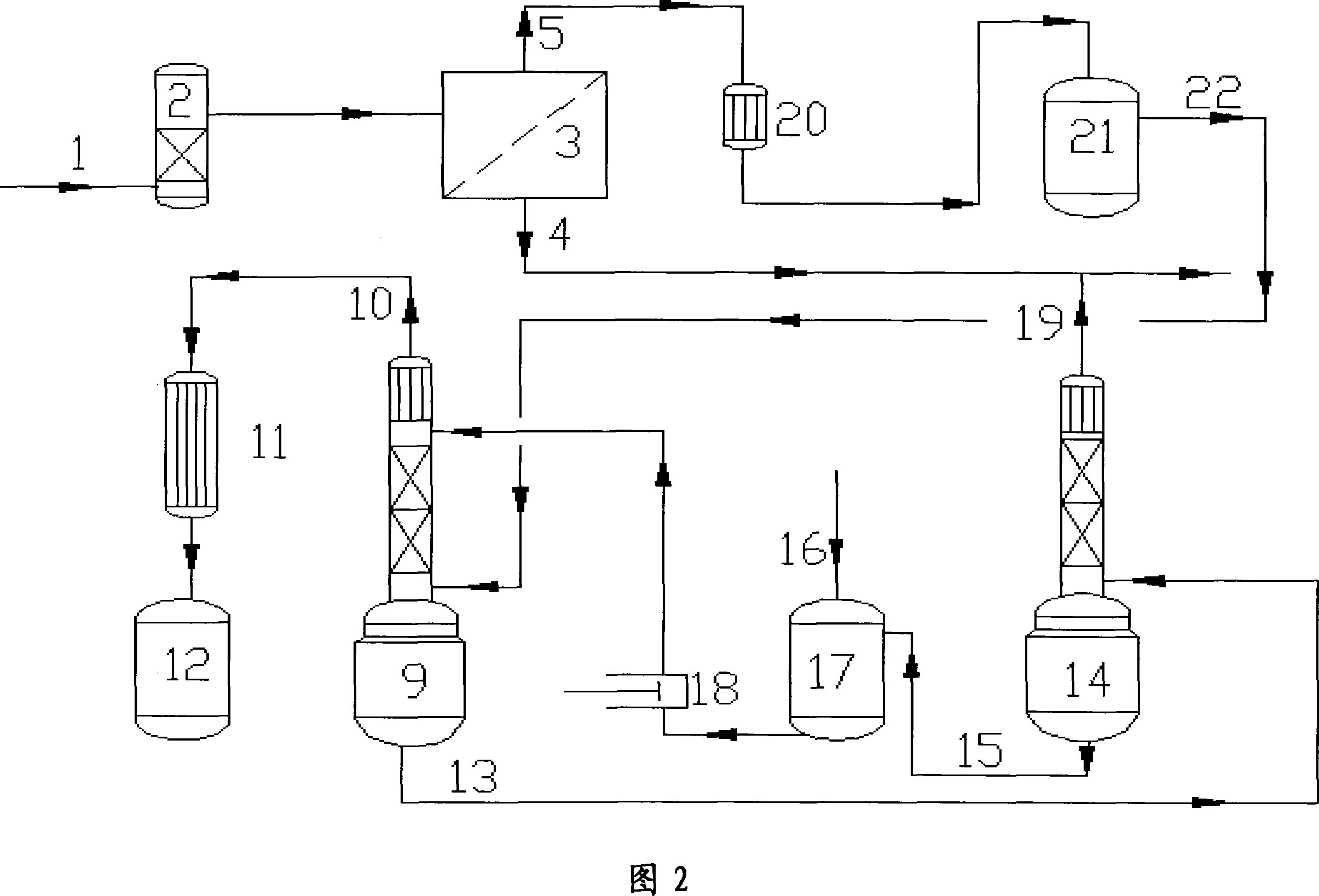

Method and device for refining chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane

ActiveCN102101651AAchieve cycle productionAvoid pollutionChlorine/hydrogen-chloride purificationHalogenated hydrocarbon separation/purificationPolyvinyl chlorideWater resources

The invention relates to a method for refining a chlorine hydride byproduct and recovering trifluoromethane in production of monochlorodifluoromethane. Refined high-purity chlorine hydride can directly serve as a raw material for synthesizing vinyl chloride monomers; and the trifluoromethane byproduct separated in the refining process can be effectively recovered, wherein the refining of the HCl comprises the following steps of: crude separation, absorption, analysis, condensation, capture of acid mist, and adsorption; and after a F23 byproduct in the production of the monochlorodifluoromethane is separated in the absorption process in the refining of the HCl, the F23 byproduct is subjected to lossless compression and rectification to form the trifluoromethane with the purity of over 99 vol percent. By combining the recovery and comprehensive utilization of the HCl and the recovery of the trifluoromethane, the high consumption of water resources and liquid caustic soda is avoided, and the production cost of the monochlorodifluoromethane is reduced; and the effective recovery of the trifluoromethane prevents environmental pollution, and the chloroalkali, the monochlorodifluoromethane and polyvinyl chloride (PVC) can be circularly produced.

Owner:SHANDONG DONGYUE CHEM

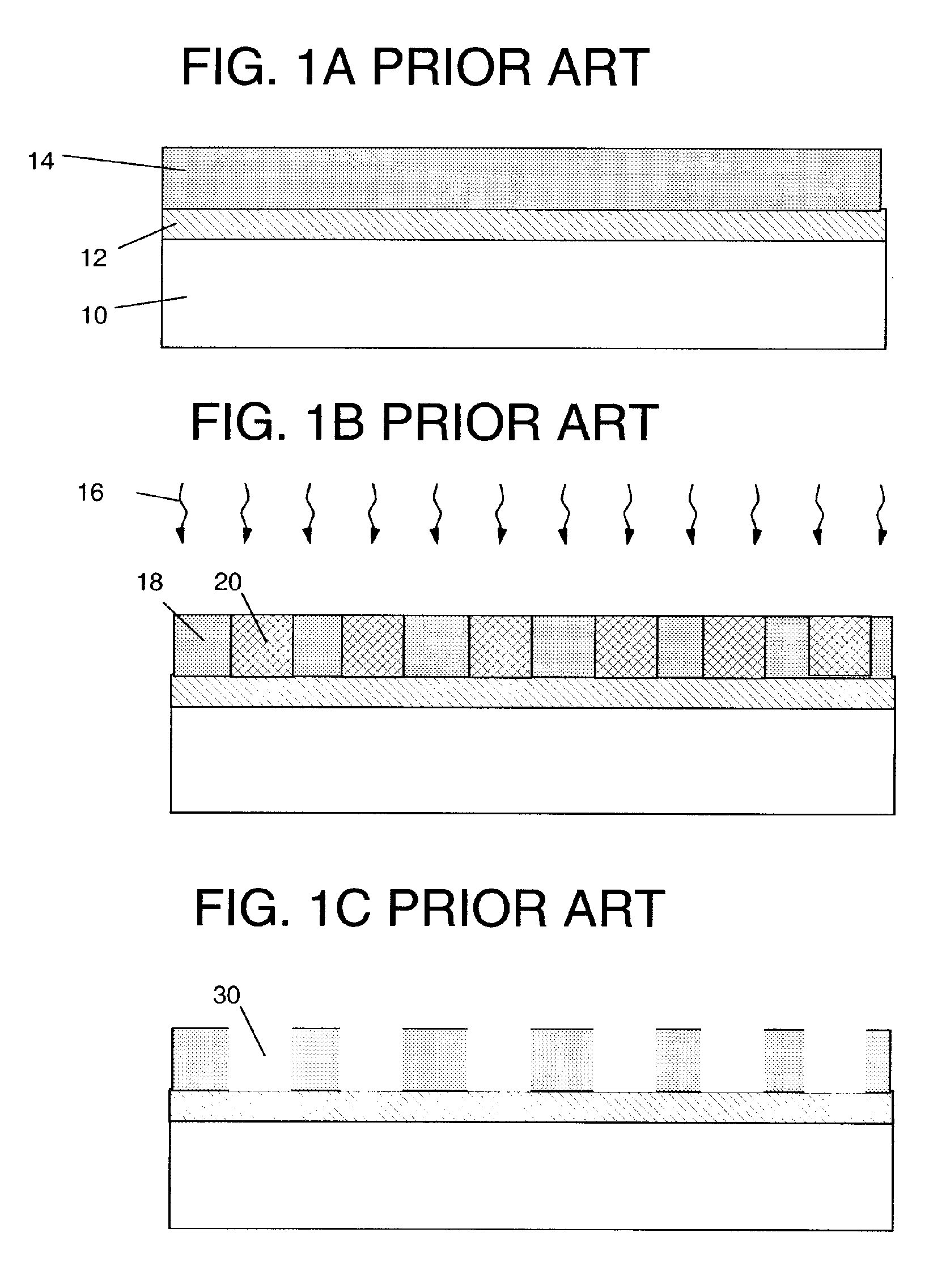

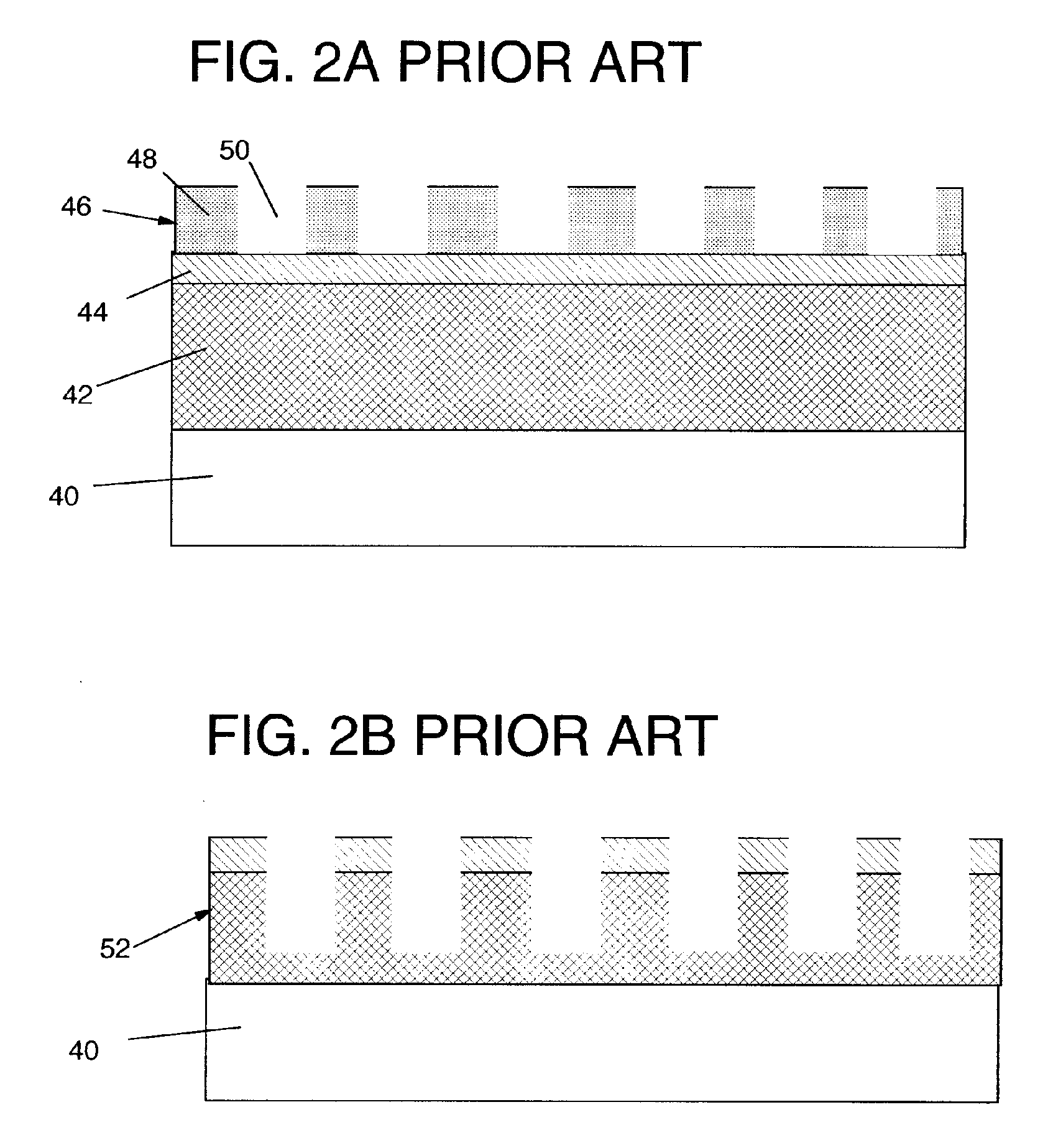

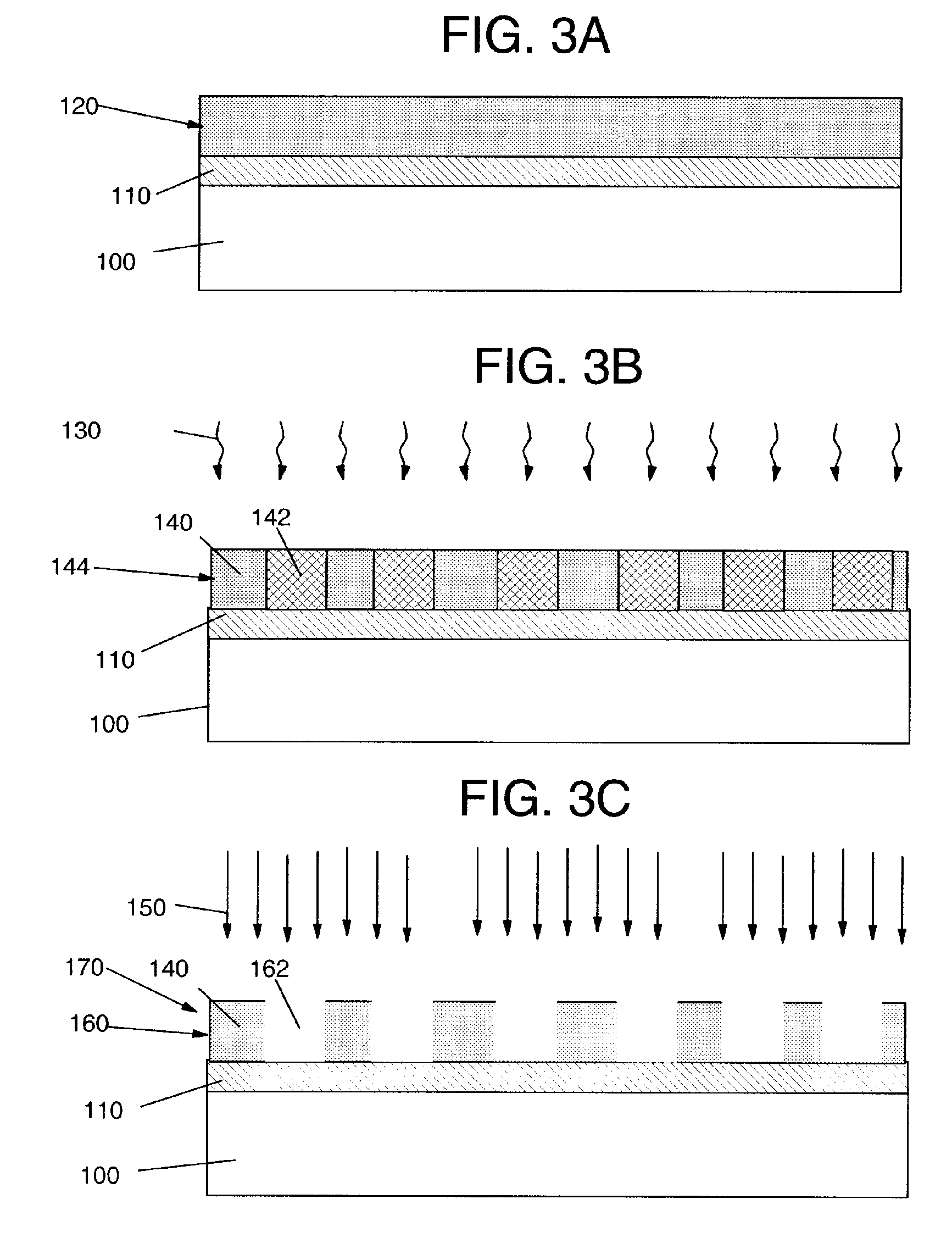

DEVELOPMENT OR REMOVAL OF BLOCK COPOLYMER OR PMMA-b-S-BASED RESIST USING POLAR SUPERCRITICAL SOLVENT

Methods of developing or removing a select region of block copolymer films using a polar supercritical solvent to dissolve a select portion are disclosed. In one embodiment, the polar supercritical solvent includes chlorodifluoromethane, which may be exposed to the block copolymer film using supercritical carbon dioxide (CO2) as a carrier or chlorodiflouromethane itself in supercritical form. The invention also includes a method of forming a nano-structure including exposing a polymeric film to a polar supercritical solvent to develop at least a portion of the polymeric film. The invention also includes a method of removing a poly(methyl methacrylate-b-styrene) (PMMA-b-S) based resist using a polar supercritical solvent.

Owner:IBM CORP

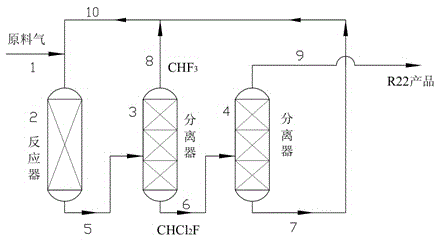

Technique for preparing monochlorodifluoromethane by decomposing trifluoromethane

ActiveCN103467239AReduce outputAvoid harmPreparation by halogen replacementChlorodifluoromethane productionHydrogen fluorideDecomposition

The invention provides a technique for preparing monochlorodifluoromethane by decomposing trifluoromethane. The technique comprises the steps of: feeding the raw materials trifluoromethane and methane chloride into a reactor filled with a catalyst in the mol ratio of 0.1-10, and carrying out a decomposition reaction at a temperature ranging from 150 to 350 DEG C for 3-30 seconds to obtain a mixture of trifluoromethane, methane chloride, dichloromonofluoromethane and monochlorodifluoromethane; obtaining monochlorodifluoromethane directly through separation, reacting dichloromonofluoromethane separated out with hydrogen fluoride to produce monochlorodifluoromethane, and separating out and recovering trifluoromethane and methane chloride in the mixture as the reaction mixture continuously. The method has the advantage that the harm on the environment caused by trifluoromethane emission is greatly avoided.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

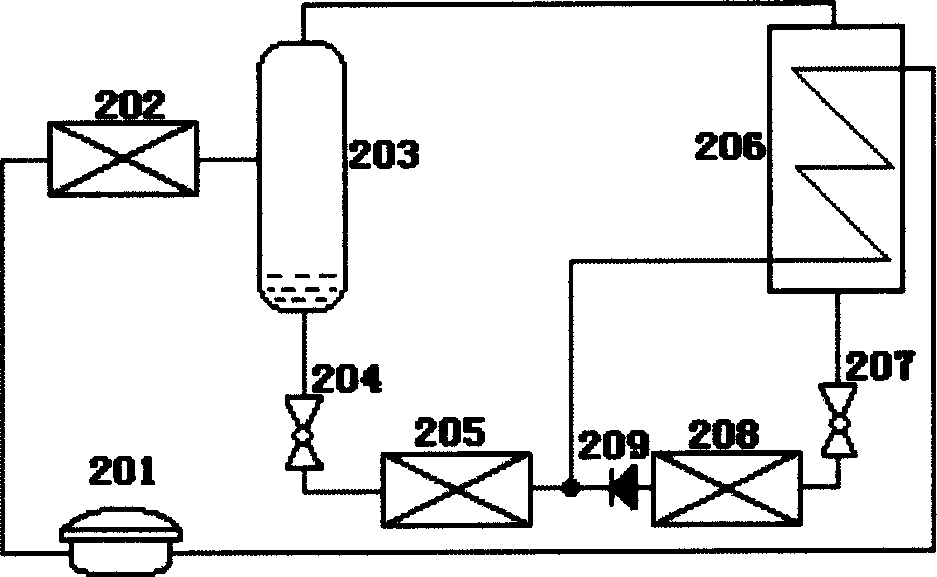

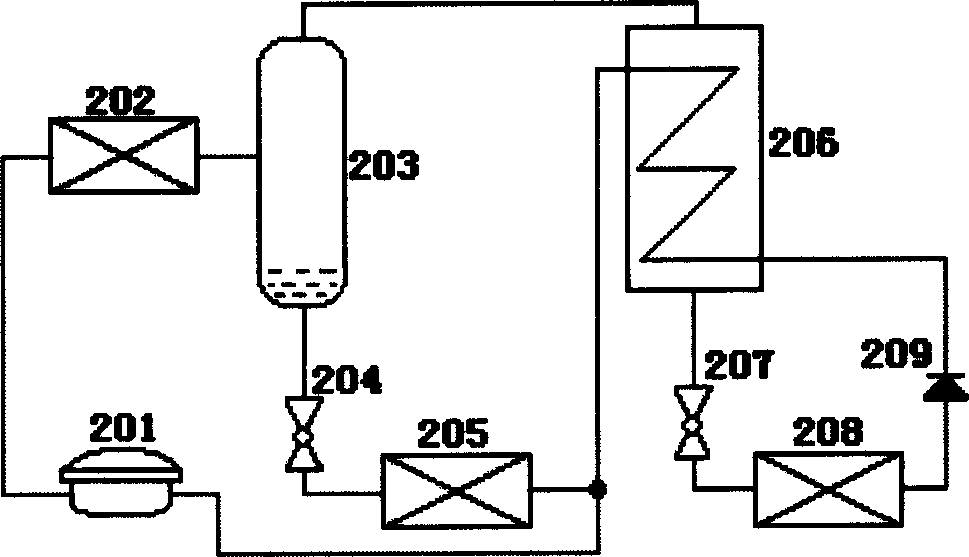

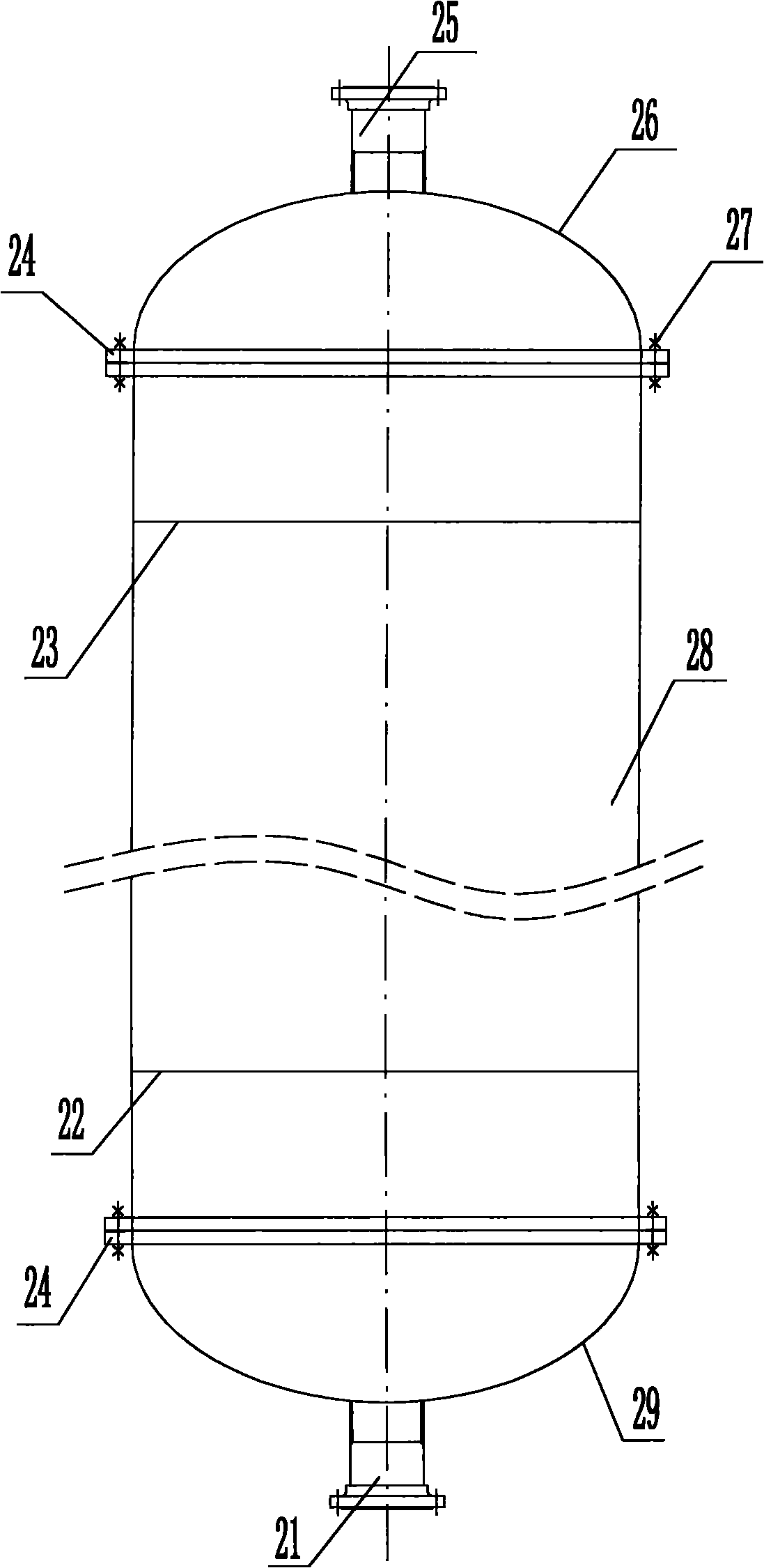

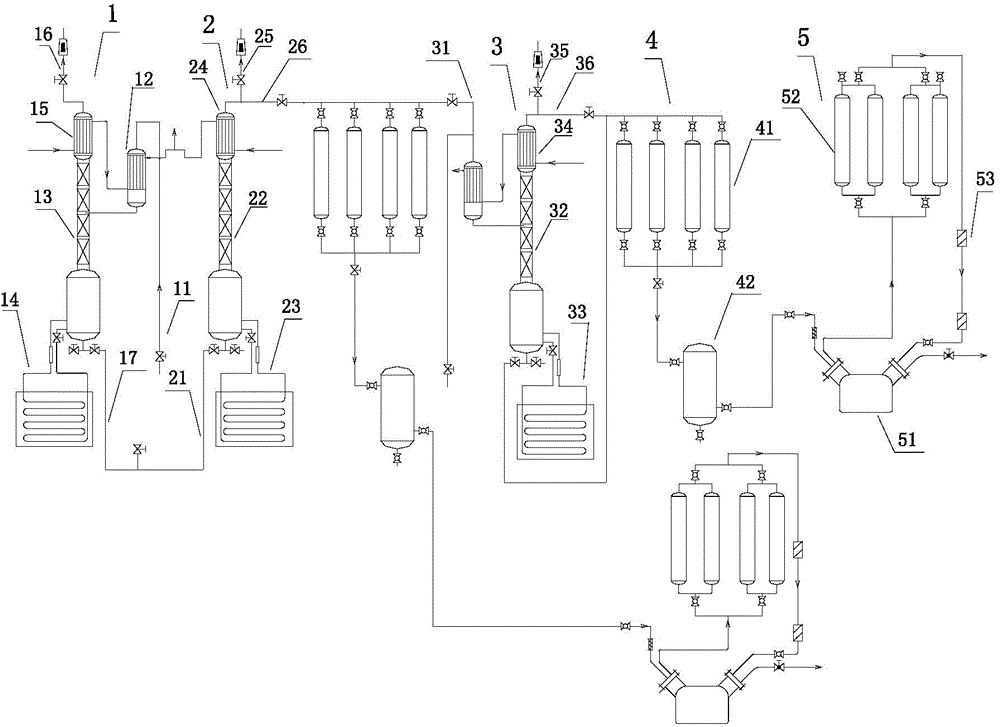

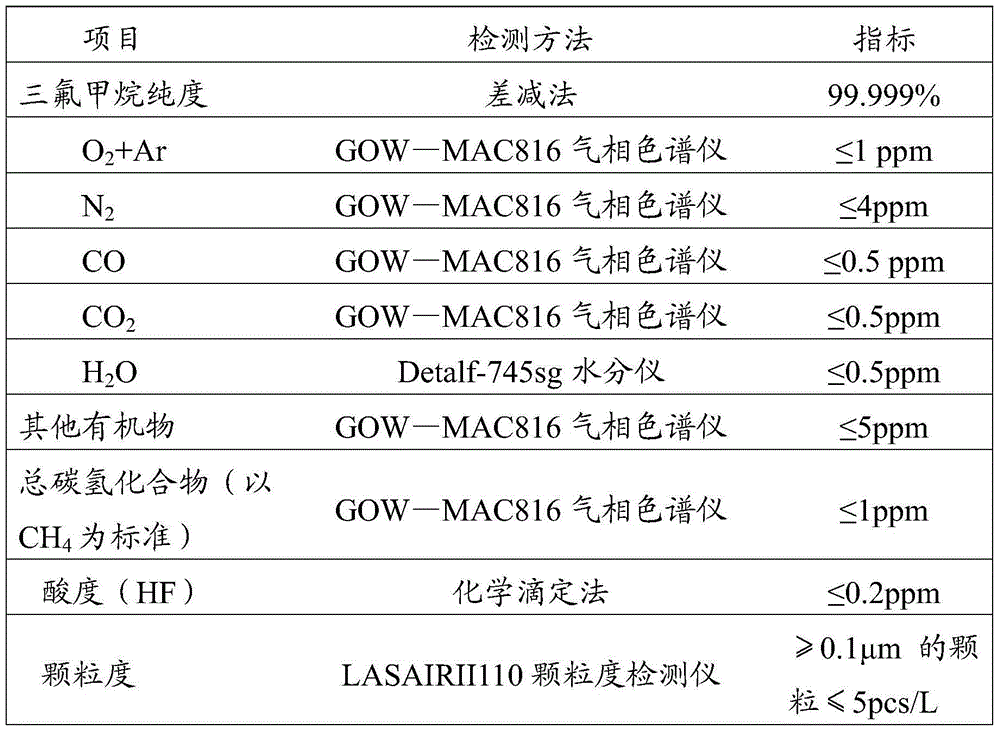

Device and method for purifying trifluoromethane

ActiveCN103951543AHigh purityMeet the requirementsHalogenated hydrocarbon separation/purificationPurification methodsCryo-adsorption

The invention discloses a device and a method for purifying trifluoromethane. The device comprises a rectification device and an adsorption device connected with the rectification device, wherein the rectification device comprises a first-stage rectification device, a second-stage rectification device and a third-stage rectification device which are connected in sequence; the adsorption device comprises a low-temperature adsorption device and a filling device which are connected in sequence; the low-temperature adsorption device of the adsorption device is connected with the rectification device. Compared with the prior art, the purity of trifluoromethane purified by adopting the device is relatively high, the device is easy to operate, and a purification process is complete, reliable and good in repeatability. The removal of conventional impurities is considered, difficultly removed carbon dioxide, monochlorodifluoromethane, pentafluoroethane, water and particles are removed to be in a qualified range, and the product purity is 99.999% and meets the use requirements of the semiconductor industry.

Owner:FOSHAN HUATE GASES

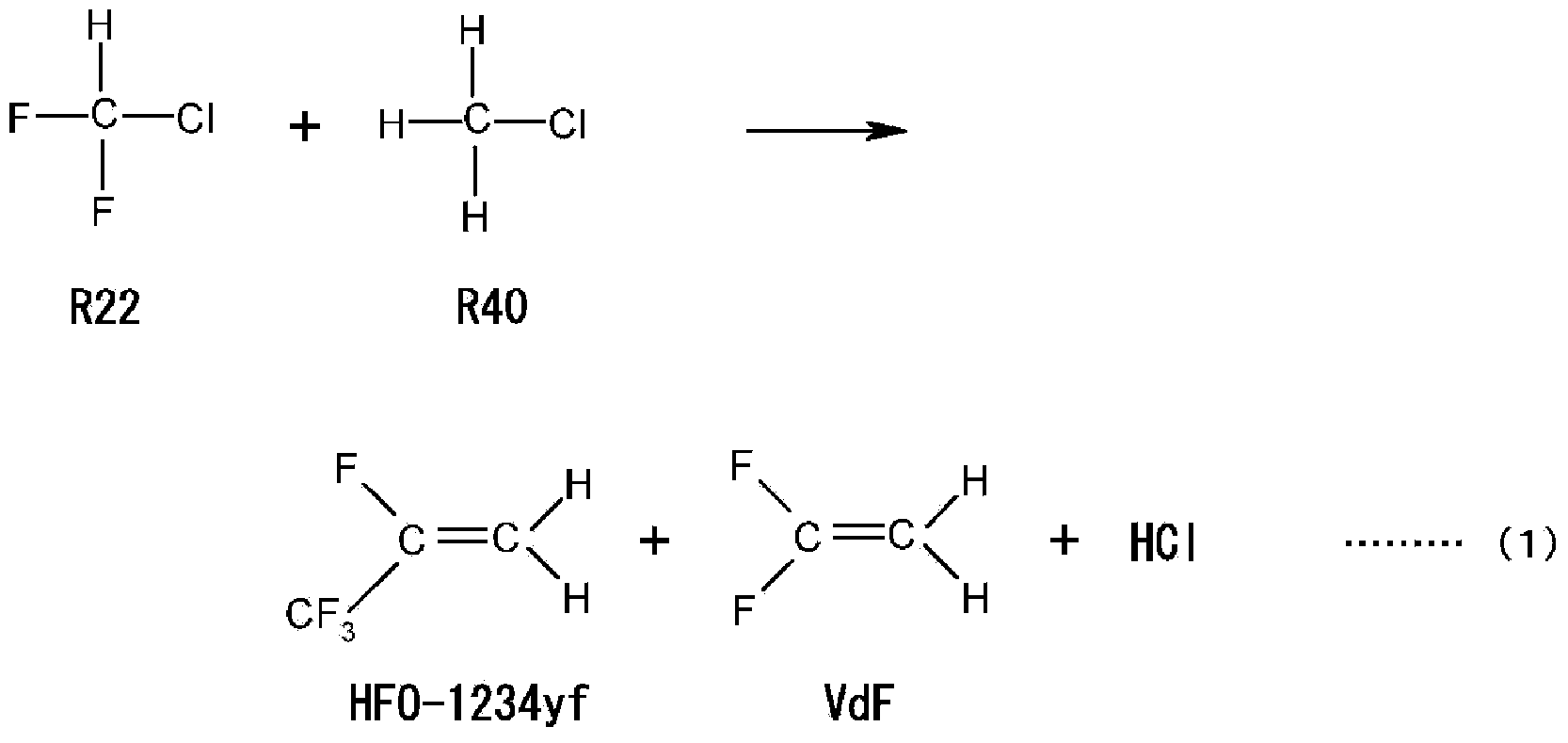

Preparation method of 2, 3, 3, 3-tetrafluoropropene

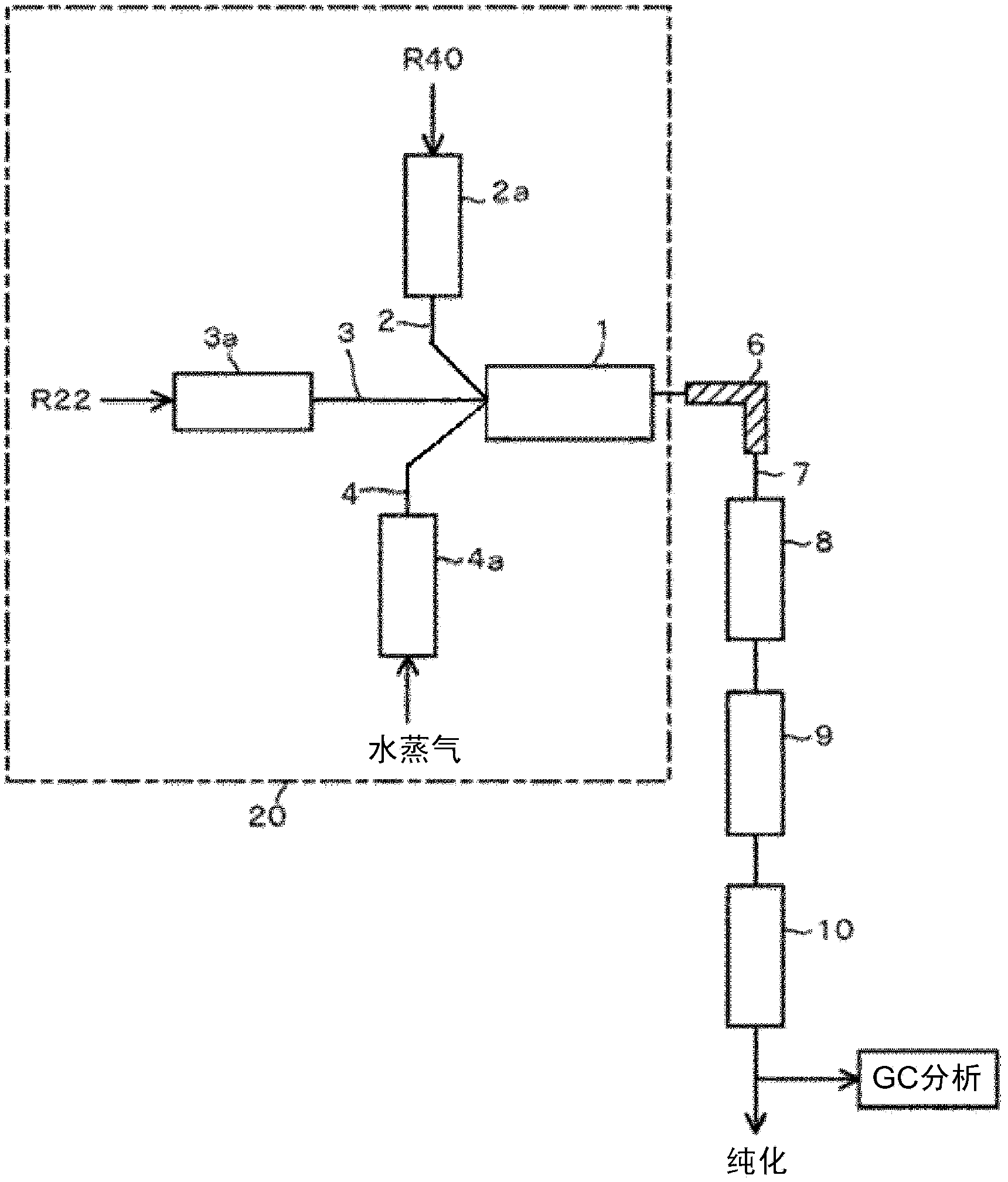

ActiveCN102675038AAccurate control of volume ratioReduce the probability of exposureHalogenated hydrocarbon preparationRetention timeProduct gas

The invention provides a preparation method of 2, 3, 3, 3-tetrafluoropropene, which comprises the following steps: taking monochlorodifluoromethane (R22) and methane chloride (methyl chloride) as raw materials and carrying out thermal cracking reaction at a high temperature of 600-1000 DEG C under the condition that N2 exits to prepare the 2, 3, 3, 3-tetrafluoropropene, wherein the volume ratio of the monochlorodifluoromethane to the methane chloride is 1-3:1, and the retention time of a reactant is 0.01-0.2 seconds. The reaction raw material used in the preparation method is easy to obtain, the defect of high cost of the used raw material in the prior art is overcome, the production cost is greatly reduced, and the reaction process is simple. The prepared 2, 3, 3, 3-tetrafluoropropene has the advantages of zero ODP and low GWP and can be used as a substitute of an automotive air-conditioning refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Purification of difluoromethane by extractive distillation

InactiveUS7371309B2Halogenated hydrocarbon separation/purificationExtractive distillationExtractive distillationOxygen

The present invention provides extractive distillation processes for removing difluoromethane (HFC-32) from a mixture comprising HFC-32 and at least one of chlorodifluoromethane (CFC-12), 1,1,1-trifluoroethane (HFC-143a), chloropentafluoroethane (CFC-115), and pentafluoroethane (HFC-125) using hydrocarbon, chlorocarbon, and oxygen-containing extractive agents.

Owner:EI DU PONT DE NEMOURS & CO

Recycling method of byproduct-trifluoromethane in HCFC-22 production

ActiveCN109748775ARealize resource utilizationIncrease valuePreparation by halogen replacementEconomic benefitsChlorodifluoromethane

The invention discloses a method of recycling trifluoromethane. The method includes: under action of at least one catalyst of MgF2, Al2O3, partially fluorinated alumina and AlF3, allowing trifluoromethane and dichloromethane to react to obtain a reaction product containing difluoromethane and monochlorodifluoromethane, and rectifying to obtain difluoromethane. The method can realize recycling of trifluoromethane, can convert the same into difluoromethane with high value and has great economic benefit.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

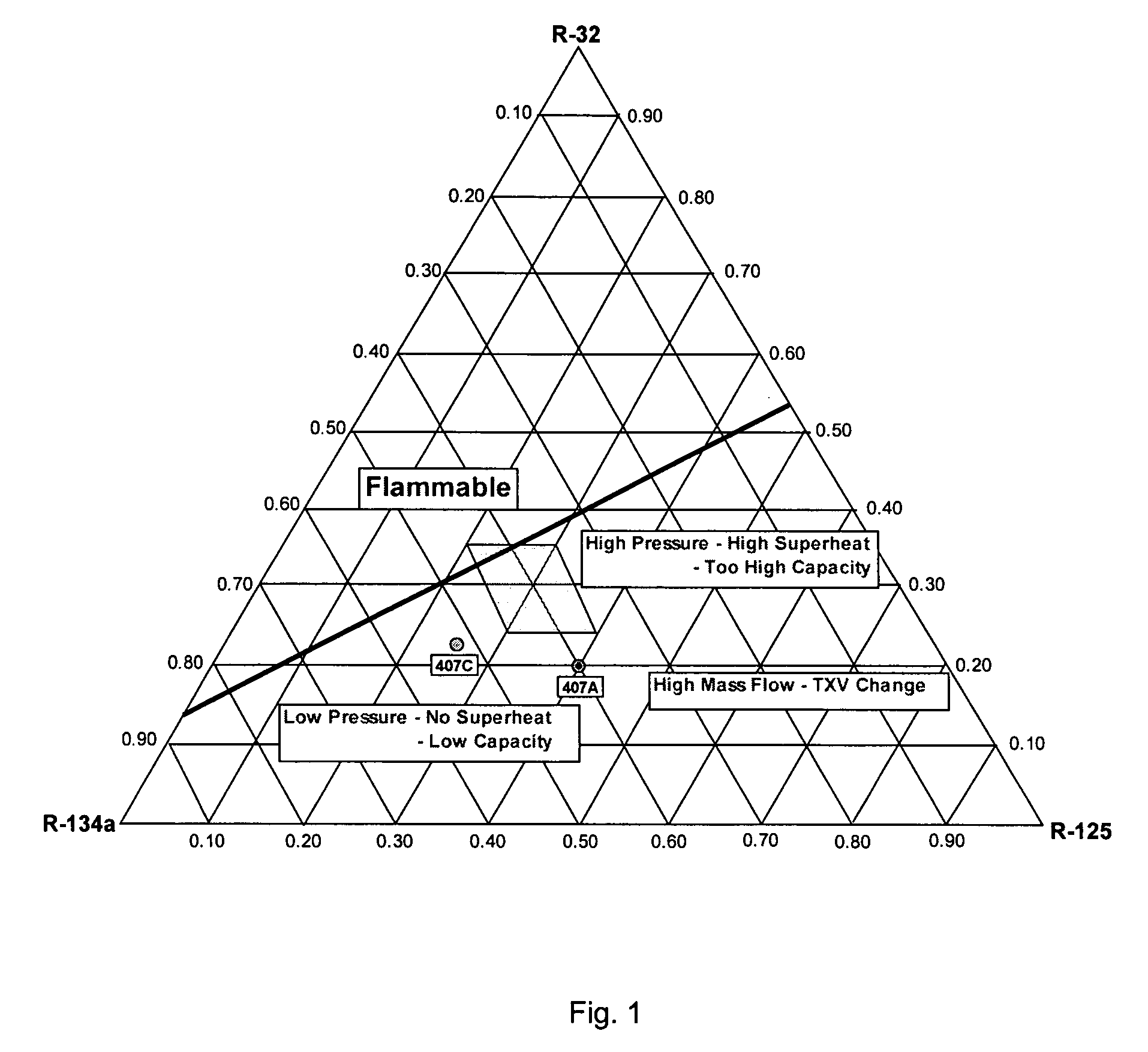

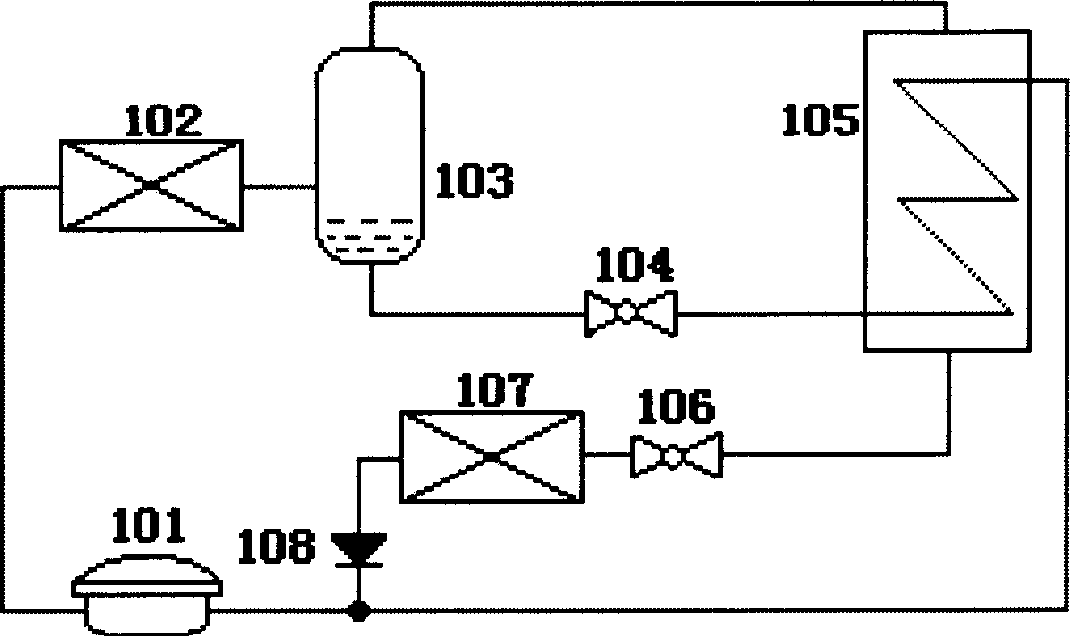

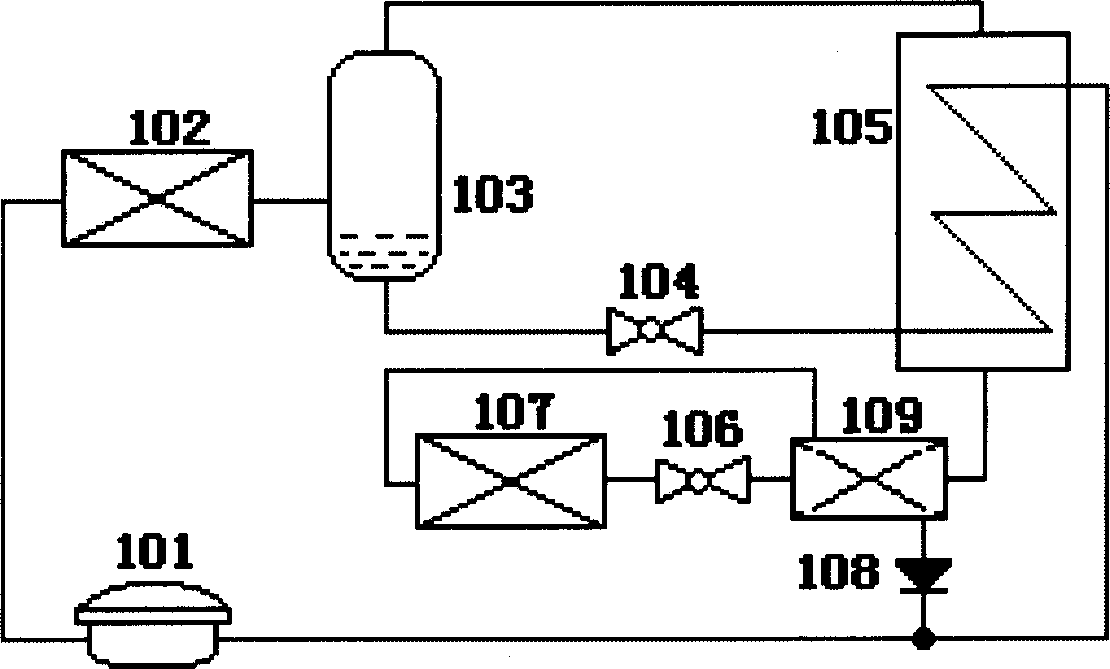

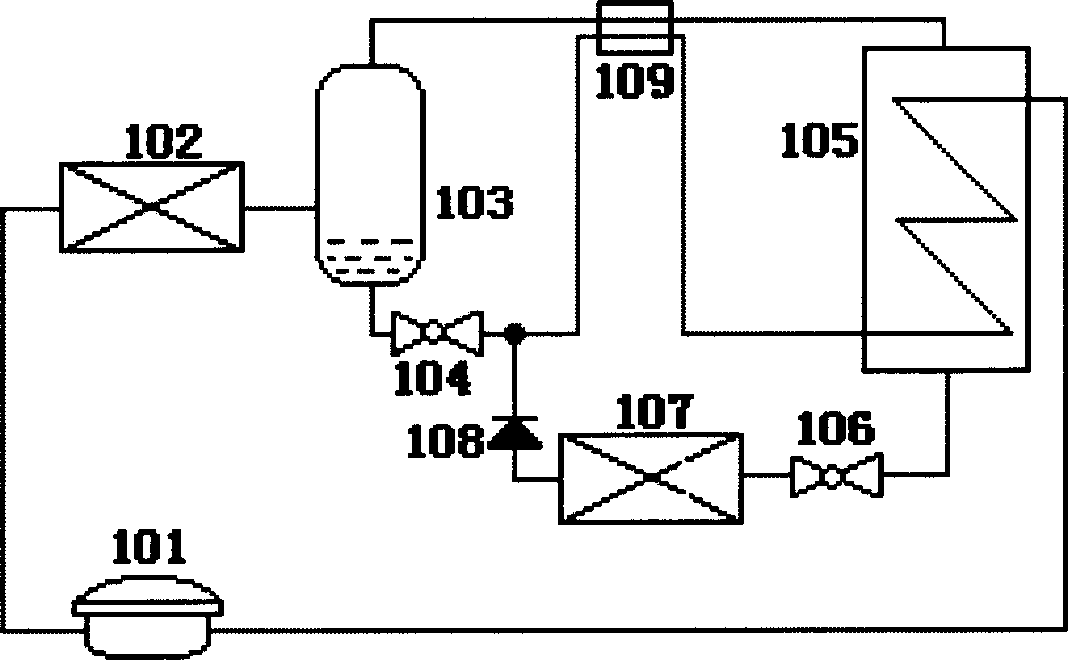

Refrigerant compositions and use thereof in low temperature refrigeration systems

ActiveUS20100019190A1Compression machines with non-reversible cycleHeat-exchange elementsSystems designEngineering

A process for obtaining low temperature refrigeration in an existing or new low temperature refrigeration system designed to operate with, or suitable for use with, or capable of being used with HCFC-22 as the refrigerant, the refrigerant composition being a refrigerant composition comprising difluoromethane (HFC-32), pentafluoroethane (HFC-125) and tetrafluoroethane (HFC134a), the three components being present in the composition in amounts such that the operating characteristic of the refrigerant composition in regard to superheat is provided at an acceptable level and the operating characteristics of the refrigerant composition in regard to cooling capacity, mass flow and efficiency (COP) characteristics, when employed as the refrigerant in a low temperature refrigeration system, are each at least 95% of the operating characteristics of chlorodifluoromethane (HCFC-22) if HCFC-22 were to be employed as the refrigerant in such low temperature refrigeration system.

Owner:HONEYWELL INT INC

Method for separating and recovery difluorochloromethane azeotropic hexafluoropropene

ActiveCN1830929AHigh purityNo pollution in the processDispersed particle separationHalogenated hydrocarbon separation/purificationTetrafluoroethyleneZeotropic mixture

A process for separating and recovering bifluoro-chloromethane-hexafluoropropene azeotrope includes such steps as passing said gas-state mixed azeotrope through gas separating membrane to obtain penetrated bifluoro-chloromethane gas and residual hexafluoropropene gas, condensing the residual gas, rectifying to obtain pure hexafluoropropene, recovering the mixed azeotrope from tower top, returning it along with said penetrated gas back to rectifying system in tetrafluoro ethene production apparatus, and rectifying separation to recover bifluoro-chloromethane.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS +1

Method for recovering hydrogen chloride gas in production process of chlorodifluoromethane and device

ActiveCN101613084AHigh purityPrevent volatilizationChlorine/hydrogen-chloride purificationGas phasePhysical chemistry

The invention discloses a method for recovering hydrogen chloride gas in production process of chlorodifluoromethane. The organic mixture of hydrogen chloride obtained in the chlorodifluoromethane production process and chlorodifluoromethane is led into a hydrogen chloride rectifying tower; after rectifying, hydrogen chloride is discharged from the top of the tower; the obtained hydrogen chloride is condensed to obtain liquid-phase hydrogen chloride and gas-phase hydrogen chloride, wherein, the liquid-phase hydrogen chloride flows back to the rectifying tower, and trace of fluorinion of the gas-phase hydrogen chloride is removed by a subsequent defluorination device so as to obtain hydrogen chloride gas. The invention can effectively recover by-product hydrogen chloride gas in the chlorodifluoromethane production process and comprehensively utilize hydrogen chloride gas to make waste profitable; in addition, the invention prevents parts of hydrogen chloride gas from volatilizing, prevents hydrochloric acid from polluting ambient environment and prevents hydrochloric acid from corroding devices and ducts.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

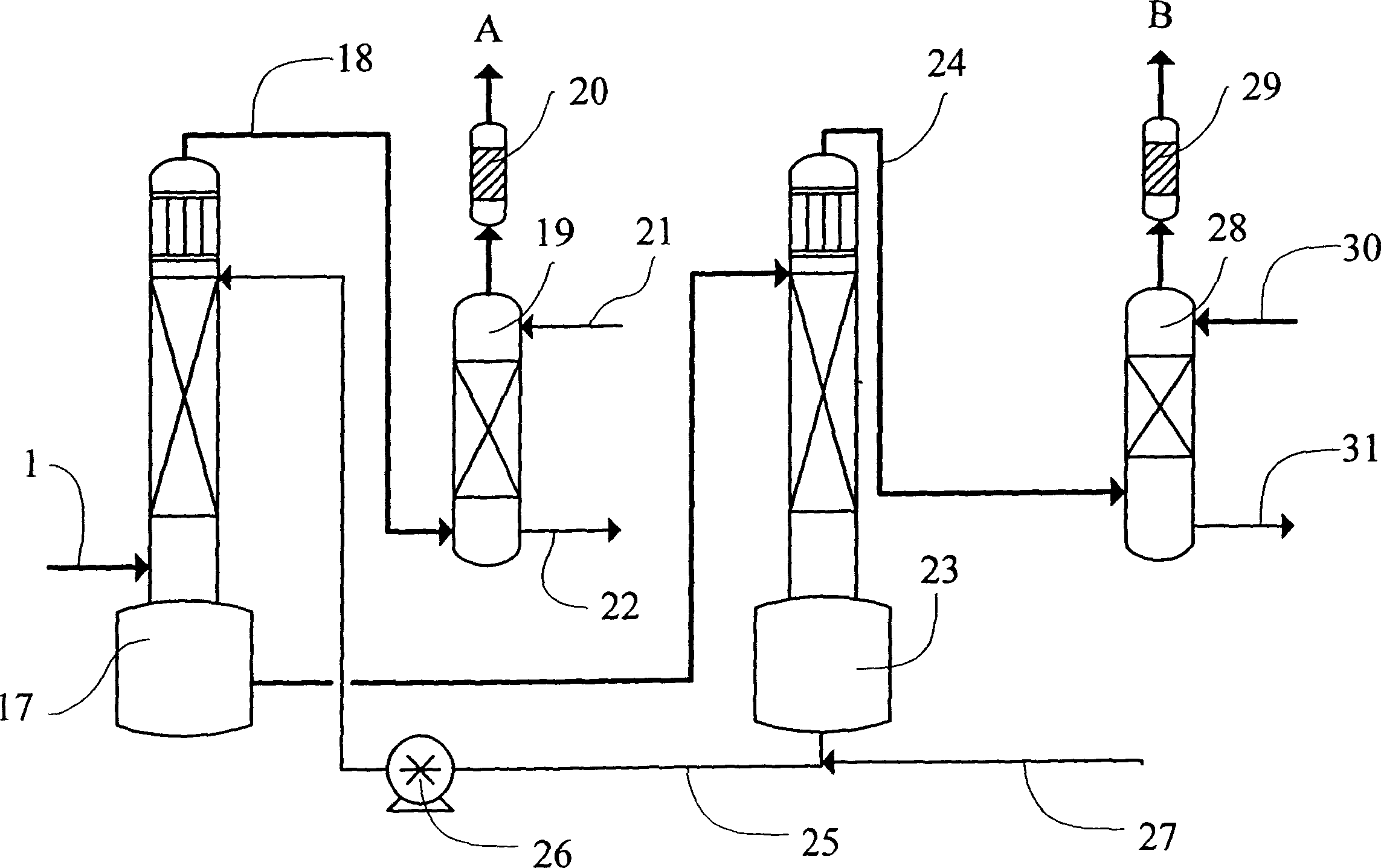

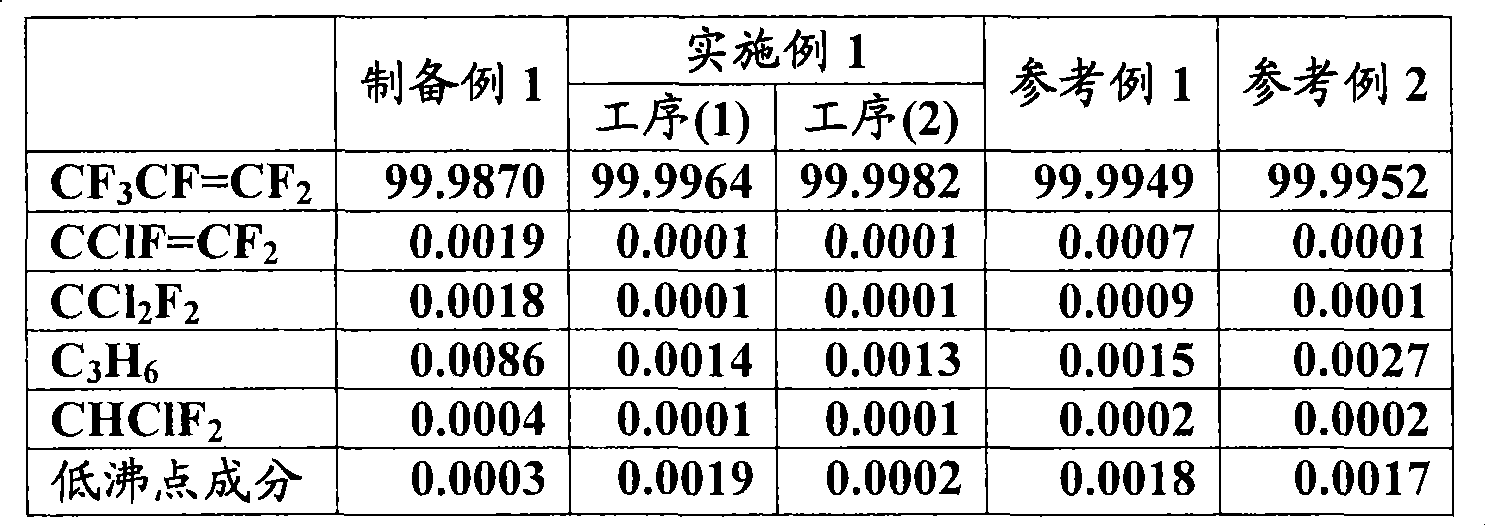

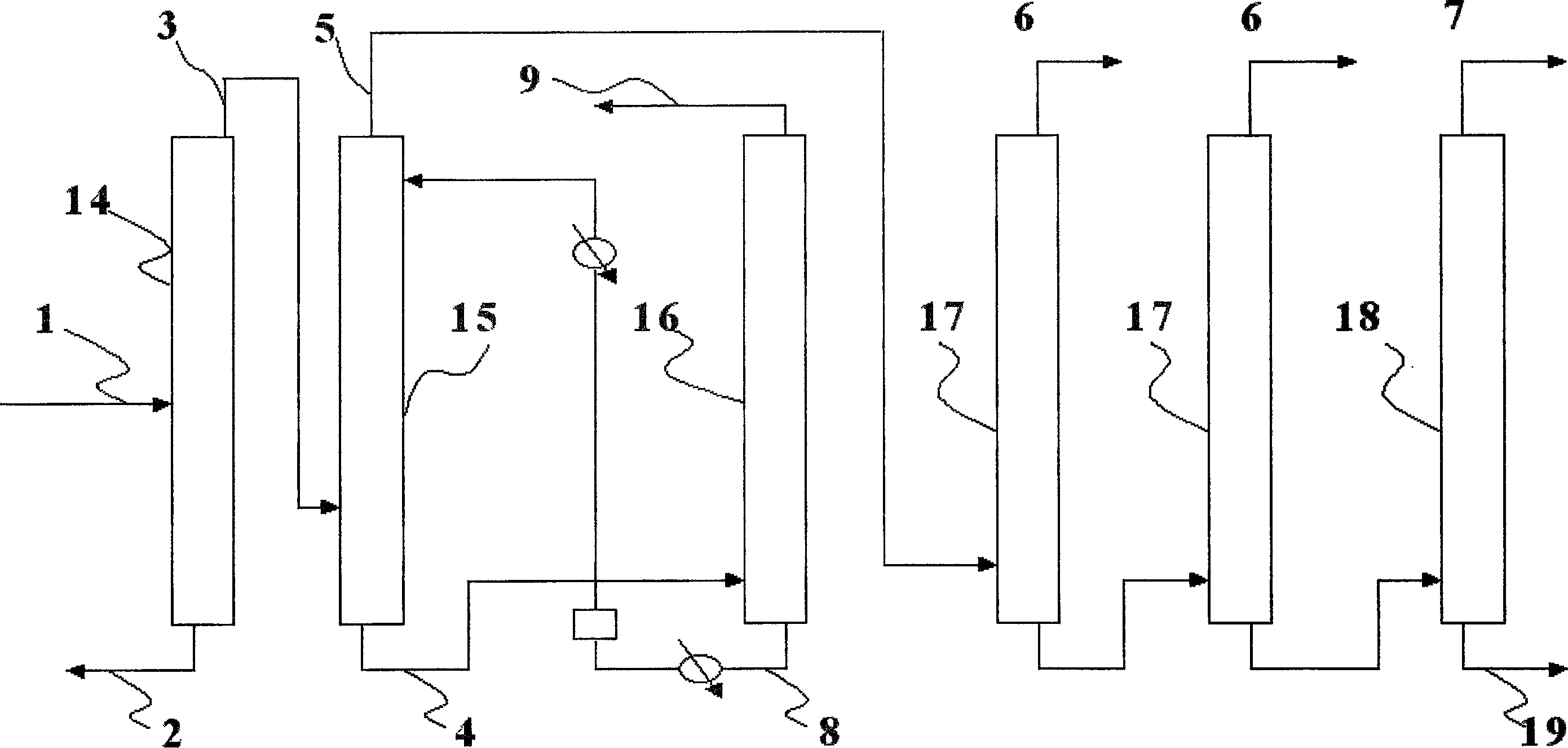

Process for producing high-purity hexafluoropropylene and cleaning gas

InactiveCN101479220AEfficient manufacturingSemiconductor/solid-state device manufacturingHalogenated hydrocarbon separation/purificationSorbentHexafluoropropylene

A process for industrially advantageously producing high-purity hexafluoropropylene; and a use of this high-purity hexafluoropropylene, specifically, a cleaning gas for removing deposits in a semiconductor manufacturing apparatus or liquid-crystal manufacturing apparatus. In the process for high-purity hexafluoropropylene production, crude hexafluoropropylene produced by the pyrolysis of chlorodifluoromethane is purified to thereby produce high-purity hexafluoropropylene. It comprises: a step (1) in which the crude hexafluoropropylene is brought into contact with an adsorbent comprising a zeolite having an average micropore diameter of 3.4-11 AA and / or a carbonaceous adsorbent having an average micropore diameter of 3.5-11 AA to reduce the content of chlorine compounds and / or hydrocarbons in the crude hexafluoropropylene; and a step (2) in which the hexafluoropropylene obtained in the step (1) is distilled to reduce the content of low-boiling ingredients therein.

Owner:SHOWA DENKO KK

Multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system

InactiveCN1810914AFully consider the operating pressure ratio rangeConsider operating pressure ratio rangeFluid heatersHeat-exchange elementsDichlorodifluoromethaneOctafluorocyclobutane

The present invention discloses one kind of multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system. The mixture work medium or mixed refrigeratant consists of two components, including one low boiling point component and one high boiling point component. The low boiling point component is one or several selected from difluro methane, trifluoro ethane, fluoro ethane, propylene, propane, pentafluoro ethane, etc. The high boiling point component is one or several selected from isobutane, n-butane, butene, isobutene, octafluoro isobutene, octafluoro cyclobutane, etc.

Owner:XI AN JIAOTONG UNIV

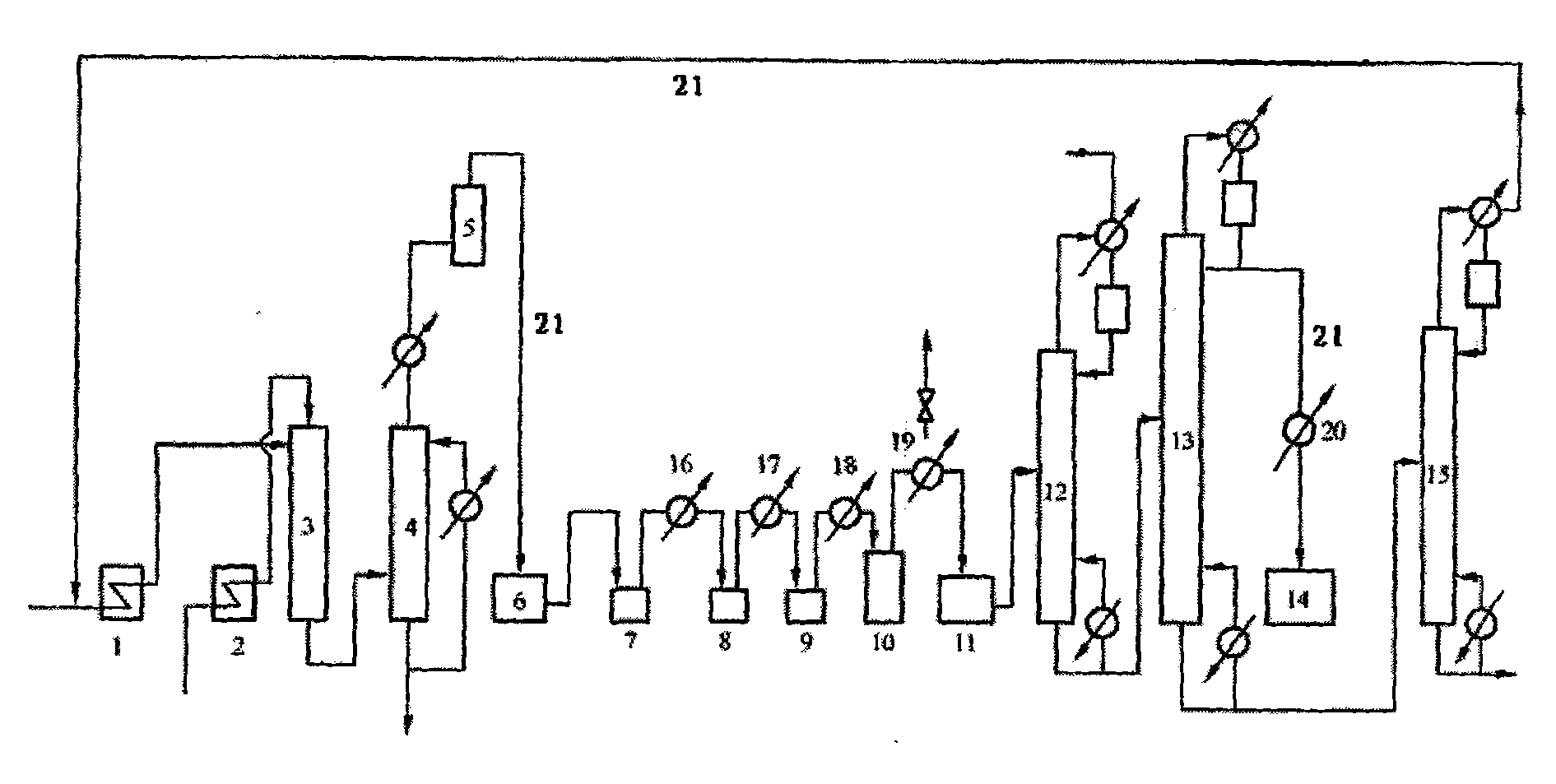

Process for the purification of pharmaceutical grade HFC-134a and polymer grade HCFC-22

InactiveUS7384519B2Clear structureEasy to moveSolid sorbent liquid separationHalogenated hydrocarbon separation/purificationMolecular sieveChloride

A method for the purification of pharmaceutical grade 1,1,1,2-tetrafluoroethane (HFC-134a) and polymer grade chlorodifluoromethane (HCFC-22) by contacting a mixture containing 1,1,1,2-tetrafluoroethane or chlorodifluoromethane and methyl chloride with a zeolite such as a molecular sieve, and recovering from said contacted mixture substantially purified 1,1,1,2-tetrafluoroethane or chlorodifluoromethane.

Owner:HONEYWELL INT INC

Process for the purification of pharmaceutical grade HFC-134a and polymer grade HCFC-22

InactiveUS20050133360A1Clear structureEasy to moveSolid sorbent liquid separationHalogenated hydrocarbon separation/purificationMolecular sieveChloride

A method for the purification of pharmaceutical grade 1,1,1,2-tetrafluoroethane (HFC-134a) and polymer grade chlorodifluoromethane (HCFC-22) by contacting a mixture comprising 1,1,1,2-tetrafluoroethane or chlorodifluoromethane and methyl chloride with a zeolite such as a molecular sieve, and recovering from said contacted mixture substantially purified 1,1,1,2-tetrafluoroethane or chlorodifluoromethane.

Owner:HONEYWELL INT INC

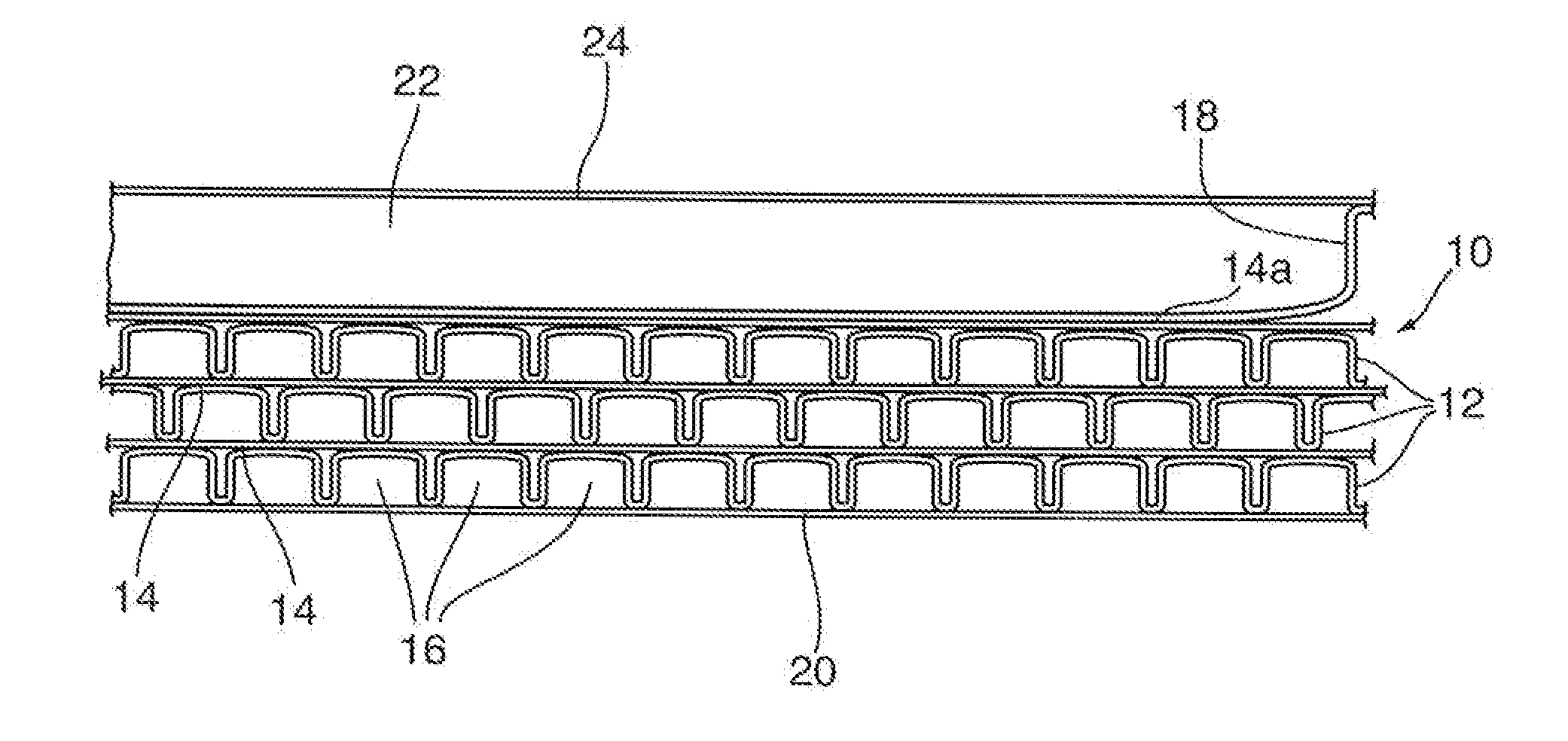

Insulation material

A flexible or rigid heat-insulation material consisting of a sheet of at least one layer of closed-cell gas bubbles 1 / 16 inch to 1 inch in size filled with a gas selected from helium, argon, neon, krypton, xenon, carbon dioxide, and chlorodifluoromethane, and mixtures thereof. At least one heat reflective layer of aluminum film is adhesively attached to the layer of gas bubbles or an aluminum film is vapor-deposited on the layer of gas bubbles.

Owner:GHALI RAGUI

Method for recovering perfluoro propylene from technique of producing tetrafluoroethlene

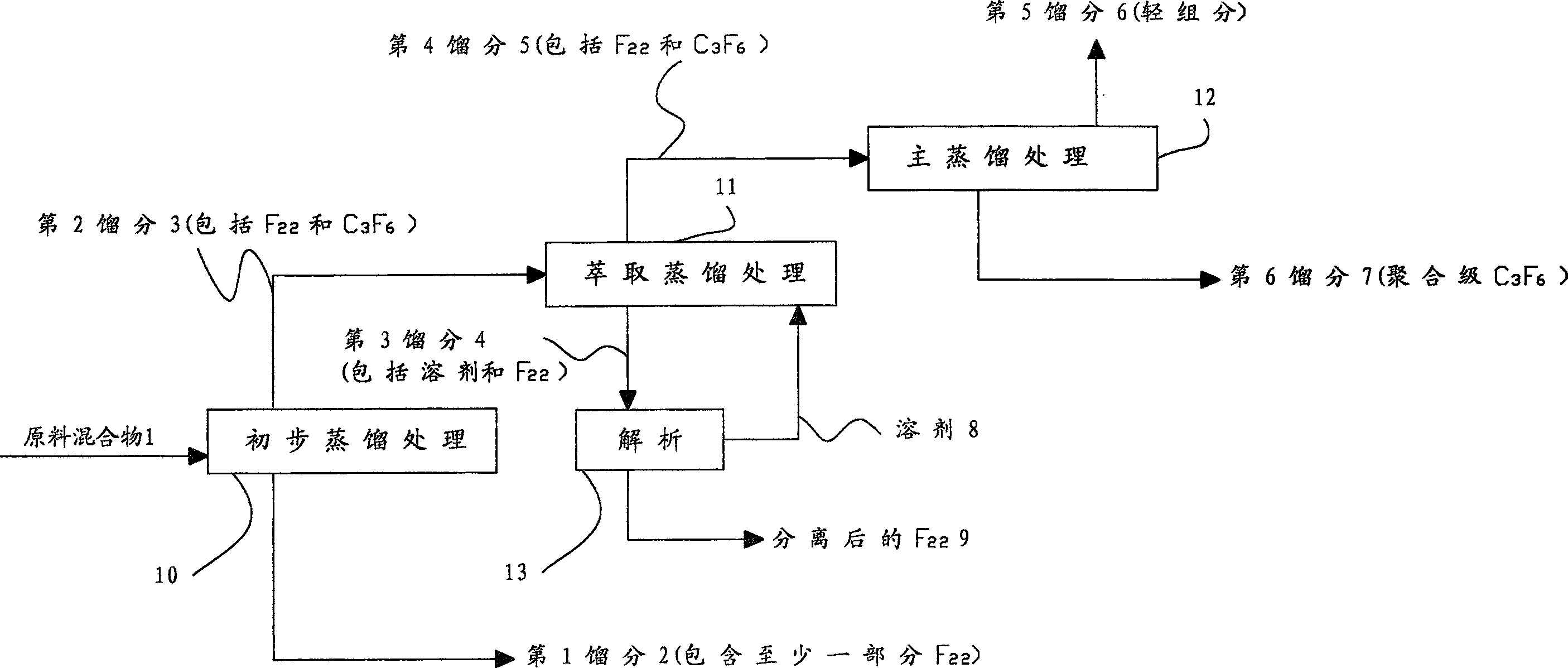

ActiveCN1872824AQuality improvementReduce the amount of azeotropeHalogenated hydrocarbon preparationHexafluoropropyleneDistillation

This invention discloses a method for recovering hexafluoropropylene from the azeotrope of hexafluoropropylene and difluorochloromethane during tetrafluoroethylene production process. The method comprises primary distillation, extractive rectification and major rectification. The method has such advantages as high hexafluoropropylene recovery rate (higher than or equal to 97.8 vol. %), low solvent loss (lower than 1.1 kg / h), and high hexafluoropropylene quality (99.99 vol. %).

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation method for roflumilast intermediate

InactiveCN102503815AThe total yield of the five-step reaction is highMild reaction conditionsOrganic compound preparationCarboxylic compound preparationBenzaldehydeRoflumilast

The invention discloses a preparation method for a roflumilast intermediate. The preparation method is characterized by comprising the following steps of: etherifying 3,4-dihydroxy benzaldehyde serving as a raw material and 3-hydroxyl by using benzene ring non-substituted, mono-substituted or poly-substituted benzyl protection 4-hydroxy and halogenated methyl cyclopropane; performing catalytic hydrogenolysis to obtain 4-hydroxy-3-cyclopropyl methoxy-benzaldehyde; etherifying and oxidizing the 4-hydroxy-3-cyclopropyl methoxy-benzaldehyde with difluoromonoch-loromethane to obtain 3-cyclopropyl methoxy-4-difluoromethoxybenzoic acid (I) serving as the roflumilast intermediate. The preparation method has the advantages of easiness and convenience for operating, mild reaction conditions, stable quality, simple post-treatment and no need of complex operation such as column chromatography and the like, and is suitable for industrial production.

Owner:NANJING TIANHAI MEDICAL TECH

Freon 22/hexafluoropropylene azeotrope separating and recovering method

InactiveCN101070266AHigh purityEasy to operateDispersed particle separationHalogenated hydrocarbon separation/purificationRecovery methodHexafluoropropylene

This invention relates to a separation and recovery method of chlorodifluoromethane / hexafluoropropylene azeotrope. The invention adopts one or multilevel membrane separation process. The chlorodifluoromethane / hexafluoropropylene azeotrope transits first order gas separation membrane assembly by gaseity; permeating gas that rich in chlorodifluoromethane enter secondary membrane separation assembly, then reclaimd to compressor first order import buffer tank of tetrafluoroethylene production process; the removeing extraction rectifier unit of firsts and seconds seeping residual air that rich in hexafluoropropylene could gain hexafluoropropylene that purity is greater than 99.9%.

Owner:阳光乐程(北京)网络科技有限公司 +4

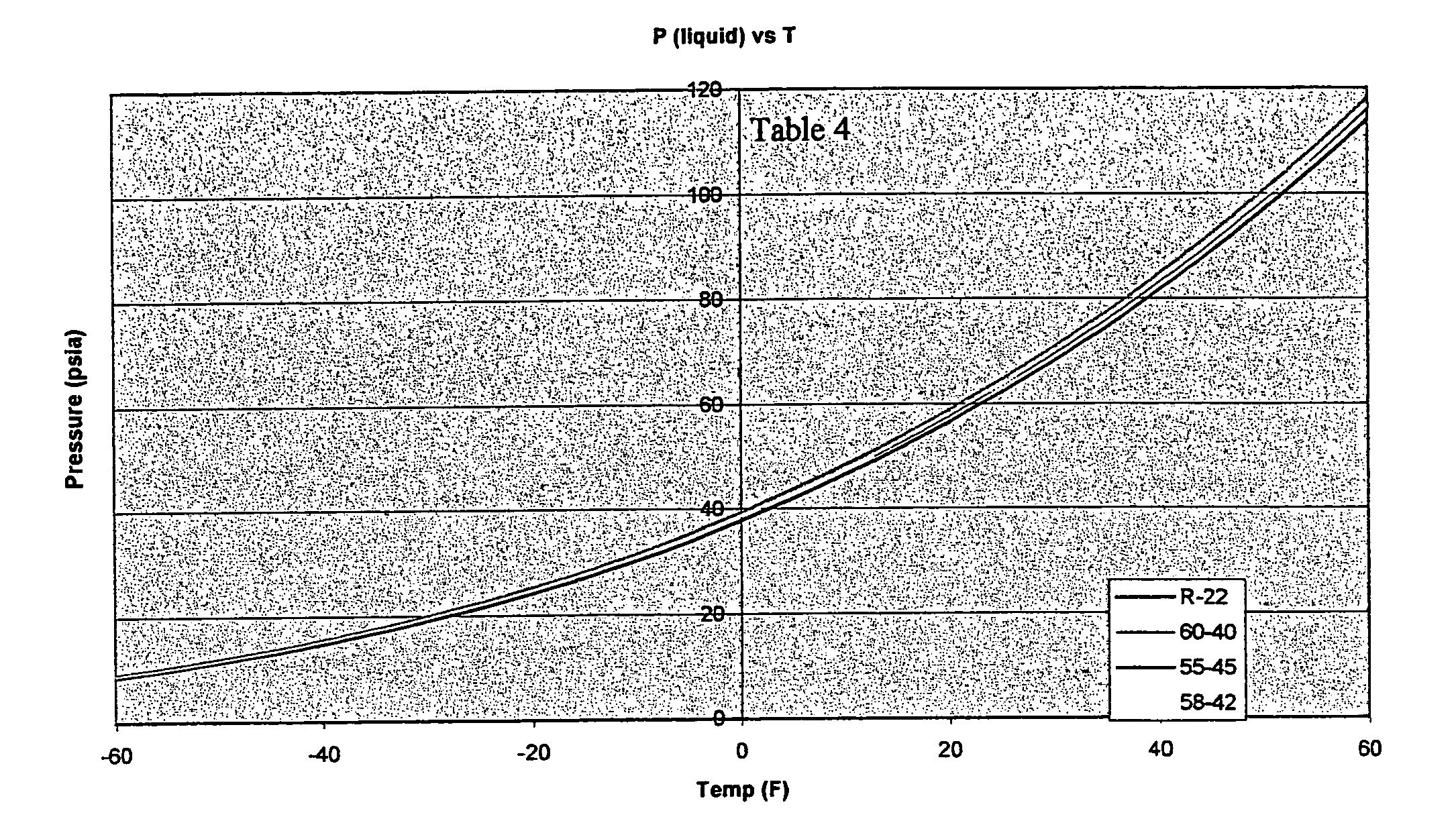

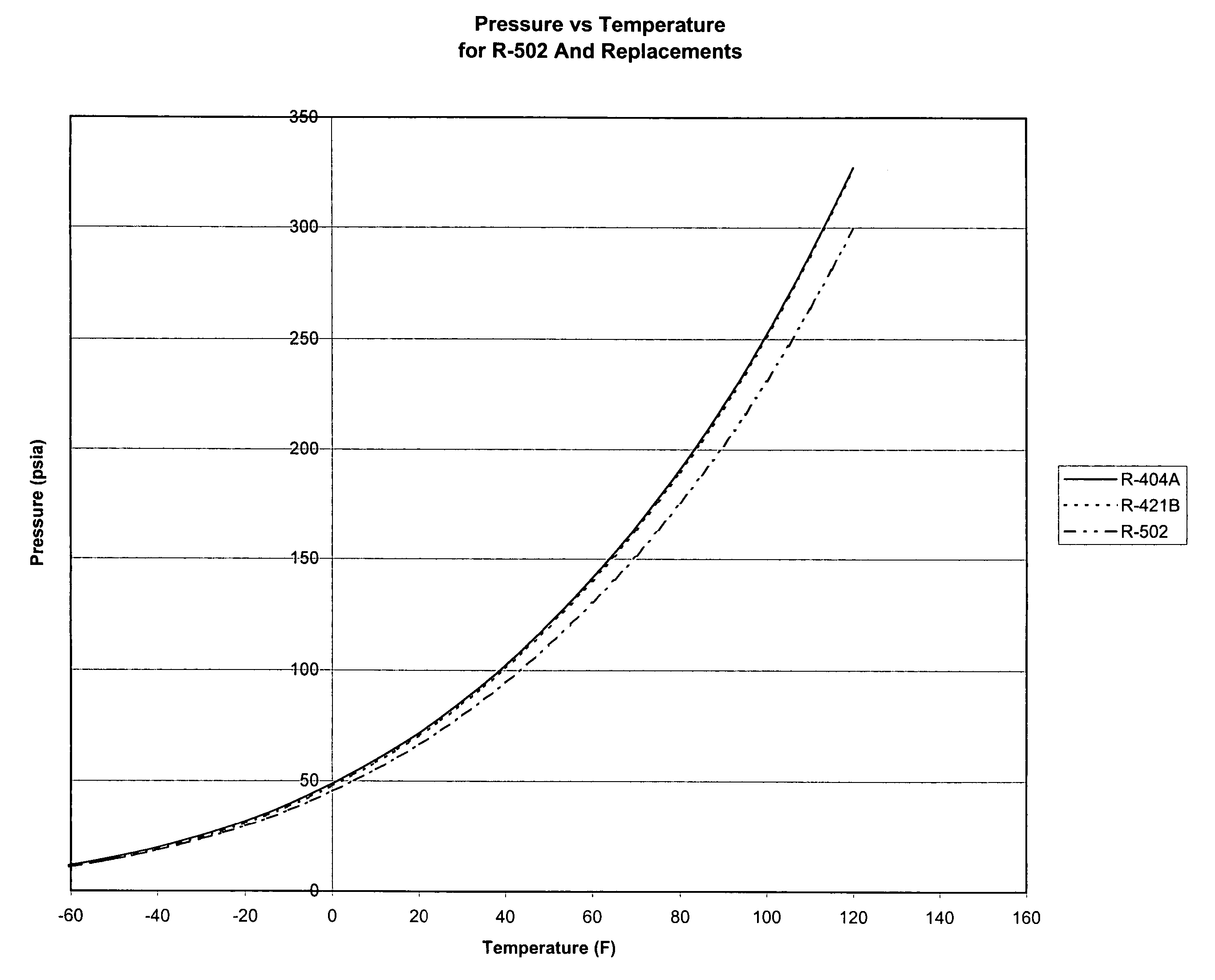

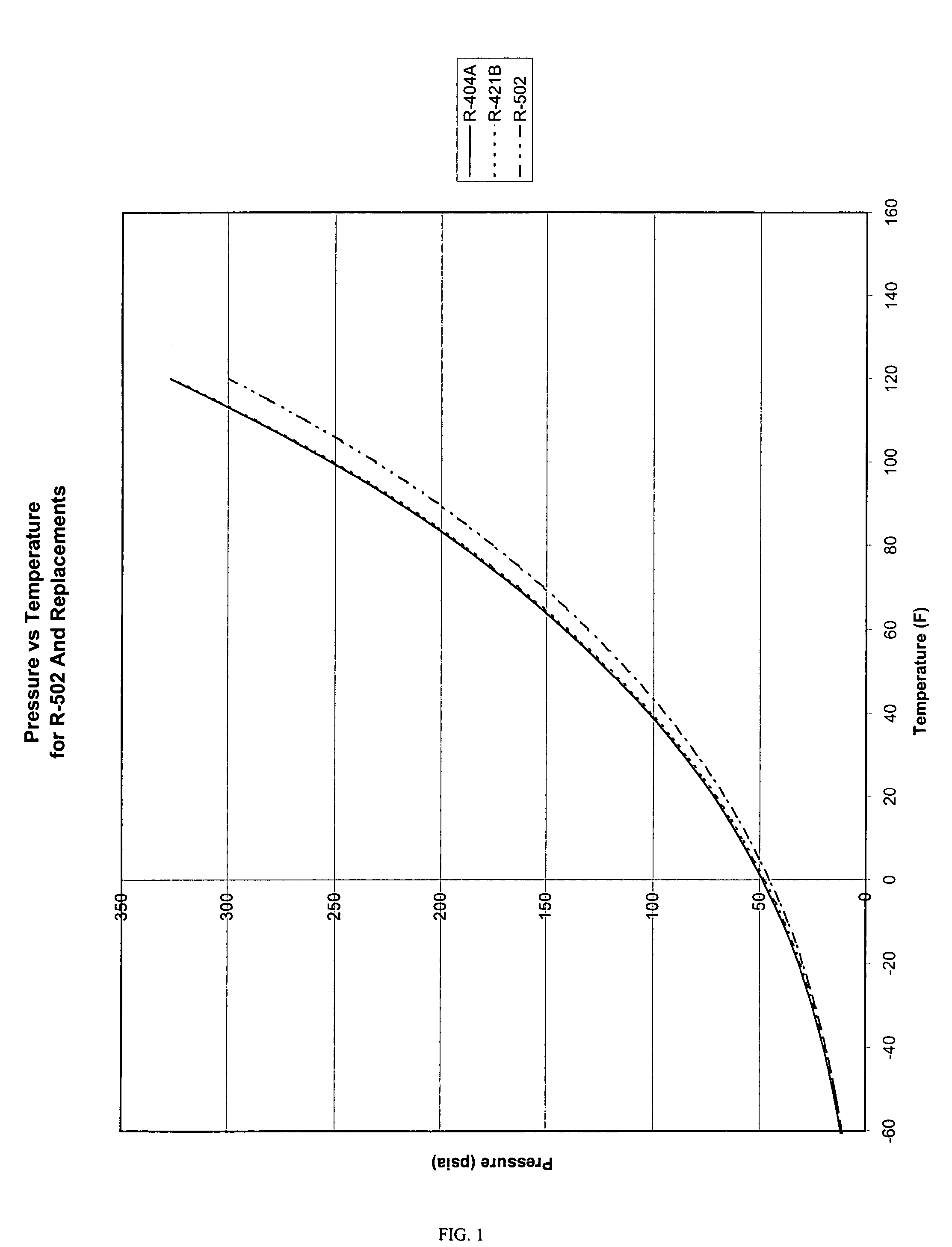

Refrigerant with lubricating oil for replacement of R22 refrigerant

InactiveUS20050082510A1Avoid damageAir-conditioning useDomestic cooling apparatusHeat-exchange elementsSystems designOzone layer

An apparatus and method wherein potential ozone layer-damaging chlorodifluoromethane (Refrigerant R-22) is substituted with a mix of less environmentally damaging refrigerants pentafluoroethane and tetrafluoroethane in chlorodifluoromethane-based air-cooling systems mainly in residential cooling. While less environmentally damaging than chlorodifluoromethane, the substitute refrigerant has a temperature-pressure relationship similar to that of chlorodifluoromethane, making the substitute refrigerant suitable for use with chlorodifluoromethane-based air-cooling systems. In this event, it is mixed with a relatively small percentage of a lubricating oil which is compatible with both the unit refrigerant and typical R-22 system design.

Owner:PONDER KENNETH M +1

Quaternary mixed refrigerant

ActiveCN109609095AWide temperature rangeReduce loadHeat-exchange elementsTrifluoroiodomethanePropane

The invention provides a quaternary mixed refrigerant and relates to the technical field of refrigerants. The quaternary mixed refrigerant comprises propane, dimethyl ether, propylene and trifluoroiodomethane. According to the refrigerant provided by the invention, the propane, the propylene, the dimethyl ether and the trifluoroiodomethane are all compounds which do not contain chlorine atoms, sothat the ozone layer is not damaged. The refrigerant does not cause the greenhouse effect, can meet requirements of environment protection, and thus is a good choice for replacing an existing dichlorofluoromethane refrigerant.

Owner:合肥蓝梦新能源科技有限公司

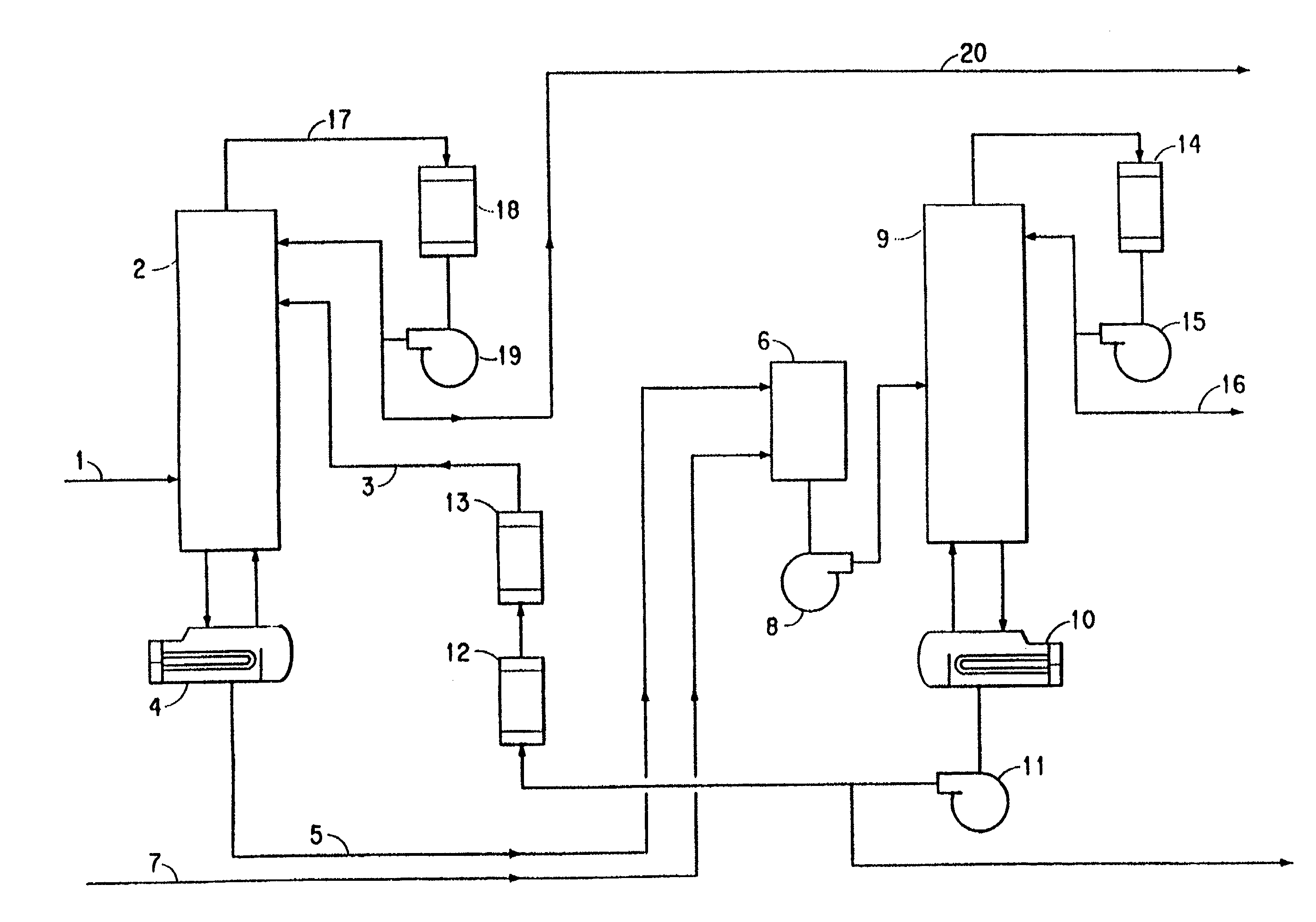

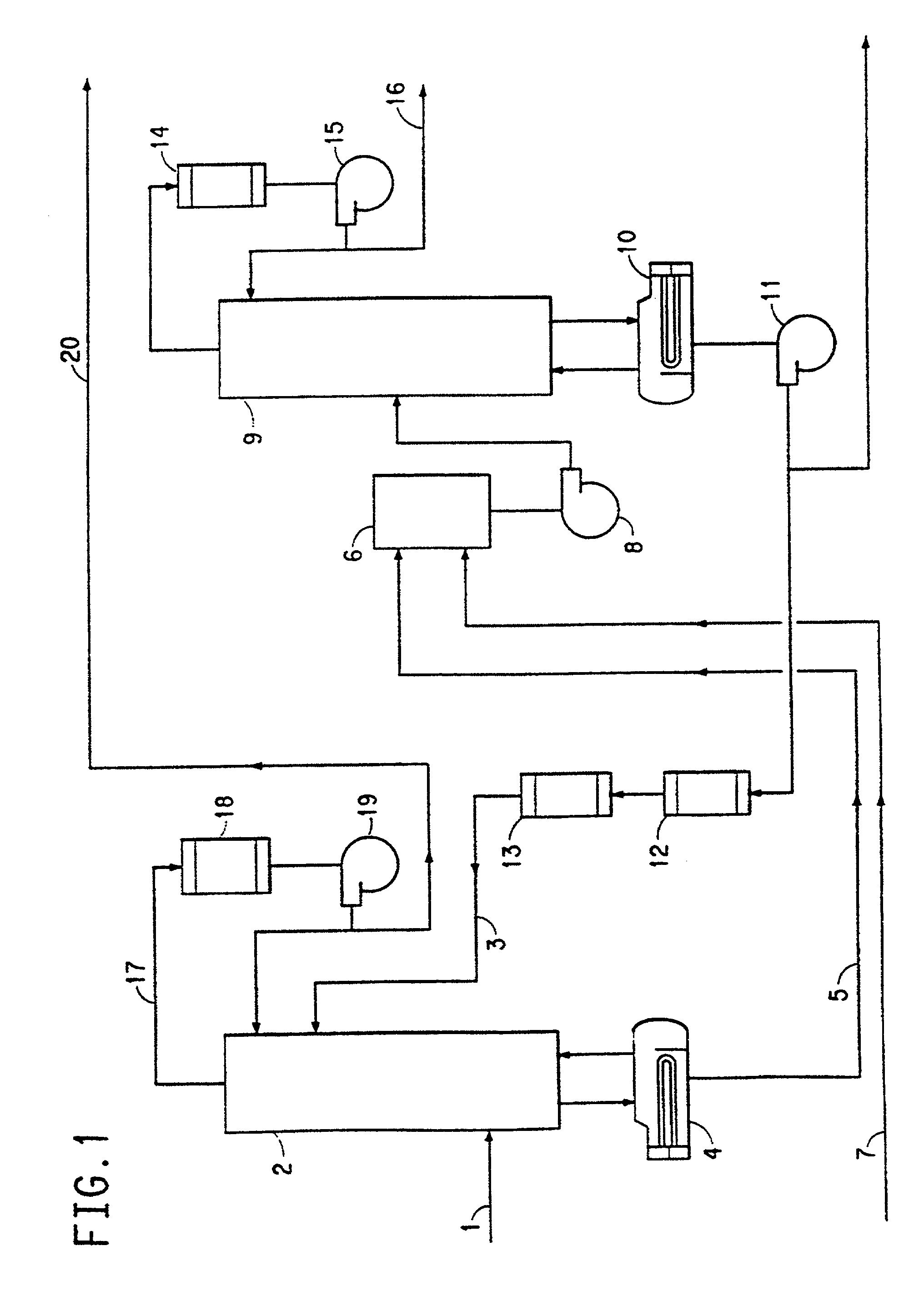

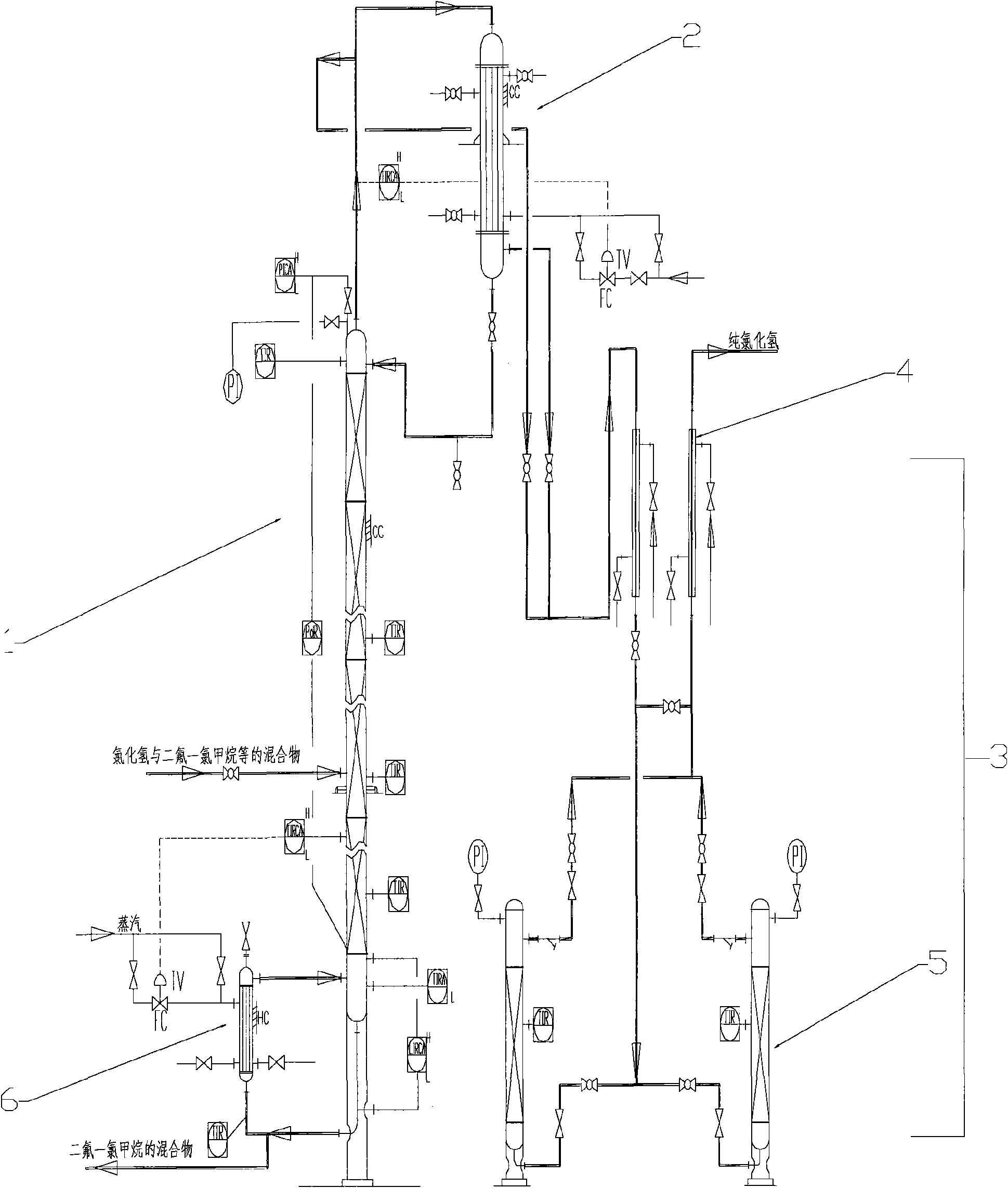

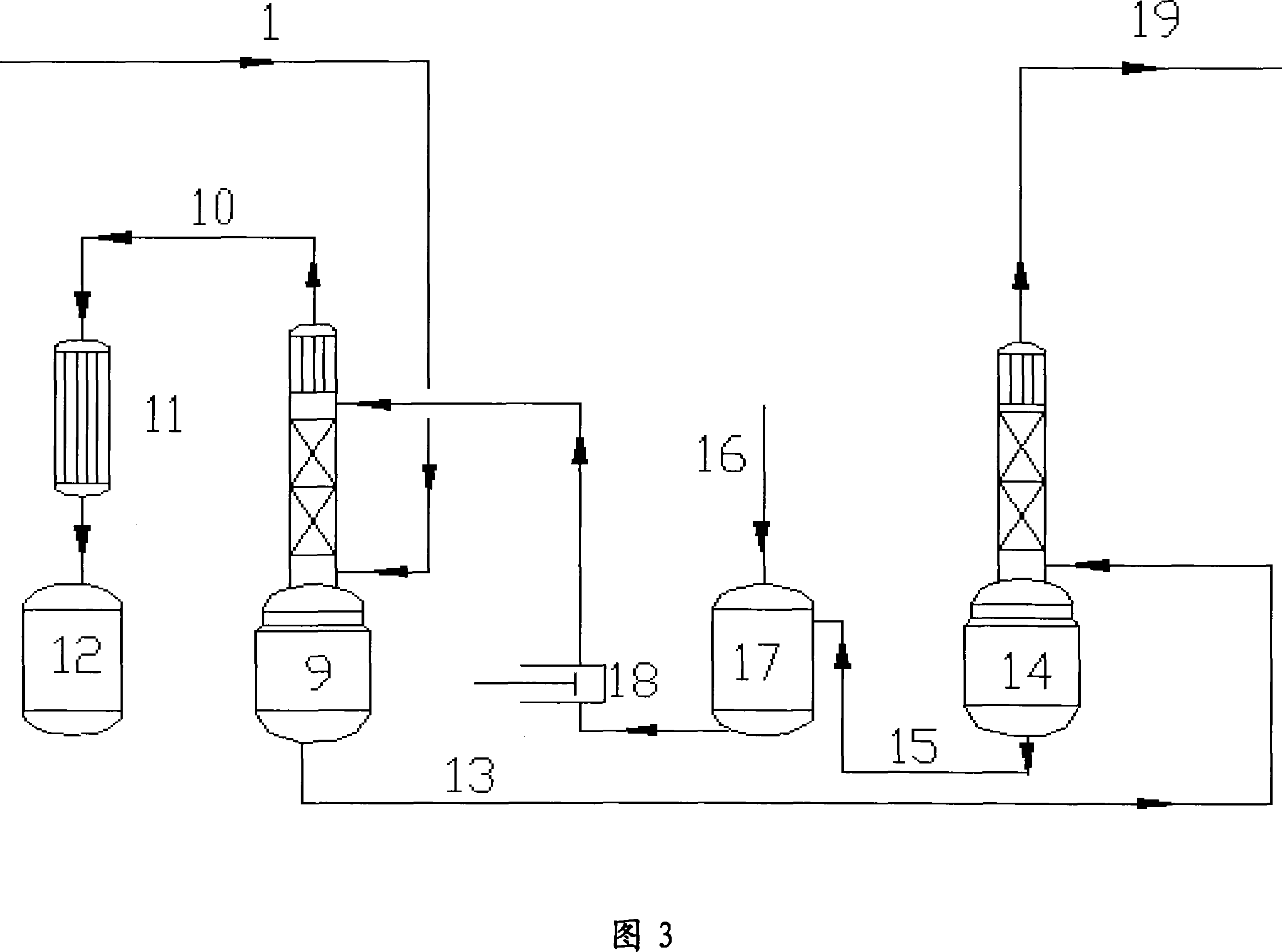

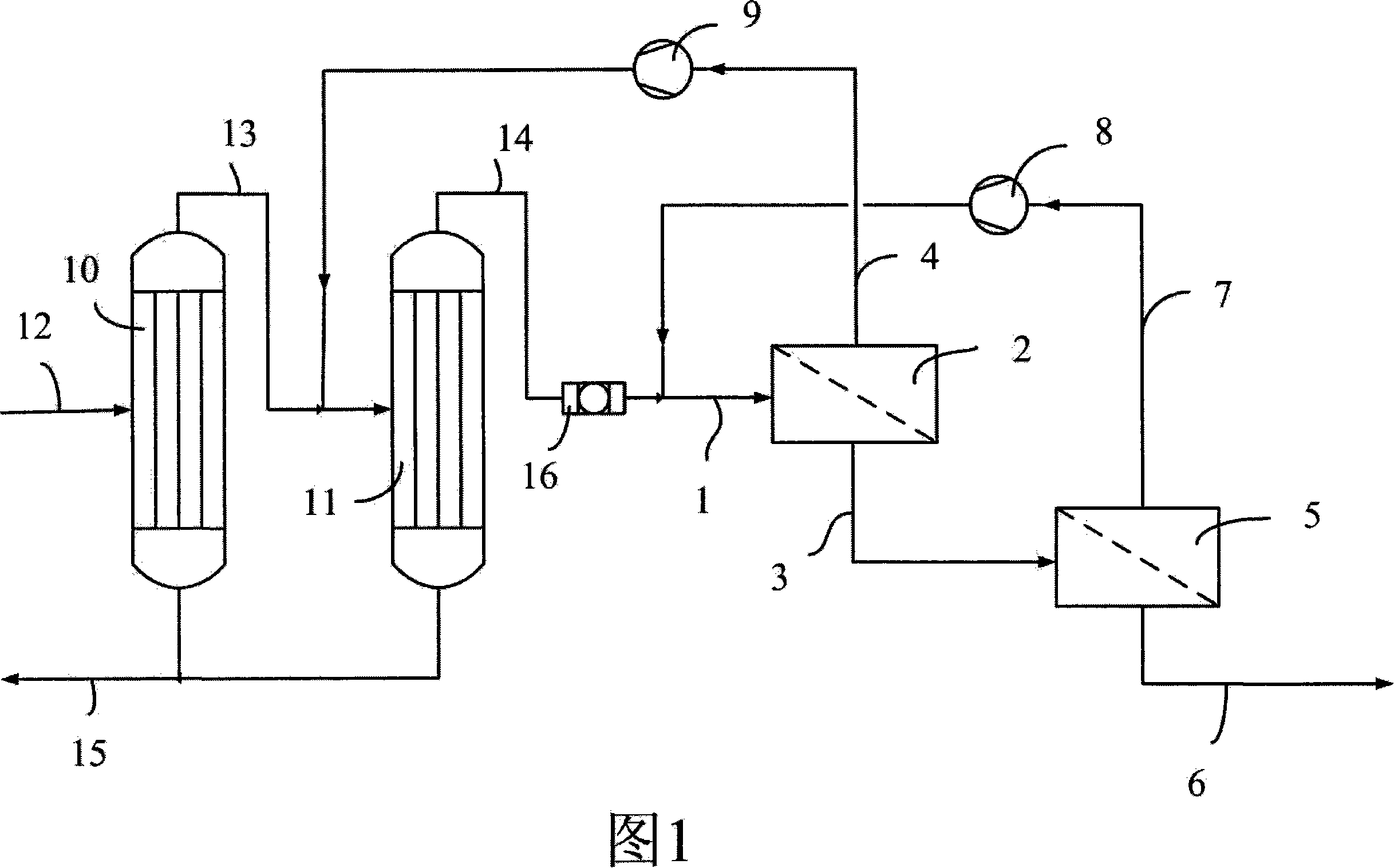

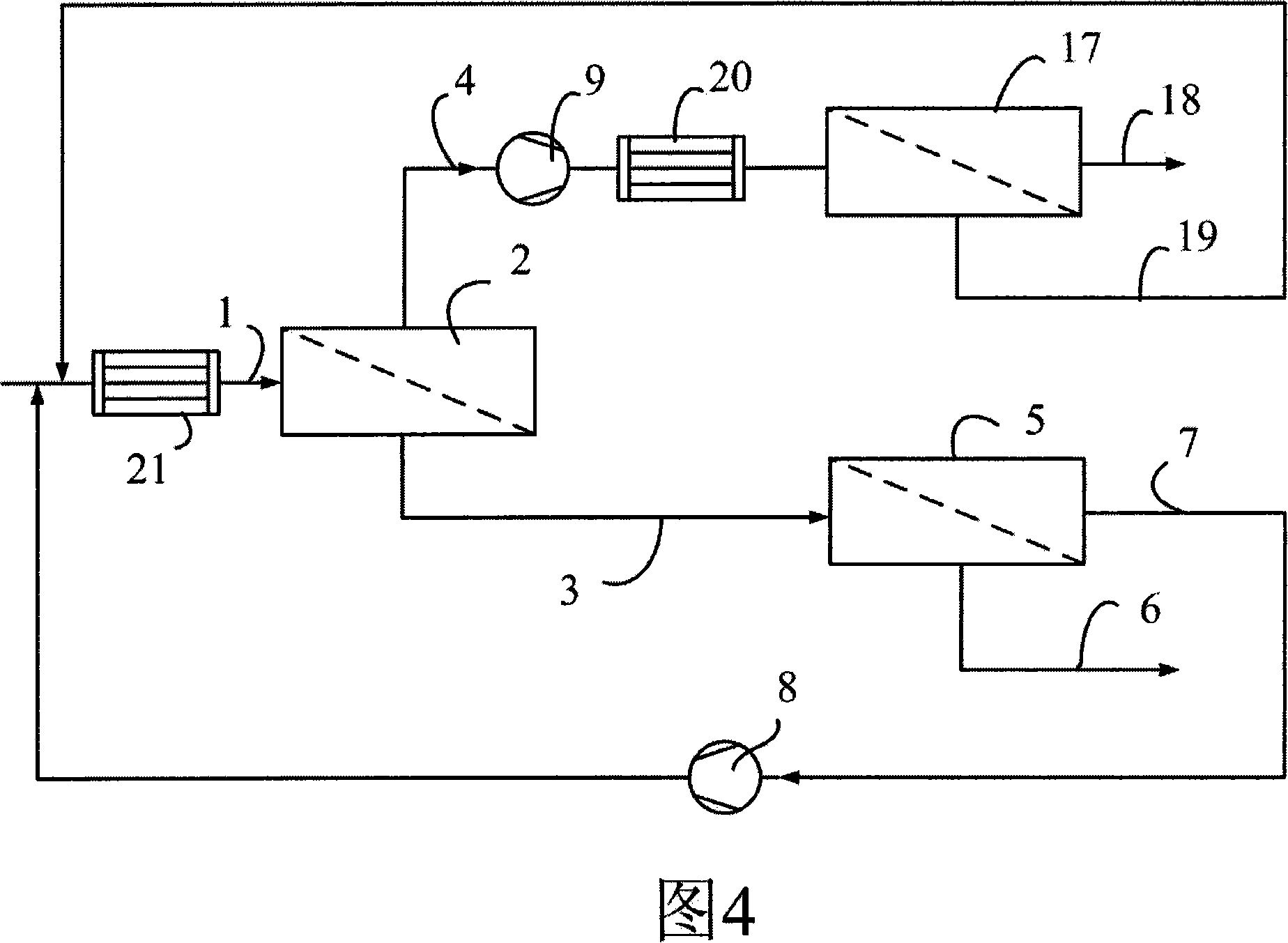

Technology for preparing tetrafluoroethylene through dilution and pyrolysis of difluorochloromethane and water vapor

InactiveCN101973843AHigh puritySolve pollutionHalogenated hydrocarbon preparationTetrafluoroethyleneWater vapor

The invention discloses technology for preparing tetrafluoroethylene through dilution and pyrolysis of difluorochloromethane and water vapor, which is characterized in that a difluorochloromethane preheater, a water vapor preheater, a reactor, a quencher, a graphite condenser, a concentrated sulfuric acid dryer, a left compressor, a left cooler, a middle compressor, a middle cooler, a right compressor, a right cooler, a deaerator, a left condenser, a reservoir, a dehydrogenation tower, a rectification tower, a right condenser, a monomer storage tank and a difluorochloromethane recovery tower are connected in sequence by connecting lines and are assembled as a whole. The technology is reasonable in process and simple in preparation, ensures the produced tetrafluoroethylene to have high purity and solves the problem of environmental pollution, thus being ideal.

Owner:天津东方宜信物流有限公司

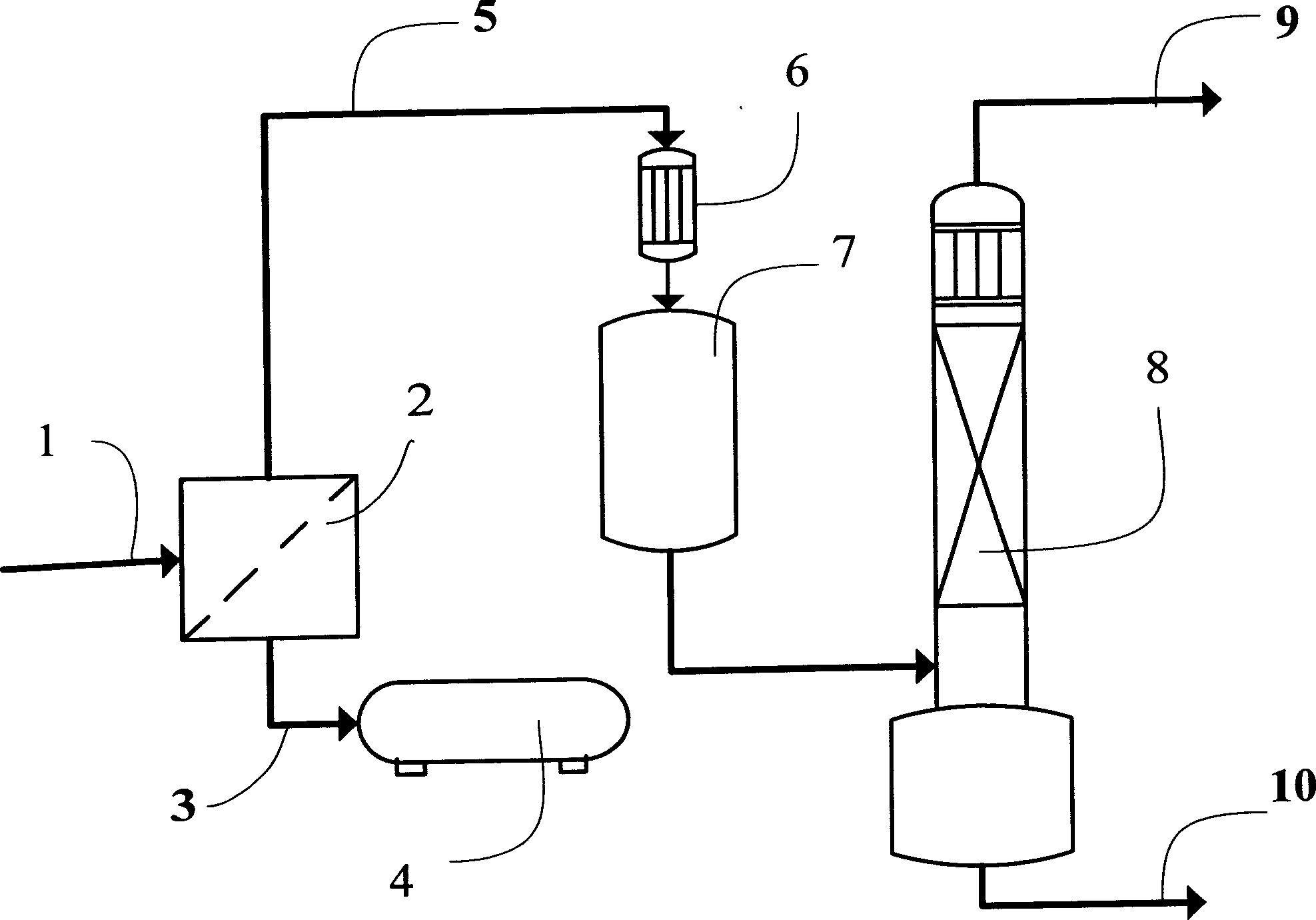

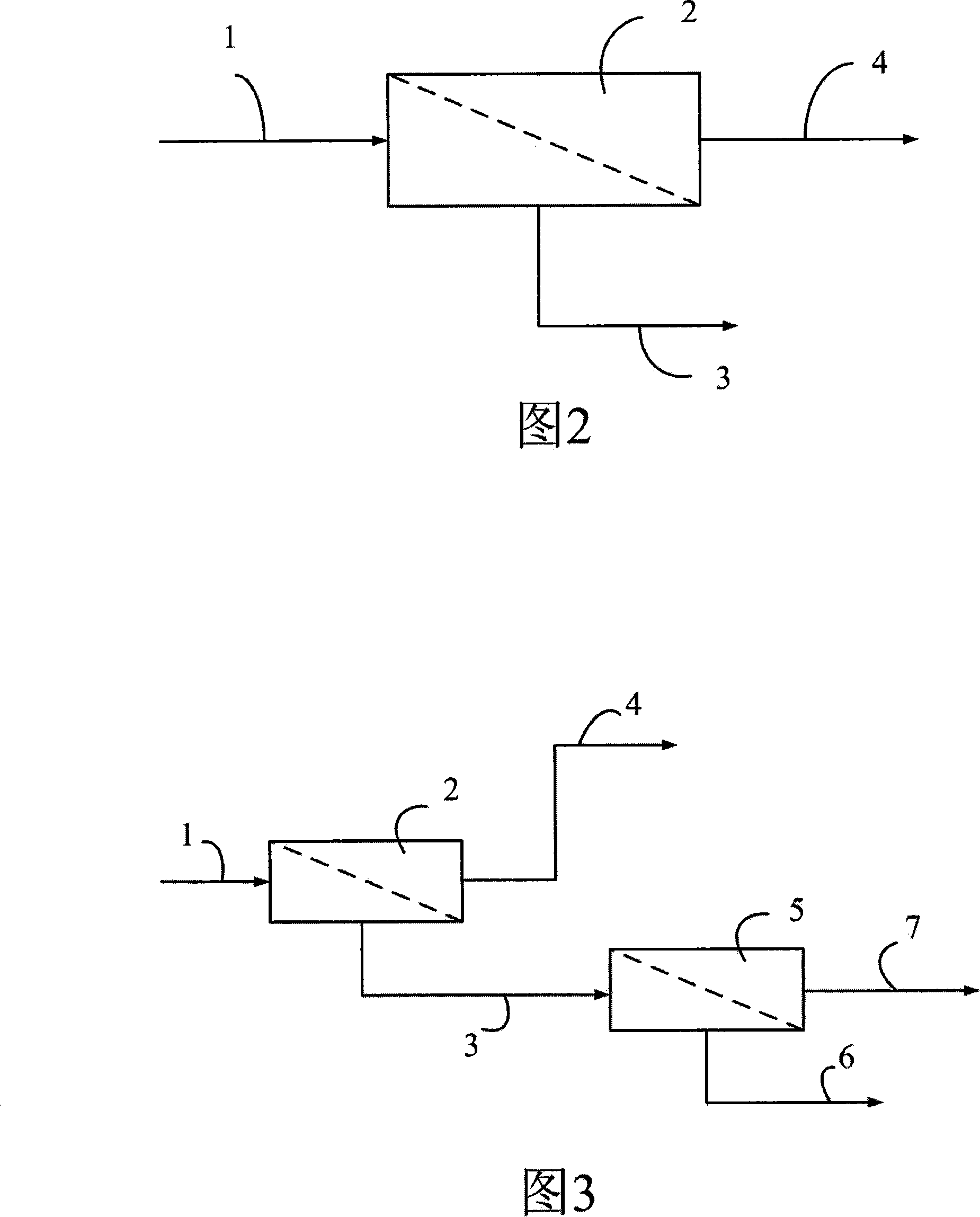

Production method for 2,3,3,3-tetra-fluoropropene

Provided is an economic method for efficiently producing, in a sufficiently controlled state and in one reaction involving thermal decomposition, industrially useful HFO-1234yf, using readily procurable raw materials. Provided is a method for producing 2,3,3,3-tetra-fluoropropene from a raw material composition including chlorodifluoromethane and chloromethane, using a synthesizing reaction involving thermal decomposition, said method characterized by having: a step (a) in which chloromethane is premixed with chlorodifluoromethane at a ratio of 0.01-3.0 mols chloromethane to 1 mol of chlorodifluoromethane and supplied to a reaction vessel, or same are supplied separately thereto; a step (b) in which a heat medium is supplied to the reaction vessel; and a step in which the heat medium is brought in contact with the chlorodifluoromethane and the chloromethane inside the reaction vessel, and 2,3,3,3-tetra-fluoropropene is generated.

Owner:AGC INC

Film separation method for difluo-monochloromethane and trifluoromethane mixture

InactiveCN101239884AHigh puritySimple processHalogenated hydrocarbon separation/purificationChlorodifluoromethane productionHigh concentrationTorch

The invention discloses a method for membrane separating gas mixture of difluo-monochloromethane and trifluoromethane, belonging to the fluorin-containing organic steam separation field. The gas mixture of difluo-monochloromethane and trifluoromethane, which is unseparated after condensation during producing refrigerants R22, passes through a gas membrane separation equipment under ambient temperature and pressure, difluo-monochloromethane first penetrates through a gas separation membrane to the other side, the gas mixture is divided into two section by the gas separation membrane, the collected difluo-monochloromethane penetration gas is compressed and reflowed into a refvigeratory-tower, difluo-monochloromethane is cooled, Liquefied and recoveried as the product, high-concentration trifluoromethane penetration gas can be directly sent to a torch to burn after standard-reach detection. The method has advantages of simple process, small device, convenient operation, high purity of obtained trifluoromethane, no secondary pollution, small investment, low operation cost and safe usage.

Owner:DALIAN UNIV OF TECH

Refrigerant mixture comprising difluoromethane and 1,1,1-trifluoroethane

A refrigerant composition useful as a substitute for chlorodifluoromethane (CHClF2, HCFC-22). The refrigerant composition has a first constituent of difluoromethane (CH2F2, HFC-32); a second constituent of 1,1,1-trifluoroethane (CH3CF3; namely, HFC-143a); and a third constituent selected from cyclopropane (C3H6, RC-270), 1,1,1,2,3,3,3-heptafluoropropane (CF3CHFCF3, HFC-227ea), 1,1,1,2,2-pentafluoropropane (CH3CF2CF3, HFC-245cb), 1,1,1,2,3,3-hexafluoropropane (CHF2CHFCF3, HFC-236ea), butane (C4H10, R-600), bis(difluoromethyl)ether (CHF2OCHF2, HFE-134) and pentafluoroethylmethylether (CF3CF2OCH3, HFE-245).

Owner:KOREA INST OF SCI & TECH

Refrigerant for low temperature applications

ActiveUS20060191665A1Avoid damageHeat-exchange elementsRegenerative heat exchangersSystems designEngineering

An apparatus and method wherein potential ozone layer-damaging chlorodifluoromethane (Refrigerant R-22) is substituted with a mix of less environmentally damaging refrigerants pentafluoroethane and tetrafluoroethane in chlorodifluoromethane-based air-cooling systems for low temperature applications. While less environmentally damaging than chlorodifluoromethane, the substitute refrigerant has a temperature-pressure relationship similar to that of chlorodifluoromethane, making the substitute refrigerant suitable for use with chlorodifluoromethane-based low temperature systems. In this event, it is mixed with a relatively small percentage of a lubricating oil which is compatible with both the unit refrigerant and typical R-22 system design.

Owner:STEFKO PROPERTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com