Device and method for purifying trifluoromethane

A trifluoromethane and purification device technology, which is applied in chemical instruments and methods, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problem of failure to meet the requirements for semiconductor use, easy formation of azeotropes, and low purity of trifluoromethane And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

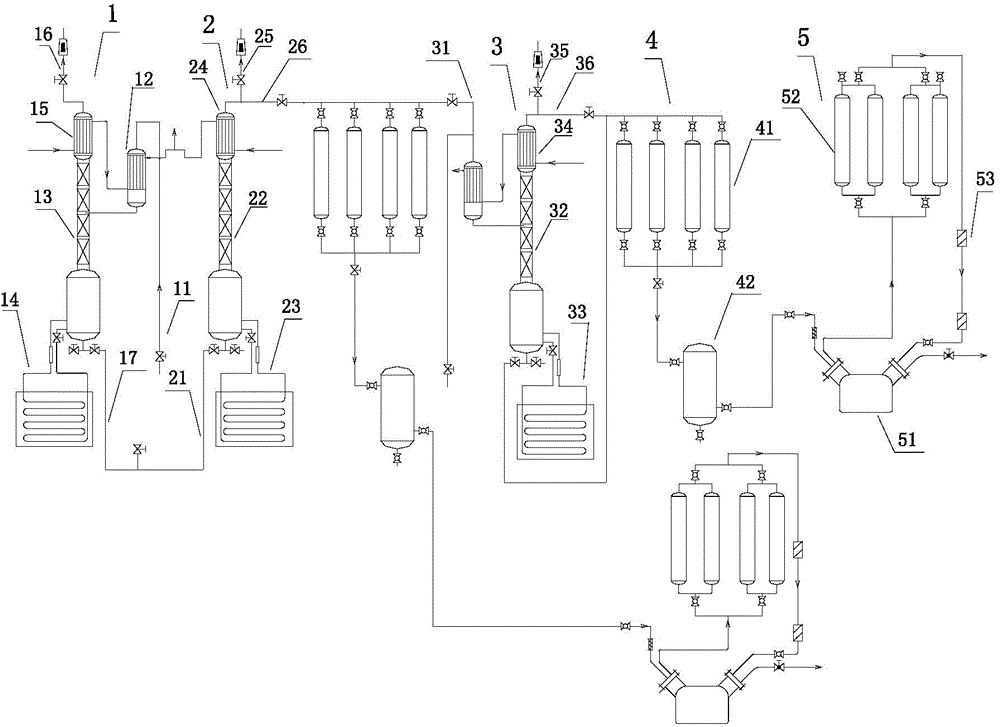

[0049] An embodiment of trifluoromethane purification device of the present invention, such as figure 1 As shown, the device includes a rectification device and an adsorption device connected with the rectification device, and the rectification device includes a primary rectification device 1, a secondary rectification device 2 and a tertiary rectification device connected in sequence 3. The adsorption device includes a low-temperature adsorption device 4 and a filling device 5 connected in sequence, and the low-temperature adsorption device 4 of the adsorption device is connected to the rectification device.

[0050] The primary rectification device 1 comprises a primary rectification tower 13, the top of the primary rectification tower 13 is connected with a primary condenser 15 and a primary discharge pipeline 16 connected with the top of the primary condenser 15 , the middle part of the primary rectification tower 13 is connected with a primary precooler 12 and a primary r...

Embodiment 2

[0061] A method for purifying trifluoromethane using the trifluoromethane purification device described in the present invention, the method is that the trifluoromethane raw material passes through a primary rectification device, a secondary rectification device, a tertiary rectification device, low-temperature adsorption After installing and filling the device, high-purity trifluoromethane is obtained.

[0062] Described trifluoromethane purification method specifically comprises the following steps:

[0063] (1) Purge the entire purification device with high-purity nitrogen, and then vacuumize the entire purification device until the pressure is below 5pa;

[0064] (2) Feed liquid nitrogen into the shell side of the primary condenser and the shell side of the primary precooler of the primary rectification unit, and pass the trifluoromethane raw material at a flow rate of 50Nm3 / h from the primary raw material inlet pipe through the primary pre-cooler The tube side of the coo...

Embodiment 3

[0070] A method for purifying trifluoromethane using the trifluoromethane purification device described in the present invention, the method is that the trifluoromethane raw material passes through a primary rectification device, a secondary rectification device, a low-temperature adsorption device and a filling device in sequence , to obtain high-purity trifluoromethane.

[0071] Described trifluoromethane purification method specifically comprises the following steps:

[0072] (1) Purge the entire purification device with high-purity nitrogen, and then vacuumize the entire purification device until the pressure is below 5pa;

[0073] (2) Feed liquid nitrogen into the shell side of the primary condenser and the shell side of the primary precooler of the primary rectification unit, and pass the trifluoromethane raw material at a flow rate of 50Nm3 / h from the primary raw material inlet pipe through the primary pre-cooler The tube side of the cooler enters the first-stage rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com