Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Dichlorodifluoromethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dichlorodifluoromethane (R-12) is a colorless gas usually sold under the brand name Freon-12, and a chlorofluorocarbon halomethane (CFC) used as a refrigerant and aerosol spray propellant. Complying with the Montreal Protocol, its manufacture was banned in developed countries (non-article 5 countries) in 1996, and developing countries (article 5 countries) in 2010 due to concerns about its damaging effect on the ozone layer. Its only allowed usage is as fire retardant in submarines and aircraft. It is soluble in many organic solvents. Dichlorodifluoromethane was one of the original propellants for Silly String. R-12 cylinders are colored white.

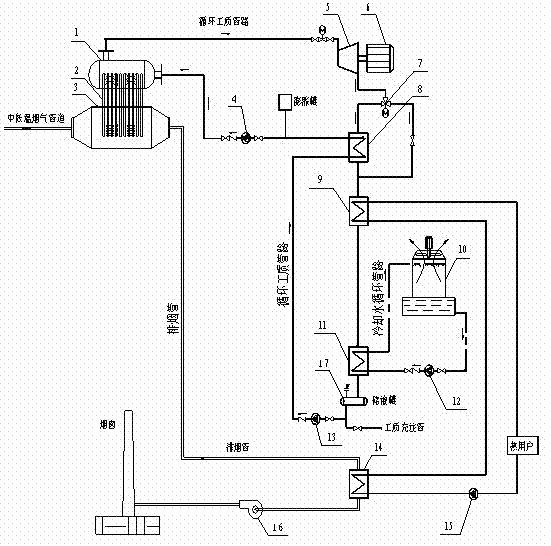

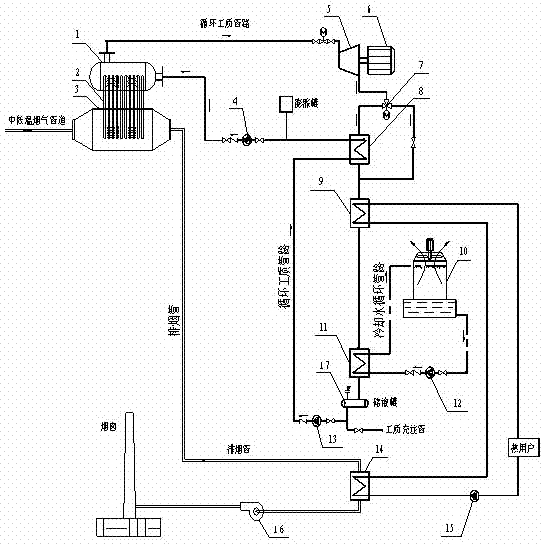

Power generation system for waste heat of medium and low temperature flue gas with heat pipe heat exchanger organic medium Rankine cycle

InactiveCN102401590AEasy to replaceImprove heat transfer performanceIndirect heat exchangersSteam engine plantsDichlorodifluoromethaneOrganic Rankine cycle

The invention provides a power generation system for waste heat of medium and low temperature flue gas with heat pipe heat exchanger organic medium Rankine cycle, and belongs to the technical field of energy and environment. The invention comprises a heat pipe heat exchanger system, a working medium circulation loop of organic Rankine cycle, a medium and low temperature flue gas exhausting pipeline, a heating hot water loop and a cooling water loop, wherein an ascending pipe and a descending pipe of a boiler are replaced by heat pipes, the heat pipe heat exchanger system is formed by a heat pipe, a flue gas heat exchanger and a boiler cylinder, evaporating section of the lower end of the heat pipe is arranged in flue gas heat exchanger, condensing section of the upper end is arranged in the boiler barrel, toluene, dichlorodifluoromethane, propane and pentafluoropropane are used as working medium, 20% volume of the softening desalted water is used as the heat pipe fluid. The invention has advantages of high efficiency of heat exchange, convenient replacement of heat pipe, being capable of avoiding corrosion and uneasy-change of the heat exchanger pipe, affecting the heat transfer efficiency and leakage of the working medium and other advantages, and being capable of adjusting exhaust heat of the organic Rankine cycle according to the demand for heating load of users.

Owner:KUNMING UNIV OF SCI & TECH

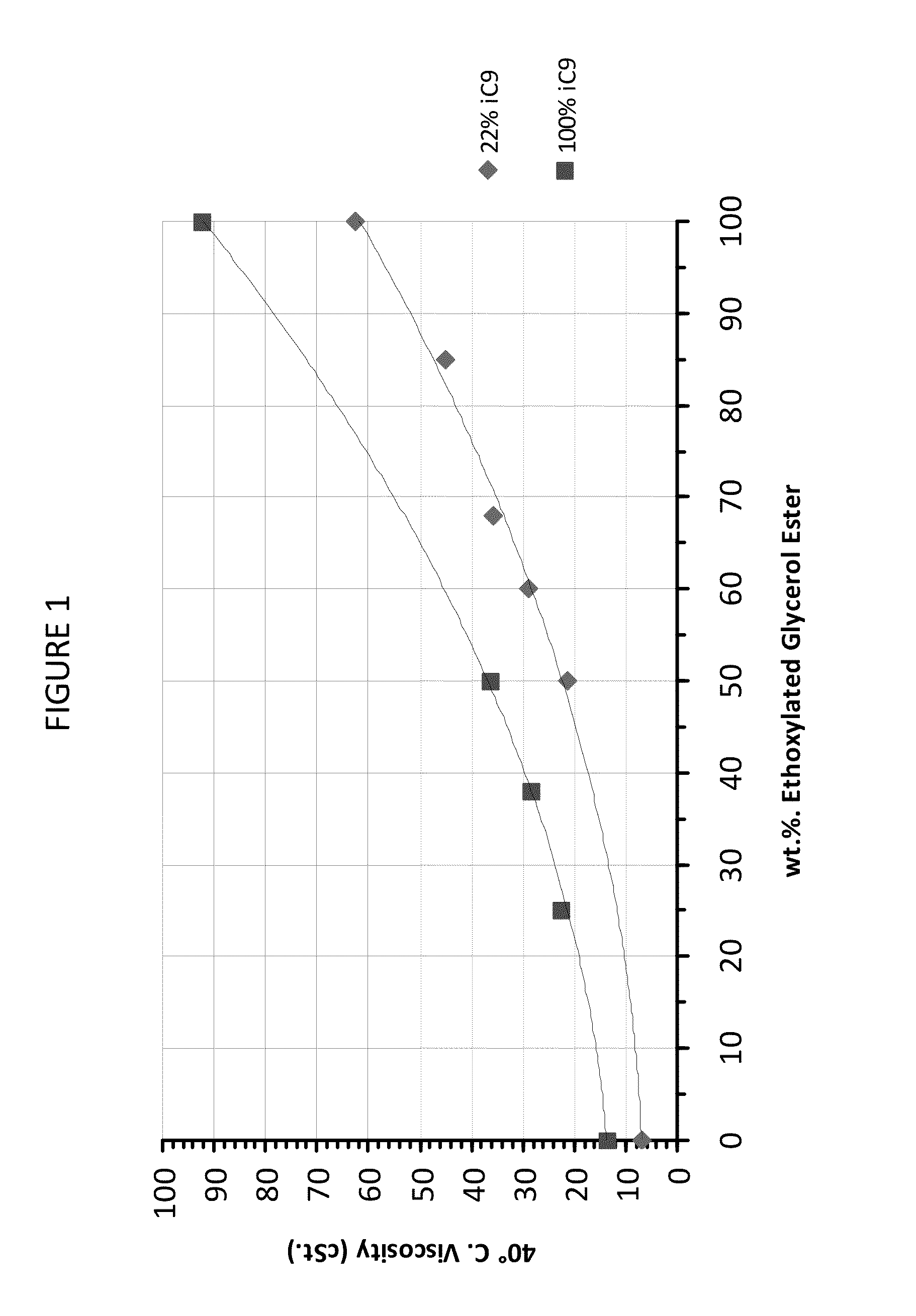

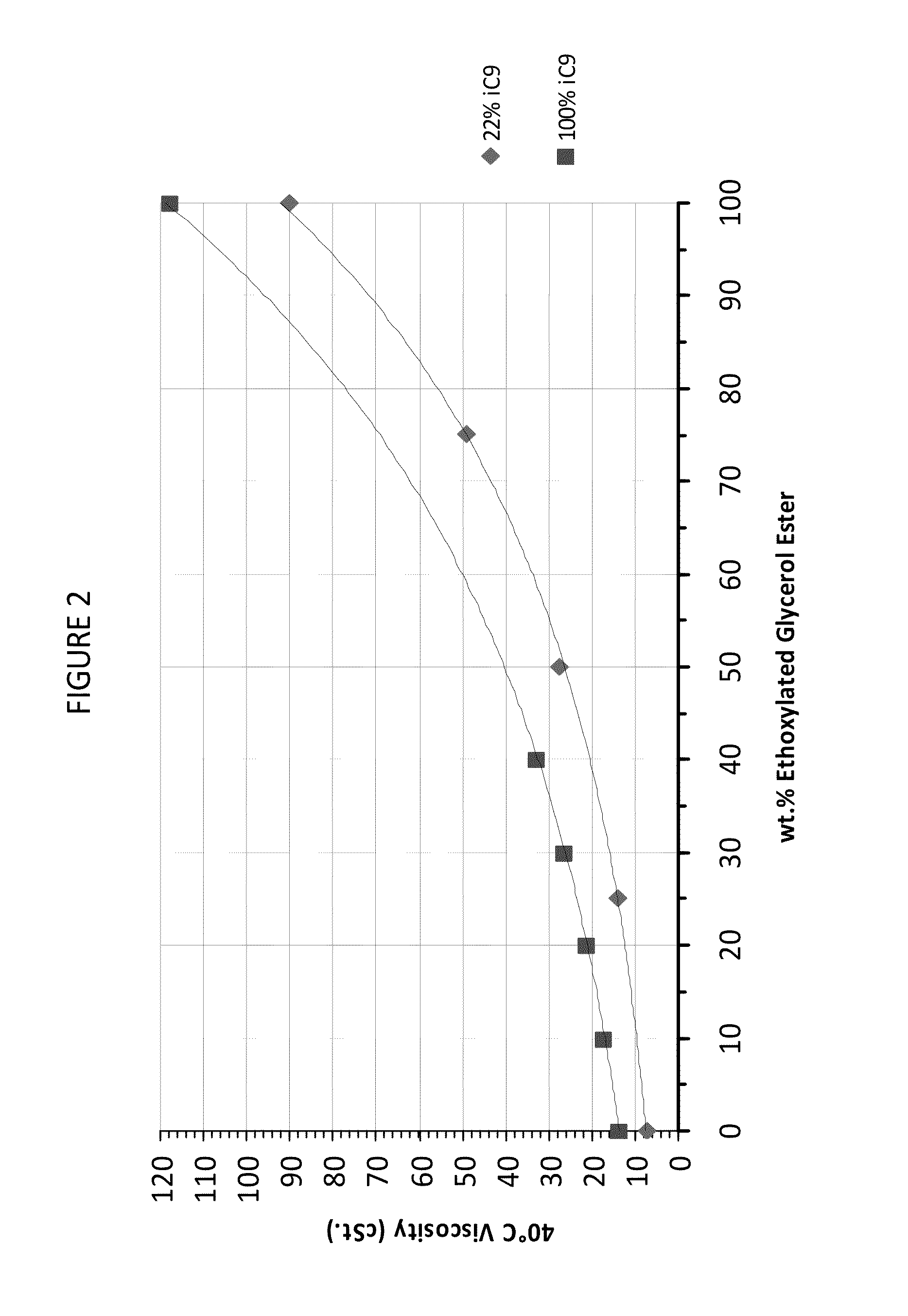

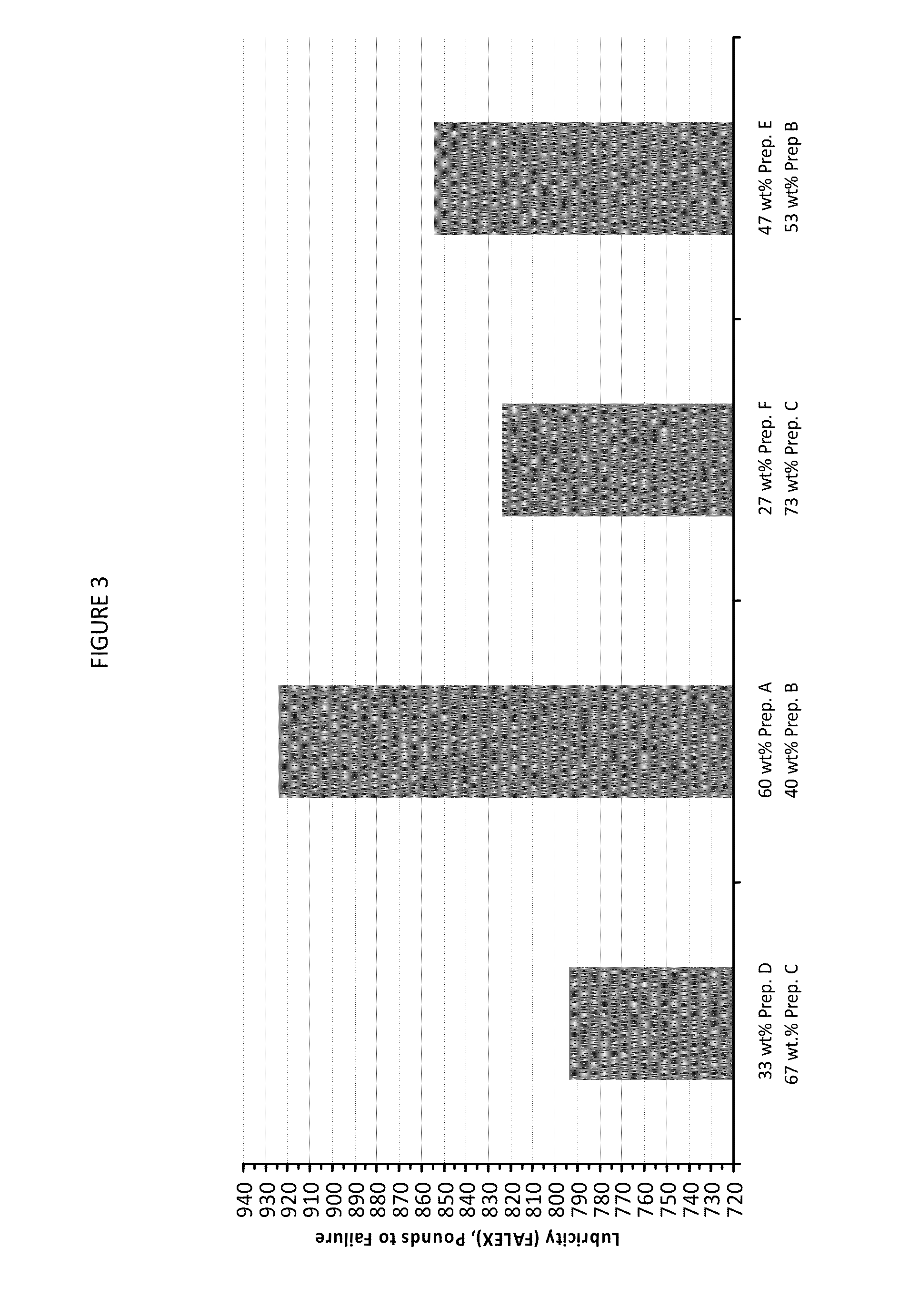

Refrigeration compressor lubricant

ActiveUS20130200295A1Good compatibilityExcellent indexHeat-exchange elementsAdditivesRefrigeration compressorDichlorodifluoromethane

Owner:COPELAND LP

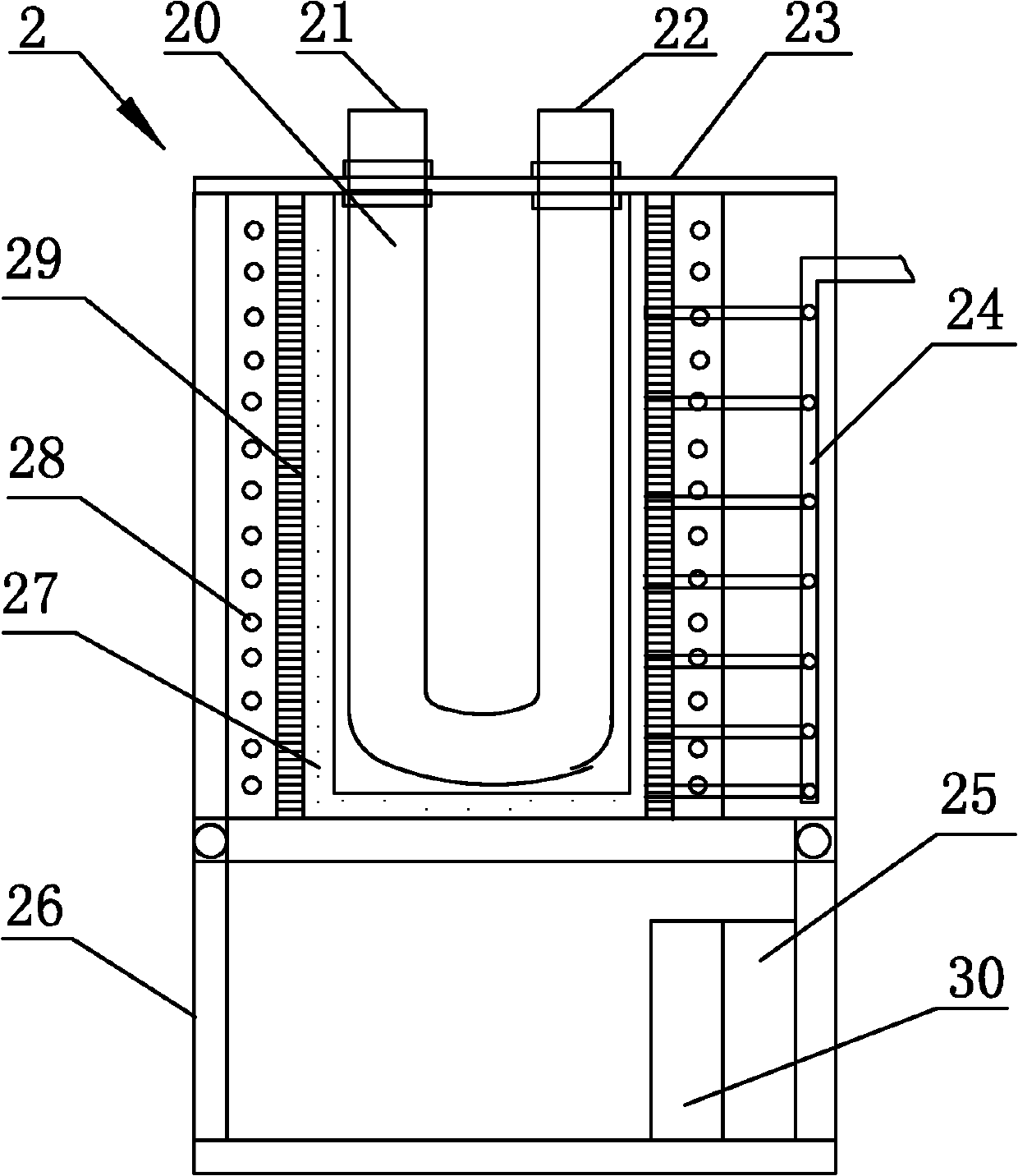

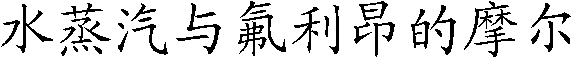

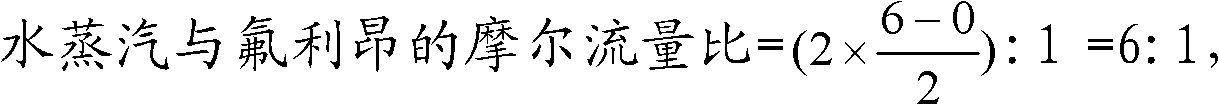

Bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and pyrolysis induction heating furnace

ActiveCN101829488ANo generationFast heatingDispersed particle separationCrucible furnacesDichlorodifluoromethaneHigh energy

The invention relates to a bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and a pyrolysis induction heating furnace. The method is characterized by comprising steps of carrying out pyrolytic reaction on a preheated feed gas which is a mixed gas of dichlorodifluoromethane, steam and air in a high-temperature environment generated by induction heating and carrying out absorption and inversion on pyrolysis products, wherein the proportioning of the feed gas is as follows: the flow ratio of the steam to the dichlorodifluoromethane is shown in the specification, the flow ratio of the air to the dichlorodifluoromethane is shown in the specification, and in the formula, a, b and c are respectively the number of carbon, hydrogen and halogen atoms of one dichlorodifluoromethane molecule. The pyrolysis induction heating furnace is characterized in that a crucible in the traditional pyrolysis induction heating furnace is internally provided with an acid corrosion resistant and thermostability bending-shaped metal coiler, the supply frequency is 10-300kHz and the power is 10-50kW. The invention has the advantages of quick warming speed, little power consumption, high energy utilization rate and pyrolysis efficiency, convenient starting operation, good operation safety and easy scale realization.

Owner:TIANJIN HEJIA VEOLIA ENVIRONMENTAL SERVICES

Multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system

InactiveCN1810914AFully consider the operating pressure ratio rangeConsider operating pressure ratio rangeFluid heatersHeat-exchange elementsDichlorodifluoromethaneOctafluorocyclobutane

The present invention discloses one kind of multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system. The mixture work medium or mixed refrigeratant consists of two components, including one low boiling point component and one high boiling point component. The low boiling point component is one or several selected from difluro methane, trifluoro ethane, fluoro ethane, propylene, propane, pentafluoro ethane, etc. The high boiling point component is one or several selected from isobutane, n-butane, butene, isobutene, octafluoro isobutene, octafluoro cyclobutane, etc.

Owner:XI AN JIAOTONG UNIV

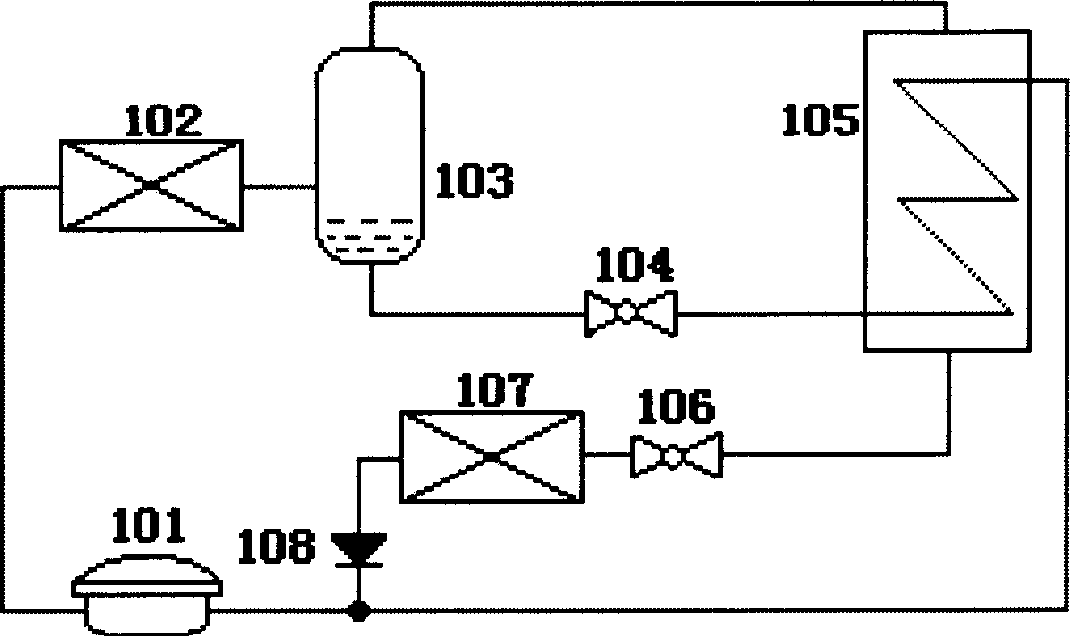

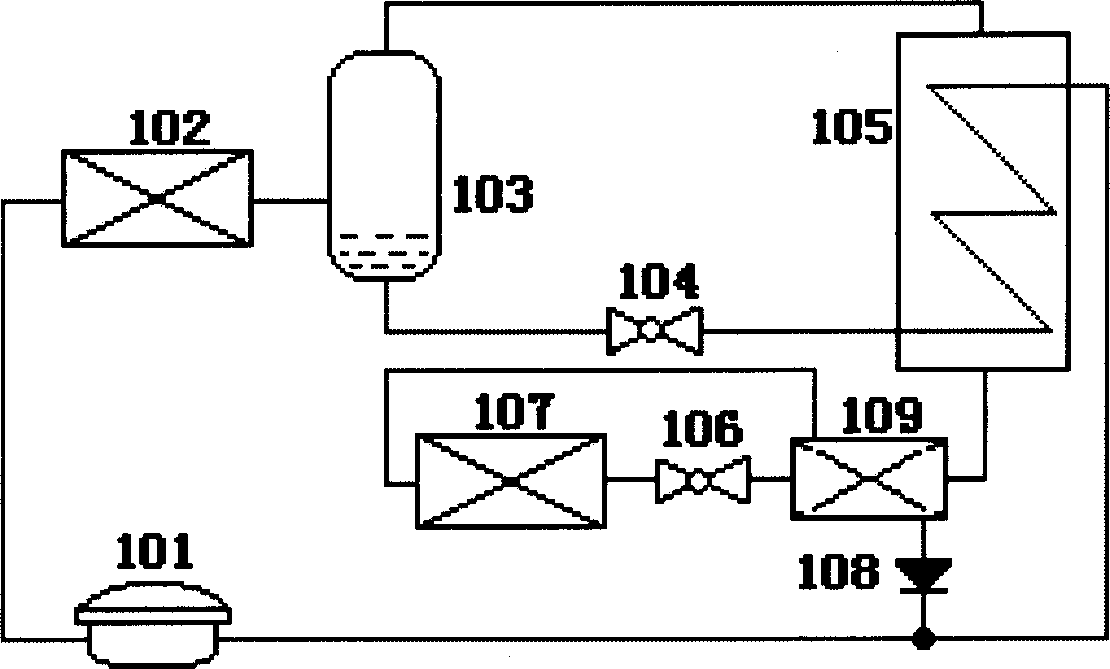

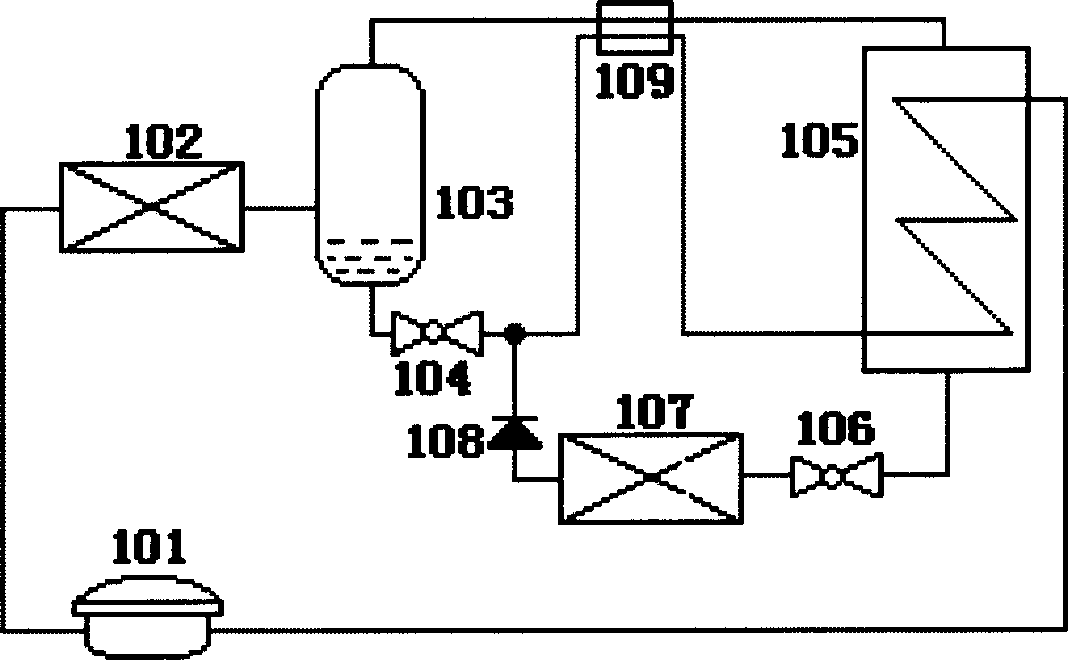

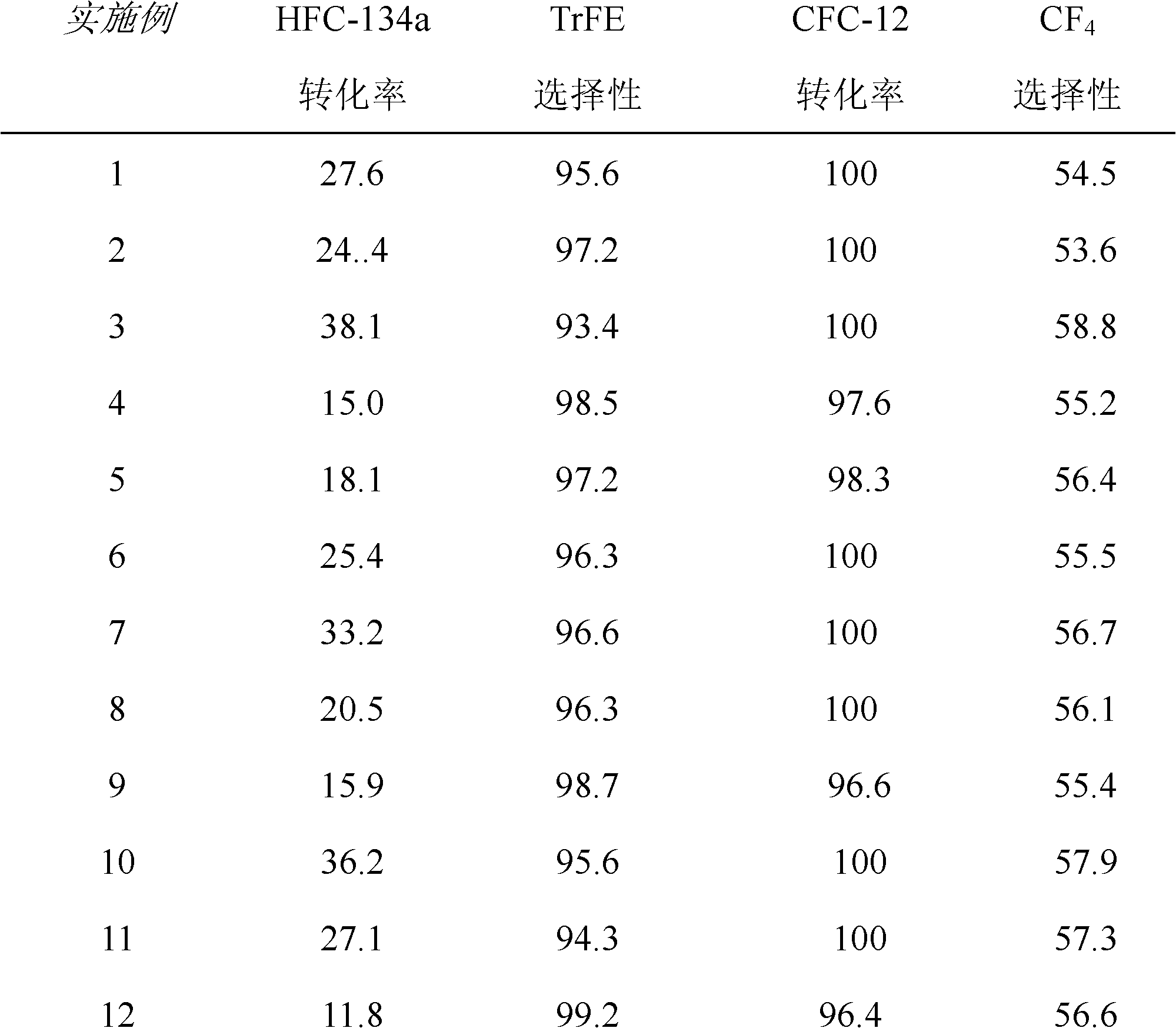

A kind of preparation method of trifluoroethylene and tetrafluoromethane

InactiveCN102267866AImprove conversion rateSolving the industrial problem of damagePreparation by hydrogen halide split-offPreparation by halogen replacementDichlorodifluoromethaneReaction temperature

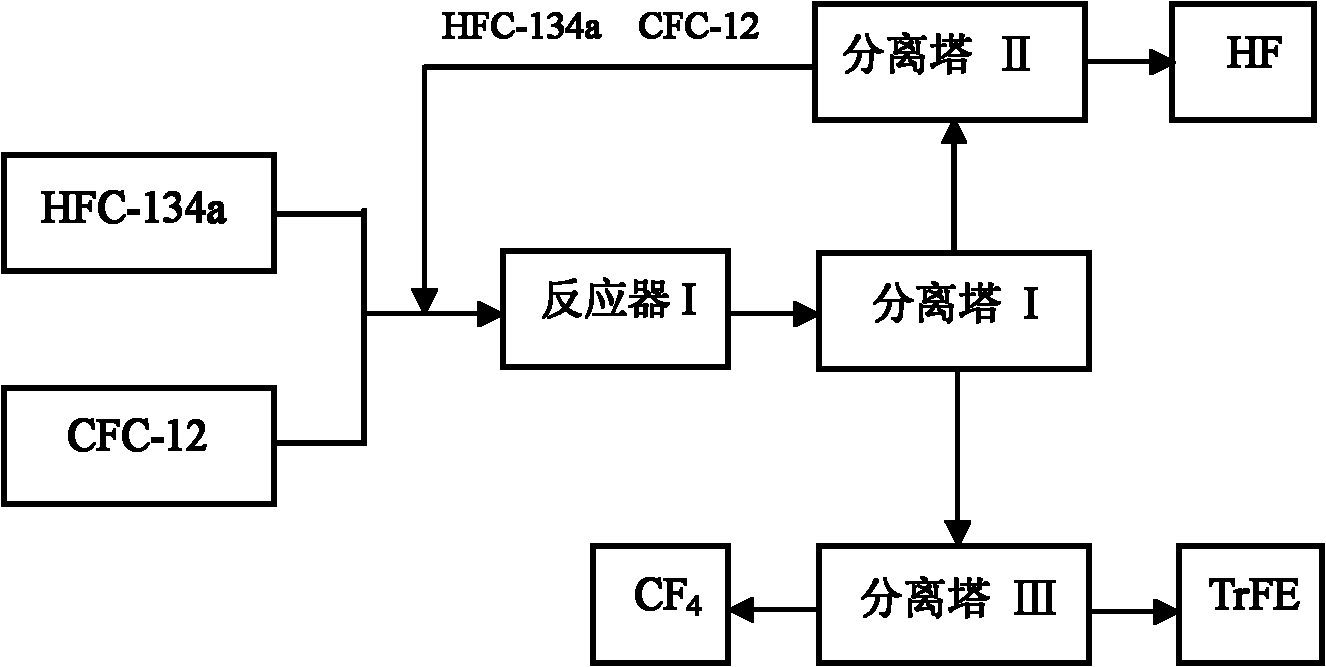

The invention relates to a preparation method for trifluoroethylene and tetrafluoromethane. The method is characterized in that: dichlorodifluoromethane and 1,1,1,2-tetrafluoroethane are mixed according to a mole ratio of the dichlorodifluoromethane to the 1,1,1,2-tetrafluoroethane of 1:2-9, and are subjected to a reaction at a temperature of 350-500 DEG C and space velocity of 700-1500 hour<-1> under normal pressure through a catalytic action of a fluorination catalyst; the resulting end gas is separated through a partition column I; the separated dichlorodifluoromethane, the separated fluoride hydrogen and the separated 1,1,1,2-tetrafluoroethane are separated through a partition column II, wherein the resulting dichlorodifluoromethane and the resulting 1,1,1,2-tetrafluoroethane are recycled, the resulting fluoride hydrogen is adopted as the by-product to be collected; the separated trifluoroethylene and the separated tetrafluoroethane are subjected to separation through a partition column III, and purification to obtain the pure trifluoroethylene and the pure tetrafluoroethane. The preparation method provided by the present invention has characteristics of low reaction temperature, low energy consumption and less damage to the equipment.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Polyurethane foam thermal insulation material

InactiveCN105693976AHigh compressive strengthHigh tensile strengthDichlorodifluoromethaneThermal insulation

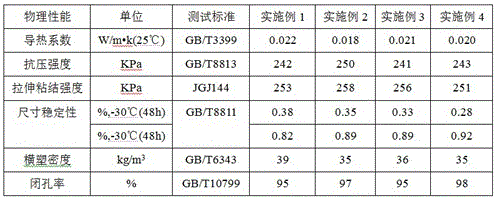

The invention relates to a thermal insulation material and discloses a polyurethane foam thermal insulation material. The thermal insulation material is prepared by mixing and foaming the following raw materials in parts by weight: 70-100 parts of toluene diisocynate, 40-80 parts of polyether polyol I, 10-30 parts of polyether polyol II, 3-6 parts of expanded vermiculite, 5-8 parts of nano silicon dioxide, 10-20 parts of dichlorodifluoromethane, 1-5 parts of catalyst and 1-5 parts of foam stabilizer, wherein the polyether polyol I is lignin polyether polyol; and the polyether polyol II is polyether polyol polymerized by taking modified soybean oil as an initiator and epoxy propane as a polymerization monomer. The thermal insulation material has better compressive strength, tensile strength and impact strength while the phenomena of water tank deformation, bulking, ridging and even cracking are avoided.

Owner:GUANGXI JISHUN ENERGY TECH

Glass detergent

InactiveCN102876514ADoes not affect light transmissionDoes not affect reflectivitySurface-active non-soap compounds and soap mixture detergentsDichlorodifluoromethanePhotochemistry

The invention discloses a glass detergent. The glass detergent consists of the following components: 18 to 20 parts of absolute ethanol, 8 to 10 parts of dichlorodifluoromethane, 3 to 5 parts of sodium hydroxide, 6 to 8 parts of polyoxyethylene lauryl ether and 40 to 50 parts of water. The glass detergent has a remarkable decontamination effect, is noncorrosive and nonflammable, does not pollute and affect the environment, does not affect the light transmission property and light reflectivity of glass, can be safely used, and meets the requirements of people.

Owner:QIDONG DONGZHOU INSTR

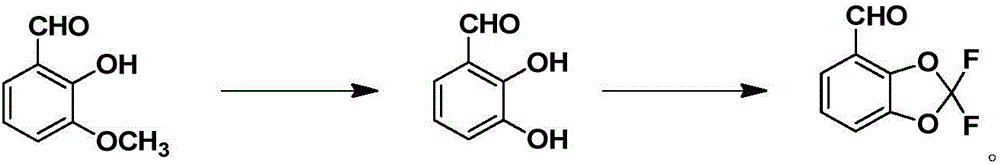

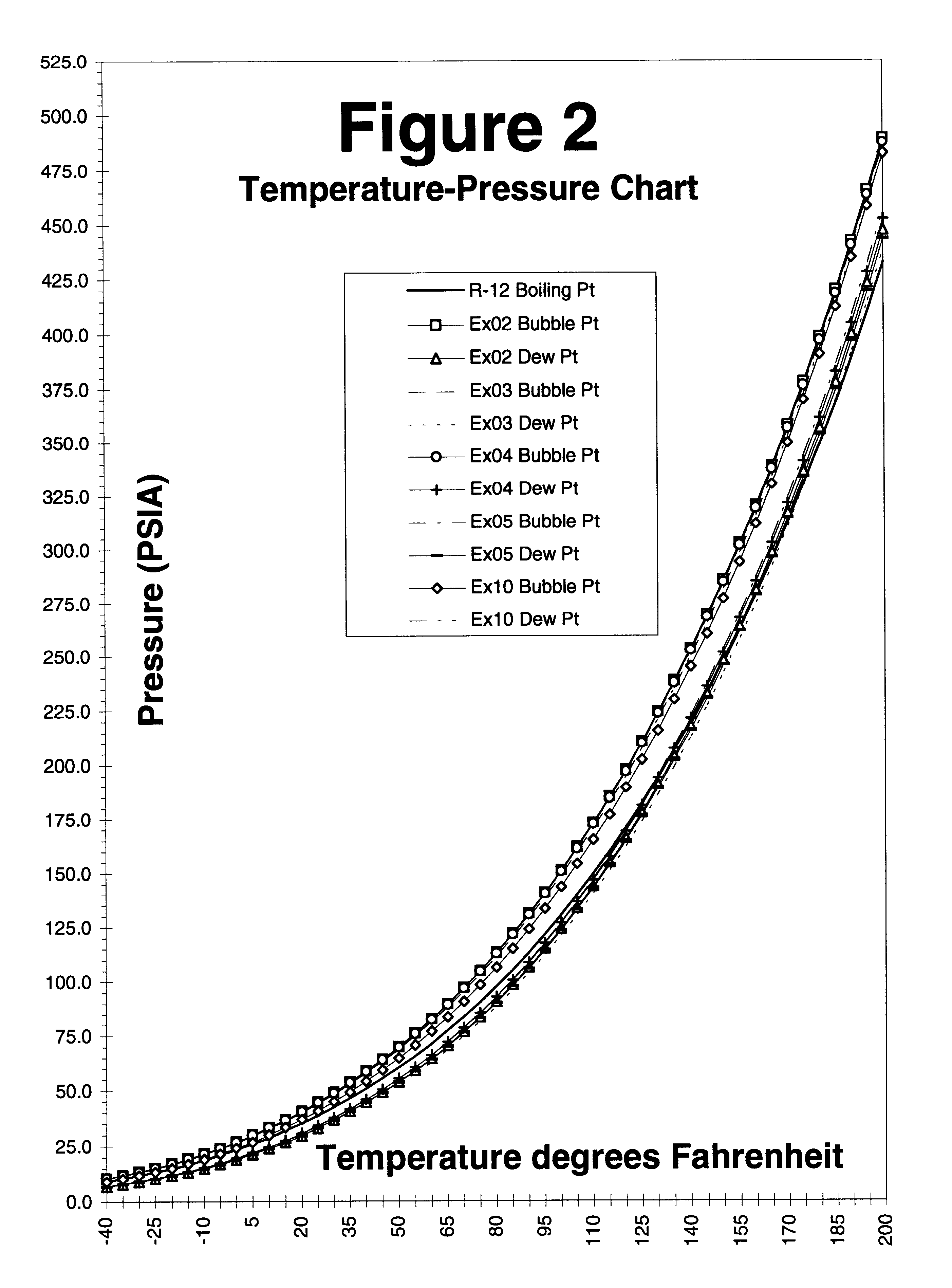

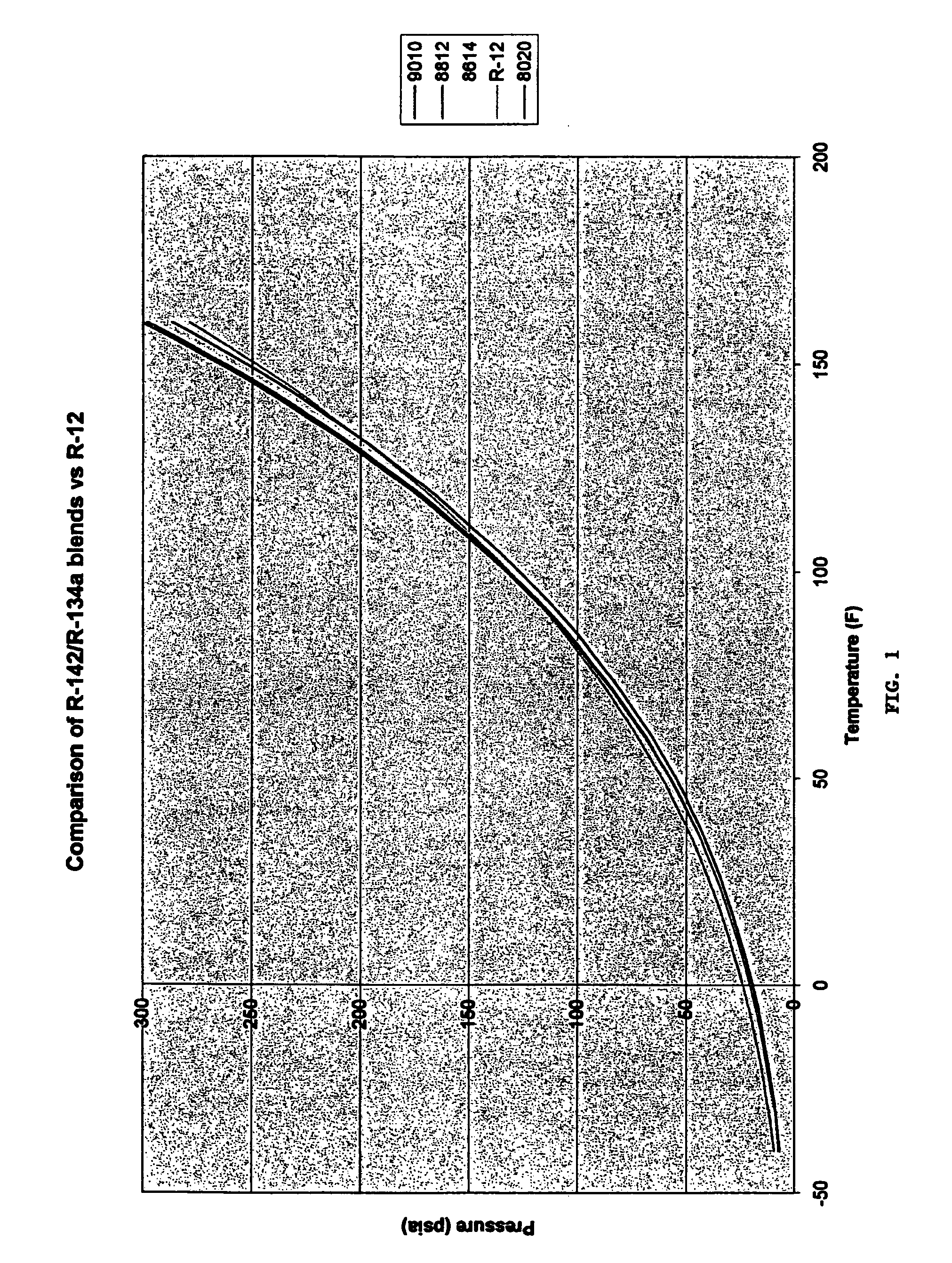

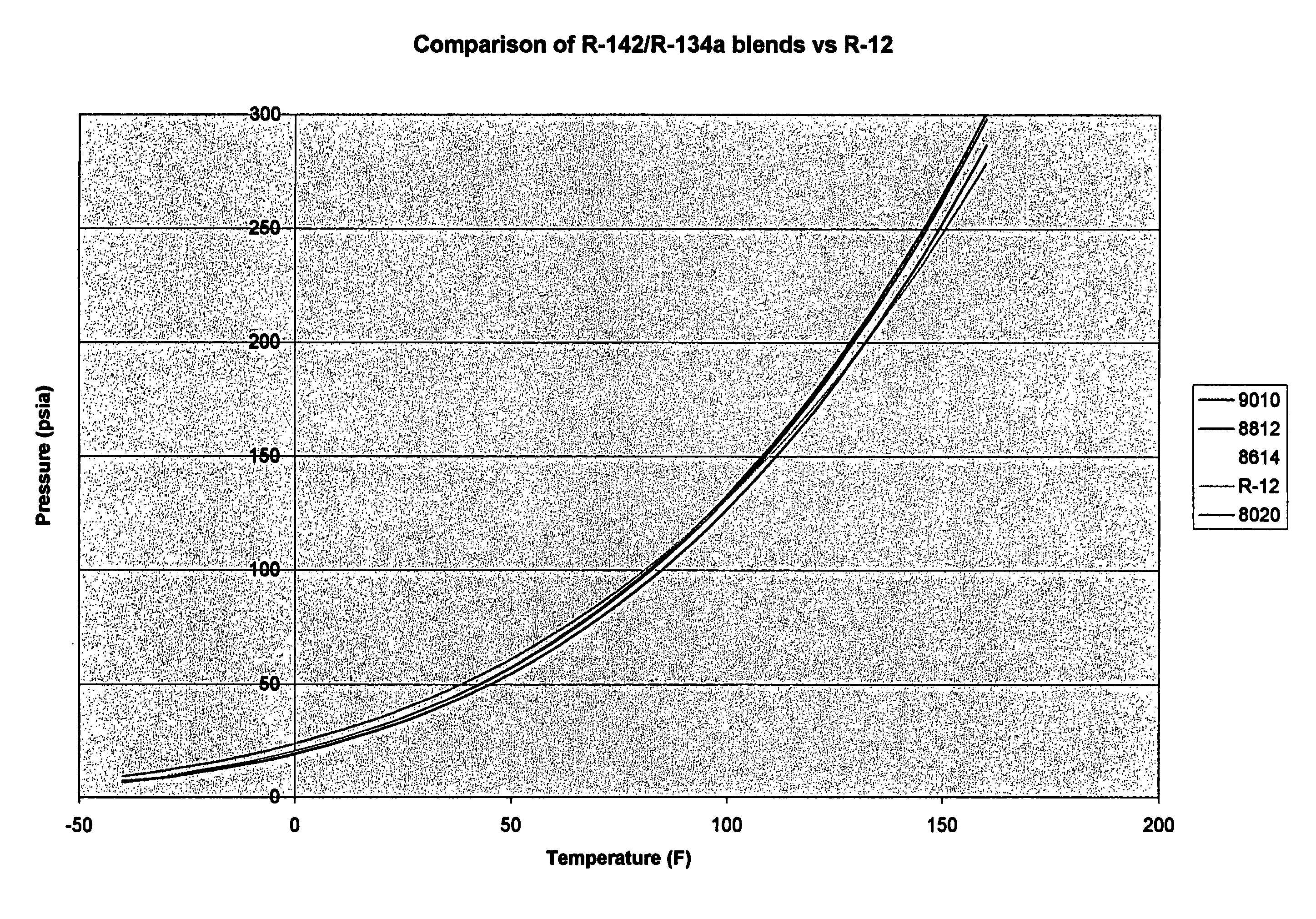

Environmentally safer replacement refrigerant for freon 12-based refrigeration systems

InactiveUS6565766B1Low vapor pressureAvoid damageCompression machines with non-reversible cycleHeat-exchange elementsDichlorodifluoromethaneEngineering

An apparatus and method wherein ozone layer-damaging dichlorodifluoromethane is substituted with a mix of less environmentally damaging refrigerants chlorodifluoroethane and tetrafluoroethane in dichlorodifluoromethane-based air-cooling systems. While less environmentally damaging than dichlorodifluoromethane, the substitute refrigerant has a temperature-pressure relationship similar to that of dichlorodifluoromethane, making the substitute refrigerant suitable for use with dichlorodifluoromethane-based air-cooling systems. The substitute refrigerant can be used alone or in combination with dichlorodifluoromethane. In either event, it is mixed with a relatively small percentage of a hydrophobic lubricating oil which is compatible with both the substitute refrigerant and with dichlorodifluoromethane.

Owner:KENNETH B RUELLO

Anti-rust cleaning liquid for mechanical processing equipment

InactiveCN105296241AThe preparation process is simpleSimple processing methodSurface-active non-soap compounds and soap mixture detergentsBiotechnologyMonoglyceride

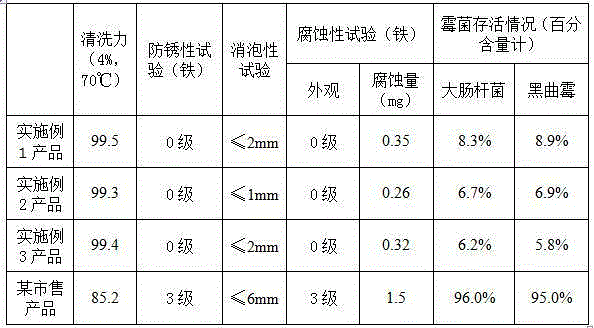

The invention relates to an anti-rust cleaning liquid for mechanical processing equipment. The anti-rust cleaning liquid consists of the following components in parts by mass: 50 to 54 parts of trisodium phosphate, 52 to 56 parts of ethoxyamine, 48 to 52 parts of octaphenyl polyoxyethyiene, 52 to 56 parts of citric acid, 48 to 52 parts of ethylene glycol butyl ether, 52 to 56 parts of benzyl triphenyl phosphorous bromide, 48 to 52 parts of malic acid, 54 to 58 parts of dichlorodifluoromethane, 48 to 52 parts of benzotriazole, 52 to 56 parts of calcium sorbate, 48 to 52 parts of caprylic / capric glycerides, 52 to 56 parts of oxalic acid, 48 to 52 parts of hard resin acid monoglyceride, 52 to 56 parts of hyclroxy acetic acid, 48 to 52 parts of biochemical fulvic acid, 48 to 52 parts of sodium nitrite, 52 to 56 parts of epoxy acid zinc, 48 to 52 parts of morpholine, 52 to 56 parts of petroleum mahogany sulfonate, 48 to 52 parts of chlorothalonil, and 1000 to 2000 parts of water. The anti-rust cleaning liquid has the advantages that the cleaning capability is better, the anti-rust and non-corrosive effects are realized, and the anti-bacteria and mildew-proof effects are realized.

Owner:龚灿锋

Method for producing tetrafluoromethane by gas phase catalysis

InactiveCN101723797AExtended service lifeImprove conversion ratePreparation by halogen replacementChromium CompoundsHydrogen fluoride

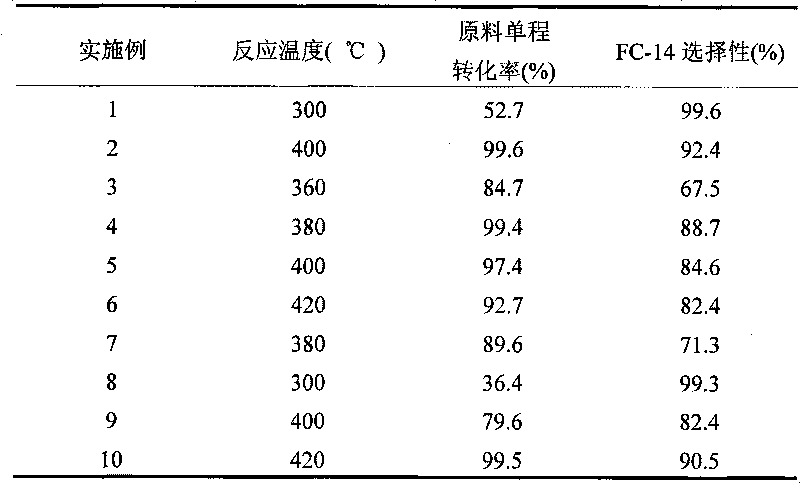

The invention discloses a method for producing a tetrafluoromethane by gas phase catalysis. Aiming at the defects of high needed reaction temperature and low conversion per pass existing in the conventional process for producing FC-14 by gas phase fluorination, the invention provides an economic and high-efficient method for producing the tetrafluoromethane by gas phase catalysis, which has the advantages of low needed reaction temperature and high conversion per pass. The method for producing the tetrafluoromethane comprises the following step: reacting halohydrocarbon with hydrogen fluoride at the presence of a gas phase fluorination catalyst in a gas phase to produce the tetrafluoromethane, wherein the molar ratio of the halohydrocarbon to the hydrogen fluoride is 1:1-10; the halohydrocarbon is one or more of the tetrafluoromethane, trichloromonofluomethane, dichlorodifluoromethane and monochlorotrifluoromethane; the used gas phase fluorination catalyst adopts a chromium compound as an active component and an aluminum compound as a carrier; and the molar ratio of the chromium to the aluminum is 1:1-19. The method for producing the tetrafluoromethane has the characteristics of long service life and high percent conversion of the halohydrocarbon.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

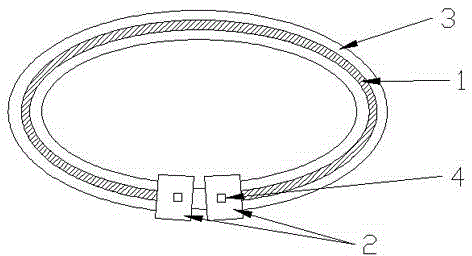

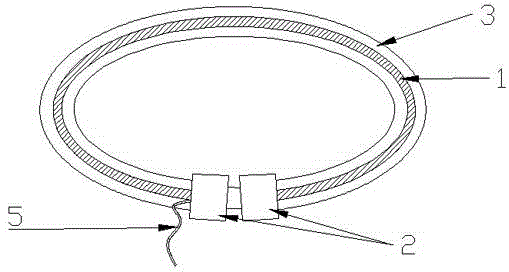

Underarm automatic inflation life buoy

The invention relates to an underwater lifesaving device, in particular to an underarm automatic inflation life buoy. The underarm automatic inflation life buoy comprises a hollow elastic plastic ring (1) with a notch, wherein two clamp buckles (2) are respectively arranged at two ends of the notch, a C-shaped air sac (3) sleeves the exterior of the hollow elastic plastic ring (1), two ends of the C-shaped air sac (3) are respectively fixed at two ends of the elastic plastic ring (1) in seal mode, a stop valve is arranged at one end of the elastic plastic ring (1), and communicates an inner space of the elastic plastic ring (1) with the C-shaped air sac (3), dichlorodifluoromethane and fluoro trichloromethane are placed in the elastic plastic ring (1), and a volume ratio between the dichlorodifluoromethane and the fluoro trichloromethane is 1:0.8-1.2. The underarm automatic inflation life buoy has the advantages of being good in safety, quick to inflate, and low in cost, and can be widely popularized and used by swimmers.

Owner:贾红晨

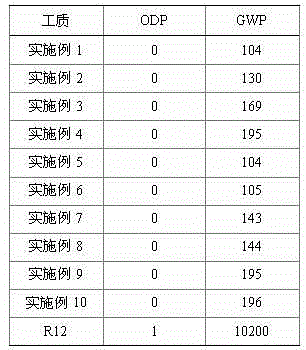

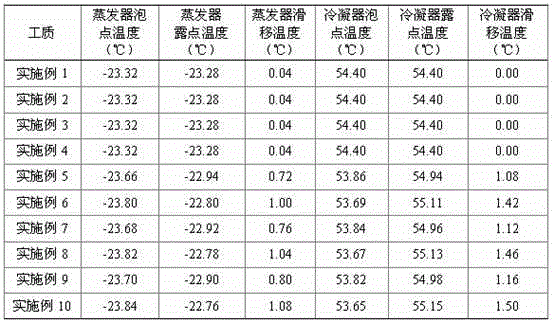

Environment-friendly and energy-saving refrigerator refrigerant

ActiveCN104974717AEnvironmentally friendlyReduce flammabilityChemical industryHeat-exchange elementsDichlorodifluoromethaneEngineering

The invention discloses a high efficient refrigerator refrigerant with a low global warming potential (GWP) value. The refrigerant comprises the following components in percentage by weight: 2 to 15% of 1,1,1,2-tetrafluoroethane (CF3CH2F, R134a), 0 to 80% of fluoroethane (C2H5F, R161), and 5 to 98% of dimethyl ether (C2H6O, DME). The ozone depression potential (ODP) of the mixed refrigerant is 0, the GWP value is less than 120, the environmental performance is excellent, moreover the unit-quality COP (coefficient of performance) of the refrigerant is better than that of R12 (dichlorodifluoromethane, namely freon); and at the same time, the unit-volume refrigerating capacity of the refrigerant is equivalent to R12, the slippage temperature is small, the evaporation and condensing pressures are approximate to those of R12, the refrigerant has the advantages of low displacement cost, energy saving, and environment-friendliness, and thus the refrigerant can be used to displace R12 in the long term.

Owner:TAIYUAN UNIV OF TECH

Medicinal composition for aerosol

ActiveCN101721368AAvoid rising costs and complex processing techniquesPressure is easy to controlAerosol deliveryOrganic non-active ingredientsDichlorodifluoromethaneMedicine

Owner:YANGTAI PHARMA SHANDONG

Fuel Additive

InactiveUS20110107657A1Improve fuel burn rateReduce polluting exhaust emissionLiquid carbonaceous fuelsFuel additivesDichlorodifluoromethaneDiethyl ether

This invention relates to a fuel additive whose composition in weight percentage is as follows: nitrogen monoxide 1˜76%, hydrogen peroxide 20˜83%, ethylene 3˜66%, acetone 1˜64%, dichlorodifluoromethane 1˜60%, benzene 1˜60%, carbon tetrachloride 1˜60%, petroleum ether 1˜60%, butanone 1˜60%, ethanol 1˜60%, methanol 1˜60%, ethyl ether 1˜60%, nitryl oil 1˜60%, isopropanol 1˜60%, dichloromethane 1˜60%, toluene 1˜60%, acetonitrile 1˜89%, n-butanol 1˜76%, 2-butanol 1˜60%, tert-butanol 1˜89%, cyclohexane 1˜76%, diethyl ether 1˜90% and nitromethane 1˜76%. Mix the above components well and dissolve them into a solution. The addition should be in the volume ratio of 1:700˜1:60000 when applied. The fuel additive using this invention can improve the combustion rate of the fuel, reduce the emission of air pollutants, cause no damage or side effect on any metal component of the engine, prolong the equipment life, accelerate the start of the engine, clear the accumulated carbon in the valves, spark plugs, cylinder, flywheel ring gear and in various engines.

Owner:CHEN YIYU

Preparation process of polyvinylidene fluoride

InactiveCN104497181AImprove thermal stabilityEasy to processDichlorodifluoromethanePolypropylene glycol

The invention discloses a preparation process of polyvinylidene fluoride. The preparation process comprises the following steps of (1) adding 2.1 parts of hydrogen peroxide and 1.8 parts of an inorganic alkaline solution into a reaction kettle, uniformly mixing, then, adding 11.3 parts of a dichlorodifluoromethane solvent and 0.2 part of a perfluorobutanesulforyl fluoride solution, and reacting while stirring at the temperature of 6 DEG C below zero for 30 minutes; (2) introducing 6.7 parts of a polypropylene glycol solution, 72 parts of vinylidene fluoride monomers and 2.5 parts of isopropylcyclopentane, reacting while stirring at the temperature of 35 DEG C, and stopping reacting when the pressure is reduced to be less than 0.21MPa; and (3) filtering, washing and drying to obtain the powdery polyvinylidene fluoride. The polyvinylidene fluoride prepared by using the preparation process is favorable in thermal stability and processability and capable of meeting the requirements of production processes such as injection molding, extrusion and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

Material of automobile thermal-insulating and sound-insulating plate and preparation method of material

The invention discloses a material of an automobile thermal-insulating and sound-insulating plate. The material is made of the following materials in parts by weight: 55-65 parts of ethylene-propylene-diene-terpolymer rubber, 70-75 parts of epoxy resin, 16-18 parts of azodicarbonamide, 4-7 parts of polystyrene, 8-15 parts of polyethylene foams, 12-14 parts of expanded vermiculite, 7-11 parts of glass fiber, 9-15 parts of nano carbon black, 20-22 parts of nano aluminum oxide, 10-14 parts of aerogel, 7-12 parts of barium sulfate, 8-14 parts of polyester, 6-10 parts of expanded perlite, 14-18 parts of ceramic cotton fiber, 8-10 parts of alumina silicate fiber, 2-6 parts of sodium silicate, 5-10 parts of N-phenyl-N'-cyclohexyl p-phenylenediamine, 11-14 parts of dichlorodifluoromethane and 16-18 parts of fatty alcohol-polyoxyethylene ether sodium sulfate. The material for the automobile thermal-insulating and sound-insulating plate, which is disclosed by the invention, has good thermal-insulating and sound-insulating effects, is good in aging resistance, and is long in service life.

Owner:芜湖天鸿汽车零部件有限公司

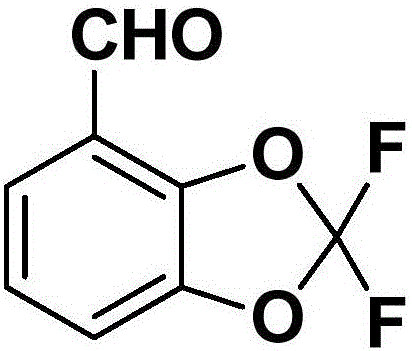

Synthesizing method for 2,2-difluoro-1,3-benzodioxole

InactiveCN105237509ASimple processReduce process wasteOrganic chemistryDichlorodifluoromethaneOrganic layer

The invention relates to a synthesizing method for 2,2-difluoro-1,3-benzodioxole. The method comprises the steps that 1, sodium hydroxide and water are added into a reaction kettle, then liquid paraffin is added, the temperature is increased to control the temperature of the reaction kettle to be under the condition of 85 DEG C, pyrocatechol is added, the temperature is kept at 85 DEG C, reacting is performed for 1 hour, and then pyrocatechol sodium salt is prepared; 2, methylbenzene, water and catalysts are added in a high-pressure kettle, the high-pressure kettle is closed, replacement is performed for three times with nitrogen, the temperature is increased to control the temperature of the high-pressure kettle to be under the condition of 95 DEG C, the pyrocatechol sodium salt prepared in the step 1 and dichlorodifluoromethane are added, the pyrocatechol sodium salt is preheated to 85 DEG C-90 DEG C in advance before being fed, the temperature of the high-pressure kettle is kept at 95 DEG C-105 DEG C, reacting is performed for 1 hour, the high-pressure kettle is cooled to 20 DEG C, an organic layer solution is separated out, washing is performed for one time, the organic layer solution is rectified to collect rectified components, and the 2,2-difluoro-1,3-benzodioxole is obtained. The synthesizing method for the 2,2-difluoro-1,3-benzodioxole has the advantages of being simple and direct in technology, few in technology waste materials, high in yield and suitable for large-scale industrialized production.

Owner:JIANGSU REPONT PESTICIDE FACTORY

Process for the synthesis of highly active modified carbon supported palladium catalyst

InactiveUS6624109B2Cheaply availableReadily availablePigmenting treatmentPreparation by dehalogenationActivated carbonDichlorodifluoromethane

The present invention relates to a process for the synthesis of highly active modified carbon supported palladium catalyst by simultaneously impregnating activated carbon with a palladium precursor and an aluminium precursor. The carbon supported palladium catalyst is useful for the hydrodechlorination of dichlorodifluoromethane to produce difluoromethane.

Owner:COUNCIL OF SCI & IND RES

Preparation method of polyvinylidene fluoride separation membrane

InactiveCN105435650AImprove corrosion resistanceImprove heat resistanceSemi-permeable membranesMembranesDichlorodifluoromethaneHexyldecanol

The invention discloses a preparation method of a polyvinylidene fluoride separation membrane. Polyvinylidene fluoride is taken as a membrane raw material; and the preparation method comprises following steps: 1) by weight, 1 to 2 parts of hexyldecanol, 0.8 part of hydrogen peroxide, and 1.1 parts of an inorganic base solution are delivered into a reaction vessel for uniform mixing, 1.6 parts of poly(ethylene glycol) monooleate, 14.5 parts of dichlorodifluoromethane solvent, and 1.8 parts of phenylmethylsulfonyl fluoride solution are subjected to 25min of reaction at -6 DEG C with stirring; 2) 1.3 parts of sodium oleoyl amino fatty acid, 2.2 parts of a hexyldecanol solution, 59 parts of vinylidene fluoride monomer, and 1.8 parts of methylcyclopentane are delivered into the reaction vessel, an obtained mixture is subjected to reaction at 18 DEG C with stirring, and reaction is stopped when pressure is reduced to be lower than 0.23MPa; and 3) an obtained product is filtered, washed, and dried so as to obtain polyvinylidene fluoride powder. The polyvinylidene fluoride separation membrane possesses corrosion resistance, heat resistance, cold resistance, oxidation resistance, and weather resistance.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

Anti-oxidation flux and preparation method thereof

InactiveCN105855750AReduce tensionPrevent oxidationWelding/cutting media/materialsSoldering mediaVegetable oilDichlorodifluoromethane

The invention discloses an anti-oxidation flux and a preparation method thereof. The anti-oxidation flux is prepared from, by weight, 100-200 parts of vegetable oil modified rosin, 120-150 parts of ethyl alcohol, 60-80 parts of carbitol, 40-120 parts of polyethylene glycol, 20-60 parts of sebacic acid, 50-80 parts of maleic acid, 90-100 parts of malic acid, 40-60 parts of citric acid, 20-30 parts of butyl acetate, 7-15 parts of malonic acid amide, 20-60 parts of nicotinamide, 10-20 parts of zinc nitrate, 20-60 parts of olein, 40-80 parts of isocyanate and 40-90 parts of dichlorodifluoromethane. The preparation method includes: adding the raw materials, performing heating reaction, adding the nicotinamide, and well stirring. The anti-oxidation flux is excellent in wettability, surface tension of welded materials is reduced, and accordingly surface oxidation of the welded materials is prevented.

Owner:傅兴琴

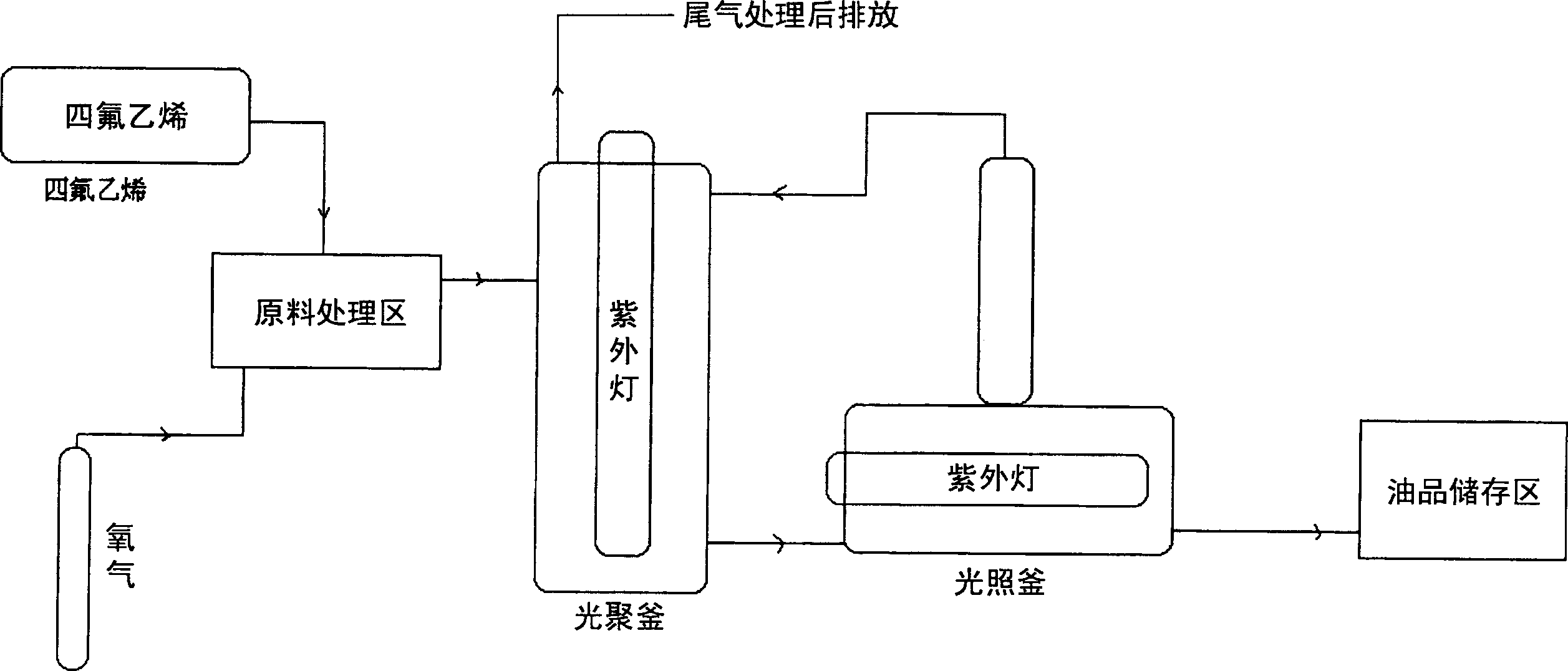

Process and apparatus for continuous photooxidation preparing polyperfluoromethylethyl ether oil

InactiveCN1401674ASolve the explosionResponse is smooth and safeTetrafluoroethyleneDichlorodifluoromethane

A process for continuously preparing polyperfluoromethylethyl ether oil by optical oxidizing method includes continuously flowing tetrafluoro ethene and O2 gas into optical polymerizer containing bifluorodichloro methane, providing low temp environment by refrigerator set, continuous optical oxidizing-polymerizing reaction at -60 - -20 deg.C under radiation of ultraviolet lamp, dischargint the resultant to radiating reactor, radiating and heating by ultraviolet lamp, and returning the bifluorodichloro methane, low-molecular polymer and unreacted substance back to said polymerizer.

Owner:CHINA PETROLEUM & CHEM CORP

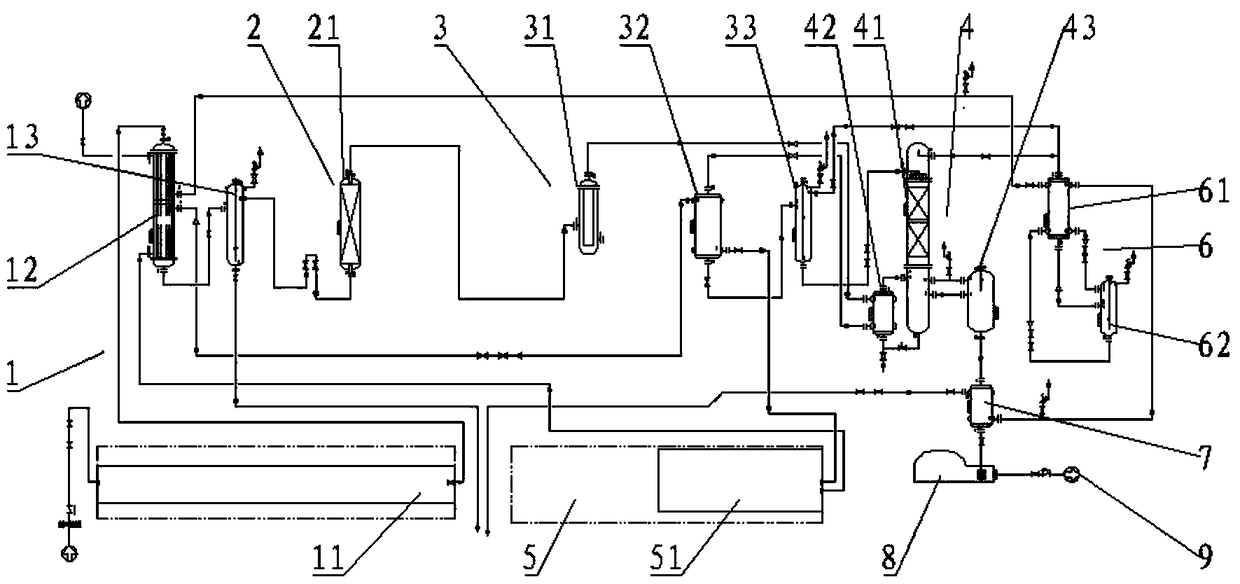

Skidded moving type carbon dioxide oil displacing production gas recovery system

ActiveCN108870868AQuick assemblySolving Recycling ProblemsSolidificationLiquefactionDichlorodifluoromethanePollution

The invention discloses a skidded moving type carbon dioxide oil displacing production gas recovery system, which mainly consists of a carbon dioxide compression unit, a drying unit, a carbon dioxidecondensing liquidation unit, a stripping unit, a refrigeration unit and a tail gas liquidation separation unit. The units are sequentially connected to form a main material pipeline loop, an auxiliarymaterial pipeline loop and a dichlorodifluoromethane pipeline loop. The cold and hot flow energy among the three loop pipelines is reasonably exchanged; the raw material gas to be cooled is used as astripping tower heat source; the self body is cooled; the discharged tail gas is used for cooling raw material gas; the cold quantity is sufficiently utilized. Two kinds of coolants and the two kindsof work conditions including the standard work condition and the ultra-low-temperature work condition are reasonably used to achieve the complementary effects; the product quality is improved; the carbon dioxide and methane are sufficiently recovered. A small amount of carbon dioxide gas is discharged at the start-stop moment, the production device realizes the whole sealed circulation, no pollution and zero discharge.

Owner:JIANGSU HUAYANG LIQUID CARBON CO LTD

Medical packaging material and preparation method thereof

InactiveCN106243653AImprove high temperature resistanceHigh tensile strengthDichlorodifluoromethaneAcrylic resin

The invention discloses a medical packaging material. The medical packaging material is prepared from, by weight, 12-23 parts of polycarbonate, 8-18 parts of polyurethane, 0.5-1.2 parts of polyethylenimine, 0.5-1.2 parts of polydimethylsiloxane diquaternary amine, 0.4-1 part of trichlorofluoromethane, 4-9 parts of dichlorodifluoromethane, 15-28 parts of polylactide, 1.5-6 parts of calcium carbonate, 0.5-1 part of sodium dibutyl naphthalene sulfonate, 15-30 parts of polyethylene glycol, 6-12 parts of acrylic resin, 4-9 parts of vinyl-vinyl acetate copolymer and 2.5-6 parts of borax. Compared with the prior art, the medical packaging material has strong resistance to high temperature and high tensile strength, does not easily deform after high temperature and high pressure sterilization treatment and is especially suitable for the medical field.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

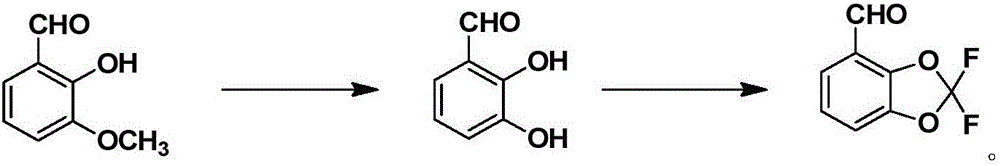

Synthetic method of 2,2-dichloro-1,3-benzodioxole-4-formaldehyde

ActiveCN106699722AReduce usageShort synthetic routeOrganic chemistryChemical reactionDichlorodifluoromethane

The invention provides a synthetic method of 2,2-dichloro-1,3-benzodioxole-4-formaldehyde. The synthetic method comprises the following steps of: adding 3-methoxyl-2-hydroxybenzaldehyde and alkali into a protonic solvent, then dropwise adding hydrogen peroxide, and performing hydrolysis reaction; after the complete reaction, performing the after-treatment to obtain 2,3-dihydroxy benzaldehyde; adding an aqueous solution of the 2,3-dihydroxy benzaldehyde and alkali into the protonic solvent, and then adding dichlorodifluoromethane to perform the reaction; and after the complete reaction, performing the after-treatment to obtain the 2,2-dichloro-1,3-benzodioxole-4-formaldehyde. According to the synthetic method, the target product can be obtained from an initial raw material 3-methoxyl-2-hydroxybenzaldehyde by virtue of two-step chemical reaction. The reaction method is moderate in reaction conditions, simple in steps, low in cost, environment-friendly, high in yield, capable of facilitating the industrialized mass production, and capable of setting a foundation for the subsequent successful synthesis of fludioxonil, so that the synthetic method has good application prospect and market potential.

Owner:SHANGHAI SHENGNONG PESTICIDE

Drop-in Substitutes for dichlorodifluoromethane refrigerant

A group of known refrigerants, (R-227ea, R-124, R-134a, R-143a, R-125, R-E125, R-E143a, R-E227ca2, R-254cb, R-600a, R-142b, R-22, R-290, R-E170, R-1270, R-1216, R-218, R-C318, R-C270), that may be combined in novel ways to produce several excellent “drop-in” substitutes for refrigerants R-12 or R-500. The performance of the preferred “drop-in” substitutes for R-12 or R-500 of the present invention often exceeds that of the refrigerant being replaced, while maintaining acceptable oil circulation with existing mineral oils used in R-12 or R-500 refrigeration and air conditioning systems.

Owner:GOBLE GEORGE H

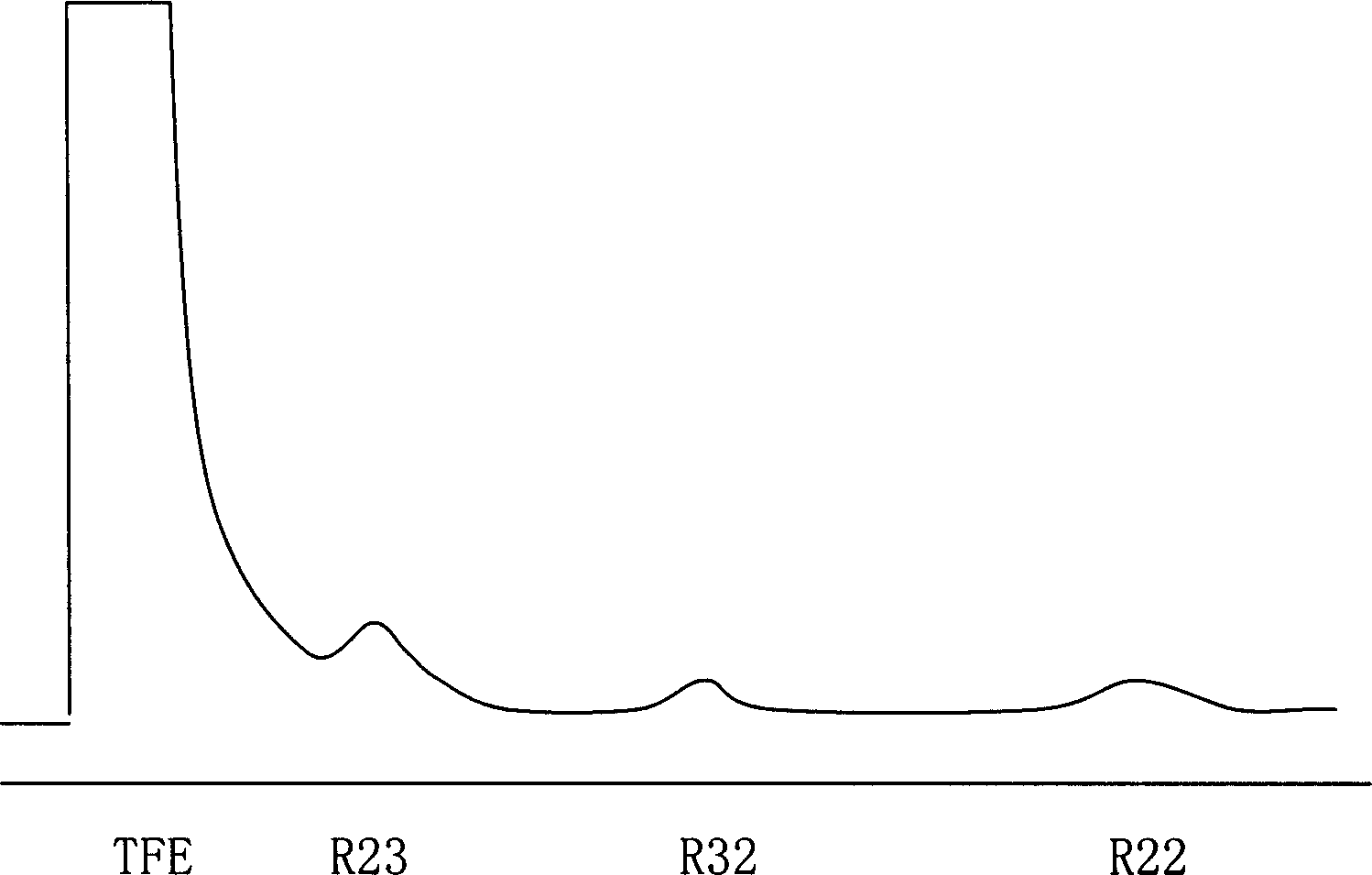

Process for implementing tetrafluoroethylene monomer continuous analysis applying on-line chromatographic technique

InactiveCN1632569AImprove real-time performanceImprove product qualityComponent separationTetrafluoroethyleneDichlorodifluoromethane

This invention discloses a method to continuously analyze the perfluoroethylene monomer by use of on-line chromatogram technique, which comprises the following steps: to choose conditions; sample alignment; analysis process; column system combination; control procedure. The trifluoromethane, dichlorodifluoromethane and chloromethane in the perfluoroethylene single body by the method effectively improve the real-time property of the TFE single body quality monitoring.

Owner:JUHUA GRP +1

Lightweight composite wall board and production method thereof

InactiveCN103450588AHigh mechanical strengthStrong wind and negative pressure capacityHeat proofingSodium metasilicateDichlorodifluoromethane

The invention discloses a lightweight composite wall board and a production method thereof. The lightweight composite wall board is characterized by being prepared from the following raw materials in parts by weight: 140-150 parts of SG-3 polyvinyl chloride, 15-20 parts of nylon PA66, 30-35 parts of straw powder, 27-30 parts of quartz sand, 3-4 parts of ethylene foamed particles, 4-5 parts of glass fiber, 3-4 parts of sodium metasilicate, 12-16 parts of modified loess powder, 2-3 parts of used oil, 2-3 parts of sodium tripolyphosphate, 1-2 parts of an ortho-hydroxybenzoic acid, and 3-4 parts of dichlorodifluoromethane. The lightweight composite wall board disclosed by the invention has a high mechanical strength, the tensile strength is at least 0.4 MPA, and the pressure-shear bond strength is at least 0.1 MPA; the lightweight composite wall board is good in sound insulation and weather resistance, strong in wind / negative pressure resistance, capable of being hung by nails, impact-resistant, fireproof, good in bearing capacity, and long in service life.

Owner:江苏亨路建设有限公司

Refrigerant with lubricating oil

ActiveUS7332102B2Reduce flammabilityReduce corrosionHeat-exchange elementsLubricant compositionOzone layerSystems design

Owner:STEFKO PROPERTIES

Refrigerant with lubricating oil

InactiveUS20050133756A1Improve compromiseReduce flammabilityHeat-exchange elementsLubricant compositionDichlorodifluoromethaneSystems design

An apparatus and method wherein potential ozone layer-damaging dichlorodifluoromethane (Refrigerant R-12) is substituted with a mix of less environmentally damaging refrigerants Chlorodifluoroethane and Tetrafluoroethane in dichlorodifluoromethane-based air-cooling systems, in particular HVAC and refrigeration applications. While less environmentally damaging than dichlorodifluoromethane, the substitute refrigerant is less flammable than presently available refrigerants, yet still has a temperature-pressure relationship close enough to that of dichlorodifluoromethane, making the substitute refrigerant suitable for use with dichlorodifluoromethane-based air-cooling systems. In this event, it is mixed with a lubricating oil that is compatible with both the unit refrigerant and typical R-12 system design.

Owner:PONDER KENNETH M +1

Rapid sealing material

ActiveCN102050937AImprove flame retardant performanceHigh densityDichlorodifluoromethaneDimethyl methylphosphonate

The invention discloses a rapid sealing material, which consists of an A group of preparations and a B group of preparations, wherein the A group of preparations consists of 70 to 80 weight parts of polyglycol ether, 5 to 10 weight parts of triethylene diamine, 5 to 10 weight parts of dimethyl methylphosphonate, 1 to 5 weight parts of alpha-methyl styrene, 5 to 10 weight parts of difluorodichloromethane and 1 to 1.5 megapascals of nitrogen; and the B group of preparations consists of 90 to 95 weight parts of diisocyanate, 5 to 10 weight parts of difluorodichloromethane and 1.0 to 1.5 megapascals of nitrogen. The rapid sealing material provided by the invention has the characteristics of high fire retardance, high density and high reaction speed, and after being injected into a plugged part, can be rapidly expanded and isolate a passage space to limit the spreading and dissemination of heat, water, fire, harmful gases and dust, thereby fulfilling the aims of plugging a passage and isolating air.

Owner:ANHUI JIATAI COAL MINING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com