Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1163results about "Preparation by halogen replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

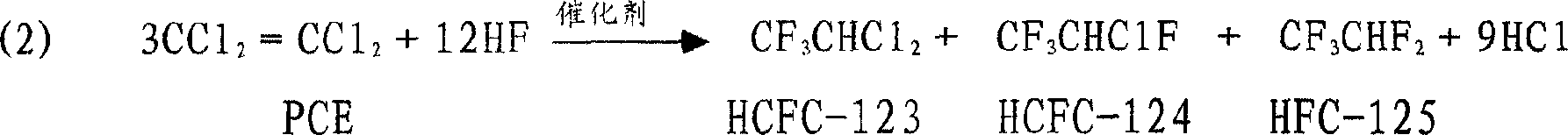

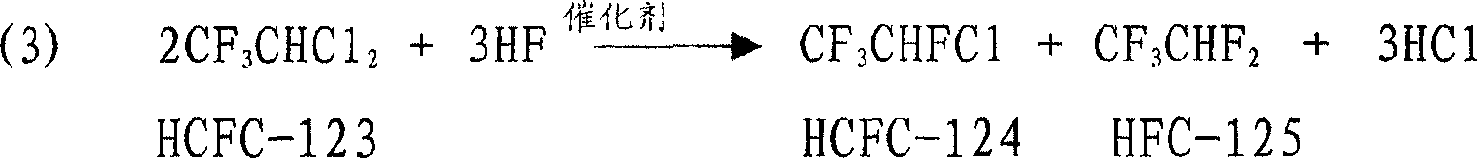

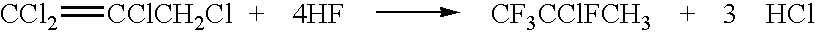

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS20090240090A1Maximize raw material utilizationMaximize product yieldPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

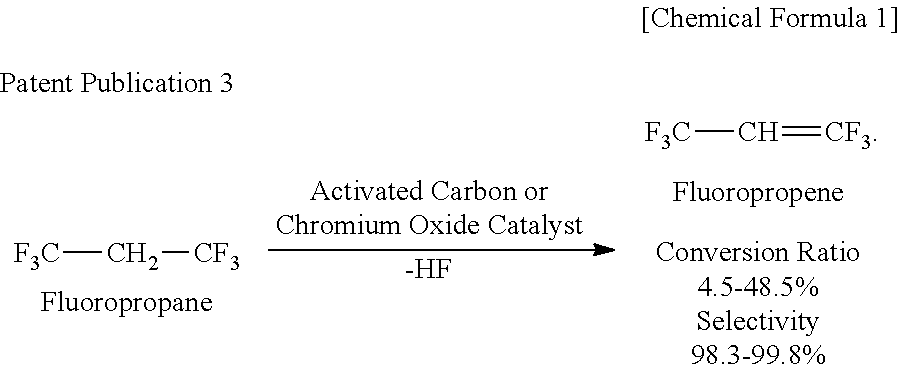

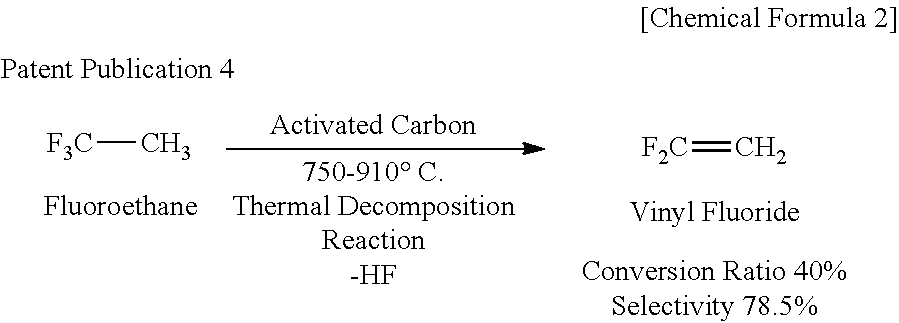

Process for producing fluoropropenes

InactiveUS7230146B2Simplifies isolationPreparation by hydrogen halide split-offPreparation by halogen halide additionHalogenHydrogen

Dehydrohalogenation processes for the preparation of fluoropropenes from corresponding halopropanes, in which the fluoropropenes have the formula CF3CY═CXNHP, wherein X and Y are independently hydrogen or a halogen selected from fluorine, chlorine, bromine and iodine; and N and P are independently integers equal to 0, 1 or 2, provided that (N+P)=2.

Owner:HONEYWELL INT INC

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS8058486B2Maximize utilizationYield maximizationPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

Processes for synthesis of tetrafluoropropene

ActiveUS7189884B2Preparation by hydrogen halide split-offPreparation by halogen halide additionBromineCombinatorial chemistry

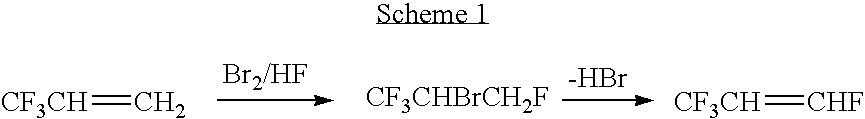

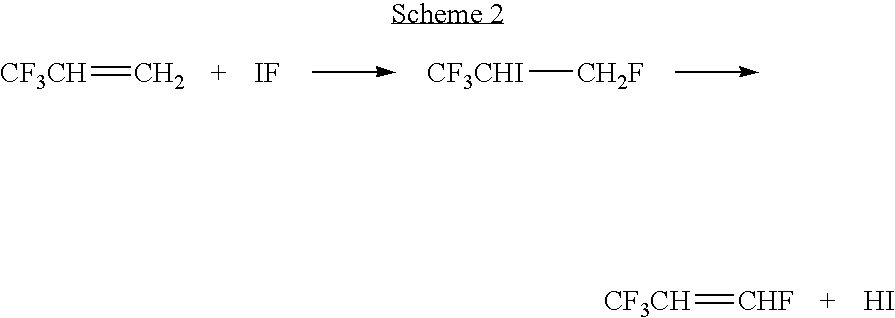

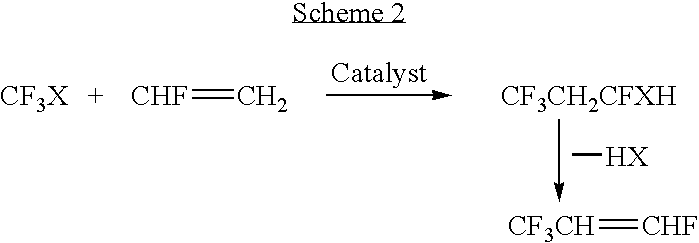

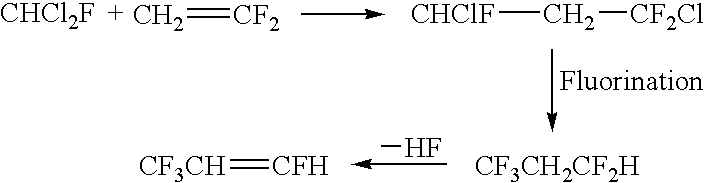

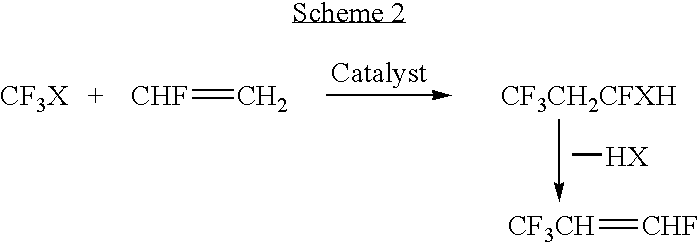

Disclosed in one embodiment is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises (a) reacting a compound of formula (I) X1X2 with a compound of formula (II) CF3CH═CH2 to produce a reaction product comprising a compound of formula (III) CF3CHX1CH2X2, wherein X1 and X2 are each independently selected from the group consisting of hydrogen, chlorine, bromine and iodine, provided that X1 and X2 are not both hydrogen; (b) when X2 in formula (III) is not fluorine, fluorinating the compound of formula (III) to produce a reaction product comprising a compound of formula (III) wherein X1 is as described above and X2 is fluorine; and (c) exposing said compound of formula (III) to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

Method for producing fluorinated organic compounds

ActiveUS8084653B2Preparation by hydrogen halide split-offPreparation by halogen replacementActivated carbonGas phase

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

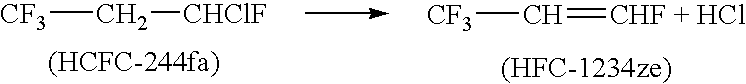

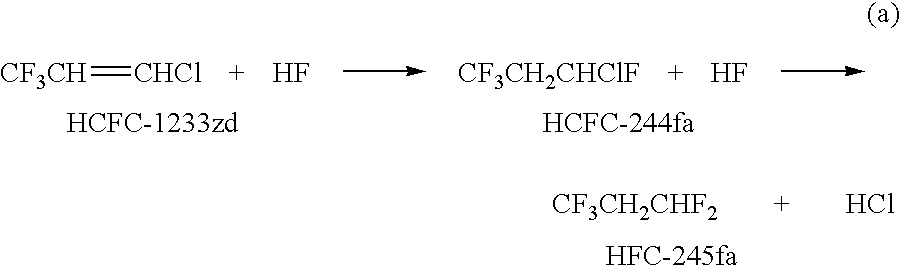

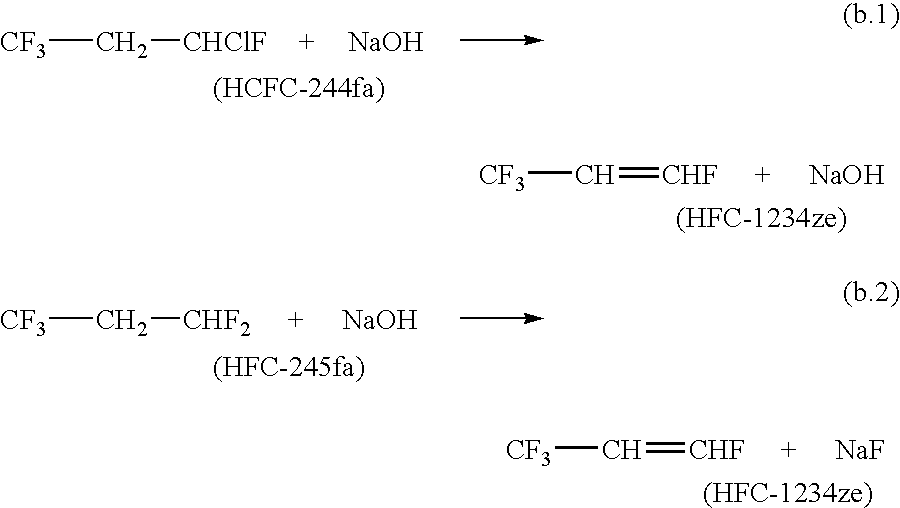

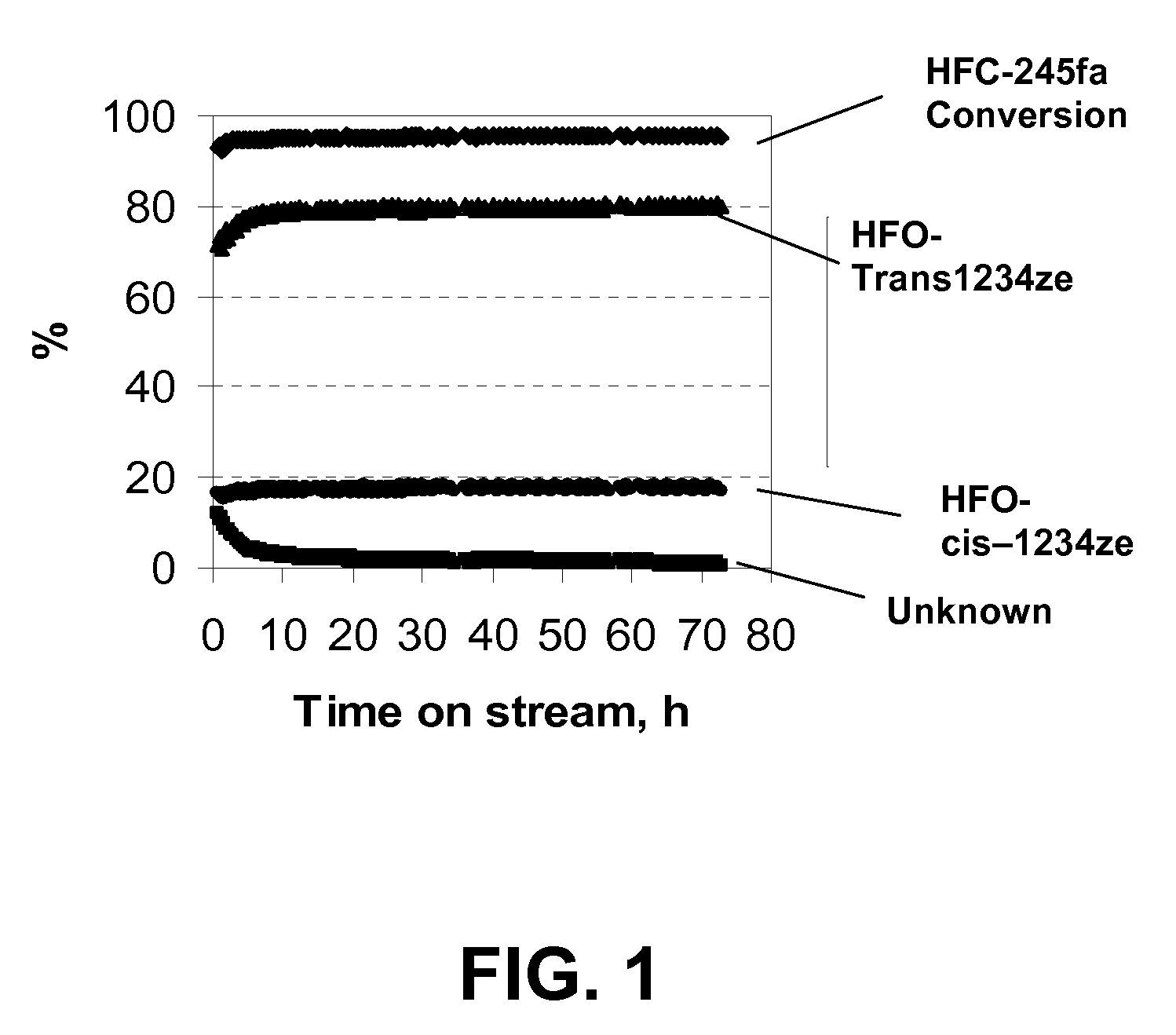

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS20050020862A1Physical/chemical process catalystsPreparation by hydrogen halide split-offPentafluoropropaneChemistry

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

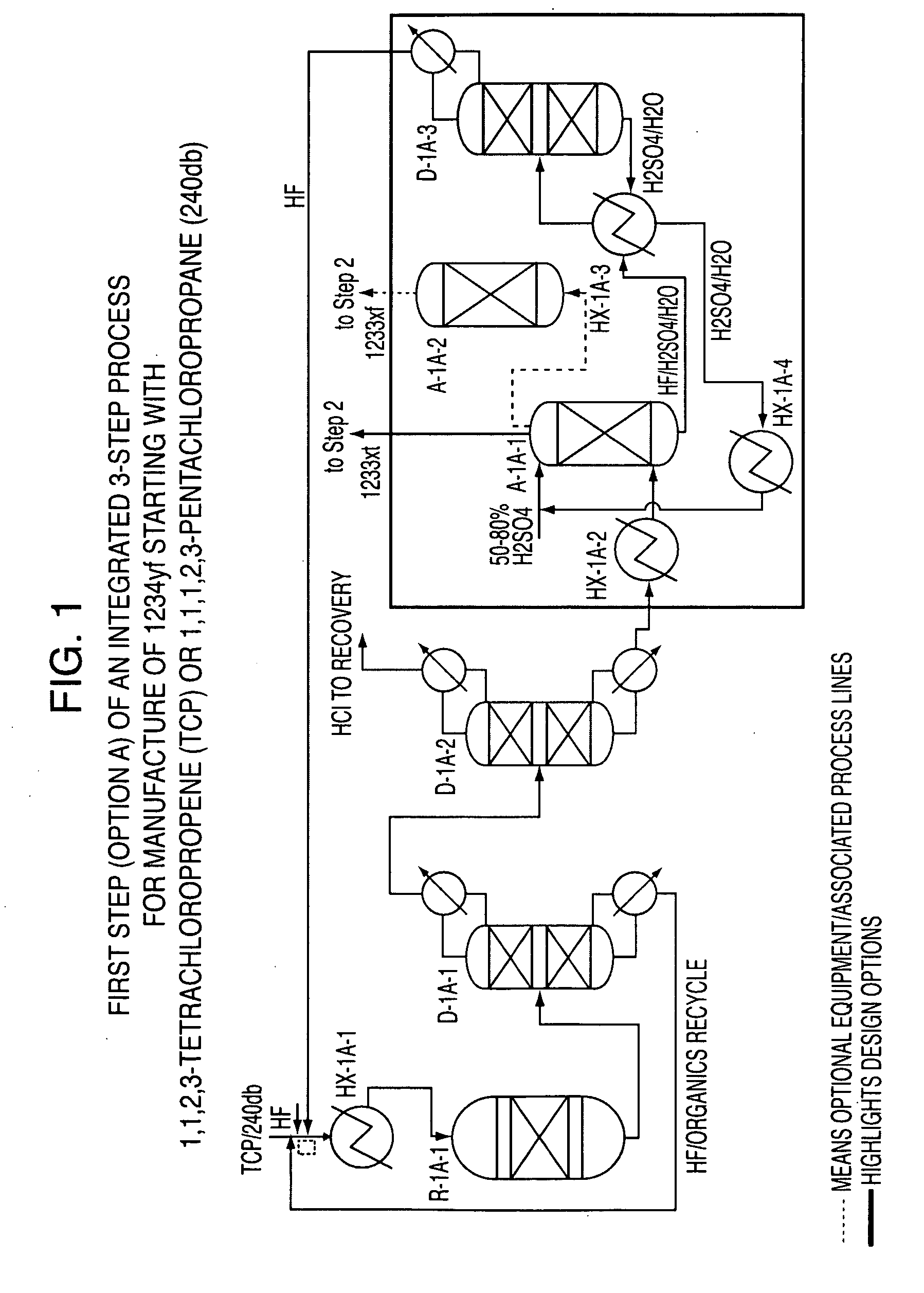

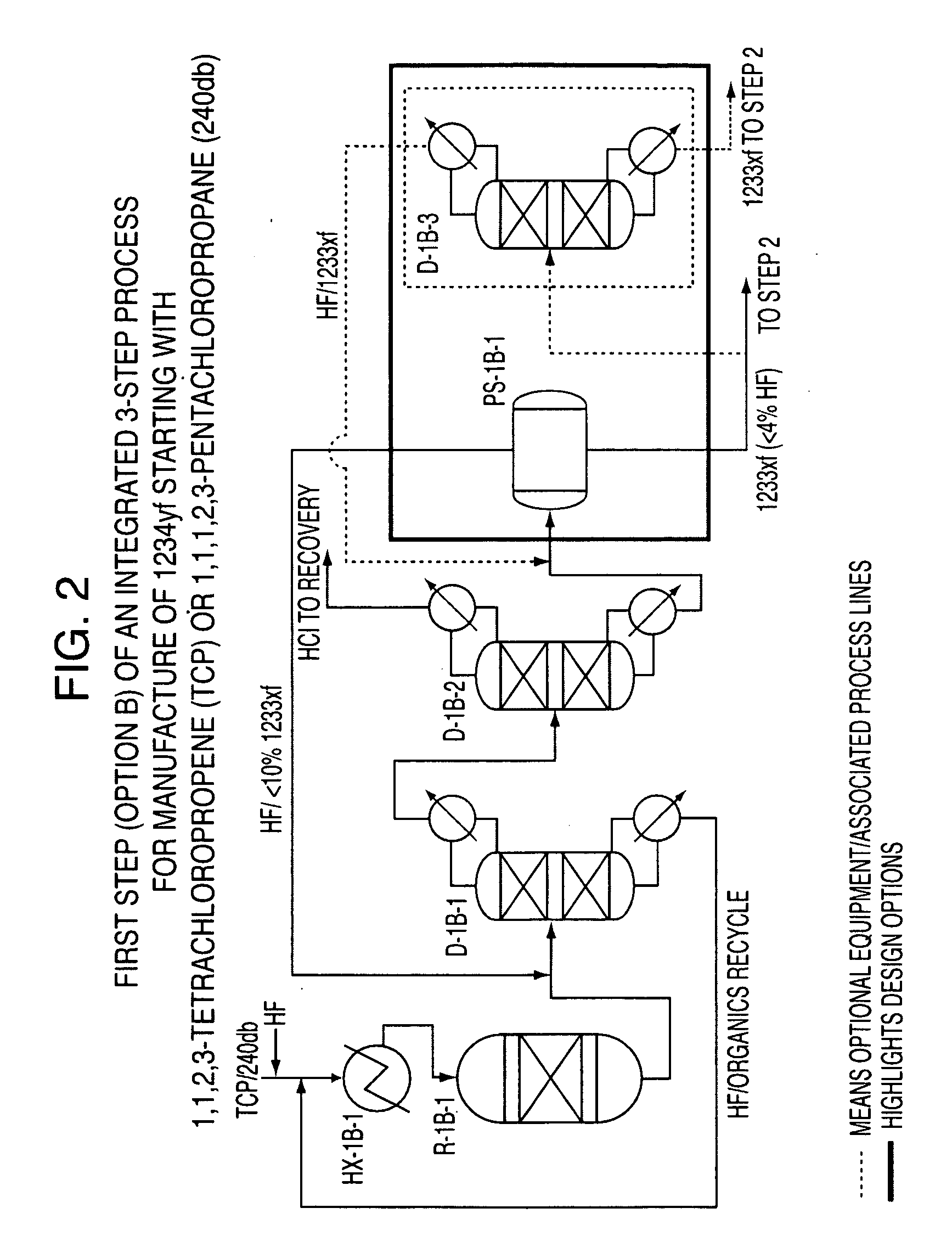

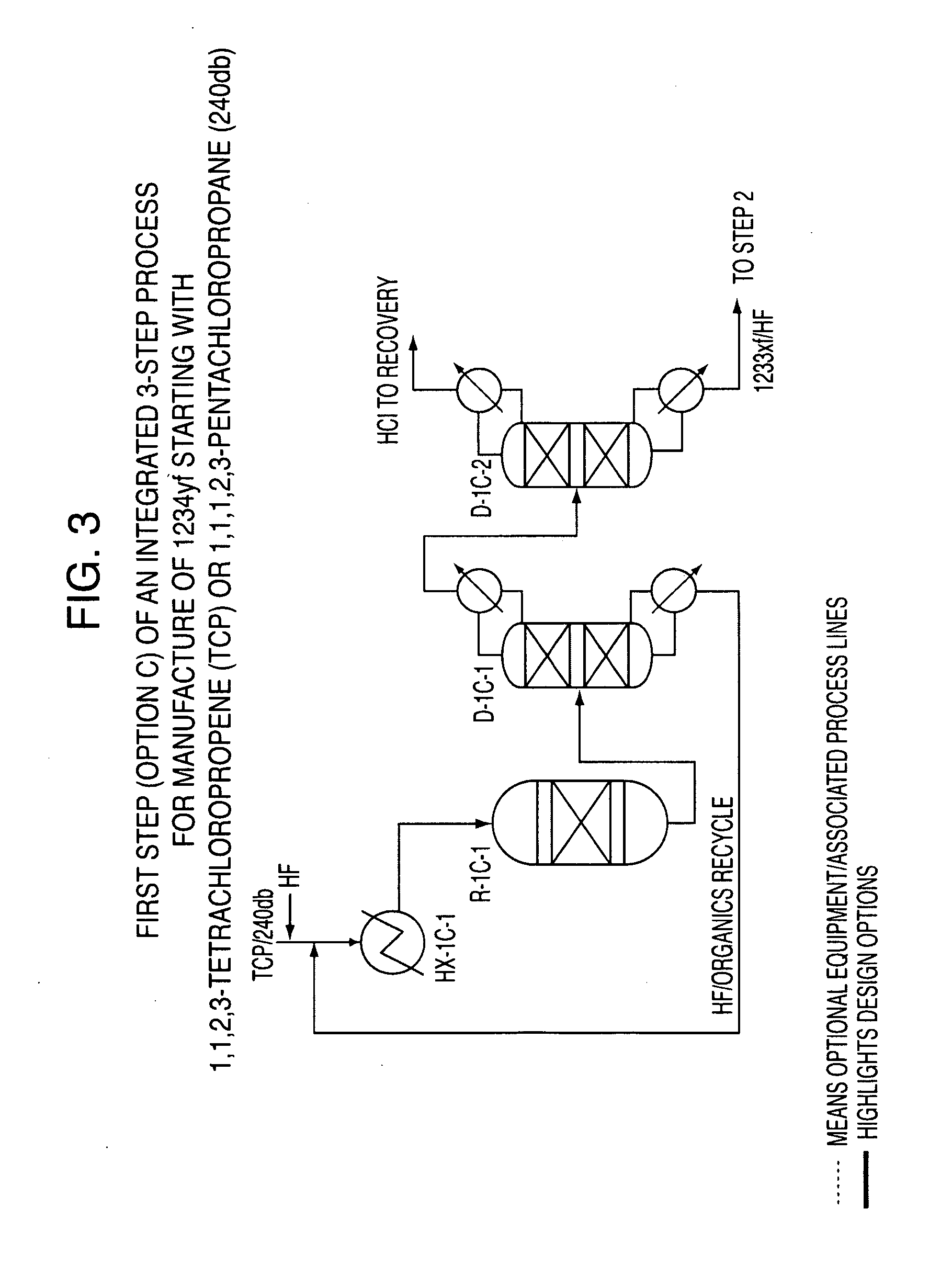

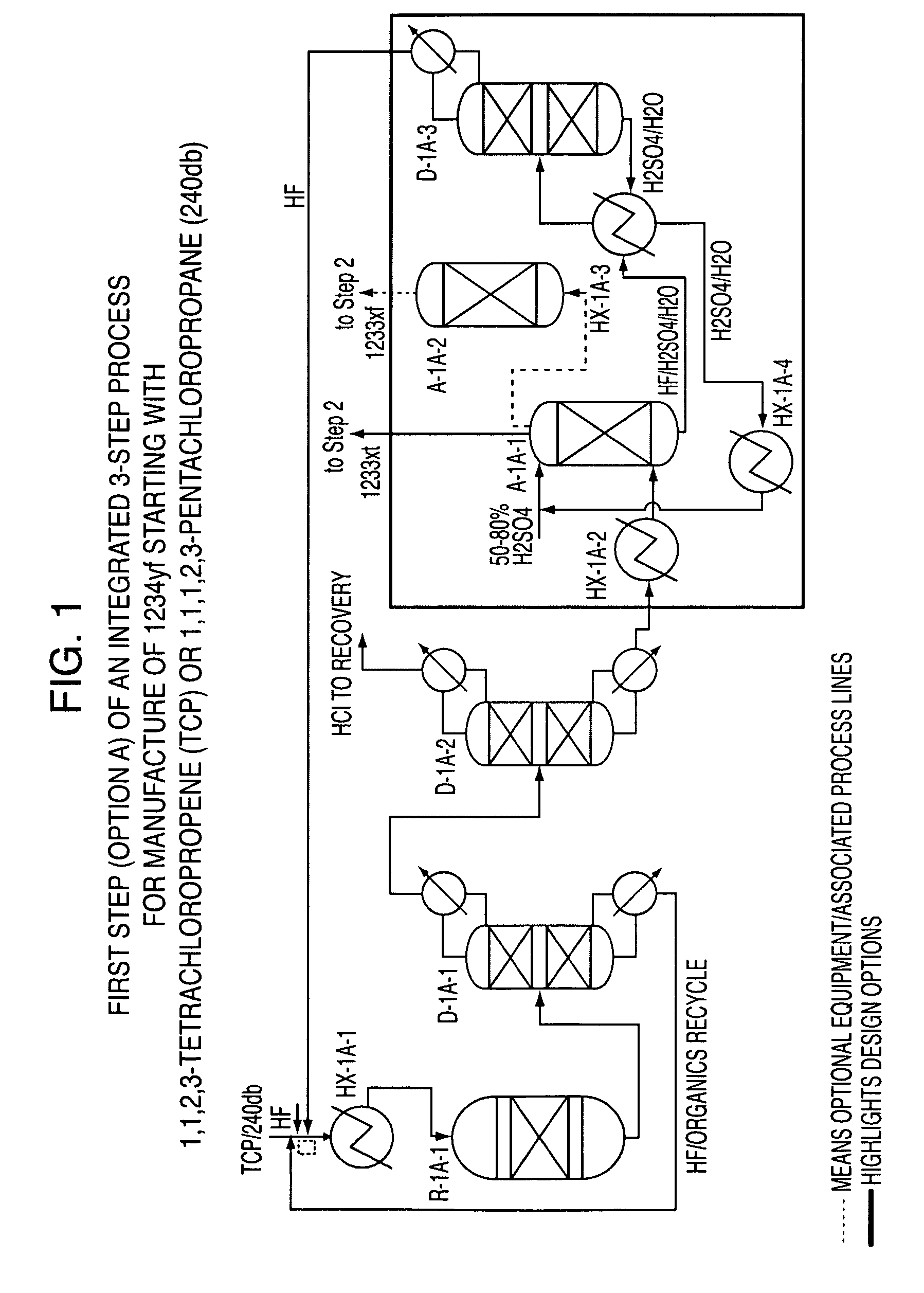

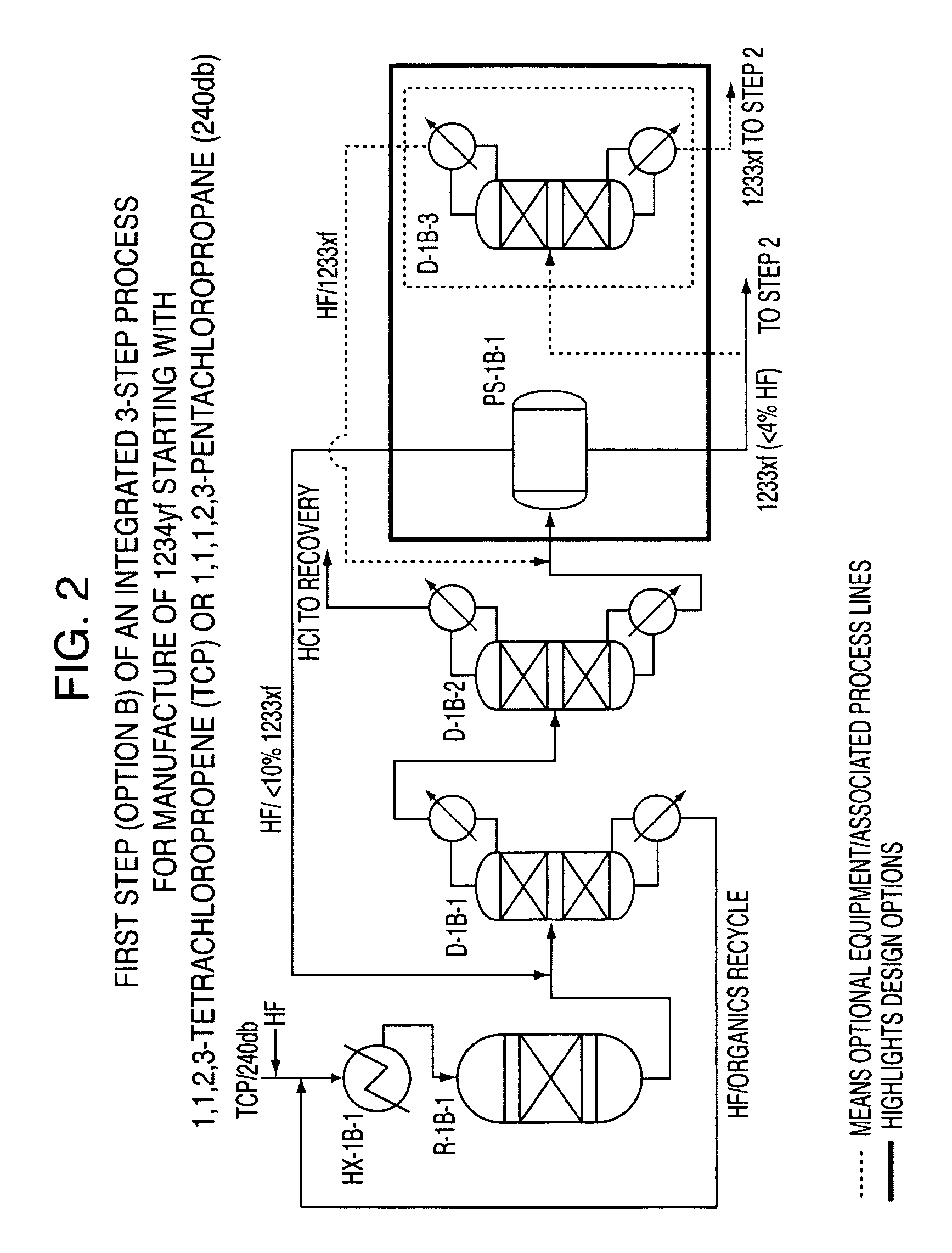

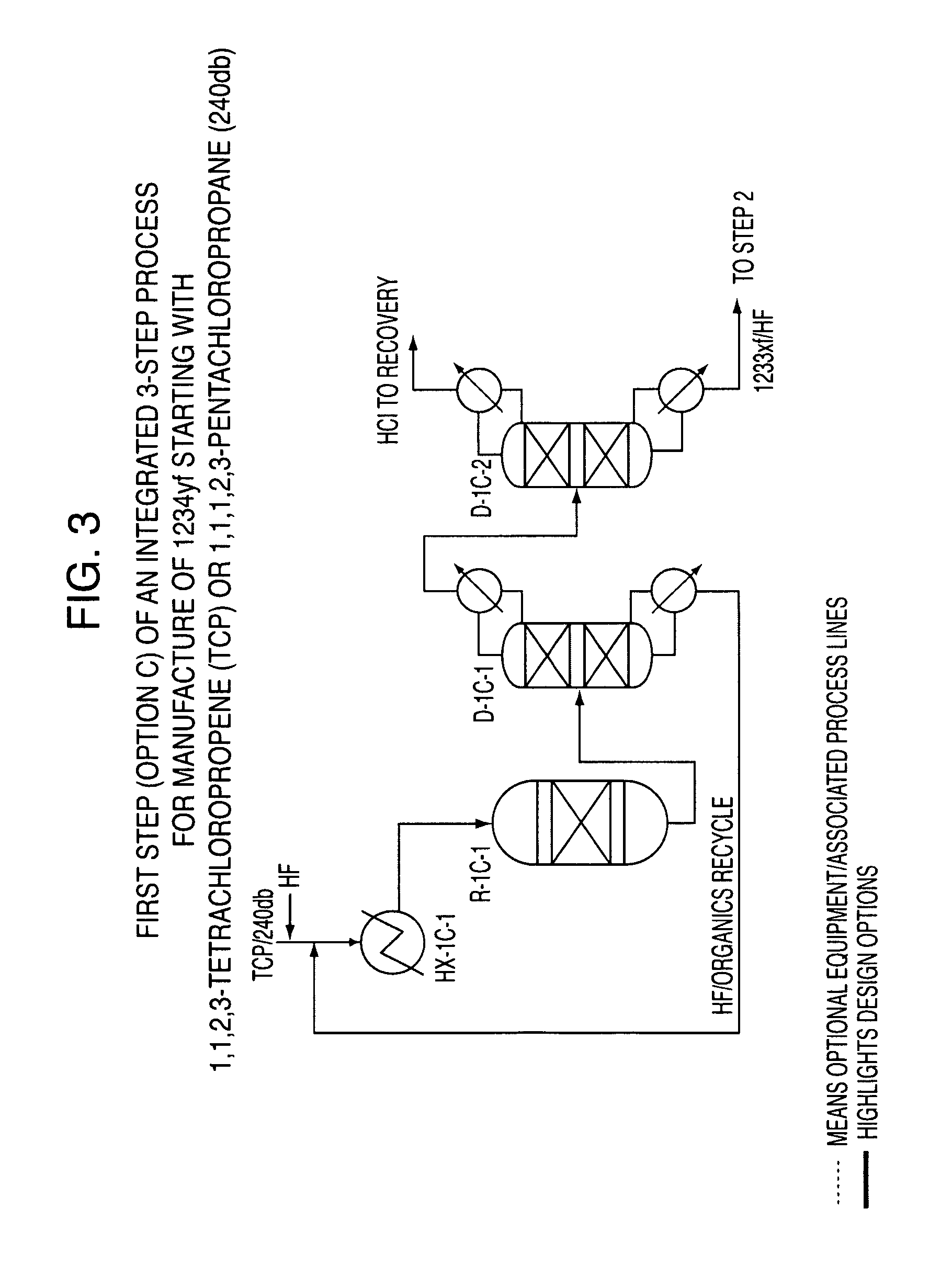

METHOD FOR PRODUCING 2-CHLORO-3,3,3-TRIFLUOROPROPENE (HCFC-1233xf)

ActiveUS20090030244A1Speed up the conversion processLess resource-intensivePreparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluorideGas phase

The present invention relates to an improved method for manufacturing 2-chloro-3,3,3,-trifluoropropene (HCFC-1233xf) by reacting 1,1,2,3-tetrachloropropene, 1,1,1,2,3-pentachloropropane, and / or 2,3,3,3-tetrachloropropene with hydrogen fluoride, in a vapor phase reaction vessel in the presence of a vapor phase fluorination catalyst and stabilizer. HCFC-1233xf is an intermediate in the production of 2,3,3,3-tetrafluoropropene (HFO-1234yf) which is a refrigerant with low global warming potential.

Owner:HONEYWELL INT INC

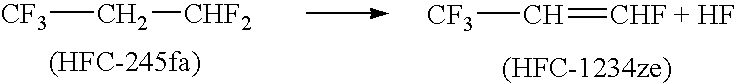

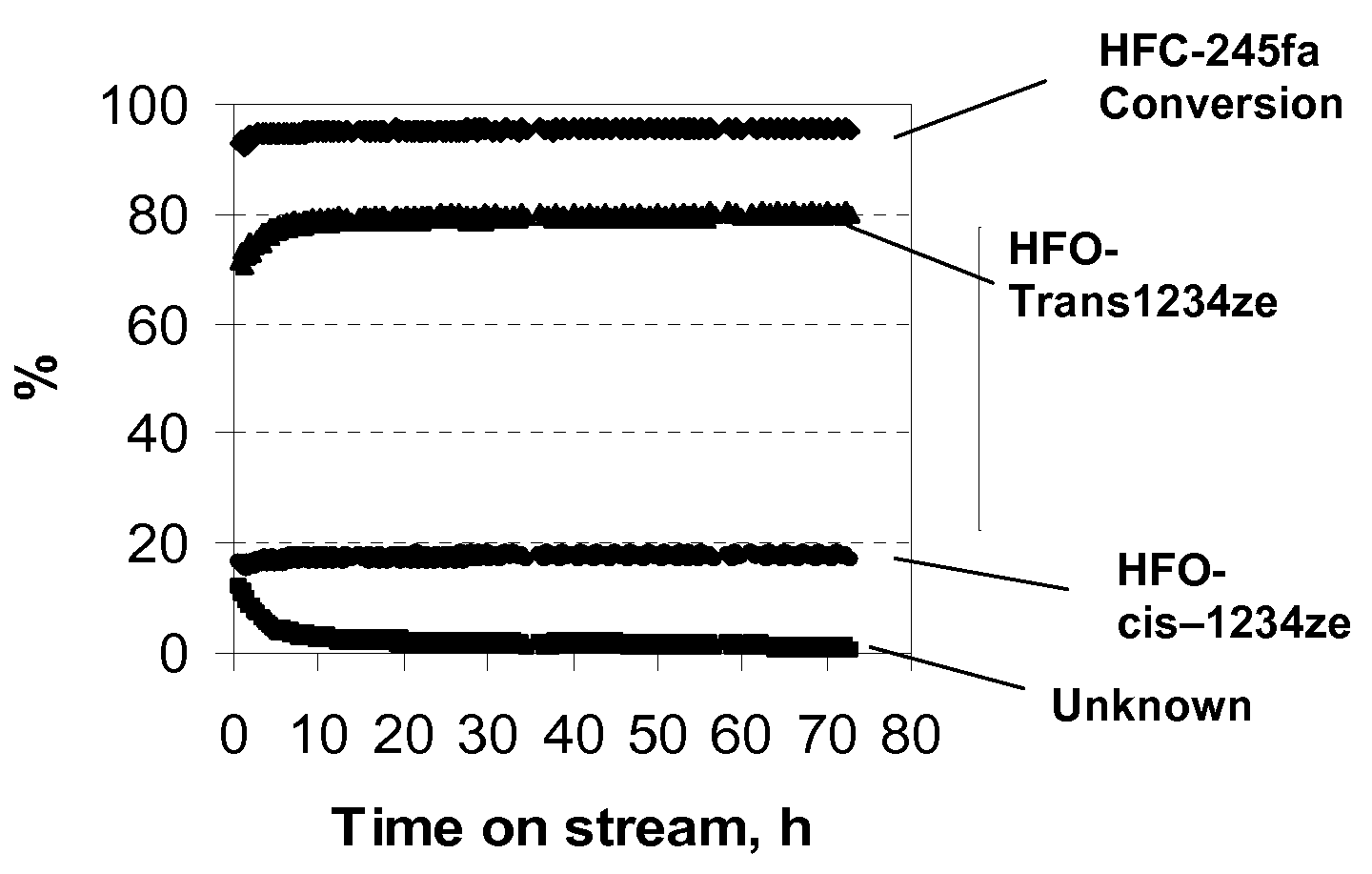

PROCESS FOR THE PRODUCTION OF HFO TRANS-1234ze FROM HFC-245fa

ActiveUS20080051611A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluoride1,3,3,3-Tetrafluoropropene

This invention relates a process for the manufacture of the HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze). More particularly, the invention pertains to a process for the manufacture of the HFO trans-1234ze by first dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride and then recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for synthesis of fluorinated olefins

ActiveUS20090099396A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogenBromine

Disclosed is a process for the synthesis of fluorinated olefins, and in particularly preferred embodiments tetrafluorinated olefins having F on an unsaturated, non-terminal carbon, such as 2,3,3,3-tetrafluoropropene. The preferred processes of the present invention in accordance with one embodiment generally comprise:(a) reacting a compound of formula (I)X1X2 (I)with a compound of formula (II)CX1X2X3CX1═CX1X2 (II)to produce a reaction product comprising a compound of formula (III)CF3CHX1CH2X2 (III), and(b) exposing said compound of formula (III) to reaction conditions effective to convert said compound of formula (III) to a compound of formula (IV)CF3CZ=CH2 (IV)wherein X1, X2, and X3 are each independently selected from the group consisting of hydrogen, chlorine, bromine, fluorine and iodine, provided that X1 and X2 in formula (I) are not both hydrogen and Z is Cl, I, Br, or F.

Owner:HONEYWELL INT INC

Process for preparing halogenated alkanes

InactiveUS7094936B1High selectivityBig advantagePreparation by hydrogen halide split-offPreparation by halogen replacementAlkaneLewis acid catalysis

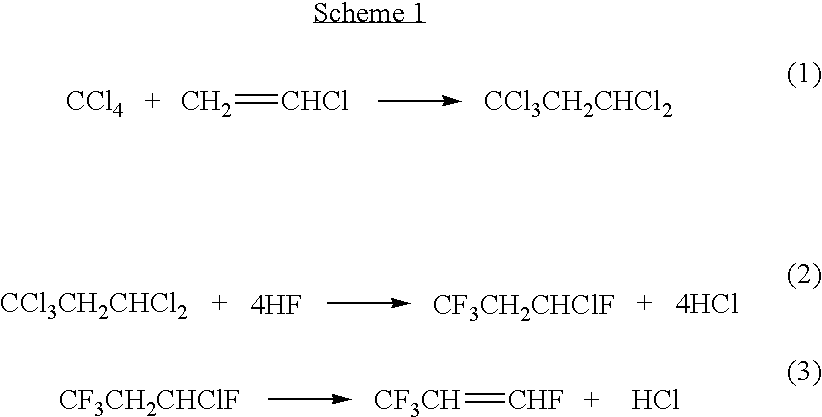

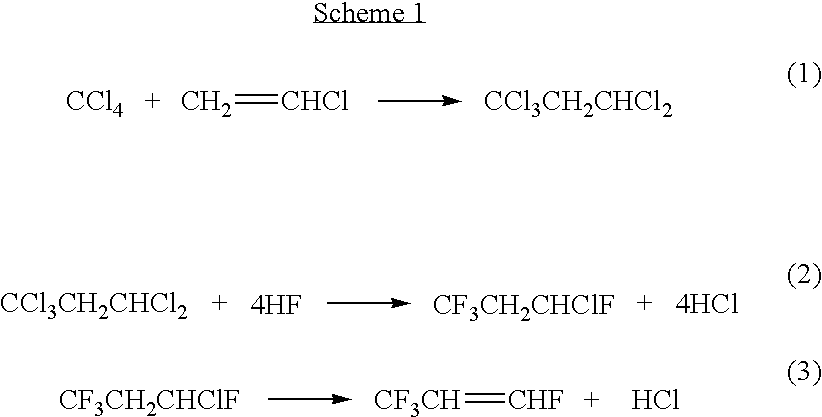

Methods and materials are provided for the production and purification of halogenated compounds and intermediates in the production of 1,1,1,3,3-pentafluoropropane. In a preferred embodiment, the process steps include: (1) reacting carbon tetrachloride with vinyl chloride to produce 1,1,1,3,3-pentachloropropane; (2) dehydrochlorinating the 1,1,1,3,3-pentachloropropane with a Lewis acid catalyst to produce 1,1,3,3-tetrachloropropene; (3) fluorinating the 1,1,3,3-tetrachloropropene to produce 1-chloro-3,3,3-trifluoropropene; (4) fluorinating the 1-chloro-3,3,3-trifluoropropene to produce a product mixture containing 1,1,1,3,3-pentafluoropropane; and (5) separating 1,1,1,3,3-pentafluoropropane from by-products.

Owner:EI DU PONT DE NEMOURS & CO

Method for producing 2-chloro-3,3,3,-trifluoropropene (HCFC-1233xf)

ActiveUS7795480B2Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluorideGas phase

The present invention relates to an improved method for manufacturing 2-chloro-3,3,3,-trifluoropropene (HCFC-1233xf) by reacting 1,1,2,3-tetrachloropropene, 1,1,1,2,3-pentachloropropane, and / or 2,3,3,3-tetrachloropropene with hydrogen fluoride, in a vapor phase reaction vessel in the presence of a vapor phase fluorination catalyst and stabilizer. HCFC-1233xf is an intermediate in the production of 2,3,3,3-tetrafluoropropene (HFO-1234yf) which is a refrigerant with low global warming potential.

Owner:HONEYWELL INT INC

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7829748B1Physical/chemical process catalystsPreparation by hydrogen halide split-offAlkaline earth metalOxidation state

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFO-1234ze) by a two stage process. A vapor phase hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and / or 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the thermal dehydrochlorination of HCFC-244fa and dehydro fluorination of HFC-245fa into HFO-1234ze in the presence of a catalyst which comprises one or more of alkali metal halides, alkaline earth metal halides, halogenated metal oxides, zero oxidation state metals, zinc halides, palladium halides, and activated carbon.

Owner:HONEYWELL INT INC

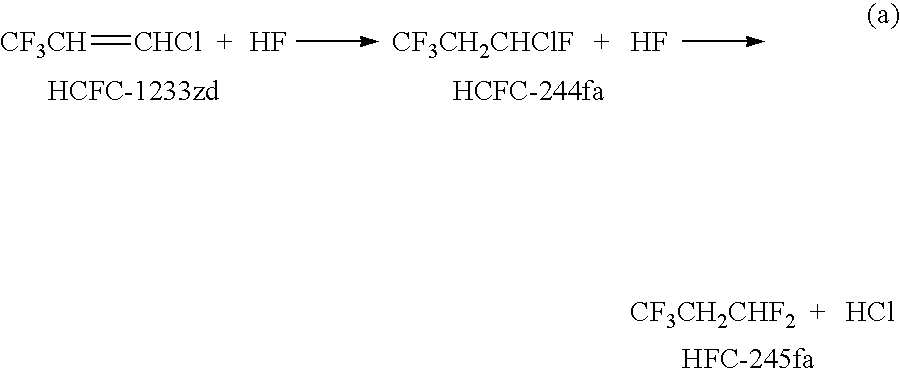

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

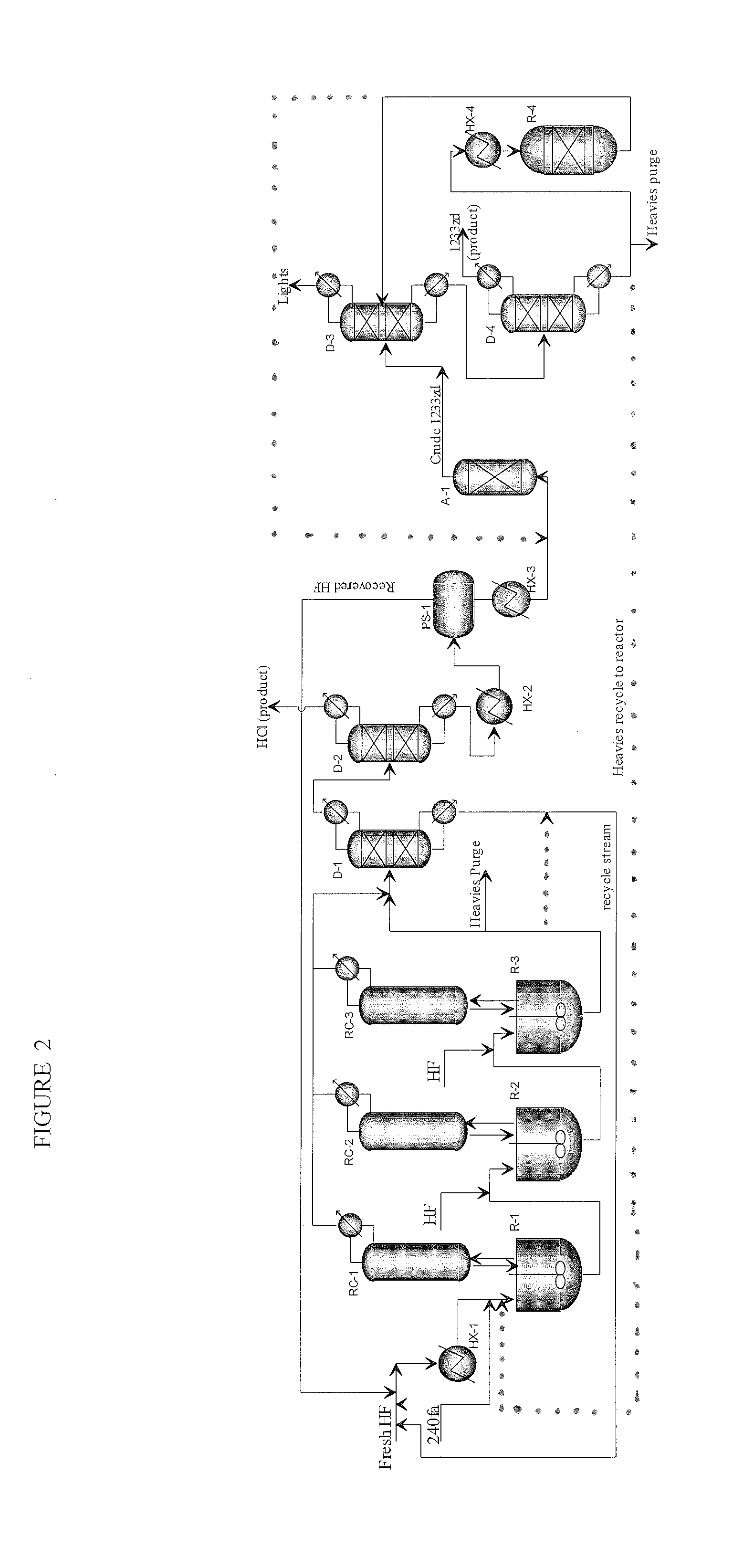

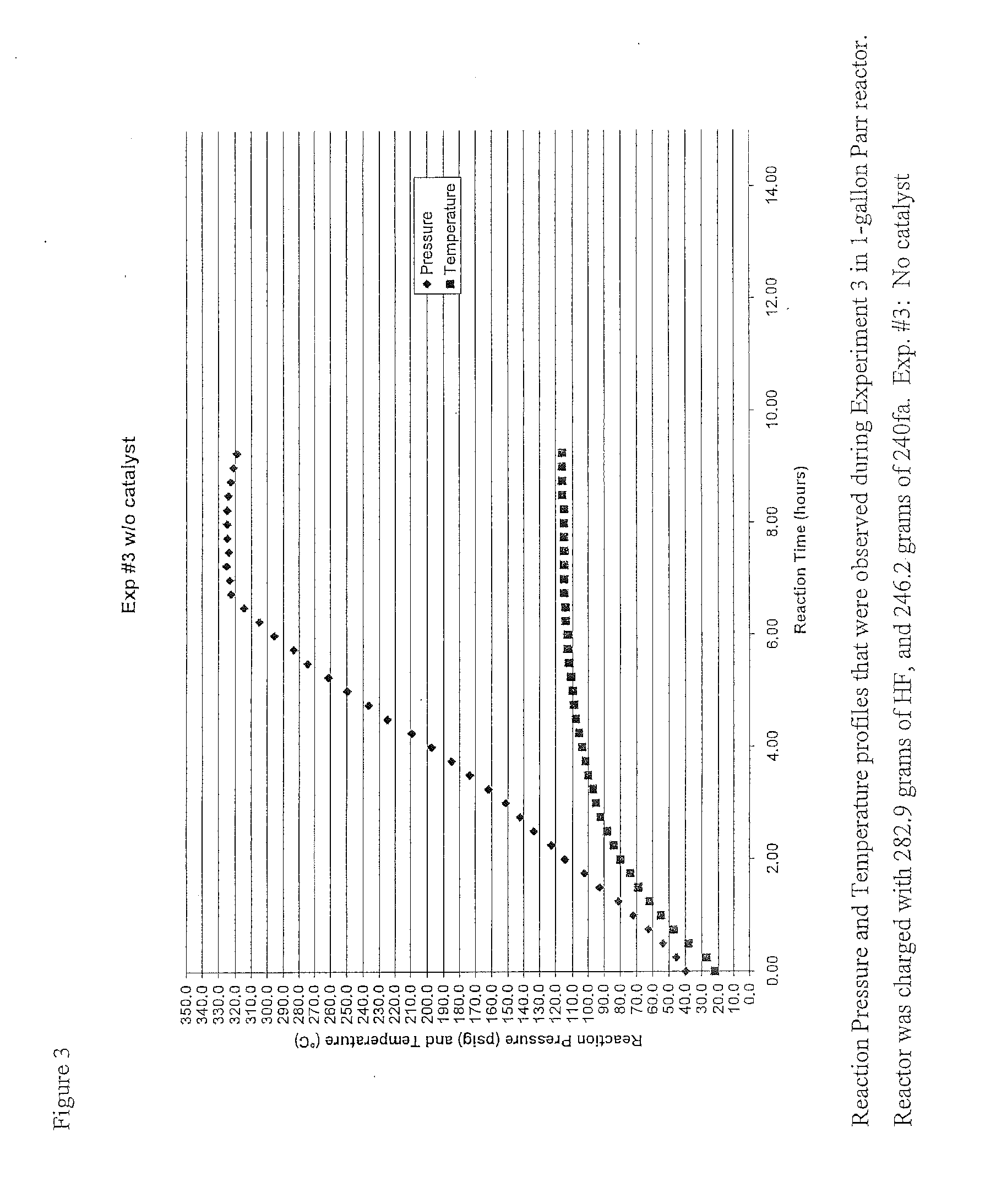

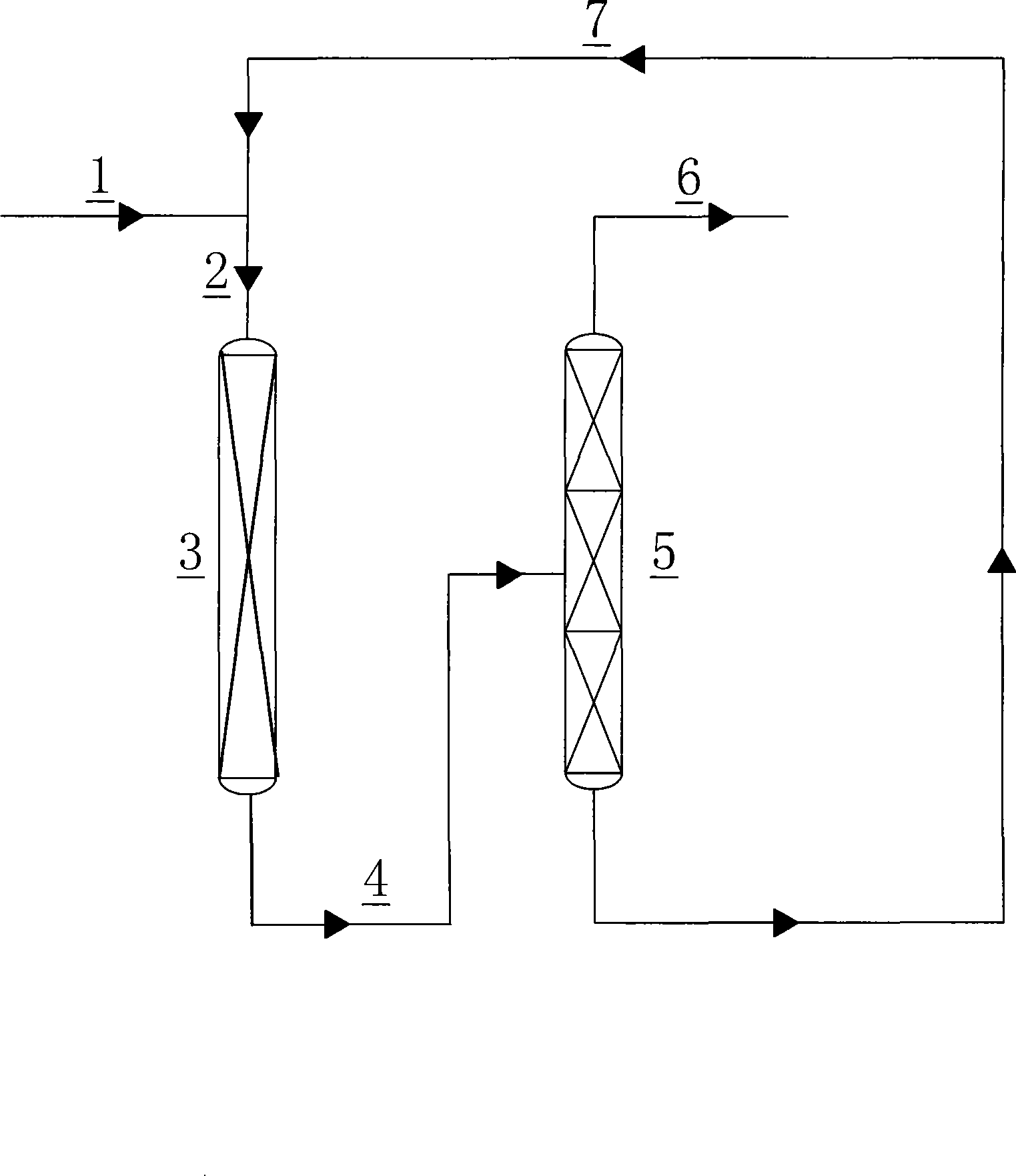

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

InactiveUS7345209B2Preparation by dehalogenationPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropeneBromine

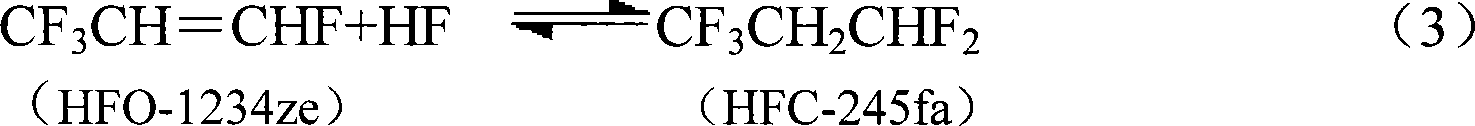

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS20090043136A1Physical/chemical process catalystsPreparation by hydrogen halide split-offHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

InactiveUS20050245773A1Overcome deficienciesPreparation by hydrogen halide split-offPreparation by halogen halide addition1,3,3,3-TetrafluoropropeneBromine

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

Process for the Preparation of 1,3,3,3-Tetrafluoropropene and/or 1,1,3,3,3-Pentafluoropropene

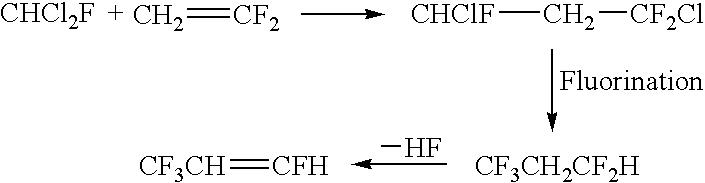

InactiveUS20090043138A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogen fluoridePtru catalyst

A process for the manufacture of CF3CH═CHF and / or CF3CH═CF2 is disclosed. The process involves involves (a) reacting HF and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or CI) to produce a product including both CF3CCI═CF2 and CF3CHCICF3; (b) reacting CF3CCI═CF2 and / or CF3CHCICF3 produced in (a) with hydrogen to produce a product including CF3CH2CHF2 and / or CF3CH2CF3; (c) dehydrofluorinating CF3CH2CHF2 and / or CF3CH2CF3 produced in (b) to produce a product comprising CF3CH═CHF and / or CF3CH═CF2; and (d) recovering CF3CH═CHF and / or CF3CH═CF2 from the product produced in (c). In (a), the CF3CCI═CF2 and CF3CHCICF3 are produced in the presence of a fluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

Integrated HFC trans-1234ze manufacture process

ActiveUS7485760B2Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Florination catalyst, its manufacturing method and use

ActiveCN1651137AInhibitionReduce the temperaturePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsHydrogen fluorideAl powder

Owner:XIAN MODERN CHEM RES INST

Method for producing fluorinated organic compounds

InactiveUS20070197841A1Preparation by dehalogenationPreparation by hydrogen halide split-offOxygenOrganic compound

Disclosed is a process for producing fluorinated organic compounds, including hydrofluoropropenes, which preferably comprises converting at least one compound of Formula (I): C(X)3CF2C(X)3 (I) to at least one compound of Formula (II) CF3CF═CHZ (II) where each X and Z is independently H, F, Cl, I or Br, said process preferably not including any substantial amount of oxygen-containing catalyst in certain embodiments. Preferably Z is H.

Owner:HONEYWELL INT INC

Compositions containing chromium, oxygen, and at least two modifier metals selected the group consisting of gold, silver, and palladium, their preparation, and their use as catalysts and catalyst precursors

InactiveUS20080207962A1Preparation by dehalogenationPreparation by hydrogen halide split-offNitrateAmmonium hydroxide

A catalyst composition is disclosed that includes chromium, oxygen, and at least two of gold, silver, and palladium as essential constituent elements. The amount of modifier metals (gold, silver, and / or palladium) in the composition is from about 0.05 atom % to about 10 atom % based on the total amount of chromium and modifier metals. Also disclosed is a process for changing the fluorine distribution (i.e., content and / or arrangement) in a hydrocarbon or halogenated hydrocarbon in the presence of the catalyst composition; and methods for preparing said catalyst composition. One preparation method involves (a) co-precipitating a solid by adding ammonium hydroxide (aqueous ammonia) to an aqueous solution of soluble salts of modifier metals and a soluble chromium salt that contains at least three moles of nitrate per mole of chromium in the solution and has a modifier metal content of from about 0.05 atom % to about 10 atom % of the total content of modifier metals and chromium in the solution to form an aqueous mixture containing co-precipitated solid; (b) drying the co-precipitated solid formed in (a); and (c) calcining the dried solid formed in (b) in an atmosphere containing at least 10% oxygen by volume. Another preparation method involves (a) impregnating solid chromium oxide with a solution of a soluble modifier metal salts; (b) drying the impregnated chromium oxide prepared in (a); and optionally; (c) calcining the dried solid. Yet another preparation method involves mixing multiple compositions, each comprising chromium, oxygen, and at least one modifier metal.

Owner:EI DU PONT DE NEMOURS & CO

Integrated HFC trans-1234ZE manufacture process

ActiveUS20080051610A1Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for the preparation of fluorine containing hydrohalocarbons

InactiveUS6187976B1Preparation by dehalogenationPreparation by halogen halide additionHydrogen fluorideHydrogen

The invention relates to the preparation of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa), useful as an intermediate in the production of 1,1,1,3,3-pentafluoropropane (HFC-245fa). The invention further relates to a process for the preparation of HFC-245fa comprising reacting HCFC-235fa with hydrogen in the presence of a reduction catalyst wherein the said HCFC-235fa is prepared by reacting CCl3CHCCl3 with hydrogen fluoride in the presence of fluorination catalyst in either the liquid phase or the vapor phase.

Owner:ALLIEDSIGNAL INC

Method for producing fluorinated organic compounds

ActiveUS8071825B2Preparation by dehalogenationPreparation by hydrogen halide split-offChemical compoundOrganic compound

Owner:HONEYWELL INT INC

Azeotropic composition, comprising 1, 1, 1, 3,3-pentafluoropropane and 1, 1, 1-trifluoro-3-chloro-2-propene, method of separation and purification of the same, and process for producing 1, 1, 1,3,3-pentafloropropane and 1, 1, 1-trifluoro-3-chloro-2-propene

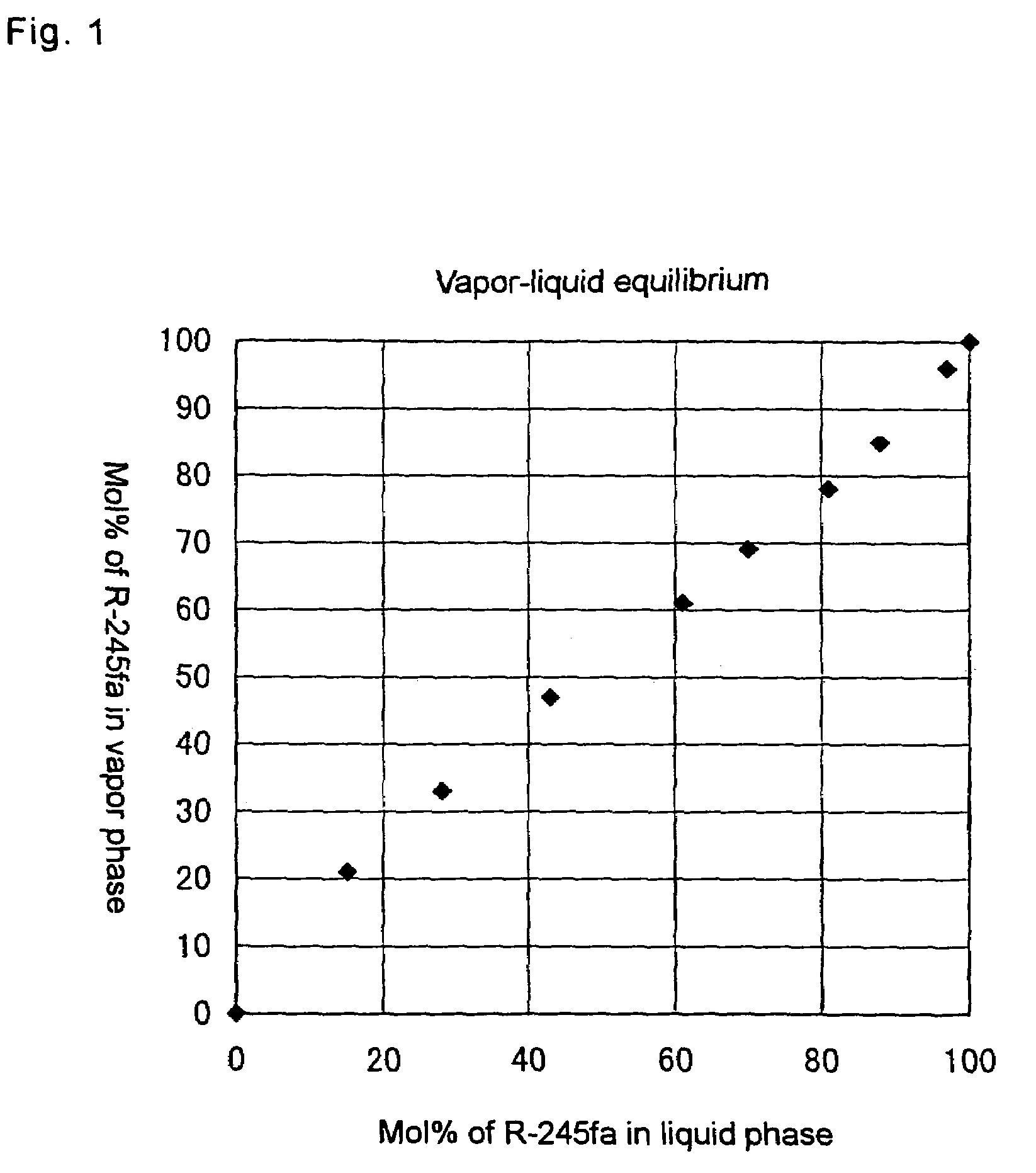

InactiveUS7183448B2Delayed recoveryIncrease production costPreparation by hydrogen halide split-offOther chemical processesDistillationPentafluoropropane

A mixture comprising at least 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is subjected to a distillation operation, and thereby, a distillate comprising an azeotropic composition consisting substantially of 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is obtained and a bottom product comprising 1,1,1,3,3-pentafluoropropane or 1,1,1-trifluoro-3-chloro-2-propene which each is separated and purified.

Owner:DAIKIN IND LTD

Process for Producing 1,3,3,3-Tetrafluoropropene

InactiveUS20110172472A1High selectivityHigh yieldChlorine/hydrogen-chloride purificationPreparation by hydrogen halide split-offHydrogen fluoride1,3,3,3-Tetrafluoropropene

According to the first characteristic of the present invention, there is provided a production process for 1,3,3,3-tetrafluoropropene including: the first step of reacting 1,1,1,3,3-pentachloropropane with hydrogen fluoride thereby obtaining 1-chloro-3,3,3-trifluoropropene; and the second step of reacting 1-chloro-3,3,3-trifluoropropene obtained in the first step with hydrogen fluoride in a gaseous phase in the presence of a fluorination catalyst. According to the second characteristic of the present invention, there is provided a dehydration process including bringing 1,3,3,3-tetrafluoropropene containing at least water into contact with zeolite.

Owner:CENT GLASS CO LTD

Preparation method for 1,1,1,3-tetrafluoropropene

InactiveCN101215220AHigh selectivityPreparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluorideAfter treatment

The invention discloses a process for preparing 1, 1, 1, 3-HFO-1234ze, which resolves the problem of low selectivity of HFO-1234ze. The invention takes 1, 1, 1, 3, 3-HCC-240fa as raw material, including the following steps that a, placing hydrogen fluoride (HF) and HCC-240fa into a reactor to react with fluorination catalyst, b, distilling and detaching the produced fluid in step a which flows into a distillation tower, the tower bottom components of 1, 1, 1, 3, 3-HCC-240fa, 1-chlorine-3, 3, 3-HCFC-1233zd and hydrogen fluoride recycle to the reactor, the tower top components of hydrogen fluoride and HFO-1234ze enter after-treatment system and obtaining object product HFO-1234ze after processes of deoxidation, dehydration and distillation and the like. The invention is mainly used to prepare HFO-1234ze.

Owner:XIAN MODERN CHEM RES INST

Method of making 1,1,3,3,3-pentafluoropropene

InactiveUS20050070746A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offFoaming agentSolvent

The invention provides an economic process for the manufacture of the hydrofluorocarbon 1,1,3,3,3-pentafluoropropene (HFC-1225zc). HFC-1225zc can be made from the dehydrochlorination of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa). Alternatively, HFC-1225zc can also be made from the dehydrofluorination of 1,1,1,3,3,3-hexafluoropropane (HFC-236fa). HFC-1225zc) is a compound that has the potential to be used as a low Global Warming Potential refrigerant, blowing agent, aerosol propellant, or solvent.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com