Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

486results about How to "Slow reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

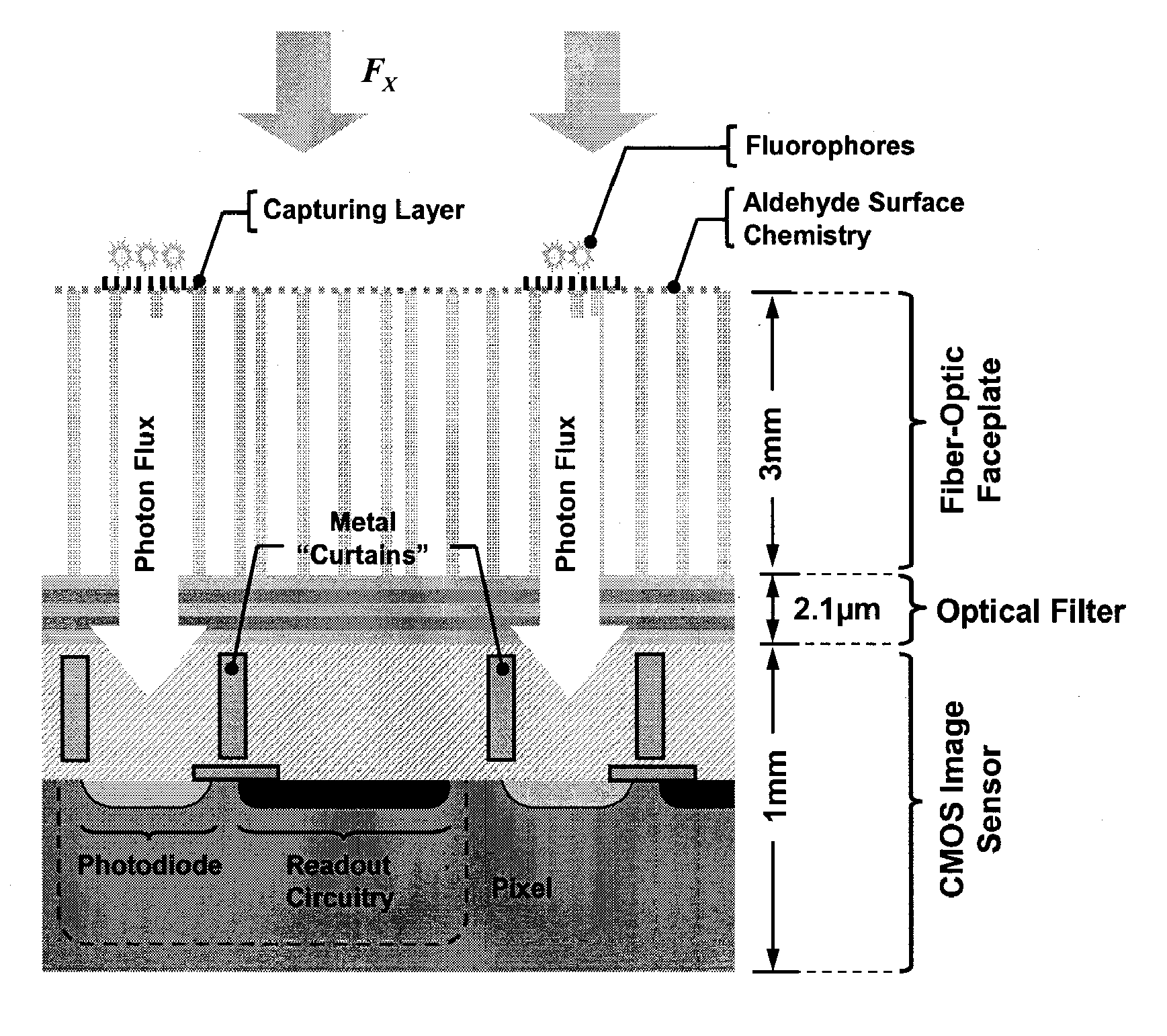

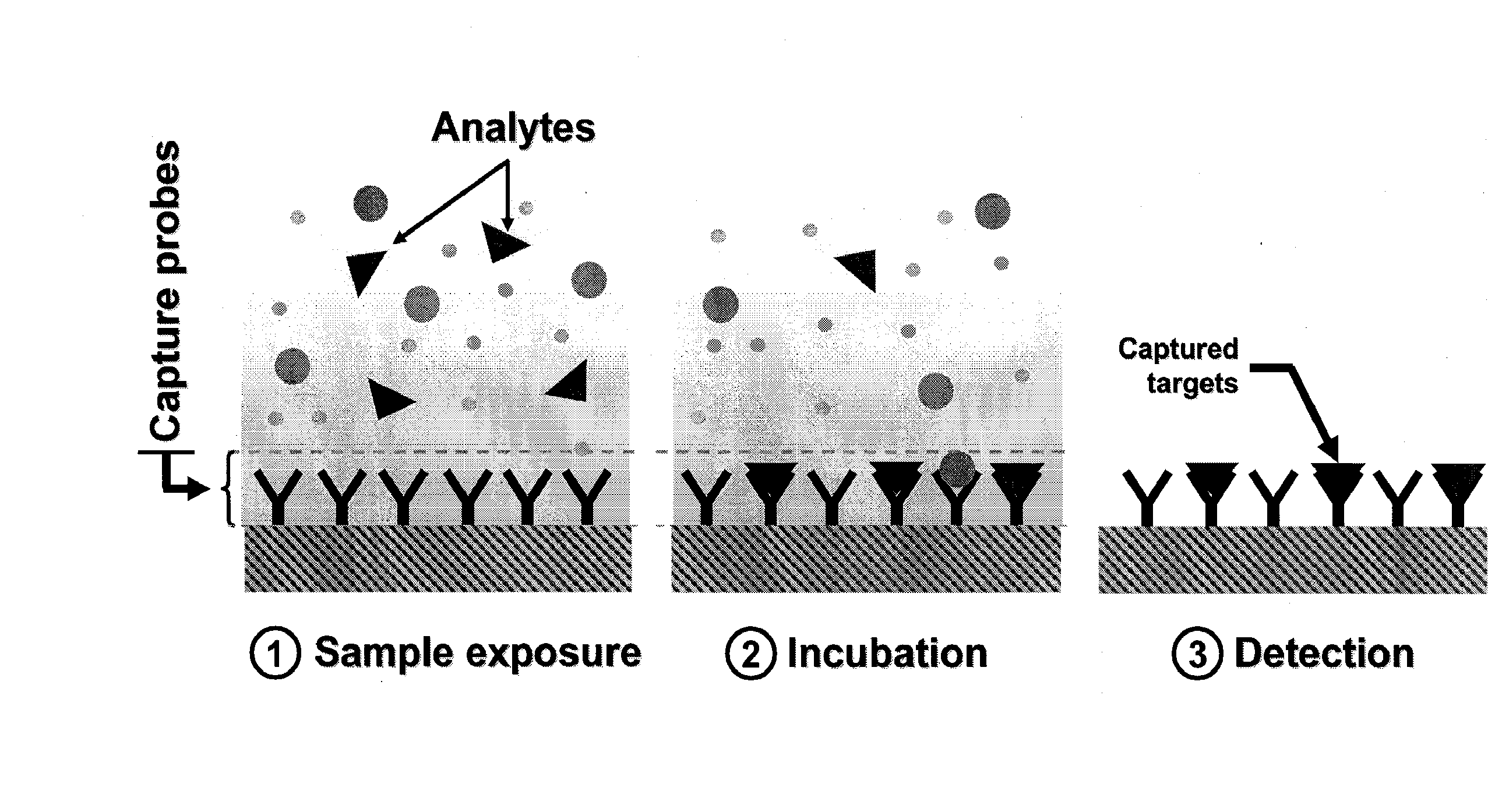

Integrated Semiconductor Bioarray

ActiveUS20080081769A1TimeSlow reaction rateMicrobiological testing/measurementLibrary screeningAnalyteBiosensor array

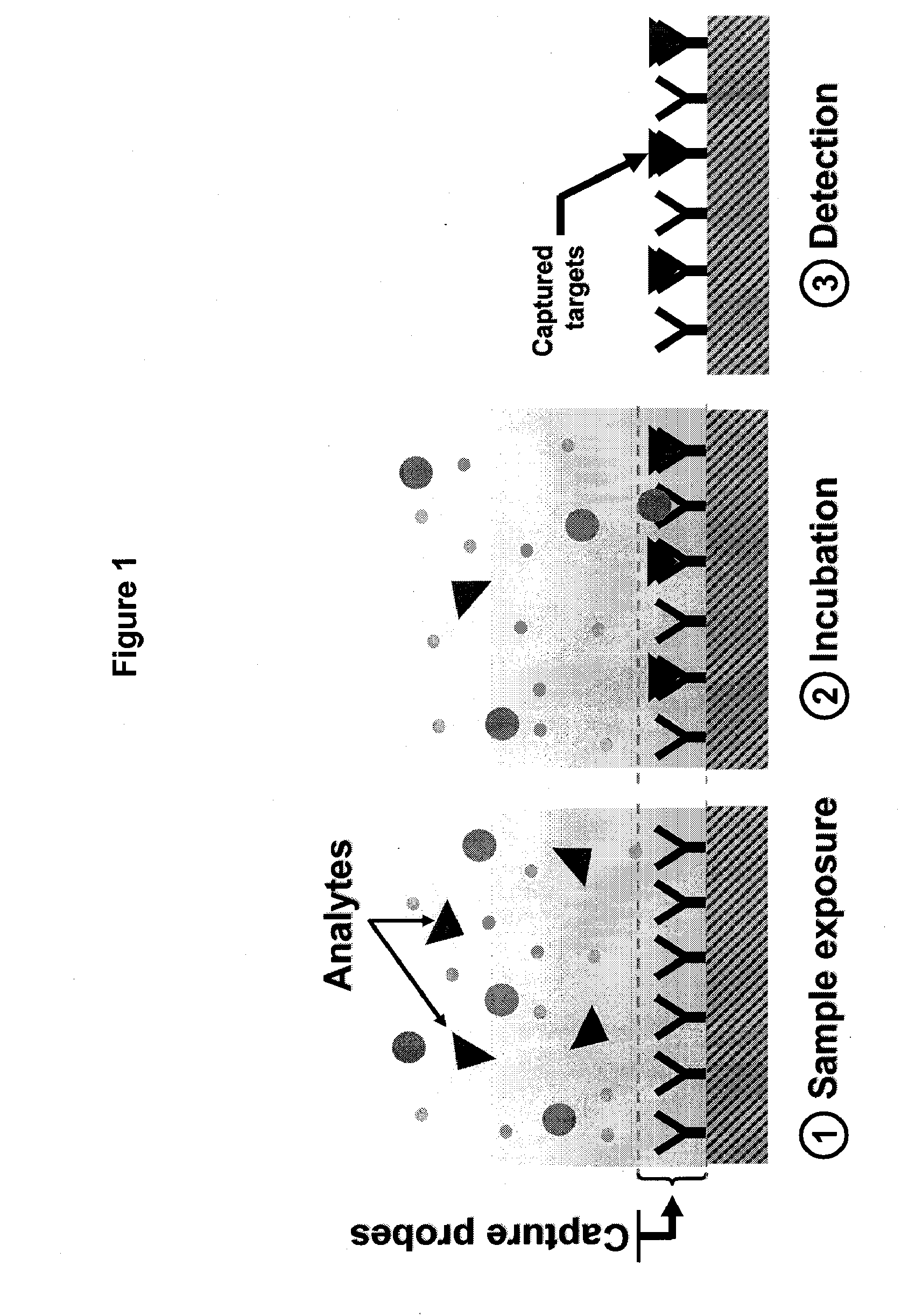

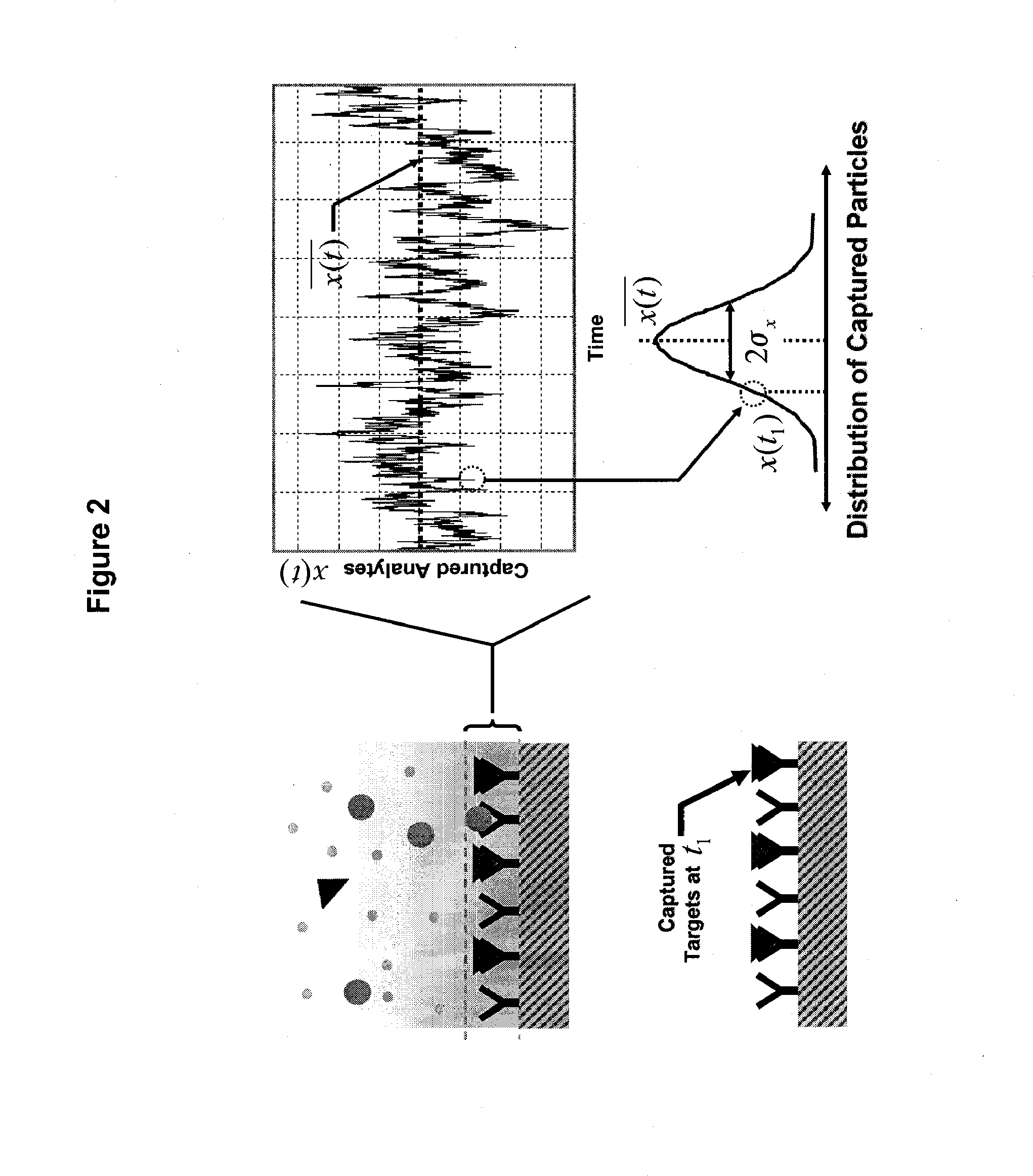

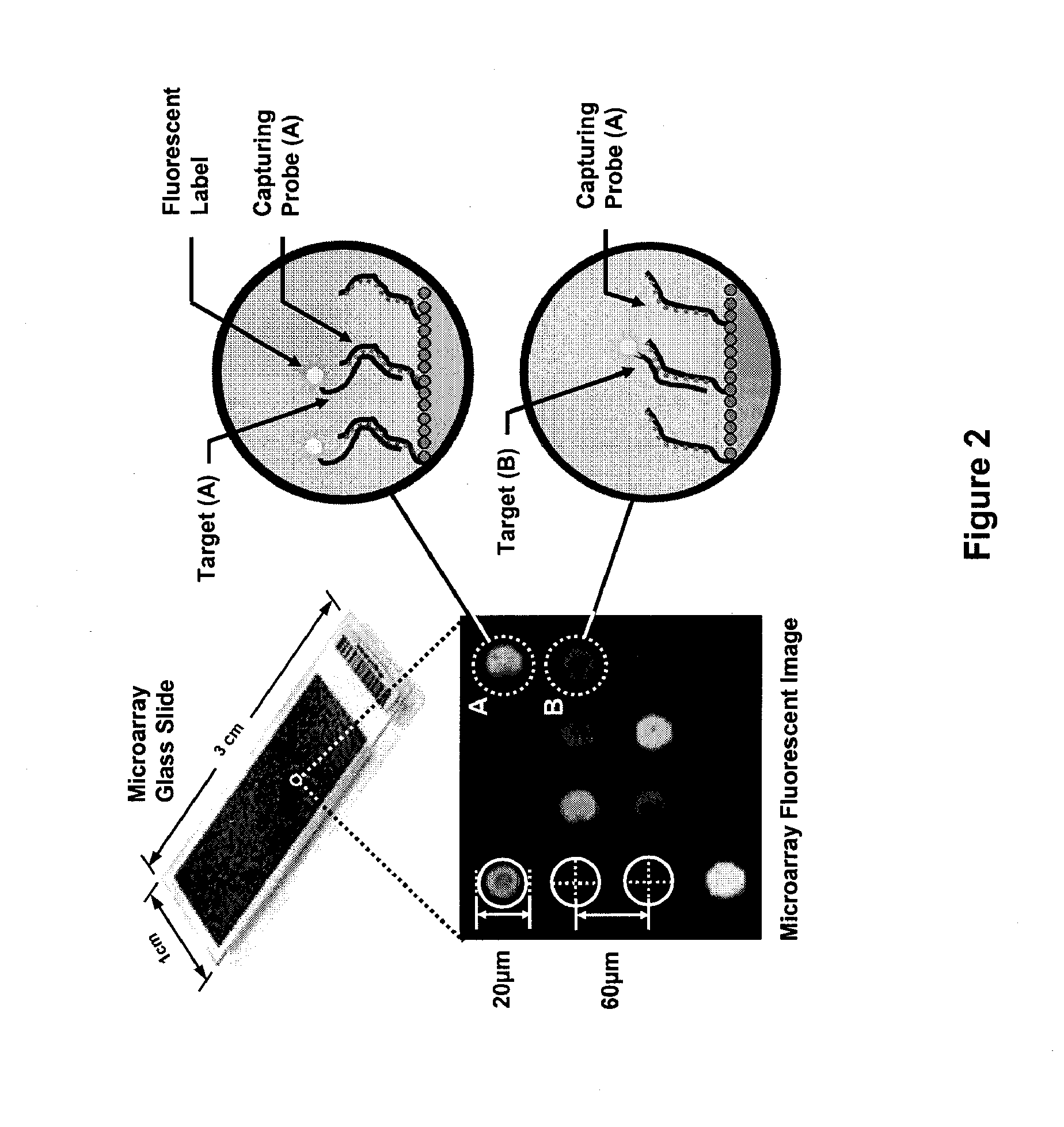

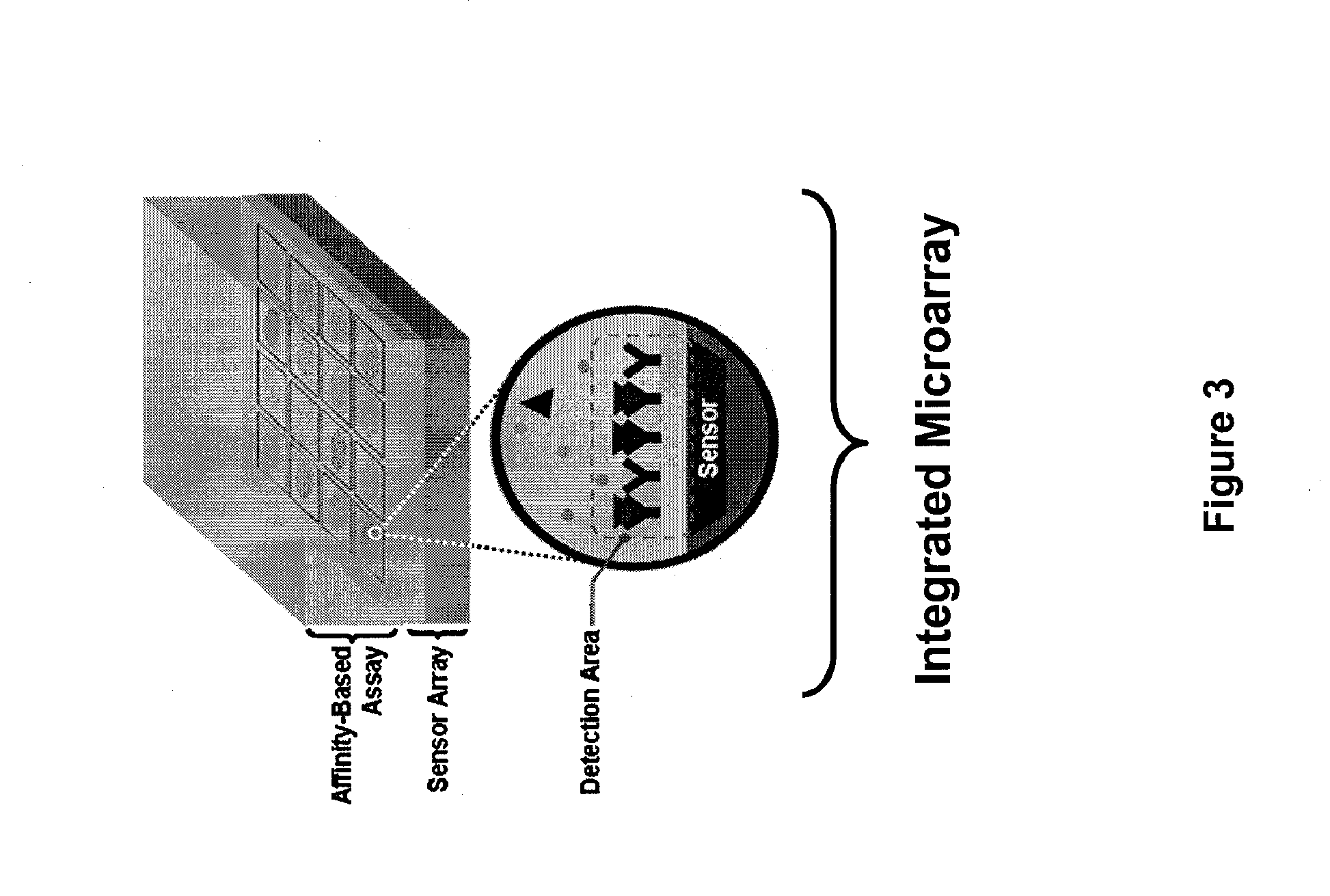

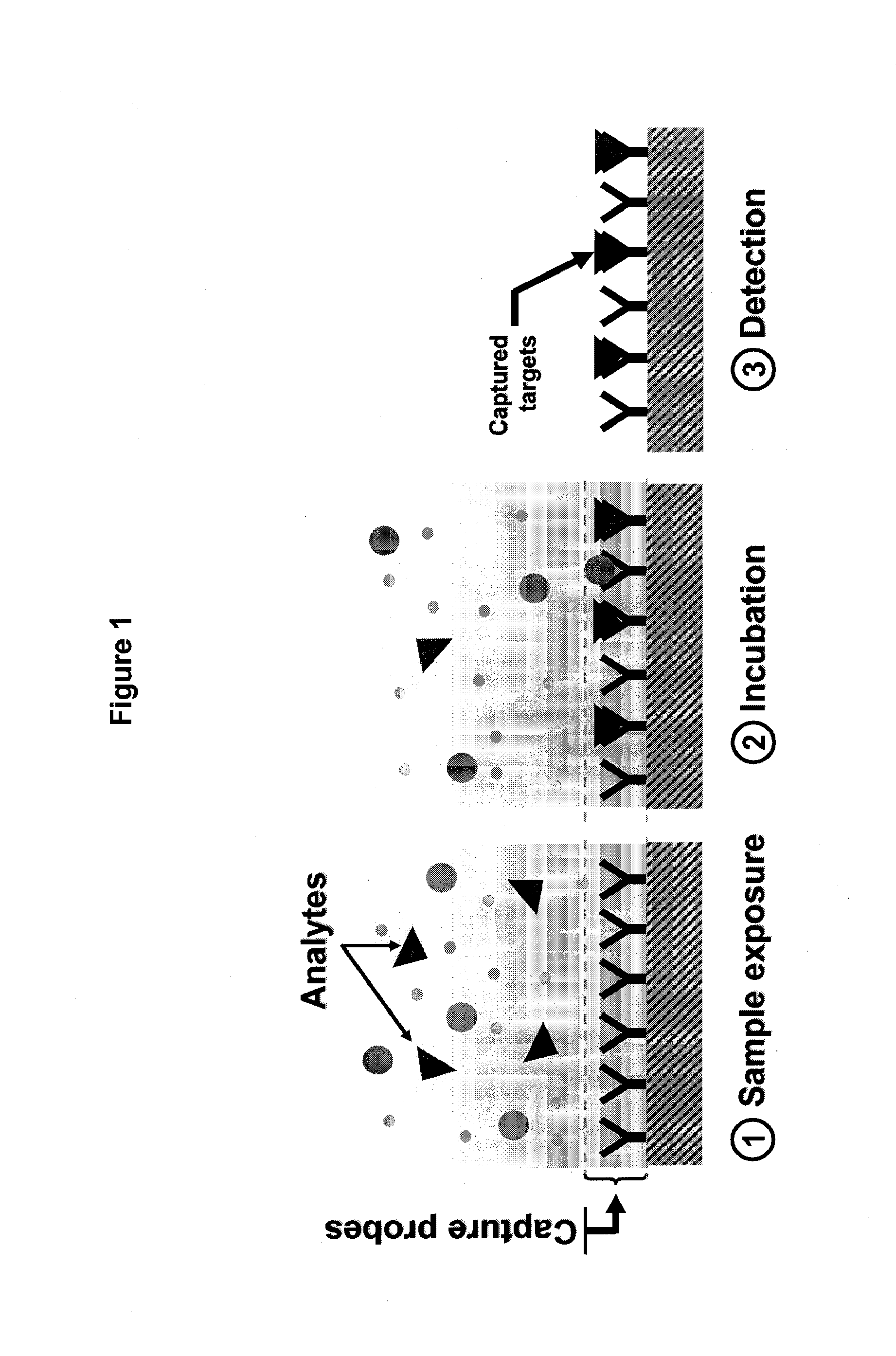

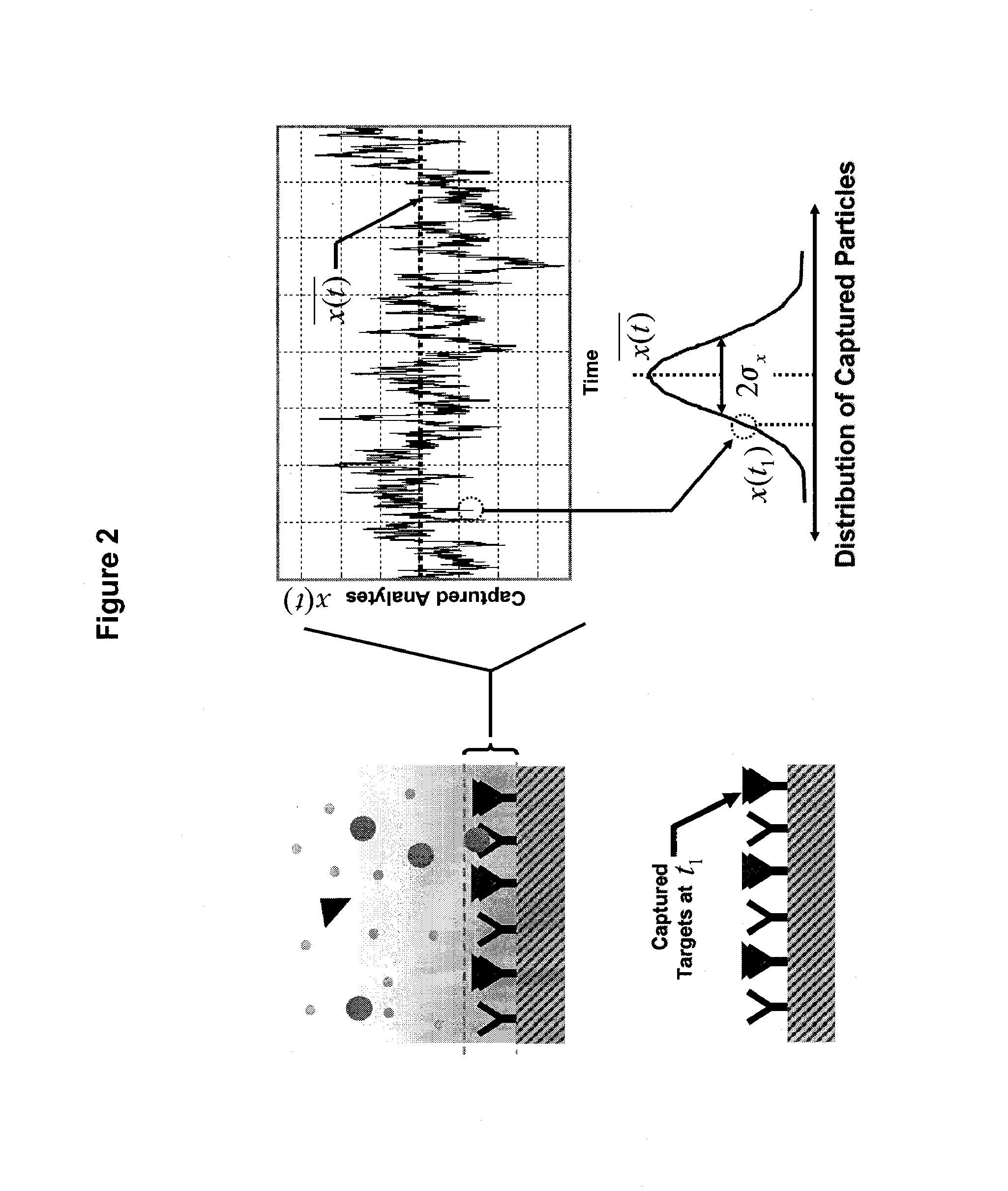

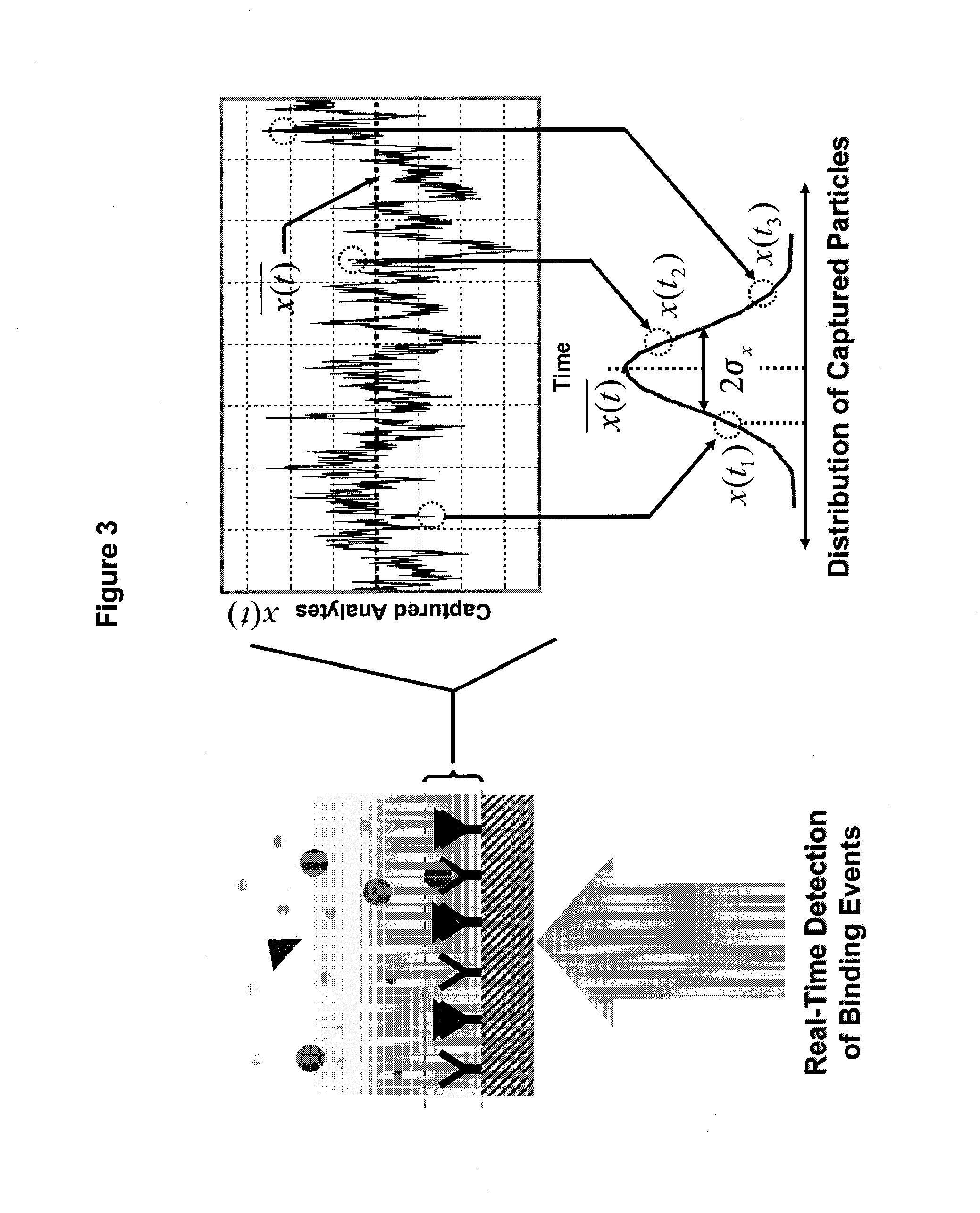

A biosensor array, system and method for affinity based assays that are able to simultaneously obtain high quality measurements of the binding characteristics of multiple analytes, and that are able to determine the amounts of those analytes in solution. The invention also provides a fully integrated bioarray for detecting real-time characteristics of affinity based assays.

Owner:CALIFORNIA INST OF TECH

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

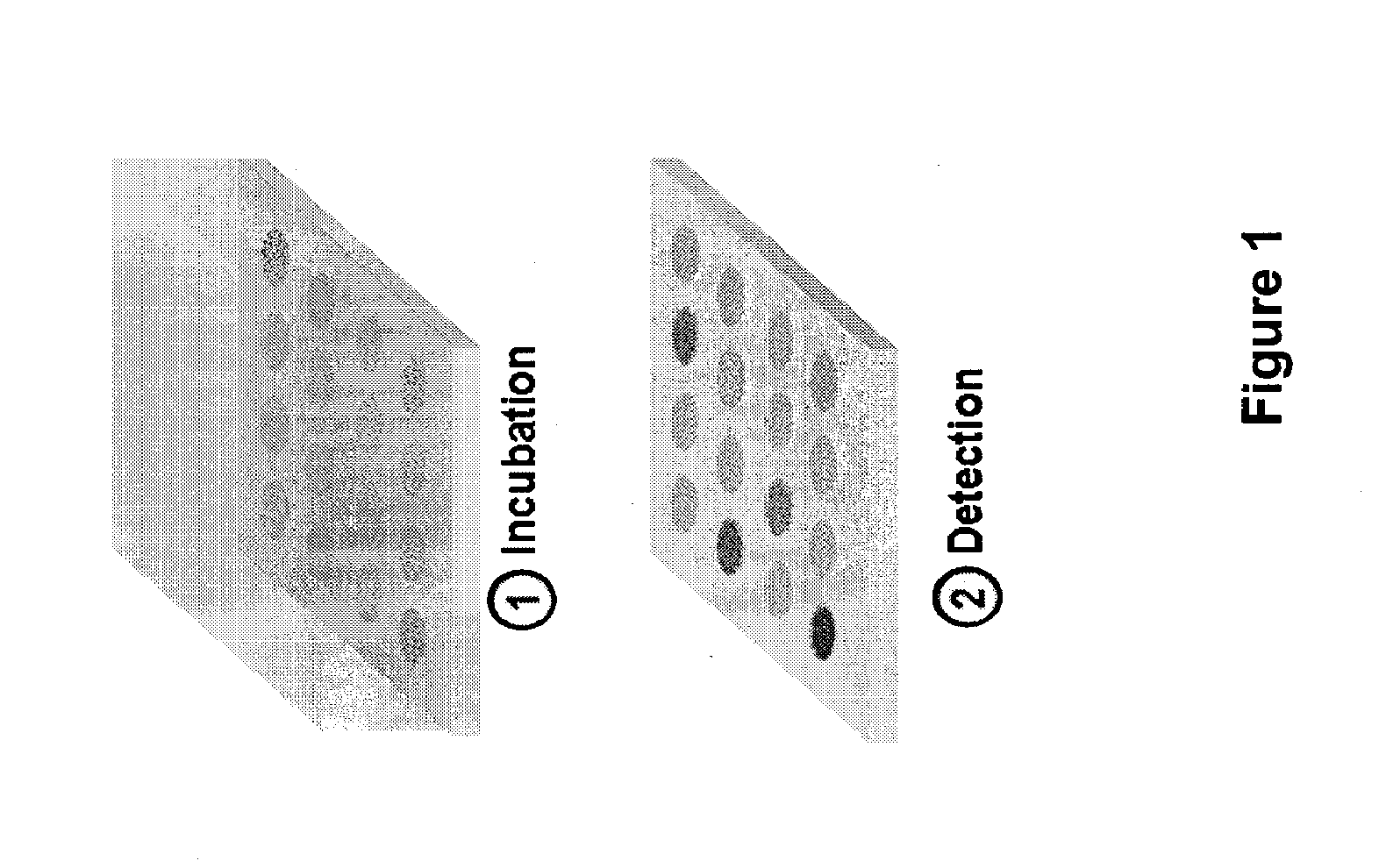

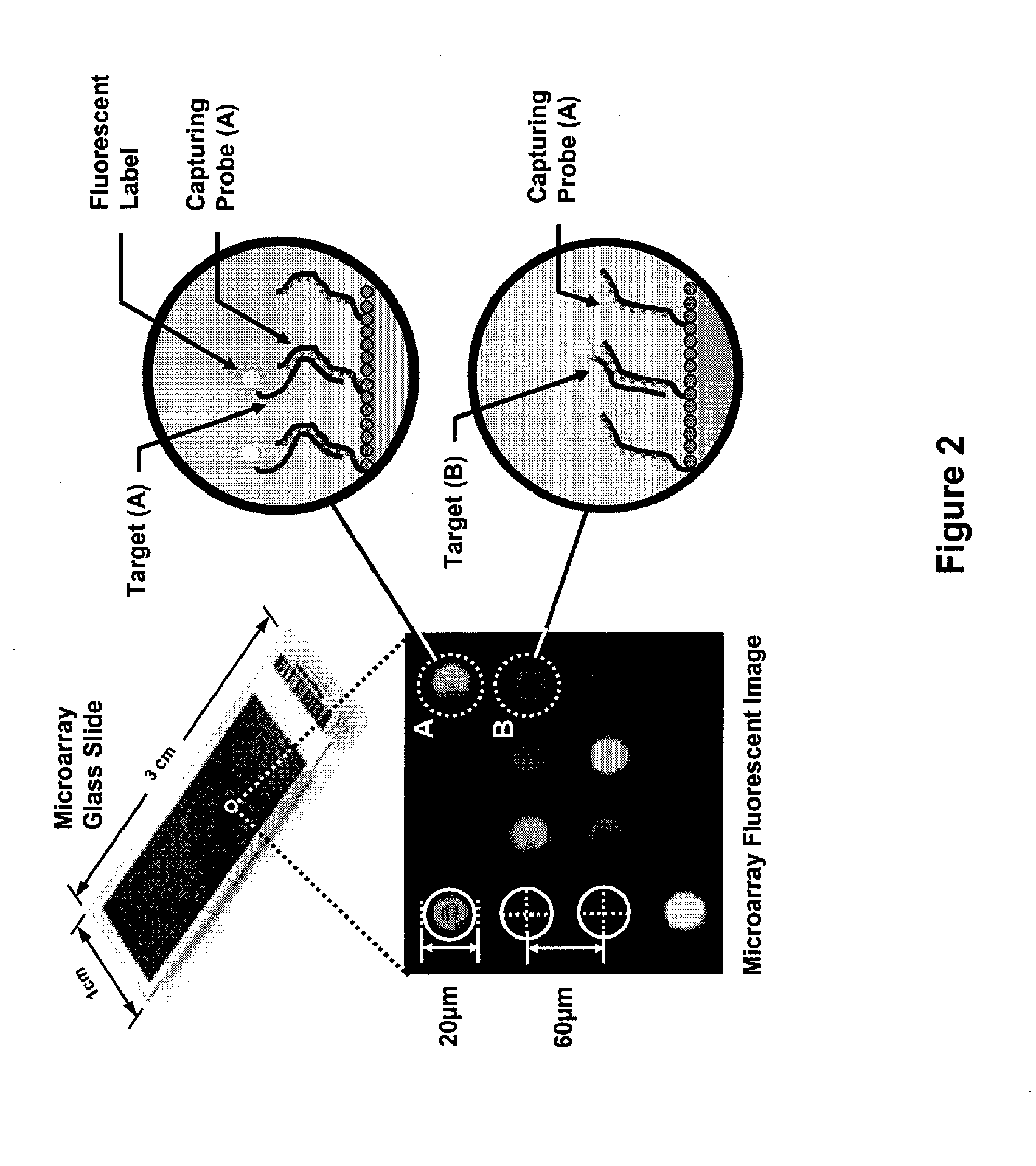

Real Time Microarrays

ActiveUS20080039339A1TimeSlow reaction rateMicrobiological testing/measurementLibrary screeningAnalyteMicroarray

Owner:CALIFORNIA INST OF TECH

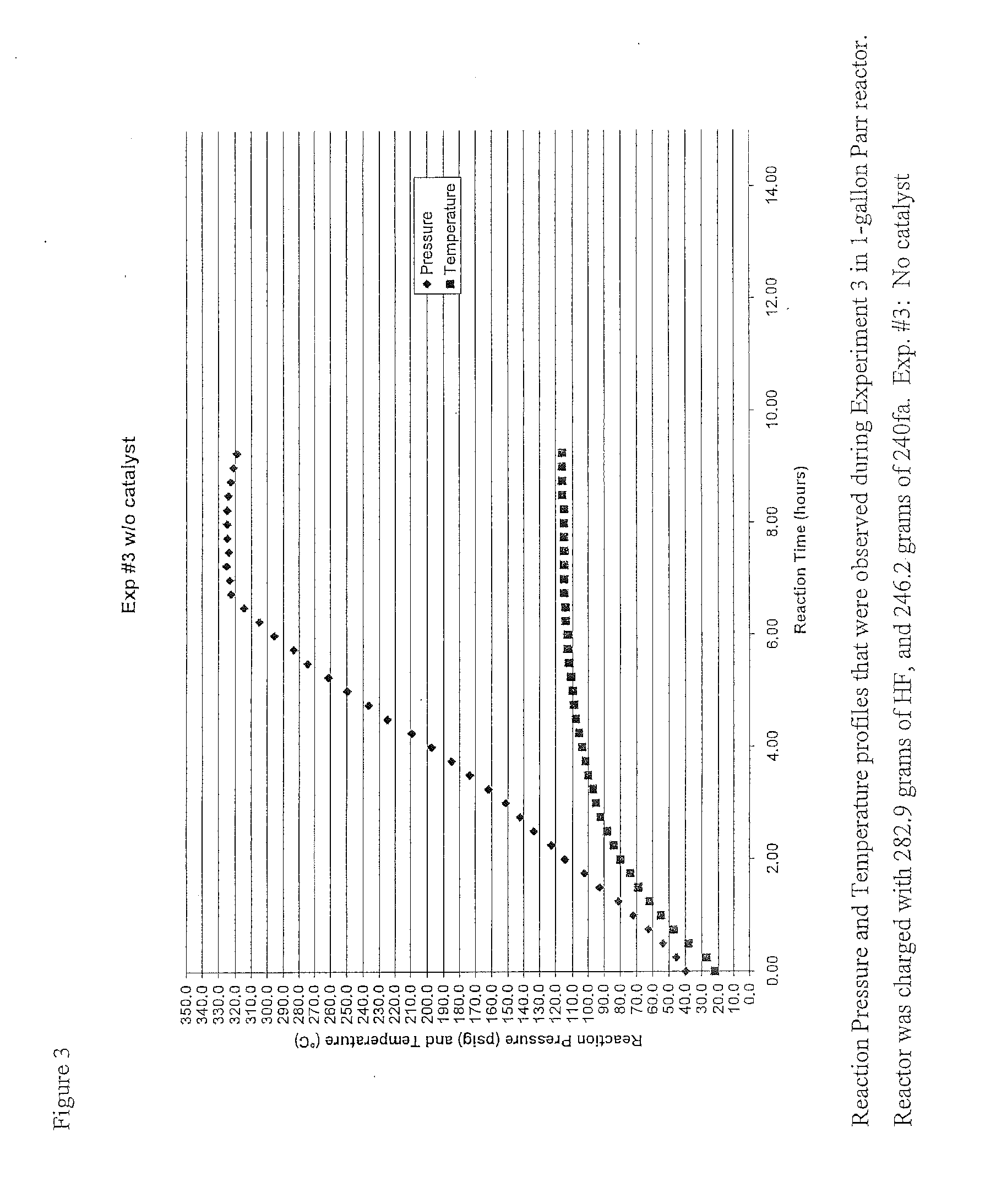

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

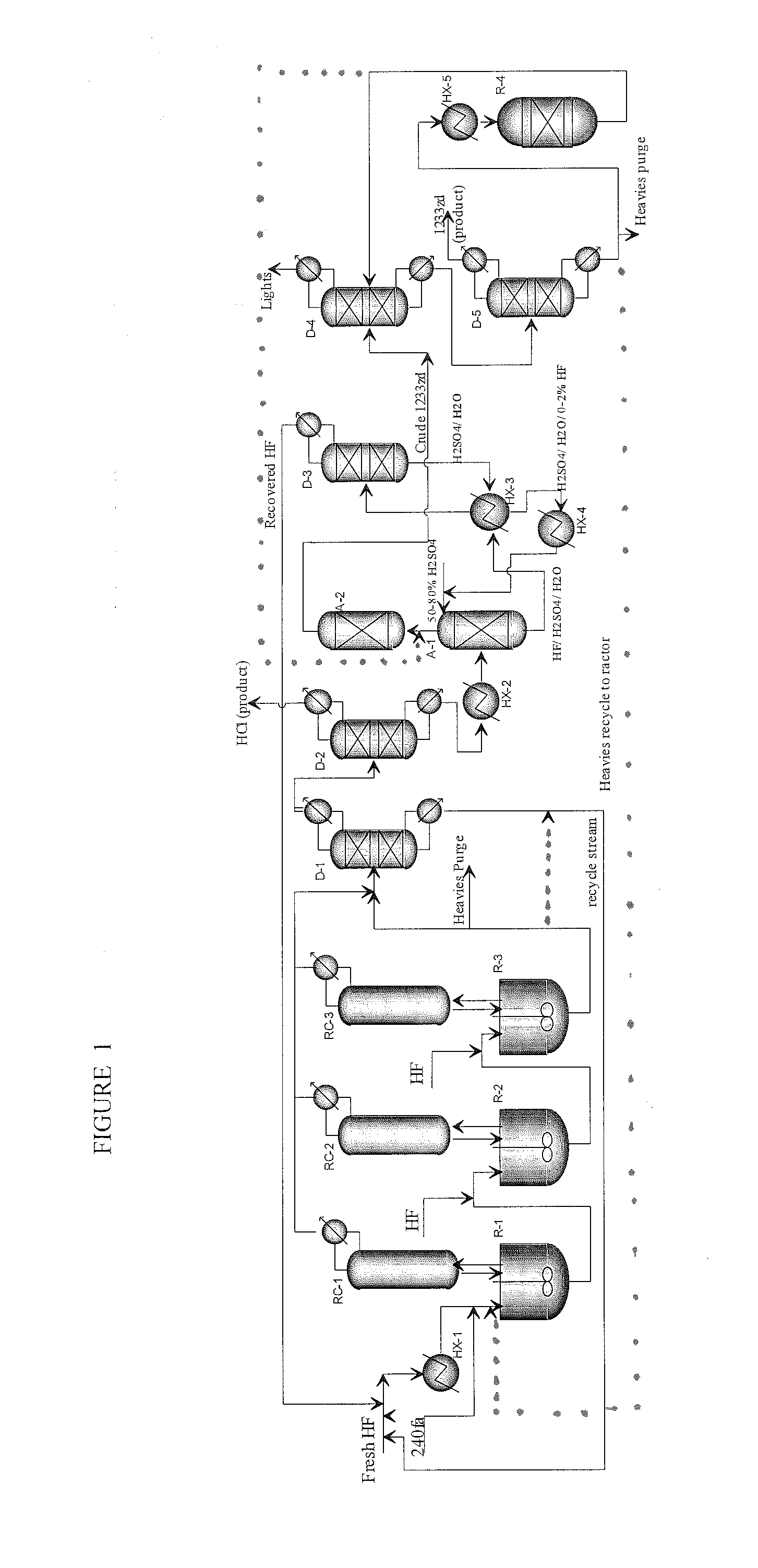

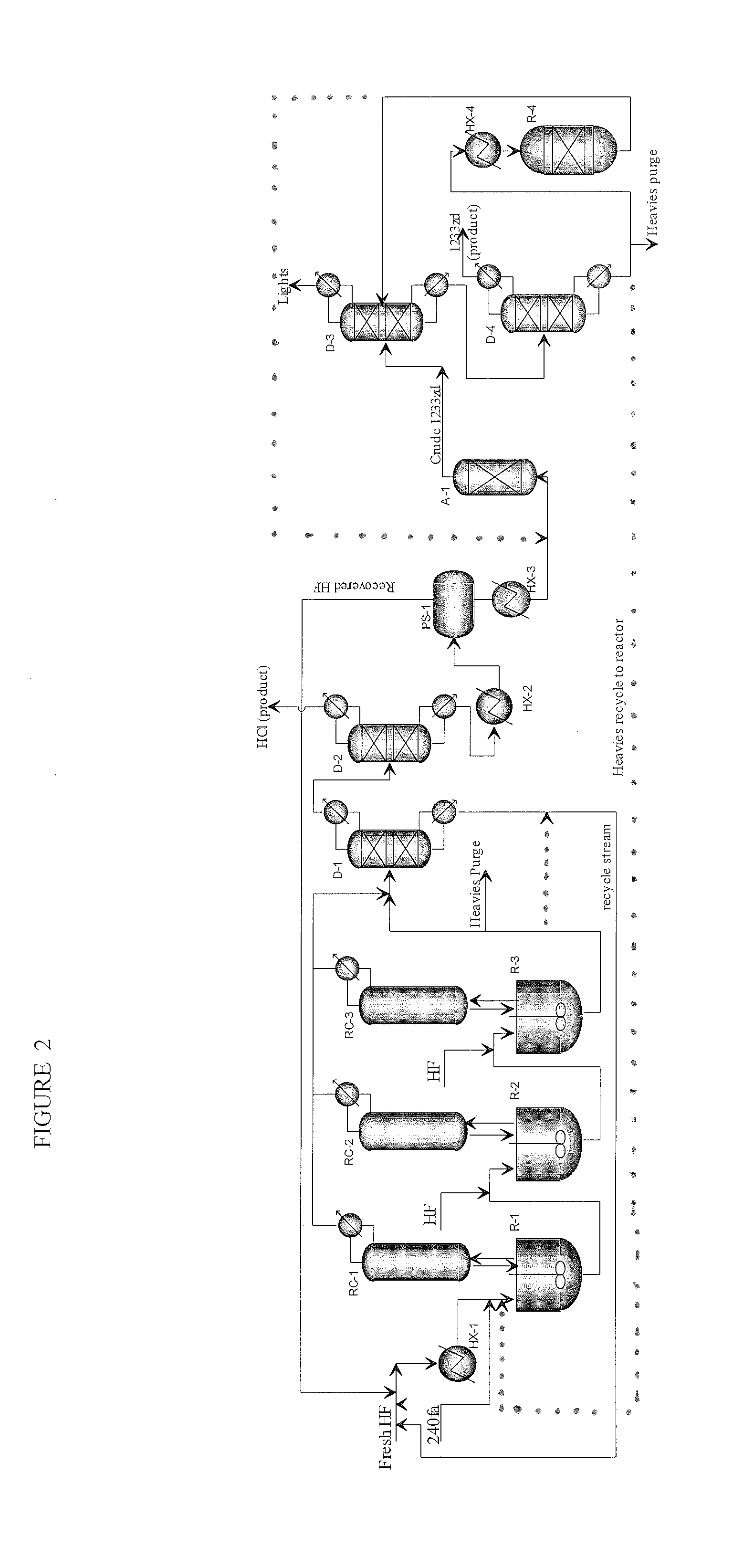

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

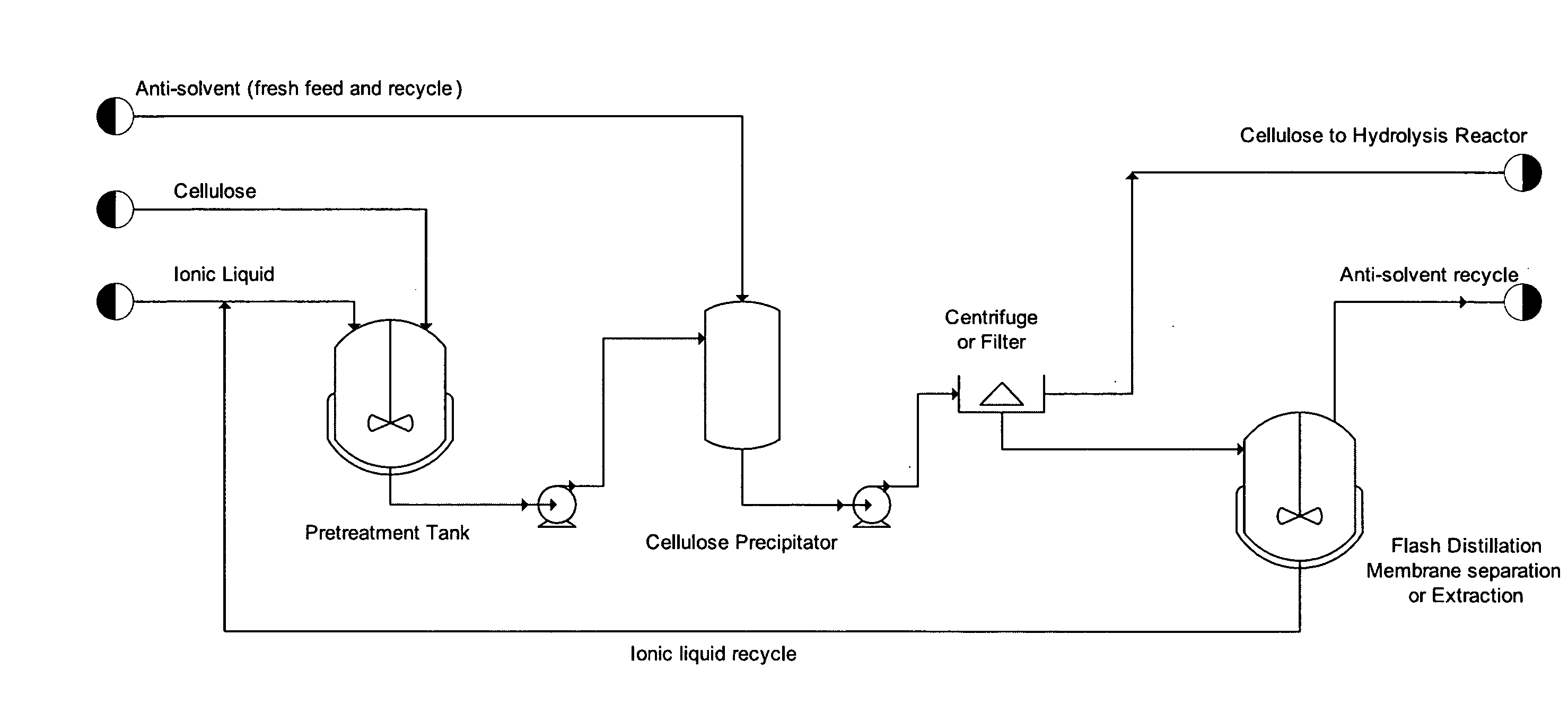

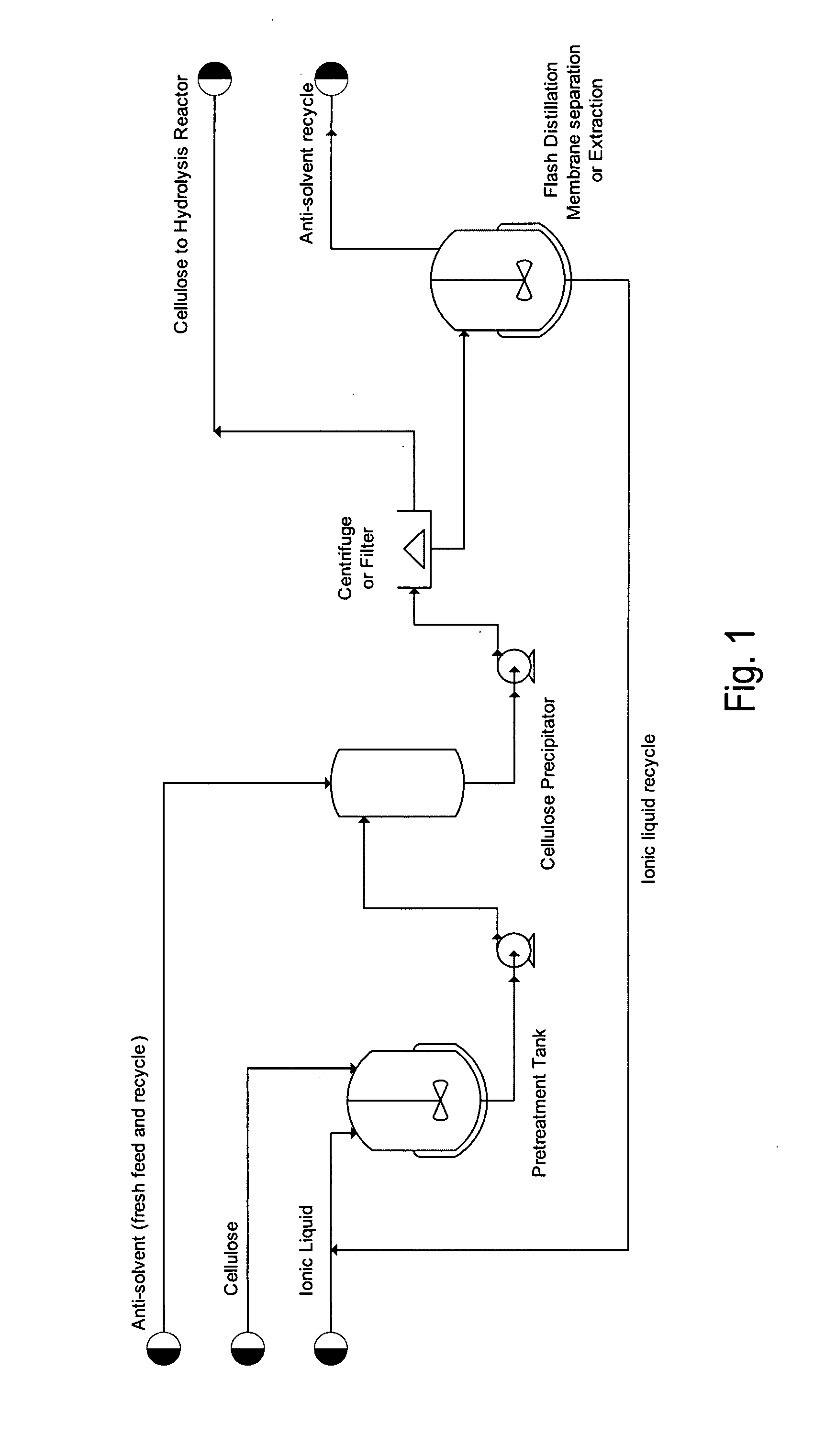

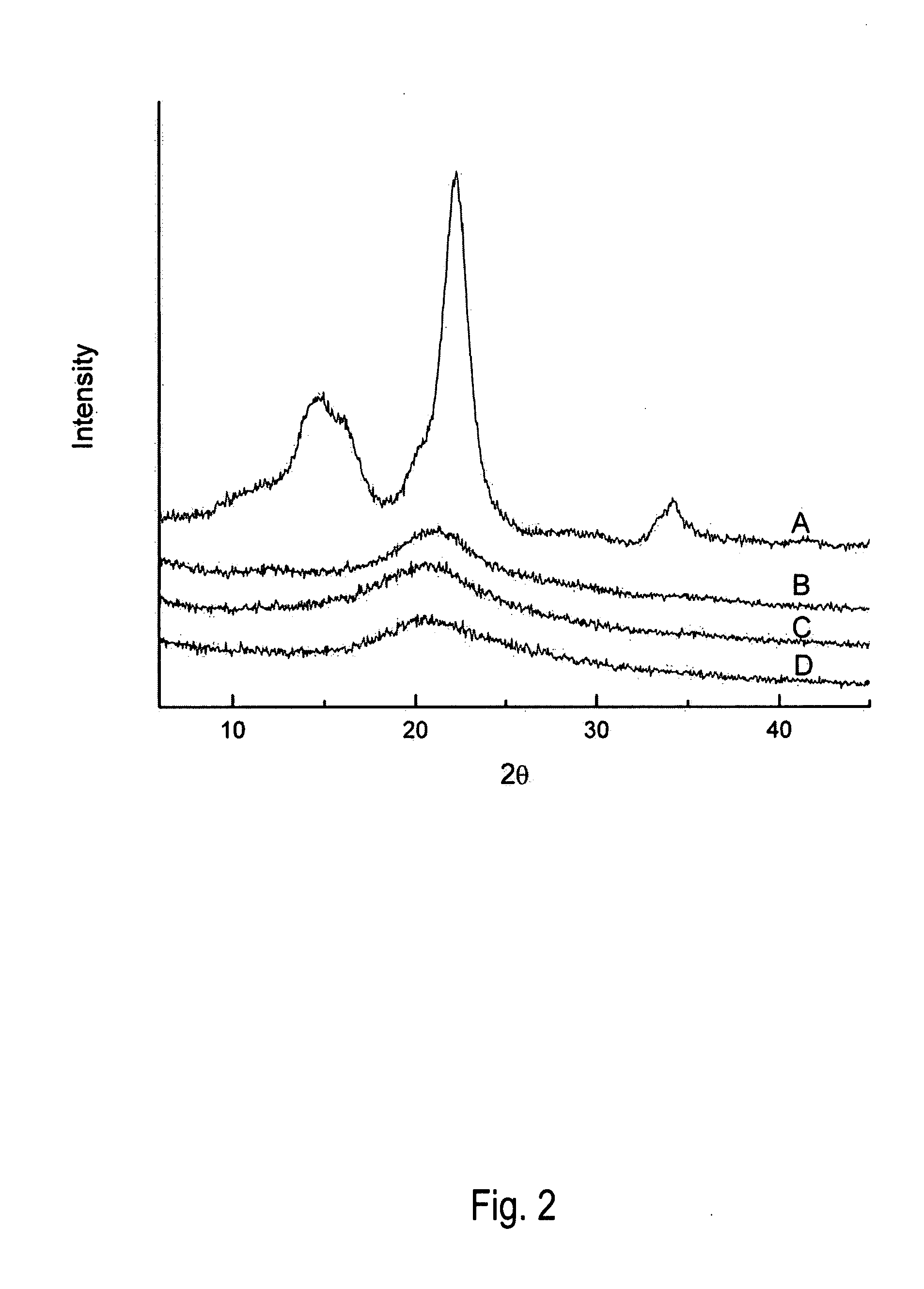

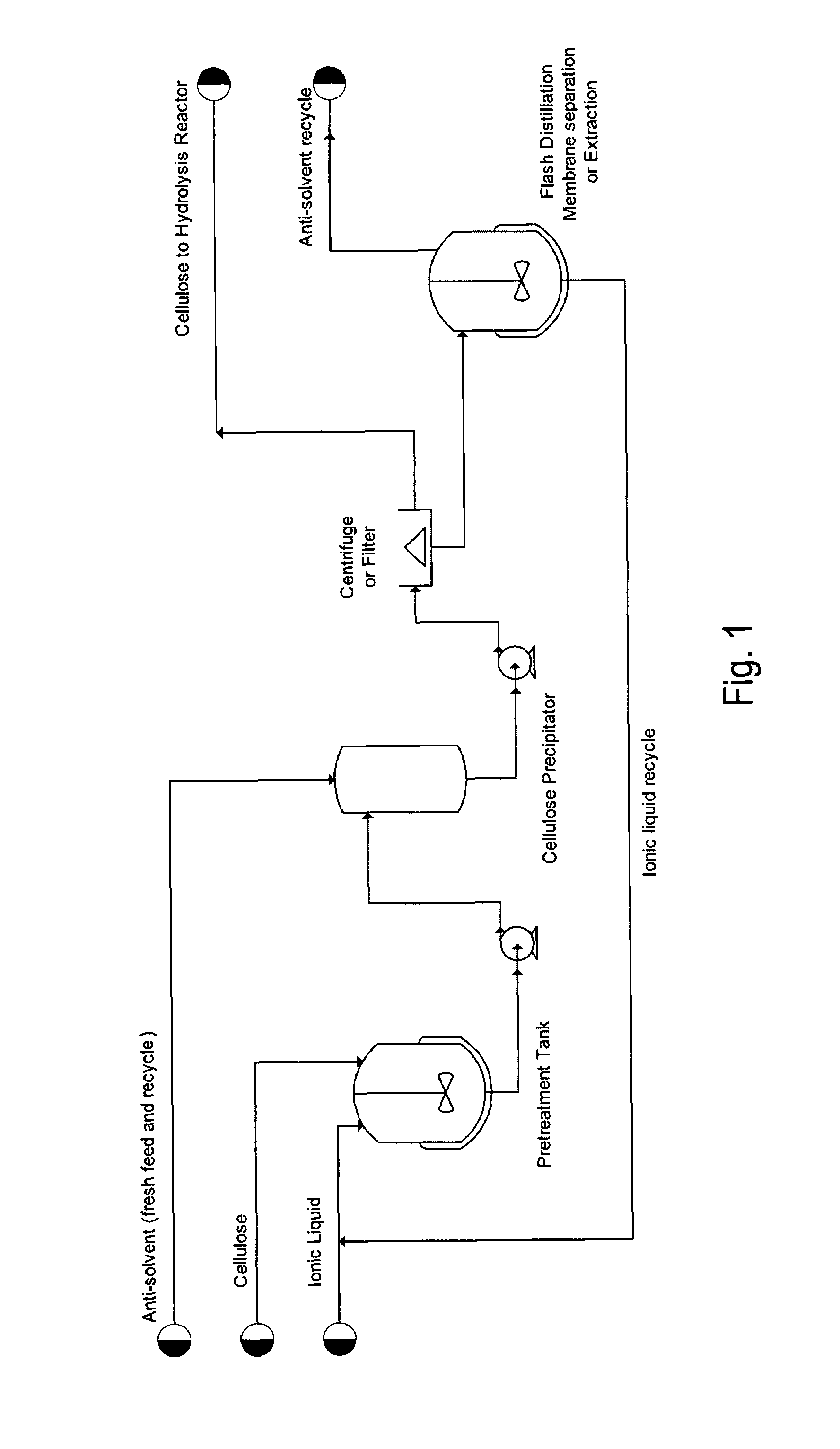

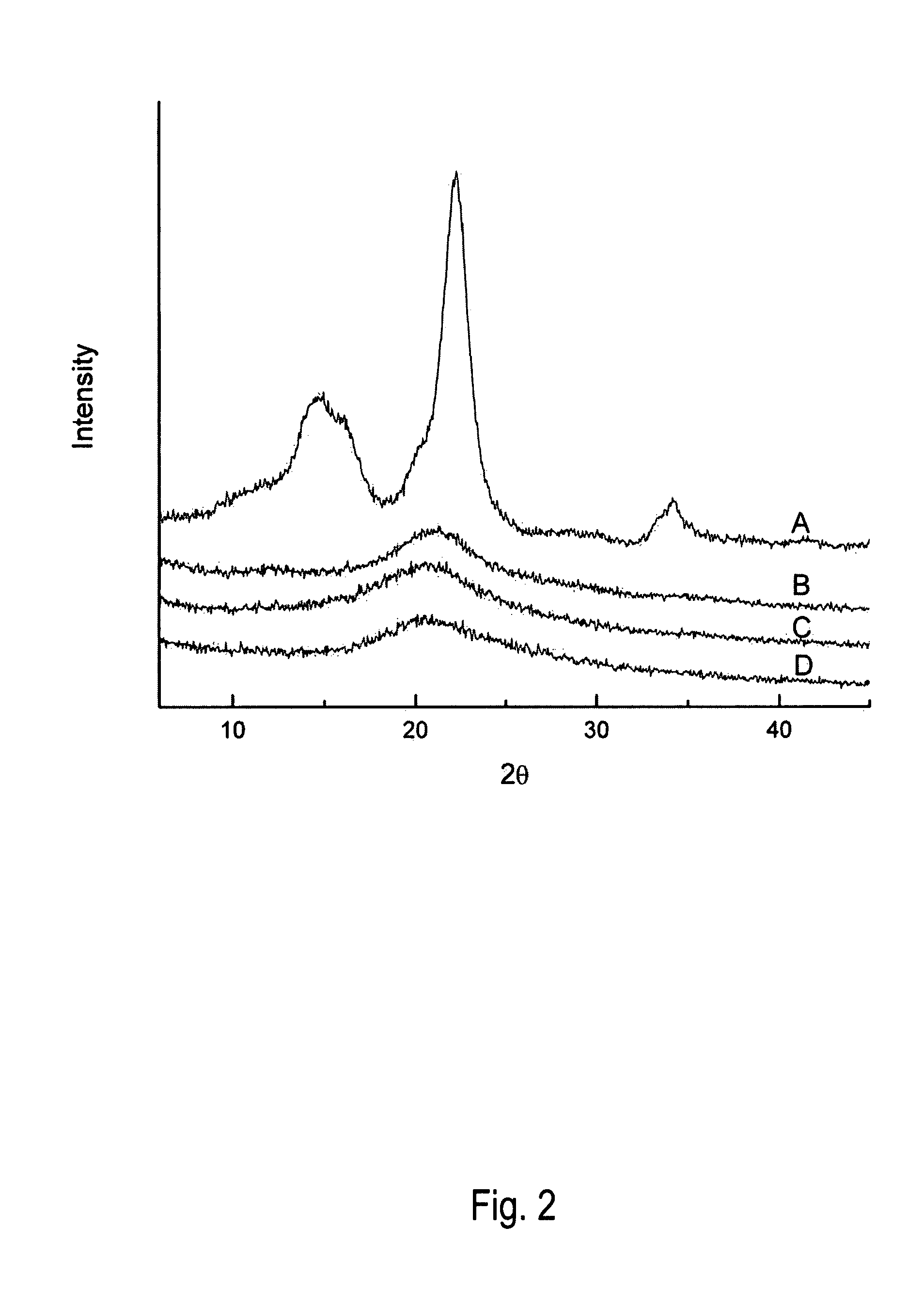

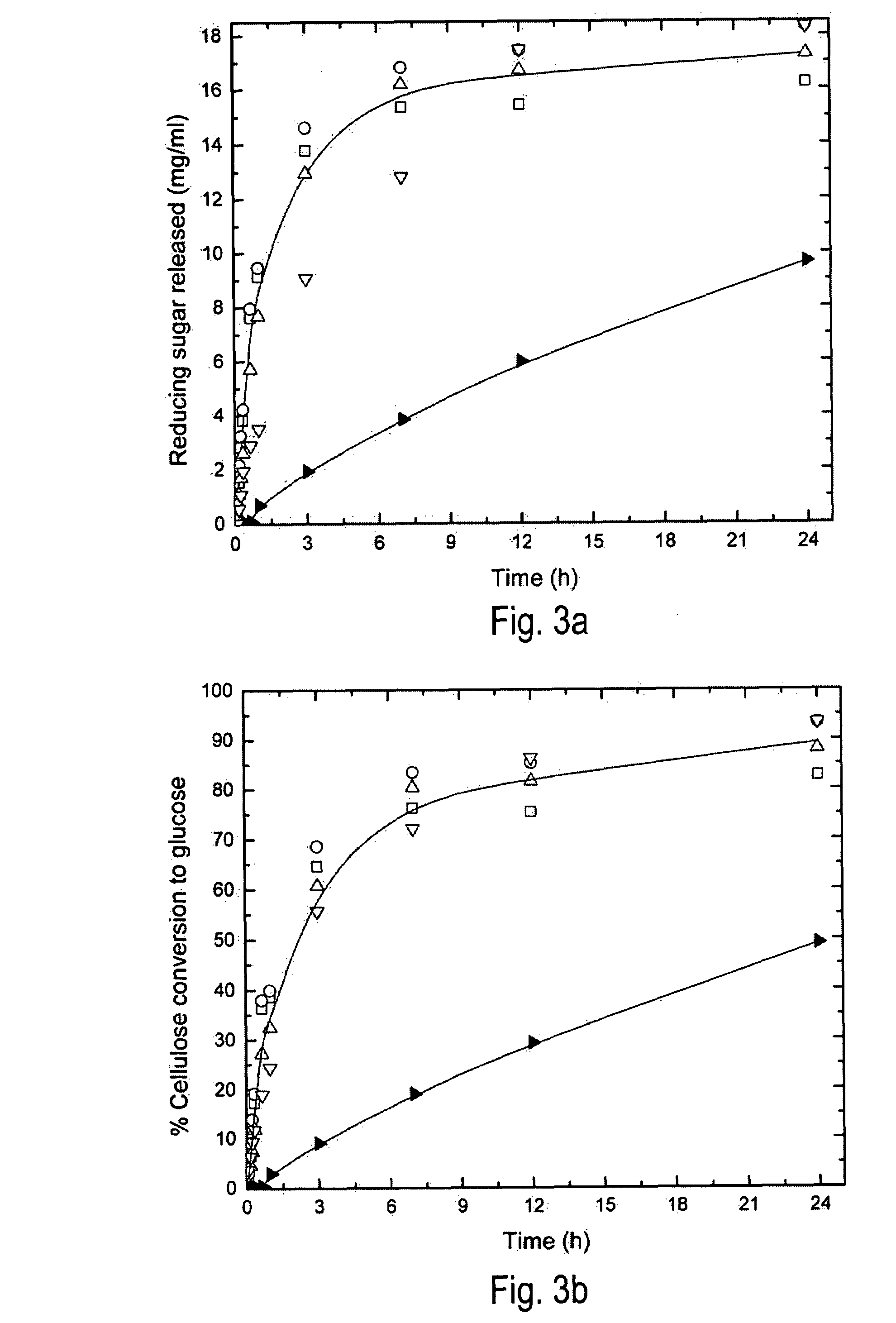

Saccharifying cellulose

Dissolution, partial dissolution or softening of cellulose in an ionic liquid (IL) and its subsequent contact with anti-solvent produces regenerated cellulose more amorphous in structure than native cellulose, which can be separated from the IL / anti-solvent mixture by mechanical means such as simple filtration or centrifugation. This altered morphology of IL-treated cellulose allows a greater number of sites for enzyme adsorption with a subsequent enhancement of its saccharification. The IL-treated cellulose exhibits significantly improved hydrolysis kinetics with optically transparent solutions formed after about two hours of reaction. This provides an opportunity for separation of products from the catalyst (enzyme) easing enzyme recovery. With an appropriate selection of enzymes, initial hydrolysis rates for IL-treated cellulose were up to two orders of magnitude greater than those of untreated cellulose. Due to the non-volatility of the IL, anti-solvent can be easily stripped from the IL / anti-solvent mixture for recovery and recycle of both the ionic liquid and anti-solvent.

Owner:TOLEDO THE UNIV OF

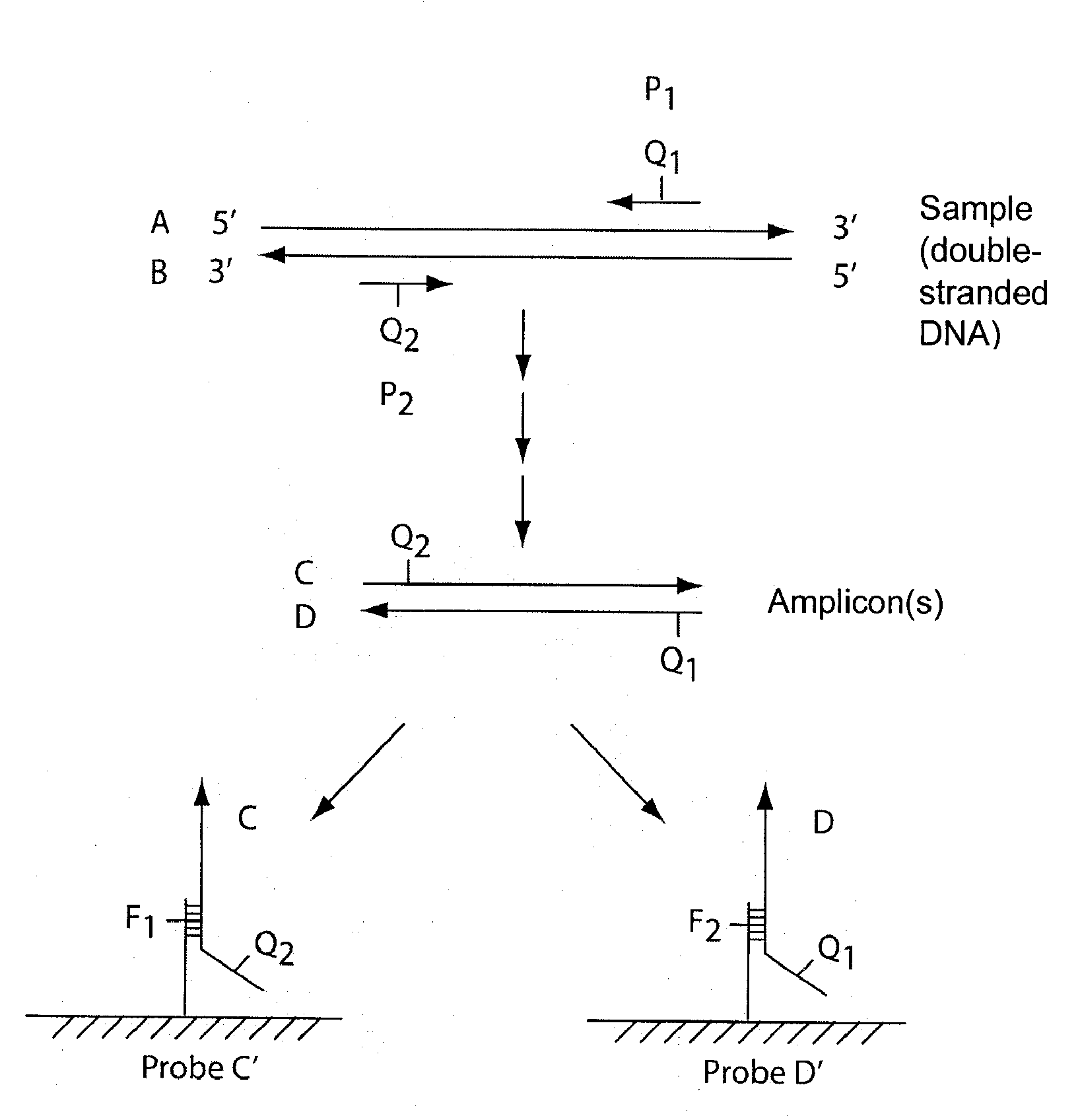

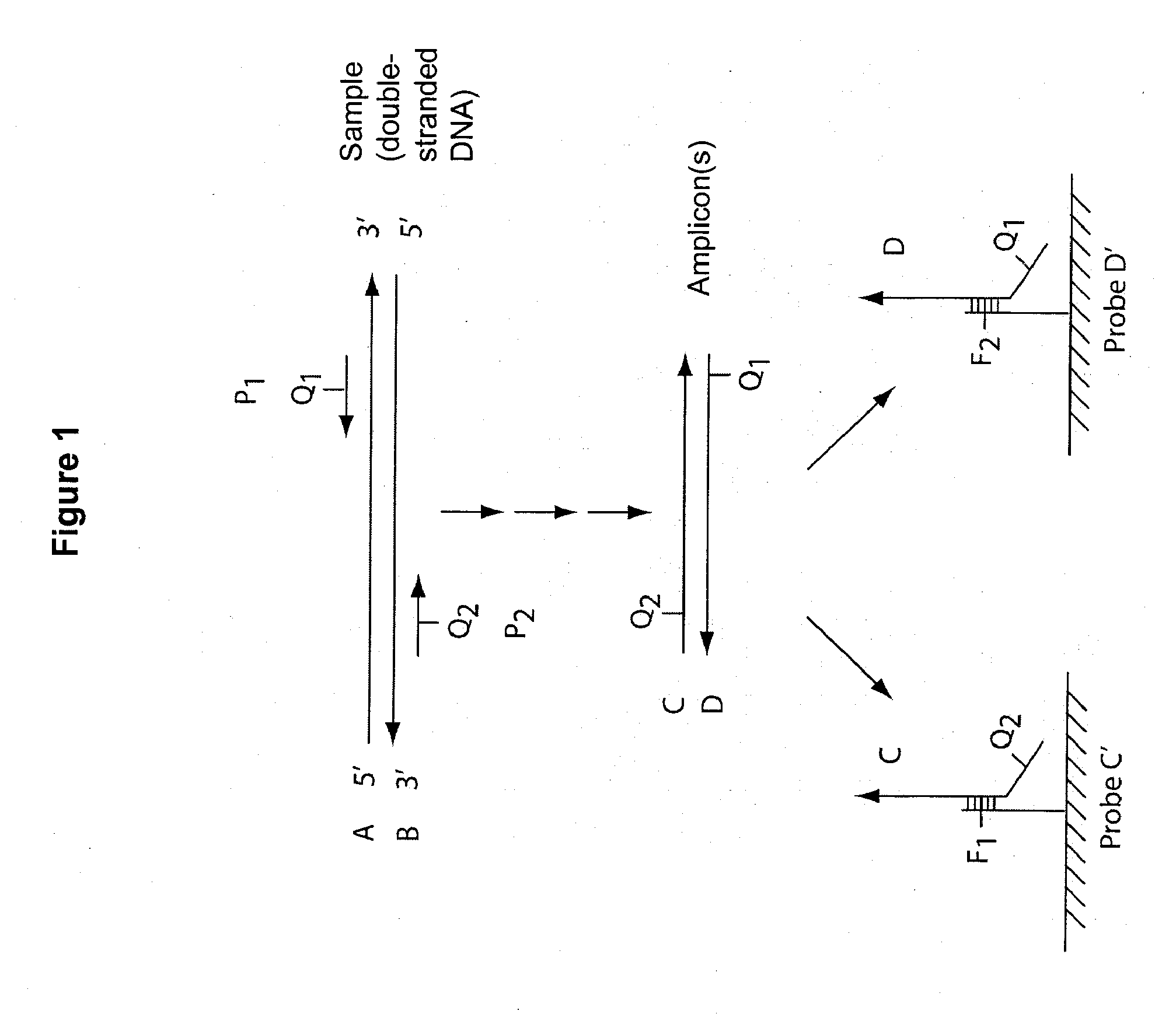

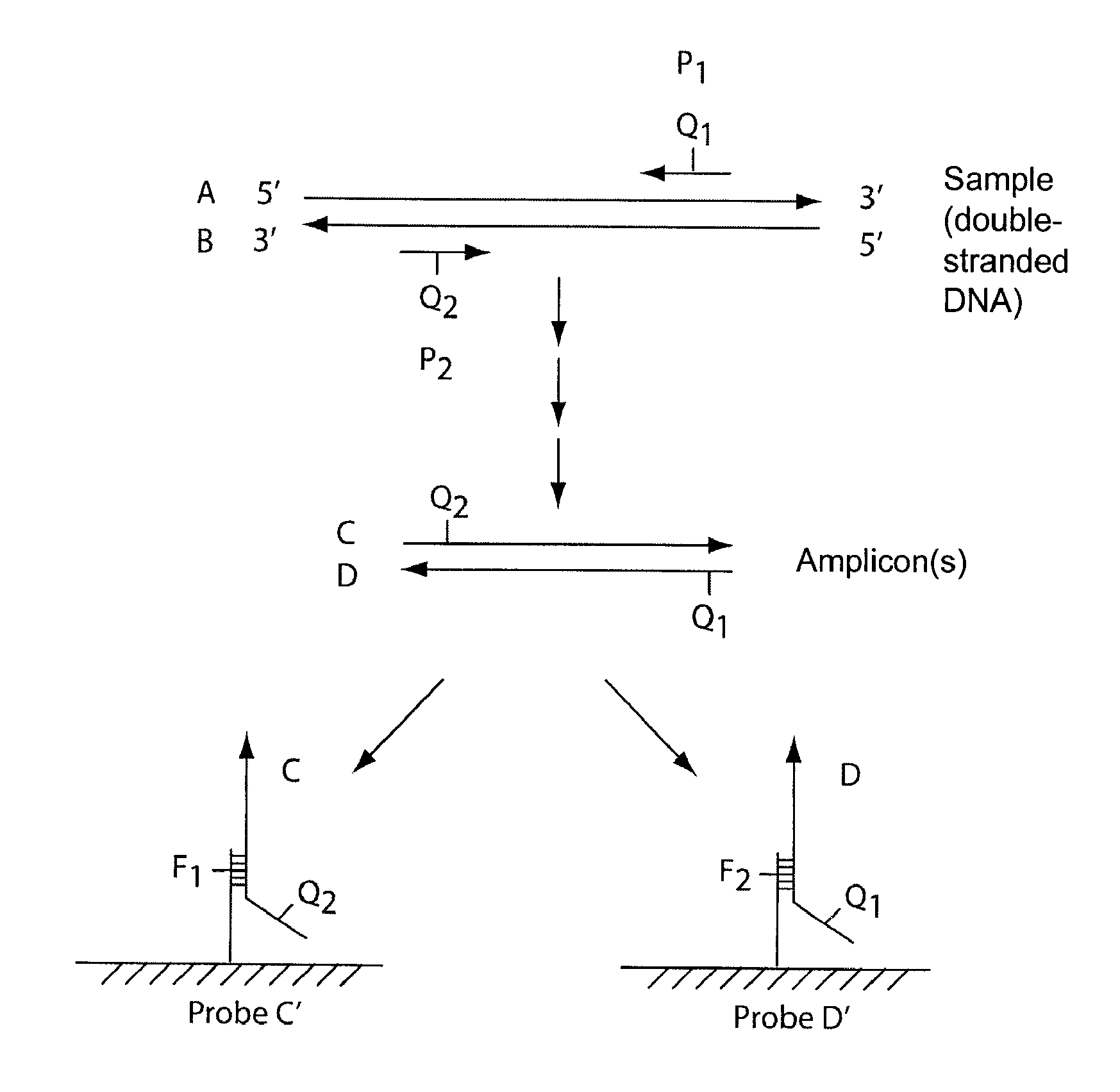

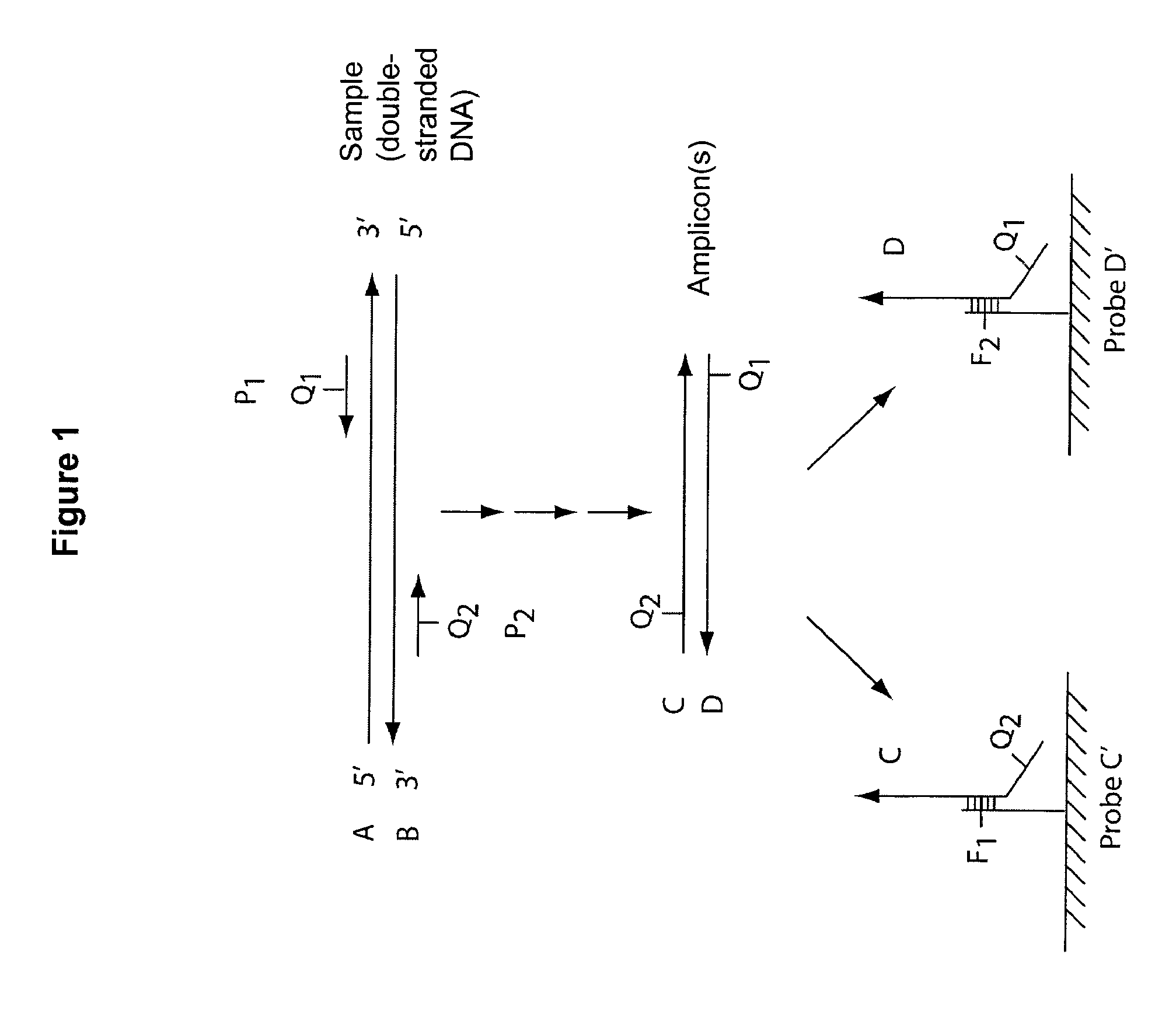

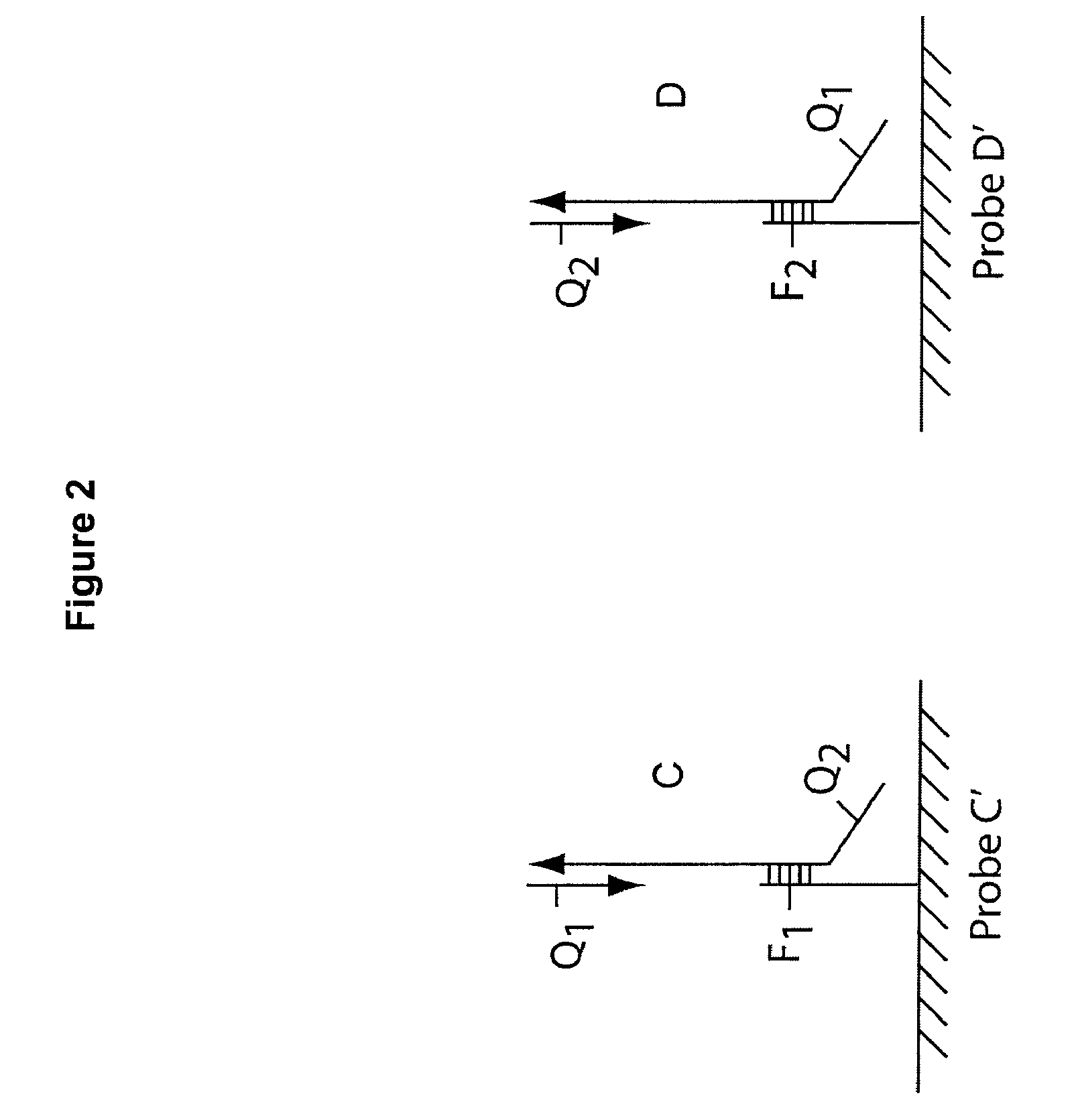

Multiplex Q-PCR Arrays

ActiveUS20080176757A1Measurement obtainedTimeBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic Acid ProbesNucleic acid sequencing

Owner:CALIFORNIA INST OF TECH

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

Integrated semiconductor bioarray

ActiveUS20130225441A1TimeSlow reaction rateMicrobiological testing/measurementLibrary screeningAnalyteBiosensor array

A biosensor array, system and method for affinity based assays that are able to simultaneously obtain high quality measurements of the binding characteristics of multiple analytes, and that are able to determine the amounts of those analytes in solution. The invention also provides a fully integrated bioarray for detecting real-time characteristics of affinity based assays.

Owner:CALIFORNIA INST OF TECH

Method for recovering vanadium and tungsten from tungsten containing vanadium-titanium based waste denitration catalyst

ActiveCN103436704ALow recovery rateReduce energy consumptionProcess efficiency improvementNonferrous metalAmmonium metavanadate

The invention relates to a method for recovering nonferrous metals from a waste denitration catalyst, and specifically relates to a method for recovering vanadium and tungsten from a tungsten containing vanadium-titanium based waste denitration catalyst. The method mainly comprises the following steps: crushing and grinding the catalyst, adding hydrogen peroxide to enable part of vanadium oxide to form pervanadic acid, and filtering to obtain a filter cake and a filtrate containing pervanadic acid; after heating the filtrate, filtering again to obtain V2O5, and mixing and circulating to use a novel filtrate and hydrogen peroxide; adding alkali liquor to the filter cake, stirring and heating, leaching the residual vanadium in form of metavanadate and leaching tungsten in form of metatungstate; filtering to obtain mixed liquor of metavanadate and metatungstate; adding ammonium salt into the mixed liquor to separate out ammonium metavanadate precipitate, further filtering to obtain an ammonium metavanadate filter cake and a third filtrate, and adding a concentrated acid into the third filtrate to separate out tungstic acid precipitate. The method and process provided by the invention are simple, and when metavanadate and tungstic acid are leached, calcination is avoided, so that the energy consumption is low, the solid-liquid reaction is good in contact, and the recovery rates of vanadium and tungsten are high.

Owner:BEIJING UNIV OF CHEM TECH

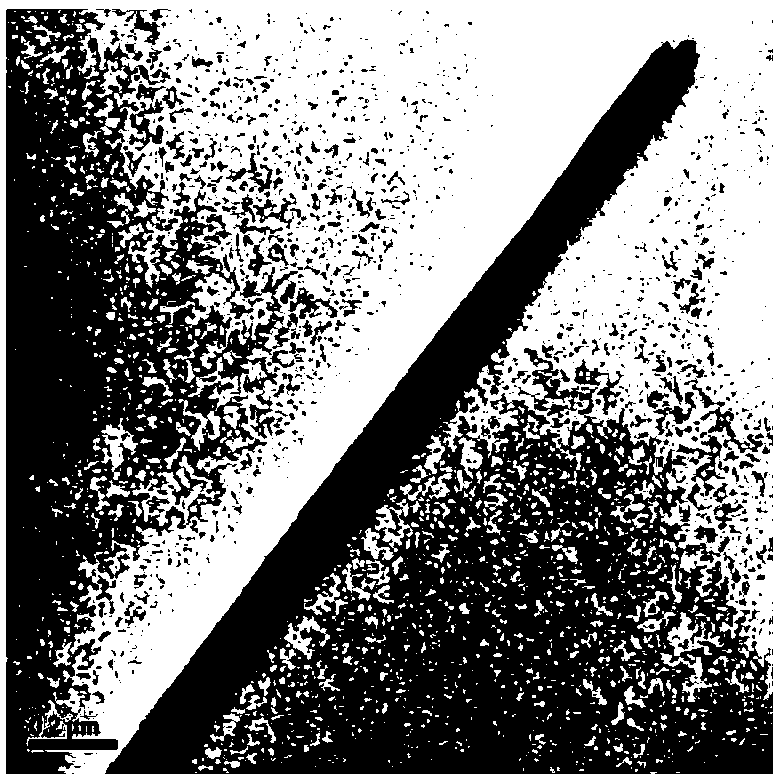

Method for synthesizing cobalt oxide/graphene composite wave-absorbing material

InactiveCN104263317AEasy to adjust dielectric constantImprove microwave absorption performanceOther chemical processesAlcoholSaline solutions

The invention discloses a method for synthesizing a cobalt oxide / graphene composite wave-absorbing material and relates to nanometer wave-absorbing materials. The method comprises the following steps: (1) dissolving a metal cobalt salt, ammonium fluoride and urea in water, thereby obtaining a metal saline solution; (2) adding the metal saline solution prepared in the step (1) into a hydrothermal kettle, and magnetically stirring to be uniform; (3) dispersing graphene solid powder into an absolute ethyl alcohol solution, thereby obtaining a graphene alcohol solution; (4) adding the graphene alcohol solution prepared by the step (3) into the metal saline solution prepared in the step (2), mixing, stirring, putting the hydrothermal kettle into a drying oven for reacting, thereby obtaining purple turbid liquid; and centrifuging, washing the obtained precipitate by using the ethanol solution, thereby obtaining a subcarbonate / graphene material; and (5) heating and drying the subcarbonate / graphene material obtained in the step (4), calcining, thereby obtaining the product cobalt oxide / graphene composite wave-absorbing material. The method is simple, high in operability, mild in preparation conditions, clean and pollution-free in reaction process, high in reaction efficiency and high in reproducibility.

Owner:XIAMEN UNIV

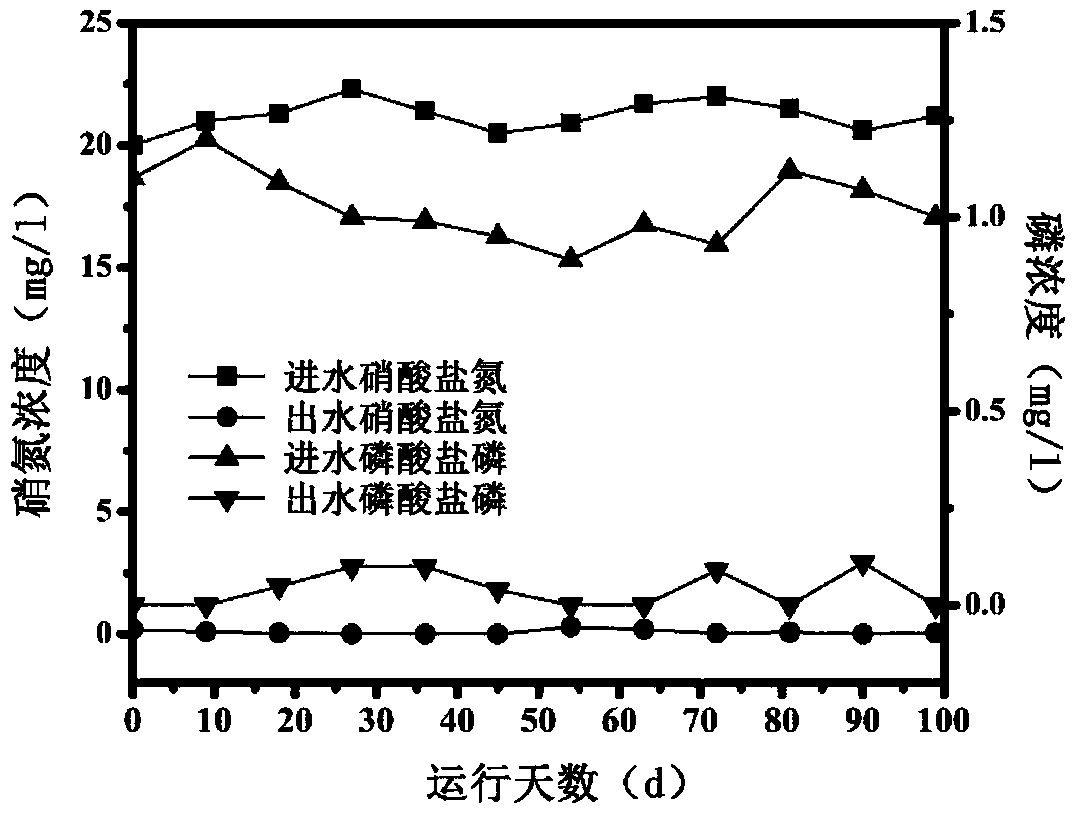

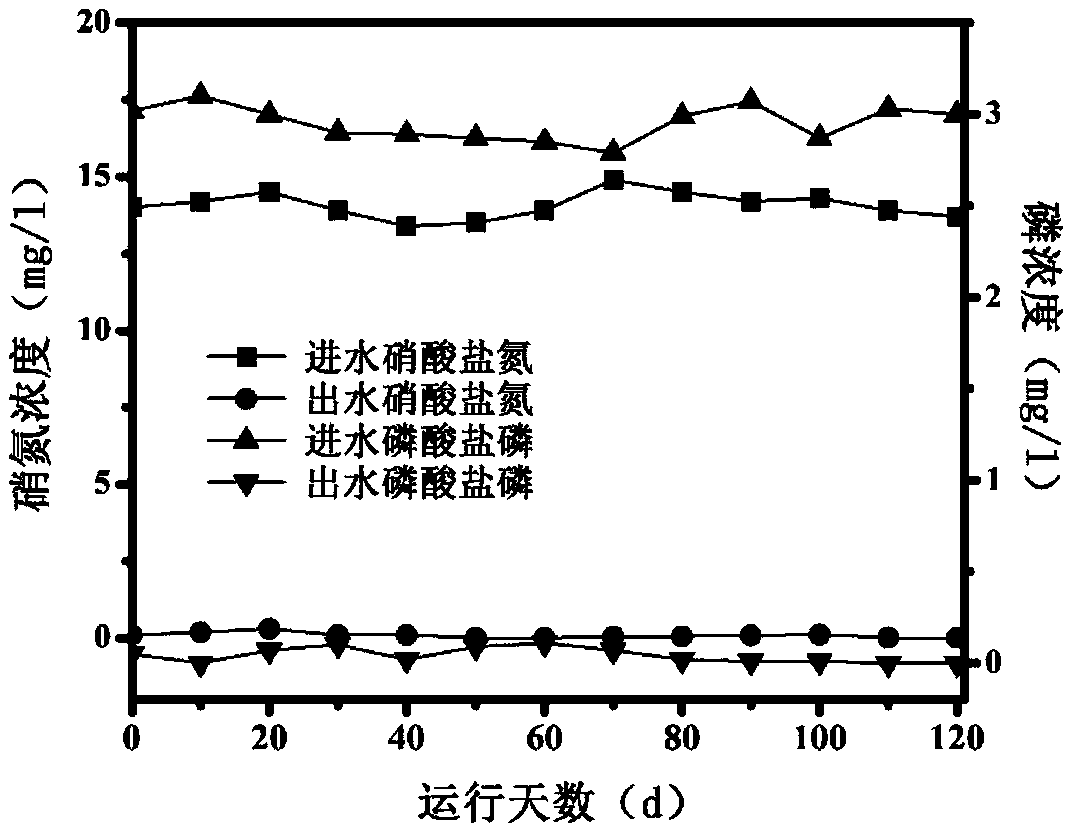

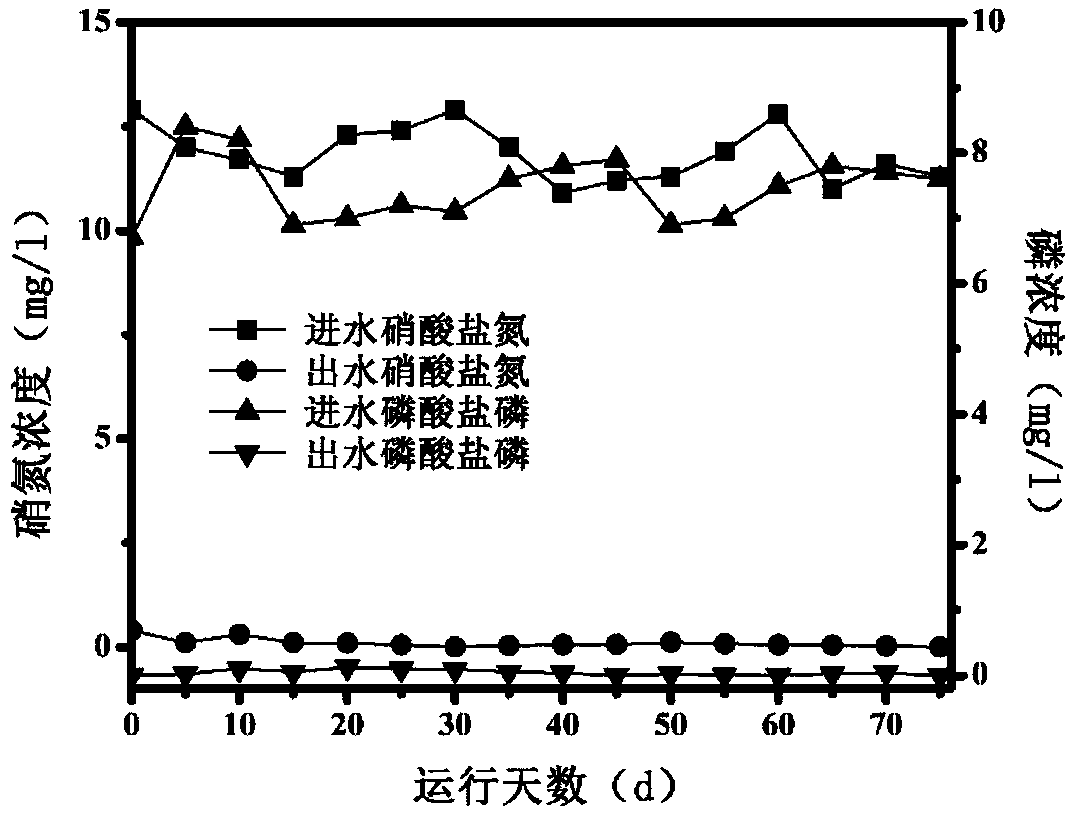

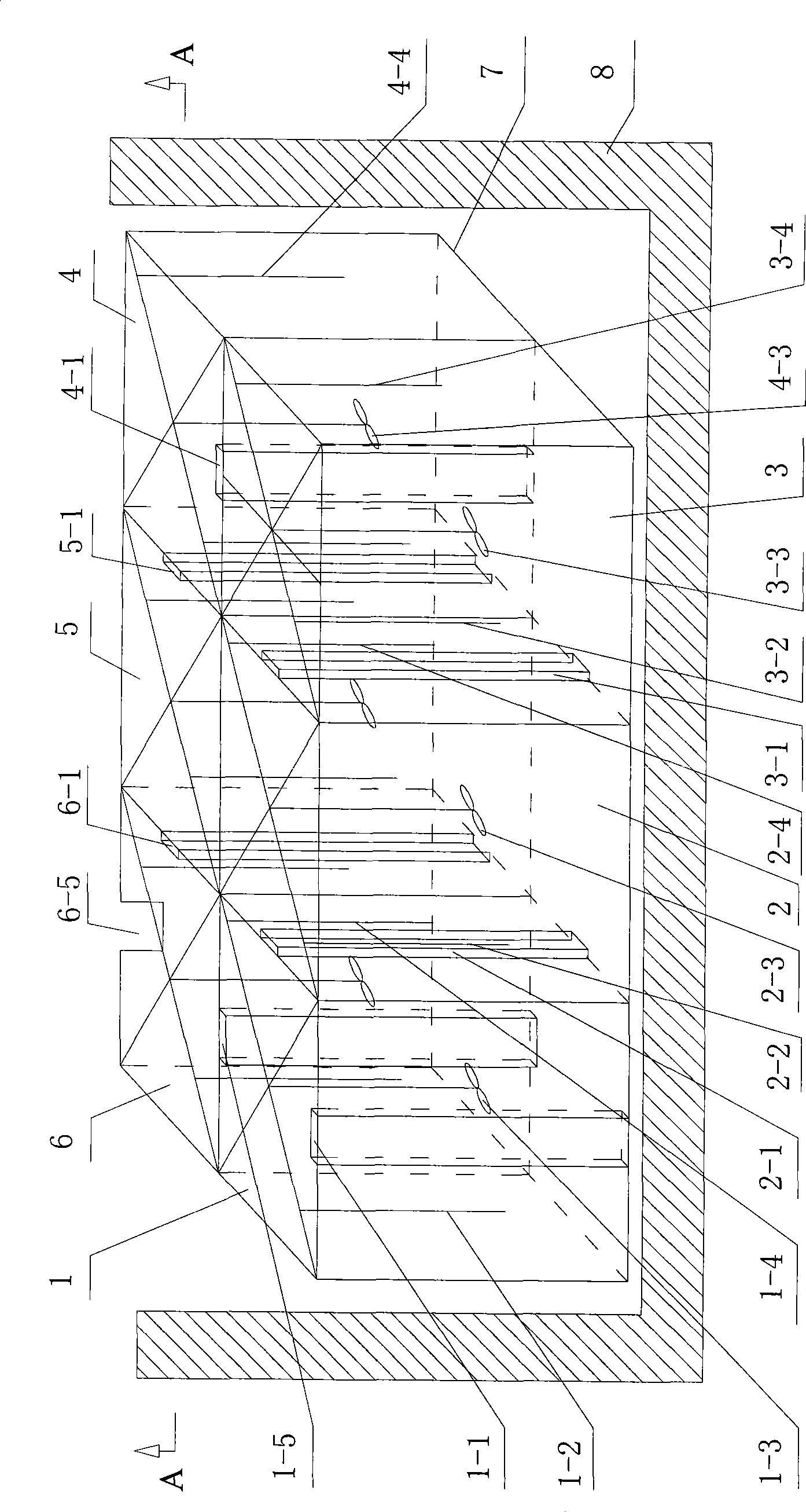

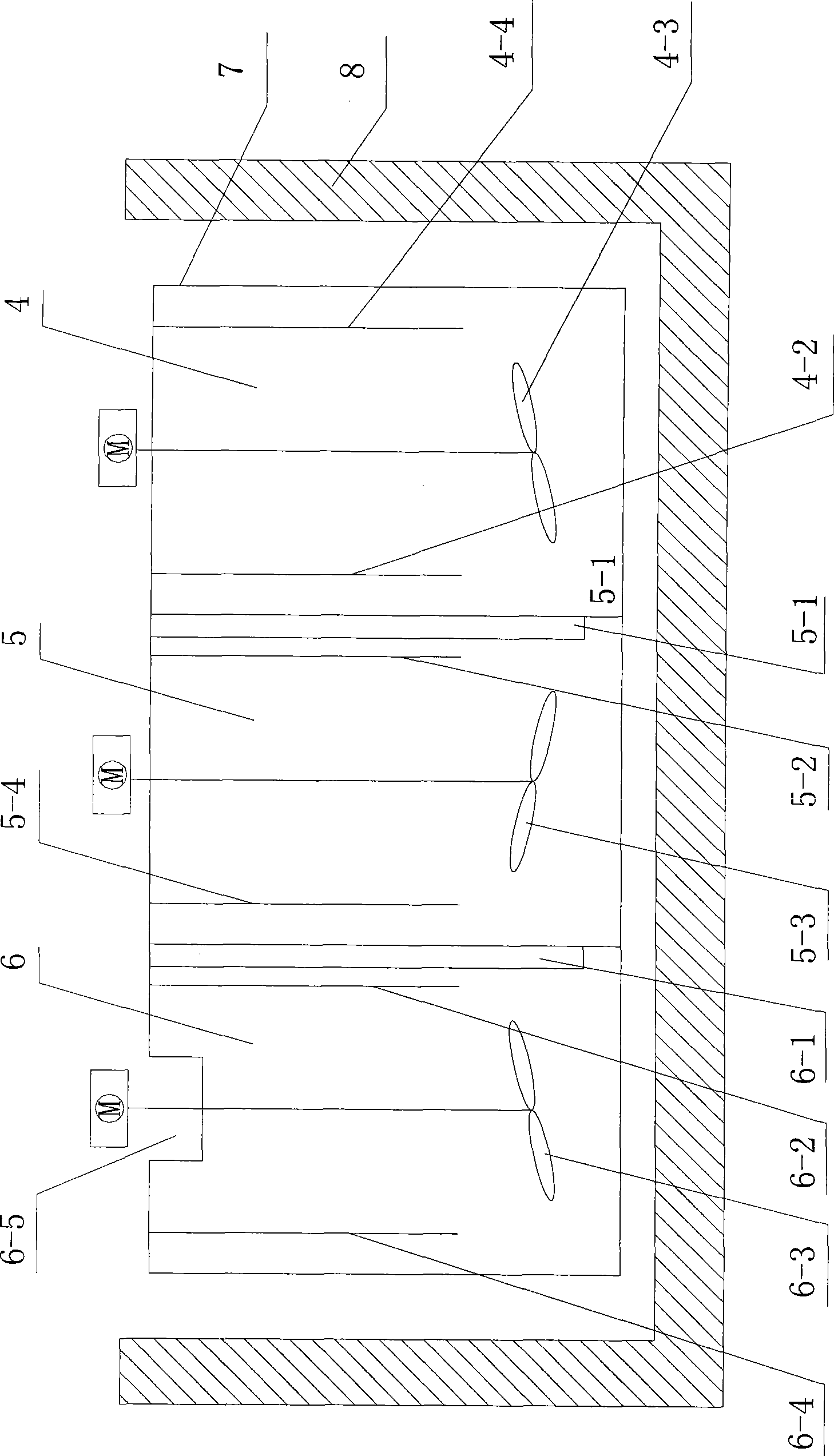

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

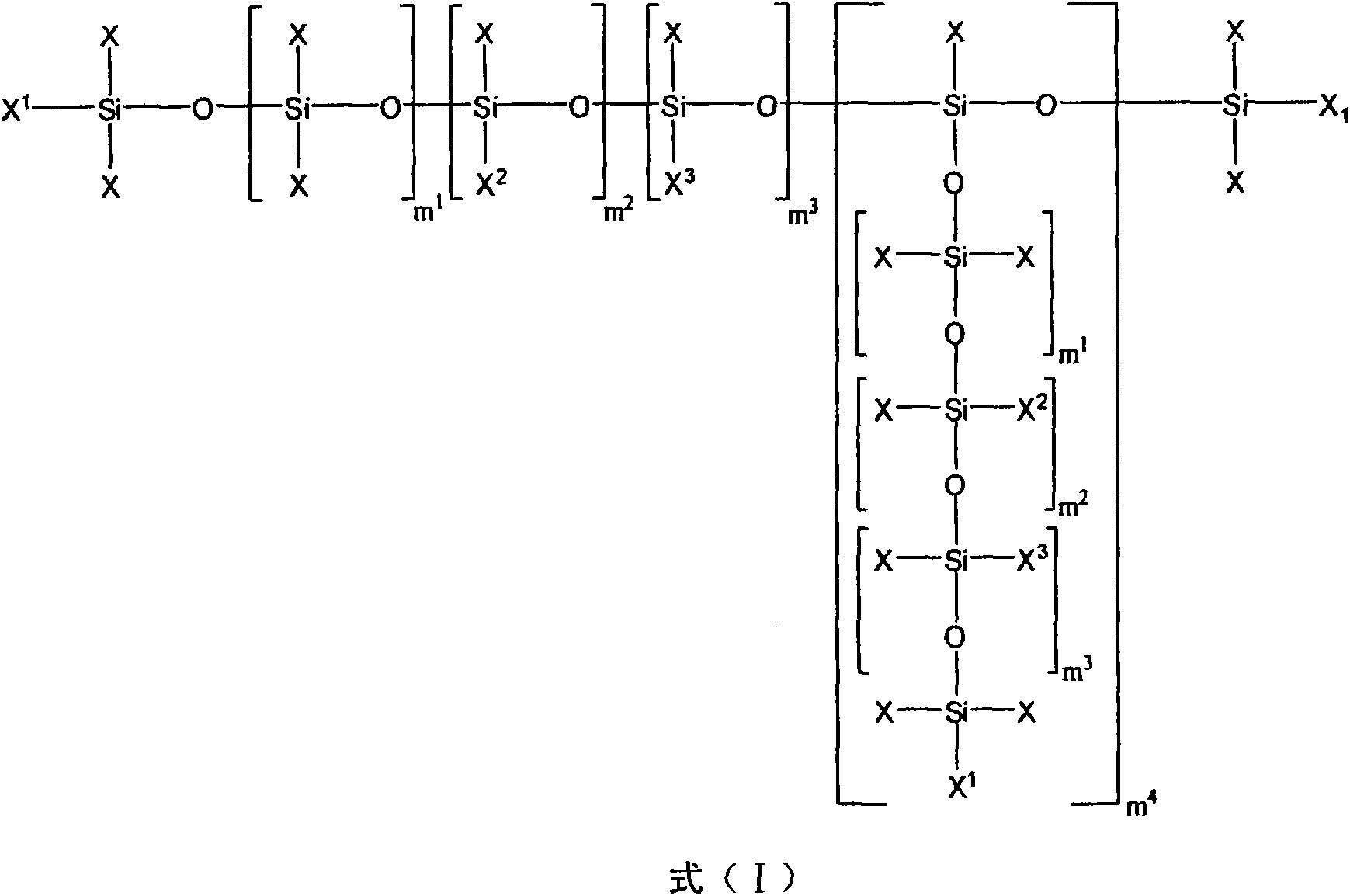

Silicone-polyether copolymer systems and process for preparing them by means of an alkoxylation reaction

ActiveCN101891894AHigh molecular weightImprove hydrophobicityTransportation and packagingMixingCyanideCopolymer

Process for the preferential alkoxylation of silicone-polyether copolymers either alone or in compositions thereof containing, for example, excess polyether by use of double metal cyanide catalysts.

Owner:EVONIK OPERATIONS GMBH

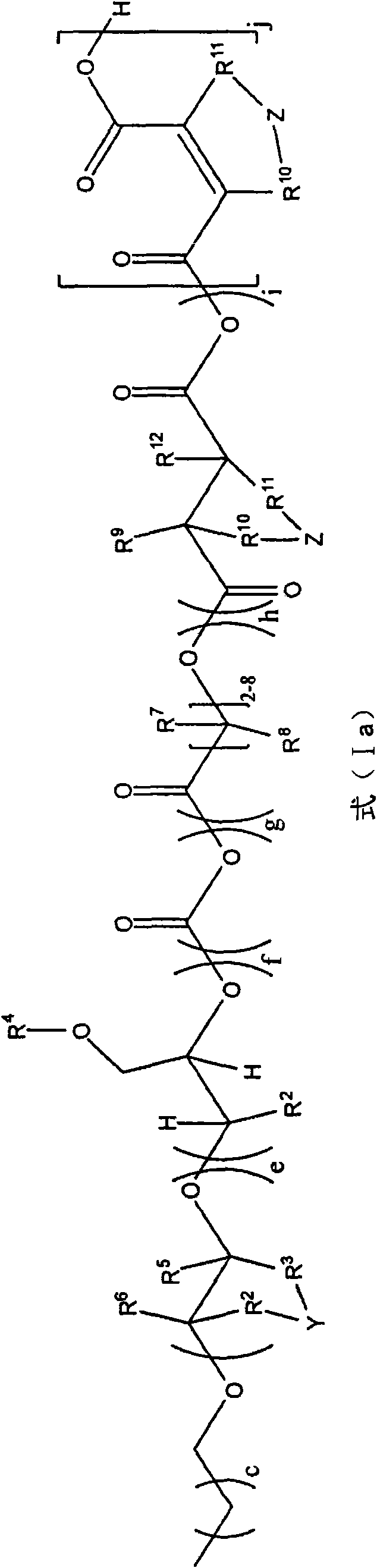

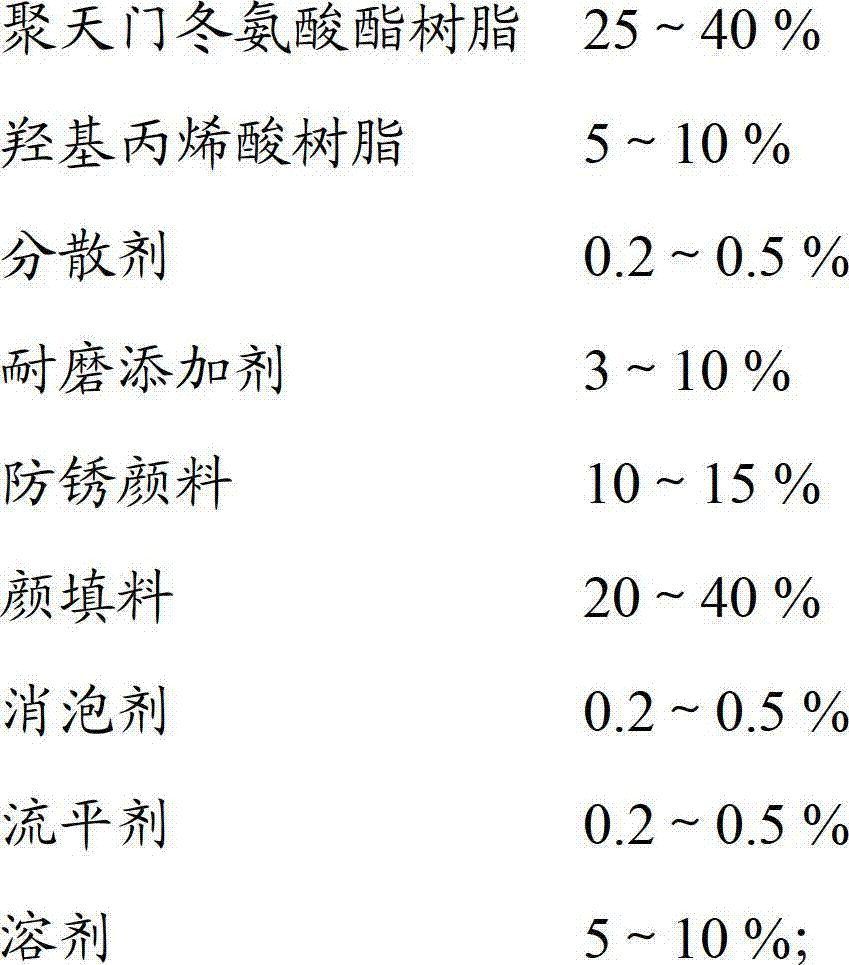

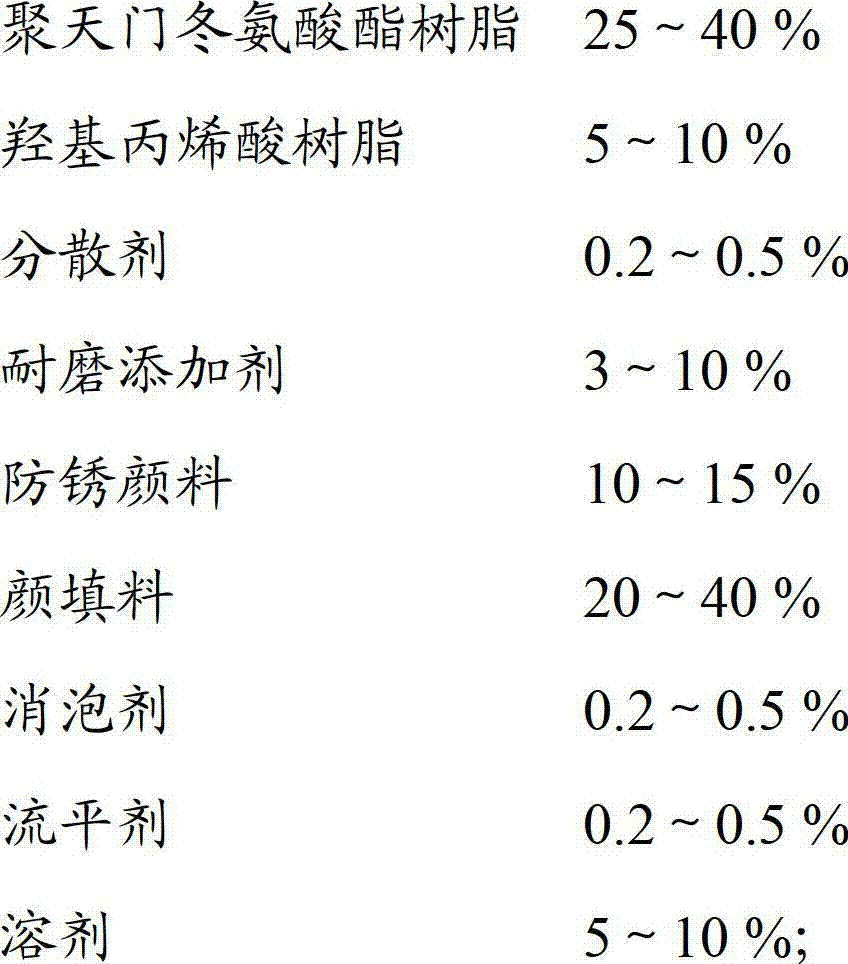

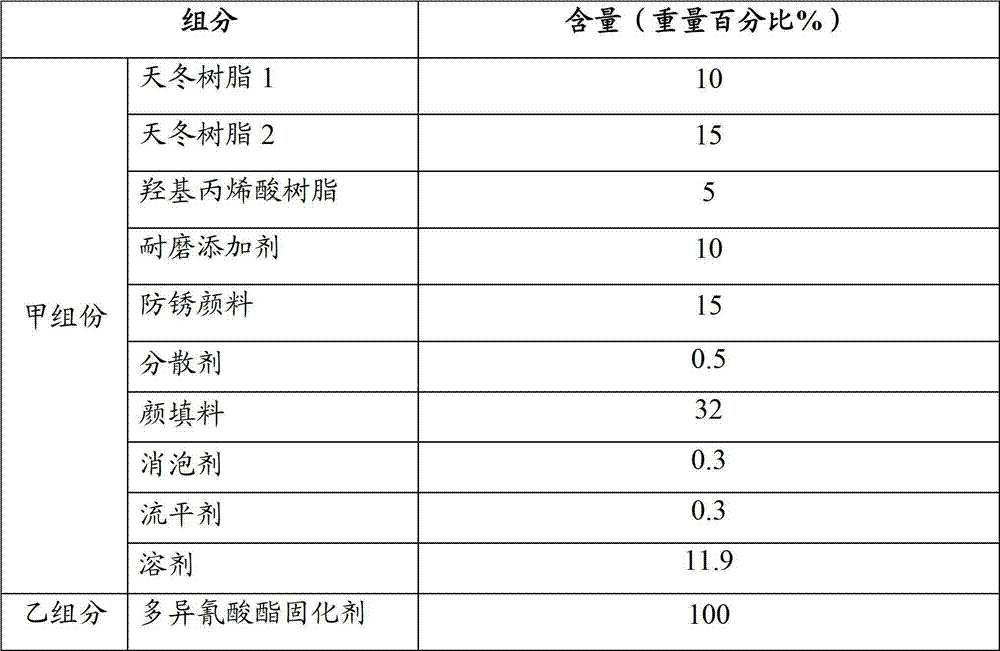

Terrace coating and preparation method thereof

ActiveCN102925041AControl and extend usage timeSlow reaction ratePolyurea/polyurethane coatingsWear resistantAcrylic resin

The invention discloses a terrace coating and a preparation method thereof. The terrace coating consists of a first component and a second component, wherein the first component comprises the following ingredients in percentage by weight: 25 to 40 percent of polyaspartic acid ester resin, 5 to 10 percent of hydroxy acrylic resin, 0.2 to 0.5 percent of dispersing agent, 3 to 10 percent of anti-wear additive, 10 to 15 percent of rustproofing pigment, 20 to 40 percent of pigment and filler, 0.2 to 0.5 percent of antifoaming agent, 0.2 to 0.5 percent of leveling agent and 5 to 10 percent of solvent. The preparation method comprises the steps of weighing the components according to a formula, preparing the first component and packaging. According to the terrace coating disclosed by the invention, slurry has long gelation time; a film layer has a good mechanical performance; and the terrace coating is wear-resistant, weather-resistant, anti-corrosive and waterproof.

Owner:中华制漆(新丰)有限公司

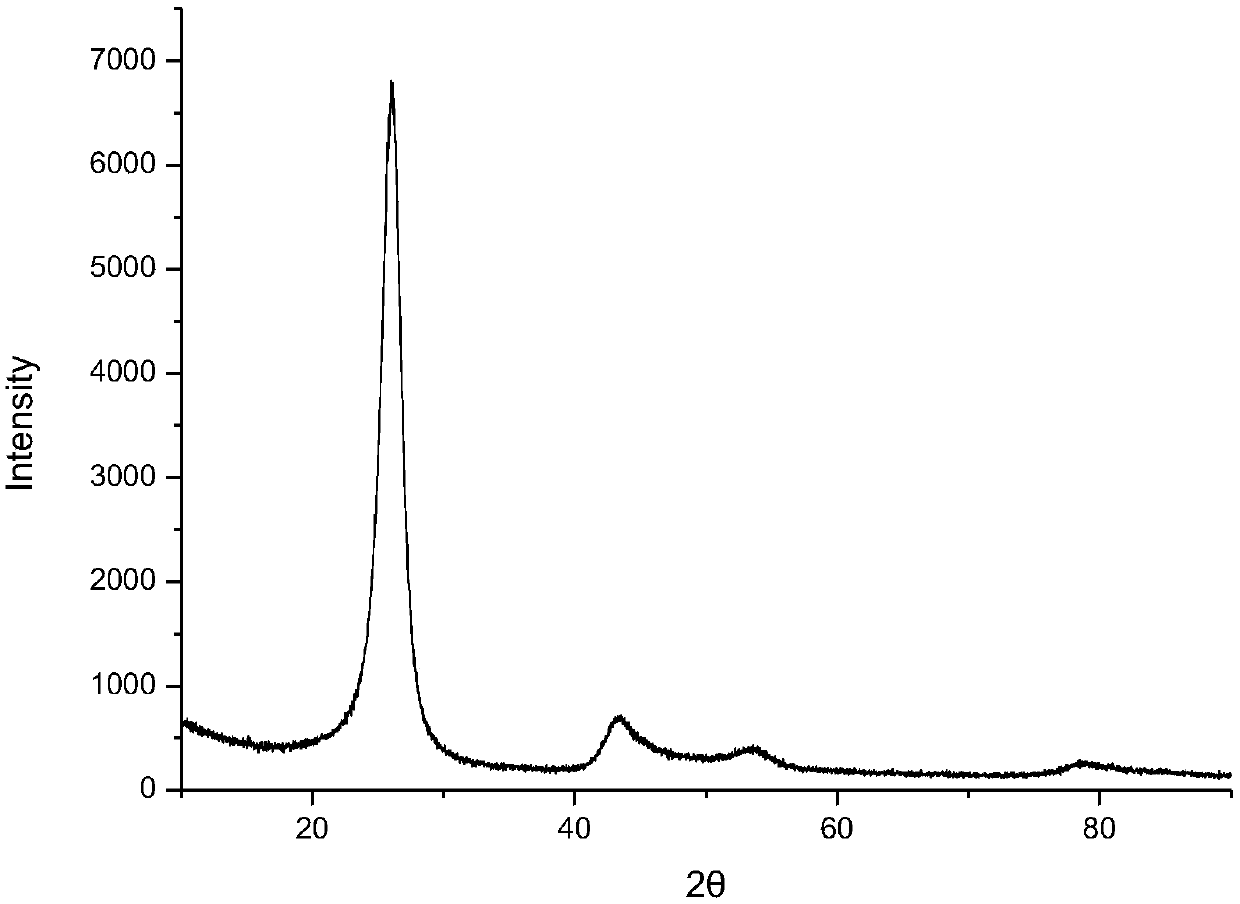

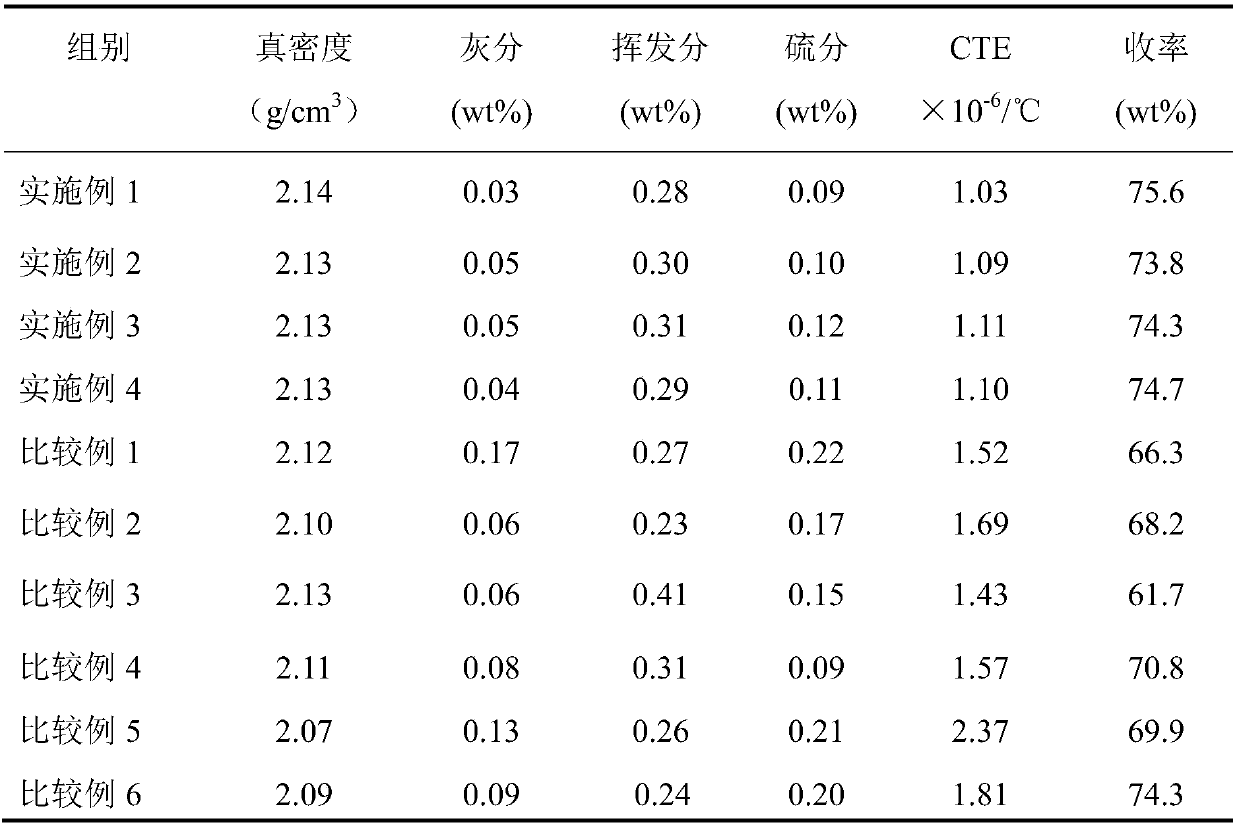

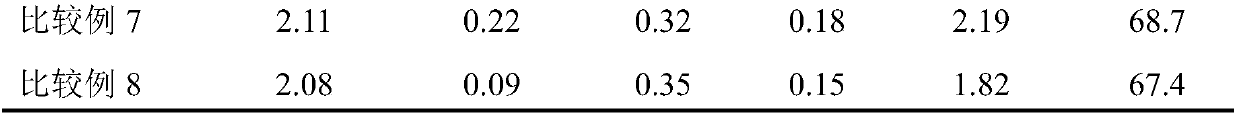

Technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as raw material

ActiveCN107694552AGood qualityHigh yieldWorking-up pitch/asphalt/bitumen by selective extractionPhysical/chemical process catalystsPre treatmentWide area

The invention relates to a technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as a raw material. The technology mainly comprises the following steps: carrying out decompression and distillation, and extraction and removal on middle-temperature and low-temperature coal tar; combining hydrogenation treatment, thermal polymerization andcalcining technologies under the action of a non-metal homogeneous mild-hydrogenation catalyst to prepare the coal-series needle coke with good performance and relatively high yield. The non-metal homogeneous mild-hydrogenation catalyst is mainly prepared from the following raw materials in percentage by mass: 55 weight percent to 79 weight percent of semi-coke, 20 weight percent to 40 weight percent of coke and 1 weight percent to 5 weight percent of graphene. According to the technology provided by the invention, after the raw material is subjected to combined pre-treatment, a refined asphalt raw material is reasonable in constitution and has a few of impurities; the catalyst has excellent modification performance and does not need to be separated subsequently; the graphene component also can be used for promoting a middle phase in a thermal polymerization process to form a wide-area and ordered fibrous structure and a high-performance needle coke product is easy to form.

Owner:NORTHWEST UNIV +1

Multiplex Q-PCR arrays

ActiveUS8048626B2TimeSlow reaction rateSugar derivativesMicrobiological testing/measurementNucleic Acid ProbesNucleic acid sequencing

This invention provides methods and systems for measuring the concentration of multiple nucleic acid sequences in a sample. The nucleic acid sequences in the sample are simultaneously amplified, for example, using polymerase chain reaction (PCR) in the presence of an array of nucleic acid probes. The amount of amplicon corresponding to the multiple nucleic acid sequences can be measured in real-time during or after each cycle using a real-time microarray. The measured amount of amplicon produced can be used to determine the original amount of the nucleic acid sequences in the sample.

Owner:CALIFORNIA INST OF TECH

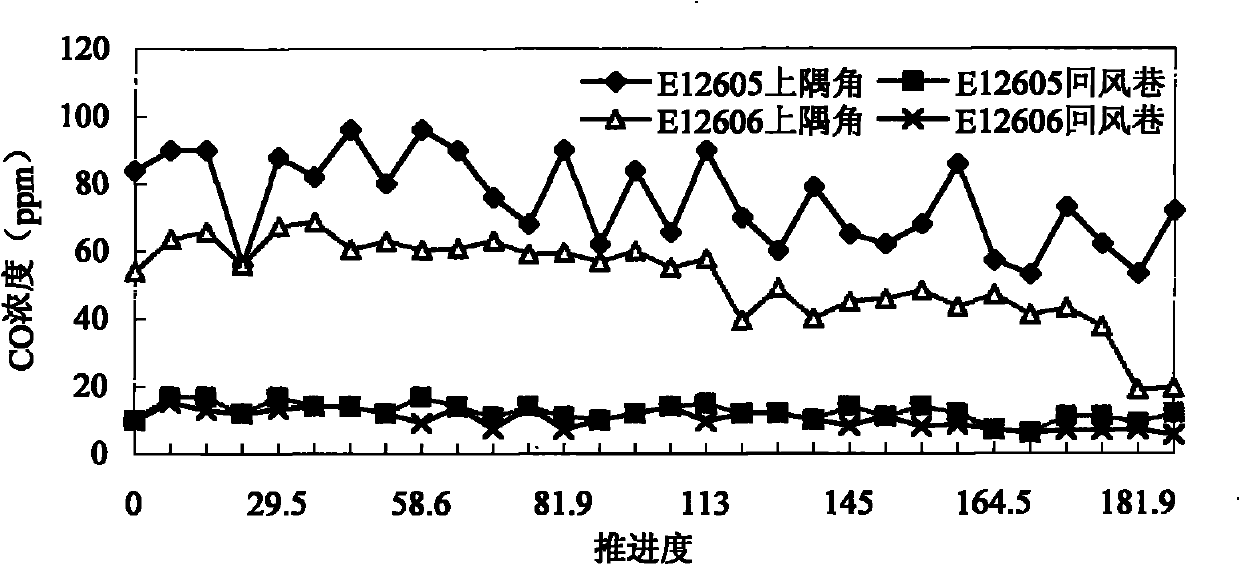

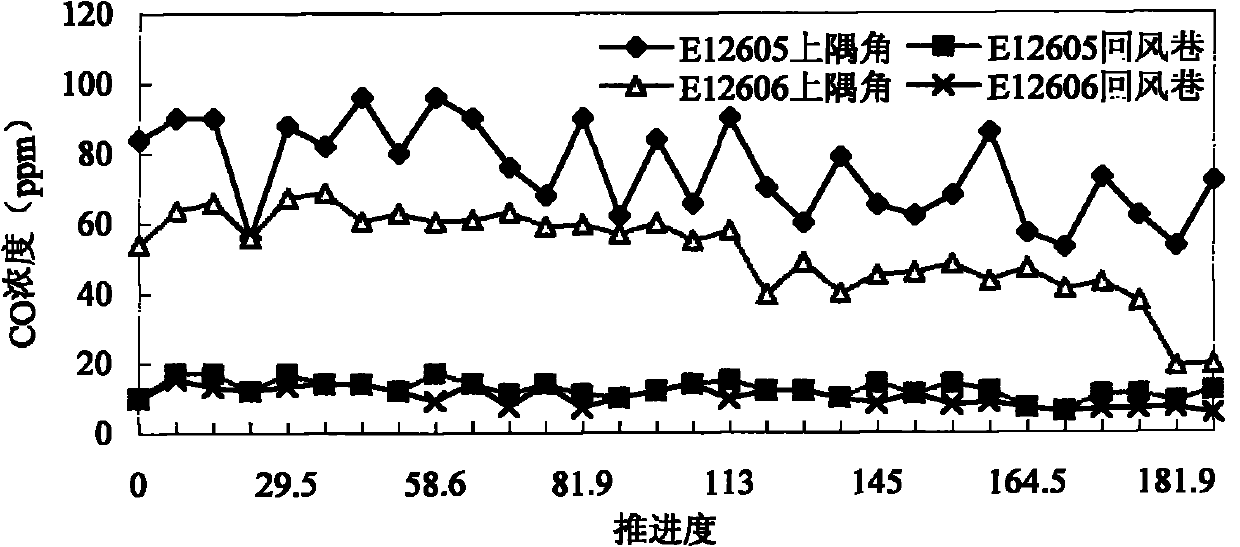

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

Liquid crystal panel copper-molybdenum membrane etching liquid

The invention relates to a liquid crystal panel copper-molybdenum membrane etching liquid. According to the total weight, the copper-molybdenum membrane etching liquid comprises the following components in percentage by weight: 1-20 percent of hydrogen peroxide, 0.01-8 percent of a hydrogen peroxide stabilizer, a pH regulator prepared by mixing 1-8 percent of ammonia water and 1-7 percent of organic phosphinate, 0.1-12 percent of a chelating agent, 0.1-5 percent of a metal corrosion inhibitor and the balance of water. According to the copper-molybdenum membrane etching liquid, the problem of stability decomposition of hydrogen peroxide caused by factors such as PH value, heat and metal ions in the working process of the etching liquid is solved, and the hydrogen peroxide can have favorable stability under the conditions of temperature increase, metal ion content increase and the like, so that the realization of uniform etching is facilitated; during etching, the reaction rate of molybdenum metal is reduced, molybdenum and copper are etched at the same rate, and finally CD LOSS and a slope angle, which meet the process requirements of a customer, can be presented; and the copper-molybdenum membrane etching liquid contains no fluoride ions and is environment-friendly.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

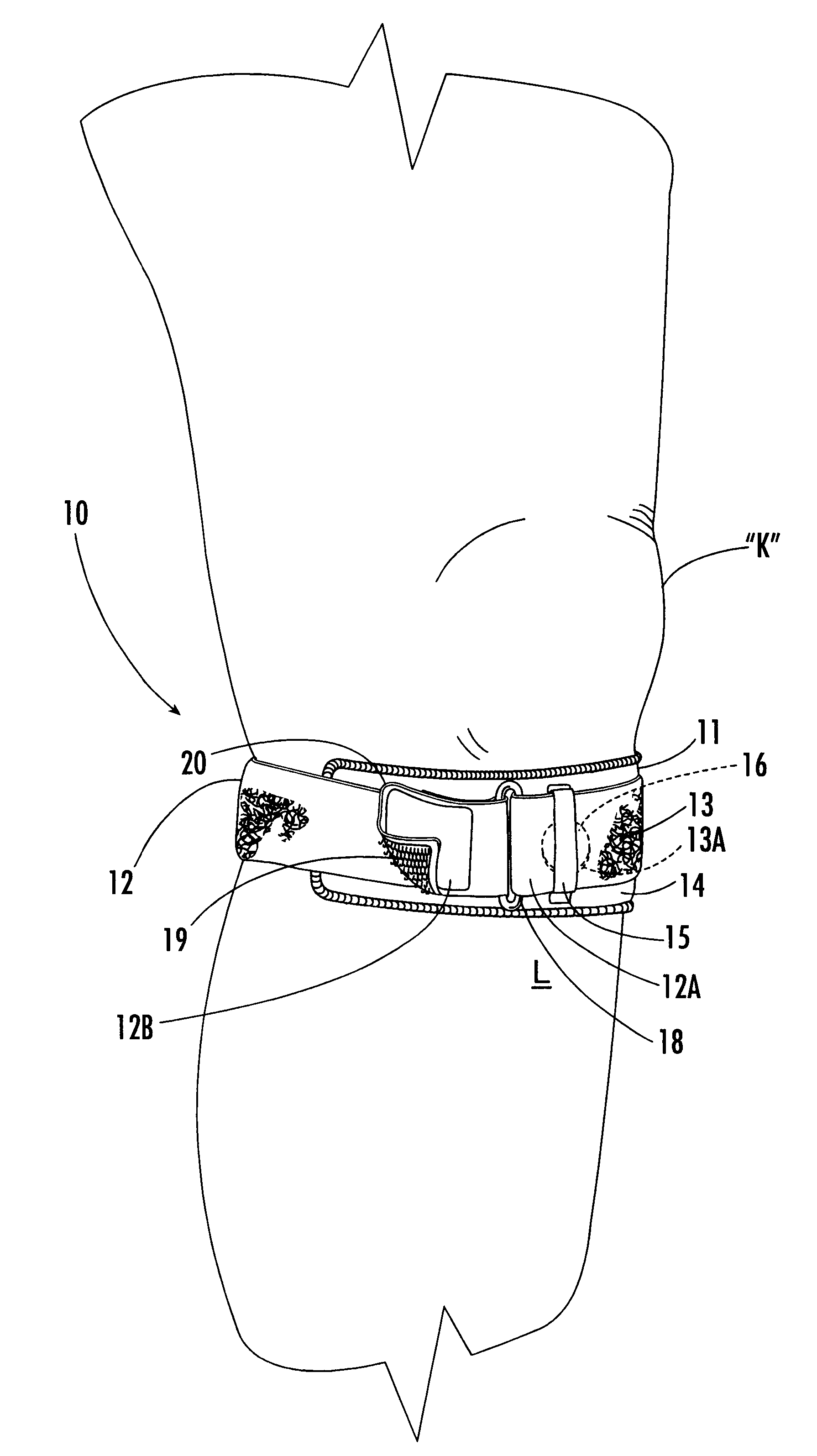

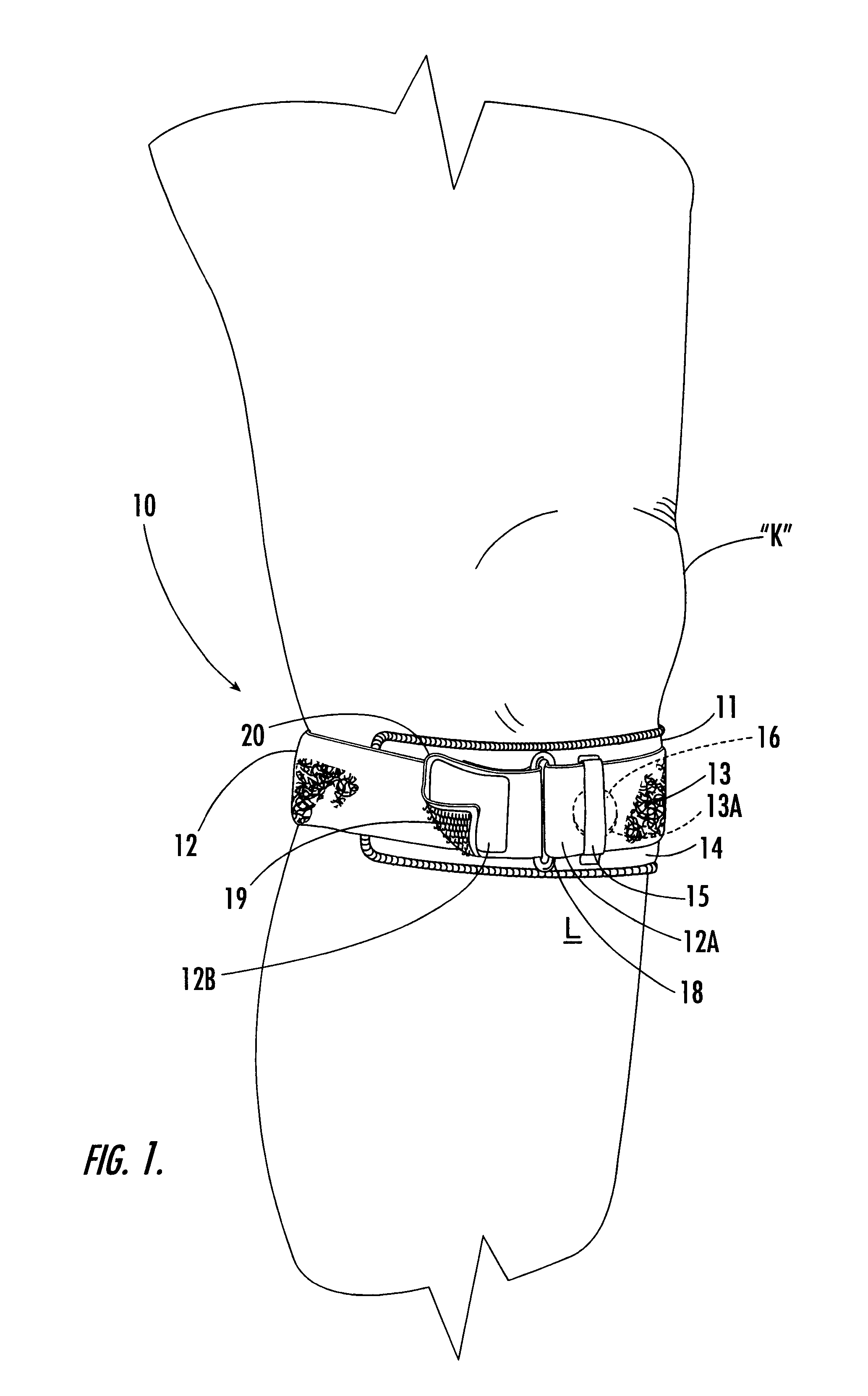

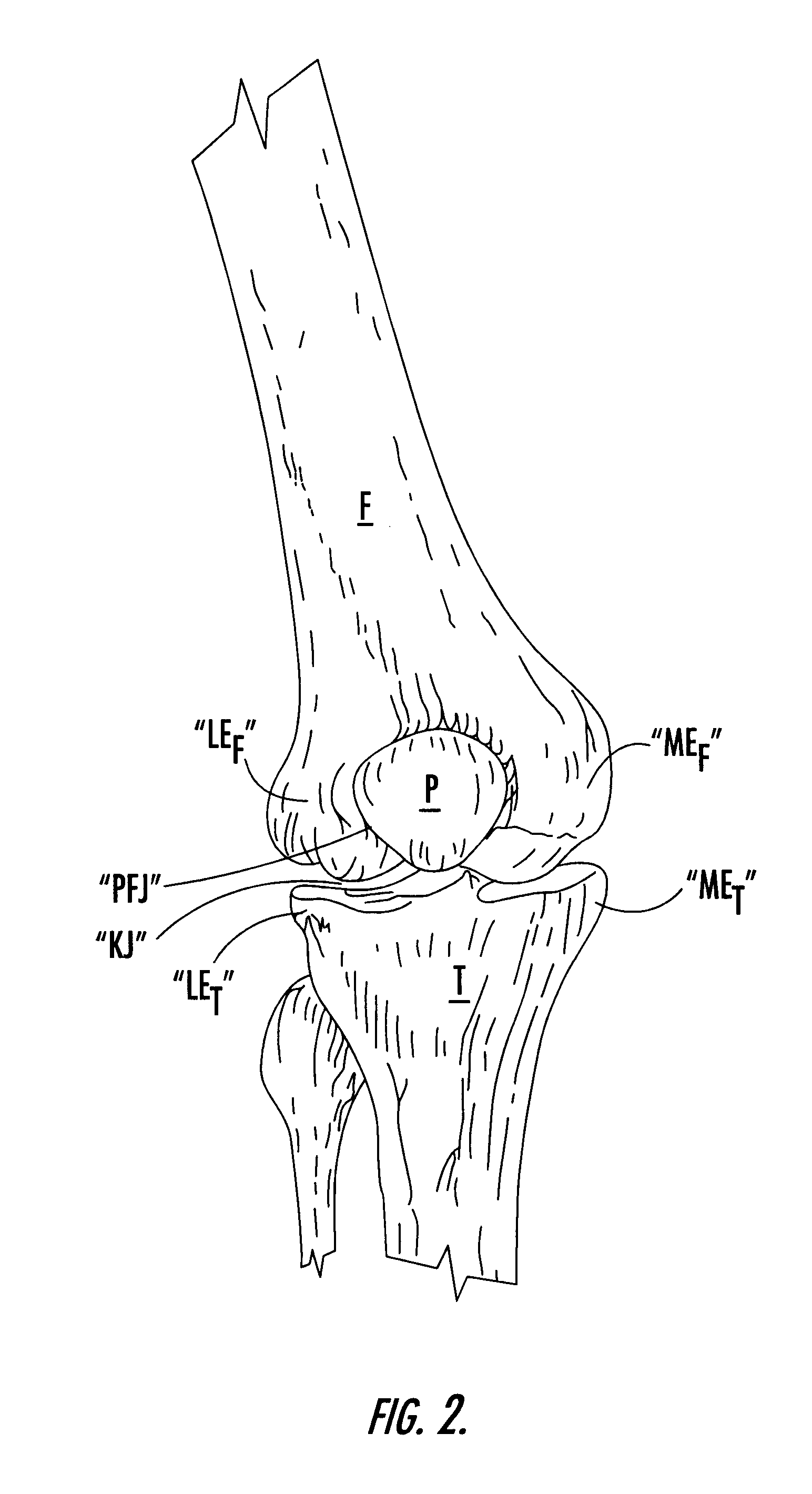

Custom-moldable support for patellar tendinitis

InactiveUS6641549B2Easy to makeSlow reaction rateFeet bandagesNon-surgical orthopedic devicesPhysical medicine and rehabilitationPatellar tendinitis

A knee pad assembly for relieving the symptoms of patellar tendinitis, including a pad adapted for being positioned against and molded onto a lower leg in the region of the knee for lying in closely-conforming relation against and applying radially-directed pressure to the attachment site of the patellar tendon to the patella, to the knee joint, and to at least one epicondyle of the tibia. The pad is hardened into a rigid structure for therapeutic use and includes an initially flexible inner substrate impregnated or coated with a reactive system. The system remains stable when maintained in substantially moisture-free conditions and hardens upon exposure to moisture to form a rigid, self-supporting structure having a shape conforming to the lower leg to which the pad is molded during curing. A flexible cover encloses the substrate, and cooperates with the pad for maintaining the pad in its closely-conforming position against the lower leg.

Owner:BSN MEDICAL INC

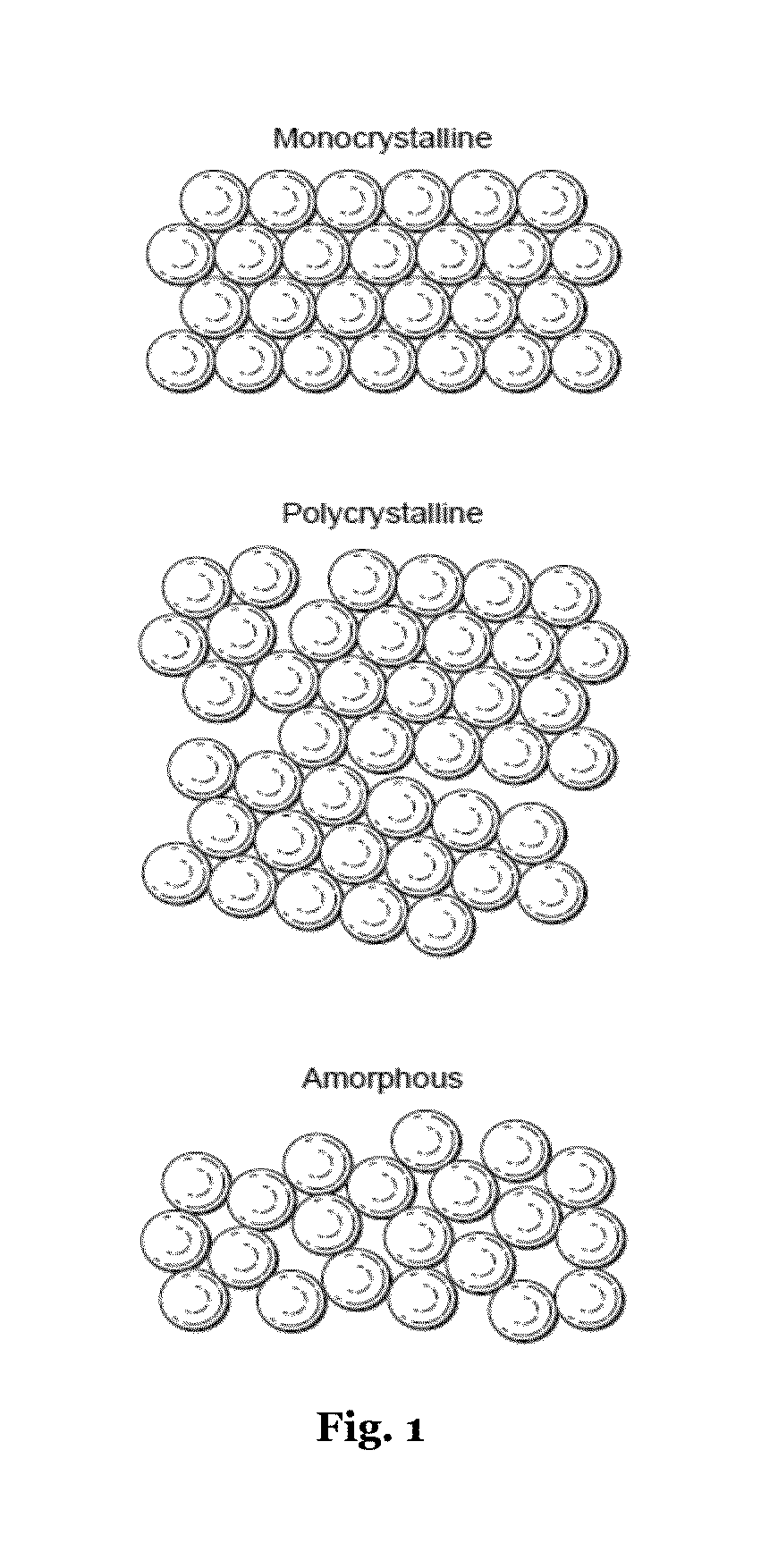

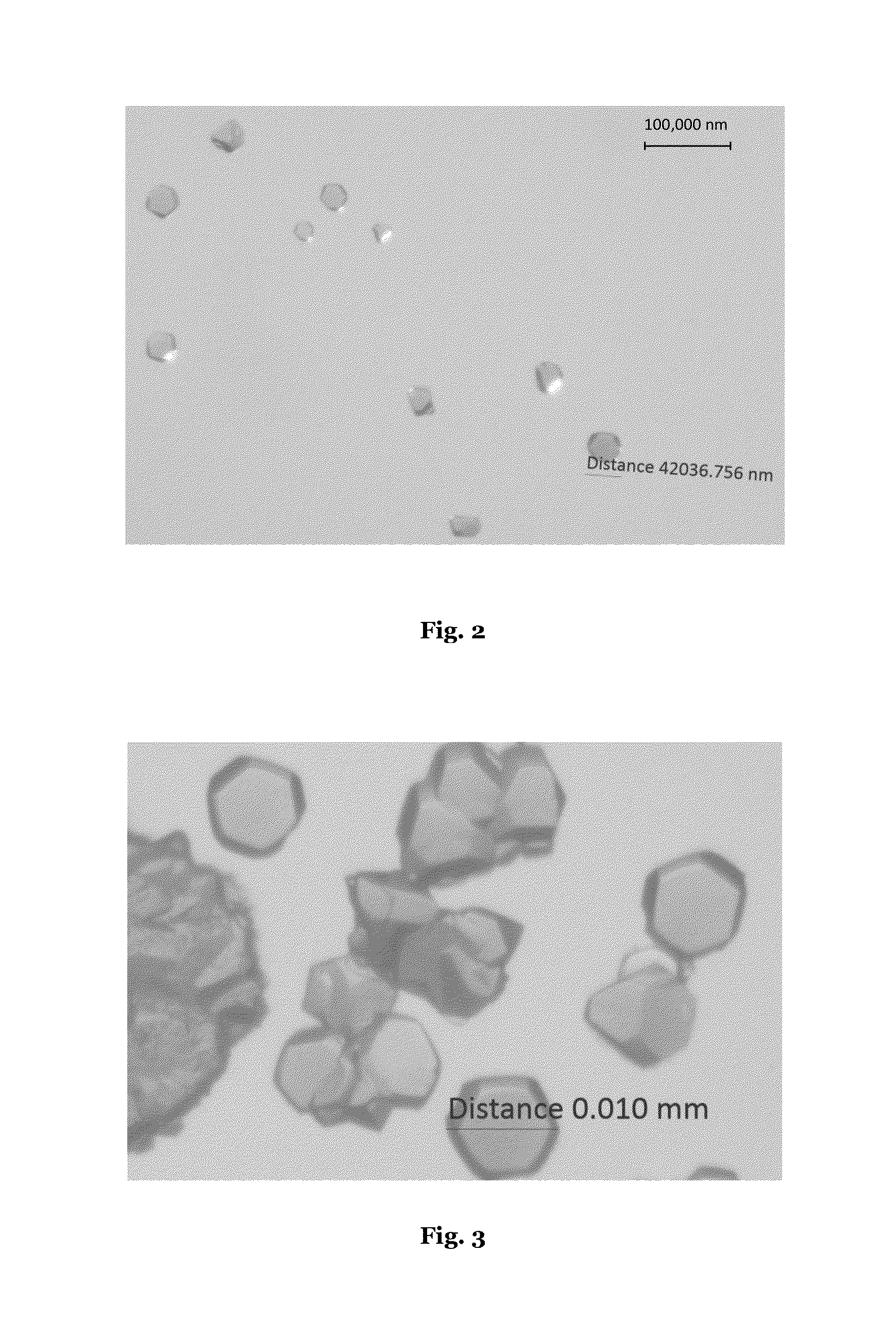

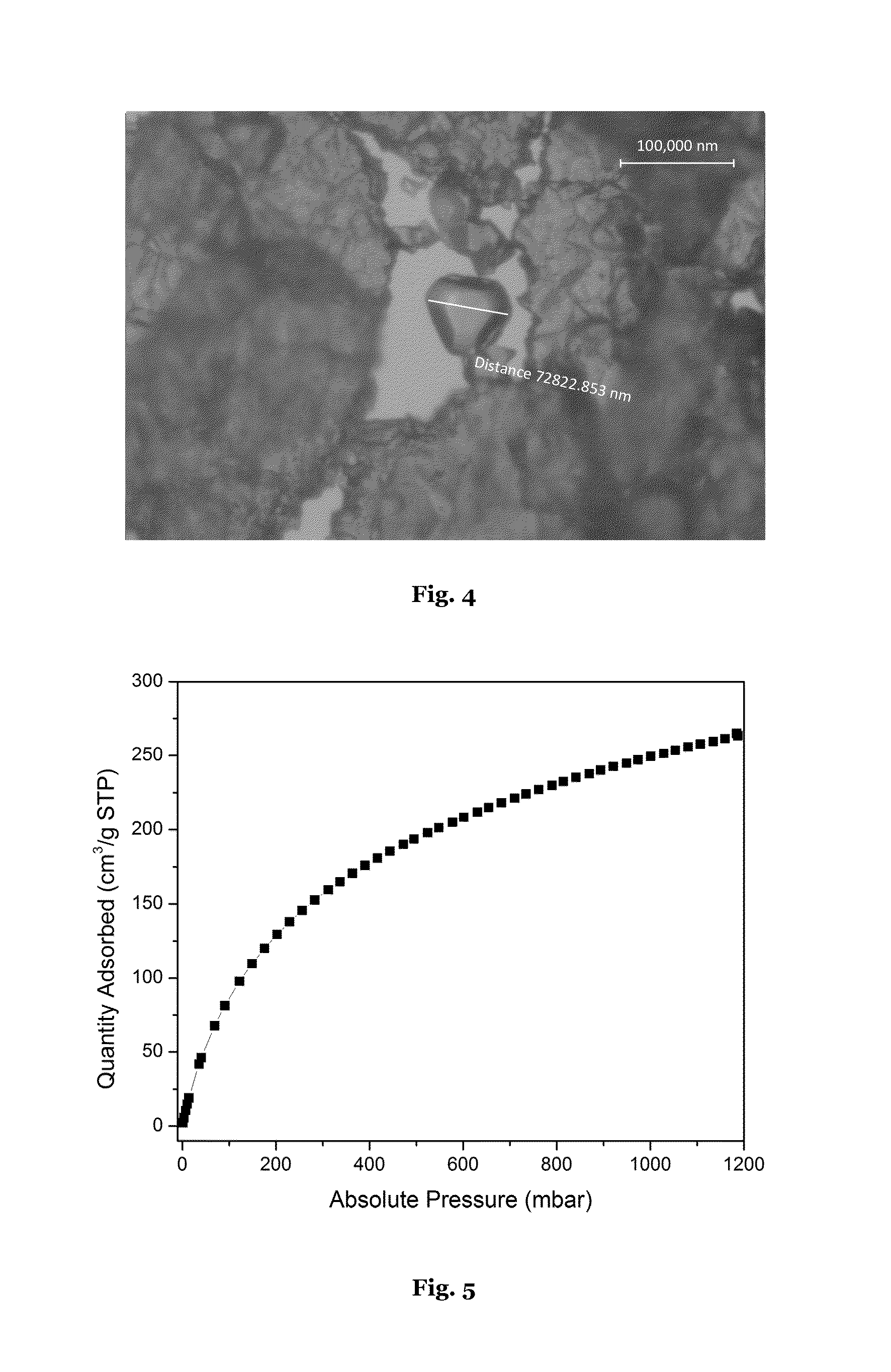

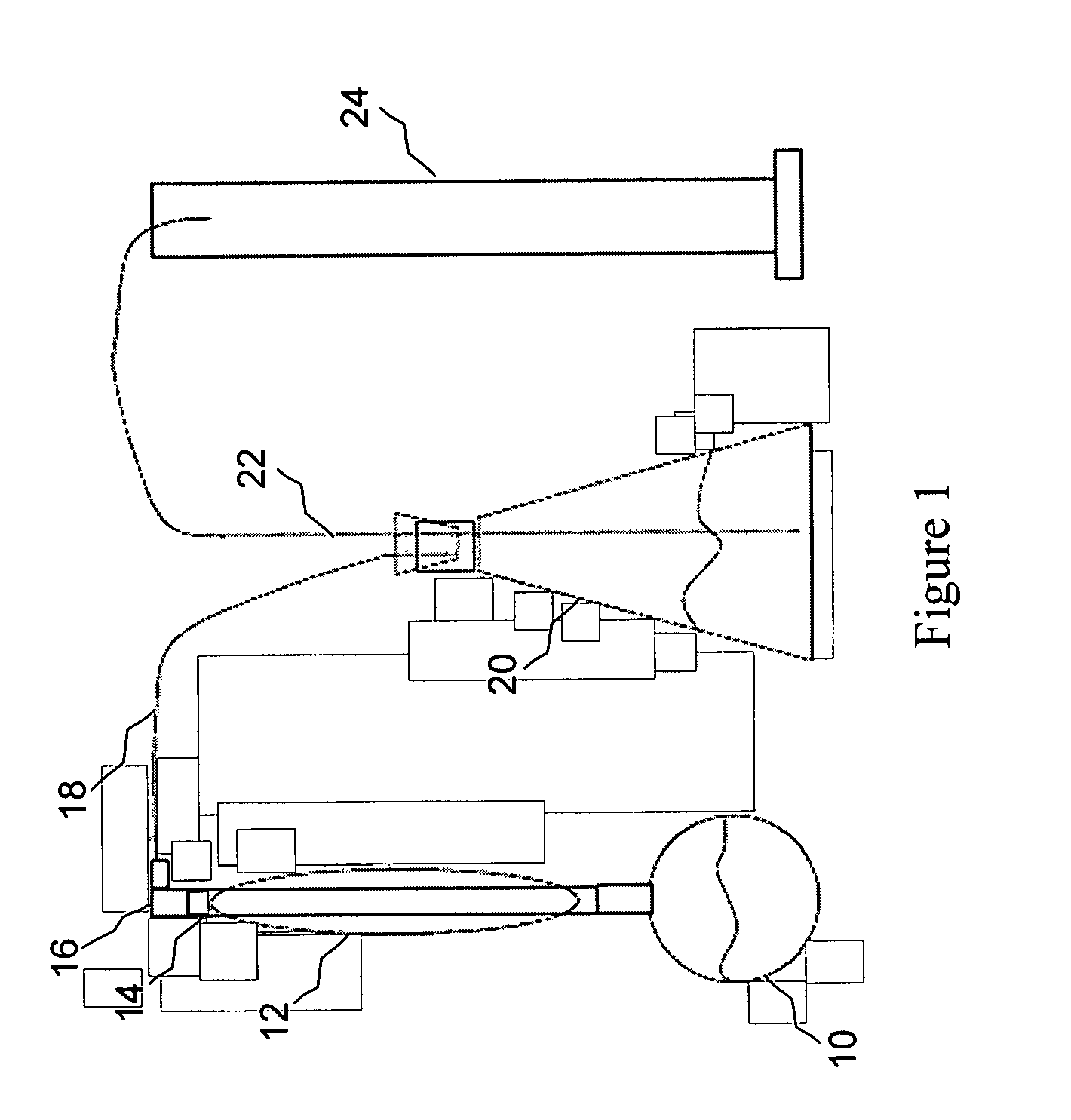

Aluminum metal organic framework materials

ActiveUS9102691B2Small sizeSlow reaction rateCarbon compoundsNickel organic compoundsPhysical chemistryMetal-organic framework

The invention relates to monocrystalline single crystals of metal-organic framework materials comprising at least one aluminum metal ion, processes for preparing the same, methods for employing the same, and the use thereof. The invention also relates to monocrystalline aluminum metal-organic frameworks.

Owner:TEXAS A&M UNIVERSITY

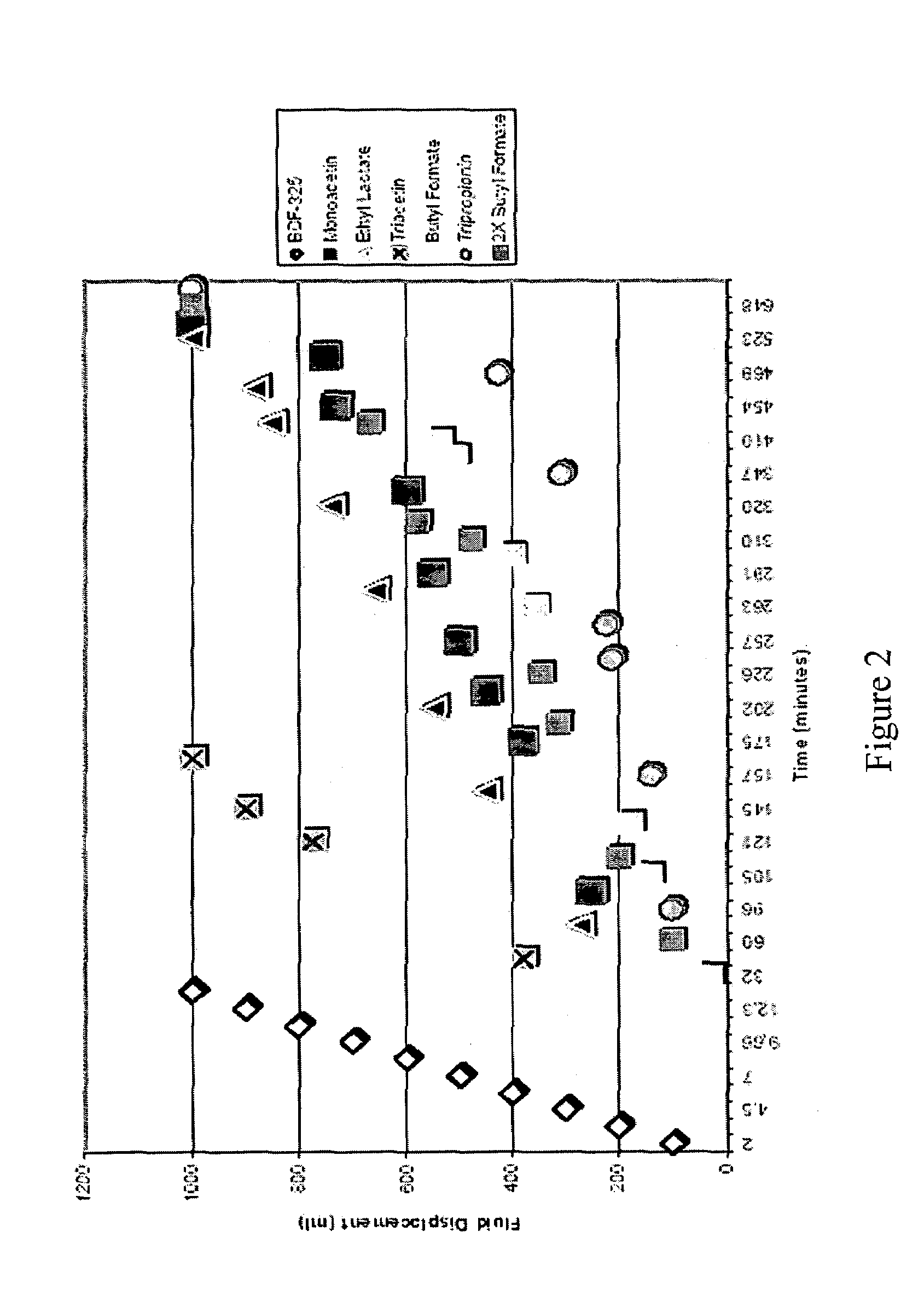

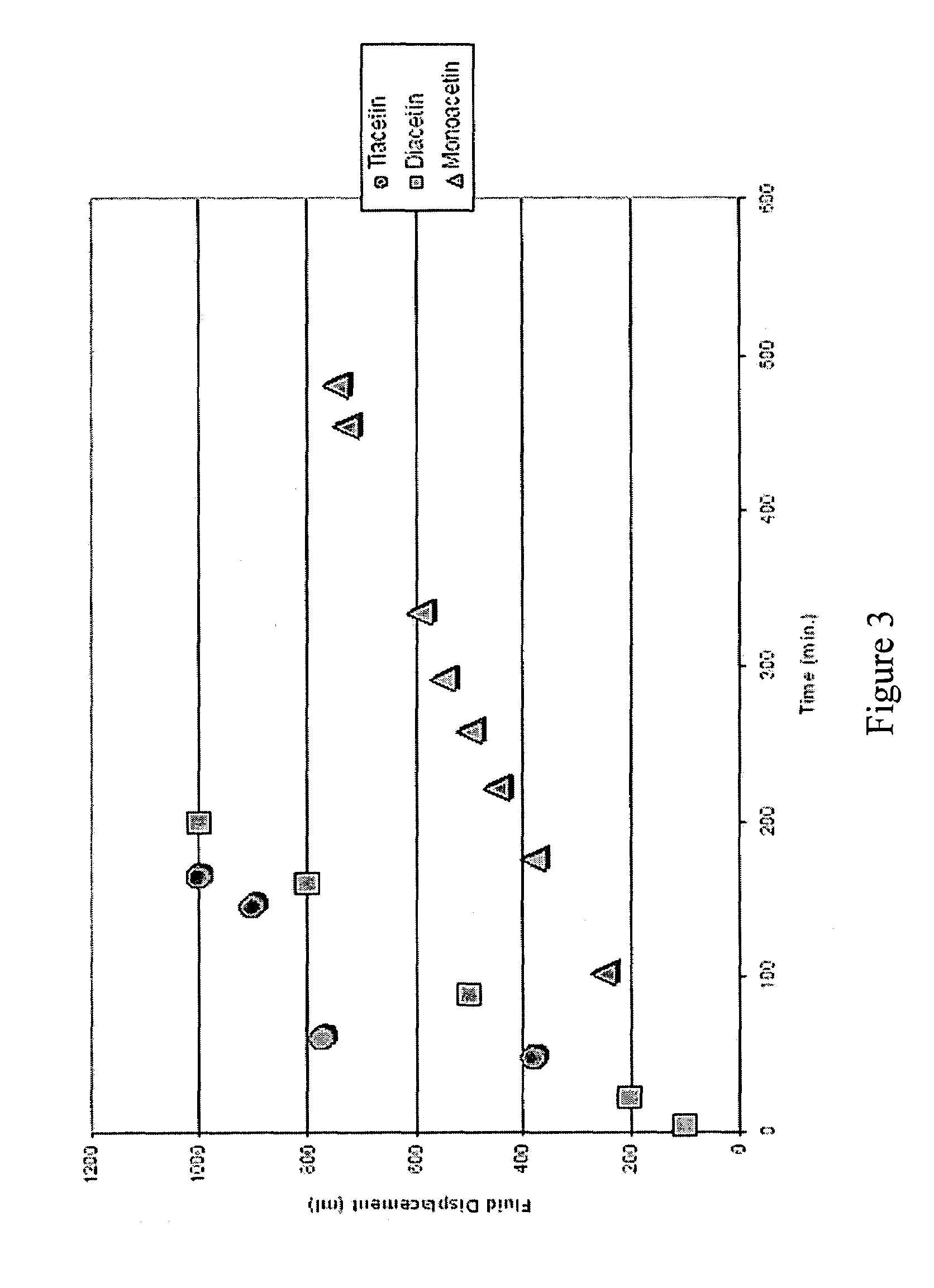

Methods of controlled acidization in a wellbore

ActiveUS7431088B2Avoid lostImprove acidificationCleaning apparatusFluid removalPolyesterEthylene glycol diformate

An improved acidization method is provided in which an aqueous solution comprising one or more esters or polyesters of lactic acid or of glycerol is placed in a well where the esters or polyesters undergo hydrolysis. The hydrolysis of the esters or polyesters occurs at a slower reaction rate than that of several other known acidization esters, such as diethyleneglycol diformate, at temperatures higher than 60° C. or even higher than 100° C. Thus, the solution may be distributed substantially throughout a region in the well where acidization is required before hydrolysis is completed, despite being exposed to relatively high temperatures.

Owner:HALLIBURTON ENERGY SERVICES INC

Process and device for continuous ultrasound desulfurization of scrapped lead paste

InactiveCN101518711AReduce the number of settingsSmall footprintDispersed particle separationIonSodium carbonate

The invention relates to a process and a device for continuous ultrasound desulfurization of scrapped lead paste. The process for continuous ultrasound desulfurization of scrapped lead paste comprises the following steps: (1) sodium carbonate or ammonium carbonate is selected as desulfurizing agent, and the desulfurizing agent and the scrapped lead paste are taken according to the mole ratio (1.2 to 2.2:1) of the Na iron or the (NH4)2 iron in the desulfurizing agent to the S iron in the scrapped lead paste; (2) the scrapped lead paste, the desulfurizing agent and water are prepared into flowing pulp with solid-liquid (S / L) weight ratio being equal to 3 / 5 to 4 / 5 in a pulping tank; (3) under the condition of ultrasonic wave, the flowing pulp enters a first reaction chamber for heating and stirring from the lower end part in the first reaction chamber, is discharged out from an overflow opening at the upper end of the first reaction chamber, then enters a second reaction chamber for heating and stirring from the lower end part of the second reaction chamber and finally, and is discharged out from a discharging opening at the upper end of an nth (ranging from 3 to 12) reaction chamber after sequent flow for reaction and discharge. The process has the advantages of low cost, small occupied area, continuous production and high efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

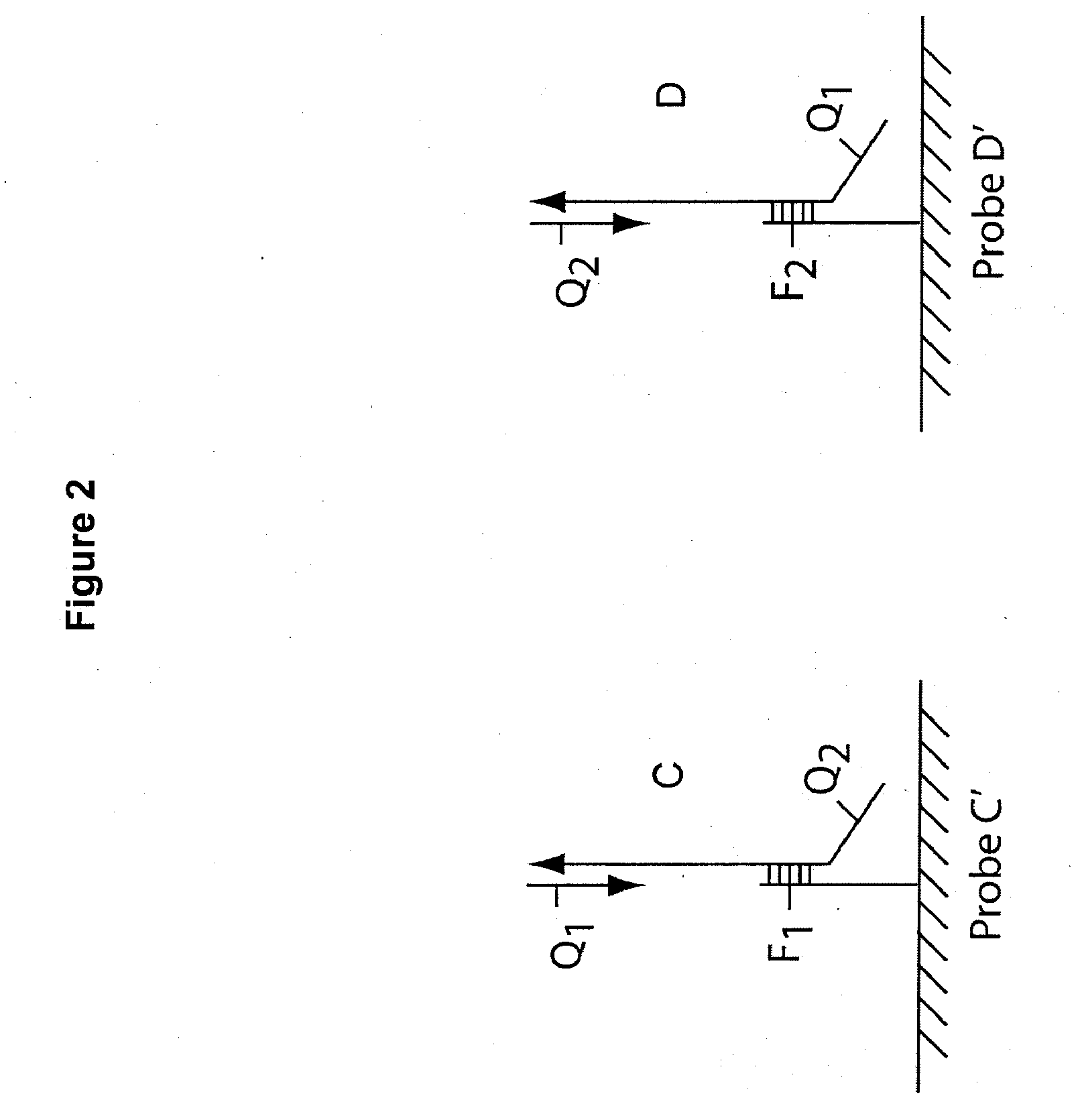

Real time microarrays

ActiveUS9133504B2TimeSlow reaction rateMicrobiological testing/measurementLibrary screeningAnalyteSolid substrate

This invention provides methods and systems for measuring the binding of analytes in solution to probes bound to surfaces in real-time. The method involves contacting a fluid volume having a plurality of different analytes with a solid substrate having a plurality of different probes. The probes are capable of specifically binding to the analytes. The method also involves measuring signals at multiple time points while the fluid volume is in contact with the substrate. The signals measured at multiple time points can be correlated with the amount of binding of the analytes with the probes. The method eliminates the need to wash the probes before measuring the binding characteristics.

Owner:CALIFORNIA INST OF TECH

Saccharifying cellulose

ActiveUS7674608B2Slow reaction rateImproving hydrolysis kinetics and conversionBiofuelsFermentationHydrolysis kineticsAnti solvent

Owner:TOLEDO THE UNIV OF

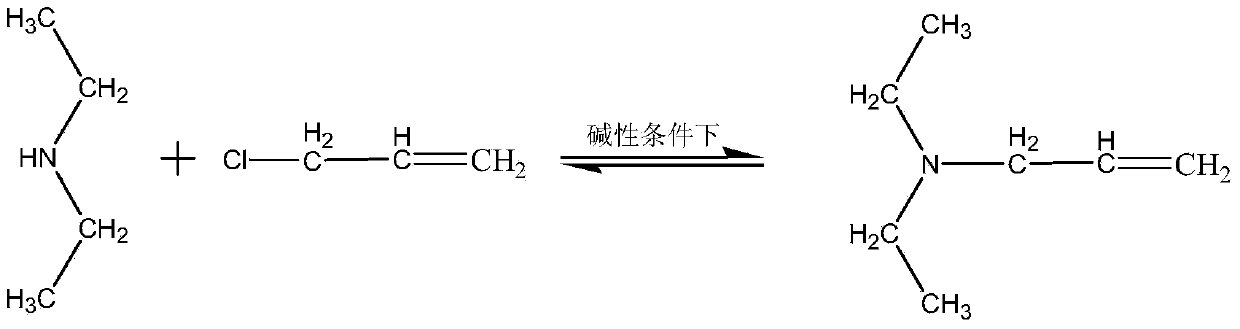

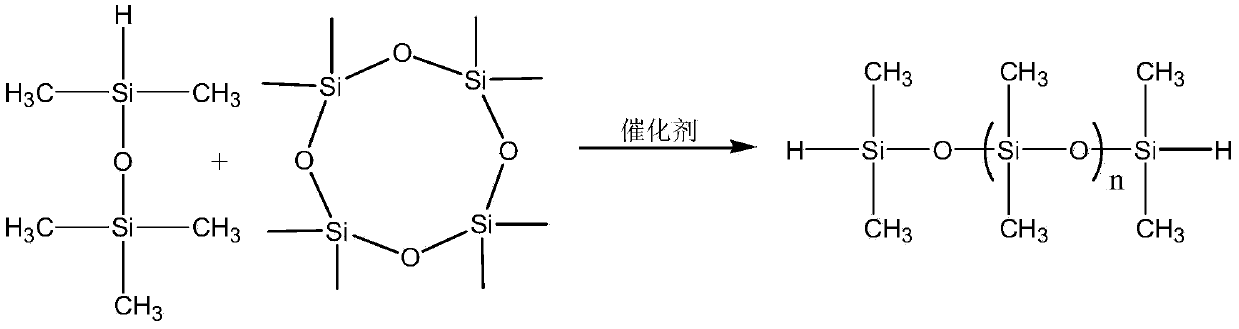

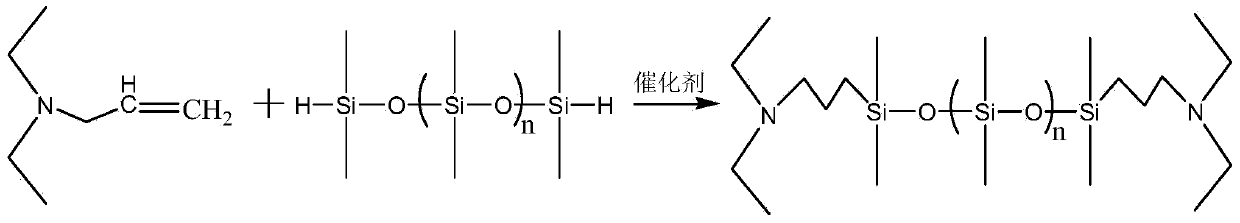

Preparation method for organosilicone positive ion waterborne polyurethane

ActiveCN104327238AEasy to separateSimple and fast operationPolyurea/polyurethane coatingsCarbonizationHydrosilylation

The invention relates to a preparation method for organosilicone positive ion waterborne polyurethane. The preparation method comprises the following steps: (1) reacting diethylamine with allyl chloride in the presence of an alkaline to generate diethyl allylamine; (2) carrying ring opening on D4 under the effect of a catalyst and blocking by using HMM (hexamethylmelamine) to generate dihydro-blocked polysiloxane; (3) carrying out hydrosilylation reaction on dihydro-blocked polysiloxane and diethyl allylamine; (4) carrying out quaternization reaction on the production of the addition reaction and chloropropanol; and (5) generating a prepolymer through reaction between HMDI and PTMEG1000 and extending chains in water by using the quaternization product to generate the organosilicone positive ion waterborne polyurethane. The preparation method provided by the invention is simple and convenient to operate, mild in reaction condition, free of carbonization and products are easily separated and recycled. Firstly, polysiloxane with amido at two terminals is salified and then chains are extended, and the conventional step of salifying positive ions with an acid and then neutralizing is cancelled, so that use of a nitrogen-containing chain extender is reduced, the cost is saved and the problem that positive ion polyurethane gets yellow is prevented.

Owner:QILU UNIV OF TECH

Metal peroxide-based oxygen slow release composite material and preparation thereof

InactiveCN101407358AImprove efficiencyExtend the life cycleWater/sewage treatment by substance additionAnhydrous Calcium SulfateReaction rate

The invention relates to the technical field of polluted groundwater bioremediation, in particular to a metal peroxide base oxygen slow-release composite material and a preparation method thereof. 40 percent to 60 percent of the metal peroxide, 20 percent to 50 percent of calcium phosphate cement, 1 percent to 3 percent of anhydrous calcium sulfate and 5 percent to 10 percent of clay are mixed evenly and added with water, then sent to a granulator for granulation; the obtained solid particles are soaked into the acrylic-itaconic acid copolymer liquid for 1 to 3 minutes and taken out, wherein,the mass ratio of the solid particles and the acrylic-itaconic acid copolymer liquid is 1:3-1:10, then drying and solidification are carried out at 18 to 25 DEG C, and then the metal peroxide base oxygen slow-release composite material is obtained. When in the polluted groundwater rehabilitation, the composite material can greatly slow the reaction rate of the metal peroxide and water, reduce unnecessary loss of the metal peroxide, and improve the service efficiency and period of the metal peroxide.

Owner:TIANJIN UNIV

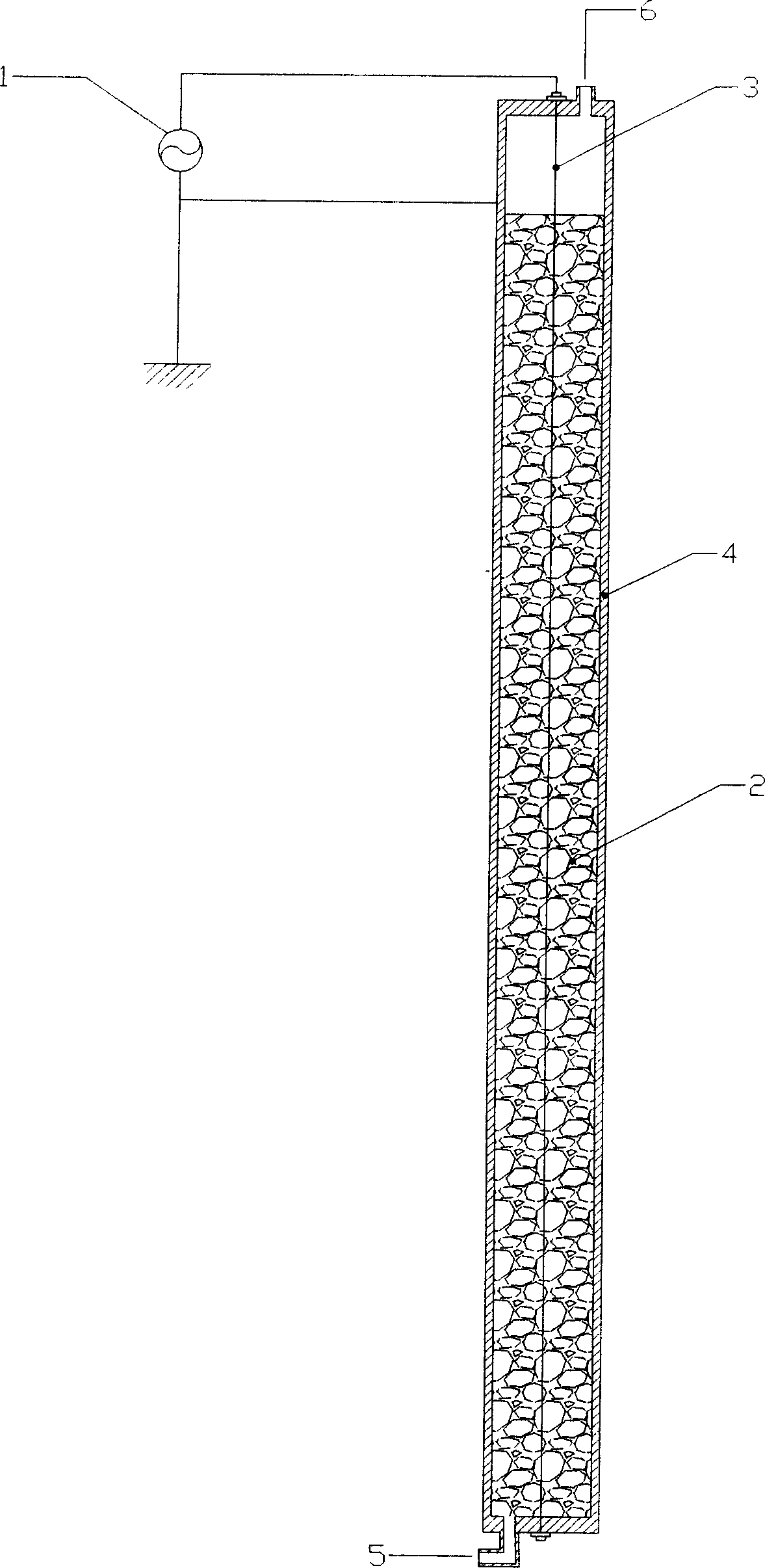

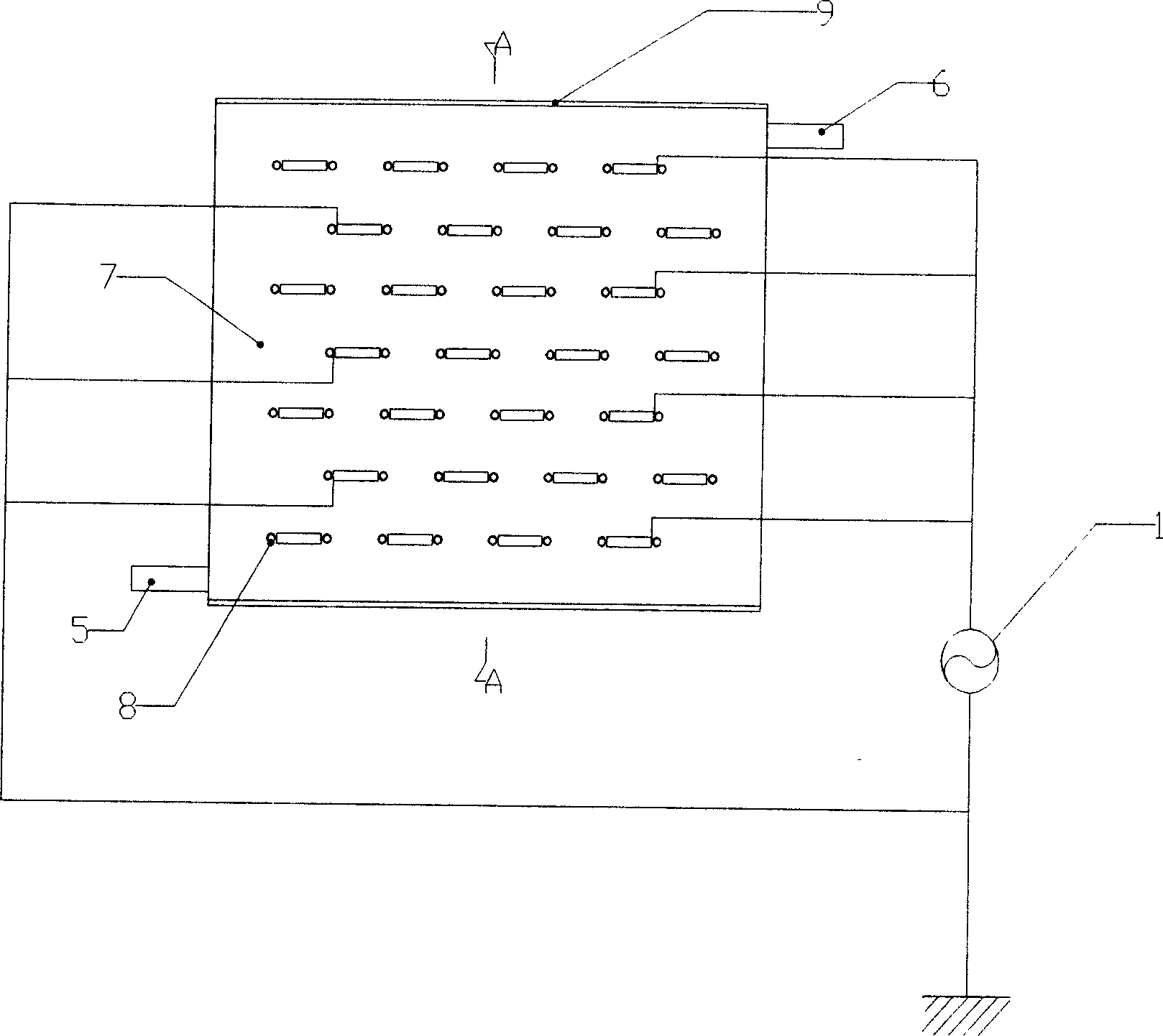

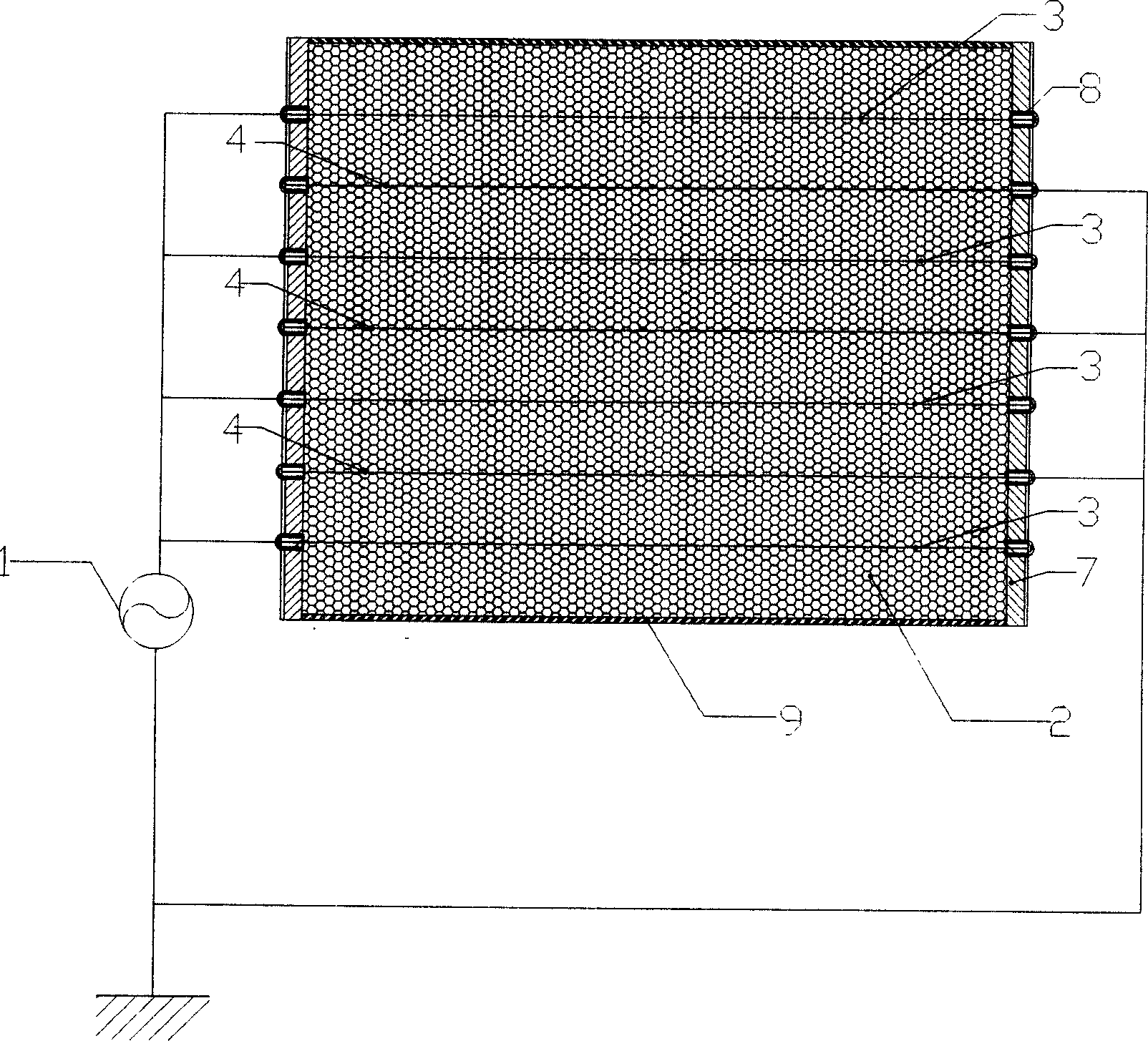

Method and apparatus for generating ozone

InactiveCN1907842AIncrease reaction rateImprove production efficiencyOzone preparationElectricityCatalytic effect

This invention relates to a method and a device for ozone production, in particular to produce ozone by synergism of discharge and catalyst. The method includes introducing air or oxygen into the discharge space between high voltage electrode and grounding electrode, and discharging, wherein catalysts with high surface area and dielectric property filled in the space has catalytic effect on ozone production. The device comprises a discharge electrode consisting of high voltage power and high voltage electrode and grounding electrode, a cavity and an outlet and an inlet thereon, catalysts (2) with high surface area and dielectric property composited between the high voltage electrode (3) and the grounding electrode (4), spaces between discharge electrode and catalysts (2) and spaces formed by catalysts (2) as flow channel for discharge gas.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of nonanal and methyl formylcaprylate

InactiveCN102126953AHigh yieldSlow reaction rateMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of nonanal and methyl formylcaprylate. The method comprises the following steps: epoxidized methyl oleate is used as a raw material to react under the action of catalyst and generate nonanal and methyl formylcaprylate, wherein the reaction temperature is 40-100 DEG C, the pressure is atmospheric pressure; the mesoporous molecular sieve which is treated with 10-35% hydrogen peroxide is taken as a carrier for the catalyst, the weight ratio of tungsten used as main catalyst to the weight of the carrier is 0.005-0.1, and the weight ratio of one of titanium and molybdenum, used as cocatalyst to the weight of the carrier is 0-0.1. The invention has the following beneficial effects: by adopting the technical scheme that the reaction temperature is 40-100 DEG C, the pressure is atmospheric pressure; the mesoporous molecular sieve is taken as a carrier for the catalyst, tungsten is used as a main catalyst and titanium or molybdenum used as cocatalyst is added or not, the problem can be solved well. The preparation method provided by the invention has mild reaction conditions, low cost and higher product yield and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

Preparation method for alpha-acetyl-gamma-butyrolactone

ActiveCN102229586AEfficient recyclingLow input costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReaction rateMethyl acetate

In order to solve the problems of a low safety factor, low yield, high cost, environmental pollution and the like existing in the prior art, the invention provides a preparation method for alpha-acetyl-gamma-butyrolactone. In the method, gamma-butyrolactone and methyl acetate are used as reaction raw materials and metallic sodium is used as a catalyst; the final product is prepared through the phases of reaction, separation, neutralization and extraction. According to the invention, methyl acetate is used as the reaction raw material and a reaction solvent, which on one hand enables production cost to be reduced, the reaction rate to be slowed and dashing out of reacting materials to be avoided, and on the other hand avoids environmental pollution and affection on product quality caused by utilization of benzene solvents; preparation of the catalyst into sodium sand can improve reaction efficiency; high purity alpha-acetyl-gamma-butyrolactone can be obtained through neutralization andextraction of the solid resultants alpha-acetyl-gamma-butyrolactone sodium salt of the reaction which have been subjected to solid-liquid separation without underpressure distillation, thereby effectively improving production efficiency and reducing production cost; the acidic neutral solution used in the invention can be used repeatedly, thereby avoiding environmental pollution by the solution.

Owner:山西三维华邦集团有限公司 +1

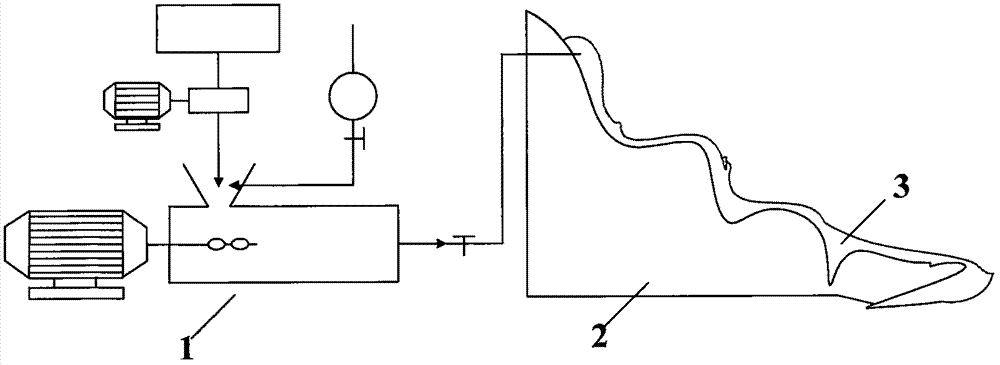

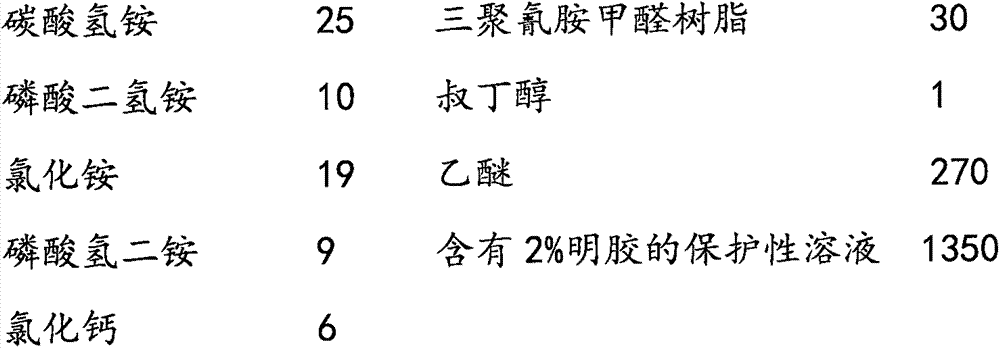

Capsule fire preventing and extinguishing material for coal bed fire and preparation method thereof

InactiveCN106913987ASmall water absorptionEasy to storeFire extinguisherWater bathsMelamine formaldehyde resin

The invention discloses a capsule fire preventing and extinguishing material for a coal bed fire and a preparation method of the capsule fire preventing and extinguishing material. The fire preventing and extinguishing material comprises a core material and a coating layer with which the outer side of the core material is coated. The core material is prepared from a powder stopping agent which is the mixed powder stopping agent comprising ammonium carbonate, ammonium dihydrogen phosphate, ammonium chloride, diammonium hydrogen phosphate and calcium chloride. The coating layer is prepared from an organic polymer which is melamine formaldehyde resin. The core material is coated with the coating layer through a water bath drying method. The mass fraction ratio of ammonium bicarbonate to ammonium dihydrogen phosphate to ammonium chloride to diammonium hydrogen phosphate to calcium chloride to melamine formaldehyde resin is 24-27:10-11:18-20:9-10:6-7:25-33:0.5. The capsule fire preventing and extinguishing material has the advantages of being nontoxic, free of pollution, convenient to store, capable of evenly covering a fire area, short in fire extinguishing period and good in effect, having the leakage stoppage, oxygen isolation, cooling and inhibition effects, being convenient to use and convenient and fast to operate and the like.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com