Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

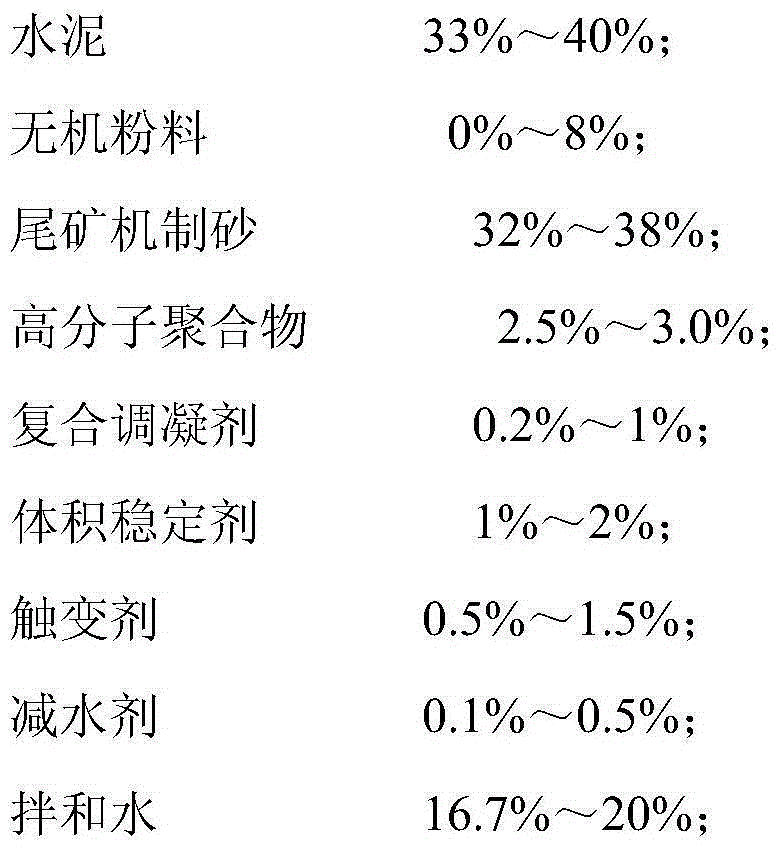

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

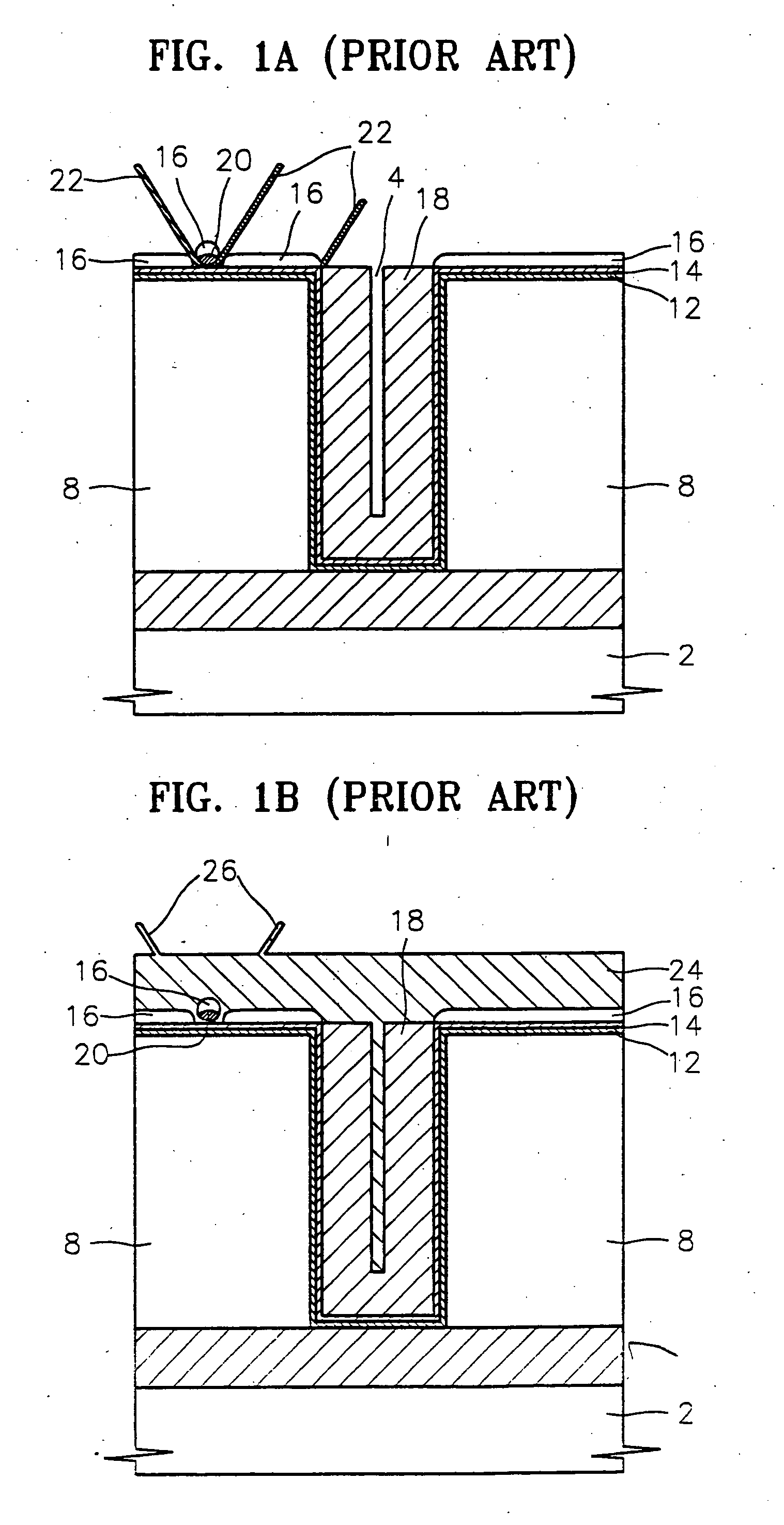

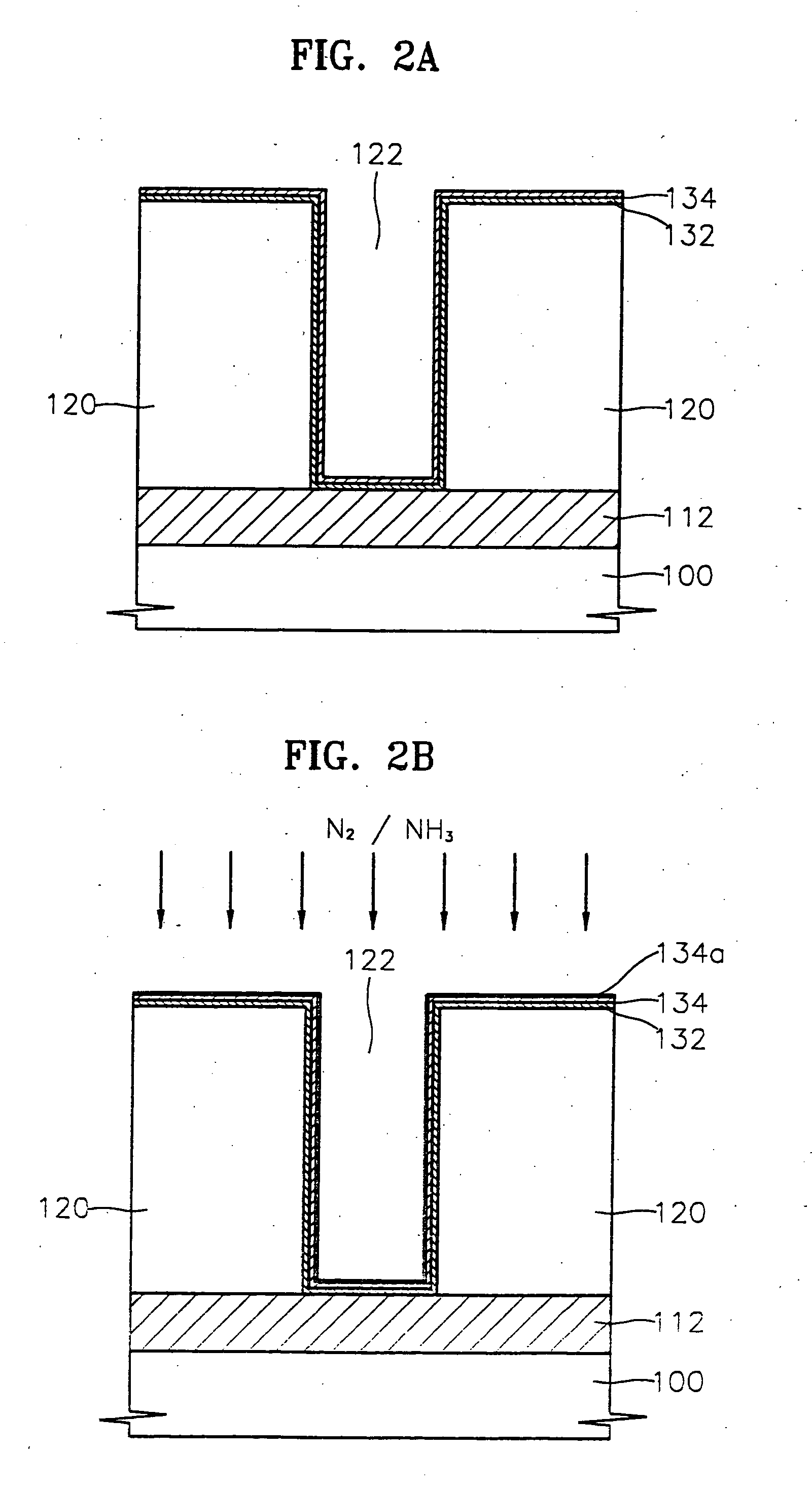

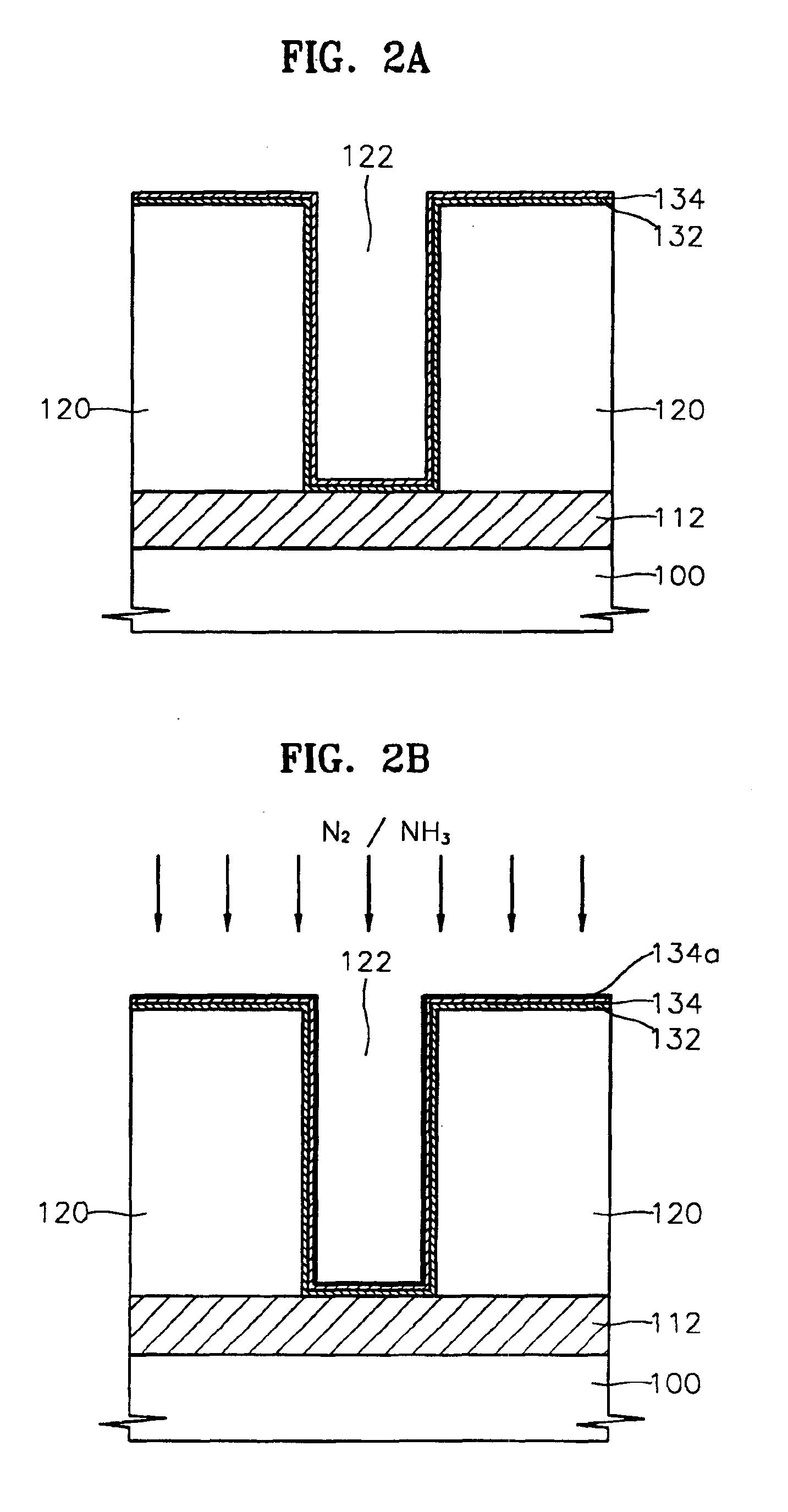

Methods of forming metal interconnections of semiconductor devices by treating a barrier metal layer

ActiveUS20050179141A1Reduce layeringReduce or prevent a metallic material from abnormally growingElectrotherapySemiconductor/solid-state device detailsMetal interconnectDevice material

A metal interconnection of a semiconductor device is fabricated by forming a dielectric pattern including a hole therein on a substrate, and forming a barrier metal layer in the hole and on the dielectric layer pattern outside the hole. At least some of the barrier metal layer is oxidized. An anti-nucleation layer is selectively formed on the oxidized barrier metal layer outside the hole that exposes the oxidized barrier metal layer in the hole. A metal layer then is selectively formed on the exposed oxidized barrier layer in the hole.

Owner:SAMSUNG ELECTRONICS CO LTD

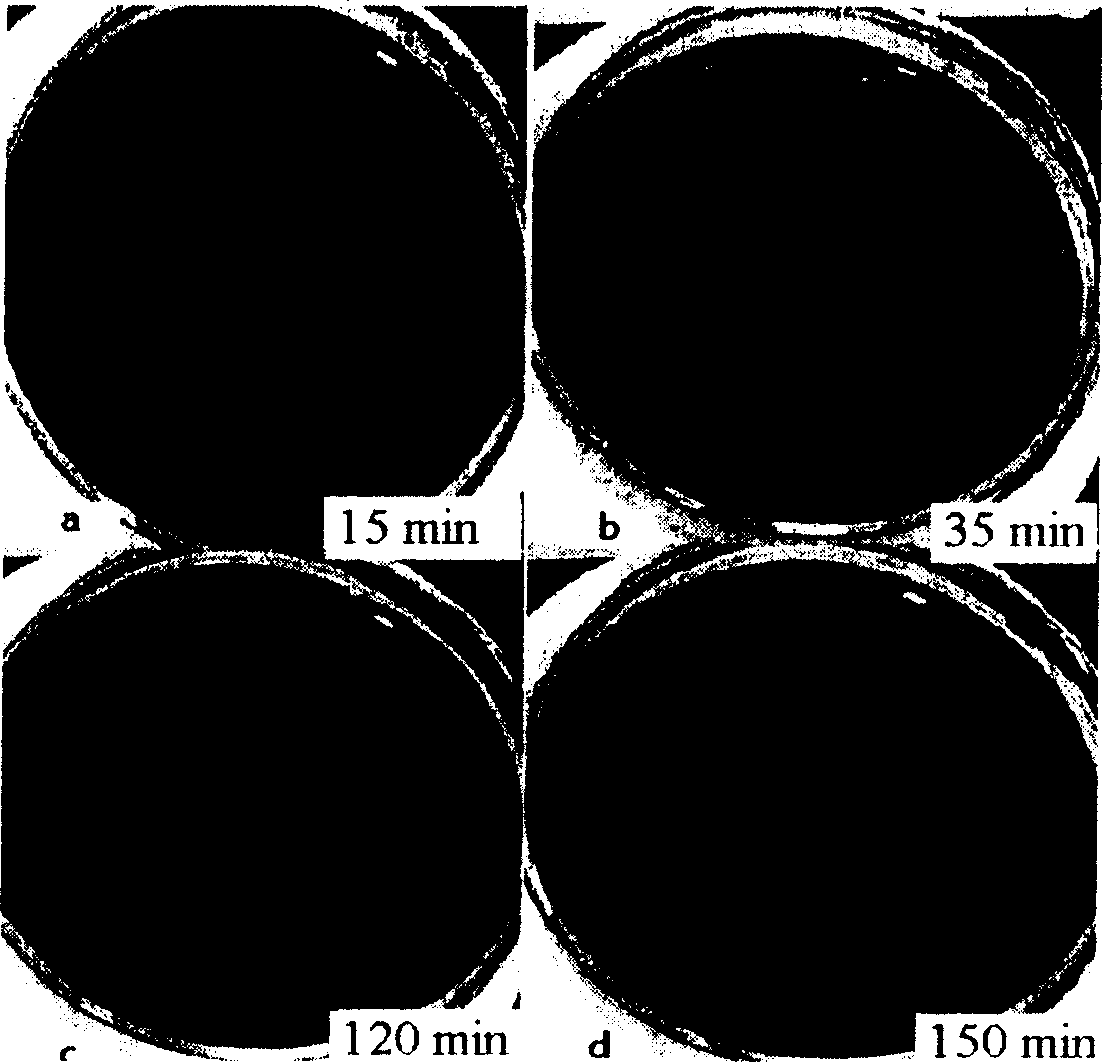

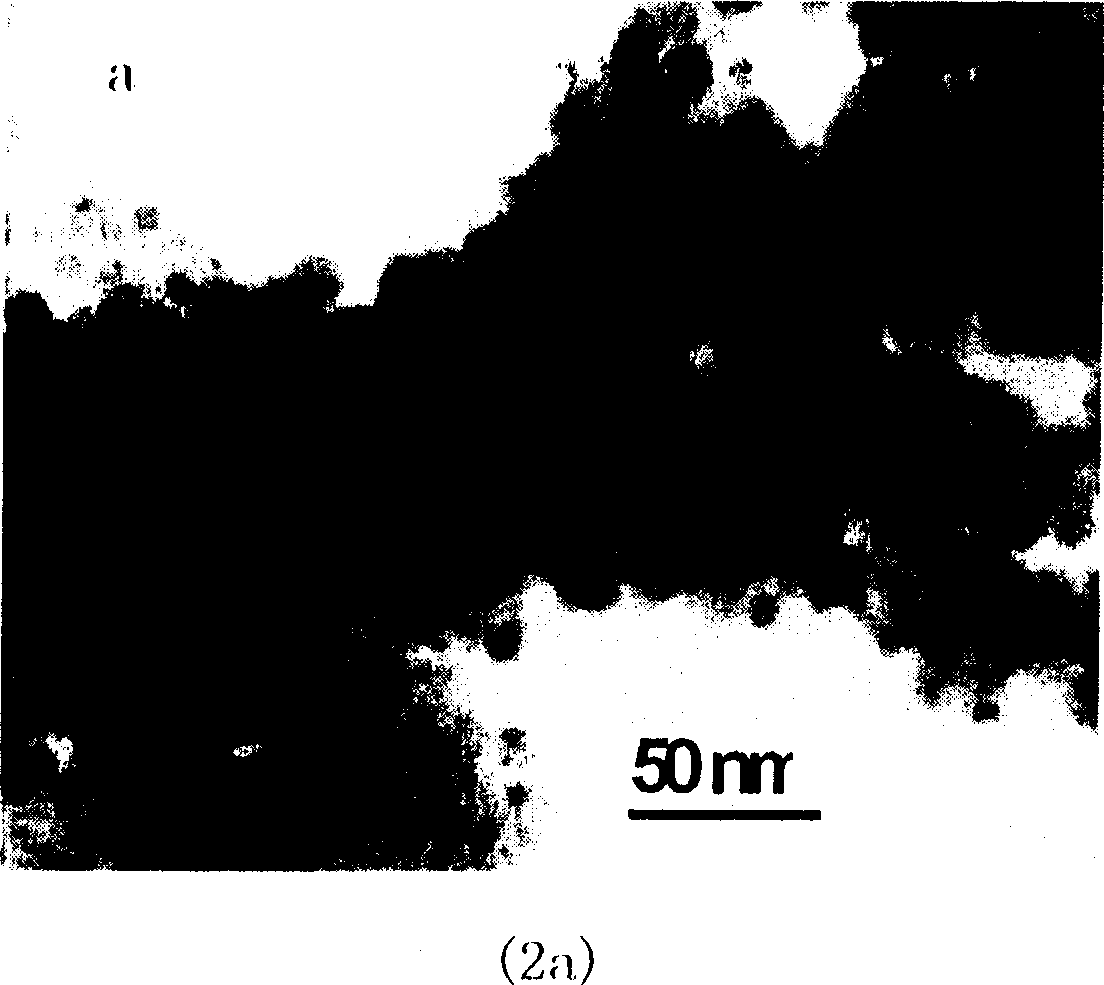

Super paramagnetic ferric oxide composite nanometre particle preparation method

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for Manufacturing Grain-Oriented Electrical Steel Sheets Having Excellent Magnetic Properties

ActiveUS20130306202A1High magnetic flux densityLow core lossFurnace typesHeat treatment furnacesSheet steelElectrical steel

Provided is a method for manufacturing a grain-oriented electrical steel sheet, the method comprising: heating a grain-oriented electrical steel sheet slab; hot-rolling the heated slab; optionally annealing the hot-rolled steel sheet; subjecting the resulting steel sheet to one cold rolling or two or more cold rollings with intermediate annealing therebetween; subjecting the cold-rolled steel sheet to primary recrystallization annealing; and subjecting the annealed steel sheet to secondary recrystallization annealing, wherein the primary recrystallization annealing sequentially comprises an ultra-rapid heating process of heating the steel sheet at an average heating rate of 300° C. / sec or higher, a rapid heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the ultra-rapid heating process, but not lower than 100° C. / sec, and a general heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the rapid heating process.

Owner:POHANG IRON & STEEL CO LTD

Method to reduce stacking fault nucleation sites and reduce forward voltage drift in bipolar devices

InactiveUS7018554B2Reduce in quantityReduce nucleationDecorative surface effectsSemiconductor/solid-state device manufacturingStacking faultOptoelectronics

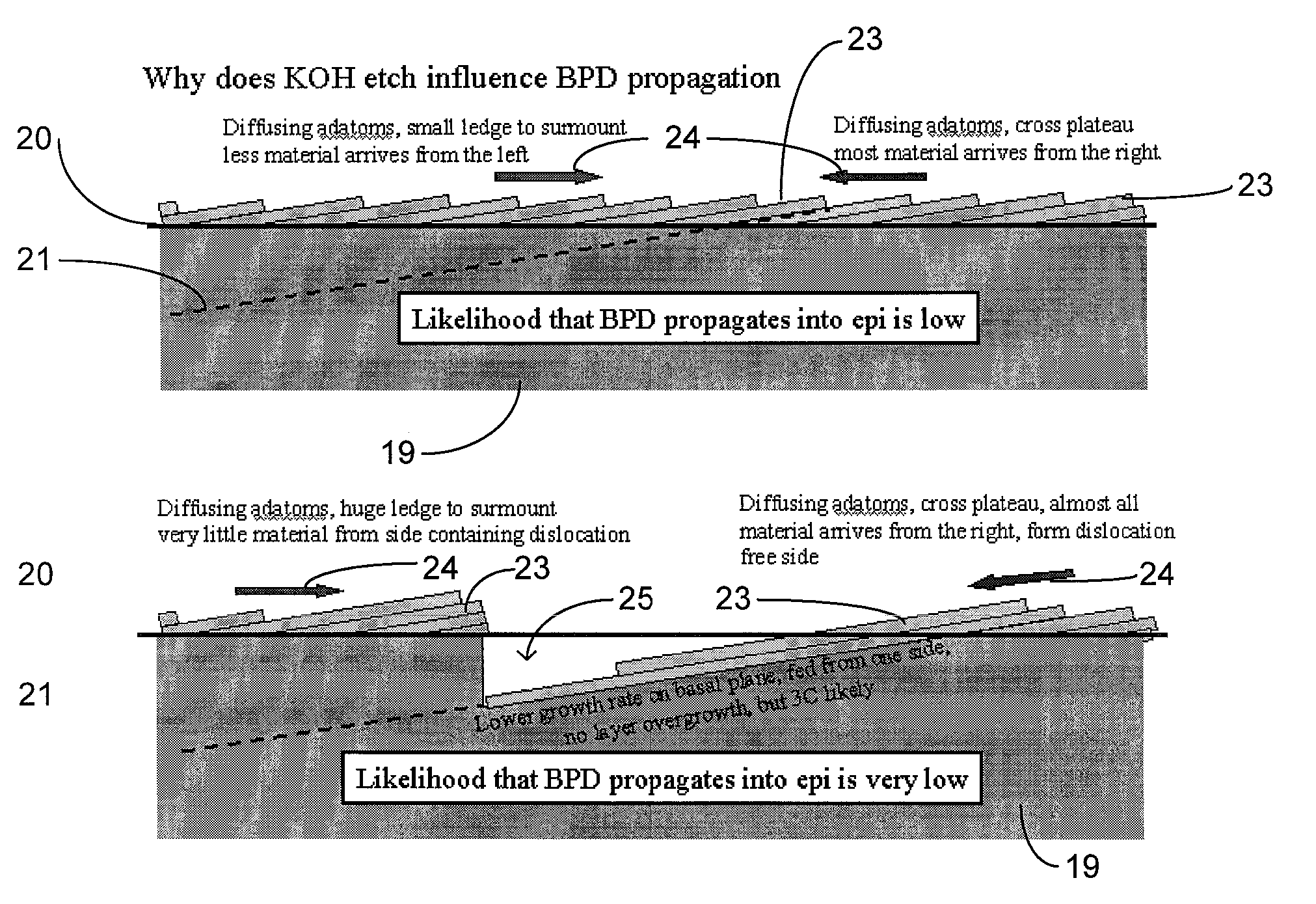

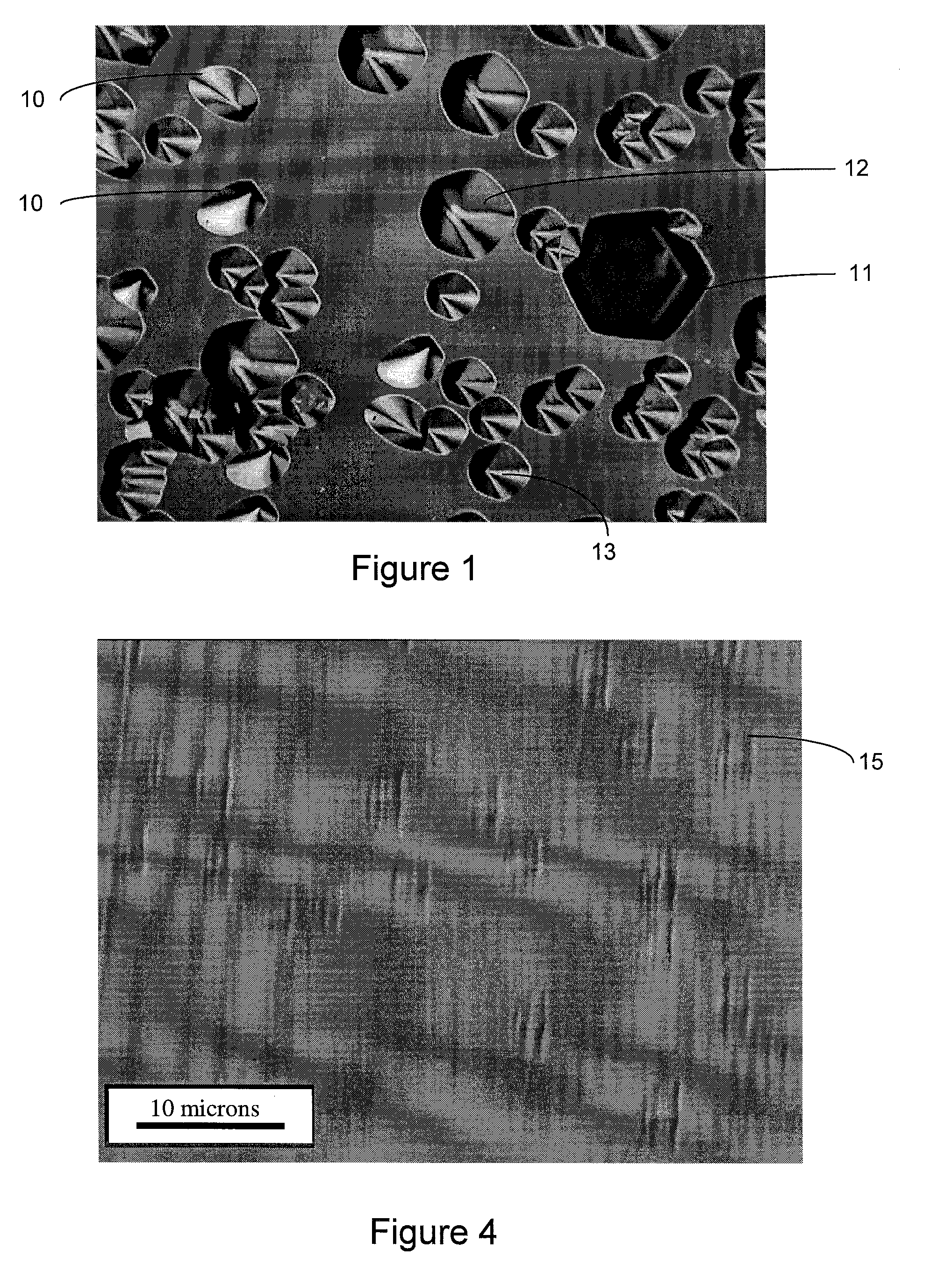

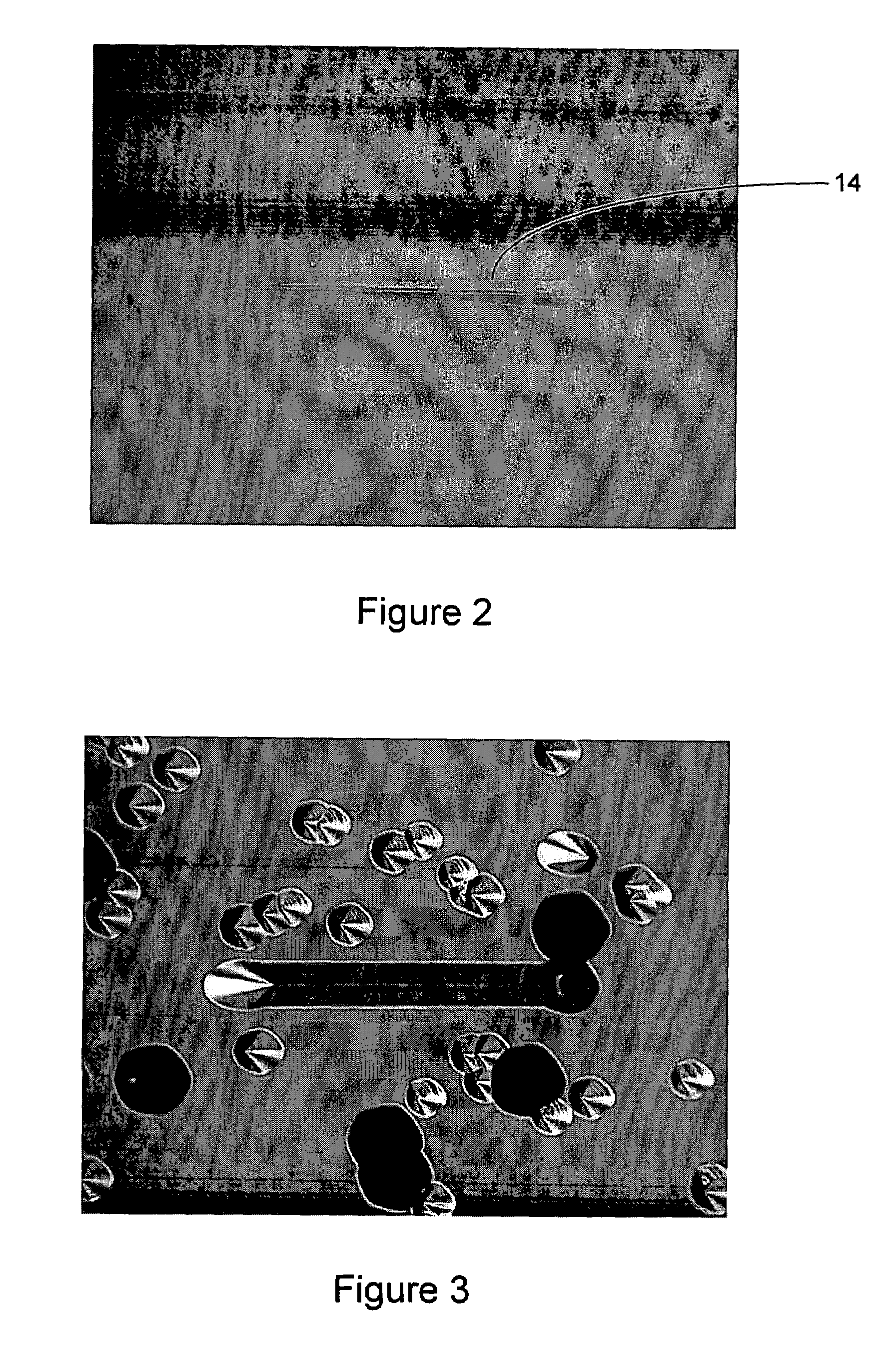

A method is disclosed for preparing a substrate and epilayer for reducing stacking fault nucleation and reducing forward voltage (Vf) drift in silicon carbide-based bipolar devices. The method includes the steps of etching the surface of a silicon carbide substrate with a nonselective etch to remove both surface and sub-surface damage, thereafter etching the same surface with a selective etch to thereby develop etch-generated structures from at least any basal plane dislocation reaching the substrate surface that will thereafter tend to either terminate or propagate as threading defects during subsequent epilayer growth on the substrate surface, and thereafter growing a first epitaxial layer of silicon carbide on the twice-etched surface.

Owner:CREE INC

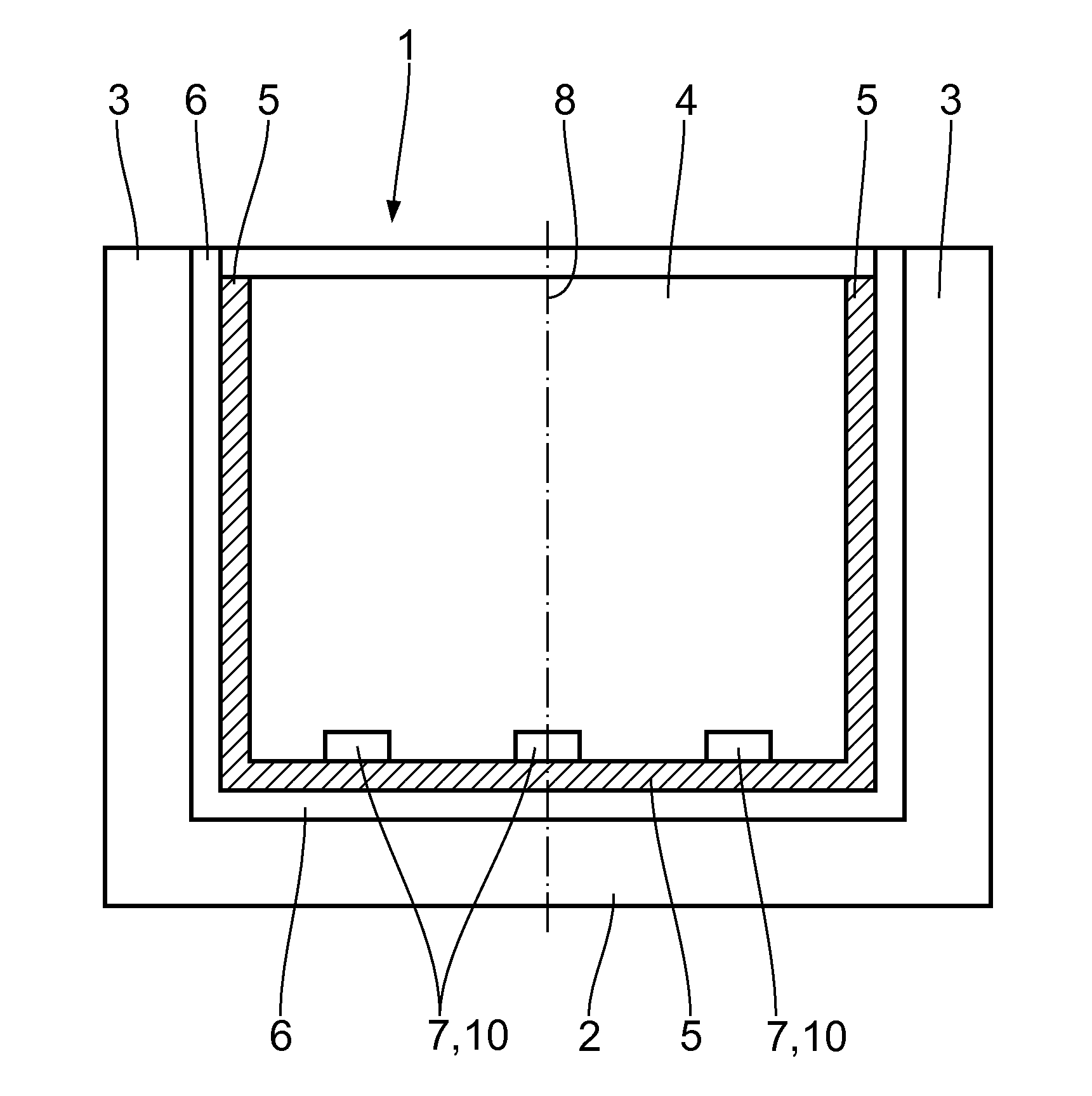

Device and method for the production of silicon blocks

InactiveUS20110203517A1Reduce nucleationReduce probabilityRadiation applicationsPretreated surfacesNucleationSilicon

A device for the production of silicon blocks comprising a vessel for receiving a silicon melt with at least one vessel wall, with the at least one vessel wall comprising a nucleation-inhibiting coating on at least part of an inside or with the at least one vessel wall consisting of a nucleation-inhibiting material.

Owner:SOLARWORLD INNOVATIONS

Method for Coating a Silicate Flourescent Substance

InactiveUS20120207923A1Improve stabilityReduce adverse effectsCoatingsSpecial surfacesFluorescencePhosphor

A method for producing a coating on a silicate phosphor, comprising the steps of preparing a solution of a precursor of the coating material; depositing the coating material on phosphor particles introduced into the solution; and heat treatment in an oxidative atmosphere at temperatures of at least 150° C.

Owner:OSRAM GMBH

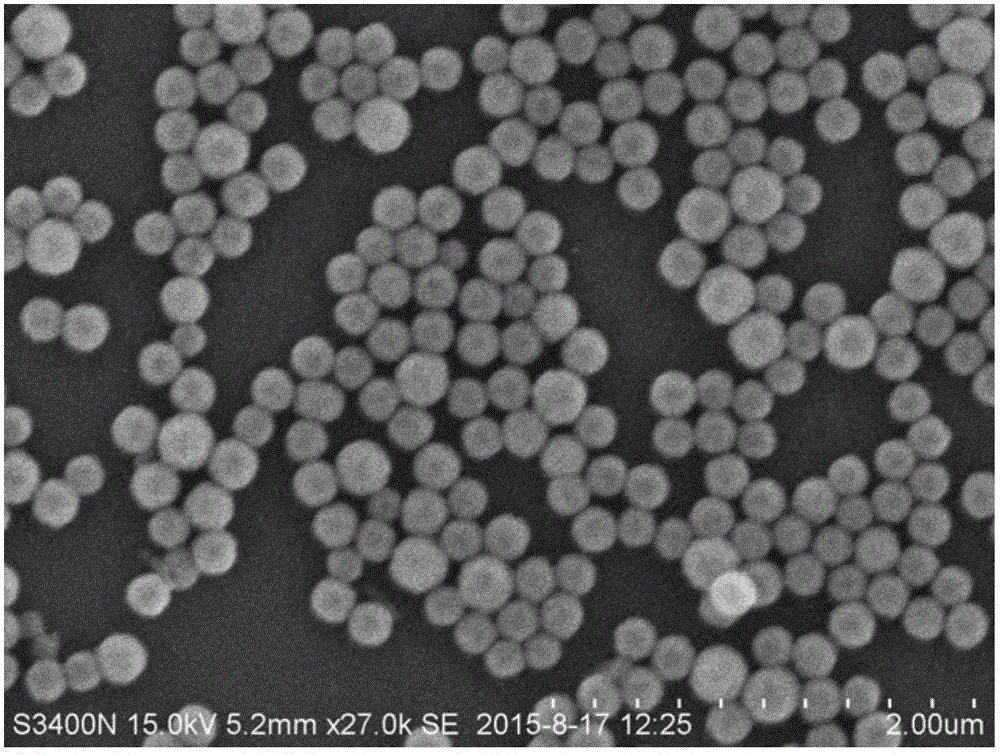

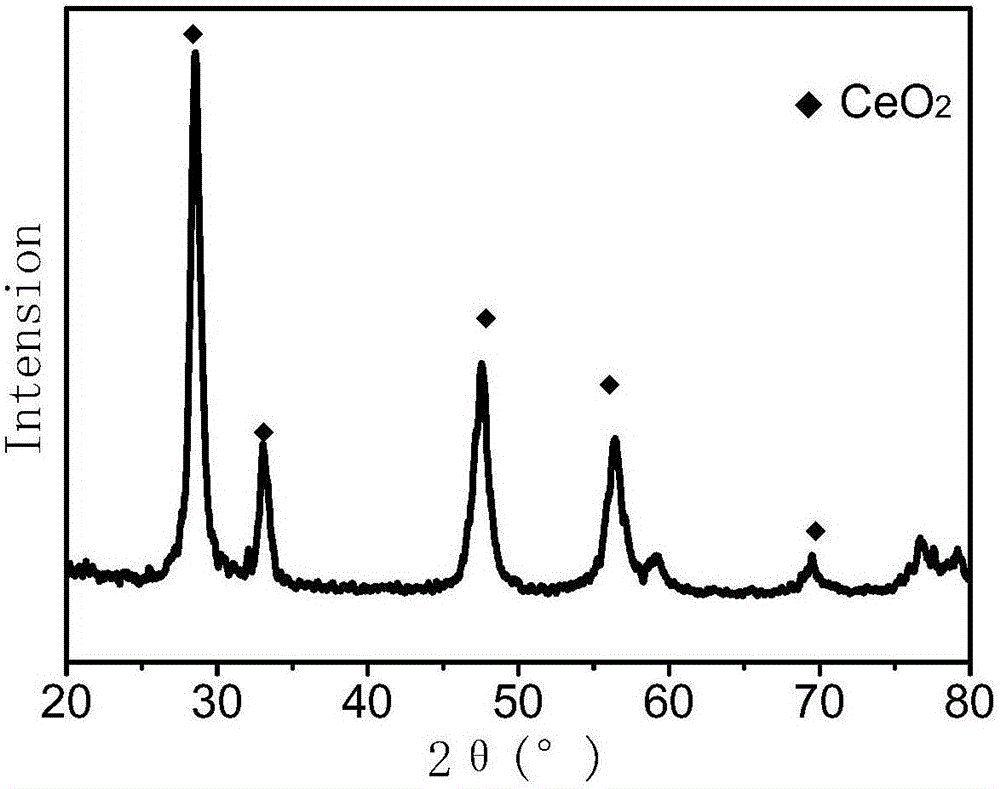

Spherical cerium dioxide

ActiveCN105948097AShort reaction timeSimple and fast operationRare earth metal oxides/hydroxidesCerium(IV) oxideThermal stability

The invention discloses a spherical cerium dioxide. The average particle size of spherical cerium dioxide is 50 nm-300 nm, and the specific surface area after roasting at 1000 DEG C is 1.5-20 m<2> / g, preferably, the specific surface area after roasting at 350 DEG C is 102-153 m<2> / g, and the specific surface area after roasting at 550 DEG C is 80-120 m<2> / g. The preparation method of the spherical cerium dioxide disclosed in the invention has short reaction time and simple operation, and is easy to control. Moreover, the prepared cerium dioxide is spherical and has regular shape, good degree of crystallization, high heat stability, and big specific surface area.

Owner:广州市威格林环保科技有限公司

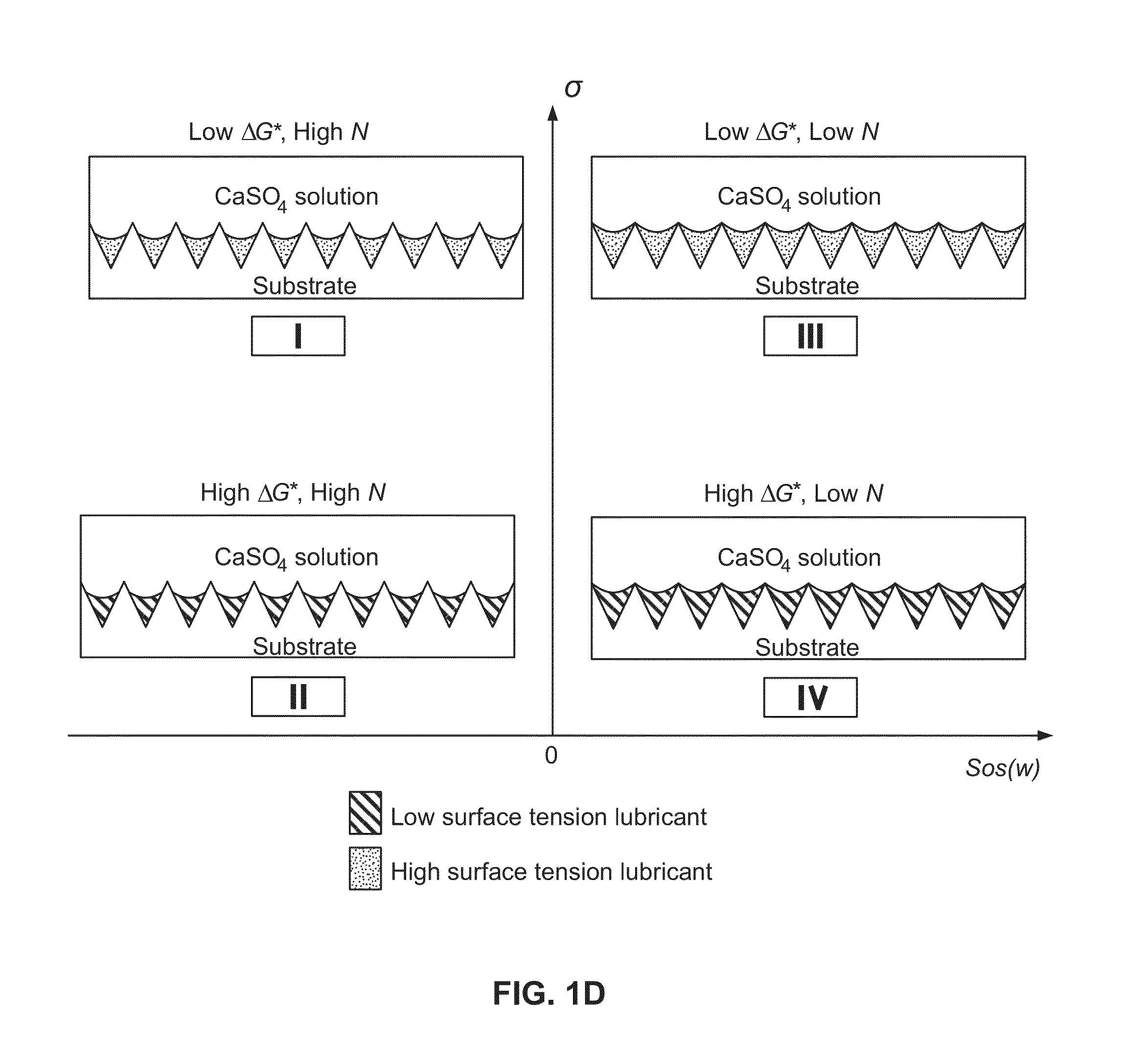

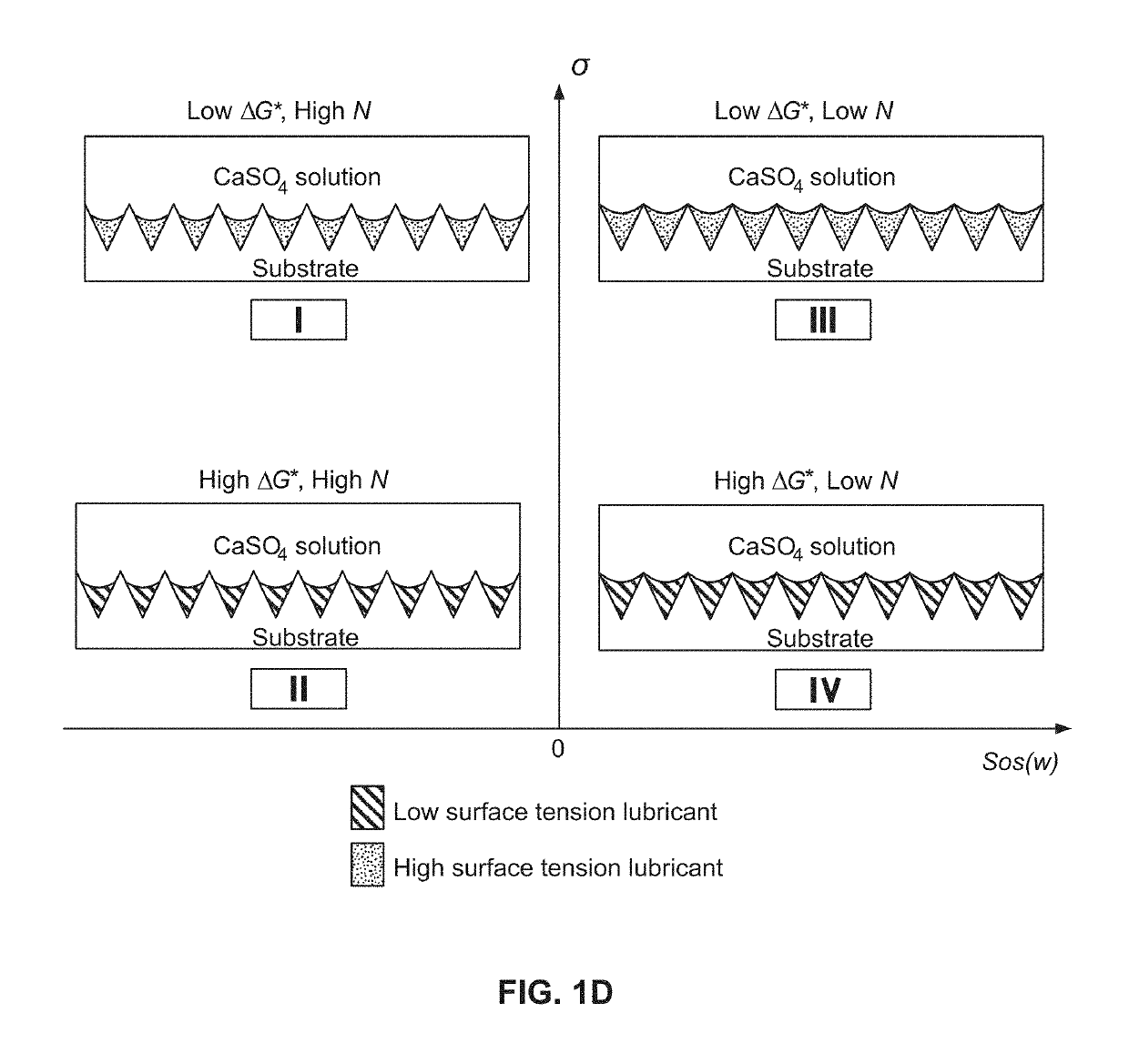

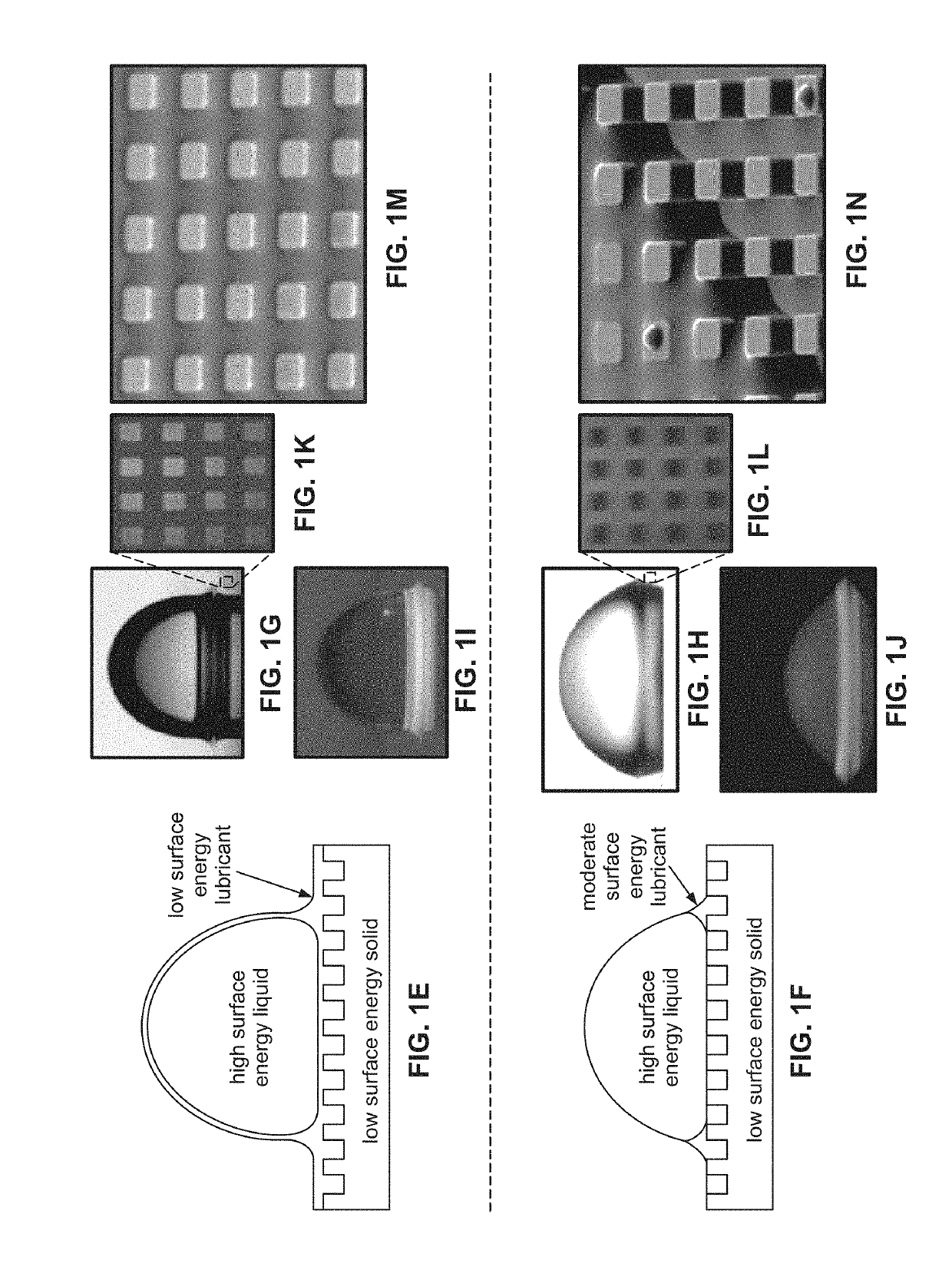

Articles and methods providing liquid-impregnated scale-phobic surfaces

InactiveUS20140290699A1Promote growthReduce nucleationHollow article cleaningCorrosion preventionVolumetric Mass DensityCharacteristic matrix

This invention relates generally to articles, devices, and methods for inhibiting or preventing the formation of scale during various industrial processes. In certain embodiments, a vessel is provided for use in an industrial process, the vessel having a textured, liquid-impregnated surface in contact with a mineral solution, wherein the liquid-impregnated surface comprises a matrix of features spaced sufficiently close to stably contain an impregnating liquid lubricant therebetween or therewithin, wherein the impregnating lubricant has a low surface energy density, and wherein the spreading coefficient Sos(w) of the impregnating lubricant (subscript ‘o’) on the substrate (subscript ‘s’) in the presence of the salt solution (subscript ‘w’) is greater than zero, such that the impregnating lubricant fully submerges the textured substrate.

Owner:MASSACHUSETTS INST OF TECH

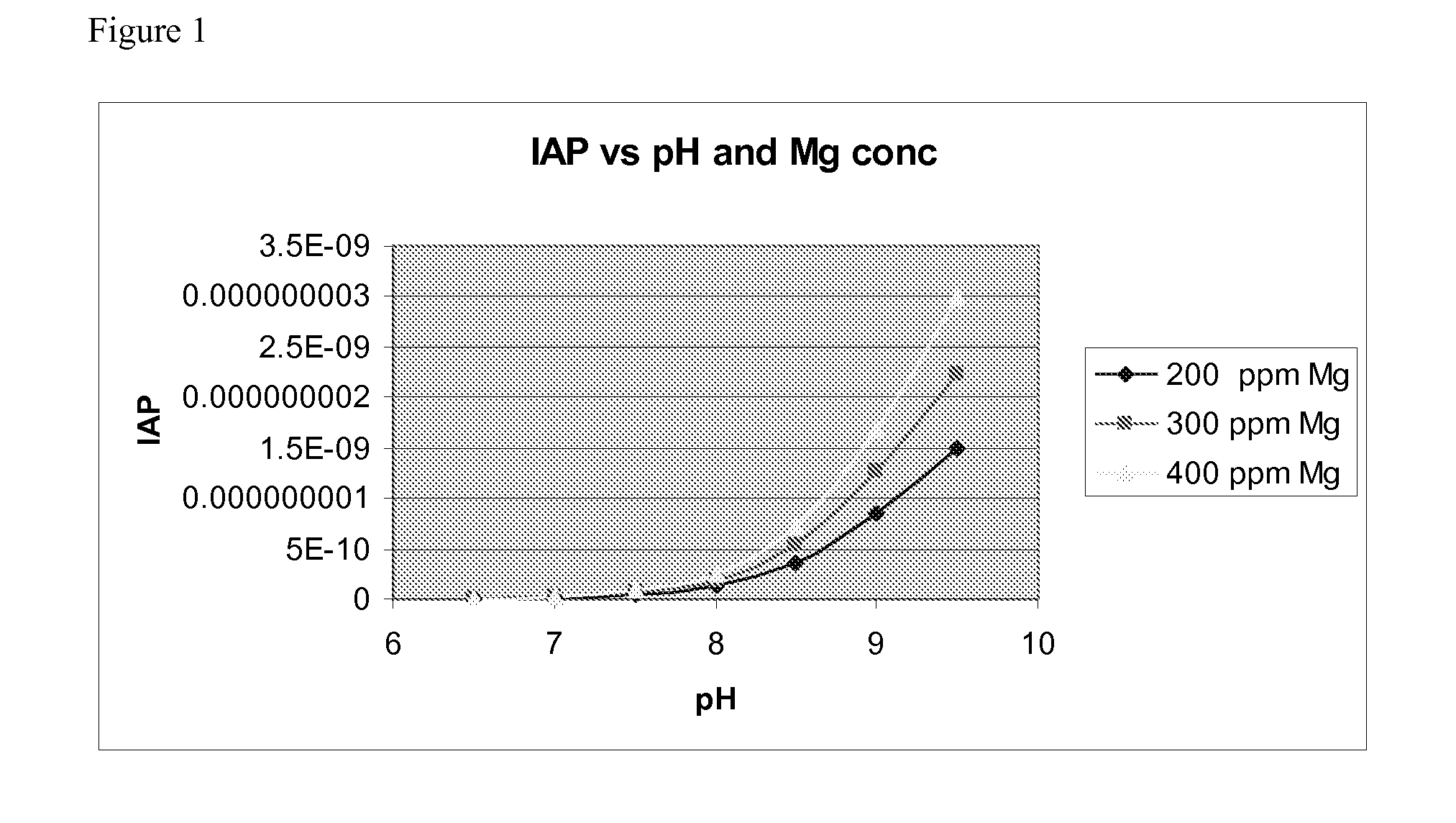

System and Process for Removal of Phosphorous and Ammonia from Aqueous Streams

InactiveUS20080308505A1Degree of reductionReduce solubilityOther chemical processesWater contaminantsWater flowAmmonia

We disclose a process for the removal of phosphorous and ammonia from an aqueous stream by contacting the aqueous stream with magnesium and base in a first zone having a first pH, to form an (n−1)th mixed stream and a first portion of struvite; separating the (n−1)th mixed stream from the first portion of struvite; removing at least some struvite from the first portion of struvite; contacting the (n−1)th mixed stream with base in an nth zone, wherein n is an integer incrementing from 2 to nmax, wherein nmax is an integer from 2 to about 5, and wherein the nth zone has an nth pH higher than the (n−1)th pH, to form an nth mixed stream and an nth portion of struvite, except no base is added and the nth pH need not be higher than the (n−1)th pH when n=nmax; separating the nth mixed stream from the nth portion of struvite; returning the nth portion of struvite to the (n−1)th zone; and, if n<nmax, incrementing n and repeating the second contacting, second separating, and returning steps, or, if n=nmax, releasing the nth mixed stream to a treated water tank. We also disclose a system which can be used for performing the method.

Owner:JANSEN ROBERT +7

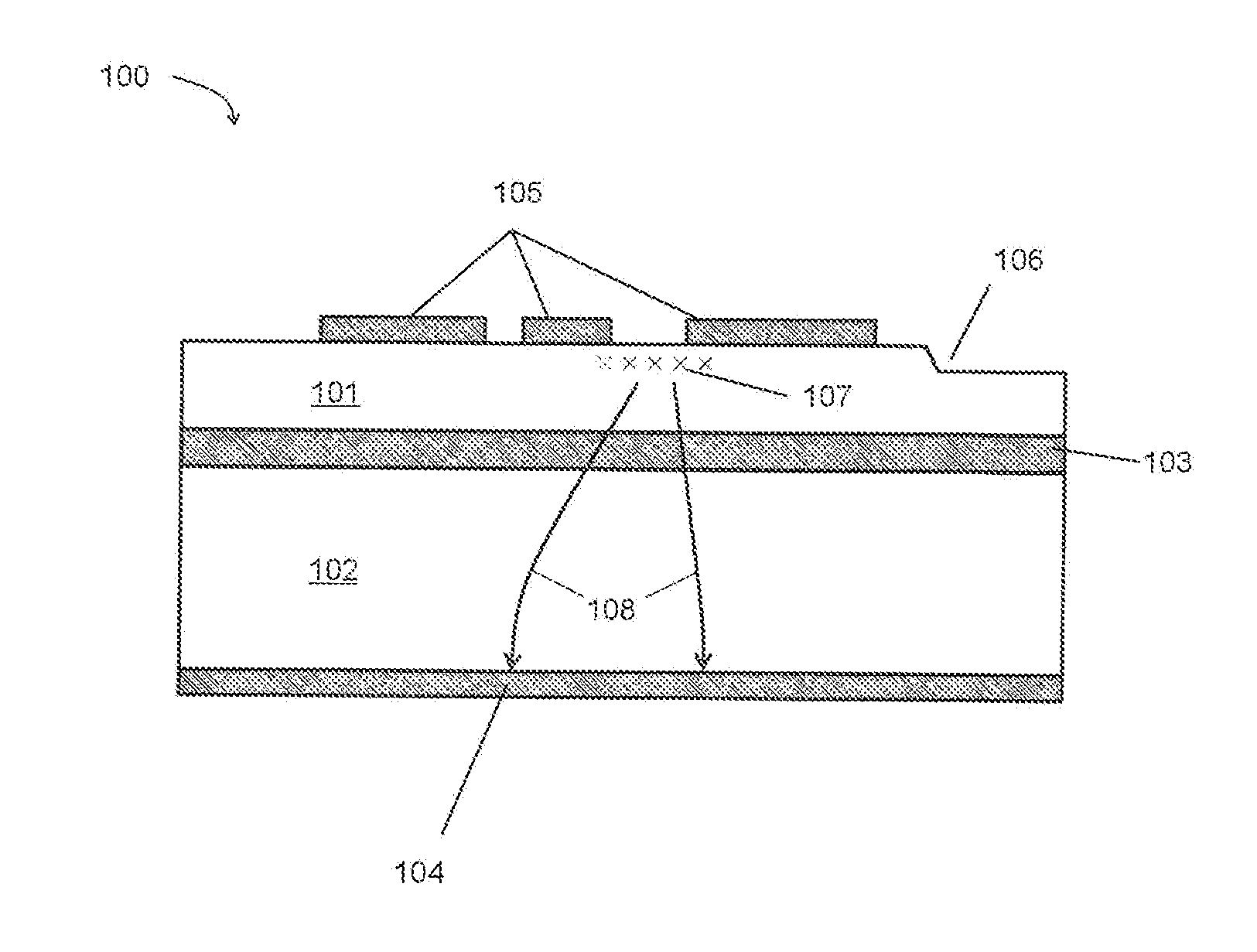

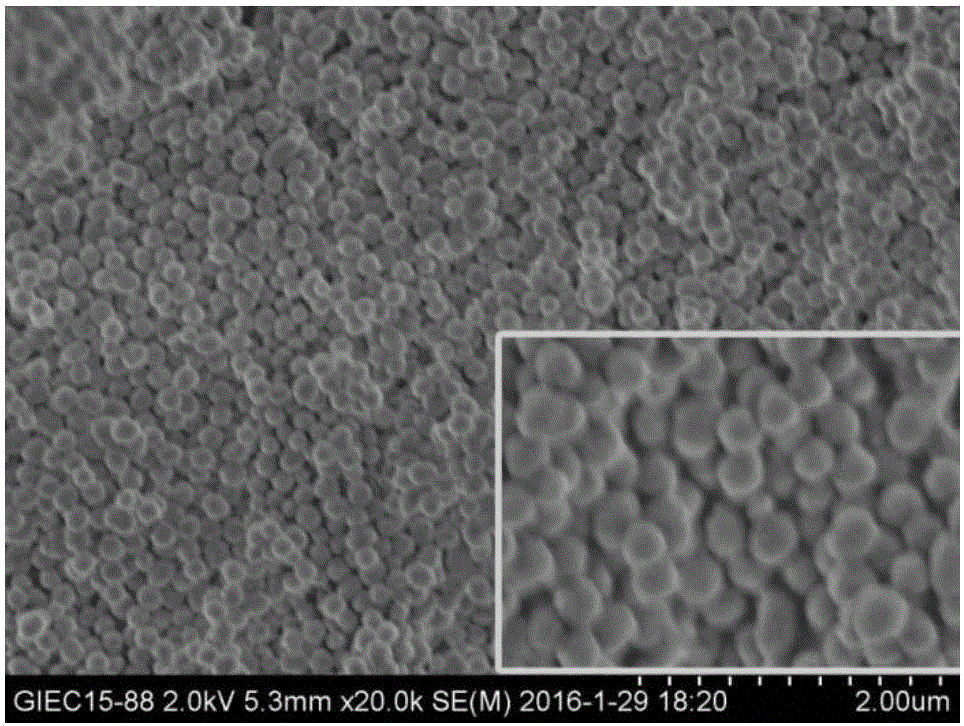

Semiconductor device structures comprising polycrystalline CVD diamond with improved near-substrate thermal conductivity

ActiveUS20160197027A1Improve thermal conductivityReduce carbon contentSemiconductor/solid-state device detailsSolid-state devicesNucleationMaterials science

A semiconductor device structure comprising:a layer of III-V compound semiconductor material;a layer of polycrystalline CVD diamond material; andan interface region between the layer of III-V compound semiconductor material and the layer of polycrystalline CVD diamond material, the interface region including a diamond nucleation layer of polycrystalline CVD diamond which is formed during an initial nucleation phase of polycrystalline CVD diamond growth over a substrate comprising the layer of III-V compound semiconductor material,wherein the diamond nucleation layer is such that a Raman signal generated by a laser focused on a region comprising the diamond nucleation layer exhibits an sp3 carbon peak at 1332 cm−1 having a full width half-maximum of no more than 5.0 cm−1,wherein the diamond nucleation layer is such that said Raman signal further exhibits one or both of the following characteristics:(i) an sp2 carbon peak at 1550 cm−1 having a height which is no more than 20% of a height of the sp3 carbon peak at 1332 cm−1 after background subtraction when using a Raman excitation source at 633 nm; and(ii) the sp3 carbon peak at 1332 cm−1 is no less than 10% of local background intensity in a Raman spectrum using a Raman excitation source at 785 nm, andwherein an average nucleation density at a nucleation surface of the diamond nucleation layer is no less than 1×108 cm−2 and no more than 1×1012 cm−2.

Owner:AKASH SYST INC

Efficient and non-corrosive hydrate inhibitor

ActiveCN101608111AReduce dosageSimplify subsequent processingDrilling compositionPetroleumCalcium nitrate

The invention provides a high-efficient non-corrosive hydrate inhibitor, relating to the technical field of oil-gas hydrate. The hydrate inhibitor is a mixture of an anti-agglomerant and a urea or a calcium nitrate and is used at the pressure of 1.5 to 25 MPa and at the temperature of minus 20 DEG C to 25 DEG C. The hydrate inhibitor overcomes the defects of the prior art, reduces the nucleary, the growth and the coalescence speed of hydrate after being filled in petroleum fluid in production or conveying by mixing at low concentration and has the characteristics of wide application, low cost and no corrosion to pipelines.

Owner:SOUTH CHINA UNIV OF TECH

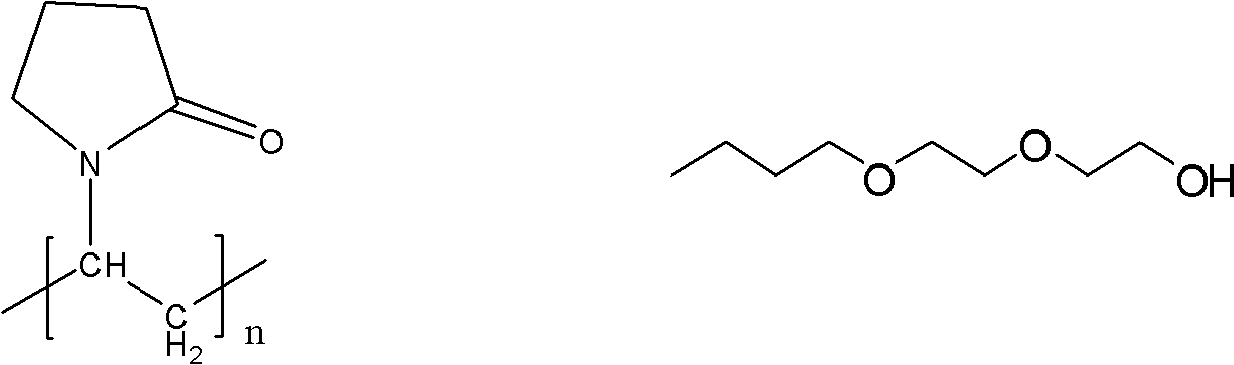

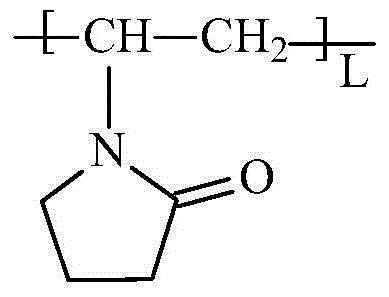

High-efficiency composite hydrate inhibitor as well as preparation method and application thereof

ActiveCN102161720ANo pollutionLow toxicity and good biocompatibilityPipeline systemsPolymer scienceBenzoyl peroxide

The invention discloses a high-efficiency composite hydrate inhibitor as well as a preparation method and an application thereof. The preparation method of the high-efficiency composite hydrate inhibitor comprises the following steps: taking N-vinyl pyrrolidone as a monomer and azodiisobutyronitrile or benzoyl peroxide as an initiator; and carrying out a polymerization reaction of a free-radical solution in a solvent to obtain the composite hydrate inhibitor, wherein the solvent is selected from at least one of the following components: carbinol, ethylene glycol, diethylene glycol, isopropanol, diethylene glycol, ethylene glycol monobutyl ether and Di(ethylene glycol) butyl ether, the volume ratio of the monomer to the solvent is (1:2)-(1:5), and the use amount of the initiator is 0.3-1.5wt% of the monomer. Compared with the method for industrially synthesizing the initiator, the method disclosed by the invention saves energy and is convenient and economic. The inhibitor synthesized by the invention can be applied to hydrate prevention and treatment in the processes of producing and transporting petroleum fluid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Production method for nucleating agent for high-strength thin-wall gray pig iron casting

The invention discloses a production method for a nucleating agent for a high-strength thin-wall gray pig iron casting. Raw materials including, by weight percent, 65%-75% of Si, 0.5%-1% of Zr, 0.5%-1% of Re, 0%-0.5% of Al, 1.5%-2.5% of Ba, 0.5%-0.8% of Ca and the balance Fe and inevitable impurities are mixed and smelted, then alloy powder with the average grain size ranging from 200 microns to 300 microns are produced, then the alloy powder is mixed with nano silicon carbide water scattering liquid, atomizing and drying are conducted, the nano silicon carbide is doped in the alloy powder, and the nucleating agent for the high-strength thin-wall gray pig iron casting is obtained. The prepared nucleating agent has a good grain refining effect, the strength of the casting is improved, the uniformity of matrix structures of the casting can be guaranteed as well, generation of inner defects of the casting is reduced, and the nucleating agent is suitable for being applied to inoculation treatment on the high-strength thin-wall gray pig iron casting.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

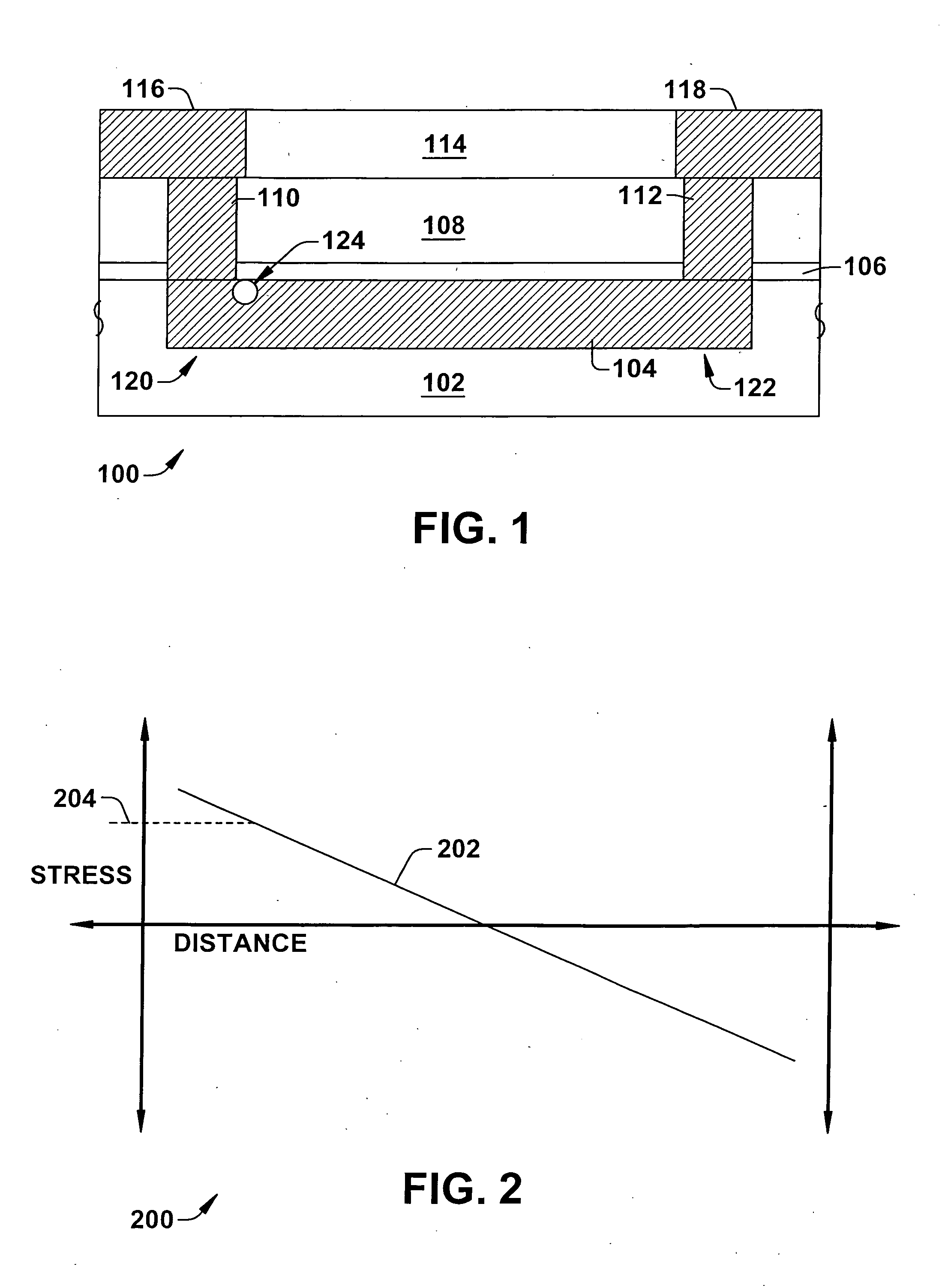

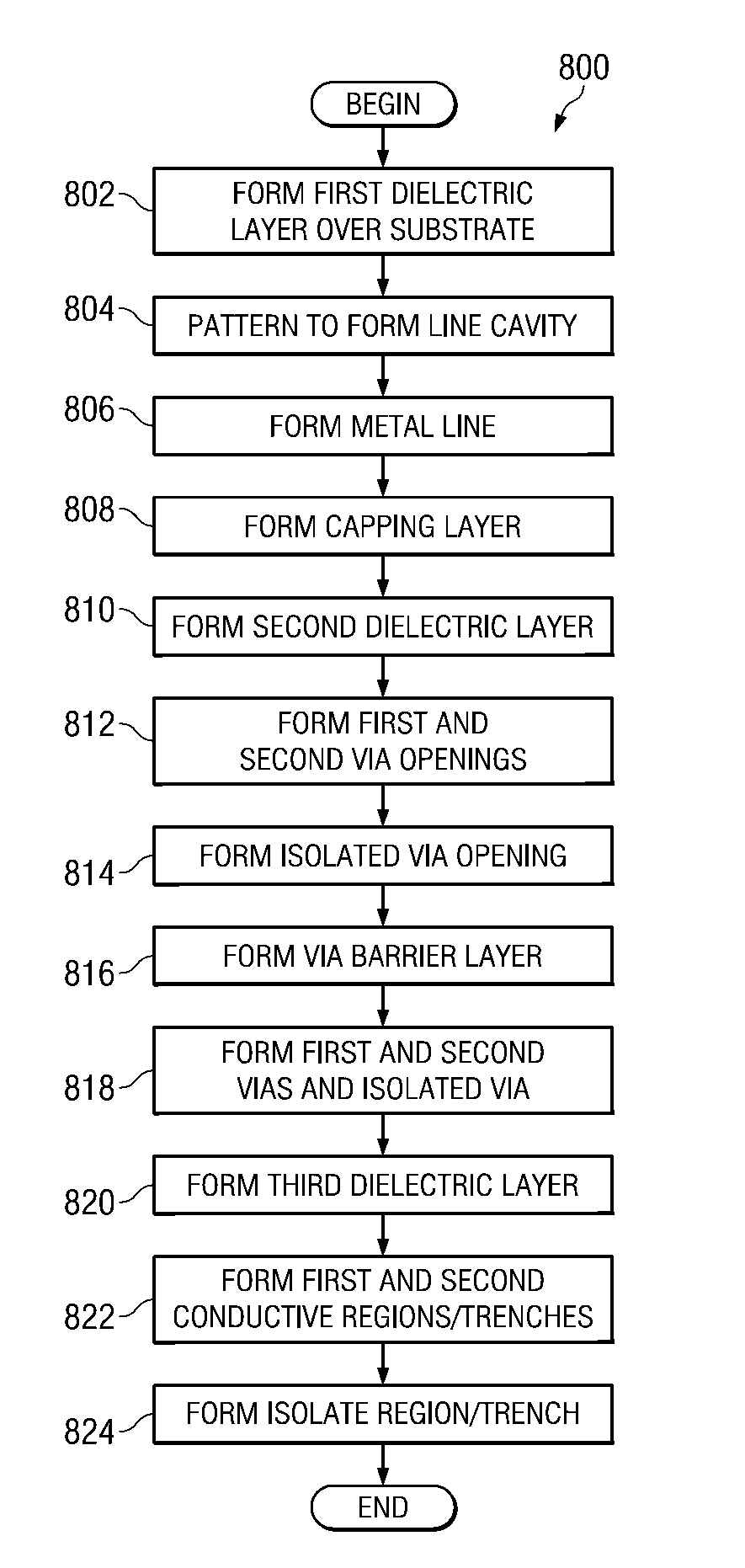

Electrically inactive via for electromigration reliability improvement

ActiveUS20080017989A1Facilitate fabricationEasy to operateSemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectron

A semiconductor device 300 includes a metal line 304 formed in a first dielectric layer 302. A capping layer 306 is formed the metal line 304. A second dielectric layer 308 is formed over the first dielectric layer 302 and the metal line 304. A first via 310 is formed in the second dielectric layer 308 and in contact with the metal line 304. A second via 312 is formed in the second dielectric layer 308 and in contact with the metal line 304, and is positioned a distance away from the first via 310. An electrically isolated via 326 is formed in the second dielectric layer 308 and in contact with the metal line 304 and in between the first via 310 and the second via 312. A third dielectric layer 314 is formed over the second dielectric layer 308. First and second trenches 316, 318 are formed in the third dielectric layer 314 and in contact with the first via 310 and the second via 312, respectively. An isolated trench 328 is formed in the third dielectric layer and in contact with the isolated via 326. The isolated via 326 mitigates void formation and / or void migration during operation / conduction with electrons traveling from the first trench 316 to the second trench 318 via the metal line 304.

Owner:TEXAS INSTR INC

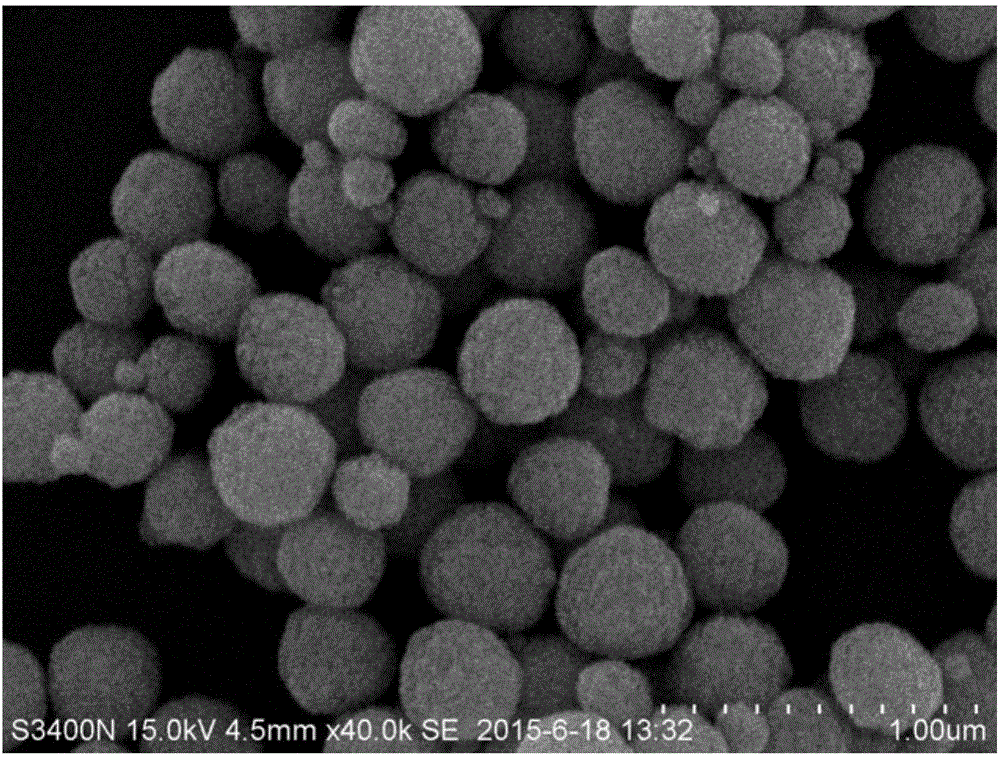

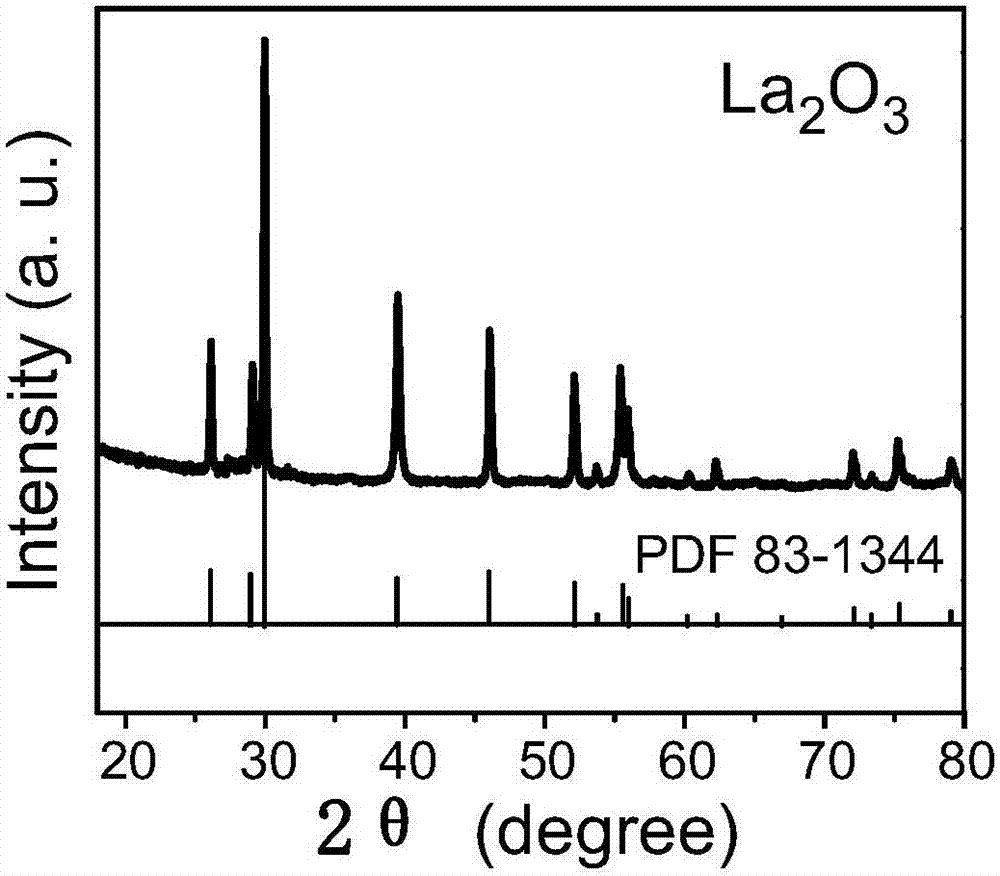

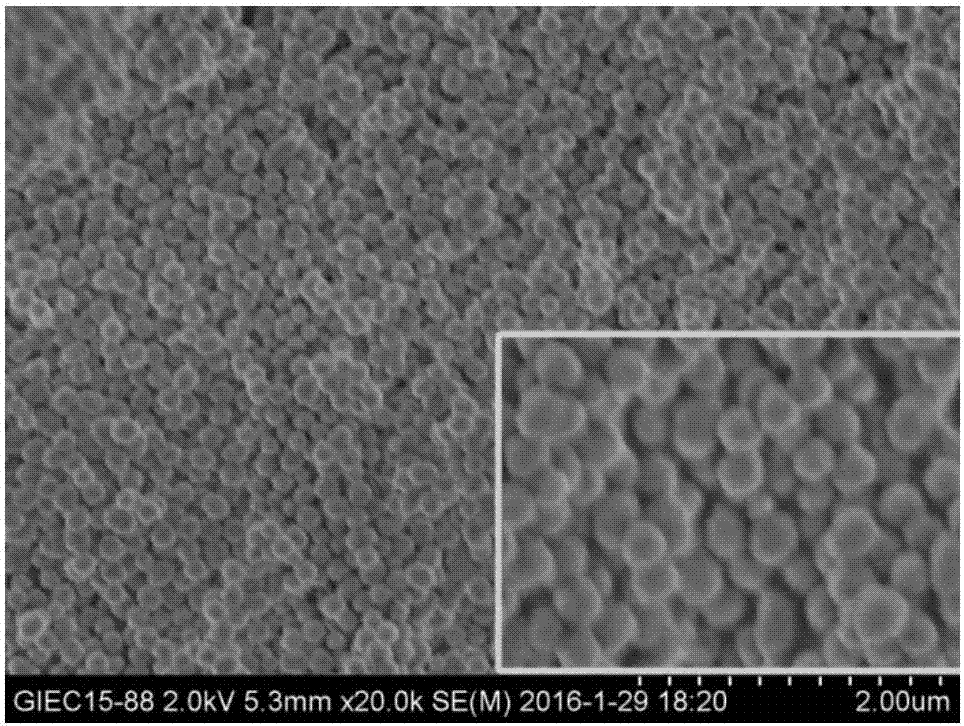

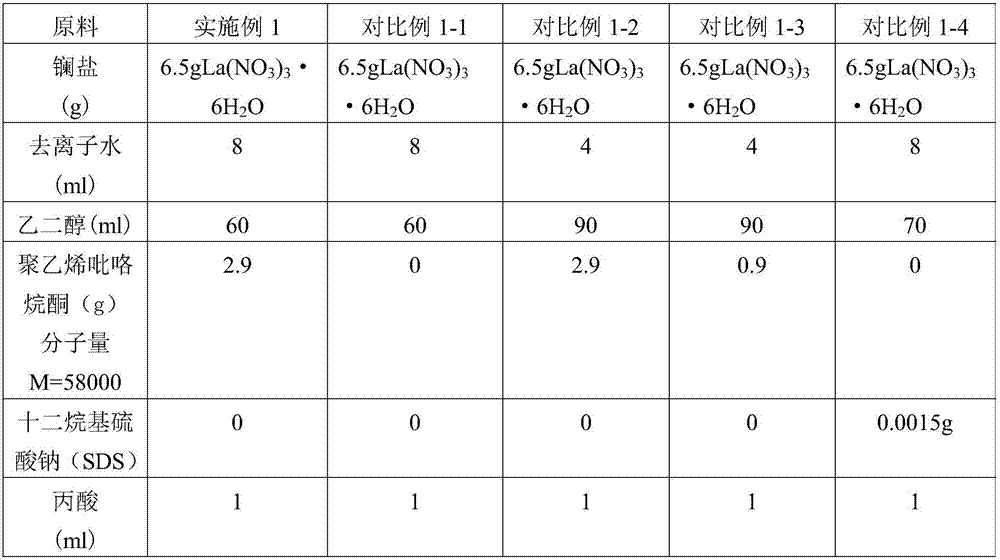

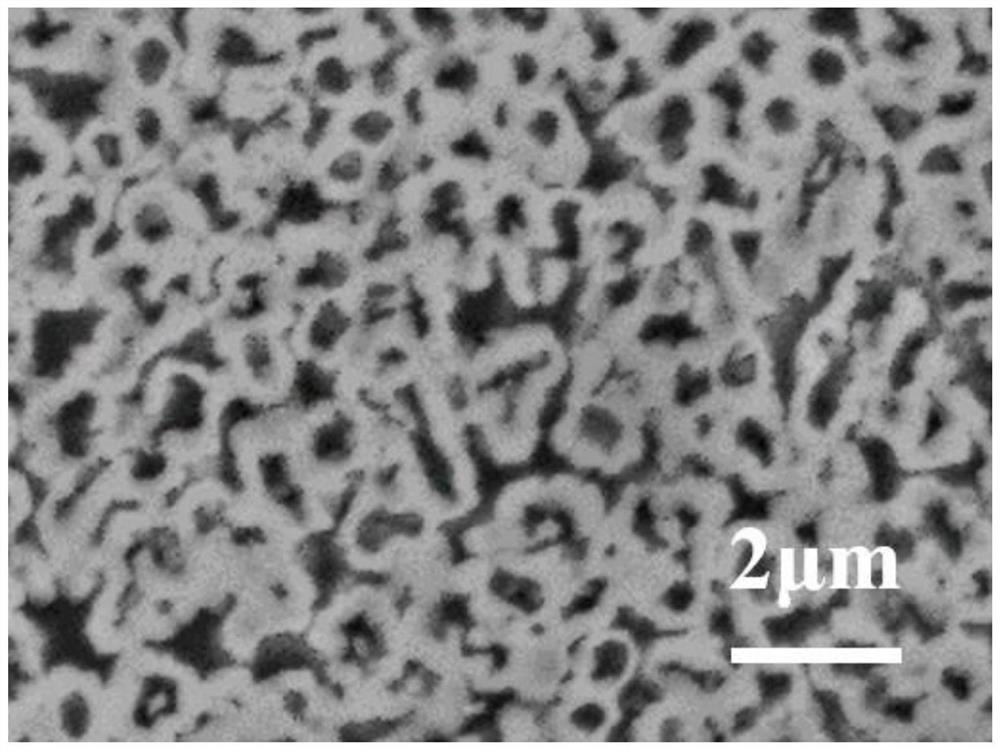

Spherical lanthanum oxide

ActiveCN105948098AShort reaction timeSimple and fast operationRare earth metal oxides/hydroxidesOrganic acidLanthanum

The invention discloses a spherical lanthanum oxide. The average particle size of spherical lanthanum oxide is 150 nm-1.2 mum, the specific surface area after roasting at 1000 DEG C is 1-7 m<2> / g, and the specific surface area after roasting at 500 DEG C is 120-144 m<2> / g. The invention also discloses a preparation method of the spherical lanthanum oxide, and the method includes the following steps: (1) mixing lanthanum salt, hydrous ethylene glycol, polyvinylpyrrolidone, and short-chain organic acid, stirring the mixture, dissolving the mixture, and performing a hydrothermal reaction; and (2) subjecting the mixture to the reaction for 1-8 hours at 160-240 DEG C, cooling the mixture to obtain the precipitate, and drying the precipitate to obtain the spherical lanthanum oxide. The lanthanum oxide prepared by the invention is spherical, has uniform morphology, good degree of crystallization, good dispersibility, high heat stability, and big specific surface area, and is suitable for the application on the motor vehicle exhaust.

Owner:GUANGDONG UNIV OF TECH +1

Methods of forming metal interconnections of semiconductor devices by treating a barrier metal layer

InactiveUS6955983B2Reduce layeringReduce or prevent a metallic material from abnormally growingElectrotherapySemiconductor/solid-state device detailsMetal interconnectMetallurgy

Owner:SAMSUNG ELECTRONICS CO LTD

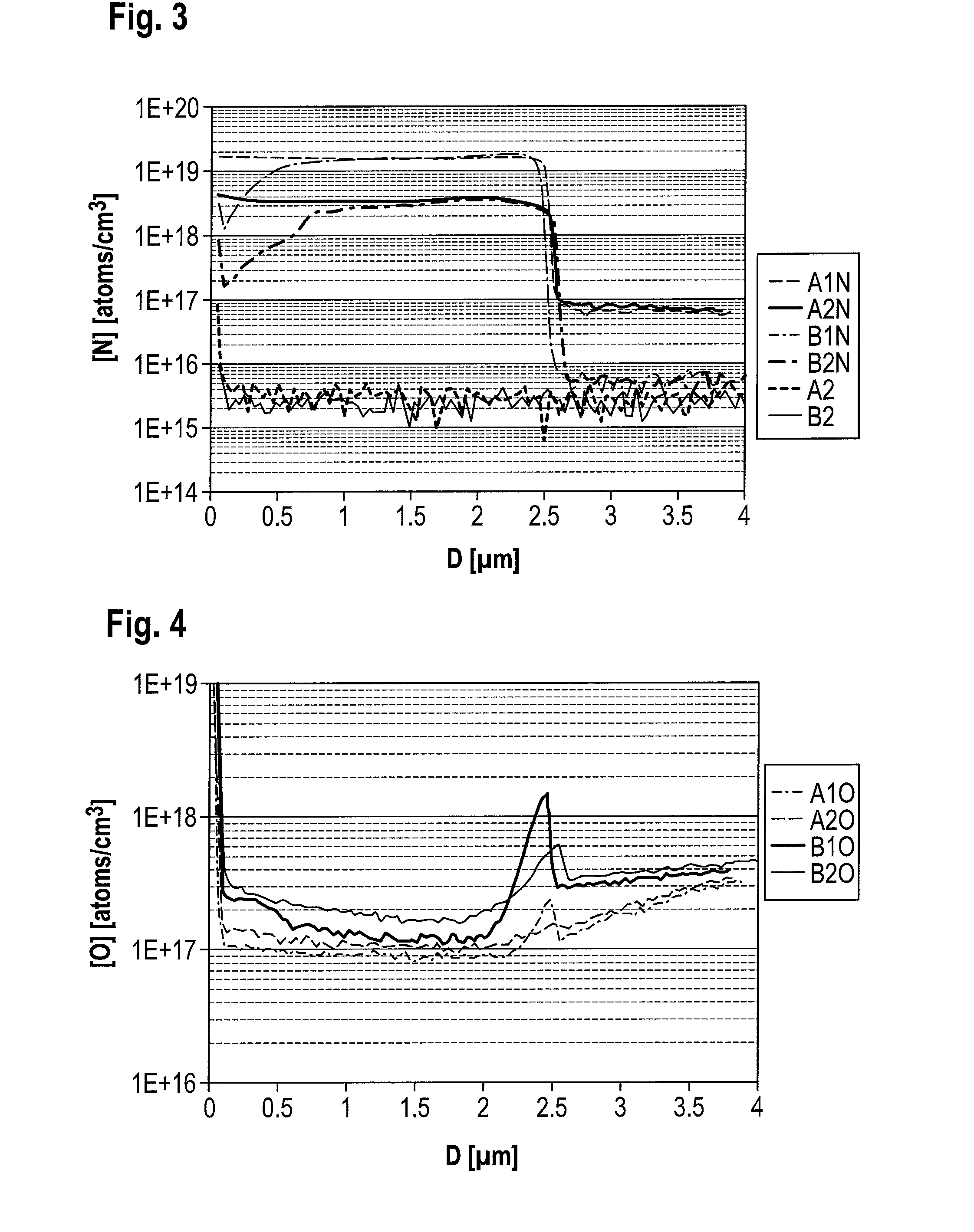

Epitaxial wafer and a method of manufacturing thereof

ActiveUS20150303071A1Reduce nucleationReduces propagationSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographyDeposition temperature

An epitaxial wafer comprises a silicon substrate wafer having first and second sides, and a silicon epitaxial layer deposited on the first side, and optionally one or more additional epitaxial layers on top of the silicon epitaxial layer, at least one of the silicon epitaxial layer or at least one of the one or more additional epitaxial layers being doped with nitrogen at a concentration of 1×1016 atoms / cm3 or more and 1×1020 atoms / cm3 or less. The epitaxial wafer is produced by depositing the silicon epitaxial layer and / or at least one of the one or more additional epitaxial layers, at a deposition temperature of 940° C. or less through chemical vapor deposition in the presence of a deposition gas atmosphere containing one or more silicon precursor compounds and one or more nitrogen precursor compounds.

Owner:SILTRONIC AG +1

Hydrate inhibitor applicable to high moisture content system

The invention discloses hydrate inhibitor applicable to a high moisture content system, and relates to the technical field of oil gas hydrate. The hydrate inhibitor is a mixture of an anticaking agent, a soluble alcohol and salt. The hydrate formed inhibitor has a using pressure of between 1.5 and 30MPa, and a temperature of between -25 and 35 DEG C. The inhibitor can overcome the defects in the prior art, can reduce the speed of nucleation, growth and coalescence of the hydrate by being injected into produced or conveyed petroleum fluid after being mixed at low concentration, has wide applicability, is particularly applicable to the high moisture content system, and has low cost.

Owner:SOUTH CHINA UNIV OF TECH

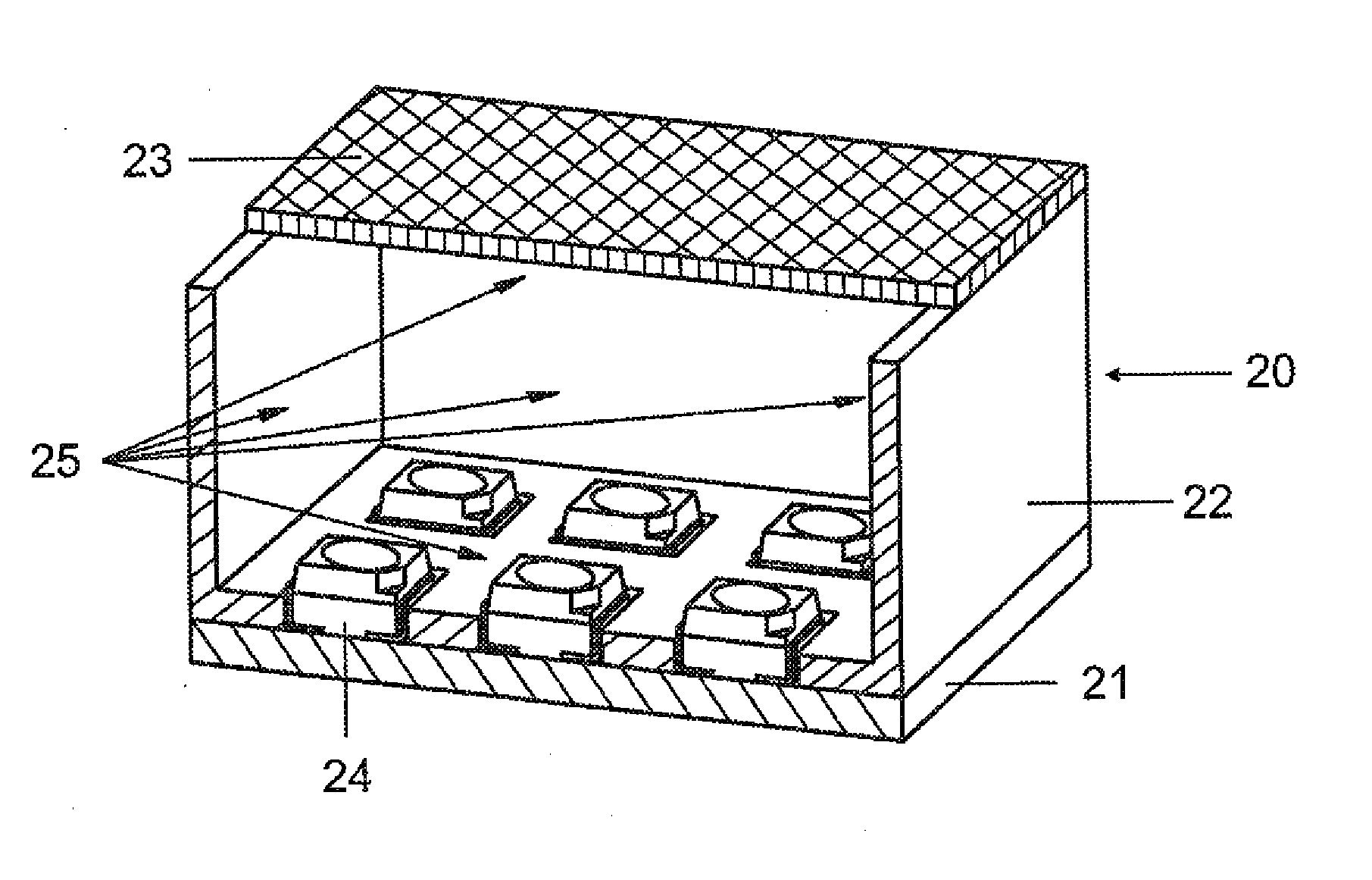

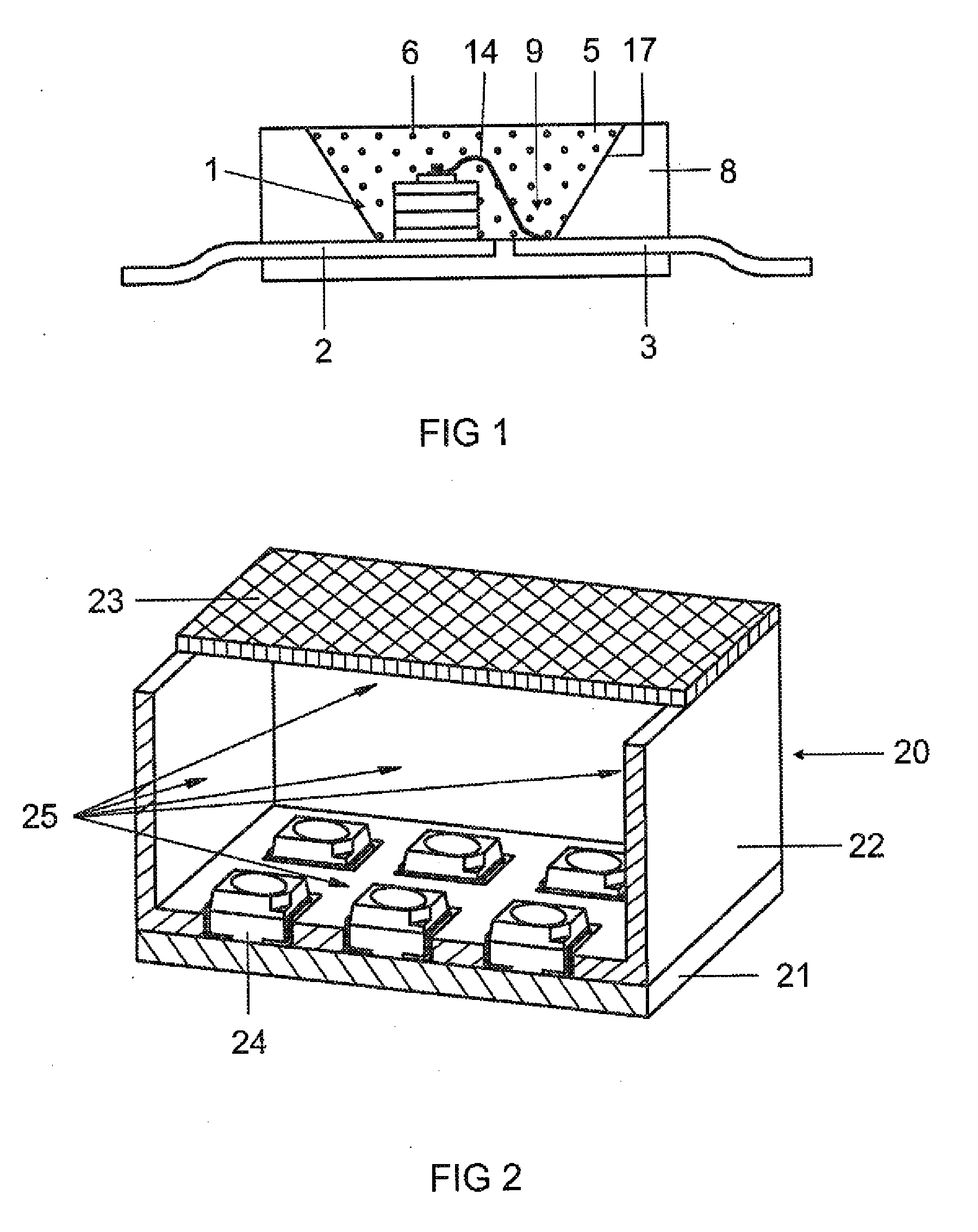

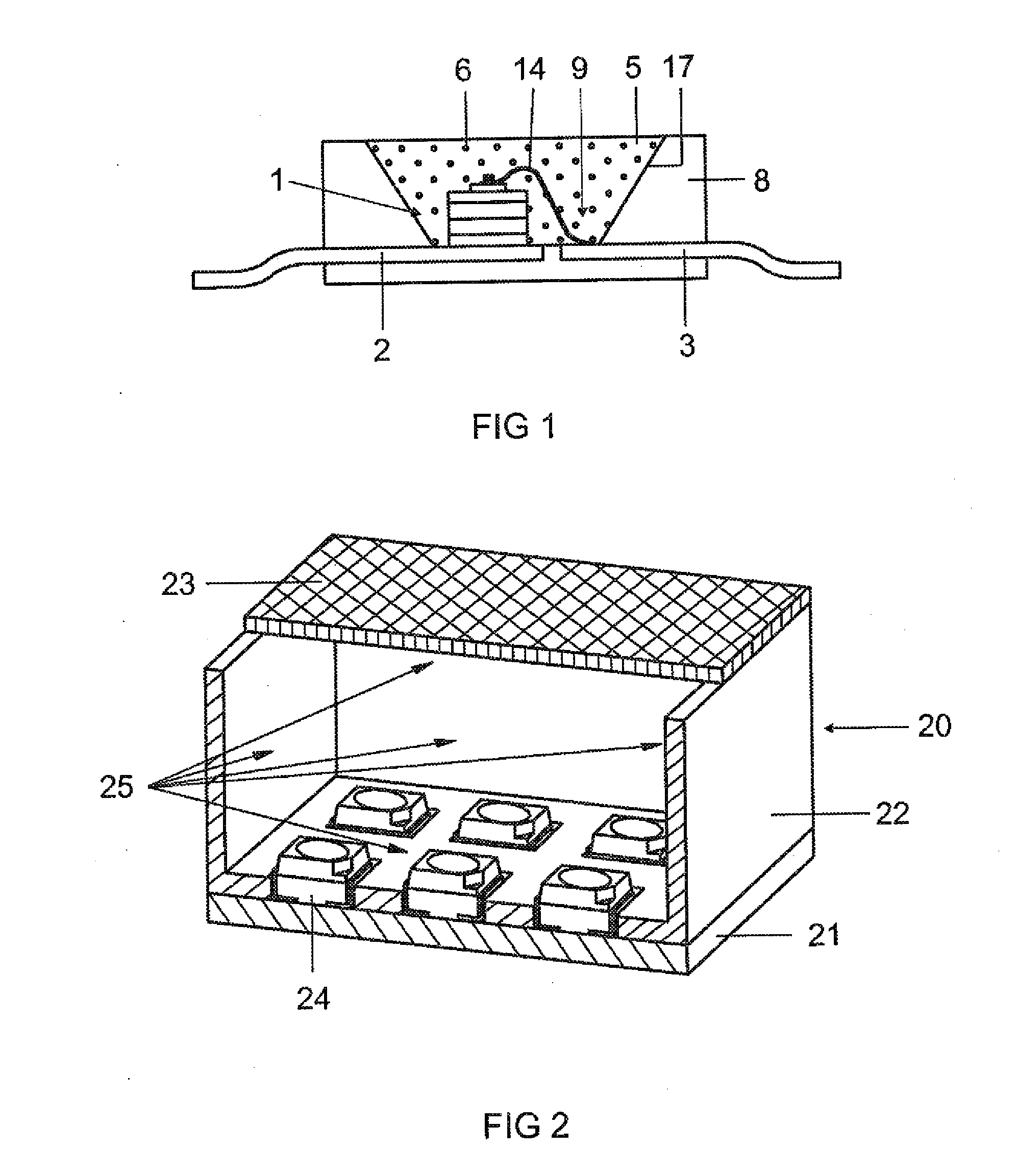

Nematic liquid crystal devices, and methods of production thereof

InactiveUS20020126245A1Reduce nucleationReduce yieldLiquid crystal compositionsNon-linear opticsEngineeringMethods of production

A liquid crystal device comprises a nematic liquid crystal, voltage means for applying a voltage across said liquid crystal, and two substrates (42, 30) each provided with an alignment layer (32, 33), wherein: said liquid crystal is sandwiched between said two substrates (42, 30); said nematic liquid crystal can be placed in at least one operating state and at least one non-operating state, and at least one of said alignment layers (32, 33) is provided with a plurality of surface protrusions (40) formed from an anisotropic material.

Owner:SHARP KK

Compound hydrate inhibitor

ActiveCN105179942AImprove performanceInhibition delays nucleationPipeline systemsSurface-active agentsCaprolactam

The invention discloses a compound hydrate inhibitor. The compound hydrate inhibitor is formed by mixing a copolymer, an emulgator and a dispersing agent. The copolymer is a mixture of one or more of polyvinylpyrrolidone, polyethylene caprolactam, polymethylacrylic acid and dimethylaminoethyl methacrylate. The emulgator is a polyhydric alcohol type non-ionic surface active agent. The dispersing agent is a quaternary ammonium salt compound. The copolymer with the dynamics inhibition performance is combined with the emulgator and the dispersing agent. Nucleation and growth of hydrate particles can be inhibited, and the purpose of dispersing the hydrate particles can also be achieved. The inhibitor can effectively inhibit the nucleation and the growth rate of a hydrate and can also achieve the purpose of preventing agglutination of the hydrate particles, and thus the flowing safety of an oil-gas-water three-phase delivery pipeline is effectively achieved. The compound hydrate inhibitor also has the advantages of being small in use amount, economical, environmentally friendly, efficient, excellent in performance and the like and has good application prospects.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Non-halogen lead-doped perovskite thin film and preparation method and application thereof

ActiveCN110767809AWell formedReduce recombination rateSolid-state devicesSemiconductor/solid-state device manufacturingSolar batterySpin coating

The invention belongs to the field of solar cells, and particularly discloses a non-halogen lead-doped perovskite thin film and a preparation method and application thereof. The perovskite thin film is prepared by adding lead oxalate into a perovskite precursor solution. According to the preparation method, a trace amount of lead oxalate is added into a perovskite precursor solution, and a perovskite thin film layer in a solar cell is obtained through spin coating by a low-temperature solution treatment method, so that the crystallization process of the perovskite material is slowed down, anda thin film with larger crystal grains and fewer crystal boundaries is obtained. The preparation process is simple, and the production cost is saved. The crystallization condition of the perovskite thin film can be well improved, defects are reduced, carrier recombination is inhibited, and the performance of the device is improved. Meanwhile, an indoor perovskite solar cell obtained by the methodhas a great prospect in the aspect of indoor low-illumination power supply in the future.

Owner:SUZHOU UNIV

Articles and methods providing liquid-impregnated scale-phobic surfaces

InactiveUS20190100353A1Promote growthReduce nucleationLiquid surface applicatorsCorrosion preventionSalt solutionMaterials science

This invention relates generally to articles, devices, and methods for inhibiting or preventing the formation of scale during various industrial processes. In certain embodiments, a vessel is provided for use in an industrial process, the vessel having a textured, liquid-impregnated surface in contact with a mineral solution, wherein the liquid-impregnated surface comprises a matrix of features spaced sufficiently close to stably contain an impregnating liquid lubricant therebetween or therewithin, wherein the impregnating lubricant has a low surface energy density, and wherein the spreading coefficient Sos(w) of the impregnating lubricant (subscript ‘o’) on the substrate (subscript ‘s’) in the presence of the salt solution (subscript ‘w’) is greater than zero, such that the impregnating lubricant fully submerges the textured substrate.

Owner:MASSACHUSETTS INST OF TECH

Cement-based composite material for 3D printing technology and its preparation method and use

ActiveCN104310918BEasy to get materialsLow costSolid waste managementComputer printingHouse building

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

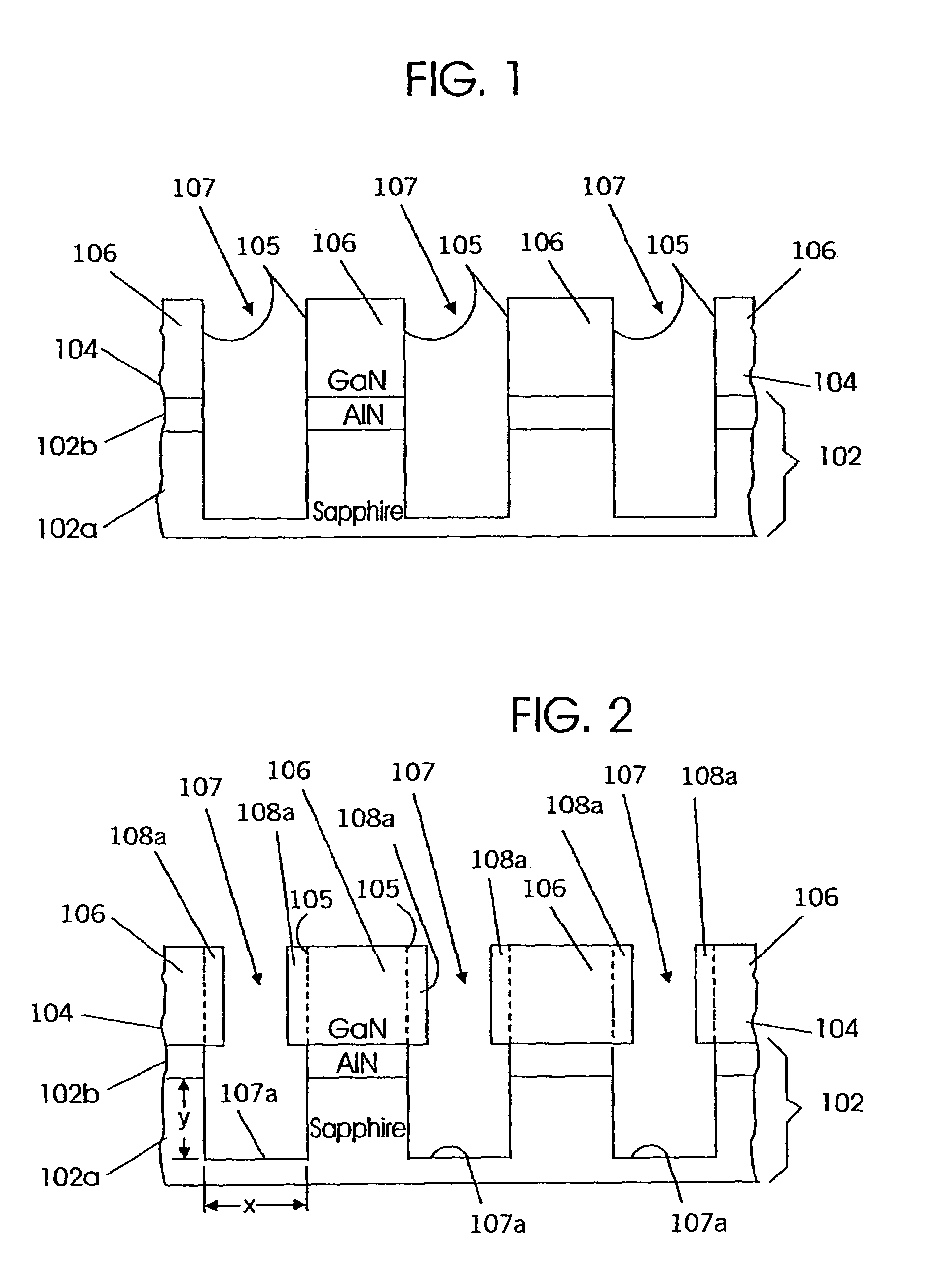

Pendeoepitaxial methods of fabricating gallium nitride semiconductor layers on sapphire substrates, and gallium nitride semiconductor structures fabricated thereby

InactiveUS7217641B2Reduce defect densityImprove usabilityLaser detailsSemiconductor laser structural detailsSemiconductor structureGallium nitride

More specifically, gallium nitride semiconductor layers may be fabricated by etching an underlying gallium nitride layer on a sapphire substrate, to define at least one post in the underlying gallium nitride layer and at least one trench in the underlying gallium nitride layer. The at least one post includes a gallium nitride top and a gallium nitride sidewall. The at least one trench includes a trench floor. The gallium nitride sidewalls are laterally grown into the at least one trench, to thereby form a gallium nitride semiconductor layer. However, prior to performing the laterally growing step, the sapphire substrate and / or the underlying gallium nitride layer is treated to prevent growth of gallium nitride from the trench floor from interfering with the lateral growth of the gallium nitride sidewalls of the at least one post into the at least one trench. Embodiments of gallium nitride semiconductor structures according to the present invention can include a sapphire substrate and an underlying gallium nitride layer on the sapphire substrate. The underlying gallium nitride layer includes therein at least one post and at least one trench. The at least one post each includes a gallium nitride top and a gallium nitride sidewall. The at least one trench includes a sapphire floor. A lateral gallium nitride layer extends laterally from the gallium nitride sidewall of the at least one post into the at least one trench. In a preferred embodiment, the at least one trench extends into the sapphire substrate such that the at least one post each includes a gallium nitride top, a gallium nitride sidewall and a sapphire sidewall and the at least one trench includes a sapphire floor. The sapphire floor preferably is free of a vertical gallium nitride layer thereon and the sapphire sidewall height to sapphire floor width ratio preferably exceeds about 1 / 4. A mask may be included on the sapphire floor and an aluminum nitride buffer layer also may be included between the sapphire substrate and the underlying gallium nitride layer. A mask also may be included on the gallium nitride top.

Owner:NORTH CAROLINA STATE UNIV

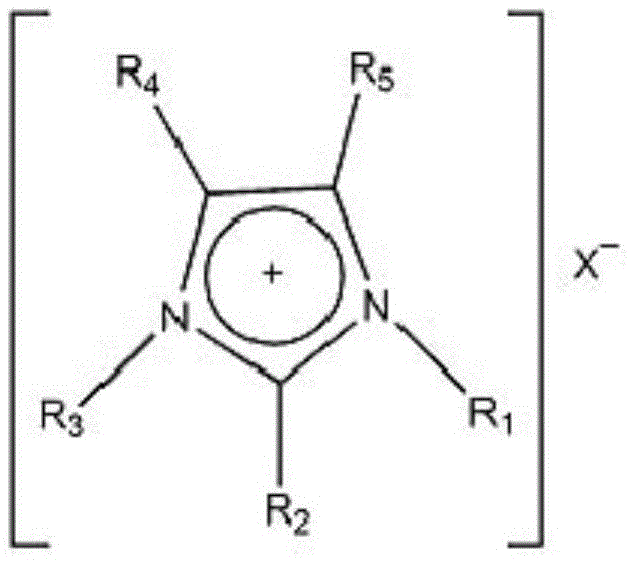

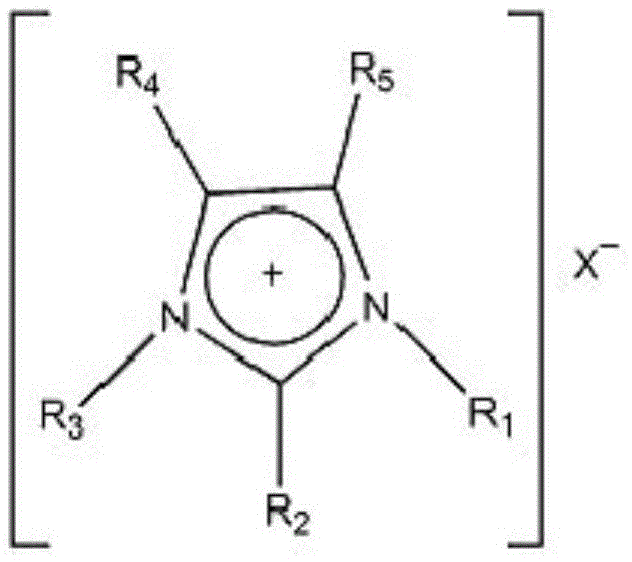

Enhanced compound natural gas hydrate inhibitor

ActiveCN105542736AChanging the thermodynamic conditions of formationReduce nucleationDrilling compositionEthyl phosphateIon

The invention relates to an enhanced compound natural gas hydrate inhibitor. The inhibitor comprises alkyl imidazole ionic liquid, an assistant and water, wherein the alkyl imidazole ionic liquid has a structural formula as shown in the specification, alkyl substituent R1 is ethyl or butyl, R3 is methyl, R2, R4 and R5 are H, and X<-> is one of tetrafluoroborate, methyl sulfate and ethyl sulfate. The alkyl imidazole ionic liquid has the characteristic of anion / cation adjustability, and the polarity and hydrophilcity / lipophilicity of the alkyl imidazole ionic liquid can be adjusted, so that the compound inhibitor is suitable for oil-gas-water three-phase or oil-water or gas-water two-phase coexistent system, and can be compounded with the assistant to further improve the hydrate inhibiting performance; and under a condition of high supercooling degree, compared with a common alcohol or sodium chloride thermodynamic inhibitor having a mass concentration of 20-60 percent, the inhibitor has the advantages that the requirement can be met under low-usage (1-10 percent), the inhibition cost can be greatly reduced, and hazard to the environment can be reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

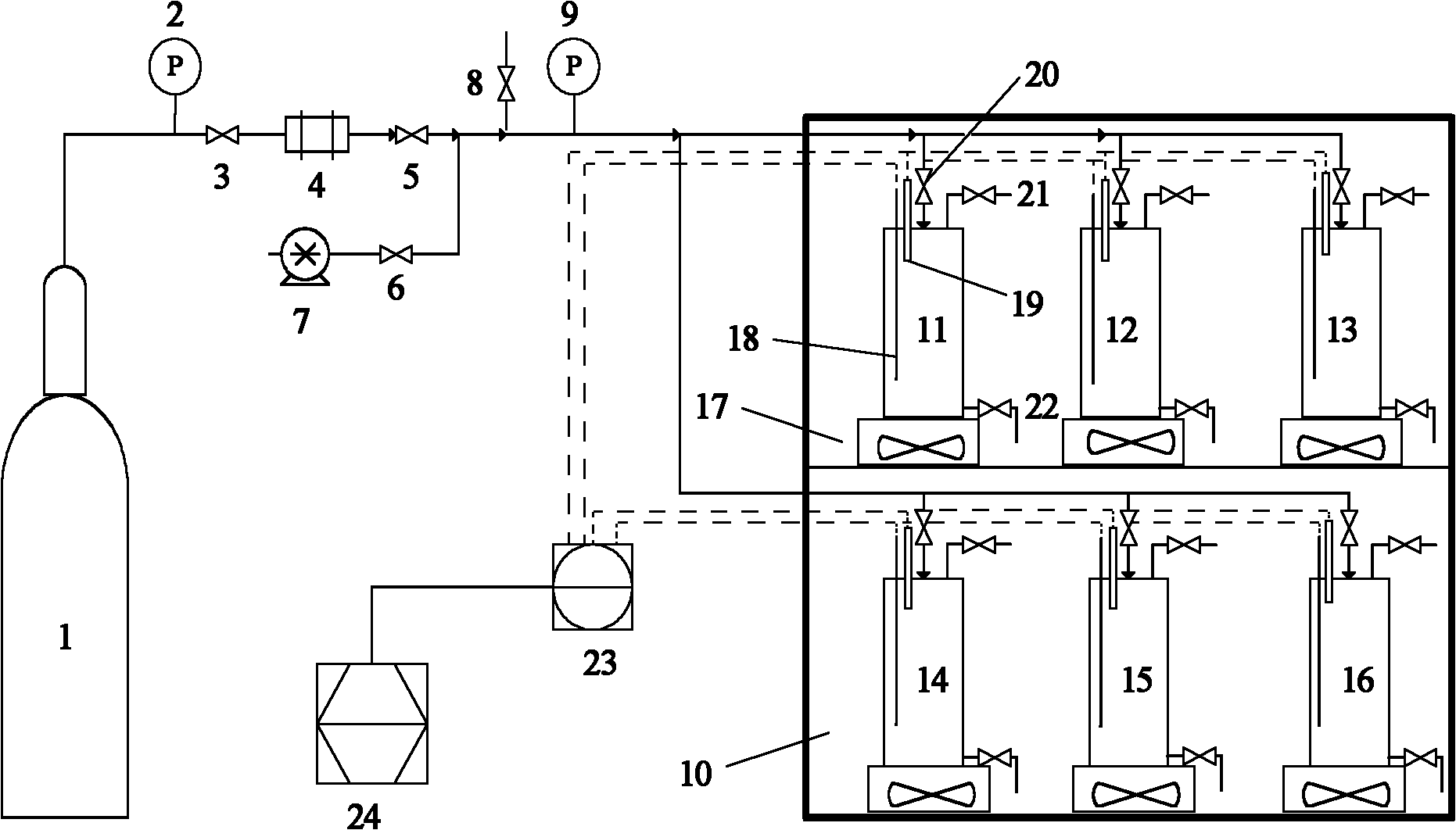

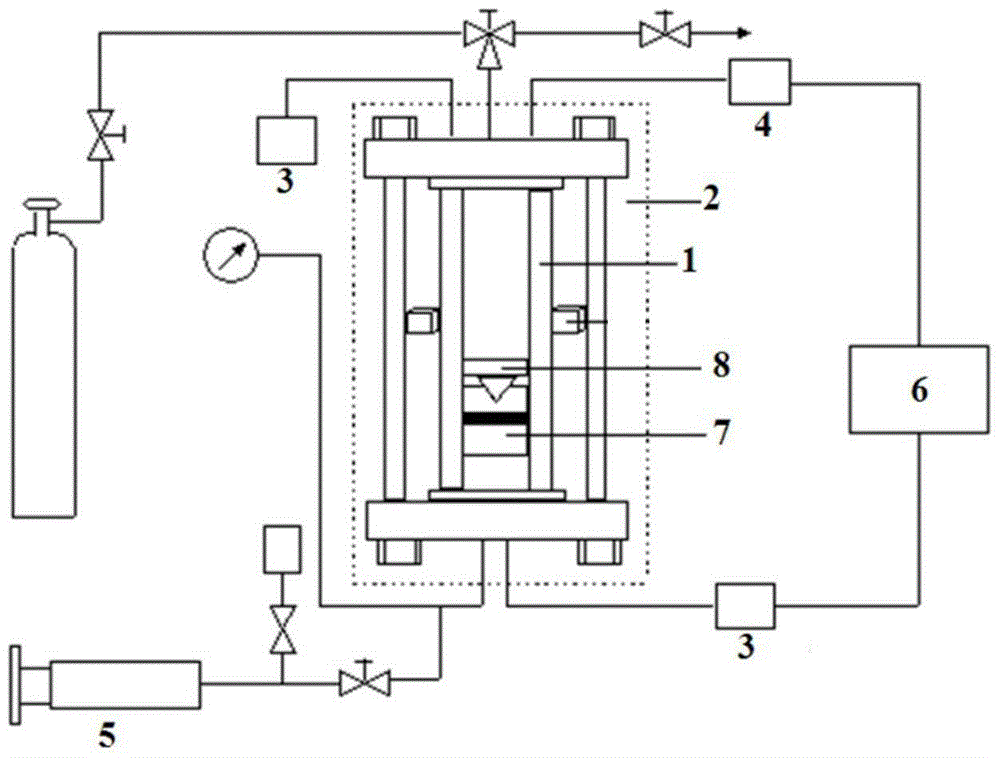

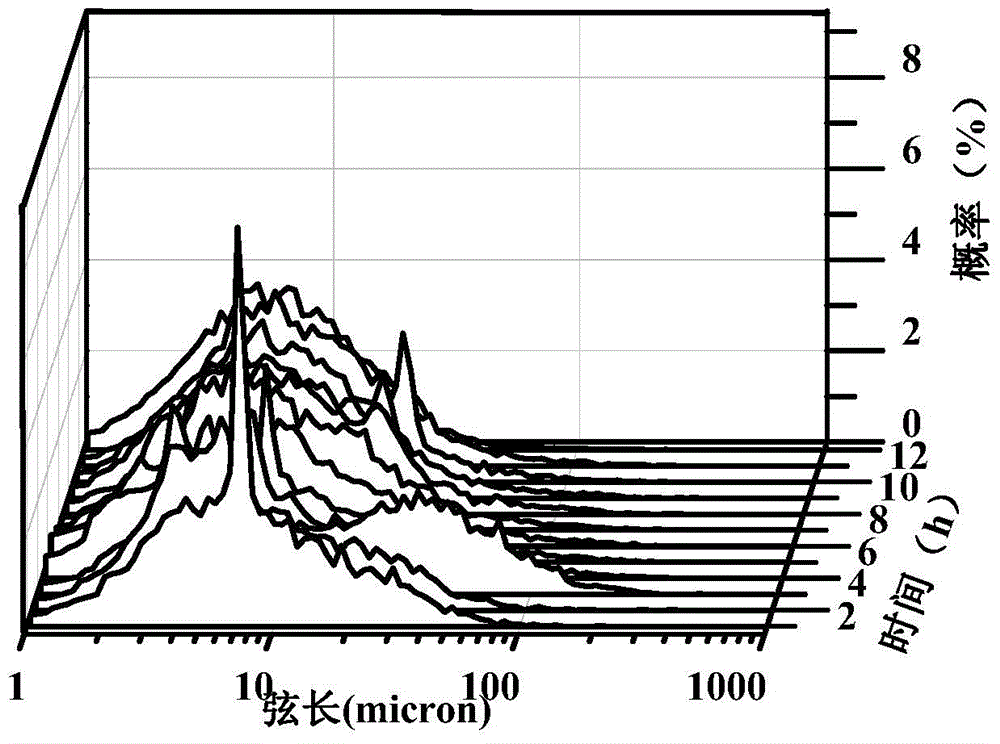

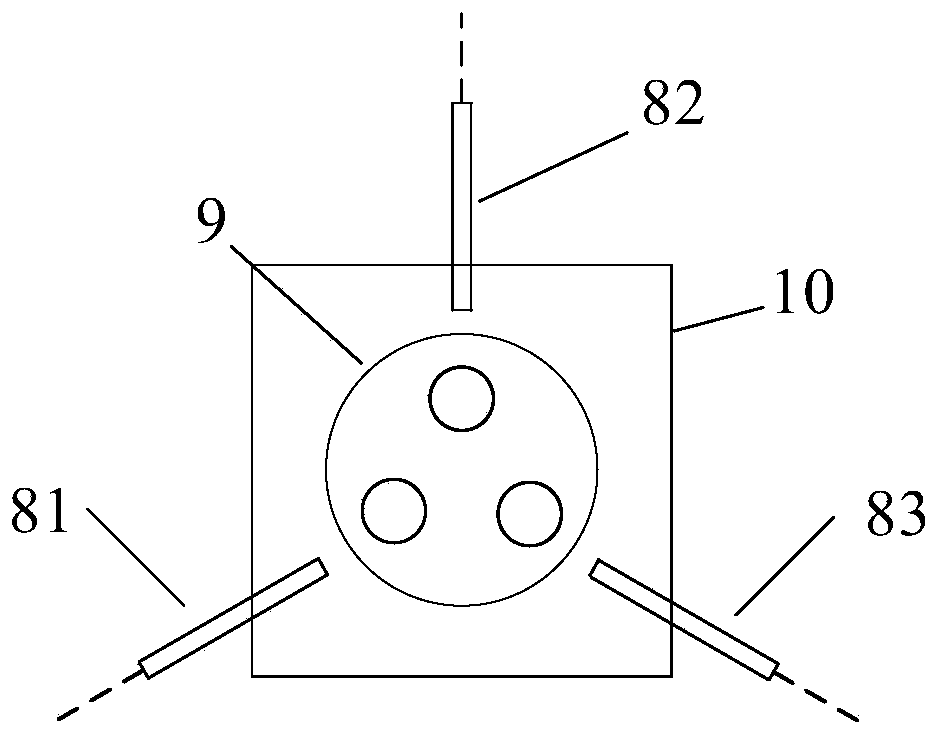

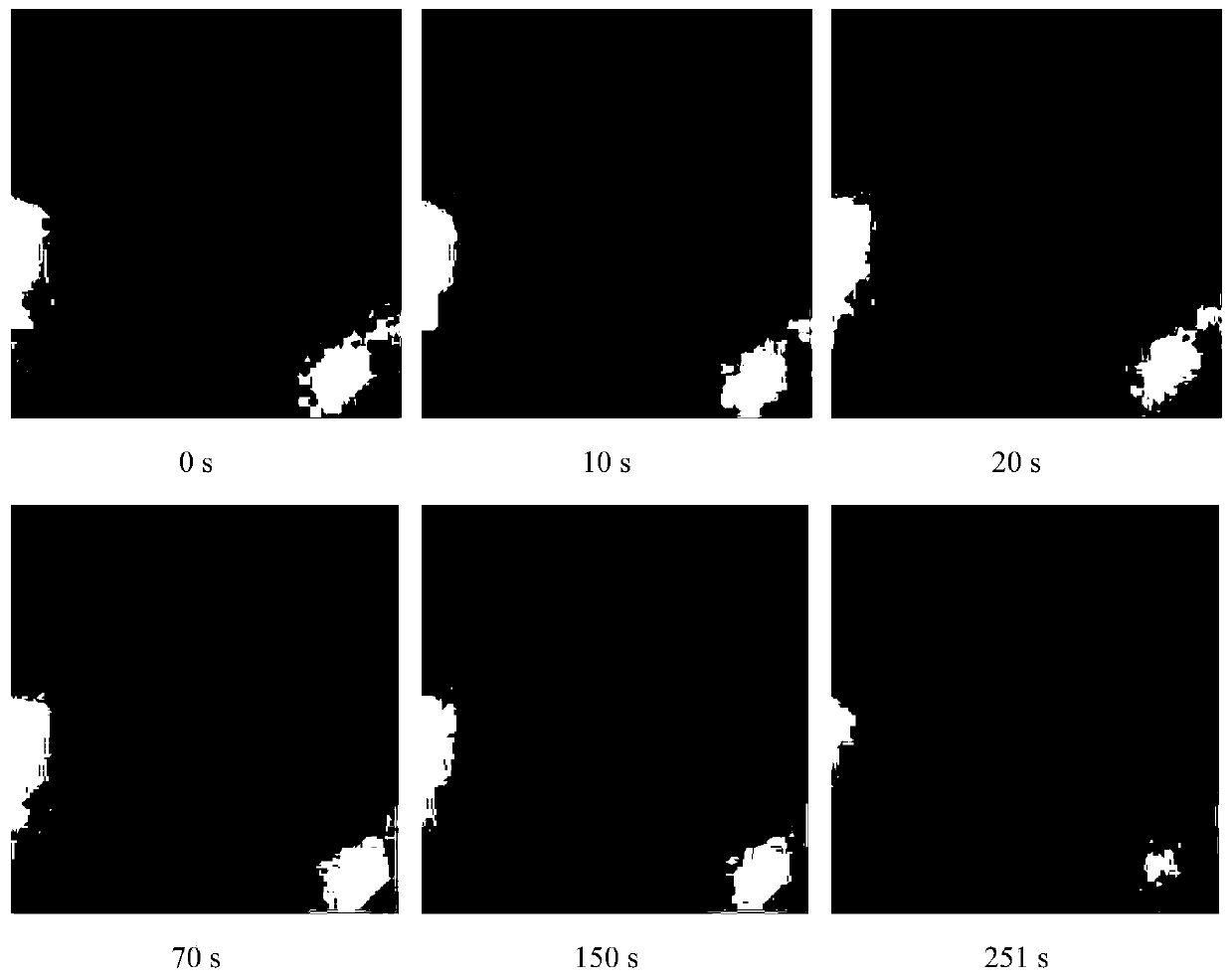

Device and method capable of achieving synchronous mesoscopic observation of formation and decomposition of gas hydrates

ActiveCN110554038AShort experiment cycleReliability of ObservationsMaterial analysis by optical meansDecompositionQuartz

The invention discloses a device and a method capable of achieving synchronous mesoscopic observation of formation and decomposition of gas hydrates. The device comprises a gas cylinder, a vacuum pump, a gas storage tank, a low-temperature thermostatic bath, a high-pressure visual reaction kettle, a sealing box, a pressure-stabilizing gas inlet system, a data acquisition instrument, a real-time display system and a pressure-stabilizing exhaust system. The high-pressure visual reaction kettle comprises a plurality of transparent sapphire inner cylinders, an upper flange, a lower flange and a quartz outer cylinder; the sapphire inner cylinder is of a hollow structure and is arranged in the transparent quartz outer cylinder, and the upper flange and the lower flange are used for sealing the inner cylinder and the outer cylinder. The upper and lower flanges are provided with a plurality of interfaces. Each sapphire inner cylinder can be used for the formation and decomposition of gas hydrates simultaneously. A drying agent is placed in the sealing box, and fogging can be avoided through observation in the sealing box. According to the invention, the formation and decomposition of gas hydrates can be researched at high pressure and low temperature; multiple groups of experiments are carried out at the same time, online real-time synchronous mesoscopic observation of morphology and dynamic changes of formation and decomposition of the gas hydrate can be achieved, and analysis is carried out through image processing software, so that the influence of hydrate nucleation and growthrandomness is reduced while the operation efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

Electrically inactive via for electromigration reliability improvement

ActiveUS7566652B2Facilitate fabricationEasy to operateSemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

A semiconductor device 300 includes a metal line 304 formed in a first dielectric layer 302. A capping layer 306 is formed the metal line 304. A second dielectric layer 308 is formed over the first dielectric layer 302 and the metal line 304. A first via 310 is formed in the second dielectric layer 308 and in contact with the metal line 304. A second via 312 is formed in the second dielectric layer 308 and in contact with the metal line 304, and is positioned a distance away from the first via 310. An electrically isolated via 326 is formed in the second dielectric layer 308 and in contact with the metal line 304 and in between the first via 310 and the second via 312. A third dielectric layer 314 is formed over the second dielectric layer 308. First and second trenches 316, 318 are formed in the third dielectric layer 314 and in contact with the first via 310 and the second via 312, respectively. An isolated trench 328 is formed in the third dielectric layer and in contact with the isolated via 326. The isolated via 326 mitigates void formation and / or void migration during operation / conduction with electrons traveling from the first trench 316 to the second trench 318 via the metal line 304.

Owner:TEXAS INSTR INC

A spherical lanthanum oxide

ActiveCN105948098BShort reaction timeSimple and fast operationRare earth metal oxides/hydroxidesOrganic acidThermal stability

Owner:GUANGDONG UNIV OF TECH +1

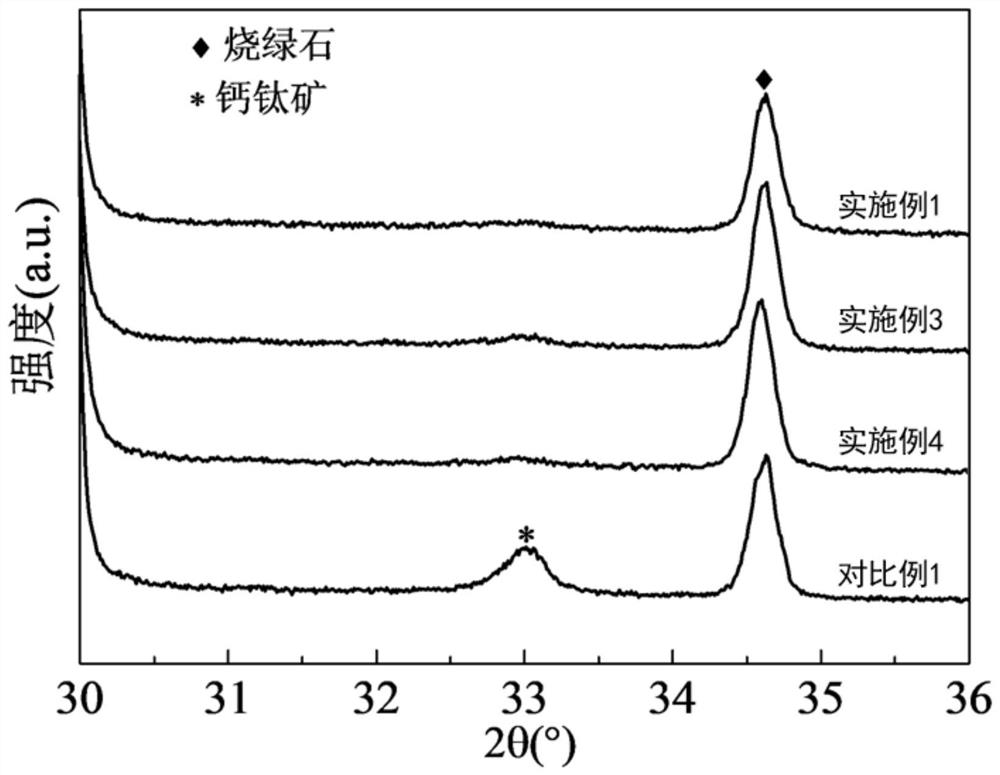

Pyrochlore-based glass ceramic for solidifying radioactive waste and preparation method of pyrochlore-based glass ceramic

InactiveCN113912297AIncrease flexibilityIncrease curing amountRadioactive decontaminationMolten stateRadioactive waste

The invention provides pyrochlore-based glass ceramic for solidifying radioactive waste and a preparation method of the pyrochlore-based glass ceramic. The pyrochlore-based glass ceramic comprises the following components: actinide nuclide raw materials, zirconium oxide, titanium oxide and aluminum oxide, the molar ratio of the actinide nuclide raw material to the zirconium oxide to the titanium oxide to the aluminum oxide is (3-5): (3-5): (3-5): (1-3); the preparation method comprises the following steps: (1) mixing actinide nuclide raw materials, zirconium oxide, titanium oxide and aluminum oxide, and pressing to obtain a blocky sample; and (2) heating the blocky sample obtained in the step (1) to a molten state, and cooling and solidifying at a cooling rate of 200-500K / s to obtain the pyrochlore-based glass ceramic. According to the preparation method provided by the invention, the curing process is simplified, the operation difficulty is reduced, the curing safety and the curing efficiency are improved, and the energy consumption and the cost are reduced.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com