Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176 results about "Methyl Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing electrocatalytic water-splitting oxygen production electrode

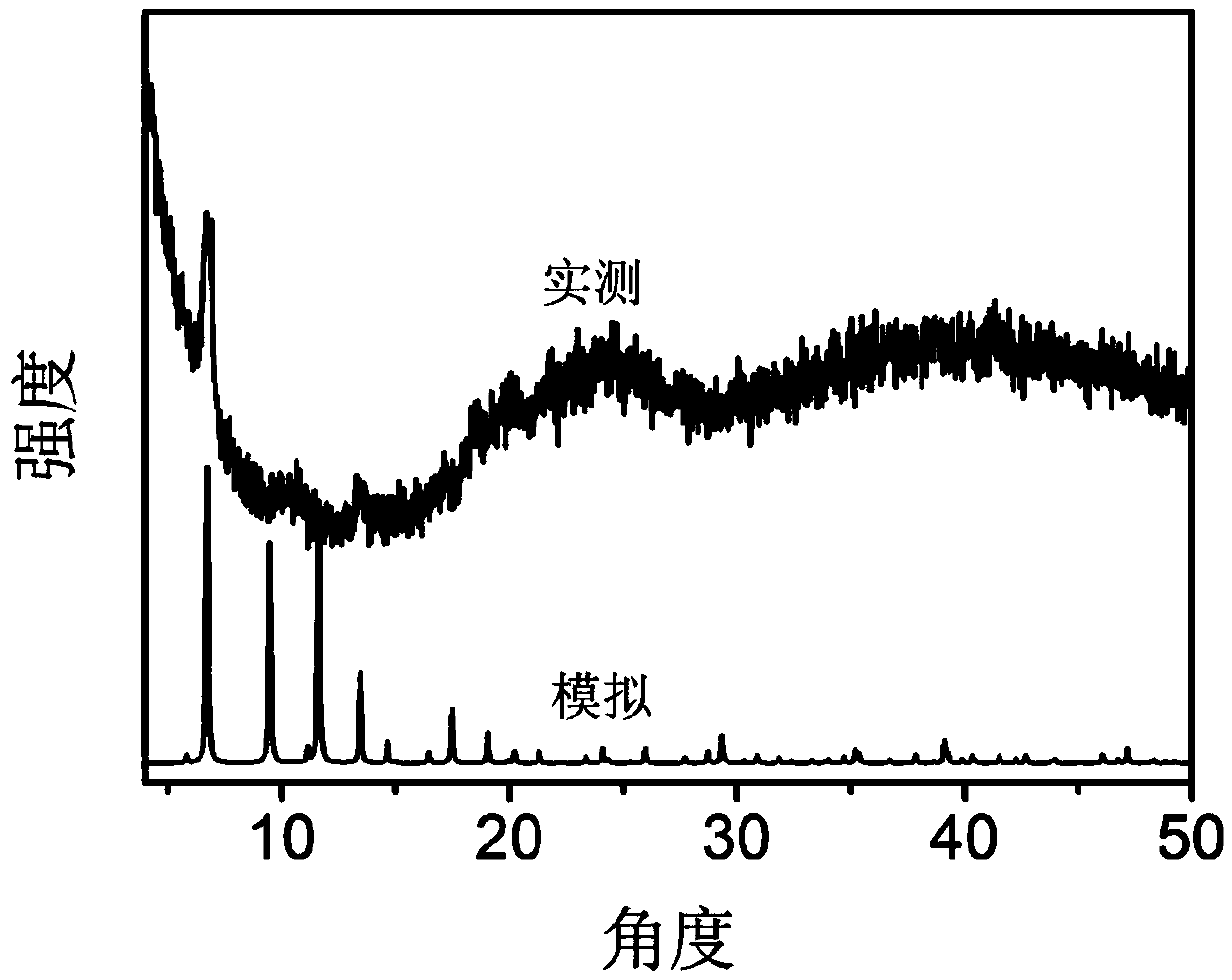

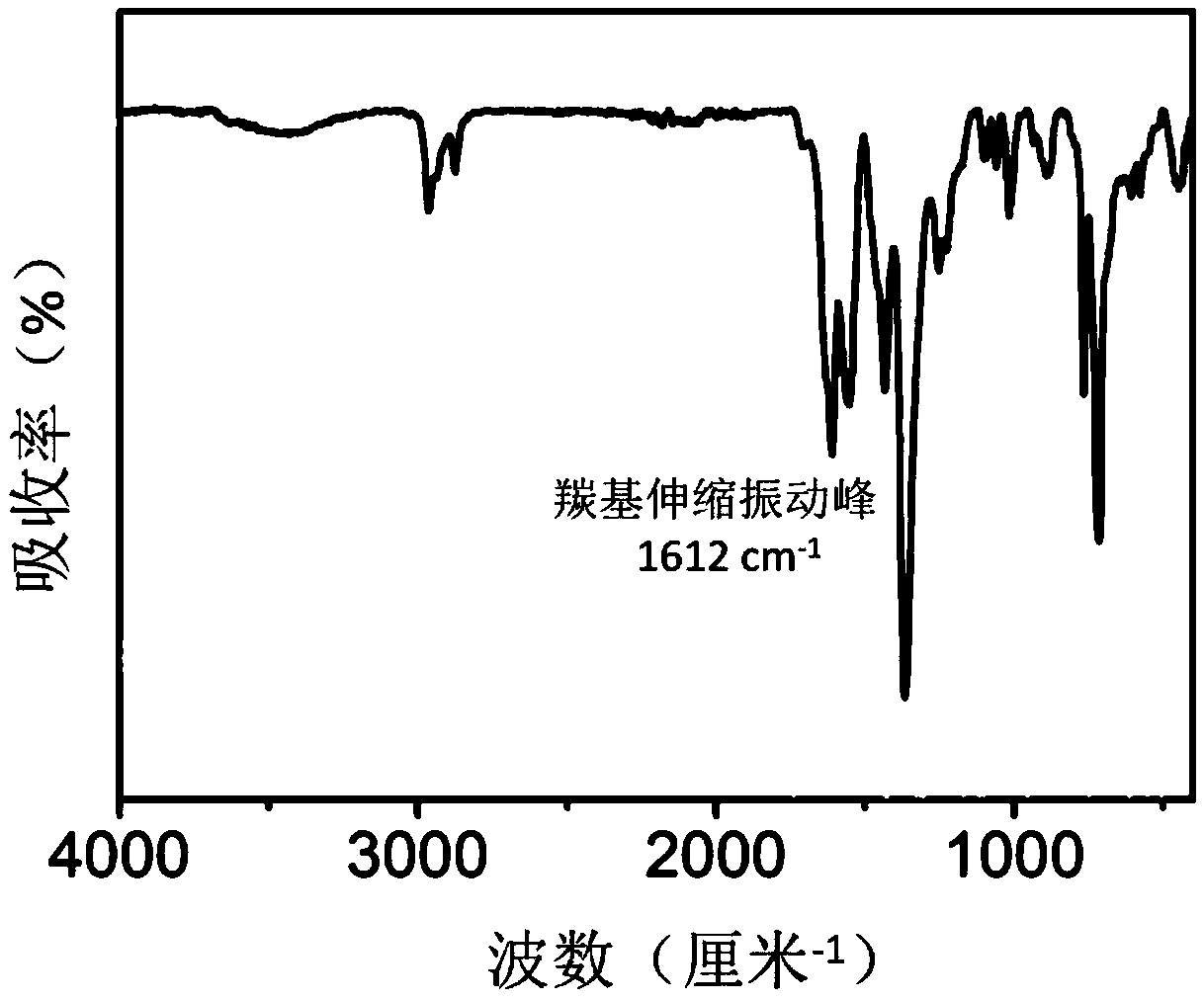

ActiveCN105369306AHigh activityImprove oxygen production efficiencyFuel and primary cellsCell electrodesN dimethylformamideMetal-organic framework

The invention particularly relates to a method for preparing an electrocatalytic water-splitting oxygen production electrode, with Fe / Ni duplex metal coordinating with trimesic acid, of a metal organic framework material and belongs to the field of electrodeposition / electrocatalysis. The method comprises the steps that (1) Ni(NO3)2.6H2O, Fe(NO3)3.9H2O and the trimesic acid are all dissolved in N,N-dimethylformamide, then tributylmethylammonium methyl sulfate is added, and sufficient stirring is conduced till all the components are completely dissolved, so that electrolyte, with the Fe / Ni duplex metal coordinating with the trimesic acid, for the metal organic framework material is obtained; (2) a standard three-electrode system is assembled by using foamed nickel as a working electrode, a silver / silver chloride saturated electrode as a reference electrode, a platinum sheet as a counter electrode and the solution prepared in the step (1) as the electrolyte; and (3) the standard three-electrode system assembled in the step (2) is connected to an electrochemical workstation, and the working electrode is taken out of the electrolyte, cleaned and dried after constant-potential electrodeposition is conducted, so that the electrocatalytic water-splitting oxygen production electrode is obtained.

Owner:理工清科(北京)科技有限公司

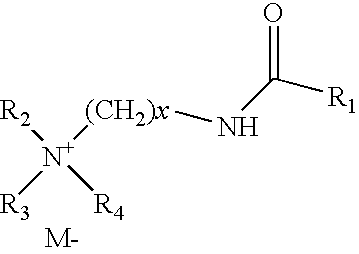

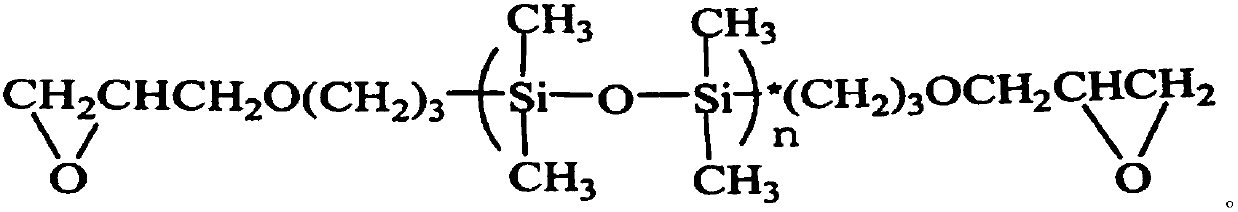

Drilling fluids containing biodegradable organophilic clay

Drilling fluids are provided that comprise an organophilic clay treated with a quaternary ammonium surfactant having an amide linkage. The quaternary ammonium surfactant may comprise a compound generally represented by the following formula: where M− is an anion such as a chloride, methyl sulfate, bromide, acetate, or iodide ion; R1 is an alkyl group such as a saturated hydrocarbon with 10 or more carbons; R2, R3, and R4 are the same or different alkyl groups such as a methyl, ethyl, or benzyl group, and x is greater than or equal to 1. The organophilic clay treated in this manner is substantially biodegradable. In embodiments, the drilling fluids comprise the foregoing organophilic clay, an oil-based fluid and a weighting agent. In still embodiments, the drilling fluids comprise the foregoing organophilic clay, an invert emulsion, an emulsifier, and a weighting agent.

Owner:HALLIBURTON ENERGY SERVICES INC

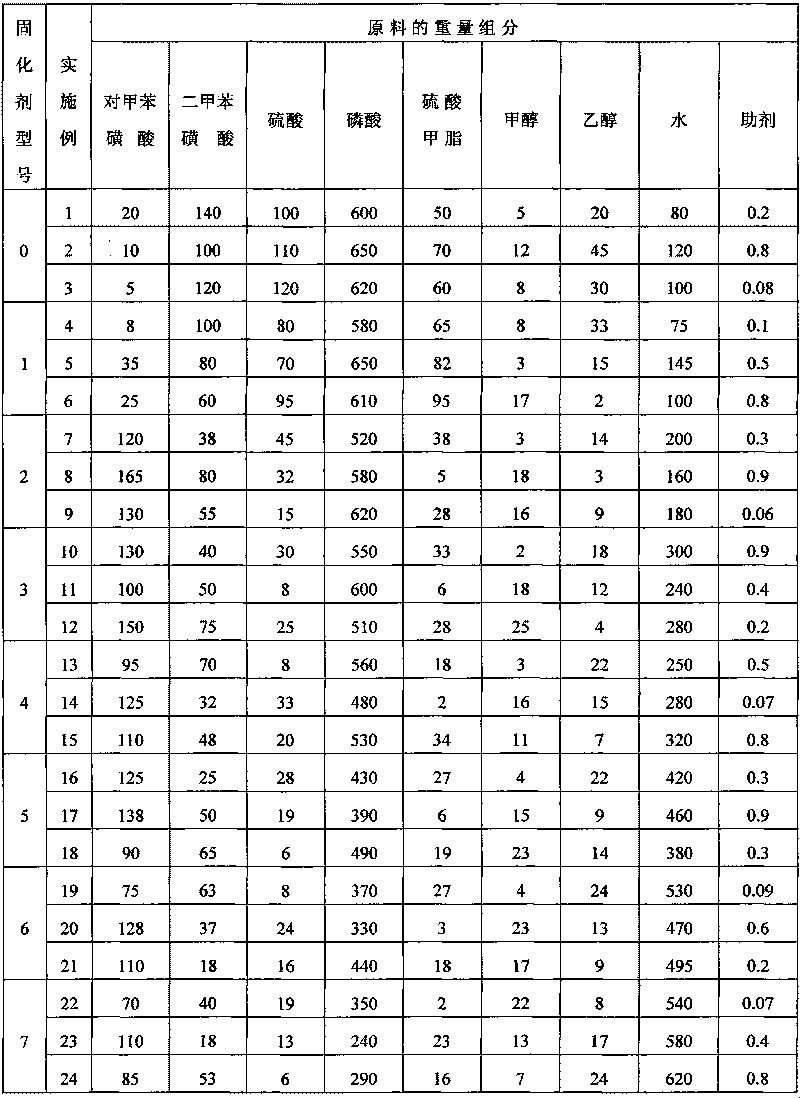

Curing agent of self-hardening furan resin sand and preparation method thereof

ActiveCN101722272ASolve the problem that the usable time is too shortSolve the difficult problems of productionFoundry mouldsFoundry coresFuranPhosphoric acid

The invention relates to a curing agent of self-hardening furan resin sand, which comprises the following components in portions by weight: 1-300 portions of toluenesulfonic acid, 10-300 portions of xylene monosulfonic acid, 1-170 portions of sulfuric acid, 200-800 portions of phosphoric acid, 1-200 portions of methyl sulfate, 1-50 portions of ethanol, 1-50 portions of methanol, 40-900 portions of water and 0.05-1.0 portion of assistant. The preparation method comprises the following steps: (1) prefabricating the toluenesulfonic acid, the xylene monosulfonic acid and the methyl sulfate; (2) preparing all the raw materials according to the proportion of the curing agent; and (3) synthesizing the curing agent by the following steps: (a) mixing the toluenesulfonic acid, the xylene monosulfonic acid, the methyl sulfate and the sulfuric acid to react for 1.0 hour; (b) cooling to 55 DEG C, adding the mixture of methanol and ethanol to react at 50-70 DEG C for 1.0 hour; (c) adding the phosphoric acid to react at 55-70 DEG C for 1.0 hour; and (d) cooling to 50 DEG C, and adding water and assistant; and discharging after evenly mixing. The curing agent can adapt to the long (super long) use time in the molding process of large castings at high air temperature (above 28 DEG C) and high sand temperature (30-50 DEG C), and solves the problem that the large (super long and large) castings are difficult to produce since the temperature of the reclaimed sand can not drop to the designed value due to various reasons in the foundry corporations.

Owner:四川东树新材料有限公司

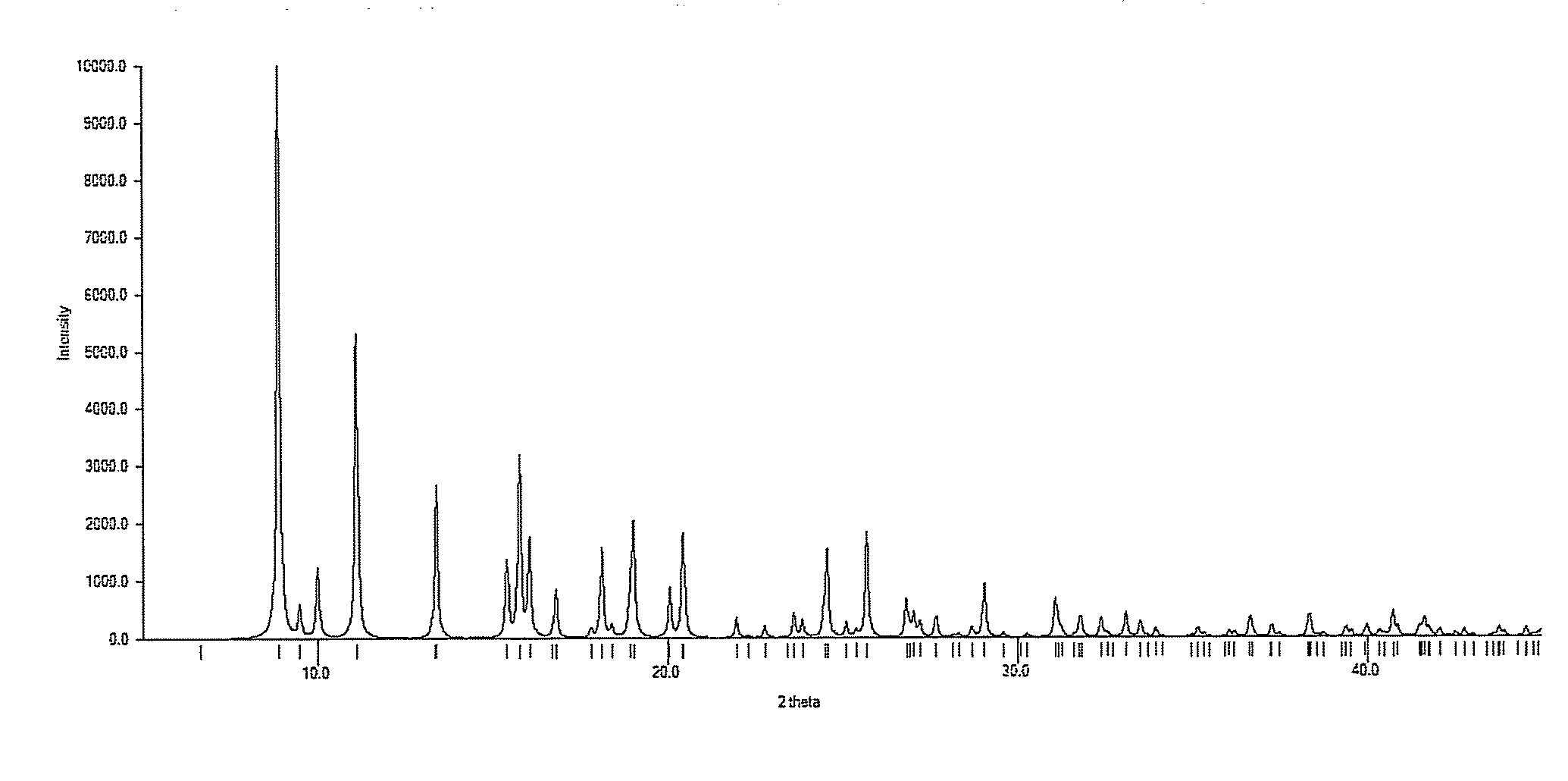

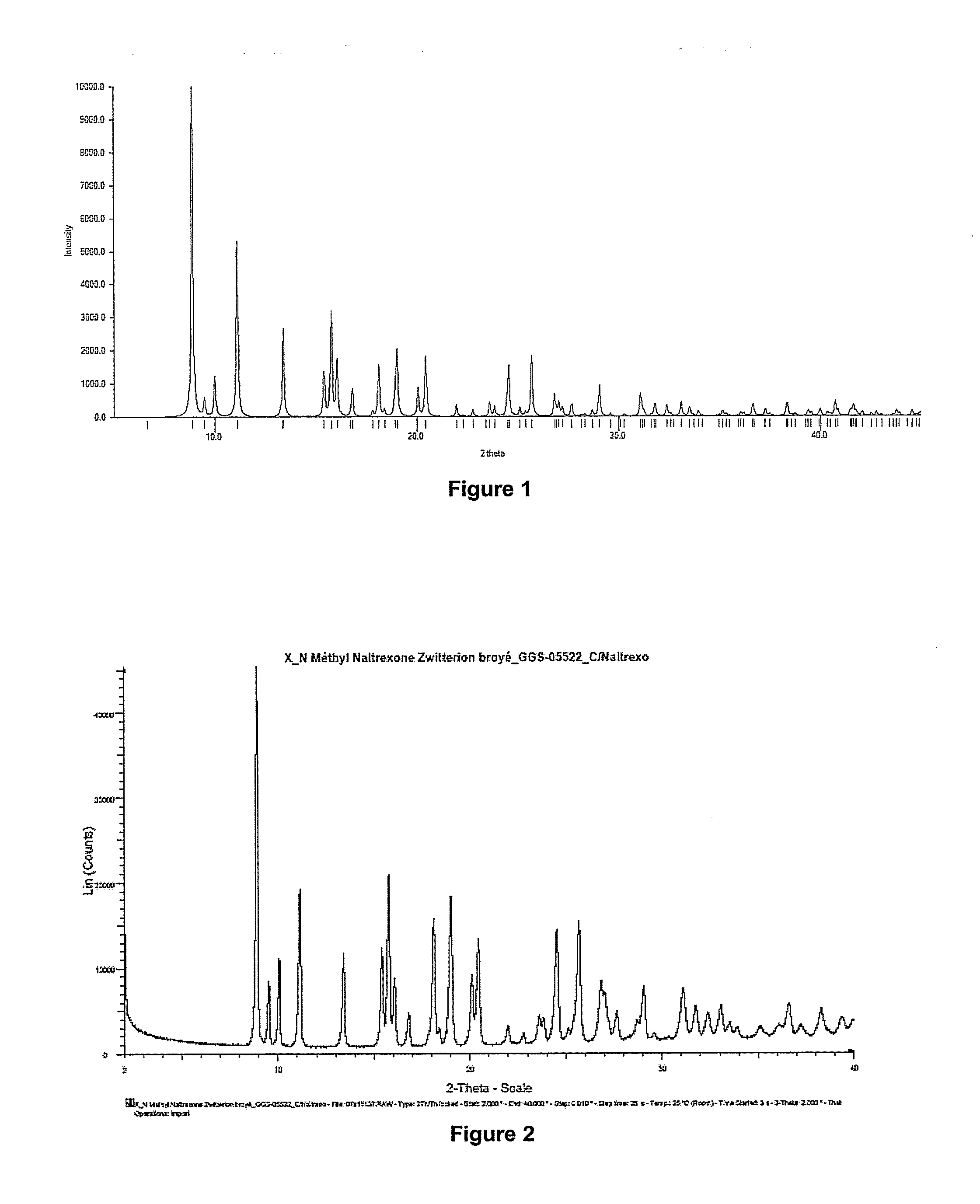

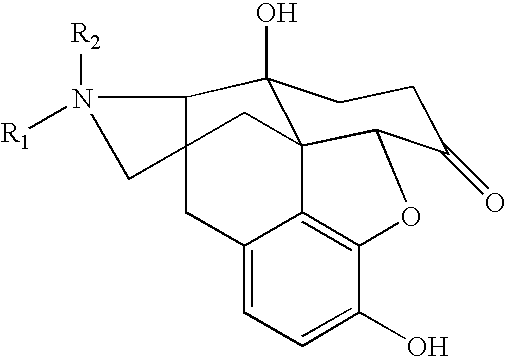

Process for preparing n-alkylnaltrexone halides

The invention relates to a novel process for preparing N-methylnaltrexone bromide, comprising at least the steps consisting in:(i) reacting N-methylnaltrexone methyl sulfate in aqueous solution with an alkaline agent chosen from the group constituted by sodium carbonate, potassium carbonate, calcium carbonate, magnesium carbonate, cesium carbonate, strontium carbonate and mixtures thereof, for a pH of the aqueous reaction medium of between 7 and 10, and then in(ii) reacting the product thus obtained with hydrobromic acid, which is added for a pH of the aqueous reaction medium of between 0.5 and 5, in order thus to obtain the N-methylnaltrexone bromide.

Owner:SANOFI SA

Method for preparing dual-curing single-component silk-screen printing photosensitive adhesive

InactiveCN103279010AIncreased sensitivityNo pollutionPhotosensitive materials for photomechanical apparatusFunctional monomerAdhesive

The invention discloses a method for preparing a dual-curing single-component silk-screen printing photosensitive adhesive, which is carried out under the light shading condition and comprises the following steps: step 1, adding polyvinyl alcohol powder into absolute methanol and stirring at room temperature to form methanol suspension; step 2, adding HMA (grafted N-hydroxymethyl acrylamide functional monomer) and SBQ (N-methyl-4-formyl styrene pyridine methyl sulfate) photosensitizers into the methanol suspension, adding a polymerization inhibitor and a catalyst, and after heating reaction, cooling to the room temperature; step 3, carrying out extraction filtration on the methanol suspension, washing a filter cake by methanol, and after drying the filter cake, obtaining purified HMA-SBQ dual-curing photosensitive resin; step 4 , dissolving the dried HMA-SBQ dual-curing photosensitive resin into water and after carrying out heating dissolution, cooling under the stirring condition; and step 5, adding vinyl acetate emulsion or acetic styrene-acrylic emulsion into the obtained aqueous solution, then adding an antifoaming agent, a photoinitiator and a colorant and stirring and mixing to obtain the dual-curing single-component silk-screen printing photosensitive adhesive. According to the method, the environment is free from pollution; and comprehensive performance of the photosensitive adhesive product is greatly improved.

Owner:浙江荣生科技有限公司

Softener

InactiveCN103541220ASoft and fluffy with good effectUse low concentrationFibre treatmentMicroorganismSilanes

The invention relates to a softener comprising the following components in percentage by mass: 20-31% of chlorohydrocarbonyl functional group silane, 5-8% of double-alkyl dimethyl quaternary ammonium salt, 11-15% of methyl sulfate, 3-6% of calcium halogenide and 40-61% of deionized water. The mass percentage of all the raw material components is 23:7:13:5:52. The chlorohydrocarbonyl functional group silane is gamma-choropropyltrimethoxysilane. The methyl sulfate is imidazolinium methyl sulfate. The calcium halogenide is calcium chloride. The softener provided by the invention has the advantages that soft and fluffy effects are good after fabrics are sterilized and washed; the use concentration is low, so that the fabrics can not be damaged; the softener is good in stability, free of injury to skins, low in cost and free of pollution to the environment; the softener has a strong killing effect on common harmful microorganisms and particularly pathogenic bacteria, and the fabrics contain no bacteria after being washed; the fabrics are good in anti-static performance and remixed wettability and free of damage and yellowing phenomena.

Owner:上海氟聚化学产品股份有限公司

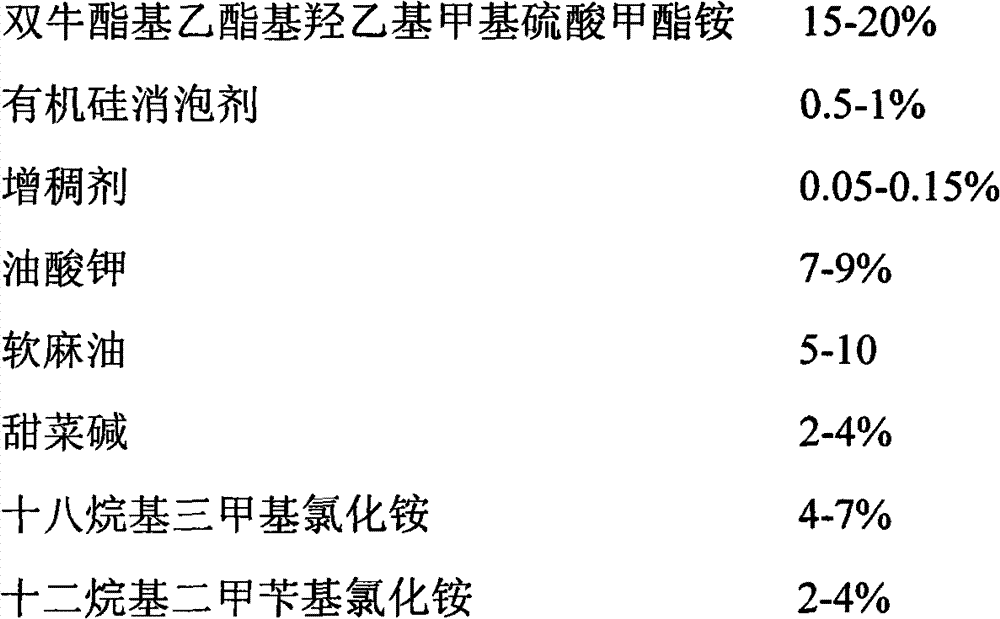

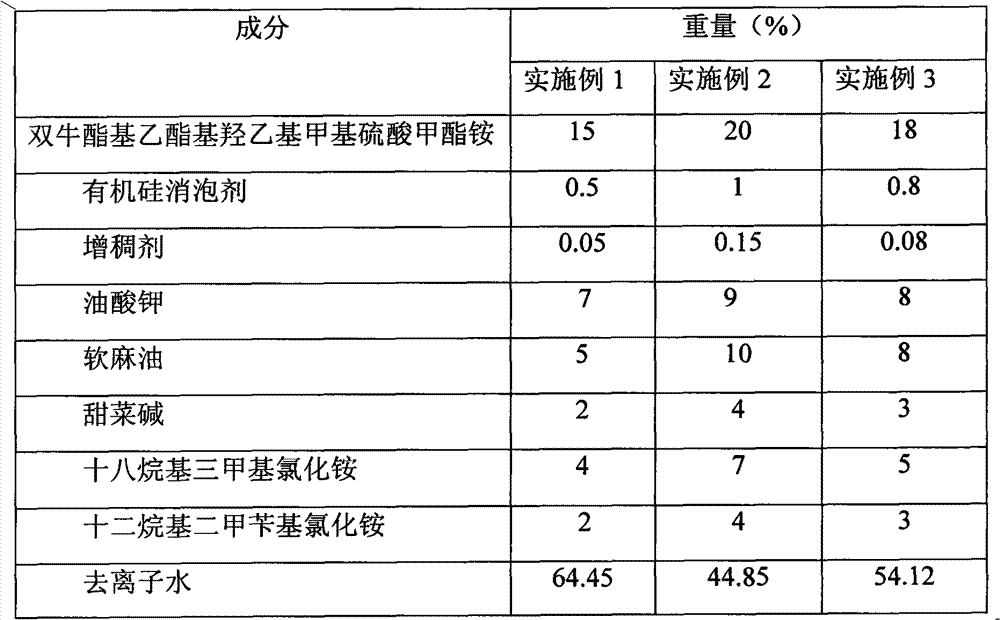

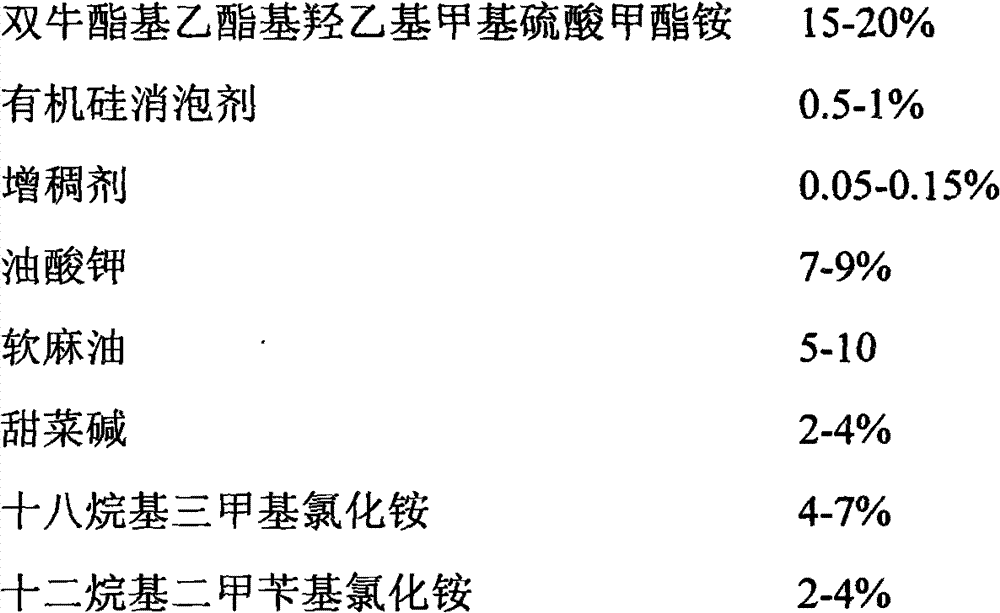

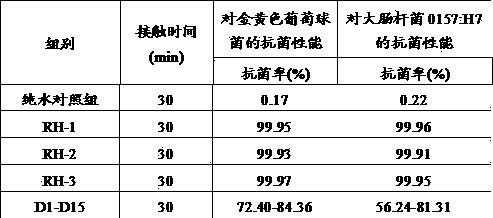

Bacteriostatic linen fiber softener

InactiveCN102877294APromote degradationBiodegradability is superior to dialkyl quaternary ammonium saltsBiochemical fibre treatmentVegetal fibresFiberAlkalinity

The invention relates to a bacteriostatic linen fiber softener, which comprises the following ingredients in percentage by weight: 15 to 20 percent of bitallow ethoxycarbonyl ethoxyl methyl sulfate, 0.5 to 1 percent of organosilicone defoamer, 0.05 to 0.15 percent of thickening agent, 7 to 9 percent of potassium oleate, 5 to 10 percent of linen softening oil, 2 to 4 percent of glycine betaine, 4 to 7 percent of octadecyl trimethyl ammonium chloride, 2 to 4 percent of dodecyl dimethyl benzyl ammonium chloride and the balance of deionized water, wherein 1 to 2 weight percent of marine biological rhzomorph and 0.3 to 0.5 weight percent of bacitracin can also be added into the softener. The clothes softener has high softness and antistatic property. By the clothes softener, clothes are soft and comfortable; and the clothes softener is faintly acidic, so that alkalinity in a detergent can be neutralized, and the clothes are close to the PH values of human bodies. The bacteriostatic linen fiber softener has high killing effect on common microbes and particularly pathogenic bacteria.

Owner:QINGDAO SANDING SANITARY PROD

Treatment additives, methods for making and methods for clarifying aqueous media

A coagulant composition includes chitosan, methacryloyloxyethyltrimethyl ammonium methyl sulfate and a redox initiator. A coagulant, method for making the coagulant and clarifying wastewater is also provided.

Owner:BL TECH INC

Antistatic PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene) alloy for automotive upholsteries and preparation method of antistatic PC/ABS alloy

The invention discloses antistatic PC (polycarbonate) / ABS (acrylonitrile-butadiene-styrene) alloy for automotive upholsteries and a preparation method of the antistatic PC / ABS alloy. The antistatic PC / ABS alloy for automotive upholsteries is prepared from the following constituents by weight: 50 parts of ABS resin, 40-60 parts of PC resin, 0.1-1.5 parts of polytetrafluoroethylene, 1-5 parts of a coupling agent and 0.1-5 parts of a composite antistatic agent; furthermore, the coupling agent is gamma-(methacryloxy) trimethoxypropylsilane; the composite antistatic agent is prepared from the constituents by weight: 10-30 parts of stearamide propyl dimethyl-beta-hydroxyethyl quaternary ammonium nitrate, 30-60 parts of sodium allylsulfonate, 20-40 parts of N,N-bi(2-hydroxyethyl)-N-(3'-dodecyloxy-2'-hydroxypropyl) methylammonium methyl sulphate, and 5-10 parts of (3-lauramidopropyl) trimethylammonium methyl sulfate. The alloy and the preparation method disclosed by the invention are low in production cost, good in processing property, good in antistatic effect and friendly to environment. The antistatic PC / ABS alloy for automotive upholsteries disclosed by the invention is particularly suitable for being prepared into various automotive upholsteries by injection molding.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

Anti-static ABS (Acrylonitrile Butadiene Styrene) plastic and preparation method thereof

The invention discloses an anti-static ABS (Acrylonitrile Butadiene Styrene) plastic and a preparation method thereof. The anti-static ABS plastic comprises the following components in parts by weight: 200 parts of ABS resin, 1-5 parts of coupling agent, and 0.1-5 parts of composite anti-static agent. Furthermore, the coupling agent is gamma-(methacryloxy) propyl trime thoxysilane; and the composite anti-static agent comprises the following components in parts by weight: 10-30 parts of stearamido propyldimethyl-beta-hydroxyethyl ammonium nitrate, 30-60 parts of sodium allyl sulfonate, 20-40 parts of N,N-bis(2-hydroxyethyl)-N-(3'-dodecyloxy-2'-hydroxypropyl)methyl ammonium methosulfate, and 5-10 parts of (3-lauramidopropyl)trimethyl ammonium methyl sulfate. The anti-static ABS plastic provided by the invention can be easily machined into be parts with various shapes through an injection molding process, and is particularly suitable for being manufactured into automotive upholsteries through injection molding.

Owner:优矿塑新材料科技(芜湖)有限公司

Fibrauretine preparation method

The invention discloses a fibrauretine preparation method. The preparation method comprises the following steps: using berberine as a raw material, using methylene chloride as a solvent, using aluminium chloride to realize demethylation so as to obtain 5,6-dihydro-2,3,9,10-tetrahydroxy-dibenzo [a, g] quinolizine inner salt, and using methyl sulfate to realize methylation so as to obtain the fibrauretine with the yield of 60 percent and the purity of 91 percent. The method has the advantages of simple manufacturing process and simplicity and convenience in operation.

Owner:SOUTHWEST JIAOTONG UNIV

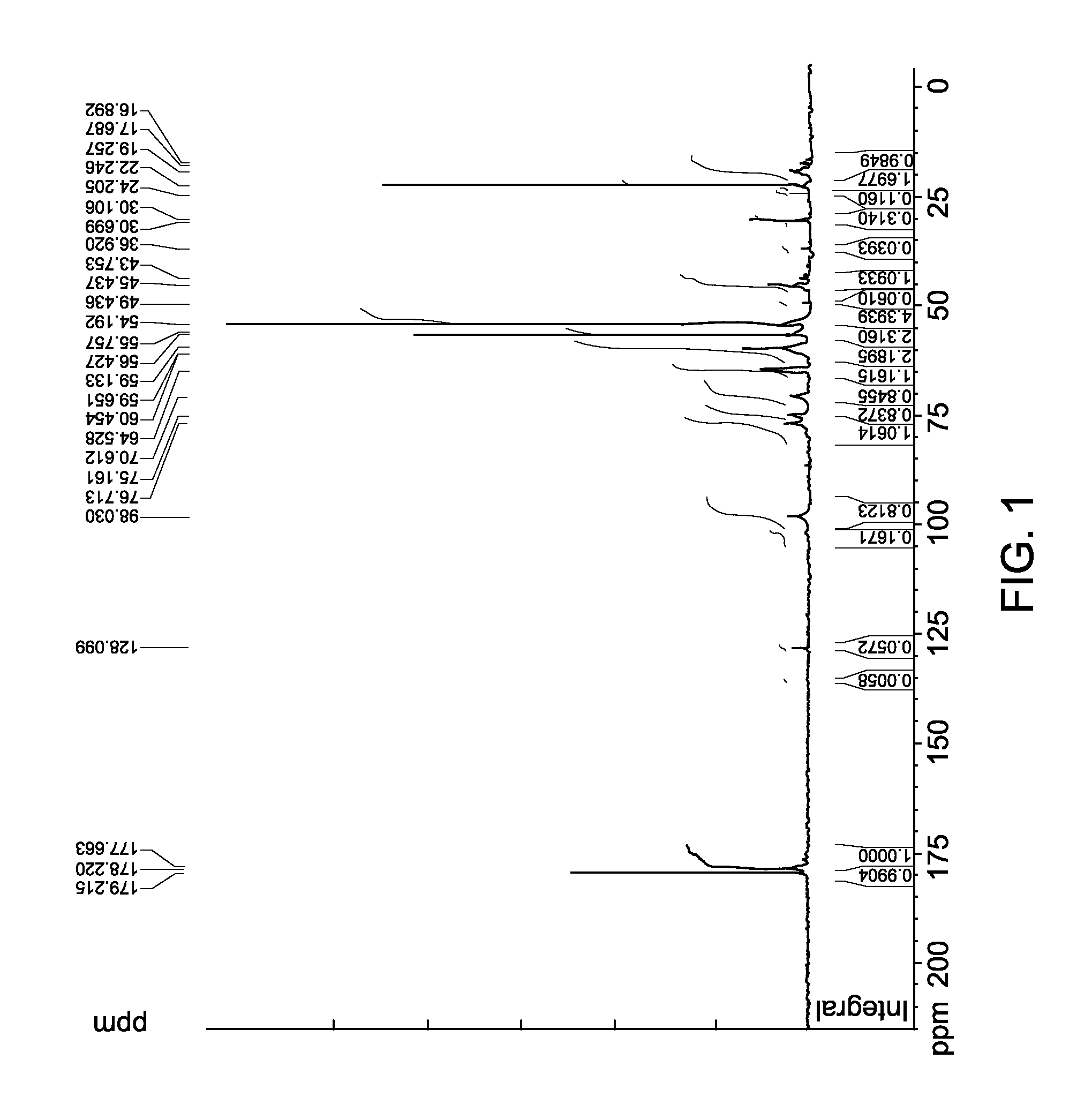

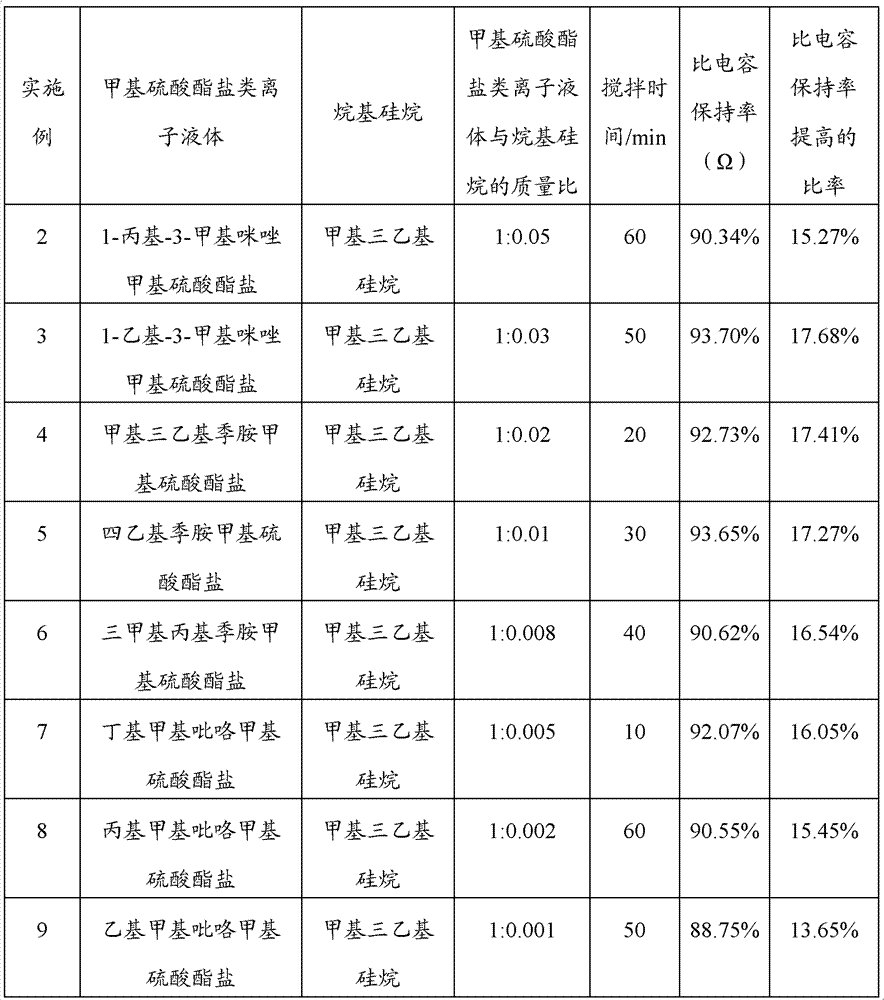

Electrolyte and preparation method thereof

InactiveCN102956373AAvoid corrosionImprove stabilityHybrid capacitor electrolytesHybrid/EDL manufactureSilanesAluminum foil

An electrolyte comprises methyl sulfate ionic liquid and alkylsilane dissolved in the methyl sulfate ionic liquid. The mass ratio of the methyl sulfate ionic liquid and the alkylsilane is 1:(0.001-1):0.05. In the above electrolyte, the added alkylsilane reacts with mineral acid impurities in the methyl sulfate ionic liquid, and accordingly the mineral acid impurities in the methyl sulfate ionic liquid are eliminated, the mineral acid impurities are prevented from corroding aluminum foil of a double-layer capacitor, stability of the double-layer capacitor using the methyl sulfate ionic liquid as the electrolyte can be greatly improved, the stability of the double-layer capacitor using the electrolyte can be enhanced by adding the alkylsilane, and cost is lowered.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Fabric Conditioner Compositions

InactiveUS20090203570A1Good fragrance retentionGood flexibilityCationic surface-active compoundsDetergent compounding agentsAmmonium compoundsPhosphate

A fabric conditioner composition comprising: (g) 0.1-20% by weight cationic fabric conditioner active; (h) 0.1-5% by weight anion quencher selected from mono-long chain quaternary ammonium compound of the general formula R(R1)3N+X- or alkyl benzyl quaternary ammonium compound of a general formula R2R3(R4)2N+X-; (i) 0.1-10% by weight organic acid having from 1 to 8 carbon atoms; where R is selected from C8-C22 alkyl or alkenyl group, R1 is selected from C1-C3 alkyl group, R2 is selected from C6-C18 alkyl or alkenyl group, R3 is benzyl group, R4 is selected from C1-C3 alkyl group, and X is an anion selected from chloride, bromide, iodide, nitrate, sulfate, methyl sulfate, ethyl sulfate, acetate and phosphate.

Owner:HENKEL IP & HOLDING GMBH

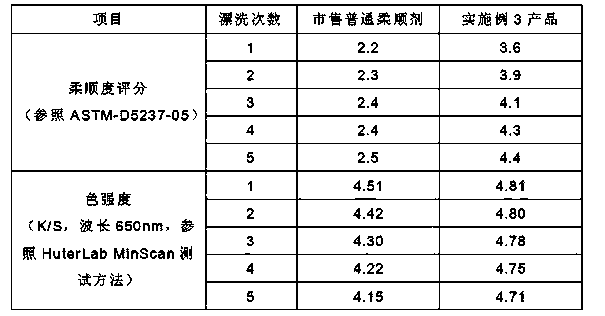

Multiple-effect softening and lubricating agent for textile fabrics as well as preparation method and use thereof

The invention relates to a multiple-effect softening and lubricating agent for textile fabrics as well as a preparation method and a use thereof. The multiple-effect softening and lubricating agent for textile fabrics is prepared from bitallow ethoxycarbonyl hydroxyethyl methyl ammonium methyl sulfate, bipolyethylene polydimethylsiloxane, glycerin monostearate, epoxy chloropropane, polyethylene glycol 2000, mycose, zinc pyrithione, nano-powder, hydroxyl cellulose sodium, pentaerythritol triacrylate, an assistant, an additive and water. The multiple-effect softening and lubricating agent has the advantages of smoothness, fixation, antistatic property, antimicrobial property and the like due to selection of special components and proportion, and has a wide industrialized application prospect in the textile field.

Owner:HEIGHTCHEM FINE CHEM CO LTD

High-strength alkali-resistant brush wires and production process thereof

InactiveCN105544012AGood alkali resistanceExtended service lifeConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberAntioxidant

The invention discloses high-strength alkali-resistant brush wires and a production process thereof, wherein the high-strength alkali-resistant brush wires are composed of the following raw materials in parts by weight: 40-45 parts of polyurethane, 10-20 parts of trimethyl ammonium methyl sulfate, 10-20 parts of a coupling agent, 30-35 parts of fatty alcohol polyoxyethylene ether, 18-20 parts of sodium laurate, 4-5 parts of phosphoric acid, 2-4 parts of monoethanolamine, 6-8 parts of a glass fiber, 3-5 parts of organic alcohol amine, 2-4 parts of azodiisobutyronitrile, 6-8 parts of amino-2-methyl-1-propanol, 12-15 parts of silica, 1-4 parts of polyethylene glycol 4000, 1-3 parts of an accelerator, 10-20 parts of a curing agent, 5-8 parts of an alkali absorption agent, and 2-3 parts of an antioxidant. Compared with the prior art, the alkali absorption agent and the antioxidant are added into abrasive wires, so that the alkali resistance of the abrasive wires and the service life of the abrasive wires in a strong alkali environment are greatly improved. At the same time, the production process is simple, special processing is not required, and the processing cost is low.

Owner:安徽天瑞塑业股份有限公司

Automobile glass anti-fog frost-prevention agent

The invention provides an antifogging and antifrost agent for car glass. It essentially comprises sodium dodecyl sulfate, alkylsulfo sodium succinate, propanediol, isopropanol, dodecanol, ethylene glycol alcohol, tri hydroxyethyl methyl ammonium methyl sulfate,sodium benzoate,essence and pure water. It can be prepared through a special process. The invention is characterized by low cost and convenient utilization.

Owner:TIANJIN SHIXIONG TECH DEV

Fog and frost preventing agent for glass

InactiveCN102994047AAvoid influenceEasy to useOther chemical processesSodium sulfateSodium succinate

The invention provides a fog and frost preventing agent for glass which comprises lauryl sodium sulfate, alkyl sulfo sodium succinate, propylene glycol, dodecanol, glycol, ethanol, trihydroxyethyl methyl quaternary ammonium methyl sulfate and water. The fog and frost preventing agent for glass is corrosion resisting, nonflammable, free from environmental-pollution, safe in use and better in fog and frost preventing effect, and suitable for glass in various purposes.

Owner:张丽华

Concrete with high tenacity

The invention discloses concrete with high tenacity. The concrete with high tenacity relates to the technical field of building materials, and is prepared from the following components: cement, gypsumpowder, mineral powder, blanc fixe, polypropylene fiber, glass fiber, fine sand, carbide slags, phosphorus slag powder, pulverized fuel ash, triethoxyl methylamine methyl sulfate salt and a plural gel. The concrete provided by the invention has a low heat conductivity coefficient. The concrete with high tenacity prepared by the invention not only has the lower heat conductivity coefficient, but also has favorable strength and anti-permeability, and particularly, the tenacity and the malleability are greatly improved.

Owner:安徽省神洲建材科技有限公司

Clothes washing rinsing synergist containing methyl sulfate-based quaternary ammonium salt

InactiveCN102586039APrevent yellowing and hardeningReduce surface tensionOrganic detergent compounding agentsFatty alcoholDimethyl siloxane

The invention provides a clothes washing rinsing synergist containing methyl sulfate-based quaternary ammonium salt. The clothes washing rinsing synergist containing the methyl sulfate-based quaternary ammonium salt consists of the following components in part by weight: 0.5-5 parts of polyethoxylated fatty alcohol, 0.5-4 parts of polyethoxylated heterogeneous fatty alcohol, 1-5 parts of citric acid, 5-15 parts of sodium citrate, 0.1-1 part of polydimethylsiloxane, 0.2-3 parts of distearate-ethoxyl-methyl-ammonium methyl sulfate, 0.1-3 parts of methyl-oleamide ethyl-oleic acid base-imidazoline ammonium methyl sulfate, 0.1-0.4 part of essence and 55-80 parts of neutral inorganic salt, wherein neutral inorganic salt is sodium sulfate, potassium sulfate, sodium chloride, potassium chloride, neutral sodium silicate and the like; and the clothes washing rinsing synergist containing the methyl sulfate-based quaternary ammonium salt is produced by the process for producing powdery washing powder.

Owner:JINGZHOU HUOLI 28 SHASHI DAILY CHEM

Flame-retardant antistatic rubber material for conveying belt covering layer and preparation method of rubber material

ActiveCN106243429AImprove flame retardant performanceImprove antistatic performanceRubber materialPolymer science

The invention provides a flame-retardant antistatic rubber material for a conveying belt covering layer and a preparation method of the rubber material. The rubber material is composed of chloroprene rubber, butadiene styrene rubber, sulfure, carbon black, ethyl tri-(2-methoxyethoxy)silane, zinc stearate, promoter, antiager, dicyclopentadiene resin, octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, trihydroxyethyl methyl quaternary ammonium methyl sulfate, stearamide propyl dimethyl-beta-ethoxy ammonium dihydrogen phosphate, aluminum hydroxide, bis(2, 3-dibromopropyl)fumaric acid and 1, 2-bis(2, 4, 6-tribromophenoxy) ethane. The rubber material is prepared through plastifying, two times of mixing and vulcanization. Due to uniform dispersion and high compatibility with polymer of an antistatic agent and a flame retardant in the rubber material in a polymer substrate, flame-retardant and antistatic effects of rubber are improved obviously.

Owner:SHANDONG LONGYUAN RUBBER

Sterilization fabric softener and preparation method thereof

ActiveCN103668963AWith color fixing effectGood flexibilityFibre treatmentPolymer scienceActive agent

The invention relates to a sterilization fabric softener and a preparation method thereof, and belongs to the technical field of daily chemicals. The sterilization fabric softener comprises the following components in parts by weight: 15-20 parts of tetramethylene-bia(lauroyloxyethyl dimethyl ammonium bromide), 8-10 parts of ditallow ethoxycarbonyl hydroxyethyl methyl ammonium methylsulfate, 2-4 parts of lavender, 5-10 parts of a ginkgo leaf, 0.1-0.5 part of a thickener, 0.2-2 parts of a color fixing agent, and 80-100 parts of deionized water. A favorable biodegradable Gemini cationic surface active agent and an esterquat surface active agent are used as active substances, so that the sterilization fabric softener not only has favorable softness and an antistatic property, but also is extremely environment-friendly, meanwhile, the sterilization fabric softener has a color fixing effect, and is excellent in sterilization effect. Besides, the preparation method is simple, and is easy to popularize and apply.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Synthesis of Lactic Acid and Alkyl Lactate from Carbohydrate-Containing Materials

PendingUS20130231497A1Easy to useOrganic compound preparationCarboxylic acid esters preparationSolventMethanol

A method for synthesizing lactic acid and lactate is invented from carbohydrates, such as monosaccharides and / or polysaccharides in the presence of the catalyst that is the combinations of nitrogen-heterocycle aromatic ring cation salts and metal compounds. In the reaction, at least one alcohol and at least one solvent are used. Specifically, in the presence of [SnCl4-1-ethyl-3-methylimidazolium chloride ([EMIM]Cl)], SnCl4-1, 3-dimethylimidazolium methyl sulfate ([DMIM] CH3SO4)], [SnCl2-1-ethyl-3-methylimidazolium chloride ([EMIM]Cl)], or SnCl2-1, 3-dimethylimidazolium methyl sulfate ([DMIM] CH3SO4)] in methanol.

Owner:MICROVAST

Anti-bacterial clothing softening agent

InactiveCN104074049AFeel comfortableGood antibacterial effectBiochemical fibre treatmentAnimal fibresTriclosanFatty acid

The invention discloses an anti-bacterial clothing softening agent. The anti-bacterial clothing softening agent is prepared from the following components by weight percent: 8-20 percent of Di(fatty acid ethyl ester)hydroxyethyl methyl ammonium methylsulfate, 0.1-1 percent of a viscosity reducer, 0.08-0.5 percent of almondamidopropyl amine oxide, 0.08-0.5 percent of bispolyethylene dimethicone, 0.15-1 percent of methyl-1-tallow amide ethyl-2-suet imidazoline methyl sulfate salt, 0.1-0.8 percent of triclosan, 0.5-1 percent of marine actinomycete, and the balance of deionized water. After using of the clothing softening agent, the clothing is softer, and the hand feeling is comfortable; main raw materials in the clothing softening agent are degradable, and can be subjected to biodegradation, so that the clothing softening agent is environment-friendly; the triclosan and the marine actinomycete are added, so that the softening agent has excellent anti-bacterial and bacteriostatic effects, and the softening agent does not stimulate human skin.

Owner:SHANGHAI SOAP GRP RUGAO

Drilling fluids containing biodegradable organophilic clay

Drilling fluids are provided that comprise an organophilic clay treated with a quaternary ammonium surfactant having an amide linkage. The quaternary ammonium surfactant may comprise a compound generally represented by the following formula:where M− is an anion such as a chloride, methyl sulfate, bromide, acetate, or iodide ion; R1 is an alkyl group such as a saturated hydrocarbon with 10 or more carbons; R2, R3, and R4 are the same or different alkyl groups such as a methyl, ethyl, or benzyl group, and x is greater than or equal to 1. The organophilic clay treated in this manner is substantially biodegradable. In embodiments, the drilling fluids comprise the foregoing organophilic clay, an oil-based fluid and a weighting agent. In still embodiments, the drilling fluids comprise the foregoing organophilic clay, an invert emulsion, an emulsifier, and a weighting agent.

Owner:HALLIBURTON ENERGY SERVICES INC

Industrial high-strength alkali-resisting brush wire and preparation method thereof

InactiveCN105803572AExtend working lifeQuality improvementConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyethylene terephtalateMethyl Sulfate

The invention discloses an industrial high-strength alkali-resisting brush wire. The industrial high-strength alkali-resisting brush wire is prepared from the following raw materials in parts by weight: 48-64 parts of polyamide resin, 18-26 parts of polybutylene terephthalate, 10-20 parts of trimethylammonium methyl sulfate, 30-35 parts of fatty alcohol polyoxyethylene ether, 2-4 parts of 2,2'-azobis(2-methylpropionitrile), 6-15 parts of amino-2-methyl-propanol, 20-25 parts of silicon carbide powder, 10-12 parts of 4-aminoheptafluorotoluene, 5-8 parts of 3,5-dichloroisothiocyanatobenzene, 5-12 parts of 1,2-bis(tosyloxy)ethane, 3-10 parts of 1,3-dichloro-2-butene, 6-8 parts of an alkali-resisting regulator, 14-20 parts of a coupling agent, 6-8 parts of a water repellent agent, 5-12 parts of an antioxidant, 1-3 parts of an accelerant and 3-8 parts of a curing agent. Compared with the prior art, the industrial high-strength alkali-resisting brush wire has the advantages that the manufacturing process is simple, and the working service life of the brush wire under an alkali-resisting environment condition is greatly prolonged; meanwhile, the machining cost is low, the quality is stable and the brush wire cannot deform easily; and furthermore, the production and machining process is easy to control, the machining precision is high and the produced brush wire has stable quality.

Owner:QIANSHAN FUDA RUBBER BRUSH IND PROD FACTORY

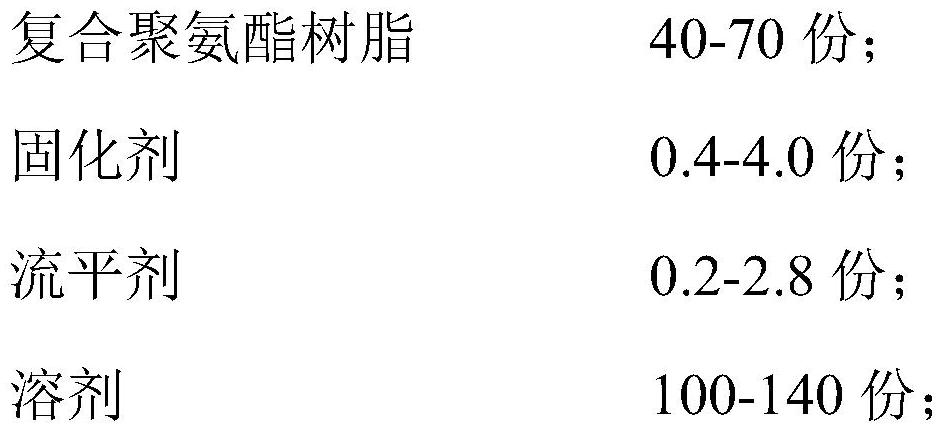

Polyurethane protective film and preparation method thereof

PendingCN113388142AImprove antistatic performanceNot easy to precipitatePolyurea/polyurethane coatingsElectrically-conductive paintsPolymer sciencePolythylene glycol

The invention relates to a polyurethane protective film and a preparation method thereof, the polyurethane protective film comprises a single-side antistatic PET base material layer, an antistatic coating and a PET antistatic release film layer, the other side of the single-side antistatic PET base material layer is coated with the antistatic coating, and the antistatic coating comprises the following components in parts by weight: 40-70 parts of composite polyurethane resin; 0.4-4.0 parts of a curing agent; 0.2-2.8 parts of a leveling agent; and 100-140 parts of a solvent, wherein the composite polyurethane resin is prepared from polyurethane resin and a modified antistatic agent; the antistatic agent comprises a trihydroxyethyl methyl quaternary ammonium methyl sulfate salt, or one or any combination of the trihydroxyethyl methyl quaternary ammonium methyl sulfate salt, polyethylene glycol stearate and polyethylene glycol laurate; the ratio of the polyethylene glycol laurate to the trihydroxyethyl methyl quaternary ammonium sulfate methyl ester salt to the polyethylene glycol stearate is (0-0.4): 1: (0-0.6). According to the polyurethane protective film disclosed by the invention, the tearing voltage generated when the protective film of the touch screen is torn is relatively low, and the modified antistatic agent is not easy to separate out under high-temperature and high-humidity conditions.

Owner:HEFEI LUCKY SCI & TECH IND

Scented soap containing fatty acid ethyl ester sulfonate

InactiveCN101921678ADecontaminationFast cleaning rateSoap detergents with organic compounding agentsCarcinogenGlycerol

The invention discloses scented soap containing fatty acid ethyl ester sulfonate (EES) which comprises the following components in parts by weight: 50-65 parts of sodium fatty acid, 6-11 parts of the fatty acid EES, 3-7 parts of a filling material, 4-8 parts of glycerol, 12-20 parts of water, wherein, pH of the scented soap is 6-8. The scented soap comprises the following raw materials in parts by weight: 70-80 parts of soap base, 8-12 parts of mixture containing the fatty acid EES, 3-7 parts of filling material and 4-8 parts of glycerol. A surfactant of the scented soap contains a carboxyl-type anionic surfactant-sodium fatty acid and a sulfonic acid group-type anionic surfactant-fatty acid EES and no fatty acid methyl ester sulfonate (MES), so the scented soap does not contain a carcinogen-methyl sulfate and is harmless to human body.

Owner:美婷生物科技(常州)有限公司

Synthesis of Lactic Acid and Alkyl Lactate from Carbohydrate-Containing Materials

InactiveUS20140024853A1Easy to useOrganic compound preparationCarboxylic acid esters preparationSolventMethanol

A method for synthesizing lactic acid and lactate is invented from carbohydrates, such as monosaccharides and / or polysaccharides in the presence of the catalyst that is the combinations of nitrogen-heterocycle aromatic ring cation salts and metal compounds. In the reaction, at least one alcohol and at least one solvent are used. Specifically, in the presence of [SnCl4-1-ethyl-3-methylimidazolium chloride ([EMIM]Cl)], SnCl4-1,3-dimethylimidazolium methyl sulfate ([DMIM]CH3SO4)], [SnCl2-1-ethyl-3-methylimidazolium chloride ([EMIM]Cl)], or SnCl2-1,3-dimethylimidazolium methyl sulfate ([DMIM]CH3SO4)] in methanol.

Owner:MICROVAST

Antibacterial additive and preparation method thereof

ActiveCN107558239AImprove stabilityImprove antibacterial propertiesFibre treatmentInstabilityDimethyl siloxane

The invention discloses an antibacterial additive and a preparation method thereof. The antibacterial additive is prepared from the following raw materials in parts by weight: 30-40 parts of ternary copolymer dimethylsiloxane, 20-25 parts of bis-(tallow amide hexyl)-polyethoxymethyl ammonium-methyl sulfate, 5-7 parts of hydroxyl modified polydimethylsiloxane, 4-8 parts of an emulsifying agent, 0.5-1 part of organic acid, 5-10 parts of a solubilizer and 50-70 parts of water. A quaternary amination and hydroxyl hybrid modification method is adopted; the obtained antibacterial additive is good instability; when the antibacterial additive is applied to fabric, the fabric is enabled to be fine, soft and smooth, and the antibacterial property of the fabric is effectively improved.

Owner:广州旭太材料科技有限公司

Antistatic ABS (acrylonitrile butadiene styrene)/PVC (polyvinyl chloride)/PETG (polyethylene terephthalate glycol) alloy and preparation method thereof

The invention discloses an antistatic ABS (acrylonitrile butadiene styrene) / PVC (polyvinyl chloride) / PETG (polyethylene terephthalate glycol) alloy and a preparation method thereof. The ABS / PVC / PETG alloy is composed of, by weight, 30-80 parts of ABS resin, 40-60 parts of PVC resin, 10-20 parts of PETG resin, 1-5 parts of compatibilizer and 0.1-5 parts of composite antistatic agent. Further, the composite antistatic agent is composed of, by weight, 10-30 parts of stearamide propyl dimethyl-beta-ethoxyl quaternary ammonium nitrate, 30-60 parts of allyl sodium sulfonate, 20-40 parts of N,N-di(2-hydroxyl ethyl)-N-(3'-dihexyloxy-2'-hydroxyl propyl) methyl ammonium methyl sulfate and 5-10 parts of (3-lauramide propyl) trimethyl ammonium methyl sulfate. The antistatic ABS / PVC / PETG alloy is excellent in antistatic performance, the preparation process is simple, product cost is low, and comprehensive performances of products are excellent. Further, the antistatic ABS / PVC / PETG alloy can be easily processed into parts of various shapes by means of injection molding and especially suitable for being made into various automotive upholsteries by means of injection molding.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com