Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2865results about How to "No corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing ethandiol by catalyzing epoxyethane hydration

InactiveCN1463960AHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEpoxideEnergy consumption

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Method for reclaiming carbon fiber reinforced epoxy resin composite material

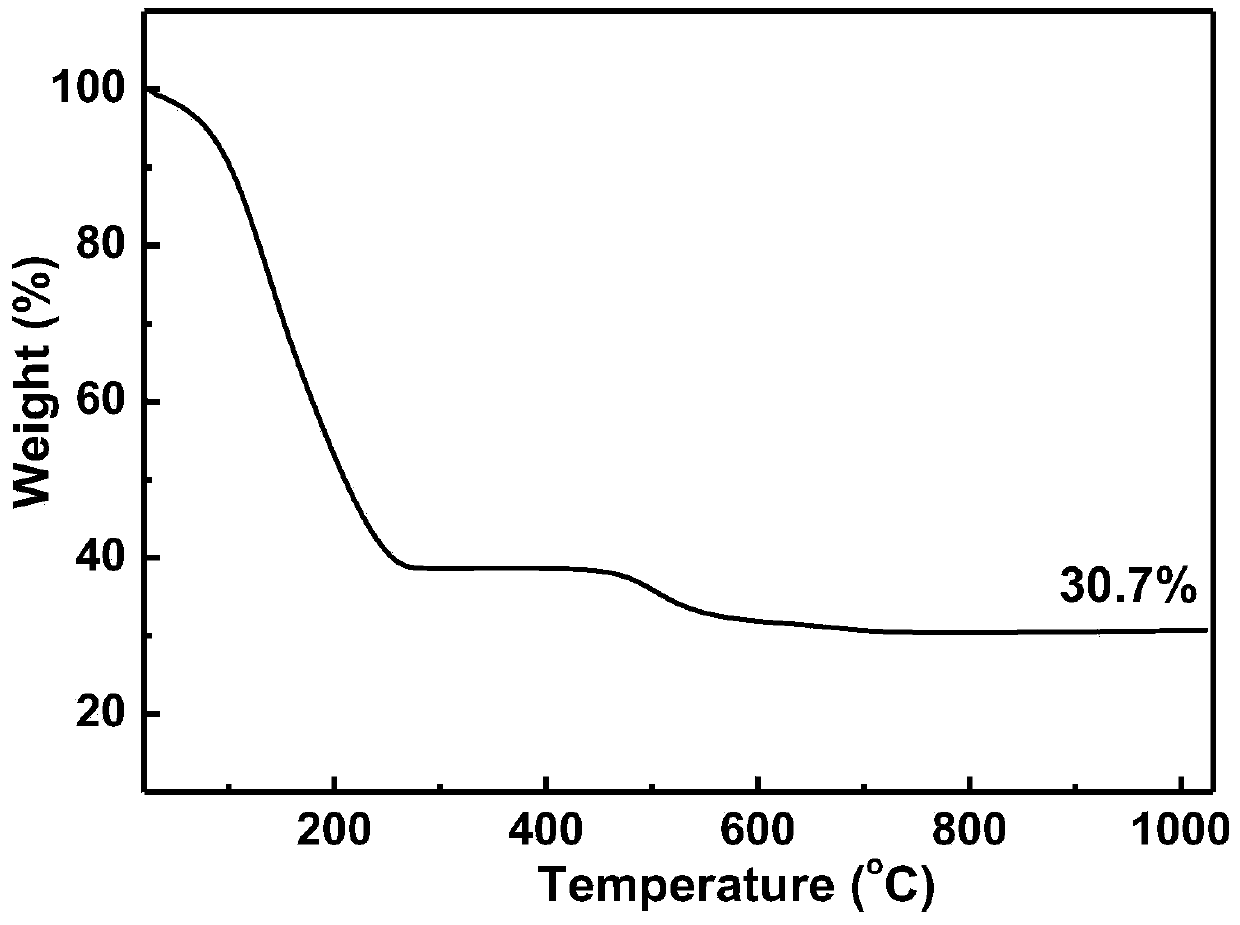

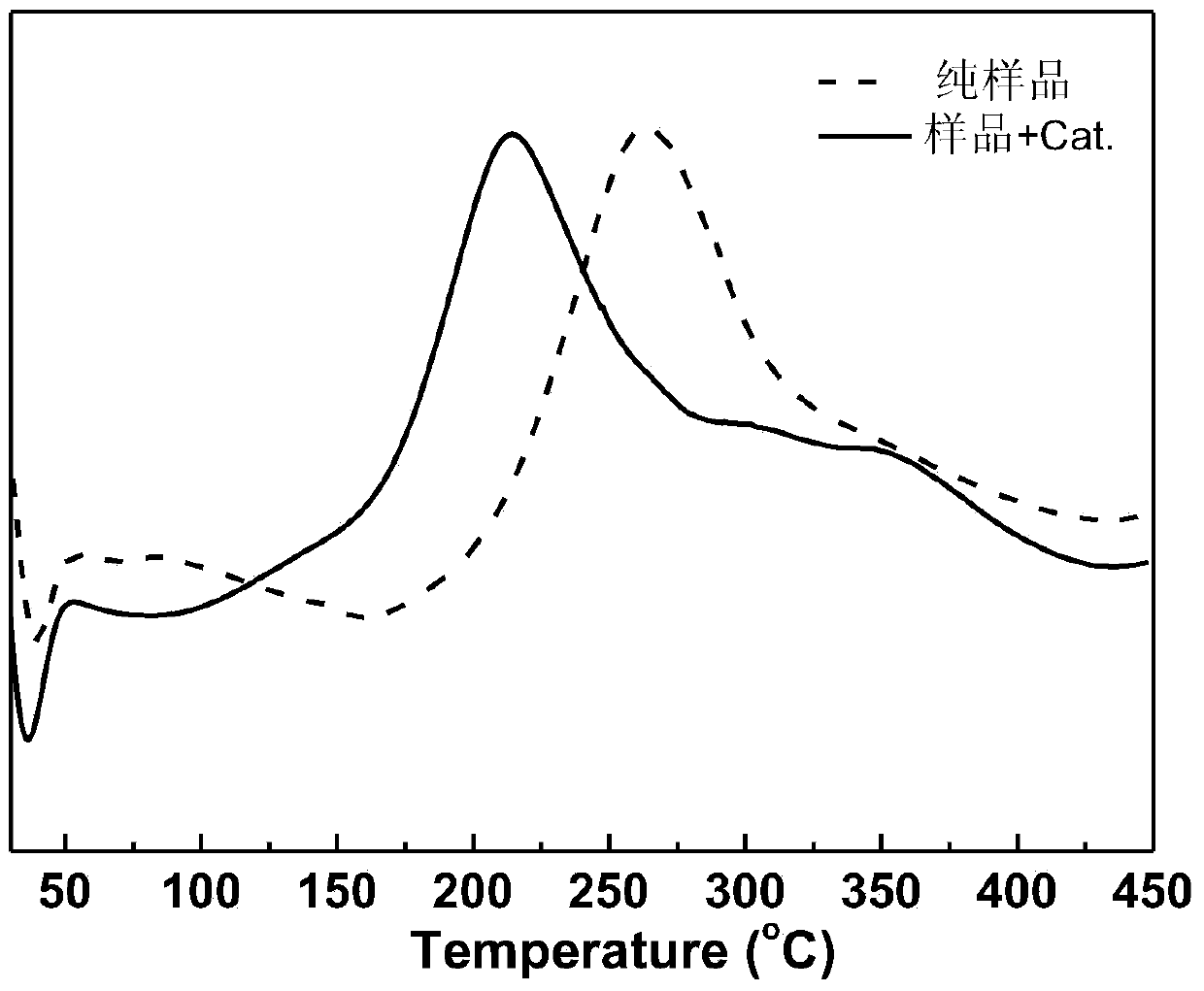

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

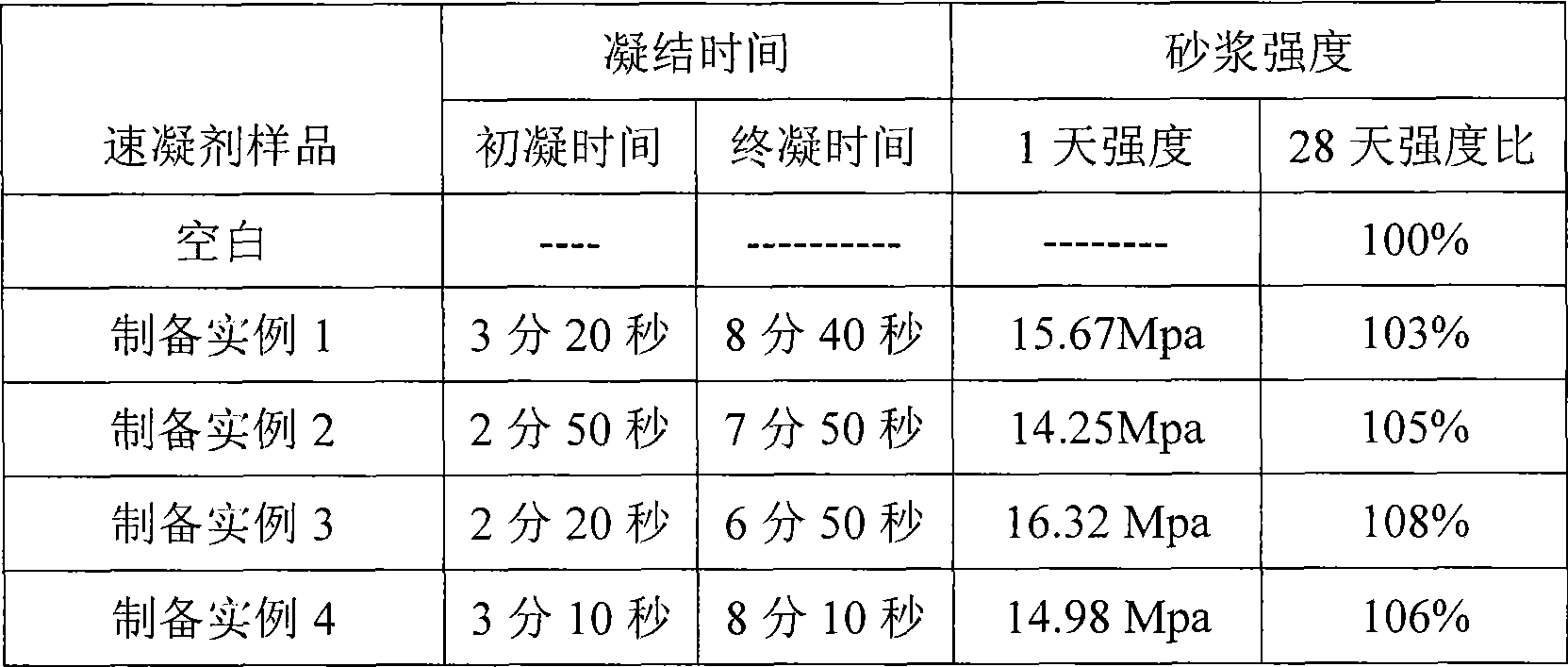

Liquid accelerator for sprayed concrete and preparation thereof

The invention relates to a liquid accelerator for shotcrete and a method for preparing the same. The liquid accelerator is prepared from the following components in percentage by weight: 25 to 70 percent of aluminum sulfate, 0 to 8 percent of metal fluoride, 1 to 10 percent of amine substance, 0.5 to 7 percent of pH regulator, 0.01 to 1 percent of thickening agent, and the balance being water. The method for preparing the liquid accelerator comprises the following steps: firstly, dissolving the fluoride into the water; secondly, adding the amine substance to the mixture and heating the solution to a temperature of between 40 and 80 DEG C; thirdly, adding the aluminum sulfate to the solution to perform heat preservation reaction until the solution becomes a uniform liquid; and fourthly, adding the pH regulator and the thickening agent to the uniform liquid and stirring the mixture evenly to finally obtain a uniform liquid substance which is the liquid accelerator for the shotcrete. The liquid accelerator is free from corrosion, has no penetrating odor, has good storage stability so that the phenomena of deposition, crystallization and the like do not appear after the storage of more than 6 months at a temperature of between 0 and 35 DEG C, and does not influence the effect in practice. Using the liquid accelerator with lower mixing proportion (5 to 8 percent), cement can be initially set within 4 minutes and finally set within 10 minutes, and the strength of cement mortar within one day is more than 10 MPa and the storage rate of the strength within 28 days is more than 100 percent.

Owner:JIANGSU SUBOTE MATERIAL

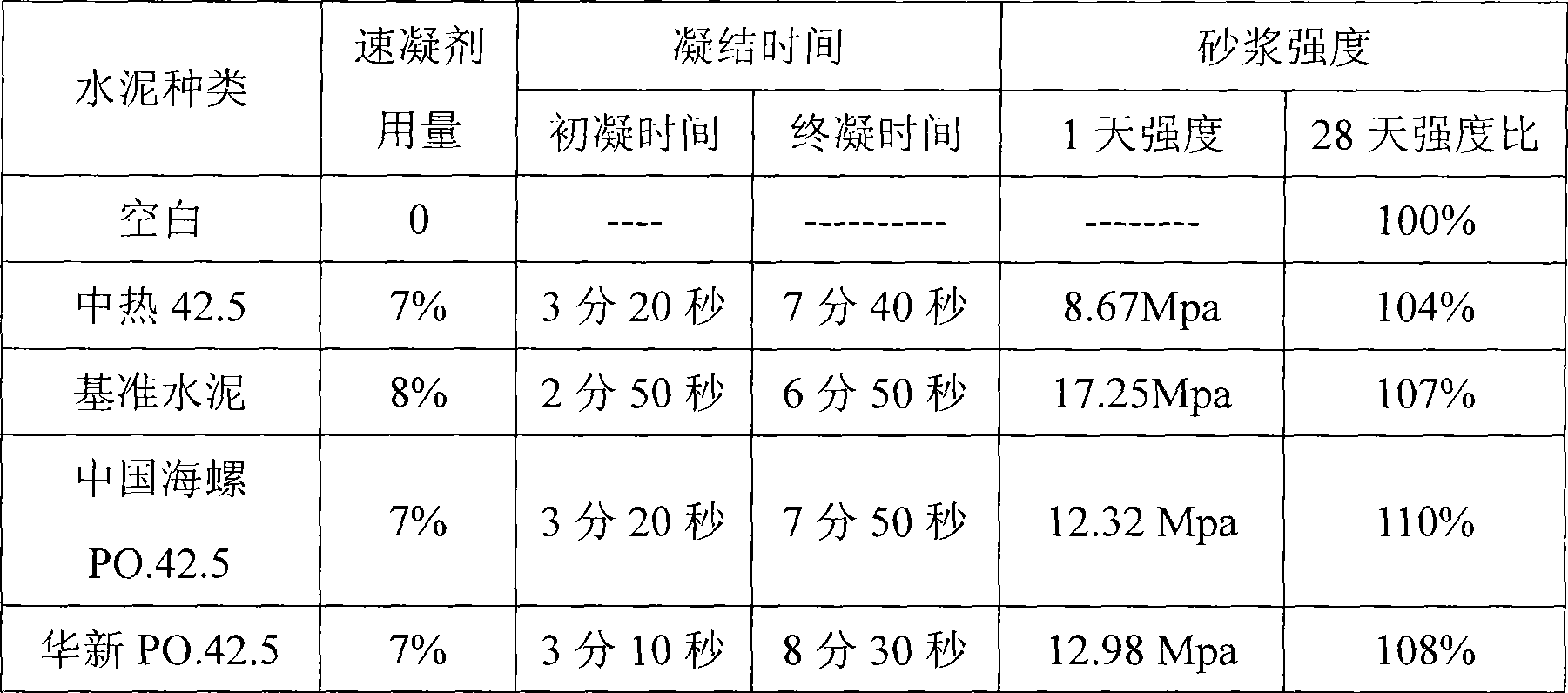

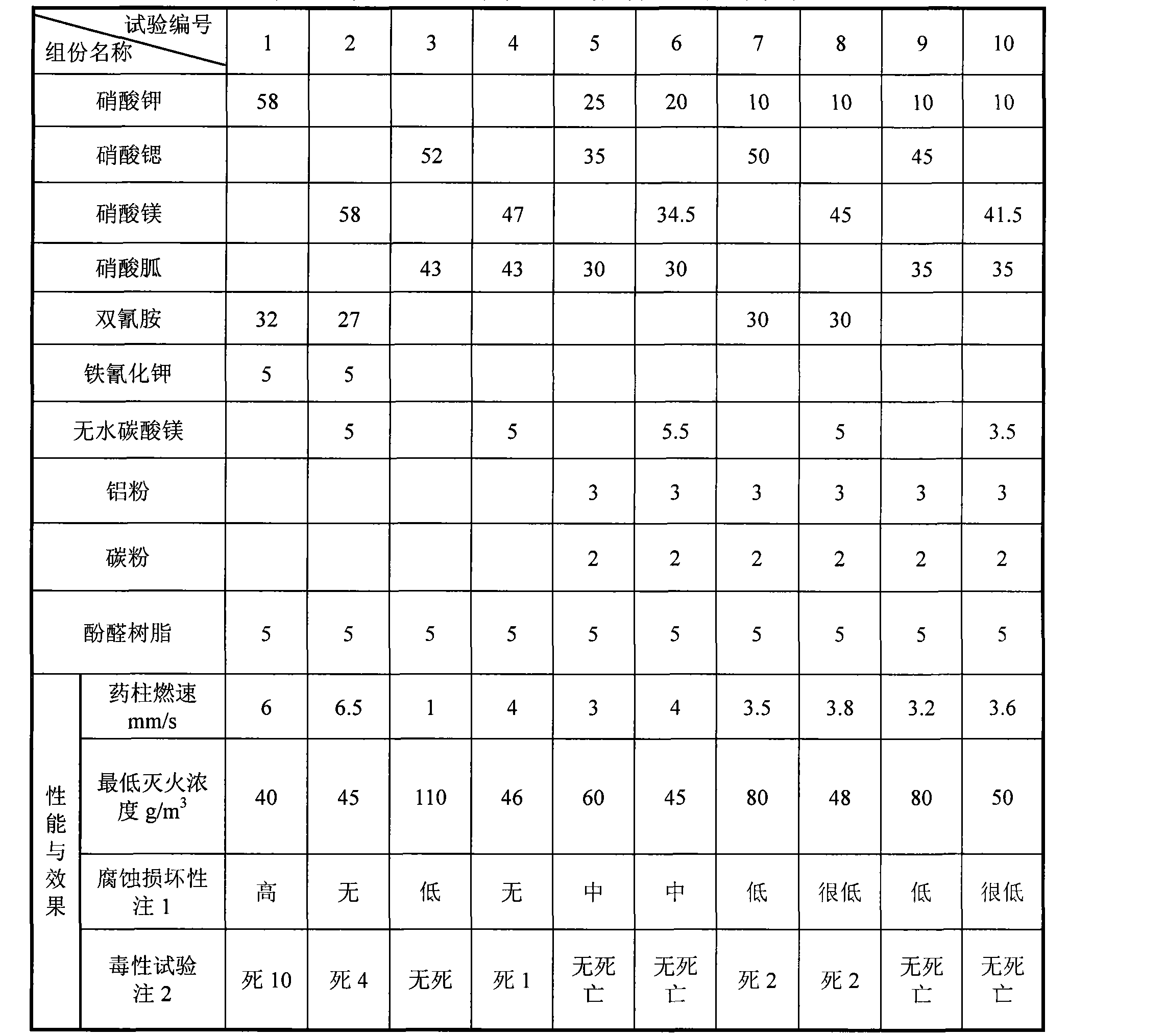

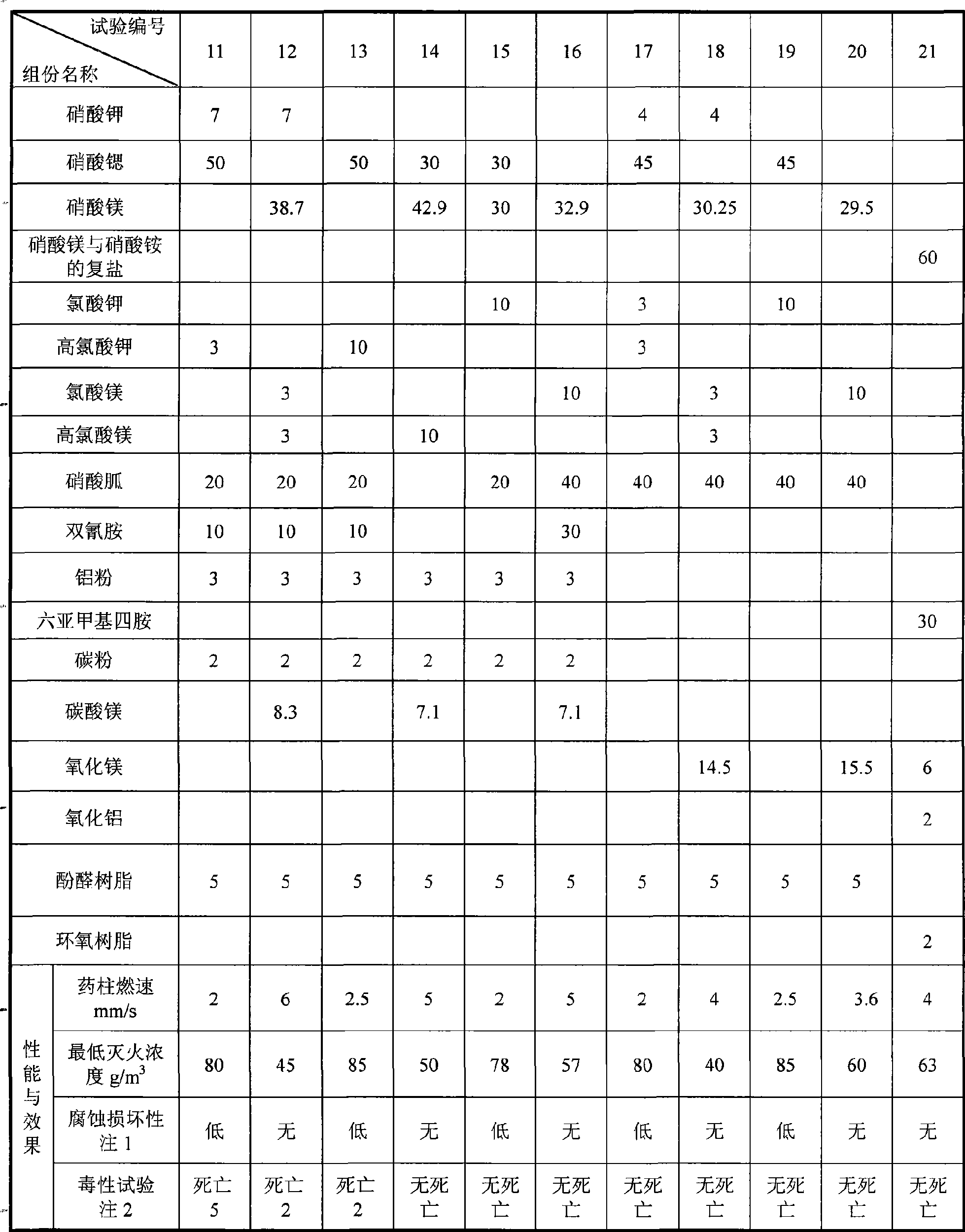

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

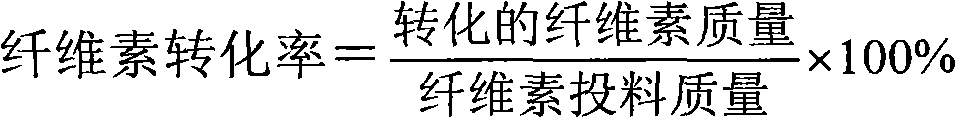

Method for preparing ethylene glycol and 1,2-propylene glycol

ActiveCN101768050ASimple processRapid responseOrganic compound preparationPreparation by OH group eliminationIsopropylene glycolPropylene glycol

The invention discloses a method for preparing ethylene glycol and 1,2-propylene glycol. In the method, fiber is placed into water to react under the action of a catalyst at the temperature of 200-250 DEG C to obtain the ethylene glycol and the 1,2-propylene glycol. In the method, the fiber is hydrolyzed in hot water; on one hand, the WO3 catalyst, the load WO3 catalyst and the Ru / C catalyst are led into for providing acidity for promoting the acid hydrolysis of the fiber, on the other hand, the intermediate products in the hydrolysis can be inverted into low-carbon matters, and hydrogenationis carried out, so as to obtain the ethylene glycol and the 1,2-propylene glycol. The method has simple process, quick reaction, high efficiency and less energy and is easy for industrialization; no liquid acid is added, and no waste acid is discharged, therefore, the method is environmentally friendly. The method has low requirement on equipment, can not cause the corrosion of the equipment and has small investment; moreover, the inversion rate of the fiber is 100% high, the yield of the ethylene glycol can reach 35%, and the yield of the 1,2-propylene glycol can reach 31%; therefore, the method has significant application value.

Owner:PEKING UNIV

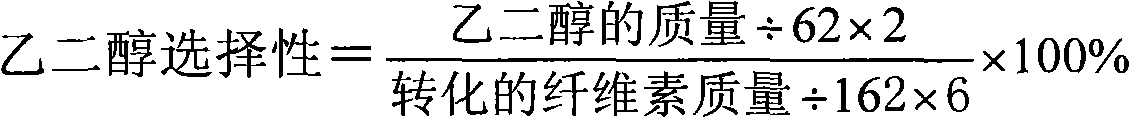

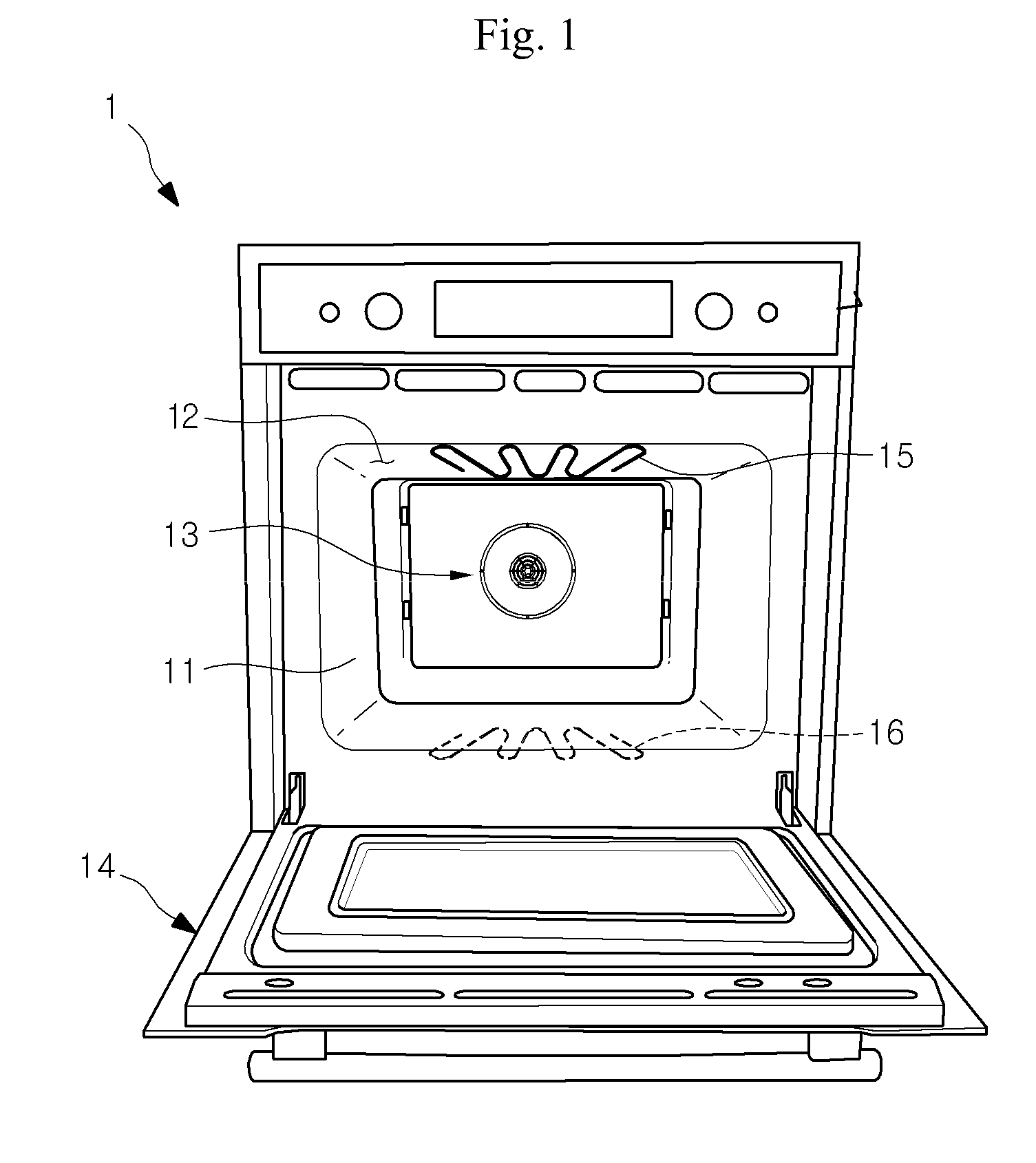

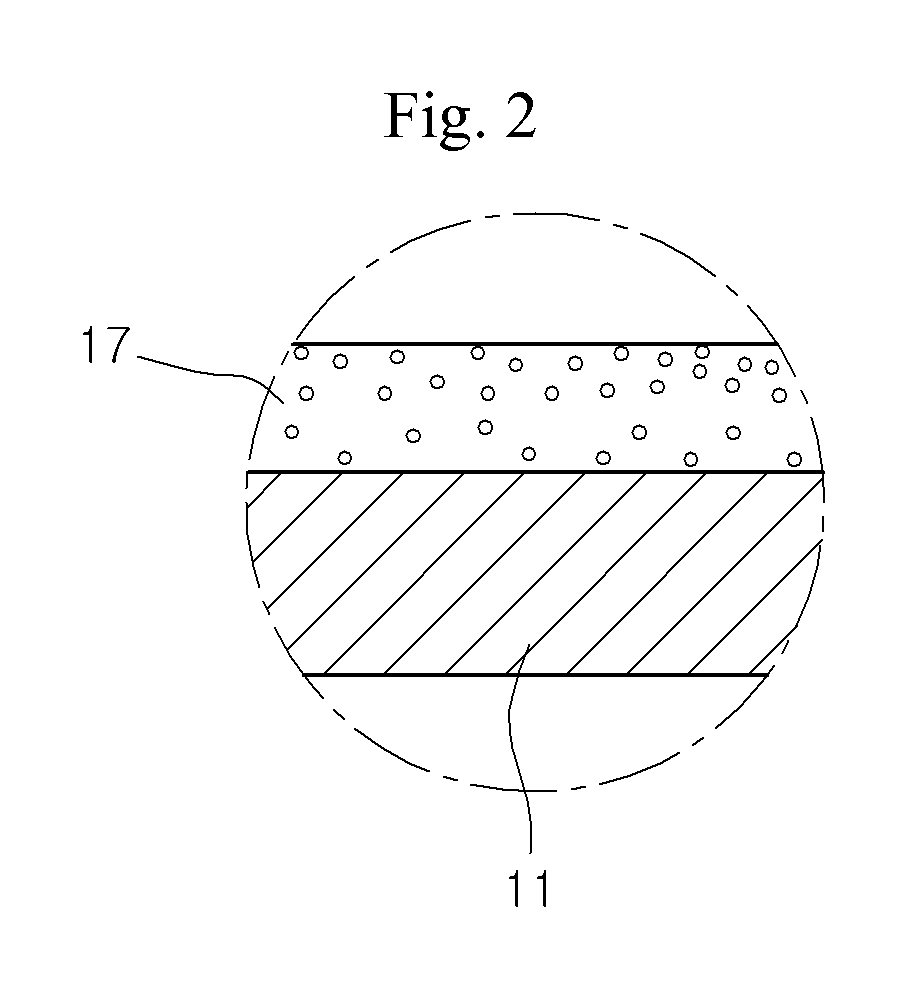

Cooking Appliance

ActiveUS20110049122A1Improve heat resistanceGood chemical resistanceElectric heating for furnacesElectric/magnetic/electromagnetic heatingHeat resistanceWear resistance

The present invention includes a cooking appliance with an enamel composition. The enamel composition includes a heat resistance, chemical resistance, wear resistance, and pollution resistance, such that the cooking appliance withstands high temperature, acid or alkali and is readily cleaned.

Owner:LG ELECTRONICS INC

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

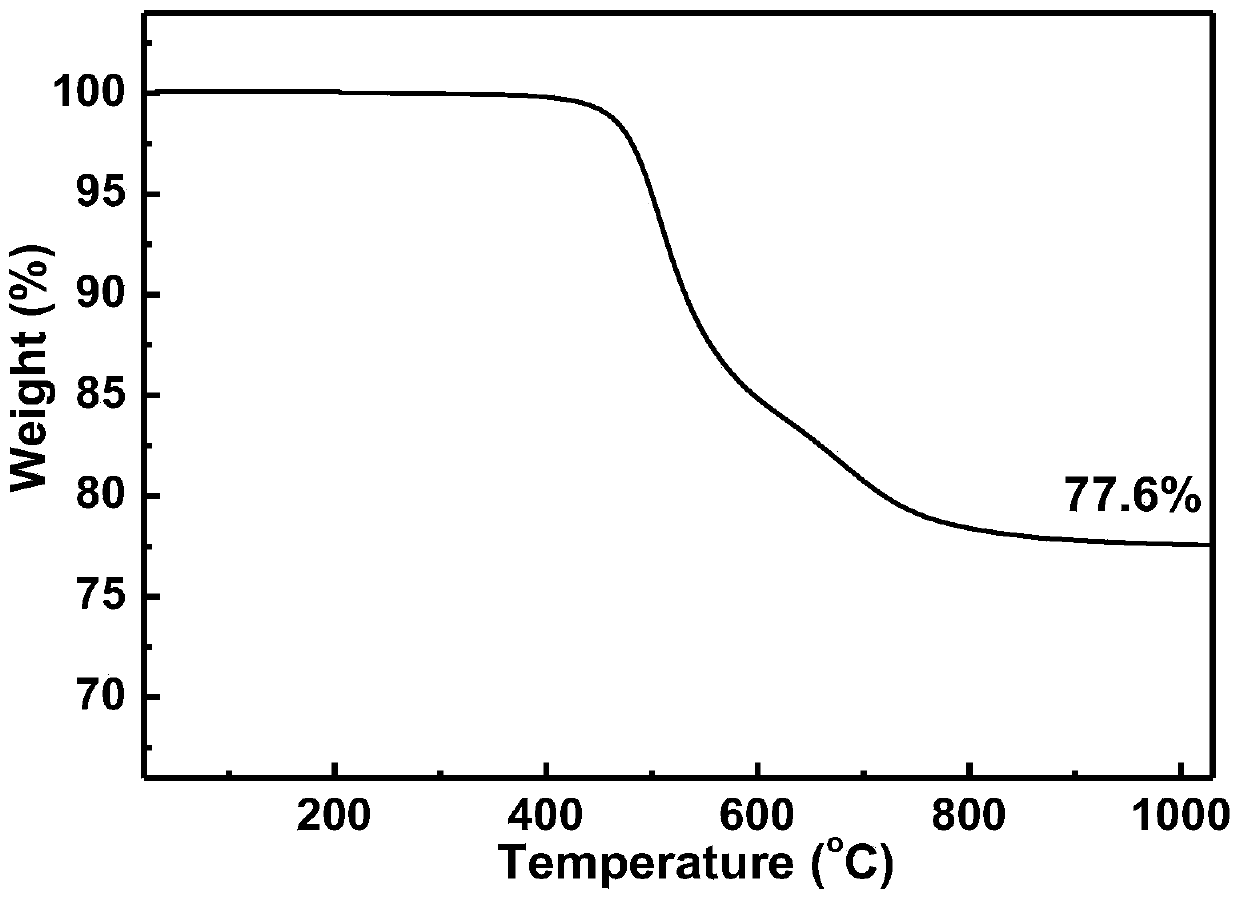

Novel liquid polycarbosilane as well as preparation method and application thereof

The invention discloses novel liquid polycarbosilane which is low in viscosity and high in storage stability and is crosslinkable, a preparation method of novel liquid polycarbosilane, and an application of novel liquid polycarbosilane. Polycarbosilane is prepared by adopting chloromethyl alkoxy silane or mixtures of chloromethyl alkoxy silane as raw materials by virtue of Grignard coupling reaction and reduction reaction, and the structure of polycarbosilane is shown in a formula (I) in the specification. The structure simultaneously contains Si-H bonds and unsaturated bonds such as C=C bonds, can be subjected to self-crosslinking and curing under a certain condition, has relatively high ceramic yield, and can be used as a silicon carbide precursor of a polymer precursor impregnation pyrolysis (PIP) process. Polycarbosilane disclosed by the invention is adjustable in structural composition, good in storage stability, low in viscosity and relatively low in boiling point, and has the utilization potentiality of being used as a silicon carbide ceramic precursor for chemical vapor deposition / chemical vapor infiltration (CVD / CVI). In addition, polycarbosilane can also be used for replacing commonly-used divinyl benzene to serve as a crosslinking agent of solid-state polycarbosilane (PCS).

Owner:淄博市临淄齐泉工贸有限公司

Method for preparing corrosion protection abrasion resistant ceramic coating with alloy surface differential arc oxidization

InactiveCN101270495ALow power density per unitFast film formationAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an antisepsis and antiwear ceramics coating layer on the surface of alloy through microarc oxidation. The method includes three steps of collocating electrolyte, arranging power electric parameters and microarc oxidation treatment; wherein, the component concentrations of the electrolyte are sodium silicate of 20 to 100g / L, sodium hydroxide of 5 to 10g / L and organic amine additive of 5 to 15ml / L; the current density of unit area is 50 to 100A / centiare; the pulse frequency is 100 to 700Hz; the pulse dutyfactor is 20 to 90 percent; the temperature of the electrolyte in the microarc oxidation treatment is not higher than 45 DEG C. The method needs lower unit power density and has fast film forming speed to prepare the ceramics coating layer on the surface of aluminum and magnesium alloys; the method adopts 100KVA power which can treat at least 2 centiares of the surface area of the aluminum alloy for one time; the growing speed of the ceramics coating layer can reach 1 to 1.5 micron / min. The formed ceramics coating layer is uniform and compact; the rigidity of the aluminum alloy can reach 1200 to 1300Hv.

Owner:SOUTH CHINA UNIV OF TECH

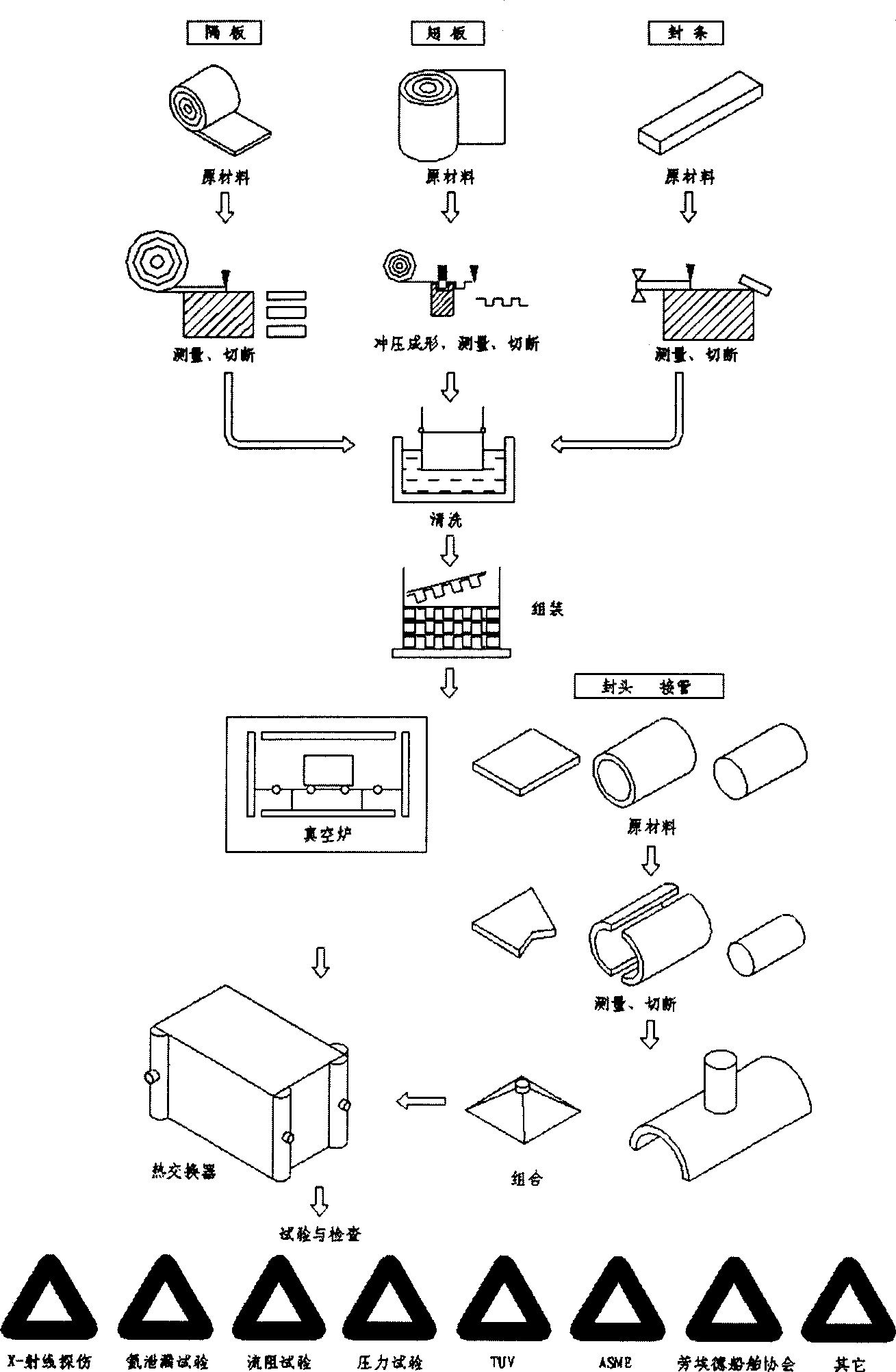

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

Cleaning agent

InactiveCN104403813AShorten cleaning timeReduce processing costsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryForeign matter

The invention belongs to the technical field of chemical products, and particularly relates to a cleaning agent. The cleaning agent comprises components as follows: 25%-40% of a stabilizer, 3%-10% of a chelating agent, 2%-10% of a penetrating agent, 1%-4% of a surfactant, 1%-5% of a dispersing agent and the balance of water. Compared with the prior art, the cleaning agent can thoroughly clean up foreign matters such as solid powder, organic matters, greasy dirt, fingerprints, various greases, abrasives, dust, dirt and the like on optical glass, plate glass, plexiglass, a mobile phone lens, a camera lens, glass lenses, sapphire glass, a ceramic wafer and a quartz optical product once, doesn't corrode surfaces of the optical glass, the plate glass, the plexiglass, the mobile phone lens, the camera lens, the glass lenses, the sapphire glass, the ceramic wafer, the quartz optical product and the like, and is not left over the surfaces.

Owner:DONGGUAN FUXING DETERGENT TECH

Process for preparing ethandiol by catalytic hydration of epoxyethane

InactiveCN1204103CHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEthylene oxideHigh activity

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Making method of and use of antibiotic surgical dressing

InactiveCN1833731AHigh strengthImprove antibacterial propertiesAbsorbent padsBandagesFiberAcetic acid

An antibacterial medical dressing for the operation wound is prepared from chitosan fibers through alkalizing to become alkaline chitosan fibers, and etherifying reaction on chloroacetic acid to become carboxymethyl chitosan fibers. When said fibers are encountered with water, it is swelling to become elastic gel. It is possible to add additive for higher curative effect.

Owner:李毅彬

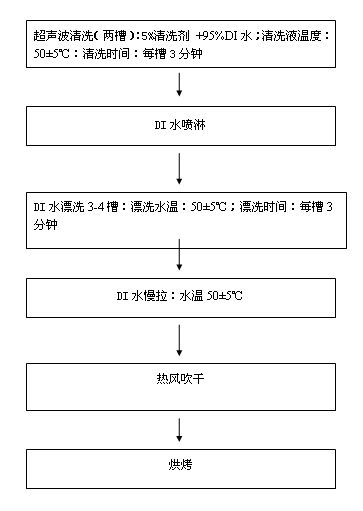

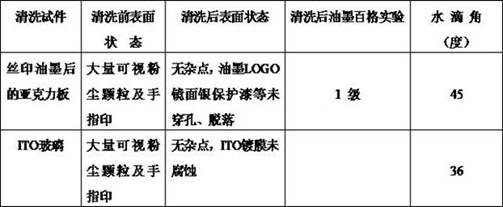

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

Method for preparing biodiesel by lowering value of high acid palm oil

InactiveCN101230309AReduce energy consumptionLow acid valueFatty acid esterificationBiofuelsChemistryAcid value

The invention provides a method which uses palm oil to prepare biologic diesel oil and can lower the high acid value. The method uses solid super acids of SO>4<2- > / ZrO2, SO4< 2- > / TiO2, and SO4< 2- > / xZrO<2- yTiO2 as catalyst, and uses low-carbon alcohol as esterifying agent to pre-treat the high acid value palm oil, can effectively lower the acid value of the oil, and can ensure the acid vale of the obtained biologic diesel oil to easily meet the standard (less than 0.8mgKOH / g, ASTM). The catalyst used by the invention has high catalytic activity, and is reusable. The process flow is simple, the production cost is decreased, and the environmental pollution is reduced greatly.

Owner:SICHUAN UNIV

Lead free solder paste and application thereof

ActiveCN101232967ADamage causedAvoid short circuitPrinted circuit assemblingWelding/cutting media/materialsDicarboxylic acidCarboxylic acid

A solder paste composed of solder alloy powder and flux, the volume expansion rate of which is 0.5% or less when the solder alloy is melted, and the flux contains bisphenol A type epoxy resin and a hardening agent selected from carboxylic anhydrides and dicarboxylic acids agent, the solder paste can be used for high temperature solder applications. In terms of mass%, the solder alloy has the following alloy composition: 70-98 mass% of Bi; 0-0.5% of Ag, Cu, Sb, In, Zn, Ni, Cr, Fe, Mo, P, Ge and One or more elements selected from Ga; the balance is composed of Sn.

Owner:SENJU METAL IND CO LTD +1

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

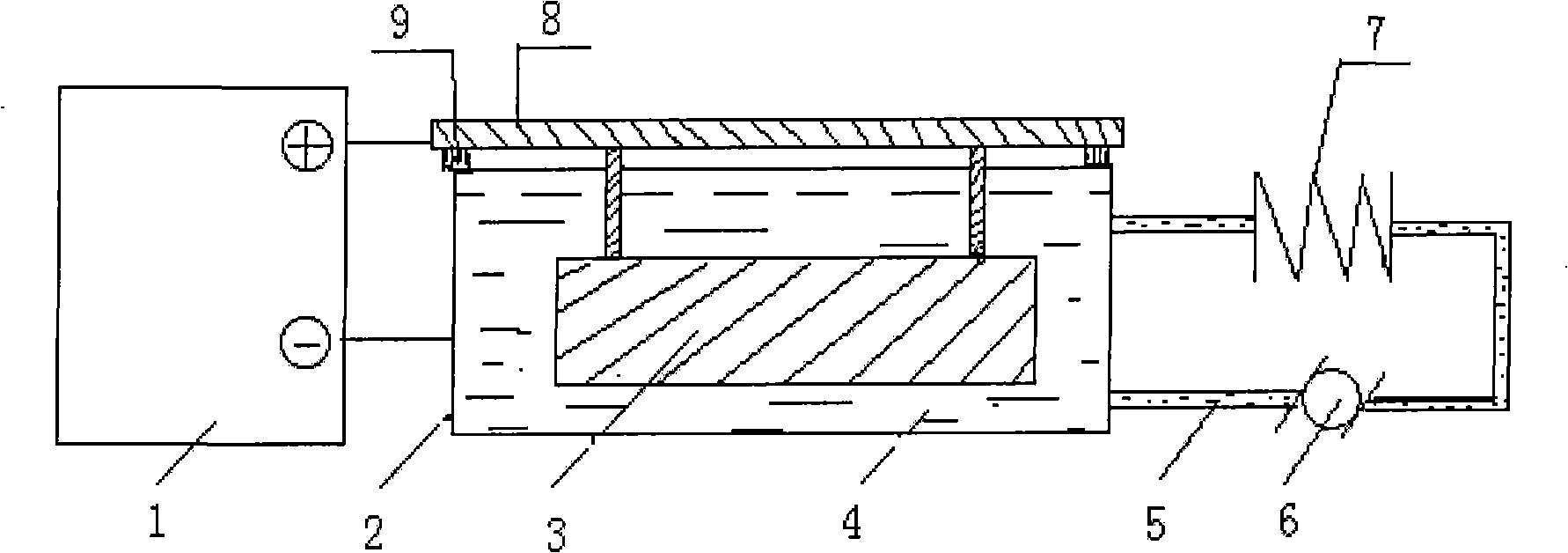

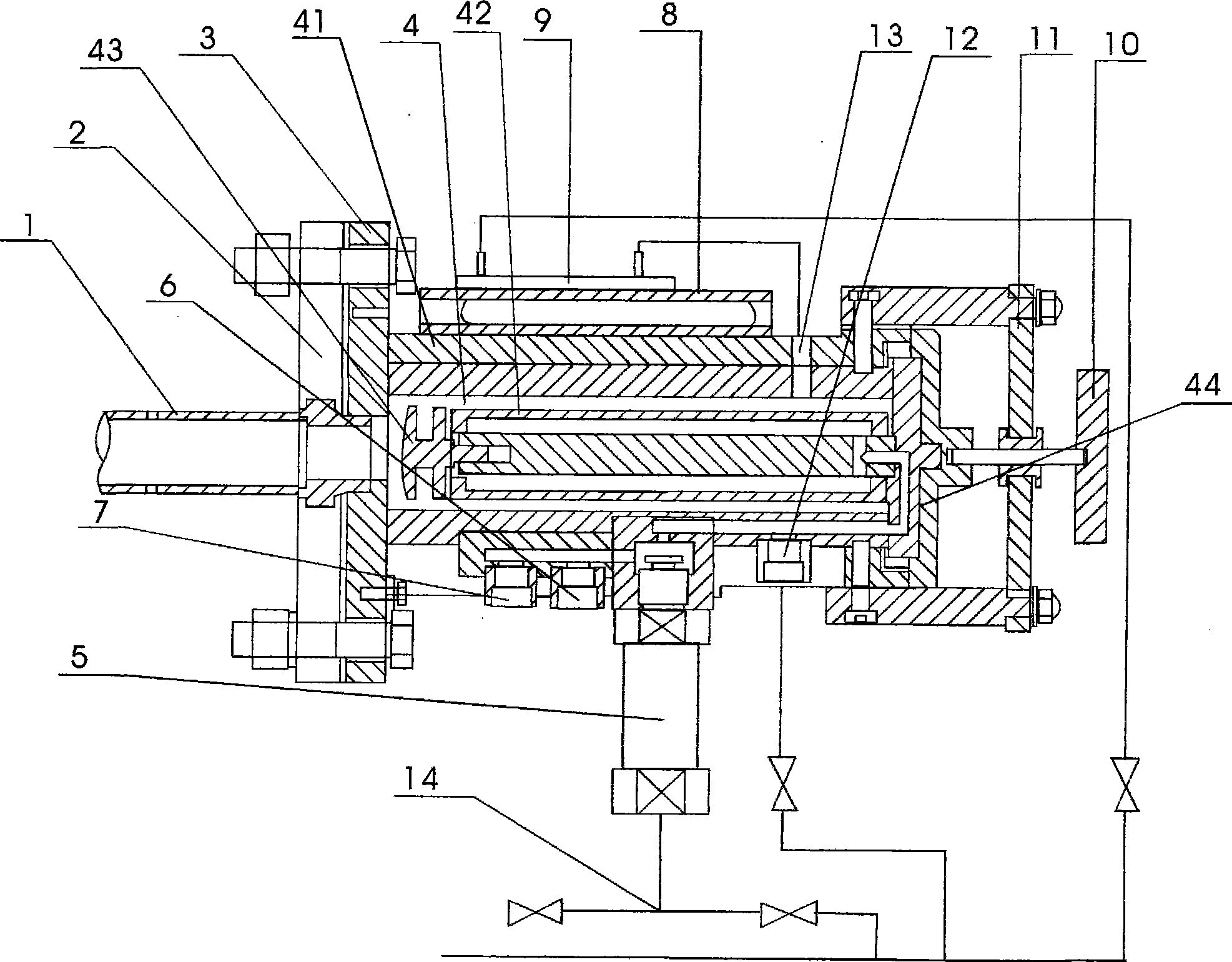

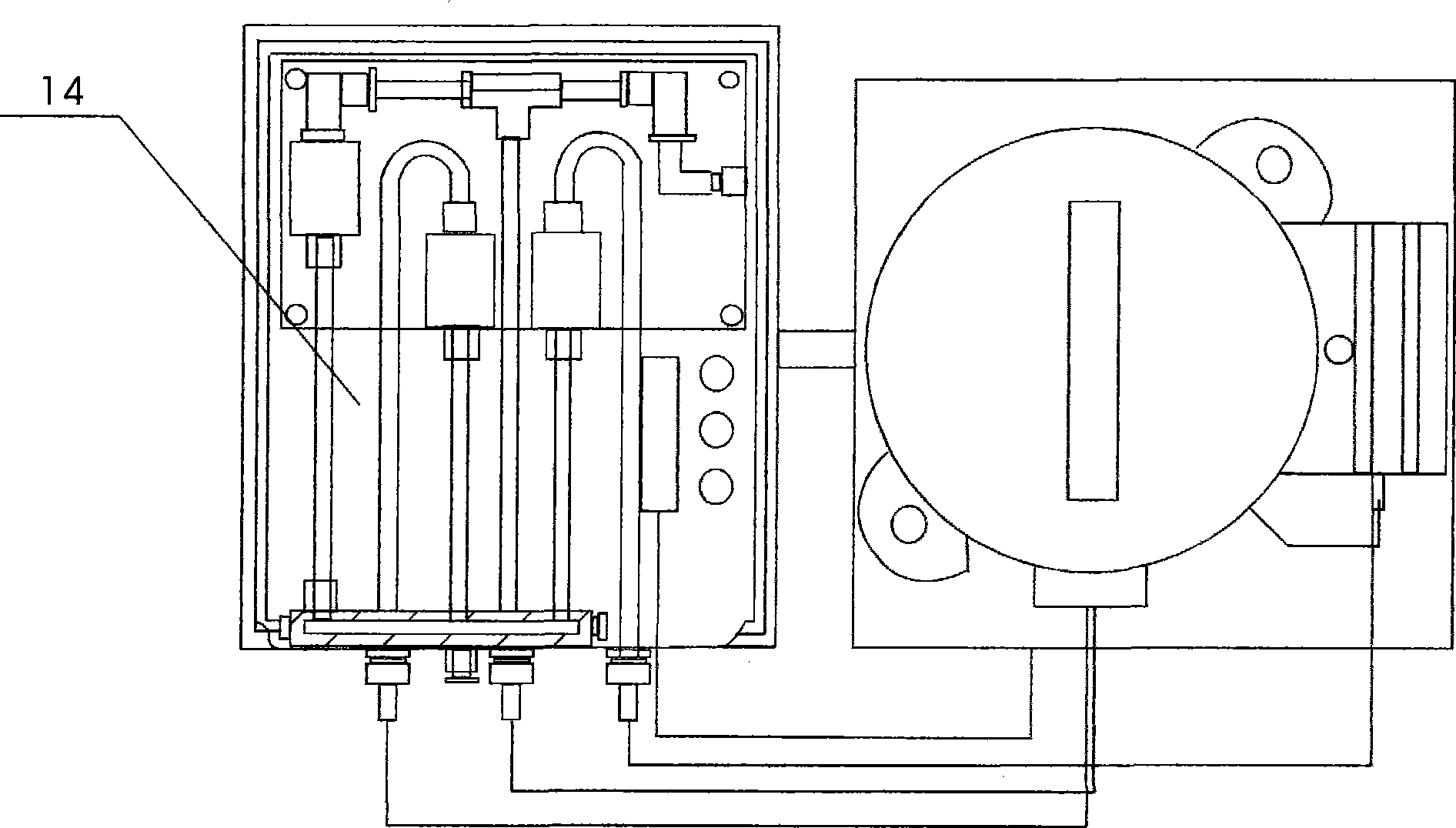

Flue gas sampling probe

ActiveCN101498629ANo corrosionReduce energy consumptionWithdrawing sample devicesFlue gasProcess engineering

The invention relates to a fume sampling probe which mainly consists of a sample pipe, a sample flange, a sample probe mounting plate, a filter, an air cylinder, a standard air inlet, a sample gas outlet, an electric heater, a backblowing air heater, a puller screw, a lever, an internal backblowing hole, an external backblowing hole, a temperature probe, a temperature controller, an electromagnetic valve, a gas-type fitting, a case body and an electrical gas circuit. The invention has the advantages that filter elements of the filter made of resistant material are changed and clean for use alternately, a special backblowing technology method is realized through the electrical gas circuit, the energy consumption is saved, the backblowing effect is good, only one maintenance is needed in one year, the heating temperature can be randomly set, the automatic backblowing period and time can be freely set according to the on-site fume condition, the service life is long, the running is stable and reliable, and the running cost is low, thereby being widely applied to a fume discharge continuous monitoring system of a fixed pollution source in the fume sampling and processing field.

Owner:广东盈峰科技有限公司

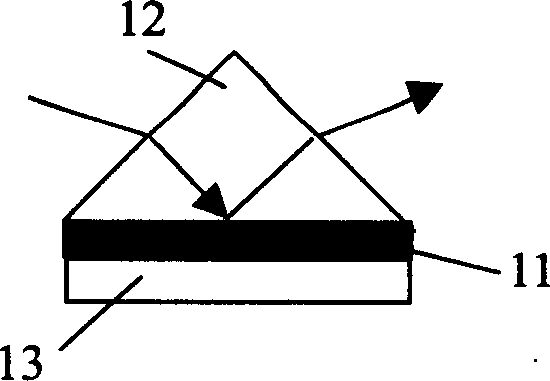

MZ interference SPR chemical and biological sensor and system with fibre-optical microstructure

InactiveCN1712928AReduce electromagnetic interferenceImprove stabilityMaterial analysis by optical meansPhysicsOptical path

A chemical and biological transducer is prepared by setting two long period fibre gratings, fibre covering and fibre core on one piece of fibre to form a MZ interferometer and then plating a metal film on fibre covering surface to form SPR transducer of fibre MZ interferometer structure. The sensing system comprises wide band light source, fibre, chemical and biological transducer formed as above, fibre spectrograph and computer as said transducer is set in gas or solution of chemical composition or biological molecule to be tested.

Owner:重庆工学院

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

Solid catalyst for hydration of epoxy compound to prepare diol and its application

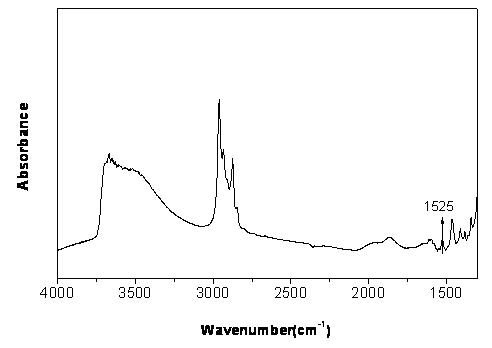

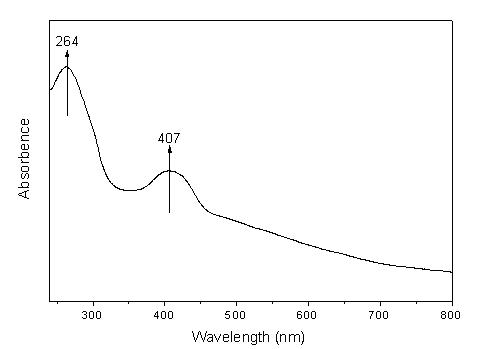

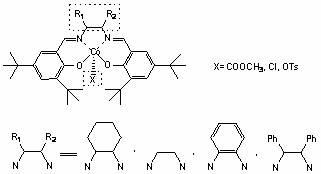

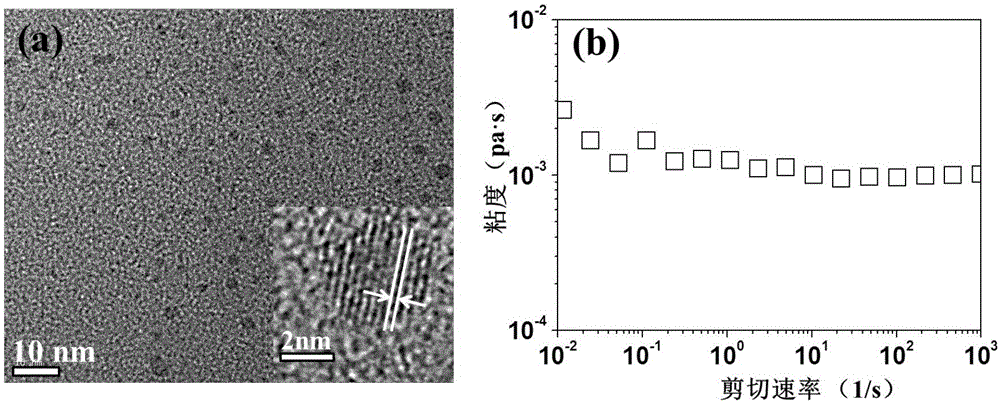

InactiveCN102688776AEfficient catalytic hydration reactionLow water ratioOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingHydration reactionEpoxy

The invention particularly relates to a solid catalyst formed by assembling a racemic Co (salen) metal complex in a nano-reactor and used for the hydration reaction of an epoxy compound to prepare diol. The expression formula of the catalyst is: Co (salen) n / R, wherein R is a nano-reactor with a cage-type pore structure and Co (salen) is a racemic metal complex. A general molecular formula is shown as the following. And n represents the mass percent content of Co in the solid catalyst and ranges from 0. 1% to 1%. The catalyst can be used for a reaction of efficient catalysis of the hydration of an epoxy compound to prepare diol. The catalyst of the invention is characterized by simple preparation method, good reproducibility and easy recycling, thus being able to be used for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Working substance pair for absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C

ActiveCN102965082AImprove solubilityLow saturated vapor pressureHeat-exchange elementsAlkaneOrganic liquids

The invention provides a working substance pair for an absorptive thermal cycling system with heat source temperature ranging from 60 to 130 DEG C. The working substance pair comprises a working substance and an absorbing substance, wherein the working substance is one or the mixture of more than two substances selected from hydrofluoroalkane, fluoro olefin, fluoro-ether, non-substituted alkane or olefin; the absorbing substance is the mixed liquid consisting of 1 to 50% by mass of ionic liquid and 50 to 99% by mass of organic liquid; and the working substance and the absorbing substance are mixed at 20 to 80 DEG C. The working substance pair can overcome the shortcomings of the conventional working substance pair, and has the characteristics of nontoxicity, safety, and environment conservation.

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

Making method of and use of antibiotic surgical dressing

InactiveCN1833732AEasy to usePrevent moisture lossAdhesive dressingsAbsorbent padsWound healingAcetic acid

An antibacterial medical dressing is prepared from chitosan fibers through alkalizing, etherifying reaction on chloroacetic acid to obtain carboxymethyl chitosan fibers, opening, netting, needling, and cutting by needed sizes, packing and disinfecting. It can be used for preparing the surgical dressing for wound, bum and scald, the anti-inflammatory staltic fiberous ball, anti-inflammtory drainage sliver, and operation dressing.

Owner:李毅彬

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Green alkaline paint remover for eliminating coating from electronic circuit board and its prepn and usage

InactiveCN1887979AReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideEngineering

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

High molecular solid/solid phase changing material with net type and comb type mixed structure and its preparing method

InactiveCN1616588APhase transition temperature is suitableSolid state goodHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The present invention relates to a kind of high molecular solid / solid phase changing material with mixed net and comb structure, and features that polyglycol with two active end radical and polyglycol with one active end radical are fixed onto the high molecular skeleton material to form 3D mixed net and comb structure. The material of the present invention has relatively great phase change enthalpy up to 120 J / g, proper phase change temperature capable of being altered in 0-65 deg.c, stable solid state before and after phase change without supercooling, separating and other unstable phenomenon, high mechanical strength, high solvent resistance, good machining performance, no toxicity, no leakage, no corrosion, no pollution, long service life and other advantages. The present invention may be used widely in solar energy utilization, afterheat recovering, intelligent air conditioner and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

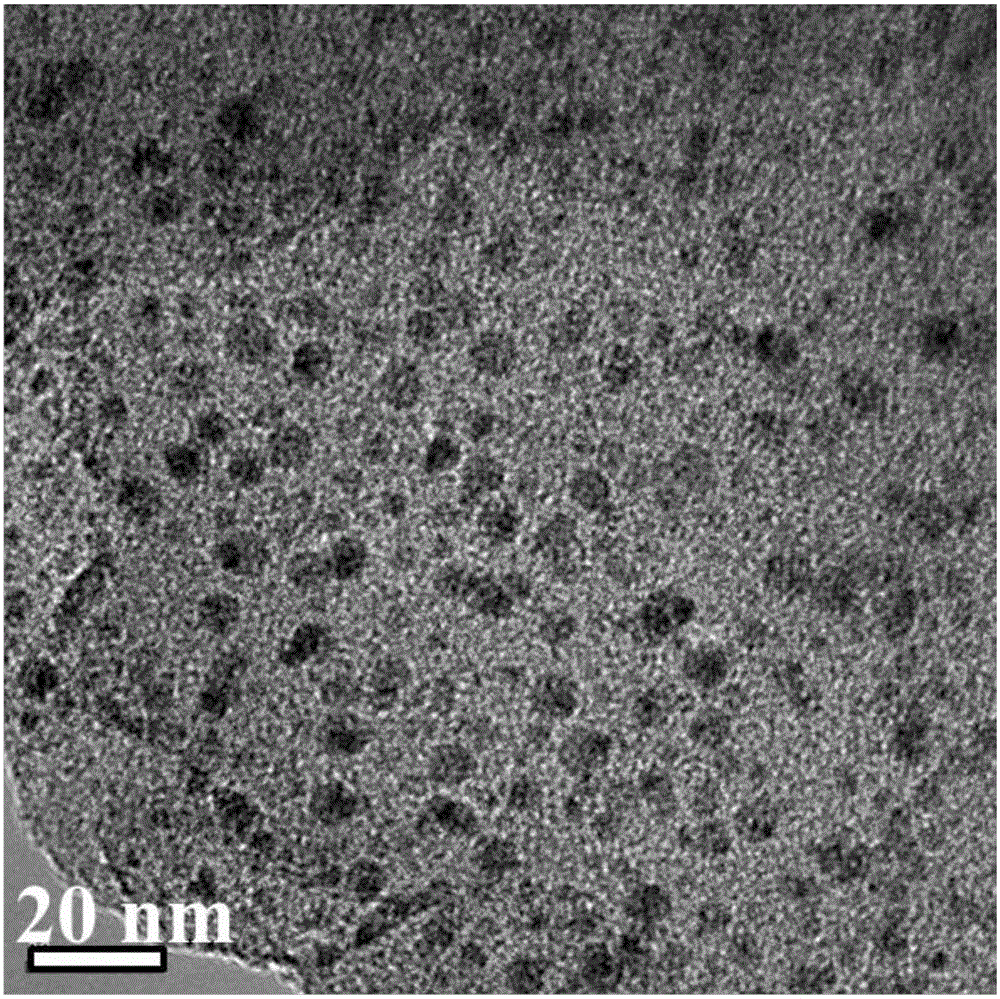

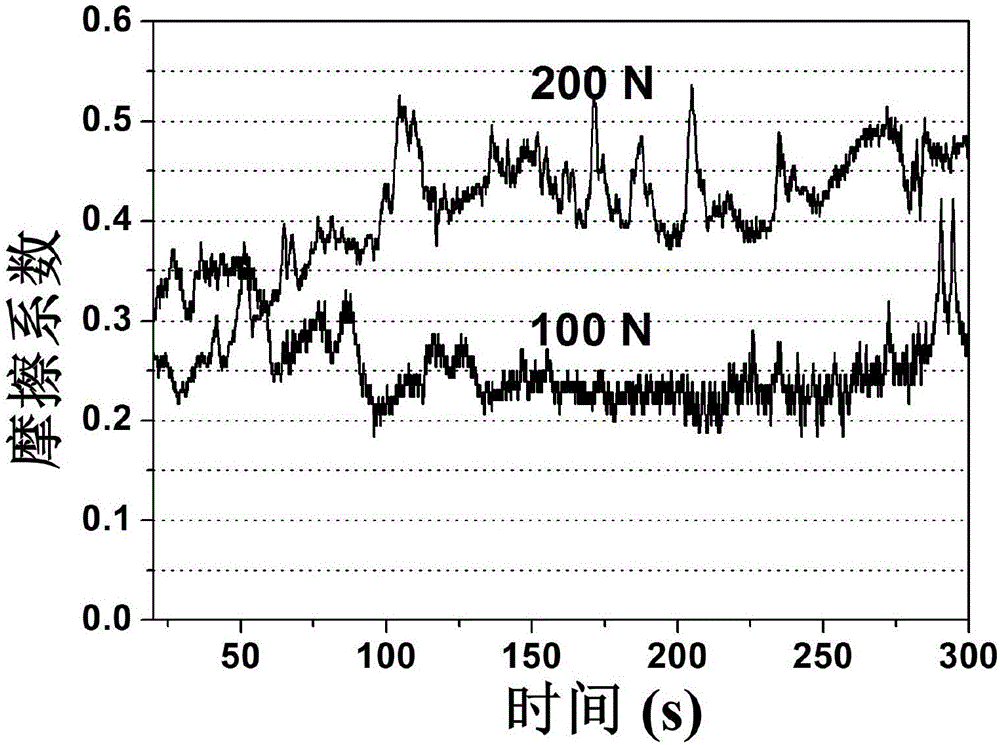

Water-based lubricant based on two-dimensional material nanosheets/carbon quantum dots and preparation method of water-based lubricant

InactiveCN106520354AReduce coefficient of frictionImprove adaptabilityLubricant compositionWater basedMaterials preparation

The invention belongs to the technical field of nano lubricant material preparation and relates to a water-based lubricant based on two-dimensional material nanosheets / carbon quantum dots and a preparation method of the water-based lubricant. Carbon quantum dot powder is first prepared, then the prepared carbon quantum dot powder is added into ultra-pure water, and ultrasonic treatment is conducted for 10 min to obtain a carbon quantum dot aqueous solution; then, two-dimensional material nanosheets are added into the carbon quantum dot aqueous solution for ultrasonic treatment to prepare the water-based lubricant based on the two-dimensional material nanosheets / carbon quantum dots, wherein the water-based lubricant comprises, by mass, 0.01-15% of the carbon quantum dots, 0.001-0.1% of the two-dimensional material nanosheets and the balance ultra-pure water. The lubricant is simple and controllable in preparation process, low in cost, environmentally friendly, clean and free of toxin, large-scale production is easy, and the prepared water-based lubricant is extremely low in friction coefficient and good in adaptability with friction pairs, and does not corrode common carbon steel.

Owner:QINGDAO UNIV +1

Low solid content halogenide-free water-based type cleaning-free scaling powder

InactiveCN101327552AHigh activitySolve the defect of insufficient wettabilityWelding/cutting media/materialsSoldering mediaWater basedAviation

The present invention relates to a medium-and-high-activity, low-solid-content halideless water-based type wash-free soldering flux which is applicable to the spraying process, the foaming process and the dipping process. The soldering flux is composed of the following weight proportions of substances: 1 percent to 4 percent of promoting agent, 0.5 percent to 1.5 percent of filmerformer, 20 percent to 40 percent of latent solvent, 0.1 percent to 2 percent of wetting agent and 0.01 percent to 0.1 percent of corrosion inhibitor, and the rest is deionized water. The soldering flux of the present invention does not contain halogen and colophony; soldering material can have good spreadability; a PCB board can have good solder permeability; soldering spots are plump and shiny; the surface of the soldered PCB board has no visible residues and is not eroded, and the surface insulation resistance is high; under the normal temperature, the soldering flux does not absorb moisture and cannot be decomposed, and a washing process can be omitted. Since the deionized water is used as solvent, the soldering flux does not contain any volatile organic substance, so the soldering flux cannot be ignited and does not explode, and therefore the soldering flux is environment-friendly. The soldering flux is applicable to the wave-soldering or dip-soldering production line of various printed boards in the fields of communication, aviation, computers, etc.

Owner:DONGGUAN YONGAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com