Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2749results about How to "Reduce electromagnetic interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

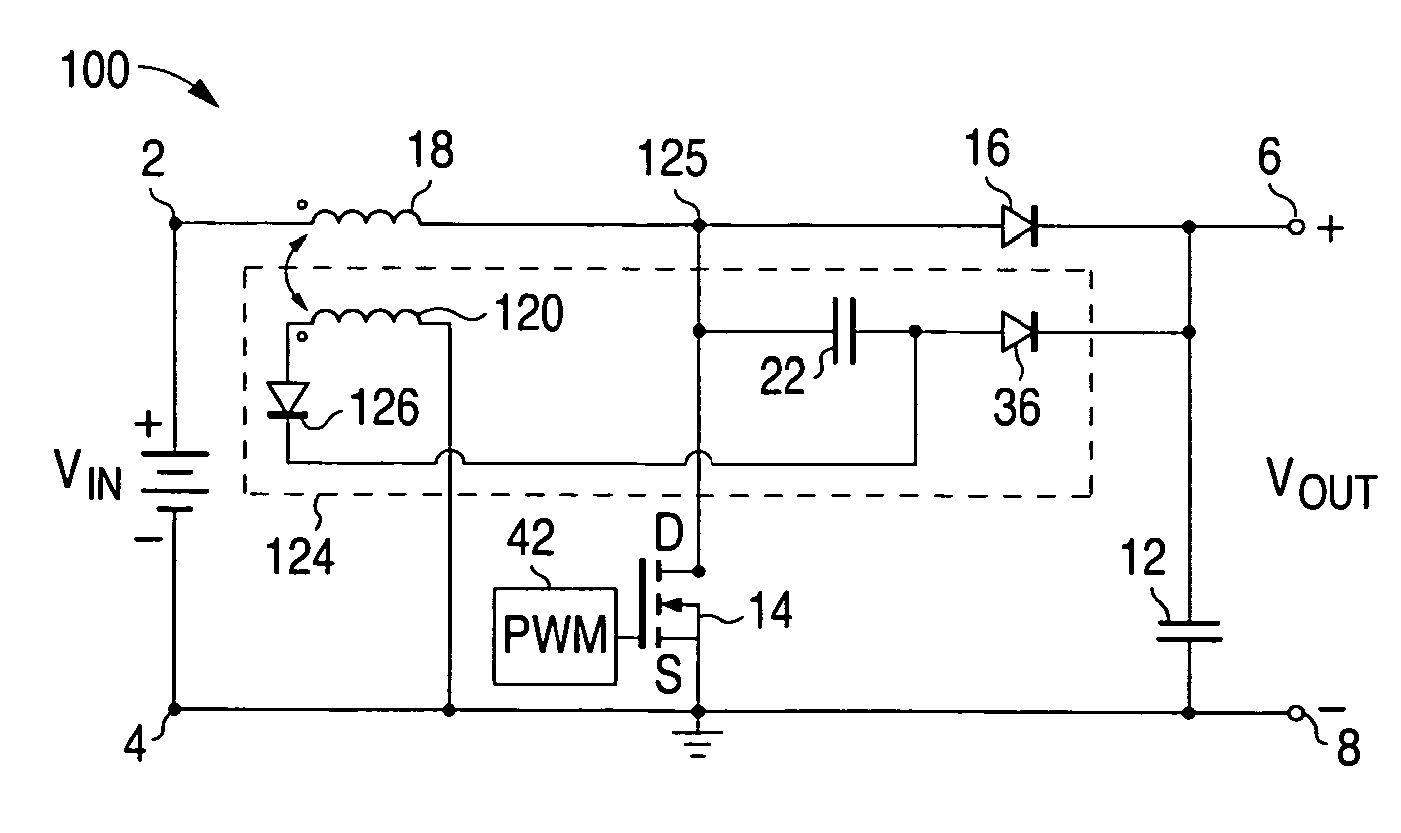

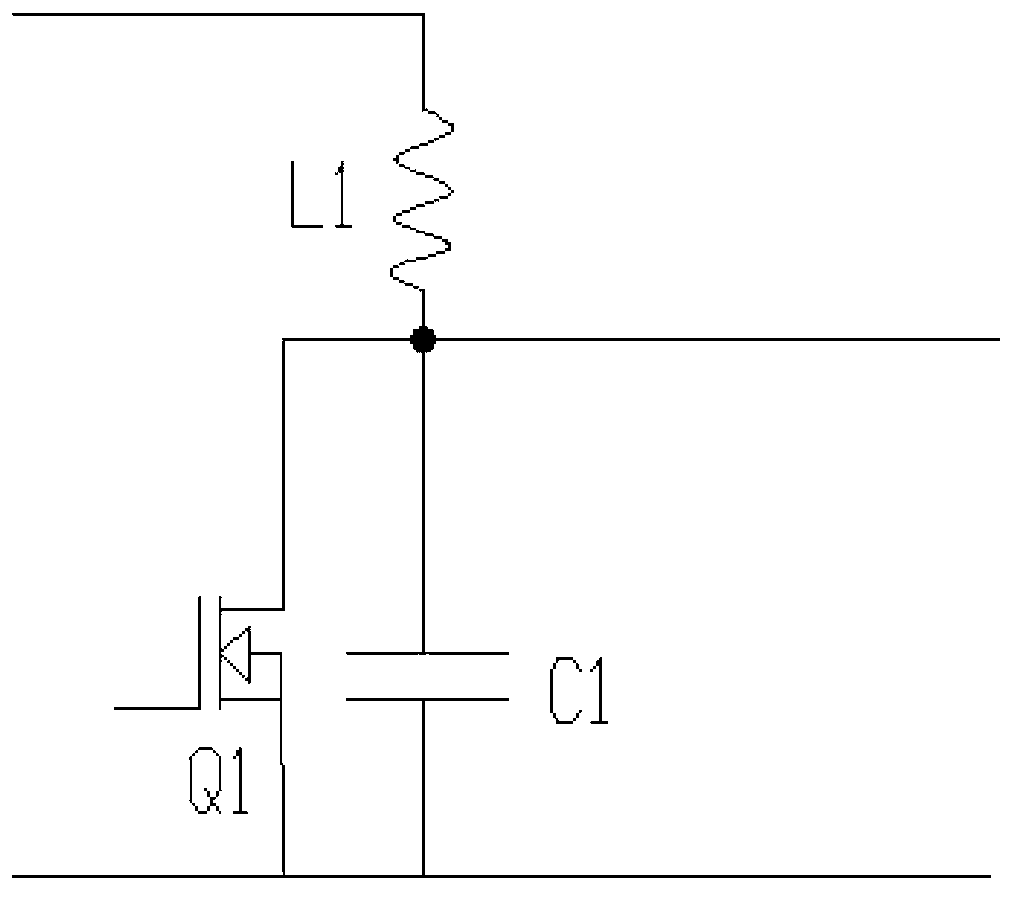

Snubber circuit for a power converter

InactiveUS7385833B2Easy to controlHigh voltageEfficient power electronics conversionDc-dc conversionTransverterEngineering

Owner:ASTEC INT LTD

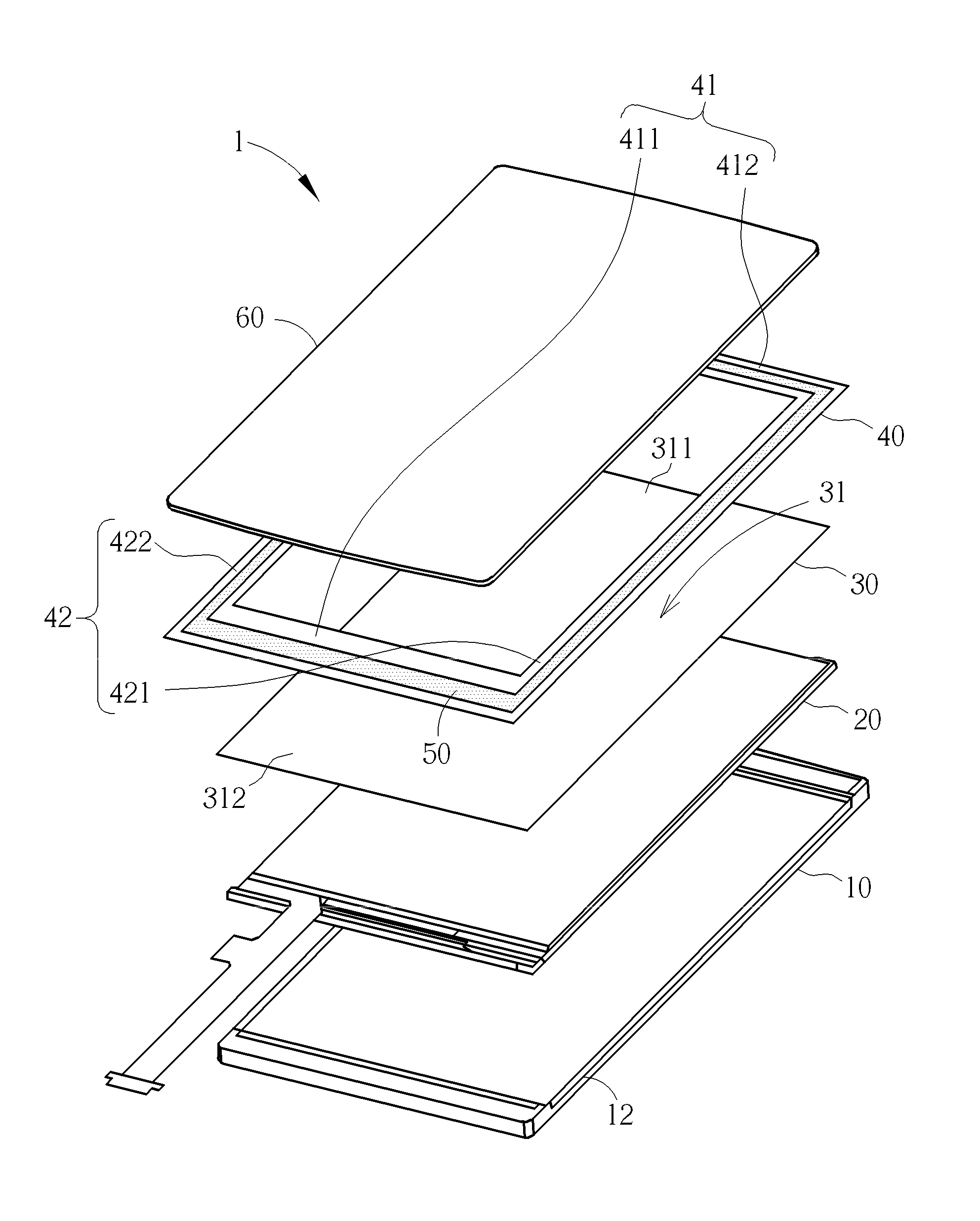

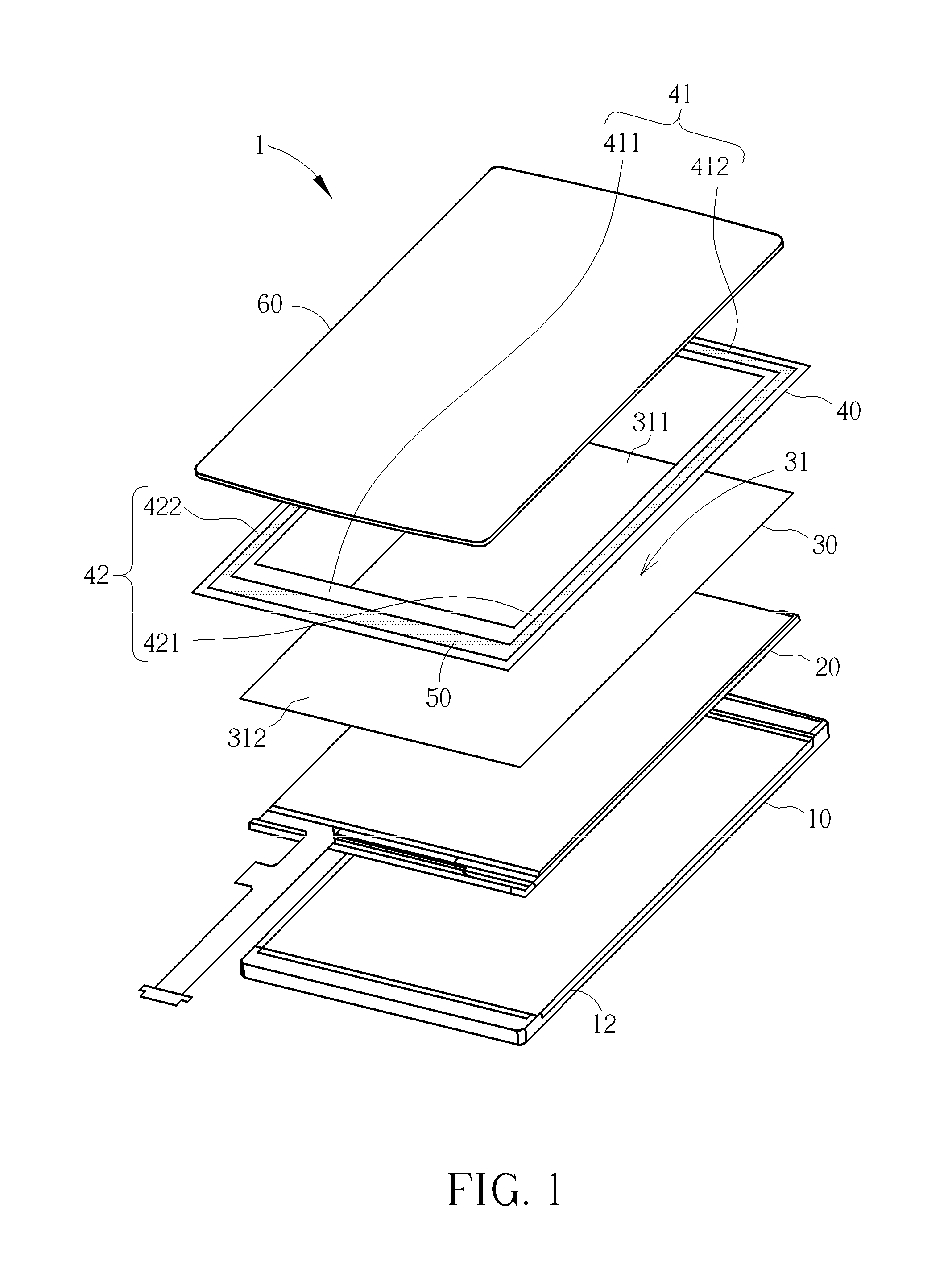

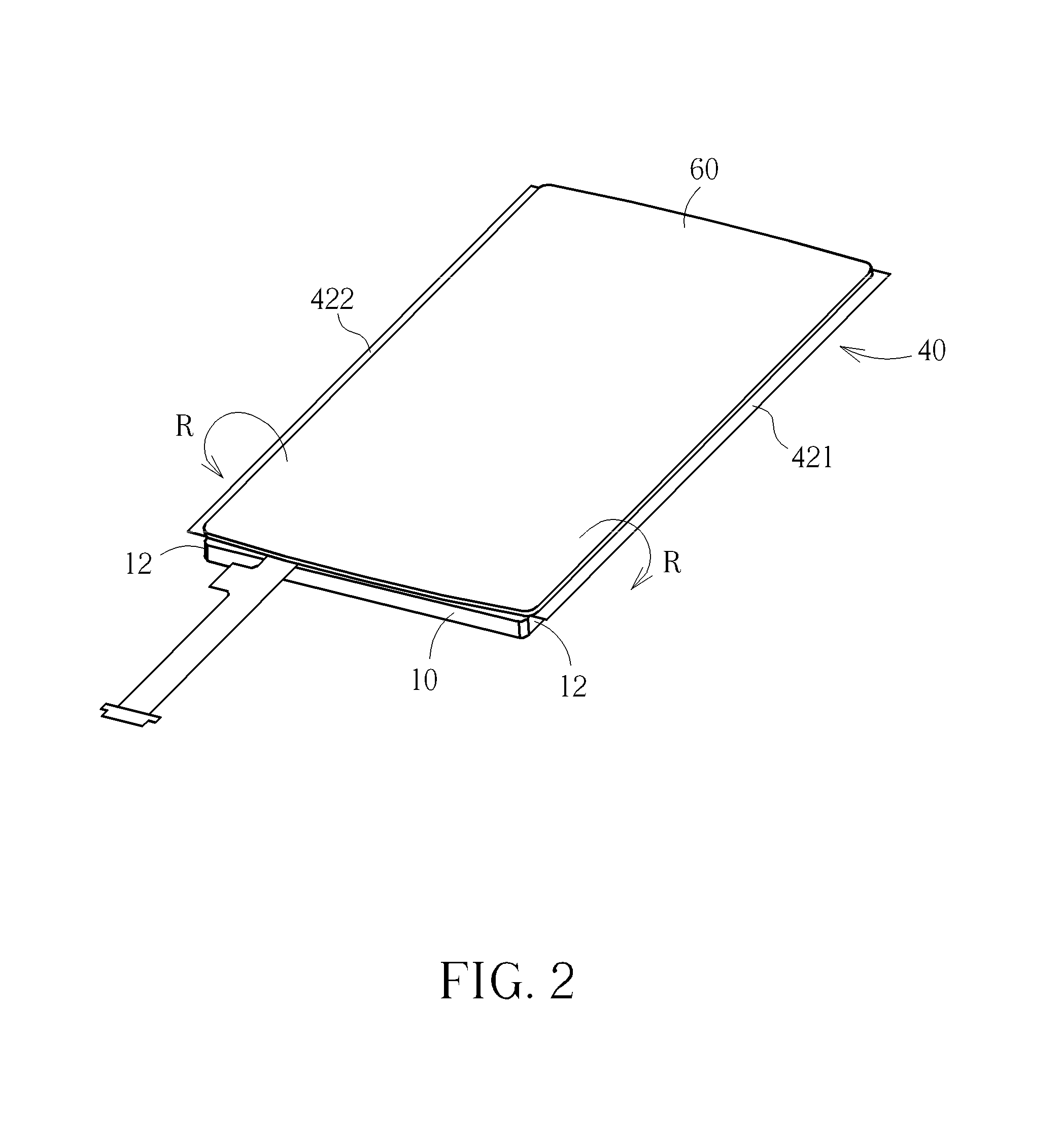

Touch panel structure, touch and display panel structure, and integrated touch display panel structure having antenna pattern and method of forming touch panel having antenna pattern

ActiveUS20140043248A1Reduce areaConvenience to workRadiating elements structural formsLoop antennasEngineeringElectronic component

In a touch panel and display panel structure or an integrated touch display panel structure, an antenna pattern is disposed on a touch module, a display module or an integrated touch display module for an increased distance between the antenna pattern and electronic components below the structure, reducing electromagnetic effect caused by the electronic components and improving the antenna performance. The antenna pattern is arranged at two opposite edges of a top surface of the touch and display module or the integrated touch display module, and also at side surfaces of a housing non-coplanar to the top surface such that the antenna pattern is located outside the displaying area of the display module. Maintaining the effective antenna area and enhancing the working bandwidth of the antenna, the side width of surface of the touch panel and display panel structure or the integrated touch display panel structure is significantly reduced.

Owner:HTC CORP

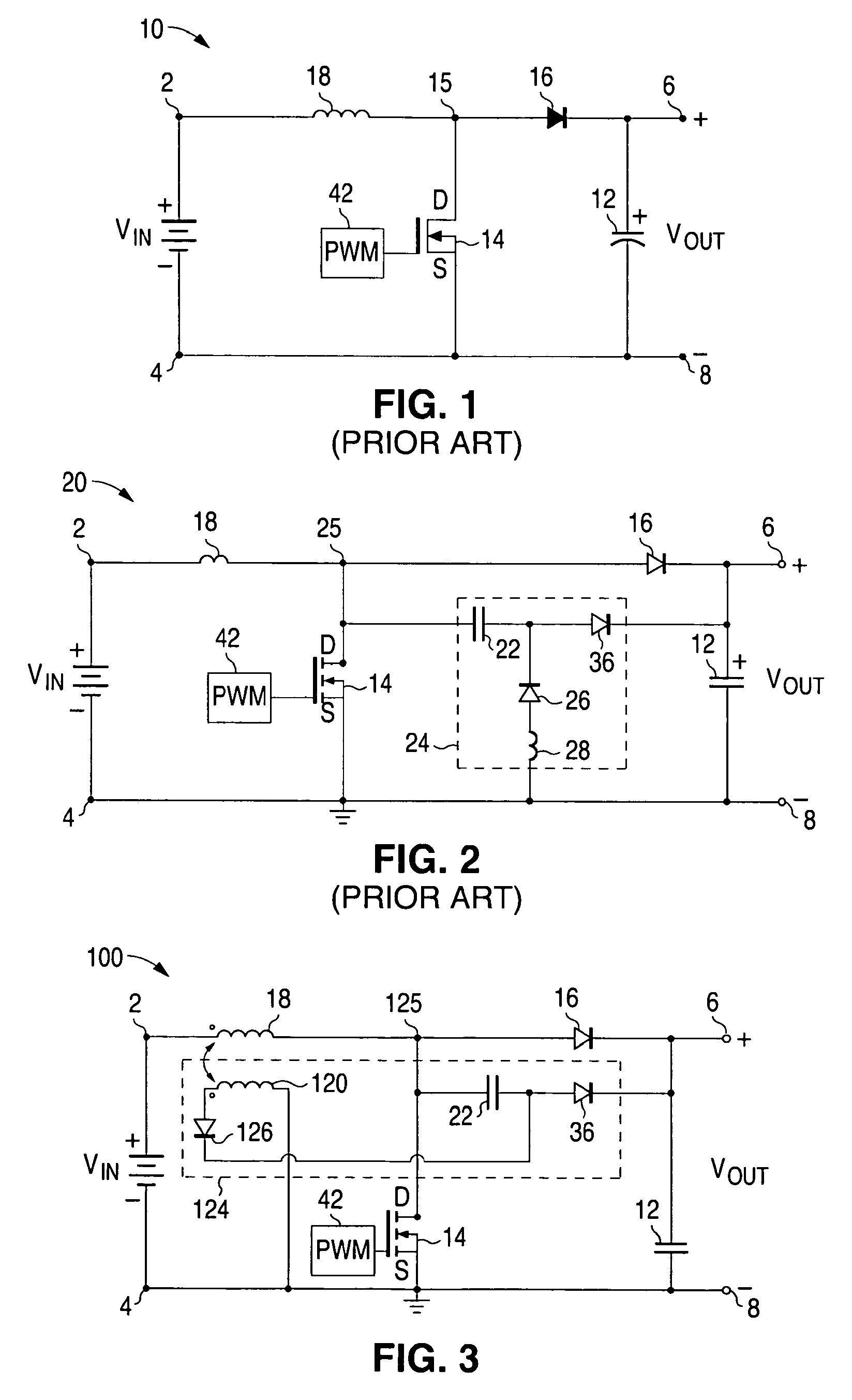

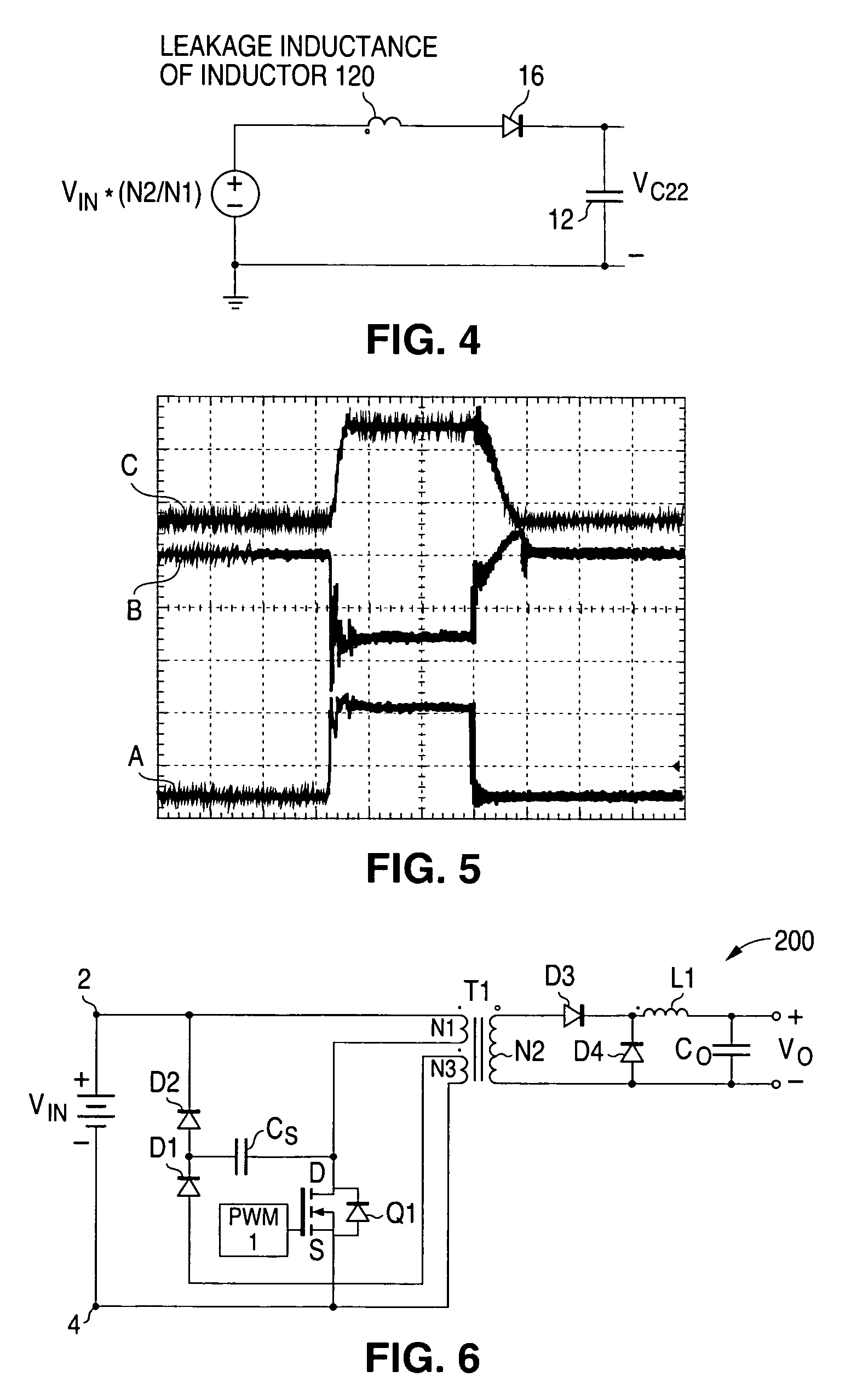

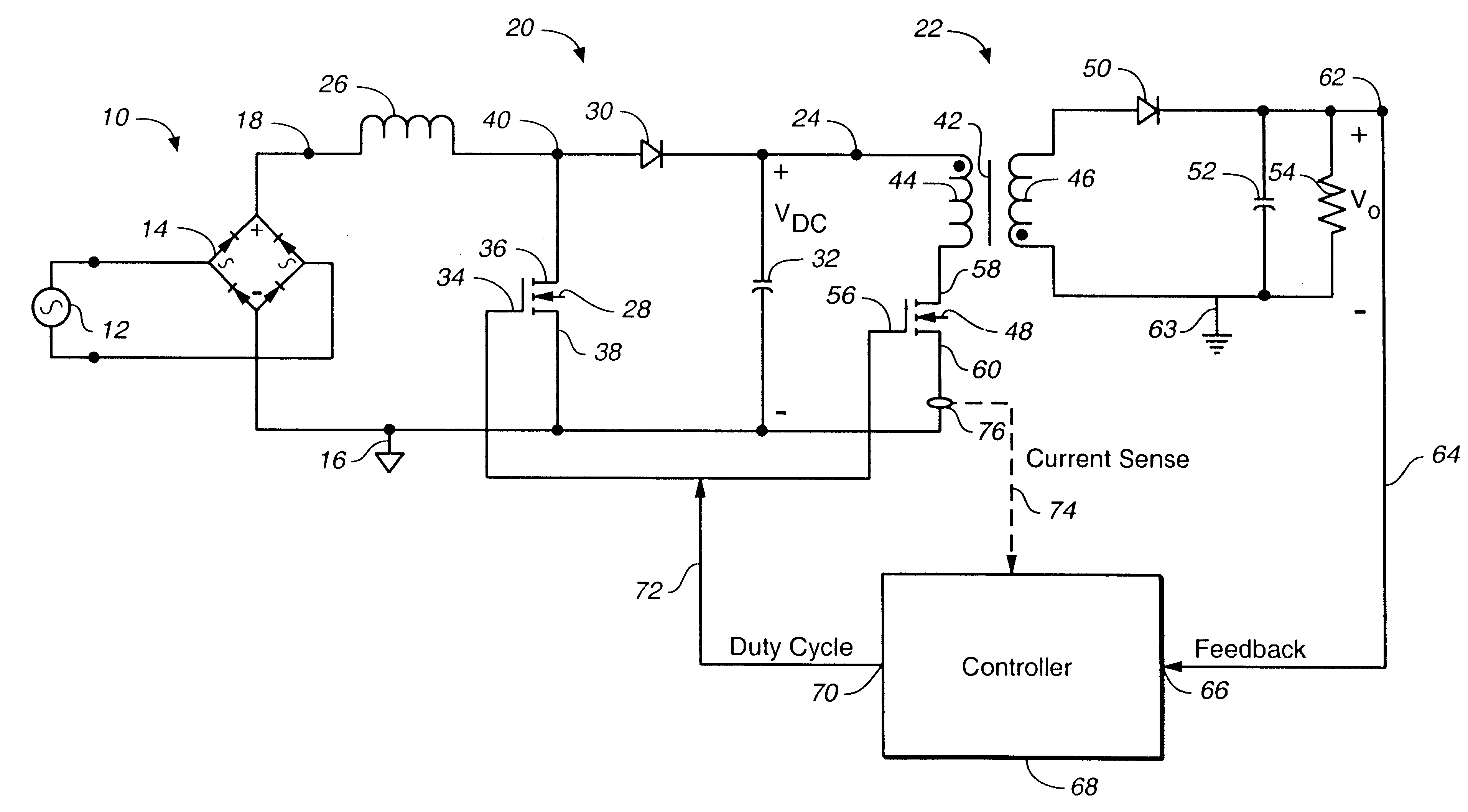

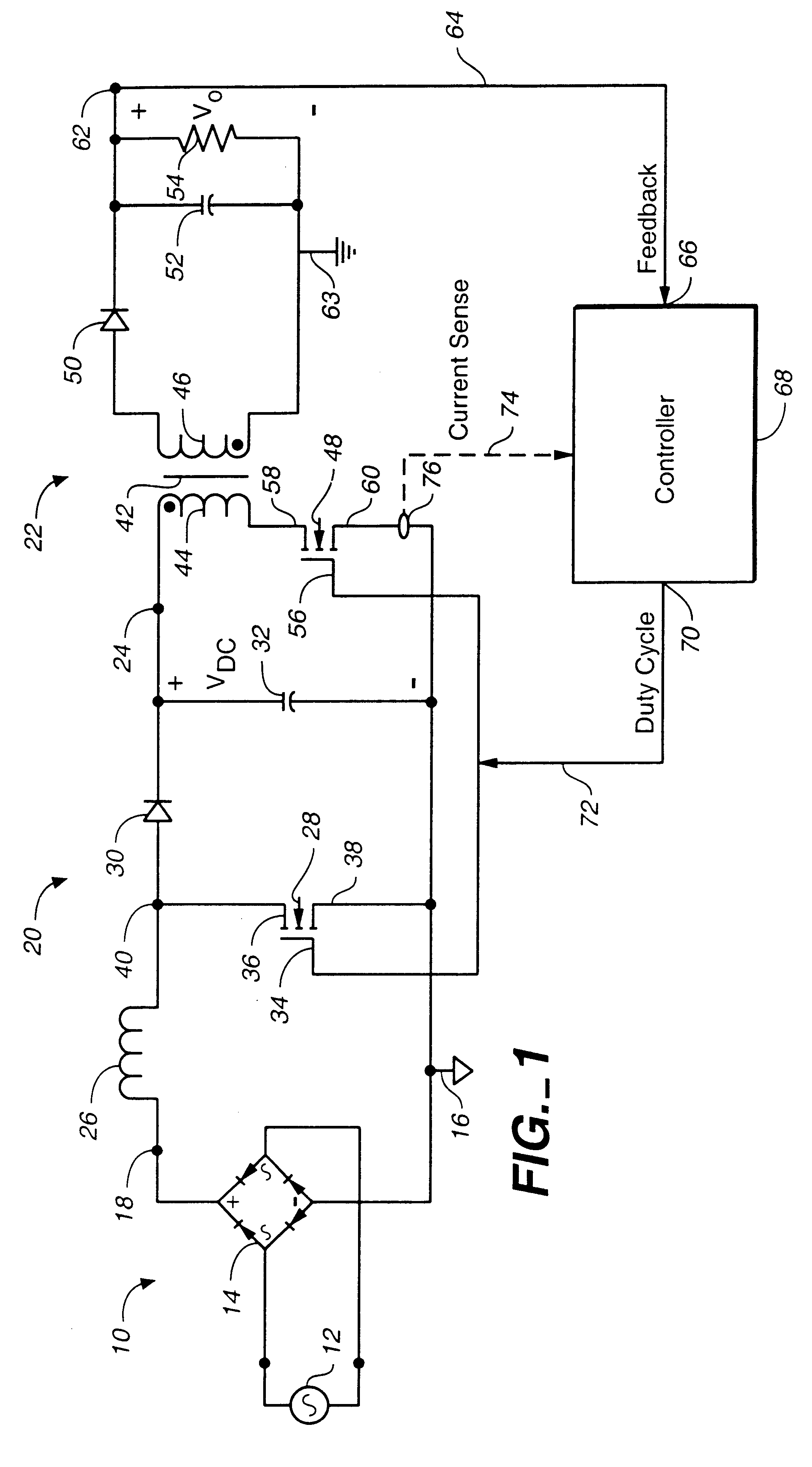

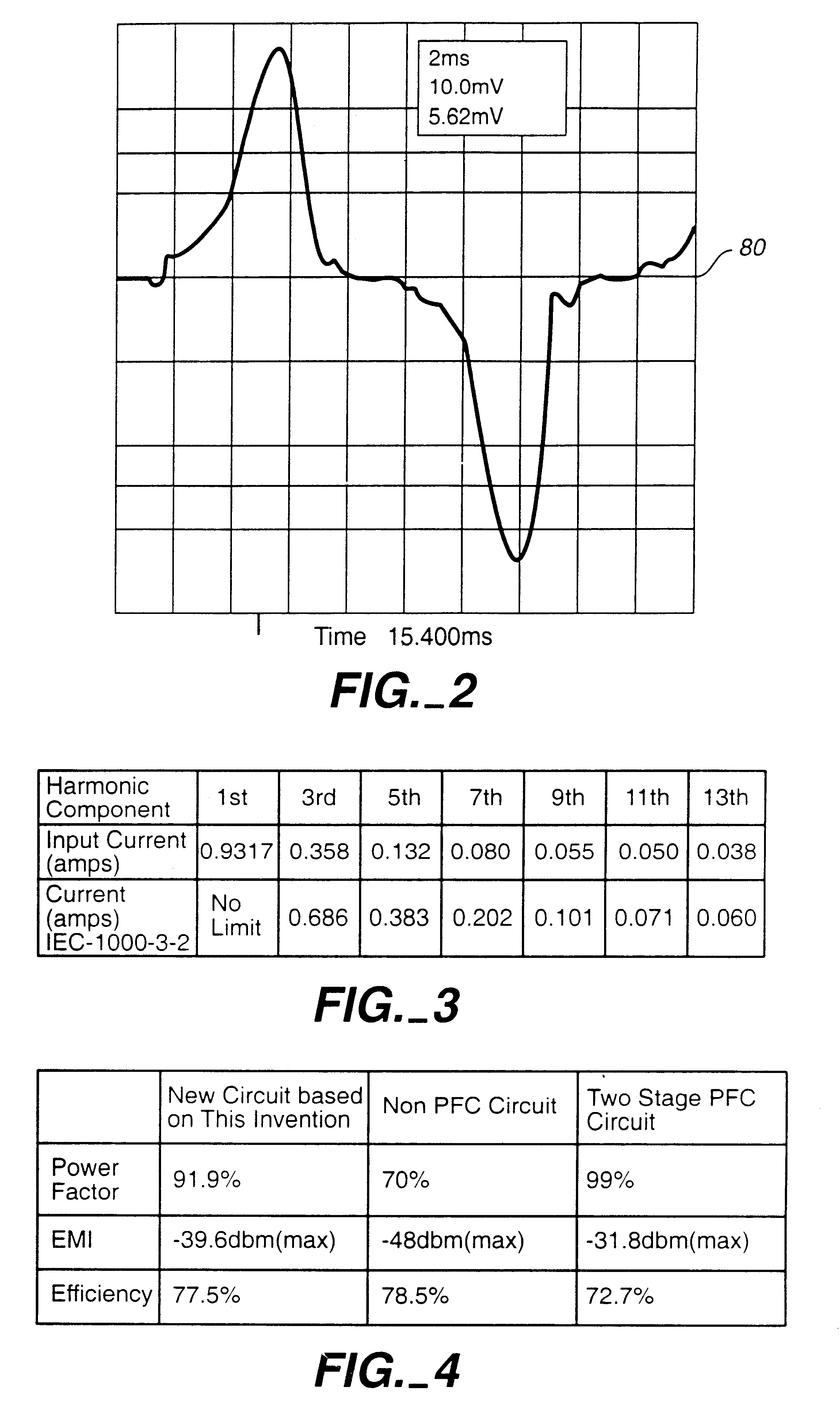

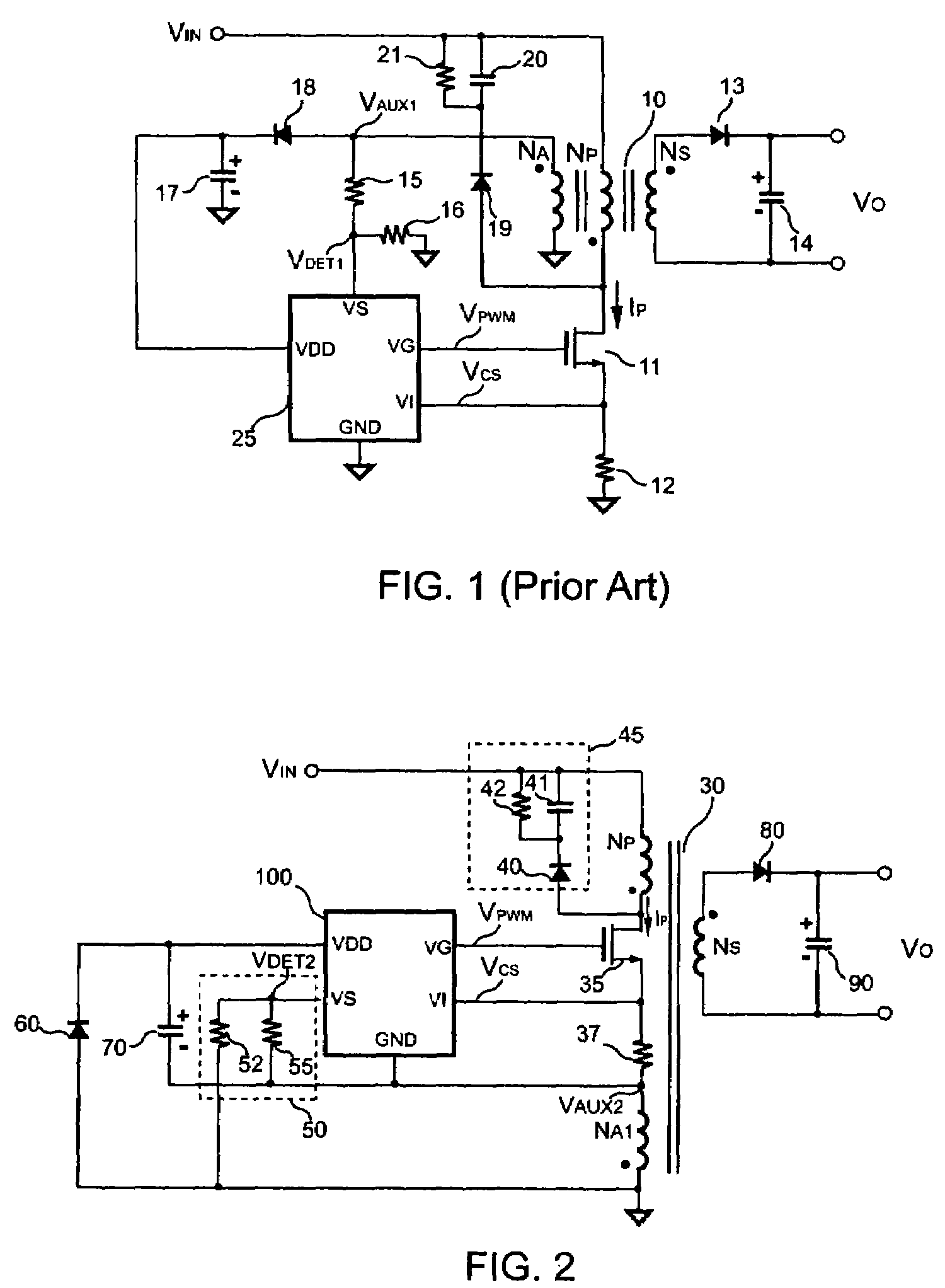

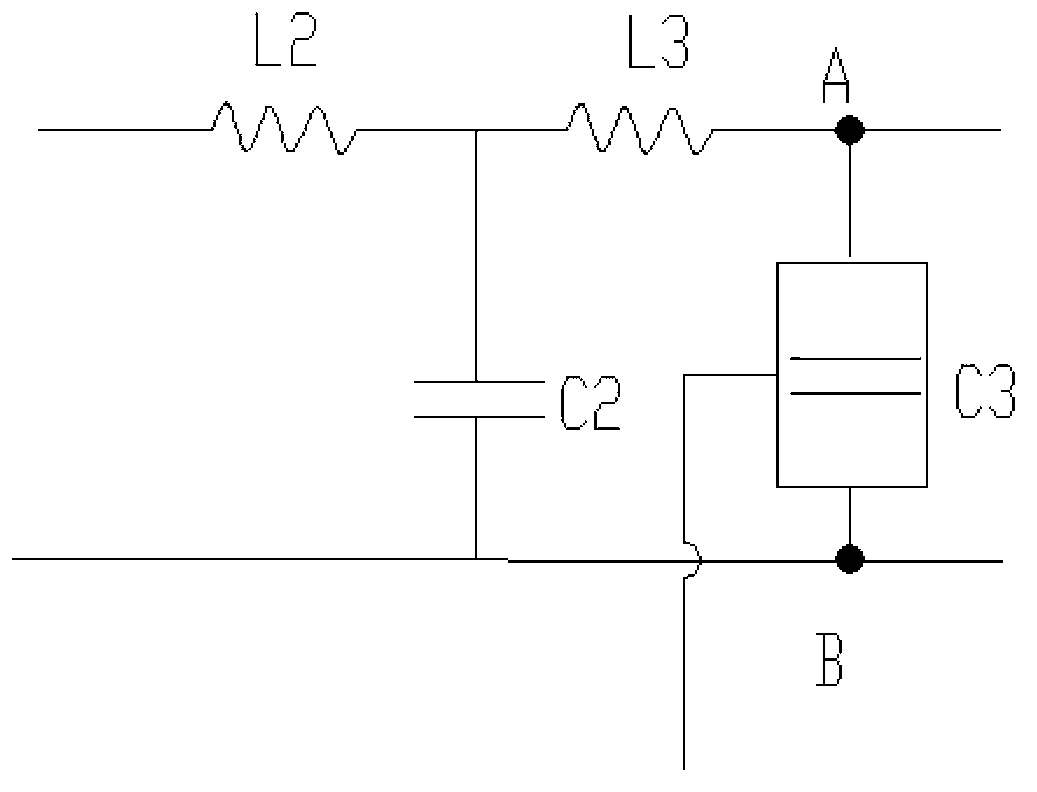

Topology and control method for power factor correction

InactiveUS6344986B1Reduce electromagnetic interferenceReduce output voltageAc-dc conversion without reversalEfficient power electronics conversionTransverterInductor

In a power factor corrected AC-to-DC power supply system, a DC-to-DC power converter is coupled to the output of an AC-to-DC power converter in order to produce a regulated DC output signal from a rectified AC input signal. The AC-to-DC power converter and the DC-to-DC power converter each includes a switch for controlling the operation of their respective power converter. The AC-to-DC converter includes an inductor. The system provides power factor correction for minimizing harmonic distortion by including a controller that receives the regulated DC output voltage as a feedback signal, and in response, produces a series of drive pulses having predetermined constant duty cycle. These pulses are simultaneously fed to each switch, to operate the respective converters alternately between ON and OFF states. When the AC-to-DC converter is driven by a fixed duty cycle of the series of pulses, power factor correction is improved since the current flowing through the inductor is substantially proportional to the waveform of the rectified AC input signal. By preselecting the value of the inductor, the AC-to-DC converter is operable in a discontinuous mode when the instantaneous rectified AC input signal is low and in a continuous mode when the instantaneous rectified AC input signal is high.

Owner:ASTEC INT LTD

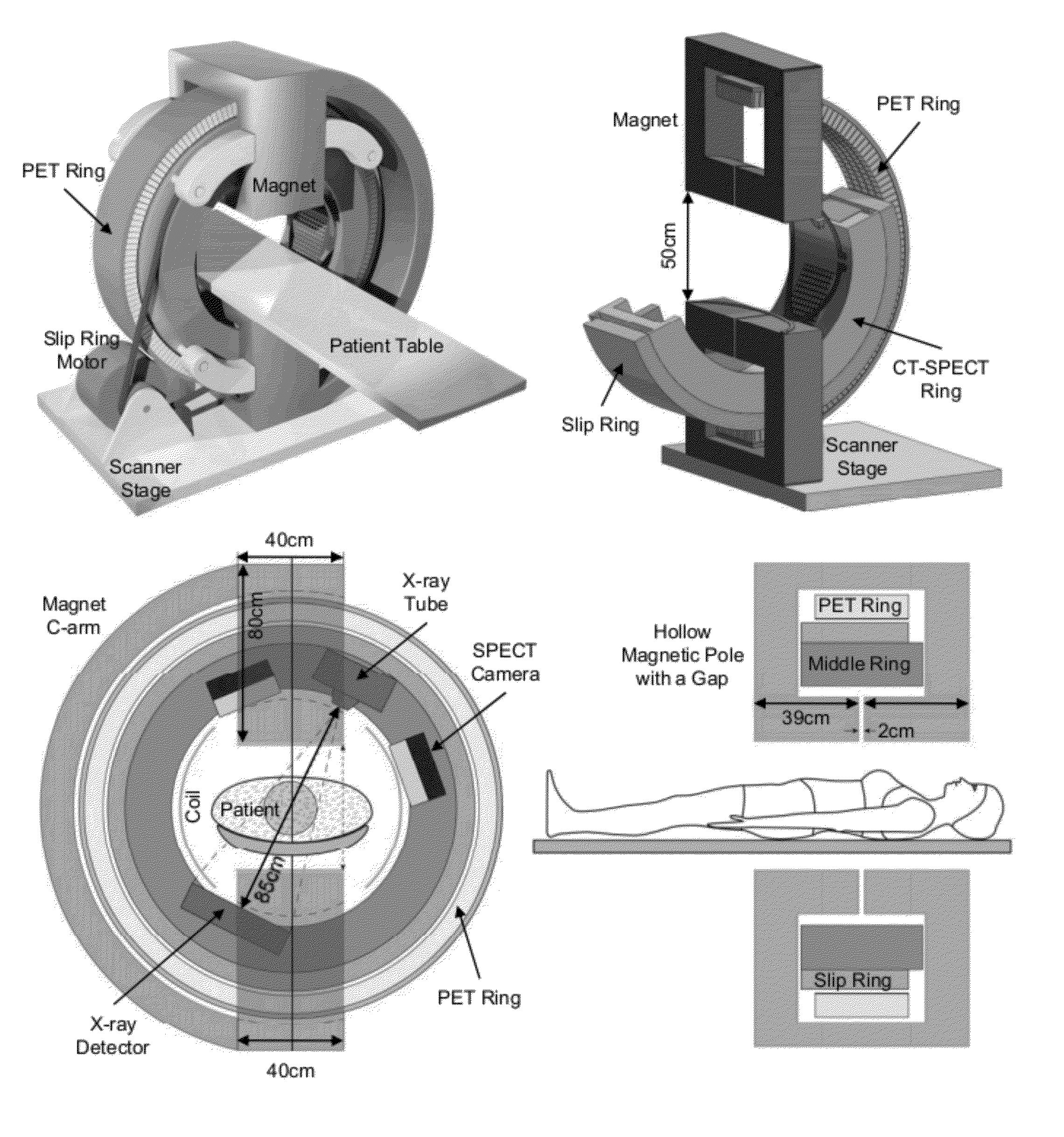

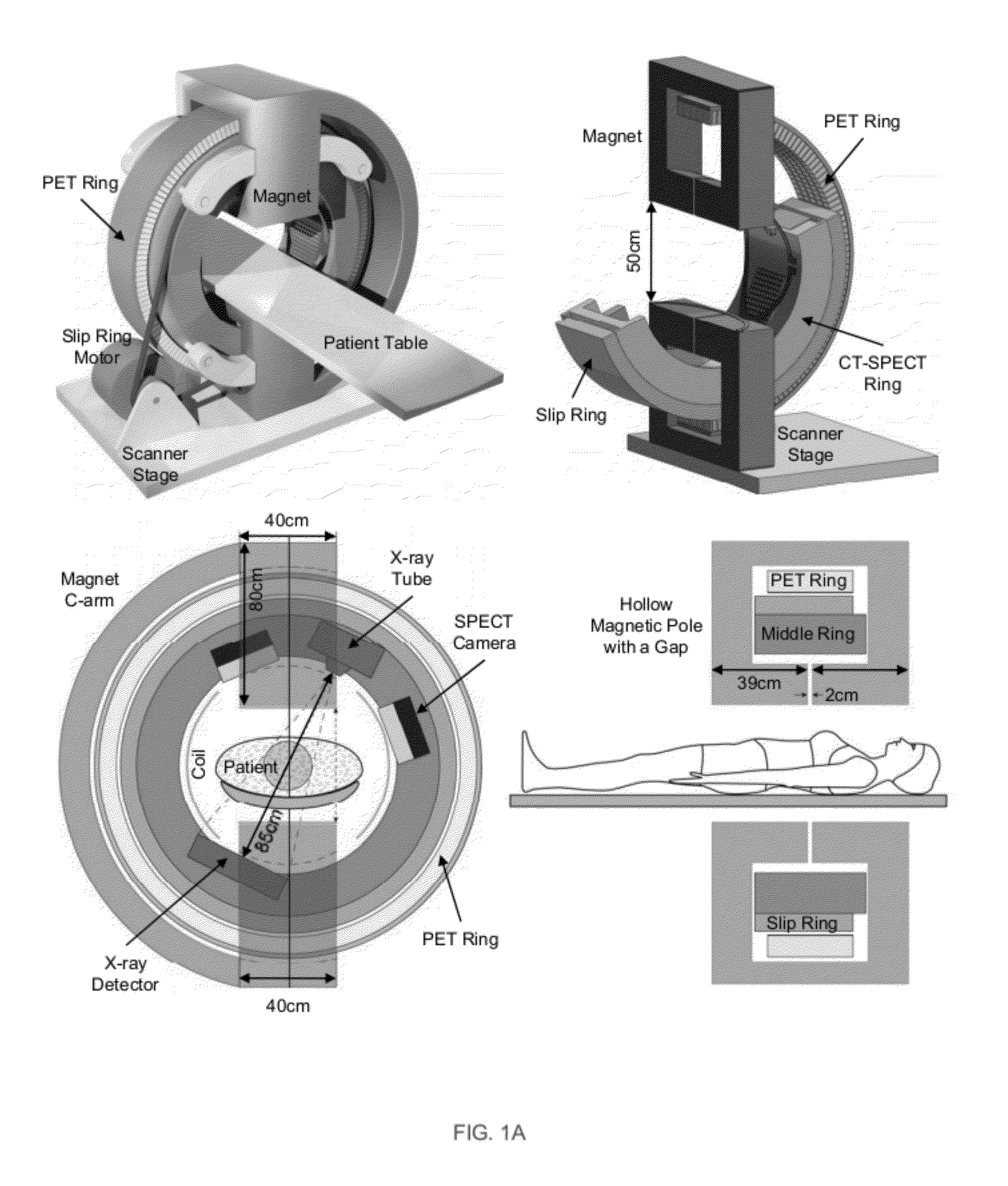

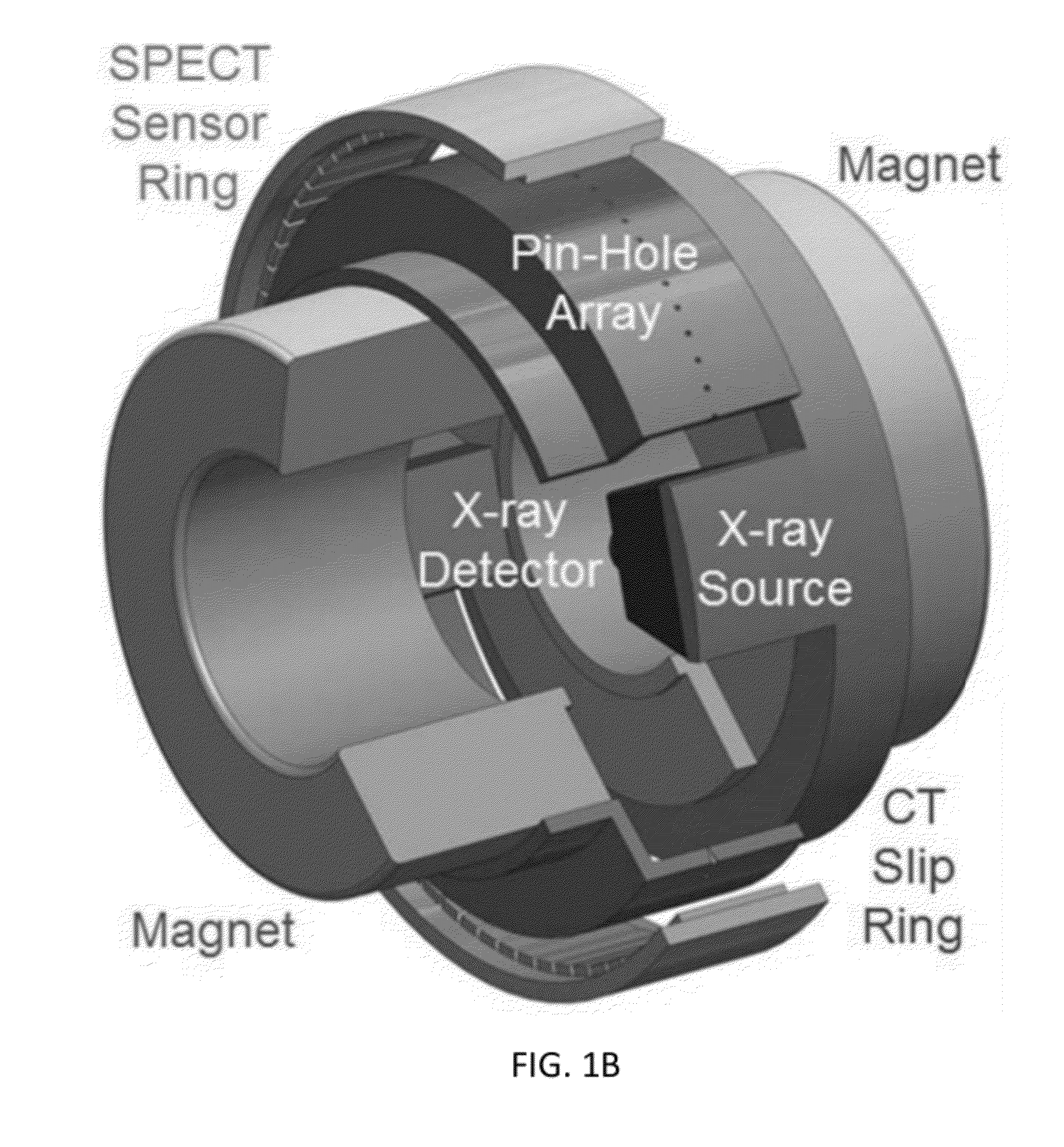

Omni-Tomographic Imaging for Interior Reconstruction using Simultaneous Data Acquisition from Multiple Imaging Modalities

InactiveUS20120265050A1Less importantLow costUltrasonic/sonic/infrasonic diagnosticsMagnetic measurementsDiagnostic Radiology ModalityModern medicine

Embodiments of the invention relate to omni-tomographic imaging or grand fusion imaging, i.e., large scale fusion of simultaneous data acquisition from multiple imaging modalities such as CT, MRI, PET, SPECT, US, and optical imaging. A preferred omni-tomography system of the invention comprises two or more imaging modalities operably configured for concurrent signal acquisition for performing ROI-targeted reconstruction and contained in a single gantry with a first inner ring as a permanent magnet; a second middle ring containing an x-ray tube, detector array, and a pair of SPECT detectors; and a third outer ring for containing PET crystals and electronics. Omni-tomography offers great synergy in vivo for diagnosis, intervention, and drug development, and can be made versatile and cost-effective, and as such is expected to become an unprecedented imaging platform for development of systems biology and modern medicine.

Owner:VIRGINIA TECH INTPROP INC

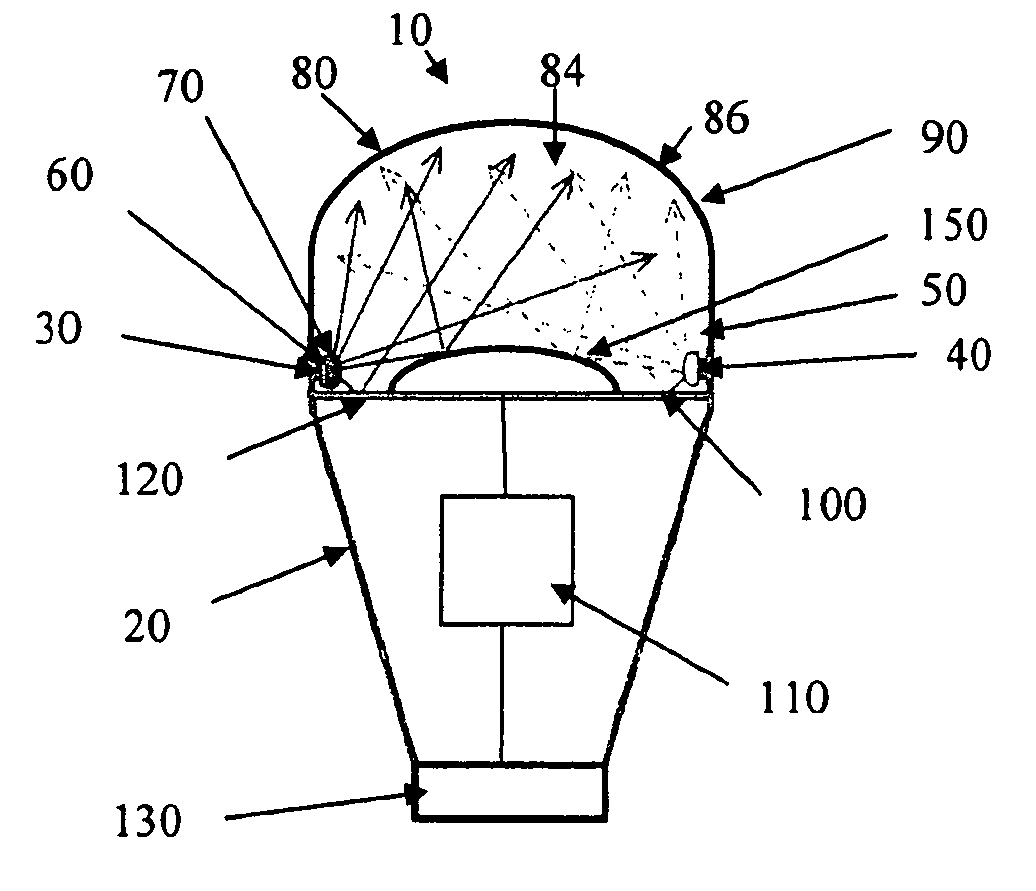

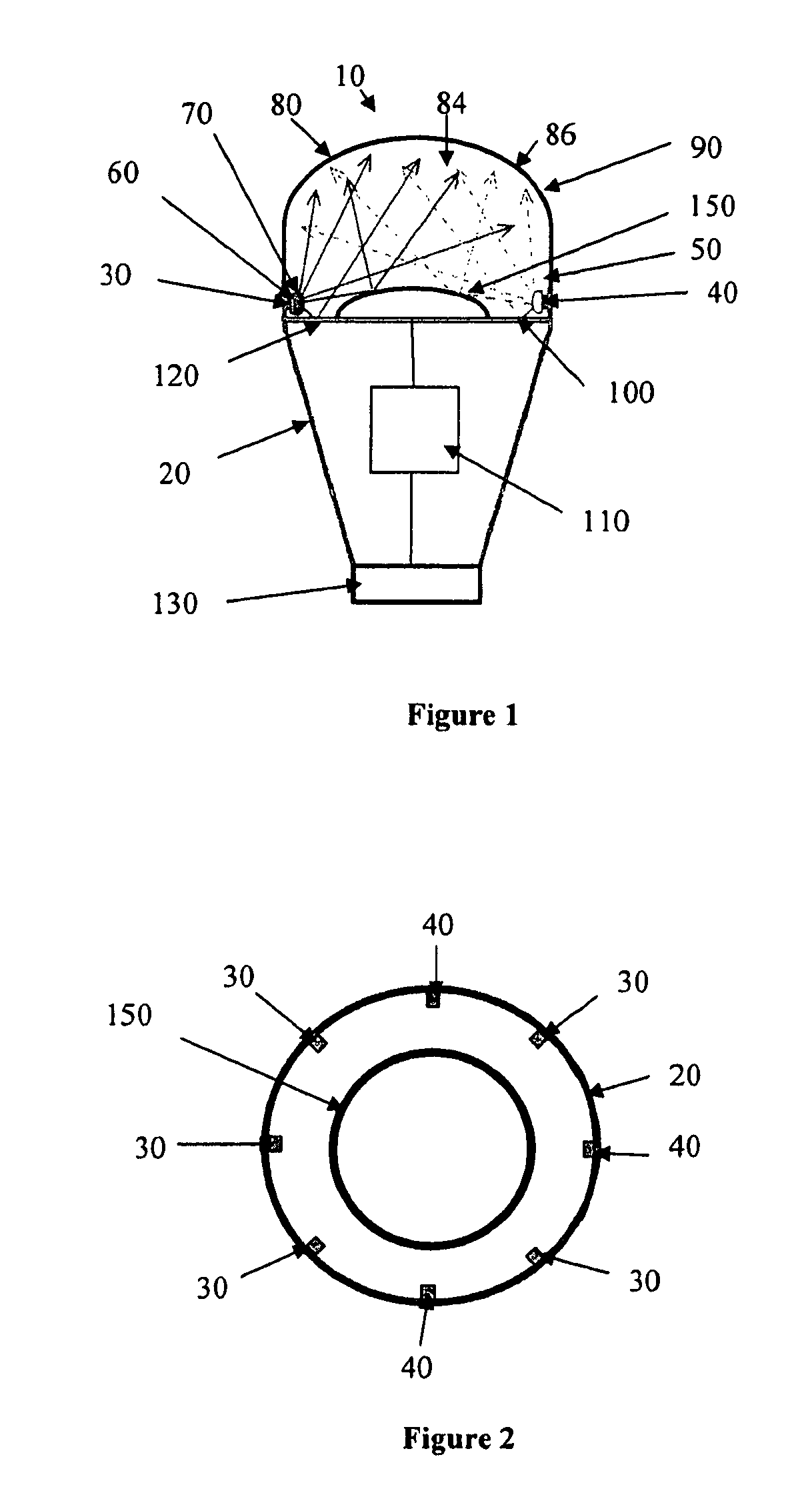

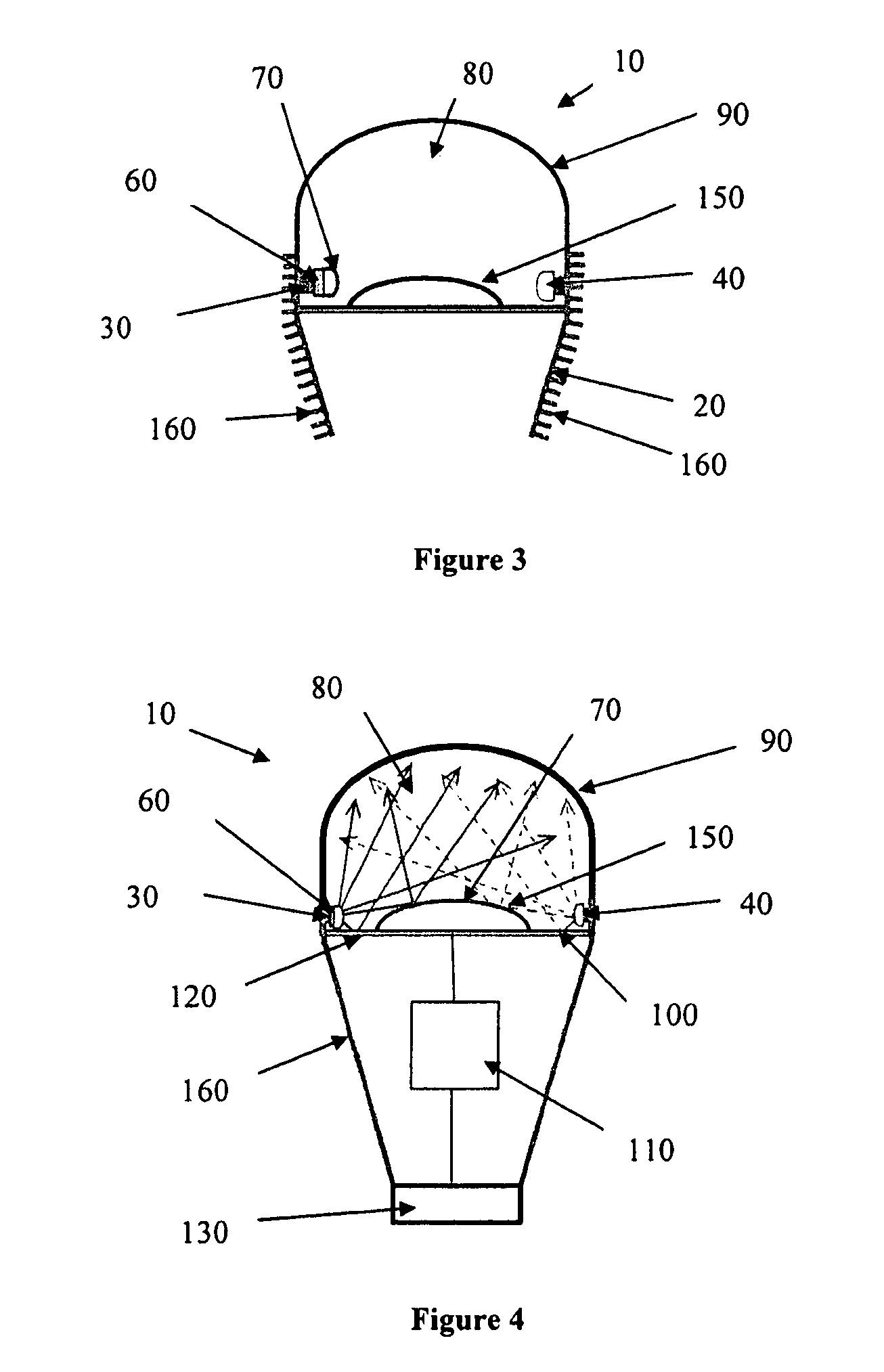

High efficiency incandescent bulb replacement lamp

InactiveUS7600882B1Good load response variationImprove efficiencyNon-electric lightingLighting support devicesColor rendering indexIncandescence

The invention discloses a high efficiency incandescent and Compact Fluorescent (CFL) bulb replacement LED lamp having a good color reproduction. The LED light bulb includes two groups of semiconductor light emitters and a luminescent material to emit four different spectrums of light. The two groups of semiconductor light emitters are enclosed around an interior wall of the light bulb housing, which has a plurality of fins at an exterior surface for effective heat dissipation. A high reflective member having a dome shape in the center is disposed under the two groups of semiconductor light emitters to redirect the emission and excitation lights from the two groups of semiconductor light emitters and recycle the backscattered light for multi-spectrum light mixing. The LED-light bulb further includes a single power line connecting to the two groups of semiconductor light emitters and a high efficiency electrical AC / DC conversion and control device. The light bulb has a diffuser dome for an output window and a conventional Edison-mount screw-type light bulb socket, a conventional fluorescent tube coupler arrangement or a conventional halogen MR-16 socket arrangement connecting to an AC power base. If a voltage is supplied to the AC / DC conversion and control device, a mixture light from the diffuser dome produces a warm white light with a color rendering index of at least 85 and a luminous efficacy of at least 80 lumens per watt.

Owner:LEDNOVATION

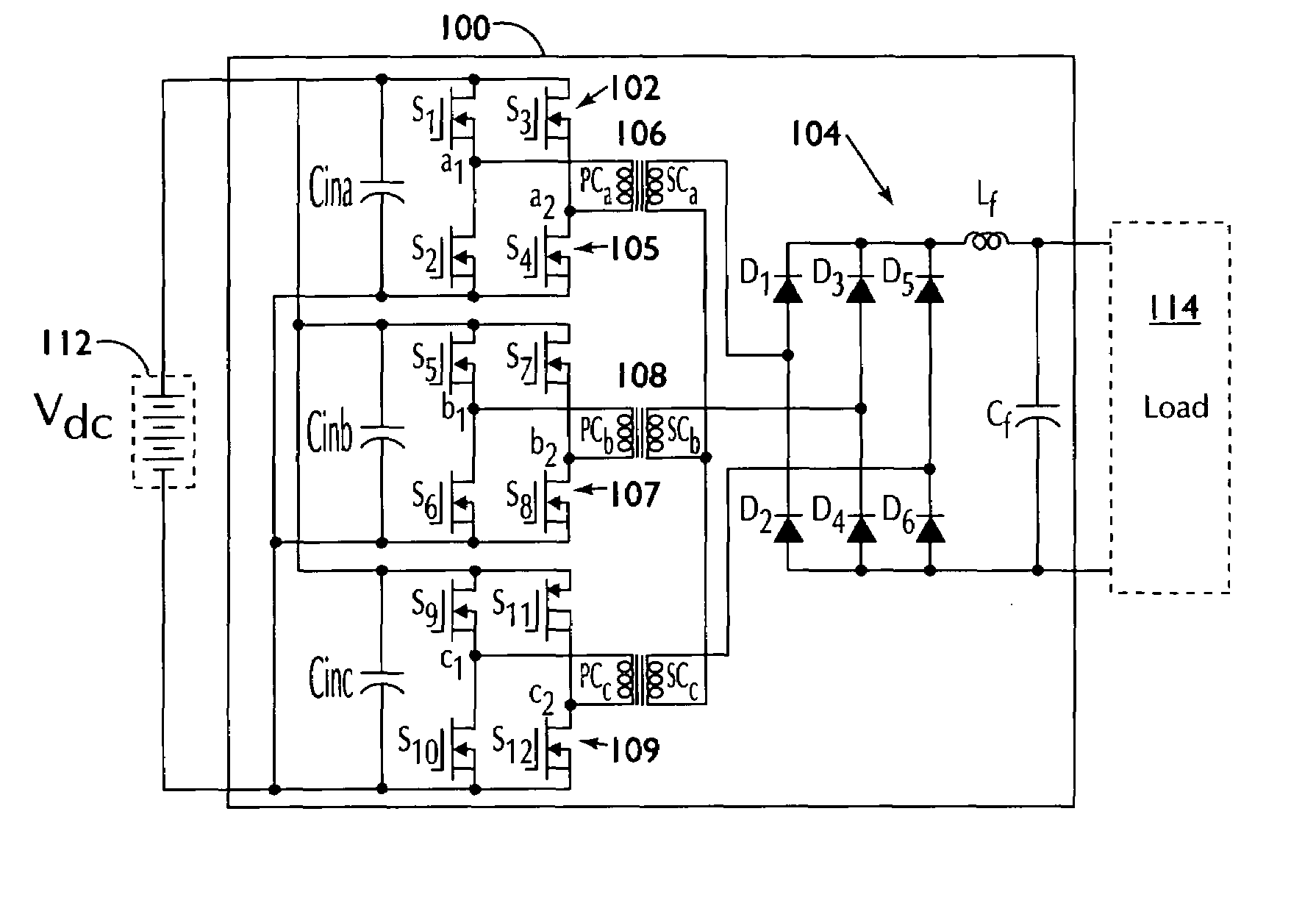

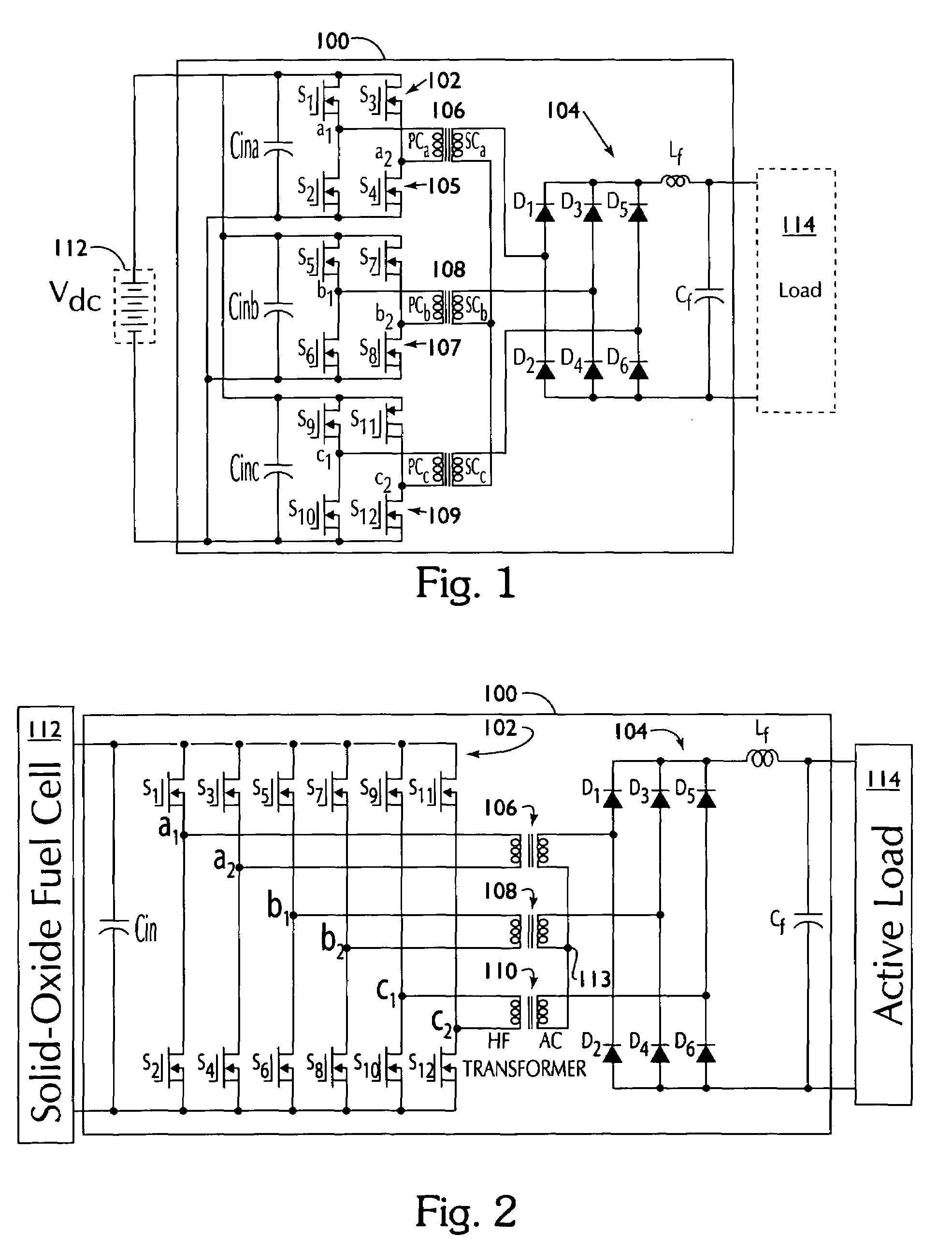

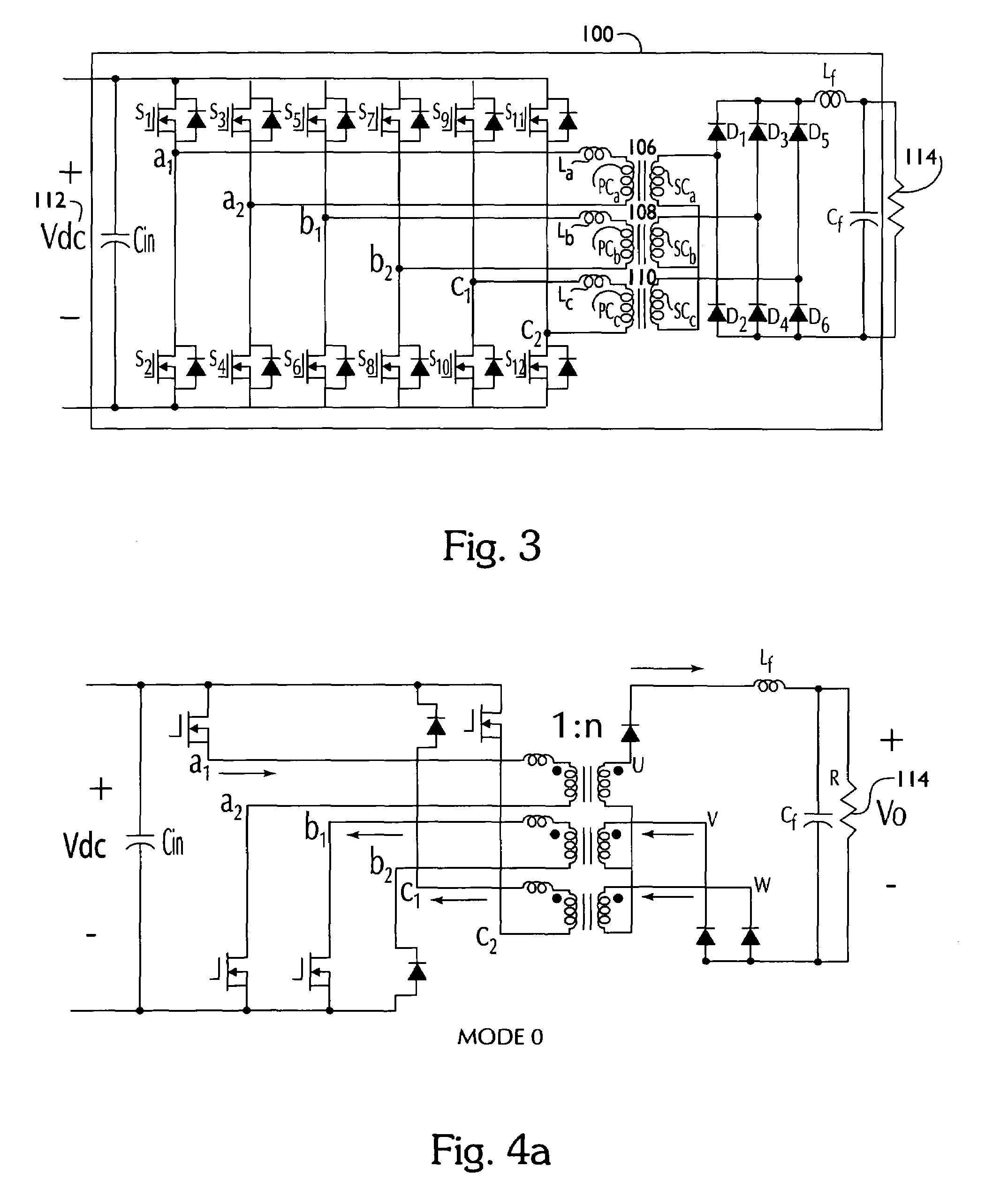

Multiphase soft switched DC/DC converter and active control technique for fuel cell ripple current elimination

ActiveUS7518886B1Cost size reductionElimination of voltage clampingDc-dc conversionDynamo-electric converter controlInner loopVoltage reference

DC / DC converter has a transformer having primary coils connected to an input side and secondary coils connected to an output side. Each primary coil connects a full-bridge circuit comprising two switches on two legs, the primary coil being connected between the switches on each leg, each full-bridge circuit being connected in parallel wherein each leg is disposed parallel to one another, and the secondary coils connected to a rectifying circuit. An outer loop control circuit that reduces ripple in a voltage reference has a first resistor connected in series with a second resistor connected in series with a first capacitor which are connected in parallel with a second capacitor. An inner loop control circuit that reduces ripple in a current reference has a third resistor connected in series with a fourth resistor connected in series with a third capacitor which are connected in parallel with a fourth capacitor.

Owner:VIRGINIA TECH INTPROP INC

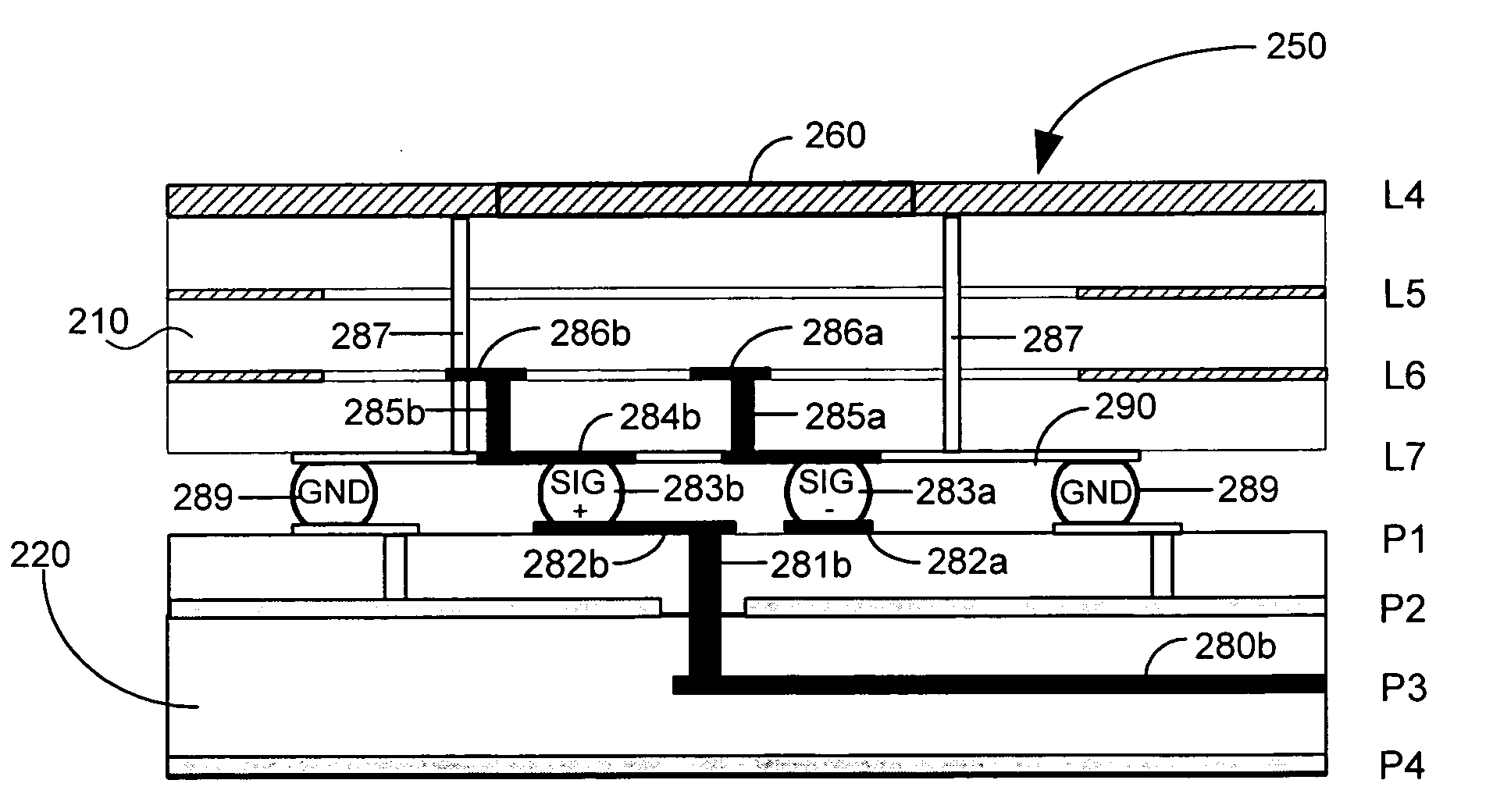

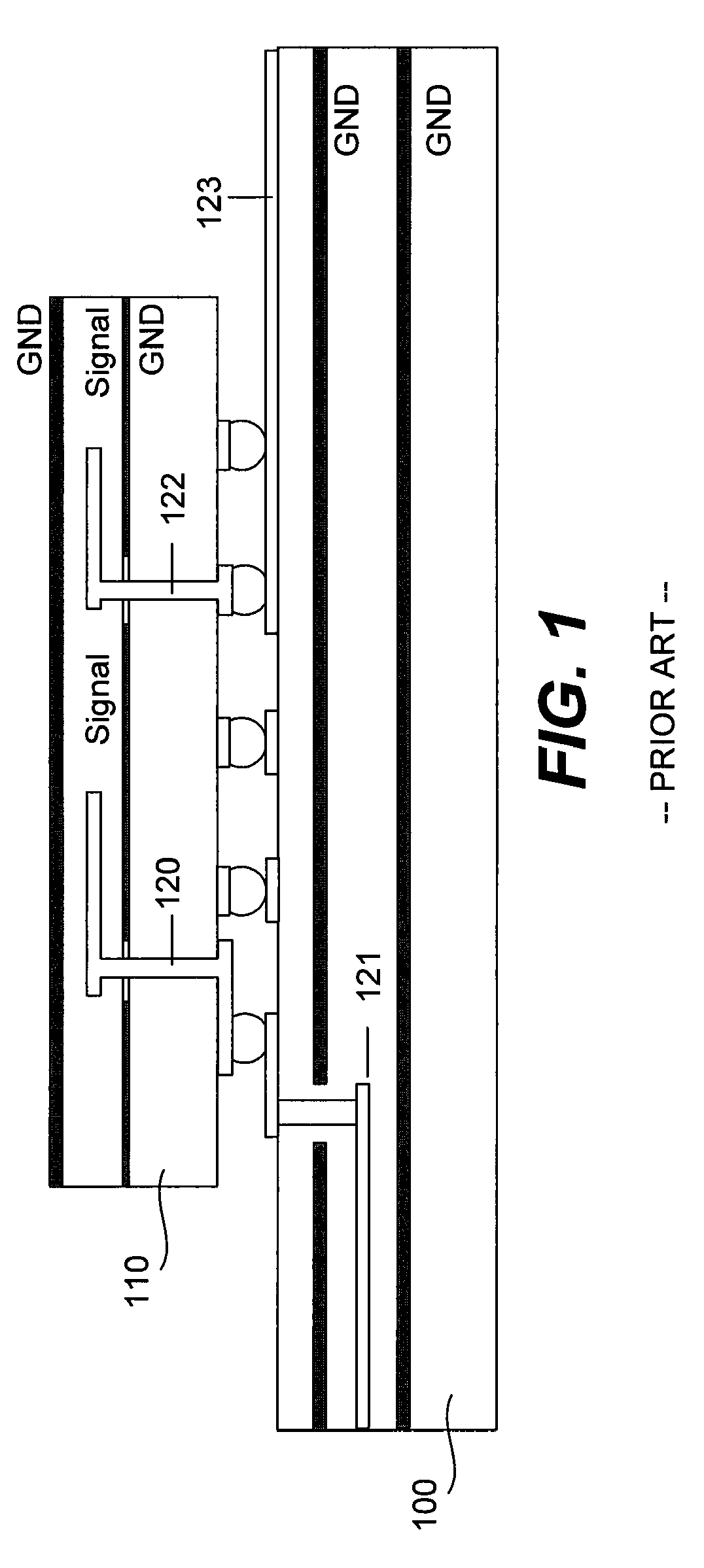

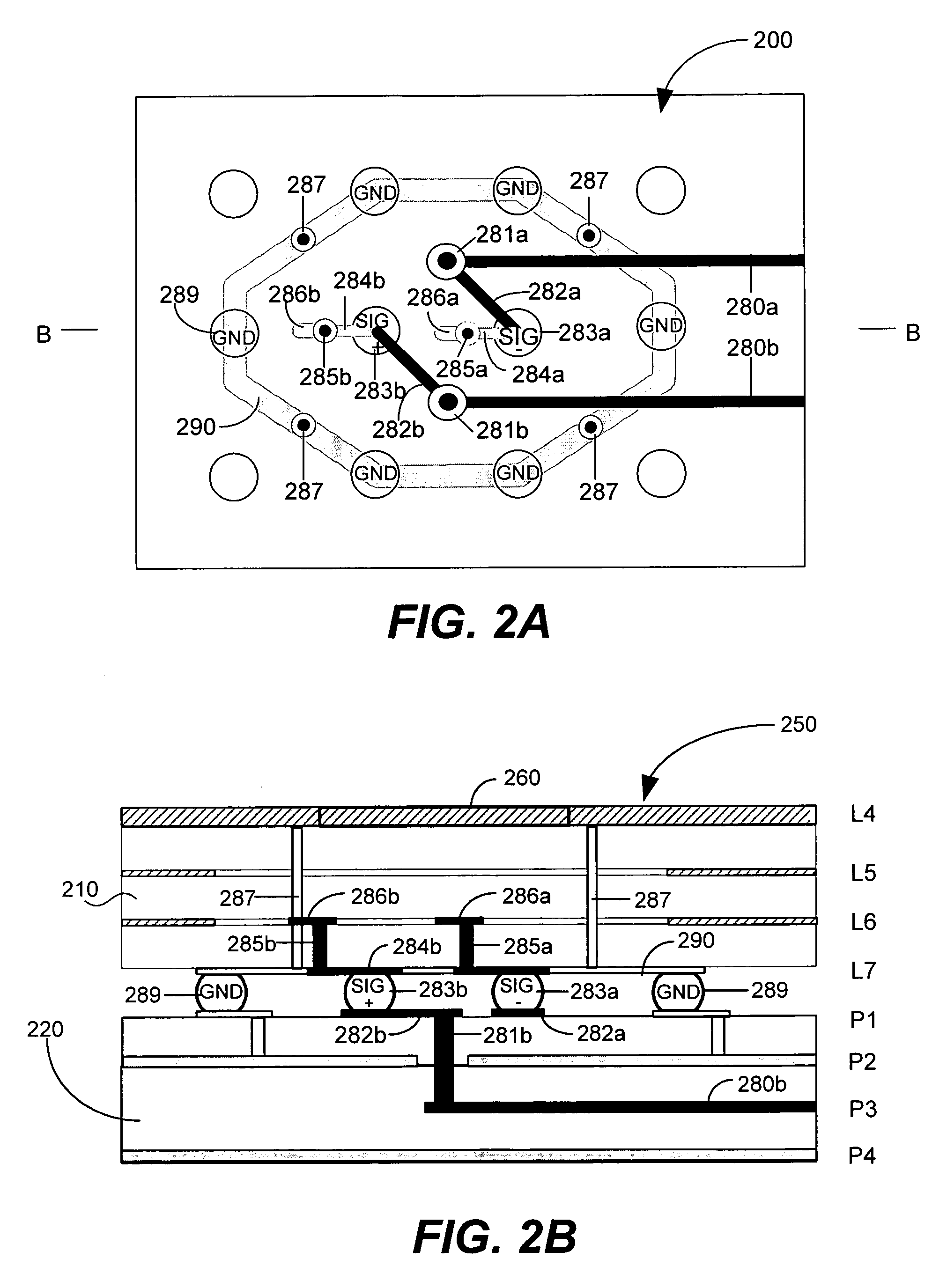

Ball grid array package-to-board interconnect co-design apparatus

InactiveUS7405477B1Signal transmission is convenientAvoid reflectionsSemiconductor/solid-state device detailsPrinted circuit aspectsCopper interconnectData stream

A package-board co-design methodology preserves the signal integrity of high-speed signals passing from semiconductor packages to application PCBs. An optimal architecture of interconnects between package and PCB enhances the signal propagation, minimizes parasitic levels, and decreases electromagnetic interference from adjacent high frequency signals. The invention results in devices with superior signal quality and EMI shielding properties with enhanced capability for carrying data stream at multiple-gigabit per second bit-rates.

Owner:TAHOE RES LTD

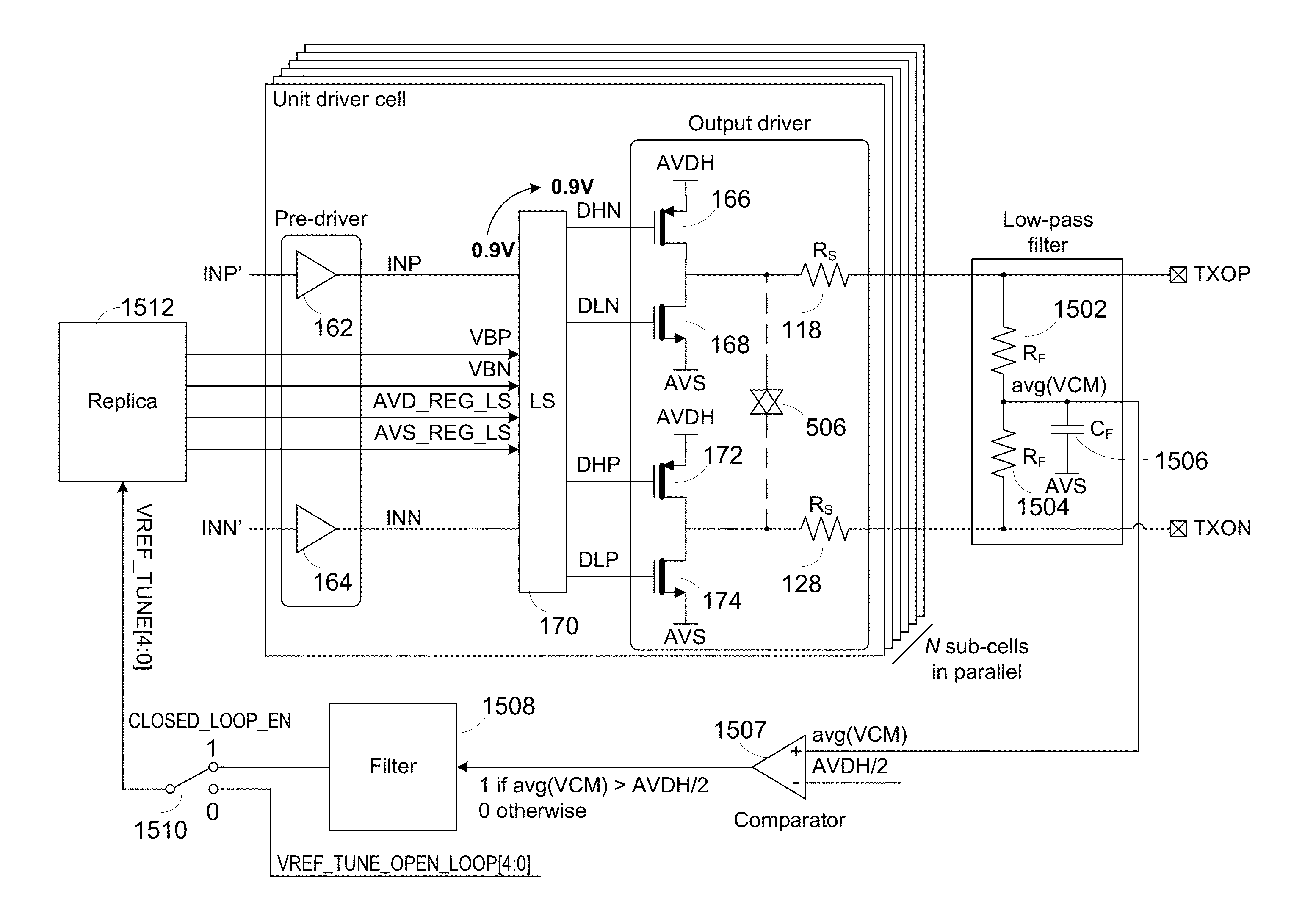

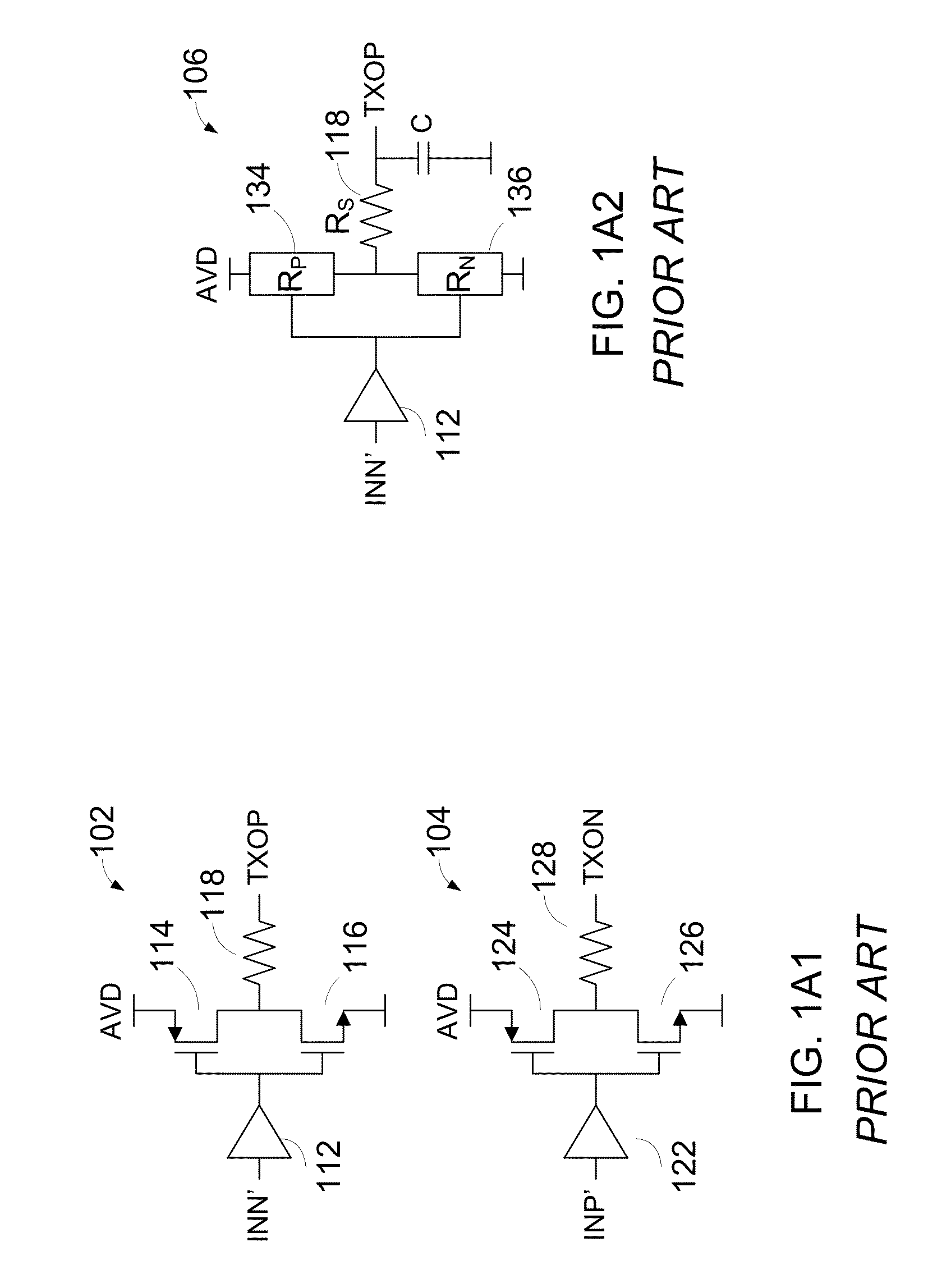

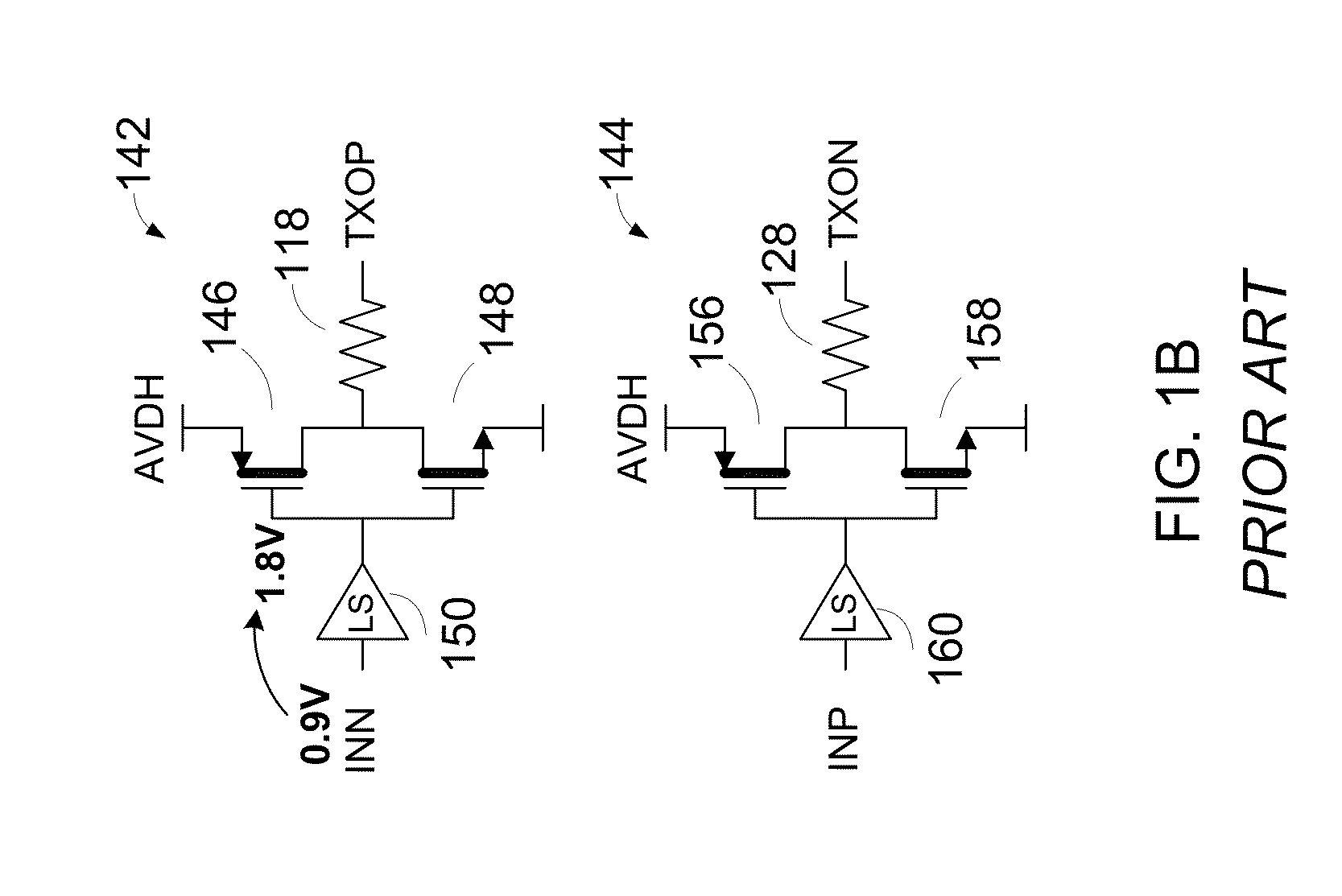

Scalable high-swing transmitter with rise and/or fall time mismatch compensation

ActiveUS8446173B1Reduce EMIImprove connectivityAmplifier with semiconductor-devices/discharge-tubesElectronic switchingEngineeringPower consumption

Disclosed is a high-swing voltage-mode transmitter or line driver. The transmitter can operate over a wide range of supply voltages. Increasing the available output swing merely involves increasing the supply voltage; the circuit adapts to maintain the desired output impedance. This allows for a tradeoff between output amplitude and power consumption. Another advantage of the proposed architecture is that it compensates for process, voltage, and temperature (PVT) and mismatch variations so as to keep rise and fall times matched. This feature reduces common-mode noise and hence EMI in systems in which the transmitter is used.

Owner:MICROSEMI STORAGE SOLUTIONS

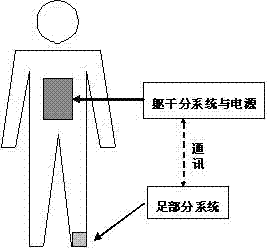

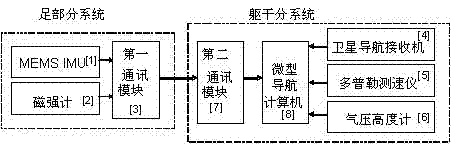

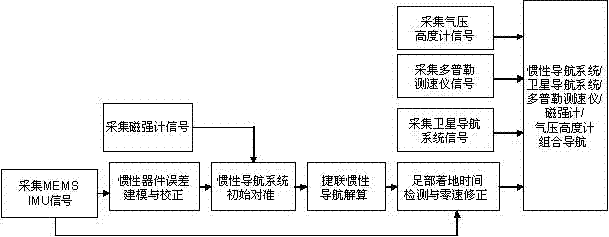

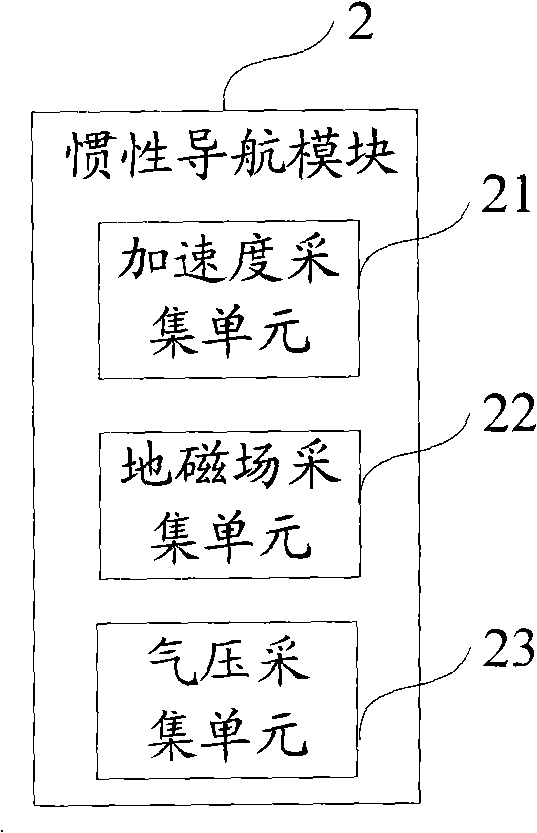

Microminiature personal combined navigation system as well as navigating and positioning method thereof

InactiveCN102445200AReduce electromagnetic interferenceSuitable for personal portabilityNavigation instrumentsAccelerometerGyroscope

The invention discloses a microminiature personal combined navigation system as well as a navigating and positioning method thereof. The system is composed of a subsystem installed on the foot part of a human body and a subsystem installed on the trunk position, wherein the subsystem installed on the foot part comprises an MEMS IMU (Micro-electromechanical Systems Inertial Measurement Unit), a magnetometer and a communication module; and the subsystem installed on the trunk position comprises a satellite navigation receiver, a Doppler velometer, an atmospheric pressure altimeter, a communication module and a microminiature navigation computer. The positioning method comprises the following steps of: collecting the MEMS IMU signal; modeling and correcting the random error of a gyroscope and an accelerometer; initially aligning an MEMS inertial navigation system; resolving strapdown inertial navigation, and correcting zero speed; carrying out combined navigation of the MEMS inertial navigation system / satellite navigation receiver / the Doppler velometer / the magnetometer / and the atmospheric pressure altimeter; and displaying the navigation result in real time. The microminiature individual combined navigation system is convenient to individually carry, individual real-time gesture fixing, velocity measurement and positioning can be realized, and whole and precise real-time navigation positioning information can be provided for pedestrians, operating personnel, soldiers, rescue workers and the like in the complex electromagnetic environment.

Owner:NANJING UNIV OF SCI & TECH

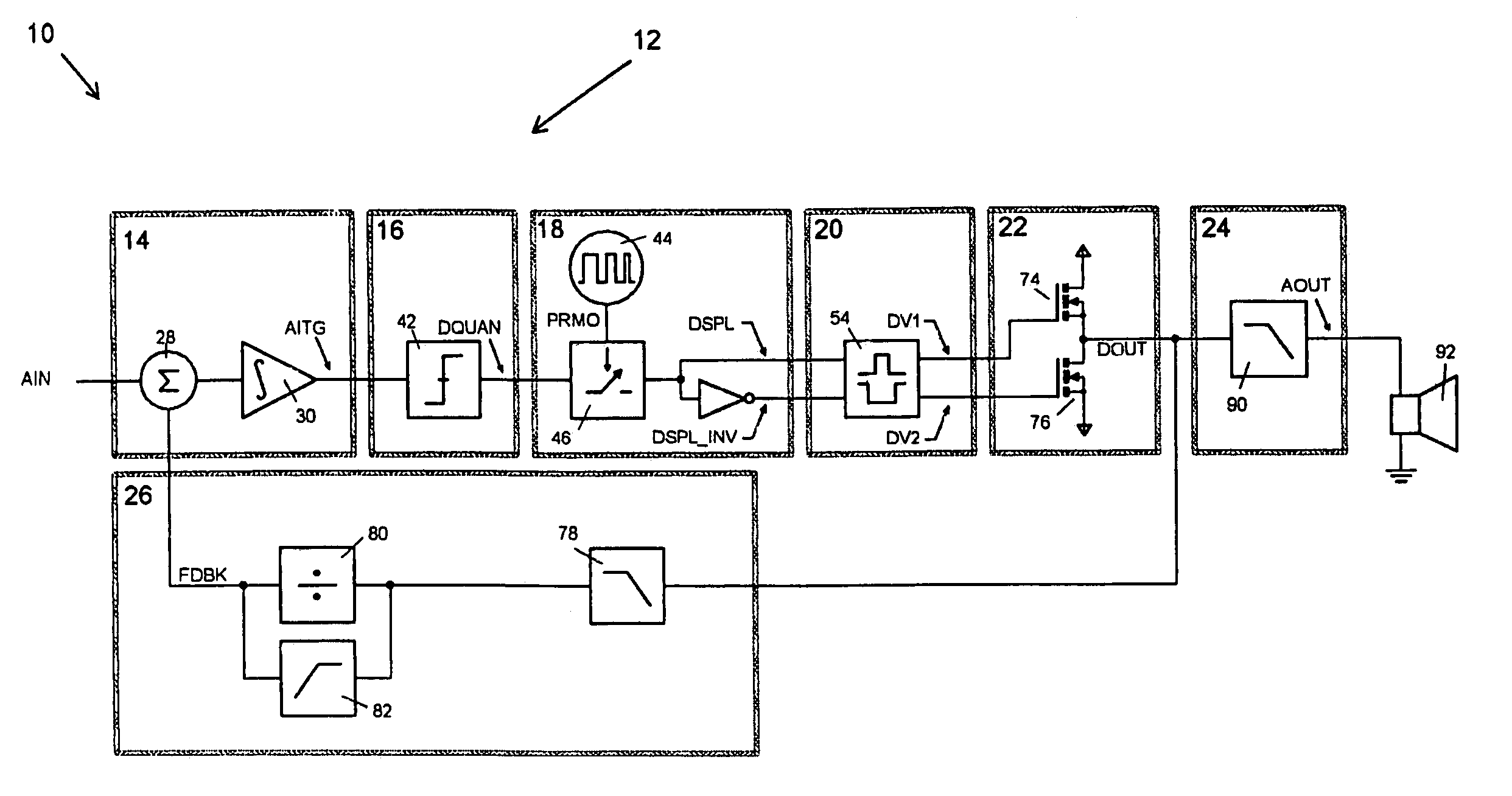

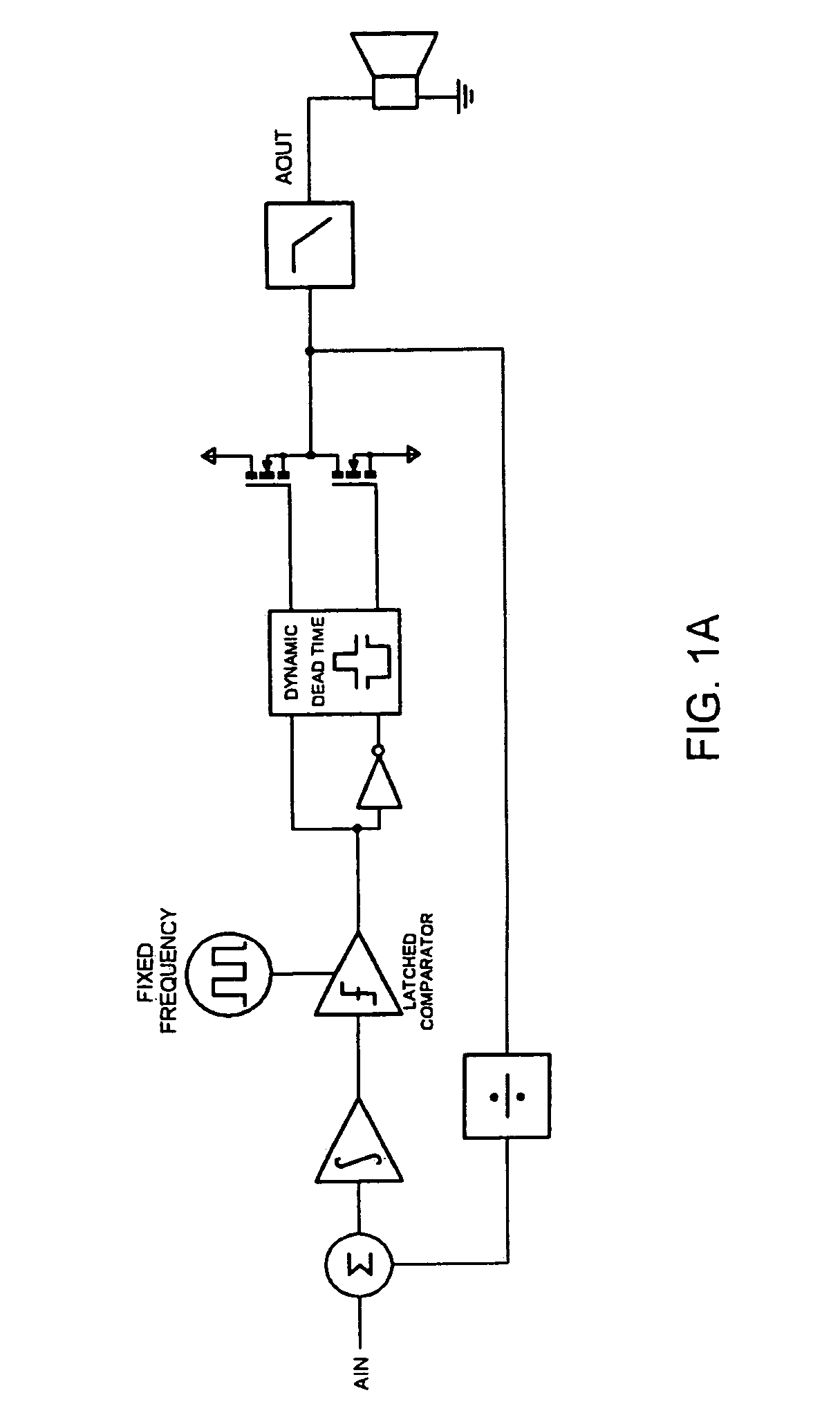

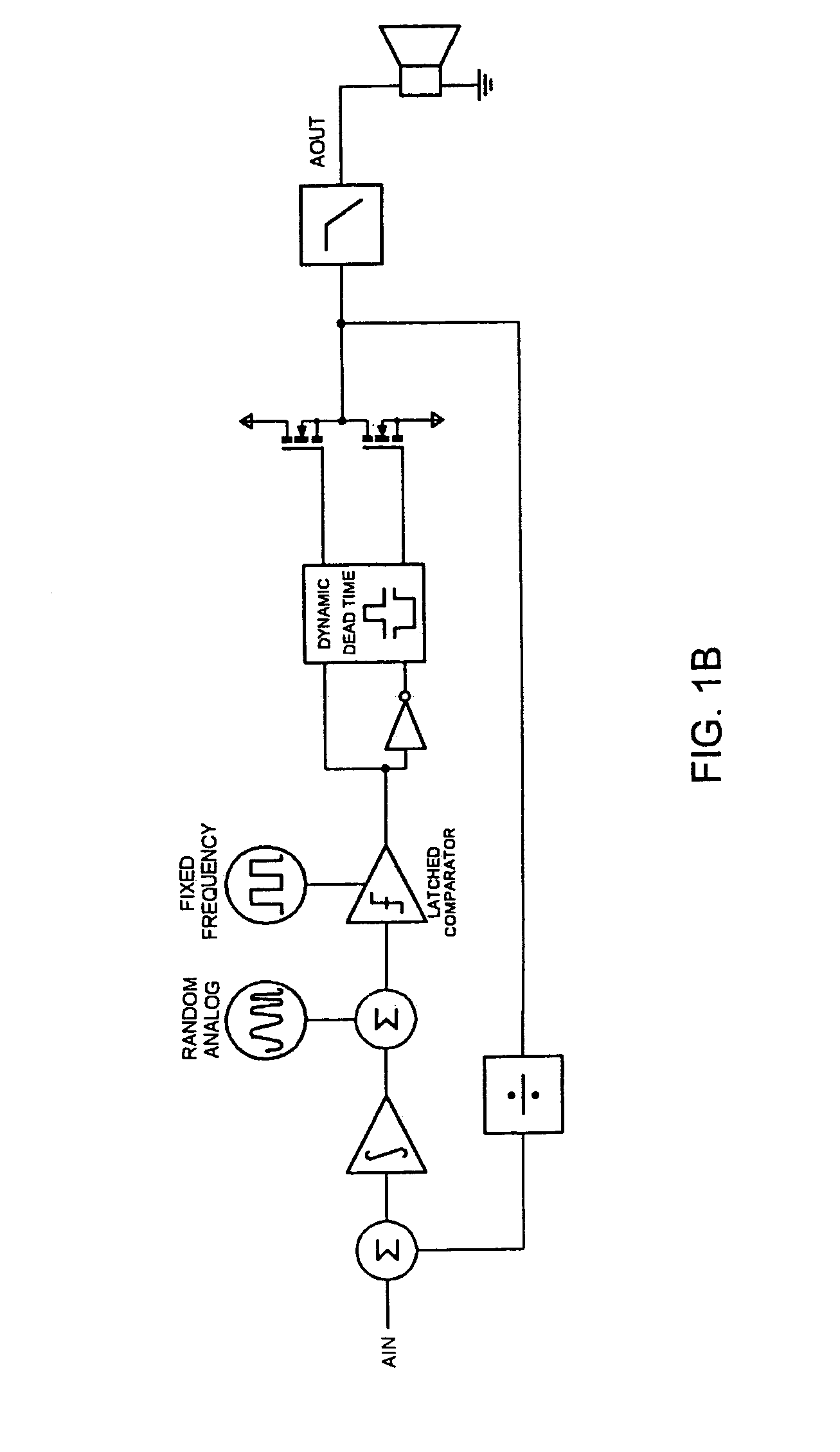

Sigma-delta modulated amplifier

ActiveUS7084799B1High efficiencyLow EMIElectric signal transmission systemsAnalogue conversionAudio frequencyAudio power amplifier

A sigma-delta modulated amplifier is disclosed that is operable to sum an input signal and a feedback signal, integrate the summed signal, asynchronously quantize the integrated signal, sample the quantized signal utilizing a pseudo-random osculating signal, and amplify the sampled signal. The amplifier enables discrete implementation of a low-cost, spread spectrum controlled, sigma delta modulated audio amplifier for spectrally pure, high efficiency, low EMI, audio power amplification.

Owner:DOLBY LAB LICENSING CORP

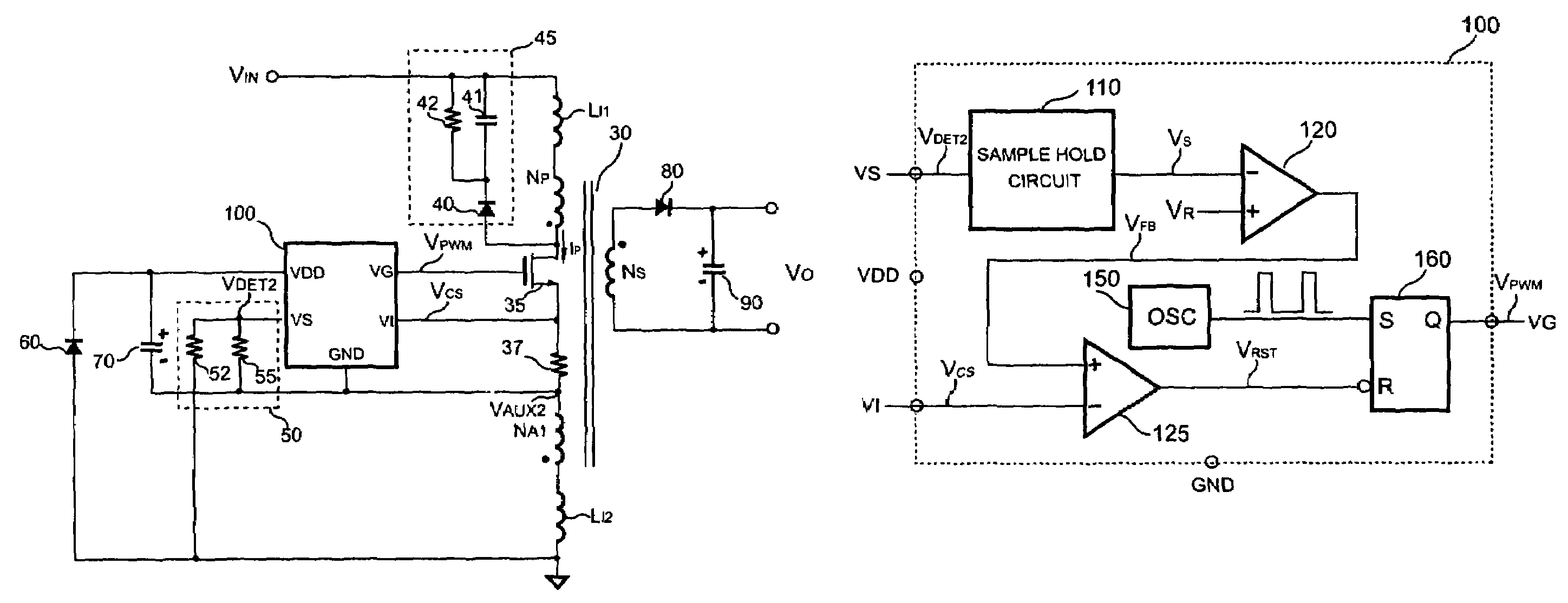

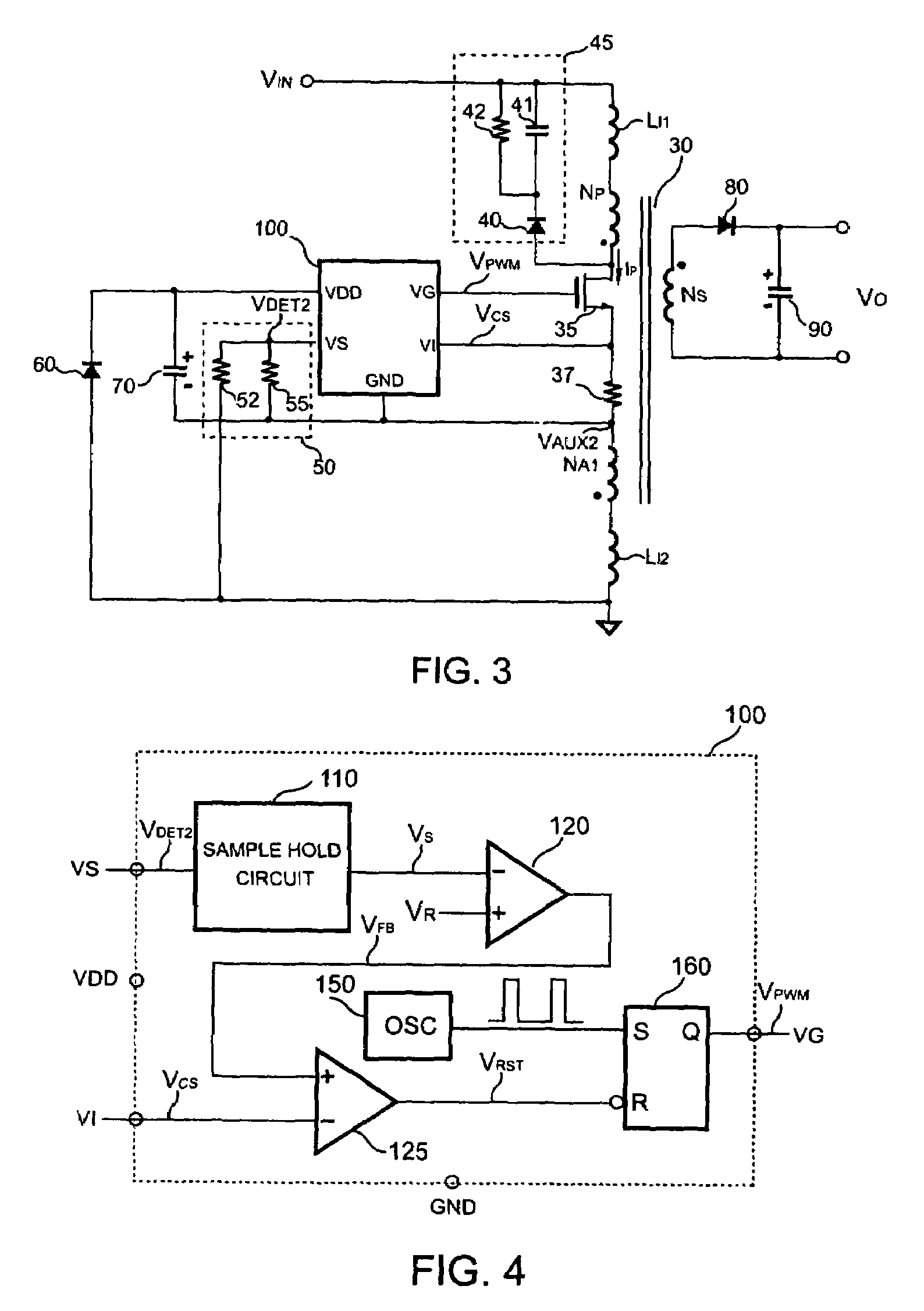

Primary side controlled switching regulator

ActiveUS7310244B2Improve efficiencyReduce electromagnetic interferenceConversion with intermediate conversion to dcDc-dc conversionStored energySwitching signal

A switching regulator includes a transformer having a primary winding and an auxiliary winding connected to the supply rail of the switching regulator. The primary winding is coupled to the positive supply rail. The auxiliary winding is coupled to the negative supply rail. A switch is connected in series with the primary winding and the auxiliary winding for switching the transformer. A control circuit is coupled to the switch and the auxiliary winding to generate a switching signal for switching the switch and regulating the output of the switching regulator. A supplied capacitor is connected to the control circuit to supply the power to the control circuit. The auxiliary winding having a leakage inductor stores a stored energy when the switch is on. A diode is coupled from the negative supply rail to the supplied capacitor. The stored energy of the leakage inductor is discharged to the supplied capacitor through the diode once the switch is off. The connection of the transformer and the switch improves the efficiency and reduces the EMI.

Owner:SEMICON COMPONENTS IND LLC

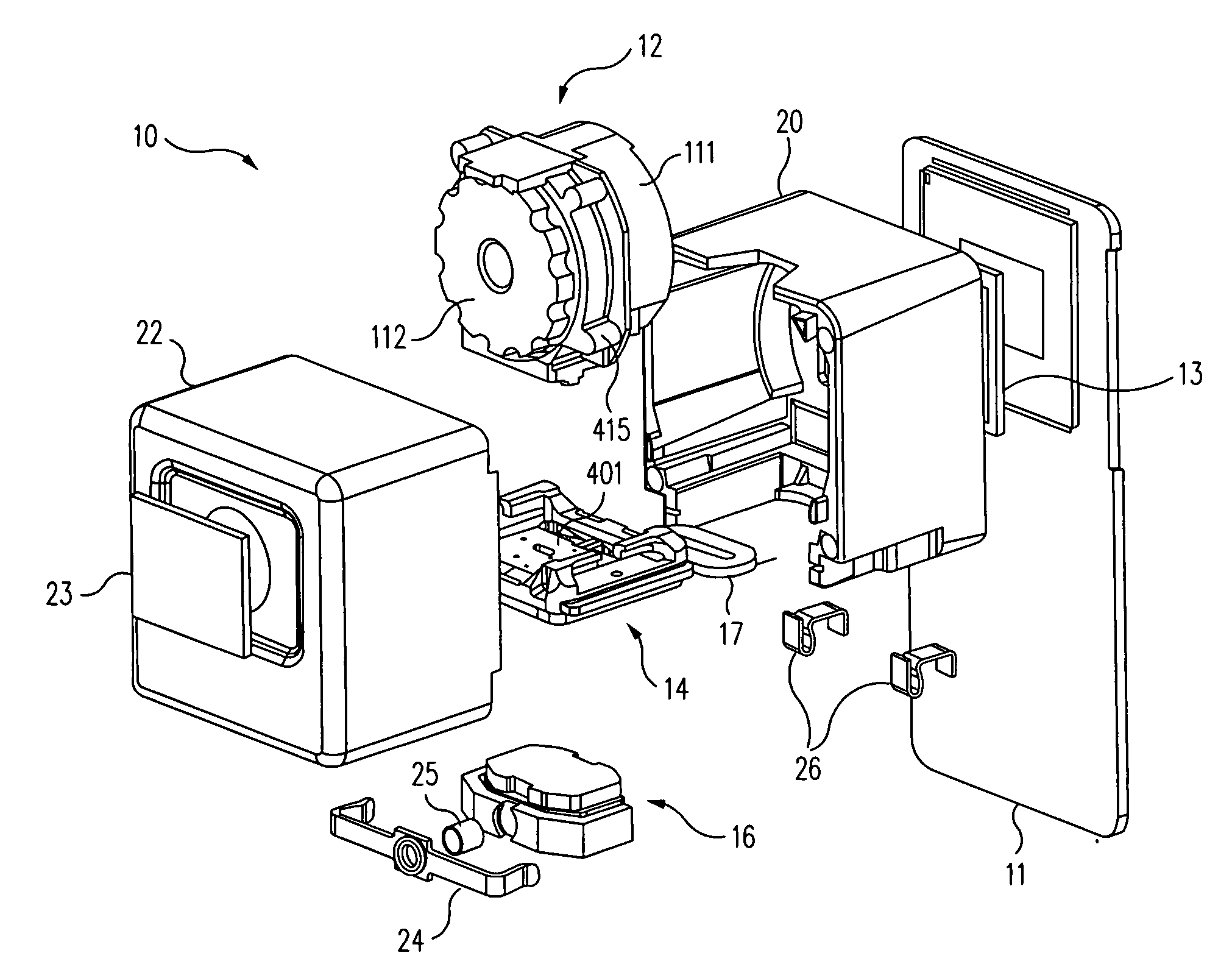

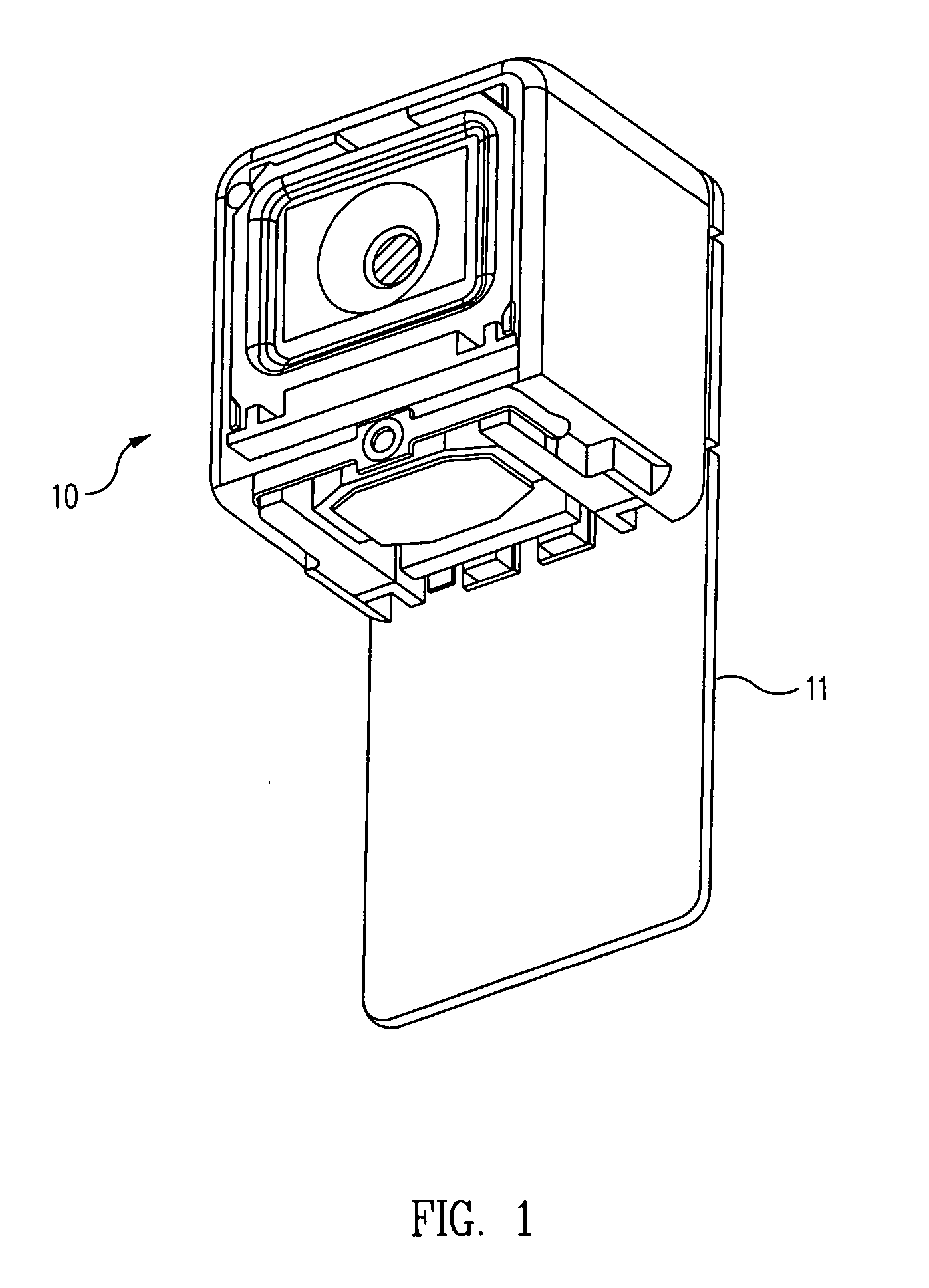

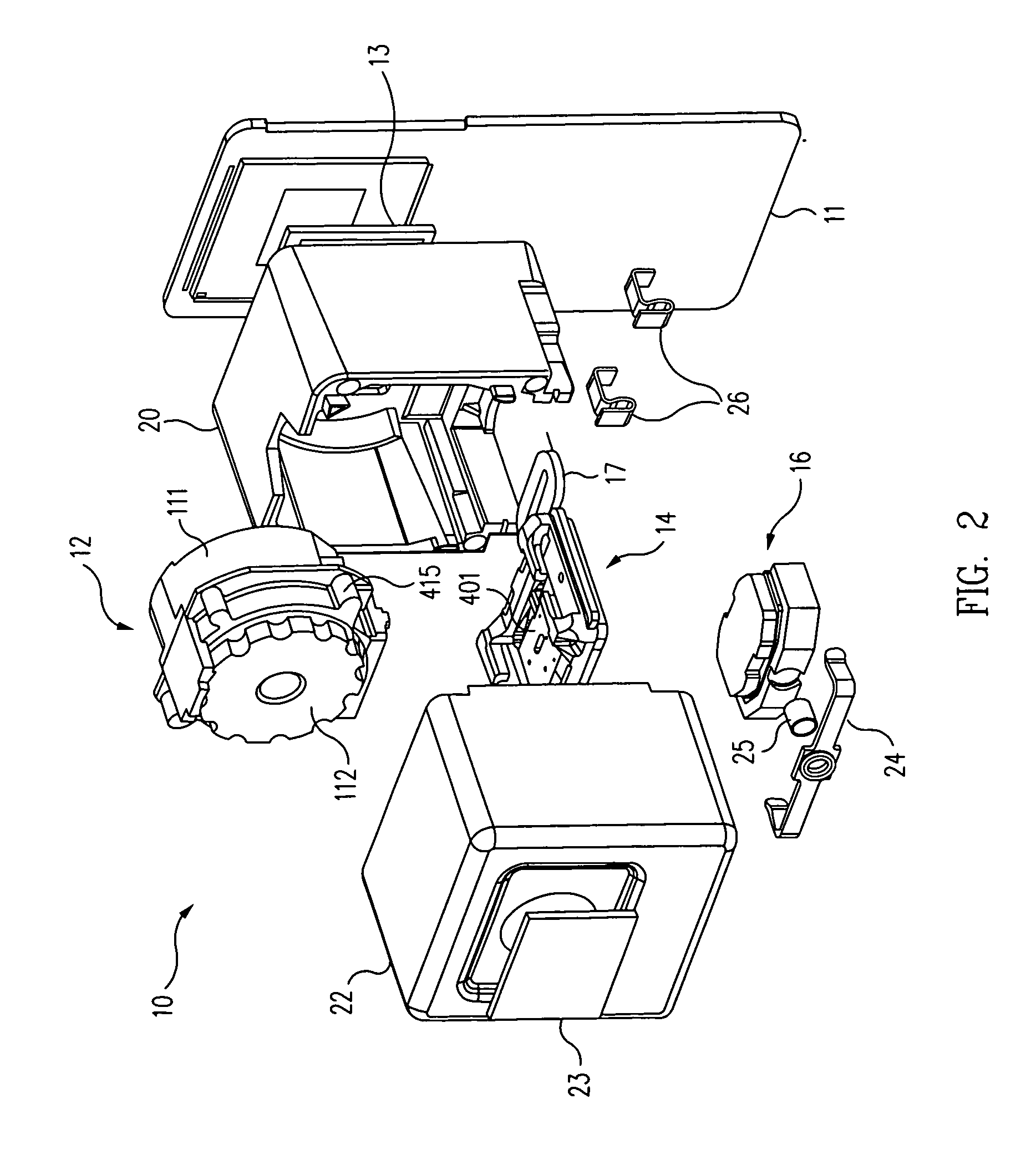

Autofocus camera

ActiveUS20060204242A1Reduce electromagnetic interferenceImprove camera performanceProjector focusing arrangementCamera focusing arrangementSingle degree of freedomElectromagnetic interference

A method and system for facilitating focusing of a miniature camera are disclosed. One or more lenses can be attached to a MEMS stage. The MEMS stage can be moved by a Lorentz actuator. The MEMS stage can be configured to limit movement of the lens(es) to a single degree of freedom to inhibit misalignment thereof with respect to an imaging sensor. The stage can be biased to a predefined position thereof, e.g., for focus at infinity. A metal cover can inhibit electromagnetic interference and can limit movement of the lens(es).

Owner:DIGITALPTICS MEMS

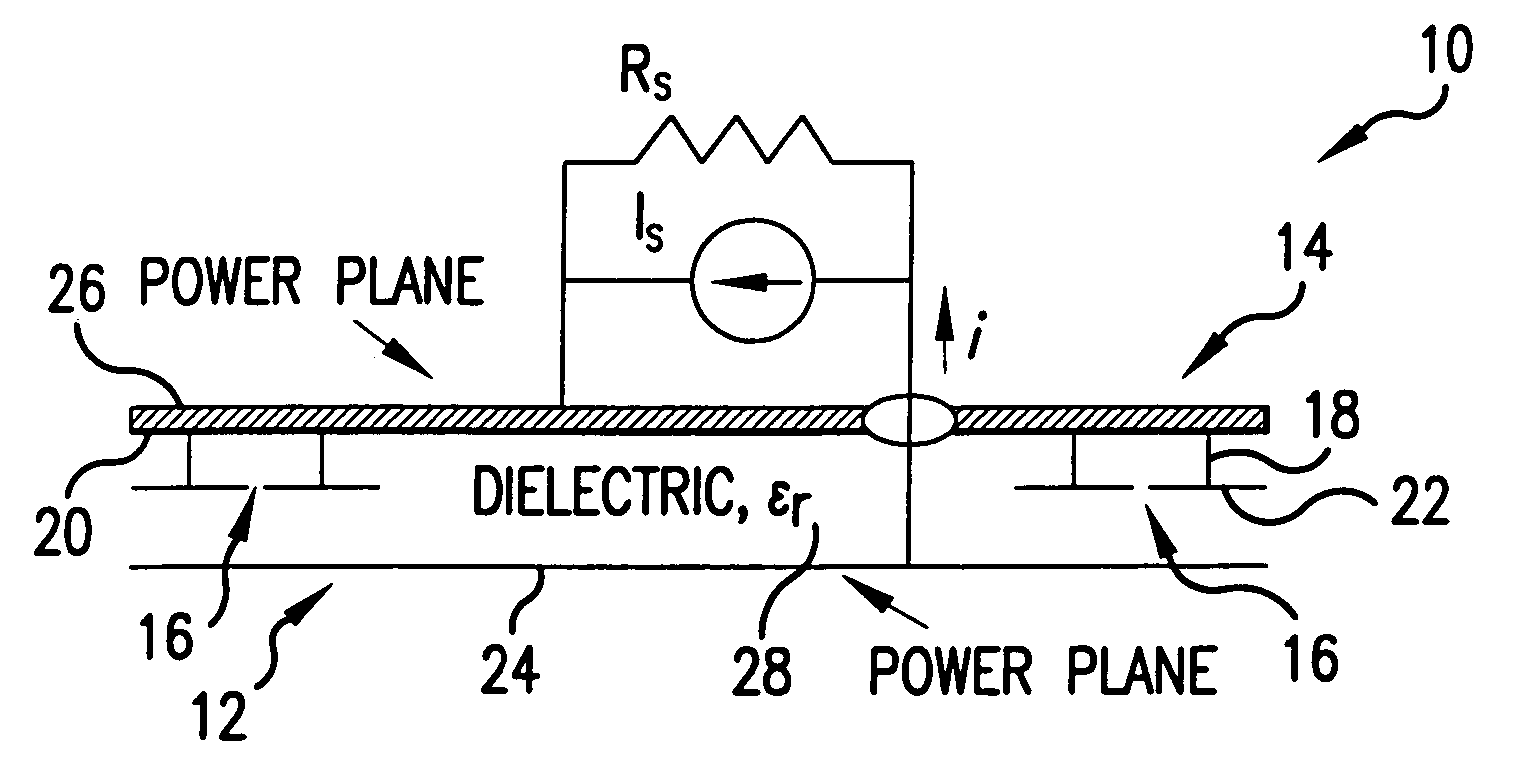

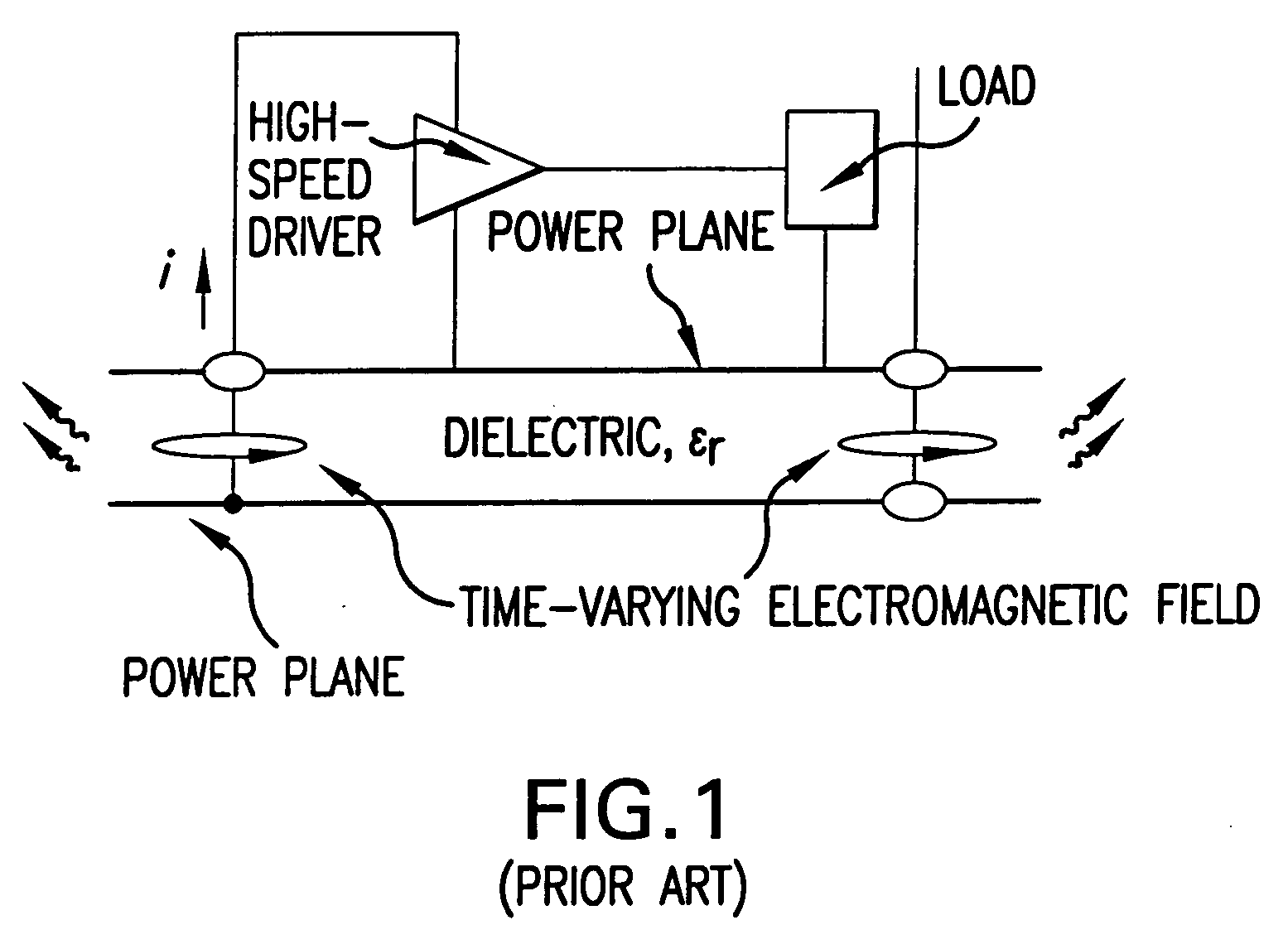

System and method for noise mitigation in high speed printed circuit boards using electromagnetic bandgap structures

InactiveUS20050104678A1Improved performance characteristicsReduce radiationCurrent interference reductionCross-talk/noise/interference reductionEngineeringElectromagnetic radiation

Electromagnetic Bandgap (EBG) structures are embedded between adjacent power planes in a multi-layer PCB to decrease the emanation of Electromagnetic radiation induced by power buses, signal layers, as well as to suppress the switching noise. EBG stages with different stop bands are cascaded to create rejection over a wider frequency region. The cascading can be performed in series, or may be formed in a variety of arrangements such as a checkerboard design or concentric ribbons positioned along the perimeter of the PCB. Each EBG stage is composed of conductive patches and via posts extending from each patch, which are positioned at a predetermined distance from each other. By surrounding the source of the noise with EBG stages, a sufficient suppression of electromagnetic noise over specific frequency bands of interest is achieved.

Owner:UNIV OF MARYLAND

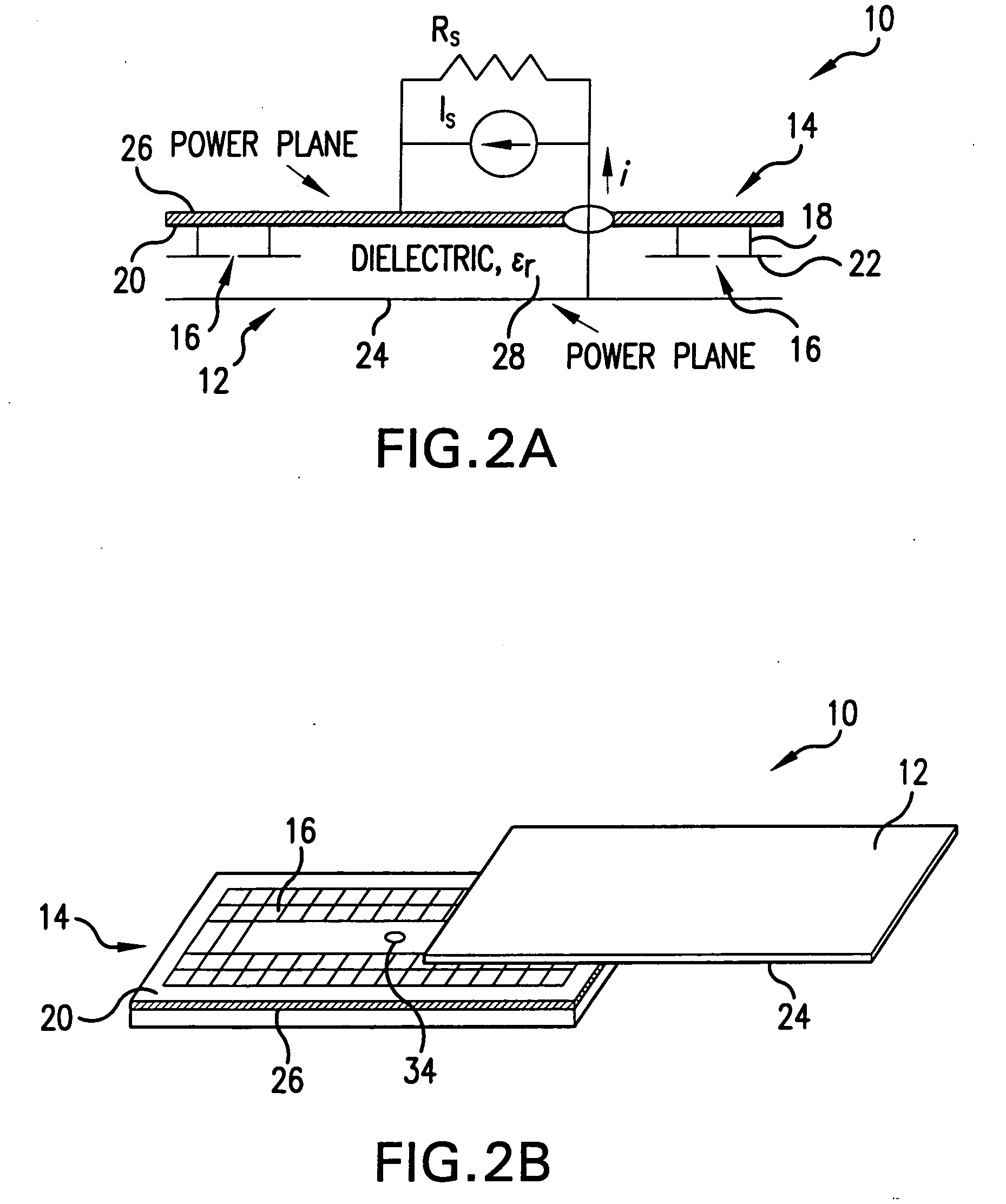

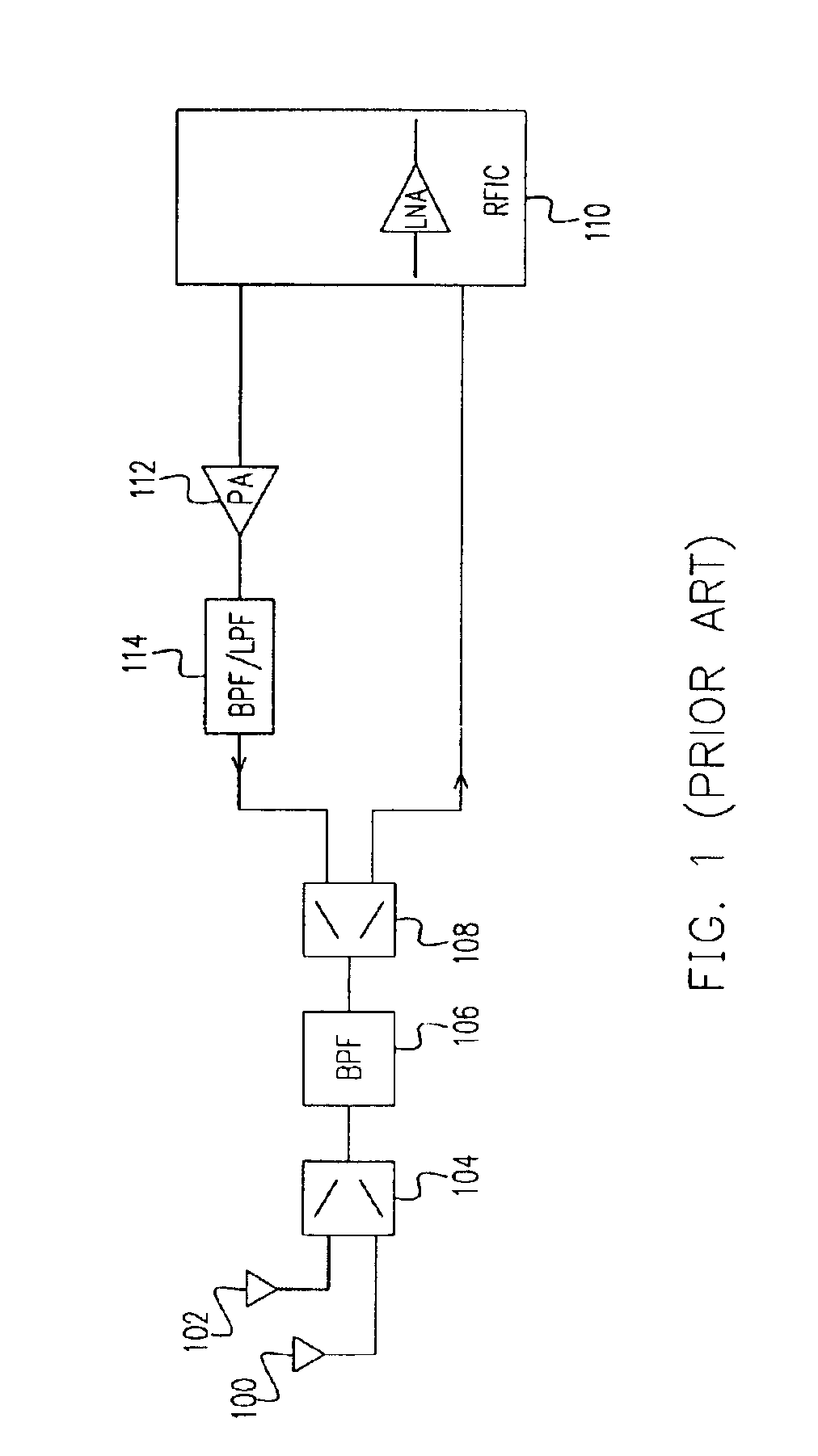

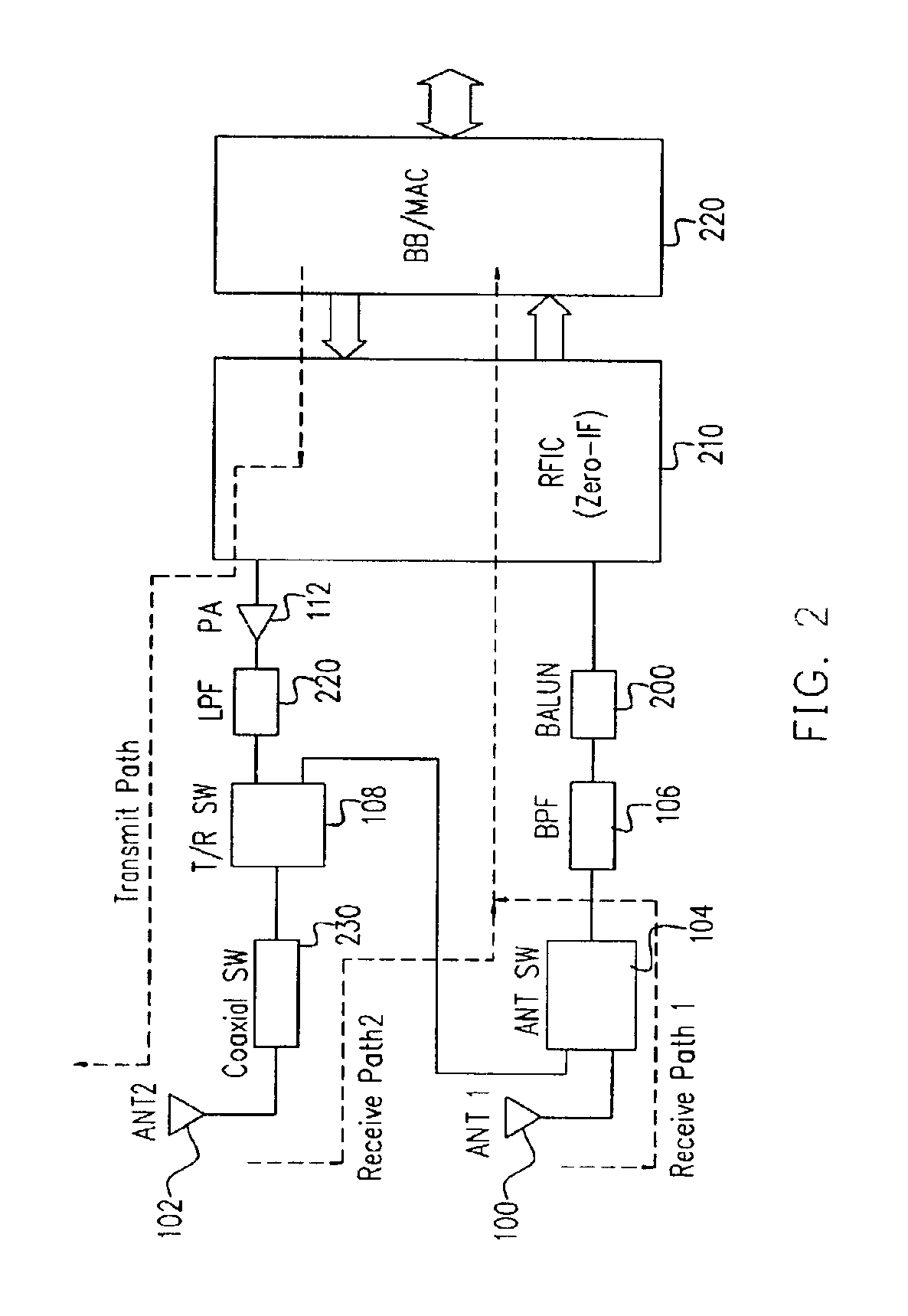

Layout of wireless communication circuit on a printed circuit board

InactiveUS6876836B2Reduce insertion power lossExpand the transmission rangeHigh frequency circuit adaptationsPrinted circuit aspectsAudio power amplifierRFIC

A layout of a wireless communication circuit on a printed circuit board (PCB), which is a rectangular board wherein a first side is a Y-axis and a second side is an X-axis. The layout has a first antenna located at a corner between the first side and the second side. An antenna switch and a first filter are located at middle y-coordinate and a X-coordinate. A RF integrated circuit (RFIC) is located after the first filter. A first regulator is located near the second side and higher than the RFIC. A media access control (MAC) is located at about a middle y-coordinate and higher than the first regulator. An oscillator is located at a corner between the second side and the third side. A second regulator is located near the fourth side and above the first regulator. A power amplifier is located near the fourth side above the RFIC. A second filter and a transmitting / receiving (T / R) switch are located before the power amplifier. A second antenna is located at a corner between the first side and the fourth side.

Owner:MEDIATEK INC

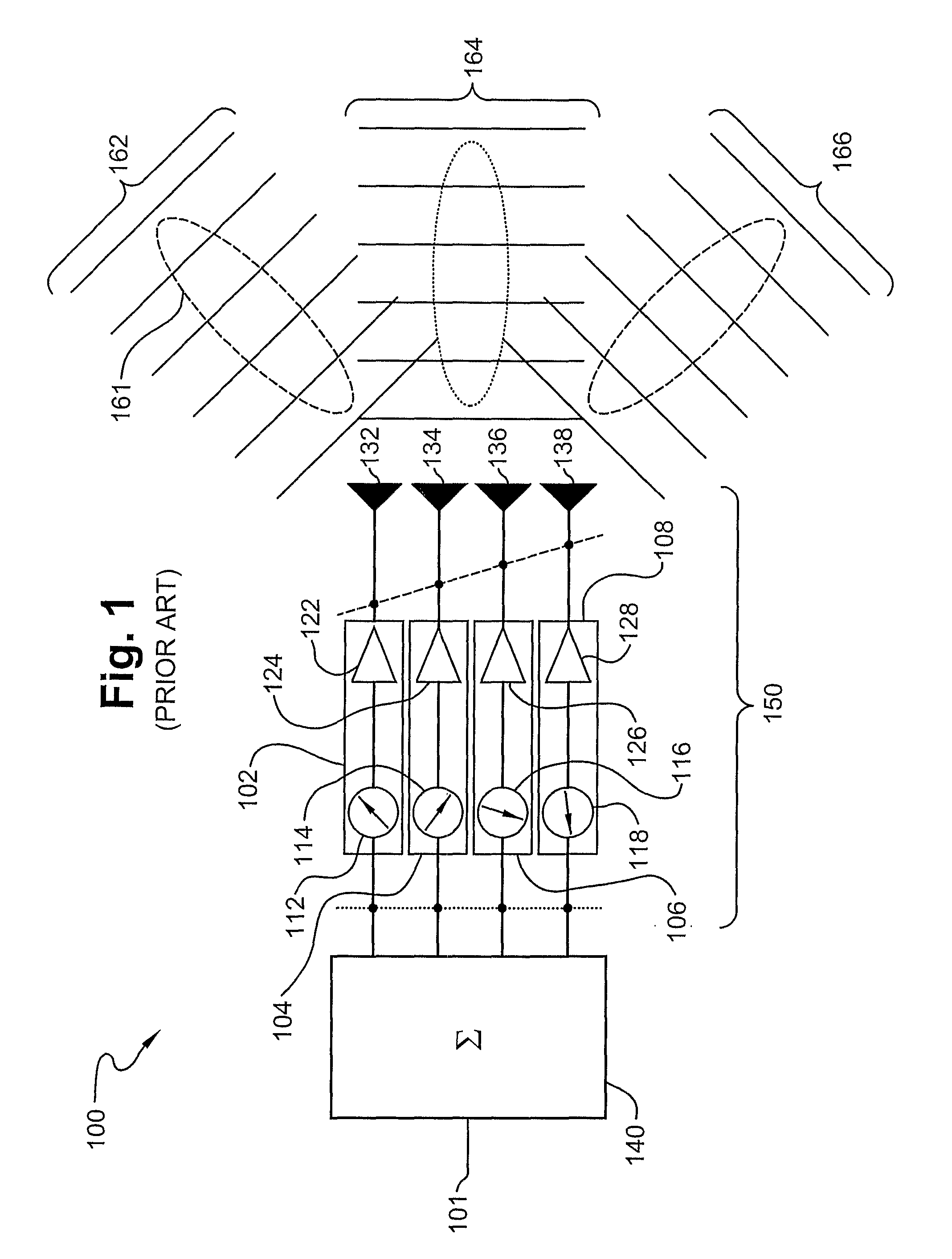

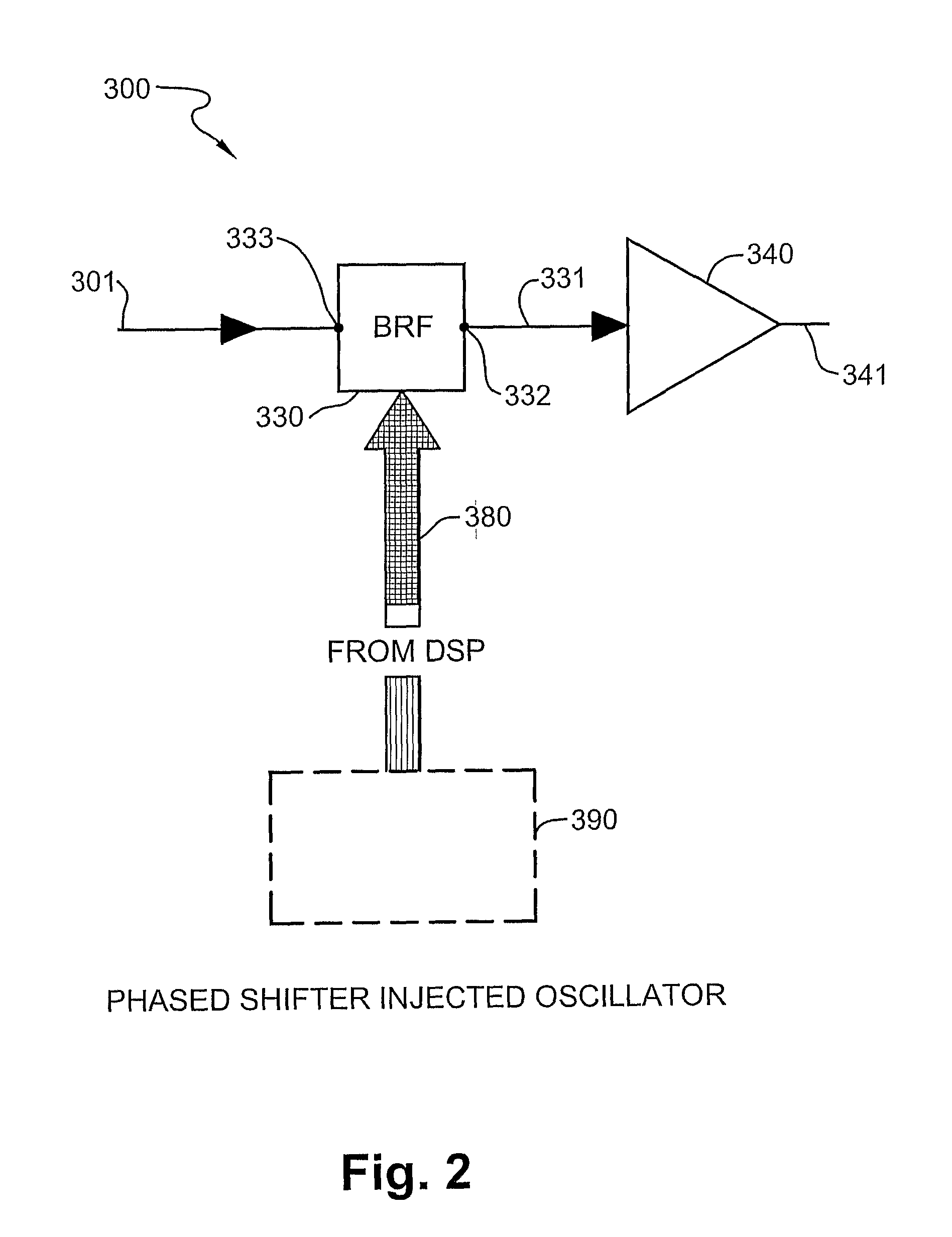

Phased shifted oscilator and antenna

ActiveUS8183935B2Low costKeep the same performancePulse automatic controlOscillations generatorsInjection lockedPhase shifted

This invention describes new and improved phased shifted injection oscillator, a phased shifted injection locked push-push oscillator and a phased array antennas (PAA). The PAAs in accordance with an exemplary embodiment of the present invention are low cost, and therefore can be used in various commercial applications, such as wireless communication or satellite mobile television.

Owner:BEAM NETWORKS

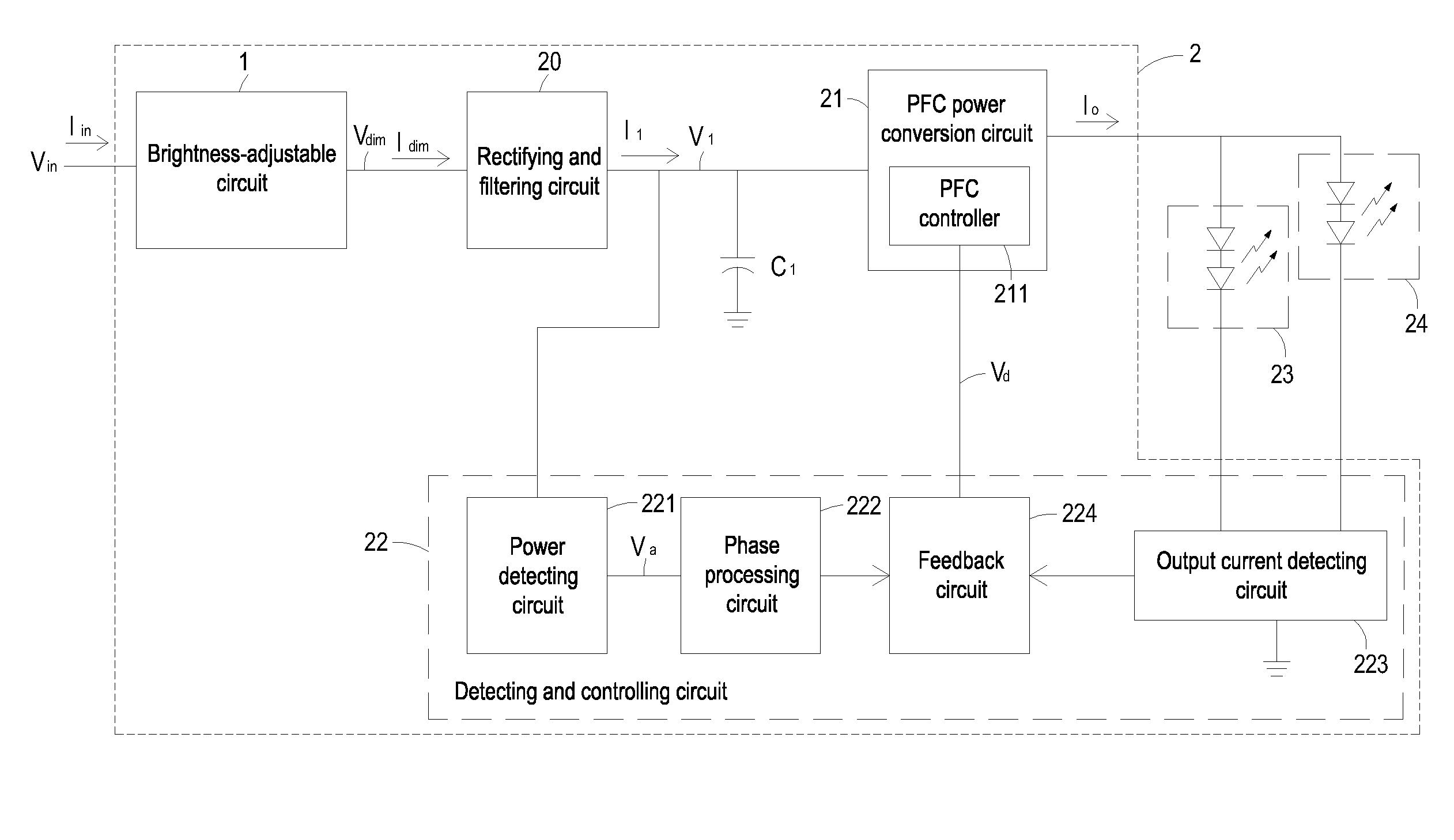

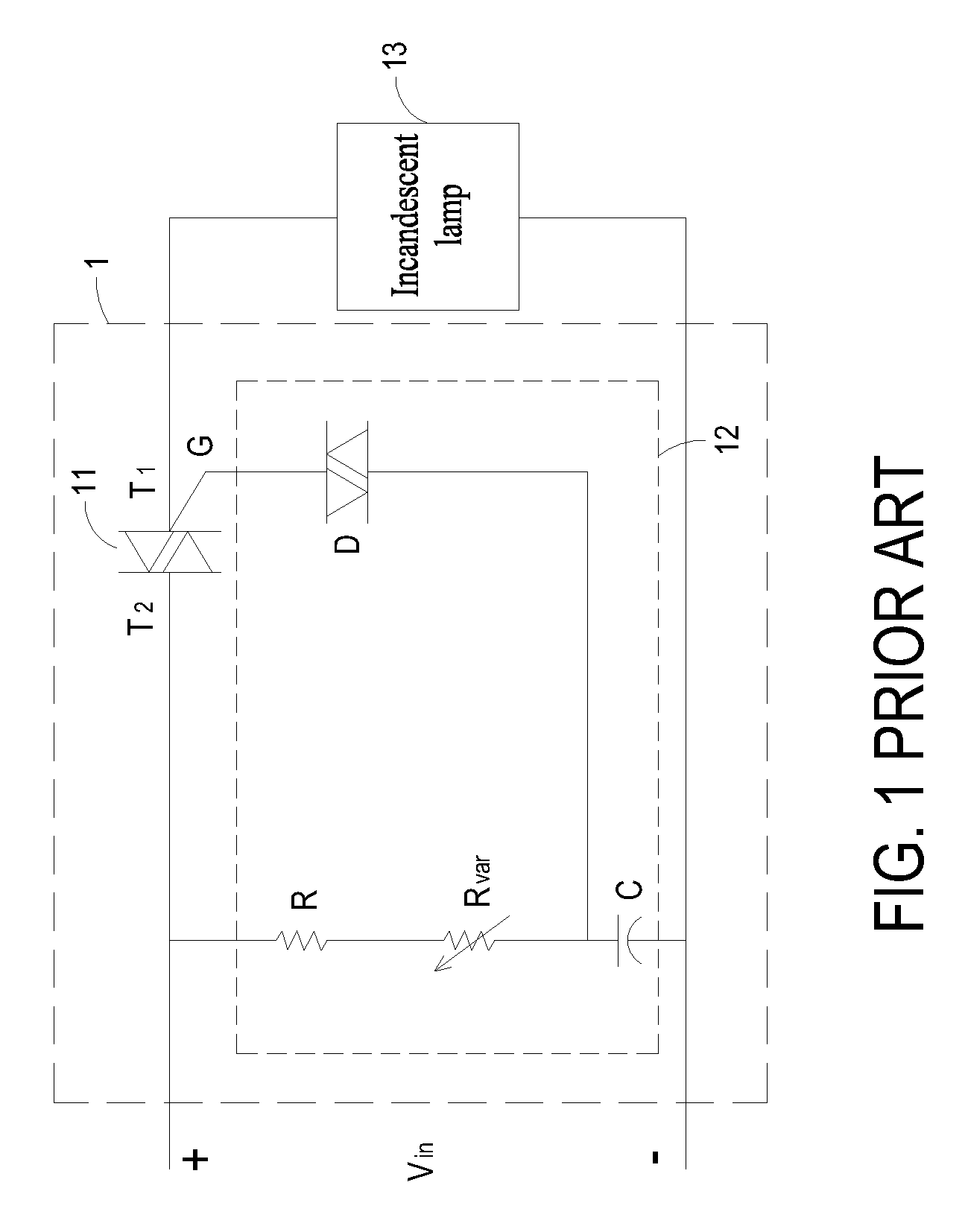

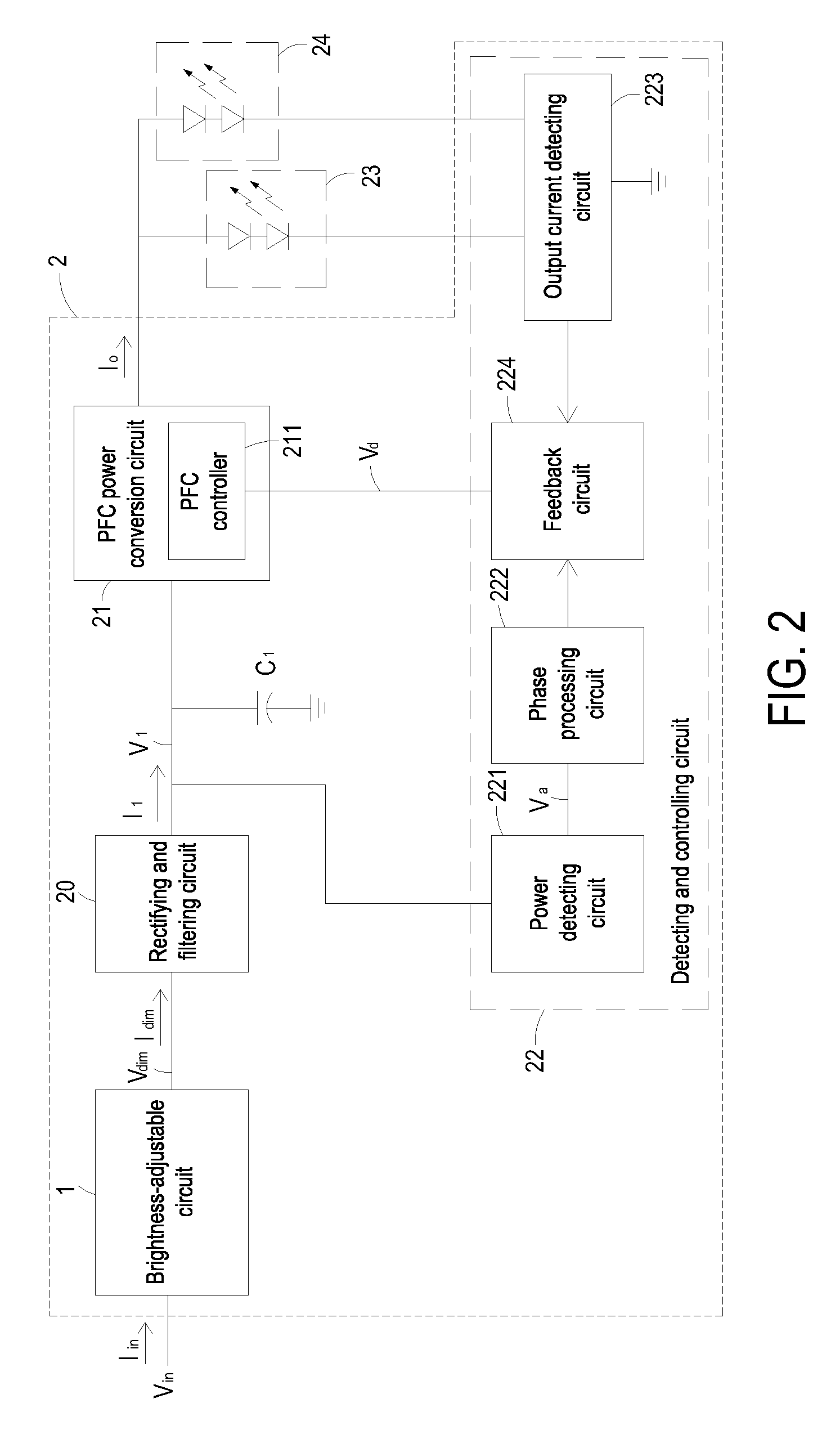

Brightness-adjustable LED driving circuit

ActiveUS20090315480A1Burn outImprove power factorElectrical apparatusElectroluminescent light sourcesControl signalEngineering

A brightness-adjustable LED driving circuit includes a rectifying and filtering circuit, a power factor correction power conversion circuit, and a detecting and controlling circuit. The rectifying and filtering circuit is used for filtering and rectifying a brightness adjusting voltage into a first DC voltage. The power factor correction power conversion circuit is electrically connected to the rectifying and filtering circuit and at least one LED string for generating an output current required for powering the at least one LED string. The detecting and controlling circuit detects phase data of the brightness adjusting voltage and the output current generated by the power factor correction power conversion circuit. The detecting and controlling circuit generates a control signal to the power factor correction controller according to the phase data of the brightness adjusting voltage, so that the magnitude of the output current is changed according to the phase data of the brightness adjusting voltage.

Owner:DELTA ELECTRONICS INC

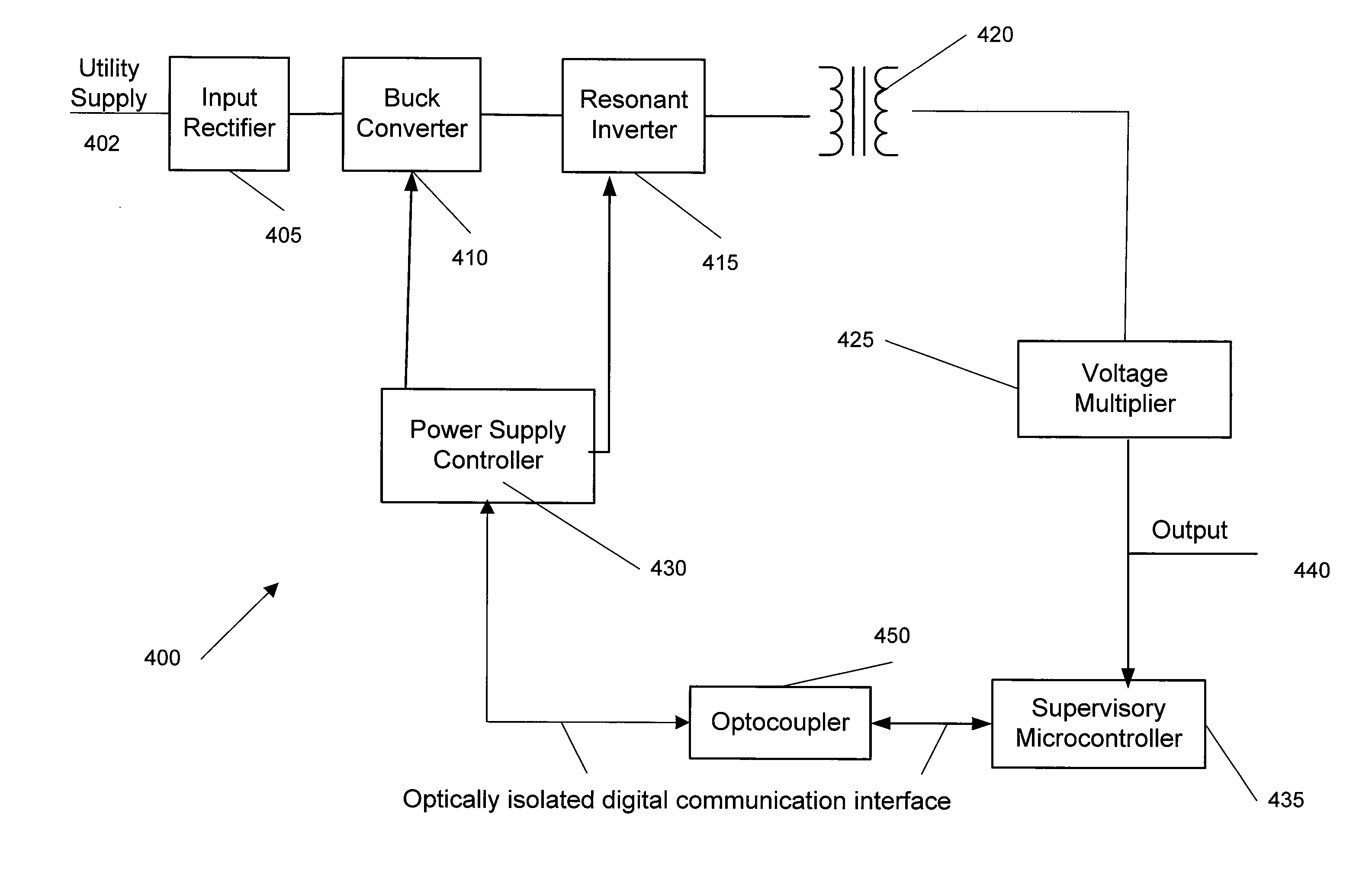

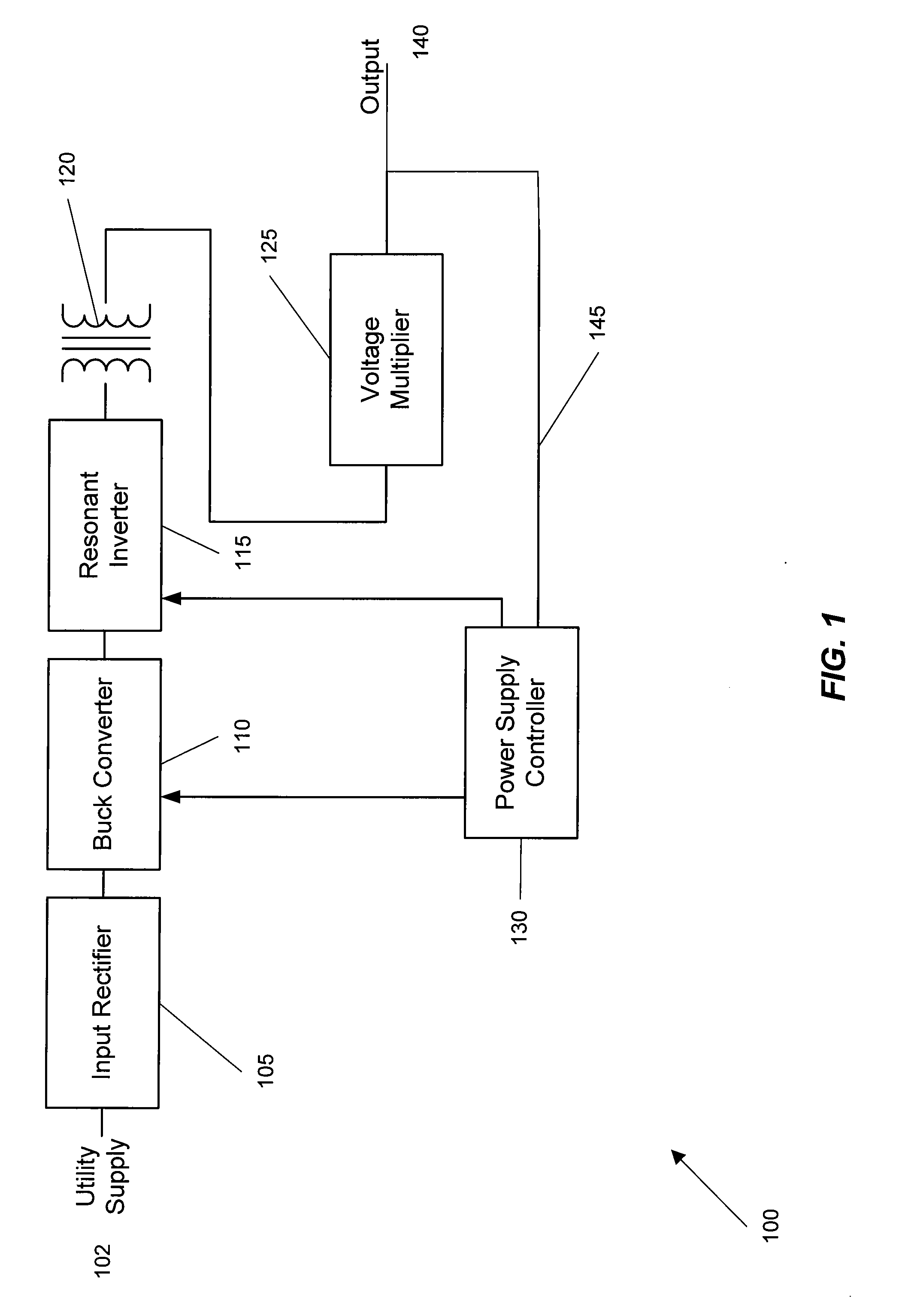

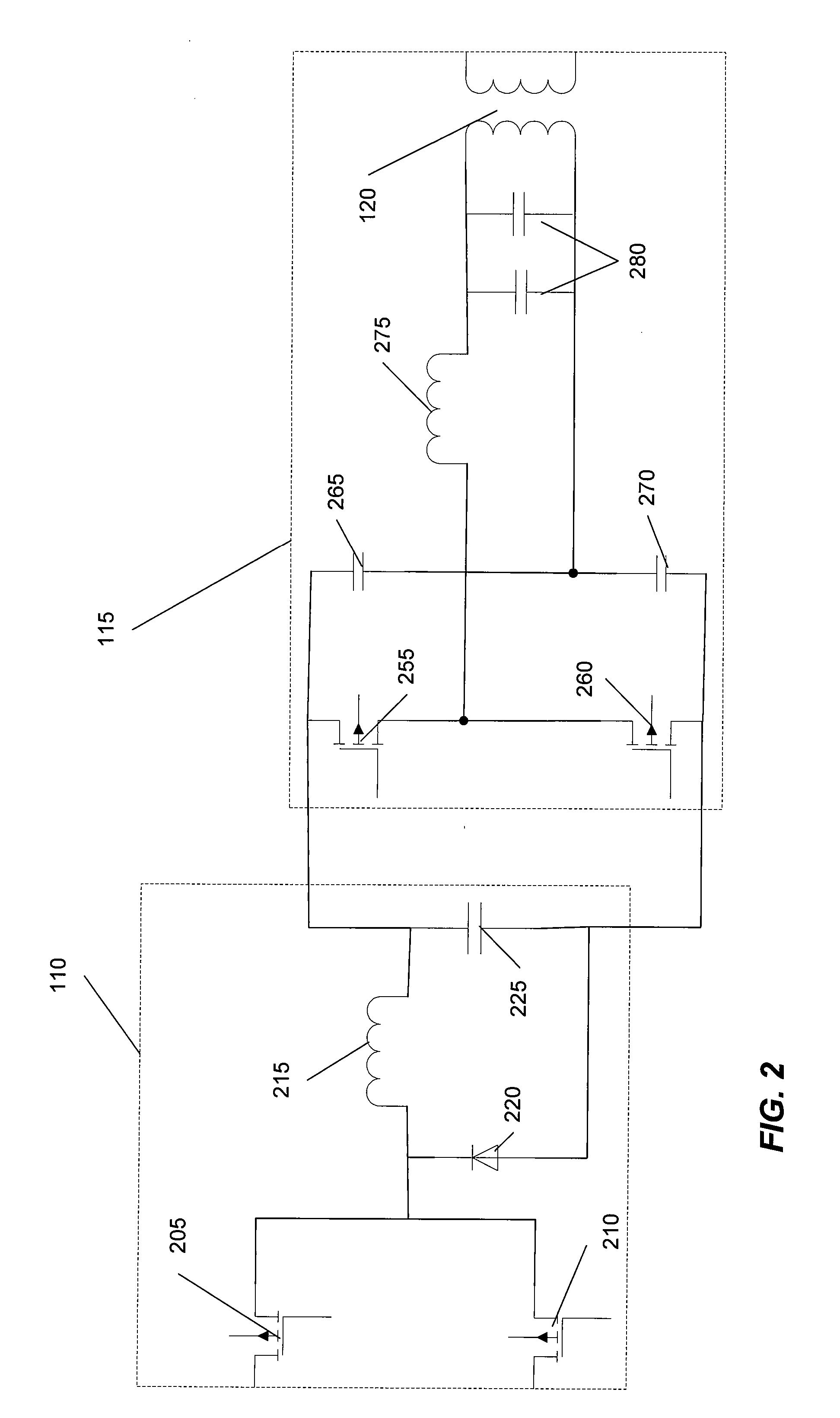

Wide range power supply

ActiveUS20070008745A1Operation efficiency is highHigh operating requirementsEfficient power electronics conversionConversion with intermediate conversion to dcResonant inverterAnalog feedback

A wide range power supply capable of delivering 20V to 5000V is provided. The power supply of the present invention uses switch mode technology to achieve high overall operating efficiency and is capable of operating from no load to full load without loss of regulation. The power supply in accordance with the embodiments of the present invention operates directly from the utility supply (e.g., 110V / 220V and 50 Hz / 60 Hz). In one embodiment, the power supply's power conversion stage includes the following stages: an input rectifier; a buck converter; a quasi-resonant inverter; and a voltage multiplier. The above indicated stages are connected in series to achieve the large output voltage range. High precision is obtained from a use of a digital feedback loop, possibly in connection with an analog feedback loop.

Owner:BIO RAD LAB INC

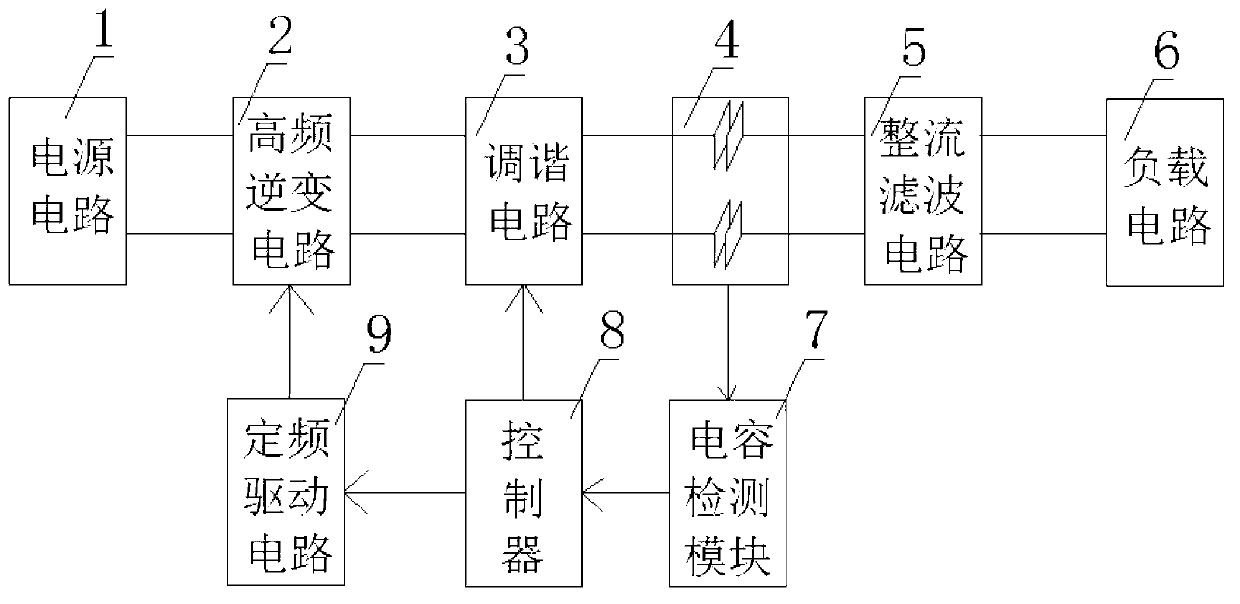

Electric field coupling-based wireless power transmission system

ActiveCN102882286AEnhanced couplingStable soft switching working stateElectromagnetic wave systemEfficient power electronics conversionCapacitanceLoad circuit

The invention discloses an electric field coupling-based wireless power transmission system. The system comprises a power supply circuit, a high-frequency inverter circuit, a tuning circuit, an electric field coupling polar plate, a rectifier filter circuit and a load circuit and is characterized by also comprising a coupling capacitance detection module, a controller and a fixed frequency drive circuit; a capacitance compensation array is arranged in the tuning circuit; the controller detects parameters of the electric field coupling polar plate and controls compensation values of the capacitance compensation array through the coupling capacitance detection module, and outputs fixed frequency control signals; and the fixed frequency signals are transmitted to the fixed frequency drive circuit, and then the high-frequency inverter circuit is driven to work. The electric field coupling-based wireless power transmission system has the advantages that based on the electric field coupling, the transmission capacity and efficiency of the system are improved by adopting an E amplifier; and by arranging the coupling capacitance detection module, the electric field coupling polar plate of the system is detected in real time, and the capacitance compensation value can be effectively controlled, so that the system is kept in the soft switching state, and the power transmission stability and reliability of the system are improved.

Owner:重庆华创智能科技研究院有限公司

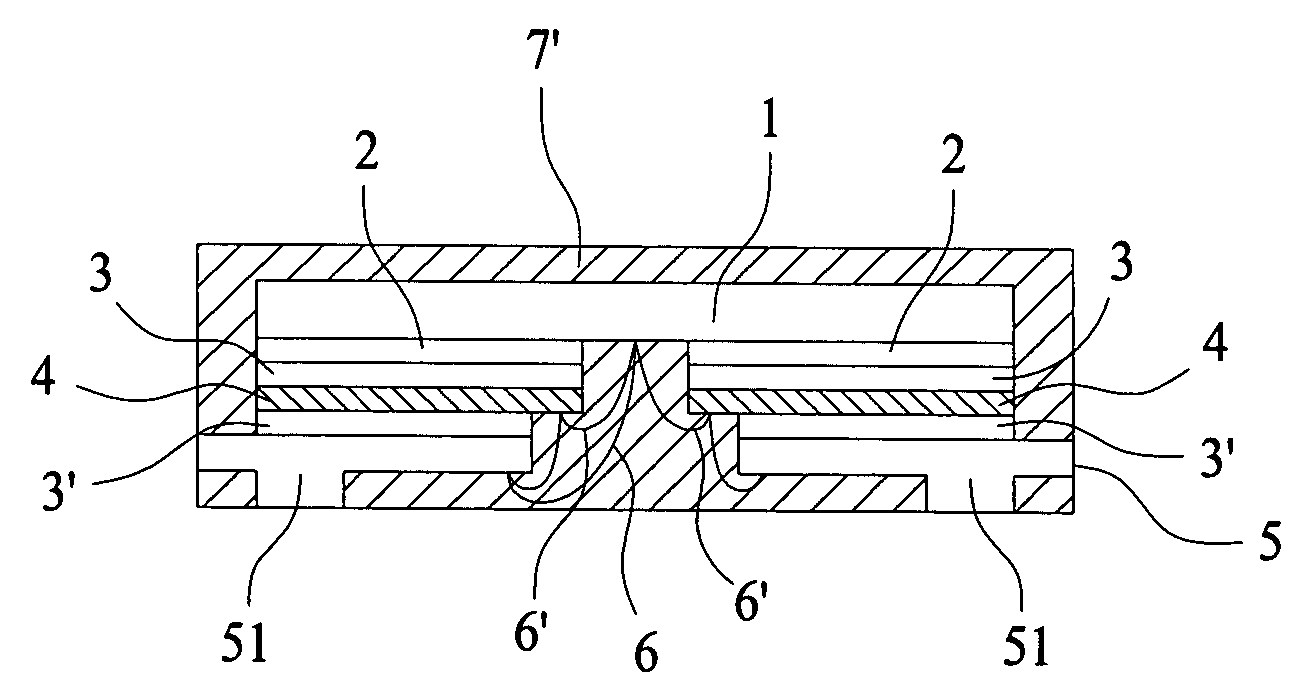

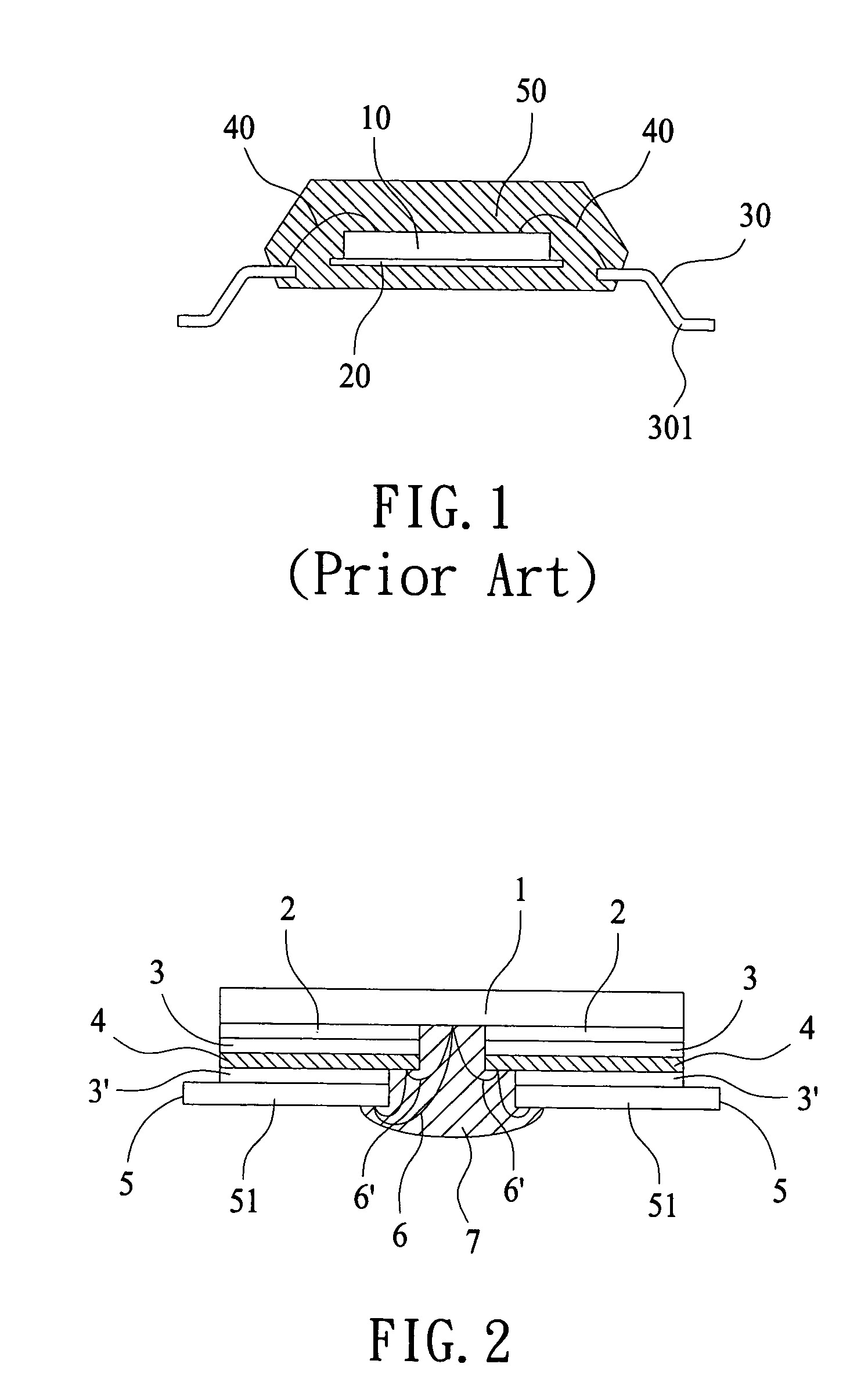

Electrical-interference-isolated transistor structure

InactiveUS7187064B2Simple structureReduce electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesFiberElectrical conductor

A transistor structure includes at least one chip; a packaging insulating layer, a first adhesive layer, a conducting layer, and a second adhesive layer sequentially provided on one side of the chip having electrical contacts thereon, so that the conducting layer is bonded between the first and the second adhesive layer; and a leadframe bonded to an outer side of the second adhesive layer. The conducting layer may be a metal sheet, a metal film, or a type of conducting fiber. The leadframe is connected to the electrical contacts on the chip via lead wires, and at least one of the electrical contacts on the chip is connected to the conducting layer via a conductor, so that the conducting layer is able to isolate electrical noises and reduce electromagnetic interferences, improve rates of transmission and heat release, strengthen chip packaging structure, and serve as a common grounding circuit.

Owner:DOMINTECH

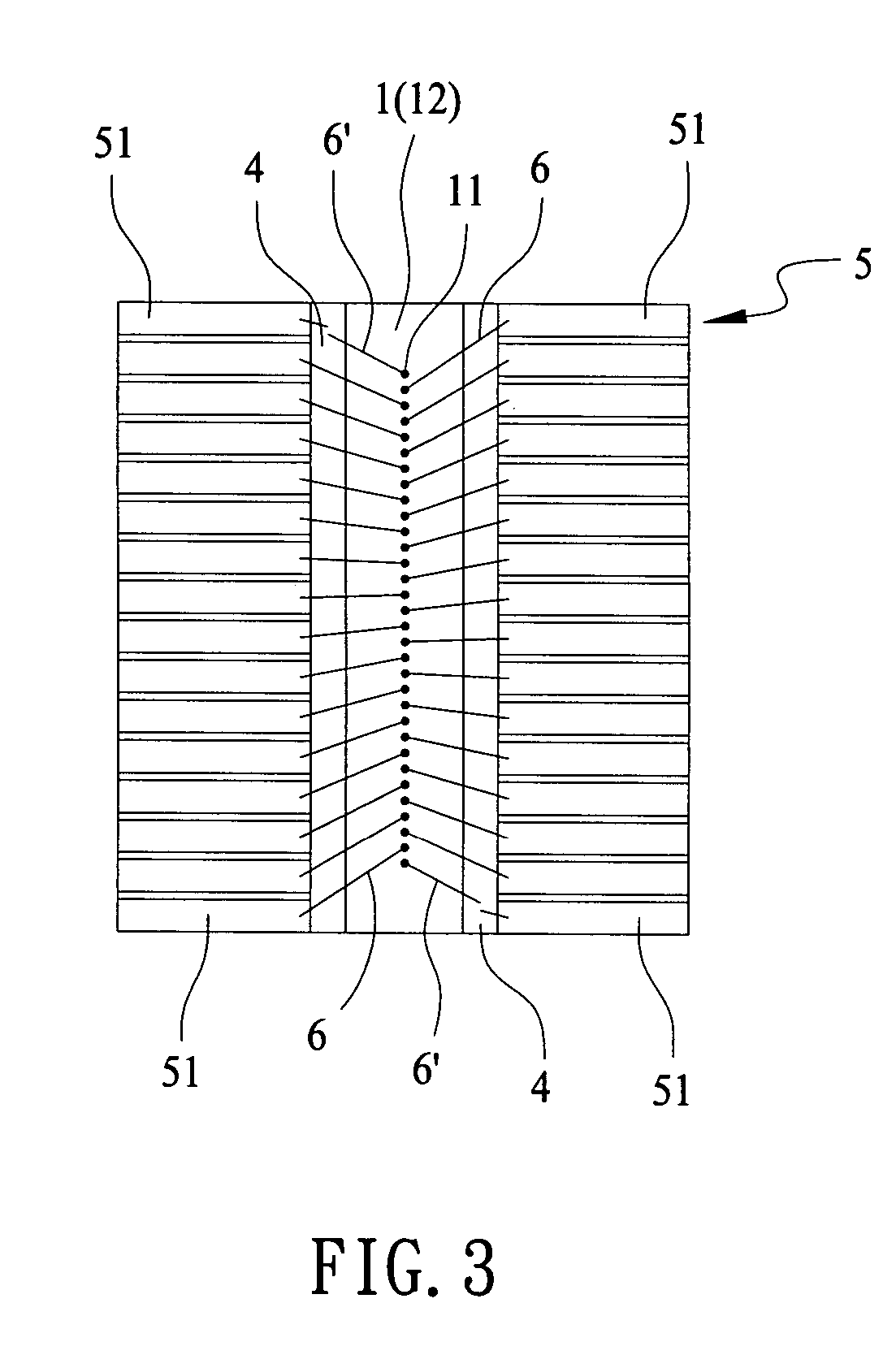

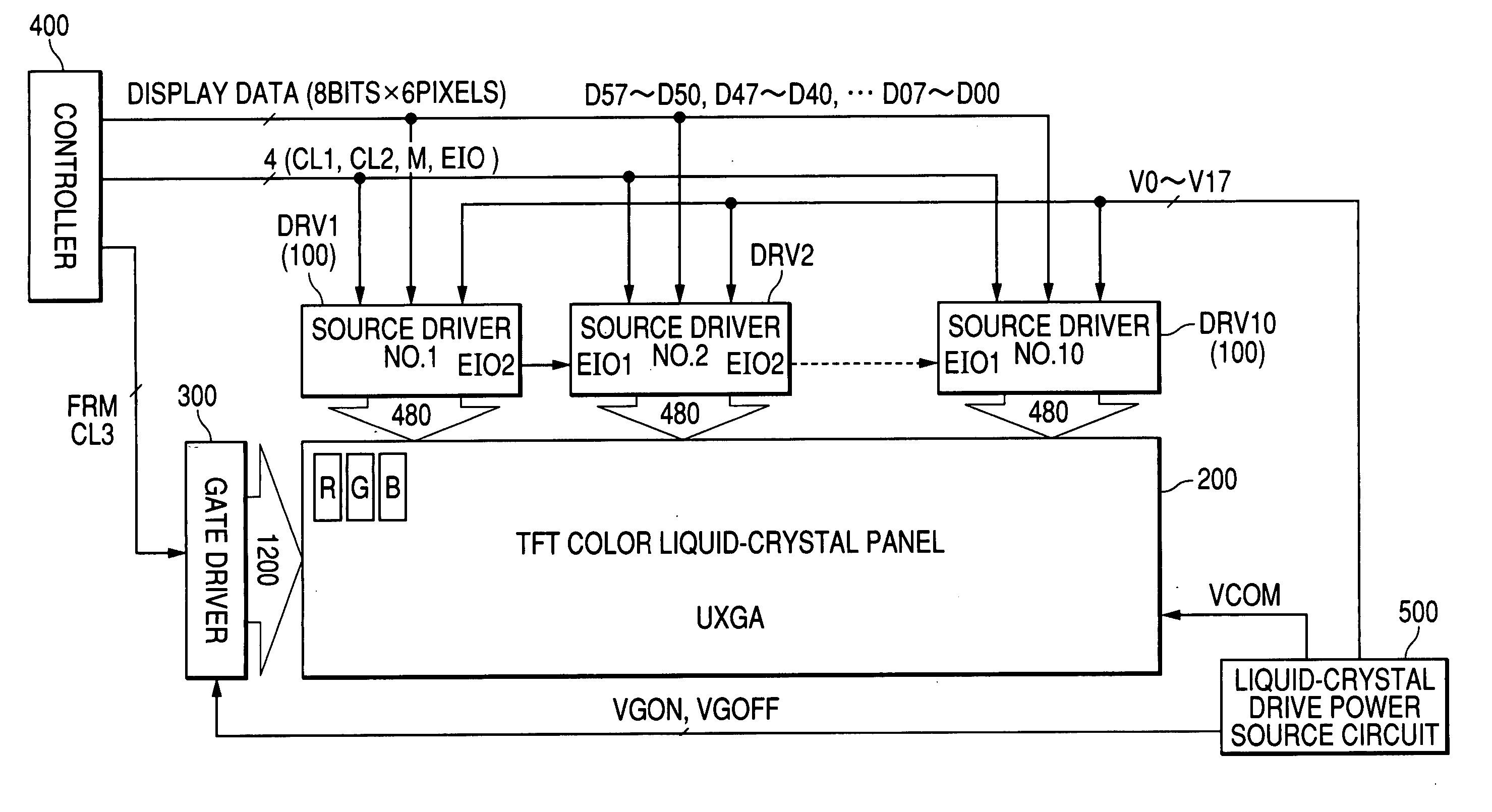

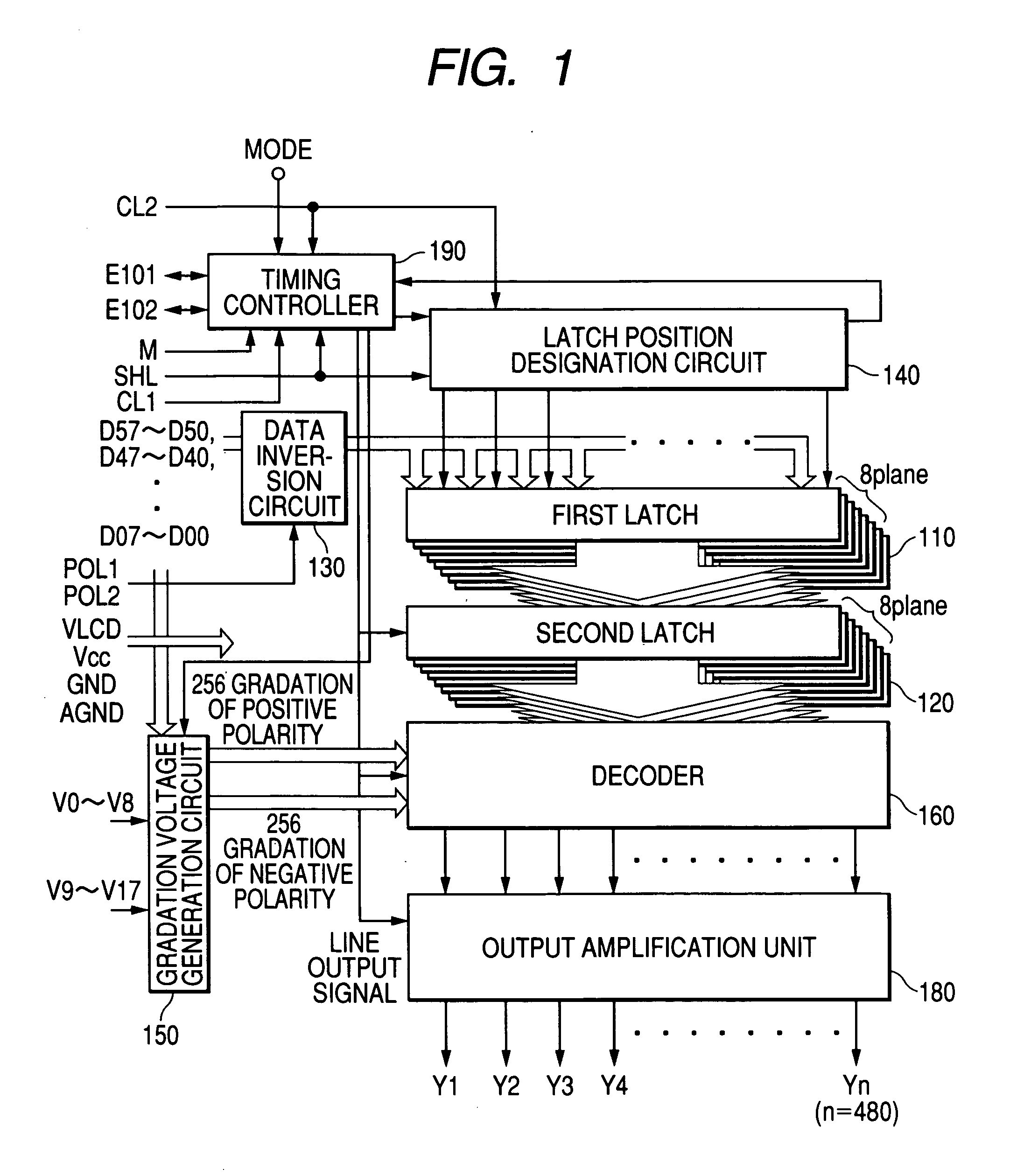

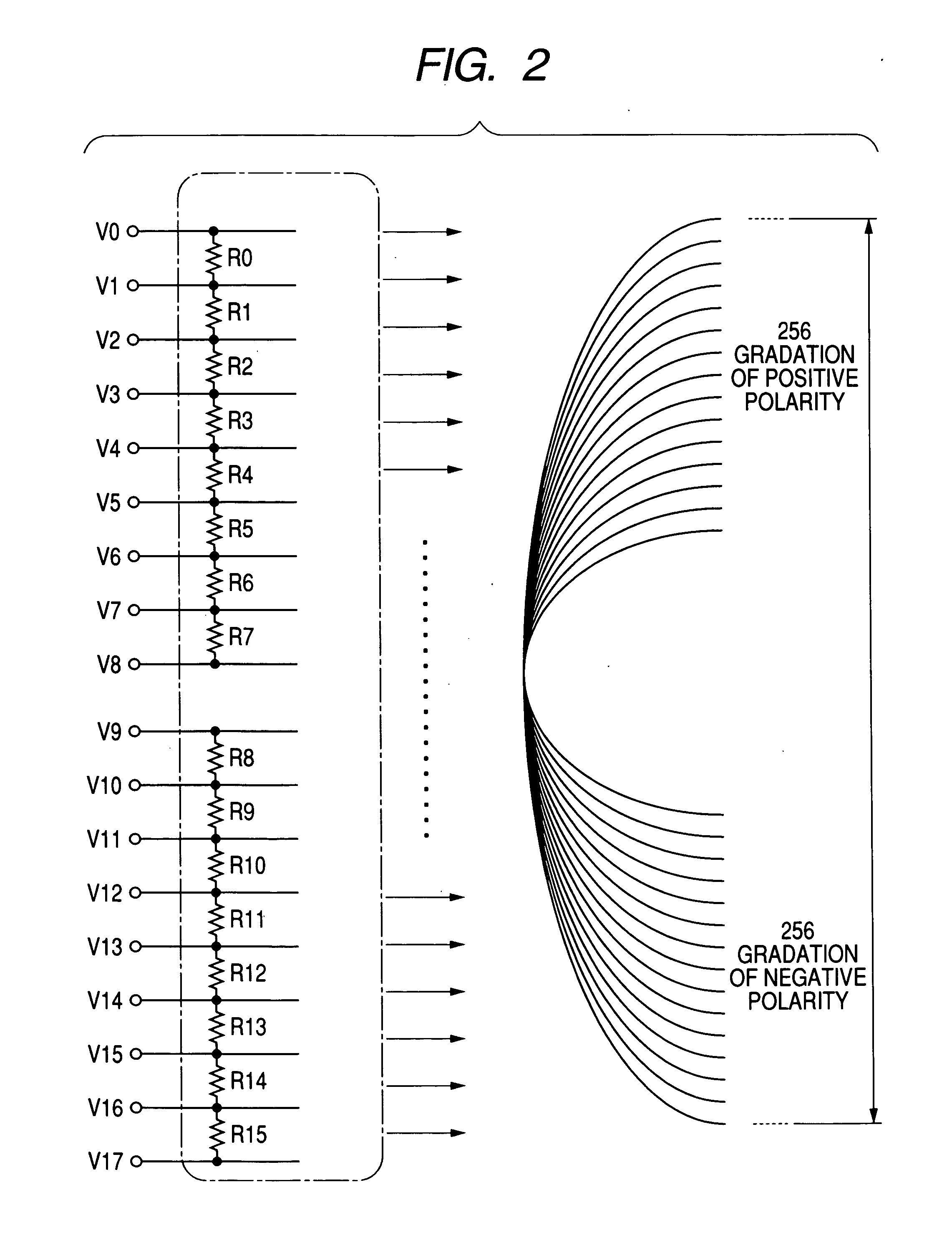

Liquid crystal display driver device and liquid crystal display system

ActiveUS20050264548A1Reduce electromagnetic interferenceAvoiding degradation in display image qualityCathode-ray tube indicatorsInput/output processes for data processingAudio power amplifierLiquid-crystal display

There is provided a display driver device (liquid crystal driver) causing no degradation in display image quality even when a plurality of signal lines (source lines) of a display panel are divided into a plurality of groups as a countermeasure against EMI. With a liquid crystal display driver device (the liquid crystal driver) for generating image signals to be impressed to respective signal lines of a display panel upon receiving display image data, and outputting the image signals in a lump, corresponding to every one line, according to an output timing signal inputted from outside, output amplifiers, in the last stage of the liquid crystal driver, for outputting the image signals, respectively, are divided into a plurality of groups, and the output amplifiers of respective groups are caused to undergo a periodical change in output sequence while the respective image signals are slightly staggered in output timing by the group.

Owner:SYNAPTICS JAPAN GK

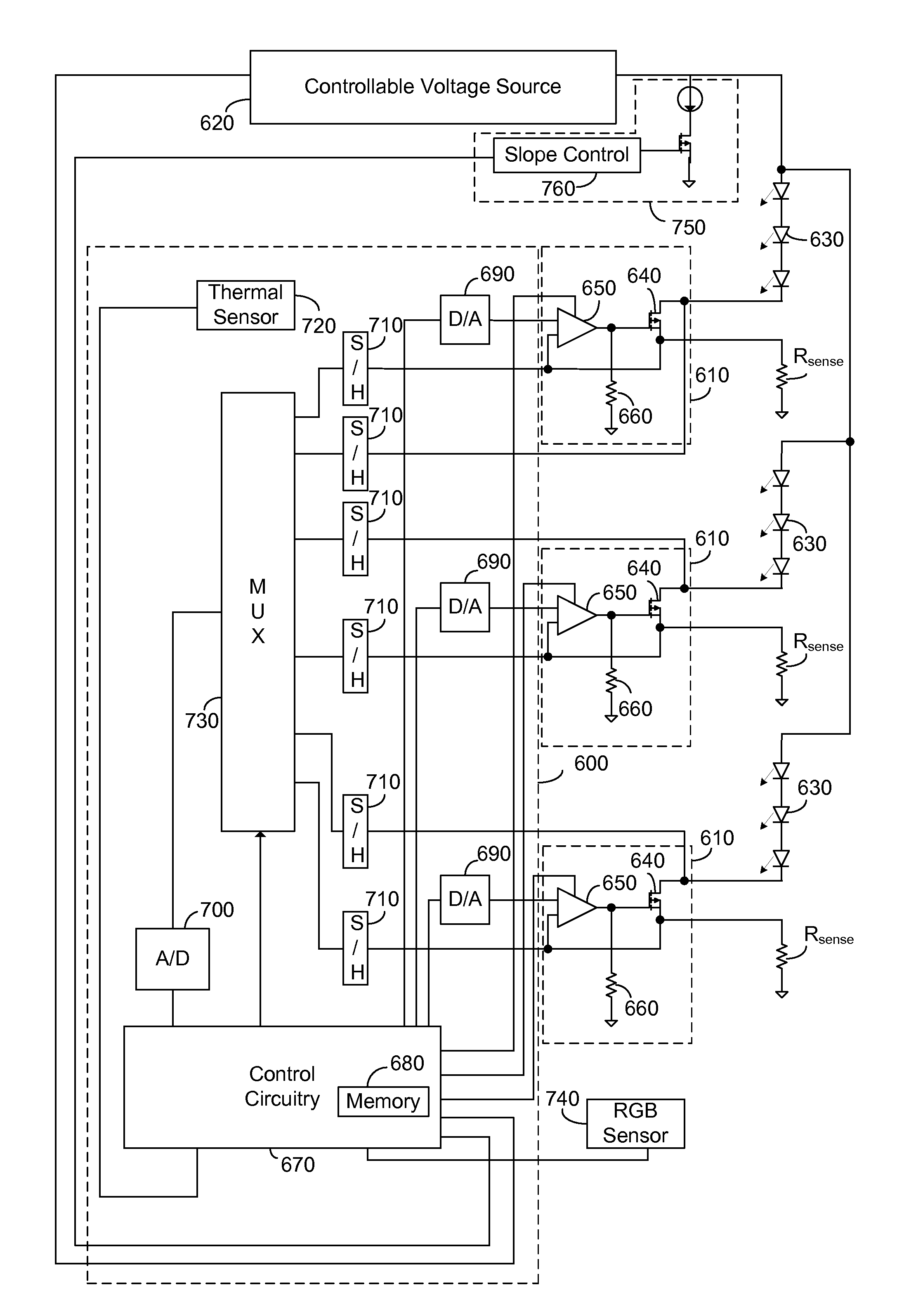

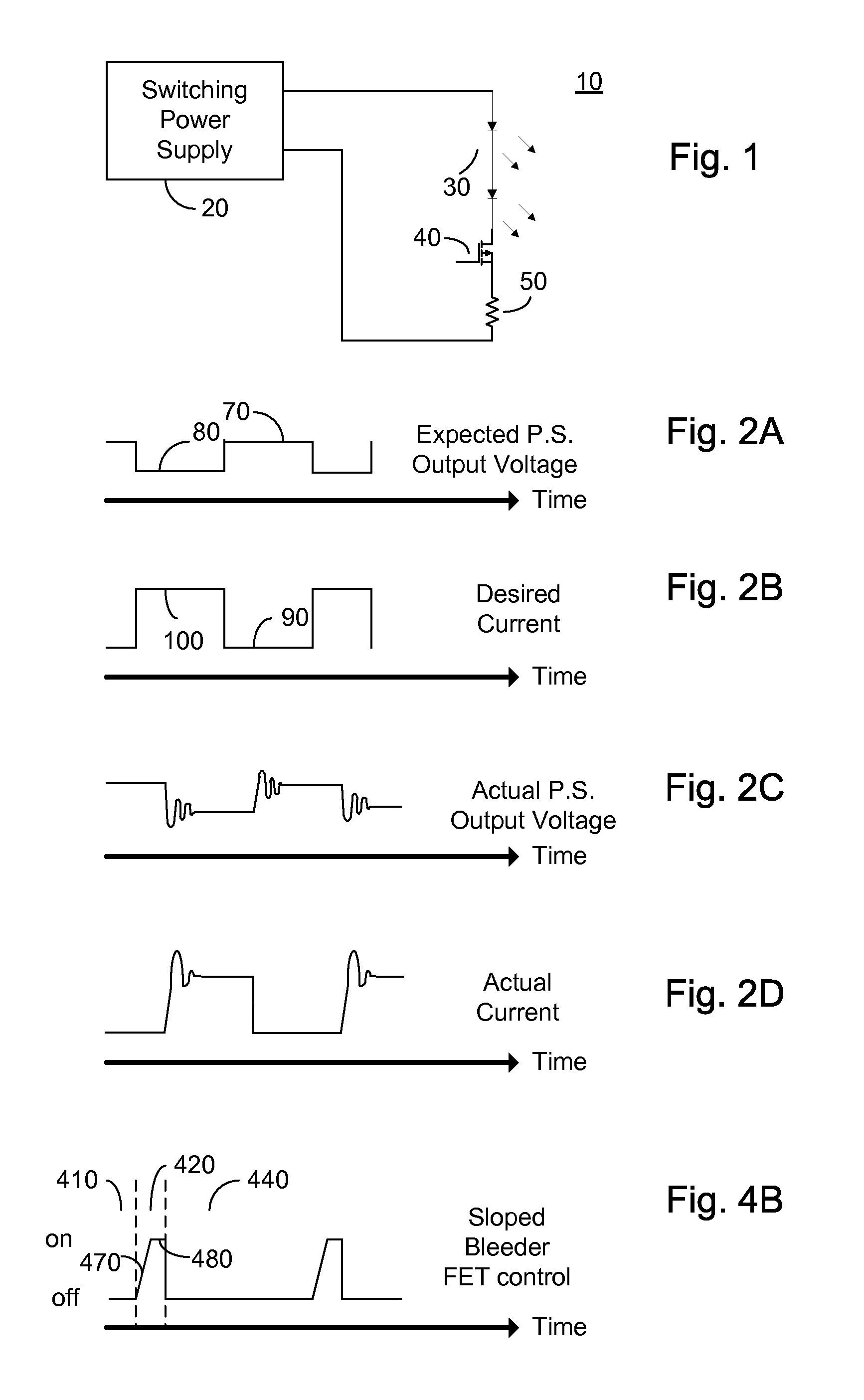

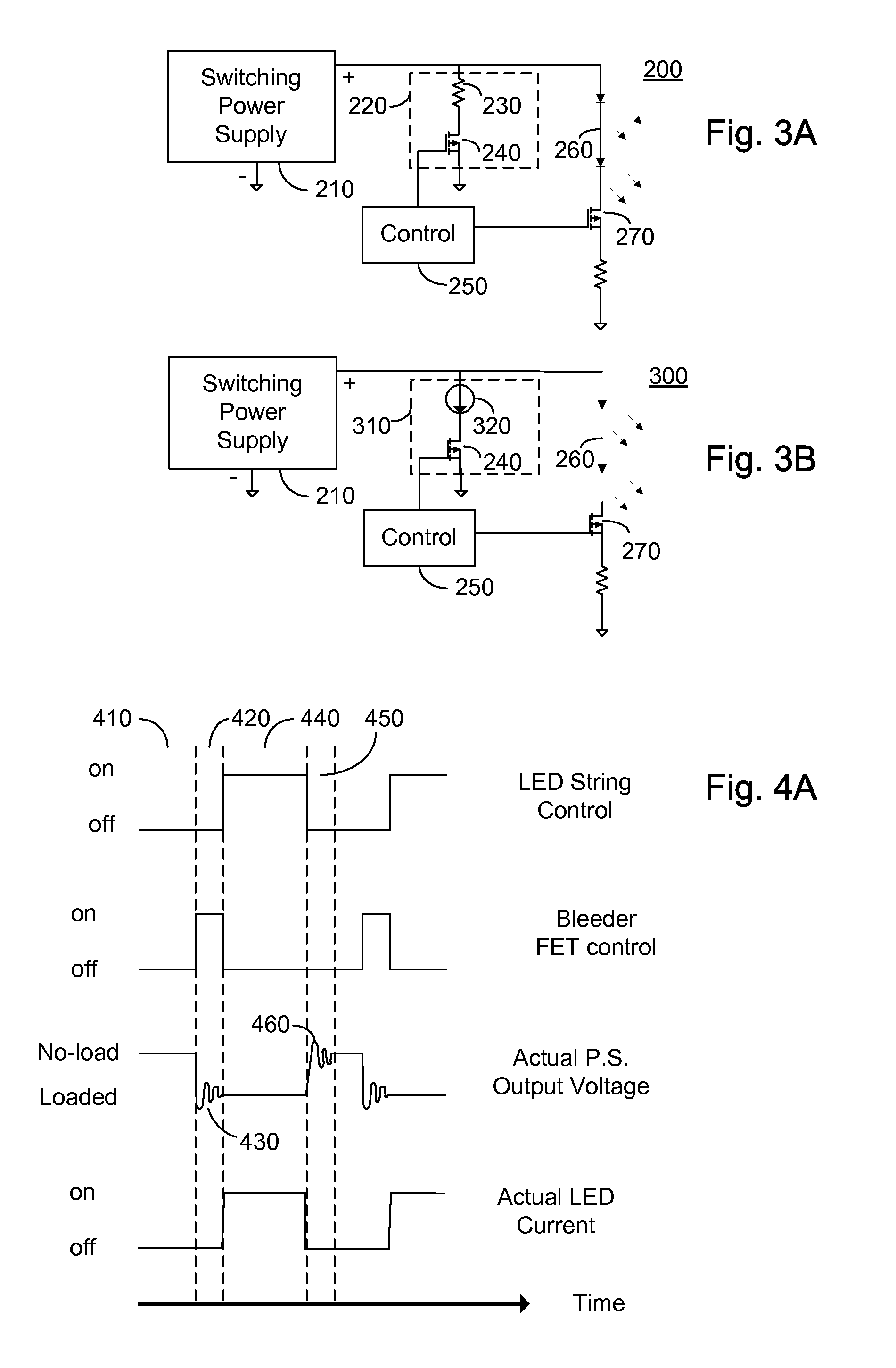

Controlled Bleeder for Power Supply

InactiveUS20080048573A1Stable strengthOvercome disadvantagesElectrical apparatusElectroluminescent light sourcesControl circuitDischarge current

An LED backlighting system including: a control circuit; a power source; at least one LED string associated with the power source, the at least one LED string being arranged to be switchably connected to alternatively draw an illumination current from the power source and not draw an illumination current from the power source; and a controlled bleeder arranged to draw a bleed current from the power source responsive to the control circuit; the control circuit being operative to draw the bleed current from the power source via the controlled bleeder for a predetermined time period associated with the alternatively drawing and not drawing the illumination current of the at least one LED string.

Owner:POLARIS POWERLED TECH LLC

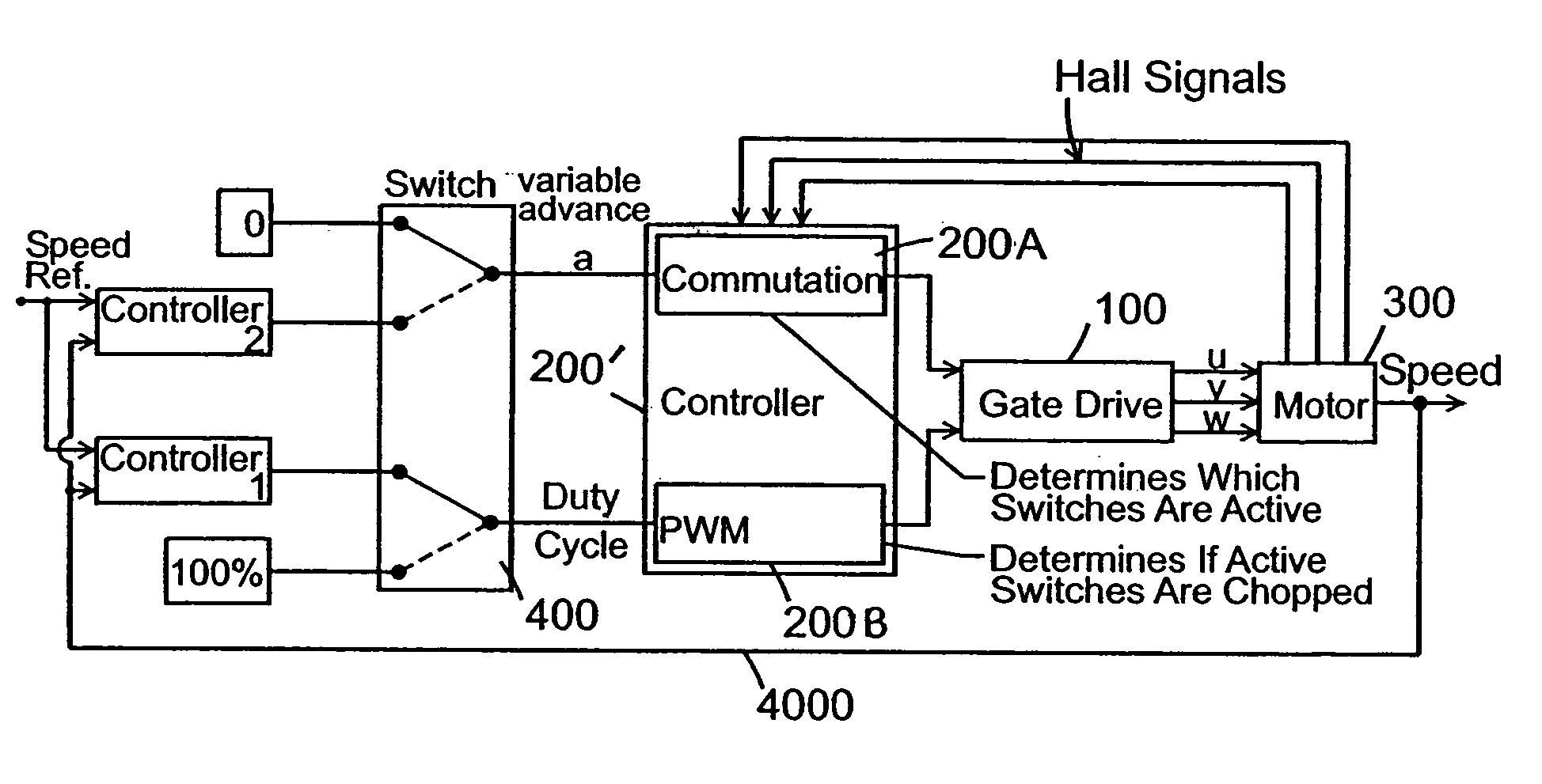

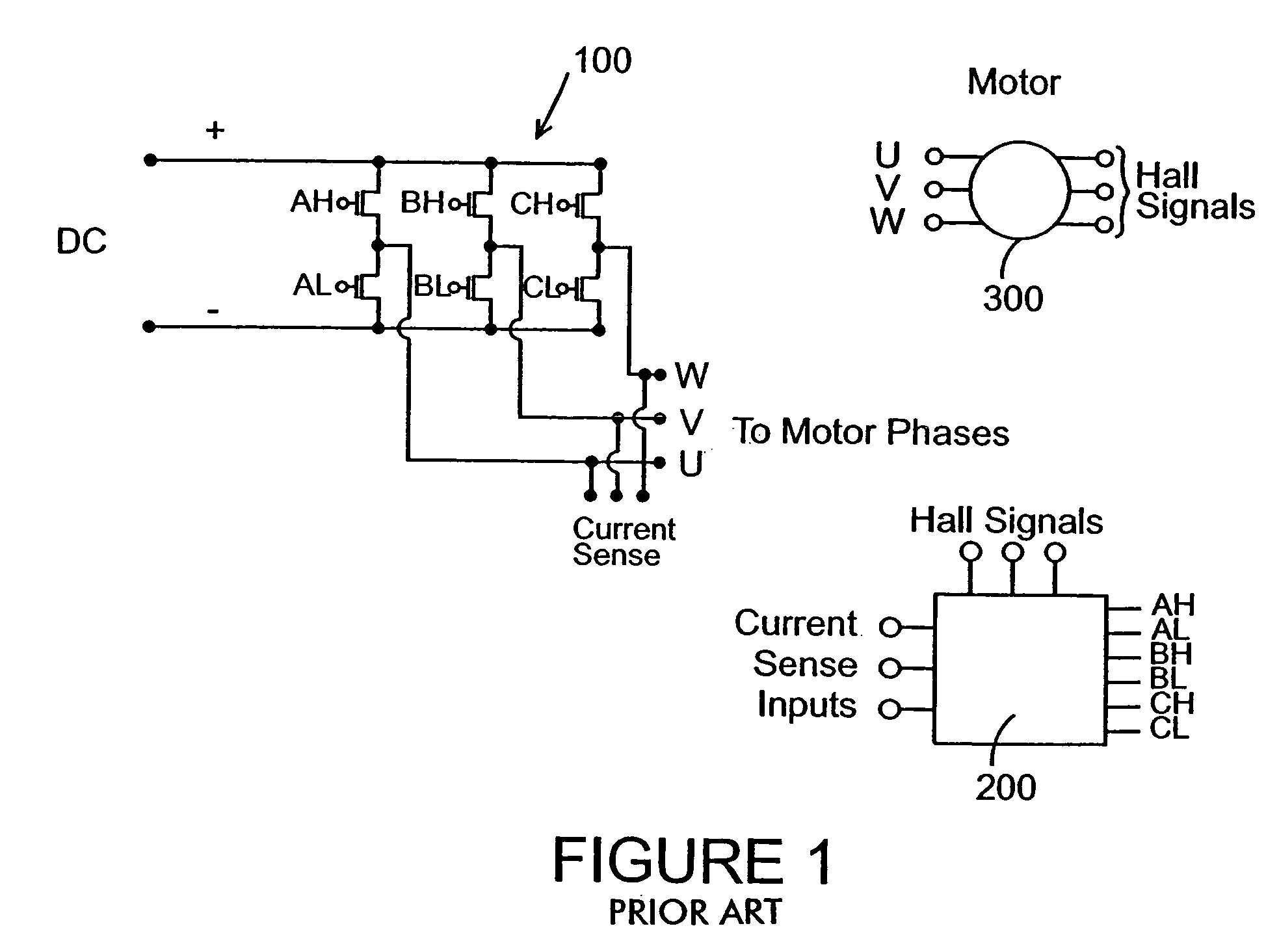

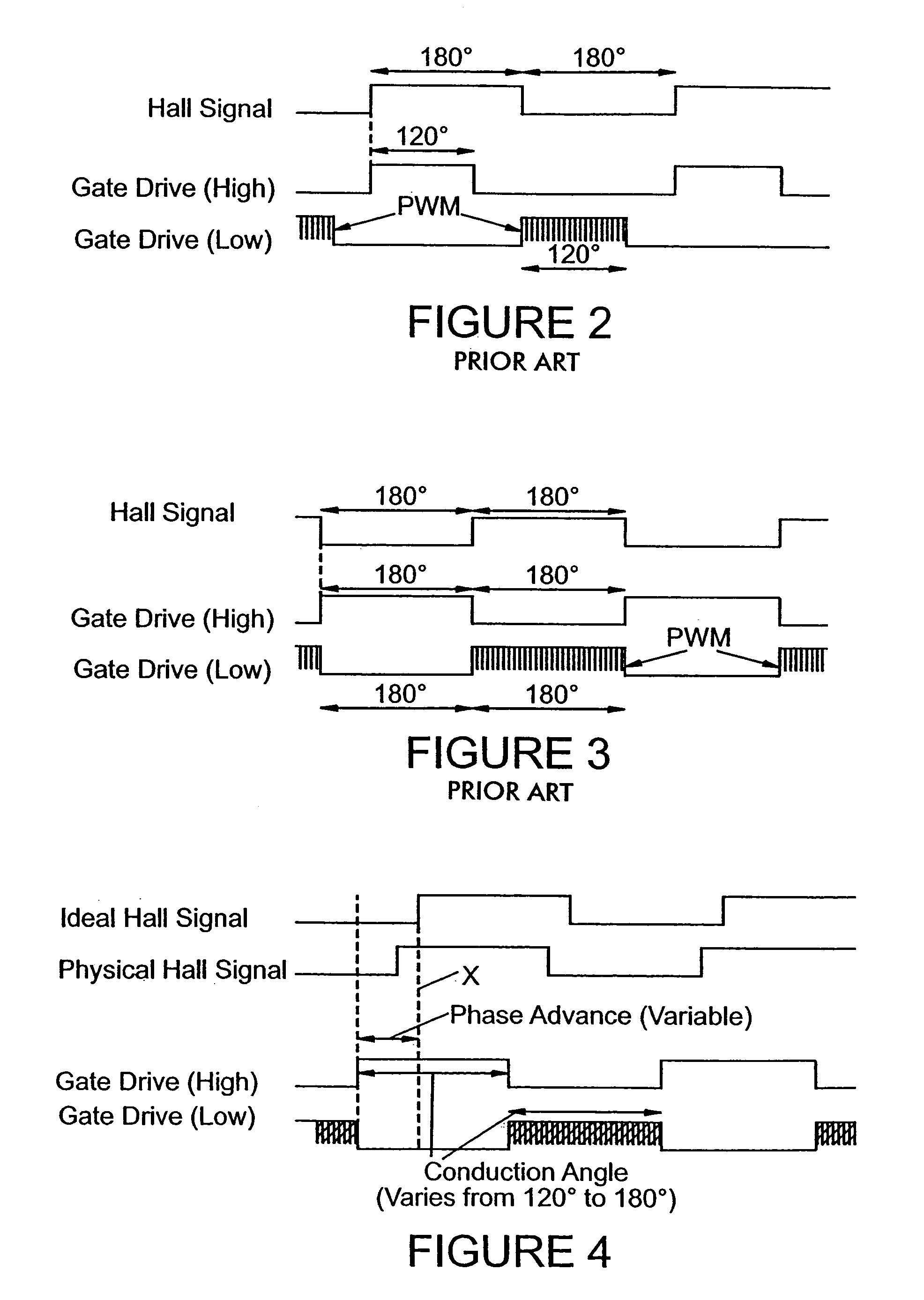

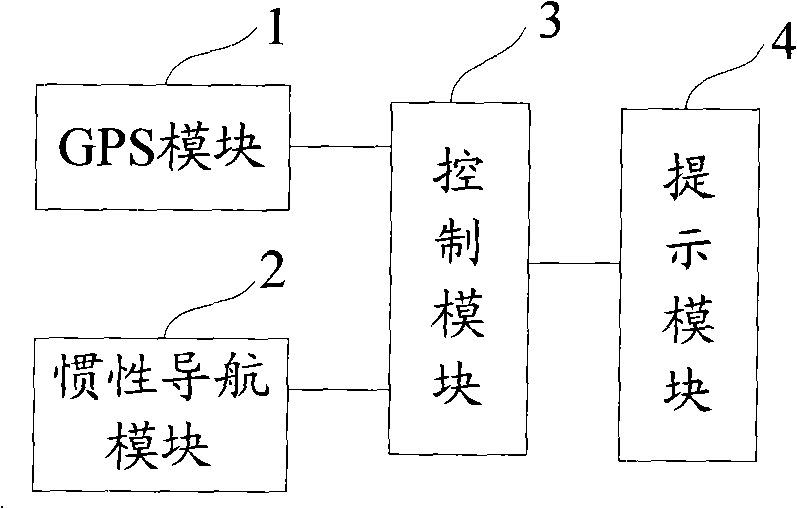

Method for controlling an electric motor to reduce EMI

InactiveUS7202622B2Reduce the amount requiredLow costDC motor speed/torque controlSynchronous motors startersPhase advanceDC-BUS

A method for reducing EMI emissions in the control of an electric motor supplied by a switching inverter fed by a DC bus comprising controlling a phase advance of a conduction angle period during which a phase of the motor is fed power by the inverter to control the conduction angle to control the speed of the motor, thereby to reduce the number of switching operations of the inverter and thereby reduce EMI.

Owner:INFINEON TECH AMERICAS CORP

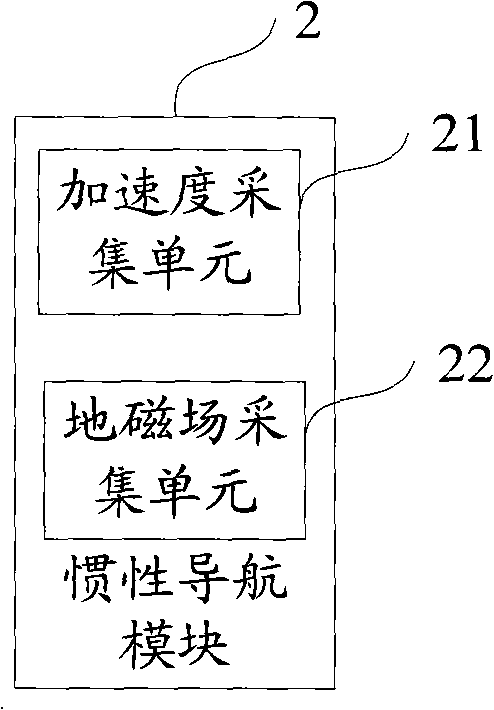

Navigation device and method

ActiveCN101403620AReduce electromagnetic interferencePrecise NavigationInstruments for road network navigationBeacon systems using radio wavesGps navigationComputer science

The invention provides a navigation device, which comprises a receiving GPS signal, a GPS module which analyzes the GPS signal to generate GPRS navigation data, an inertial navigation module which collects inertial navigation data, a control module which calibrates the inertial navigation data and the GPS navigation data according to the GPS signal strongness or weakness determined by the GPS navigation data, and a hint module which outputs in an image or a sound mode. The invention also provides a navigation method, which comprises the steps of: receiving the GPS navigation signal, and resolving to generate the GPS navigation data; collecting the inertial navigation data; calibrating the inertial navigation data and the GPS navigation data according to the GPS signal strongness or weakness determined by the GPS navigation data, and generating the navigation information; and outputting the navigation information. The inertial navigation data and the GPS navigation data are calibrated according to the GPS signal strongness or weakness, and the navigation information is generated, therefore, the navigation accuracy can be improved.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

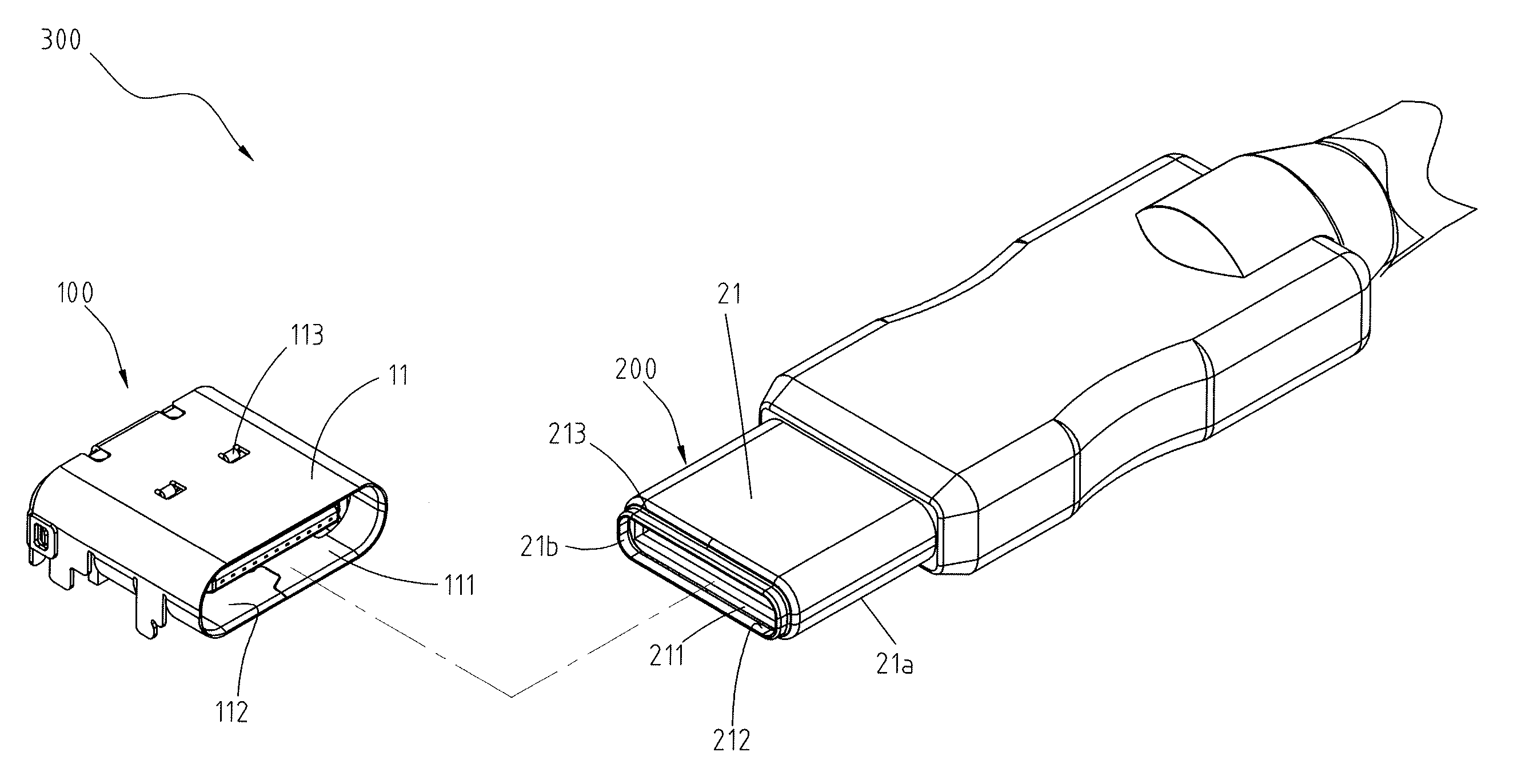

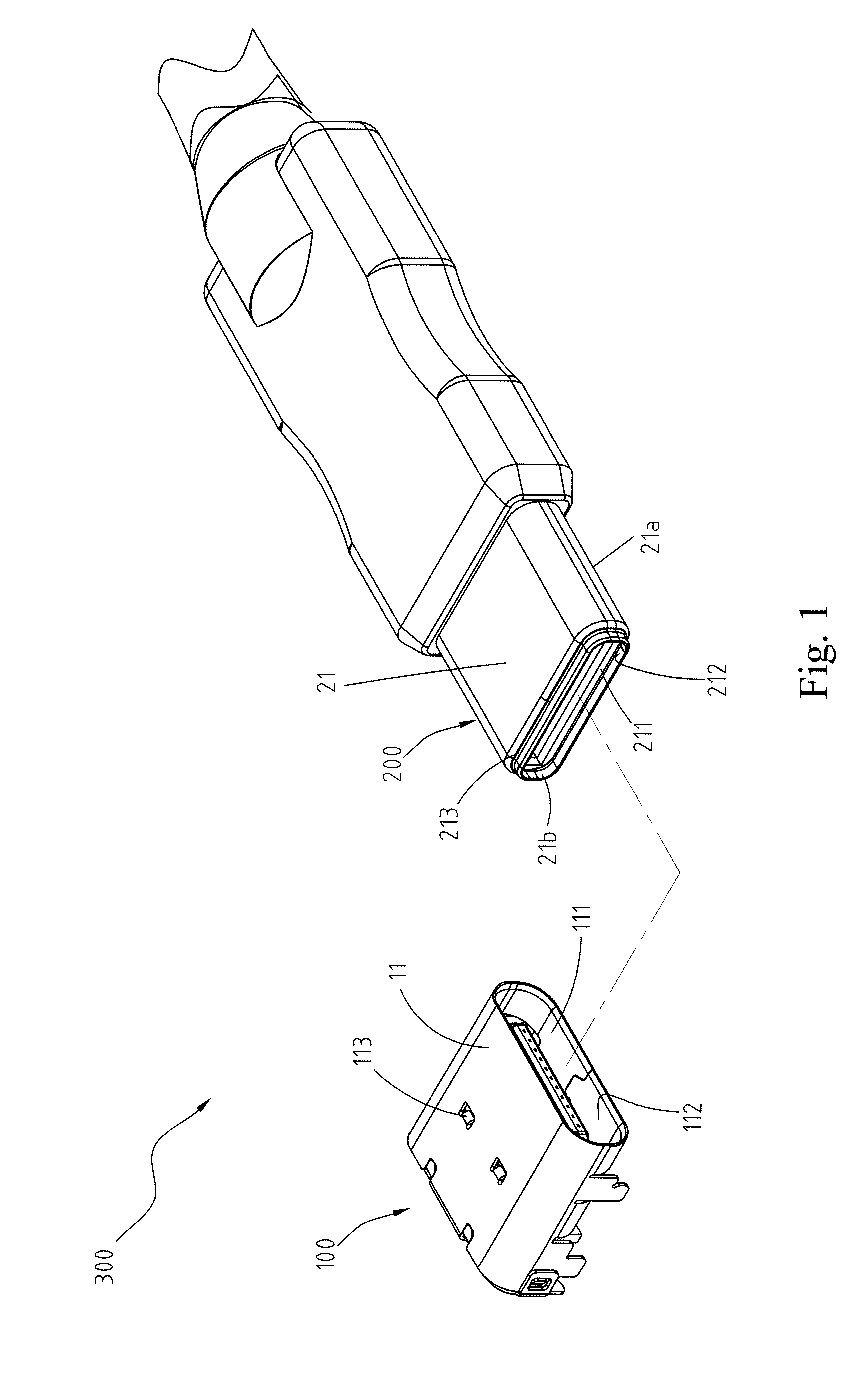

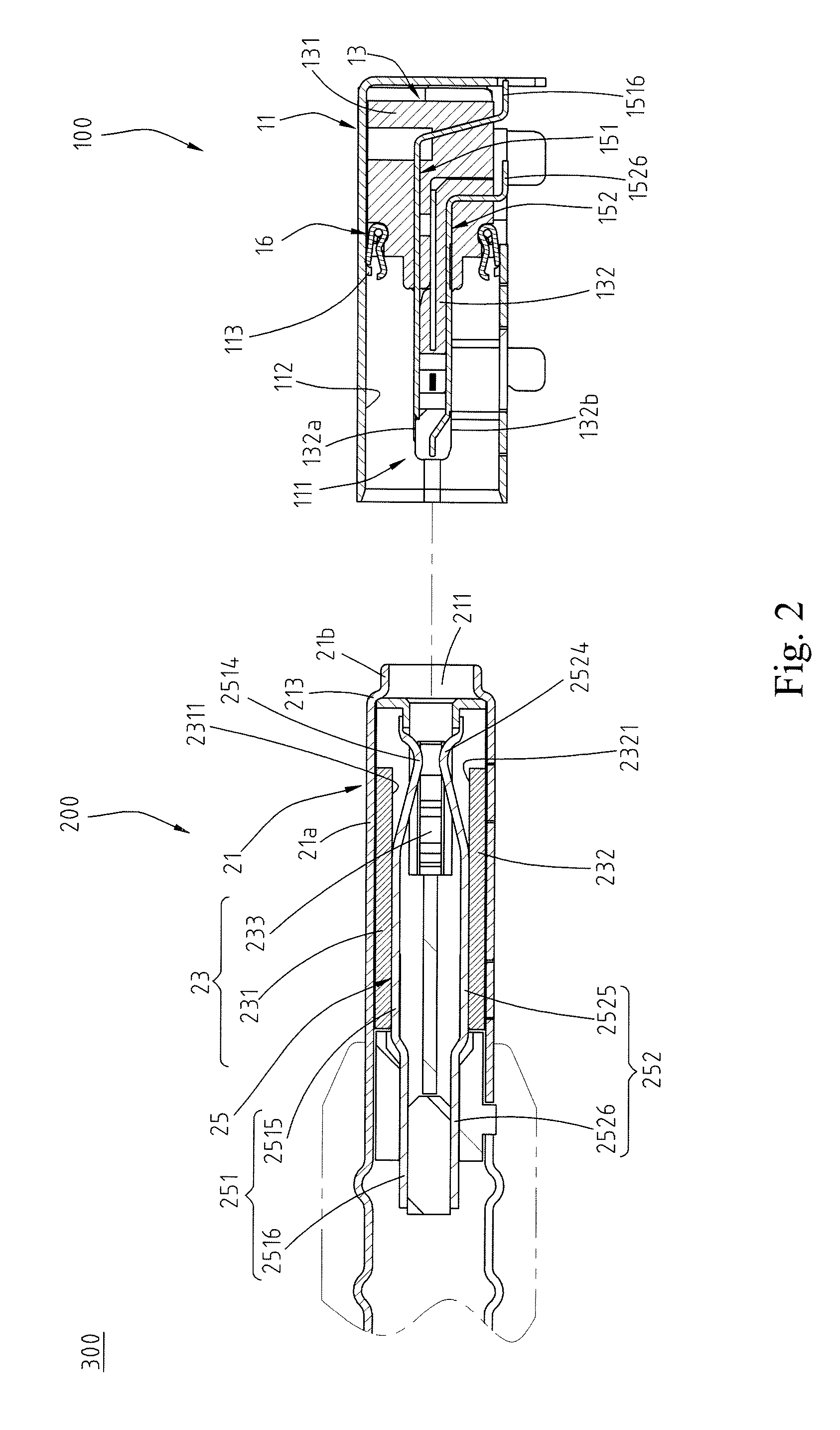

Electrical receptacle connector and electrical plug connector

ActiveUS9318856B2Reduce electromagnetic interferenceAmount of resistanceTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectrical connectorElectrical and Electronics engineering

Owner:ADVANCED CONNECTEK INC

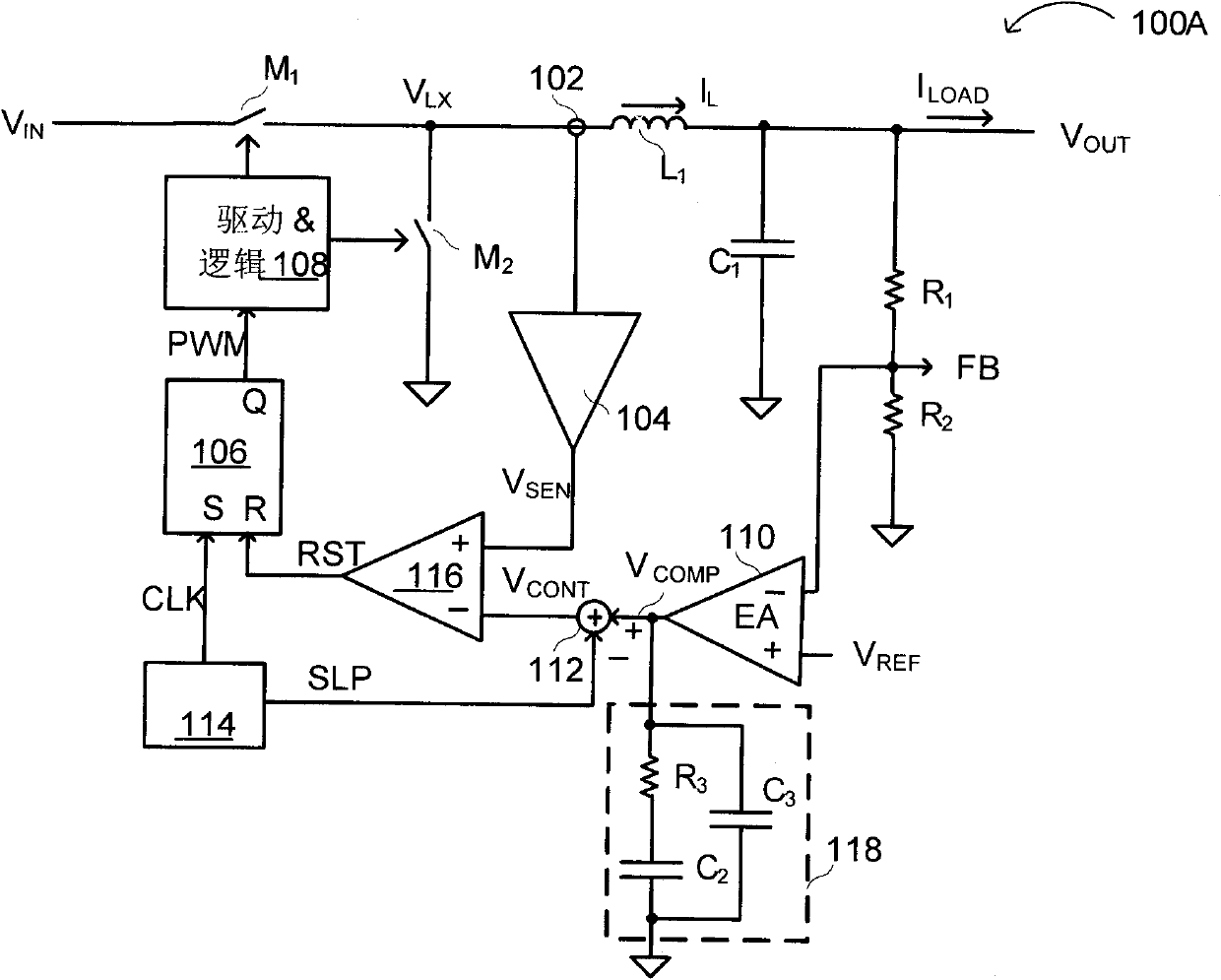

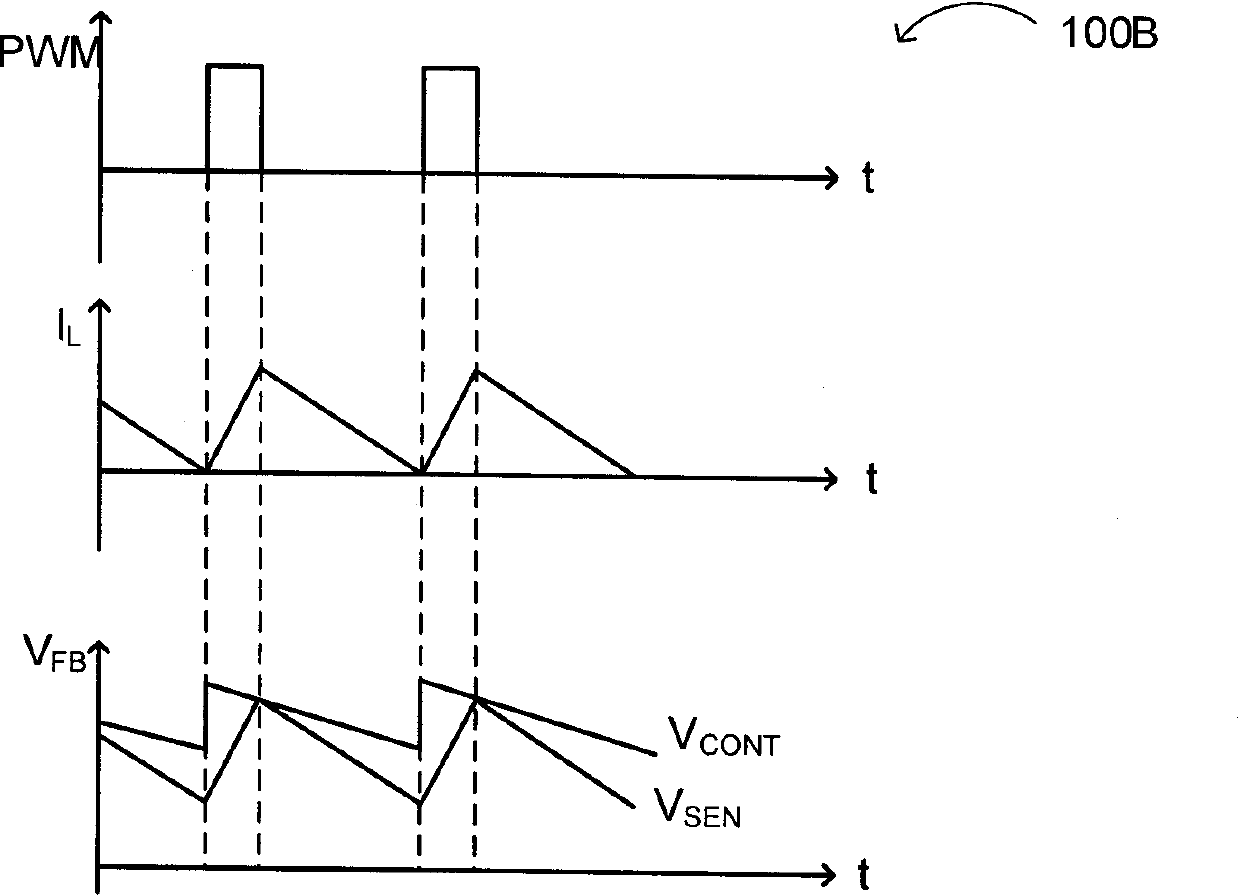

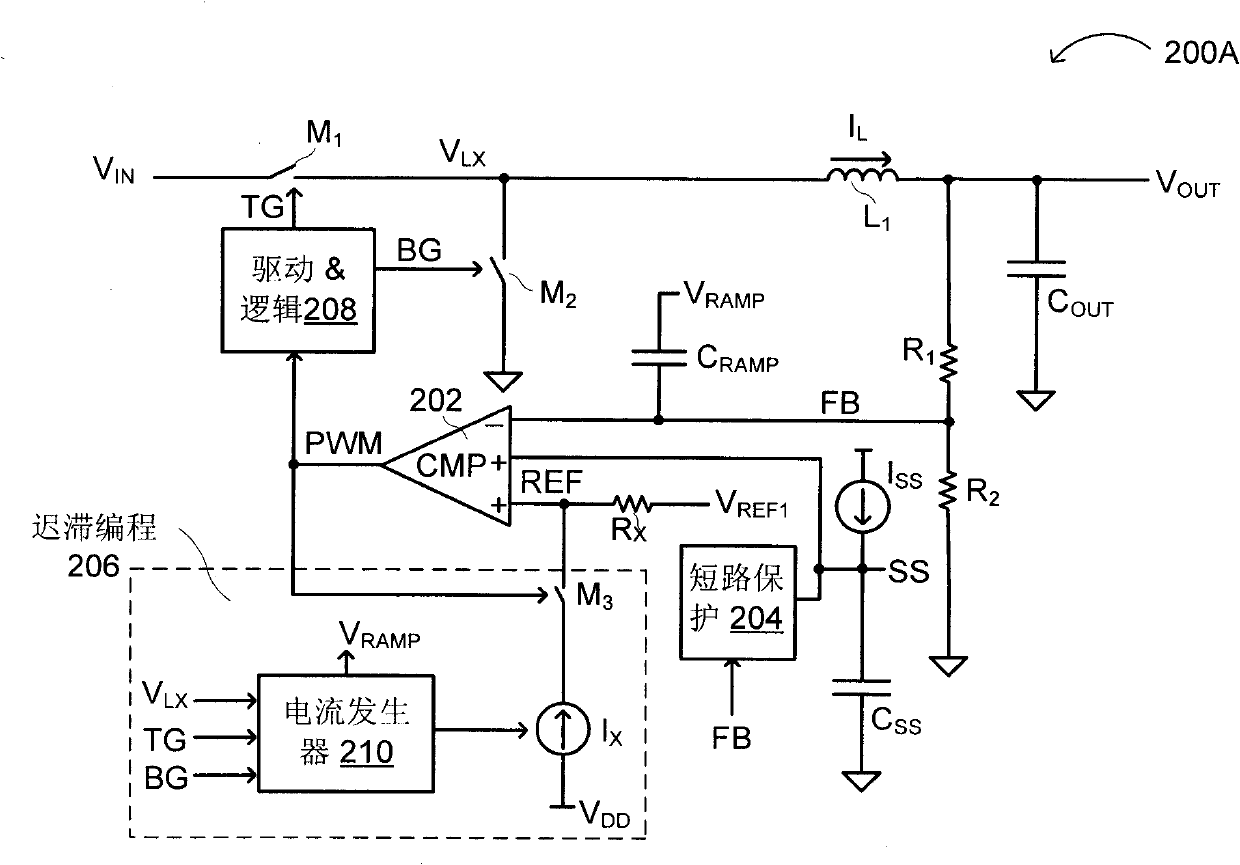

Switch type regulator and control method thereof

ActiveCN101795068ALow costReduce electromagnetic interferenceDc-dc conversionElectric variable regulationConstant frequencyControl signal

The present invention relates to a circuit layout of a switch type regulator and control method thereof. The switch type regulator according to one embodiment of the invention includes: (1) a filter network connected to the output terminal, wherein the output voltage of the output terminal is generated by an input source; (2) an active switch connecting the input source to a wave filter circuit, wherein the active switch is periodically connected and disconnected, and the conducting duty cycle of the switch period is modulated by a PWM control signal; (3) a comparator, which receives output feedback signals, a delay signal and a reference delay, and provides the PWM control signal; (4) a delay programming circuit for generating the delay signal and a ramp control signal, wherein the delay signal is set up based on the status of the input source and the output voltage, to obtain an operating status with fundamentally constant frequency.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

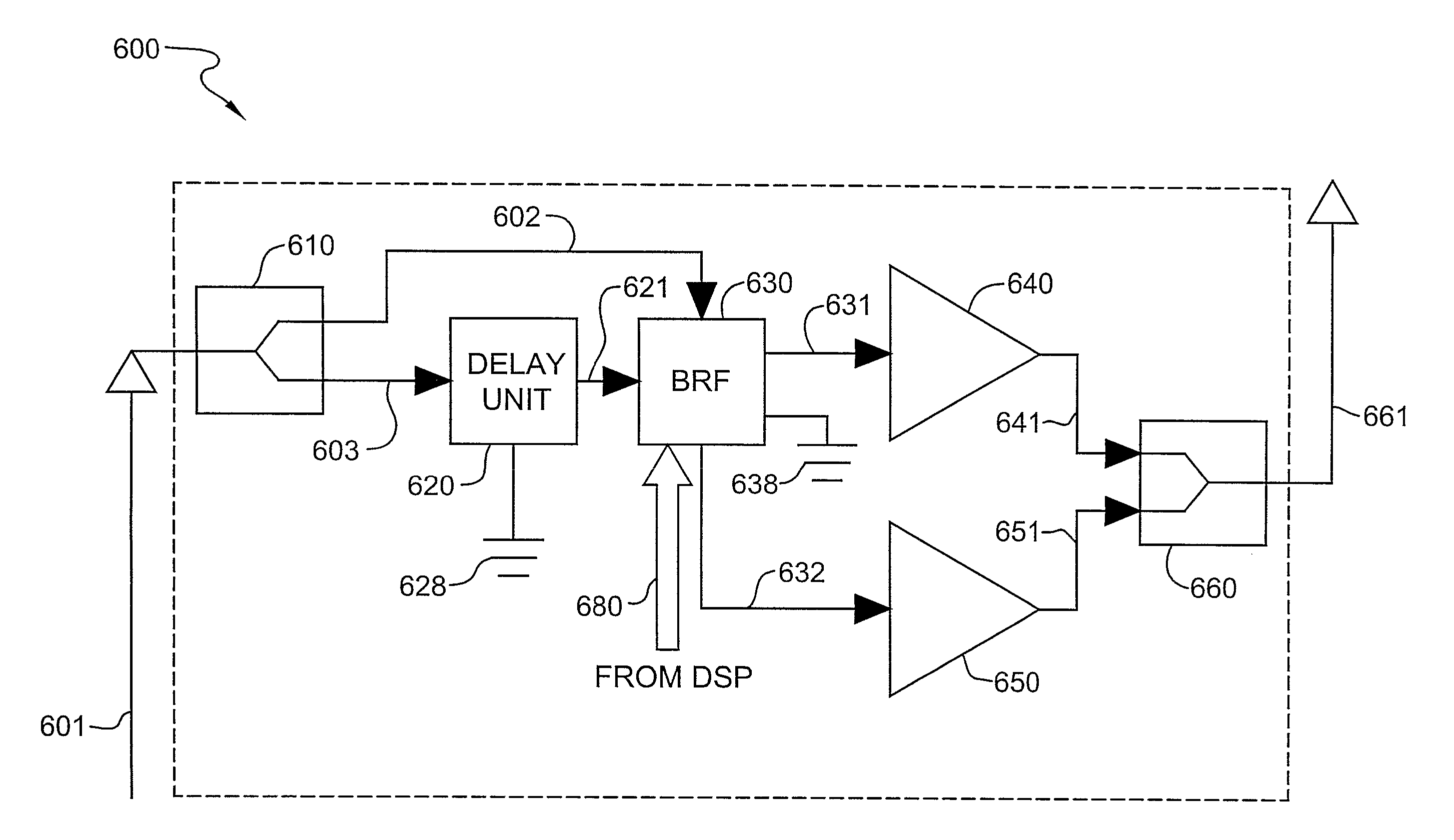

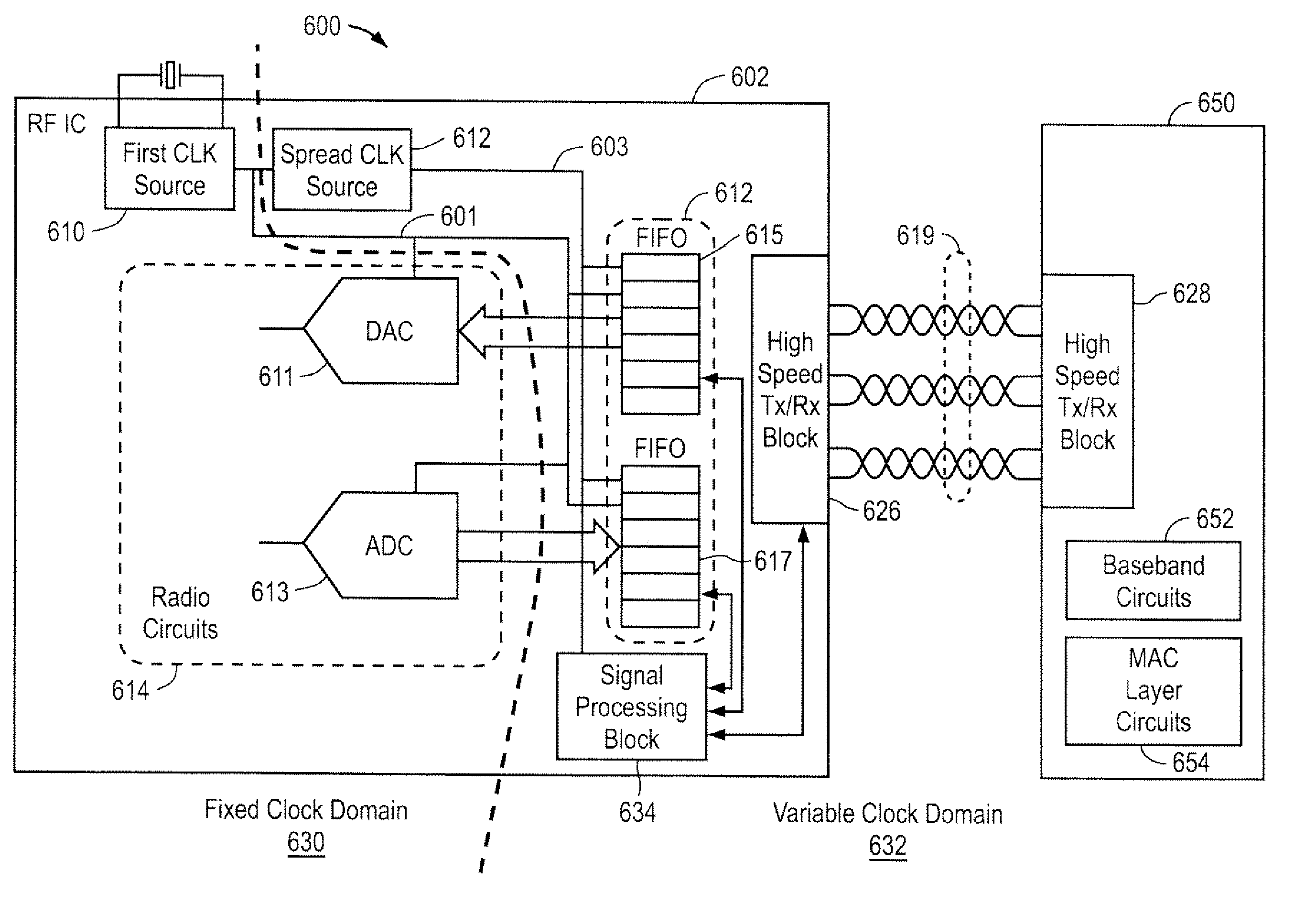

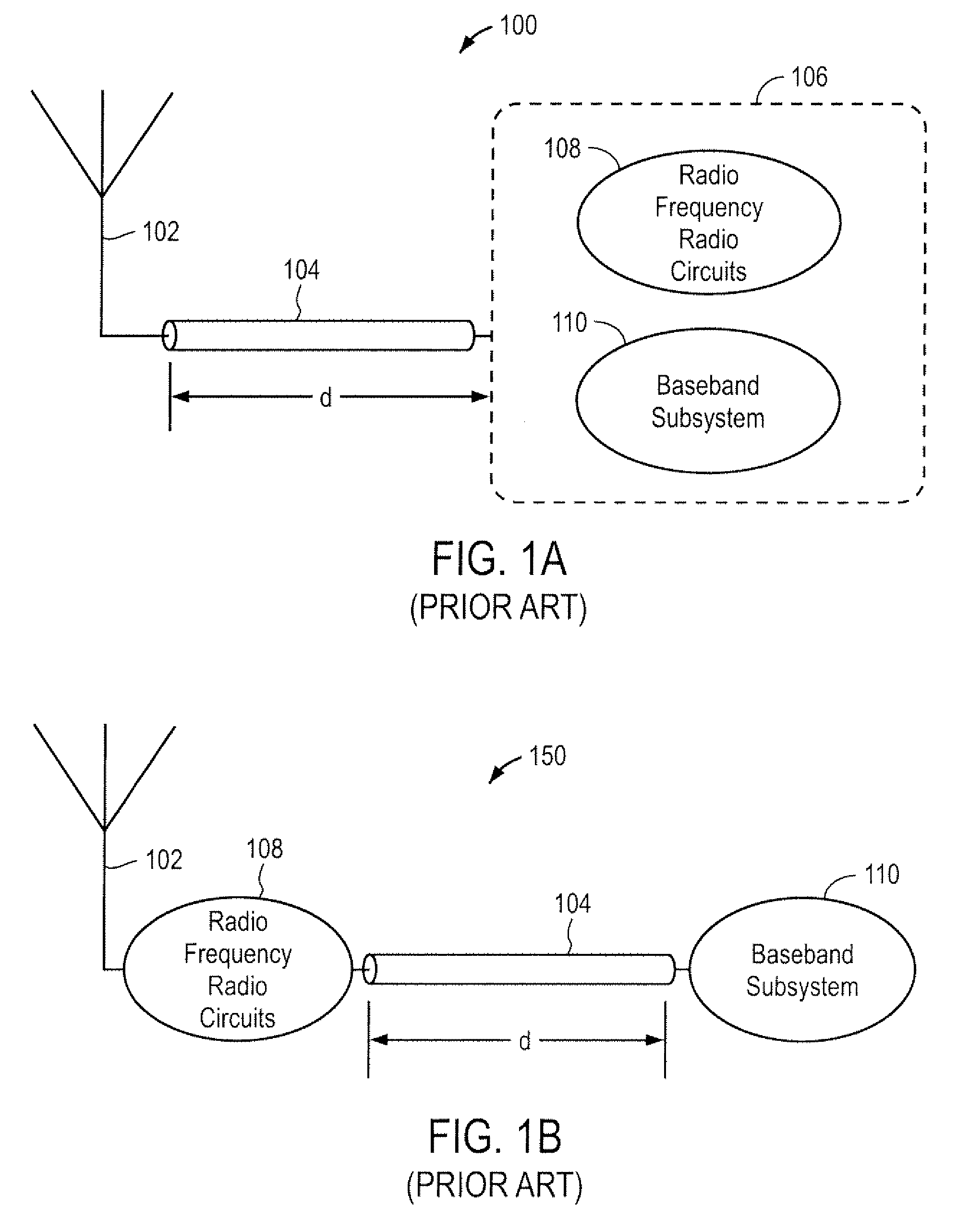

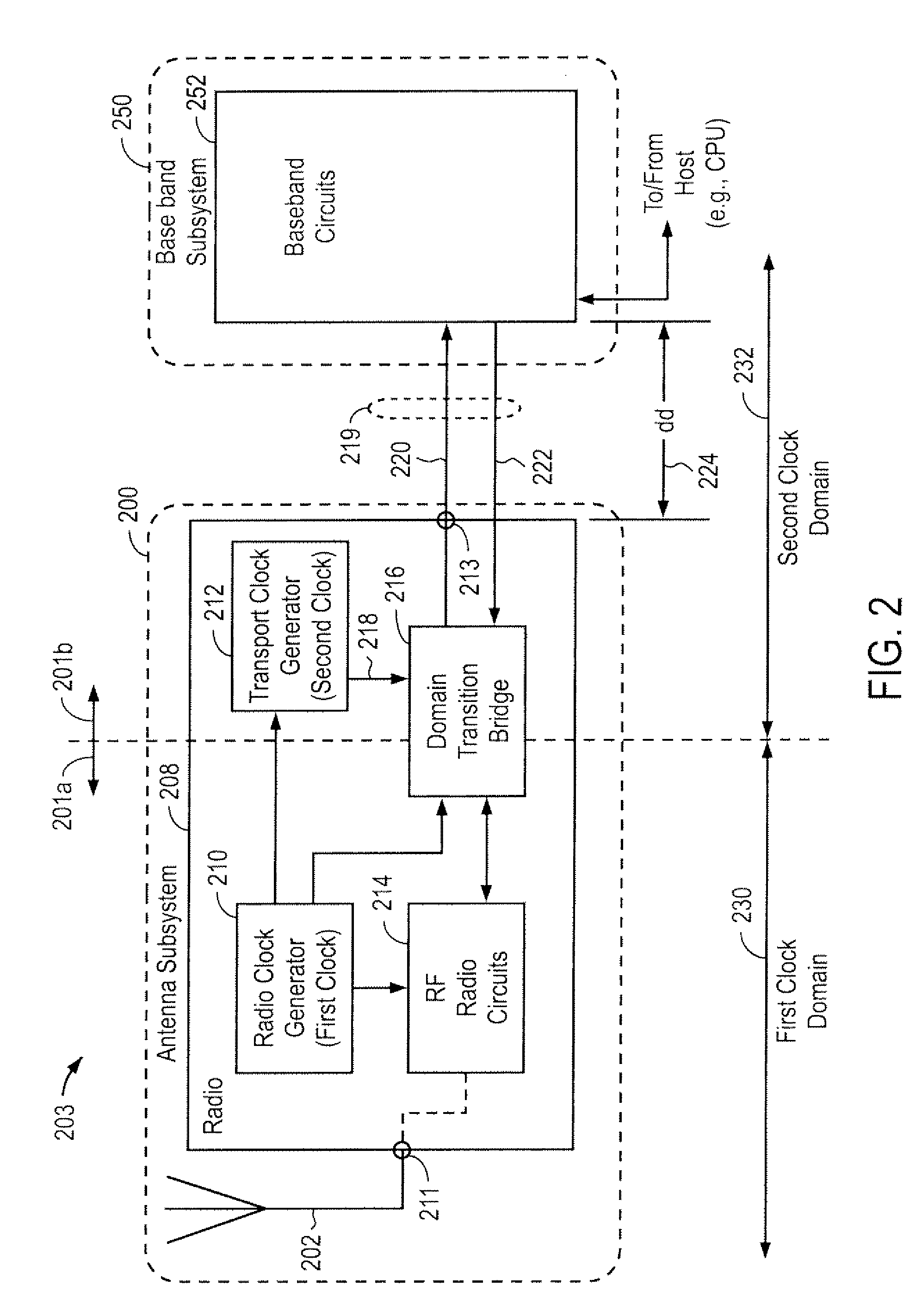

Radio frequency antenna system and high-speed digital data link to reduce electromagnetic interference for wireless communications

ActiveUS7558348B1Reduce electromagnetic interferenceReduce manufacturing complexity associateError preventionPulse automatic controlRadio frequencyFrequency band

A radio frequency antenna system and high-speed digital data link are disclosed to, among other things, reduce electromagnetic interference (“EMI”) at relatively high data rates while reducing the manufacturing complexities associated with conventional data links. In one embodiment, a radio frequency (“RF”) antenna system includes an antenna and an RF radio coupled to the antenna for receiving wireless RF signals. In particular, the RF radio is configured to digitize RF signals at a fixed data rate to form digitized data signals and to apply the digitized data signals at a variable data rate to a high-speed digital link. The variable data rate distributes the signal energy of the digitized data signals over one or more bands of frequencies, thereby beneficially altering an EMI spectral profile describing emissions that develop as the digitized data signals are transported through a channel.

Owner:NVIDIA CORP

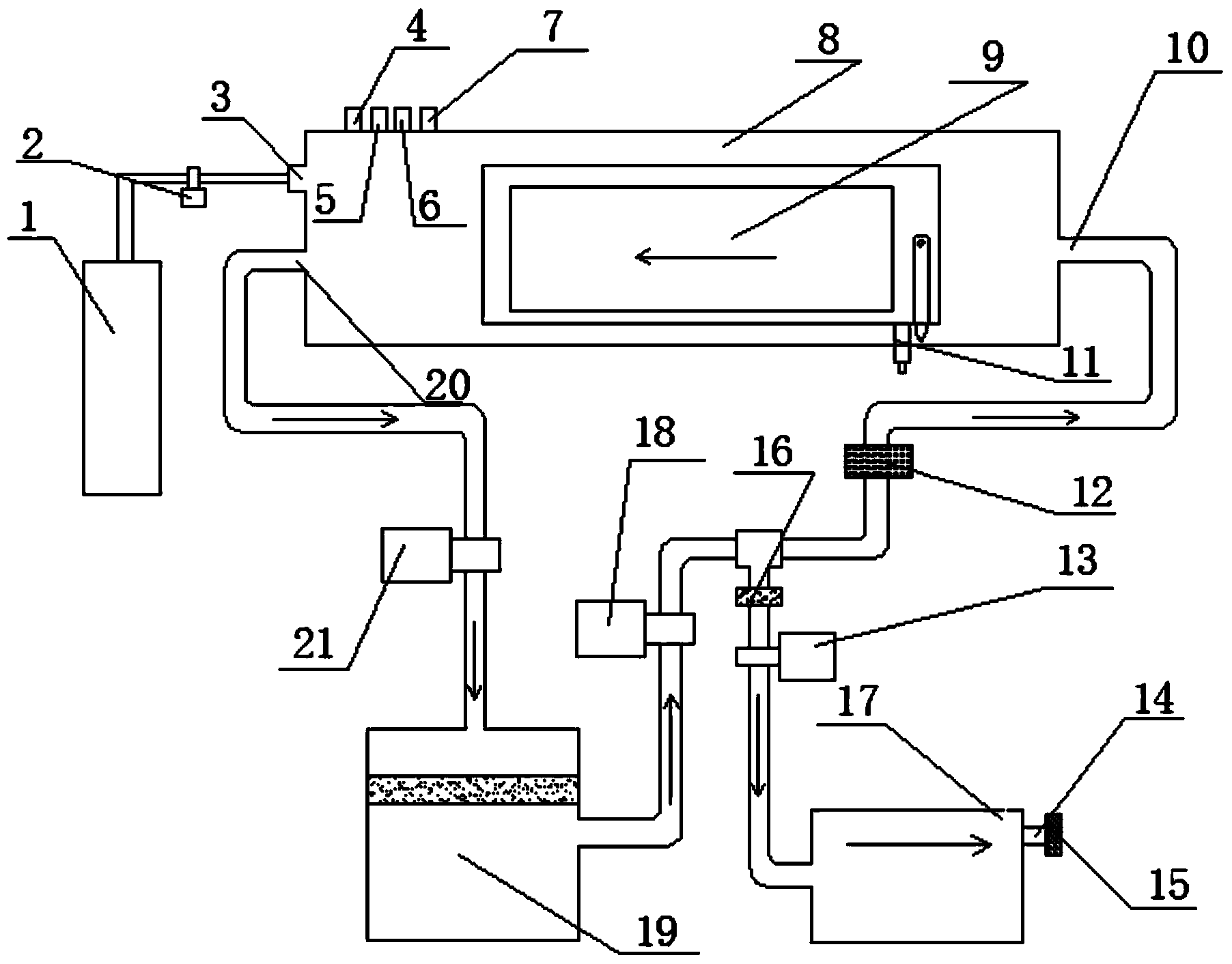

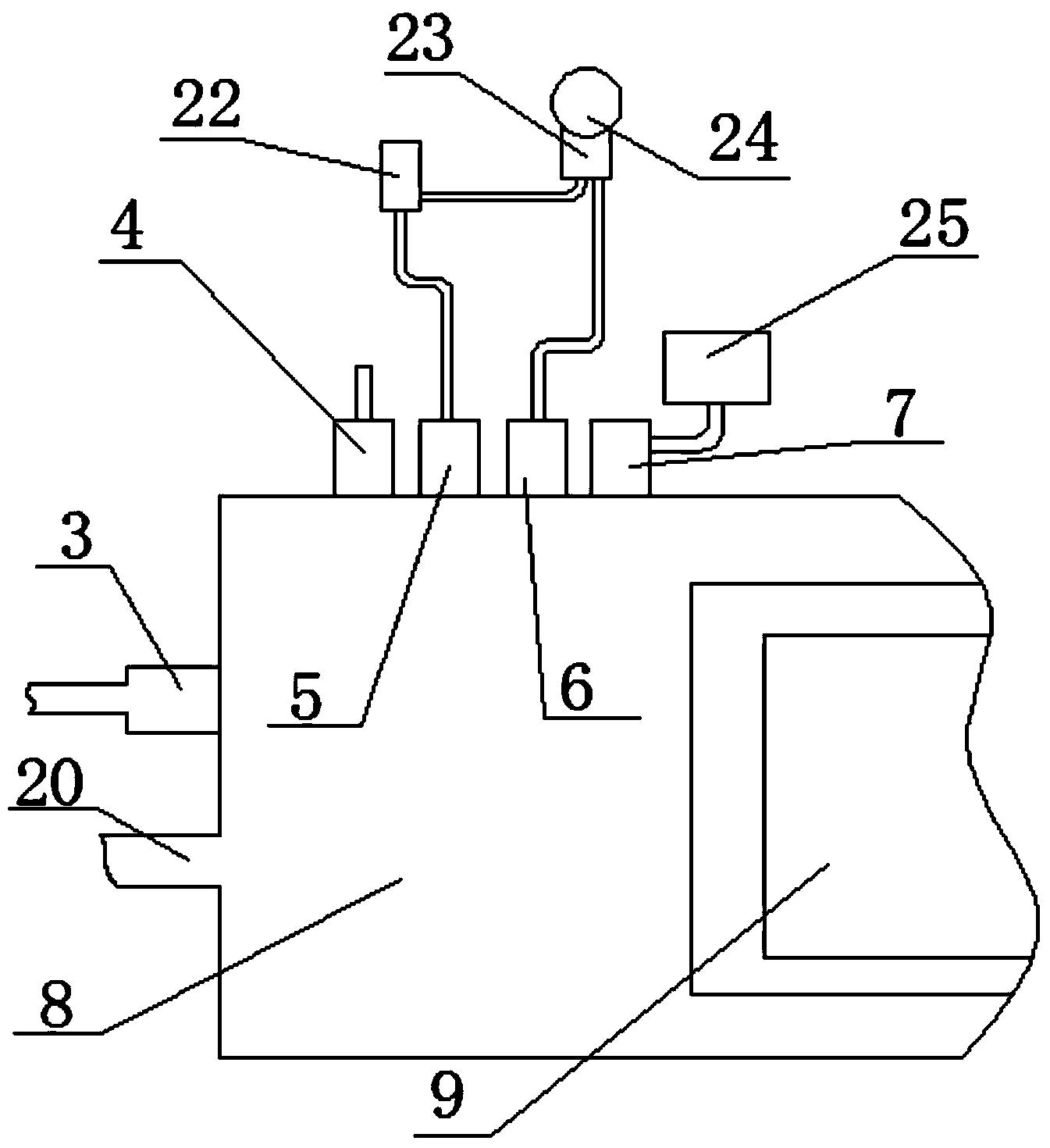

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

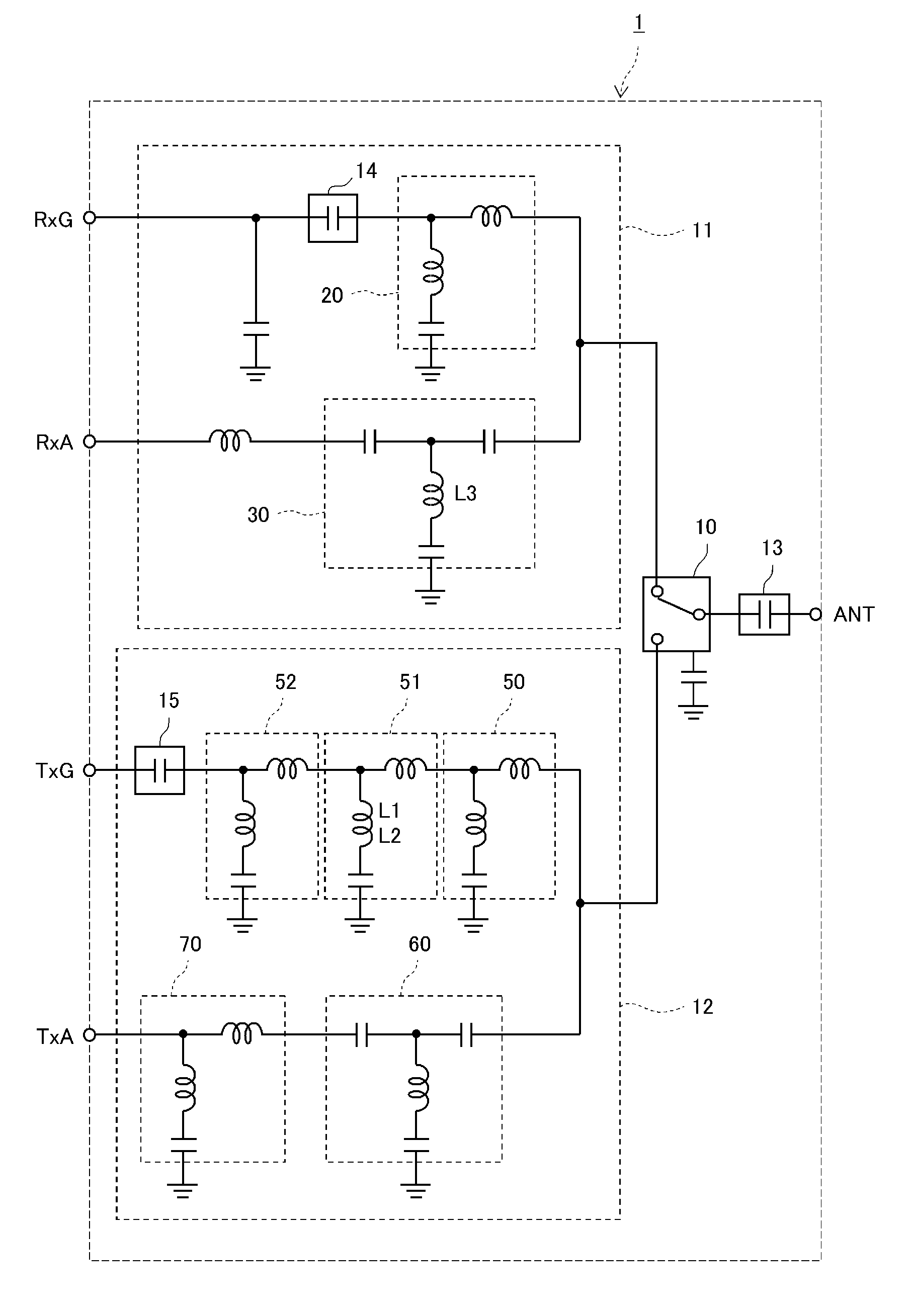

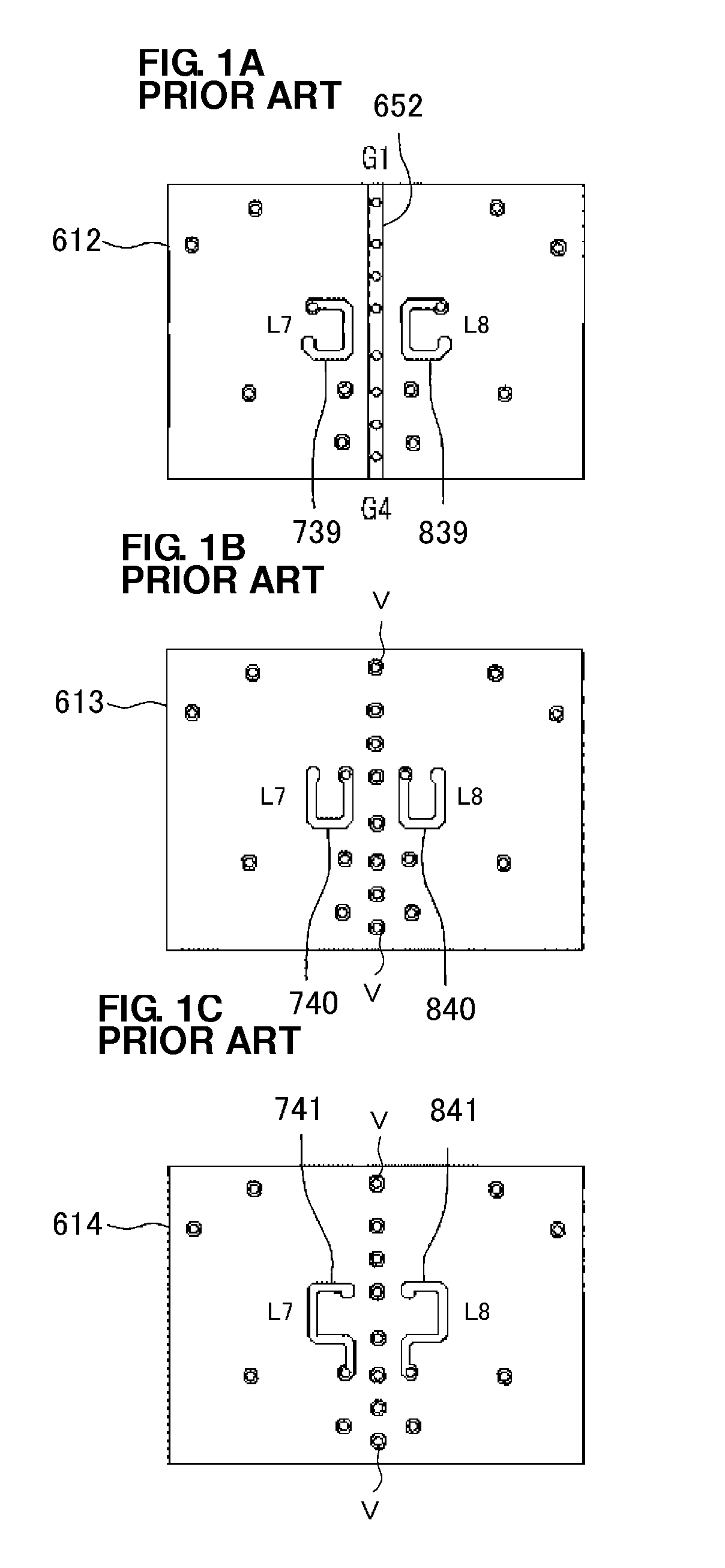

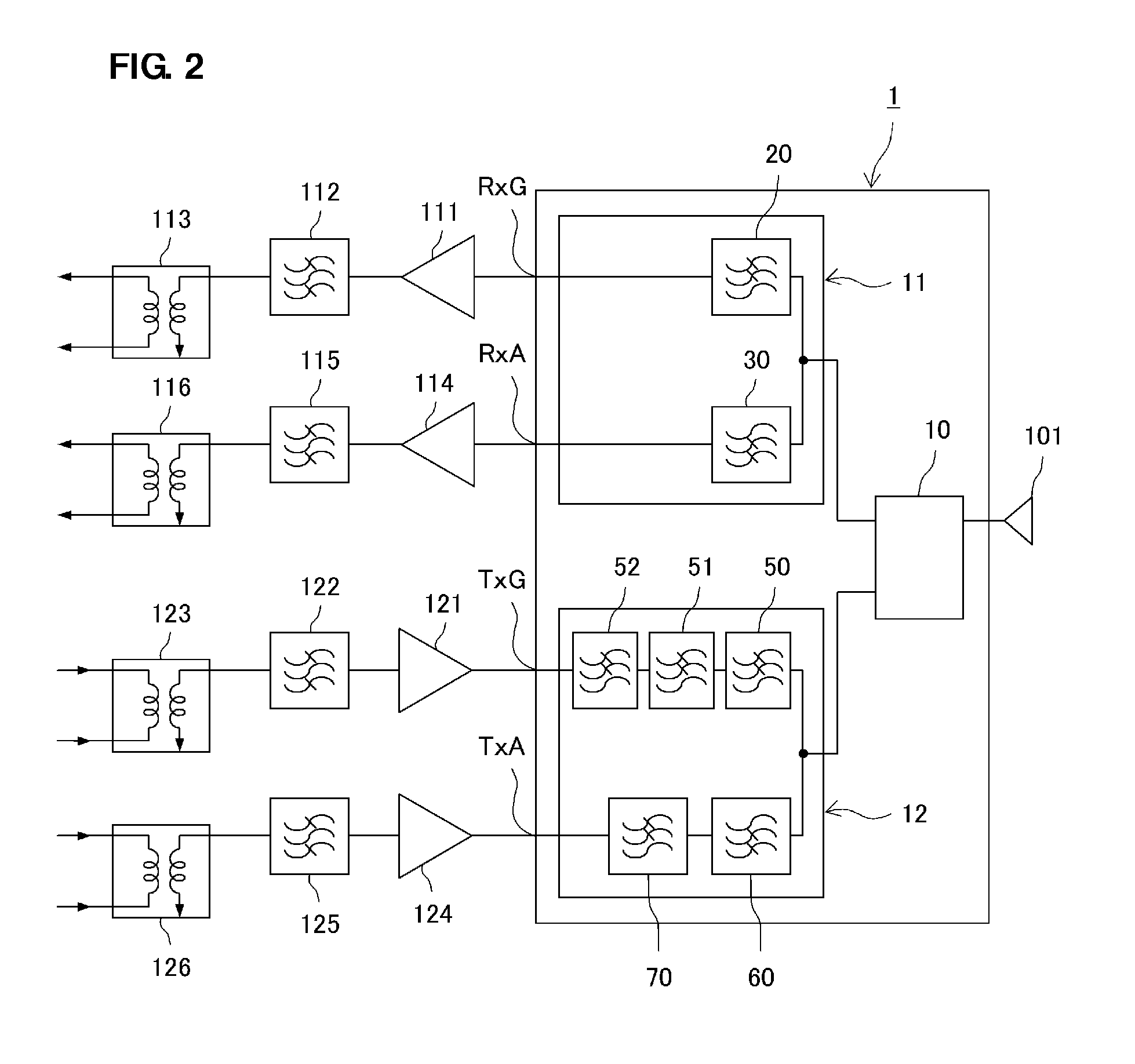

Branching device

ActiveUS20120081192A1Reduce electromagnetic interferenceReduce problem sizeMultiple-port networksTransmissionElectrical conductorInductor

In a branching device, an LPF includes a first inductor arranged such that some conductor layers from among conductor layers are wound in a clockwise direction, and a second inductor arranged such that a conductor layer from among the conductor layers is wound in an counterclockwise direction. In addition, an HPF includes a third inductor arranged such that conductor layers are wound in the same clockwise direction as the first inductor. Therefore, when a high-frequency signal passes through the LPF, a winding direction is reversed. In addition, when a high-frequency signal passes through the HPF, a winding direction is reversed.

Owner:MURATA MFG CO LTD

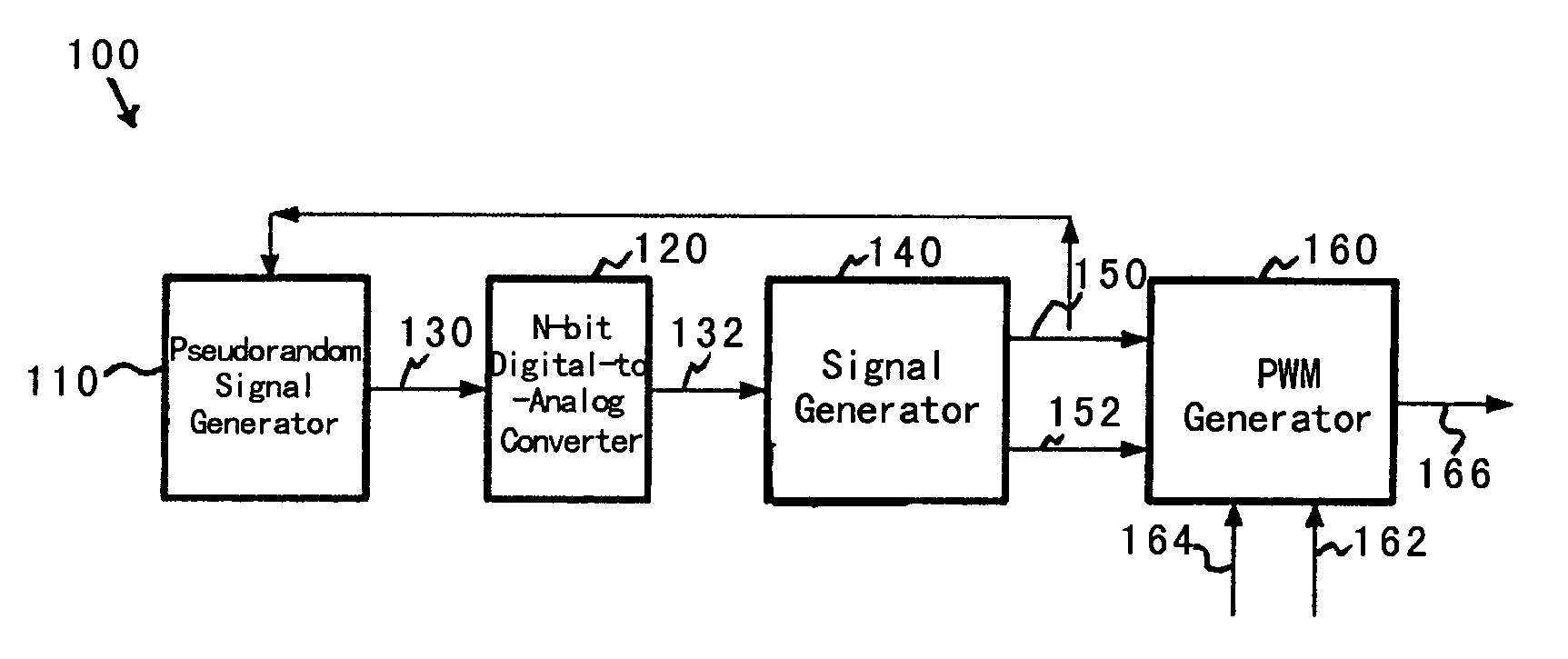

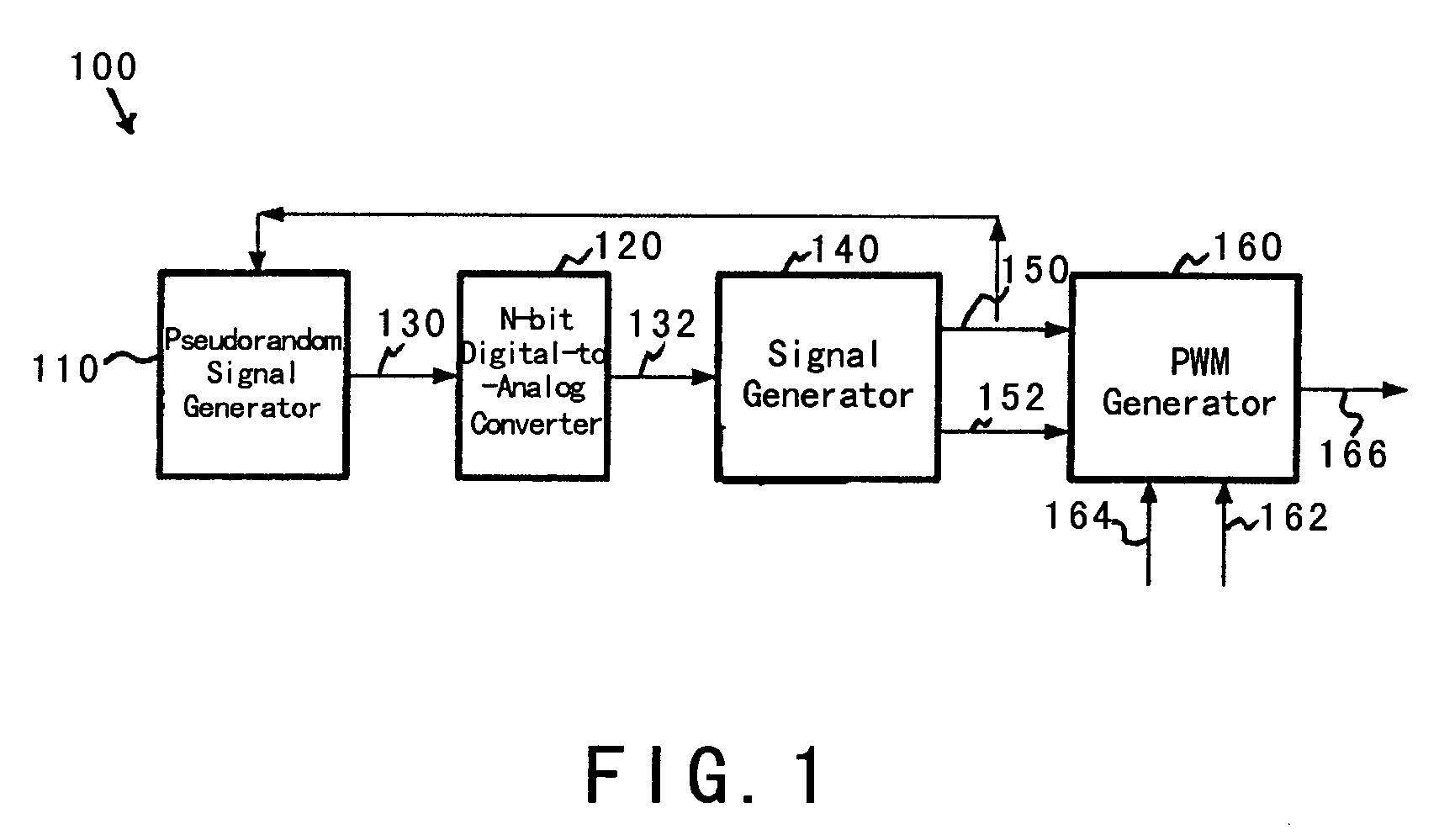

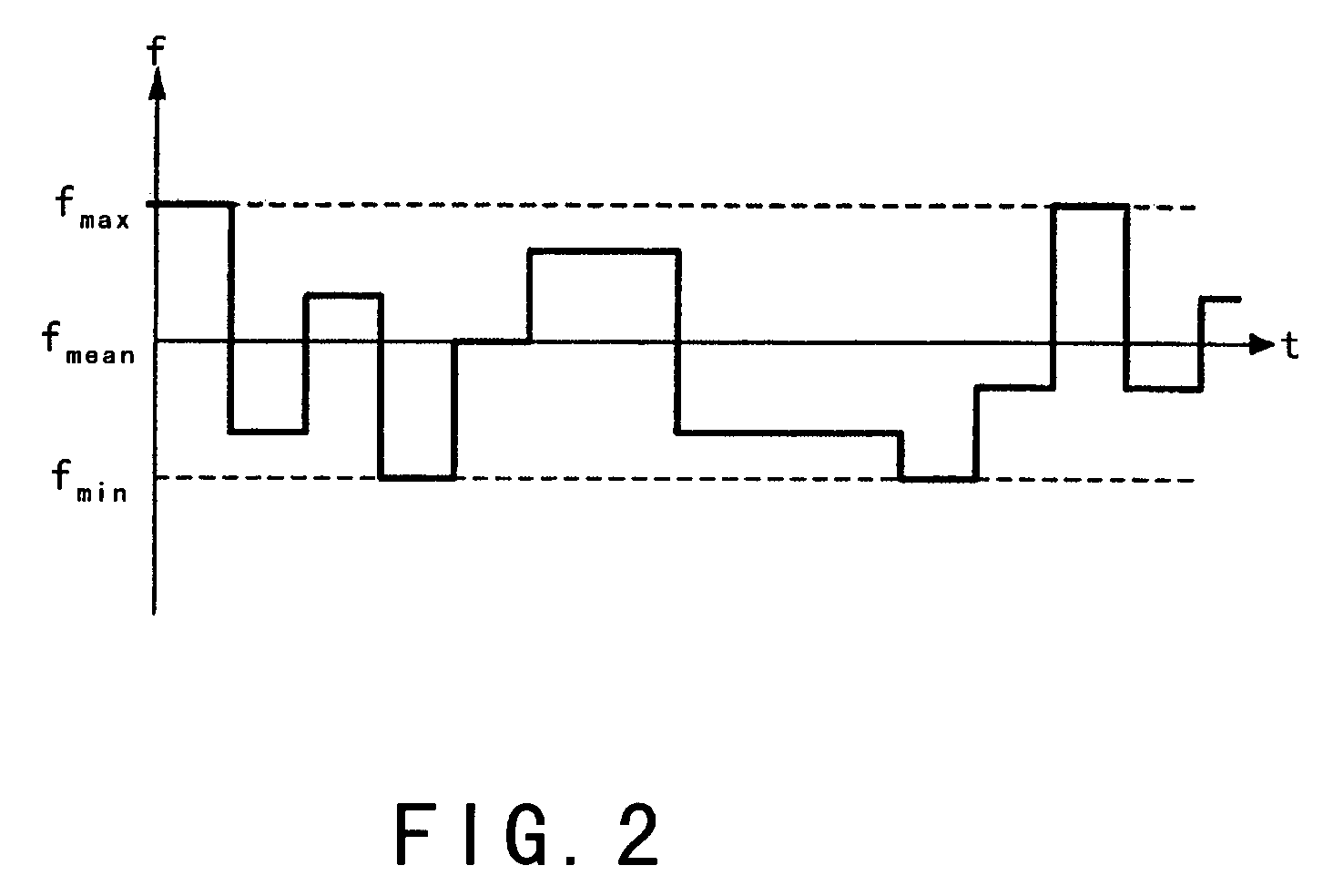

System and method for controlling variations of switching frequency

ActiveUS20060221646A1Reduce electromagnetic interferenceEasy to migrateRandom number generatorsAc-dc conversionControl signalSwitching frequency

System and method for providing frequency control to a power converter. The system includes a pseudorandom signal generator configured to generate a digital signal. The digital signal is associated with at least an N-bit datum, and N is a positive integer. Additionally, the system includes a digital-to-analog converter configured to receive the digital signal and generate a first control signal, an output signal generator configured to receive the first control signal and generate at least a first output signal associated with a frequency, and a pulse-width-modulation generator configured to receive at least the first output signal. The N-bit datum represents a pseudorandom number.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

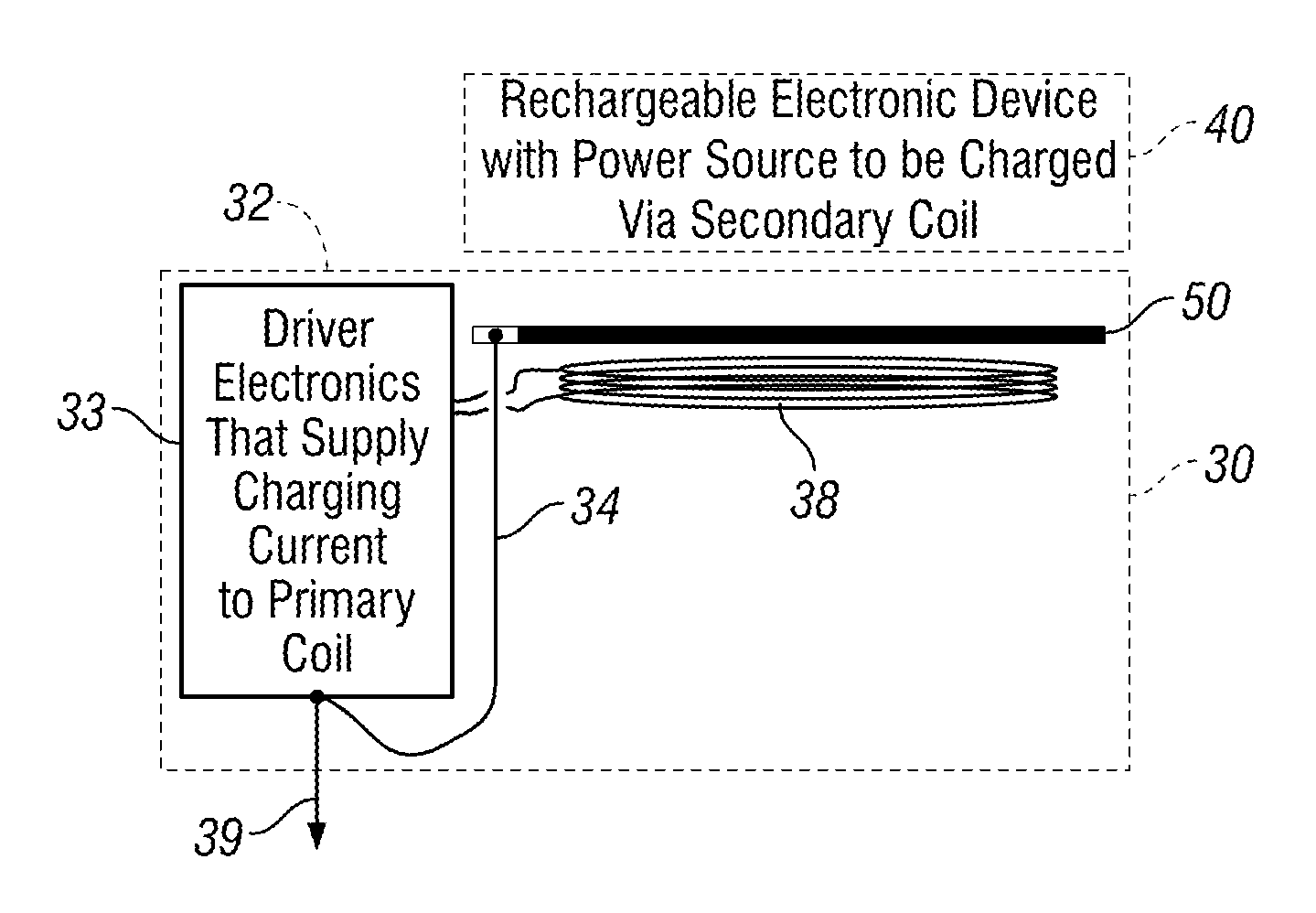

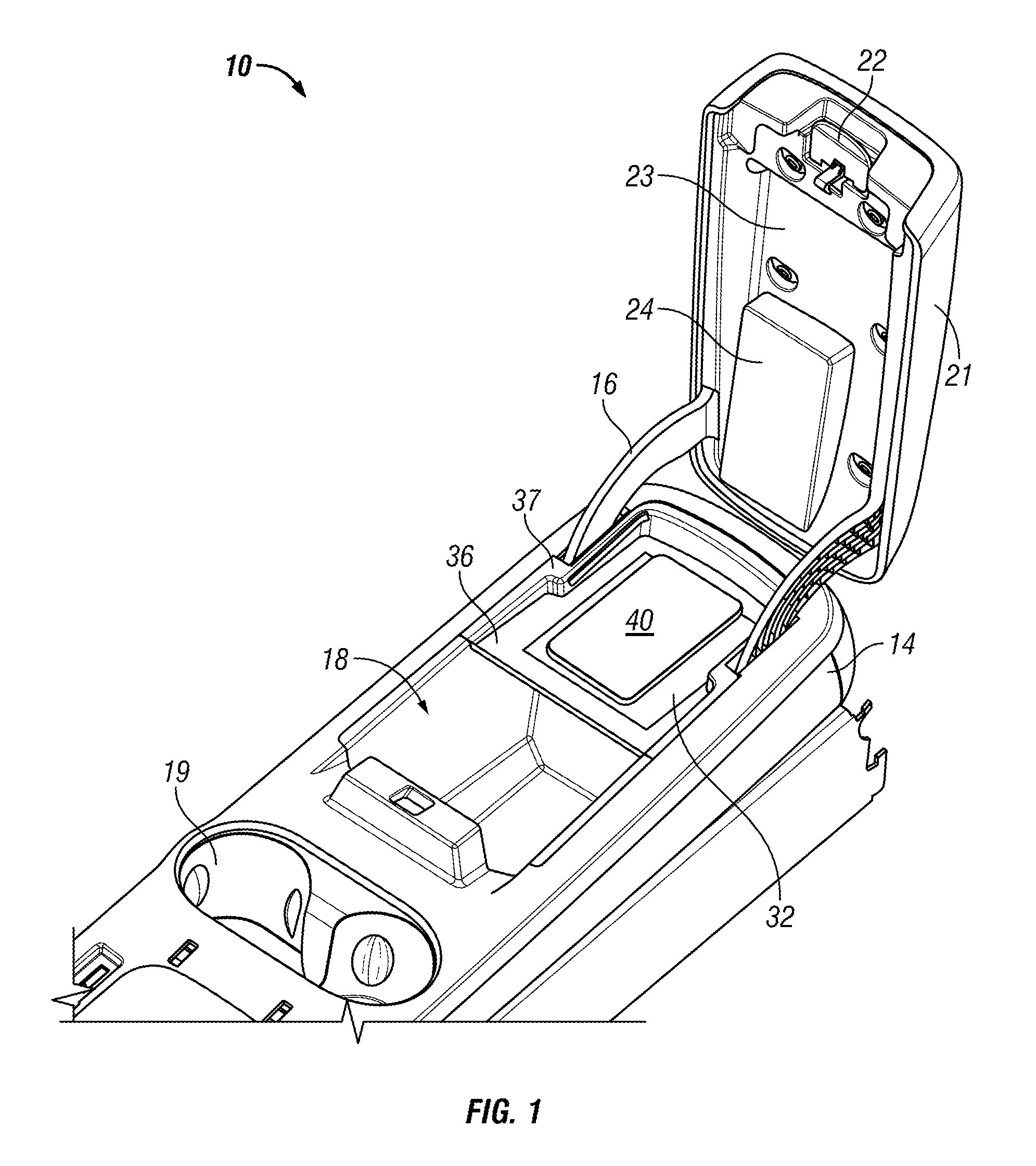

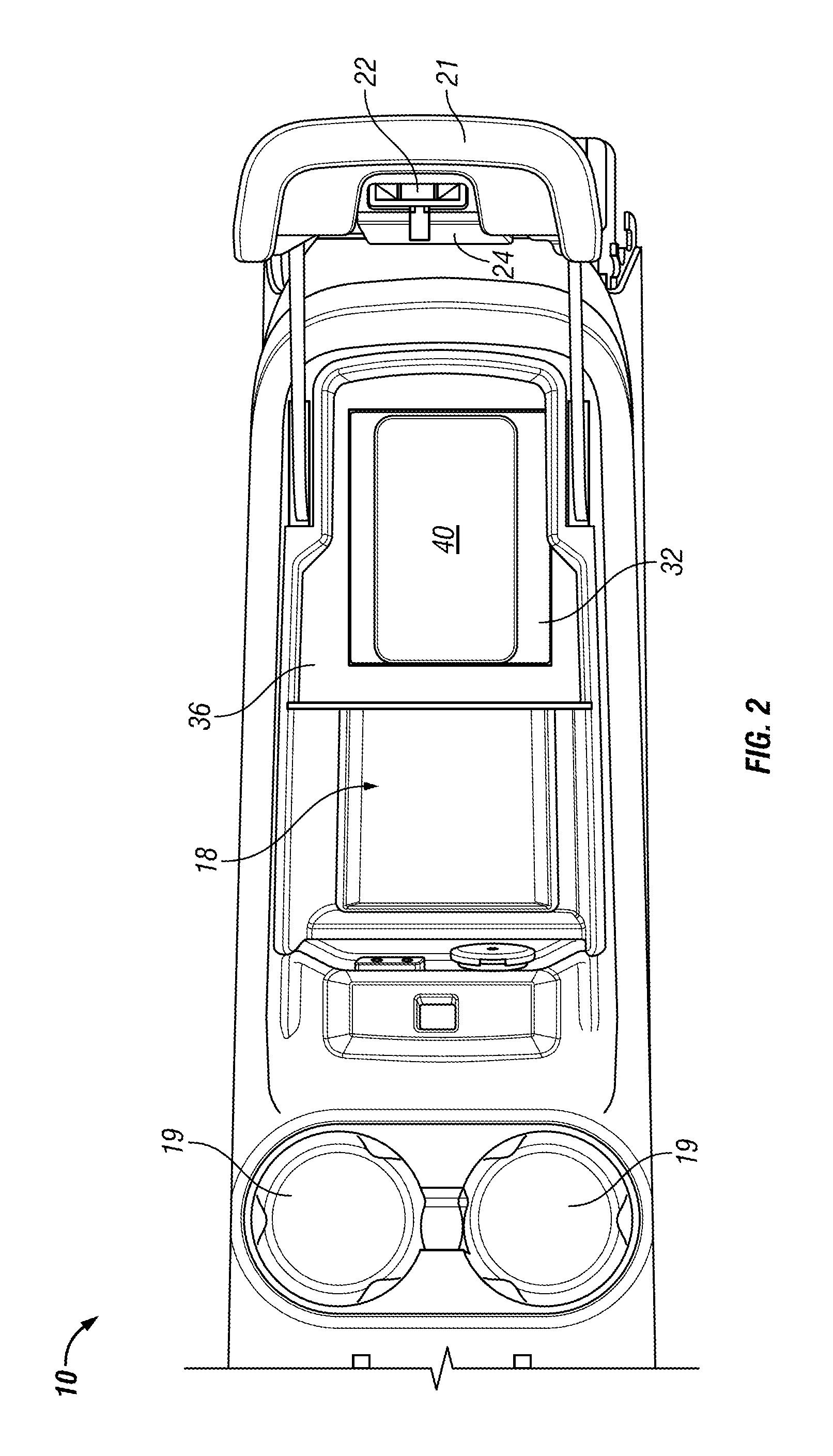

Wireless battery charging apparatus mounted in a vehicle designed to reduce electromagnetic interference

ActiveUS9018904B2Reducing and preventing electromagnetic interferenceReduce electromagnetic interferenceLocalised screeningBatteries circuit arrangementsBattery chargeElectromagnetic interference

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com