Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

883results about How to "Reduce problem size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

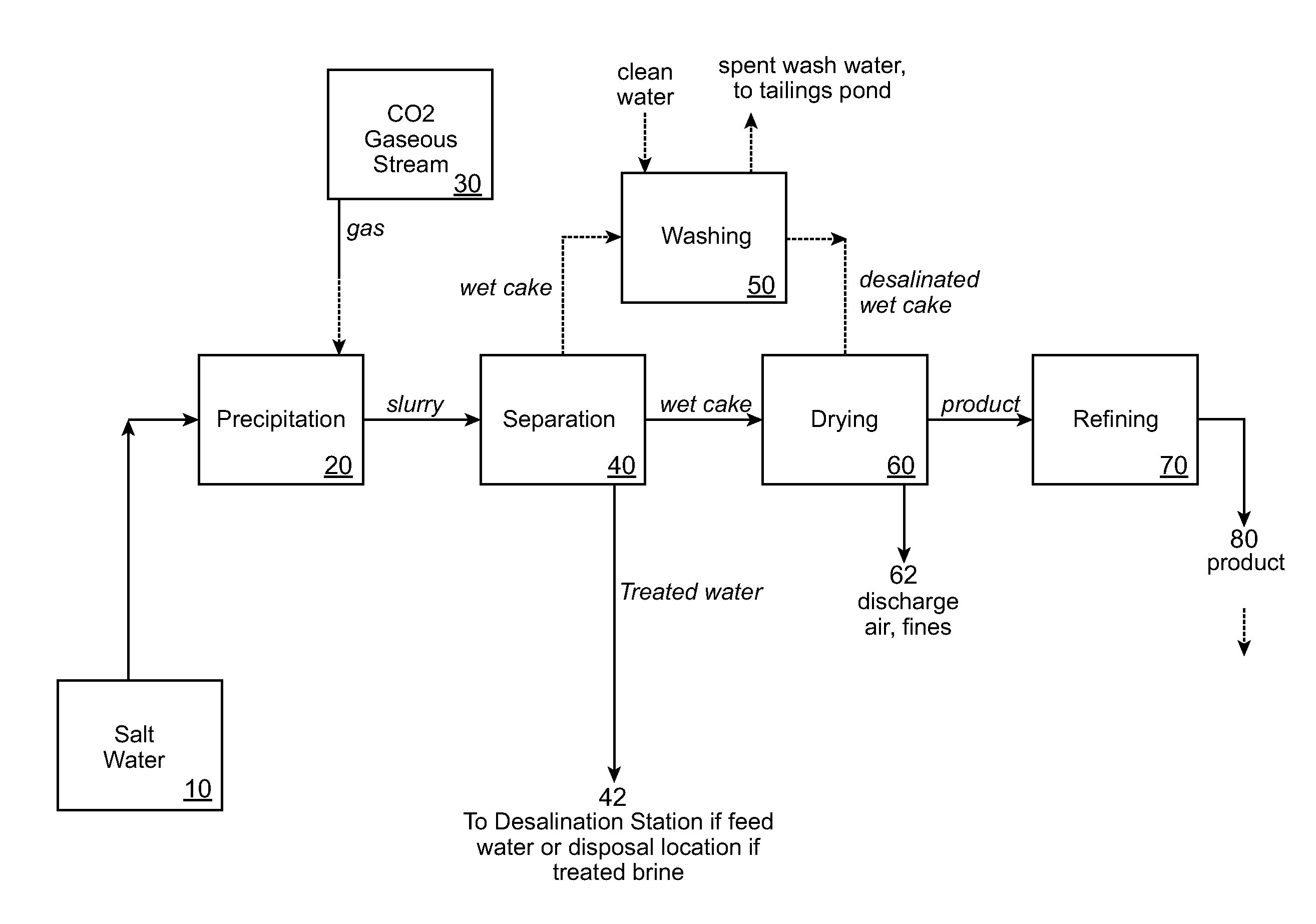

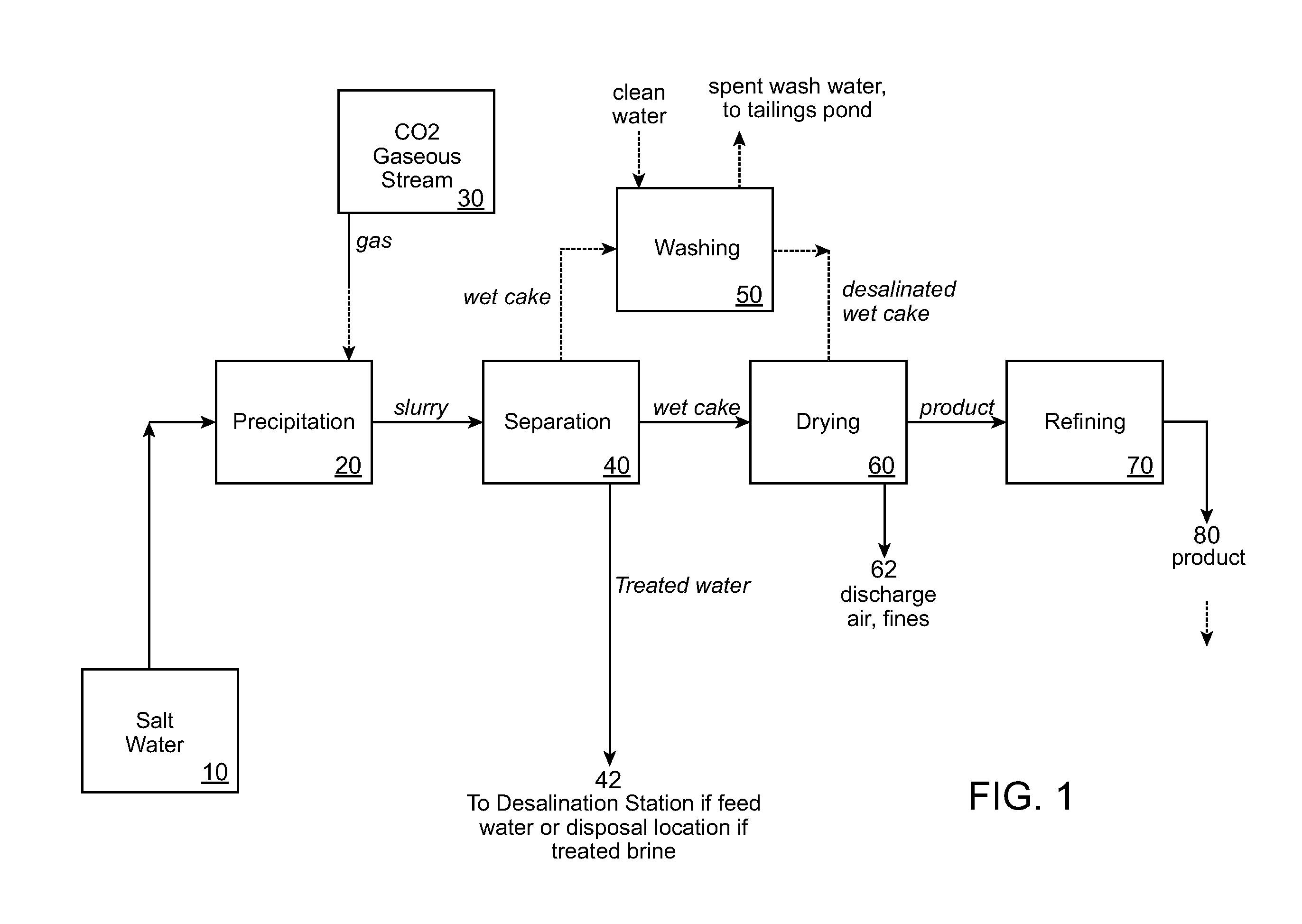

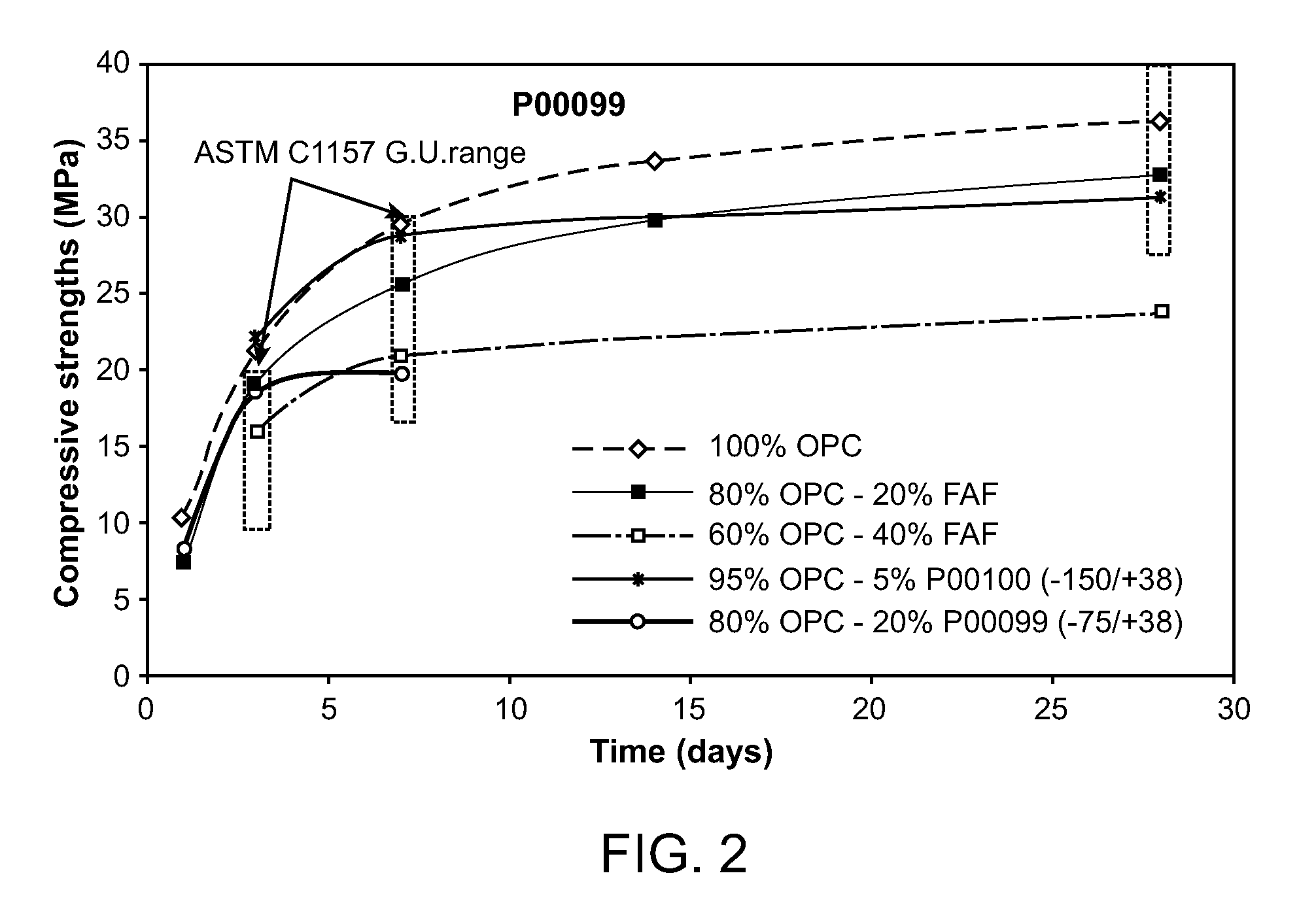

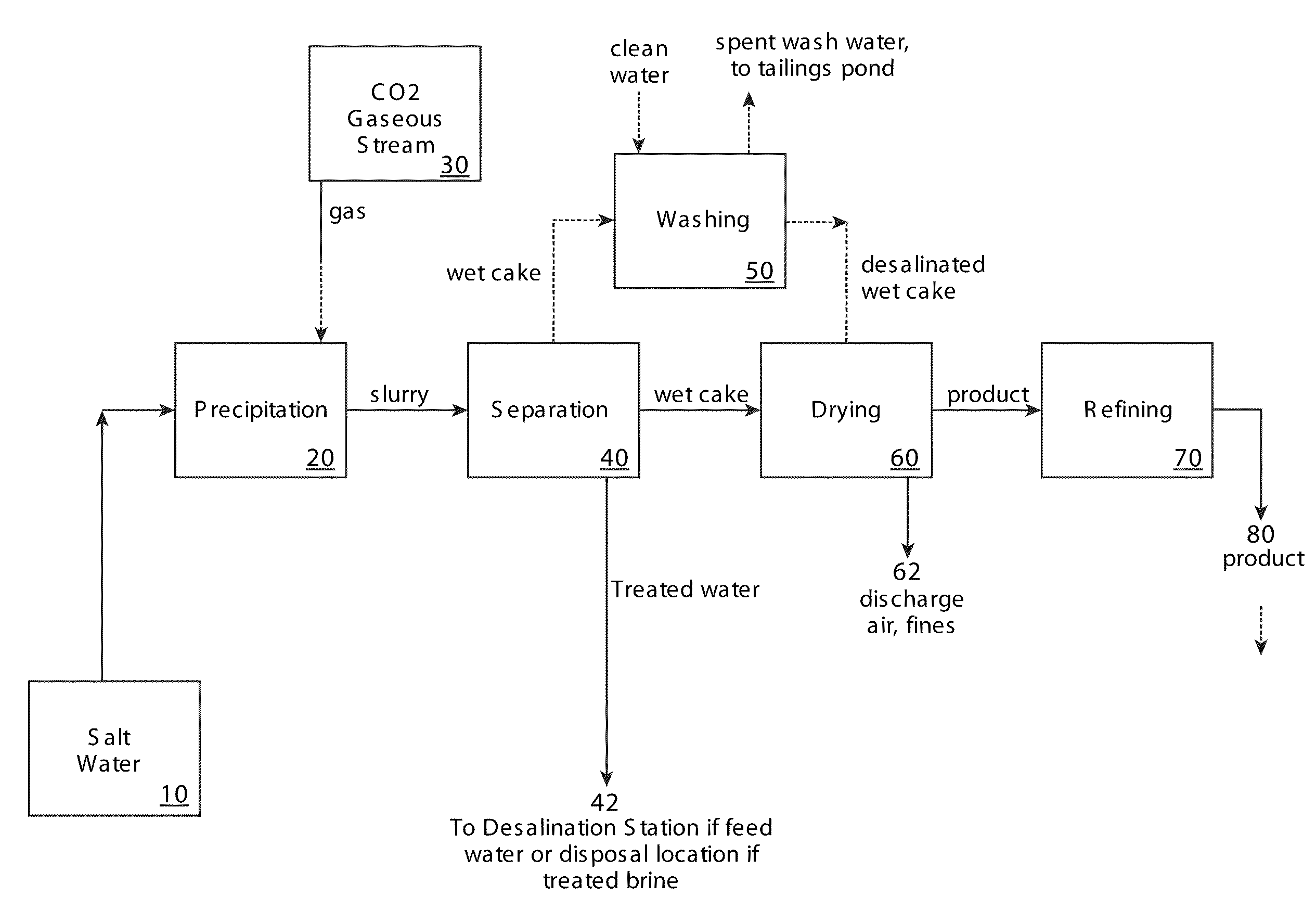

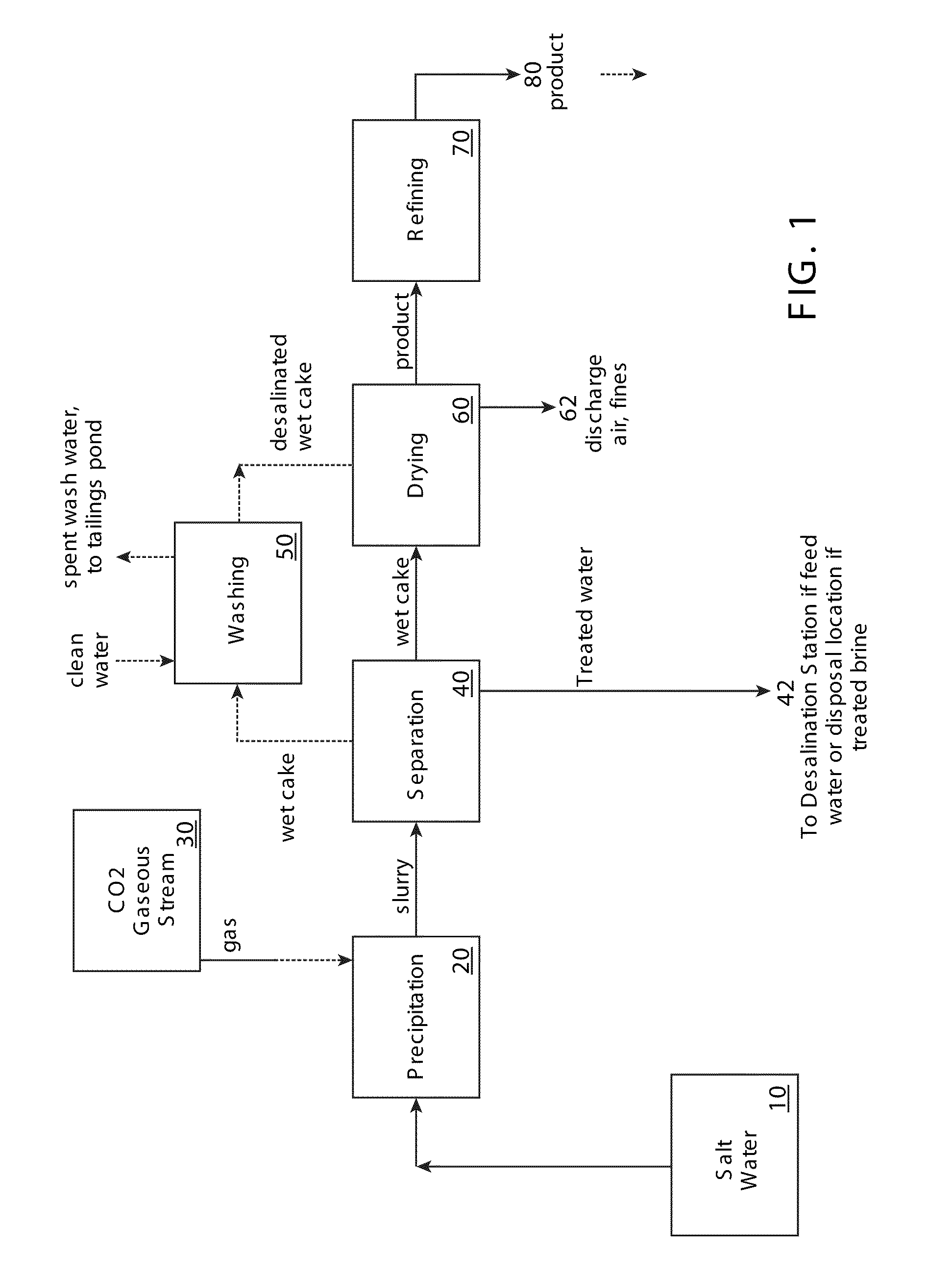

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

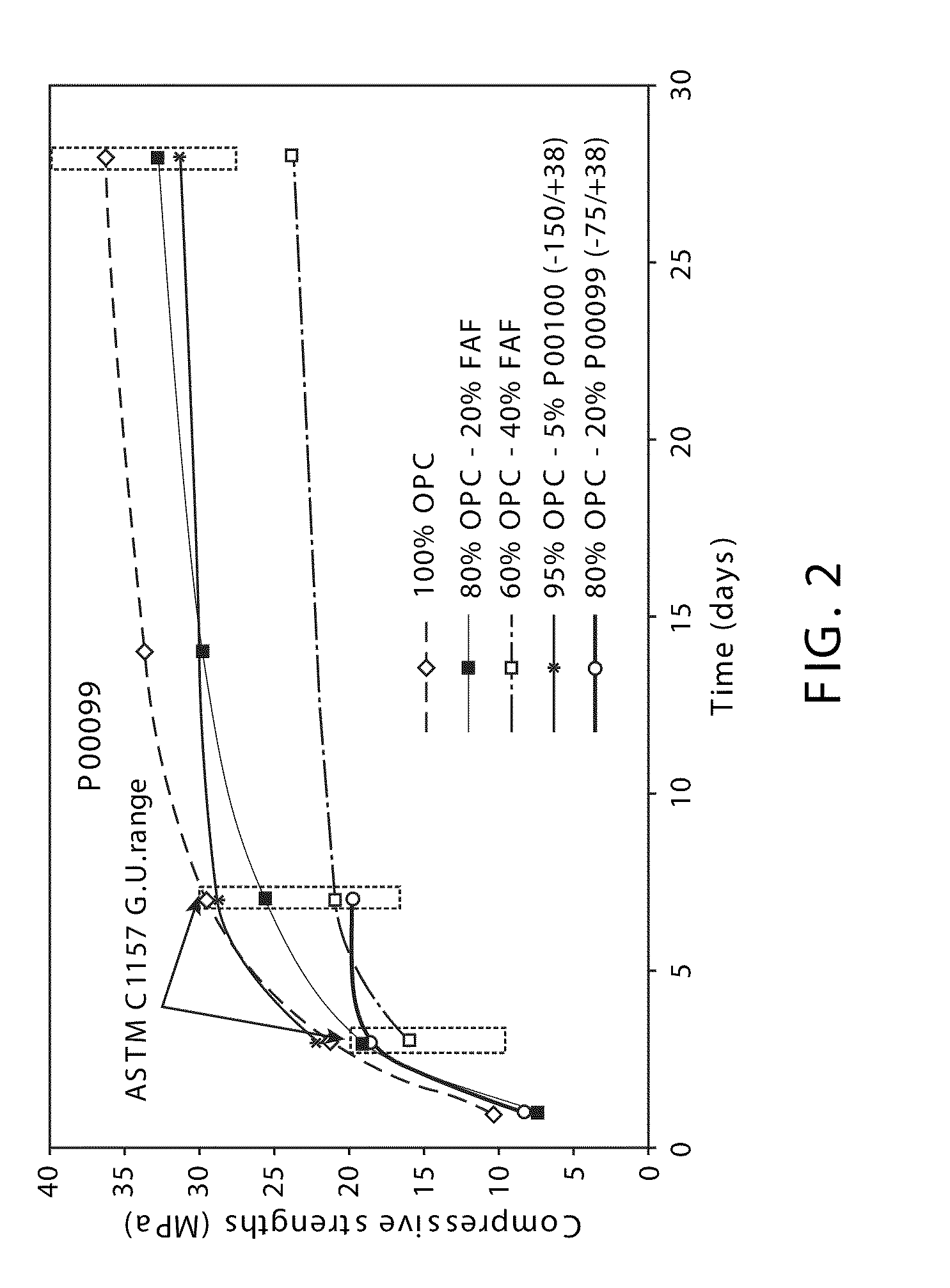

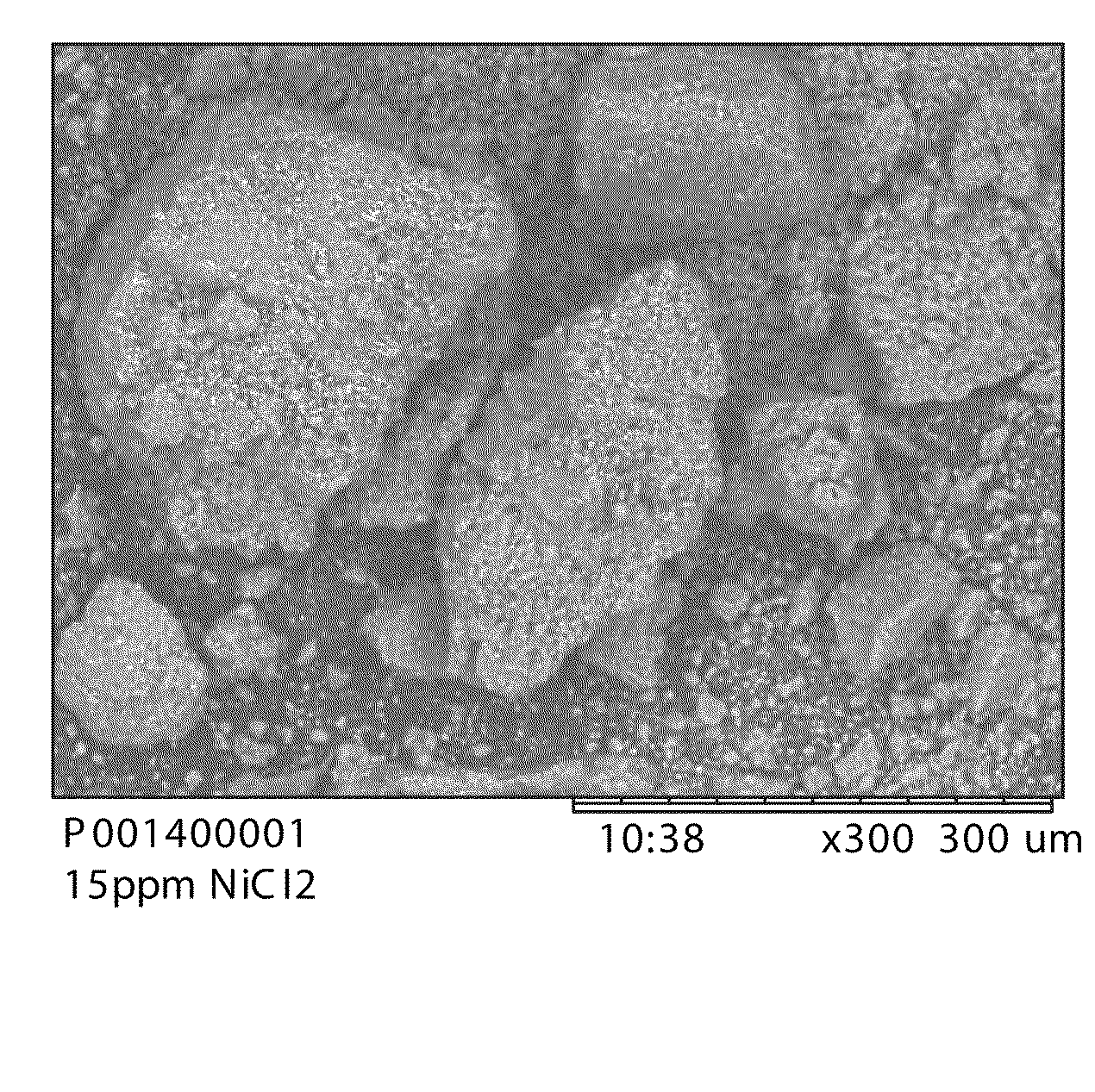

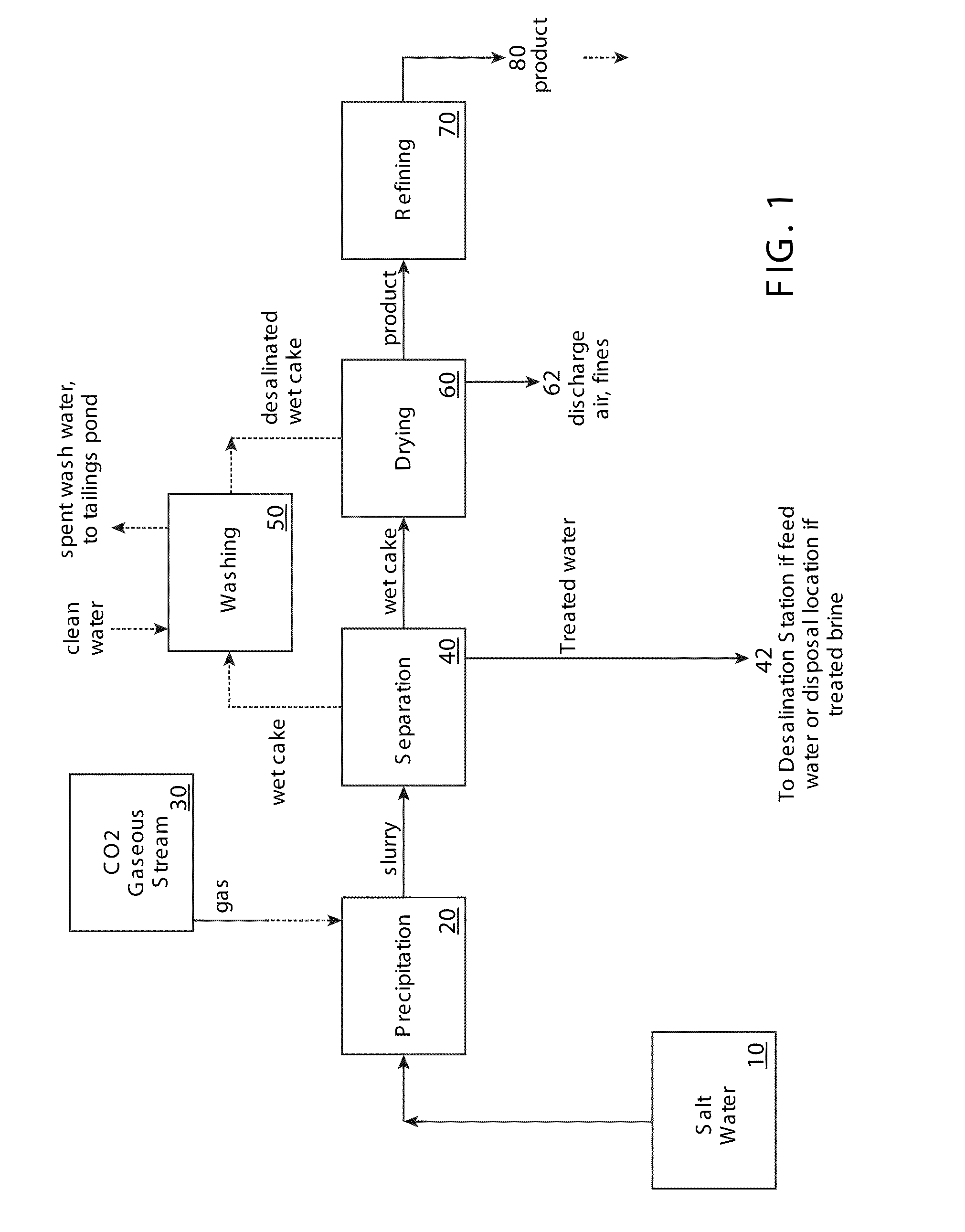

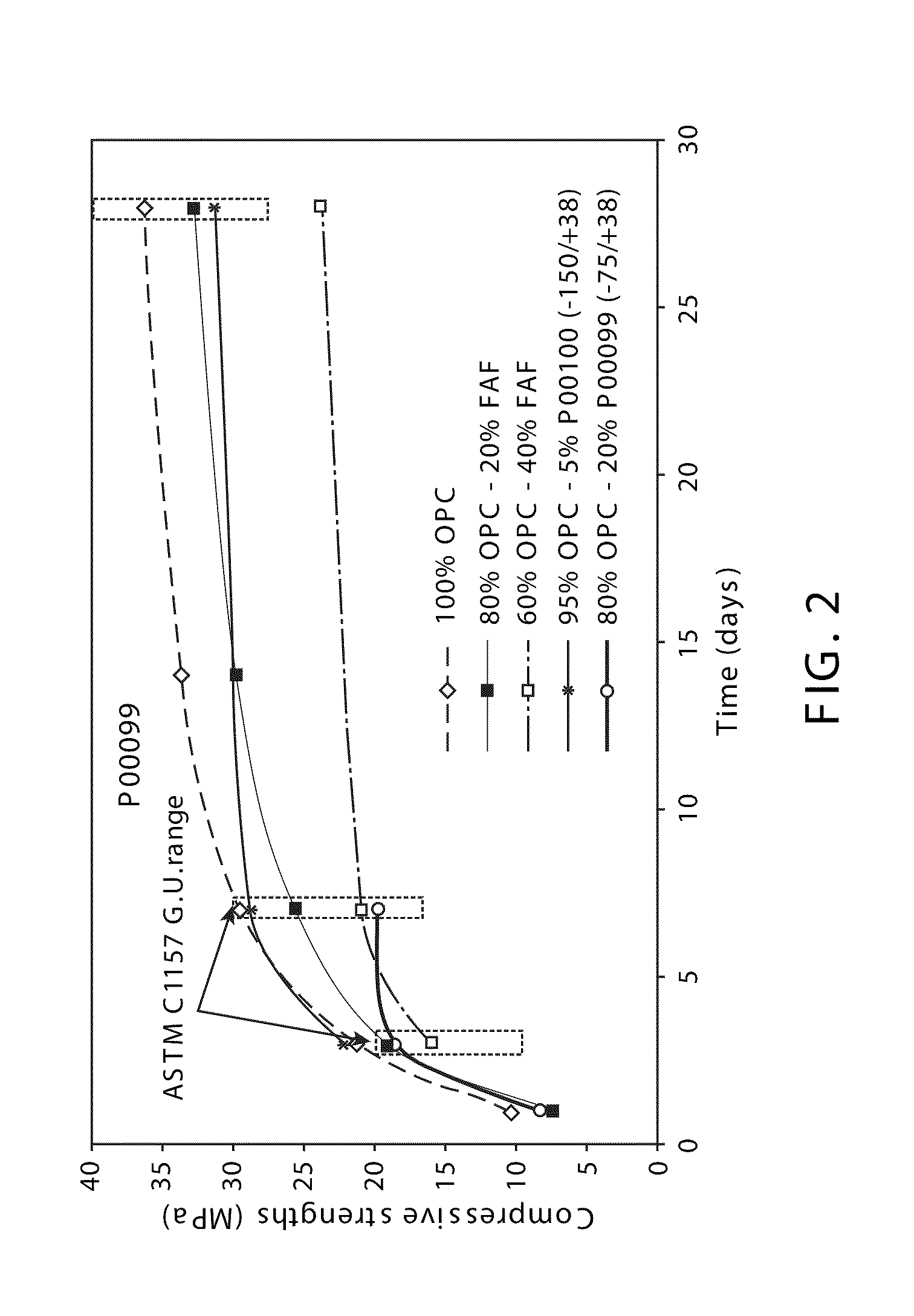

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

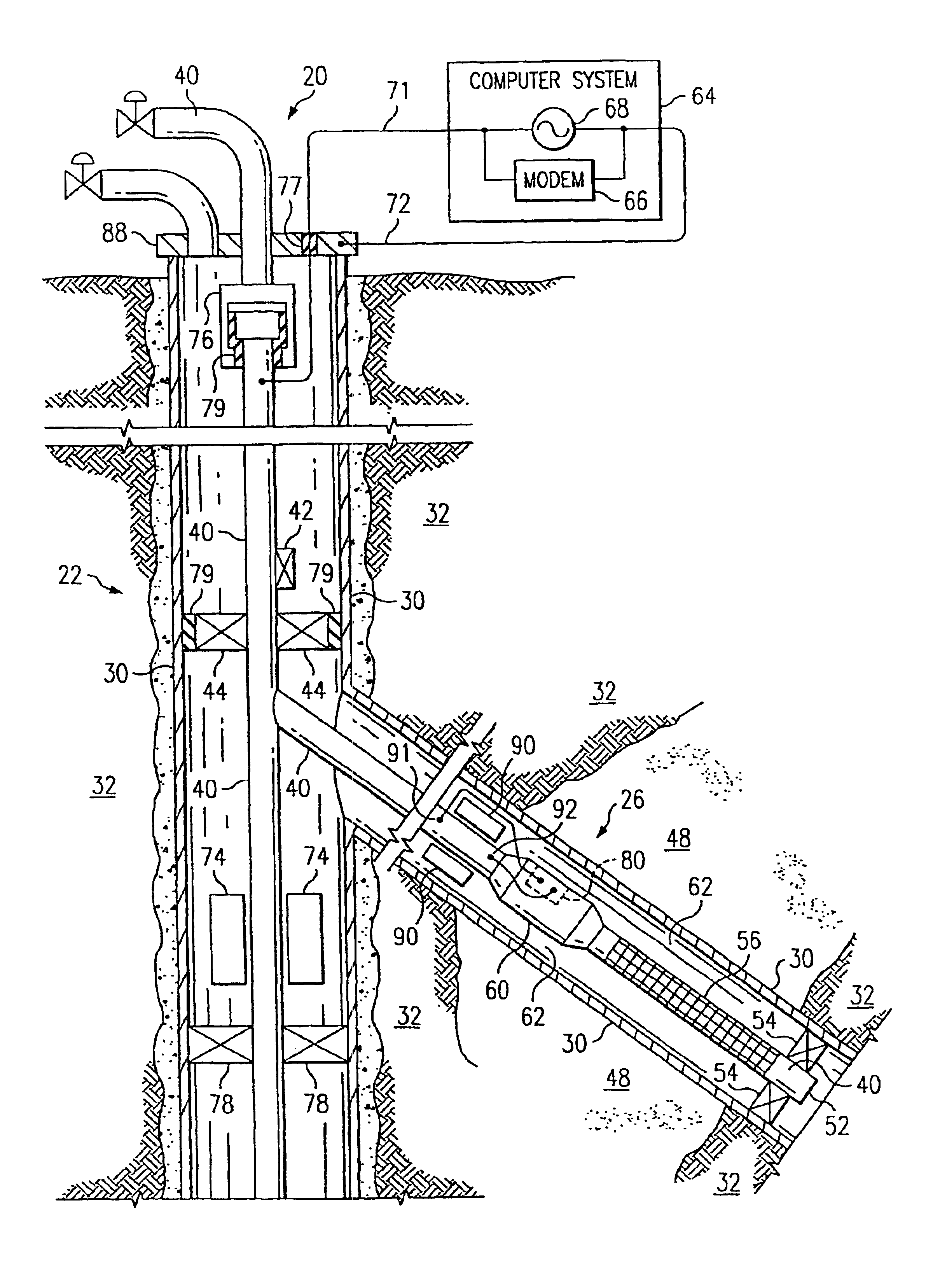

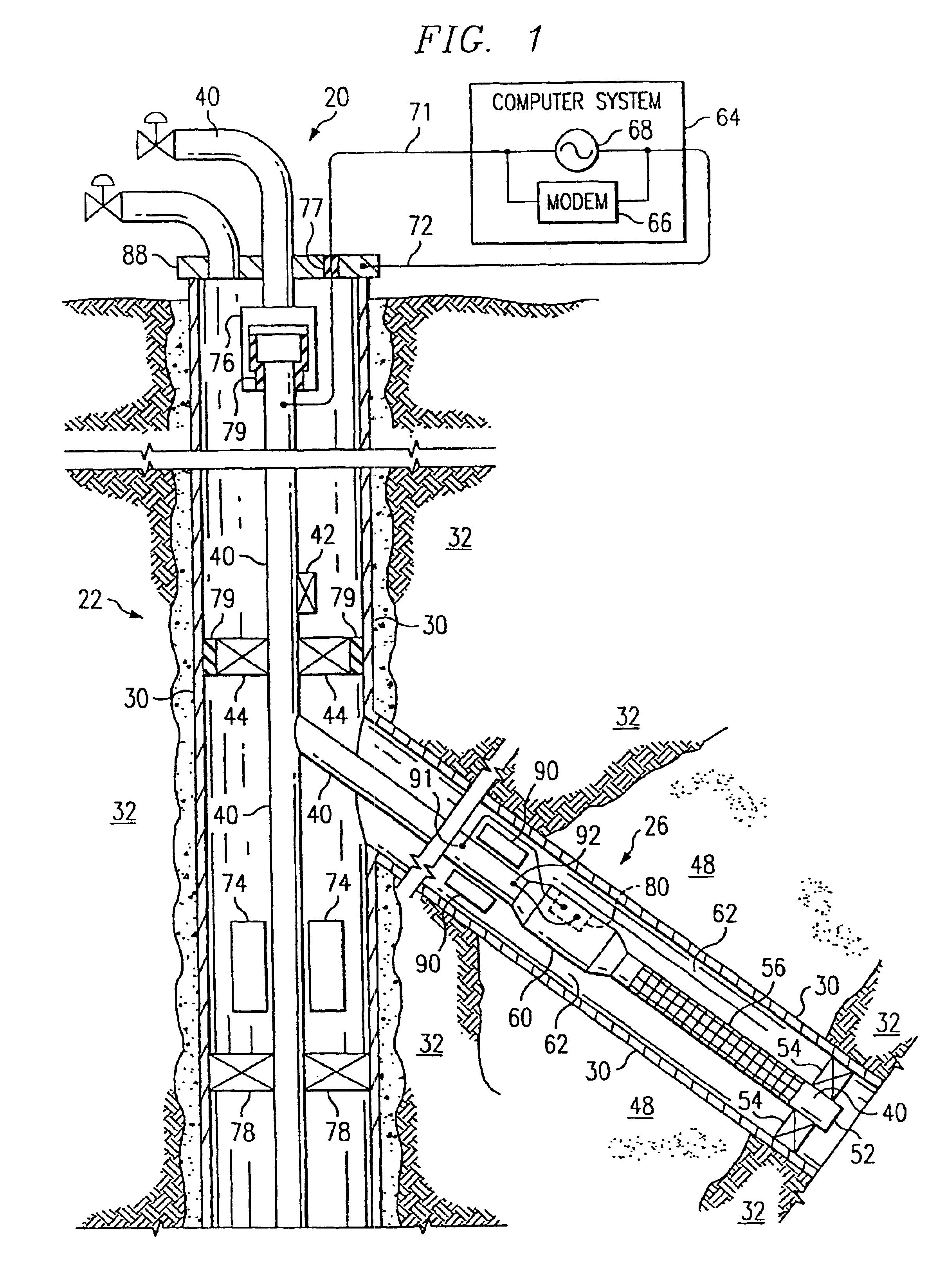

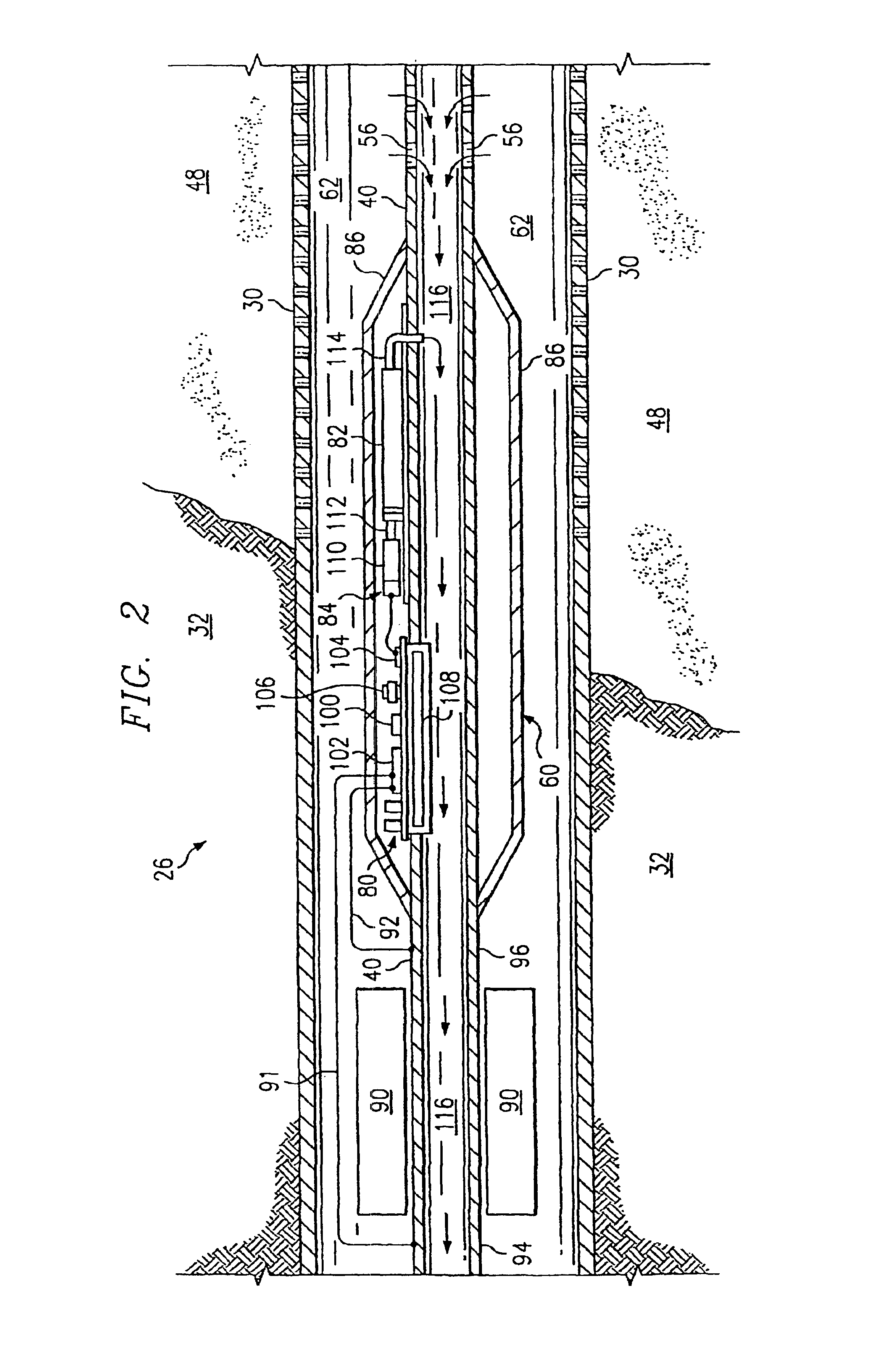

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

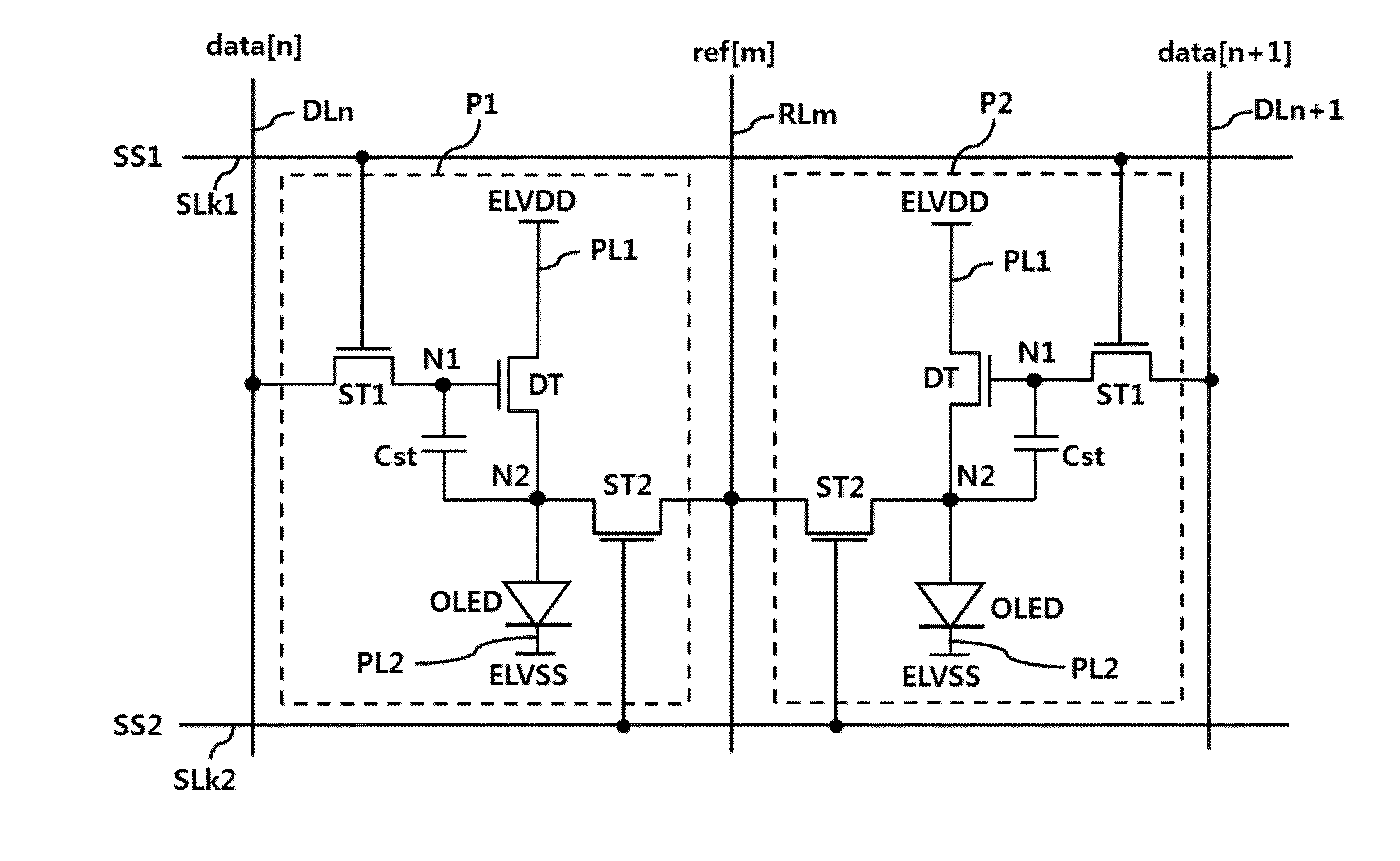

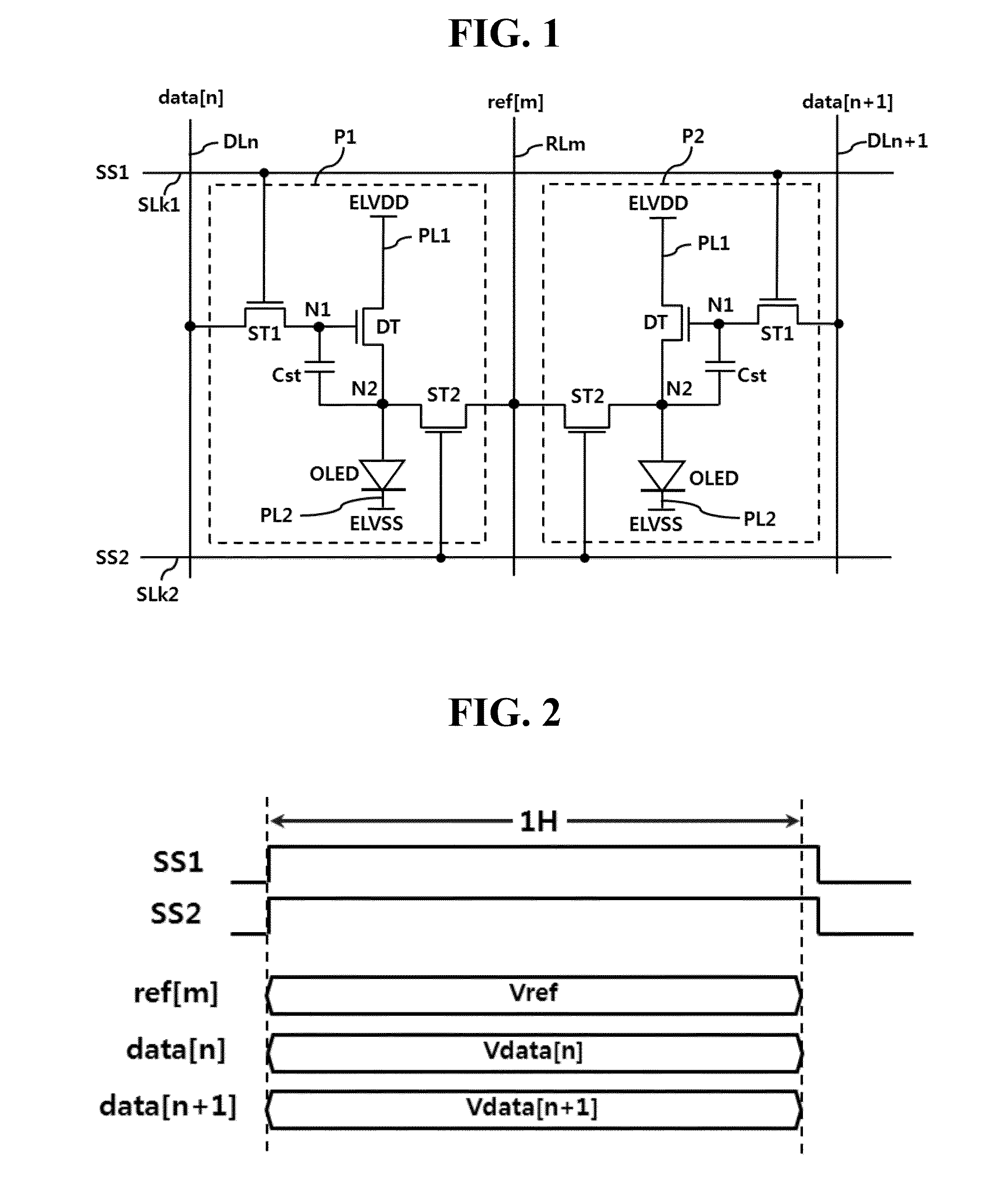

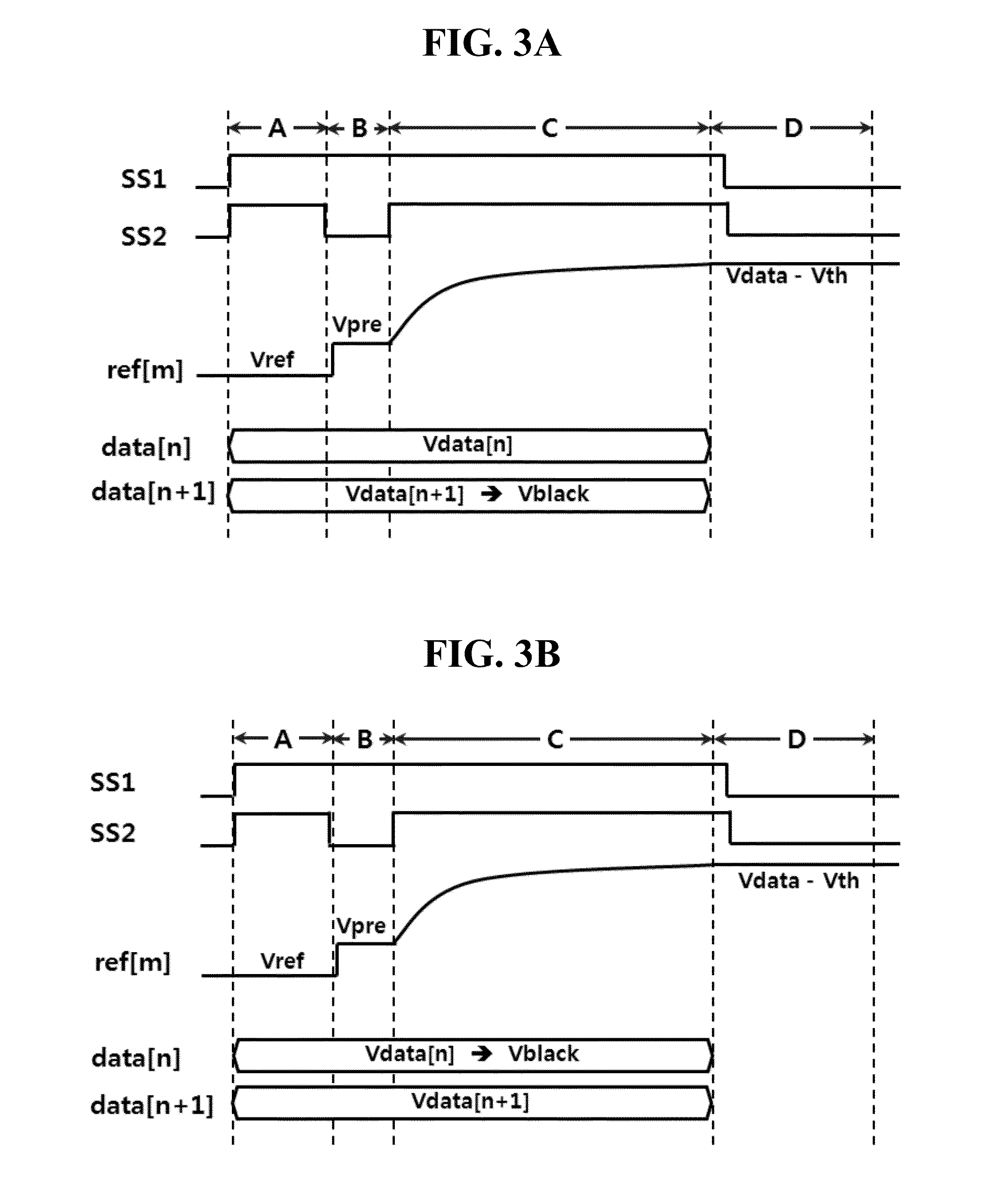

Organic Light Emitting Diode Display Device for Sensing Pixel Current and Pixel Current Sensing Method Thereof

ActiveUS20140022289A1Improve pixel aperture ratioSmall sizeCathode-ray tube indicatorsInput/output processes for data processingDriving currentDisplay device

The present invention relates to an organic light emitting diode display device capable of sensing driving current of each pixel with a simple configuration to compensate for a luminance deviation between pixels and a pixel current sensing method thereof. The organic light emitting diode display device includes a display panel including 2N (N being a natural number) pixels that share a reference line though which a reference signal is supplied and are respectively connected to 2N data lines through which data signals are applied, and a data driver for driving the 2N pixels sharing the reference line in a time division manner through the data lines, sensing currents of the time-division-driven 2N pixels as voltages through the shared reference line and outputting the sensed currents, in a sensing mode.

Owner:LG DISPLAY CO LTD

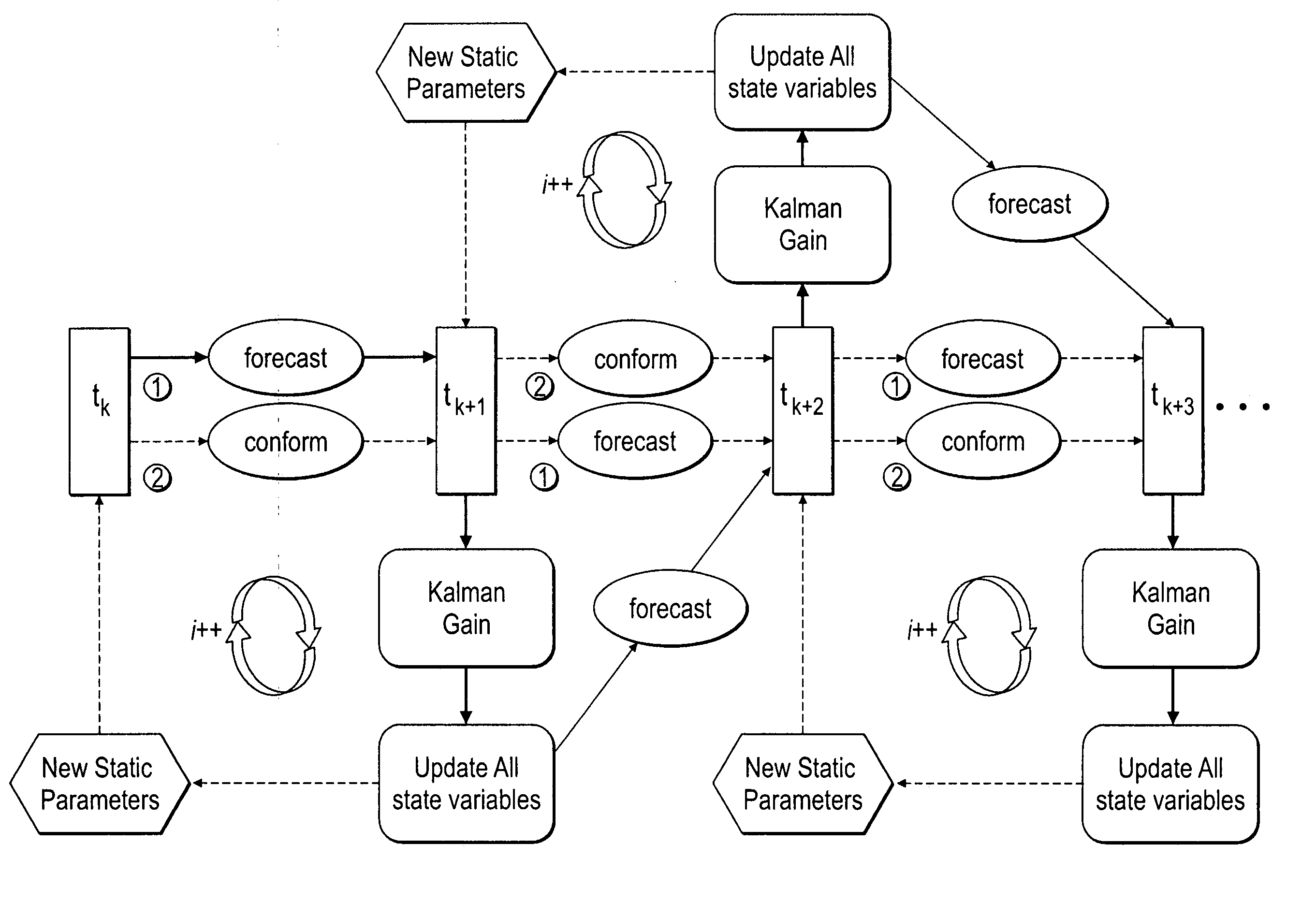

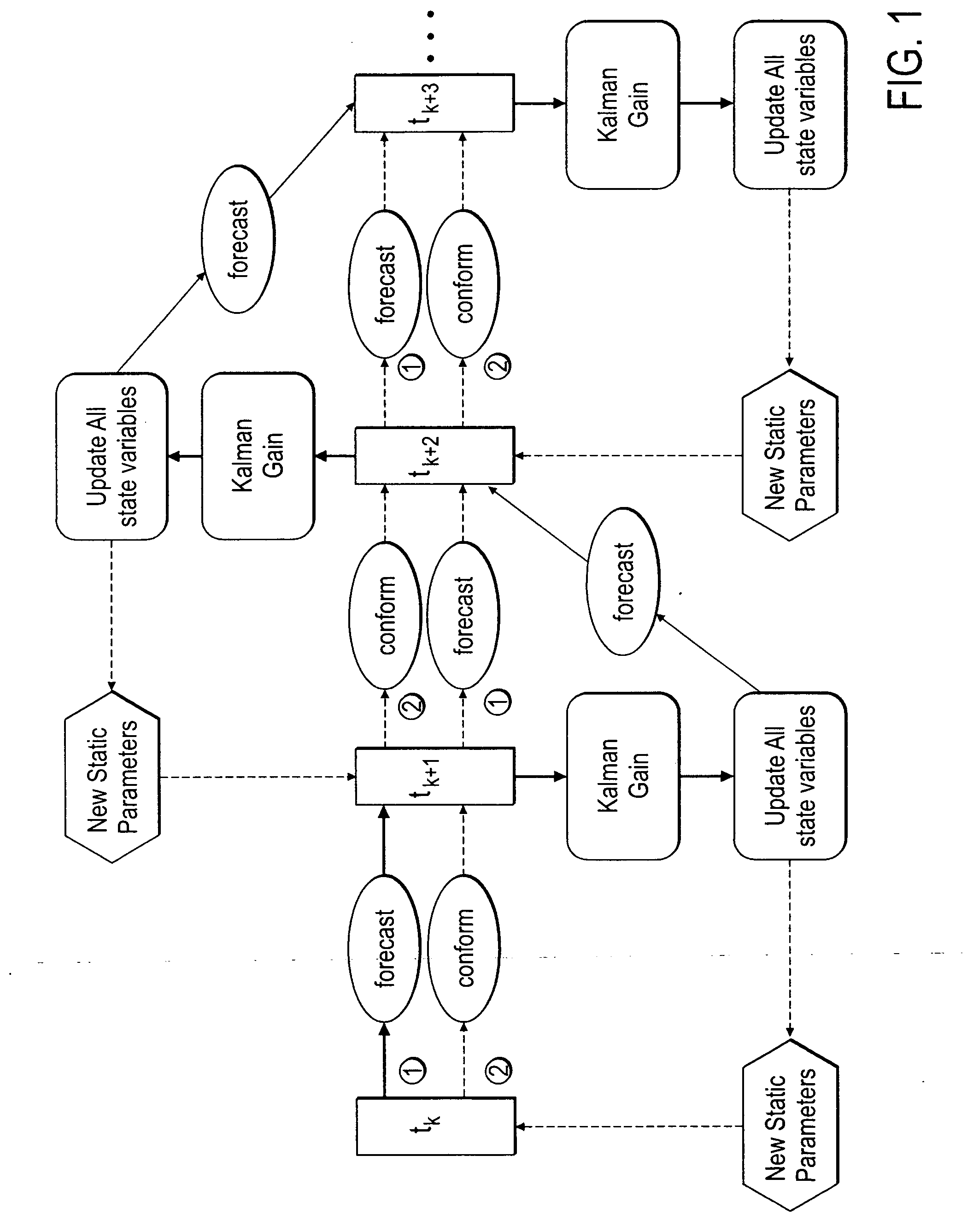

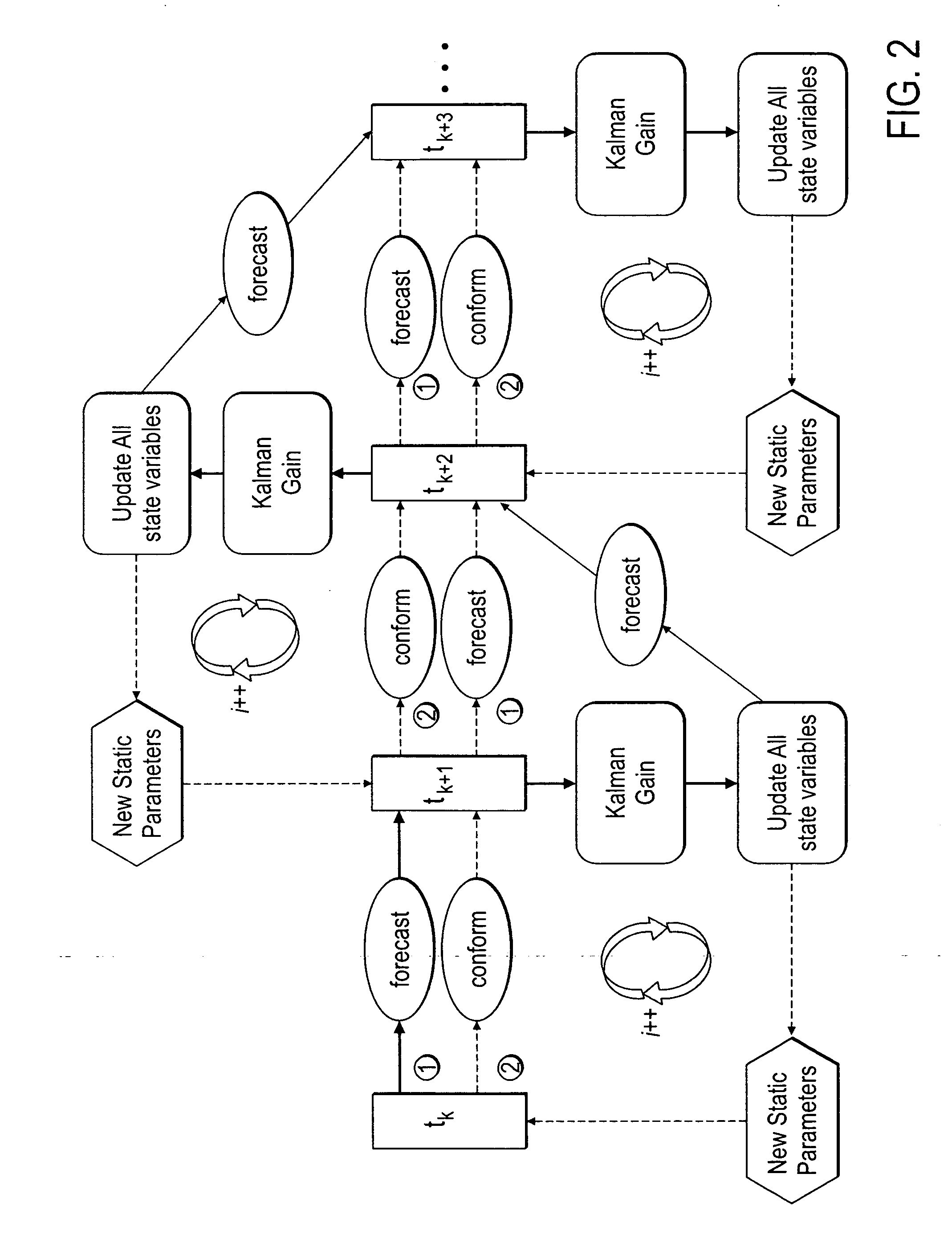

Method, system and apparatus for real-time reservoir model updating using ensemble Kalman filter

ActiveUS20070118346A1Reduce in quantityEnsure correct executionFluid removalComputation using non-denominational number representationKaiman filterState variable

A method, system and apparatus for real-time reservoir model updating using ensemble Kalman filters is described. The method includes a conforming step for bring bringing static and dynamic state variables into conformance with one another during a time step of the updating. Also, an iterative damping method is used in conjunction with the conformance step to account for nonGaussian and nonlinear features in a system. Also, a re-sampling method is described which reduces the ensemble size of reservoir models which are to be updated.

Owner:CHEVROU USA INC

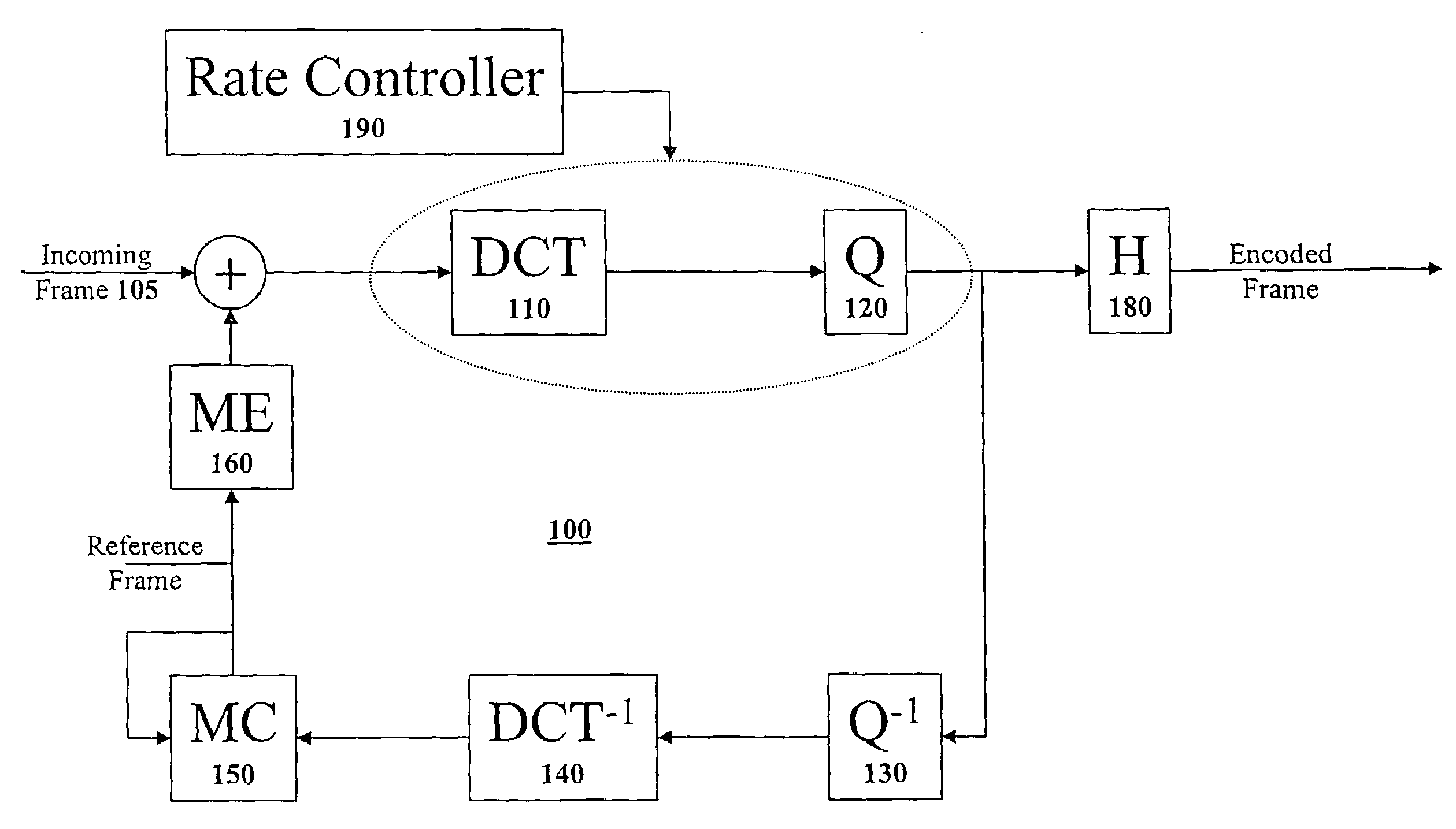

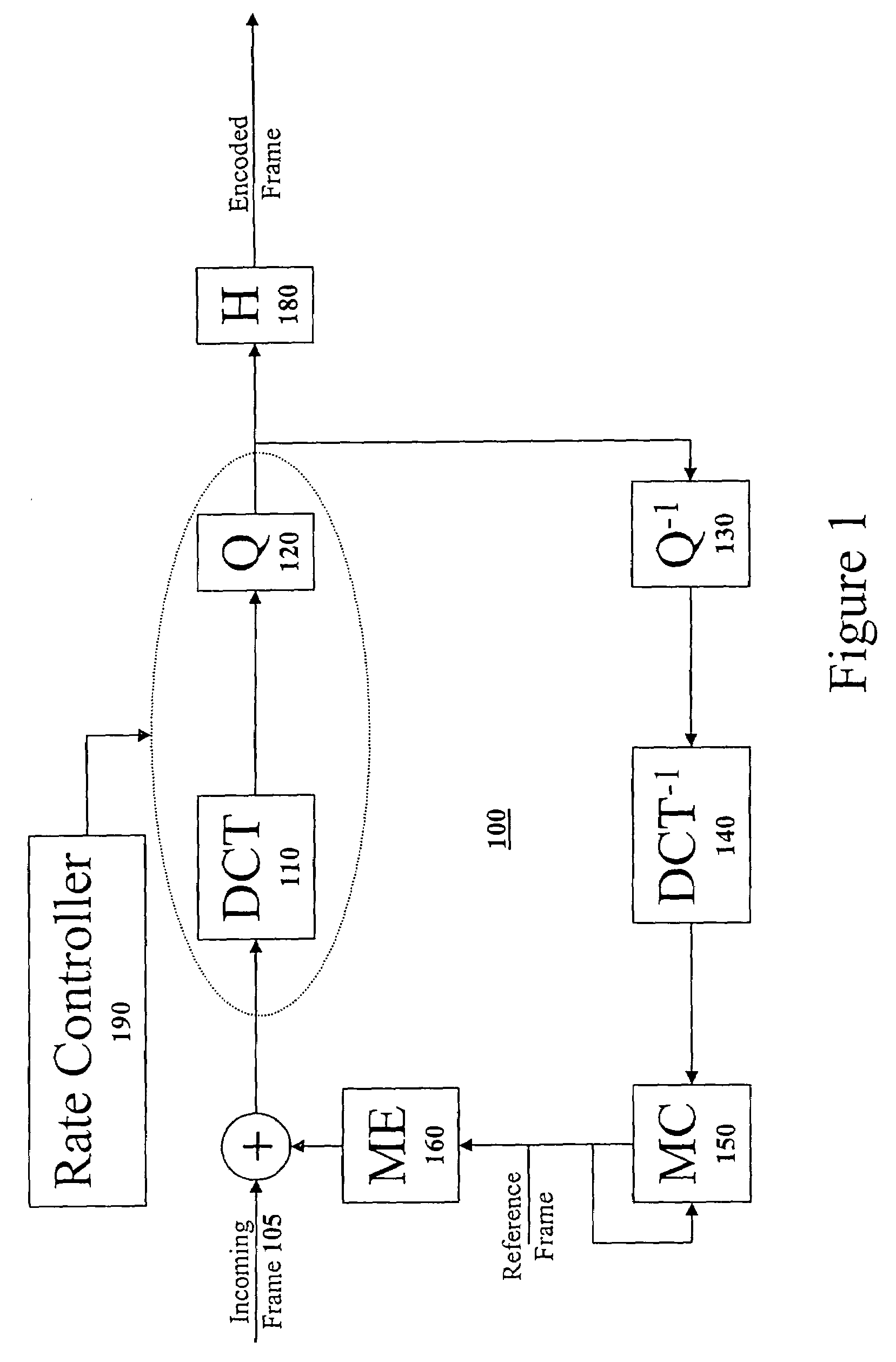

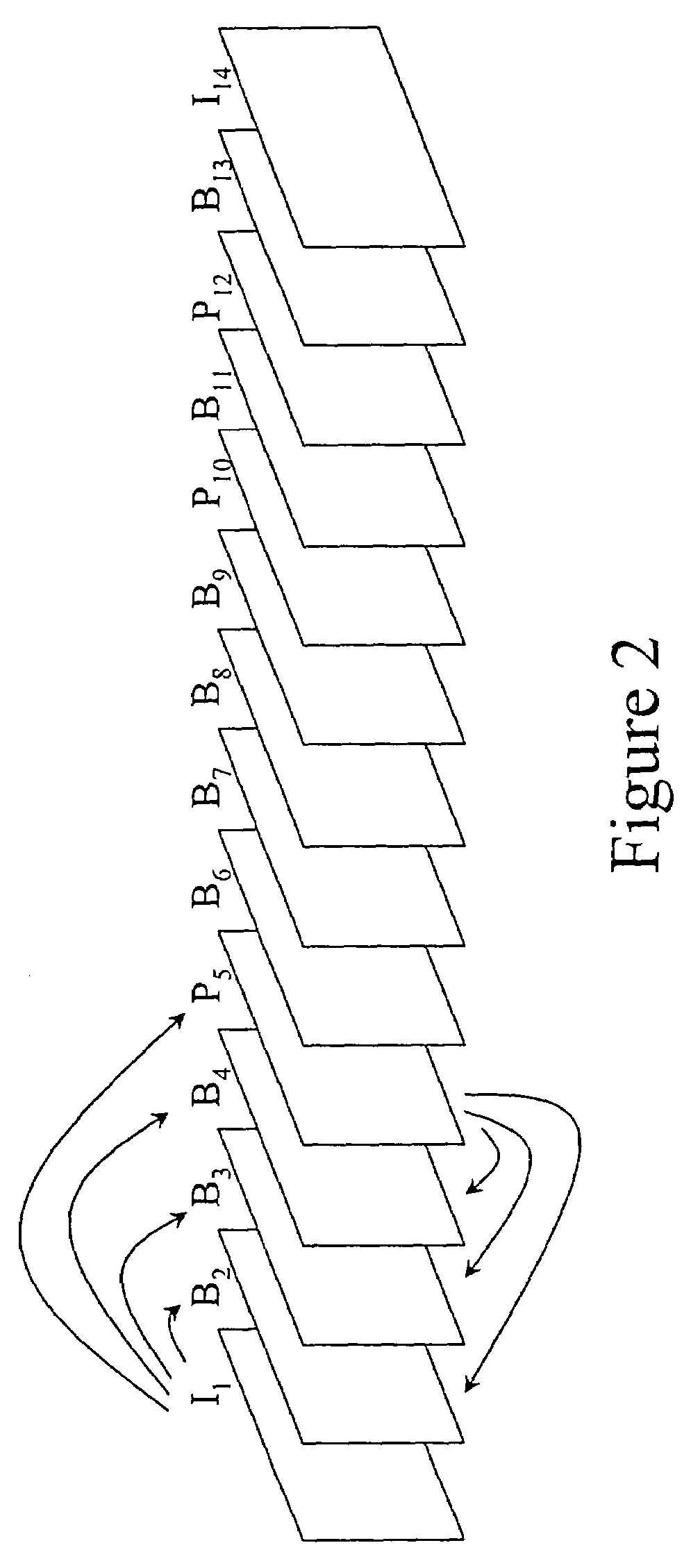

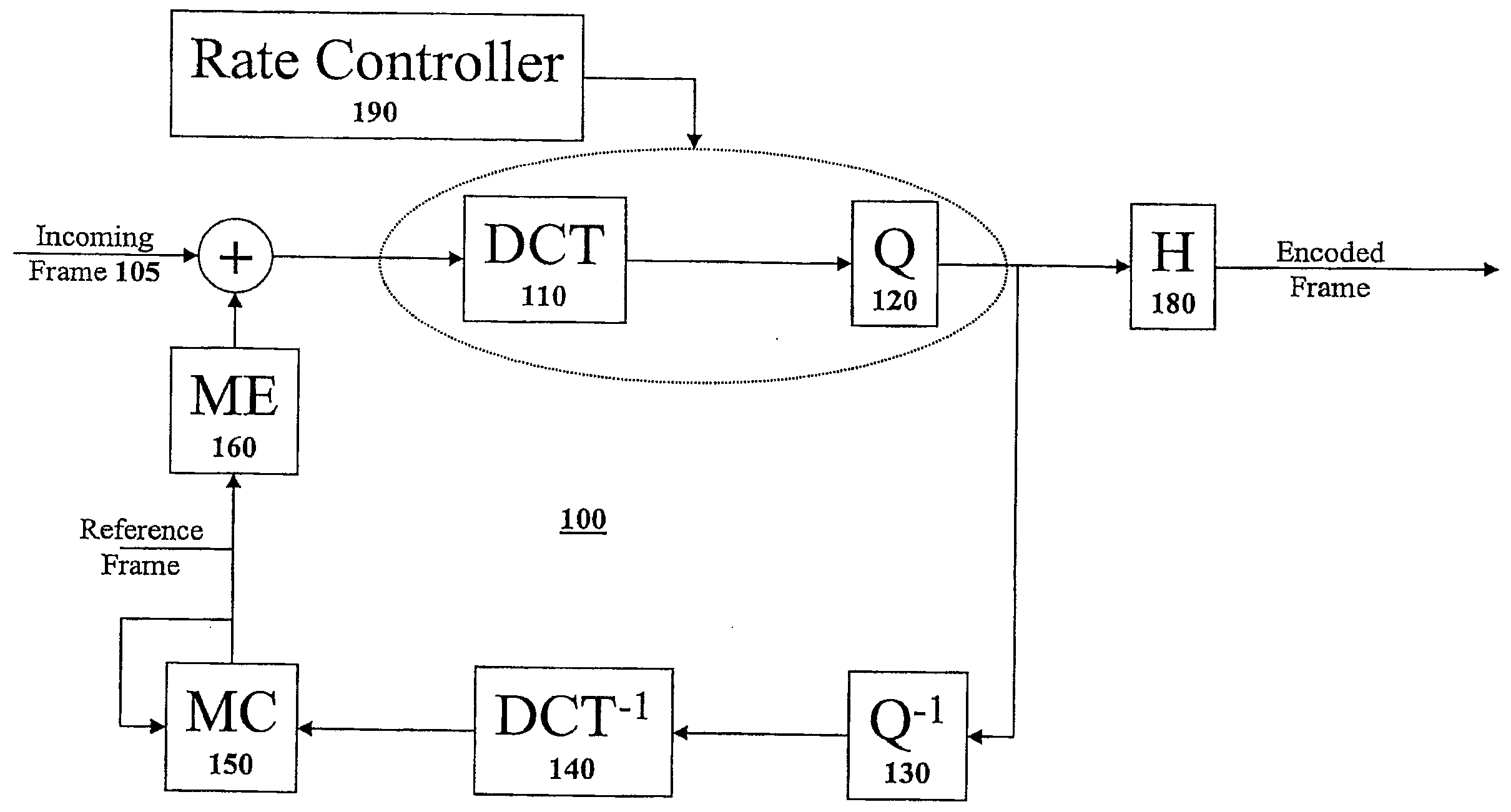

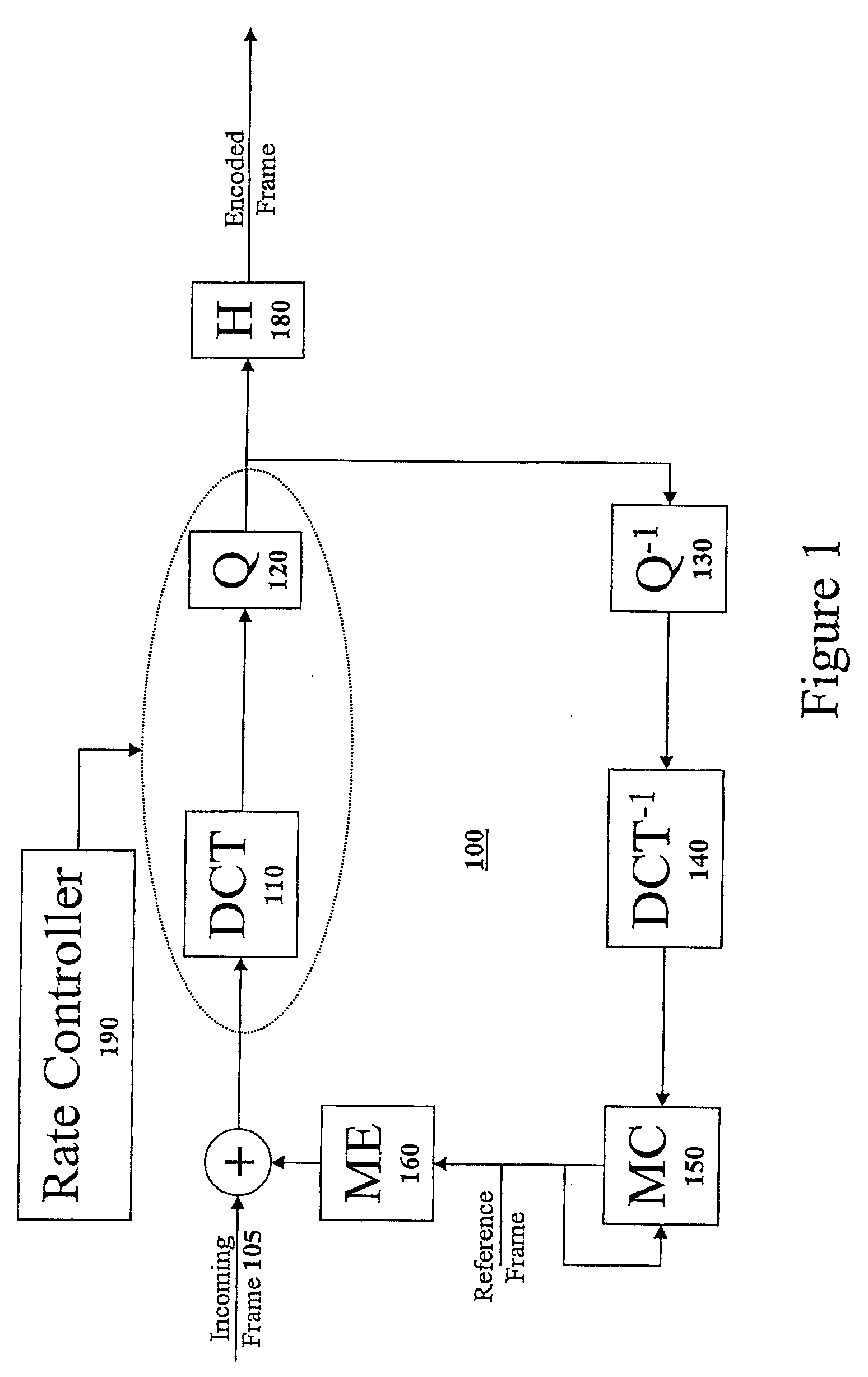

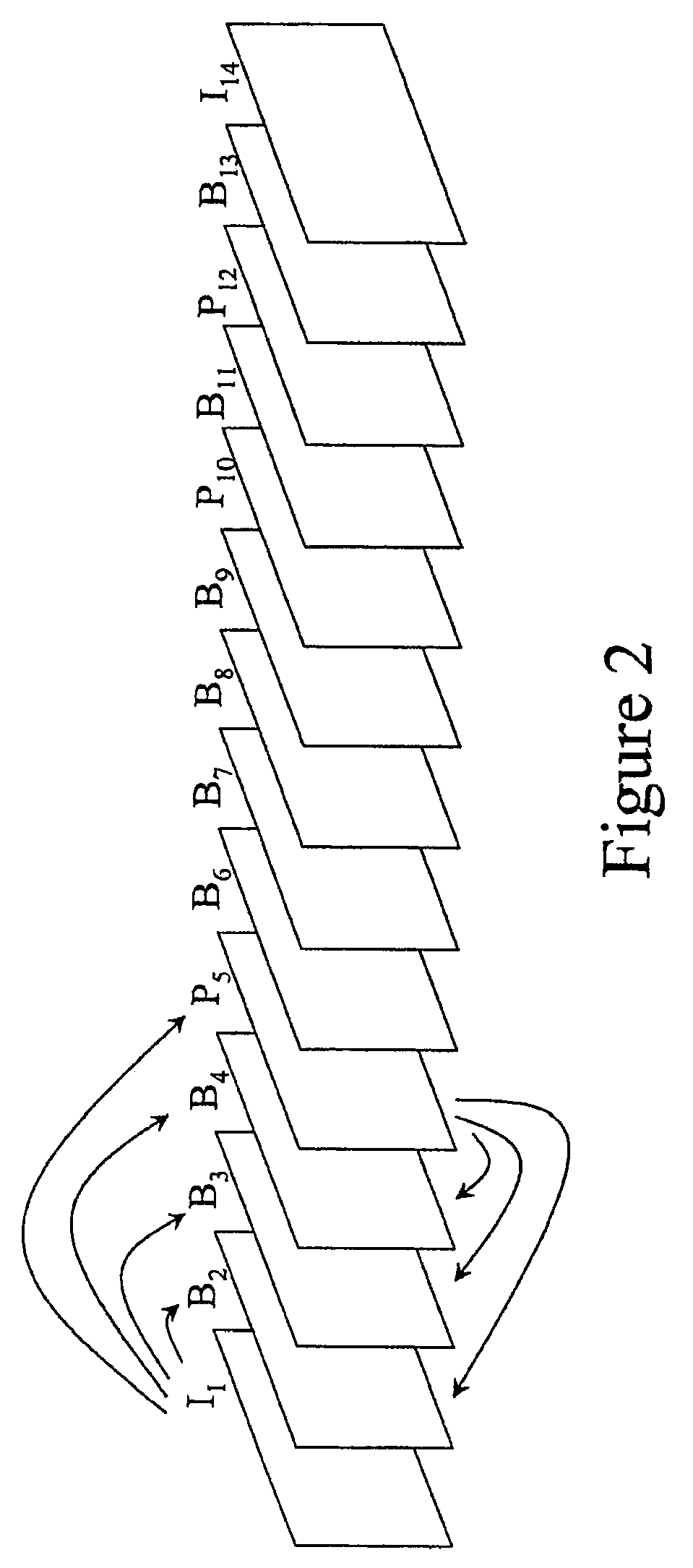

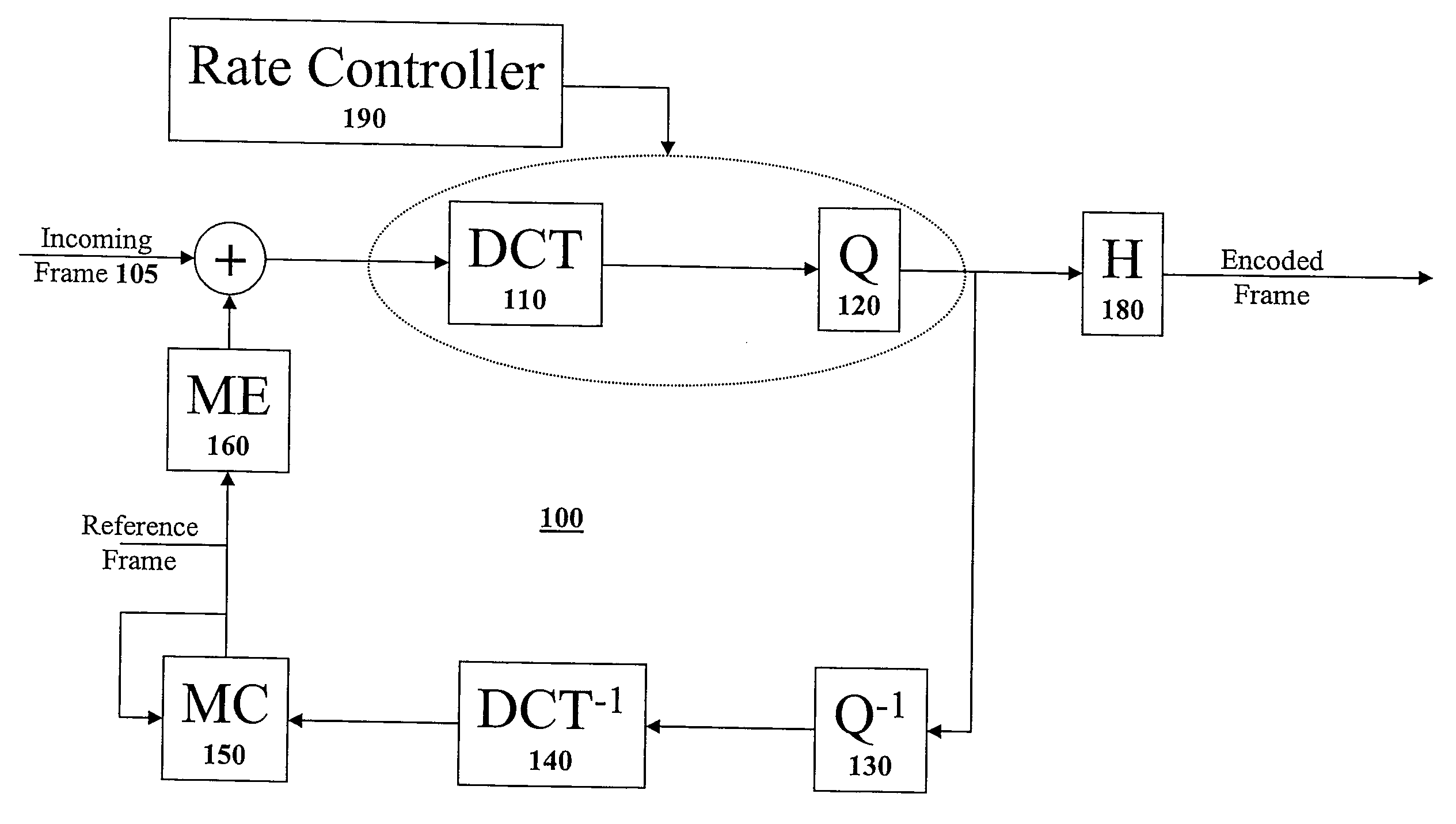

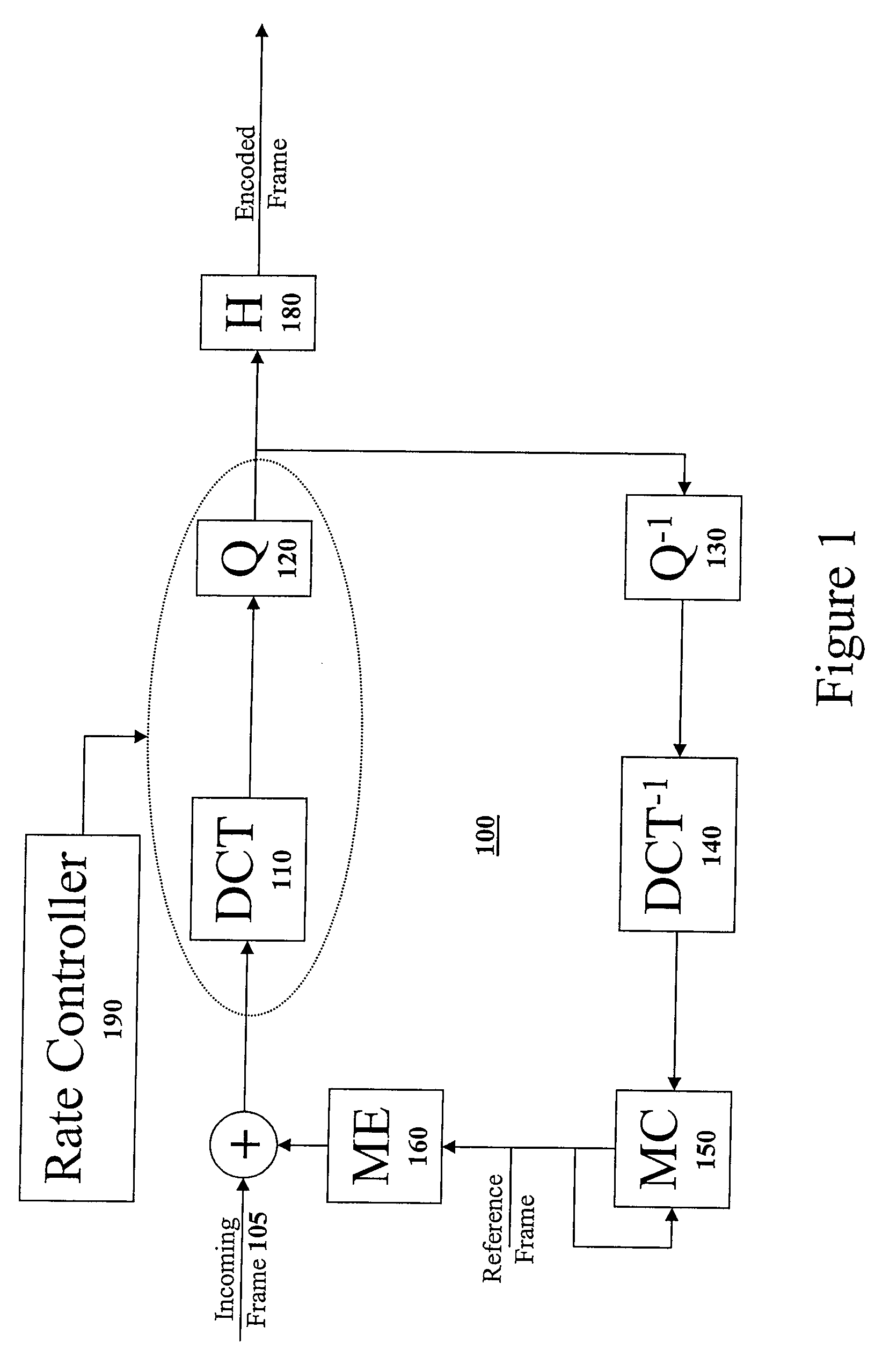

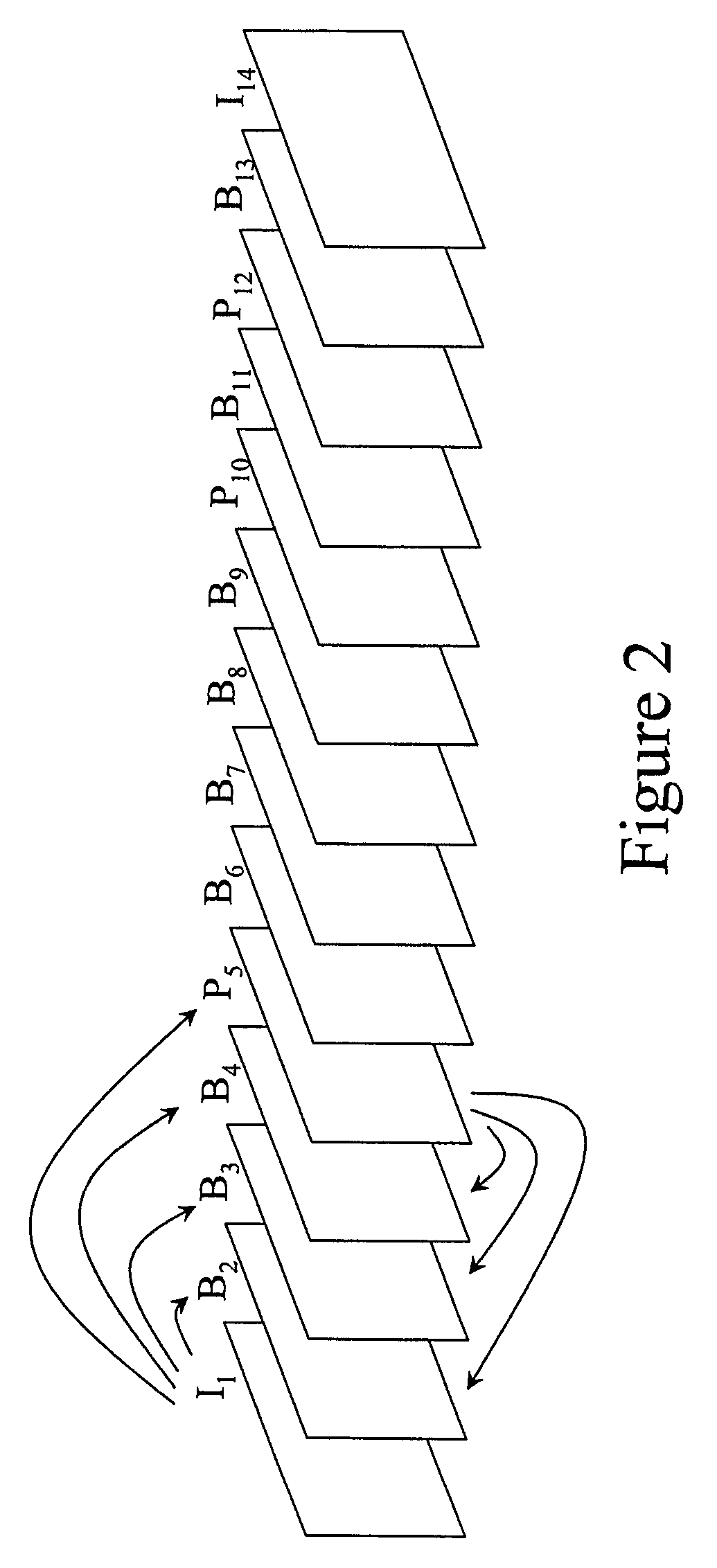

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements of division operations

ActiveUS7339991B2Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoComputer graphics (images)

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

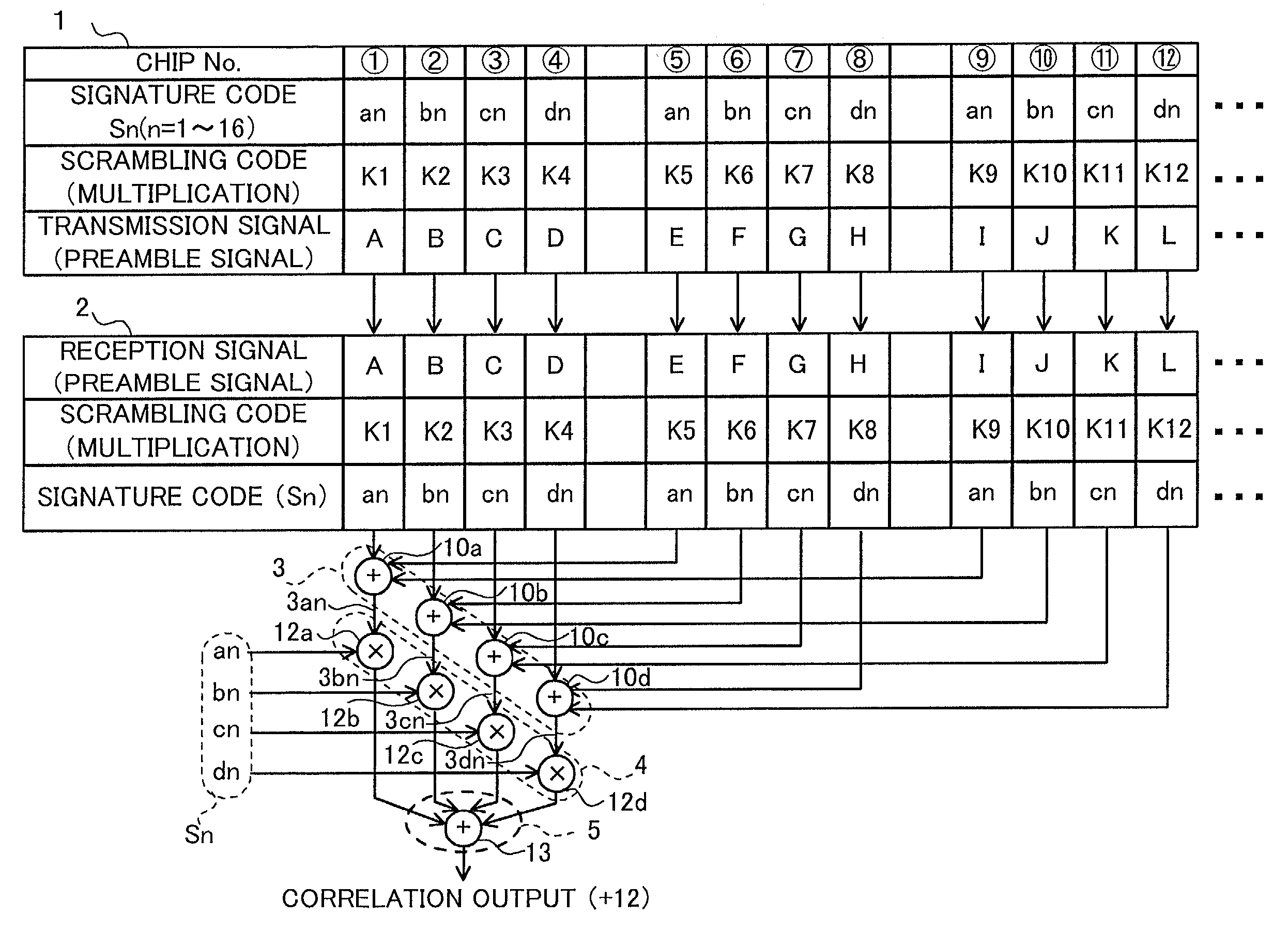

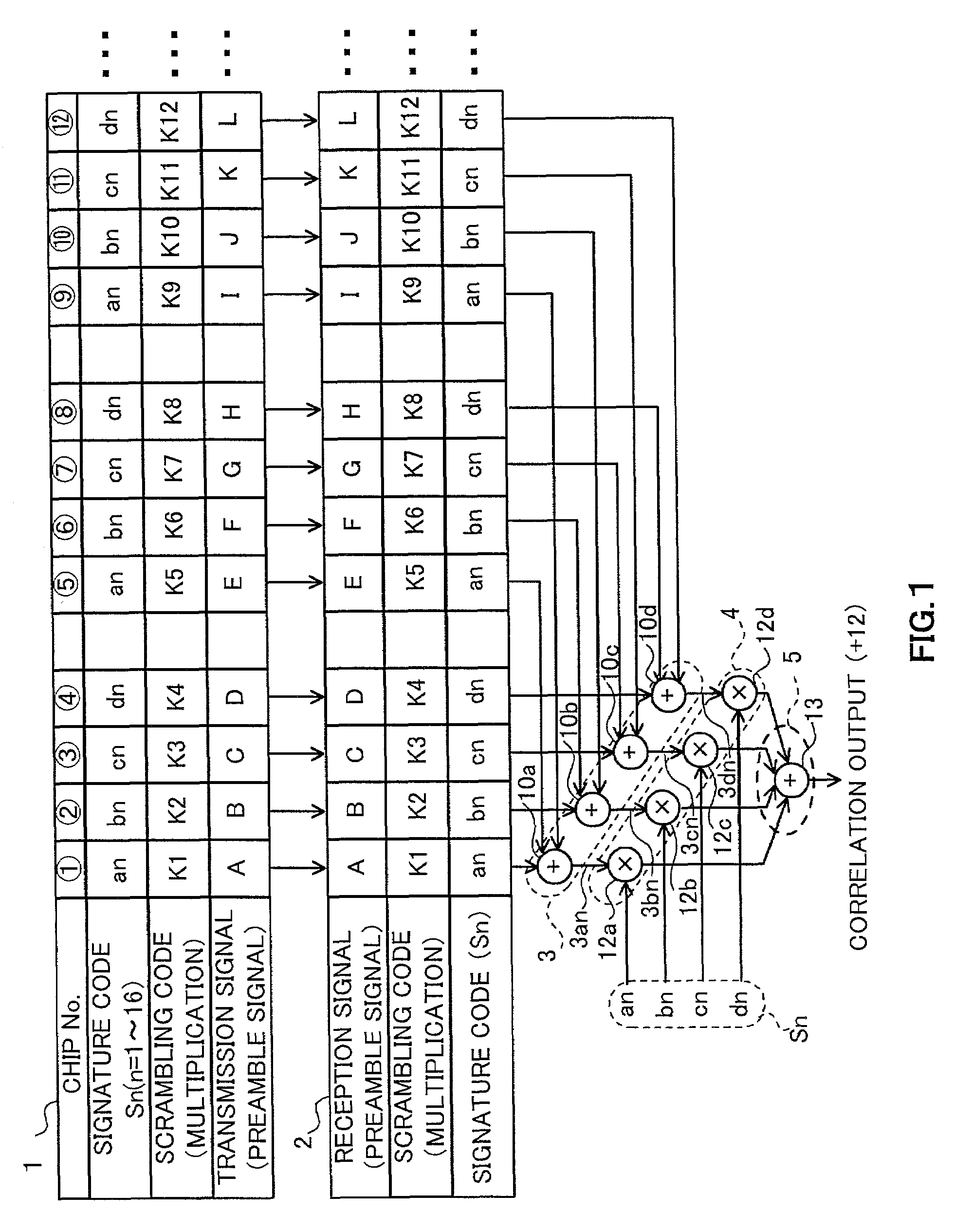

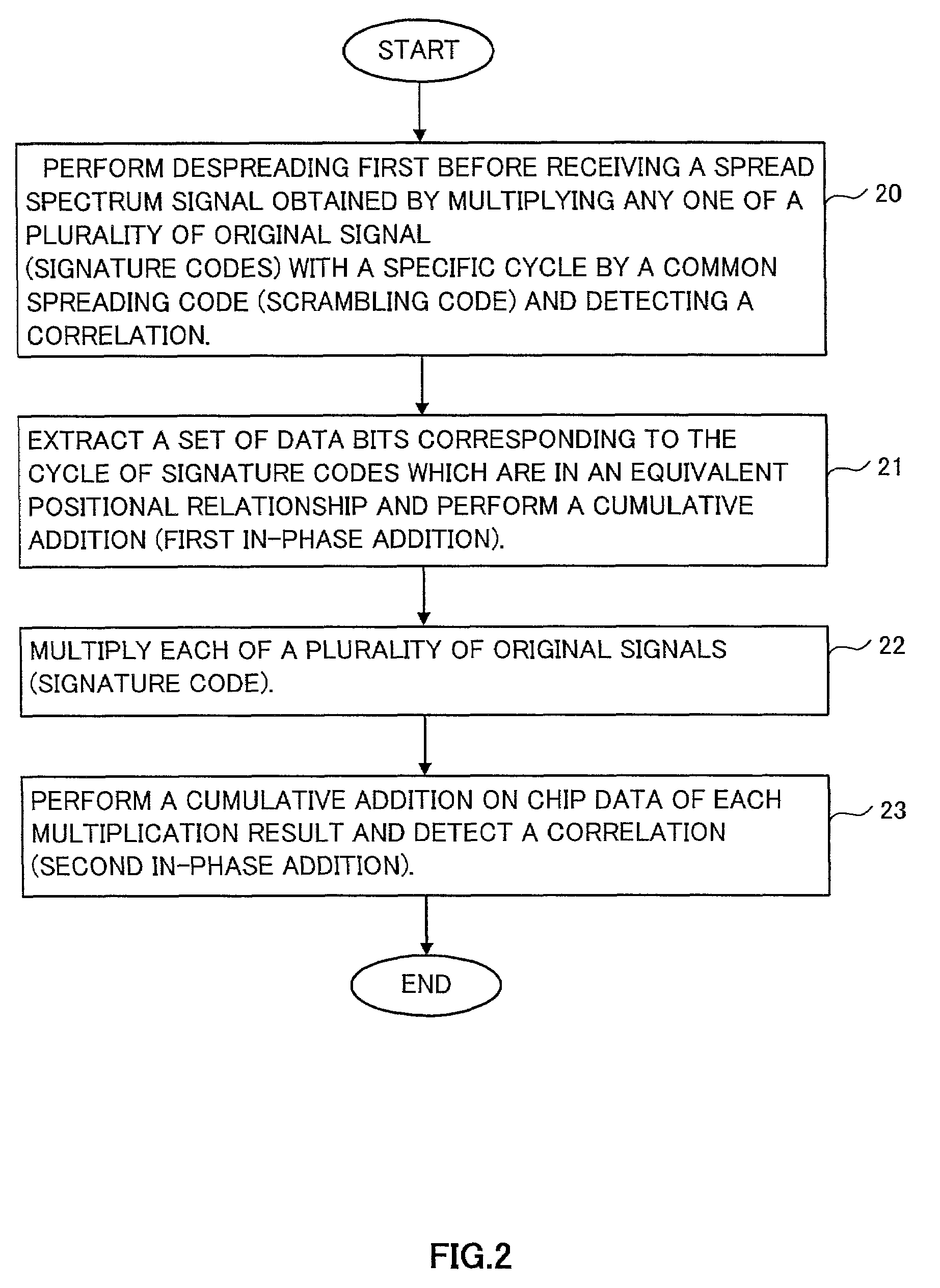

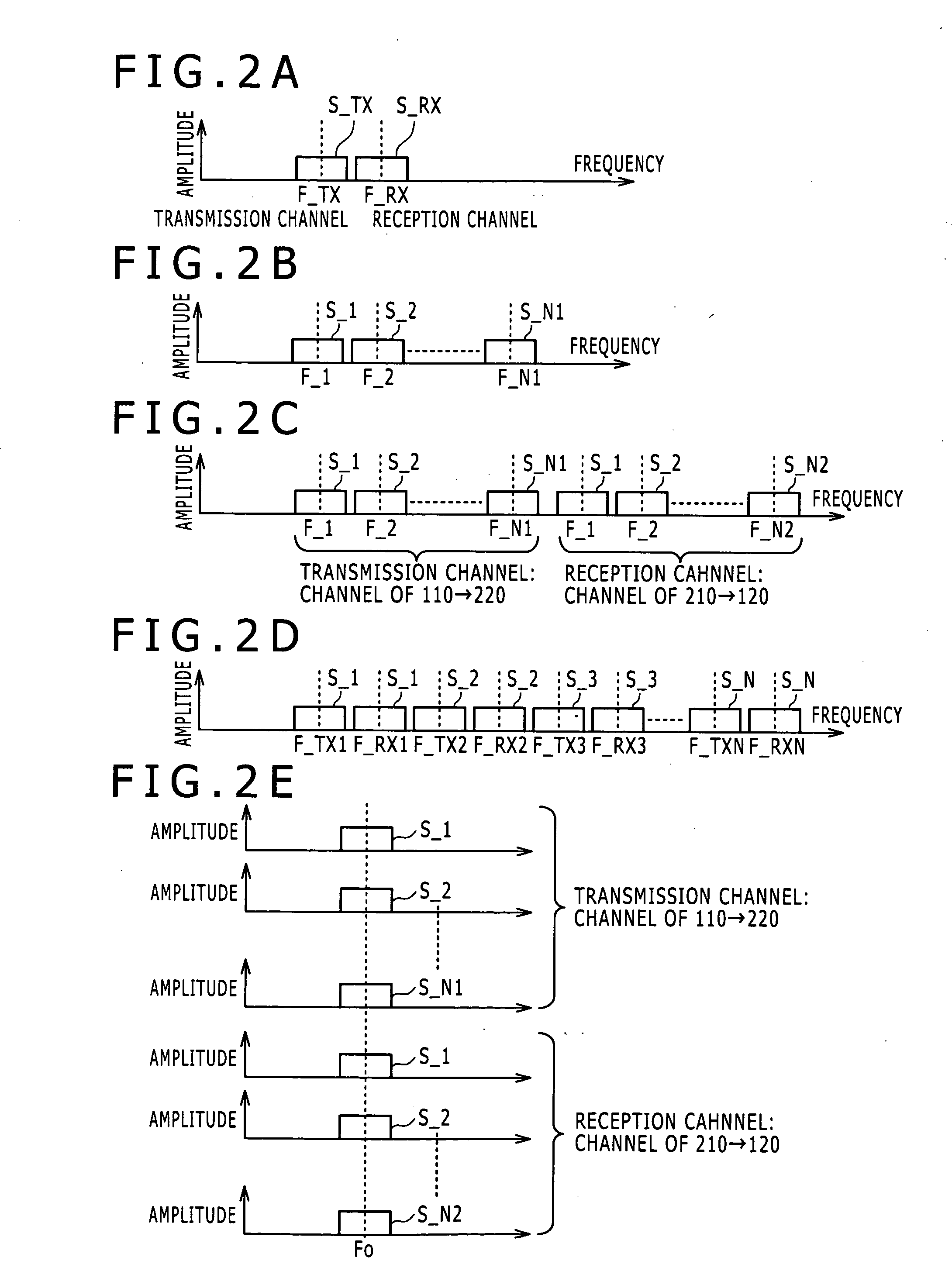

Matched filter and correlation detection method

InactiveUS6985517B2Reduction in circuit scaleSecure degree of freedomSynchronisation arrangementRadio transmission for post communicationMatched filterMobile station

The present invention provides a matched filter and correlation detection method that carries out correlation detection on a time-division basis on a reception signal with known periodic codes inserted as in the case of a preamble search by a base station that carries out a CDMA communication. The mobile station multiplies 16 types of signature codes by a common scrambling code, generates a preamble signal and carries out transmission. The base station carries out despreading by multiplying the scrambling code and reproduces the signature codes. Then, the first cumulative addition section carries out a cumulative addition on a plurality of sets of data portions at a same position corresponding to the cycle of the signature codes and then the multiplication section multiplies signature codes. Finally, the second cumulative addition section adds up symbols and detects a correlation.

Owner:PANASONIC CORP

Desalination methods and systems that include carbonate compound precipitation

InactiveUS20100154679A1Easy complianceImprove desalination efficiencyAuxillariesGeneral water supply conservationSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbon dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:CALERA CORP

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20100158786A1Easy complianceImprove desalination efficiencyCalcium/strontium/barium carbonatesAuxillariesSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

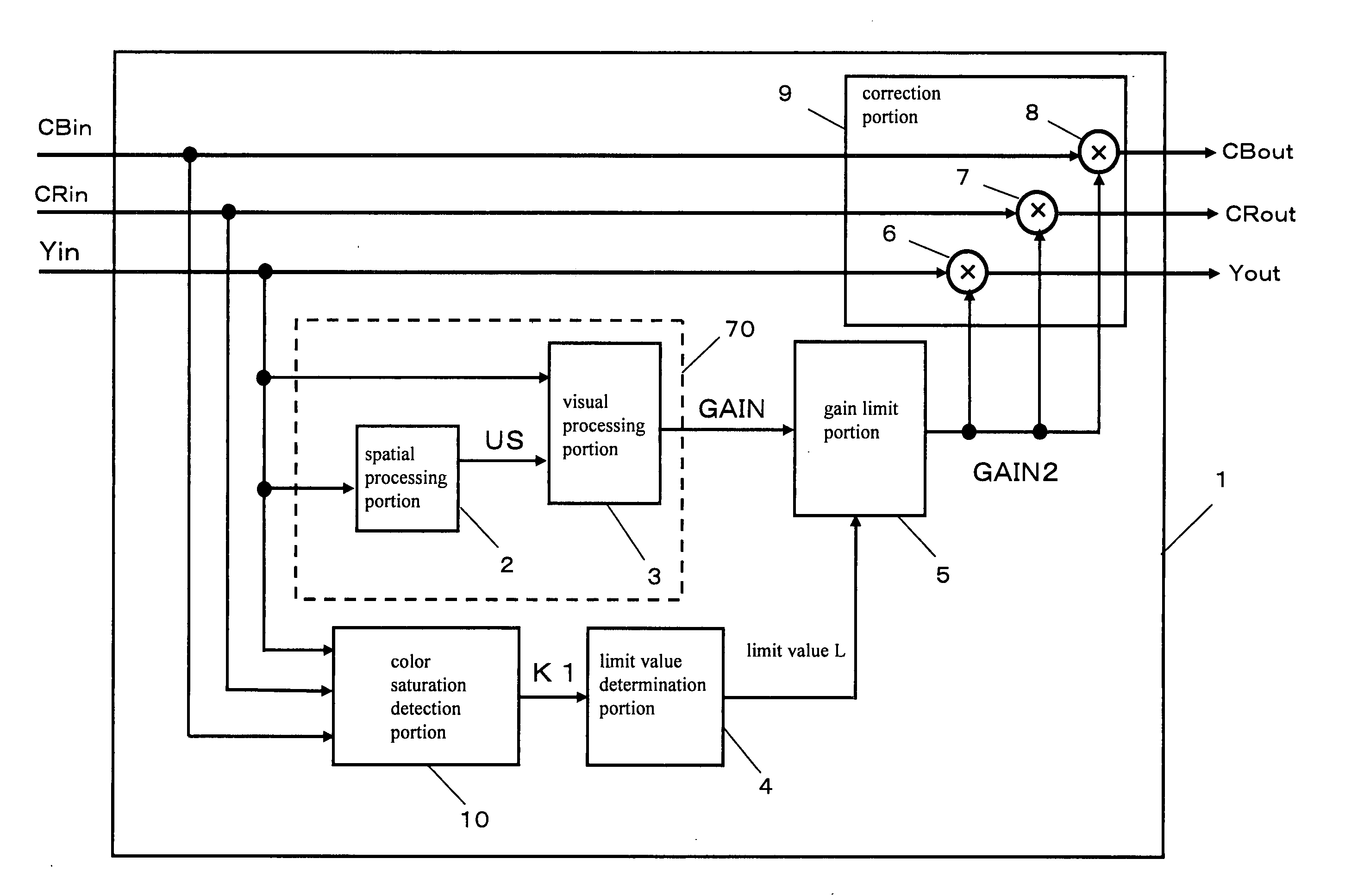

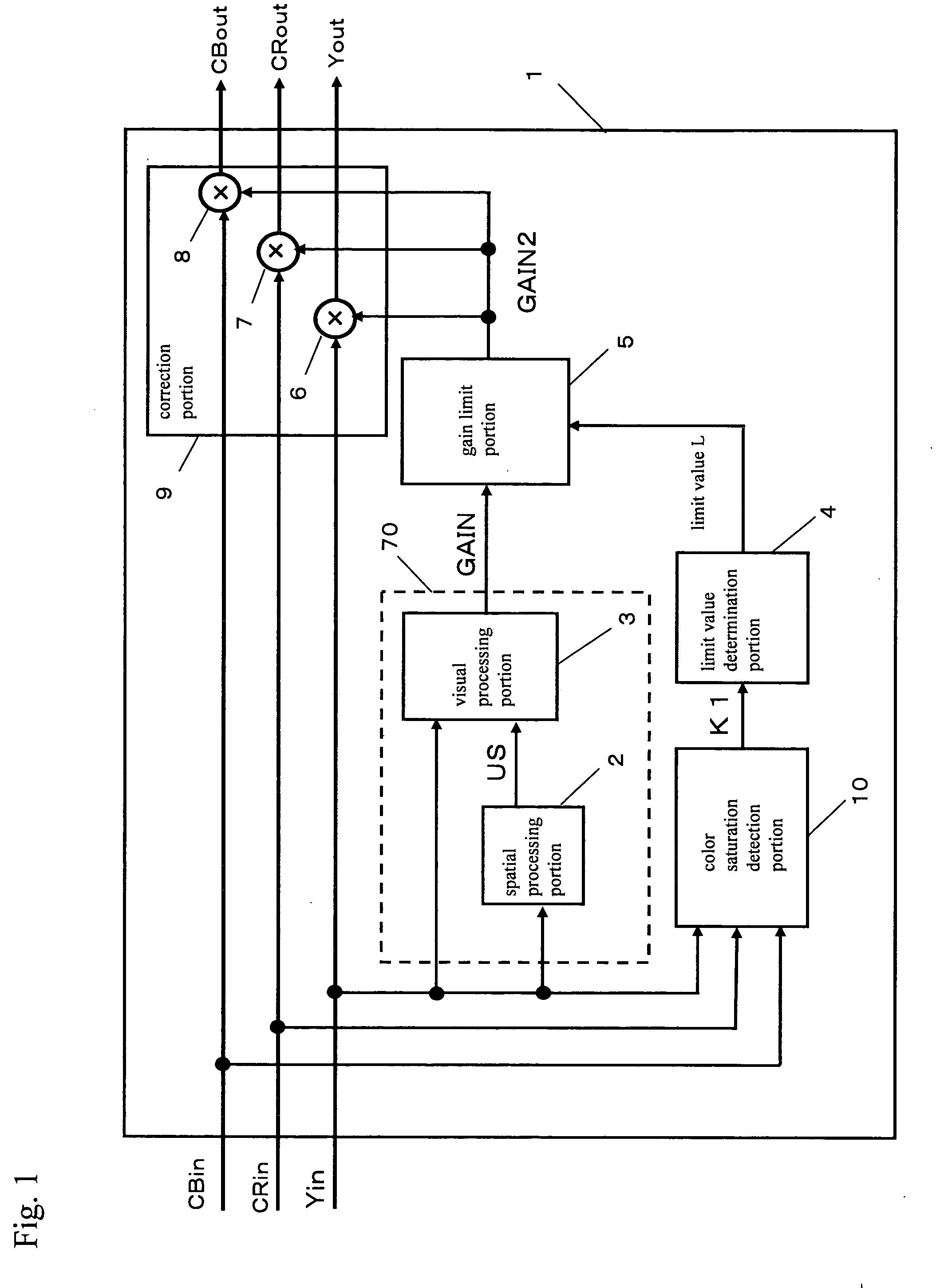

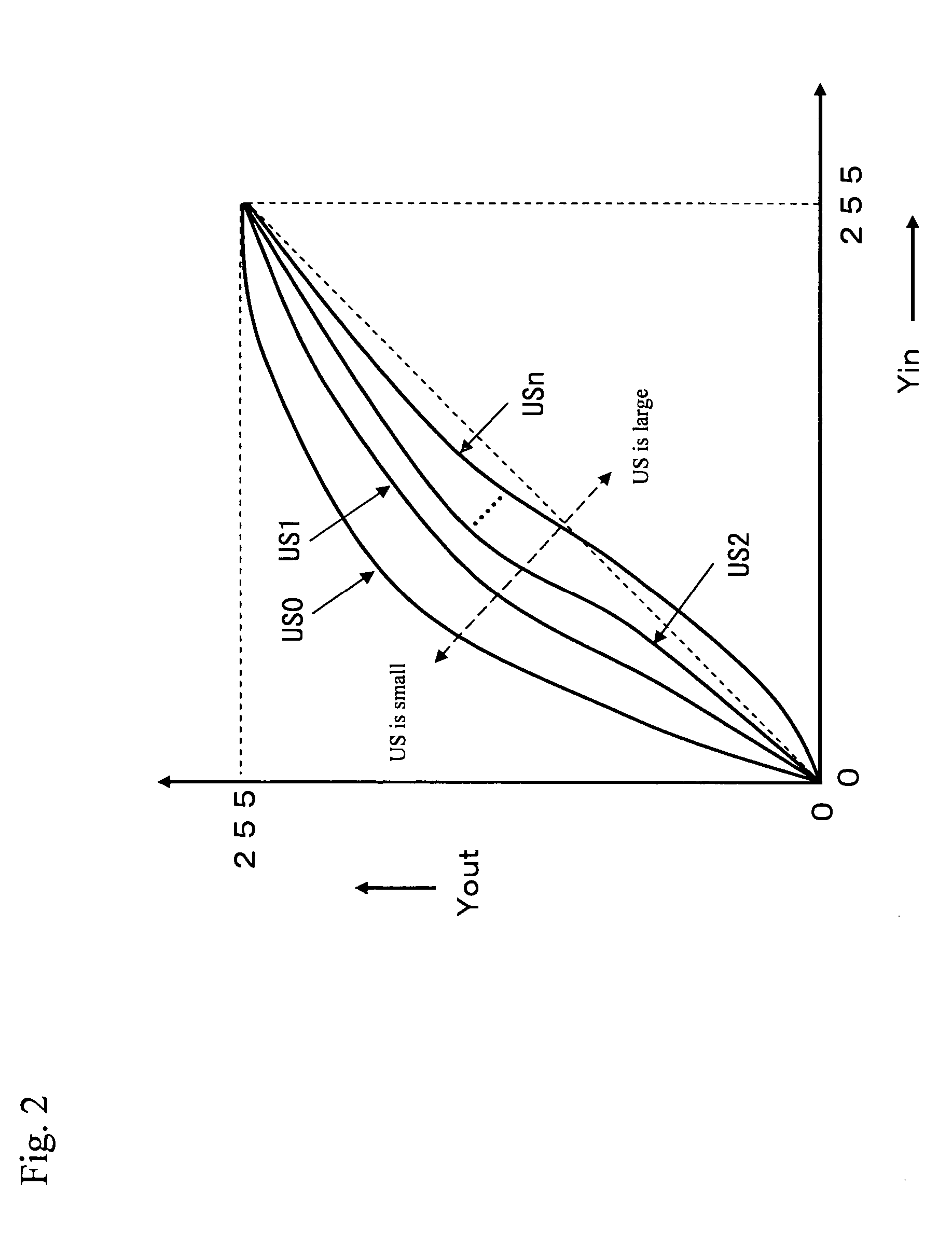

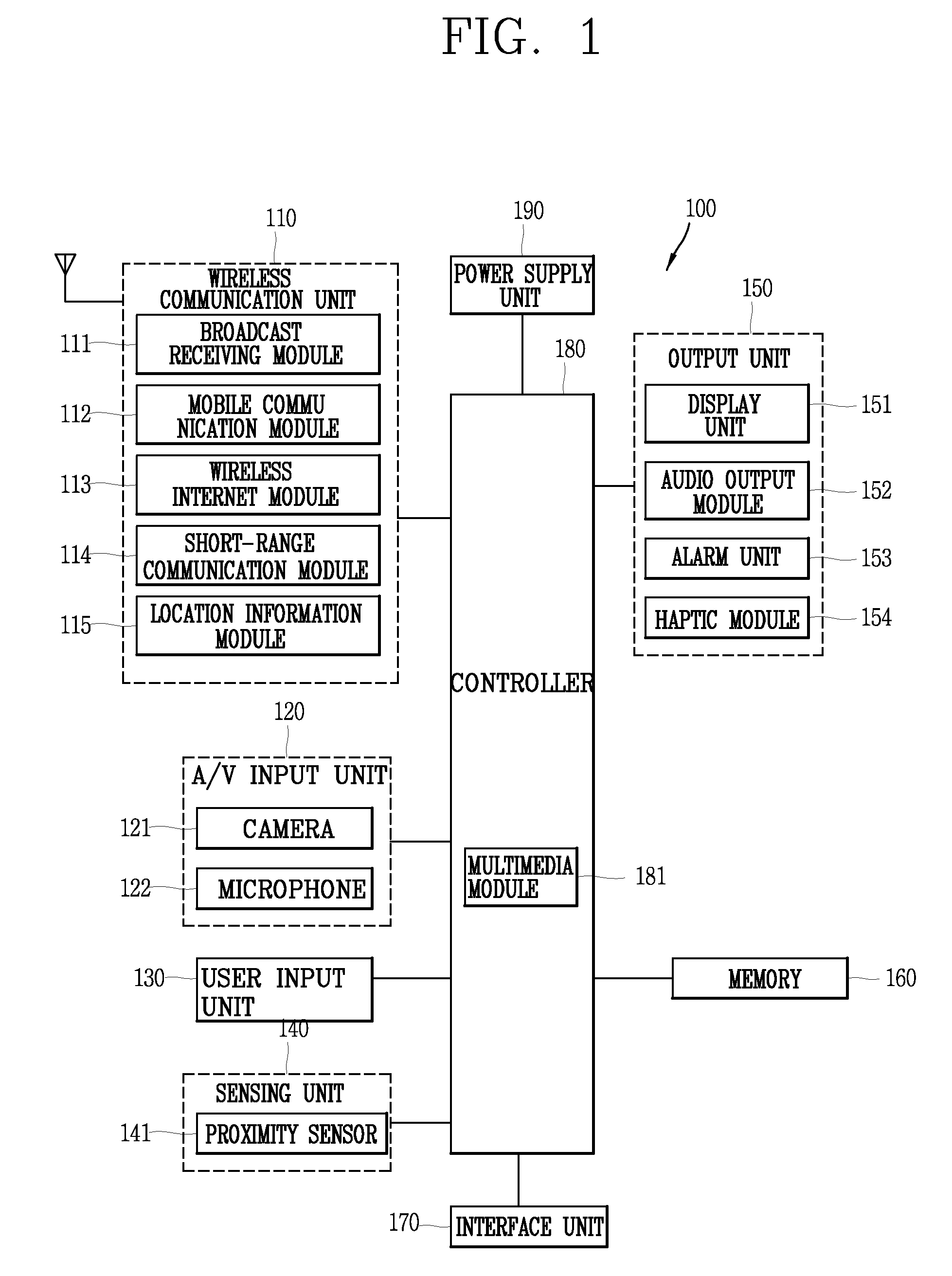

Visual processing device, display device, and integrated circuit

ActiveUS20070080975A1Precise processingSimple structureTelevision system detailsImage enhancementPattern recognitionDisplay device

The invention achieves a visual processing device that can execute precise contrast adjustment on image signals that have been input and that does not cause discrepancies in the output timing of the image signals that are output. The visual processing device is provided with a gain-type visual processing portion that outputs a first gain signal having predetermined gain characteristics with respect to the input image signal, and a correction portion that corrects the input image signal based on the first gain signal.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

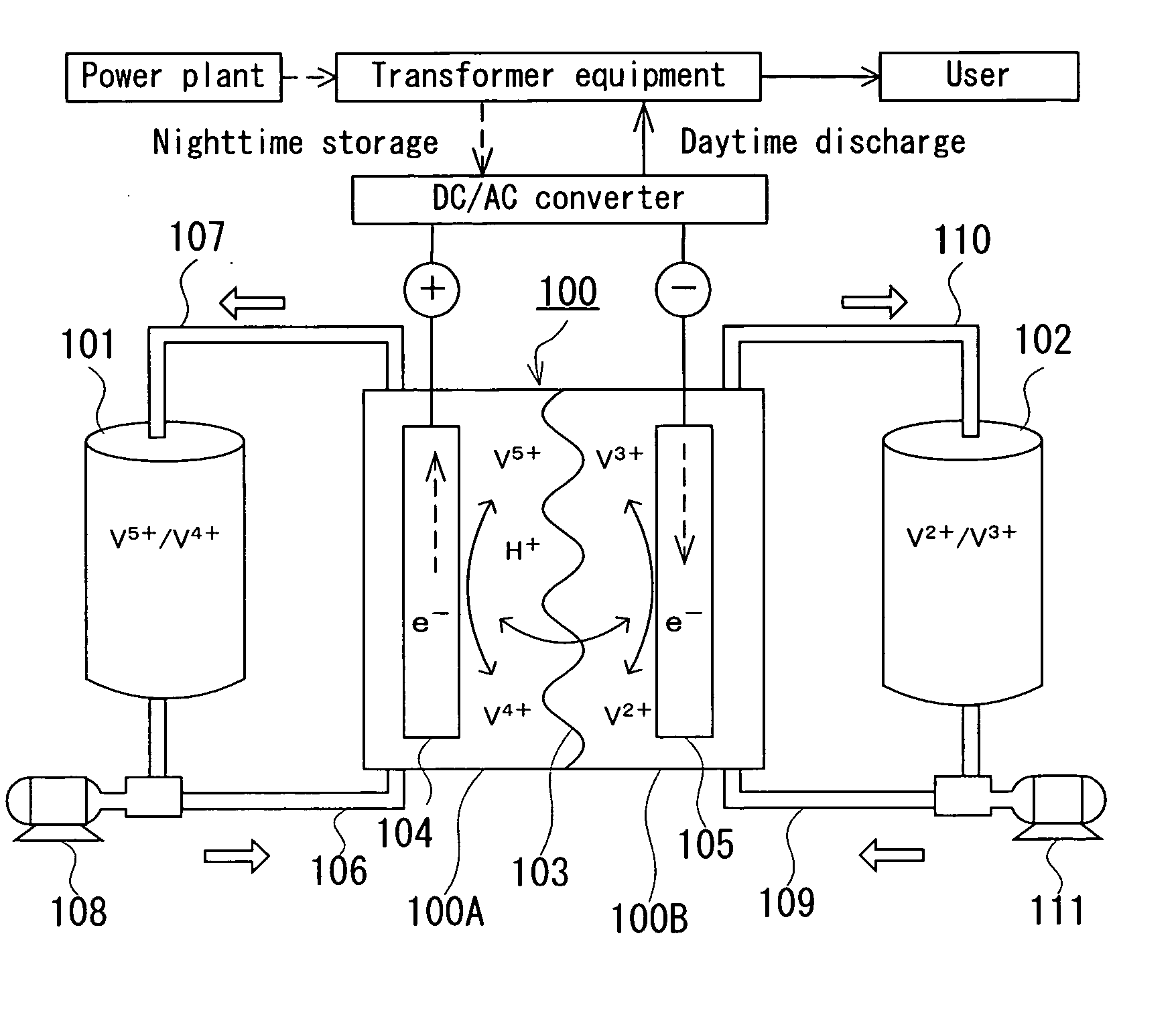

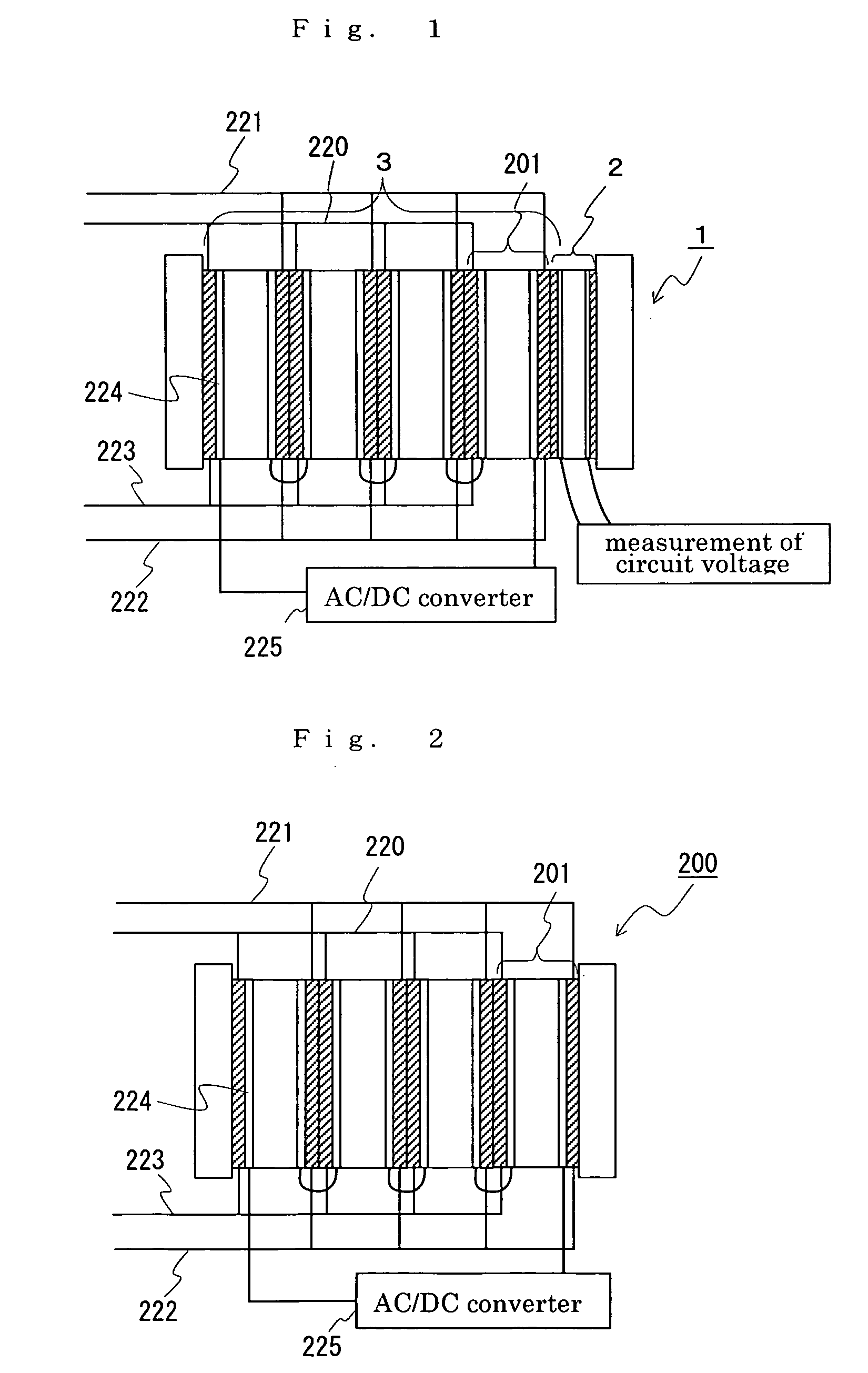

Method for operating redox flow battery and redox flow battery cell stack

InactiveUS20050164075A1Cost reductionImprove output performanceFuel cell combinationsFuel cells groupingAuxiliary cellEngineering

Owner:KUMAMOTO TAKAHIRO +1

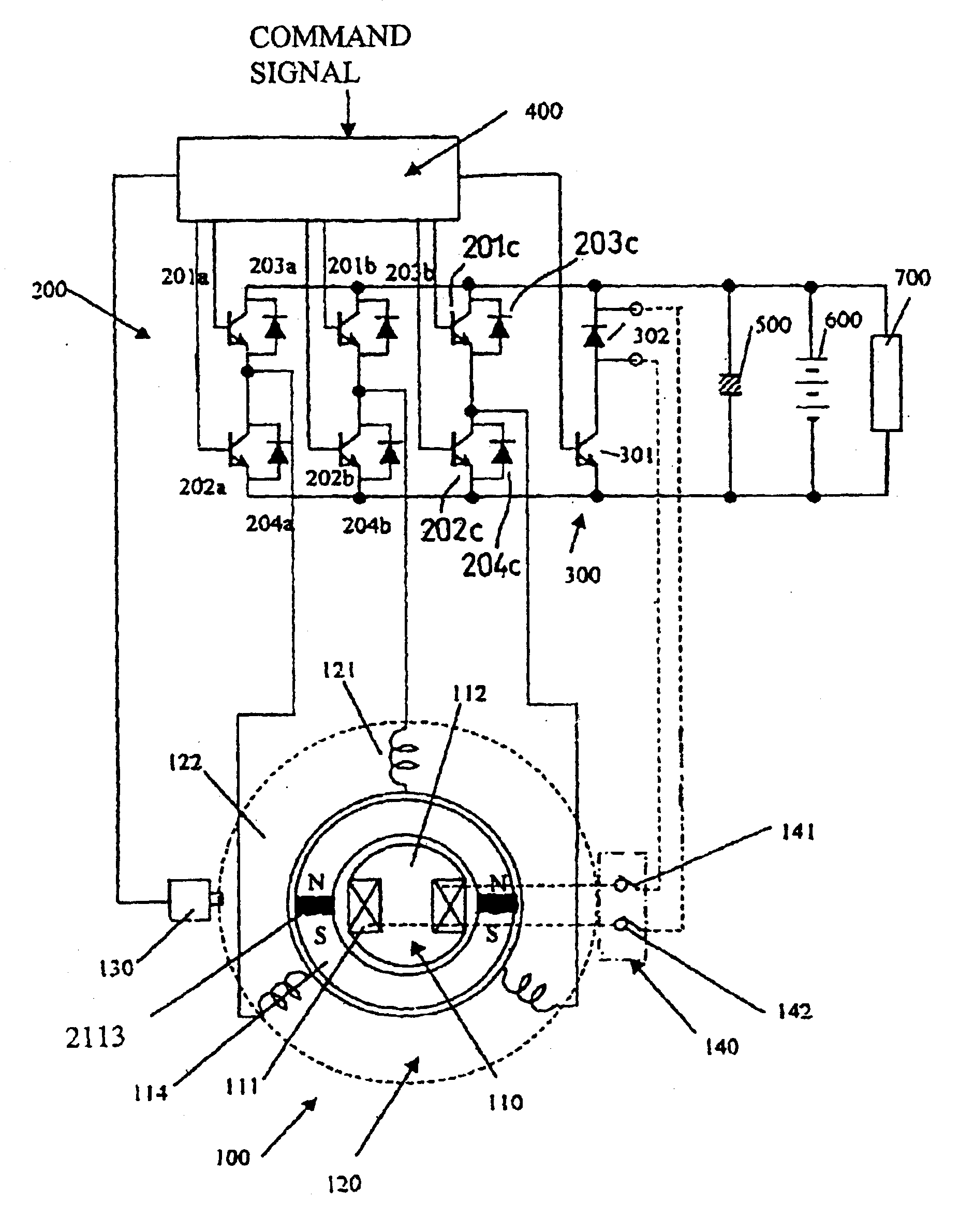

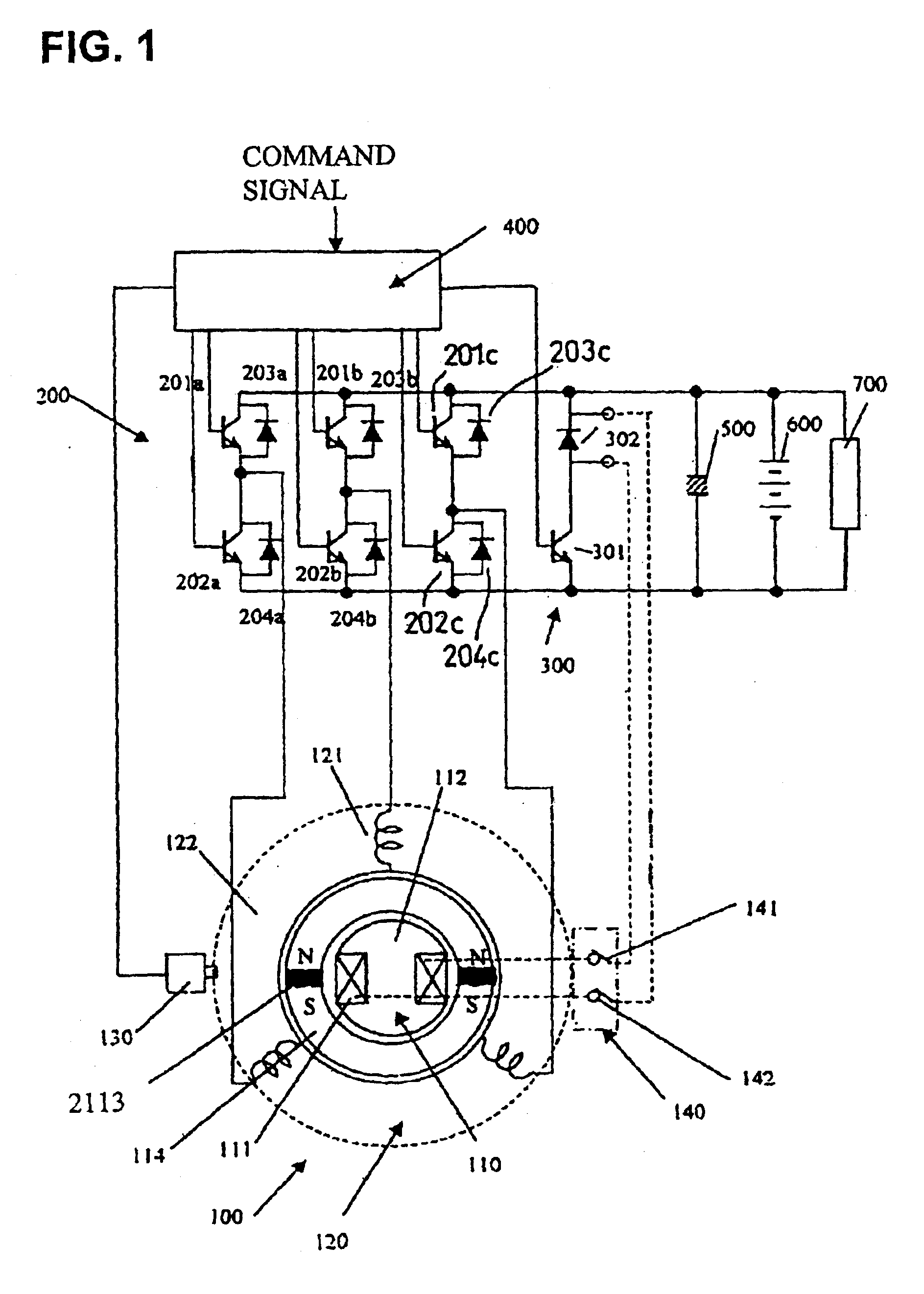

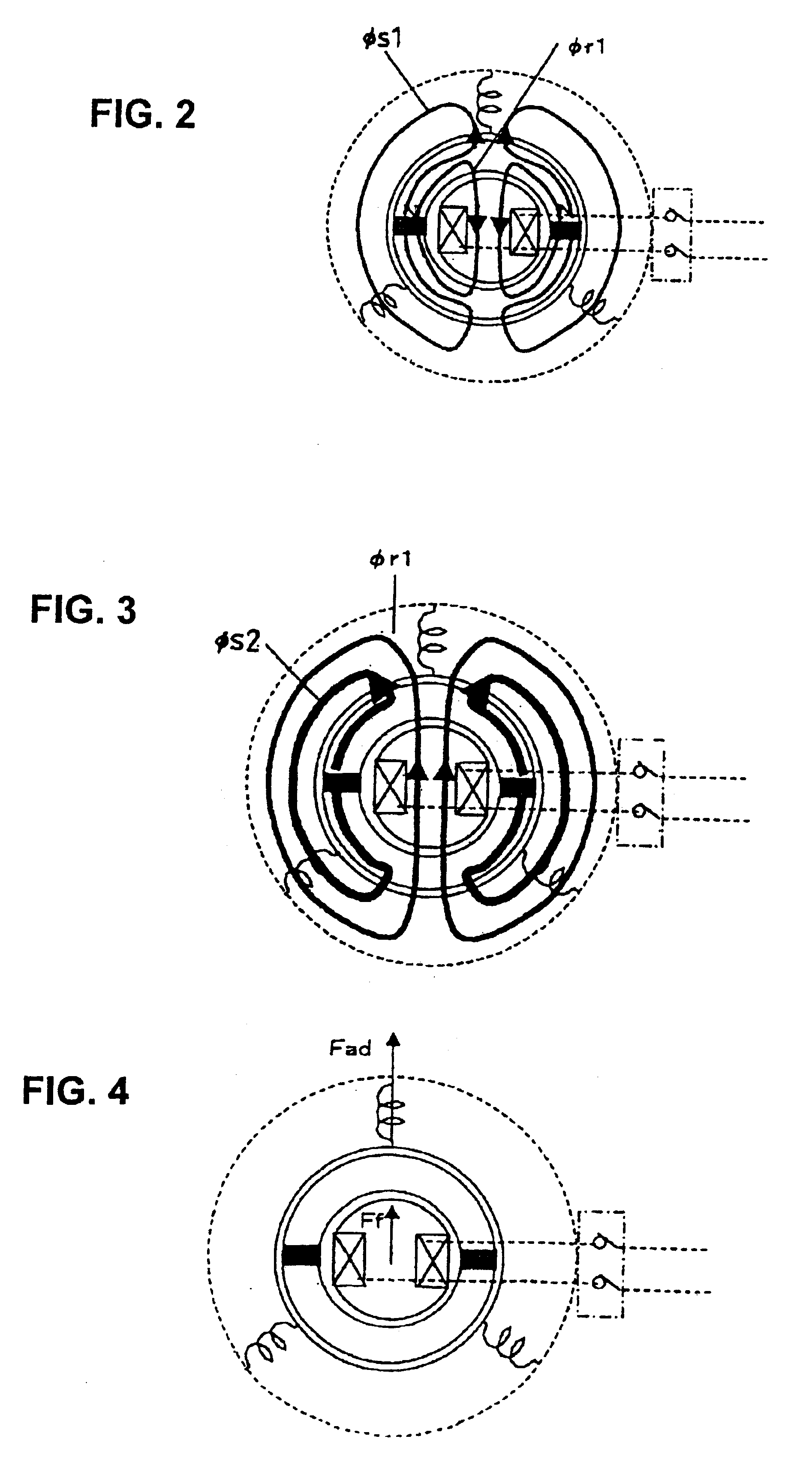

Vehicle motor-generator apparatus utilizing synchronous machine having field winding

InactiveUS6713888B2Improve the level ofIncrease power generationCircuit monitoring/indicationDifferent batteries chargingPower inverterMaximum torque

A vehicle motor-generator apparatus based on a field winding type of synchronous machine coupled to a power inverter and a battery, wherein the synchronous machine is controlled to operate as a motor to perform engine starting and thereafter be driven by the engine as an electrical generator, wherein during a short time interval at the commencement of engine starting, the armature winding of the synchronous machine is driven by a current such that magnetic flux is produced by the armature winding acting in the same direction as magnetic flux produced by the field winding, to thereby achieve increased torque during the time when maximum torque is required. In addition, the supplied field current is set at a maximum value during only an initial period when engine starting begins, until the first compression stroke of the engine has been completed, and thereafter set to a reduced value until the completion of engine starting, thereby reducing the amount temperature rise within the field winding during engine starting, while ensuring a sufficiently high value of initial torque.

Owner:DENSO CORP

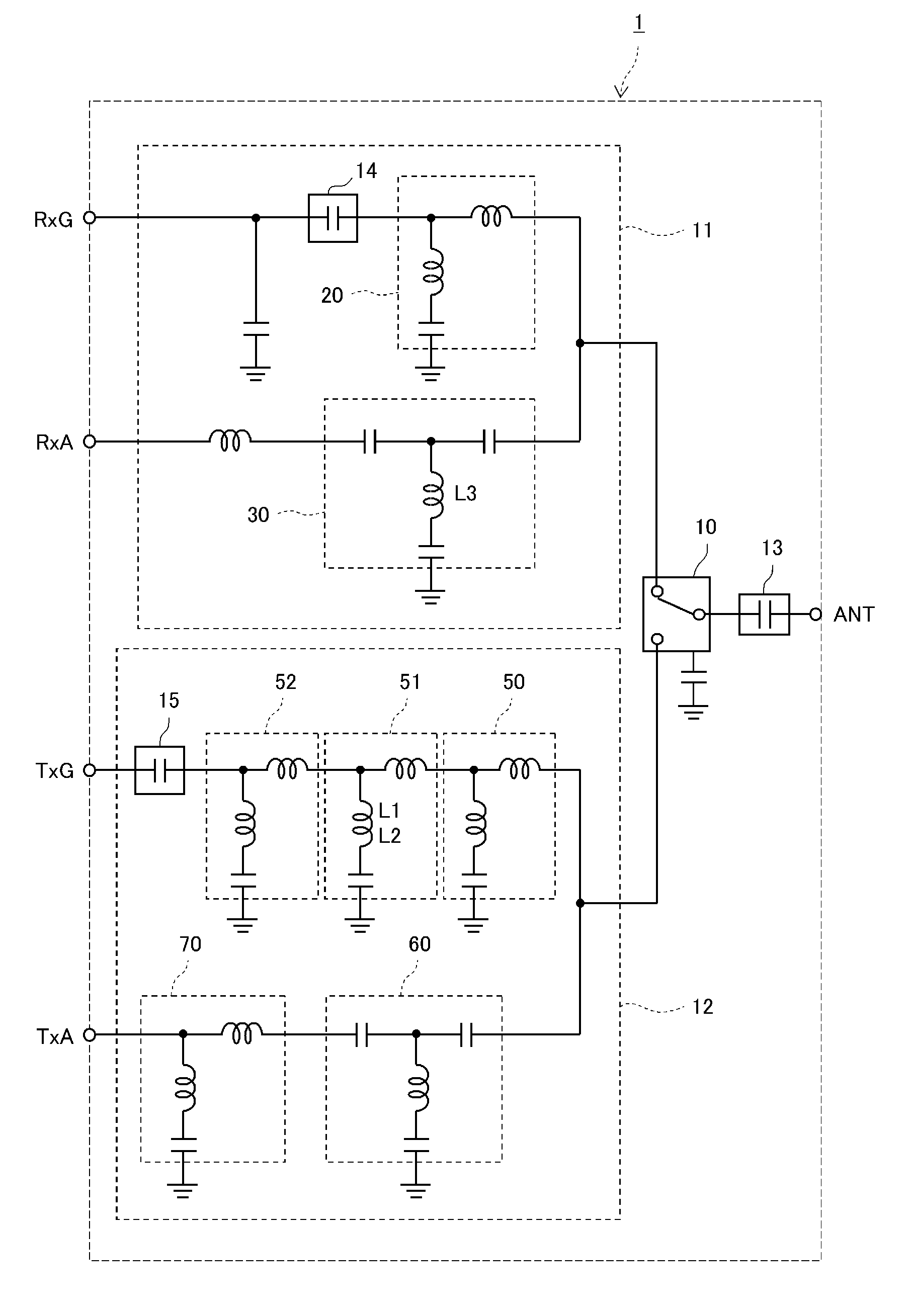

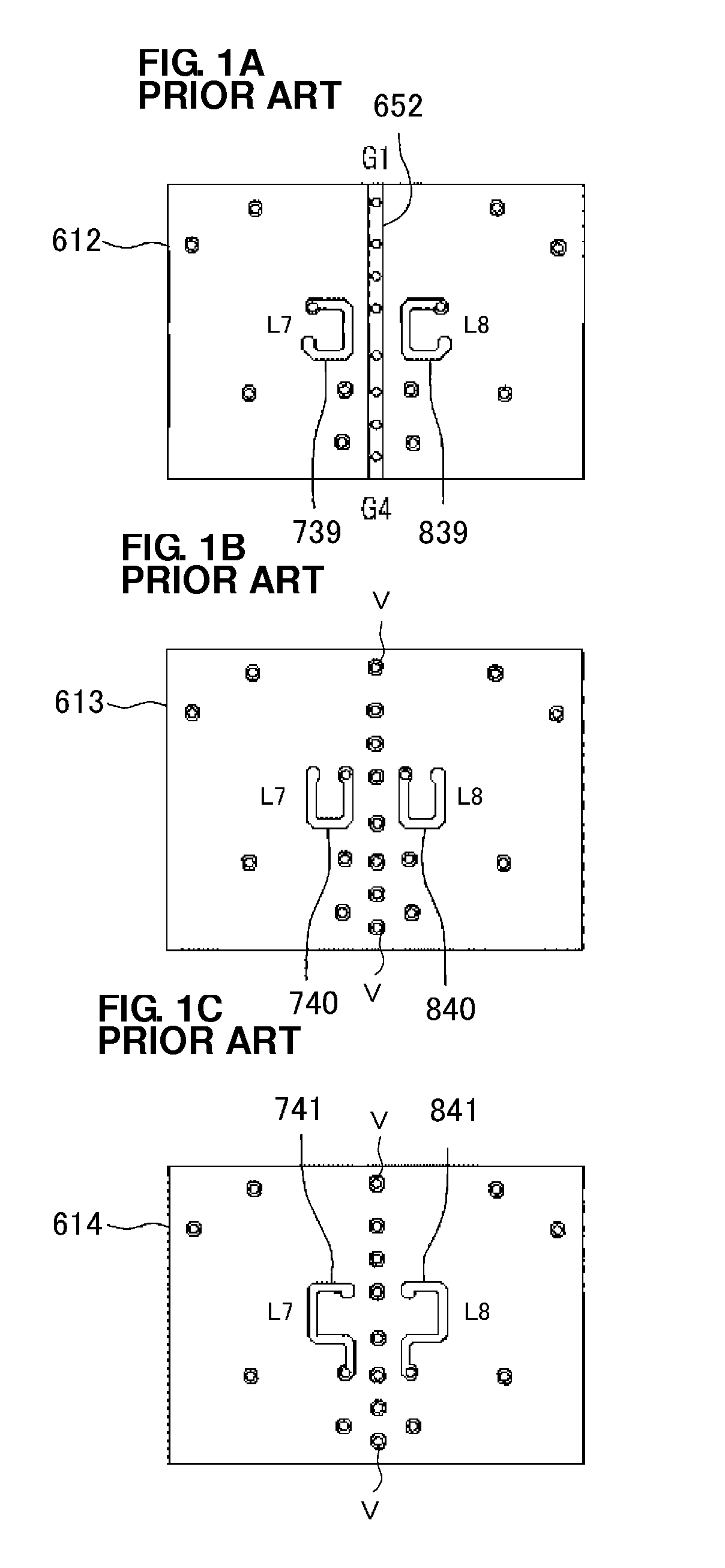

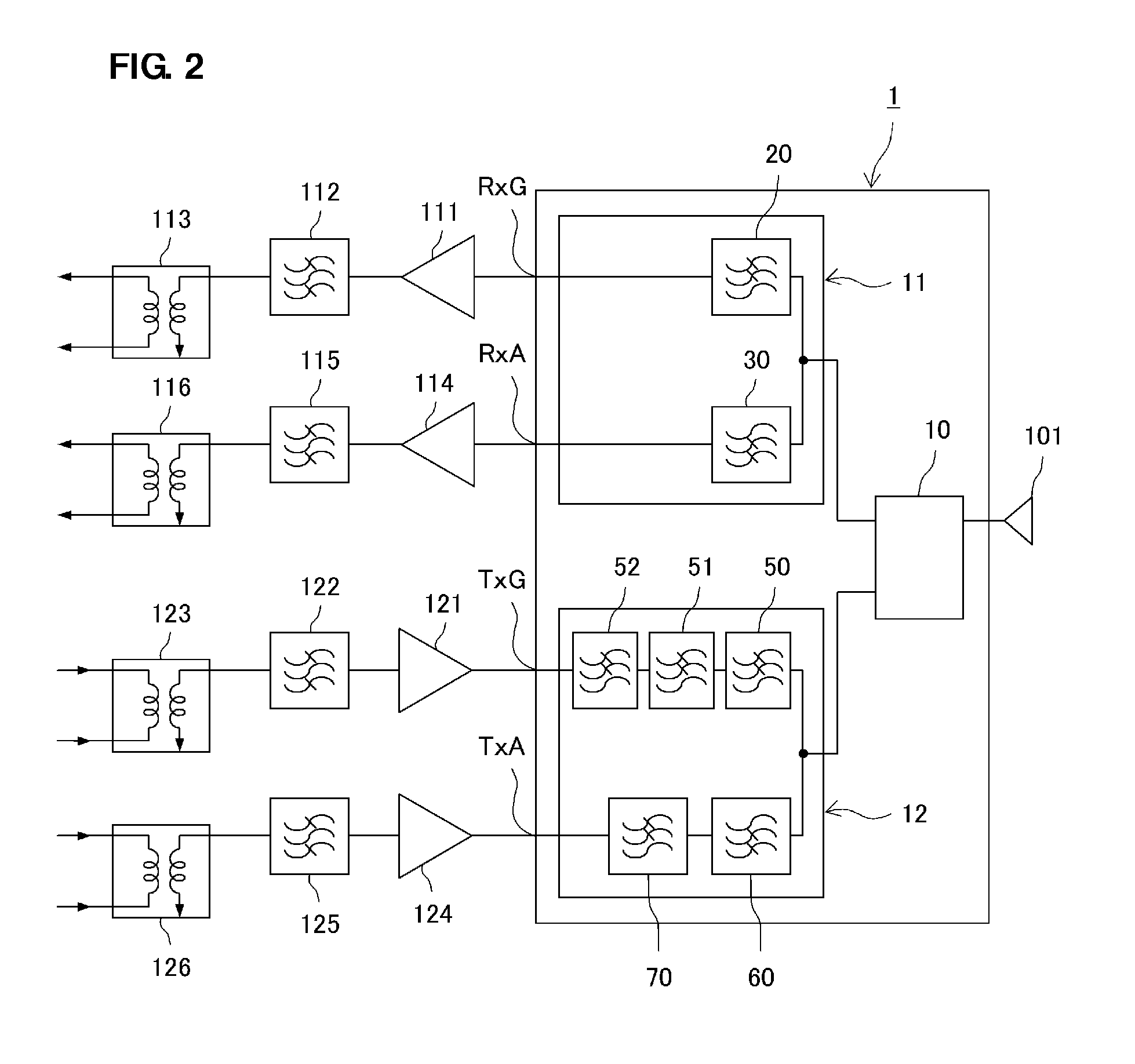

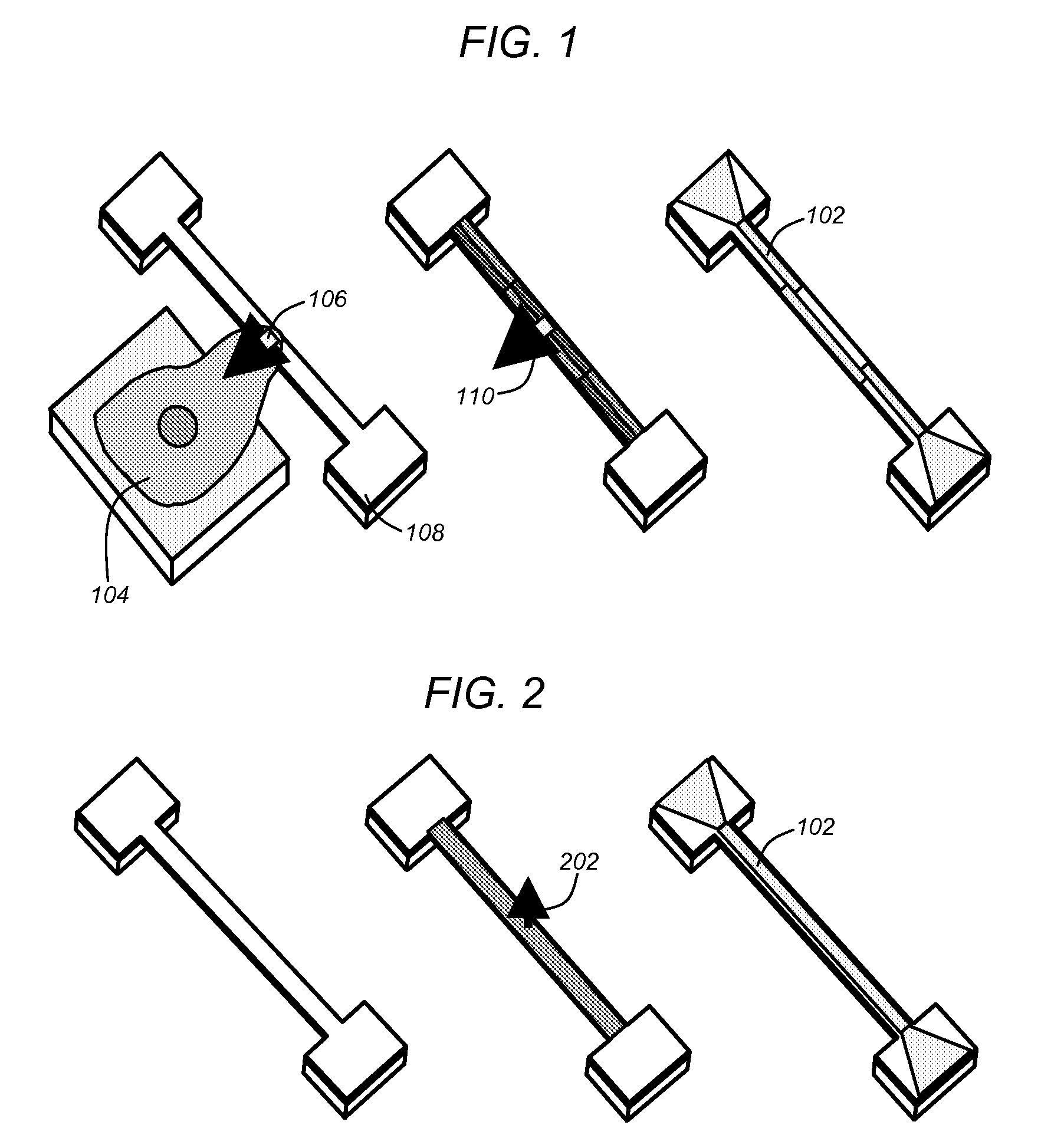

Branching device

ActiveUS20120081192A1Reduce electromagnetic interferenceReduce problem sizeMultiple-port networksTransmissionElectrical conductorInductor

In a branching device, an LPF includes a first inductor arranged such that some conductor layers from among conductor layers are wound in a clockwise direction, and a second inductor arranged such that a conductor layer from among the conductor layers is wound in an counterclockwise direction. In addition, an HPF includes a third inductor arranged such that conductor layers are wound in the same clockwise direction as the first inductor. Therefore, when a high-frequency signal passes through the LPF, a winding direction is reversed. In addition, when a high-frequency signal passes through the HPF, a winding direction is reversed.

Owner:MURATA MFG CO LTD

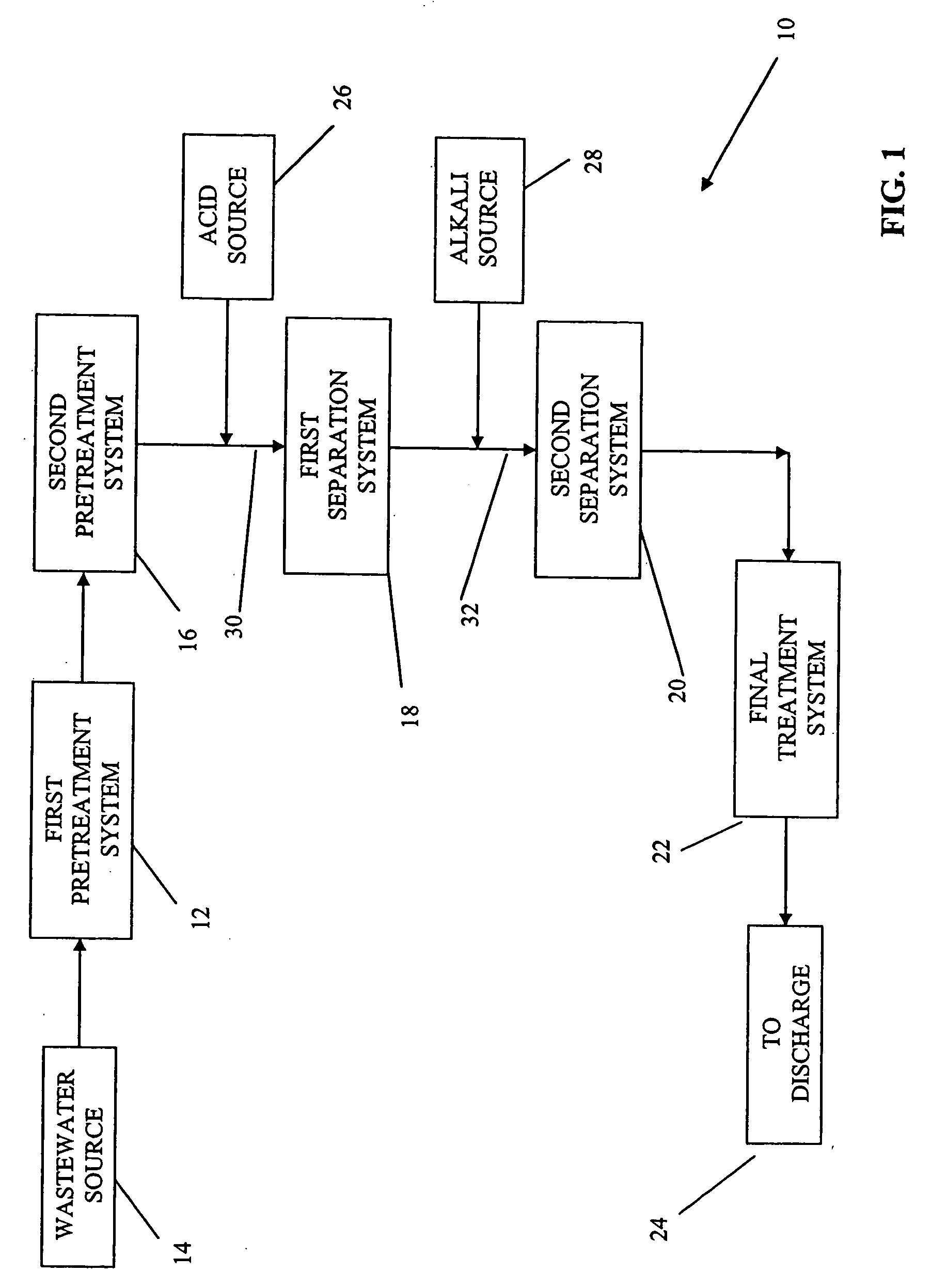

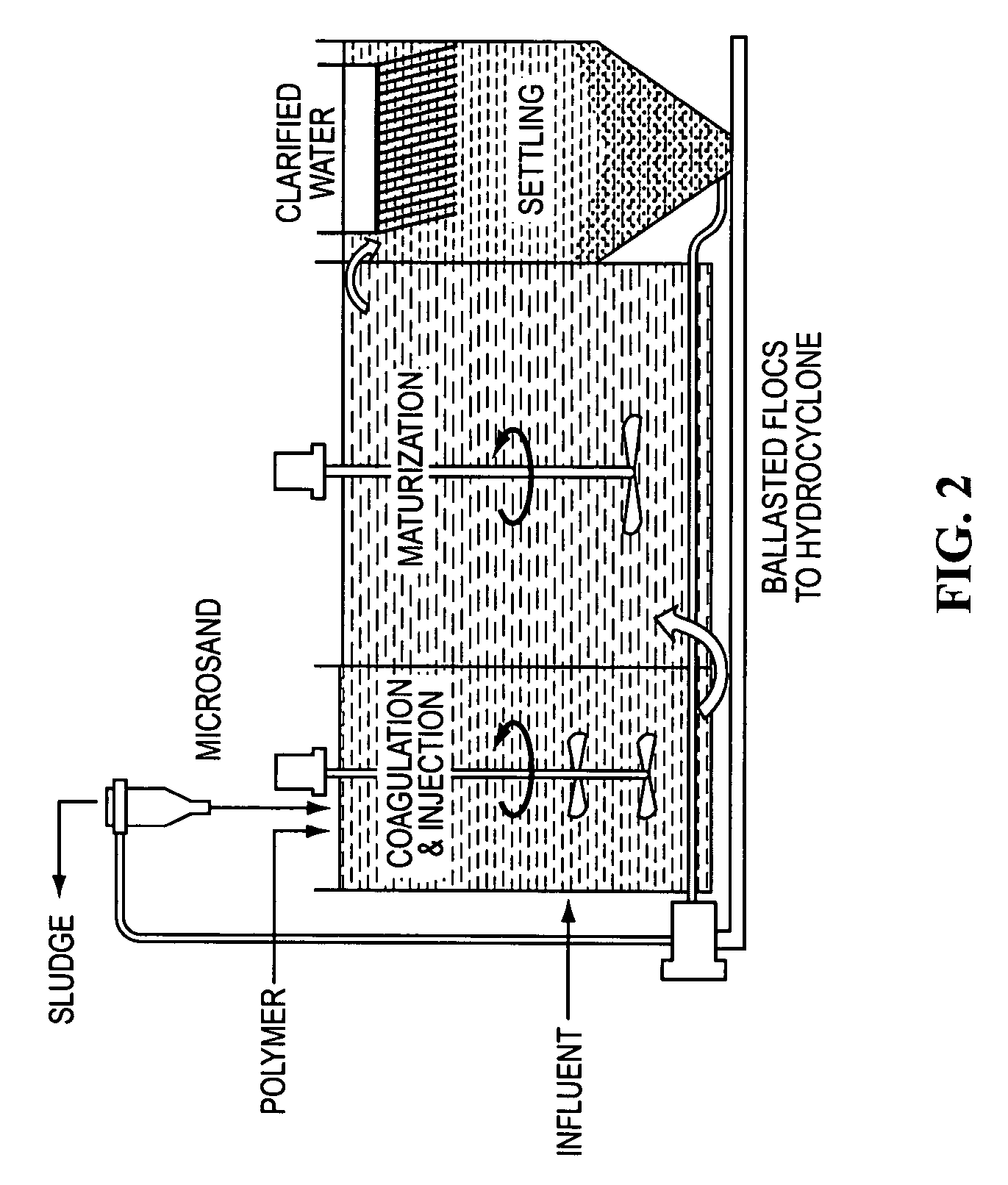

System and method for treatment of acidic wastewater

InactiveUS20050051488A1Reduce problem sizePromote formationTreatment involving filtrationSolid sorbent liquid separationUnit operationReverse osmosis

A wastewater treatment system comprising separation unit operations inhibits or promotes the formation and precipitation of species by controlling the pH of wastewater to be treated entering into the separation unit operations. The separation unit operations include first and second reverse osmosis devices. The first reverse osmosis device treats wastewater having pH that is less than about 3.5 and the second reverse osmosis device treats wastewater, from the first reverse osmosis device, having a pH that is about 6 or higher.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

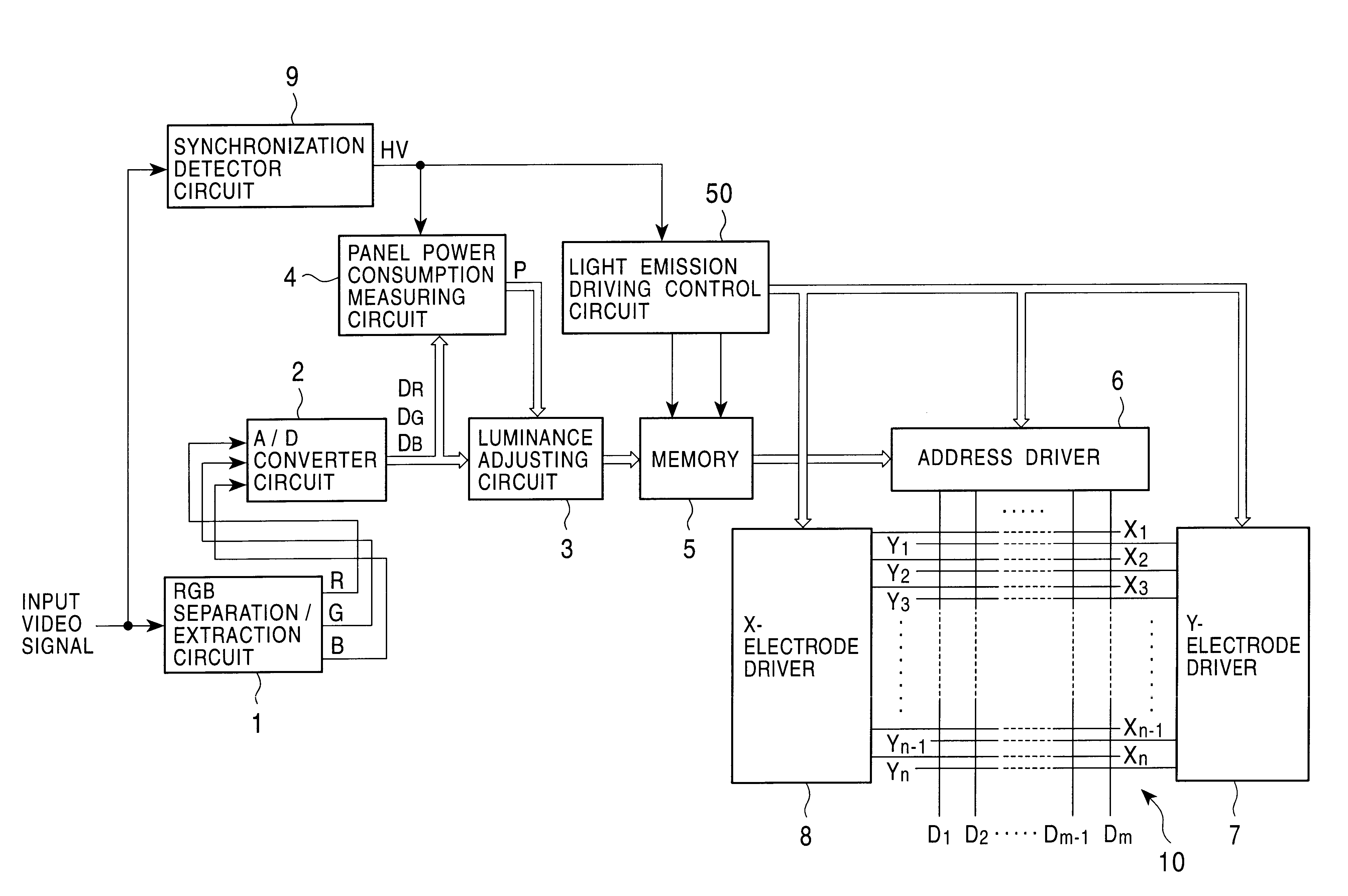

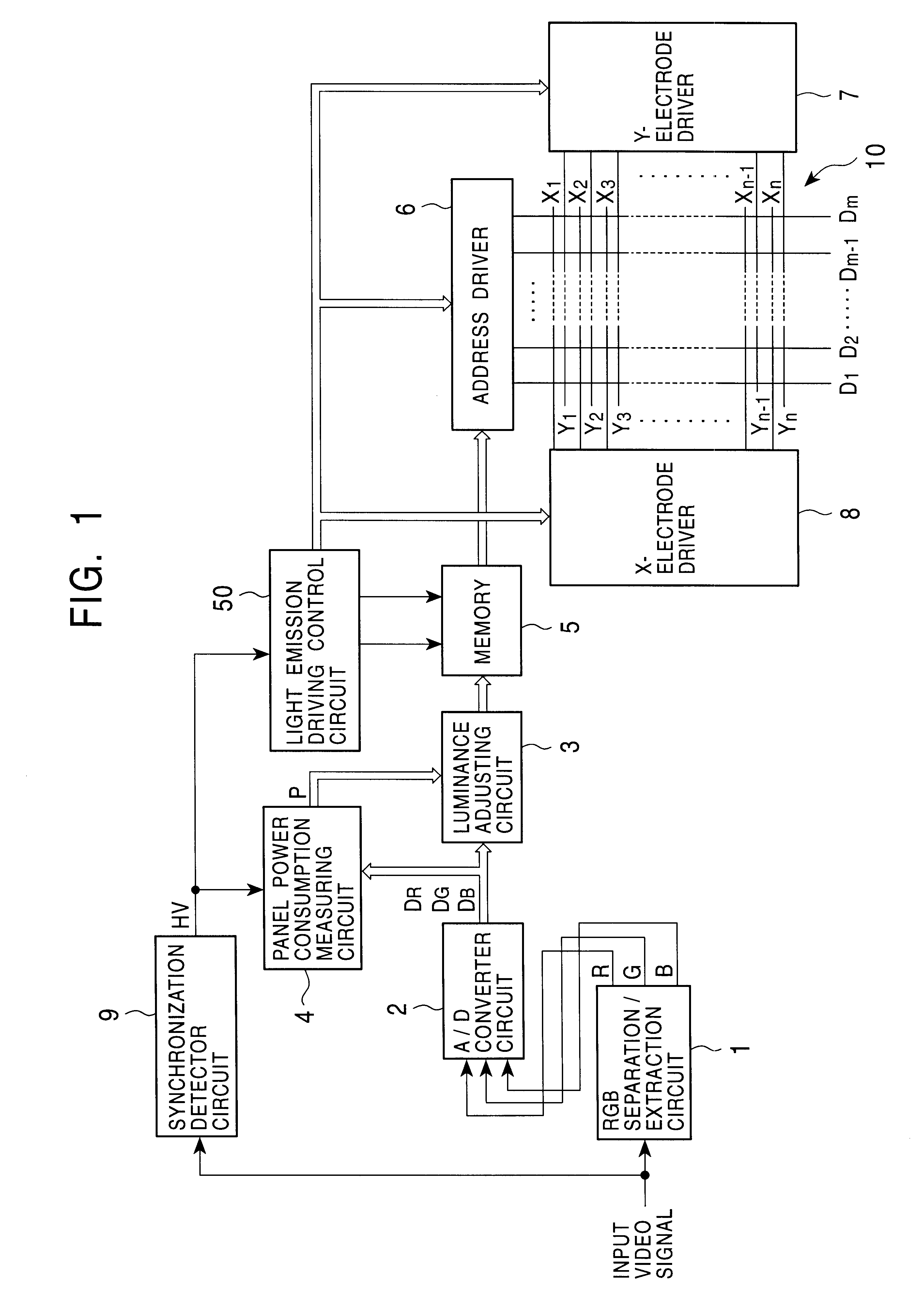

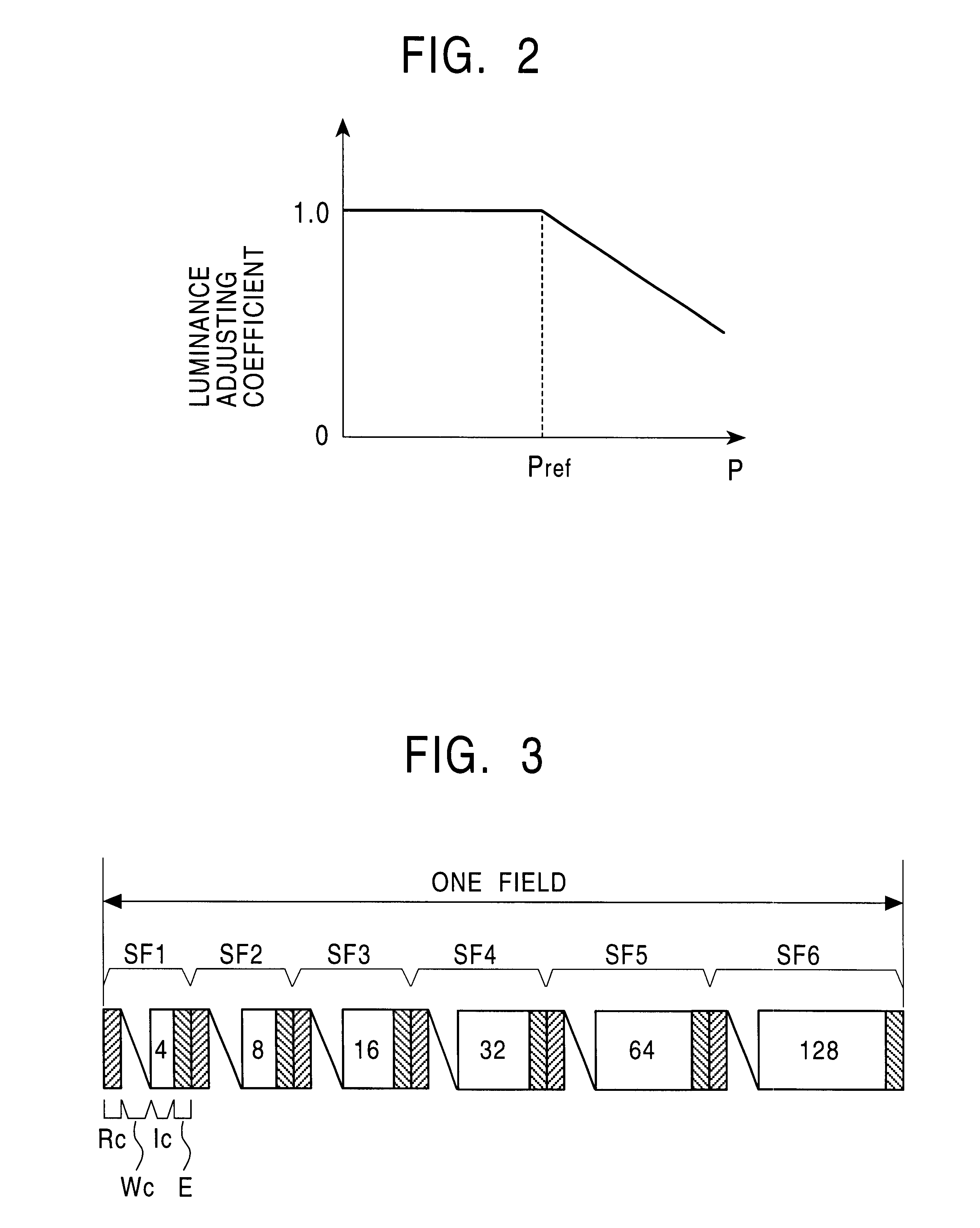

Driving apparatus for driving a plasma display panel based on power consumed during a non-light emitting period of a unit display period

InactiveUS6496165B1Reduce problem sizeSuppress power consumptionCathode-ray tube indicatorsInput/output processes for data processingEngineeringLight-emitting diode

A driving apparatus of a plasma display panel which is capable of reducing the scale of the driver itself while limiting power consumed by the plasma display panel. The value of power consumed during a non-light emitting period in one field (frame) period is added to an average luminance level of an input video signal to derive average power consumption, and the power consumed by the plasma display panel is controlled on the basis of the average power consumption.

Owner:PANASONIC CORP

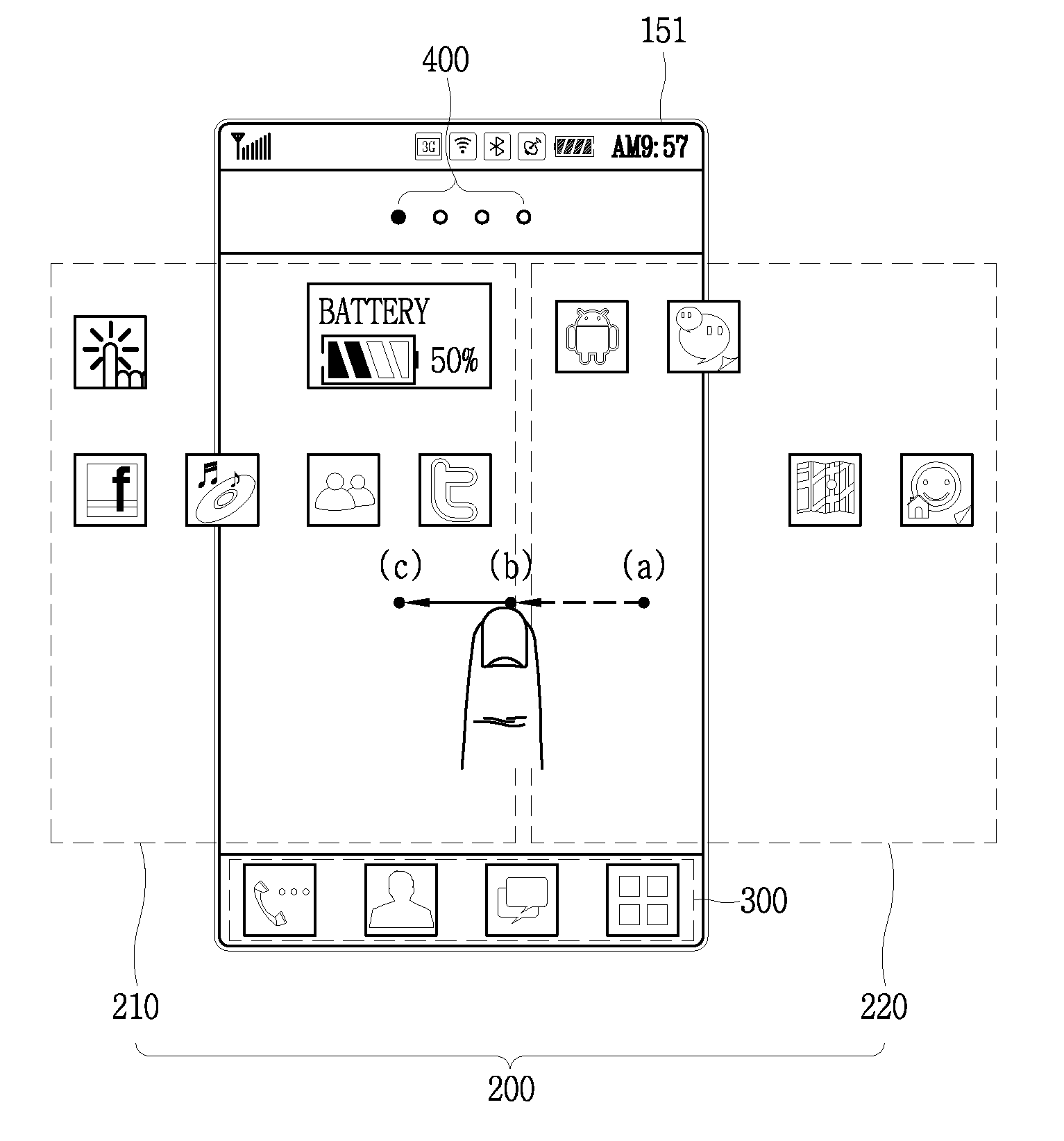

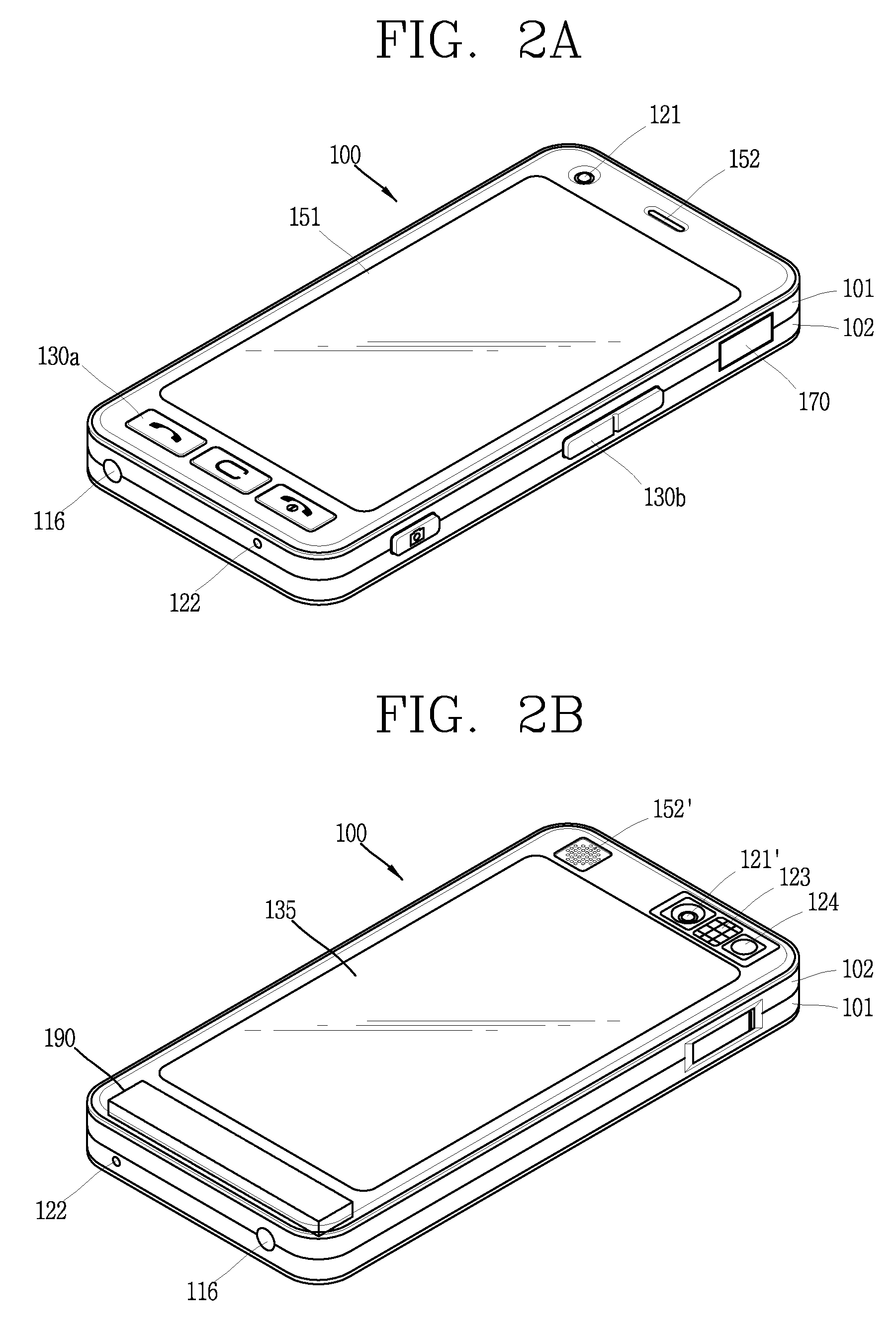

Mobile terminal and control method thereof

InactiveUS20130268883A1Enhancing user 's convenienceReduce problem sizeInput/output processes for data processingHuman–computer interaction

Owner:LG ELECTRONICS INC

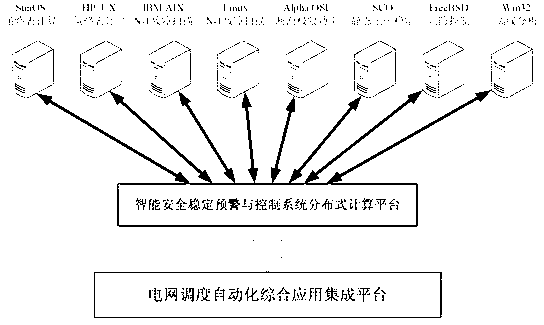

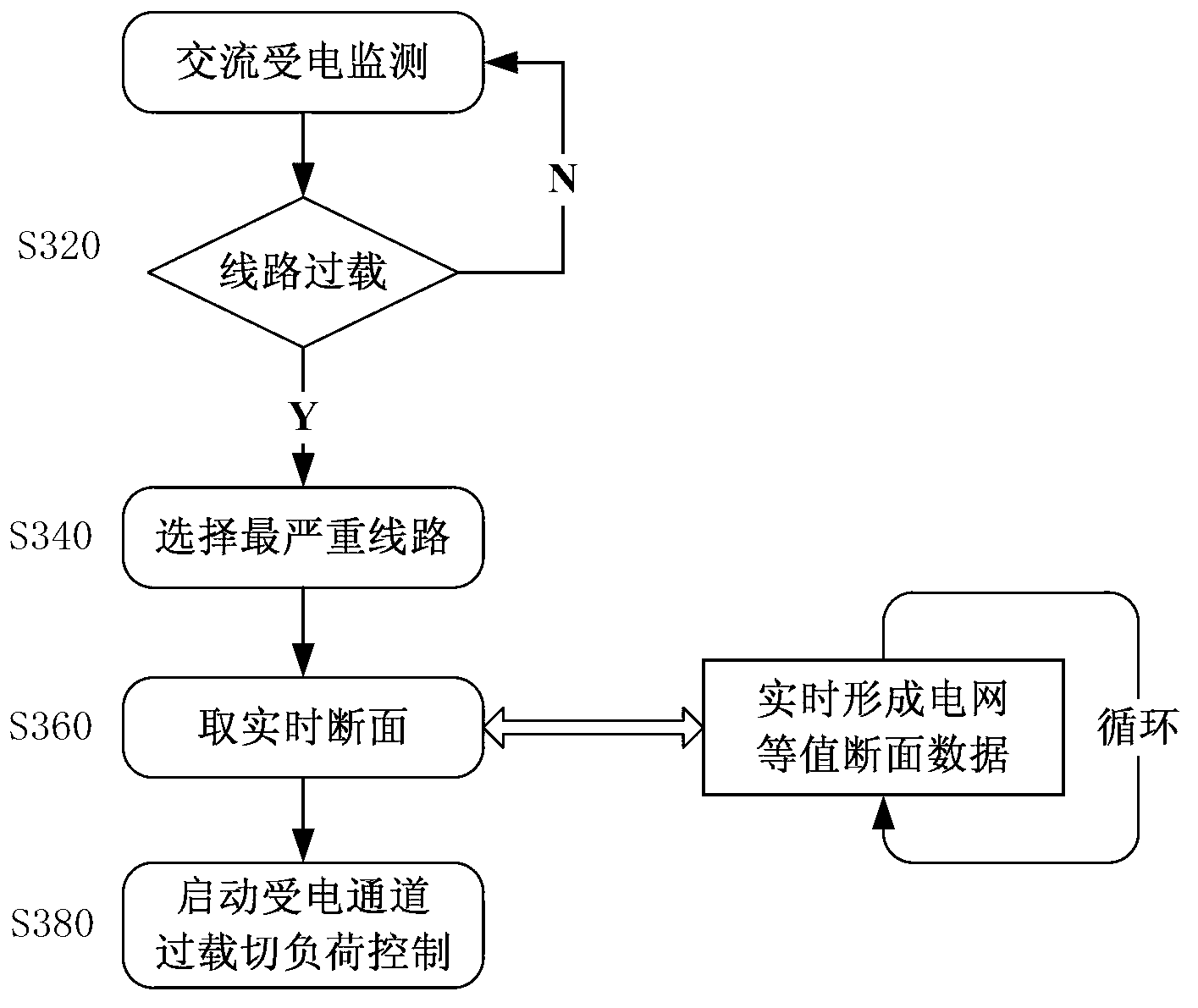

Intelligent power grid safety and stability early-warning and control system

ActiveCN102938588ASecurity and Stability ControlEasy to controlCircuit arrangementsInformation technology support systemElectric power systemControl system

The invention relates to an emergency protection circuit device capable of completing automatic switching when an AC-DC power grid is in an abnormal state, and in particular relates to an intelligent warning and control system dedicated for ensuring safety and stability of a power grid. The intelligent safety and stability early-warning and control system comprises a distributed computing platform and a multilevel zone control network, wherein the multilevel zone control network is composed of an intelligent control master station, intelligent control substations controlled by the intelligent control master station and arranged in each zone, and a plurality of intelligent control terminal stations respectively connected with each intelligent control substation; and two-way connections are constructed between the intelligent control master station and the intelligent control substations, between every two intelligent control substations and between the intelligent control substations and the subordinate intelligent control terminal stations. The real-time running data of the power grid is used to provide safety and stability early-warning information of the power grid so as to realize safety and stability control of the power grid and to realize the function of the second line of defense of the power system. The system provided by the invention can ensure safe and stable operation of the power grid by regulating a stability control device according to the running condition of the power grid.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

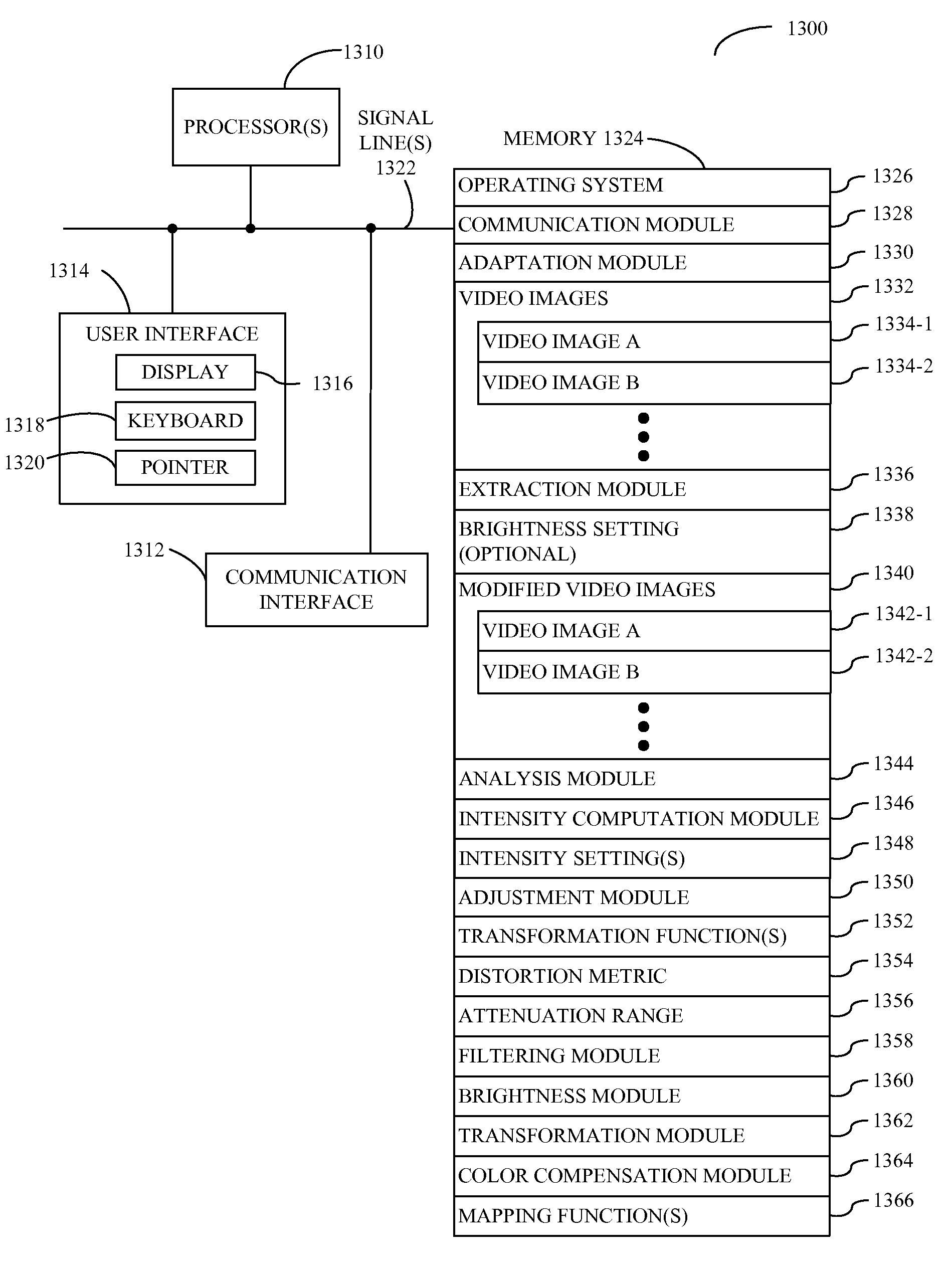

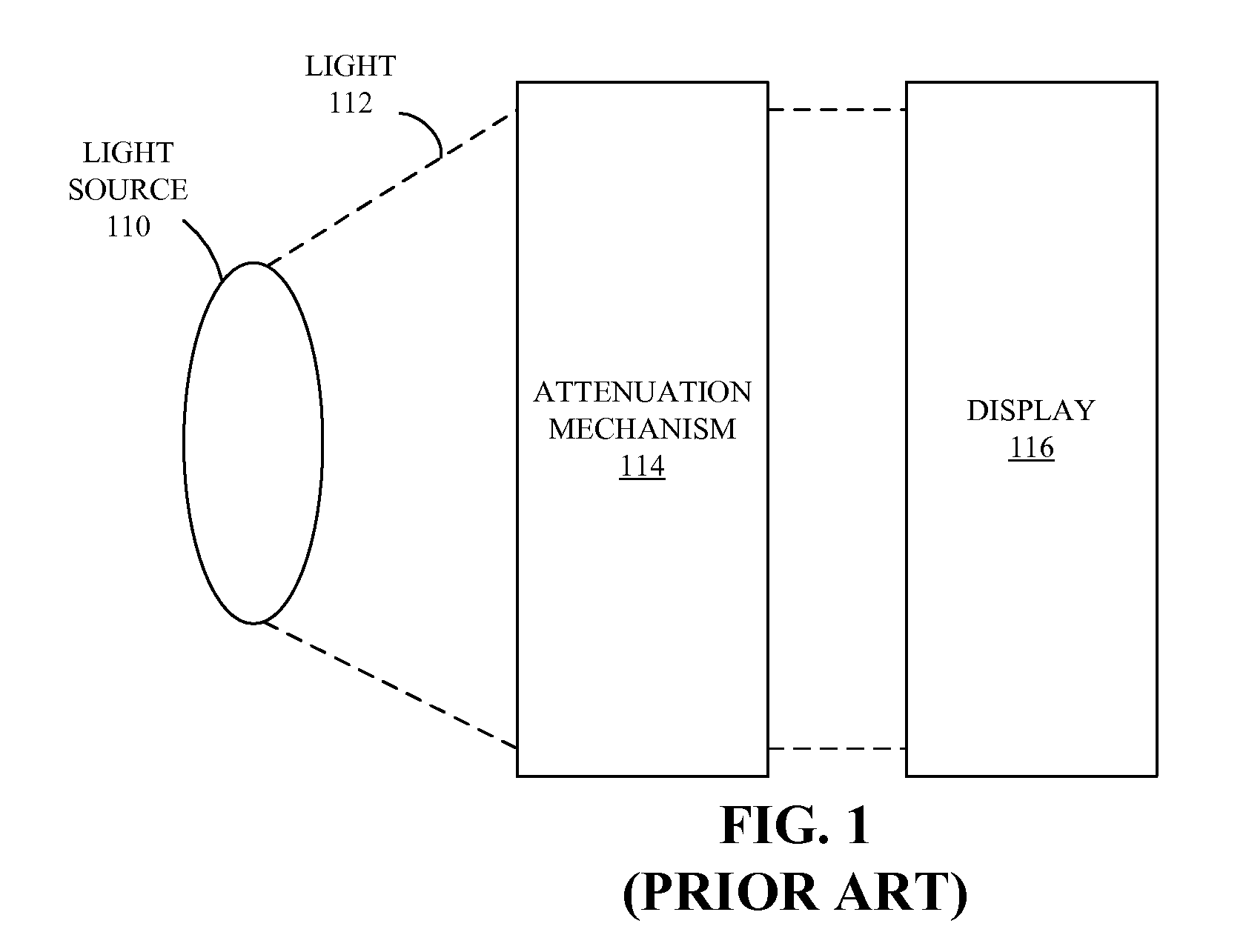

Technique for adjusting a backlight during a brightness discontinuity

InactiveUS20090002564A1Reduce noiseReduce power consumptionTelevision system detailsStatic indicating devicesDisplay deviceVideo image

Embodiments of a system that includes one or more integrated circuits are described. During operation, the system receives a sequence of video images, and calculates brightness metrics associated with the video images in the sequence of video images. Then, the system determines an intensity setting of a light source, which illuminates a display that is configured to display the sequence of video images, and scales brightness values of a given video image in the sequence of video images based on a given brightness metric associated with the given video image. Next, the system changes the intensity setting and scaling the brightness values when there is a discontinuity in the brightness metrics between two adjacent video images in the sequence of video images.

Owner:APPLE INC

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20090022225A1Avoid slow motionEliminate needColor television with pulse code modulationColor television with bandwidth reductionDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

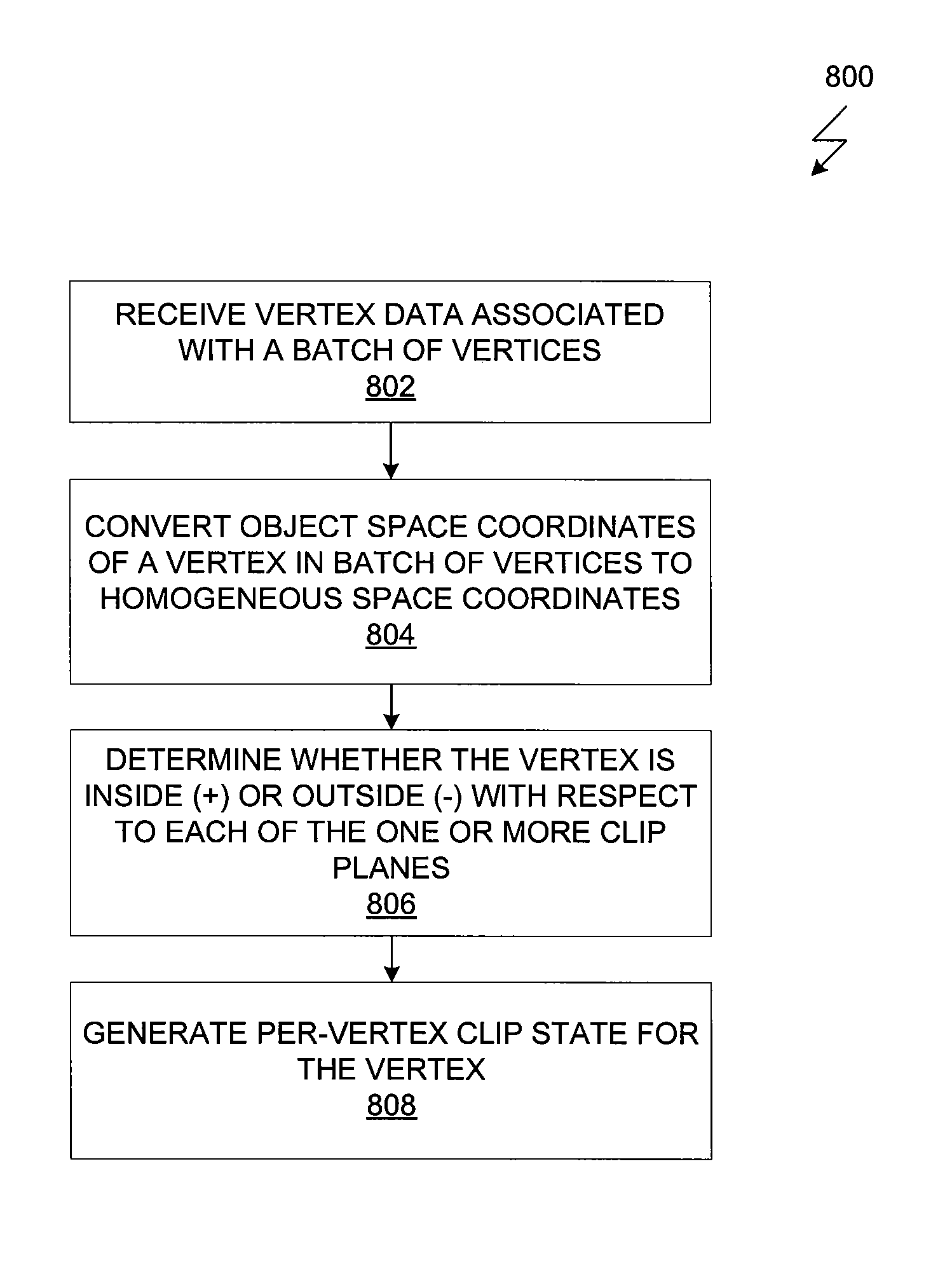

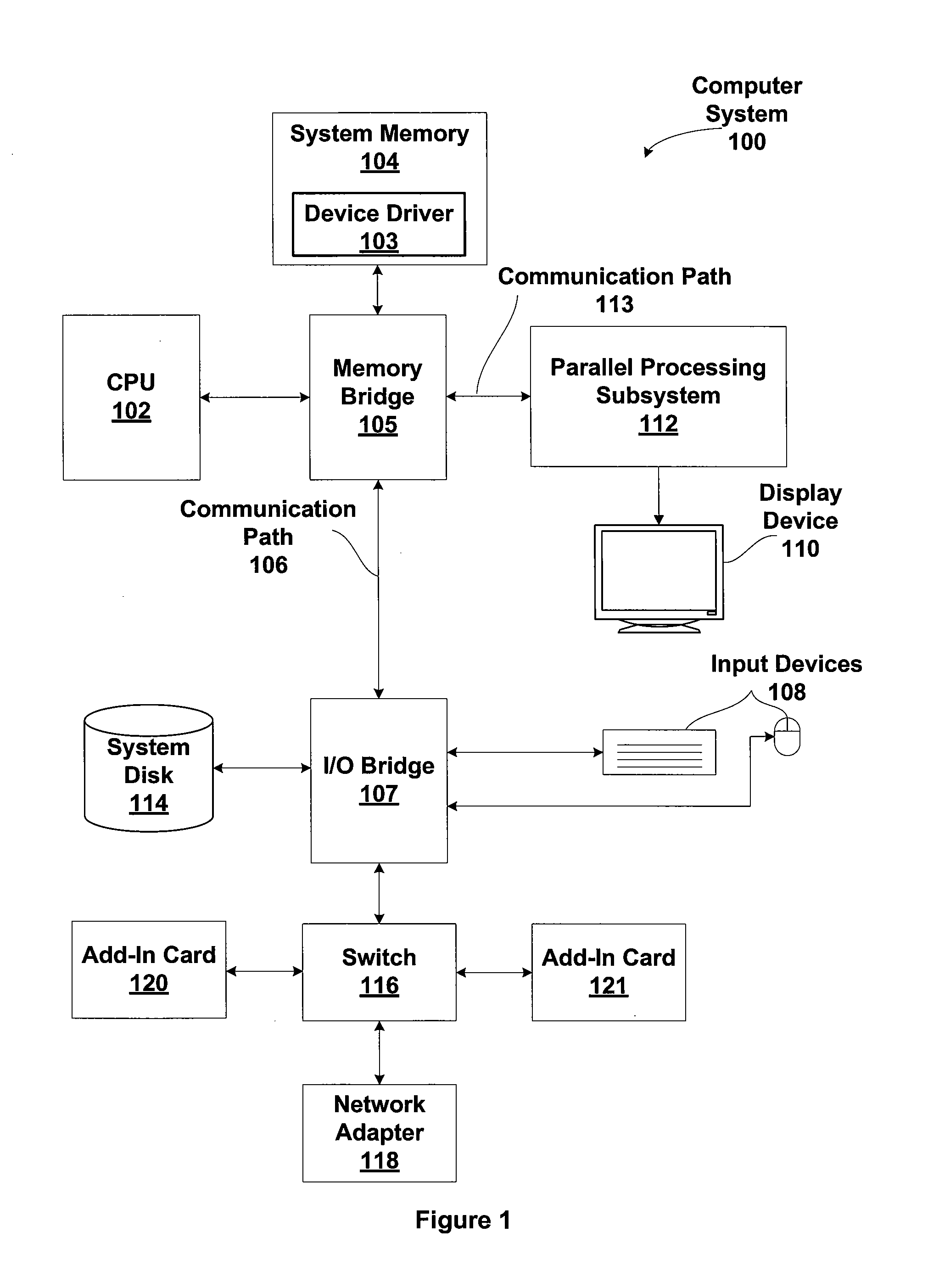

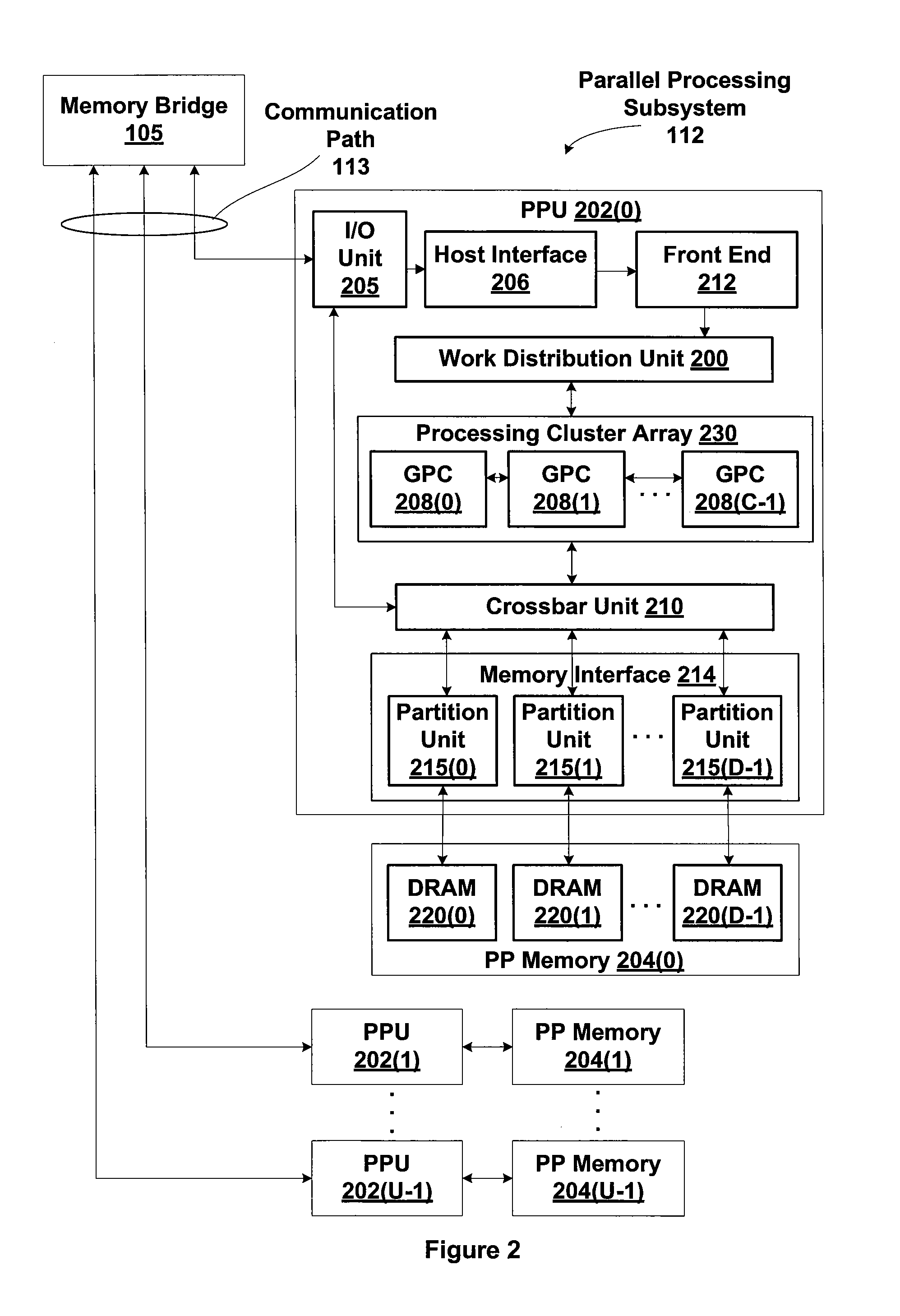

Generating clip state for a batch of vertices

ActiveUS8976195B1Conserve processing bandwidthReduce problem sizeCathode-ray tube indicators3D-image renderingGraphicsGraphics pipeline

One embodiment of the present invention sets forth a technique for generating a batch clip state stored in clip state machine (CSM) associated with a batch of vertices. Per-vertex clip state is generated for each vertex in the batch of vertices based on the position of each vertex relative to each clip plane. For a given vertex, per-vertex clip state indicates whether the vertex is inside or outside each of the one or more clip planes. The per-vertex clip states of all the vertices in the batch of vertices are coalesced into a batch clip state by determining whether each vertex in the batch of vertices is inside every clip plane, each vertex is outside at least one clip plane or neither. The batch clip state is stored in the CSM associated with the thread group that processes the batch of vertices that can be accessed by further stages of the graphics pipeline.

Owner:NVIDIA CORP

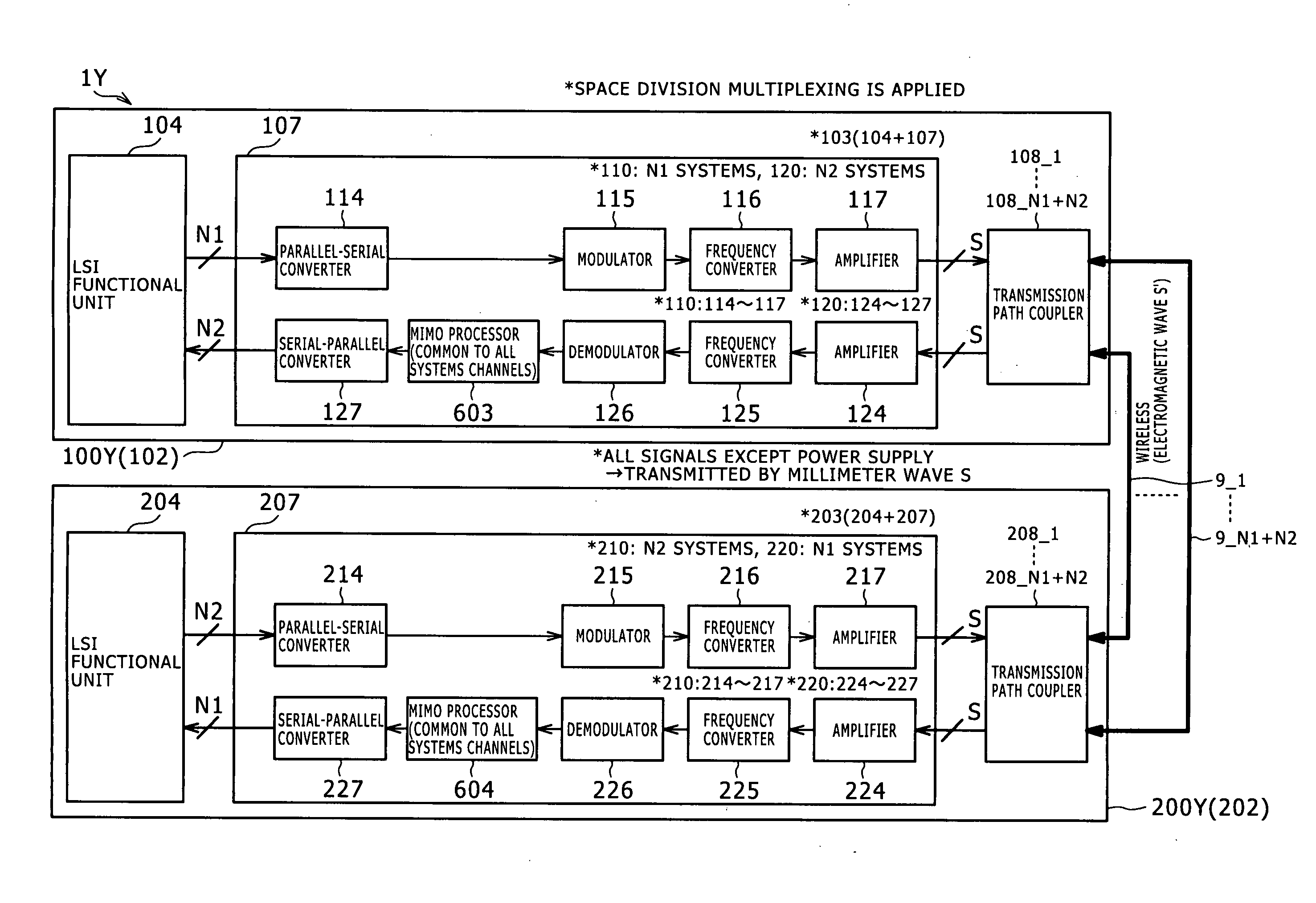

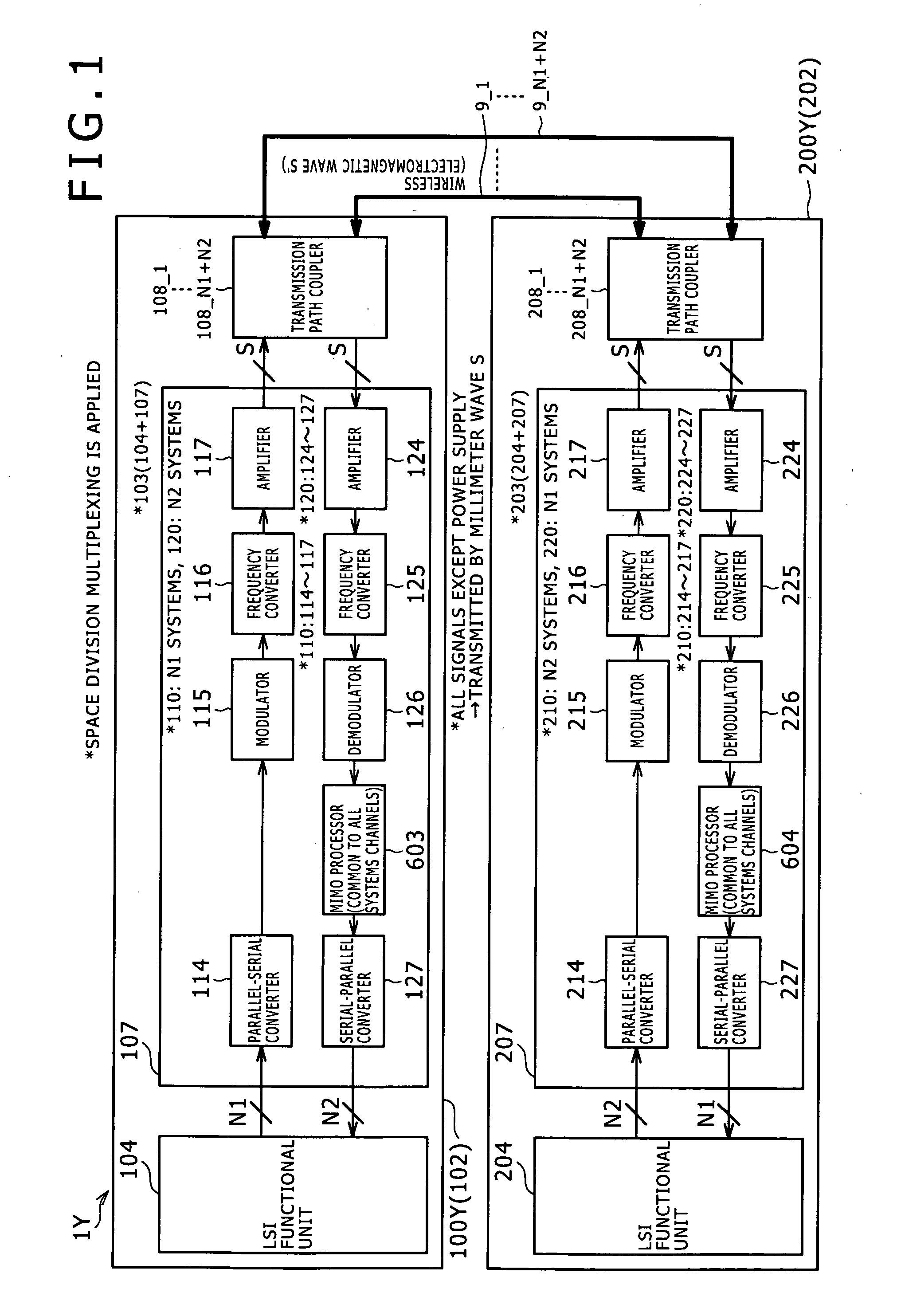

Wireless transmission system, wireless communication device and wireless transmission method

ActiveUS20110075581A1Reduce distanceEasy to processFrequency-division multiplex detailsTransmission systemsVIT signalsEngineering

Disclosed herein is a wireless transmission system including a plurality of antenna pairs; a demodulation functional unit; and a transmission characteristic correction unit. The plurality of antenna pairs each including a transmission antenna and a reception antenna. A wireless signal transmitted from a transmission antenna directly arrives as a desired wave at a corresponding reception antenna. Meanwhile, a wireless signal transmitted from a different transmission antenna directly arrives as an unnecessary wave at the reception antenna. The demodulation functional unit corresponding to each antenna pair demodulates a modulation signal received by the reception antenna. The transmission characteristic correction unit carries out correction calculation based on a transmission characteristic of a transmission space between the transmission and reception antennae based on demodulation signals demodulated by the demodulation functional units to acquire an output signal corresponding to a transmission subject signal.

Owner:SONY CORP

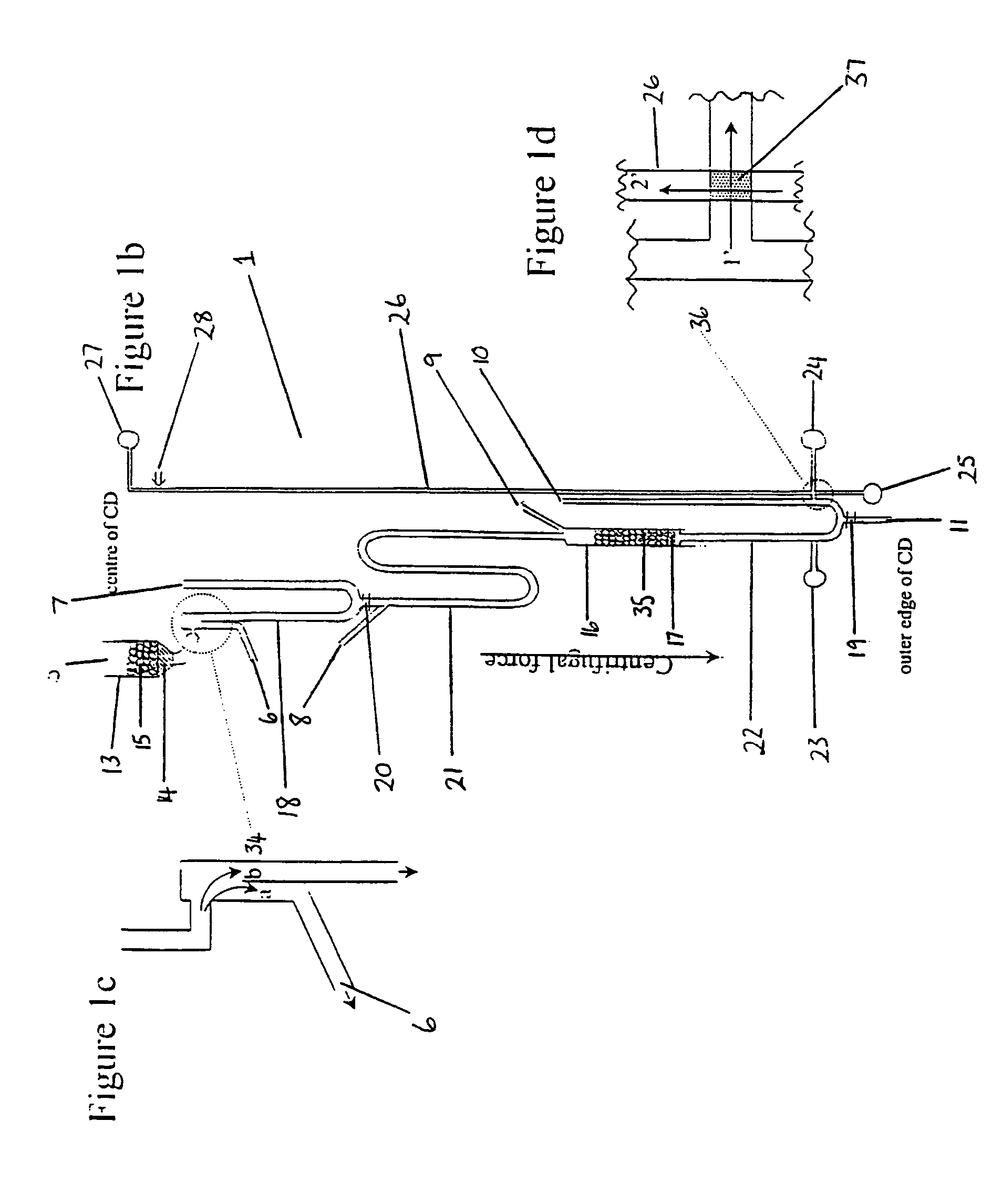

Integrated microfluidic disc

InactiveUS7332126B2Reduce consumptionLow costHeating or cooling apparatusIon-exchanger regenerationOrganic chemistryNucleic acid

Disclosed is a method for performing the steps of nucleic acid template purification, thermocycling reaction and purification of the products of the thermocycling reaction characterized in that the steps take place sequentially in a microfluidic disc. Also disclosed is a microstructure for fluids comprising at least one inlet opening connected to a first chamber incorporating a means for purifying template nucleic acid which, in turn, is connected to a second chamber incorporating a means for a thermocycling reaction which, in turn, is connected to a third chamber incorporating a means for purifying products of the thermocycling reaction, and a microfluidic disc comprising a plurality of such microstructures.

Owner:GYROS

Polymer nems for cell physiology and microfabricated cell positioning system for micro-biocalorimeter

ActiveUS20100024572A1Rapid and parallel implementationShorten the timeBioreactor/fermenter combinationsForce measurement by measuring frquency variationsParyleneThermopile

A microfluidic embedded nanoelectromechanical system (NEMs) force sensor provides an electrical readout. The force sensor contains a deformable member that is integrated with a strain sensor. The strain sensor converts a deformation of the deformable member into an electrical signal. A microfluidic channel encapsulates the force sensor, controls a fluidic environment around the force sensor, and improves the read out. In addition, a microfluidic embedded vacuum insulated biocalorimeter is provided. A calorimeter chamber contains a parylene membrane. Both sides of the chamber are under vacuum during measurement of a sample. A microfluidic cannel (built from parylene) is used to deliver a sample to the chamber. A thermopile, used as a thermometer is located between two layers of parylene.

Owner:CALIFORNIA INST OF TECH

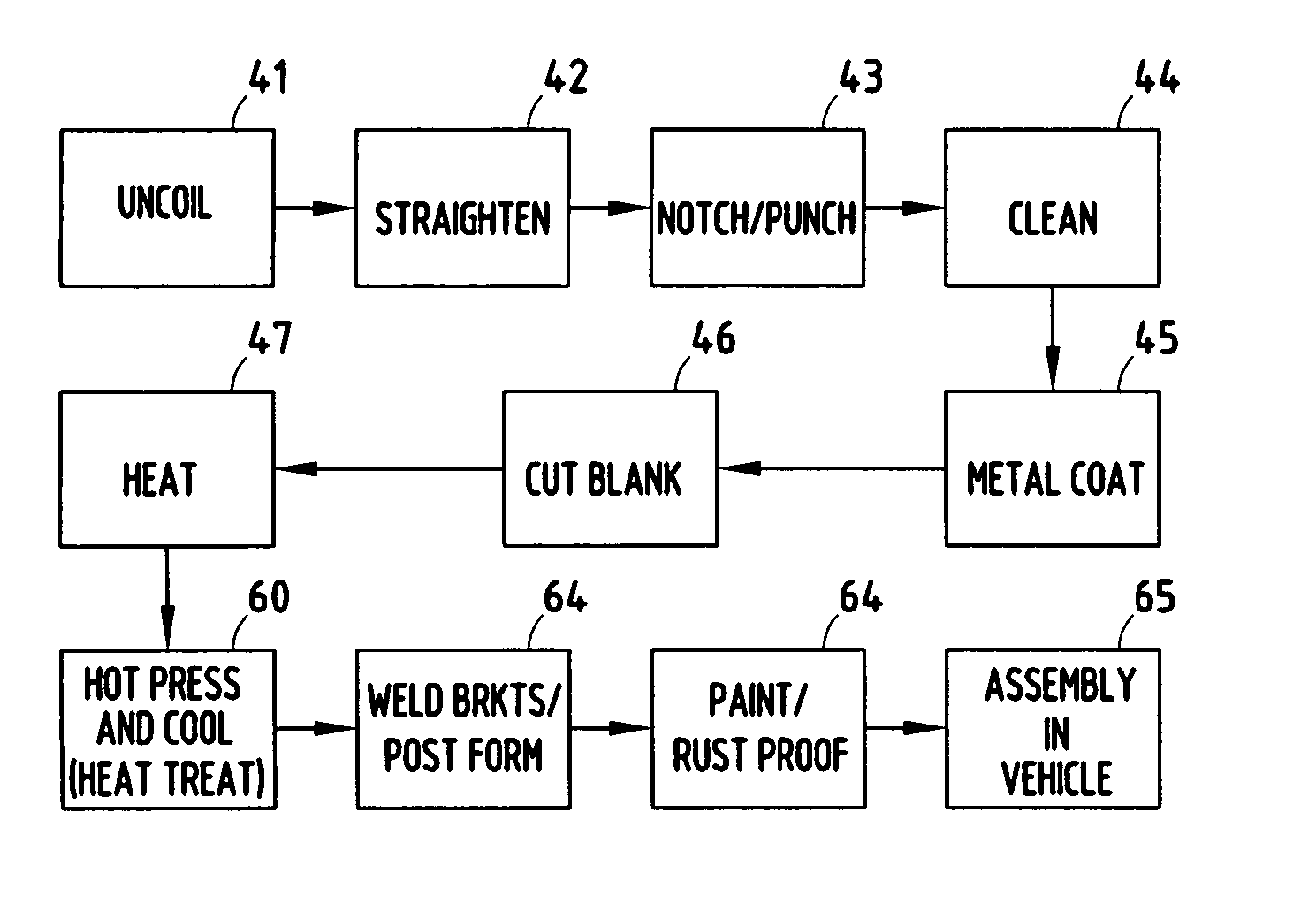

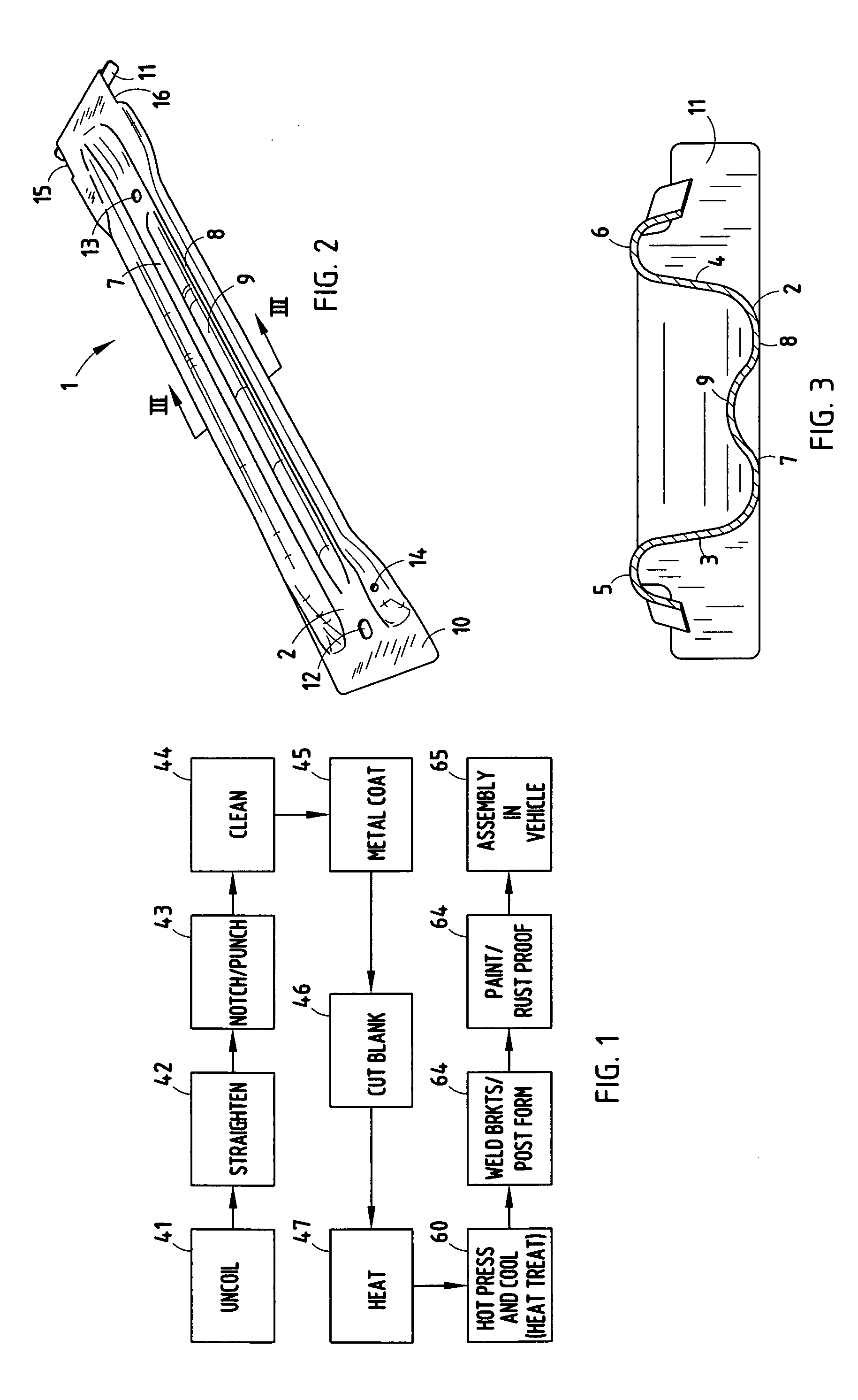

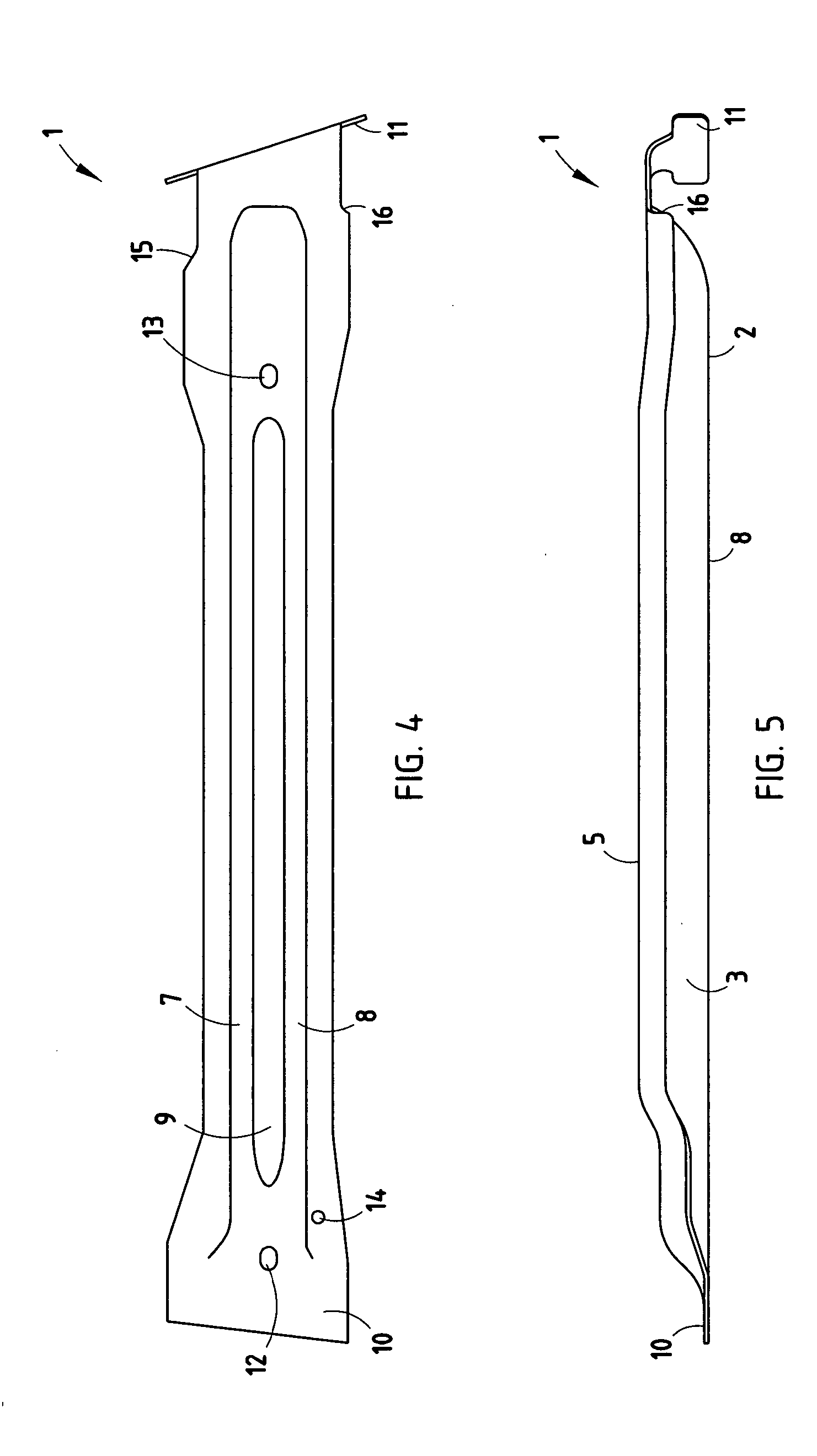

Method for making structural automotive components and the like

InactiveUS20060130940A1Reduce scaleReduced decarburizationVacuum evaporation coatingSurface reaction electrolytic coatingHigh intensityPhase change

A method for making structural automotive components and the like provides a strip of high strength steel having a selected thickness. A predetermined thickness of a metal coating, such as nickel, is applied to the opposite faces of the steel strip. The coated steel strip is cut to form a blank. The blank is heated in a generally open atmosphere to a temperature in the range of 800° C. to 1000° C. within less than ten minutes, thereby diffusing at least a portion of the metal coating a predetermined distance into the faces of the steel strip portion of the blank to alleviate scale formation, and simultaneously raise the temperature of the blank for hot forming the same. The heated blank is hot formed in a pressing tool, and cooled therein to heat treat the formed component through microstructure phase change, without substantial scale formation, such that the component need not be descaled prior to post-form processing and / or assembly in a vehicle.

Owner:BENTELER AUTOMOTIVE CORP

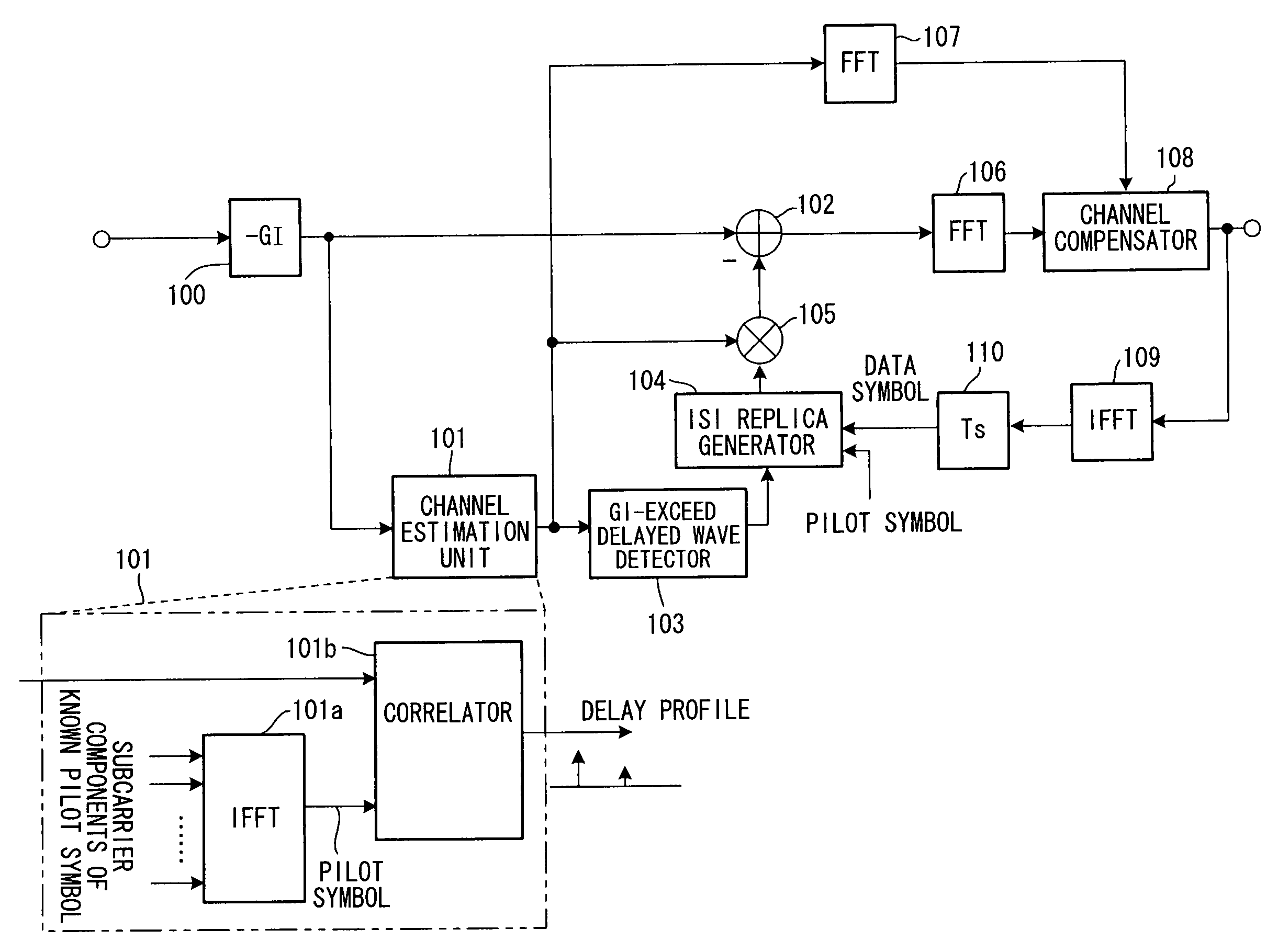

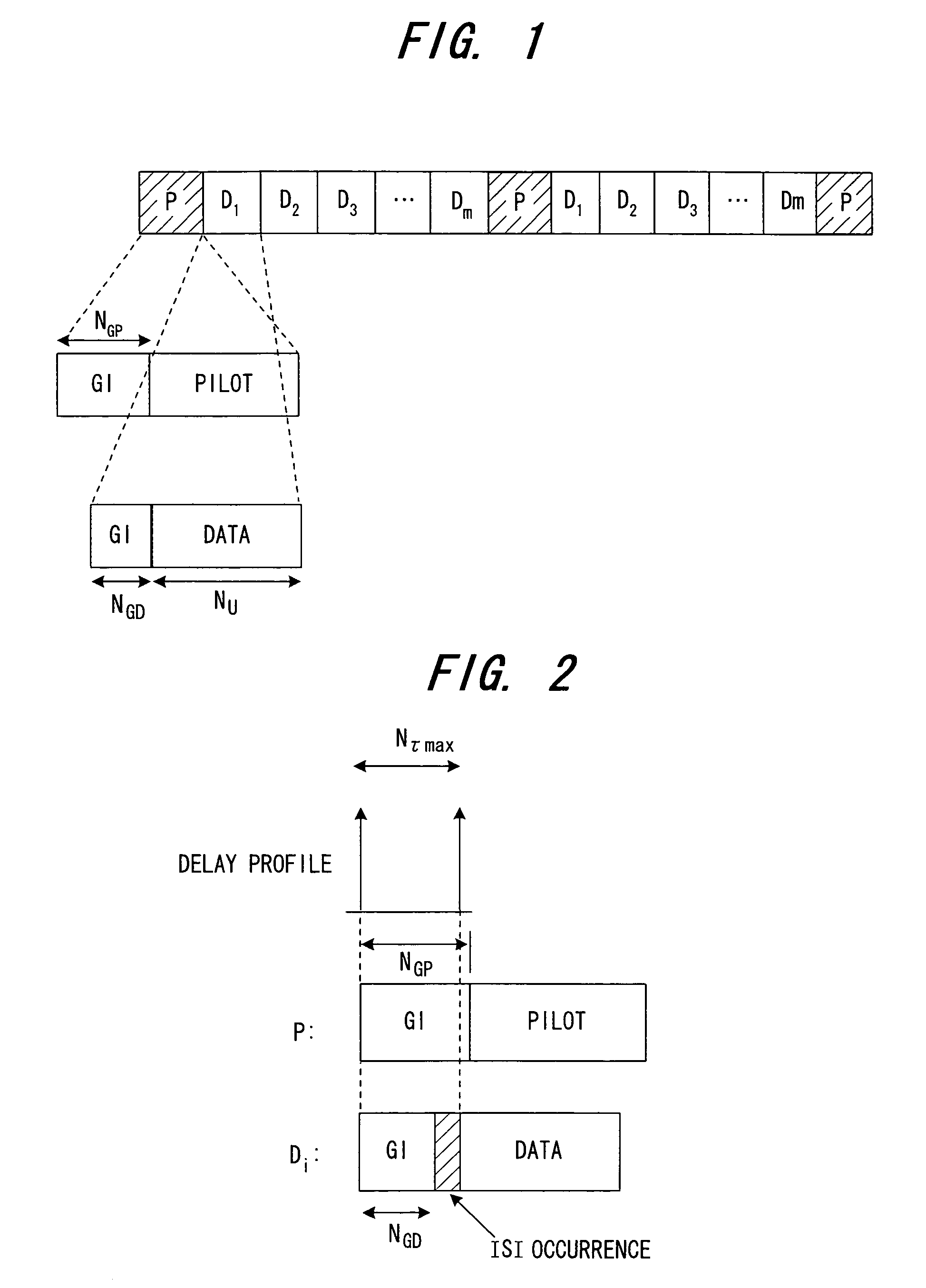

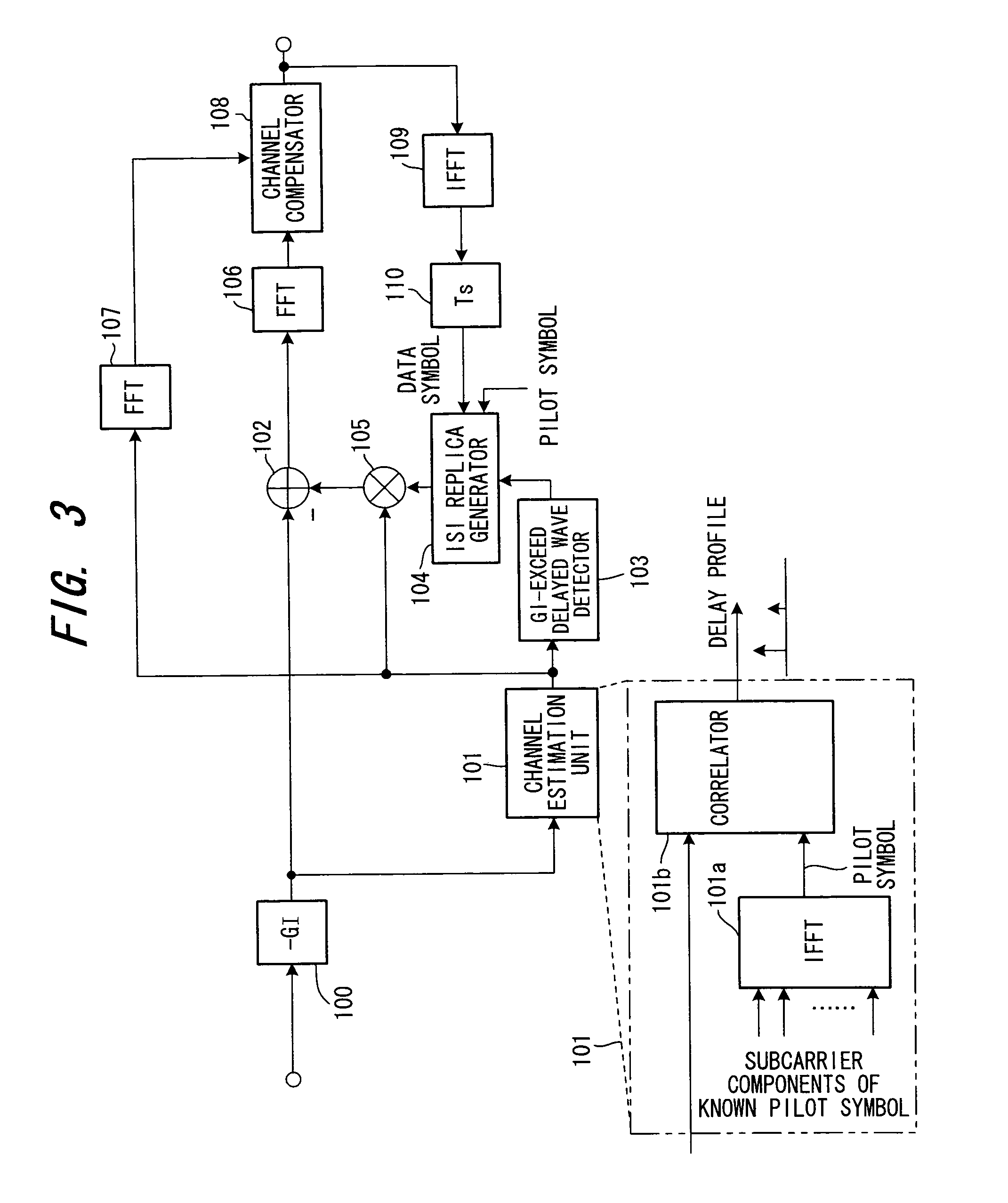

Receiving apparatus in OFDM transmission system

InactiveUS7362832B2Easy to codeIncrease in the BER can be suppressedError preventionLine-faulsts/interference reductionTransfer systemGuard interval

A receiving apparatus in an OFDM transmission system includes a channel estimation unit (101) for measuring a delay profile of a delayed wave having a delay greater than a guard interval of data; a guard-interval-exceed delayed wave detector (103) for detecting, from the delay profile as an intersymbol interference (ISI) portion, a delay-time portion greater than the guard interval of the data; a ISI replica generator (104) for generating, as the ISI replica, a time-waveform portion of a known symbol conforming to the ISI portion, or a time-waveform portion of the preceding symbol; subtractor (102) for subtracting the ISI replica from a receive signal; and an FFT arithmetic unit (106) for demodulating data by applying FFT processing to the result of subtraction.

Owner:FUJITSU LTD

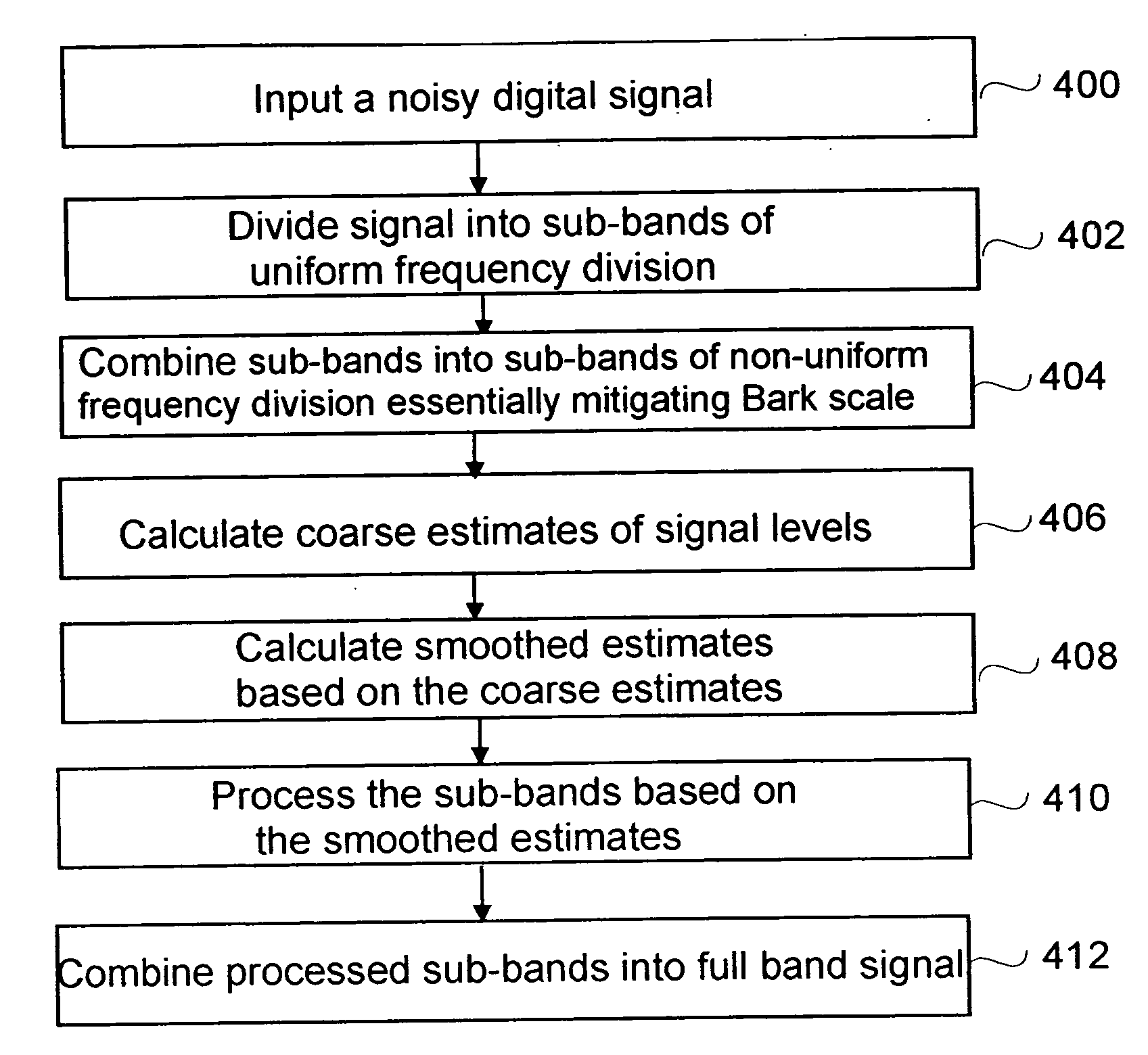

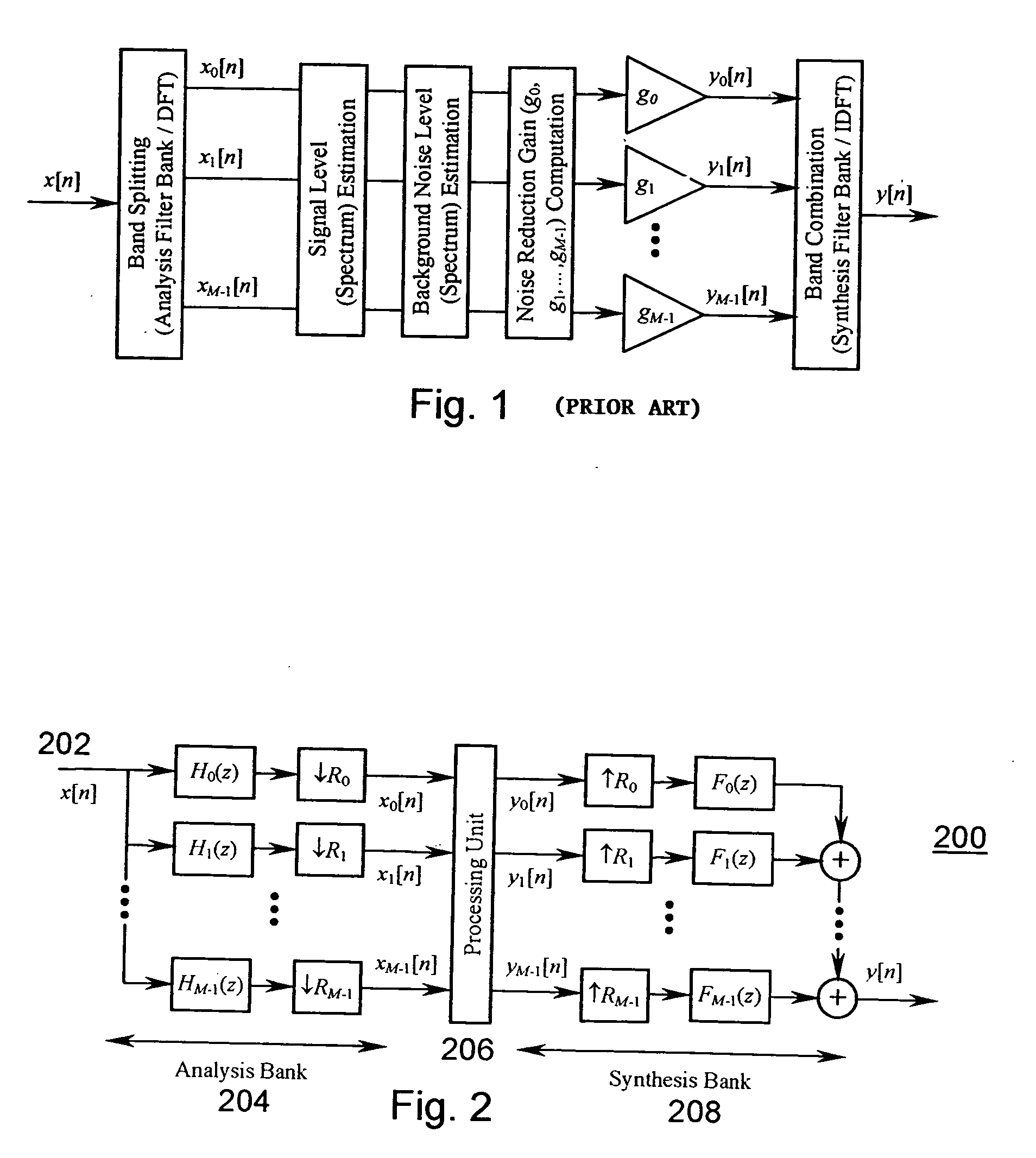

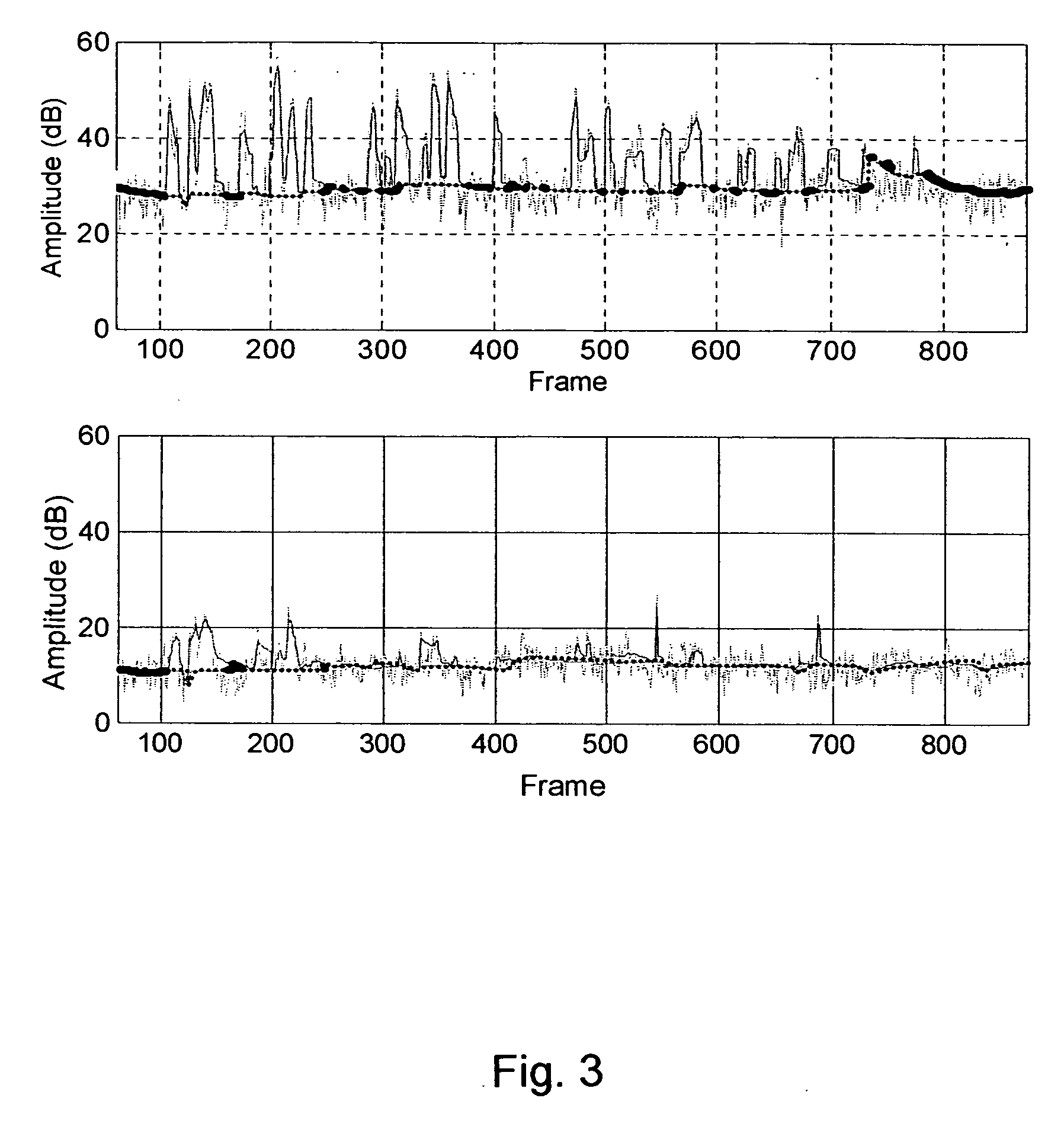

Filterbank-based processing of speech signals

InactiveUS20070078645A1Reduce problem sizeGood synchronizationSpeech analysisDigital audio signalsComputer science

A method for suppressing noise from a digital audio signal, the method comprising: obtaining the digital signal; dividing the digital audio signal into sub-bands of non-uniform frequency division essentially mitigate Bark scale, corresponding sub-band signals having downsampling ratios by which a frame rate of an audio encoder, expressed in a number of samples in each frame, is divisible; calculating coarse estimates of signal levels for the non-uniform sub-bands; calculating smoothed signal level estimates for the non-uniform sub-bands based on the coarse estimates; and combining the processed sub-band signals into a digital output signal.

Owner:SPYDER NAVIGATIONS L L C

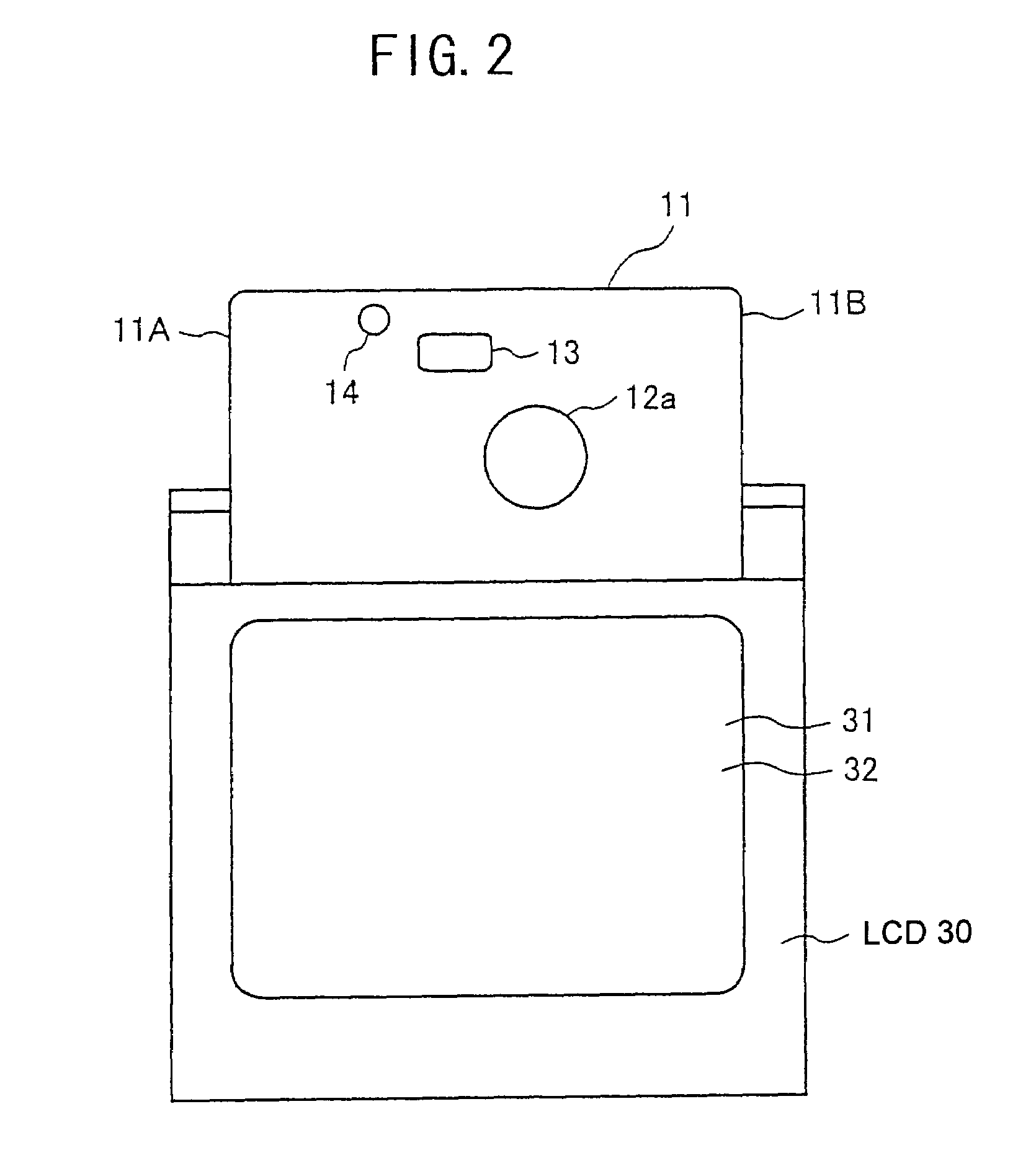

Makeup counseling apparatus

InactiveUS7088386B2Small scaleSimple structureTelevision system detailsColor television detailsImaging processingComputer graphics (images)

The present invention is composed of a computer positioned at a basal portion of an apparatus for conducting image processing and counseling processing; a first image display means for displaying a computer-processed image to a subject, mounted upright in the computer, a second image display means for displaying the computer-processed image to a counselor, mounted upright in the computer so that a display screen thereof is directed in a direction opposite the first display means; and photographic means, positioned near the first image display means, for photographing a subject directed in a direction of the first display means and feeding a facial image of the subject into the computer, thus making the apparatus small in scale and simple in composition, and suitable for a counselor to provide counseling on make-up to a subject.

Owner:SHISEIDO CO LTD

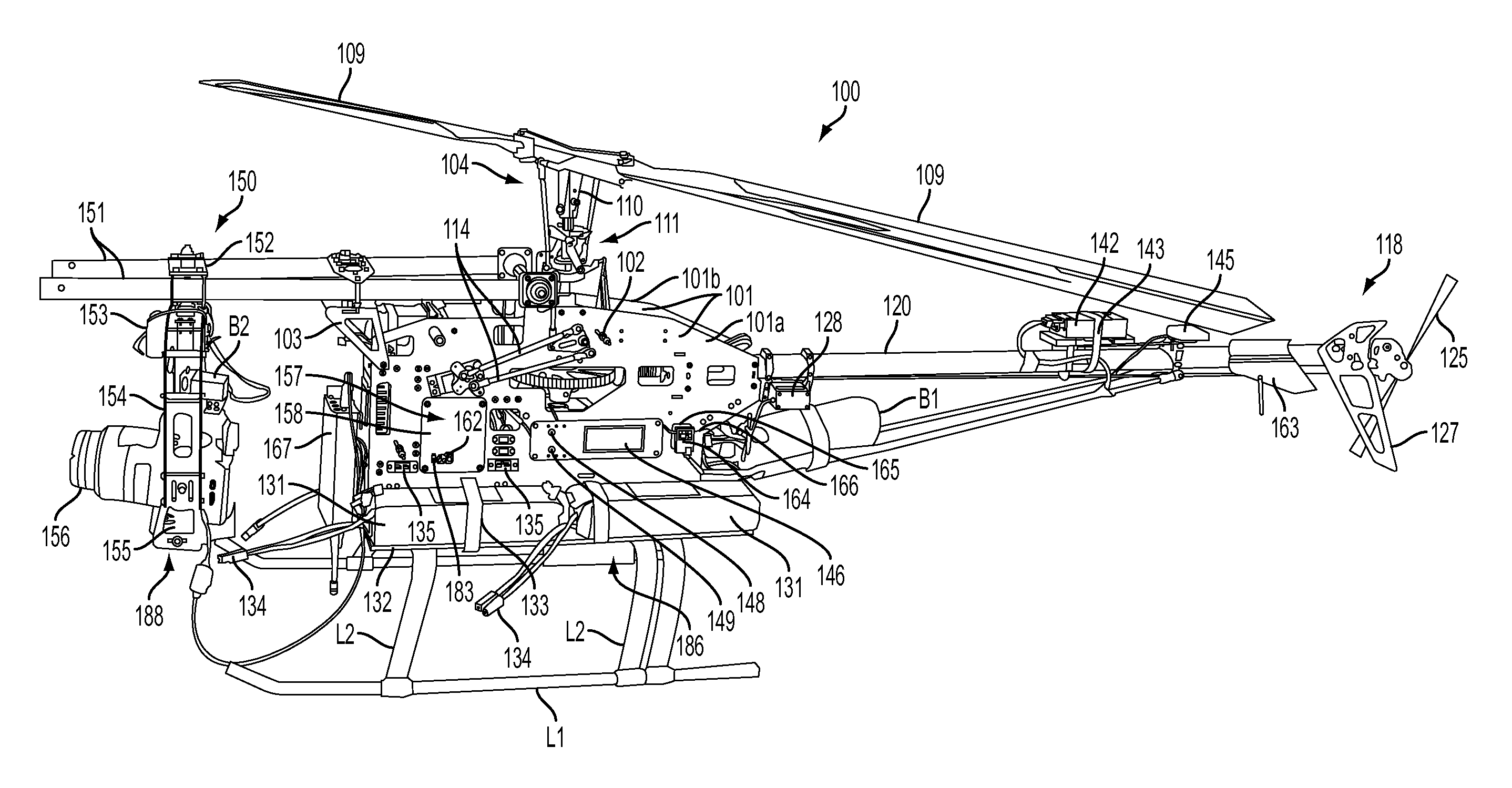

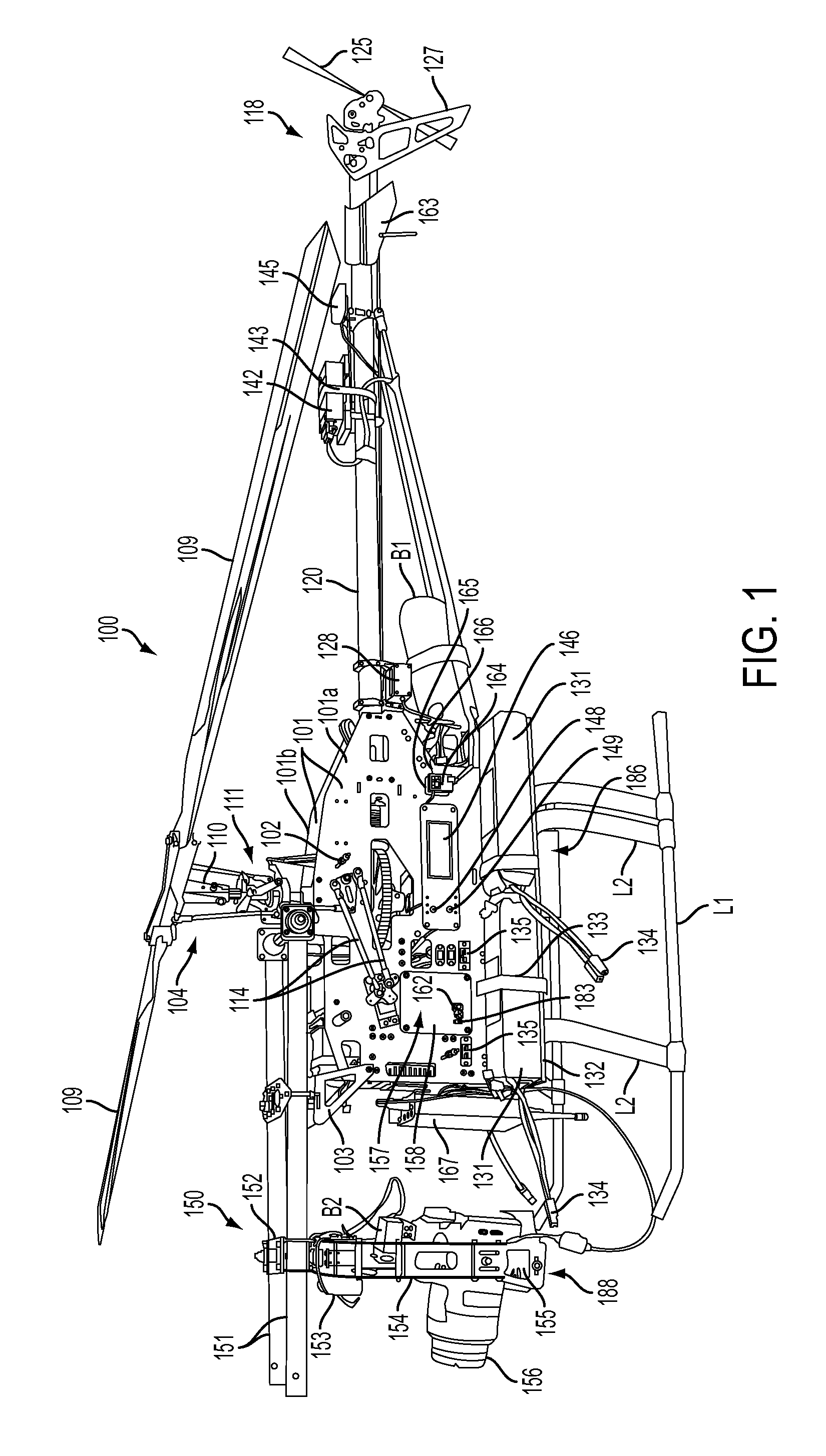

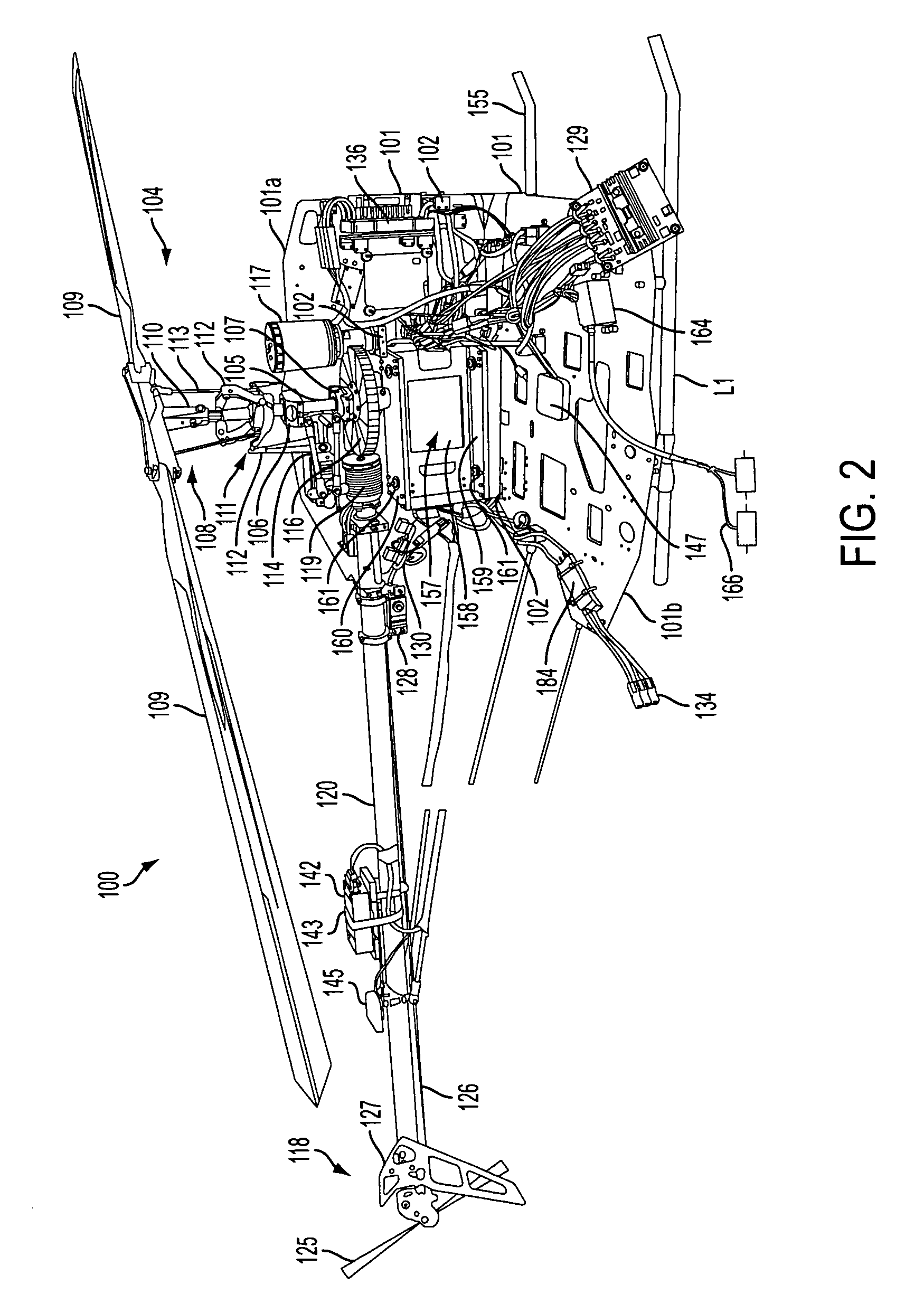

Helicopter

ActiveUS9456185B2Reduce problem sizeEasy to flyAircraft componentsUnmanned aerial vehiclesRemote controlMission plan

The present invention relates to a reduced scale industrial helicopter, with an integrated automatic flight control system, that includes core autopilot functions, GPS management, and full-function navigation systems. The autopilot technology includes rapid launch capability, real-time in-flight switching between one or more of a) remote control, b) autopilot-directed, c) ground station controlled, and d) home modes, and is upgradeable. The helicopter is used for high or low altitude surveillance, and can handle various payloads, including photographic missions. The helicopter may include onboard batteries and / or a unique battery unit disposed beneath the helicopter, and includes autonomous features such as automatic takeoff, automatic landing, safety return to home base, and predetermined mission plans.

Owner:GEOTECH ENVIRONMENTAL EQUIP

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20070183501A1Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

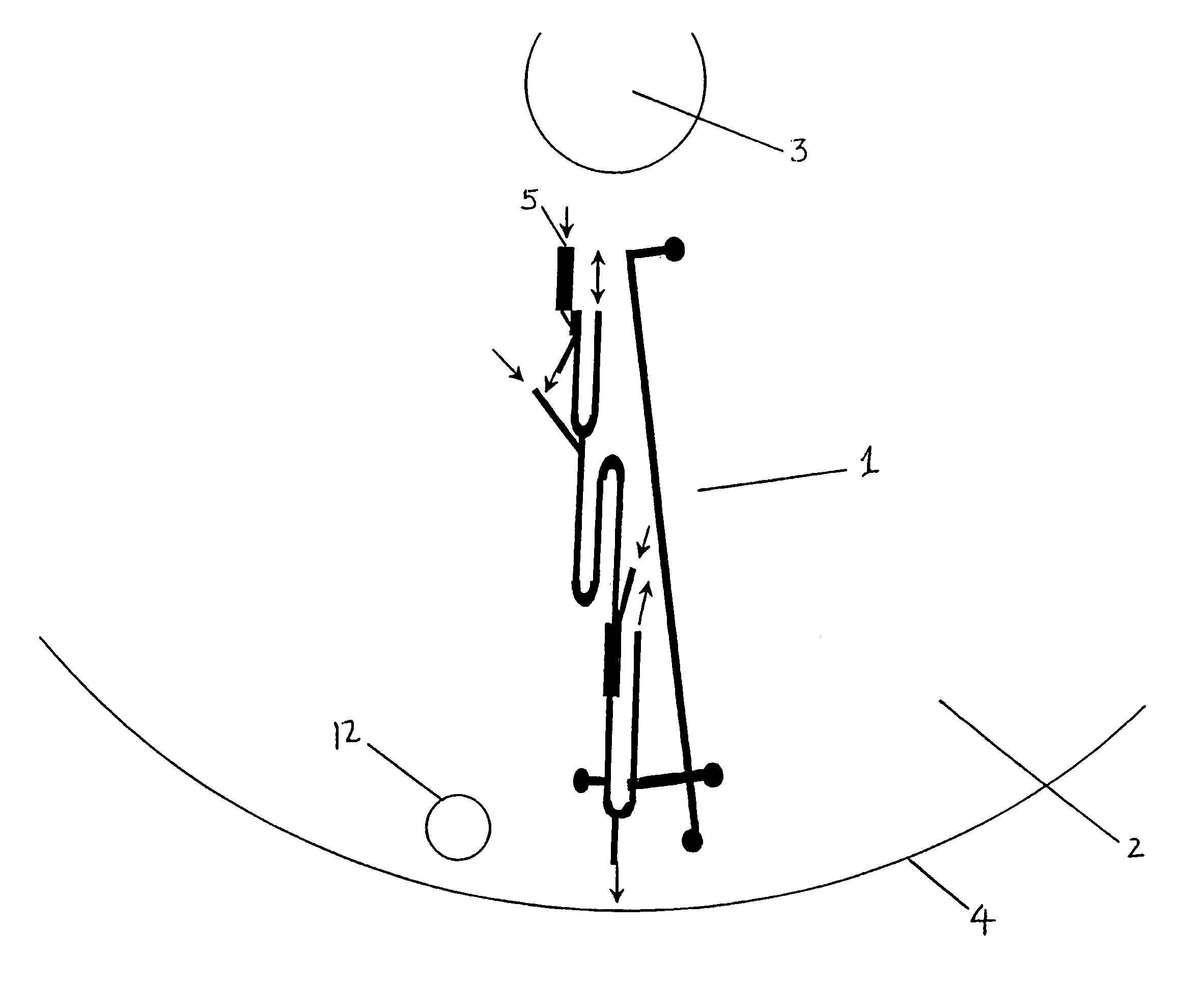

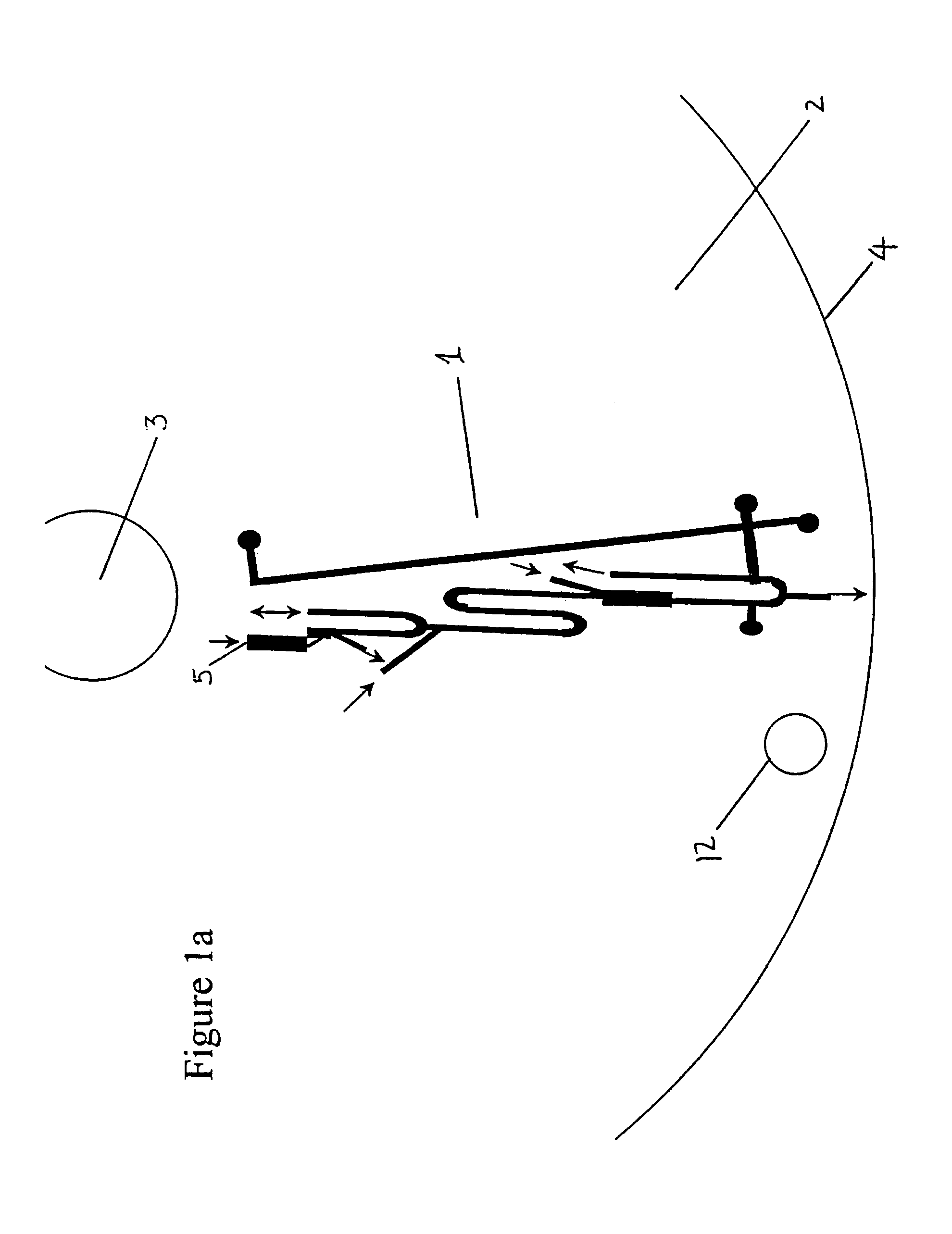

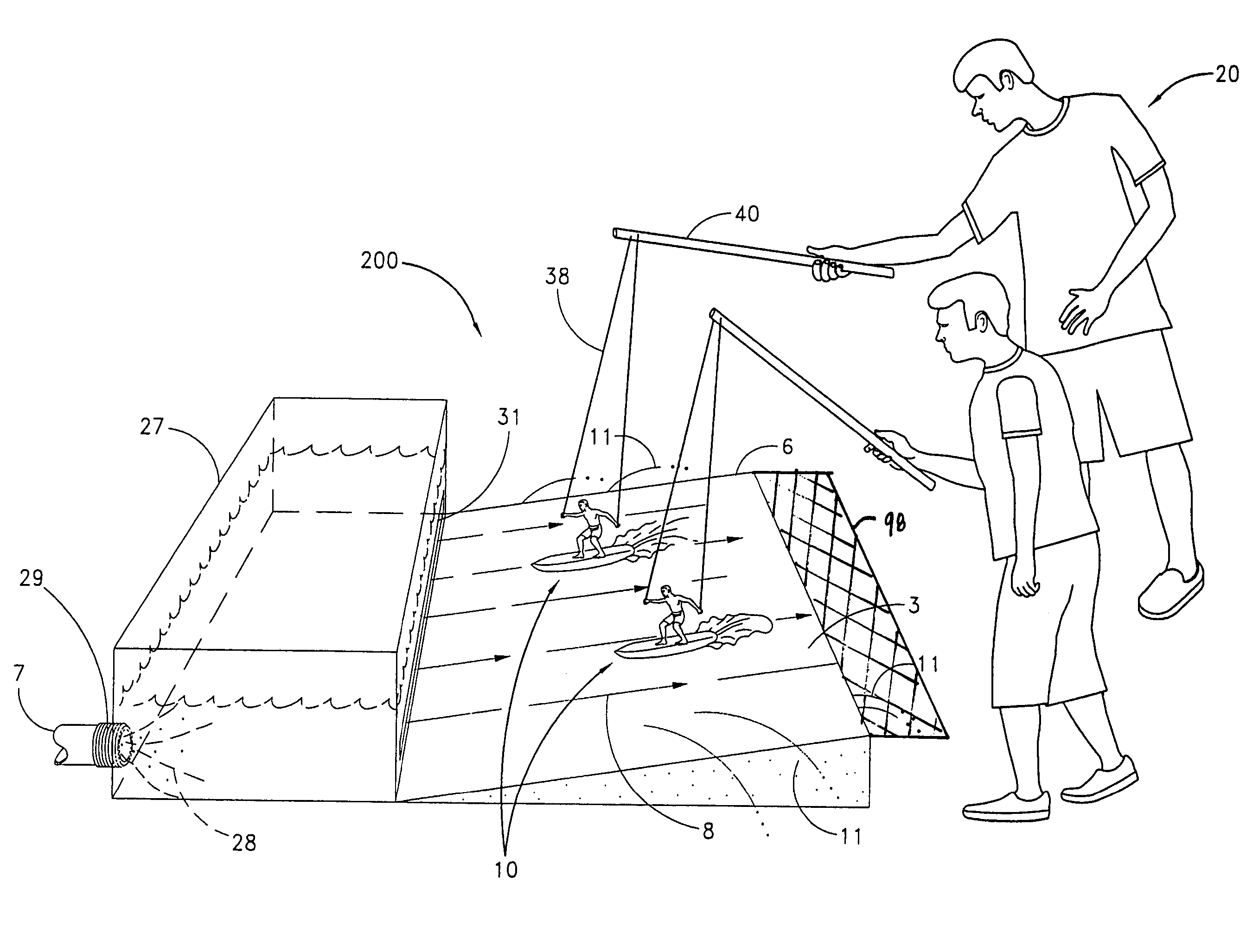

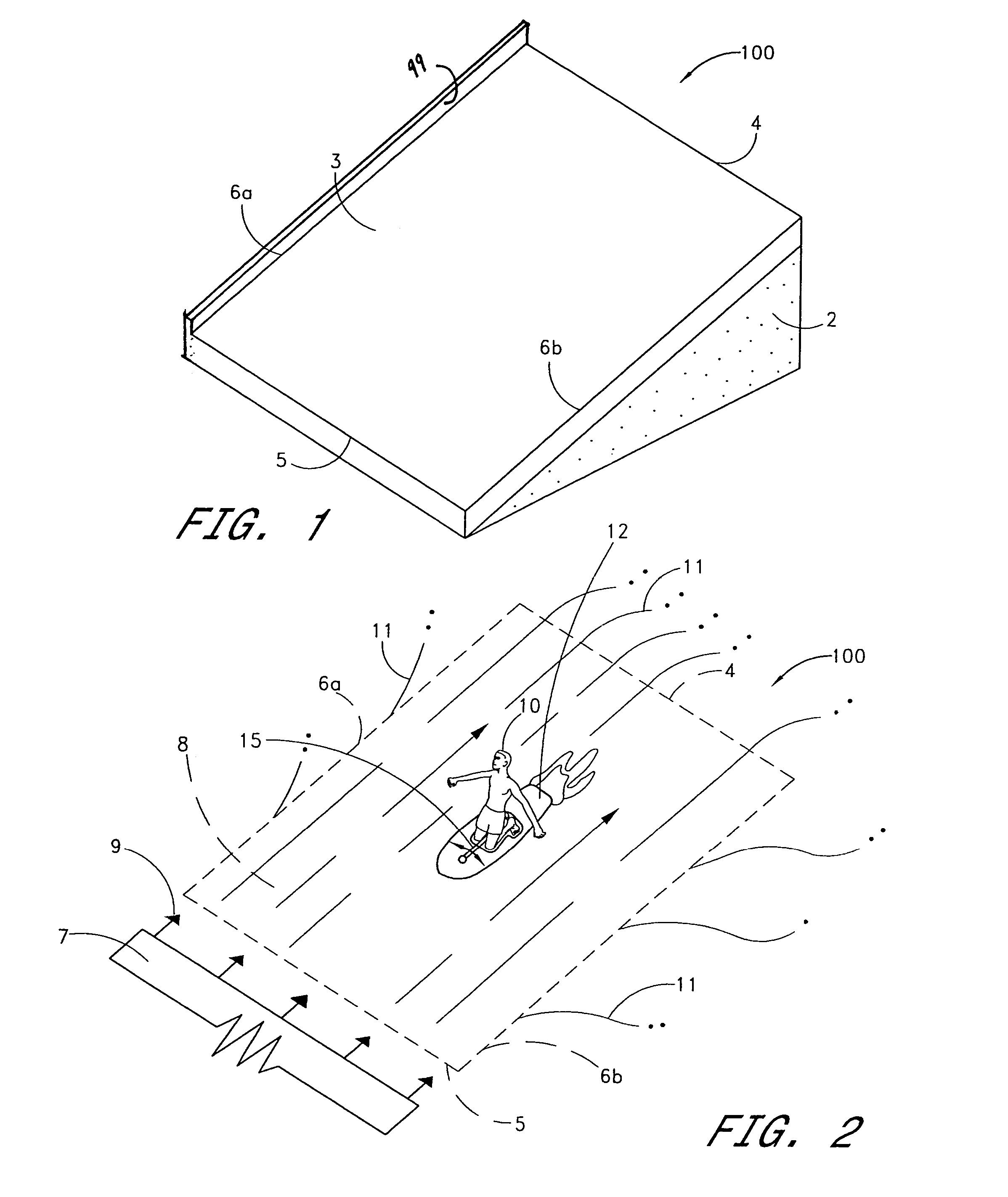

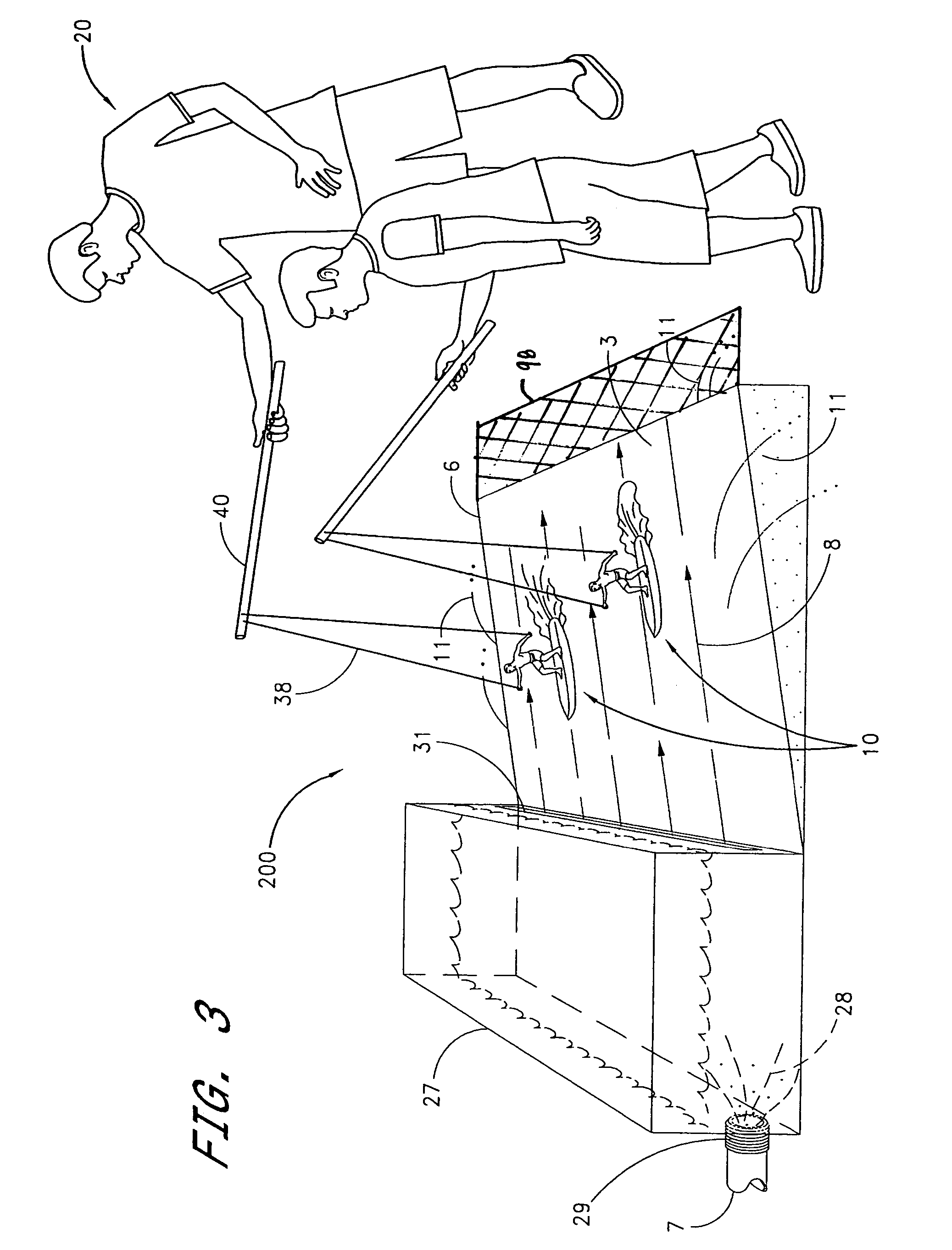

Surf toy action figure and simulated surfing game

The present invention provides a miniature live-action surfing attraction and associated surf game specifically adapted for use with one or more surf toy action figures. The surf toy action figures are mountable to a surf board appropriately sized and weighted to provide relatively stable or semi-stable surf-riding action upon a sheet flow of water flowing up an inclined ride surface of the reduced scale attraction. Various surf action figures may be set free upon the ride surface, or they may be constrained or partially constrained by wires, strings, magnets or the like, as desired. Alternatively, or in addition, they may be controlled via a remote control, or radio control transmitter, as desired. Thus, a fun and entertaining game is created that provides realistic live-action surfing within a relatively small or confined area.

Owner:LIGHT WAVE

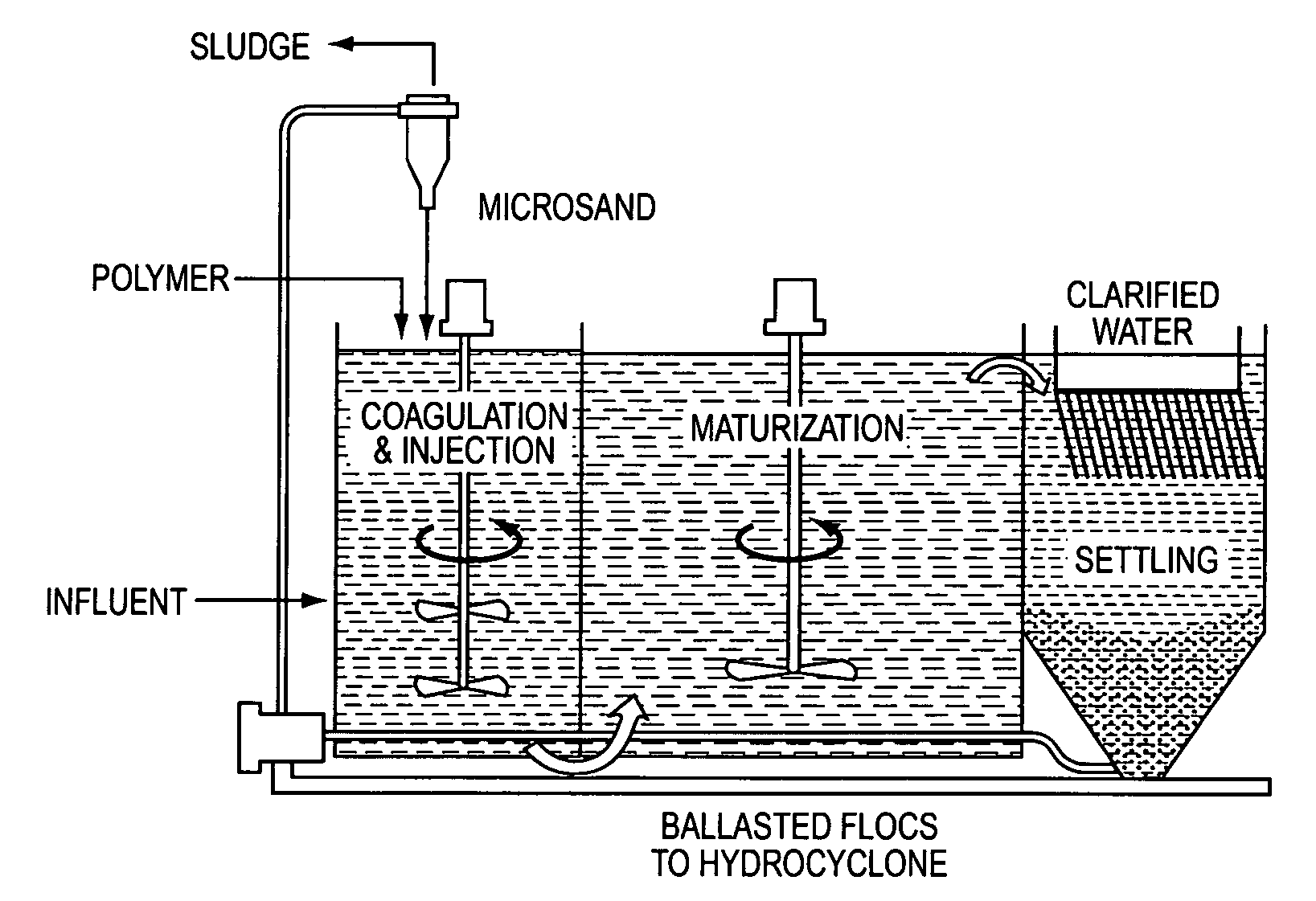

Water treatment process

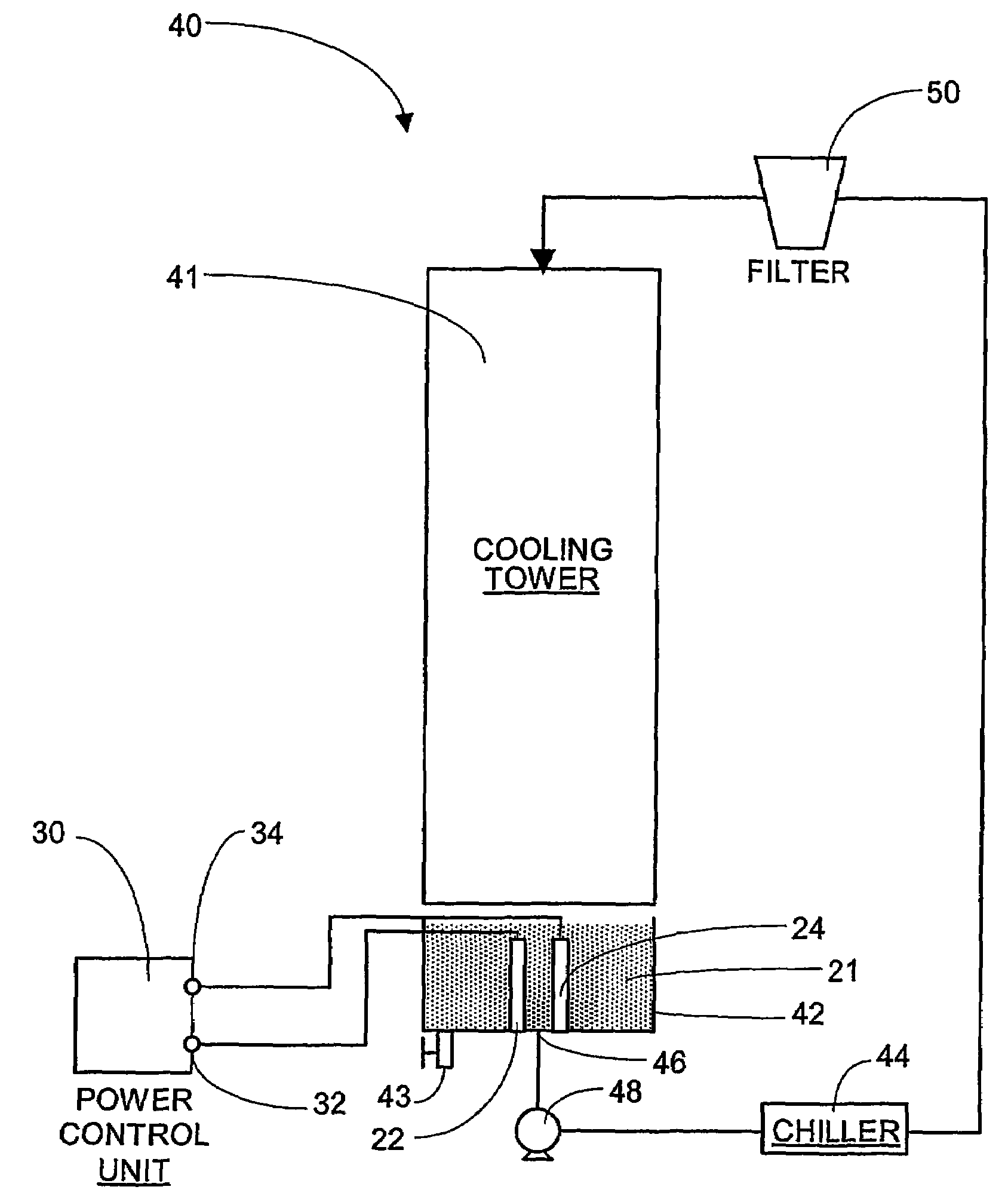

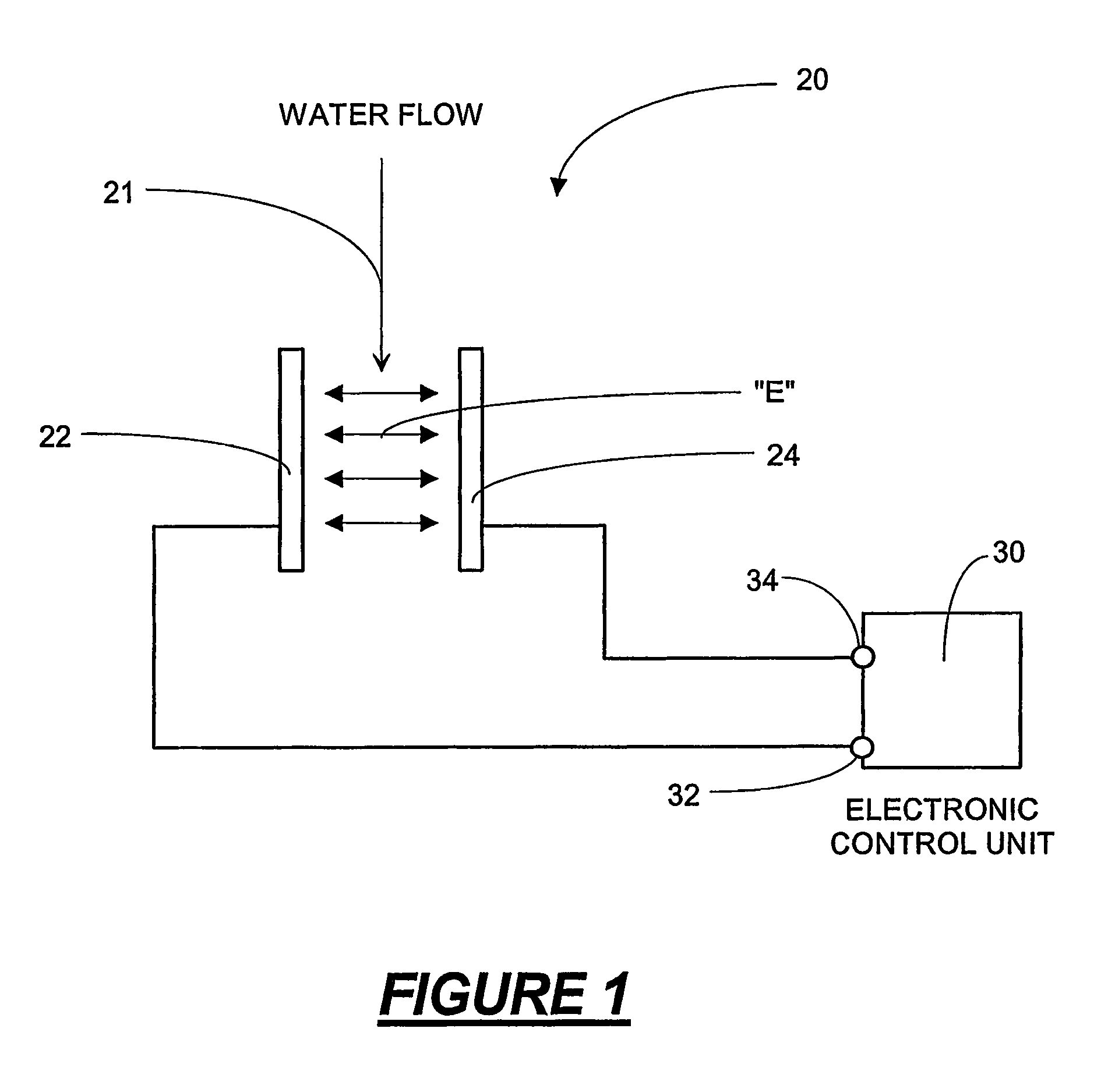

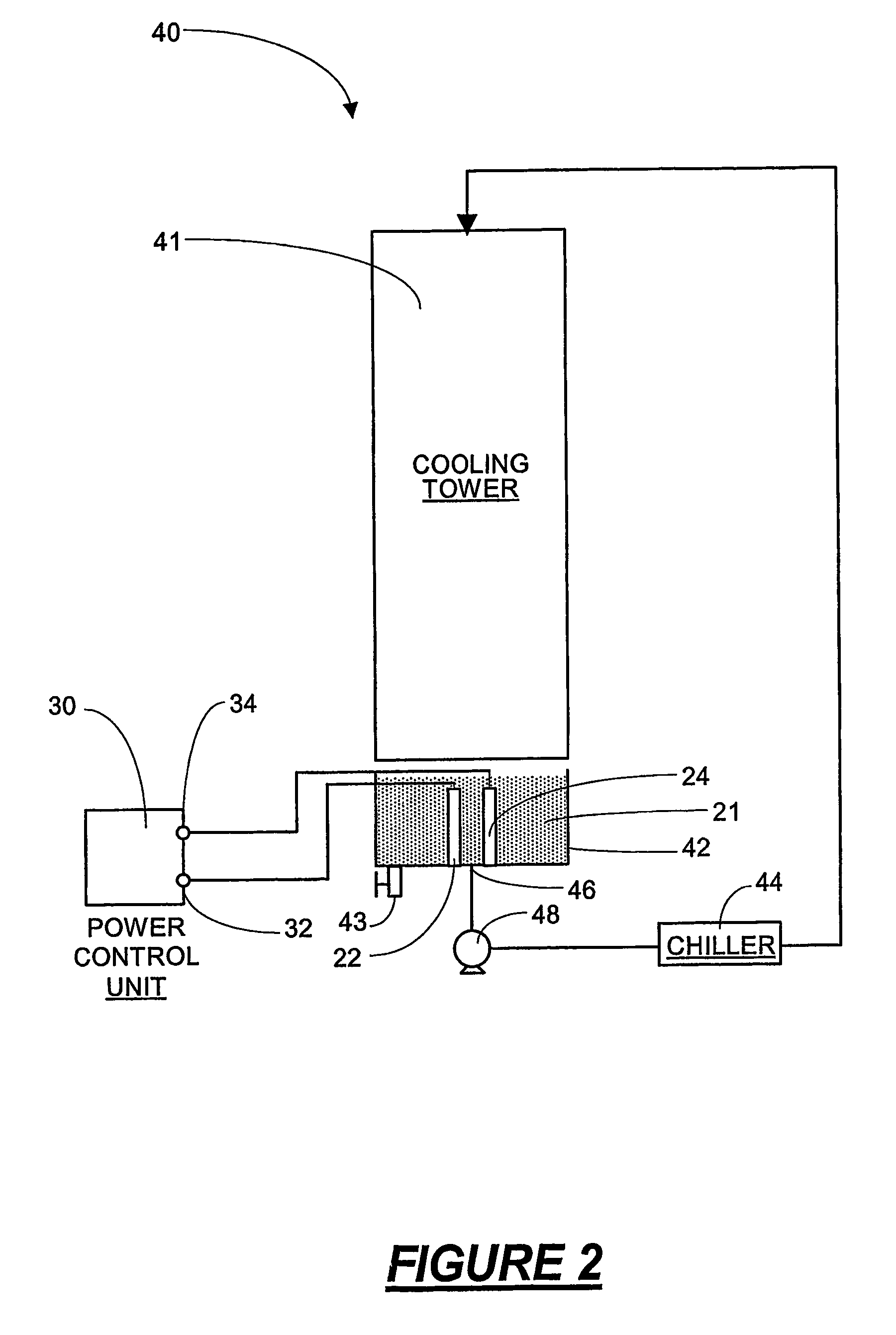

InactiveUS7244360B2Reduce scaleEnhance separationScale removal and water softeningTreatment involving filtrationIonVoltage

The present invention provides a physical water treatment (PWT) method and apparatus to treat liquid coolants. Electrodes (22, 24) are provided in a coolant stream (21), and an alternating voltage is applied across the electrodes (22, 24) to produce an electric field through the coolant. The alternating voltage creates an oscillating electric field in the coolant that promotes the collision of dissolved mineral ions. The ions collide to form seed particles that precipitate out of solution. Bulk precipitation of seed particles decreases the availability of ions in solution which can crystallize on heat transfer surfaces. The seed particles adhere to additional ions that separate out of solution and form larger particles that may be removed from the coolant stream (21) using a variety of treatment measures. In addition to precipitating mineral ions, the electric field may be applied to destroy bacteria, algae and microorganisms that accumulate in the coolant stream (21).

Owner:DREXEL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com