Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid slow motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements of division operations

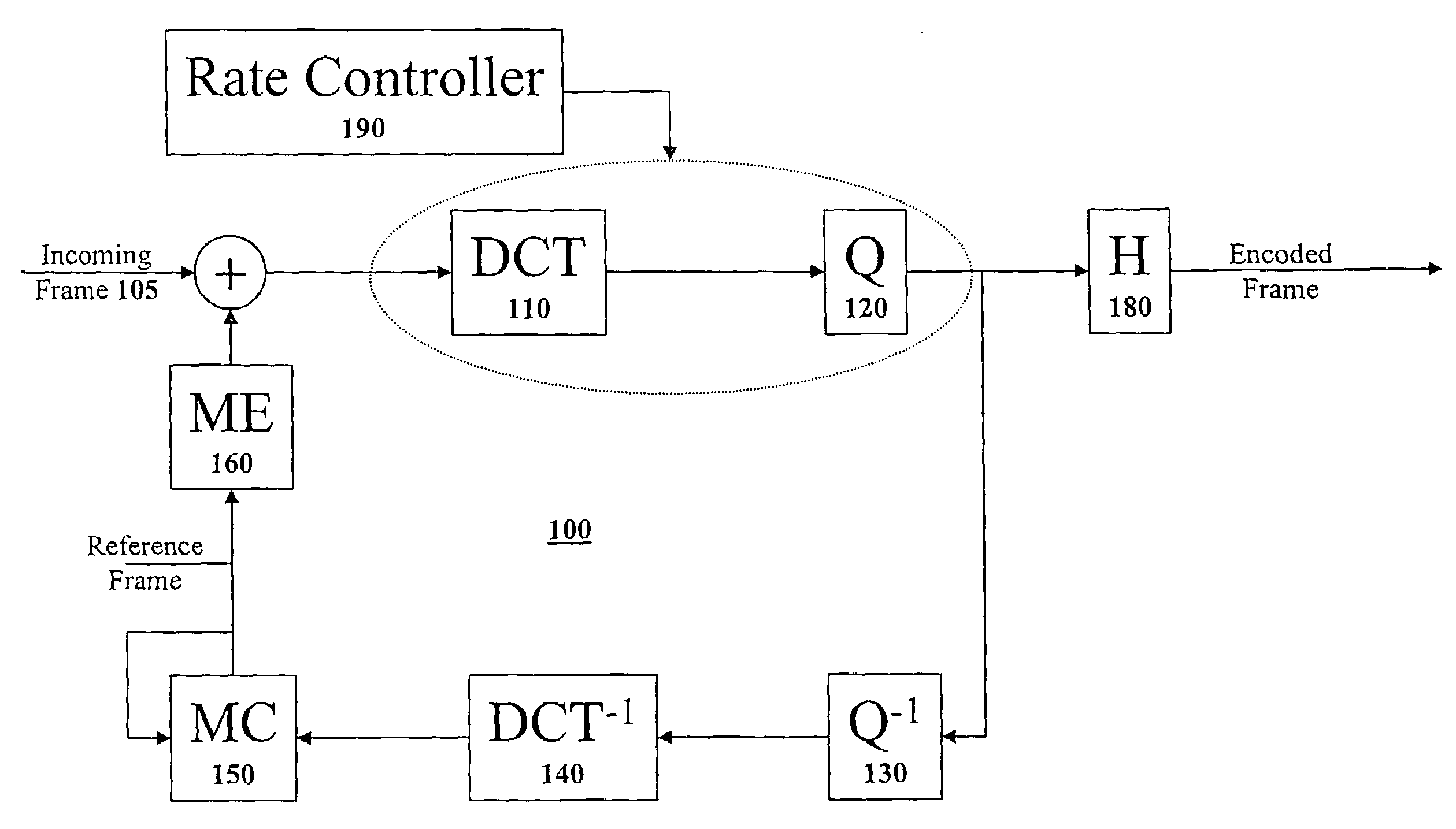

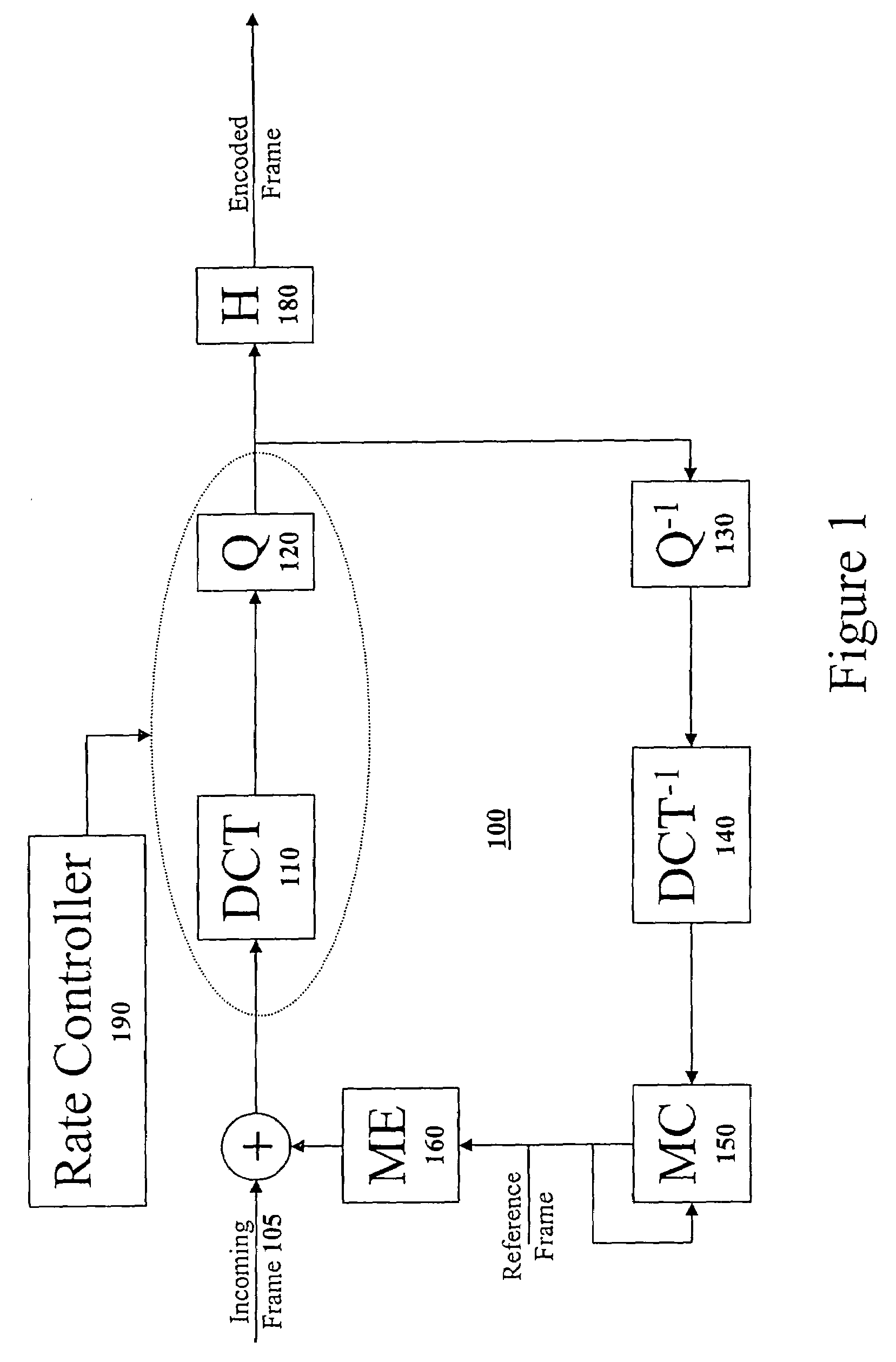

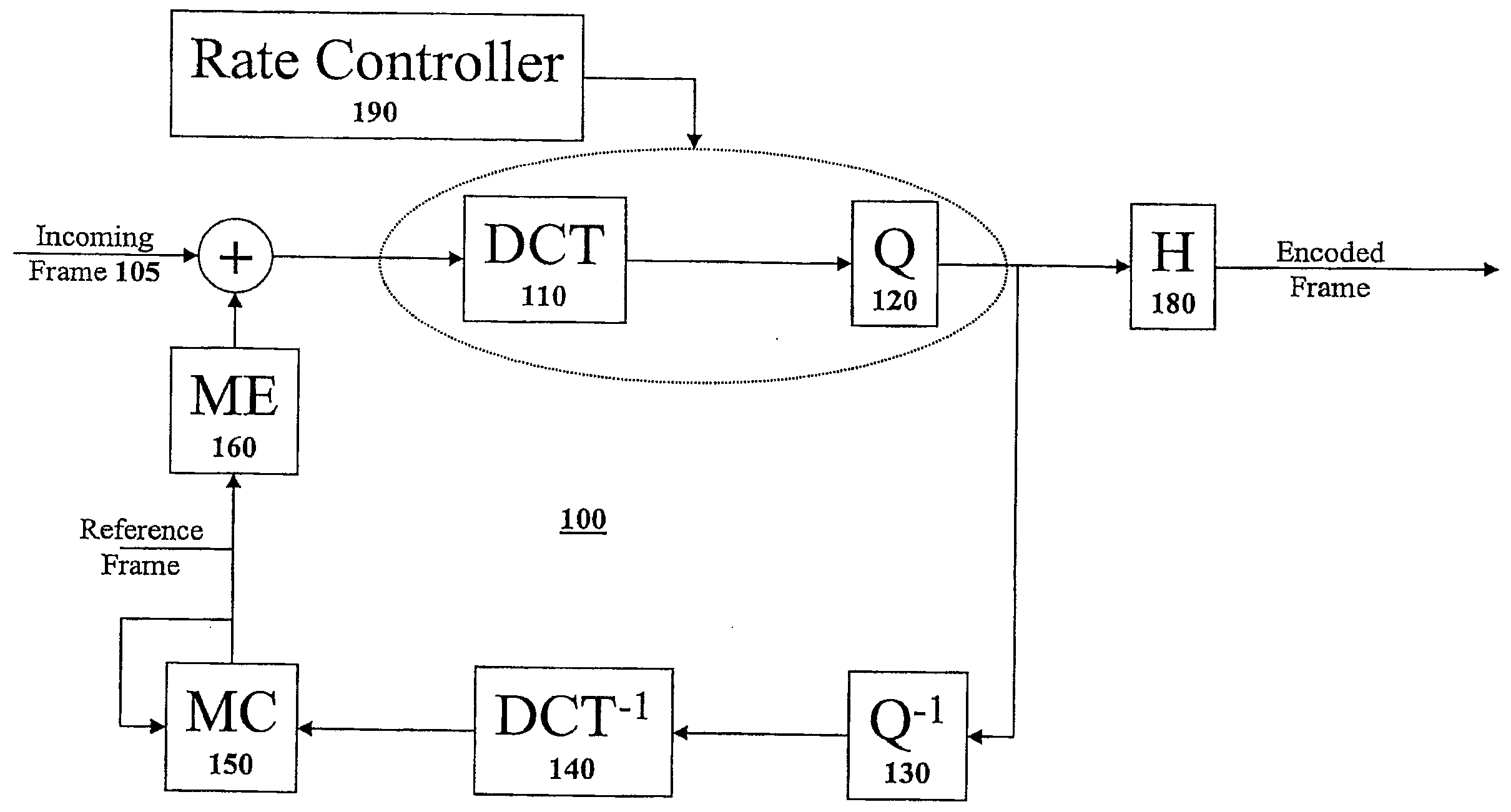

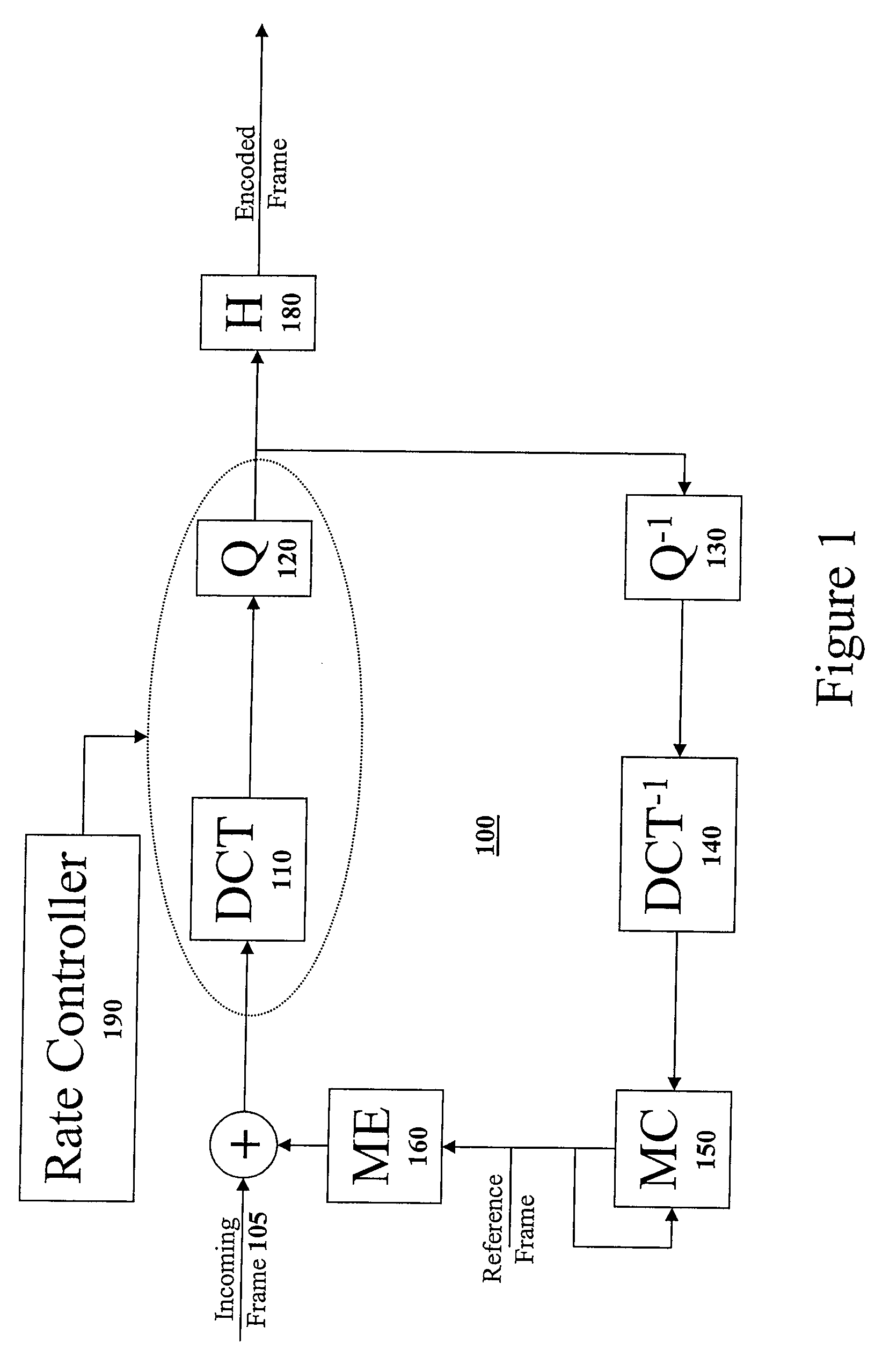

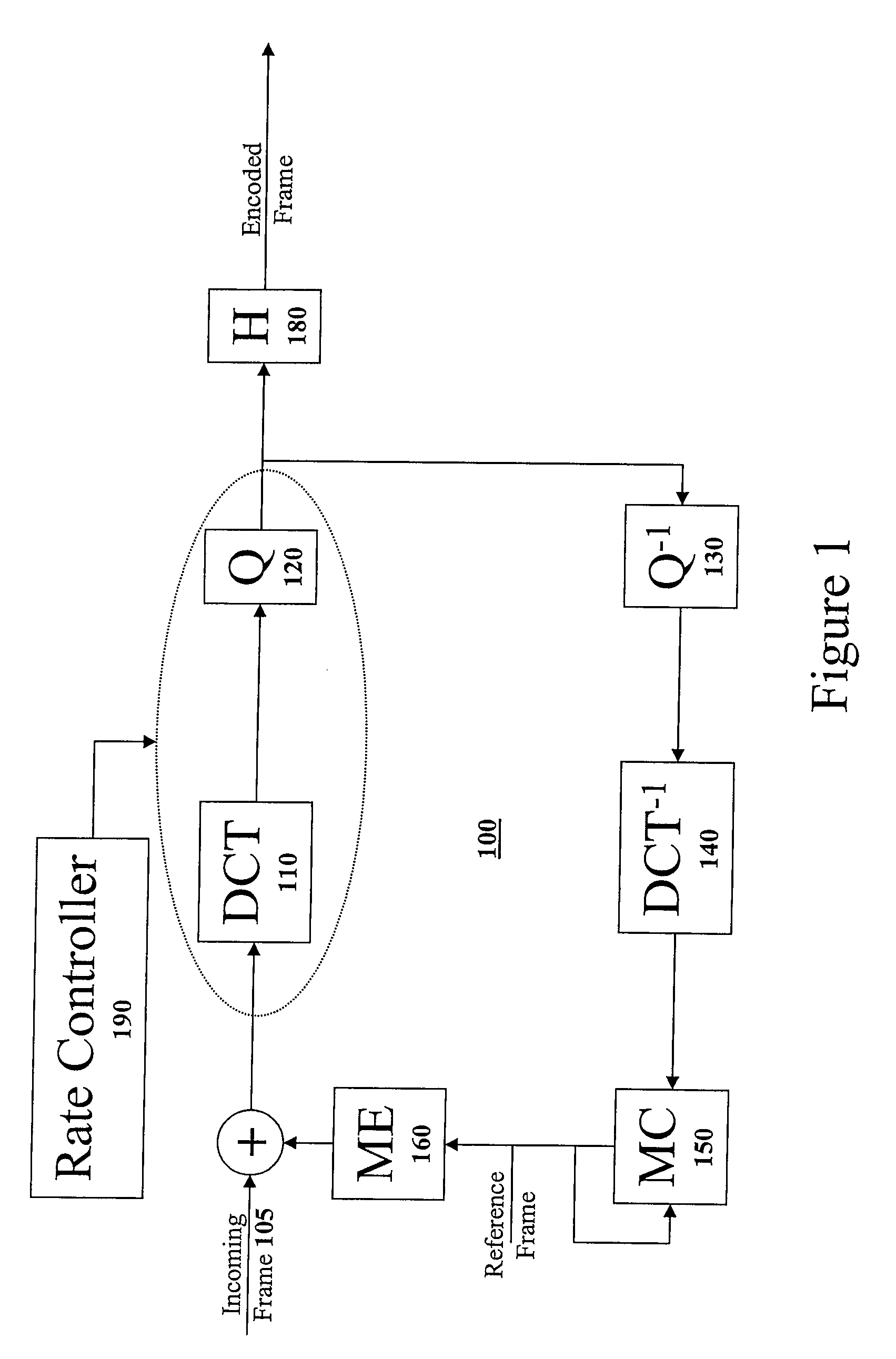

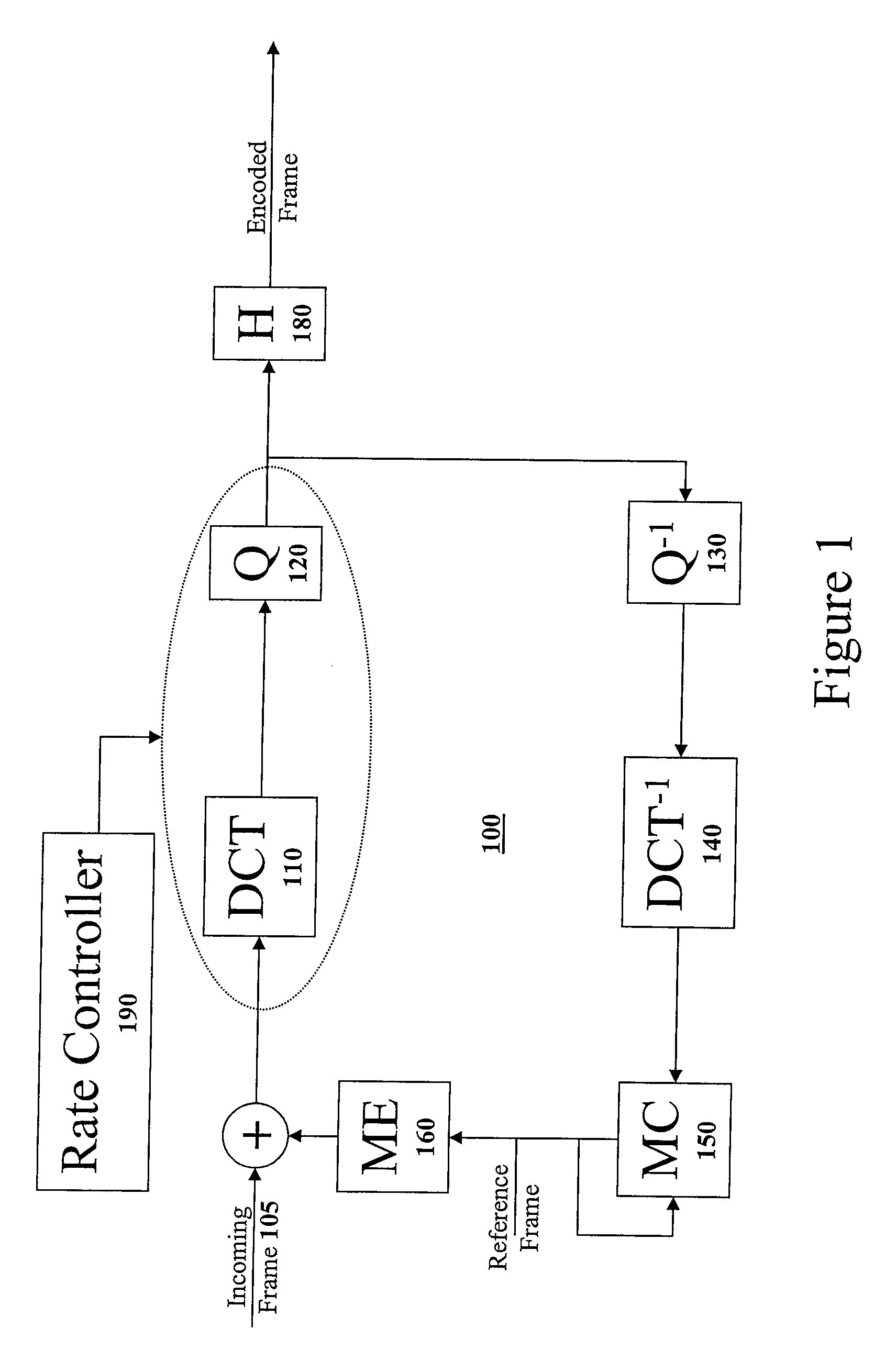

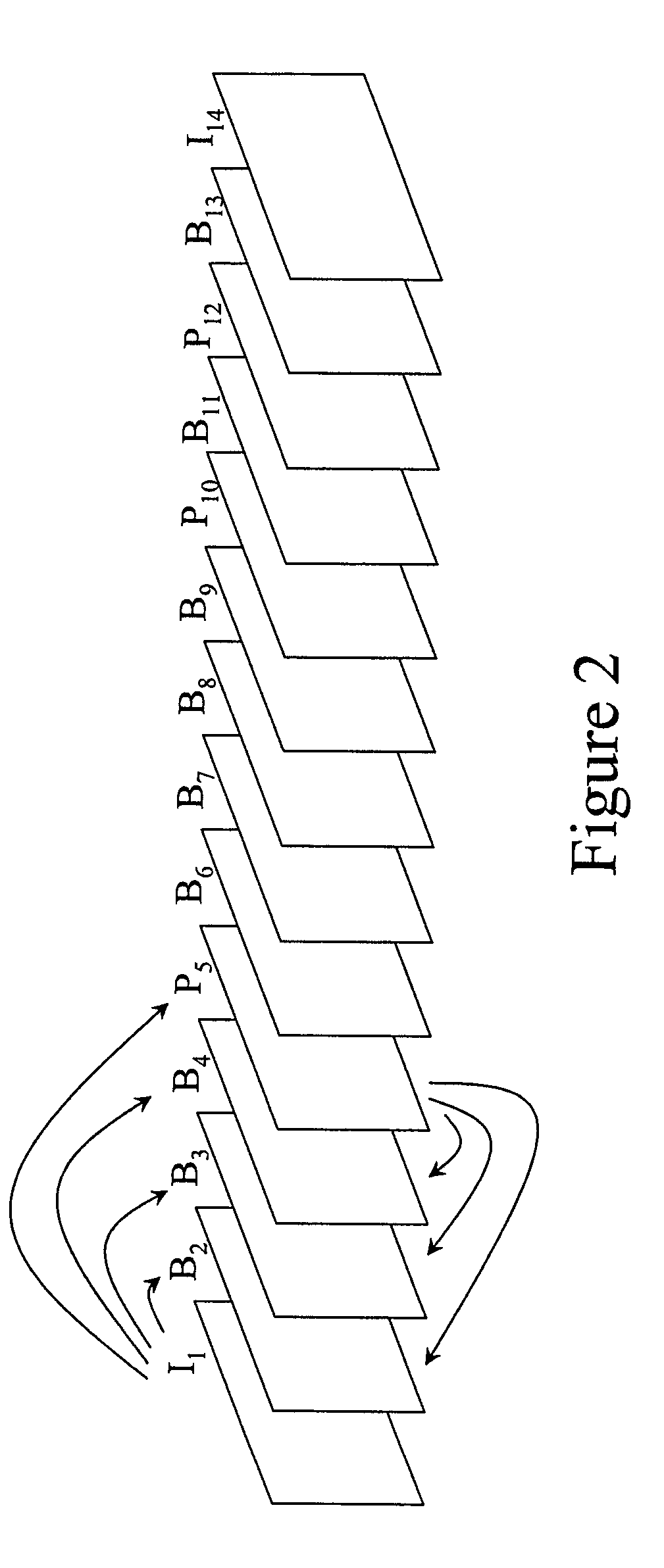

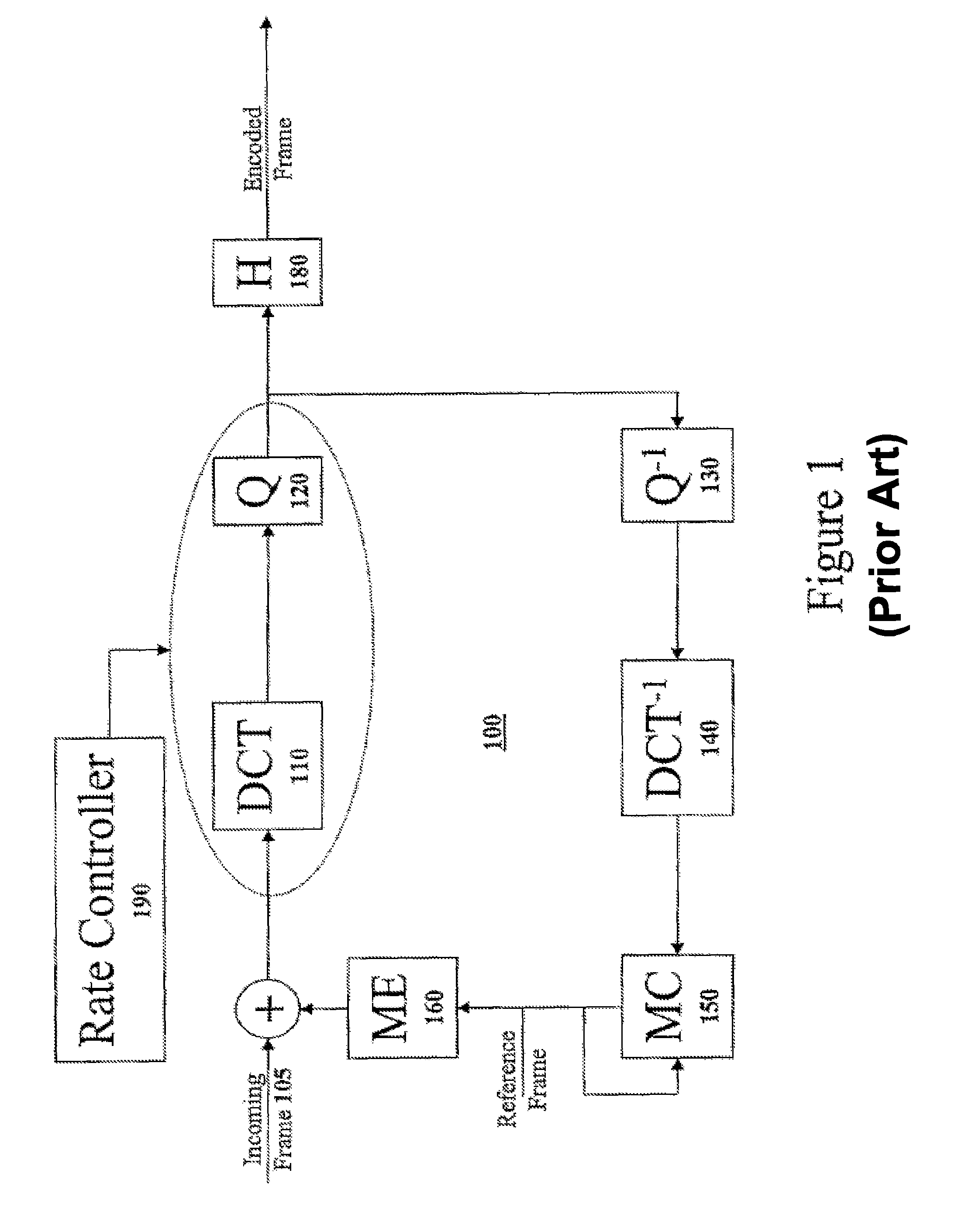

ActiveUS7339991B2Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoComputer graphics (images)

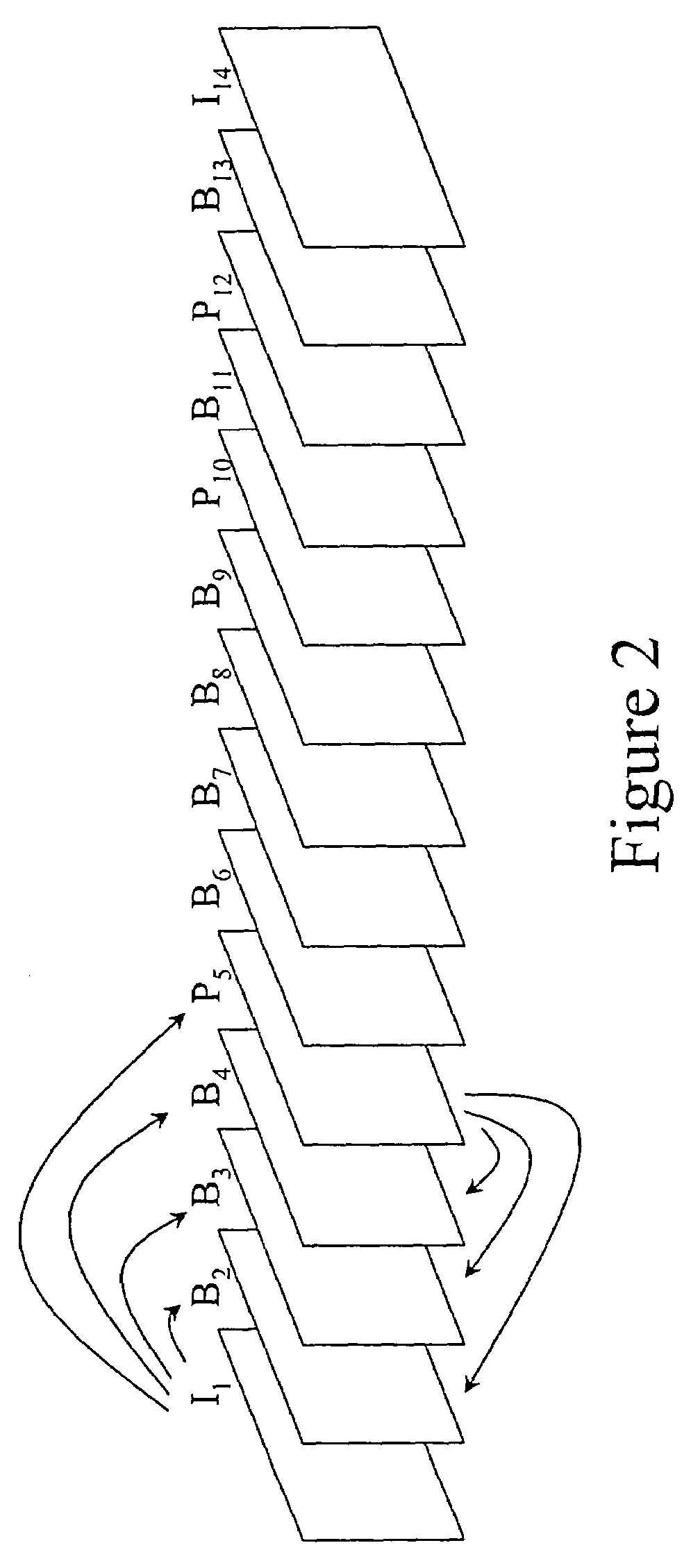

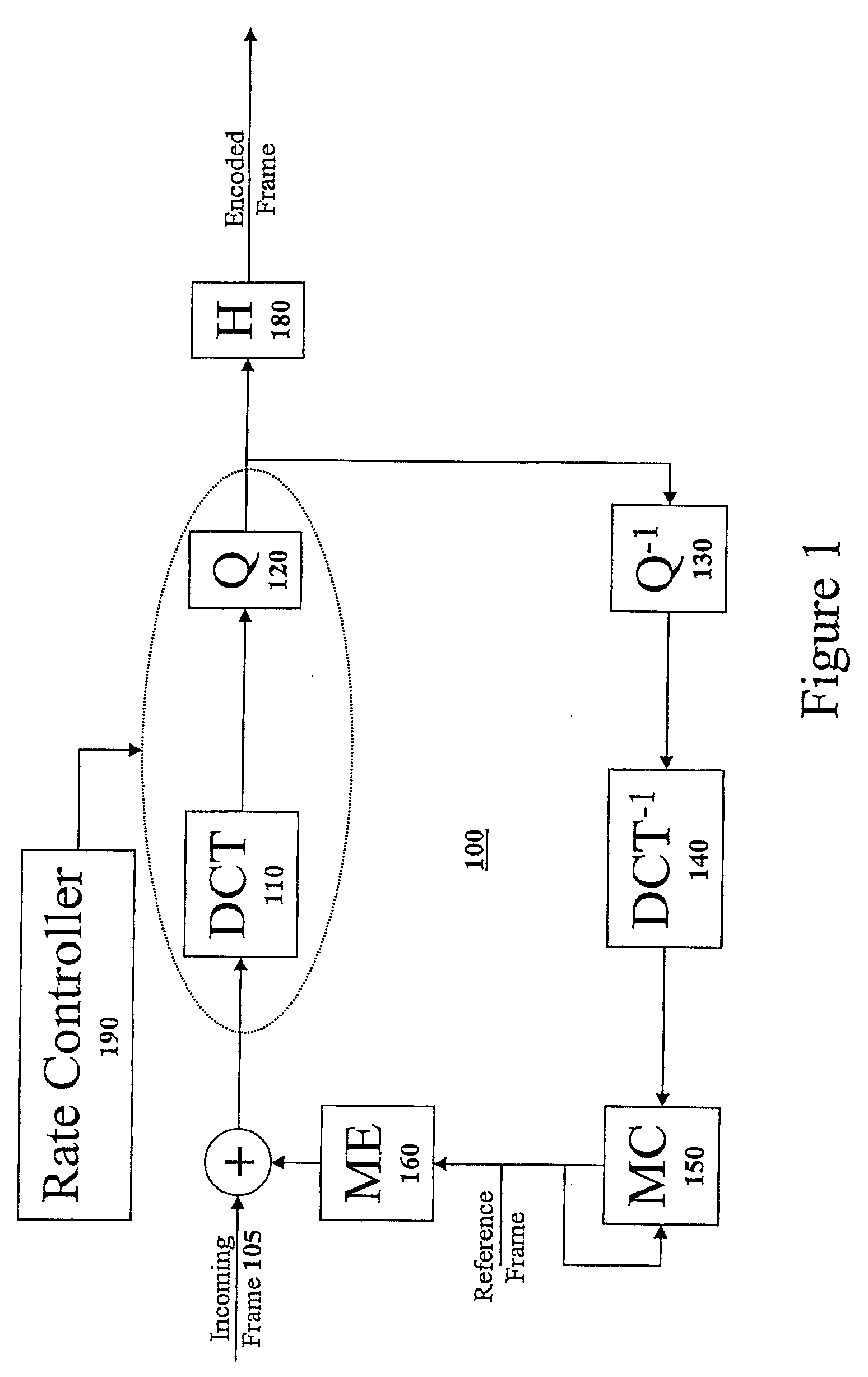

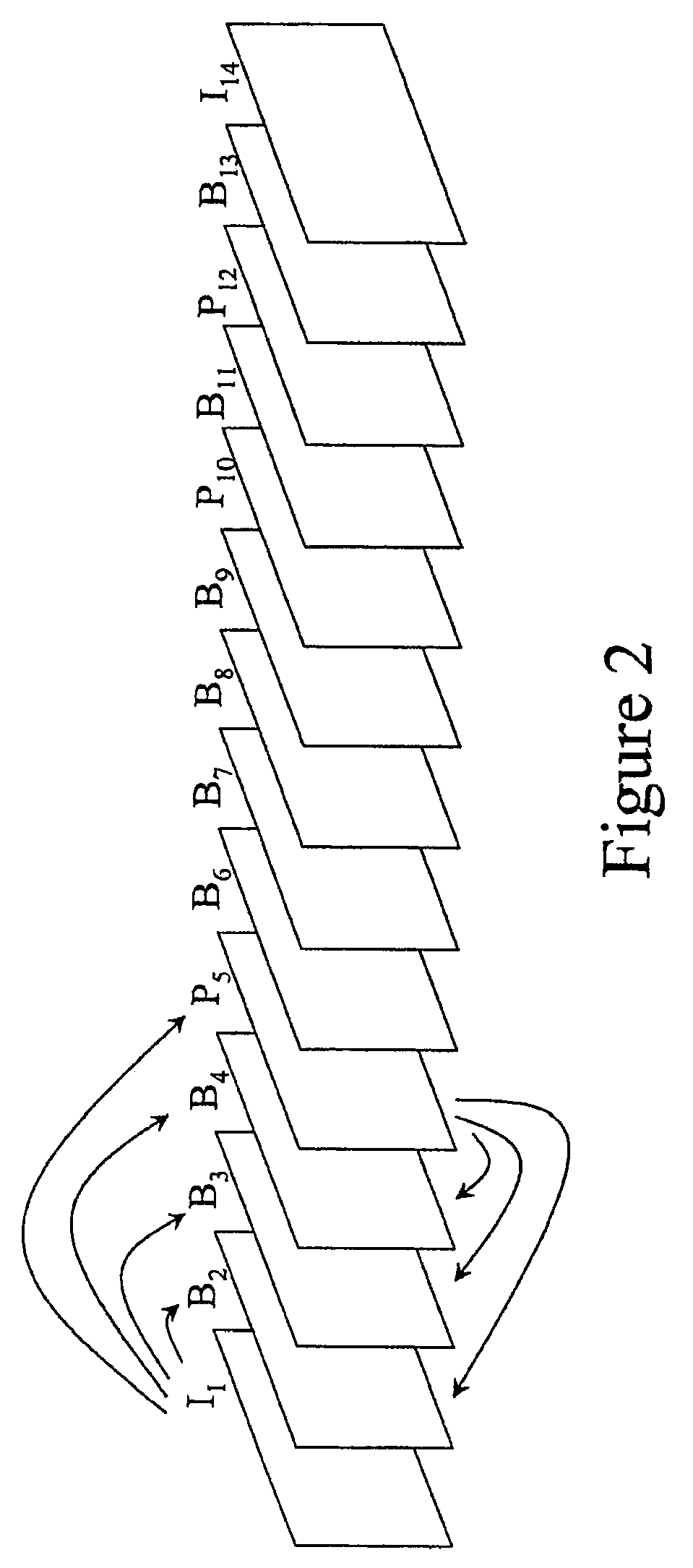

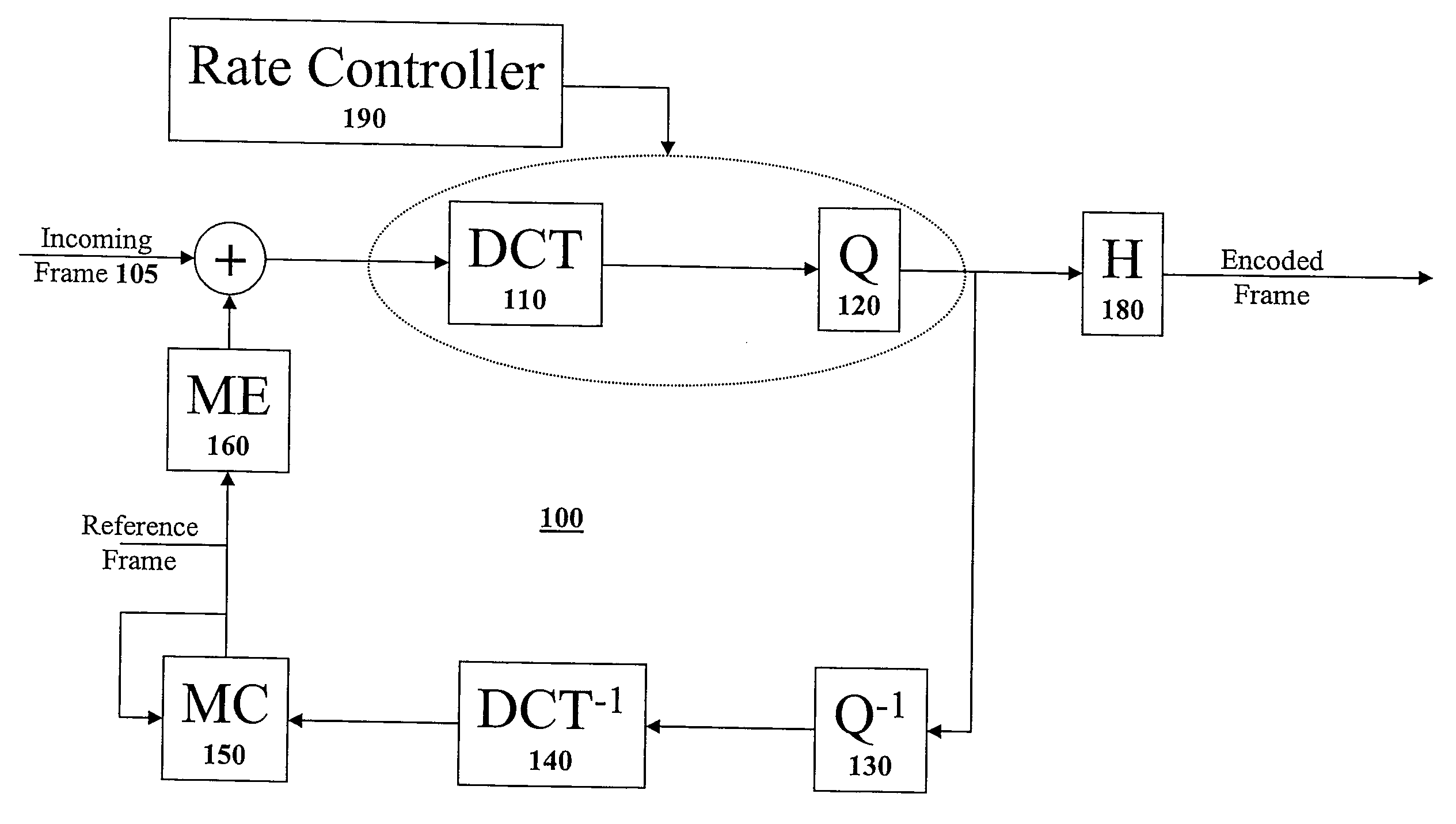

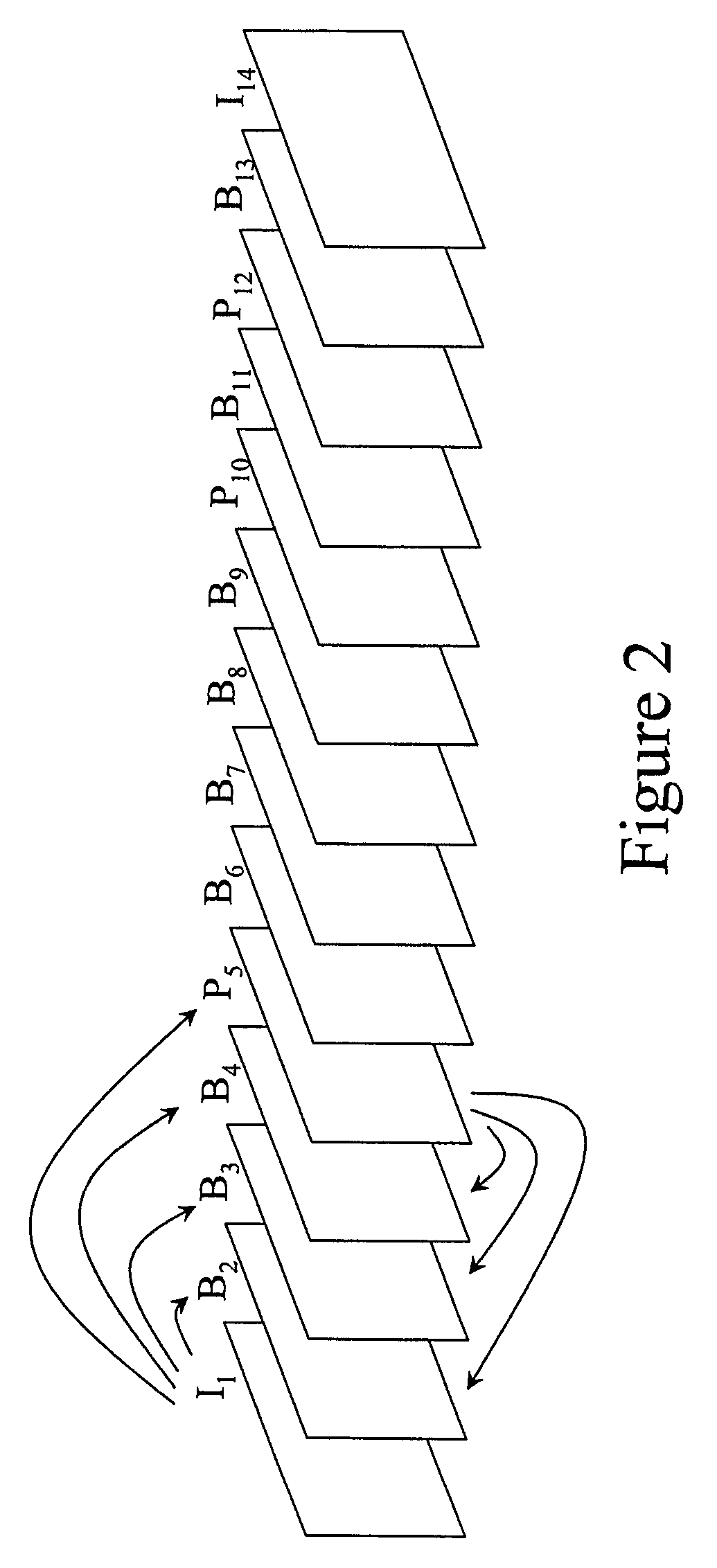

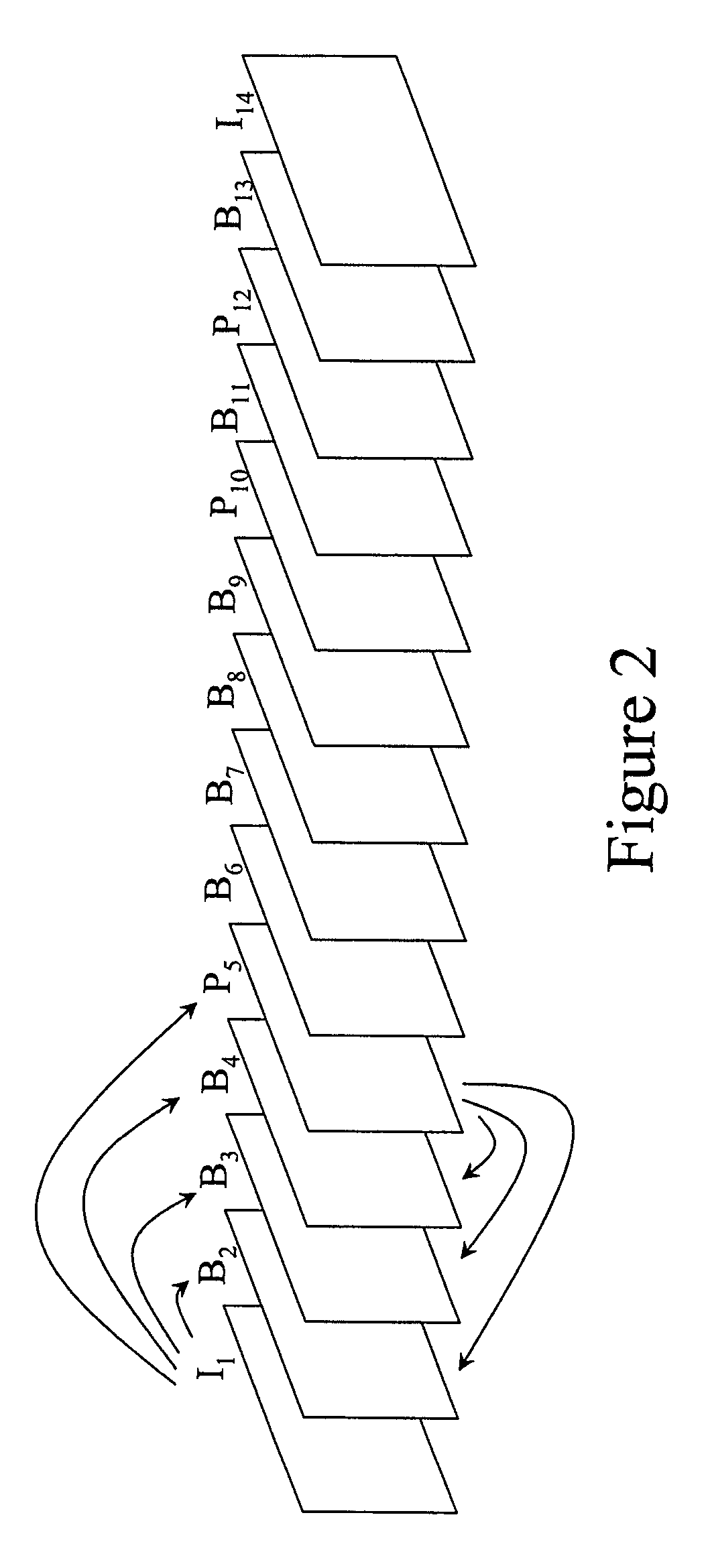

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20090022225A1Avoid slow motionEliminate needColor television with pulse code modulationColor television with bandwidth reductionDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

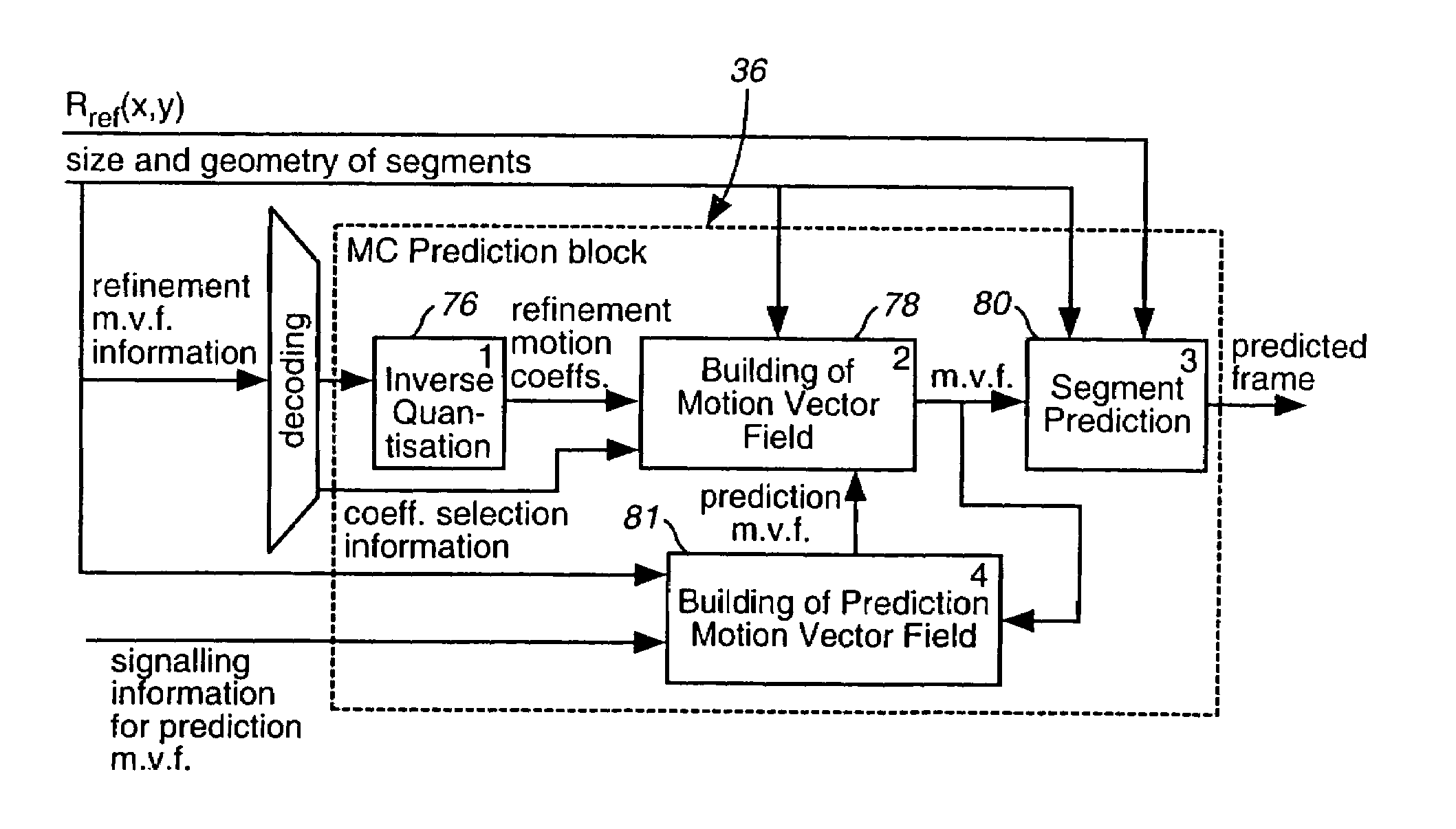

Apparatus, and associated method, for forming a compressed motion vector field utilizing predictive motion coding

InactiveUS20070140342A1Avoid slow motionReduce mistakesColor television with pulse code modulationColor television with bandwidth reductionMotion vectorVideo sequence

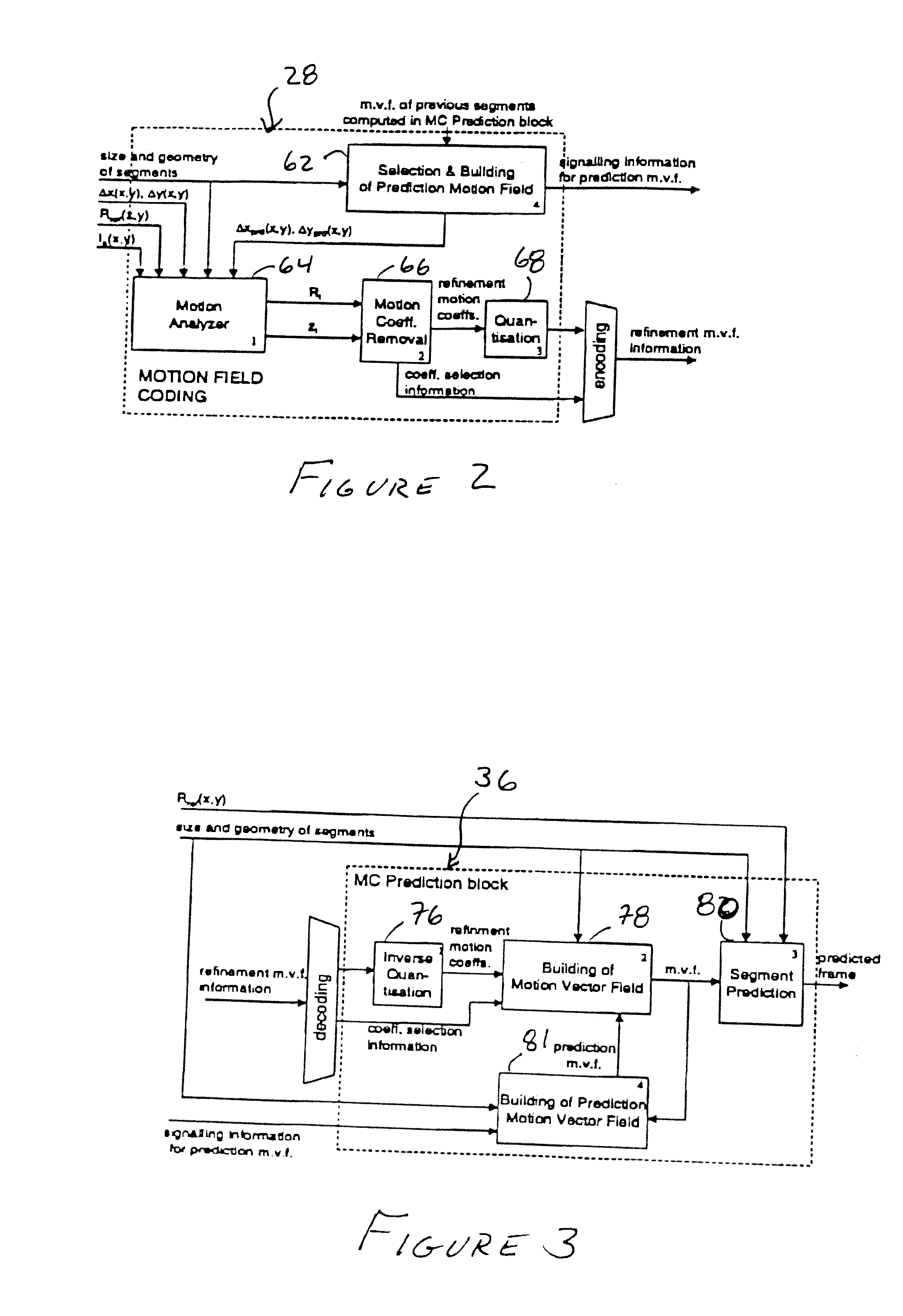

Apparatus, and an associated method, motion compensates coding of video sequences. Motion compensated prediction is utilized in the representation of motion vector fields. Reduced numbers of bits are required to represent the motion vector field while maintaining a low prediction error, thereby facilitating improved communication of, and recreation of, video frames forming a video sequence.

Owner:NOKIA TECH OY

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20070183501A1Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20070183502A1Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20070183503A1Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS8254461B2Avoid slow motionEliminate needColor television with pulse code modulationColor television with bandwidth reductionDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

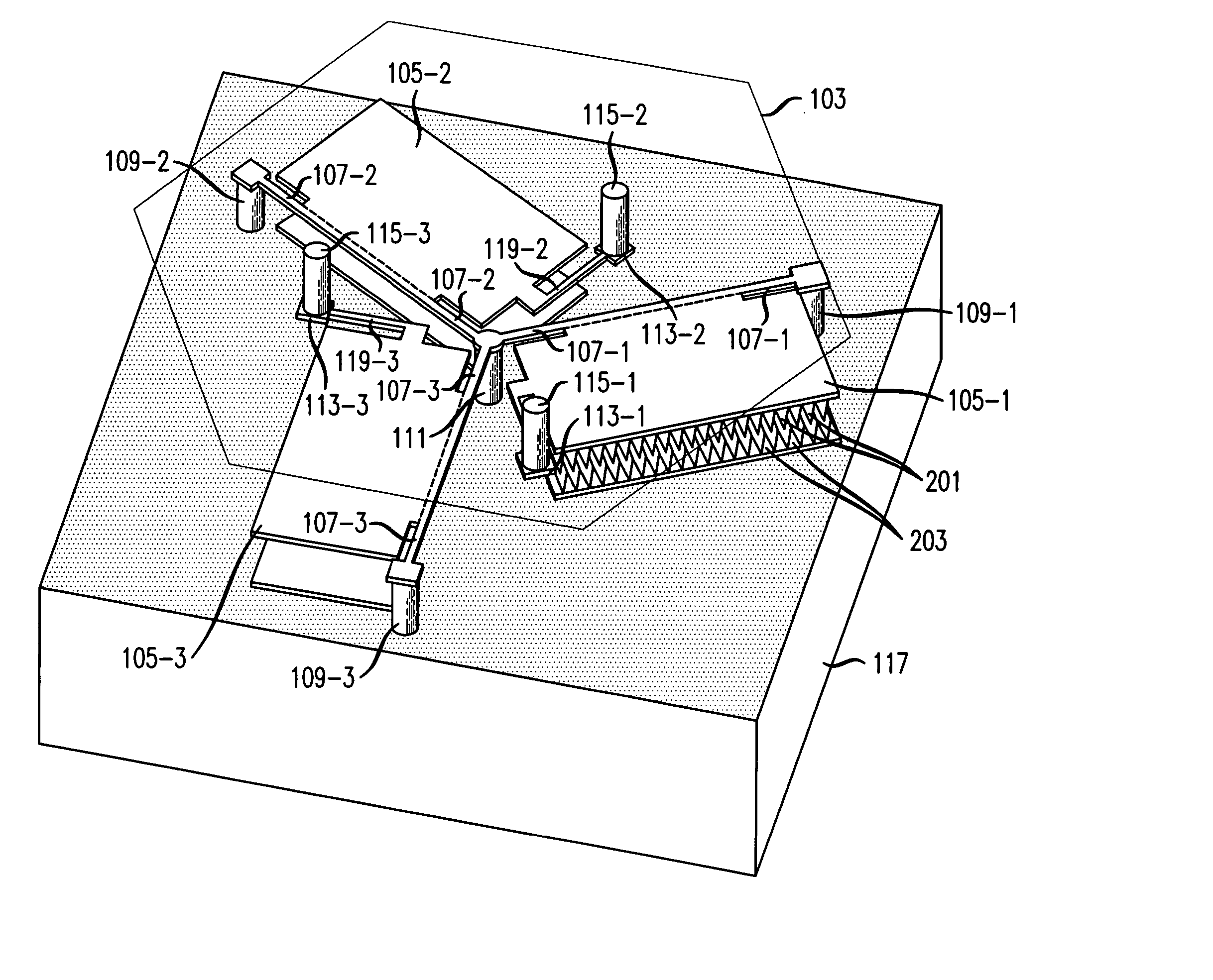

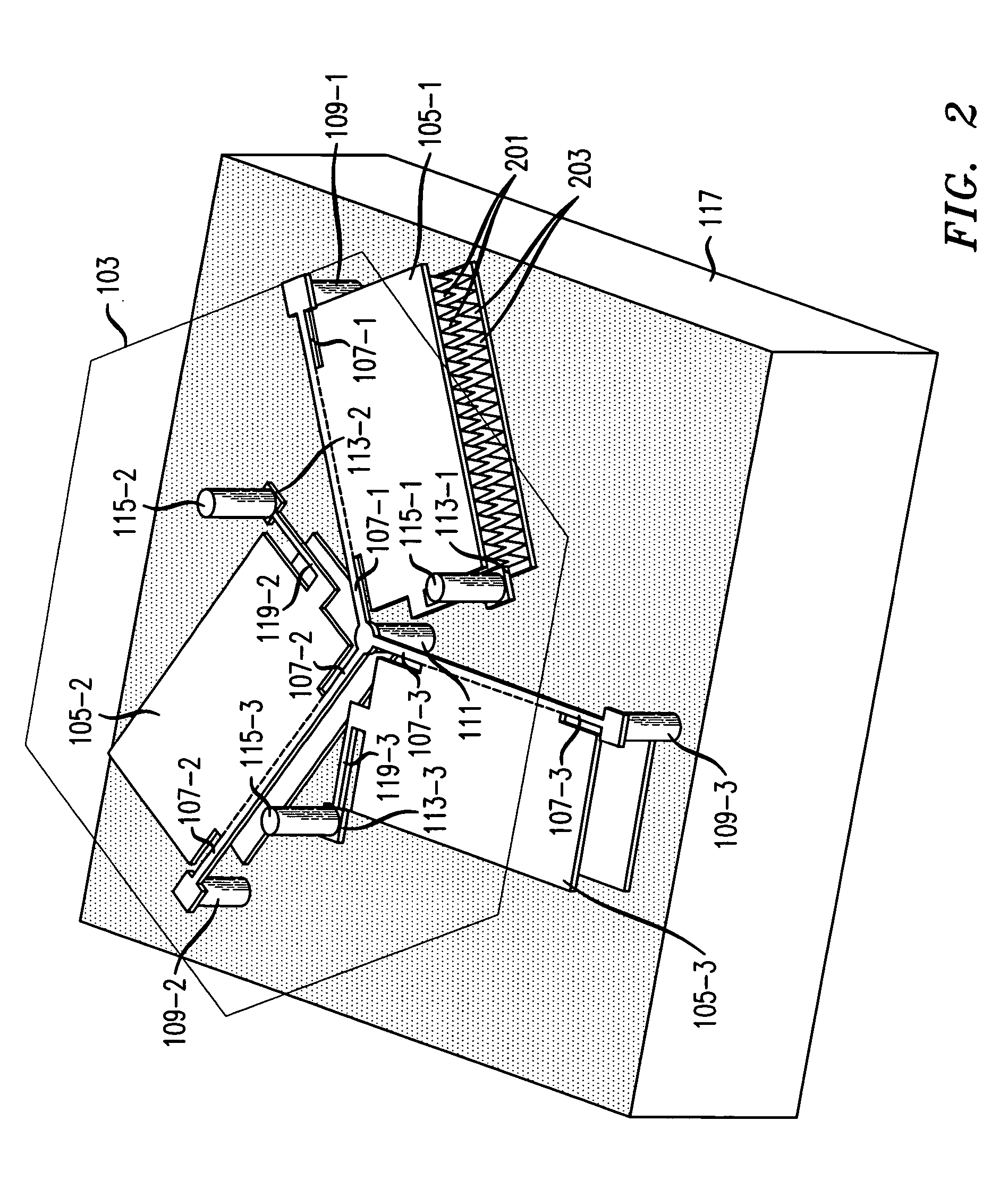

Tip-tilt-piston actuator

ActiveUS20050219675A1Avoid slow motionHigh frequency responseMirrorsElectrostatic generators/motorsKinematic couplingEngineering

A freely rotatable micromechanical plate is achieved by employing at least three rotatable plates that are each suspended from a substrate via respective springs, and are coupled via other respective springs to at least three moveable plate attachment points, so that rotation of the rotatable plates about an axis transfers motion to the moveable plate attachment points. Respective posts couple the movement of each respective moveable plate attachment point to a moveable plate. In operation, the rotatable plates may be individually rotated, and the resulting motion of each rotatable plate is passed to its respective moveable plate attachment point. The combined motion of the moveable plate attachment points is passed to the moveable plate via the posts. Using proper control, the plate may be made to tip, tilt and piston. Advantageously, the piston motion may achieve a high vertical movement frequency response.

Owner:WSOU INVESTMENTS LLC +1

Method and apparatus for variable accuracy inter-picture timing specification for digital video encoding with reduced requirements for division operations

InactiveUS20070286282A1Avoid slow motionEliminate needPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDigital videoMotion vector

A method and apparatus for performing motion estimation in a digital video system is disclosed. Specifically, the present invention discloses a system that quickly calculates estimated motion vectors in a very efficient manner. In one embodiment, a first multiplicand is determined by multiplying a first display time difference between a first video picture and a second video picture by a power of two scale value. This step scales up a numerator for a ratio. Next, the system determines a scaled ratio by dividing that scaled numerator by a second first display time difference between said second video picture and a third video picture. The scaled ratio is then stored calculating motion vector estimations. By storing the scaled ratio, all the estimated motion vectors can be calculated quickly with good precision since the scaled ratio saves significant bits and reducing the scale is performed by simple shifts.

Owner:APPLE INC

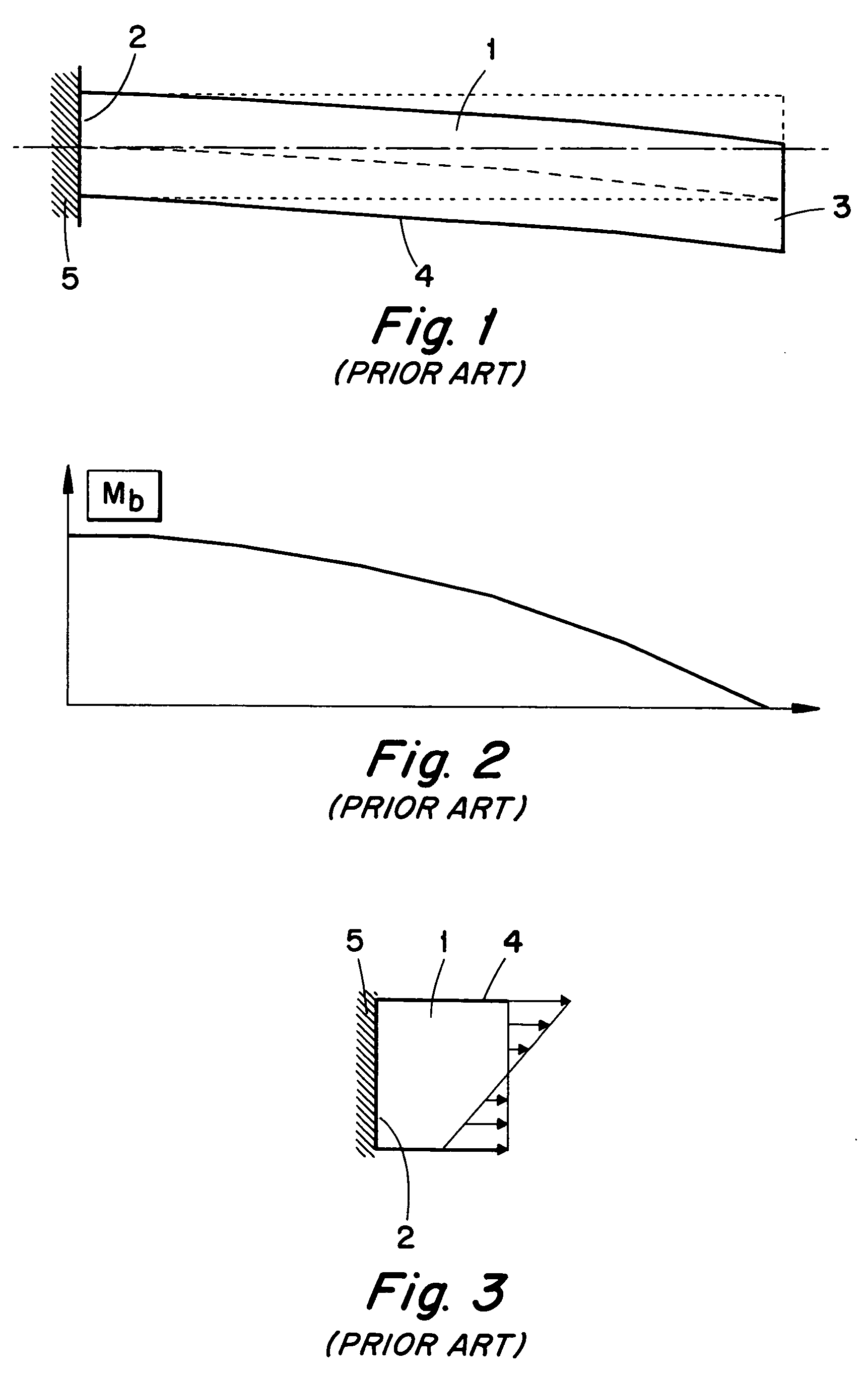

Metal cutting apparatus and method for damping feed-back vibrations generated thereby

Feed back vibrations of a metallic tool generated during the machining of metallic workpieces are damped by detecting an oscillatory motion of the tool, identifying a frequency of the oscillatory motion and generating a mechanical camping force having the same frequency as the oscillatory motion and applied to the tool in counter-direction to a velocity of the oscillatory motion. The damping force can be of constant amplitude or gradually decreasing amplitude.

Owner:SANDVIK AB

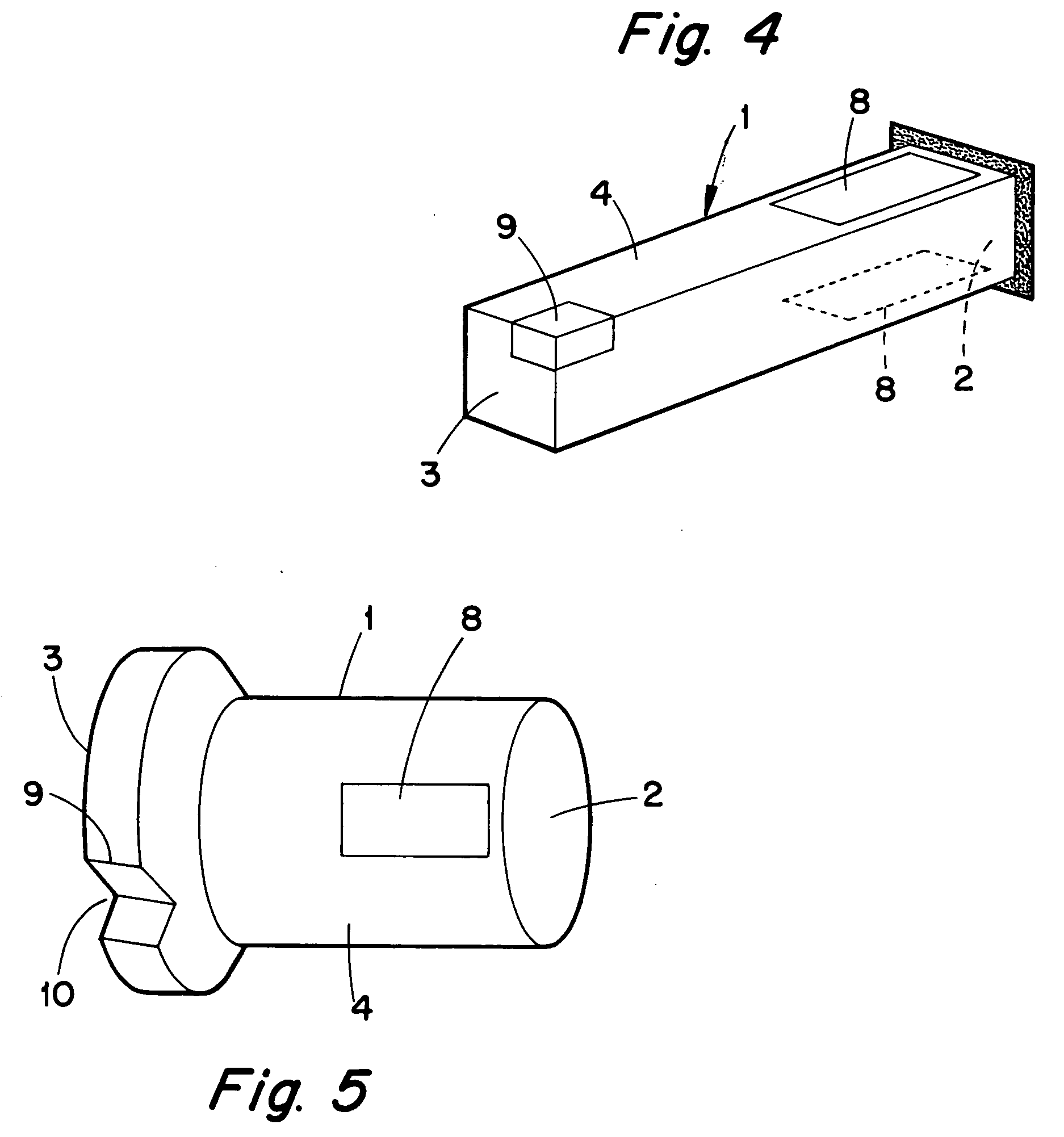

Combination yo-yo and top

The present invention is directed to a combination yo-yo and top device comprising first and second yo-yo body halves, a hollow dowel element detachably connecting one of the yo-yo body halves to the other, a ball bearing element mounted on the hollow dowel element between the yo-yo body halves, a first flywheel assembly having an elongated flywheel axle, wherein the first flywheel assembly is adapted for attachment to the yo-yo body, a second flywheel assembly adapted for attachment to the yo-yo body, a string element having a first end coupled to the hollow dowel element, a power element adapted for attachment to either the first flywheel assembly or the second flywheel assembly to activate both flywheel assemblies, and, at least one removable top component adapted to be secured to the yo-yo body to convert the device from a yo-yo to a top.

Owner:WSZALEK TOM +1

Tip-tilt-piston actuator

ActiveUS7068409B2Avoid slow motionHigh frequency responseMirrorsElectrostatic generators/motorsKinematic couplingEngineering

Owner:WSOU INVESTMENTS LLC +1

Apparatus, and associated method, for forming a compressed motion vector field utilizing predictive motion coding

InactiveUS7149251B2Avoid slow motionReduce mistakesTelevision system detailsPicture reproducers using cathode ray tubesMotion vectorVideo sequence

Apparatus, and an associated method, motion compensates coding of video sequences. Motion compensated prediction is utilized in the representation of motion vector fields. Reduced numbers of bits are required to represent the motion vector field while maintaining a low prediction error, thereby facilitating improved communication of, and recreation of, video frames forming a video sequence.

Owner:NOKIA TECHNOLOGLES OY

Metal cutting apparatus and method for damping feed-back vibrations generated thereby

Owner:SANDVIK AB

Combination yo-yo and top

The present invention is directed to a combination yo-yo and top device comprising first and second yo-yo body halves, a hollow dowel element detachably connecting one of the yo-yo body halves to the other, a ball bearing element mounted on the hollow dowel element between the yo-yo body halves, a first flywheel assembly having an elongated flywheel axle, wherein the first flywheel assembly is adapted for attachment to the yo-yo body, a second flywheel assembly adapted for attachment to the yo-yo body, a string element having a first end coupled to the hollow dowel element, a power element adapted for attachment to either the first flywheel assembly or the second flywheel assembly to activate both flywheel assemblies, and, at least one removable top component adapted to be secured to the yo-yo body to convert the device from a yo-yo to a top.

Owner:WSZALEK TOM +1

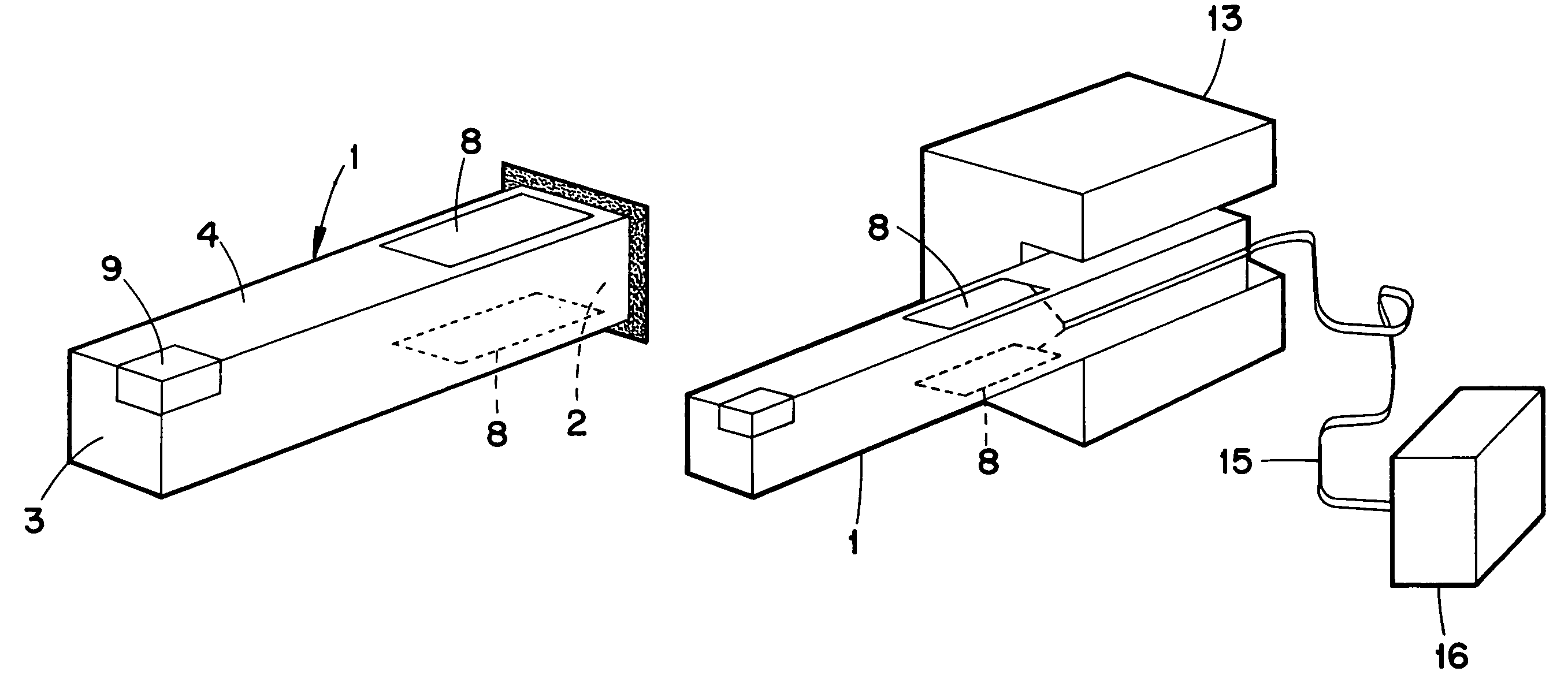

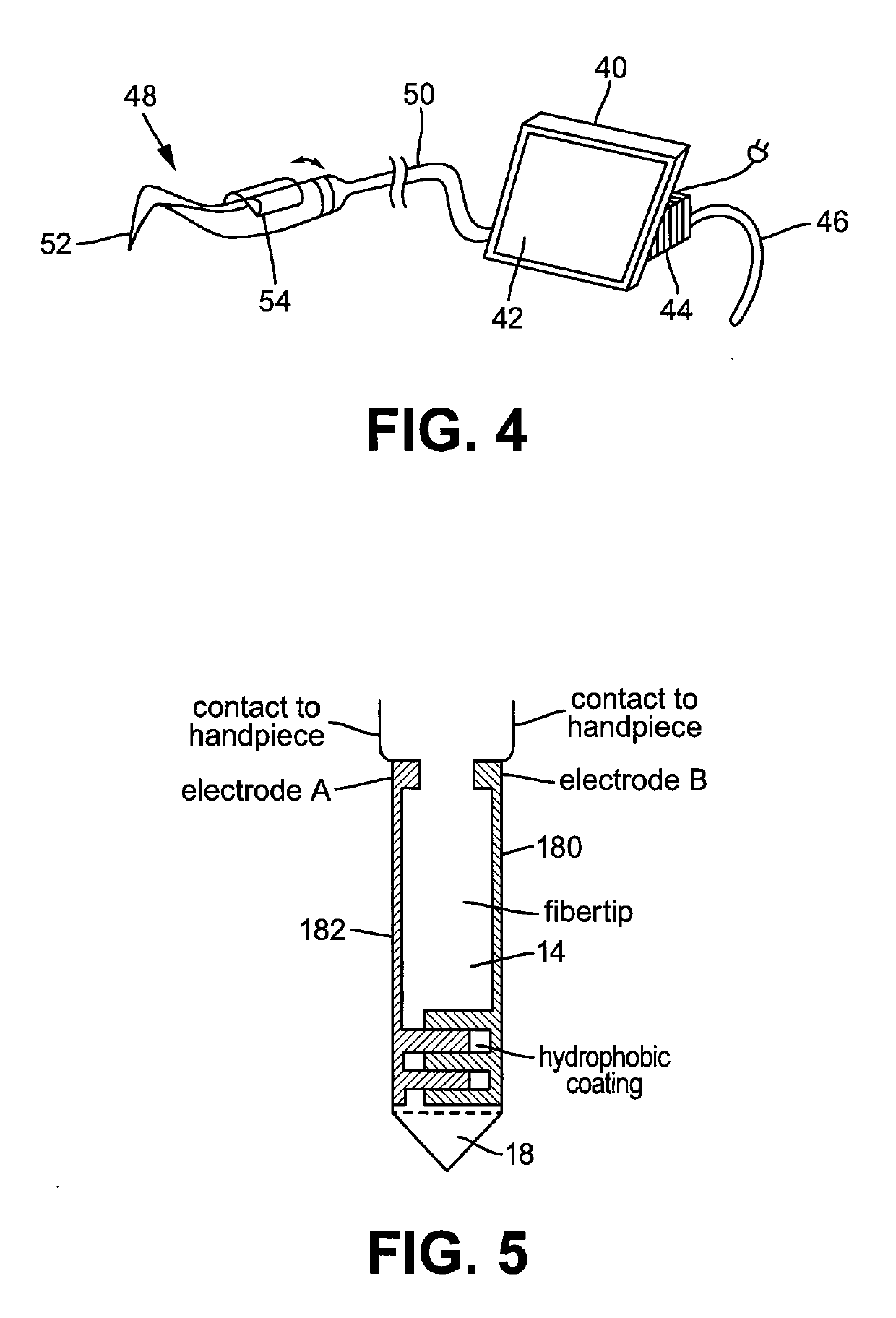

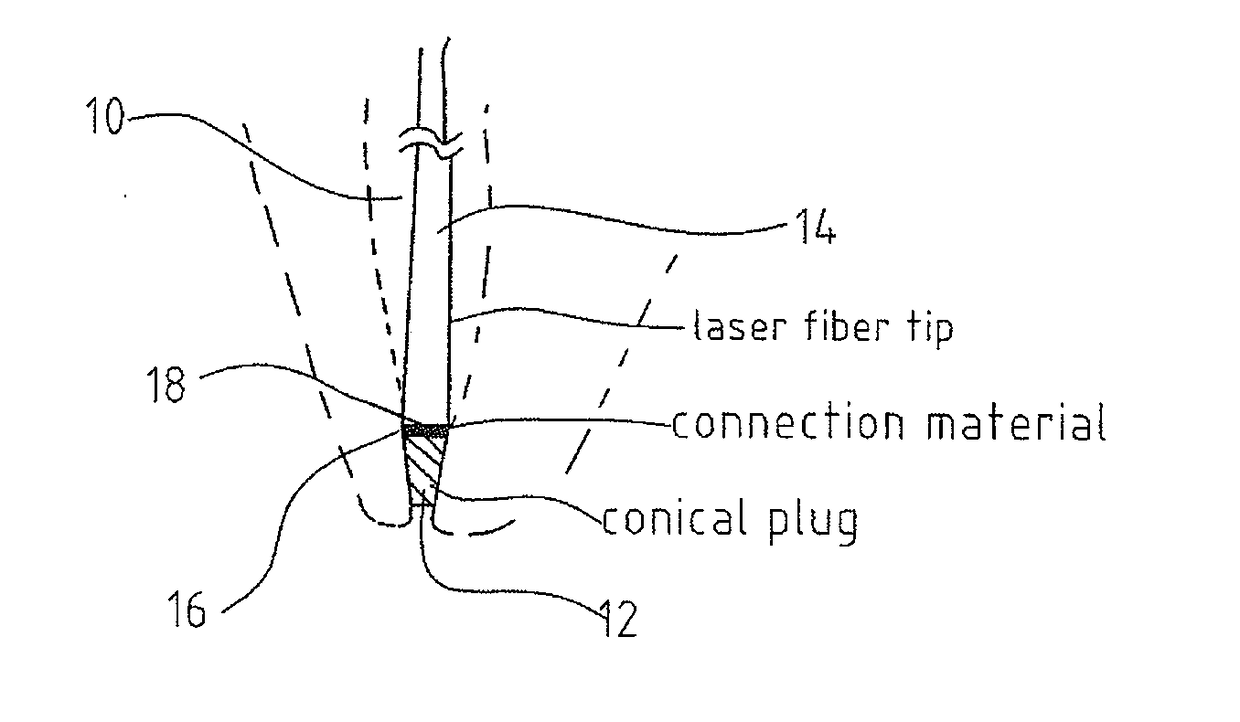

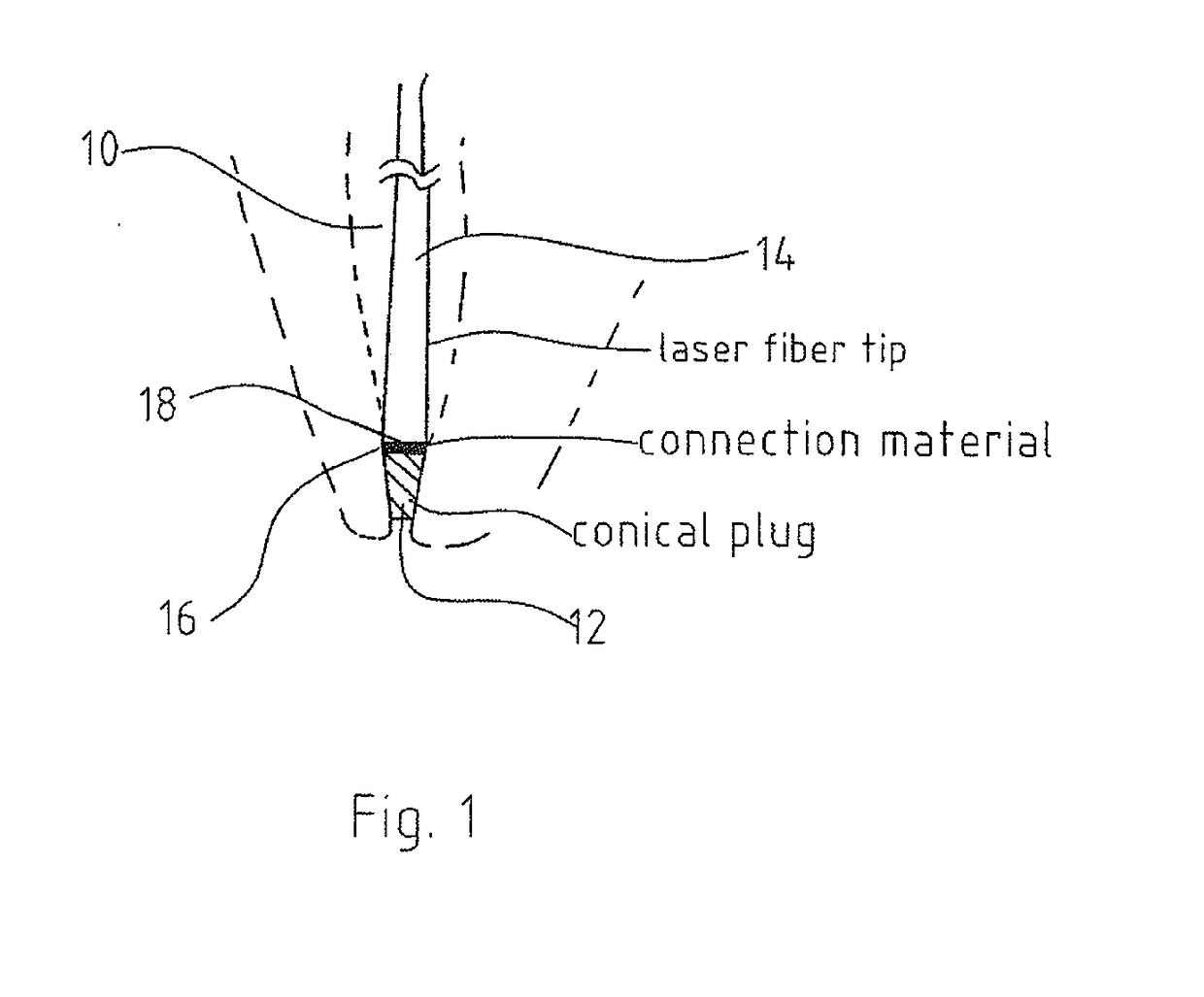

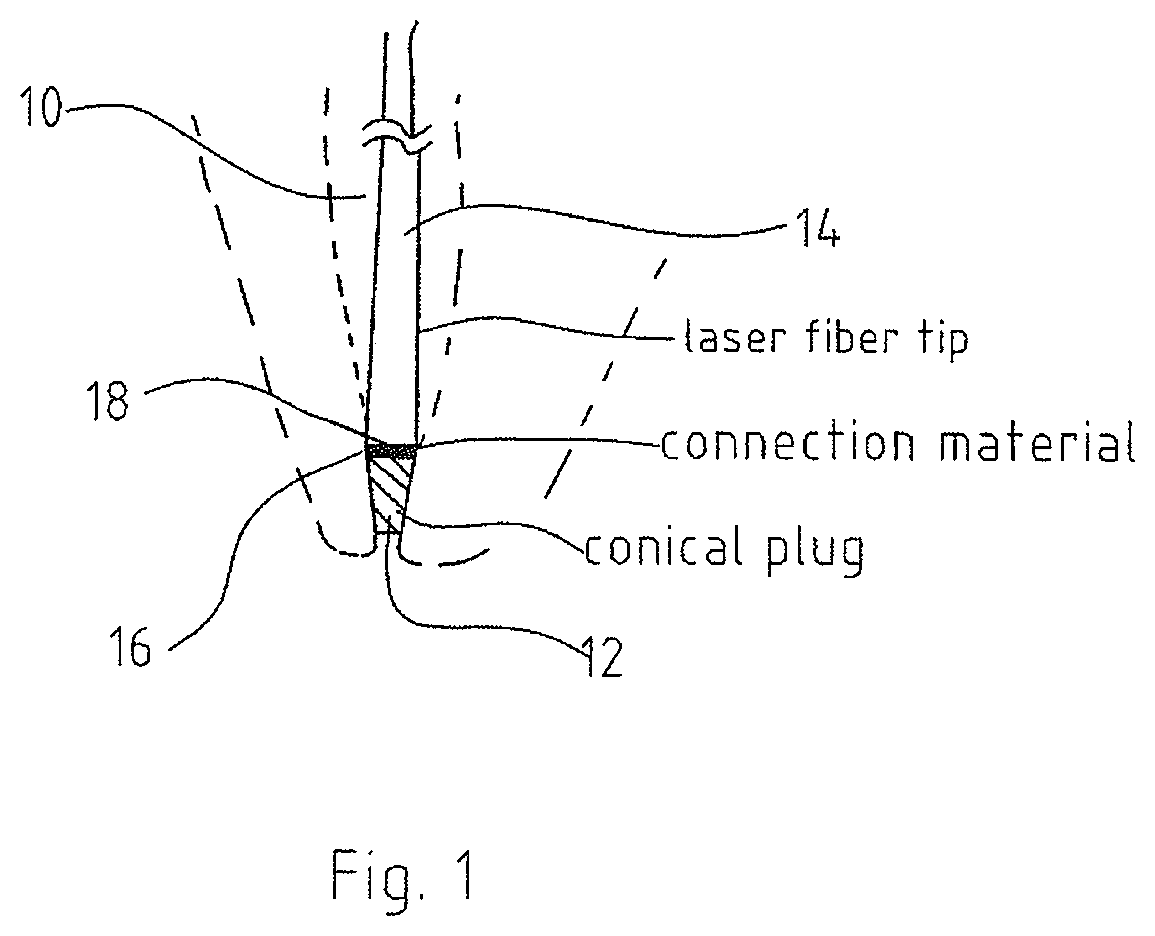

Method and arrangement for cleaning of a canal

ActiveUS20170274220A1Avoid mistakesNot to damageTeeth fillingSurgical instrument detailsOptical radiationLight guide

The invention relates to a method and an arrangement for the cleaning of a circumferentially closed canal by means of a light guide conducting a laser beam. The entry of the laser beam into the light guide is interrupted when the free end of the light guide is outside of the canal and / or the movement of the light guide within the canal is monitored and that if there is no movement or the movement is below a threshold value then a signal is triggered and / or the laser radiation is turned off or its output is reduced.

Owner:DENTSPLY SIRONA INC

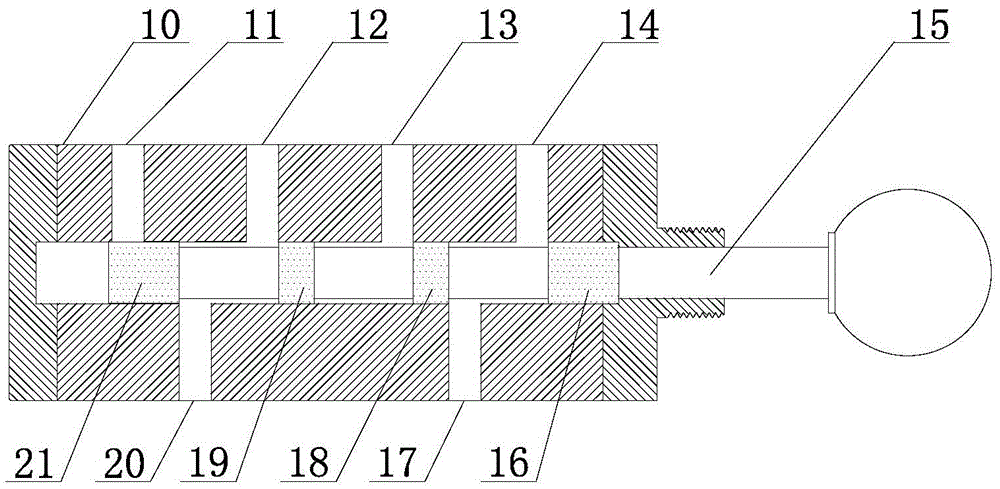

Hydraulic system of mechanically operated quadruple pump

ActiveCN101857173AEliminate pressure shocksAvoid slow motionLoad-engaging elementsTraffic volumeModularity

The invention relates to a hydraulic system of a mechanically operated quadruple pump, comprising a first oil pump, a second oil pump, a third oil pump, a rotary hydraulic system, a boom expansion hydraulic system, a control hydraulic system, a lifting hydraulic system, a boom amplitude hydraulic system and a pilot oil-source valve group; the opening and closing characteristics of a rotary brake and main and accessory hoisting brakes all adopt a constant-pressure oil-source control mode and intelligently and automatically control the brakes according to the operation of various actions without the need of additional external force operation; according to the different opening and closing characteristics of each mechanism, a rotary structure is in a quick-opening slow-closing control mode,main and accessory hoisting mechanisms are in a slow-opening quick-closing control mode, and the pressure impaction of the system is effectively eliminated; a flow distribution valve adopts a flow distribution mode which is unrelated to load and effectively prevents slow action or no action of a high-load-pressure actuating mechanism for pressure interference among actuating mechanisms; and in a complete vehicle system, elements are highly integrated and modularized, thereby reducing pipelines of the complete vehicle system and being convenient for maintenance.

Owner:YUZHOU HYDRAULIC EQUIP FACTORY

Method and arrangement for cleaning of a canal

The invention relates to a method and an arrangement for the cleaning of a circumferentially closed canal by means of a light guide conducting a laser beam, wherein the entry of the laser beam into the light guide is interrupted when the free end of the light guide is outside of the canal and / or the movement of the light guide within the canal is monitored and if there is no movement or the movement is below a first threshold value then a signal is triggered and / or the laser radiation is turned off or its output is reduced, and wherein the turning off of the laser radiation or its reducing is controlled in dependency of at least one signal change and / or a second threshold and / or a signal change relative to the second threshold determined during at least one course of time starting before and including the entry of the light guide into the canal.

Owner:DENTSPLY SIRONA INC

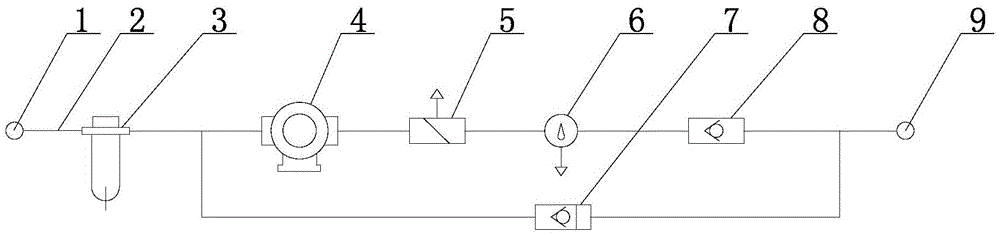

Positive-pressure sampling pump station for sampling system

ActiveCN105527134ARealize long-distance fast transportationSolve the problem of slow movement speedWithdrawing sample devicesPreparing sample for investigationPositive pressureBeam tube

The invention belongs to the field of beam tube monitoring, and particularly relates to a positive-pressure sampling pump station for a sampling system. The positive-pressure sampling pump station comprises an A-path positive-pressure sampling device, a B-path positive-pressure sampling device and a gas branching switching device. By adopting the positive-pressure sampling pump station, the A-path positive-pressure sampling device and the B-path positive-pressure sampling device can perform independent conveying work respectively, the A-path positive-pressure sampling device and the B-path positive-pressure sampling device can be combined into one path to be used for conveying, and switching between the two conveying ways is mainly completed by the gas branching switching device. The positive-pressure sampling pump station can meet the actual working condition requirement under a coal mine, the conveying ways are configured flexibly, and sampling work of a coal mine safe beam tube monitoring system can be performed conveniently.

Owner:淄博祥龙测控技术有限公司

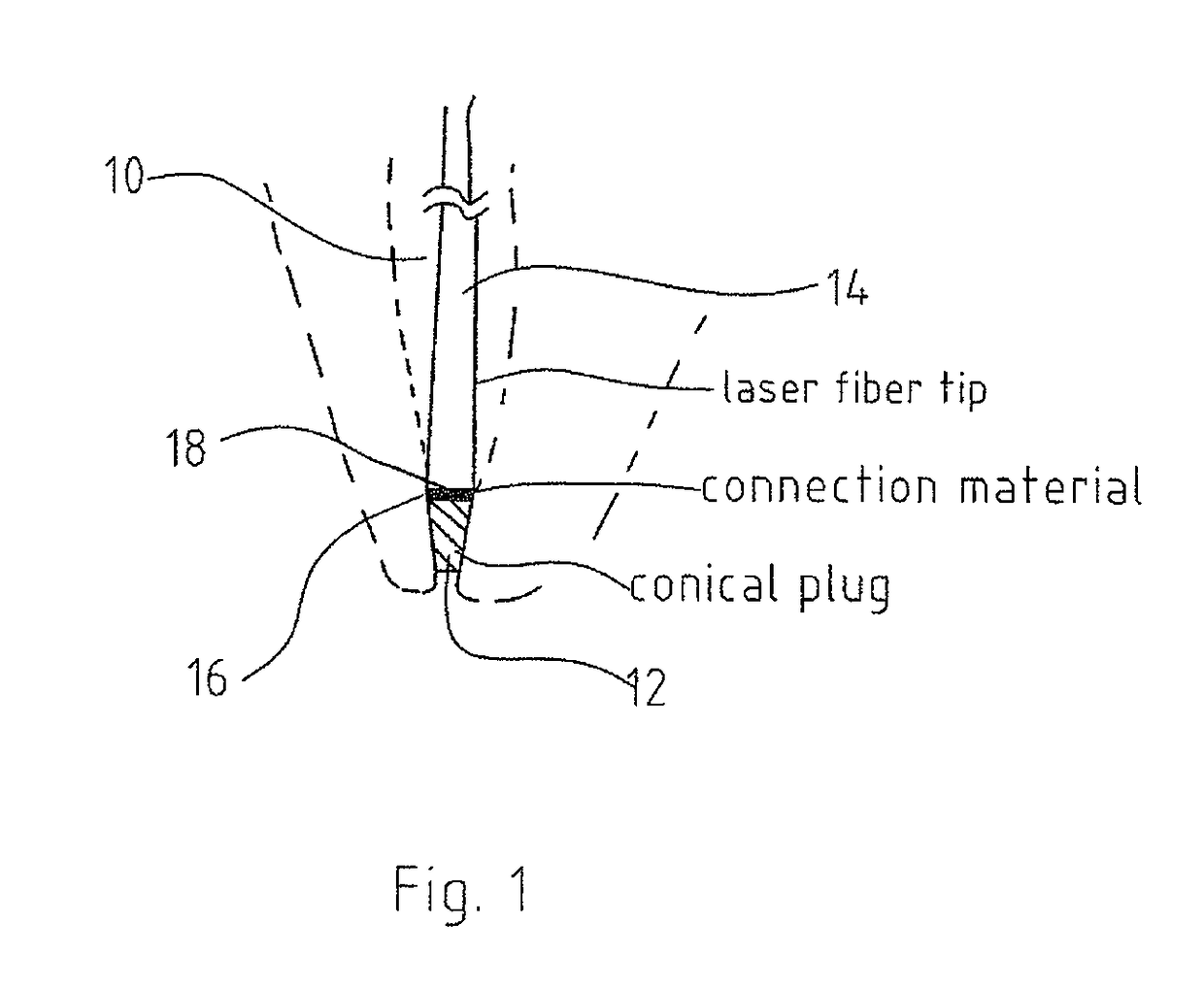

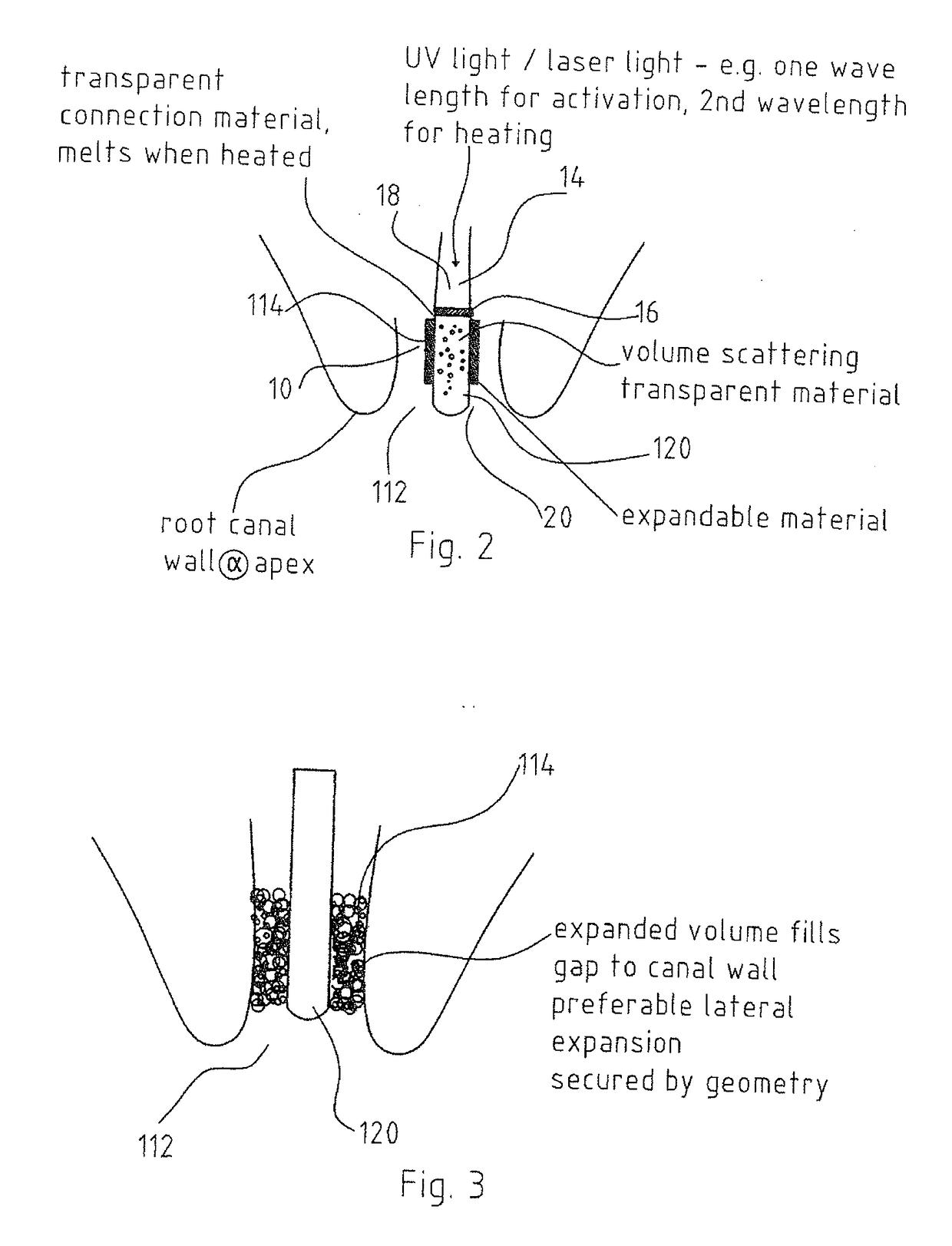

Method for sealing of a canal

ActiveUS20170273755A1Low viscosityAvoid mistakesTeeth fillingSurgical instrument detailsLight guideLaser beams

The invention relates to a method for sealing of a circumferentially closed canal. A closure element is secured to one free end of a light guide conducting a laser beam. The light guide with the closure element is introduced into the canal. The closure element is positioned in the region of the canal to be sealed and after positioning of the closure element energy is introduced, so that the closure element melts or softens and remains in this position in the canal and seals it tightly.

Owner:DENTSPLY SIRONA INC

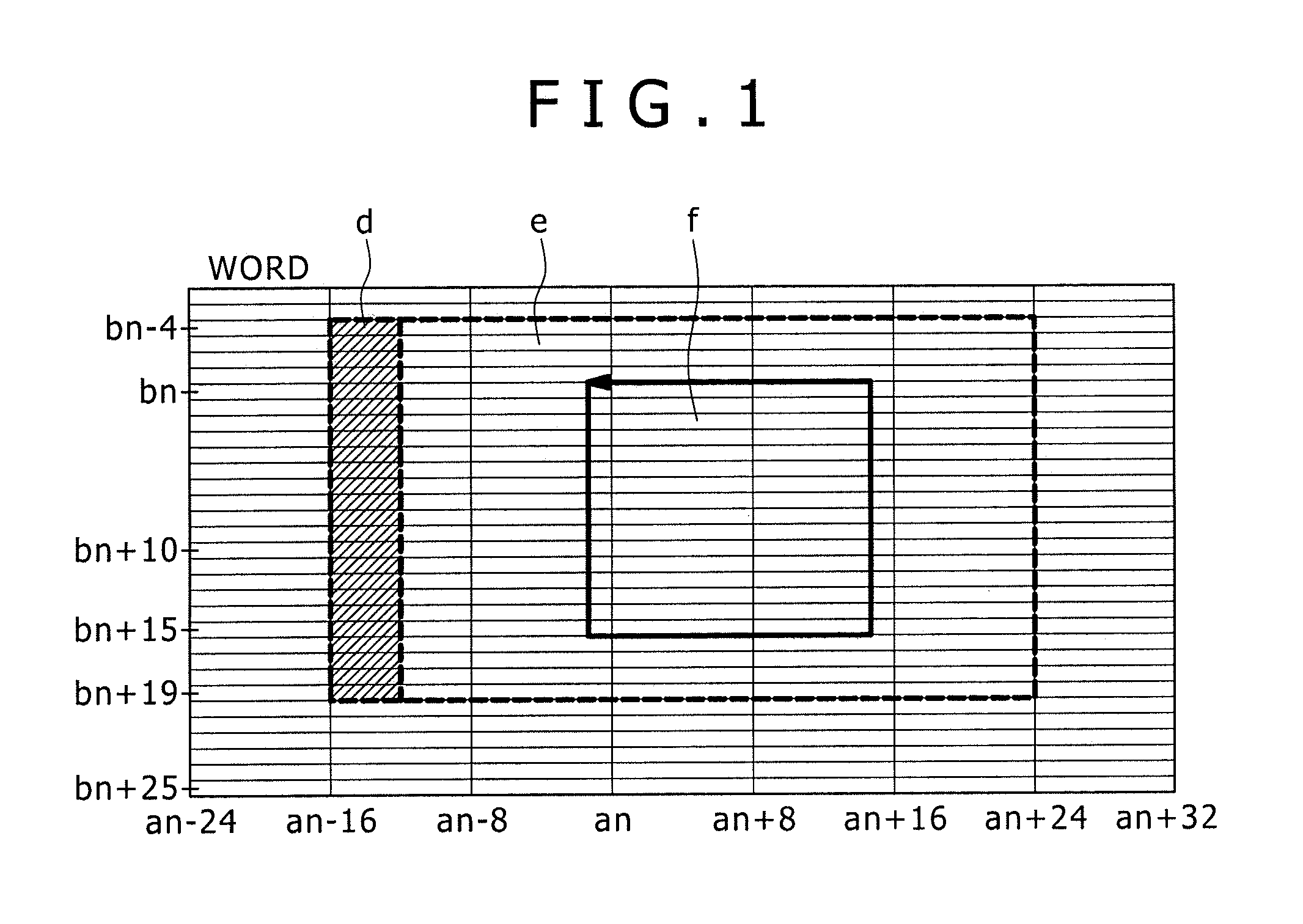

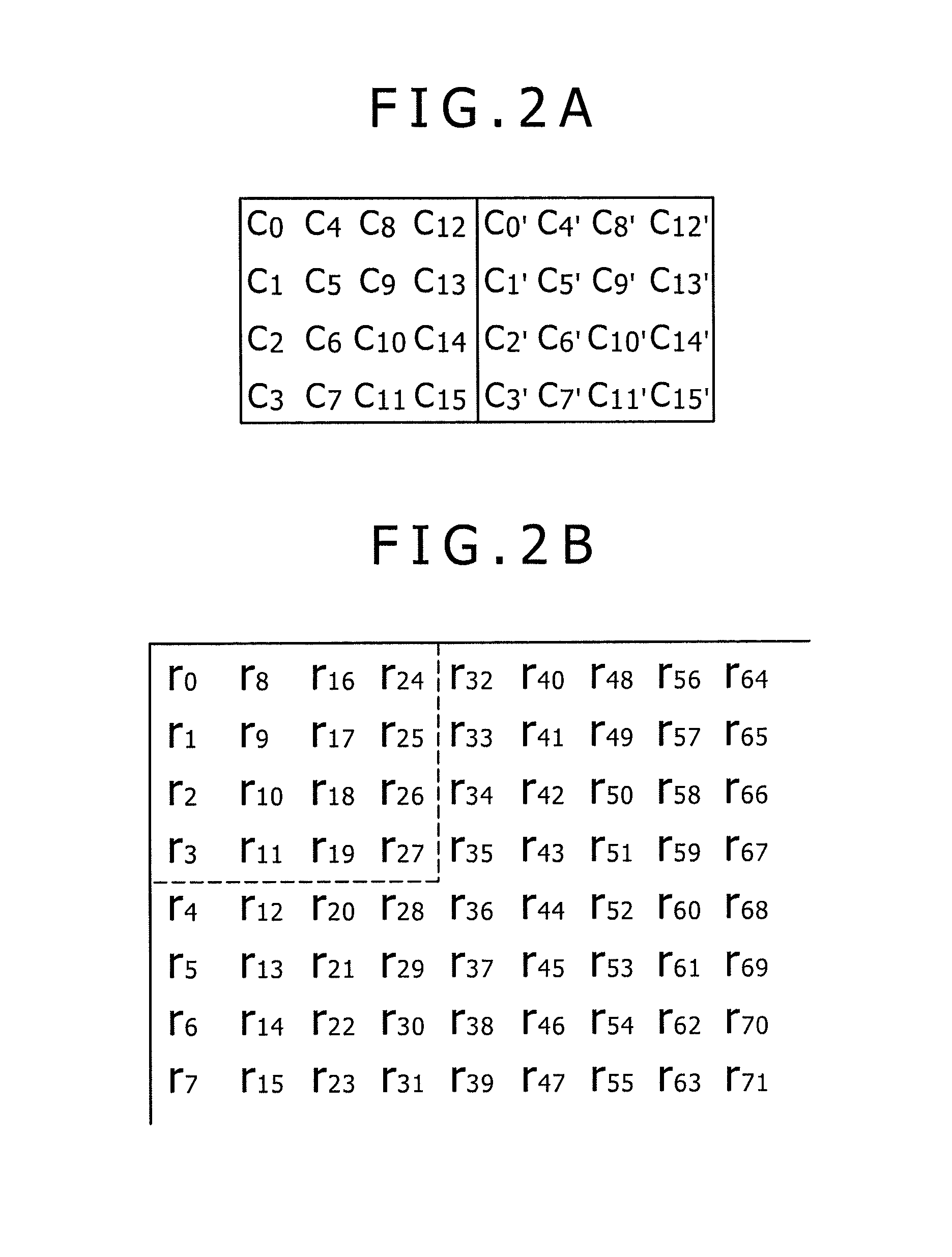

Image processing method and image information coding apparatus using the same

ActiveUS8565312B2Reduce in quantityAvoid slow motionColor television with pulse code modulationColor television with bandwidth reductionImaging processingMotion vector

An image information coding method for performing a motion vector search based on hierarchical search in an image compression information device adapted to output image compression information. The image information coding method includes the steps of, compressing a plurality of frame images at a predetermined compression ratio to generate a plurality of reduced screens of lower hierarchical levels, searching for a first motion vector using the plurality of reduced screens, switching between search areas in a memory in which the frame images are stored, and searching for a second motion vector using the first motion vector in the switched search area.

Owner:SONY SEMICON SOLUTIONS CORP

Positive pressure sampling system and positive pressure sampling pump station for same

ActiveCN105466736ASmooth start without loadAchieve drying pretreatmentWithdrawing sample devicesStopped workPositive pressure

The invention belongs to the field of beam tube monitoring, and particularly relates to a positive pressure sampling system. The positive pressure sampling system comprises a pressure pump, a pressure relief device and an automatic filtered water drainer. An inlet of the pressure pump is connected with a gas inlet, and an outlet of the pressure pump is connected with a gas inlet of the pressure relief device. A gas outlet of the pressure relief device is connected with the gas inlet end of the automatic filtered water drainer. The gas outlet end of the automatic filtered water drainer is connected with a gas outlet. A check valve is installed on a pipeline between the gas outlet and the gas outlet end of the automatic filtered water drainer. Remote and rapid conveying of gas of the beam tube system is achieved, gas mixed pollution can be avoided, and the monitoring result is ensured; due to the pressure relief device, gas inside a pump body can be exhausted when the pressure pump stops working, it is ensured that no load is formed when the pressure pump is started again, and use is safe and reliable. The invention further relates to a positive pressure sampling pump station for the sampling system. The positive pressure sampling pump comprises at least two sets of the positive sampling systems, and multi-way sampling gas conveying is achieved.

Owner:淄博祥龙测控技术有限公司

Image processing method and image information coding apparatus using the same

ActiveUS20100272181A1Faster refinement searchImprove compression efficiencyColor television with pulse code modulationColor television with bandwidth reductionImaging processingMotion vector

Disclosed herein is an image information coding method for performing a motion vector search based on hierarchical search in an image compression information device adapted to output image compression information, the image information coding method including the steps of, compressing a plurality of frame images at a predetermined compression ratio to generate a plurality of reduced screens of lower hierarchical levels, searching for a first motion vector using the plurality of reduced screens, switching between search areas in a memory in which the frame images are stored, and searching for a second motion vector using the first motion vector in the switched search area.

Owner:SONY SEMICON SOLUTIONS CORP

Toothbrush conforming to dental arch and corresponding devices and methods

ActiveUS20200179091A1Rapid oscillatory motionAvoid slow motionBrush bodiesBristle carriersBristleLingual surface

A toothbrush (10) includes a brush assembly (16) with at least three bristle arrangements (12), each having opposing inwardly-directed bristles (122, 124, 126) for simultaneously contacting facial and lingual surfaces (52, 54), and preferably also occlusal surfaces (56) of the teeth (50). Flexible linkages (14), interconnecting the bristle arrangements (12), maintain a relative spacing between the bristle arrangements (12) while allowing variation of an effective curvature of the brush assembly (16) such that the bristle arrangements (12) can ride along, and conform to a non-uniform curvature of, the arch of teeth. The toothbrush (TO) preferably also includes an actuation mechanism (22) for generating to-and-fro motion of the brush assembly (16) along the arch of teeth, most preferably combined with a more rapid small-amplitude oscillatory motion.

Owner:DENTVER LTD

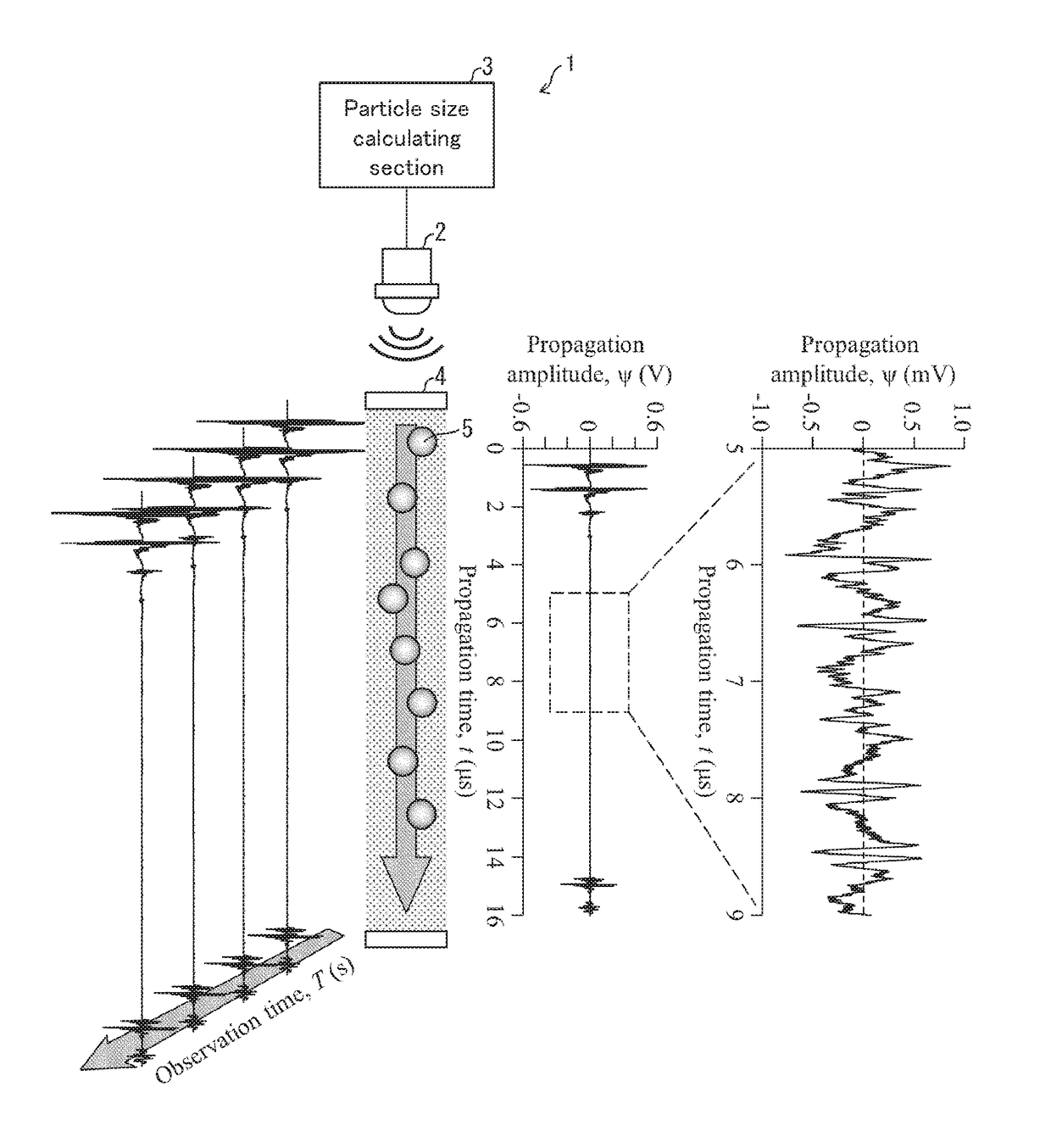

Ultrasonic particle size measurement device and ultrasonic measurement device

ActiveUS10101256B2Move quicklyImprove accuracyProcessing detected response signalParticle size analysisMeasurement deviceParticle size measurement

An ultrasonic particle size measurement device includes: a transducer for (i) receiving an ultrasonic pulse scattered after being emitted to a fine particle and (ii) generating a first scattering amplitude Ψ; and a particle size calculating section for calculating a particle size of the fine particle by calculating an amplitude r and a phase θ in accordance with a real part and an imaginary part, respectively, of a second scattering amplitude Ψ obtained by subjecting the first scattering amplitude Ψ to a Fourier transform.

Owner:NAT UNIV KYOTO INST OF TECH

Pilot oil source control block of front high-pressure filter

ActiveCN102758808BAvoid enteringAvoid slow motionServomotor componentsFluid-pressure actuator componentsFuel tankHigh pressure

The invention belongs to the technical field of fluid pressure actuating mechanisms, and particularly discloses a pilot oil source control block of a front high-pressure filter, which has the structure that the oil inlet and oil outlet of the throttle valve of the control block are connected with the outlet of a main pump and the oil inlet of the high-pressure filter; the oil outlet of the high-pressure filter is connected with the oil inlet of a reducing valve; the oil outlet of the reducing valve is connected with the oil inlet of an one-way valve; the oil outlet of the one-way valve is connected with the oil inlets of an overflow valve, a first electromagnetic directional valve and a second electromagnetic directional valve as well as an energy accumulator respectively; and the oil outlets of the reducing valve, the overflow valve, the first electromagnetic directional valve and the second electromagnetic directional valve are all connected with the oil return opening of an oil tank. The pilot oil source control block of the front high-pressure filter has the benefits that the valve core of the reducing overflow valve can be prevented from being stuck by the impurities in the oil, and the slow motion or non-motion of the whole hydraulic excavator can be prevented.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

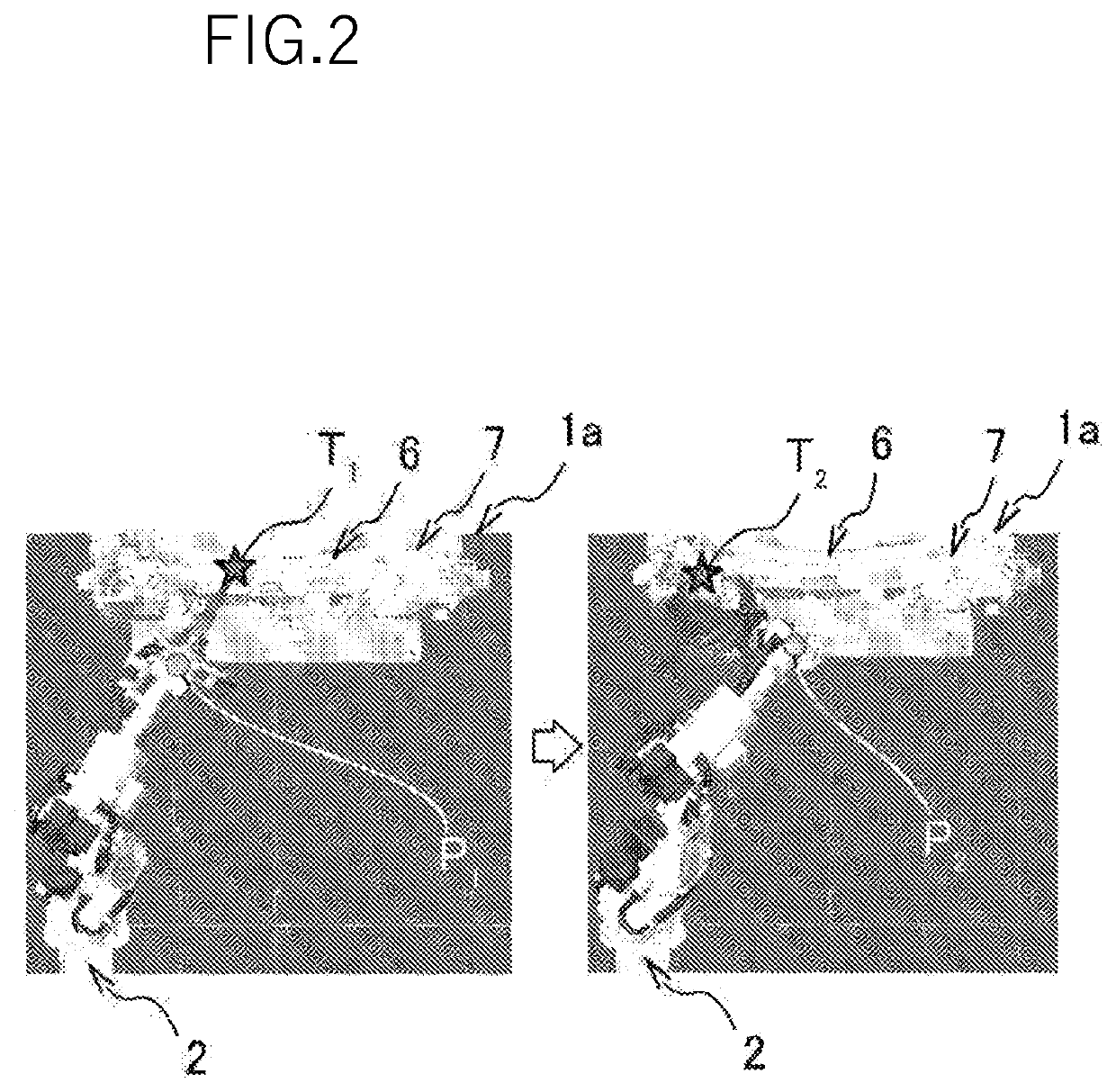

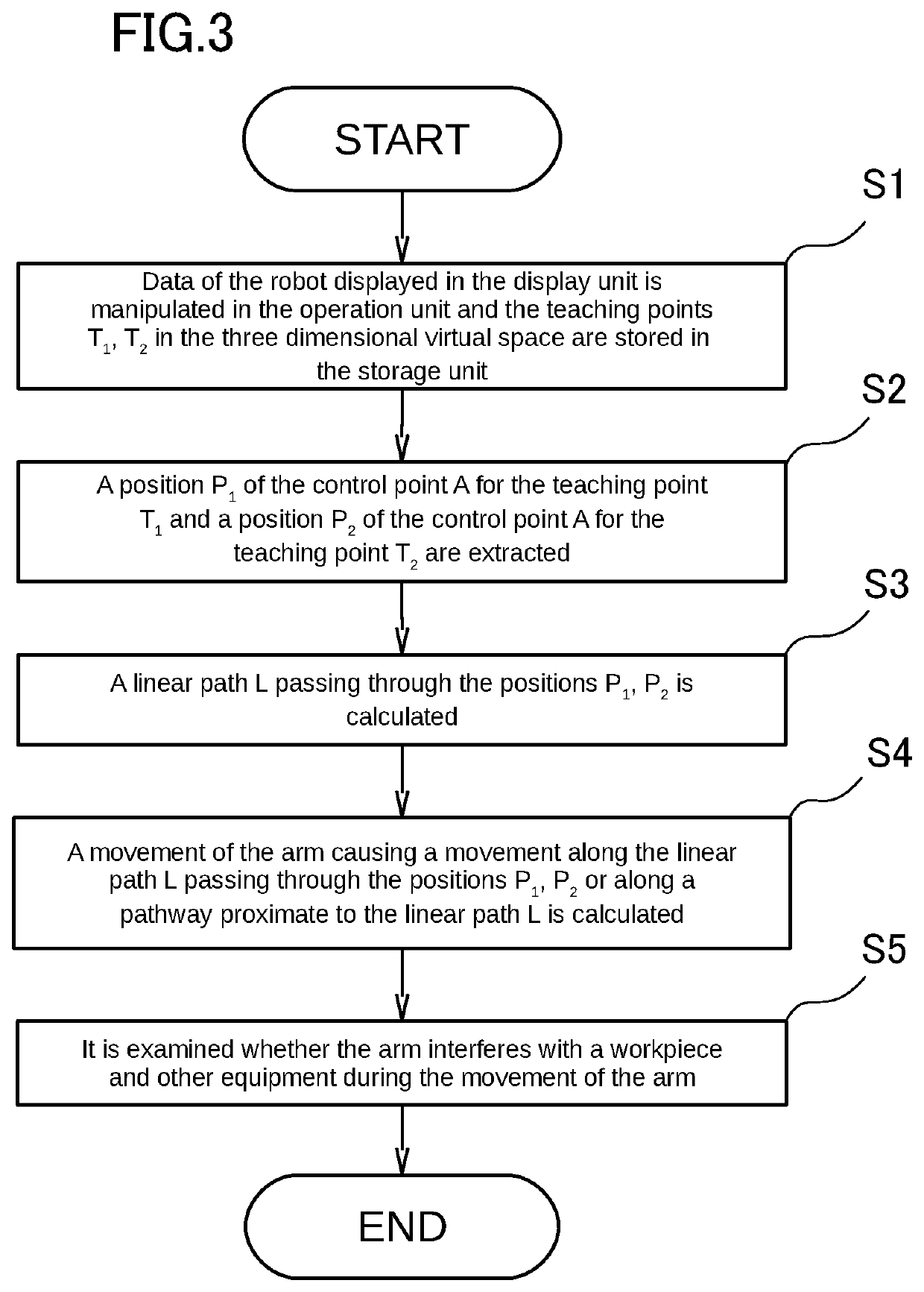

Teaching data generation system for vertical multi-joint robot

ActiveUS11203117B2Avoid interferenceReduce correction of movementProgramme-controlled manipulatorRecording and playback systemsSimulationControl theory

A control point extraction unit (1d) is configured to extract, when a center of a joint portion (V) of a fifth rotary shaft (C5) is defined as a control point (A), a position (P1) of the control point (A) for a teaching point (T1) and a position (P2) of the control point (A) for a teaching point (T2). A linear path calculation unit (1e) is configured to calculate a linear path (L) that passes through the position (P1) and the position (P2). An arm movement calculation unit (1f) is configured to generate teaching data (D1) by calculating a movement of an arm (3) to cause the control point (A) to move along the linear path (L) from the position (P1) to the position (P2).

Owner:KEYLEX CORP

Teaching Data Generation System For Vertical Multi-Joint Robot

ActiveUS20200238512A1Large rotation angleLong operating timeProgramme-controlled manipulatorRecording and playback systemsSimulationControl theory

A control point extraction unit (1d) is configured to extract, when a center of a joint portion (V) of a fifth rotary shaft (C5) is defined as a control point (A), a position (P1) of the control point (A) for a teaching point (T1) and a position (P2) of the control point (A) for a teaching point (T2). A linear path calculation unit (1e) is configured to calculate a linear path (L) that passes through the position (P1) and the position (P2). An arm movement calculation unit (1f) is configured to generate teaching data (D1) by calculating a movement of an arm (3) to cause the control point (A) to move along the linear path (L) from the position (P1) to the position (P2).

Owner:KEYLEX CORP

Method for sealing of a canal

ActiveUS11311360B2Low viscosityAvoid mistakesTeeth fillingSurgical instrument detailsLight guideEngineering

Owner:DENTSPLY SIRONA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com