Positive-pressure sampling pump station for sampling system

A positive pressure sampling and sampling system technology, which is applied in the preparation of test samples and sampling devices, etc., can solve the problems of slow gas movement and achieve the effects of ensuring monitoring results, ensuring dry transportation, and flexible configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

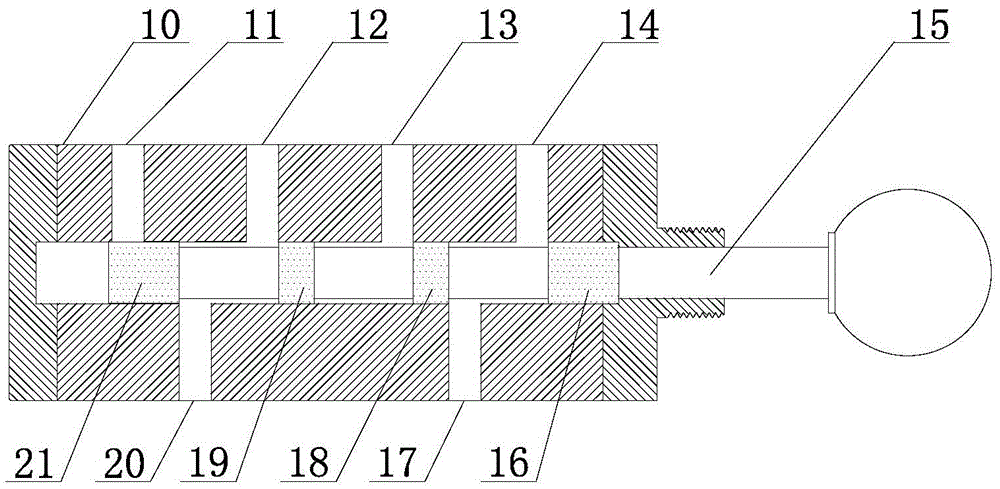

[0029] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0030] Such as figure 1 As shown, the positive pressure sampling pump station for sampling system according to the present invention includes two positive pressure sampling devices A and B and a gas shunt switching device 9; positive pressure sampling device A includes a first dust filter 2 -1, the first pressurizing pump 3-1, the first pressure relief device 4-1, the first automatic water filter drain 5-1, the first check valve 6-1 and the first check valve 7-1, The inlet end of the first dust filter 2-1 is connected to the A gas input port 1-1, and the outlet end is connected to the inlet of the first booster pump 3-1, and the outlet of the first booster pump 3-1 is connected to the first The air inlet 24 of the pressure relief device 4-1 is connected, and the air outlet 22 of the first pressure relief device 4-1 is connected with the air inlet end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com