Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7053results about "Milling cutters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

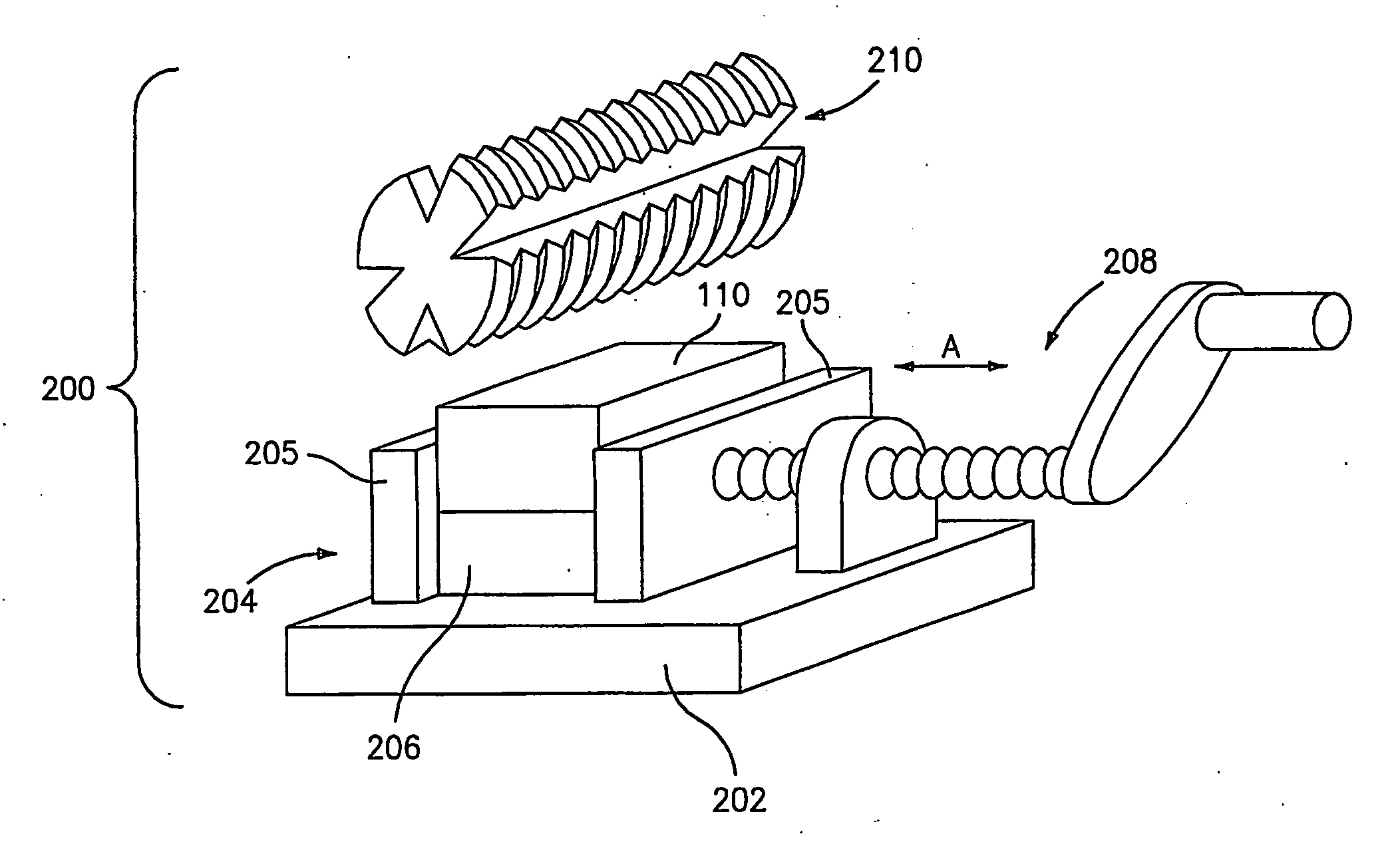

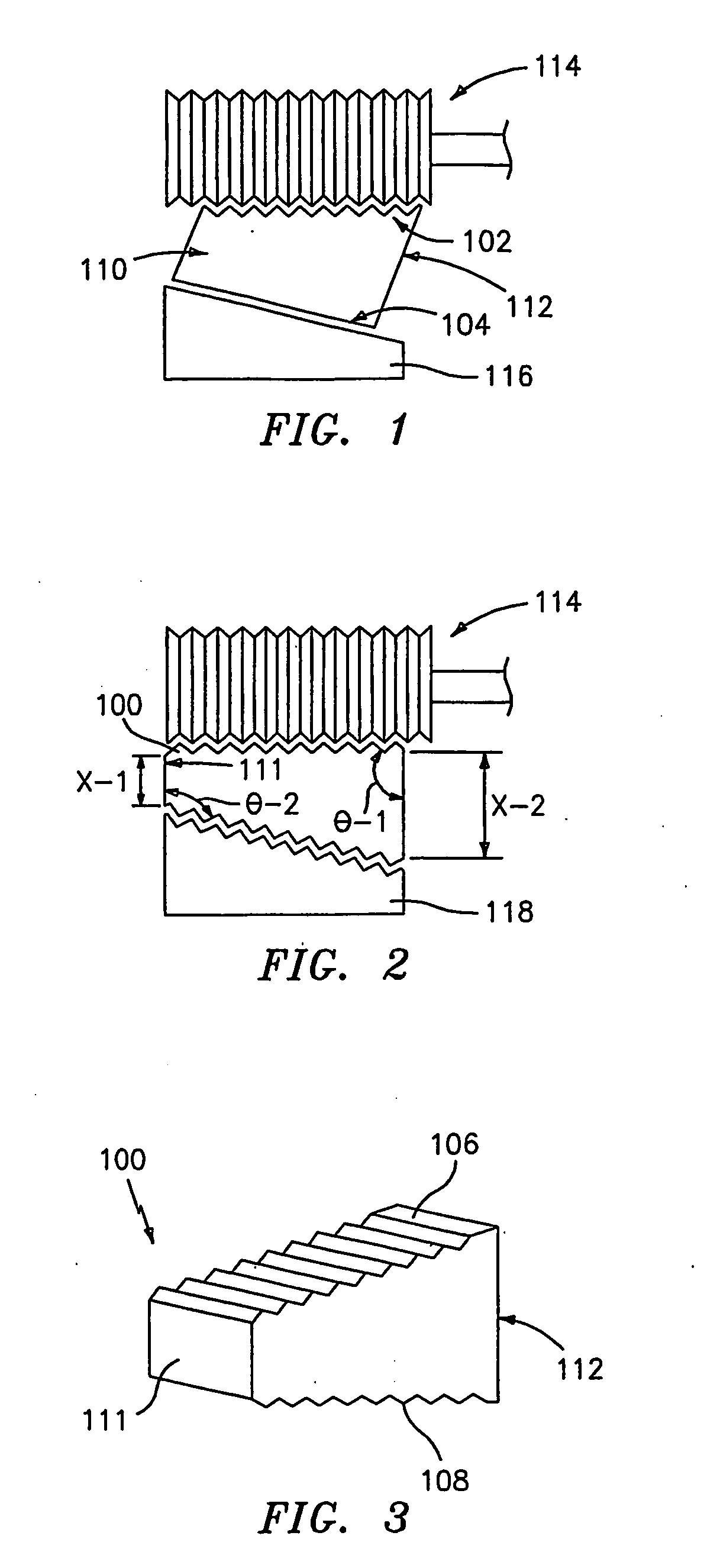

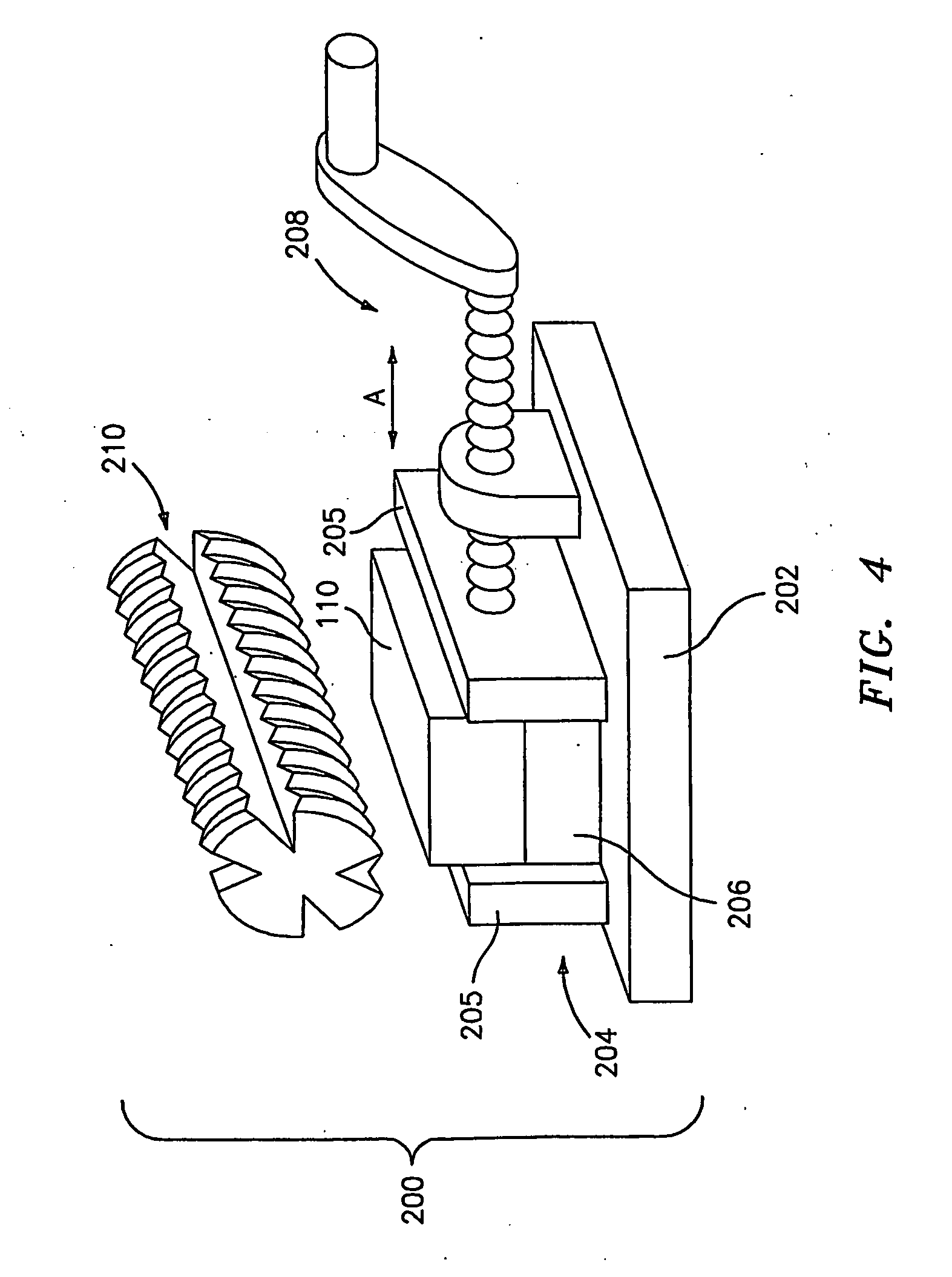

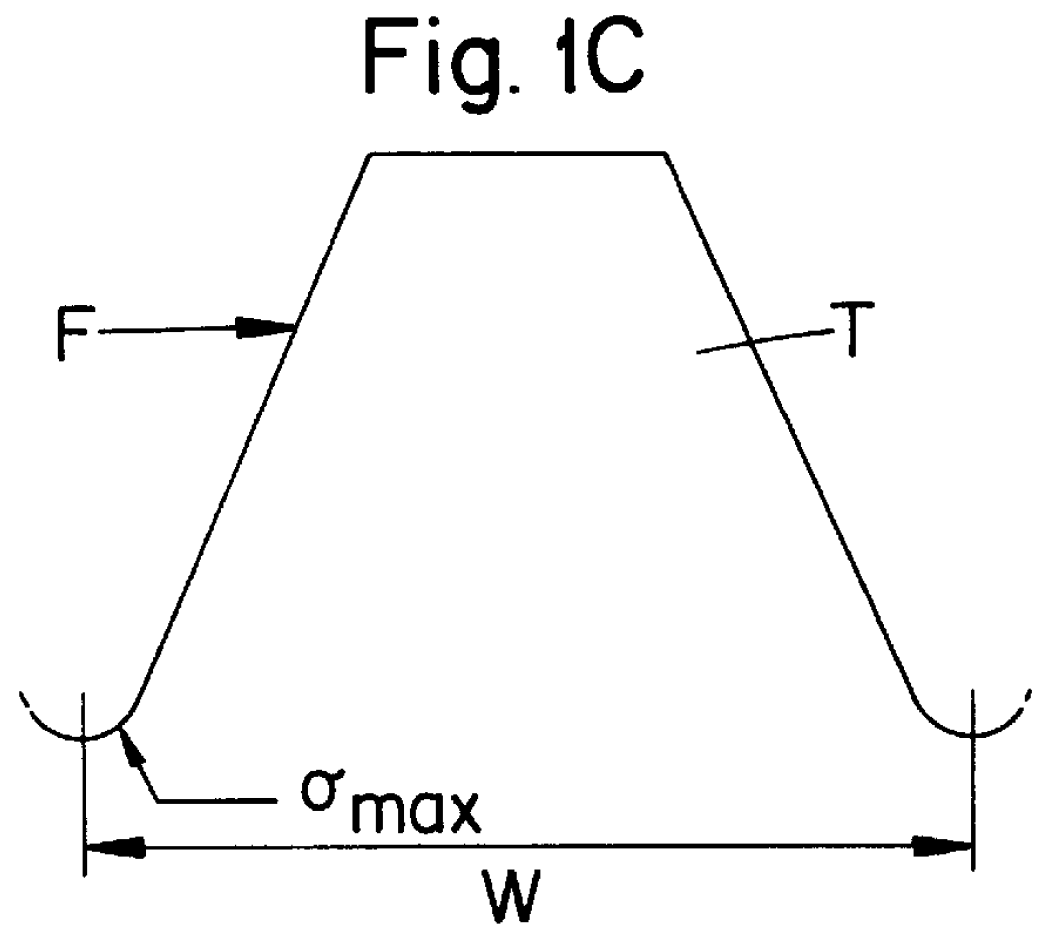

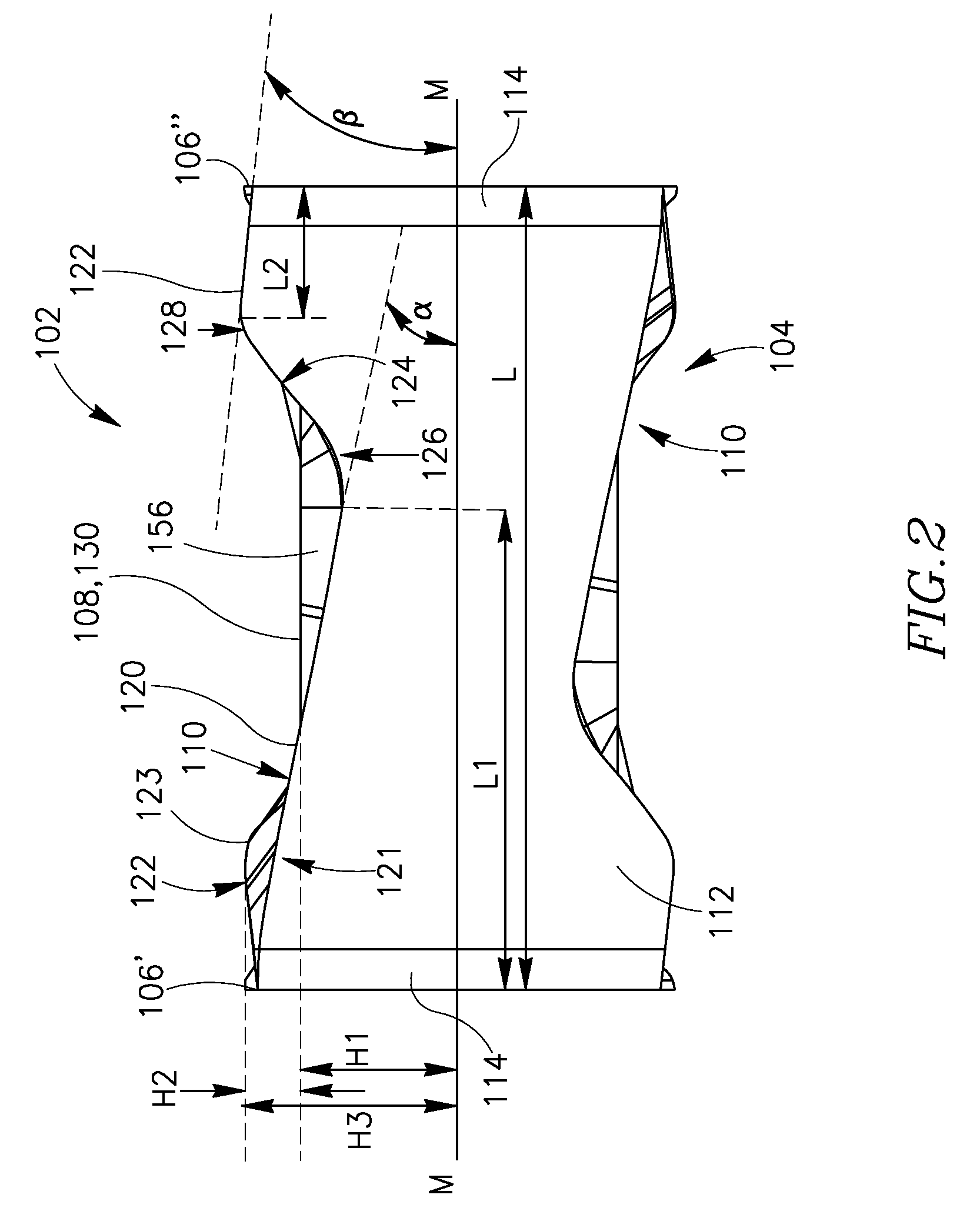

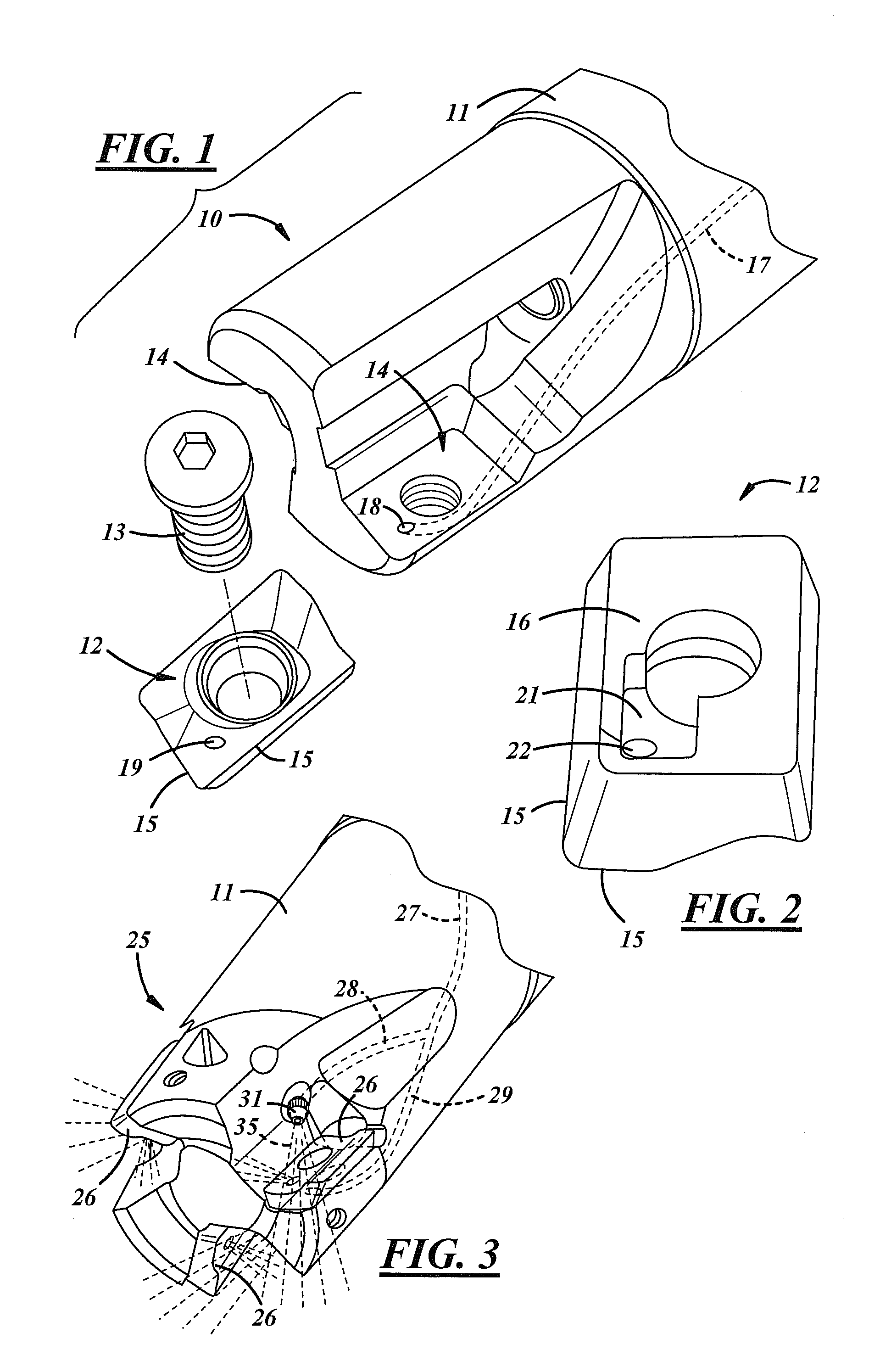

Method and apparatus for machining a surgical implant

InactiveUS20050244239A1Permit adjustment of overall mechanical propertyReduced strengthBone implantMilling cuttersEngineeringBiomedical engineering

A method is provided for machining a customized surgical implant in the operating room provided. Apparatus and a kit for carrying out the method are also provided.

Owner:OSTEOTECH

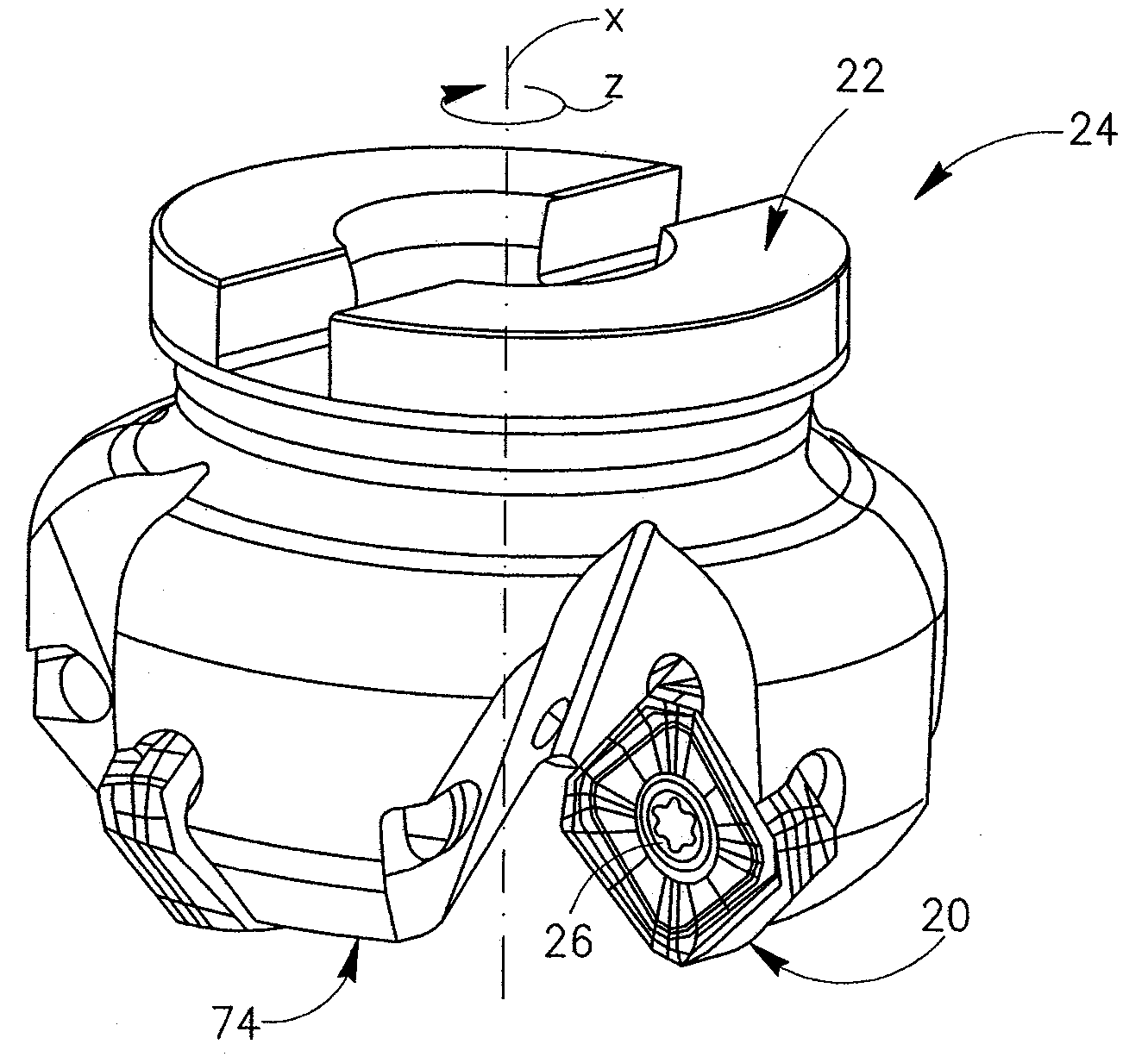

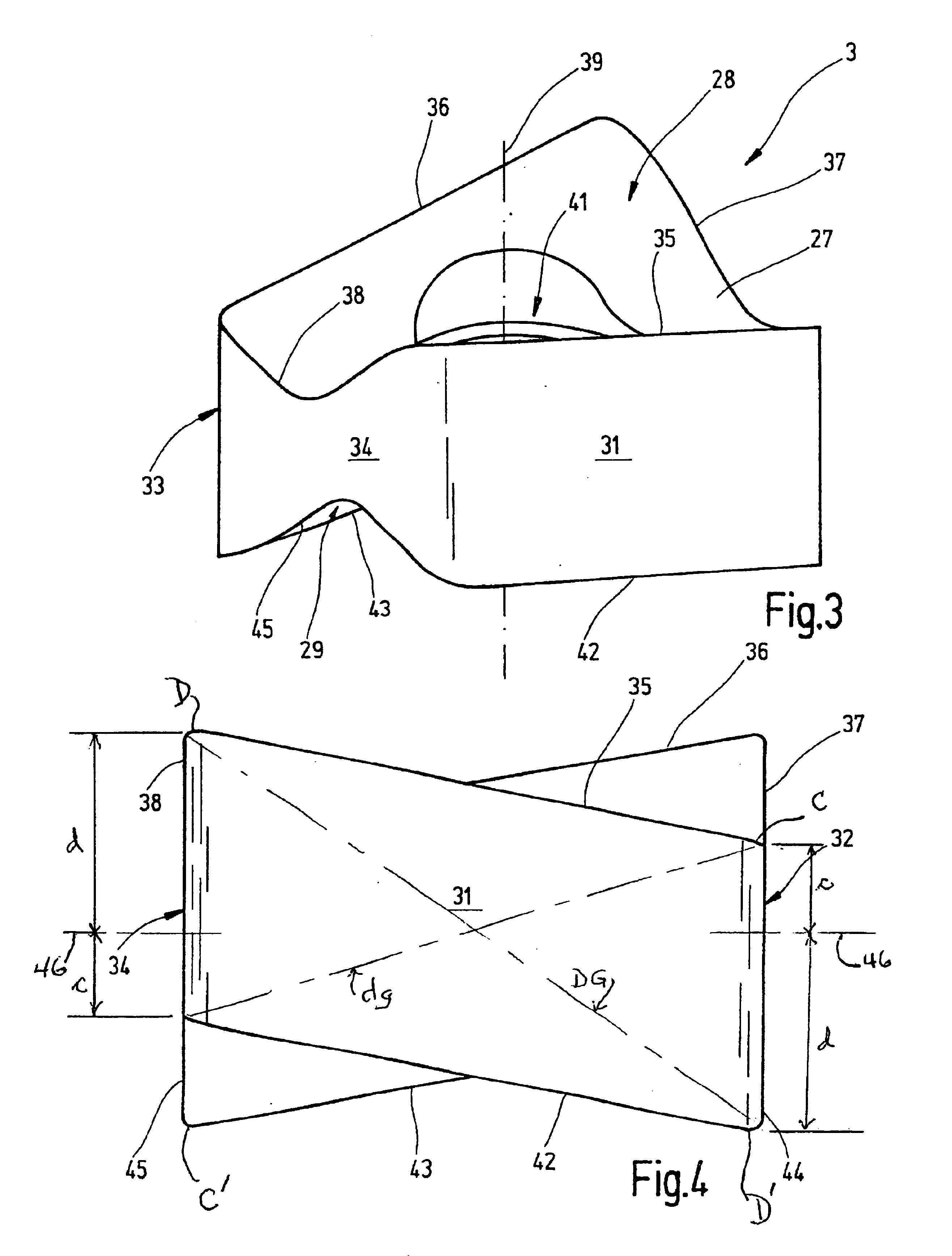

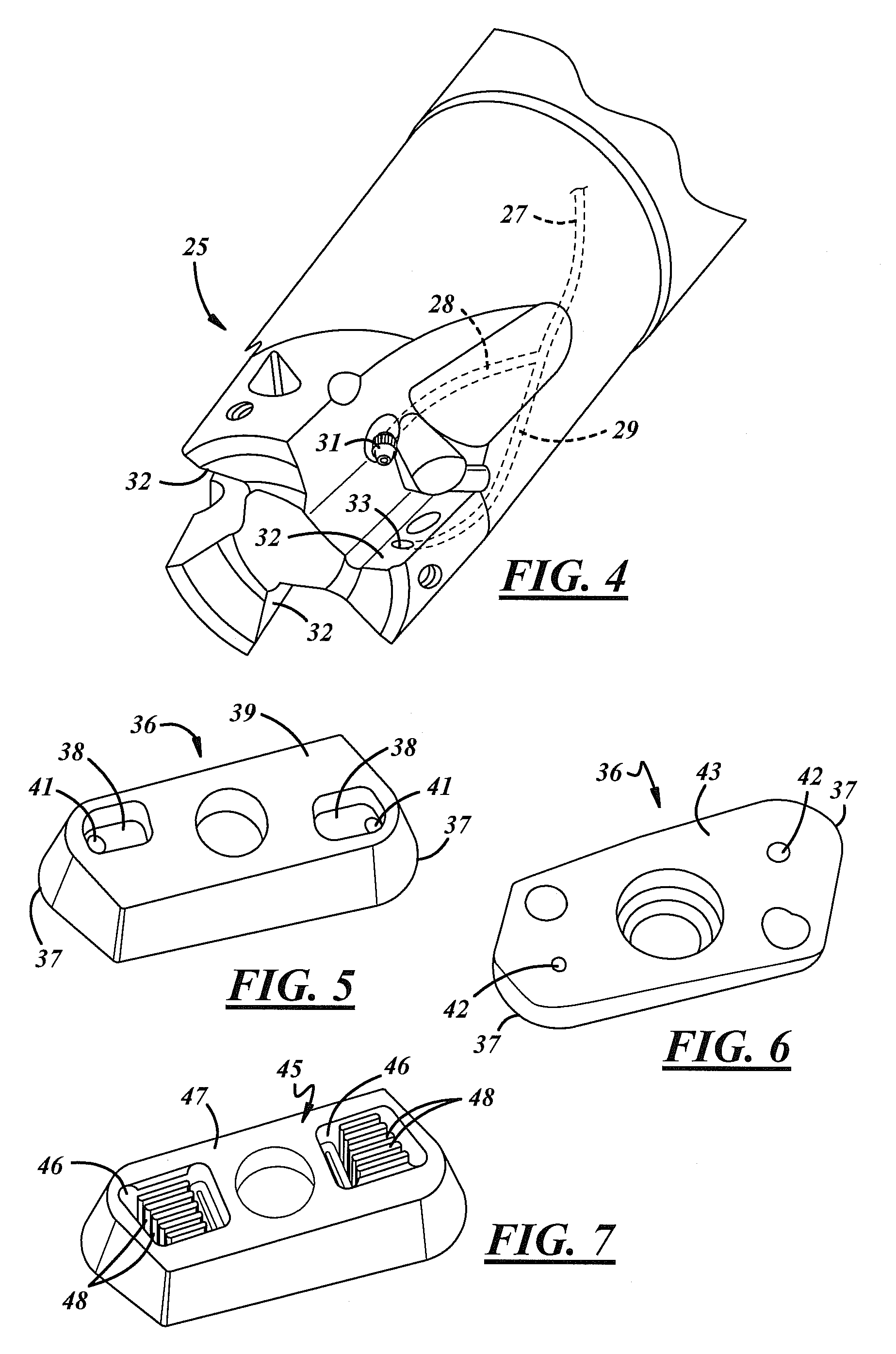

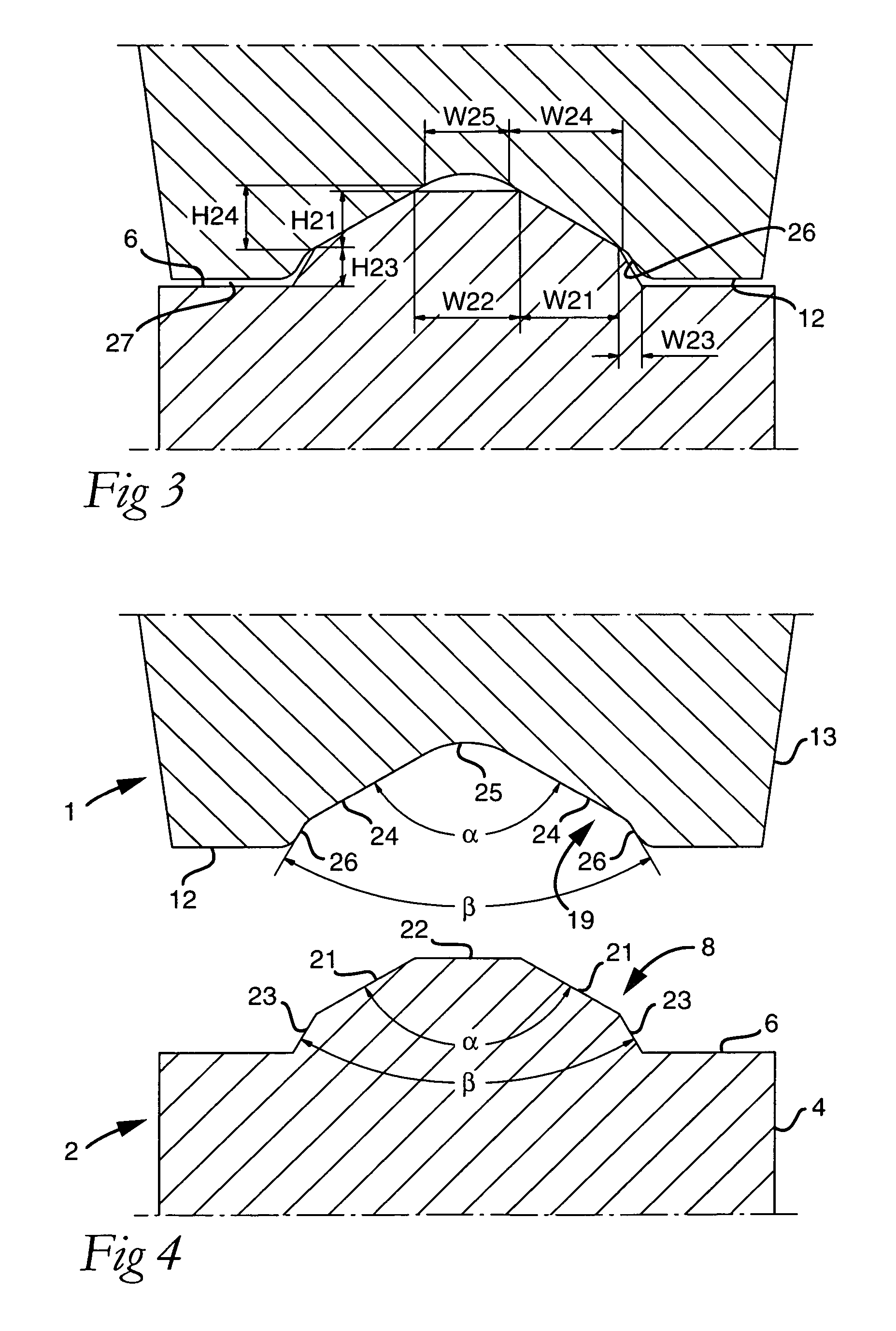

Tool coupling and method for coupling two tool parts

A tool includes a cutting head and a holder, wherein the cutting head and the holder form two cooperating surfaces that are pressed together. The surfaces possess rows of alternating parallel grooves and ridges for locking the surfaces to each other. Each of the surfaces has two rows of grooves, one row oriented 90 DEG relative to the other row. On one of the surfaces, some of the grooves of one row are in non-intersecting relationship with the grooves of the other row. On the other surface, the rows extend completely across one another, whereby the rows together form a waffle-like pattern. The cooperating surfaces allow at least four separate relative positions between the cutting head and holder.

Owner:SECO TOOLS AB

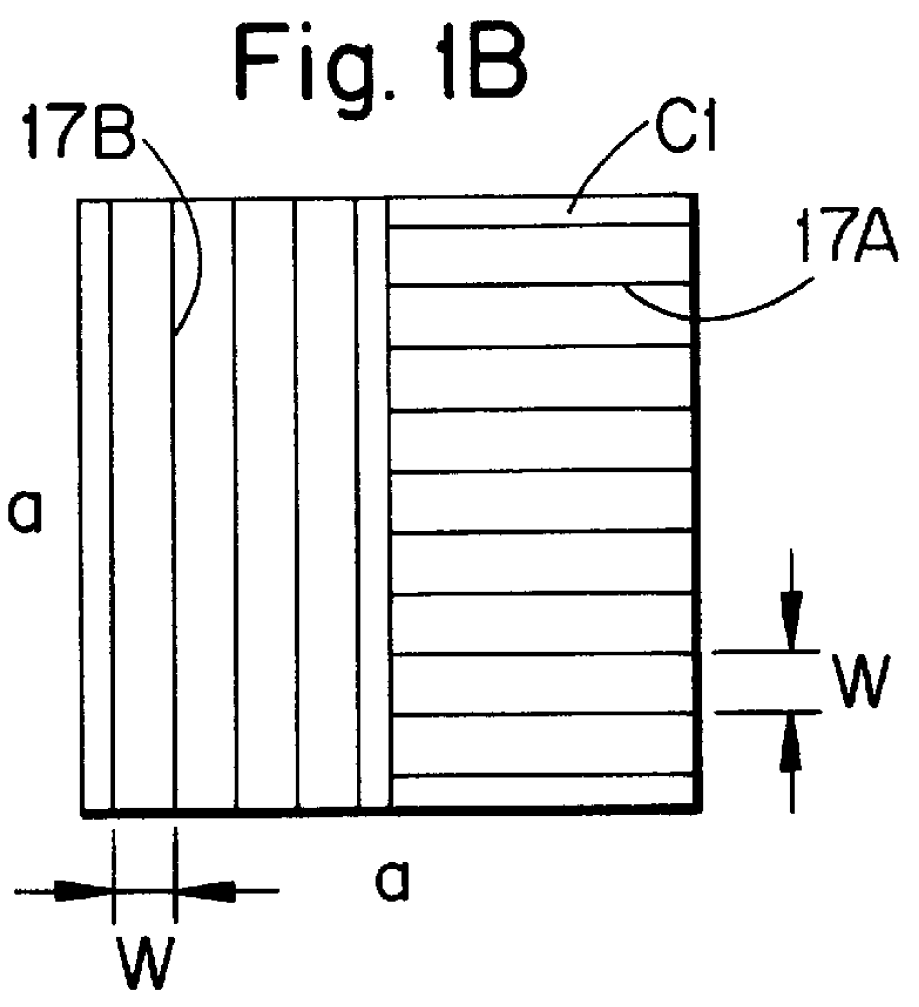

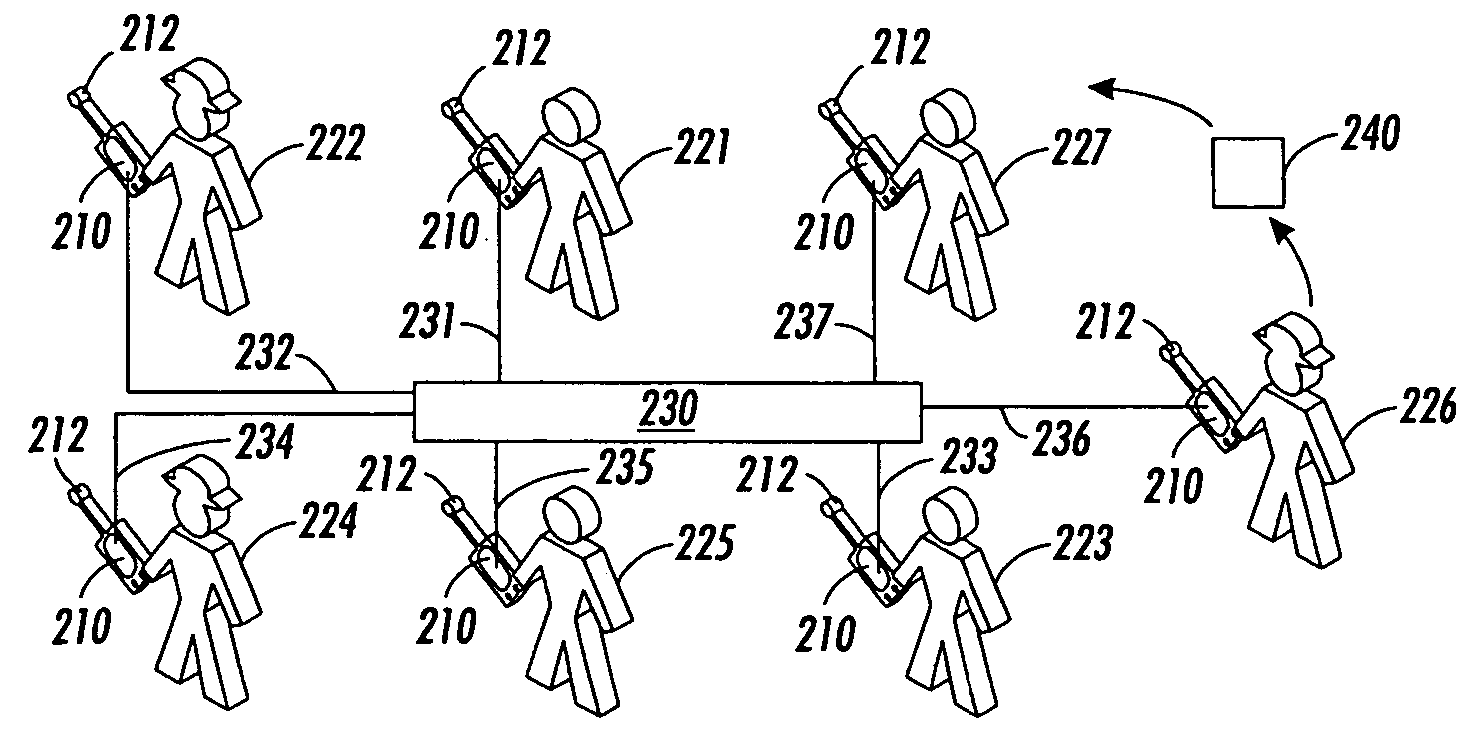

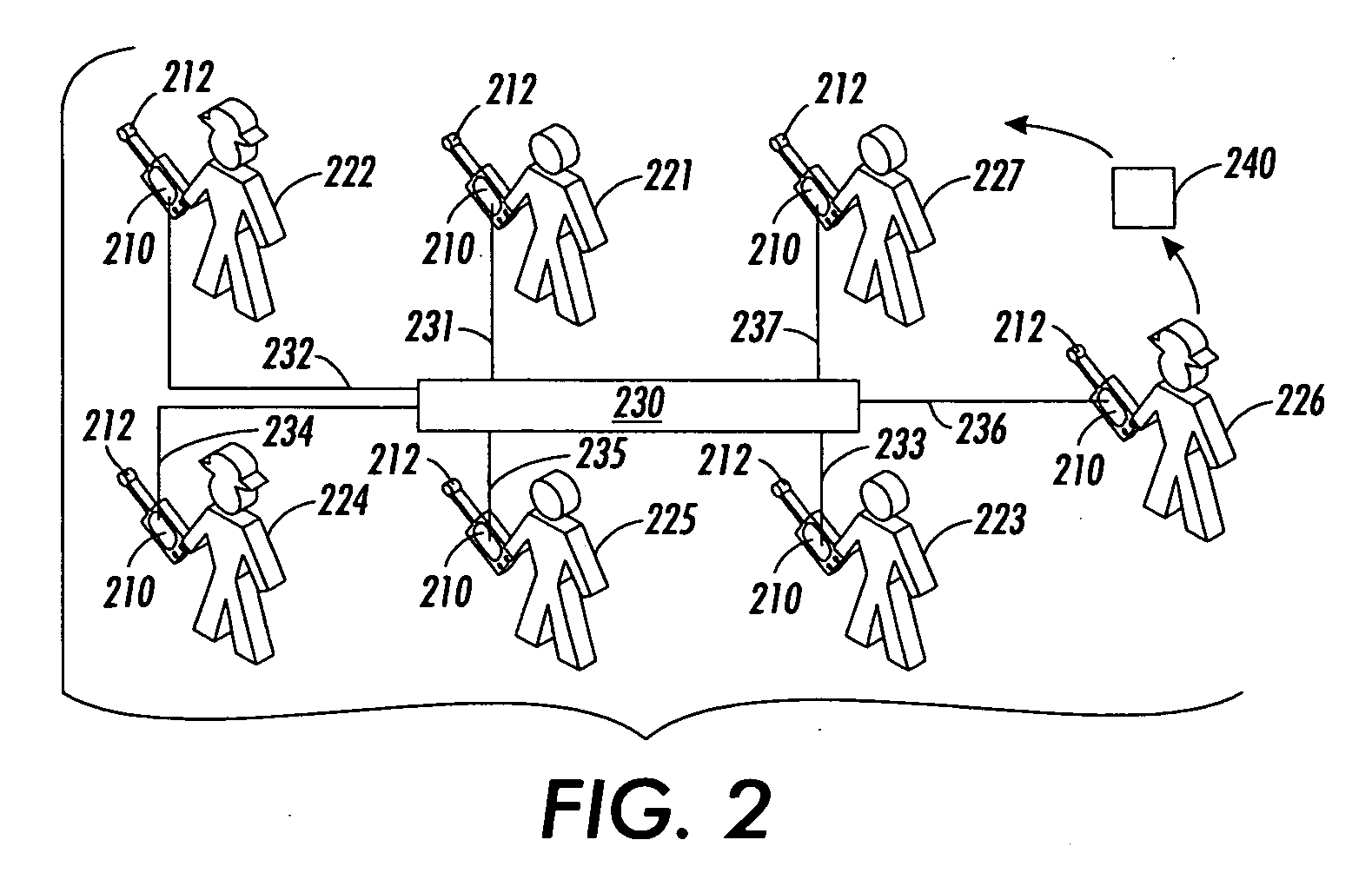

Systems and methods for authenticating communications in a network medium

InactiveUS20050100166A1Efficiently exchanging authentication credentialSimple and efficientDigital data processing detailsMilling cuttersProtocol for Carrying Authentication for Network AccessNetwork media

A location-limited channel is implemented using physical exchanges of physical tokens. The physical tokens are implemented using writeable or re-writeable storage media. Location-limited channels, when used to implement pre-authentication protocols, provide demonstrative identification and authenticity. A group originator loads pre-authentication information and a network location from a communication device onto the location-limited physical token channel. The location-limited physical token channel is passed to another participant, who copies the originator's pre-authentication information and location onto that participant's communication device. That participant then adds that participant's own pre-authentication information and network location onto the location-limited physical token channel. This is repeated until the last participant passes the location-limited physical token channel back to the group originator. The originator thus has pre-authentication information and network locations for all other participants. The originator establishes secure communications with each participant based on the originator' and that participant's shared information.

Owner:PALO ALTO RES CENT INC

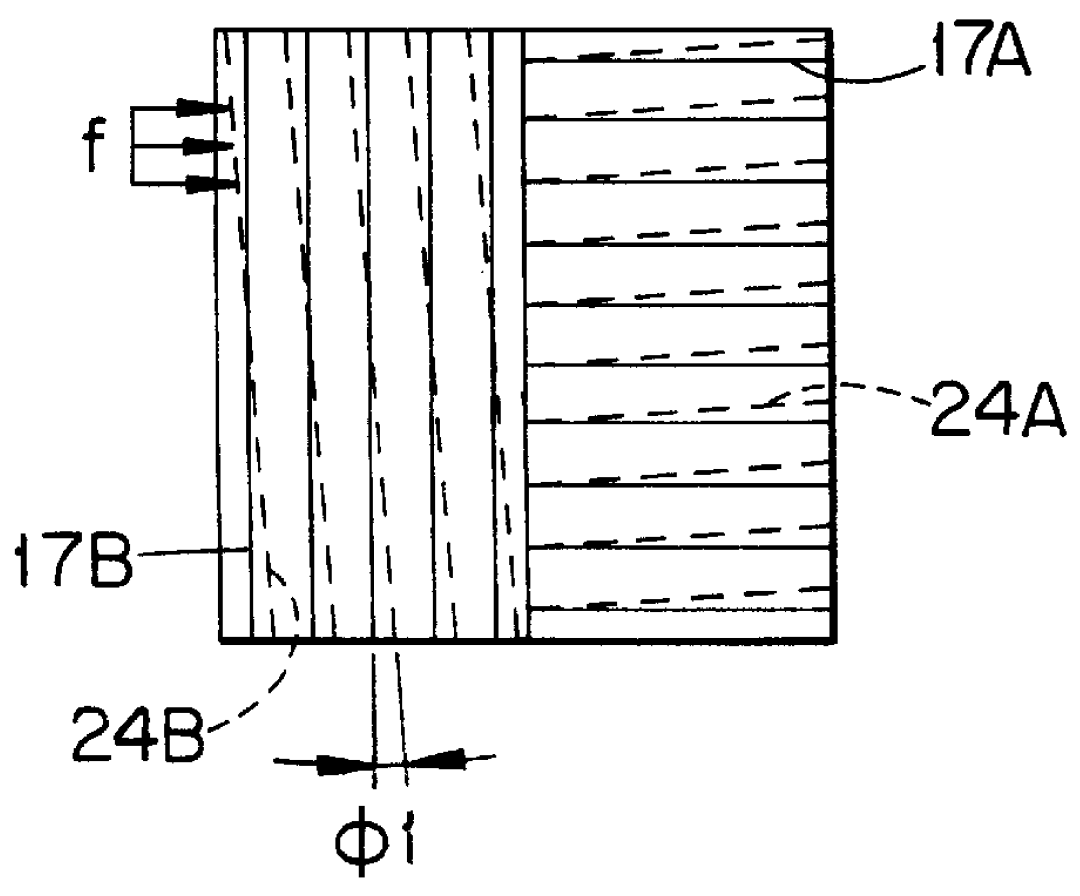

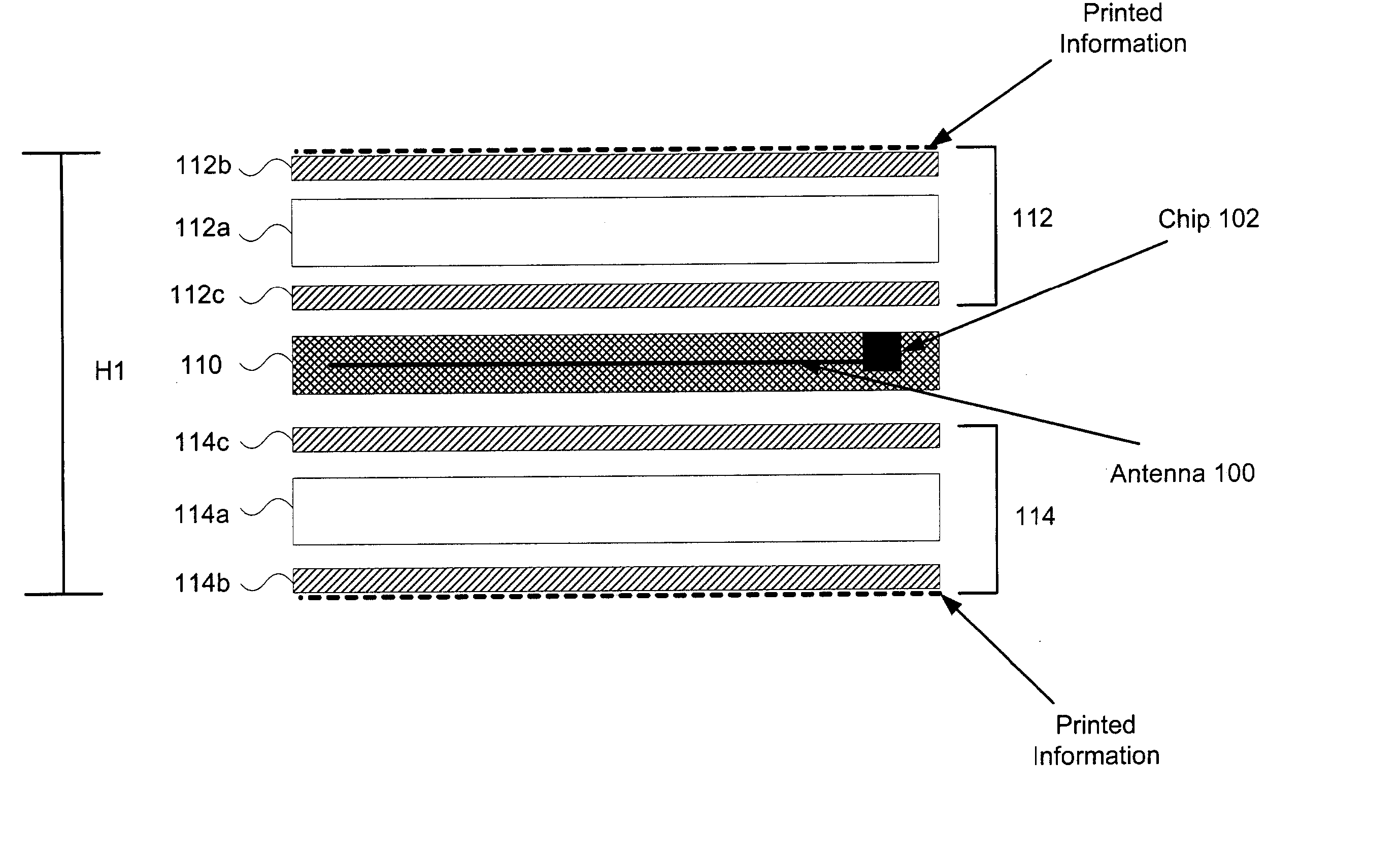

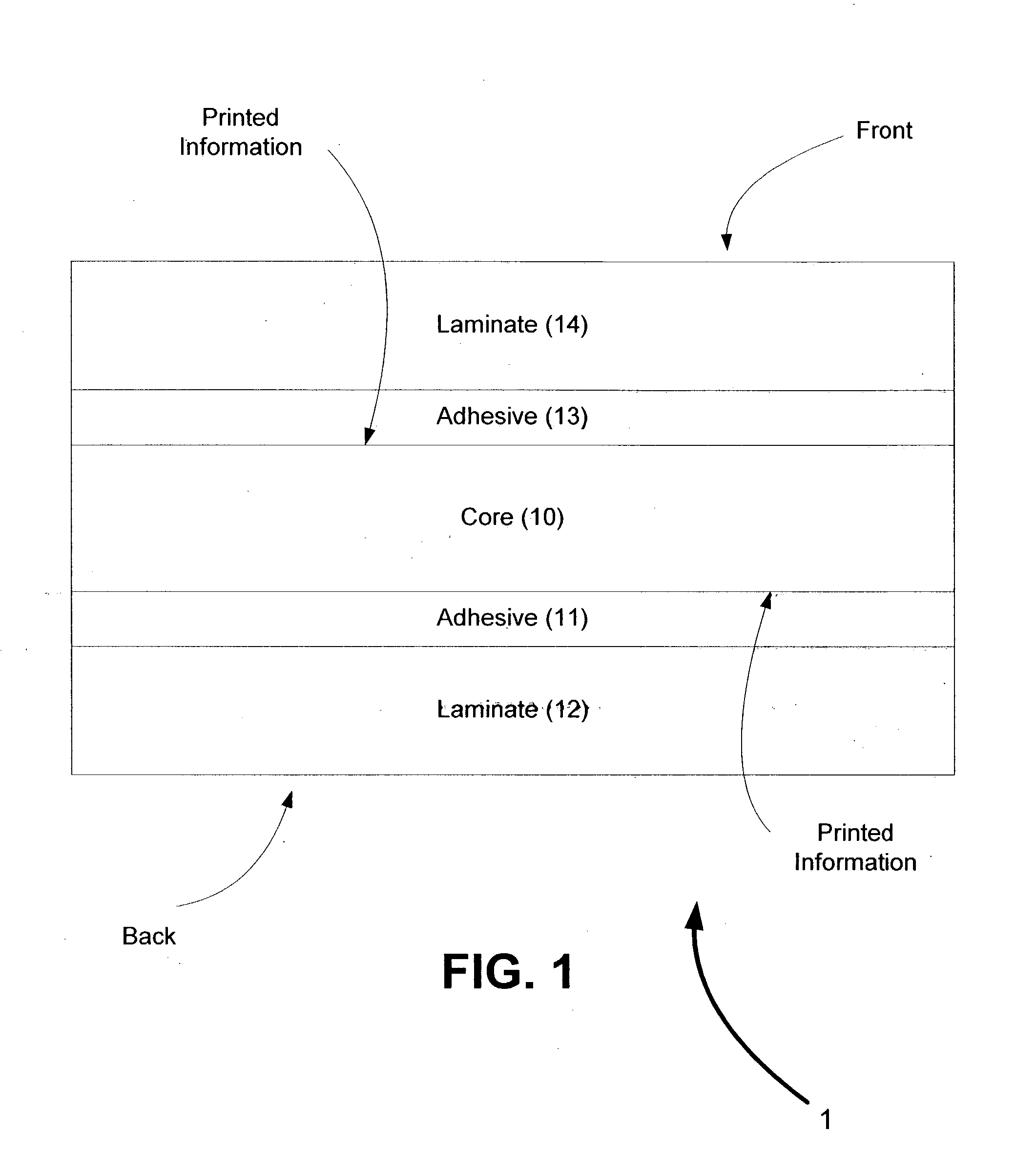

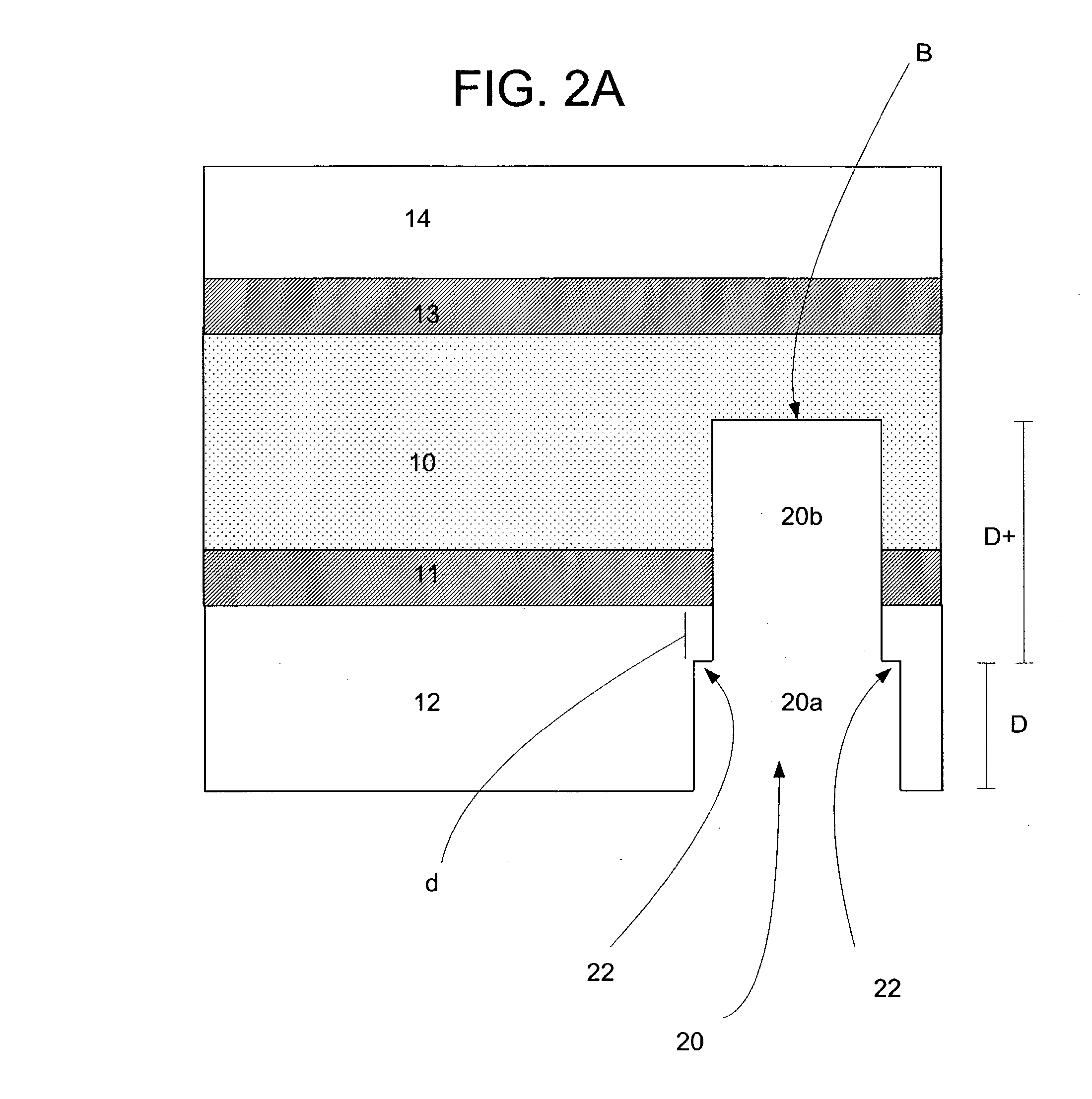

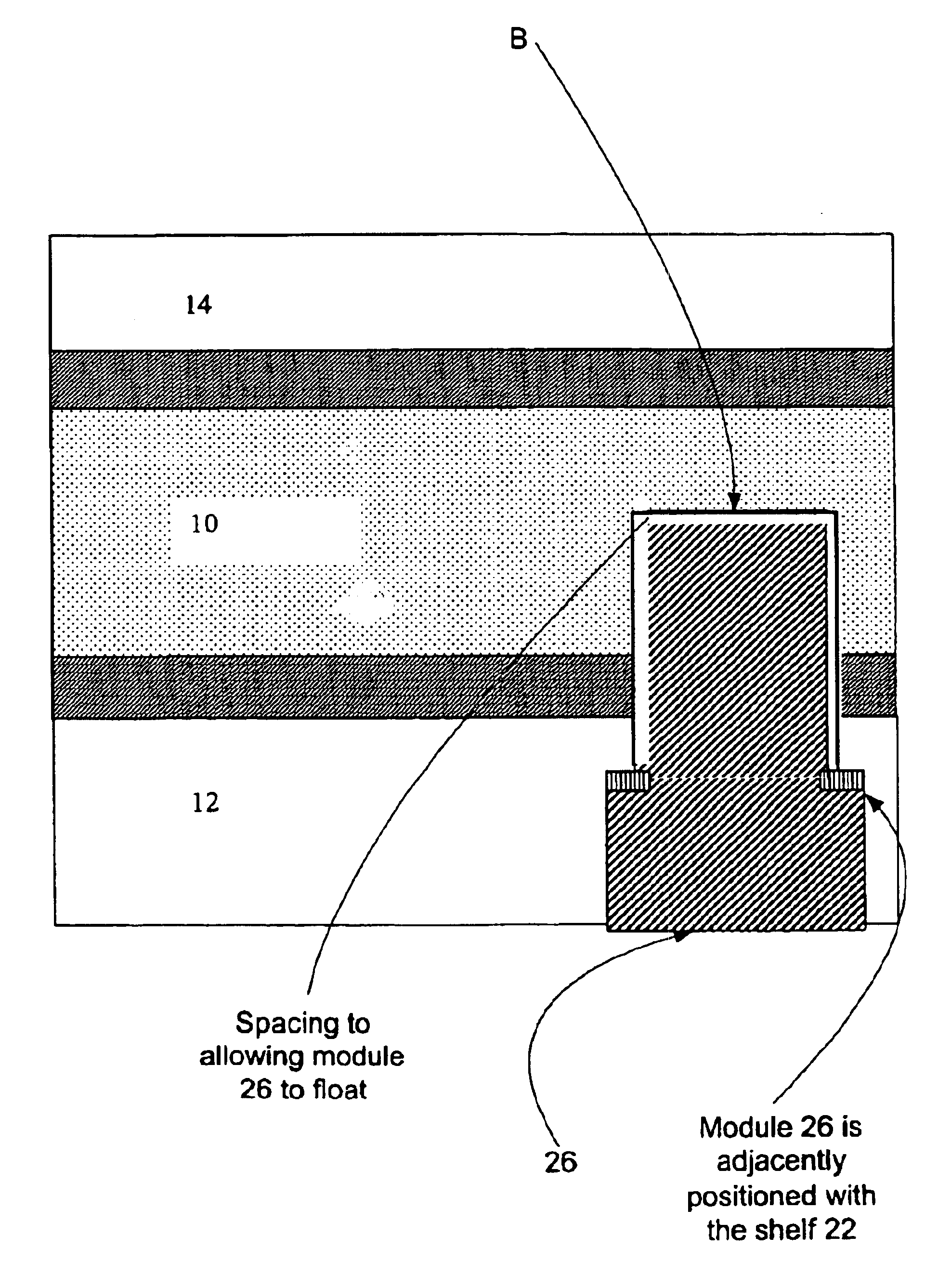

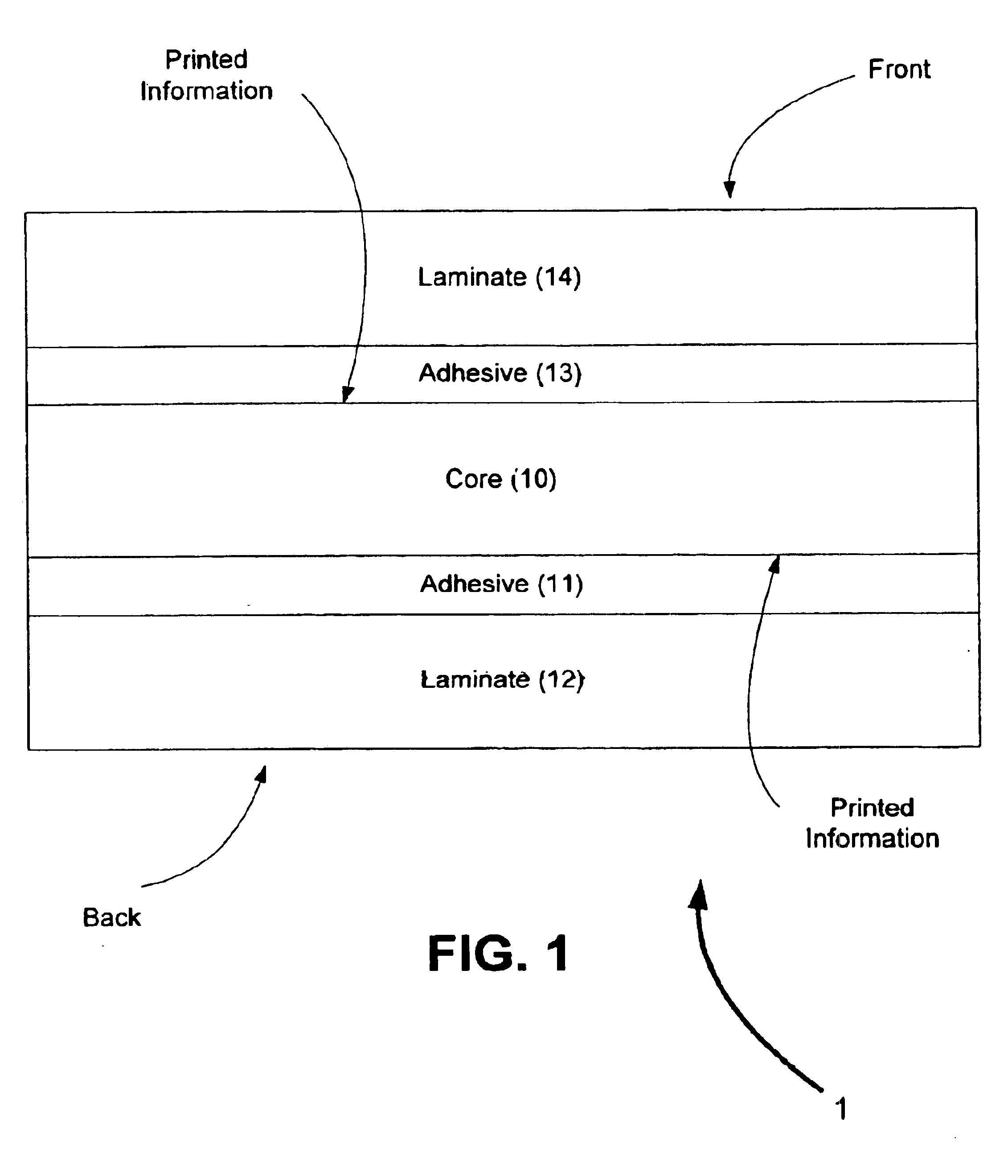

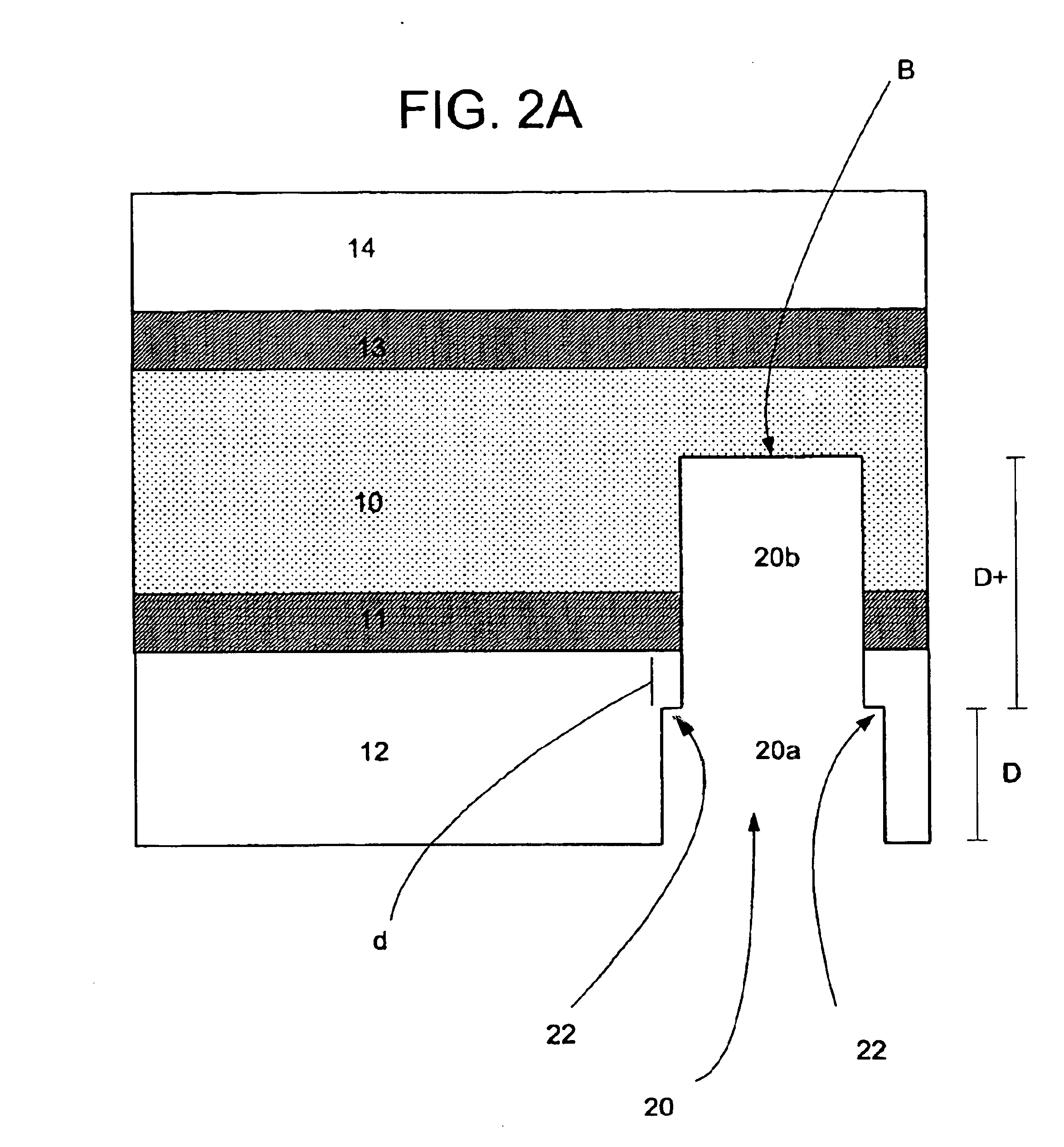

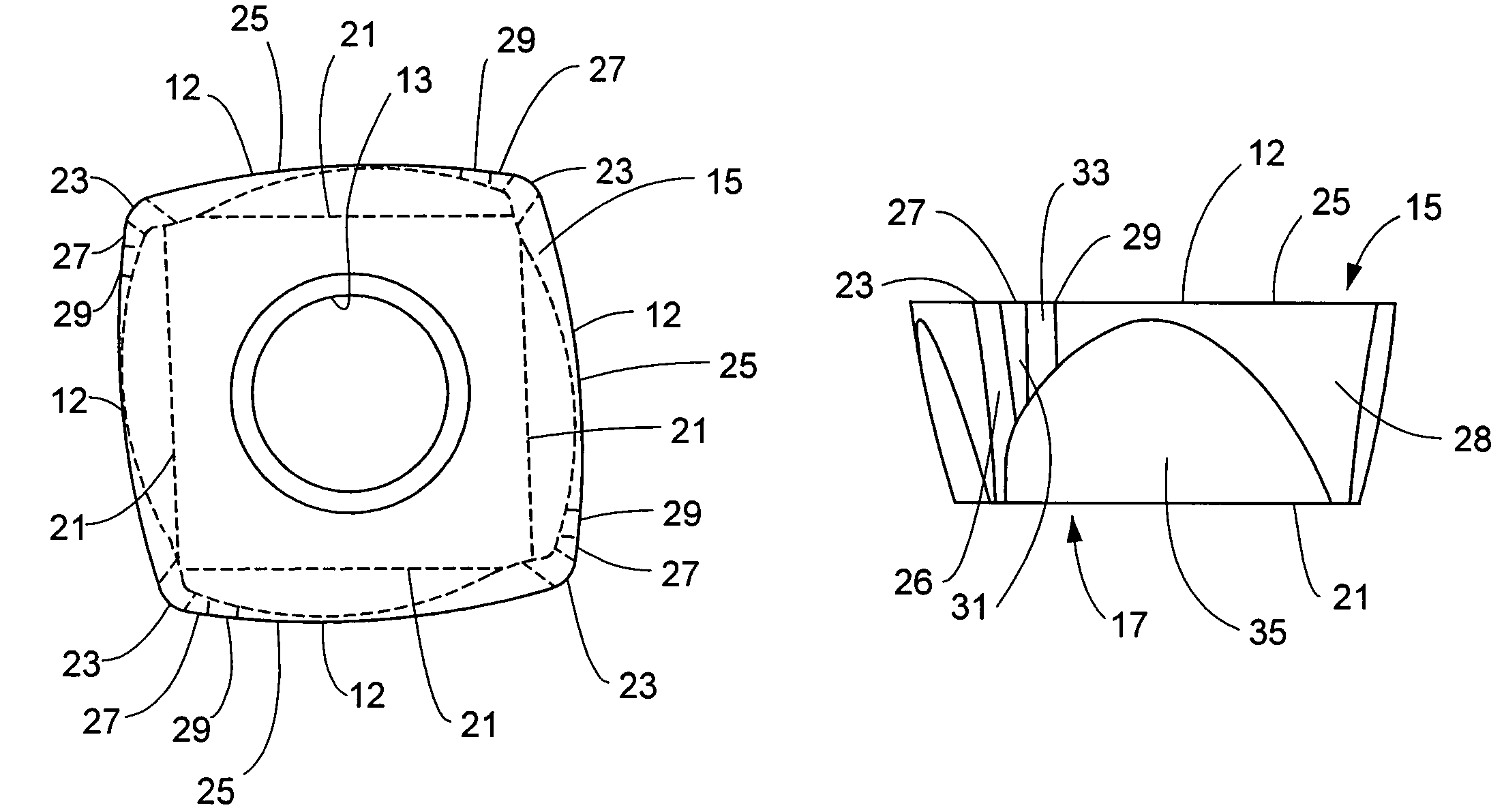

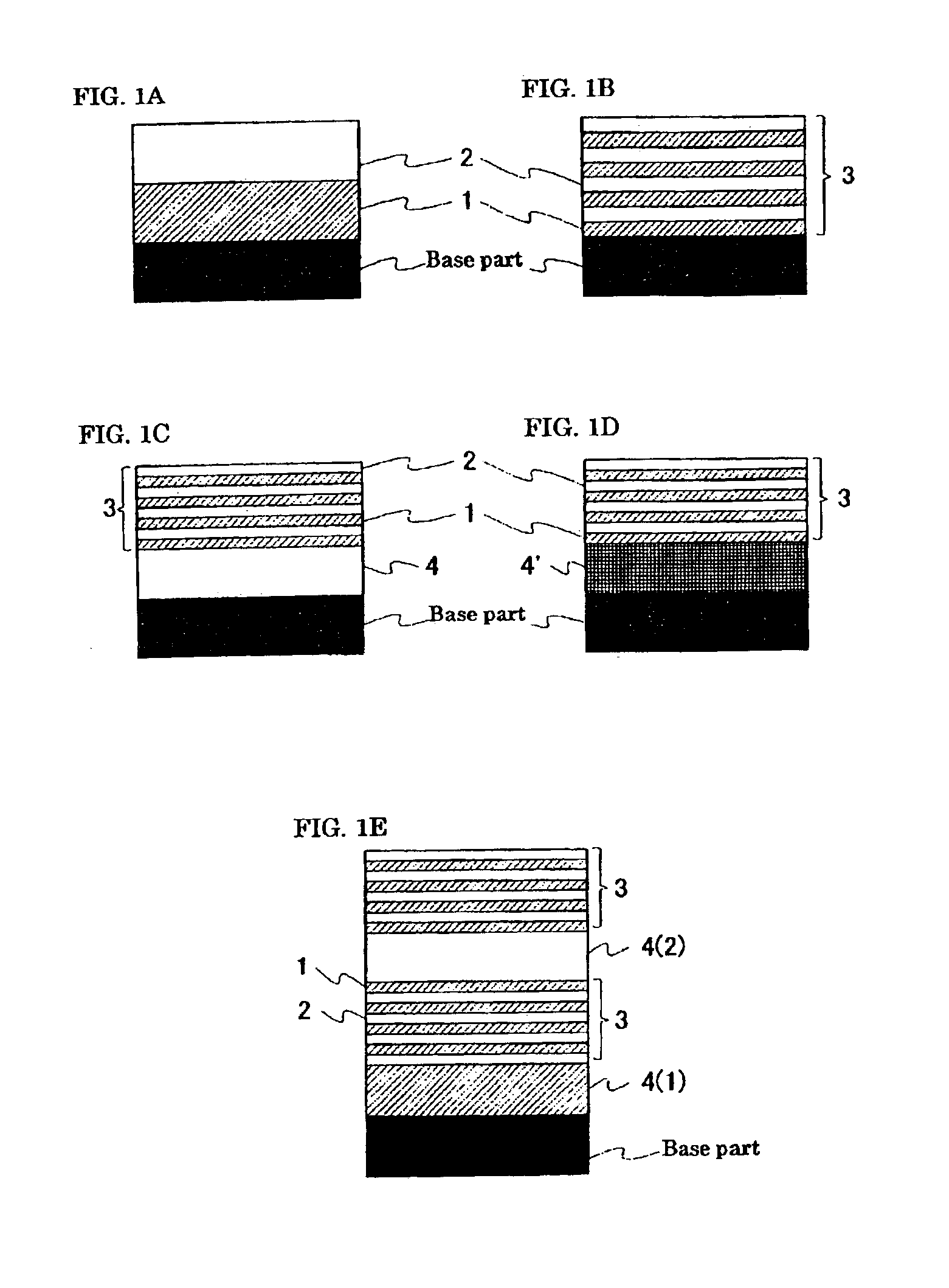

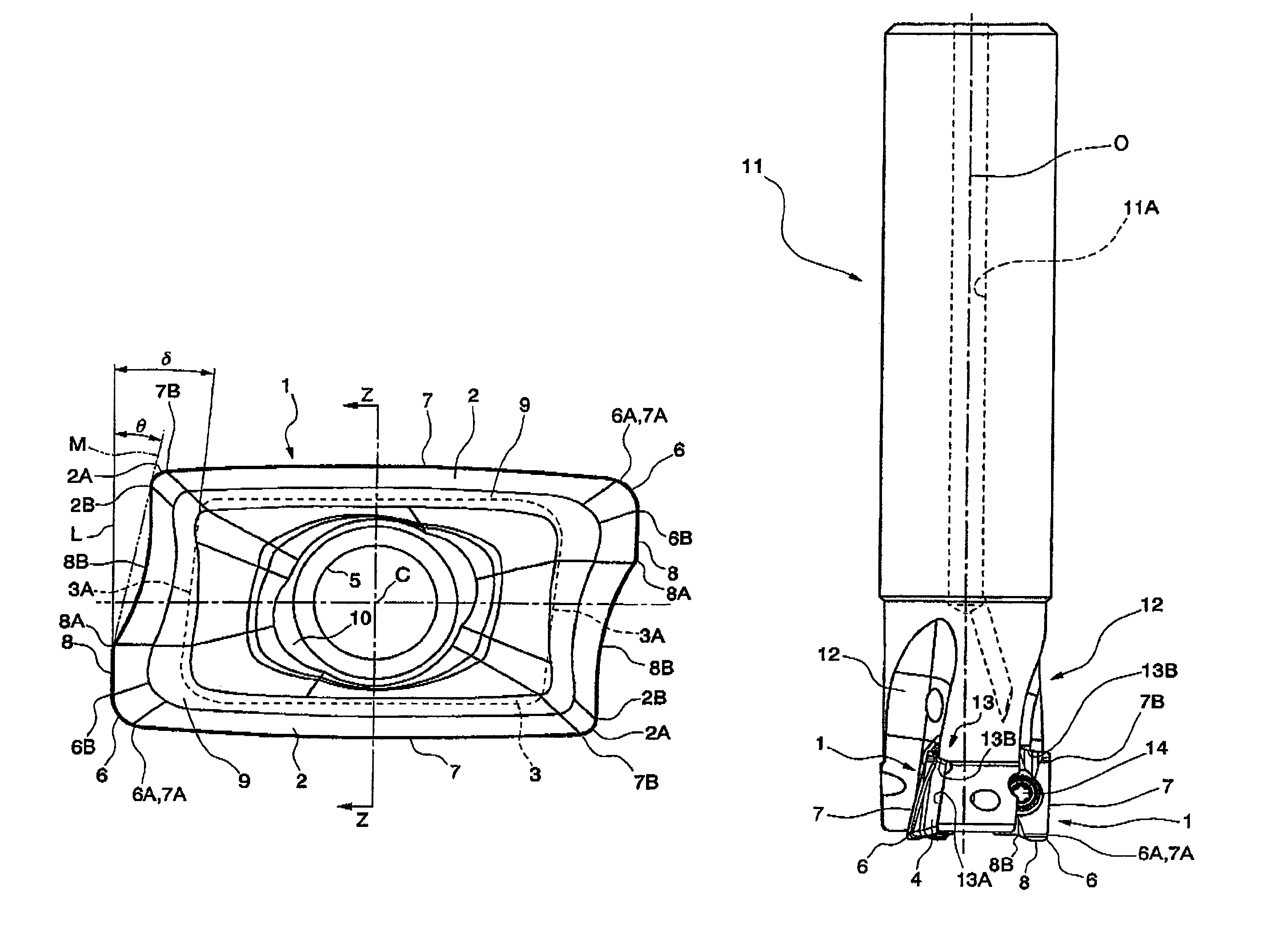

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS20030178495A1Improve security levelReduce chanceLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS6843422B2Reduce crackingQuality improvementLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

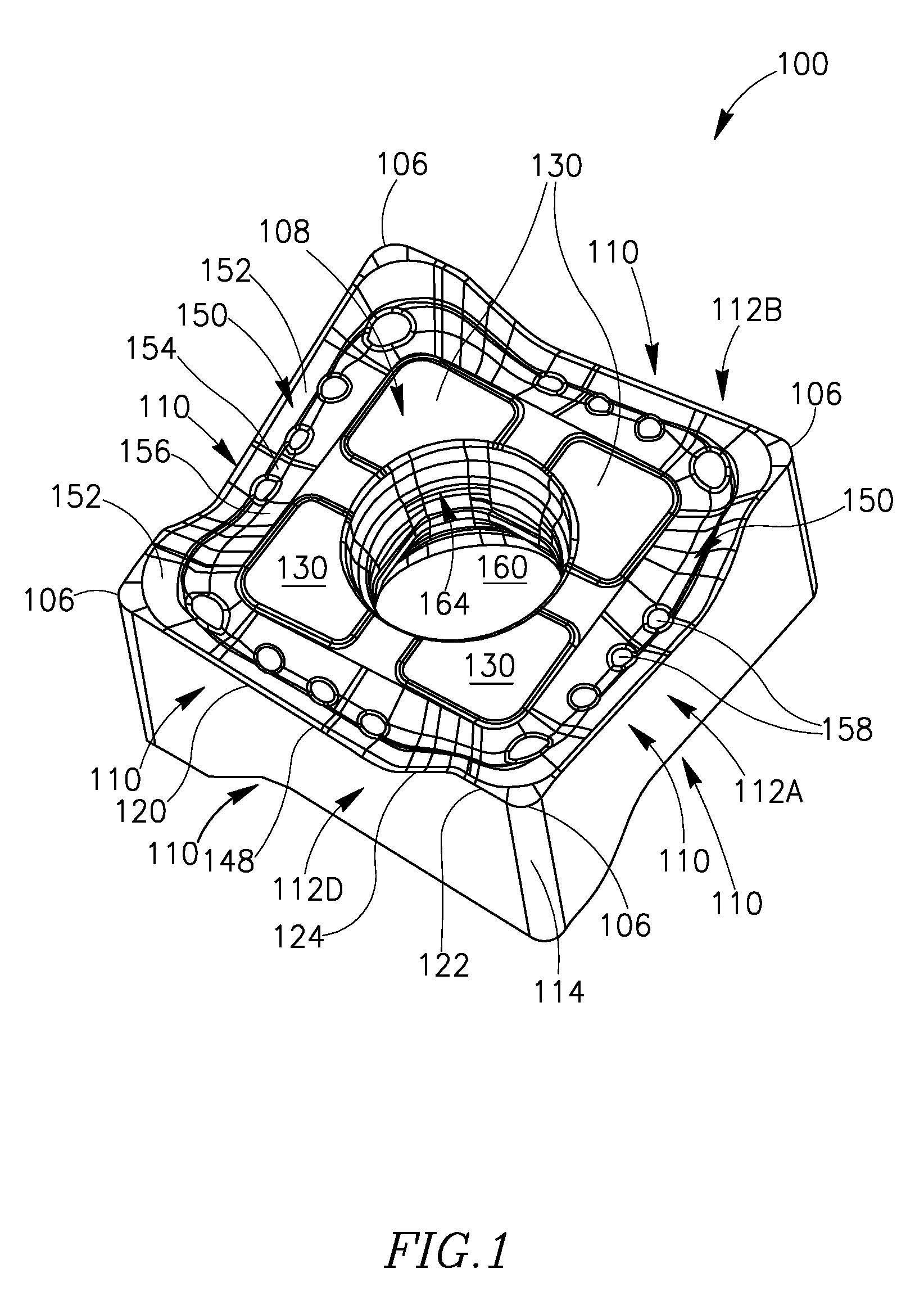

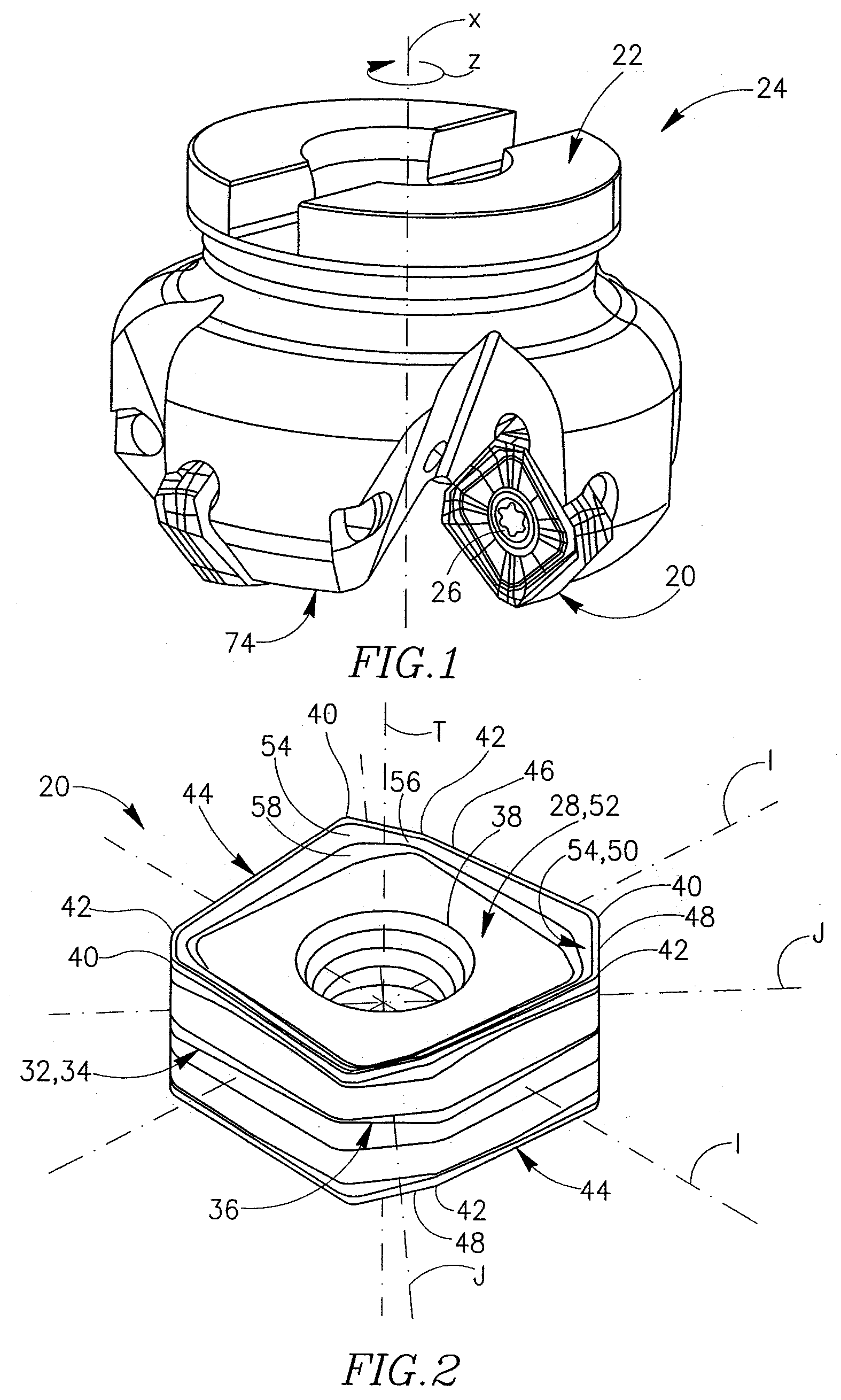

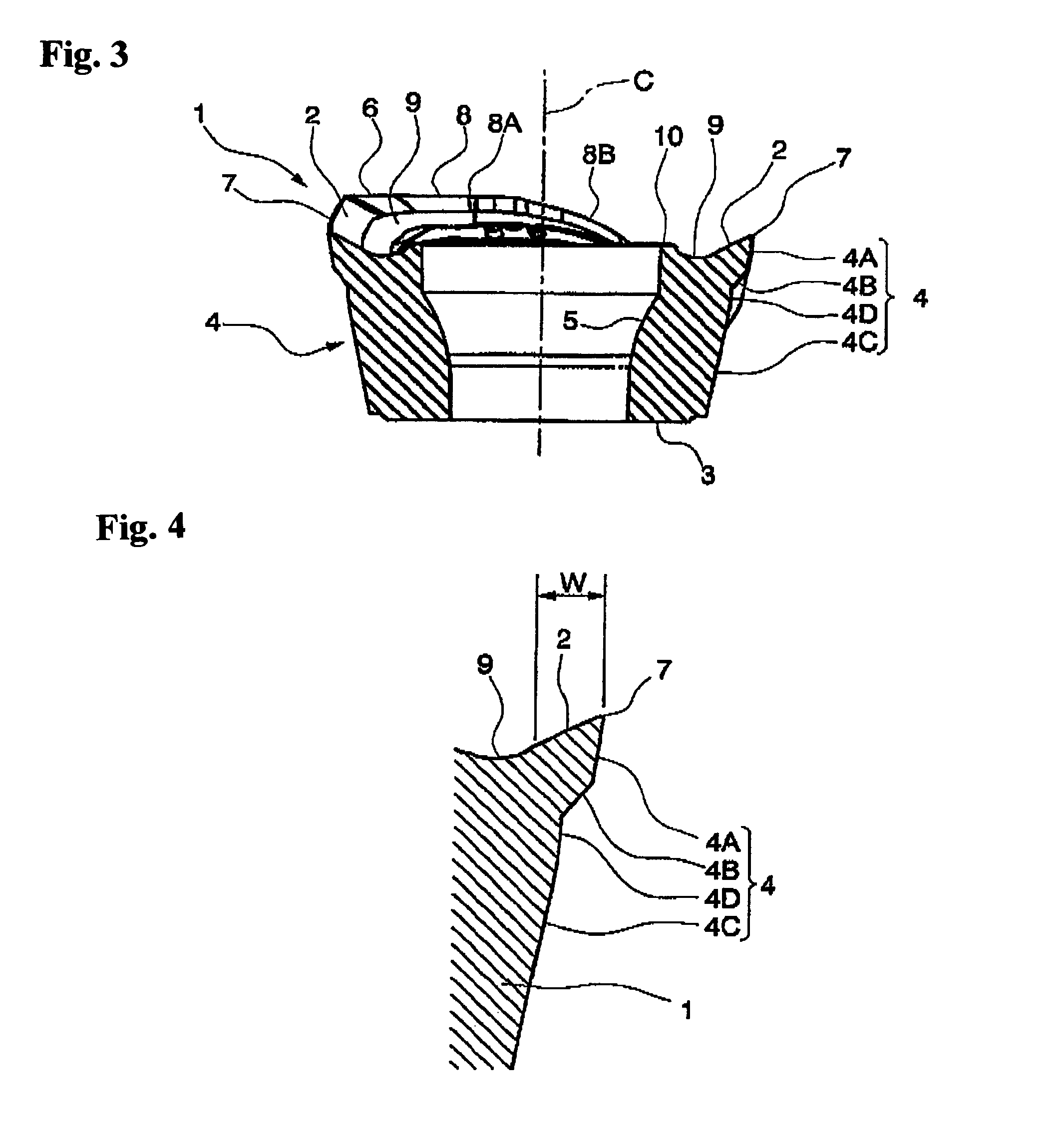

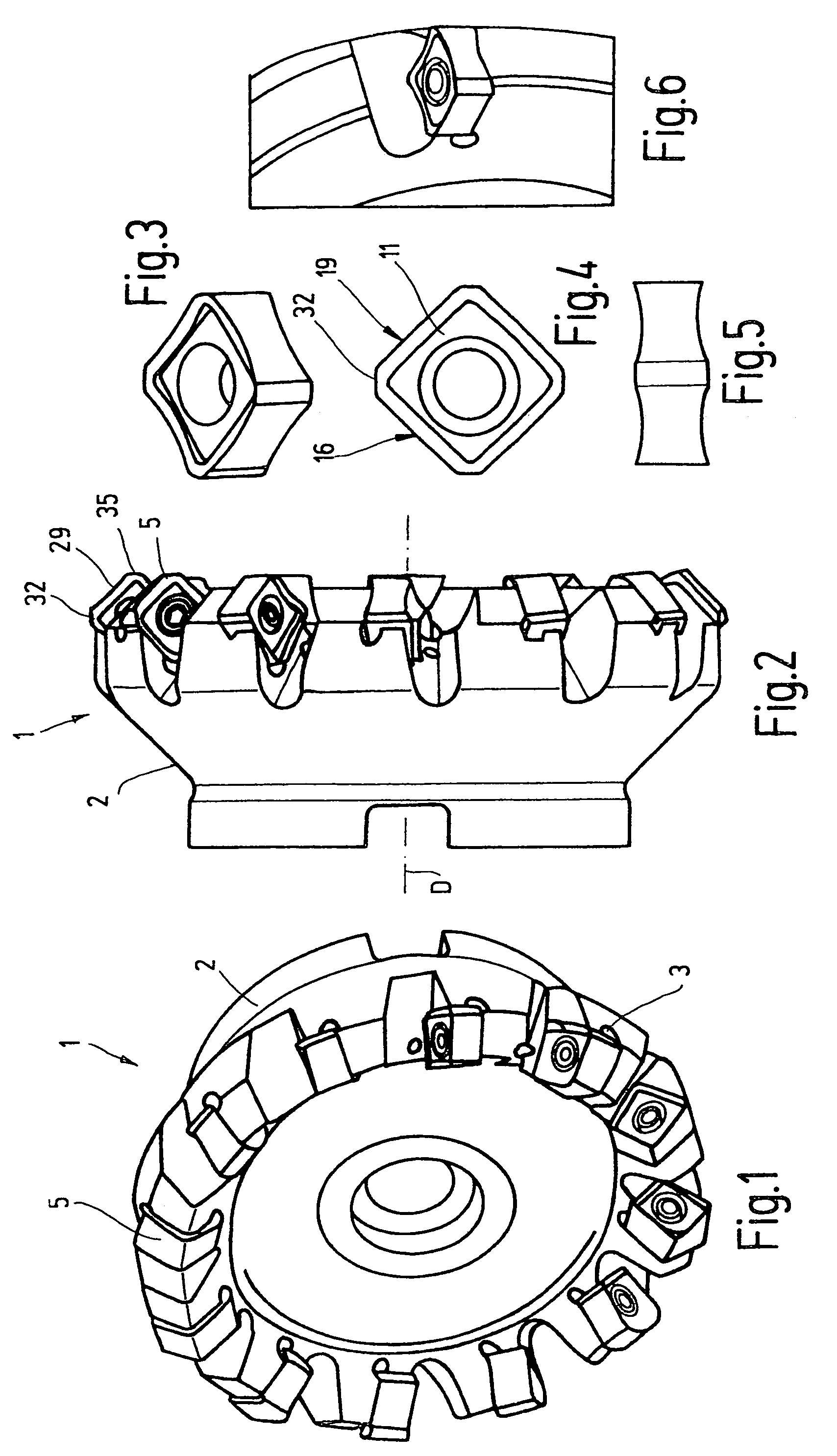

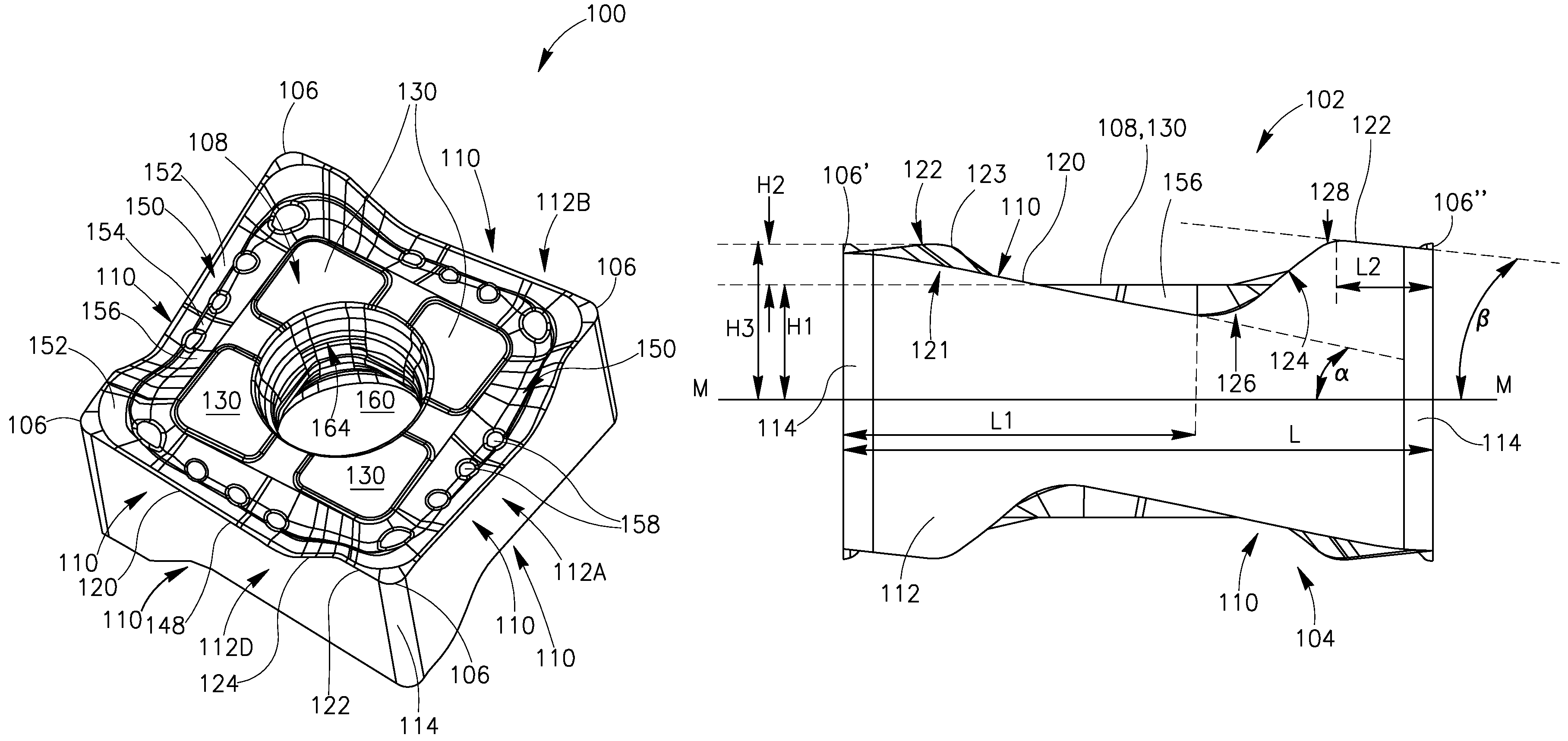

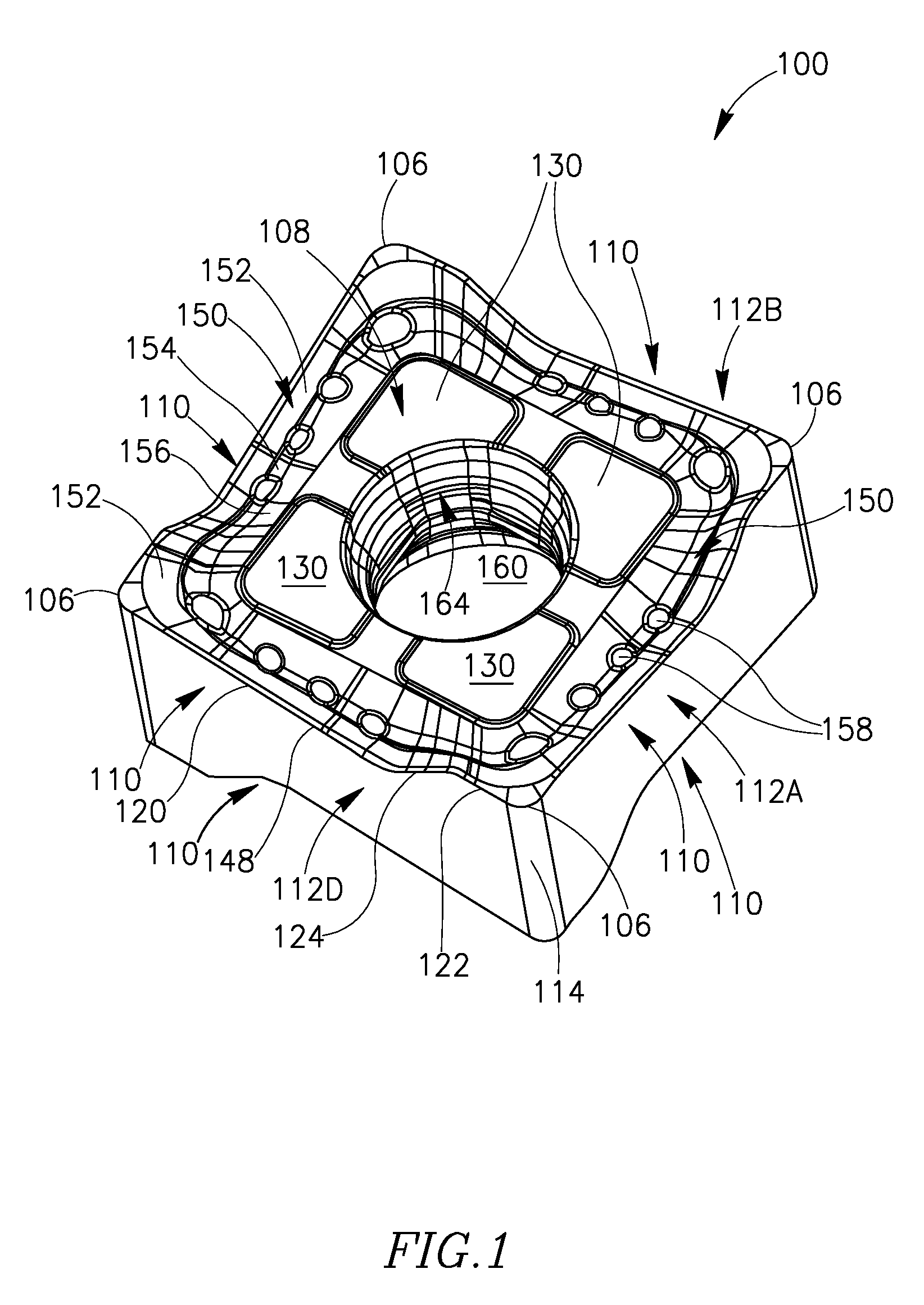

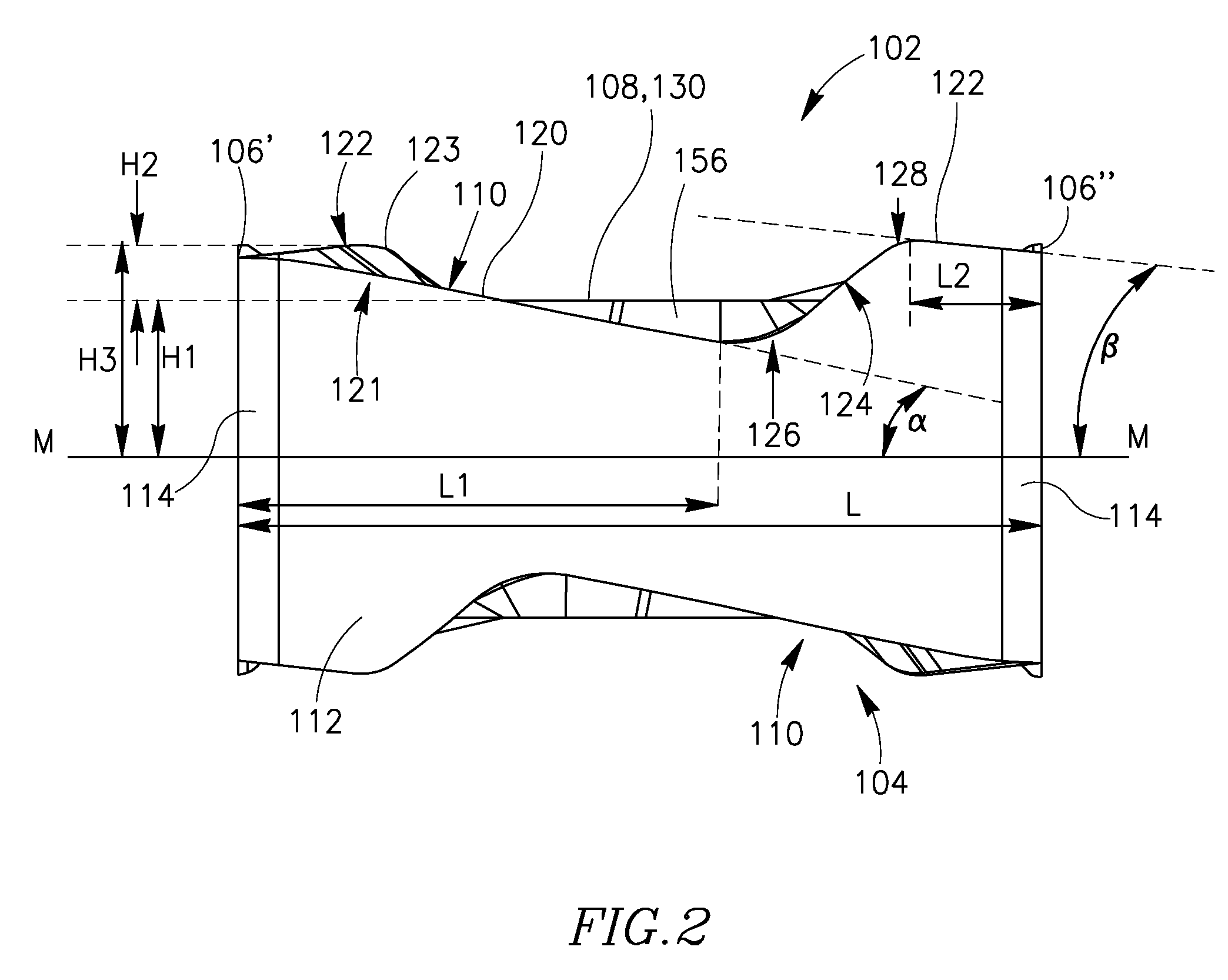

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

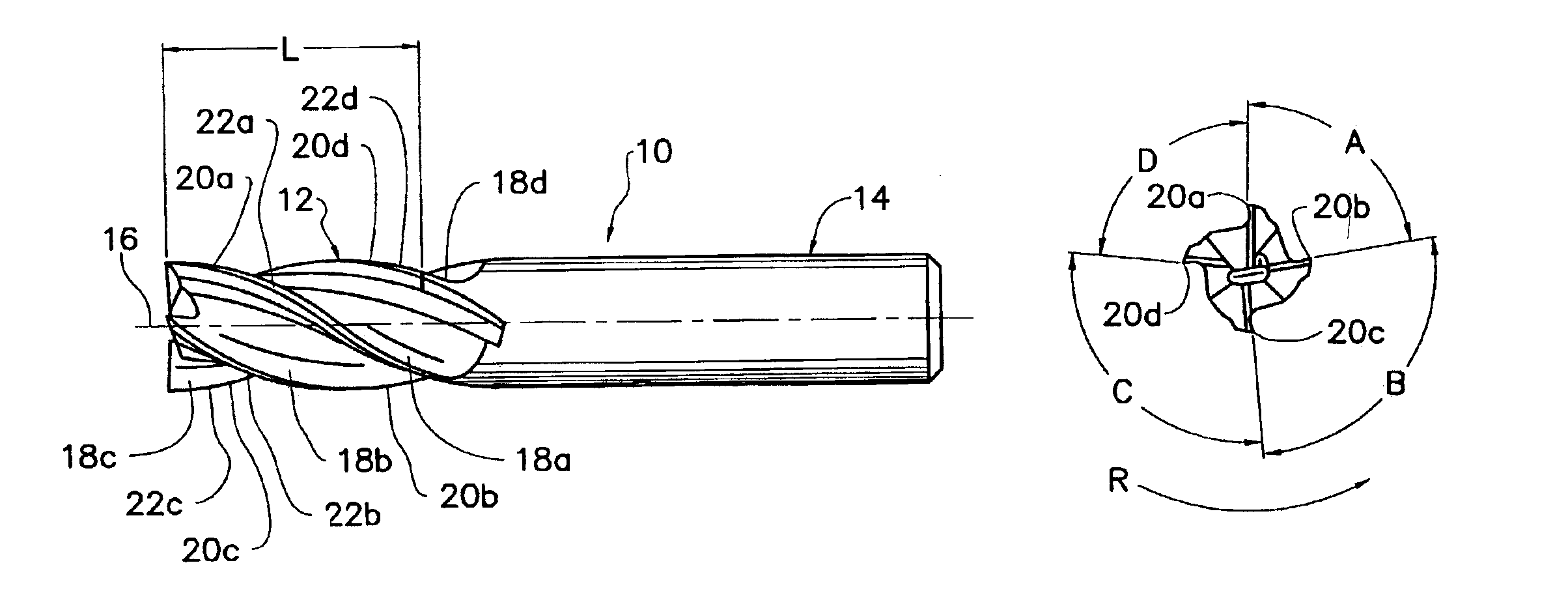

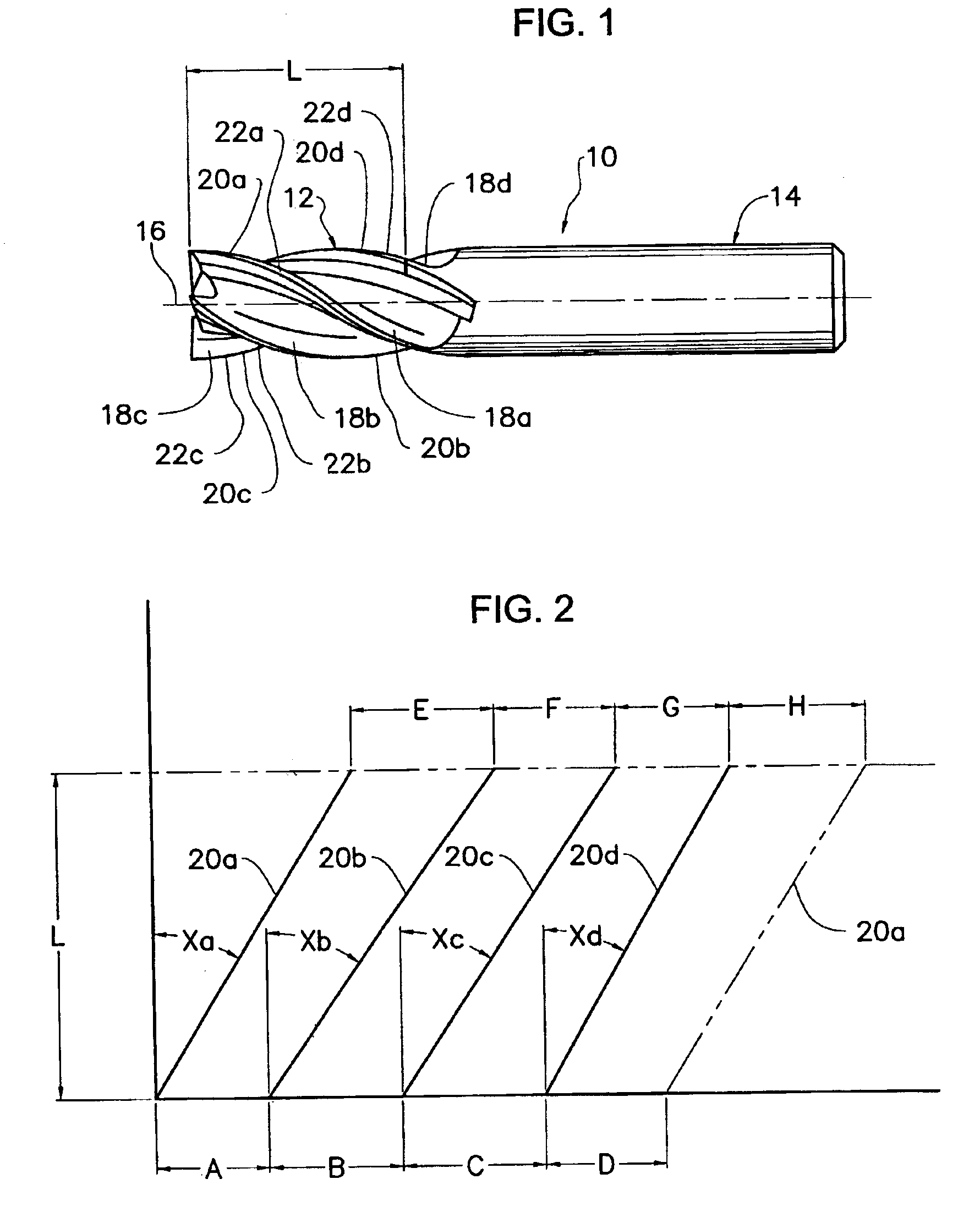

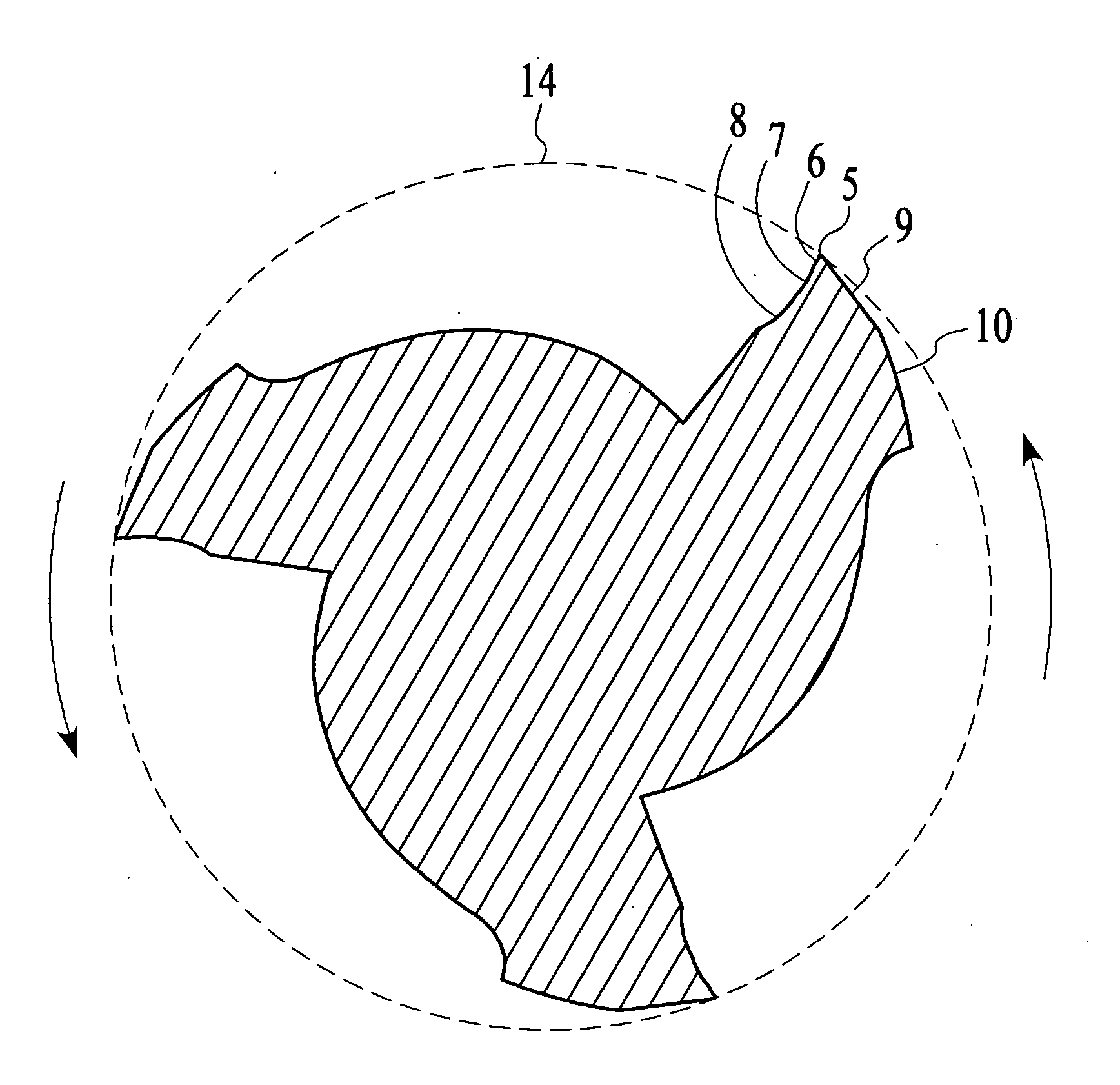

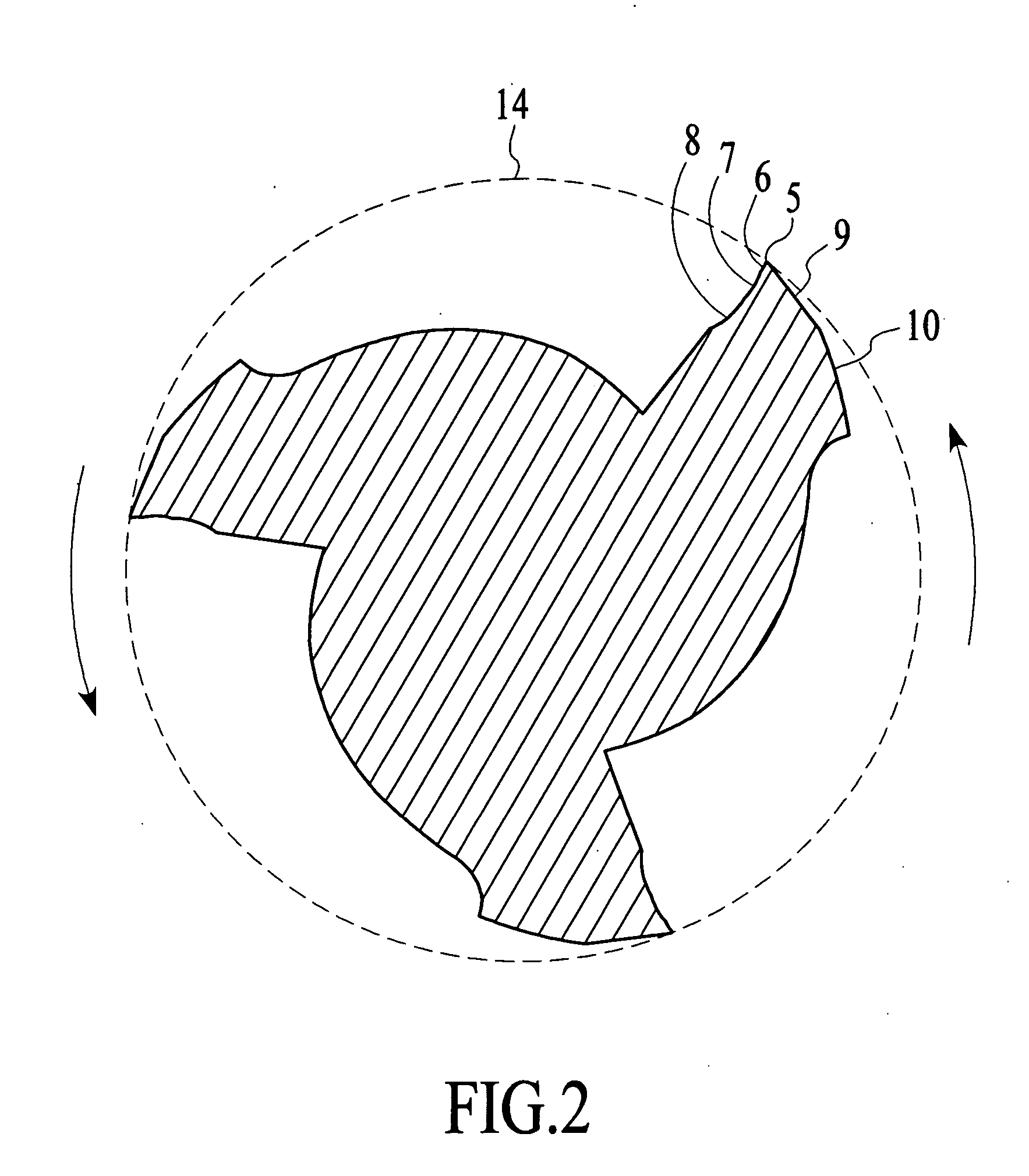

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

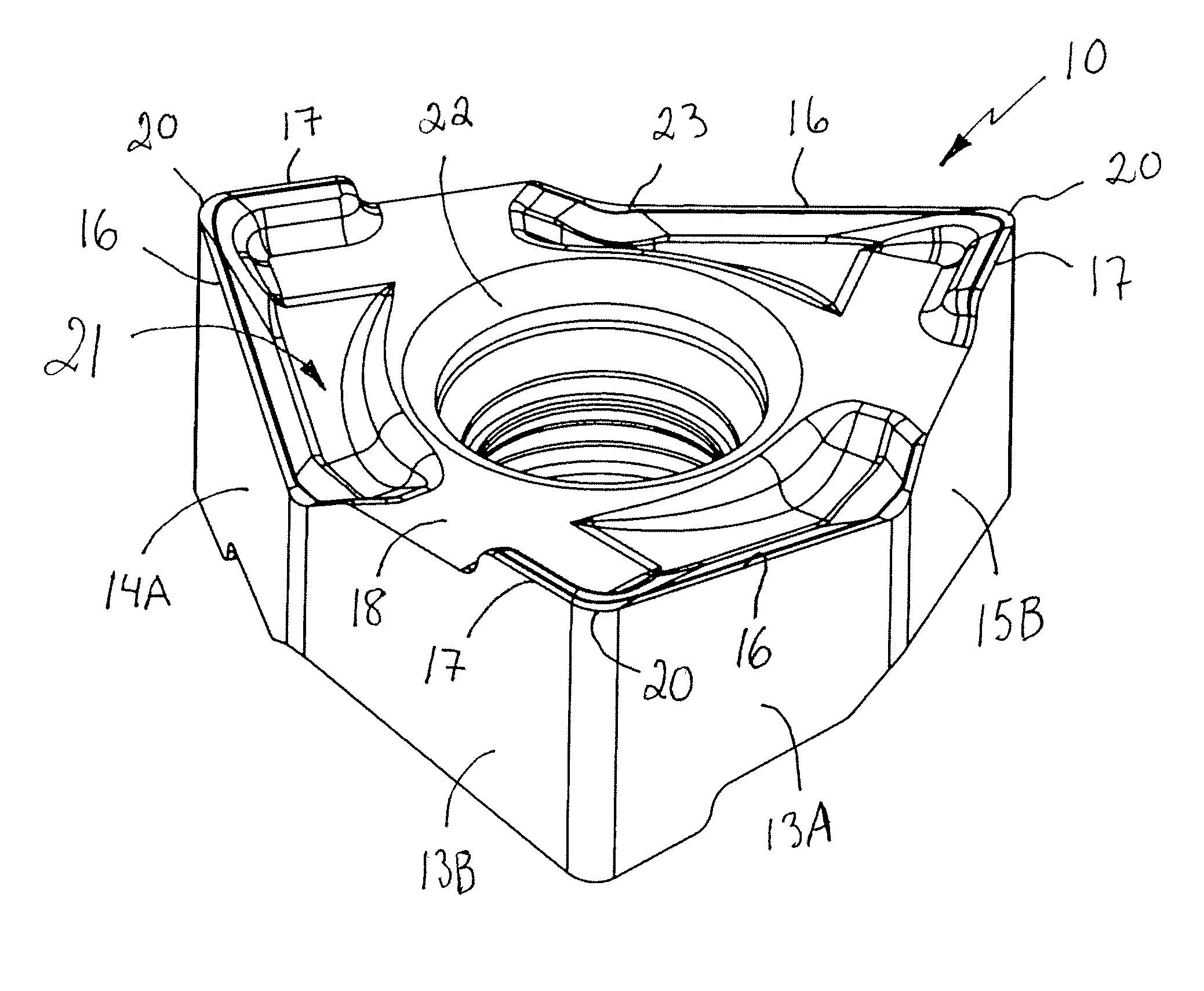

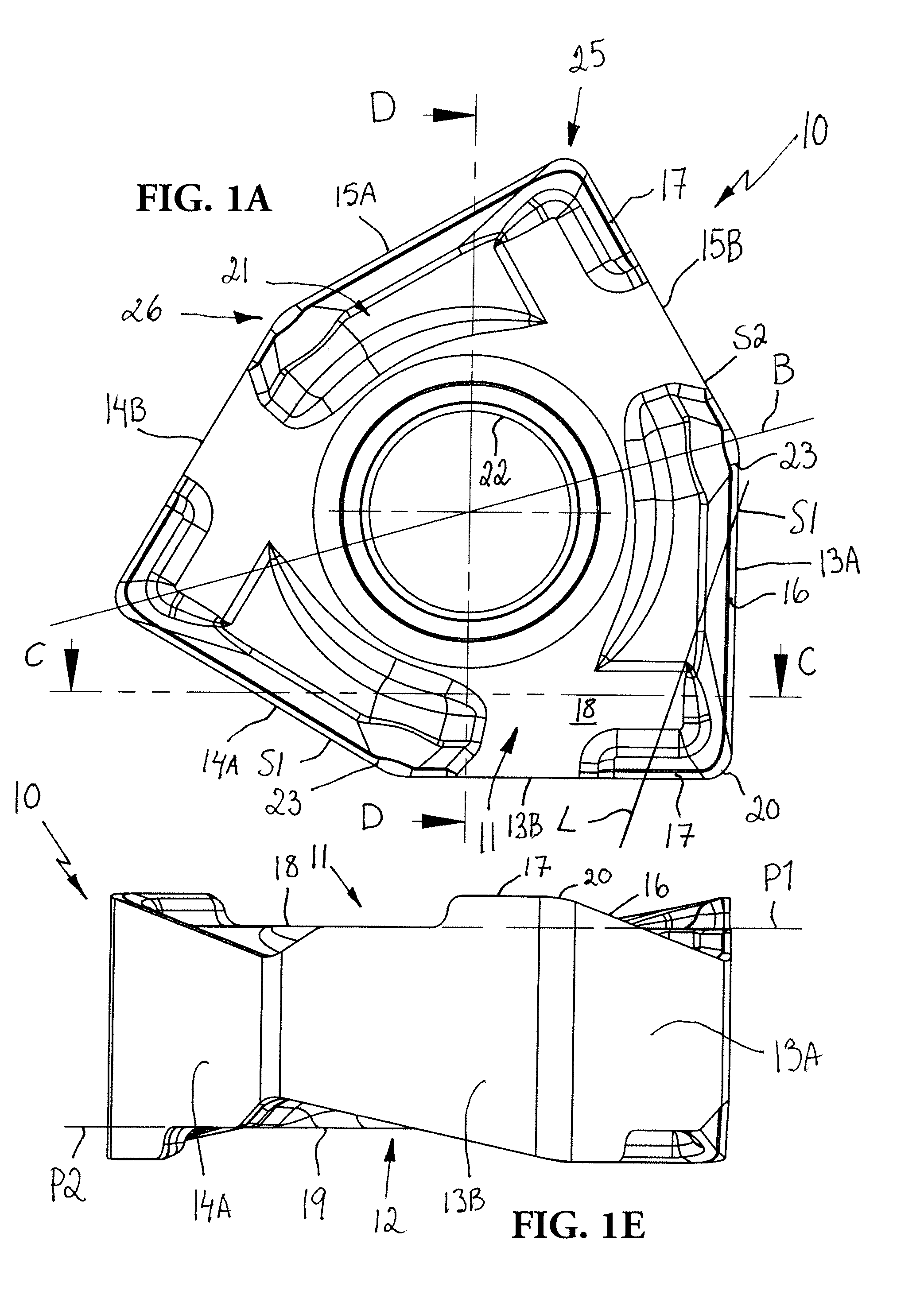

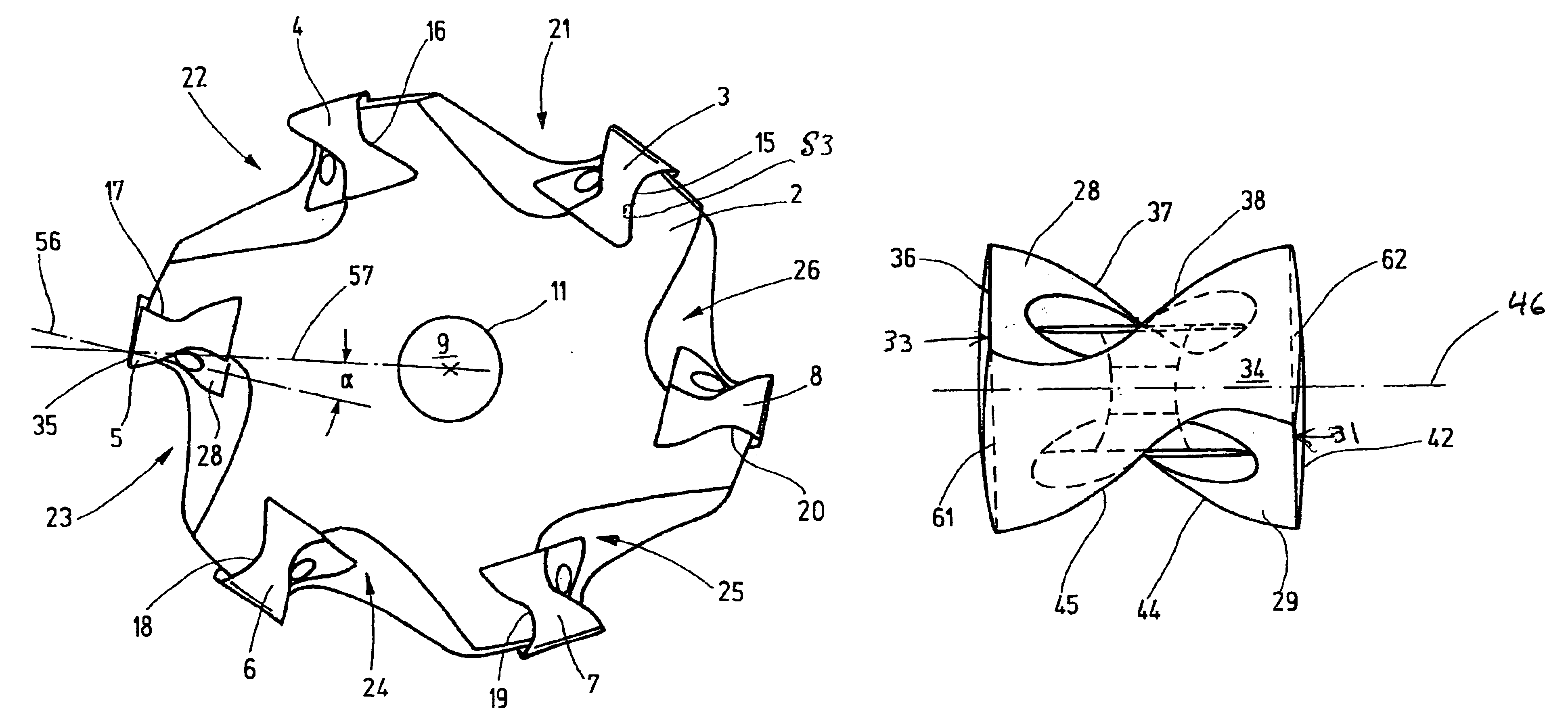

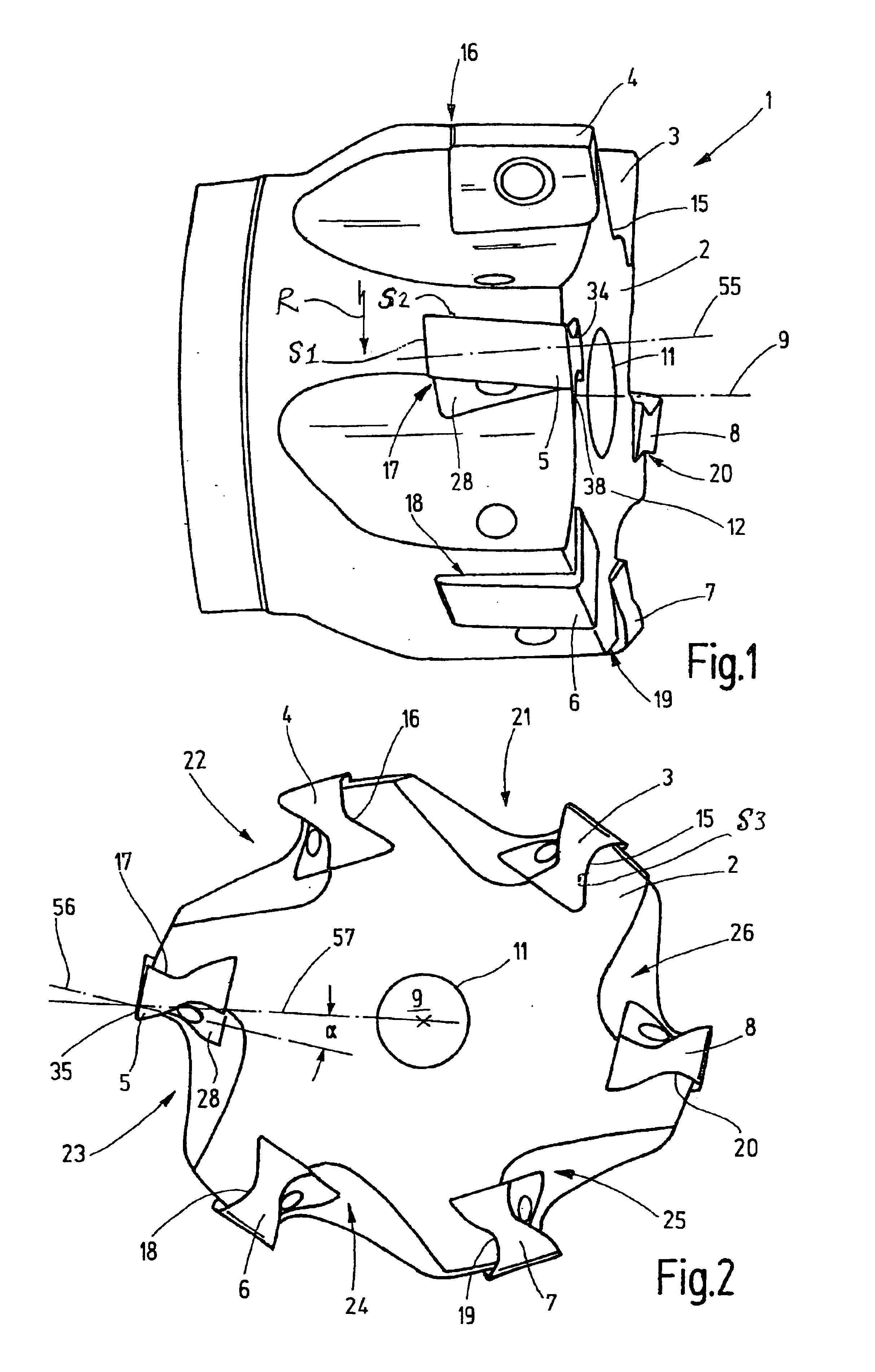

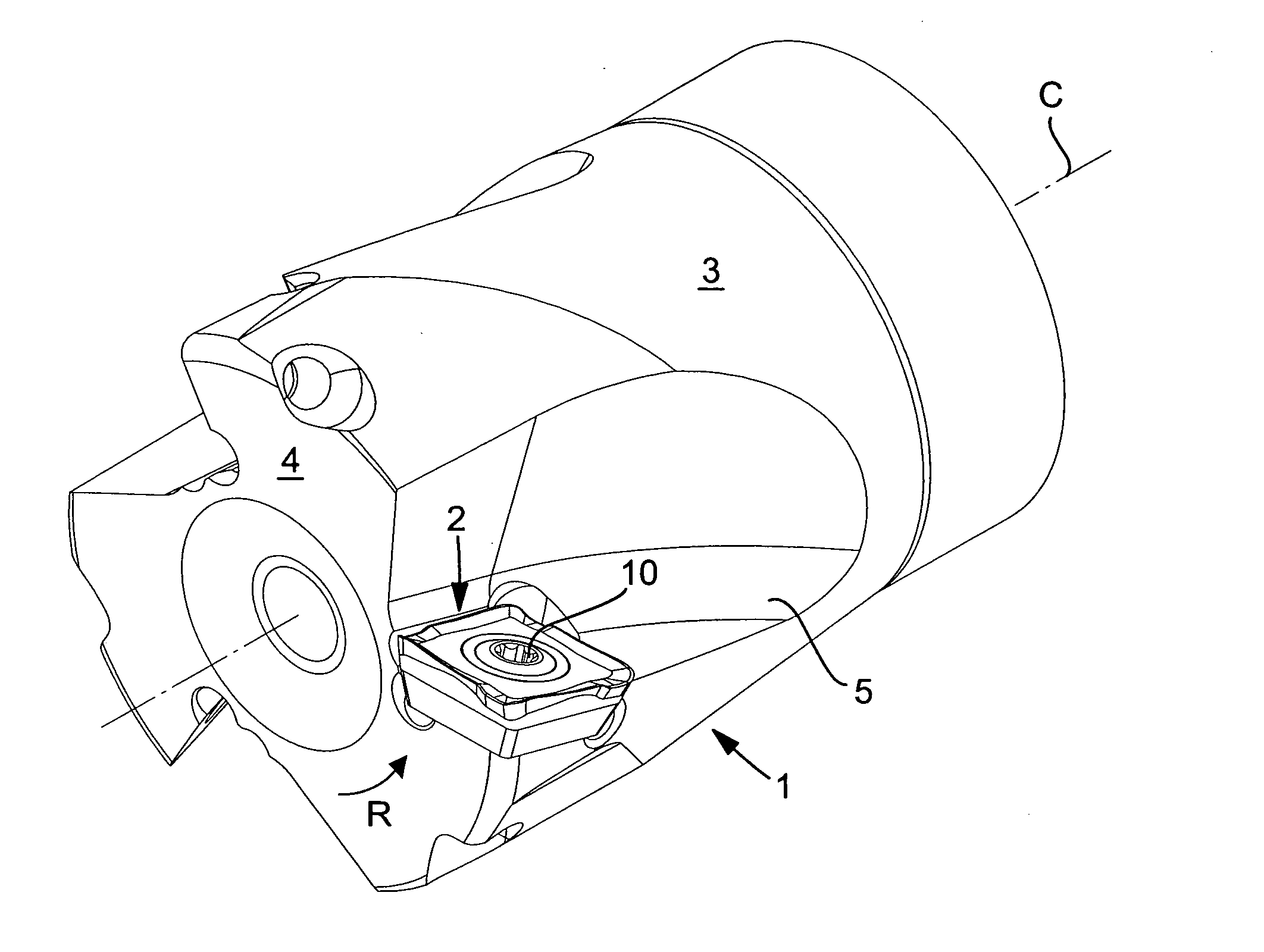

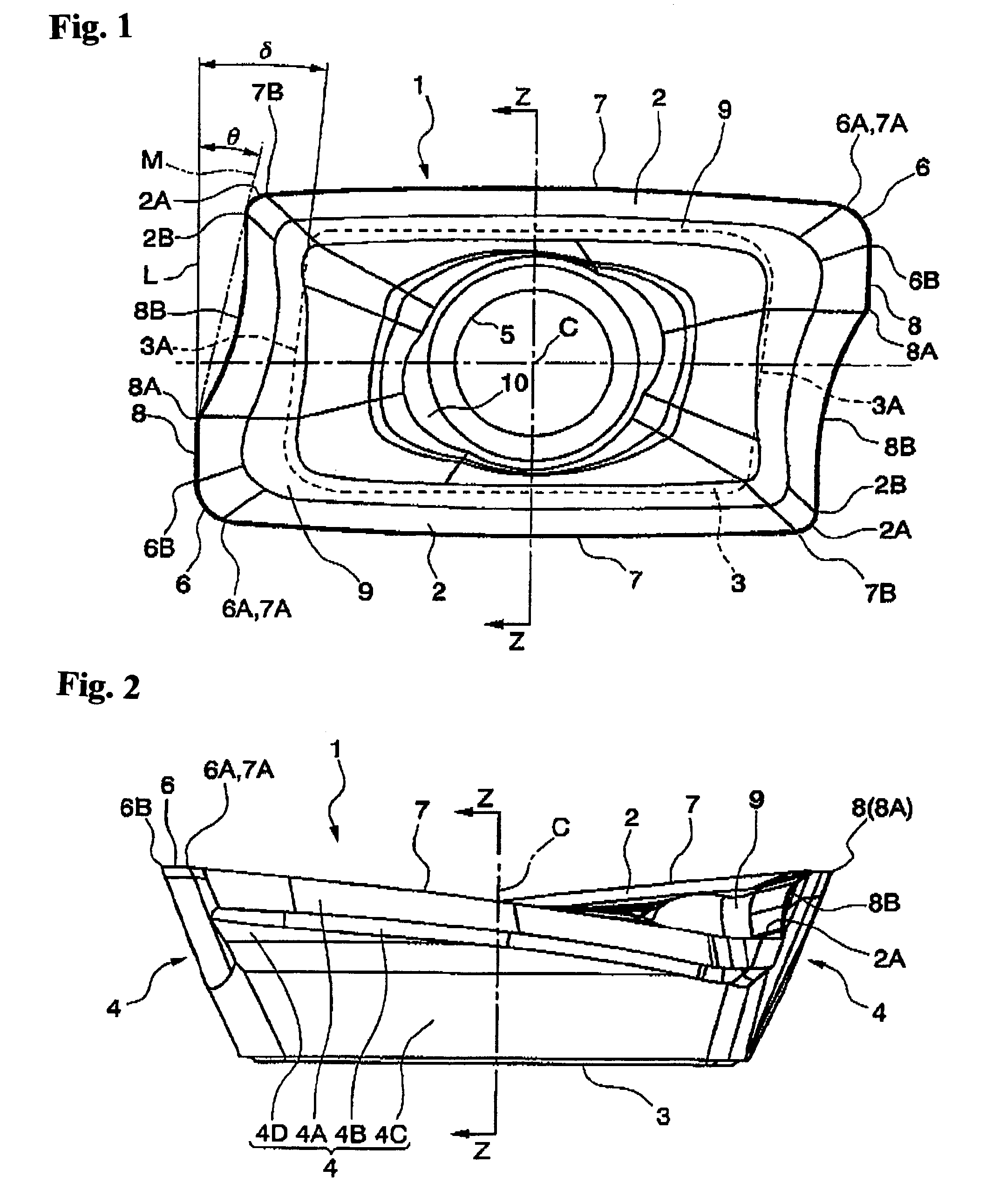

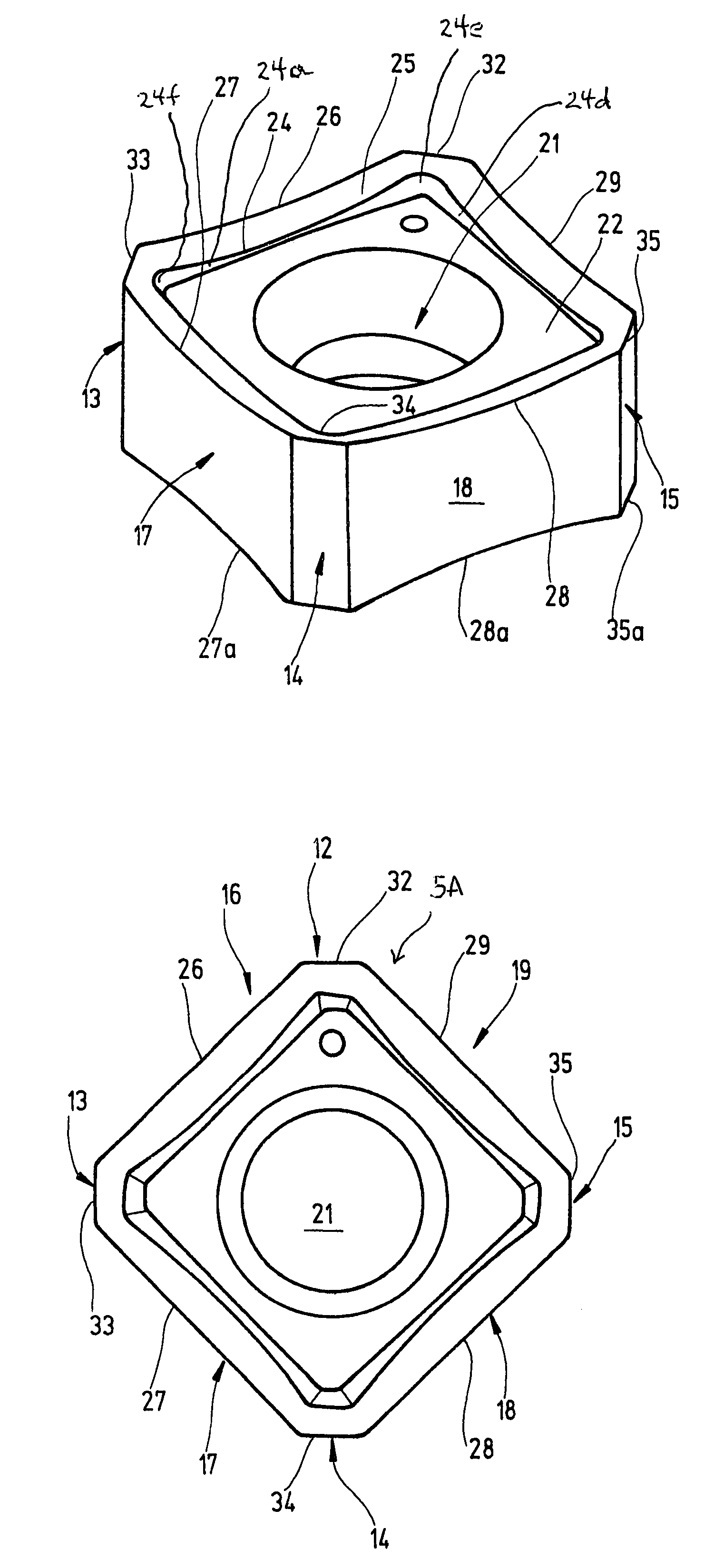

Milling insert and a milling tool

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

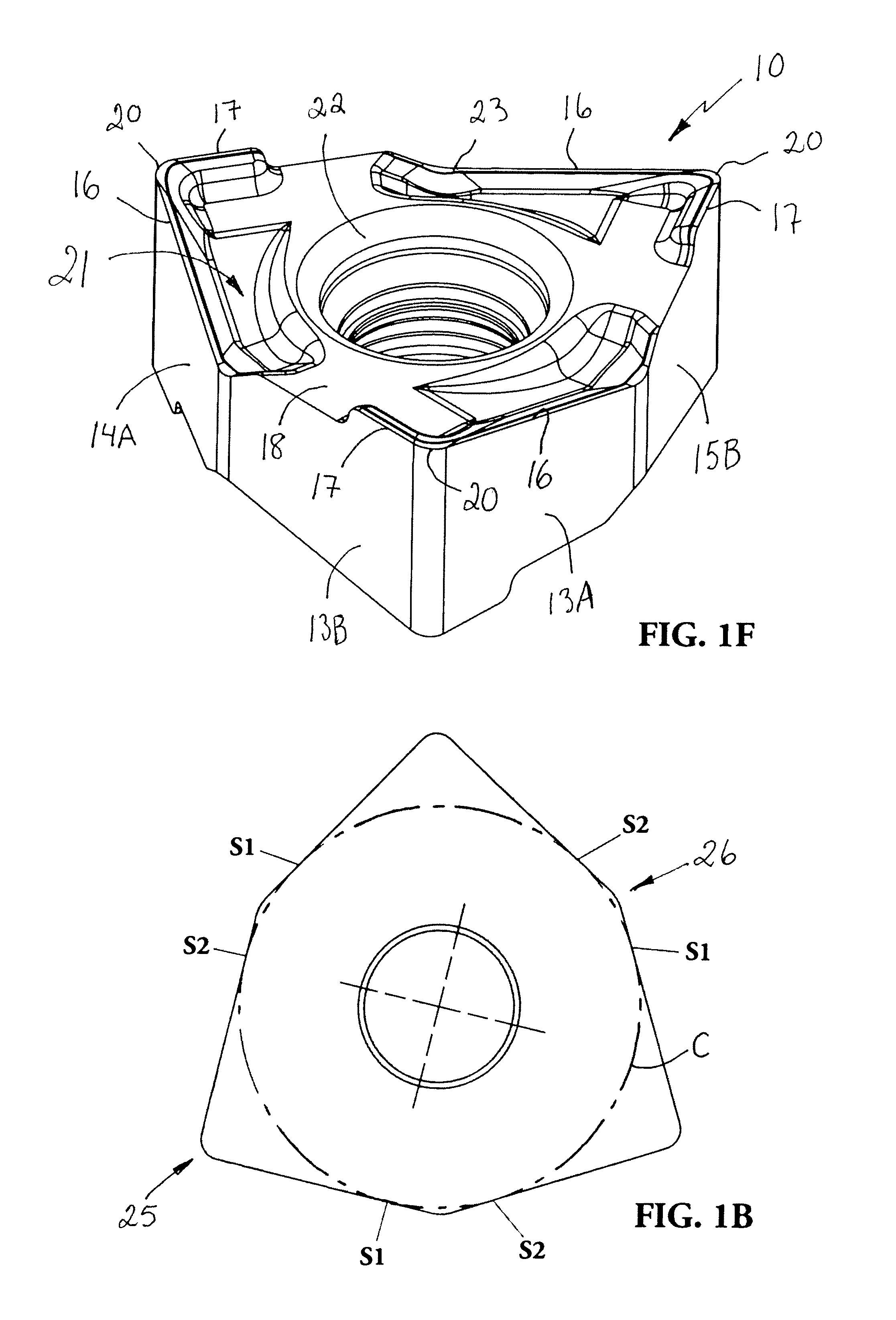

Double-sided cutting insert and milling cutter

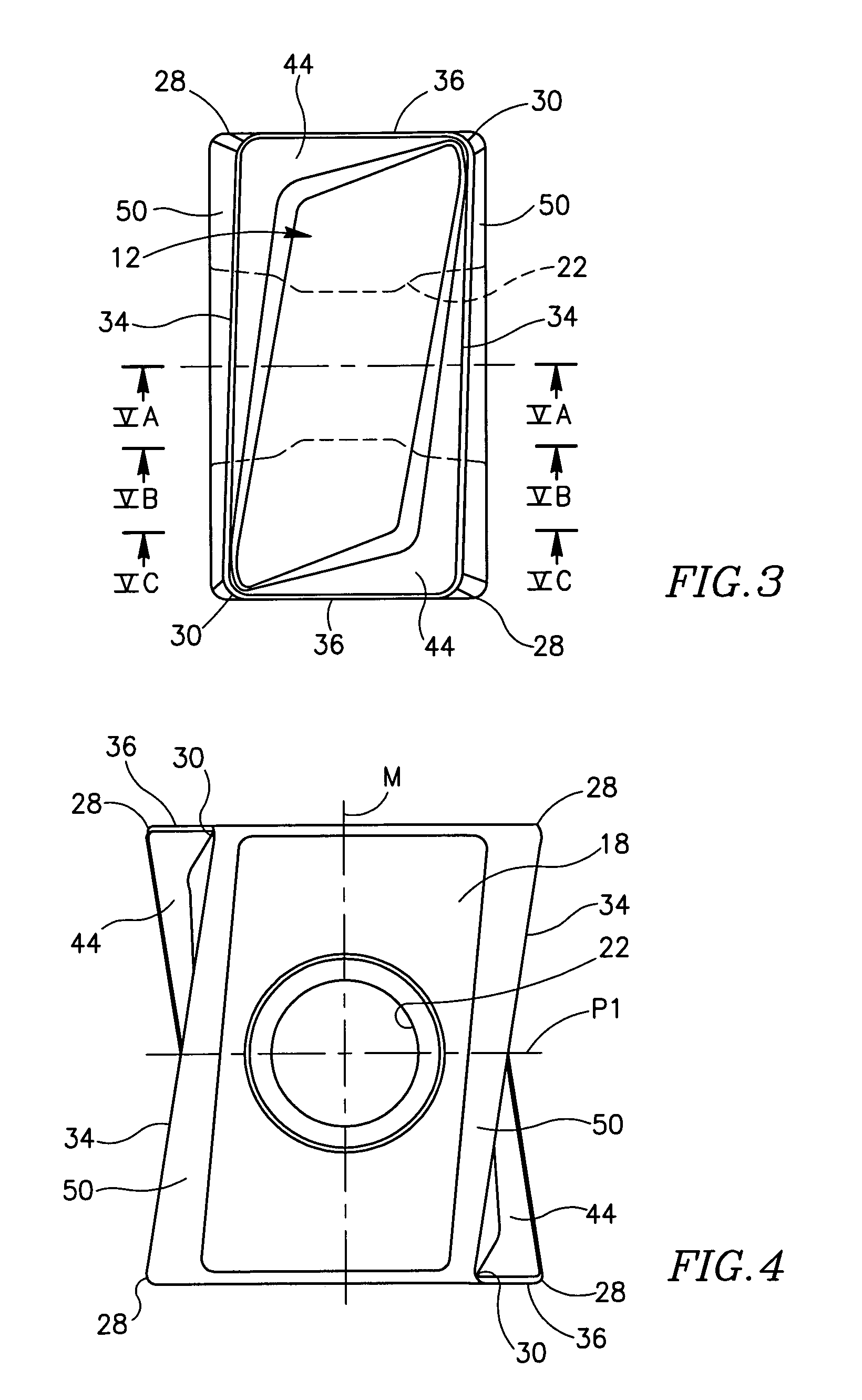

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

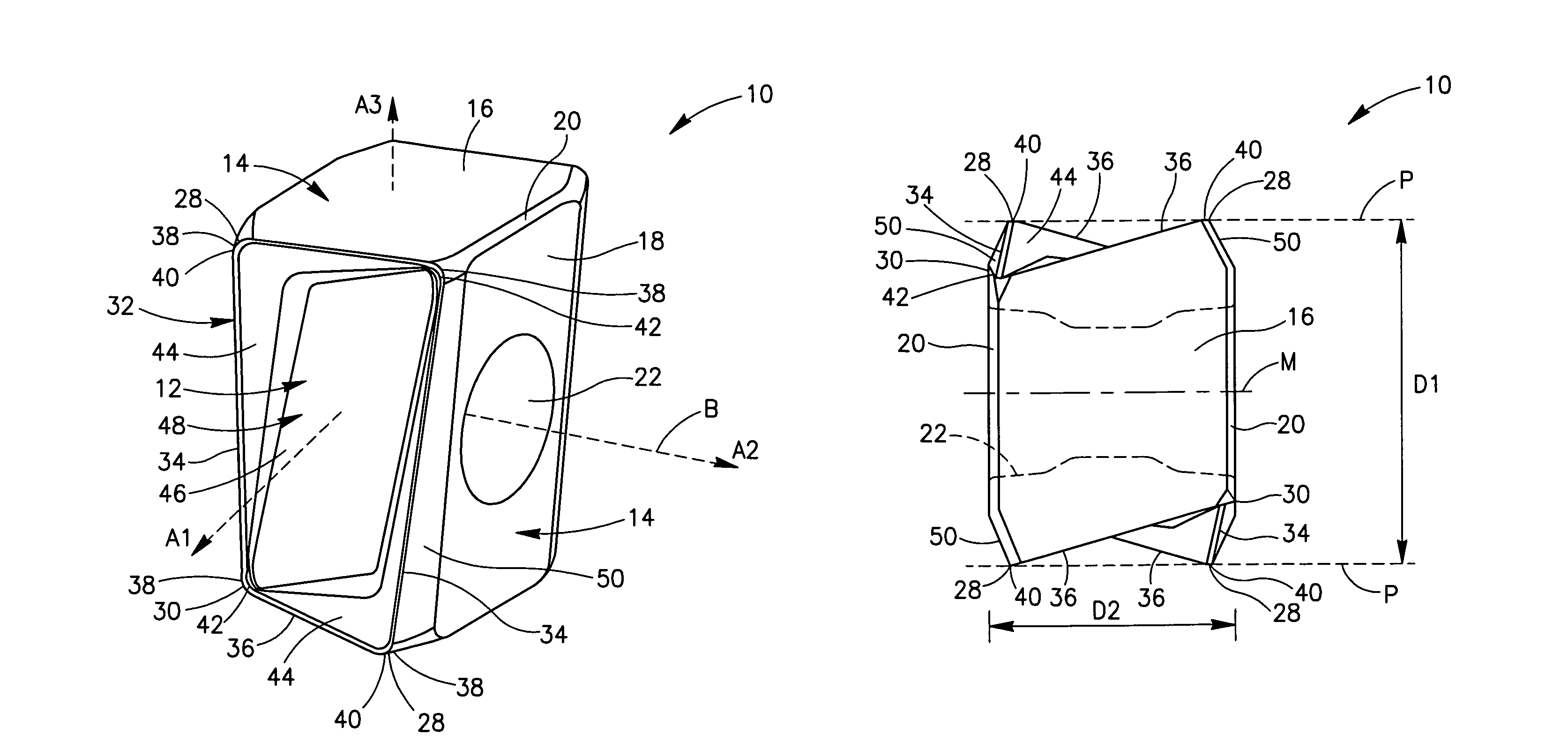

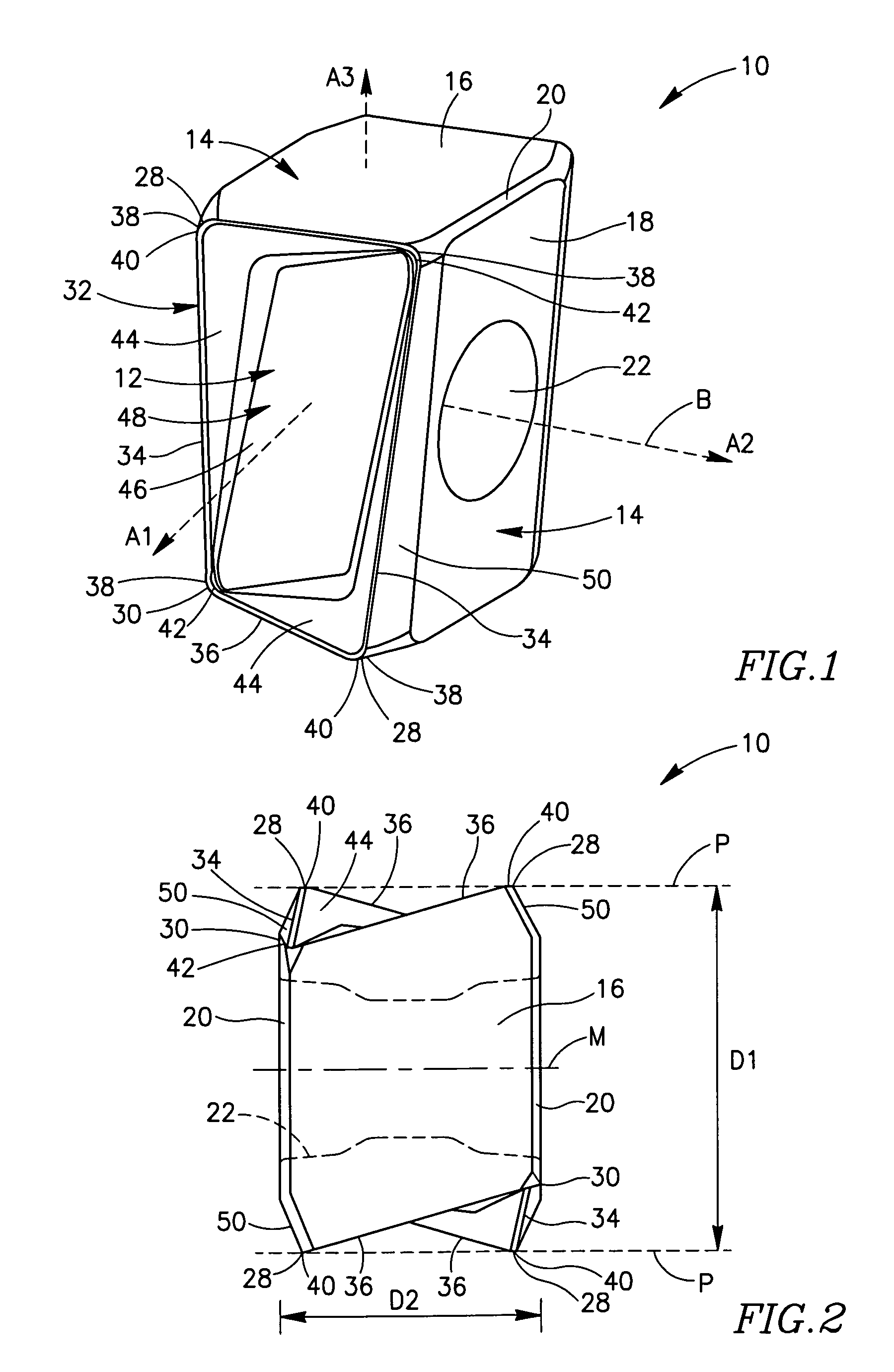

Cutting Insert Having Cylindrically Shaped Side Surface Portions

ActiveUS20070003384A1Reduced cutting performanceReduce the impactMilling cuttersCutting insertsRotational symmetryMedian plane

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

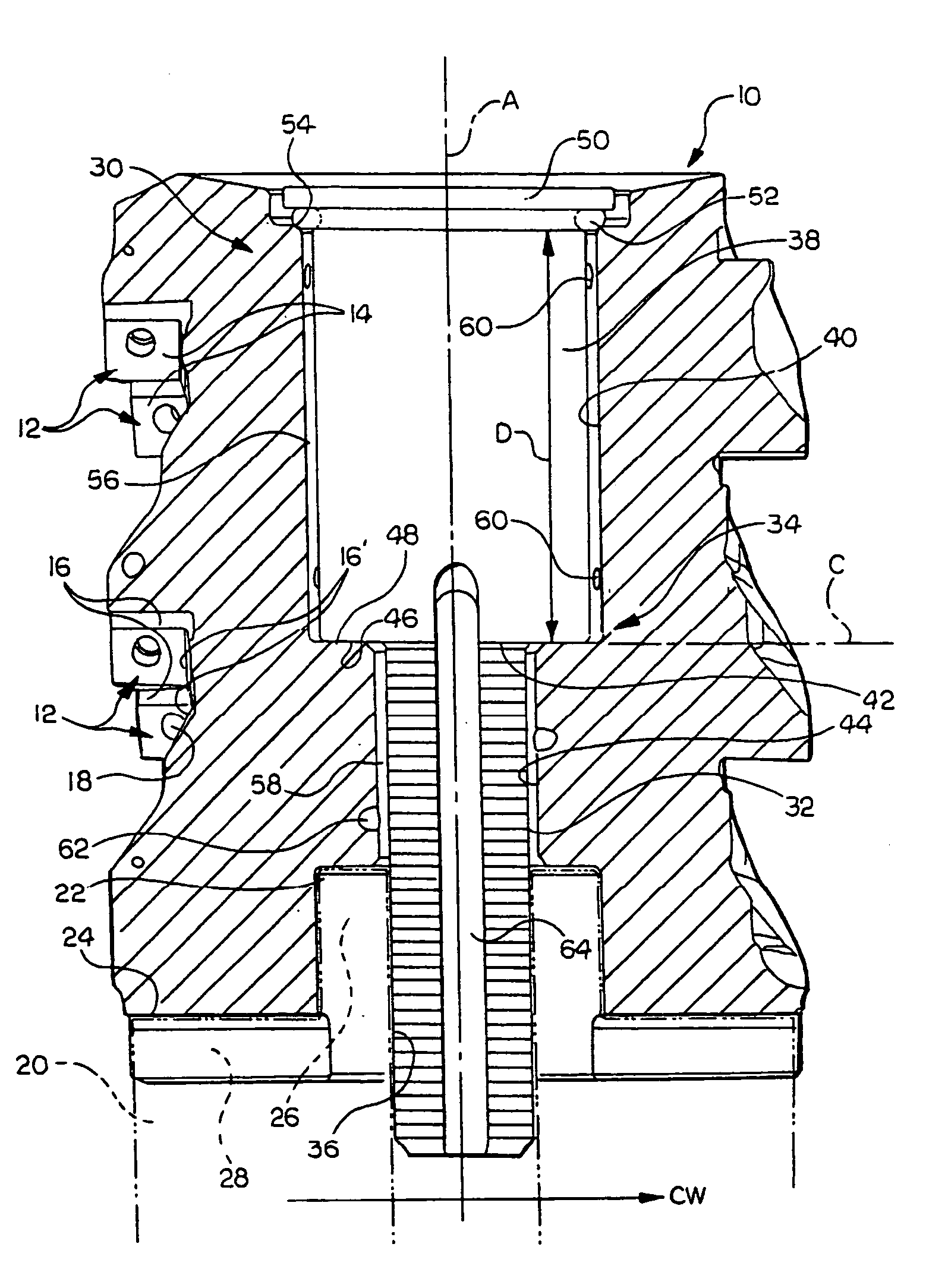

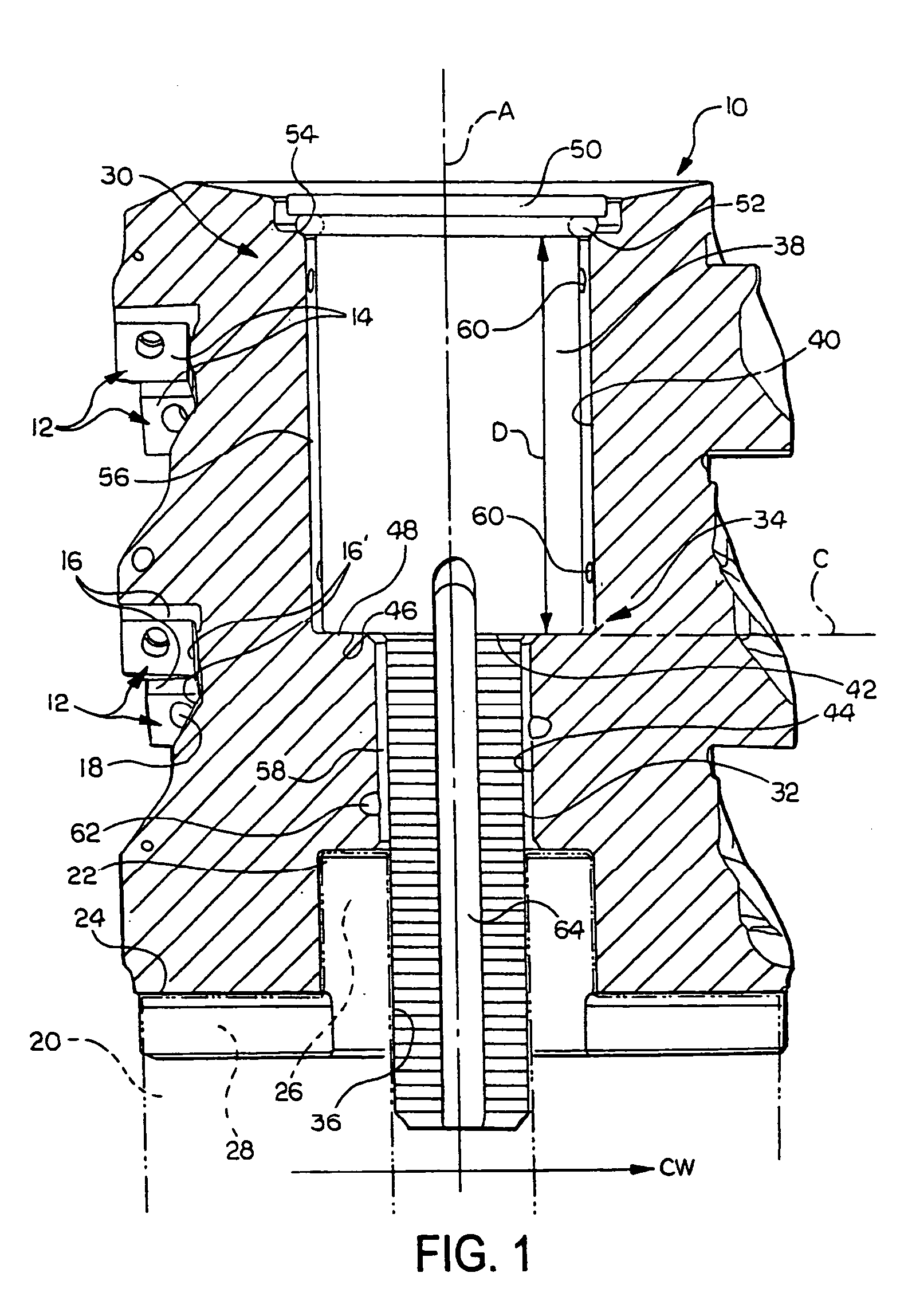

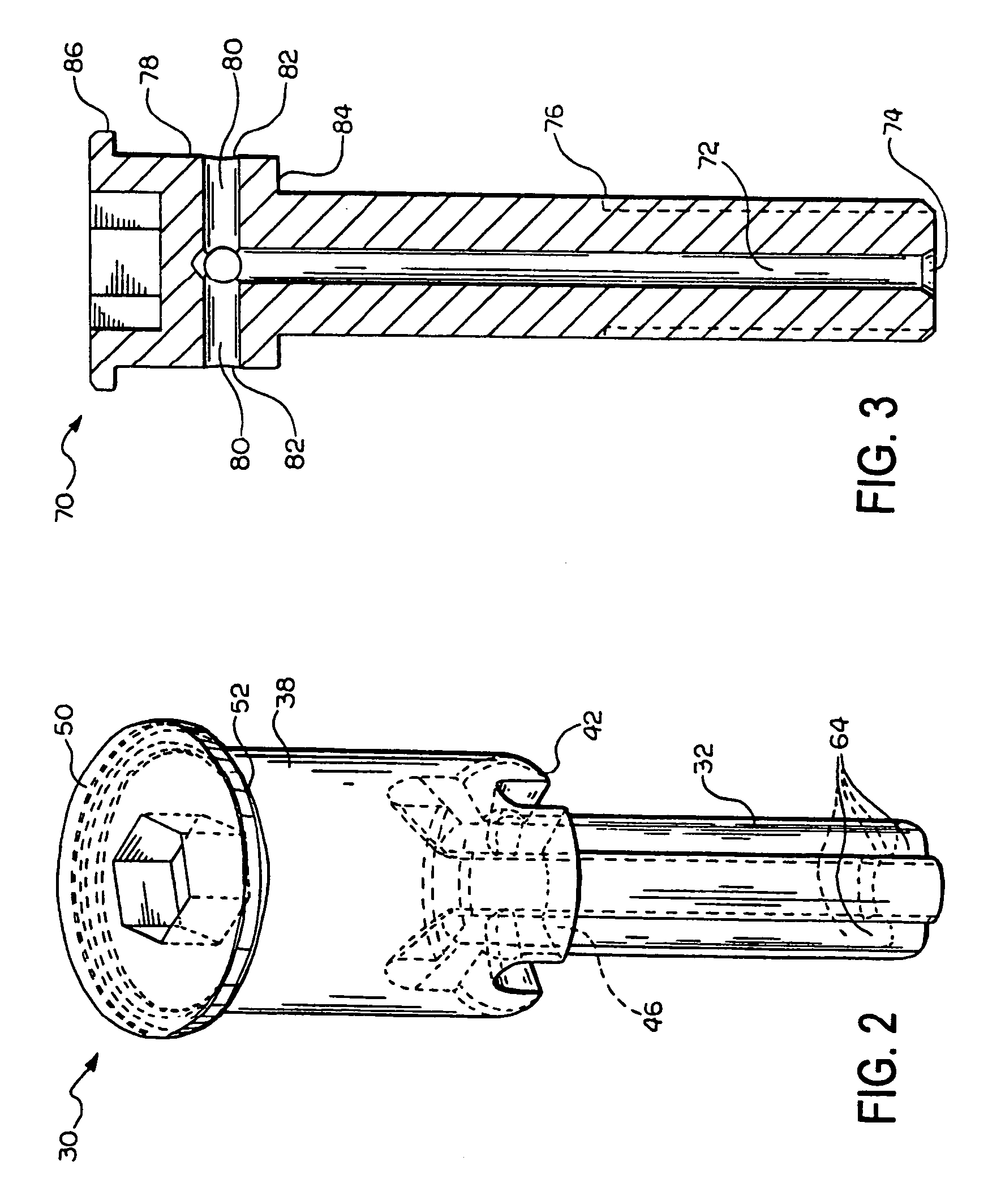

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

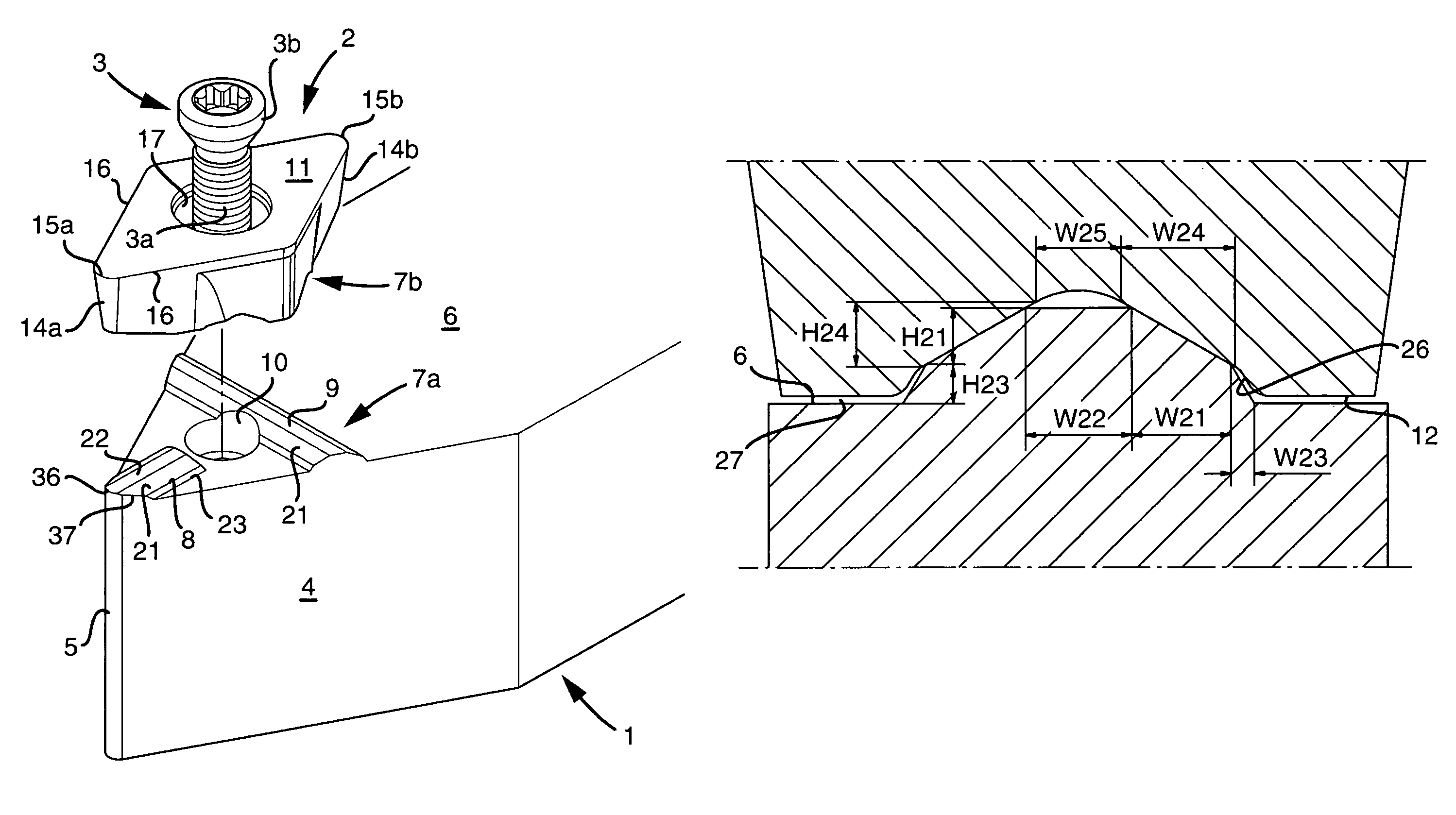

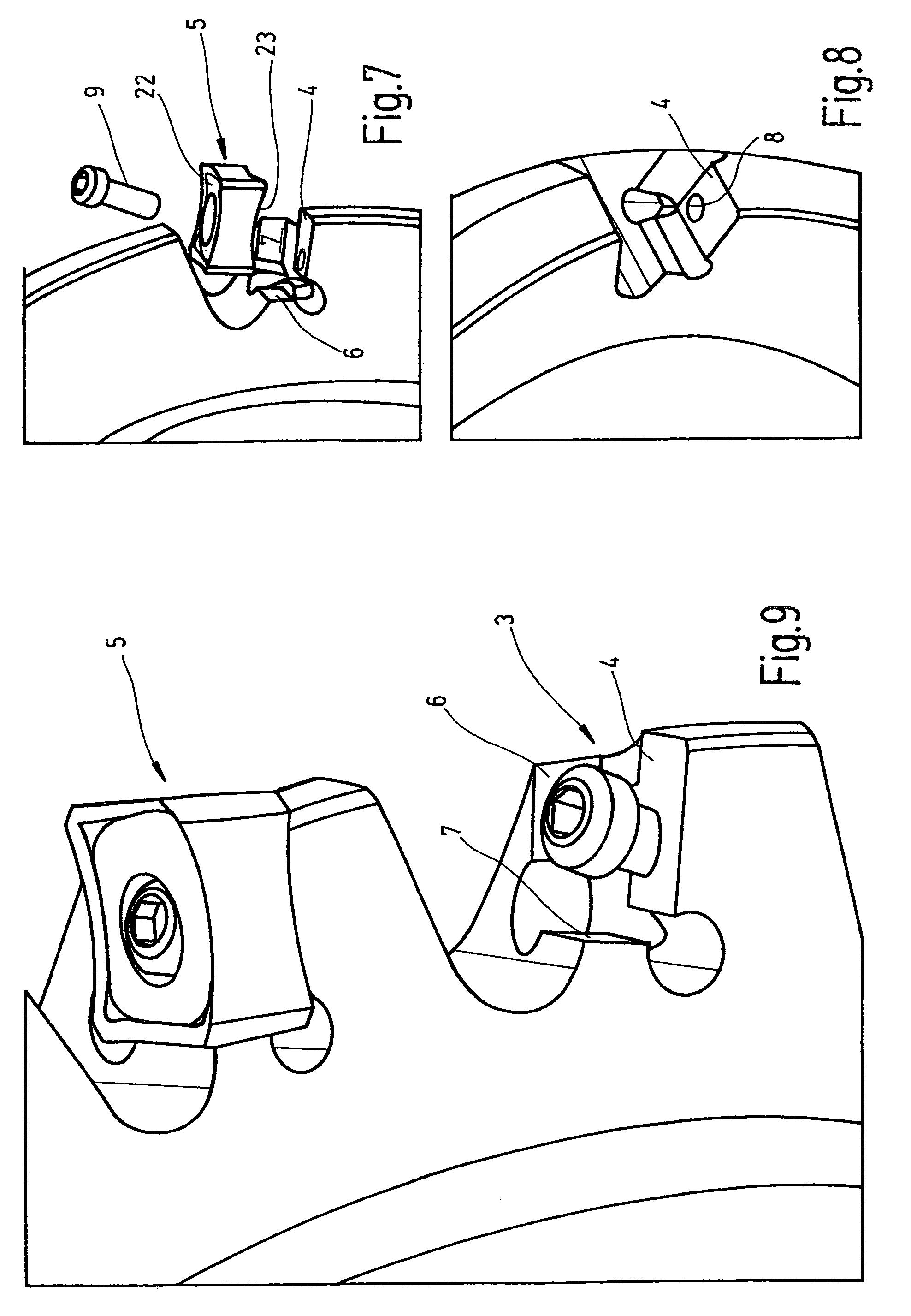

Tool and insert for chip removal machining

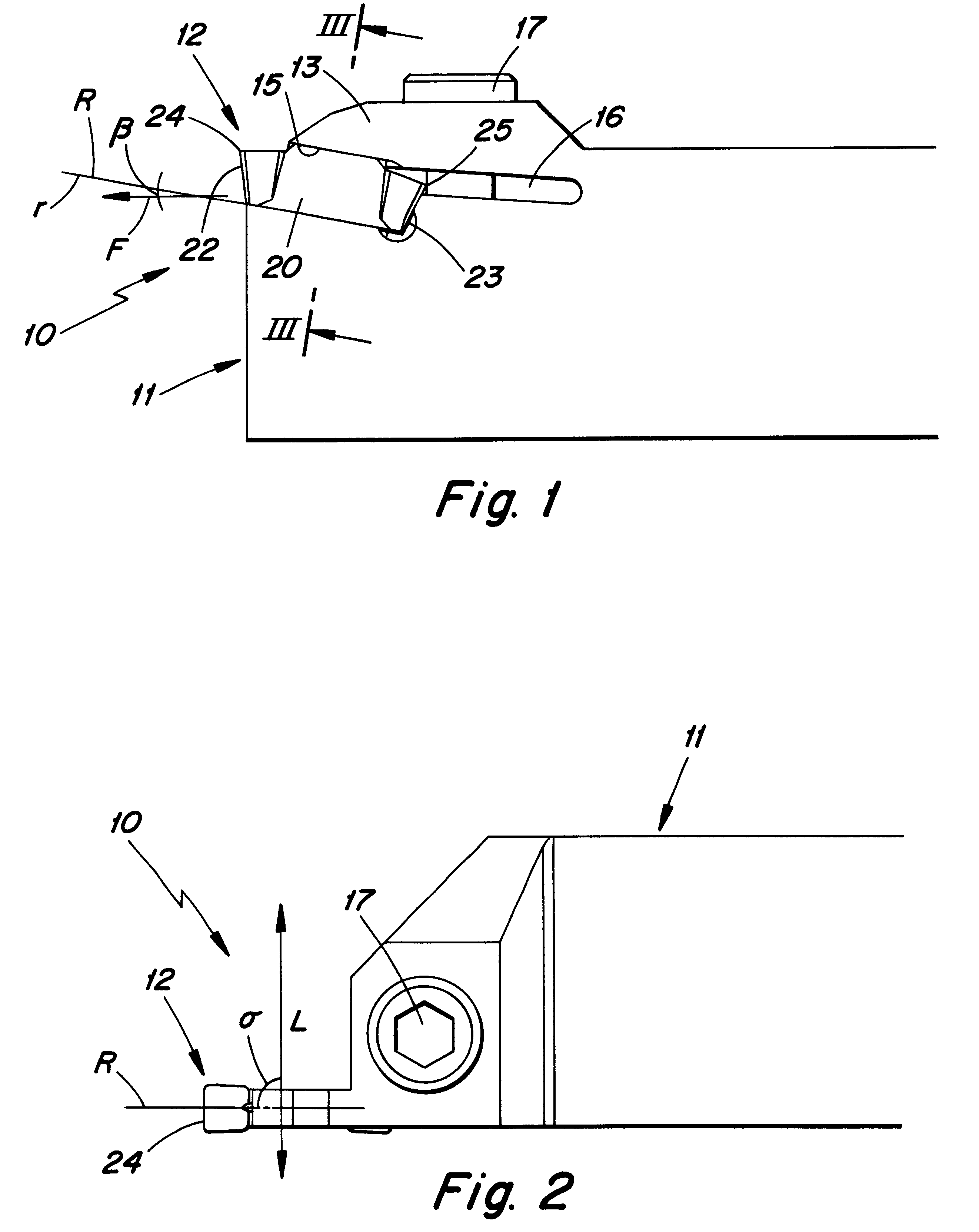

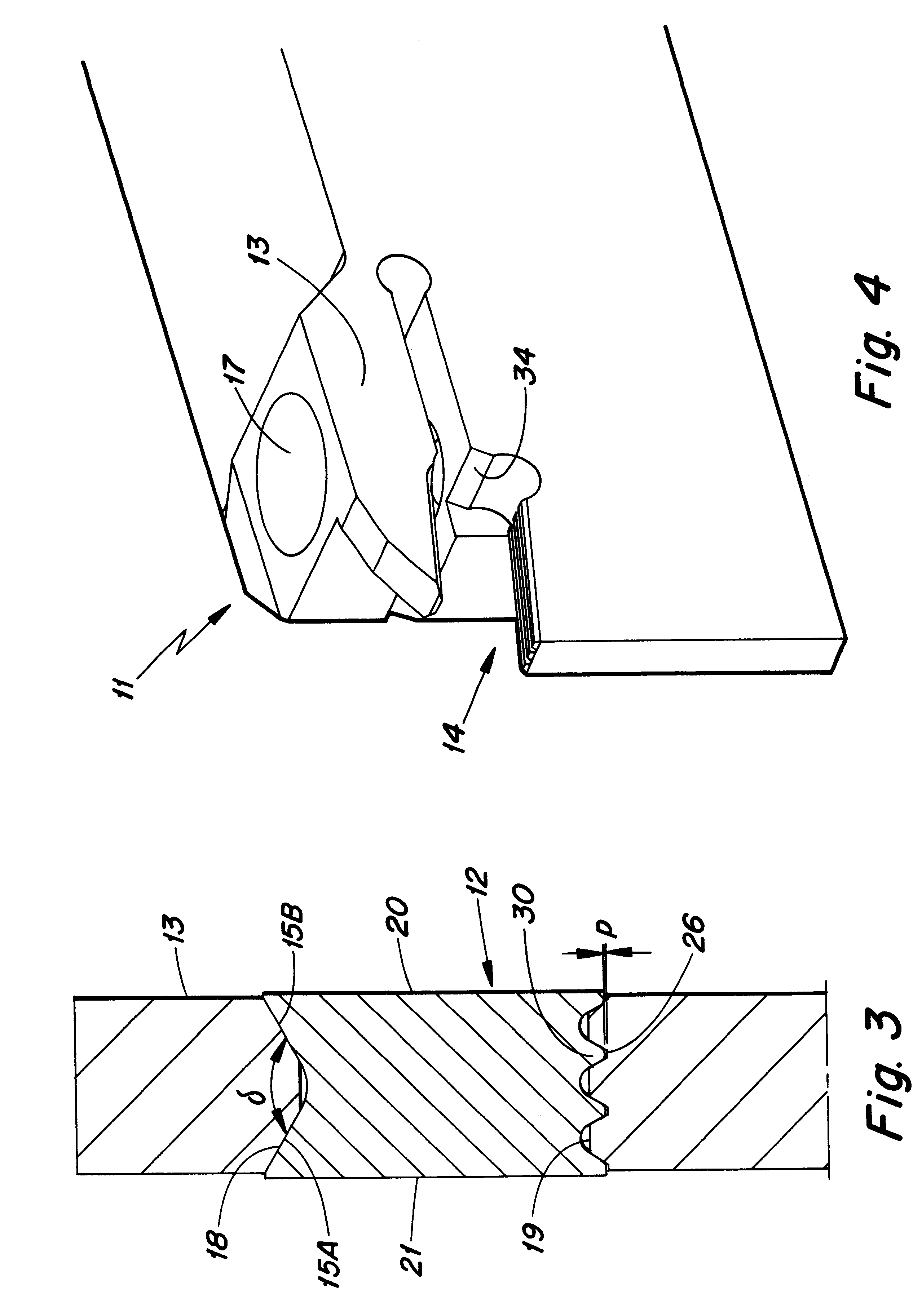

A tool for chip removing machining includes a holder and a cutting insert clamped within a pocket of the holder. The pocket has upper and lower sides, and the cutting insert comprises an upper surface and a lower surface. The upper side of the pocket and the upper surface of the cutting insert comprise first cooperating contact surfaces defining a first flank angle. The lower side of the pocket and the lower surface of the cutting insert comprise second cooperating contact surfaces which define a second flank angle. The first flank angle is larger than the second flank angle. The lower surface of the cutting insert and the lower side of the pocket form intermeshing projections and recesses which define the second contact surfaces.

Owner:SECO TOOLS AB

Cutter insert and milling tool

ActiveUS6921233B2Easy to useEasy to manufactureMilling cuttersTurning toolsEngineeringMechanical engineering

A cutter insert for milling tools includes a base body having a base surface, a top surface, and four side surfaces. The four side surfaces, together with each of the base surface and the top surface, define respective cutting edges. The base body is twisted about each of two perpendicular, coplanar axes of the base body. Each side surface has two opposite corner edges that are offset from one another in a direction parallel to a center axis of the base body.

Owner:WALTER AG

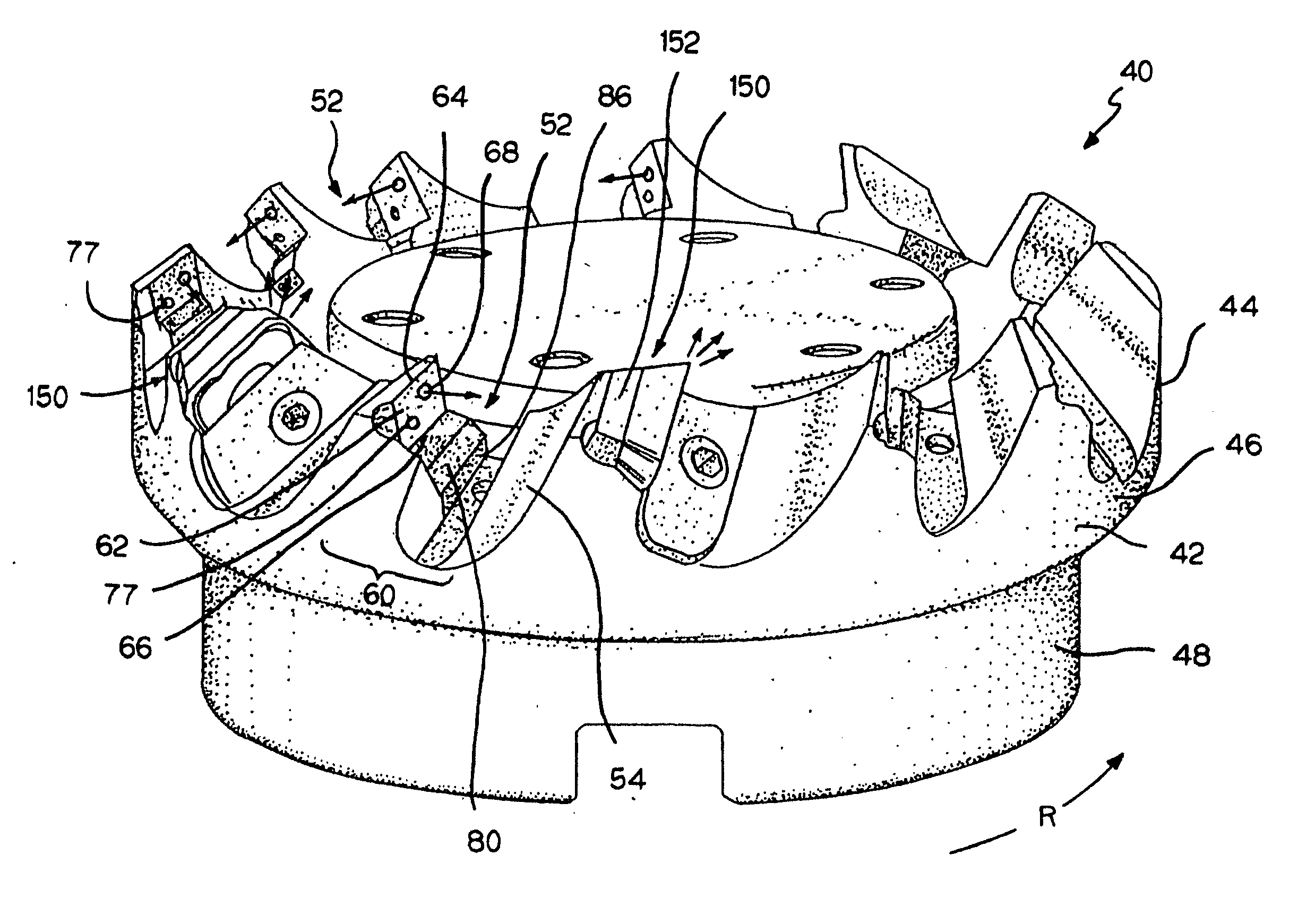

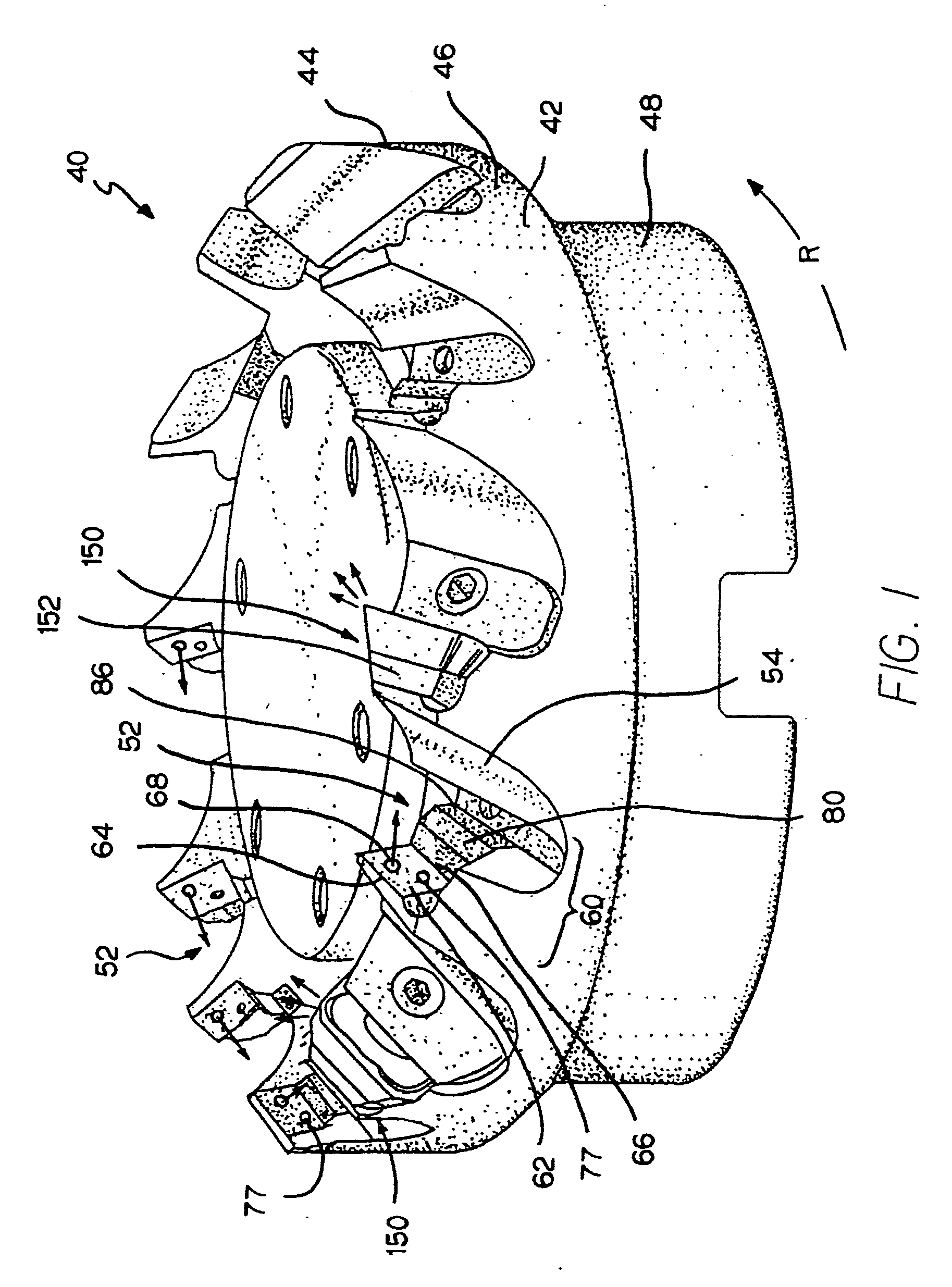

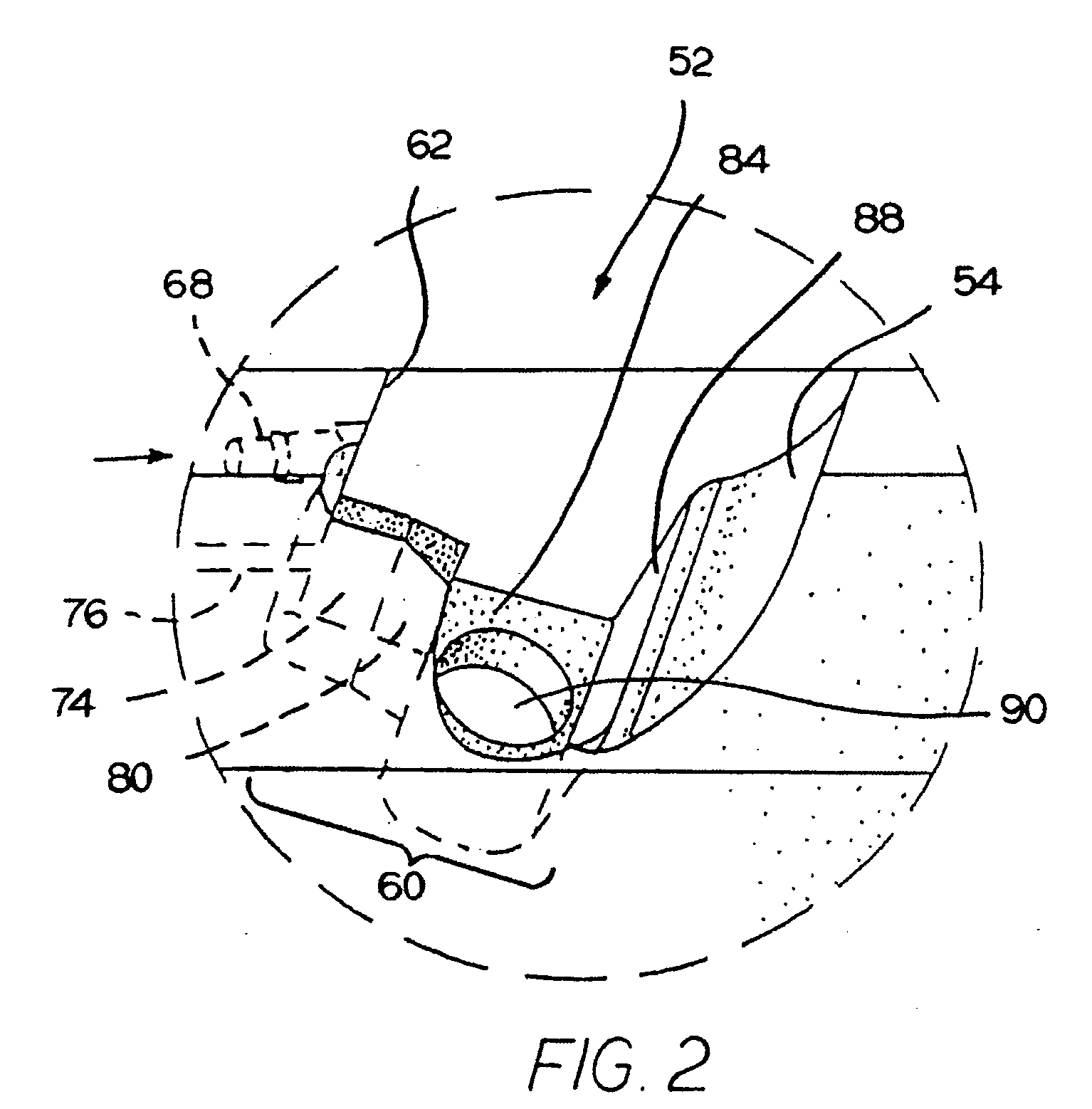

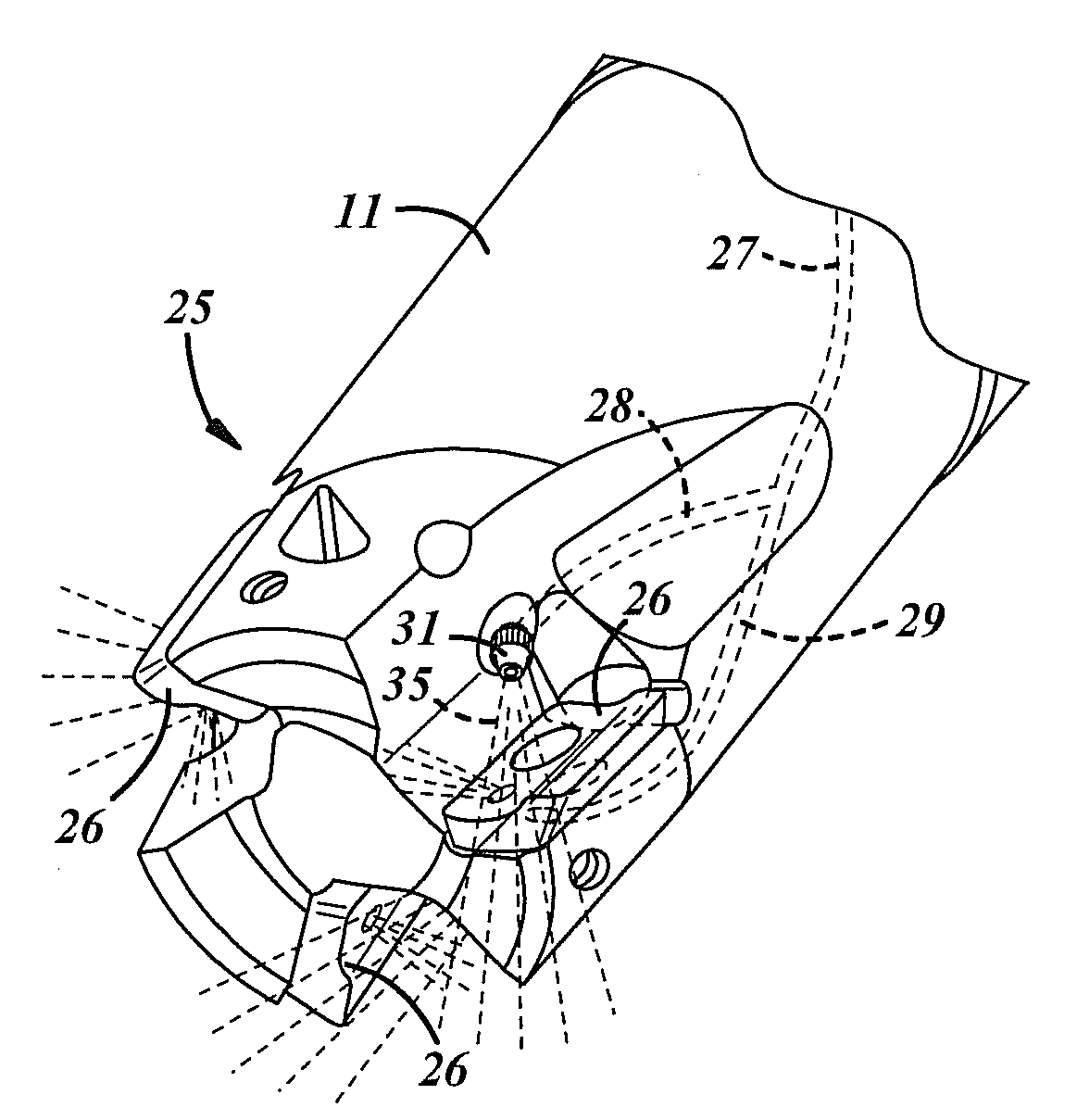

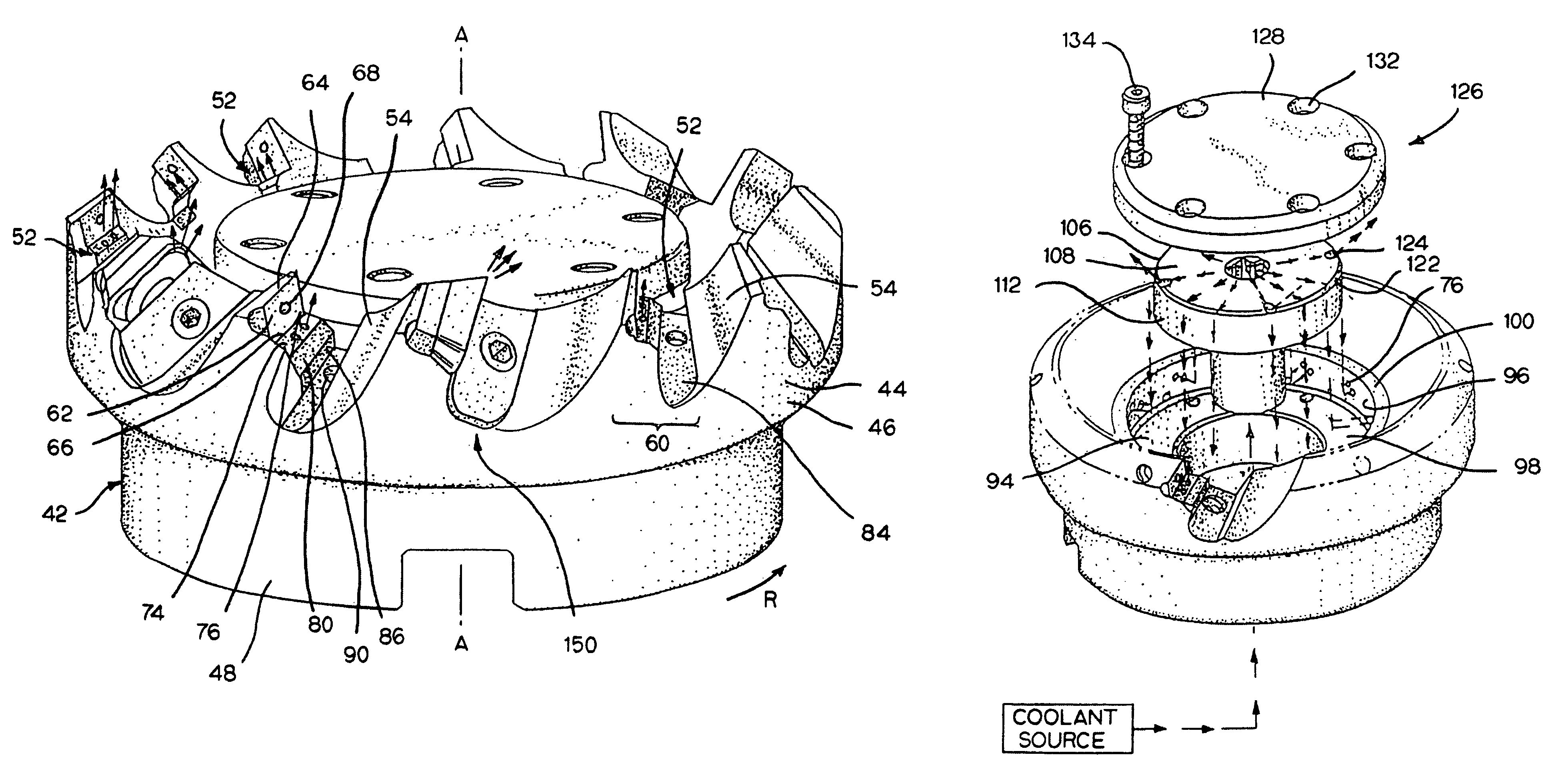

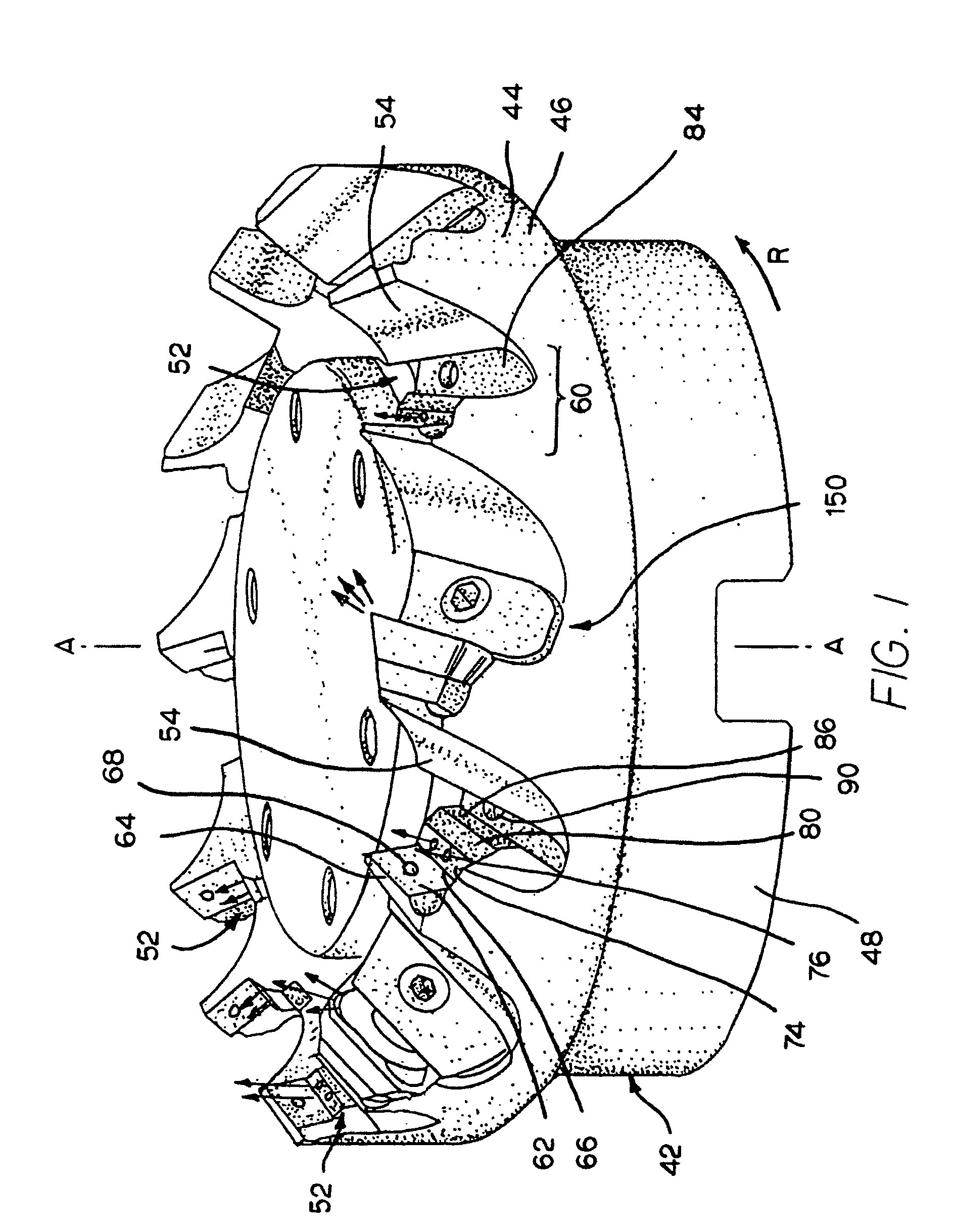

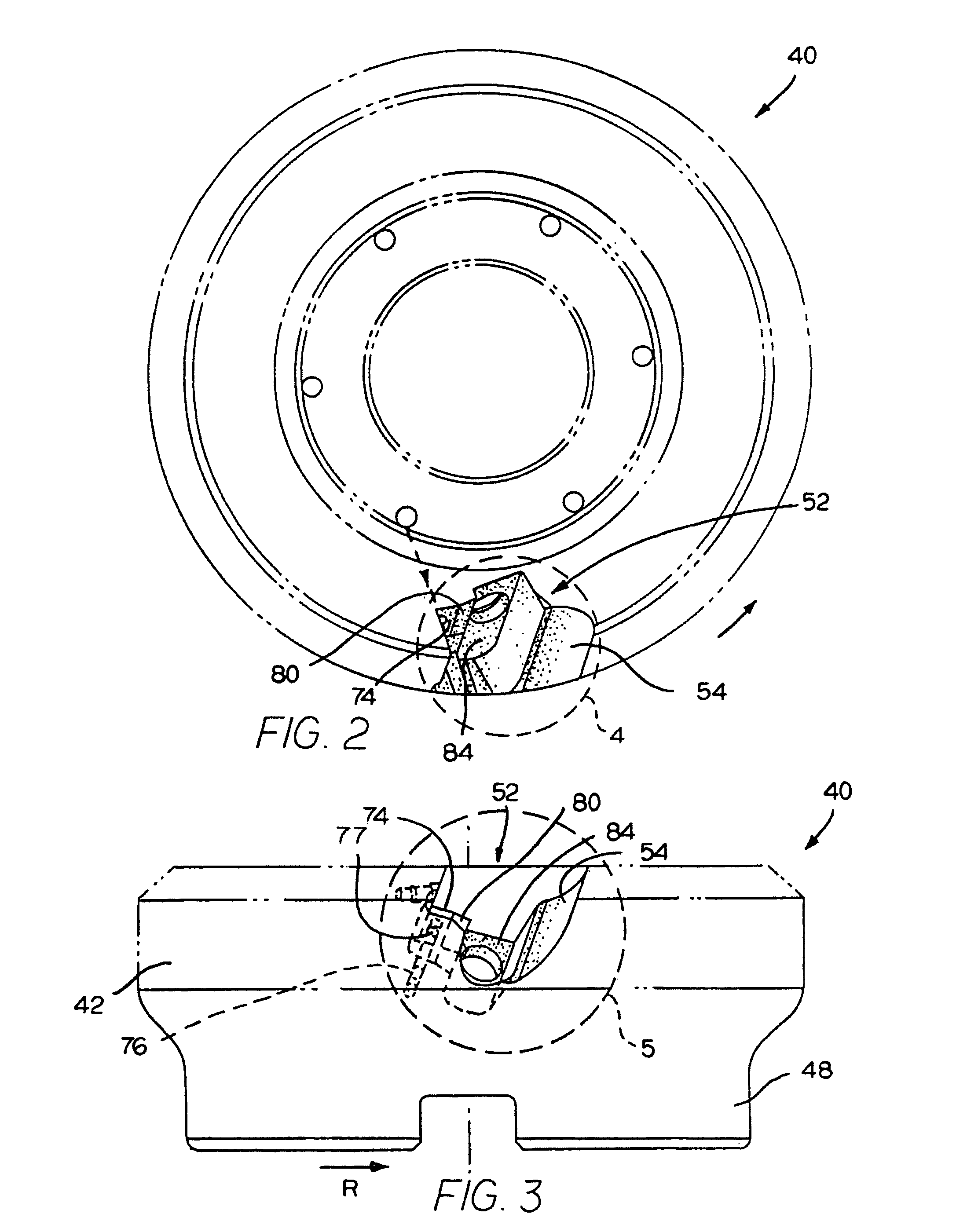

Milling cutter and milling insert with coolant delivery

A cutting insert for use in chipforming and material removal from a workpiece wherein coolant is supplied to the cutting insert from a coolant source. The cutting insert includes at least one discrete cutting location and at least one distinct internal channel that corresponds to the cutting location. The internal channel has an inlet to receive coolant and an outlet to exit coolant. The outlet is proximate to the cutting location, and the inlet is radial inward of the outlet.

Owner:KENNAMETAL INC

Indexable end-milling insert

ActiveUS20080304924A1Good chip formationWorn evenly and slowlyTransportation and packagingMilling cuttersEngineeringKnife blades

An indexable end-milling insert including an underside, an upperside and a plurality of cutting edges that are formed between the upperside and a number of clearance sides and that include a chip-removing main edge as well as a surface-wiping wiper edge. The cutting insert has a square basic shape and includes four main edges and four wiper edges that are countersunk to a lower level than the main edges. The wiper edge is included in a lip projecting in relation to a secondary clearance surface and has a tertiary clearance surface, which laterally transforms into a primary clearance surface. The primary clearance surface has a width that decreases from the two opposite ends thereof toward a section having a smallest width therebetween.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

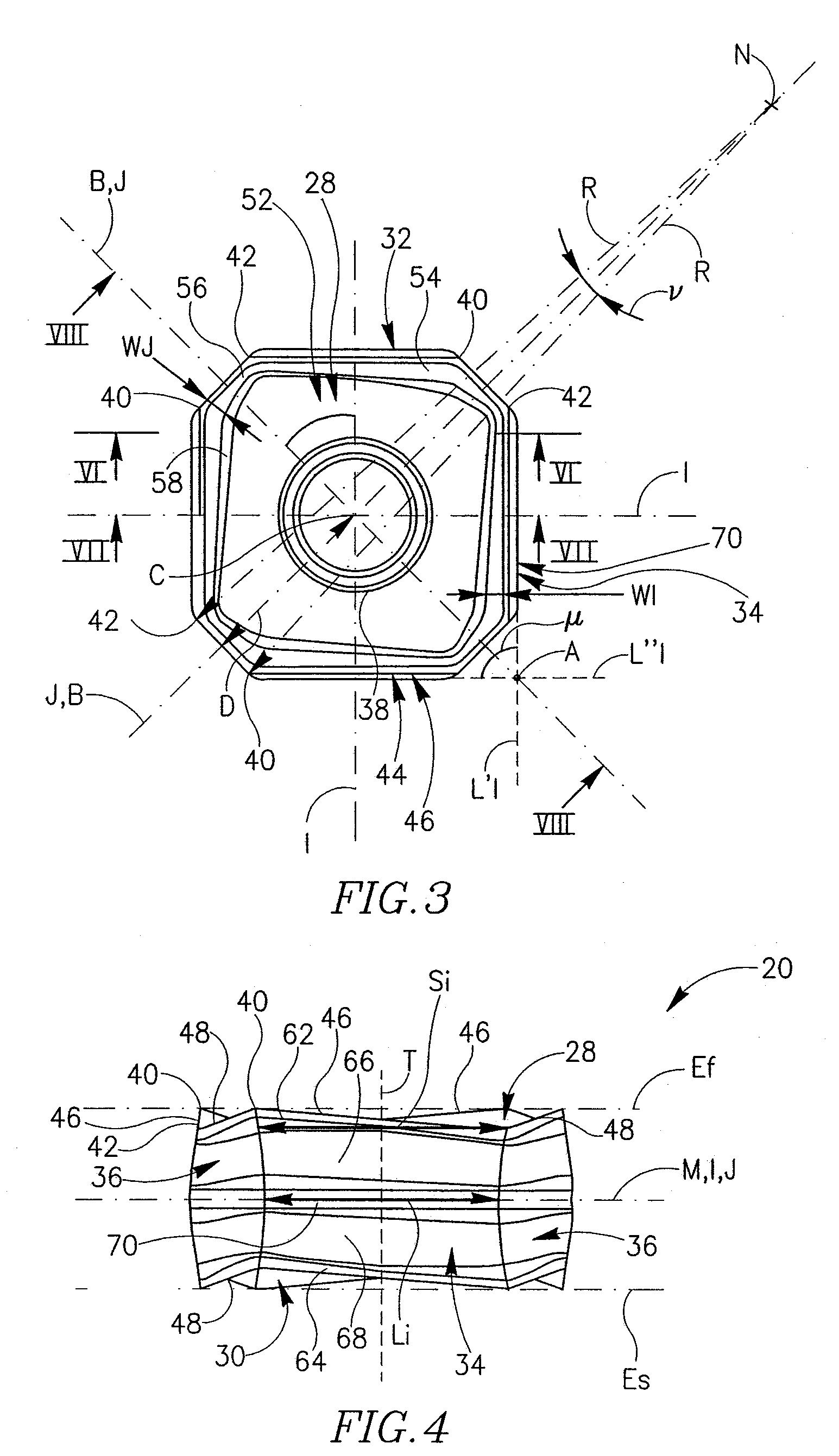

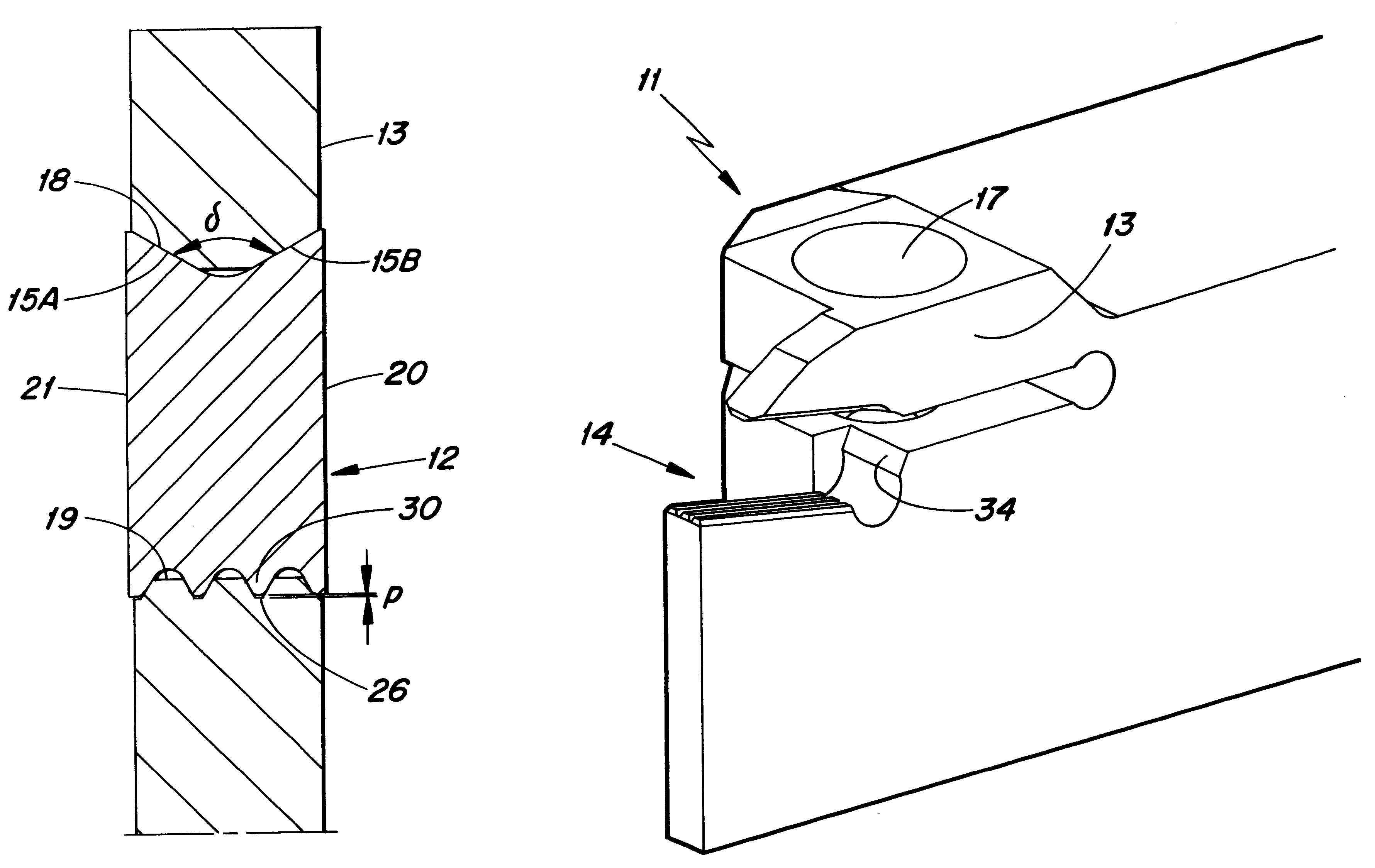

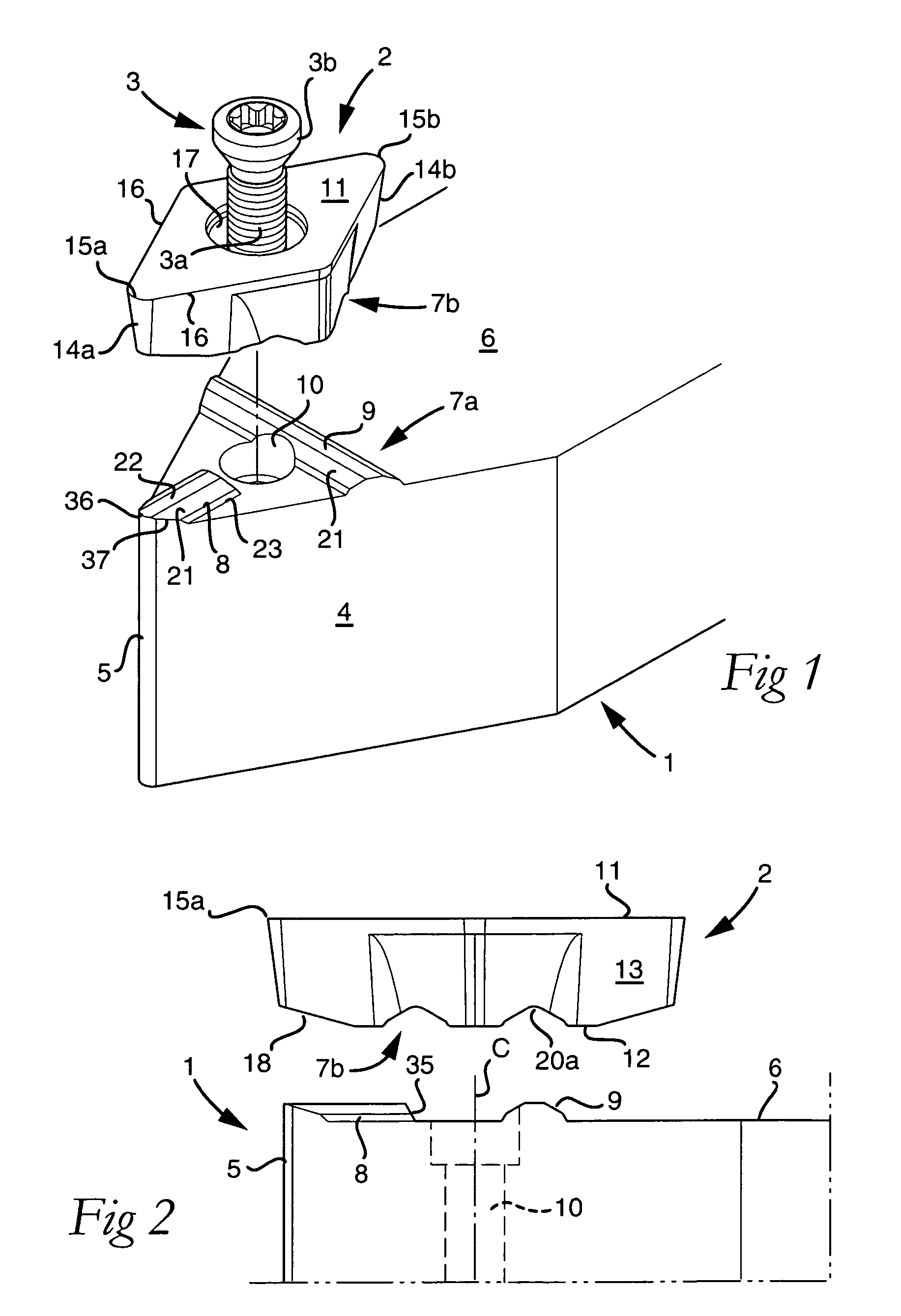

Cutting insert and a tool for chip removing machining, as well as an attachment for such tools

ActiveUS7387474B2Reduced dimensional accuracy requirementsMilling cuttersCutting insertsEngineeringKnife blades

A cutting insert having a front cutting edge and a connecting surface including male- and / or female-like engagement portions, in order to rigidly secure the cutting insert, a geometrically predetermined reference locus serving as a force-application spot for the clamping of the cutting insert. Simultaneously active engagement portions are of only two types—a first, elongate engagement portion, which is located between the front cutting edge and the reference locus, and a second, elongate engagement means, which is oriented at an angle to the first engagement portion and situated at a greater distance from the front cutting edge than the reference locus. In such a way, it is guaranteed that a tightening force always is applied to the cutting insert in a substantially triangular area, which is defined by the free ends of the engagement portions. Furthermore, a tool for chip removing machining, as well as an attachment, e.g., a shim plate, for such tools is provided.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

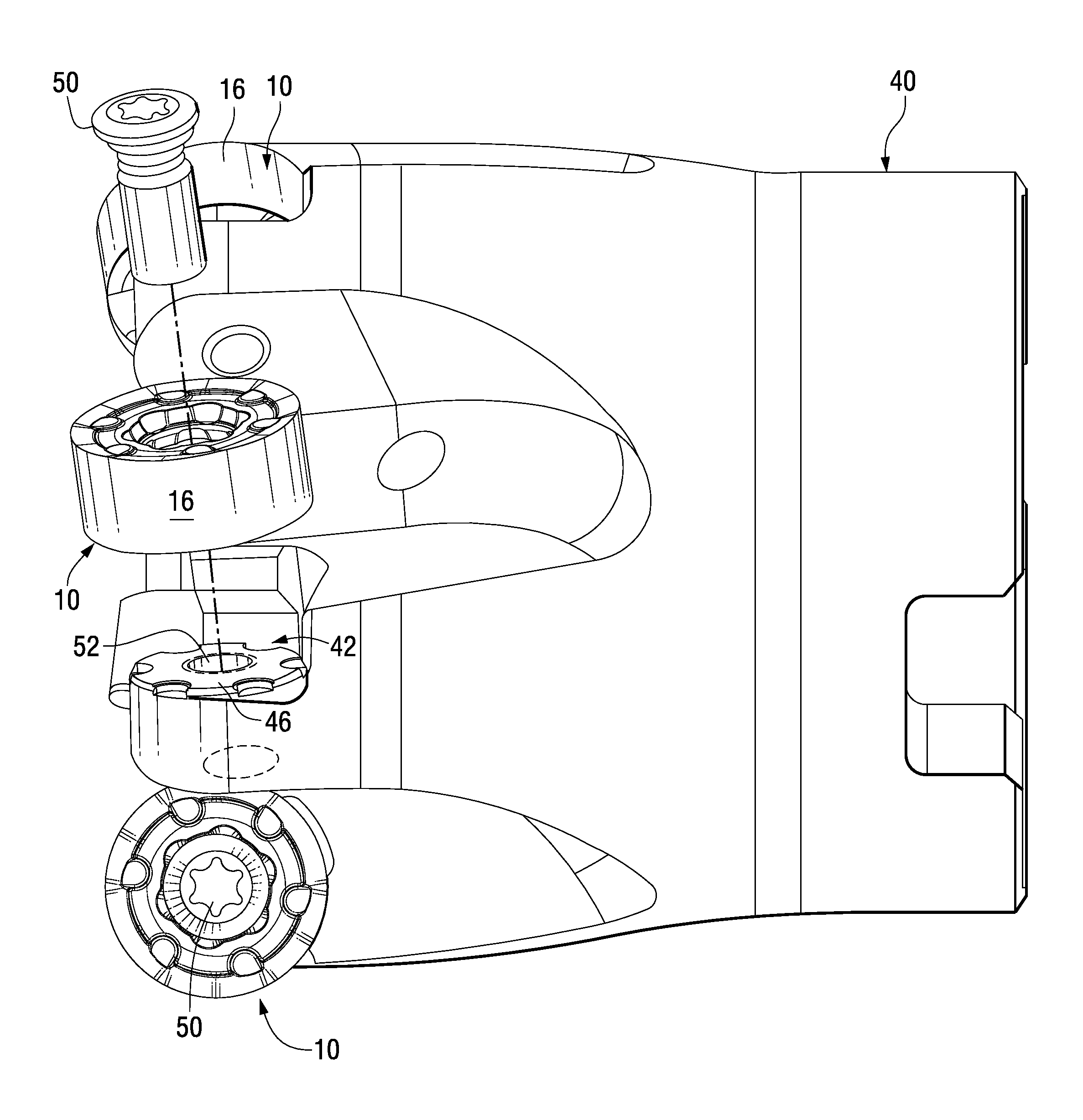

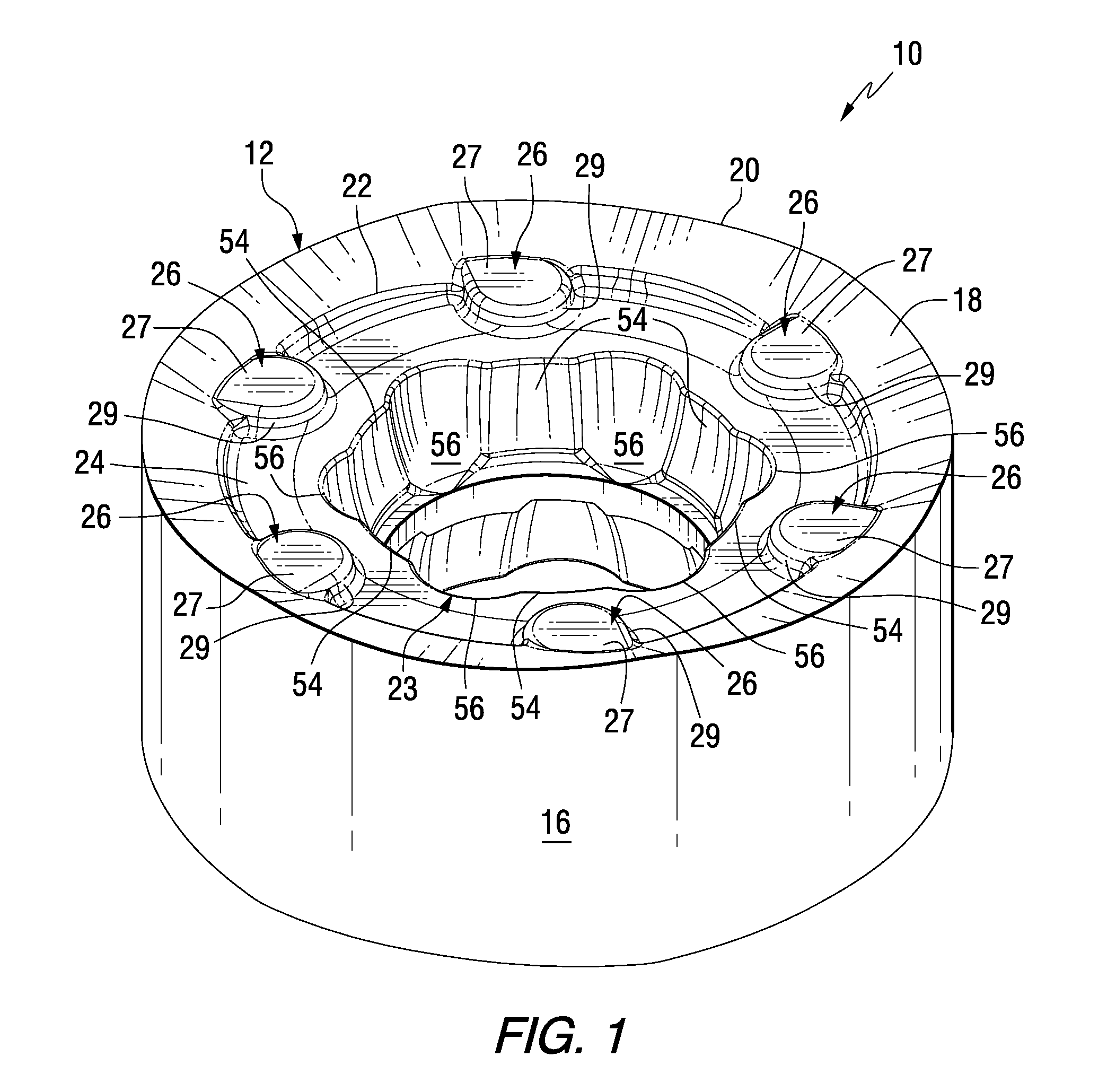

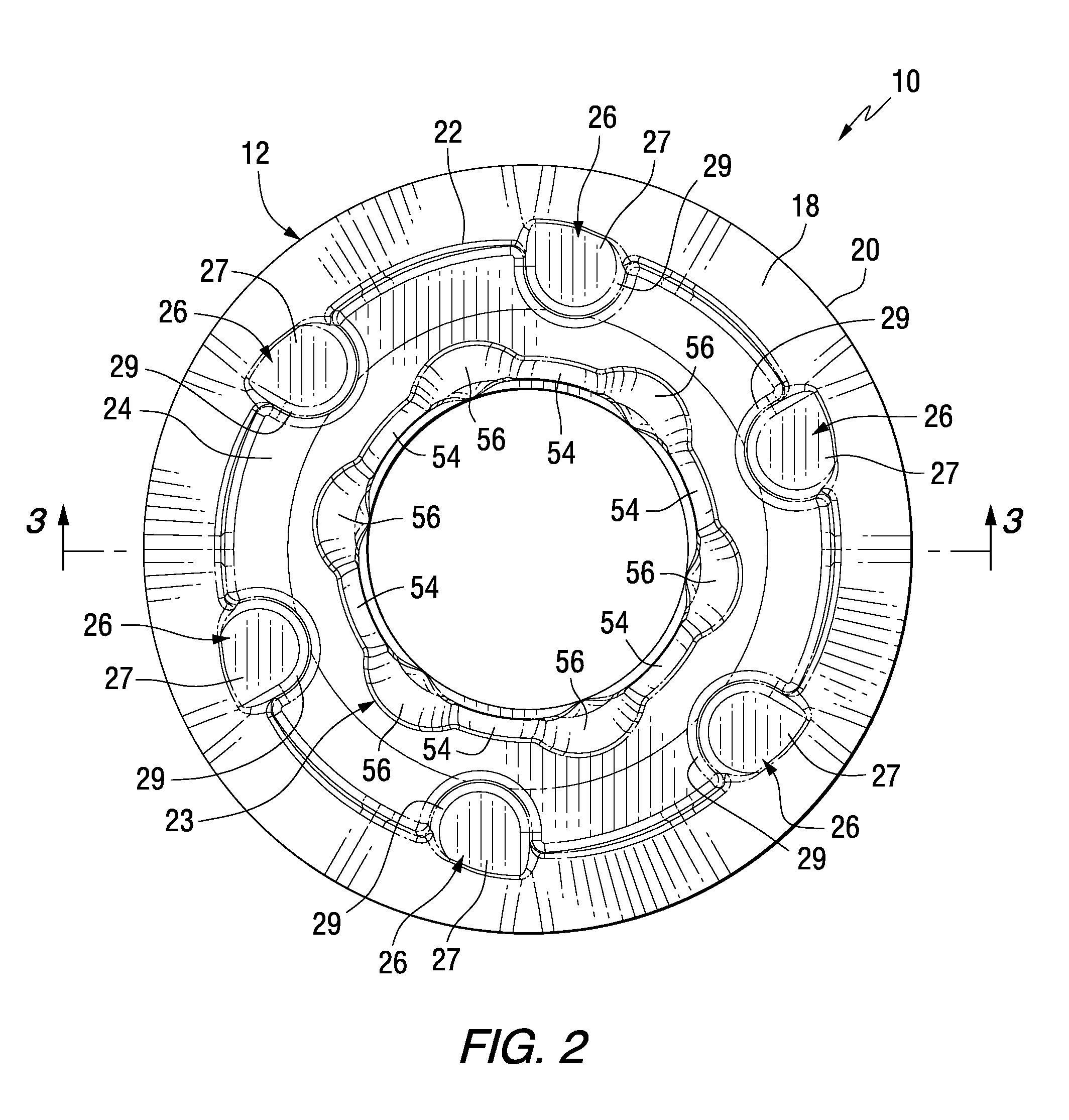

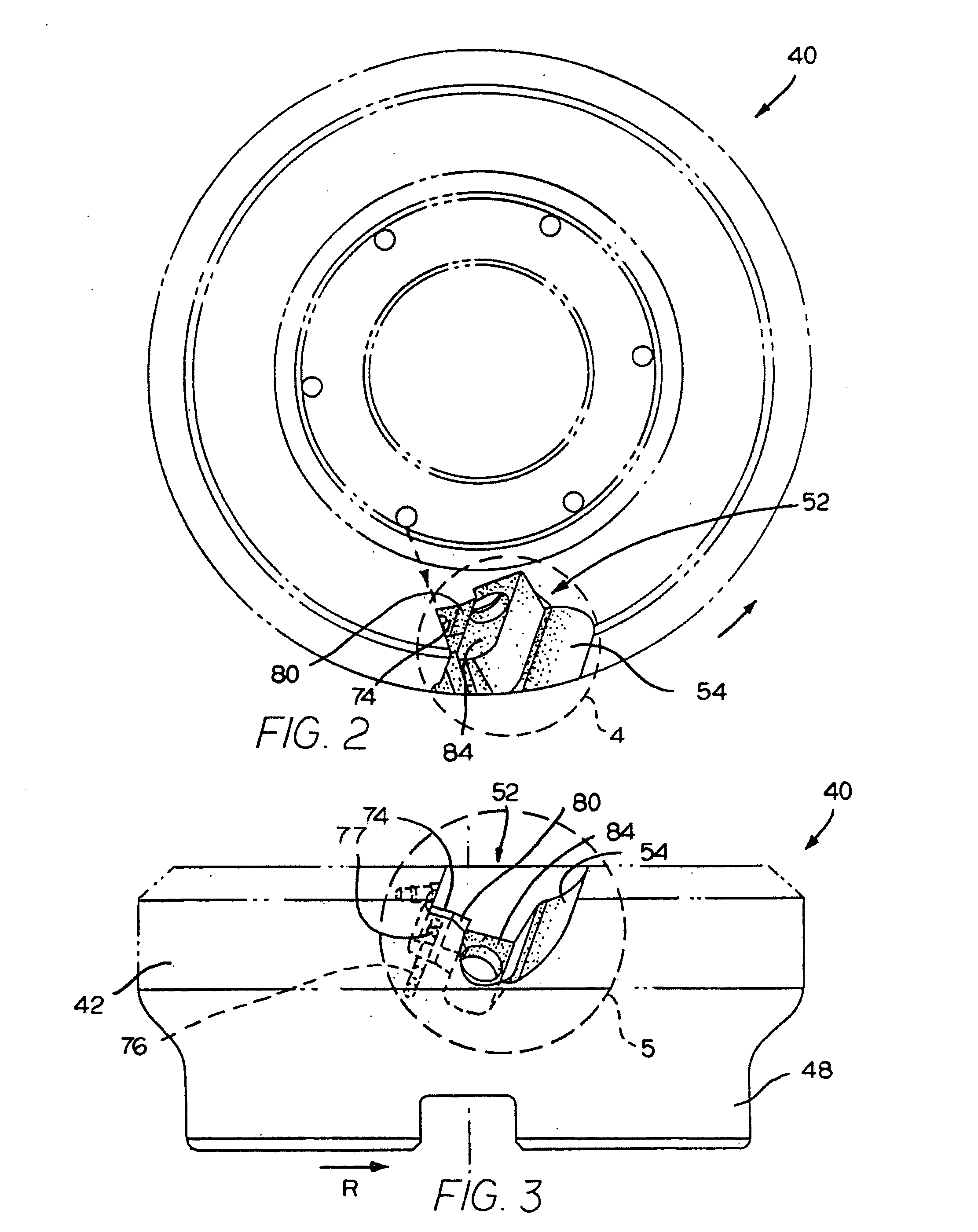

Round Cutting Insert With Anti-Rotation Feature

A round cutting insert with an anti-rotation feature. The round cutting insert includes a plurality of projections formed on a first surface and another plurality of projections formed on an opposing surface. The round cutting insert is reversible and indexable. The round cutting insert is removably received in an insert receiving pocket in a tool body wherein the insert receiving pocket includes a plurality of dimples for receiving one of the plurality of first projections or the plurality of second projections. This arrangement prevents rotation of the round cutting insert while mounted in the insert receiving pocket.

Owner:KENNAMETAL INC

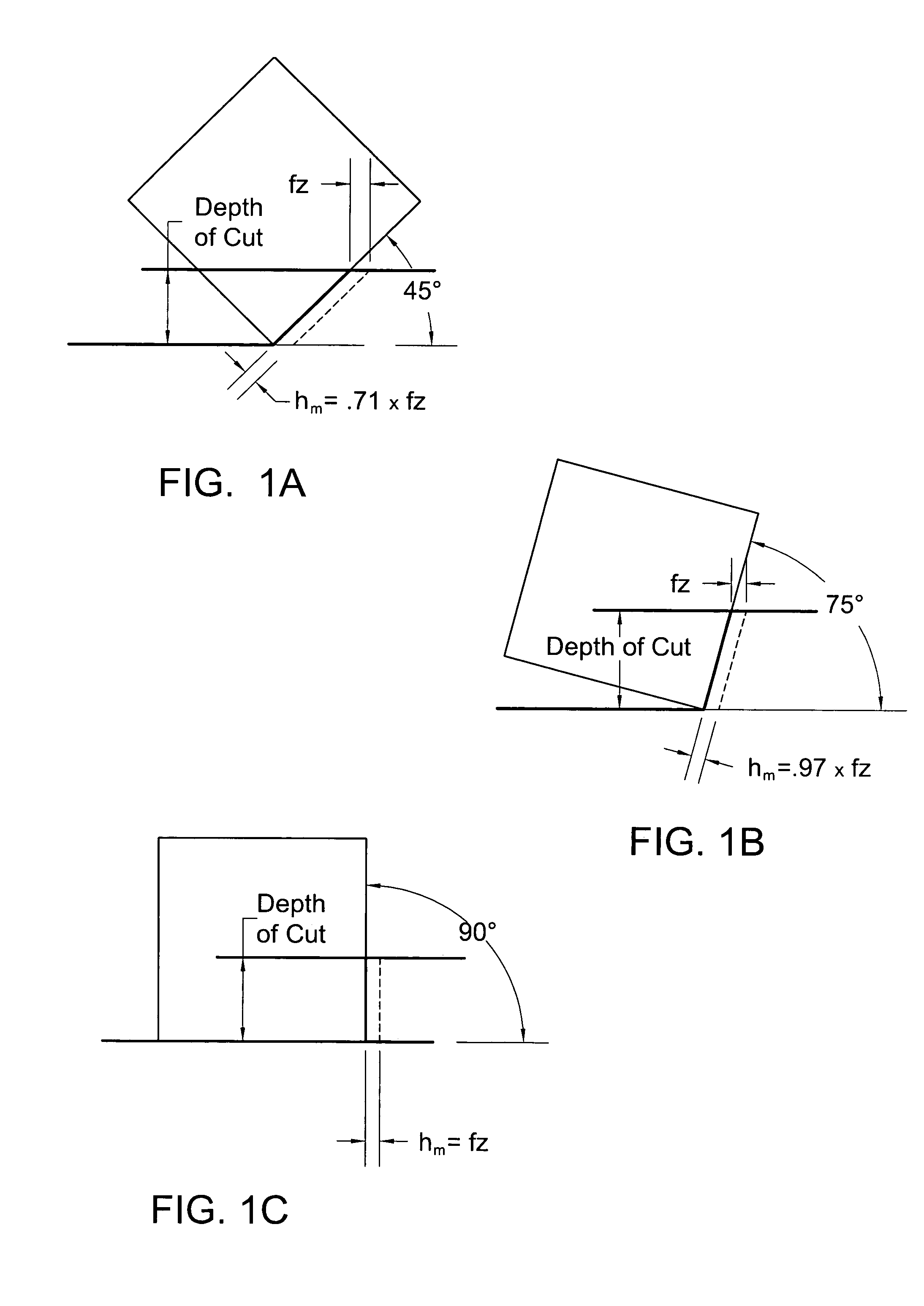

Cutting insert for high feed face milling

InactiveUS7220083B2Increase feed rateReduce forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

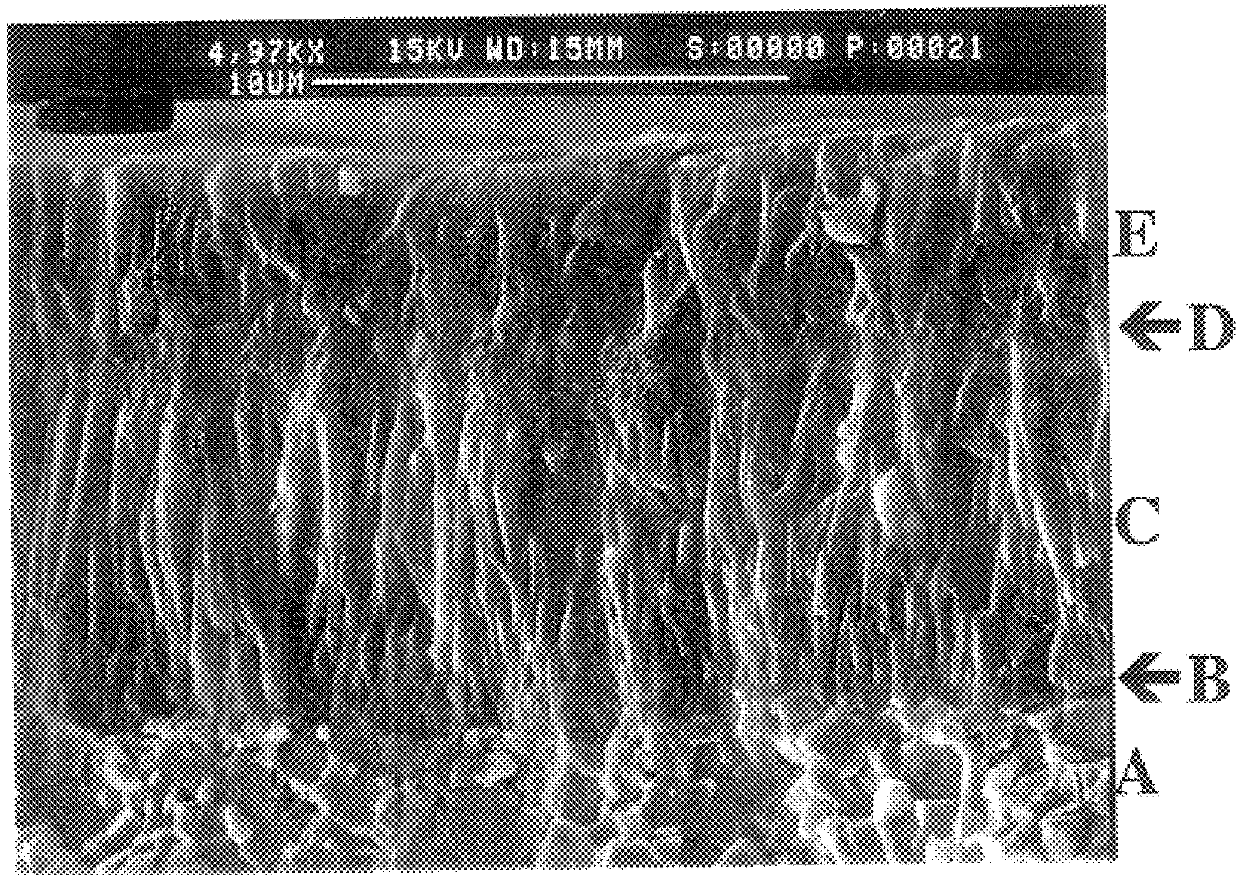

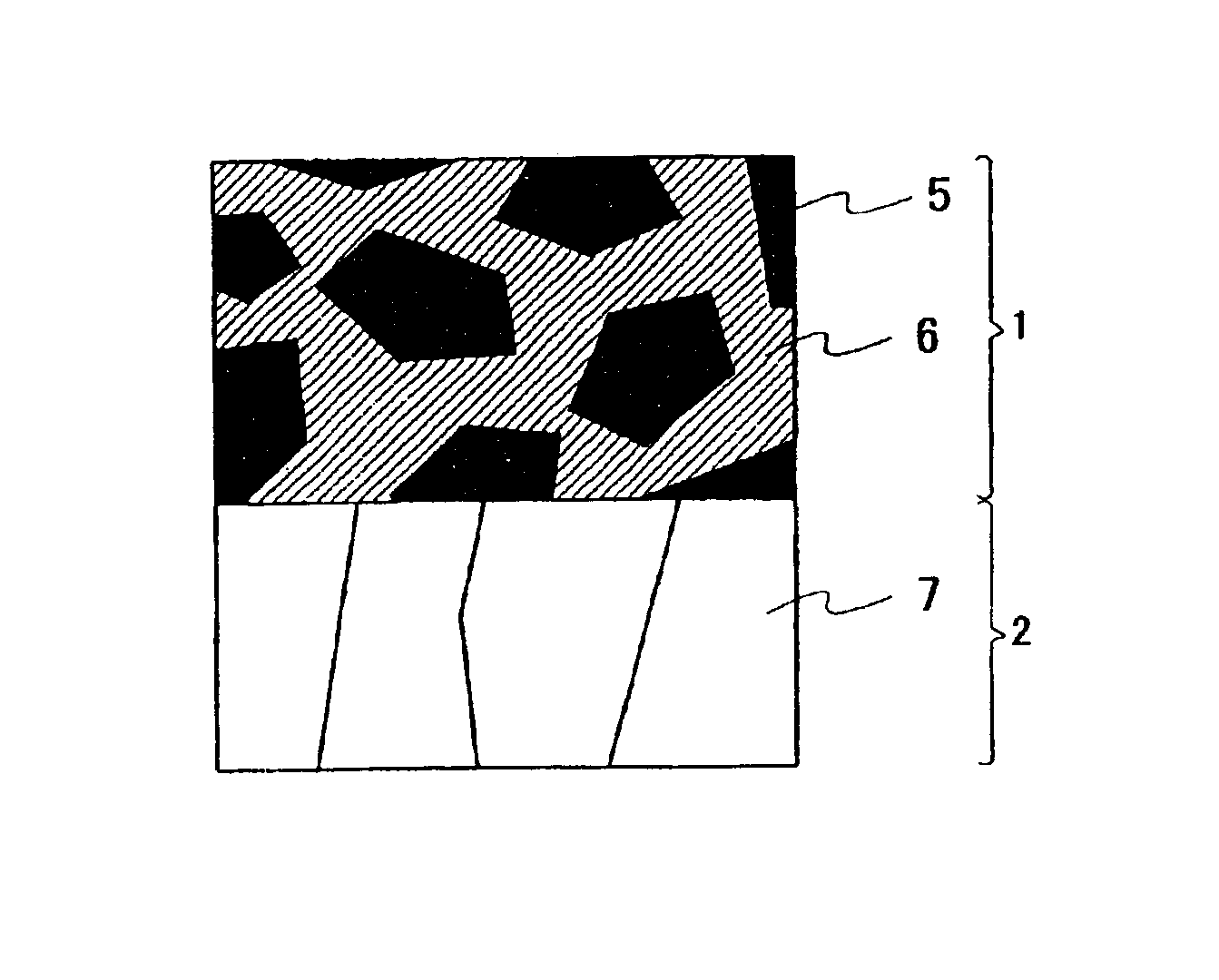

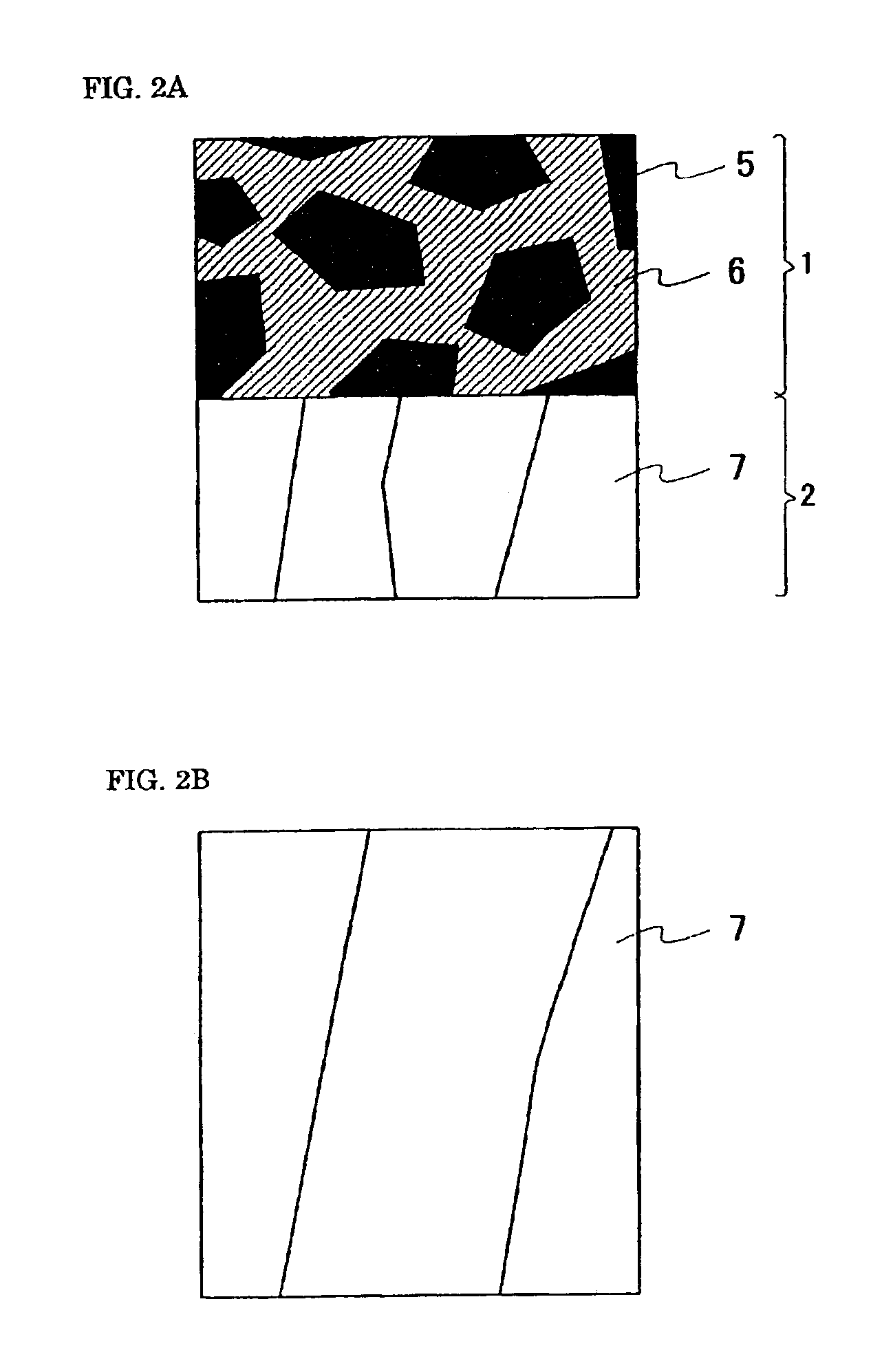

Coated cutting insert

The present invention discloses a coated cutting insert particularly useful for dry milling of grey cast iron. The insert is characterized by a WC-Co cemented carbide substrate and a coating including an innermost layer of TiCxNyOz with columnar grains and a top coating of a fine grained alpha-Al2O3 layer.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Coated tool

ActiveUS7060345B2High hardnessImprove wear resistancePigmenting treatmentMilling cuttersCarbideNitrogen oxide

Coating-film furnished coated tools that are lubricative while maintaining resistance to wear are realized by coated tools in which a plurality of coating films is furnished on a base part. Furnished as the coating are one or more layers of, respectively: a first film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of TiSi; and a second film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of one metal M selected from Ti, Cr, and TiCr. The first film and the second film are laminated in alternation.

Owner:SUMITOMO ELECTRIC IND LTD

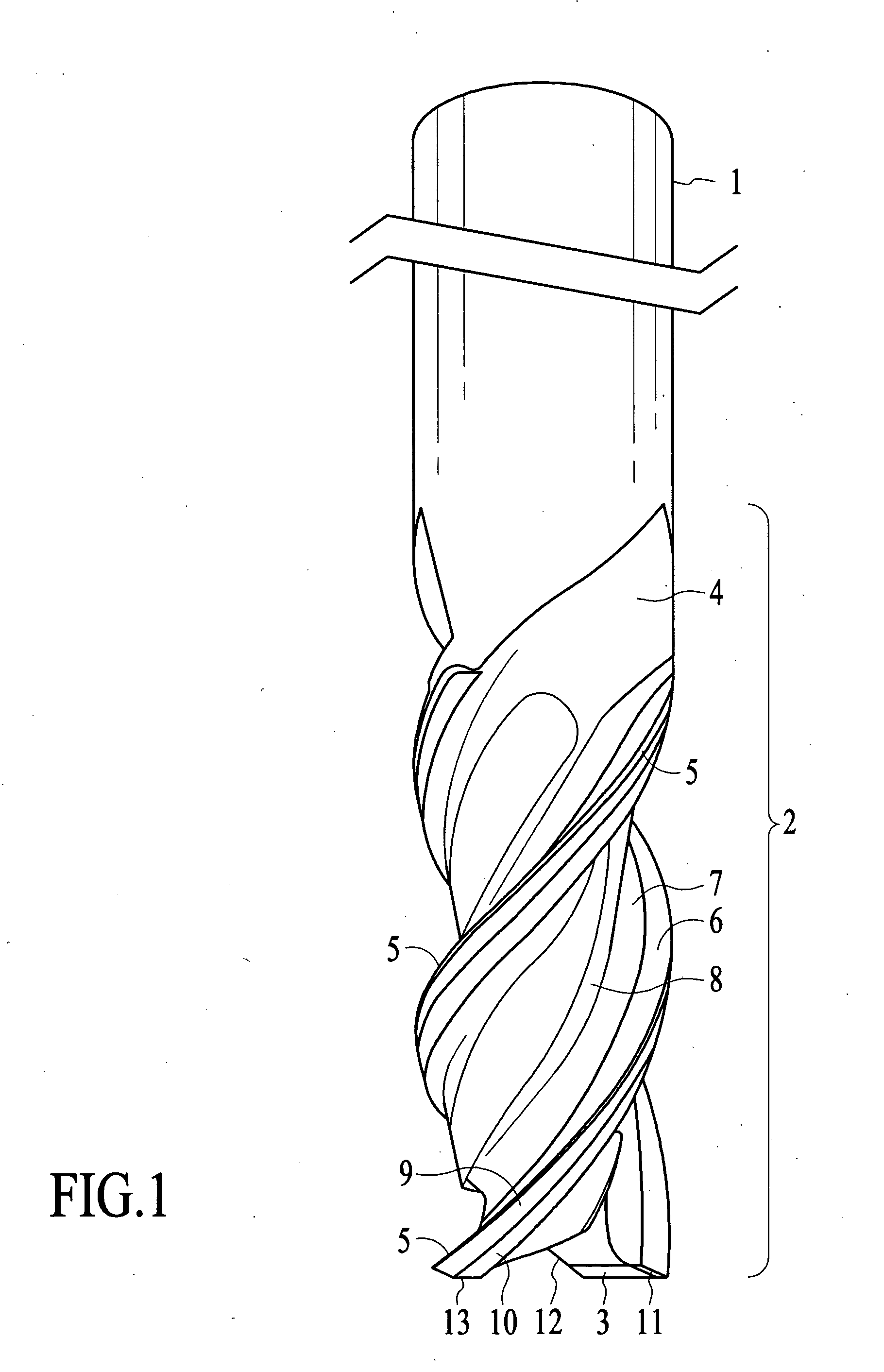

End mill

InactiveUS20060067797A1Aggressive and deep cutLess forceMilling cuttersWorkpiecesUltra fineEngineering

An end mill with a peripheral margin which increases in width from the terminal end of the tool to the shank portion of the tool. The end mill also has a tooth face made up of three tooth-face walls The depth of the tool face gradually decreases from the terminal end to the shank portion of the tool. The end mill also has an end cutting face which includes a flat, narrow land at the outmost region of the end cutting end. The end mill has chip breakers with rounded peripheral corners. The end mill can be made up of ultra-fine micro grain tungsten carbide with a cobalt content which varies throughout the length of the tool.

Owner:CALAMIA GUY ALLEN

Throwaway insert and throwaway-type rotary cutting tool

ActiveUS7040844B1Improve accuracyImprove chip separationMilling cuttersAdverse effect compensationProjection lineCurve line

A tool main cutting edge extends rearward in a rotating direction as it approaches a rear end at the outer periphery. The main cutting edge is a convexly curved line protruding toward the outside of a rake face viewed from the top and another convexly curved line extending toward the seat face, convexly curving from one end of the main cutting edge to the other, viewed from the side. When mounted, an inclination angle defined by the rake face gradually decreases from one end toward the other, and a projection line of a rotation about a rotation axis of the tool forms a convex arc smoothly coming, at a middle portion of the main cutting edge, into contact with a cylindrical surface about the axis and gradually retreats inward from the cylindrical surface as it approaches both ends of the main cutting edge.

Owner:MITSUBISHI MATERIALS CORP

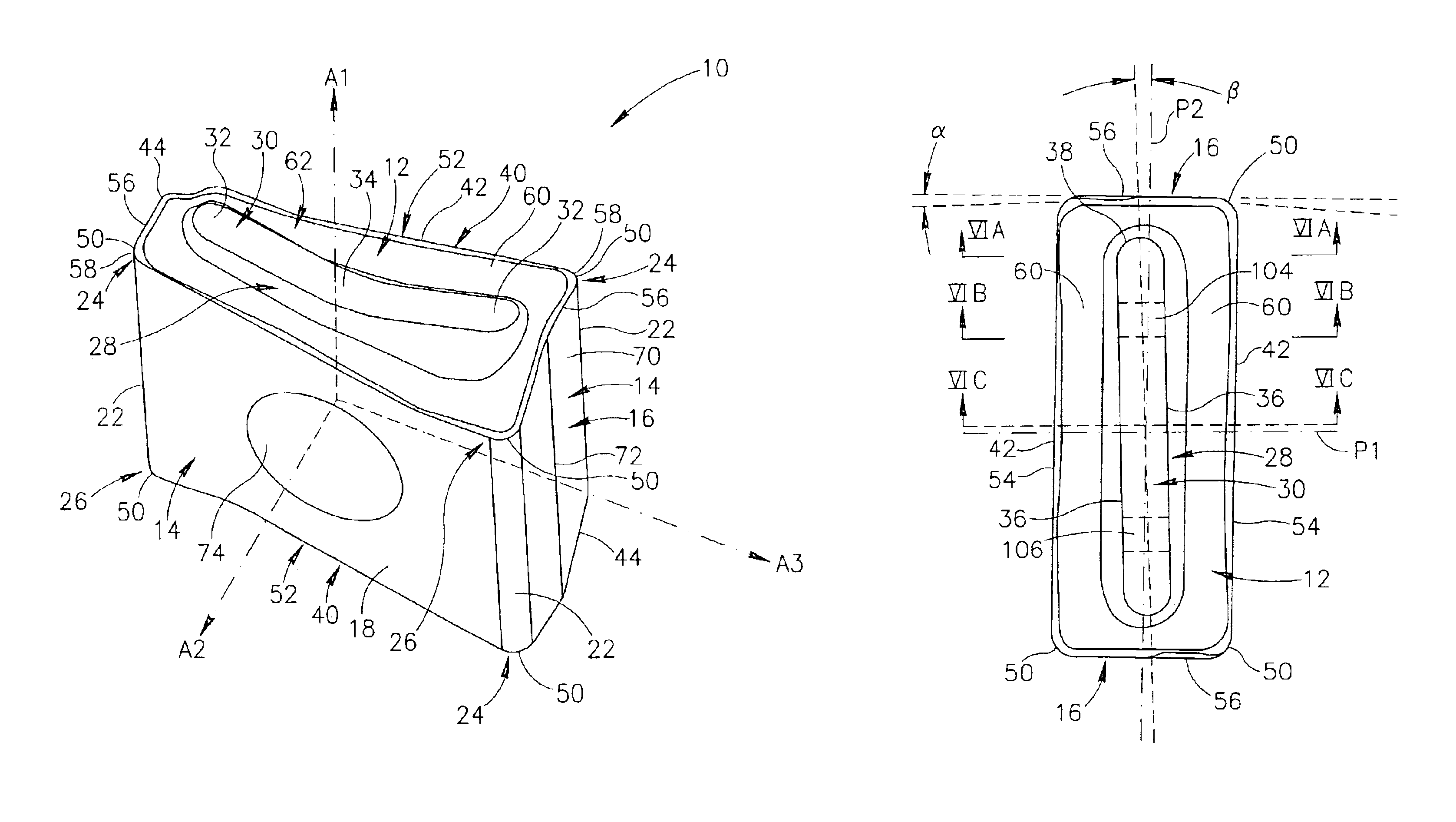

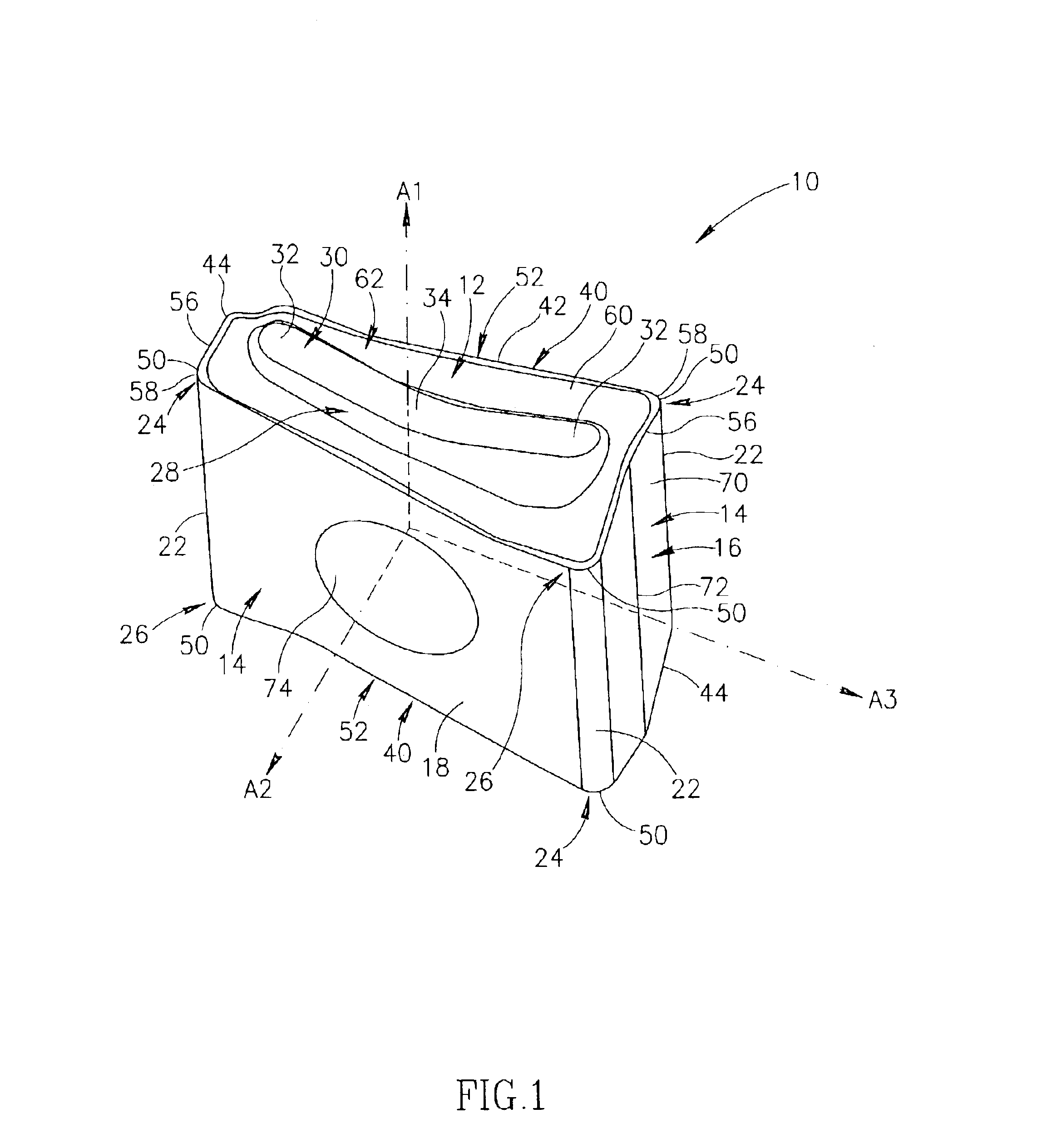

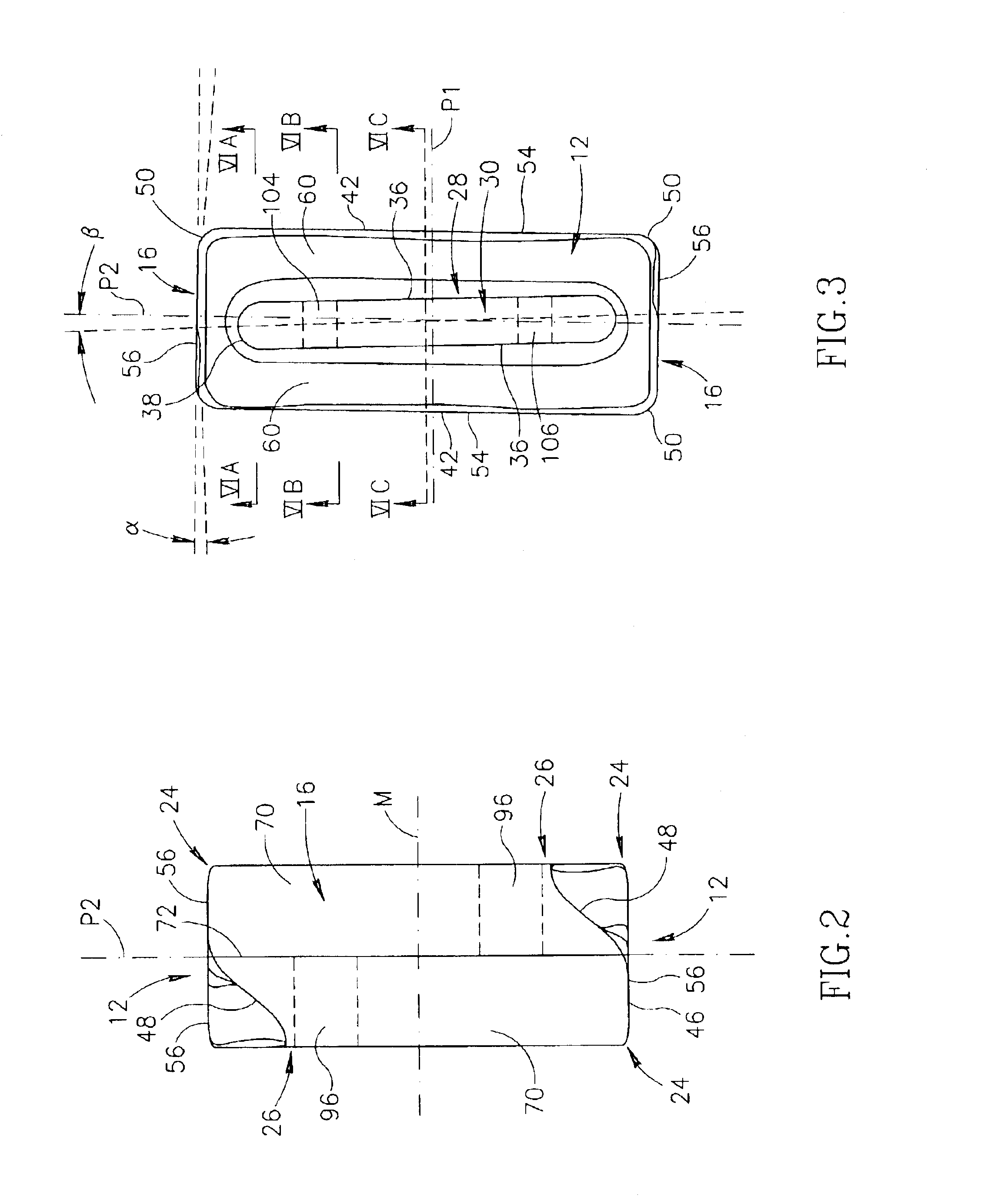

Tangential cutting insert and milling cutter

A tangential cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces and two identical opposing minor side surfaces extending between them. Each end surface has a peripheral edge containing cutting edges and four corners of which two are lowered and two are raised. Each end surface is provided with at least one projecting abutment member having a projecting abutment surface, wherein in a side view of either major side surface, the at least one projecting abutment surface is concave.

Owner:ISCAR LTD

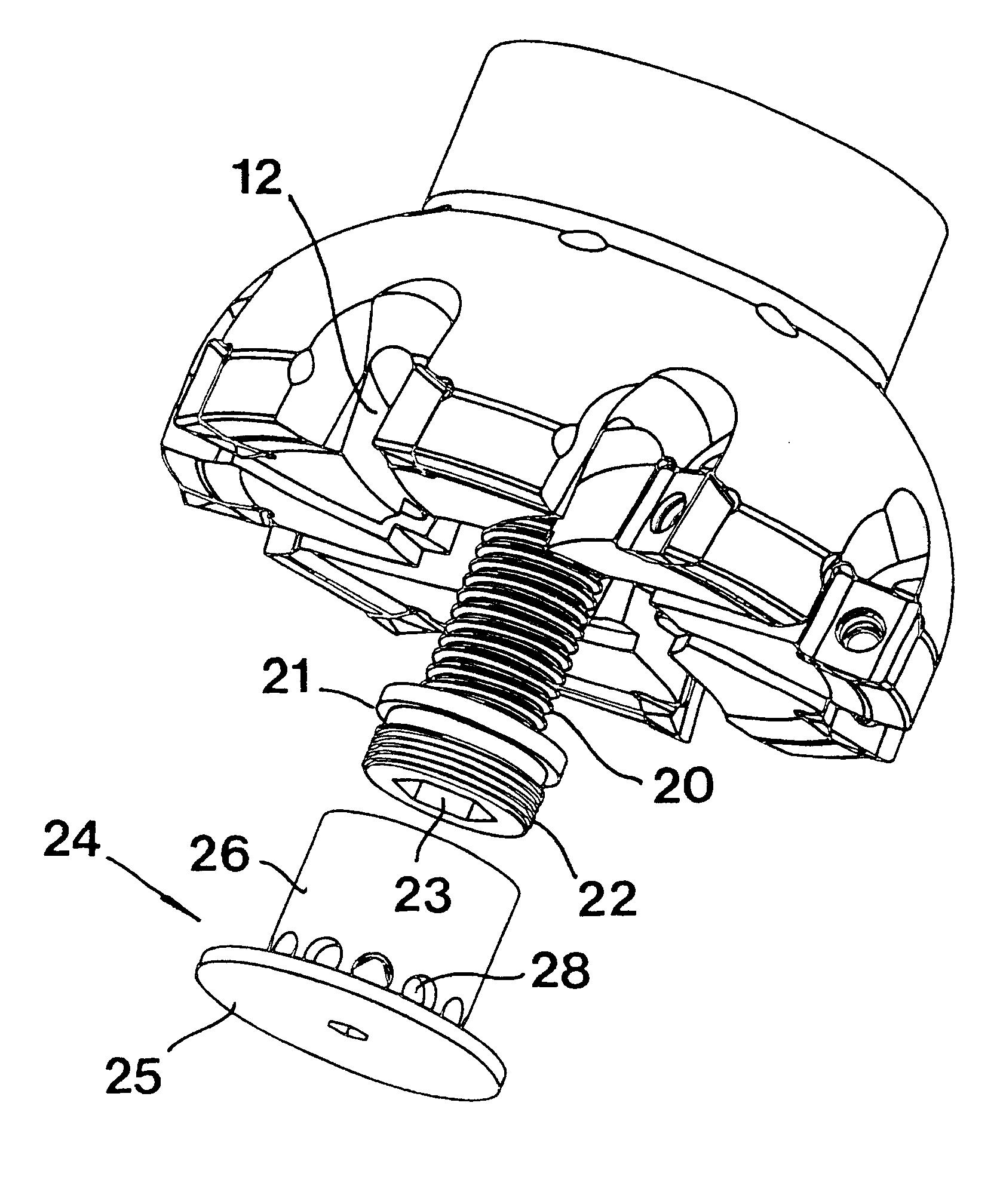

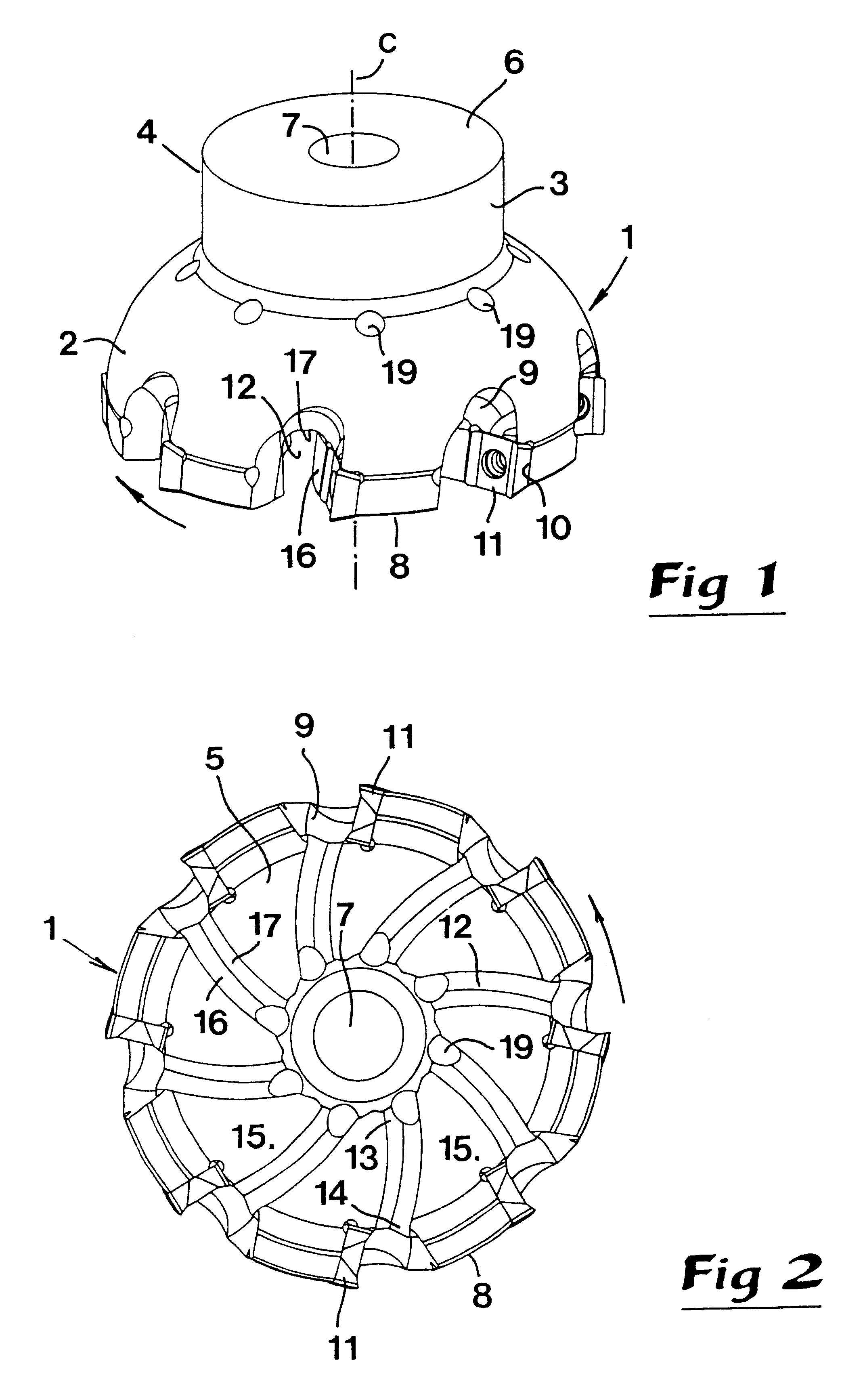

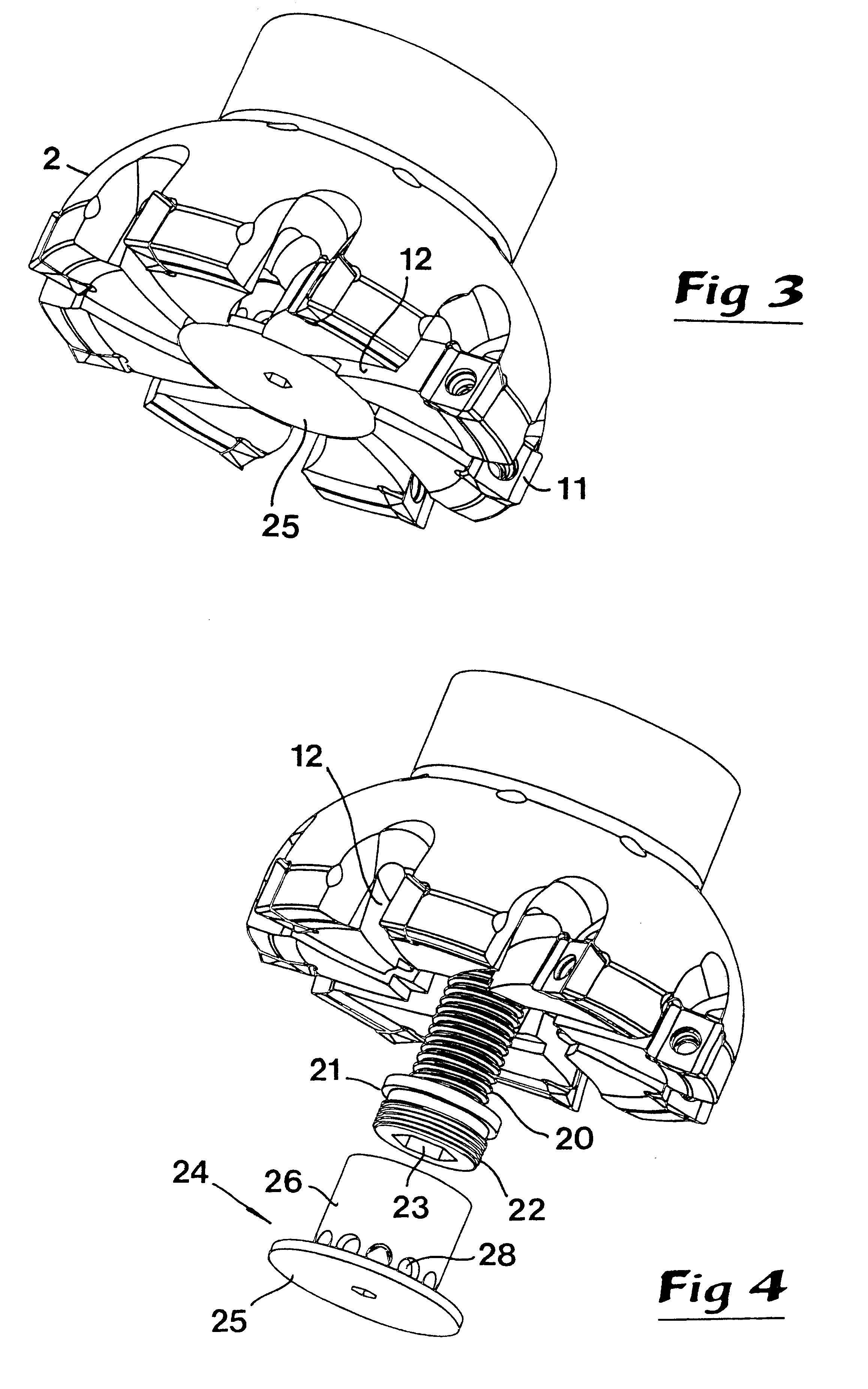

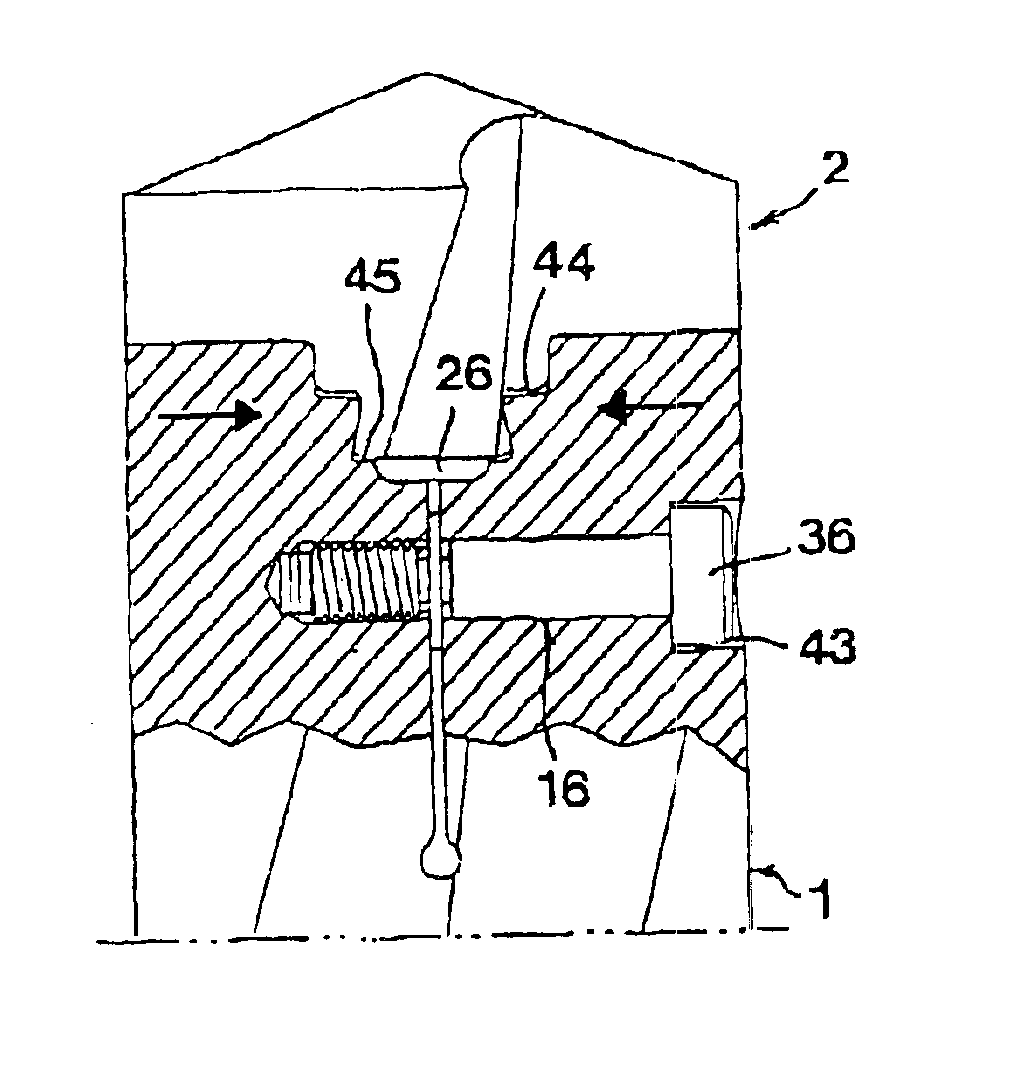

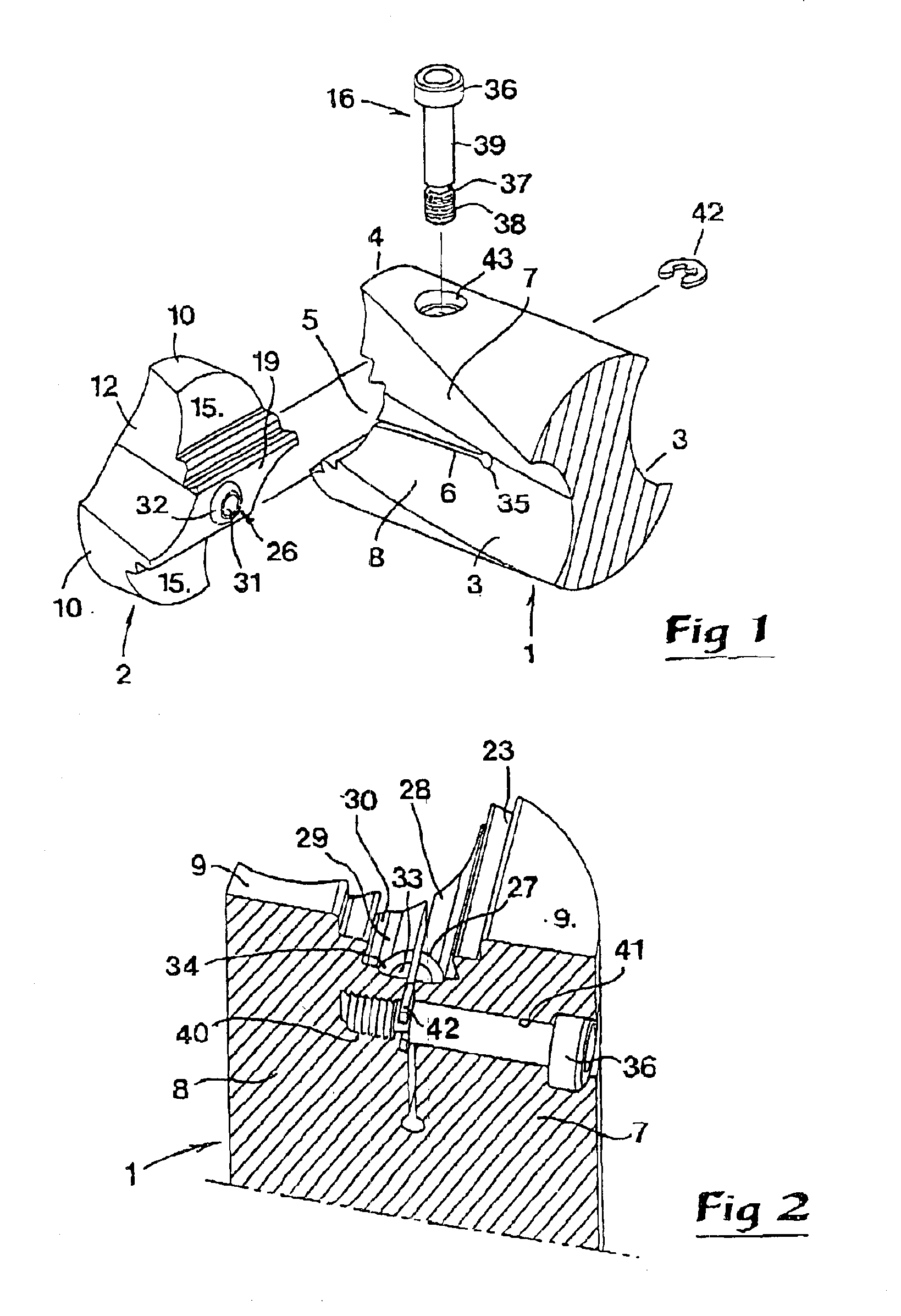

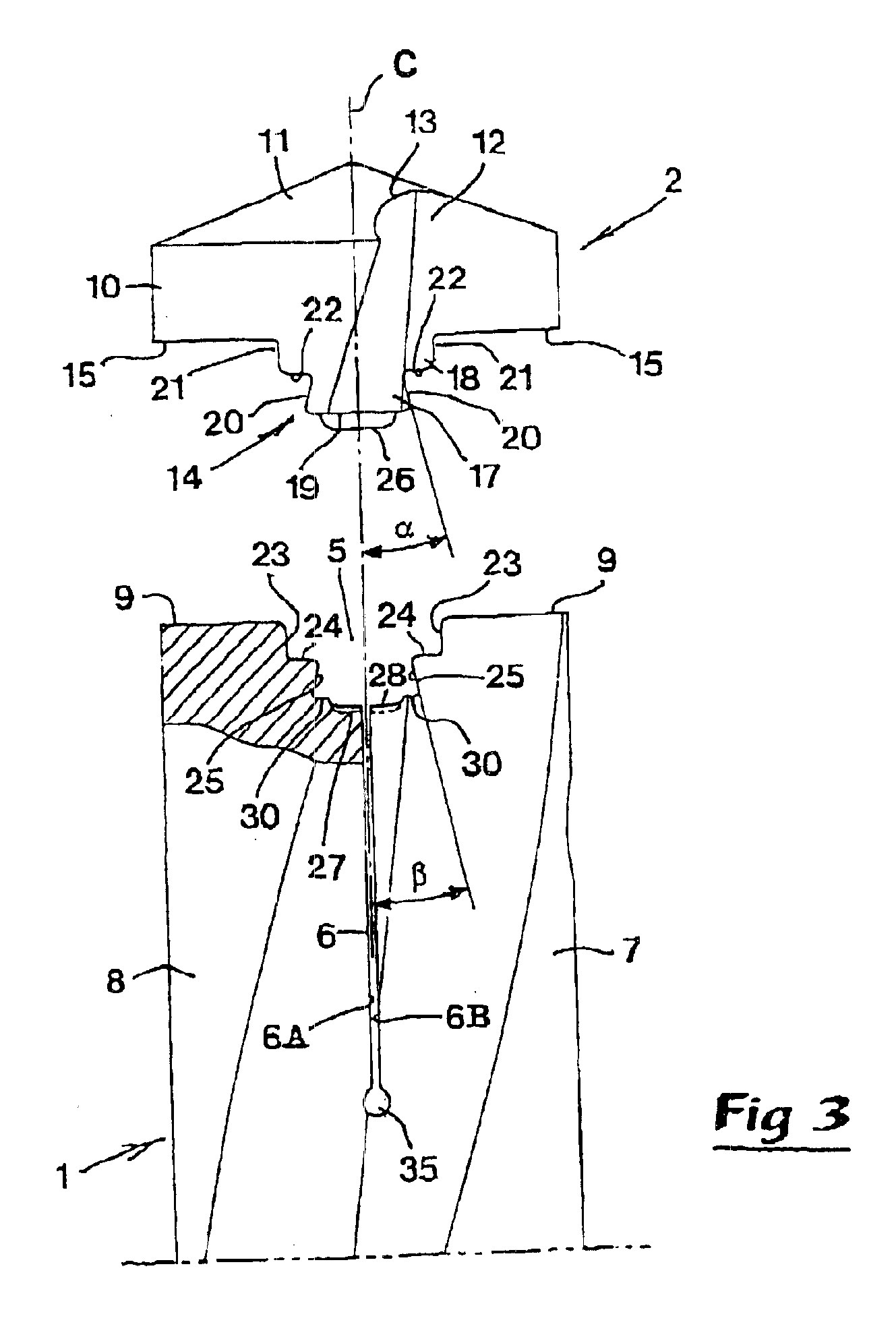

Rotatable tool for chip removing machining and appurtenant cutting part therefor

A rotatable tool for chip removing machining includes two parts, viz. a holder part, rotatable around a geometrical center axis, and a replaceable cutting part, which is rigidly connectable to a front end of the holder part via a male / female coupling. The coupling includes a tapering seat in the holder part and a tapering male member, protruding rearwardly from the cutting part. In the seat, there is a slot, which separates two elastically deflectable projections, that may be inwardly deflected towards each other during clamping of the male member in the seat. The male member is elongated in a radial direction, and the seat is in the form of a radial groove into and out of which the sheath body is transversely movable. The male member includes a dove-tail shaped portion received in a dove-tail shaper portion of the groove. A centering button on the male member enters a depression in the holder part to axially center the cutting part.

Owner:PROCTER & GAMBLE CO +1

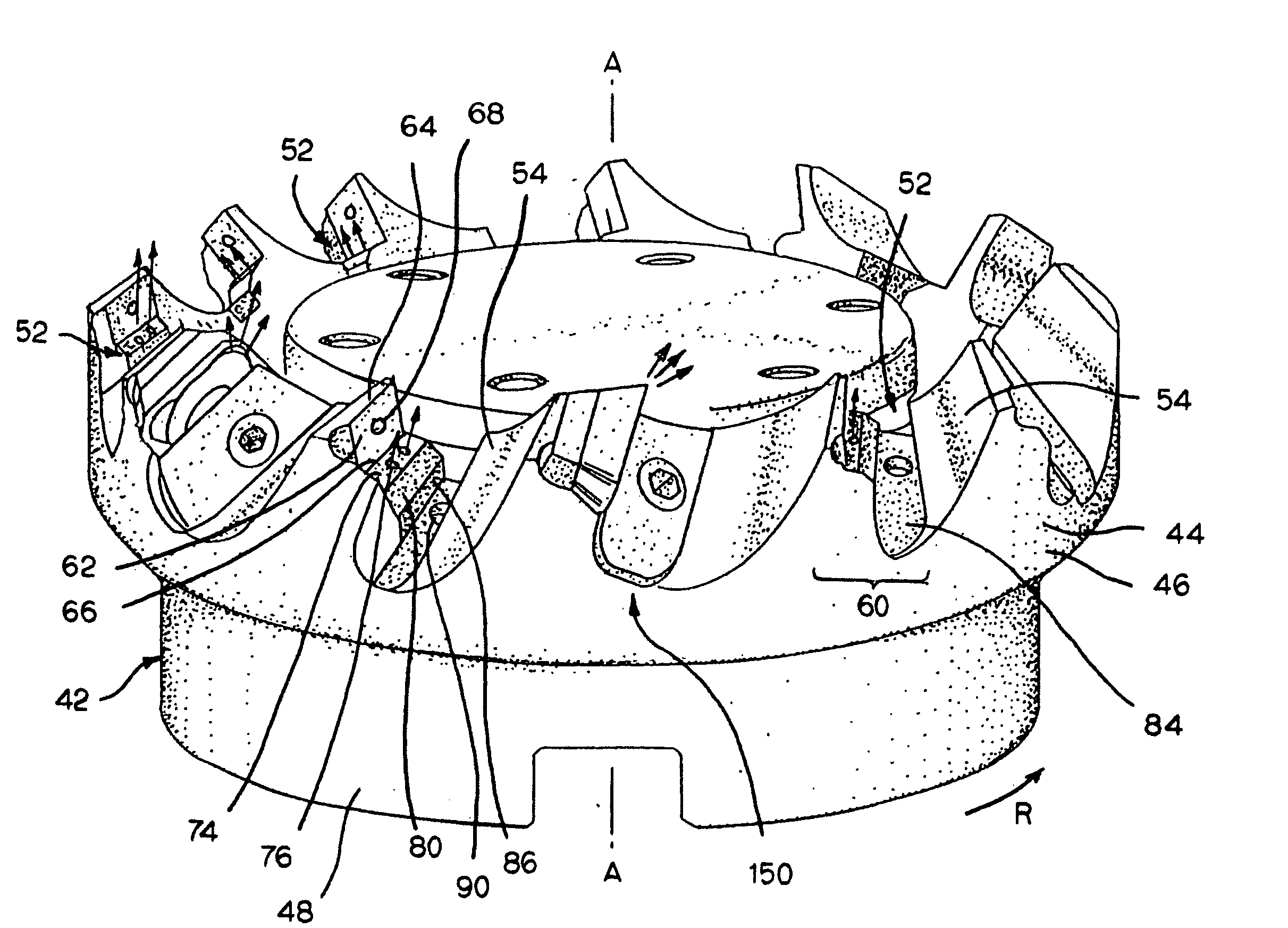

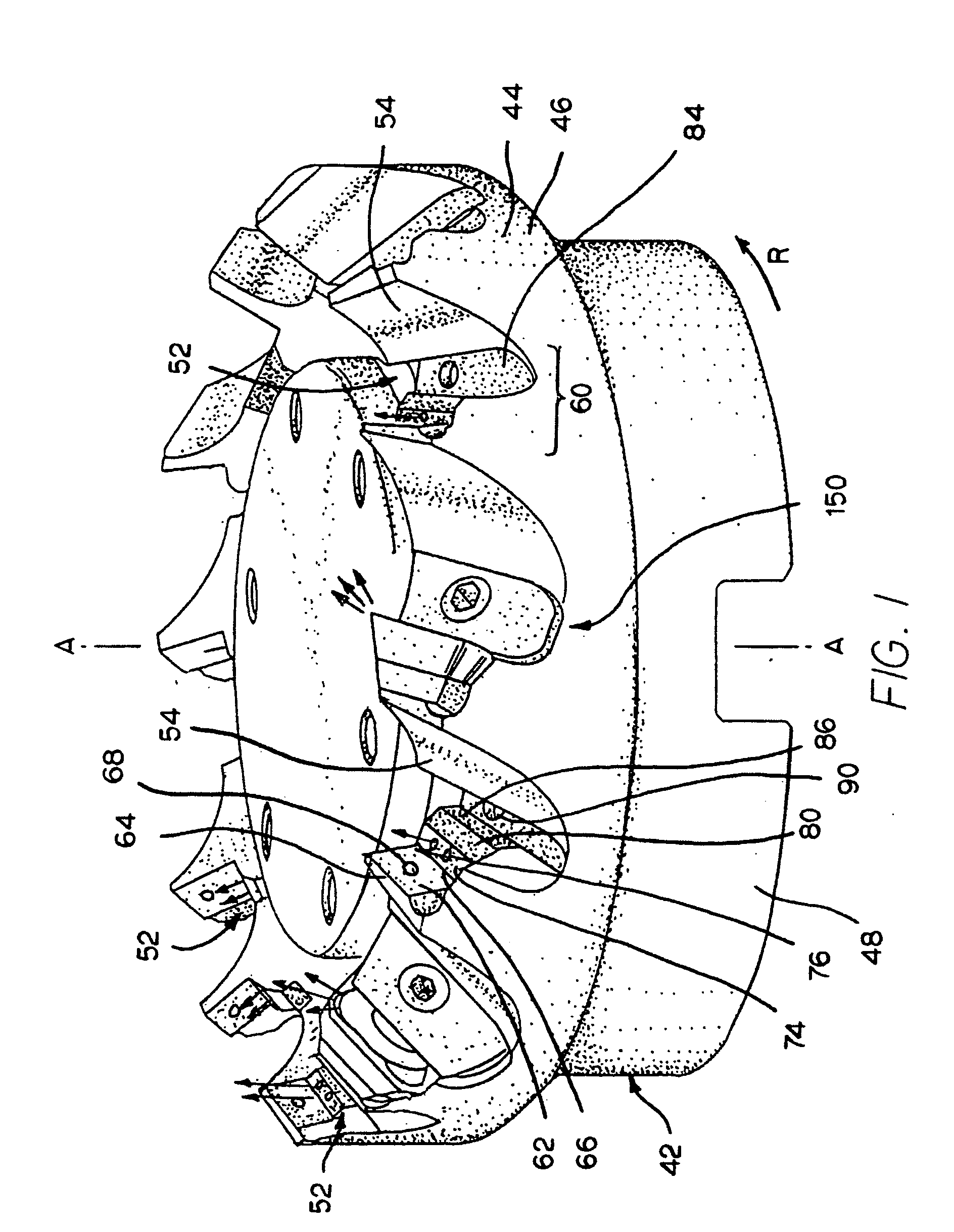

Milling cutter and milling insert with coolant delivery

A cutting insert assembly for use in chipforming and material removal wherein the cutting insert assembly is received in a pocket of a cutter body wherein coolant can flow out of a pocket opening contained in the pocket. The cutting insert assembly includes a cutting insert body that presents at least two discrete cutting locations. The cutting insert body contains a coolant entry passage aligned with the pocket opening for coolant to flow through the coolant entry passage. The cutting insert body has a rake surface that contains at least two of the discrete depressions wherein each one of the discrete depressions corresponds to one of the cutting locations. Each one of the discrete depressions extends toward its corresponding cutting location. The assembly includes a diverter that is positioned adjacent to the cutting insert body wherein the diverter has a receiving opening aligned with the coolant entry passage to receive coolant through the coolant entry passage. The diverter includes a coolant trough in communication with the receiving opening wherein the coolant trough is aligned toward a selected one of the cutting locations whereby the coolant trough and the discrete depression corresponding to the selected cutting location define a conduit for the flow of coolant toward the selected cutting location.

Owner:KENNAMETAL INC

Cutting insert having a rake surface and a plateau surface separated by a step

ActiveUS7306409B2Convenient heightImprove protectionTransportation and packagingMilling cuttersMilling cutterPlateau

A cutting insert intended exemplarily for use in a face-milling cutter, has an all-around extending rake surface which changes into a plateau surface by an uninterrupted step. The step reaches its greatest height in the corner regions of the cutting insert. The rake surface defines a positive rake angle. The step prevents the produced chips from running onto the plateau surface. As a result of such a measure, a smear-on of material onto the plateau surface from a chip is prevented.

Owner:WALTER AG

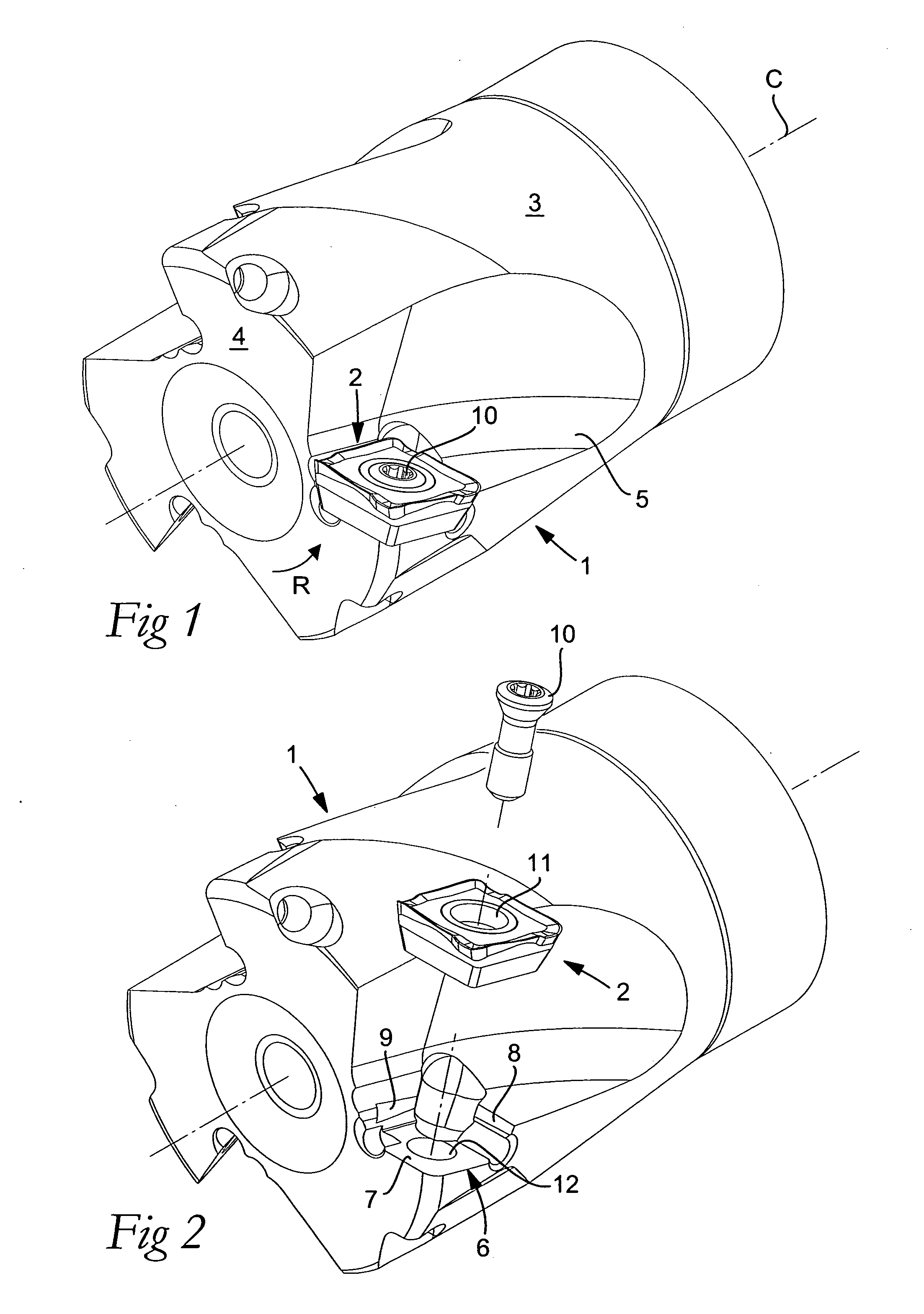

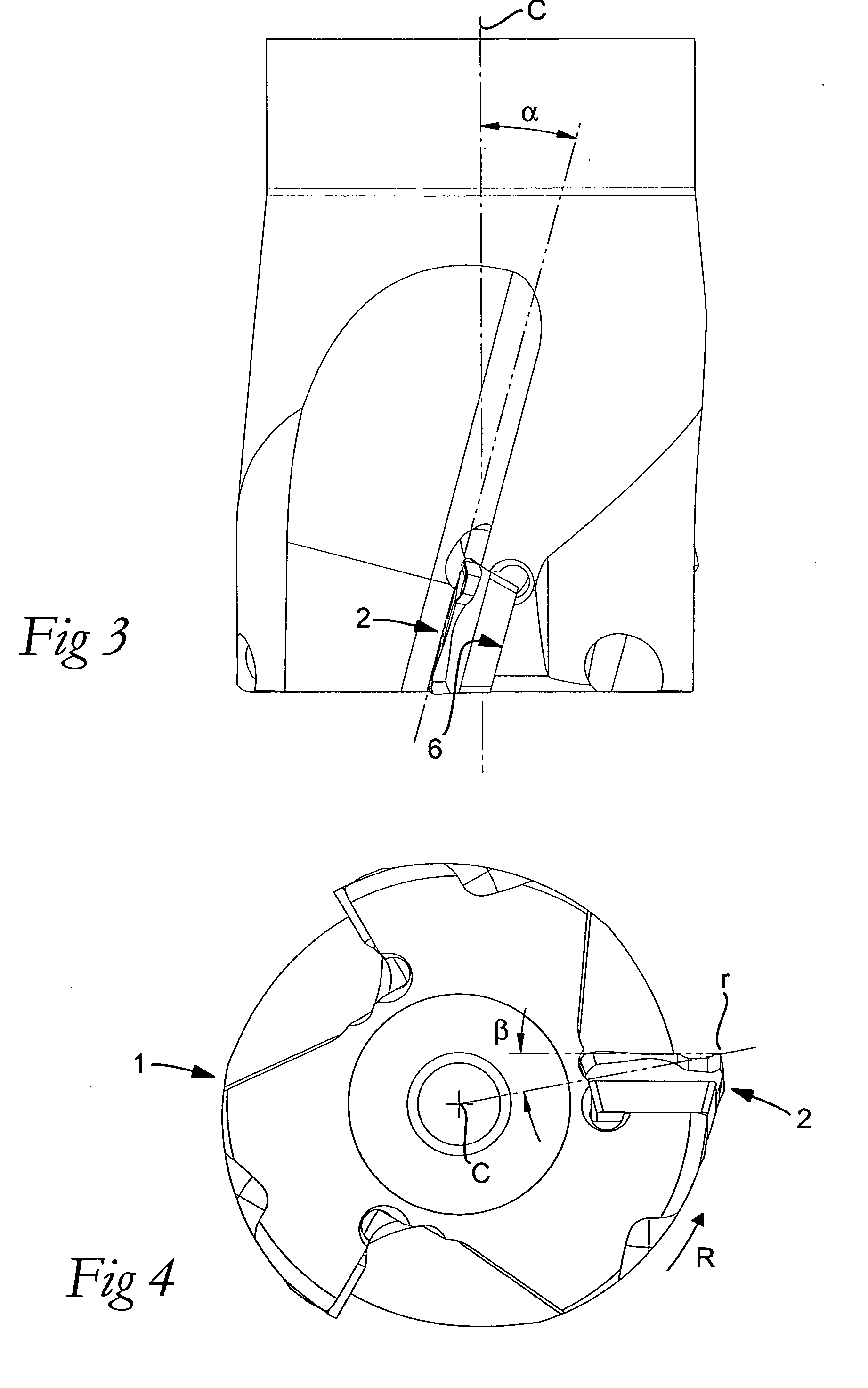

Cutting insert for a milling cutter

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

Milling cutter and milling insert with coolant delivery

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com