Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

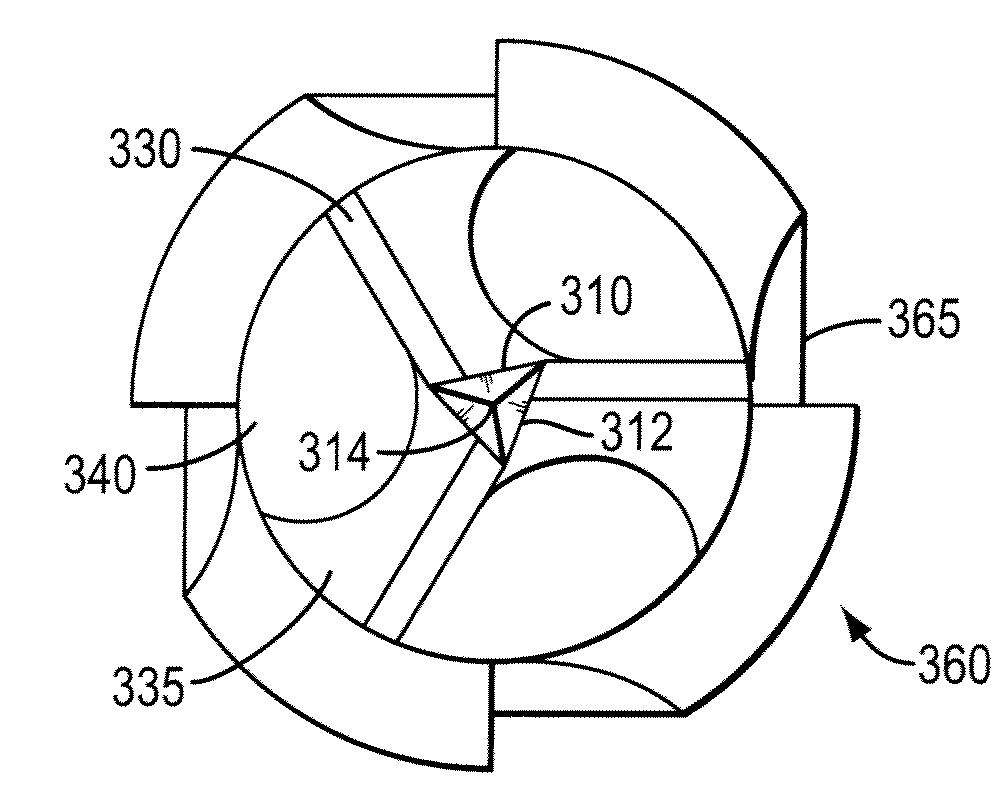

1449results about "Twist drills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

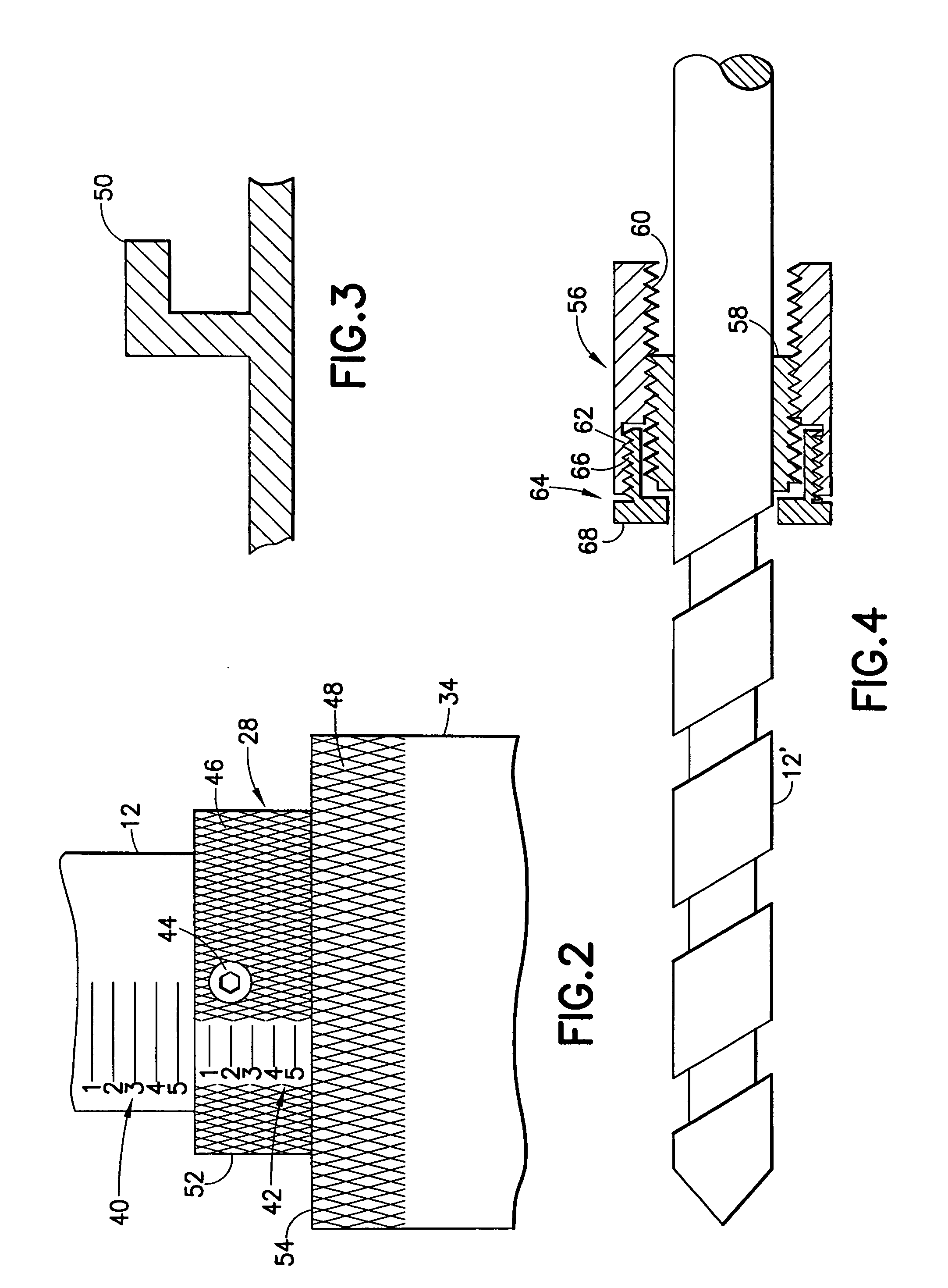

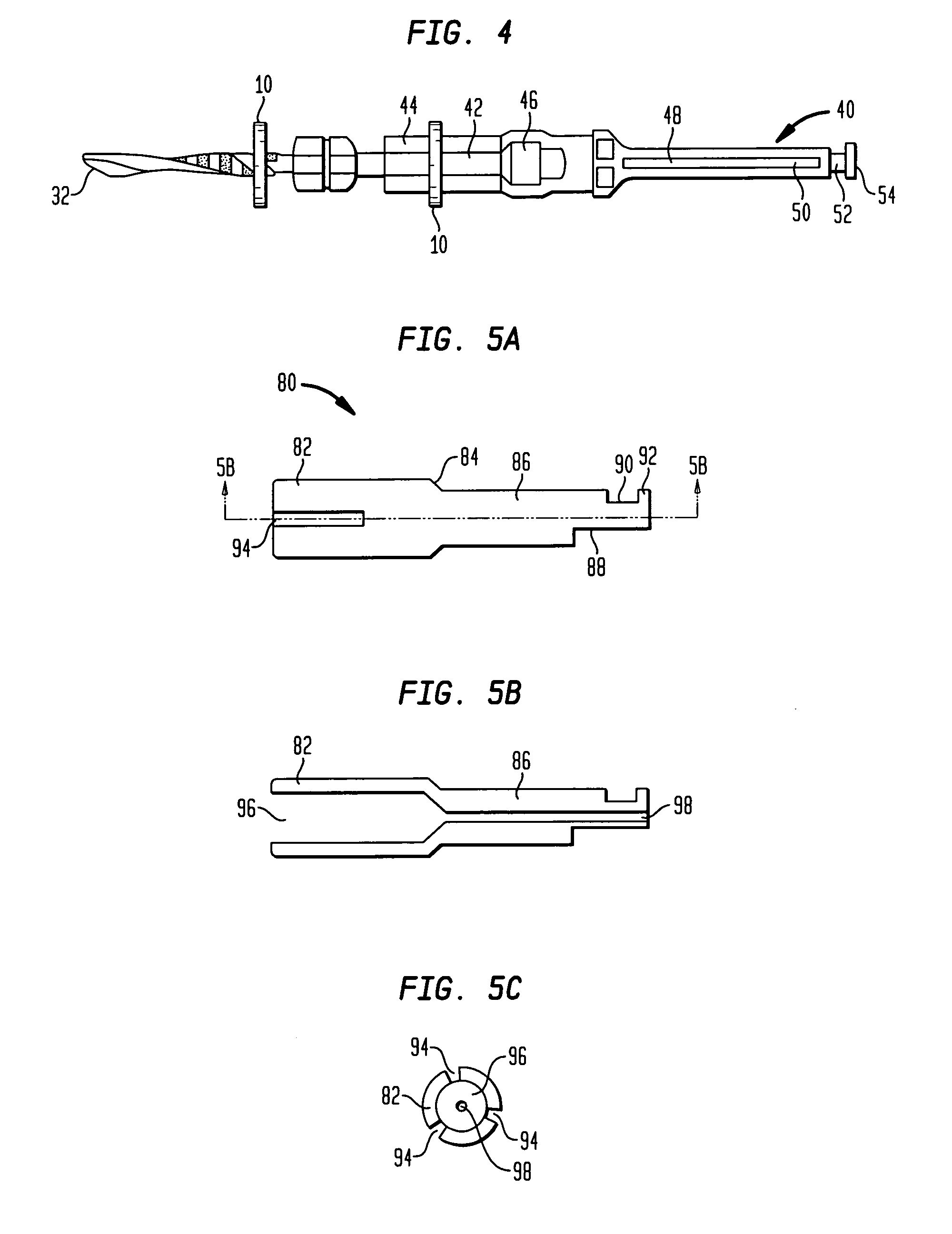

Sleeved stop for a drill bit

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

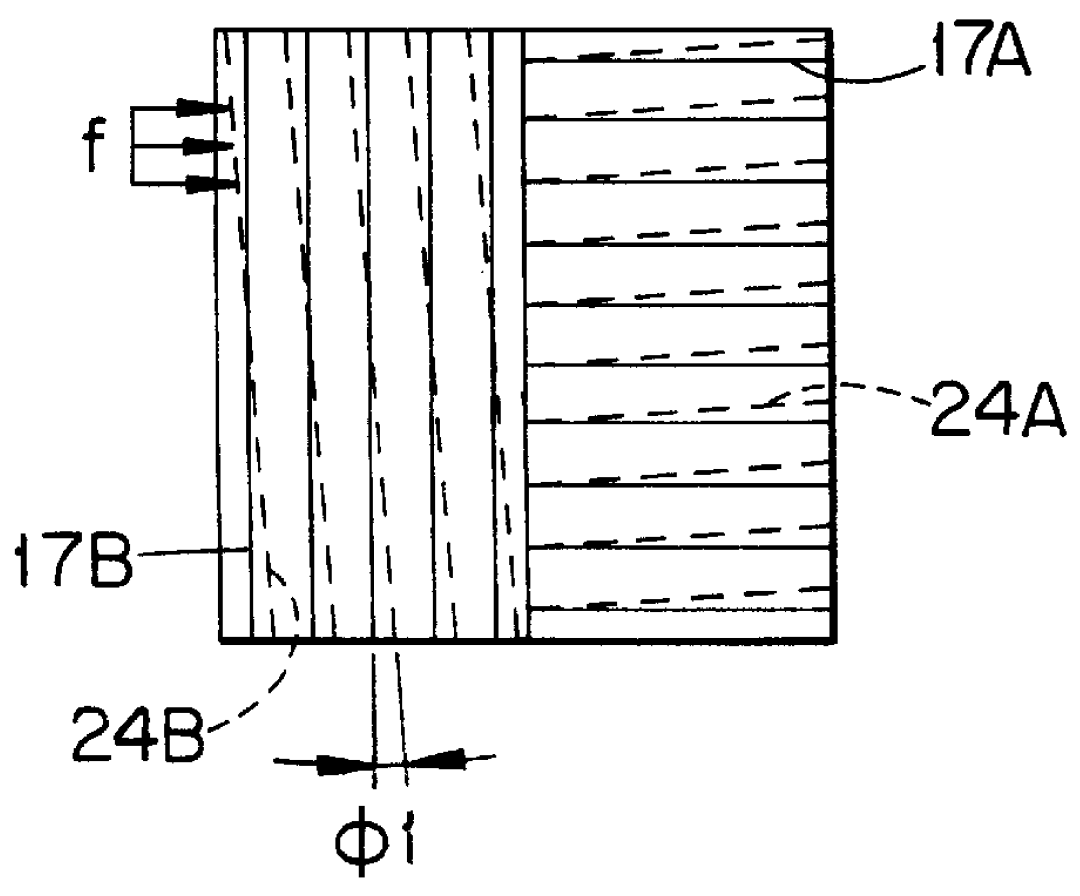

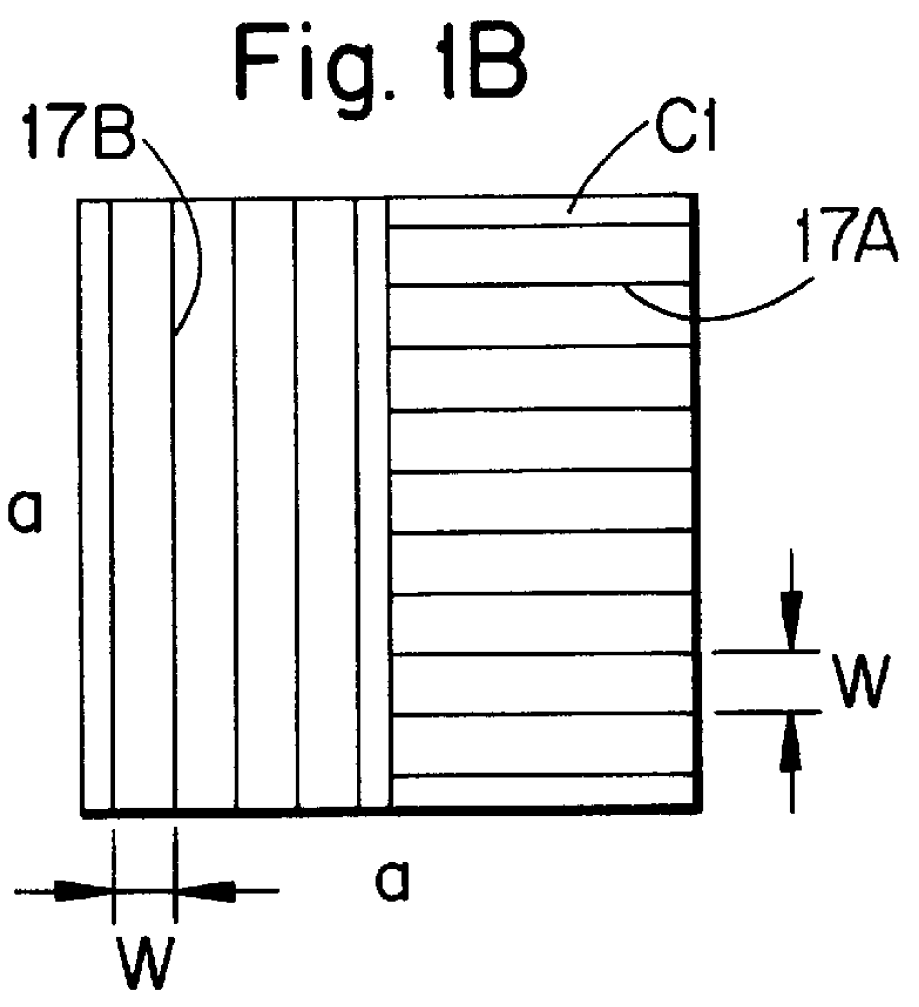

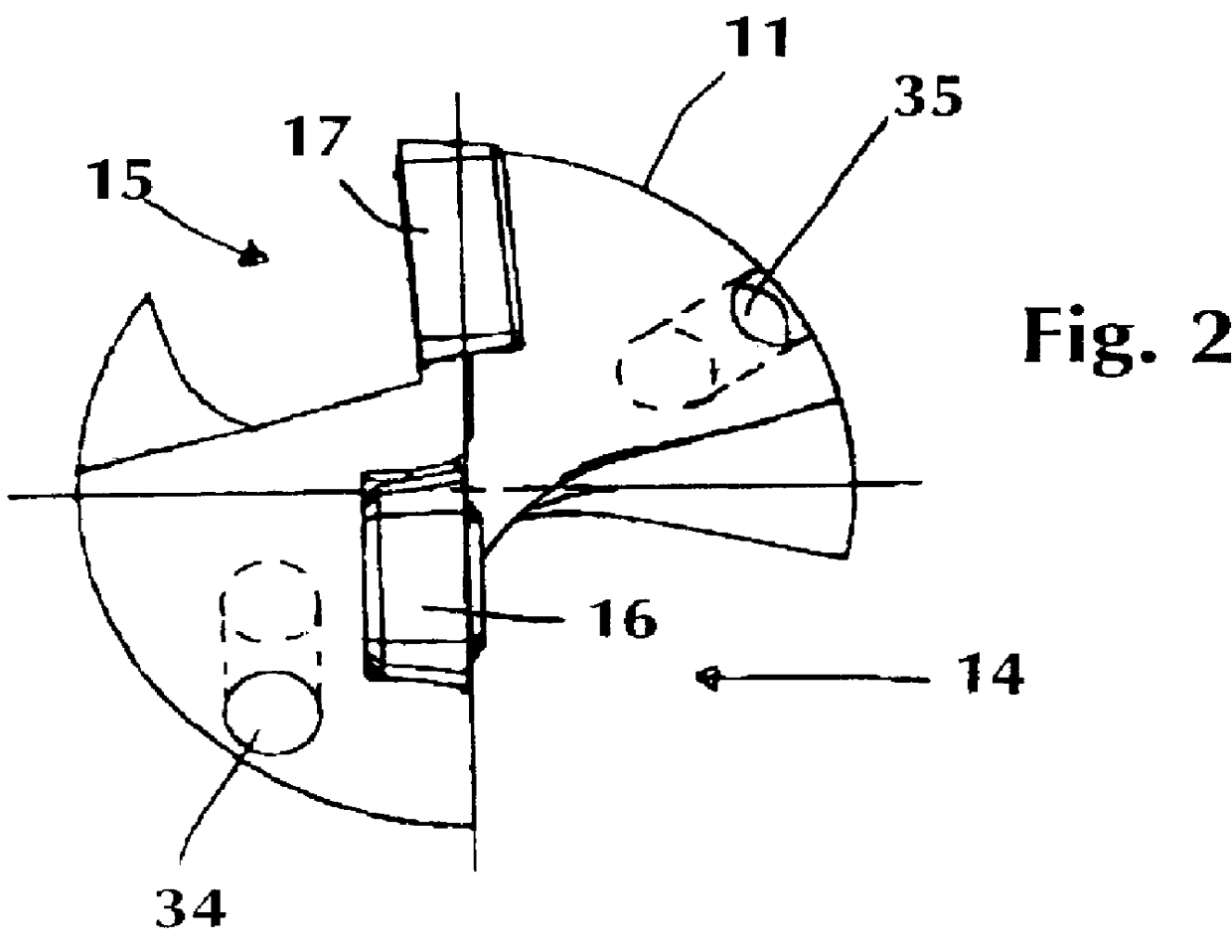

Tool coupling and method for coupling two tool parts

A tool includes a cutting head and a holder, wherein the cutting head and the holder form two cooperating surfaces that are pressed together. The surfaces possess rows of alternating parallel grooves and ridges for locking the surfaces to each other. Each of the surfaces has two rows of grooves, one row oriented 90 DEG relative to the other row. On one of the surfaces, some of the grooves of one row are in non-intersecting relationship with the grooves of the other row. On the other surface, the rows extend completely across one another, whereby the rows together form a waffle-like pattern. The cooperating surfaces allow at least four separate relative positions between the cutting head and holder.

Owner:SECO TOOLS AB

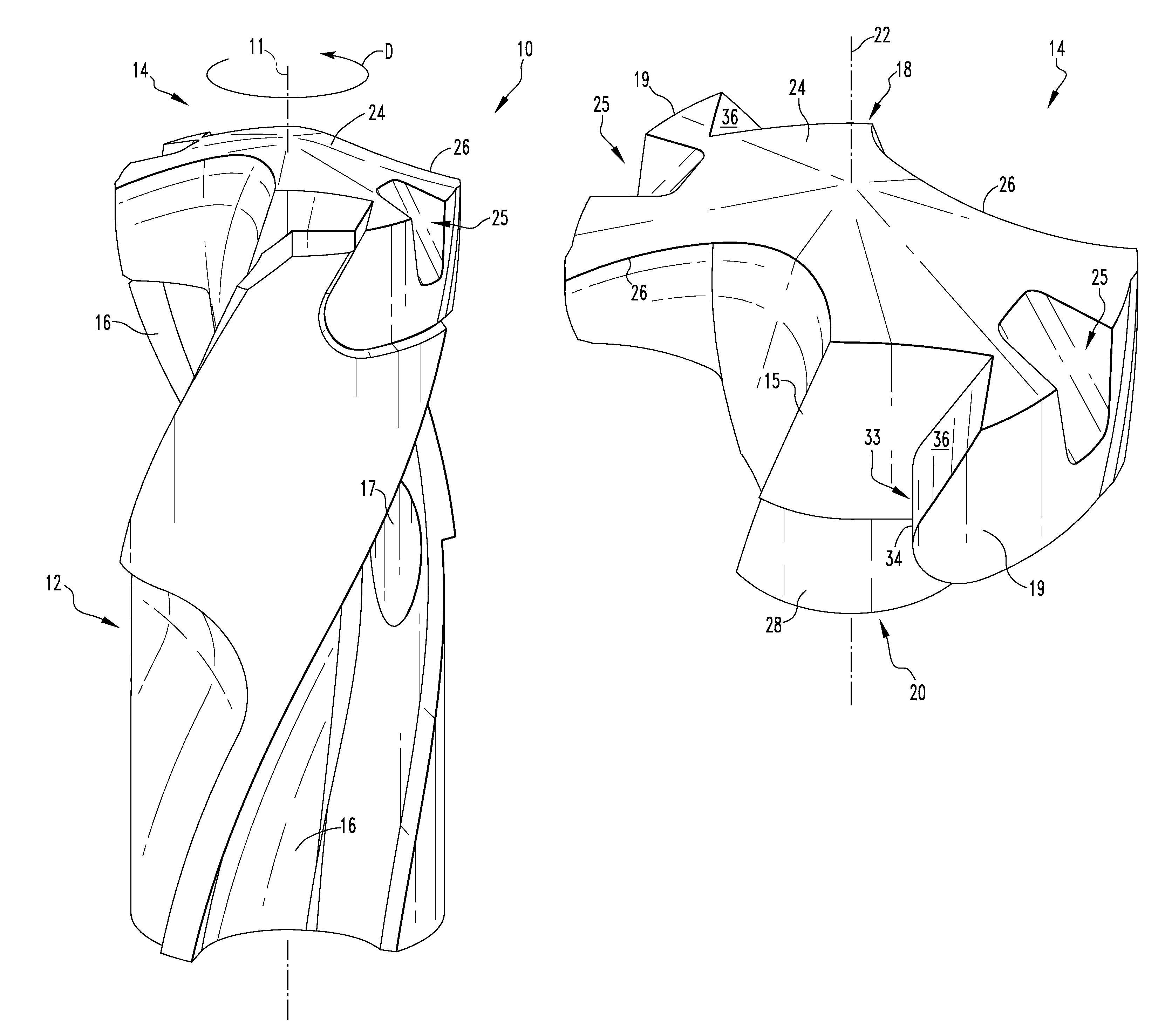

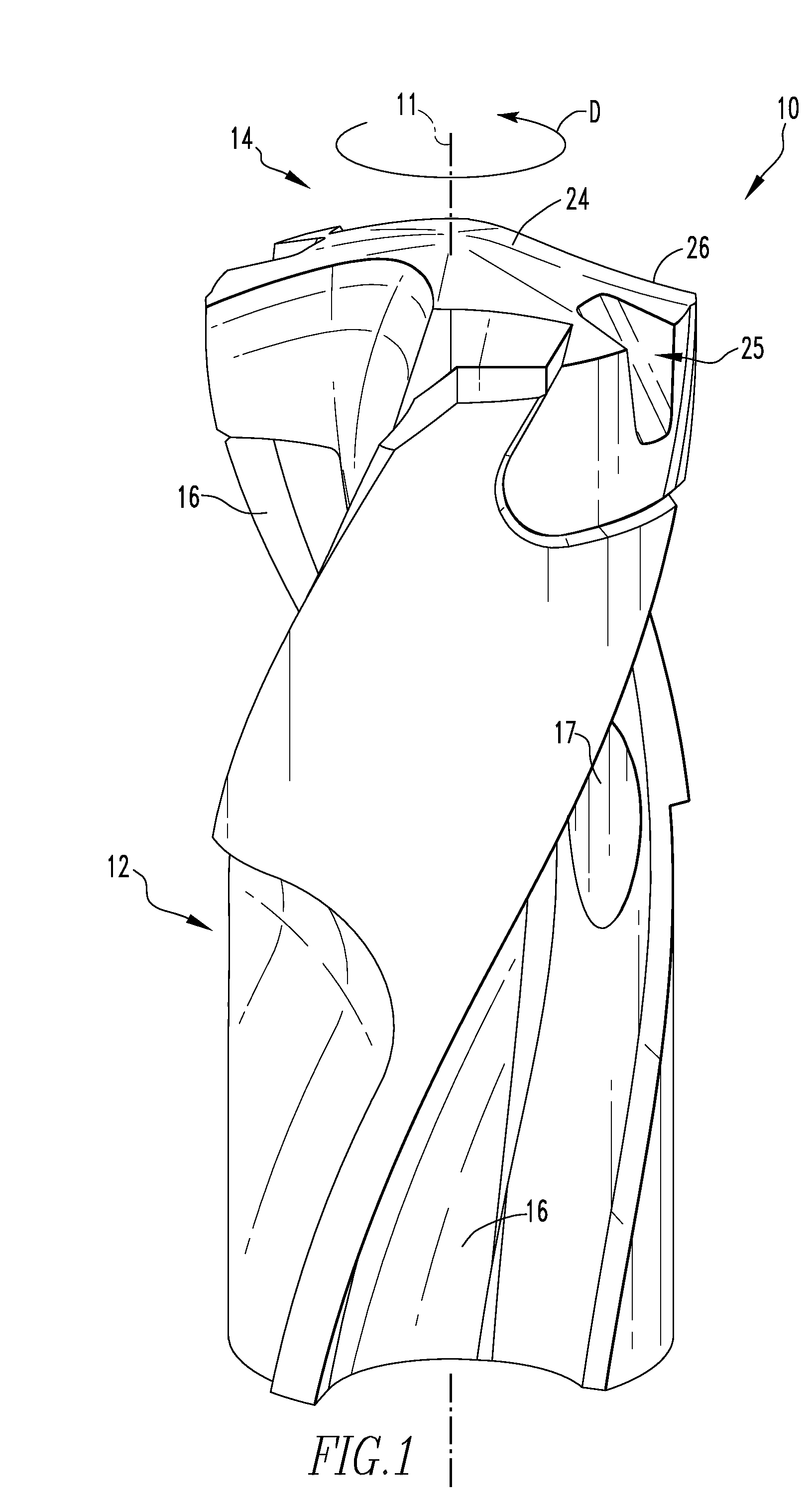

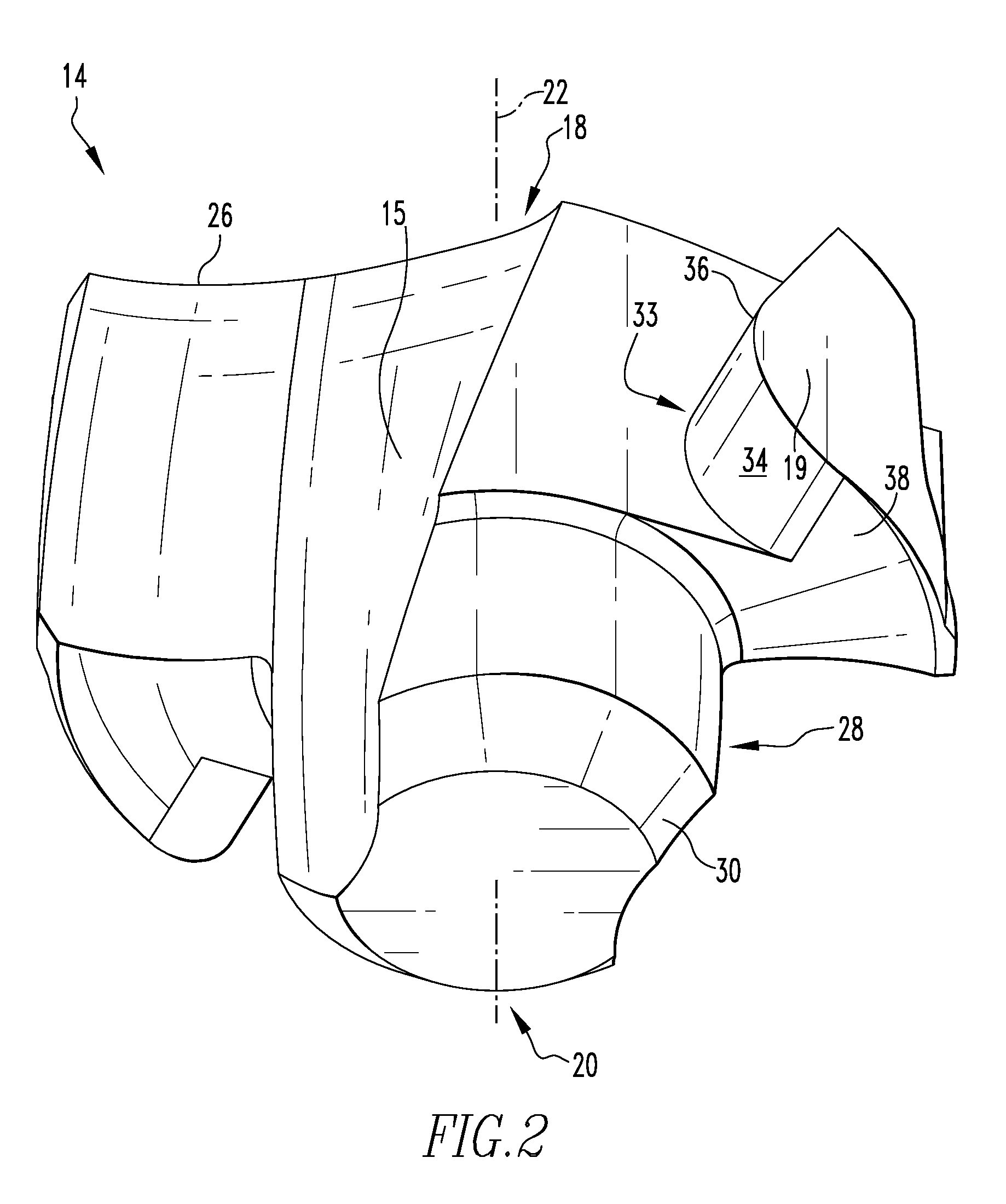

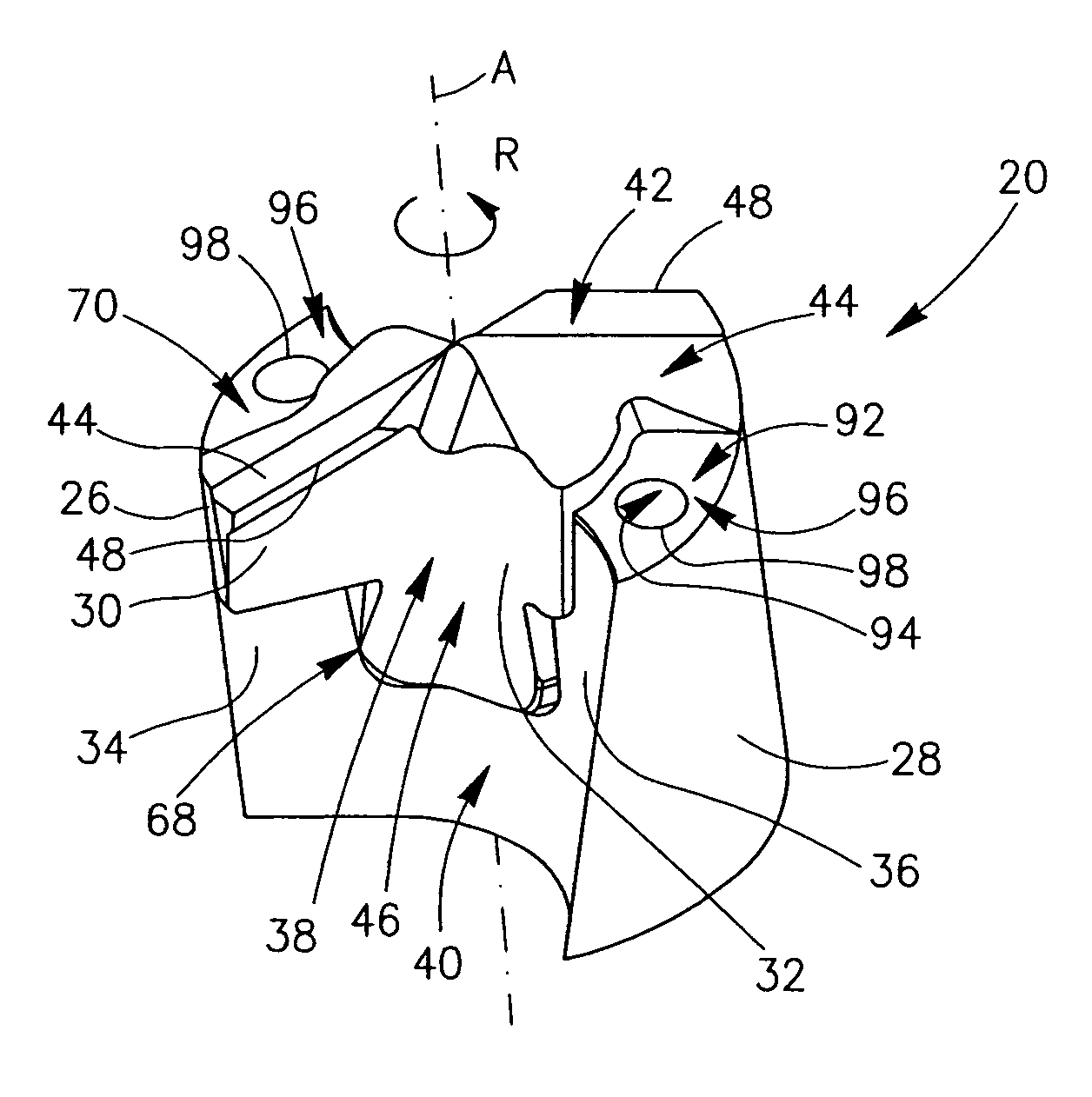

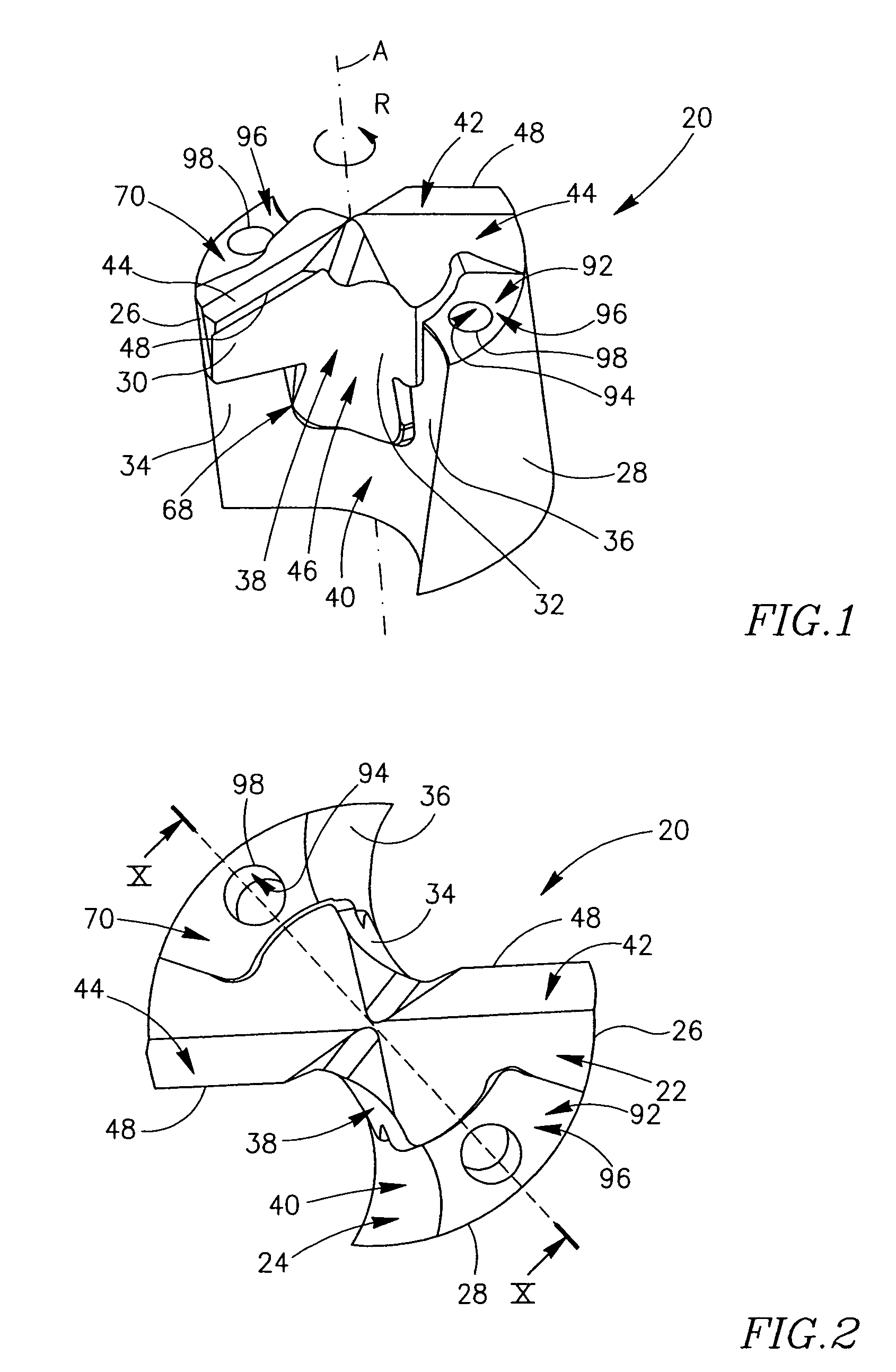

Rotary cutting tool assembly and cutting insert and tool shank therefor

A tool shank and a replaceable cutting insert are provided for a rotary cutting tool assembly. The tool shank has a drive surface including a central portion, a first portion of generally planar shape extending away from the central portion and a second portion of generally planar shape extending away from the central portion in a direction generally transverse to a central axis of the tool shank. The replaceable cutting insert has a driven surface including another central portion, a first portion of generally planar shape extending away from the other central portion and a second portion of generally planar shape extending away from the other central portion in a direction generally transverse to a central axis of the insert. The central portion of the driven surface has a curved surface transitioning between the first portion and the second portion of the driven surface. A portion of the driven surface of the replaceable cutting insert is engaged by a corresponding portion of the drive surface of the tool shank.

Owner:KENNAMETAL INC

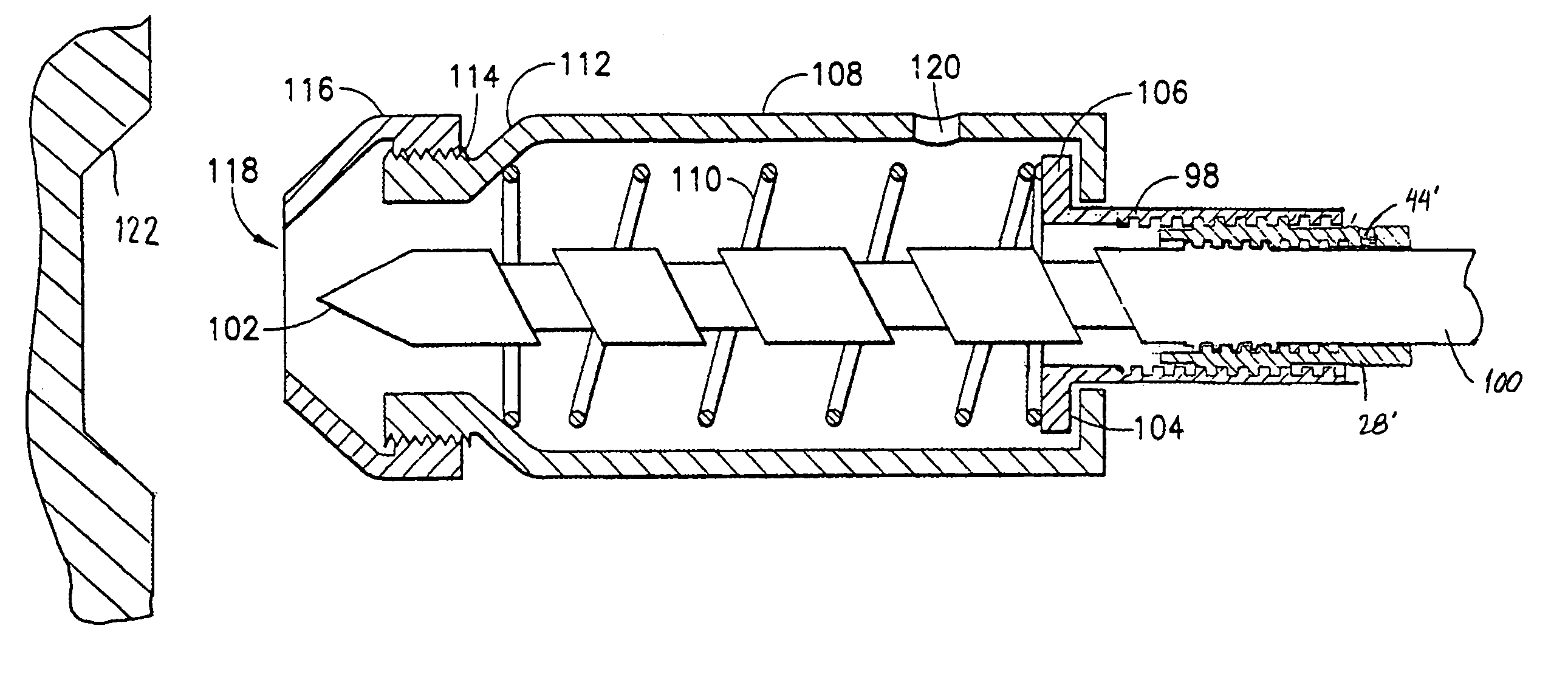

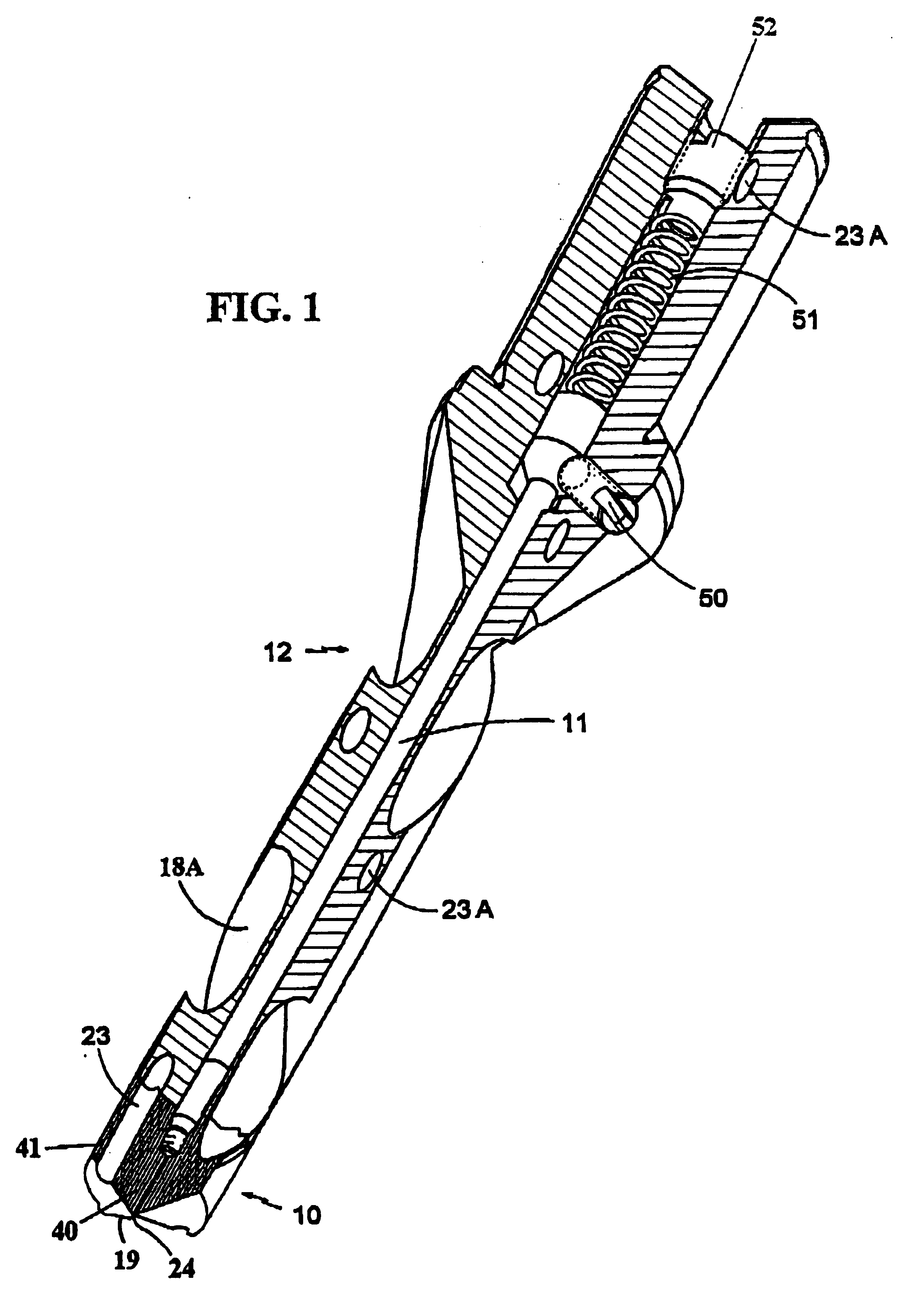

Tool with deployable cutting blade

A tool having a deployable cutting blade for making an undercut in a substrate is disclosed. The tool has a chamber positioned between its cutting tip and its tang. The cutting blade is movably mounted within the chamber. The blade is movable by sliding, pivoting or deflecting on a cantilever mounting and is movable between a retracted position within the chamber and an extended position projecting outwardly to engage and cut the substrate. Actuators for moving the blade include an eccentric cam mounted on a camshaft, a push rod and an inflatable balloon. Blades are also resiliently mounted and oriented so that their engagement with the substrate will cause them to retract into the chamber when the tool rotates in one direction and deploy into the extended position when the tool rotates in the opposite direction.

Owner:STOUT MEDICAL GROUP

Drill having radially overlapping indexable cutting inserts

A drill includes a shank, a central insert and a peripheral insert. The shank defines a central axis of rotation and has pockets which carry the peripheral and central inserts. Chip flutes are formed in an outer periphery of the shank for conducting chips cut by the respective inserts. The peripheral insert includes a first operative cutting edge, and the central insert includes a second operative cutting edge which overlaps the first cutting edge at an overlap region. The central insert forms a rake surface adjacent to the second cutting edge. The rake surface includes a first portion disposed at the overlap region, and a second portion disposed at the axis of rotation of the shank. The first portion has a larger rake angle than the second portion.

Owner:SECO TOOLS AB

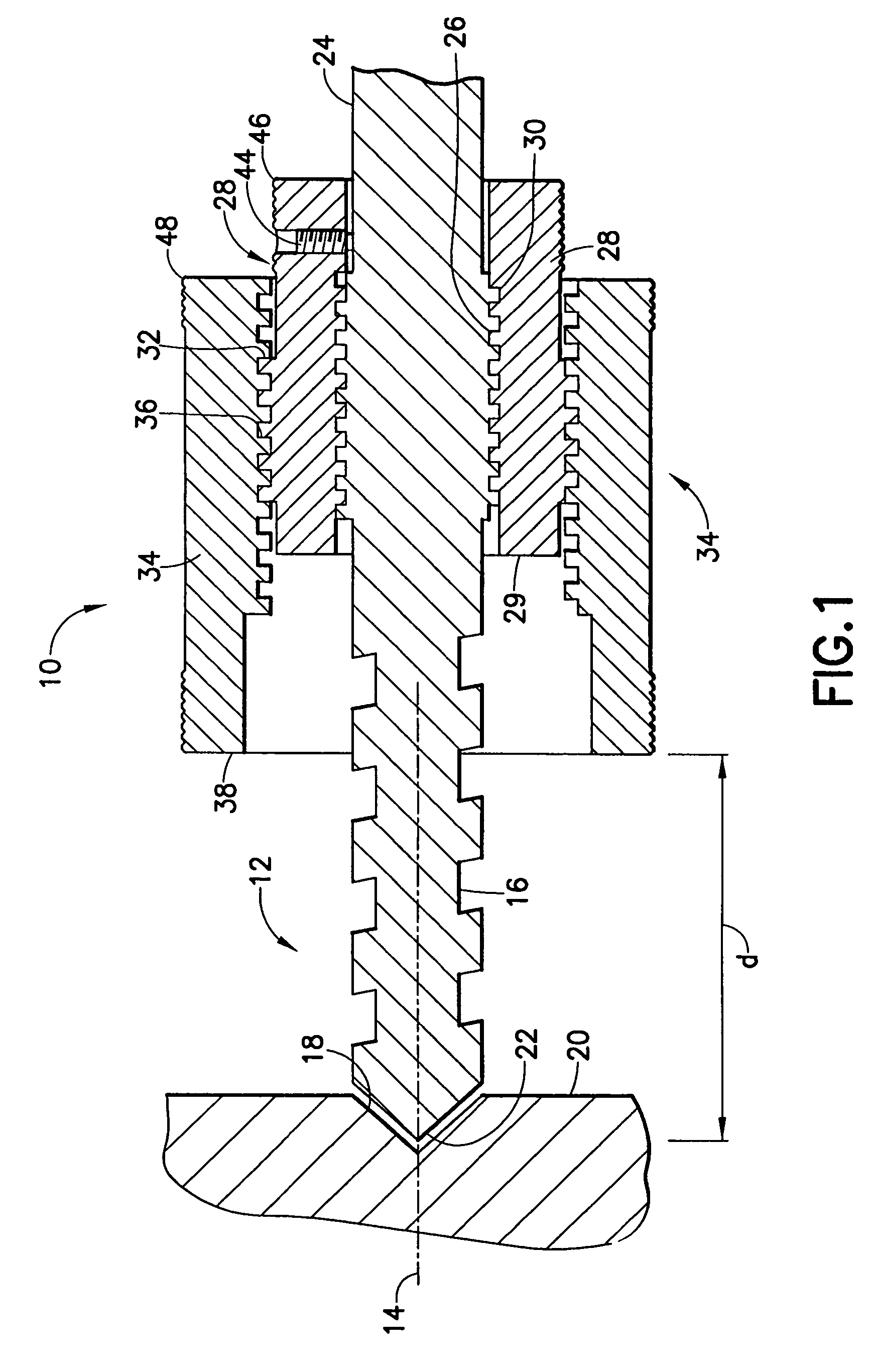

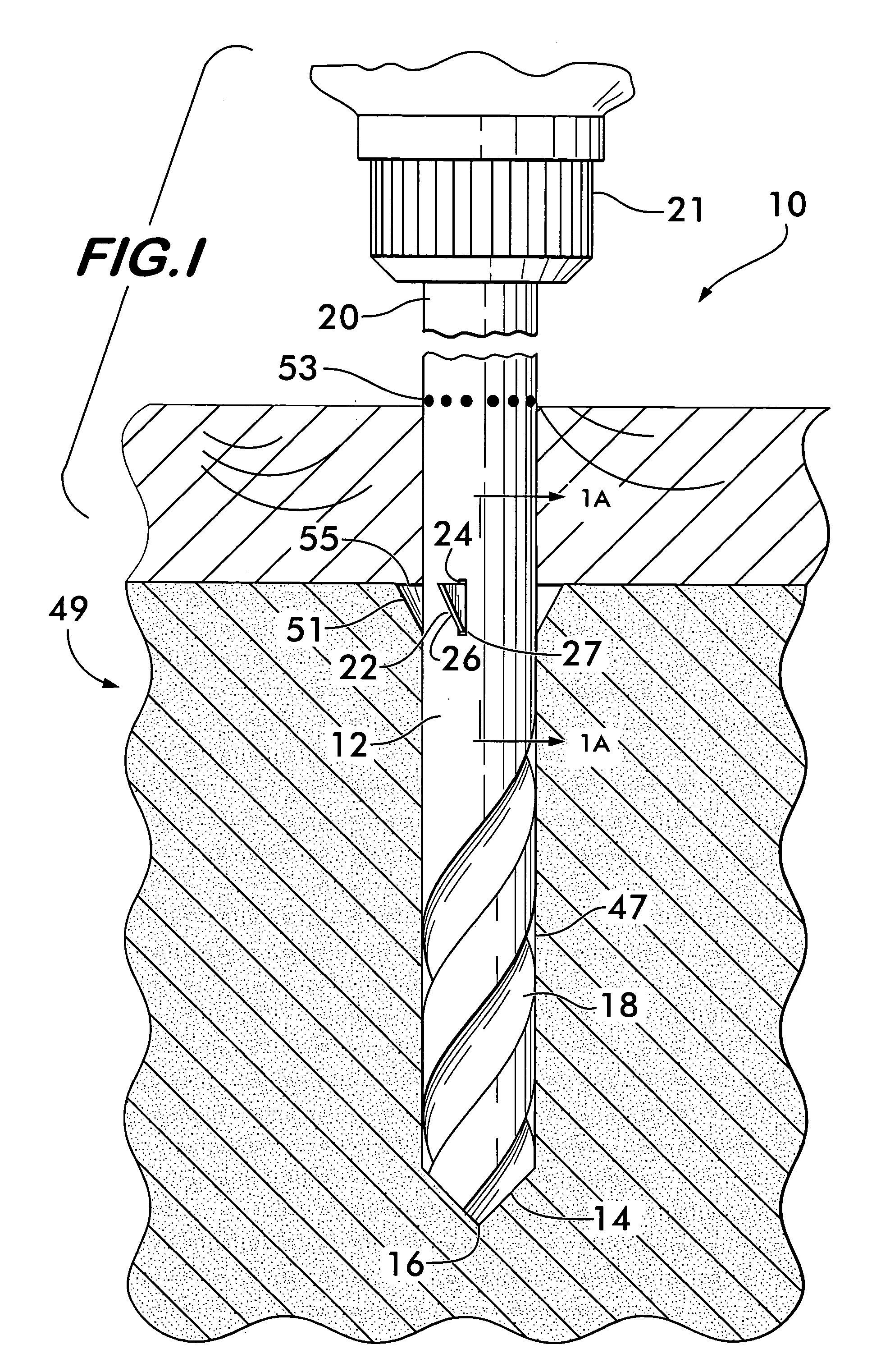

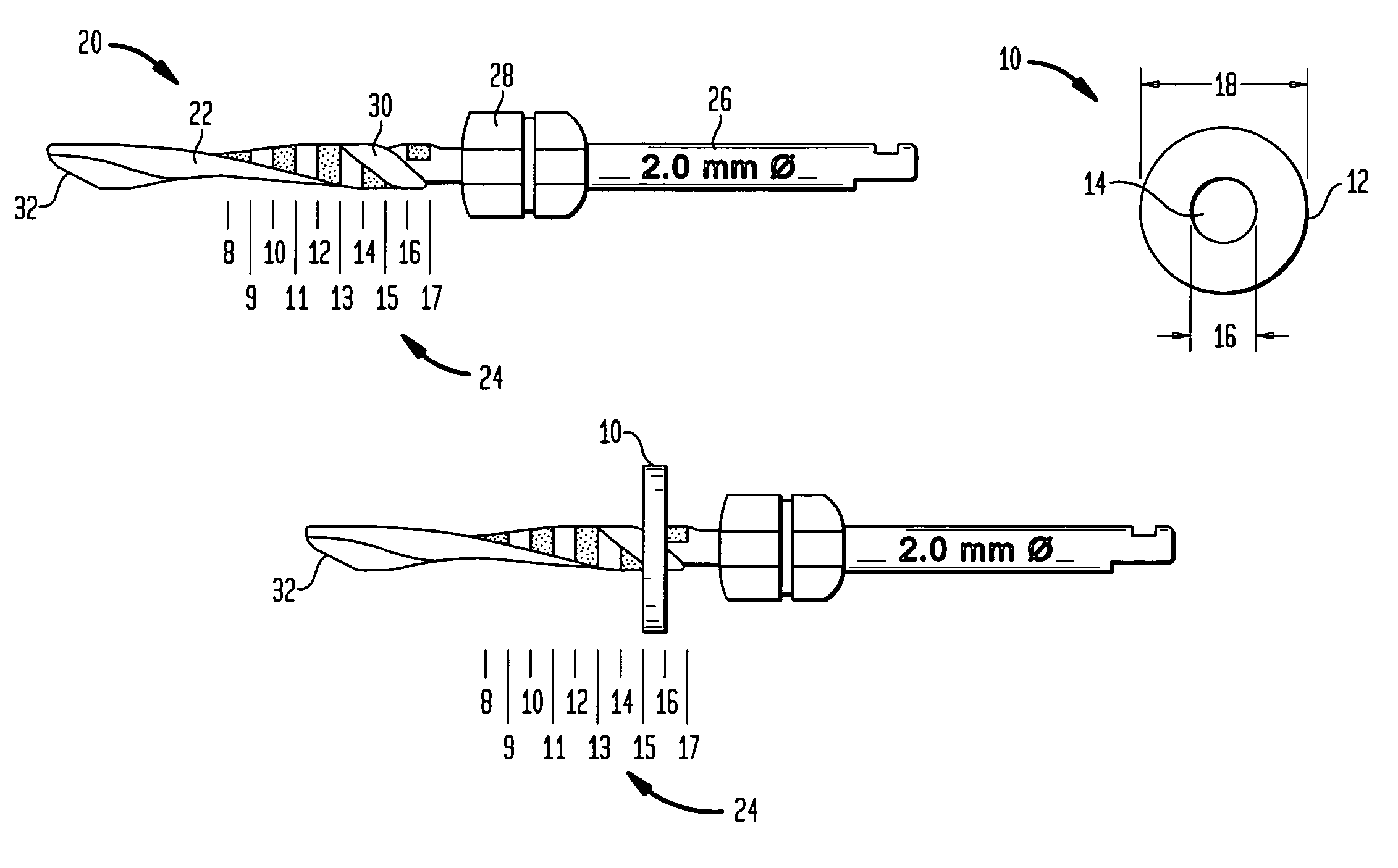

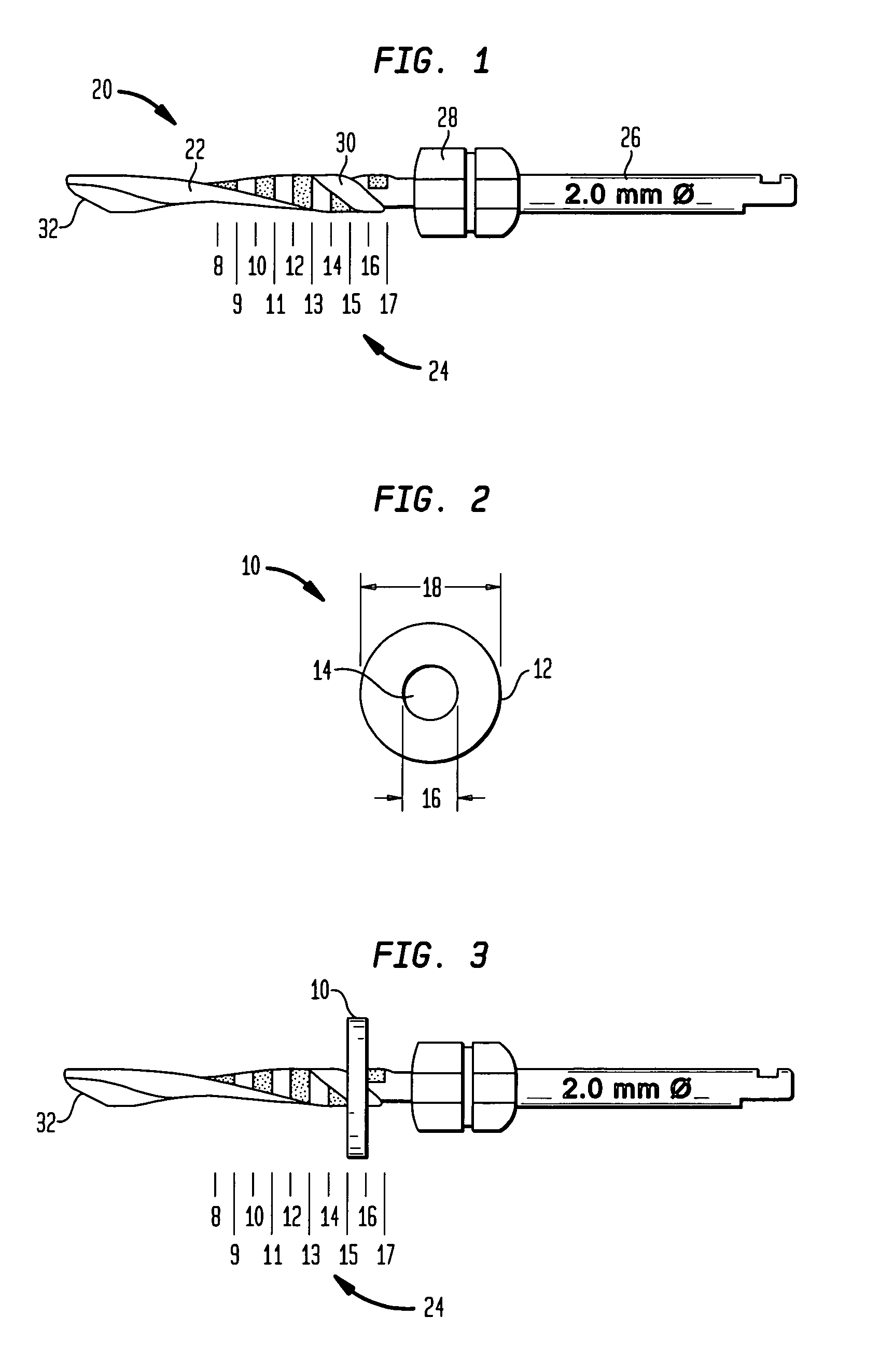

Drill measurement stops

InactiveUS7048477B2Easy to identifyReduce manufacturing costThread cutting toolsDental implantsEngineeringVisual perception

A depth stop for use with a drill bit comprises a tubular body having an opening therethrough. Used with a drill bit whose bit portion includes a cutting end, and a shank portion, the depth stop is frictionally positionable on the bit portion at a specified point from the cutting end, thereby indicating a specified depth. Depth stops are manufactured in different colors, each color corresponding to a specified range of drill bits that the depth stops will fit. The depth stops, manufactured from a sterilizable material, are intended for single use. The depth stop can be used with a drill bit and drill extender, where one or more depth stops provide multiple visual points of reference for the operator. The depth stops can be quickly mounted onto most any manufacturer's drill bits.

Owner:IDMS

Tool for rotary chip removal, a tool tip and a method for manufacturing a tool tip

InactiveUS6551035B1Eliminate the problemWood turning toolsTransportation and packagingCouplingScrew thread

A rotary chip-removing tool includes a rotary tool body and a tool tip fastened on a front end thereof. The tool tip is formed of an injection molded body which has an integral cutting edge at its front end, and a coupling structure at its rear end. The coupling structure can be in the form of a threaded hole, or a rearward projection, for coupling the tool tip against the tool body. The tool tip is formed of first and second materials. The first material forms at least part of the cutting edge, and the second material forms the coupling structure. The first material is more brittle than the second material, and the second material is tougher than the first material.

Owner:SECO TOOLS AB

Rotatable tool for chip removing machining and appurtenant cutting part therefor

A rotatable tool for chip removing machining includes two parts, viz. a holder part, rotatable around a geometrical center axis, and a replaceable cutting part, which is rigidly connectable to a front end of the holder part via a male / female coupling. The coupling includes a tapering seat in the holder part and a tapering male member, protruding rearwardly from the cutting part. In the seat, there is a slot, which separates two elastically deflectable projections, that may be inwardly deflected towards each other during clamping of the male member in the seat. The male member is elongated in a radial direction, and the seat is in the form of a radial groove into and out of which the sheath body is transversely movable. The male member includes a dove-tail shaped portion received in a dove-tail shaper portion of the groove. A centering button on the male member enters a depression in the holder part to axially center the cutting part.

Owner:PROCTER & GAMBLE CO +1

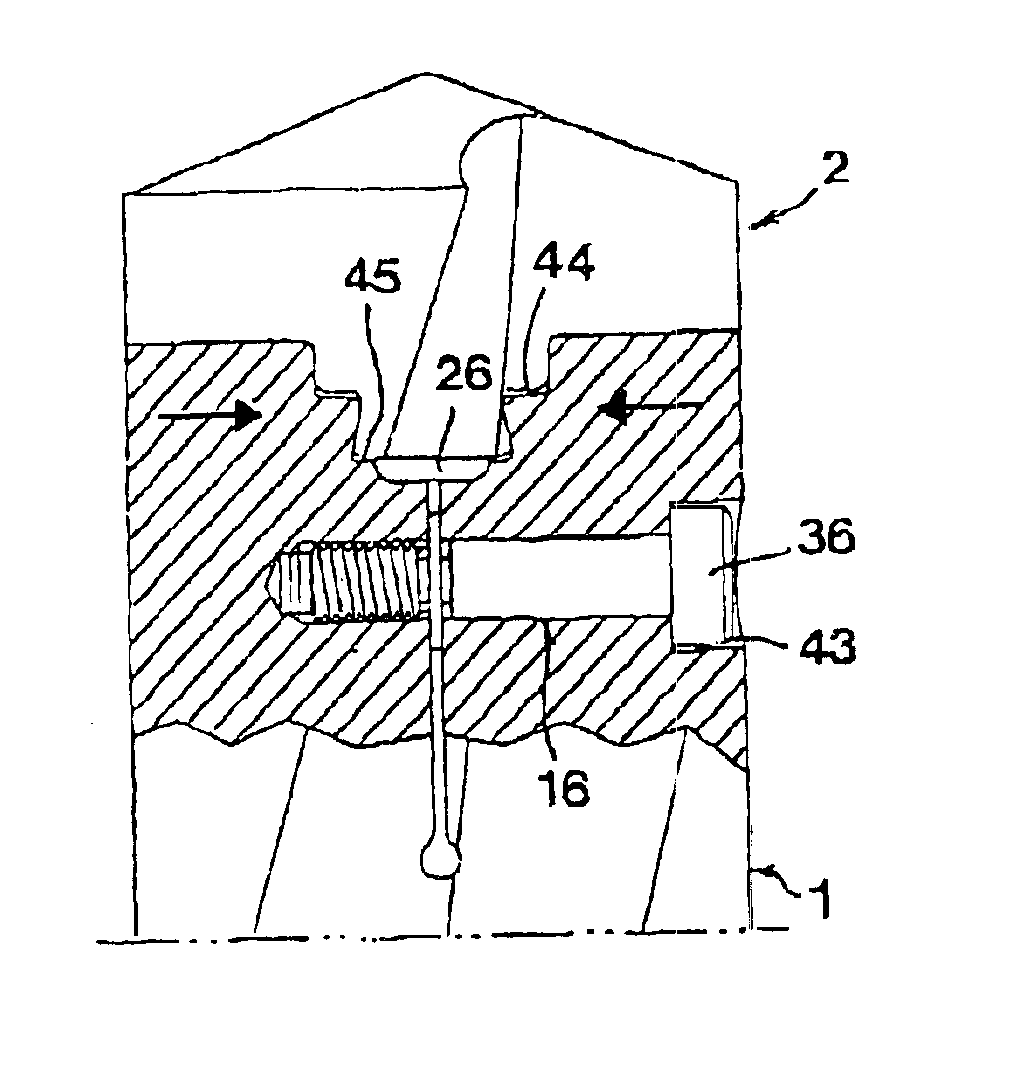

Drilling tool including a shank and a cutting body detachably secured thereto

InactiveUS6481938B2The way is simple and fastImprove cooling effectWood turning toolsTransportation and packagingPre stressPre stressing

A drilling tool includes a shaft having a front end to which a cutting body provided with cutting edges is detachably connected. In the front end of the shaft, a seat is formed which is delimited by spaced-apart protrusions between which there is a bottom surface. In the protrusion, there is a threaded hole for a screw, which when tightened applies pre-stressing forces to the cutting body. On the inside of the opposite protrusion, there is a supporting shoulder against which the cutting body is pressed when the screw is tightened and applies a lateral pre-stressing force to the cutting body. The protrusions are laterally displaced in relation to each other in order to freely expose the screw beside one of the protrusions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

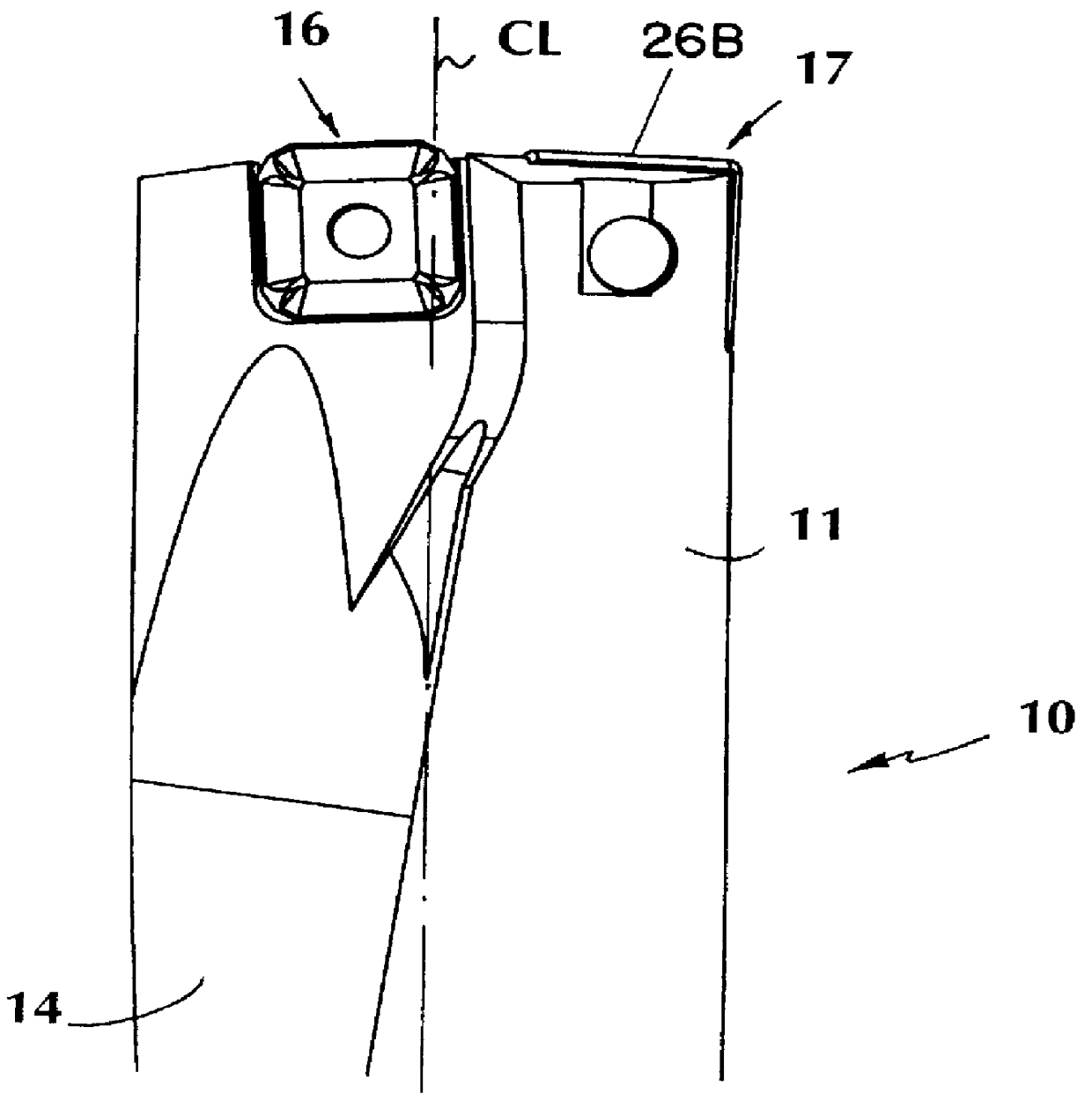

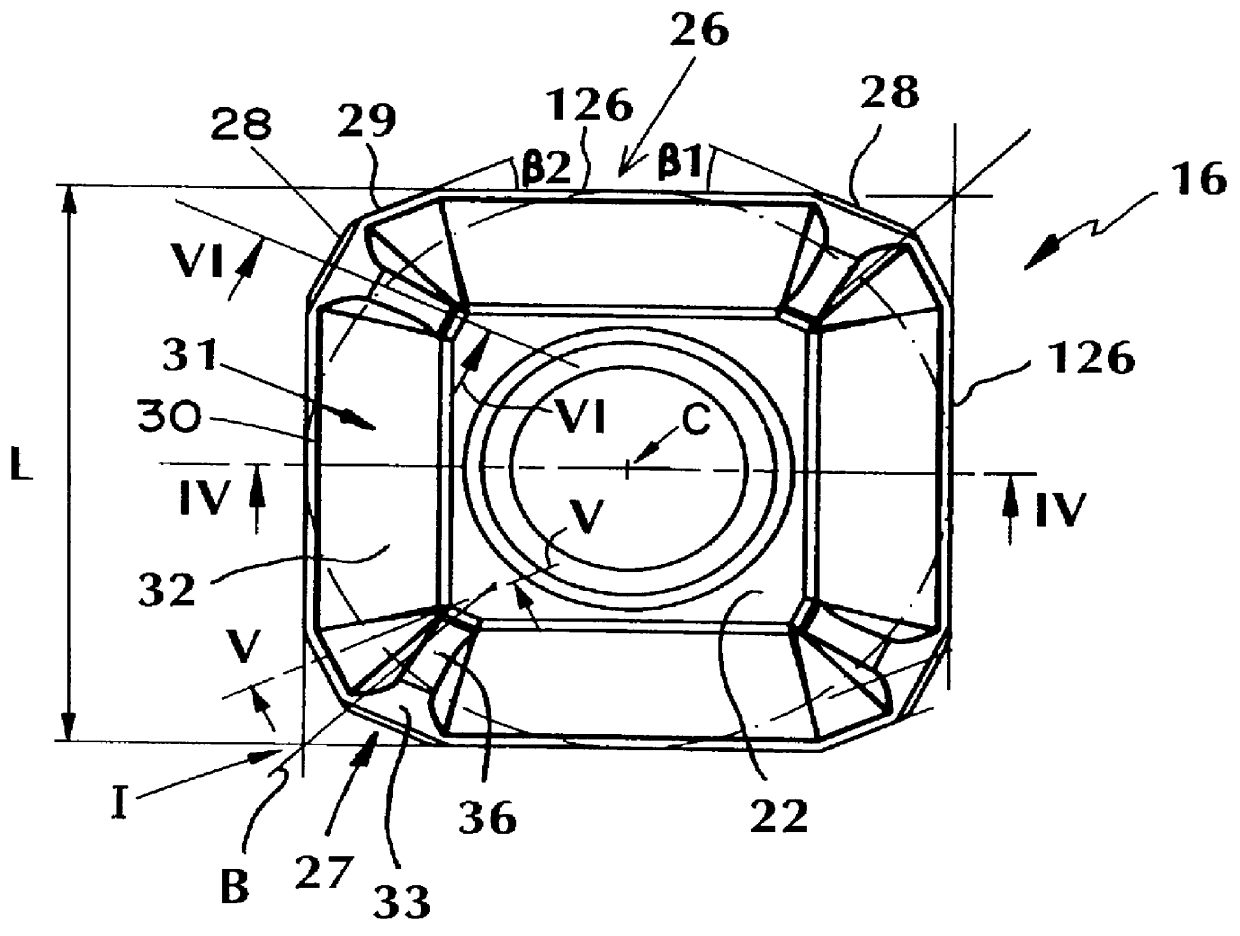

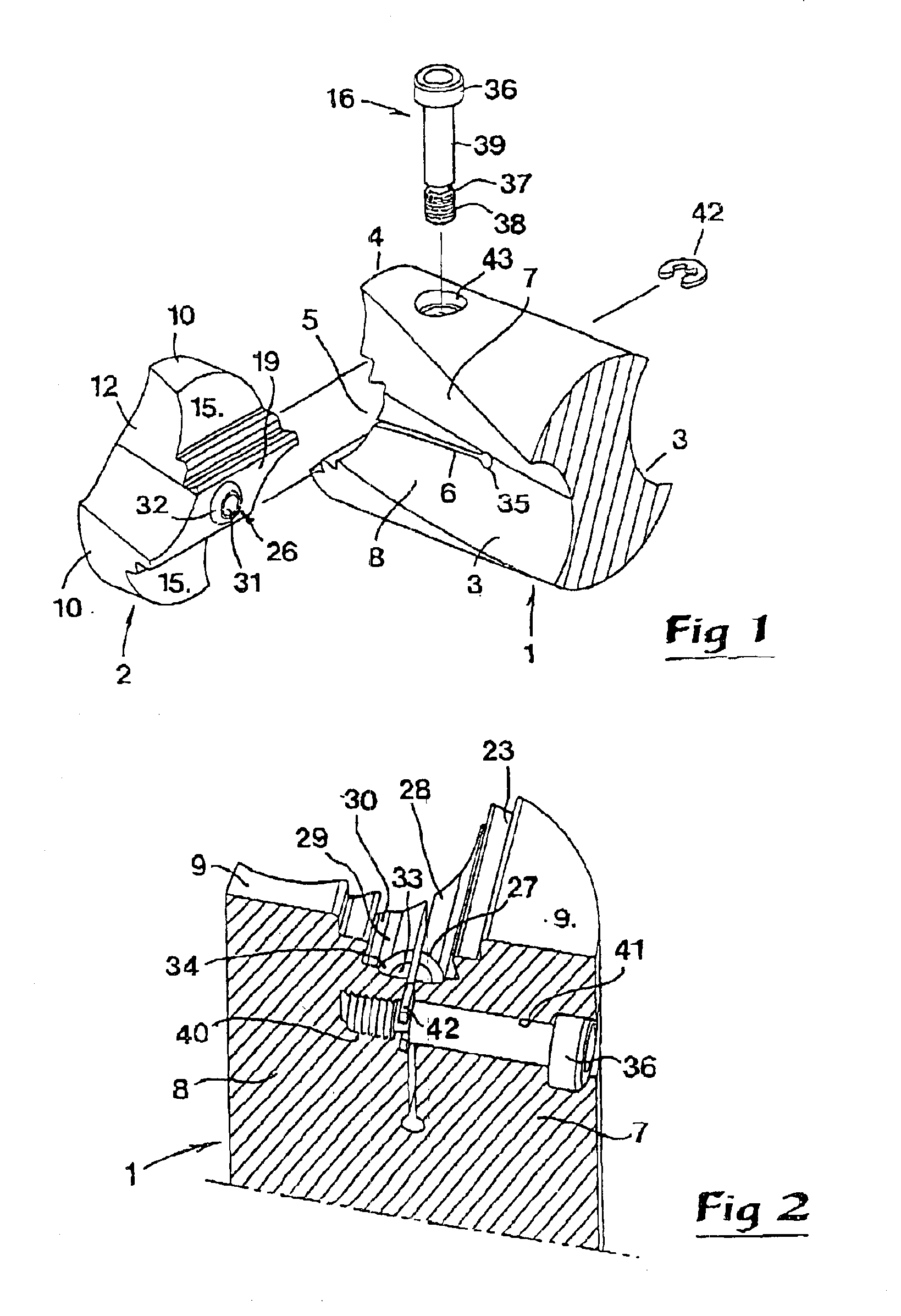

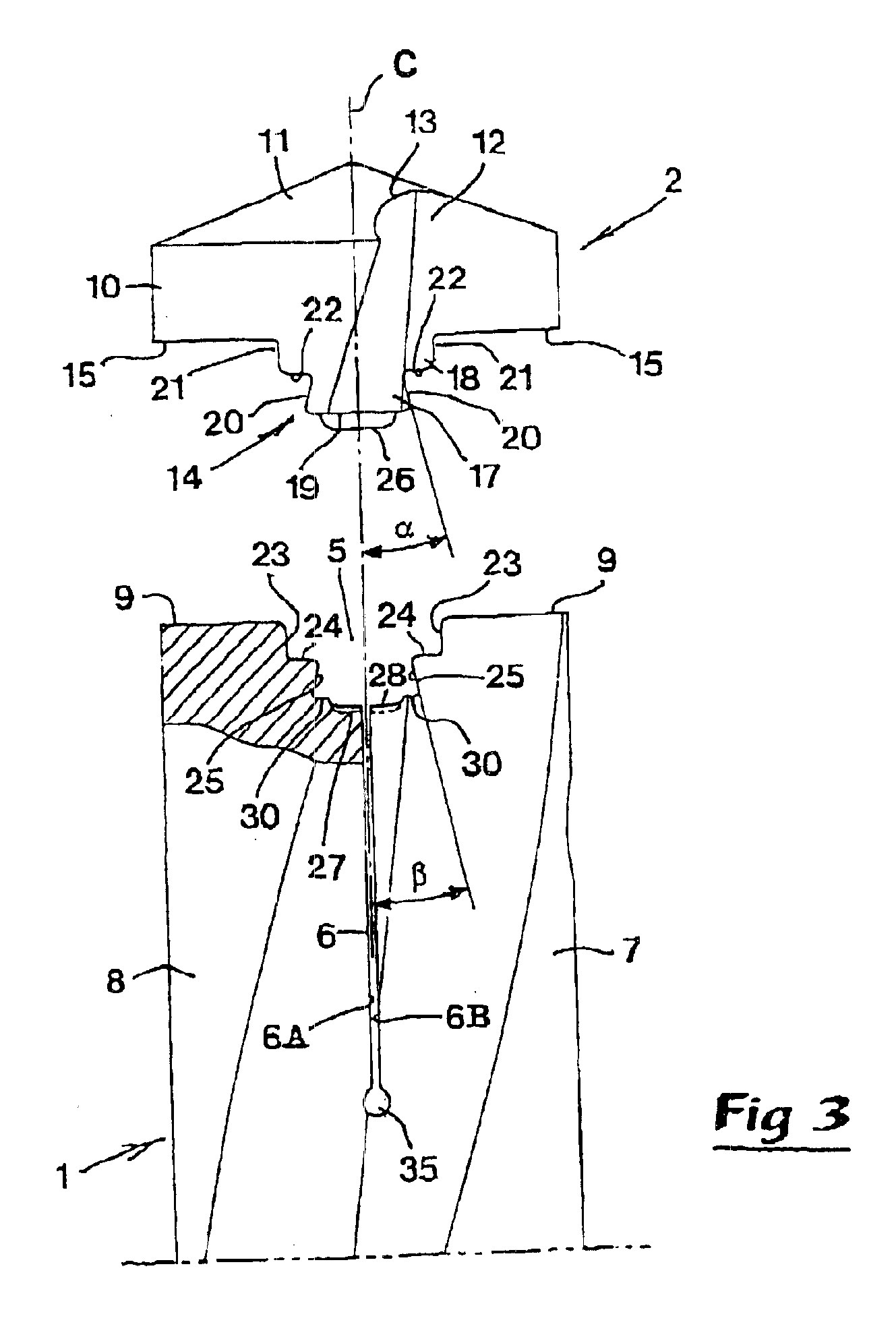

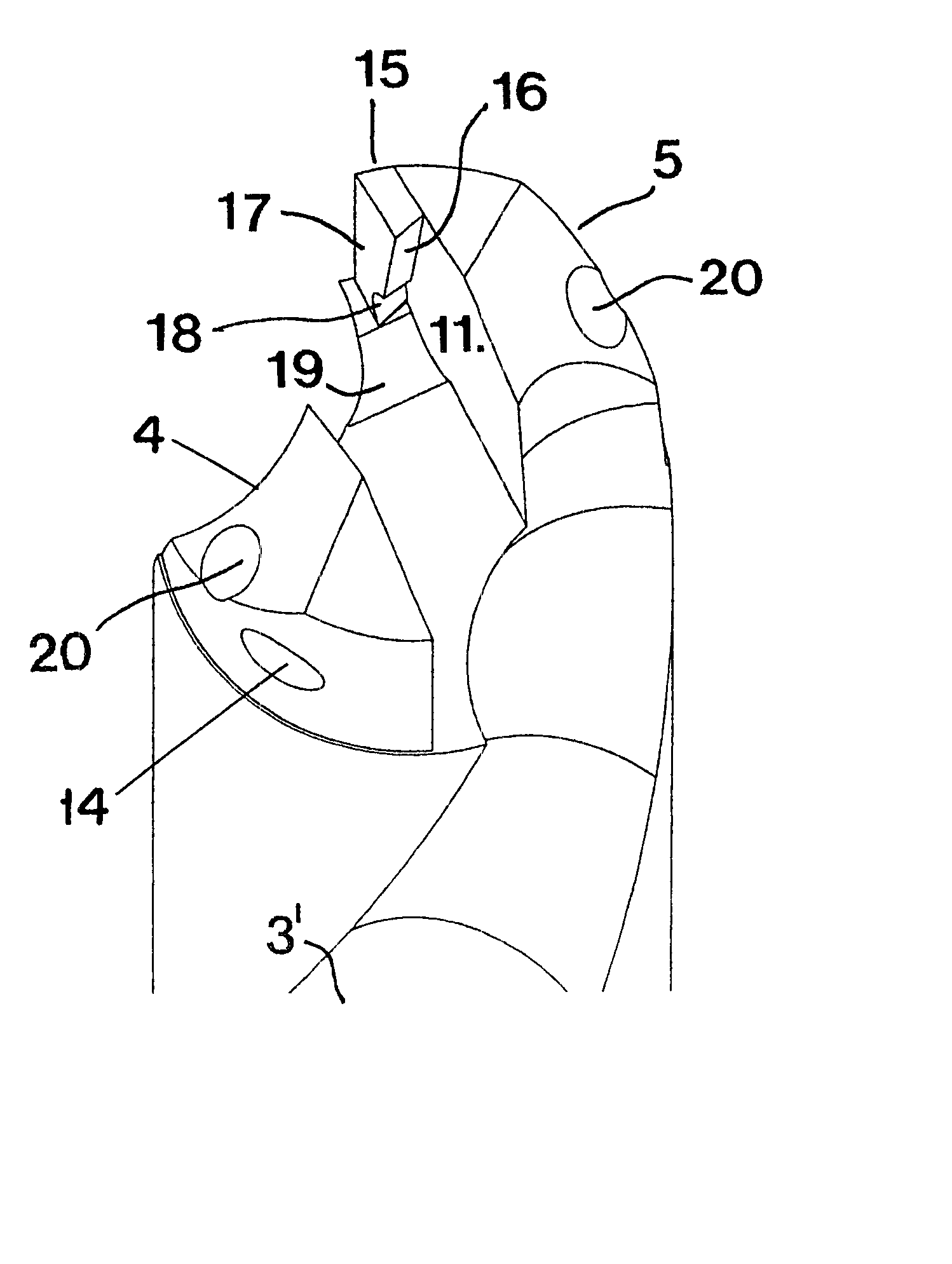

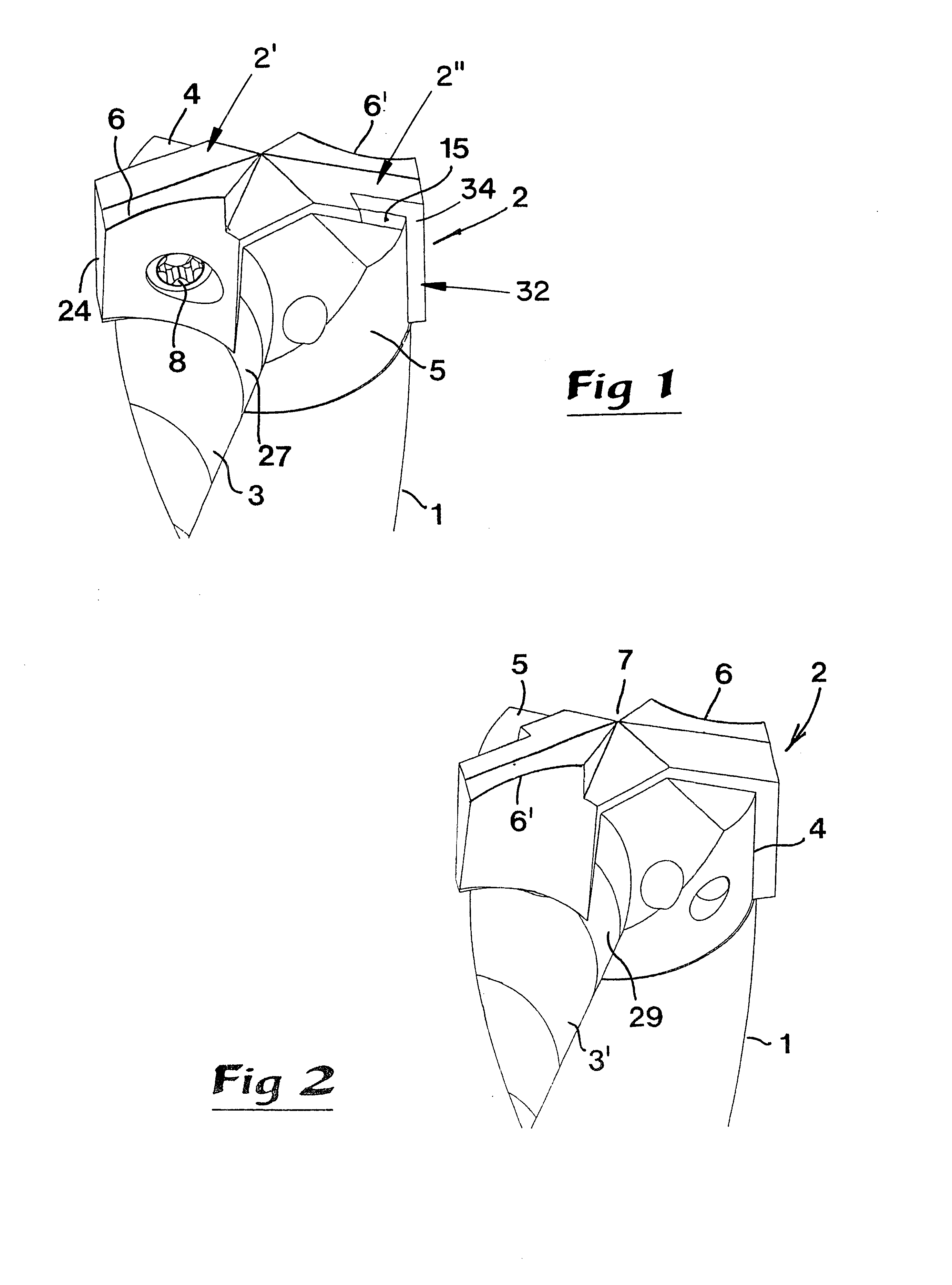

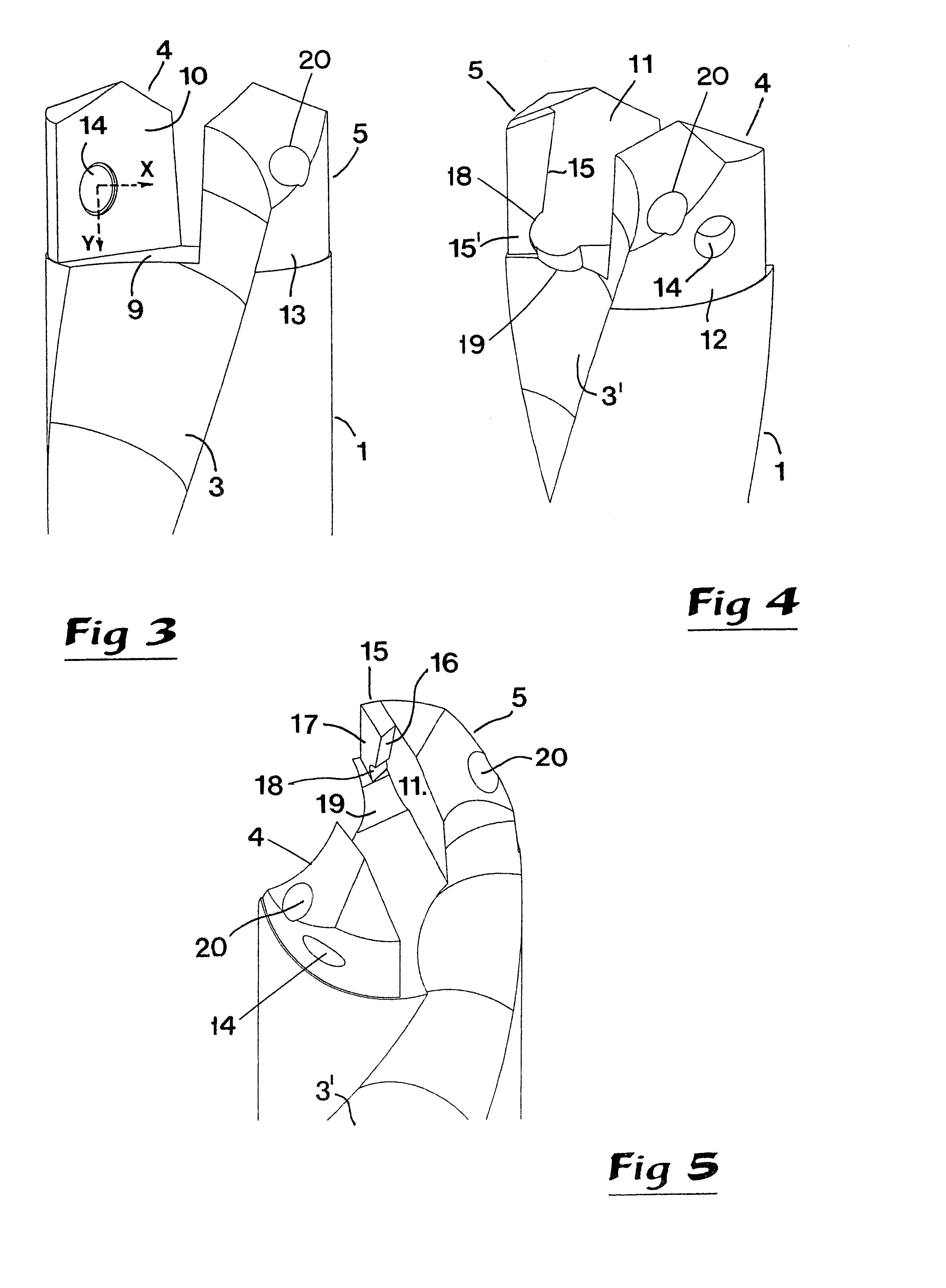

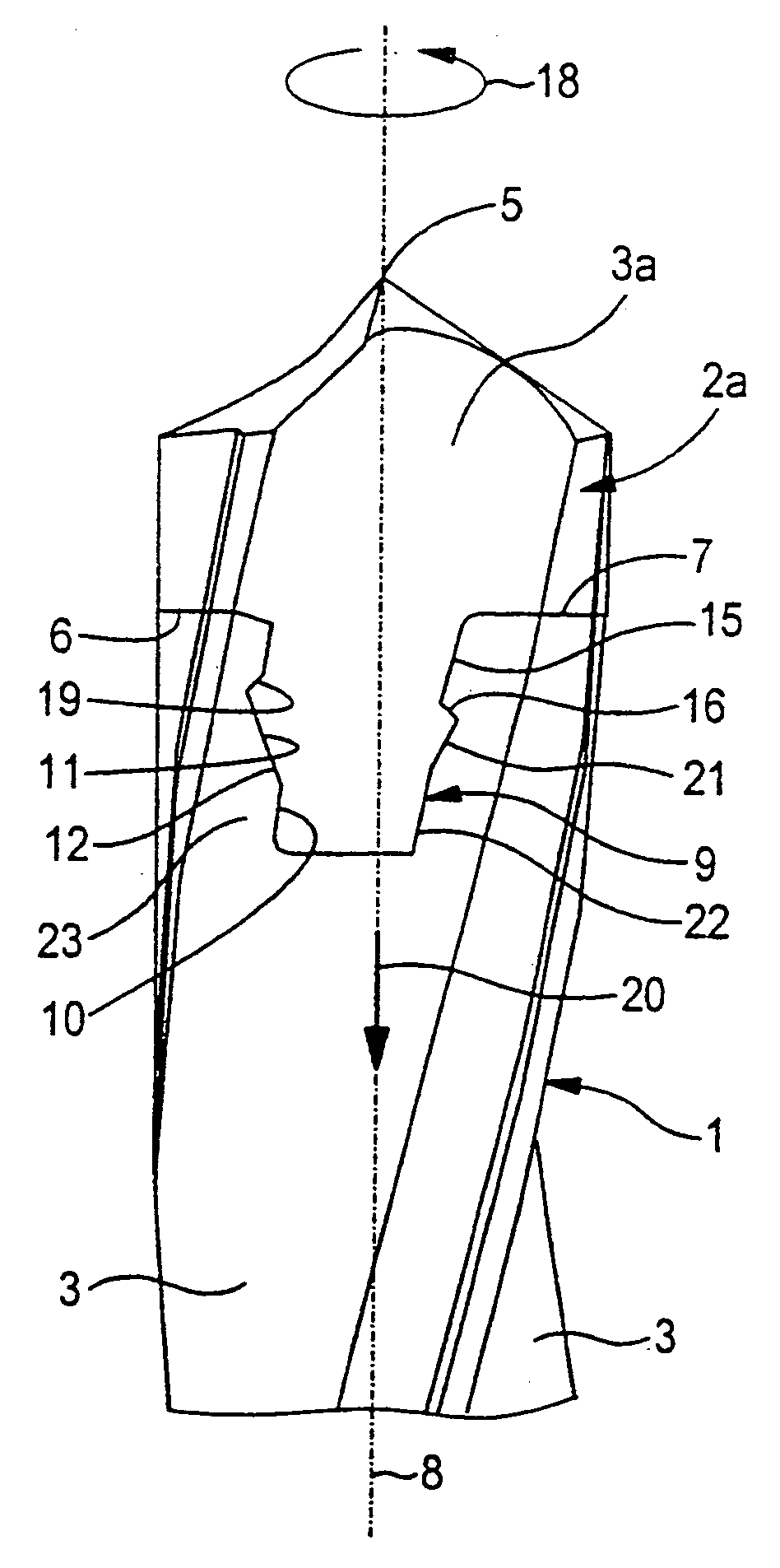

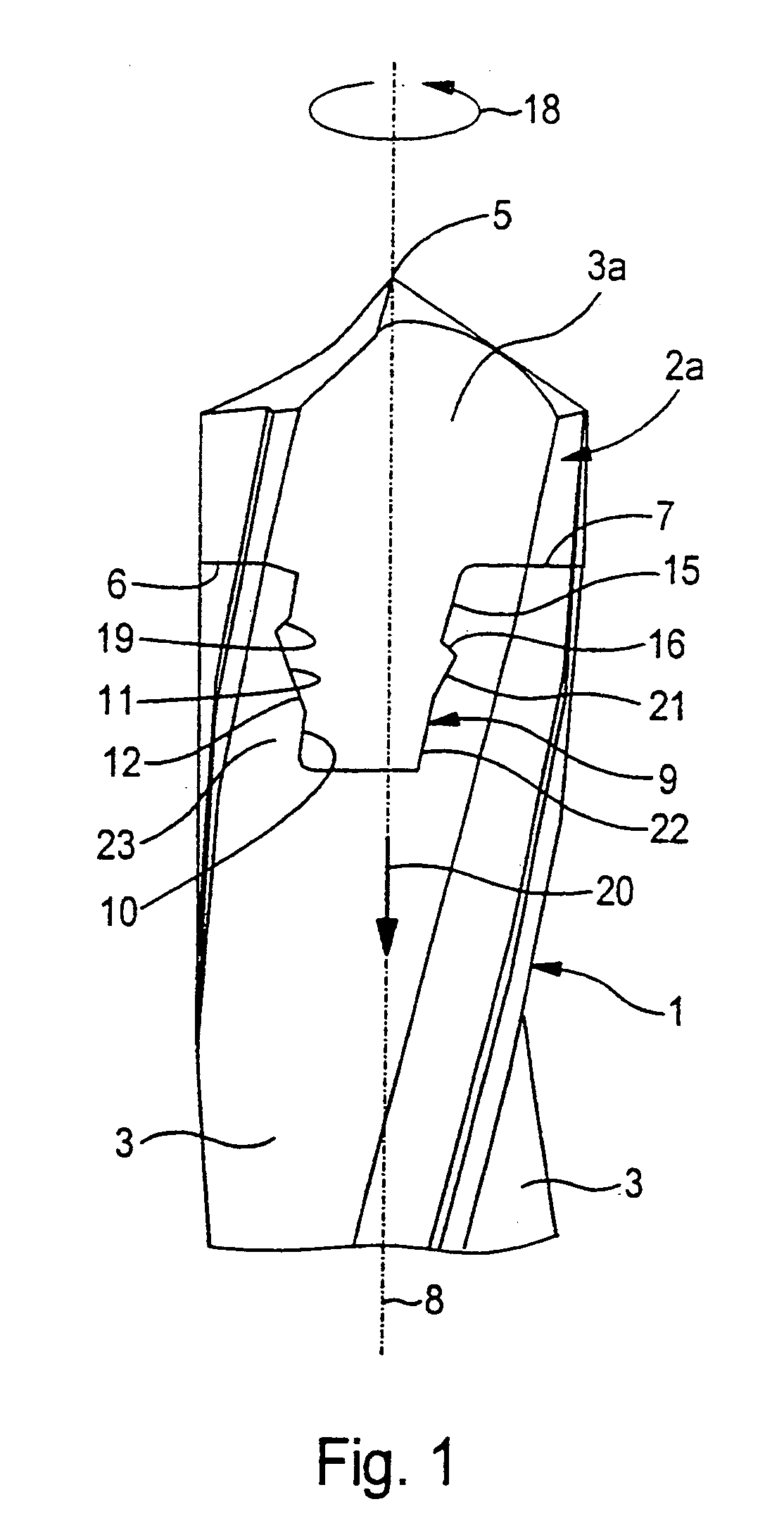

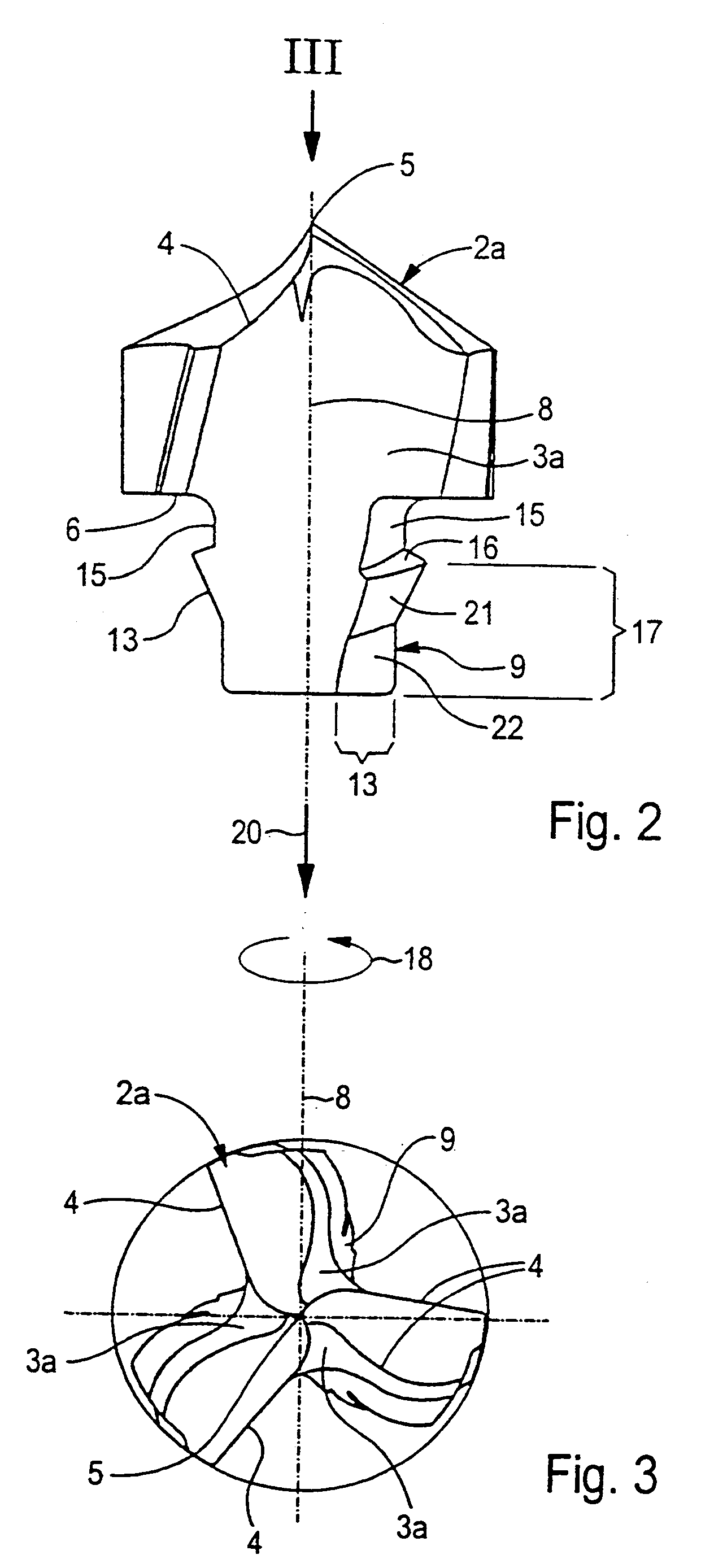

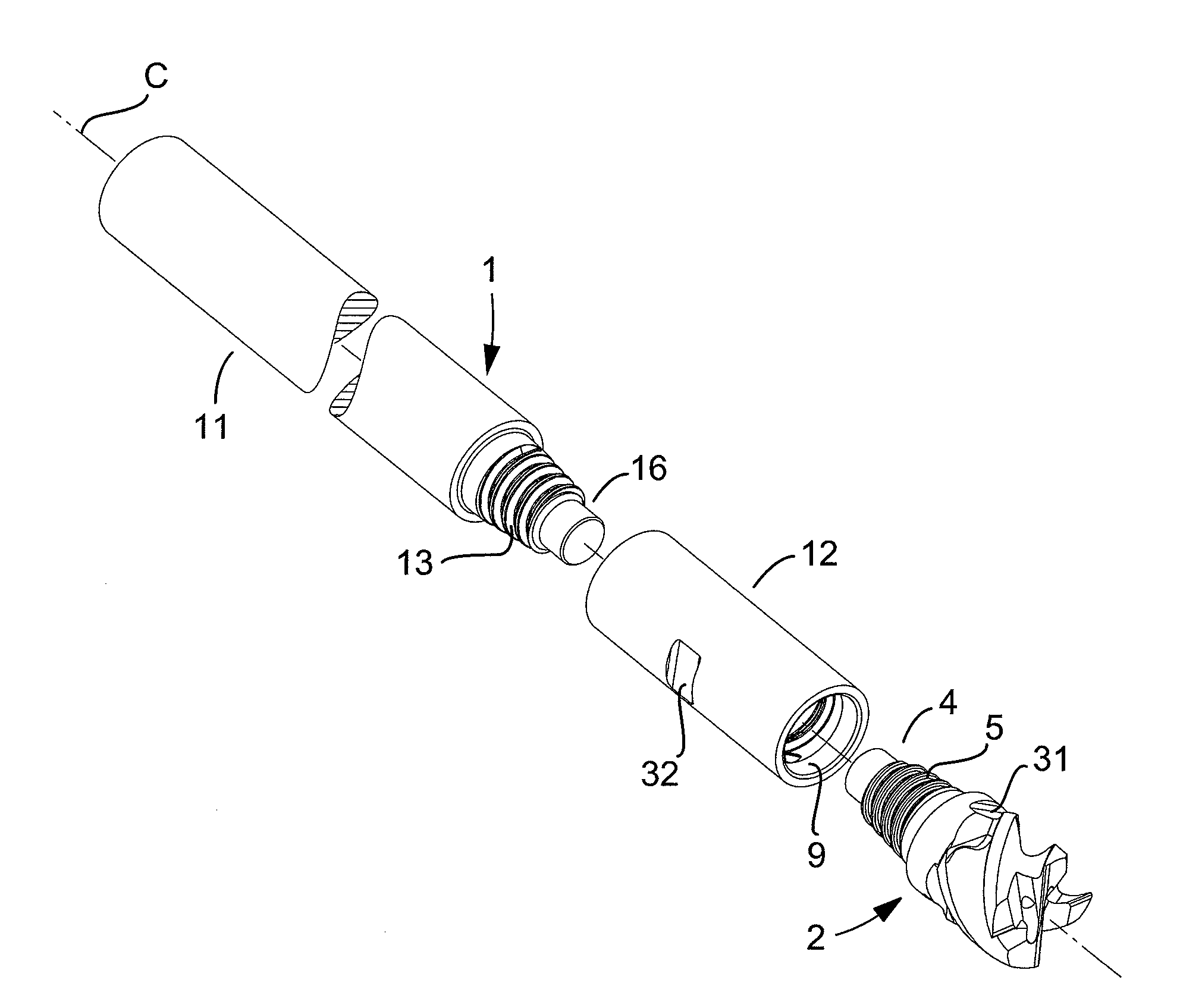

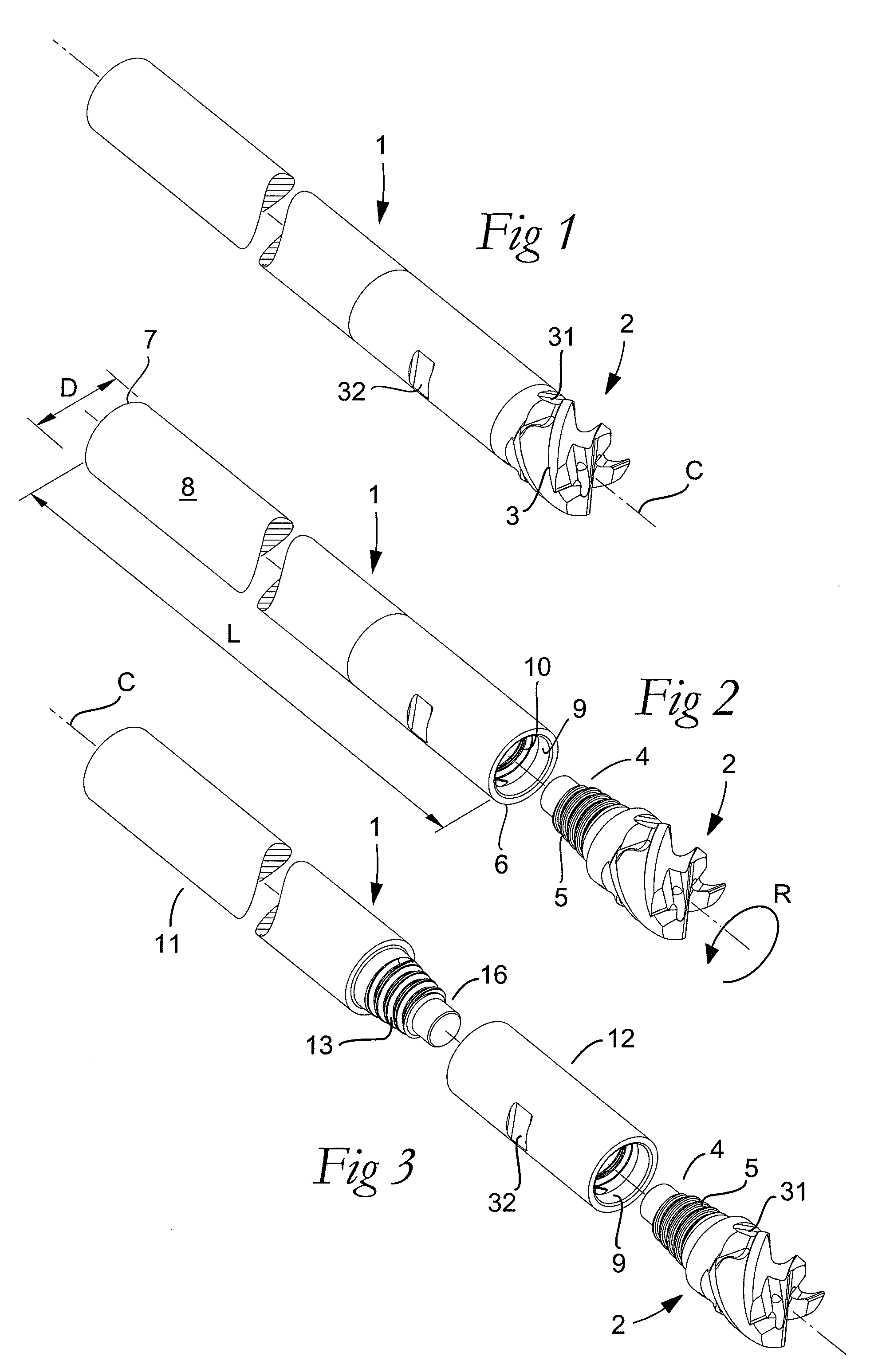

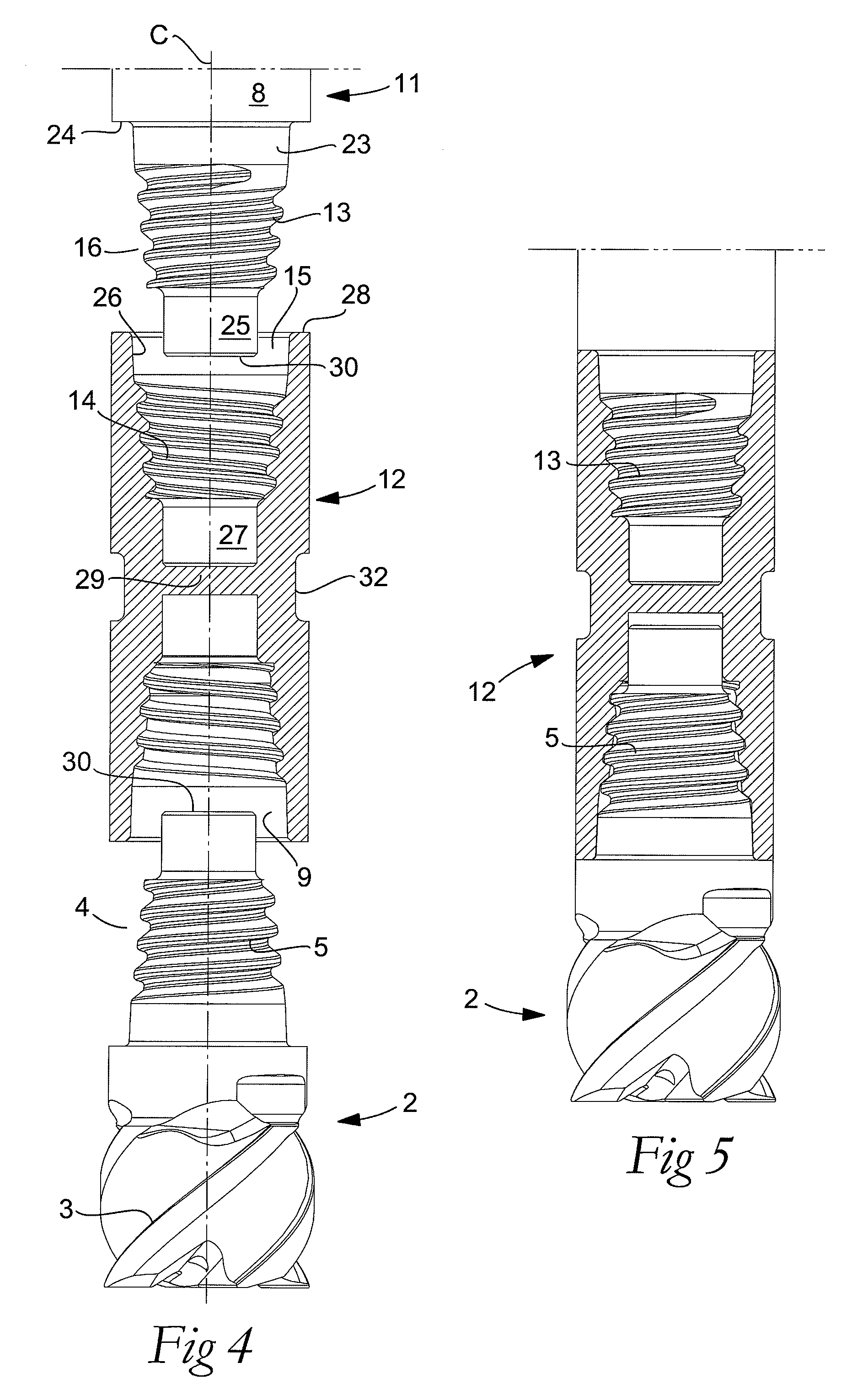

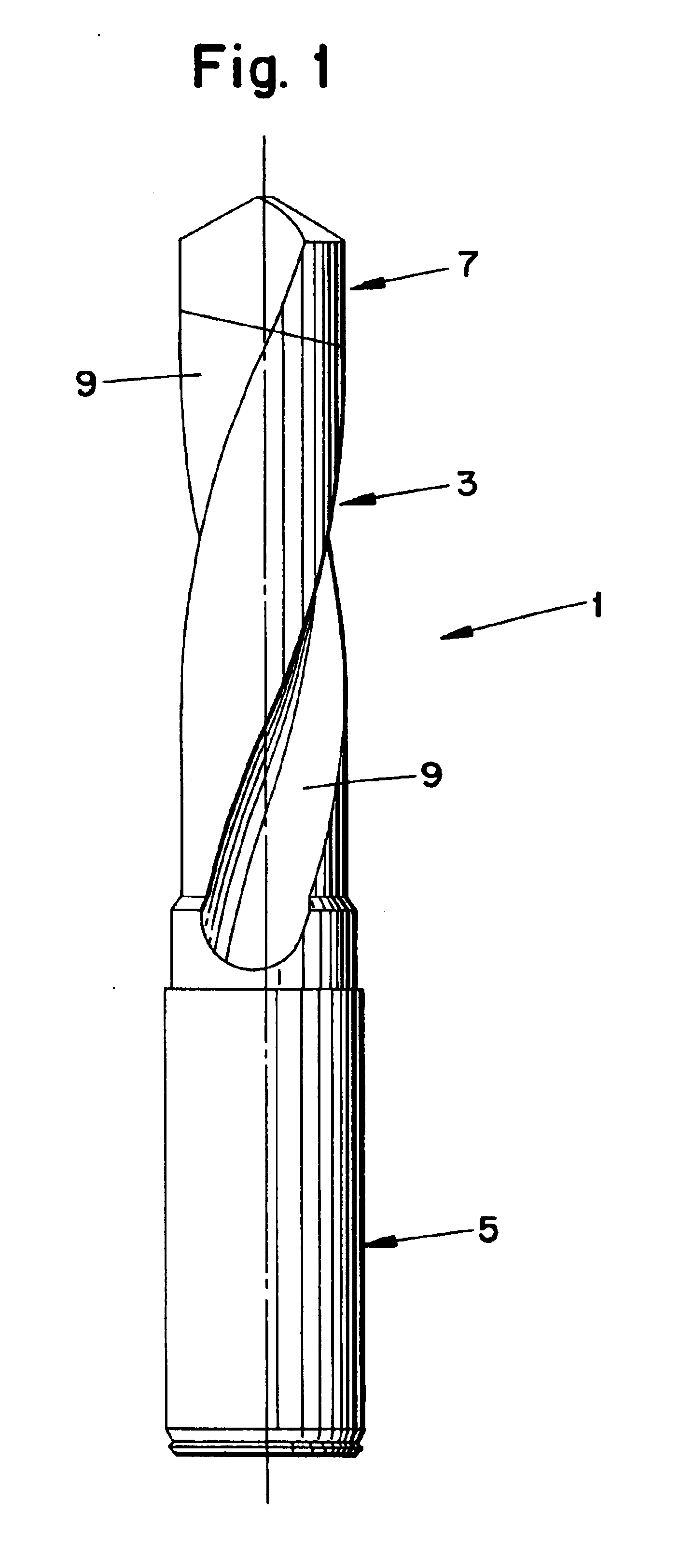

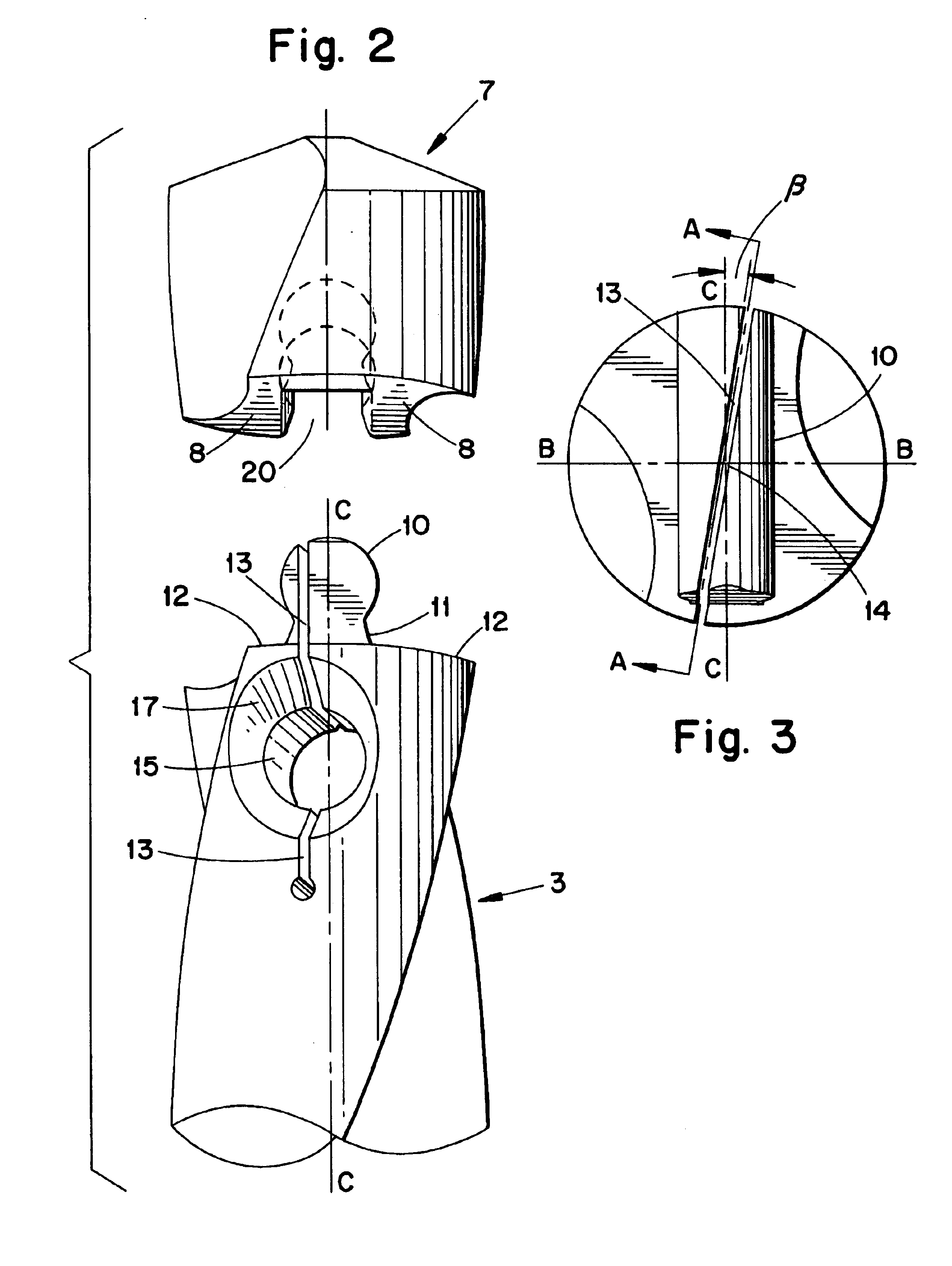

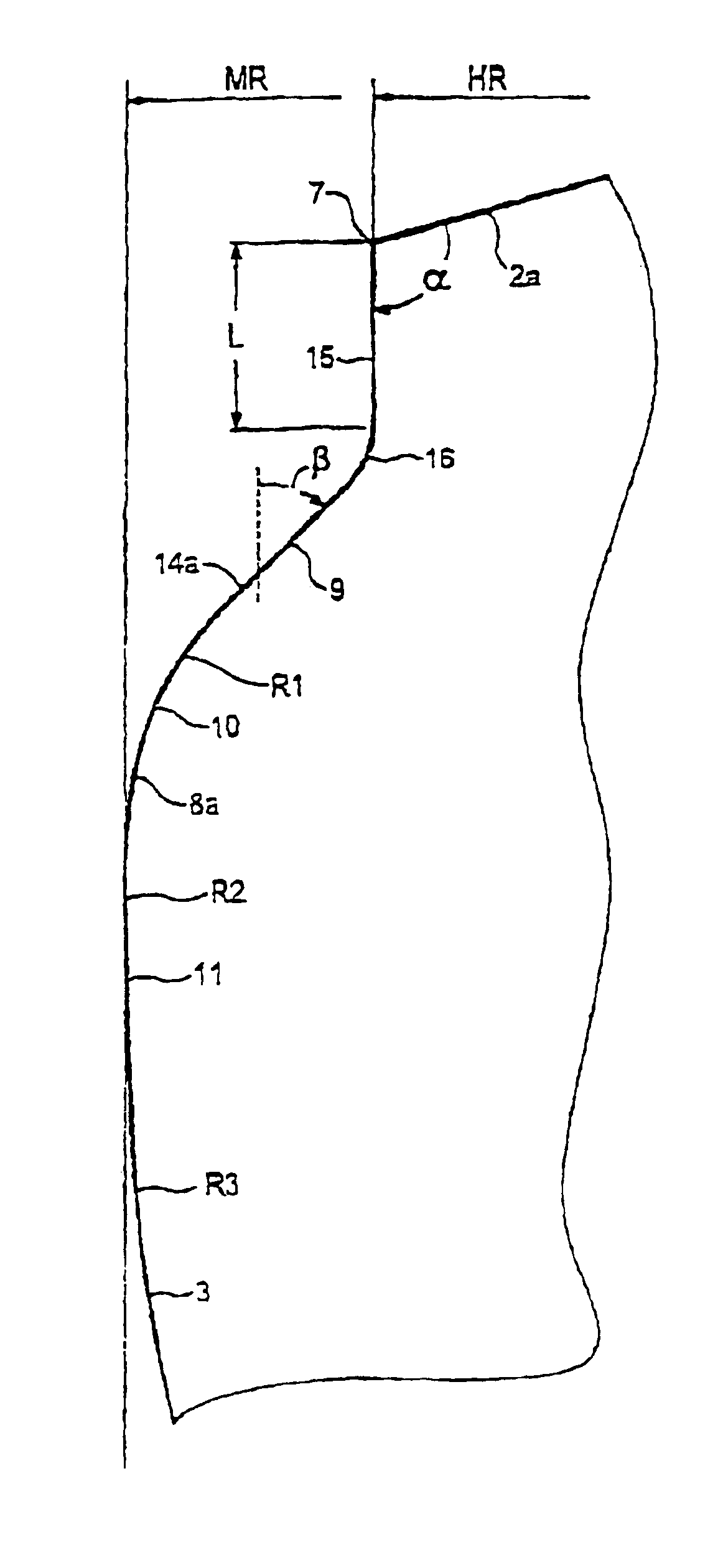

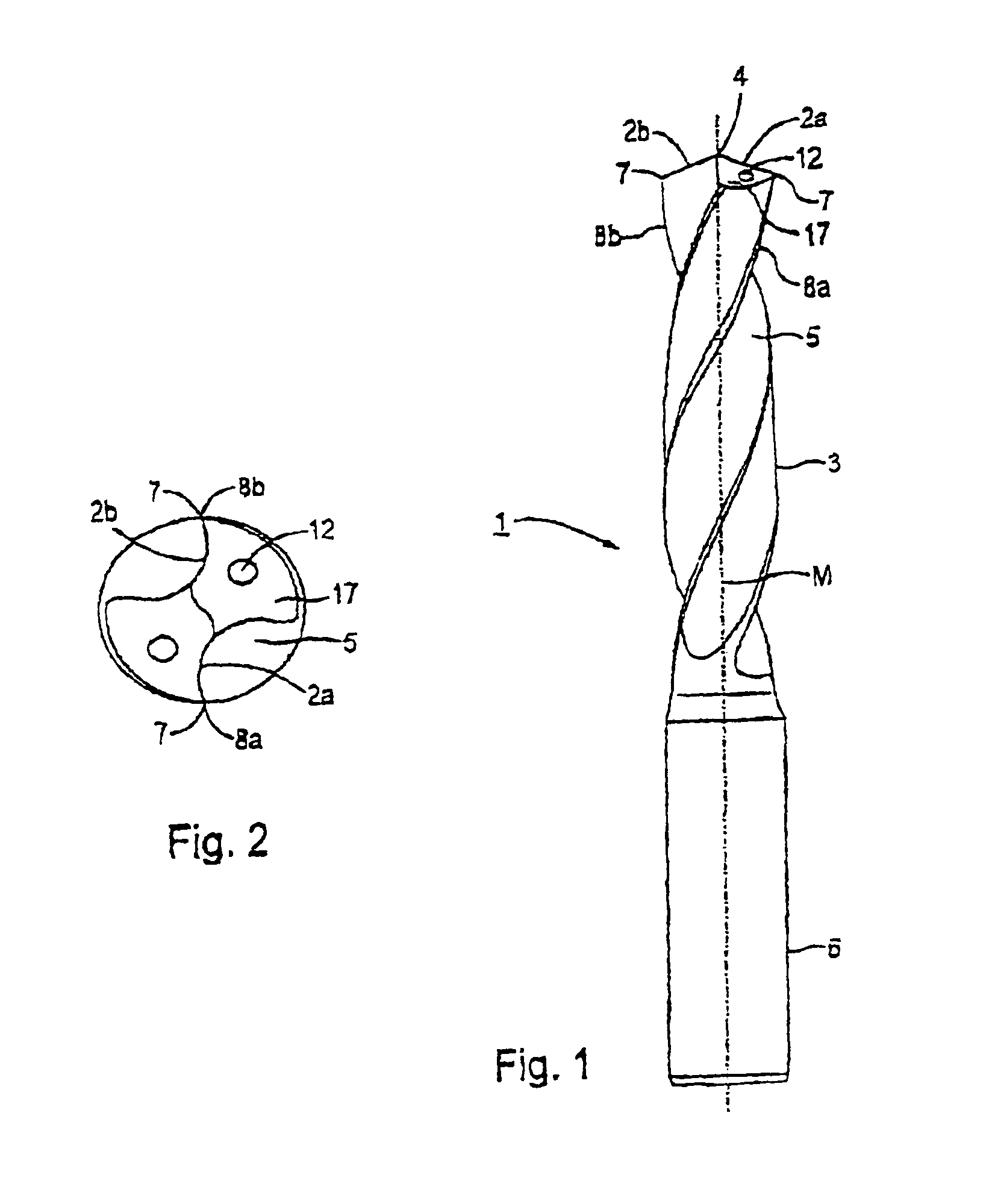

Twist drill for drilling having a replaceable drill tip, and a replaceable drill tip for use in a twist drill

InactiveUS7070367B2Avoid damageAvoid pullingWood turning toolsTransportation and packagingFluteEngineering

A twist drill, having a replaceable drill tip, comprising a drill bit shaft (1), a cutting insert (2) which is detachably fixed thereto and which forms the tip area of the twist drill, and comprises a flute (3) that continues into the cutting insert (2). The cutting insert rests, with a bearing surface (6) extending orthogonal to the center longitudinal axis (8) of the drill bit, on the face (7) of the drill bit shaft (1) and extends with a fixing stud (9), which centrally protrudes from the bearing surface (6), into a receiving recess (10) which is configured complementary thereto and which is provided in the face (7) of the drill bit shaft (1). At least one peripheral section (13) of the fixing stud (9) comprises a first longitudinal section (15) that, with a screw surface (16) which points away from the drill bit shaft (1), which slopes upward to the drill bit tip (5) in a direction of rotation of the drill bit, and which interacts with an opposite surface (19) on the inner wall (14) of the receiving recess (10), merges into a second longitudinal section (17).

Owner:KENNAMETAL INC

Cutting tool assembly and cutting head therefor

A rotary cutting tool comprising a solid cutting head mounted to a shank. The cutting head comprises a cutting portion adjacent a cutting head front face and a mounting portion integrally formed therewith and extending rearwardly therefrom. The shank comprises a receiving portion extending rearwardly from a shank front face. When the cutting head is secured to the shank, the mounting portion is received in the receiving portion, and the shank front face is forwardly exposed and adjacent the cutting head front face.

Owner:ISCAR LTD

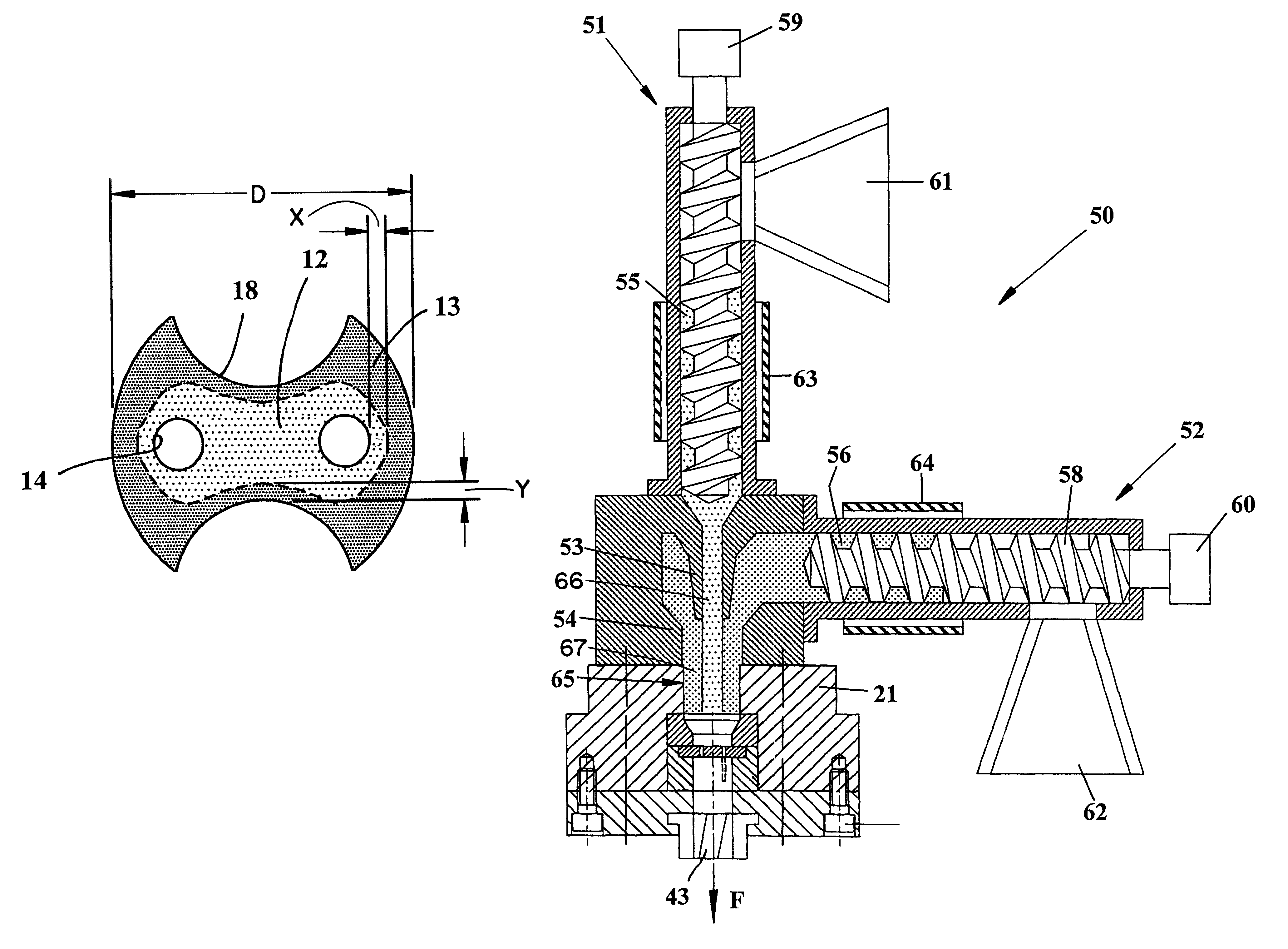

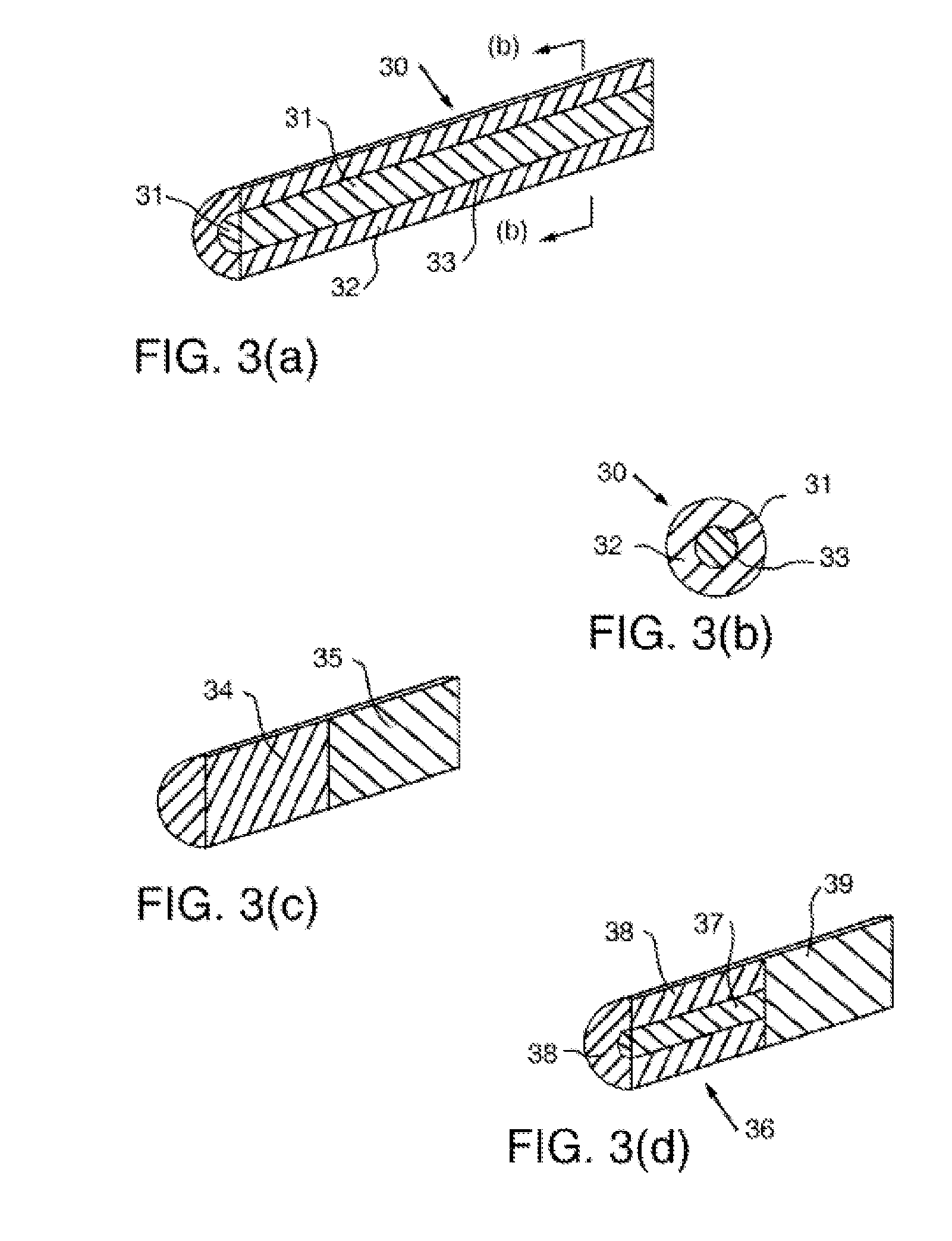

Tool for chip removing machining and methods and apparatus for making the tool

InactiveUS6450739B1Drawback can be obviatedDrawbacks of the known technique are eliminatedMetal-working drilling toolsTransportation and packagingWear resistantEngineering

A tool for chip-forming machining is made by passing first and second compounds through first and second coaxial dies, respectively, whereby the first material forms a center core of the tool, and the second material forms an outer rod of the material. The material of the core is tougher and less wear-resistant than the material of the outer rod. The coaxial first and second compounds are passed through a shaping die and then through a flute-forming structure which forms chip flutes in the outer rod.

Owner:SECO TOOLS AB

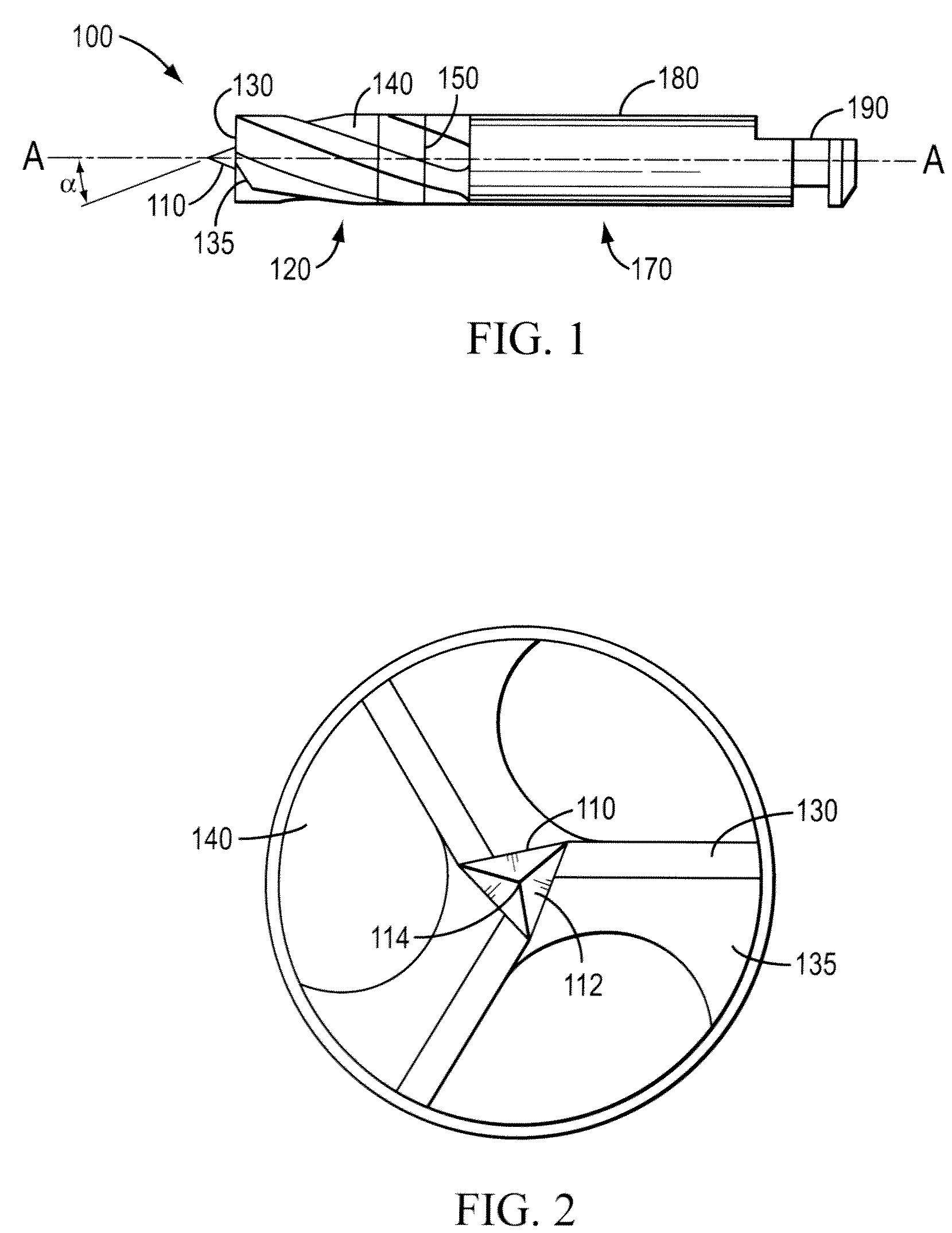

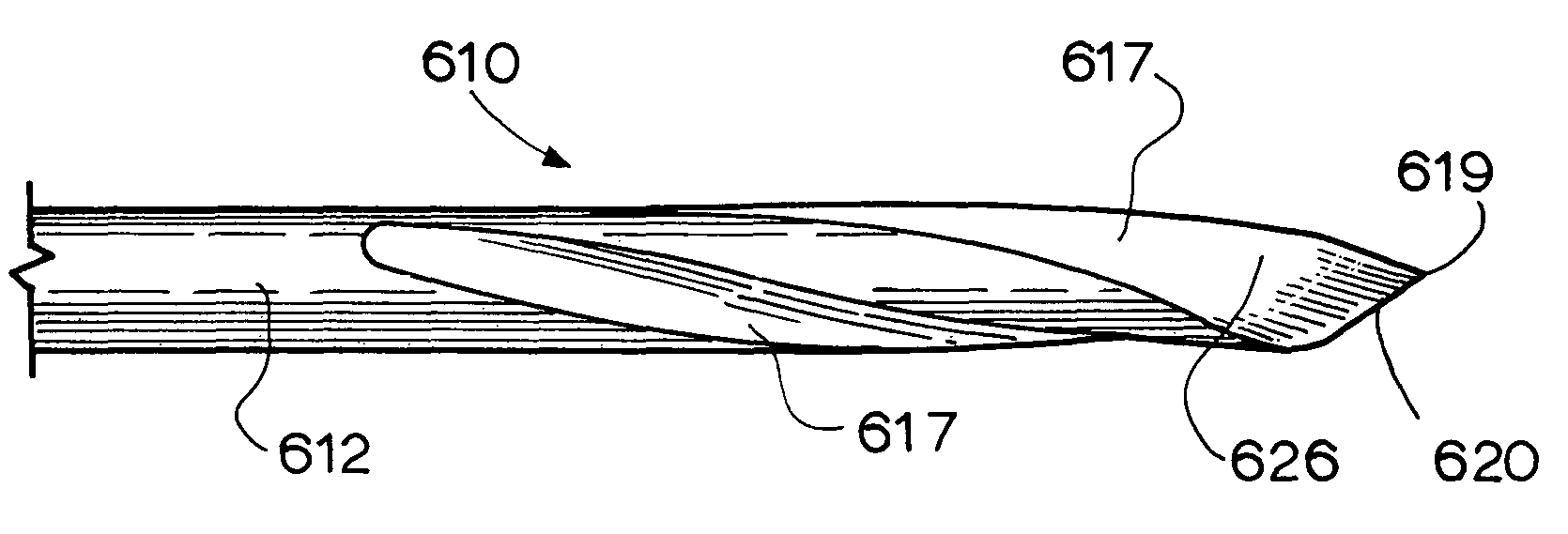

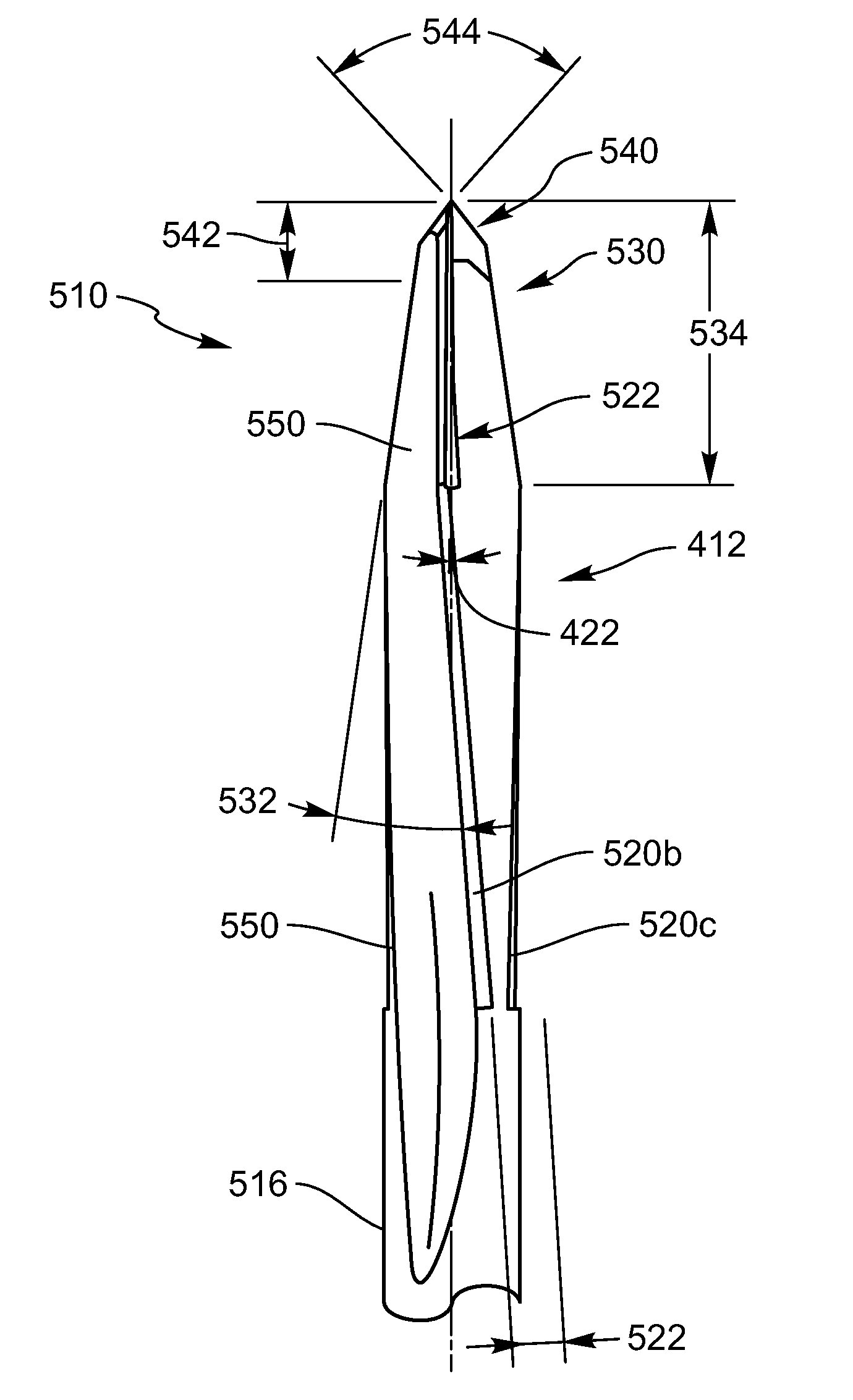

Trocar-tipped drill bit

InactiveUS20100145341A1Reduce in quantityDental implantsWood turning toolsBiomedical engineeringAbdominal trocar

Owner:AETON MEDICAL

Tool for chip removing machining as well as a basic body therefore

InactiveUS7713004B2Easy to processImprove accuracyTool workpiece connectionTransportation and packagingCouplingAxial force

A tool for chip removing machining, including a long narrow basic body having an envelope surface which is concentric with a center axis, and two opposite ends, and a replaceable loose top which is connected to the basic body via a first coupling that includes a first seating formed in one end of the basic body and a first male element formed in one end of the loose top. The basic body includes a primary part body made of a first material having a first modulus of elasticity, and a secondary part body which includes the first seating and is made of a second material having a second modulus of elasticity which is lower than the first modulus of elasticity. The two part bodies of the basic body are interconnected via a second coupling which includes a second seating in the secondary part body as well as a second male element that is formed on the primary part body and has one or more precision machined flank surfaces that are arranged to apply, together with one or more co-operating and precision machined flank surfaces of the second seating, joining axial forces to the part bodies by turning the part bodies in relation to each other.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

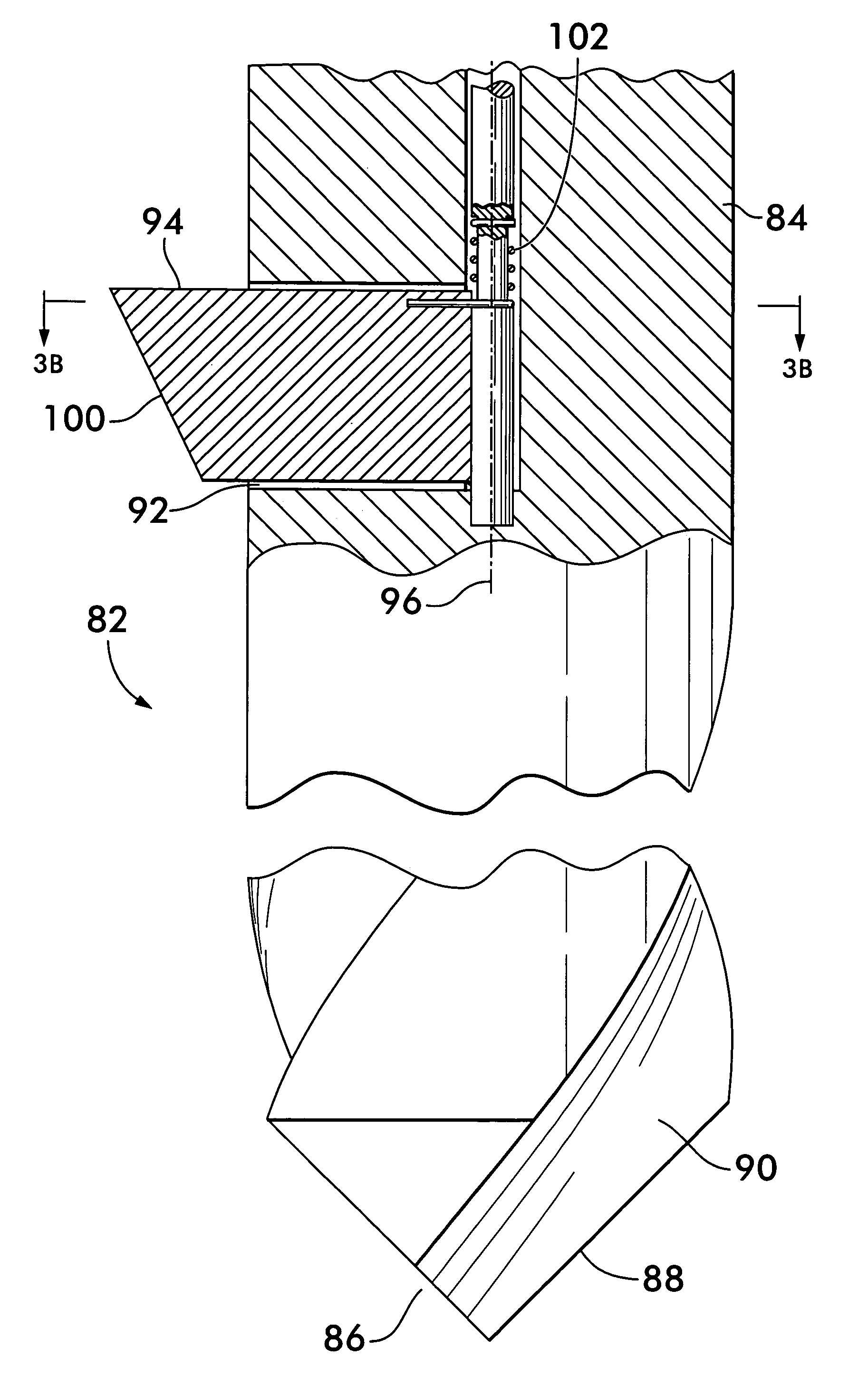

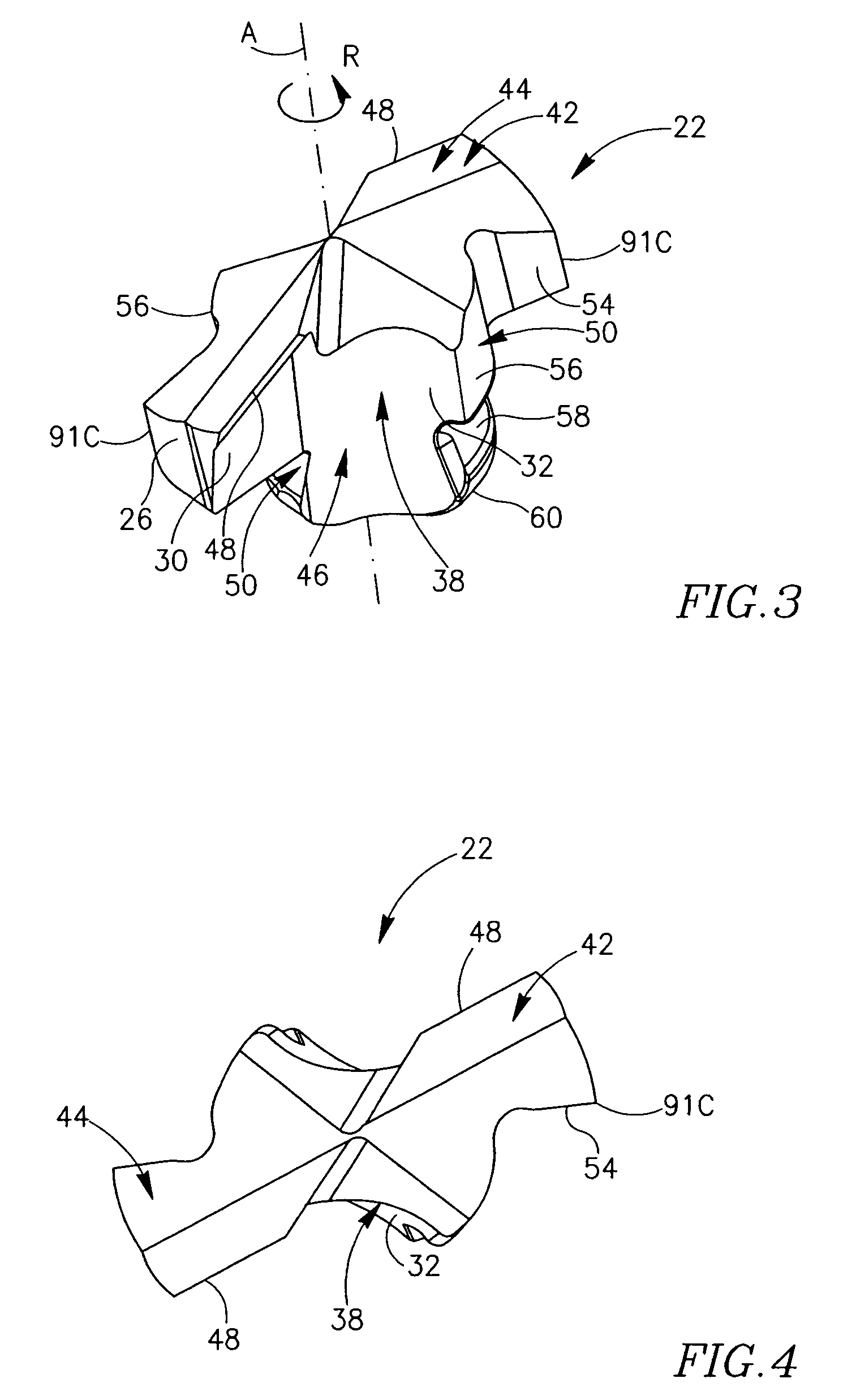

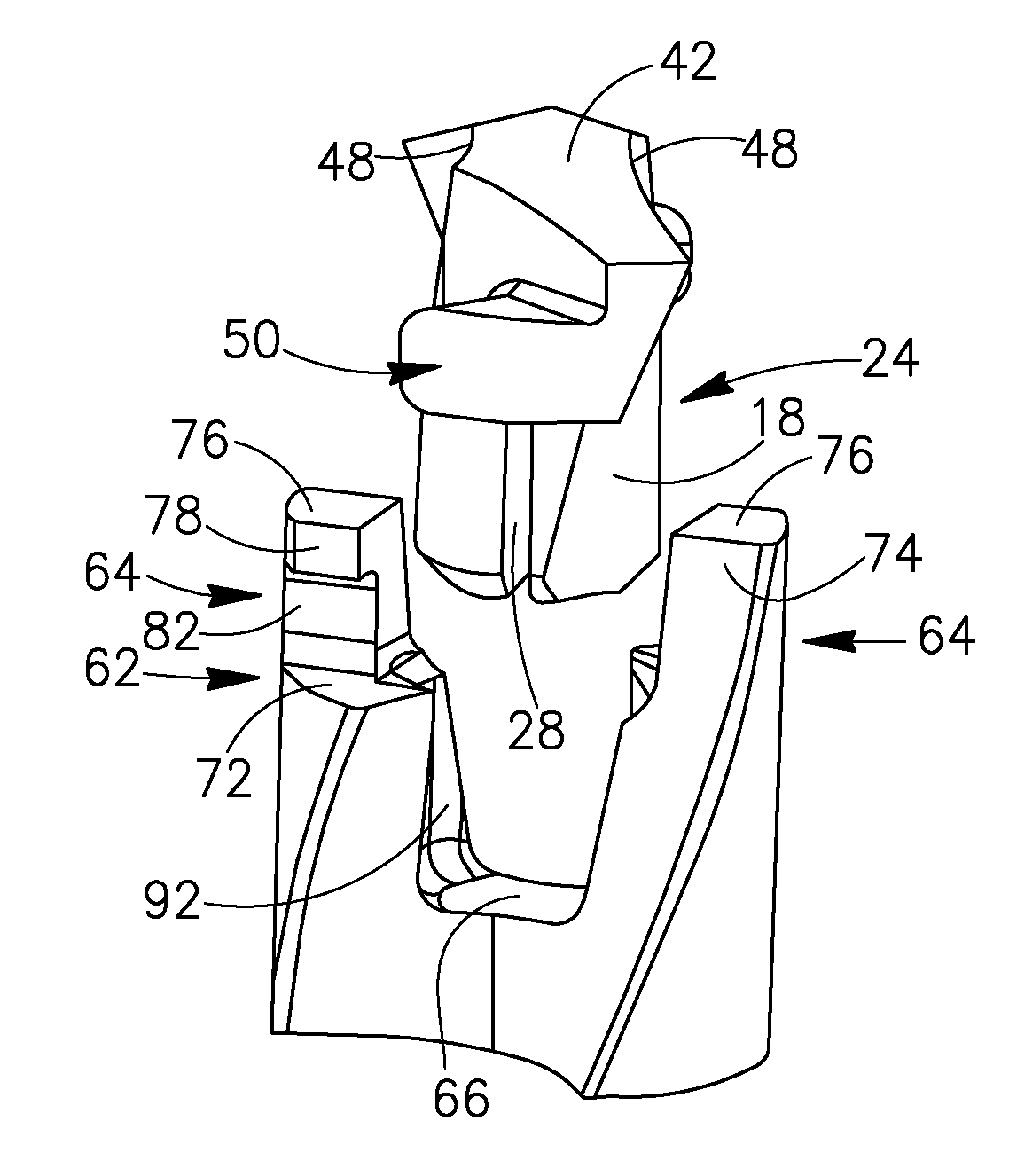

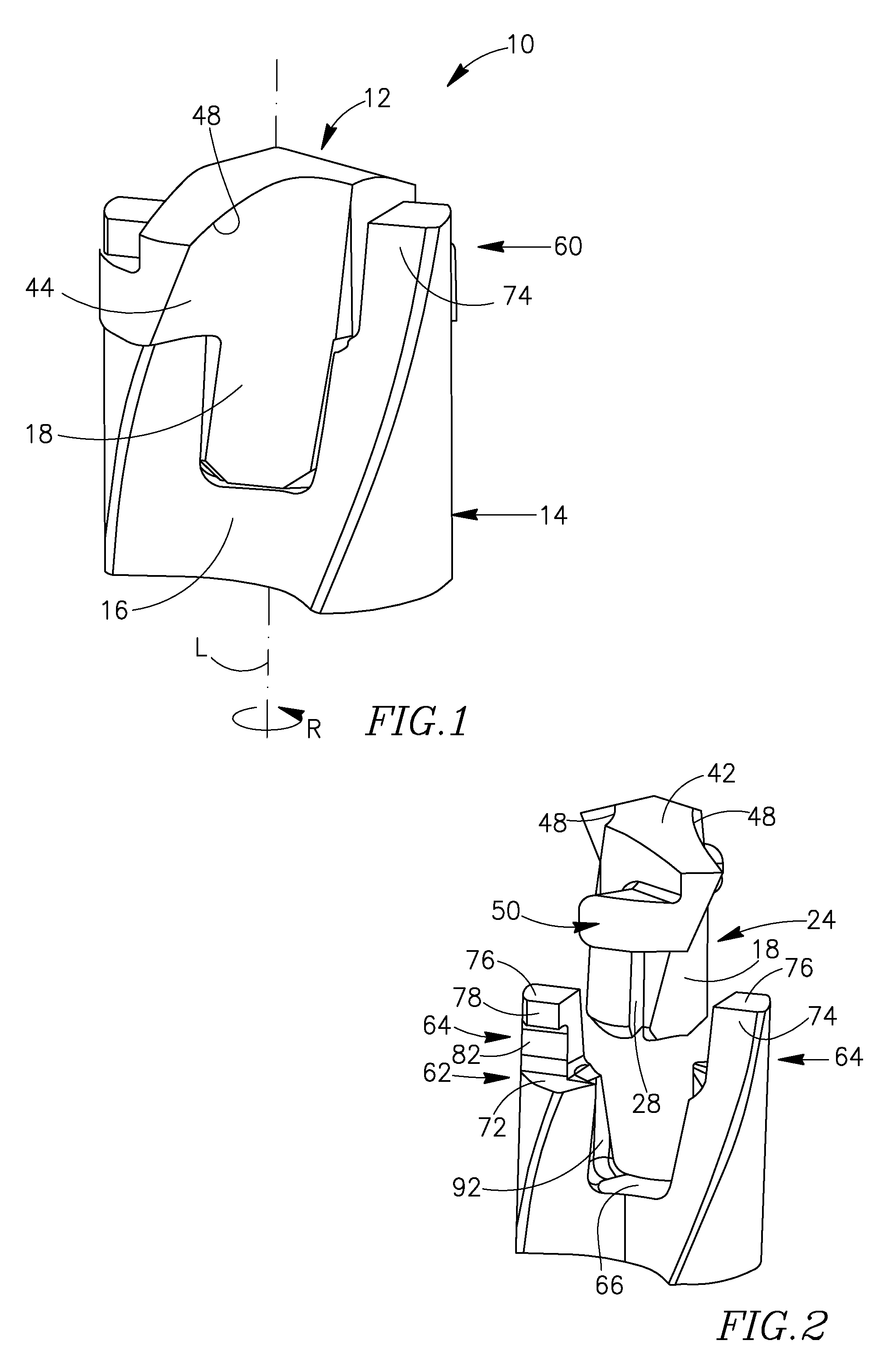

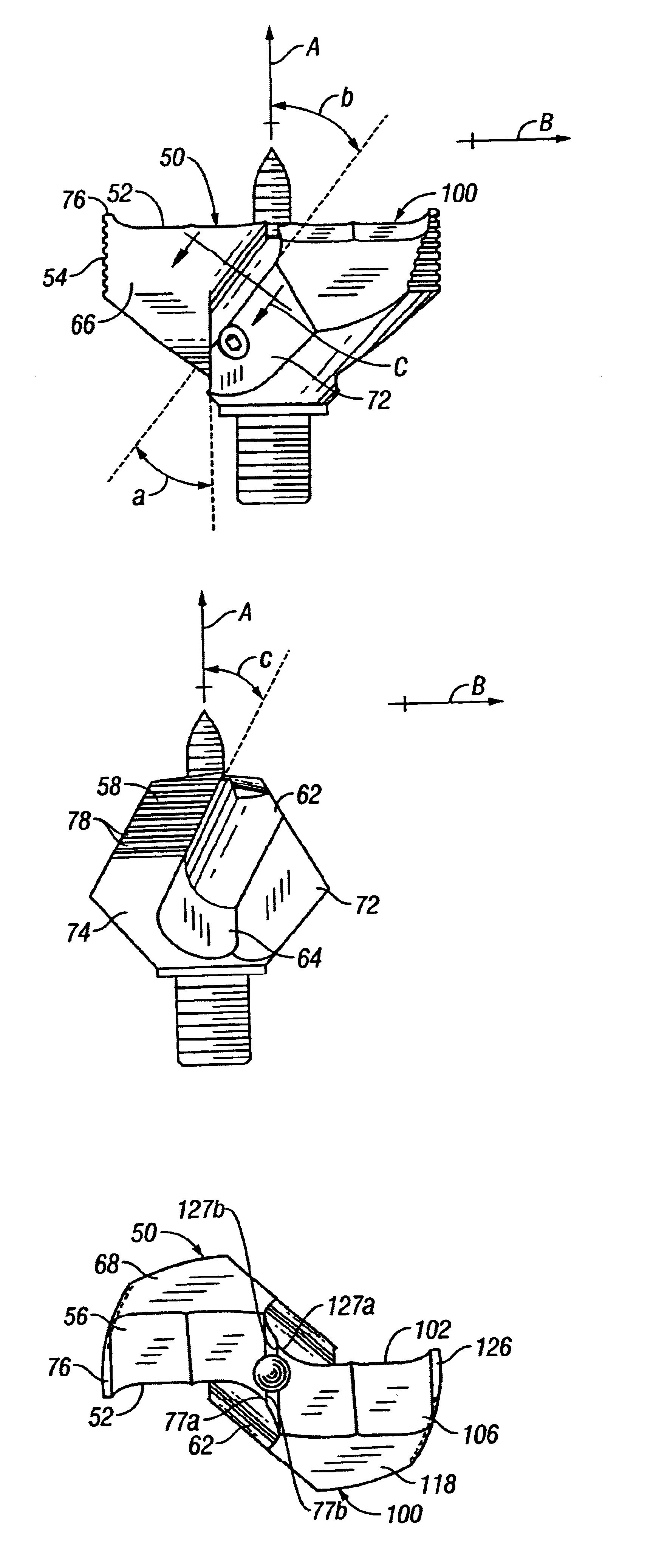

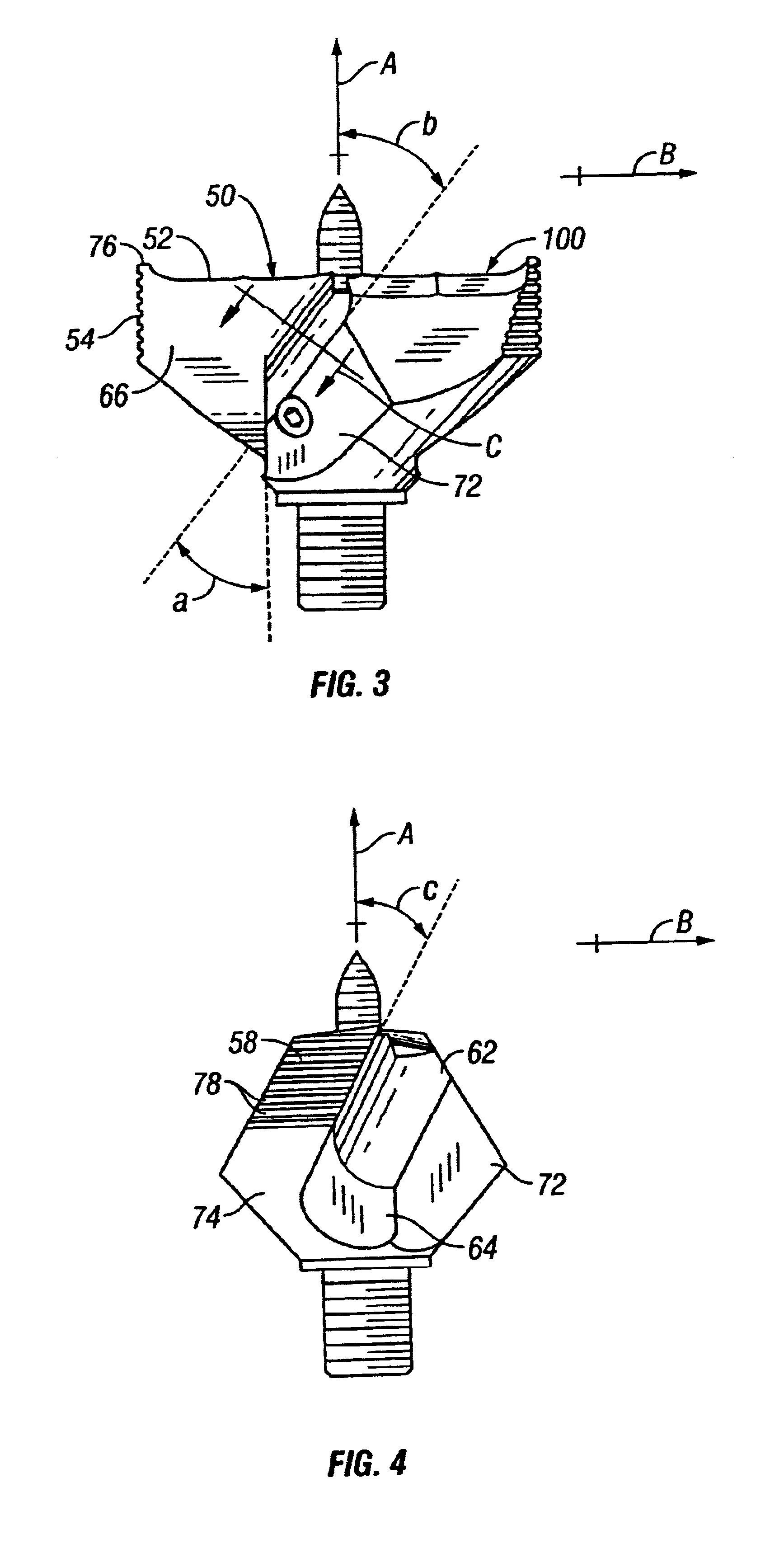

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

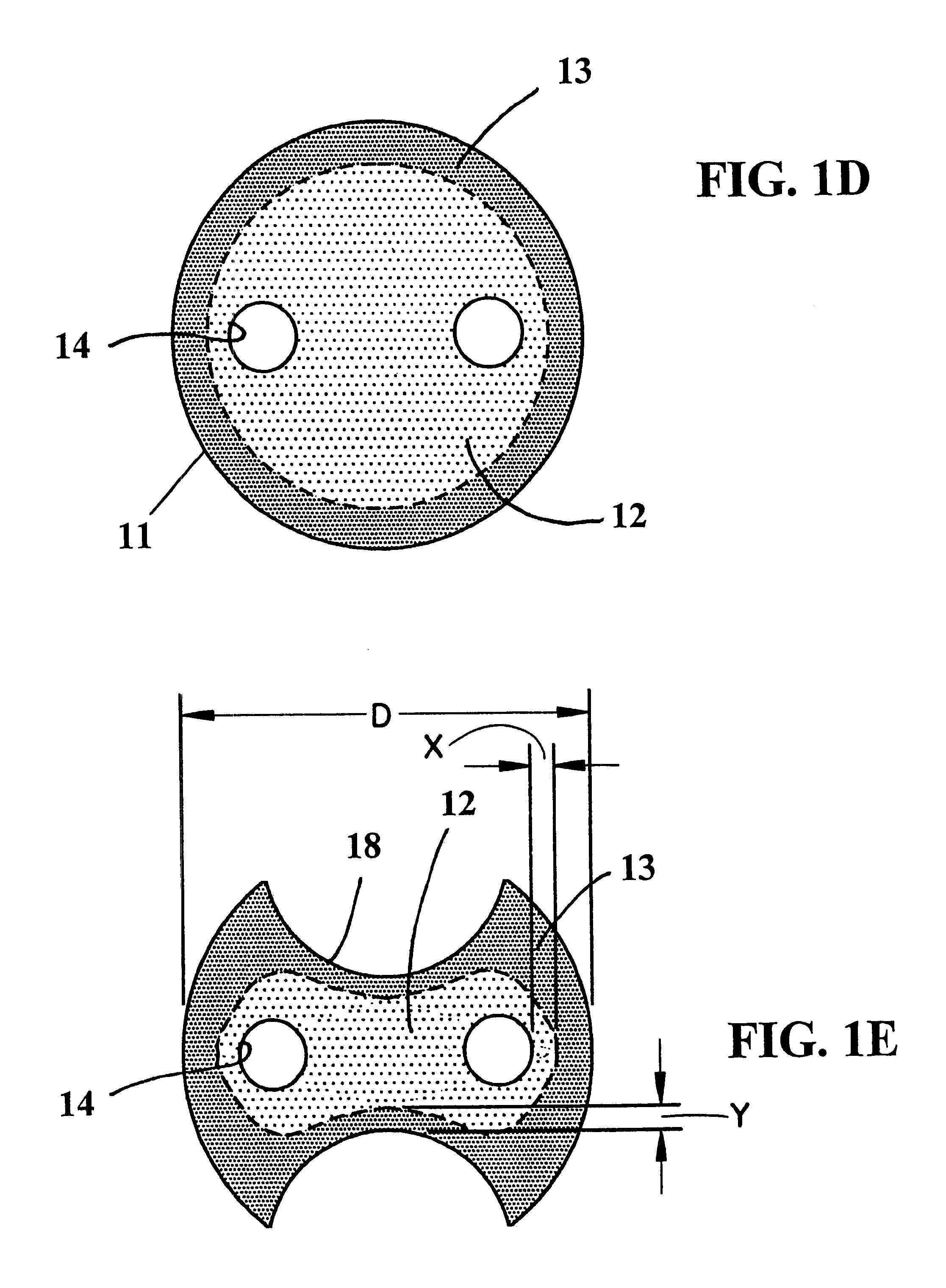

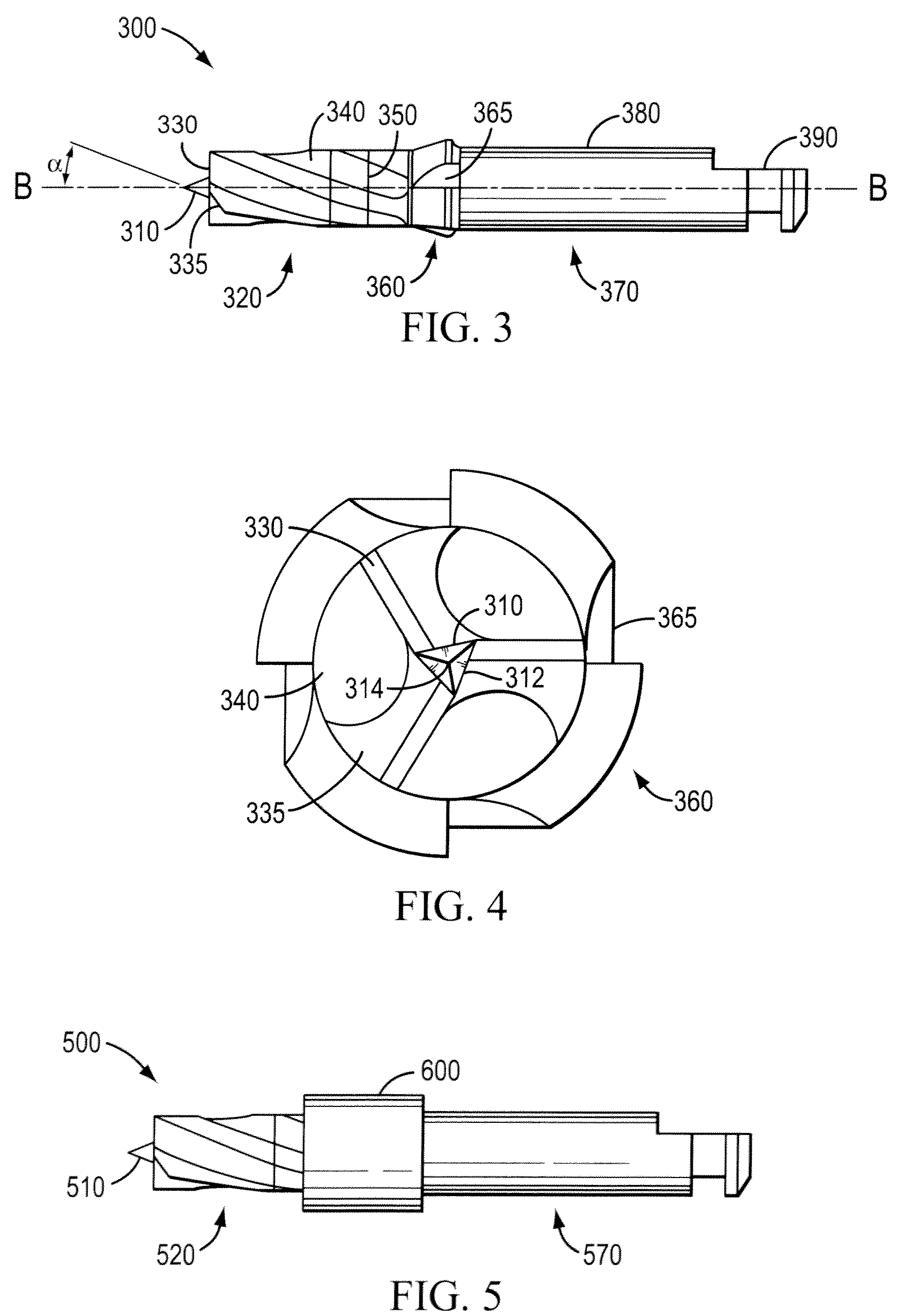

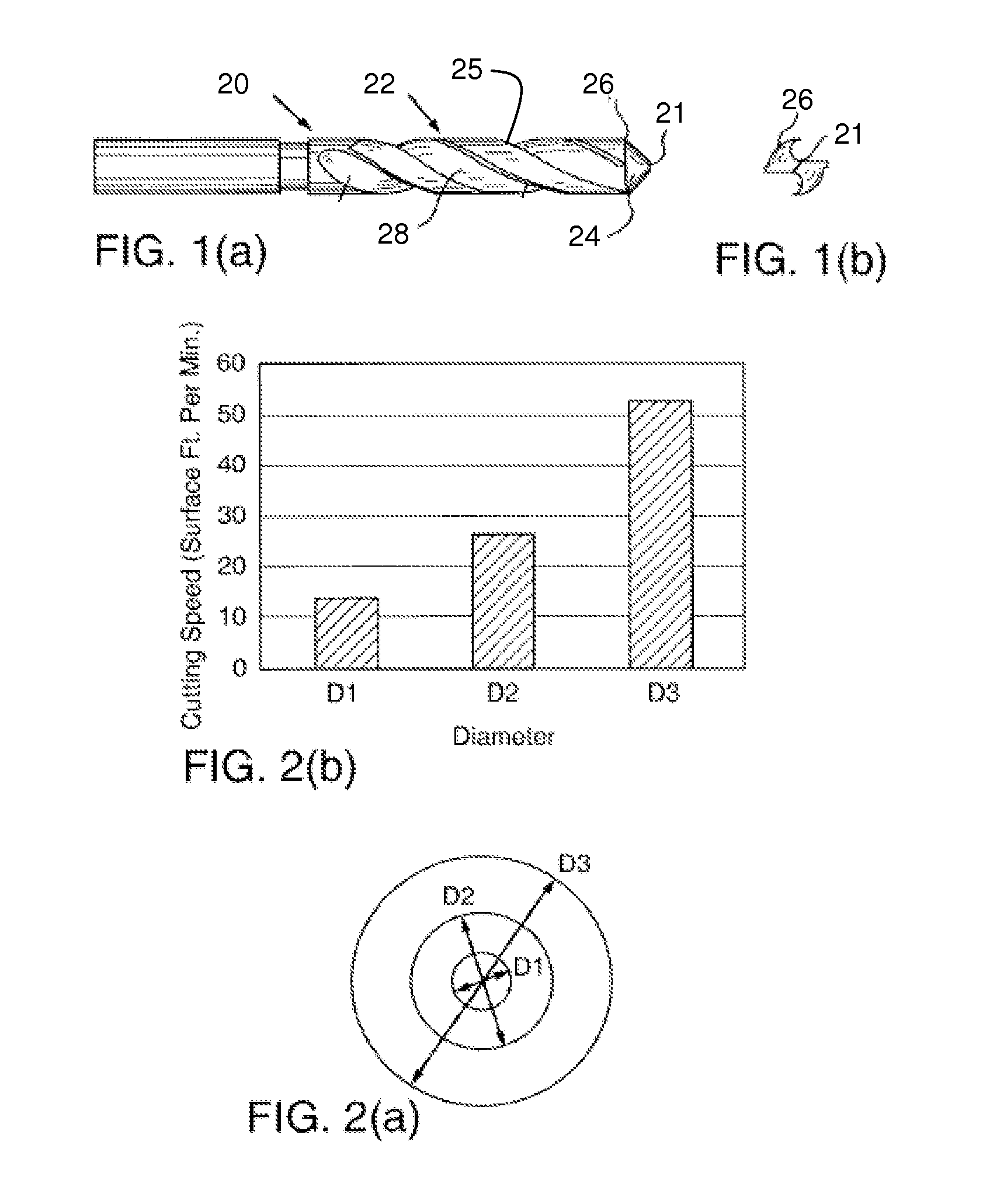

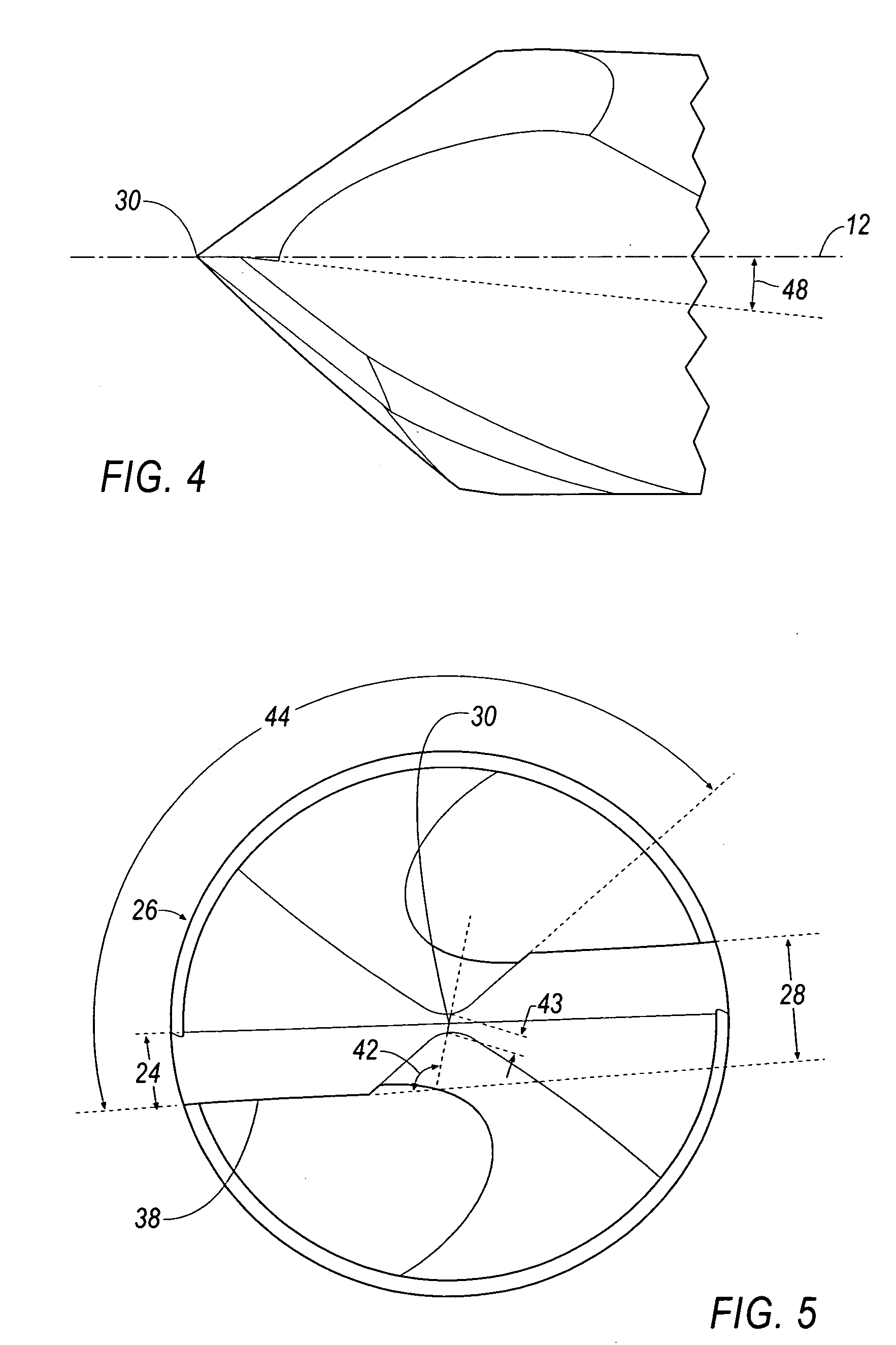

PCD drill for composite materials

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

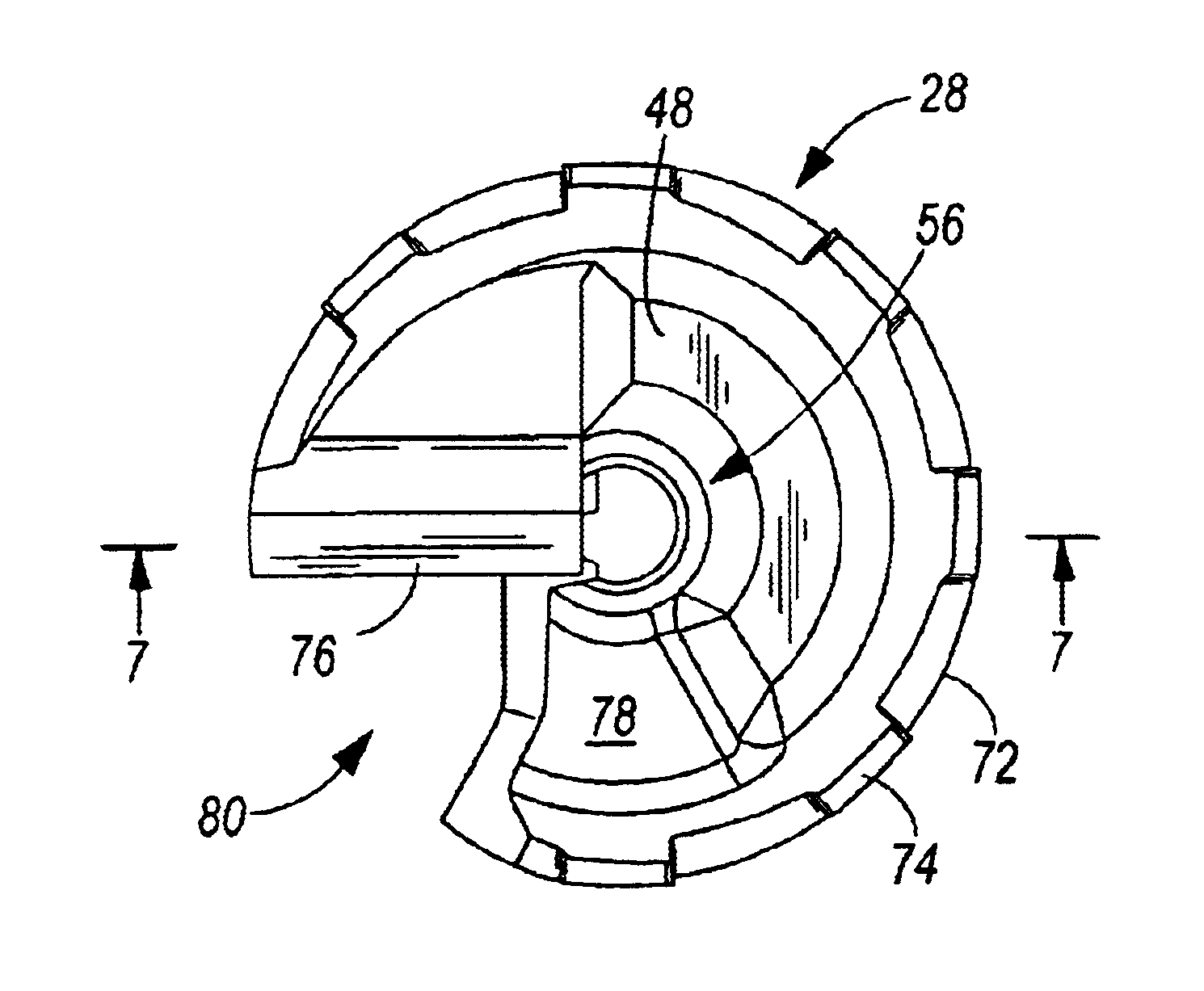

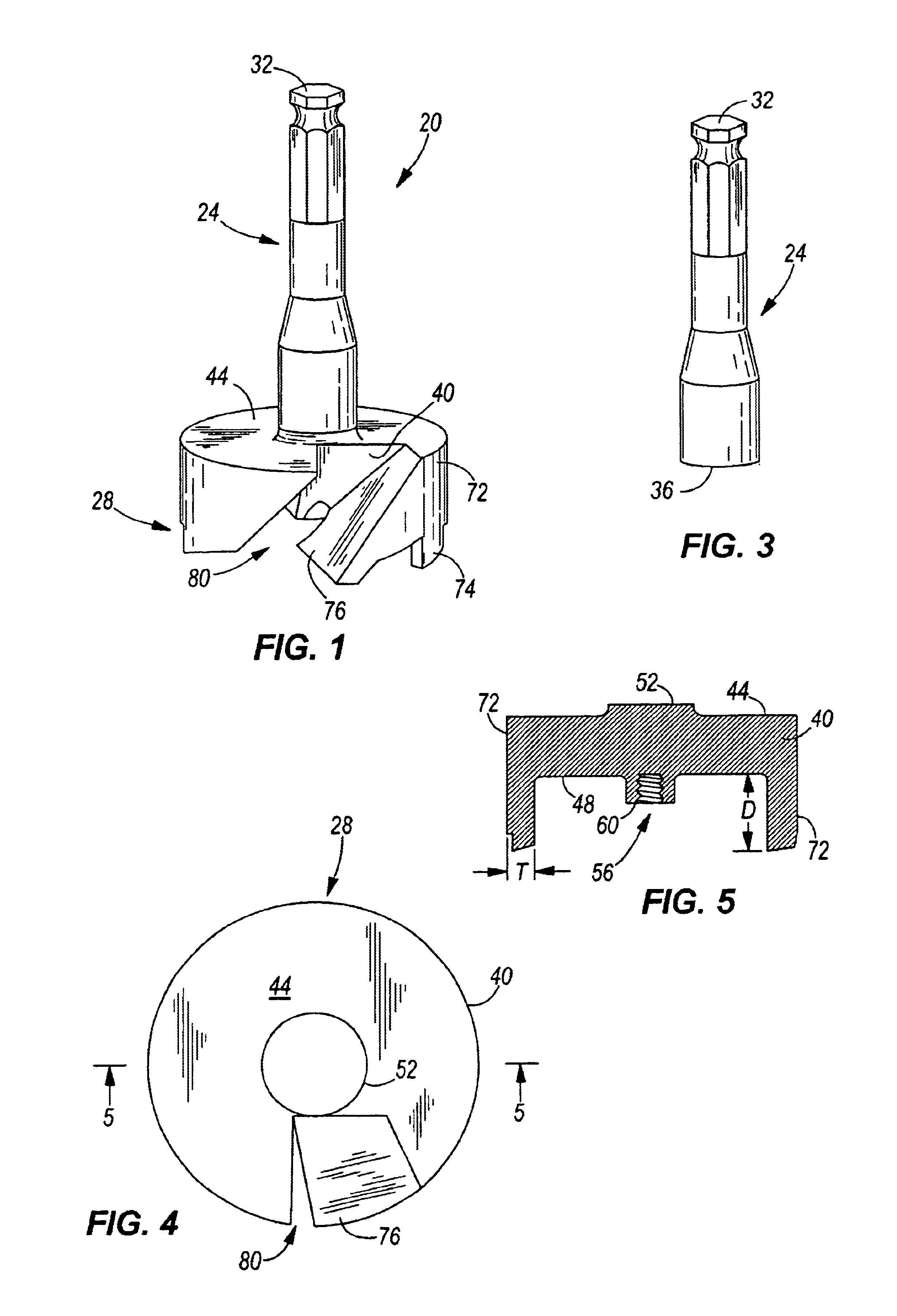

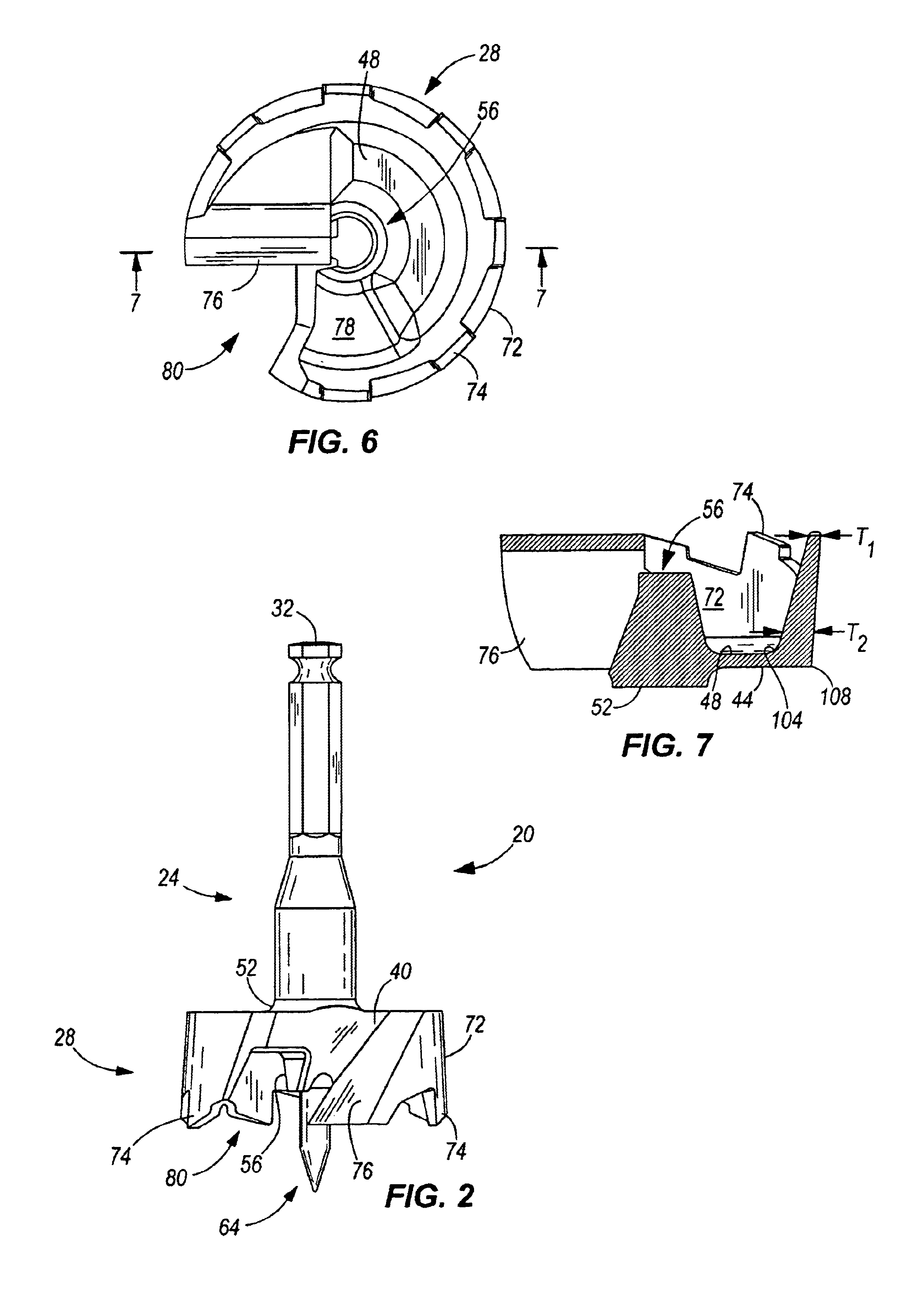

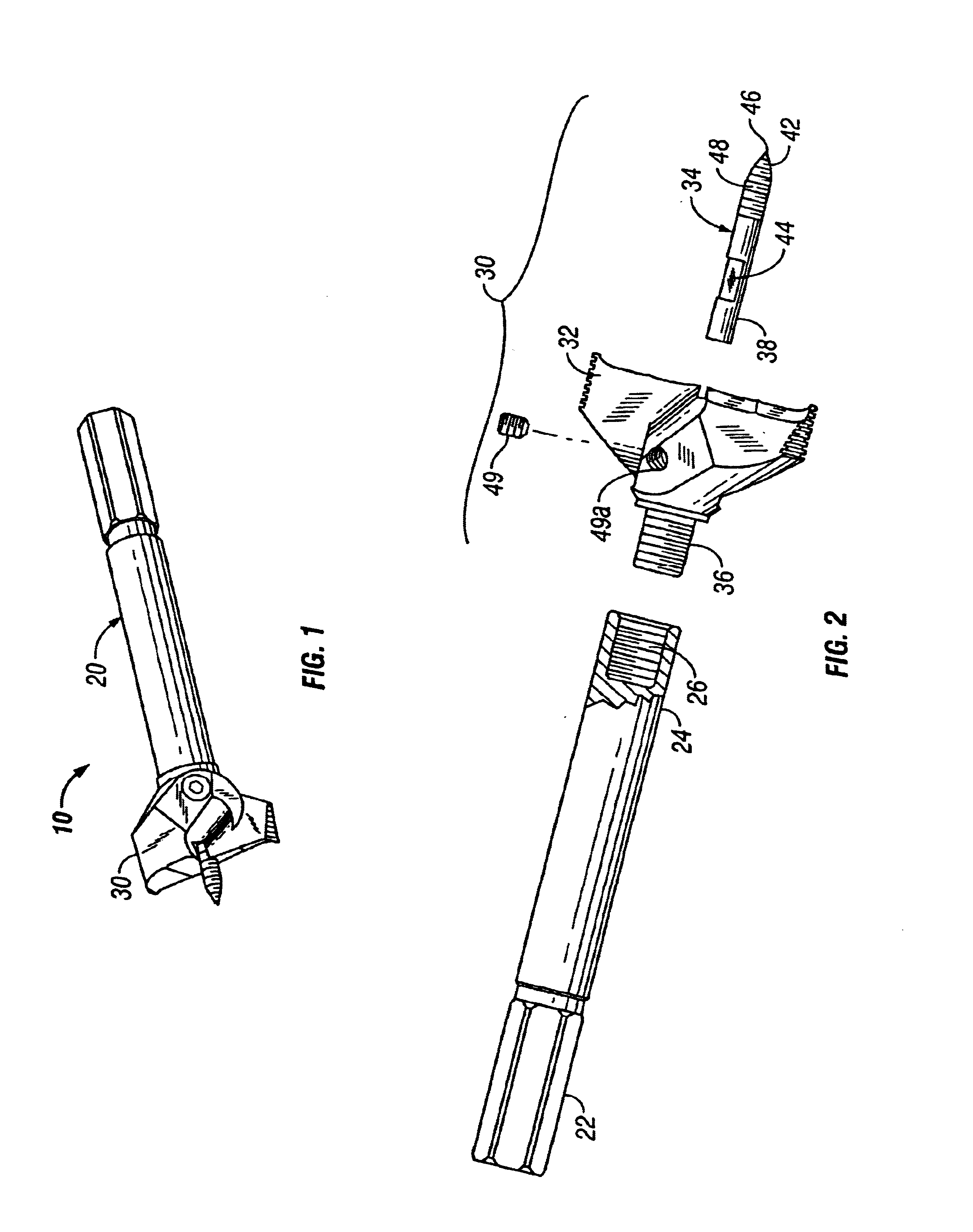

Boring bit and methods for manufacturing boring bits

InactiveUS6874978B2Reduce extra spaceReduce spacingThread cutting toolsWood turning toolsEngineeringPower tool

Boring bits and methods for manufacturing boring bits. The method includes the acts of forming a shank including one end connectable to a power tool and an opposite end, molding a cutting head separate from the shank, the cutting head including a base wall and a side wall extending from the base wall, the base wall having an interior base surface and an exterior base surface, and bonding the shank and the cutting head as a unit including bonding the opposite end of the shank to the exterior base surface.

Owner:MILWAUKEE ELECTRIC TOOL CORP

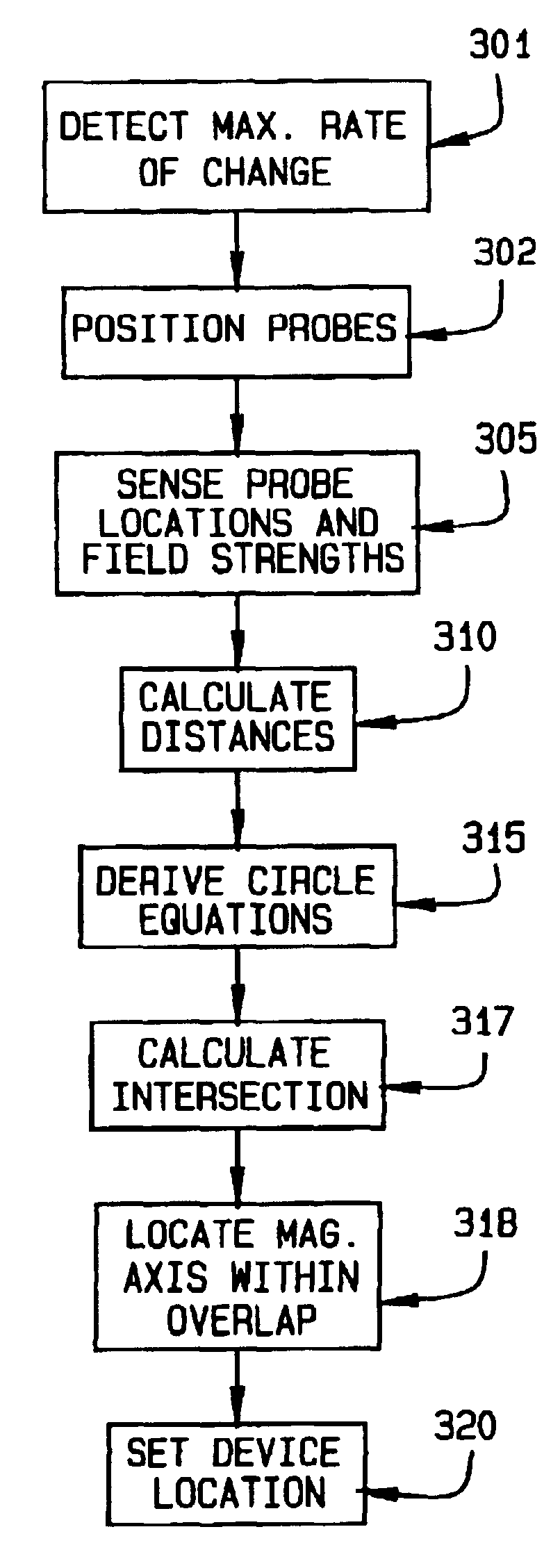

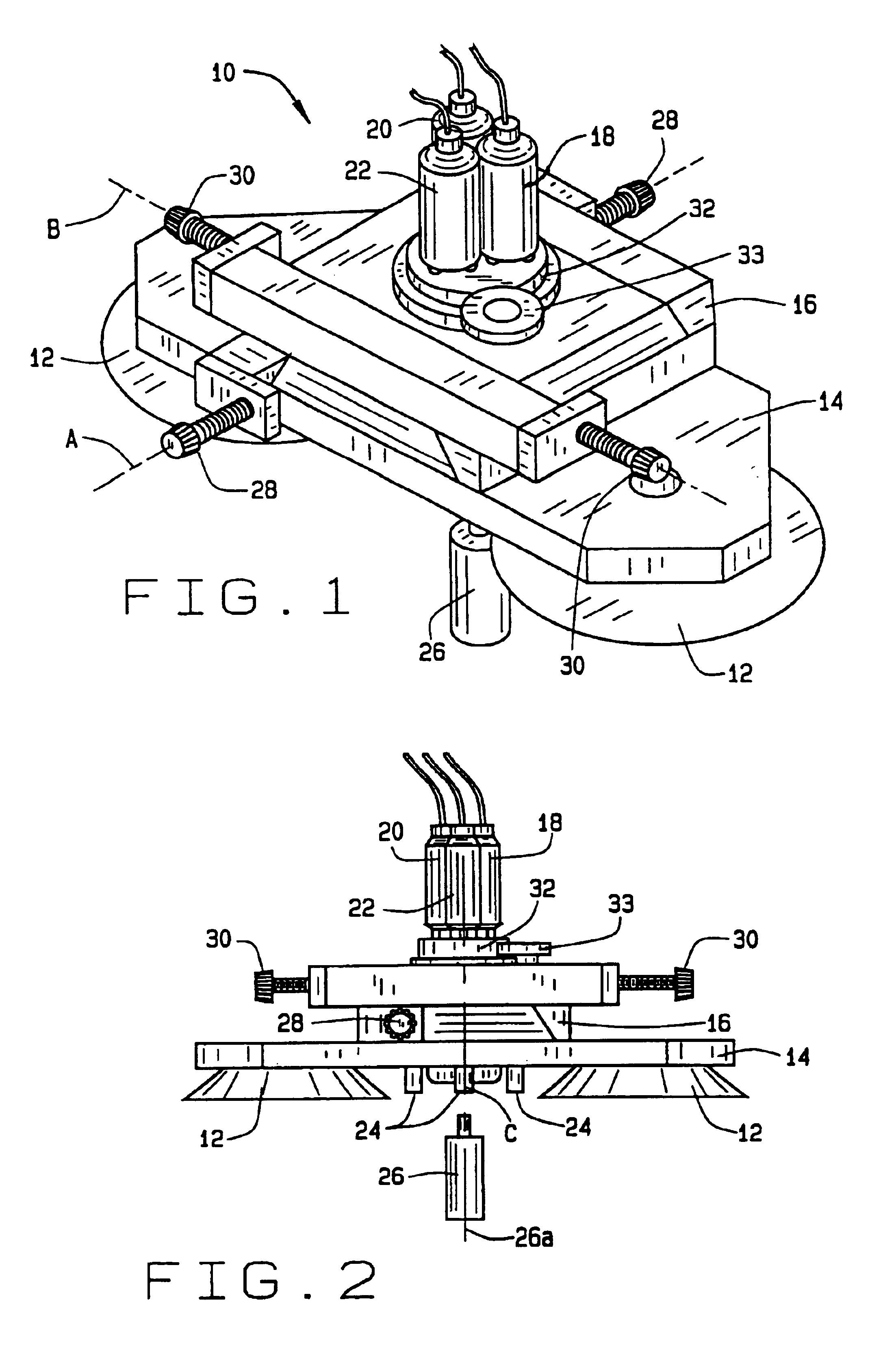

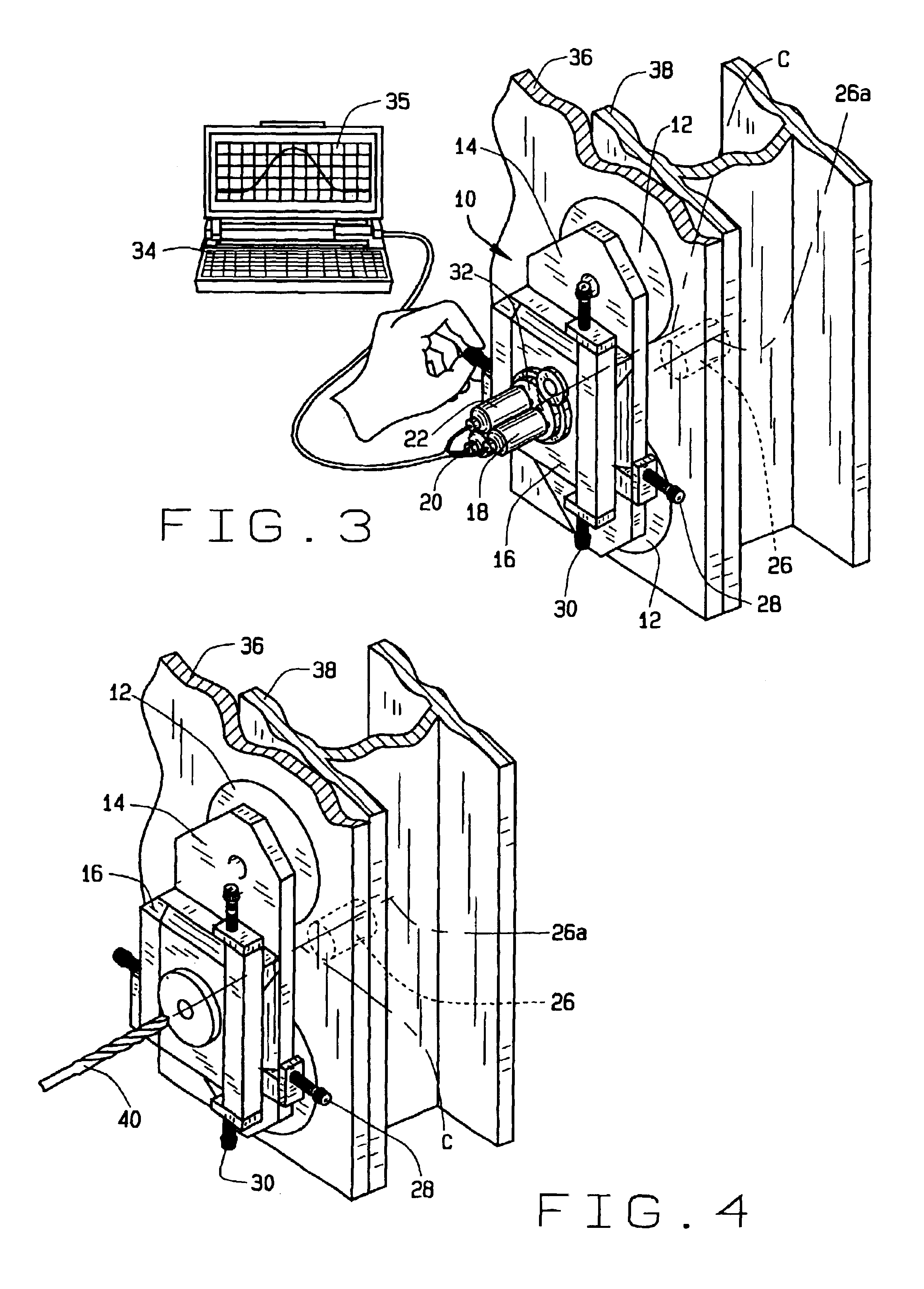

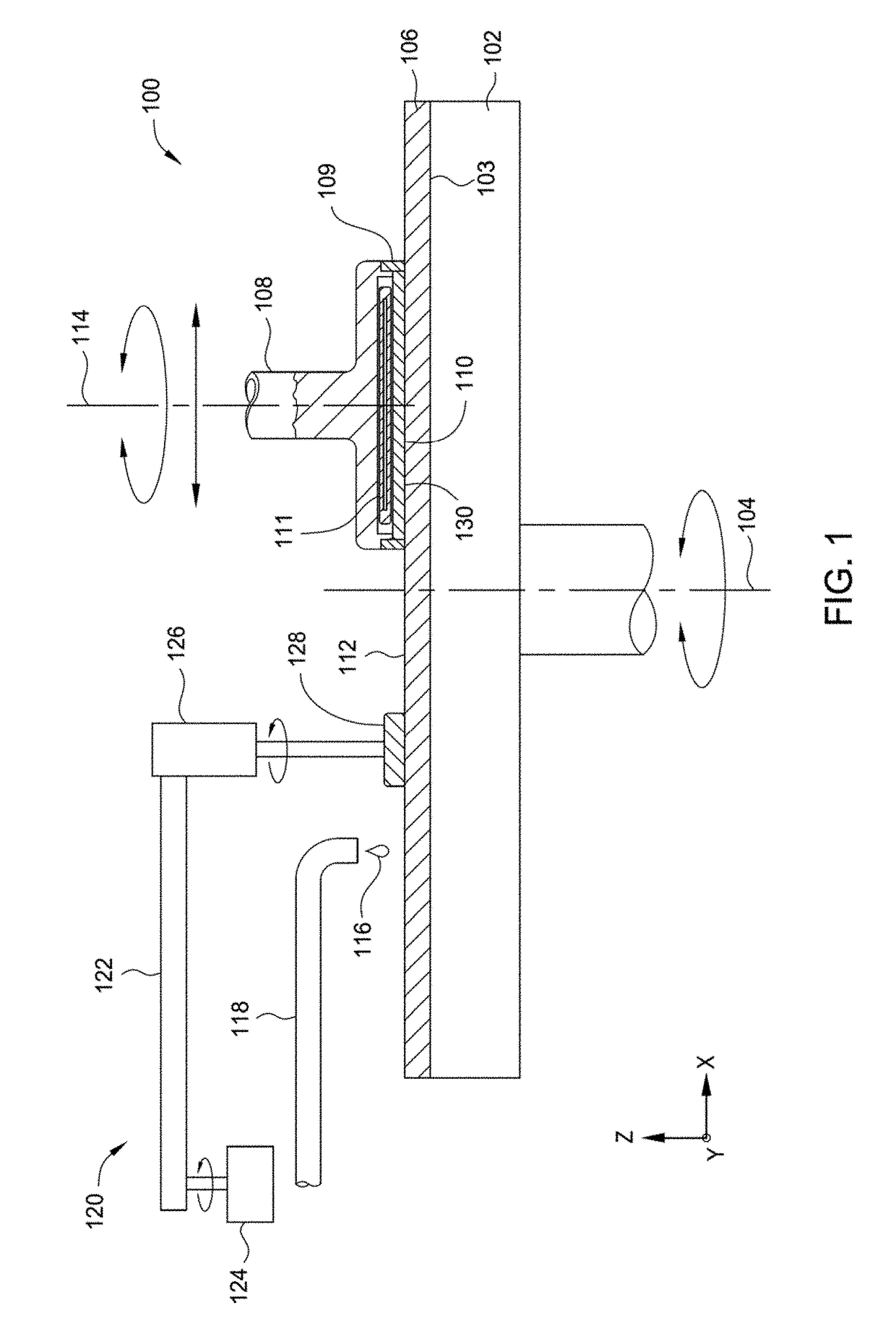

Control system and method for a magnetic indexer for high accuracy hole drilling

InactiveUS6927560B2Accurately work surfacePrecise positioningAircraft componentsDrilling/boring measurement devicesControl systemUltimate tensile strength

A method for locating a device producing a magnetic field in a blind or inaccessible position of a work piece. A magnet is initially placed on a first side of the work piece such that a magnetic field produced by the magnet extends through the work piece. Probes are then positioned over a second surface of the work piece to determine the location of the axis of the magnet via the strength of the sensed magnetic field and the location where the strength measurements are made. Once the position of the axis of the magnet is determined, the work surface is either marked or worked on through the platform on which the probes are positioned. In particular, the present invention allows a very accurate positioning of a work tool on the second surface without the need to first visualize the first surface of the work piece.

Owner:THE BOEING CO

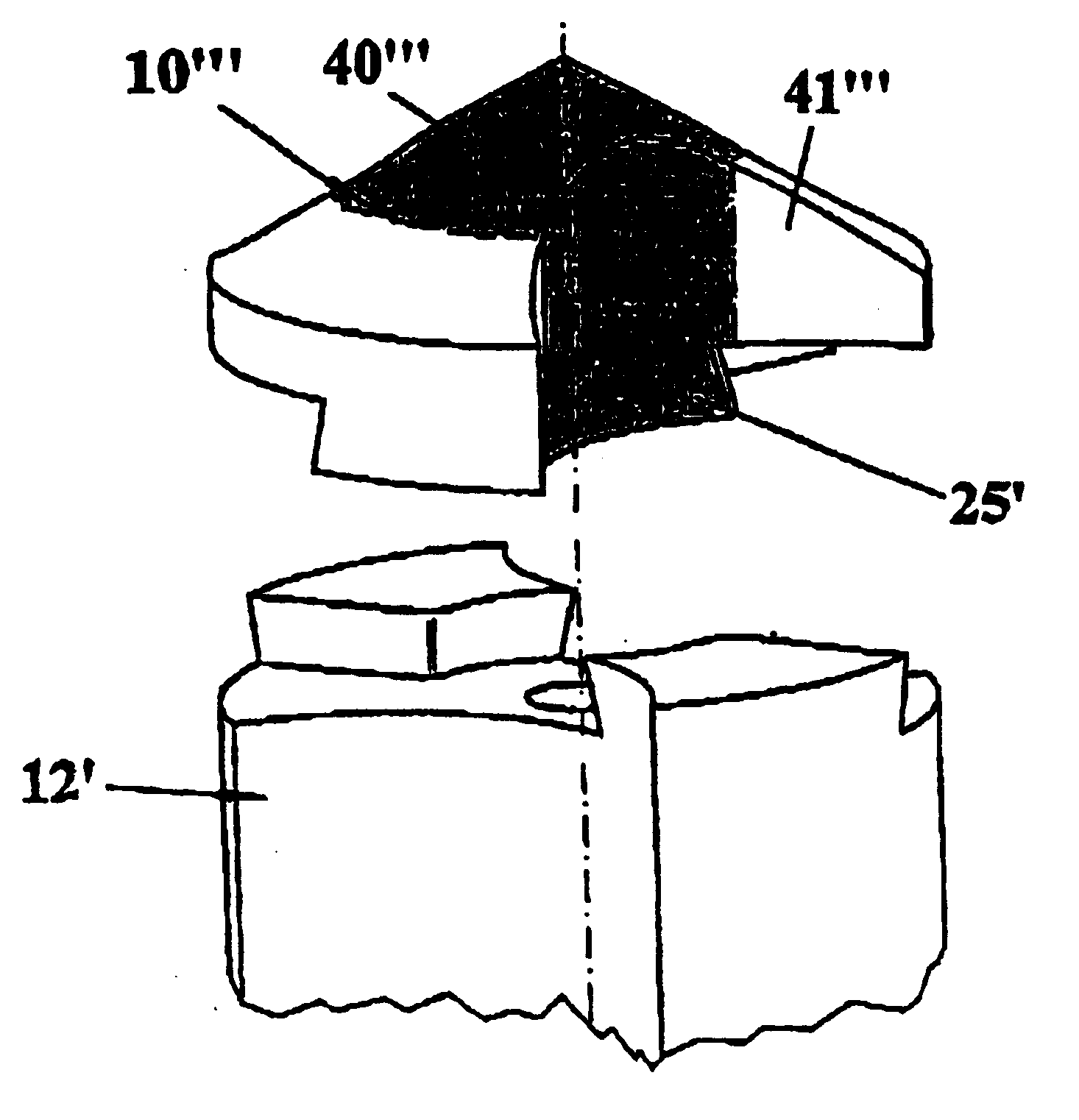

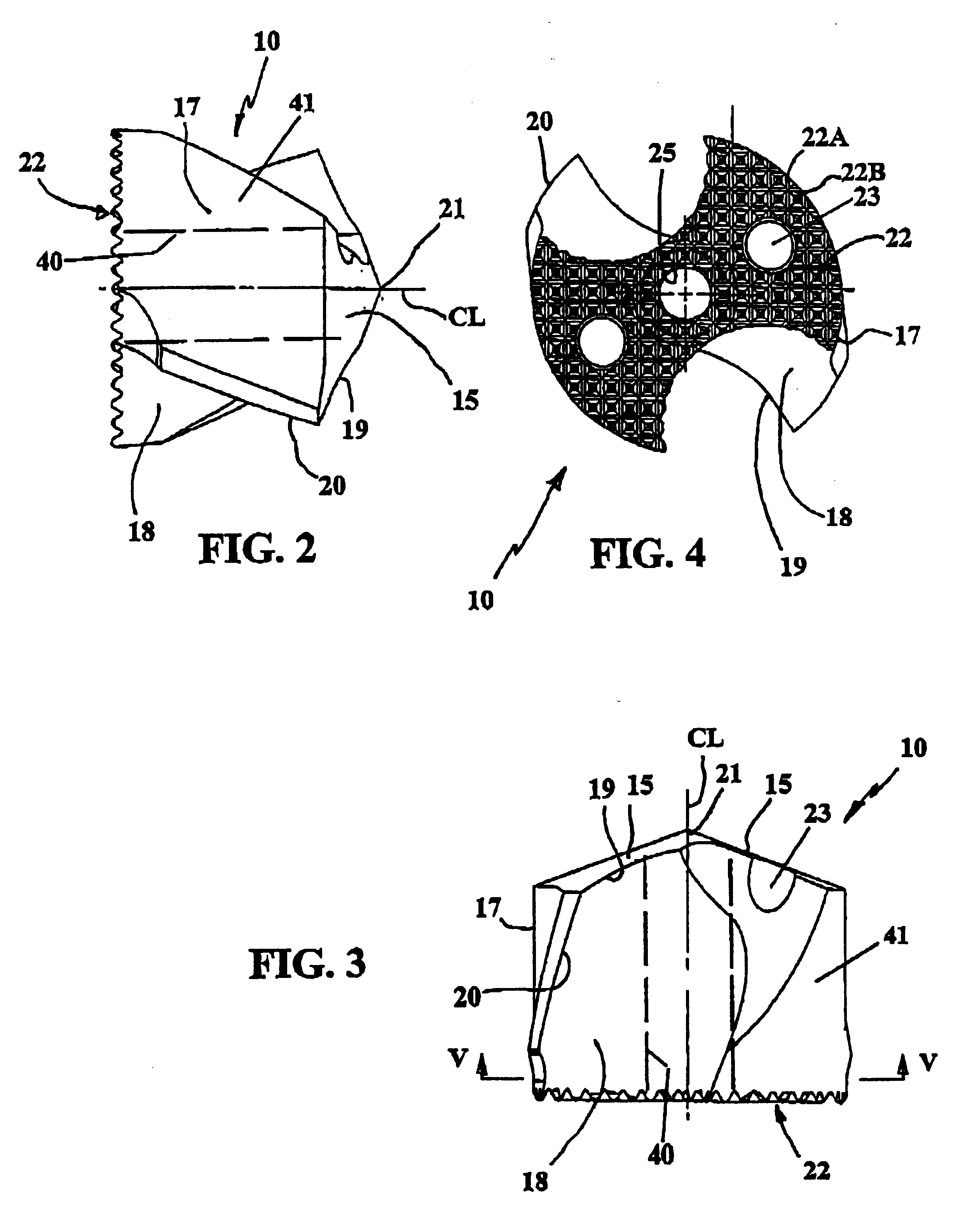

Drill bit and method for producing a drill bit

InactiveUS7892235B2Prevent movementIncrease guideTransportation and packagingSurgeryEngineeringPyramid

A drill bit including a shaft which has a pyramidal shaped end defining a drill tip with a plurality of edges defining the pyramidal shape. One or more recesses are provided for directing away debris produced whilst drilling, the at least one recess having a first portion extending along the shaft and a second portion which extends along the drill tip. The second portion of the at least one recess extends along an edge of the drill tip.

Owner:SURGIBIT IP HLDG

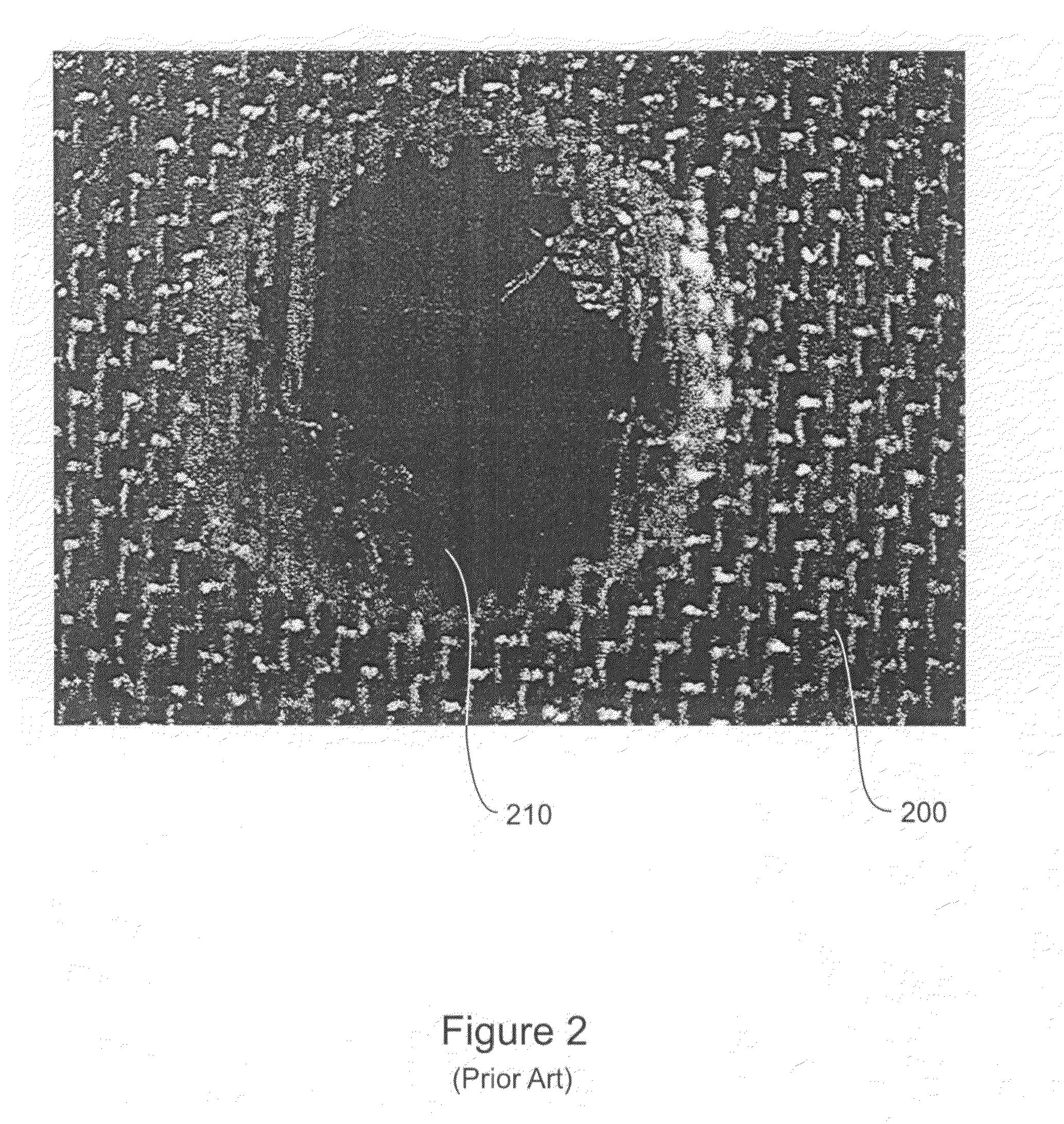

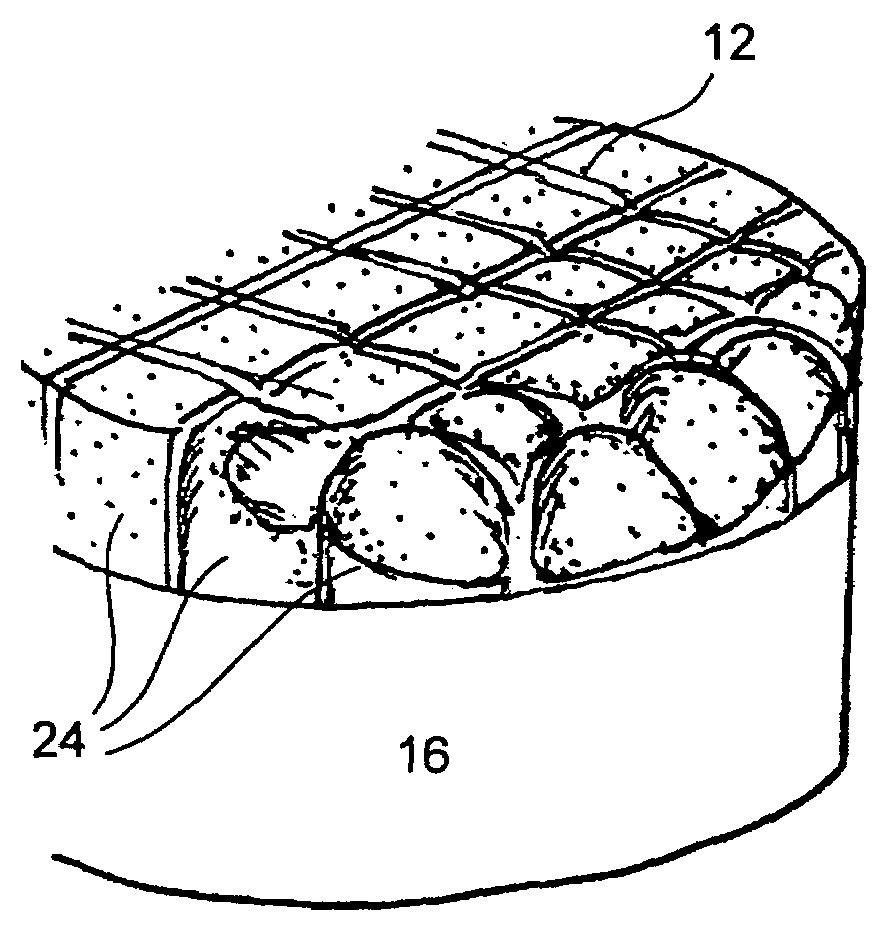

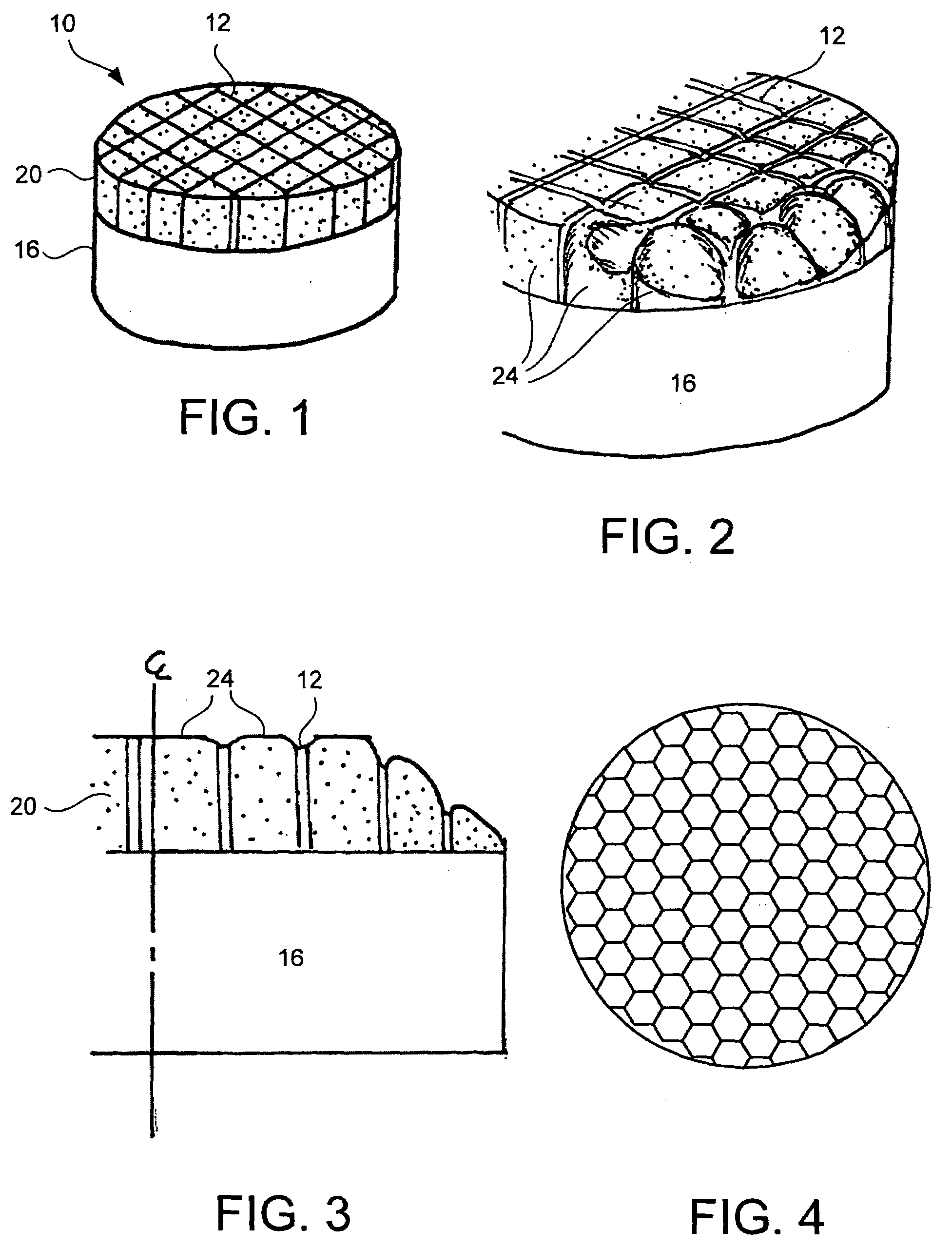

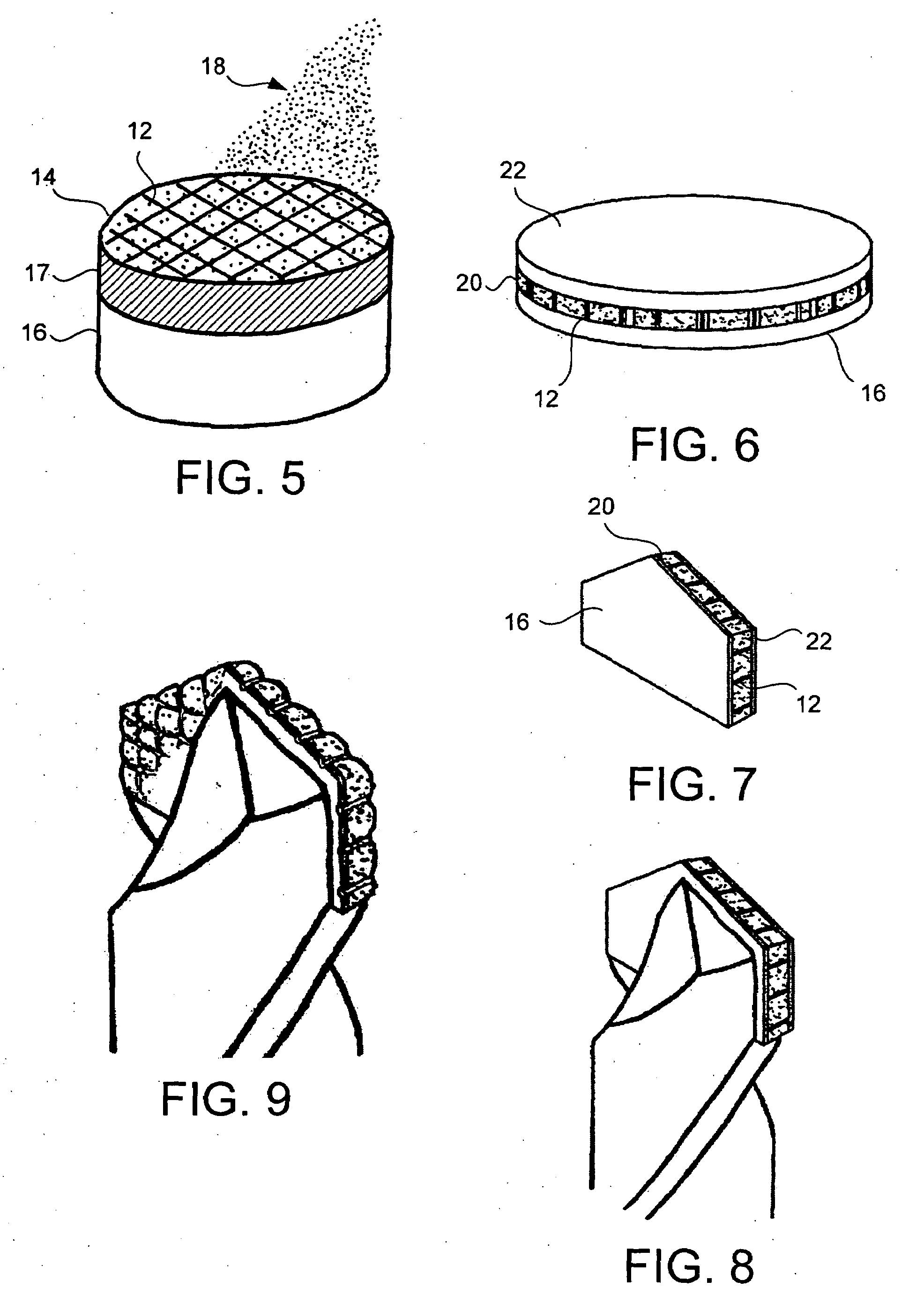

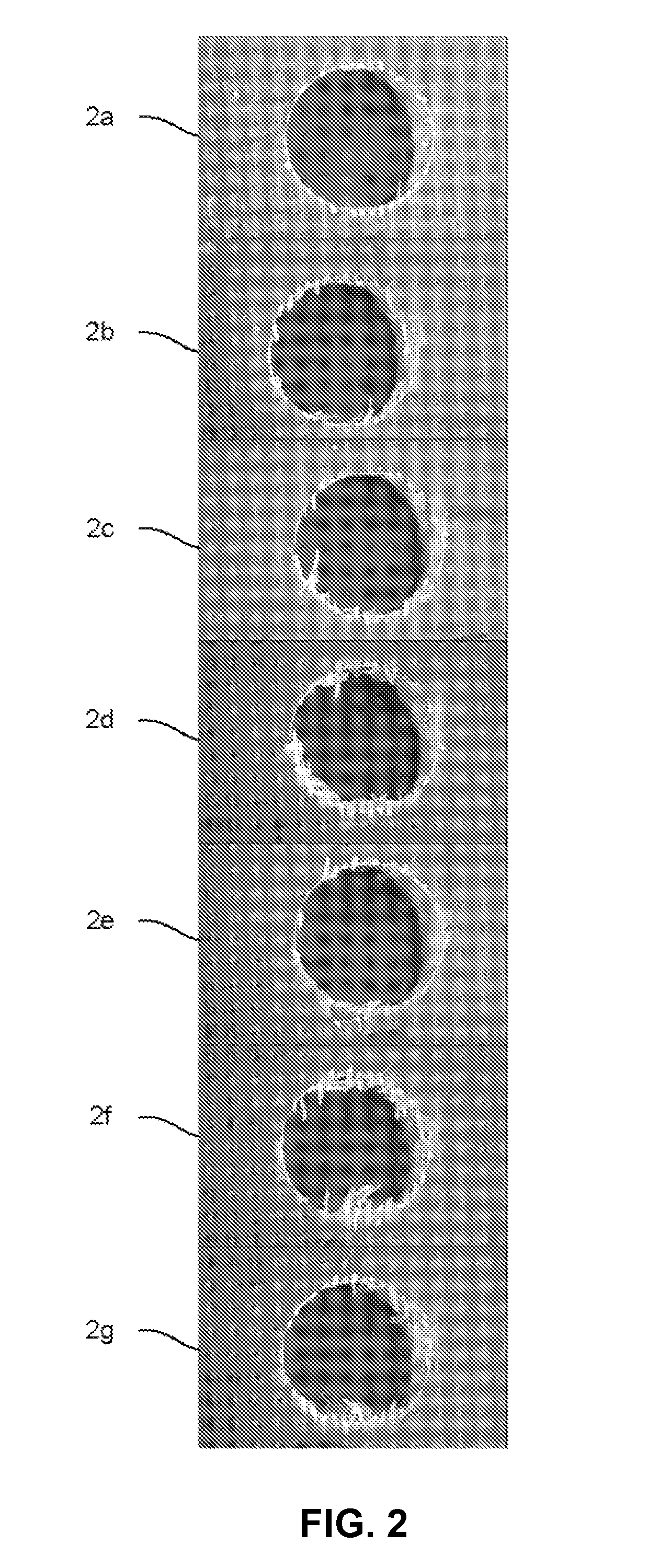

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

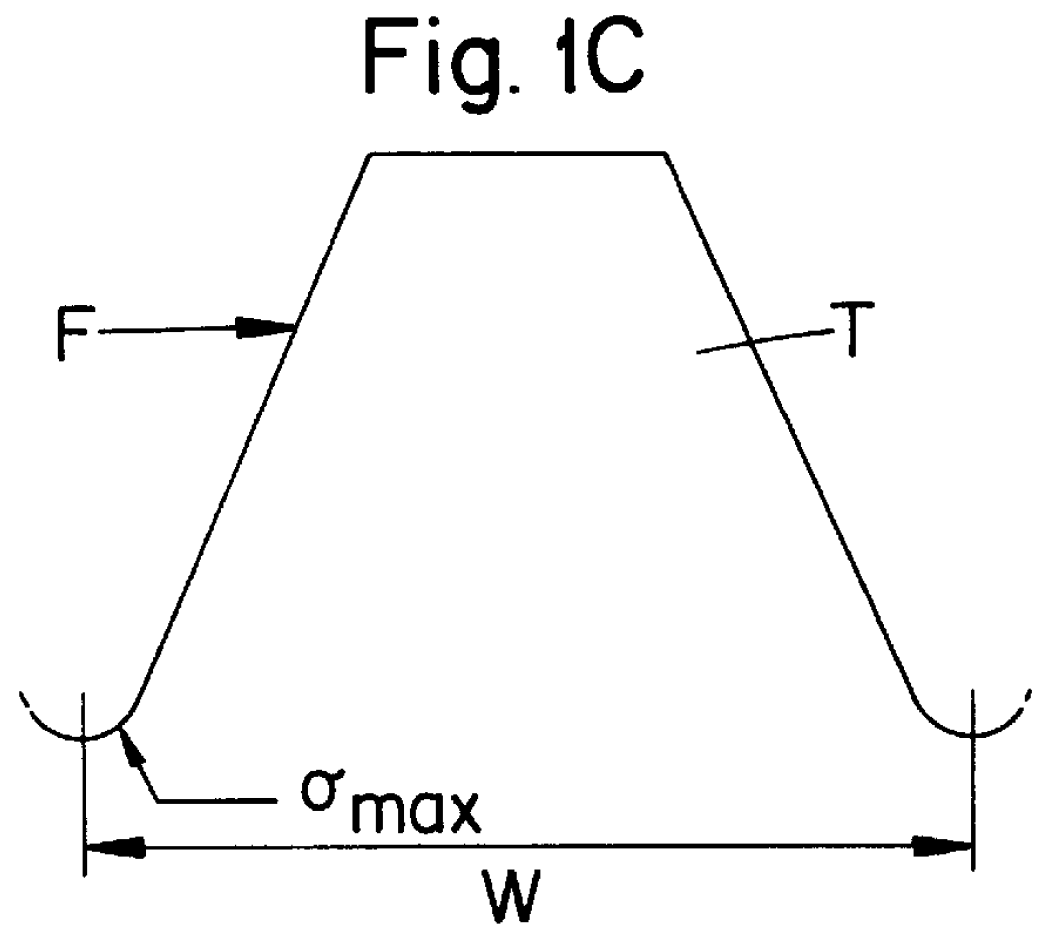

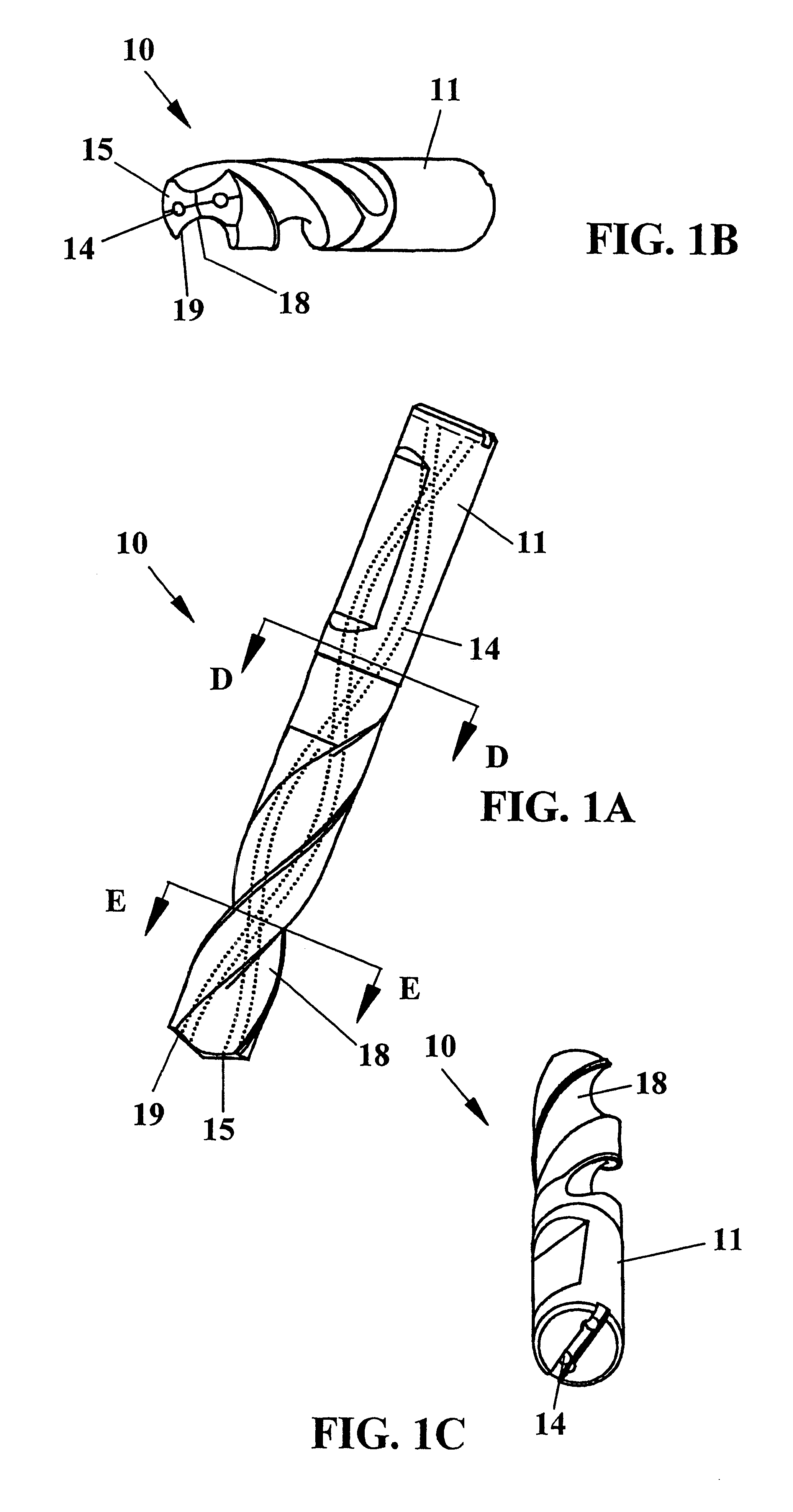

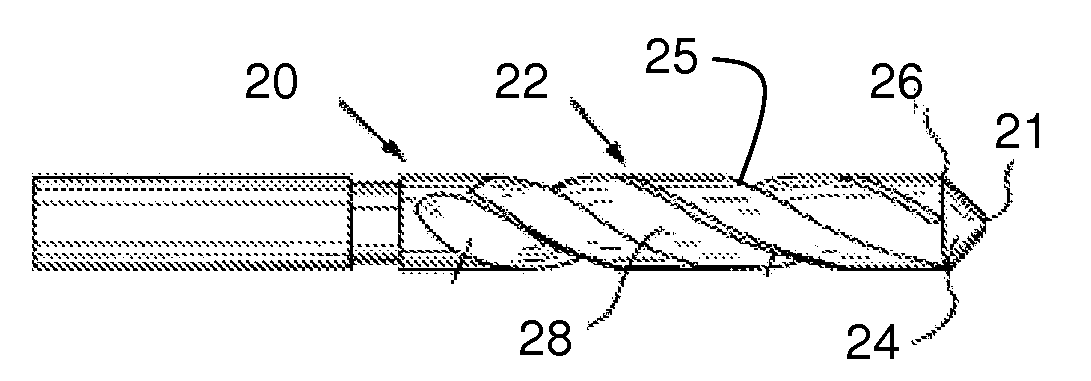

Composite cemented carbide rotary cutting tools and rotary cutting tool blanks

ActiveUS20100290849A1Reduce strength and mechanical wear resistanceReduce wearWood turning toolsMetal-working drilling toolsAlloyCemented carbide

Composite articles, including composite rotary cutting tools and composite rotary cutting tool blanks, and methods of making the articles are disclosed. The composite article includes an elongate portion. The elongate portion includes a first region composed of a first cemented carbide, and a second region autogenously bonded to the first region and composed of a second cemented carbide. At least one of the first cemented carbide and the second cemented carbide is a hybrid cemented carbide that includes a cemented carbide dispersed phase and a cemented carbide continuous phase. At least one of the cemented carbide dispersed phase and the cemented carbide continuous phase includes at least 0.5 percent by weight of cubic carbide based on the weight of the phase including the cubic carbide.

Owner:KENNAMETAL INC

Cutting Tool Having Releasably Mounted Self-Clamping Cutting Head

A cutting tool has a tool shank and a replaceable cutting head resiliently secured to the tool shank by an interference fit between a male fixation member of the cutting head and a female fixation member of the tool shank. The male fixation member has a resilience slit. In each cross section of the cutting tool taken perpendicular to an axis of rotation of the cutting tool through mutual abutment regions, the cross sectional profiles of the mutual abutment regions are arcuate sectors.

Owner:ISCAR LTD

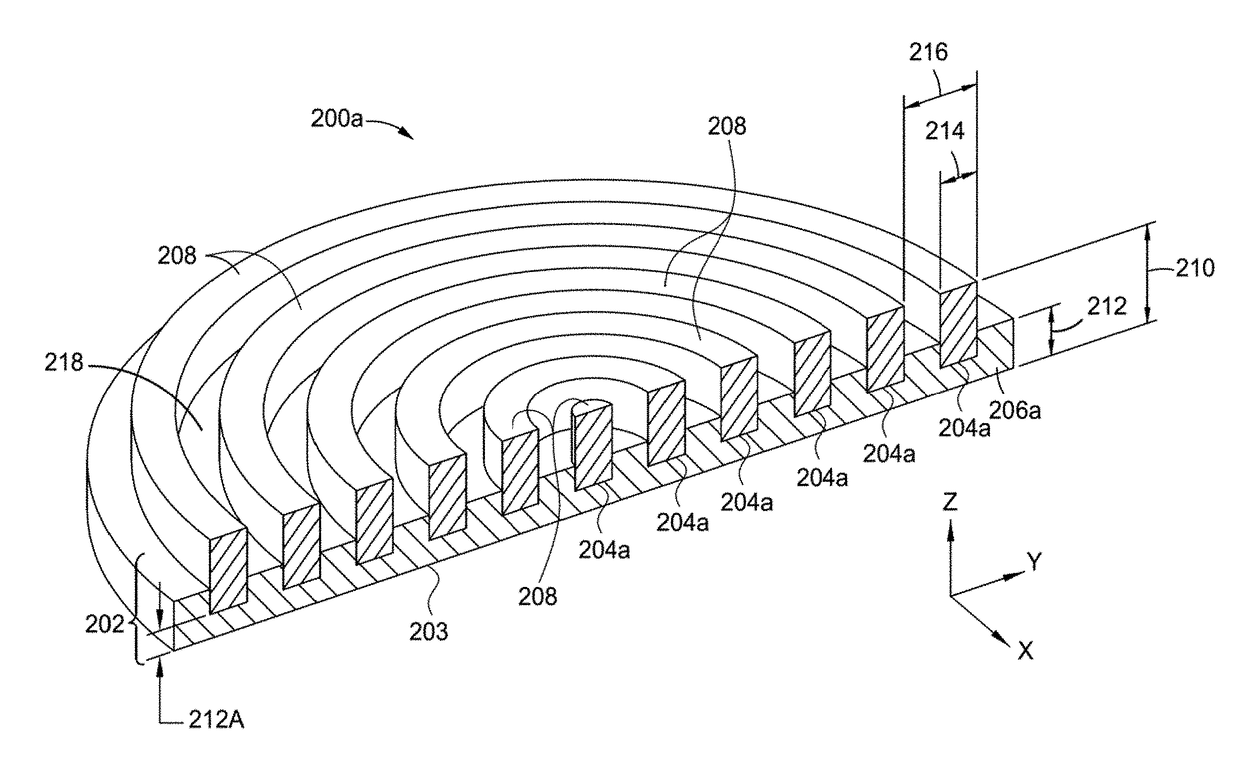

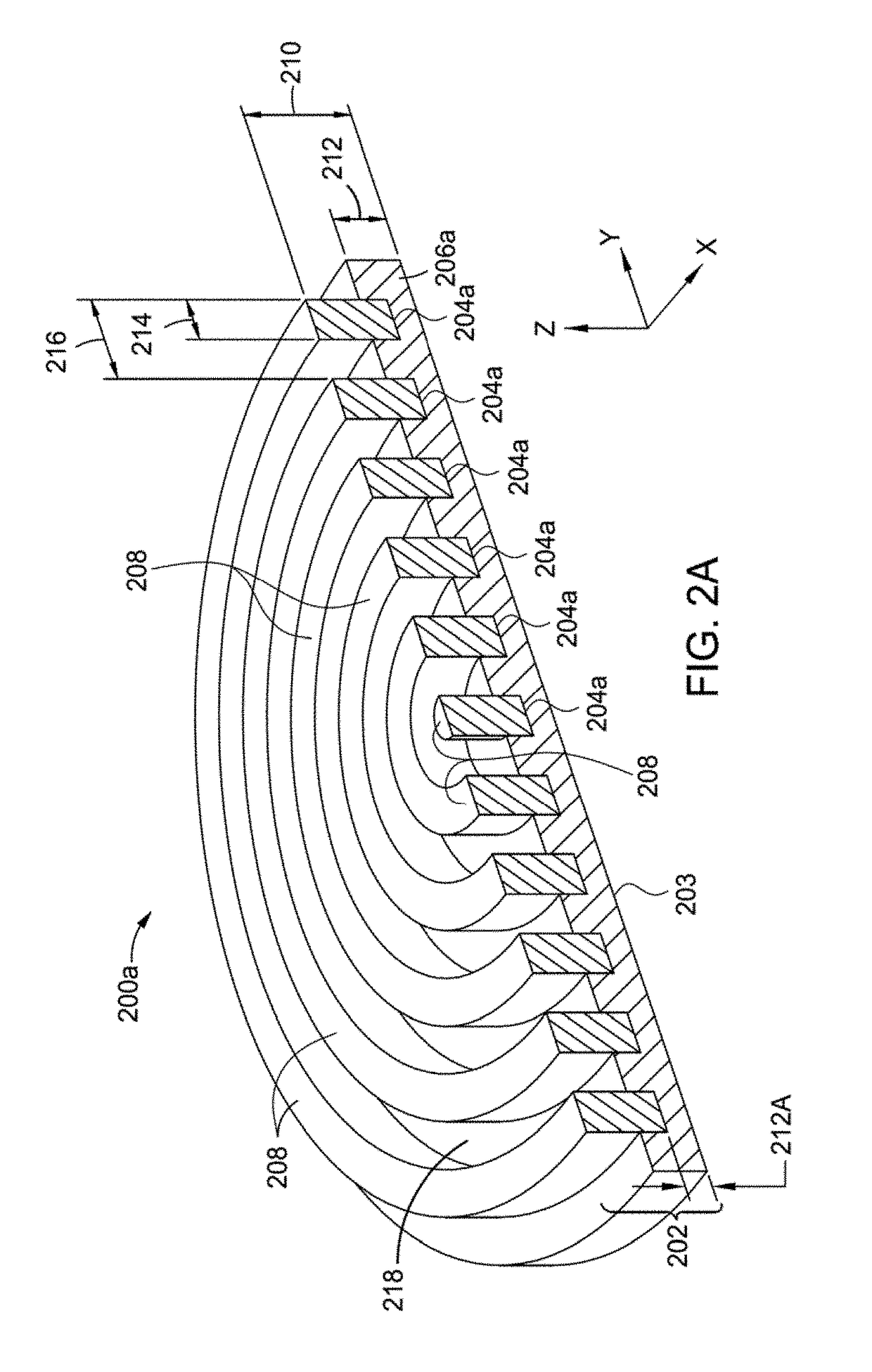

Porous chemical mechanical polishing pads

ActiveUS20170203406A1Enhancing positive zeta potentialIncrease ratingsAdditive manufacturing apparatusAbrasion apparatusAdditive layer manufacturing3D printing

Implementations disclosed herein generally relate to polishing articles and methods for manufacturing polishing articles used in polishing processes. More specifically, implementations disclosed herein relate to porous polishing pads produced by processes that yield improved polishing pad properties and performance, including tunable performance. Additive manufacturing processes, such as three-dimensional printing processes provides the ability to make porous polishing pads with unique properties and attributes.

Owner:APPLIED MATERIALS INC

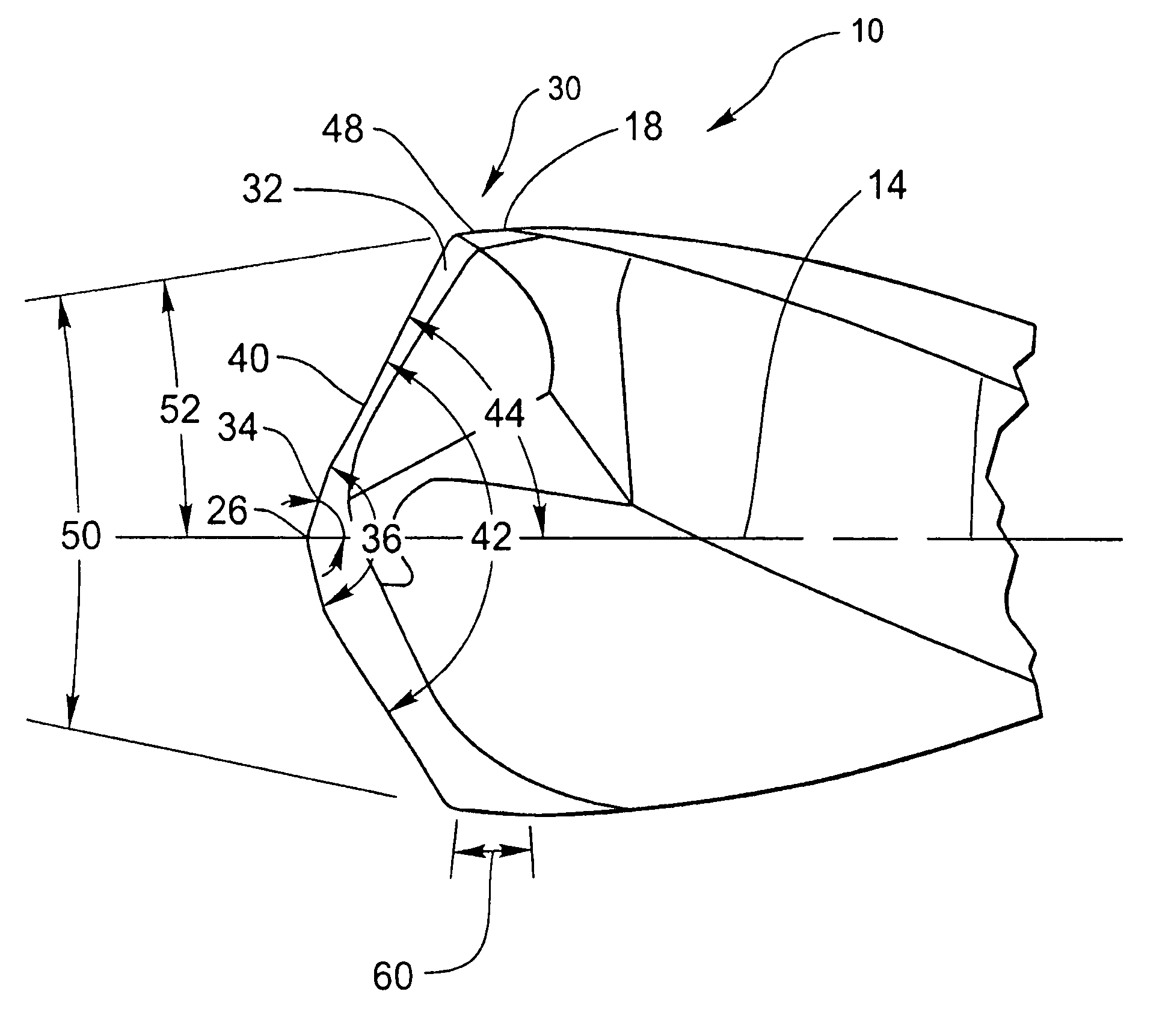

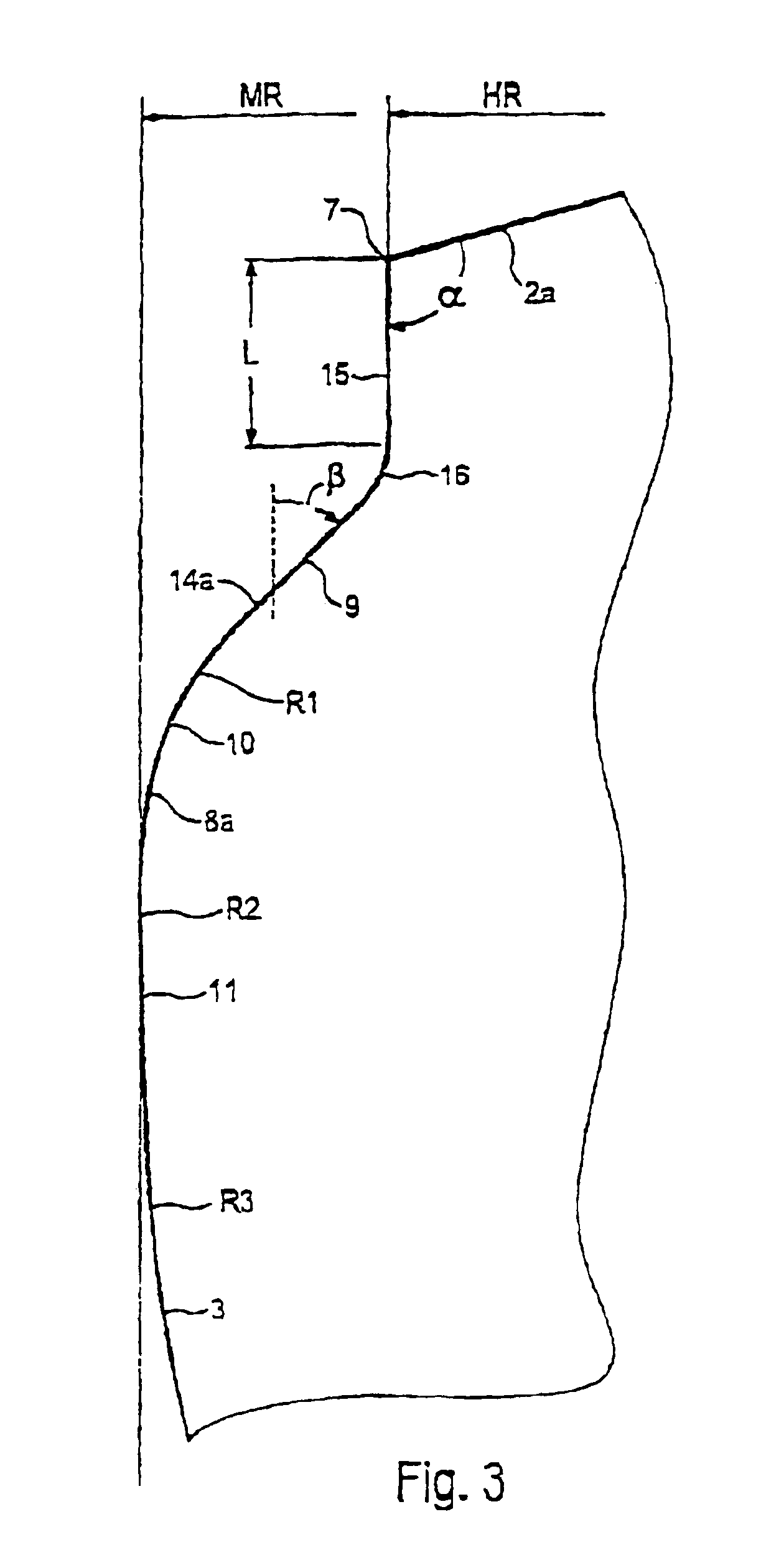

Rotary cutting tool

InactiveUS6929434B2High chip forming productivityImprove surface qualityWood turning toolsTransportation and packagingEngineeringDrill bit

There is now provided a rotary cutting tool, particularly a drill, that has at least two cutting edges that respectively comprise a main cutting edge and that respectively are disposed, particularly symmetrically, with respect to the central axis of a cutter portion, whereby the radius of the main cutting edges is less than the maximal cutting edge radius of the cutter portion. A secondary cutting edge is associated with a main cutting edge, this secondary cutting edge is curvilinear in at least a portion and is configured as smooth finishing cutting edge, this secondary cutting edge comprises a plurality of curve-forming radii, whereby in an outer smooth finishing region within the region of the maximal cutting edge radius, the curve-forming radius of the smooth finishing cutting edge is greater than the maximal cutting edge radius. The cutter portion that is adjacent to the outer smooth finishing region is tapered by a taper that diminishes the size in the direction away from the main cutting edges.

Owner:KENNAMETAL INC

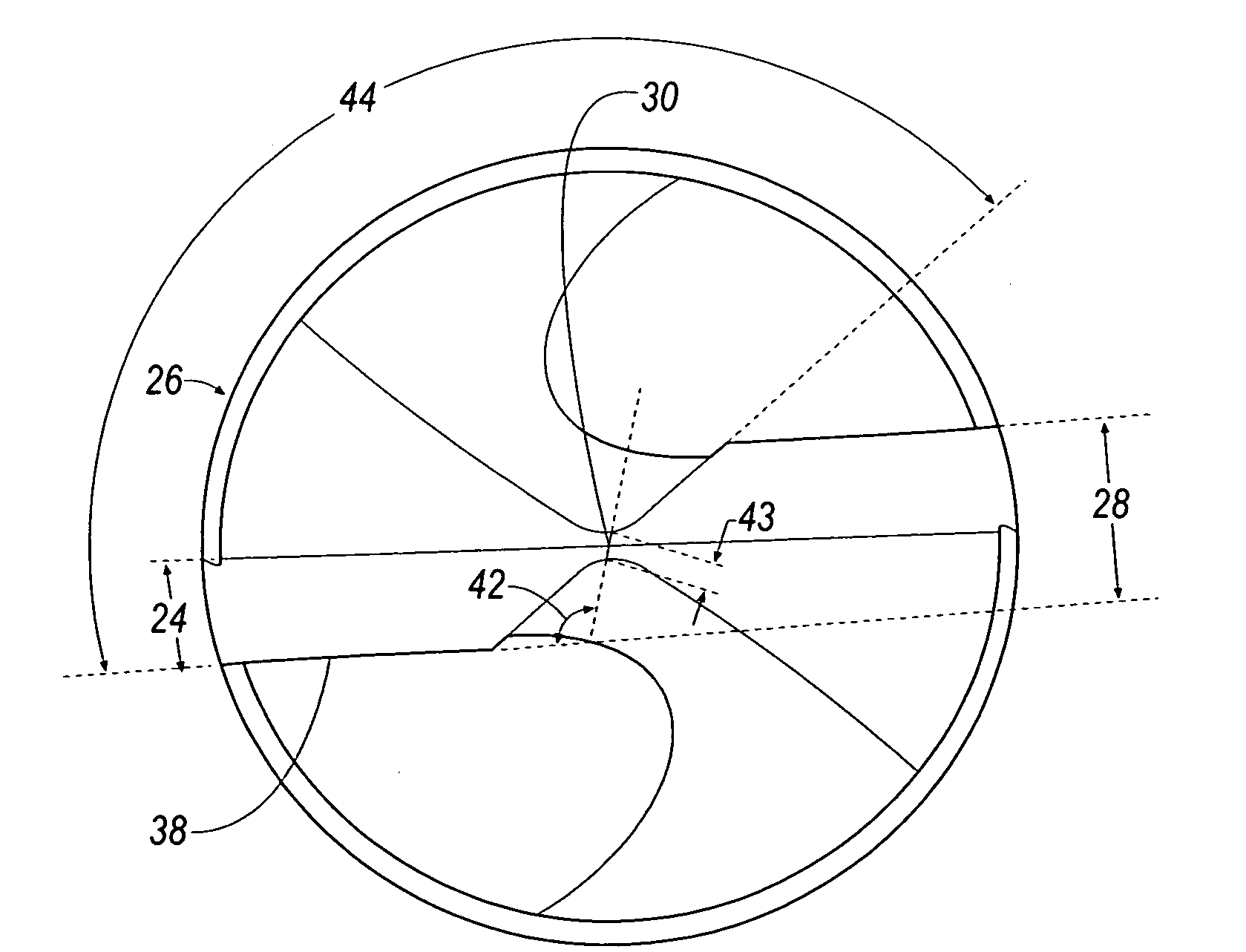

Drill for machining fiber reinforced composite material

InactiveUS20080019787A1Wood turning toolsTransportation and packagingFiber-reinforced compositeSplit point

A diamond coated drill capable of drilling holes in fiber reinforced composite materials. The drill is made from a tungsten carbide (WC) substrate with cemented cobalt (Co) in a range between about 3 to 10 wt. % and a diamond coating having a thickness in a range between 3 to 20 microns. The drill includes a shank, a longitudinal axis and includes two flutes at a helix angle that is in a range between 25 and 35 degrees with respect to the axis. A margin width is maintained between about 5 to 10 percent of the drill diameter. A body clearance diameter is maintained at between about 92 to 96 percent of the drill diameter. A web thickness before splitting is about 20 to 30 percent of the drill diameter. A clearance angle or lip relief angle is between about 10 and 20 degrees. A chisel edge angle is between about 105 and 120 degrees. A chisel edge length is up to about 0.035 mm. A splitting angle is between about 130 and 150 degrees. A notch angle is between about 30 and 40 degrees with respect to the drill axis. A notch rake angle lies between about −5 and 10 degrees. A split point angle is between about 70 and 100 degrees, and preferably about 90 degrees.

Owner:KENNAMETAL INC

Drill bit apparatus and method of manufacture of same

InactiveUS6652202B2Low production costIncreased durabilityWood turning toolsTransportation and packagingEngineeringDrill bit

A drill bit for use in association with a power or hand drill comprising a drill bit head and shaft. The drill bit head includes a drill bit cutting head and a guide point. The drill bit cutting head includes a first and a second cutting vane. Each cutting vane includes a first cutting edge which extends perpendicular to the axis of rotation and is provided for removing workpiece material, a second cutting edge which extends parallel to the axis of rotation and is provided for forming a substantially smooth workpiece bore, and a channel for facilitating the expulsion of removed workpiece material away from the first cutting surface as the drill bit passes through the workpiece.

Owner:QUICK TURN MFG

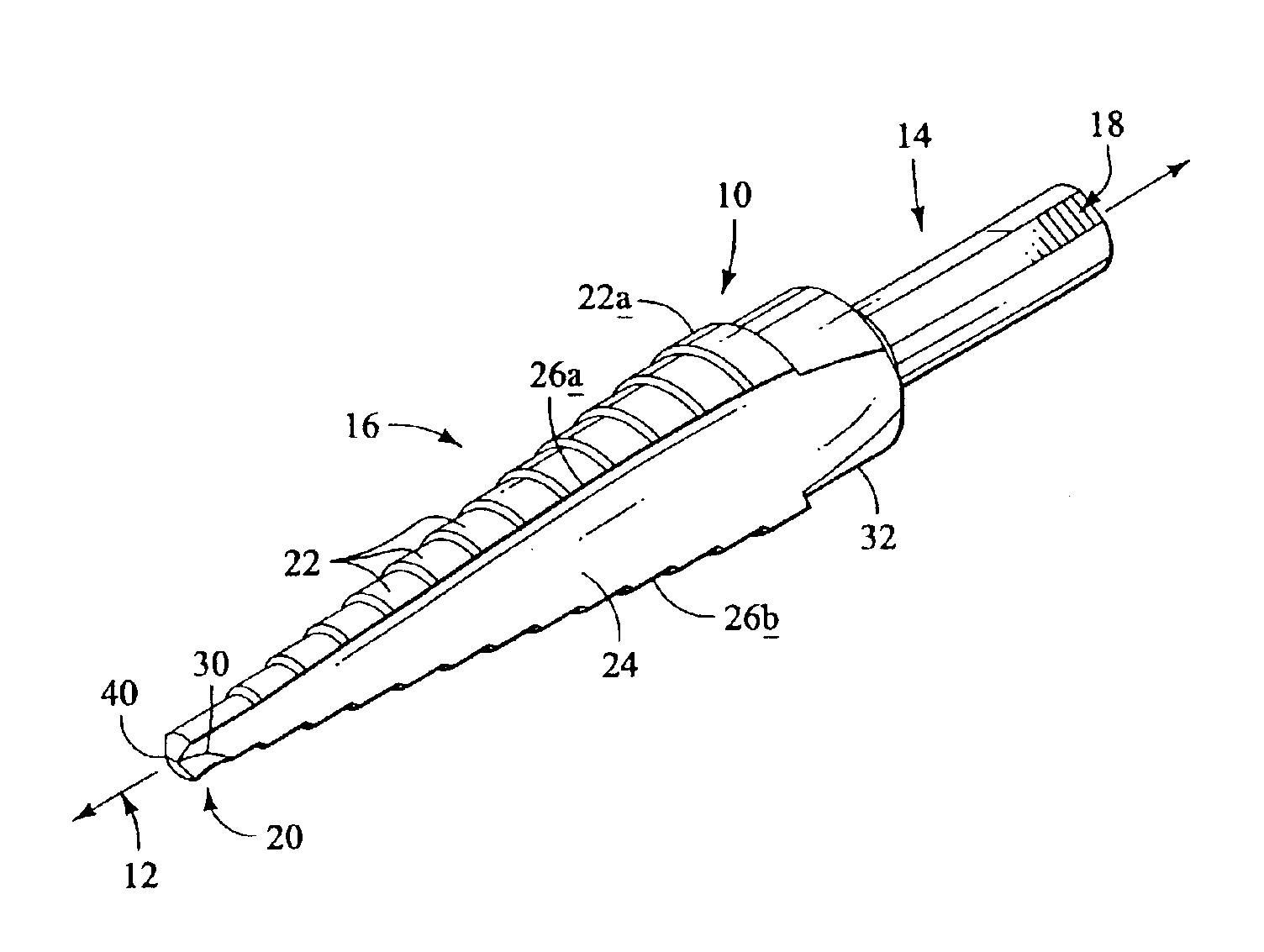

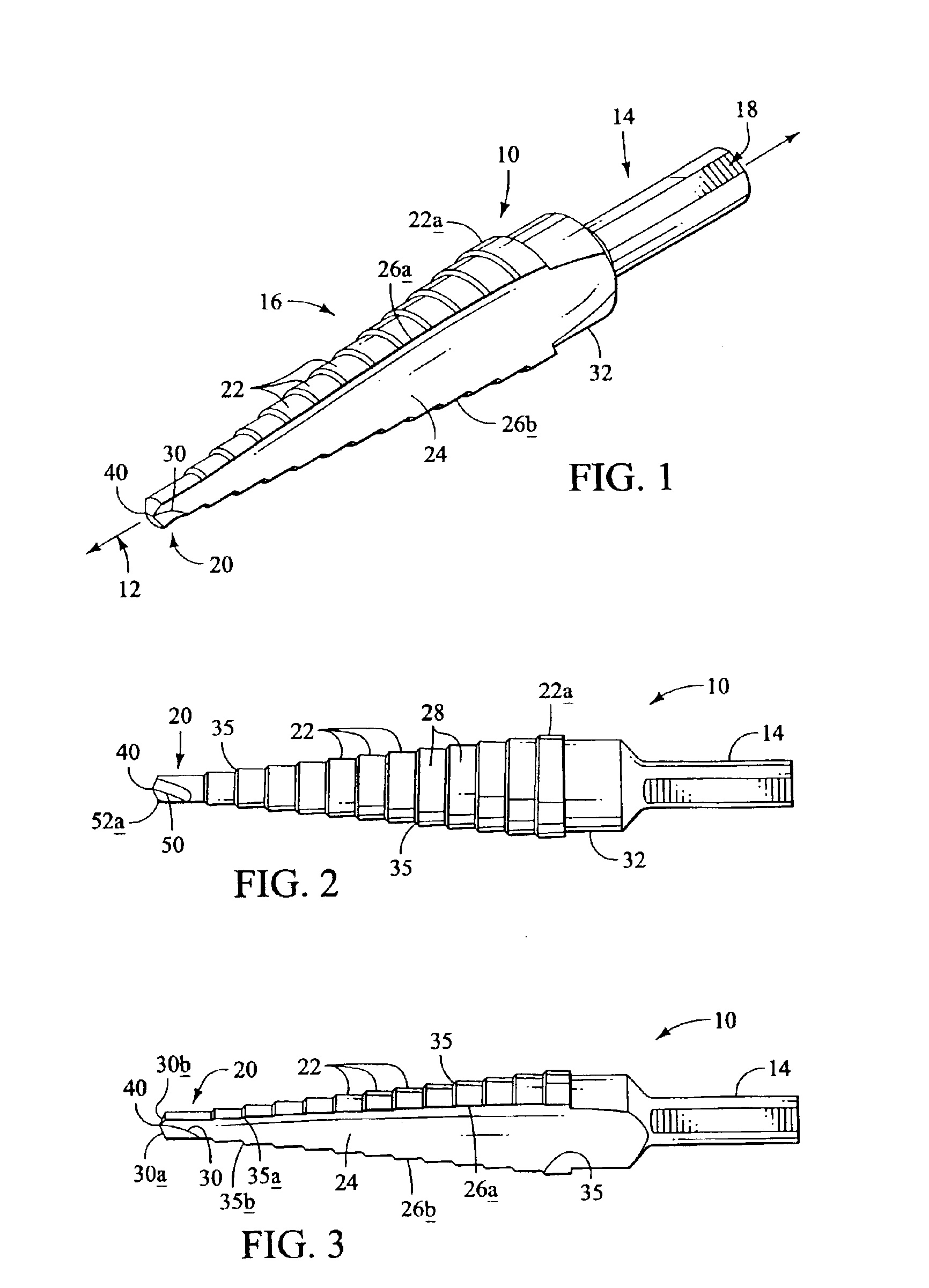

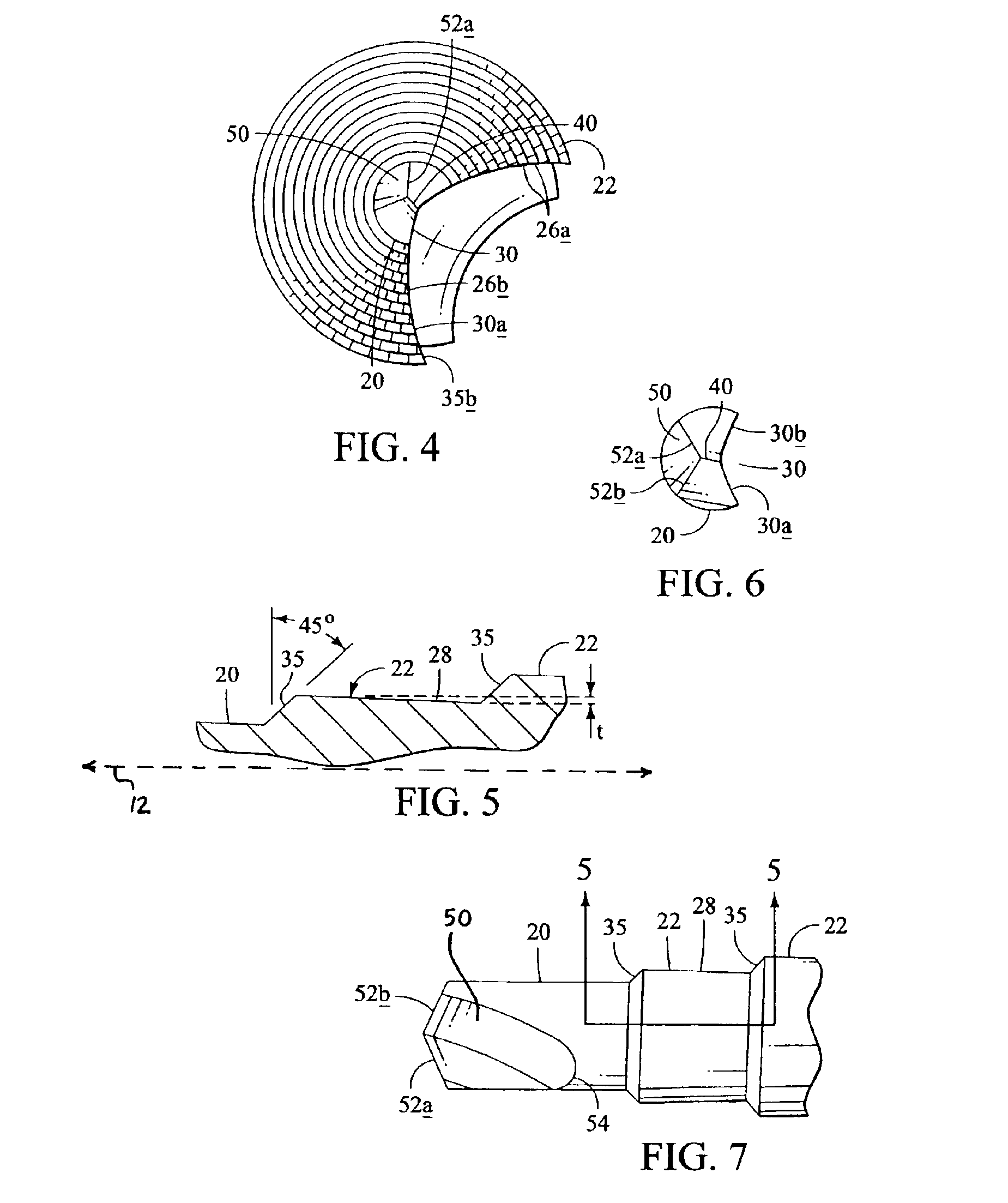

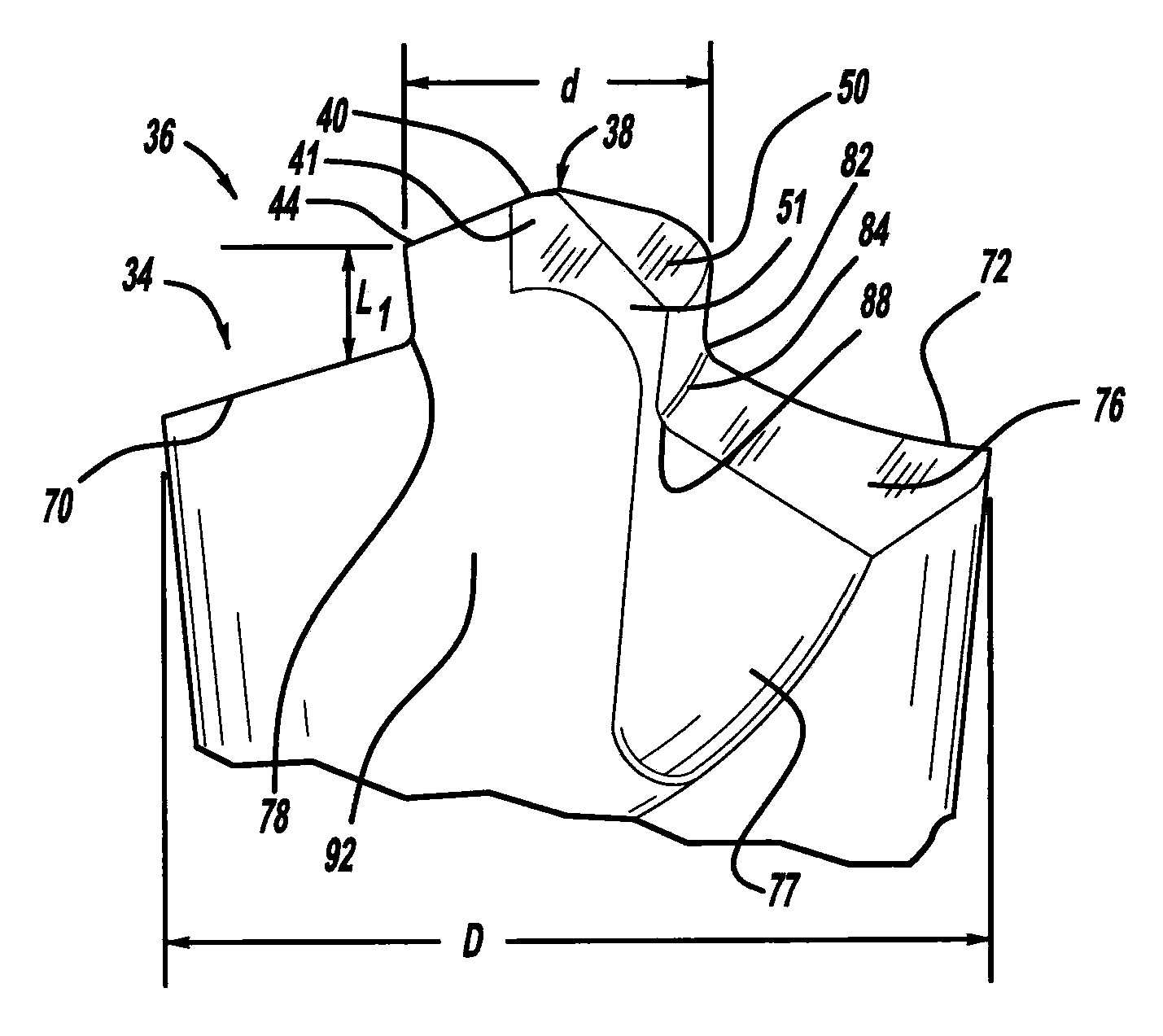

Stepped drill bit having split tip

InactiveUS6890133B2Maintain convenienceEffectively bore holeWood turning toolsTransportation and packagingEngineeringMechanical engineering

A drill bit is disclosed having a cutting portion having a plurality of axially aligned, graduated cutting members. Each of the members has cutting edges defined by a single slot extending therethrough. A tip portion at one end of the cutting portion defines at least a pair of cutouts therein, wherein one of the cutouts is aligned with the slot.

Owner:BLACK & DECKER INC

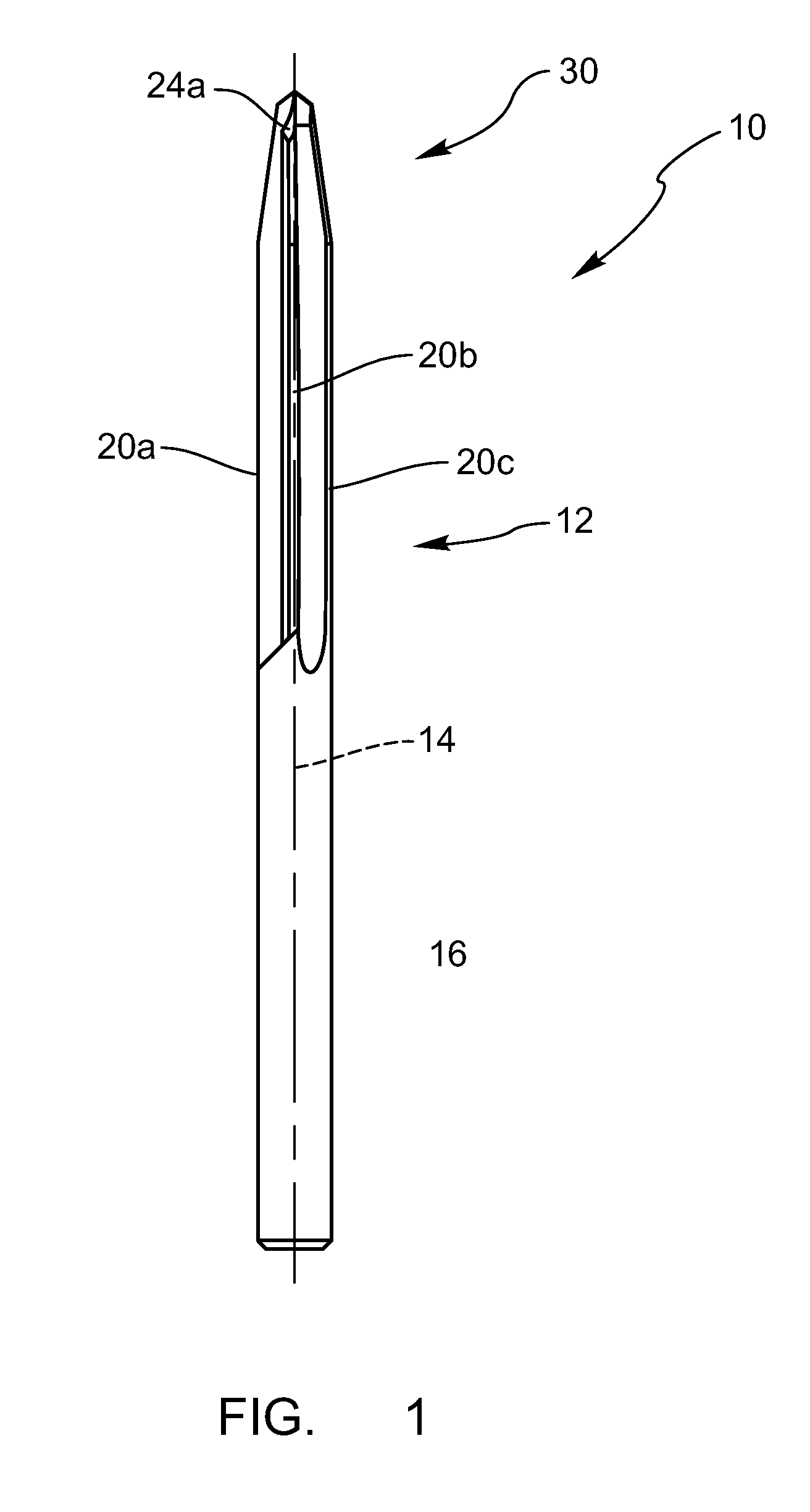

Twist drill with a pilot tip

ActiveUS7520703B2Increase speedSolution to short lifeWood turning toolsTransportation and packagingFluteEngineering

Owner:BLACK & DECKER INC

Drill having internal chip channel and internal flush channel

InactiveUS6948890B2Easy to manufactureTransportation and packagingMulti-purpose machinesSurface roughnessCemented carbide

Owner:SECO TOOLS AB

Carbide drill bit for composite materials

A drill bit for producing holes in composite materials is disclosed. The drill bit includes an elongate drill bit body having a drill bit diameter. The drill bit also includes at least two helical flutes. The helical flutes have a reverse helix angle and a primary cutting edge. The primary cutting edge may have a positive rake angle. The drill bit further includes a point having a point length. The drill bit may also include a cutting tip with a tip angle and a tip length. The tip length is at least twice the drill bit diameter.

Owner:PRECORP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com