Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1557 results about "Flute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The flute is a family of musical instruments in the woodwind group. Unlike woodwind instruments with reeds, a flute is an aerophone or reedless wind instrument that produces its sound from the flow of air across an opening. According to the instrument classification of Hornbostel–Sachs, flutes are categorized as edge-blown aerophones. A musician who plays the flute can be referred to as a flute player, flautist, flutist or, less commonly, fluter or flutenist.

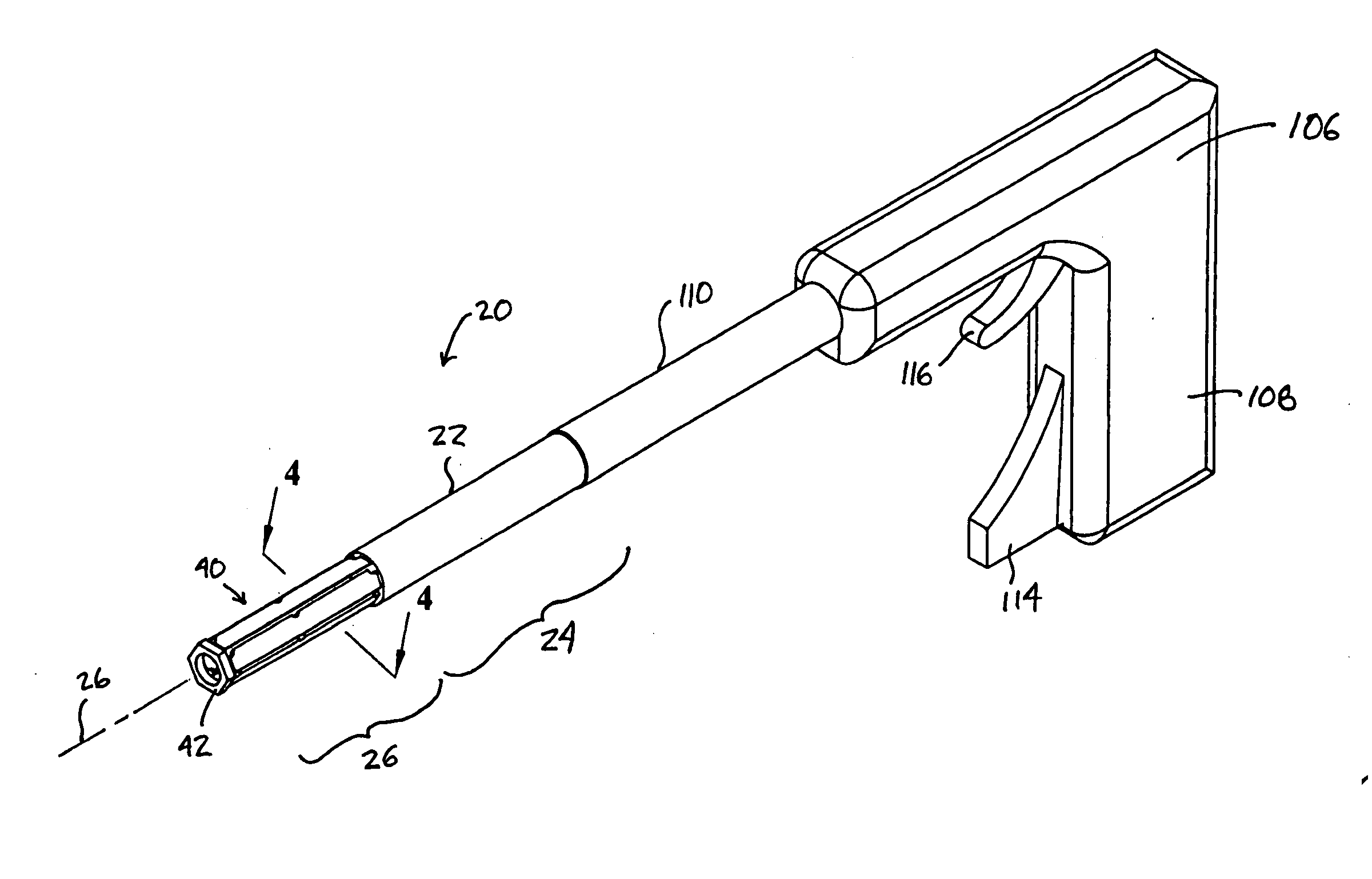

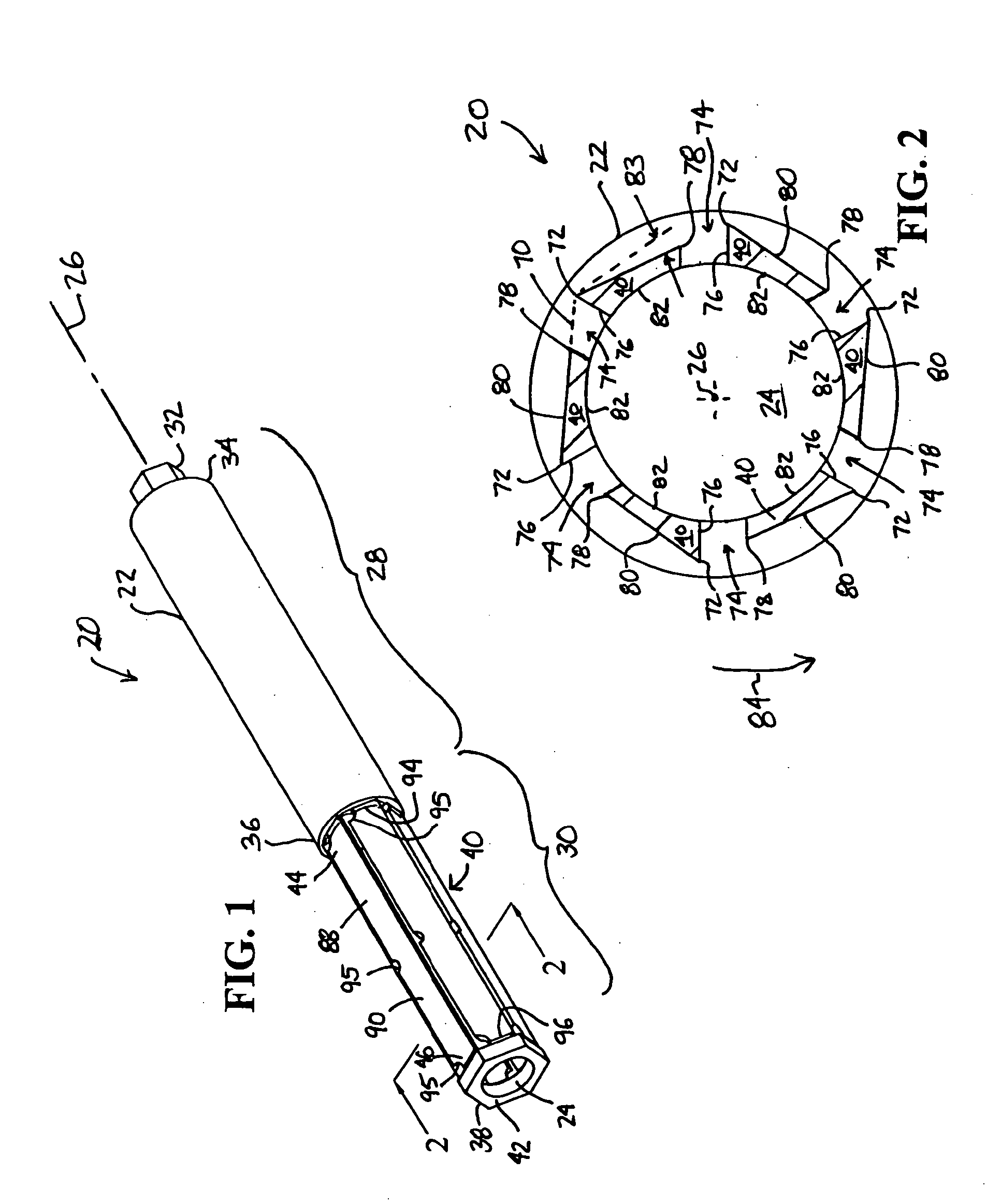

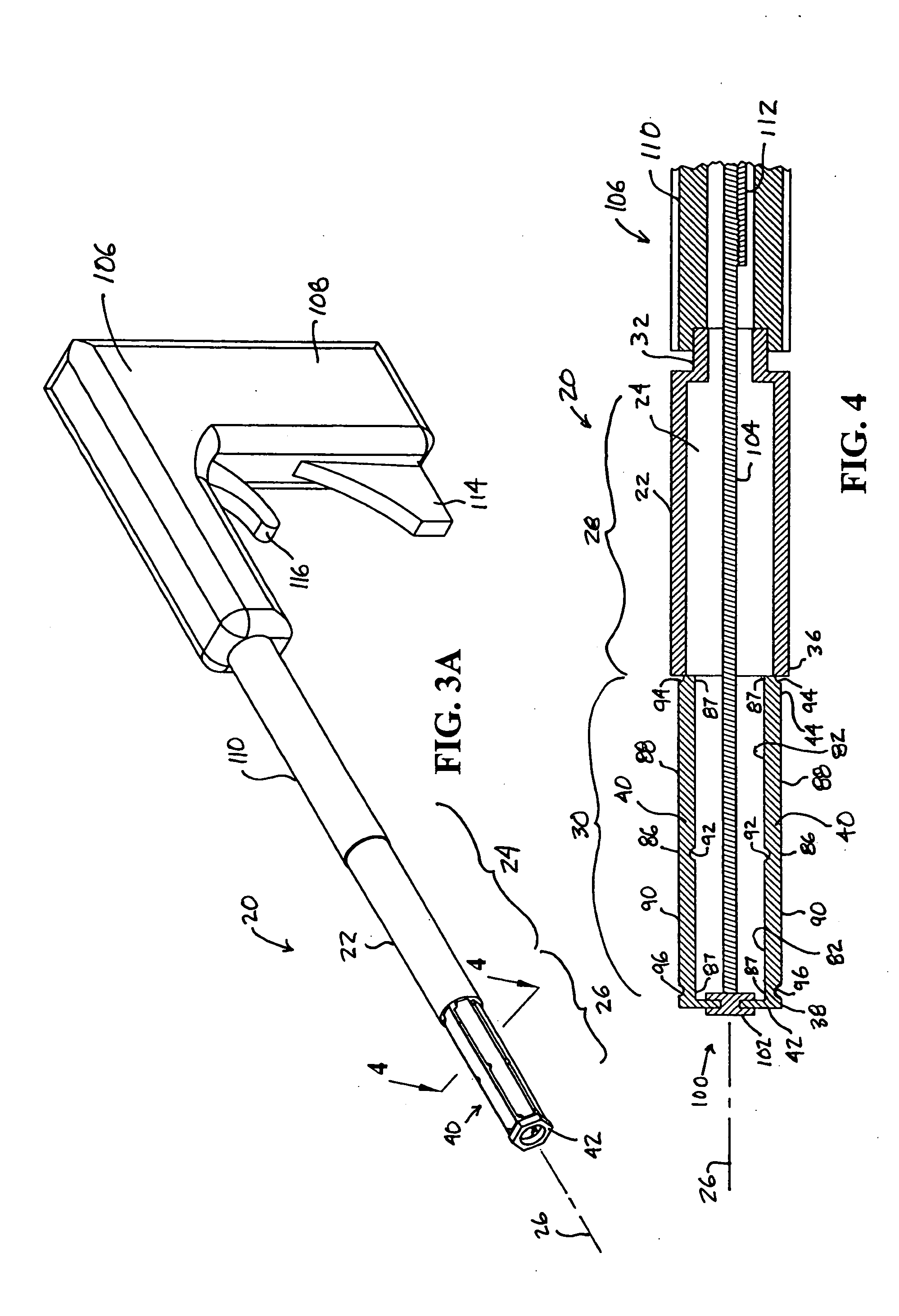

Expandable reamer

An expandable reamer includes, in one exemplary embodiment thereof, a cannulated shaft and a plurality of straight cutting blades having deformable points. The blades are hingably outwardly rotatable at the deformation points between a contracted position and an expanded position. In the contracted position, the blades are substantially parallel to the longitudinal axis of the cannulated shaft and, in the expanded position, the blades have at least a portion oriented radially outward from the longitudinal axis, thereby forming a larger diameter cutting surface in the expanded position and in the contracted position. The blades are formed from a portion of the cannulated shaft by, e.g. milling longitudinally extending slots through the wall of the cannulated shaft, the slots serving as flutes dividing the cutting edge and trailing edge of each adjacent blade. Each blade may also include more than one segment arranged along its length, the segments coupled by deformation points. The expandable reamer may be used for cutting a cavity in a bone or other structure that is larger than the diameter of the entry point into the bone and greater than the diameter of the contracted reamer.

Owner:ZIMMER TECH INC

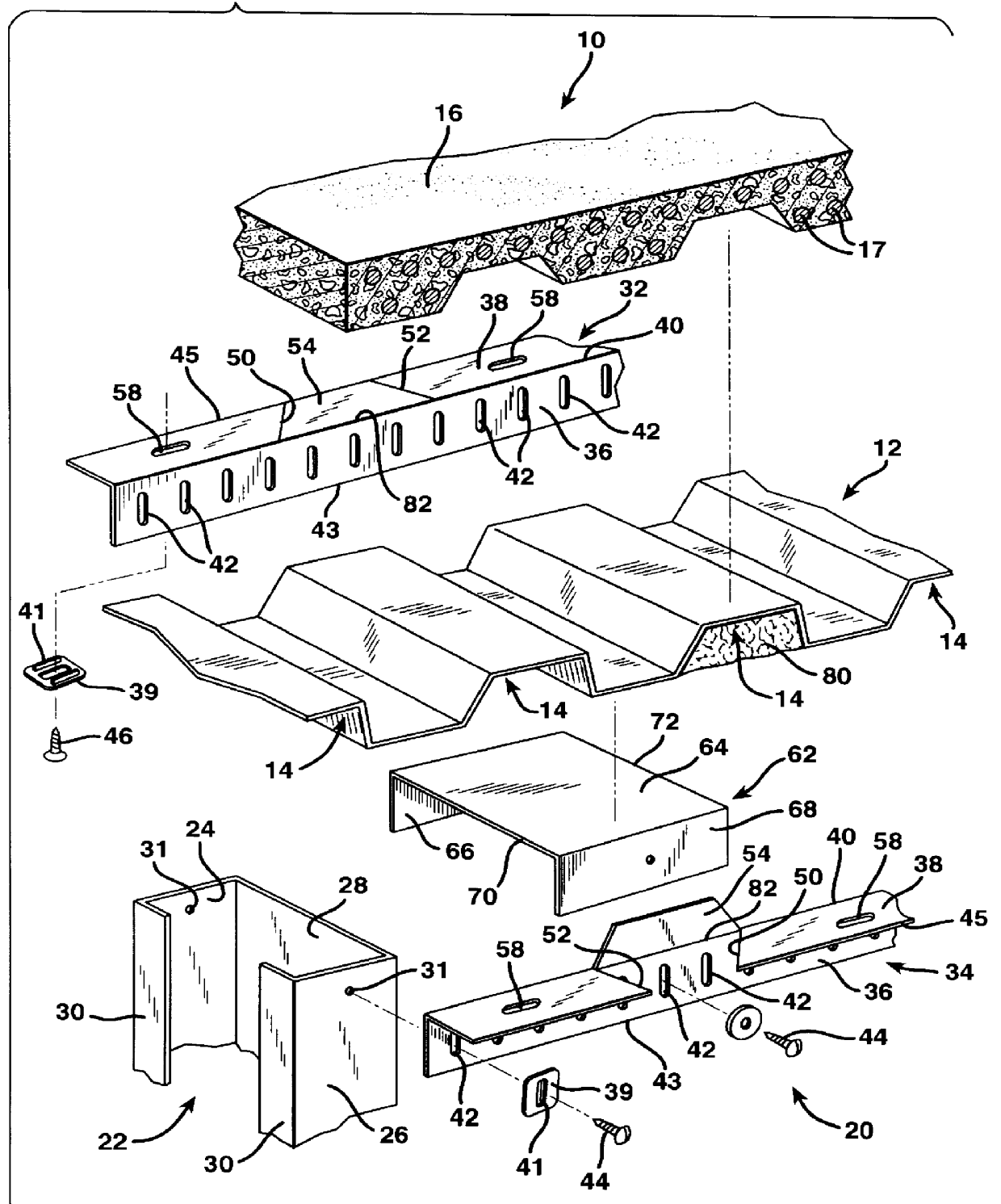

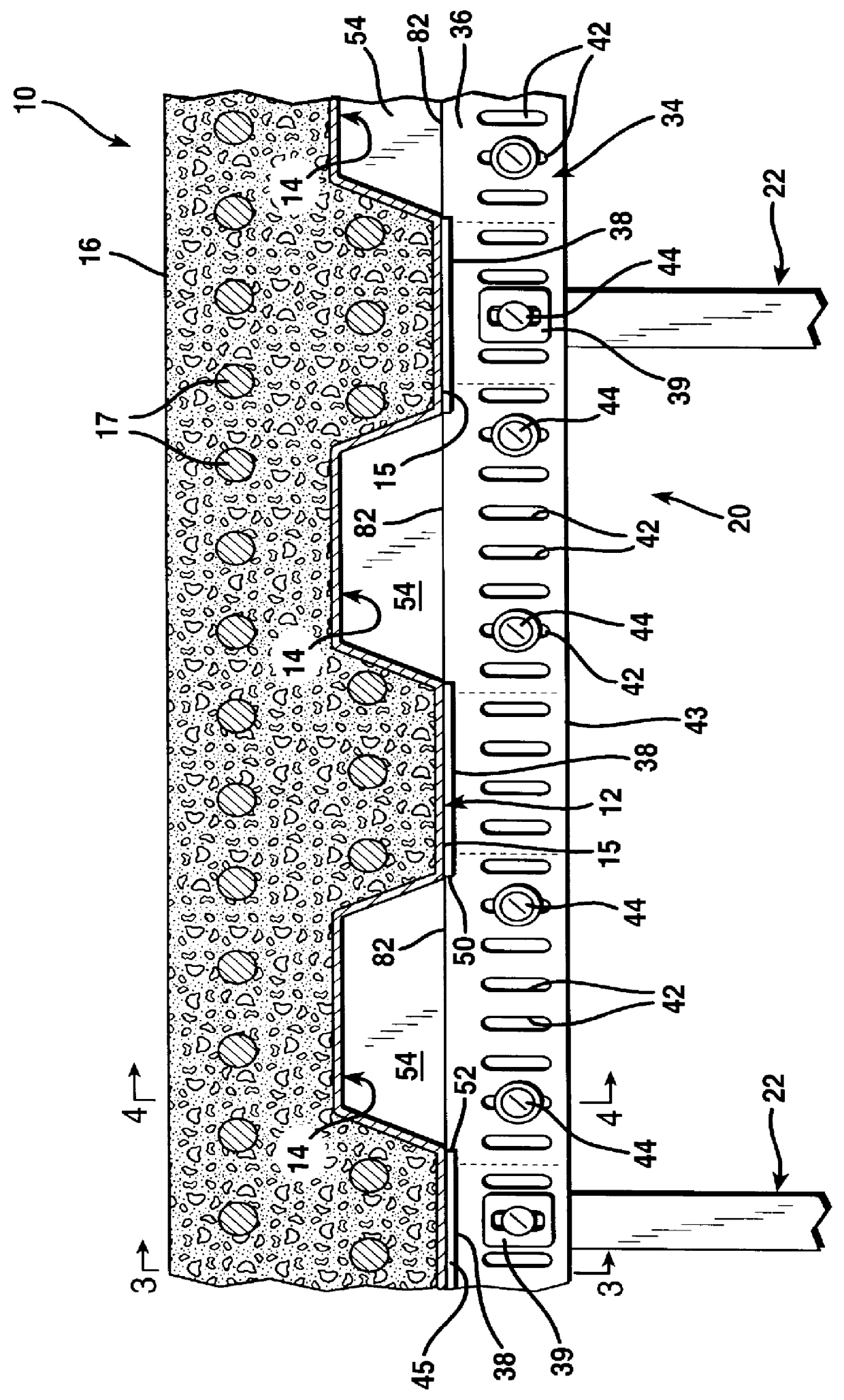

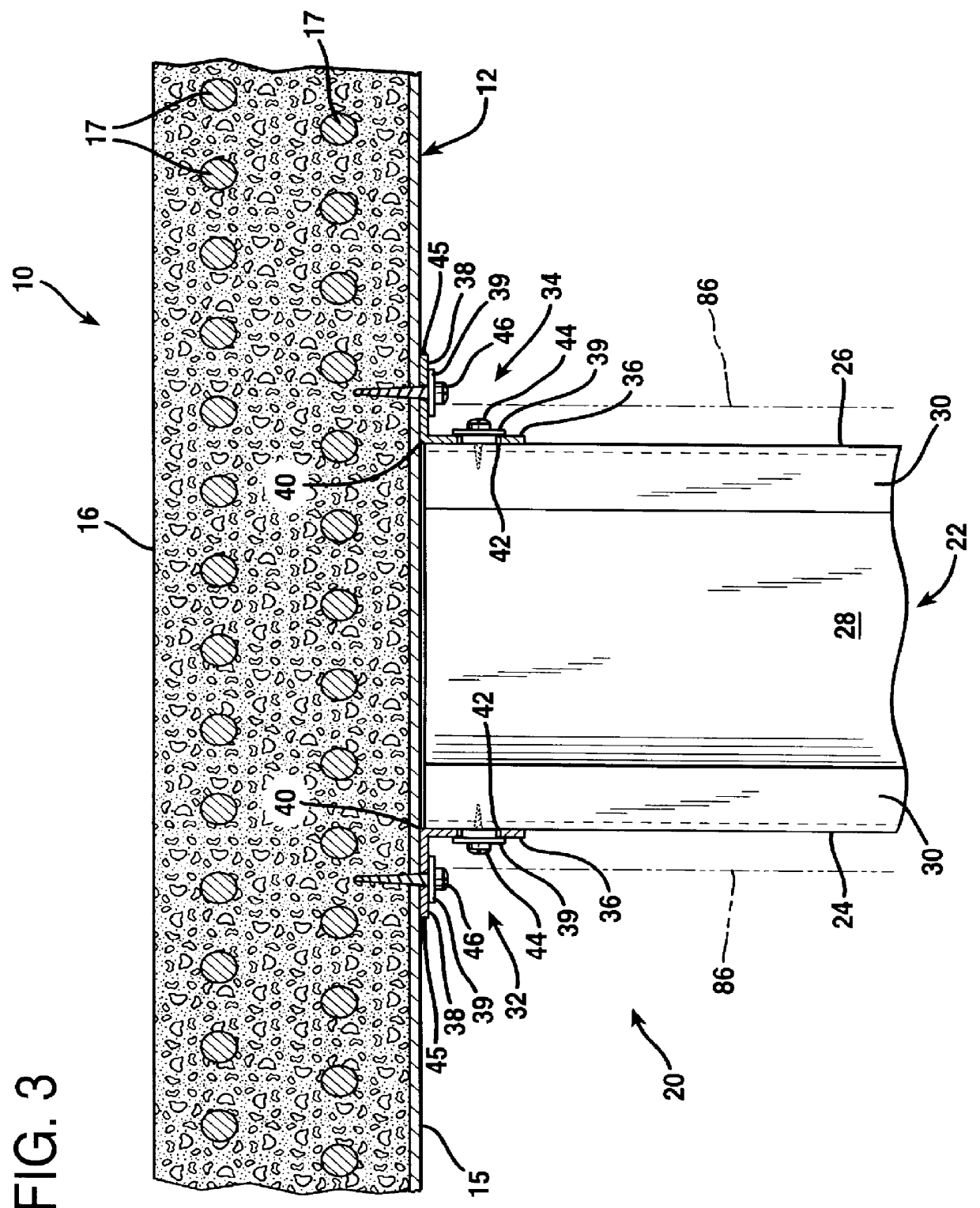

Seismic and fire-resistant head-of-wall structure

An improved head-of-wall structure for an interior, nonload-bearing building wall is provided in which a pair of elongated angle strips are employed to connect the upper ends of to the upright metal studs fluted metal decking above in a seismic and fire-resistant manner. A plurality of uniformly spaced pop-up tabs are defined in the horizontal legs of the angle strips directly beneath the open flutes or channels of the metal decking above. Insulation supports are located beneath the ceiling flutes to span the distance between the angle strips. The insulation supports are connected to the vertical legs of the angle strips to form flat, horizontal platforms directly beneath the portions of the flutes that cross the line of studs. Batts of fire-proofing insulation are located atop the insulation supports and are held in position by bending up the pop-up tabs from their original horizontal disposition into a generally vertical orientation.

Owner:HERREN THOMAS R

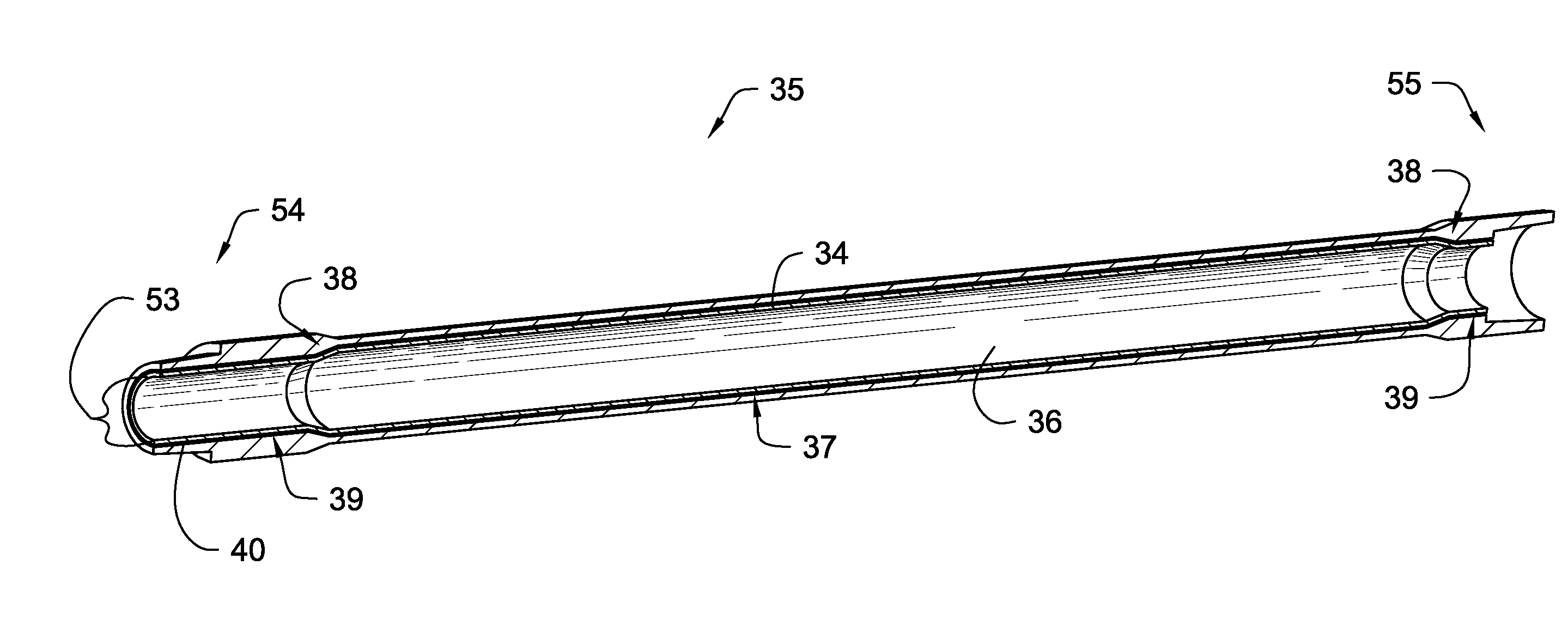

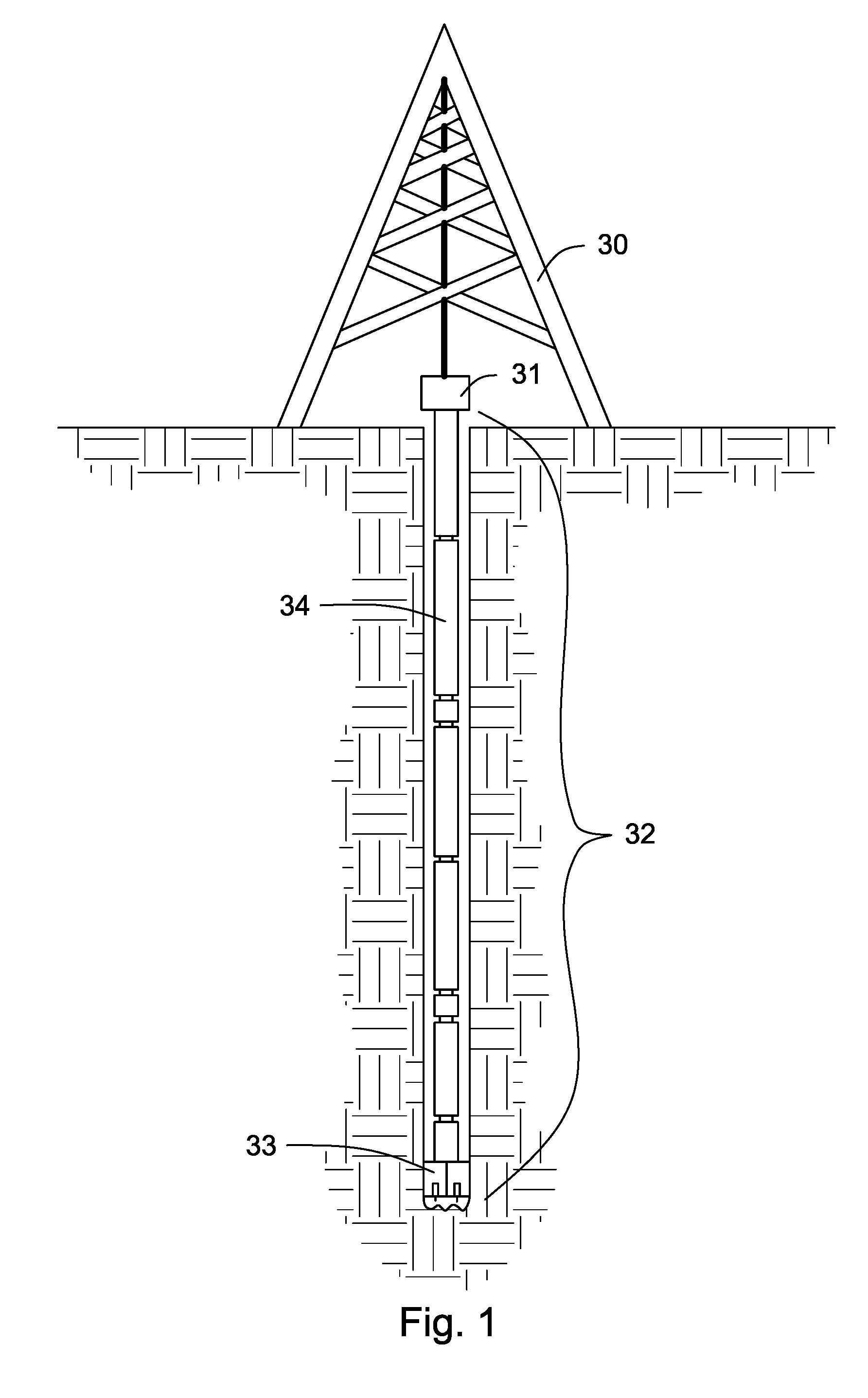

Conformable Apparatus in a Drill String

An apparatus in a drill string comprises an internally upset drill pipe. The drill pipe comprises a first end, a second end, and an elongate tube intermediate the first and second ends. The elongate tube and the ends comprising a continuous an inside surface with a plurality of diameters. A conformable metal tube is disposed within the drill pipe intermediate the ends thereof and terminating adjacent to the ends of the drill pipe. The conformable metal tube substantially conforms to the continuous inside surface of the metal tube. The metal tube may comprise a non-uniform section which is expanded to conform to the inside surface of the drill pipe. The non-uniform section may comprise protrusions selected from the group consisting of convolutions, corrugations, flutes, and dimples. The non-uniform section extends generally longitudinally along the length of the tube. The metal tube may be adapted to stretch as the drill pipes stretch.

Owner:INTELLISERV

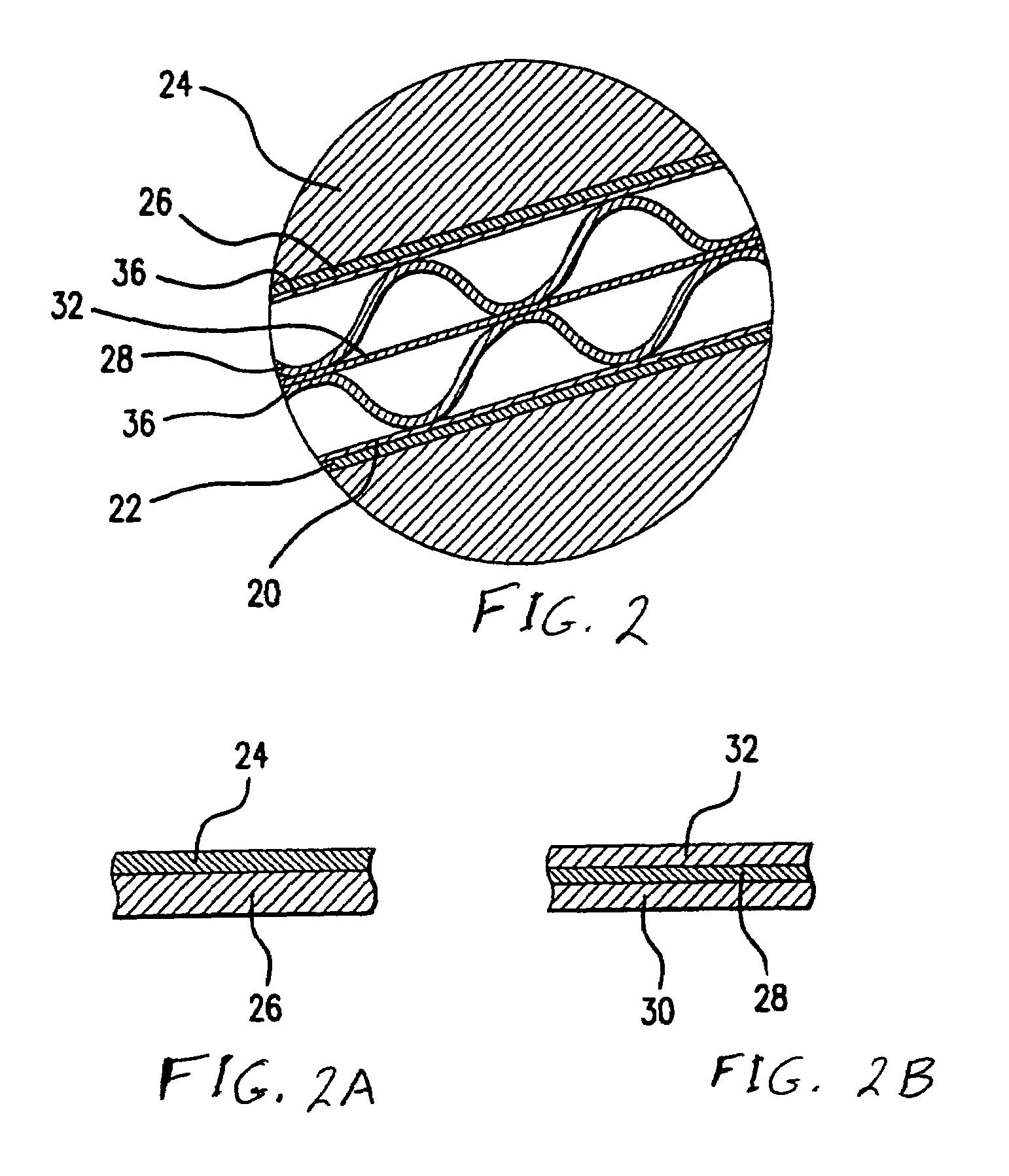

Filter element having center piece and methods

A core construction for use in a filter element includes a tubular member having a wall with opposite first and second ends. The first end is adaptable for engagement with structure, such as a frame utilized with a filter element. The second end is also engageable with external structure, such as a handle. Preferably, a filter element is constructed by rolling a media construction around the core construction. The media construction includes a corrugated sheet secured to a flat sheet rolled around the core construction into a coiled construction. The coiled construction has inlet flutes and outlet flutes. Methods for using and assembling filter elements preferably use core constructions as described herein.

Owner:DONALDSON CO INC

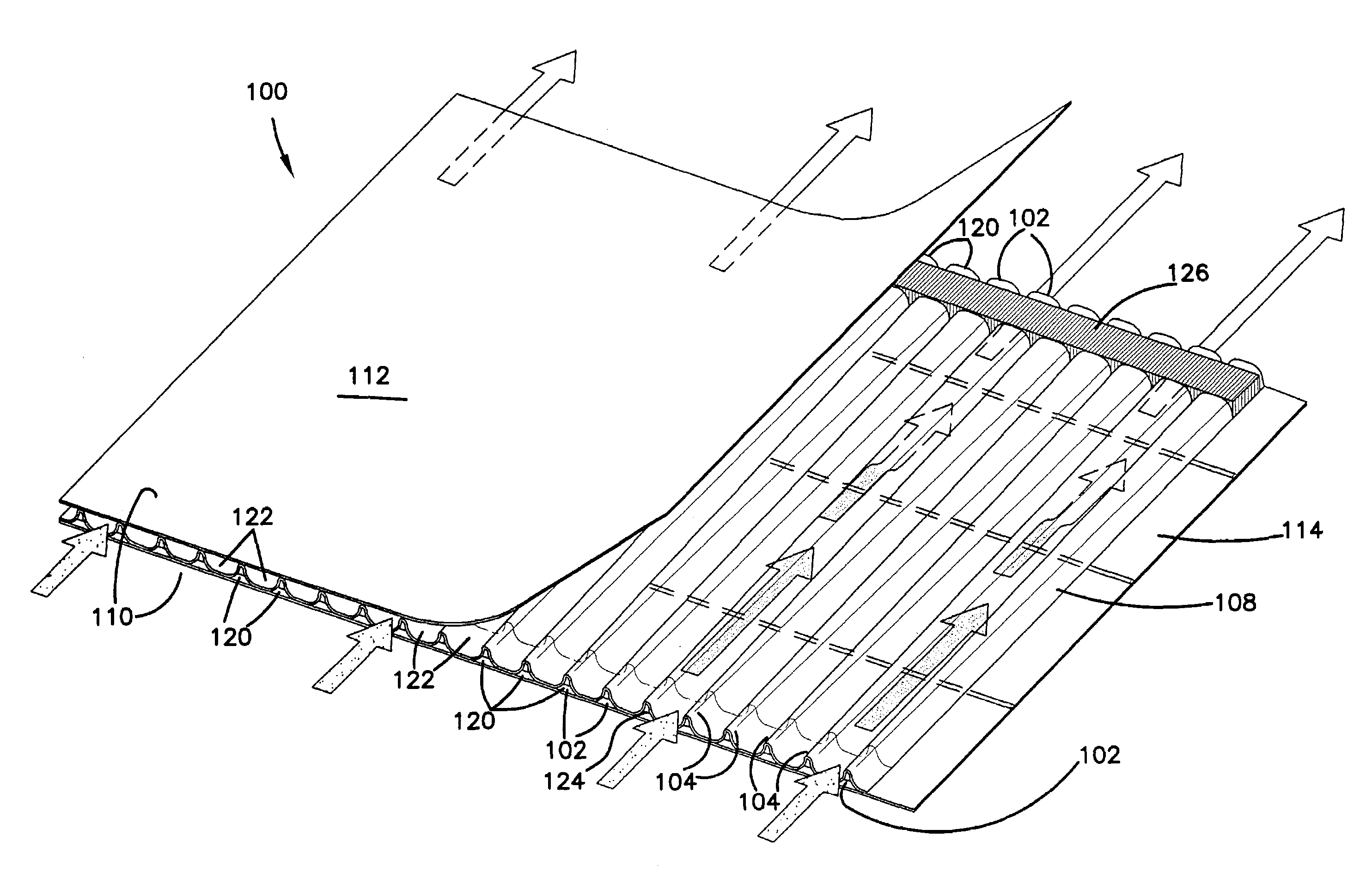

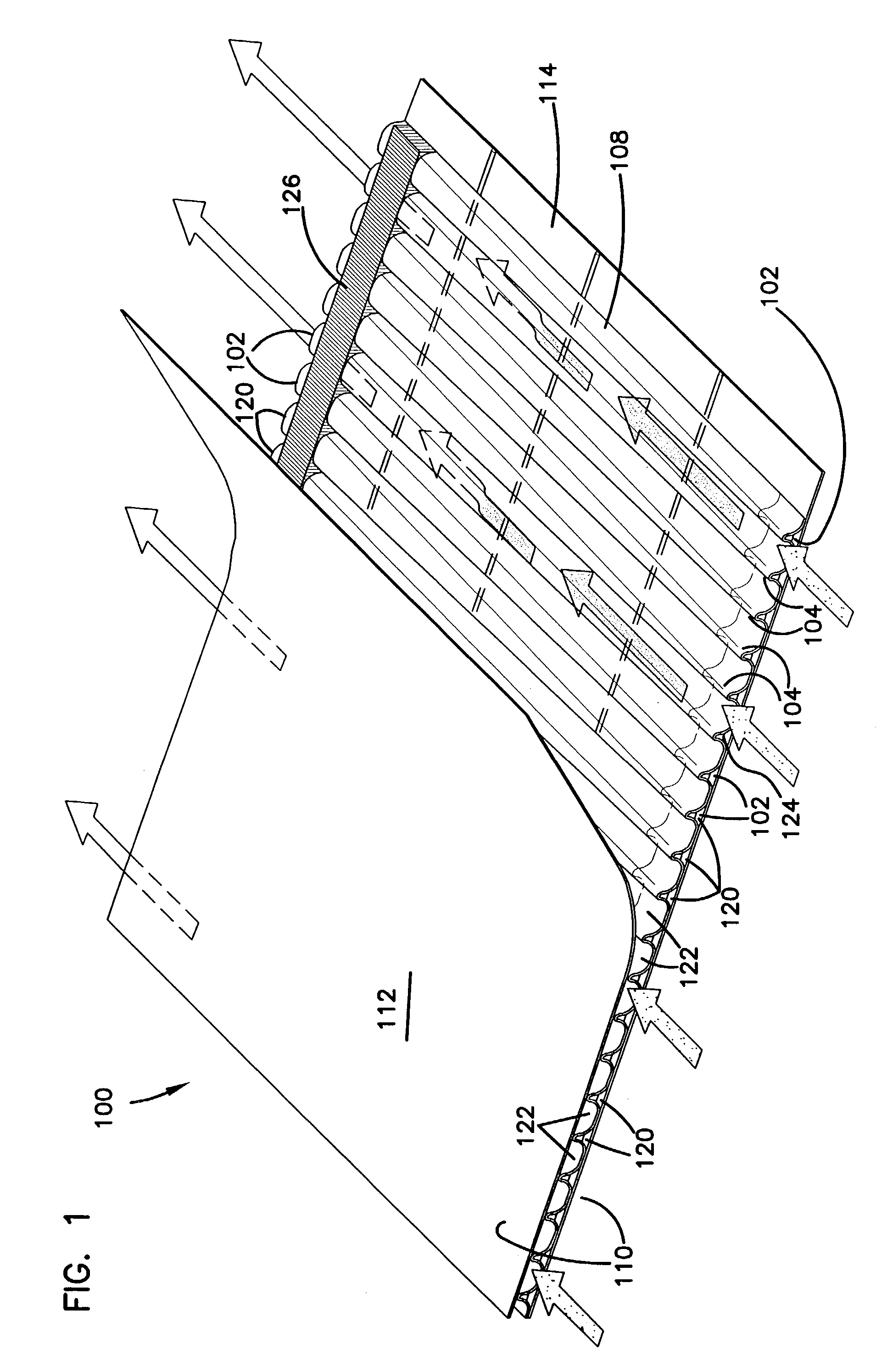

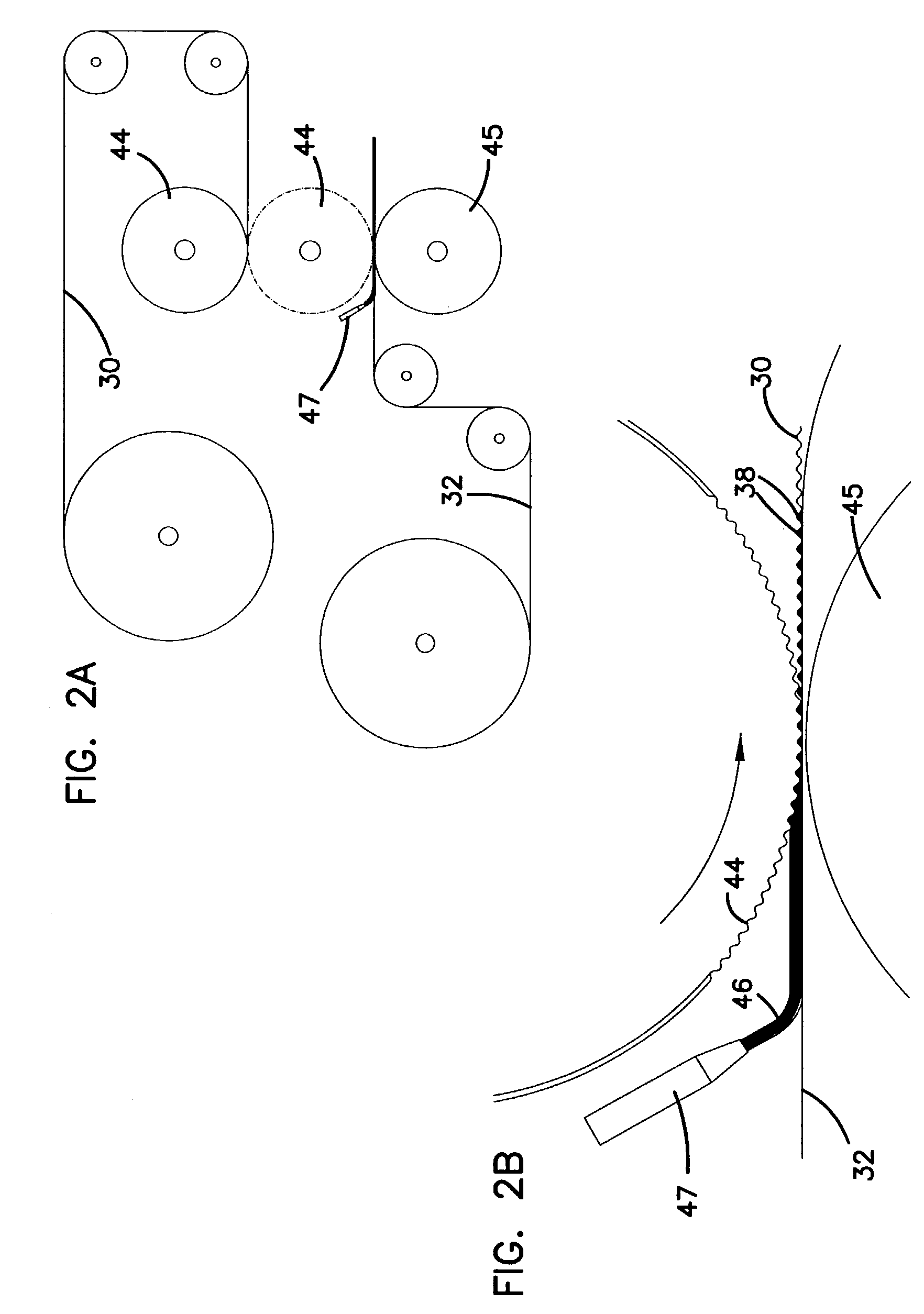

Method of making a fluted filter media for air filter

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

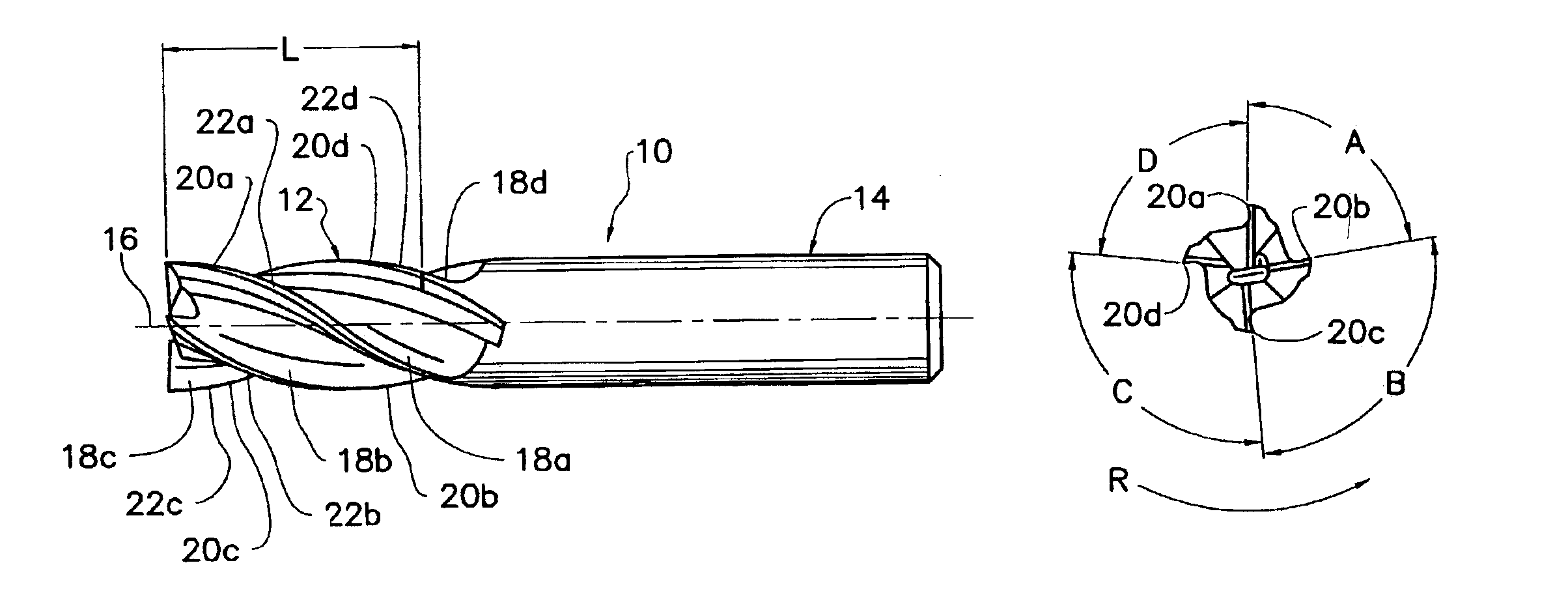

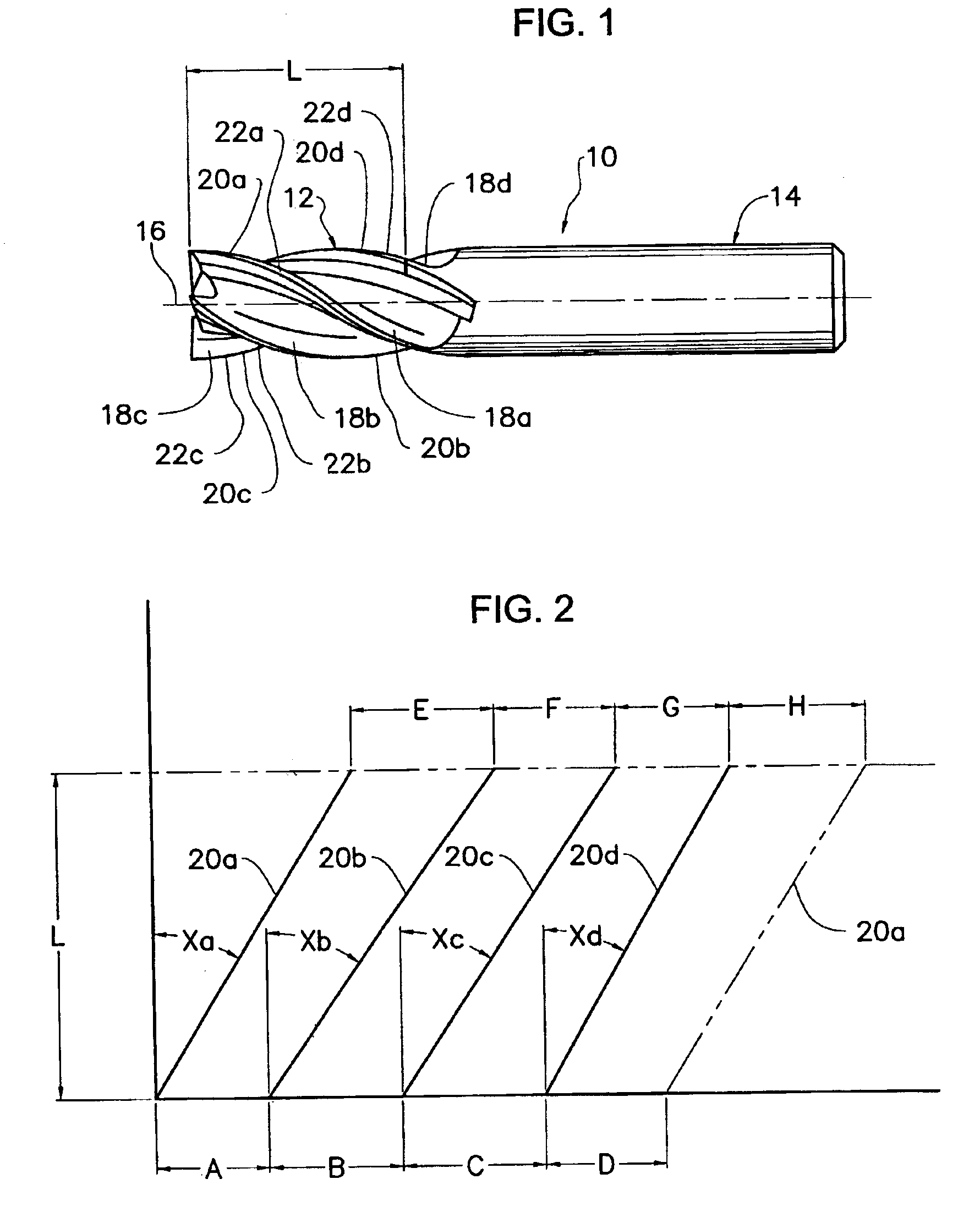

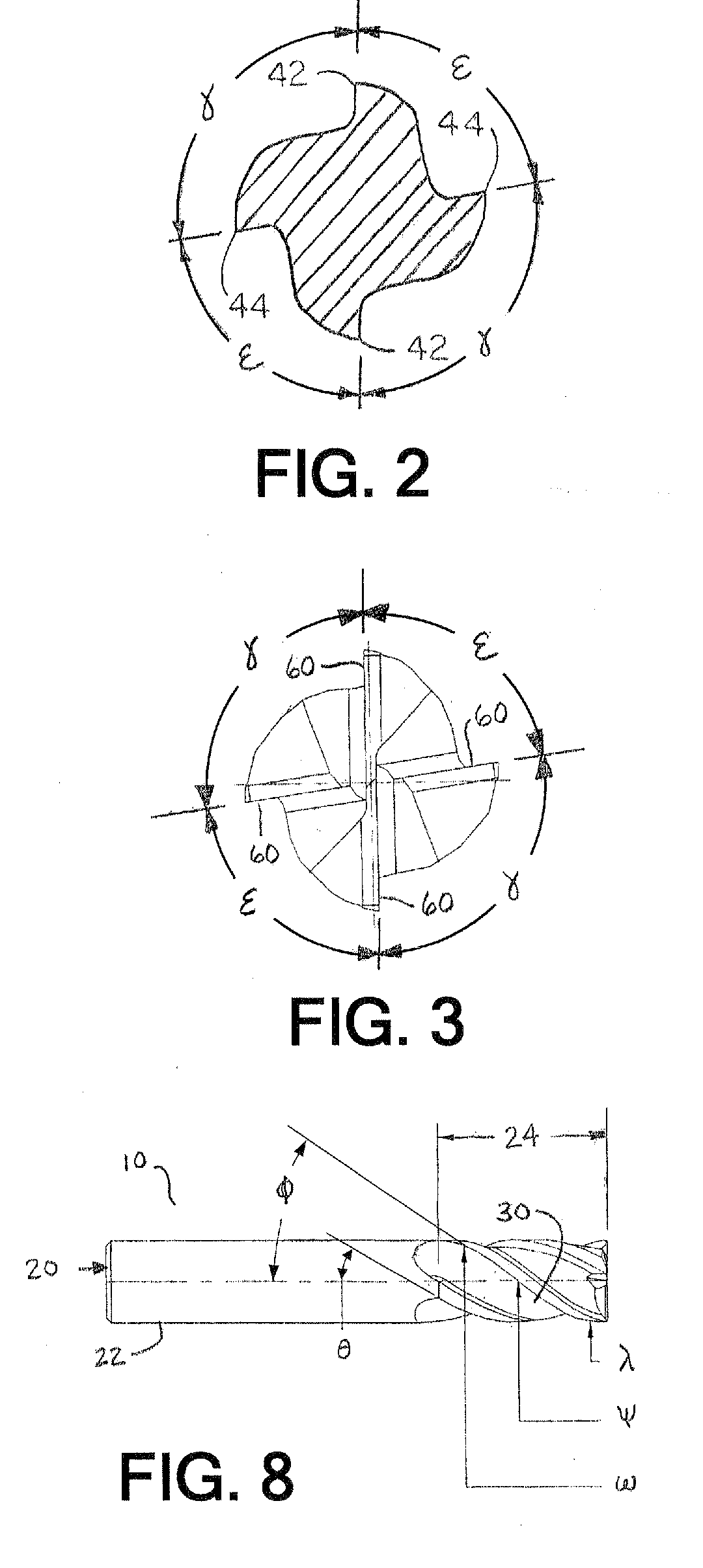

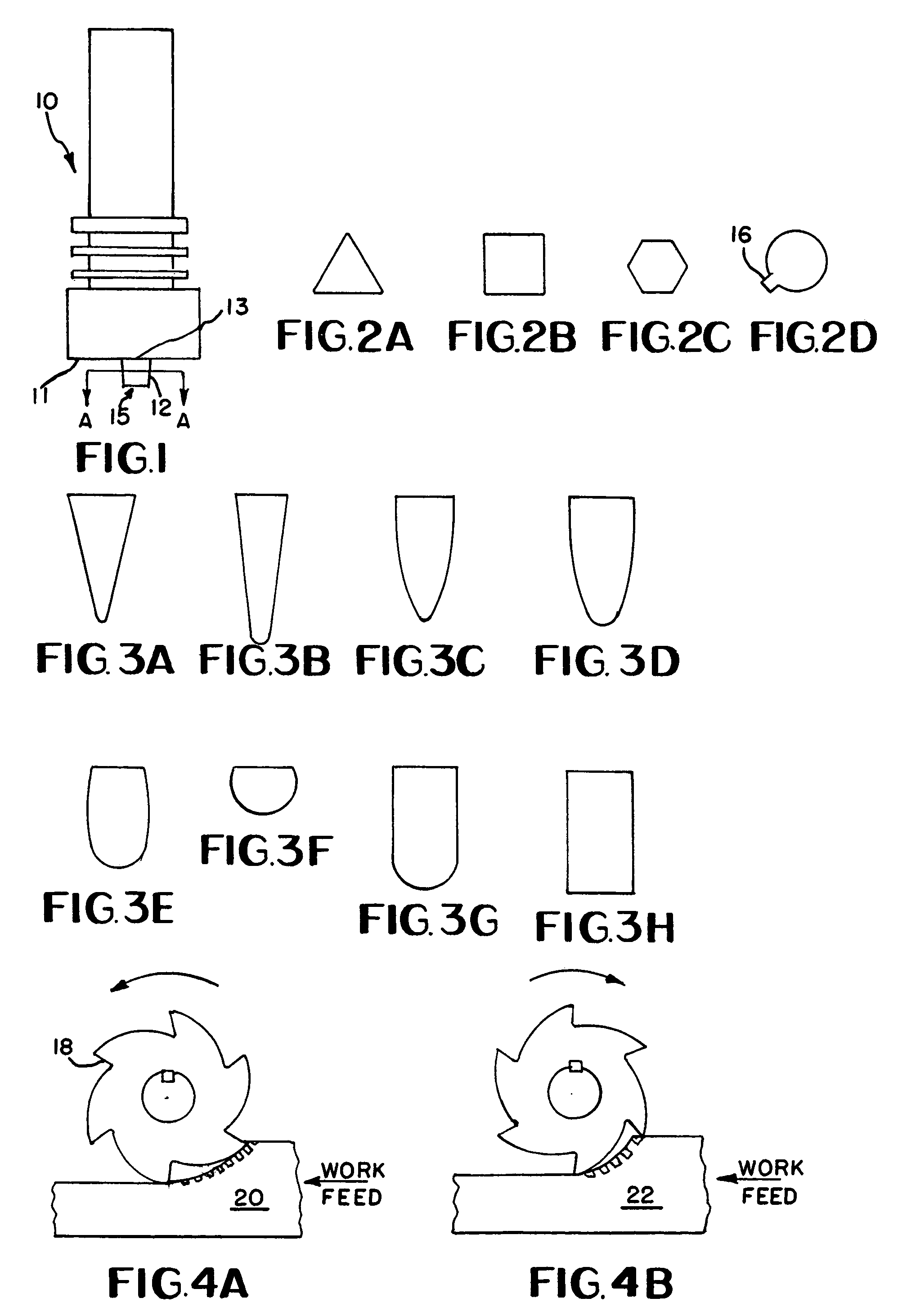

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

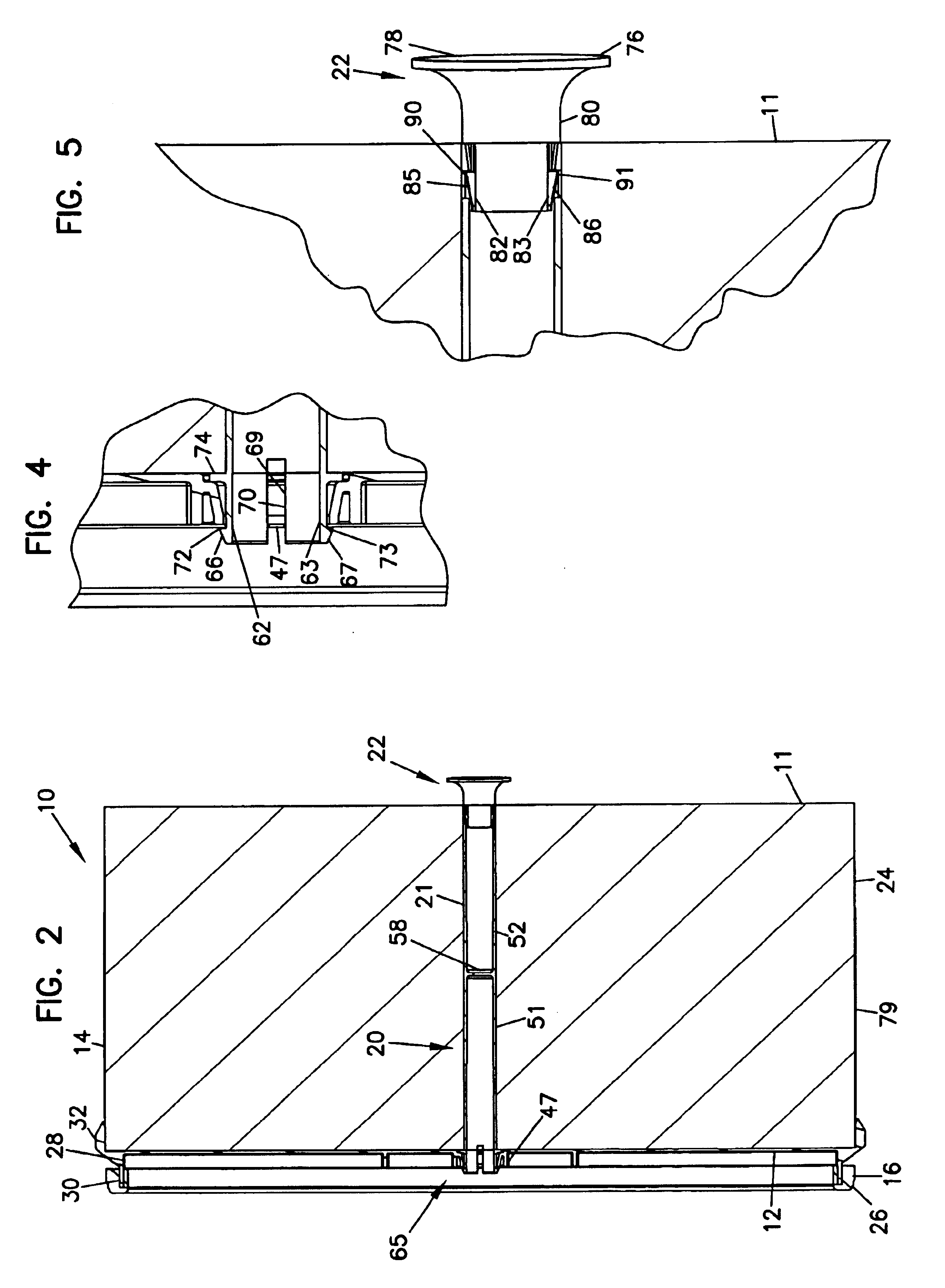

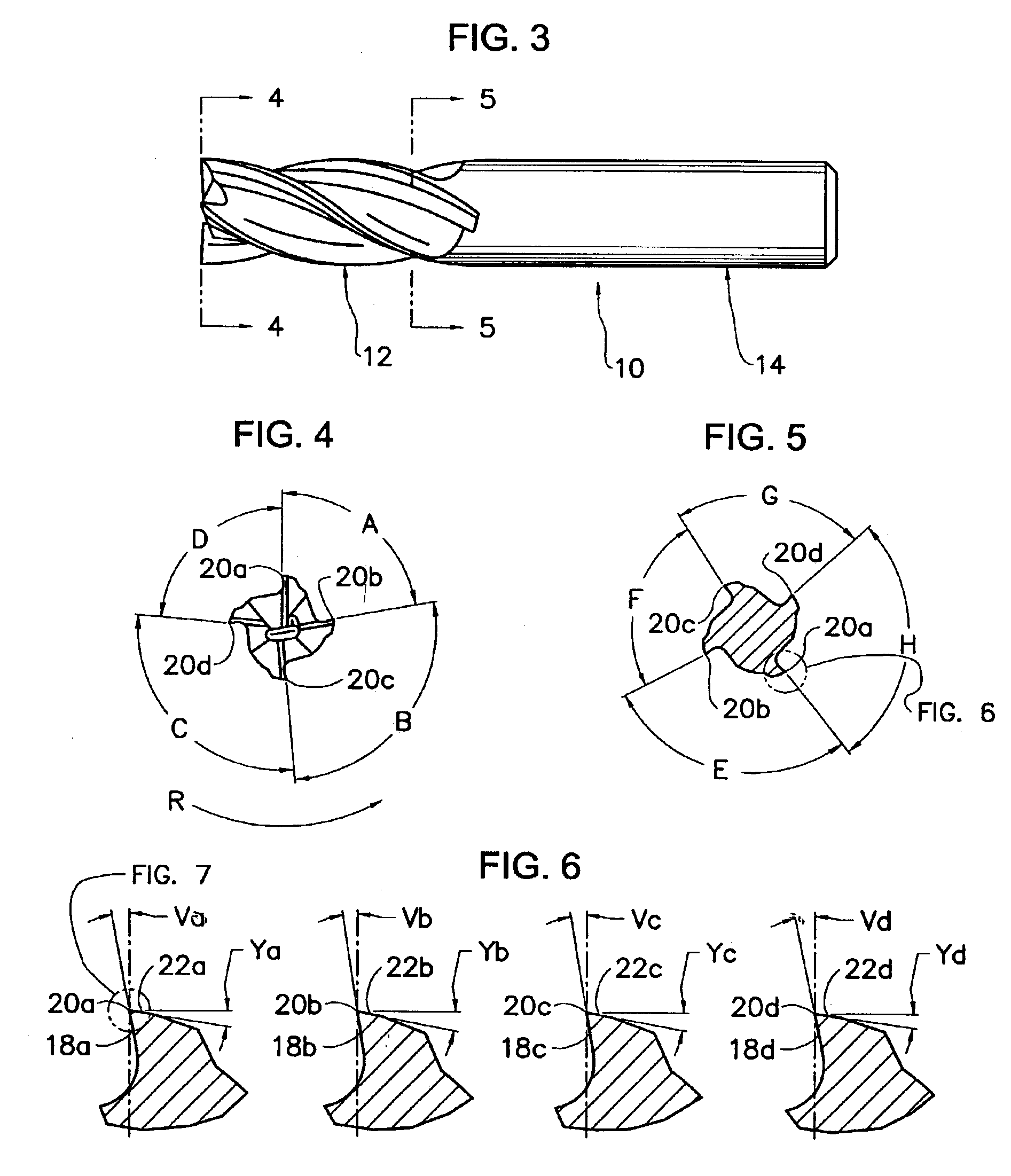

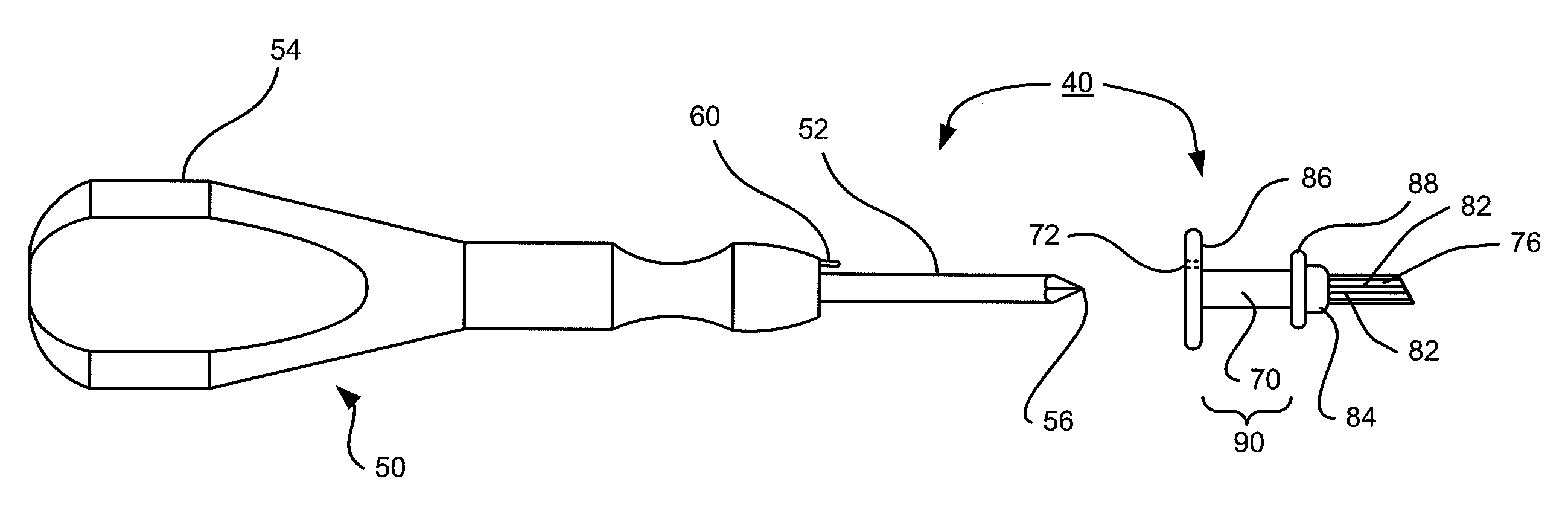

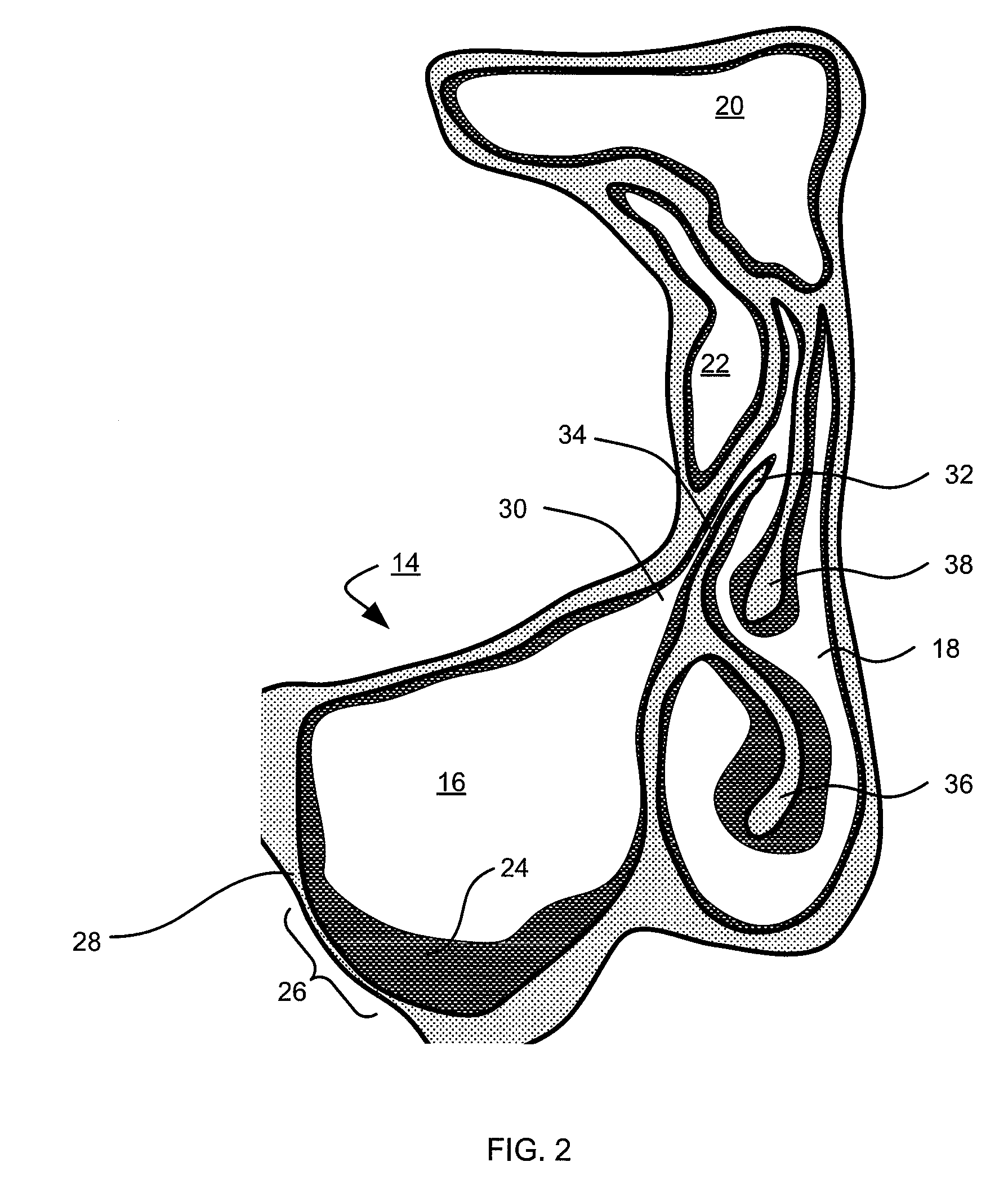

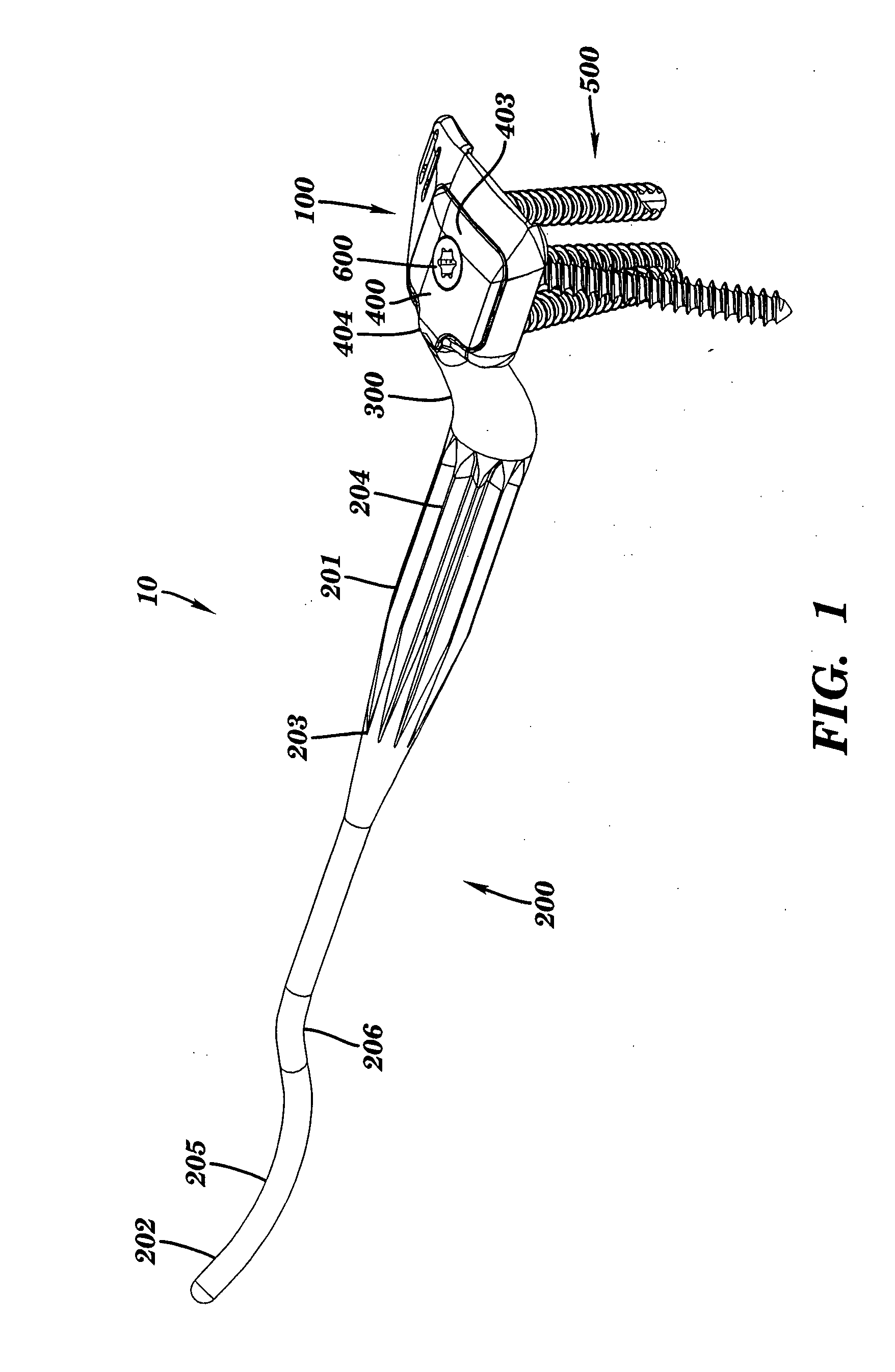

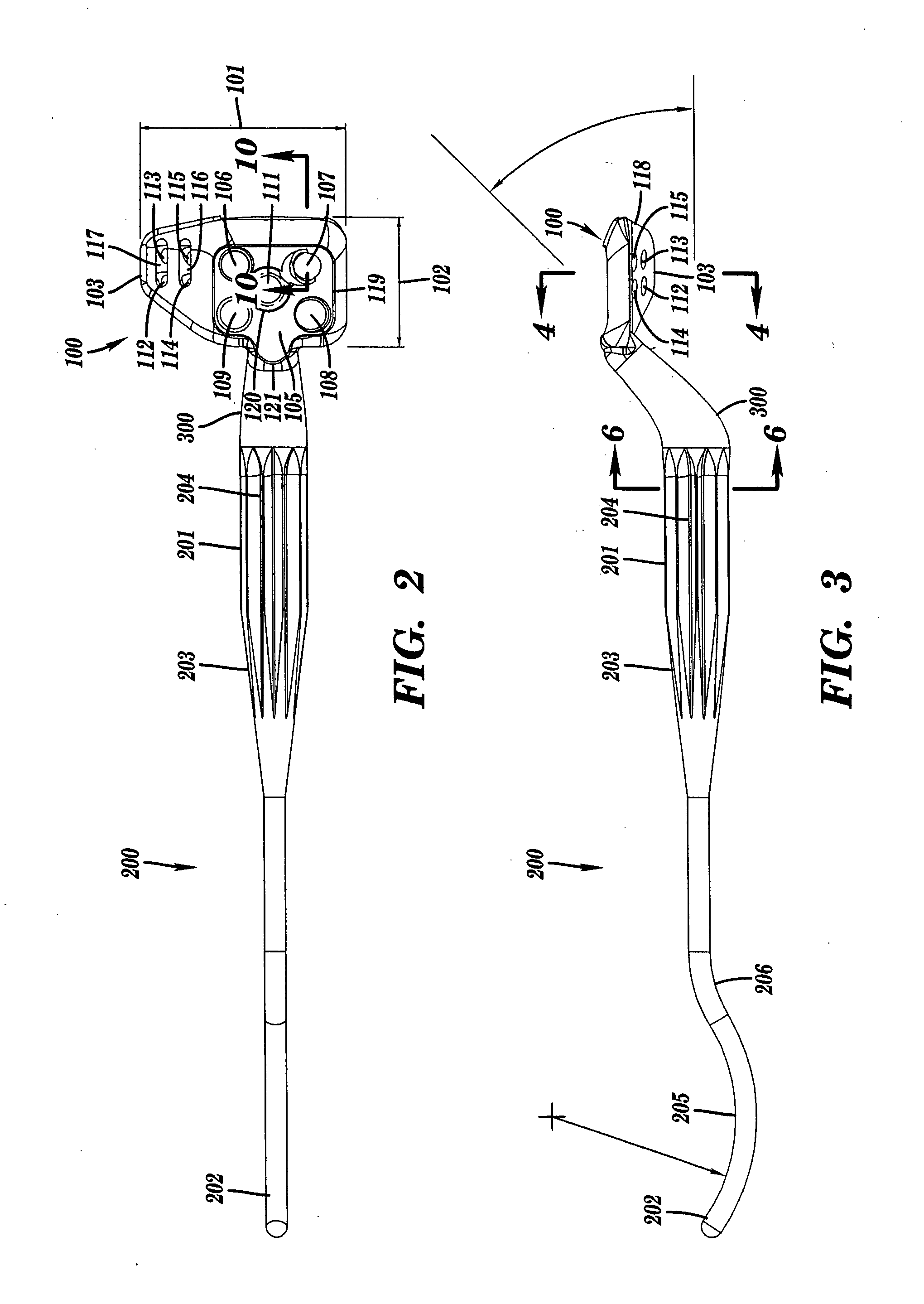

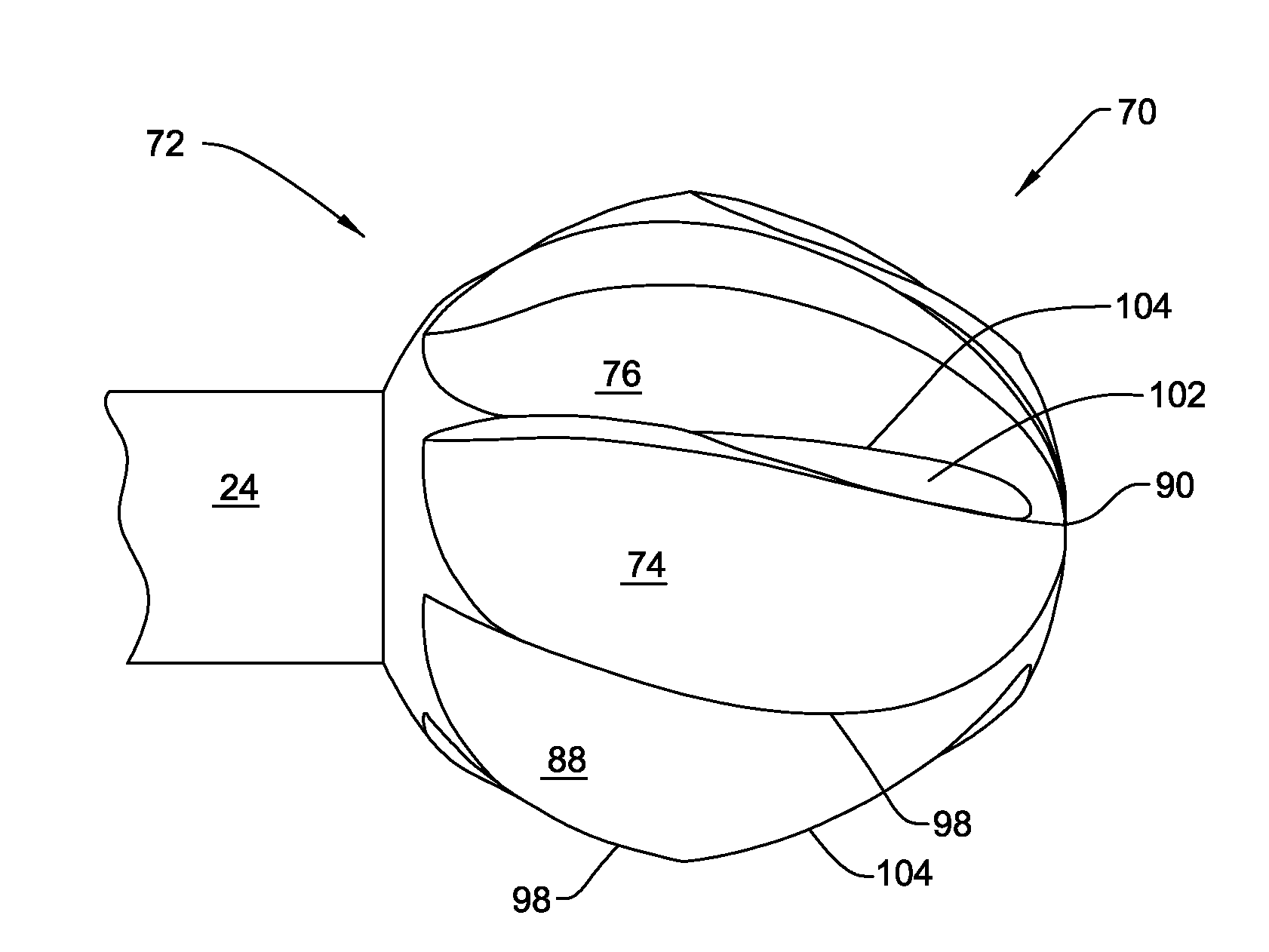

Apparatus and method for accessing a sinus cavity

A system for accessing a sinus cavity of a subject includes an access tool configured to penetrate into the sinus cavity from a location external the subject. The system further includes an access sheath having a distal tubular portion, a lumen extending through the access sheath and the distal tubular portion and dimensioned to receive the access tool, the distal tubular portion comprising one or more cutting surfaces disposed about an external surface thereof. The one or more cutting surfaces may include a plurality of longitudinally oriented grooves for flutes disposed about the periphery of the distal tubular member.

Owner:ENTELLUS MEDICAL

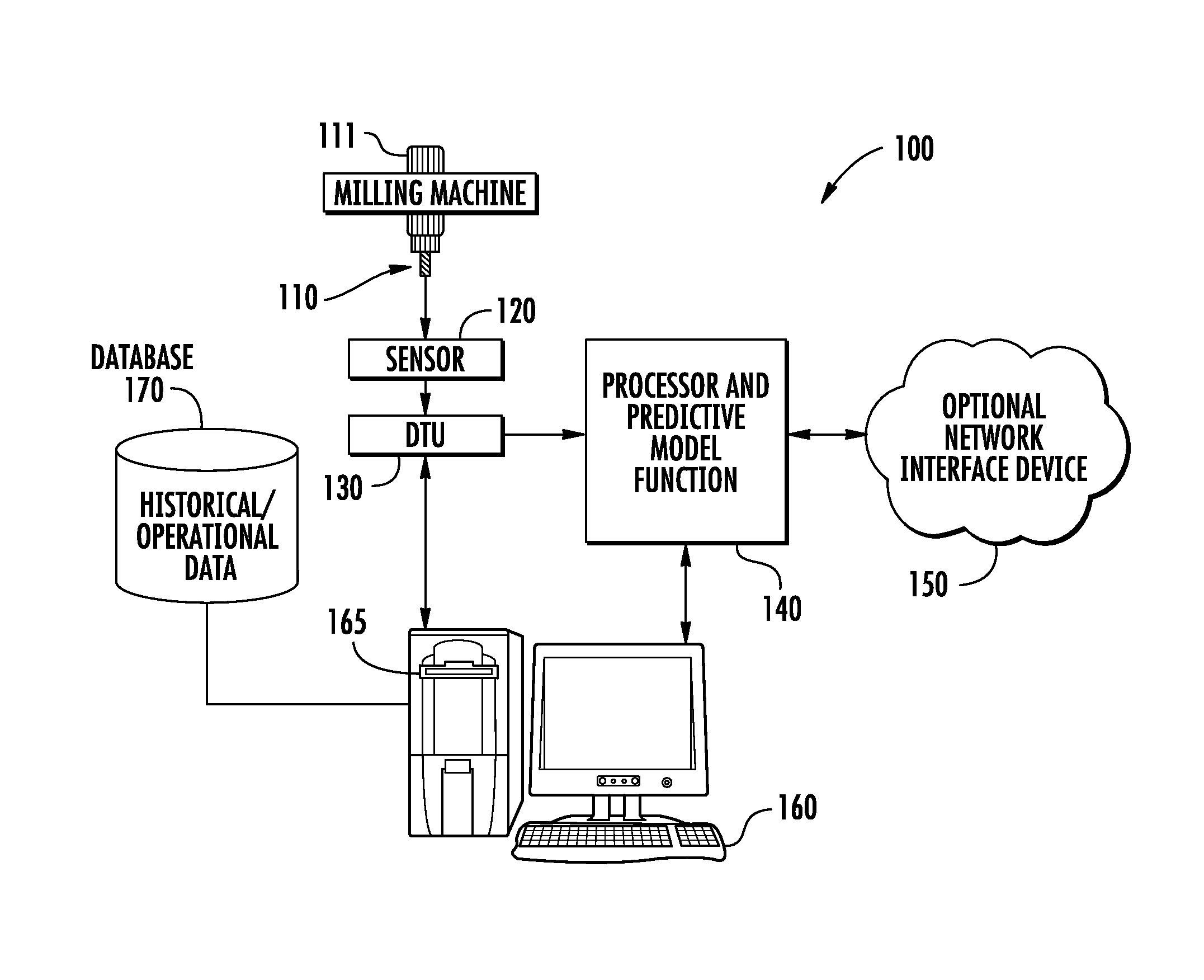

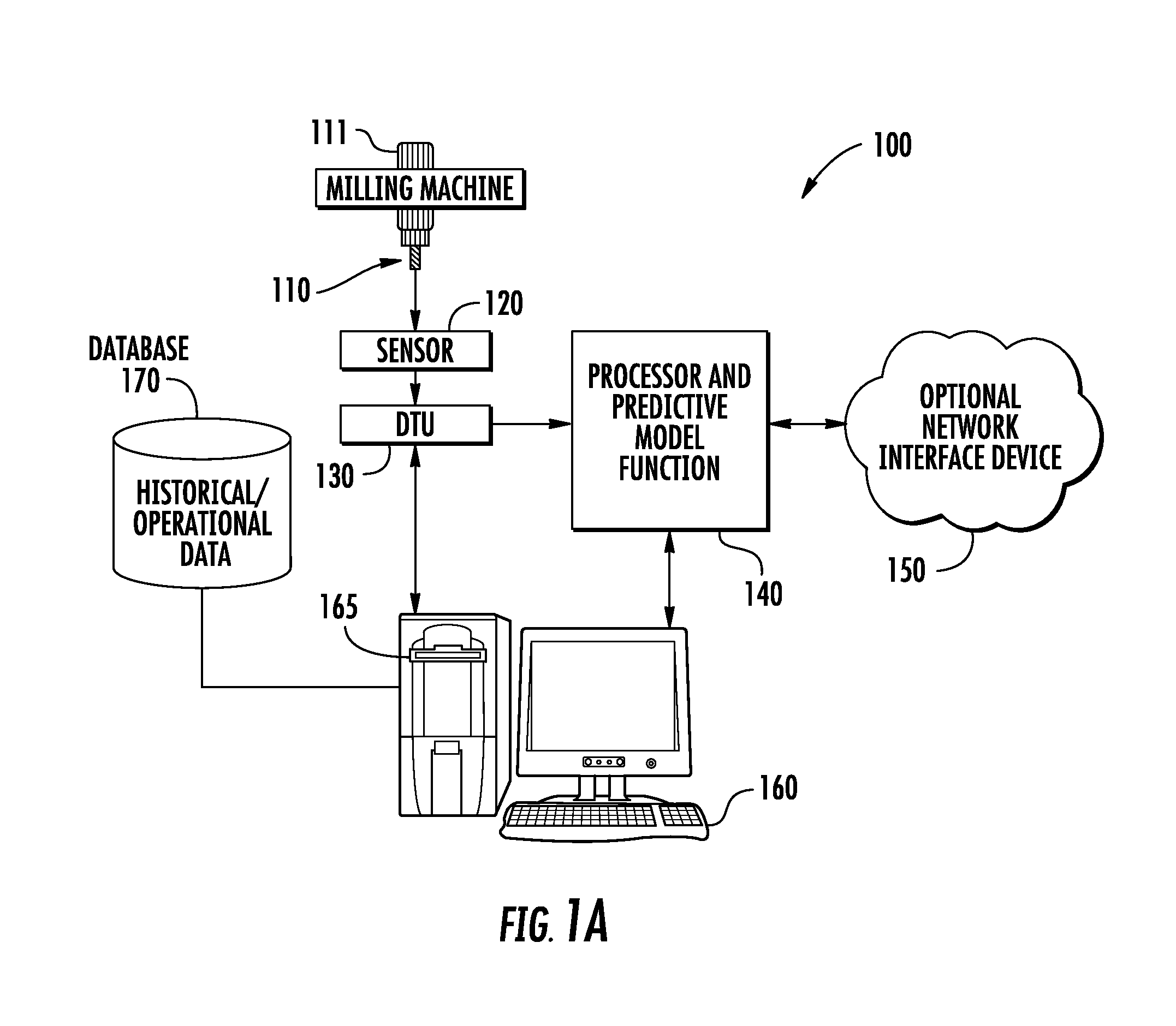

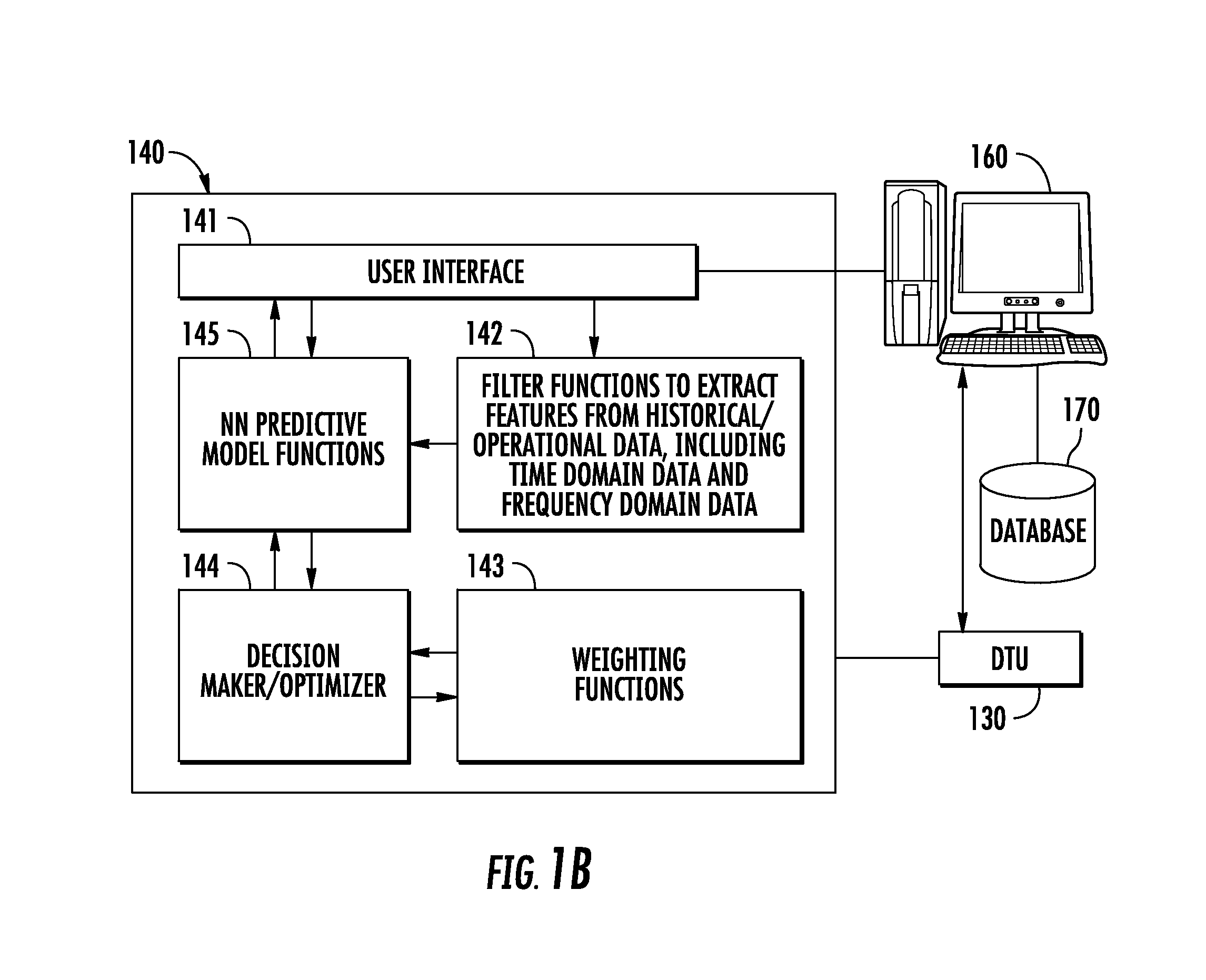

System and method for estimating remaining useful life

ActiveUS8781982B1Avoid failureTesting/monitoring control systemsDigital computer detailsFluteMachine learning

Mechanisms for predicting a remaining useful life of a cutter head of a milling machine that includes a plurality of flutes are disclosed. Features are extracted from reference data associated with a plurality of reference cutter heads. The reference data includes reference vibration data and reference wear data. At least two Neural Network predictive models are trained in parallel for predicting the remaining life of a new cutter head based upon the extracted features. Operational data associated with the new cutter head is obtained. The operational data includes operational vibration data and operational wear data. Features extracted from the operational data are input into an optimal predictive model of the at least two Neural Network predictive models. A remaining useful life of the new cutter head is estimated by the optimal predictive model.

Owner:LOCKHEED MARTIN CORP

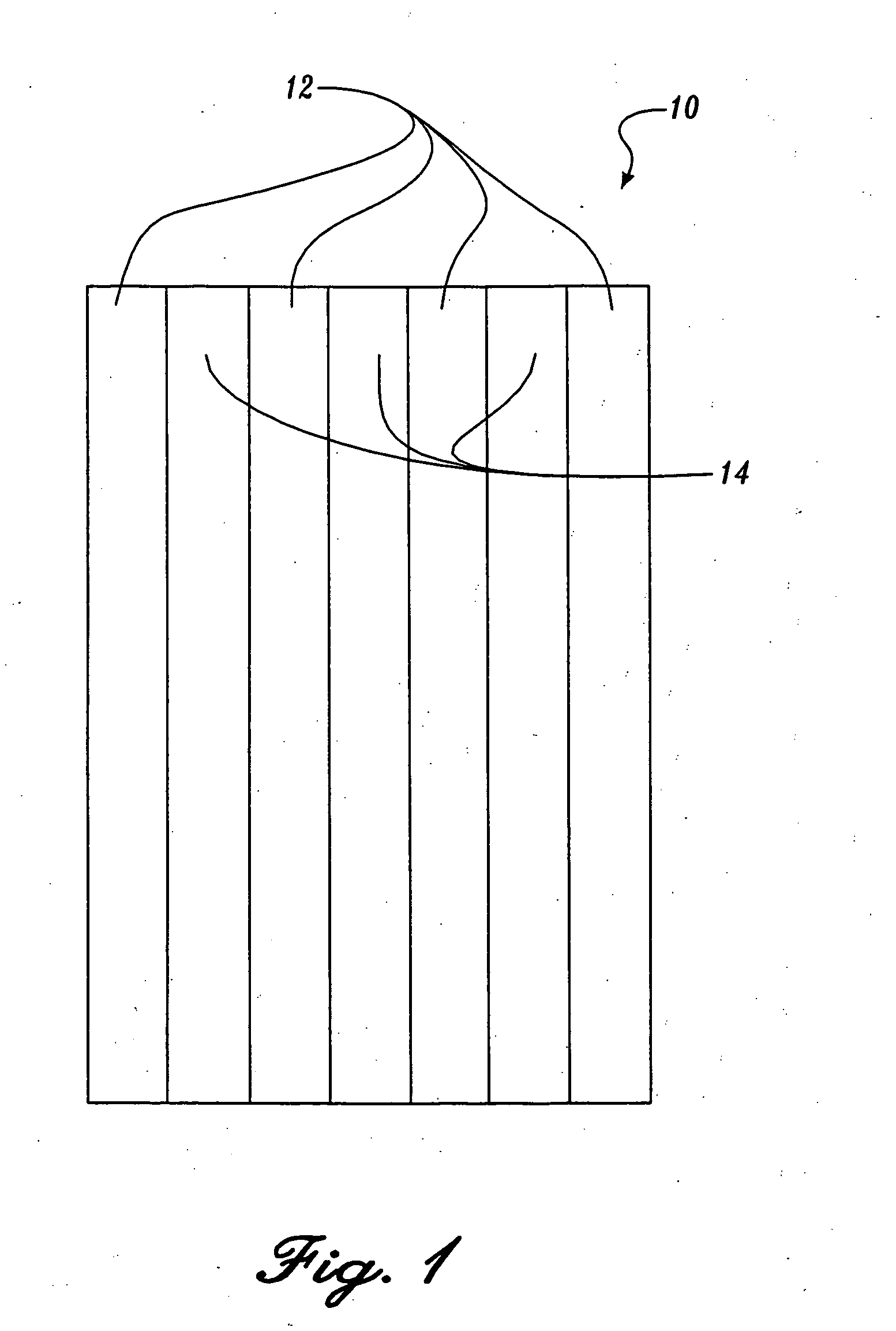

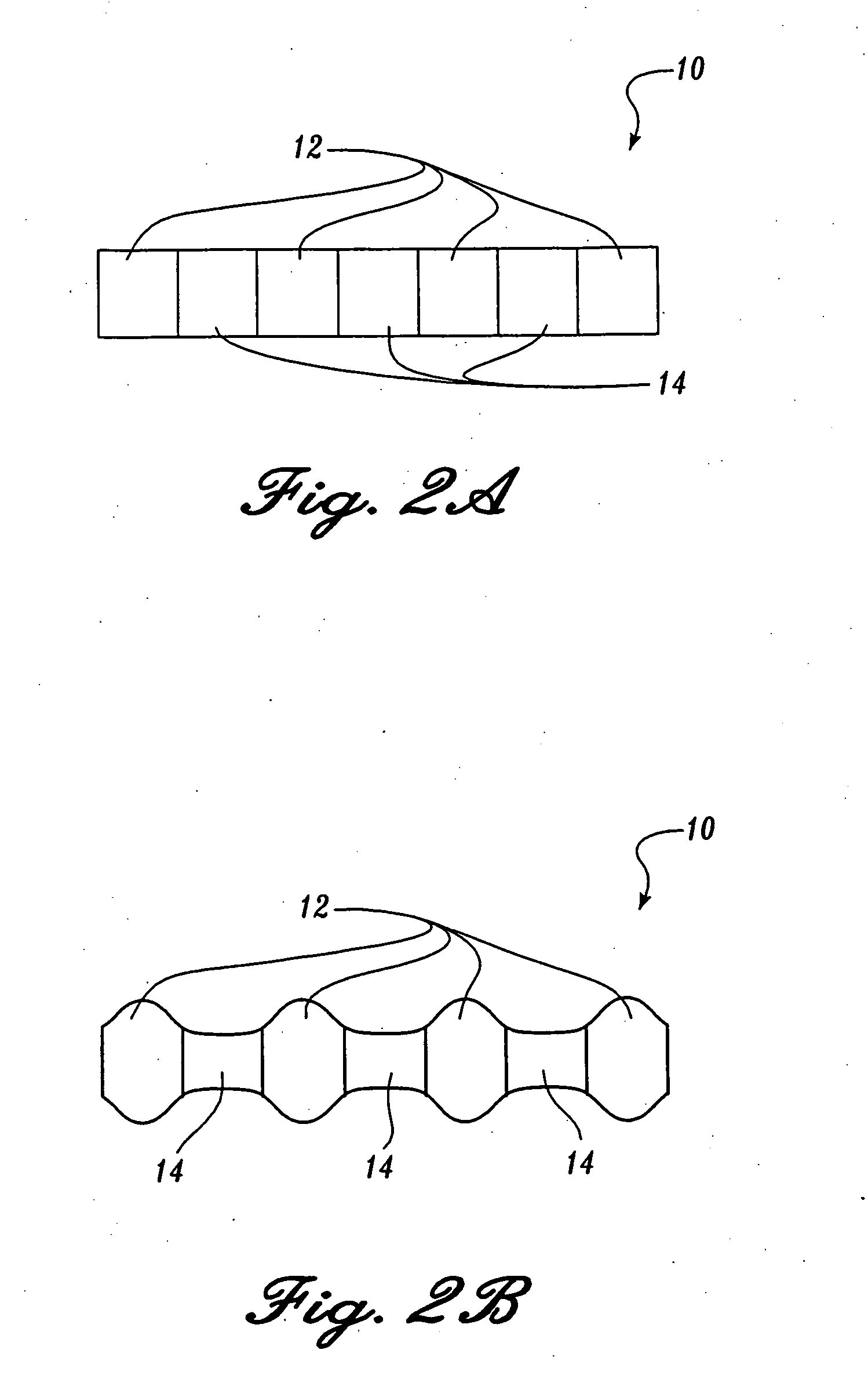

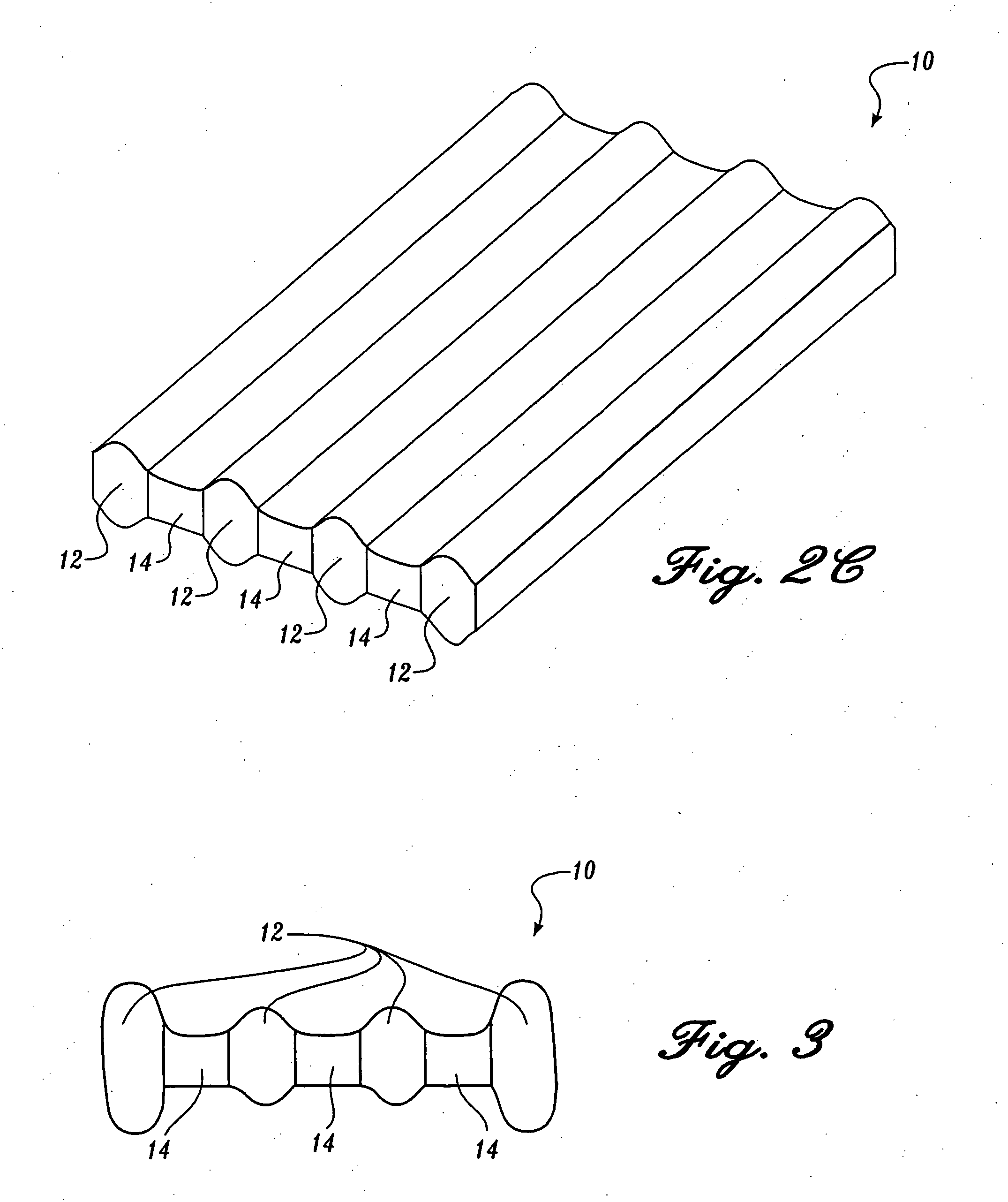

Fluted composite and related absorbent articles

InactiveUS20060081348A1Improve acquisitionImprove distributionNon-fibrous pulp additionNatural cellulose pulp/paperFiberFlute

An absorbent composite that includes a fibrous matrix having absorbent material dispersed in bands along the composite's length is disclosed. The bands define liquid distribution zones. On liquid contact, absorbent material swelling occurs and produces a wetted composite having flutes that include swollen absorbent material separated by distribution zones, regions of the composite that are substantially free of absorbent material. Absorbent articles that include the composite are also disclosed.

Owner:GRAEF PETER A +6

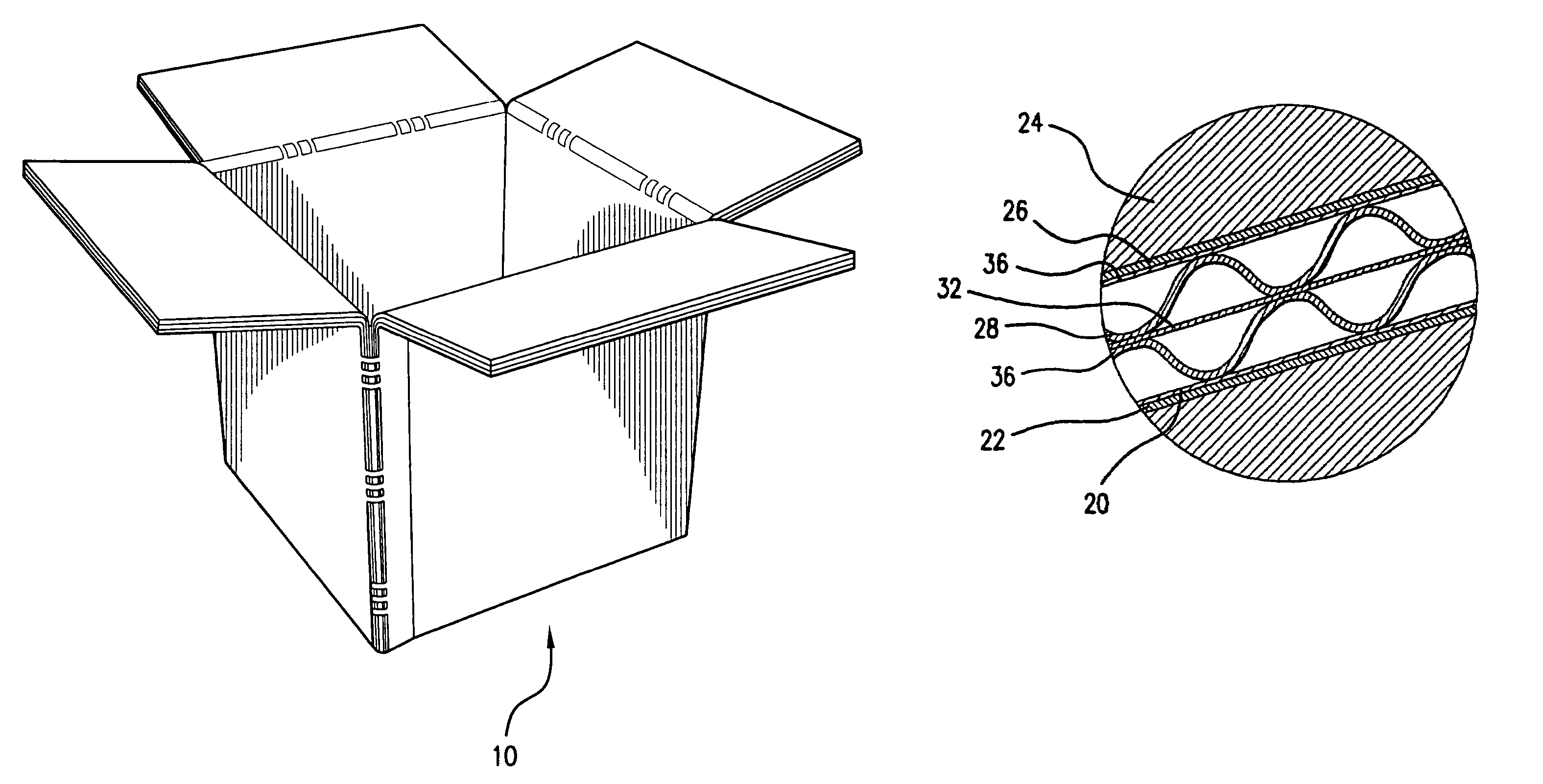

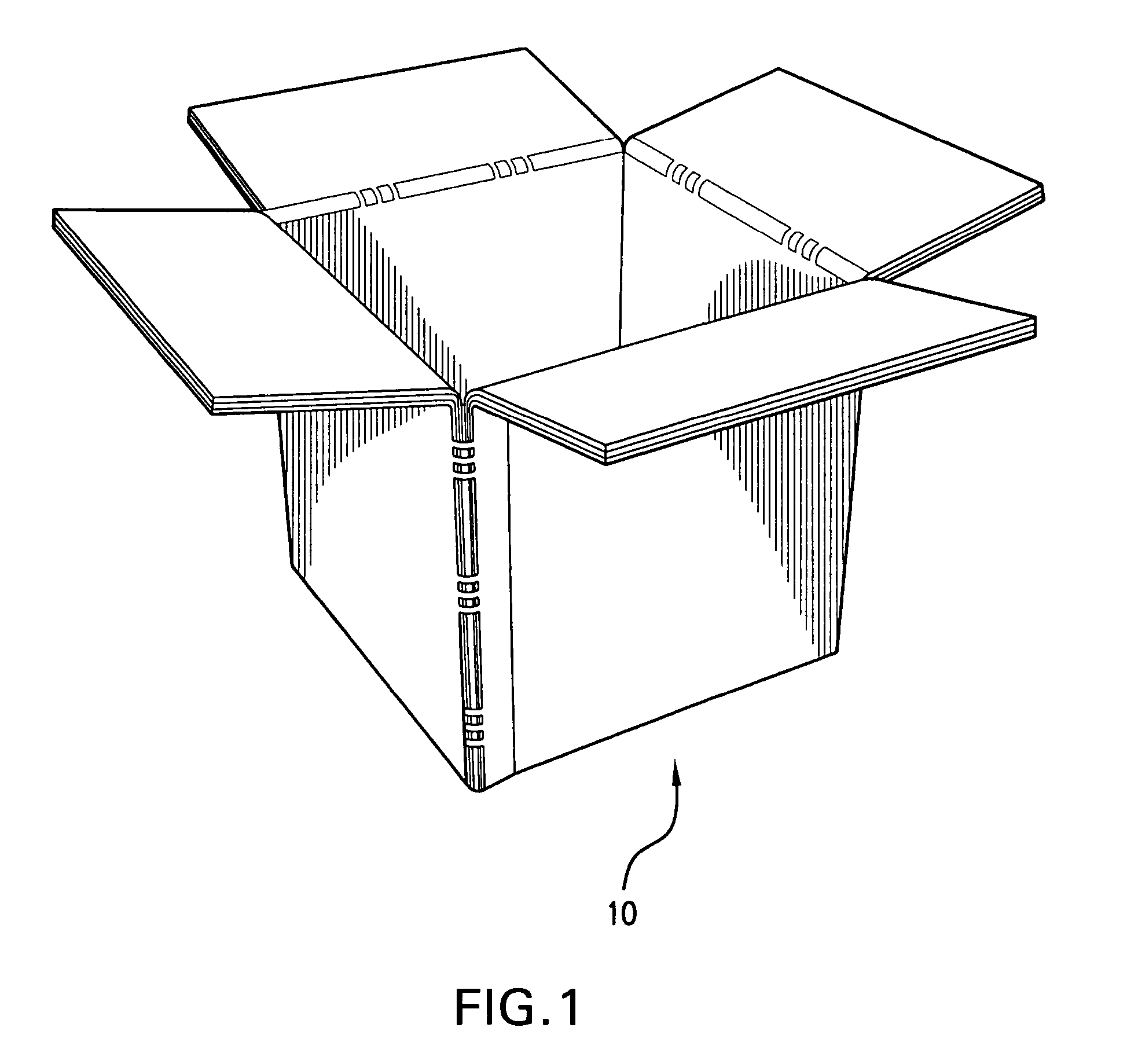

Knockdown corrugated box for temperature control and method of making

ActiveUS7094192B2Envelopes/bags making machineryBoxes/cartons making machineryTemperature controlFlute

A box for shipping temperature sensitive or perishable goods made from a double walled combined web having an inside barrier layer, a first paper liner bonded to the inside barrier layer, a first paper flute medium bonded to the first paper liner, an outside barrier layer, a second paper liner bonded to the outside barrier layer, a second paper flute medium bonded to the second paper liner, and a sandwich of a barrier layer bonded between third and fourth paper liners. The flute mediums are bonded, respectively, to the third and fourth paper liners.

Owner:MILLER DRAYTON +1

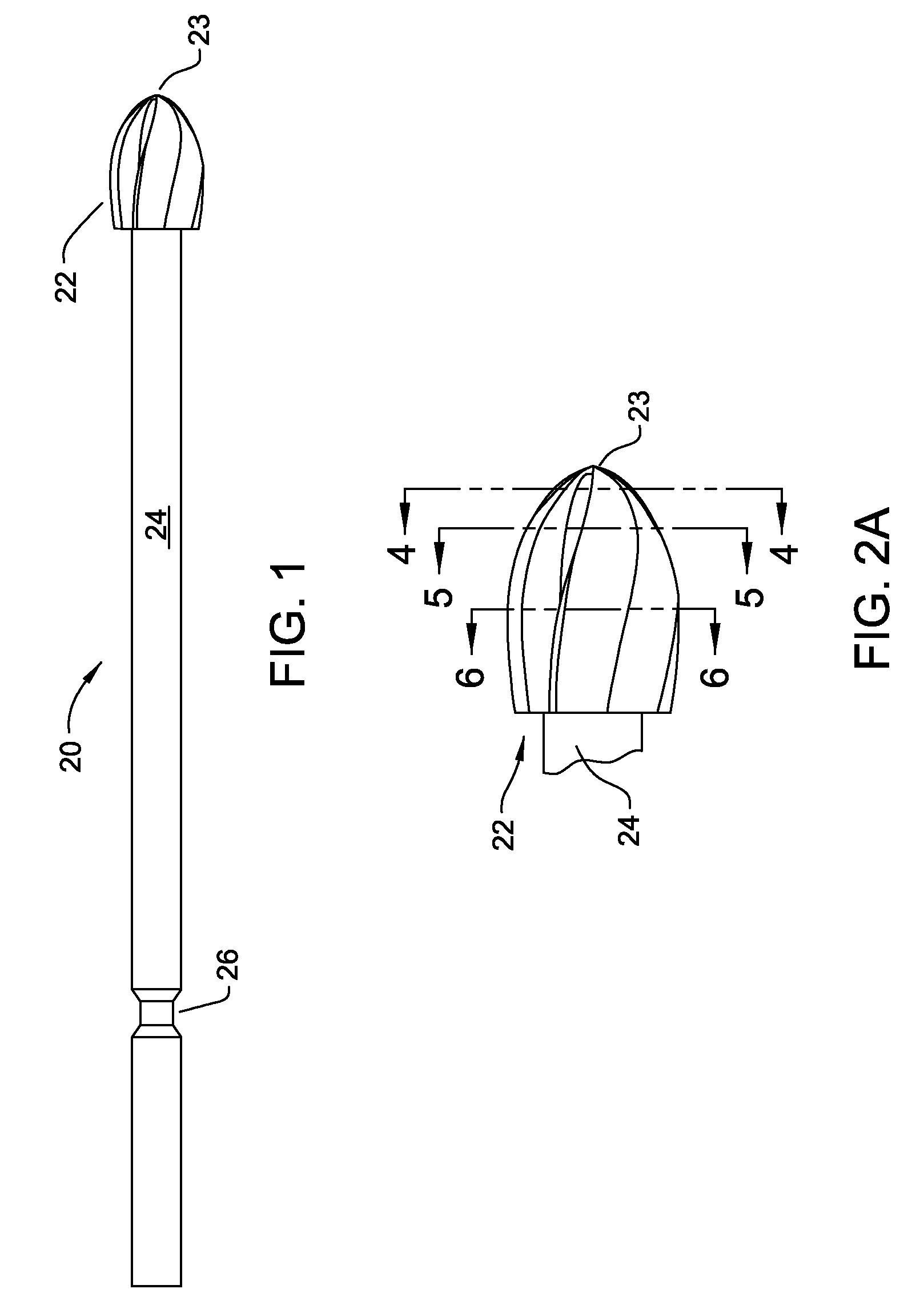

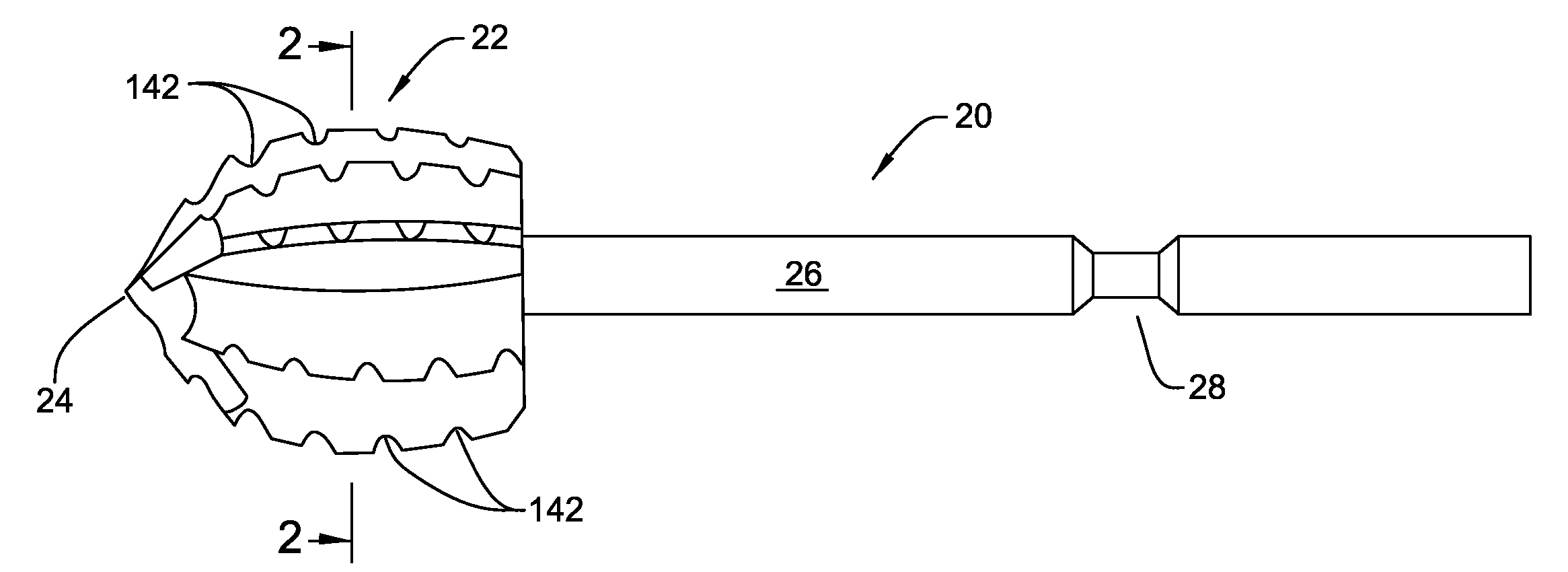

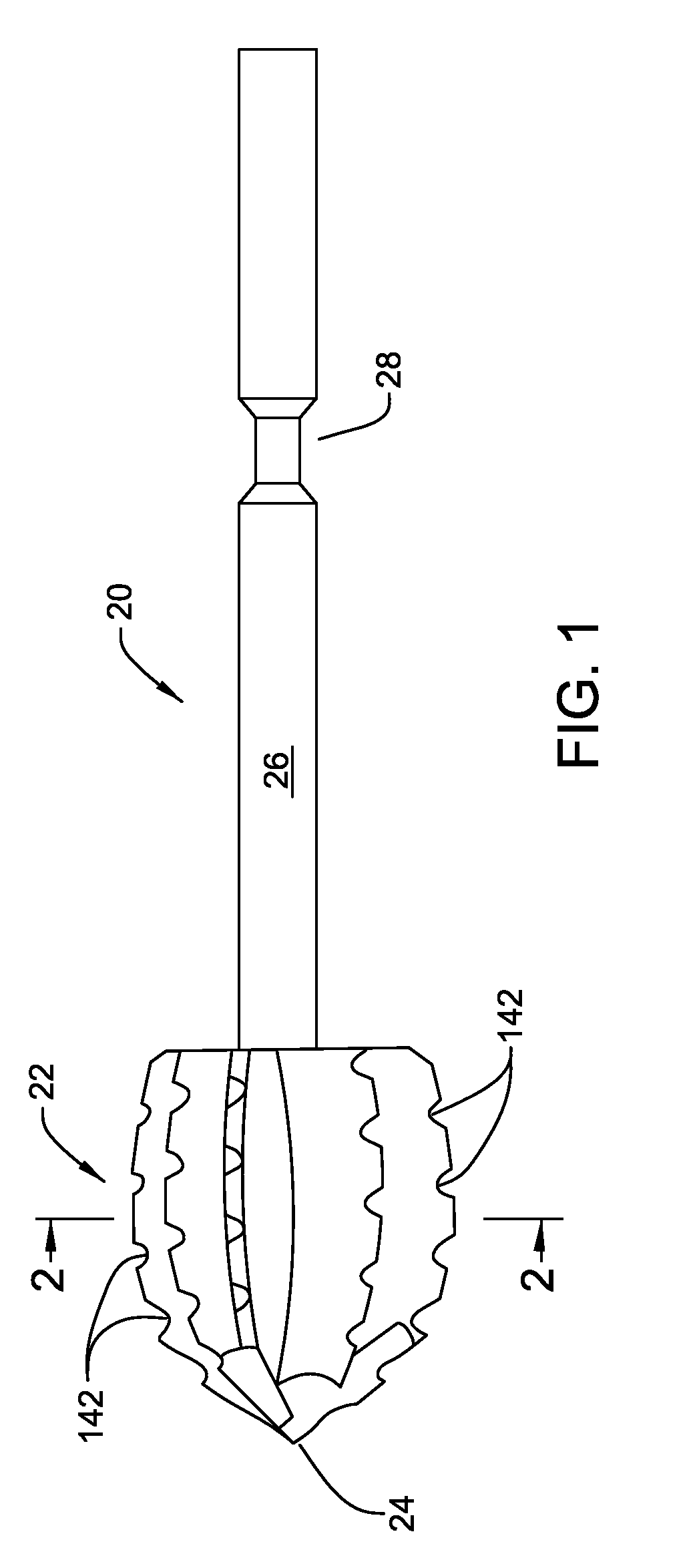

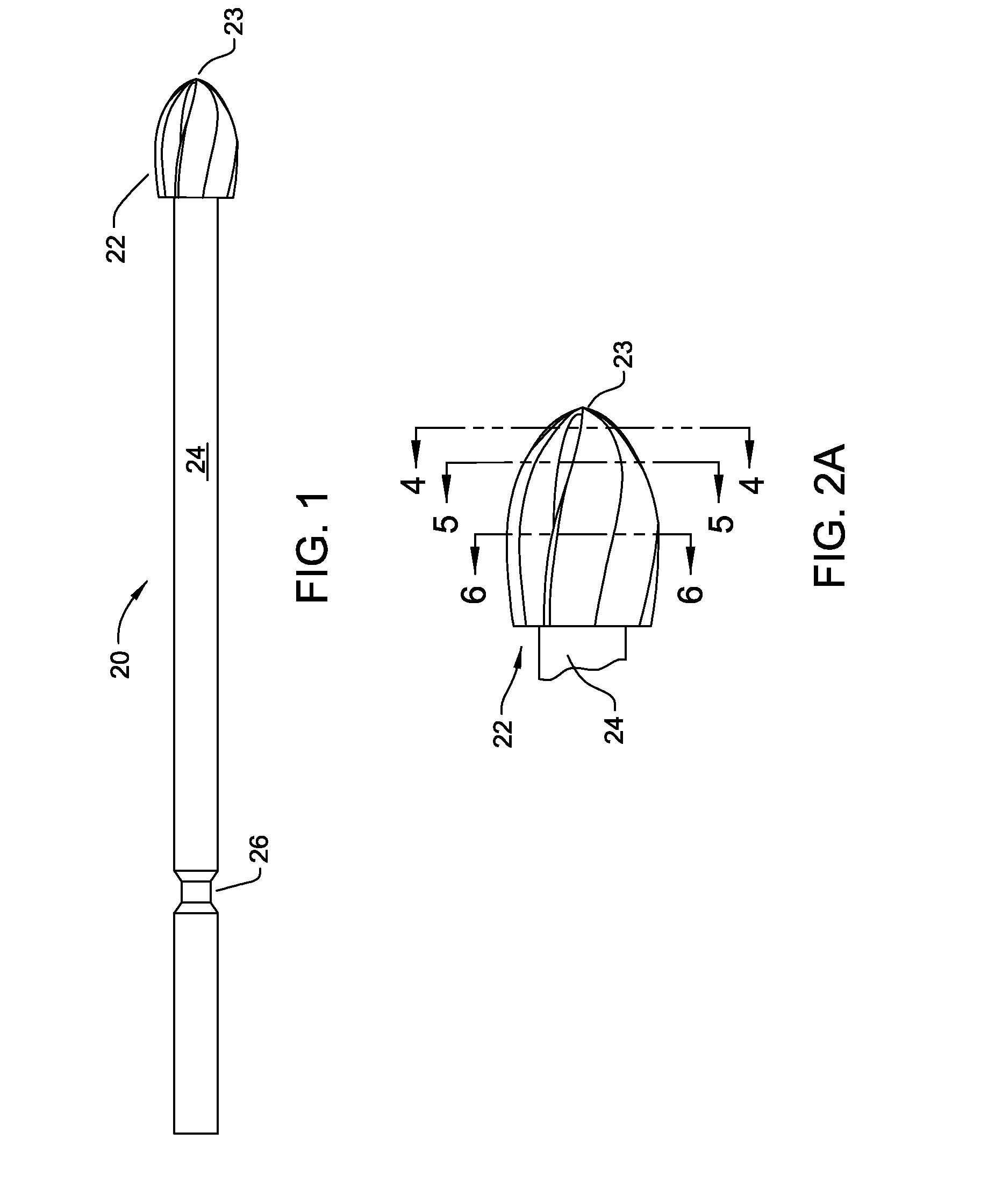

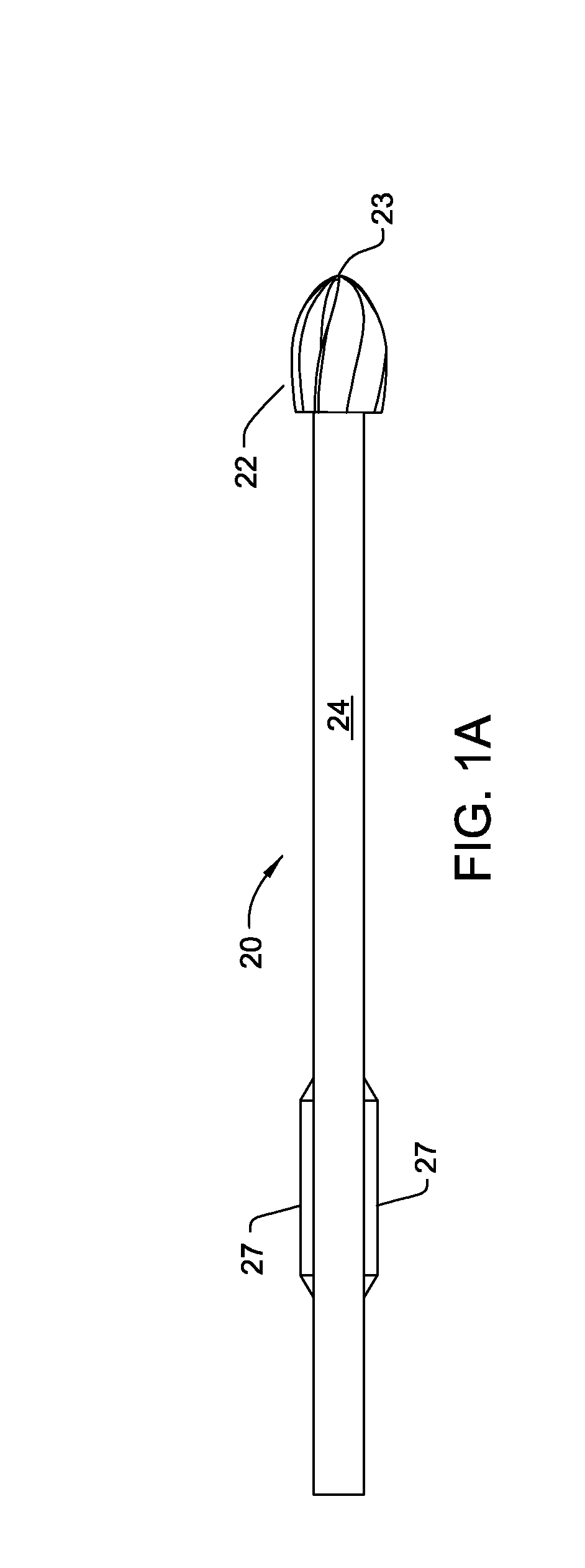

Surgical bur with Anti-chatter flute geometry

InactiveUS20080132929A1Reduce, if not eliminate, chatterEndoscopic cutting instrumentsFluteEngineering

A surgical bur (20) including a shaft with a bur head. A number of flutes are formed on the bur head. Each flute has a cutting edge (54). The flutes are formed so that some of the flutes having cutting edges emerge from the bur head at locations relatively close to the distal end tip of the head. Still other flutes are formed so as to have cutting edges that start, extend proximally rearward, from locations that are, spaced proximal from the distal end tip.

Owner:STRYKER EURO OPERATIONS HLDG LLC

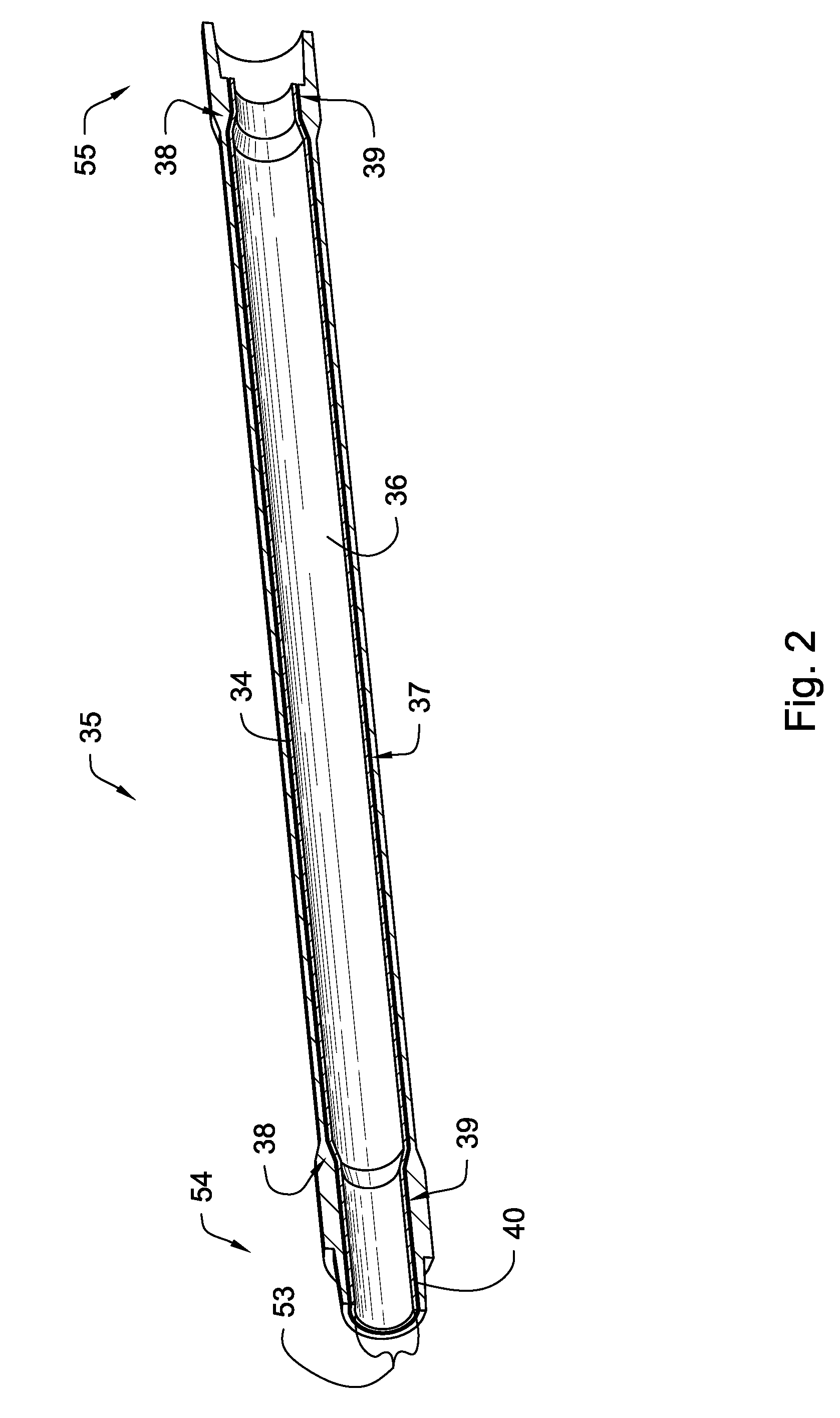

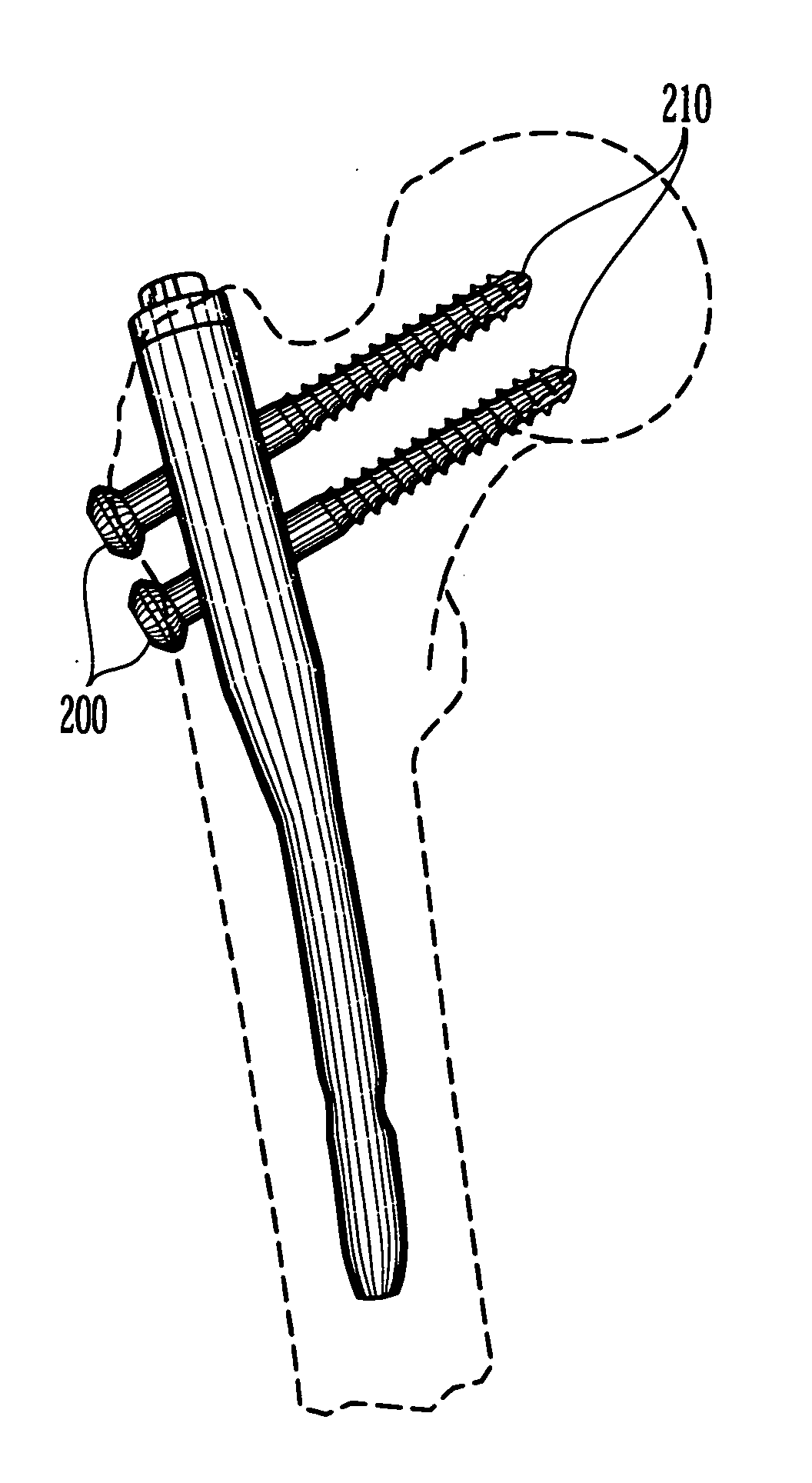

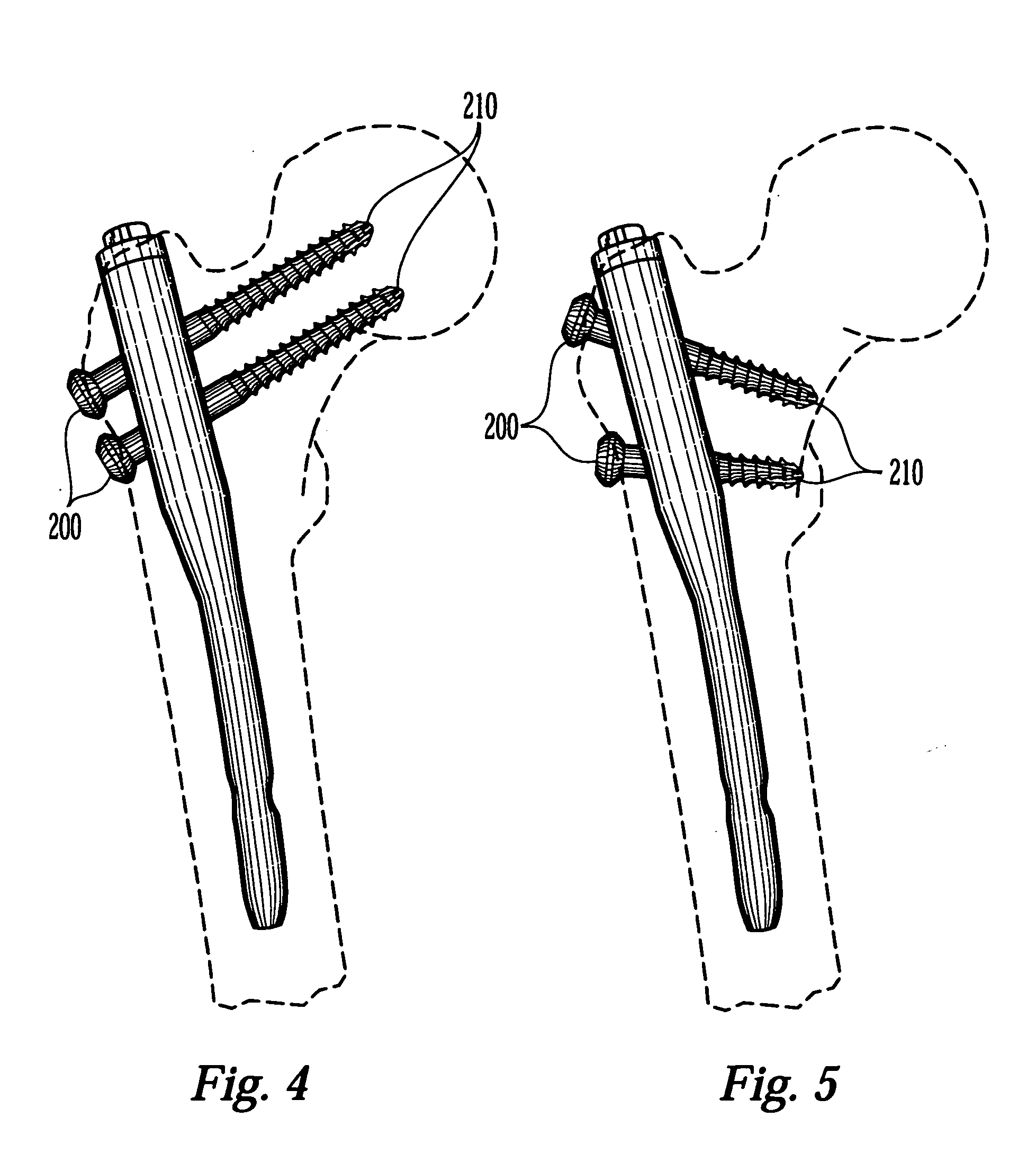

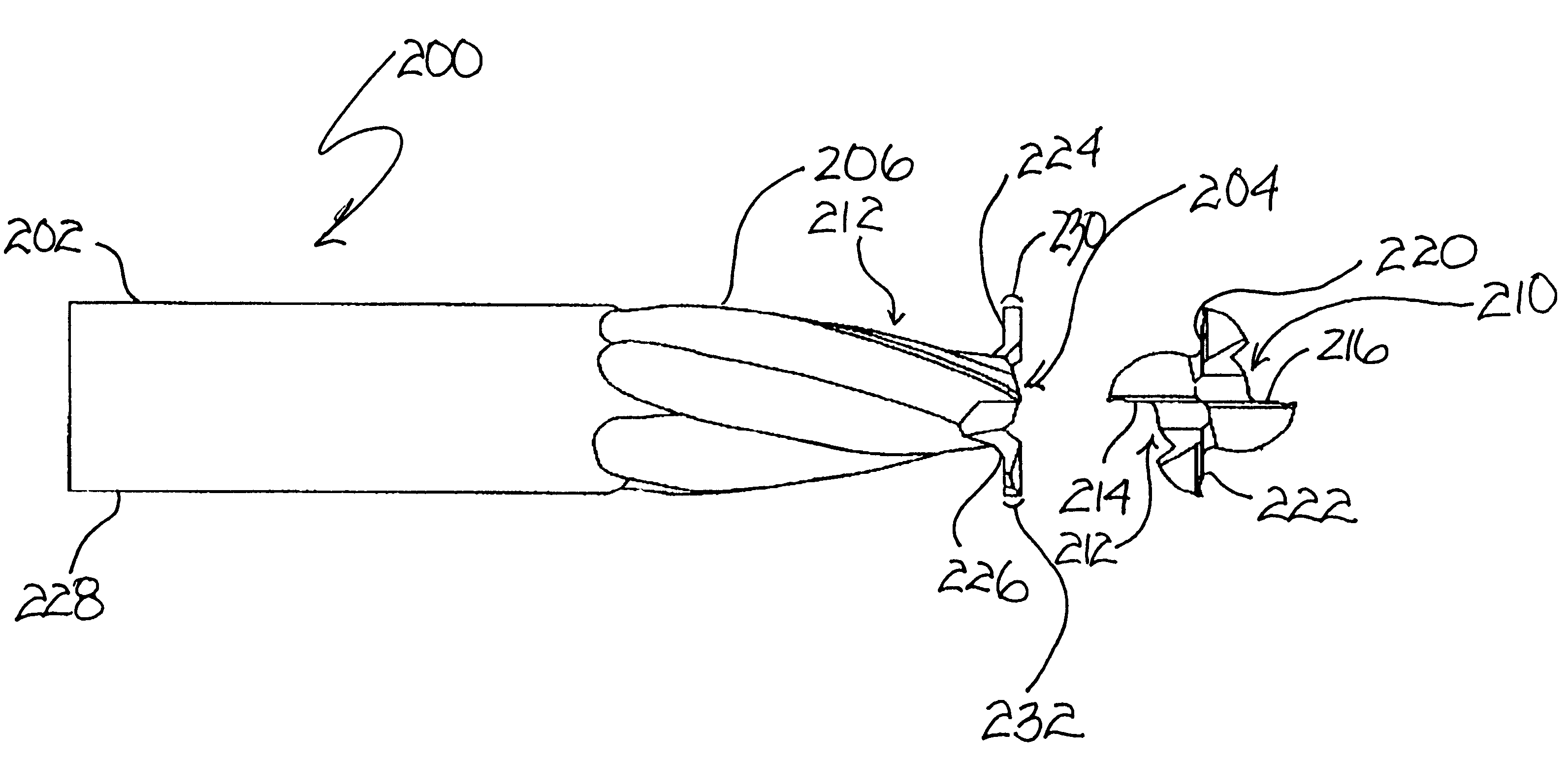

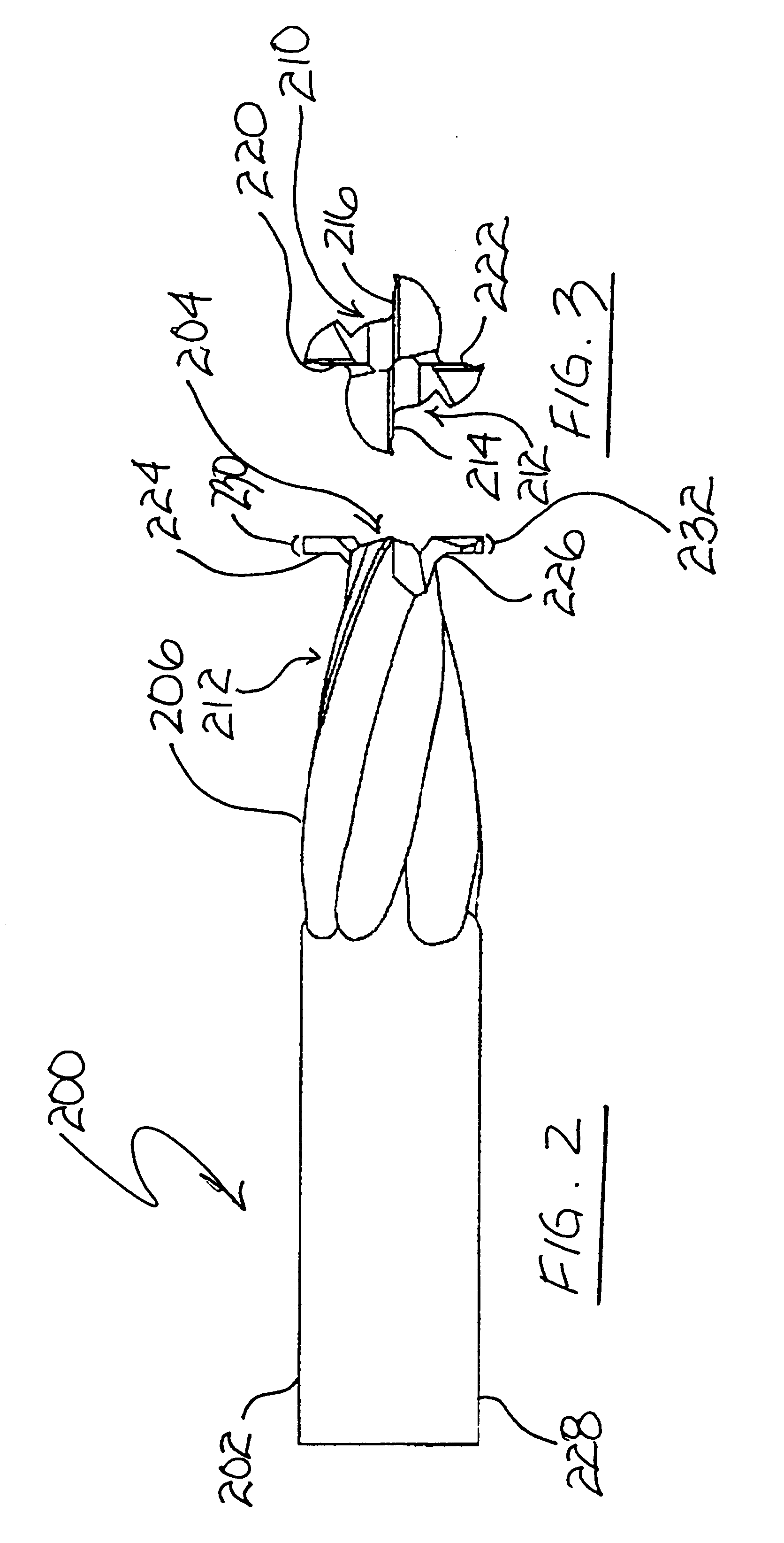

Intramedullary rod with spiraling flutes

ActiveUS20050277936A1Reduce usageLower potentialInternal osteosythesisJoint implantsFluteIntramedullary rod

This invention relates generally to devices, systems and methods for the internal fixation of bone fractures, and particularly, to intramedullary fracture fixation devices such as those used in, for example, the treatment of long bone fractures. An IM rod preferably is provided with multiple curved sections in different planes preferably designed to conform with the long bones of a patient, both during insertion and in the rod's final position in the long bone. In addition, the overlap of portions of the curved sections results in a co-planar curvature of portions of the IM rod which assist in the insertion process by guiding the proper rotation of the IM rod as it is inserted into the bone. Spiraling flutes extending down the distal portion of the rod also assist in properly guiding and orienting the rod about its longitudinal axis during insertion such that the appropriate segment of the curved rod conforms with the appropriate portion of the long bone at the appropriate place.

Owner:SYNTHES USA

Grouping of session objects

ActiveUS20060015568A1Multiple digital computer combinationsSelective content distributionFluteComputer science

An object delivery session, such as a File Delivery over Unidirectional Transport (FLUTE) session, is joined and a description of a plurality of objects provided by the session are provided. The description indicates one or more groupings of the plurality of objects. An interesting object is determined from the plurality of objects. Based on the interesting object and the description of the plurality of objects, one or more of the plurality of objects are identified for downloading.

Owner:NOKIA TECHNOLOGLES OY

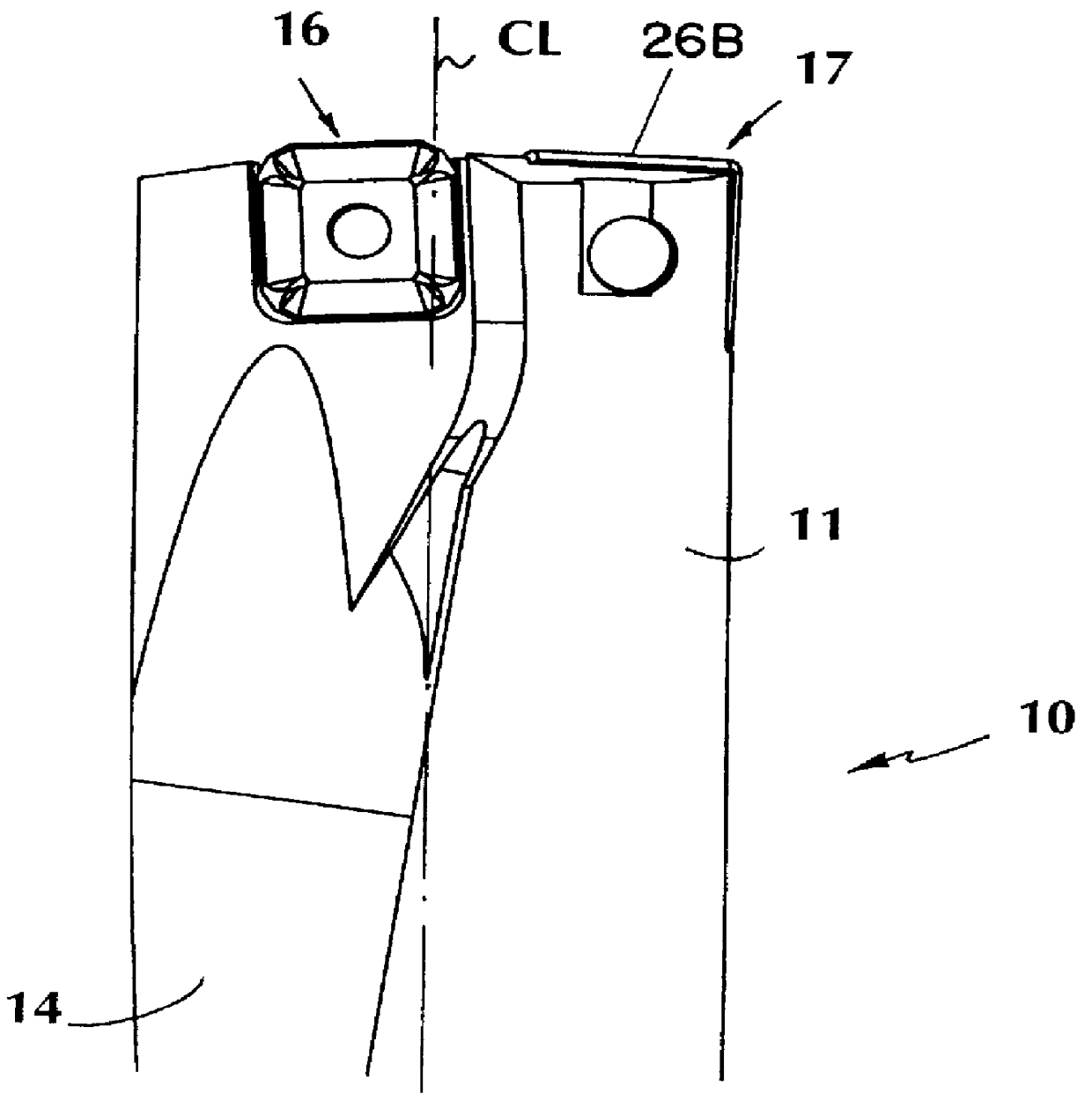

Drill having radially overlapping indexable cutting inserts

A drill includes a shank, a central insert and a peripheral insert. The shank defines a central axis of rotation and has pockets which carry the peripheral and central inserts. Chip flutes are formed in an outer periphery of the shank for conducting chips cut by the respective inserts. The peripheral insert includes a first operative cutting edge, and the central insert includes a second operative cutting edge which overlaps the first cutting edge at an overlap region. The central insert forms a rake surface adjacent to the second cutting edge. The rake surface includes a first portion disposed at the overlap region, and a second portion disposed at the axis of rotation of the shank. The first portion has a larger rake angle than the second portion.

Owner:SECO TOOLS AB

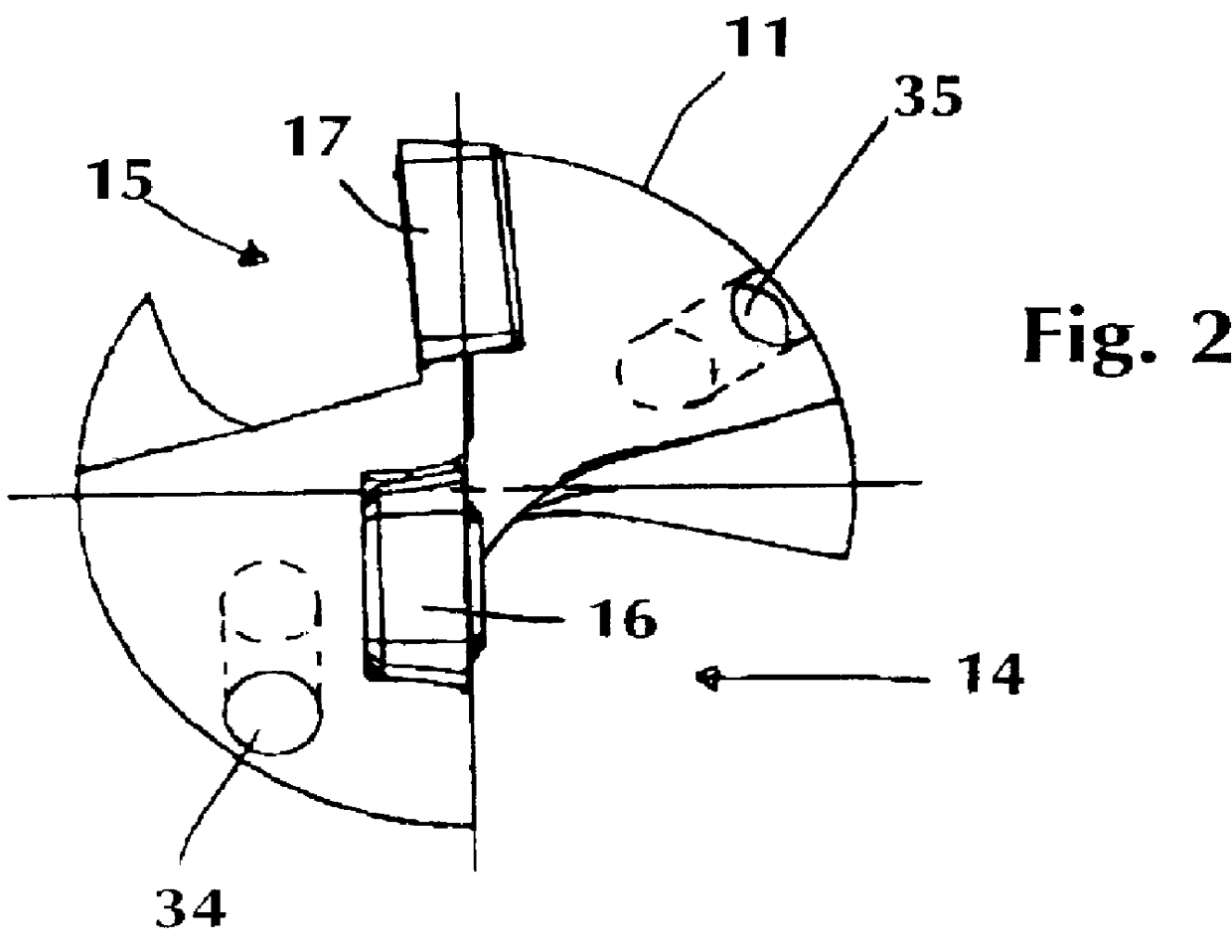

Tool for chip removing machining

A tool for chip-removing machining includes an insert holder and an insert that is mechanically connected with the holder via upper and lower interfaces. Each interface includes a pair of contact surfaces that extend at an obtuse angle relative to each other. Disposed centrally between one of those pairs of contact surfaces is a ridge, and disposed centrally between the other pair of contact surfaces there is a flute. Each of the recess and flute is defined by side surfaces that extend at an acute angle relative to each other. When the ridge engages the flute, a proper absorption of transverse forces acting upon the insert is guaranteed, whereby the insert is maintained essentially immovable in its position in order to guarantee a proper machining accuracy.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Apparatus and method for accessing a sinus cavity

A system for accessing a sinus cavity of a subject includes an access tool configured to penetrate into the sinus cavity from a location external the subject. The system further includes an access sheath having a distal tubular portion, a lumen extending through the access sheath and the distal tubular portion and dimensioned to receive the access tool, the distal tubular portion comprising one or more cutting surfaces disposed about an external surface thereof. The one or more cutting surfaces may include a plurality of longitudinally oriented grooves for flutes disposed about the periphery of the distal tubular member.

Owner:ENTELLUS MEDICAL

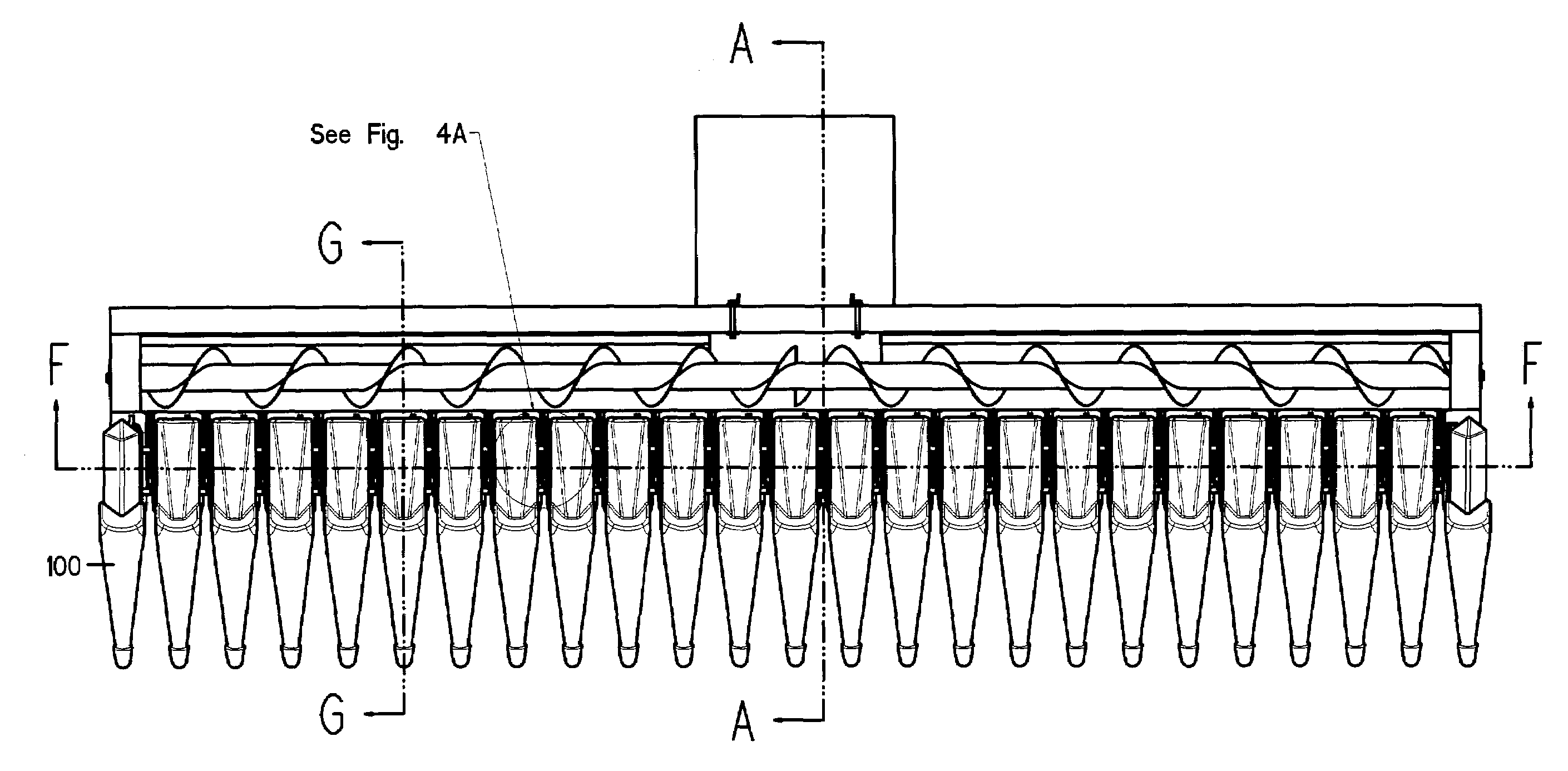

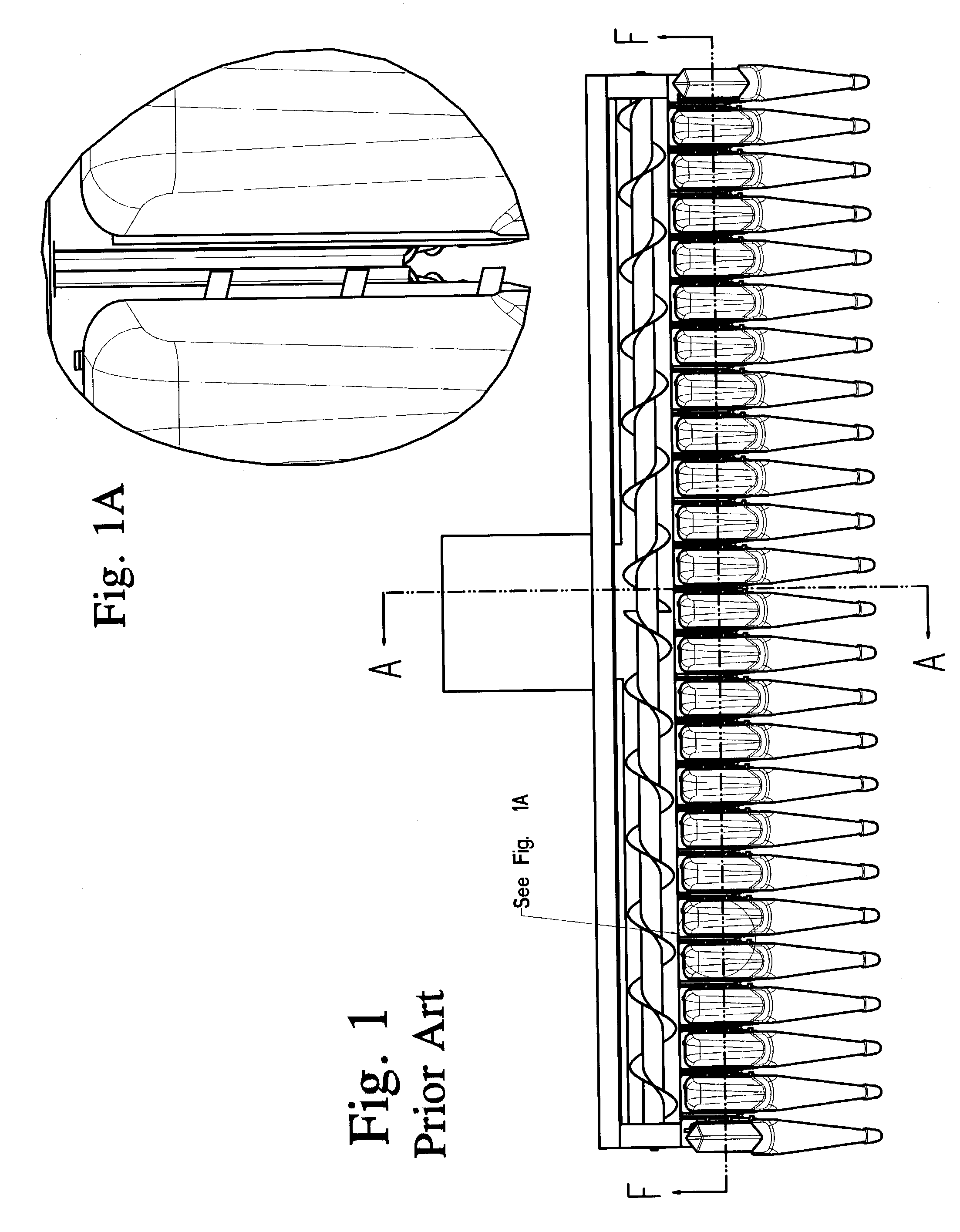

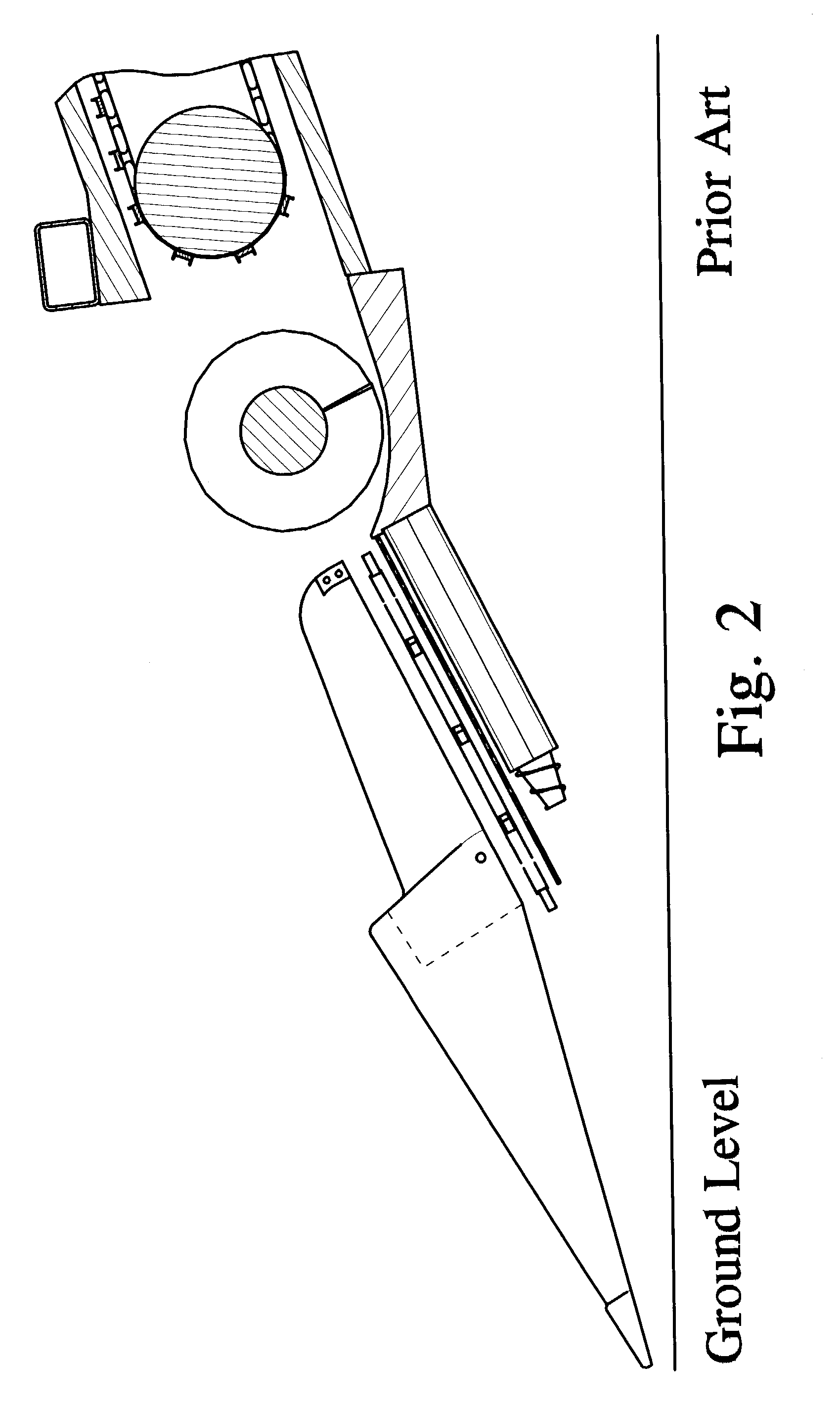

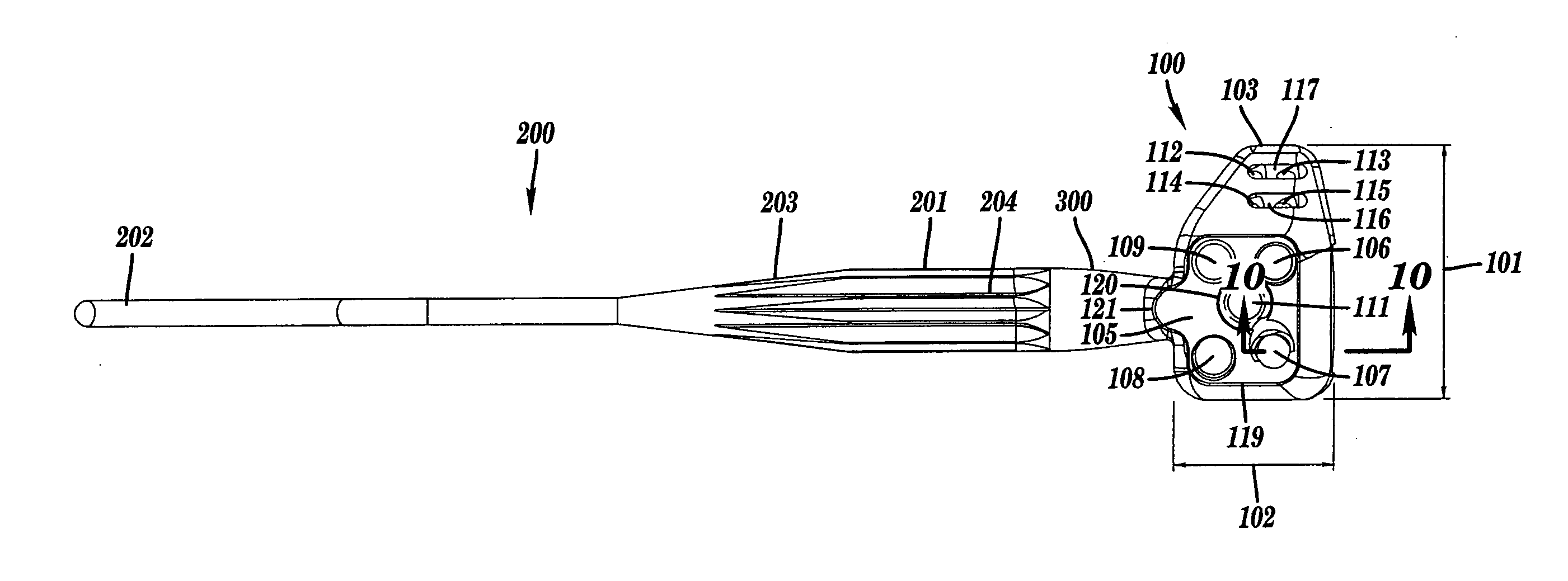

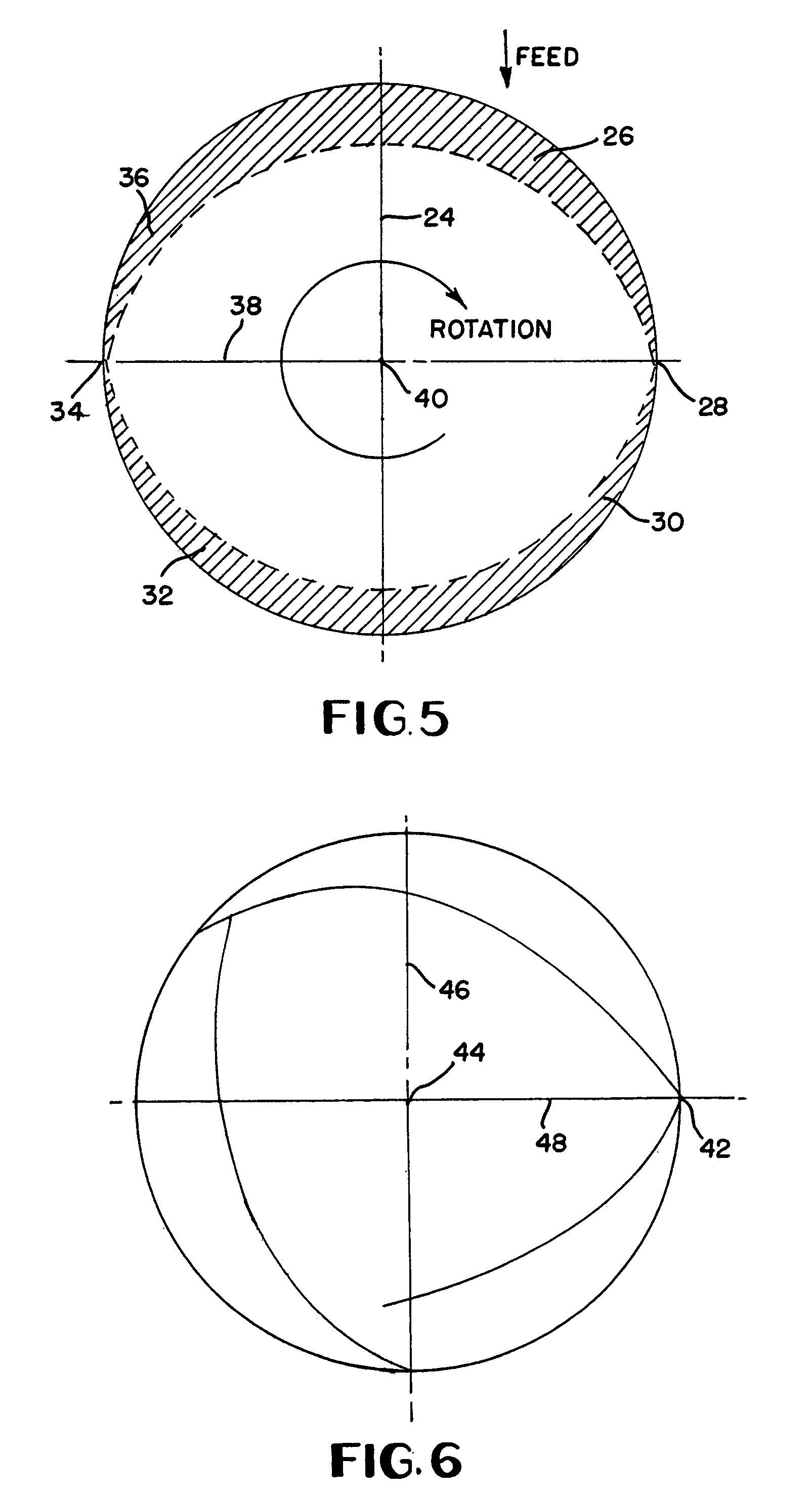

Corn head row unit

This row unit utilizes an improved multi-zone, multi-functional stalk roll, which contains a novel revolving entry window to improve entry and increase engagement of the fluted portion of the stalk roll flutes with the corn stalk. The stalk rolls described are multi-sectional and contain multi-length variable flutes. The number of flutes described for each zone may vary as well as whether the flutes are meshing or non-meshing and angled or non-angled. The stalk rolls described allow a constant speed drive shaft to create lower and / or higher effective circumferential contact speeds within each zone of the stalk roll. The invention provides that the rotating transport vanes located on the helical nose cone at the entry area to the stalk roll flutes lock the corn stalk into a revolving entry window. This novel row unit contains a multi-zone, multi-functional stripper plate that ensures minimal ear wedging and maximum discharge of material other than ears. This row unit utilizes a novel gathering / conveying chain(s), which reduces the number of and increases the angle and size of the paddles. This row unit design optimizes operation between the components imparting force to the corn plant and ears. The invention has a smooth uninterrupted improved flow of corn stalk material through the ear separation chamber and is the first row unit designed to be environmentally friendly by ensuring that the majority of the corn plant remains connected to its original root system which prevents it from rapidly decomposing, blowing or washing away. The row unit cover is spatially designed for improved flow in down, damp and tough harvesting conditions.

Owner:CALMER MARION

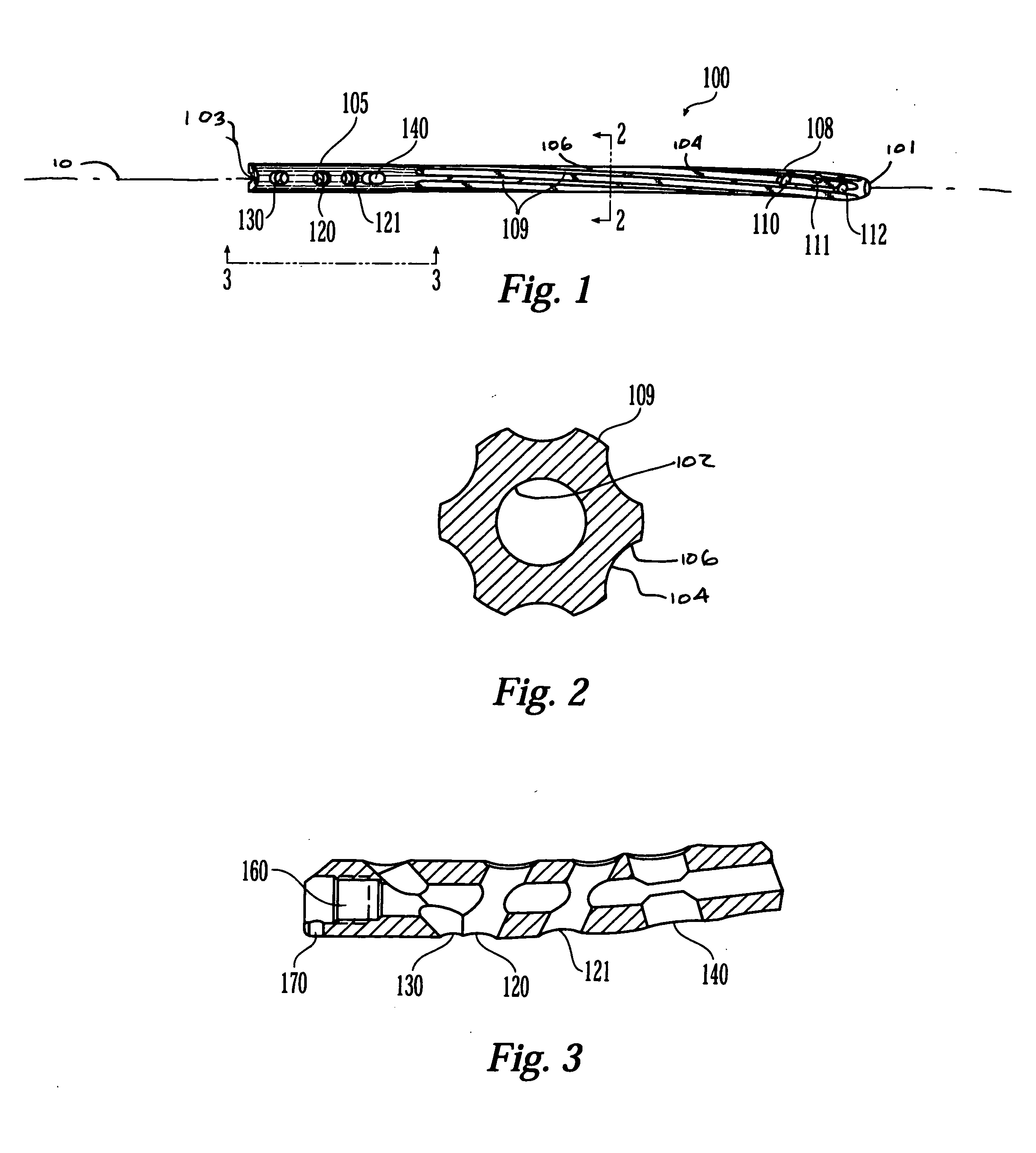

Intramedullary bone plate with sheath

InactiveUS20070083202A1Enhance bone fixationImprove fixation stabilityInternal osteosythesisJoint implantsFluteSagittal plane

An intramedullary bone plate with sheath having an intramedullary stem, a bone plate head and a neck that connects the intramedullary stem to the bone plate head in a manner where the stem and head are offset from each other longitudinally and axially in the sagittal plane. The bone plate head includes a sheath recess wherein non-threaded bone screw holes and a threaded sheath screw hole are located. Bone screws are inserted through the sheath recess and oriented at set angles allowing for bone fragment fixation and fracture reduction. A sheath element is placed within the boundaries of the sheath recess and secured with the sheath screw. The intramedullary stem includes longitudinal flutes in its distal portion and a bi-arced geometry in its proximal portion providing for stabilization of the implanted device. The bone plate head configuration provides for more complete fracture capture and multiple fixation modalities.

Owner:TORNIER INC

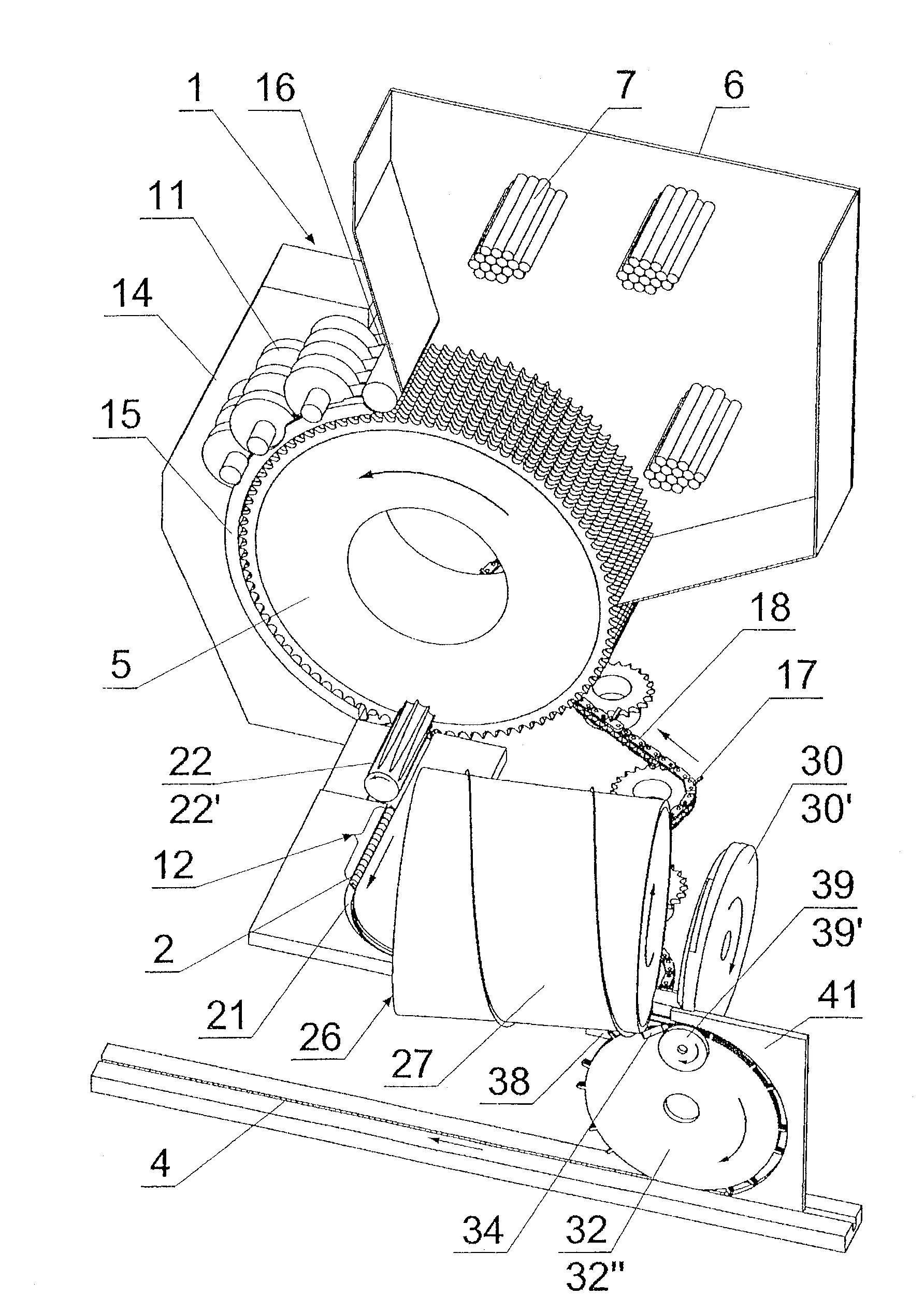

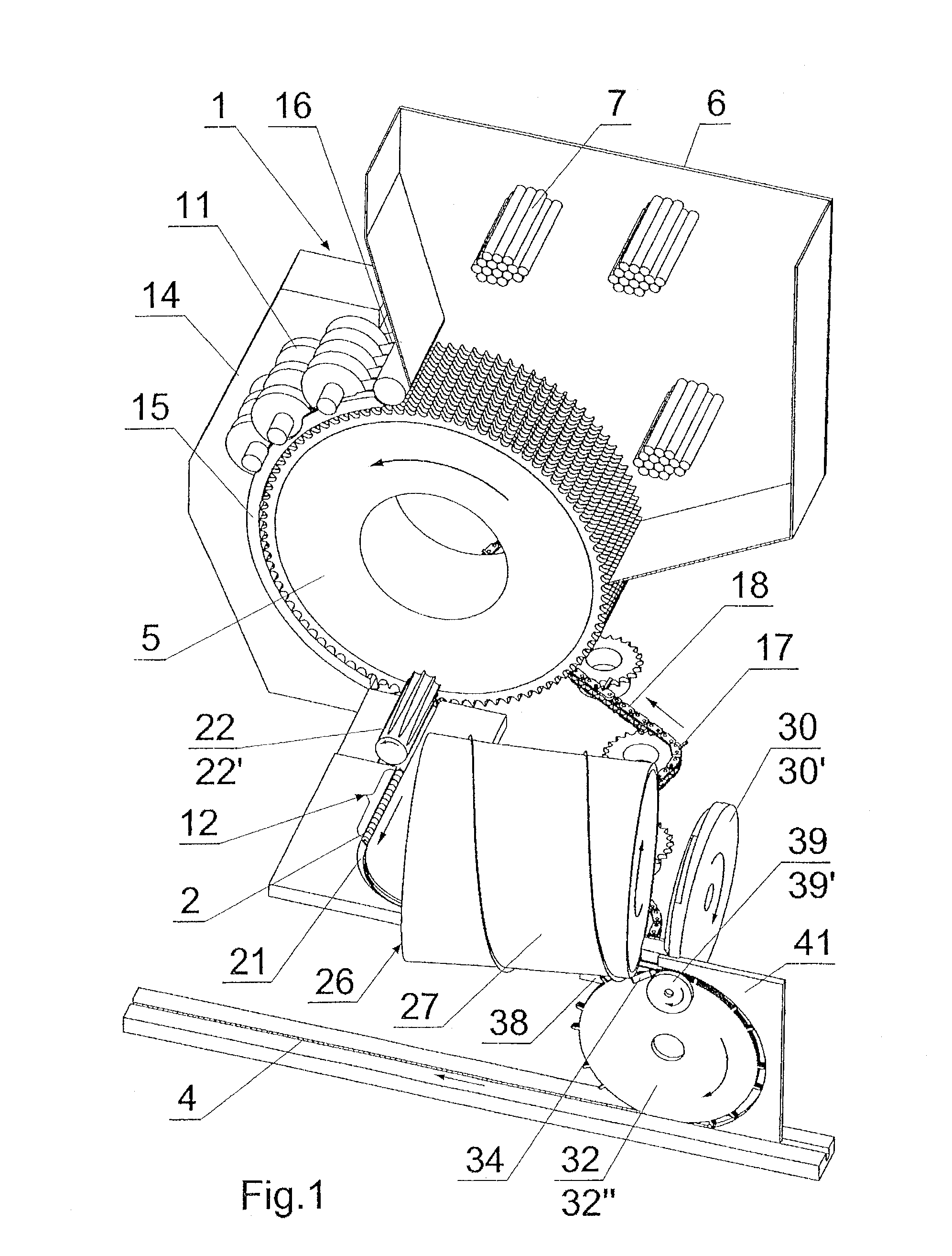

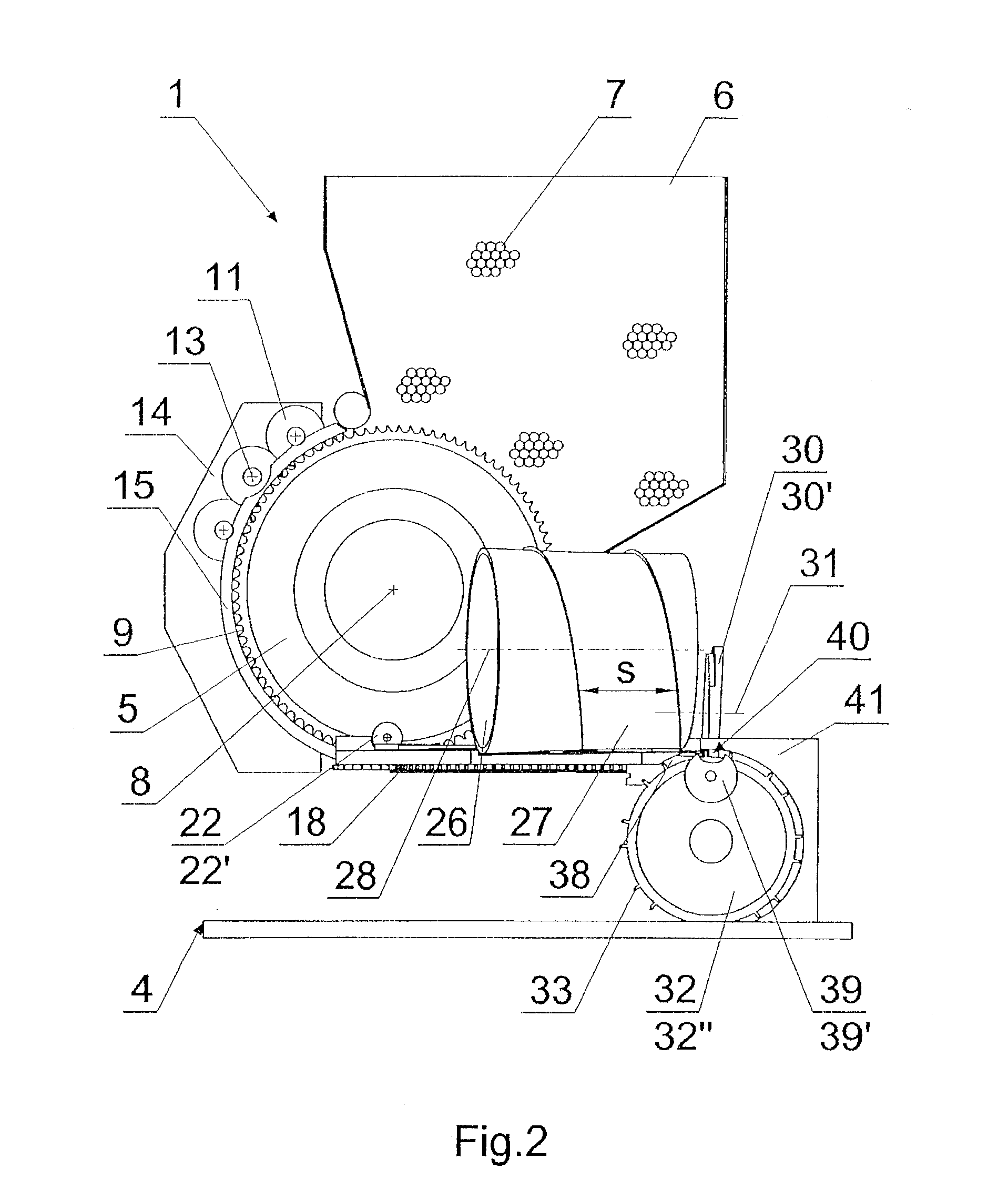

Method and apparatus for compiling groups of filter segments when producing multi-segment filter asemblies

ActiveUS20090145449A1Increase speedEnsure controlCigar manufacturePaper/cardboard wound articlesFluteComputer module

A method of making segmented filters including moving substantially identical segments of one type at uniform rate to a transferring element, which places each segment separately on an exit path. Setting of the filter segments in a repeating group on the exit path is accomplished by delay in collecting segments by a transferring element in each module of the apparatus. Uniform positioning is effected using the transferring element which includes uniformly spaced drivers, and non-uniform positioning is effected using the transferring element with non-uniformly spaced drivers. The apparatus includes a guiding element positioned adjacent to a cutting drum and has a wall closing a channel for a set of segments drawn out of a flute on the drum. The filter set is led through the channel with the aid of a dog of a chain and is advanced by a worm surface of a pushing together drum. A separator positioned at the end of the channel which separates single filter segments and may be a disc cam pushing out the segment onto the transferring element between two neighbouring drivers into a chamber created by a supporting element. A stream of compressed air from nozzle directed towards the area between a shoe guide and separator helps separate and stabilize the filter segment.

Owner:PHILIP MORRIS USA INC

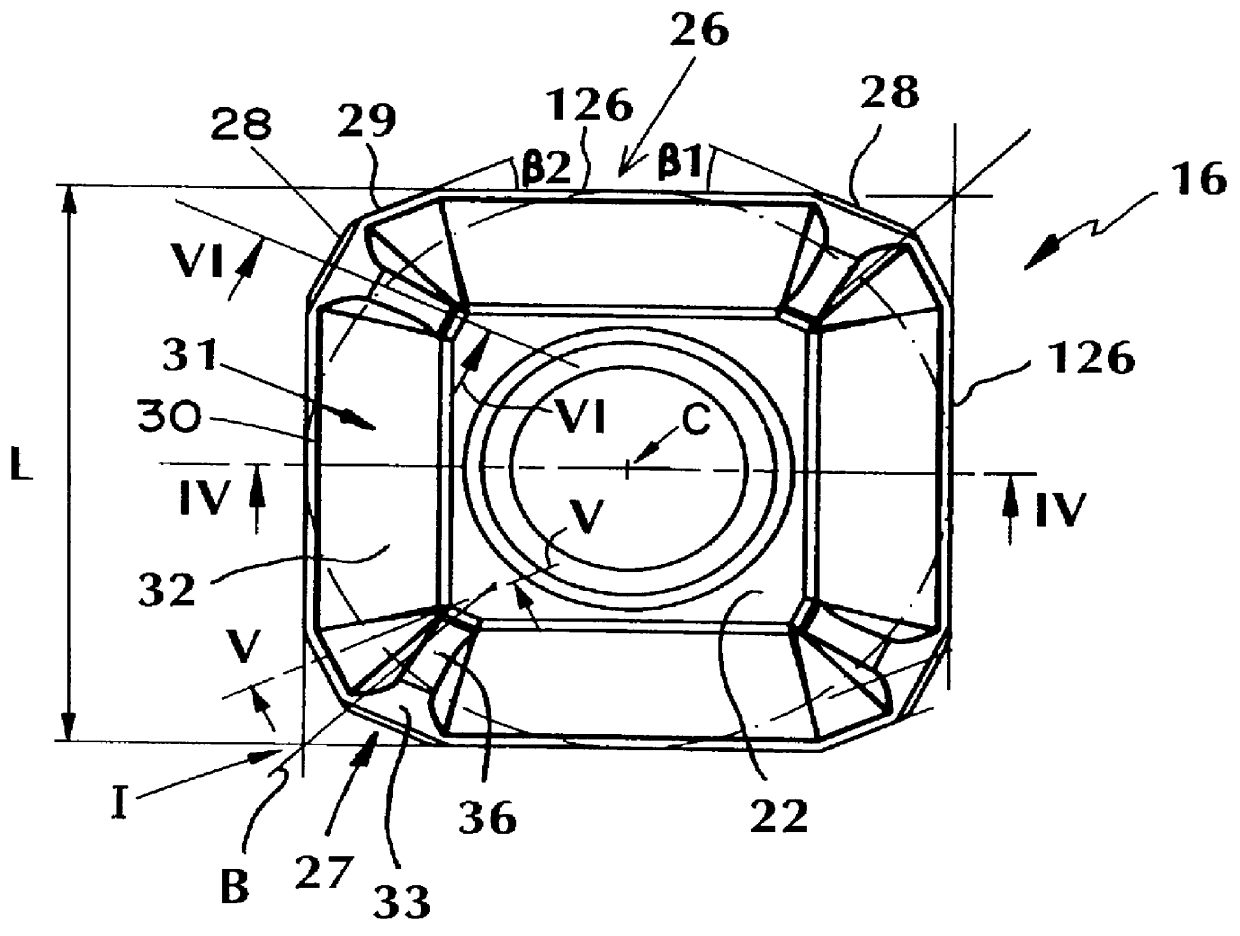

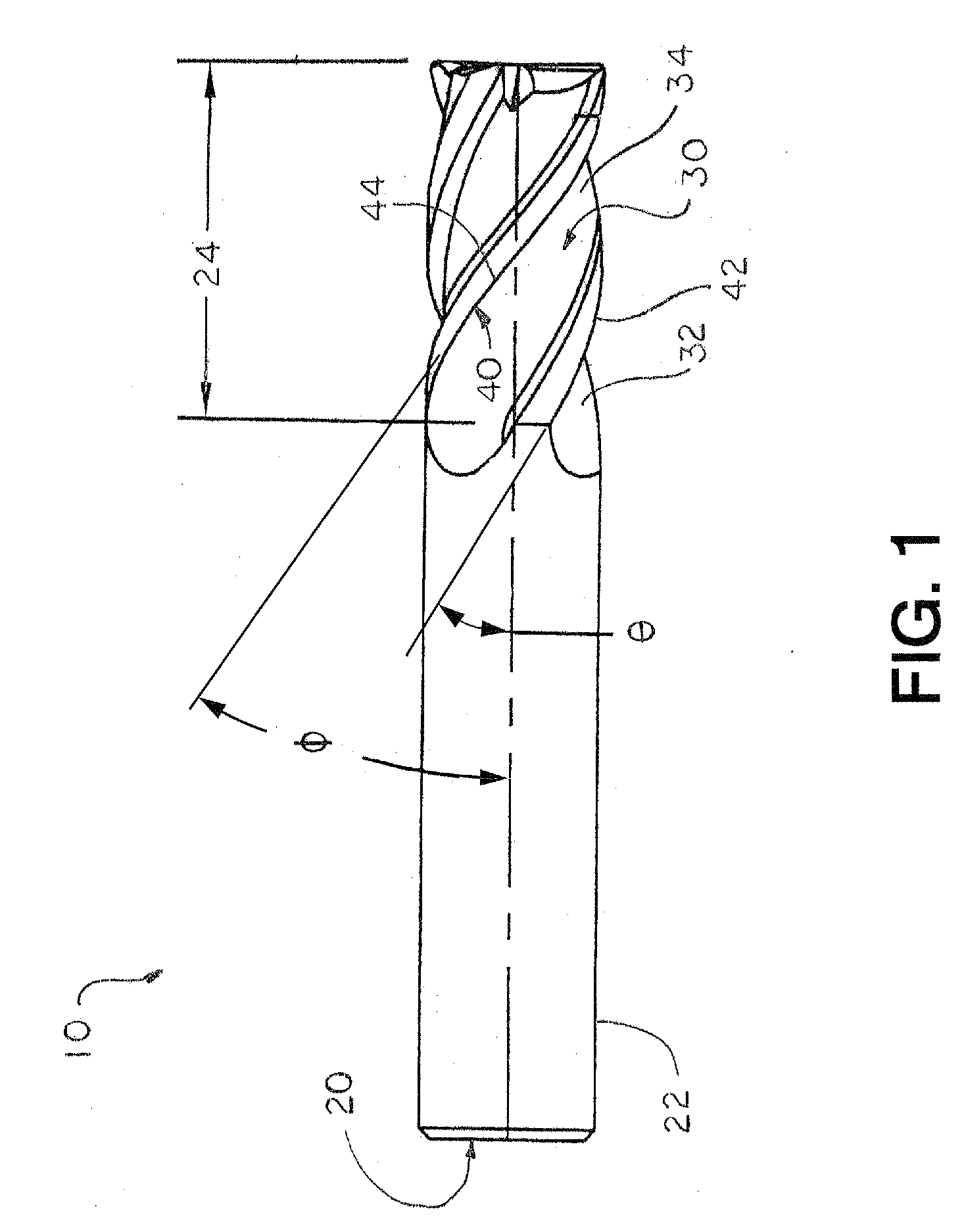

Rotary cutting tool

ActiveUS20070154272A1Overcome disadvantagesMilling cuttersAdverse effect compensationFluteRadial plane

A rotary cutting tool or end mill is provided, the tool comprising a plurality of pairs of diametrically-opposed, symmetrical, helical flutes formed in a cutting portion of the tool body, wherein the pitch between at least one pair of adjacent helical flutes is less than or greater than the pitch of at least one other pair of adjacent helical flutes in at least one radial plane along the axial length of the flutes, a plurality of peripheral cutting edges, wherein at least one of the peripheral cutting edges has a radial rake angle different from radial rake angle of a peripheral cutting edge of a different helical flute.

Owner:KYOCERA SGS PRECISION TOOLS INC

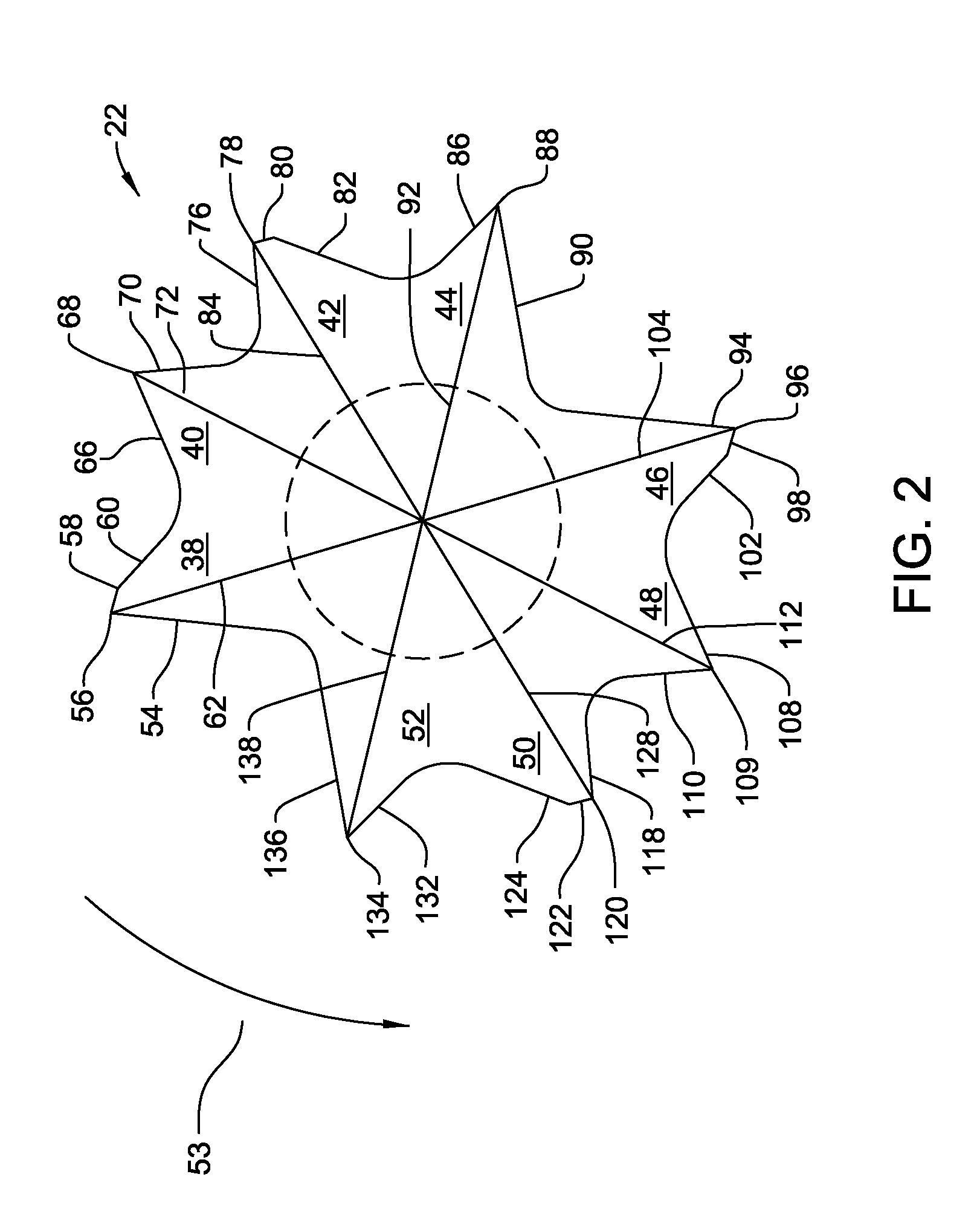

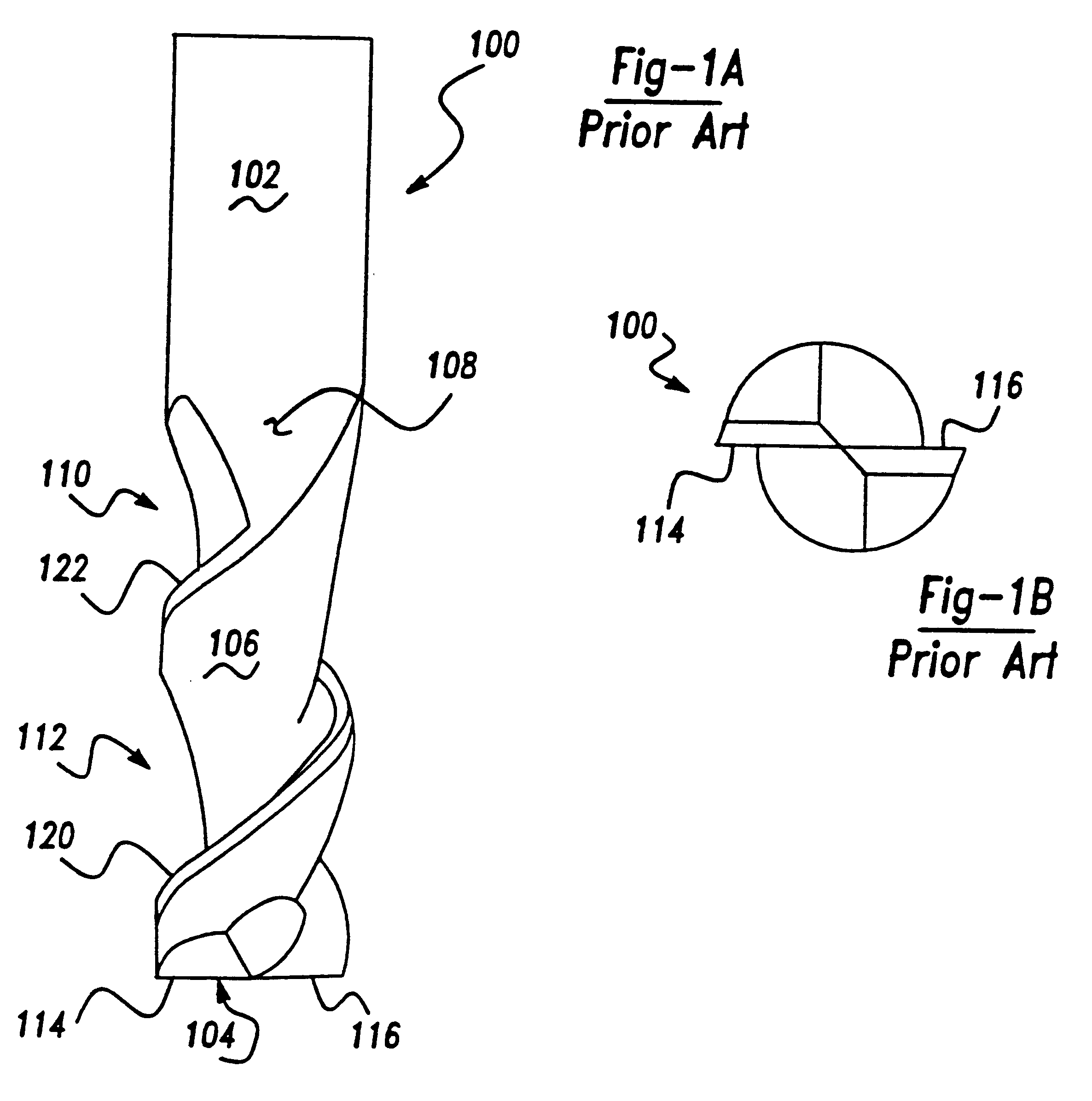

Surgical bur with unequally spaced flutes, flutes with different rake angles and flutes with alternating reliefs

A surgical bur including a shaft with a head on the distal end of the shaft. A number of flutes extend outwardly from the head, each flute having a rake surface and a clearance surface. On some flutes the rake and clearance surfaces meet to form the flute cutting edges. Other flutes have relief surfaces between the rake and cutting surfaces. On these flutes, the cutting edges are the edges where the rake and relief surfaces meet. The flutes are further designed to have rake angles that are less negative, than the flutes without the relief surfaces. The flutes are radially spaced apart around the head such that between any three adjacent flutes, the first and second flutes are spaced apart a first angle; the second and third flutes are spaced apart a second angle different from the first angle.

Owner:STRYKER EURO OPERATIONS HLDG LLC

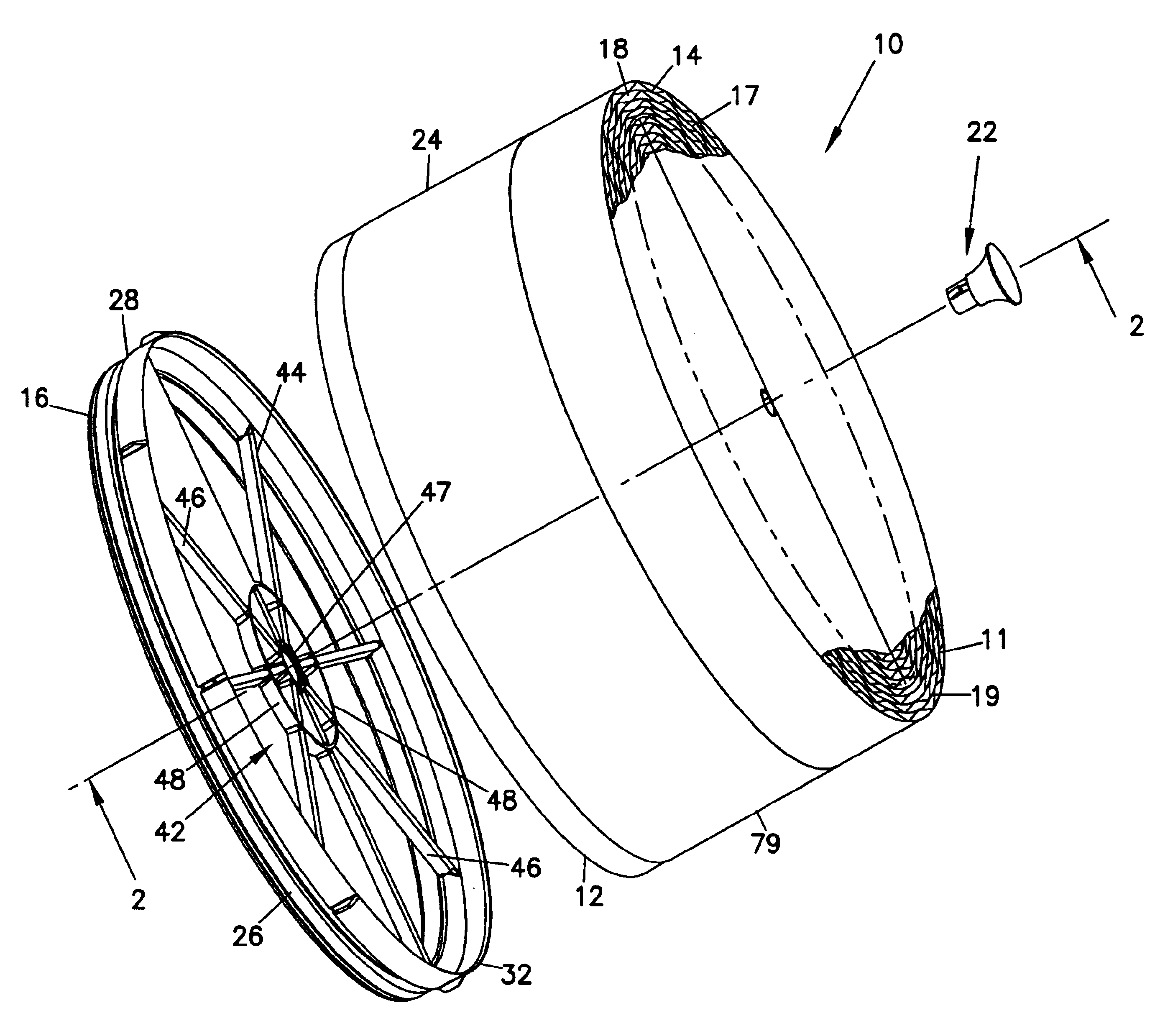

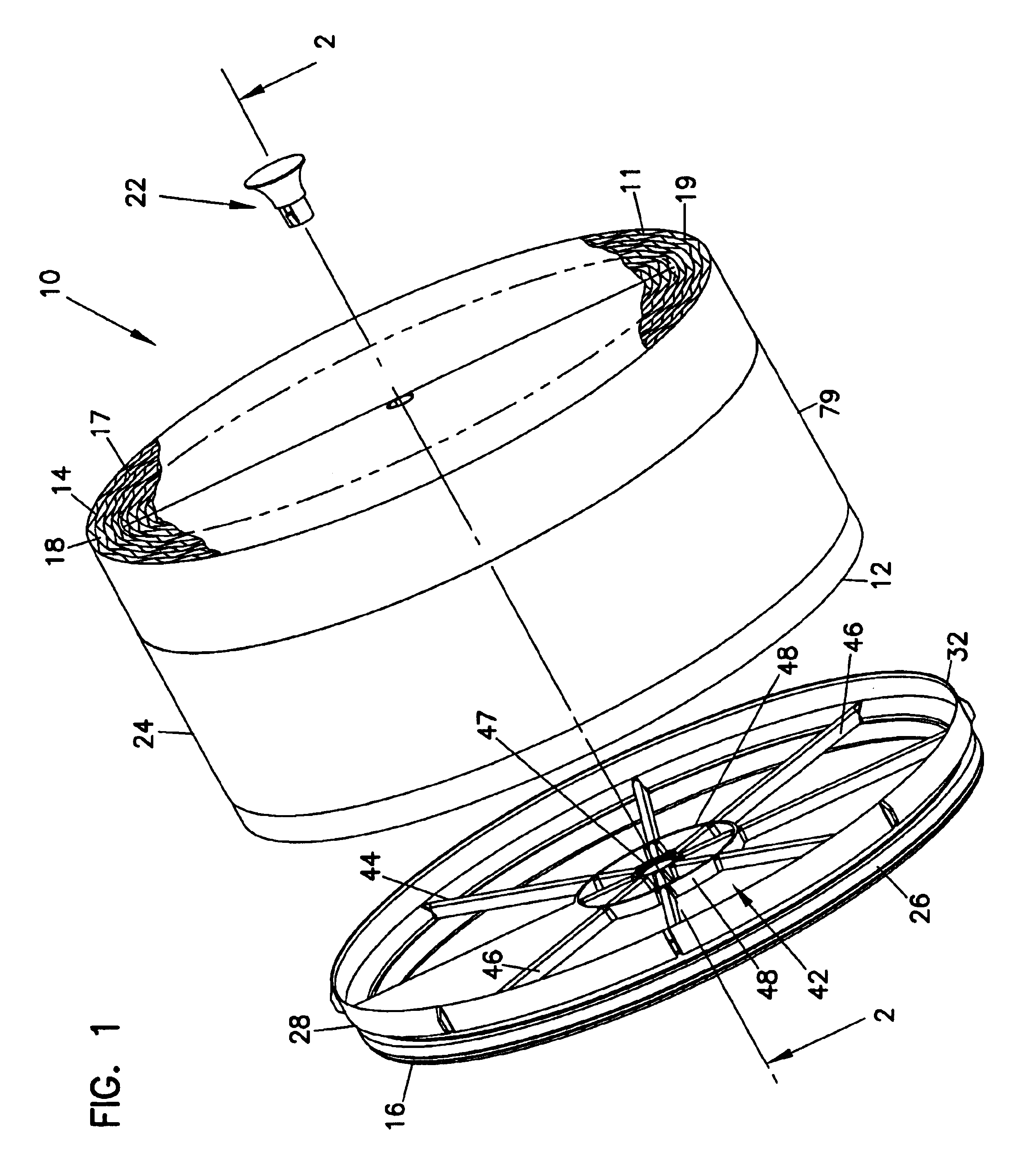

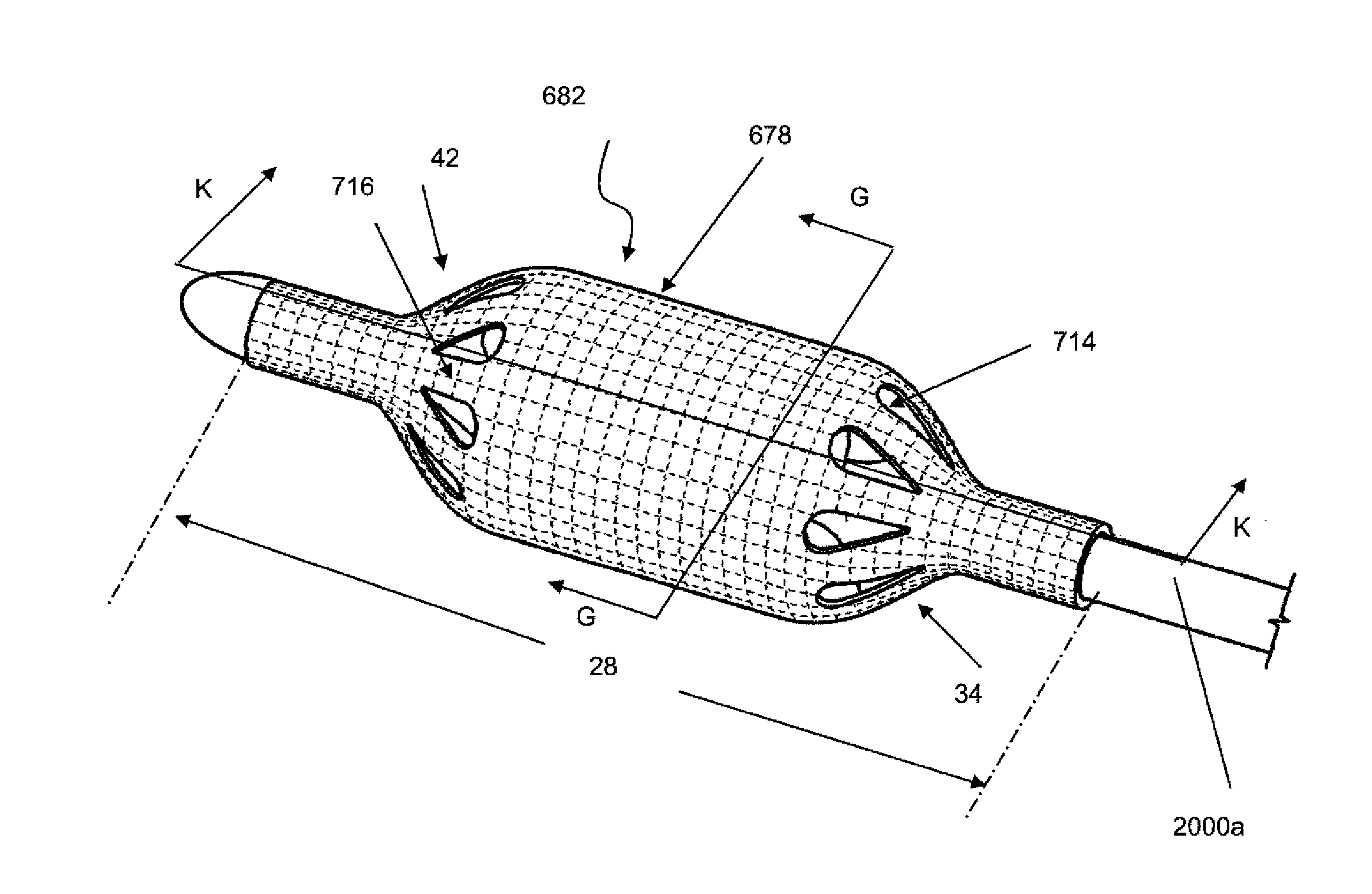

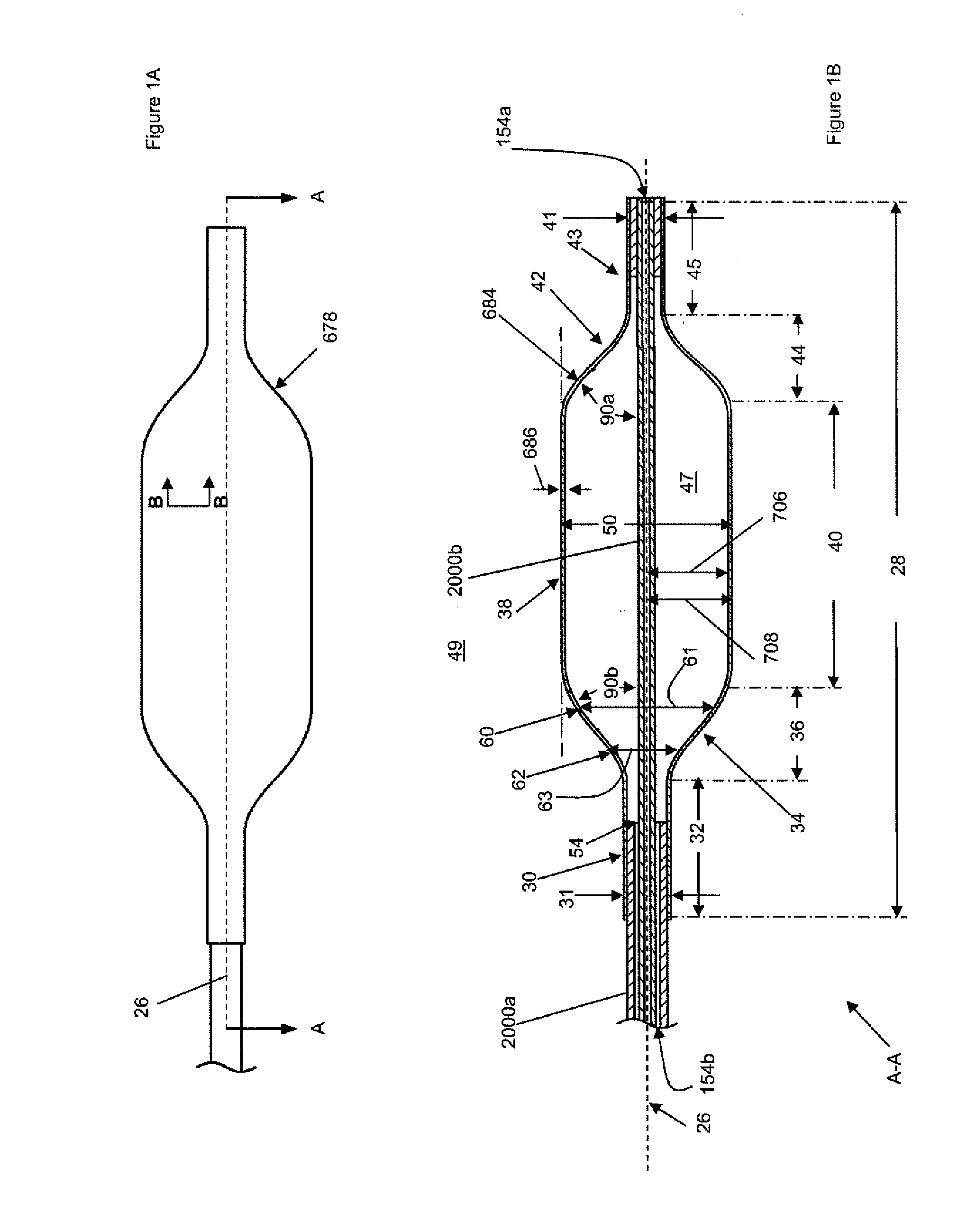

Reinforced inflatable medical devices

ActiveUS20150272732A1Increased longitudinal stiffnessProvide stability and stiffnessStentsBalloon catheterFluteEngineering

An inflatable structure for use in biological lumens and methods of making and using the same are disclosed. The structure can have an inflatable balloon formed into a plurality of cells encircled by a shell. A strap can extend between the cells. The shell can have proximal and distal tapered necks, longitudinally-oriented flutes, and apertures at the proximal and distal ends of the shell. The shell can include a reinforcement having tapered sections over the necks and strips extending between the tapered sections. A semi-compliant or compliant balloon can be placed around the outside of the inflatable structure.

Owner:LOMA VISTA MEDICAL

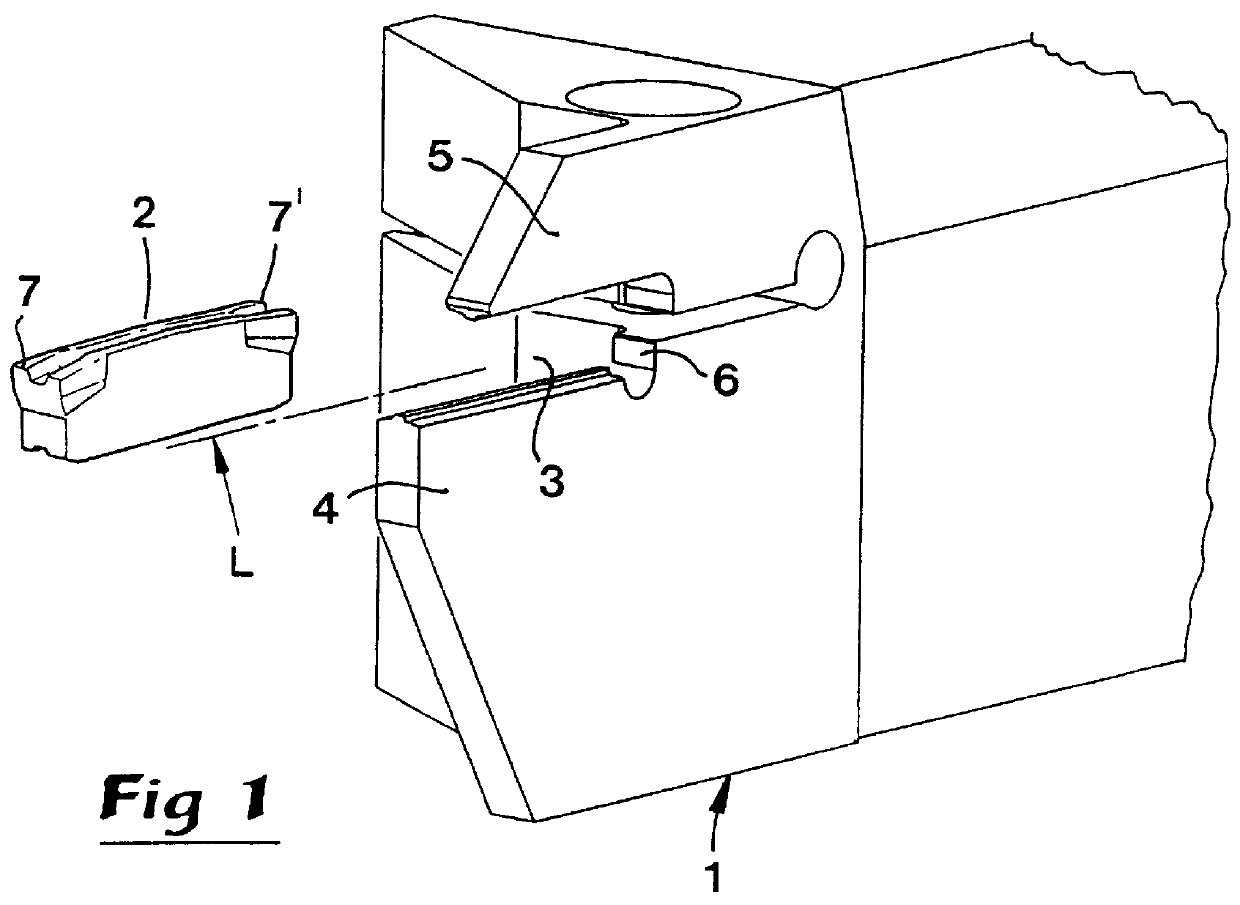

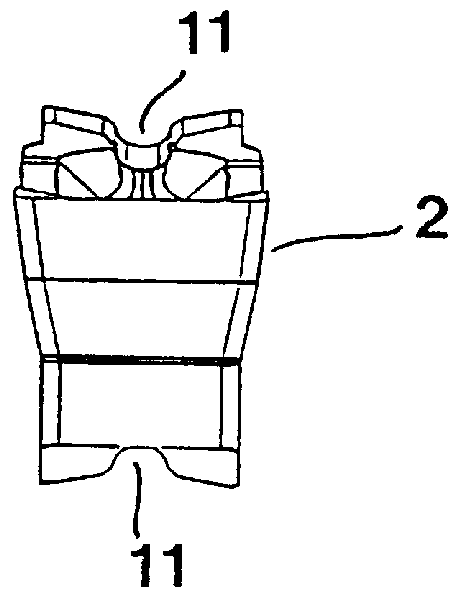

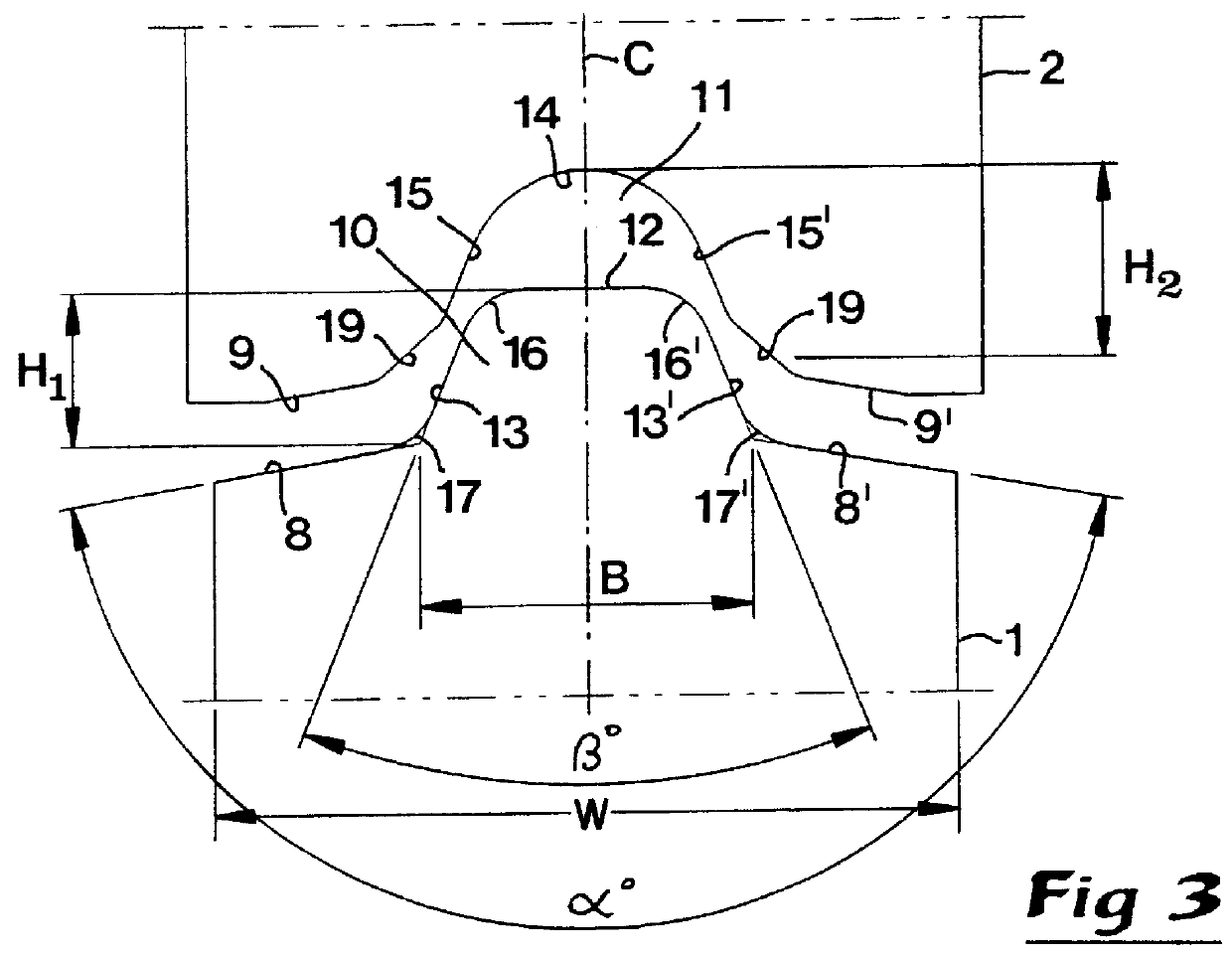

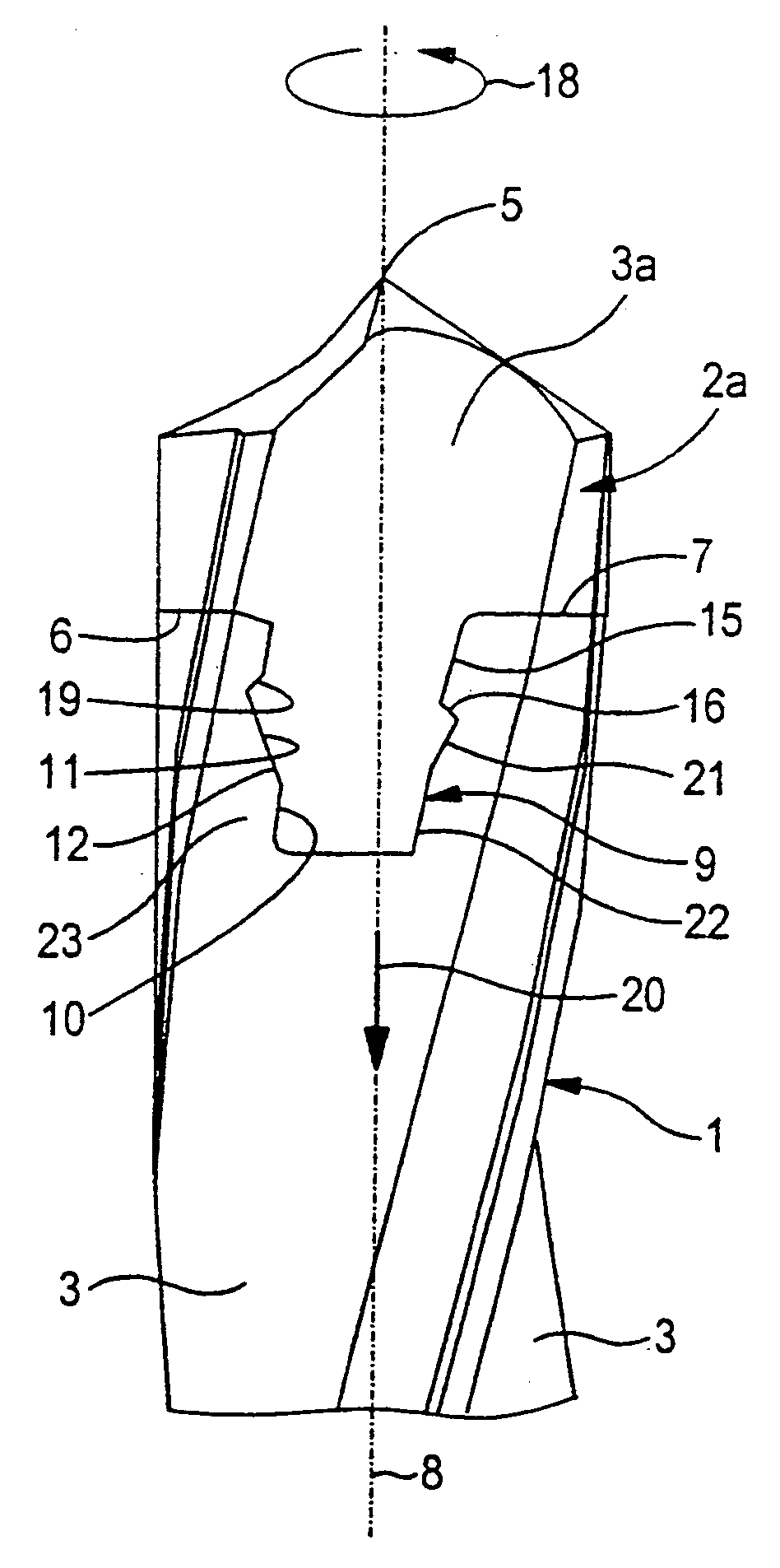

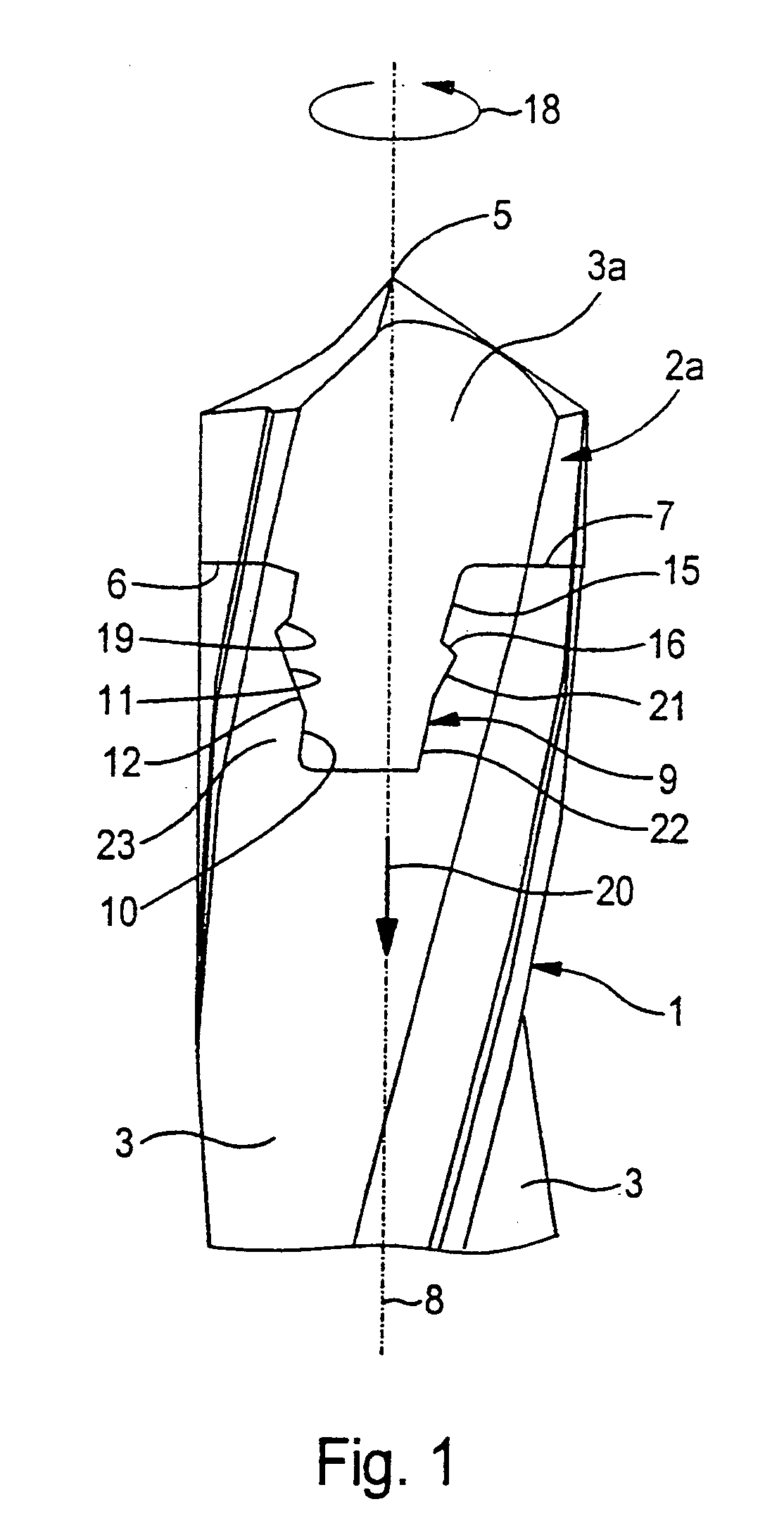

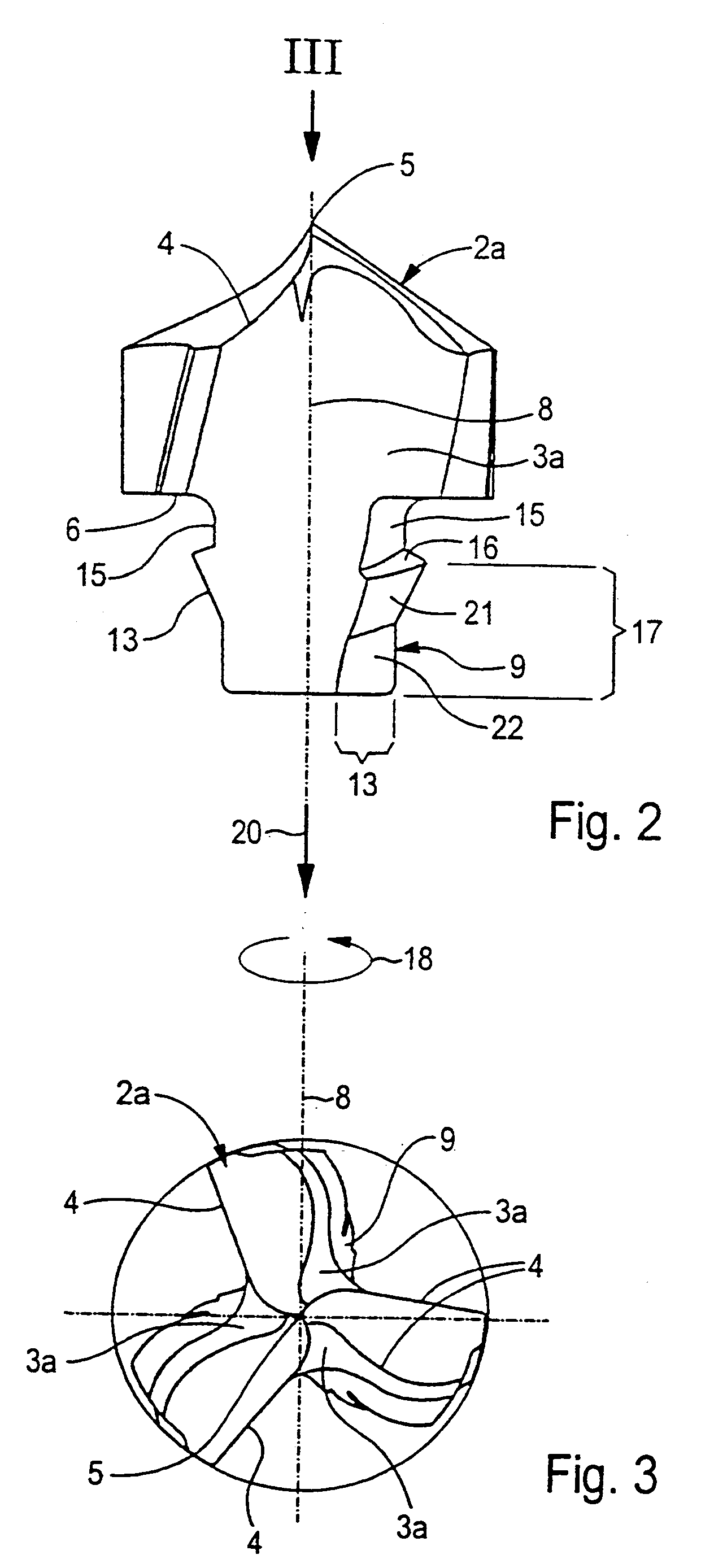

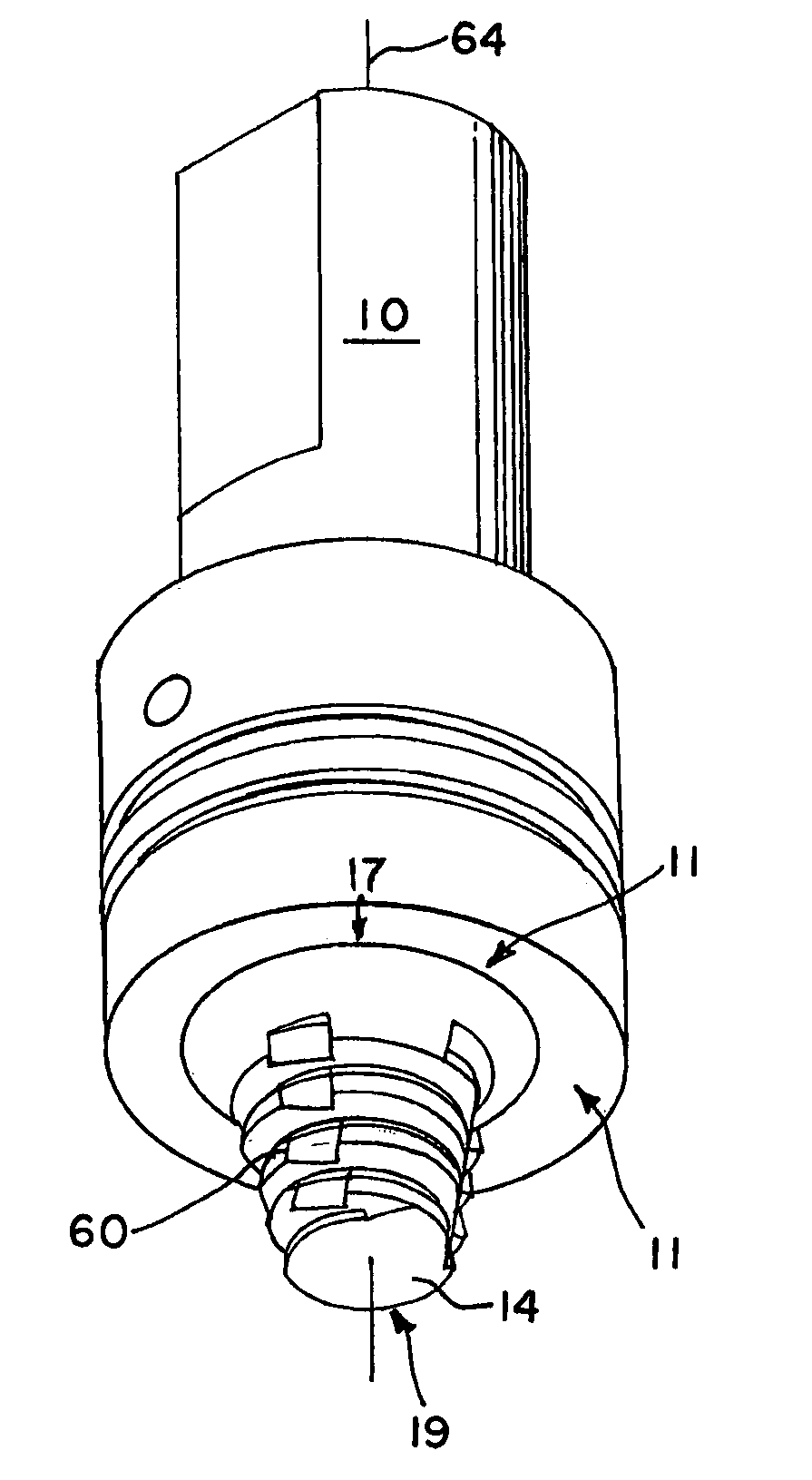

Twist drill for drilling having a replaceable drill tip, and a replaceable drill tip for use in a twist drill

InactiveUS7070367B2Avoid damageAvoid pullingWood turning toolsTransportation and packagingFluteEngineering

A twist drill, having a replaceable drill tip, comprising a drill bit shaft (1), a cutting insert (2) which is detachably fixed thereto and which forms the tip area of the twist drill, and comprises a flute (3) that continues into the cutting insert (2). The cutting insert rests, with a bearing surface (6) extending orthogonal to the center longitudinal axis (8) of the drill bit, on the face (7) of the drill bit shaft (1) and extends with a fixing stud (9), which centrally protrudes from the bearing surface (6), into a receiving recess (10) which is configured complementary thereto and which is provided in the face (7) of the drill bit shaft (1). At least one peripheral section (13) of the fixing stud (9) comprises a first longitudinal section (15) that, with a screw surface (16) which points away from the drill bit shaft (1), which slopes upward to the drill bit tip (5) in a direction of rotation of the drill bit, and which interacts with an opposite surface (19) on the inner wall (14) of the receiving recess (10), merges into a second longitudinal section (17).

Owner:KENNAMETAL INC

Surgical bur with Anti-chatter flute geometry

InactiveUS20100121365A1Reduce, if not eliminate, chatterEndoscopic cutting instrumentsSurgical operationFlute

A surgical bur including a shaft with a bur head. A number of flutes are formed on the bur head. Each flute has a cutting edge. Chamfer surfaces form the front, distally directed faces of some of the burs. The flutes without chamfer surfaces having cutting edges emerge from the bur head at locations relatively close to the distal end tip of the head. The flutes over which the chamfer surfaces extend have cutting edges that start, extend proximally rearward, from locations that are, spaced proximal from the distal end tip.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Friction stir weld tools

InactiveUS7275675B1Traverse speed is fastImprove tool lifeWelding/cutting auxillary devicesAuxillary welding devicesFluteToughness

A friction stir weld tool sleeve is supported by an underlying support pin. The pin material is preferably selected for toughness and fracture characteristics. The pin sleeve preferably has a geometry which employs the use of an interrupted thread, a plurality of flutes and / or eccentric path to provide greater flow through. Paddles have been found to assist in imparting friction and directing plastic metal during the welding process.

Owner:NASA

End-mill tool with multiple cutting edges

The present invention provides an end-mill tool which includes a shank, a point, and a main body portion located intermediate the shank and the point. A first flute is formed on the main body portion along a first helix. A second flute is formed on the main body portion along a second helix. The first and second flutes preferably extend helically along the body of the tool. Two distinct helical cutting surfaces are defined by the first flute and the second flute. The point of the tool includes two additional cutting edges formed by ears extending outward from the point of the tool adjacent the first flute and the second flute.

Owner:WARDELL LON J

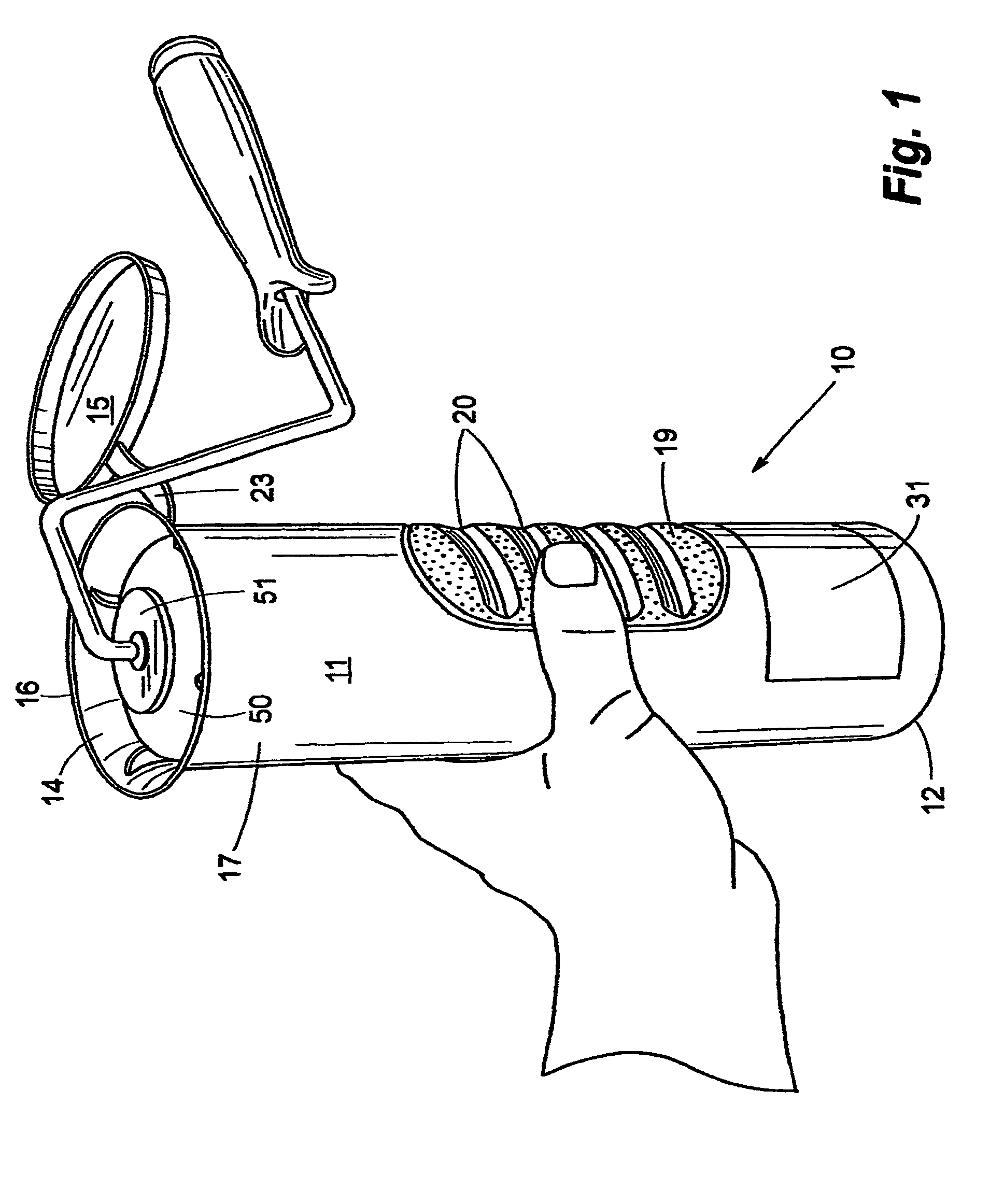

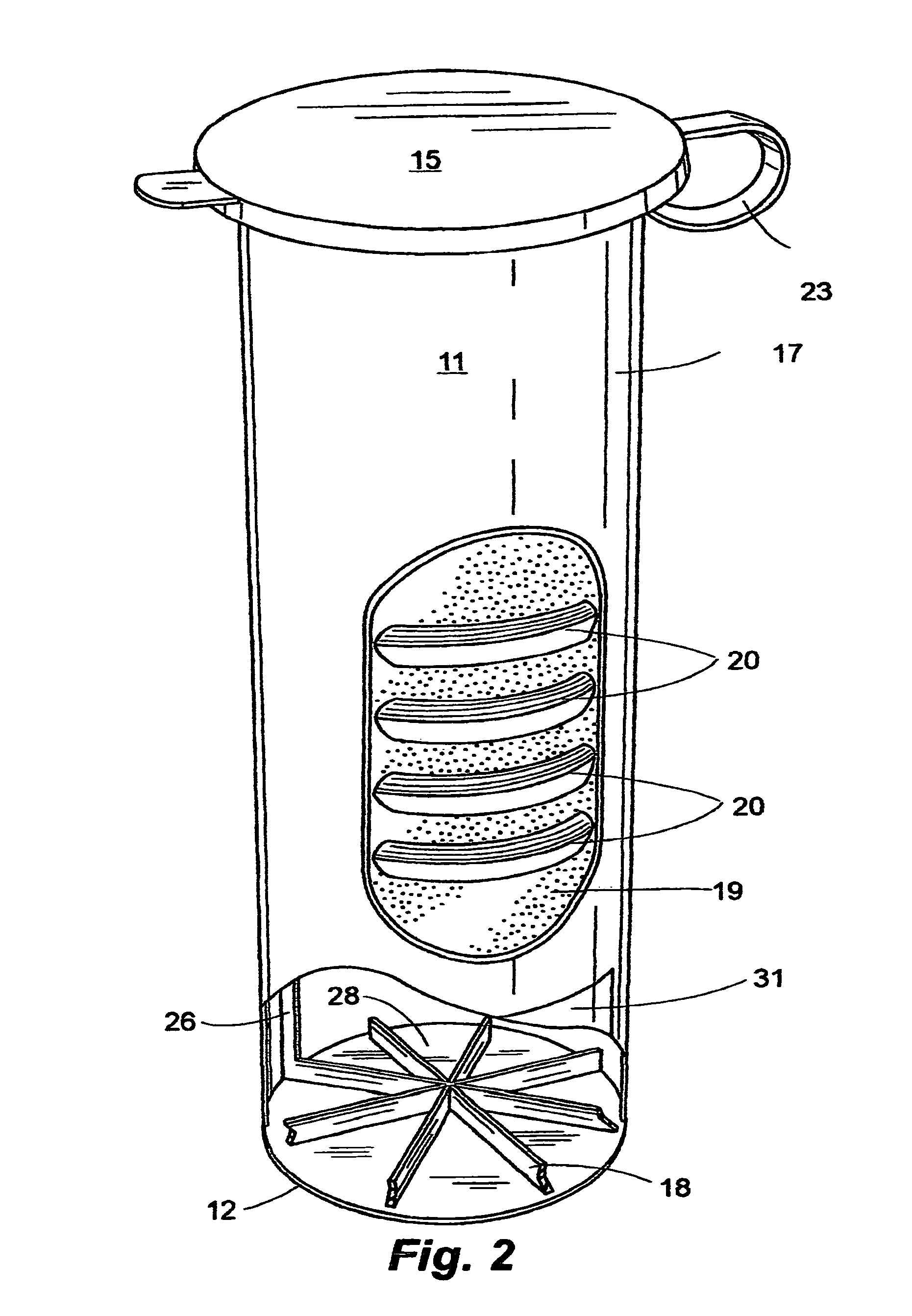

Paint roller sleeve storage container

A storage container for paint roller sleeve includes a set of flutes on at least two opposing sides of an interior surface of said cylinder for stabilizing a roller cover in place from rattling inside of the housing and for holding said roller cover in place when extracting a roller frame from said roller cover. Each set of flutes includes three interior flutes that located between said two exterior flutes. The interior flutes include a middle flute that is set back a distance from the other two interior flutes so that when the exterior surface of the container is pressed inward said middle interior flute cuts into a paint roller sleeve housed within the container and the other two interior flutes bend outward around a nap of said roller sleeve to better hold said roller sleeve in place when a roller frame is being extracted from said roller sleeve.

Owner:OBVIOUS SOLUTIONS

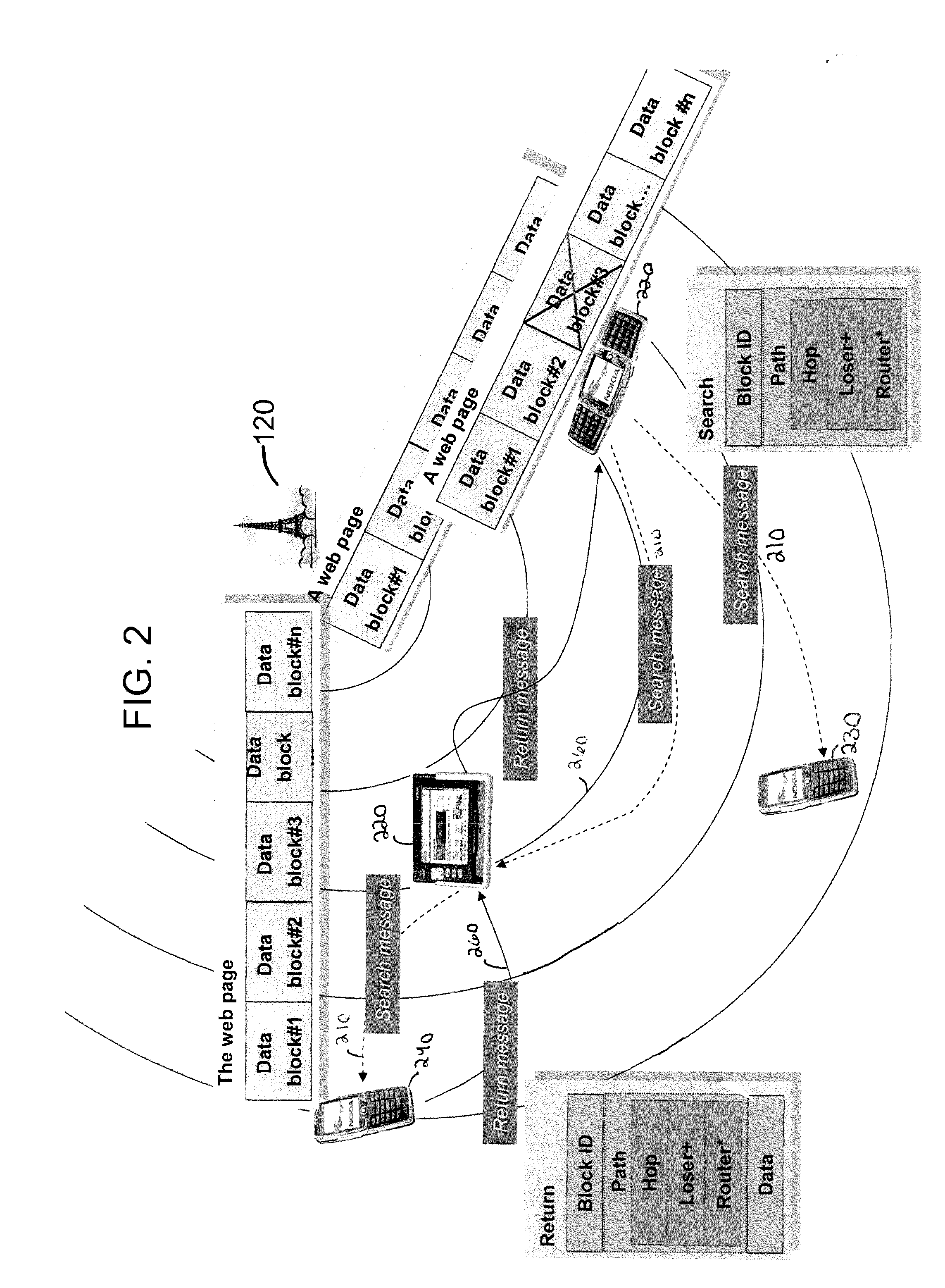

System and method for using a peer to peer mechanism to repair broadcast data in wireless digital broadcast networks

An improved system and method for repairing and / or retrieving lost or crushed data, such as files carried by the FLUTE protocol, by using a P2P network in wireless digital broadcast networks. According to various embodiments, when a peer device has failed to receive a data packet from operator, or when a data packet contains errors, the peer device sends a Search request to neighboring devices. The neighboring devices can either return the data packet in integrated form to the peer device or, if they do not possess the data packet in integrated form, reroute the request to other devices. Mechanisms are also provided for each peer device to maintain and update a table of neighboring devices including an identification of the devices and their connection capabilities.

Owner:NOKIA CORP

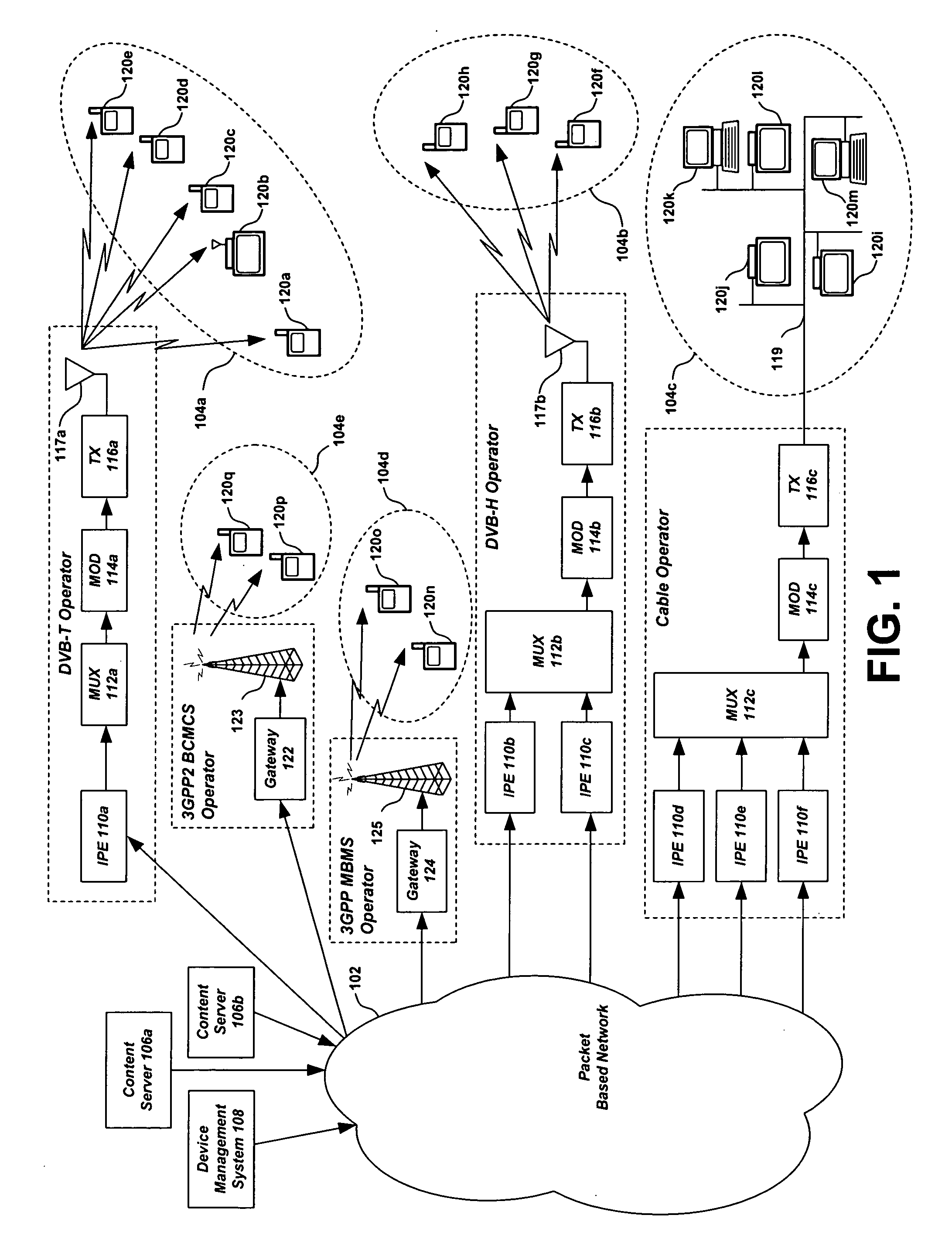

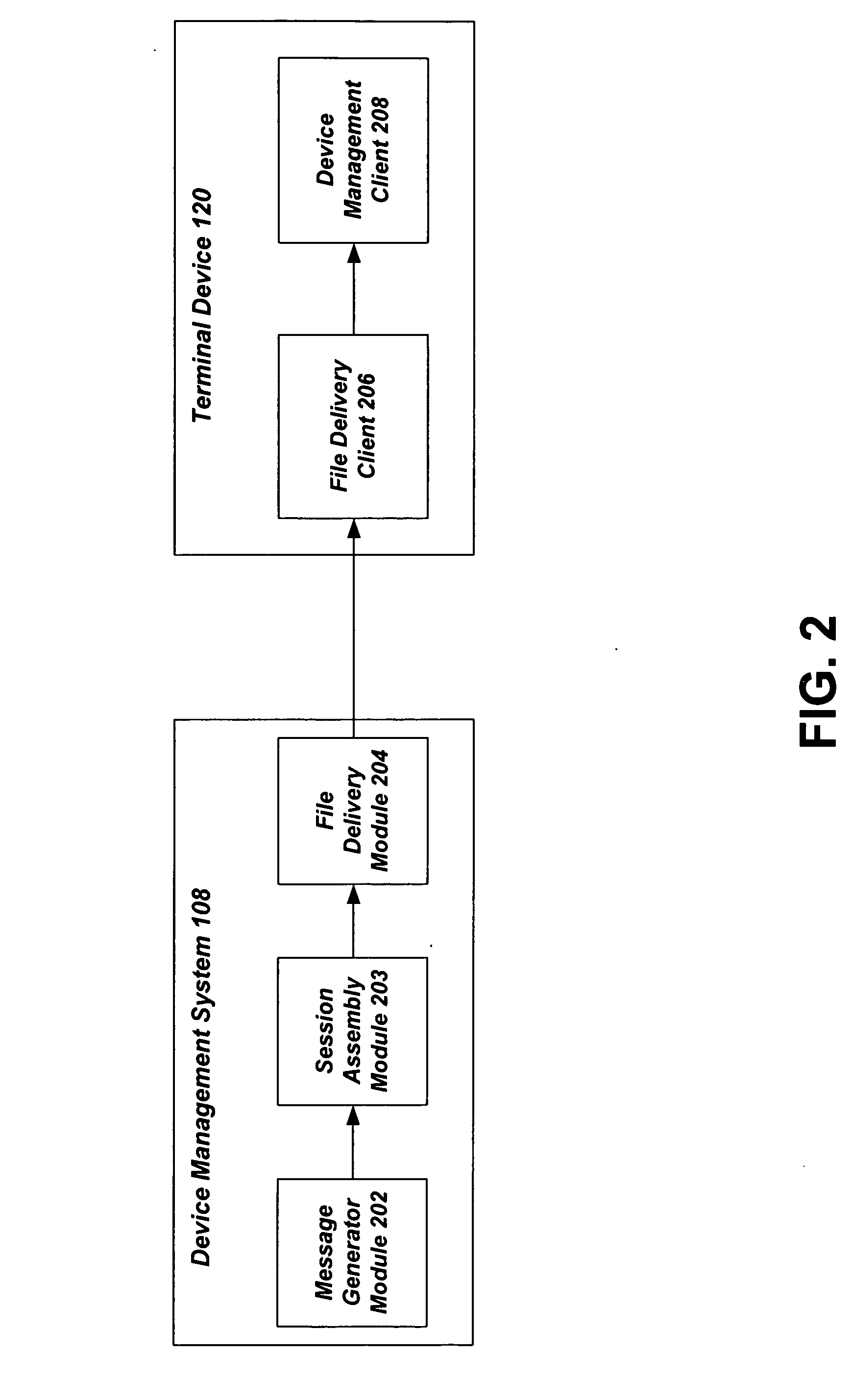

Device management broadcast operation

InactiveUS20060193337A1Network traffic/resource managementAssess restrictionFluteShort Message Service

An indication of a device management broadcast is received. This device management broadcast is in the form of a file delivery session, such as a FLUTE session. Further, a transport object of the device management broadcast is received. This transport object may include one or more device management messages in compressed or uncompressed form. Moreover, the indication of the broadcast may be received in various forms. Examples of such forms include an electronic service guide (ESG), one or more short messaging service (SMS) messages, and / or one or more session description protocol (SDP) messages.

Owner:NOKIA CORP

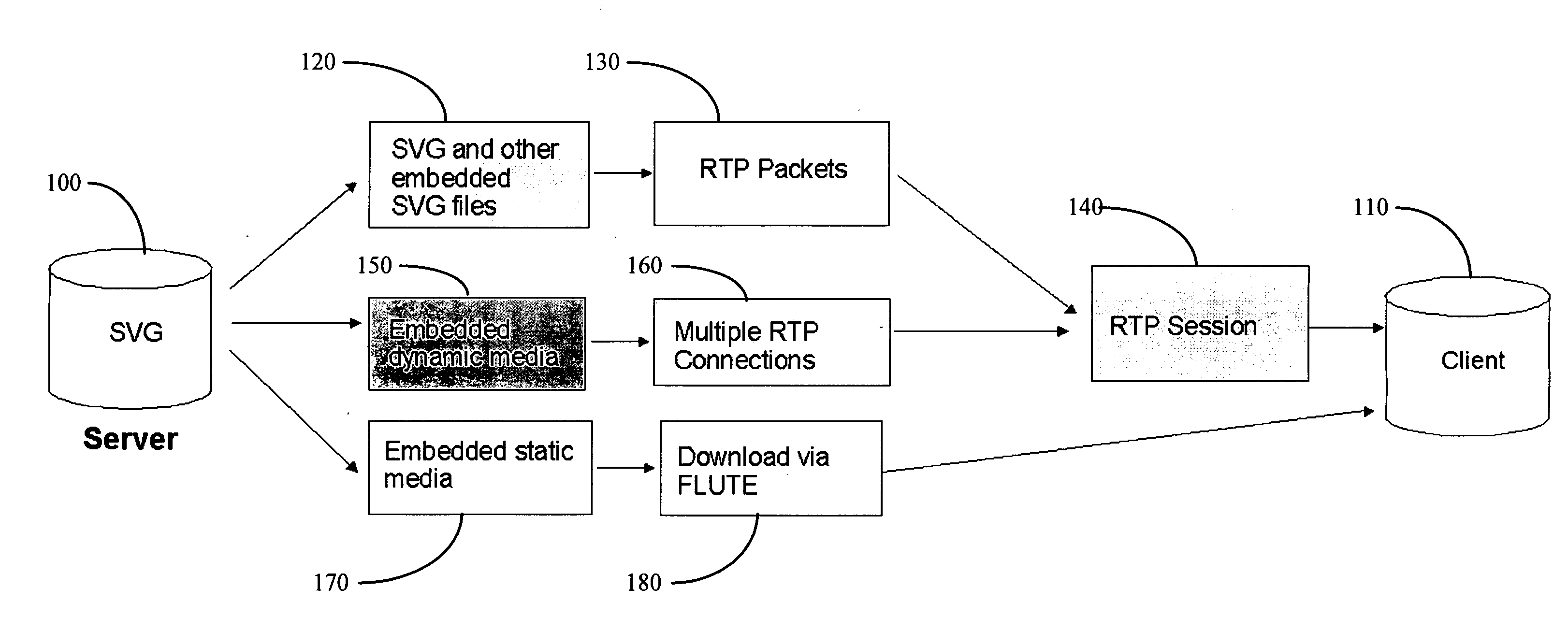

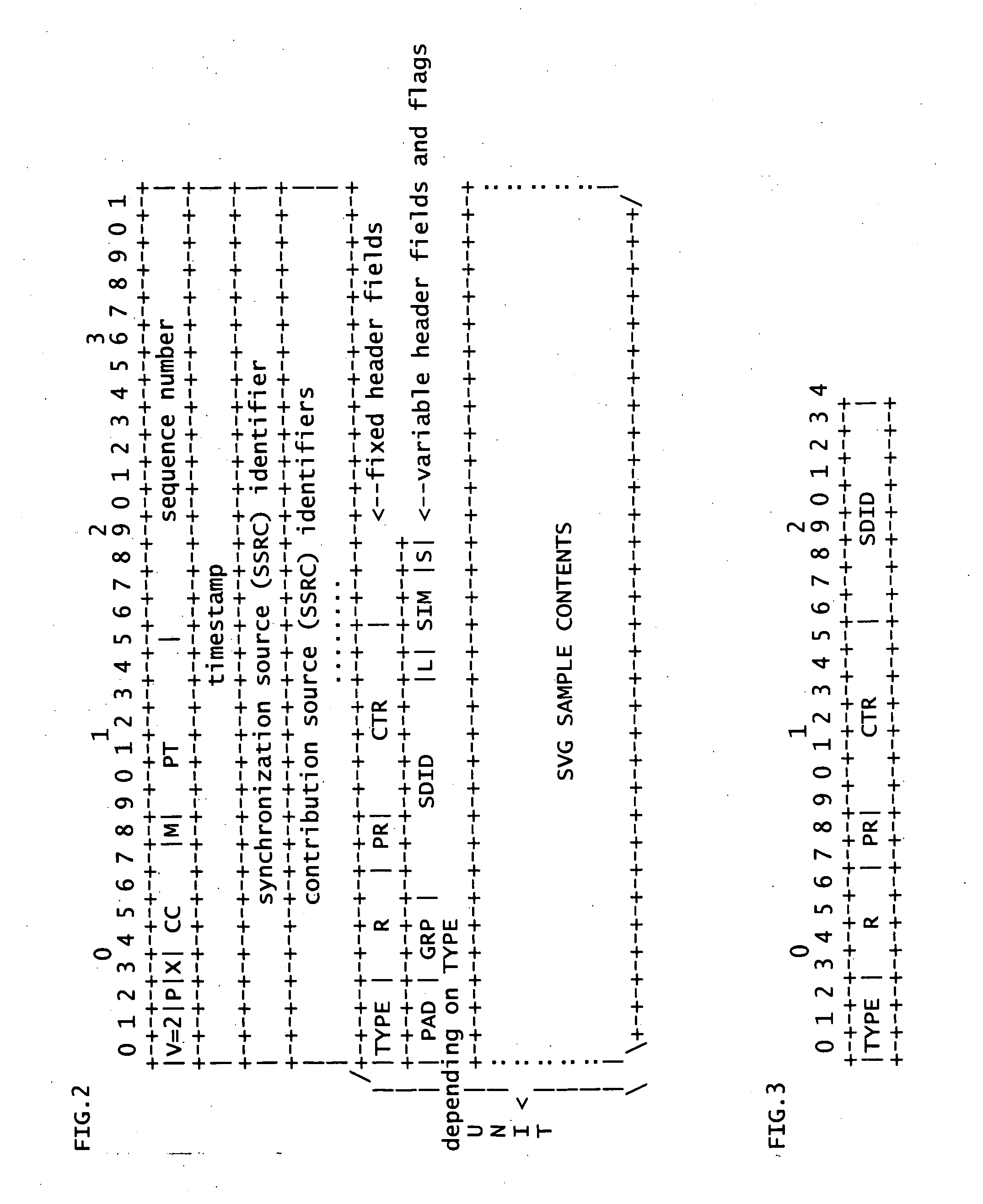

Transport mechanisms for dynamic rich media scenes

ActiveUS20070157283A1Analogue secracy/subscription systemsMultiple digital computer combinationsFluteLive streaming

Owner:CONVERSANT WIRELESS LICENSING LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com