Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1420results about "Boxes/cartons making machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

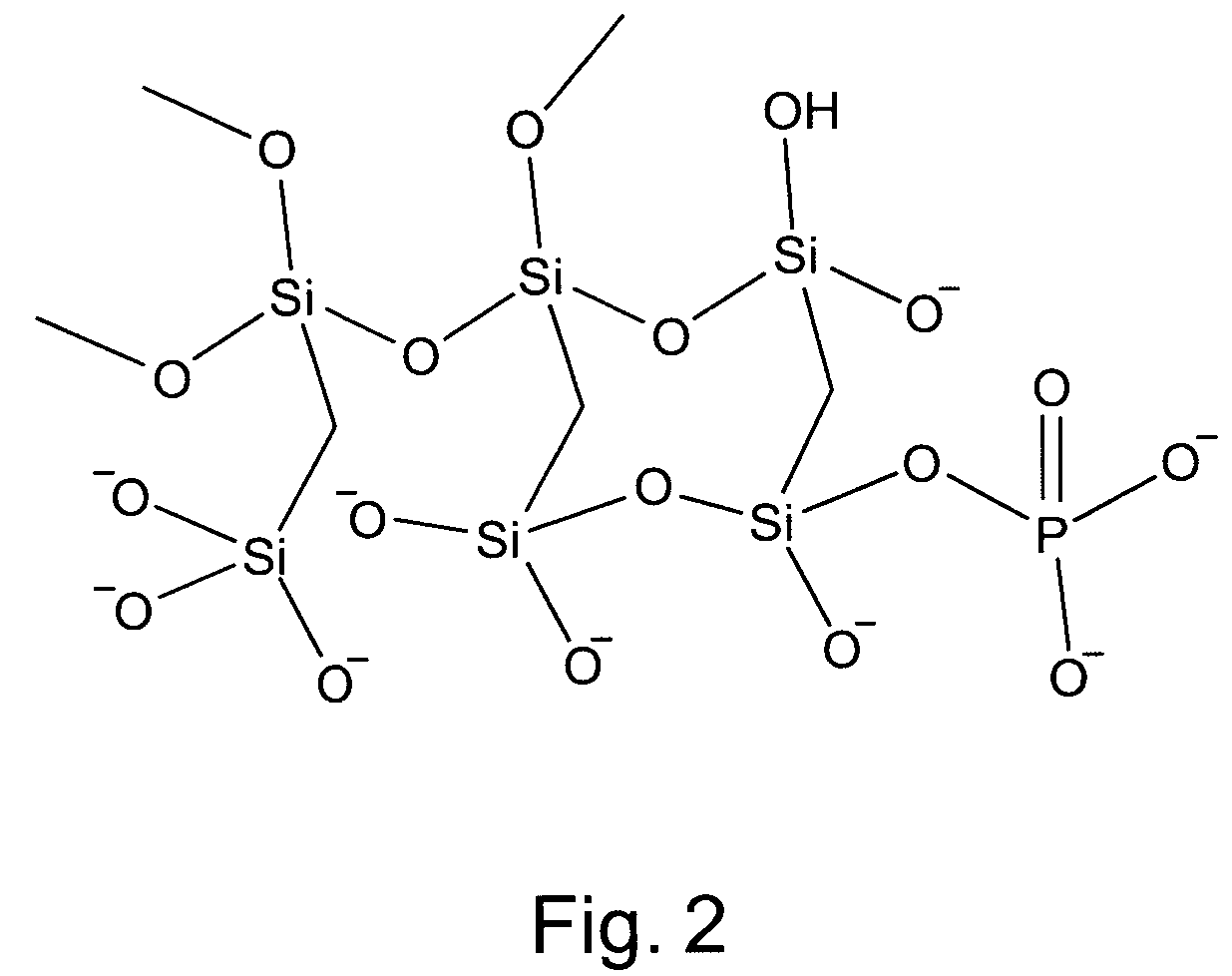

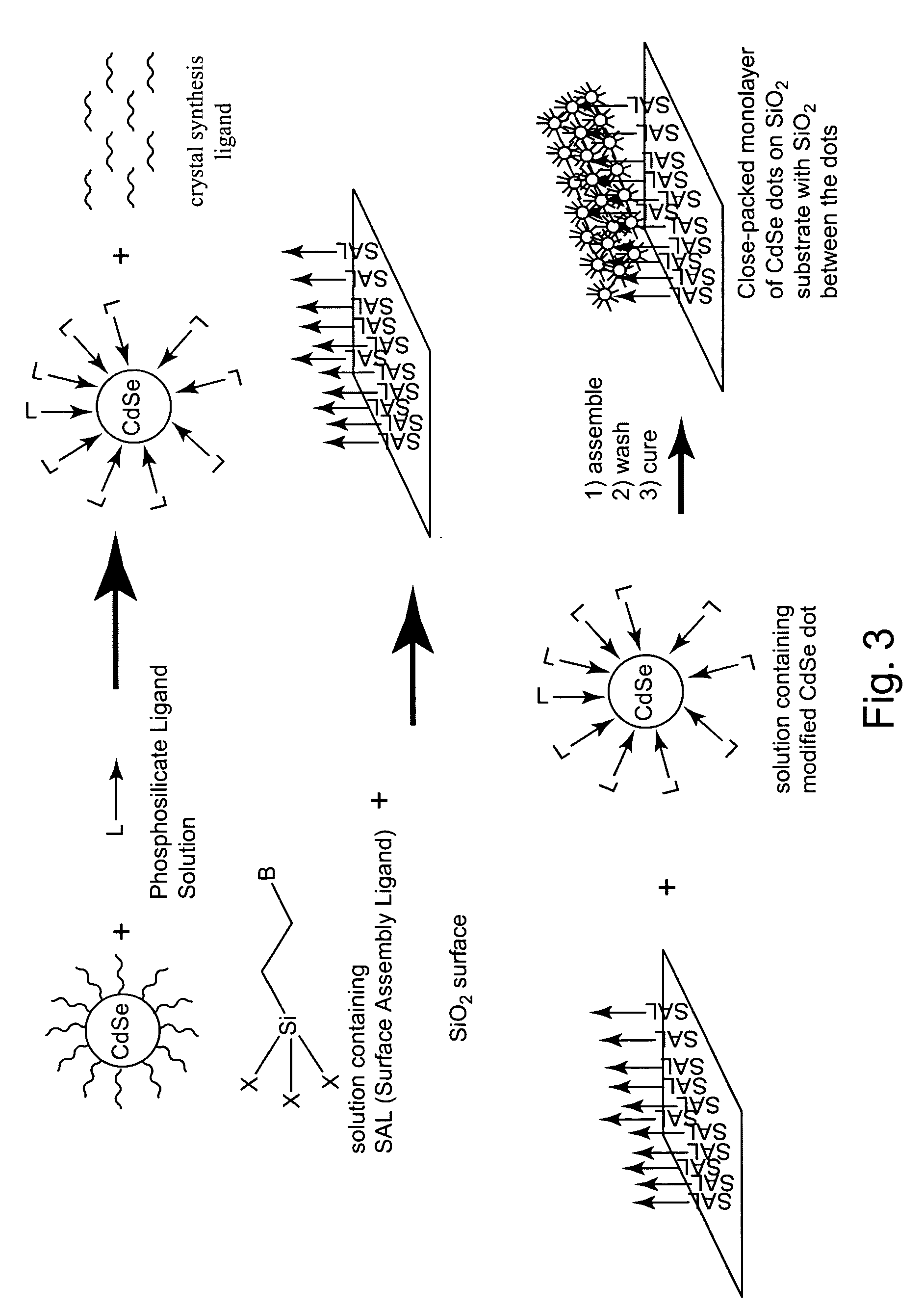

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS20060040103A1Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS7267875B2Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

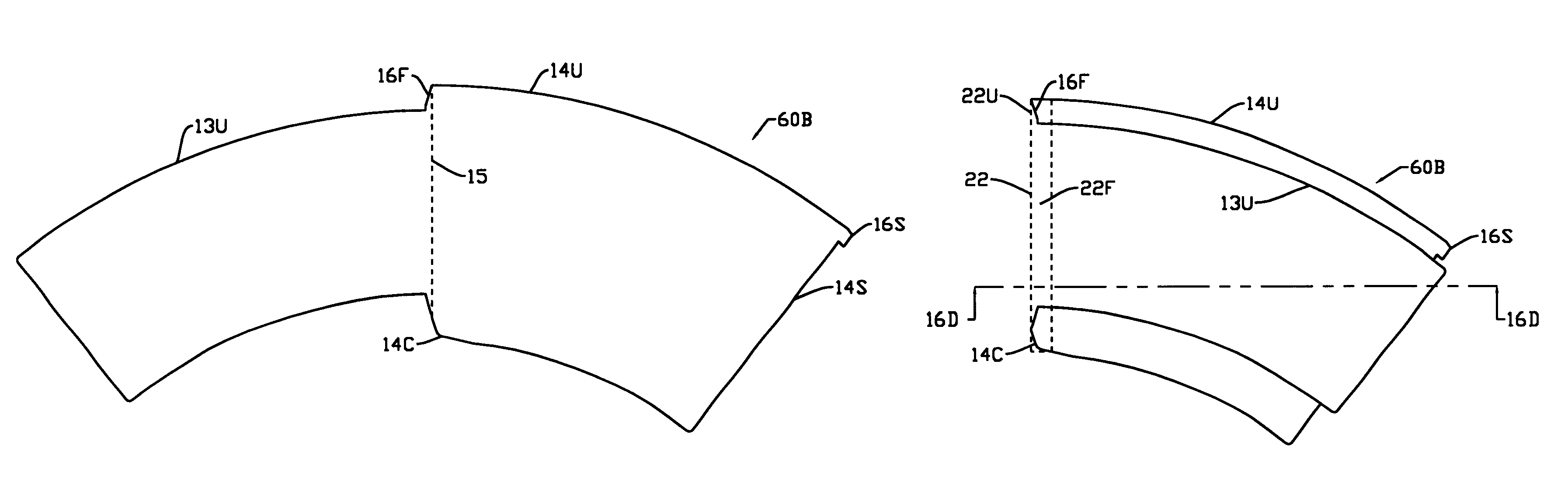

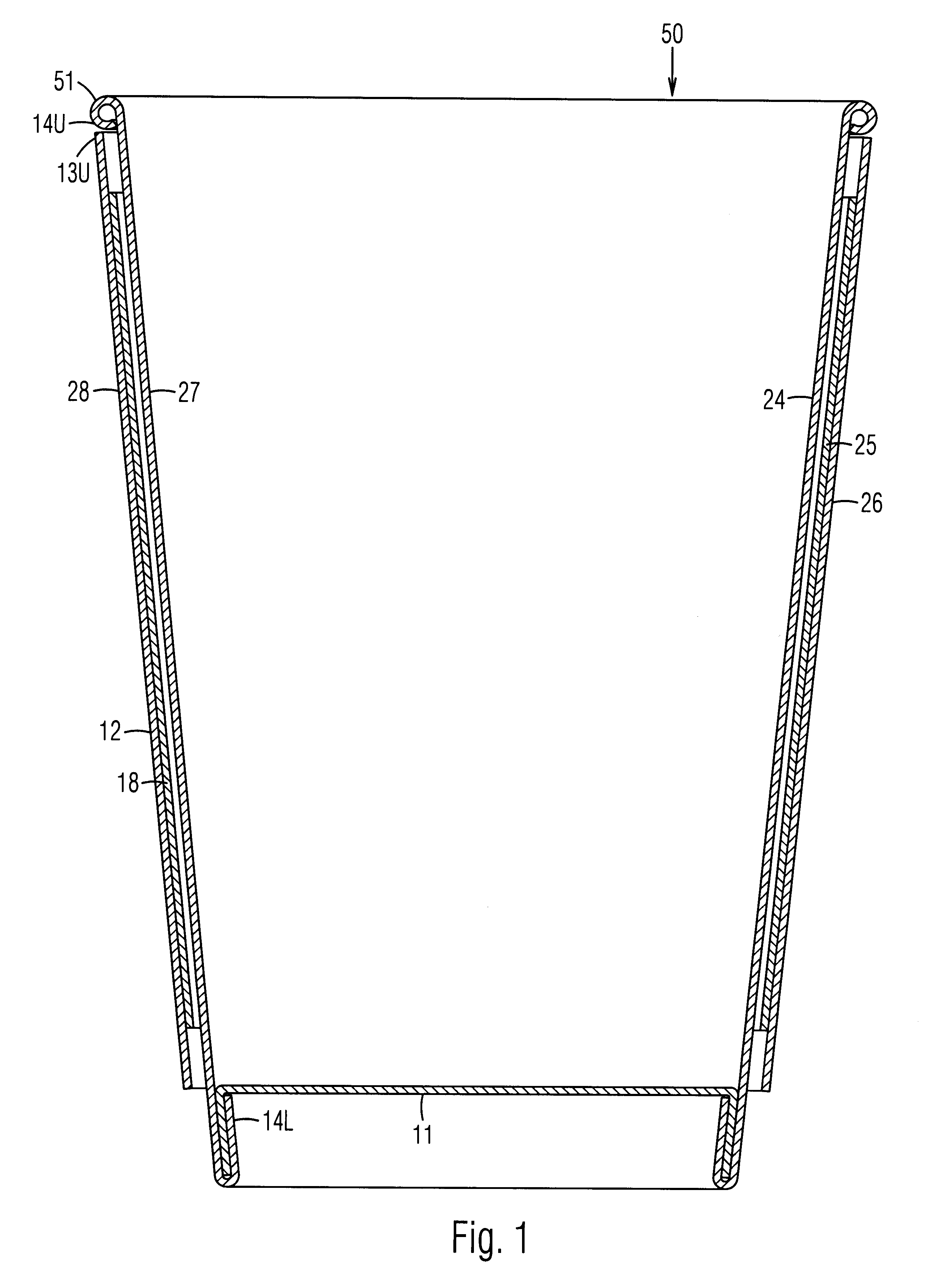

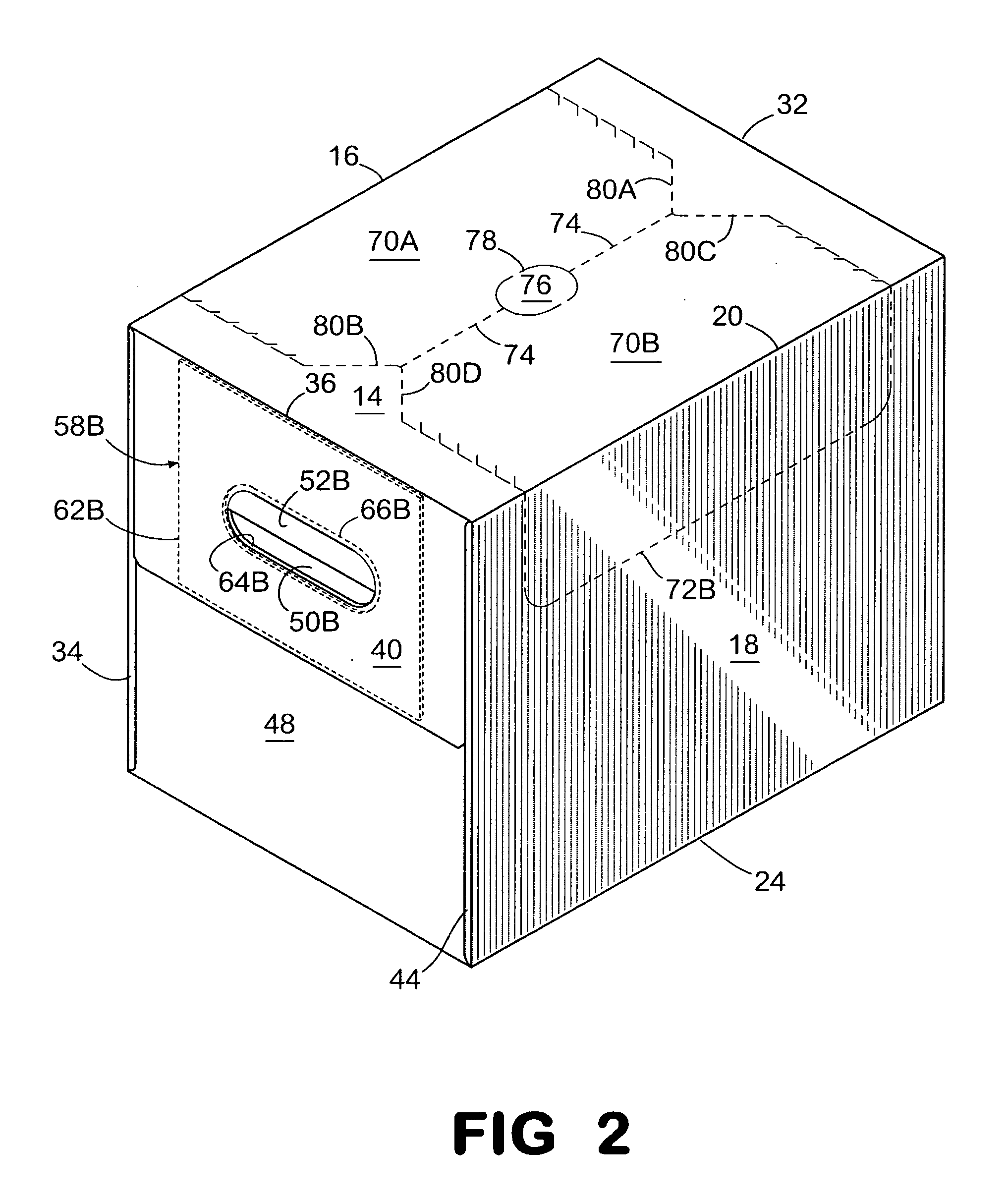

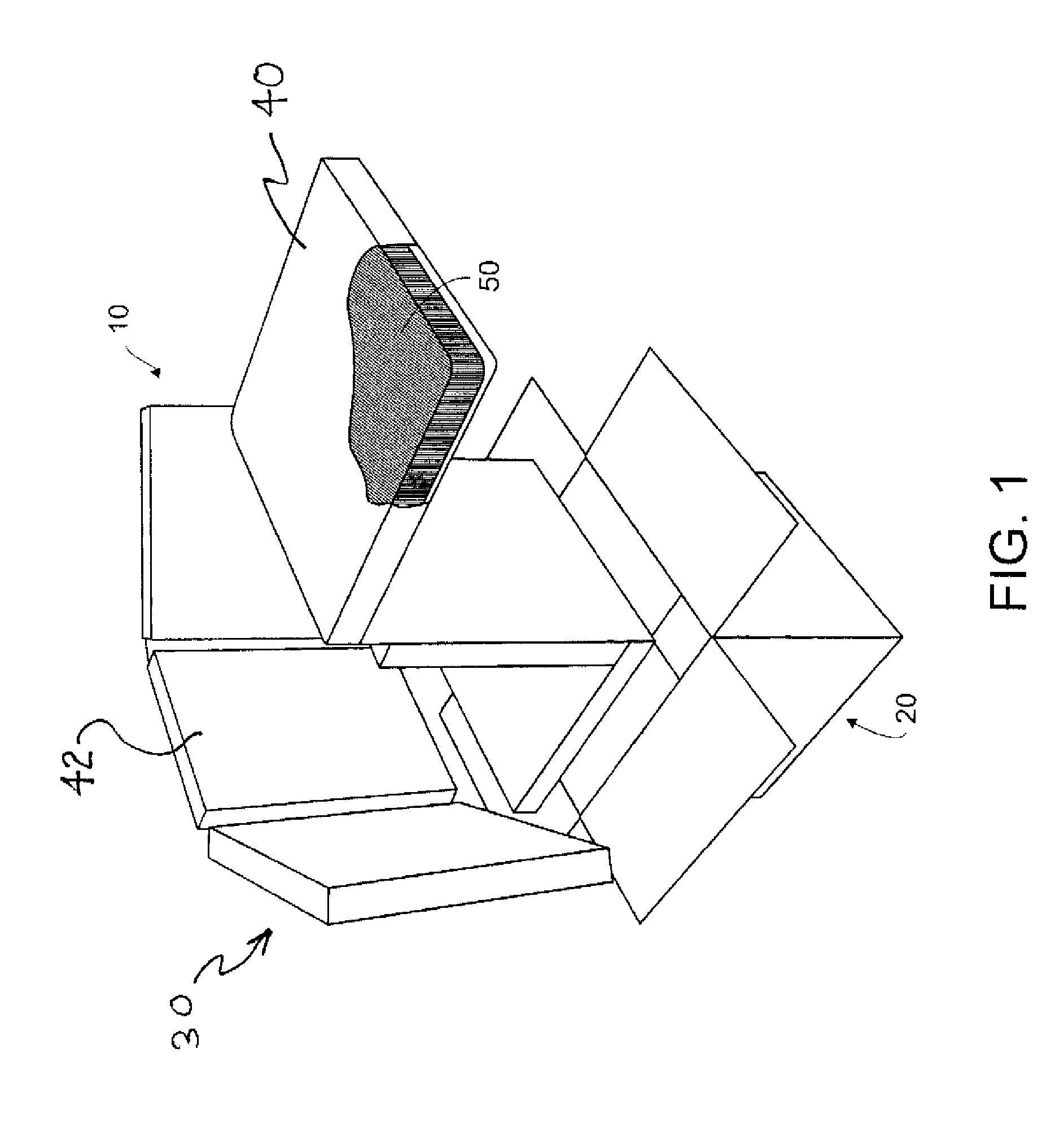

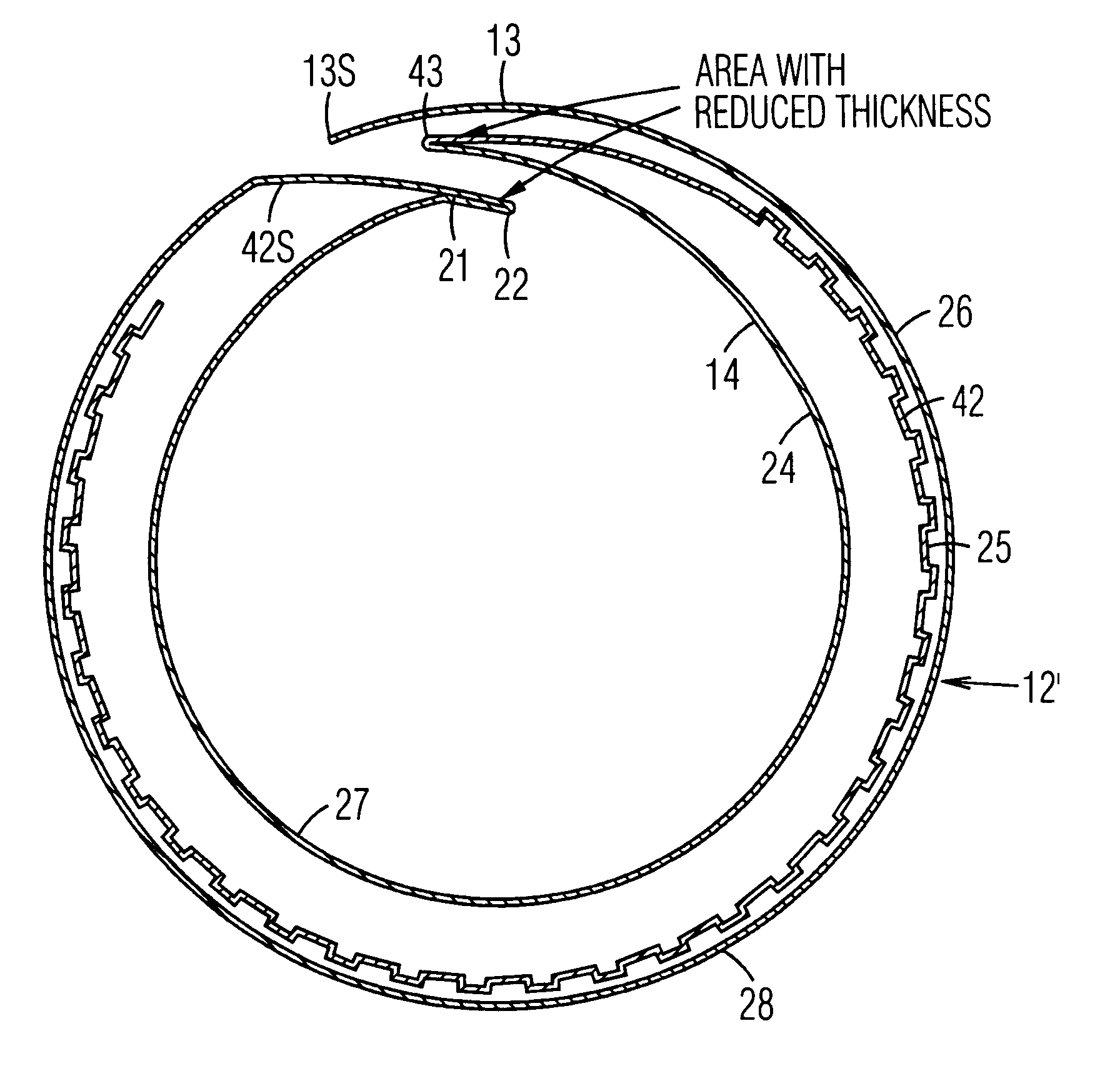

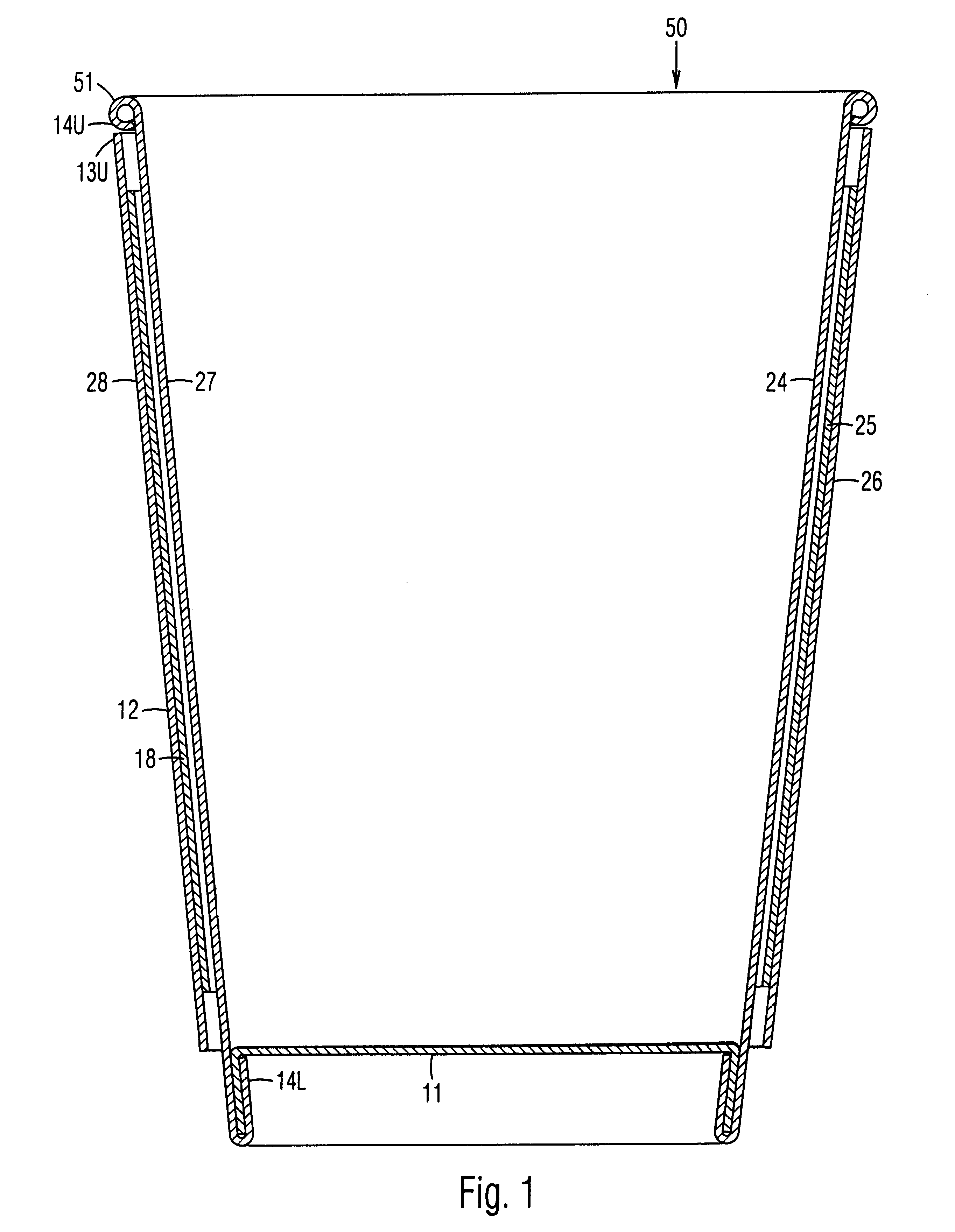

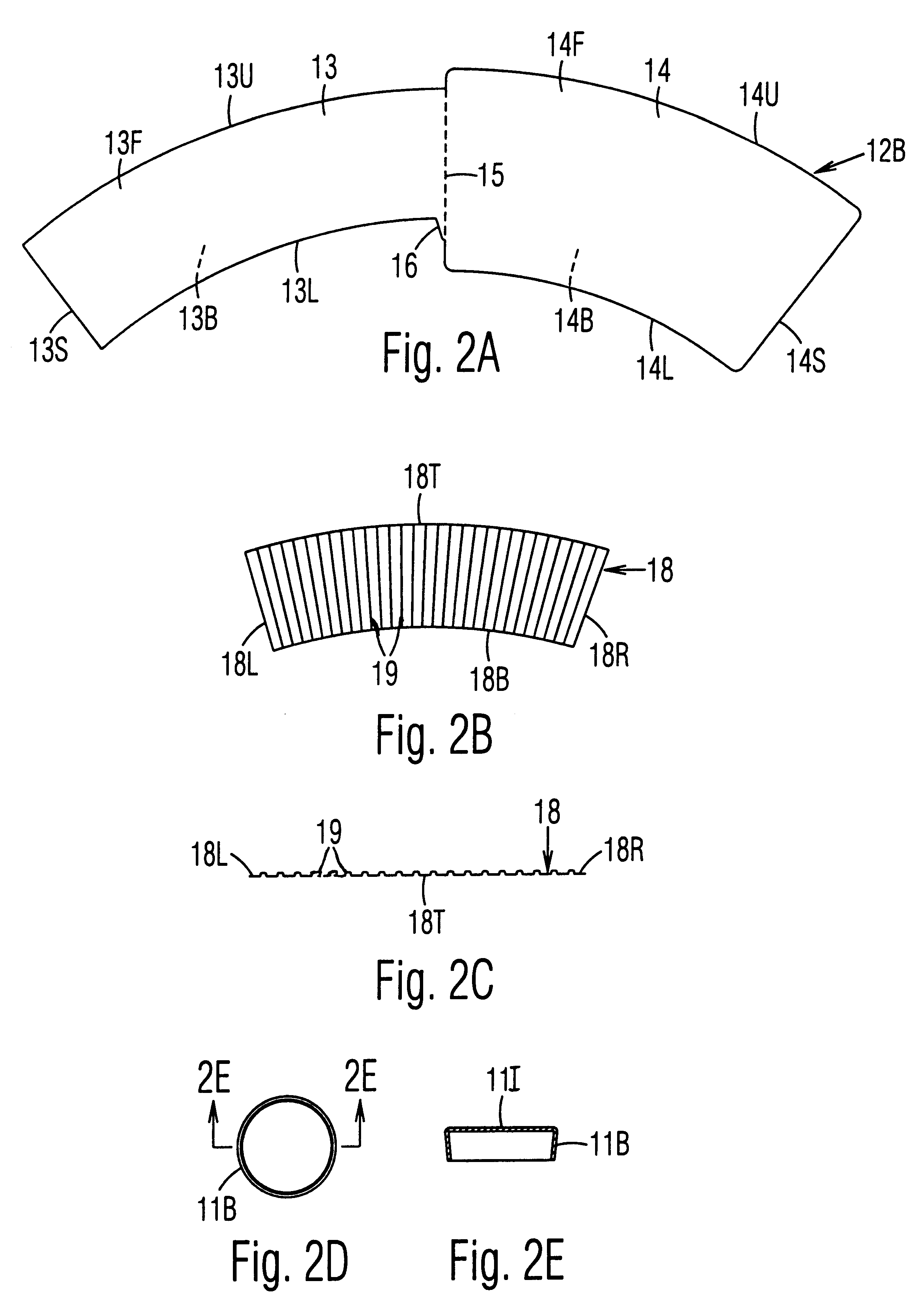

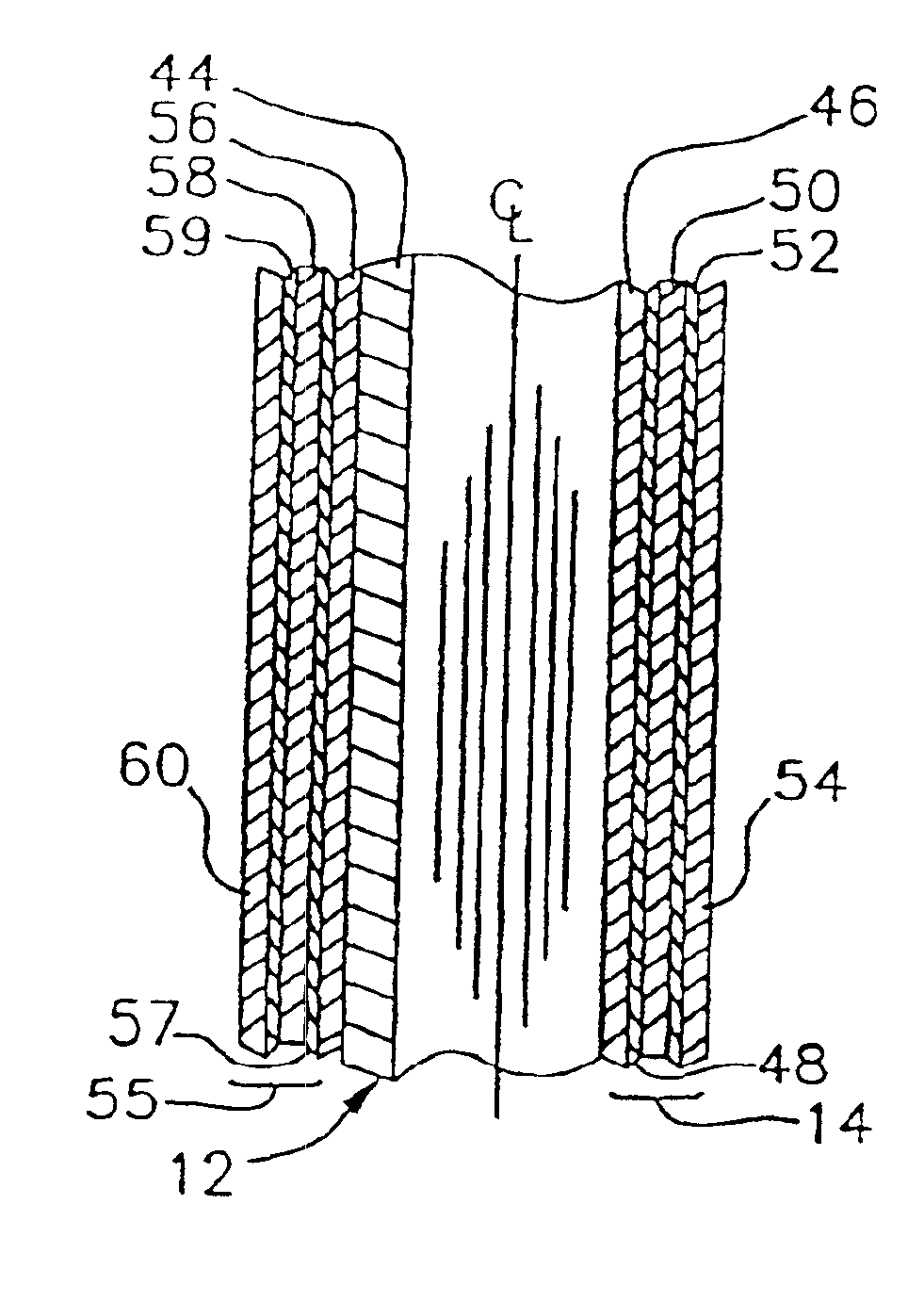

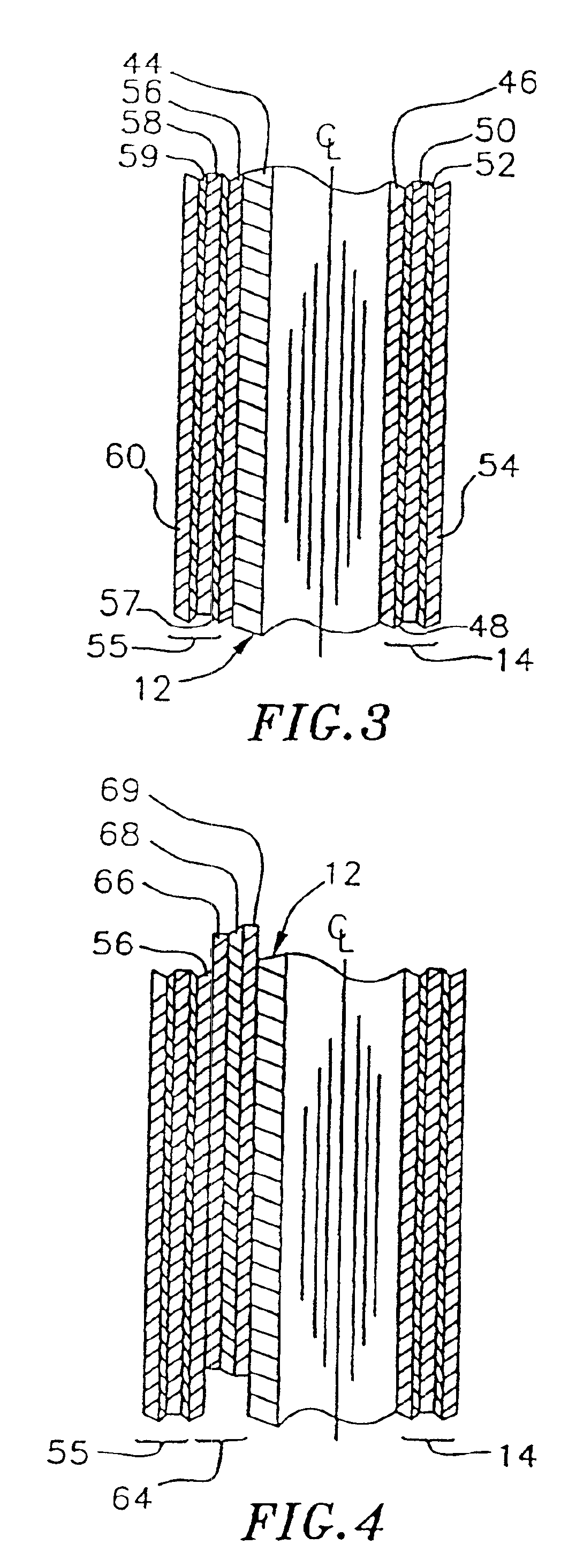

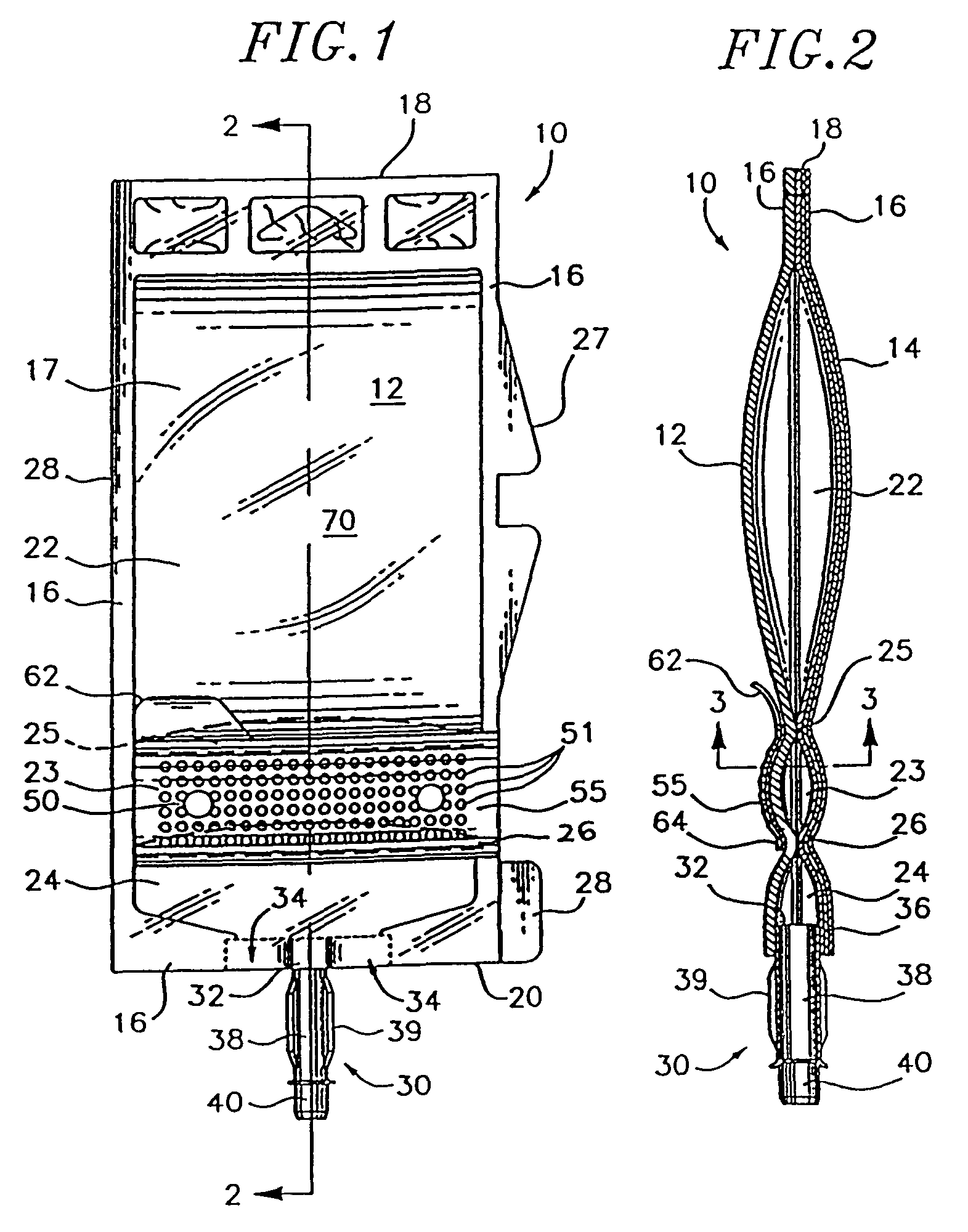

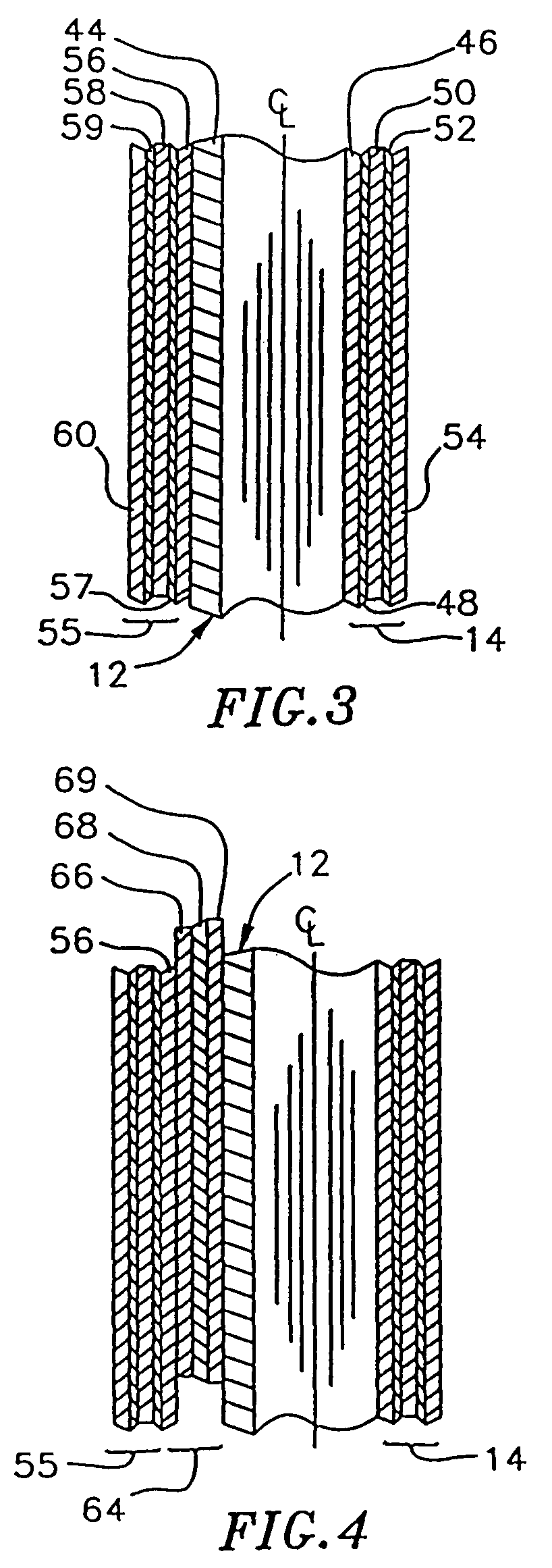

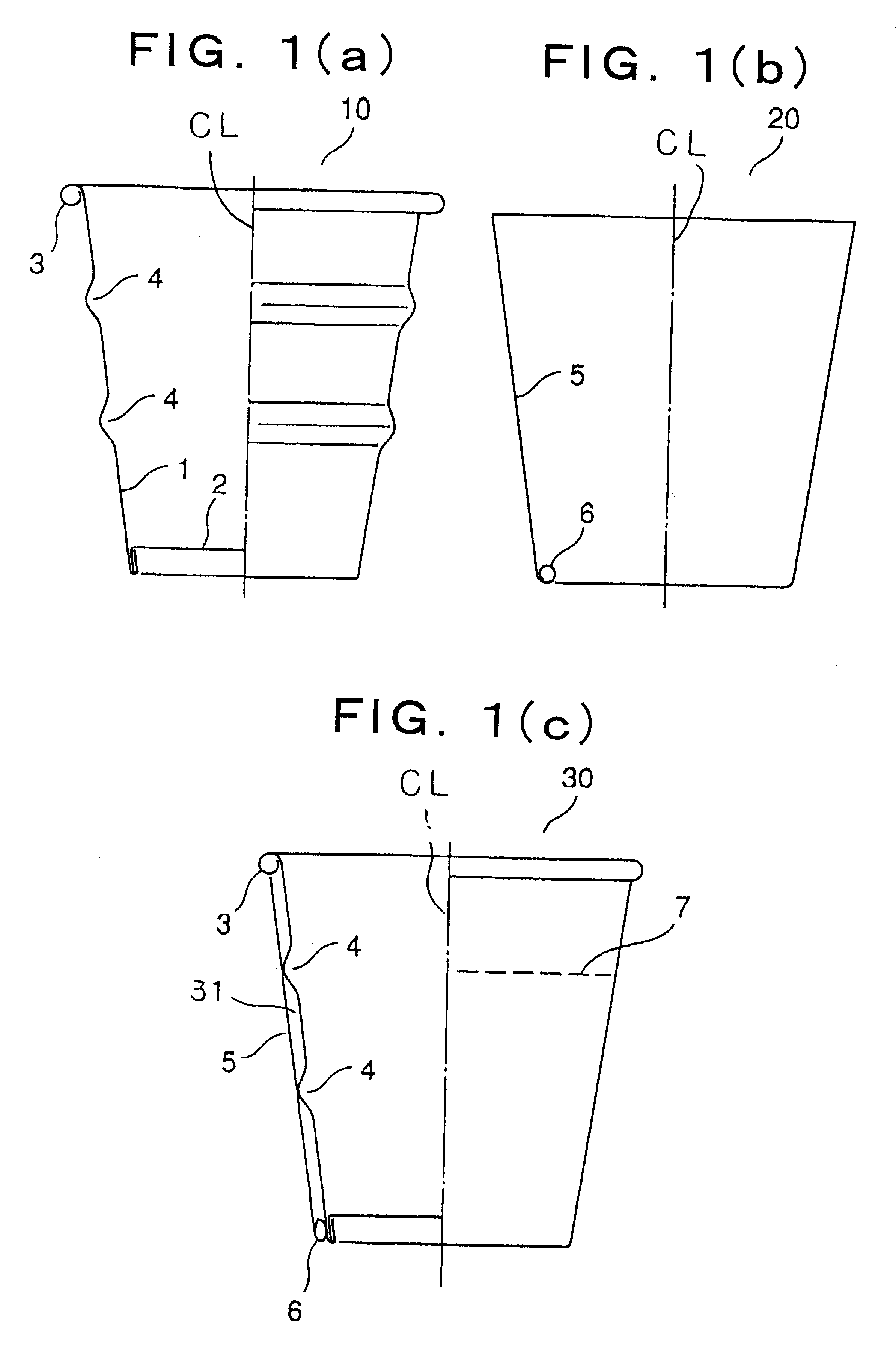

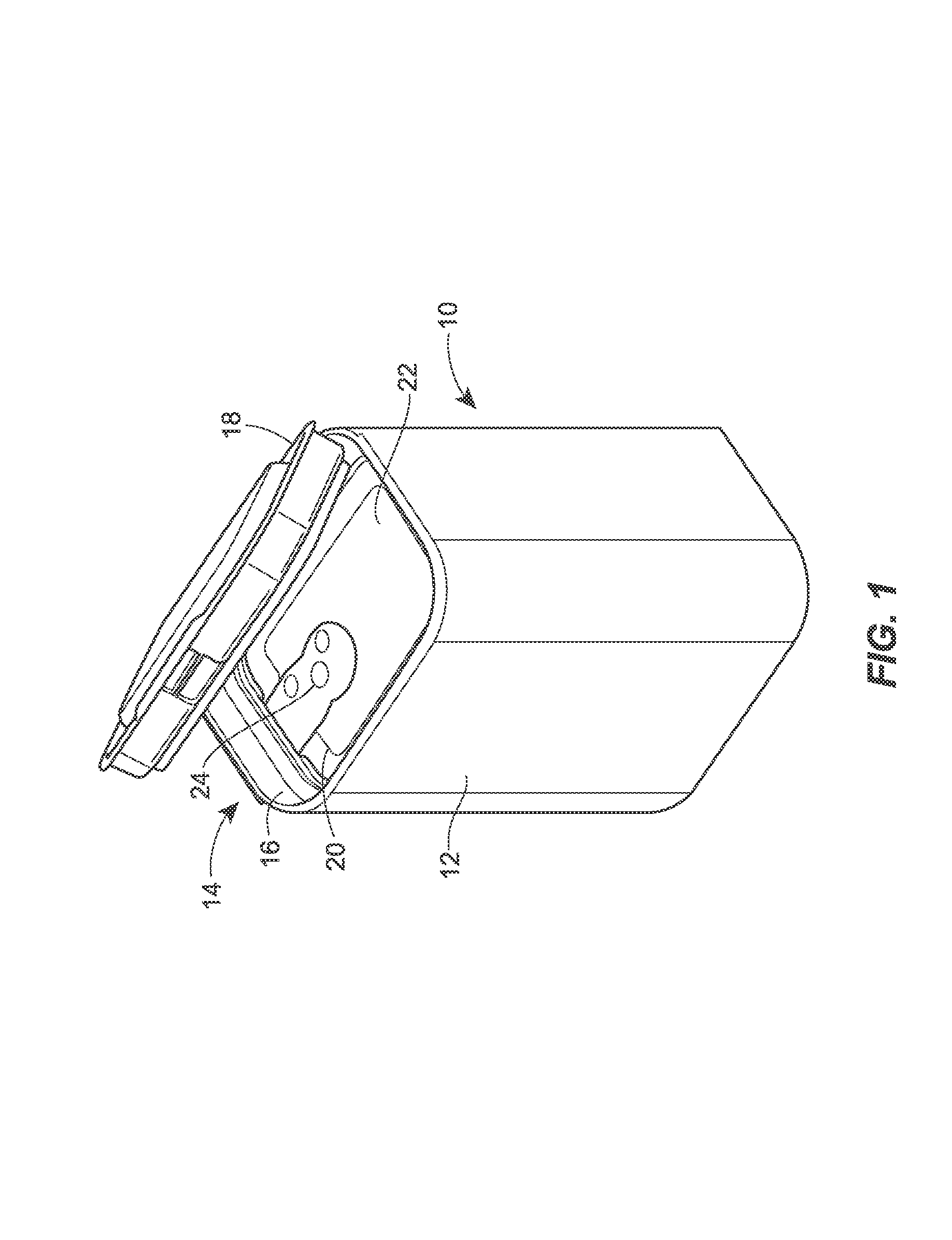

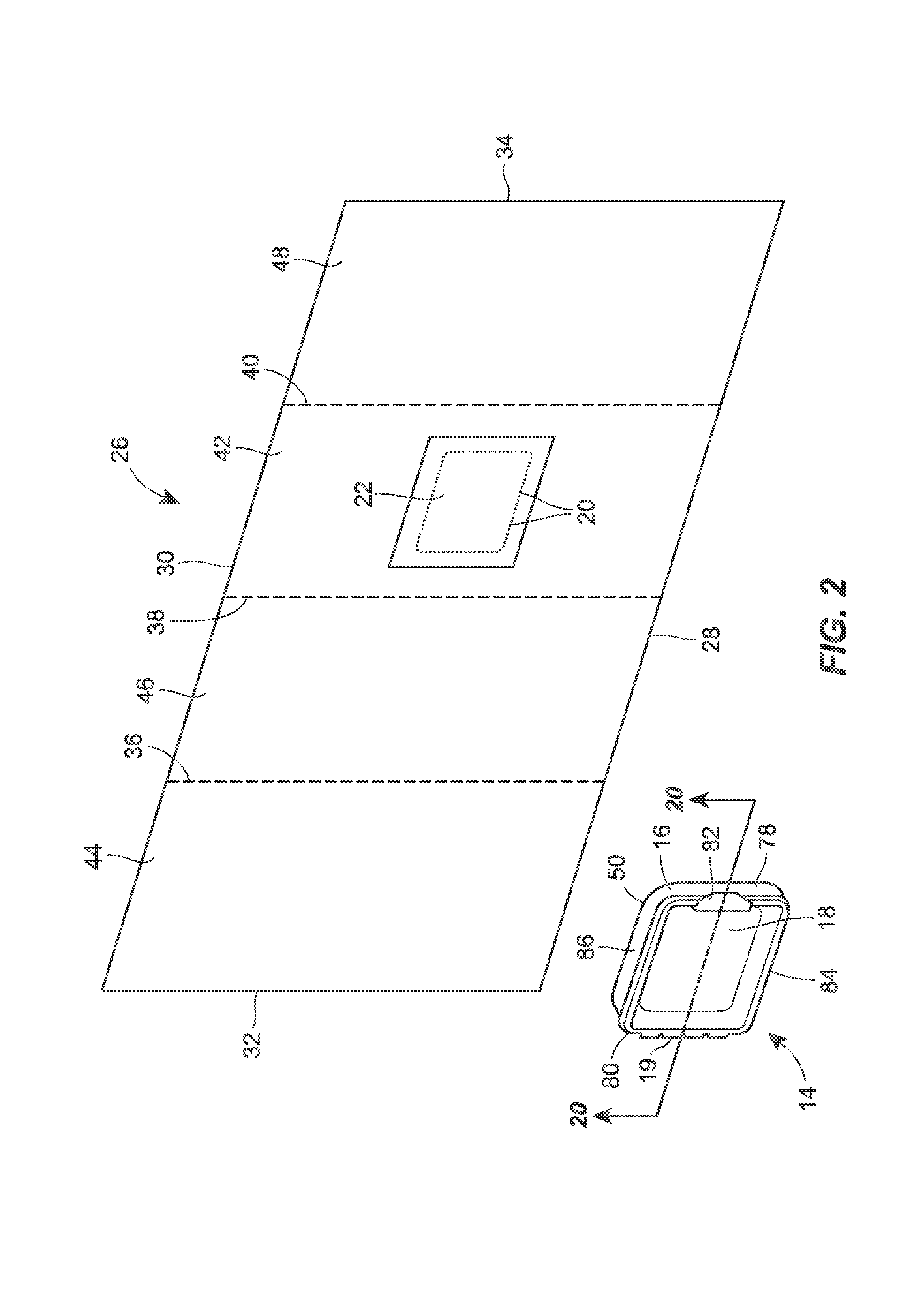

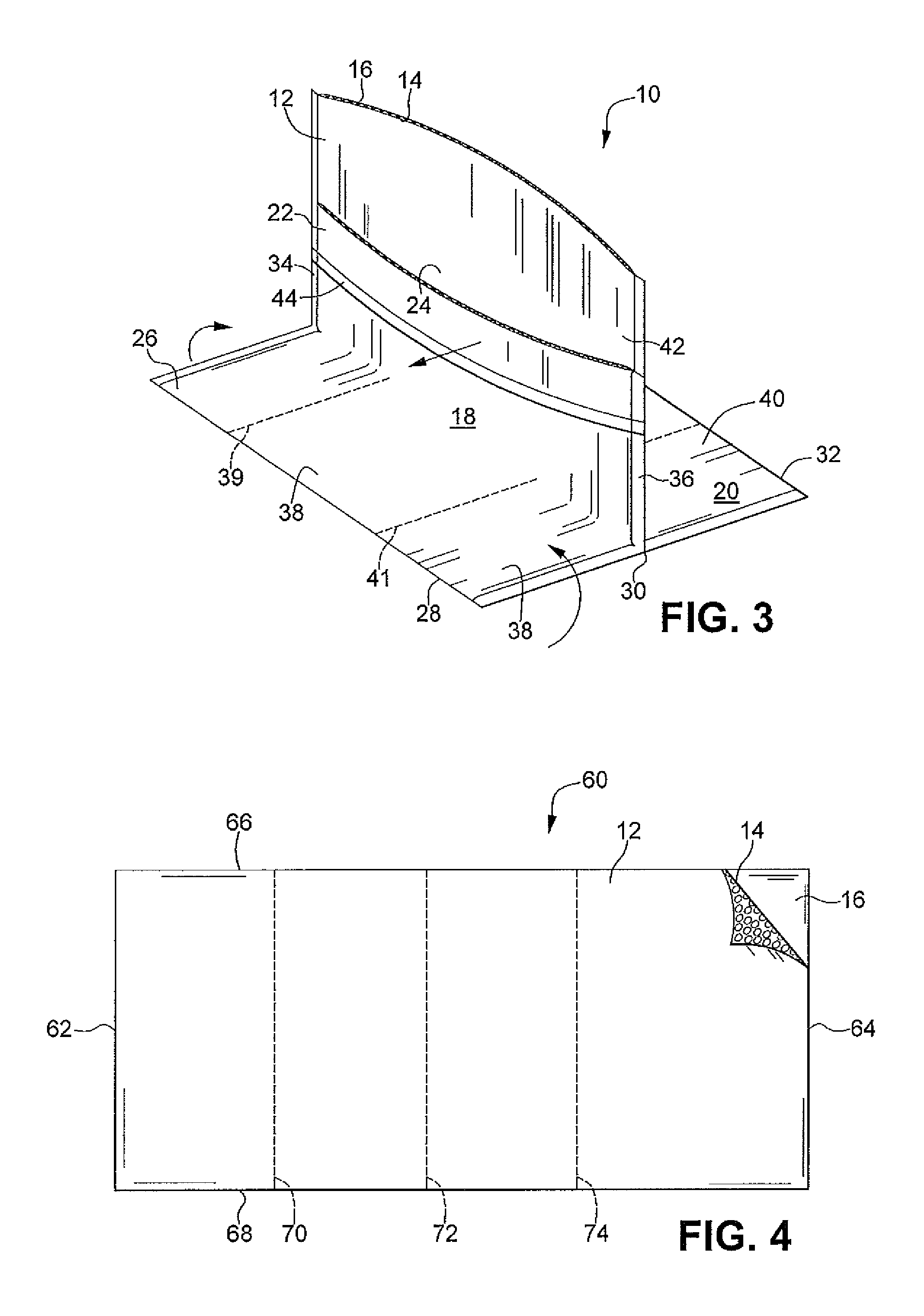

Insulated cup and method of manufacture

InactiveUS6257485B1Boxes/cartons making machineryDomestic cooling apparatusEngineeringMechanical engineering

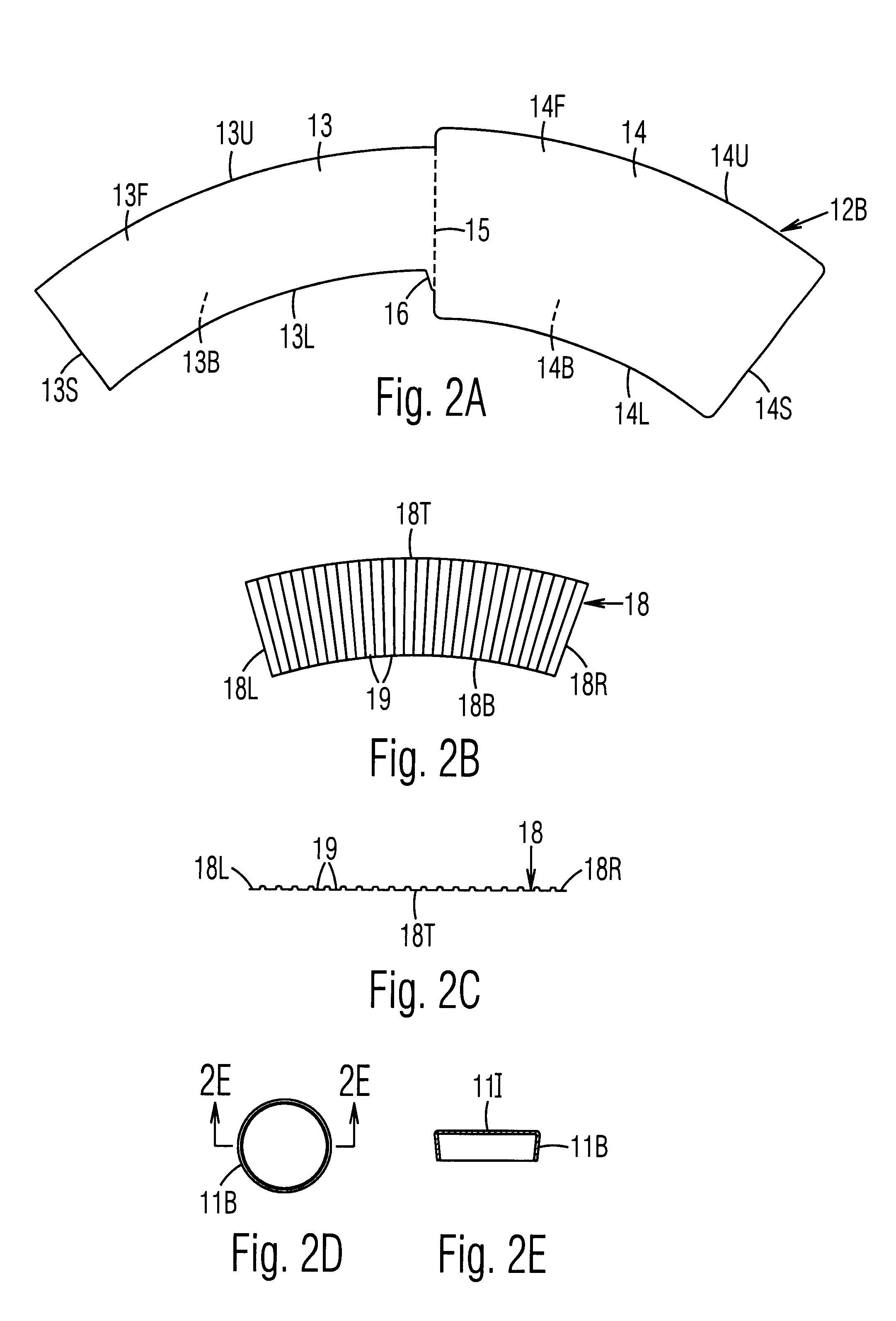

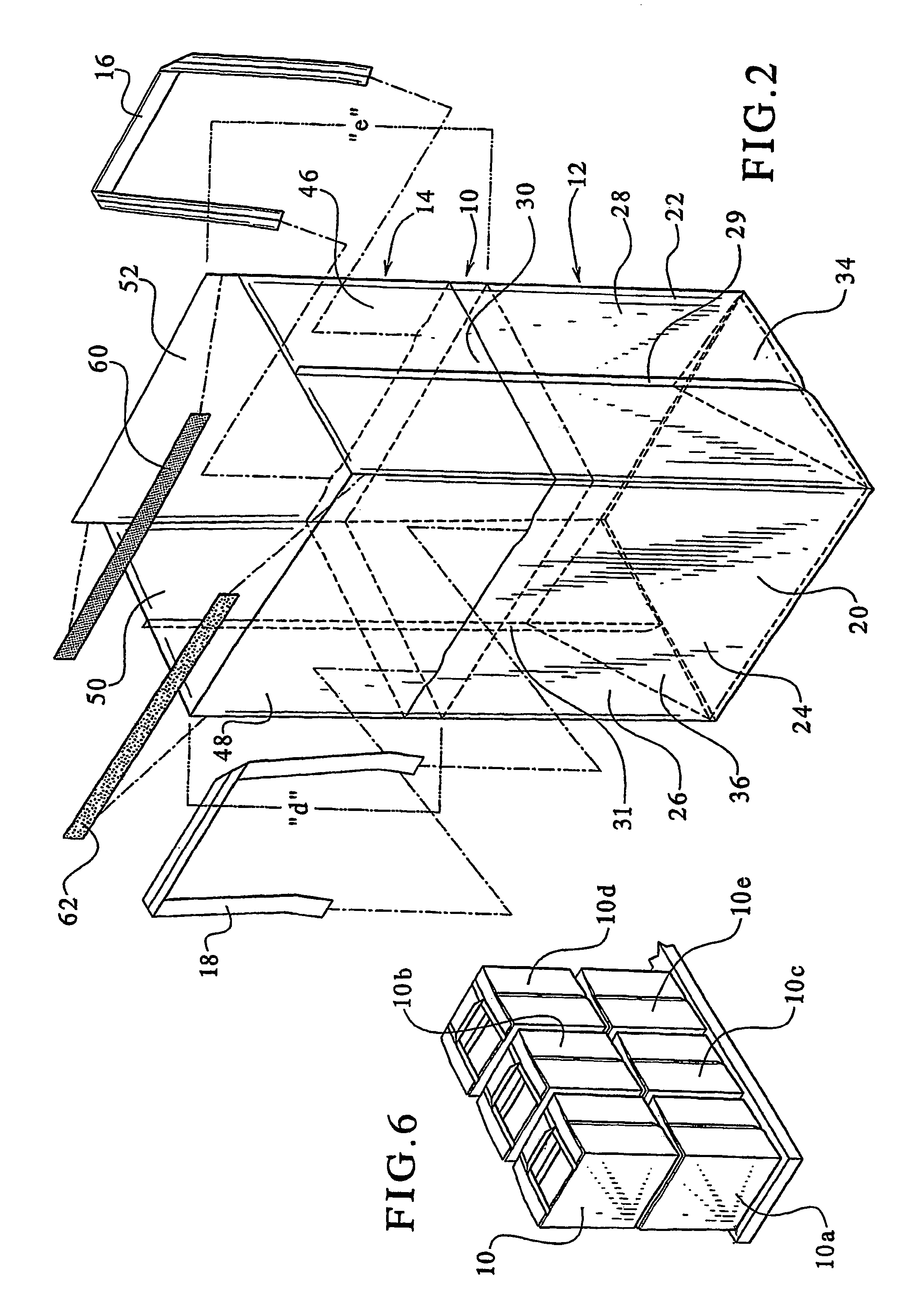

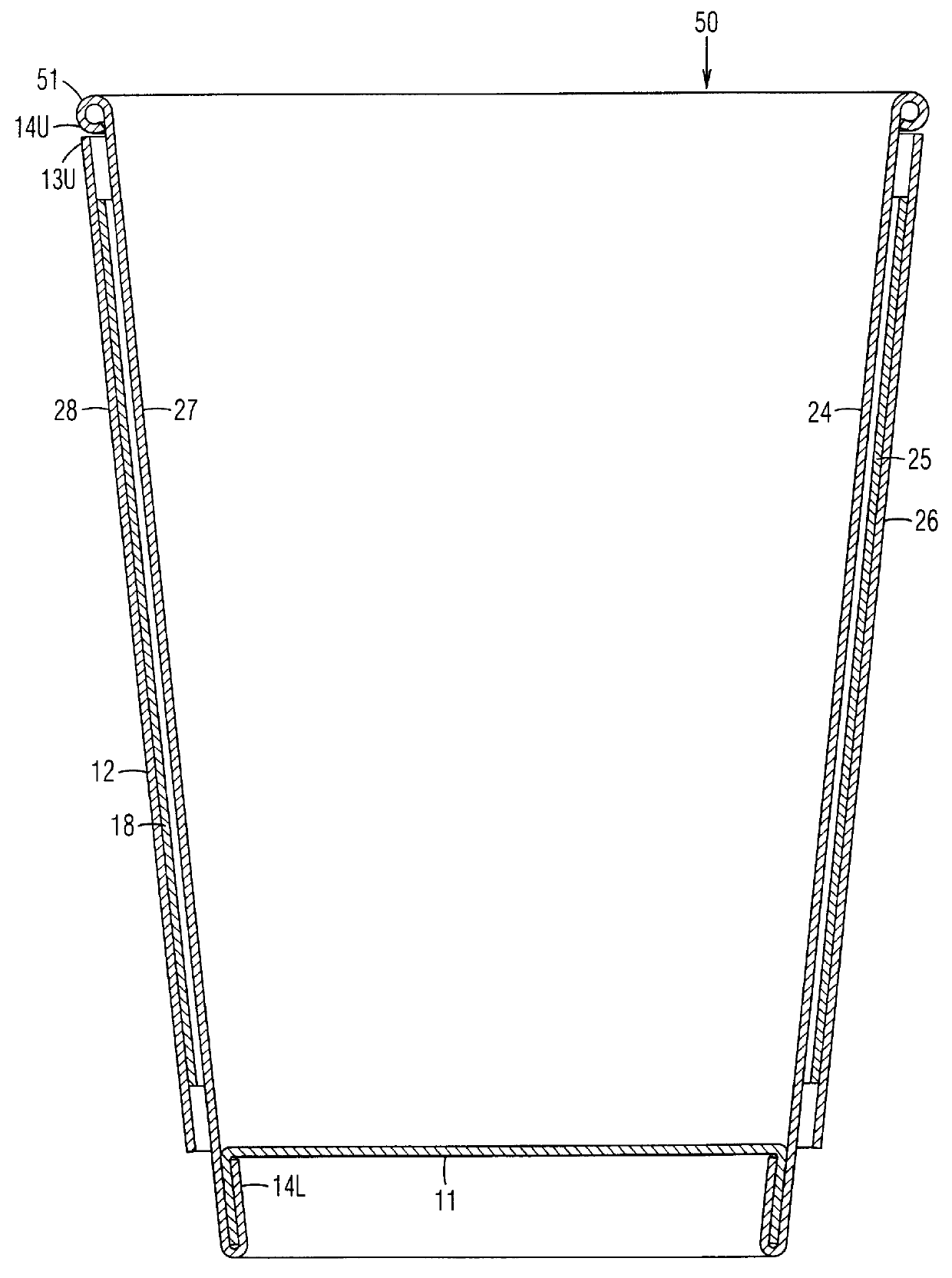

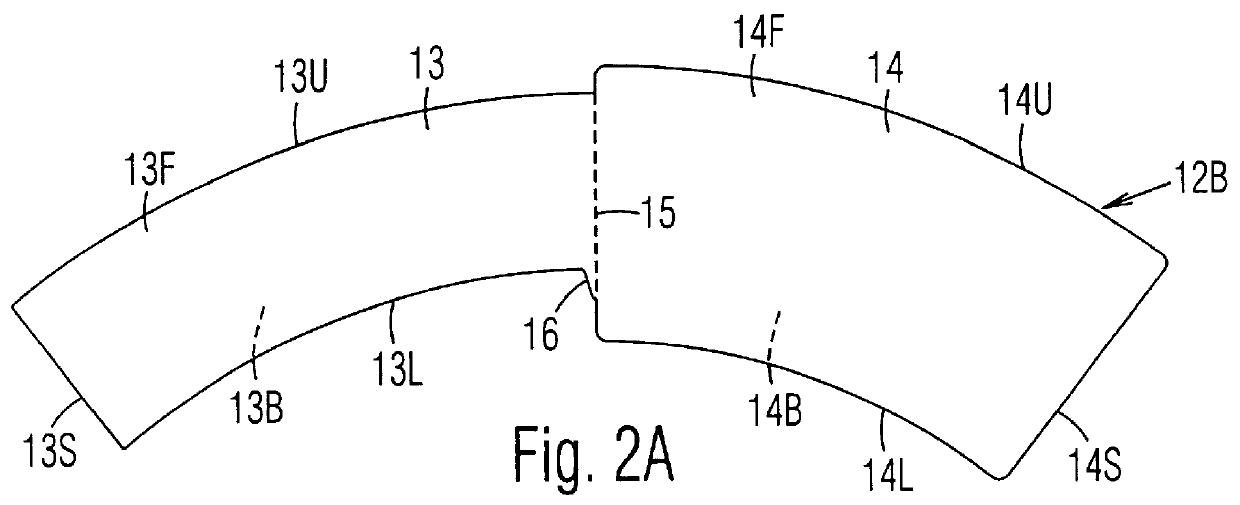

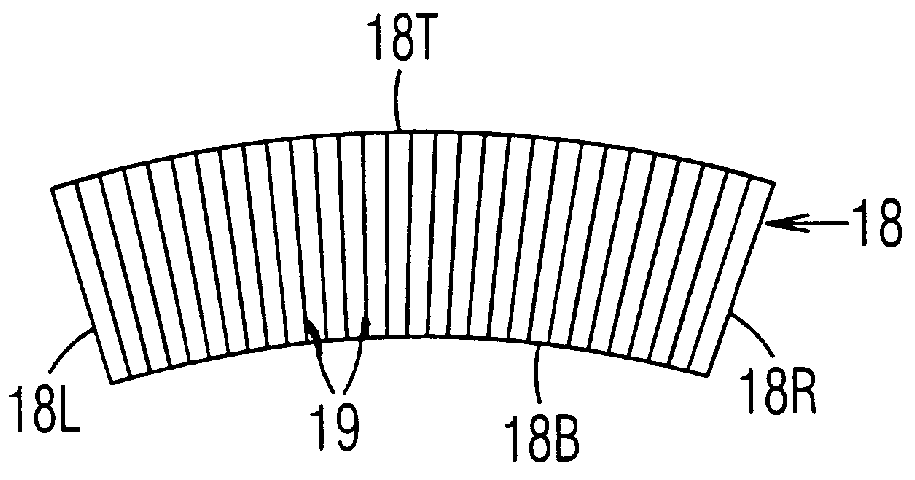

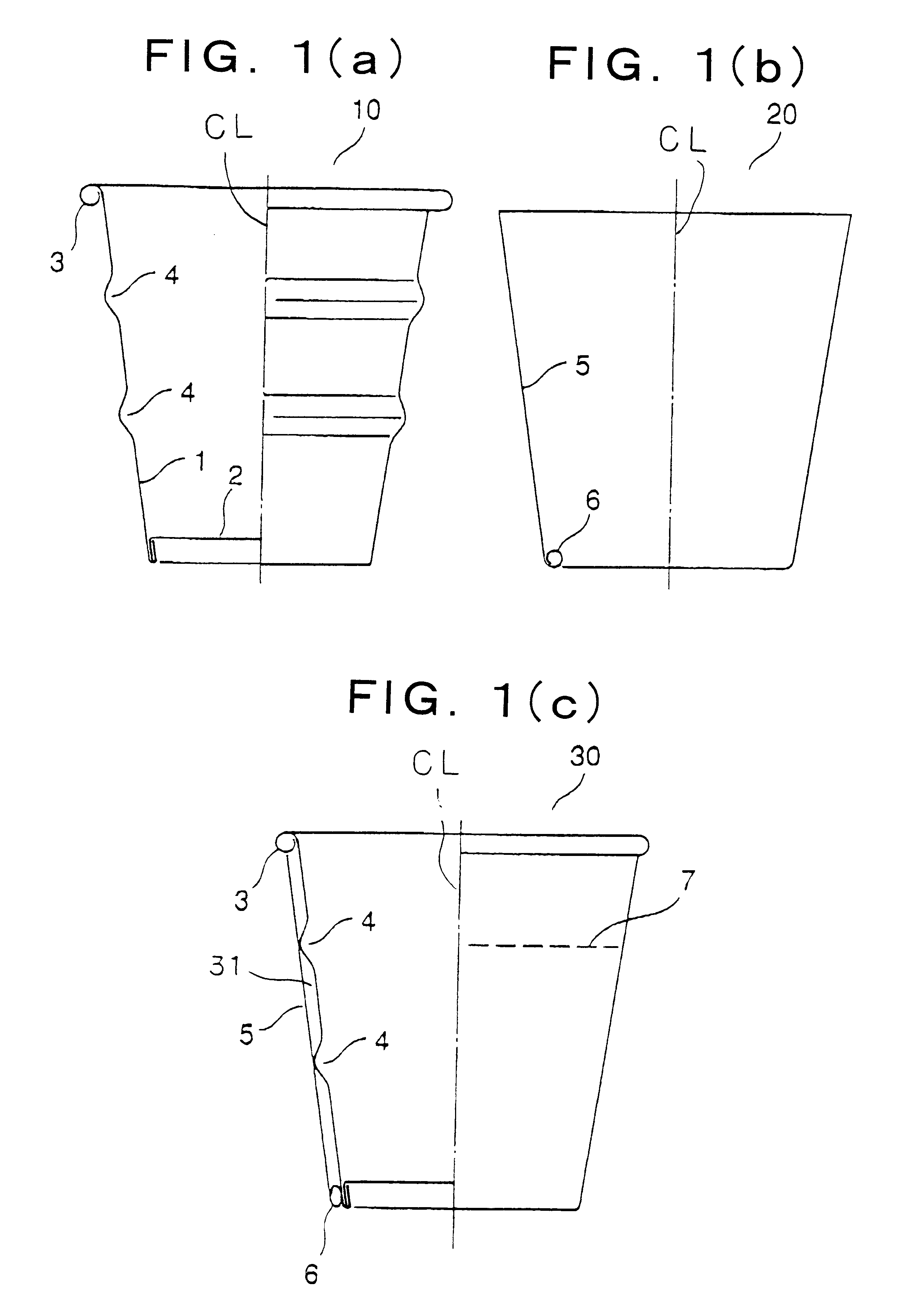

An insulating cup or container (50) and a method of manufacturing it comprises (first embodiment) providing a sidewall blank (12B) having two sections separated by a fold score (15), and a separate insulating sheet (18) (corrugated, ribbed, embossed, foamed, perforated, etc.) which is adhesively fastened to one of the sections. The blank is folded in half along the fold score, to form a three-layered assembly with the insulating sheet in the middle. To reduce the thickness of the seam, the blank is thinned in the area adjacent a fold score prior to folding. The assembly is wrapped around a mandrel to bring the outer edges together at a side seam (22S) to form a sidewall 12. The side seam is sealed, the bottom is added, and the rim is formed. In a second embodiment, the insulating layer can be a coating on one or both of the sections of the two-section starting blank. In a third embodiment, the insulating section (40) is integral with, and extends from, one edge of the starting blank. It is folded over first to form the middle layer of the wrappable assembly. The width of the seam is reduced while being reinforced at the top by using edge tabs, thereby providing a rounder cup and one which is less susceptible to top leakage due to an unsealed top curl. One tab extends at the fold line from the top edge of one section, which is shorter, to the top edge of the adjacent and higher section. A second tab extends out from the top of the side edge of the higher section so that it overlaps and seals the other tab when the cup is formed.

Owner:GPCP IP HLDG LLC

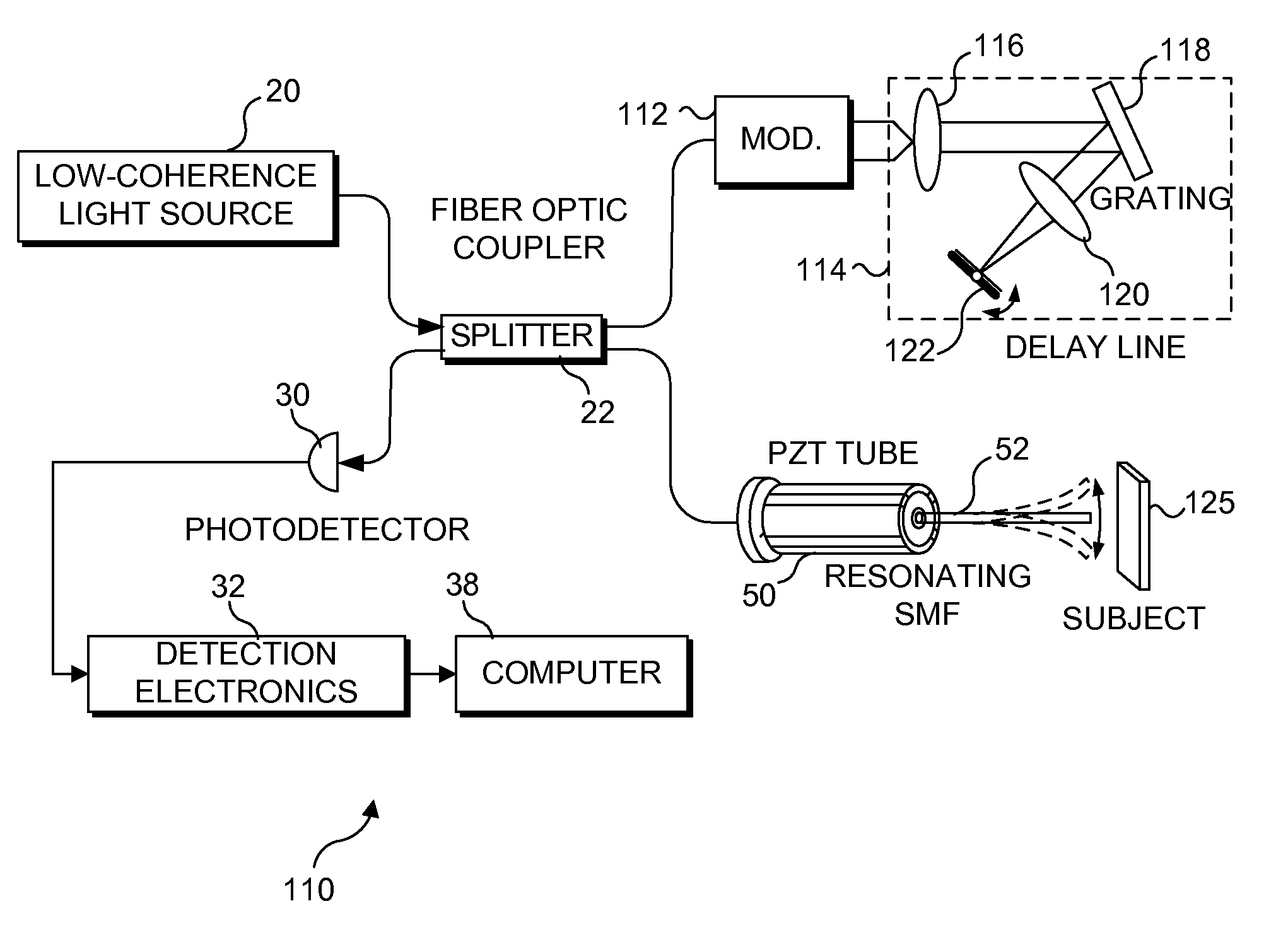

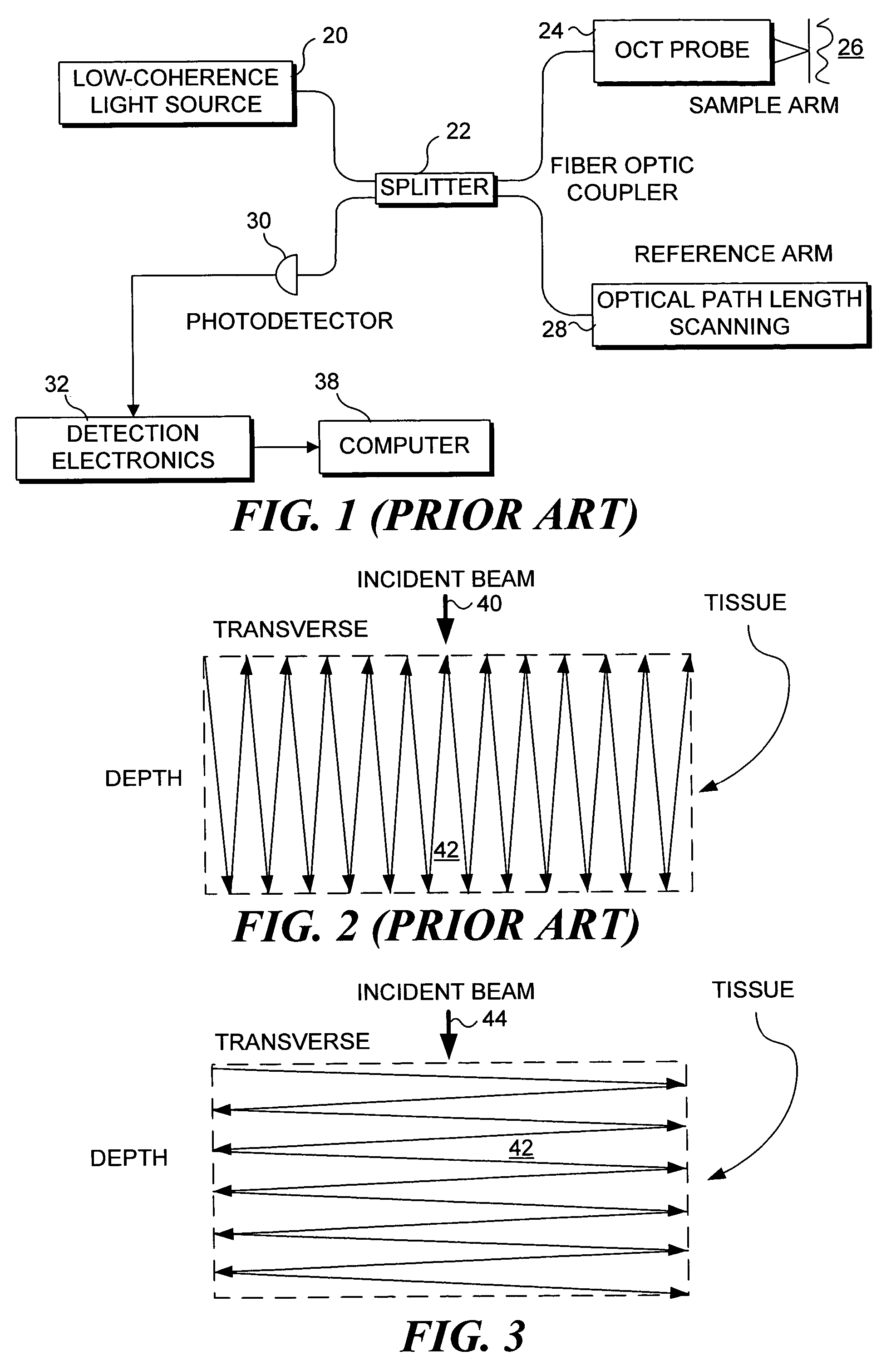

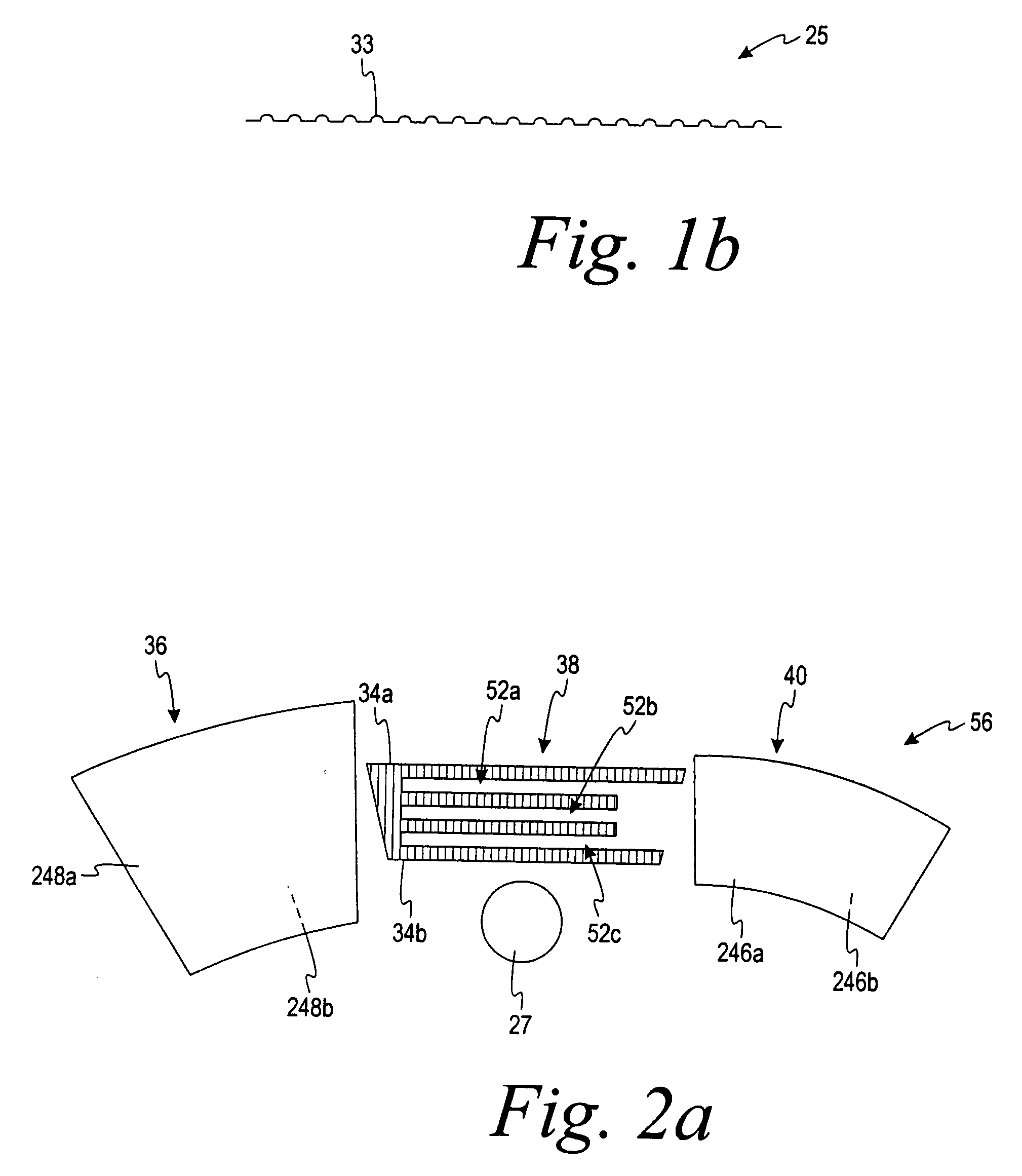

Optical fiber scanner for performing multimodal optical imaging

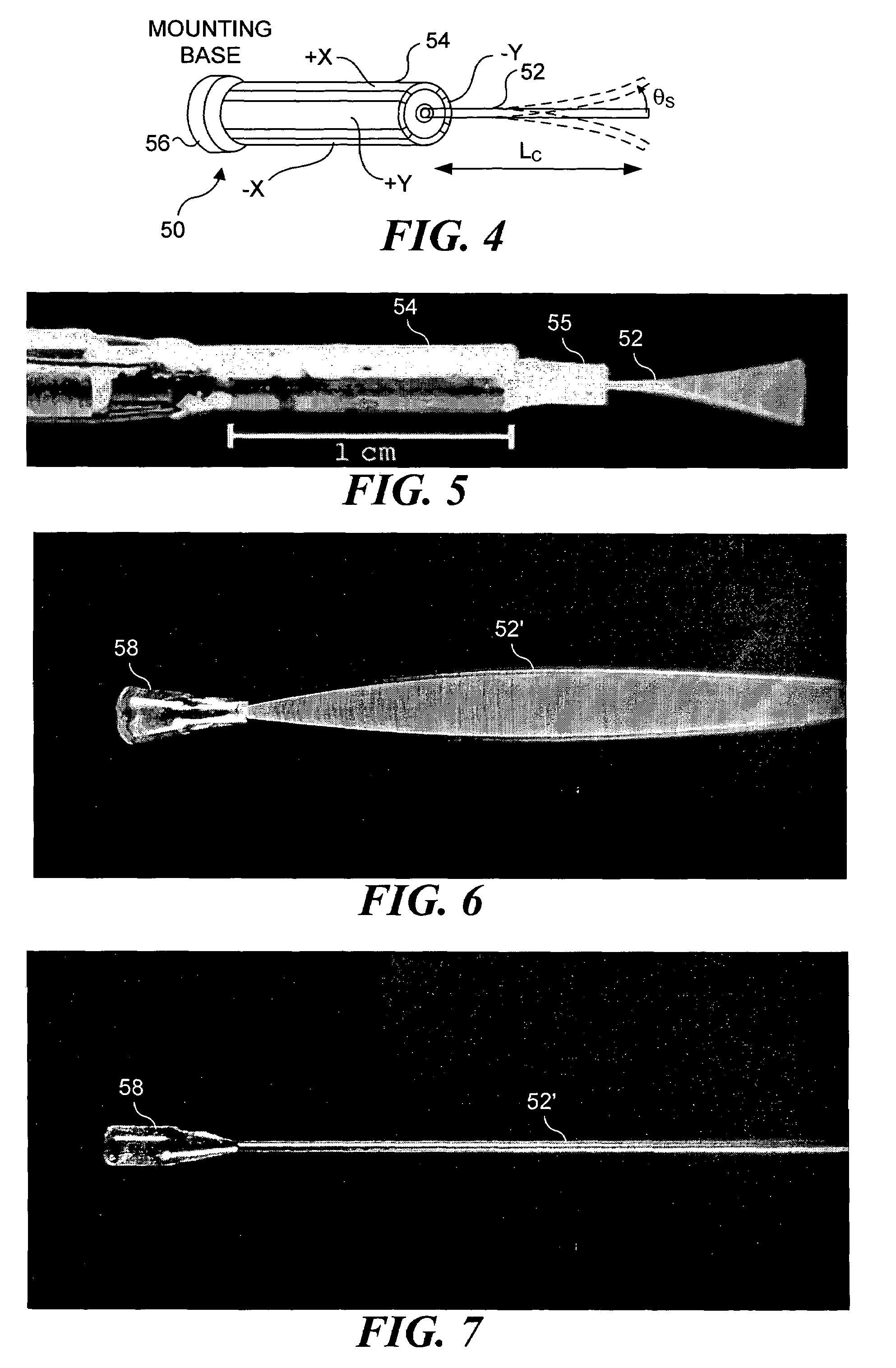

InactiveUS7616986B2Focus shiftReduce back reflectionBoxes/cartons making machineryBox making operationsActuatorFrequency modulation

An optical fiber scanner is used for multiphoton excitation imaging, optical coherence tomography, or for confocal imaging in which transverse scans are carried out at a plurality of successively different depths within tissue. The optical fiber scanner is implemented as a scanning endoscope using a cantilevered optical fiber that is driven into resonance or near resonance by an actuator. The actuator is energized with drive signals that cause the optical fiber to scan in a desired pattern at successively different depths as the depth of the focal point is changed. Various techniques can be employed for depth focus tracking at a rate that is much slower than the transverse scanning carried out by the vibrating optical fiber. The optical fiber scanner can be used for confocal imaging, multiphoton fluorescence imaging, nonlinear harmonic generation imaging, or in an OCT system that includes a phase or frequency modulator and delay line.

Owner:UNIV OF WASHINGTON

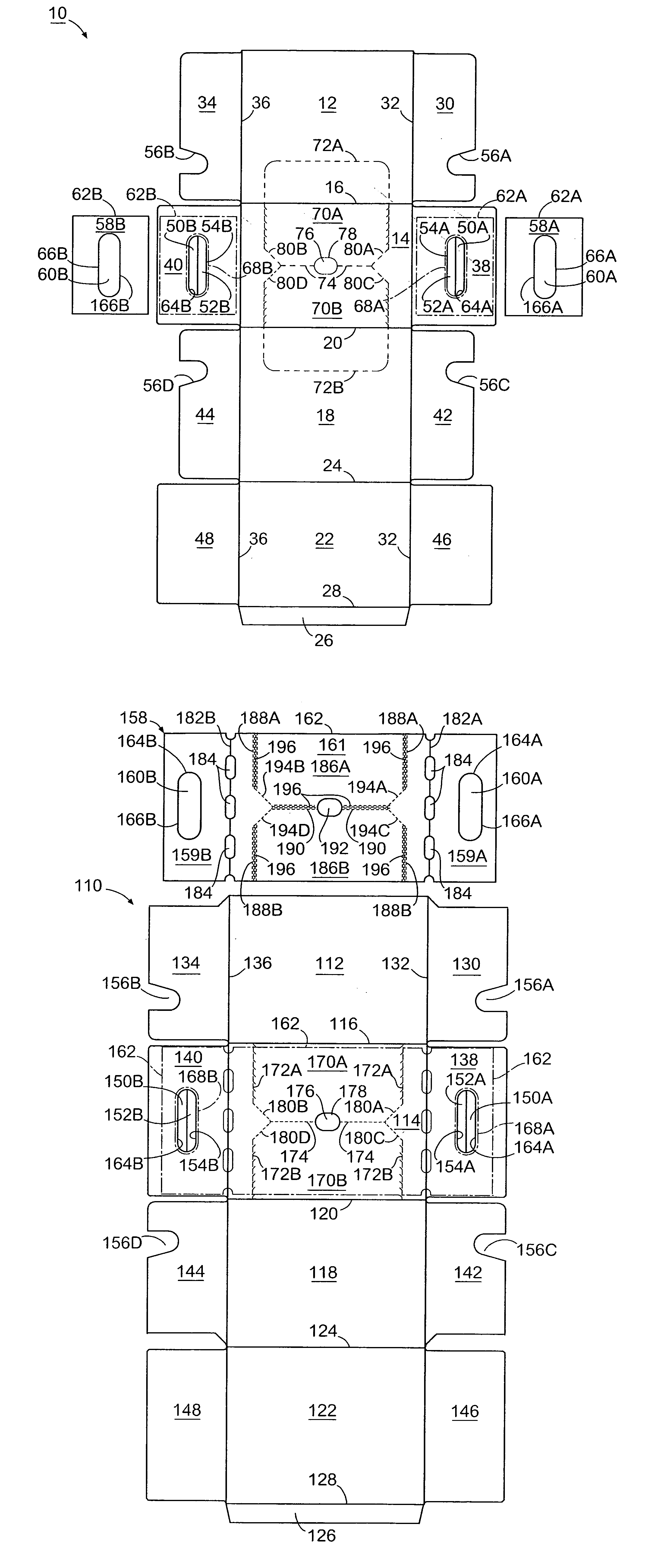

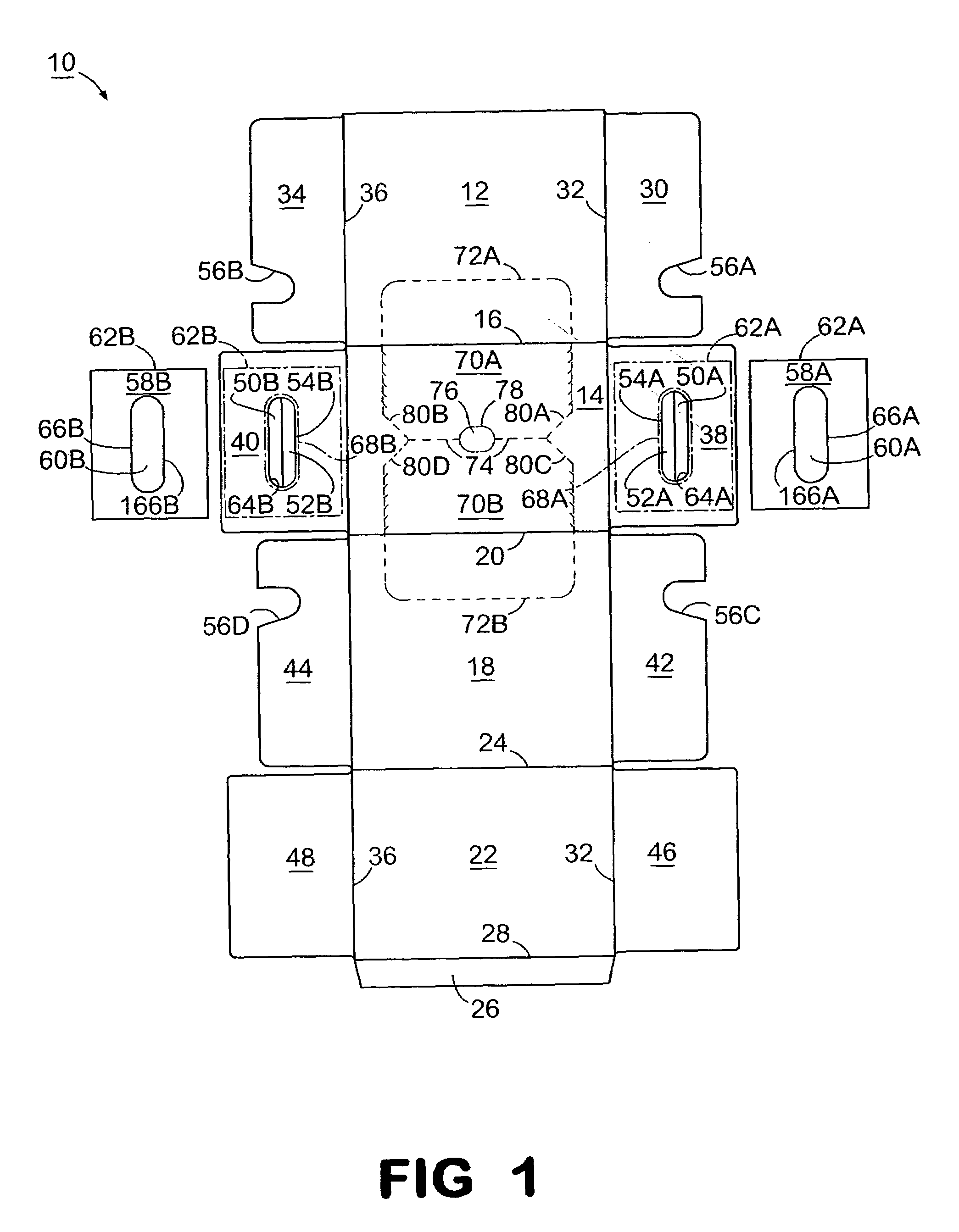

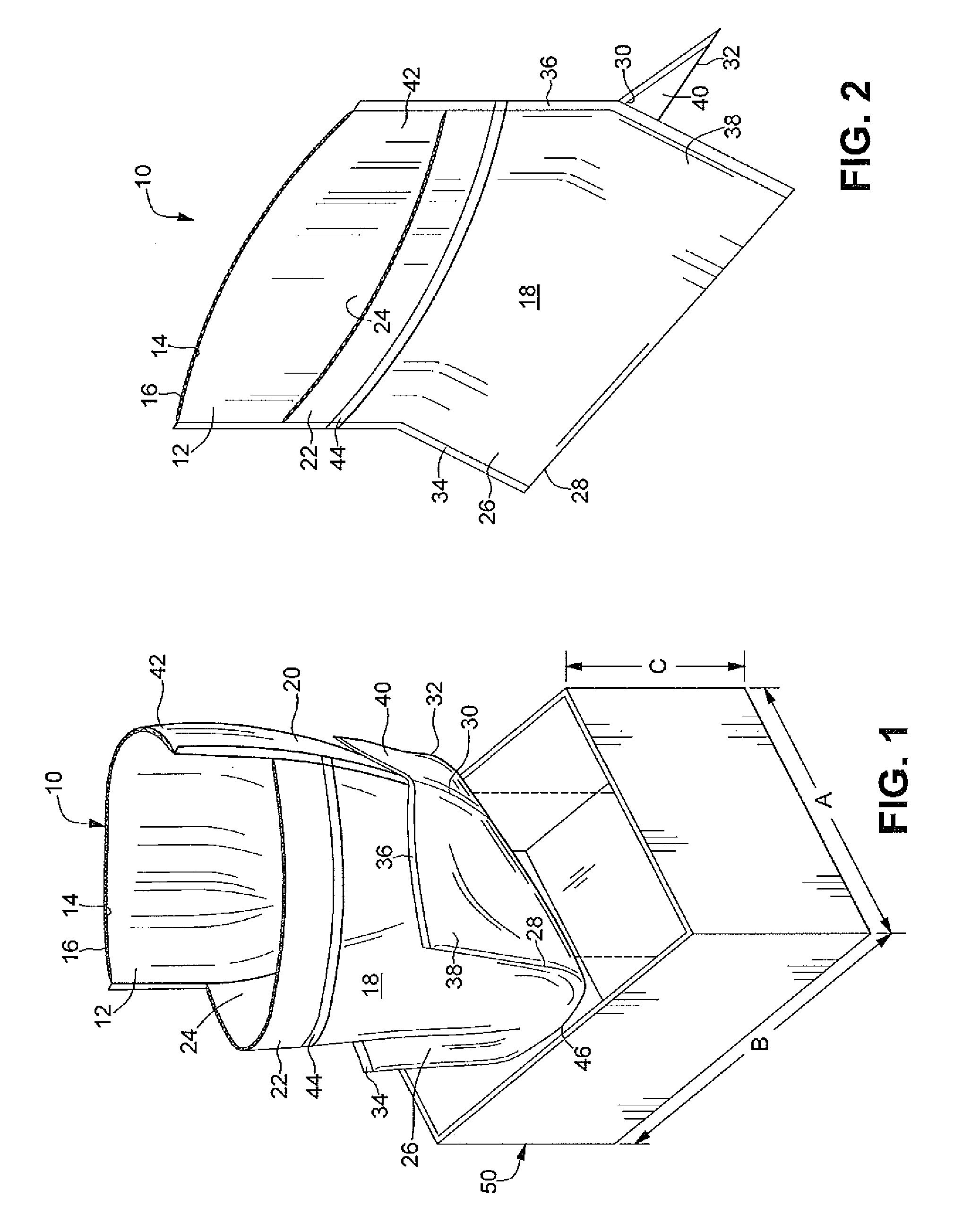

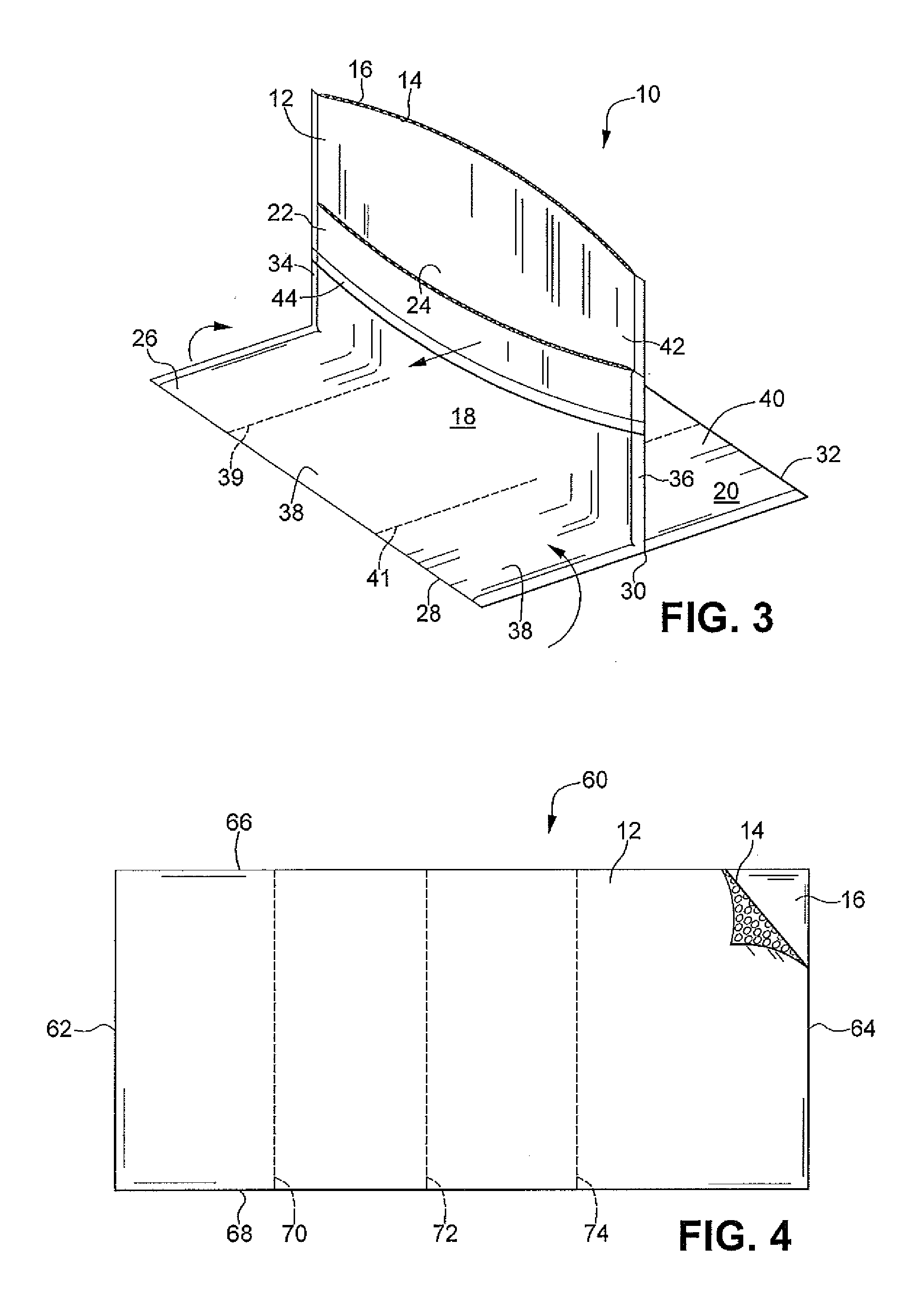

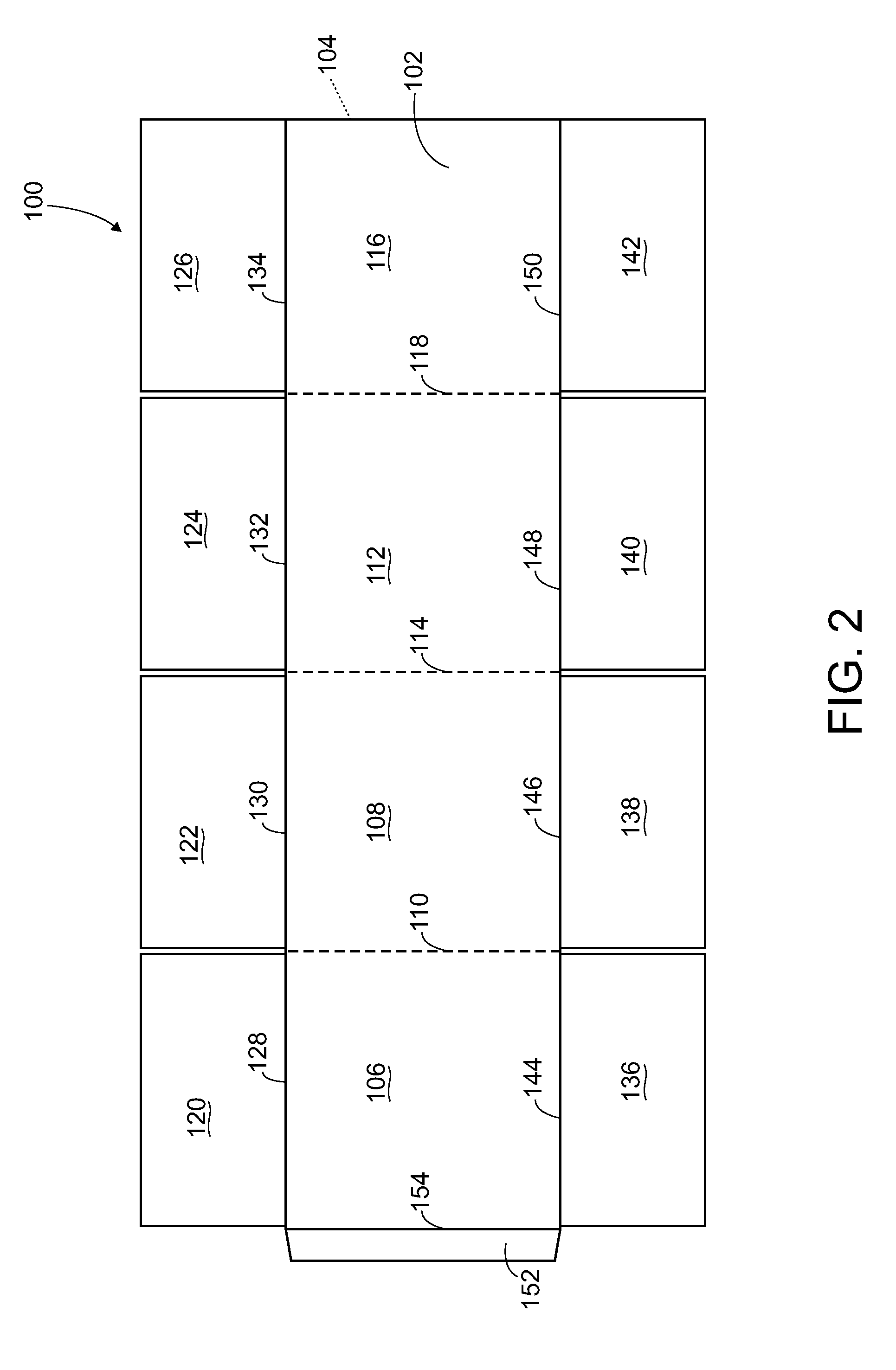

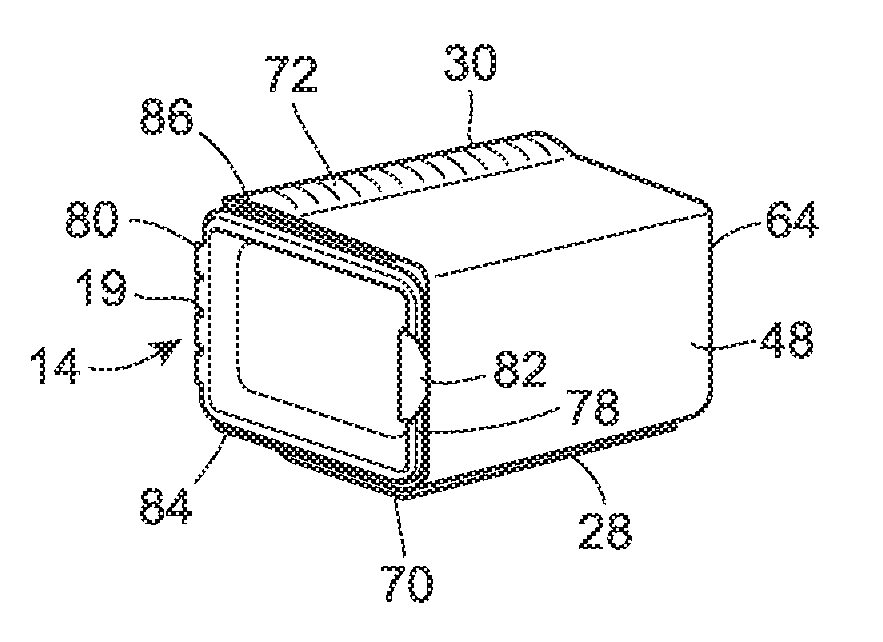

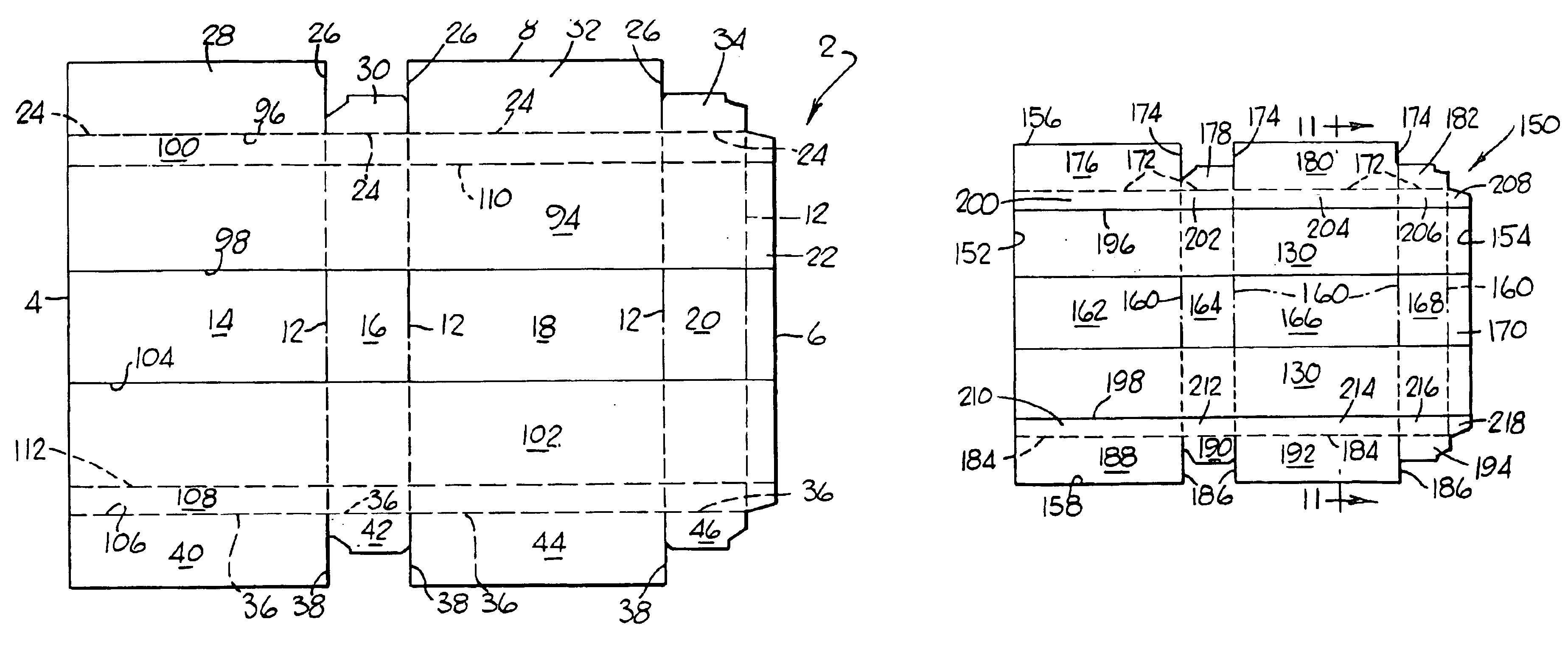

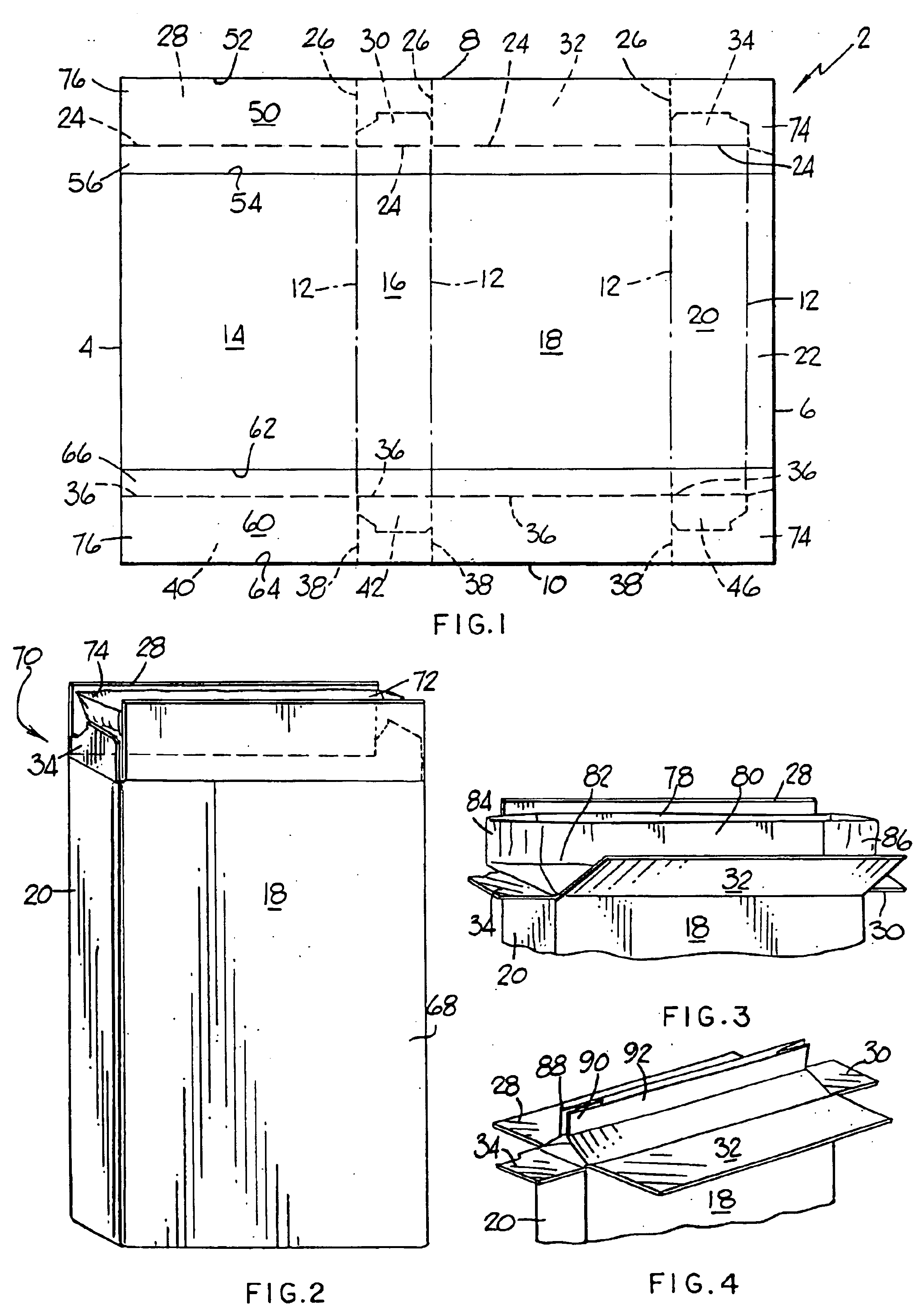

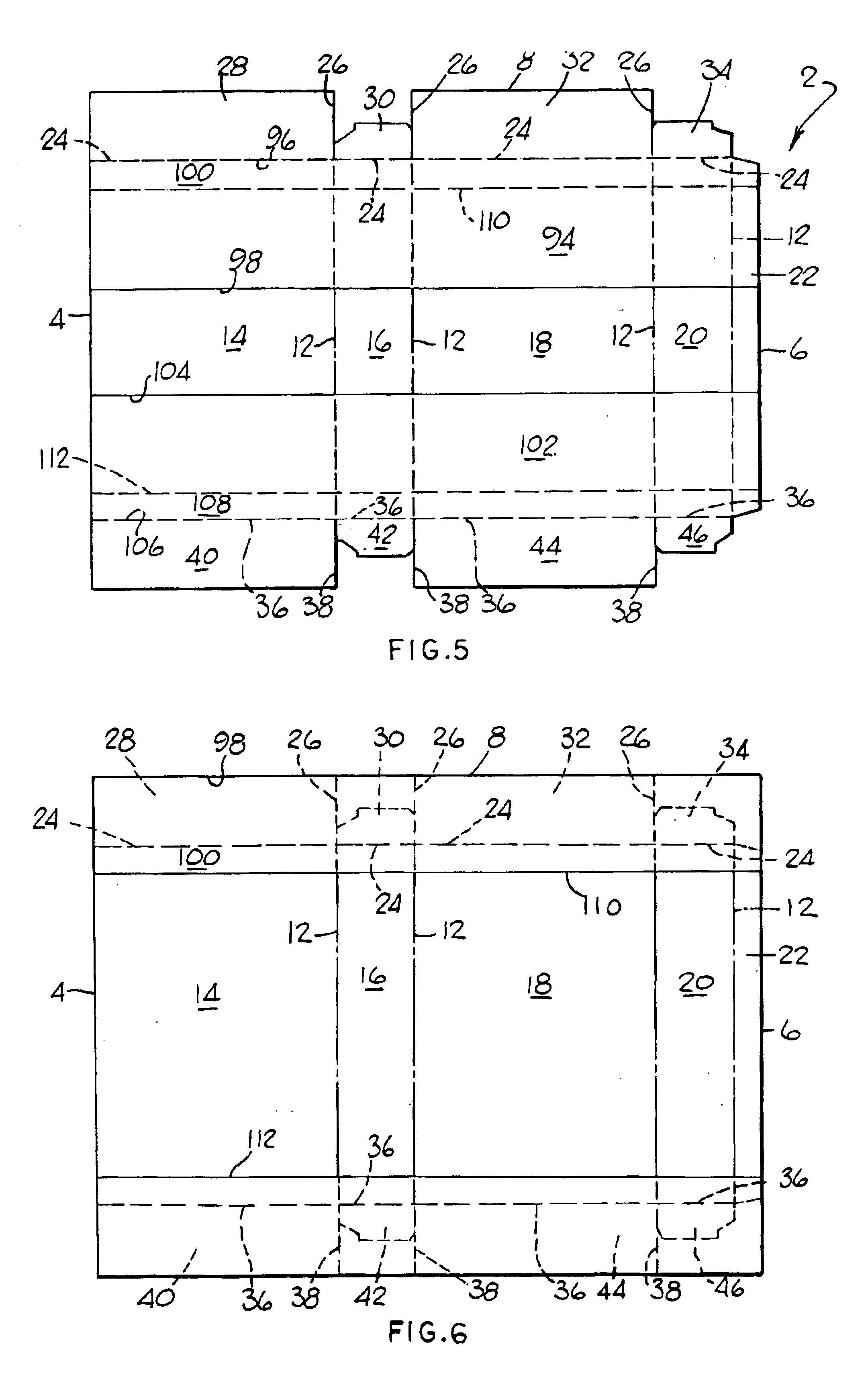

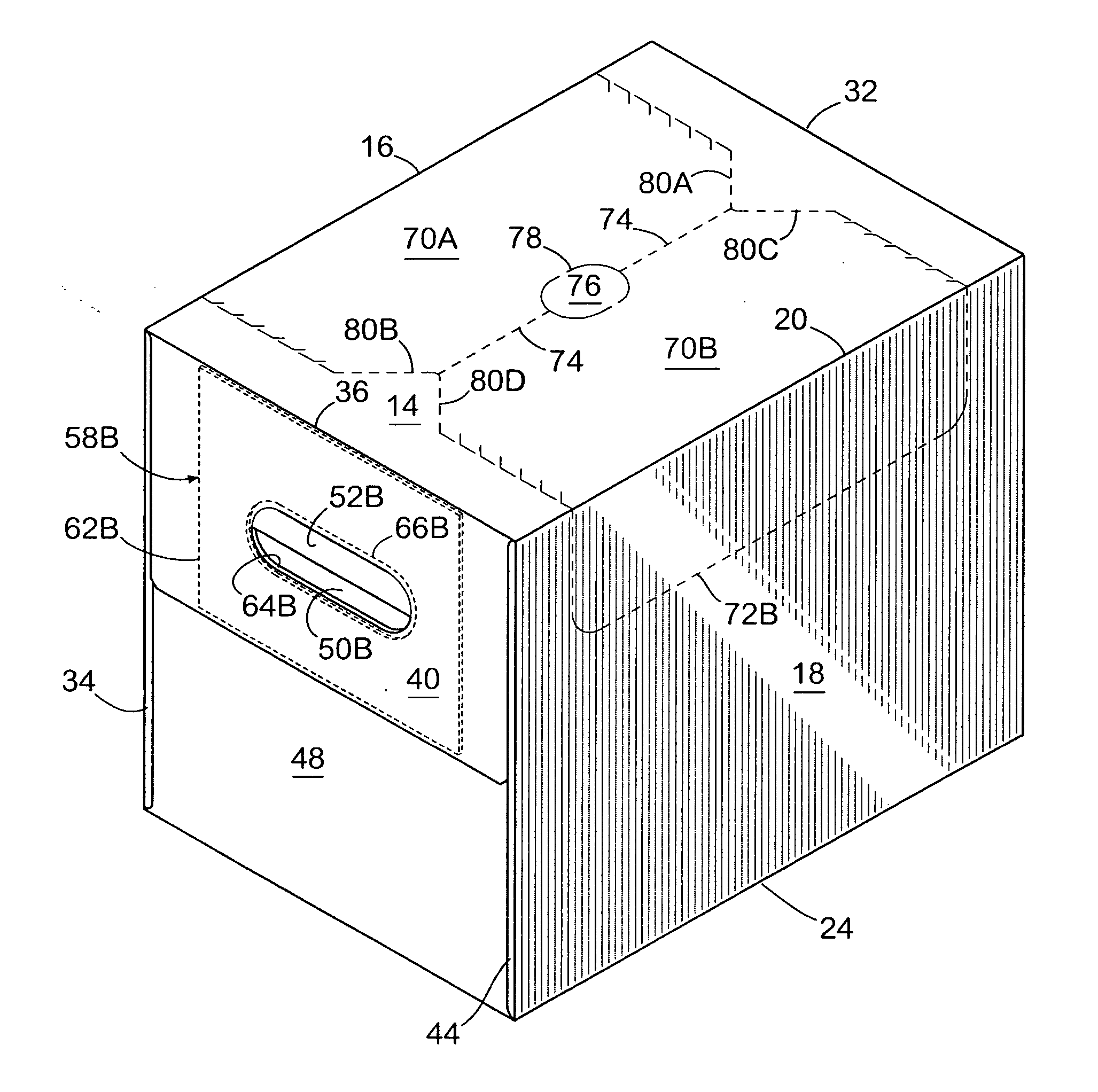

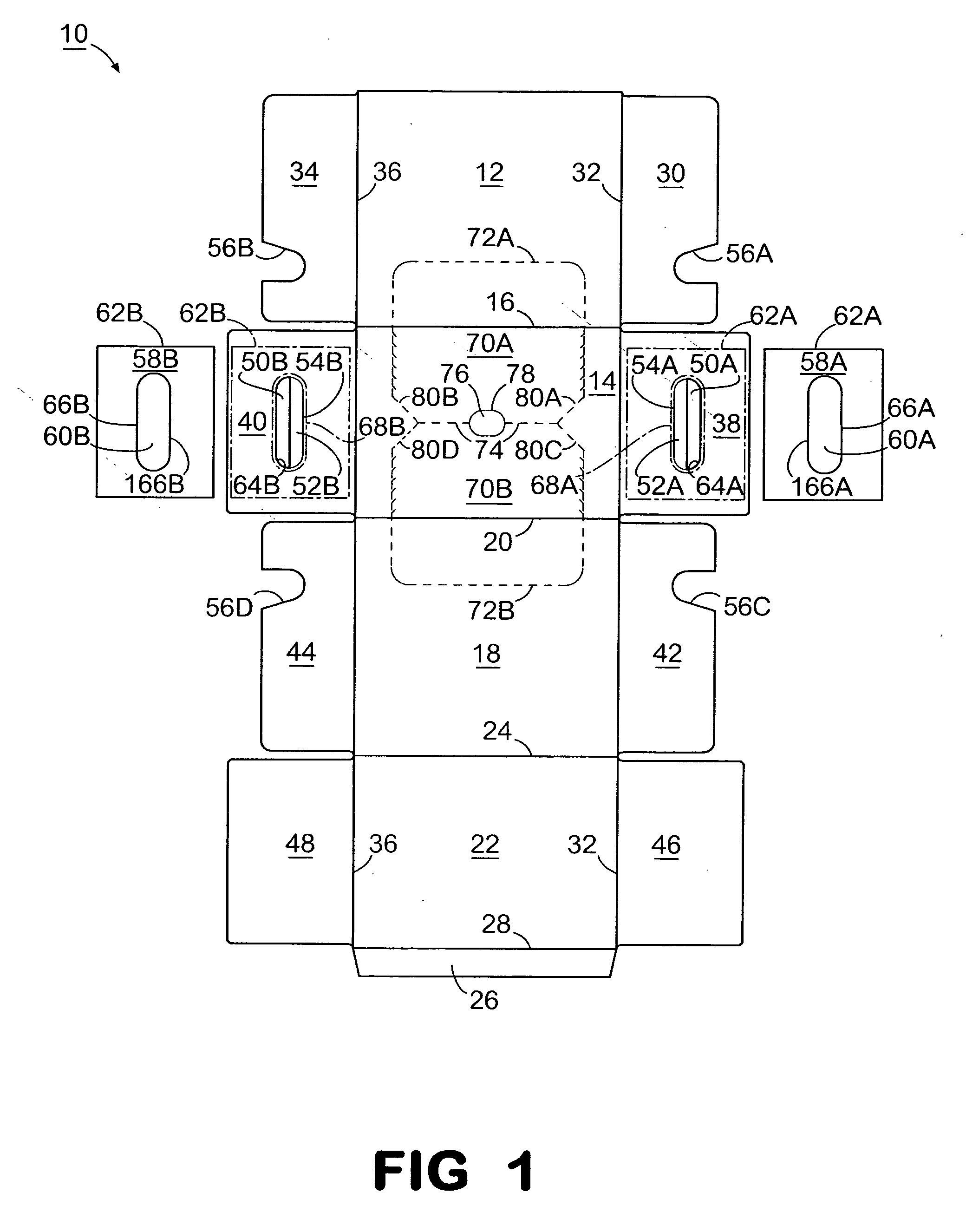

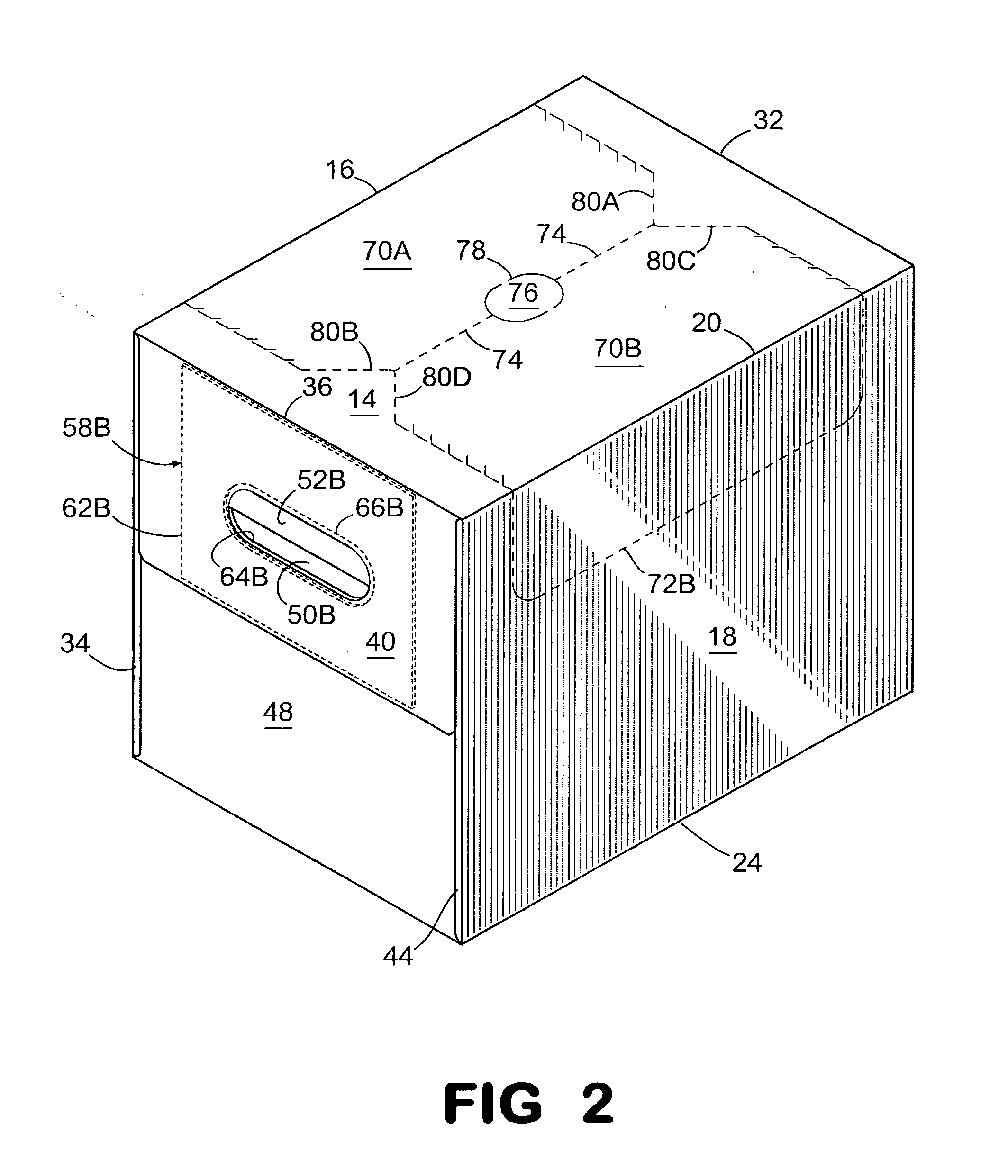

Handle and top handle reinforcement for a paperboard carton

A fully enclosed carton for carrying heavy loads with a reinforcement insert for the handle apertures located in the top end flaps of the carton. The paperboard reinforcing insert may be extended as a bridge across the top panel of the carton to prevent tearing of the handle apertures in the top end flaps and also tearing in the top panel of the carton when carrying a heavy load. The carton may have one or more dispensers in the top panel which may extend into an adjoining side panel. Multiple tear lines may be formed for the dispenser flap in the insert that extends across the top panel to permit easy access to the containers, such as bottles, in the carton.The paperboard reinforcing insert may have a larger aperture than the handle aperture in each top end flap to adjust for any imprecision in the alignment of the paperboard insert in forming the carton sleeve from the paperboard blank. When the paperboard insert extends across the top panel and one or more dispensers are formed in the top panel, multiple tear lines may be used to form the flaps in the insert to compensate for any imprecision in the insertion of the insert that extends across the top panel into the carton sleeve when it is being formed.

Owner:GRAPHIC PACKAGING INT

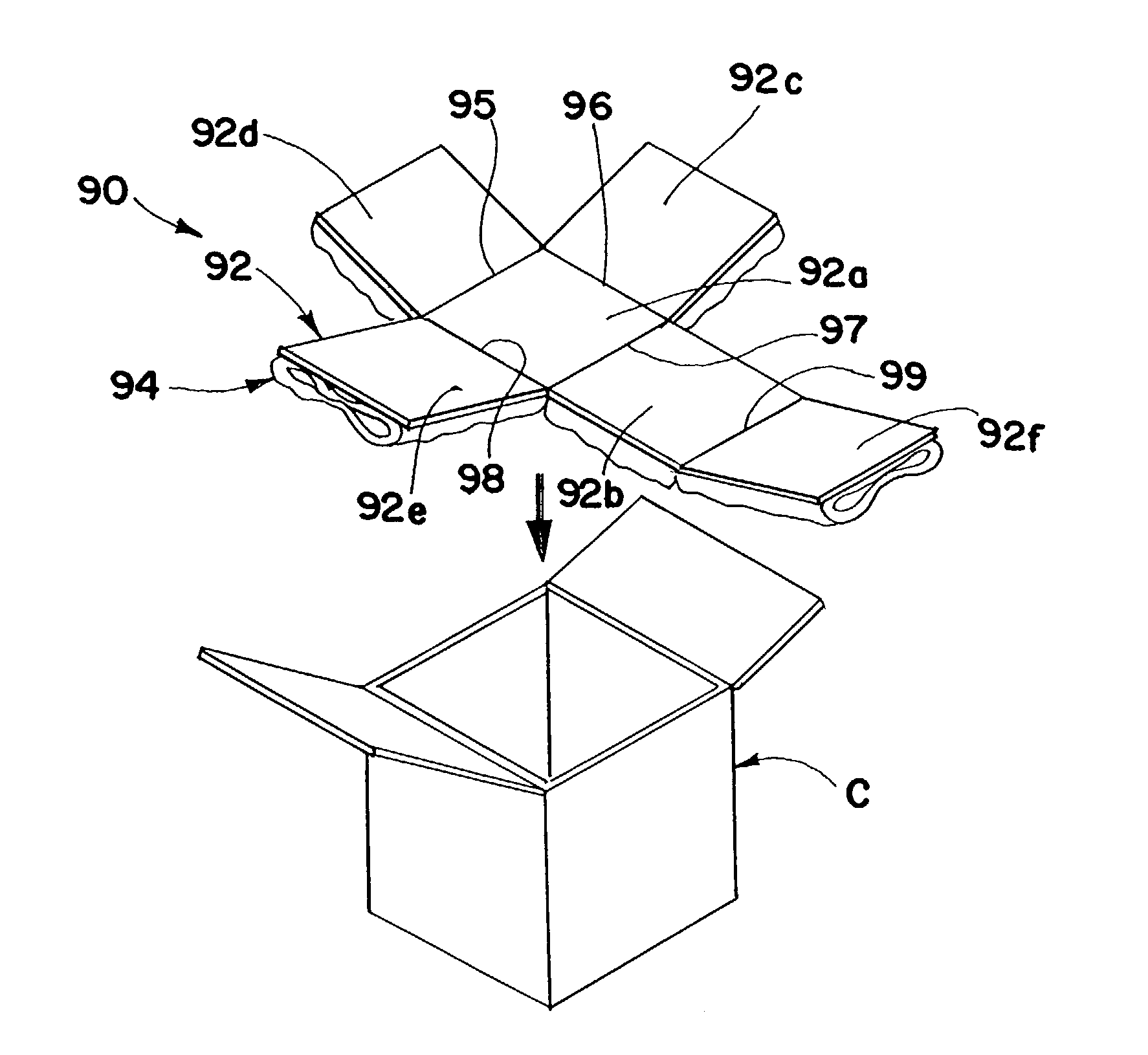

Container insert apparatus and method

InactiveUS20100284634A1Reduce laborLow costEnvelopes/bags making machineryWrappersInterior spaceEngineering

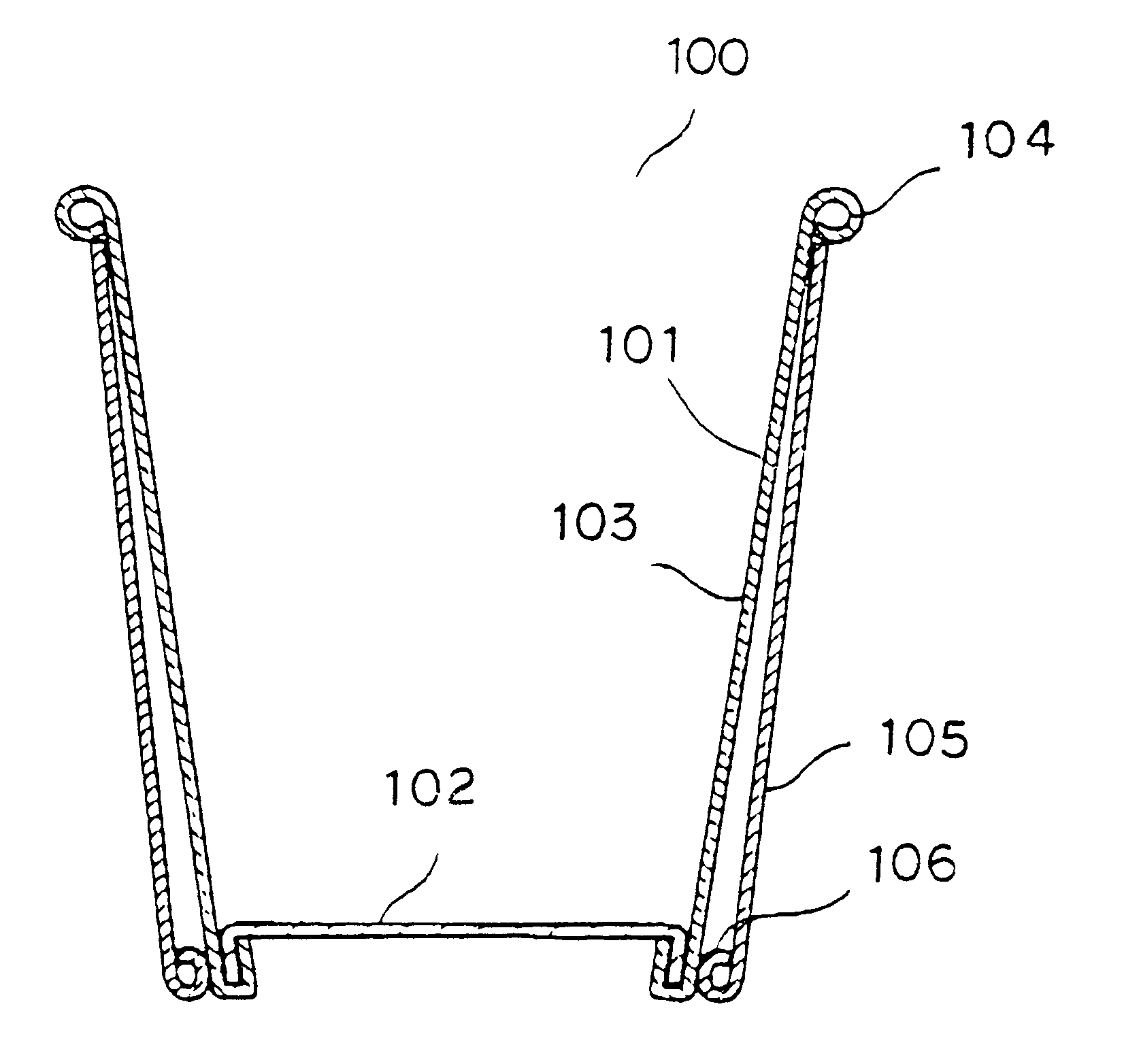

A container insert, and an apparatus and a method of producing the container insert. The container insert is formed as a deformable pouch adapted to be received in an interior of an associated container. The pouch has a closed lower end, an open upper end, and spaced apart sealed edges. The lower end of the pouch includes two leg portions. The pouch is manipulatable to generally conform to the interior of the contained and form a hollow interior space therein for receiving an object and providing a lining for the interior of the container. The apparatus and the method for producing the insert provides for a substantially automatic and continuous production of the insert from a roll of material.

Owner:CUTTING EDGE CONVERTED PROD

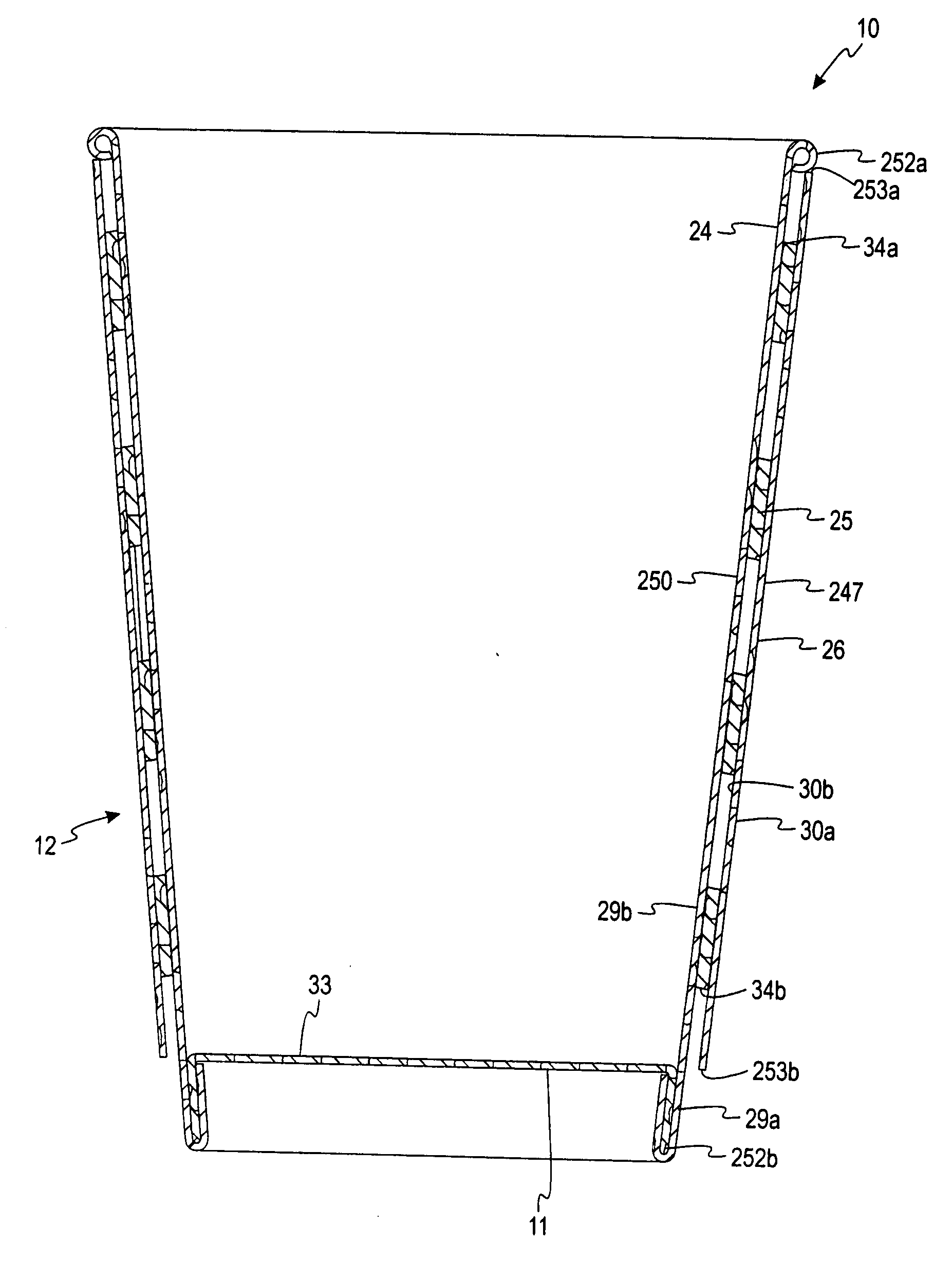

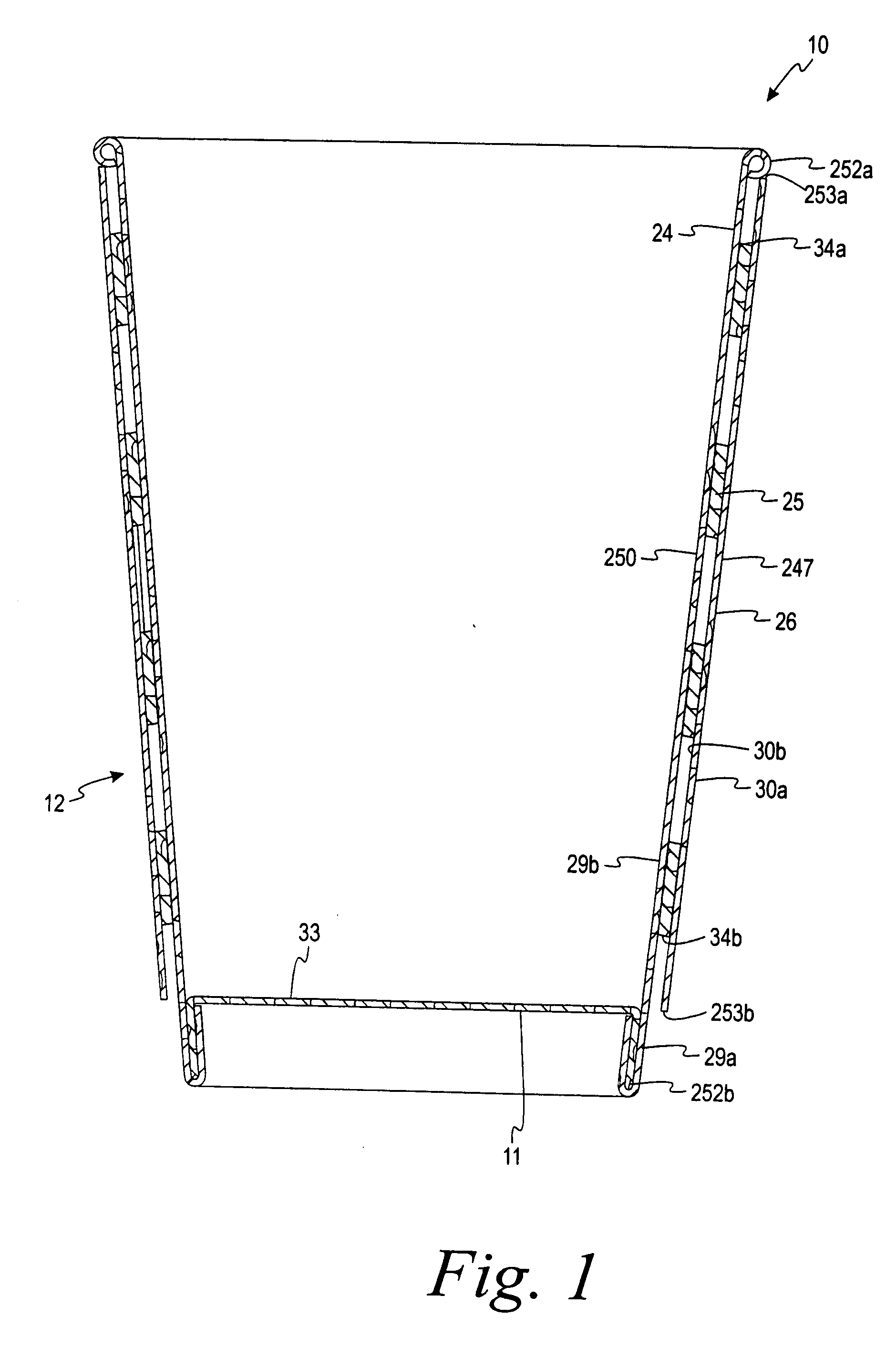

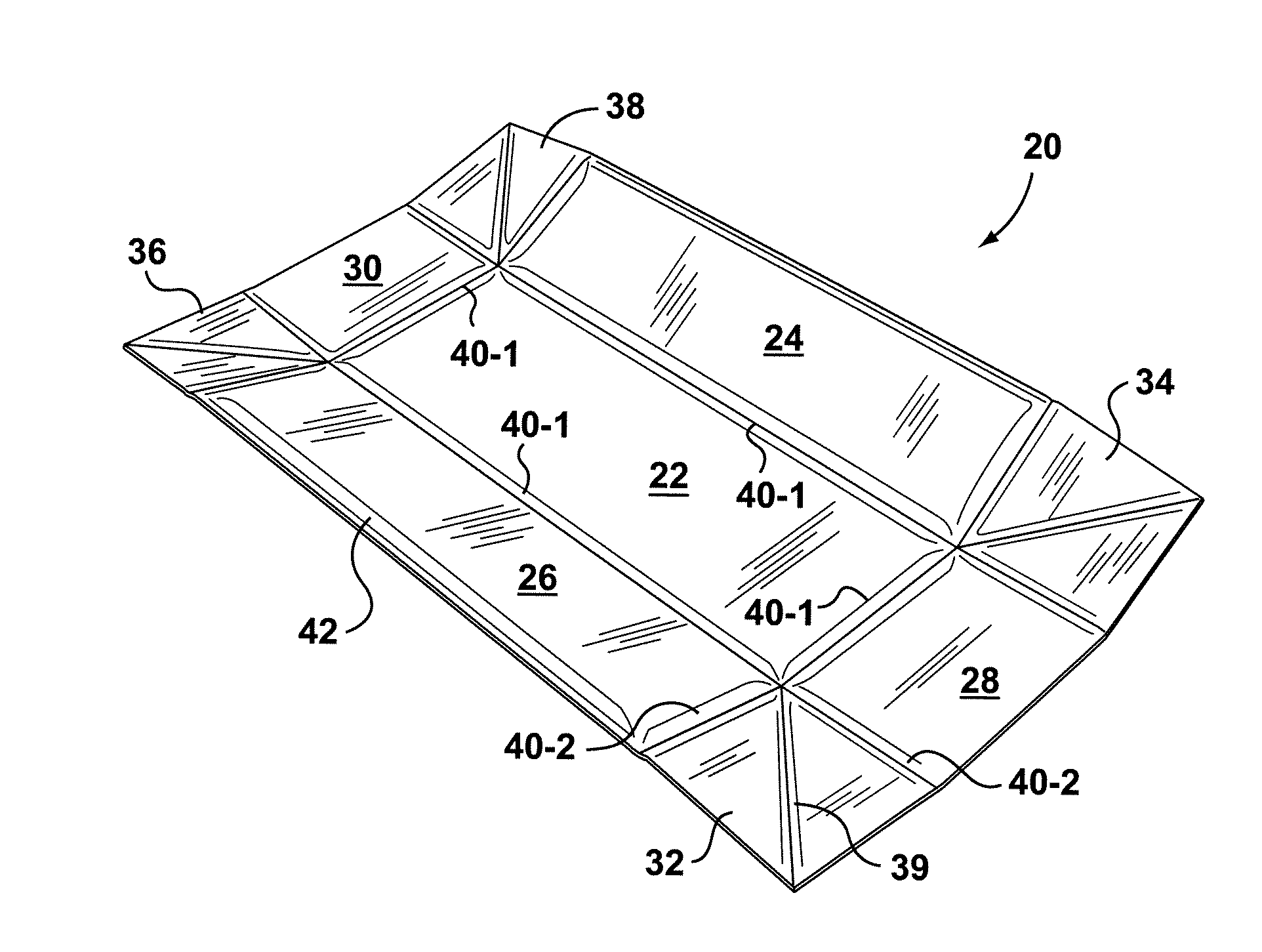

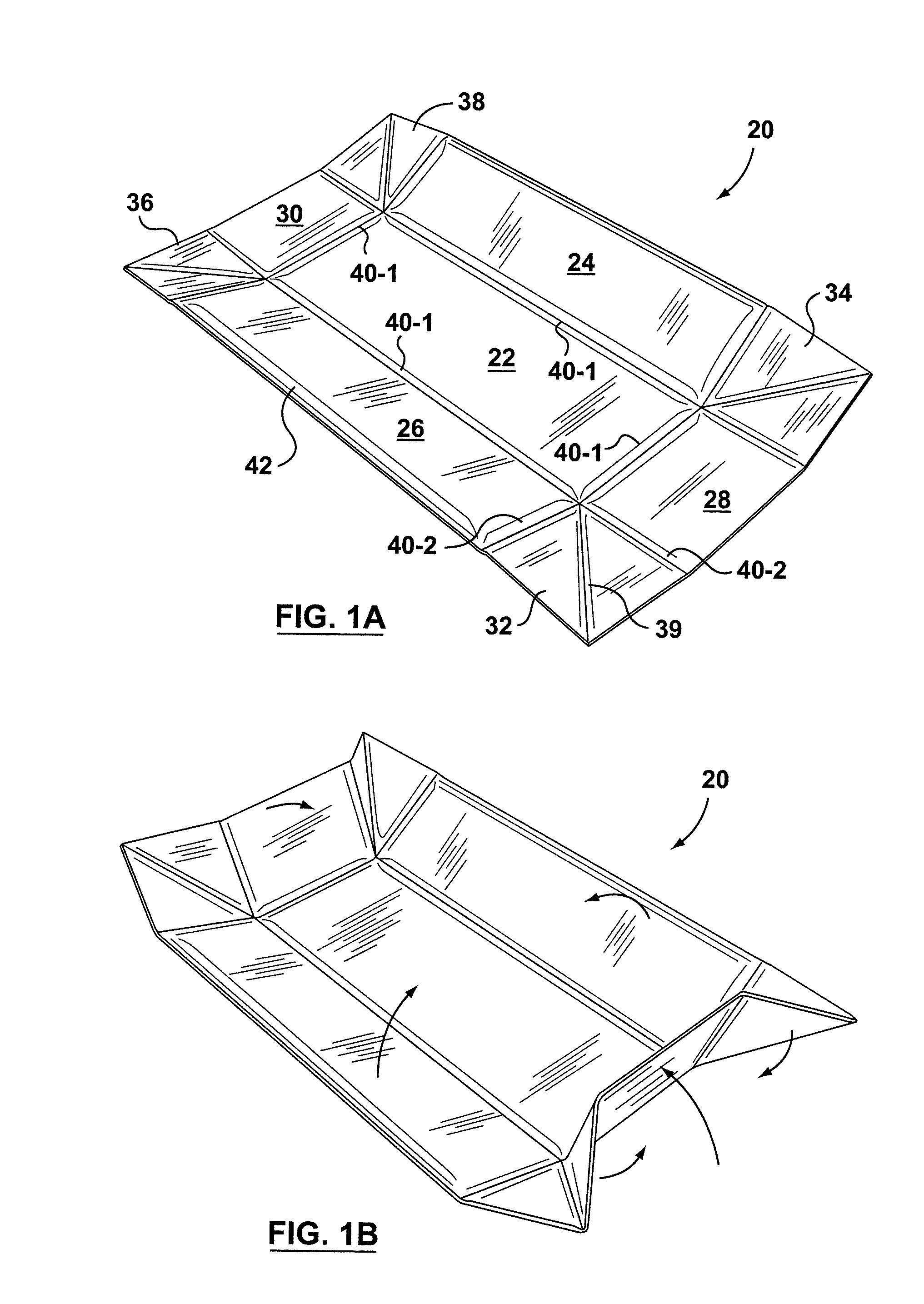

Flexible container having flat walls

InactiveUS7207716B2Improve stabilitySimple methodEnvelopes/bags making machineryBoxes/cartons making machineryPlastic materialsFlat panel

Owner:NESTEC SA

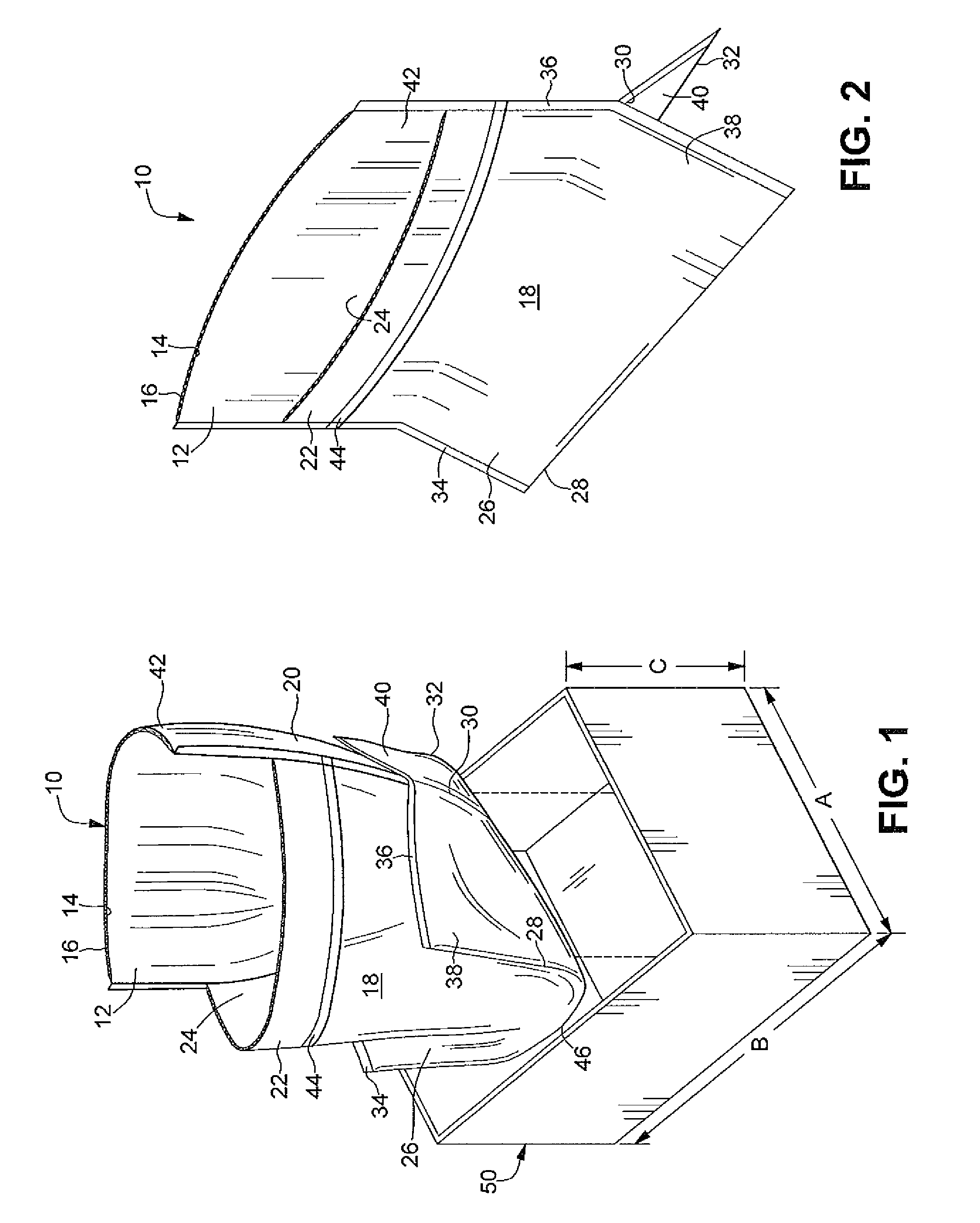

Insulated cup and method of manufacture

An insulating cup or container (50) and a method of manufacturing it comprises (first embodiment) providing a sidewall blank (12B) having two sections separated by a fold score (15), and a separate insulating sheet (18)(corrugated, ribbed, embossed, foamed, perforated, etc.) which is adhesively fastened to one of the sections. Adhesive is applied to an area (21) adjacent the fold score. The blank is folded in half along the fold score, to form a three-layered assembly with the insulating sheet in the middle. The adhesive that was applied adjacent the fold score bonds the two sections together at an area (21) adjacent a fold edge (22) on the inside surfaces of the folded blank. The assembly is wrapped around a mandrel to bring the outer edges together at a sideseam (22S) to form a sidewall 12. The side seam is sealed, the bottom is added, and the rim is formed. The placement of the adhesive is critical, in that it holds the blank in its folded state and allows it to be wrapped properly at high production speeds. In a second embodiment, the insulating layer can be a coating on one or both of the sections of the two-section starting blank. In a third embodiment, the insulating section (40) can be integral with, and extend from, one edge of the starting blank. It is folded over first to form the middle layer of the wrappable assembly.

Owner:GPCP IP HLDG LLC

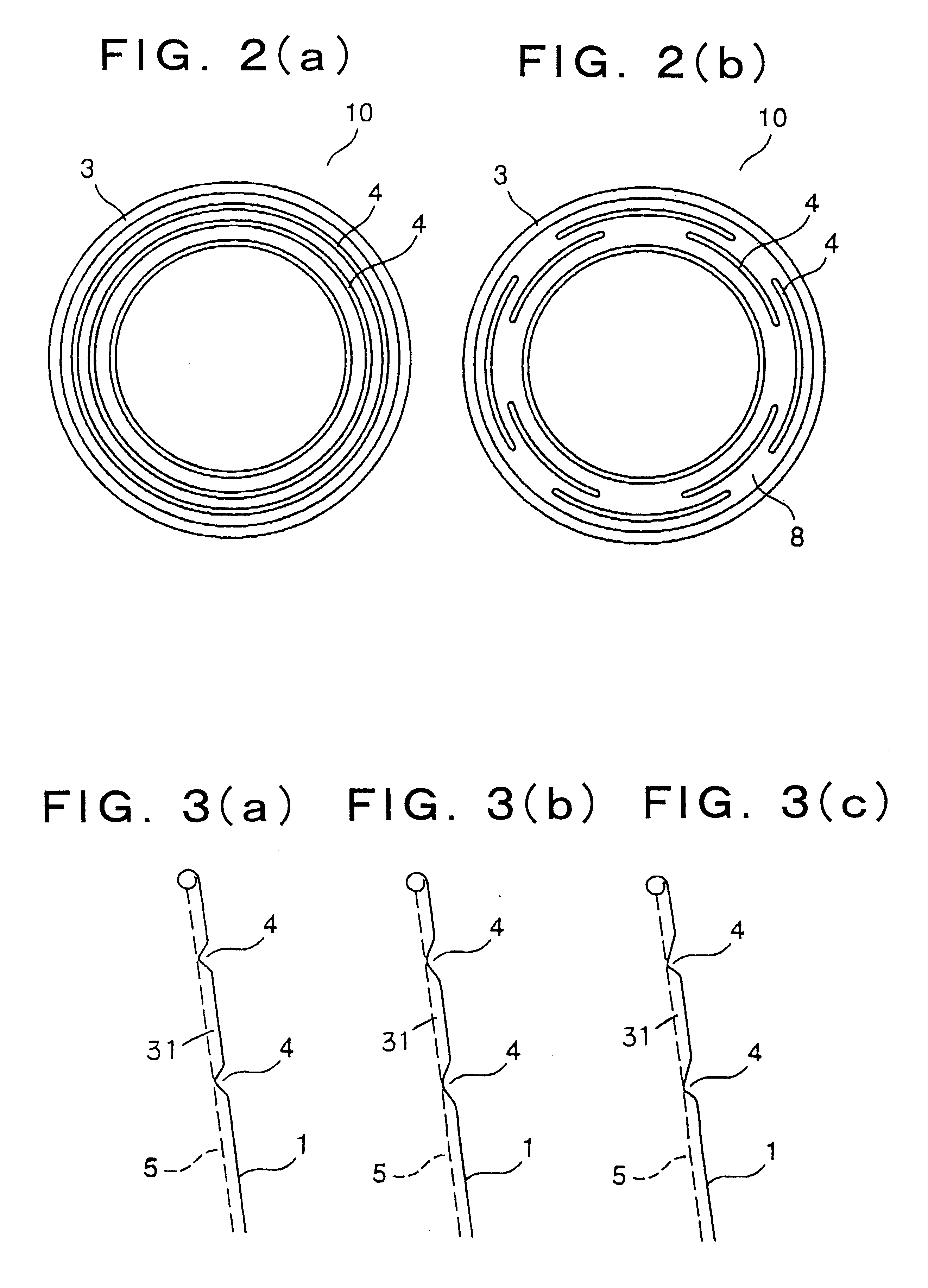

Insulating container

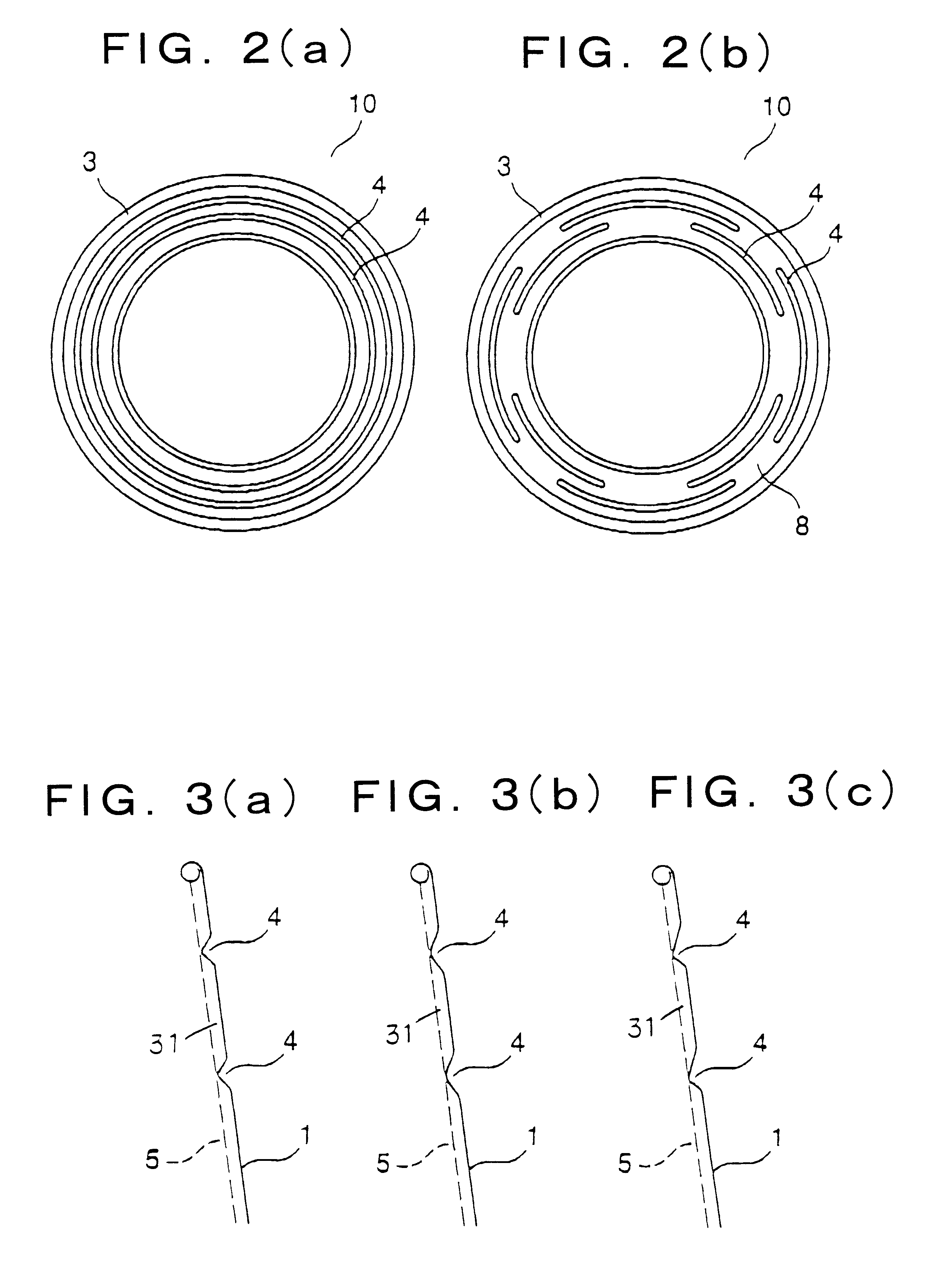

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

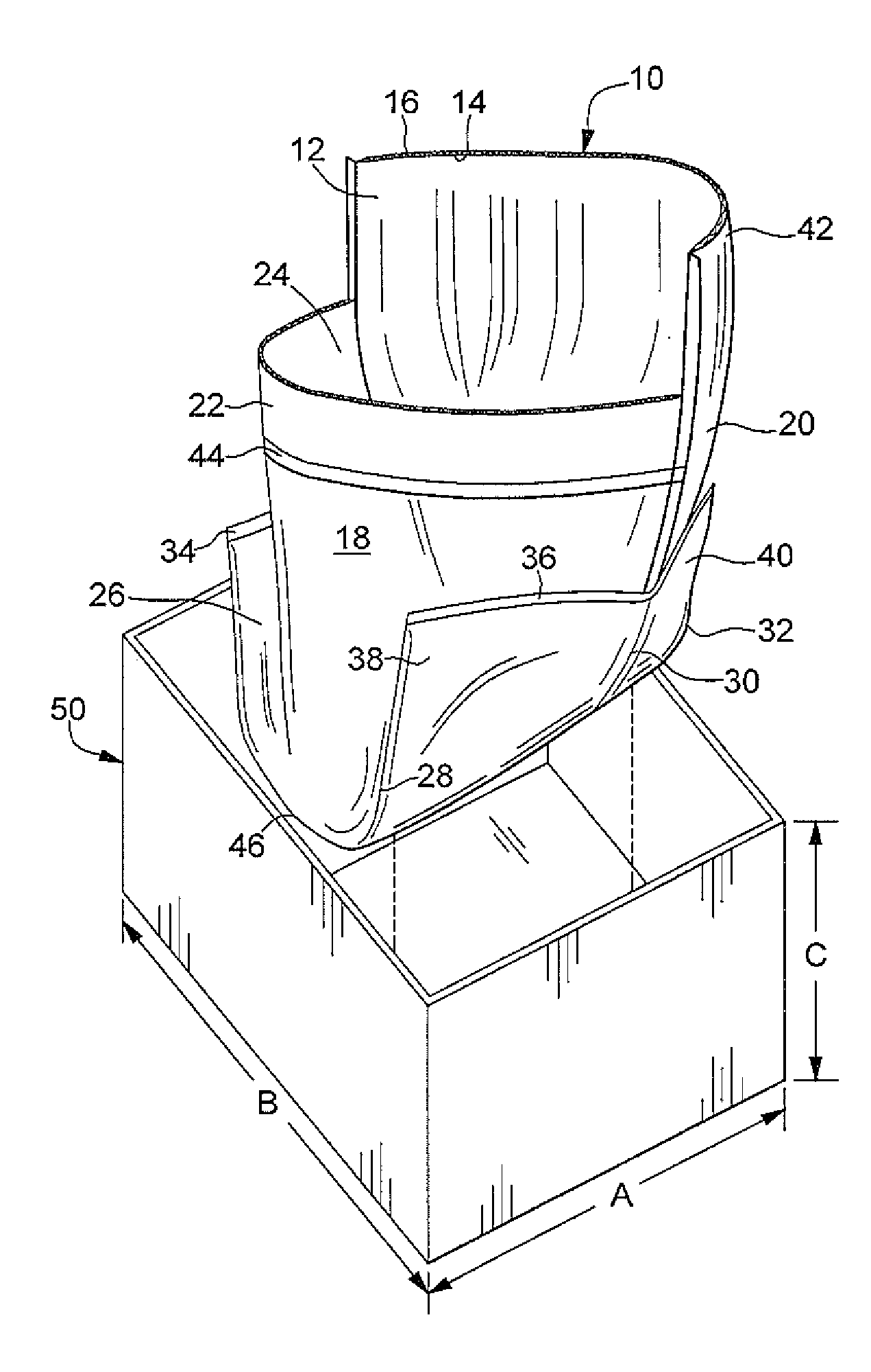

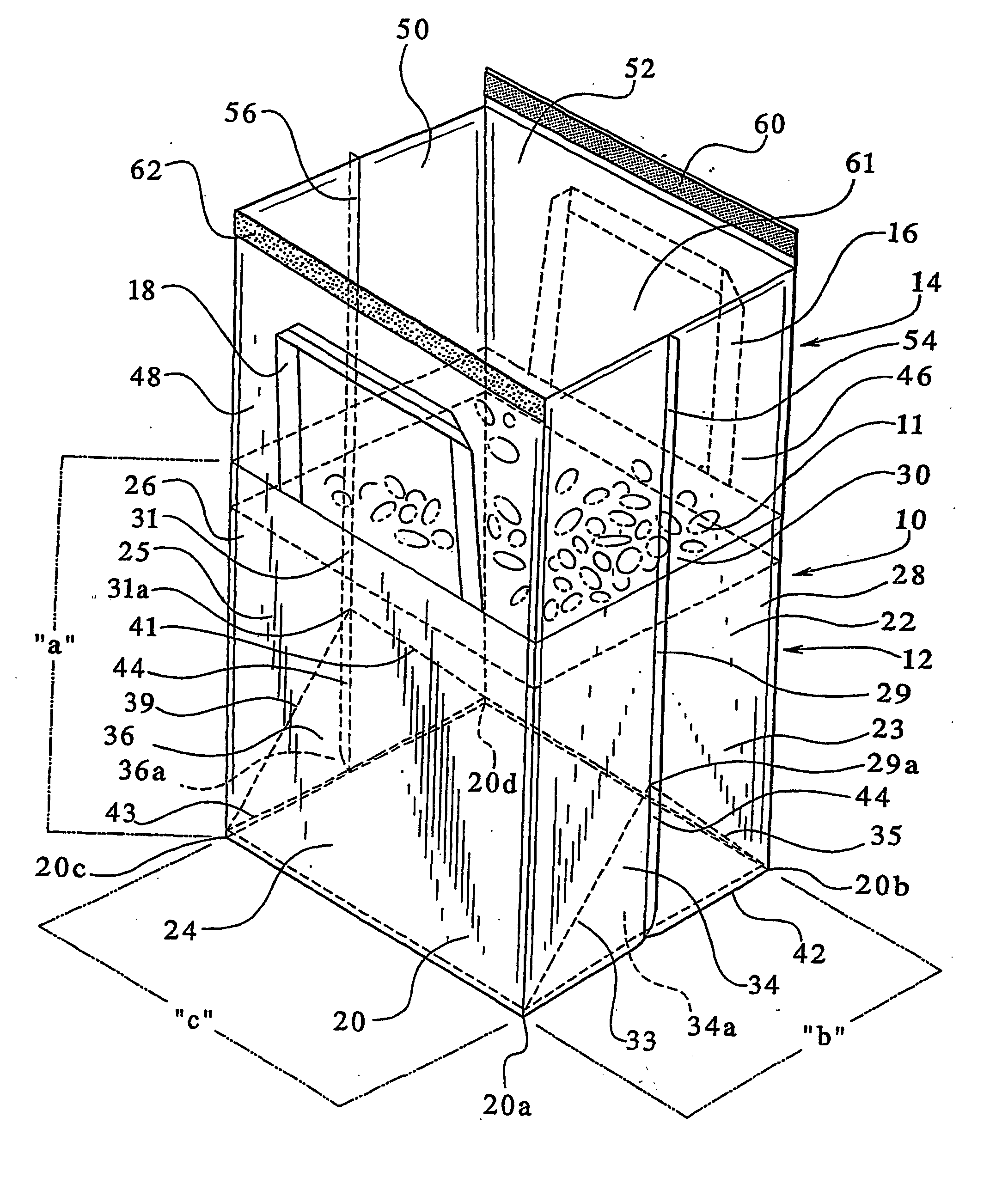

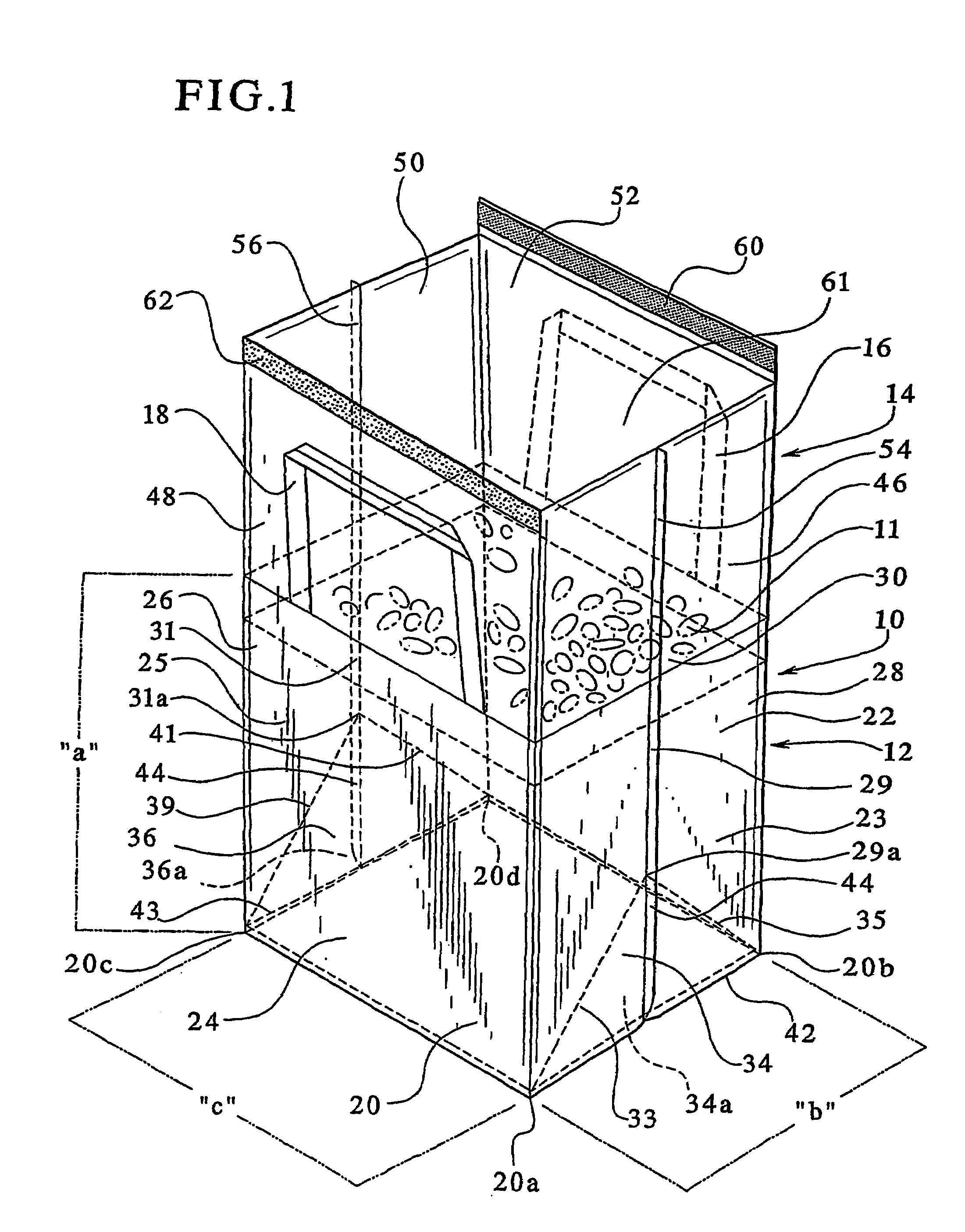

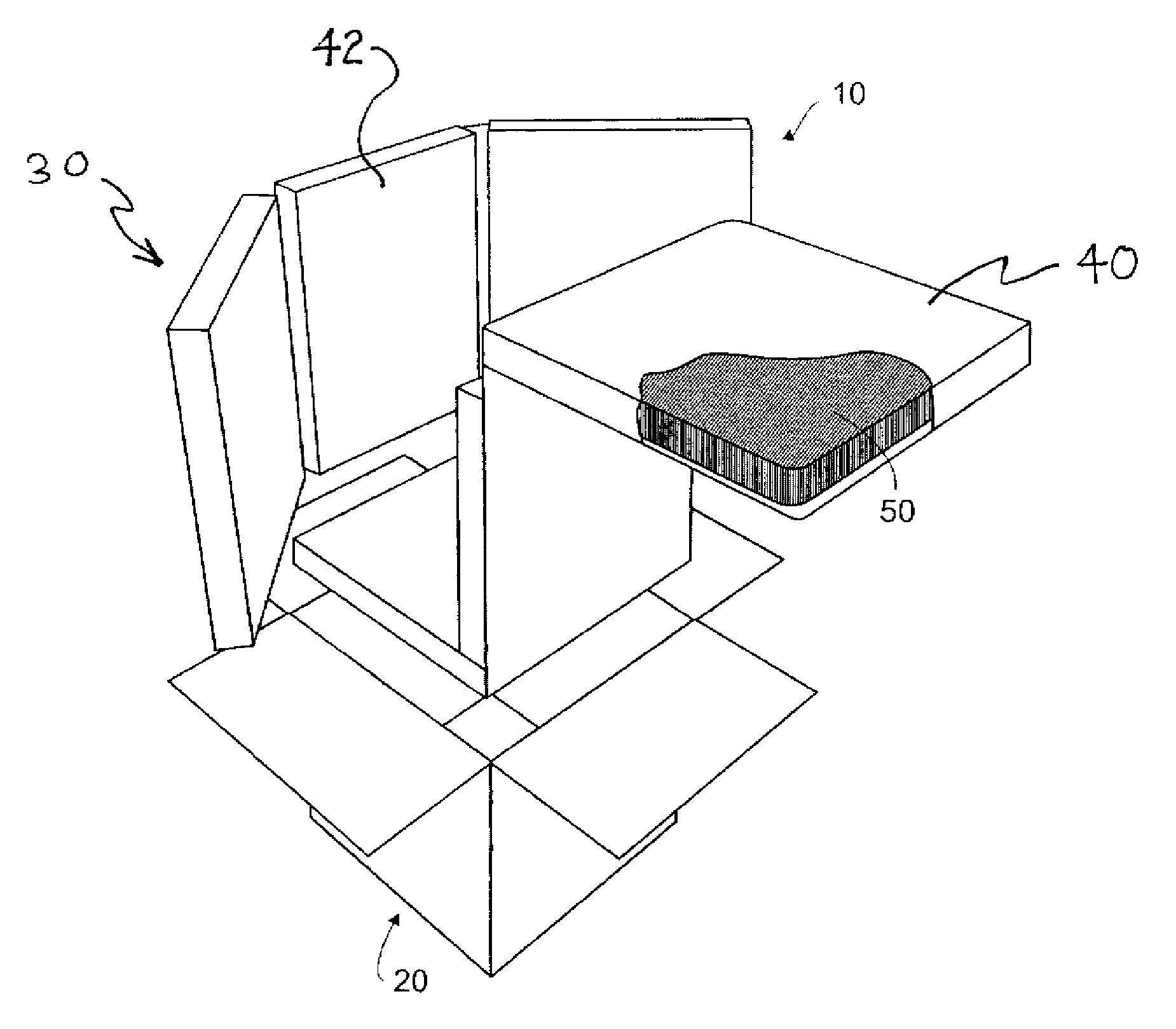

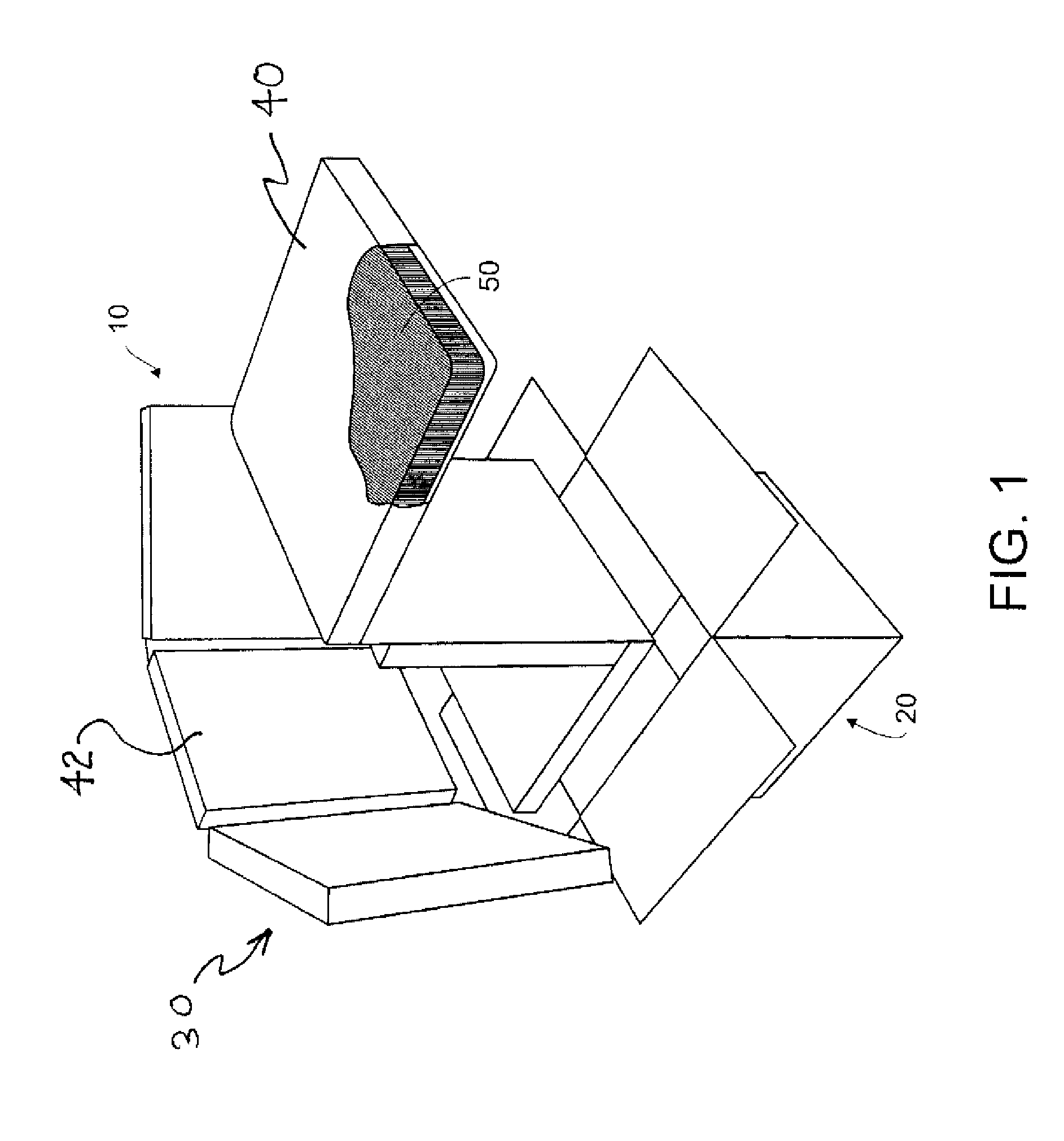

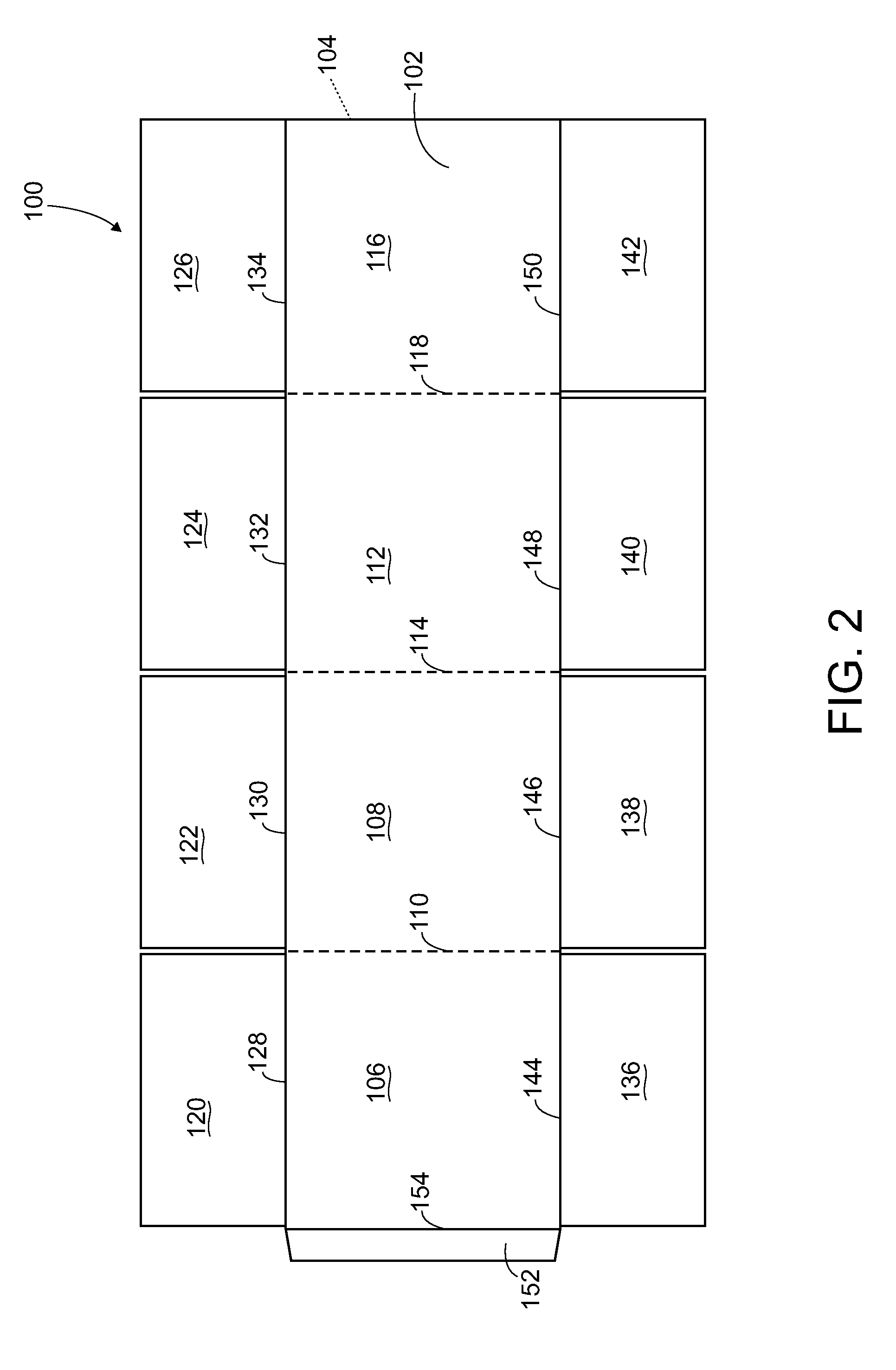

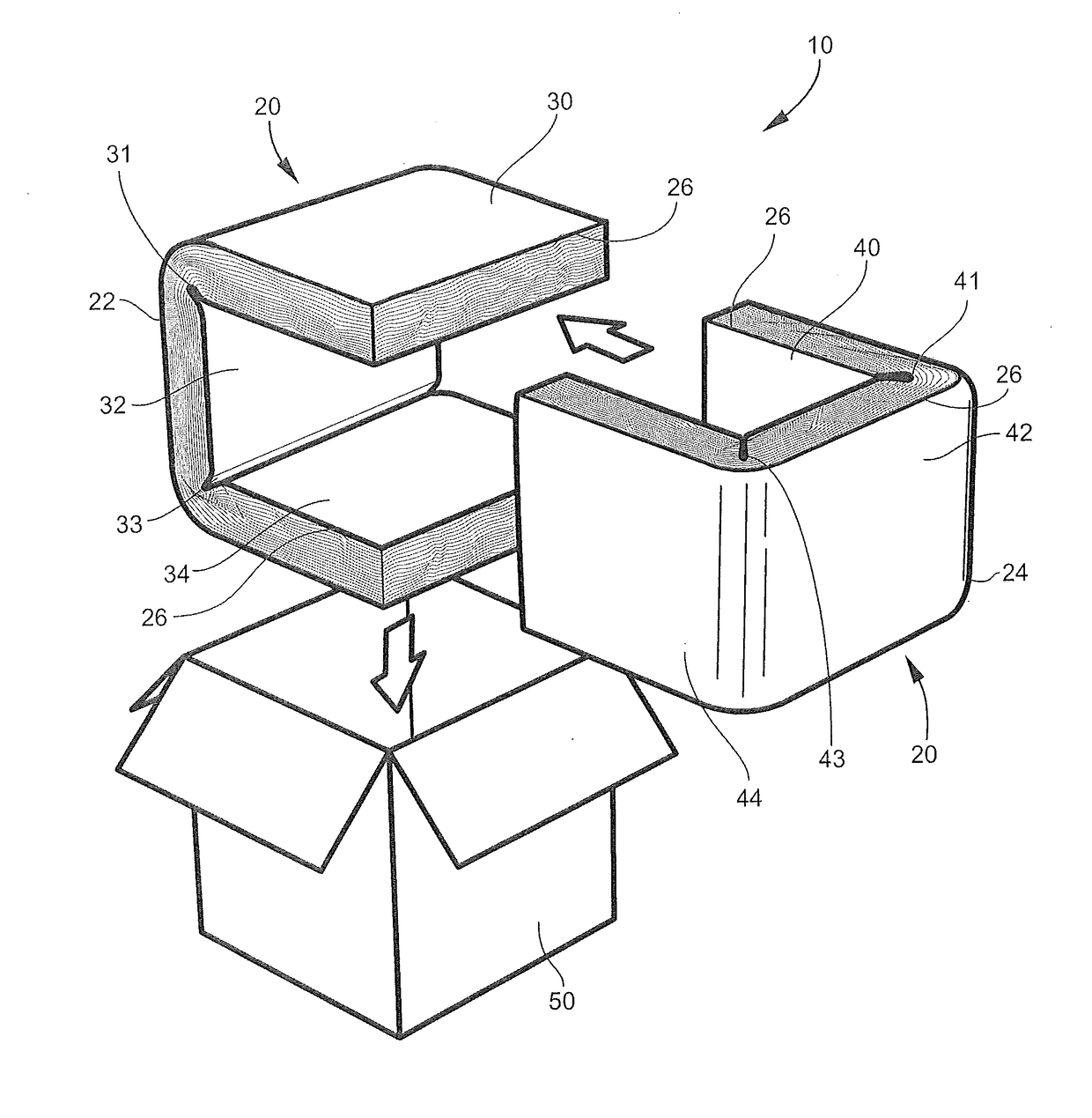

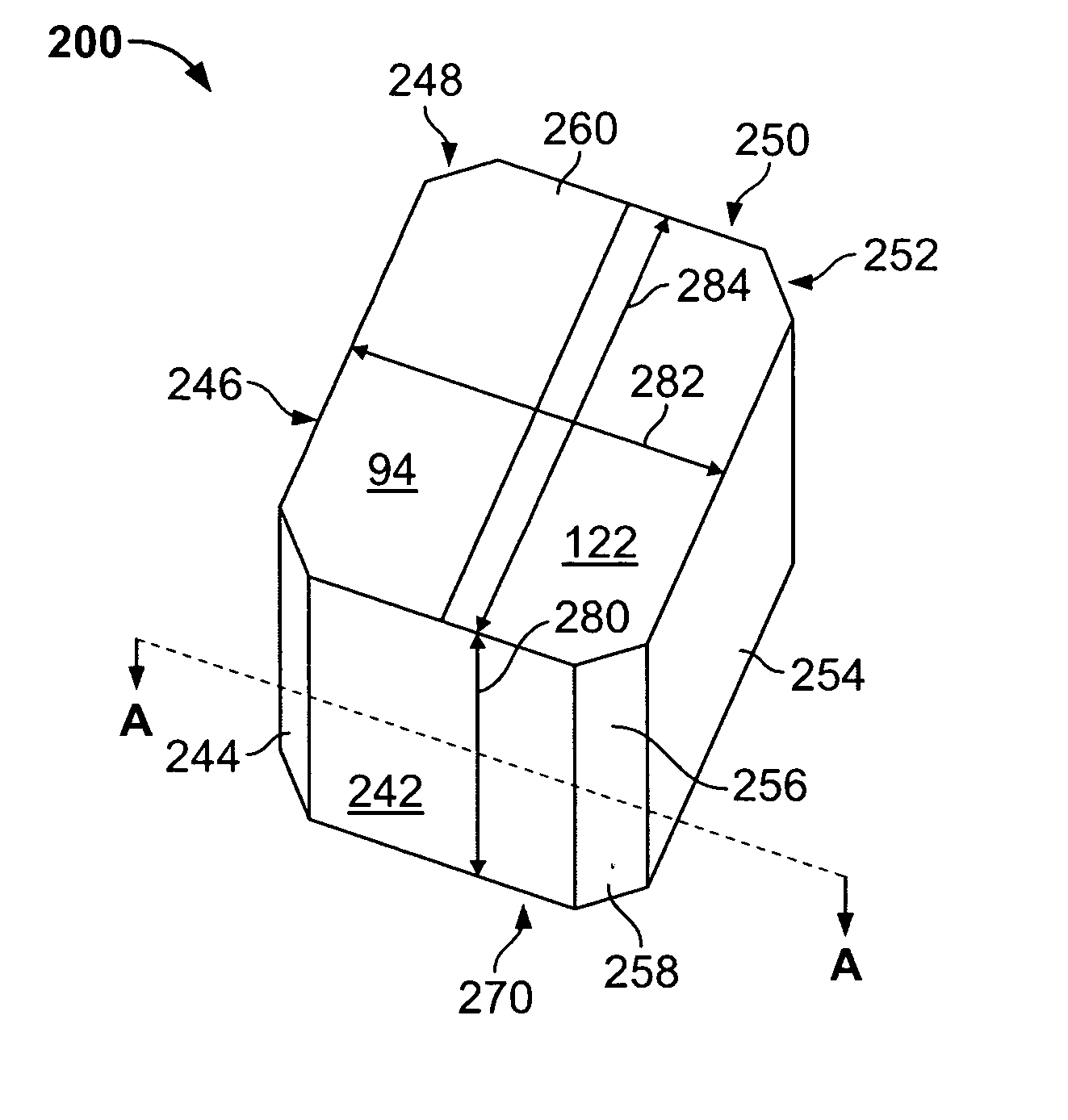

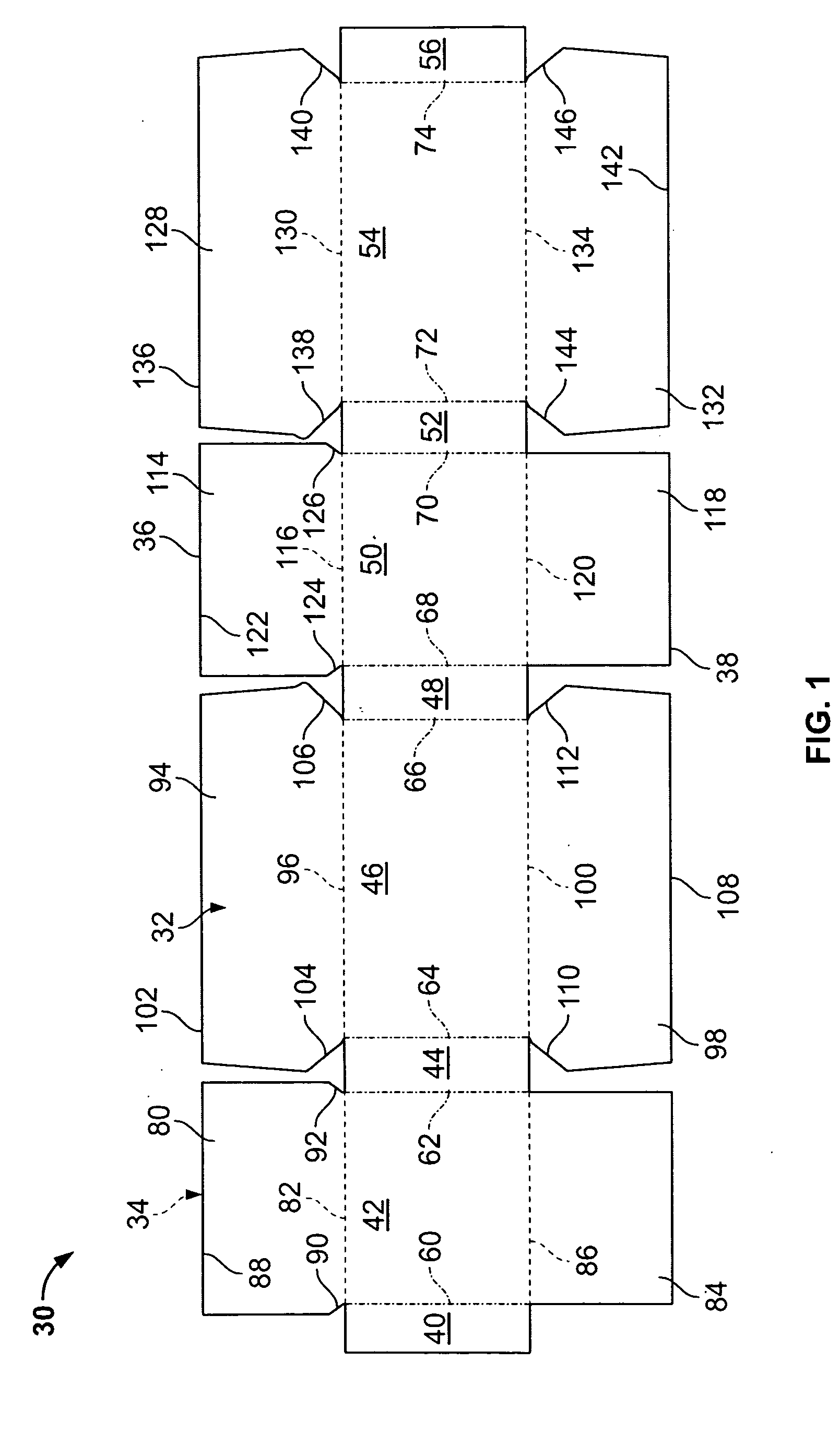

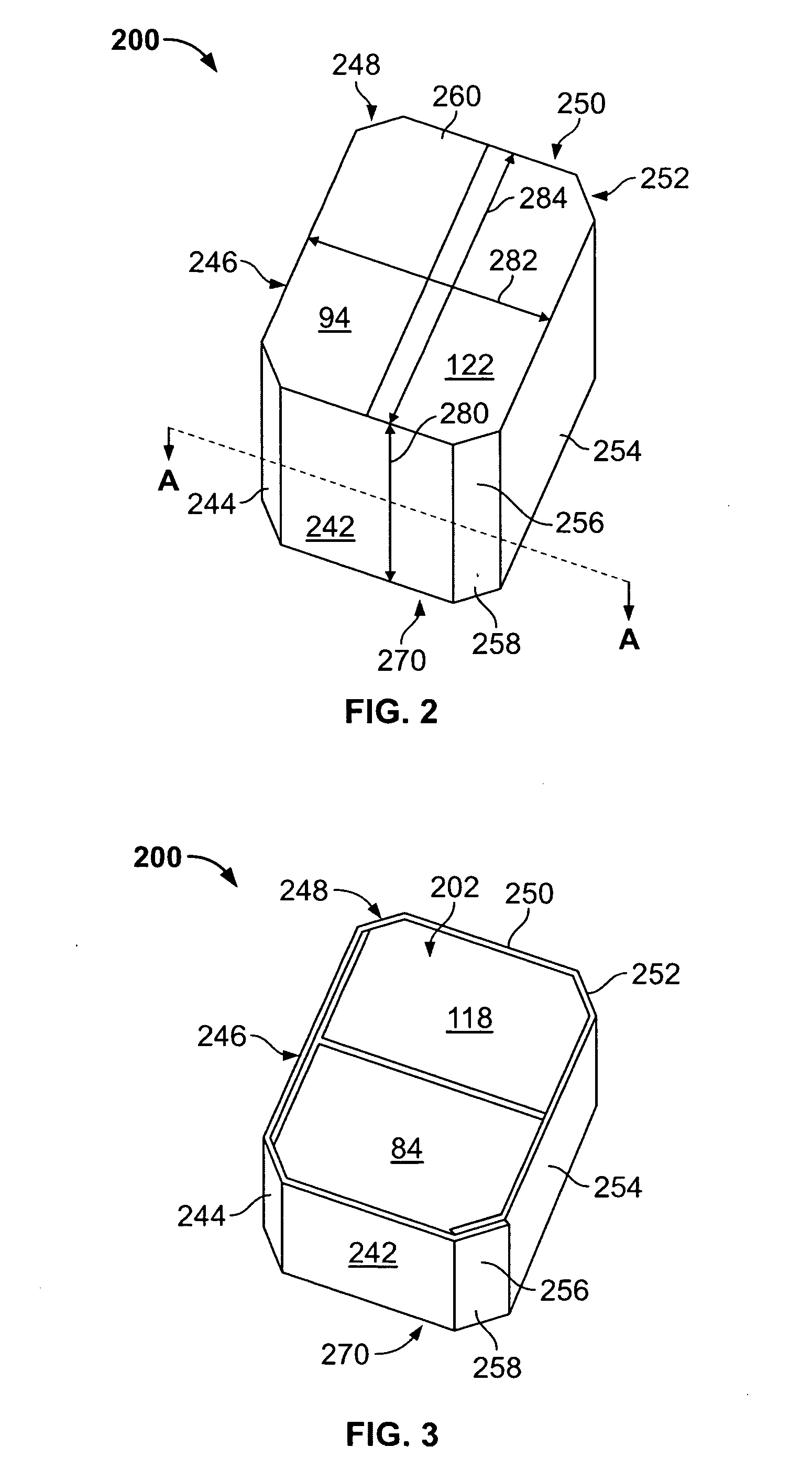

Insulating shipping system

An insulating shipping system may include a container and an insert assembly which may include an insert configured to be inserted into the container. The insert may have a first blank that may include a center panel, two bottom panels emanating from opposite side edges, wherein each bottom panel has at least one slot, at least one top panel emanating from a top edge of each of the bottom panels, wherein each top panel has at least one tab or flange, and at least one foldable line of weakness disposed between each top panel and bottom panel, wherein the at least one slot is sized to receive the at least one tab or flange. The insert further may include a second blank have a center panel, wherein the center panel is configured to couple to the center panel of the first blank to form at least one walled cavity.

Owner:EKOPAK INC

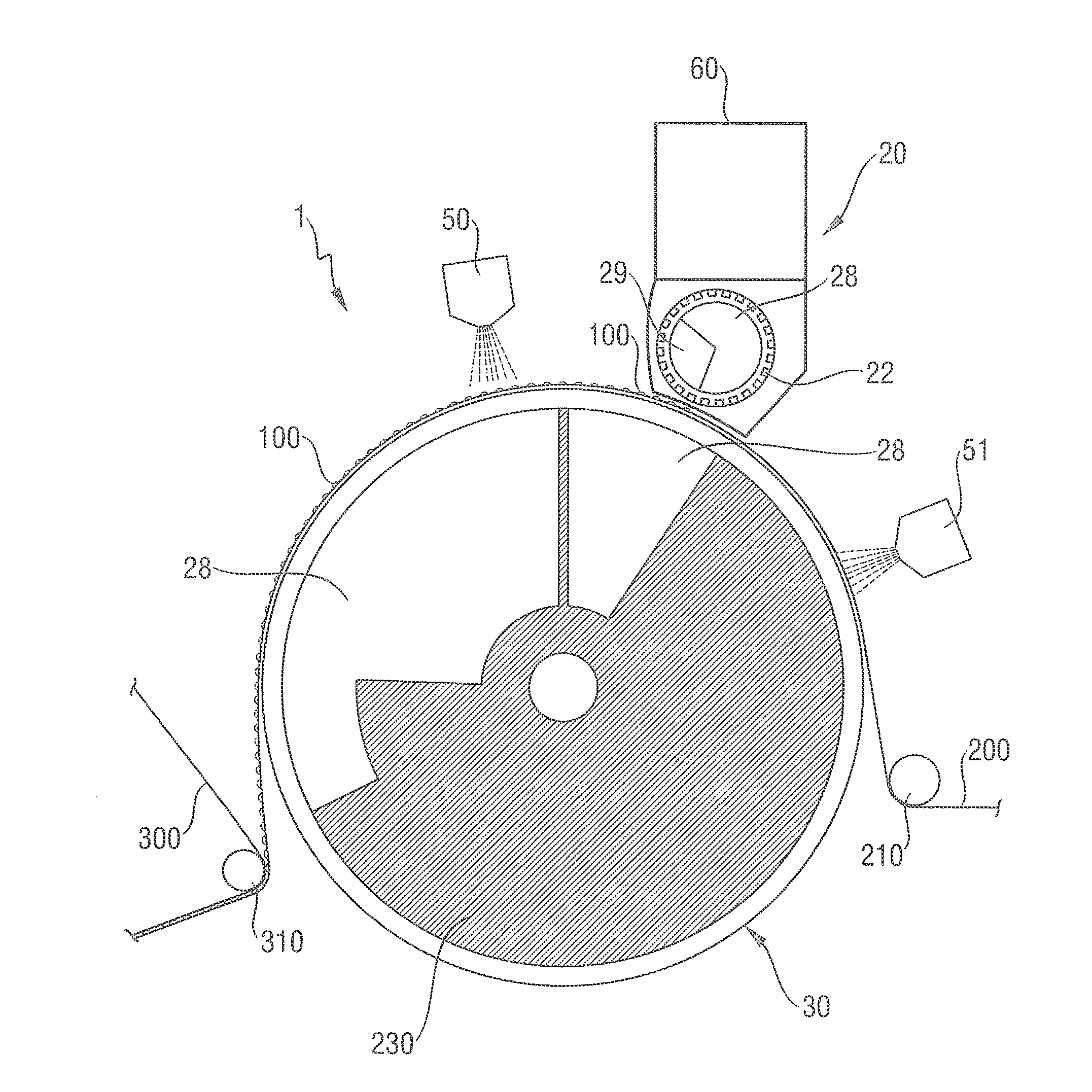

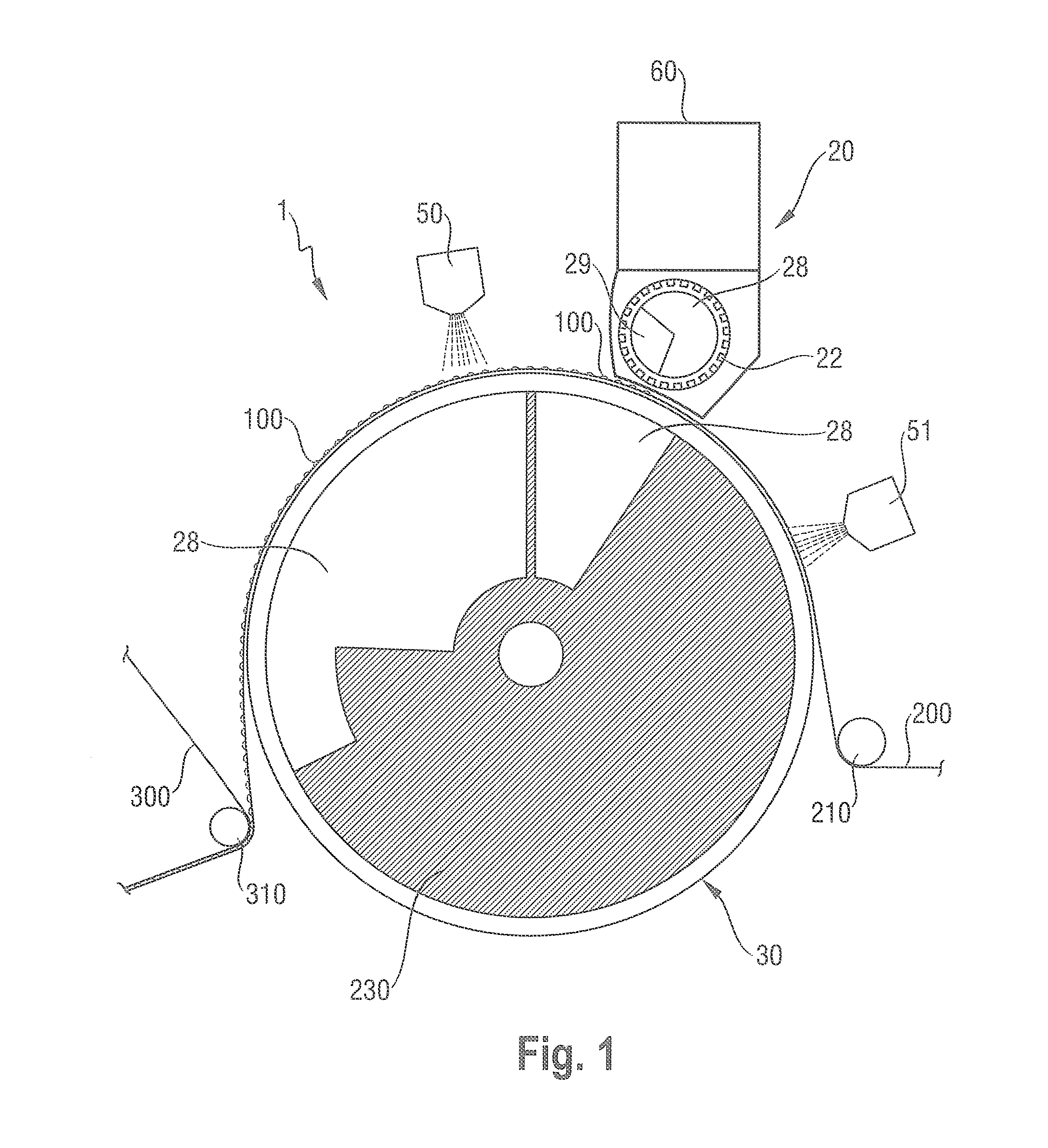

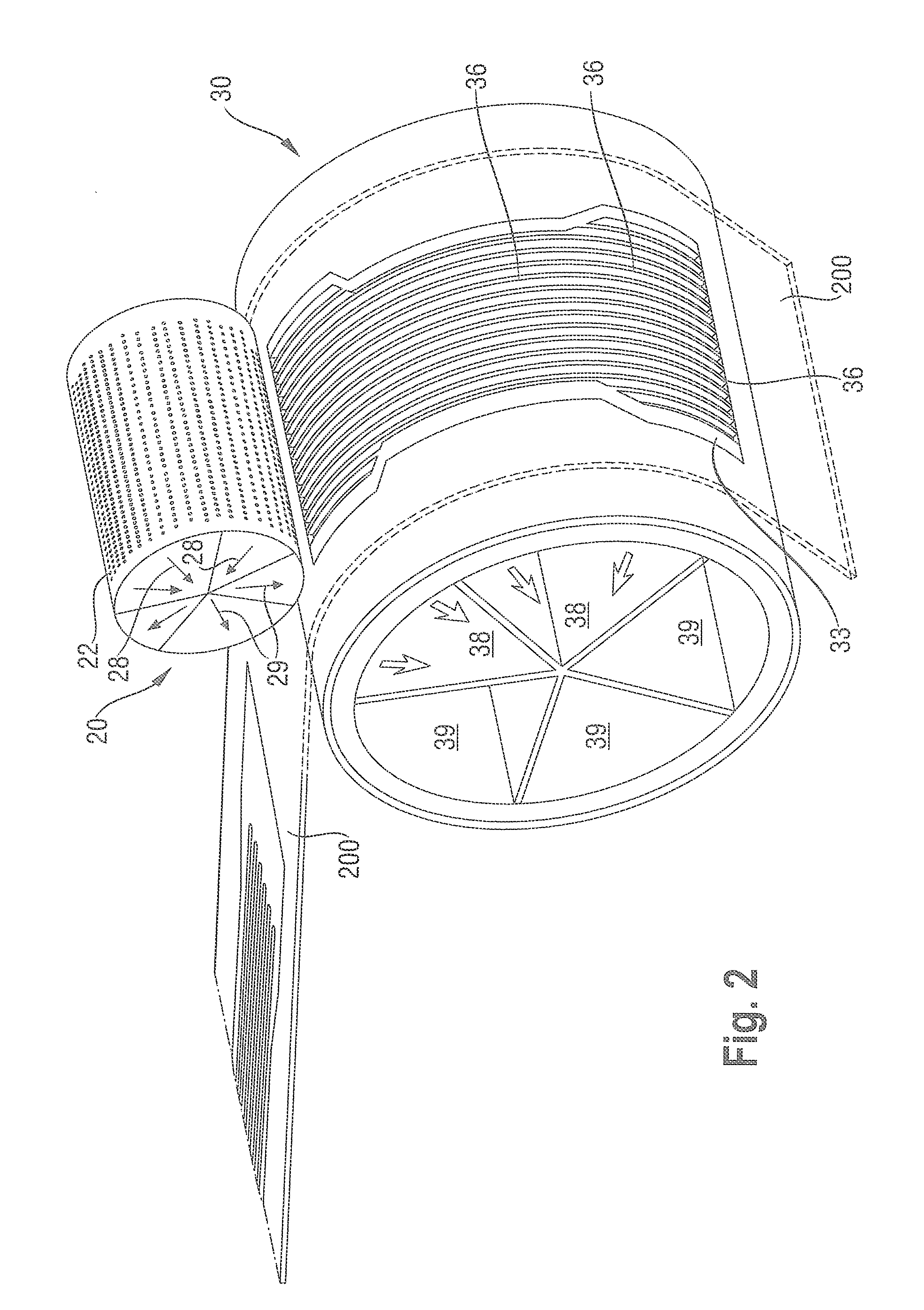

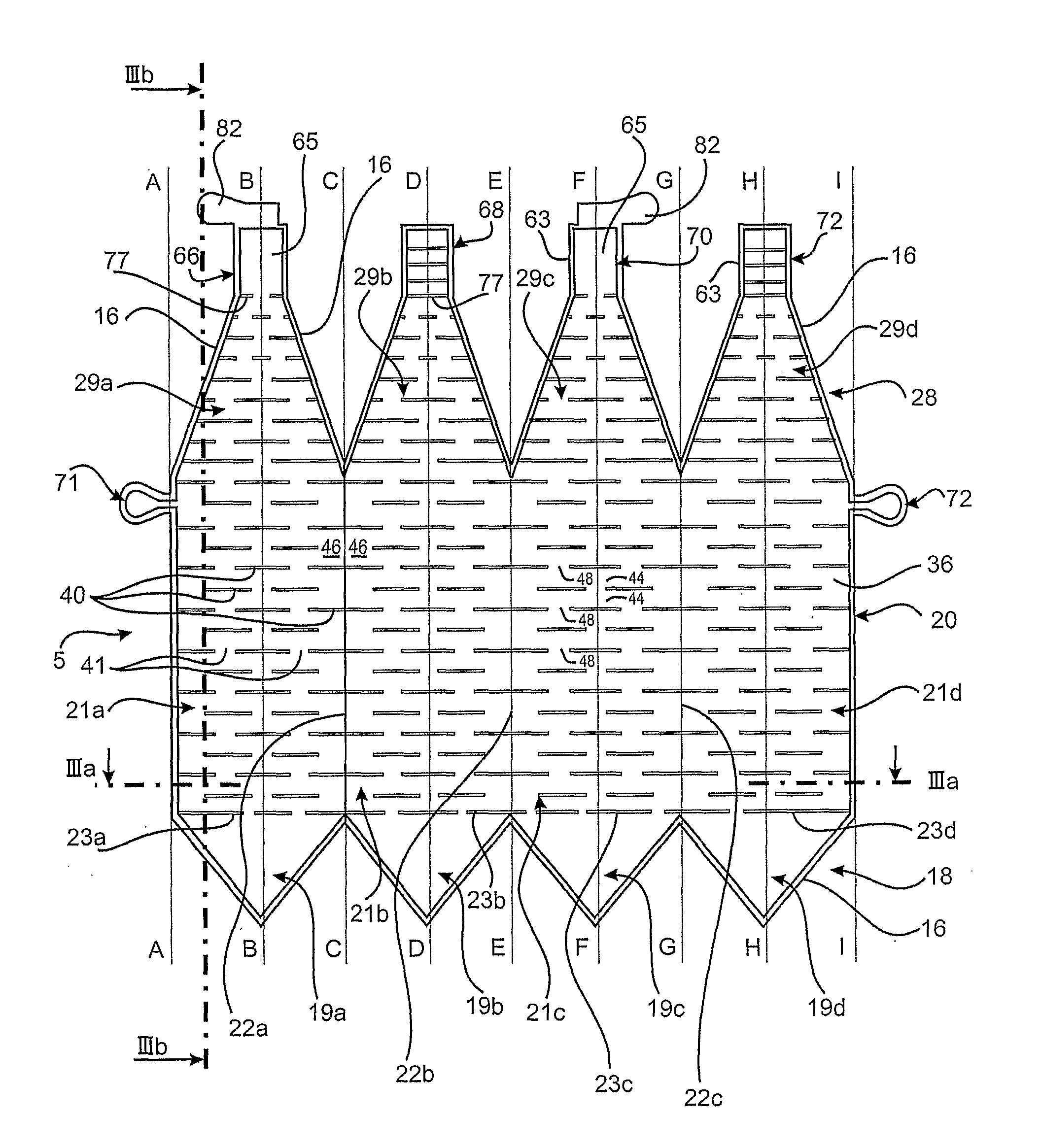

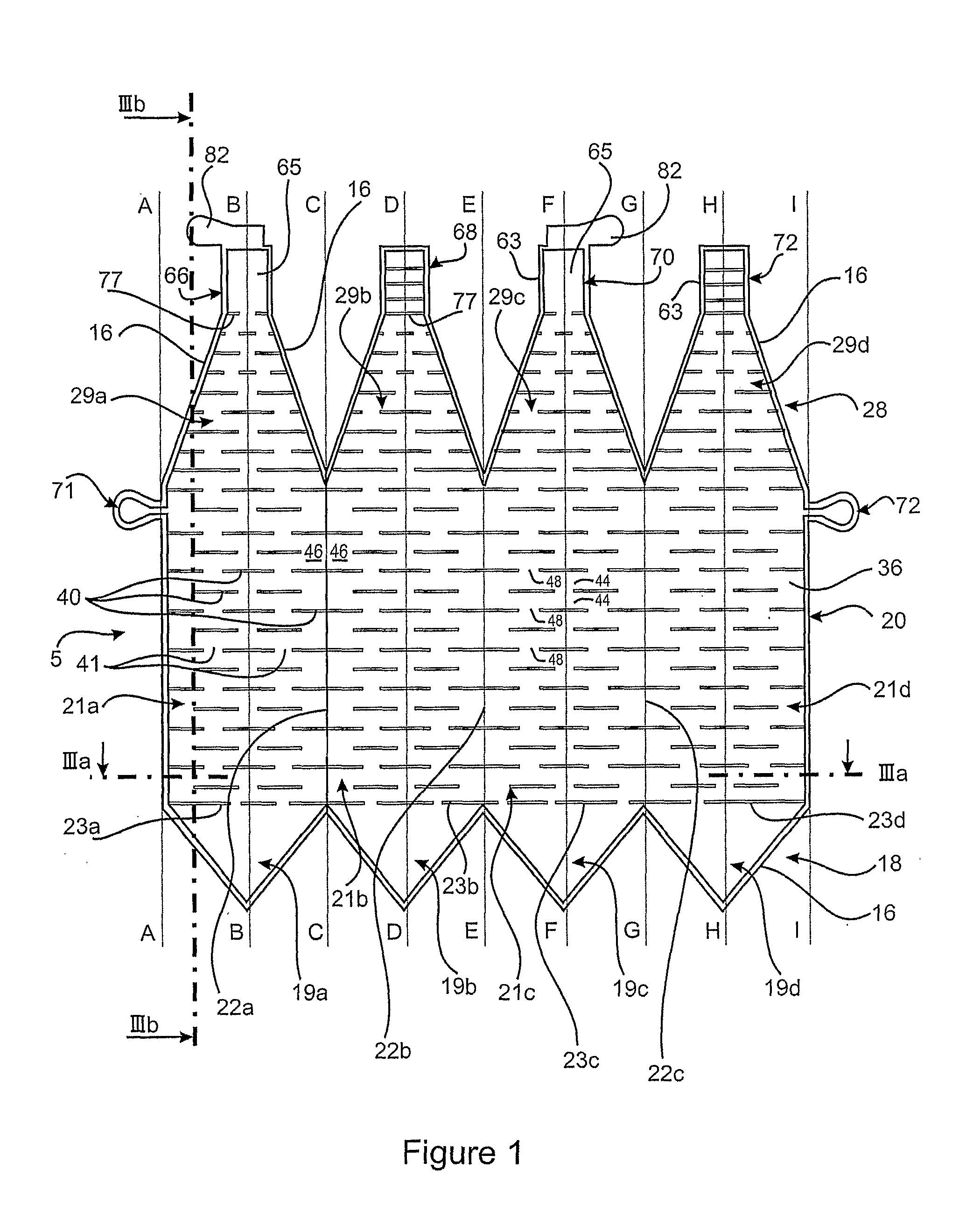

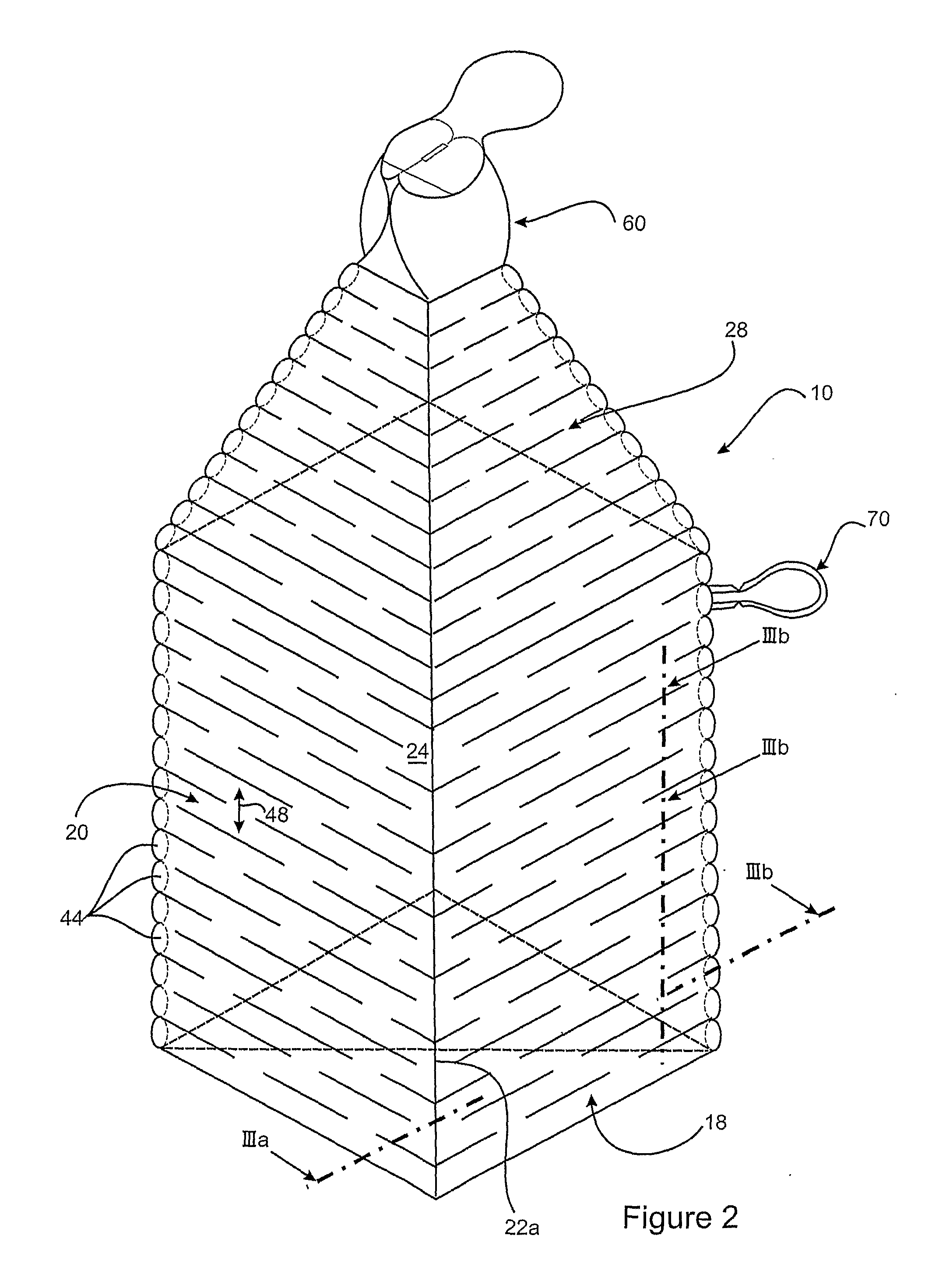

Method and Apparatus for Making Absorbent Structures with Absorbent Material

ActiveUS20120316046A1Boxes/cartons making machineryPaper/cardboard articlesAbsorbent materialMechanical engineering

A method and apparatus for making specific absorbent structures with an absorbent layer with absorbent material with therein substantially longitudinally extending strips that are free of absorbent material, using or having thereto a moving endless surface with receptacle(s) with specific longitudinally extending rods; and specific absorbent structures obtained therewith, suitable for absorbent articles, such as diapers and sanitary napkins.

Owner:THE PROCTER & GAMBLE COMPANY

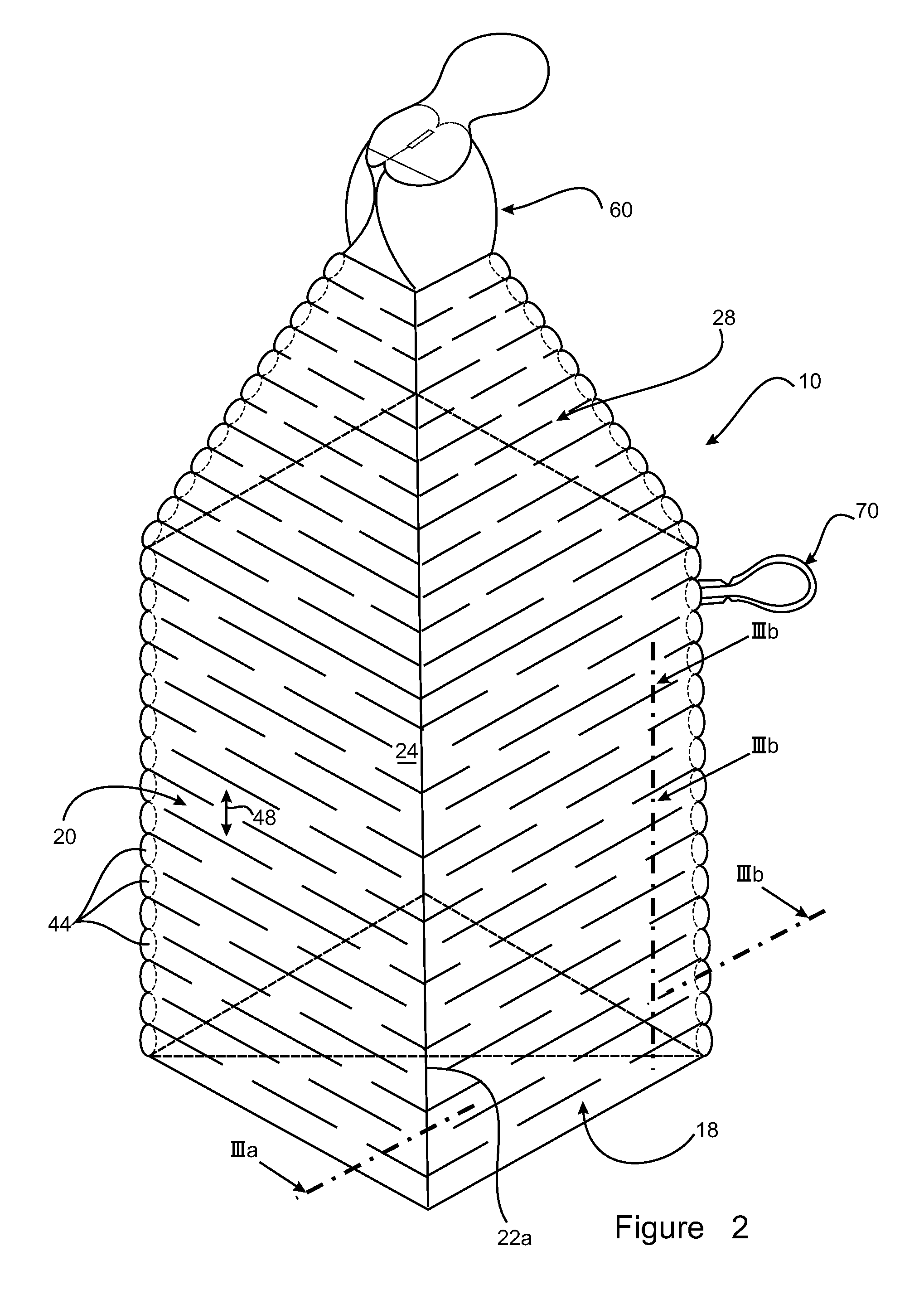

Collabsible Bottle, Method Of Manufacturing A Blank For Such Bottle And Beverage-Filled Bottle Dispensing System

InactiveUS20120097634A1Increase stiffnessIncrease resistanceEnvelopes/bags making machineryBoxes/cartons making machineryEngineeringBottle

The present invention concerns a double-skinned inflatable bottle blank and its method of manufacturing which comprises: (i) stacking two sheets of liquid impermeable, flexible foil material, preferably in coplanar arrangement; (ii) blanking the sheets to create respective, preferably shape-congruent blanks having each a contoured perimeter edge; (iii) bonding the two blanks along joining seams that follow the contoured perimeter edges, but for at one or more inflation locations, thereby to define a double skinned blank into which an inflating fluid can be introduced through the inflation location; (iv) additionally bonding the two blanks at a plurality of discrete stiffening seams which are arranged in a predetermined grid or pattern thereby defining a grid-work of intersecting, inflatable stiffener structures in at least such part of the double skinned blank which will provide an upstanding peripheral wall of the bottle when erected through inflation; (v) folding the double skinned blank; and (vi) selectively bonding together portions of the joined perimeter edge of the double skinned blank, but for at a predetermined filling / dispensing location, to define a double-skinned, inflatable bottle blank with an internal cavity surrounded by a bottom wall for standing the bottle upright, said peripheral wall and a top wall, the filling / dispensing location located preferentially in the top wall such as to define a dispensing orifice for filling and dispensing liquid into and from the internal cavity, the inflatable stiffener structures providing an exoskeleton about the internal cavity when inflated.

Owner:RIEDL JOHN THOMAS

Insulated cup and method of manufacture

InactiveUS6196454B1Boxes/cartons making machineryDomestic cooling apparatusEngineeringMechanical engineering

An insulating cup or container (50) and a method of manufacturing it comprises (first embodiment) providing a sidewall blank (12B) having two sections separated by a fold score (15), and a separate insulating sheet (18)(corrugated, ribbed, embossed, foamed, perforated, etc.) which is adhesively fastened to one of the sections. The blank is folded in half along the fold score, to form a three-layered assembly with the insulating sheet in the middle. To reduce the thickness of the seam, the blank is thinned in the area adjacent a fold score prior to folding. The assembly is wrapped around a mandrel to bring the outer edges together at a side seam (22S) to form a sidewall 12. The side seam is sealed, the bottom is added, and the rim is formed. In a second embodiment, the insulating layer can be a coating on one or both of the sections of the two-section starting blank. In a third embodiment, the insulating section (40) can be integral with, and extend from, one edge of the starting blank. It is folded over first to form the middle layer of the wrappable assembly.

Owner:GPCP IP HLDG LLC

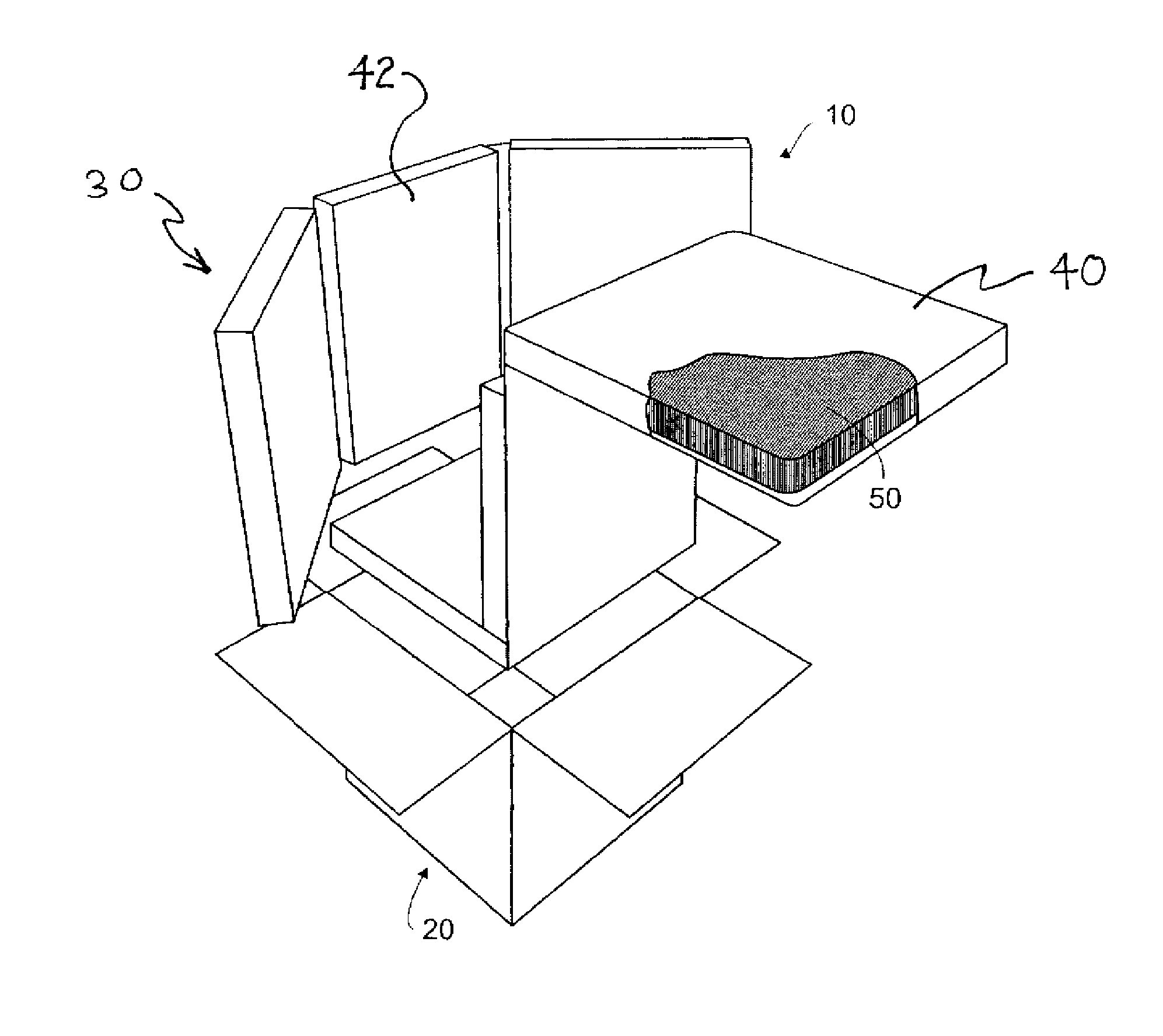

Packing product and apparatus and method for manufacturing same

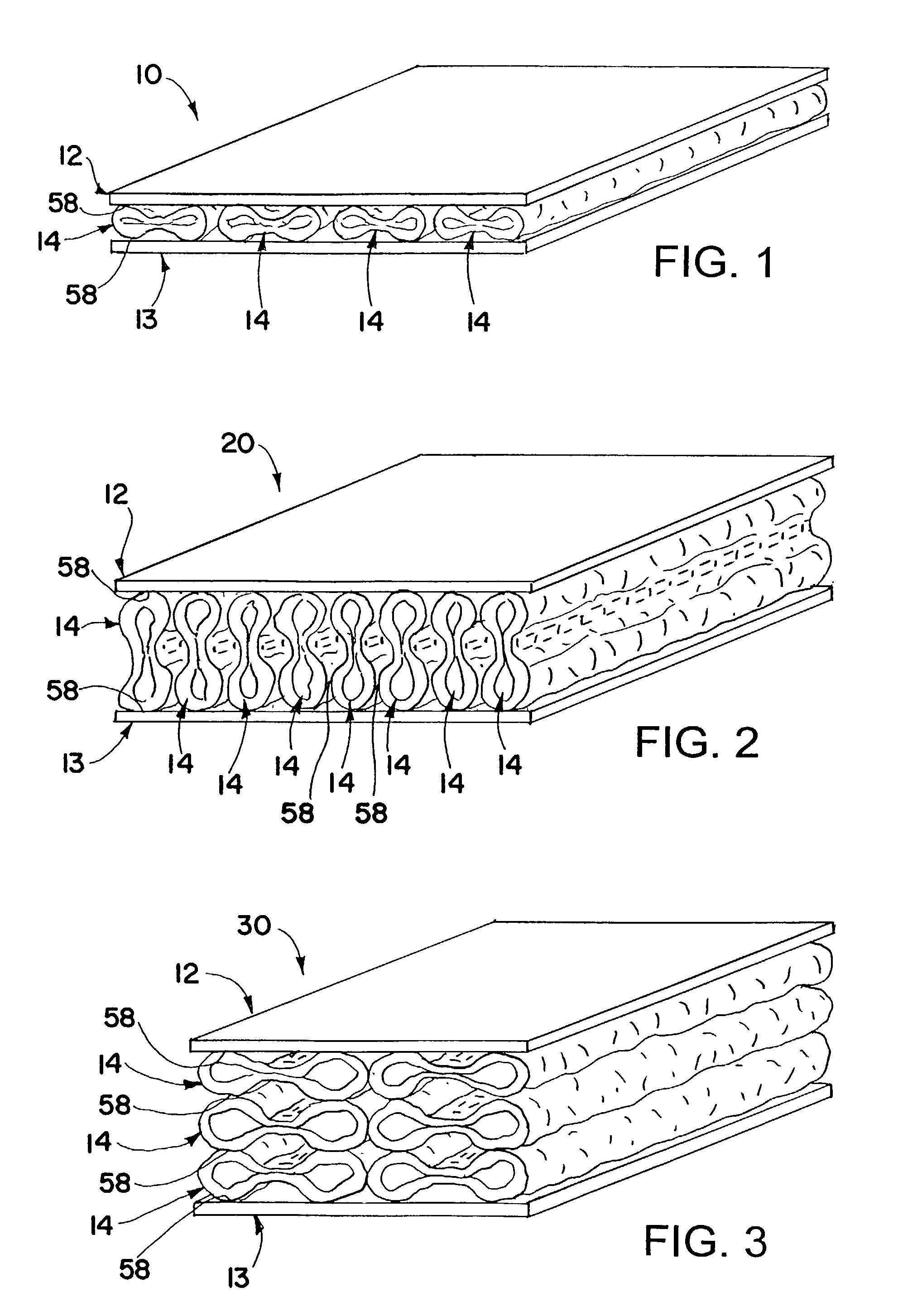

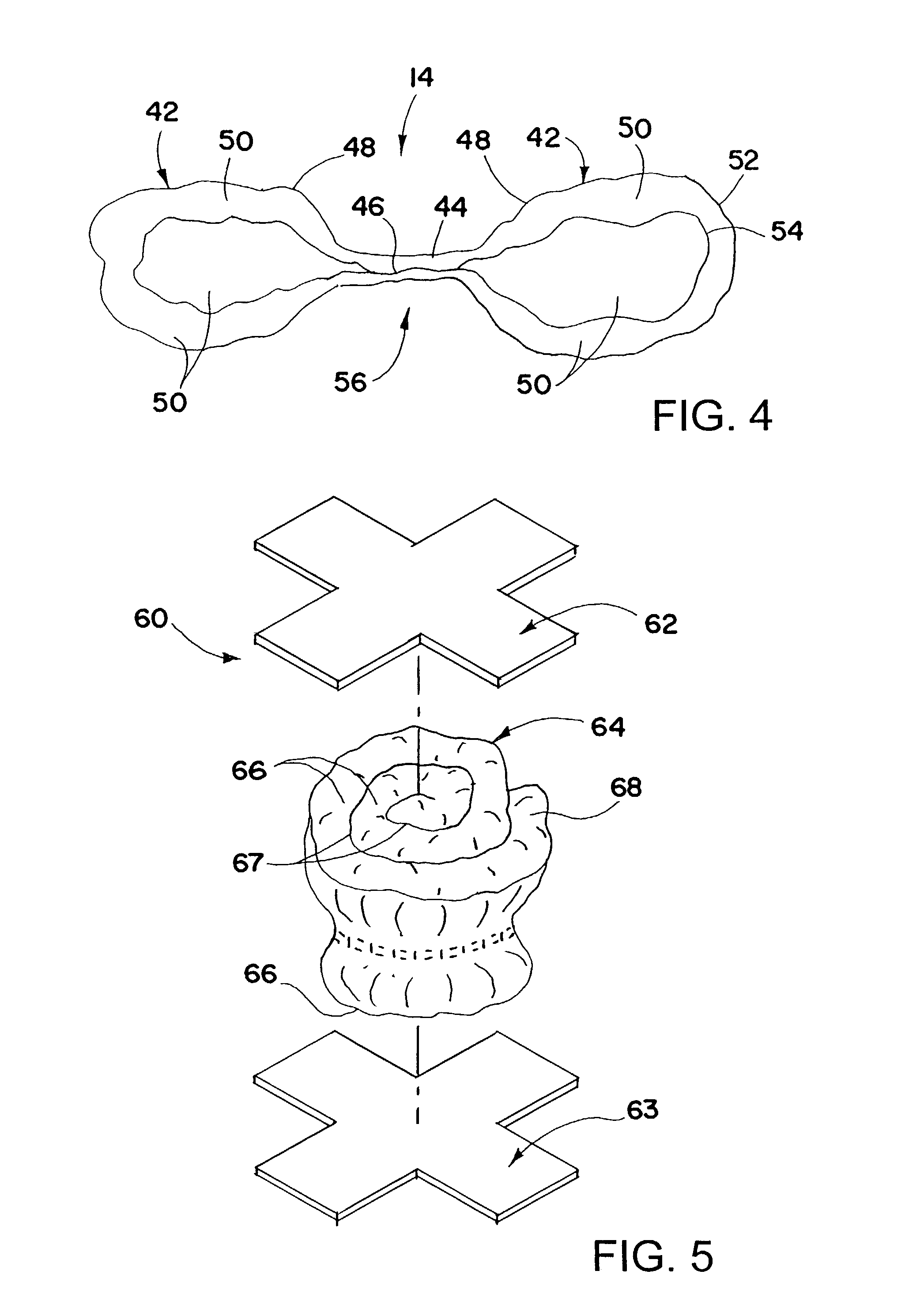

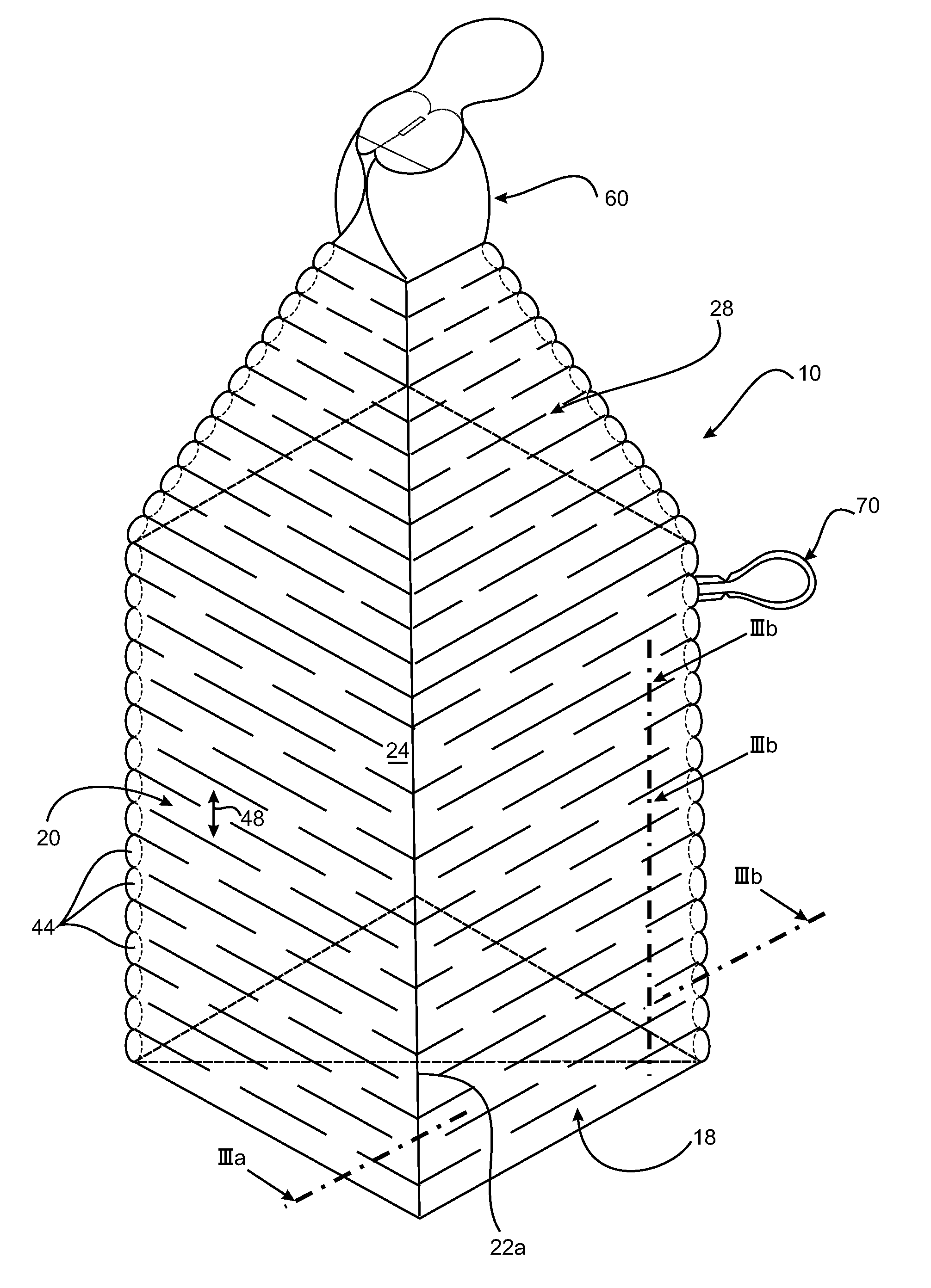

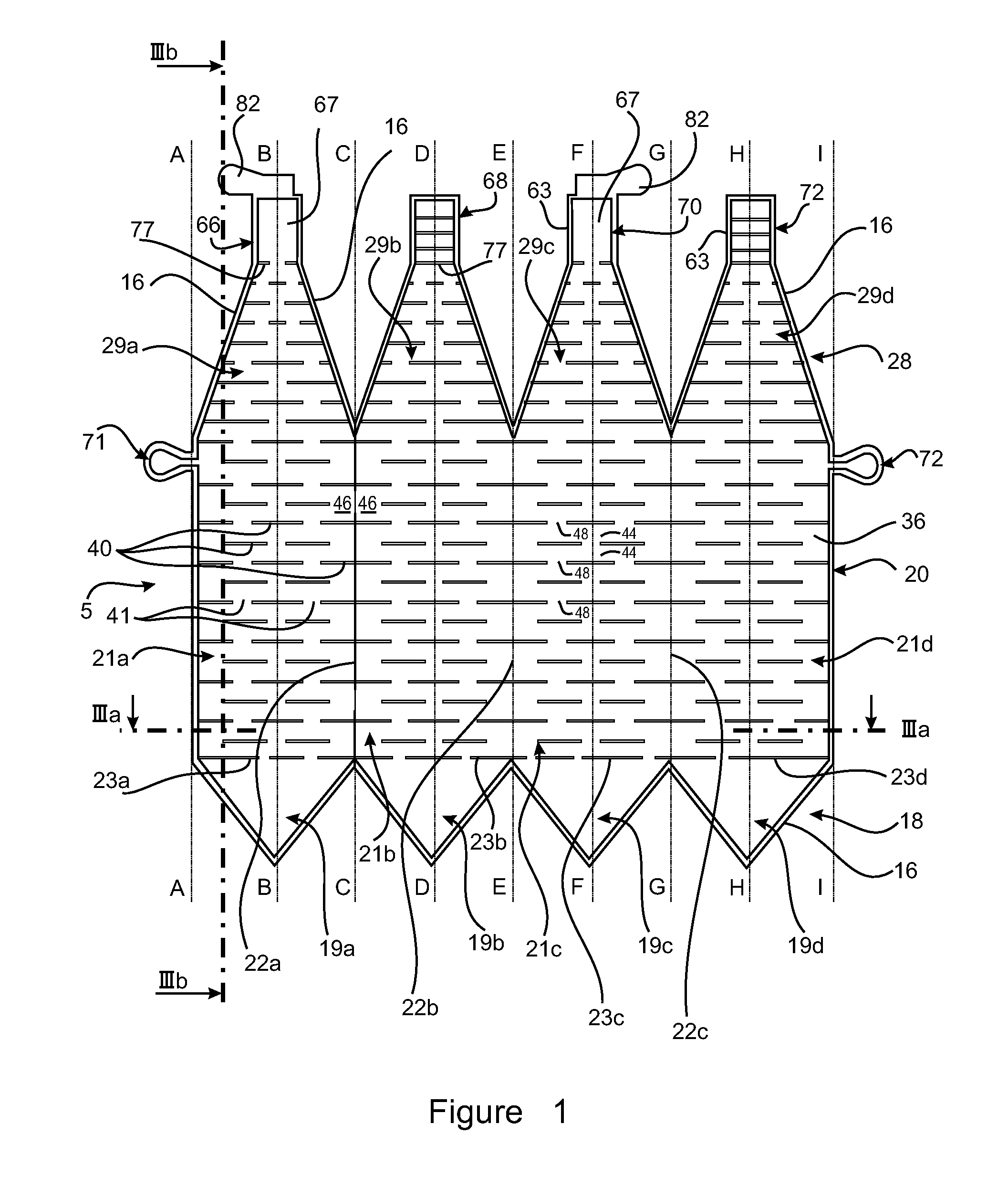

ActiveUS7452316B2Wide range of resiliencySpreading capabilityBoxes/cartons making machineryPaper-makingDunnageEngineering

A packing product and apparatus and method for manufacturing same are disclosed. The packing product includes at least one face sheet and at least one crumpled sheet pad attached to the face sheet. A package and method of packaging an article are also disclosed, the package including a container, one or more crumpled sheet pads positioned in the container, one or more face sheets positioned adjacent to the crumpled sheet pads, and an article positioned in the container in at least partial abutting relation to the one or more face sheets. The one or more face sheets may have portions that are folded to envelop the article. Also, the face sheet may include an opening having a pattern corresponding to a shape of the article. A pad producing apparatus includes a dunnage supply machine for supplying a strip of dunnage, a folding device for forming a fold line in and transverse to the strip of dunnage, and a capture chute for guiding and accumulating the folded strip of dunnage so that a first layer downstream of the fold line overlaps a second layer upstream of the fold line, thereby forming an accordion-like pad.

Owner:RANPAK CORP

Collapsible bottle, method of manufacturing a blank for such bottle and beverage-filled bottle dispensing system

InactiveUS8540094B2Increase stiffnessIncrease resistanceBoxes/cartons making machineryLayered productsBottleInflatable

A double-skinned inflatable bottle blank is manufactured by: (i) stacking two sheets of liquid impermeable, flexible foil material; (ii) blanking the sheets; (iii) bonding the two blanks along joining seams that follow contoured perimeter edges to define a double skinned blank which can be inflated through an inflation location; (iv) additionally bonding the two blanks at in a predetermined grid of seams to provide an upstanding peripheral wall with intersecting, inflatable stiffener structures; (v) folding the double skinned blank; and (vi) selectively bonding together portions of the joined perimeter edge of the double skinned blank to define a double-skinned, inflatable bottle blank with an internal cavity surrounded by a bottom wall, peripheral wall and top wall with a dispensing orifice, the inflatable stiffener structures between the seams providing an exoskeleton about the internal cavity when inflated.

Owner:RIEDL JOHN THOMAS

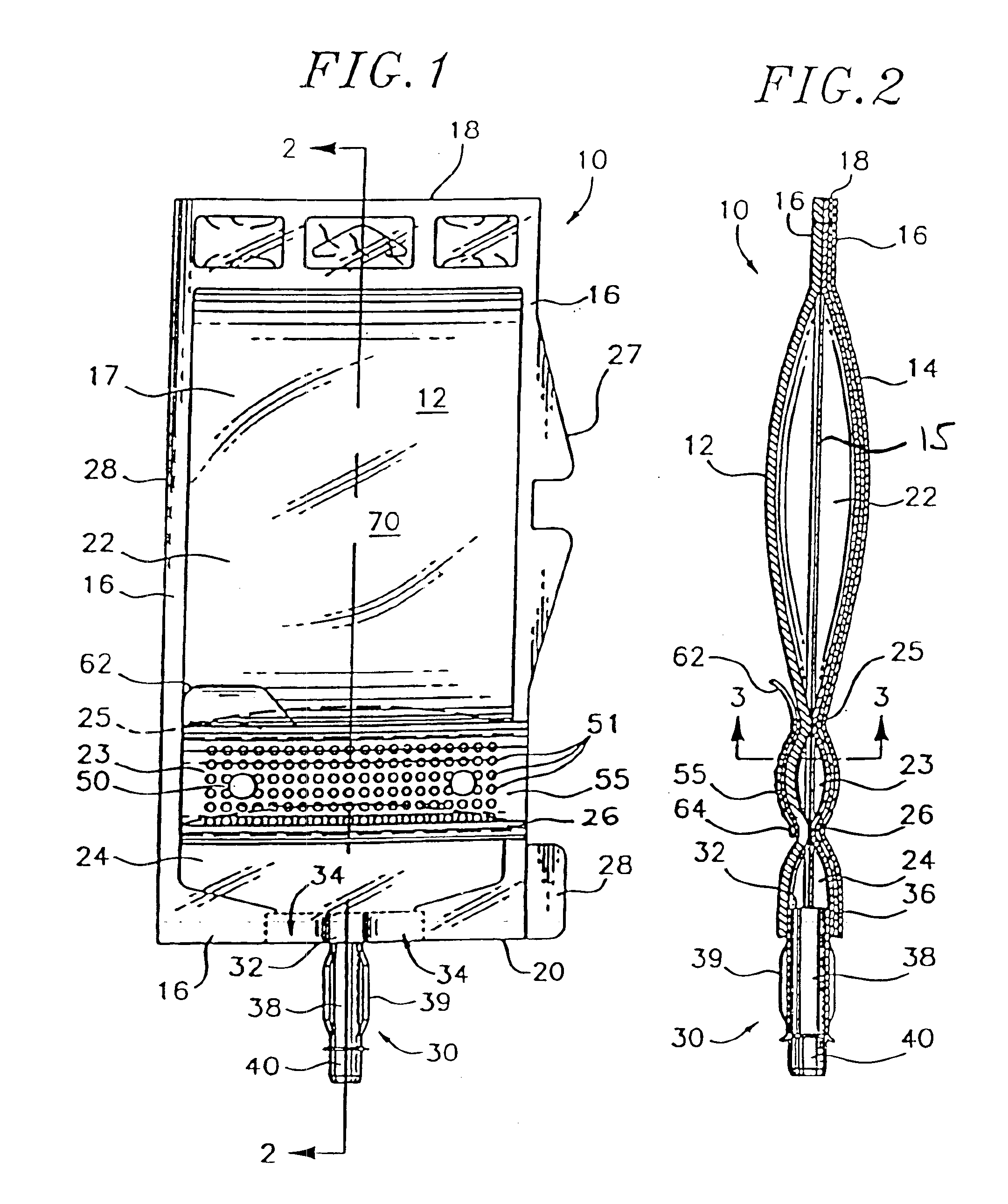

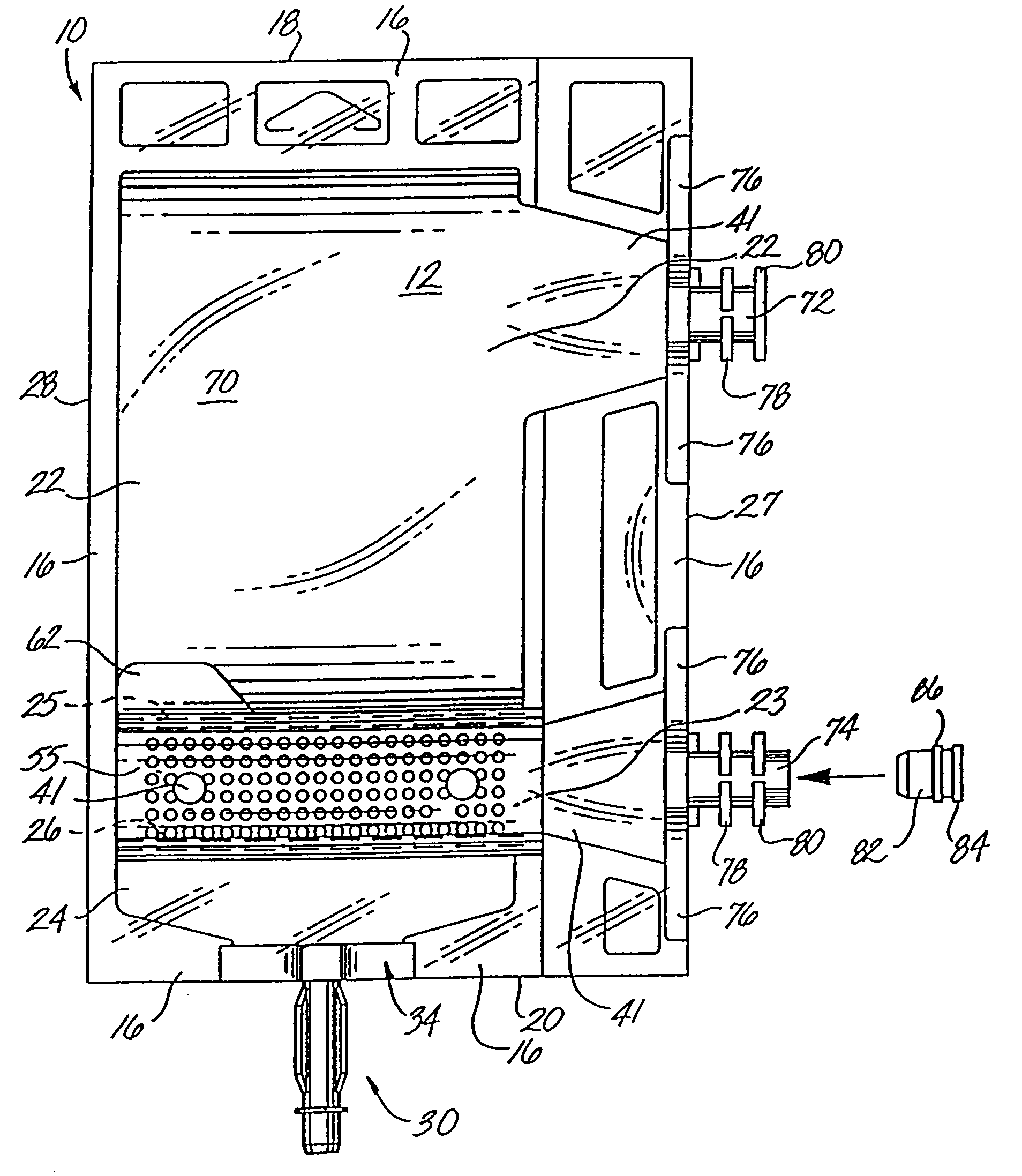

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6846305B2Increase capacityIncrease storage capacityWrappersMedical devicesThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

Insulating Shipping System

An insulating shipping system may include a container and an insert assembly which may include an insert configured to be inserted into the container. The insert may have a first blank that may include a center panel, two bottom panels emanating from opposite side edges, wherein each bottom panel has at least one slot, at least one top panel emanating from a top edge of each of the bottom panels, wherein each top panel has at least one tab or flange, and at least one foldable line of weakness disposed between each top panel and bottom panel, wherein the at least one slot is sized to receive the at least one tab or flange. The insert further may include a second blank have a center panel, wherein the center panel is configured to couple to the center panel of the first blank to form at least one walled cavity.

Owner:EKOPAK INC

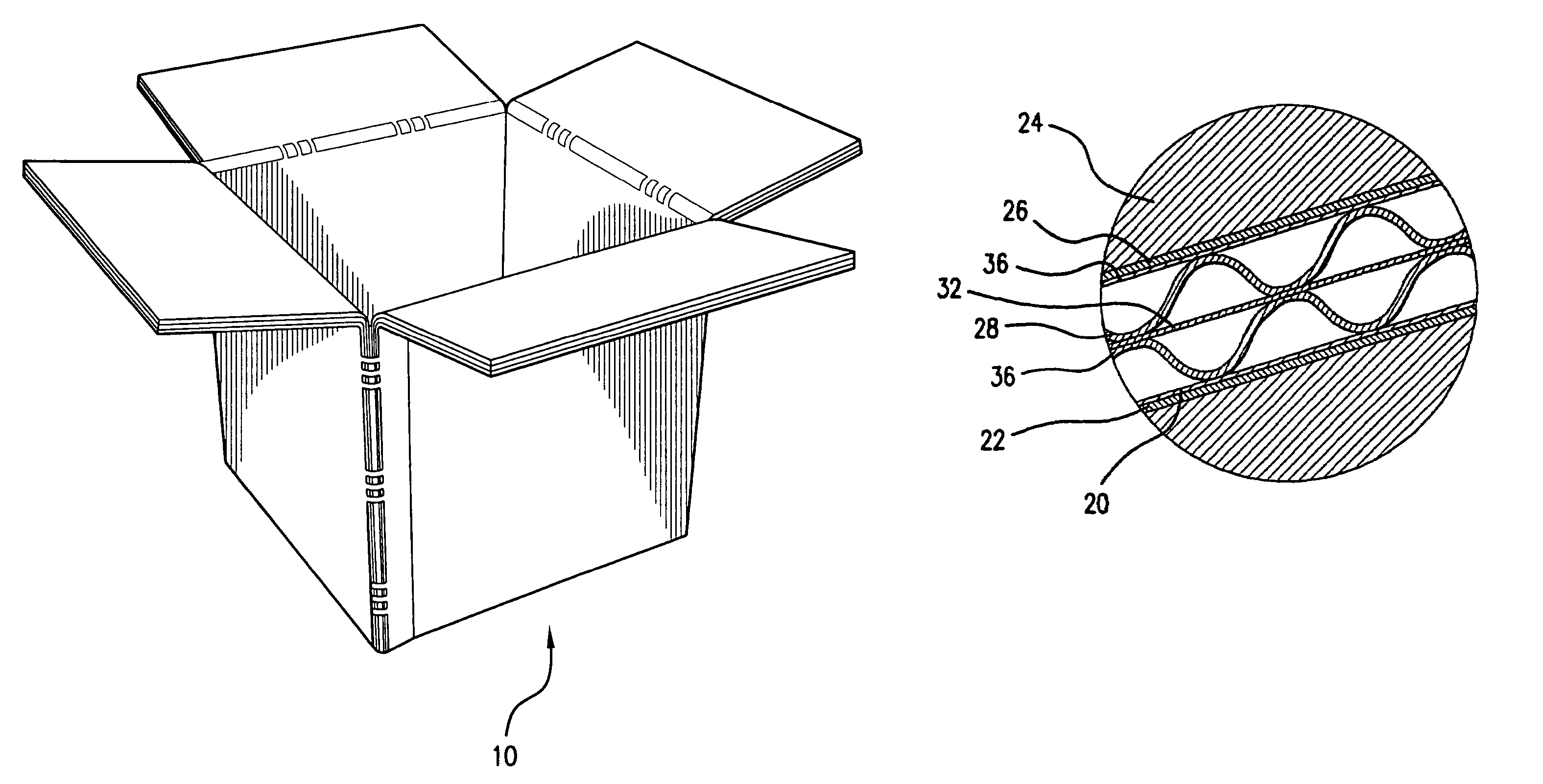

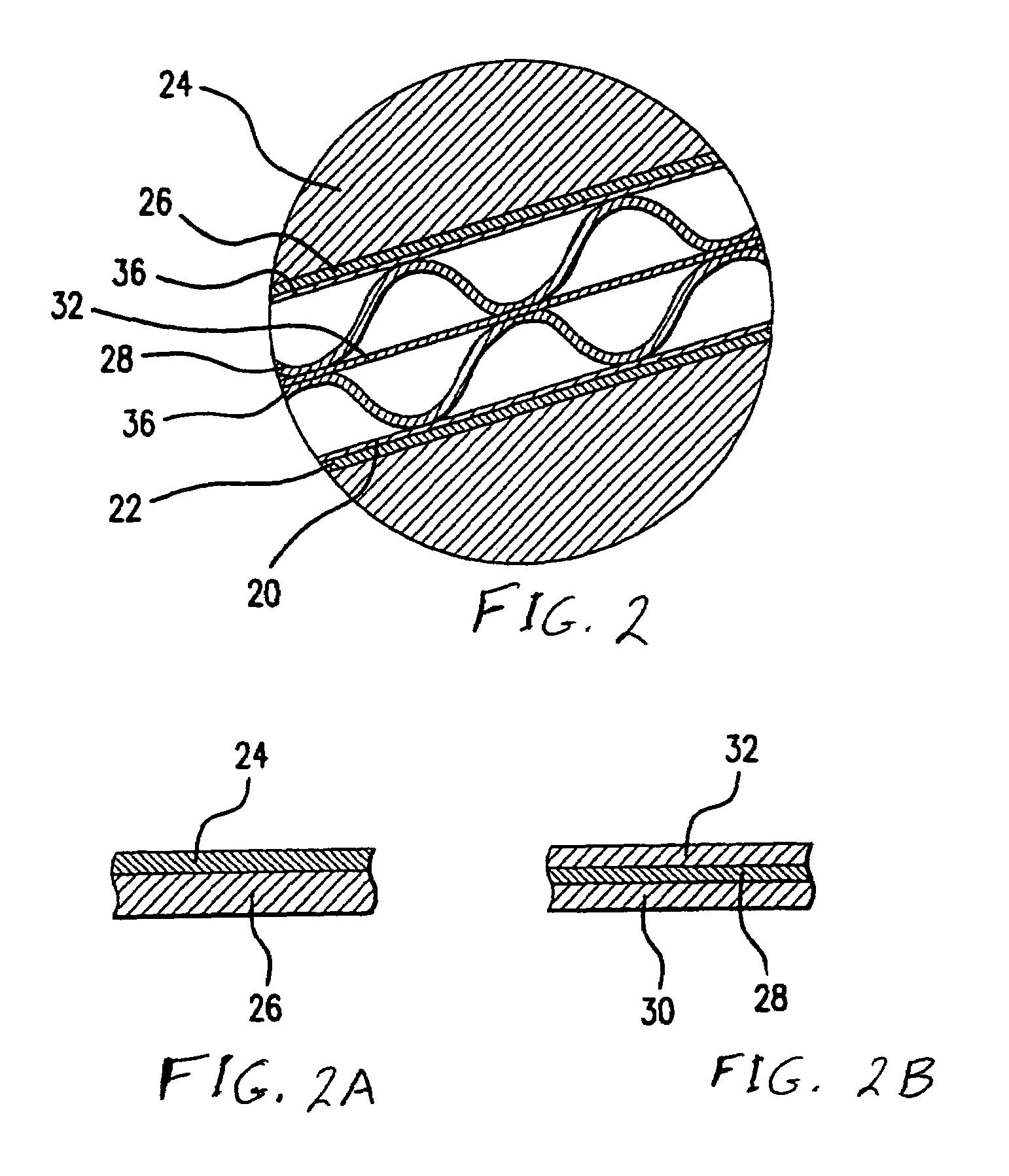

Knockdown corrugated box for temperature control and method of making

ActiveUS7094192B2Envelopes/bags making machineryBoxes/cartons making machineryTemperature controlFlute

A box for shipping temperature sensitive or perishable goods made from a double walled combined web having an inside barrier layer, a first paper liner bonded to the inside barrier layer, a first paper flute medium bonded to the first paper liner, an outside barrier layer, a second paper liner bonded to the outside barrier layer, a second paper flute medium bonded to the second paper liner, and a sandwich of a barrier layer bonded between third and fourth paper liners. The flute mediums are bonded, respectively, to the third and fourth paper liners.

Owner:MILLER DRAYTON +1

Three-layered containers and methods of making the same

ActiveUS20080121681A1Boxes/cartons making machineryDomestic cooling apparatusEngineeringElectrical and Electronics engineering

Owner:PACTIV CORP

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6996951B2Increase storage capacityIncrease capacityEnvelopes/bags making machineryBoxes/cartons making machineryThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

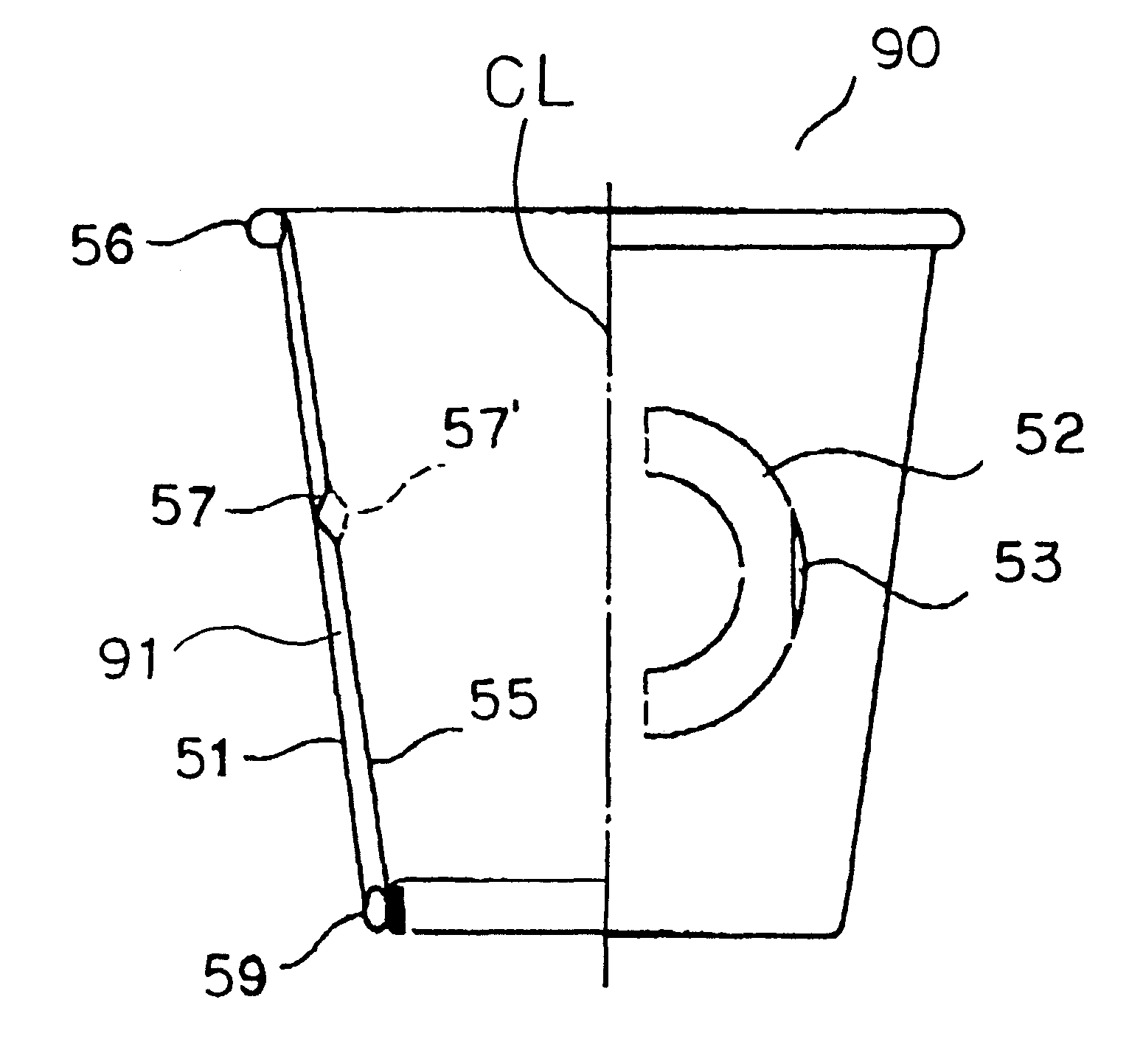

Heat-insulating container

InactiveUS6260756B1Improve insulation performanceIncrease freedomBoxes/cartons making machineryDomestic cooling apparatusPolyolefinEngineering

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

Web material advance system for web material applicator

InactiveUS6893528B2Easy to changeMechanical working/deformationBoxes/cartons making machineryEngineeringSide band

Owner:ADALIS

Insulated food crate

InactiveUS20080296356A1Easy to cleanThe process is simple and effectivePackage recyclingBoxes/cartons making machineryDouble wallEngineering

An insulated food crate comprises a generally rectangular, typically cardboard box having separable top and bottom portions with double walls providing insulative properties and also insulating inserts fitted into the top and bottom portions. The box may also have ventilation holes or slots and / or compartments for serving utensils and may be disposable. In alternate embodiments, the insulated food crate may be made from a heat-resistant composite material, such as a reinforced plastic or stainless steel, as a more permanent, durable, and reusable solution. This inexpensive, accessible catering box keeps hot foods hot and cold foods cold while allowing quick and easy access to the foods inside.

Owner:HATCHER JOHN AUGUST +1

Insulated container

ActiveUS20170334622A1Efficient and economically manufacturedMinimize negative impactWrappersBoxes/cartons making machineryInsulation layerIsolation layer

An insulated container may include a rigid container surrounding an insulation layer formed from a post-industrial, pre-consumer card waste. The insulation layer may be characterized by a lack of any wrapping material. The insulation layer may be manufactured using a variety of converting processes including, carding, airlay, and needle punch to form a non-woven material for providing consistent density throughout the insulation layer. The insulation layer may include a natural fiber lamination layer on an outer surface of the insulation layer. The insulation layer may be biodegradable in an anaerobic environment.

Owner:AIRLITE PLASTICS

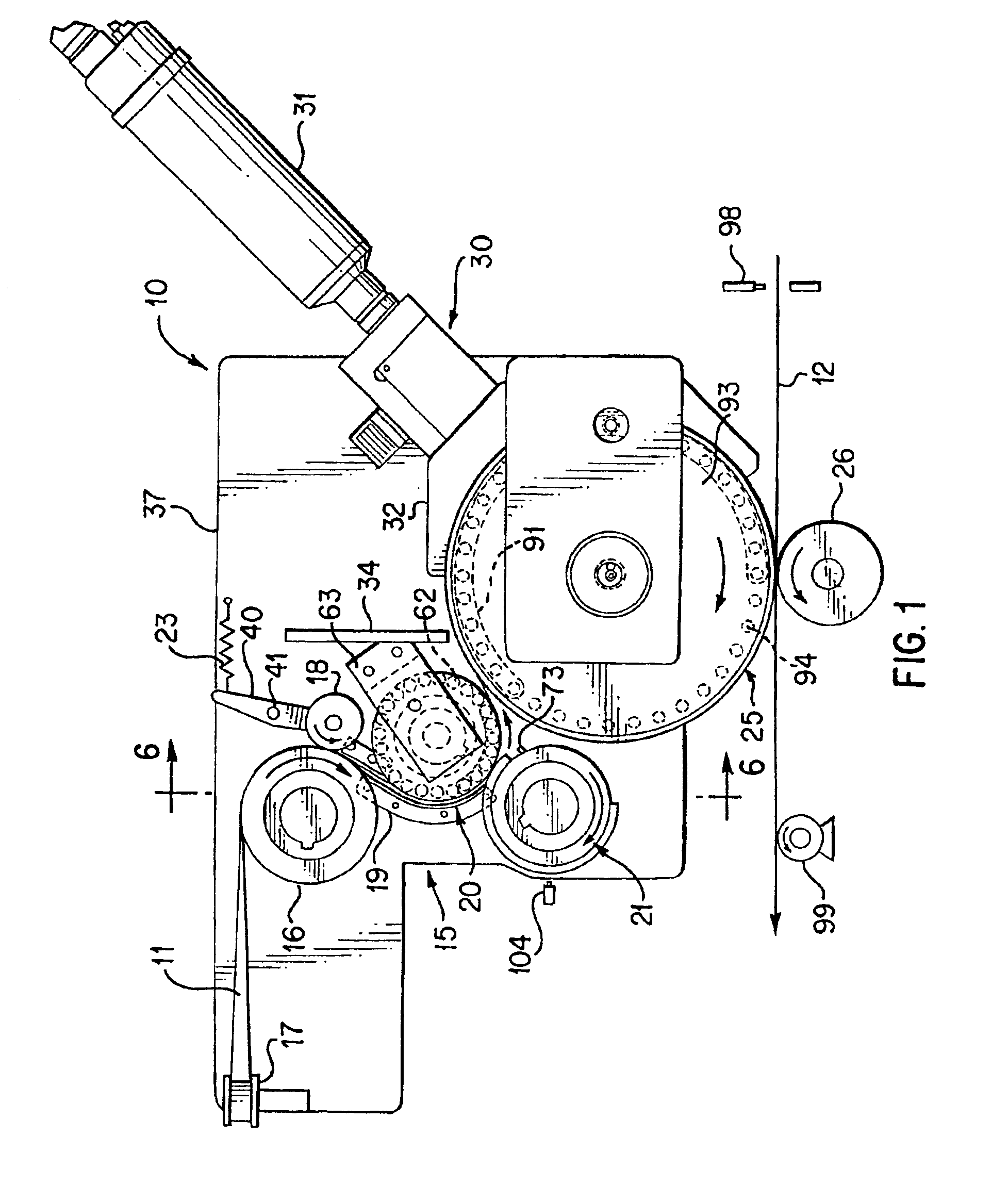

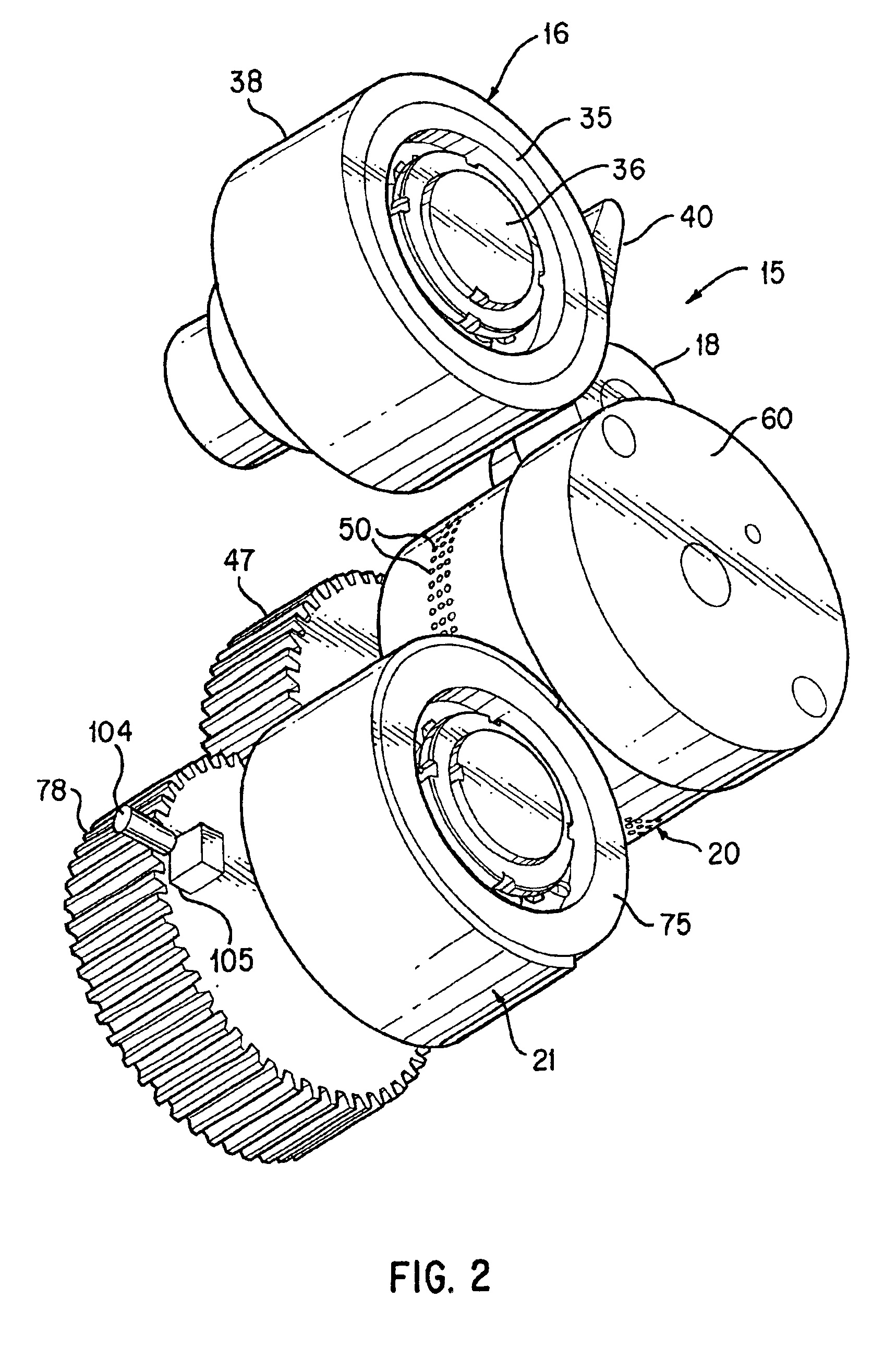

Blank, apparatus and method for constructing container

ActiveUS20070228119A1Easy to shapeBoxes/cartons making machineryBox making operationsRotational axisEngineering

An apparatus for constructing a container from a continuous blank of sheet material including a plurality of panels coupled together at a plurality of fold lines is provided. The apparatus includes a mandrel that is rotatable about a rotational axis. The mandrel includes a rotary head that defines a plurality of exterior surfaces each corresponding to a panel of the continuous blank of sheet material. The rotary head forms an opening in at least one exterior surface configured to receive at least one panel for facilitating forming the blank of sheet material into a configuration with respect to a shape of the rotary head as the mandrel rotates about the rotational axis.

Owner:WESTROCK SHARED SERVICES LLC

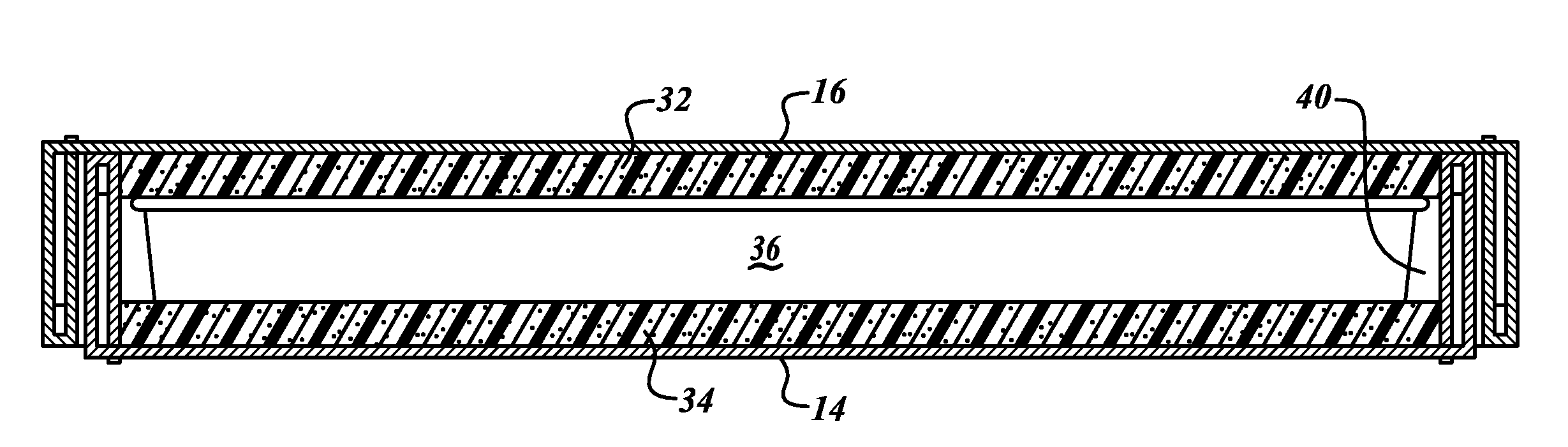

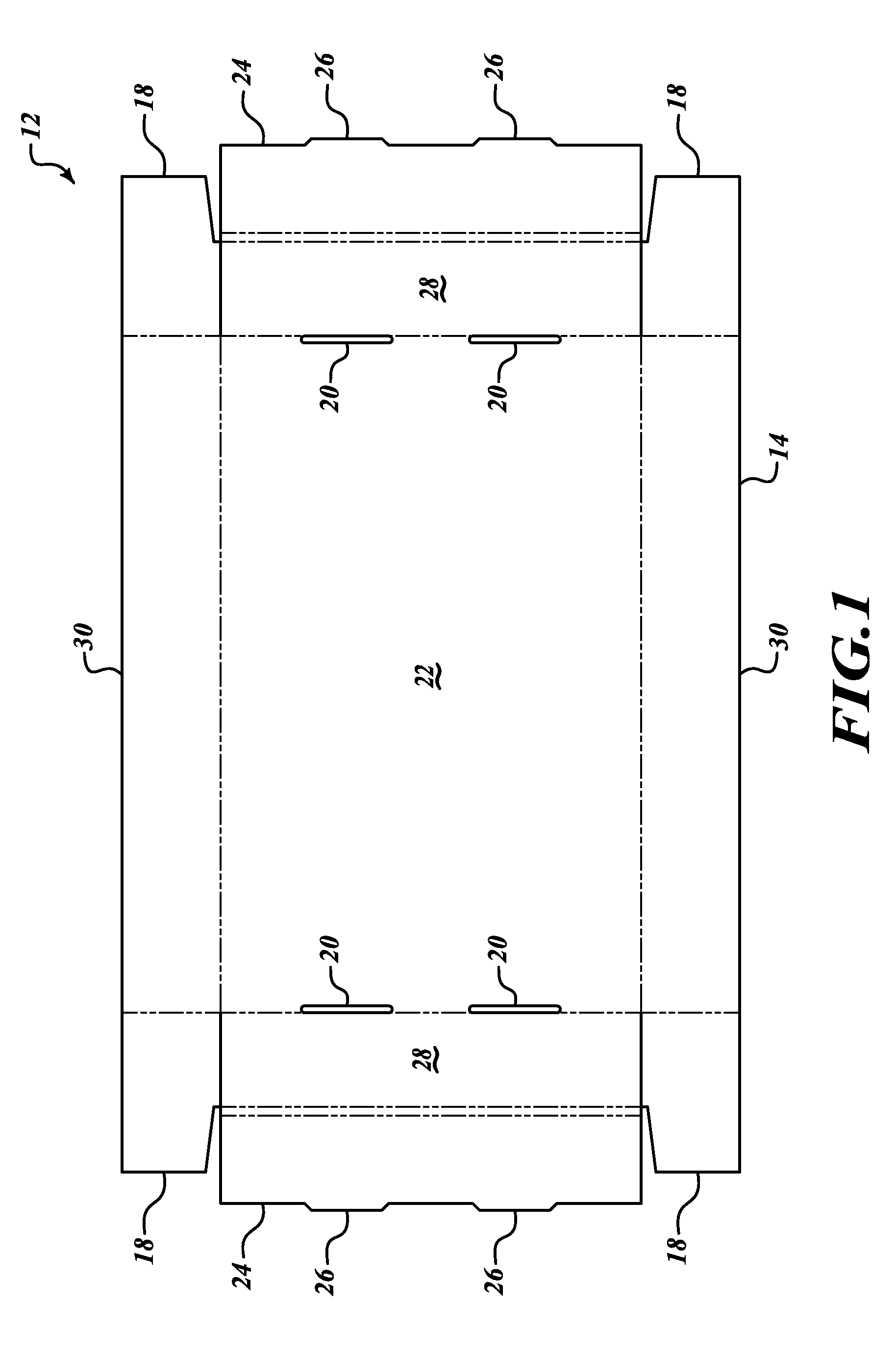

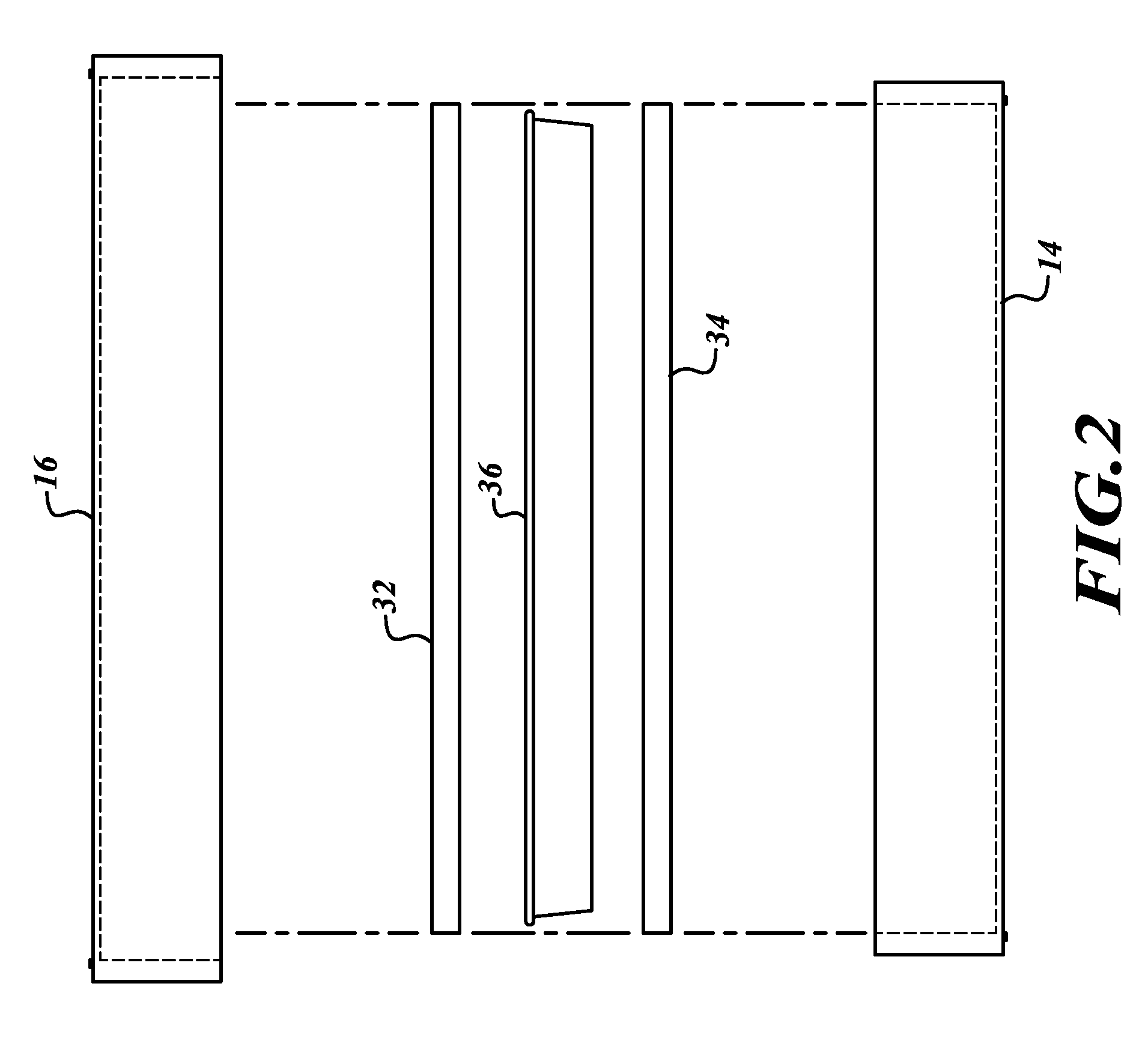

Thermal container

ActiveUS20100006630A1Reduce thicknessMechanical working/deformationBoxes/cartons making machineryMetal foilKnife blades

A thermal insulating liner for a container lid has a top sheet and a bottom sheet spaced by a core. The bottom sheet has an exterior metal foil layer. A side edge-to-side edge transverse cut line extends through the bottom sheet proximate each of two opposed ends of the liner. The liner has reduced thickness end margins extending between each said side edge-to-side edge transverse cut line and each of the opposed ends. A die to make the lid liner has a central well and, proximate each end of the die, an upward step to a land with an inside edge of the step having a ramp surface. A first cutting blade protrudes upwardly from the land and a second cutting blade protrudes upwardly above the land at each end of the die and above the level of the first cutting blade.

Owner:FRESH BAILIWICK

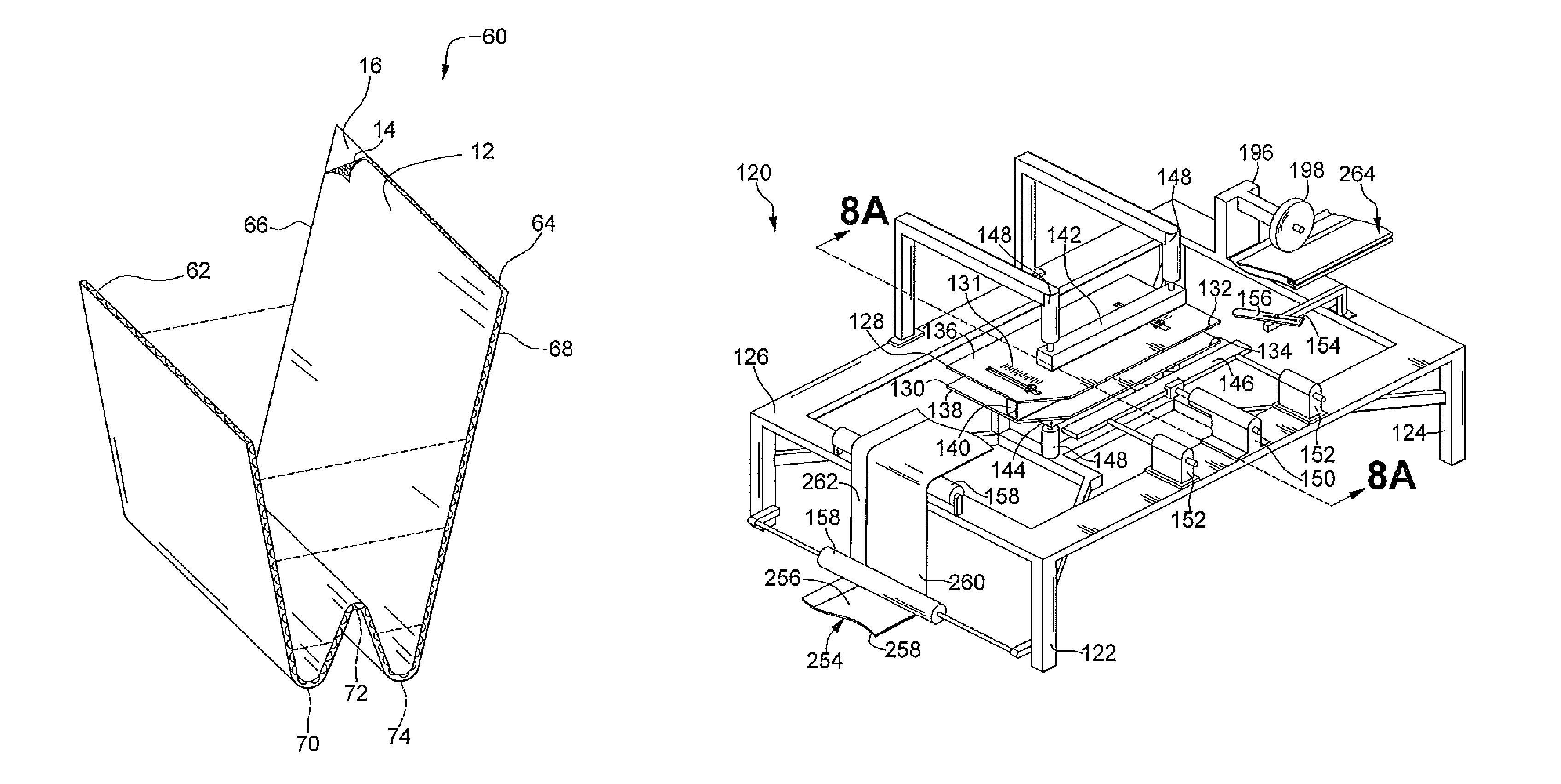

Container insert apparatus and method

InactiveUS8465404B2Reduce laborLow costEnvelopes/bags making machineryWrappersInterior spaceEngineering

A container insert, and an apparatus and a method of producing the container insert. The container insert is formed as a deformable pouch adapted to be received in an interior of an associated container. The pouch has a closed lower end, an open upper end, and spaced apart sealed edges. The lower end of the pouch includes two leg portions. The pouch is manipulatable to generally conform to the interior of the contained and form a hollow interior space therein for receiving an object and providing a lining for the interior of the container. The apparatus and the method for producing the insert provides for a substantially automatic and continuous production of the insert from a roll of material.

Owner:CUTTING EDGE CONVERTED PROD

Carton blank and method of forming a carton blank

A carton blank may be formed from a first sheet of relatively rigid material and a second sheet of relatively flexible fluid impervious material. The second sheet of relatively flexible fluid impervious material may cover some but not other portions of the first sheet of relatively rigid material in order to facilitate gluing of the other portions of the first sheet of relatively rigid material when the carton blank is assembled into a carton.

Owner:GRAPHIC PACKAGING INT

Handle and top handle reinforcement for a paperboard carton

A fully enclosed carton for carrying heavy loads with a reinforcement insert for the handle apertures located in the top end flaps of the carton. The paperboard reinforcing insert may be extended as a bridge across the top panel of the carton to prevent tearing of the handle apertures in the top end flaps and also tearing in the top panel of the carton when carrying a heavy load. The carton may have one or more dispensers in the top panel which may extend into an adjoining side panel. Multiple tear lines may be formed for the dispenser flap in the insert that extends across the top panel to permit easy access to the containers, such as bottles, in the carton. The paperboard reinforcing insert may have a larger aperture than the handle aperture in each top end flap to adjust for any imprecision in the alignment of the paperboard insert in forming the carton sleeve from the paperboard blank. When the paperboard insert extends across the top panel and one or more dispensers are formed in the top panel, multiple tear lines may be used to form the flaps in the insert to compensate for any imprecision in the insertion of the insert that extends across the top panel into the carton sleeve when it is being formed.

Owner:GRAPHIC PACKAGING INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com