Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19083 results about "Continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production.

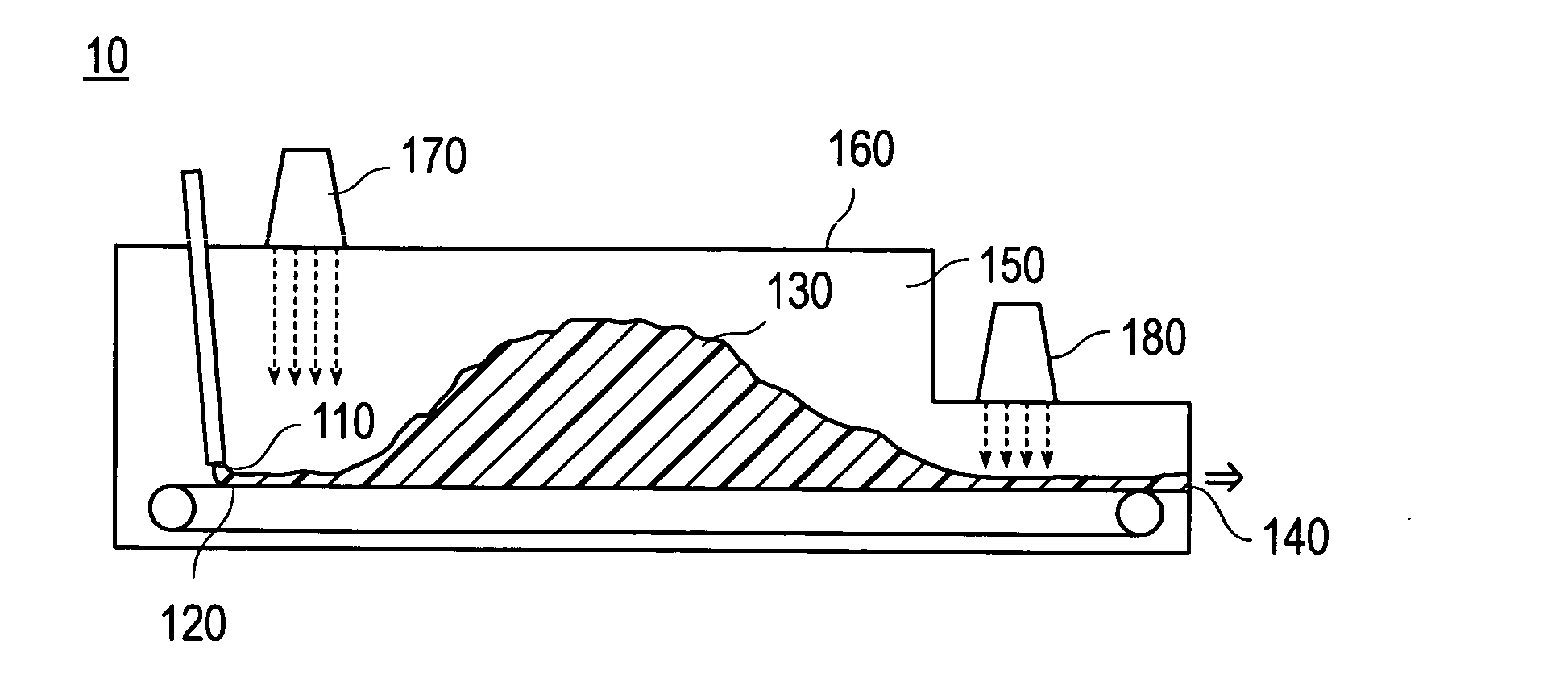

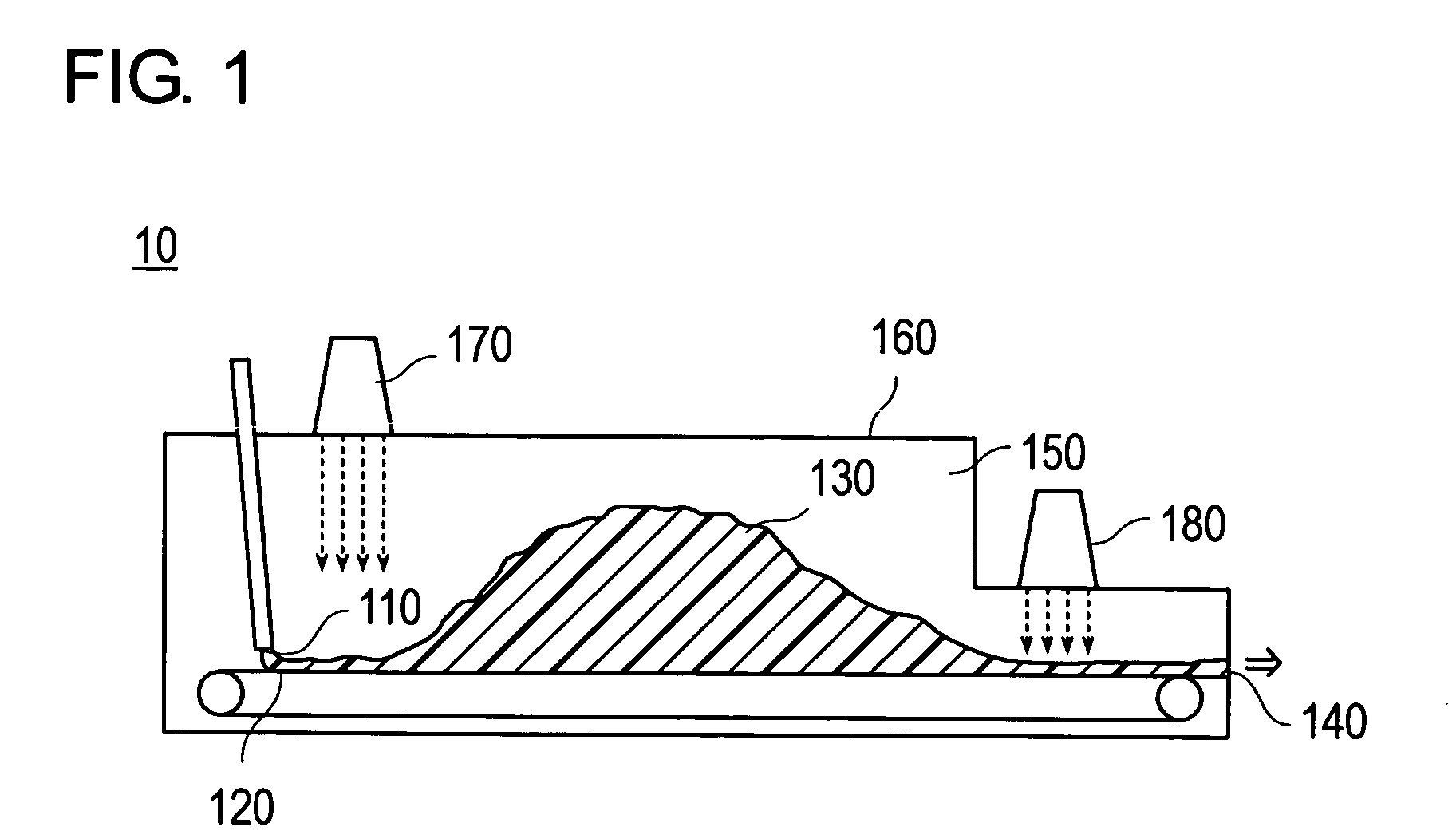

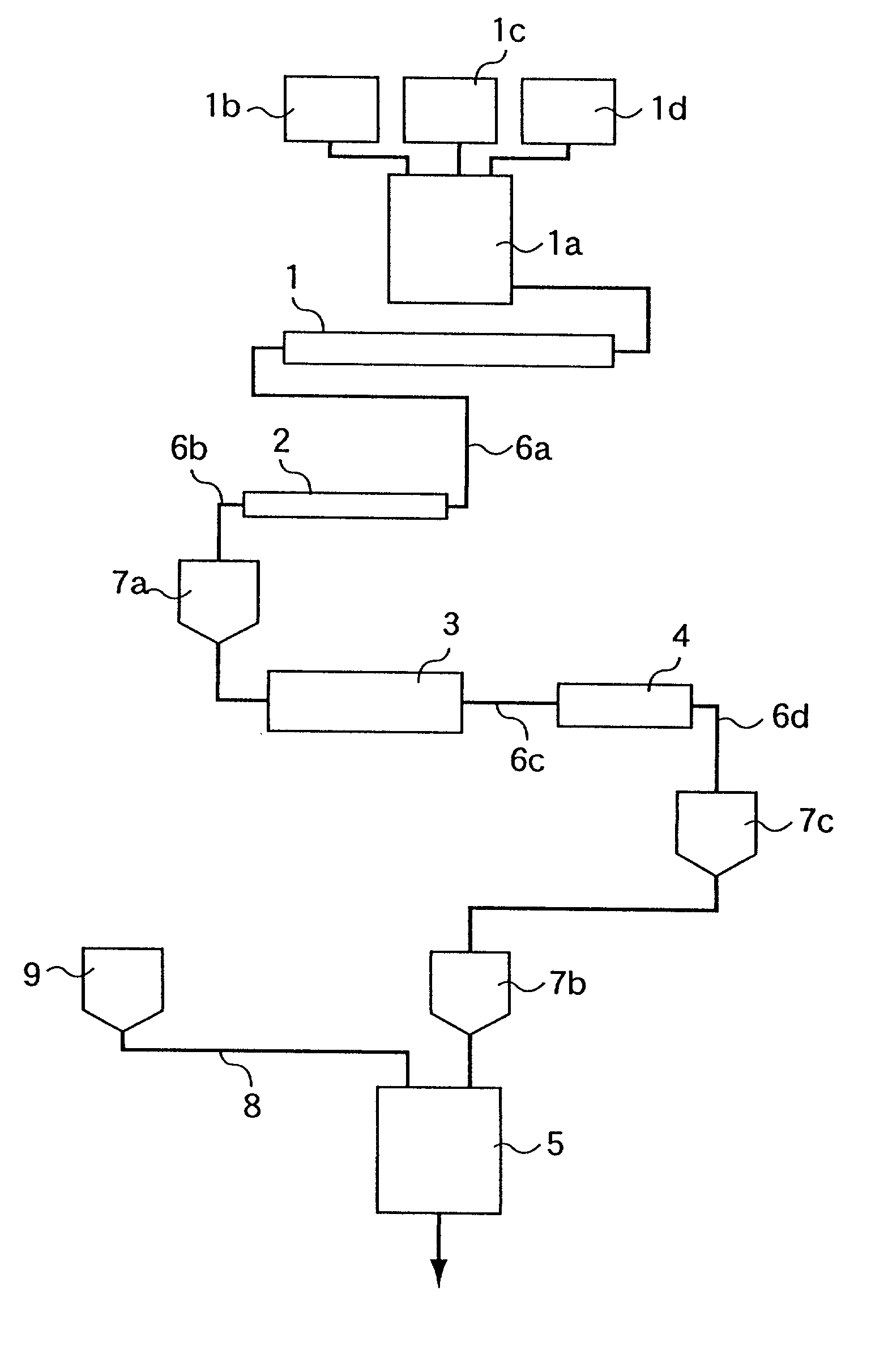

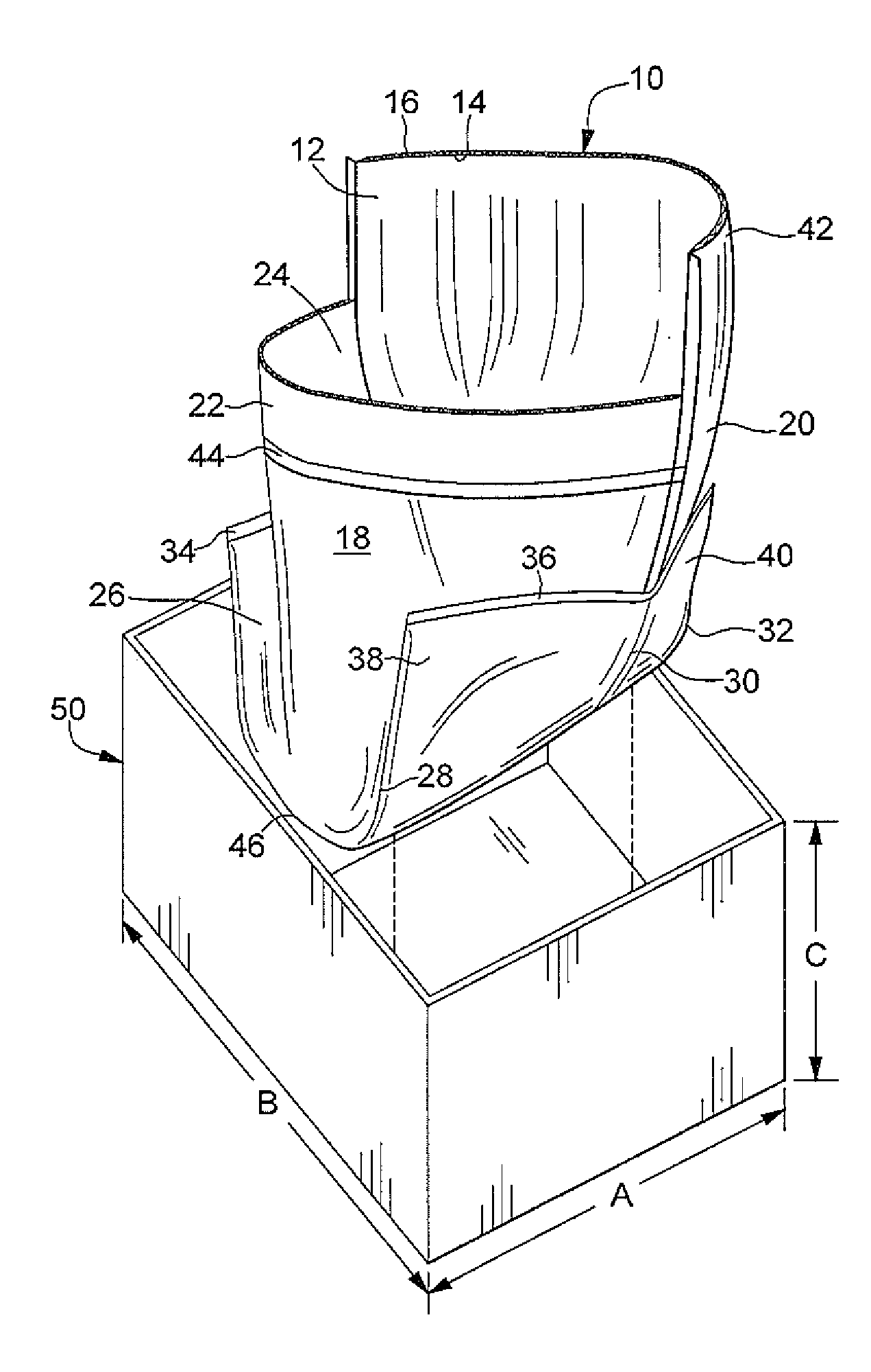

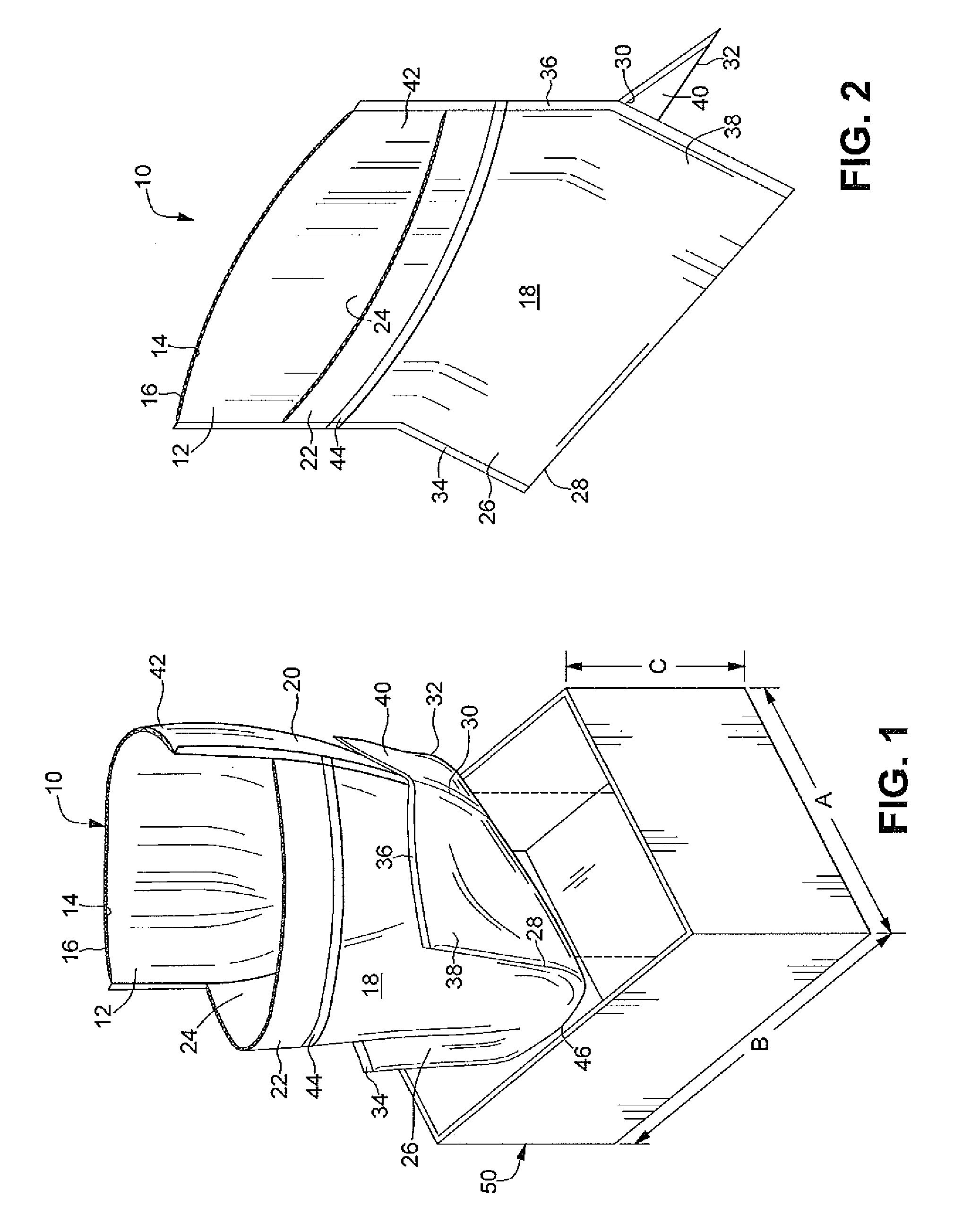

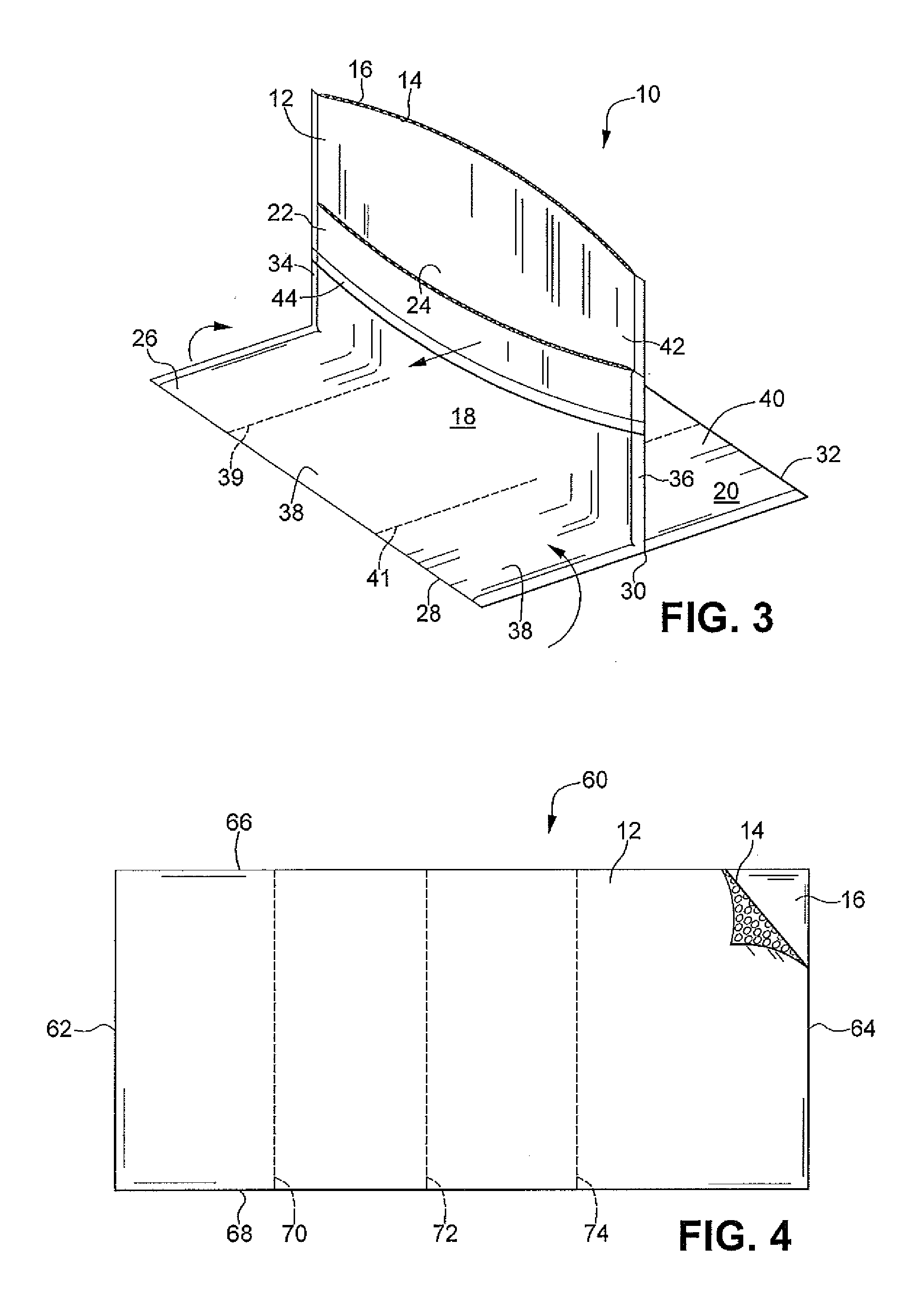

Method for continuous production of water-absorbent resin

The present invention relates to a method for continuous production of a water-absorbent resin by use of an continuous polymerization device having a charge part of a monomer aqueous solution; an endless belt on which the monomer and a hydropolymer formed are conveyed; and a discharge part of the hydropolymer, wherein the continuous polymerization device has side walls and a ceiling, and the space ratio in the device represented by the equation, “space ratio in the device=B / A”, is in the range of 1.2 to 20. In the equation, A is a maximum cross-sectional area (cm2) of the hydropolymer during the polymerization in the width direction of the endless belt, and B is a maximum cross-sectional area (cm2) of the space between the endless belt of the continuous polymerization device and the ceiling of the continuous polymerization device in the width direction of the endless belt.

Owner:NIPPON SHOKUBAI CO LTD

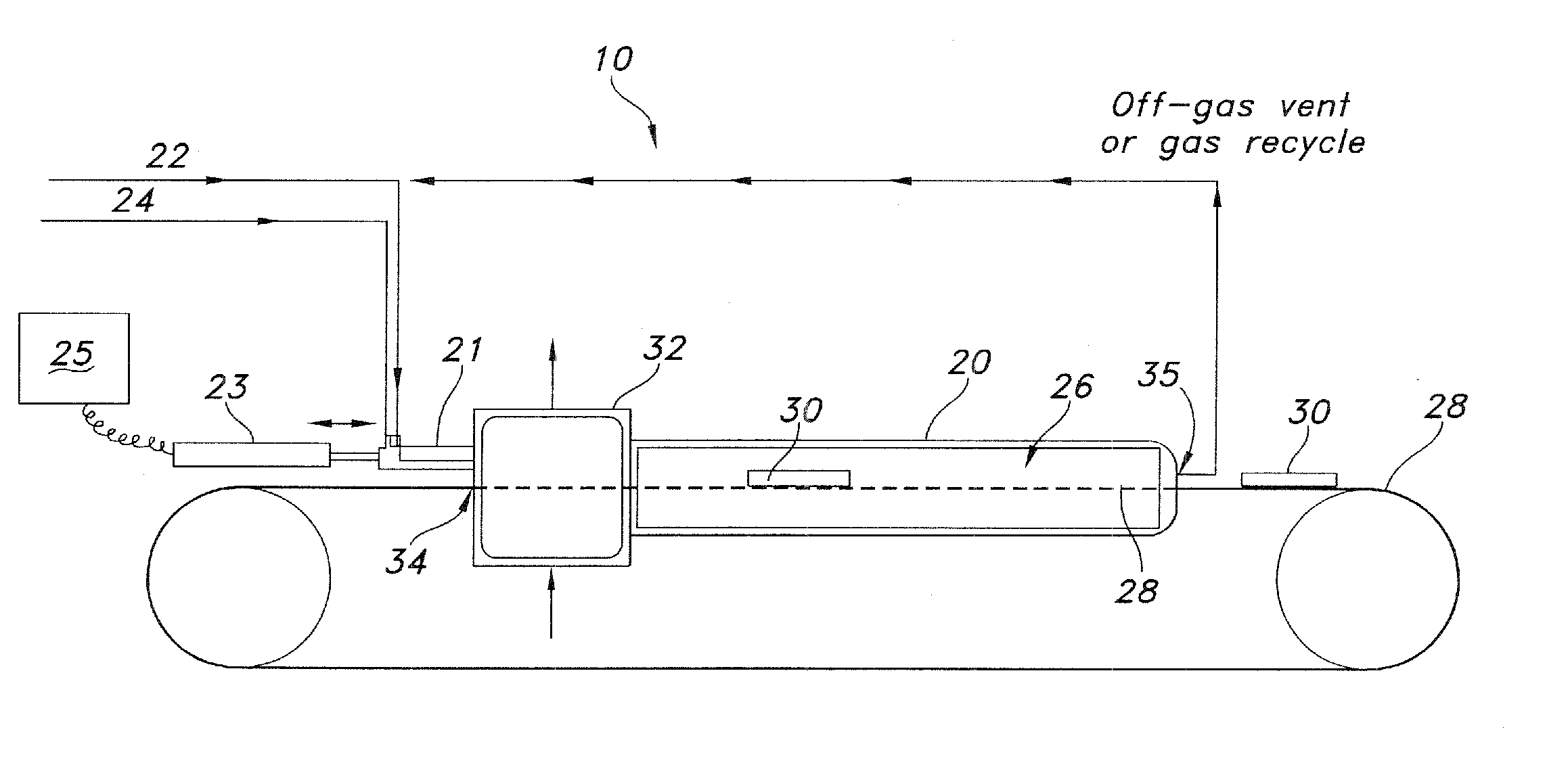

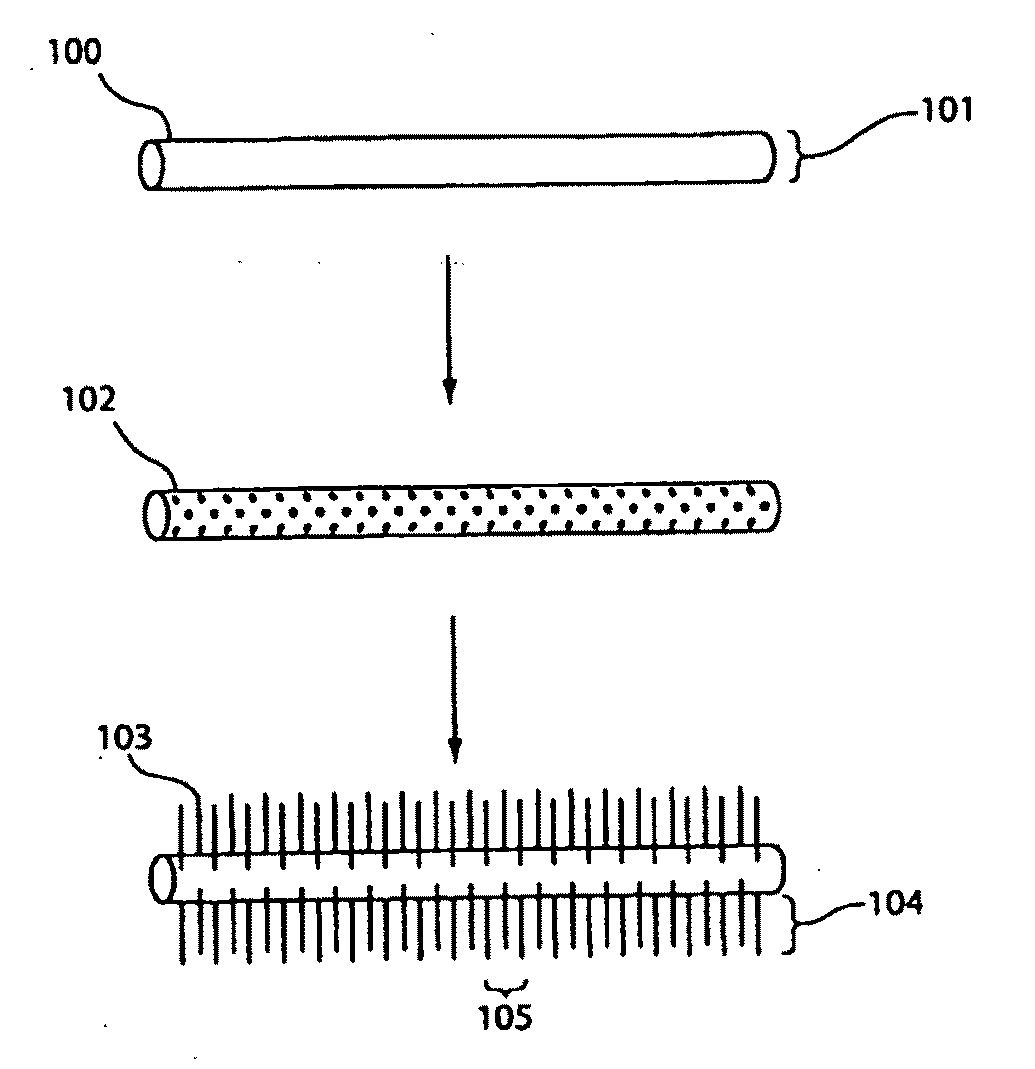

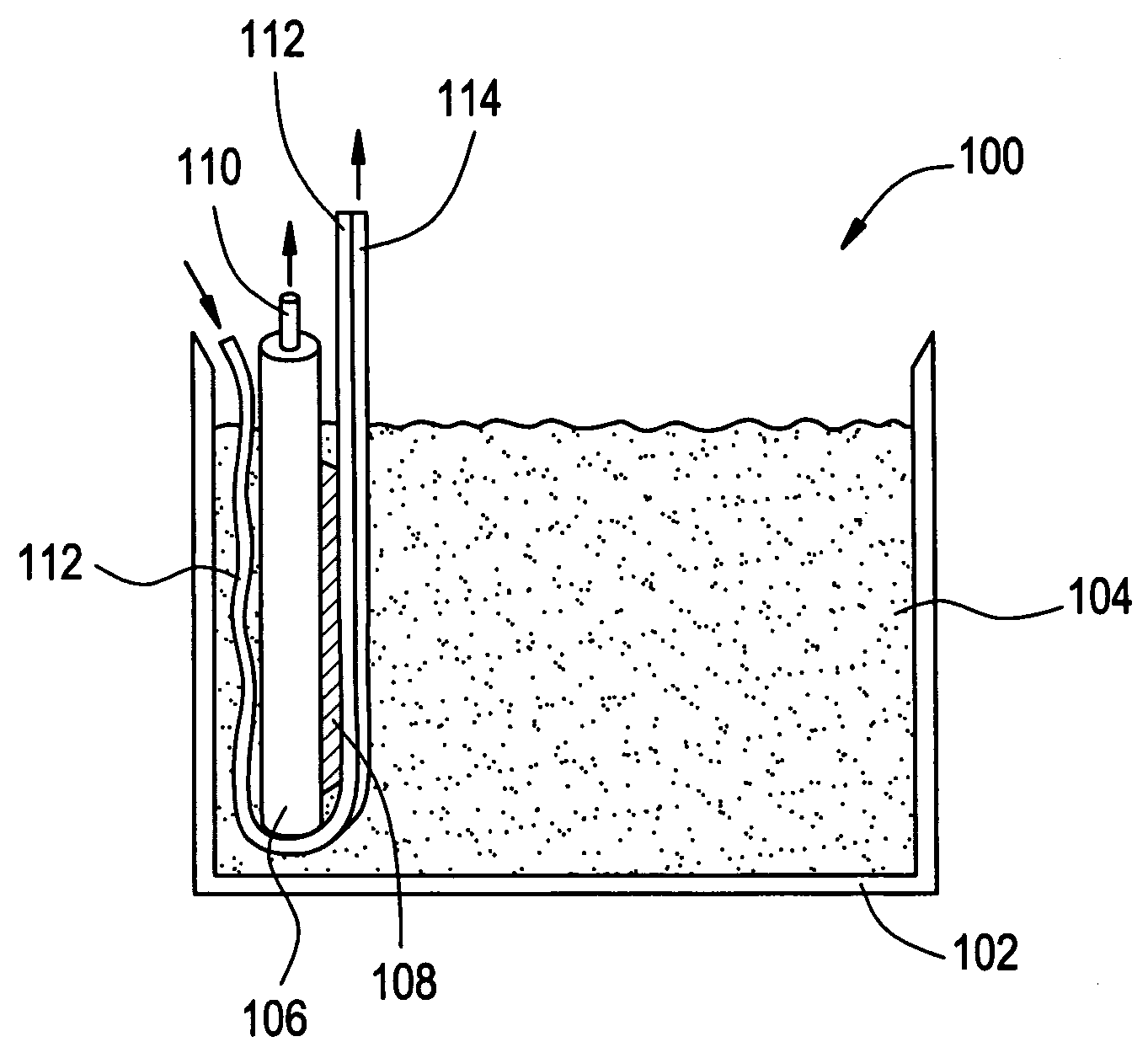

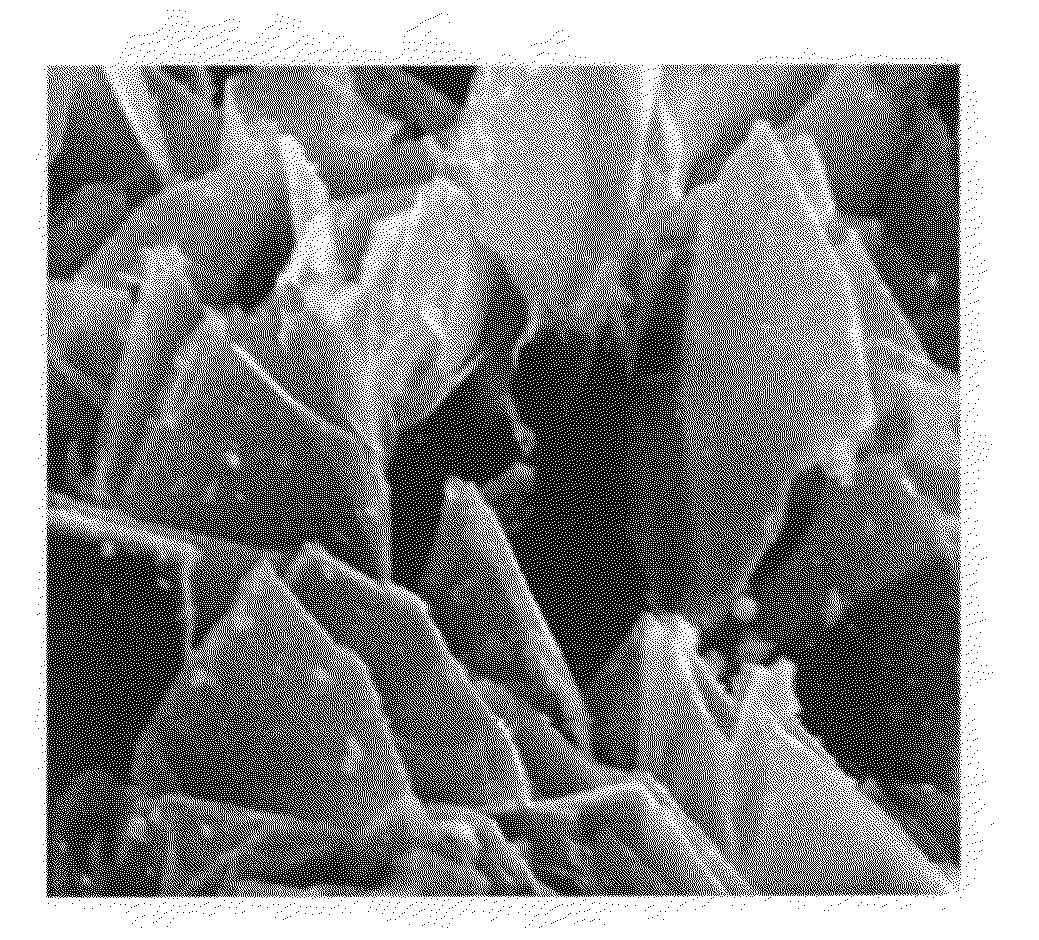

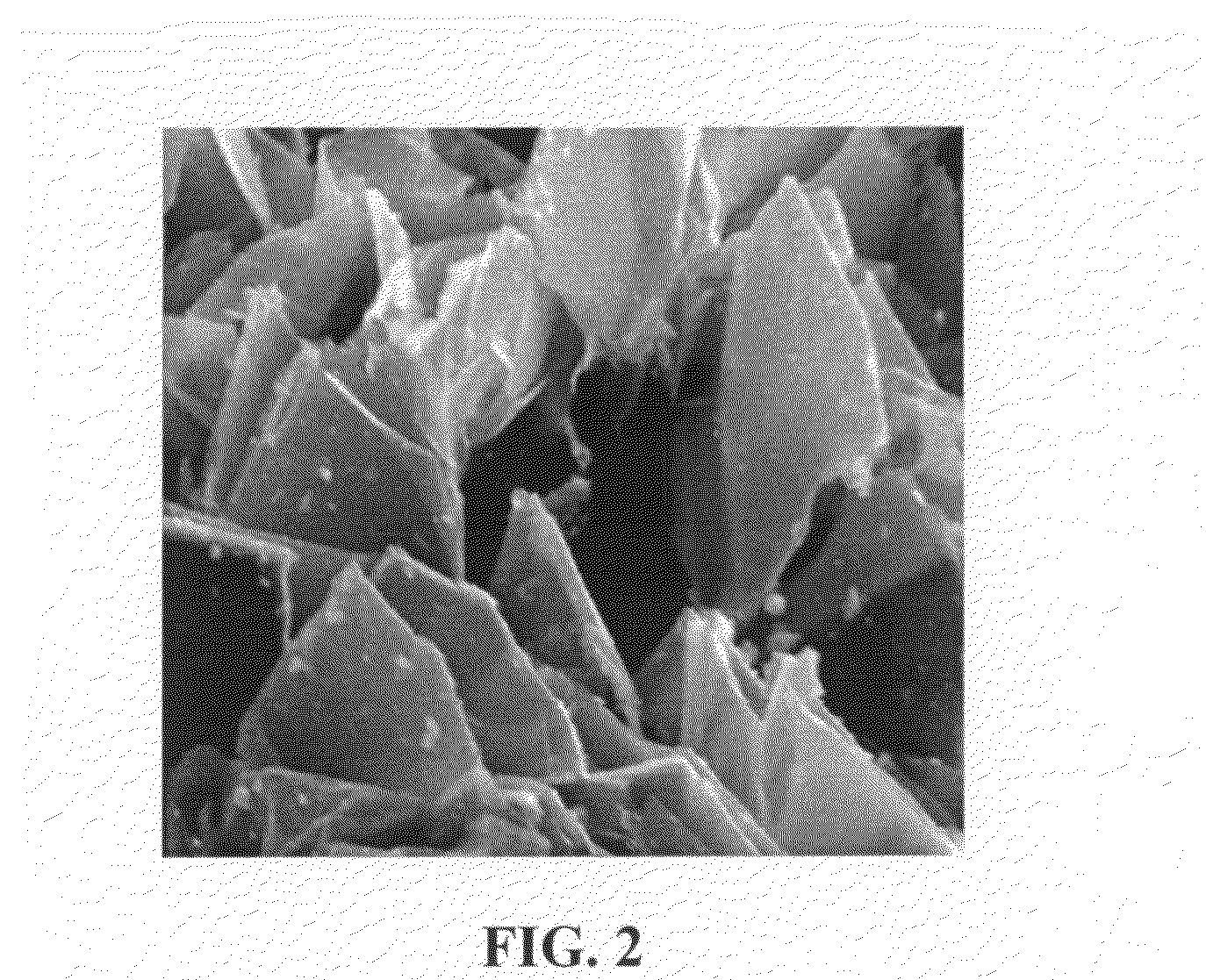

Process for the continuous production of aligned carbon nanotubes

ActiveUS7160531B1Improve flow characteristicsMaterial nanotechnologyCarbon compoundsMetal catalystPorous medium

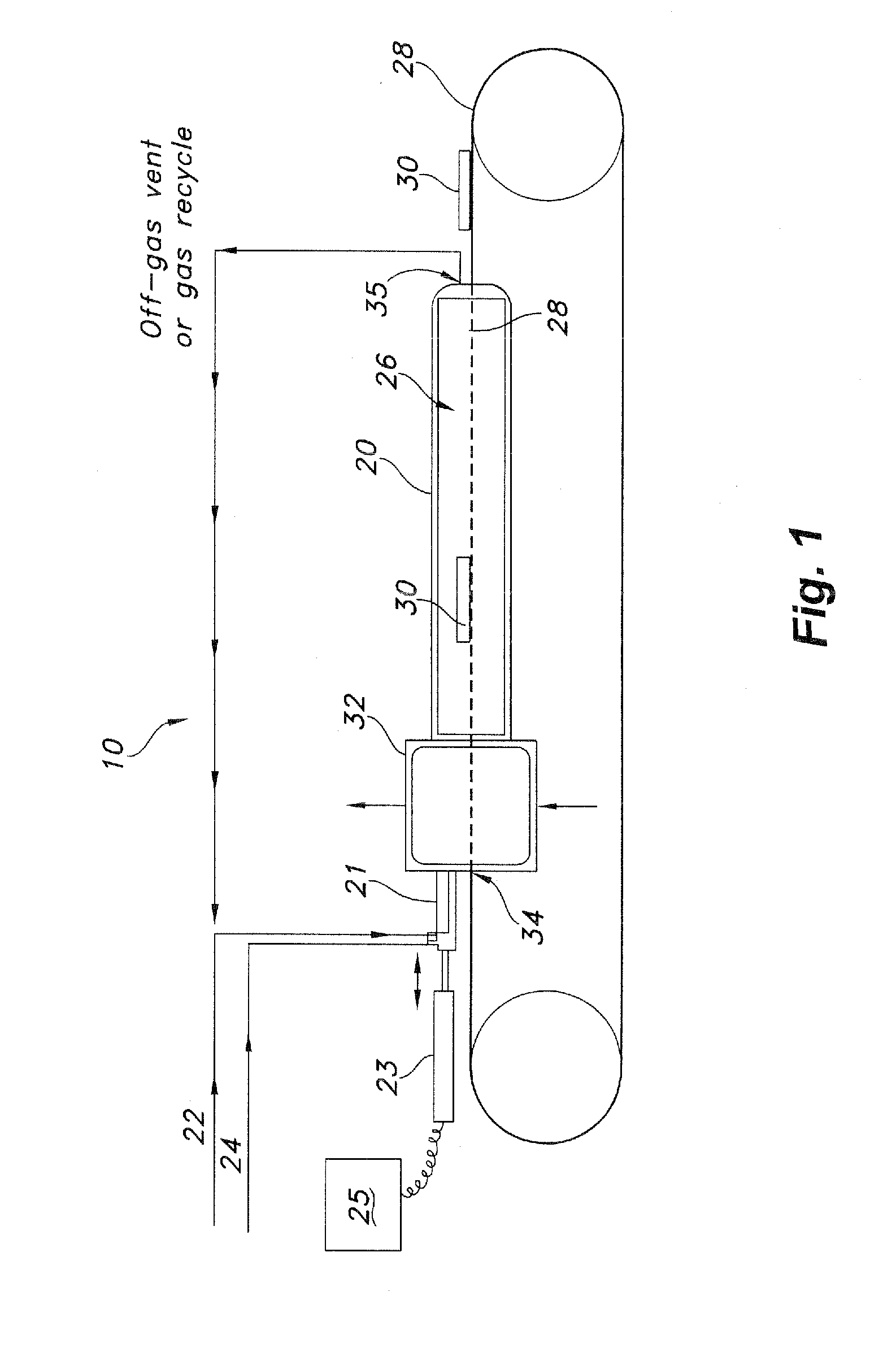

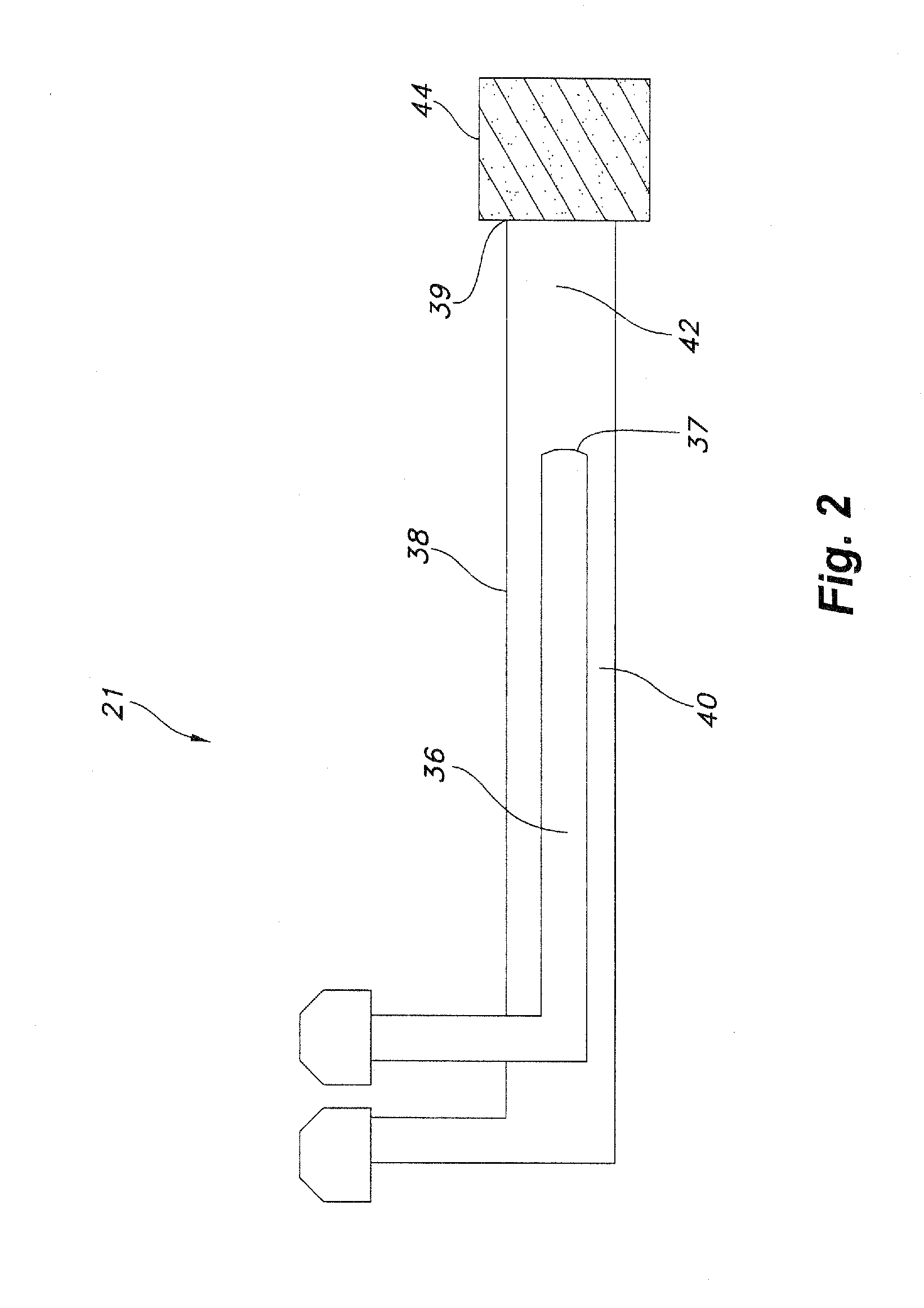

Novel methods and apparati for continuous production of aligned carbon nanotubes are disclosed. In one aspect, the method comprises dispersion of a metal catalyst in a liquid hydrocarbon to form a feed solution, and volatilizing the feed solution in a reactor through which a substrate is continuously passed to allow growth of nanotubes thereon. In another aspect, the apparatus comprises a reactor, a tube-within-a-tube injector, and a conveyor belt for passing a substrate through the reactor. The present invention further discloses a method for restricting the external diameter of carbon nanotubes produced thereby comprising passing the feed solution through injector tubing of a specified diameter, followed by passing the feed solution through an inert, porous medium. The method and apparati of this invention provide a means for producing aligned carbon nanotubes of a particular external diameter which is suitable for large scale production in an industrial setting.

Owner:UNIV OF KENTUCKY RES FOUND

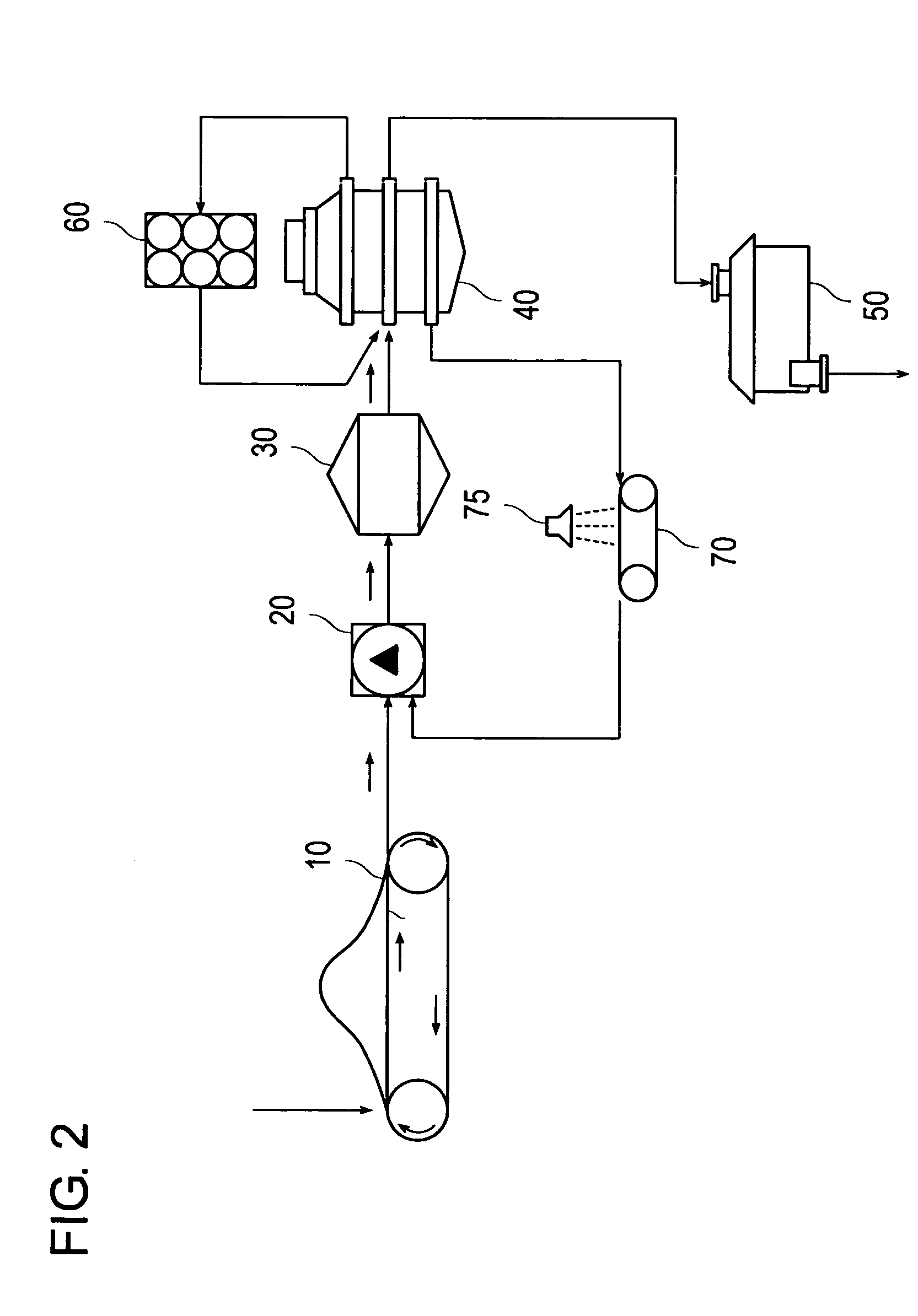

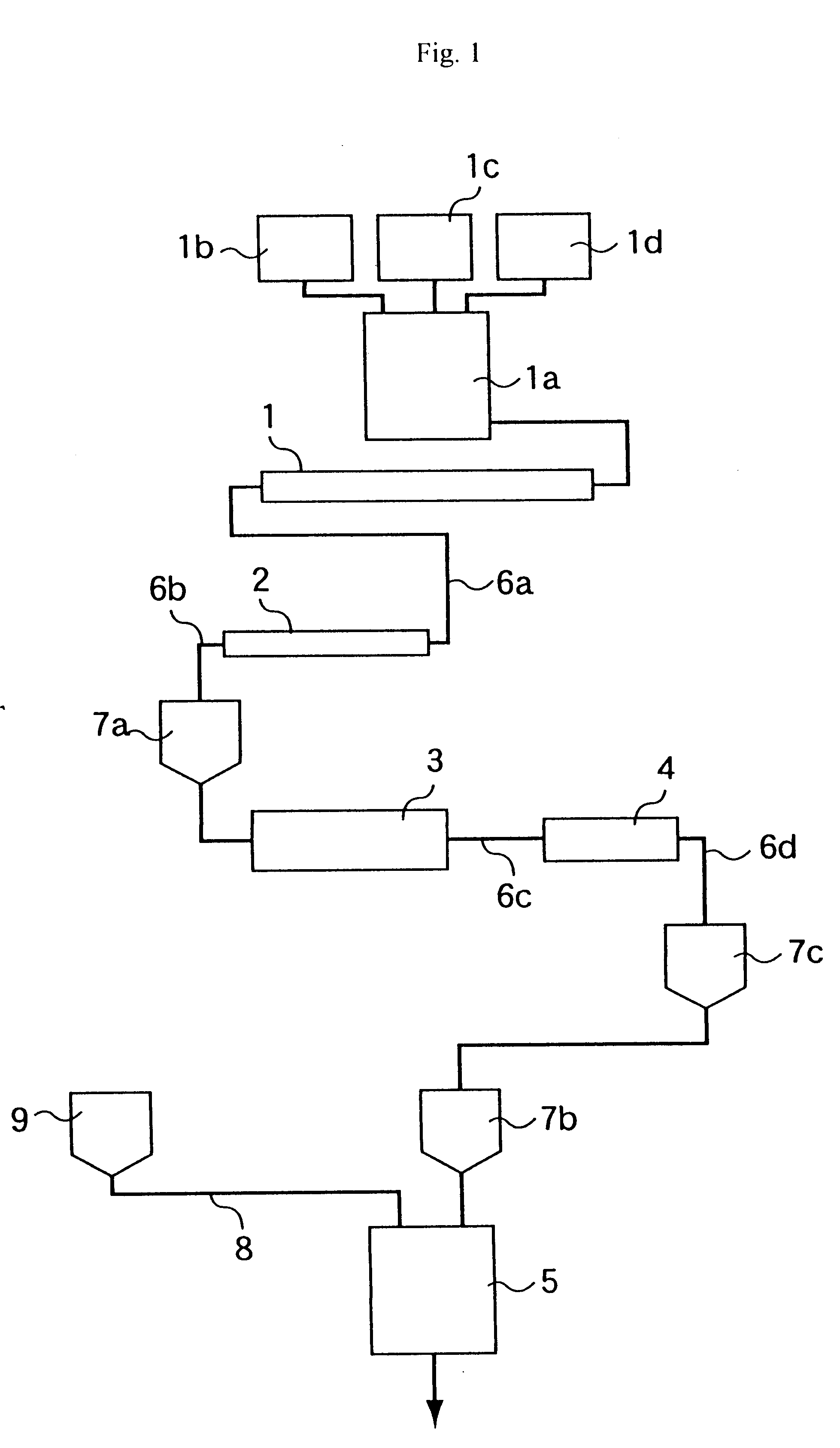

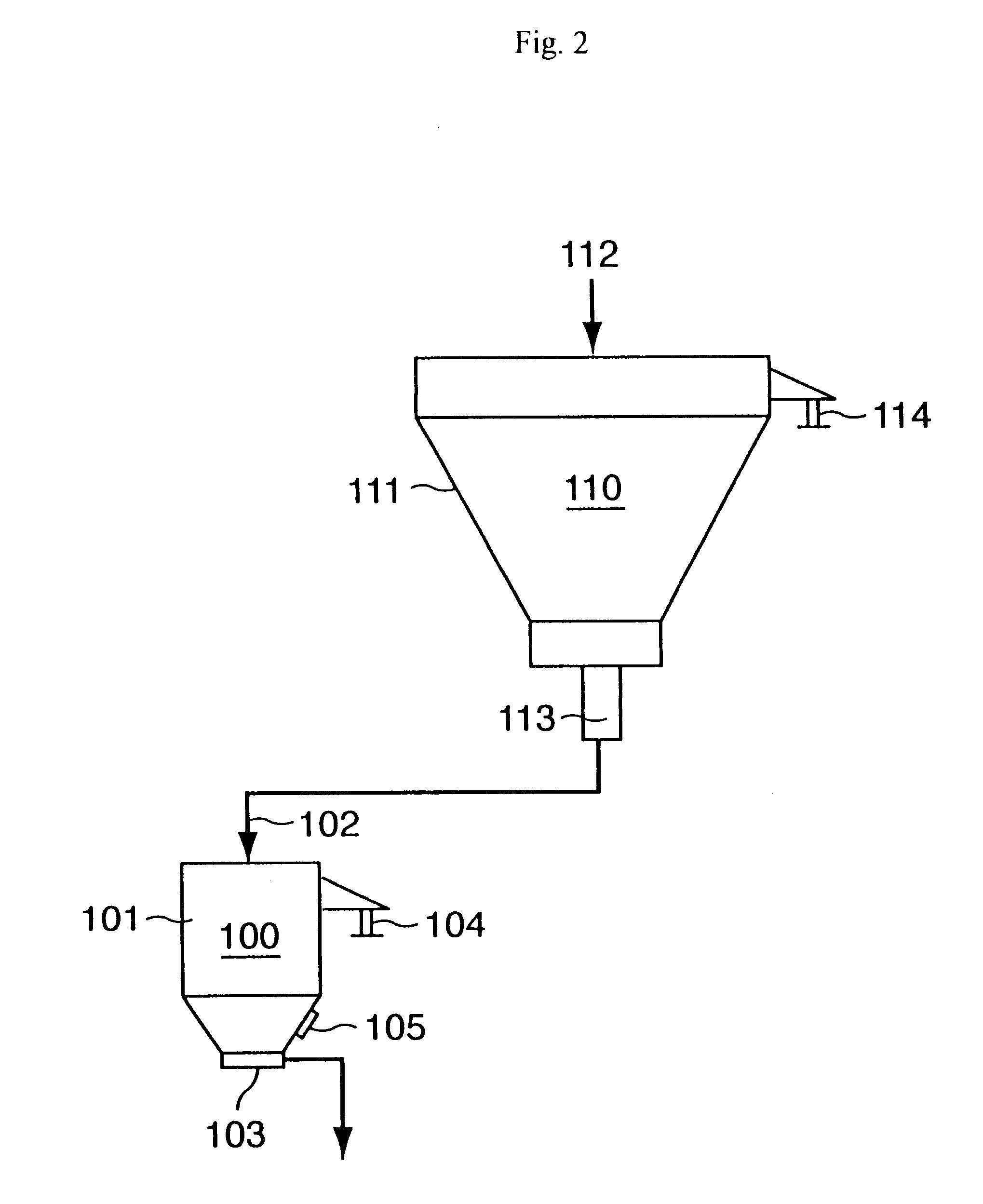

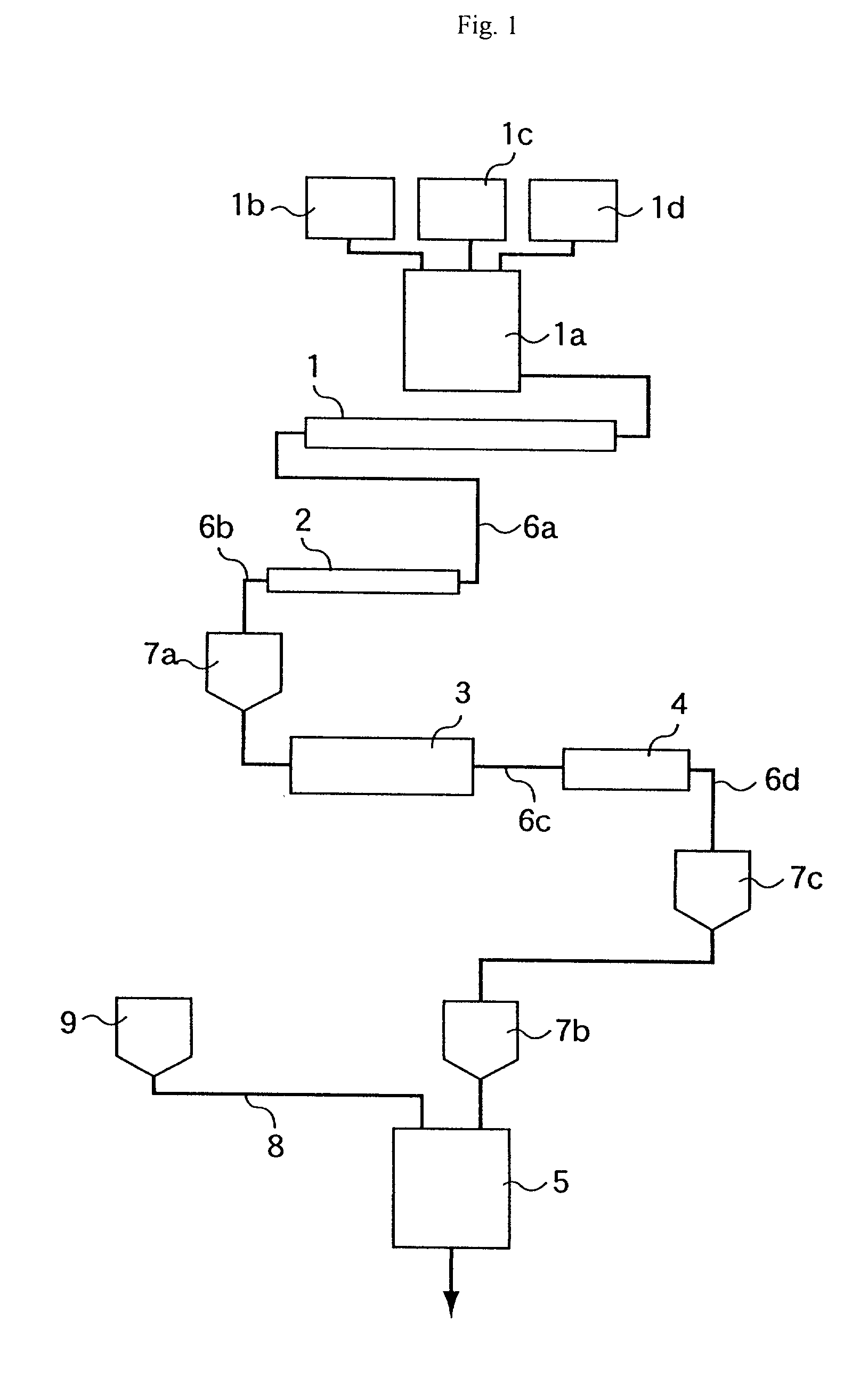

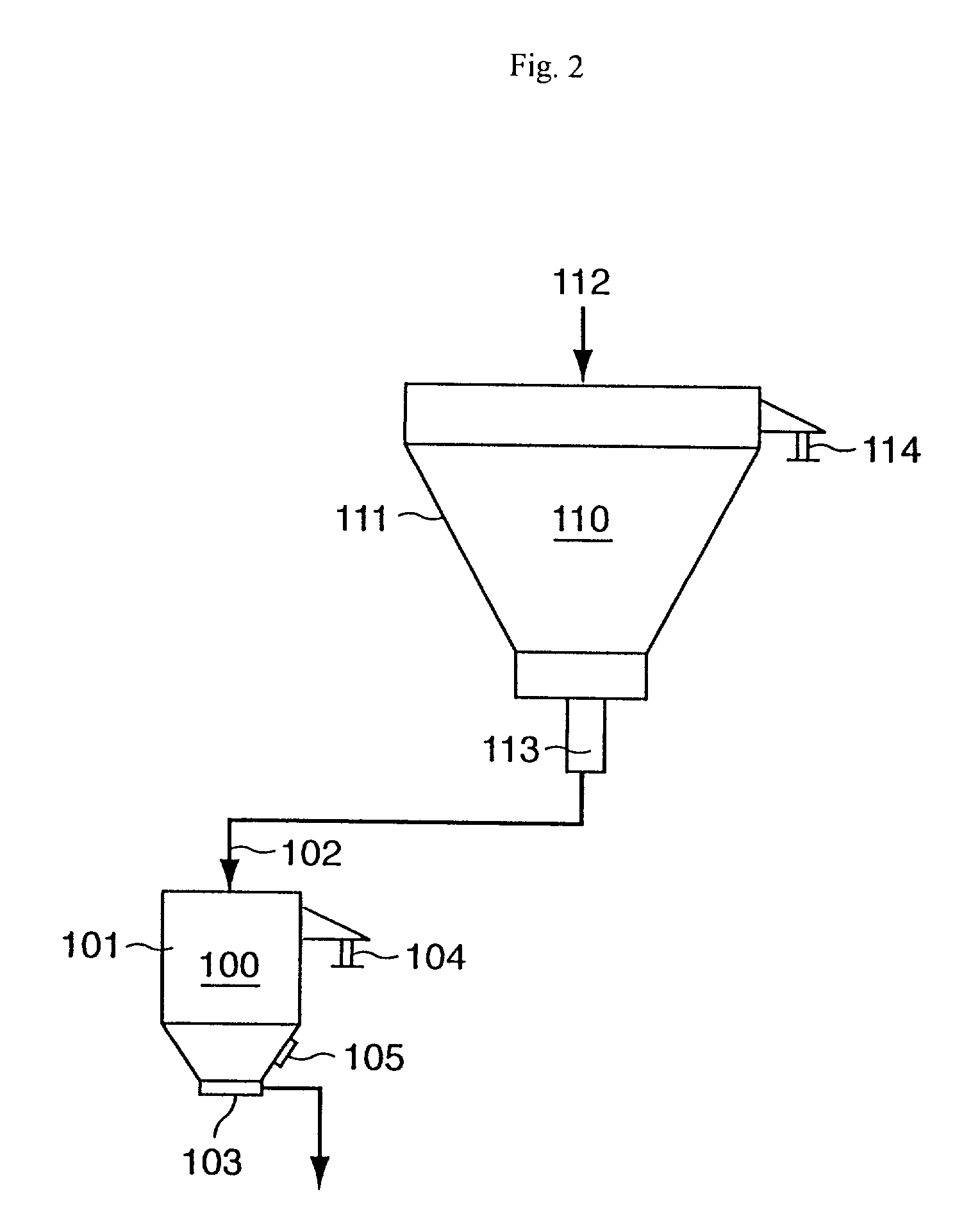

Continuous production process for water-absorbent resin powder and powder surface detector used therefor

A surface-modified water-absorbent resin powder is produced continuously with high productivity in a state where the particle diameter distribution is narrow and where the properties are high by a process comprising a polymerizing step, a drying step, a pulverizing step, a classifying step, and a surface-modifying step, and further, conveying steps of connecting them, wherein the conveying steps include at least two hoppers for storing the water-absorbent resin powder. A powder surface detector used favorably for this process includes a float hung down by a hanging line.

Owner:NIPPON SHOKUBAI CO LTD

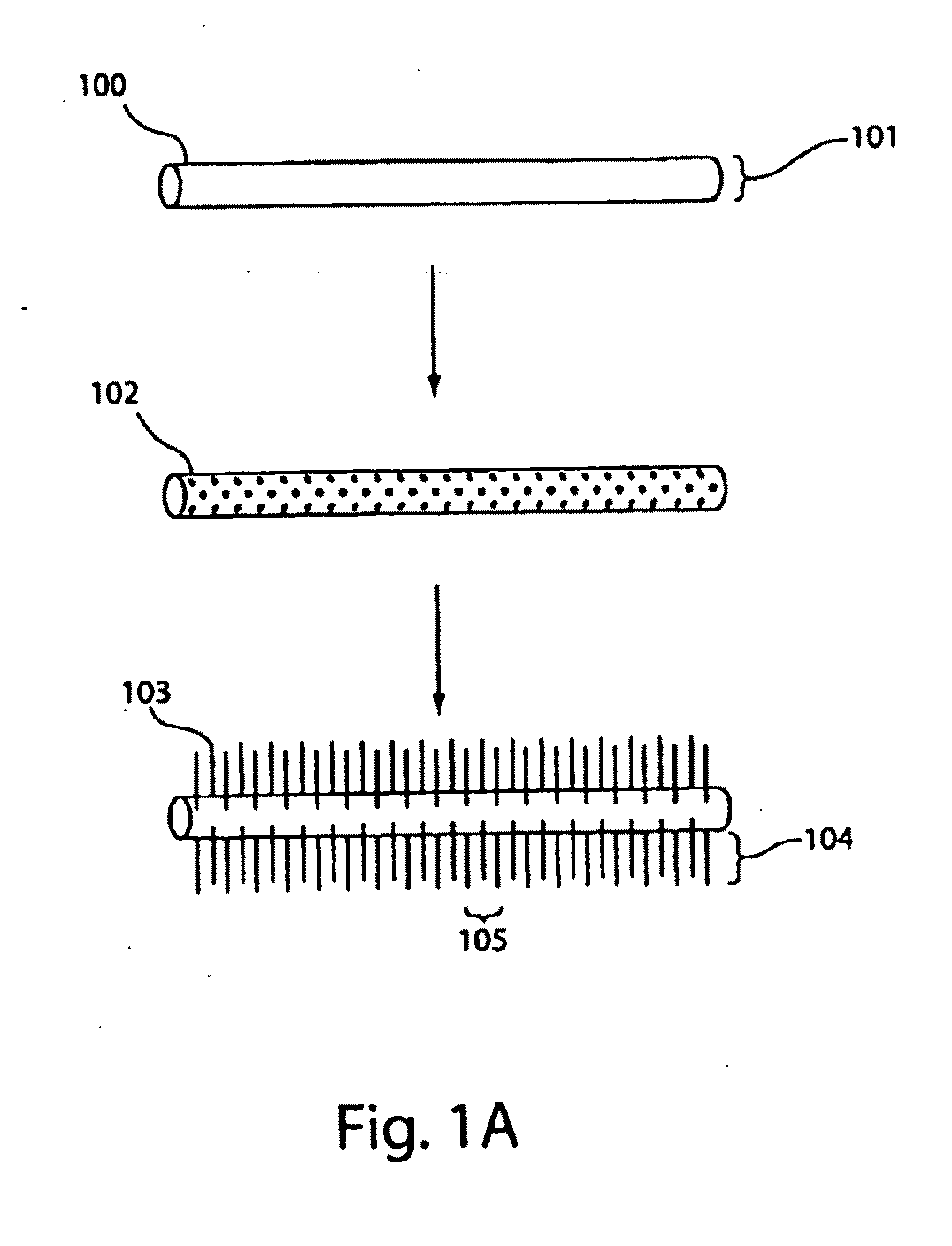

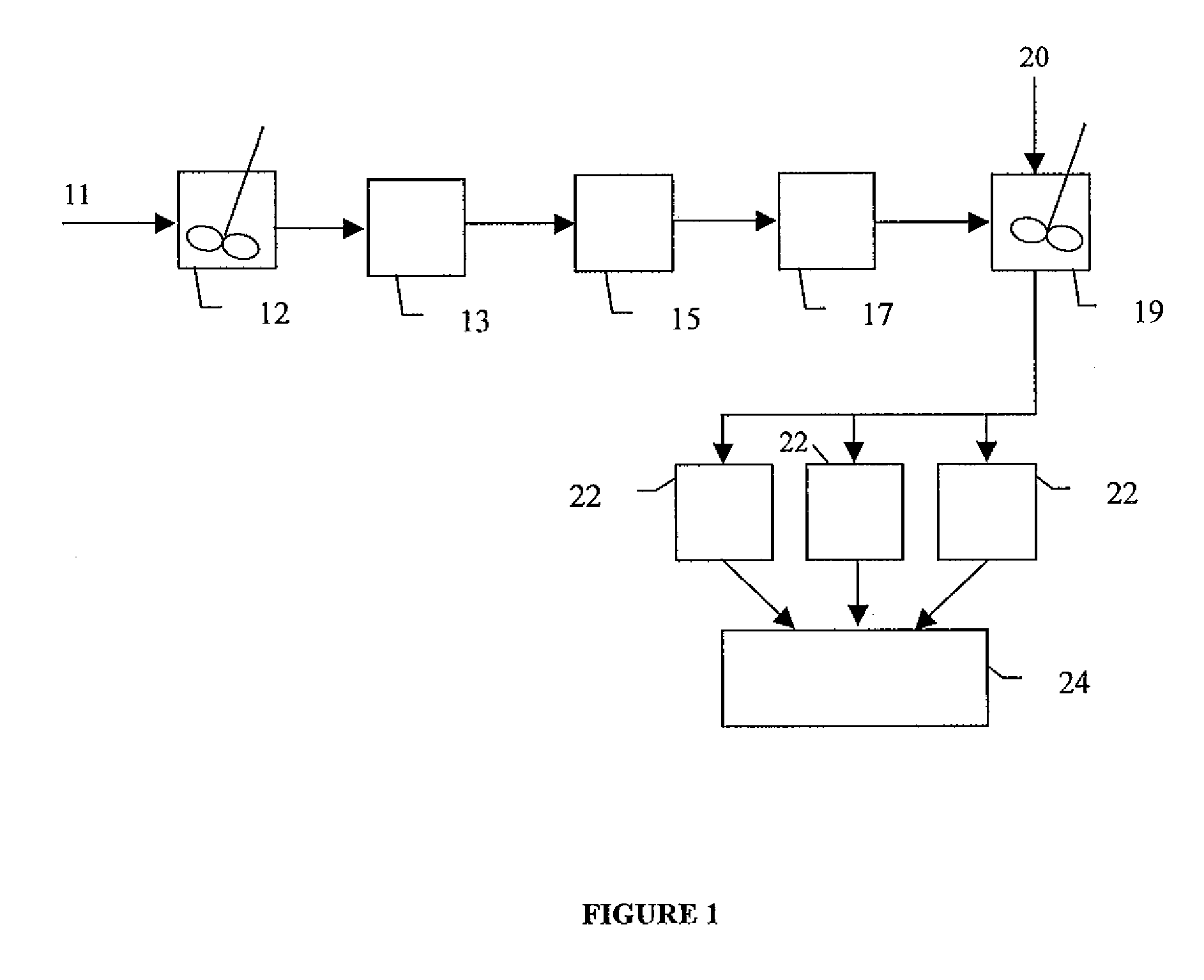

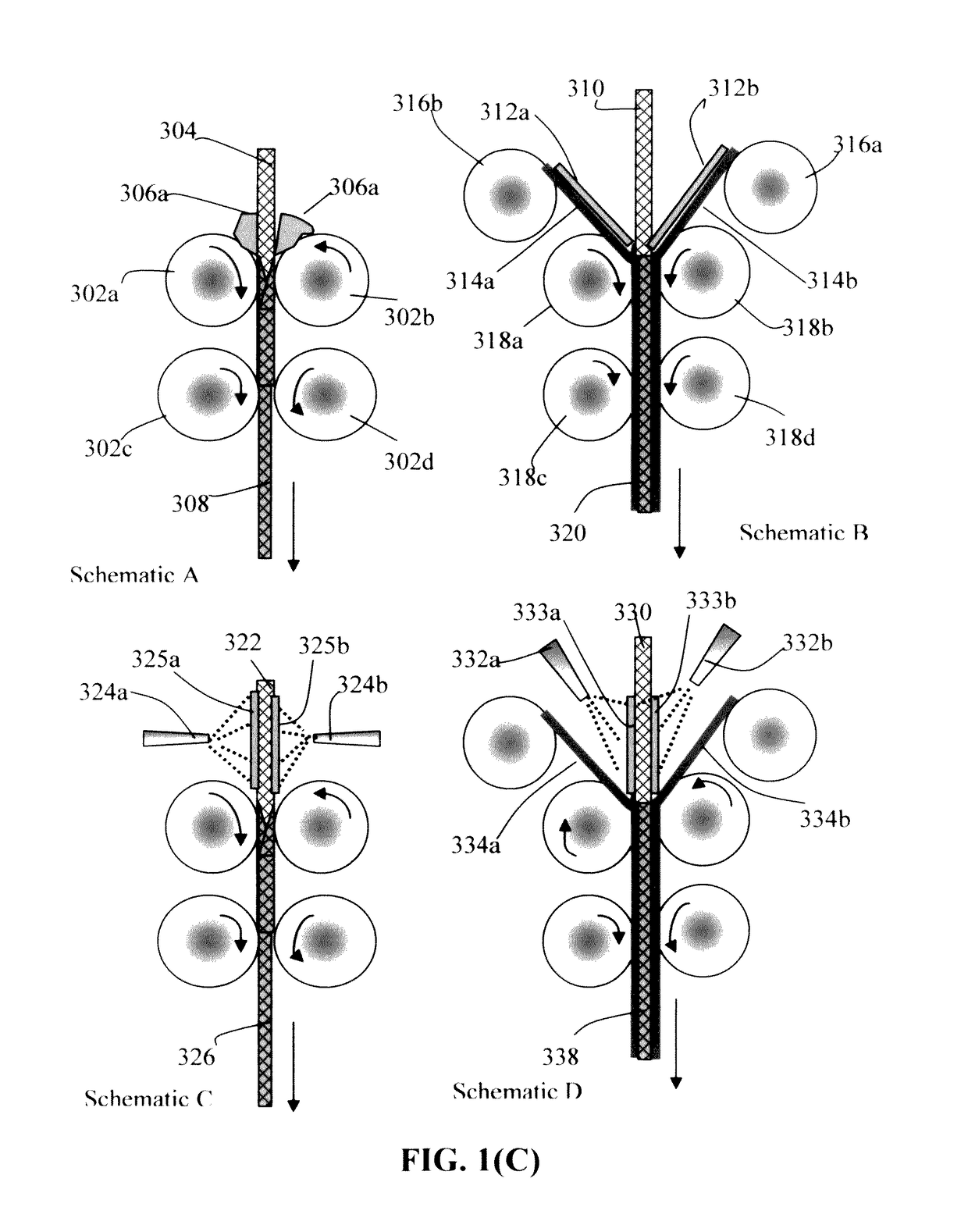

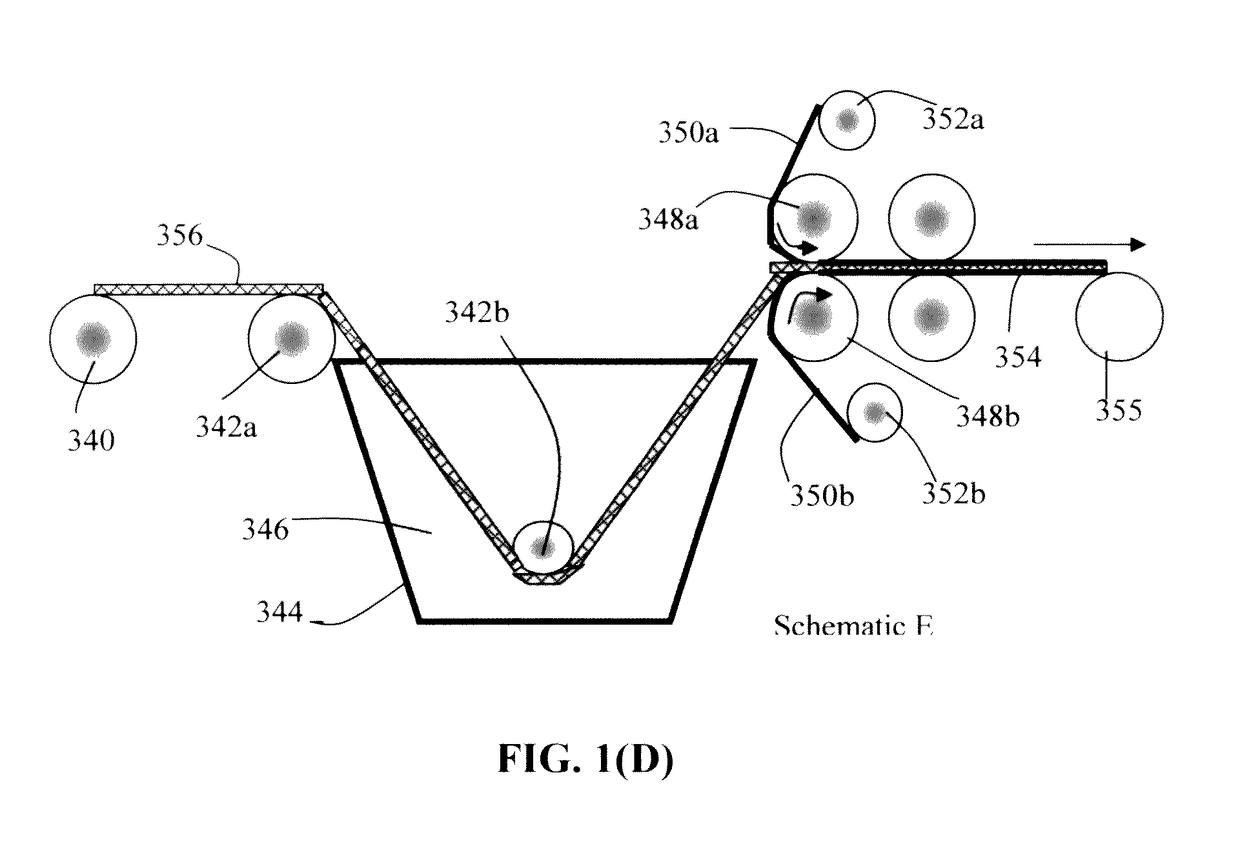

Continuous Process for the Production of Nanostructures Including Nanotubes

The present invention provides methods for uniform growth of nanostructures such as nanotubes (e.g., carbon nanotubes) on the surface of a substrate, wherein the long axes of the nanostructures may be substantially aligned. The nanostructures may be further processed for use in various applications, such as composite materials. For example, a set of aligned nanostructures may be formed and transferred, either in bulk or to another surface, to another material to enhance the properties of the material. In some cases, the nanostructures may enhance the mechanical properties of a material, for example, providing mechanical reinforcement at an interface between two materials or plies. In some cases, the nanostructures may enhance thermal and / or electronic properties of a material. The present invention also provides systems and methods for growth of nanostructures, including batch processes and continuous processes.

Owner:MASSACHUSETTS INST OF TECH

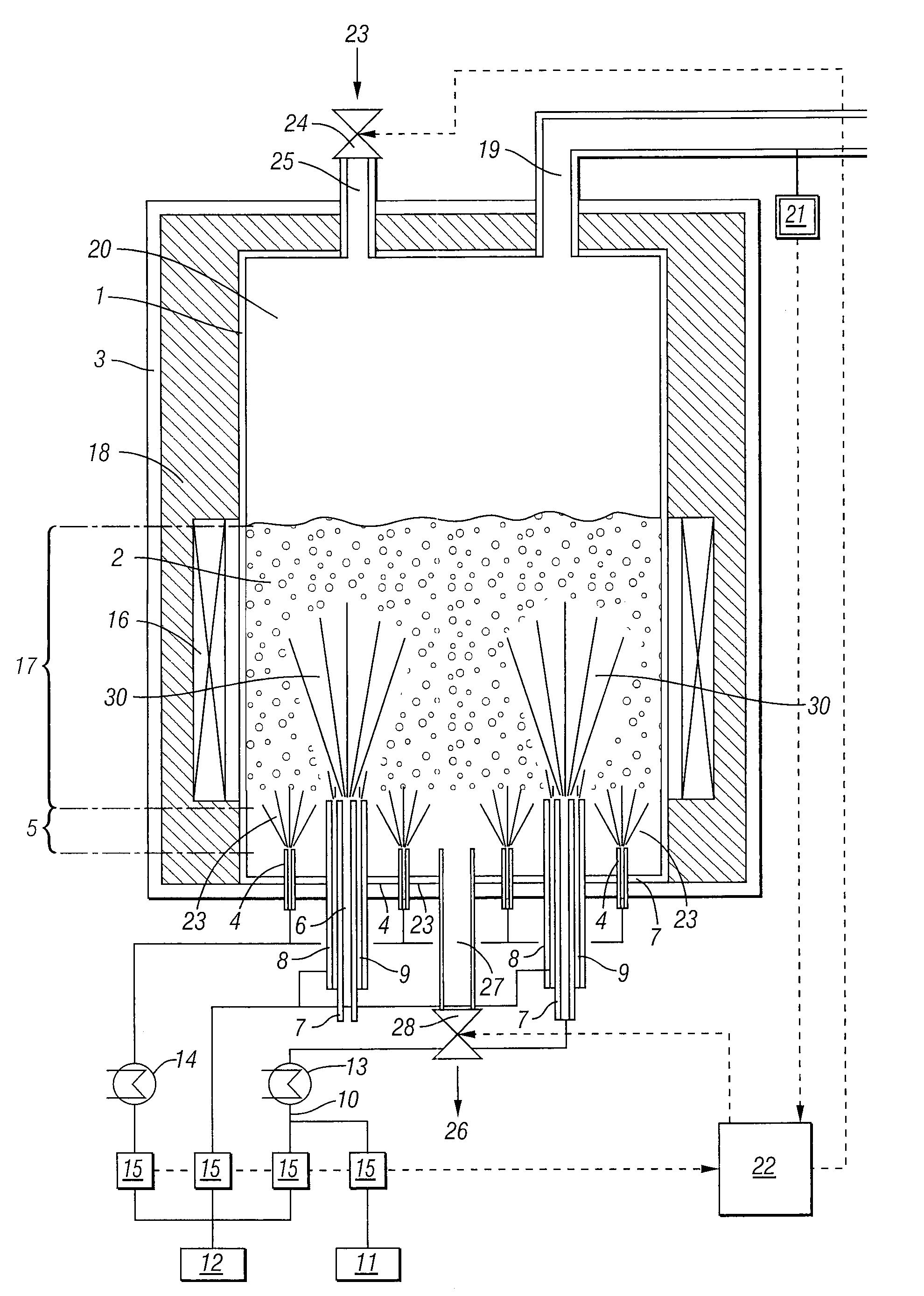

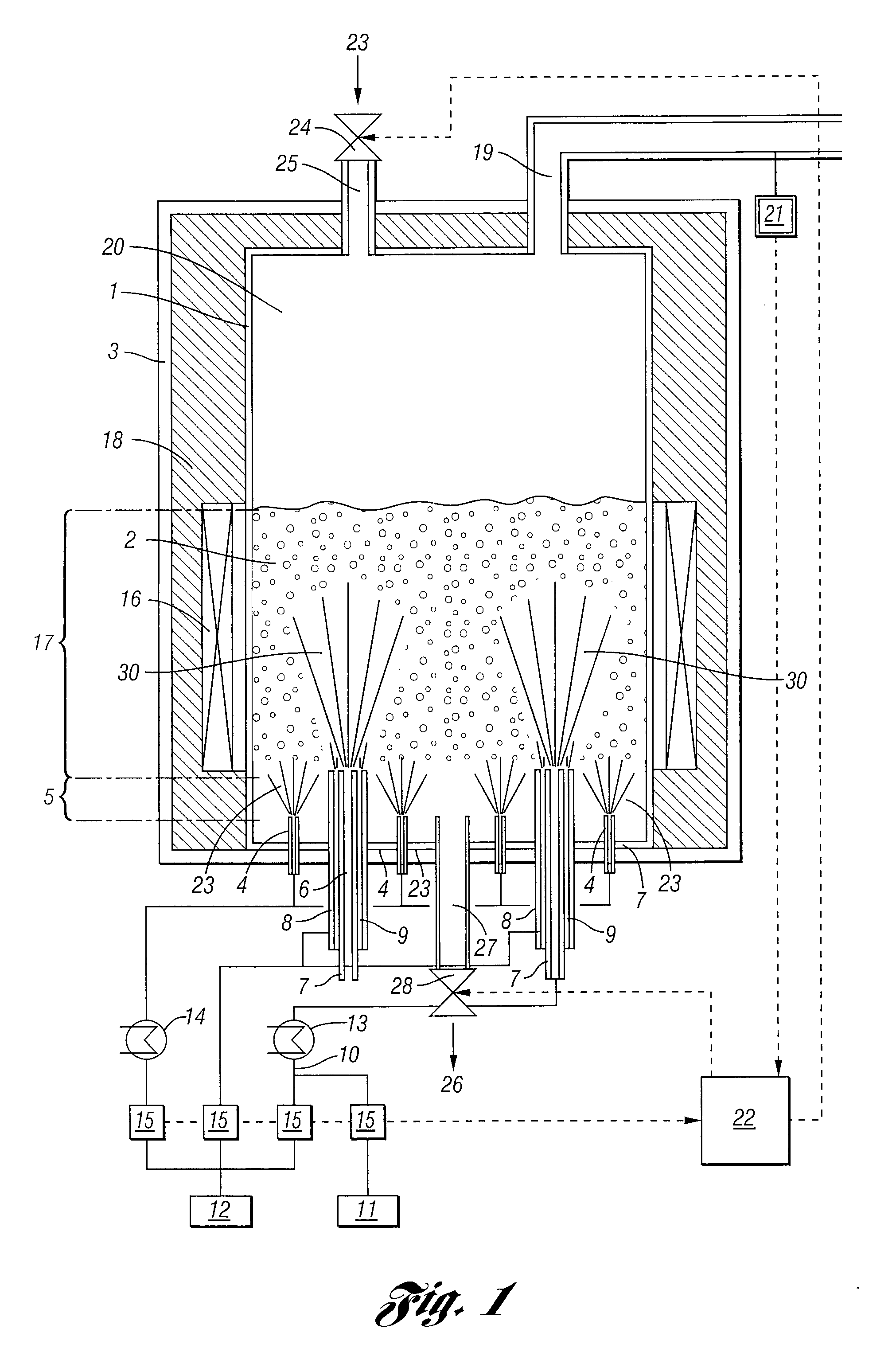

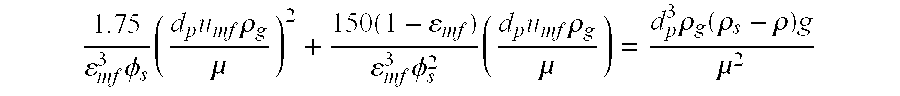

Process For The Continuous Production Of Polycrystalline High-Purity Silicon Granules

ActiveUS20080299291A1Efficient heatingLong operating campaignPolycrystalline material growthLiquid surface applicatorsFluidized bedReaction zone

High-purity polysilicon granules are prepared by depositing reaction gas on silicon granules in a fluidized bed reactor having:a reactor space comprising at least two zones lying one above the other, the lower zone weakly fluidized by introduction of a silicon-free gas into silicon granules in the lower zone by a plurality of individual dilution gas nozzles, and a second, reaction zone directly abutting the lower zone,the reaction zone heated via its outwardly bounding wall,introducing silicon-containing reaction gas as a vertical high speed gas jet into the reaction zone by reaction gas nozzle(s), forming local reaction gas jets surrounded by bubble-forming fluidized bed, gas decomposing leading to particle growth,wherein the reaction gas has fully or almost fully reacted to chemical equilibrium conversion before reaching the wall or bed surface.

Owner:WACKER CHEM GMBH

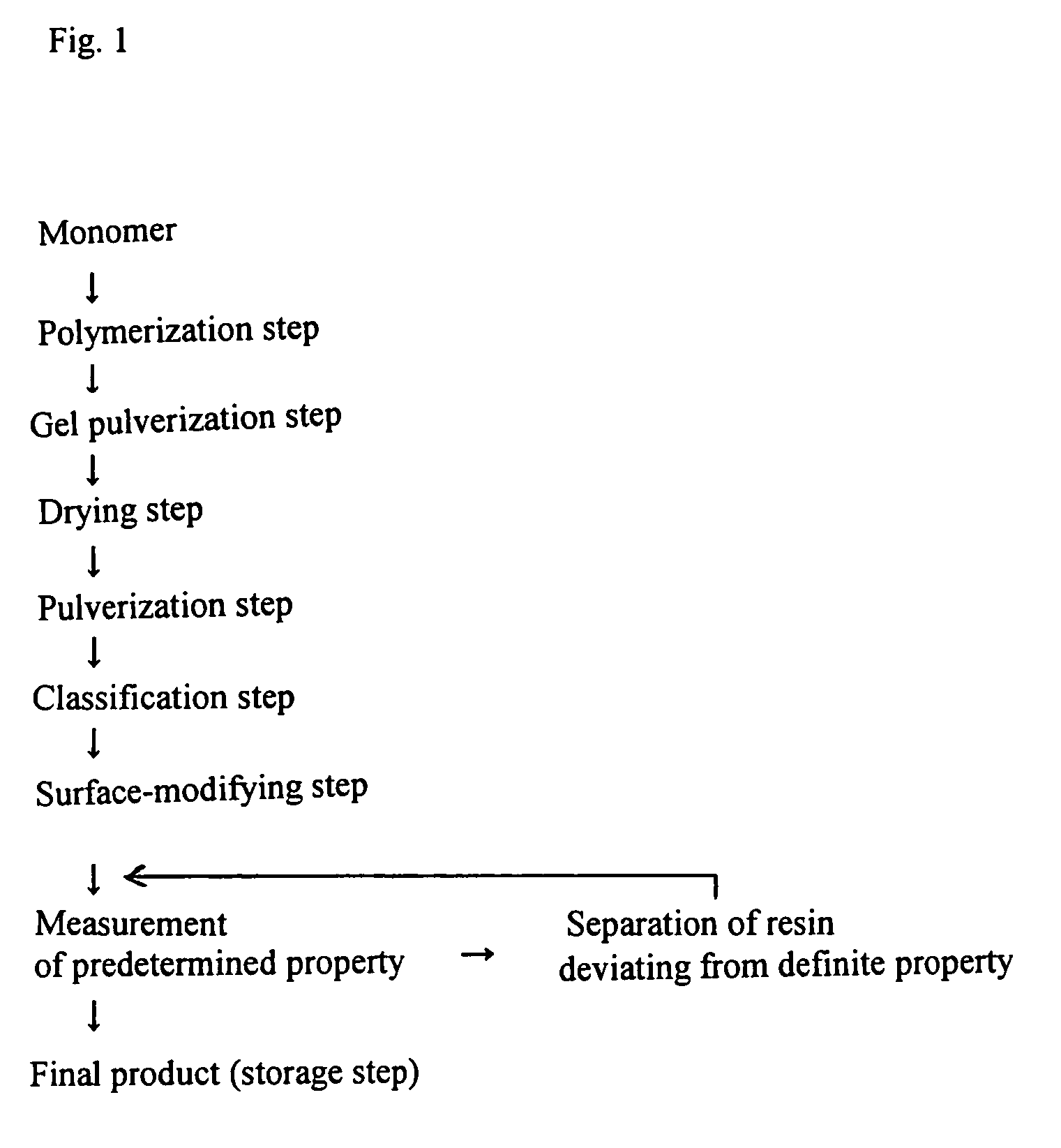

Process for continuous production of water-absorbent resin product

ActiveUS7193006B2Quality improvementHigh propertySynthetic resin layered productsCellulosic plastic layered productsProduction linePolymer science

There is disclosed a process for continuous production of a water-absorbent resin product by which the water-absorbent resin product having high properties can continuously be produced easily and inexpensively with stable constant quality. In addition, there is disclosed a water-absorbent resin product having high properties and being stable in quality. The process comprises the following steps of: (A) measuring a water-absorbent resin by its predetermined property and / or its predetermined component content, wherein the water-absorbent resin comes being continuously produced via a classification step and / or a surface-modifying step; (B) separating a predetermined amount of water-absorbent resin (a) from the water-absorbent resin that comes being continuously produced, wherein the water-absorbent resin (a) is a water-absorbent resin which displays not less than a definite value and / or a water-absorbent resin which displays not more than a definite value as to the predetermined property and / or the predetermined component content in accordance with results of the aforementioned measurement; and (C) mixing at least a portion of the aforementioned separated predetermined amount of water-absorbent resin (a) into a water-absorbent resin that comes being continuously produced via a classification step and / or a surface-modifying step on the same or another production line.

Owner:NIPPON SHOKUBAI CO LTD

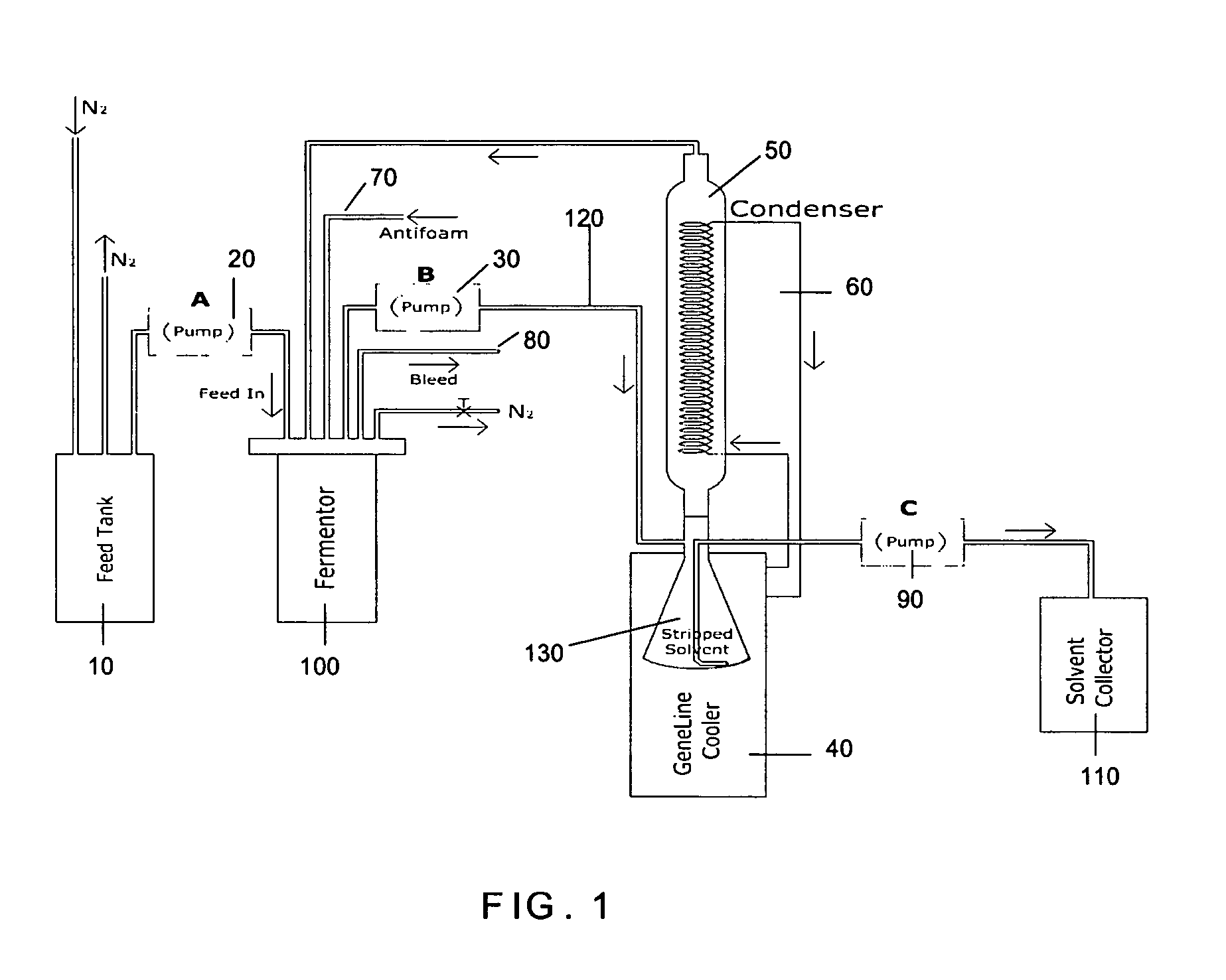

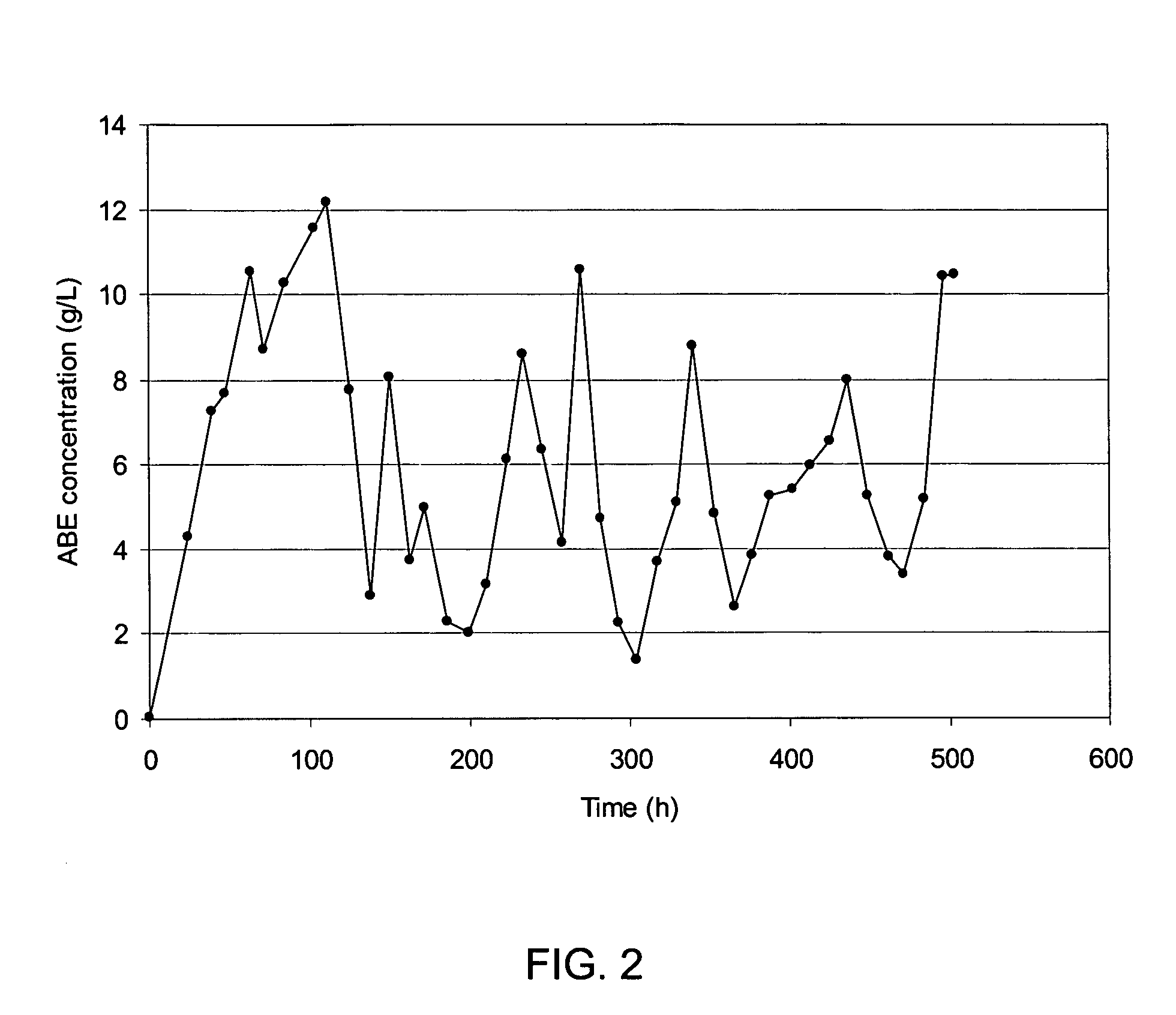

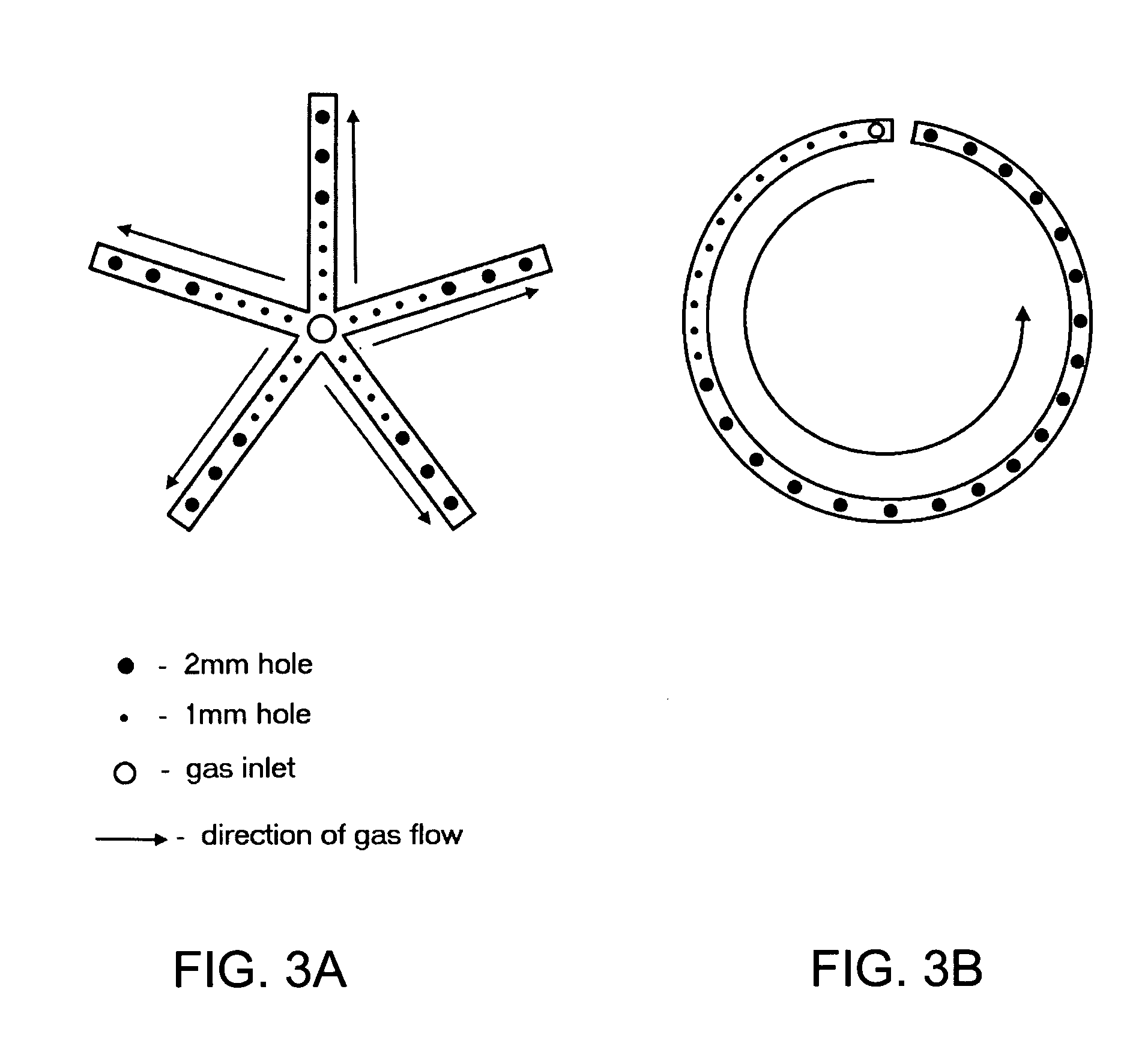

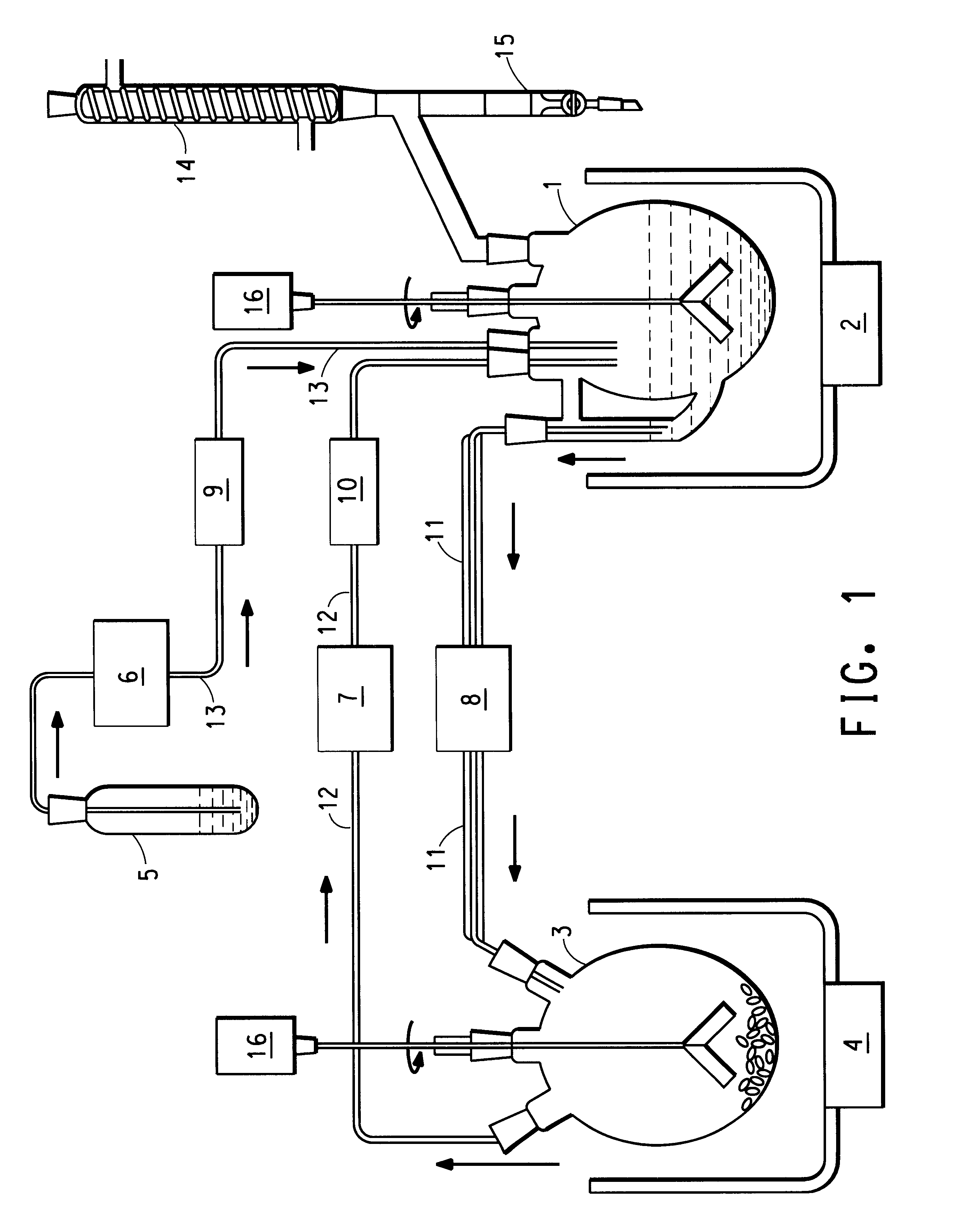

Process for continuous solvent production

InactiveUS20050089979A1High solventProducing strainBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationSolvent

A continuous process for production of solvents, particularly acetone-butanol-ethanol (ABE) using fermentation of solventogenic microorganisms and gas stripping is provided. The solventogenic microorganisms are inoculated in a nutrient medium containing assimilable carbohydrates (substrate) and optional other additives. Control of the solventogenic microorganism concentration in the fermentor (cell concentration) and the assimilable carbohydrate concentration in the fermentor, along with removal of solvents formed results in a continuous process for production of solvents.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Continuous production process for water-absorbent resin powder and powder surface detector used therefor

InactiveUS20030020199A1Quality improvementImprove productivityFilament/thread formingMachines/enginesProduction rateMaterials science

A surface-modified water-absorbent resin powder is produced continuously with high productivity in a state where the particle diameter distribution is narrow and where the properties are high by a process comprising a polymerizing step, a drying step, a pulverizing step, a classifying step, and a surface-modifying step, and further, conveying steps of connecting them, wherein the conveying steps include at least two hoppers for storing the water-absorbent resin powder. A powder surface detector used favorably for this process includes a float hung down by a hanging line.

Owner:NIPPON SHOKUBAI CO LTD

Container insert apparatus and method

InactiveUS20100284634A1Reduce laborLow costEnvelopes/bags making machineryWrappersInterior spaceEngineering

A container insert, and an apparatus and a method of producing the container insert. The container insert is formed as a deformable pouch adapted to be received in an interior of an associated container. The pouch has a closed lower end, an open upper end, and spaced apart sealed edges. The lower end of the pouch includes two leg portions. The pouch is manipulatable to generally conform to the interior of the contained and form a hollow interior space therein for receiving an object and providing a lining for the interior of the container. The apparatus and the method for producing the insert provides for a substantially automatic and continuous production of the insert from a roll of material.

Owner:CUTTING EDGE CONVERTED PROD

Method for continuous production of fermented dairy products

The invention provides continuous methods for preparing a fermented dairy product, the methods including steps of fermenting a dairy base with agitation while measuring the viscosity change of the fermentation mixture until an initial fermented dairy base having a target viscosity is achieved. The initial fermented dairy base is then preferably further fermented to a final fermented dairy base without agitation.

Owner:GENERAL MILLS INC

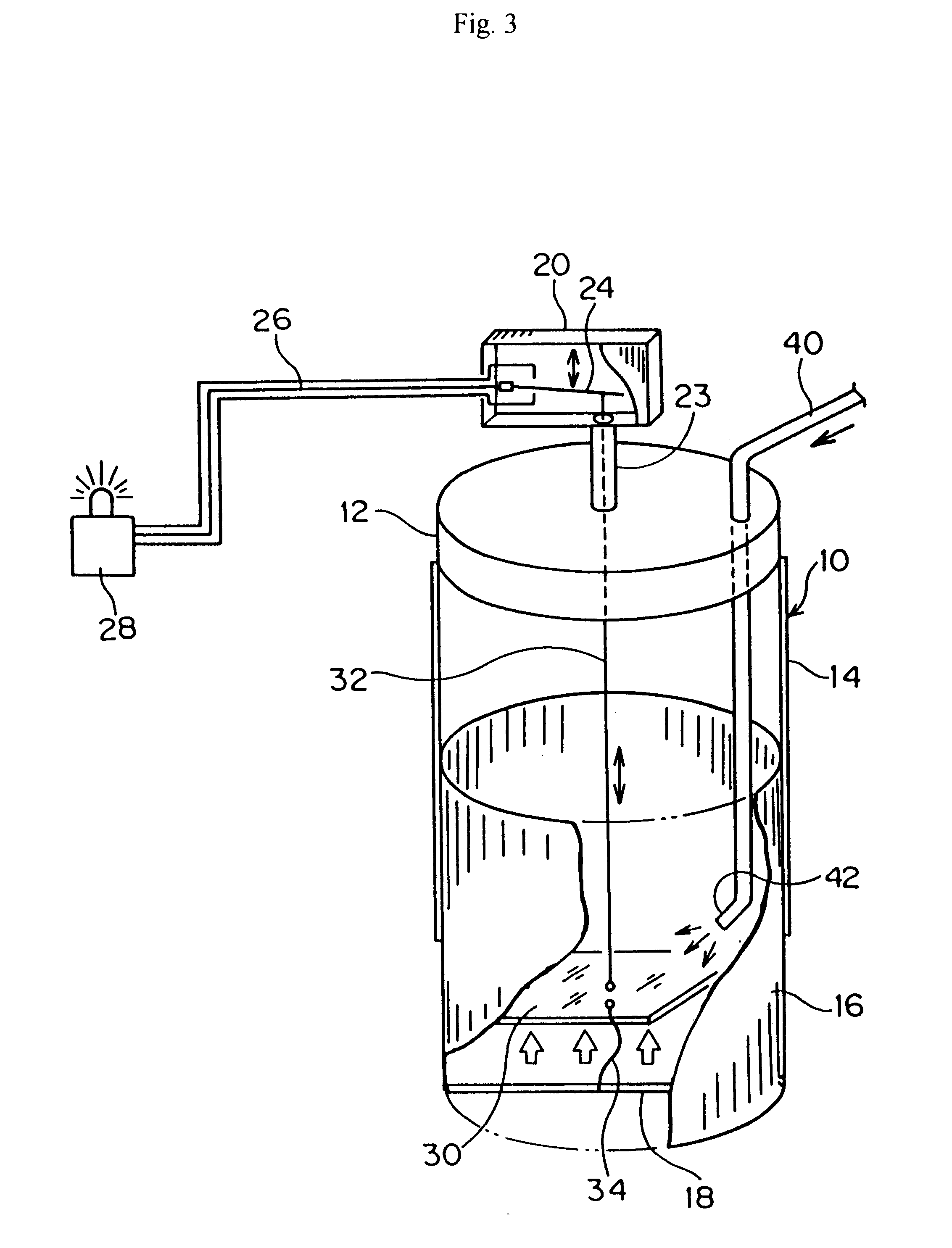

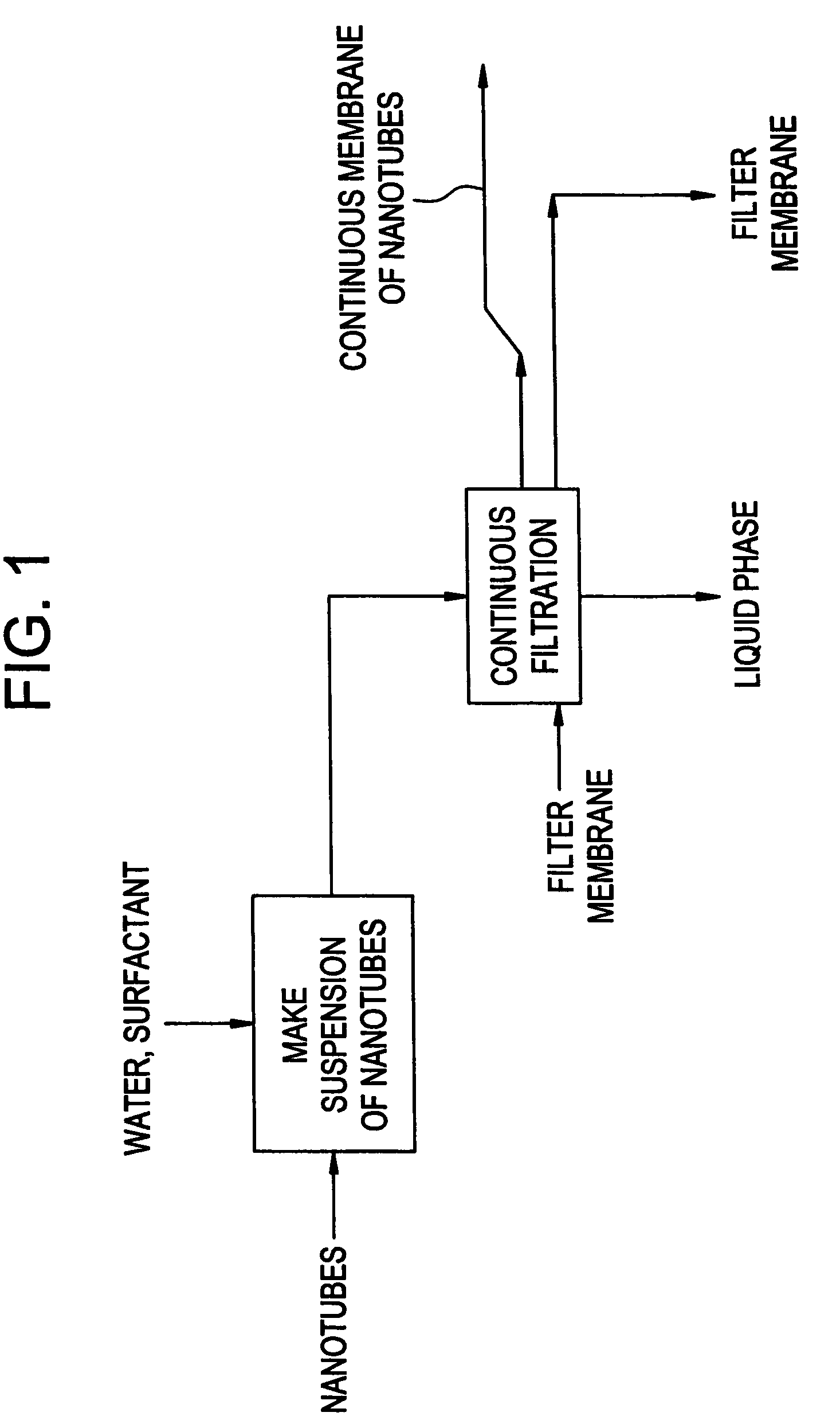

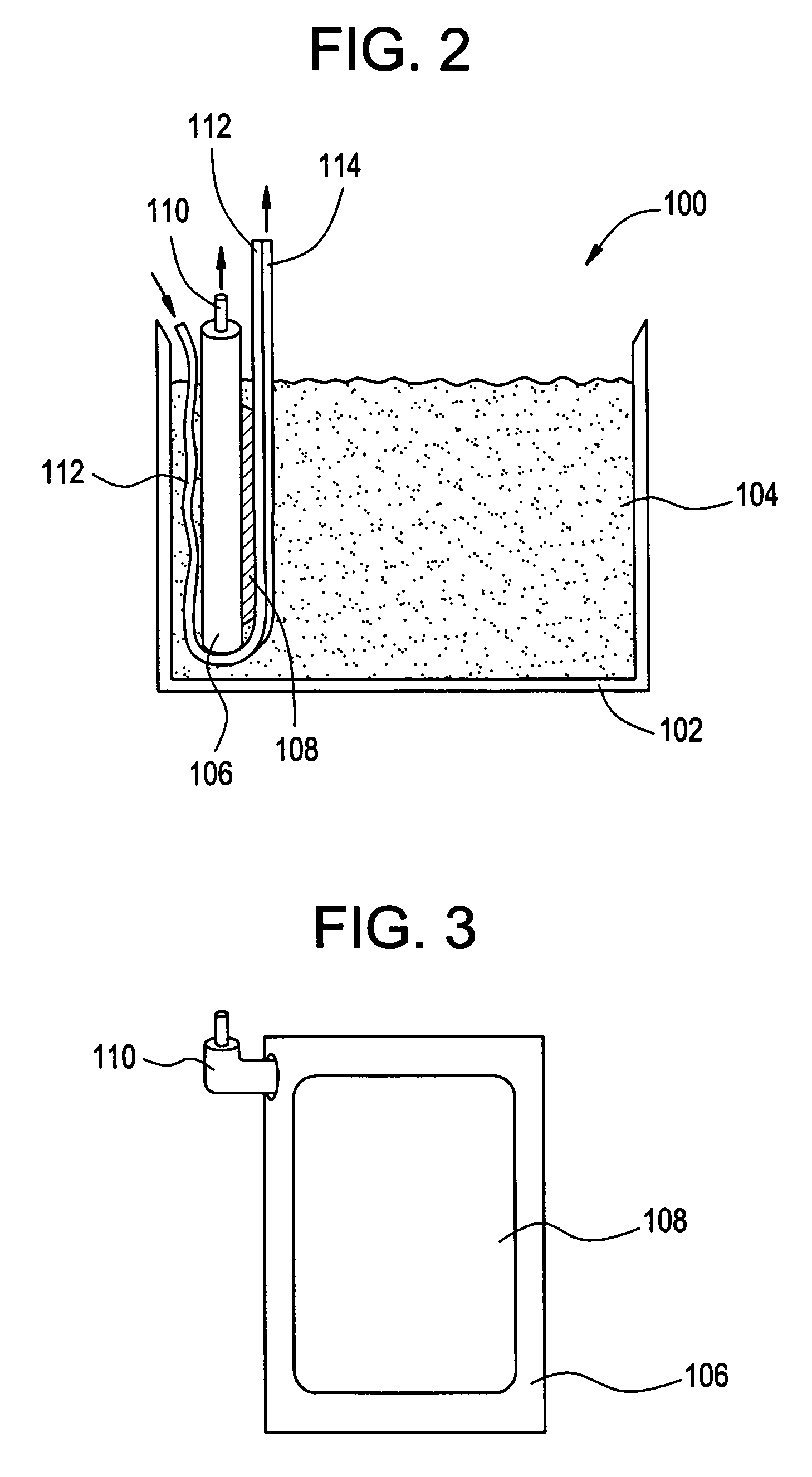

Method for continuous fabrication of carbon nanotube networks or membrane materials

Methods and devices are provided for the continuous production of a network of nanotubes or other nanoscale fibers. The method includes making a suspension of nanoscale fibers dispersed in a liquid medium, optionally with surfactant and / or sonication, and filtering the suspension by moving a filter membrane through the suspension, such that the nanoscale fibers are deposited directly on the filter membrane as the fluid medium flows through the filter membrane, thereby forming a continuous membrane of the nanoscale fibers. The deposition of the nanoscale fibers can occur when and where the filter membrane moves into contact with a static, porous filter element or a dynamic, porous filter element. The filtering can be conducted within a magnetic field effective to align the nanoscale fibers, and / or with the aid of vacuum to pull water through the filter membrane, applied pressure to press water though the filter membrane, or a combination thereof.

Owner:FLORIDA STATE UNIV RES FOUND INC

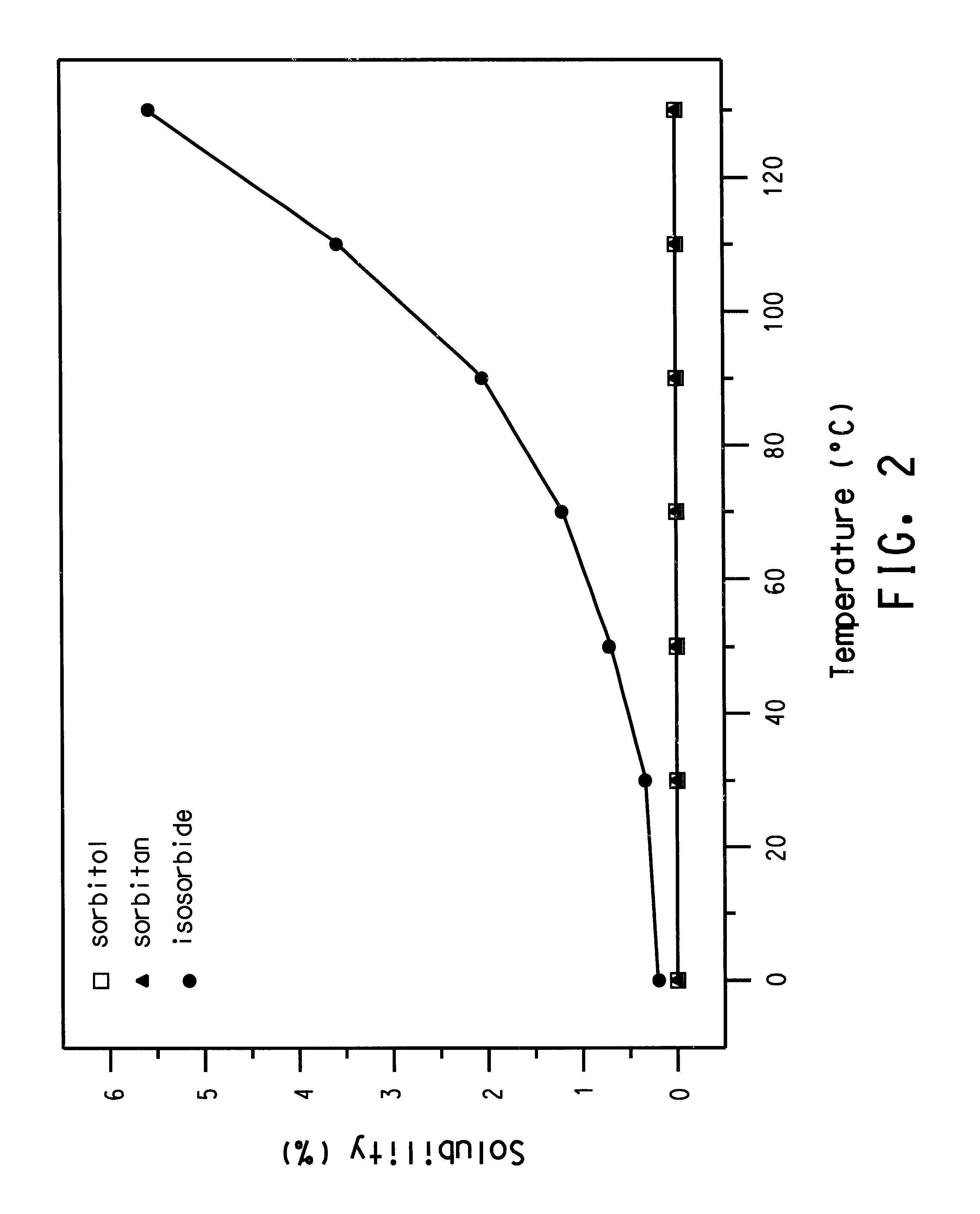

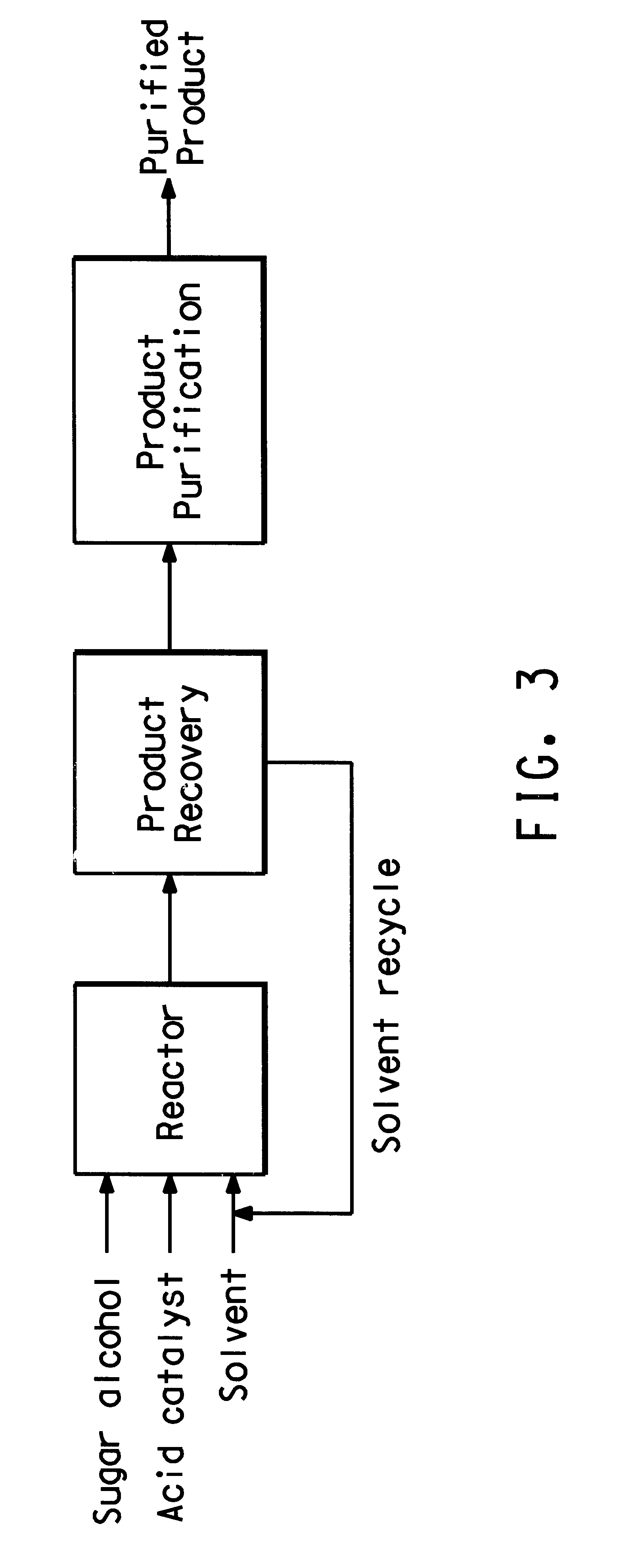

Continuous process for the production of anhydrosugar alcohols

A process is described for continuous production of anhydrosugar alcohol by continuous introducing of sugar alcohols and / or monoanhydrosugar alcohols into a reaction vessel and dehydration in the presence of an acid catalyst and solvent in which the resultant reaction product is soluble. Water and the solvent having the dissolved reaction product are each cointinuously removed from the reaction vessel. The reaction product is separated from the removed solvent and the product is optionally purified to a purity of 99.0% the solvent is recycled in the reaction vessel.

Owner:EI DU PONT DE NEMOURS & CO

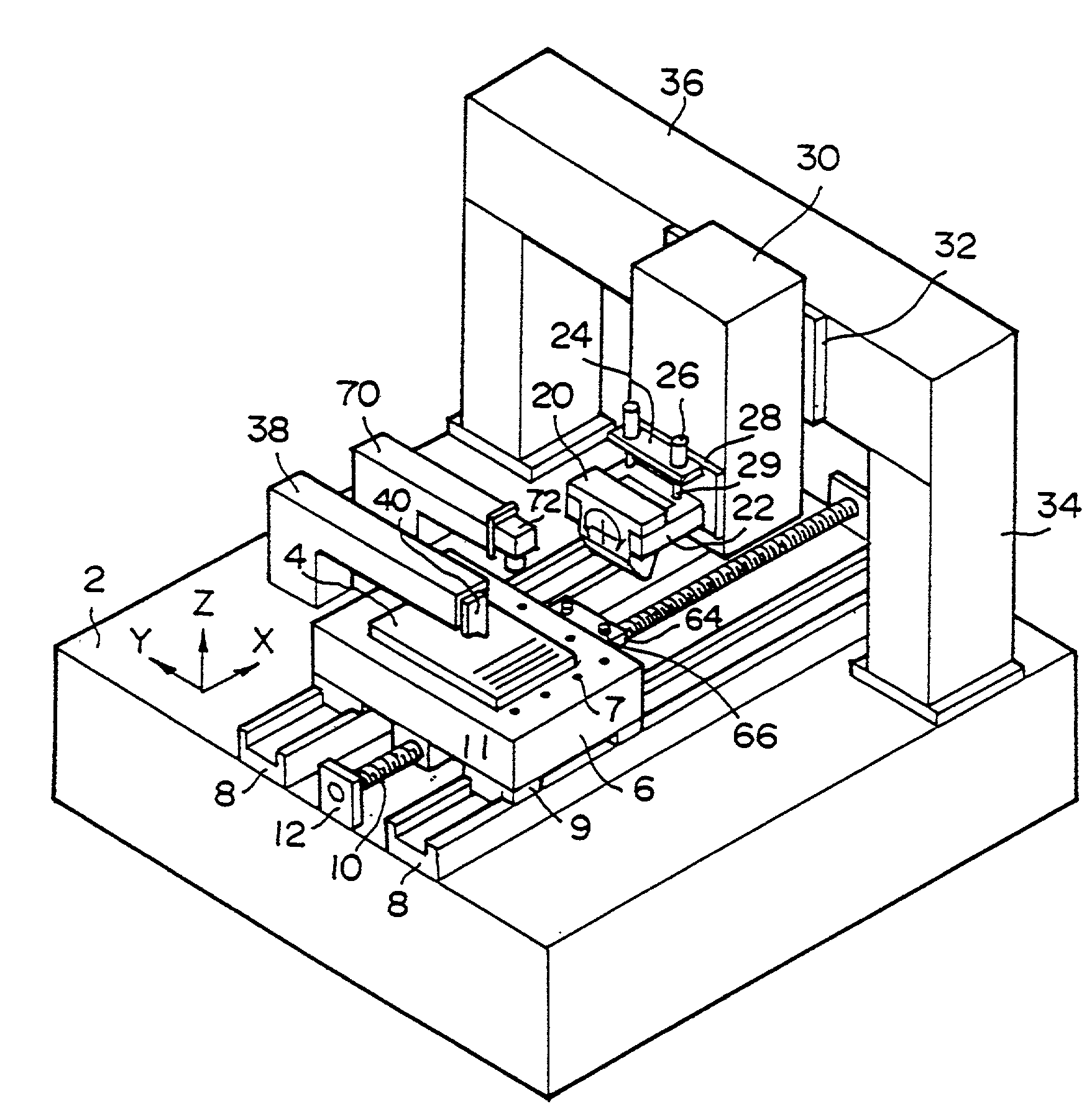

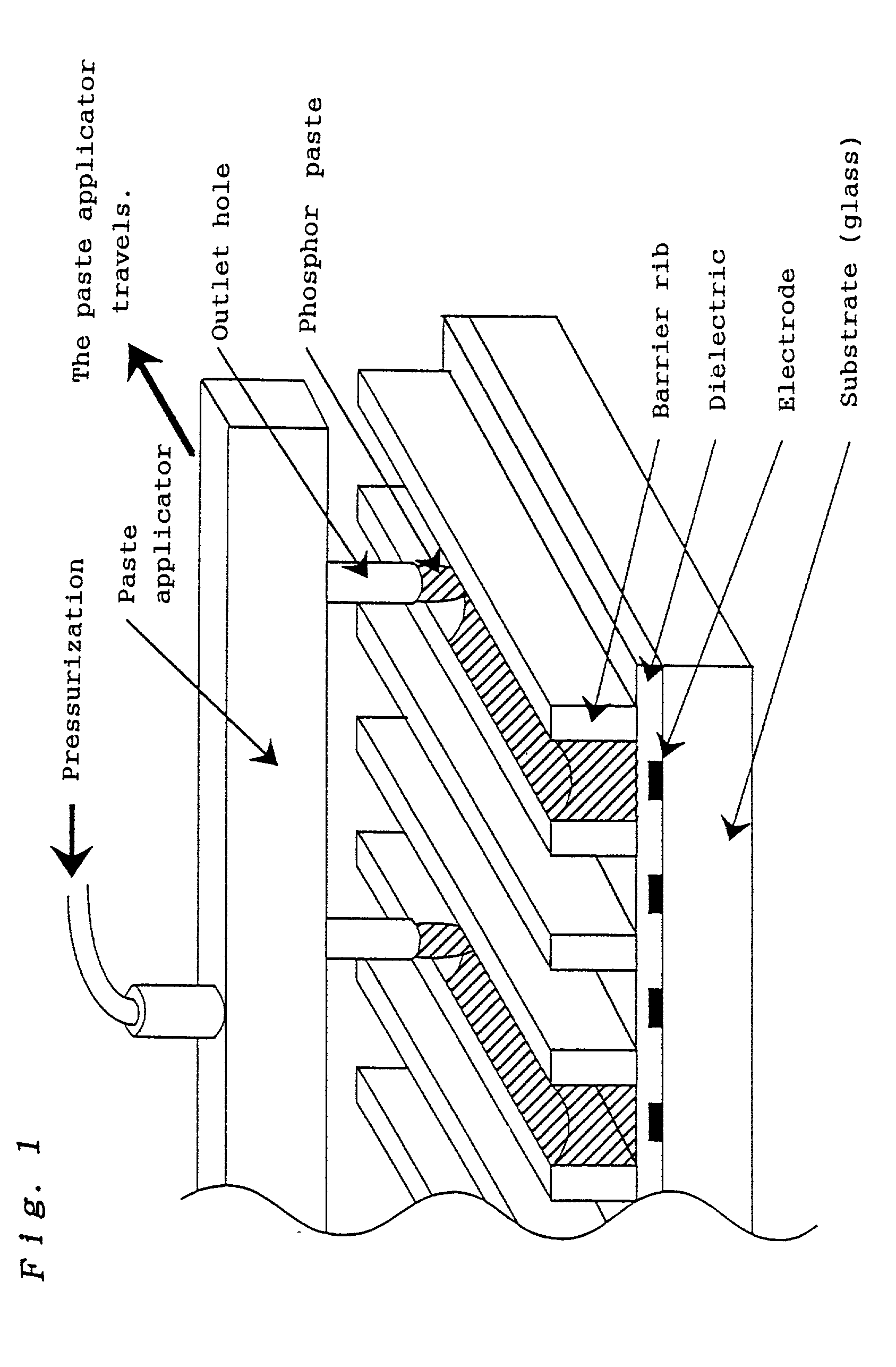

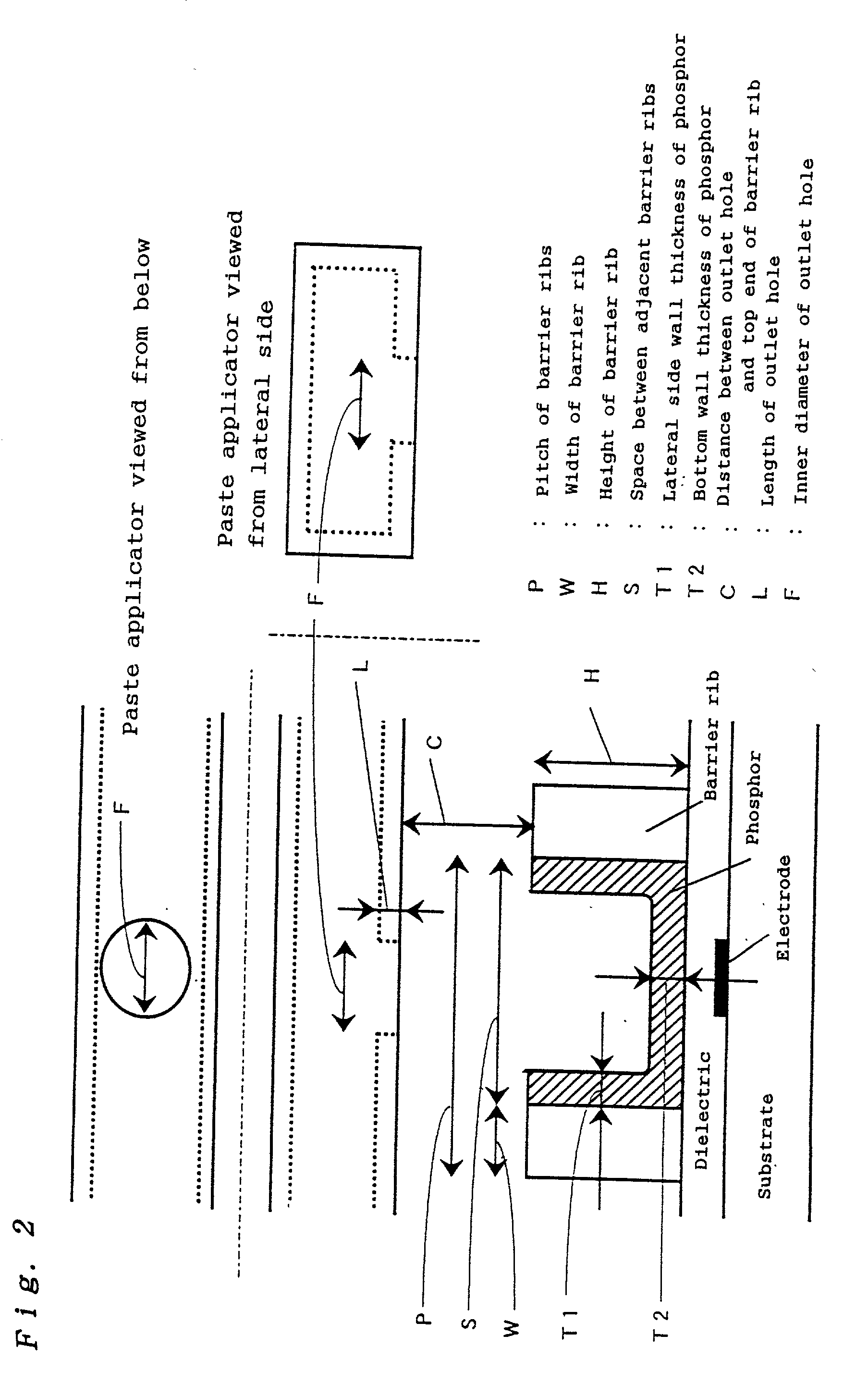

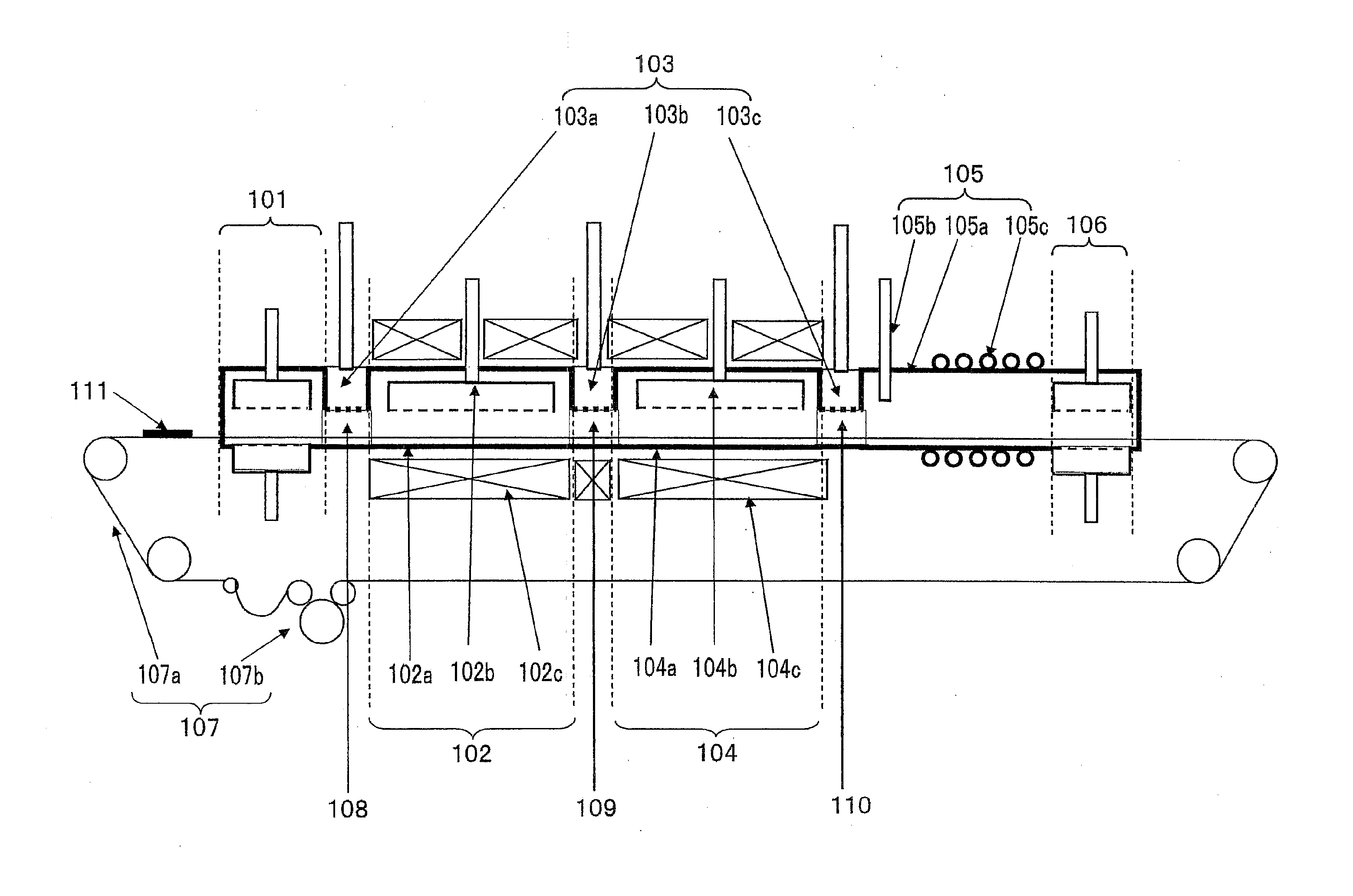

Method and apparatus for producing a plasma display

InactiveUS20020009536A1High levelElectric discharge tubesVacuum evaporation coatingProduction rateFluorescence

Since a widely applicable high quality plasma display equipped with a phosphor layer suitable as a highly precise plasma display can be produced continuously at a high productivity level, an industrially advantageous method and apparatus for producing a plasma display can be provided. The highly precise plasma display obtained in the present invention can be widely used in the display field, for example, for wall mounted television sets, information displays, etc. The method for producing a plasma display of the present invention comprises the step of continuously applying a phosphor paste containing a phosphor powder and an organic compound onto a substrate with a plurality of barrier ribs from a paste applicator with a plurality of outlet holes. Furthermore, the present invention comprises the steps of coating a substrate with a plurality of barrier ribs, with three phosphor pastes respectively containing a phosphor powder emitting light of red, green or blue, as stripes in the spaces between the respectively adjacent barrier ribs on the substrate, from a paste applicator with outlet holes, and heating to form a phosphor layer. Moreover, the apparatus for producing a plasma display of the present invention comprises a table for fixing a substrate with a plurality of barrier ribs, a paste applicator with a plurality of outlet holes to face the barrier ribs of the substrate, a supply means for supplying a phosphor paste to the paste applicator, and a moving means for three-dimensionally moving the table and the paste applicator relatively each other.

Owner:PANASONIC CORP +1

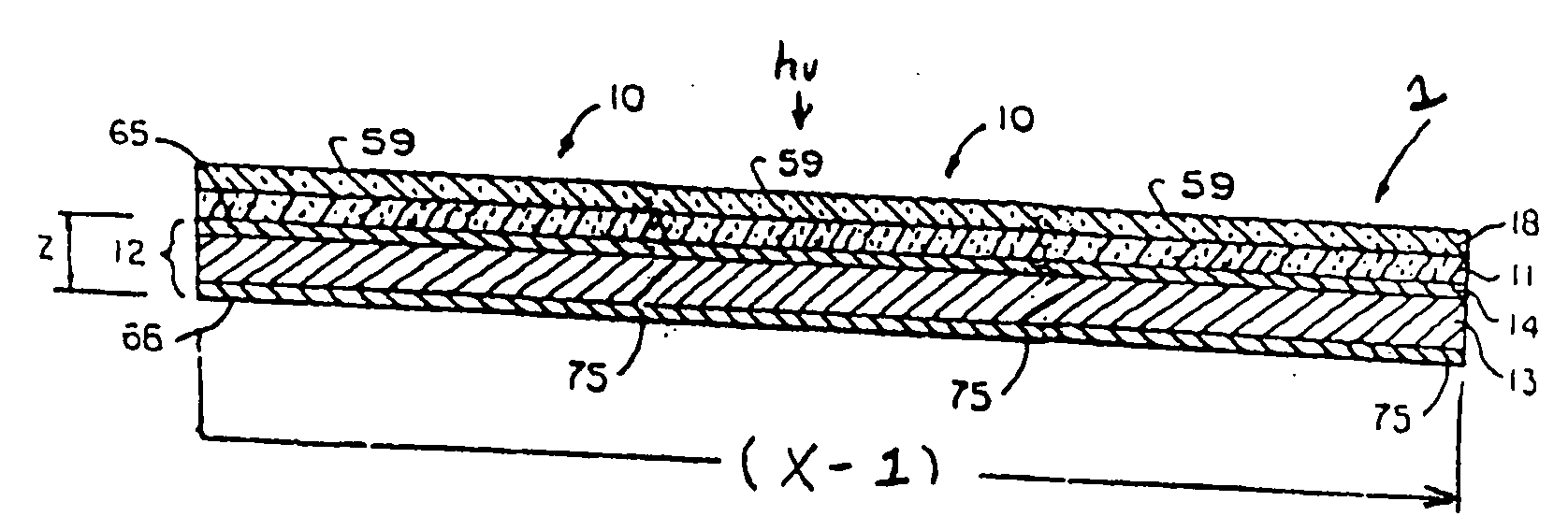

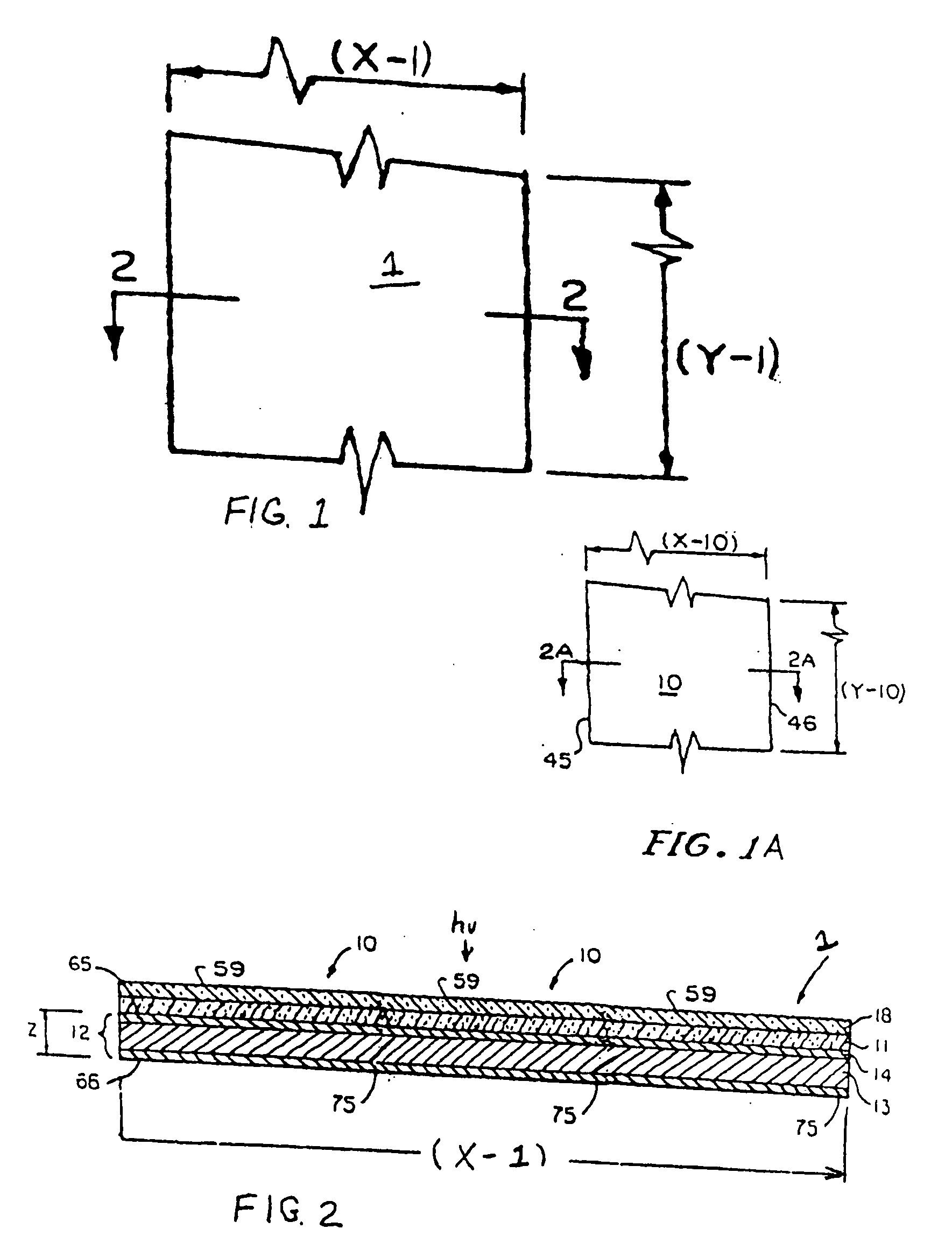

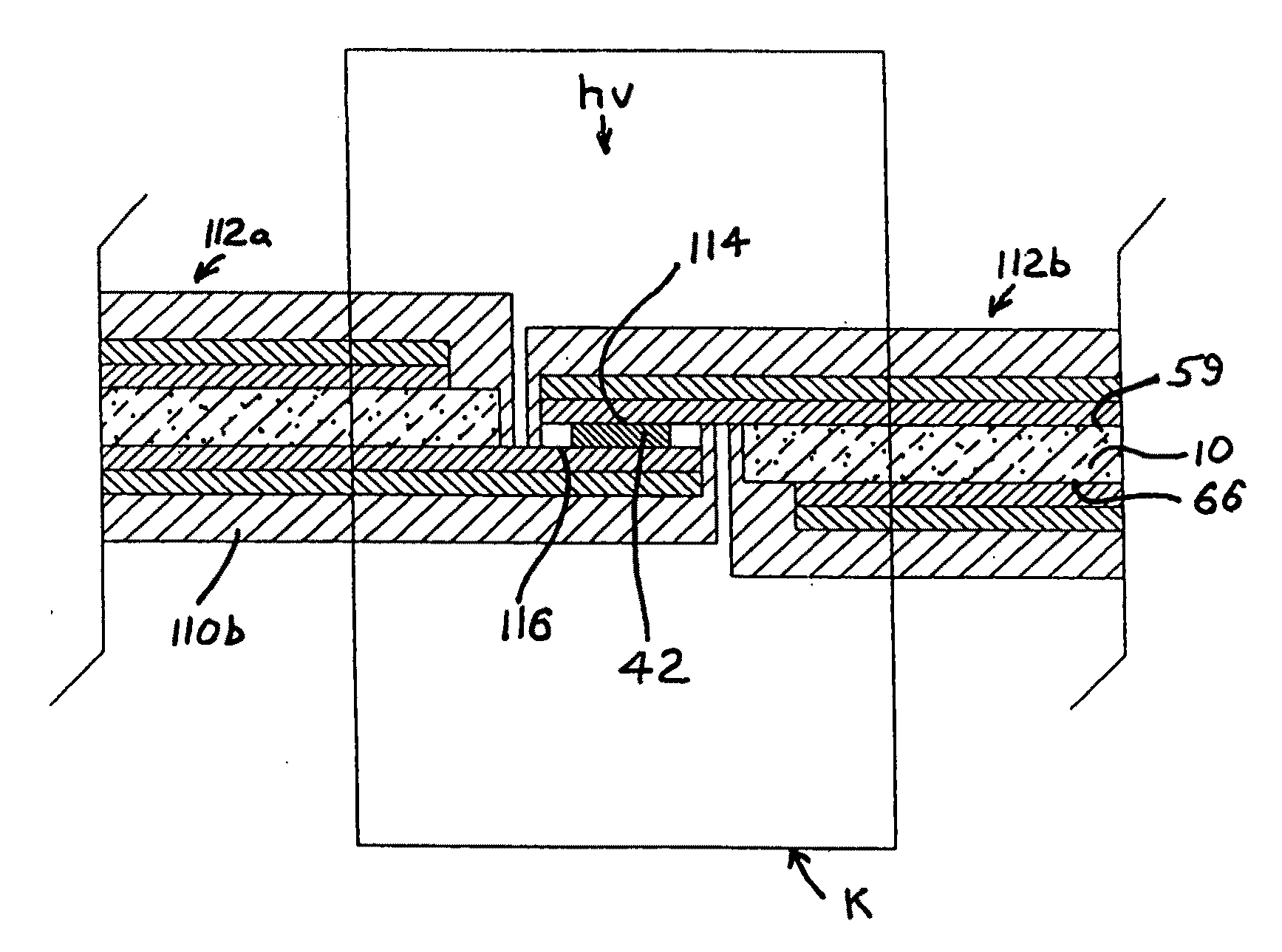

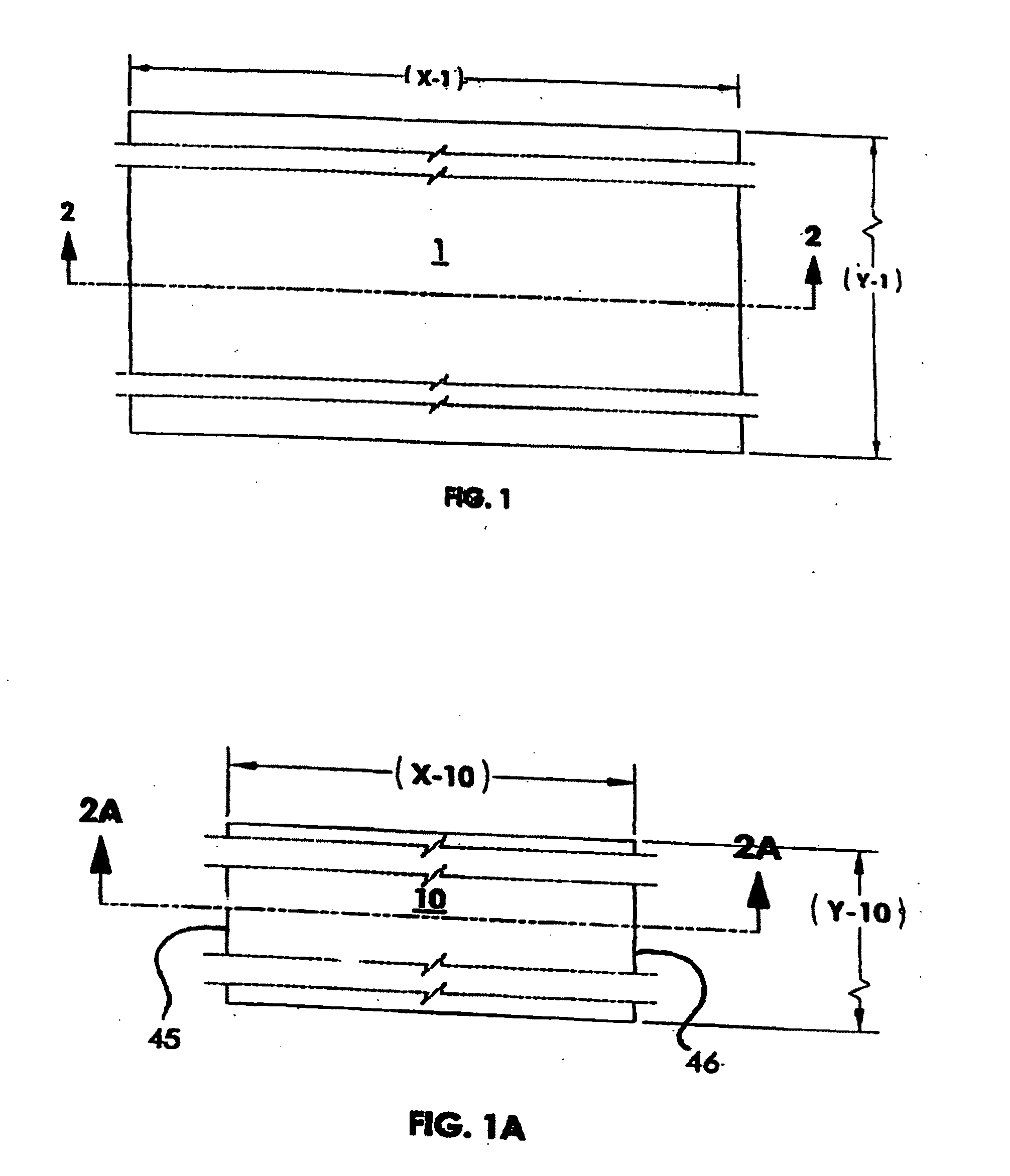

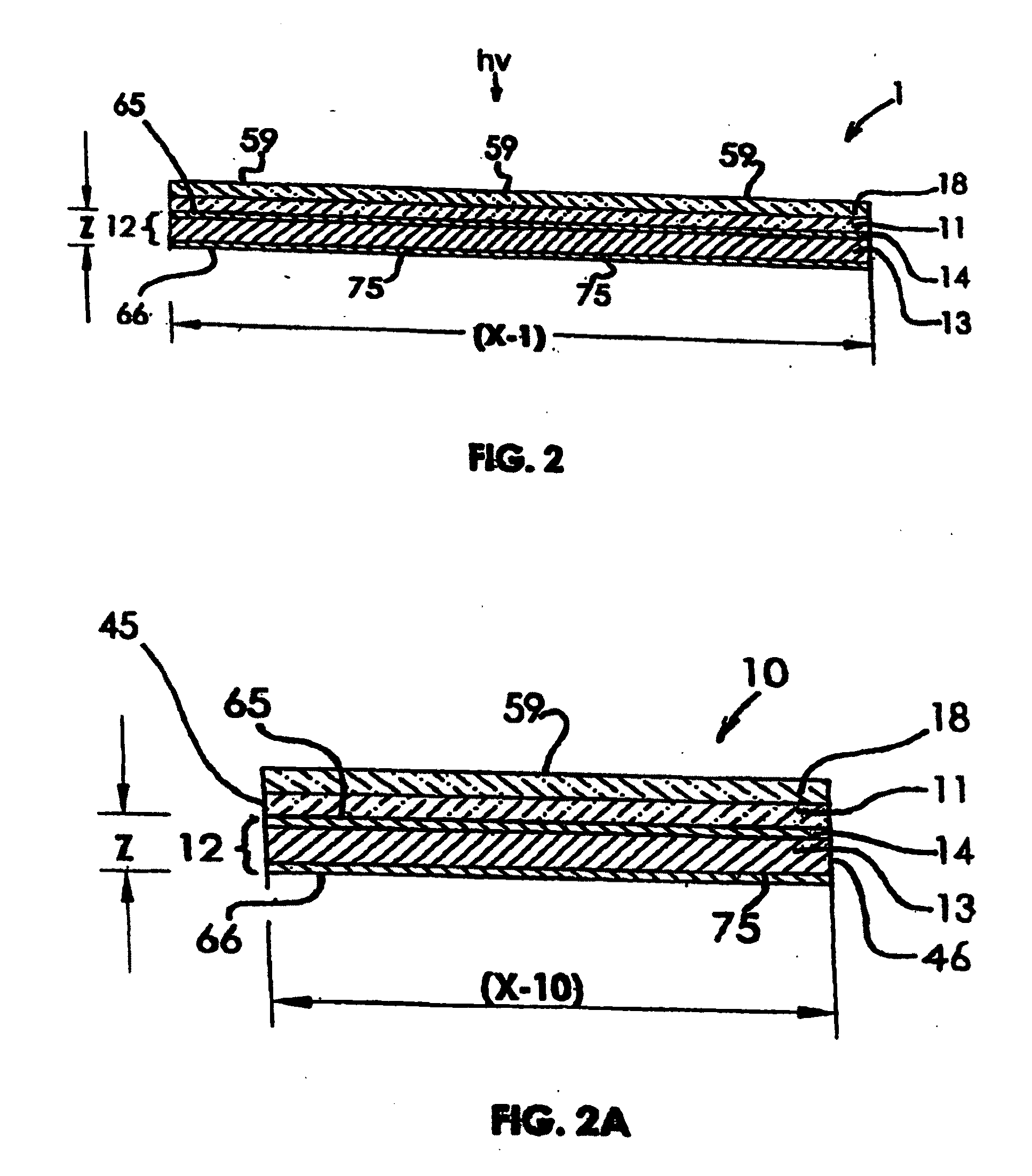

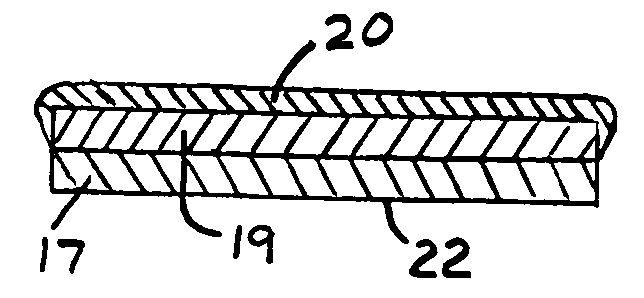

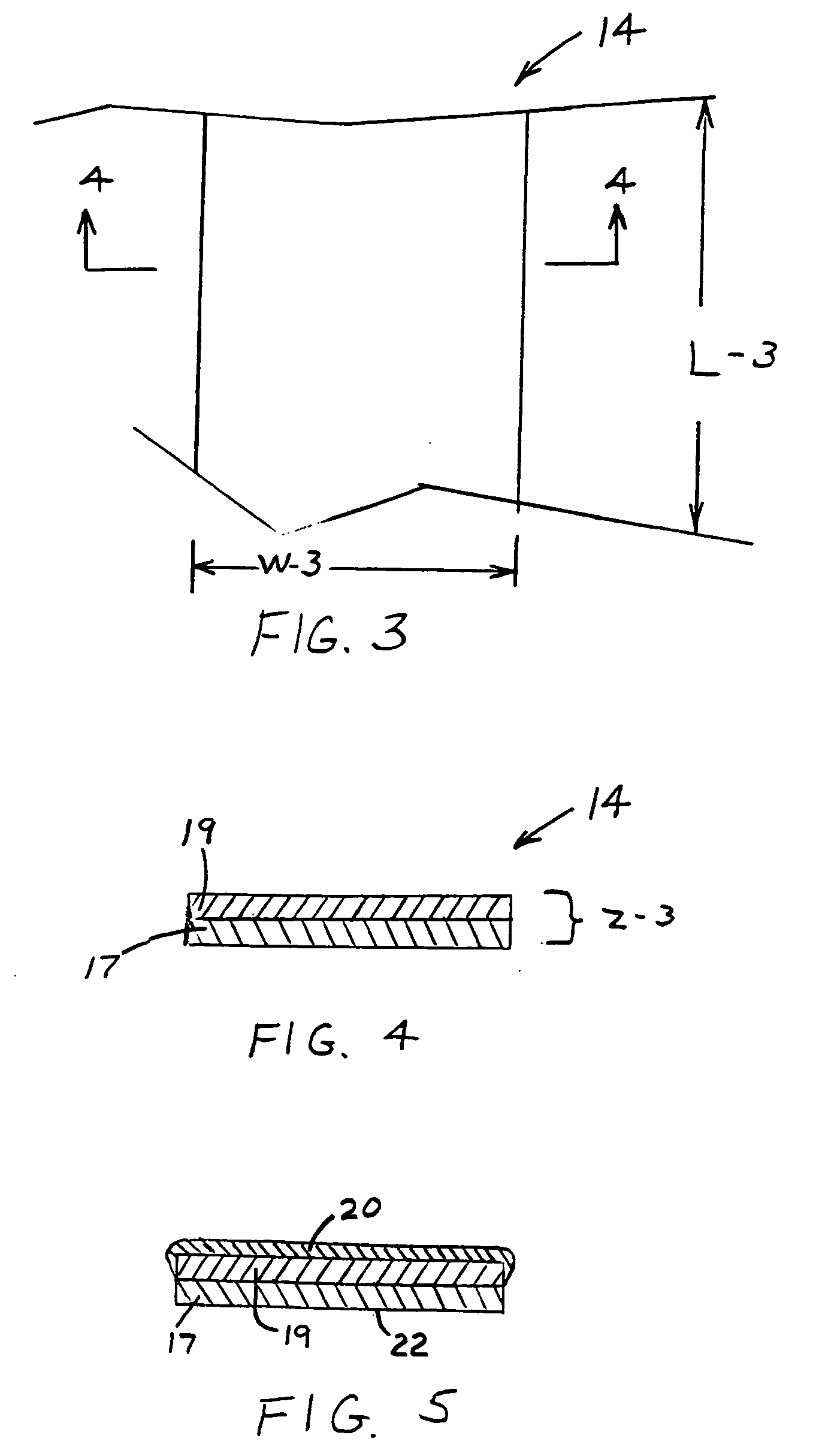

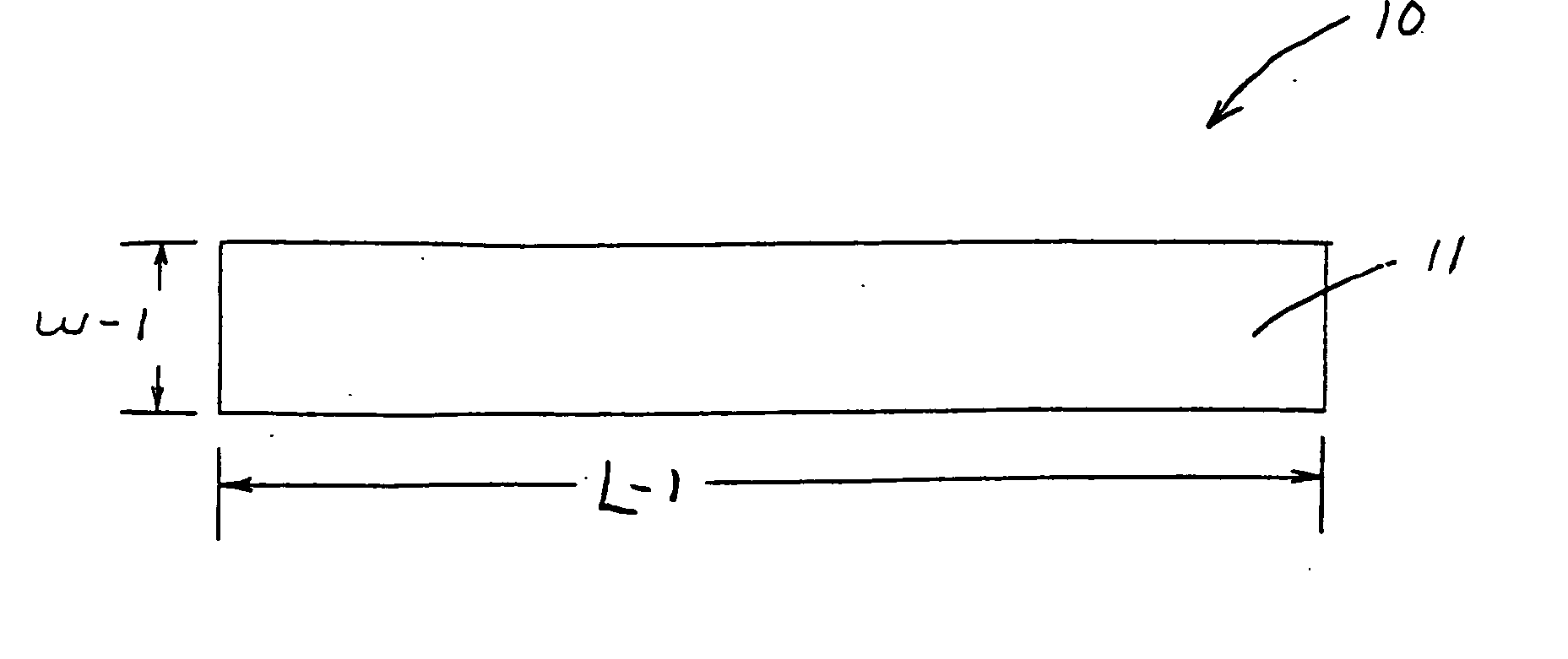

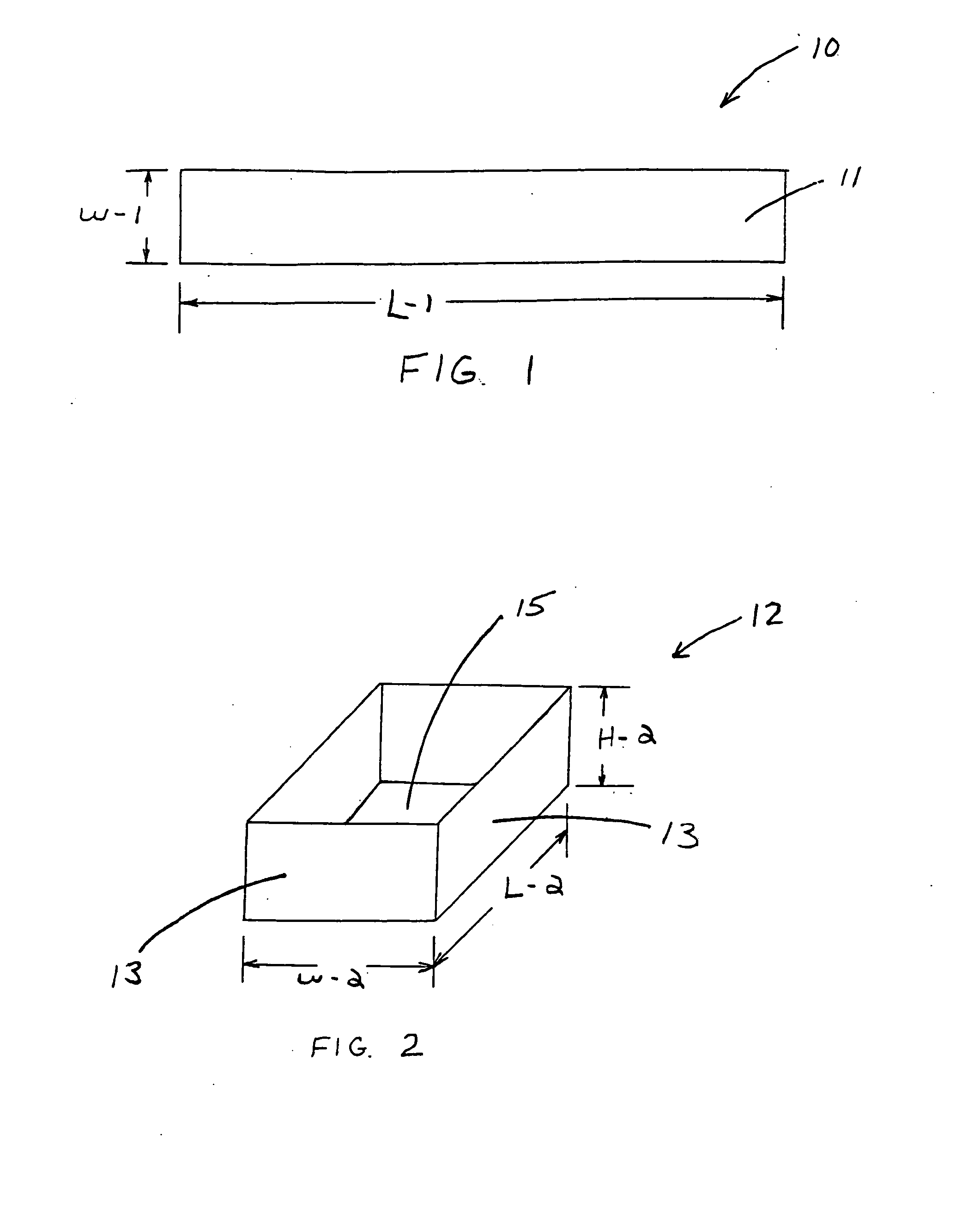

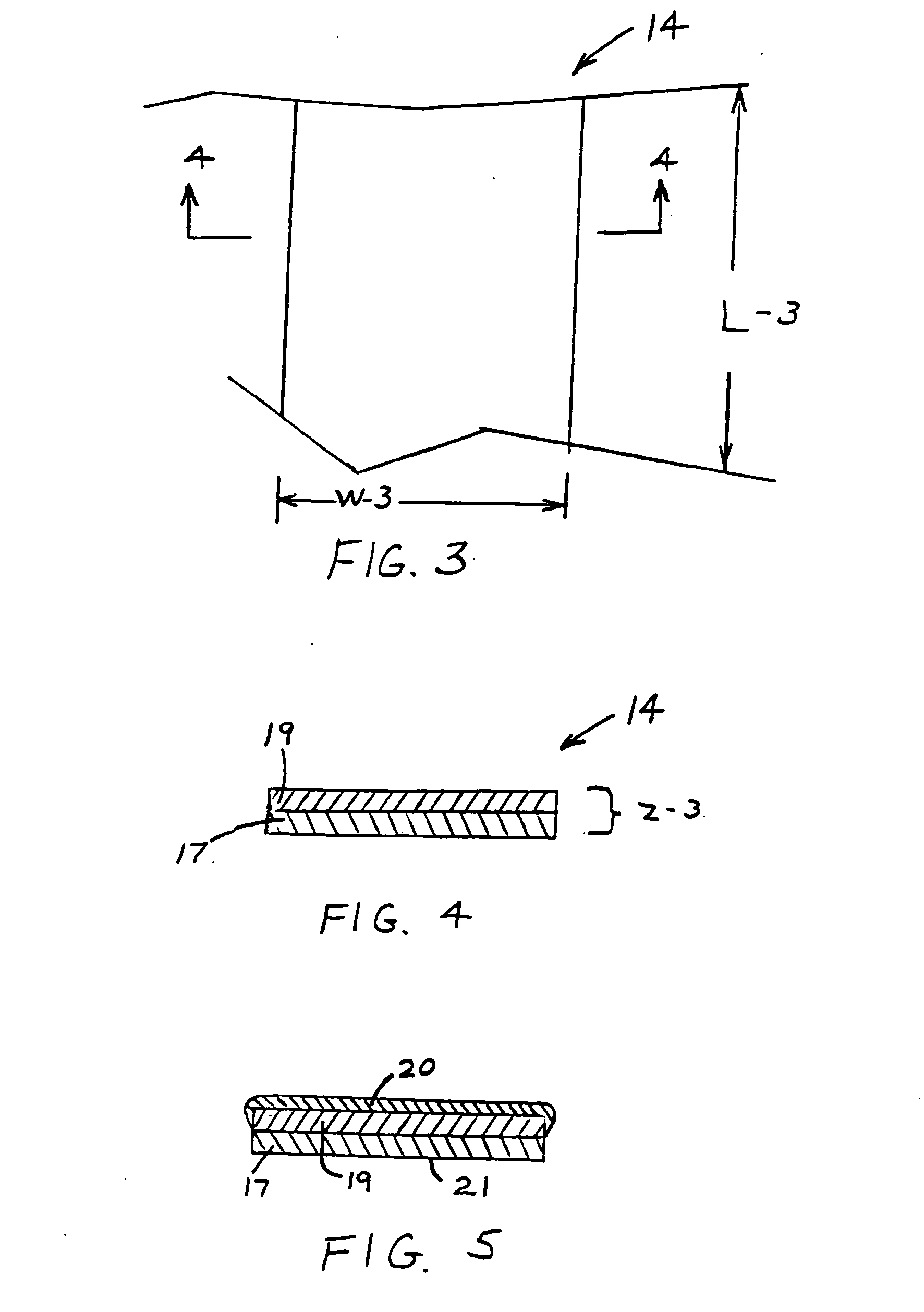

Collector grid and interconnect structures for photovoltaic arrays and modules

InactiveUS20090107538A1Ease of mass productionLamination ancillary operationsLayered product treatmentPhotovoltaic arraysEngineering

An interconnected arrangement of photovoltaic cells is achieved using laminating current collector electrodes. The electrodes comprises a pattern of conductive material extending over a first surface of sheetlike substrate material. The first surface comprises material having adhesive affinity for a selected conductive surface. Application of the electrode to the selected conductive surface brings the first surface of the sheetlike substrate into adhesive contact with the conductive surface and simultaneously brings the conductive surface into firm contact with the conductive material extending over first surface of the sheetlike substrate. Use of the laminating current collector electrodes allows facile and continuous production of expansive area interconnected photovoltaic arrays.

Owner:SOLANNEX

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

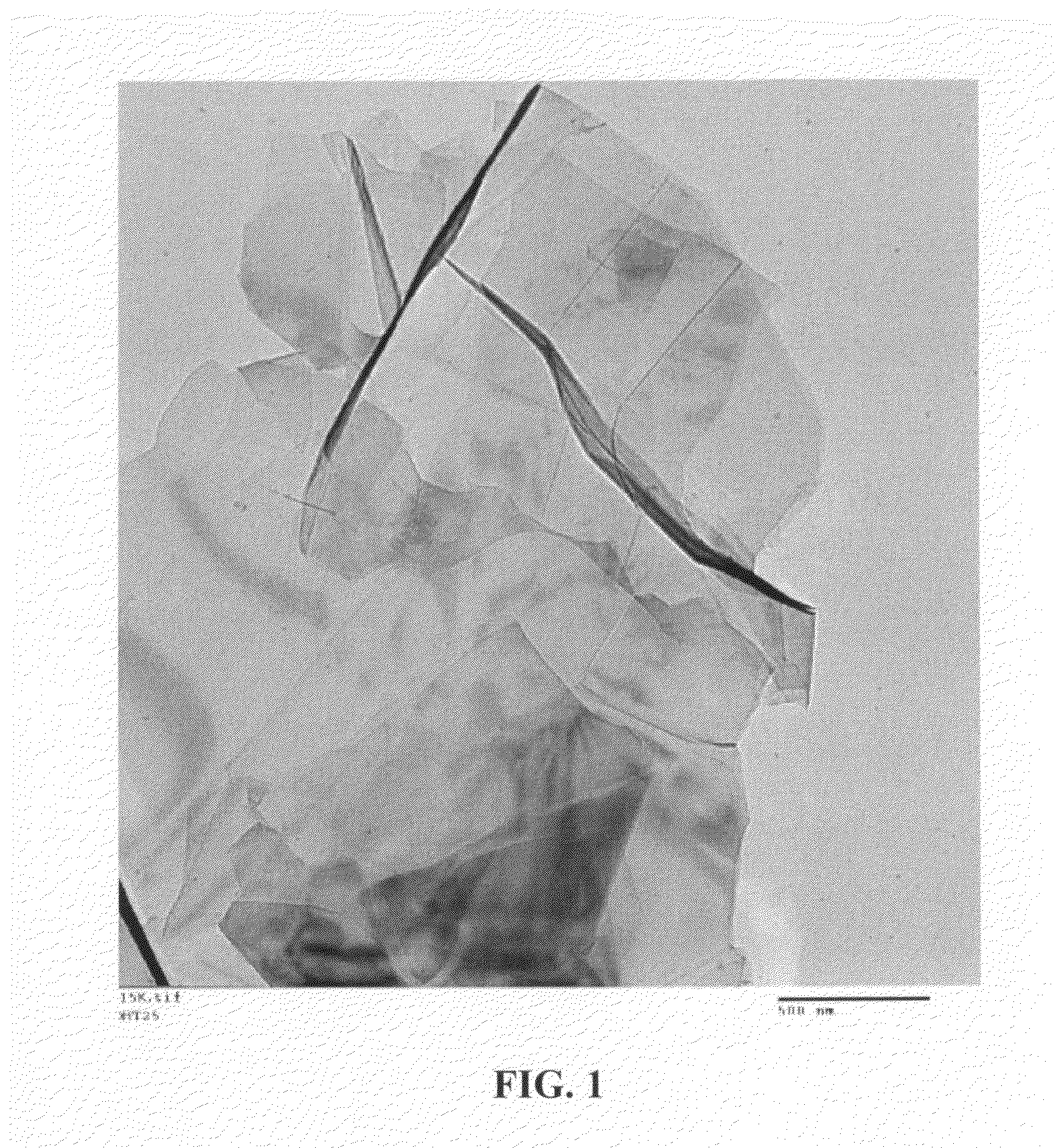

Continuous process for producing spacer-modified nano Graphene electrodes for supercapacitors

ActiveUS20110165321A1Increase surface areaMaterial nanotechnologyElectrolytic capacitorsSupercapacitorSolvent

A specific embodiment of the present invention is a process for continuously producing a porous solid film of spacer-modified nano graphene platelets for supercapacitor electrode applications. This process comprises: (a) dissolving a precursor material in a solvent to form a precursor solution and dispersing multiple nano graphene platelets into the solution to form a suspension; (b) continuously delivering and forming the suspension into a layer of solid film composed of precursor material-coated graphene platelets overlapping one another, and removing the solvent from the solid film (e.g., analogous to a paper-making, mat-making, or web-making procedure); (c) continuously converting the precursor material into nodules bonded to surfaces of graphene platelets to form a porous solid film composed of spacer-modified graphene platelets; and (d) continuously collecting the porous solid film on a collector (e.g., a winding roller). The roll of porous solid film (mat, paper, or web) can then be cut into pieces for used as supercapacitor electrodes.

Owner:NANOTEK INSTR GRP LLC

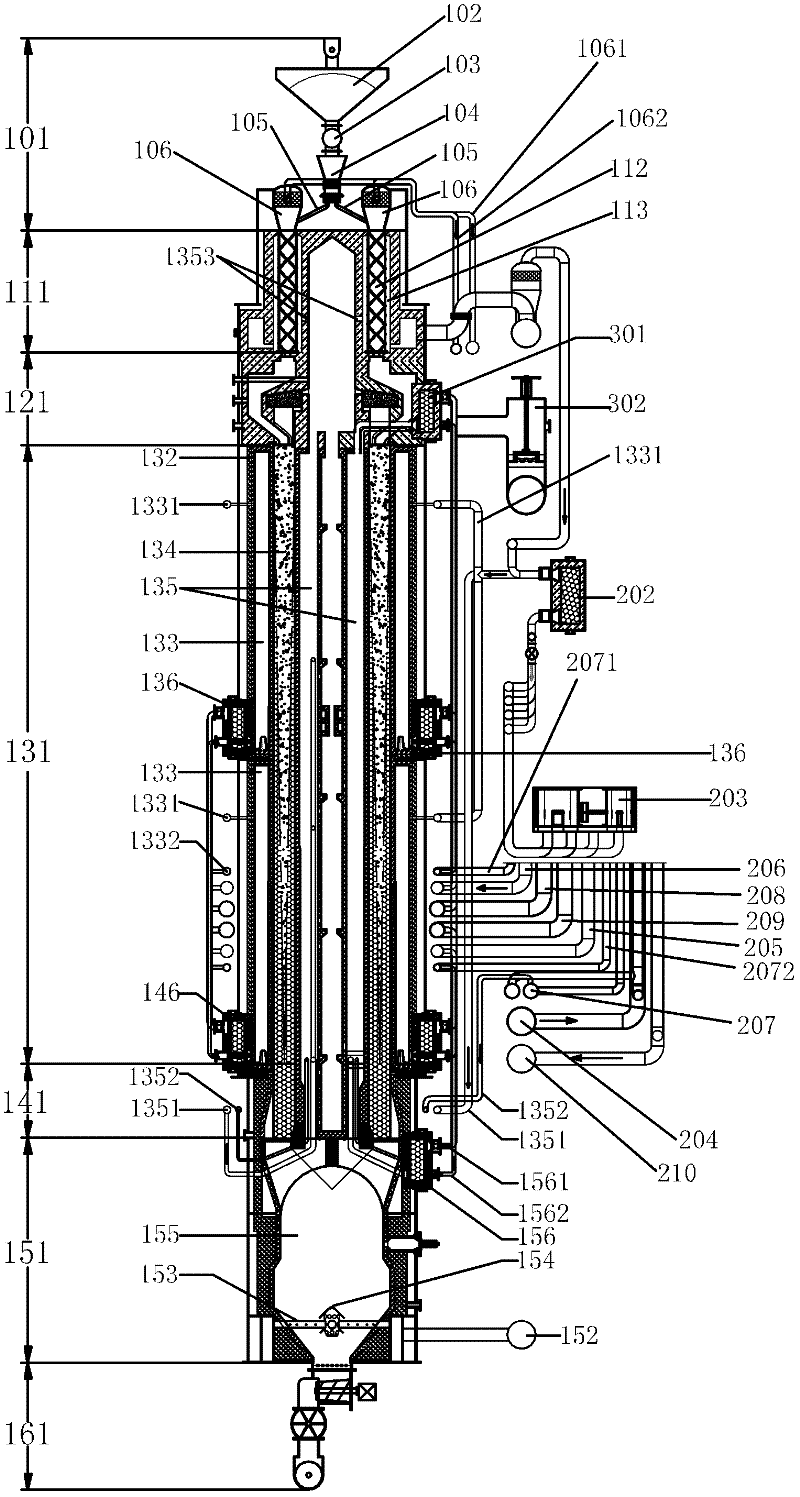

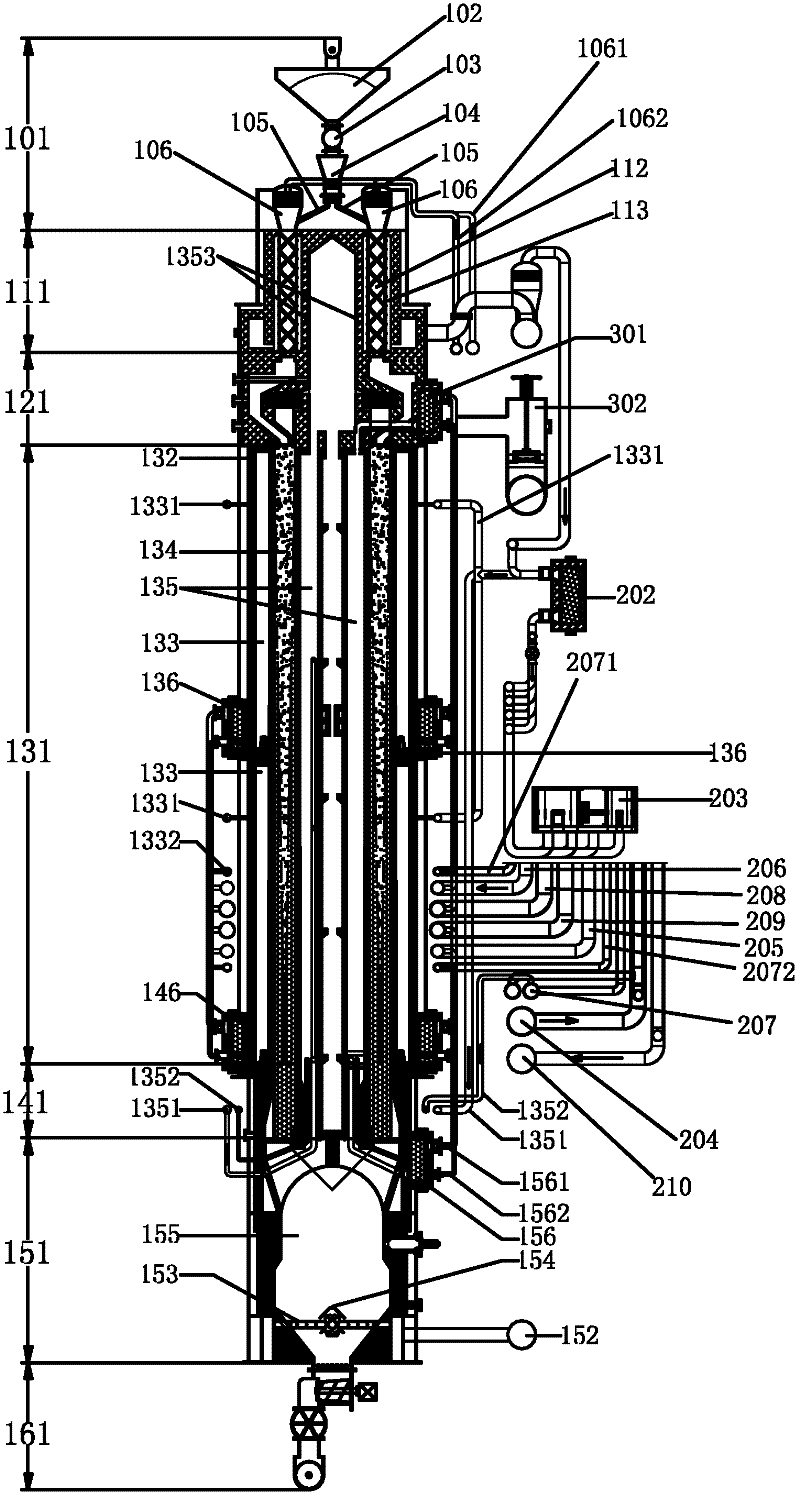

Coking furnace capable of recycling heat energy and coking method

InactiveCN102250629AExtend the industrial chainReduce pollutionCoke quenchingGas purification with selectively adsorptive solidsThermal energyCombustion

The invention discloses a coking furnace capable of recycling heat energy, and the coking furnace comprises a furnace body, an exhaust gas recycling system and a raw coal gas treatment system, wherein the furnace body sequentially comprises a coal feeding segment, a rapid coal heating segment, a raw coal gas leading-out segment, a coal carbonization coking segment, a coke quenching and tempering segment, a dry coke quenching segment and a coke discharging segment from top to bottom; the exhaust gas recycling system comprises an exhaust gas leading-out unit, an exhaust gas heat exchanger, a commutator and the like; and the raw coal gas treatment system comprises a raw coal gas leading-out unit. By using the coking furnace disclosed by the invention, continuous coal carbonization coking canbe achieved and the exhaust gas after combustion is used for dry coke quenching in the furnace; pre-dried coal can be quickly heated to 300 DEG C during entering the furnace, the coal is carbonized and coked in the furnace body, and the exhaust gas generated by self-combustion is used for dry coke quenching at the furnace bottom after the exhaust gas is cooled by heat exchange with air, thus continuously producing coke; the pollution is less in the production process; the coal industrial chain is extended, the coking cost is lowered, the coking coal types are broadened, and the product quality is improved; the profit margins are expanded in a large extent; and the maintenance cost is low.

Owner:山西华天新能源发展有限公司

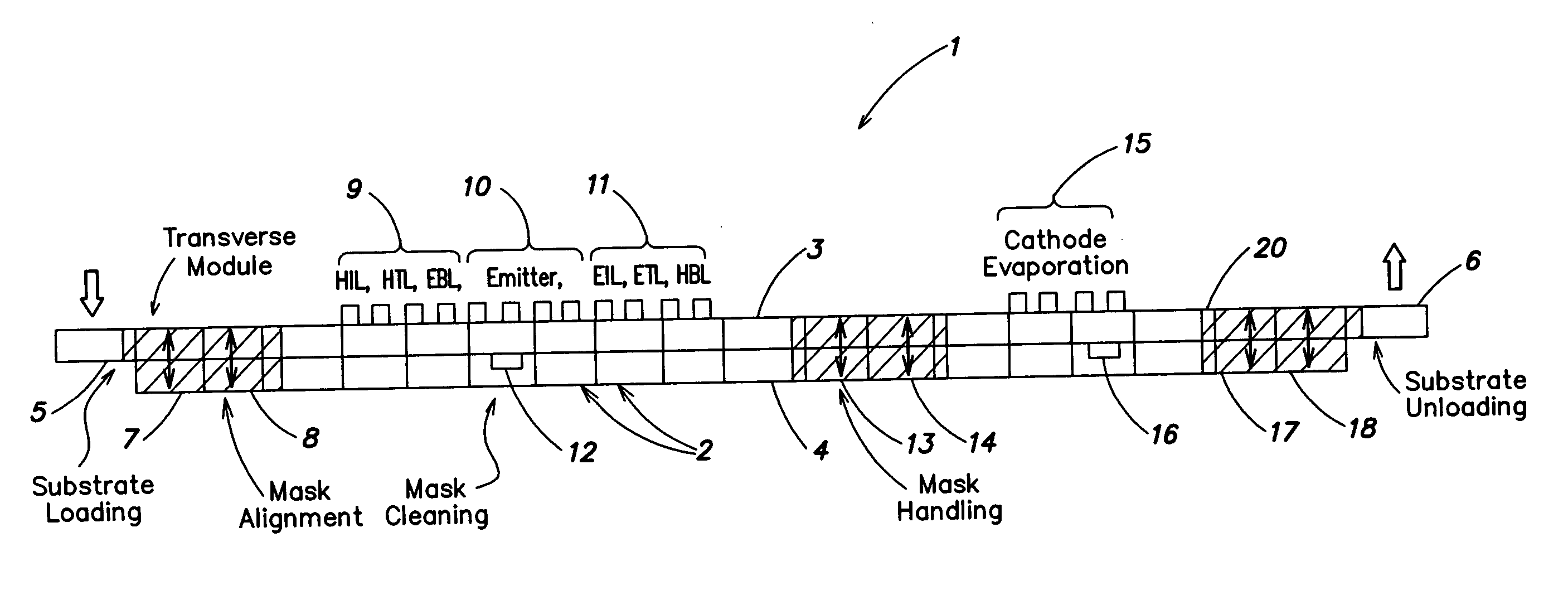

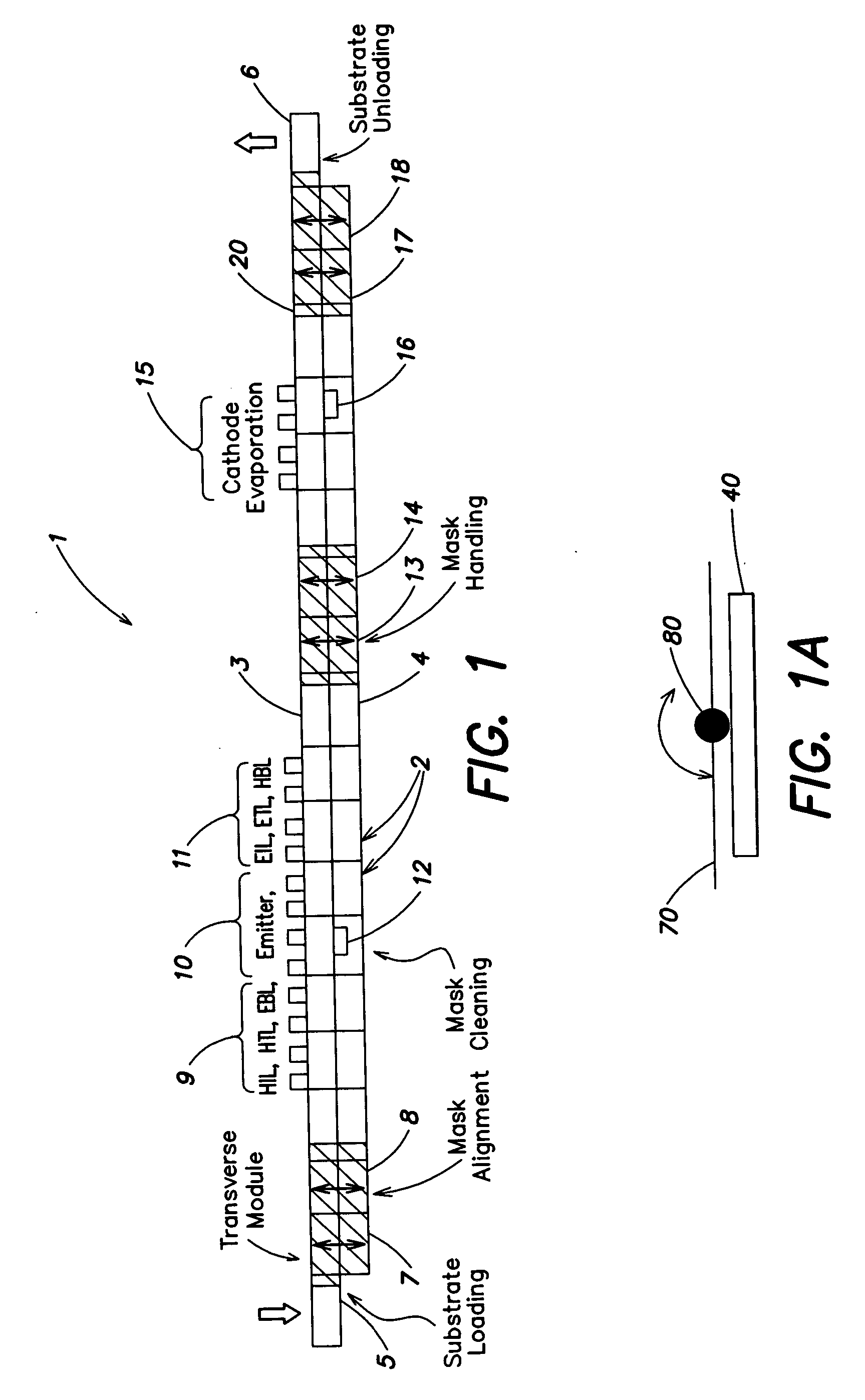

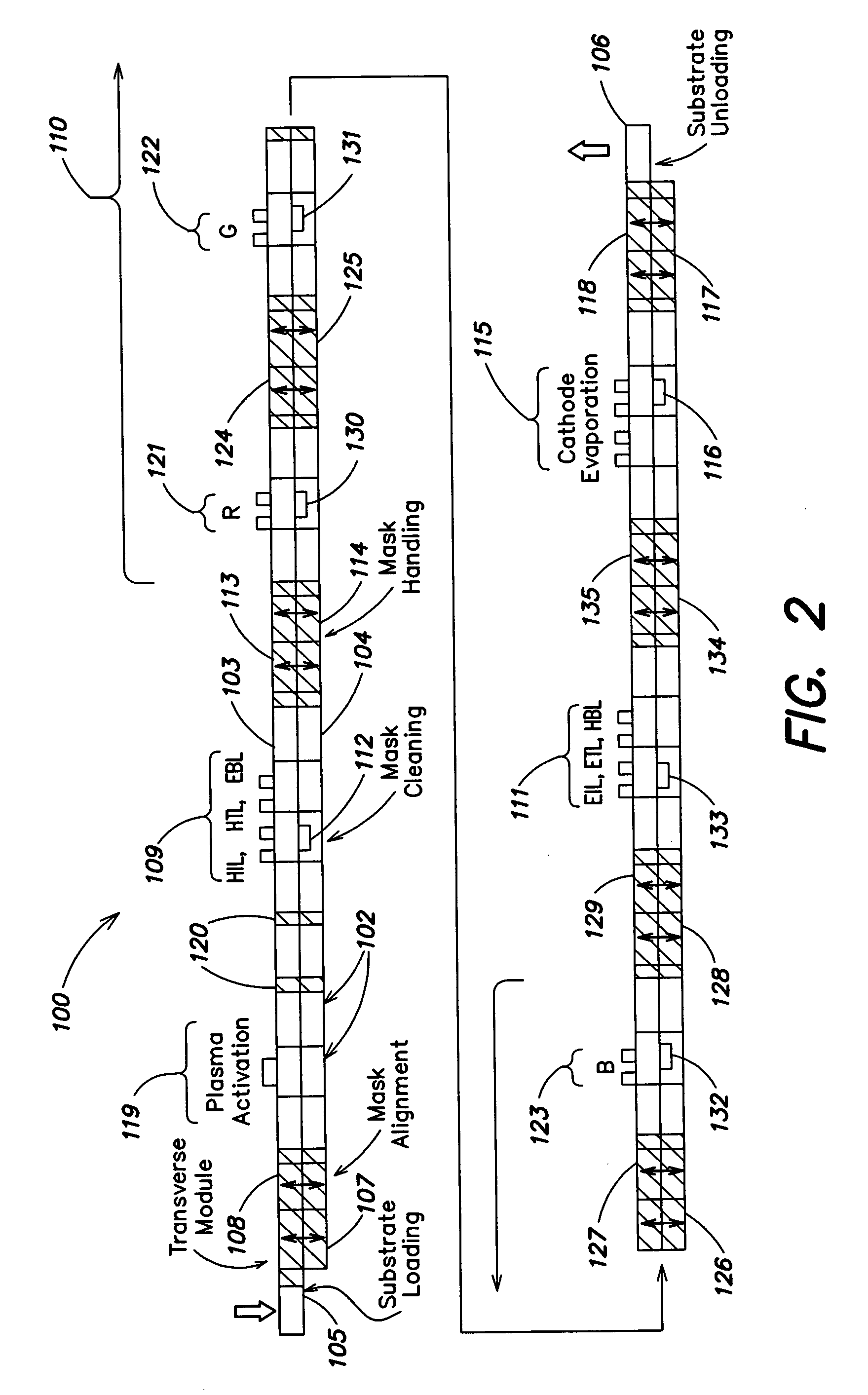

Continuous OLED coating machine

InactiveUS20070009652A1Avoid and reduce mask stockpilingMinimize the numberElectroluminescent light sourcesVacuum evaporation coatingOrganic electroluminescenceCoating

Aspects of the present invention concern a device and a process for continuous production of substrates provided with organic electroluminescent materials (OLED), especially OLED displays, screens, panels or other lighting elements, in which the device has a vacuum space and a transport device for transporting the substrates to be coated, which is at least partially arranged along the vacuum space and comprises carriers for the substrates, with the transport device comprising at least one endless loop for transport of the carriers and with the vacuum space being divided at least into two with a first part, in which is provided a first section of the transport device for transporting the carriers in a first direction (substrate-transport direction), and with a second part, in which is provided a second section of the transport device for transport of the carriers in a second direction (carrier-return-transport direction). Correspondingly, the masks necessary for structuring the OLED coatings are cleaned advantageously directly during return transport and no mask stockpiling is required.

Owner:APPLIED MATERIALS GMBH & CO KG

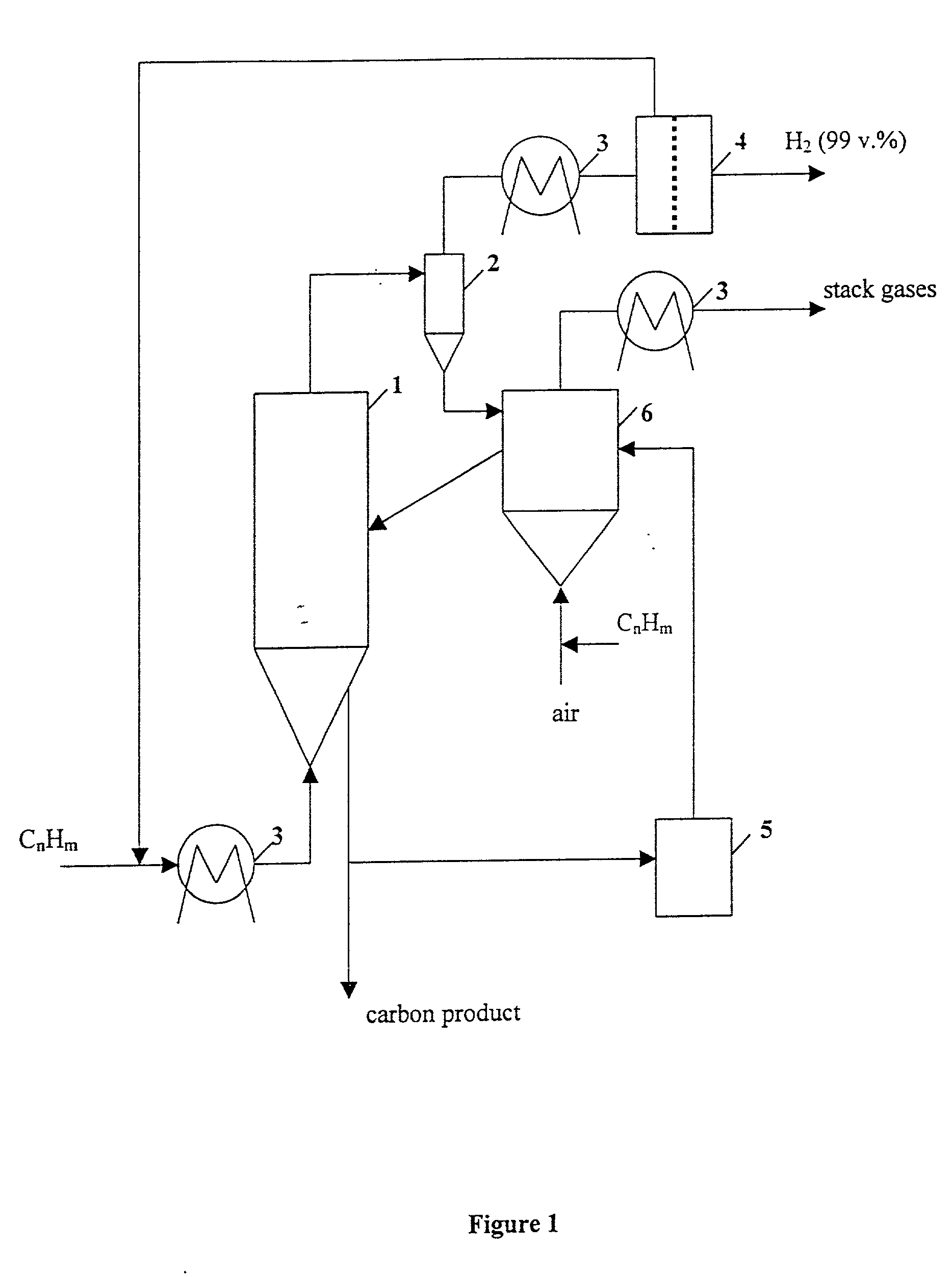

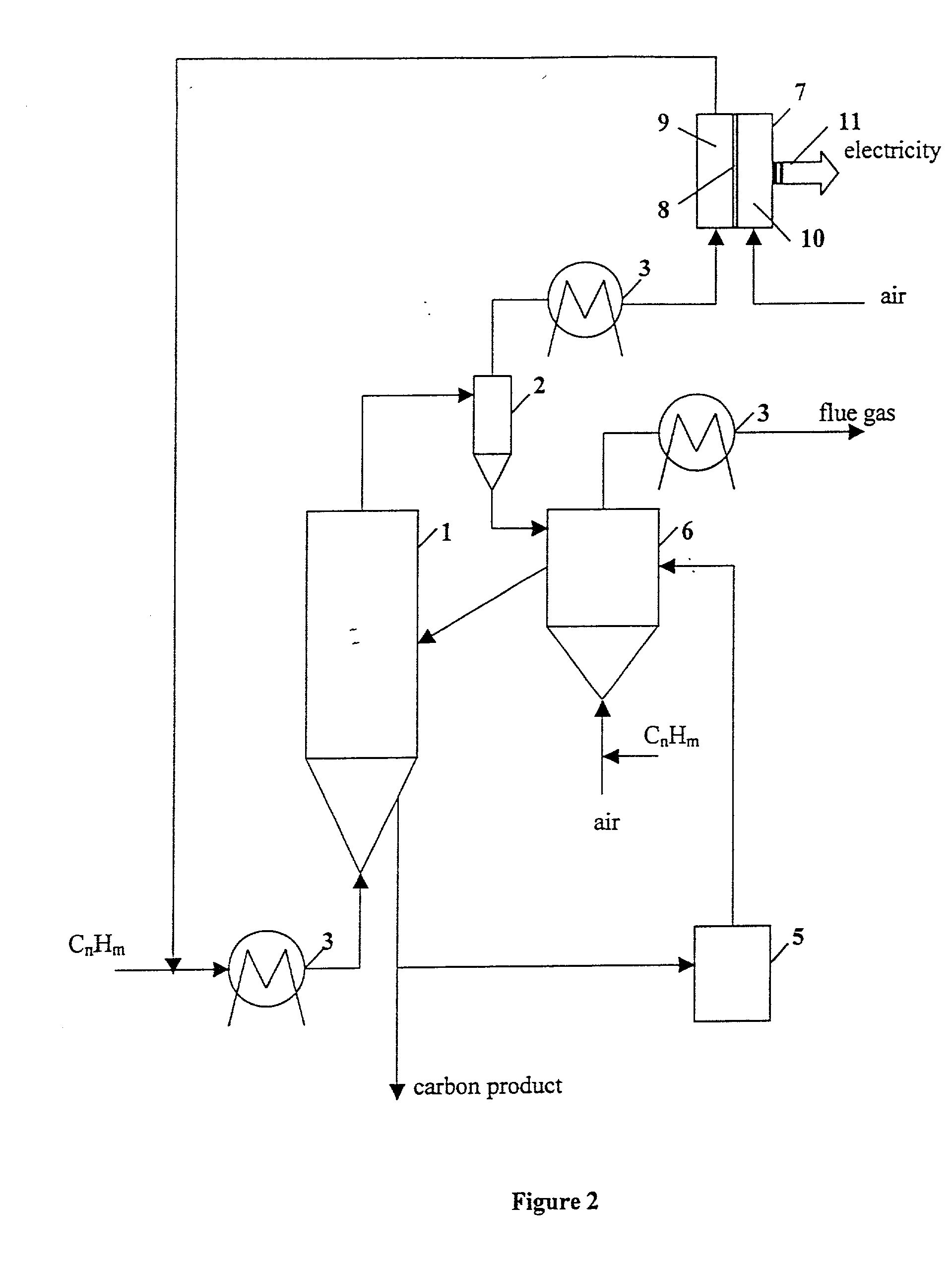

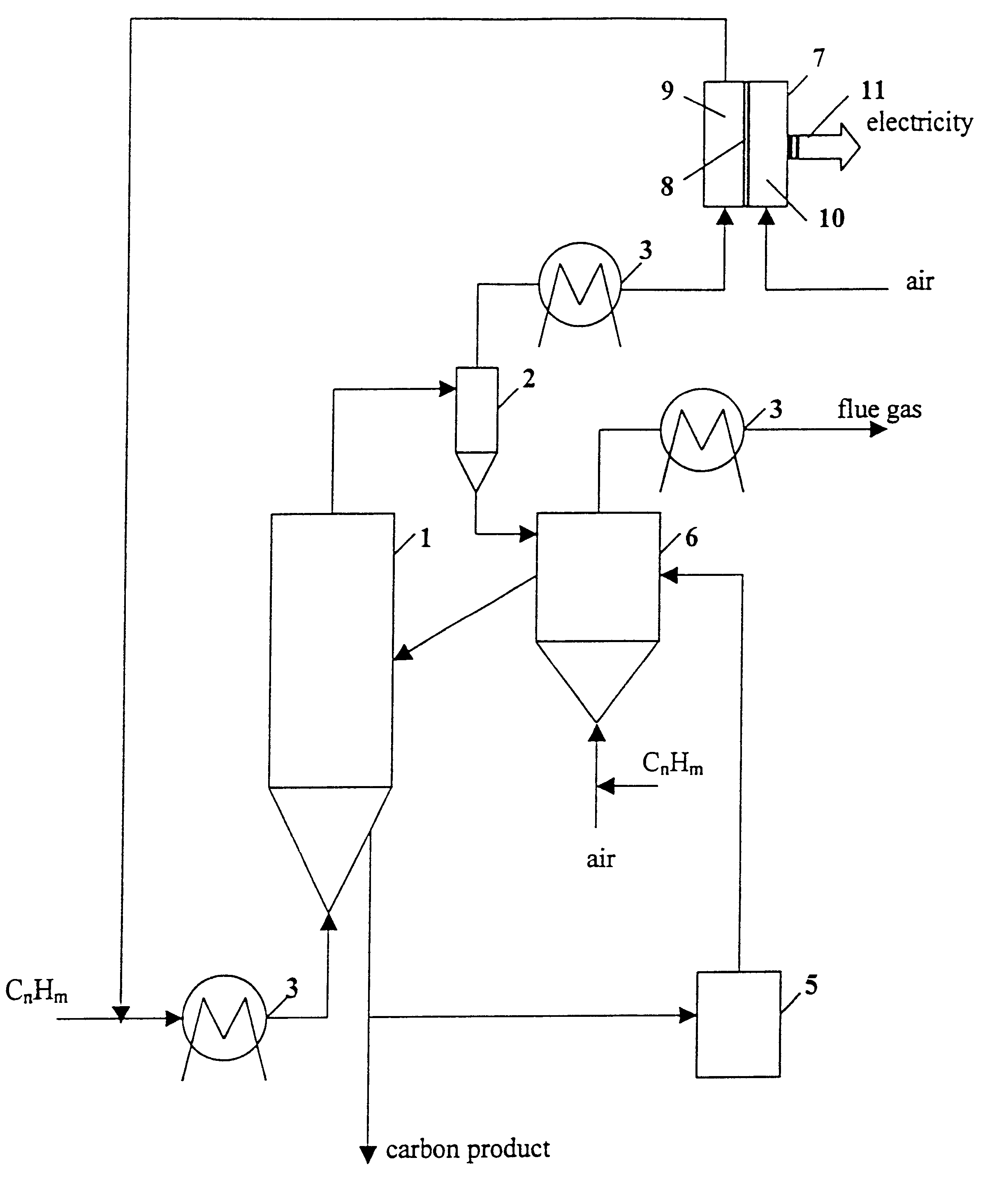

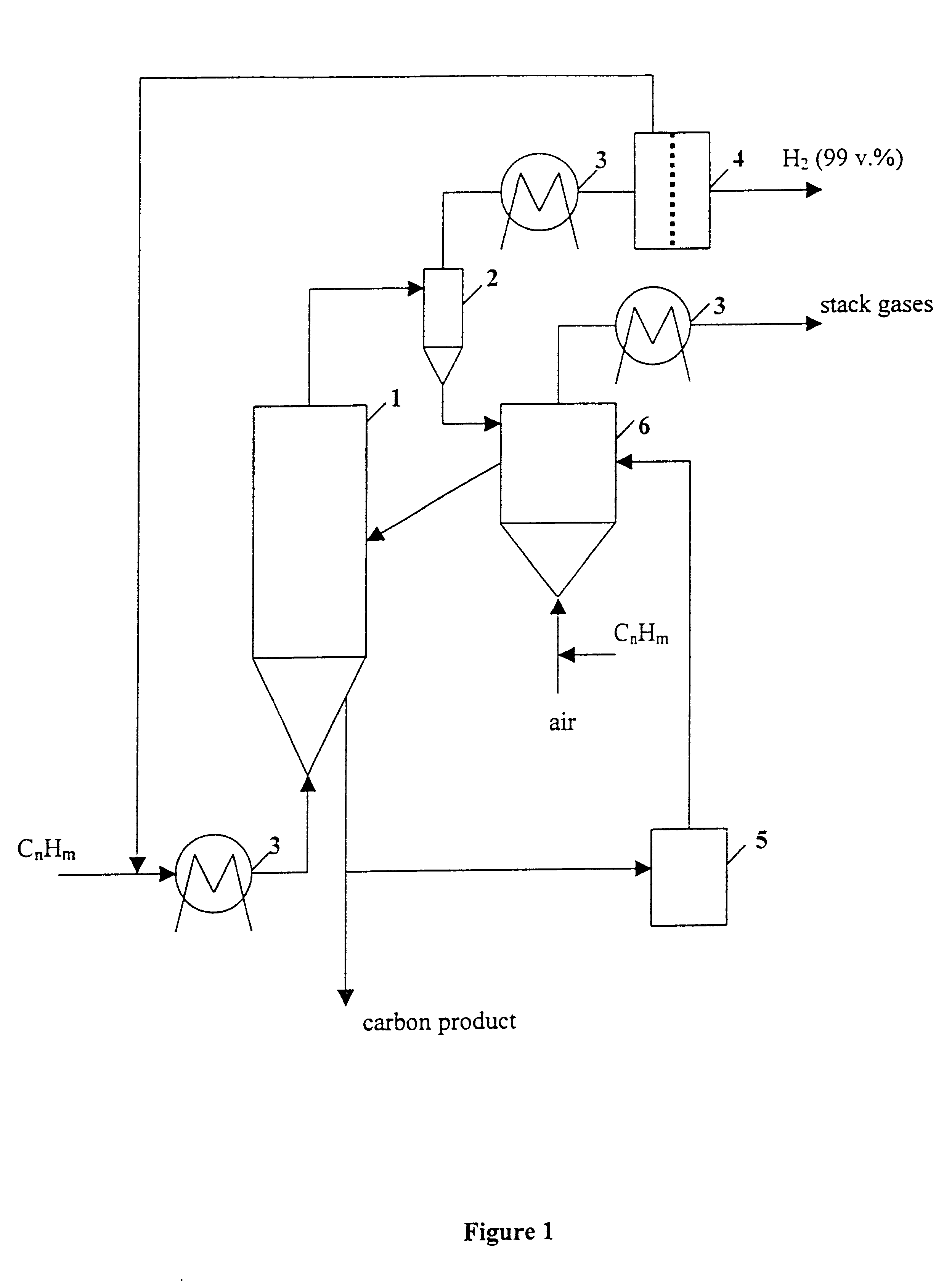

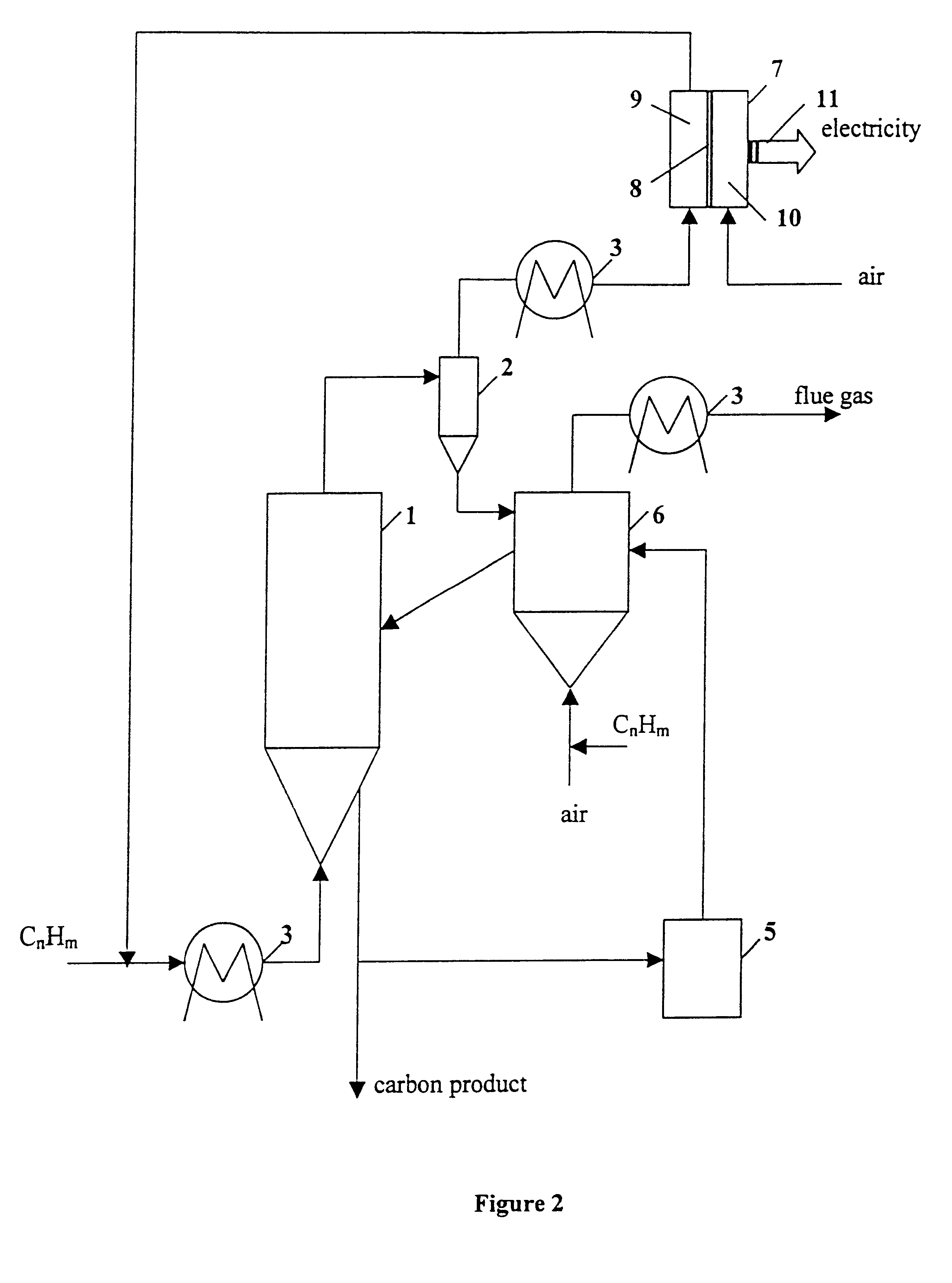

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

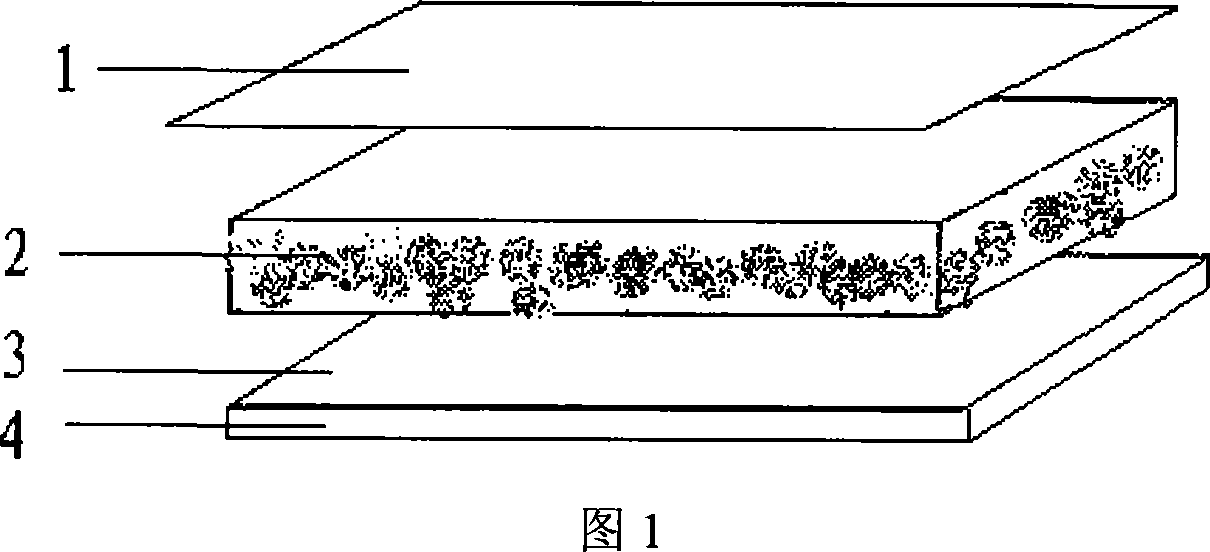

Polyurethane composite thermal insulation board, manufacturing method and application of the same

InactiveCN101220614AImprove thermal insulation performanceImprove fire and flame retardant performanceCovering/liningsLaminationProduction lineAlcohol

The invention provides a polyurethane compound heated board and a manufacturing method and application, which relates to a heated board and supplies a polyurethane compound heated board that has good heat-insulating effect, high fire-fighting and flame-retardant performance, convenient using performance and high constructing efficiency and the manufacturing method and the application. The invention includes a polyurethane rigid foam insulating layer, a bonding layer and an inorganic material composite board; the bonding layer is arranged between the polyurethane rigid foam insulating layer and the inorganic material composite board; the thickness of the polyurethane rigid foam insulating layer is 20-80mm and the thickness of the inorganic material composite plate is 3-10mm. The inorganic material composite board can be continuously produced for further use; an adhesive treatment agent is coated on the inorganic material composite board; polyhydric alcohol combination material and isocyanate combination material are added into the continuous production line for mixed foaming and curing to obtain the polyurethane compound heated board; the mass ratio of the polyhydric alcohol combination material and the isocyanate is 100:95-160.

Owner:厦门高特高新材料有限公司

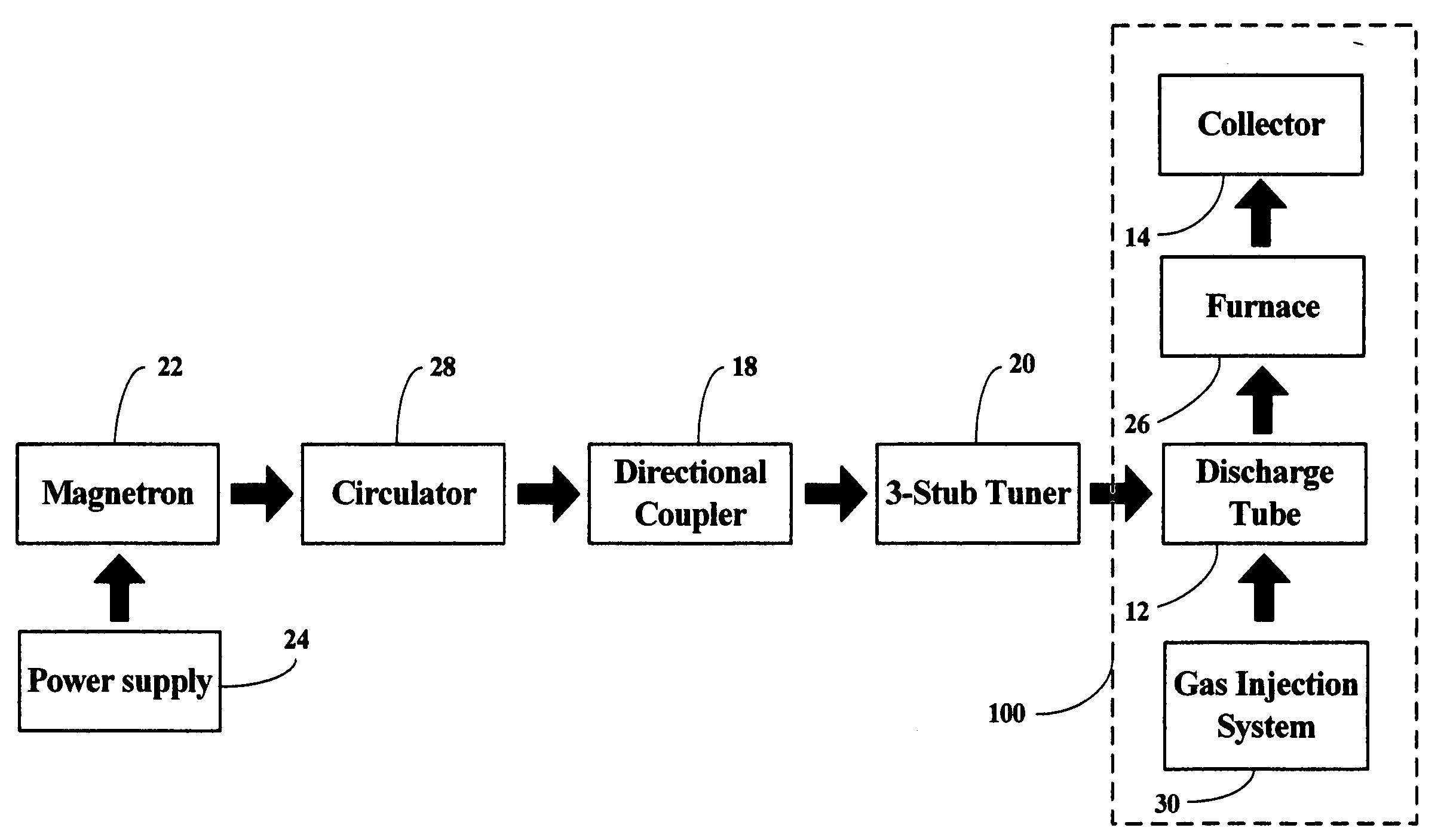

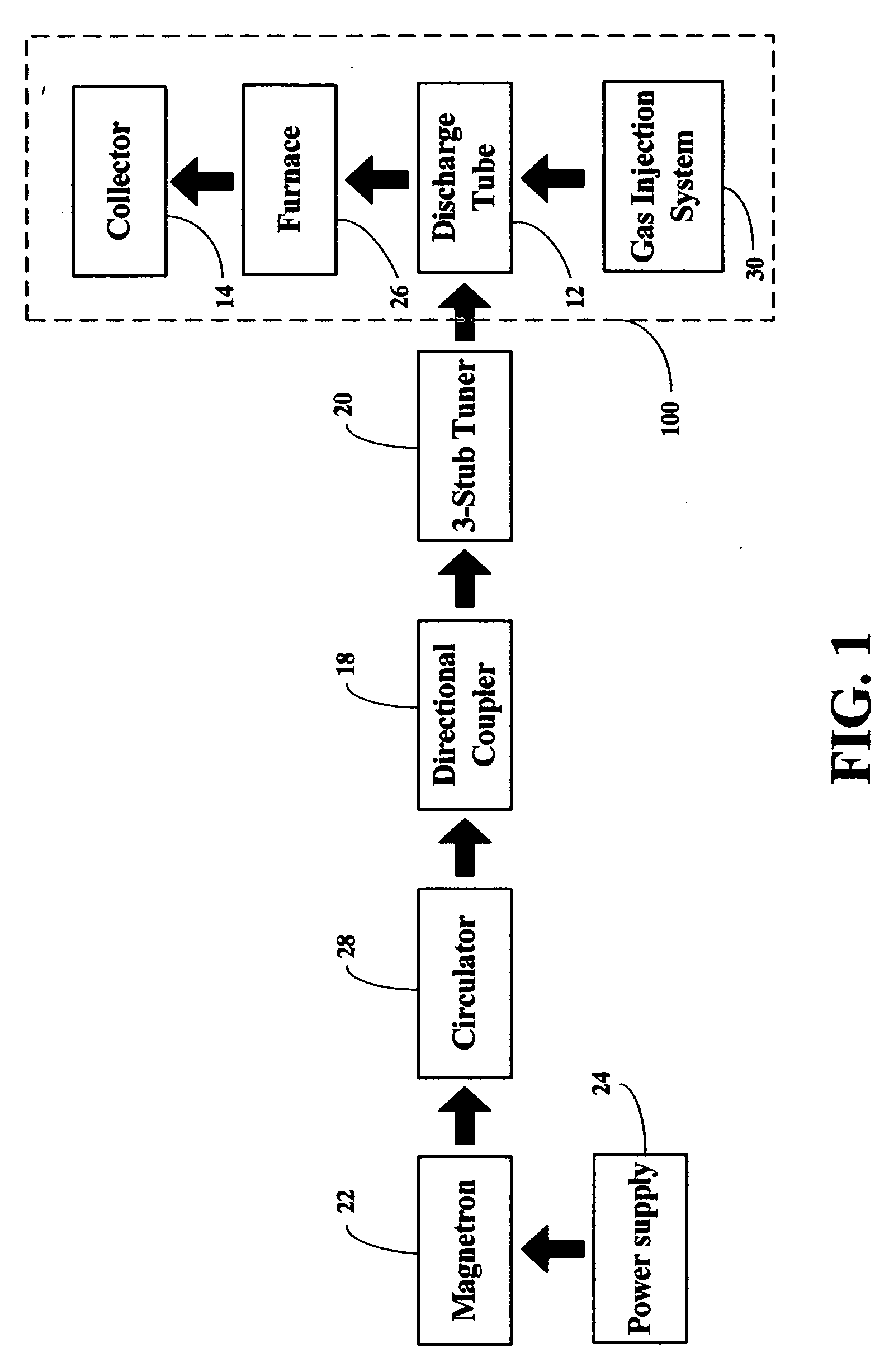

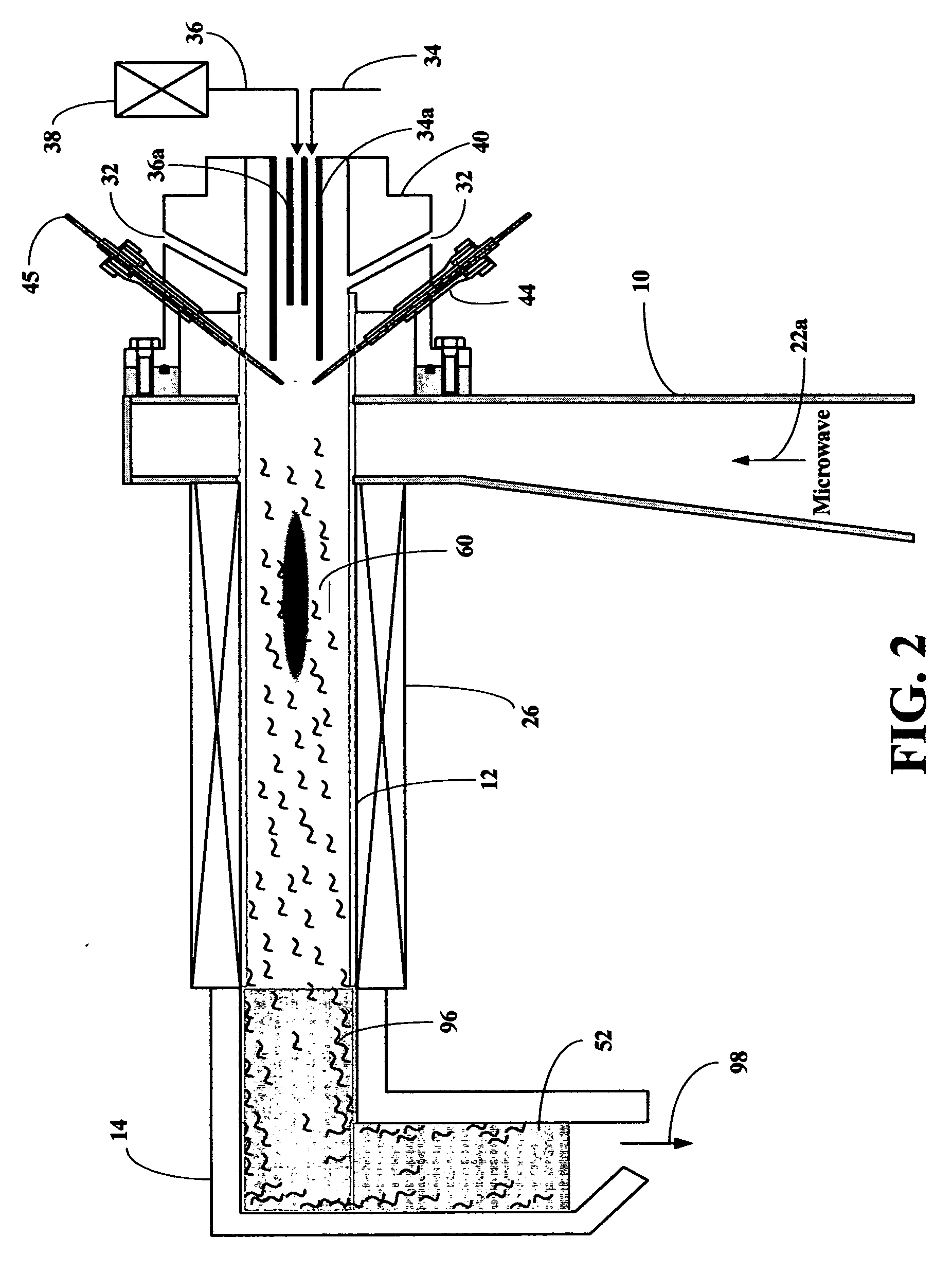

Synthesis of carbon nanotubes by making use of microwave plasma torch

InactiveUS20050163696A1Increase the electric field strengthInexpensive, commercially available and compactMaterial nanotechnologyNanoinformaticsGas phaseSynthesis methods

The present invention relates to a synthesis method of carbon nanotubes, and more particularly to an apparatus for a mass synthesis of carbon nanotubes in gas phase using an atmospheric-pressure microwave plasma torch. The method and apparatus is described for the continuous production of carbon nanotubes by making use of a microwave plasma torch operated at a frequency of 2.45 GHz, by introducing a transition metal catalyst precursor and a carbon containing gas into the microwave plasma torch to produce atomized catalyst metal and to decompose the carbon containing gas, by passing the resulting gaseous mixtures through a furnace, and by quenching rapidly and collecting the products so formed at the exit of the furnace. The resultant products are the carbon nanotubes.

Owner:UHM HAN S

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

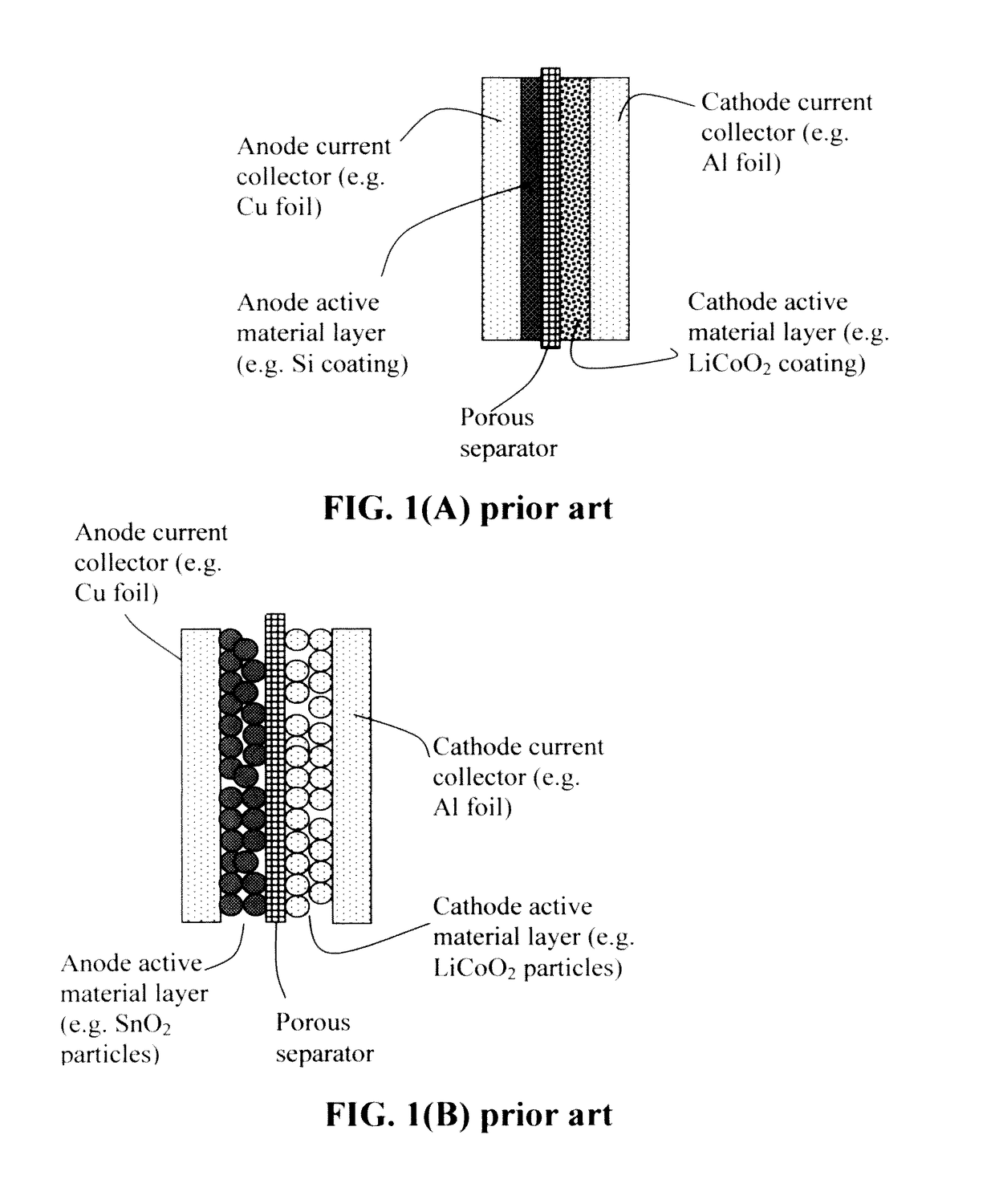

Continuous process for producing electrodes and alkali metal batteries having ultra-high energy densities

ActiveUS20170104204A1Increase energy densityImprove power densityFinal product manufactureElectrode carriers/collectorsTectorial membraneHigh energy

A process for producing an electrode for an alkali metal battery, comprising: (a) Continuously feeding an electrically conductive porous layer to an anode or cathode material impregnation zone, wherein the conductive porous layer has two opposed porous surfaces and contain interconnected conductive pathways and at least 70% by volume of pores; (b) Impregnating a wet anode or cathode active material mixture into the porous layer from at least one of the two porous surfaces to form an anode or cathode electrode, wherein the wet anode or cathode active material mixture contains an anode or cathode active material and an optional conductive additive mixed with a liquid electrolyte; and (c) Supplying at least a protective film to cover the at least one porous surface to form the electrode.

Owner:GLOBAL GRAPHENE GRP INC

Collector grid and interconnect structures for photovoltaic arrays and modules

InactiveUS20100224230A1Eliminate deficienciesPV power plantsPhotovoltaic energy generationConductive materialsMesh grid

Owner:SOLANNEX

Methods and structures for the production of electrically treated items and electrical connections

InactiveUS20050176270A1Printed circuit assemblingPrinted circuit aspectsElectricityConductive polymer

This invention involves unique electroplated items comprising electrically conductive polymers. In addition, continuous production of electrically treated items is facilitated using electrically conductive resins. Many embodiments employ directly electroplateable resins for particular advantage. Unique methods of establishing electroplated electrical connections are taught.

Owner:LUCH DANIEL

Method for producing coarse cereals rice by extruding double screw

ActiveCN101558904ASolve the problem of rough tasteSimple structureFood preservationFood shapingSmall footprintEngineering

The invention relates to a method for producing coarse cereals rice by extruding a double screw, wherein, the coarse cereals rice takes five cereals as raw materials. The method comprises the following steps: pretreating the raw materials, stirring the raw materials in a mixing way, extruding and curing the raw materials at one time with a double screw extruder and a double screw extruding technology; graining and shaping the raw materials; drying the raw materials; and cooling the raw materials, etc. The coarse cereals rice absolutely takes five cereals as raw materials without any additives and ancillary materials. The coarse cereals rice has various external shapes according to requirements, has a compact structure without the need for polishing, stable quality, good edible quality, balanced nutrition and strong health function, is free of cleaning and convenient, can be stored for a long time, has good heat stability when being cooked, and can be eaten as staple food as the common rice. The invention has the advantages of high production, continuous production process which is especially suitable for large-scale industrialization production, stable product quality, low cost, small production floor space, etc.

Owner:湖南富马科食品工程技术有限公司

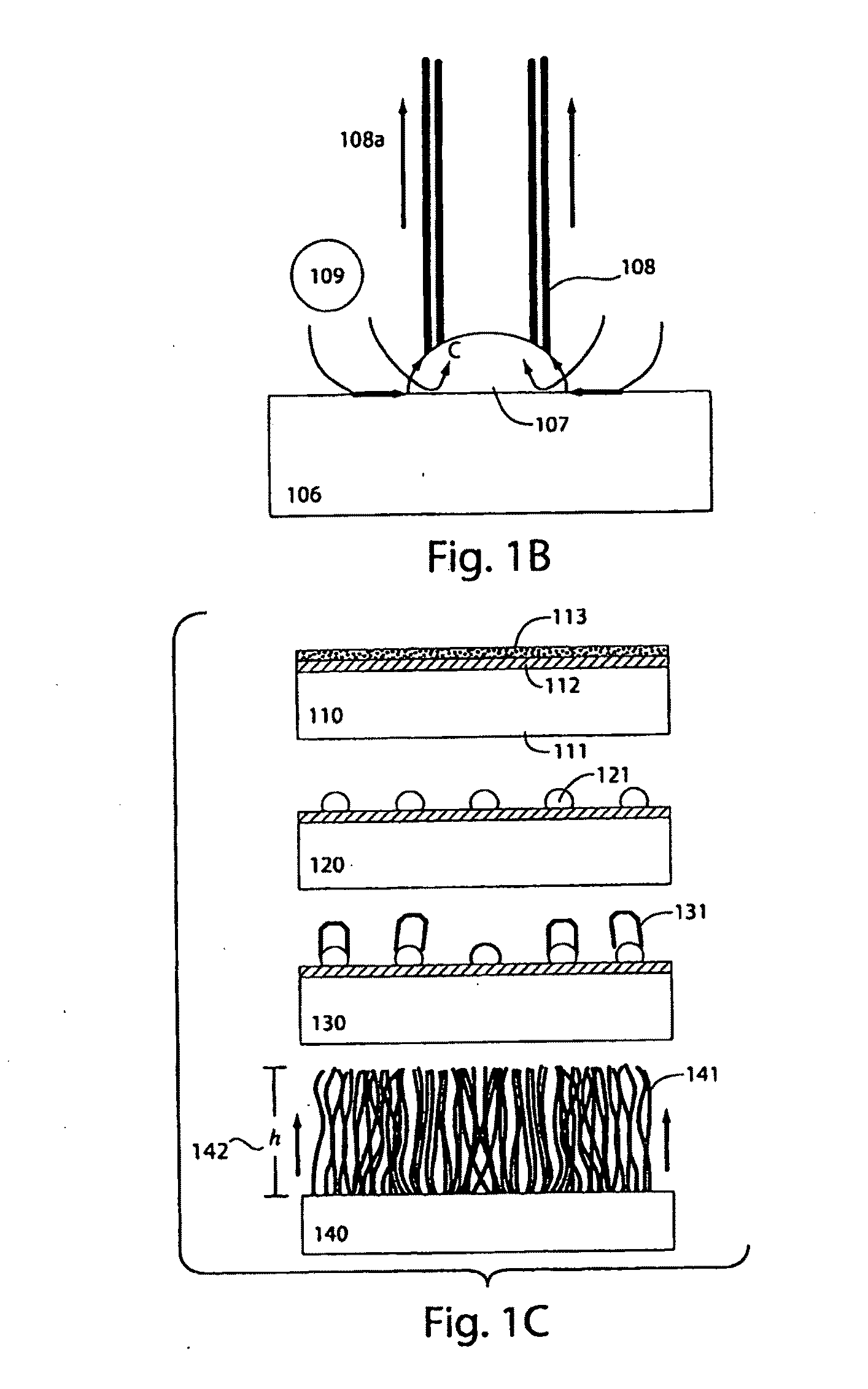

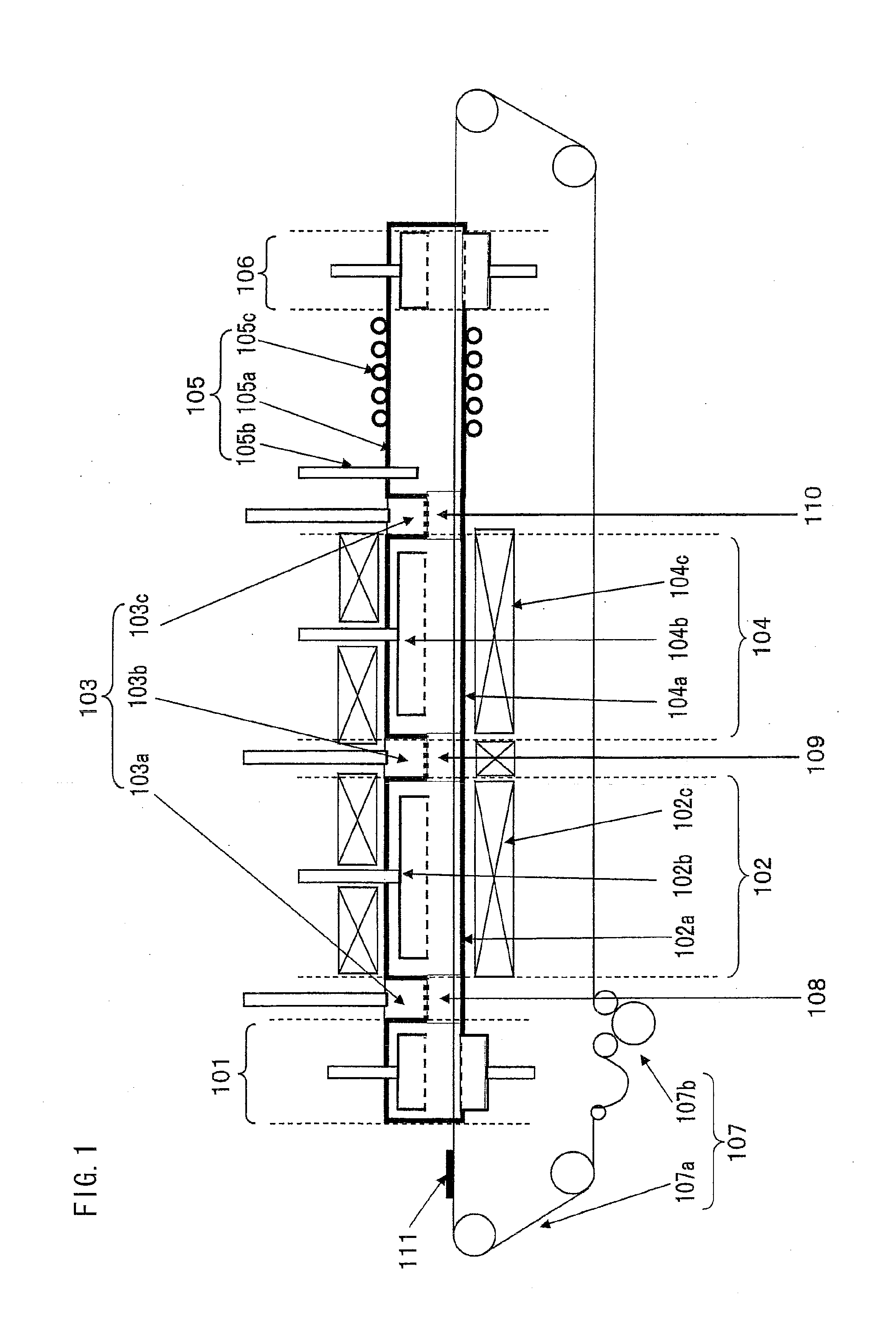

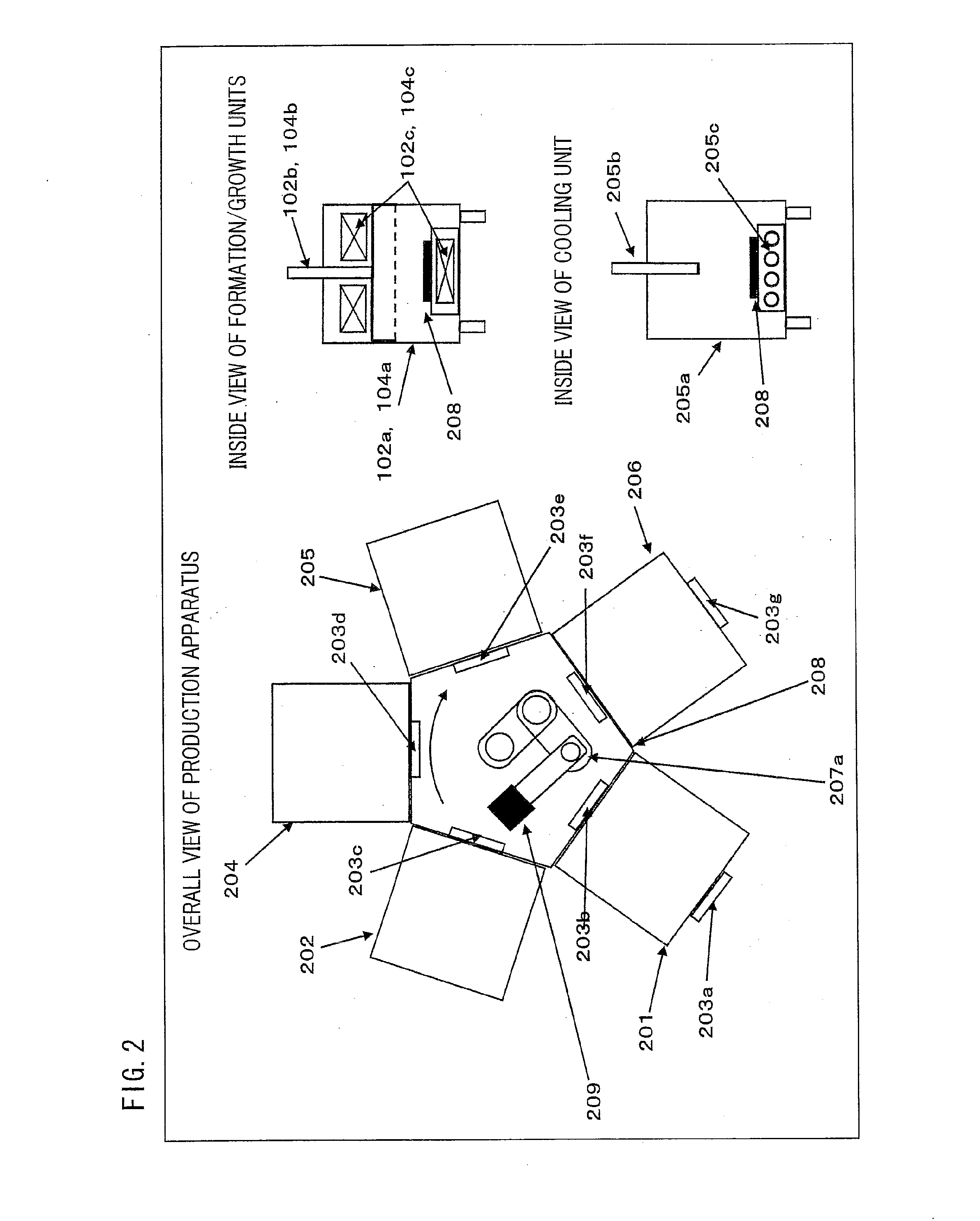

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS20100196600A1Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

Methods and structures for the production of electrically treated items and electrical connections

InactiveUS20060032752A1Reduces cost and complexityReduce capacityPrinted circuit assemblingPrinted circuit aspectsConductive polymerElectrical connection

This invention involves unique electroplated items comprising electrically conductive polymers. In addition, novel processing is taught to facilitate continuous production of electrically treated items. Many embodiments employ directly electroplateable resins for particular advantage. Unique methods of establishing electroplated electrical connections are taught.

Owner:LUCH DANIEL

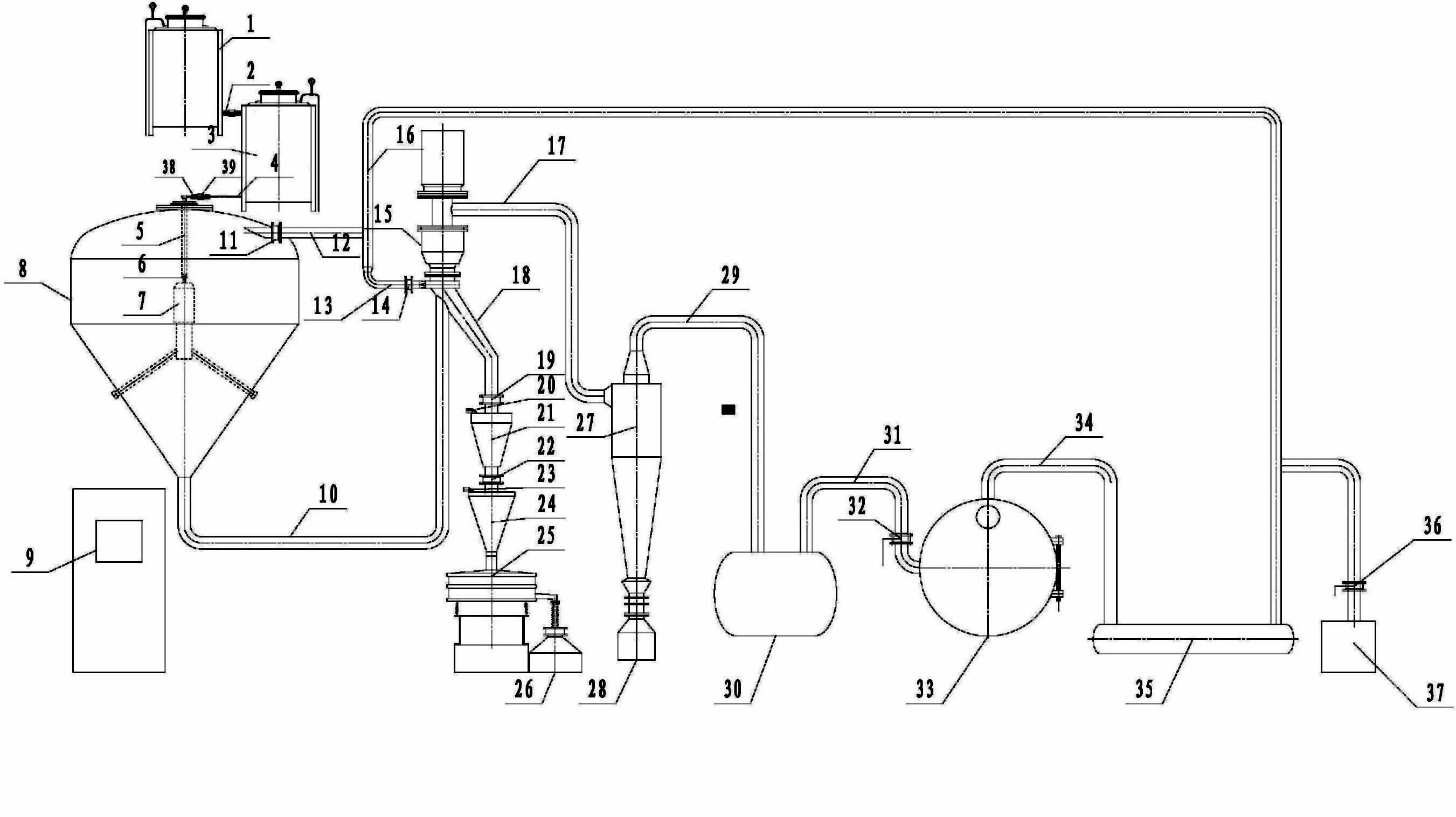

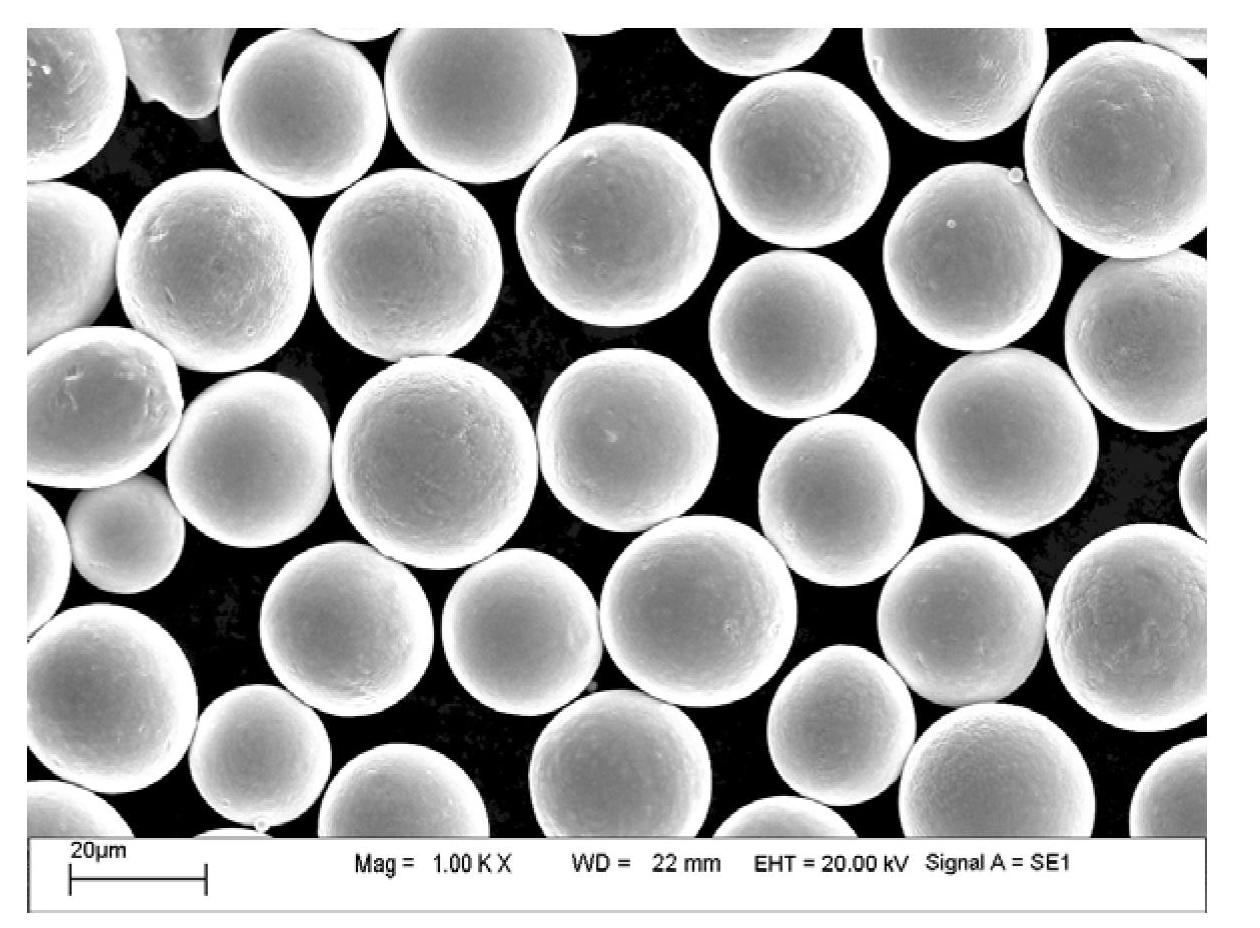

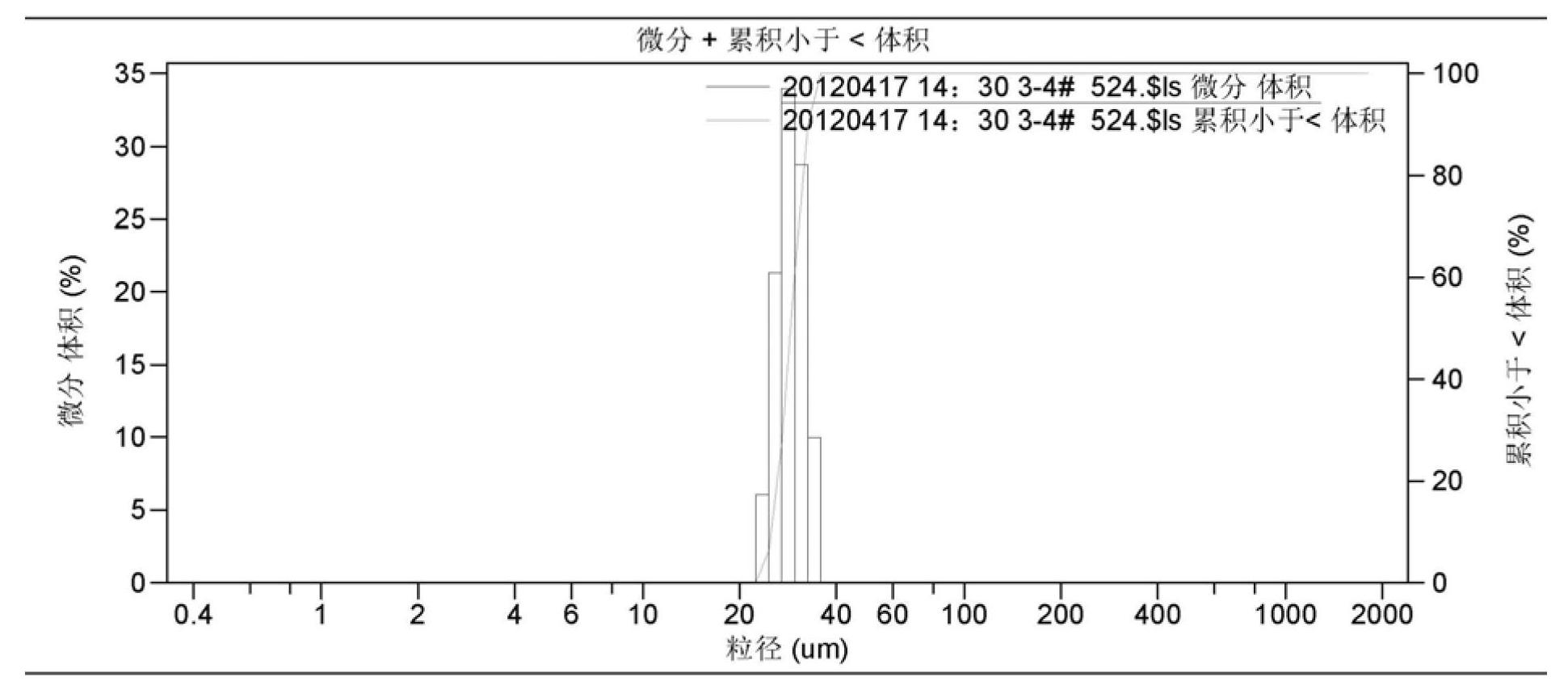

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

Production of liquid center filled confections

InactiveUS20050260329A1Reduce the amount requiredLow viscosityMeat/fish preservationConfectioneryEngineeringSignificant difference

Liquid center filled confections, such as gummy or jelly candies or fruit snacks are continuously produced by co-deposition into a mold without candy tailing to obtain products with substantially uniform top and bottom walls and little, if any, shell breakage and liquid filling leakage or bleed-out problems. Excessive vertical decentering of the filling caused by substantial differences in specific gravity between the liquid filling component and the shell component and its accompanying production of thin or weak shell walls is substantially reduced or eliminated. A non-gellable liquid filling is deposited vertically off-center within a gellable shell, and the amount of sinking or floating is controlled so as to achieve an at least substantially centered product. The filling migration is limited by rapidly cooling the shell component below its gelling or setting temperature by use of a much colder filling component which itself does not gel or set at low temperatures.

Owner:WM WRIGLEY JR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com