Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

585 results about "Liquid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

'Liquid content' as a term refers to web content that is highly shared - where the desire for sharing is driven by contagious or 'viral ideas' within the content. Liquid content may be described as memorable or significant content, which people become highly motivated to share via social networks such as twitter or pintrest.

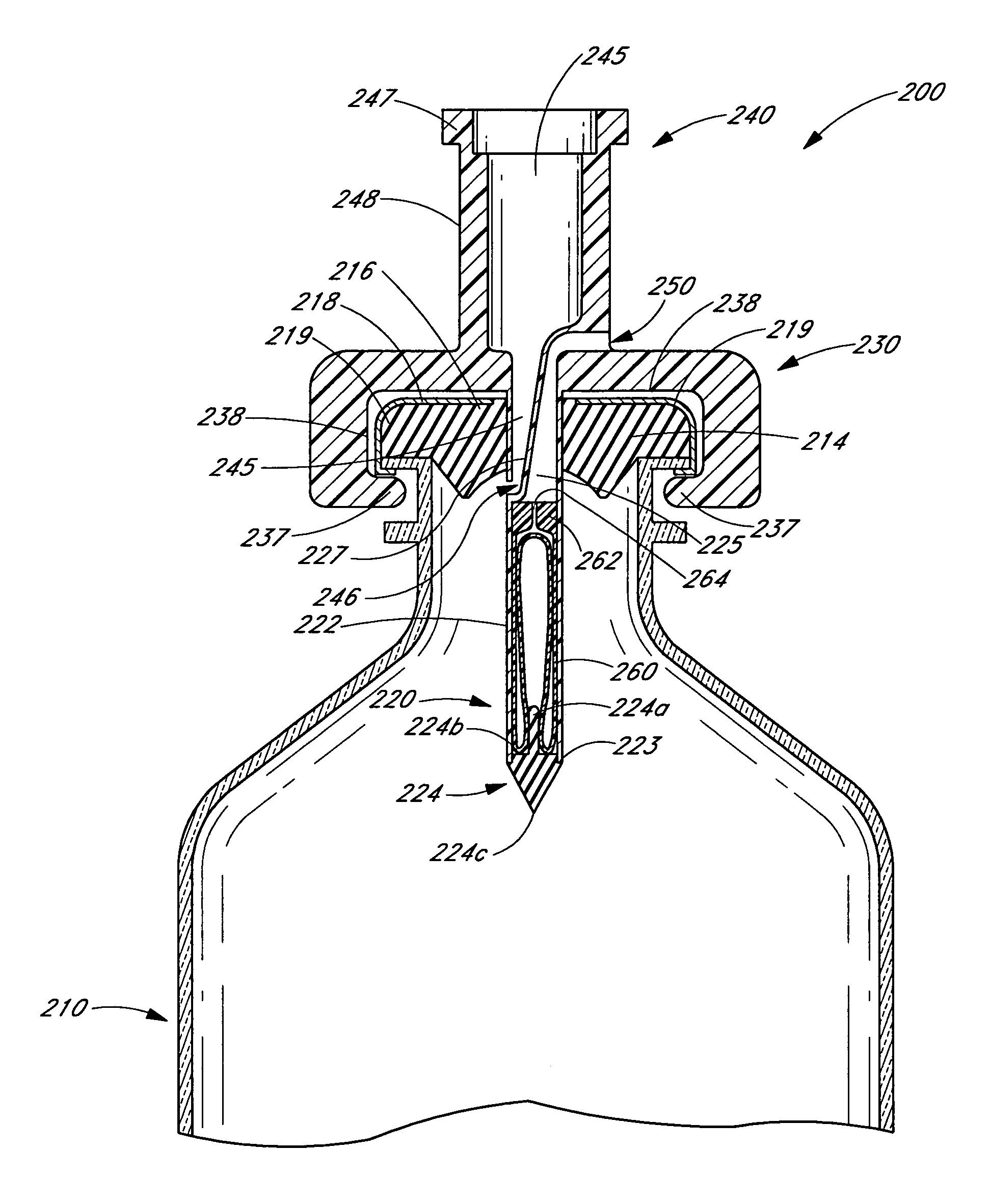

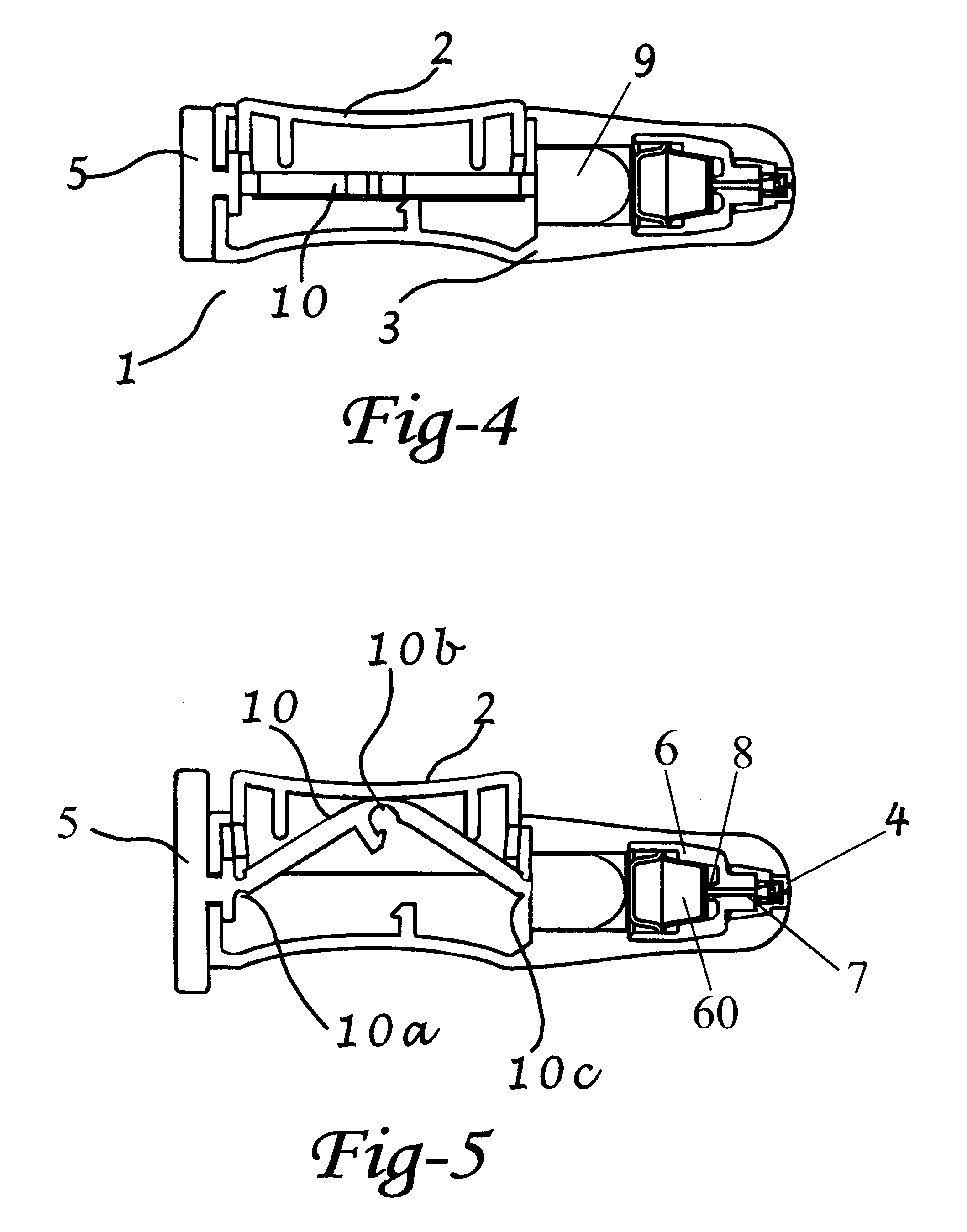

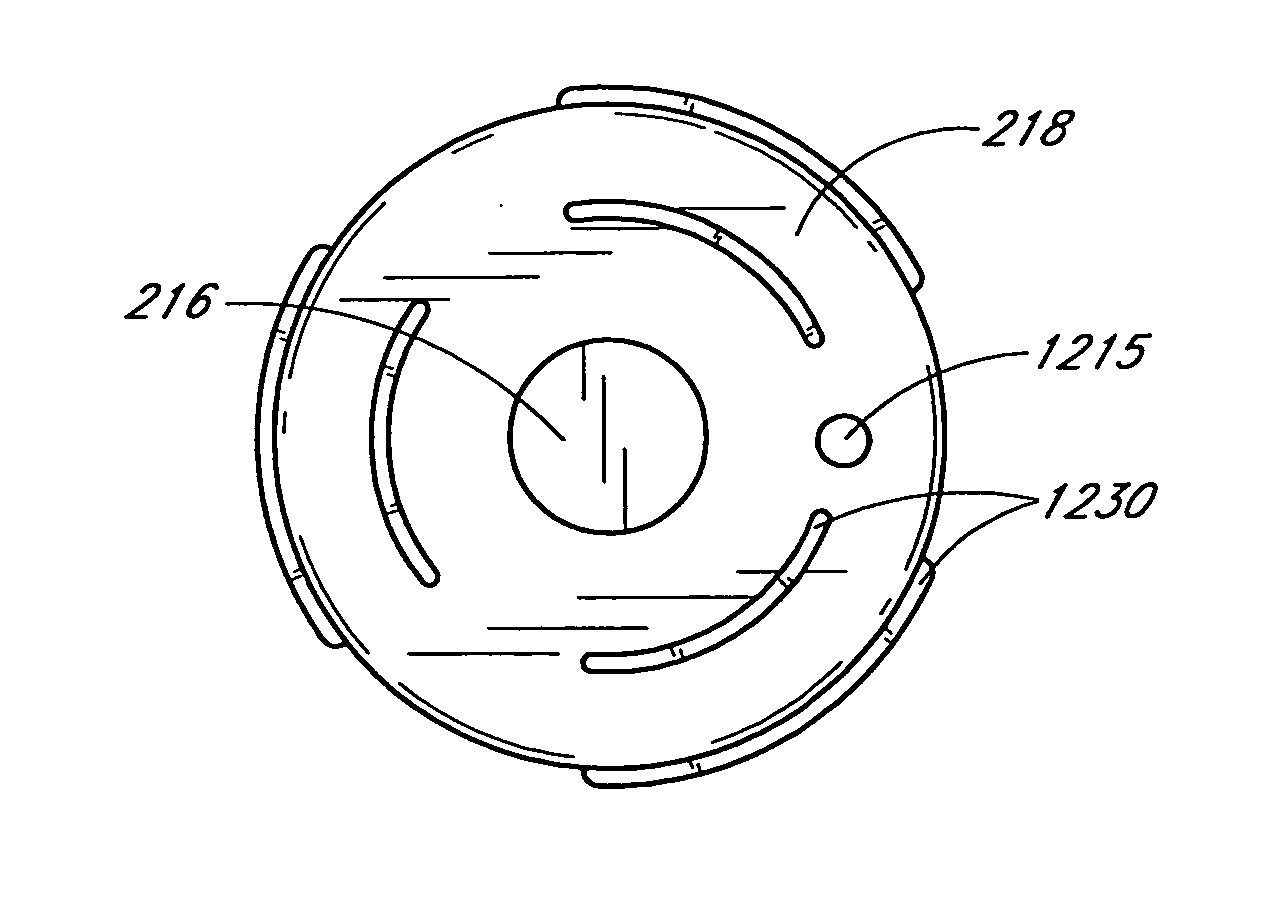

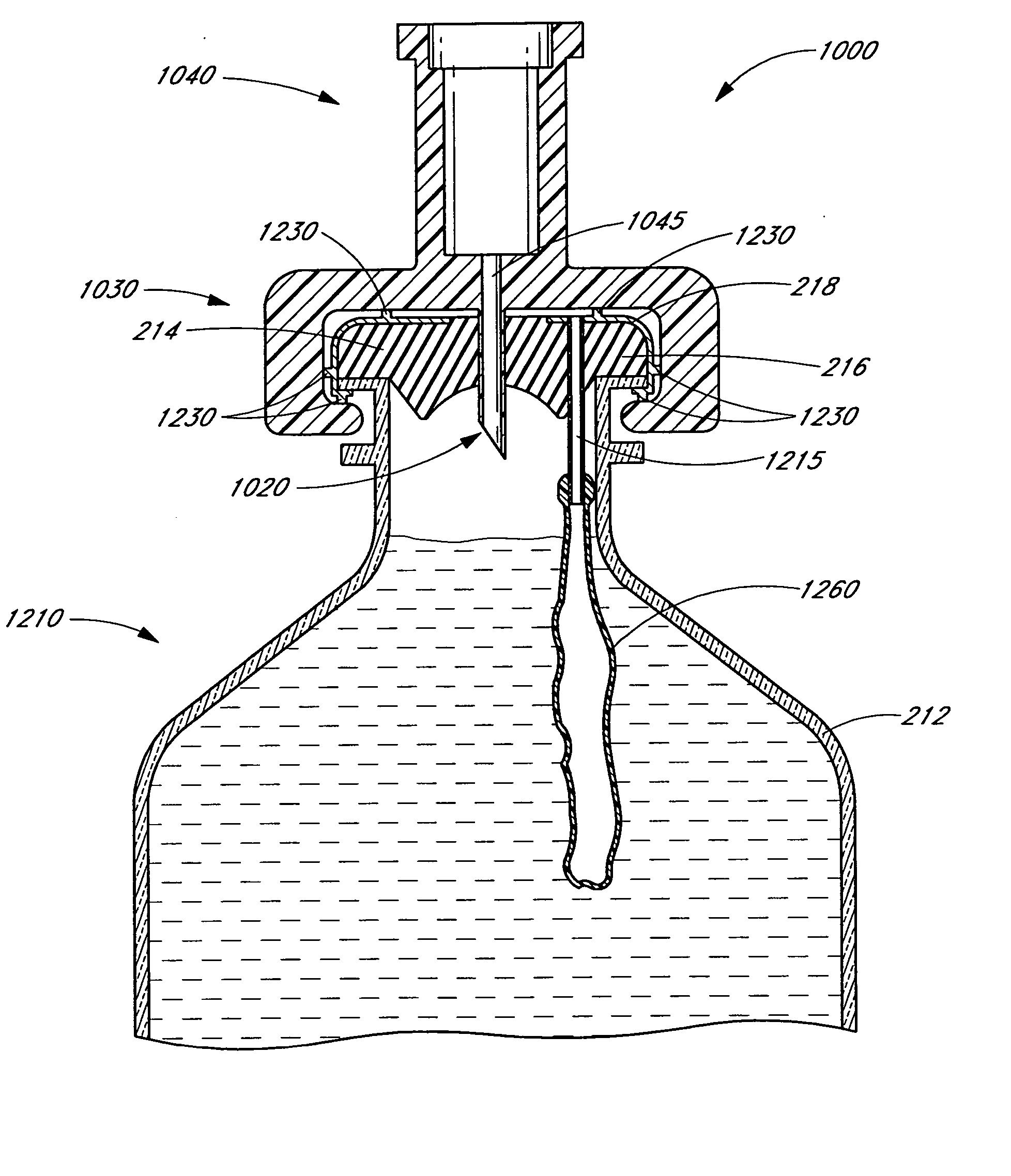

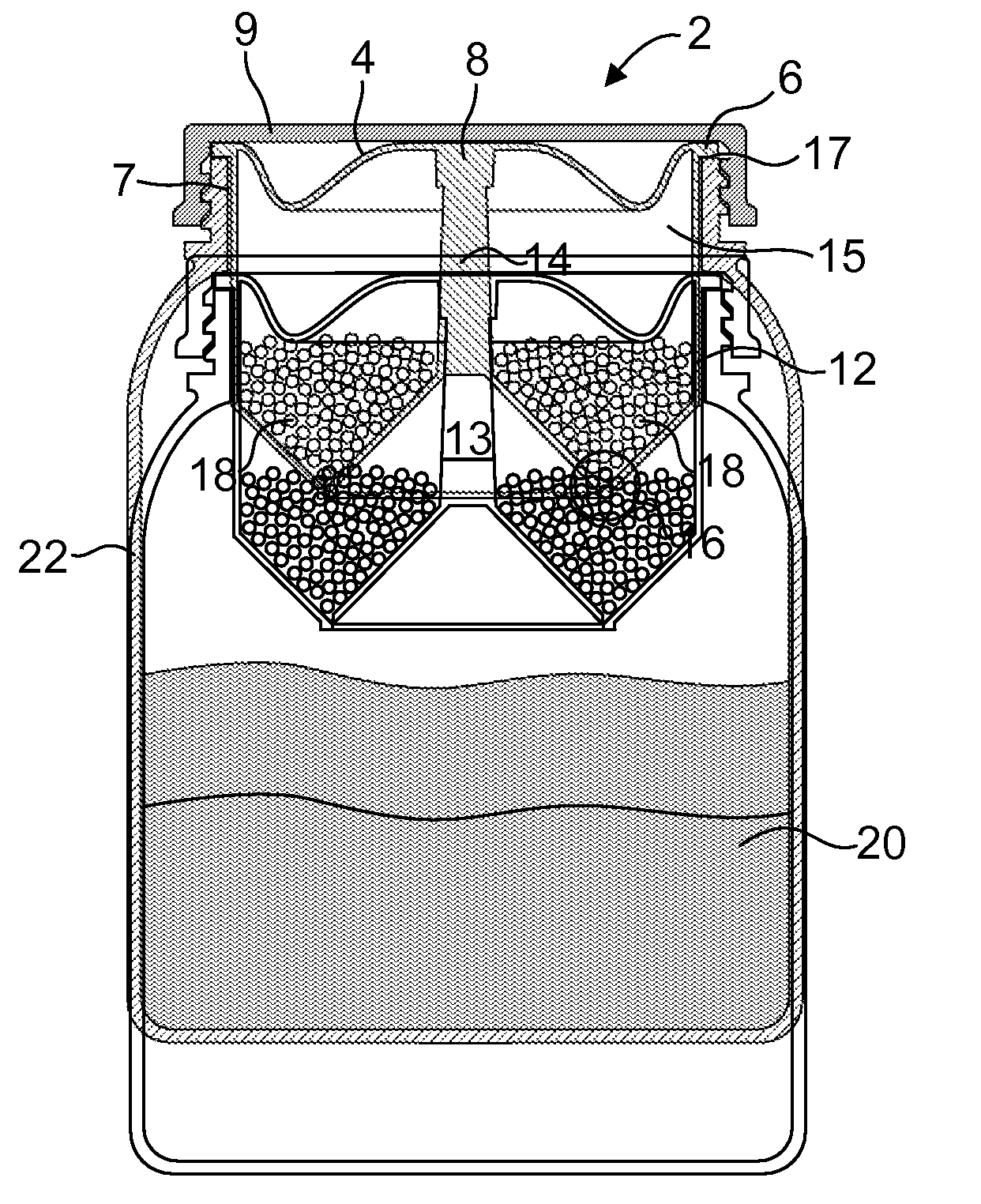

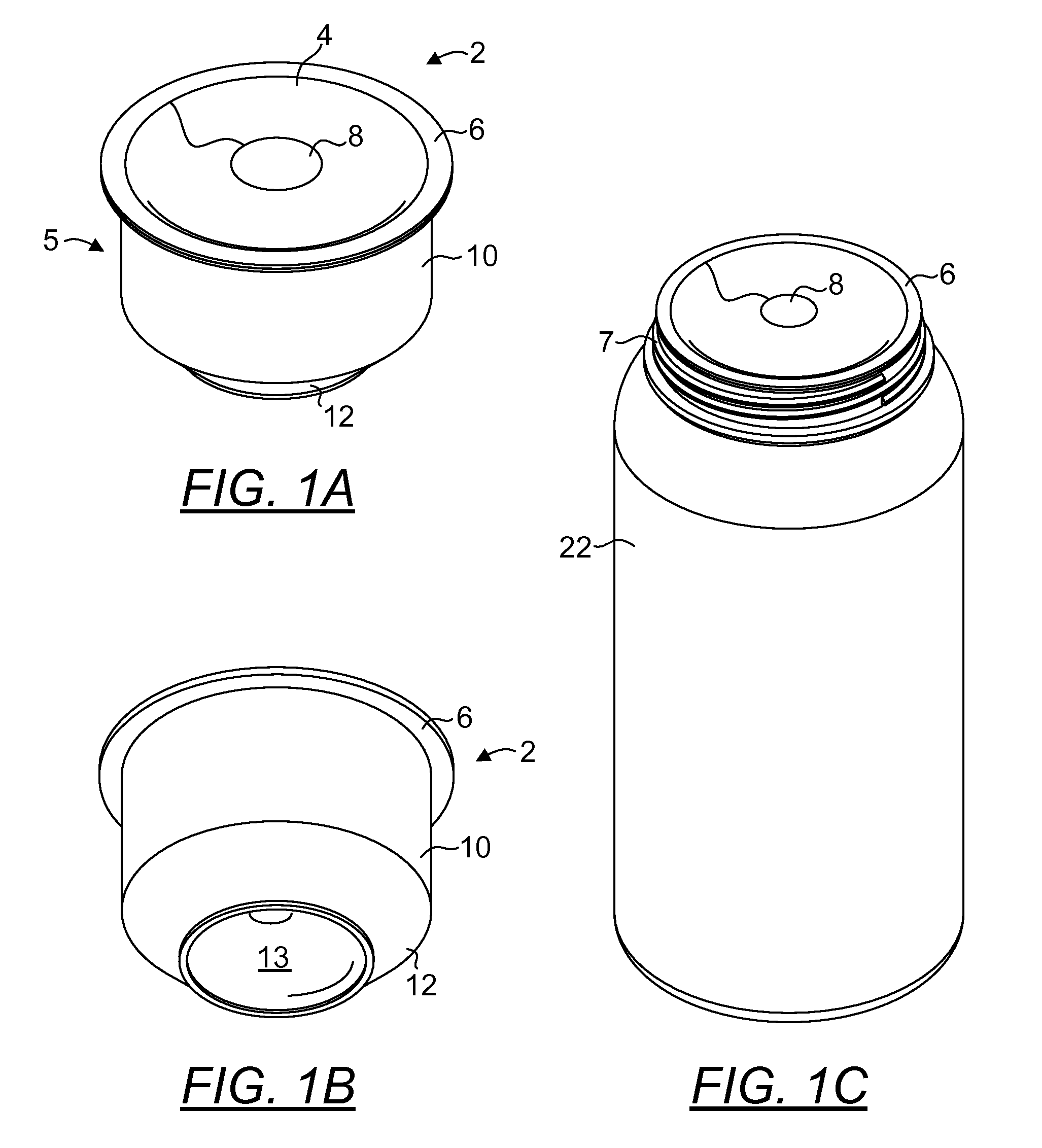

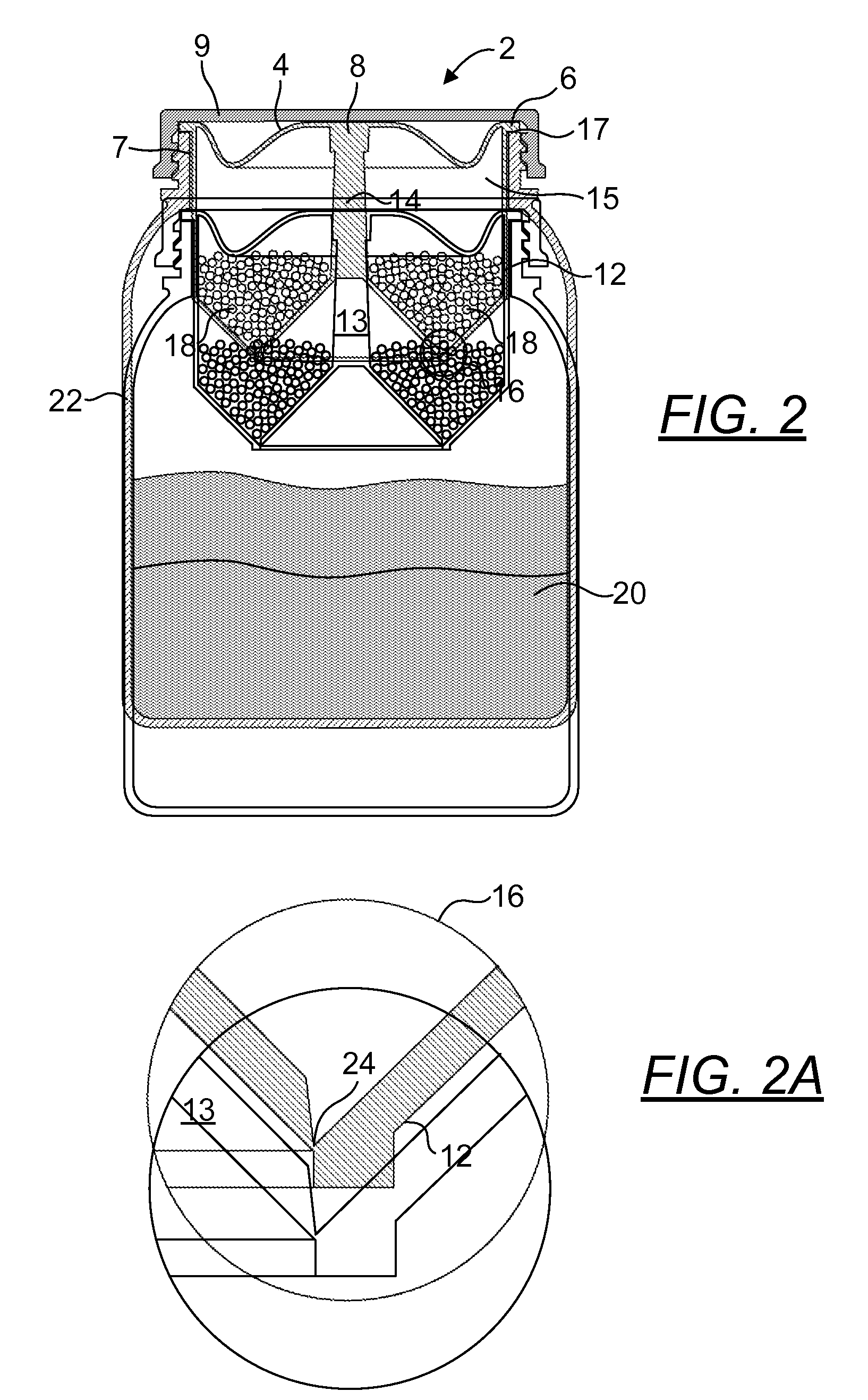

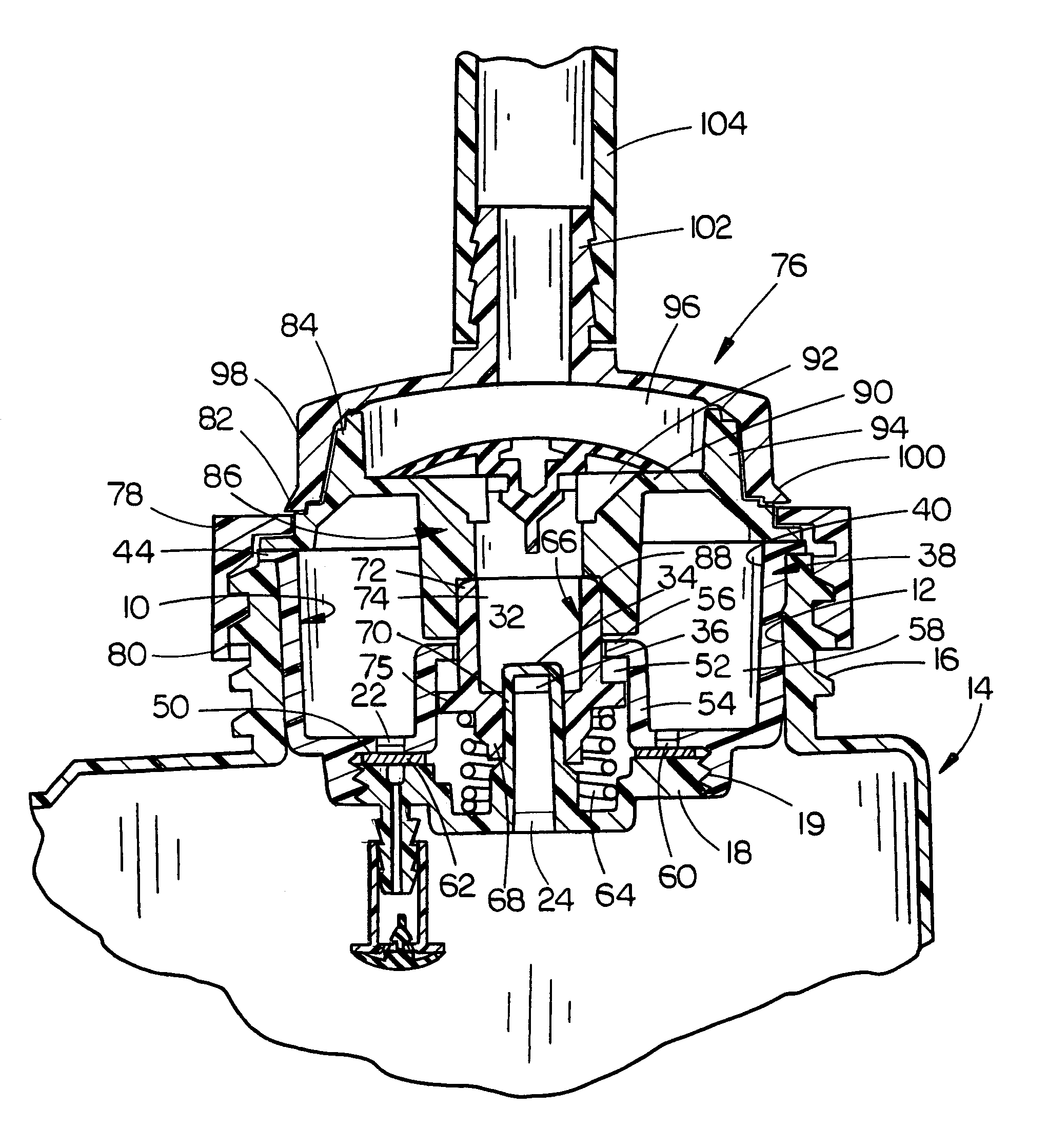

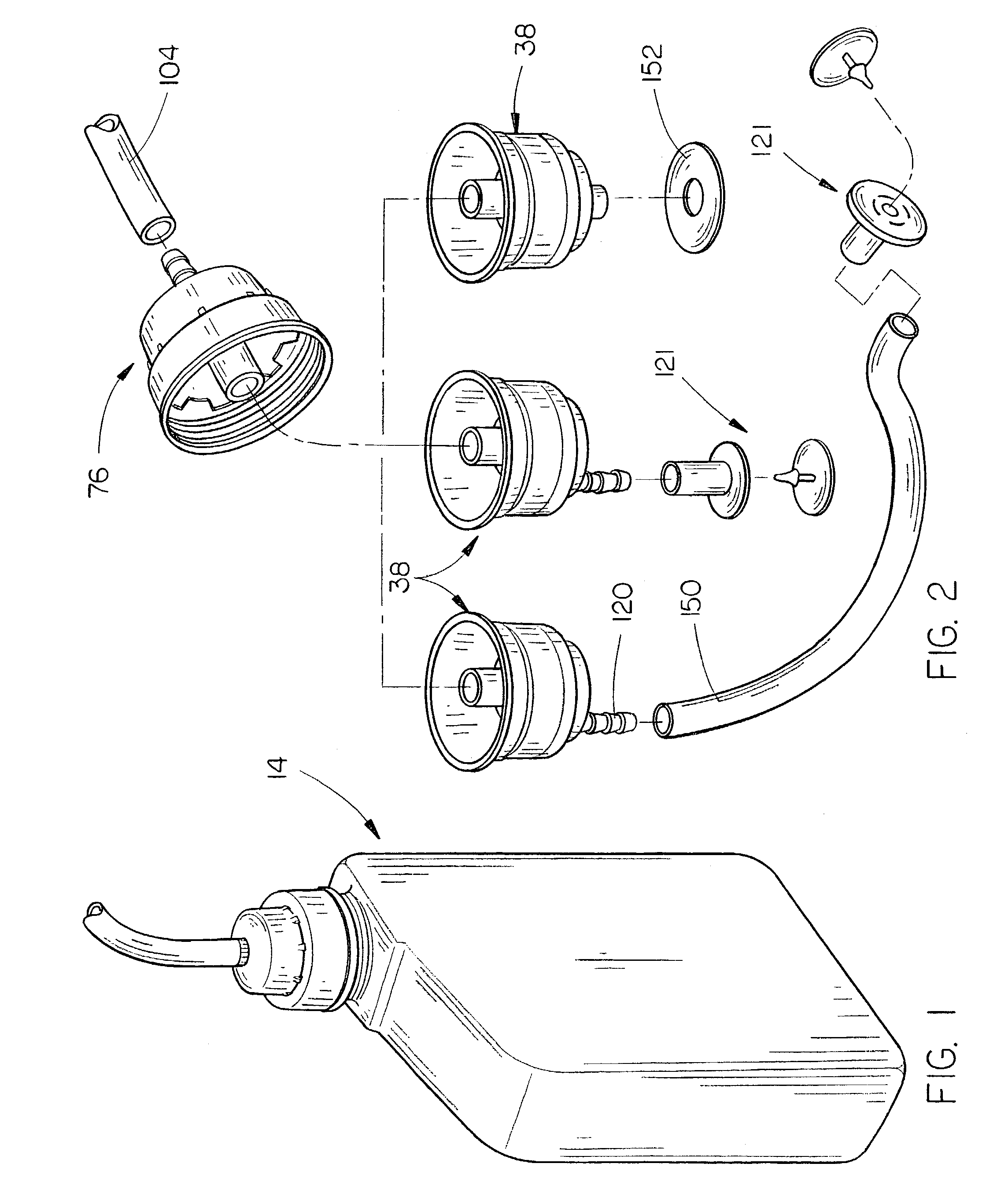

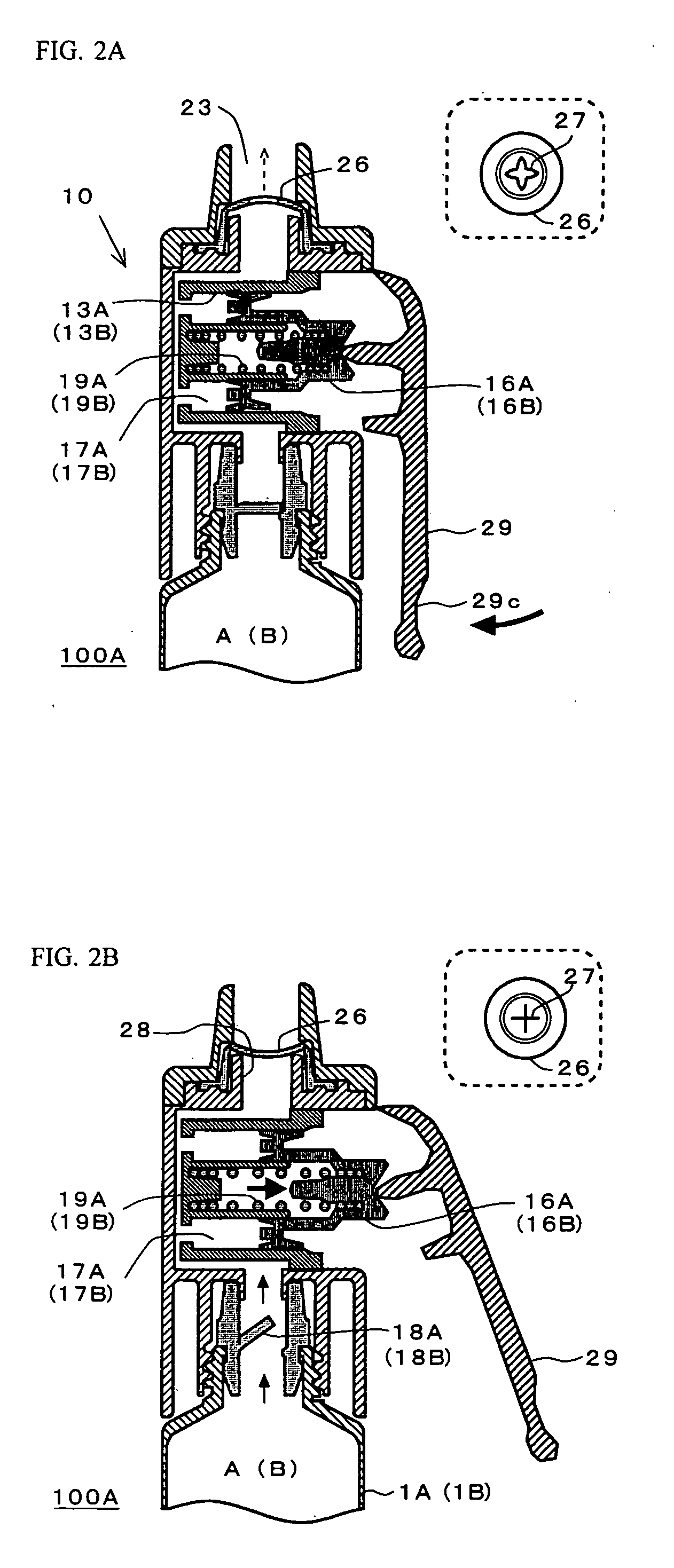

Vial adaptor for regulating pressure

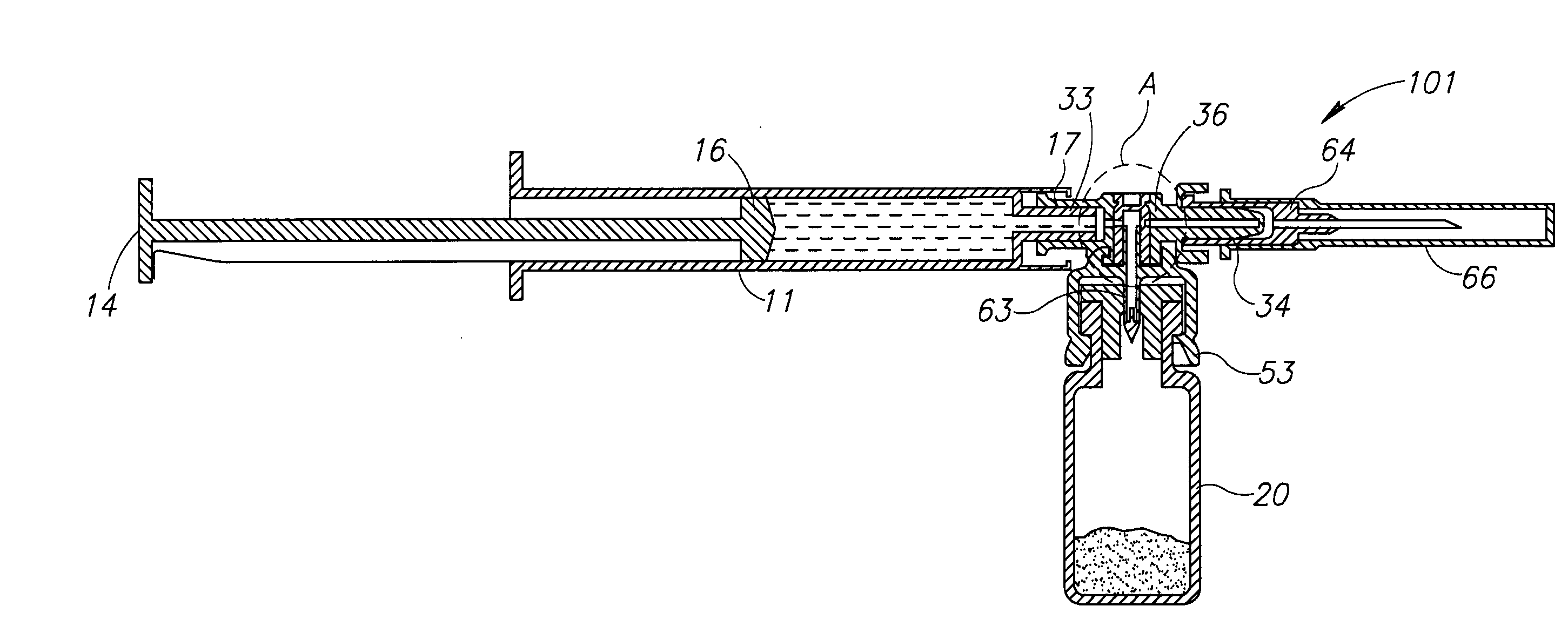

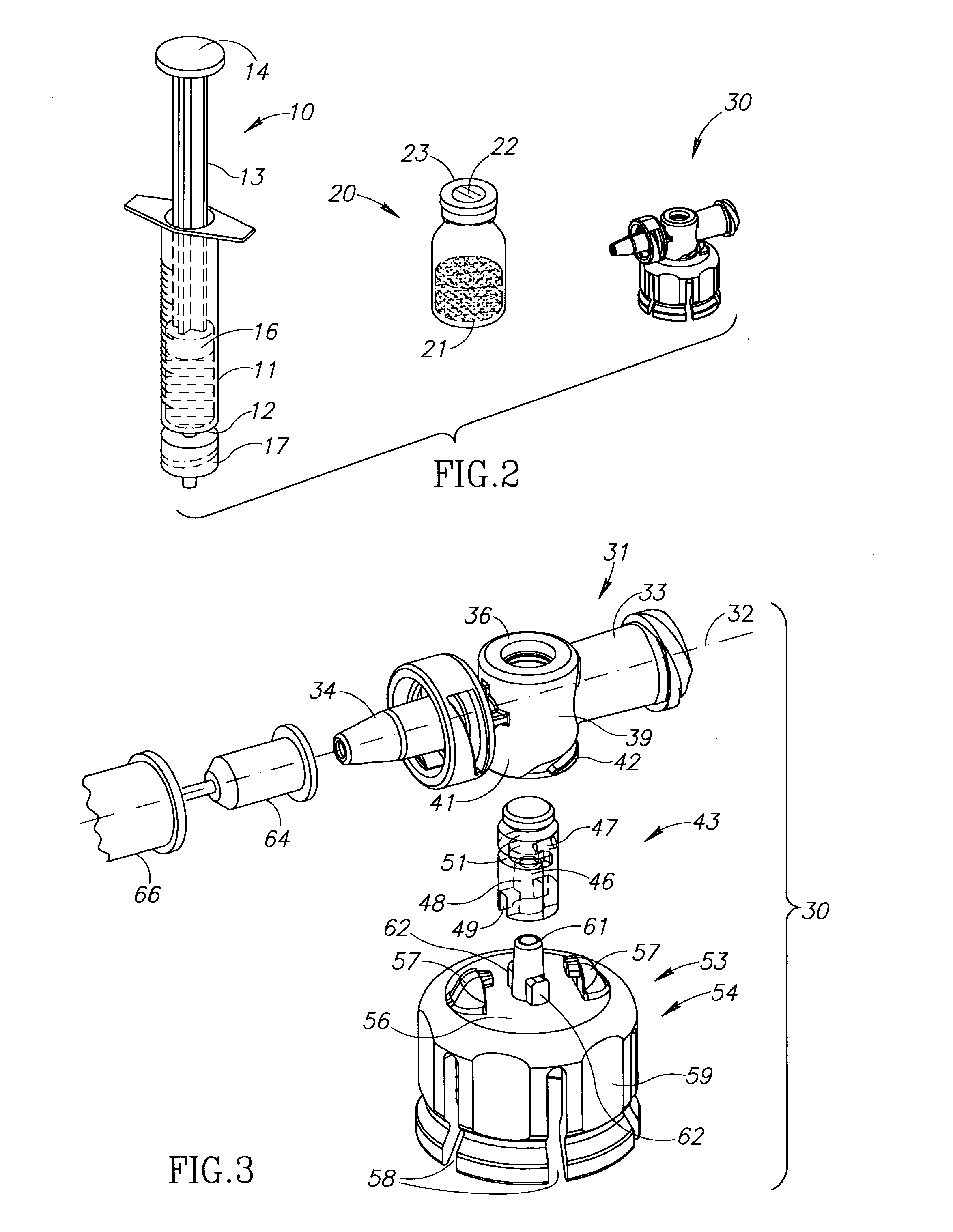

In certain embodiments, a vial adaptor for removing liquid contents from a vial includes a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial includes a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

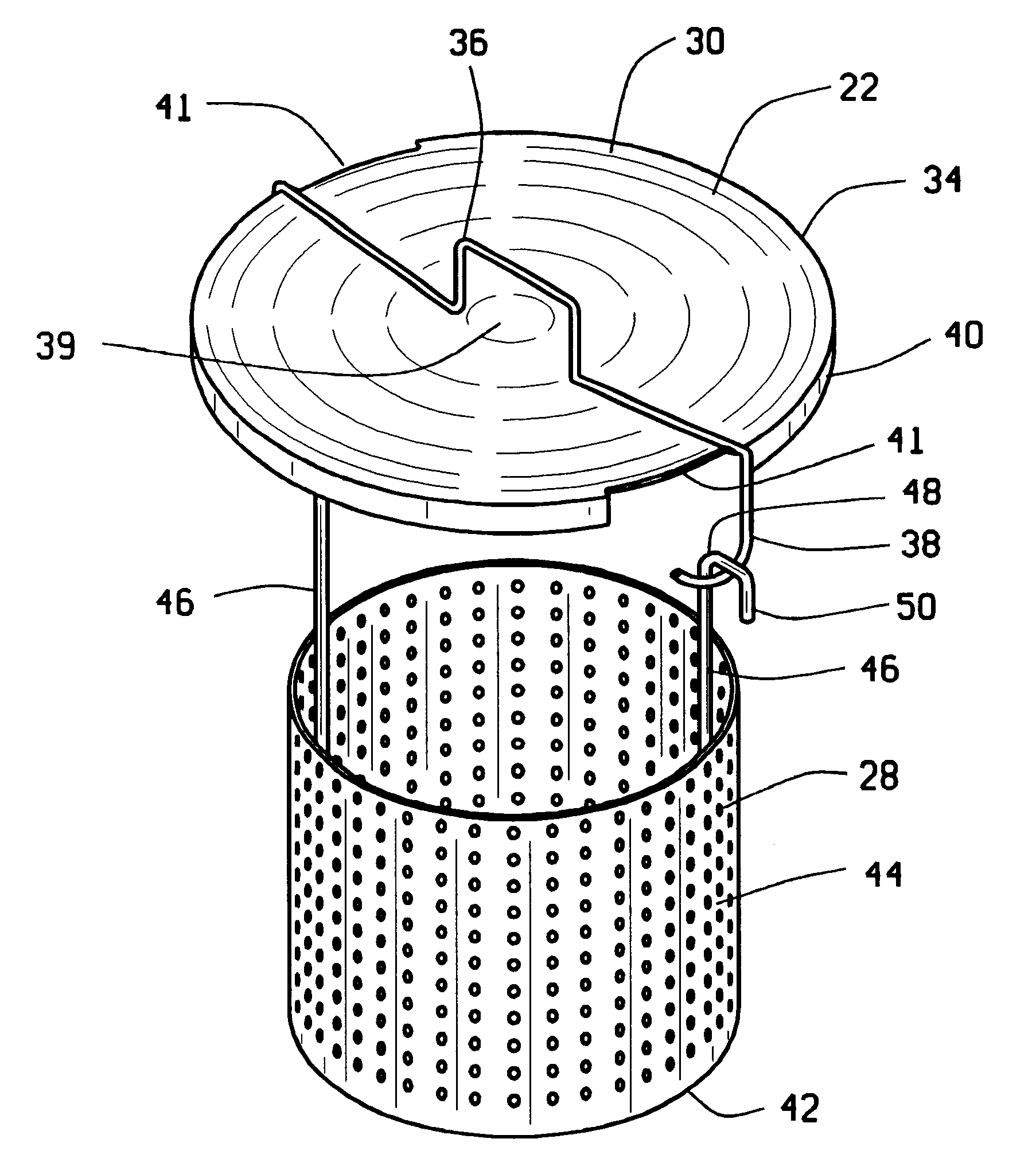

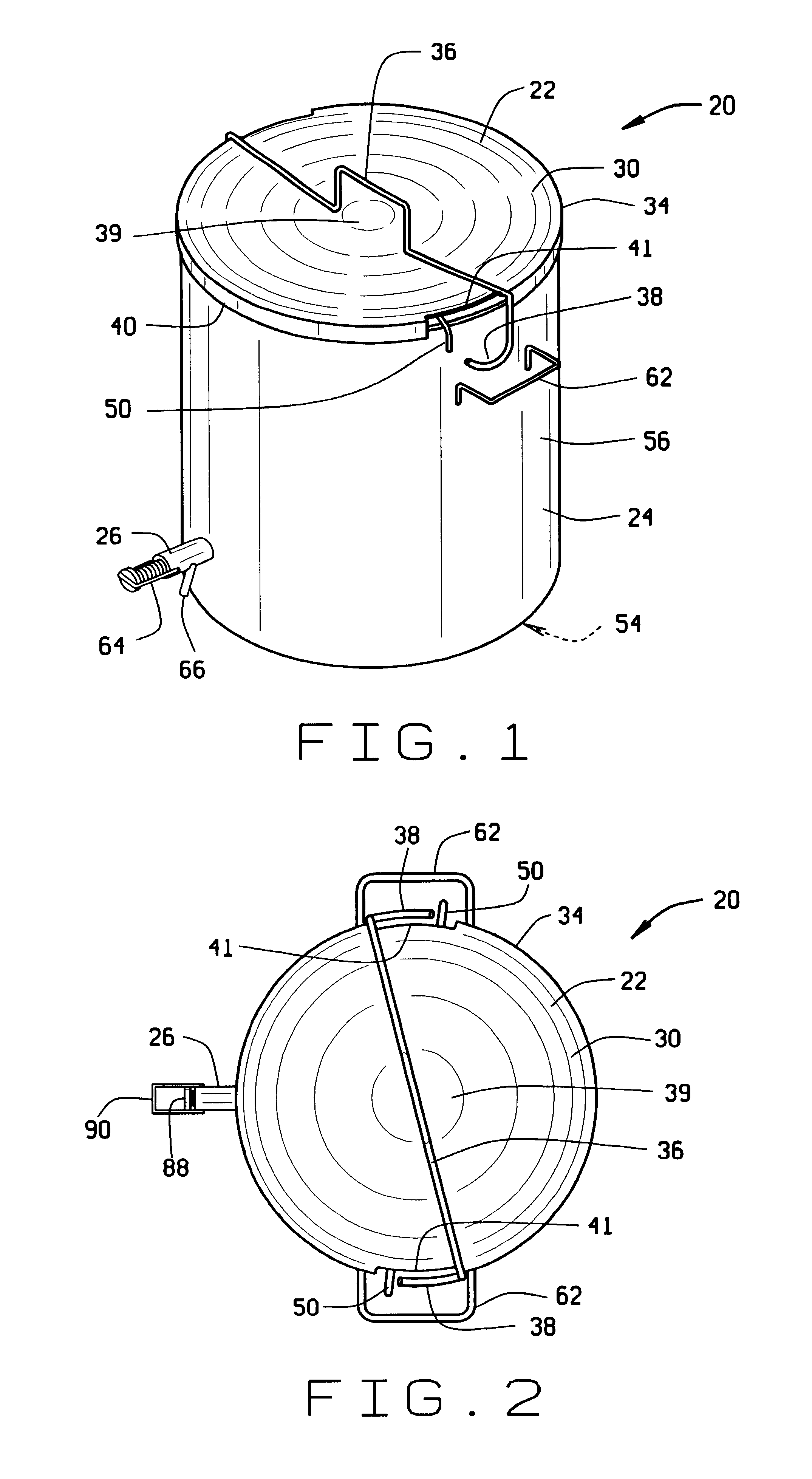

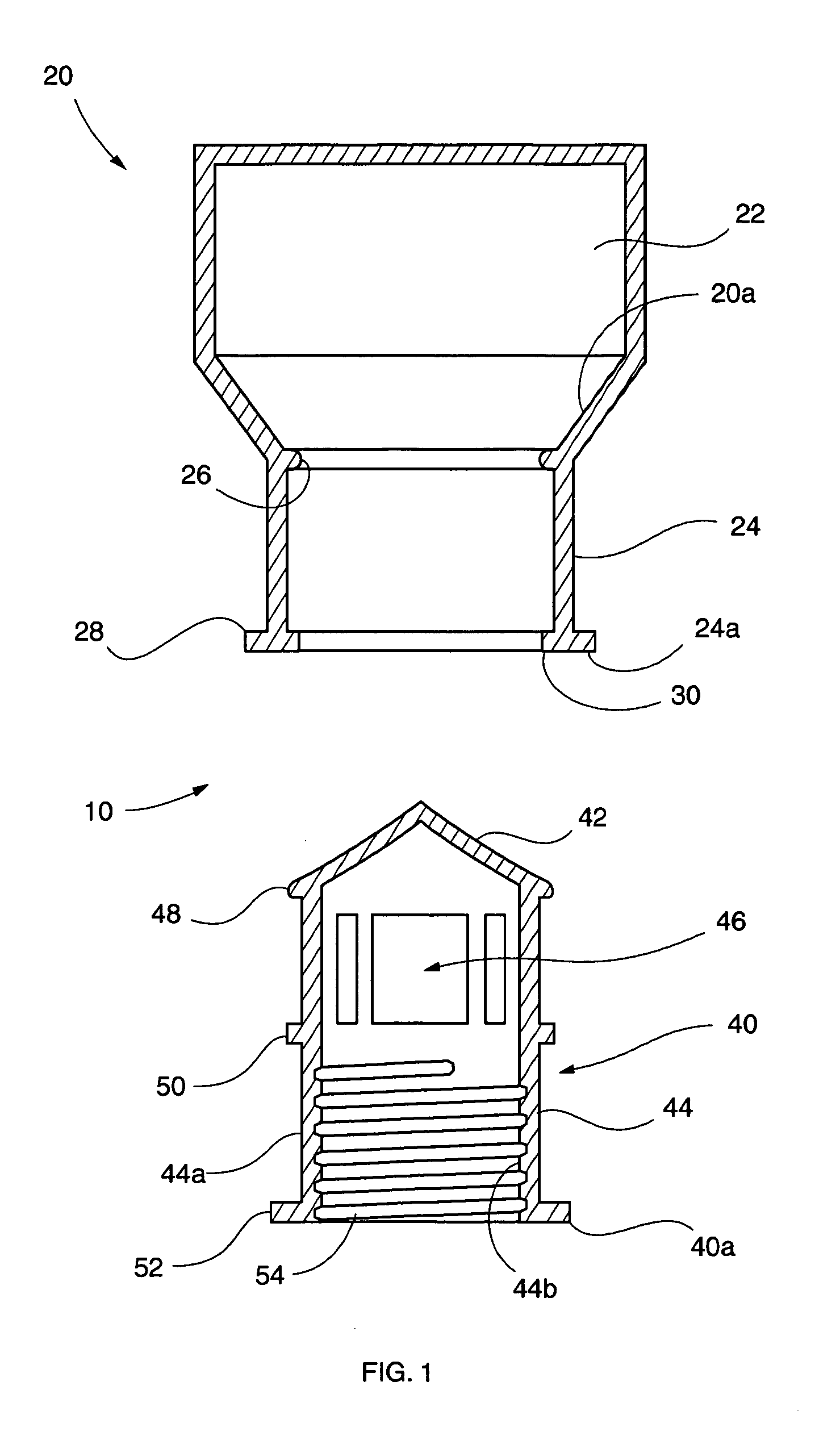

Food cooking apparatus

InactiveUS6269737B1Lighting and heating apparatusWater-bath cooking vesselsMechanical engineeringLiquid content

Owner:EMPIRE COMFORT SYST

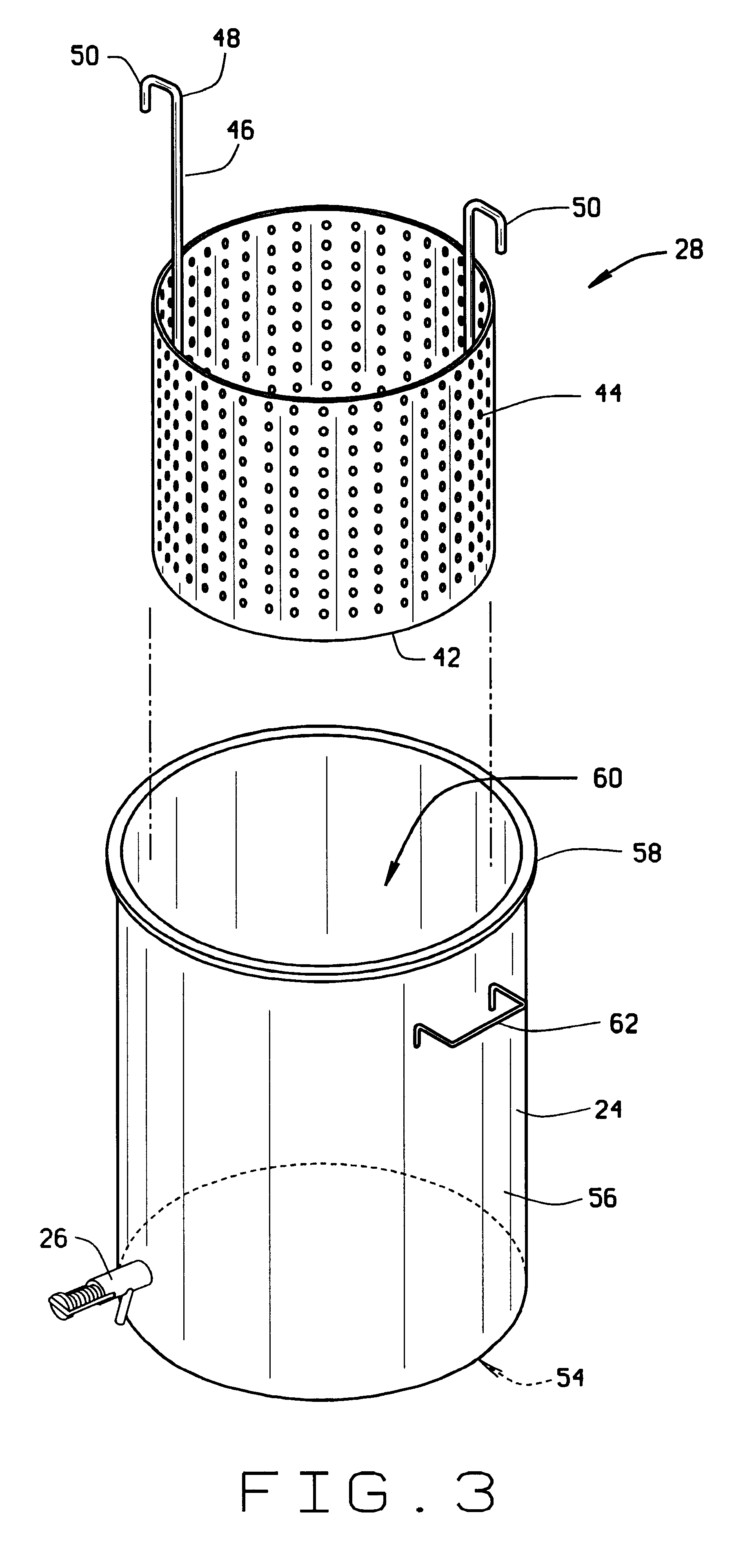

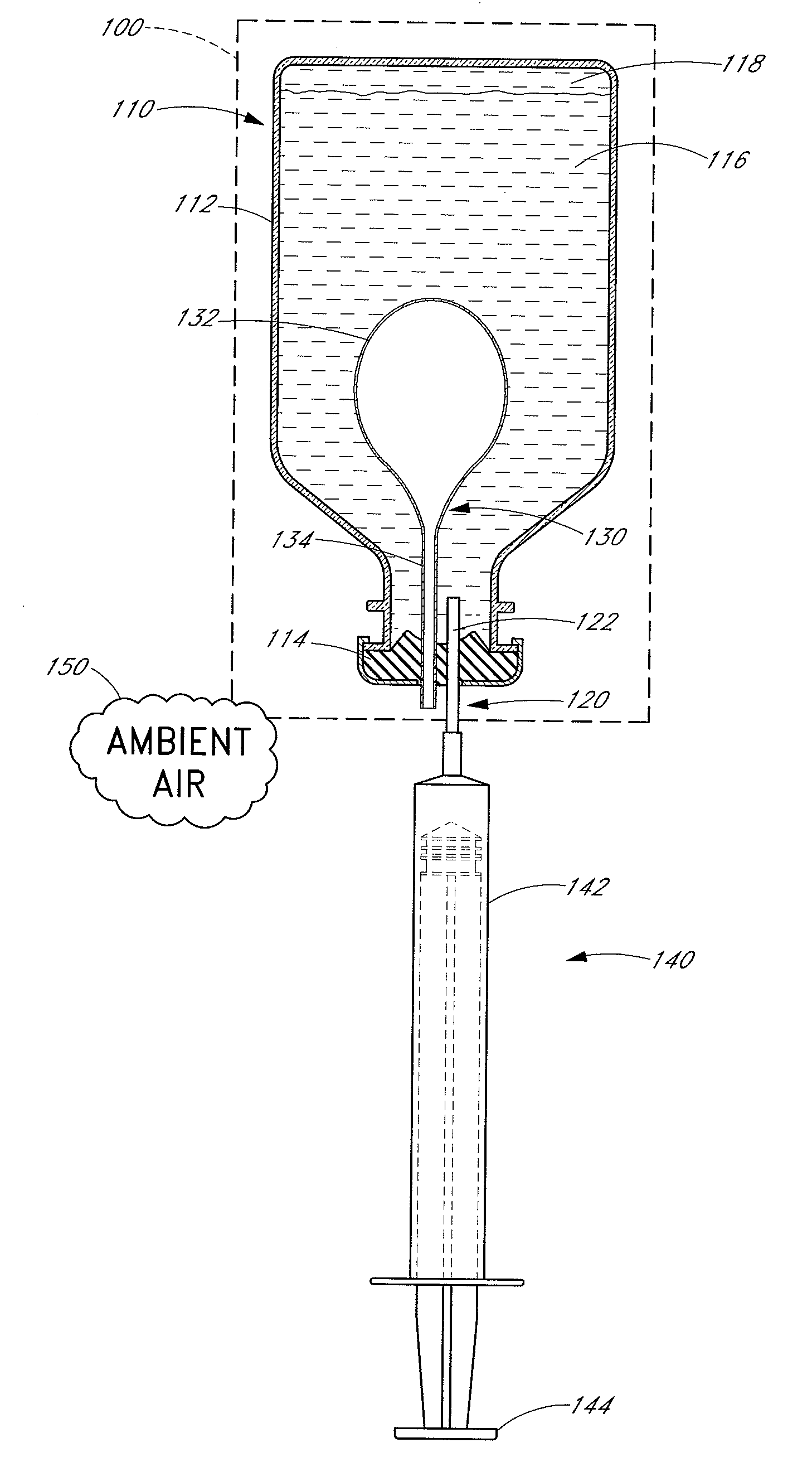

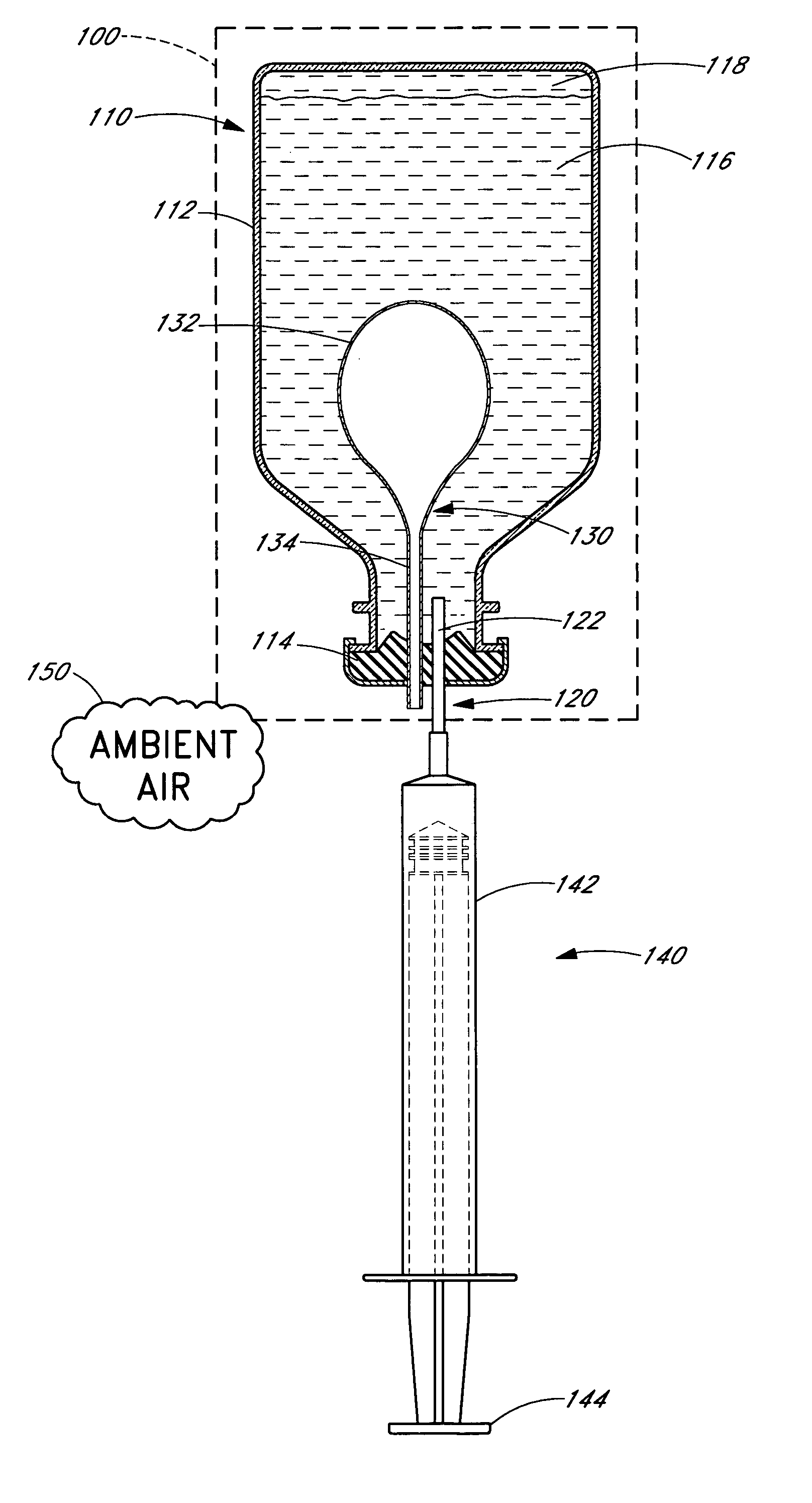

Vial adaptors and vials for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial includes a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial includes a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

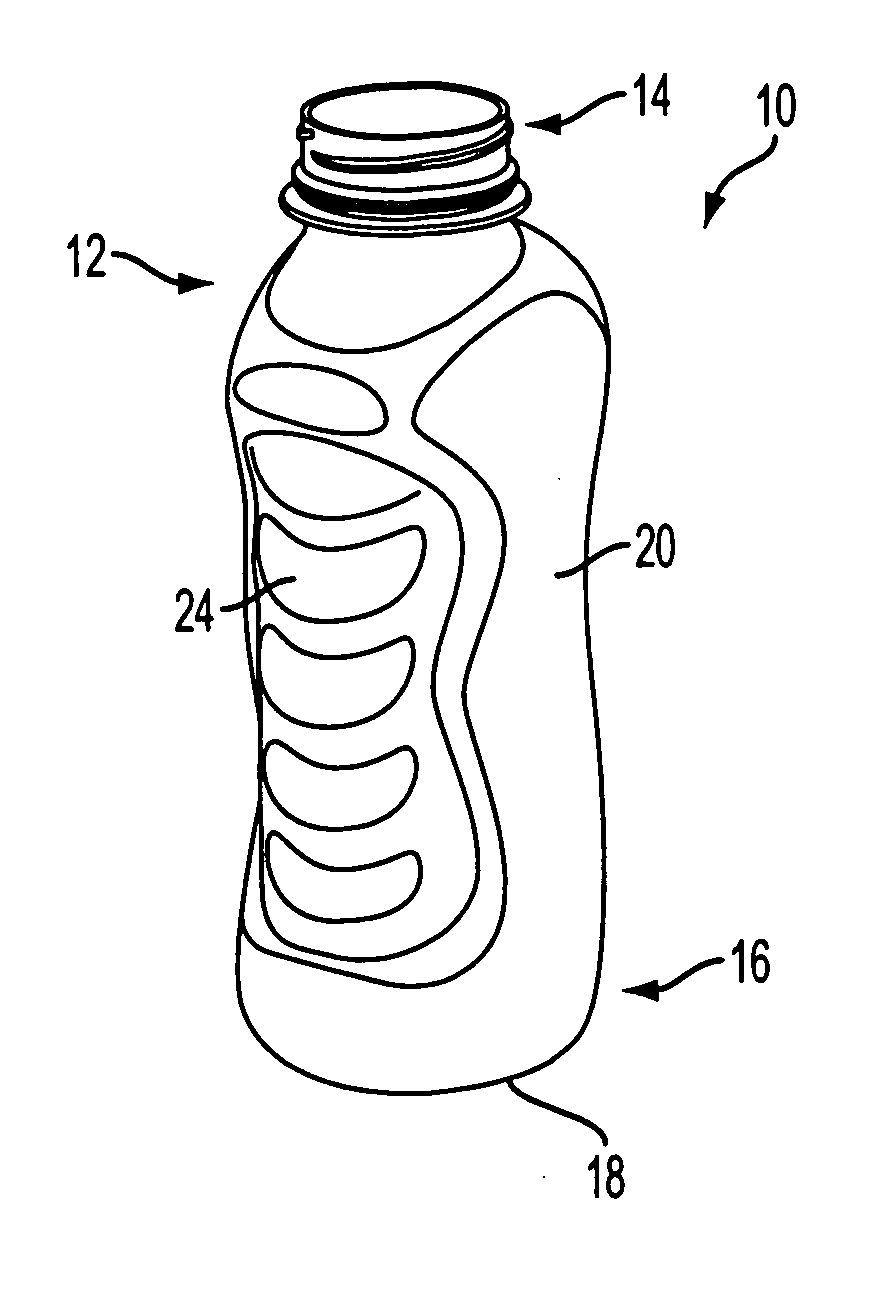

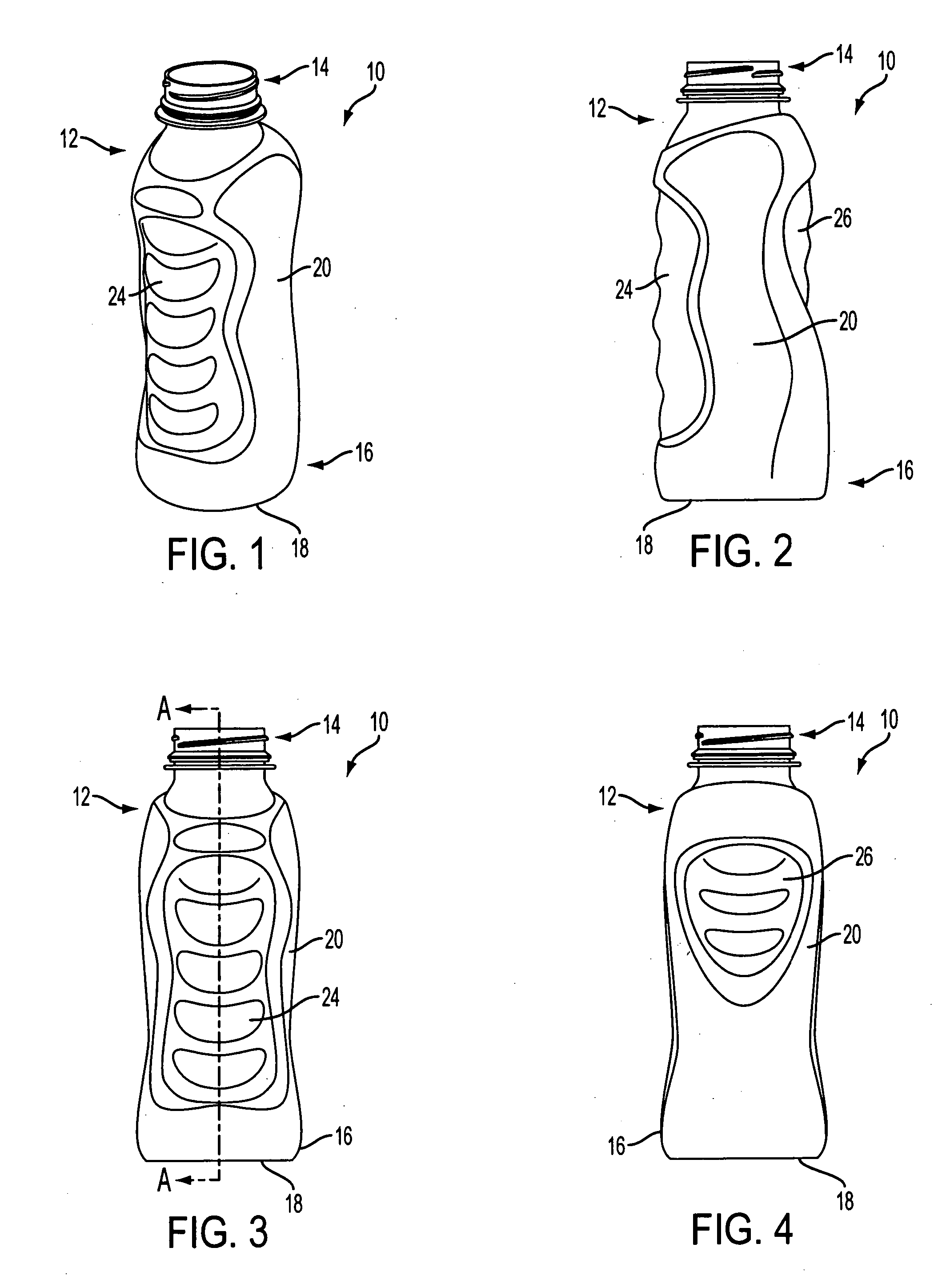

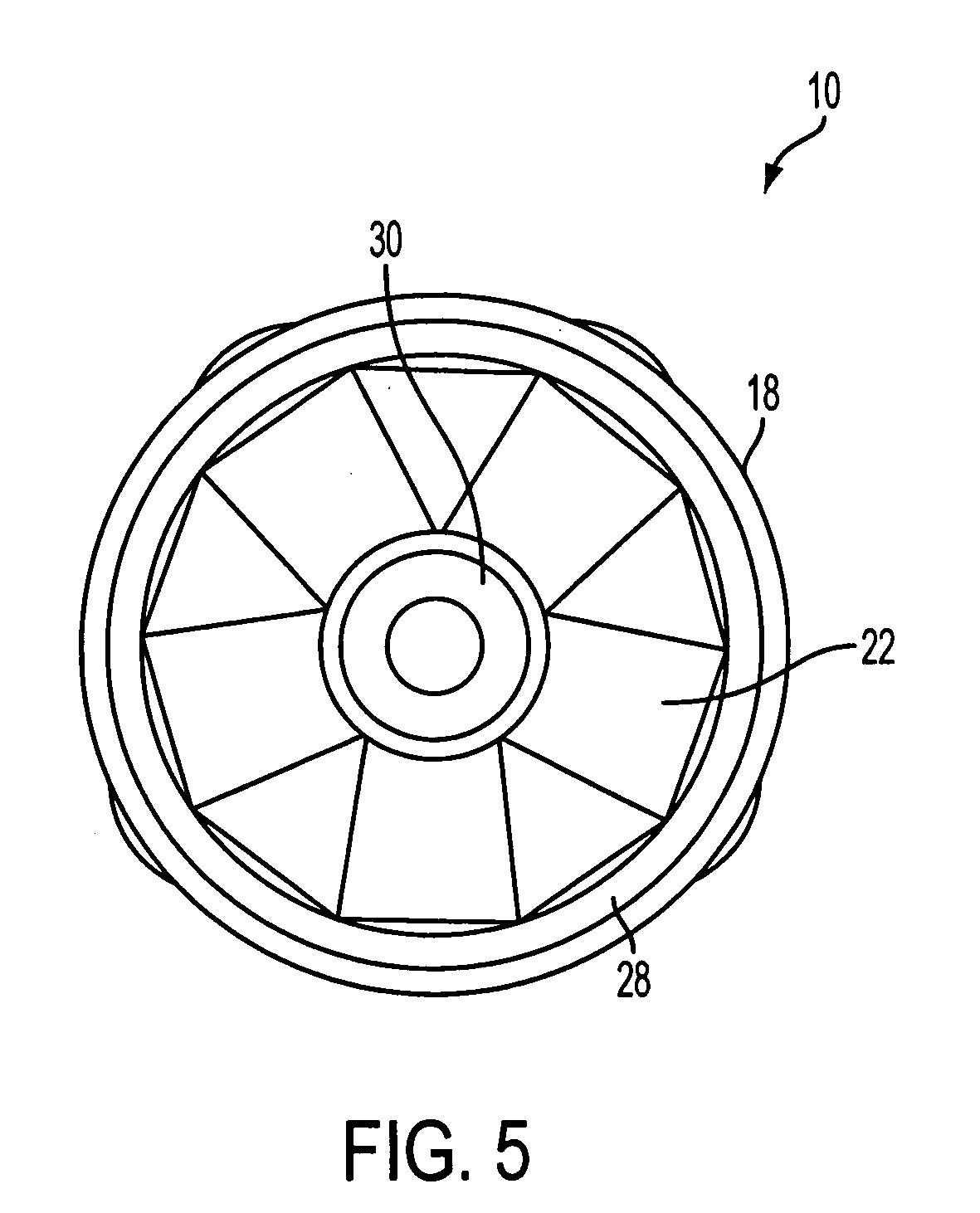

Pressure reinforced plastic container and related method of processing a plastic container

InactiveUS20060255005A1Reduce internal volumeReduce needCapsThreaded caps applicationPositive pressureEngineering

A plastic container comprises an upper portion including a finish adapted to receive a closure, a lower portion including a base, and a sidewall extending between the upper portion and the lower portion. The upper portion, the lower portion, and the sidewall define an interior volume for storing liquid contents. The plastic container further comprises a pressure panel located on the container and moveable between an initial position and an activated position. The pressure panel is located in the initial position prior to filling the container, and is moved to the activated position after filling and sealing the container. Moving the pressure panel from the initial position to the activated position reduces the internal volume of the container and creates a positive pressure inside the container. The positive pressure reinforces the sidewall. A method of processing a container is also disclosed.

Owner:CO2 PAC

Vial adaptors and vials for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial includes a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial includes a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

Mixing cap and method for use thereof

A mixing cap and method for use thereof, wherein the mixing cap is preferably pre-loaded during time of manufacture with a selected dry or liquid ingredient to facilitate subsequent consumer use. The mixing cap comprises an apertured inner tube threadably-engagable to the mouth of a bottle, and an outer housing cooperatively-engaged to the inner tube and slidably-restricted thereover via a flange arrangement. Preloaded ingredients contained within the outer housing may be introduced or discharged into the bottle by simply depressing the outer housing over the inner tube, thereby permitting the ingredients to flow through the apertures of the inner tube and into the liquid contents of the bottle. The combined ingredients and liquid within the bottle may subsequently be shaken without fear or risk of leakage or spillage.

Owner:ABRIGO

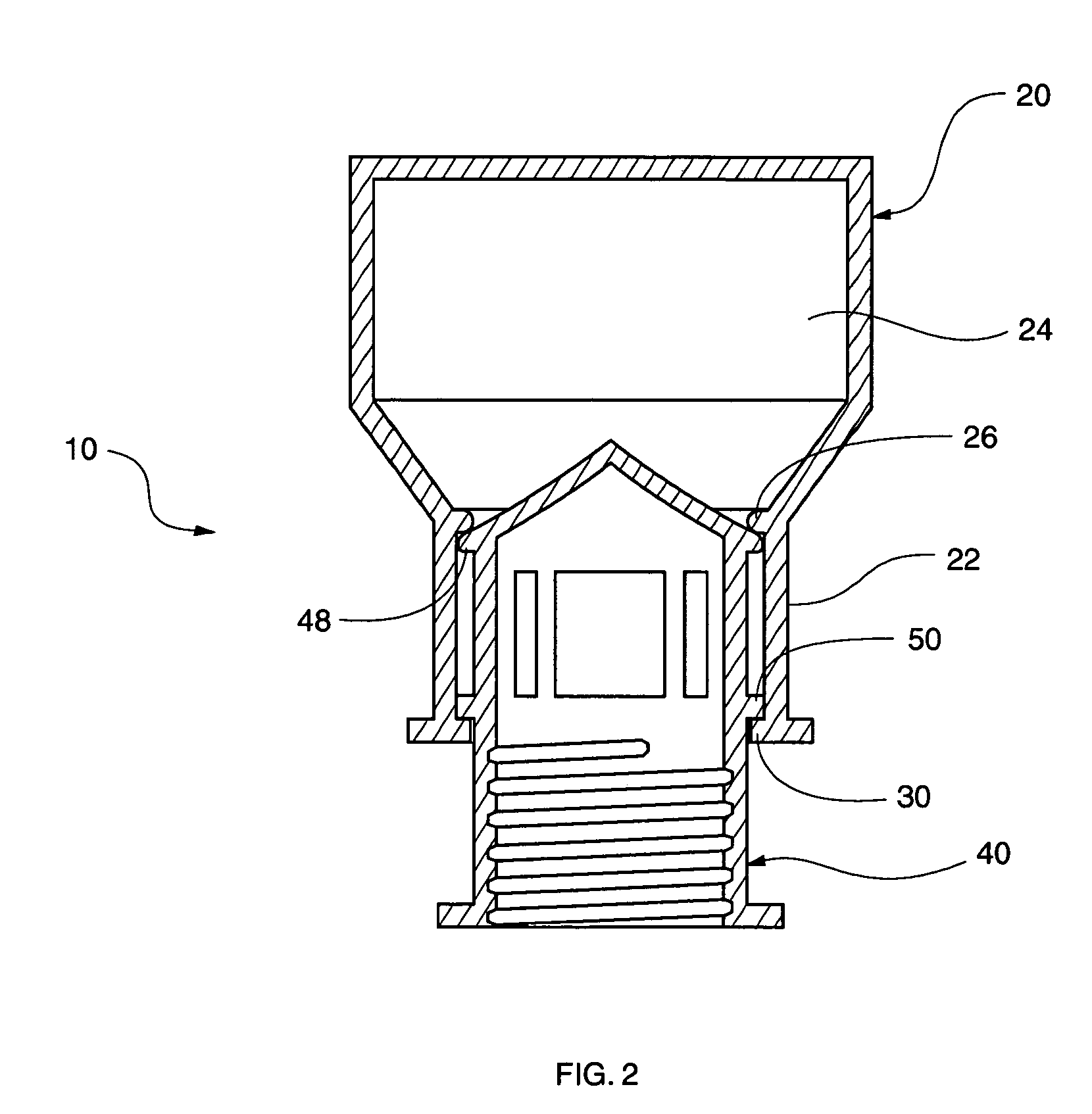

Intranasal Cartridge Devices

ActiveUS20080177246A1Precise alignmentProvide stabilityAmpoule syringesJet injection syringesNasal passageNasal passages

Intranasal delivery devices include dosage forms containing medical compositions for use in the intranasal devices, and methods of delivering medical compositions to the nasal mucosa of users. The devices dispense a predetermined quantity of fluid into the nasal passage of a user, in which the predetermined quantity of fluid is contained in, or produced in a dosage form or blister that is crushed by a plunger with sufficient force to drive the dosage form against a piercing mechanism, piercing the dosage form and forcing the liquid contents from the dosage form and through a delivery channel into a spray to be directed into the nasal passage of a user. The plunger is connected to a trigger device by a linkage that confers a mechanical advantage to the trigger mechanism.

Owner:MYSTIC PHARMA INC

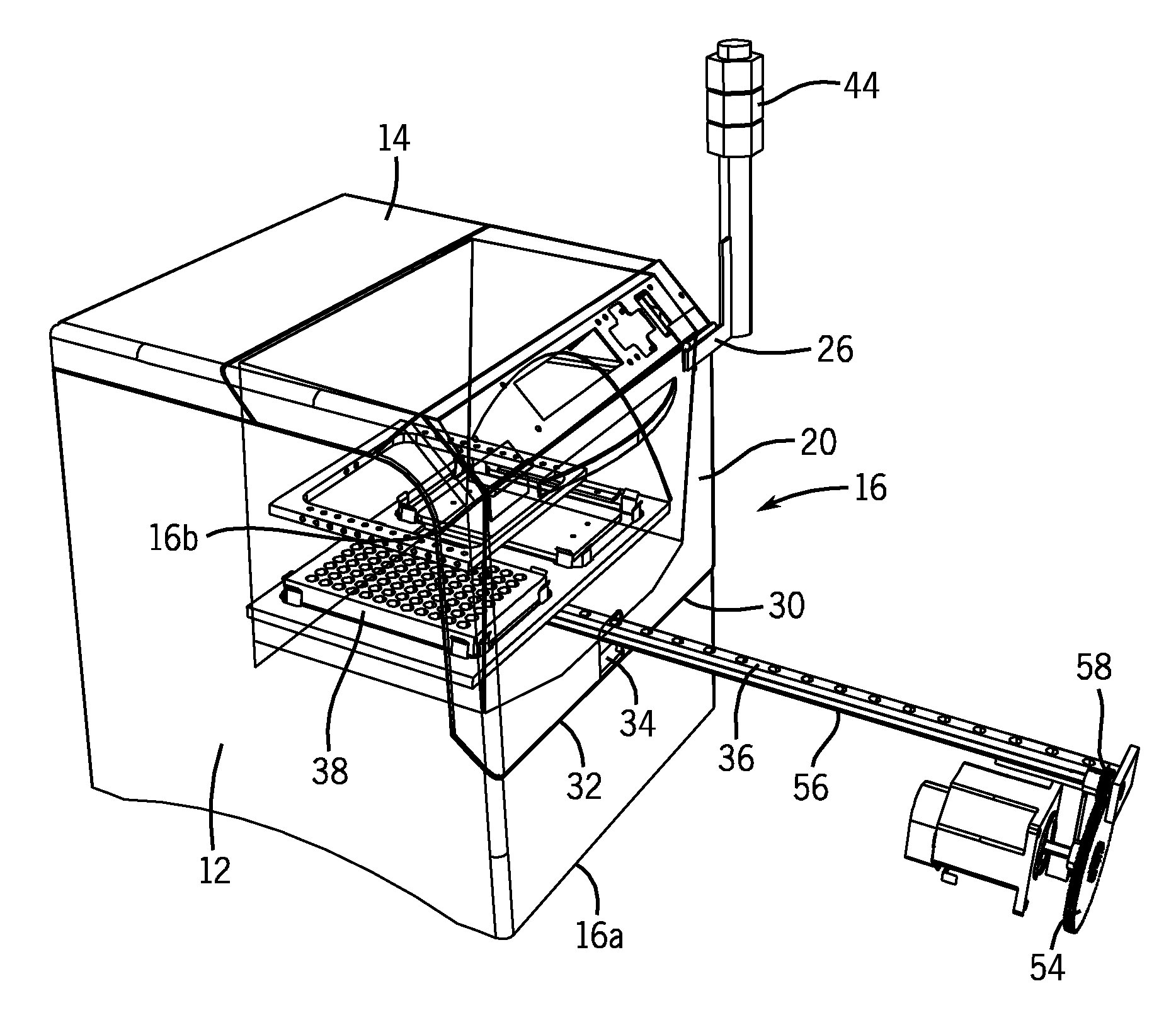

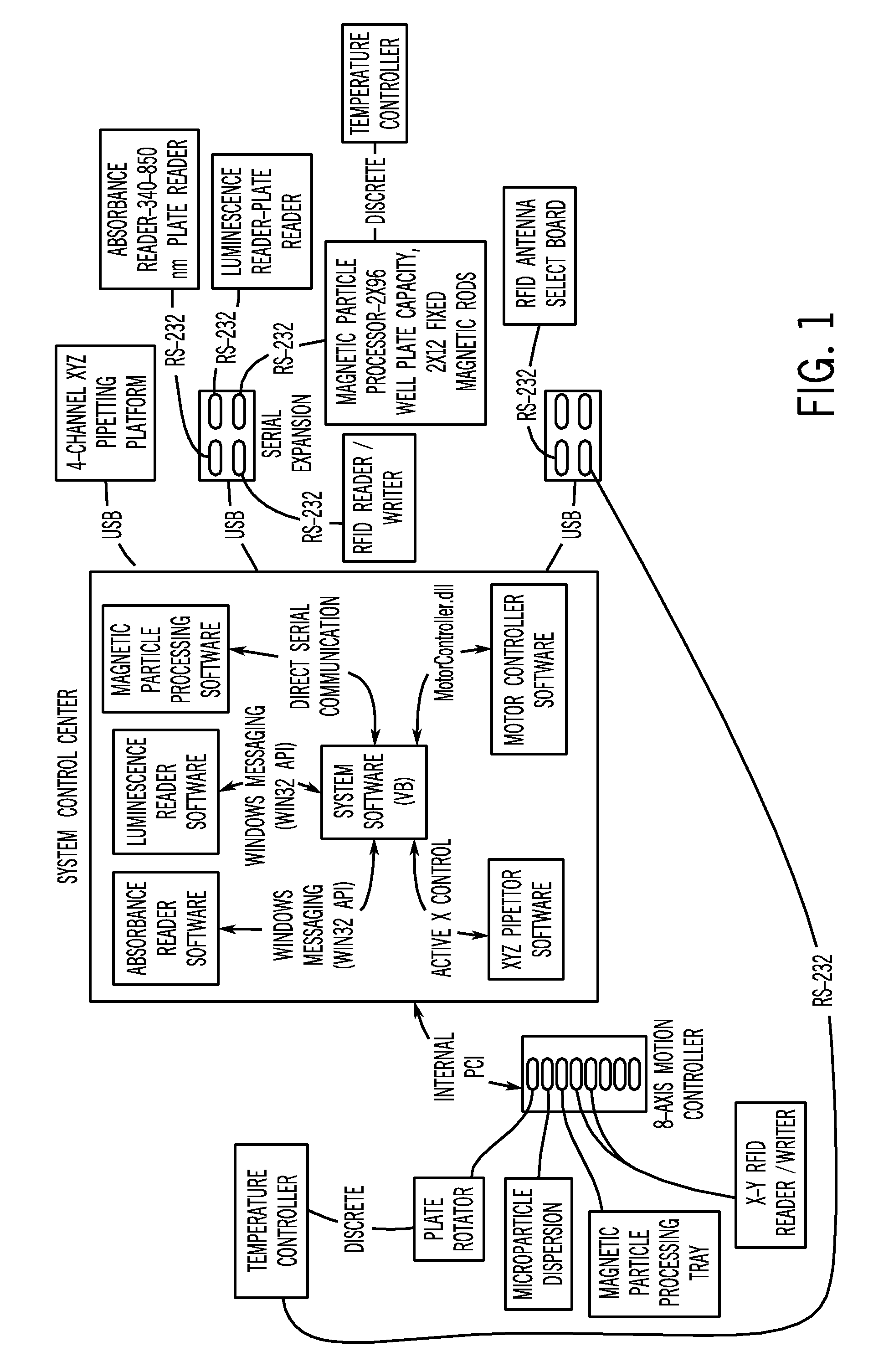

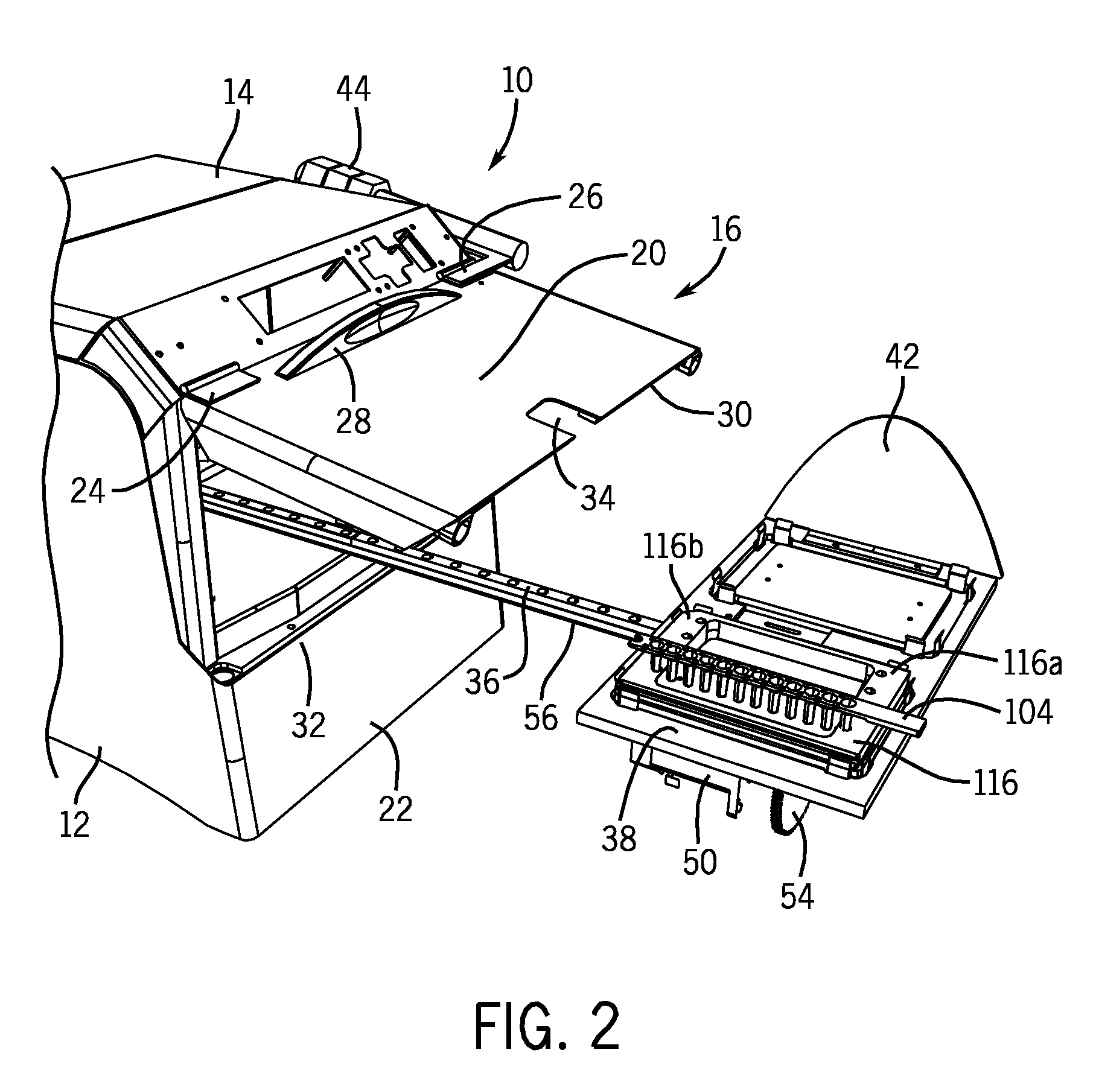

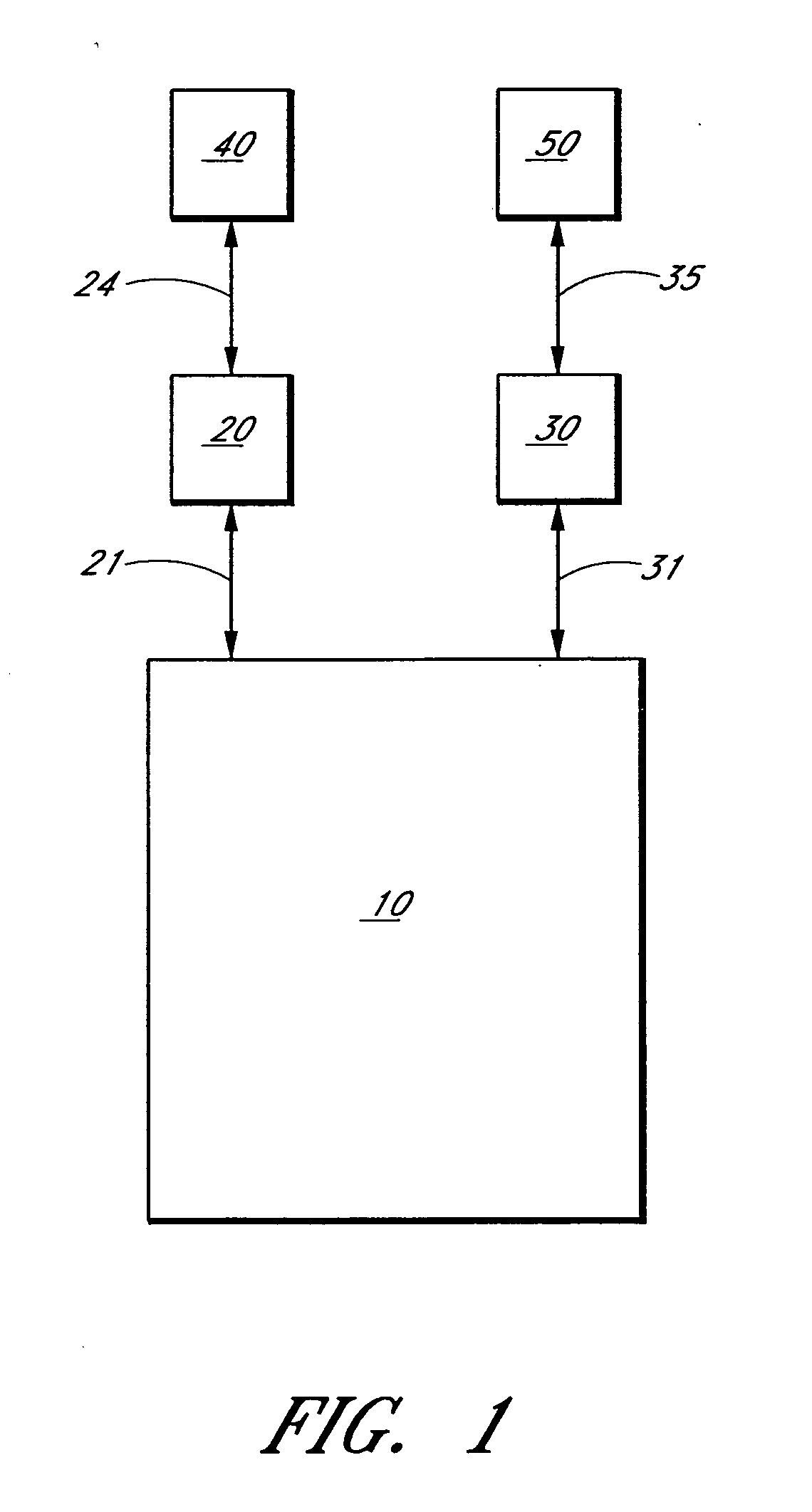

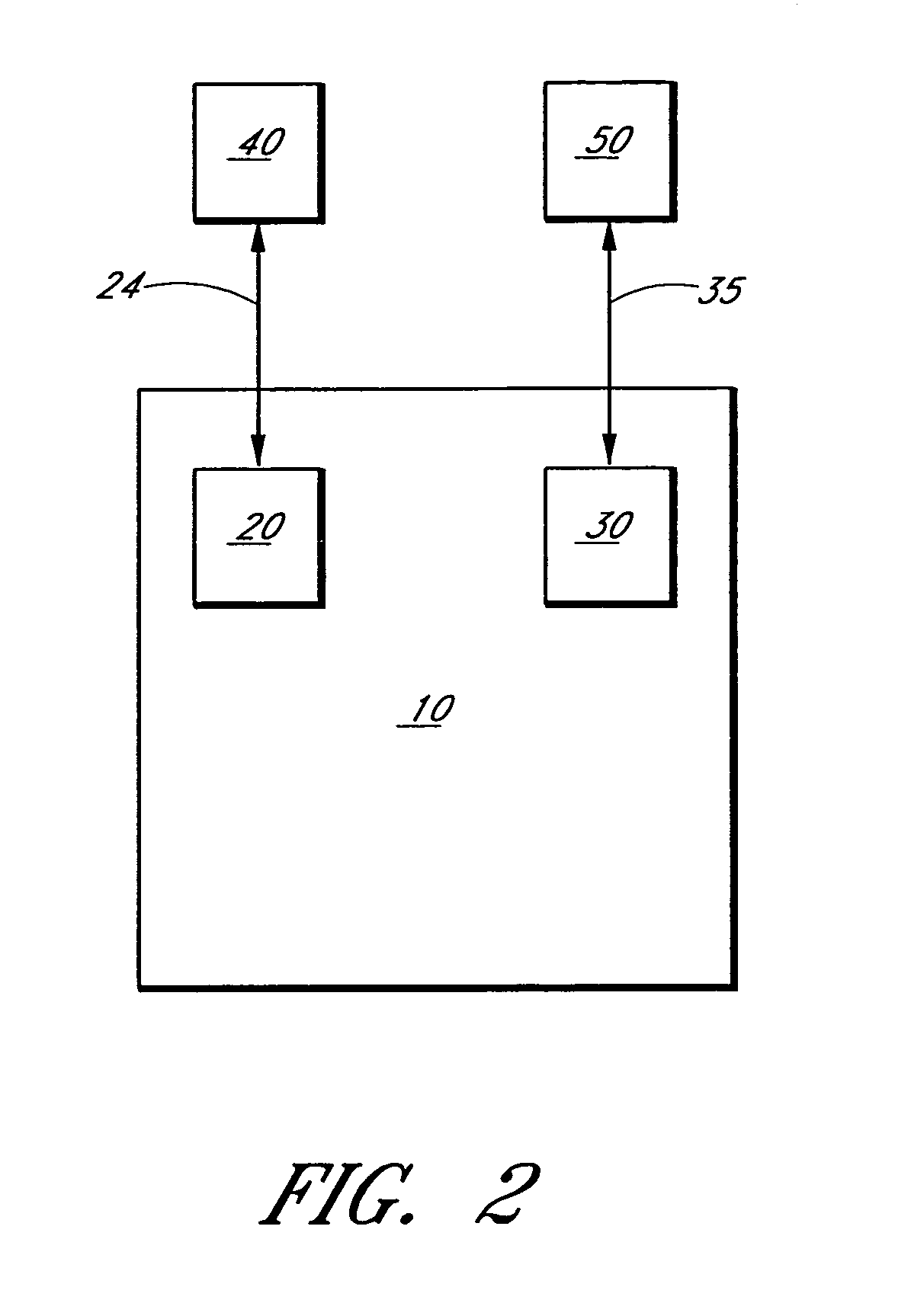

System for automatically loading immunoassay analyzer

ActiveUS20090117004A1Small and reliableLess complexMaterial analysis by optical meansLaboratory glasswaresLiquid contentBiomedical engineering

A component of a laboratory automation system that integrates (a) separating a solid magnetic substrate from the liquid contents of a reaction vessel, (b) management of the thermal characteristics of the component of the laboratory automation system, (c) automated loading of multi-well plates and tip combs into the component of the laboratory automation system, (d) automated unloading of multi-well plates and tip combs from the component of the laboratory automation system, and (e) reading of radio frequency identification tags attached to multi-well plates.

Owner:ABBOTT LAB INC

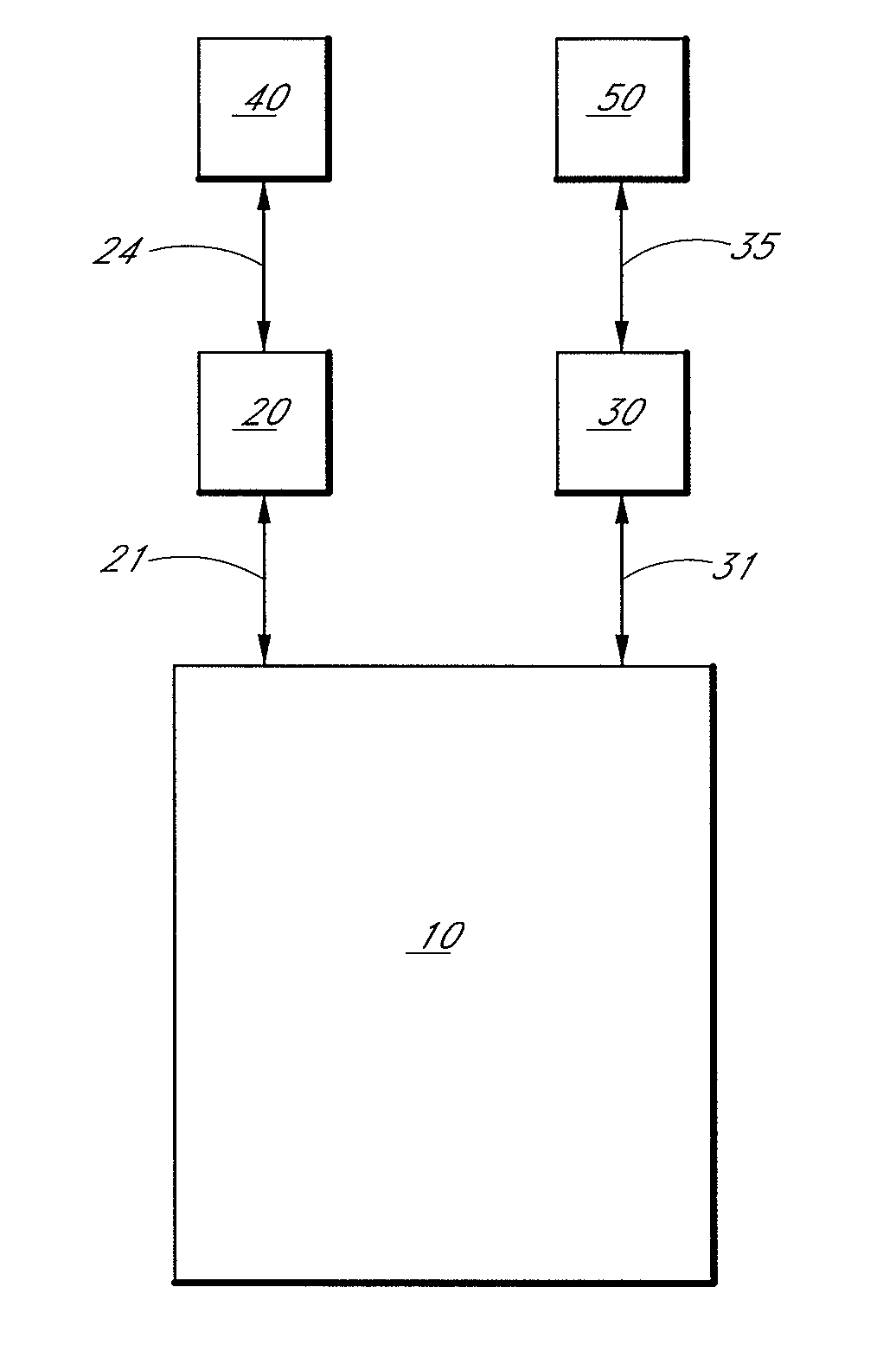

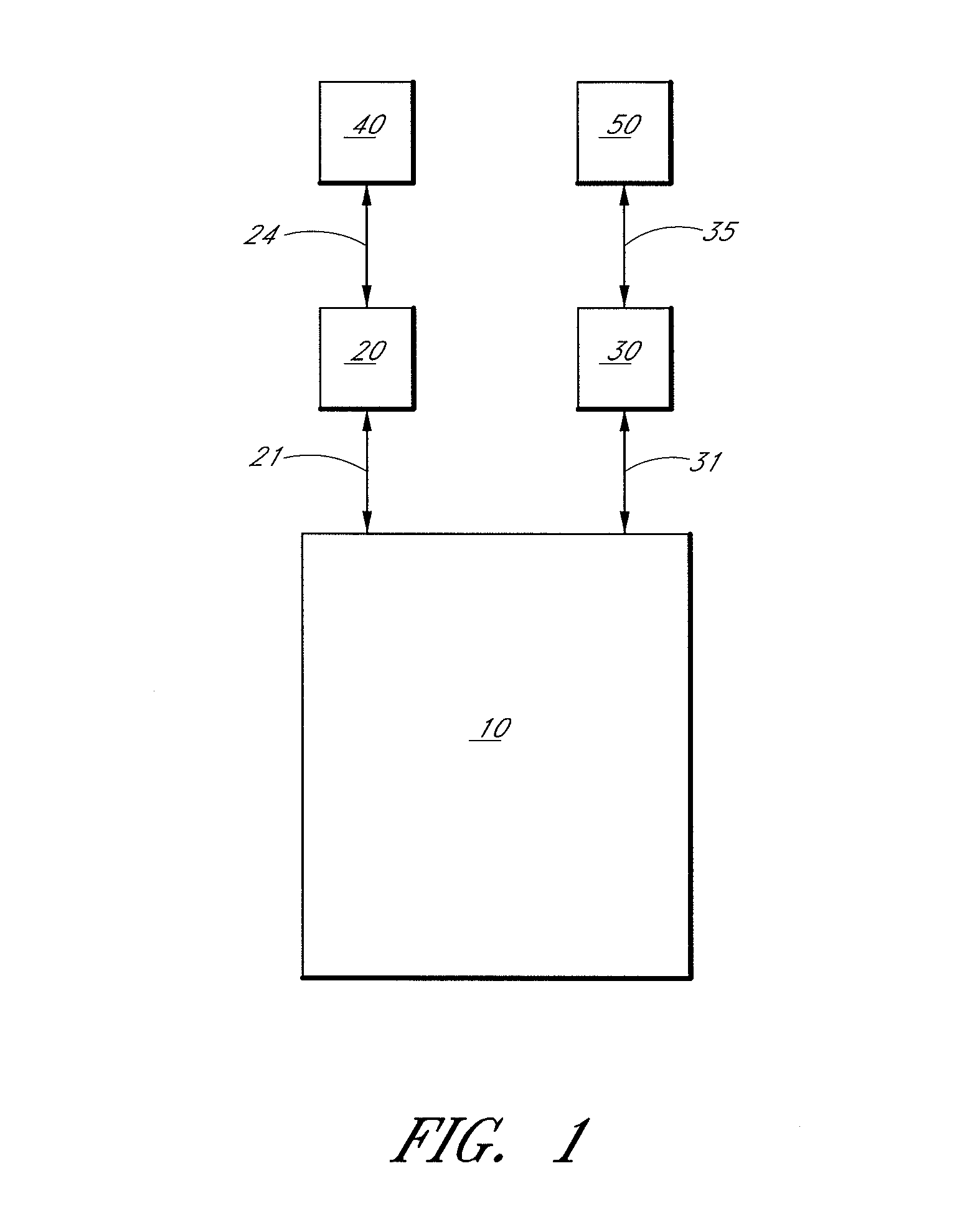

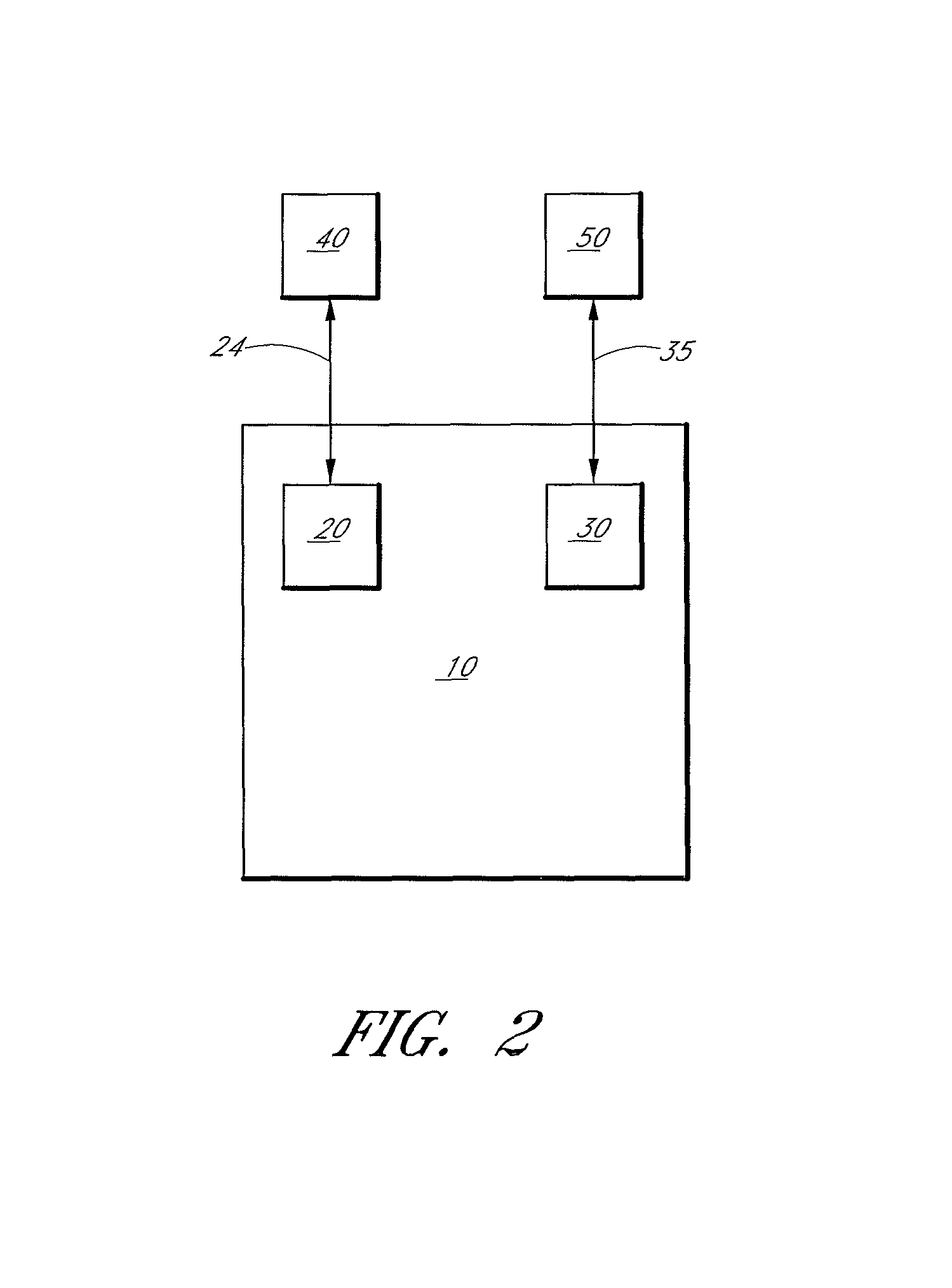

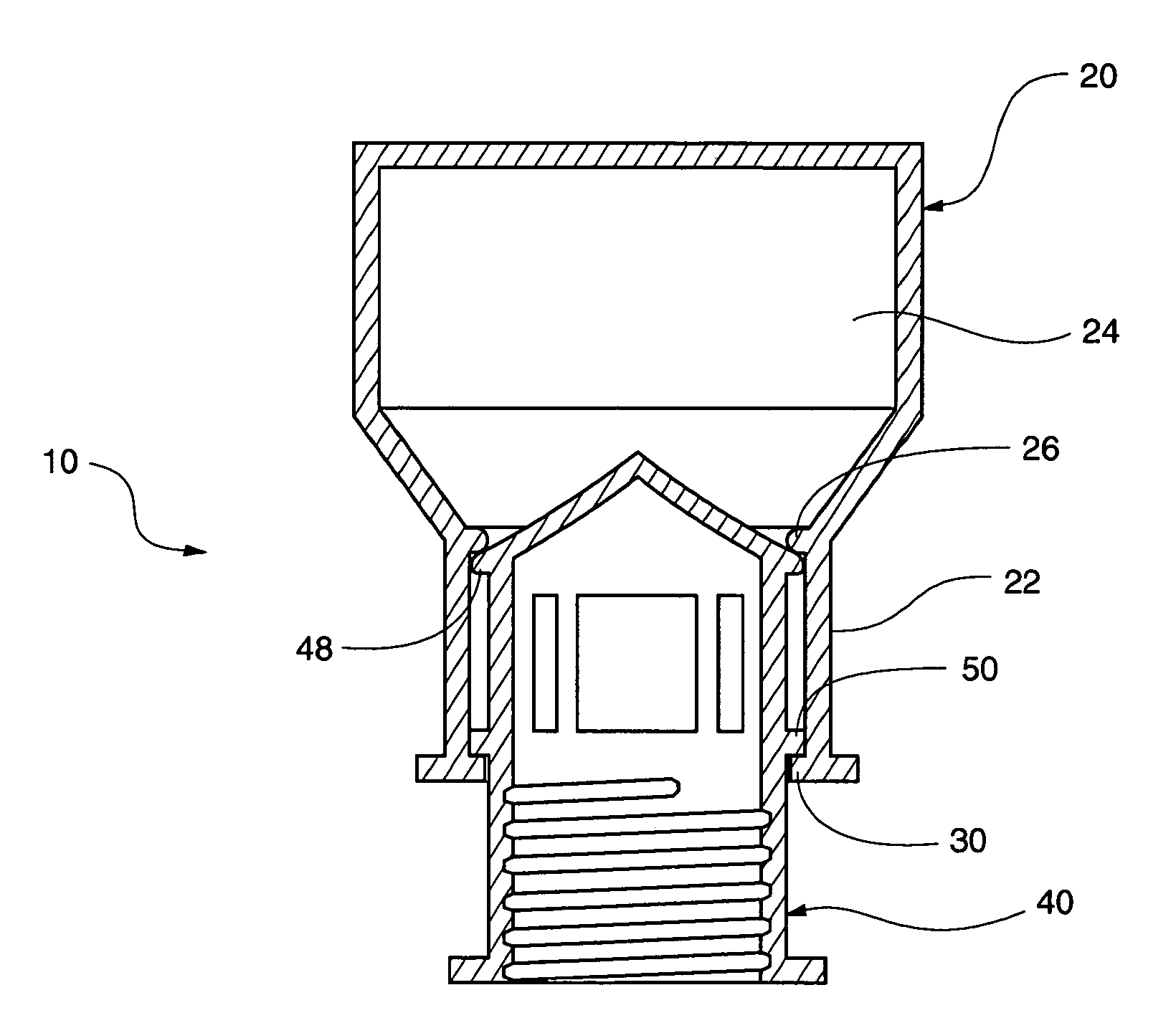

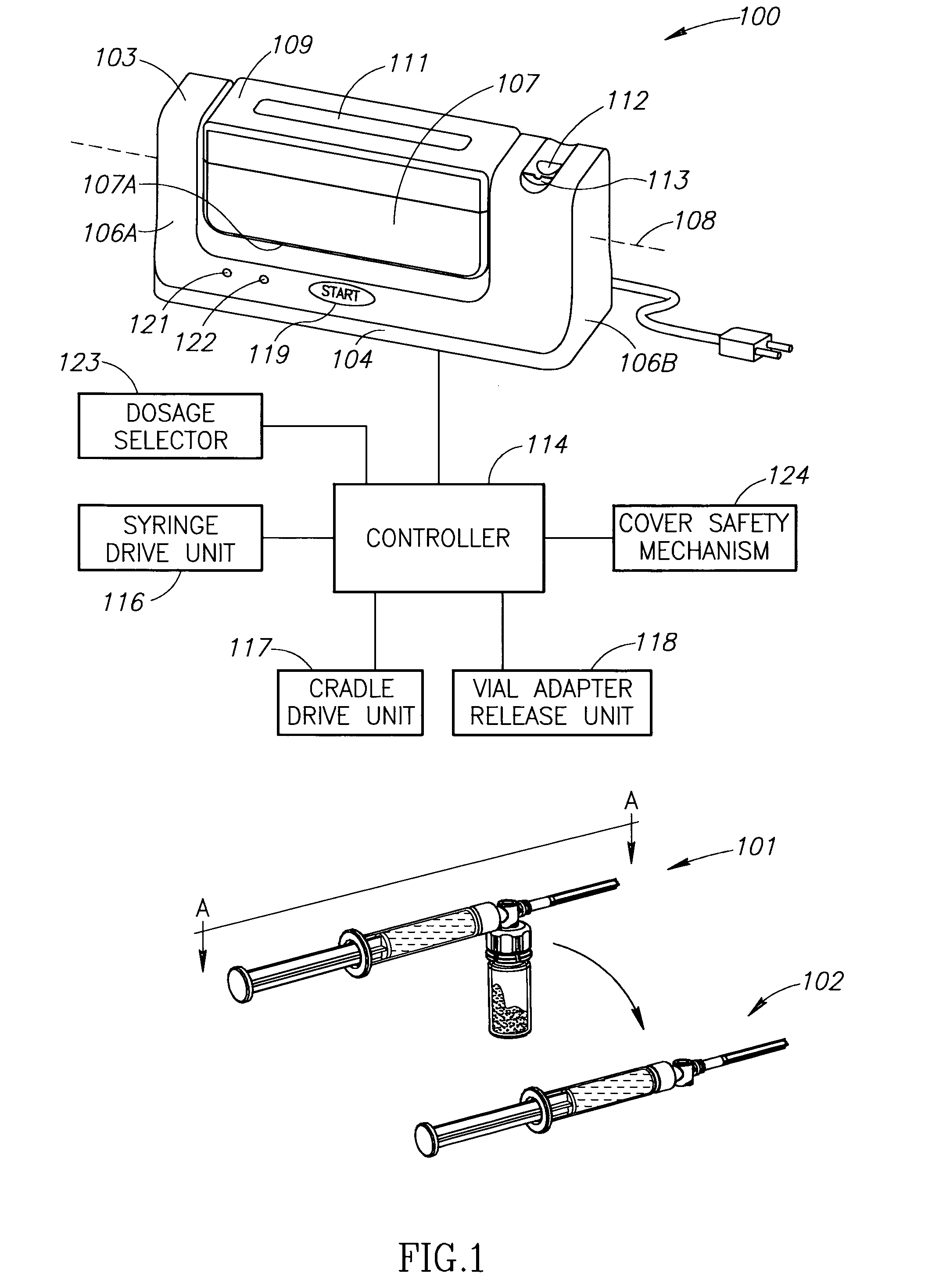

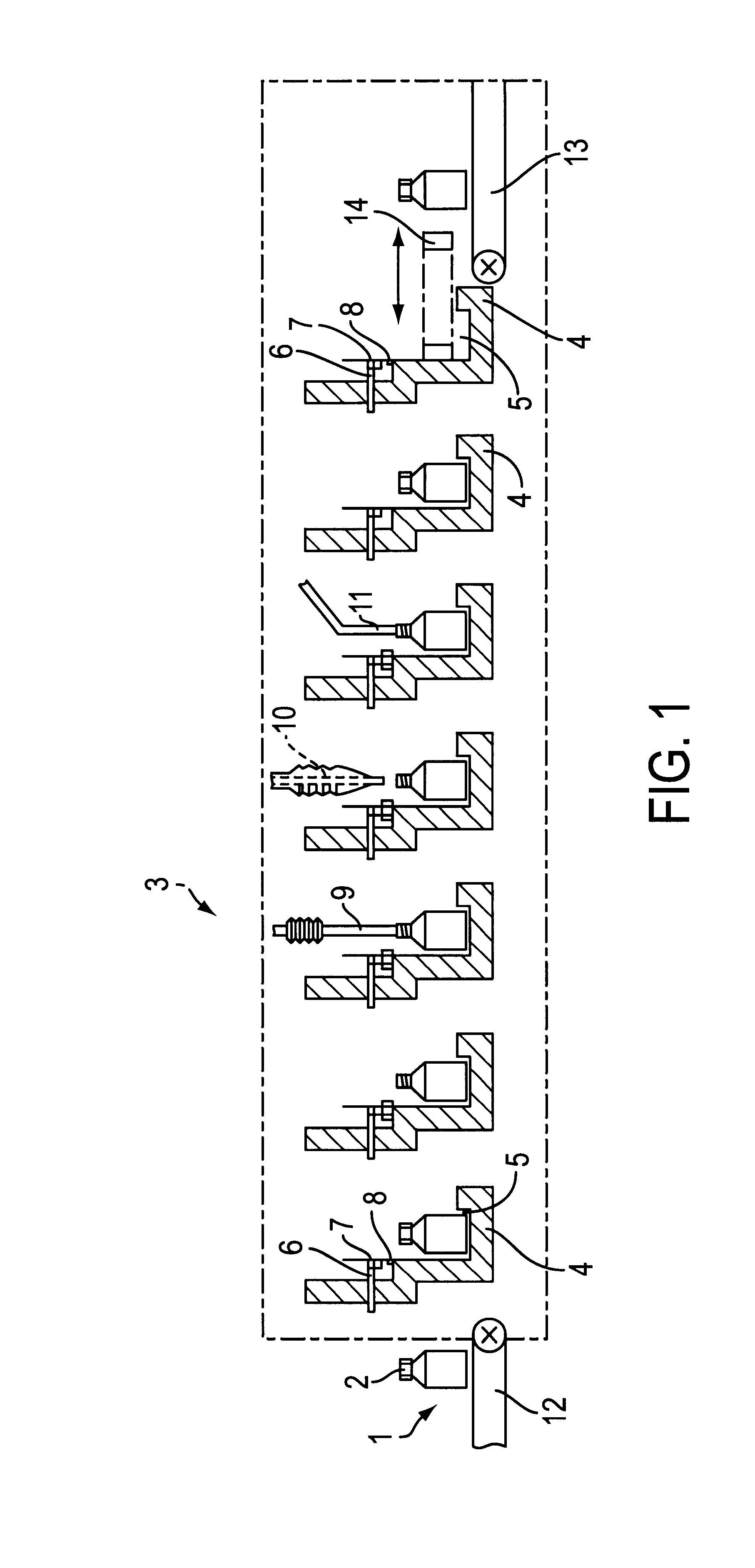

Automatic Liquid Drug Preparation Apparatus for the Preparation of a Predetermined Dosage of Liquid Drug

Automatic liquid drug preparation apparatus for preparing a liquid drug assemblage with a predetermined dosage of liquid drug. The liquid drug assemblage is prepared from a preparatory assemblage including a fluid control device having a body member with a syringe port, a vial adapter, and an administration port, a vial pre-filled with powder or liquid medicament, and a syringe pre-filled with diluent for mixing with the medicament. The automatic liquid drug preparation apparatus includes a housing, a cradle for receiving the preparatory assemblage, and a controller for controlling a motorized syringe drive unit for selectively transferring liquid contents between the syringe and the vial, a motorized cradle drive unit for selectively rotating the cradle relative to the housing, and a motorized vial adapter release unit for selectively detaching the vial adapter with its attached spent vial from the body member to form the liquid drug assemblage.

Owner:MEDIMOP MEDICAL PROJECTS

Water soluble package and liquid contents thereof

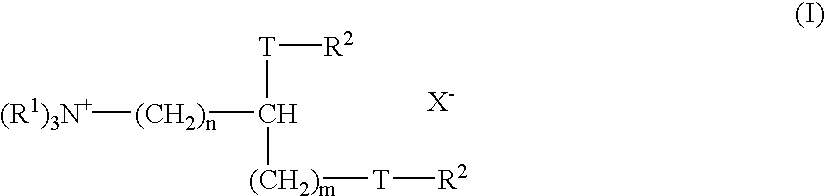

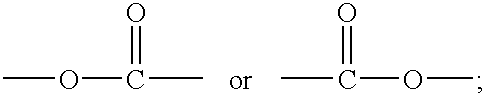

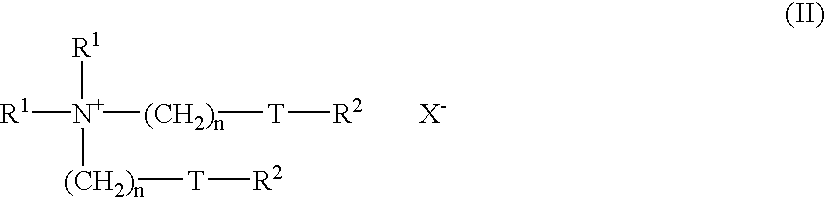

InactiveUS6451750B2AvoidanceDissolve fastInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydrogen ion bindingHydrogen

A water soluble package formed from a copolymeric polyvinyl alcohol film, wherein the comonomer comprises a carboxylate function, the package containing a substantially non-aqueous liquid composition which comprises: at least one ionic ingredient with an exchangeable hydrogen ion; and a molar excess (with respect to the amount of exchangeable hydrogen ions in the at least one ionic ingredient) of a stabilizing compound effective for combining with the exchangeable hydrogen ions to hinder the formation of lactones within the film, but can be as low as 95 mole % if the stabilizing compound comprises an inorganic base and / or ammonium hydroxide.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

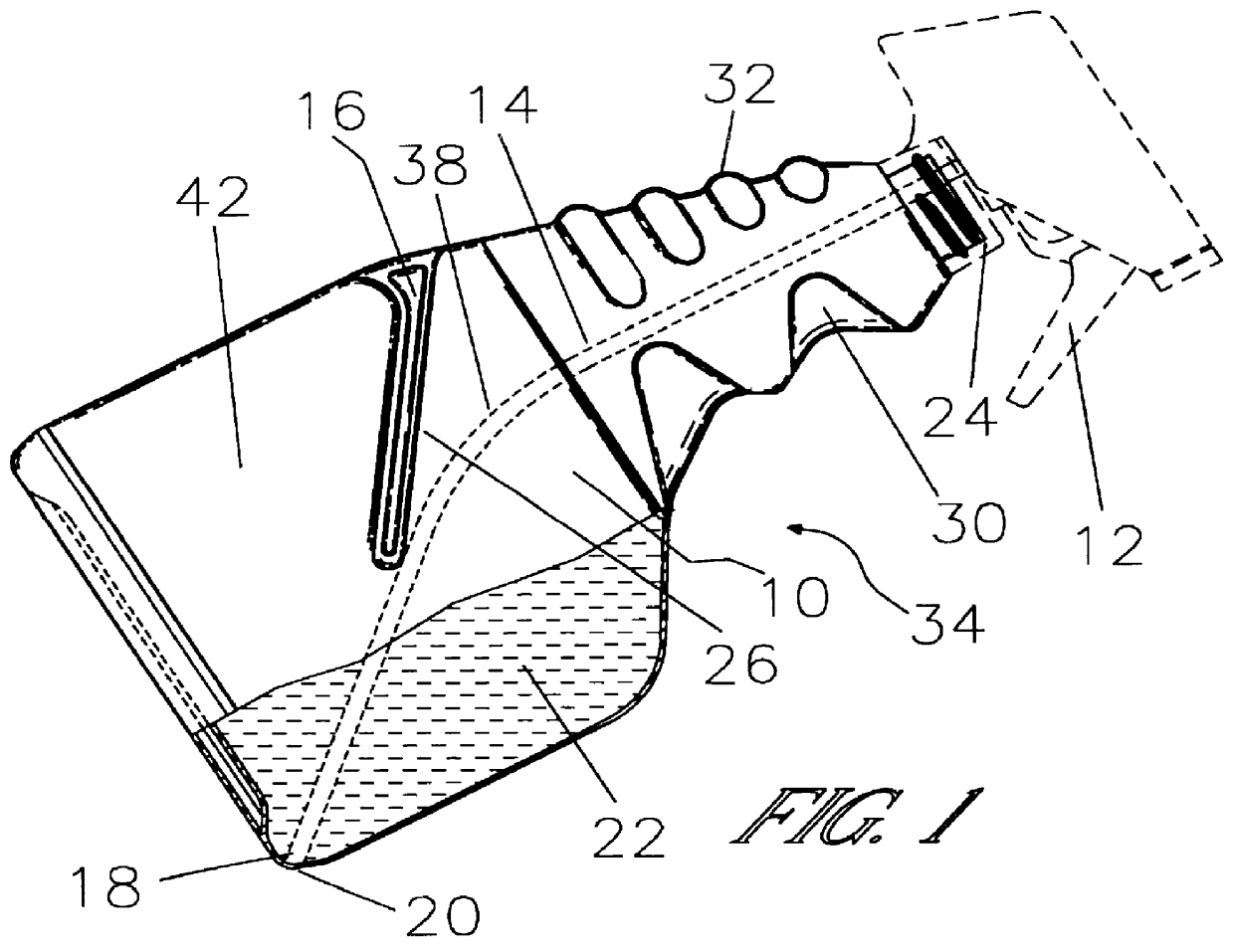

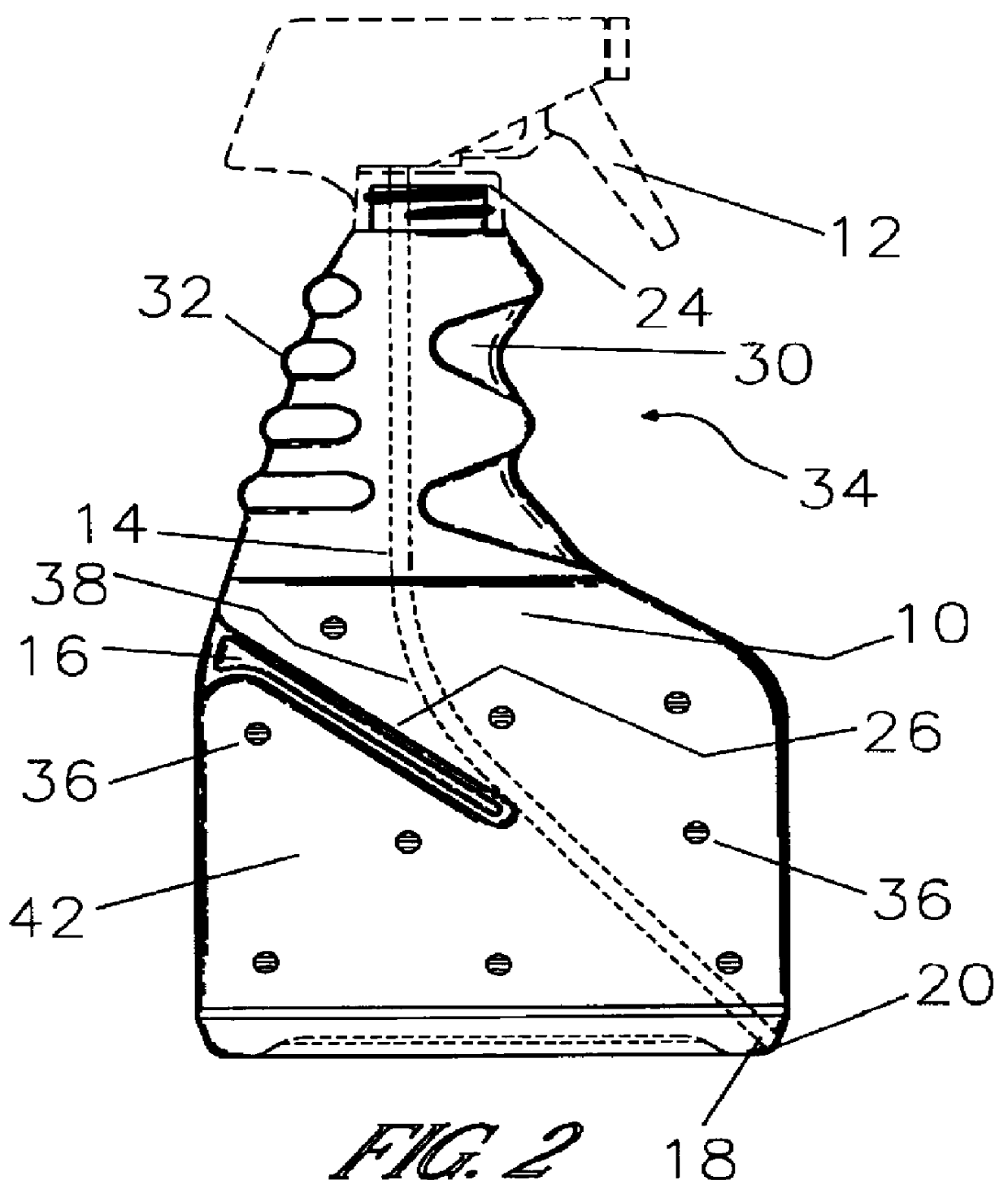

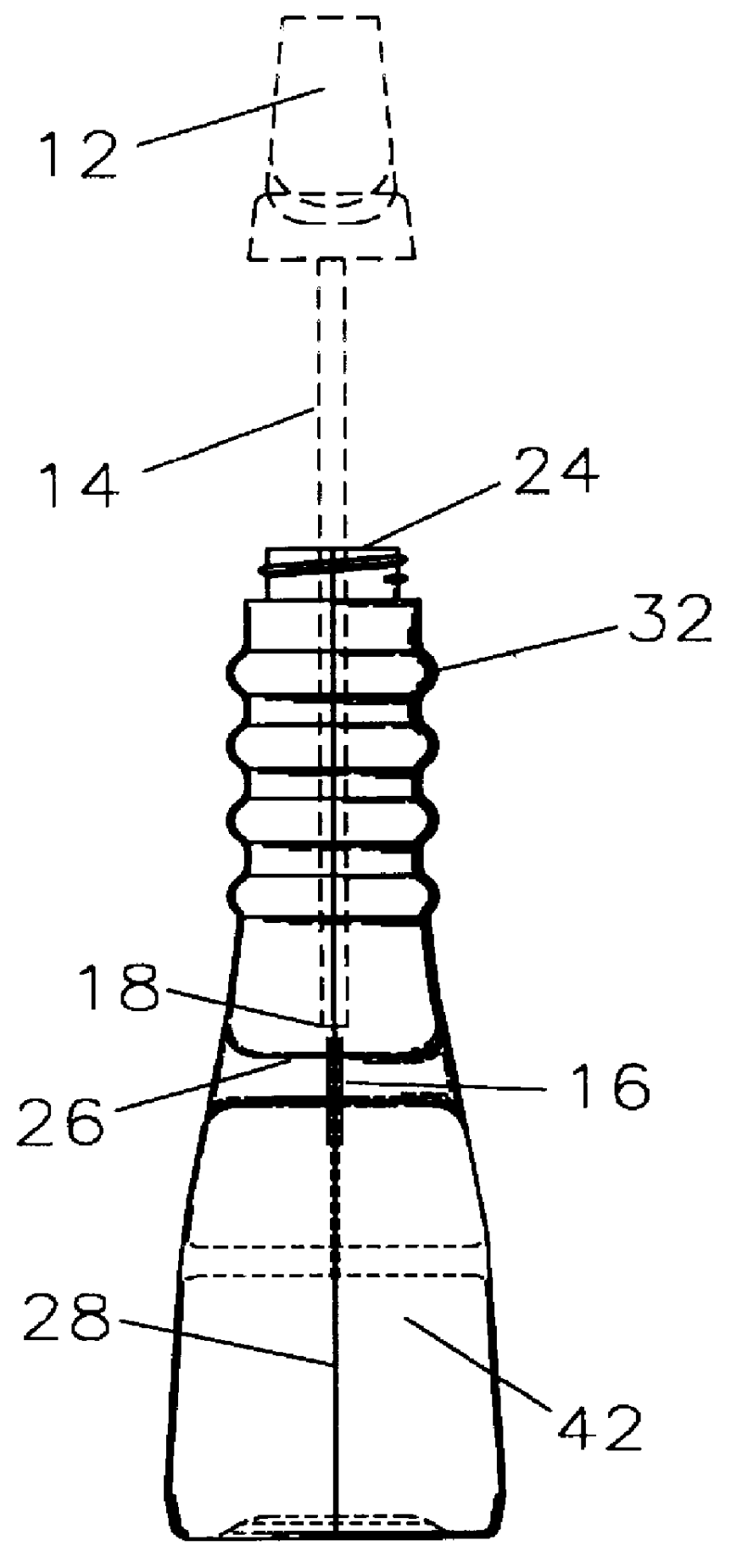

Trigger spray container with integral straw guide

A trigger spray container that prevents dry firing and solves the problem of interupted spray as the containers contents are dispensed and reduced to a level that allows the end of straw tip of trigger spray apparatus to become disengaged with liquid as the container is tilted towards the users target. As the user inverts or rotates the container from a vertical position, downwardly, towards a horizontal plain and aims the spray tip output nozzel towards the intended target, the liquid level adjusts within the container. Therefore, it becomes advantageous for end of straw tip to be positioned at the lowest point on container base, side of container base nearest target. This is achieved by forming an integral straw guide molded into the container body that provides a ramp for the straw to be guided on, thereby directing the straw tip to this position. The straw length of the trigger spray apparatus is of sufficient length such that it travels on ramp of integral straw guide and engages with intended base corner as trigger spray apparatus becomes securably attached to the mouth opening of container. The liquid contents of the container can now be fully consumed, without pumping air during operation, as the consumer uses the product in its entirety.

Owner:MAYFIELD TODD A

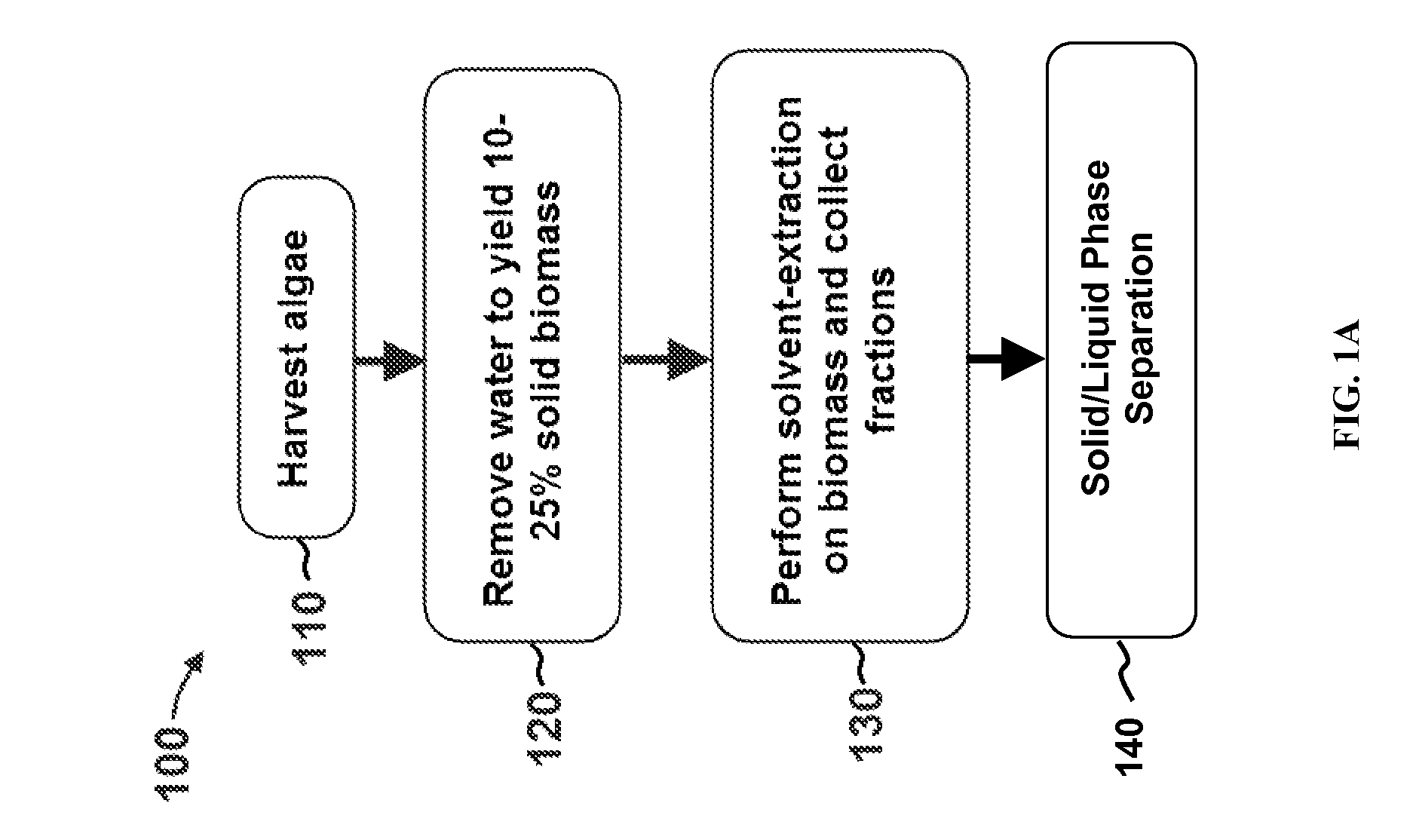

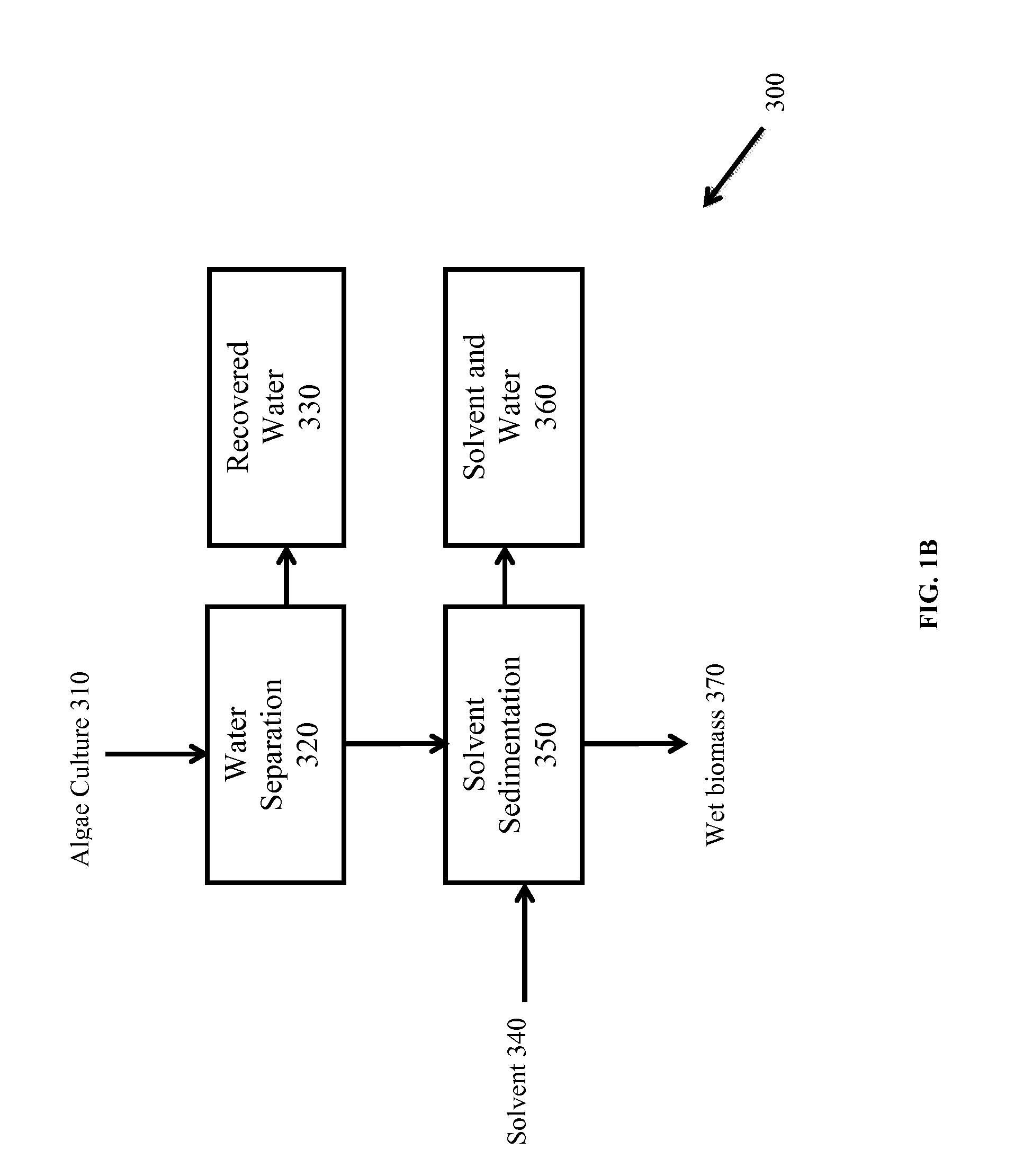

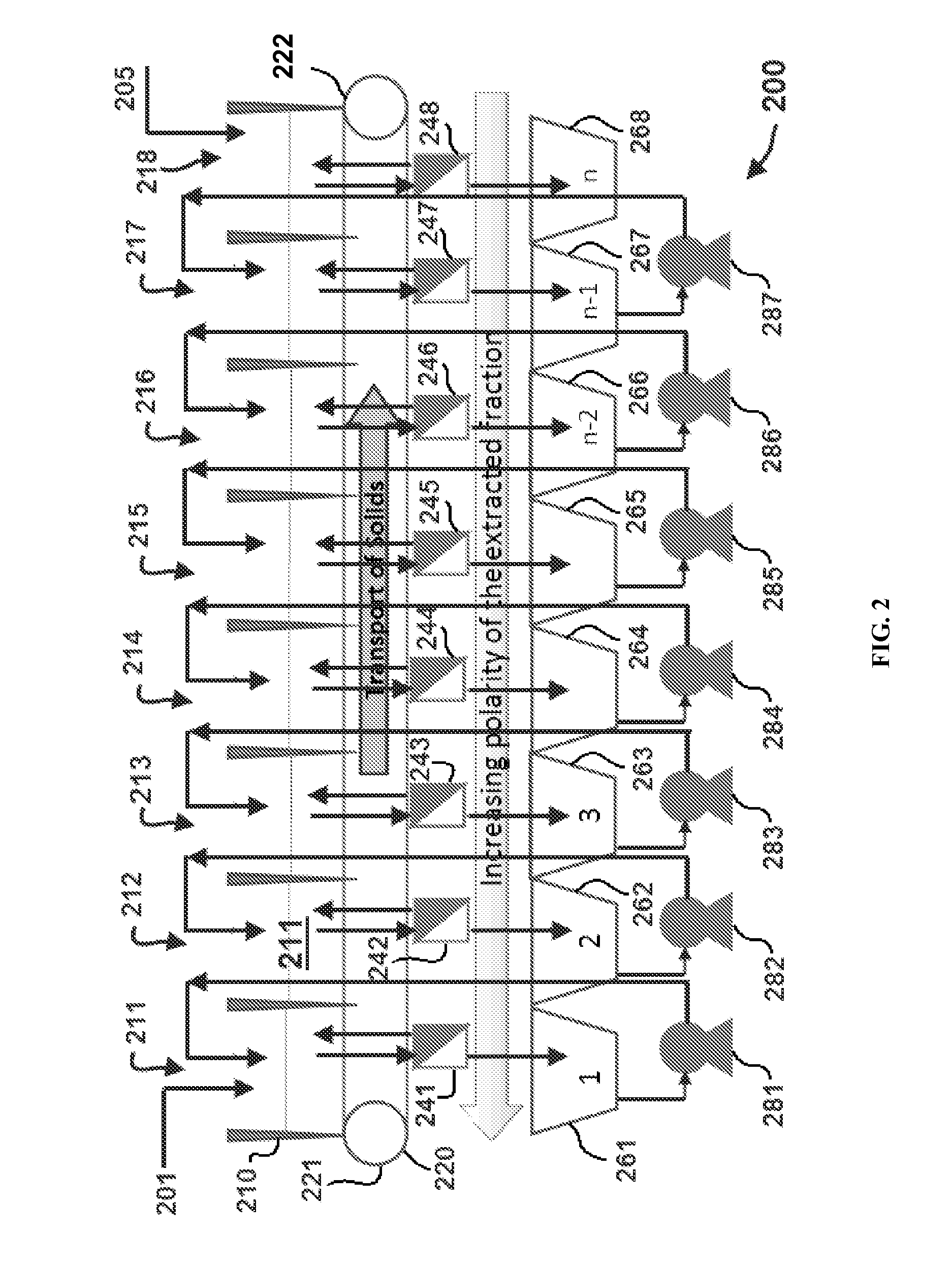

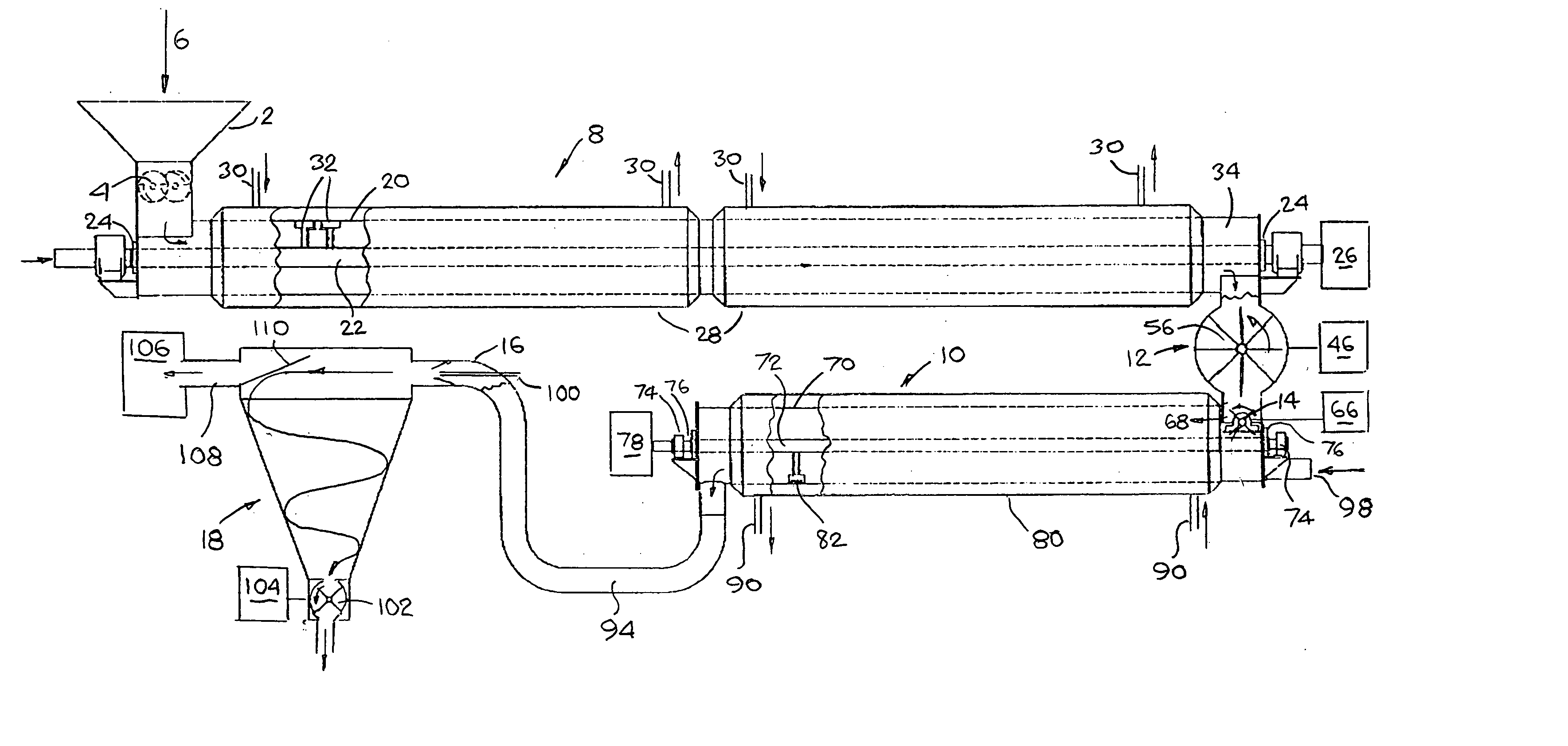

Methods of and Systems for Dewatering Algae and Recycling Water Therefrom

A method of dewatering algae and recycling water therefrom is presented. A method of dewatering a wet algal cell culture includes removing liquid from an algal cell culture to obtain a wet algal biomass having a lower liquid content than the algal cell culture. At least a portion of the liquid removed from the algal cell culture is recycled for use in a different algal cell culture. The method includes adding a water miscible solvent set to the wet algal biomass and waiting an amount of time to permit algal cells of the algal biomass to gather and isolating at least a portion of the gathered algal cells from at least a portion of the solvent set and liquid of the wet algal biomass so that a dewatered algal biomass is generated. The dewatered algal biomass can be used to generated algal products such as biofuels and nutraceuticals.

Owner:HELIAE DEVMENT

Water soluble package and liquid contents therof

InactiveUS20020013243A1AvoidanceDissolve fastNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrogen ion bindingHydrogen

A water soluble package formed from a copolymeric polyvinyl alcohol film, wherein the comonomer comprises a carboxylate function, the package containing a substantially non-aqueous liquid composition which comprises: at least one ionic ingredient with an exchangeable hydrogen ion; and a molar excess (with respect to the amount of exchangeable hydrogen ions in the at least one ionic ingredient) of a stabilizing compound effective for combining with the exchangeable hydrogen ions to hinder the formation of lactones within the film, but can be as low as 95 mole % if the stabilizing compound comprises an inorganic base and / or ammonium hydroxide.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

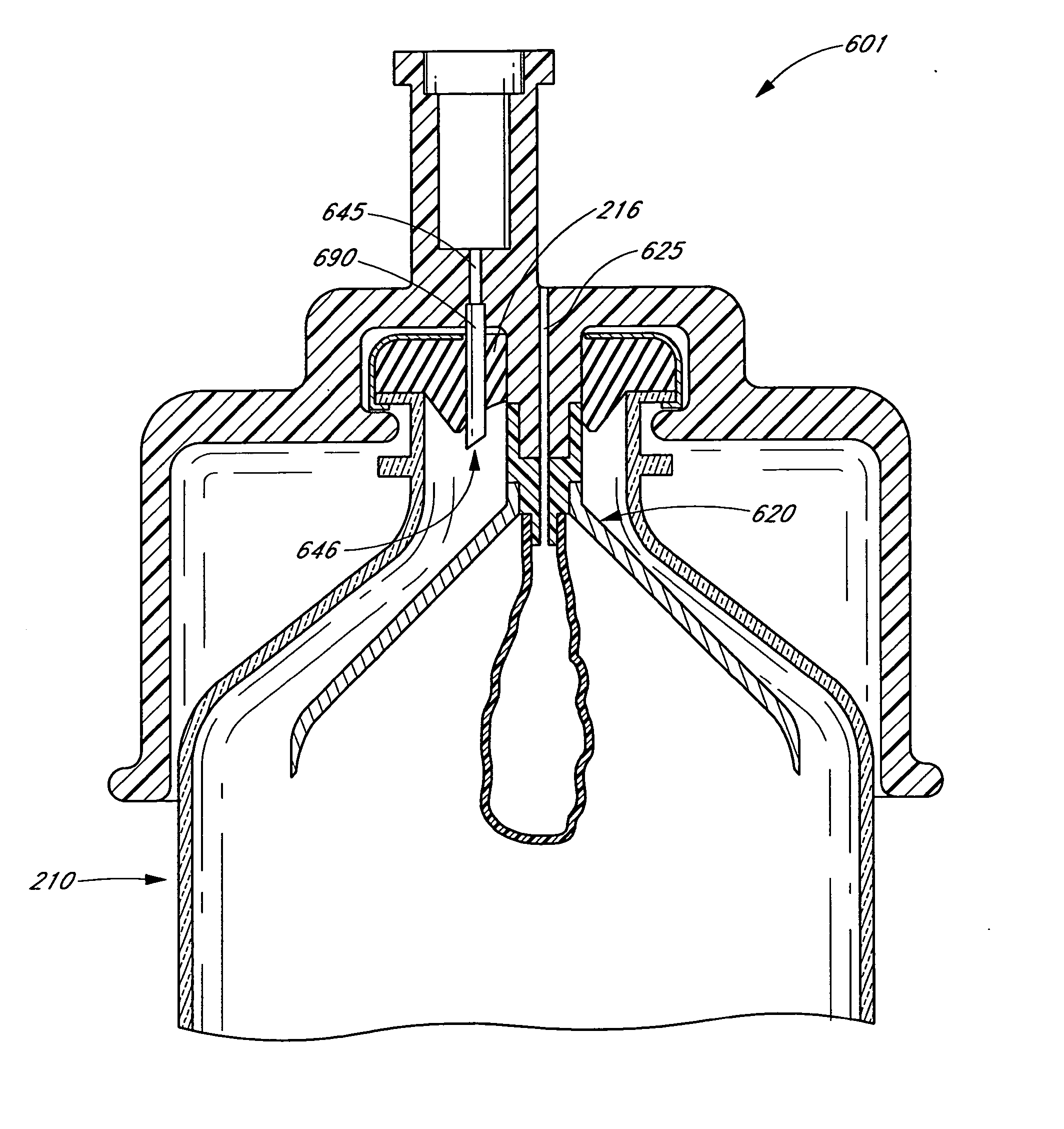

Vial for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial comprises a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial comprises a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

Vial adaptor for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial comprises a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial comprises a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

Vial adaptor for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial comprises a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial comprises a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

Water soluble package and liquid contents thereof

InactiveUS20020198125A1Improve adhesionIncrease humidityDetergent materialsDetergent compounding agentsDecompositionWater soluble

A water soluble package and a substantially non-aqueous liquid rinse conditioning composition therein, wherein the water soluble package comprises a polymeric film provided one or more modifying protective functional groups. The modifying protective functional groups are arranged to protect the active functional groups that may be present in the film so as to prevent decomposition of the film during the wash cycle but to allow or accelerate decomposition of the film during the rinse cycle.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

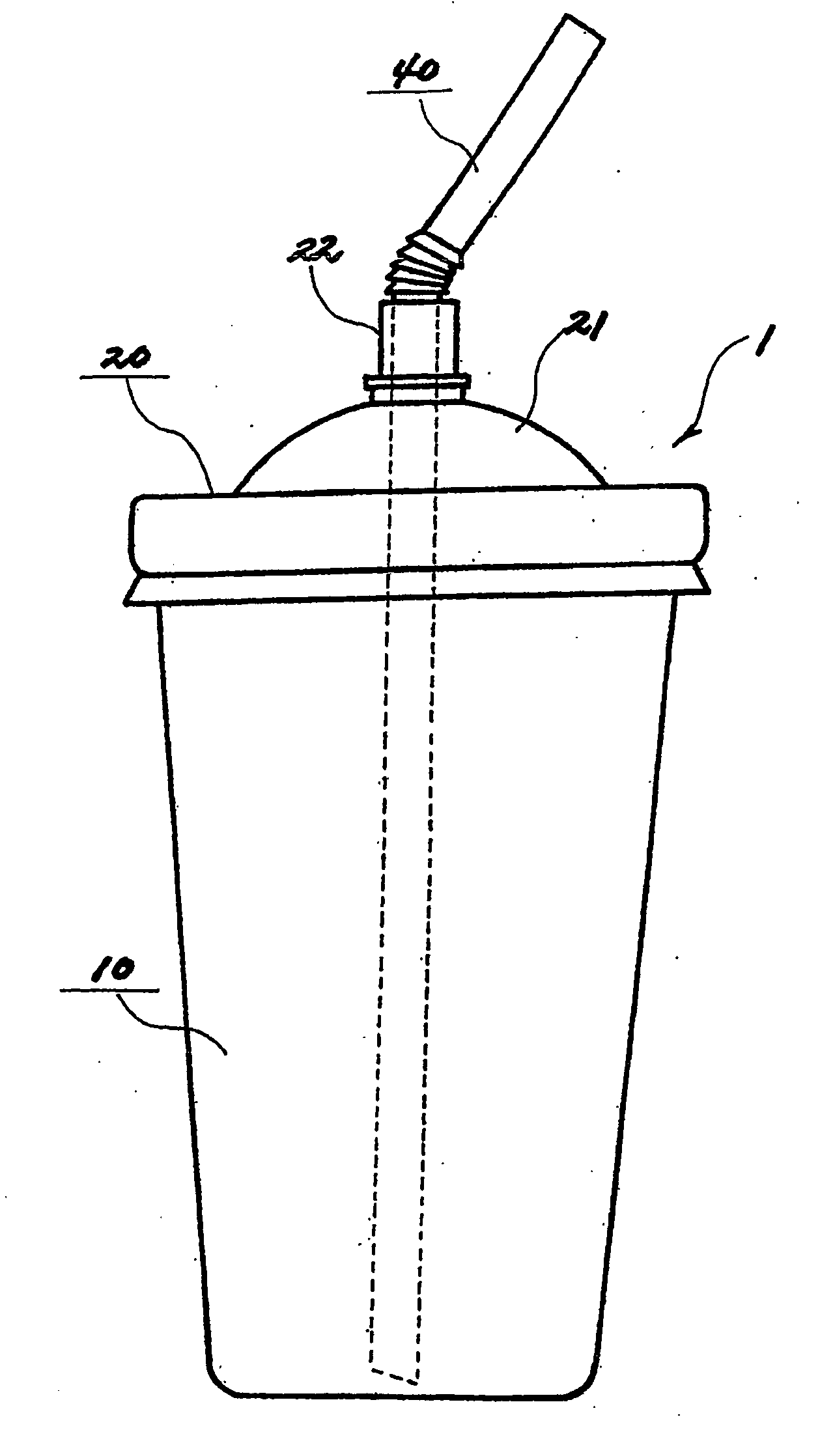

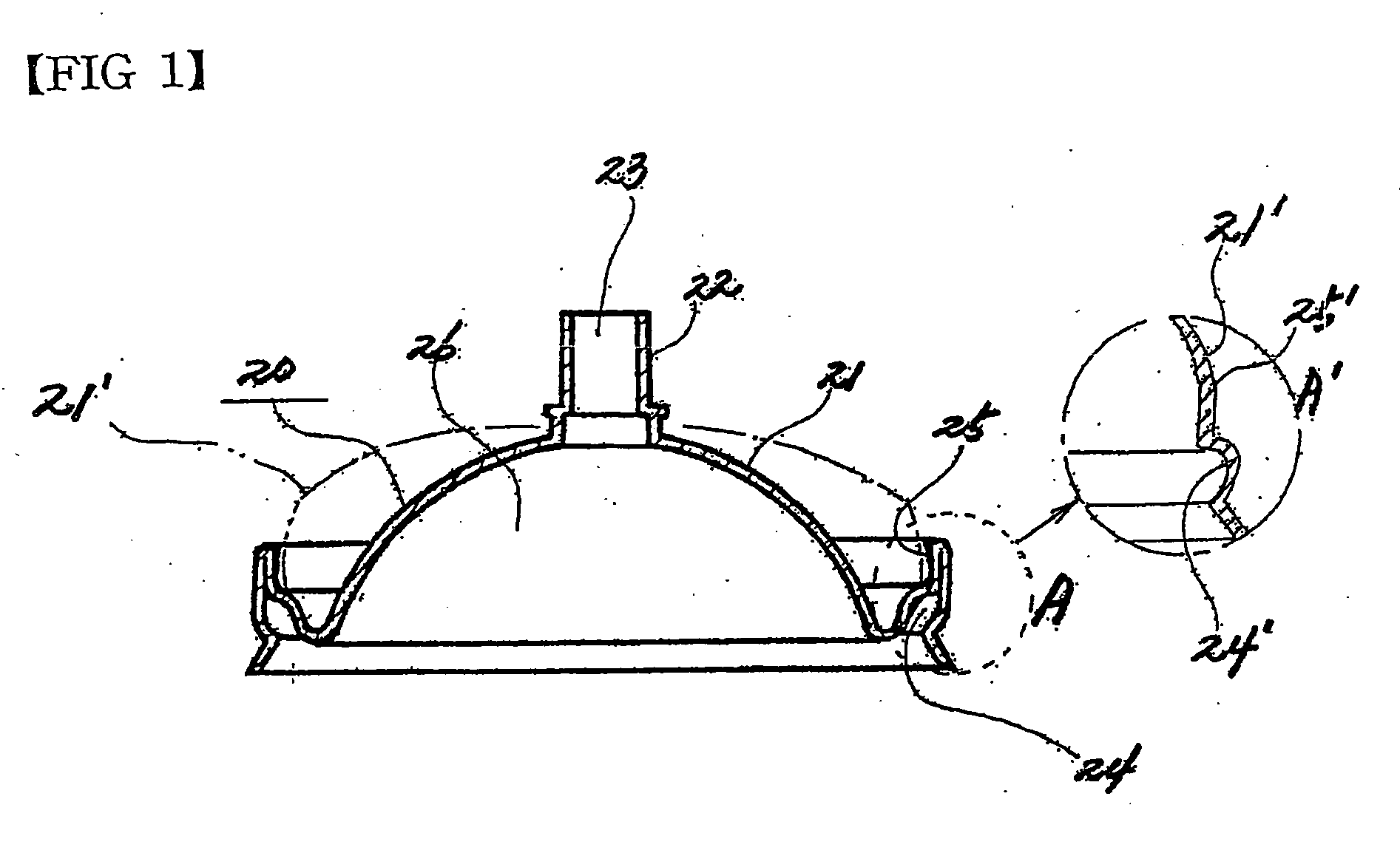

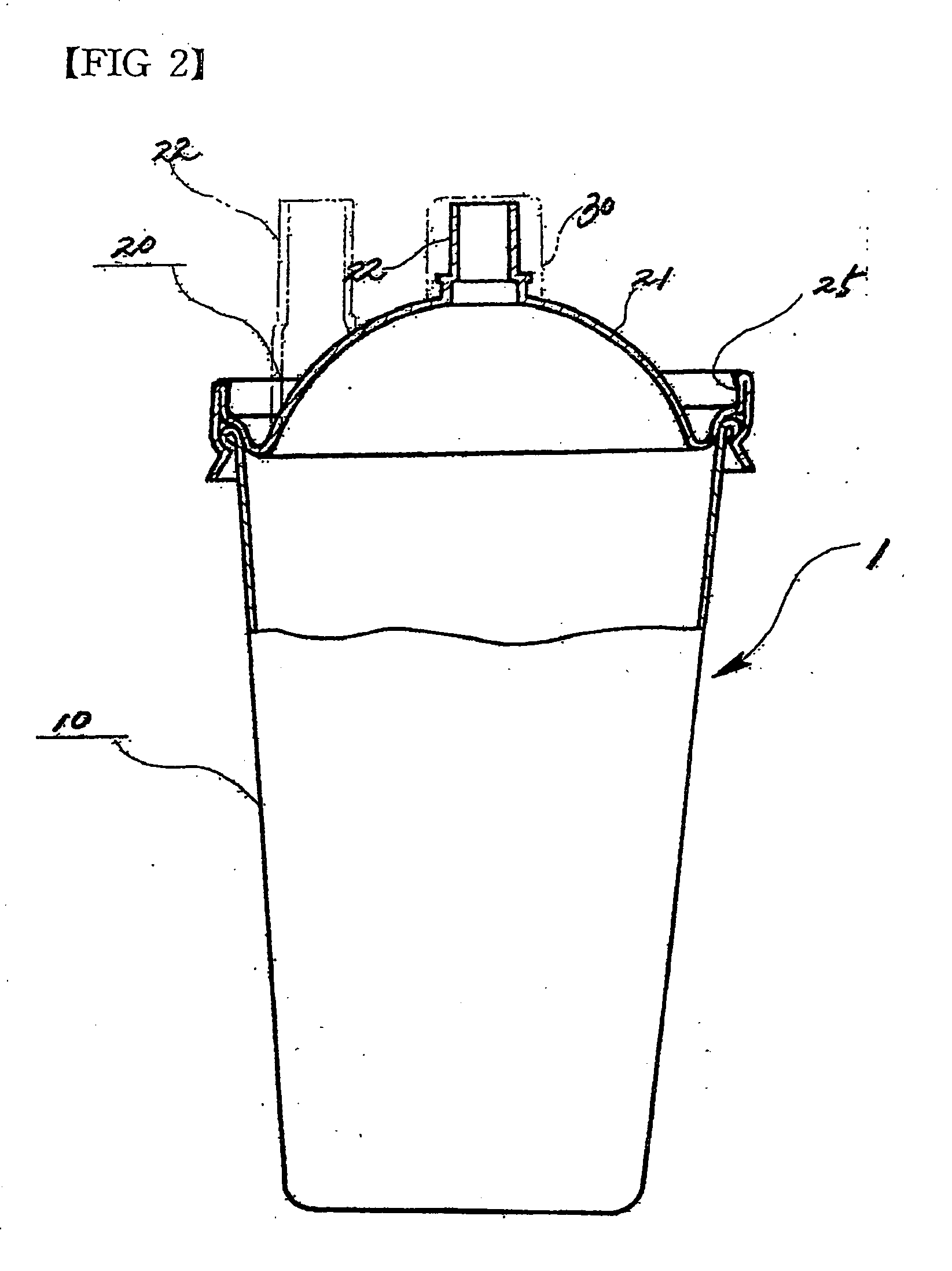

Container for food and beverage

A food / beverage container includes a cup-shaped main body for containing liquid content, and a cap having a hemisphere body provided with a spouting portion. The cap is designed to be normally or inversely fitted on the cup-shaped main body.

Owner:LEE IN OK

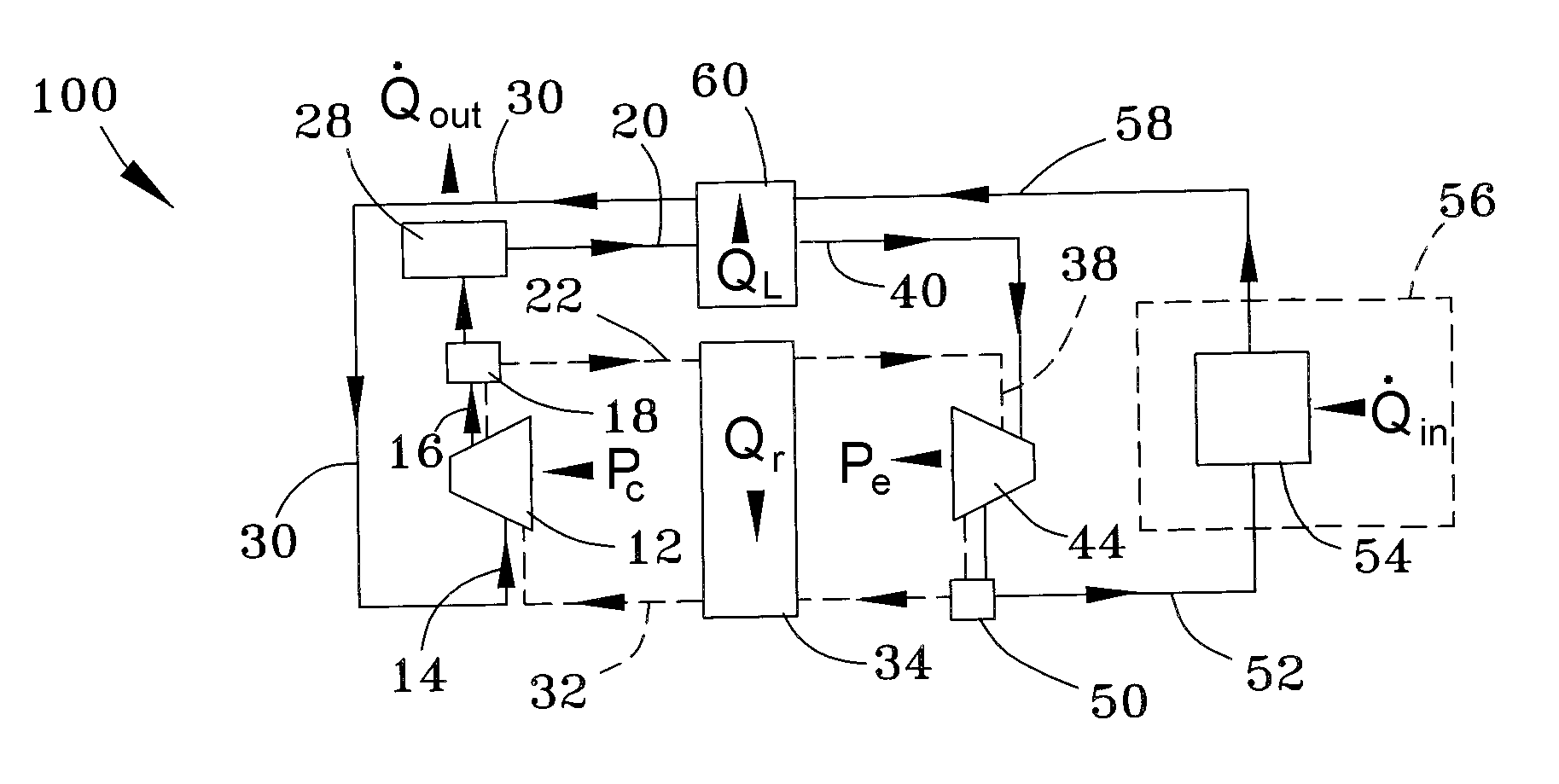

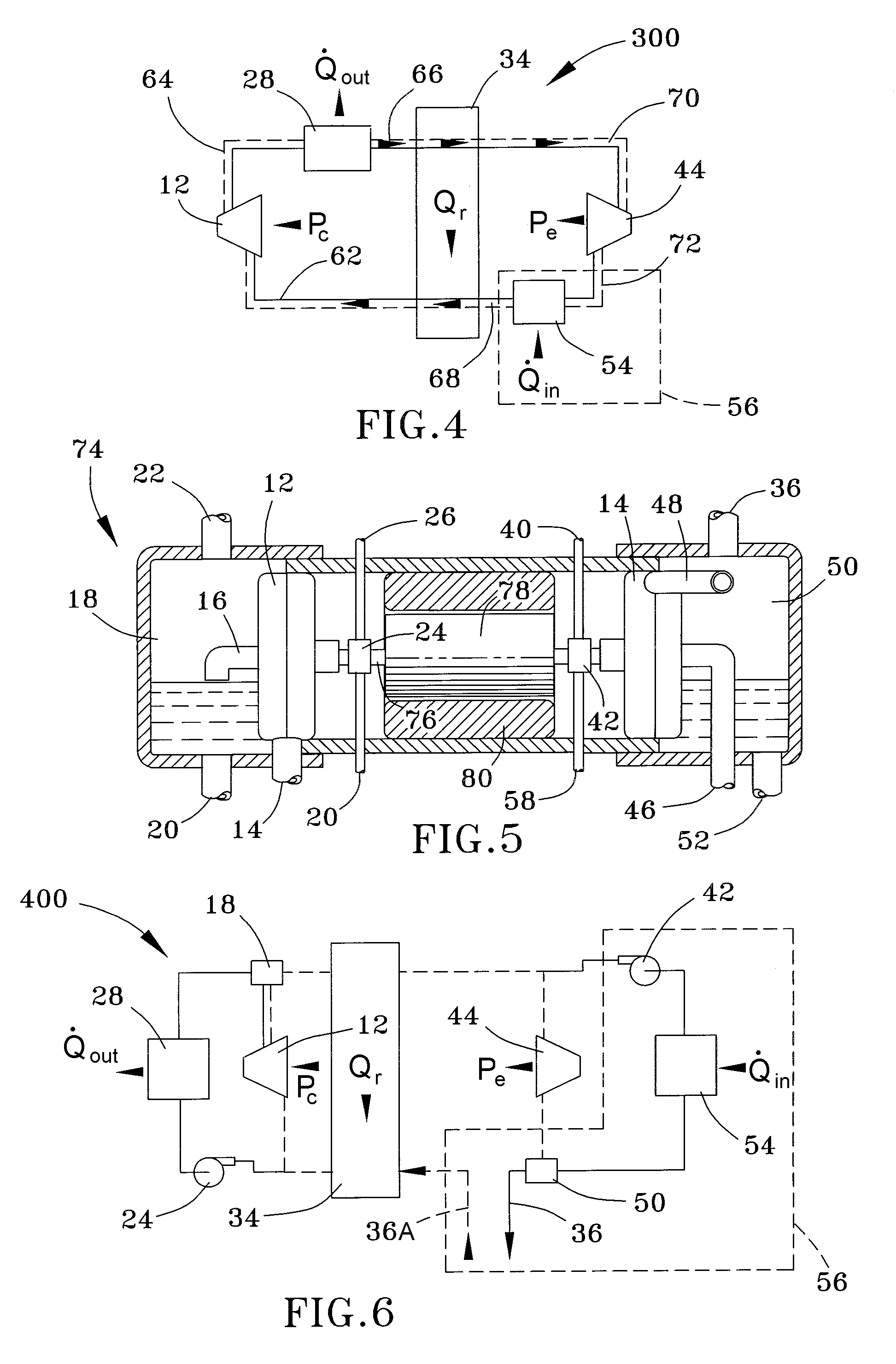

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS20070074533A1Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleEngineering

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

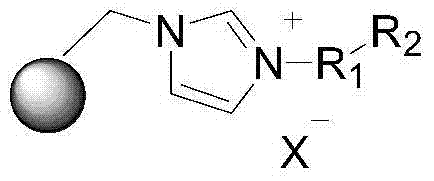

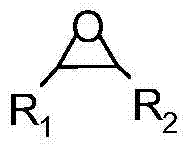

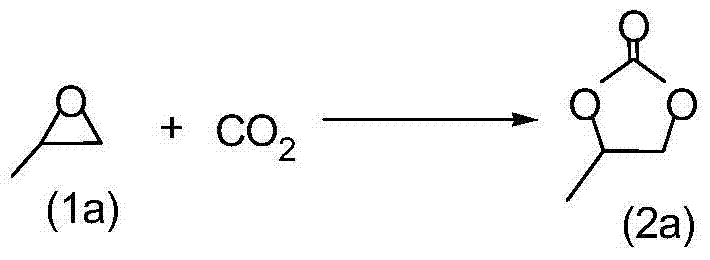

Supported ionic liquid catalyst, as well as preparation and application thereof

InactiveCN103495437AChemical choice goodMild reaction conditionsProductsOrganic chemistryEpoxyCycloaddition

The invention discloses a supported ionic liquid catalyst. The supported ionic liquid catalyst is characterized in that imidazole is immobilized onto chloromethylated FDU mesoporous phenolic resin by nucleophilic reaction and reacts with halides containing different functional groups to prepare a mesoporous material supported functional imidazole type ionic liquid catalyst. The preparation of the catalyst comprises the following steps: chloromethylation of a mesoporous material, imidazolation and supporting of ionic liquid. The catalyst is used for synthesizing a cyclic carbonate by cyclic addition reaction of carbon dioxide and an epoxy compound, and the using quantity of the catalyst is 0.1-2mol% of the liquid content of the epoxy compound. Compared with the prior art, a large number of hydroxyl groups exist in the mesoporous material, and the supported ionic liquid catalyst has the double advantages of an inorganic mesoporous material and an organic polymer, as well as large specific surface area, adjustable pore structure, good hydrophobicity and chemical stability, high catalytic activity, good chemical selectivity, easiness in separation and recovery, mild reaction conditions, environmental friendliness and easiness in industrial implementation.

Owner:EAST CHINA NORMAL UNIV

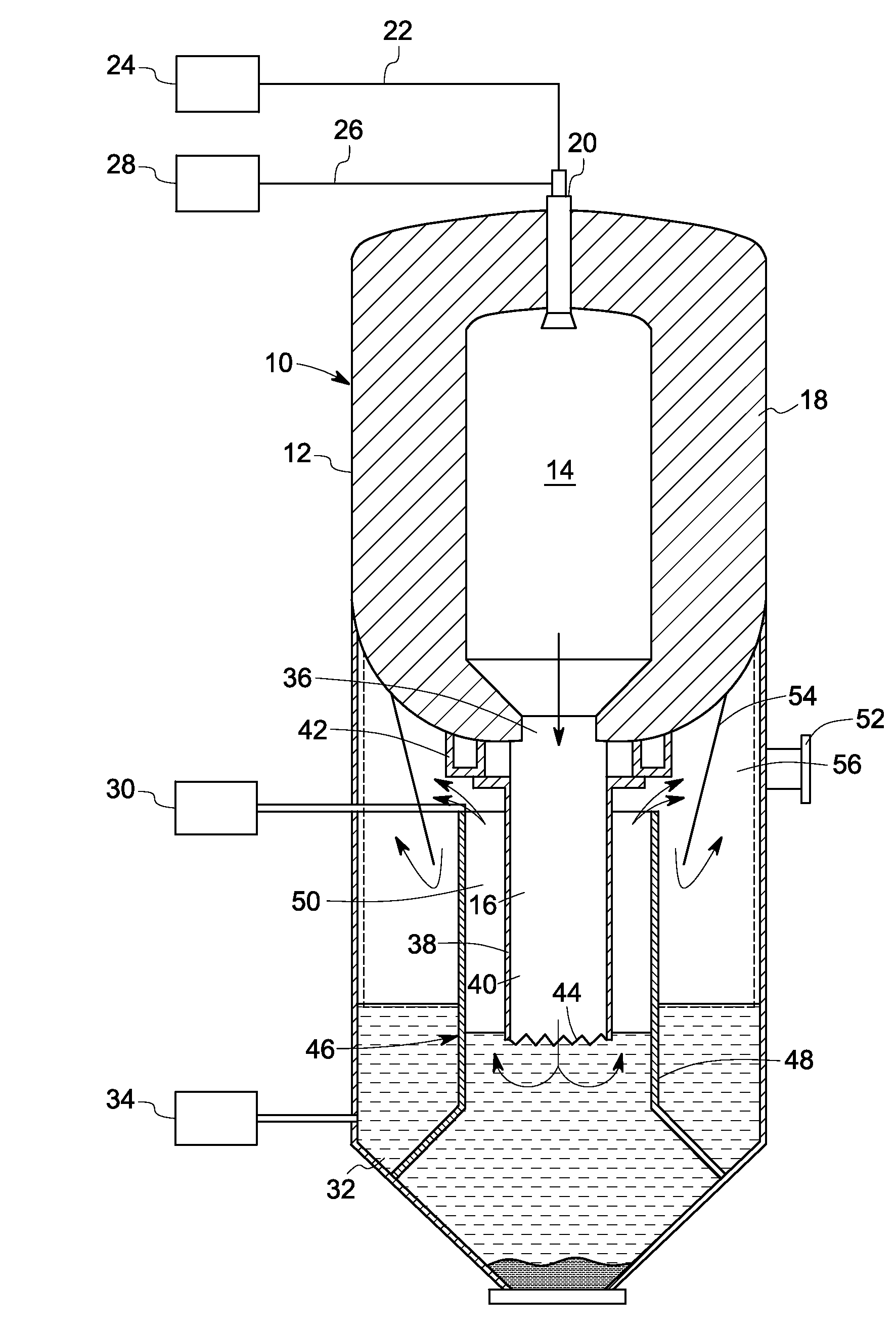

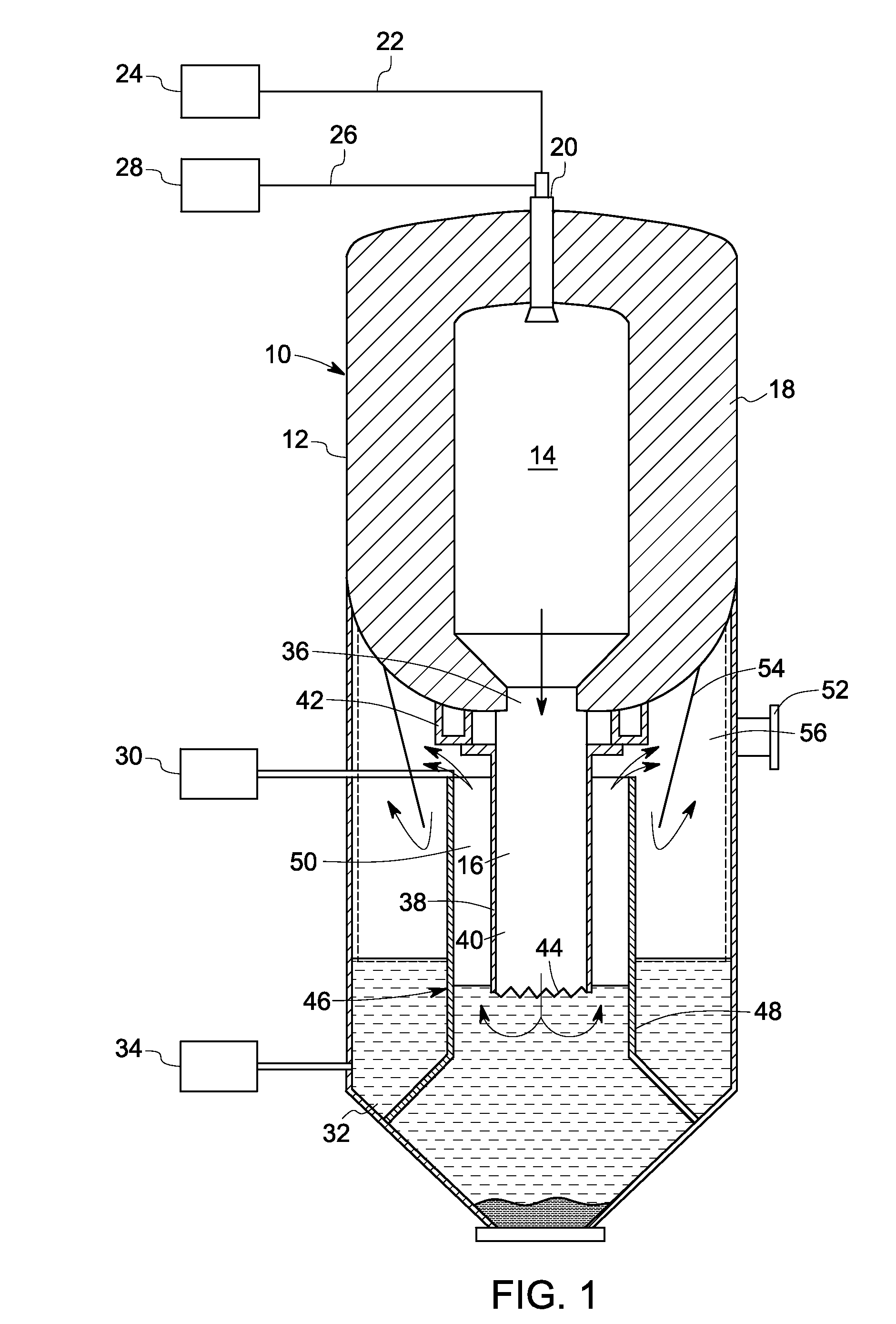

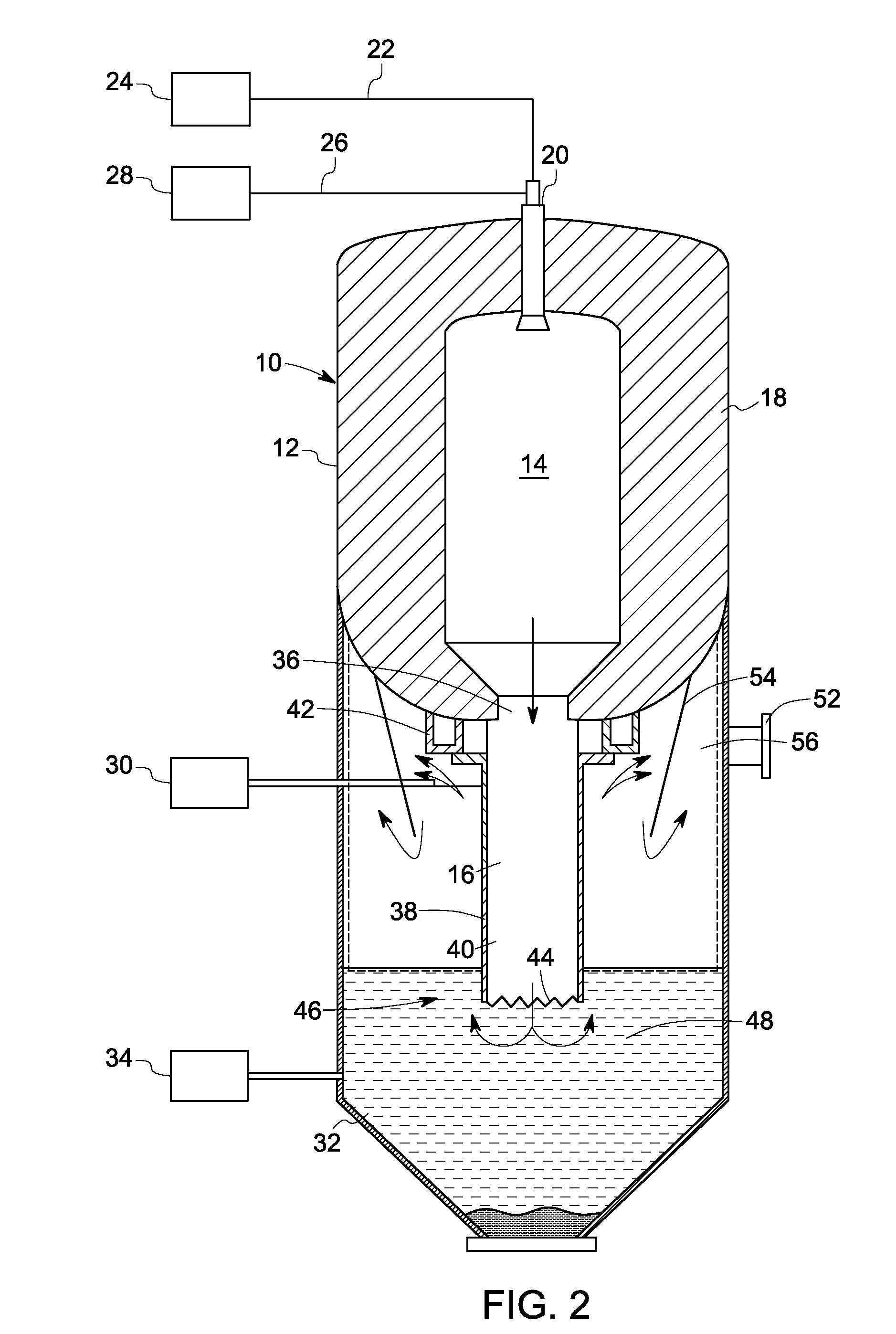

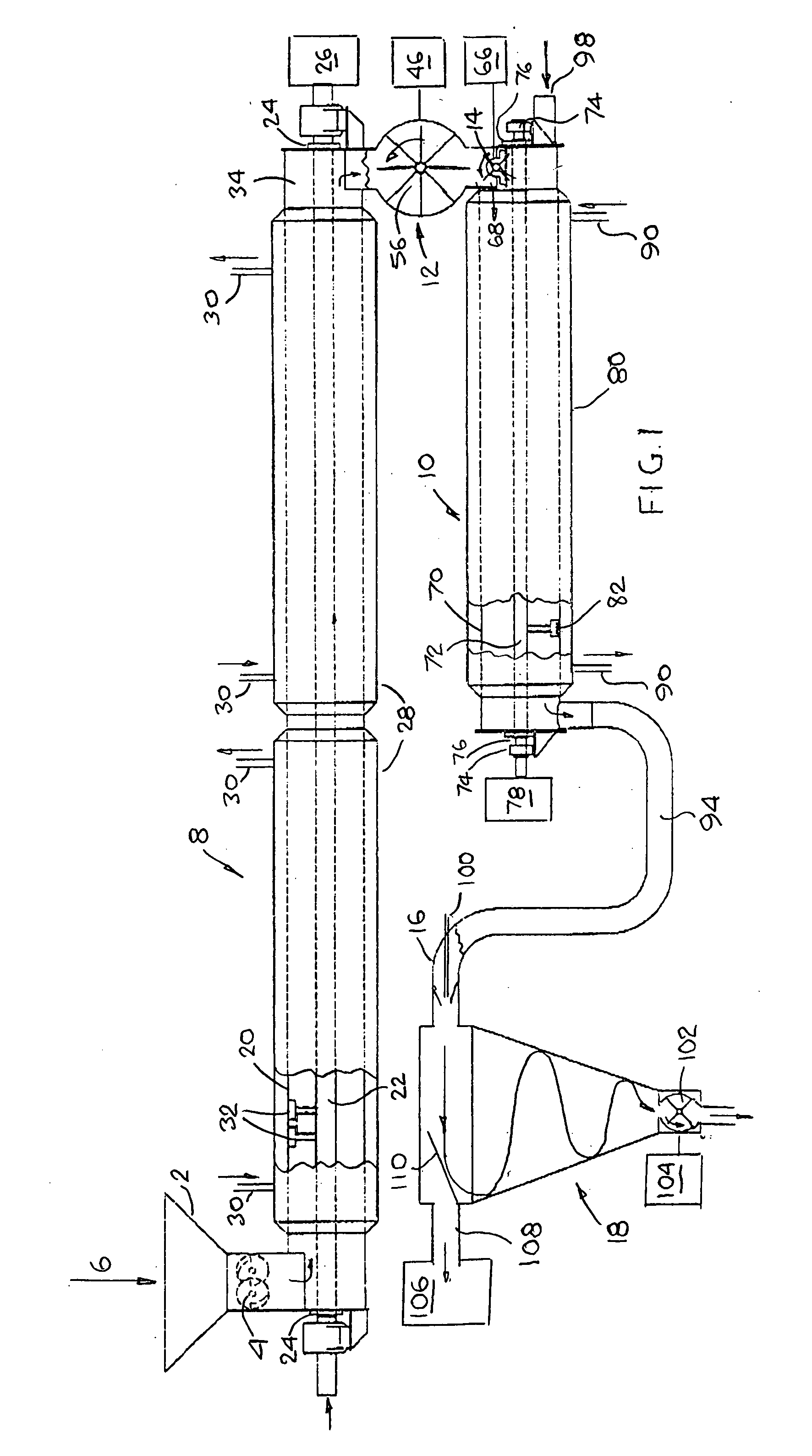

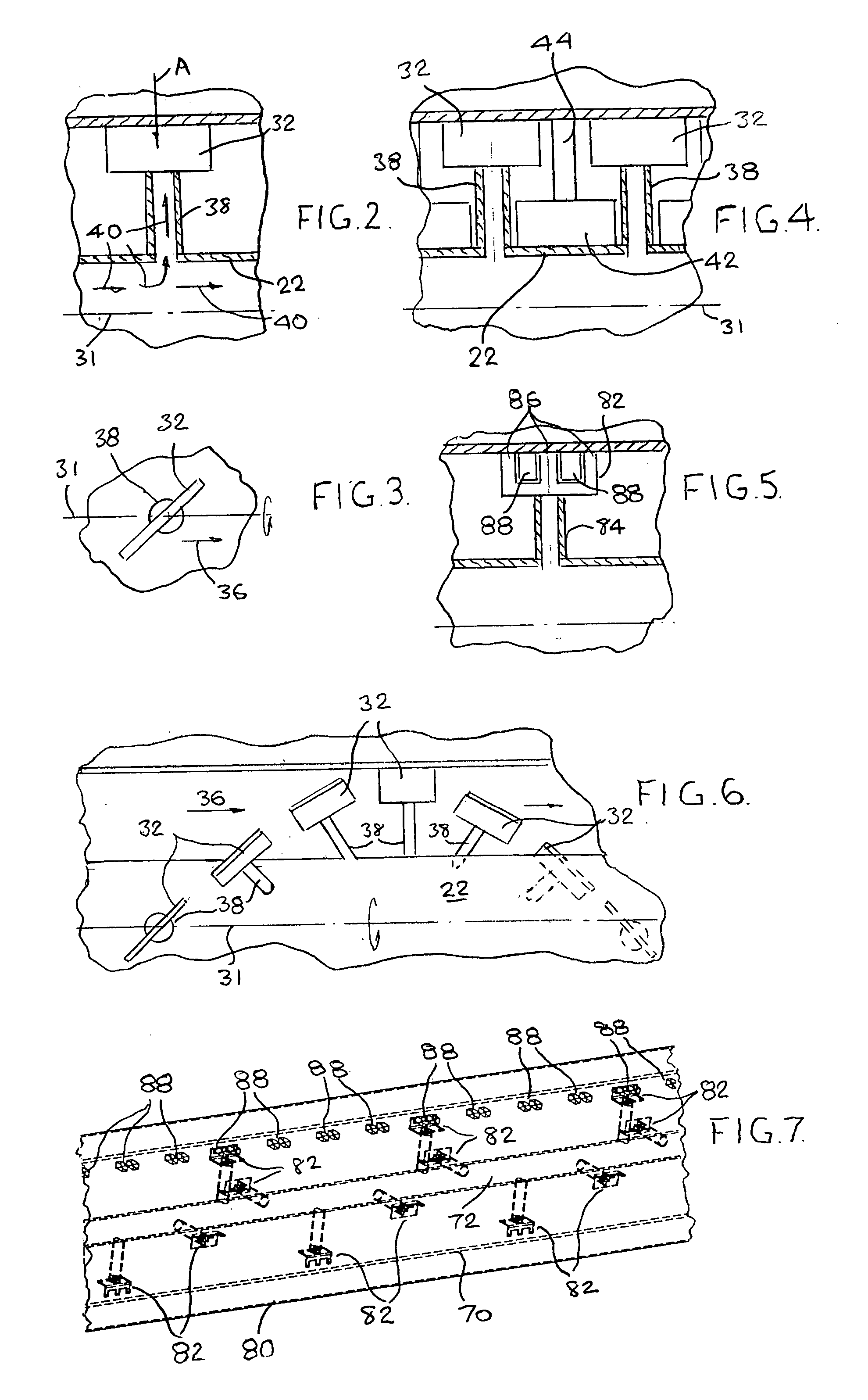

Quench chamber assembly for a gasifier

InactiveUS20100325954A1Avoid shakingGasifier mechanical detailsGas purification by liquid washingSyngasCombustion chamber

A gasifier includes a combustion chamber in which a combustible fuel is burned to produce a syngas and a particulated solid residue. A quench chamber having a liquid coolant is disposed downstream of the combustion chamber. A dip tube is disposed coupling the combustion chamber to the quench chamber. The syngas is directed from the combustion chamber to the quench chamber via the dip tube to contact the liquid coolant and produce a cooled syngas. A draft tube is disposed surrounding the dip tube such that an annular passage is formed between the draft tube and the dip tube. An asymmetric or symmetric baffle is disposed proximate to an exit path of the quench chamber. The cooled syngas is directed through the annular passage and impacted against the asymmetric or symmetric baffle so as to remove entrained liquid content from the cooled syngas before the cooled syngas is directed through the exit path.

Owner:GENERAL ELECTRIC CO

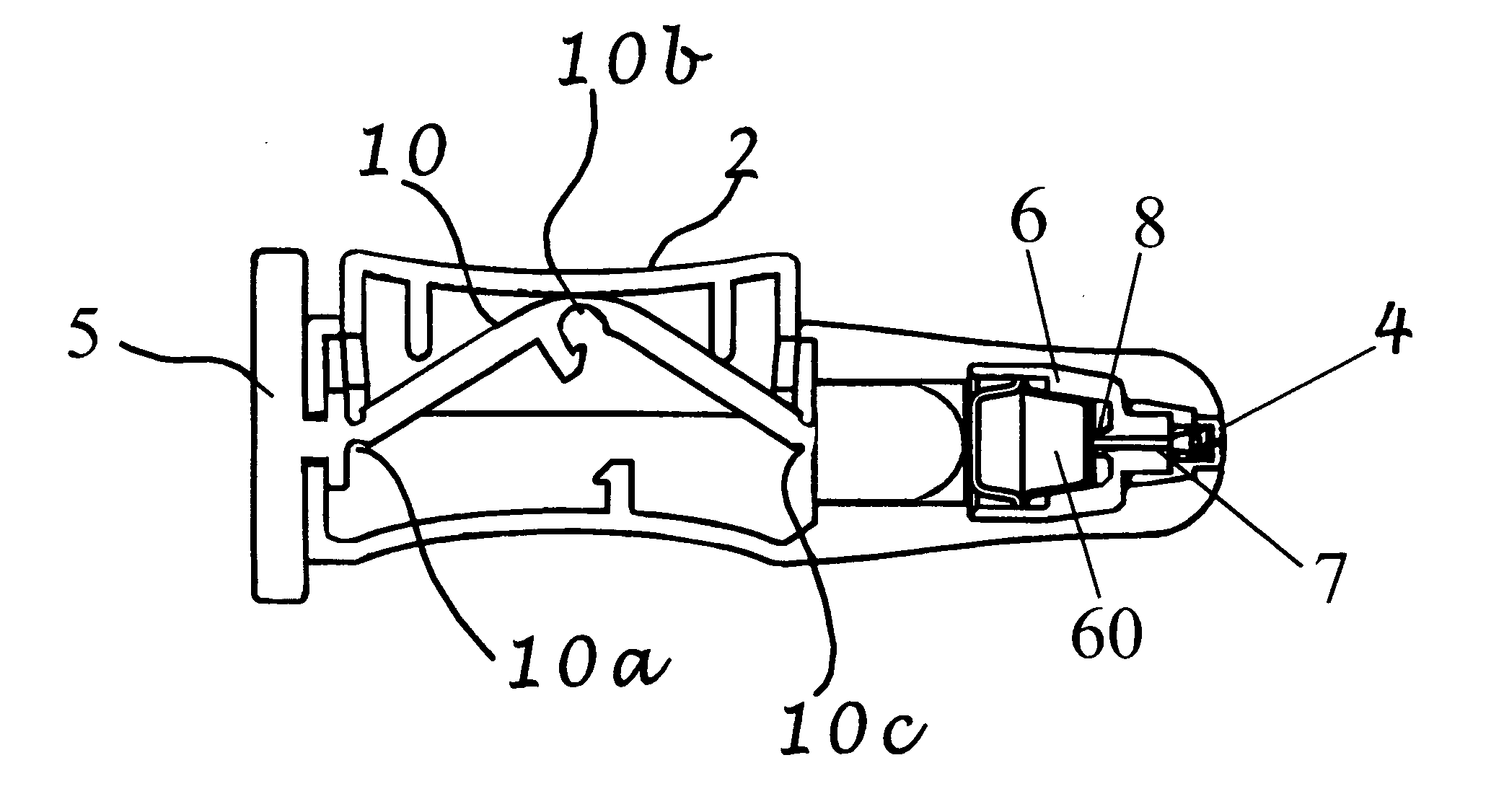

Dispensing Capsule

ActiveUS20100200437A1Minimizing failure of sealOvercomes shortcomingLiquid transferring devicesRigid containersHand heldBottle

A dispensing capsule and method for use thereof, wherein the dispensing capsule is preferably pre-loaded during time of manufacture with a selected dry or liquid ingredient to facilitate subsequent consumer use. The dispensing capsule comprises an apertured housing removably-engagable to the opening of a bottle or container containing a fluid. Preloaded ingredients contained within a cavity in the housing may be introduced or discharged into the bottle by simply depressing a button on the diaphragm of the housing, thereby actuating a breakaway plunger to open an aperture in the opposing base plate of the housing, permitting the contents to flow through the aperture and into the liquid contents of the bottle. The combined contents and liquid within the bottle may subsequently be agitated (e.g., shaken or mixed) without fear or risk of leakage or spillage. A hand held dispensing capsule is also disclosed.

Owner:GENESEE REGIONAL BANK

Sludge dryer

InactiveUS20050000108A1Avoid lostPrevent partial lossDrying solid materials without heatRotary drum furnacesSludgeEvaporation

Owner:RAGNARSSON ANDERS T

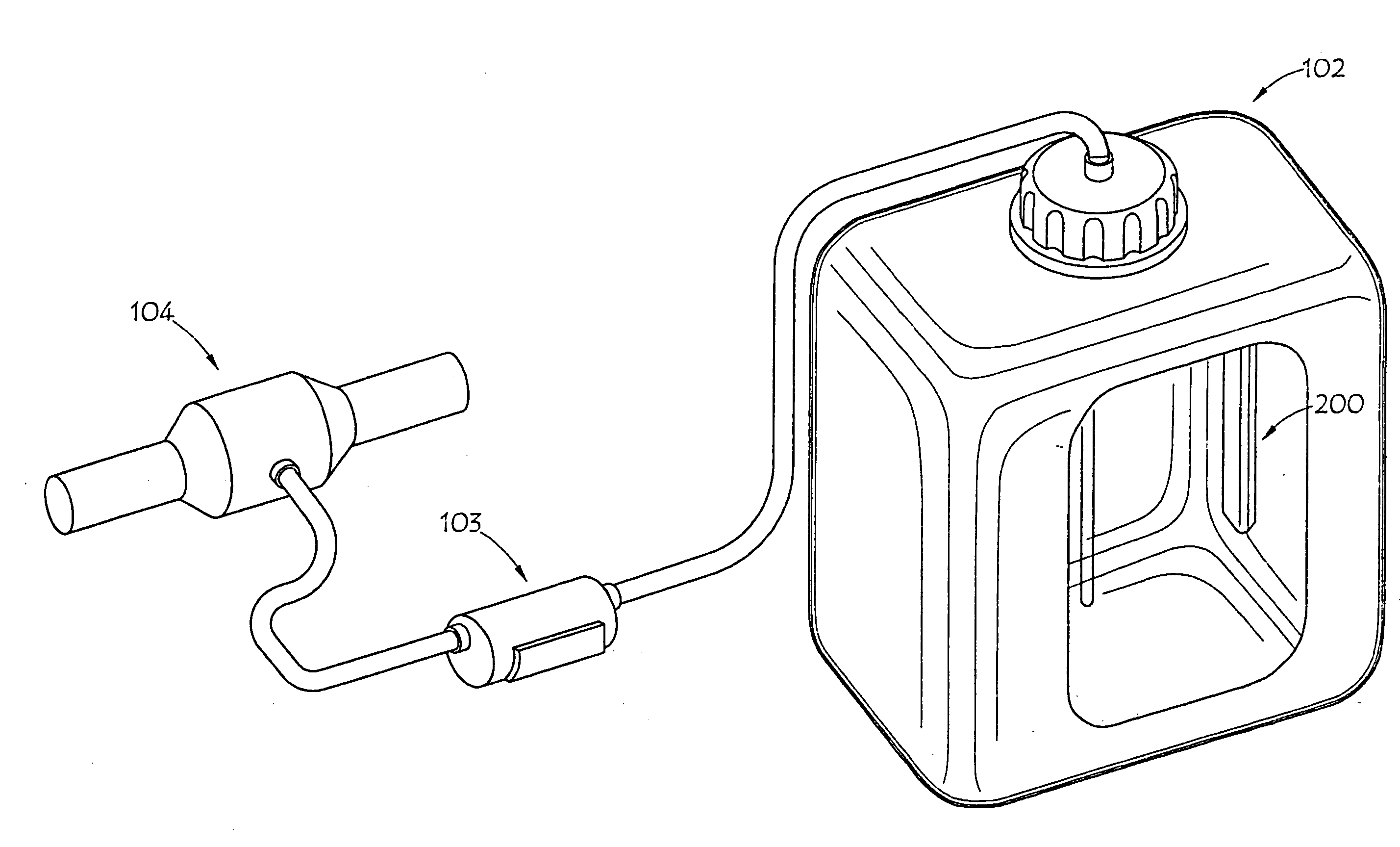

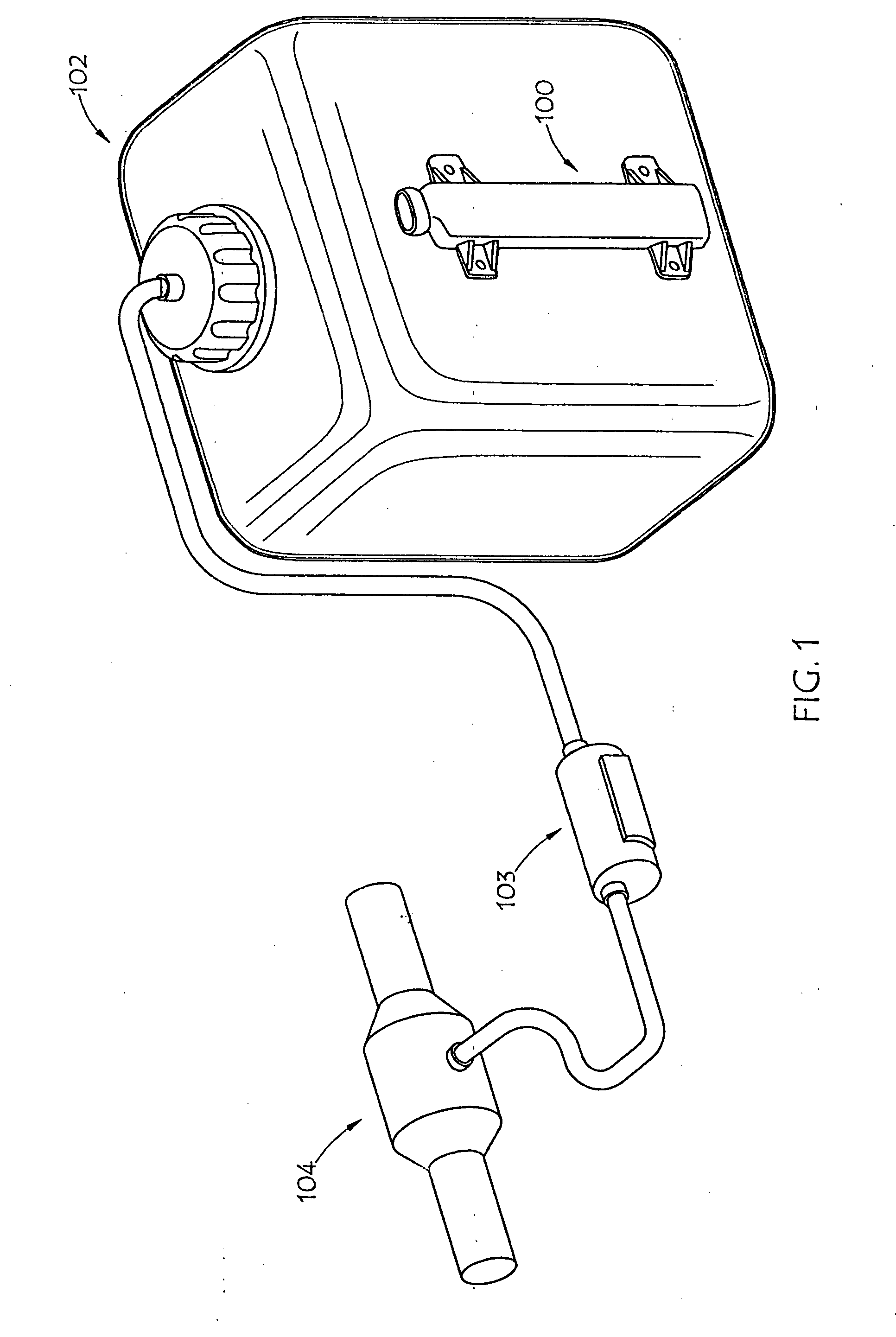

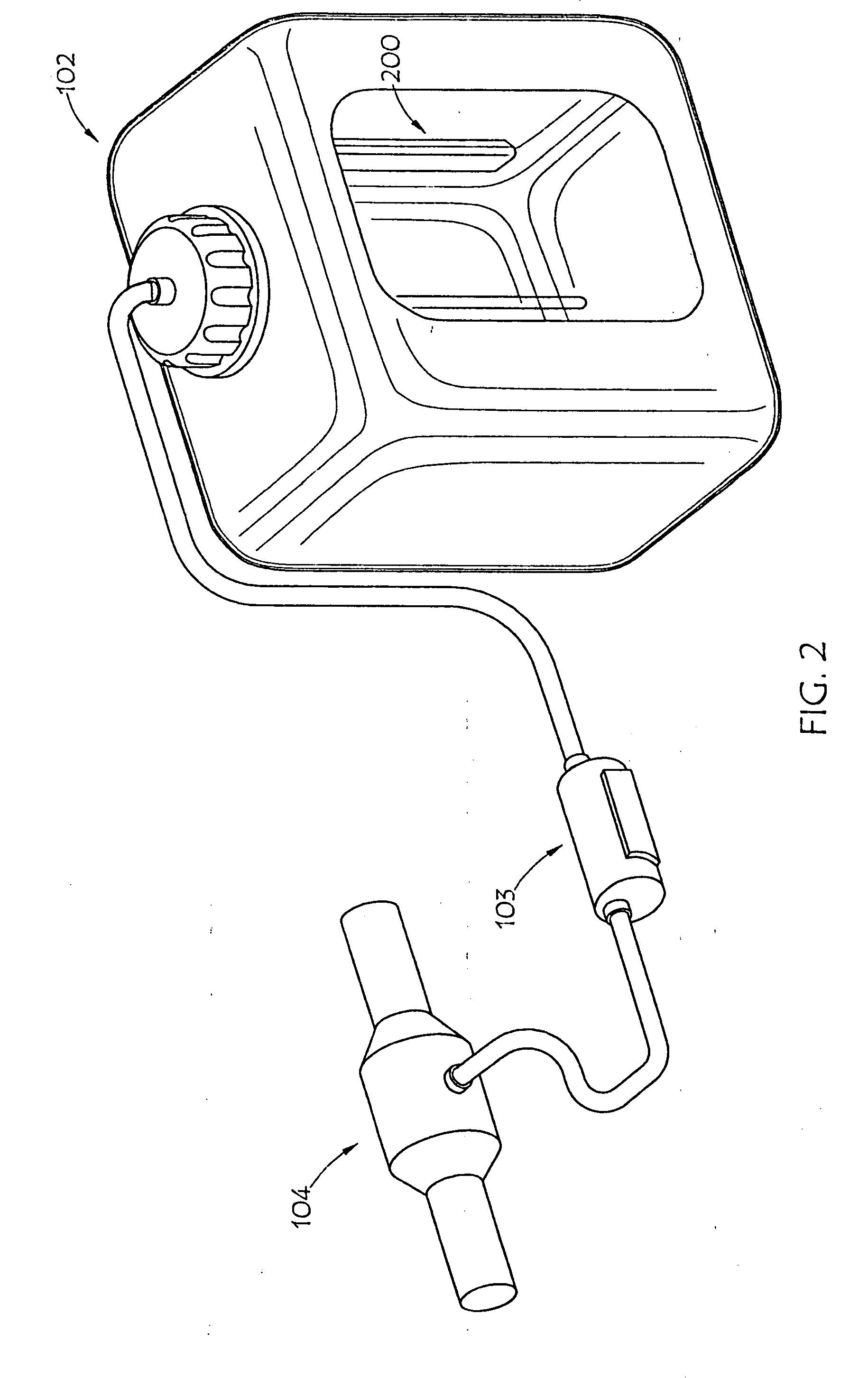

Closed loop dispensing system

InactiveUS6968983B2Prevent backflowAvoid flowLiquid flow controllersLiquid transferring devicesClosed loopEngineering

A closed loop dispensing system for use on a liquid container such as a bottle or the like for dispensing the liquid contents from the bottle. The outlet opening of the bottle is closed by a throat plug having a valve positioned therein which is open when the container cap is mounted on the container, but which automatically closes when the cap is removed from the container. An inlet opening is provided in the container insert so that liquid may be drawn therethrough. A closure cap is mounted on the bottle and has a dispensing tube extending therefrom for dispensing liquid from the container to a mixing machine or the like. A check valve is associated with the cap for preventing backflow from the dispensing tube to the container and for permitting liquid flow from the container to the dispensing tube in response to suction being applied to the dispensing tube. A precise discharge metering orifice is provided in the valve body as a substitution for proportioners which are normally located downstream of the dispensing system. A valve permits ambient air to enter the interior of the container as liquid is drawn therefrom. The valve prevents the flow of liquid therethrough.

Owner:RD IND INC

Liquid level and quality sensing apparatus, systems and methods using EMF wave propagation

InactiveUS20100327884A1Reduce and negate dependenceReduce and eliminate effectInternal combustion piston enginesResistance/reactance/impedenceResonanceRefractive index

A liquid level, composition and contamination sensor generates an RF signal across a resonant circuit that includes a variable inductor and capacitor. The resulting electromagnetic radiation is propagated into the liquid and changes in impedance and resonance of the resonant circuit that result from changes in the conductivity and dielectric properties of the liquid, which are proportional to liquid content and volume, are detected. The conductivity and dielectric properties of the liquid are measured, based on the changed impedance and resonance of the resonant circuit, and are compared to determine aging and contamination of the urea solution by other liquids. Also, an optical sensor may be submerged in the liquid to determine the refractive index of the liquid. The refractive index of the liquid may be used to determine: if the liquid is water or a urea solution; the concentration of a urea solution.

Owner:SCHRADER ELECTRONICS LTD

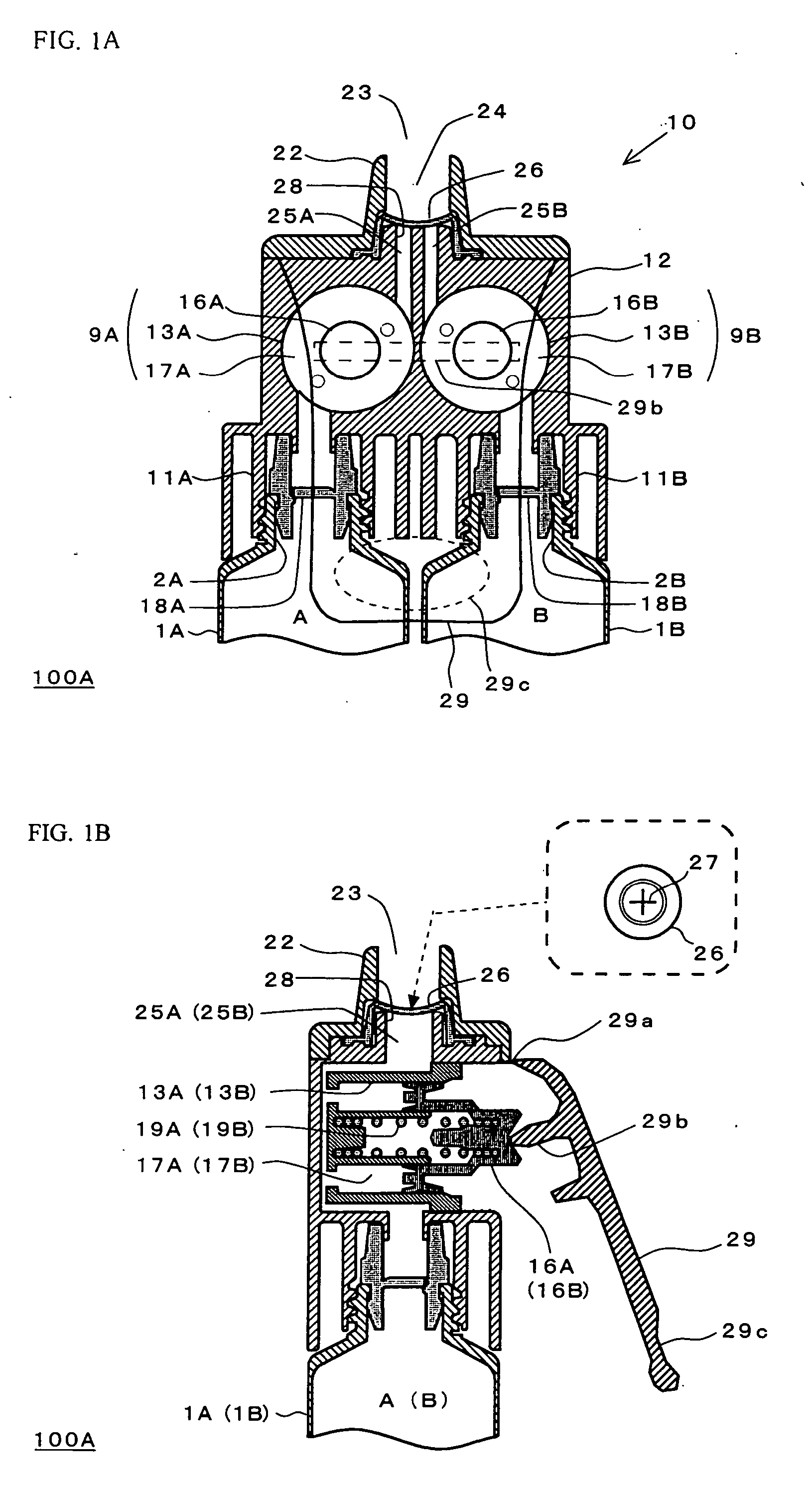

Dispensing device

InactiveUS20060163282A1Easy to operateAvoid mixingBrushesLiquid transferring devicesLiquid contentVALVE PORT

A dispensing device including a plurality of containers respectively accommodating liquid contents, and a pump device in fluid communication with the plurality of containers. The pump device includes a first cylinder in fluid communication with the first container, a first piston provided inside the first cylinder, a second cylinder in fluid communication with the second container, and a second piston provided inside the second cylinder. The pump device further includes a lever type handle that simultaneously operates the first and second pistons. Liquid content discharge paths being respectively in fluid communication with the cylinders communicate with one discharge valve upstream of a discharge outlet, allowing the liquid contents discharged from each cylinder to pass through the discharge valve to join into one.

Owner:KAO CORP

Method of handling, filling and sealing packaging containers

InactiveUS6256964B1Simplify handling and transportAvoid damage and dirt contaminationOpening closed containersPower operated devicesHermetic packagingProcessing plants

A method of handling, filling and sealing prefabricated packaging containers that are provided with a closure device is disclosed. The packaging containers are transported in the closed state to a processing plant in which the closure device is opened, the packaging container and closure device are sterilized, and thereafter the packaging container is filled with the desired liquid contents. The same closure device that was removed from the packaging container is then reapplied to seal the container.

Owner:TETRA LAVAL HLDG & FINANCE SA

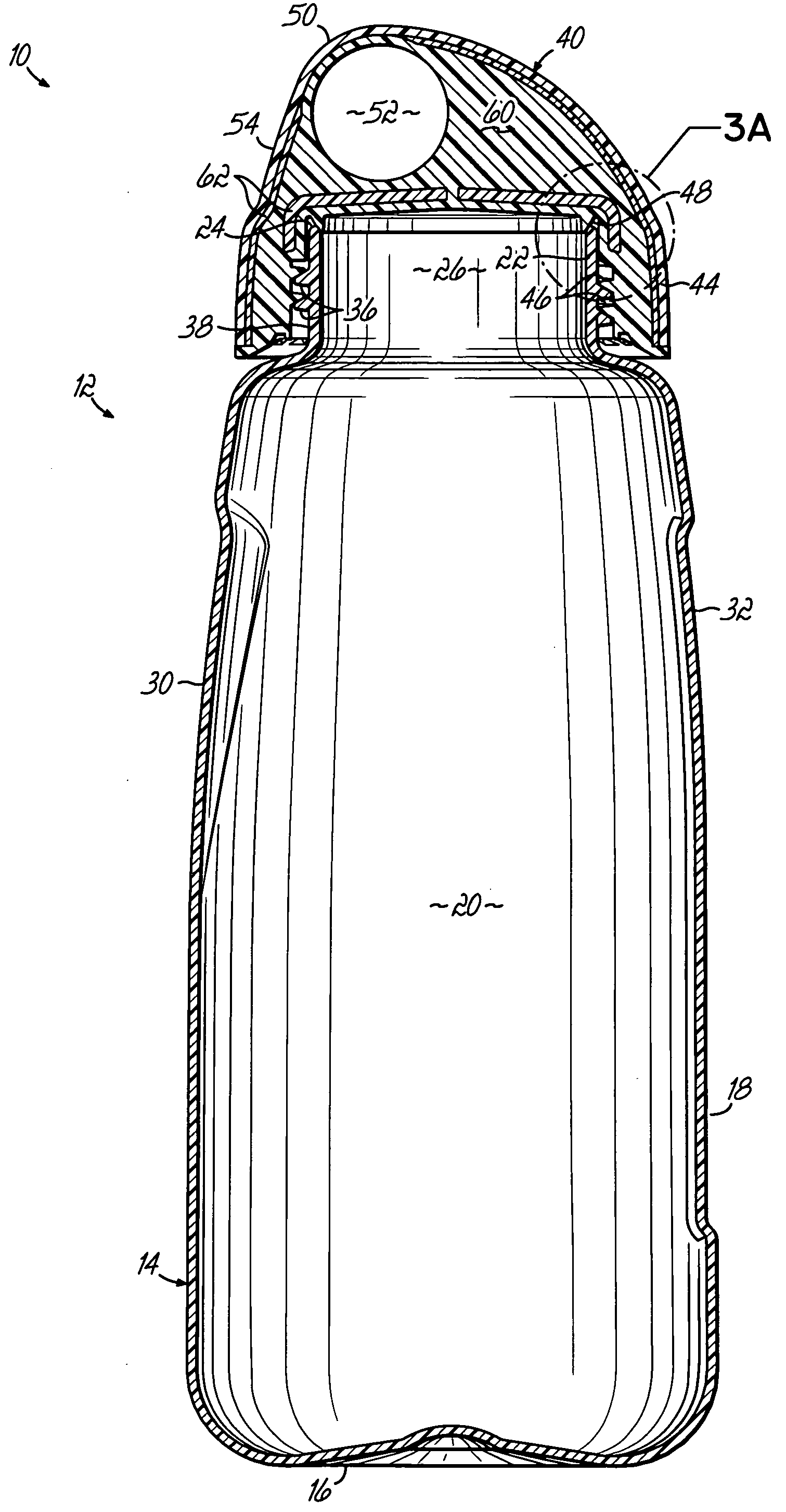

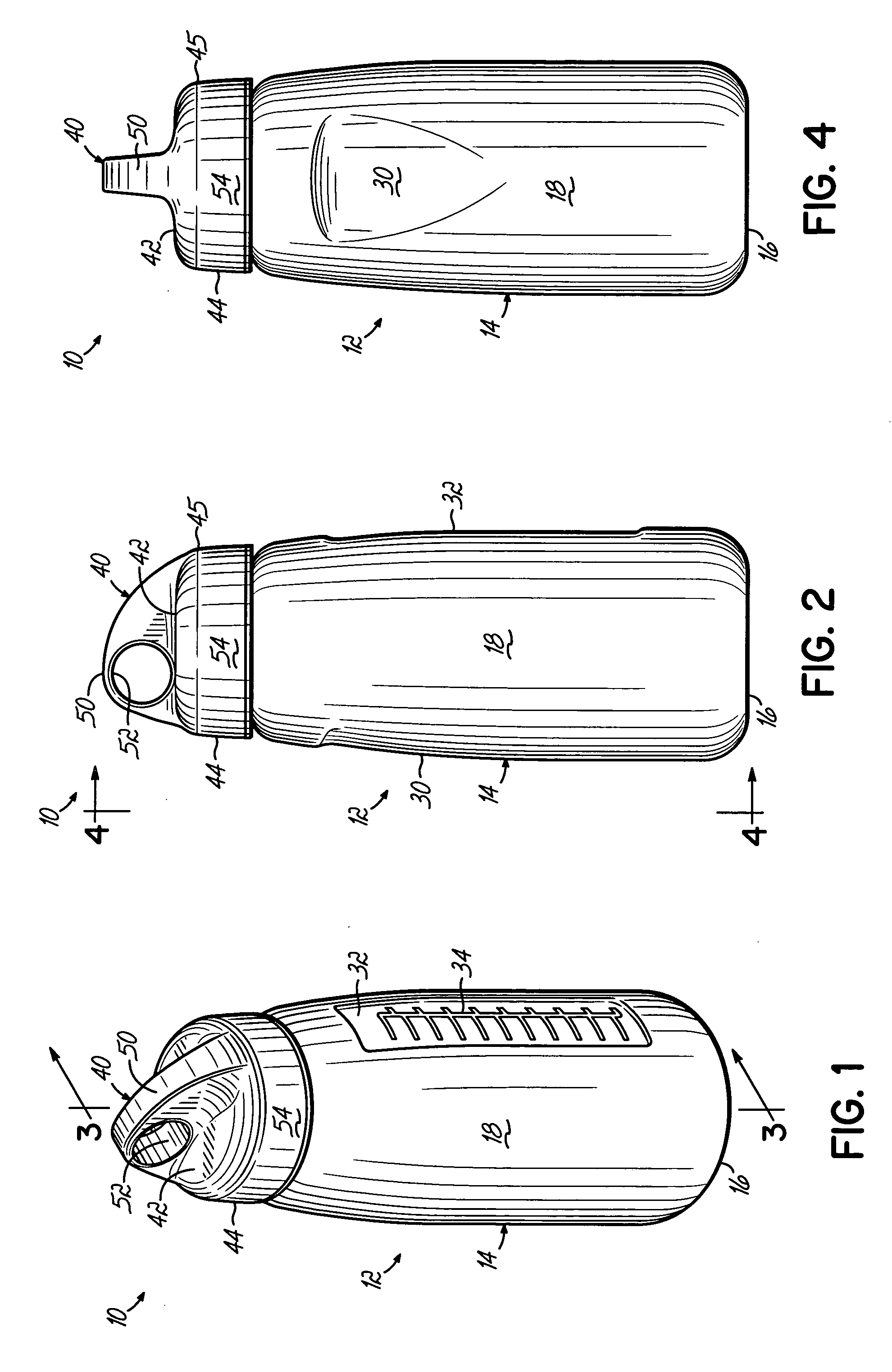

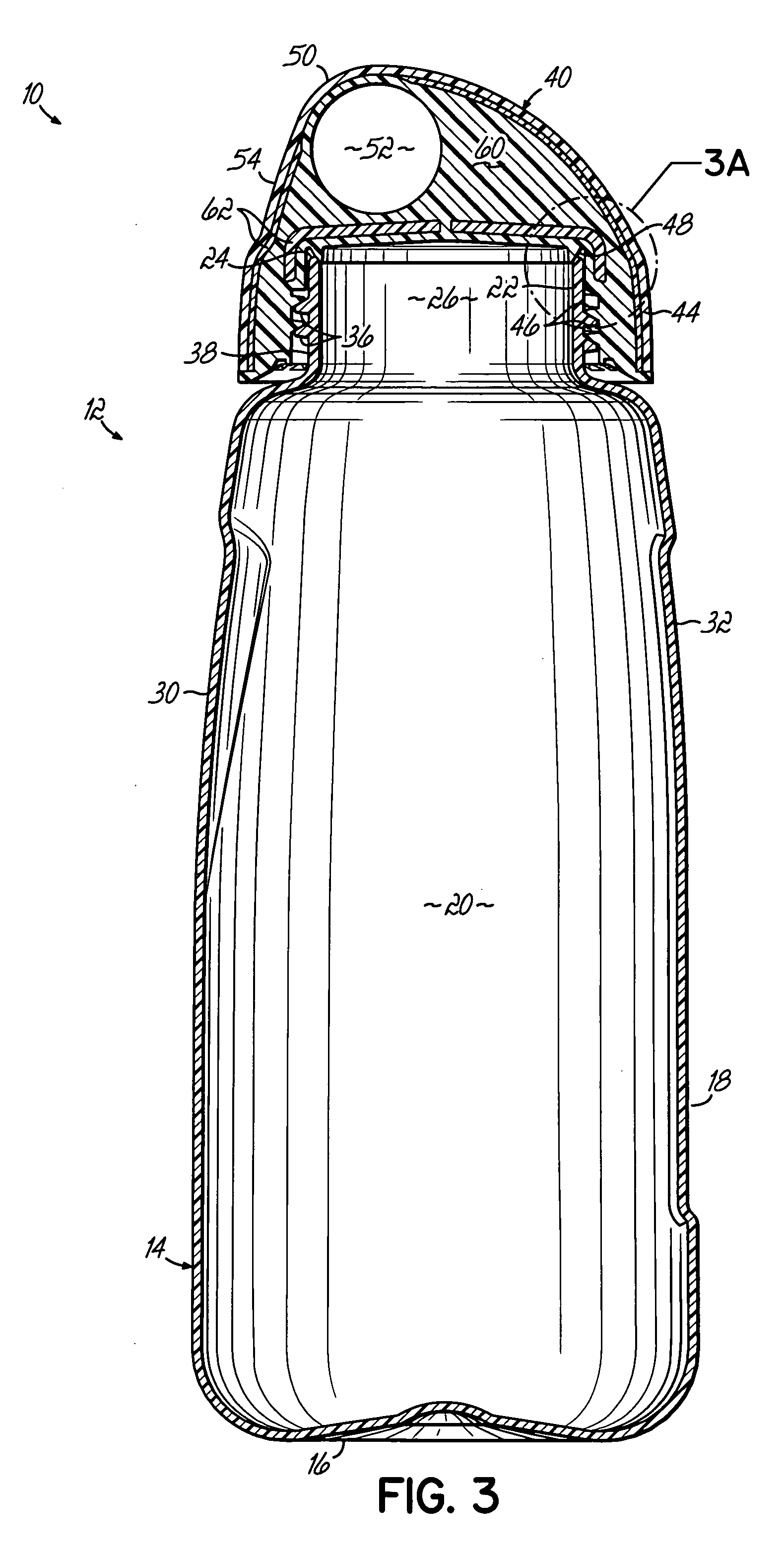

Drinking container with multilayer leak-proof closure

ActiveUS20050115966A1Easy to carryEasy to disassembleCapsClosures with lifting/suspending meansEngineeringBottle

A drinking container comprises a bottle and a permanently leak-proof closure. The bottle is formed with contours that facilitate grasping by a user and has an opening sized to facilitate placing ice cubes into the bottle. Graduations on the sidewall of the bottle provide an indication of the volume of fluid within the bottle. The closure has threads configured to engage corresponding threads on the bottle and has a seal ring for sealing the liquid contents within the bottle. The closure further includes a lobe having an aperture.

Owner:NALGE NUNC INTERNATIONAL

Vial adaptor for regulating pressure

In certain embodiments, a vial adaptor for removing liquid contents from a vial comprises a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial comprises a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com