Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

746 results about "Hermetic packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electronic package is a hermetic housing that protects delicate circuitry for high reliability applications. Often the hermetic housing is the last assembly step before our customers ship their product.

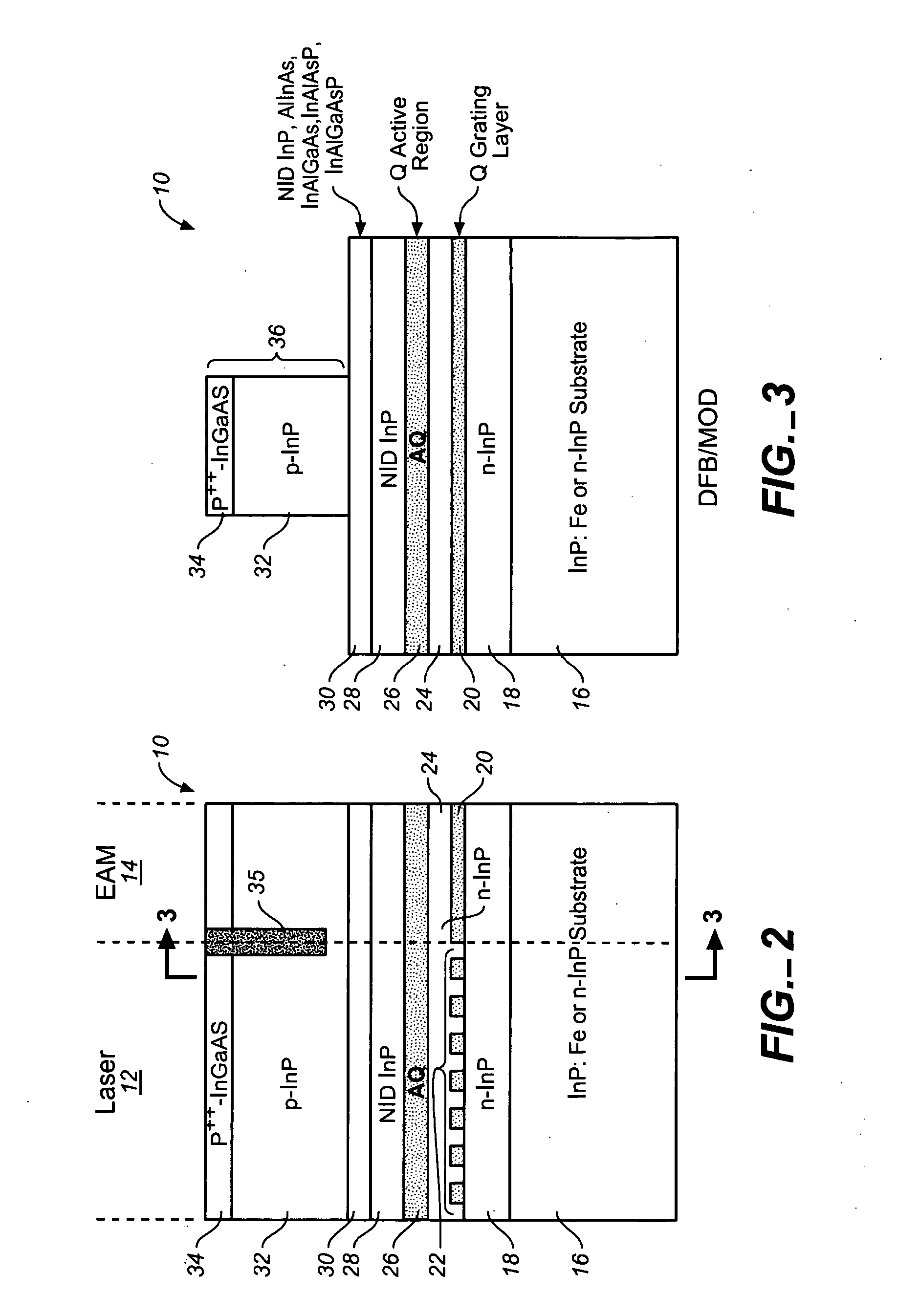

Coolerless photonic integrated circuits (PICs) for WDM transmission networks and PICs operable with a floating signal channel grid changing with temperature but with fixed channel spacing in the floating grid

ActiveUS20050249509A1Requirements for a hermetically sealed package are substantially relievedEasy to controlLaser optical resonator constructionSemiconductor laser arrangementsElectro-absorption modulatorHermetic packaging

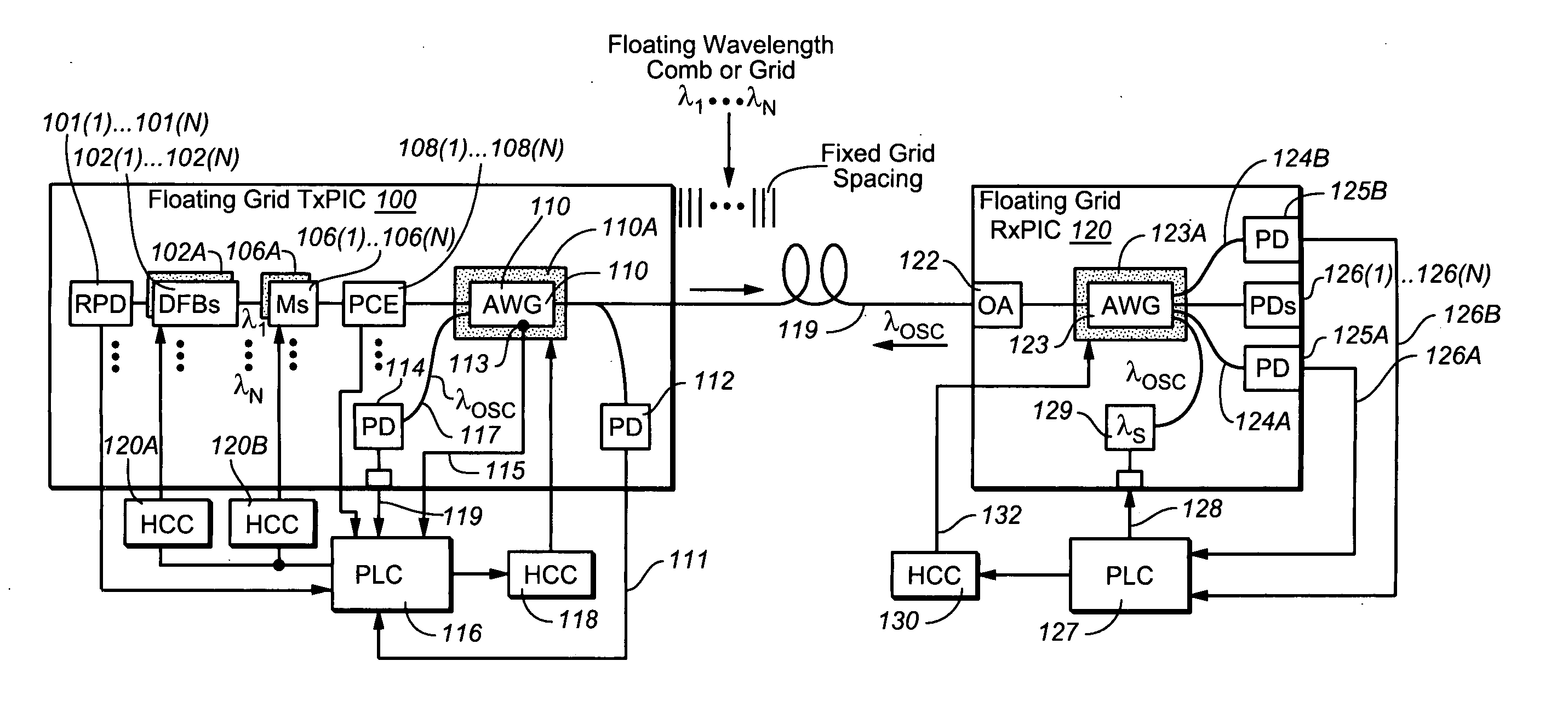

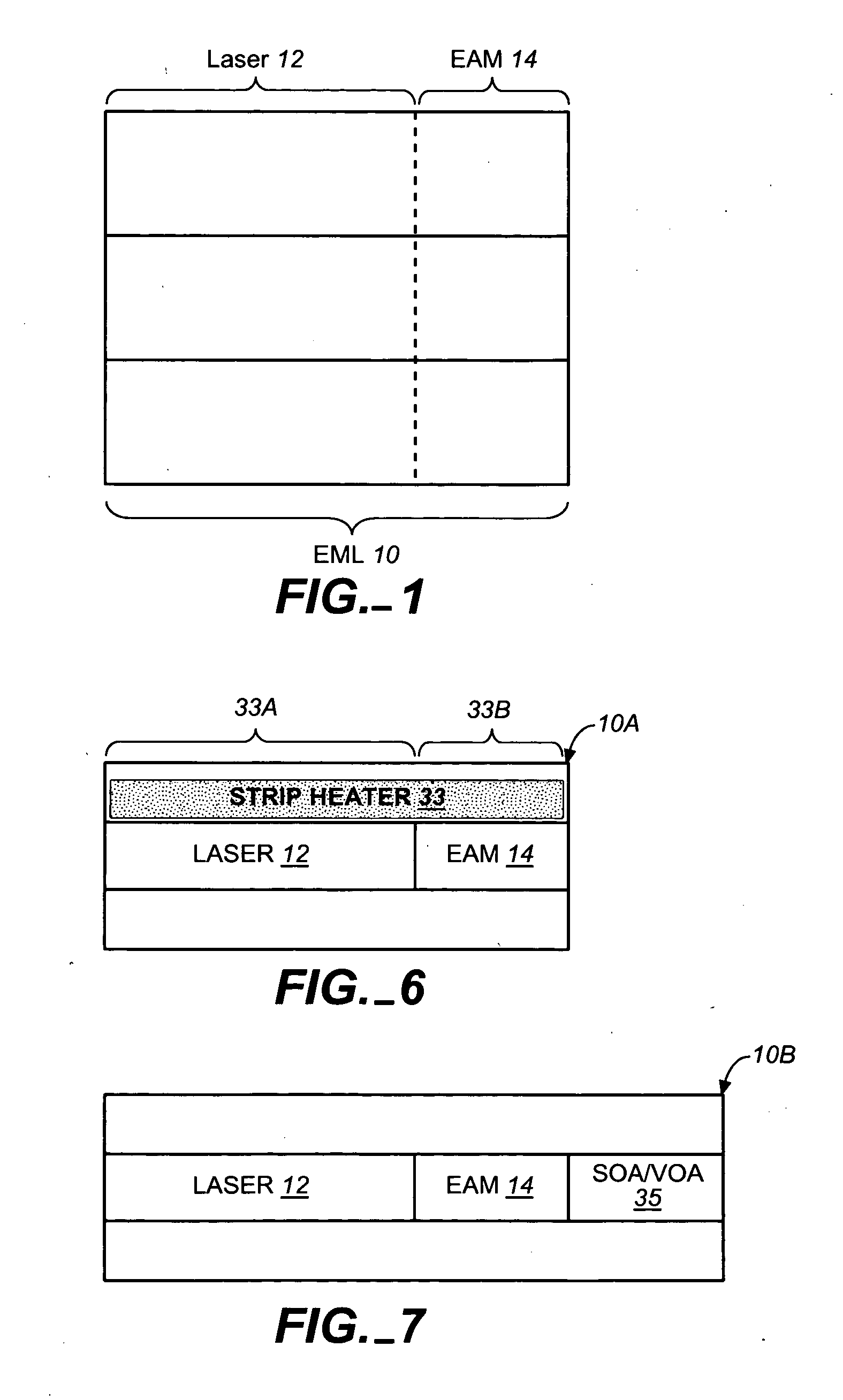

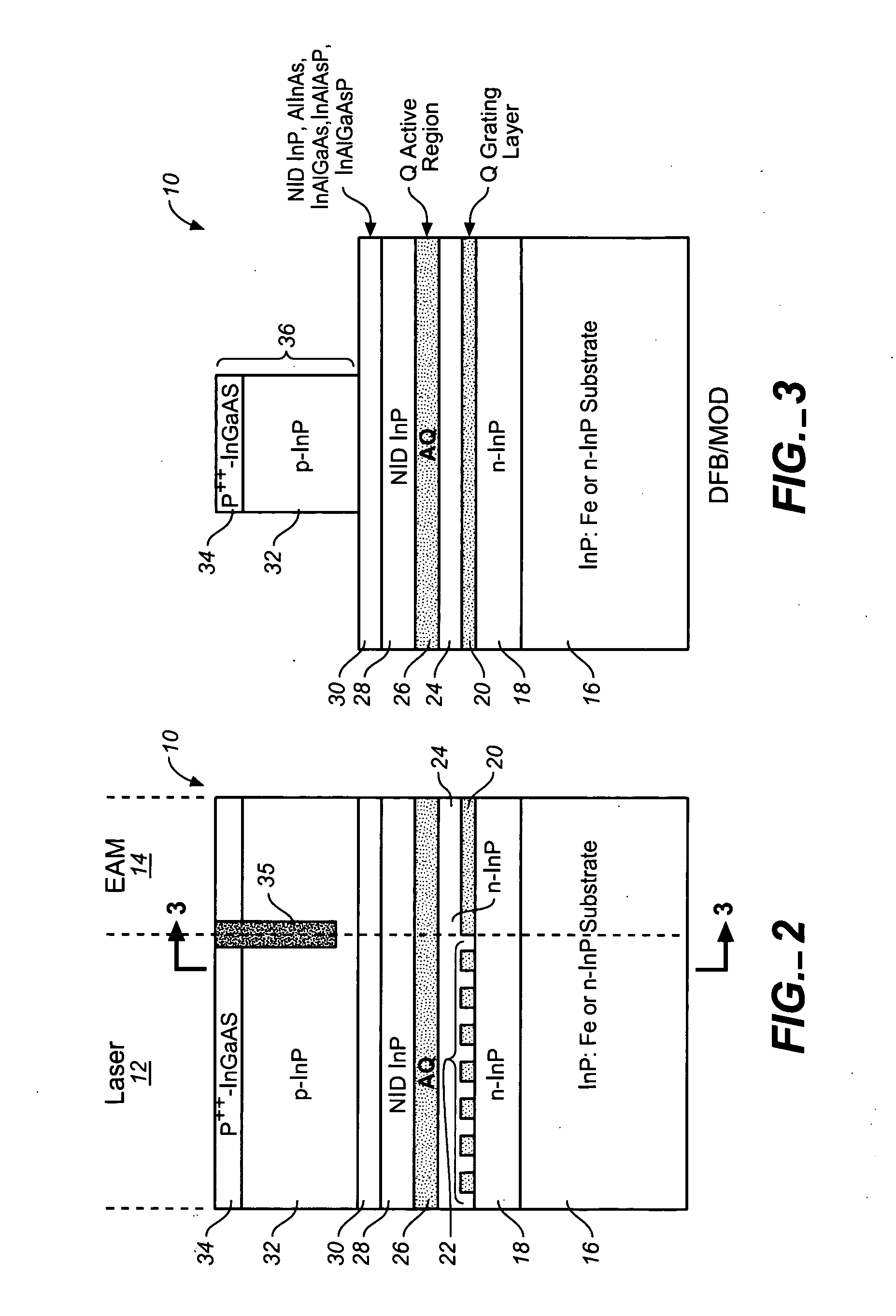

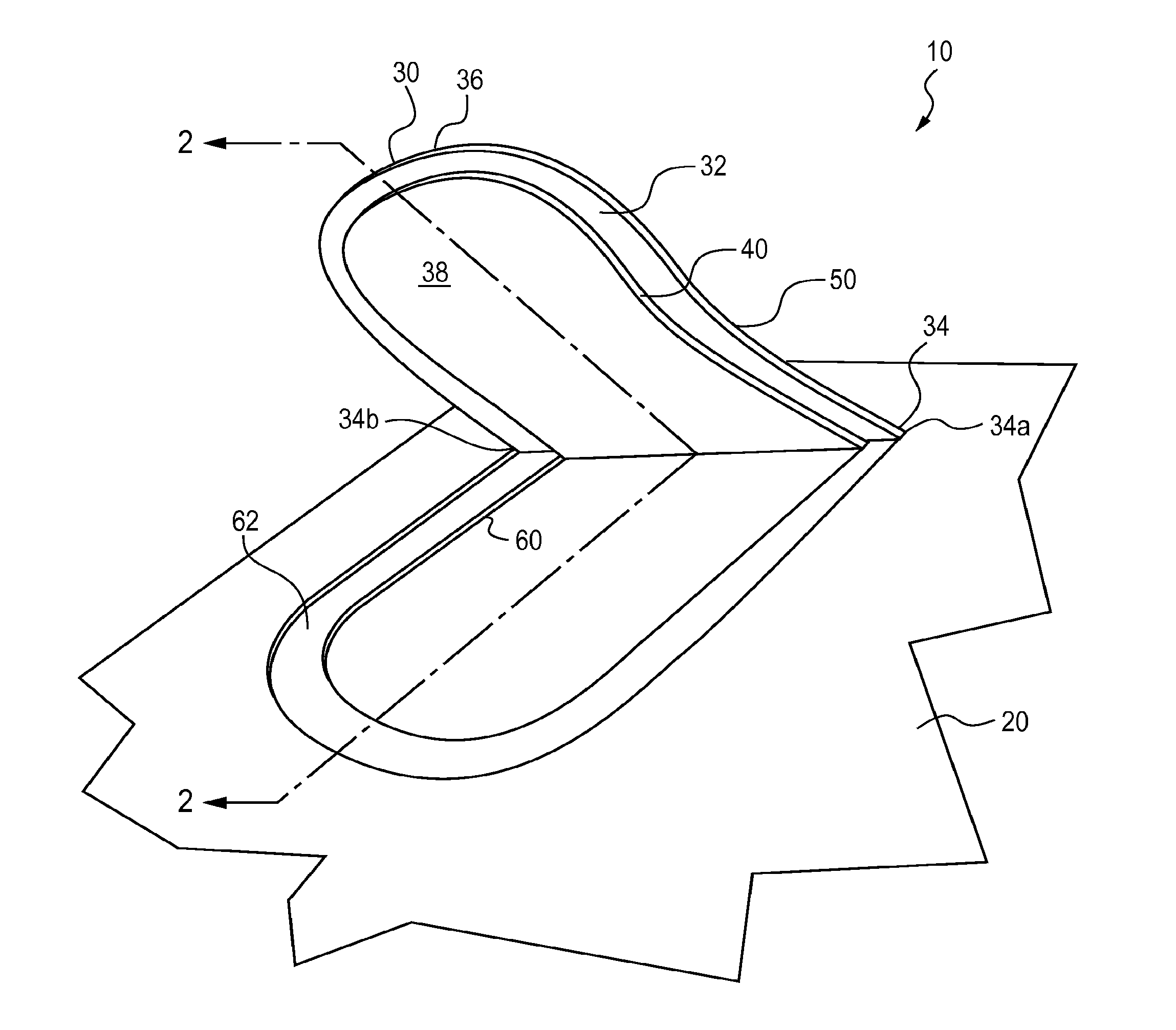

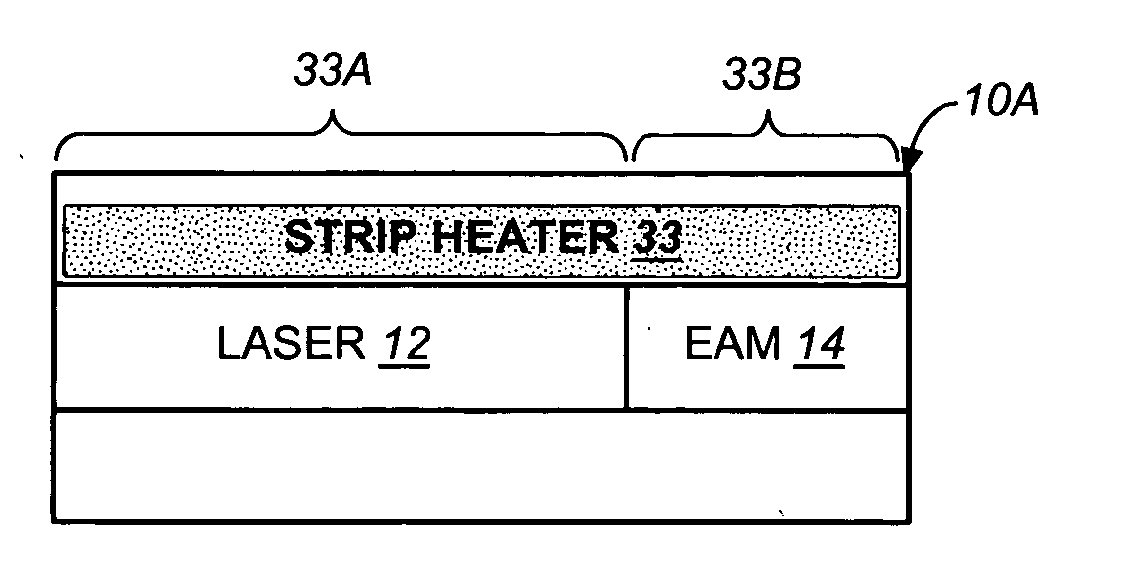

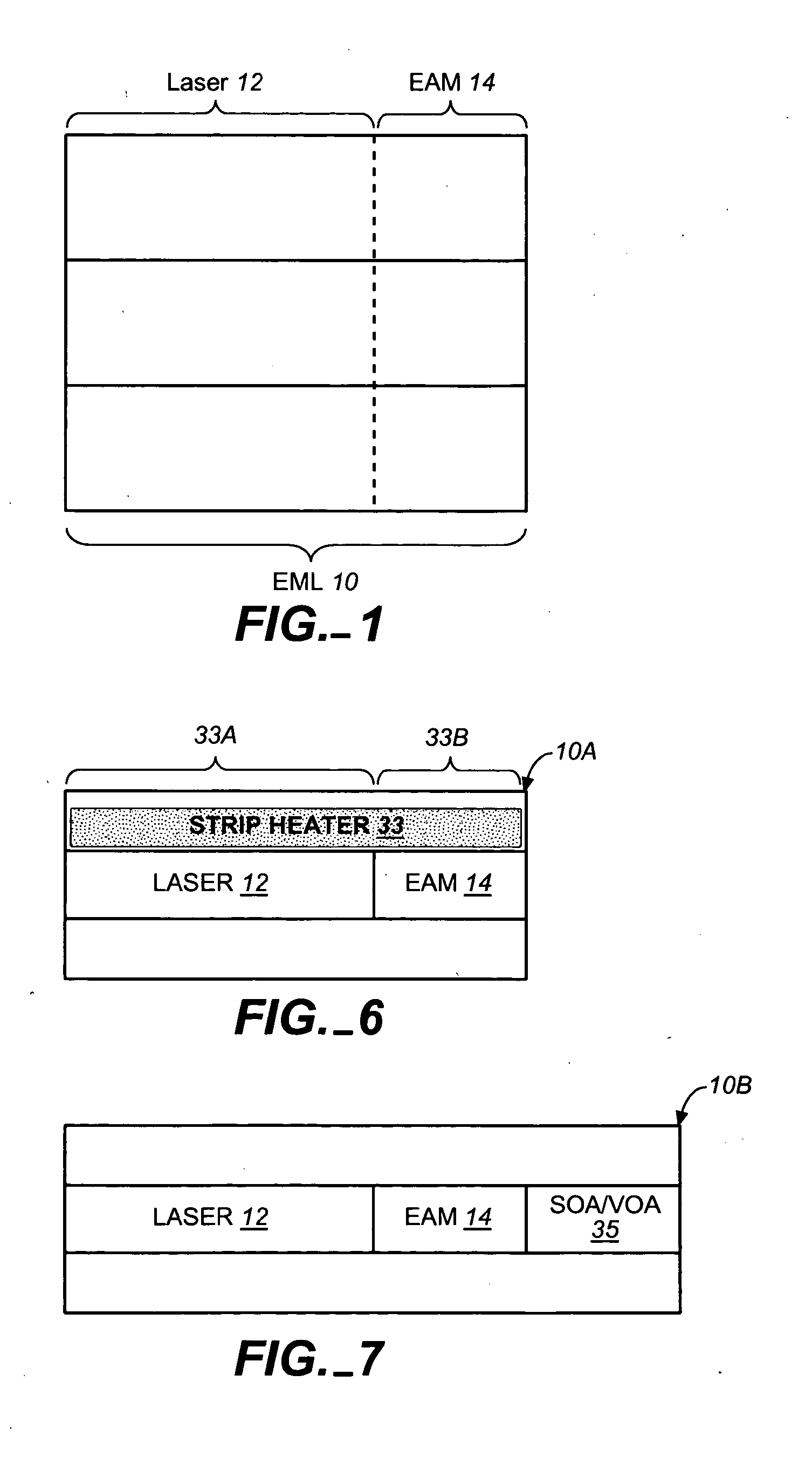

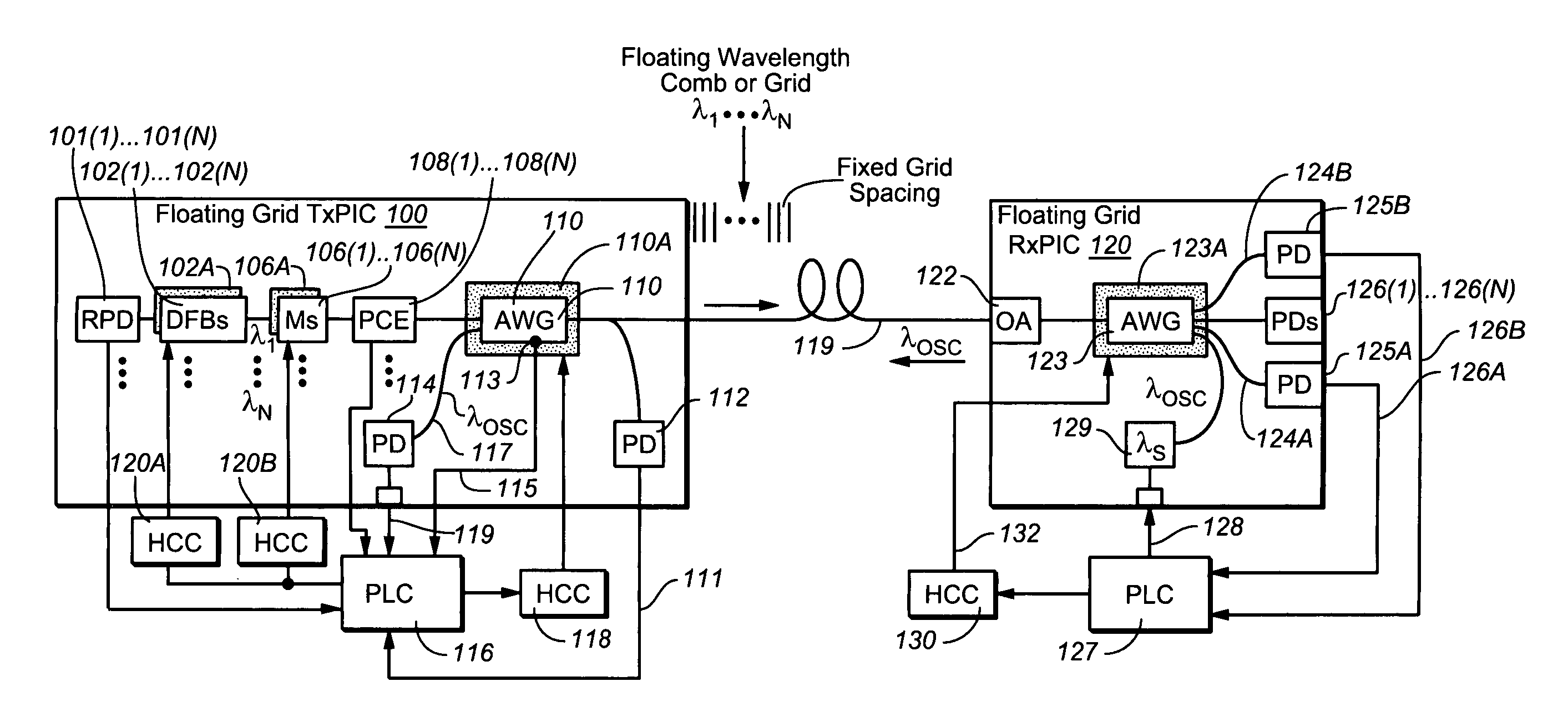

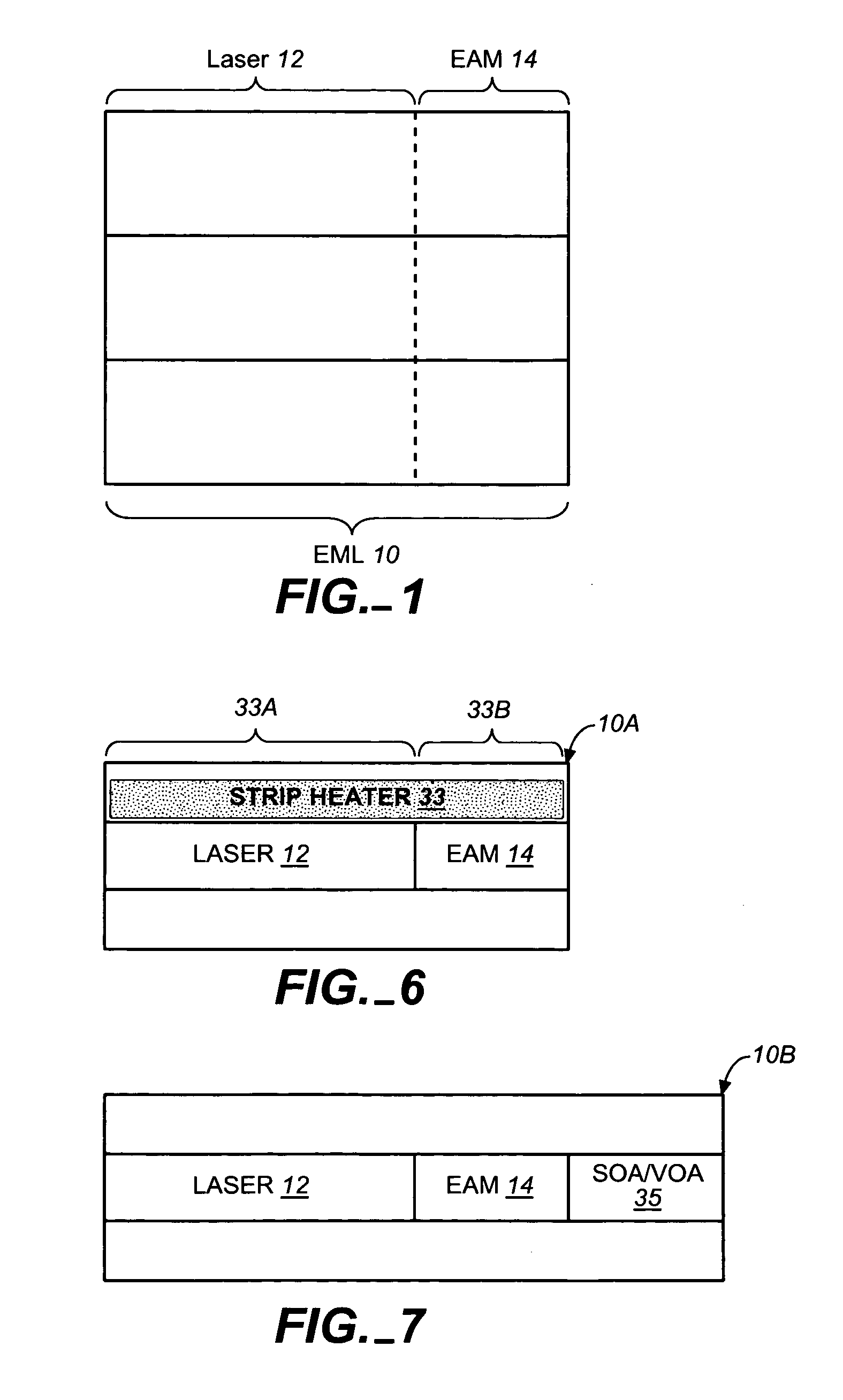

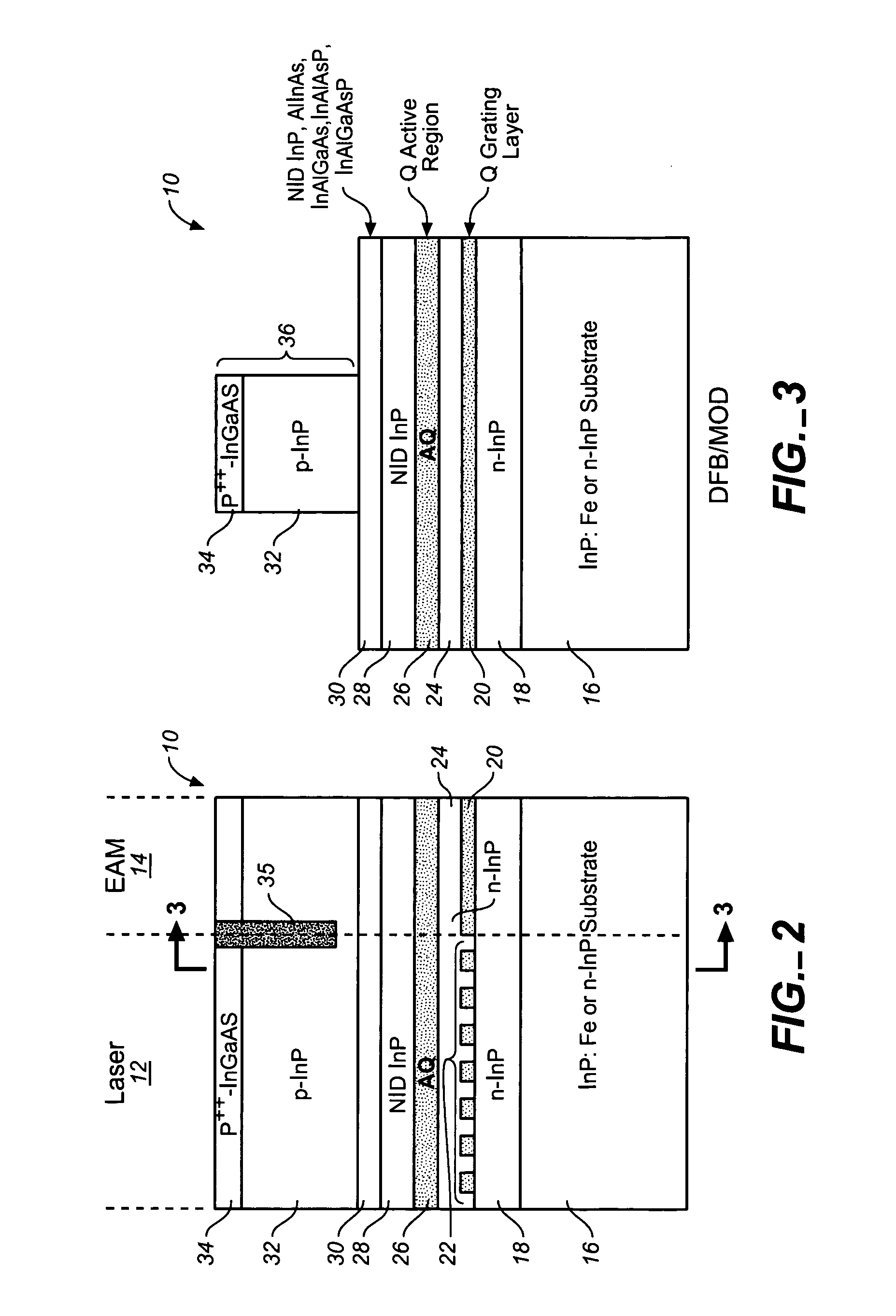

A coolerless photonic integrated circuit (PIC), such as a semiconductor electro-absorption modulator / laser (EML) or a coolerless optical transmitter photonic integrated circuit (TxPIC), may be operated over a wide temperature range at temperatures higher then room temperature without the need for ambient cooling or hermetic packaging. Since there is large scale integration of N optical transmission signal WDM channels on a TxPIC chip, a new DWDM system approach with novel sensing schemes and adaptive algorithms provides intelligent control of the PIC to optimize its performance and to allow optical transmitter and receiver modules in DWDM systems to operate uncooled. Moreover, the wavelength grid of the on-chip channel laser sources may thermally float within a WDM wavelength band where the individual emission wavelengths of the laser sources are not fixed to wavelength peaks along a standardized wavelength grid but rather may move about with changes in ambient temperature. However, control is maintained such that the channel spectral spacing between channels across multiple signal channels, whether such spacing is periodic or aperiodic, between adjacent laser sources in the thermally floating wavelength grid are maintained in a fixed relationship. Means are then provided at an optical receiver to discover and lock onto floating wavelength grid of transmitted WDM signals and thereafter demultiplex the transmitted WDM signals for OE conversion.

Owner:INFINERA CORP

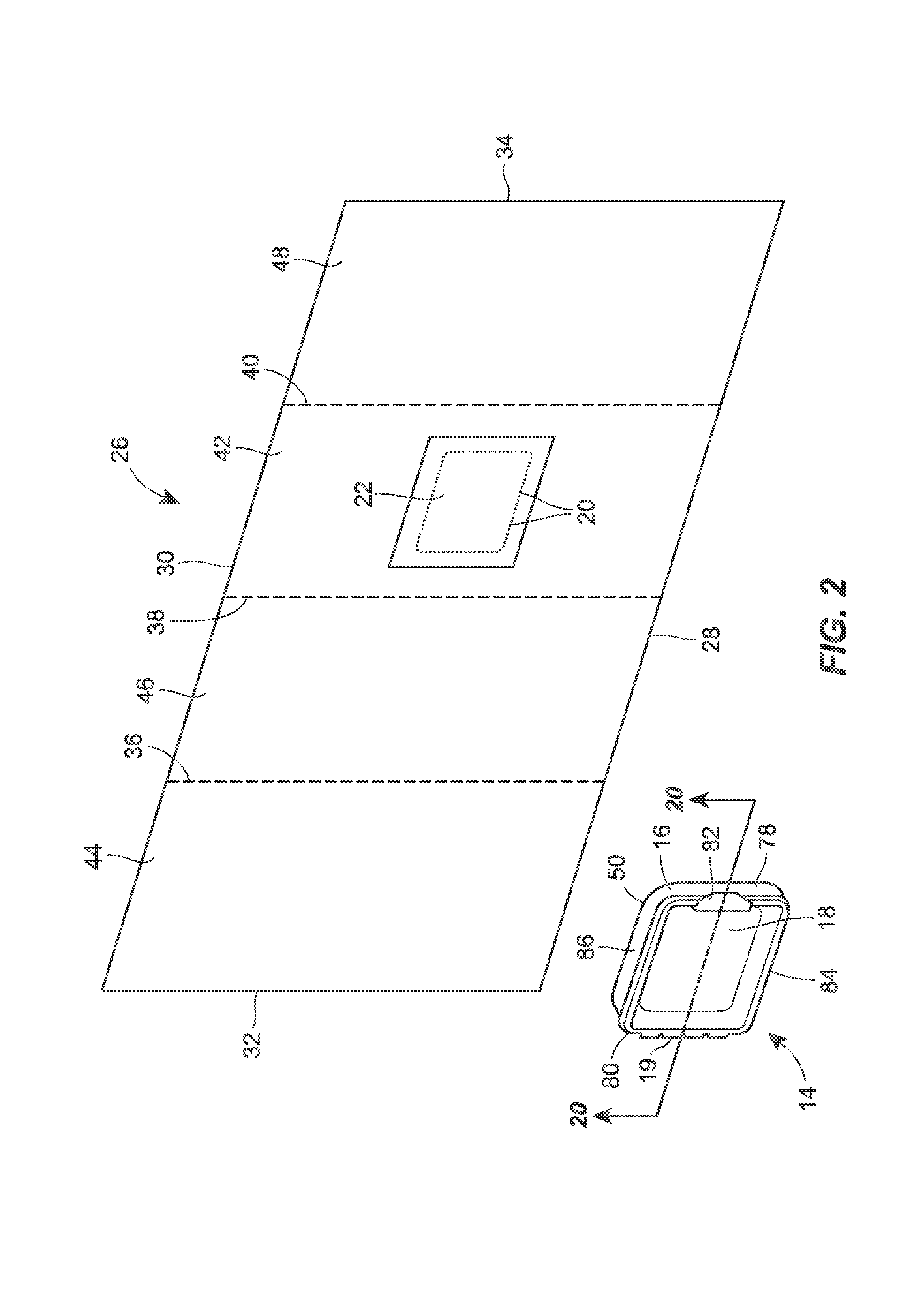

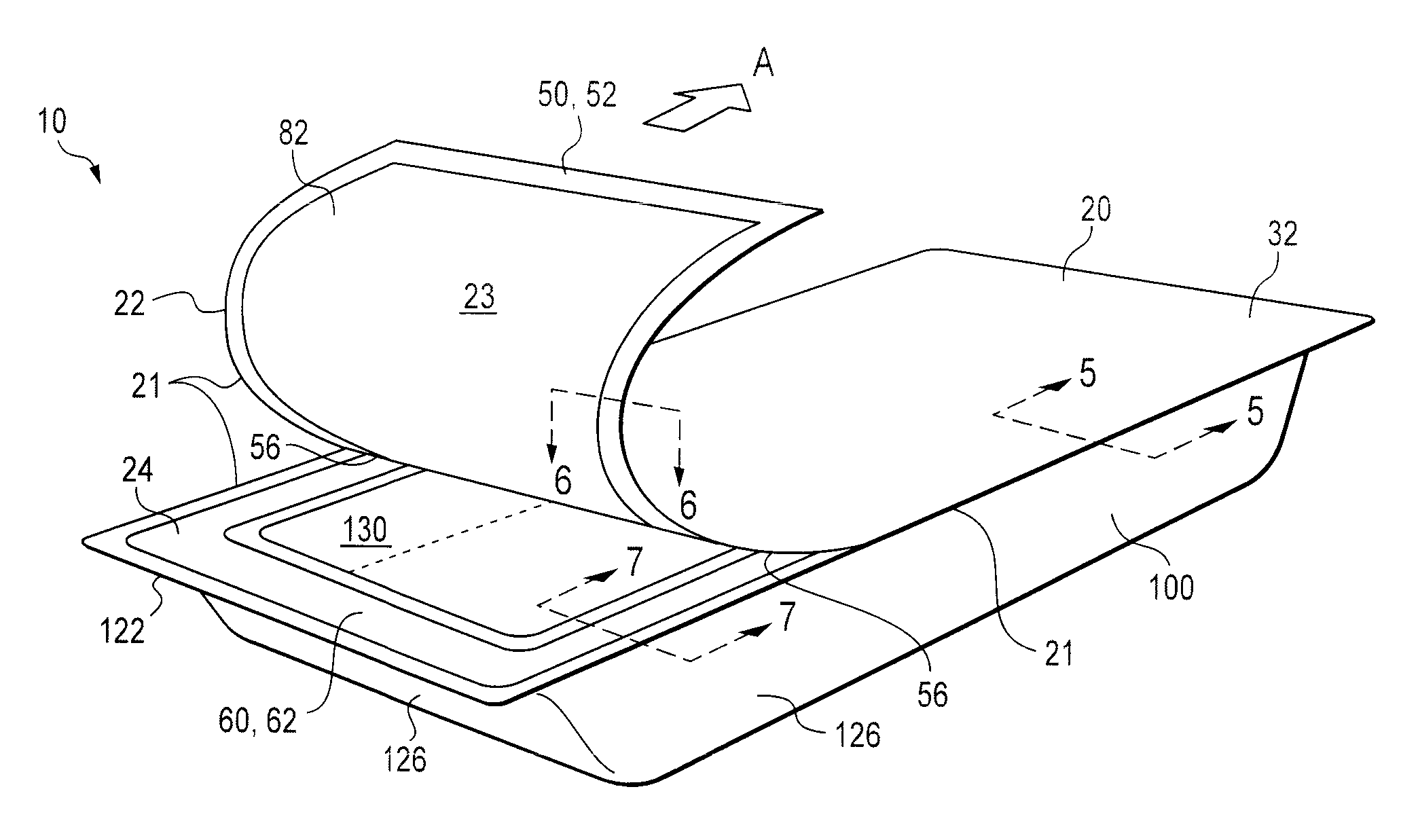

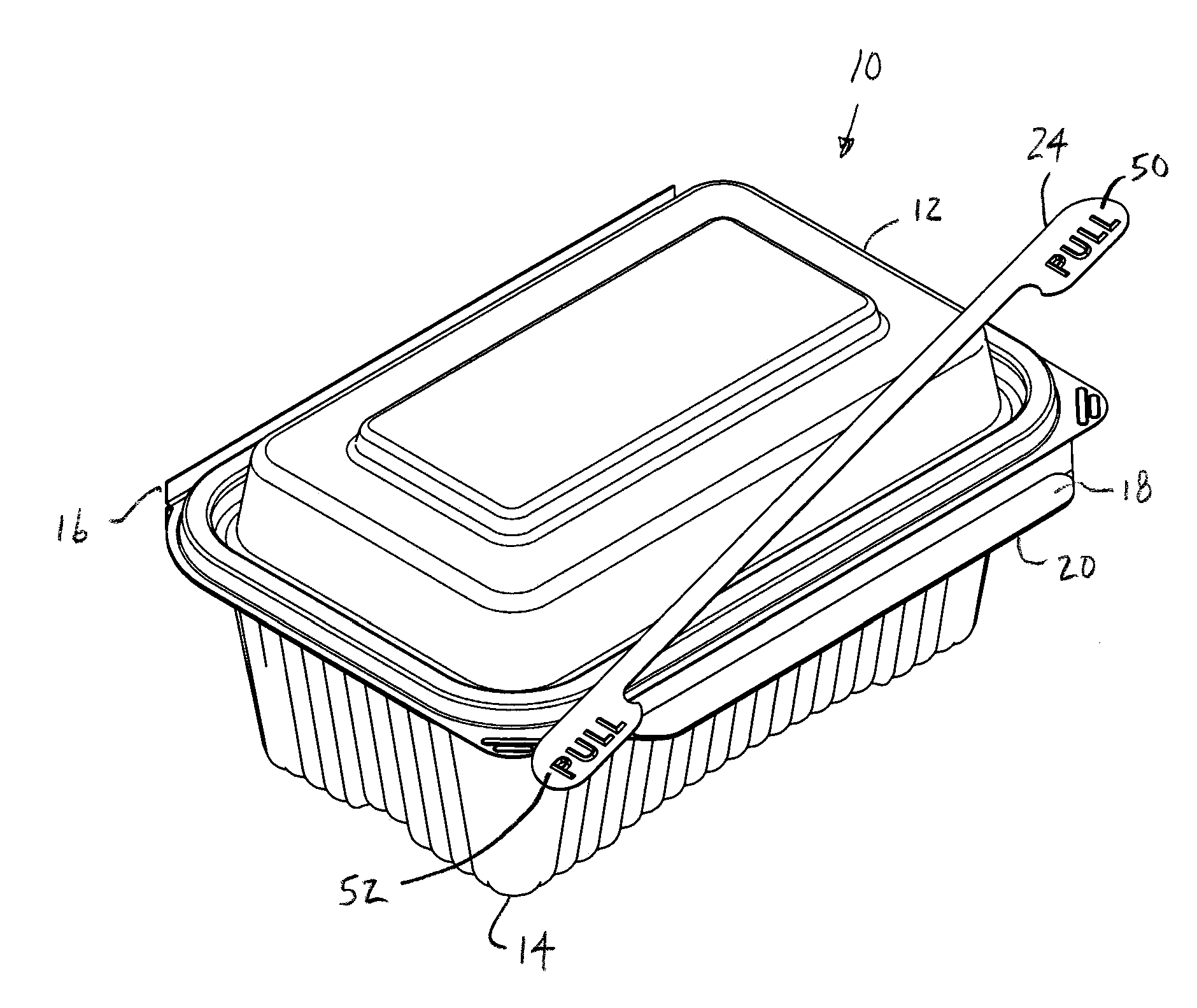

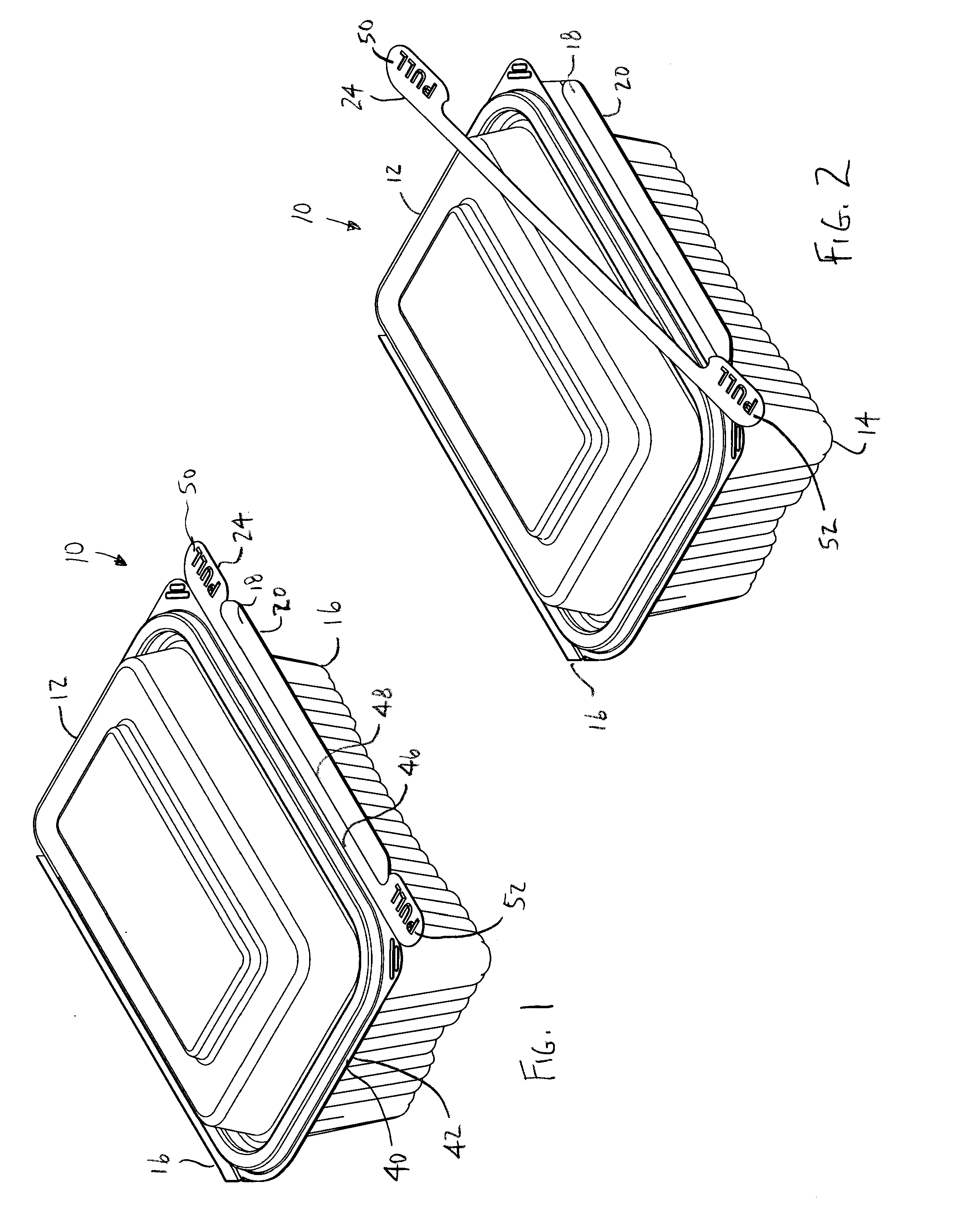

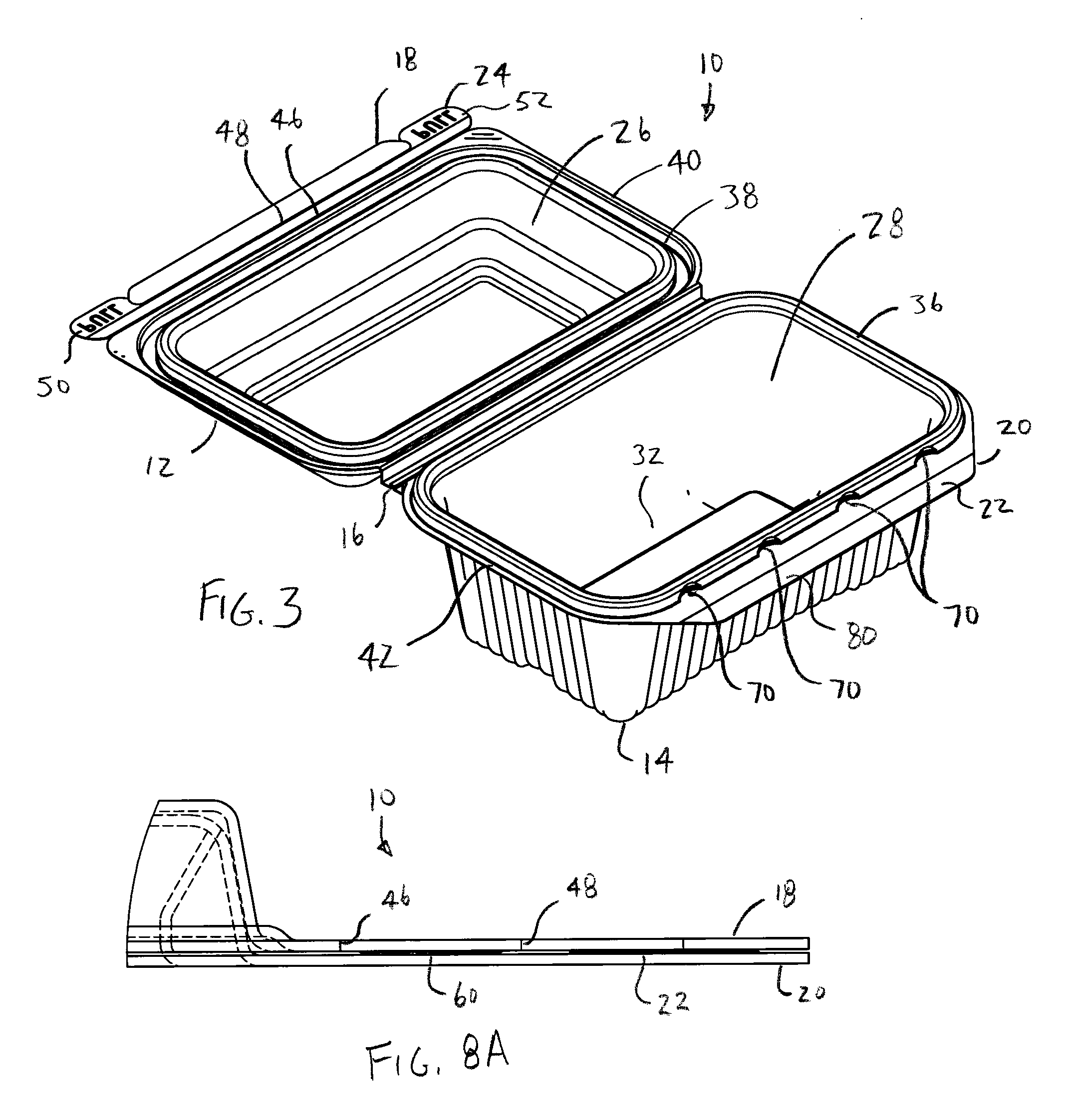

Resealable Laminate for Heat Sealed Packaging

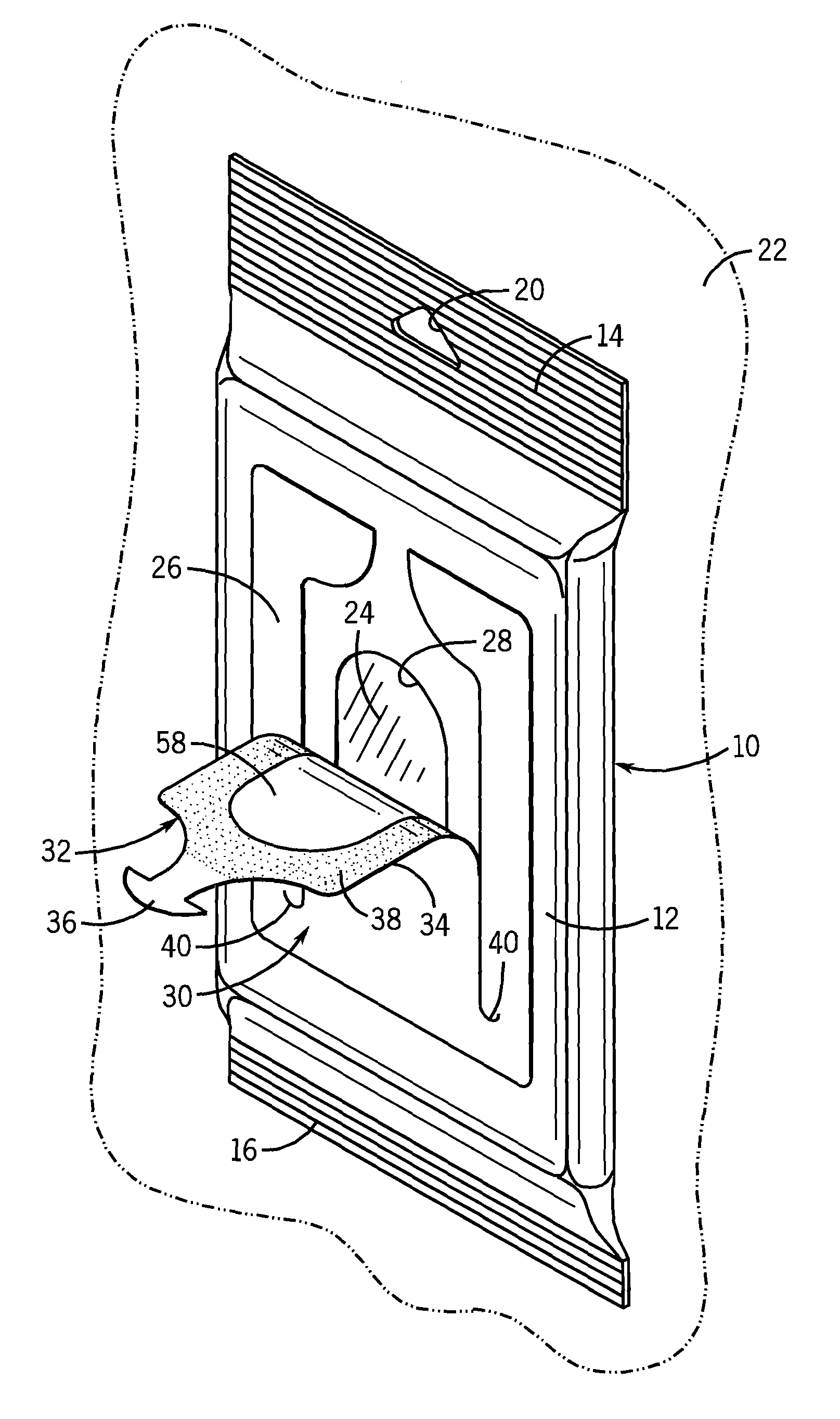

A resealable package assembly is described. The package assembly includes a selectively positionable flap that covers an aperture or enables access through the aperture into the package. The flap and package include provisions for releasably engaging the flap to the package to seal the interior of the package. Provisions for grasping the tab and indicating whether tampering has occurred are also described.

Owner:AVERY DENNISON CORP

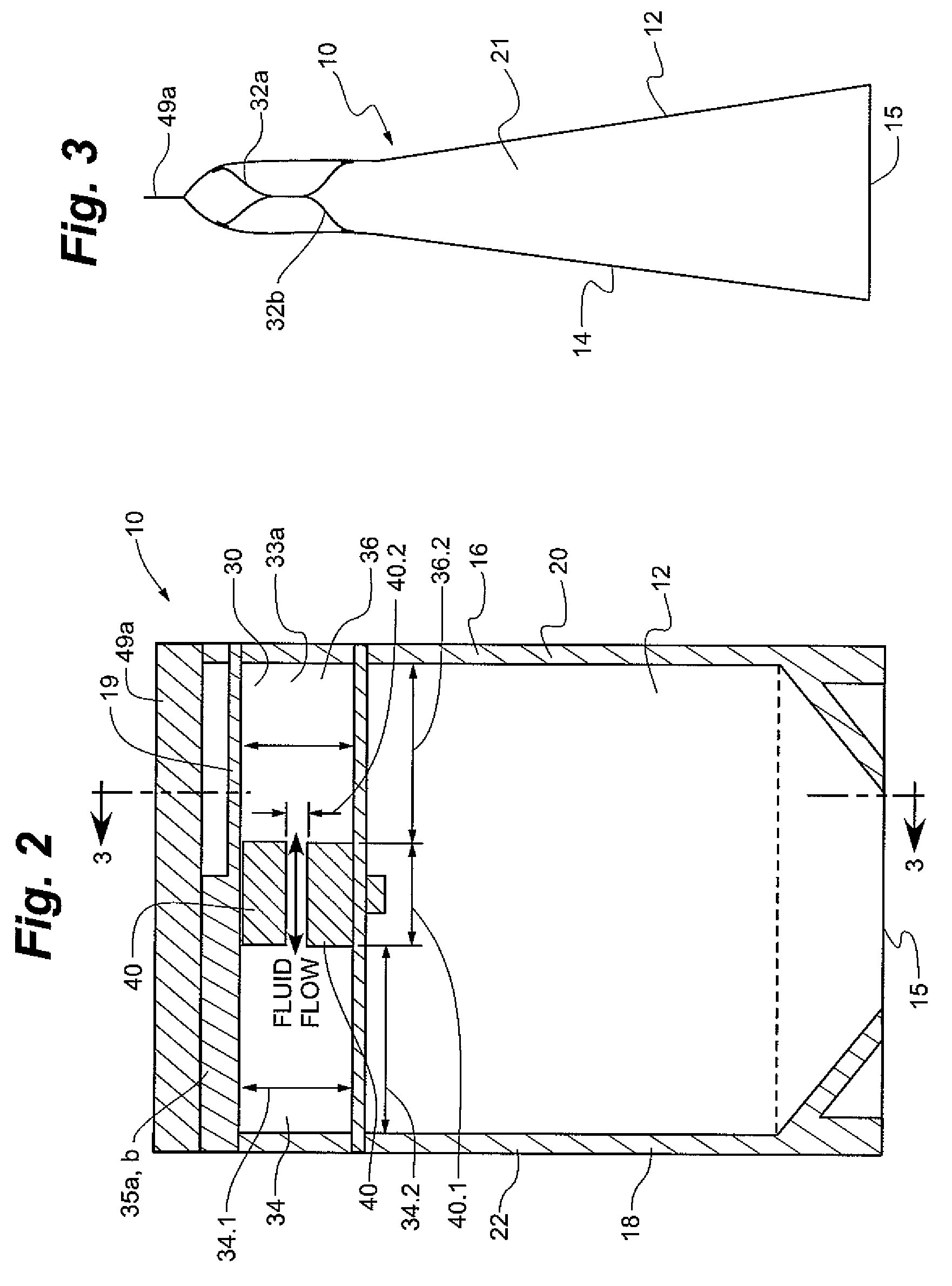

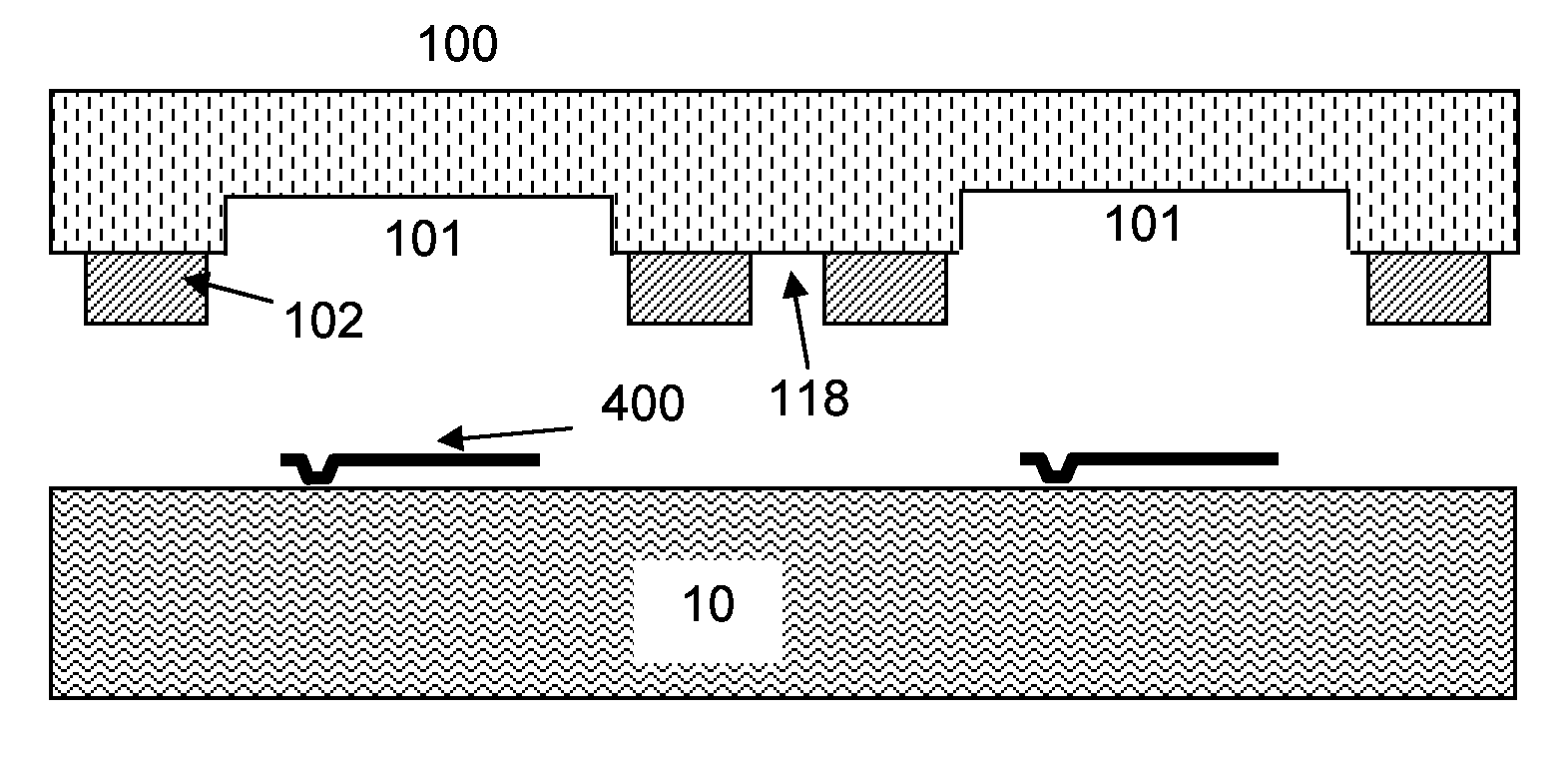

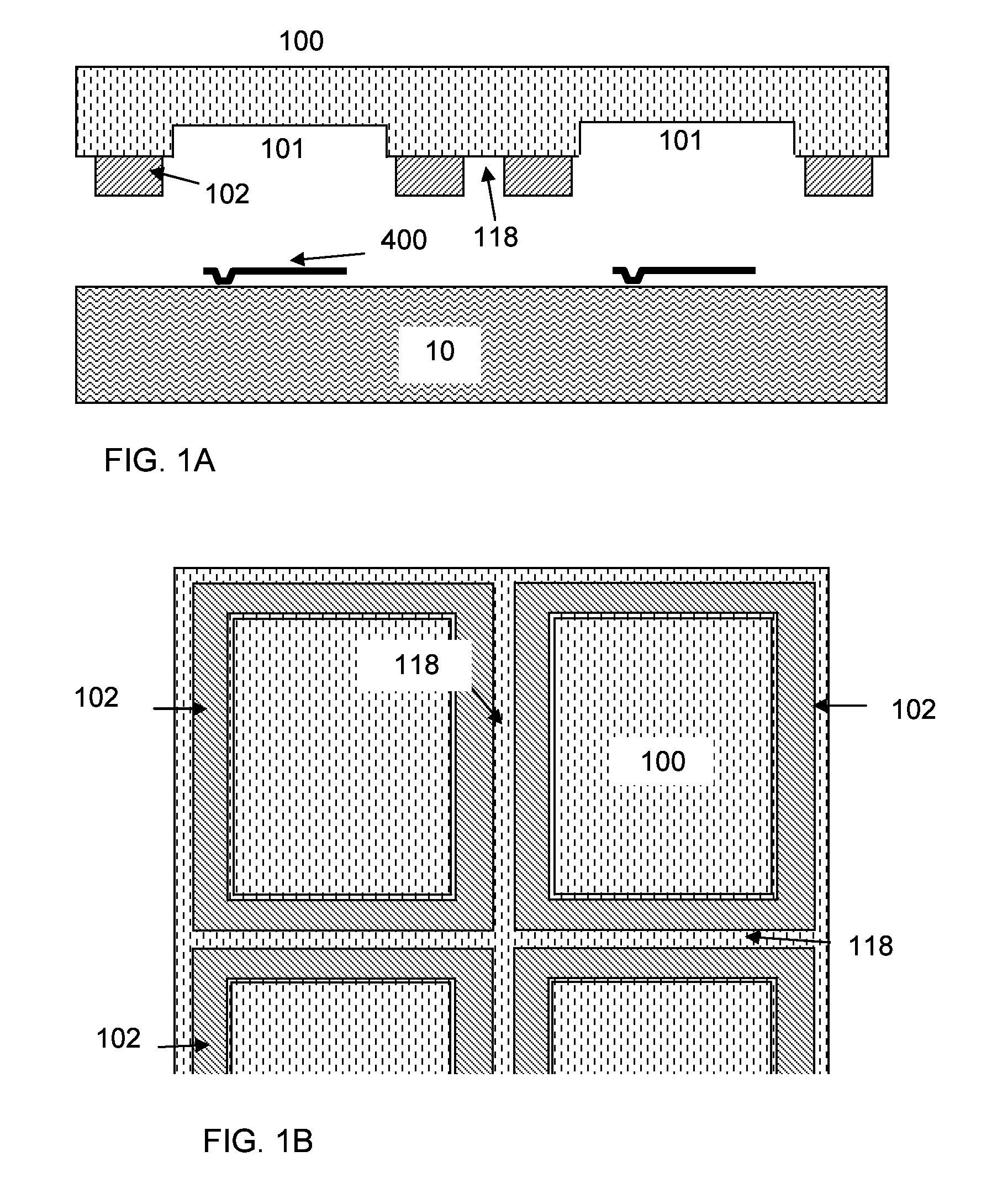

Hermetic pacakging and method of manufacture and use therefore

InactiveUS20050263866A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringHermetic packaging

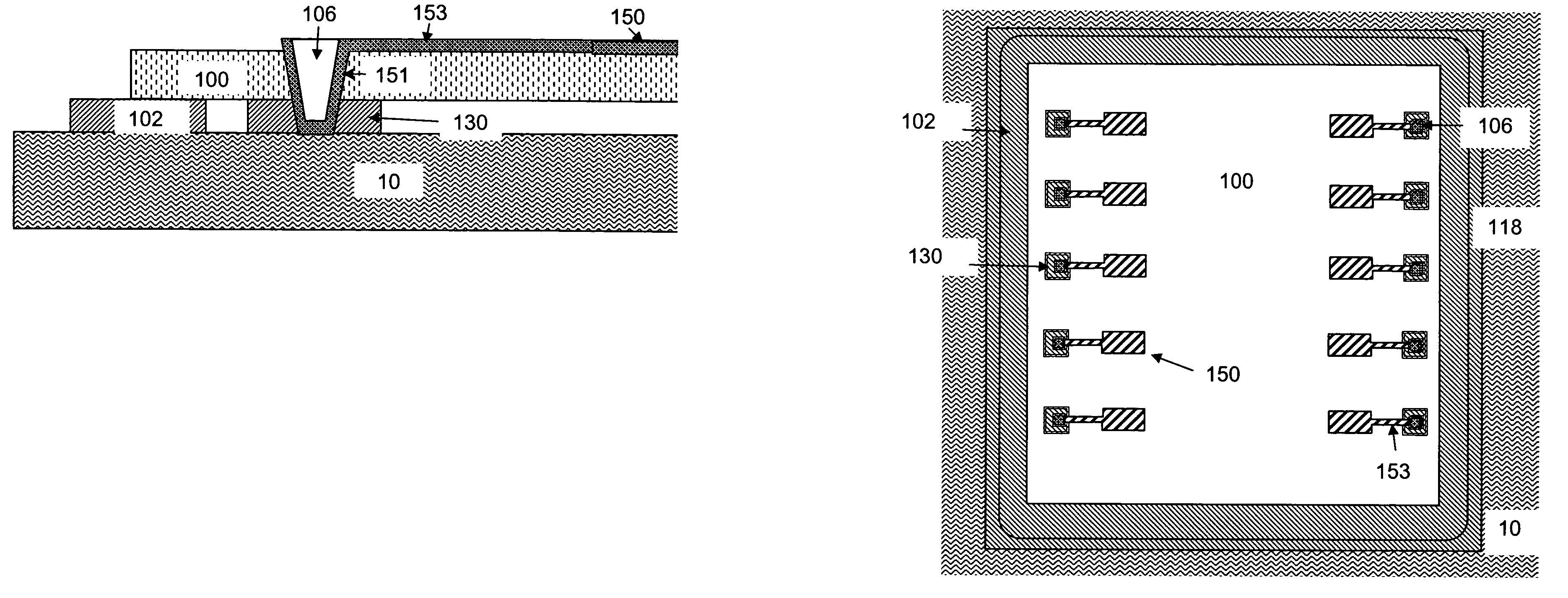

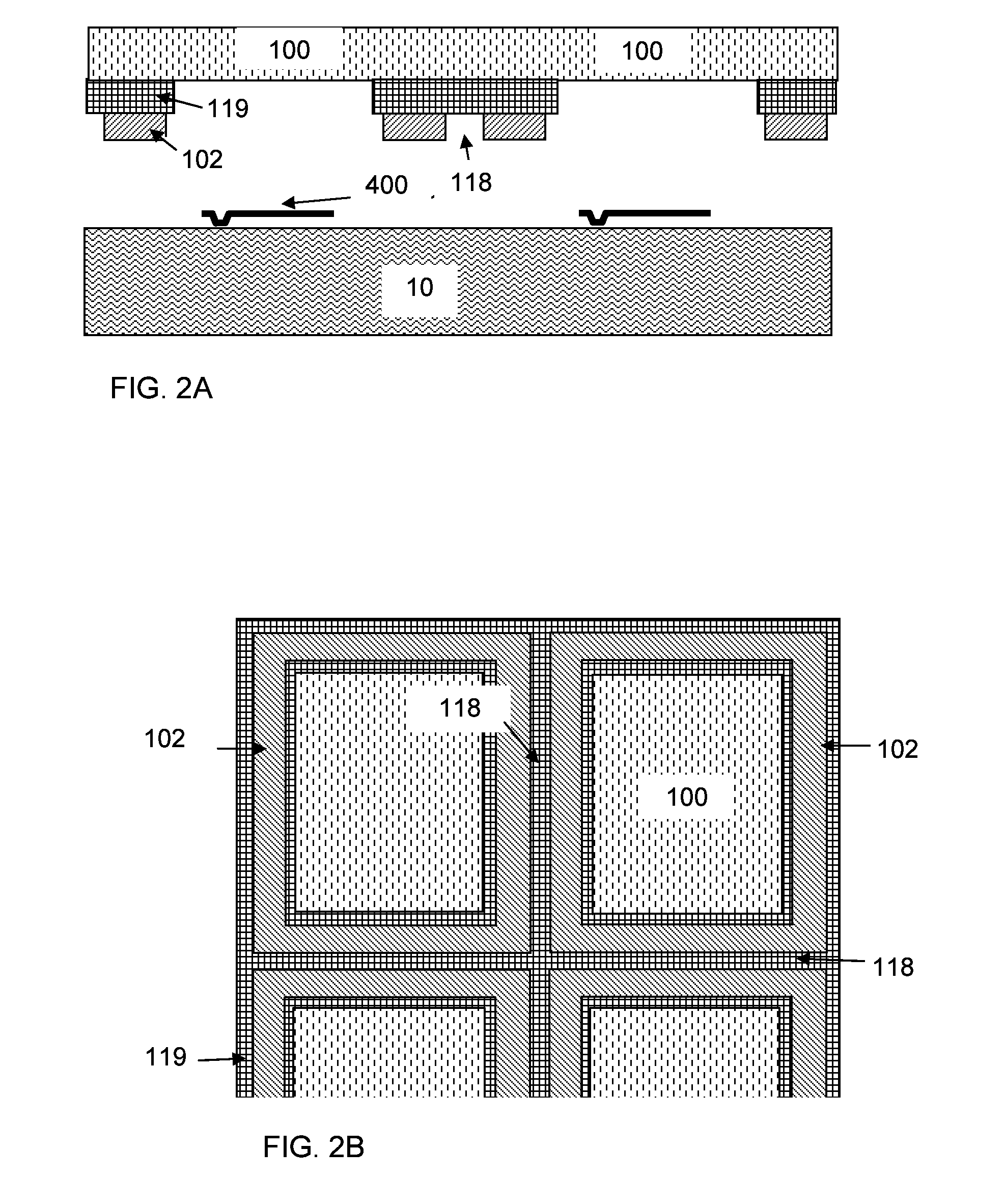

An embodiment of the present invention provides a method of manufacturing hermetic packaging for devices on a substrate wafer, comprising forming a plurality of adhesive rings on a cap wafer or the substrate wafer, bonding the cap wafer to the substrate wafer with an adhesive layer, forming trenches in the cap wafer and the adhesive rings along outer rim of the adhesive rings, and covering sidewall of the trenches by at least one deposited film to provide a diffusion barrier to moisture or gas.

Owner:WAN CHANG FENG

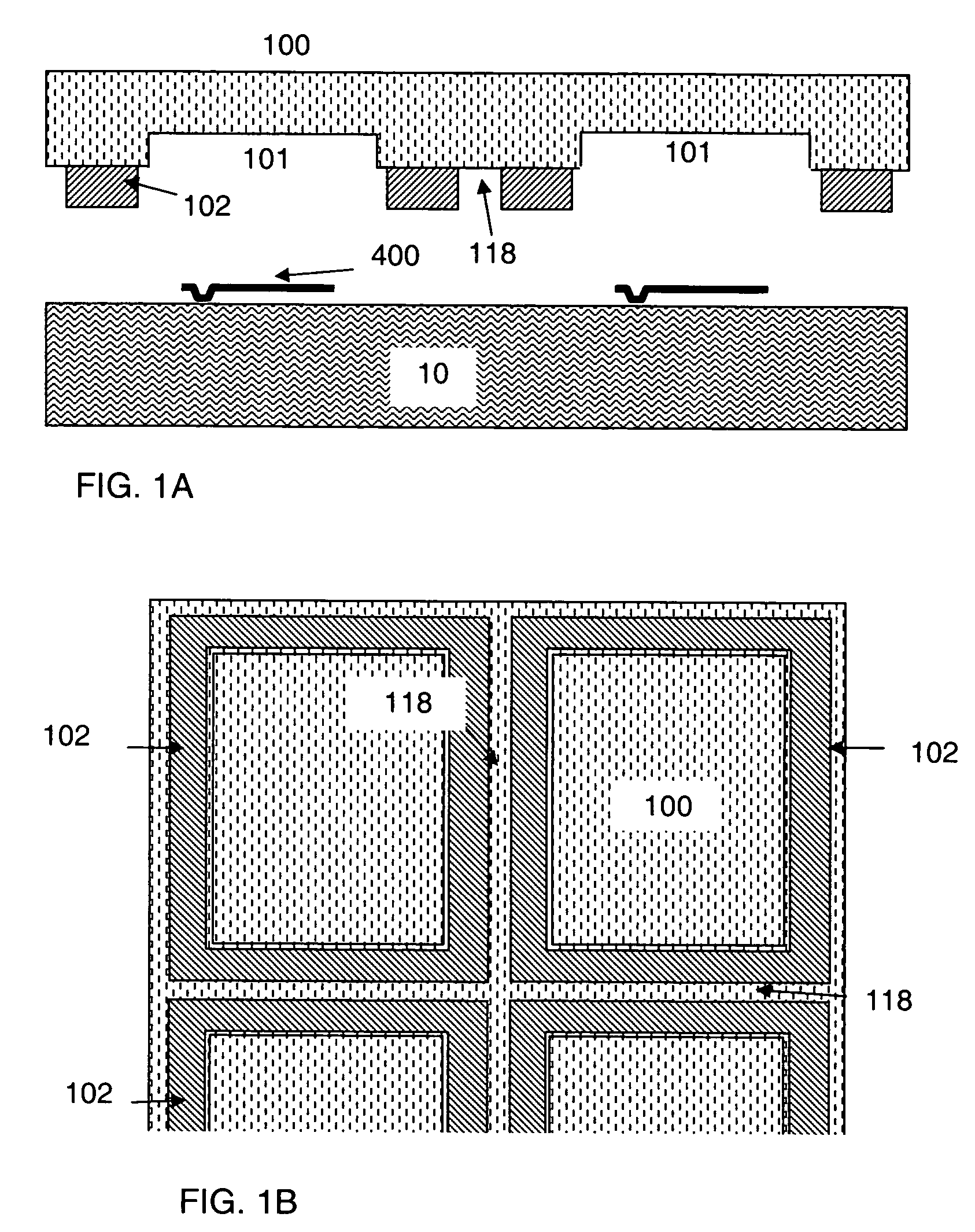

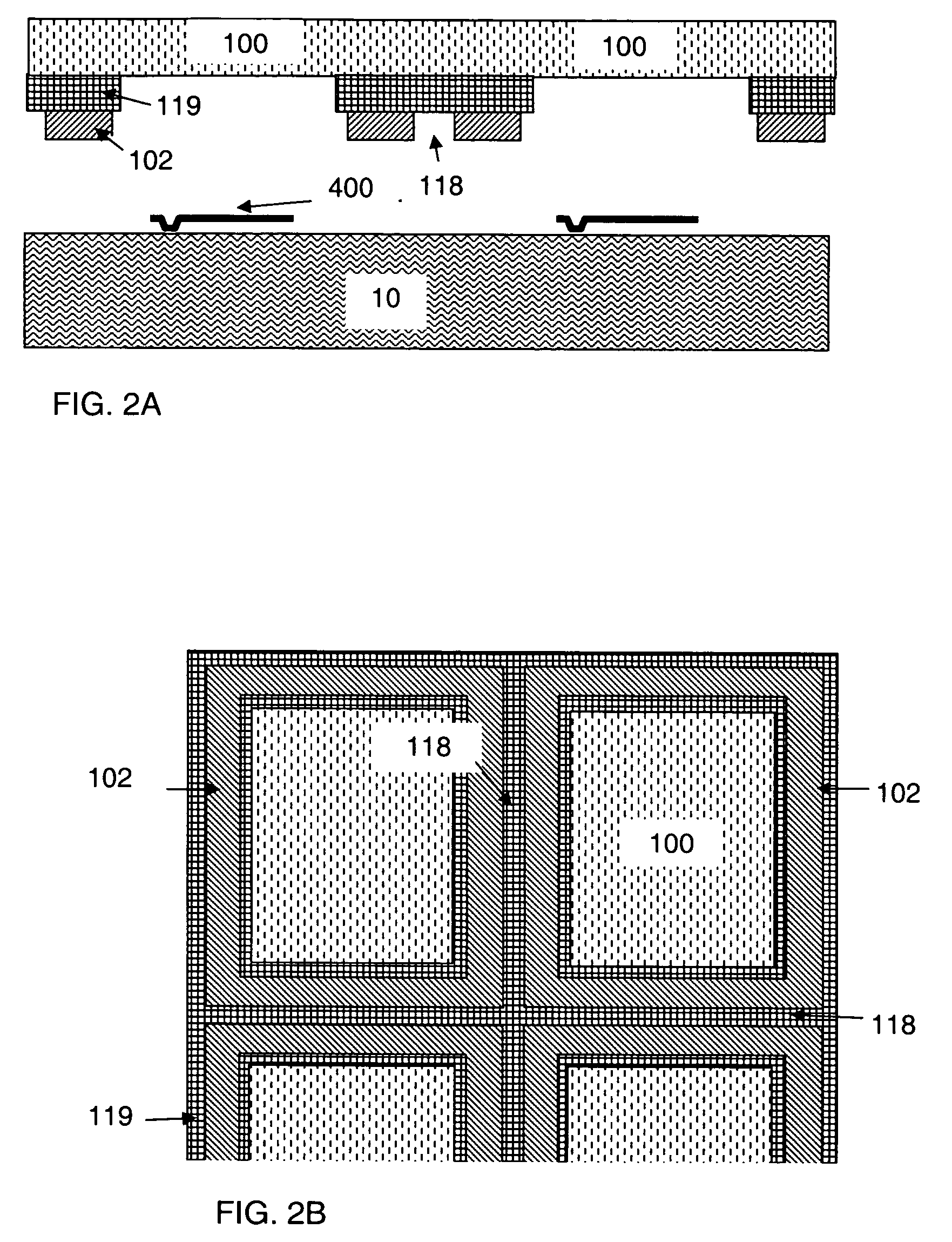

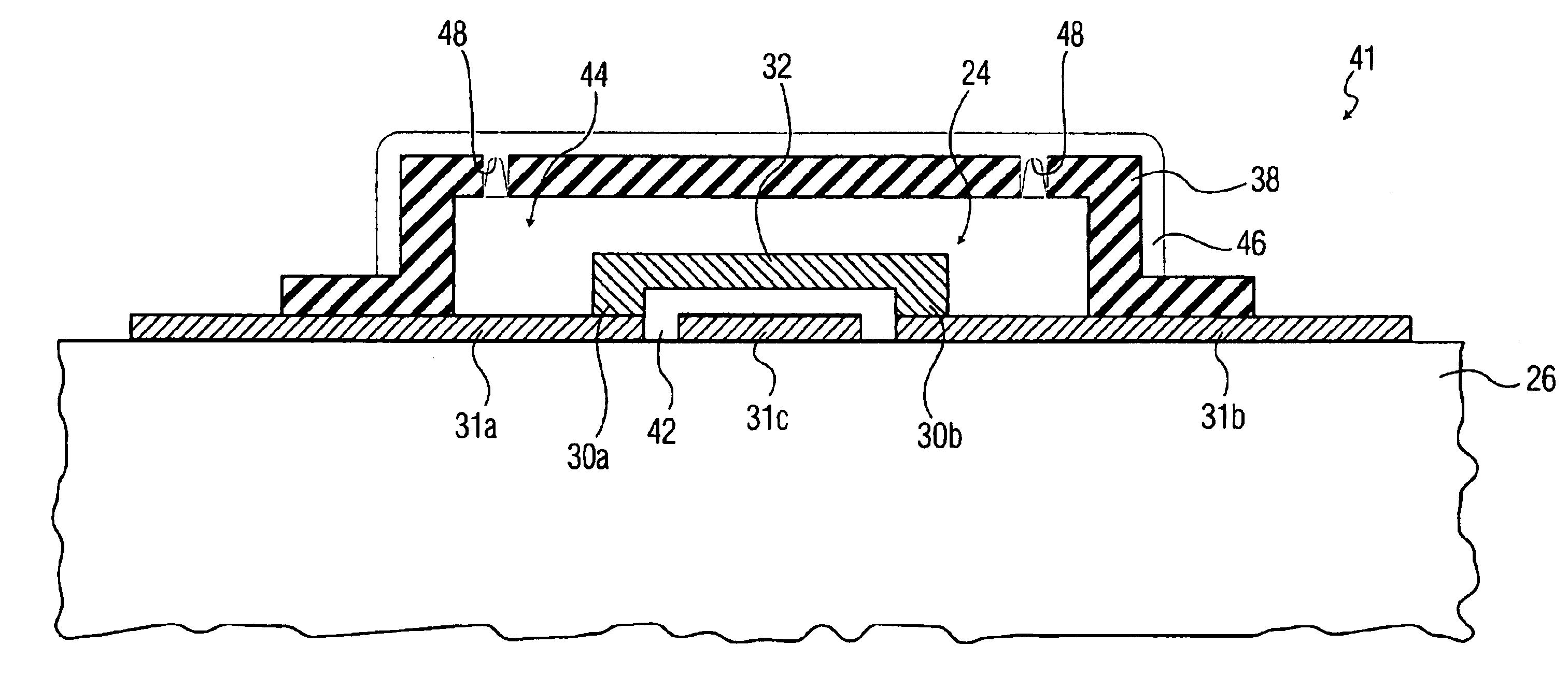

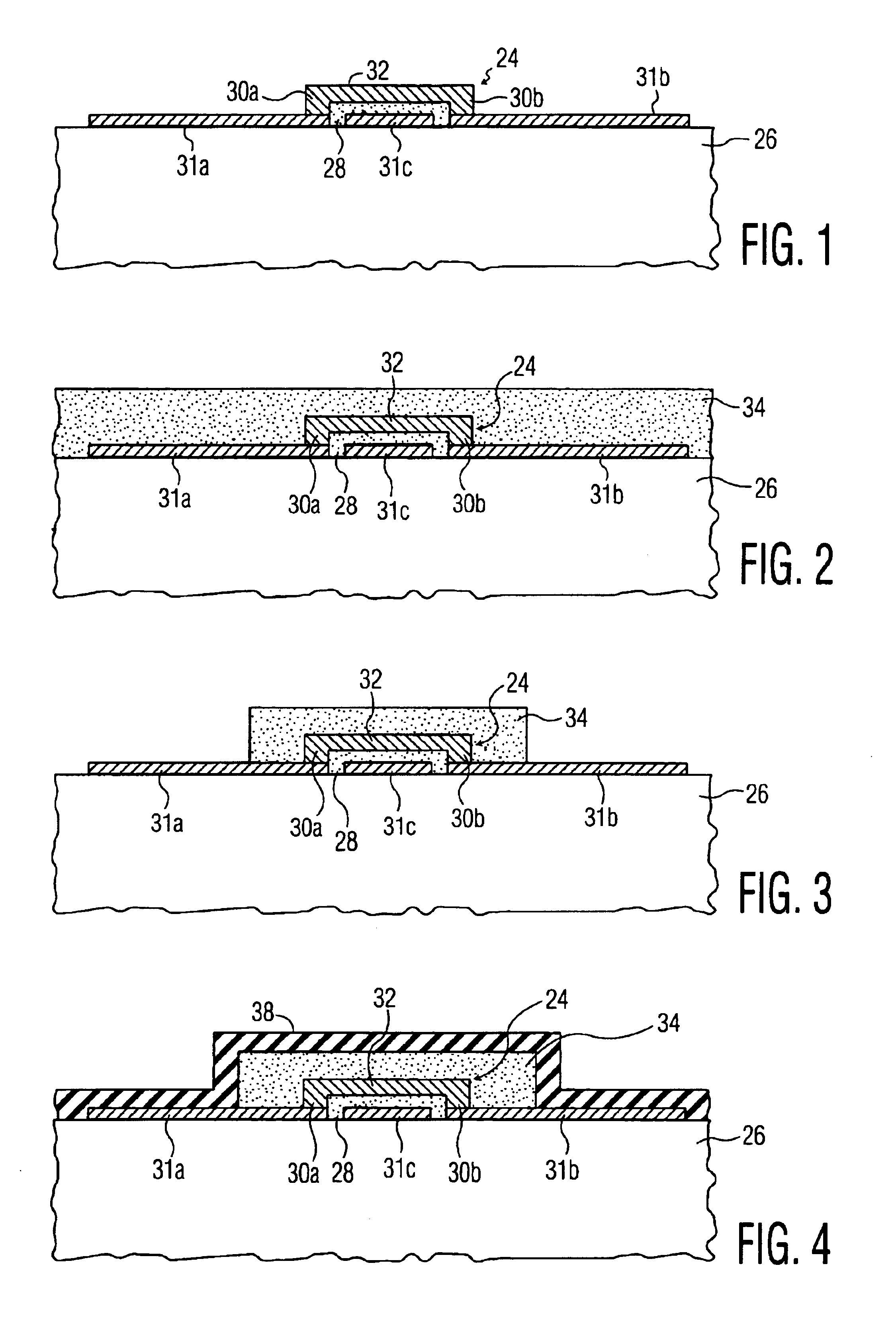

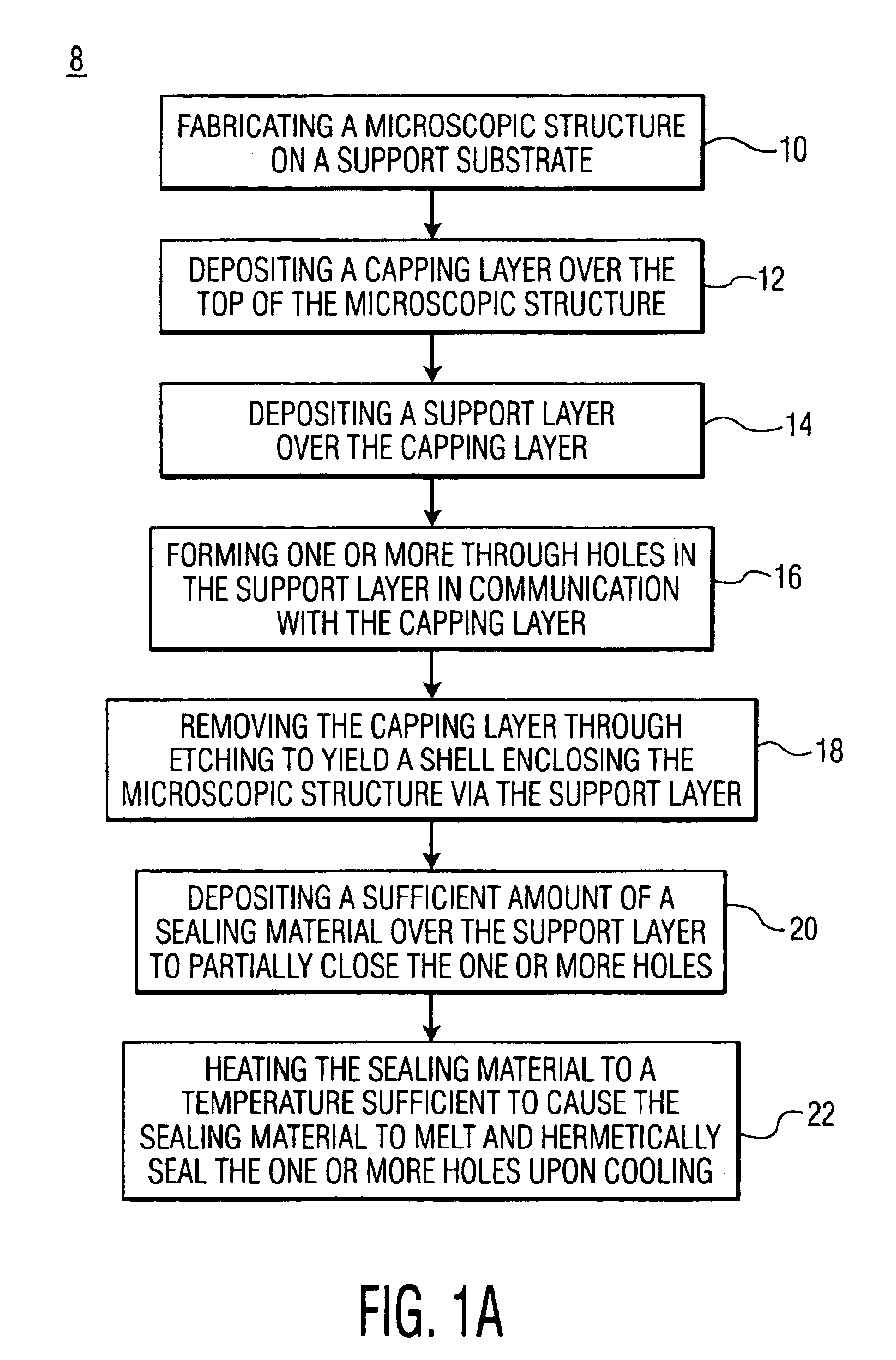

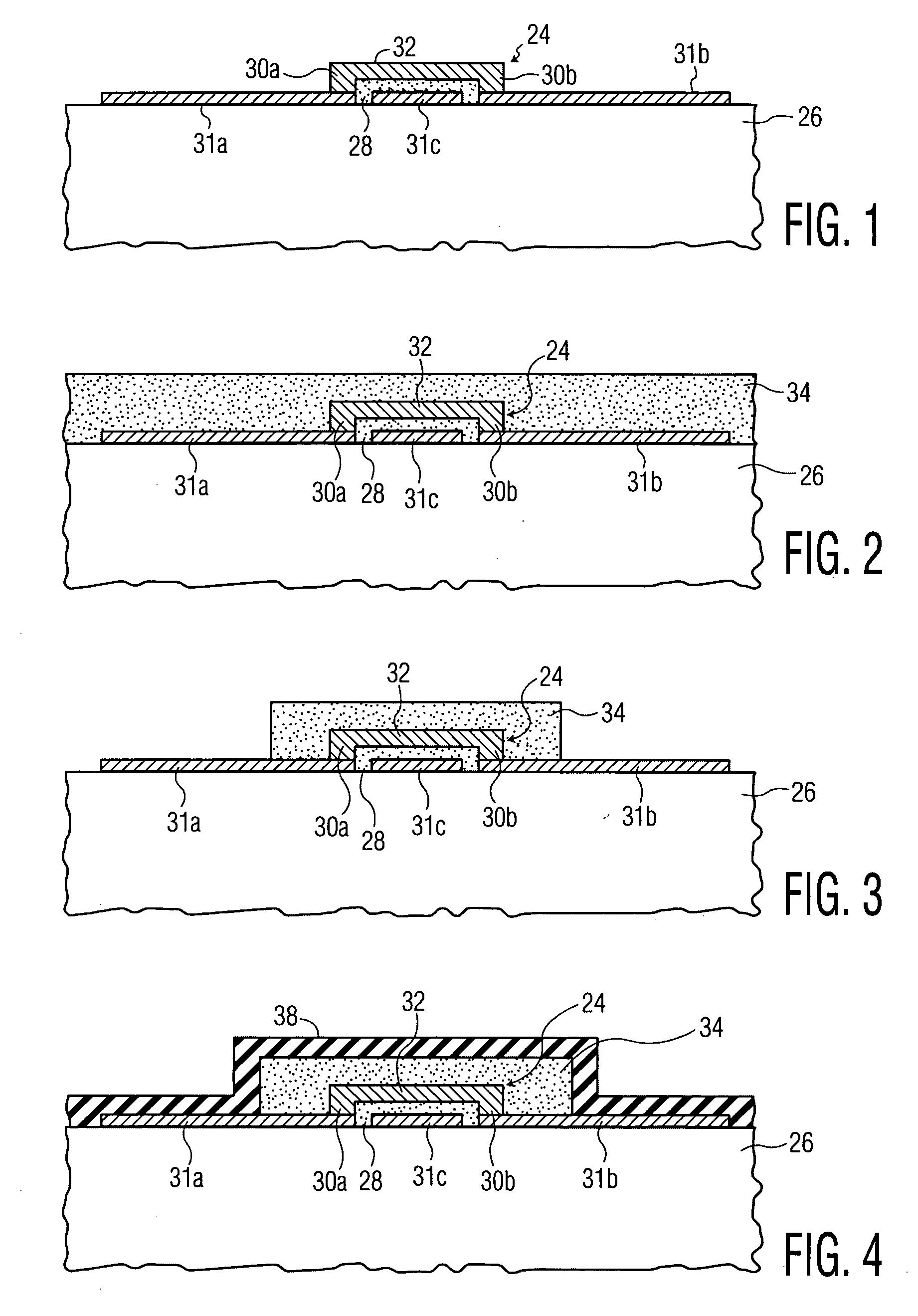

Processes for hermetically packaging wafer level microscopic structures

InactiveUS6936494B2AdaptableImprove integrityDecorative surface effectsSolid-state devicesEtchingLithographic artist

A process for hermetically packaging a microscopic structure including a MEMS device is provided. The process for the present invention includes the steps of depositing a capping layer of sacrificial material patterned by lithography over the microscopic structure supported on a substrate, depositing a support layer of a dielectric material patterned by lithography over the capping layer, providing a plurality of vias through the support layer by lithography, removing the capping layer via wet etching to leave the support layer intact in the form of a shell having a cavity occupied by the microscopic structure, depositing a metal layer over the capping layer that is thick enough to provide a barrier against gas permeation, but thin enough to leave the vias open, and selectively applying under high vacuum a laser beam to the metal proximate each via for a sufficient period of time to melt the metal for sealing the via.

Owner:RUTGERS THE STATE UNIV

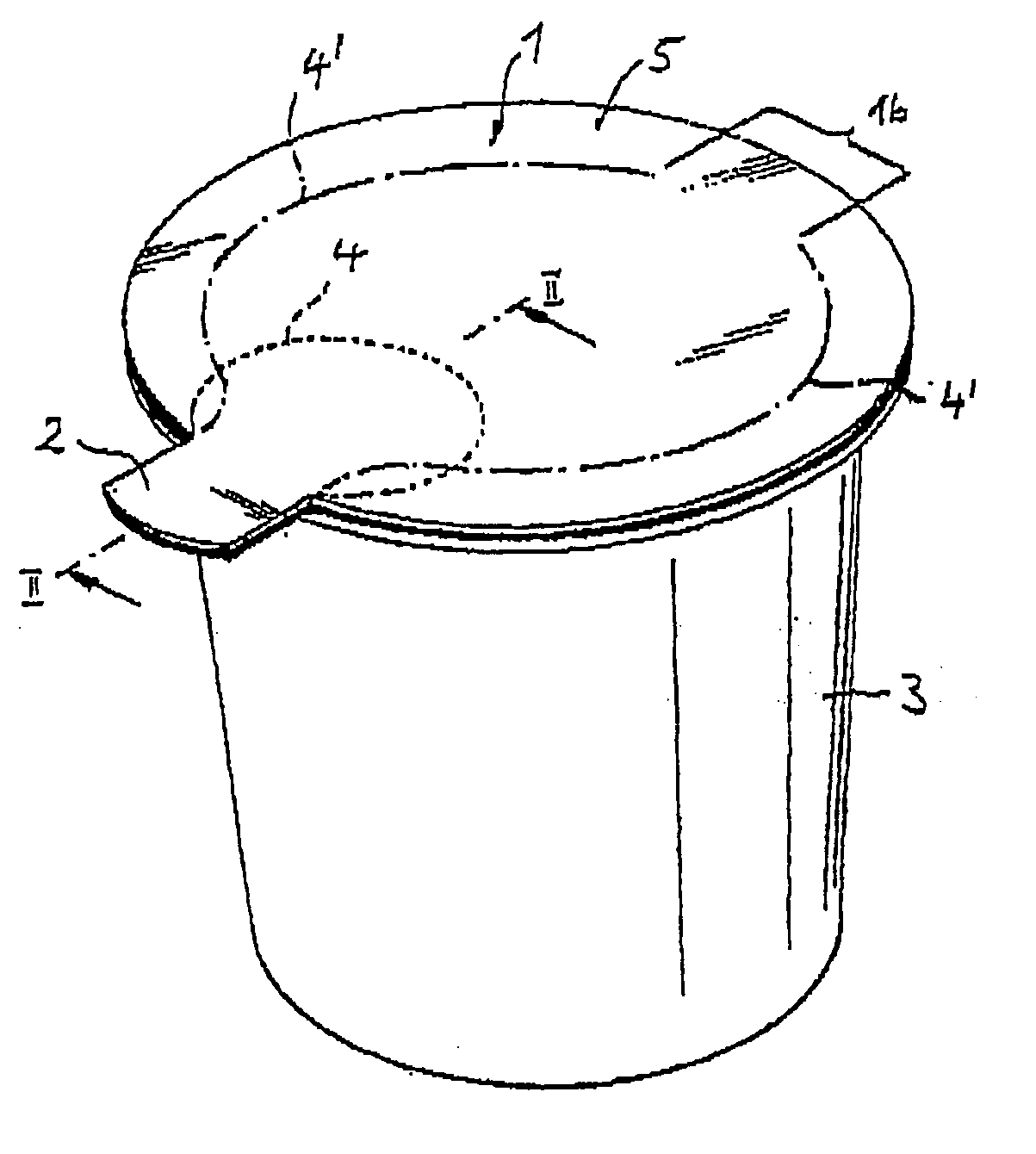

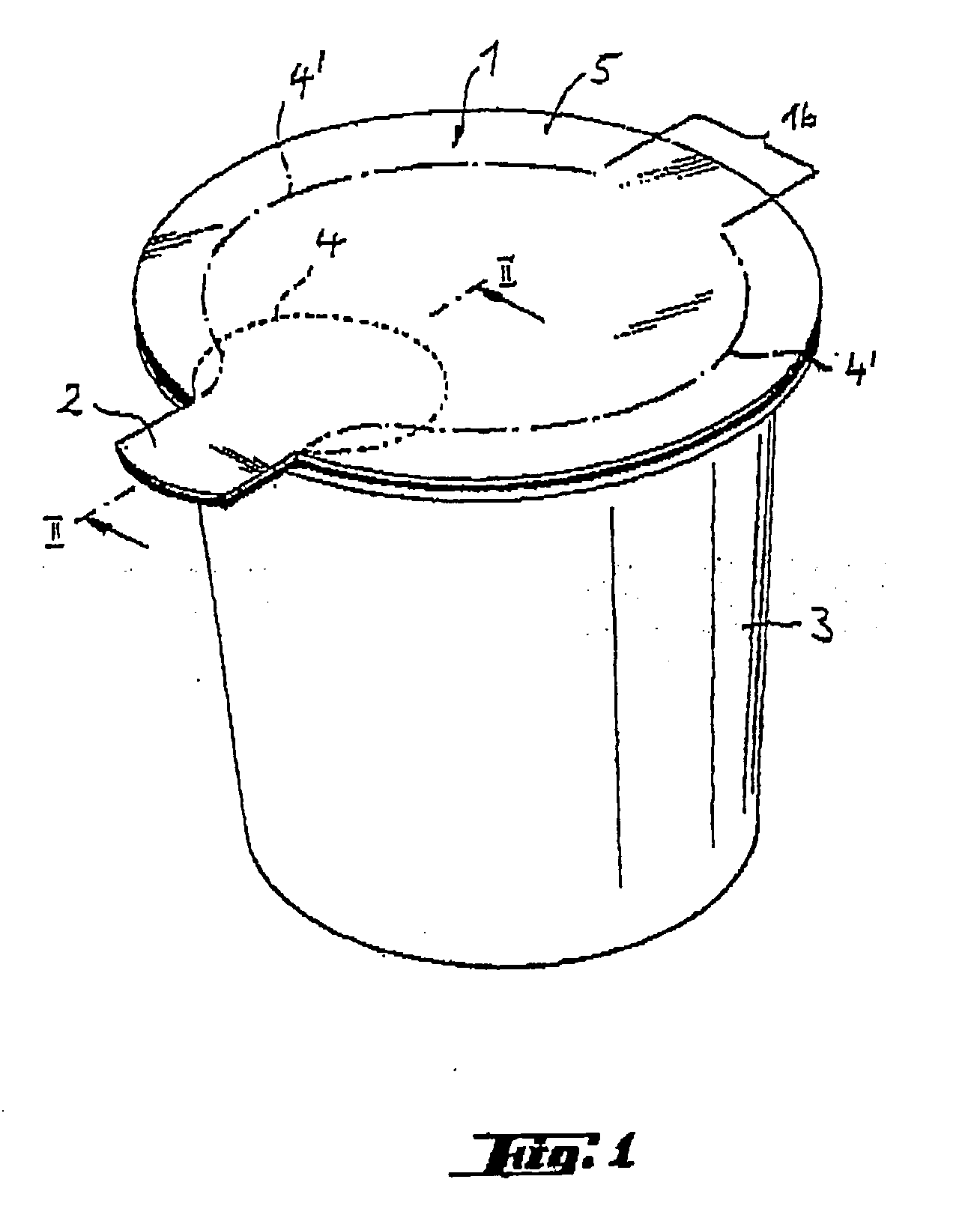

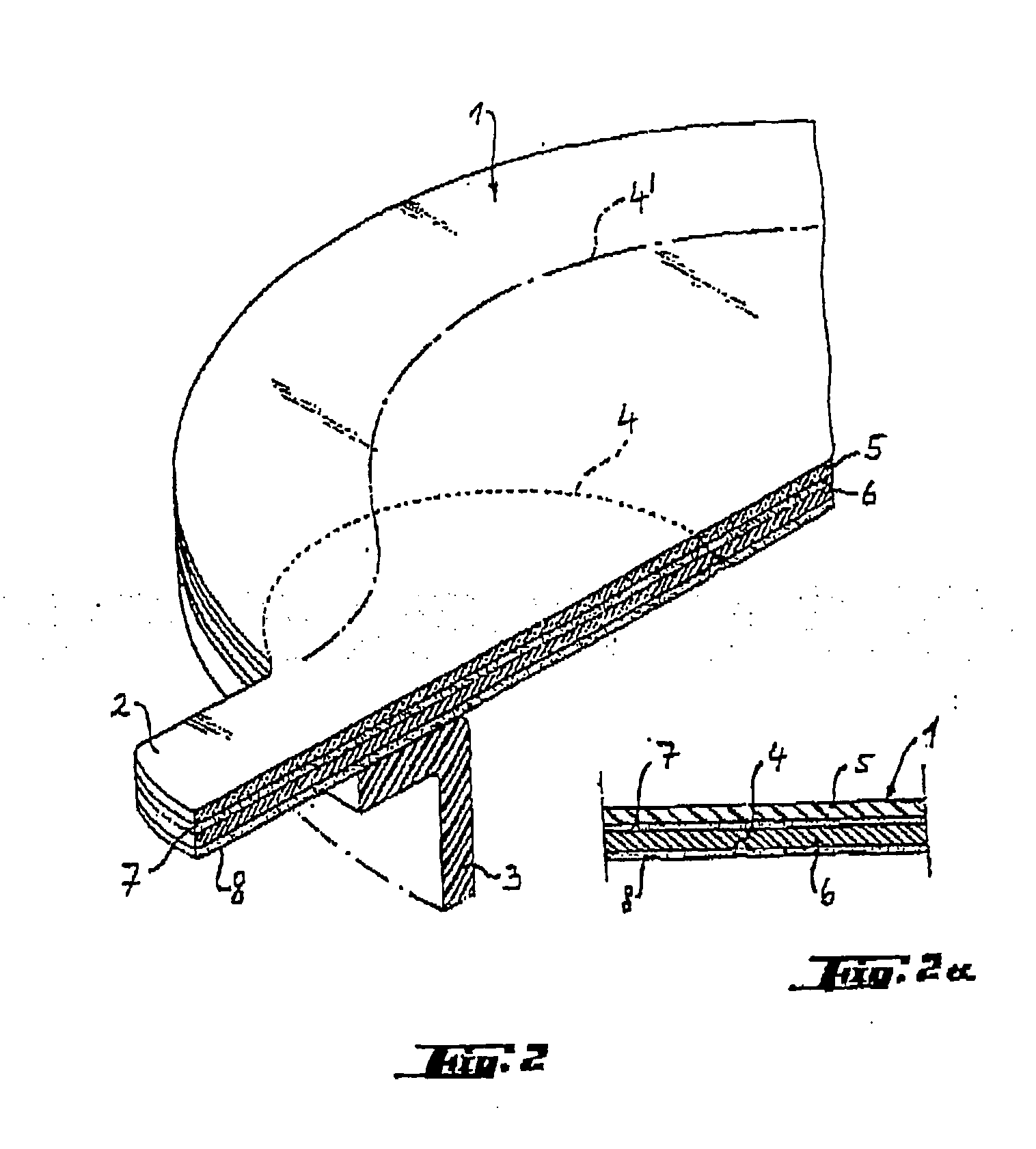

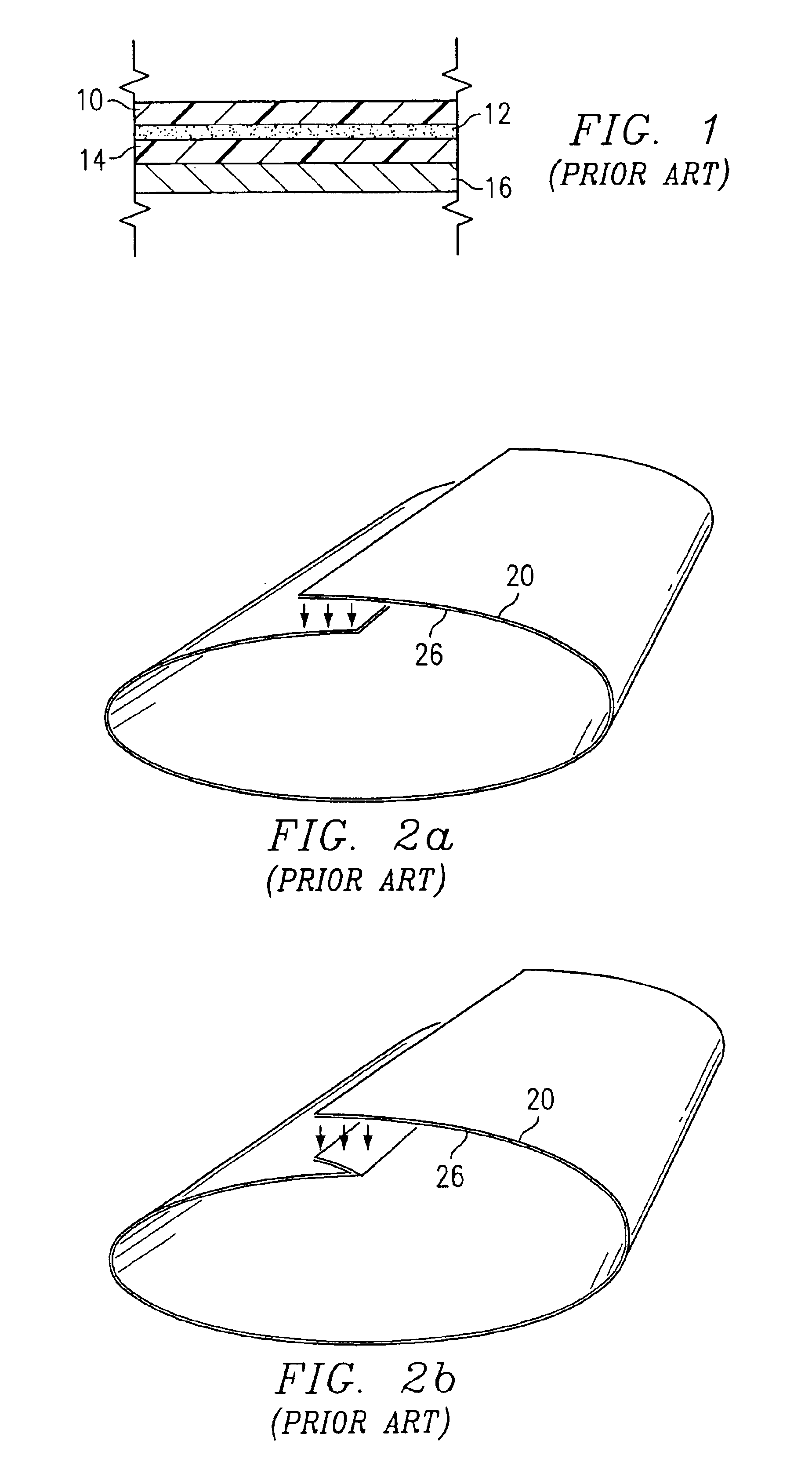

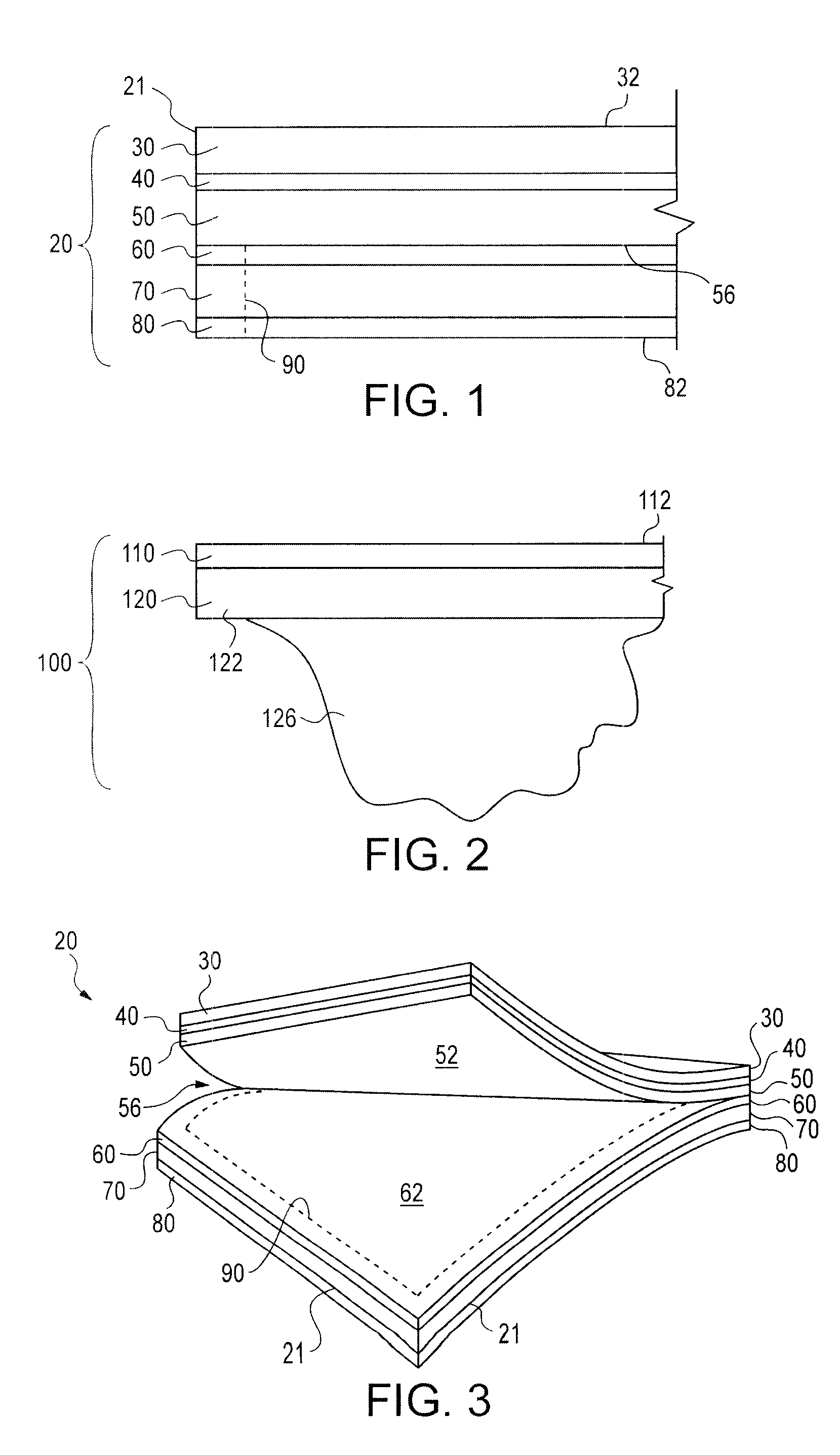

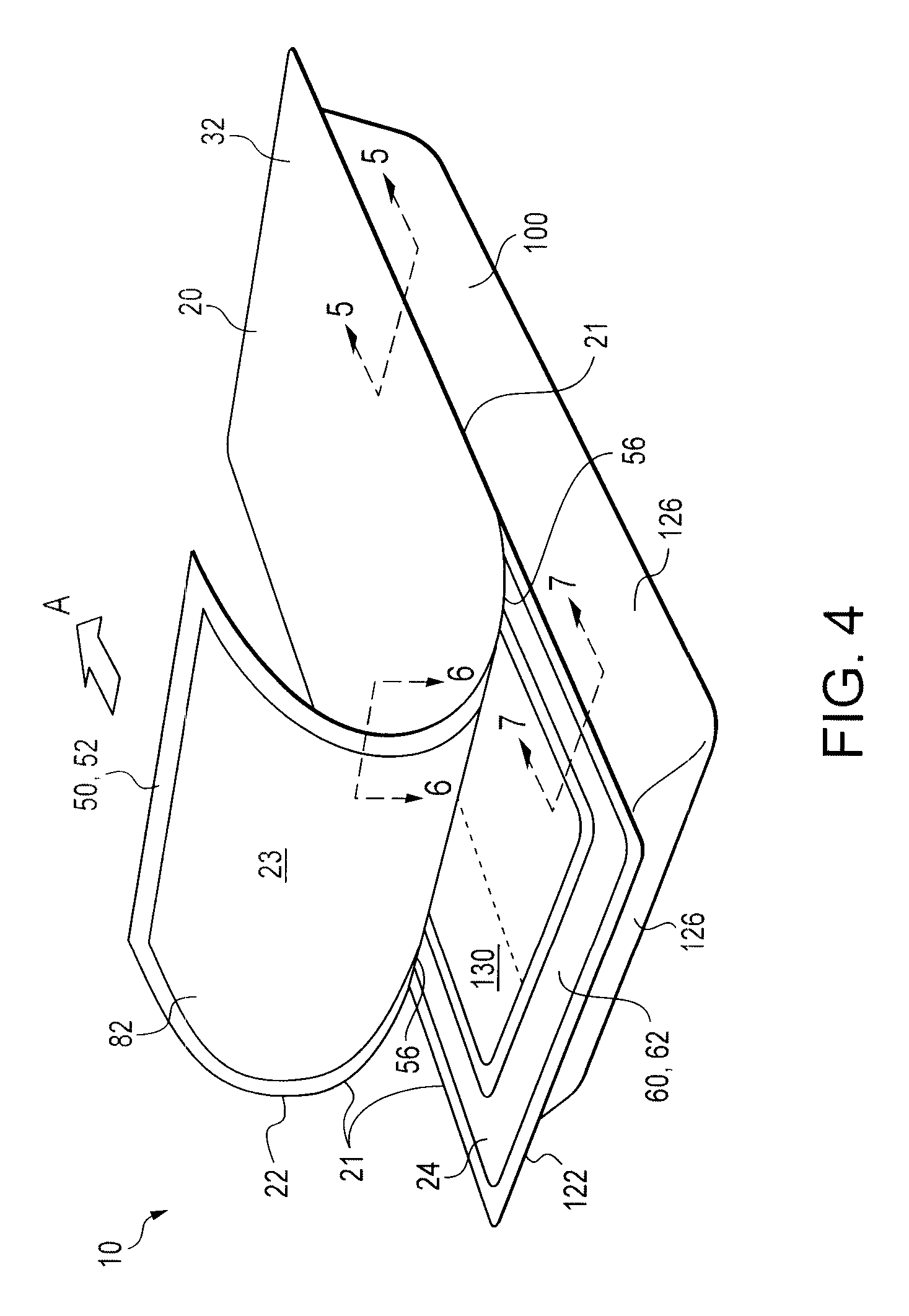

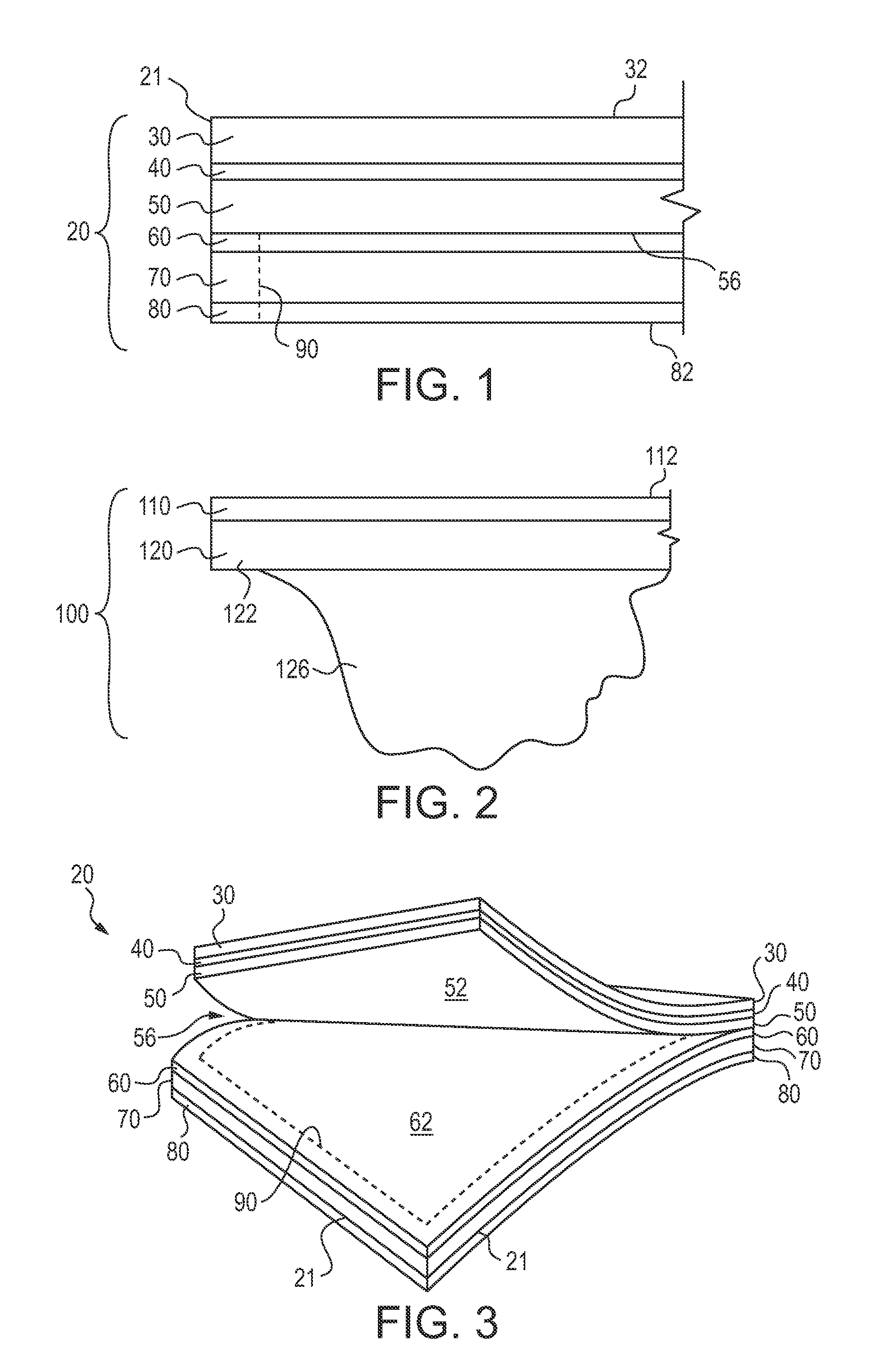

Thermally-sealable multilayer film for resealable packages

InactiveUS20040013827A1Envelopes/bags making machineryPipe laying and repairEngineeringHermetic packaging

A thermally-sealable multilayer film, for packages which may be resealed after opening, includes an outer layer and a support layer, with a thermally-sealable layer on the side facing the packaged material. A self-adhesive layer made from pressure sensitive adhesive is provided between the support layer and the outer layer. The support layer has weakening lines, which define an opening for the removal of packaged material. For resealing a container, by using the thermally-sealable multilayer film, the user may simply open the defined opening for removal of the contents of the container, by application of an opening force and then reseal the container, by pressing the opened outer layer on to the self-adhesive layer. The above process may be repeated several times, until all the contents of the container are used, whereby the above are protected from possible contamination.

Owner:TEICH AGSELLSCHAFT

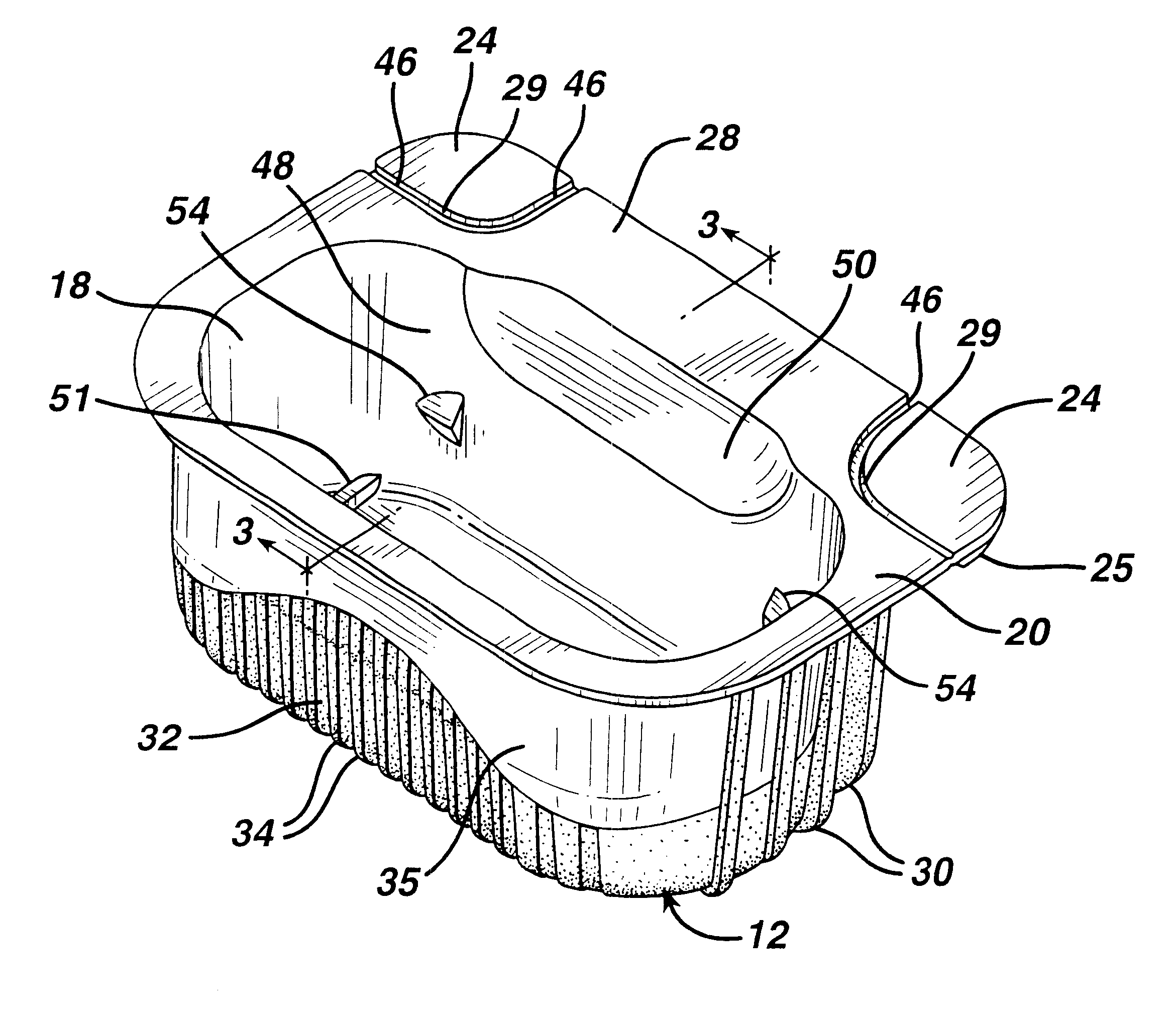

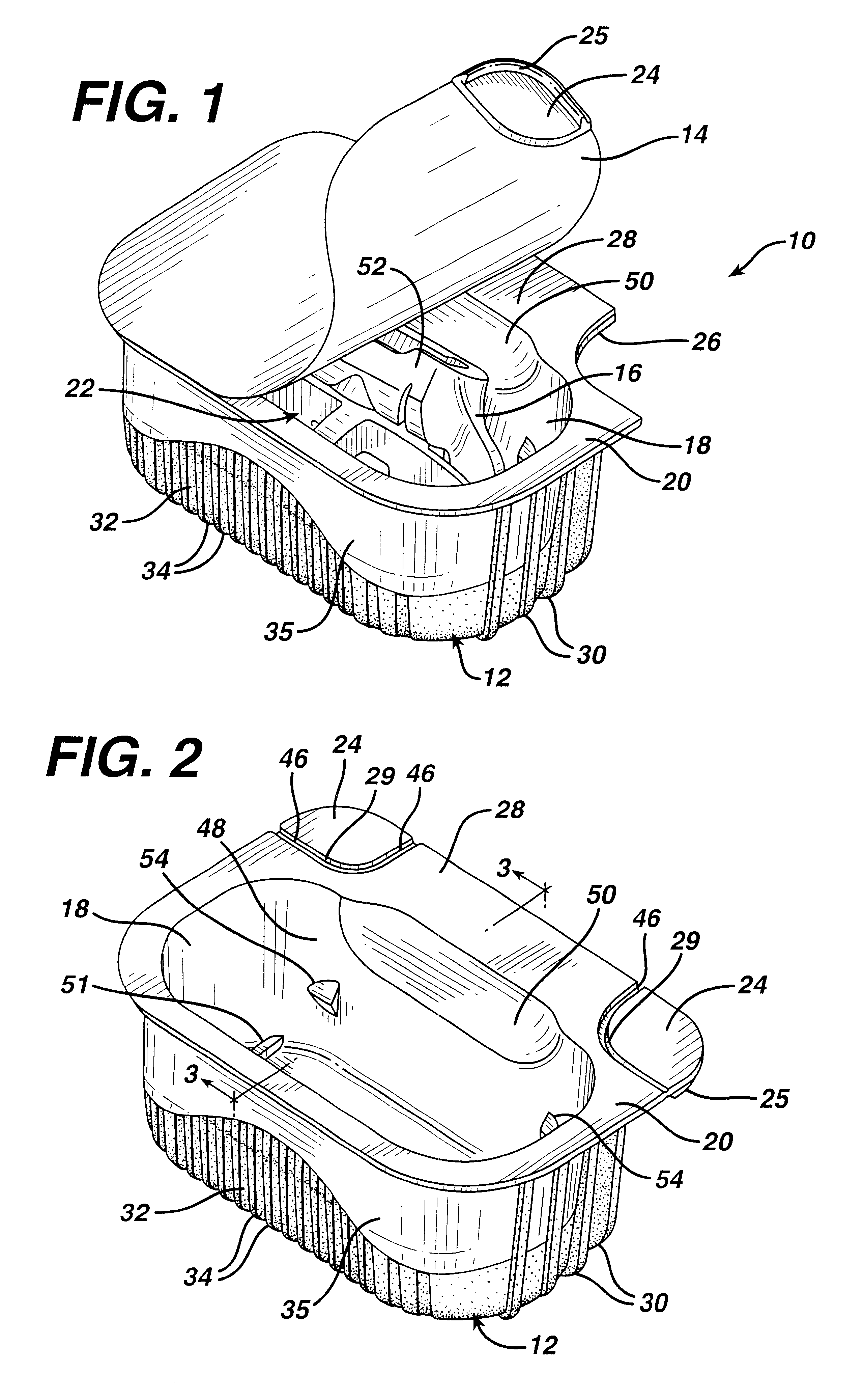

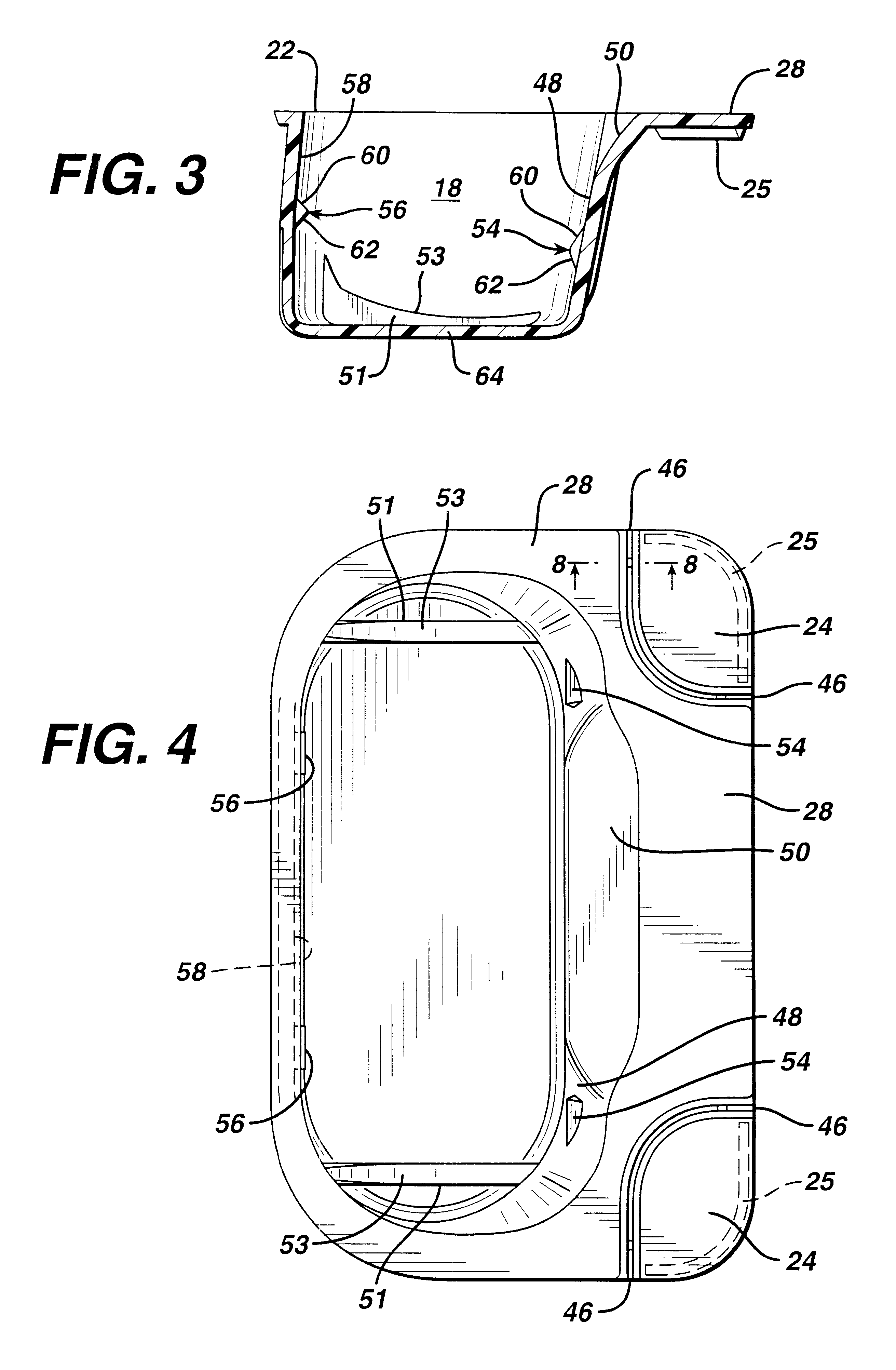

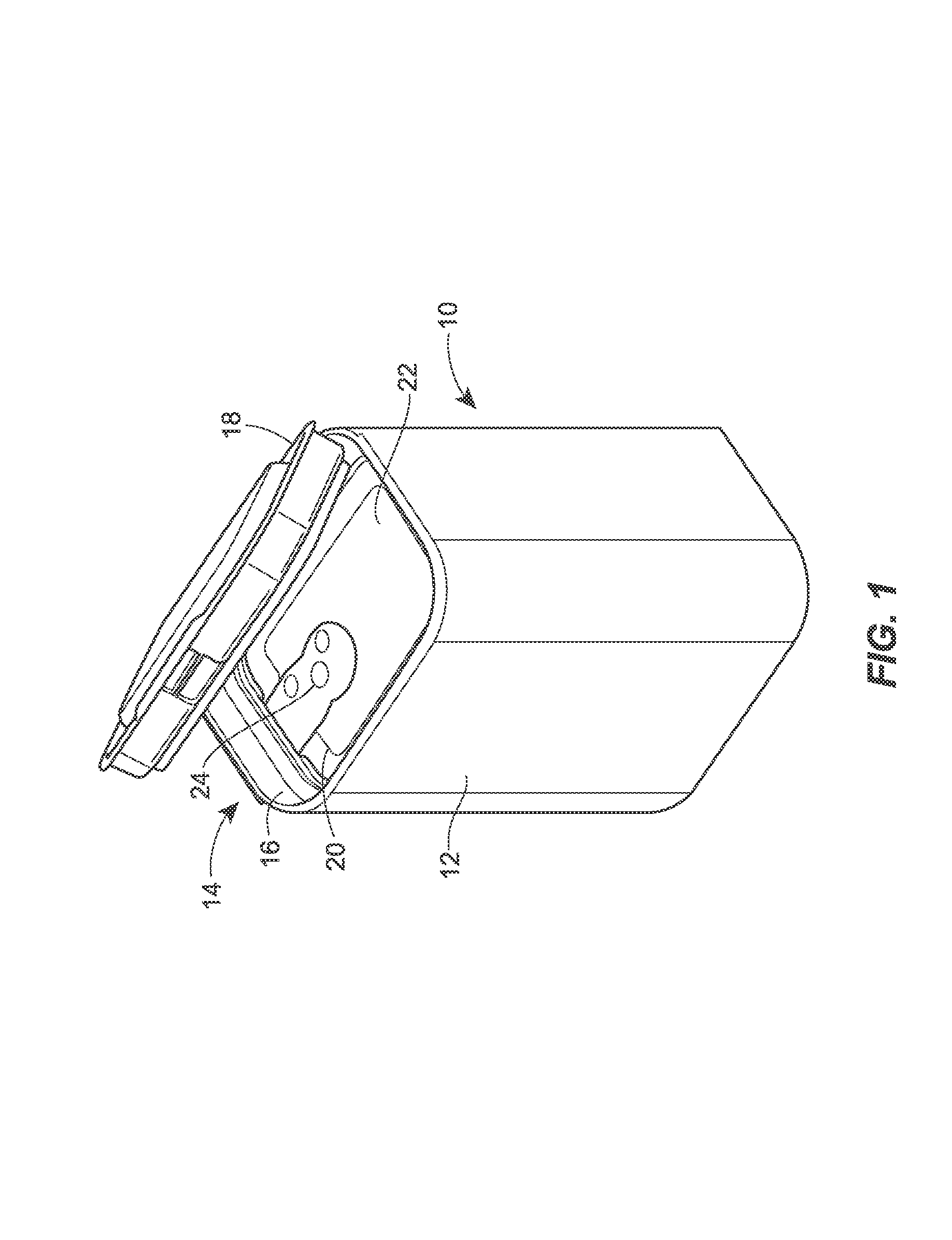

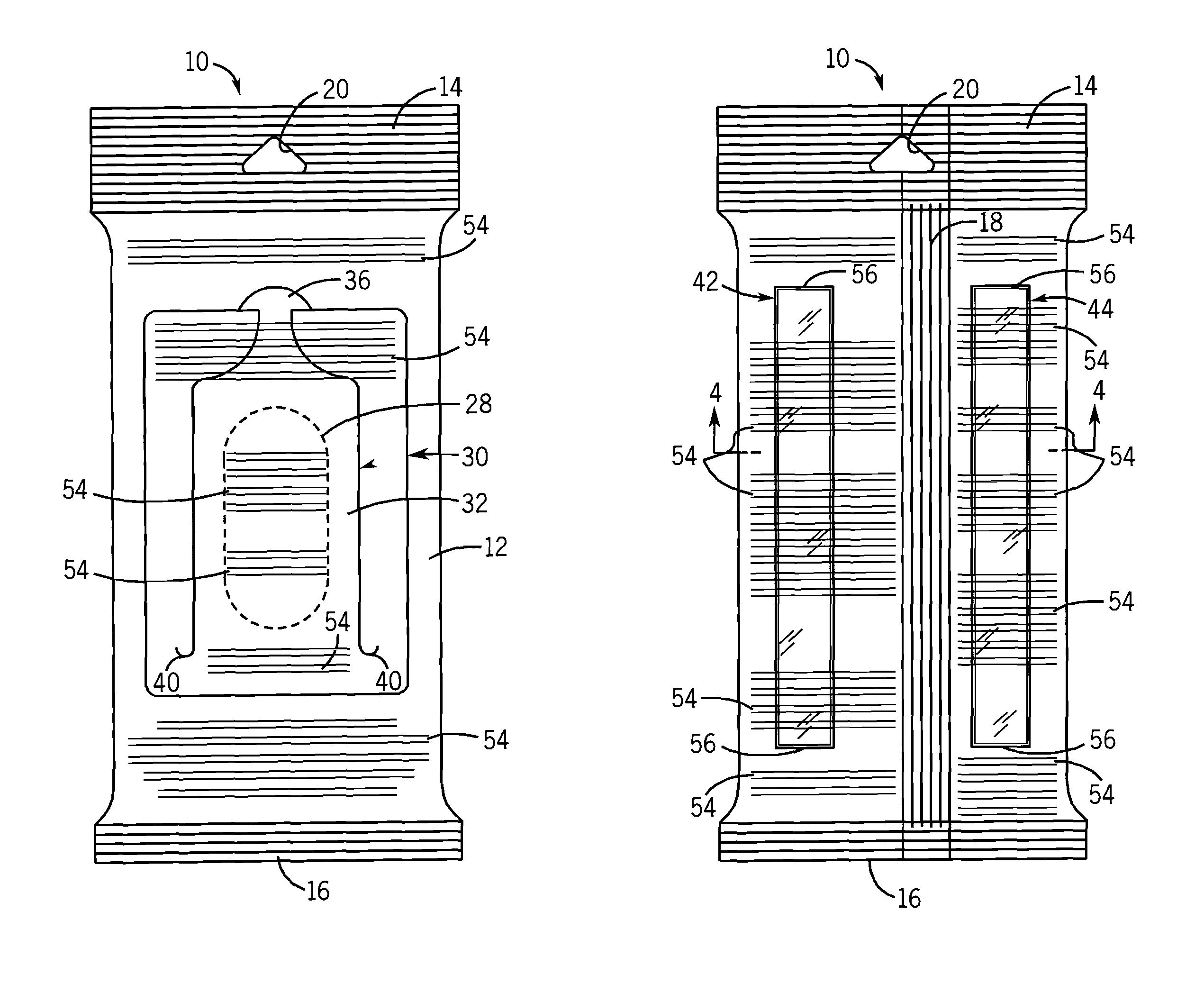

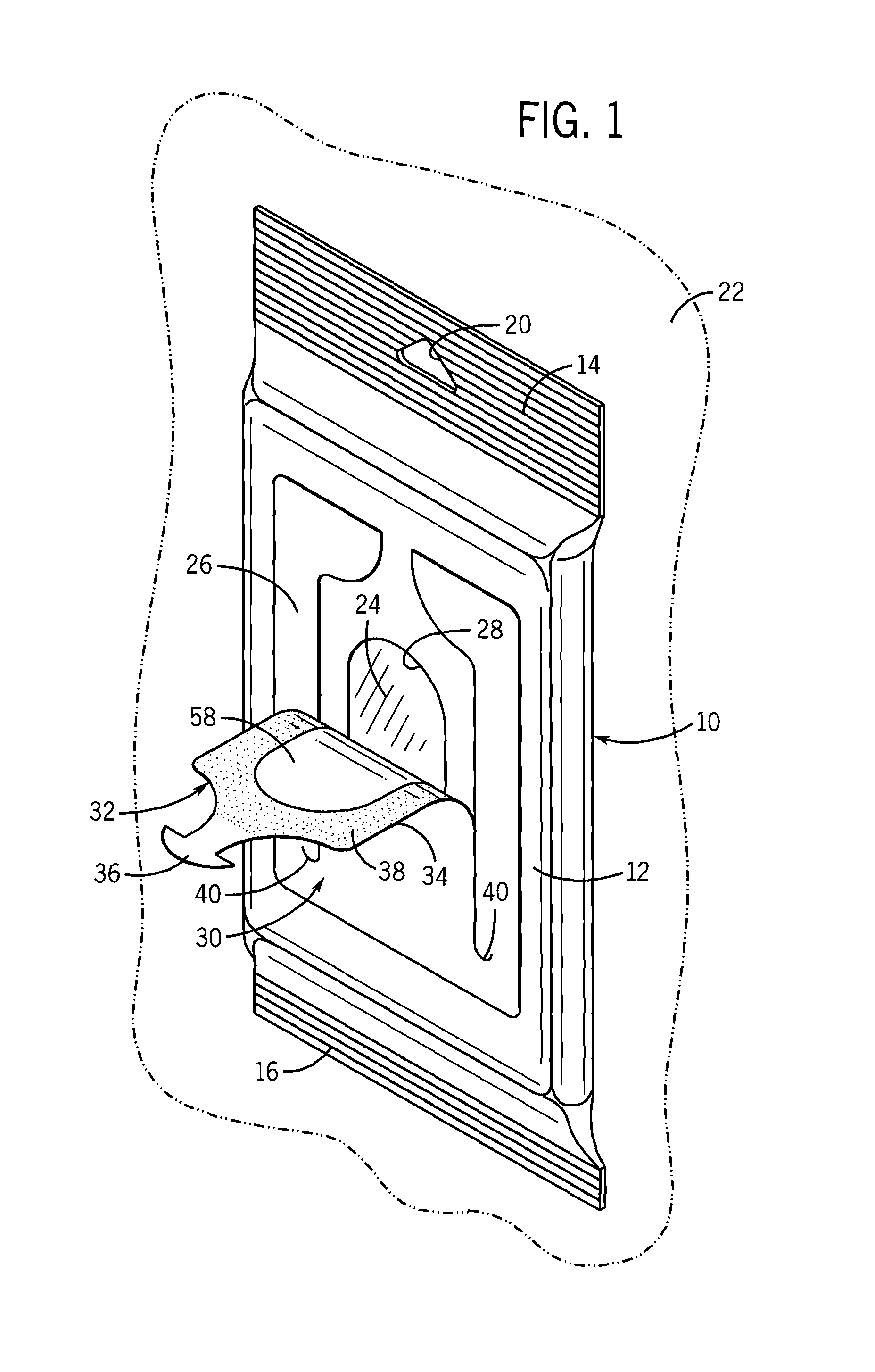

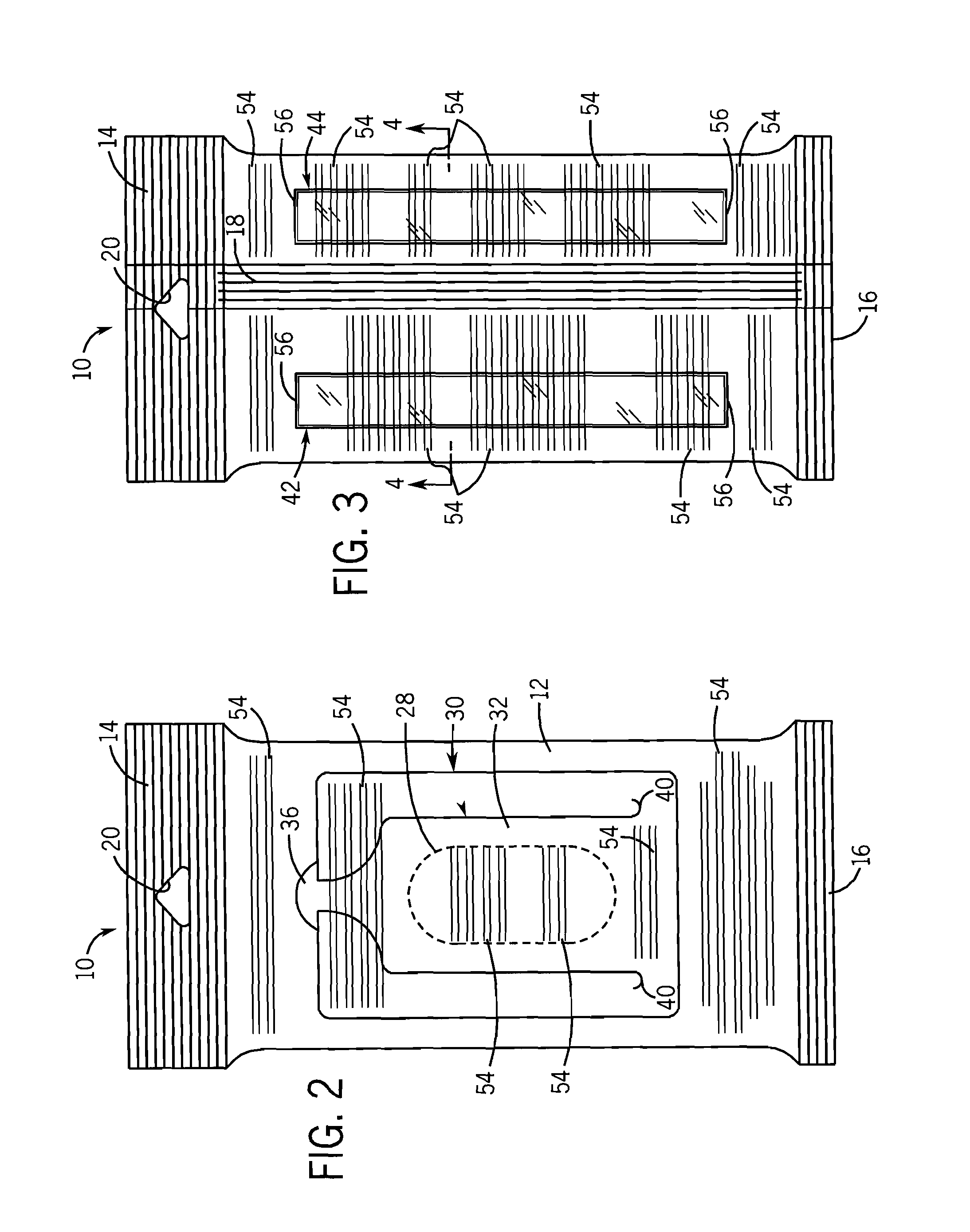

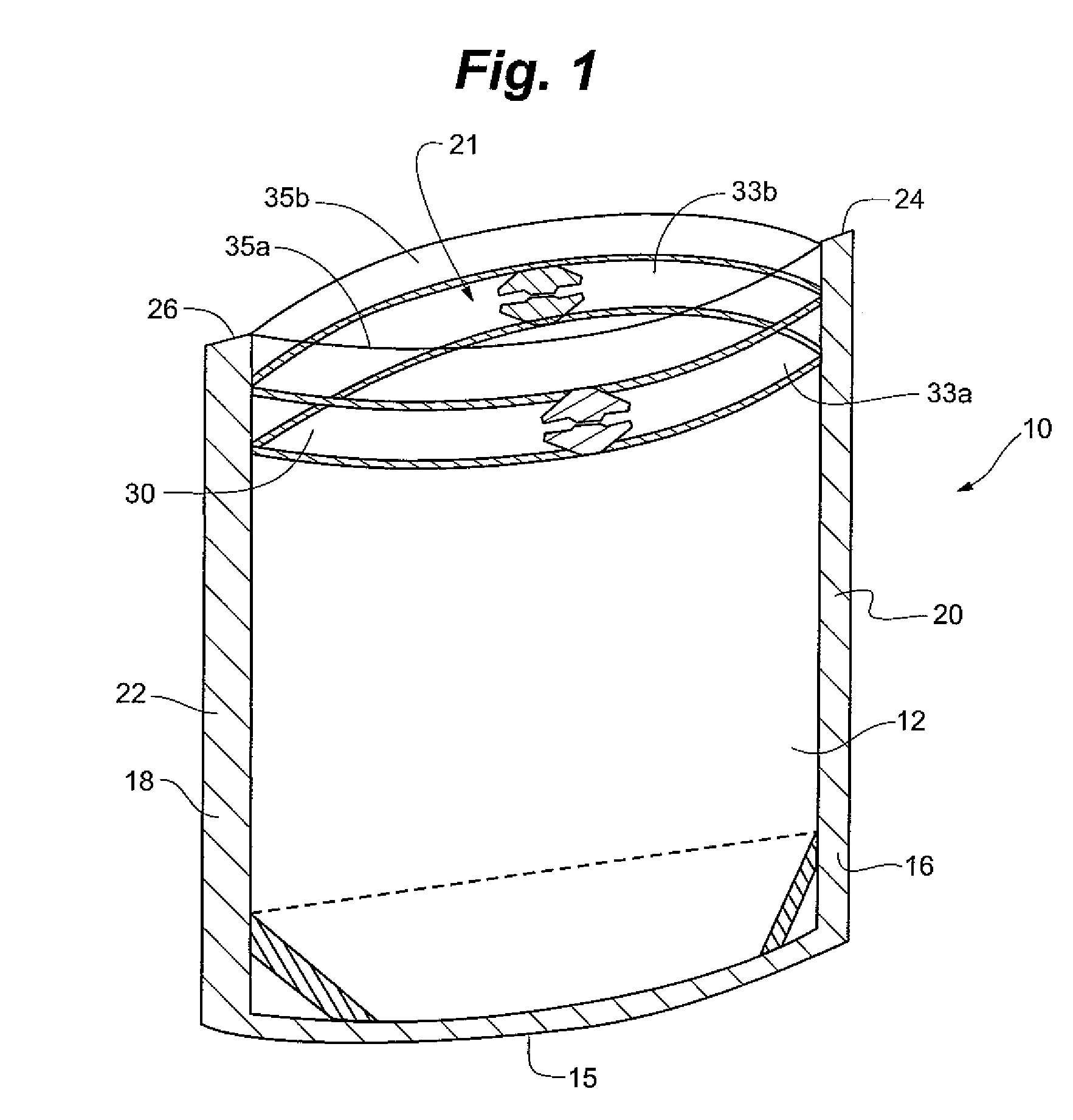

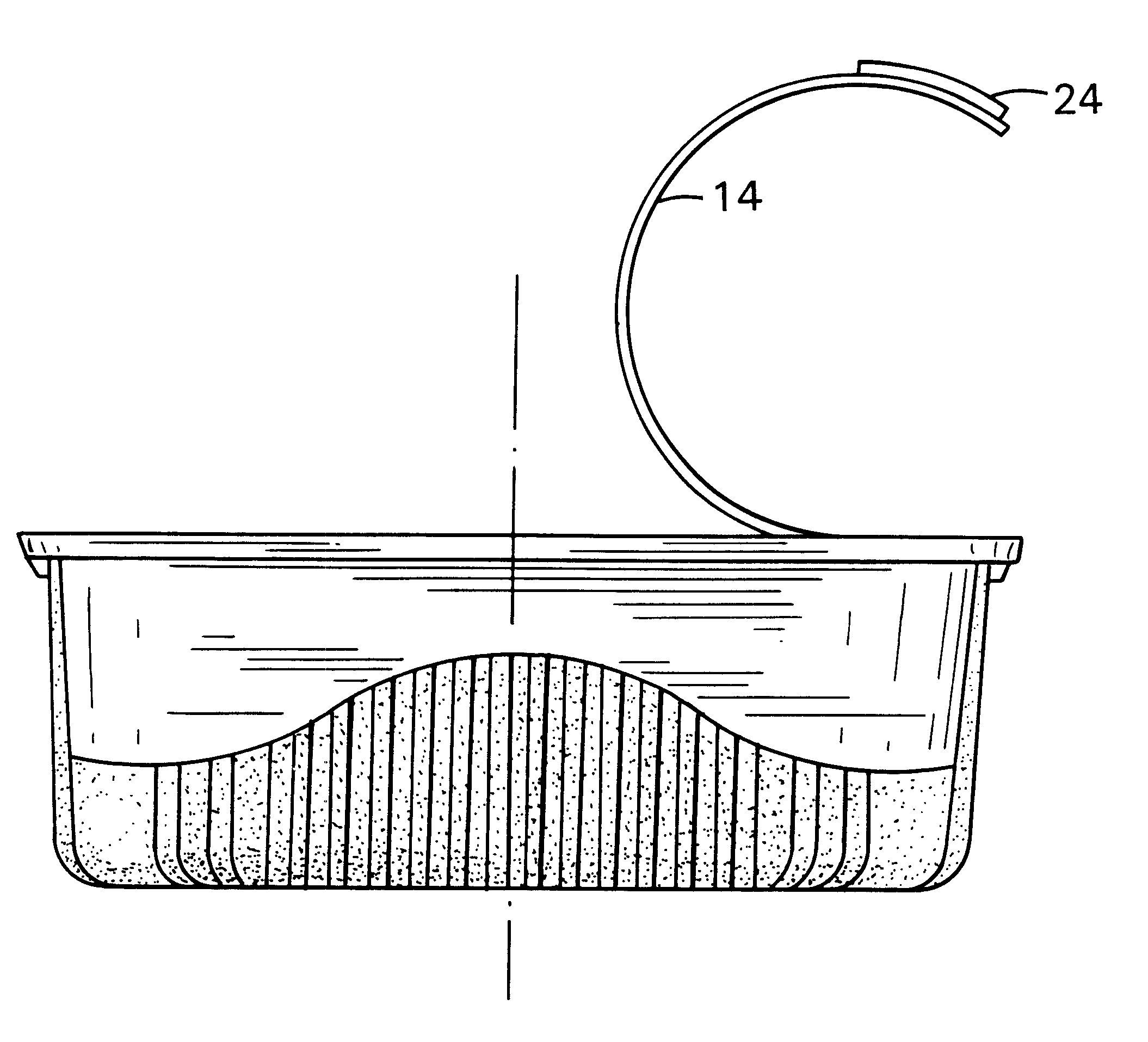

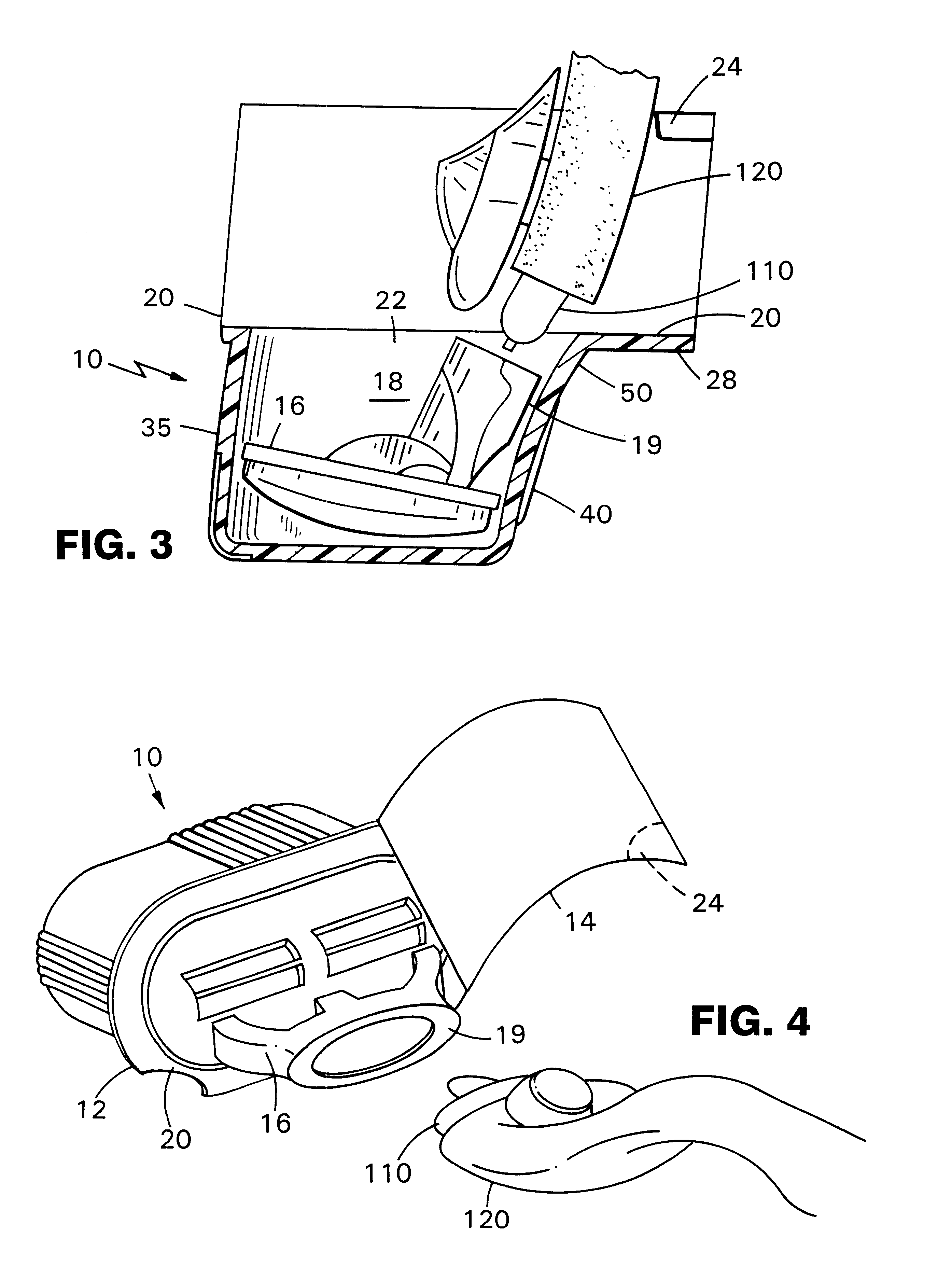

Container for shaving cartridge or other stored item

InactiveUS6648140B2Fine surfaceConnecting packagesDispensing apparatusHermetic packagingMechanical engineering

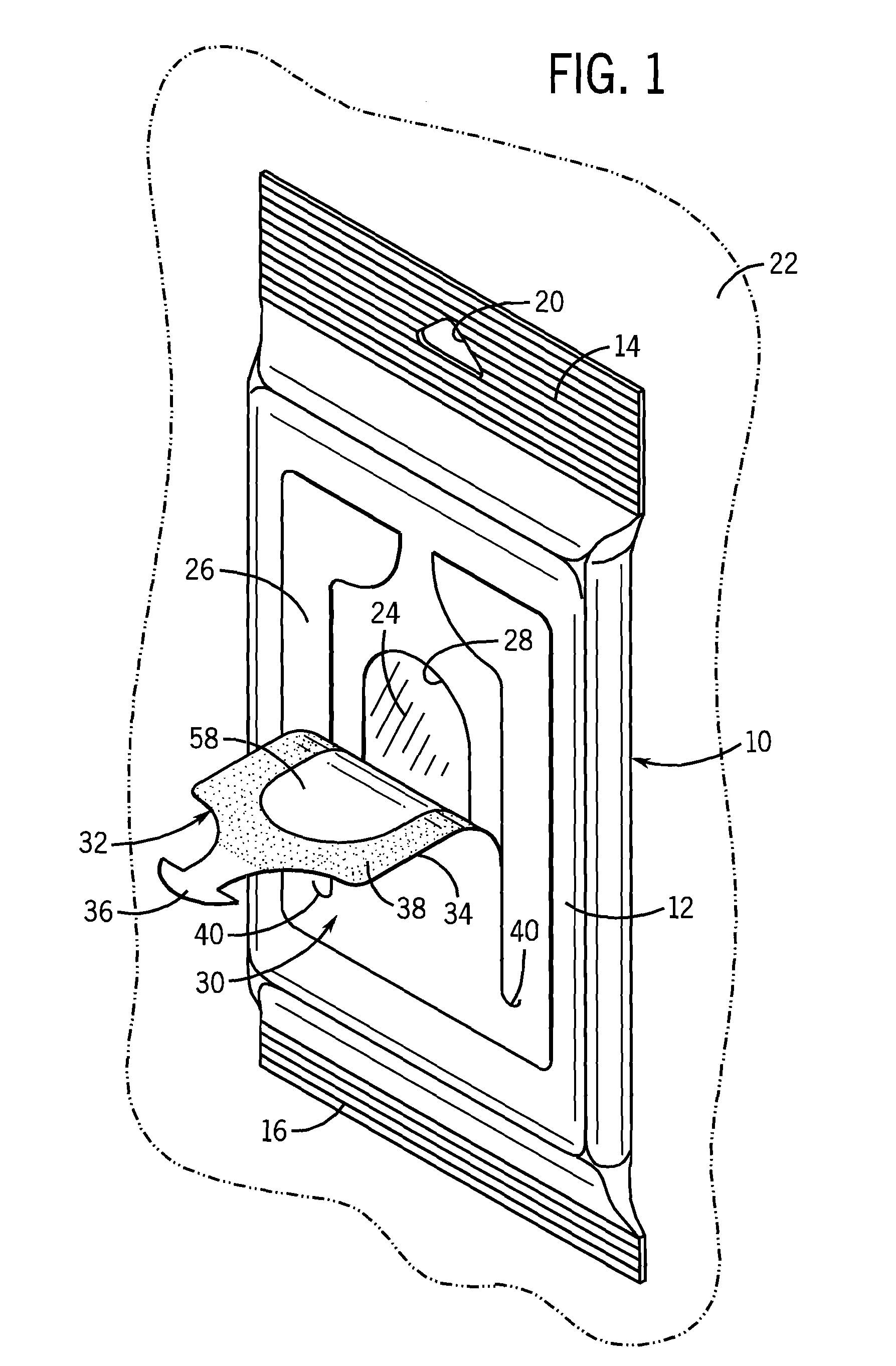

Sealed package that includes a formed plastic container, a shaving cartridge (or other stored unit) in a storage region in the container, and a removable film that covers and is sealed to a sealing surface around an entrance to the storage region. Side walls of the container have retaining structure that protrudes inward and retains the shaving cartridge (or other stored unit). The container has a lip adjacent to and extending from a side wall of the container at an entrance to the storage region to space a user's finger or thumb from the entrance during removal of the cartridge. The removable film has deadfold characteristics which facilitate removal of the cartridge when the film is still partially connected at the rear of the container. A plastic tab is attached to a portion of the film extending beyond the sealing surface of the container to initiate peeling of the film from the sealing surface. The plastic tab is spaced from the formed plastic container by a gap.

Owner:THE GILLETTE CO

Process for detecting leaks in sealed packages

InactiveUS20060121613A1Chemiluminescene/bioluminescenceSynthetic resin layered productsLength waveChemistry

The present invention relates to a process for detecting a leak in a package. The process comprises preparing a package by covering at least a portion of an O2-sensitive product with a multilayer film comprising (i) a leak-indicator layer in which a O2-sensitive indicator is present throughout the leak-indicator layer; and (ii) an O2-barrier layer outward of the leak-indicator layer. A low O2-environment is provided within the package. The leak-indicator layer is then illuminated with light containing a wavelength absorbed by the O2-sensitive indicator, so that the O2-sensitive indicator produces an emission of radiation in an amount inversely proportional to a level of O2 present with the O2-sensitive indicator. Then the multilayer film is scanned while the O2-sensitive indicator is emitting radiation, the scanning being carried out by sensing and comparing the amount of radiation emitted from at least two different regions of the multilayer film.

Owner:CRYOVAC ILLC

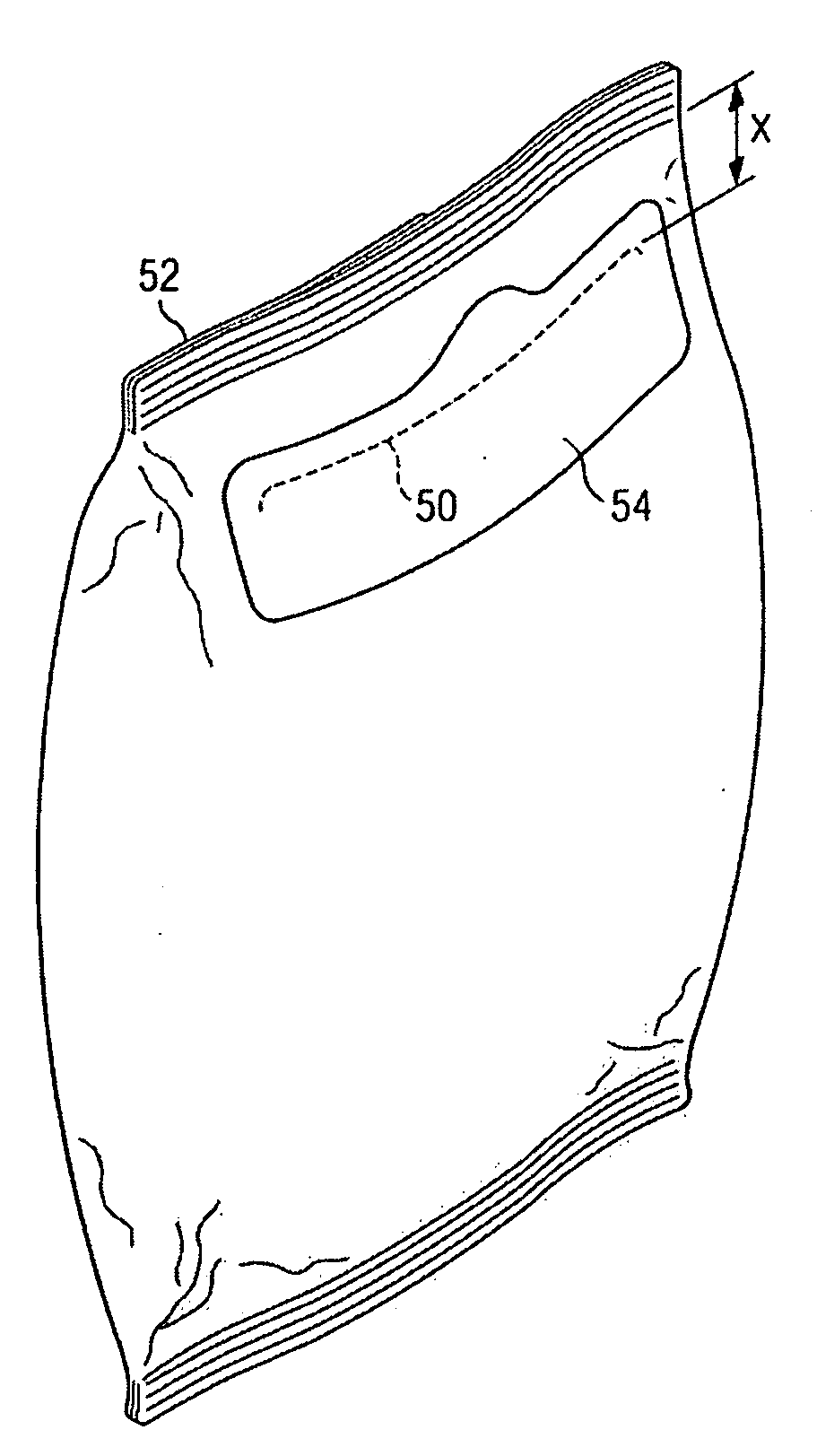

Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

InactiveUS20100111453A1Prevent premature deterioration of qualityAvoid damageCapsDecorative coversSheet filmHermetic packaging

Two side cut reseal with pressure sensitive adhesive. A flexible package having a reseal integrated within the opposite layers of its film is constructed using existing vertical form fill and seal packaging machines. The invention involves a single sheet of flexible packaging film web having at least three layers. In a preferred embodiment, the reseal is comprised of two offsetting score lines on interior and exterior sides of the film and spaced apart by 0.5 to 1 inch. The scoring creates lines of weakness, which define an opening in the package. Upon opening, a pressure sensitive adhesive layer, which is pattern applied in between the offsetting score lines, is exposed from an interior side of the film. The adhesive releasably adheres the inner and outer layers of the film back together once separated by a consumer.

Owner:FRITO LAY NORTH AMERICA INC

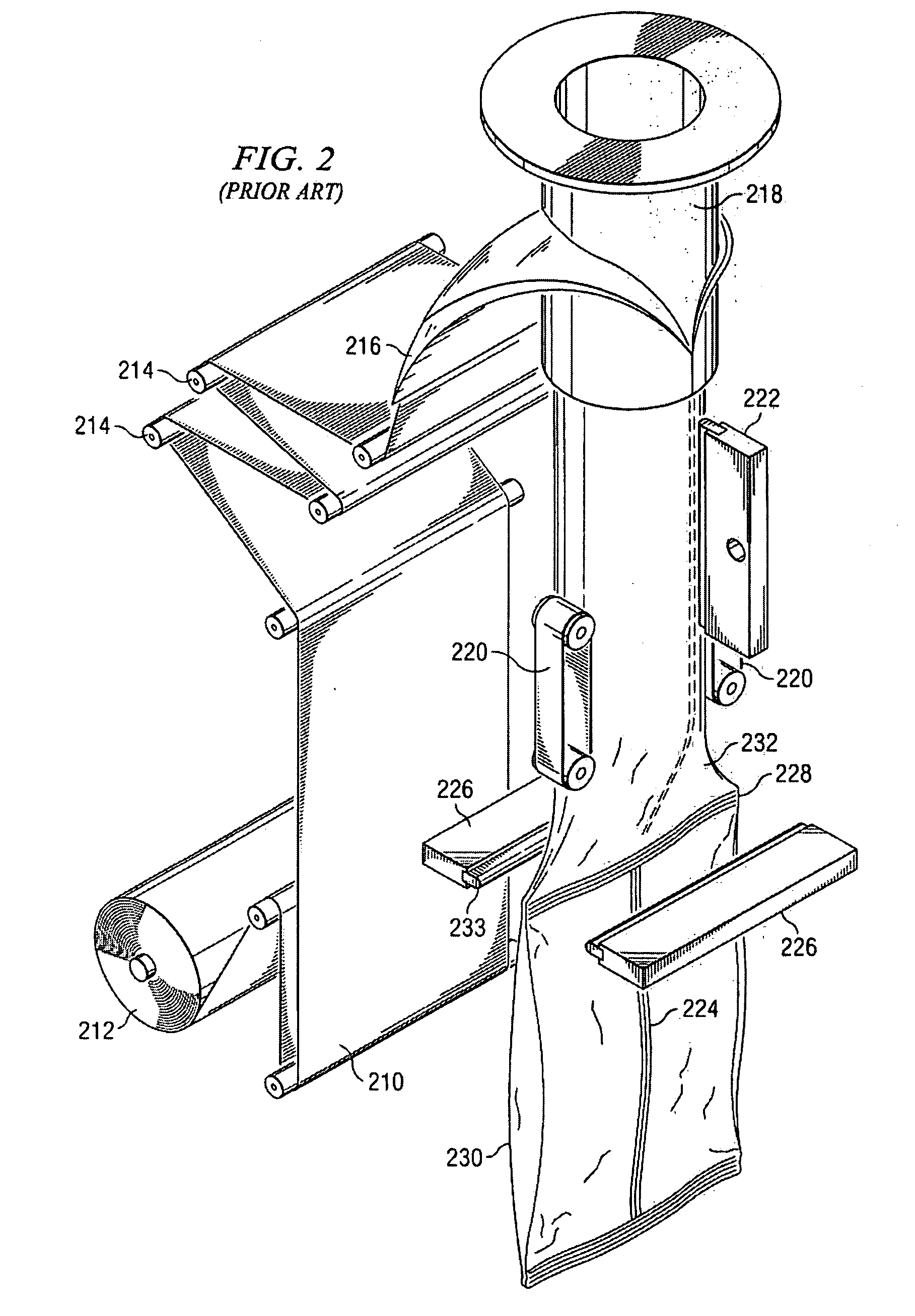

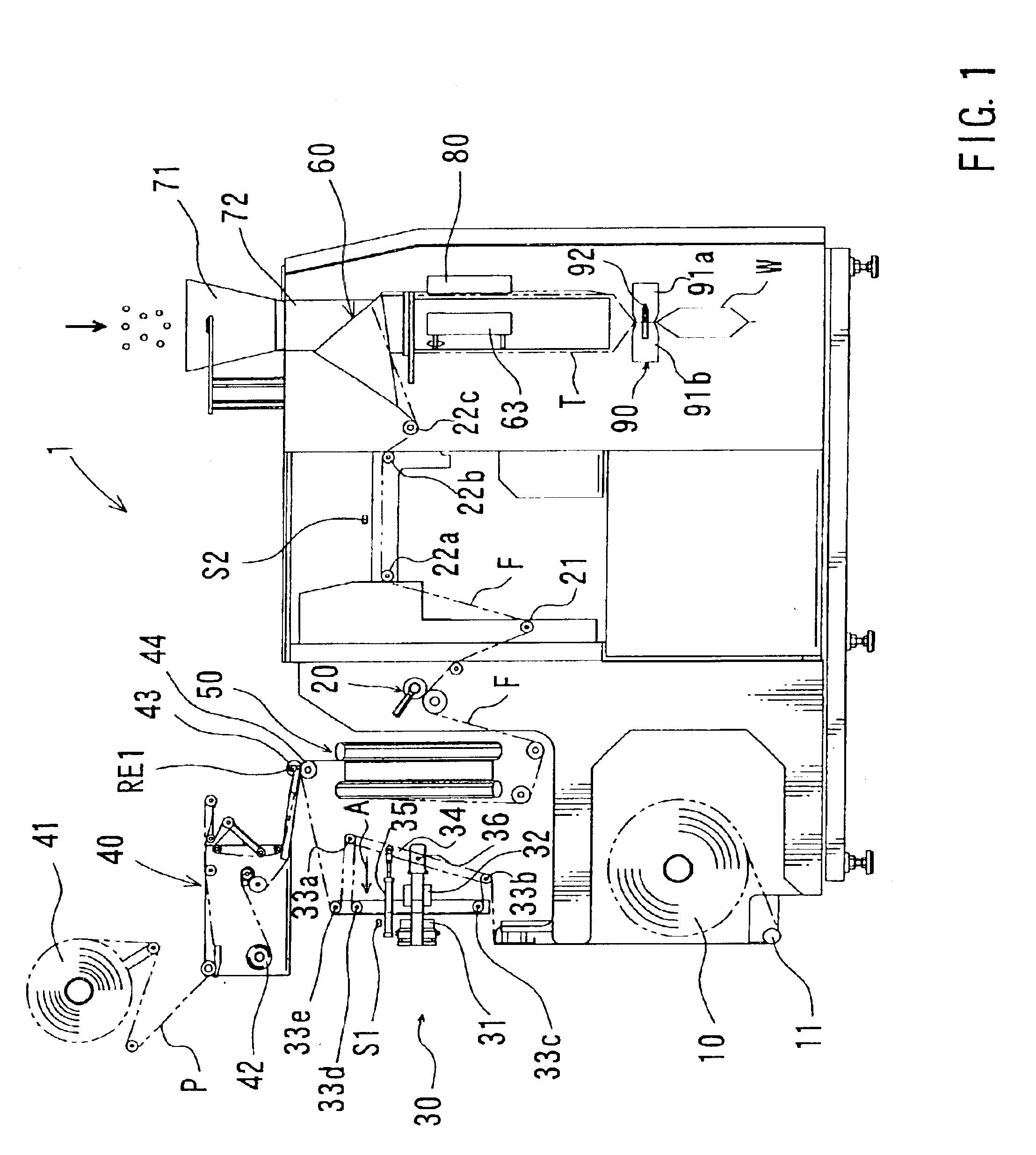

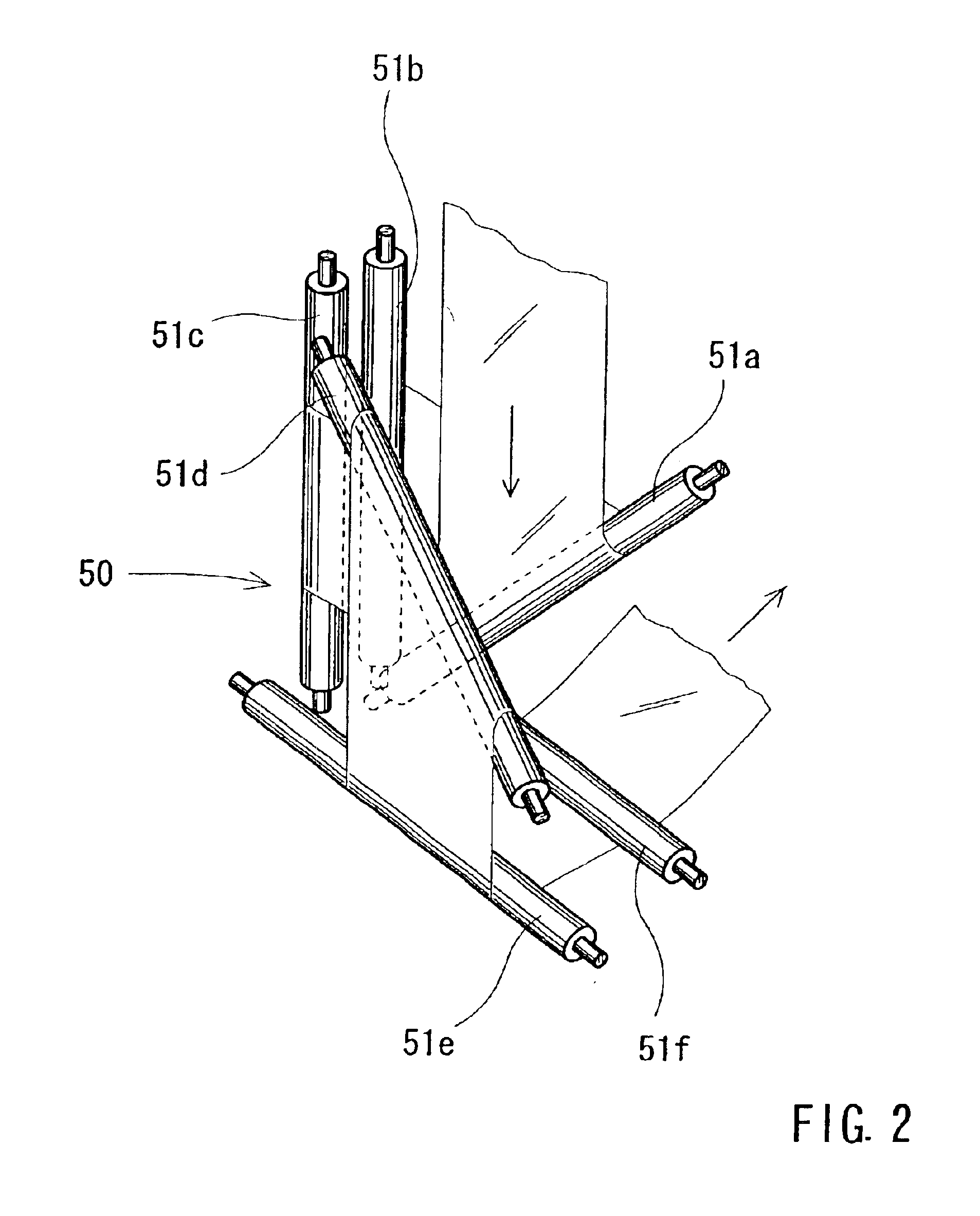

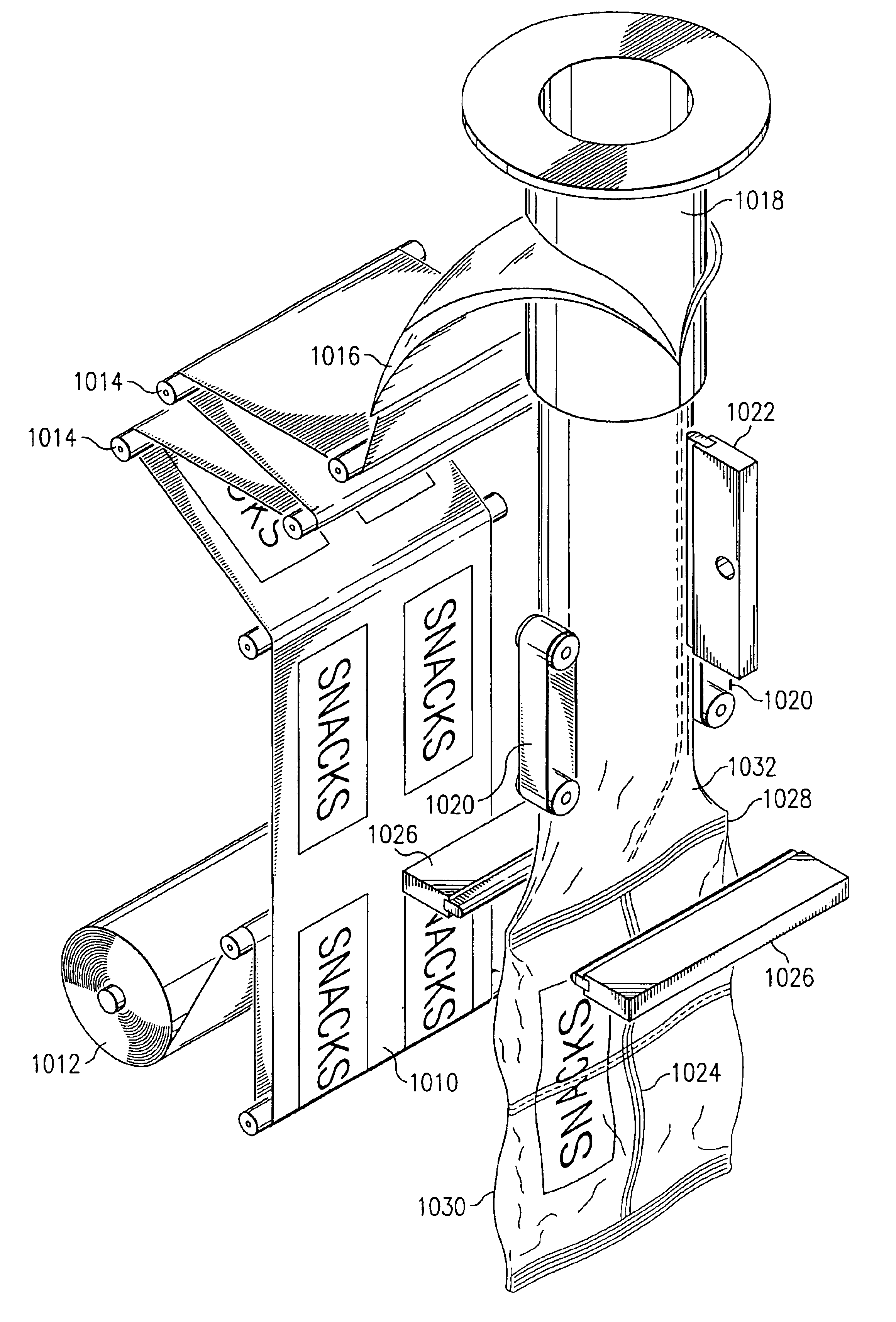

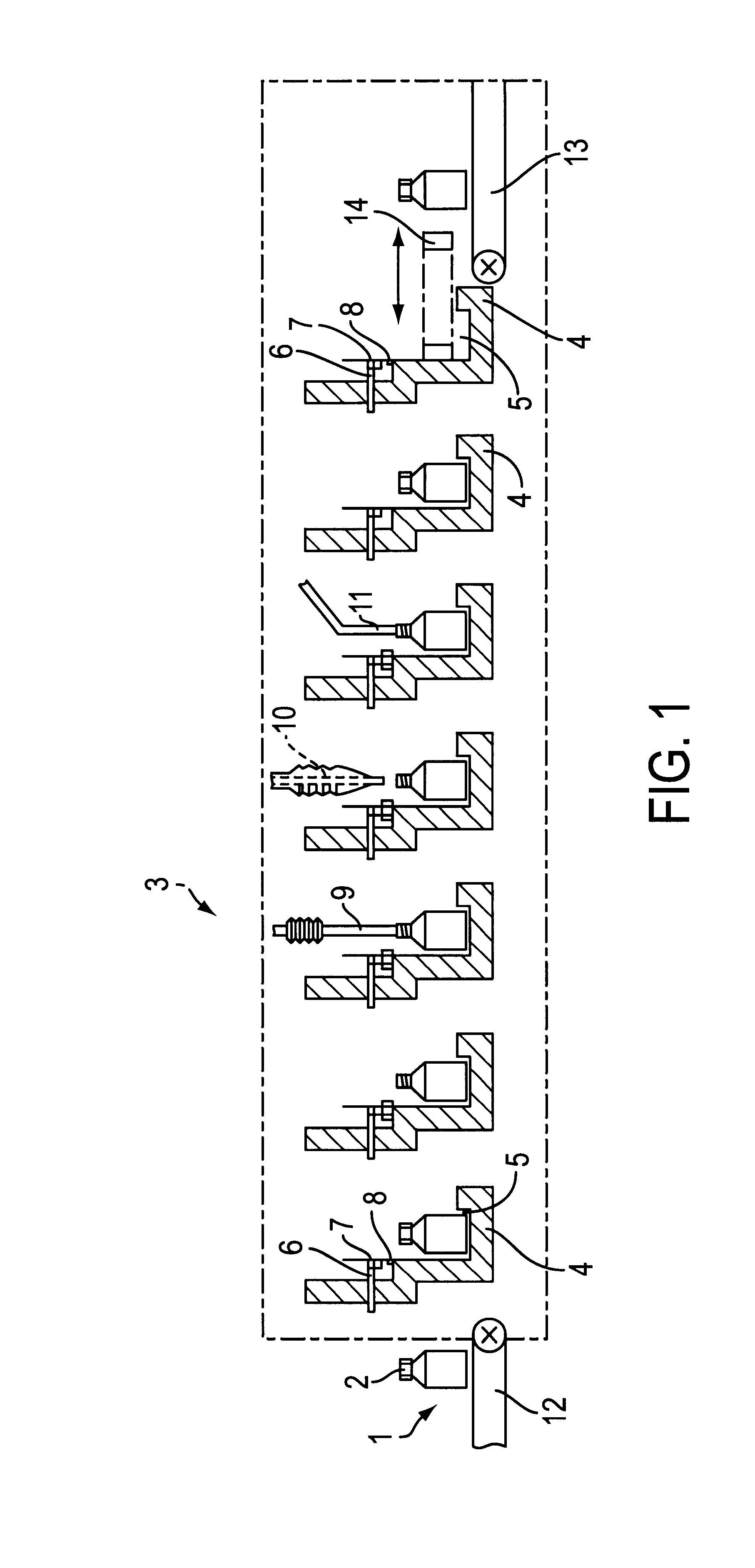

Form-fill sealing machines, resealable flexible packages and methods of manufacturing resealable flexible packages

InactiveUS6865860B2Hinders its propagationReliable stopWrapping material feeding apparatusBagsHermetic packagingEngineering

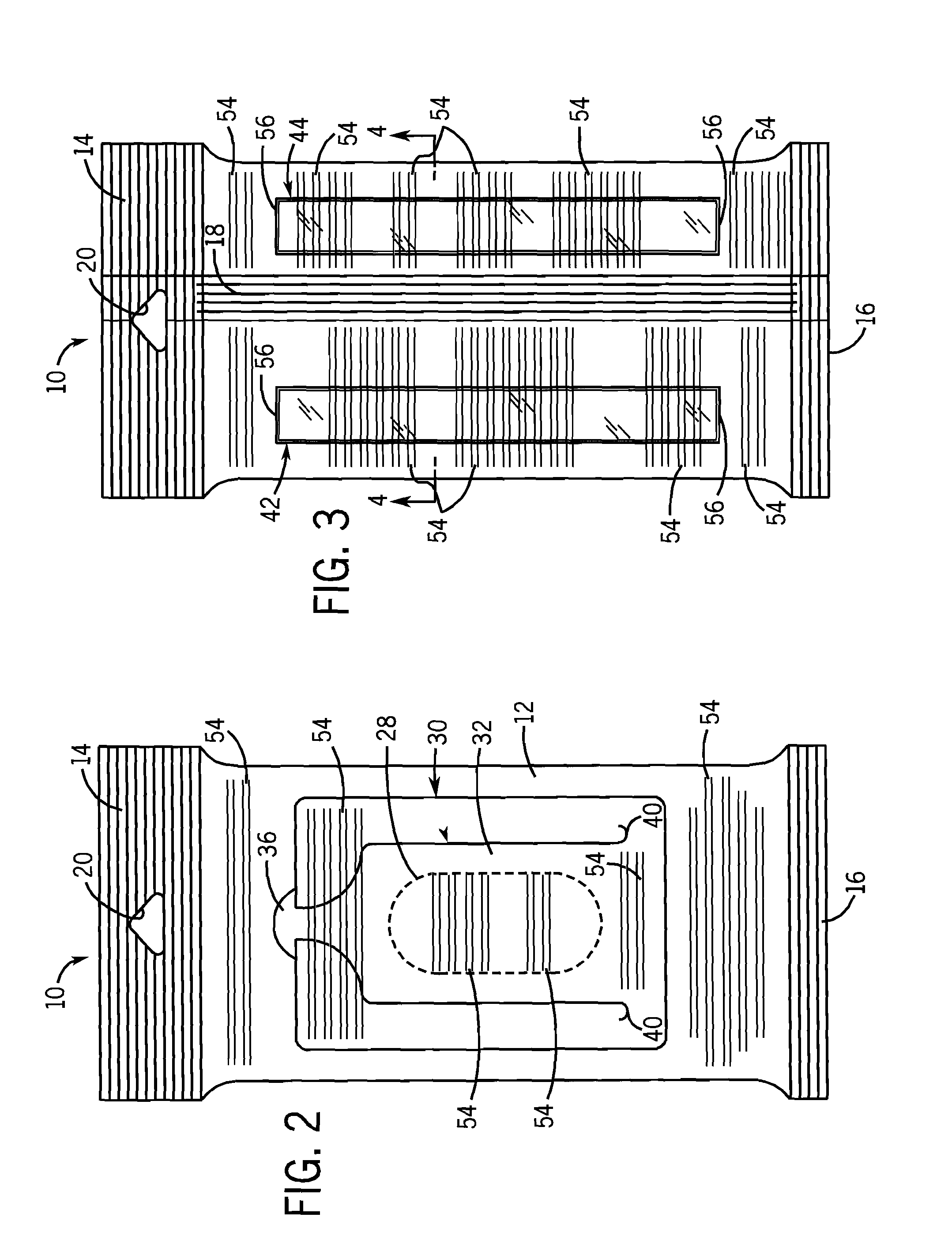

A form-fill sealing machine (1) for manufacturing resealable packages (W) includes a tearable line forming device (30) that serves to form tearable lines (104) in a film (F). A labeling device (40) serves to stick re-stickable labels (103) onto the film in positions to cover respective tearable lines. A tube forming device (60) serves to form the film into a tubular film (T). A first sealing device (80) serves to seal lapped edges of the tubular film so as to form a lengthwise sealed portion (111). A second sealing device (90) serves to seal the tubular film in a crosswise direction, so that crosswise sealed portions (109) are formed on the tubular film. Each tearable line is positioned between two adjacent crosswise sealed portions and adjacent to one of two adjacent crosswise sealed portions.

Owner:FUJI KIKAI KK

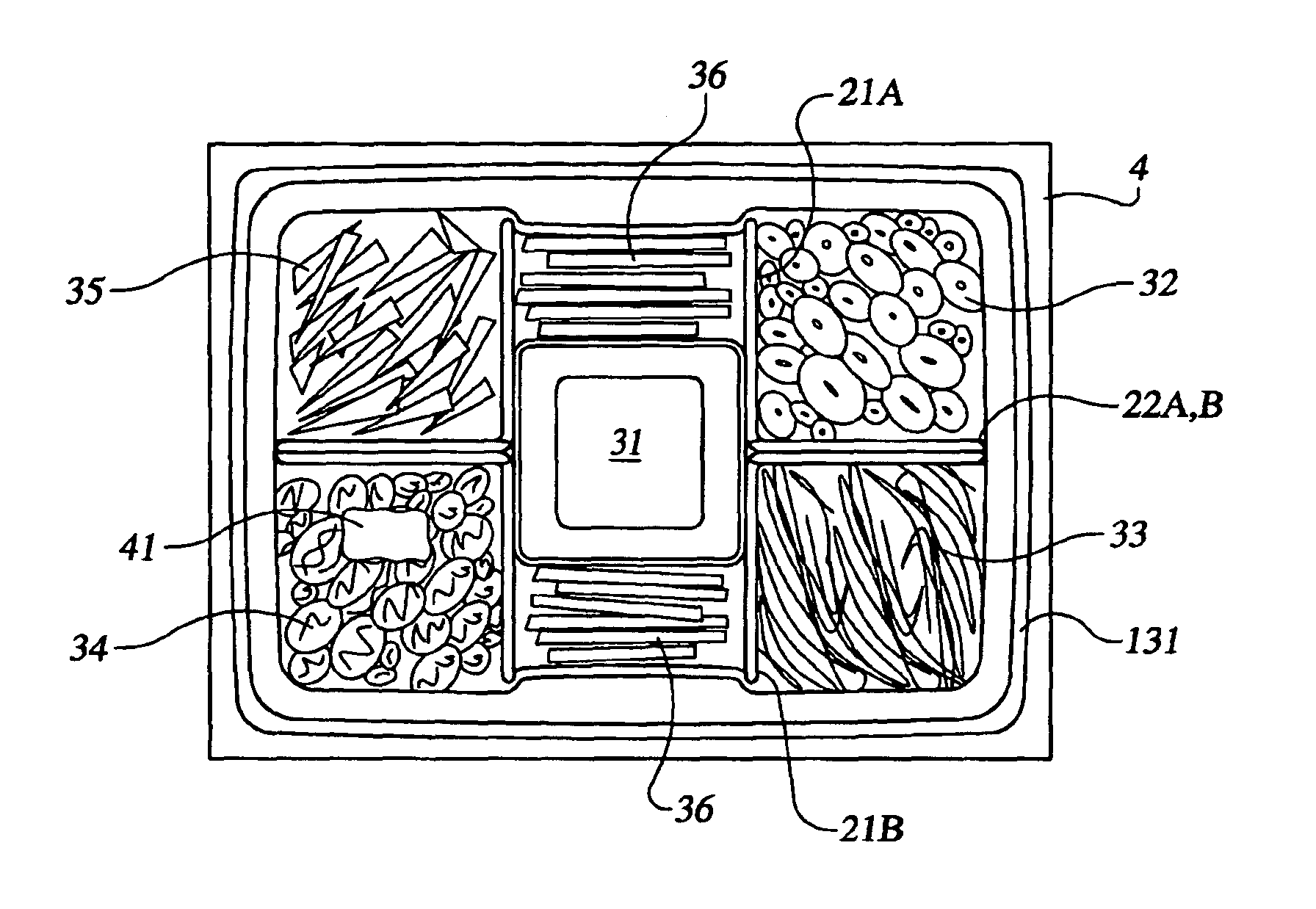

Party tray

InactiveUS7083818B2Small proportionPackaging protectionThin material handlingHermetic packagingMechanical engineering

A party tray includes a support tray and, on the support tray, a sealed package made up of transparent container body and a polymeric sealing sheet sealed to the rim of the container body. The sealed package contains foodstuffs, in particular respiring foodstuffs such as fresh fruits and vegetables, which rest on the sealing sheet; the sealing sheet is in turn supported by the support tray. The sealed package may include an atmosphere control member. When the party tray is on display, its contents are viewed through the single thickness of the container body.

Owner:CURATION FOODS INC

Stick-on, flexible, peel and seal package dispenser

A stick-on, flexible peel and seal, wet wipes package includes a flexible package body having a front surface, a rear surface, and an internal space sized to contain a plurality of removable wet wipes. An elongated opening extends through the package body to the internal space for accessing and permitting dispensing of the removable wet wipes. A substantially self-closing, resealable label flap is positioned on the front surface of the package body to cover the opening formed therein. The label flap has a bottom surface provided with a sealing adhesive that creates a seal entirely around the periphery of the opening and permits repeated application and removal of the label flap relative to the package body. The label flap further has a starting tab non-adhesively positionable in contact with the front surface of the package body. An adhesive layer structure is provided on the rear surface of the package body for adhering the package body to a support surface. A removable peel-off release layer structure covers and protects the adhesive layer structure prior to use thereof. The package body and the adhesive layer structure are removable from the support surface following emptying of the wet wipes from the package body.

Owner:STARLINER

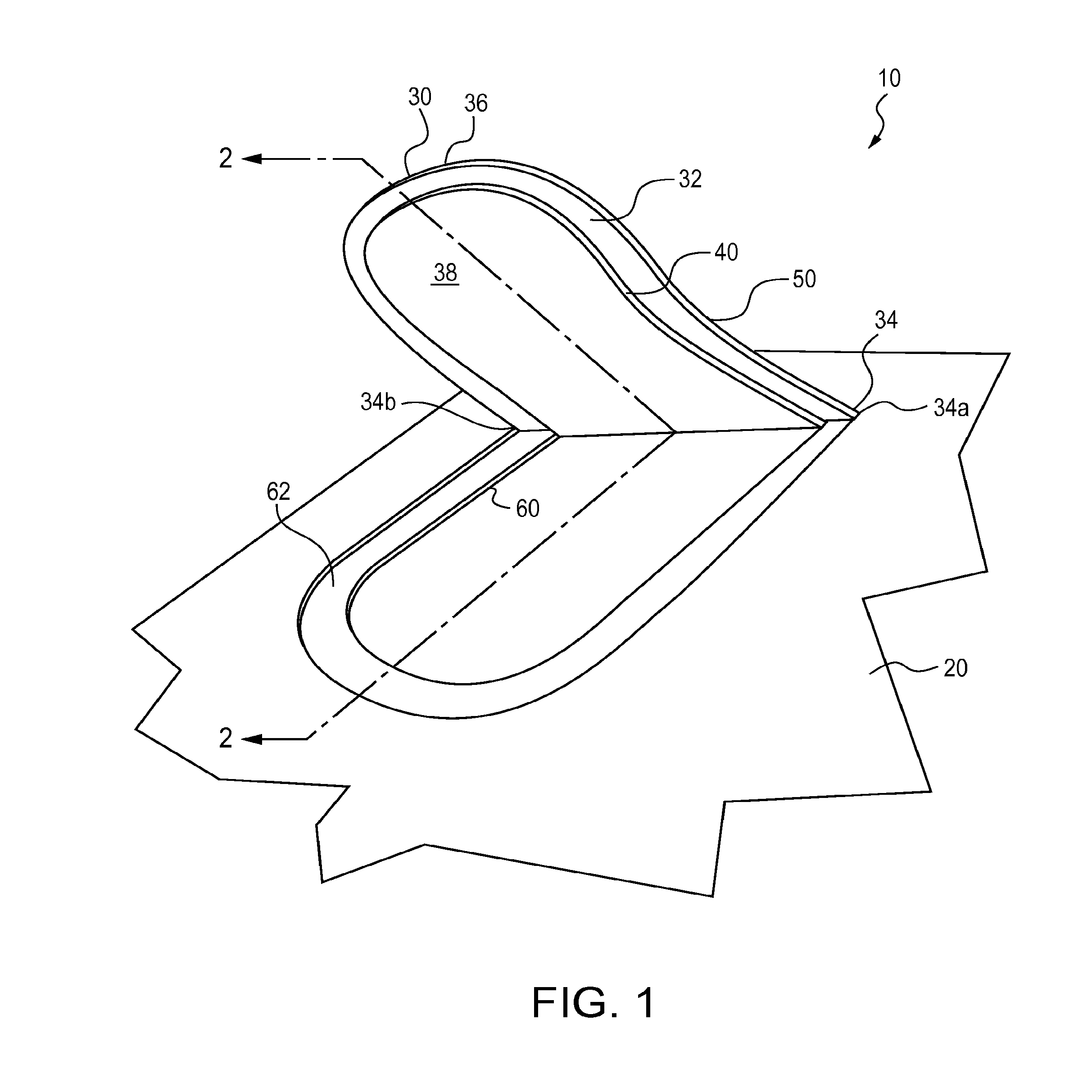

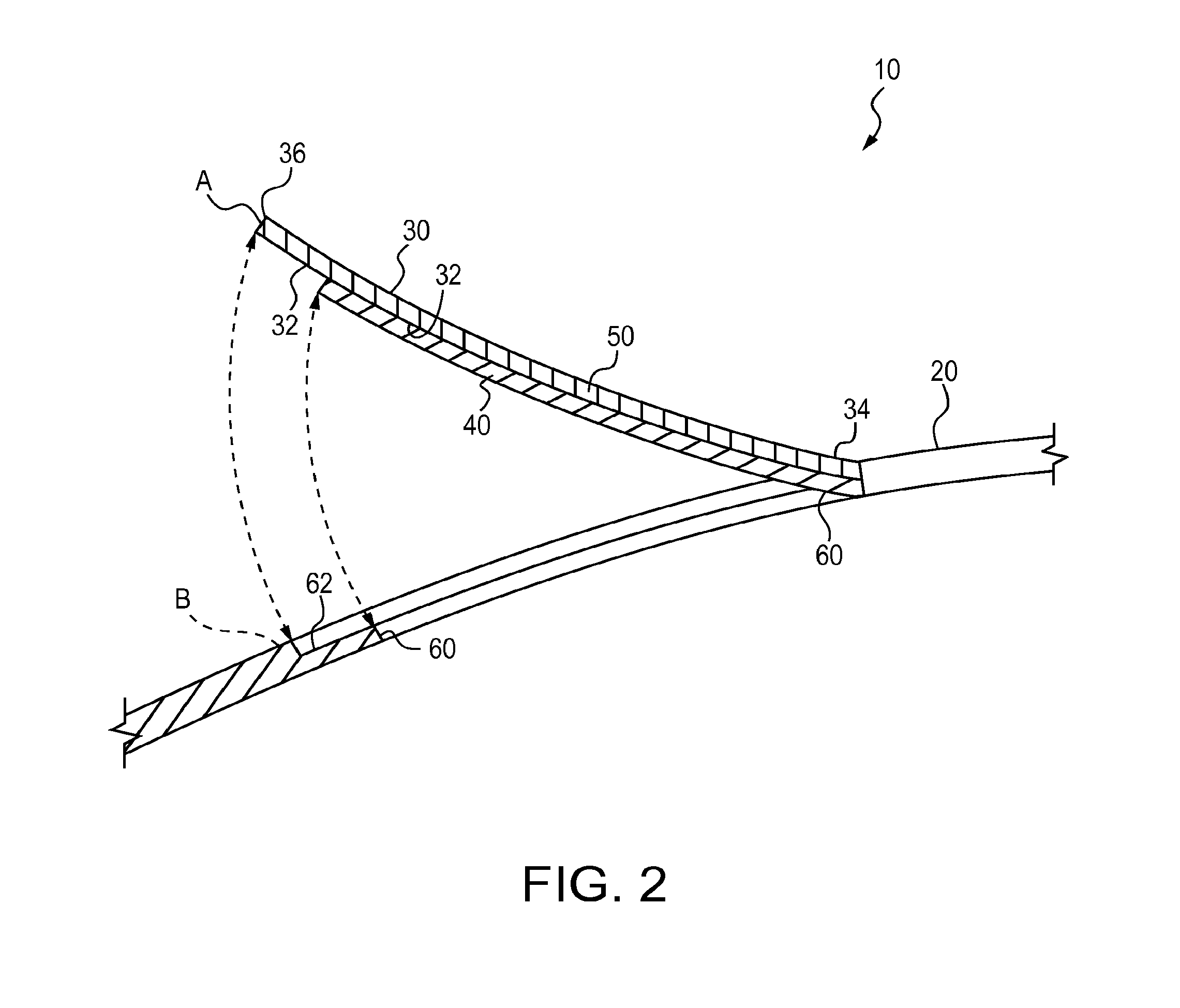

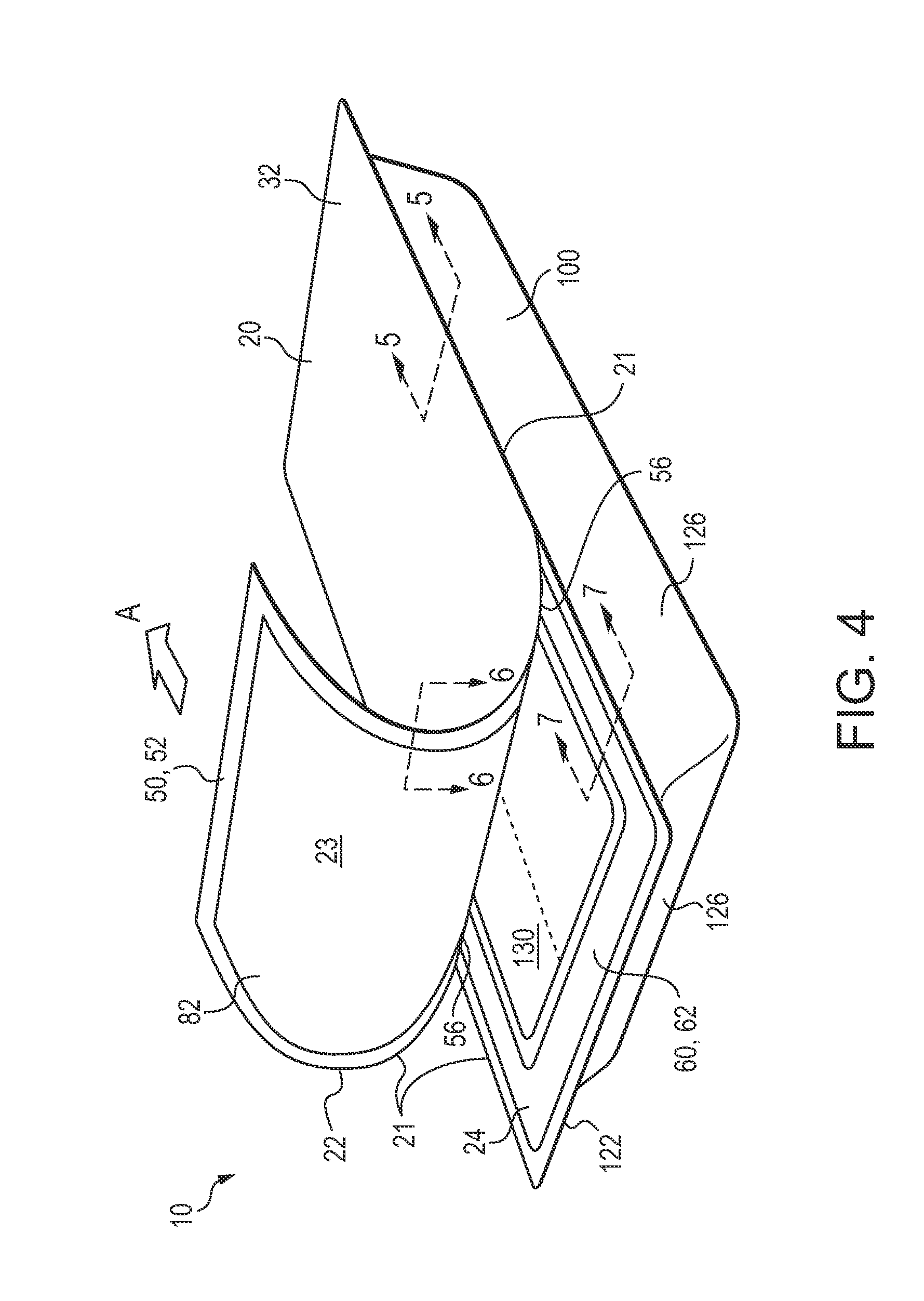

Packages having bubble-shaped closures

ActiveUS8613547B2Repeatable sealing performanceEnvelopes/bags making machineryBag making operationsEngineeringHermetic packaging

Owner:STEELE MARK

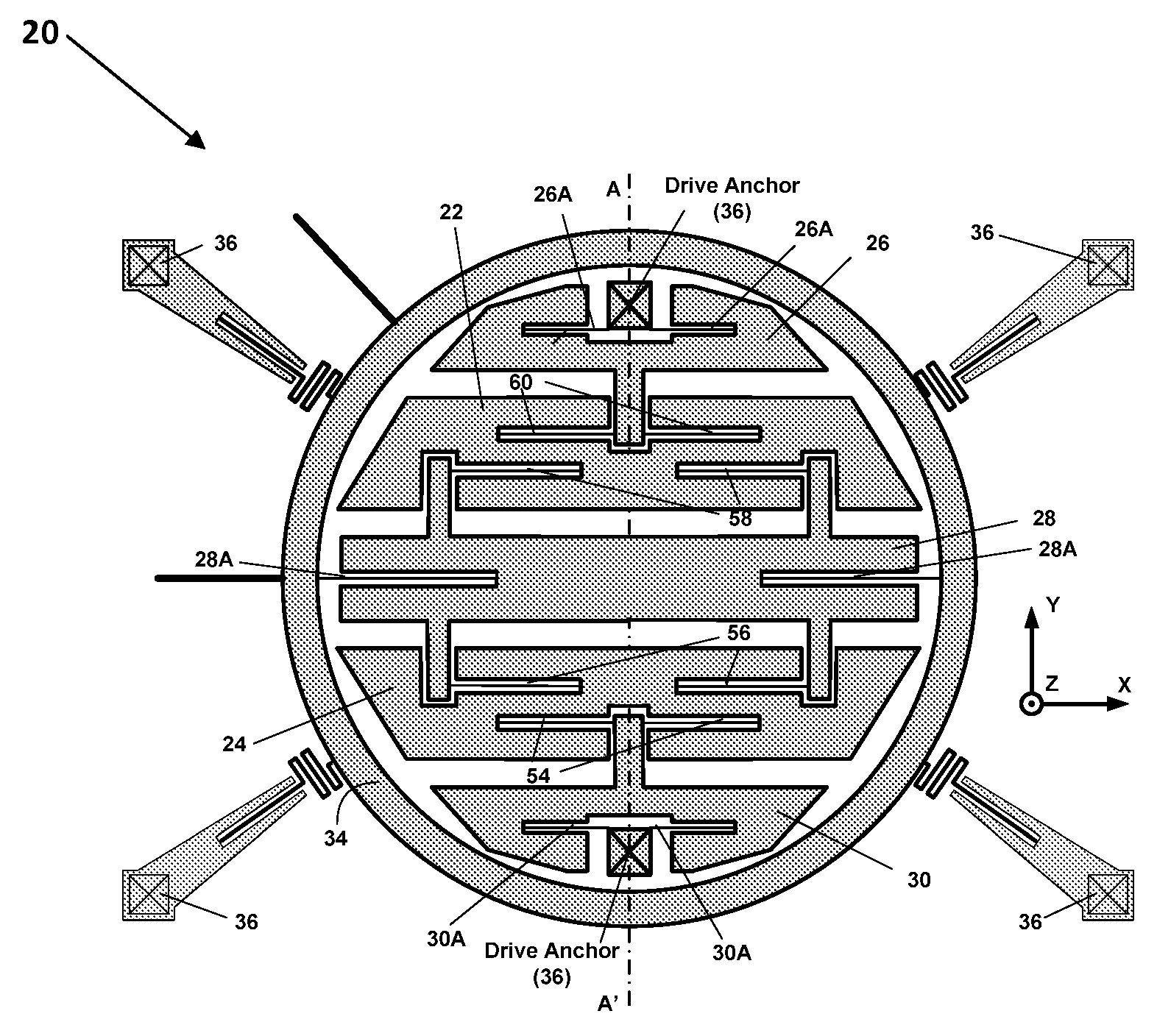

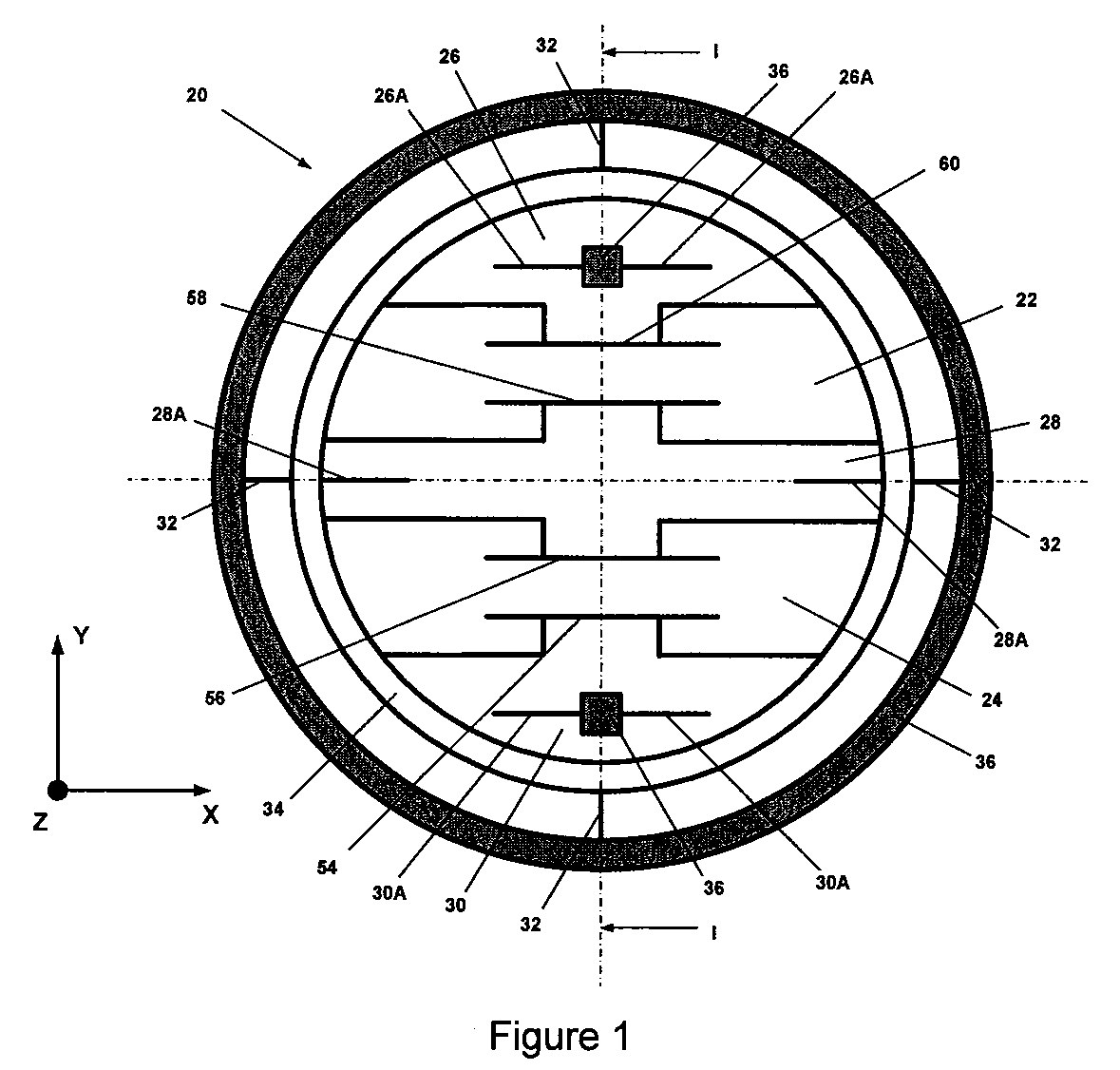

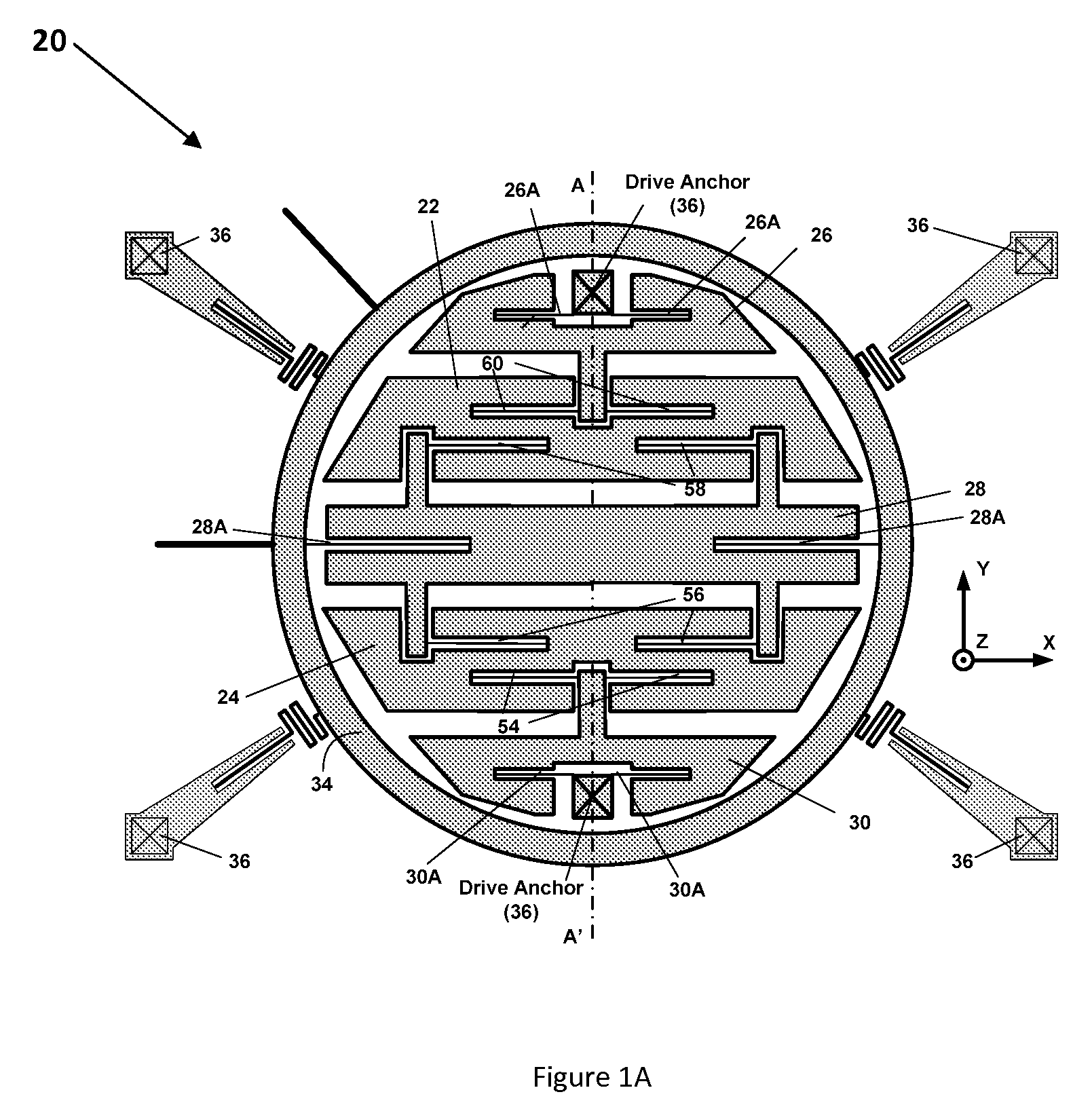

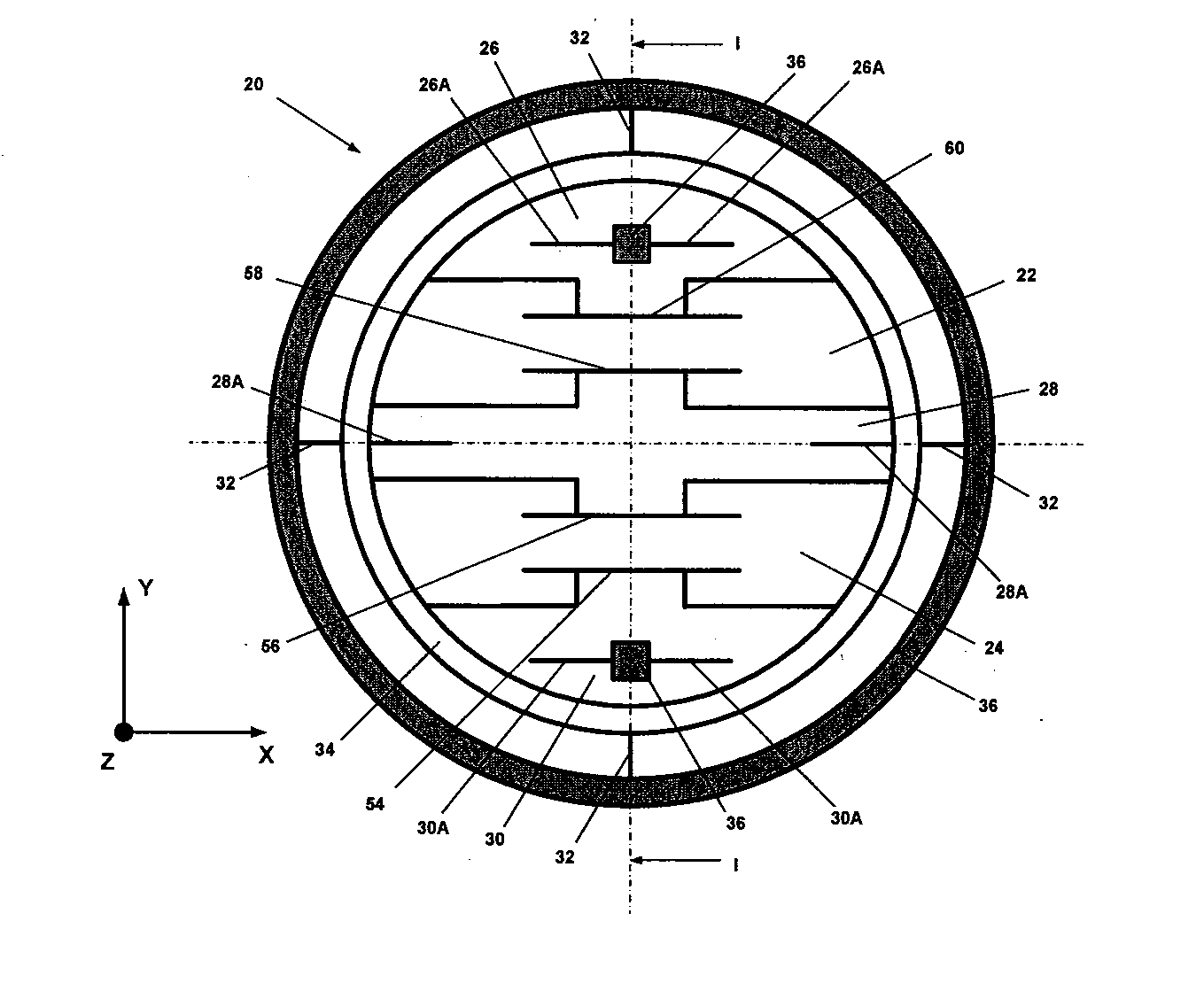

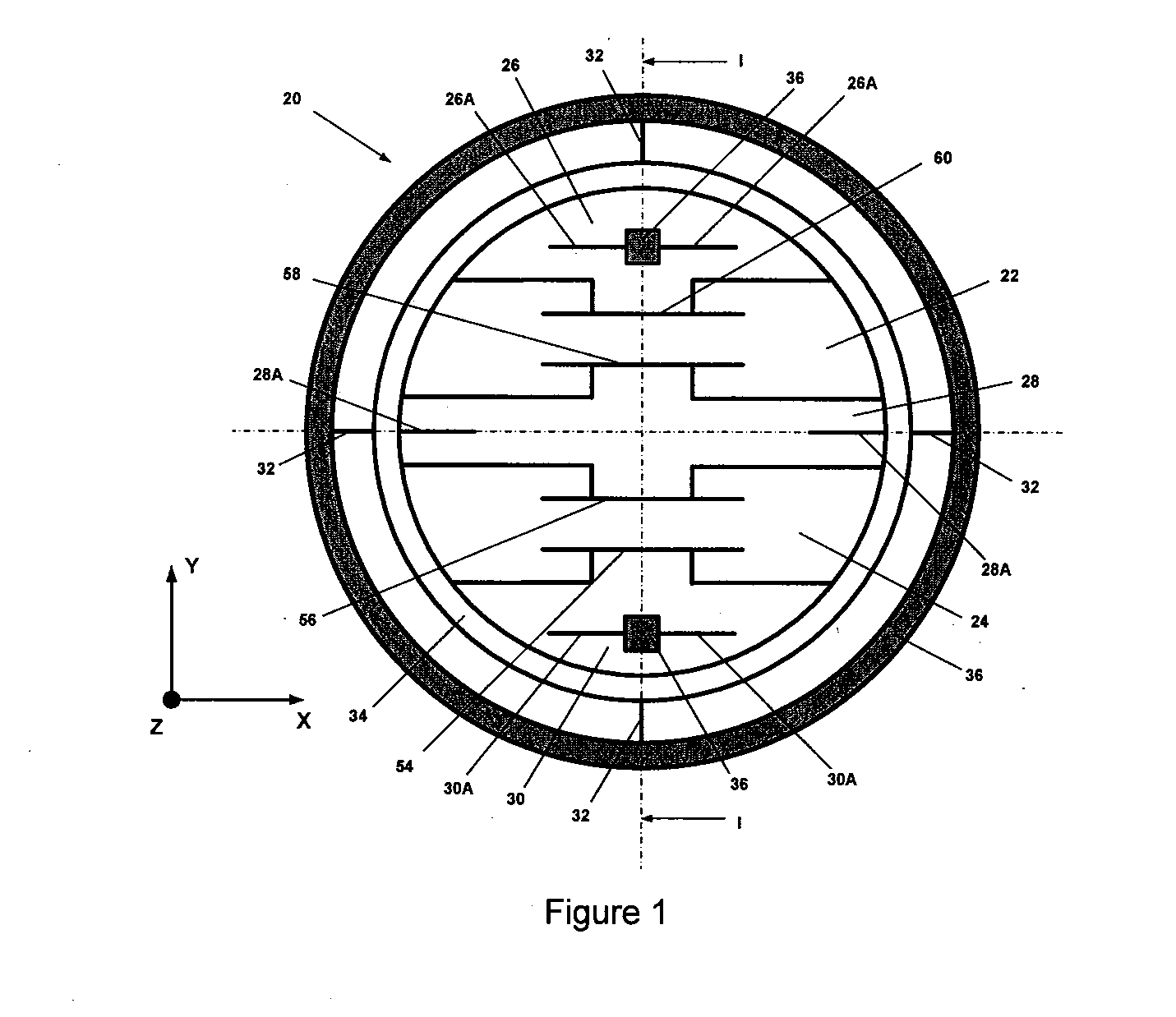

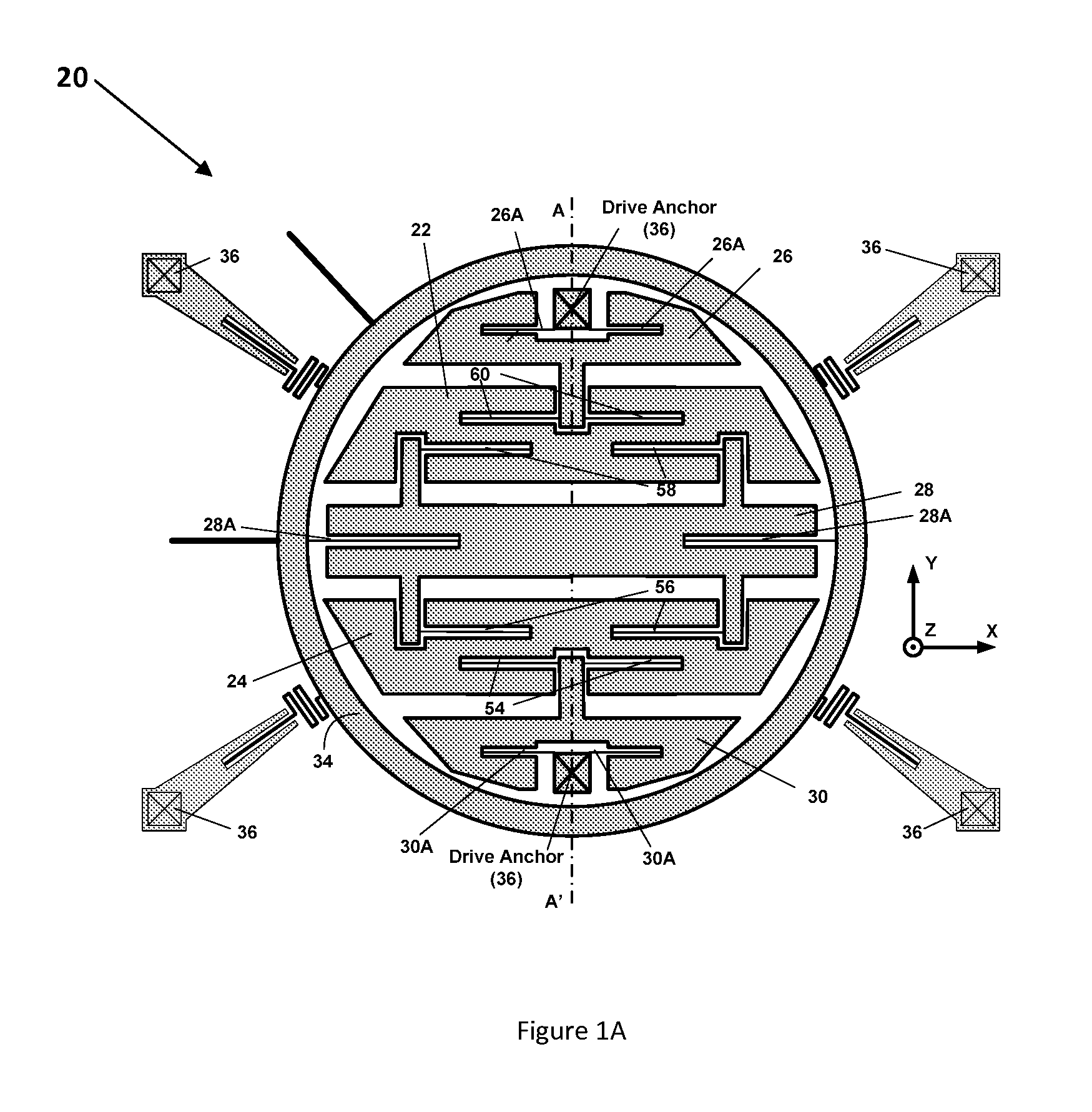

X-Y axis dual-mass tuning fork gyroscope with vertically integrated electronics and wafer-scale hermetic packaging

InactiveUS7621183B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkWafering

An angular velocity sensor has two masses which are laterally disposed in an X-Y plane and indirectly connected to a frame. The two masses are linked together by a linkage such that they necessarily move in opposite directions along Z. Angular velocity of the sensor about the Y axis can be sensed by driving the two masses into Z-directed antiphase oscillation and measuring the angular oscillation amplitude thereby imparted to the frame. In a preferred embodiment, the angular velocity sensor is fabricated from a bulk MEMS gyroscope wafer, a cap wafer and a reference wafer. In a further preferred embodiment, this assembly of wafers provides a hermetic barrier between the masses and an ambient environment.

Owner:INVENSENSE

X-y axis dual-mass tuning fork gyroscope with vertically integrated electronics and wafer-scale hermetic packaging

ActiveUS20080115579A1High measurement accuracyGood Common Mode RejectionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkGyroscope

An angular velocity sensor has two masses which are laterally disposed in an X-Y plane and indirectly connected to a frame. The two masses are linked together by a linkage such that they necessarily move in opposite directions along Z. Angular velocity of the sensor about the Y axis can be sensed by driving the two masses into Z-directed antiphase oscillation and measuring the angular oscillation amplitude thereby imparted to the frame. In a preferred embodiment, the angular velocity sensor is fabricated from a bulk MEMS gyroscope wafer, a cap wafer and a reference wafer. In a further preferred embodiment, this assembly of wafers provides a hermetic barrier between the masses and an ambient environment.

Owner:INVENSENSE

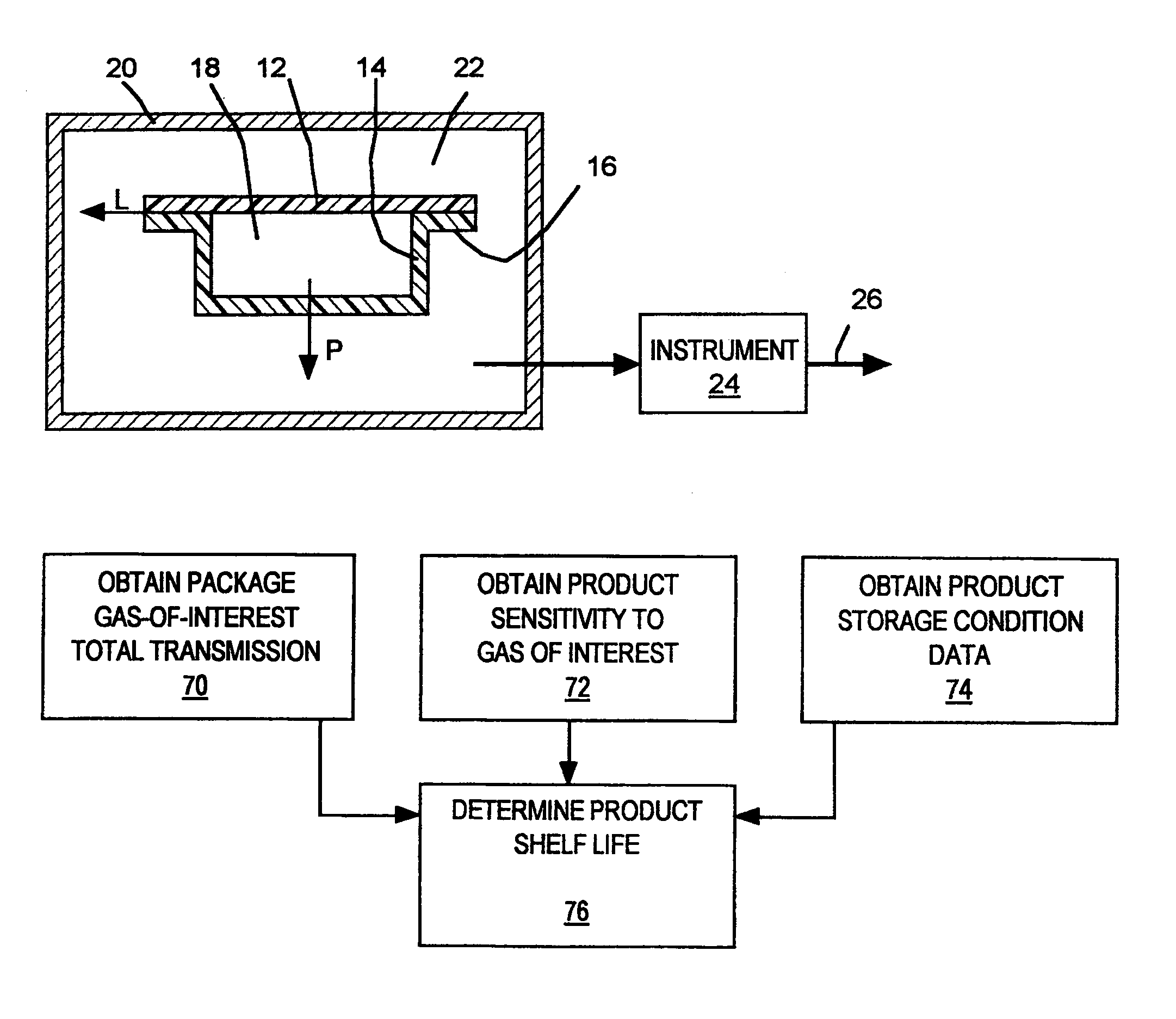

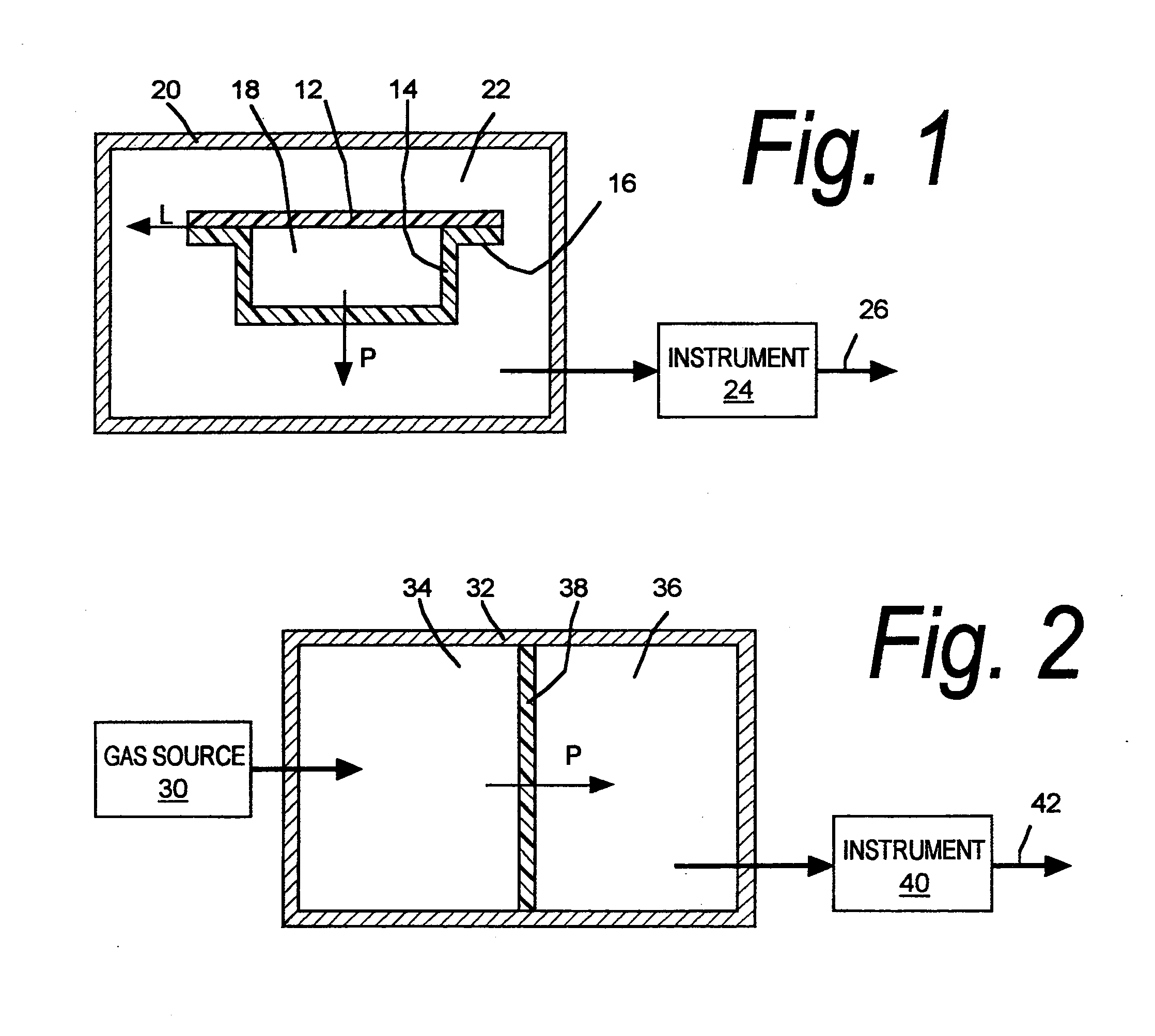

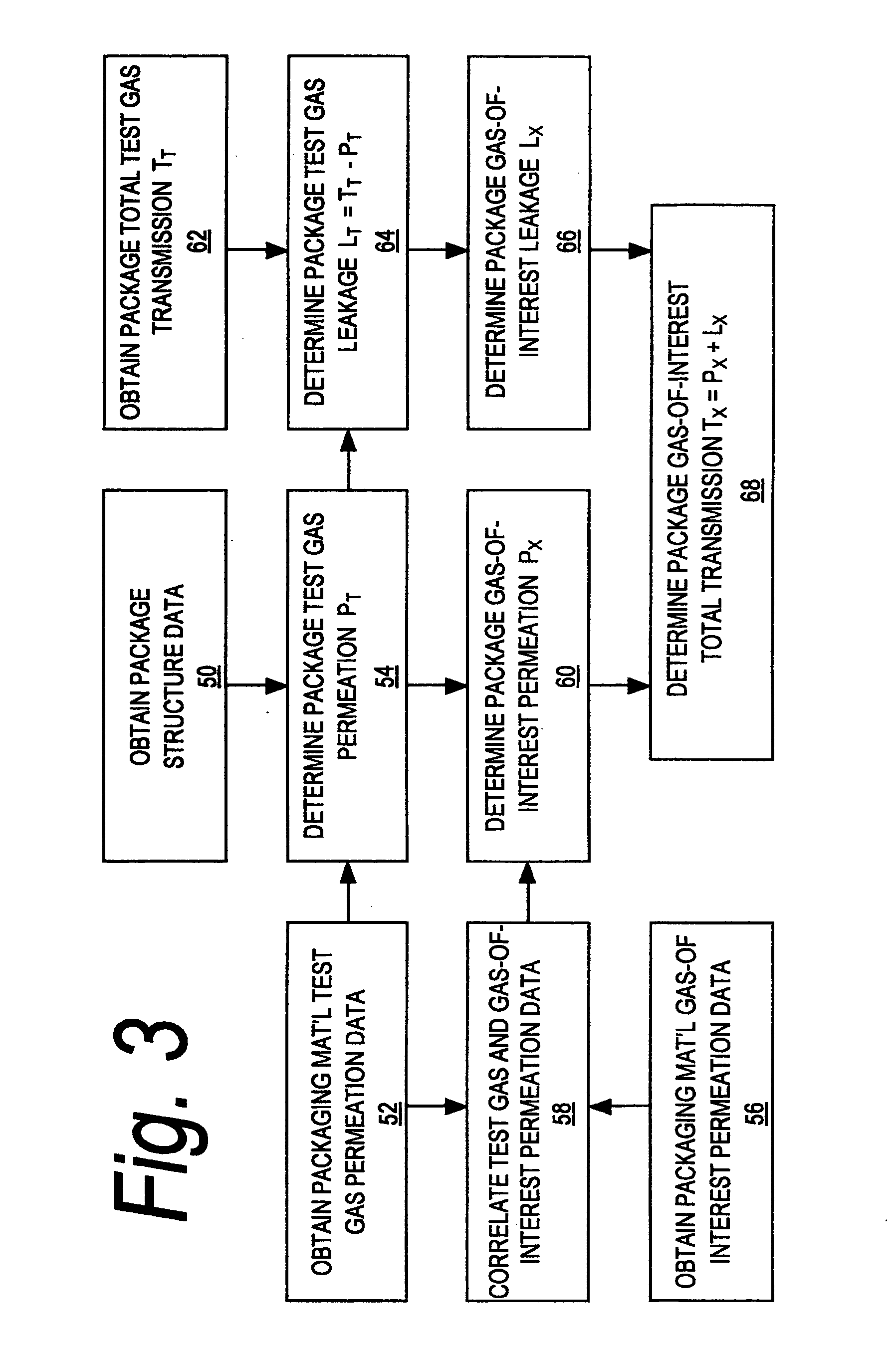

System for determing the integrity of a package or packaging material based on its transmission of a test gas

InactiveUS6892567B1Detection of fluid at leakage pointPermeability/surface area analysisWater vaporTransmittance

A sealed package's transmission of oxygen, water vapor, carbon dioxide, or other gas or vapor that is of interest because of its potential adverse effects on the package contents is determined indirectly, based upon the package's transmission of a different gas selected as a test gas. Helium is preferred as a test gas. The package's total transmission of the test gas is separated into its components of leakage through the package seals and permeation through the packaging material itself. The package's leakage of the gas of interest is determined based on its leakage of the test gas, in accordance with the molecular weights of the gases. The package's permeation of the gas of interest is determined based on its permeation of the test gas, in accordance with data correlating the permeation of the gas of interest and permeation of the test gas for the materials from which the package is made, and with package structure data relating to the size, shape, and disposition of the materials from which the package is made. The package's total transmission of the gas of interest is determined by adding its leakage and permeation components so determined. Such data may be used with other data to determine a packaged product's shelf life or its sensitivity to a gas of interest.

Owner:MORROW DARRELL R

Stick-on, flexible, peel and seal package dispenser

Owner:STARLINER

COOLERLESS PHOTONIC INTEGRATED CIRCUITS (PICs) FOR WDM TRANSMISSION NETWORKS AND PICs OPERABLE WITH A FLOATING SIGNAL CHANNEL GRID CHANGING WITH TEMPERATURE BUT WITH FIXED CHANNEL SPACING IN THE FLOATING GRID

ActiveUS20100166424A1Requirements for a hermetically sealed package are substantially relievedLaser optical resonator constructionSemiconductor laser arrangementsElectro-absorption modulatorPeak value

A coolerless photonic integrated circuit (PIC), such as a semiconductor electro-absorption modulator / laser (EML) or a coolerless optical transmitter photonic integrated circuit (TxPIC), may be operated over a wide temperature range at temperatures higher then room temperature without the need for ambient cooling or hermetic packaging. Since there is large scale integration of N optical transmission signal WDM channels on a TxPIC chip, a new DWDM system approach with novel sensing schemes and adaptive algorithms provides intelligent control of the PIC to optimize its performance and to allow optical transmitter and receiver modules in DWDM systems to operate uncooled. Moreover, the wavelength grid of the on-chip channel laser sources may thermally float within a WDM wavelength band where the individual emission wavelengths of the laser sources are not fixed to wavelength peaks along a standardized wavelength grid but rather may move about with changes in ambient temperature. However, control is maintained such that the channel spectral spacing between channels across multiple signal channels, whether such spacing is periodic or aperiodic, between adjacent laser sources in the thermally floating wavelength grid are maintained in a fixed relationship. Means are then provided at an optical receiver to discover and lock onto floating wavelength grid of transmitted WDM signals and thereafter demultiplex the transmitted WDM signals for OE conversion.

Owner:INFINERA CORP

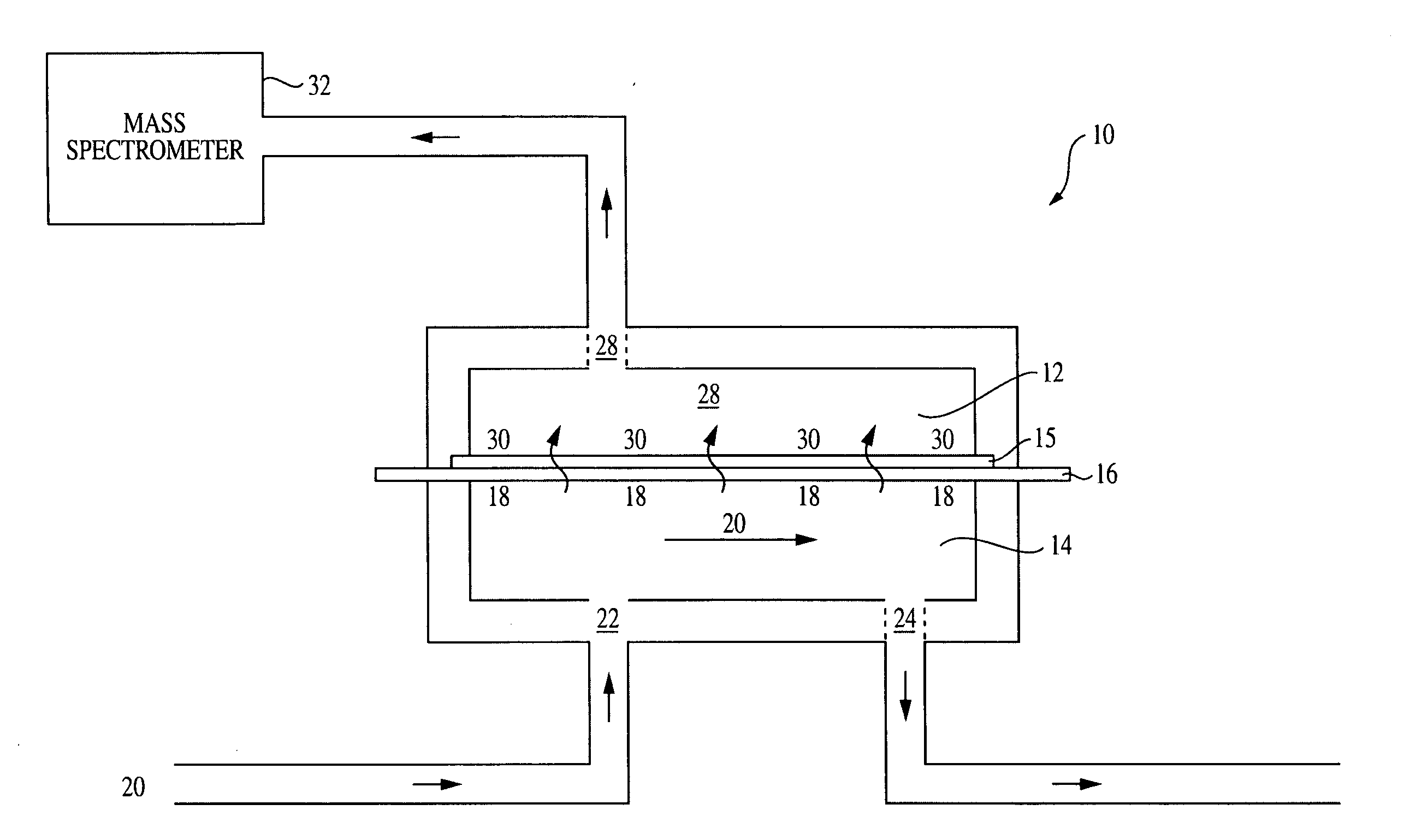

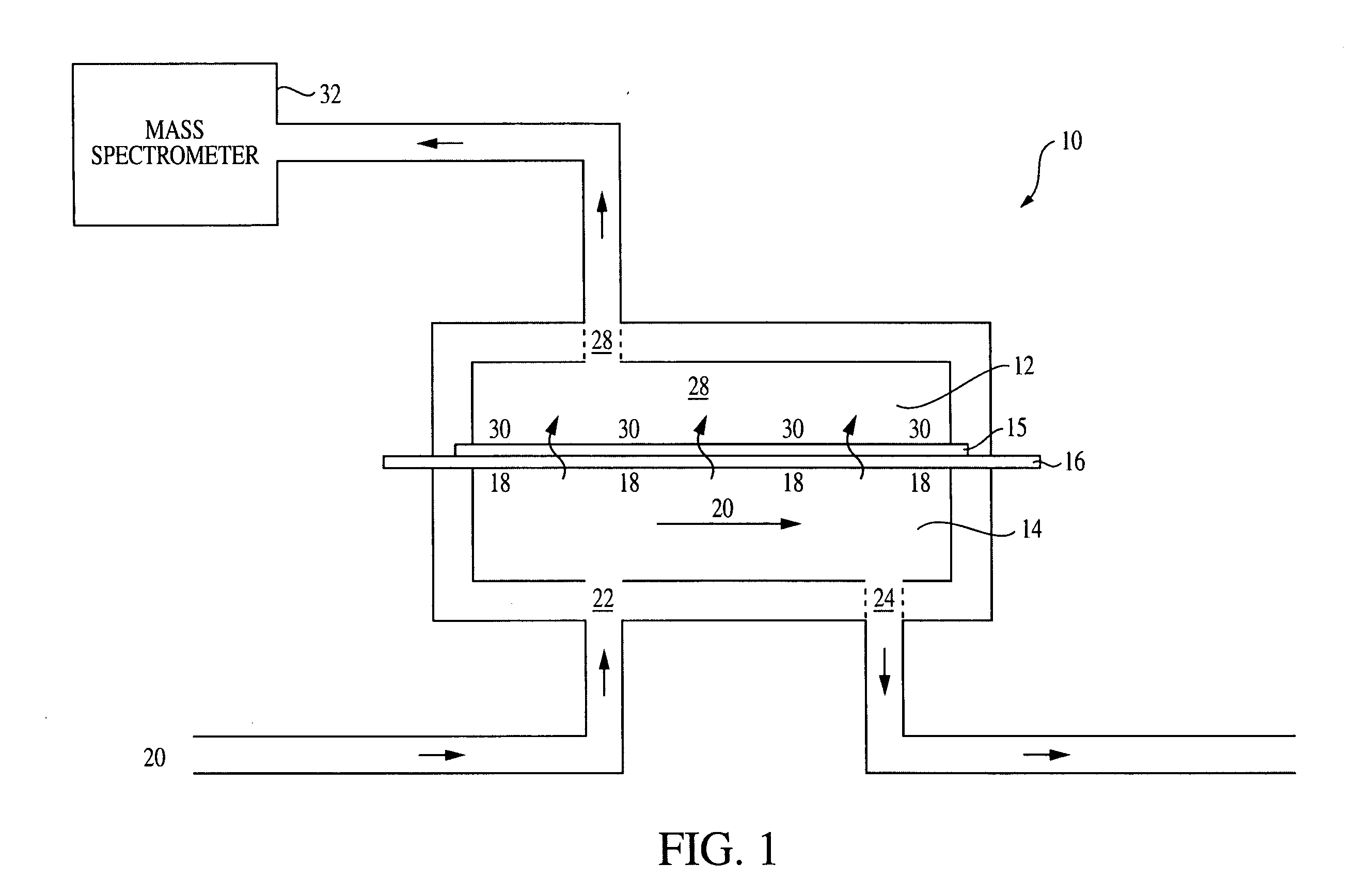

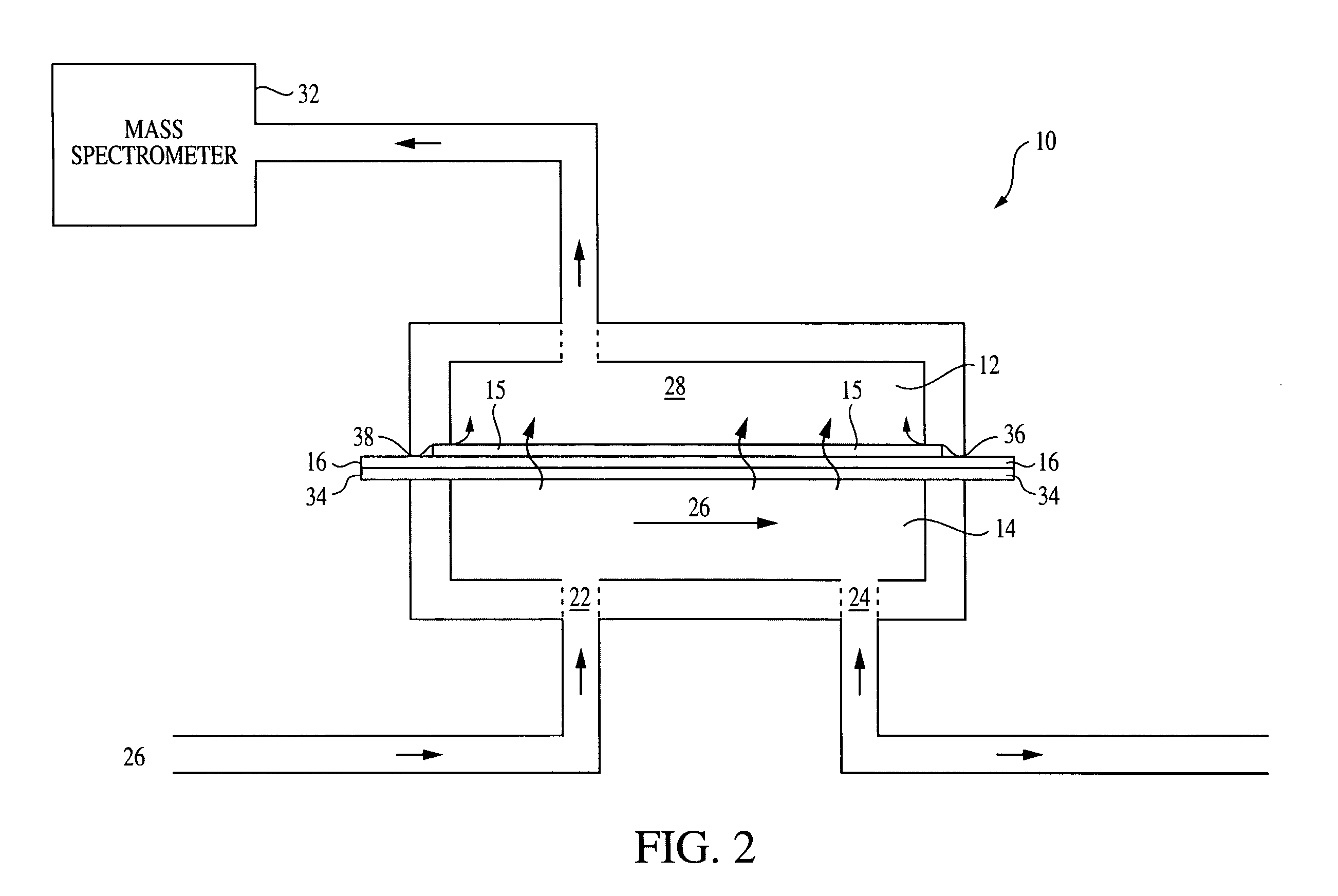

Method and apparatus for measuring gas transmission rates of deformable or brittle materials

ActiveUS20050092068A1Apparent advantageHigh precisionParticle spectrometer methodsPermeability/surface area analysisTest roomEngineering

Provided are an apparatus and a method for measuring gas transmission rates and nanoleaks of deformable and brittle materials. The apparatus includes a test chamber having an upper and lower diffusion cells that when closed form a chamber wall seal, a gas inlet and a gas outlet in fluid communication with the lower diffusion cell, the upper diffusion cell being fluidly connected to a high-vacuum mass spectrometer. The method of measuring gas transmission rates and nanoleaks includes placing a sealed package containing the test gas in the lower diffusion cell, closing the upper and lower diffusion cells, flushing the lower diffusion cell with a source of a second gas other than the test gas, closing off the source of the second gas; and measuring the leak rate of the sealed package.

Owner:MODERN CONTROLS

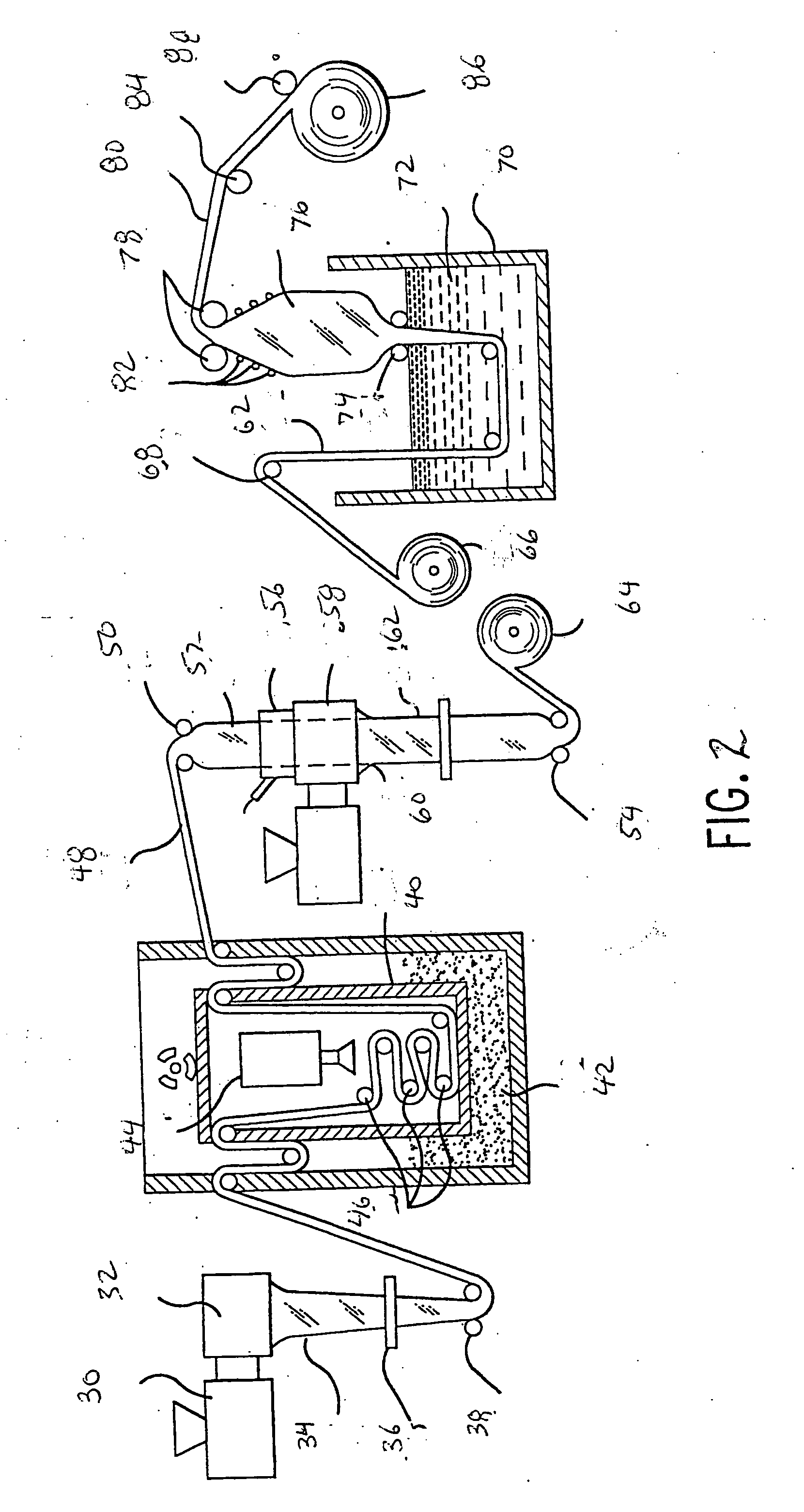

Double-bag package and perforation knife

A double-bag package, and method for manufacturing same, constructed by modification to existing vertical form and fill packaging machines and perforation knives. In a preferred embodiment, the invention involves producing a double-bag package from a single sheet of packaging film by feeding a roll of film having graphics printed sideways rather than vertically into a vertical form, fill and seal packaging machine and using a novel perforating / cutting knife to alternately cut and perforate transverse seals. The perforating / cutting knife has teeth in the shape of oblique triangular pyramids, with each tooth having three cutting edges. The perforating / cutting knife produces self-correcting T-shaped perforation patterns capable of capturing and redirecting errant tears for fail-safe directional separation.

Owner:FRITO LAY NORTH AMERICA INC

Hermetic pacakging and method of manufacture and use therefore

InactiveUS20090029500A1Lamination ancillary operationsDecorative surface effectsEngineeringHermetic packaging

An embodiment of the present invention provides a method of manufacturing hermetic packaging for devices on a substrate wafer, comprising forming a plurality of adhesive rings on a cap wafer or the substrate wafer, bonding the cap wafer to the substrate wafer with an adhesive layer, forming trenches in the cap wafer and the adhesive rings along outer rim of the adhesive rings, and covering sidewall of the trenches by at least one deposited film to provide a diffusion barrier to moisture or gas.

Owner:WAN CHANG FENG

Coolerless photonic integrated circuits (PICs) for WDM transmission networks and PICs operable with a floating signal channel grid changing with temperature but with fixed channel spacing in the floating grid

ActiveUS7636522B2Requirements for a hermetically sealed package are substantially relievedLaser optical resonator constructionSemiconductor laser arrangementsElectro-absorption modulatorPeak value

Owner:INFINERA CORP

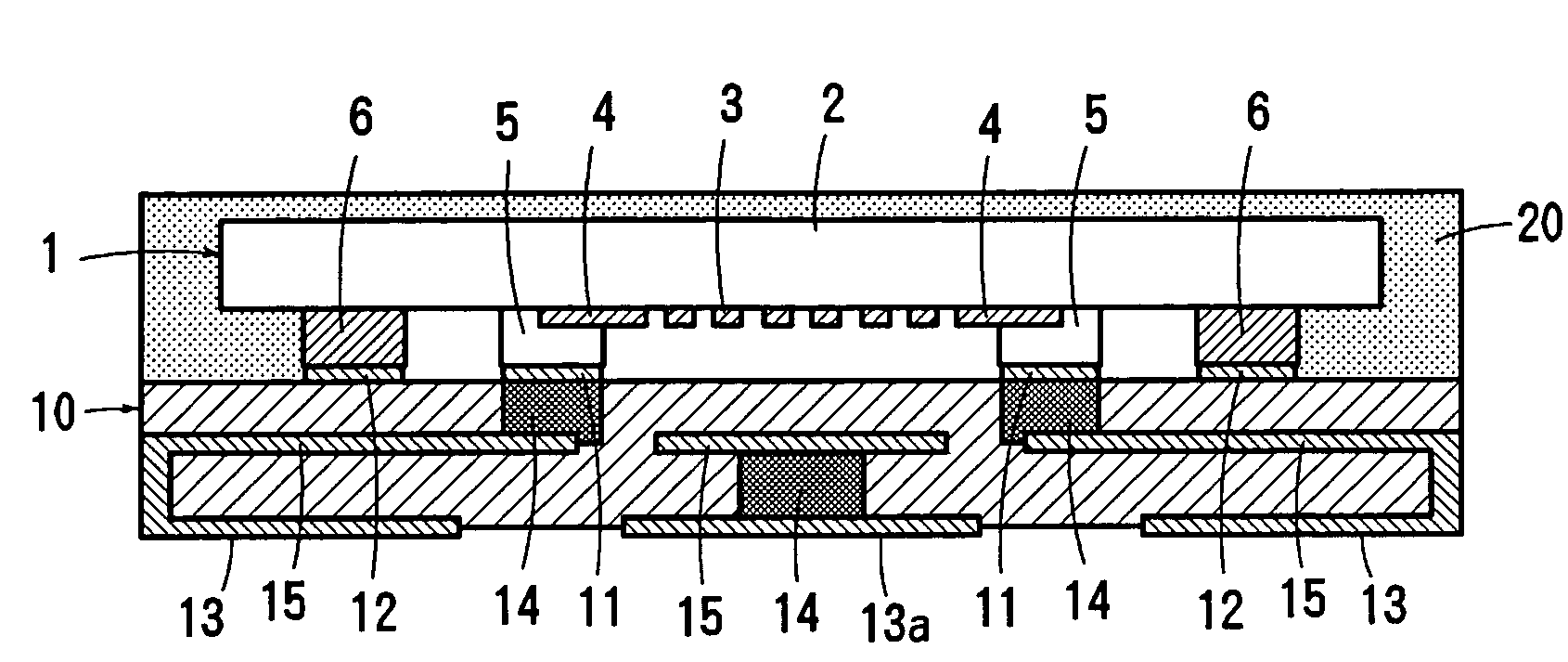

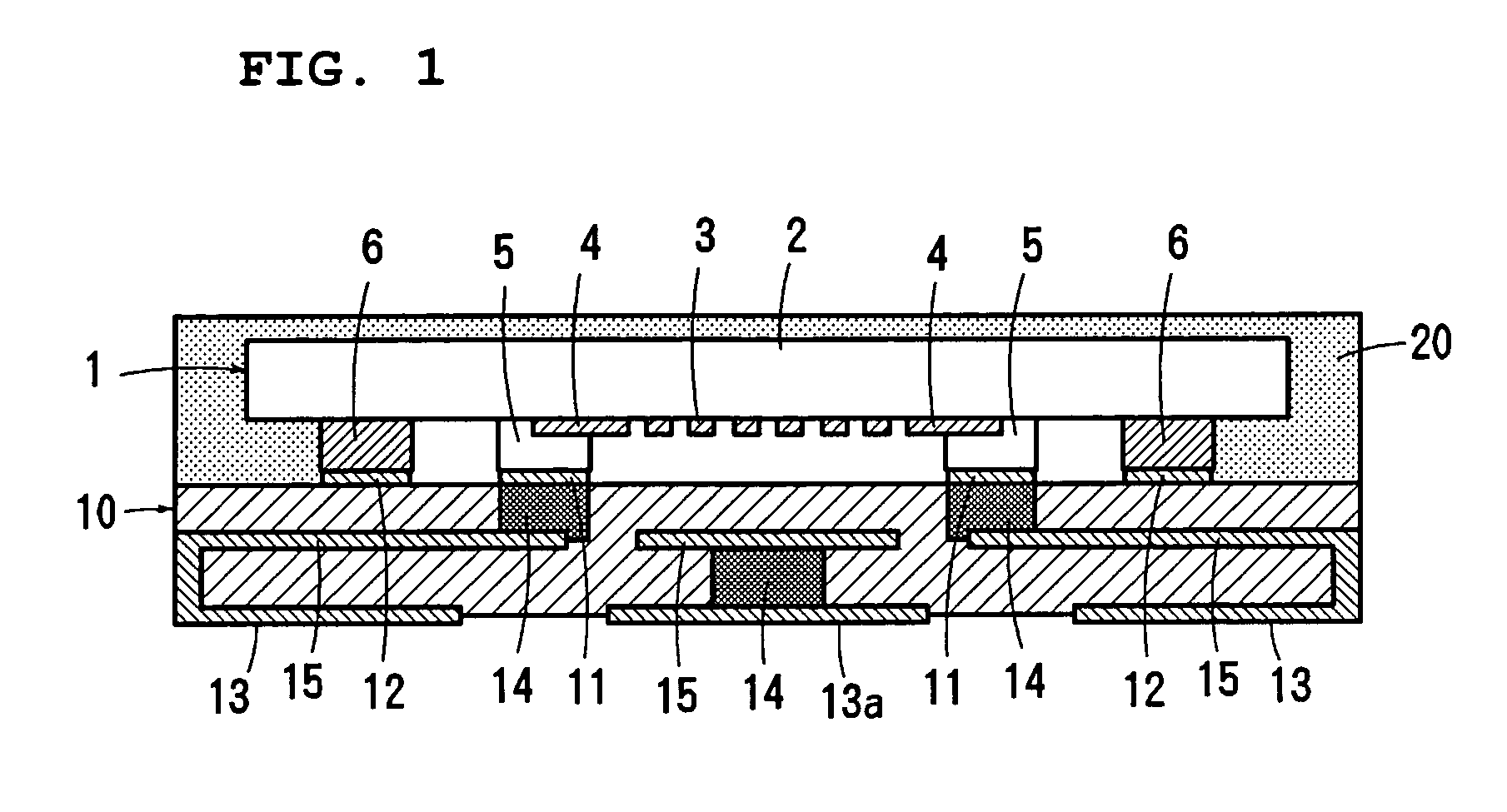

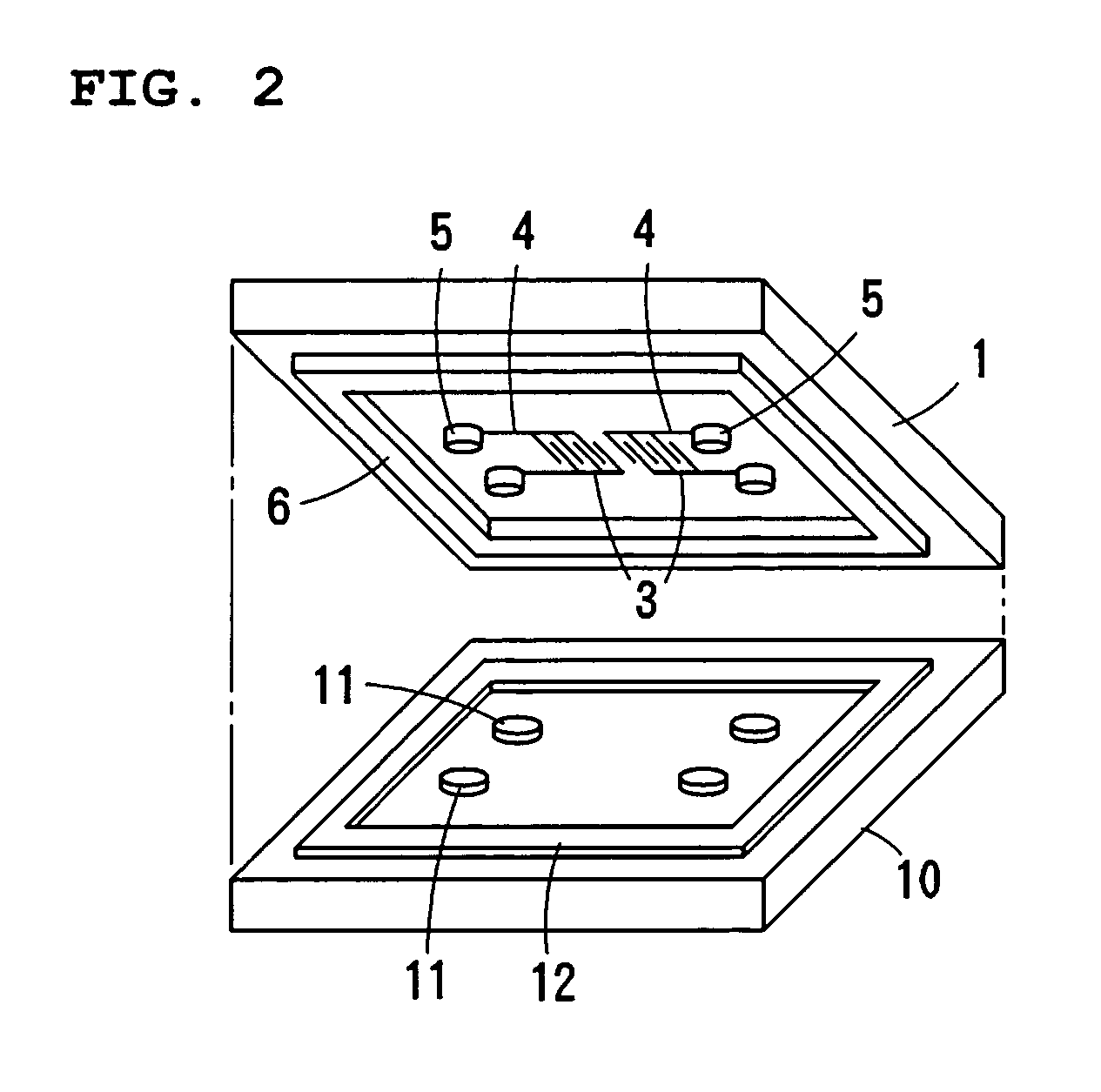

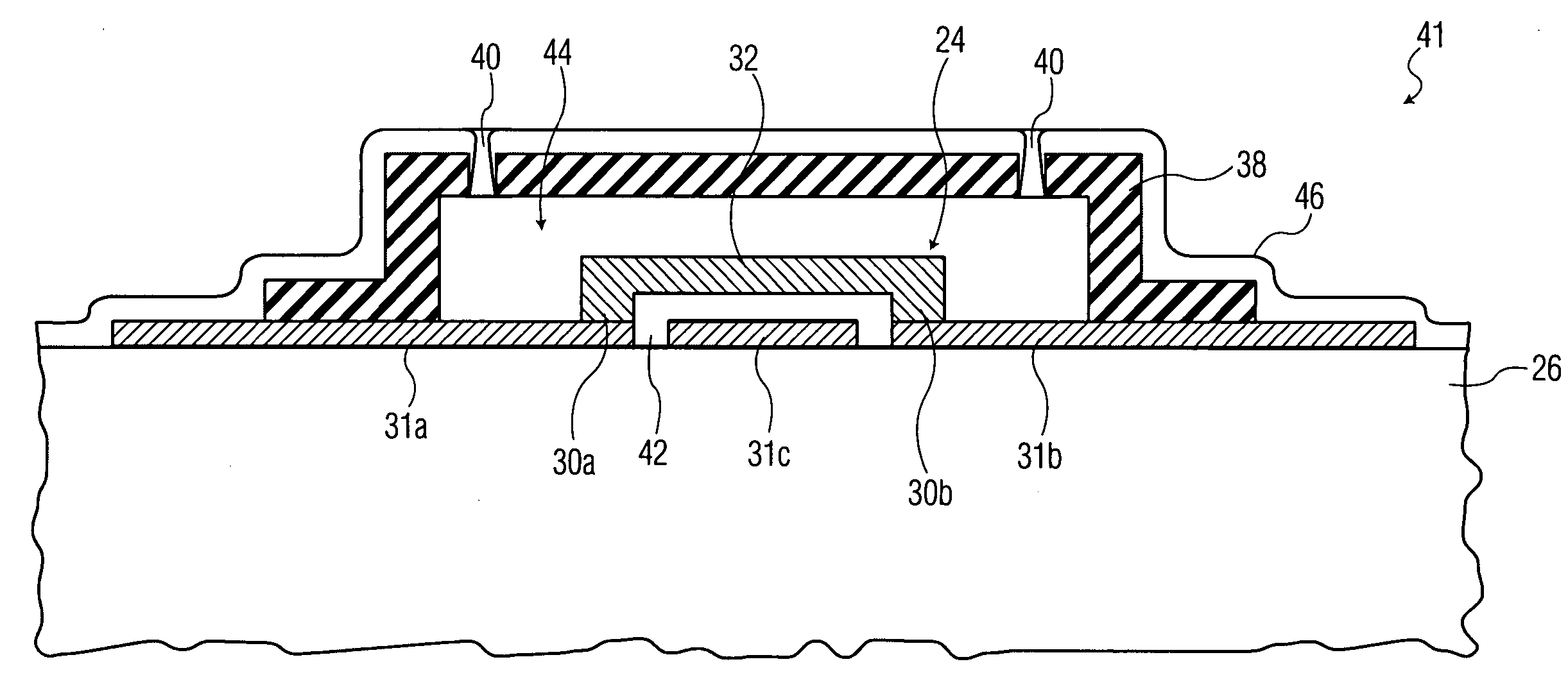

Hermetically sealing a package to include a barrier metal

ActiveUS7259032B2Good adhesionReliable sealing propertyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksResistHermetic packaging

A method for manufacturing an electronic device includes the steps of forming a first resist pattern on a primary surface of a SAW element, the first resist pattern having openings at positions corresponding to those at which bumps and a sealing frame are to be formed, sequentially forming metals over the first resist pattern, the metals being formed into adhesion layers, barrier metal layers, and solder layers, removing the first resist pattern on the SAW element such that the bumps and the sealing frame are simultaneously formed. When the bumps and the sealing frame of the SAW element are bonded to bond electrodes of the bond substrate, the solder layers are melted and alloyed by heating.

Owner:MURATA MFG CO LTD

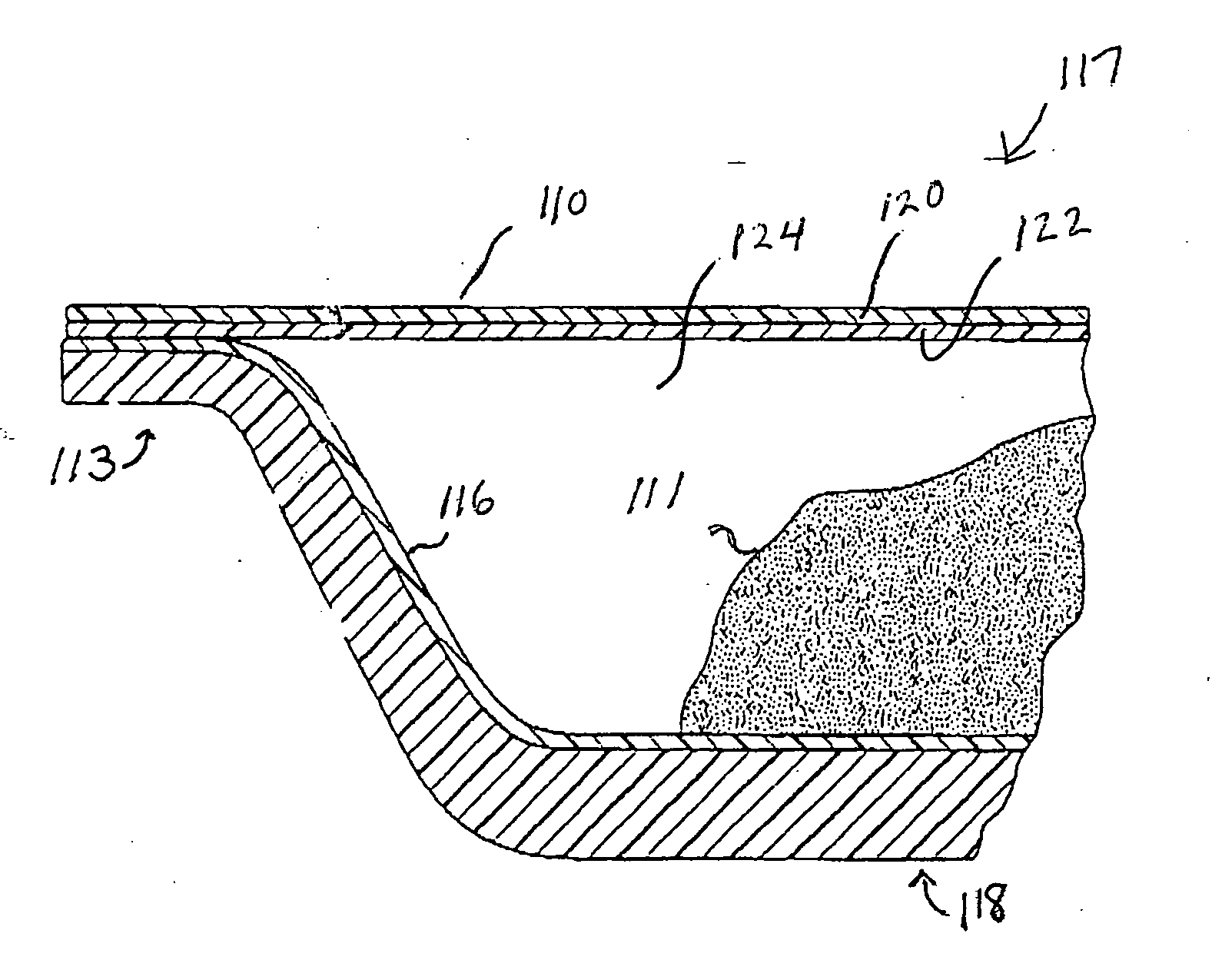

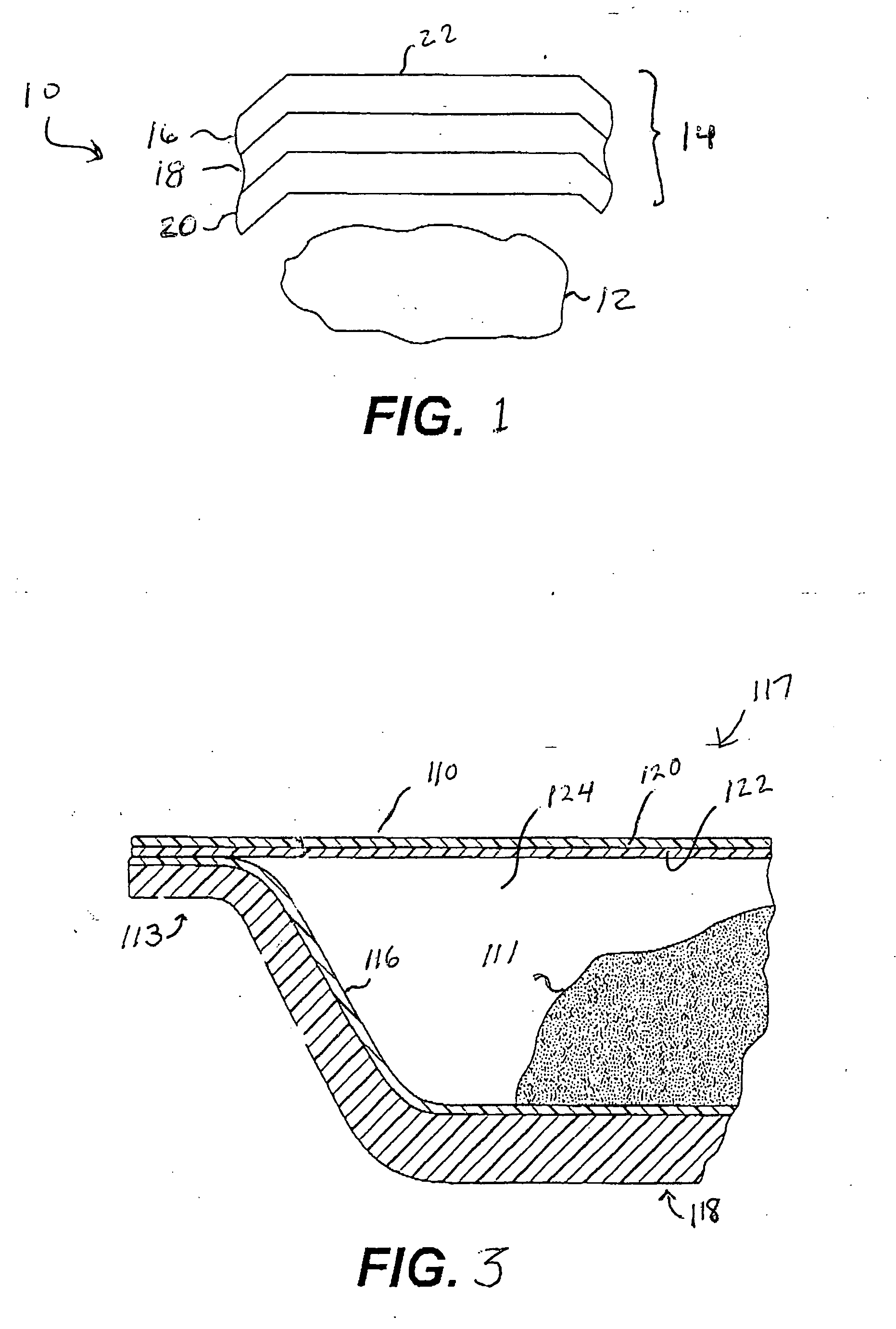

Resealable Laminate for Heat Sealed Packaging

A resealable and disposable package assembly is described. The assembly includes a container and a multilayer cover laminate that are bonded to one another to initially seal the contents of the package. The package can then be easily opened by at least partially separating the cover laminate along a predesignated interface. The package can be reliably and effectively sealed by recontacting the previously separated cover portions to one another.

Owner:AVERY DENNISON CORP

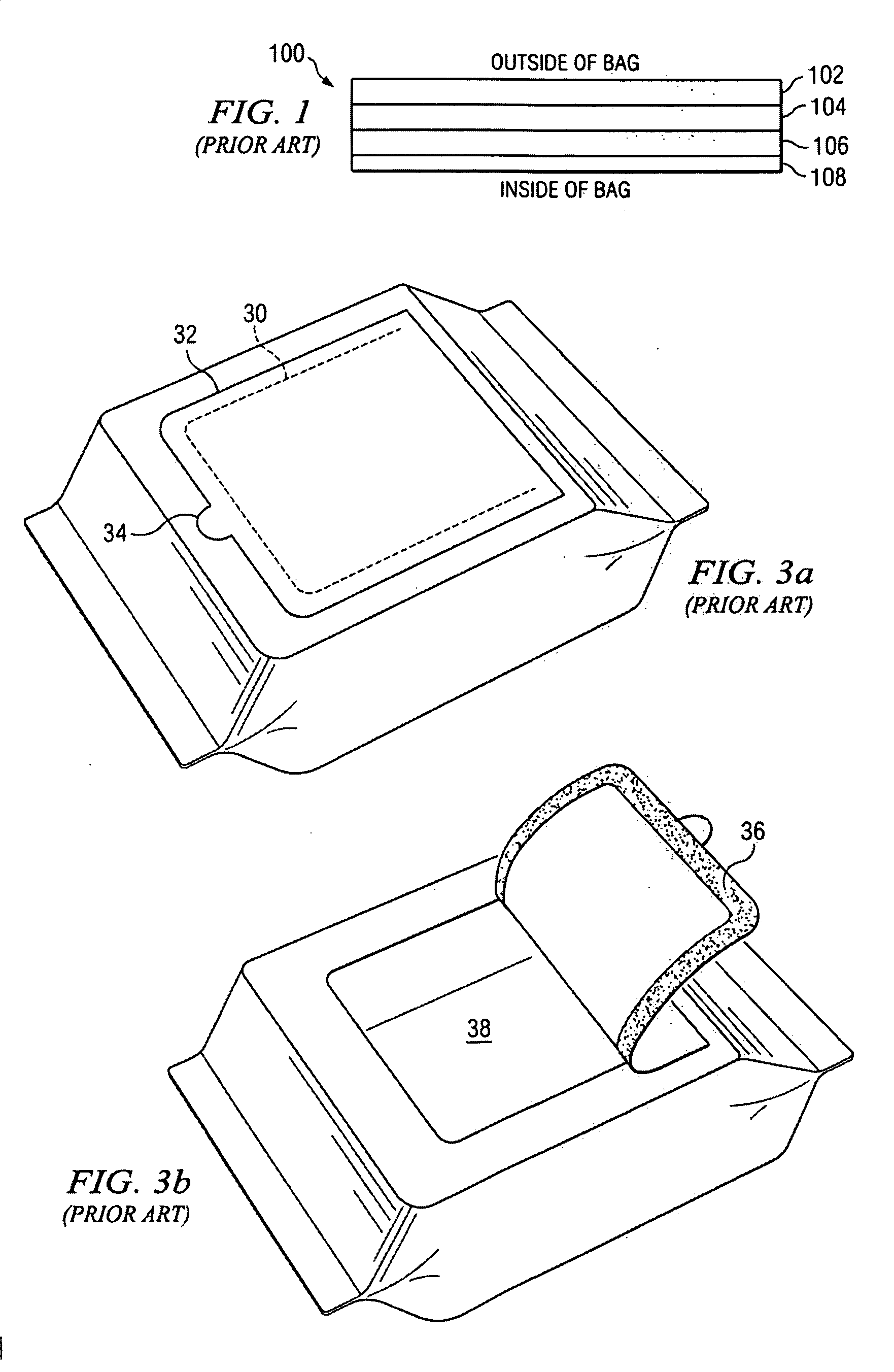

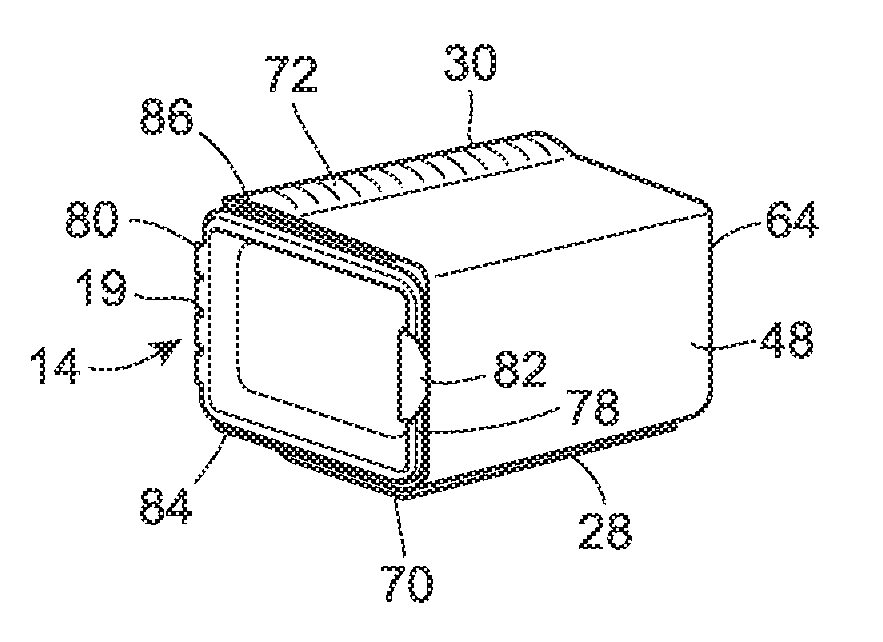

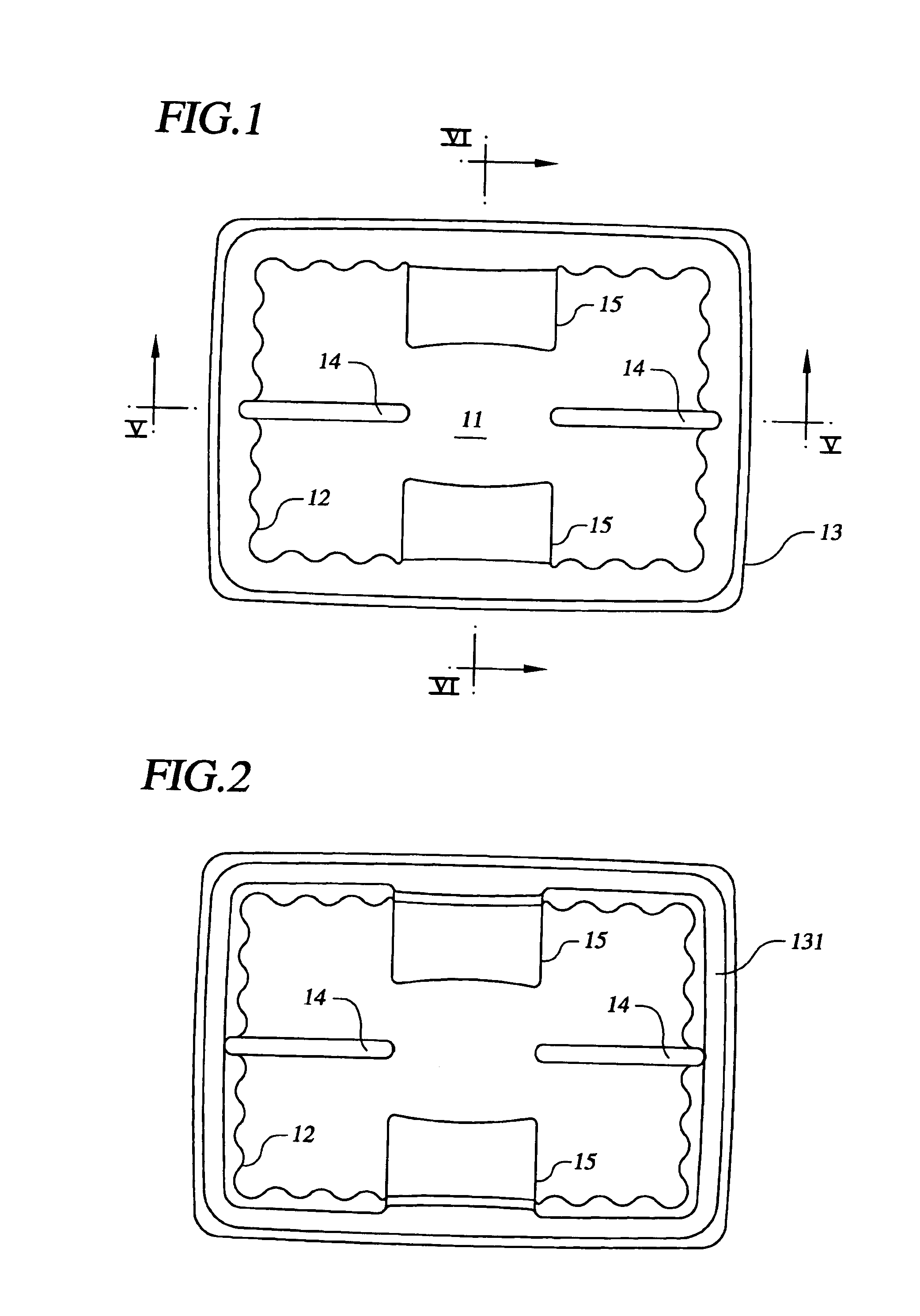

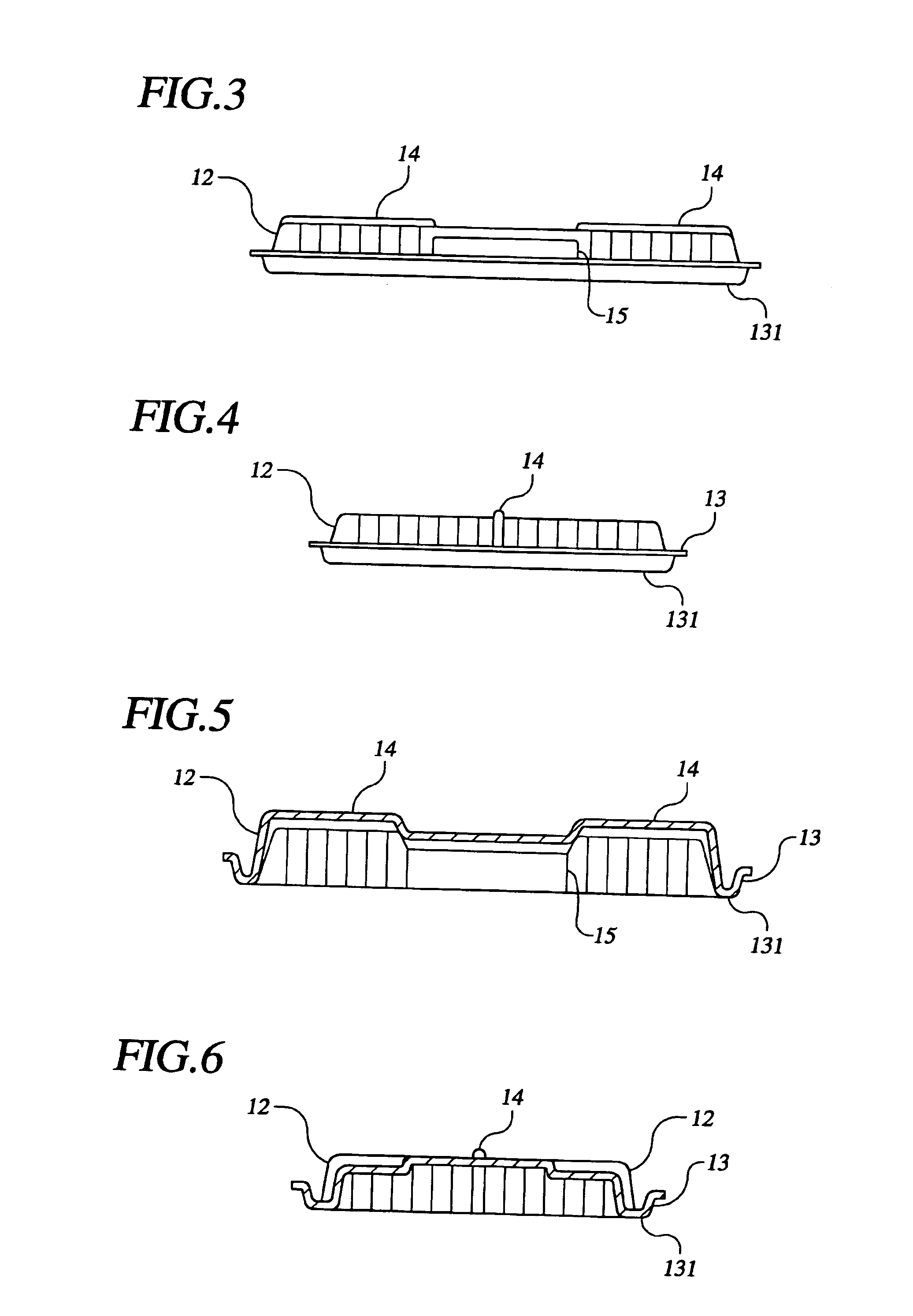

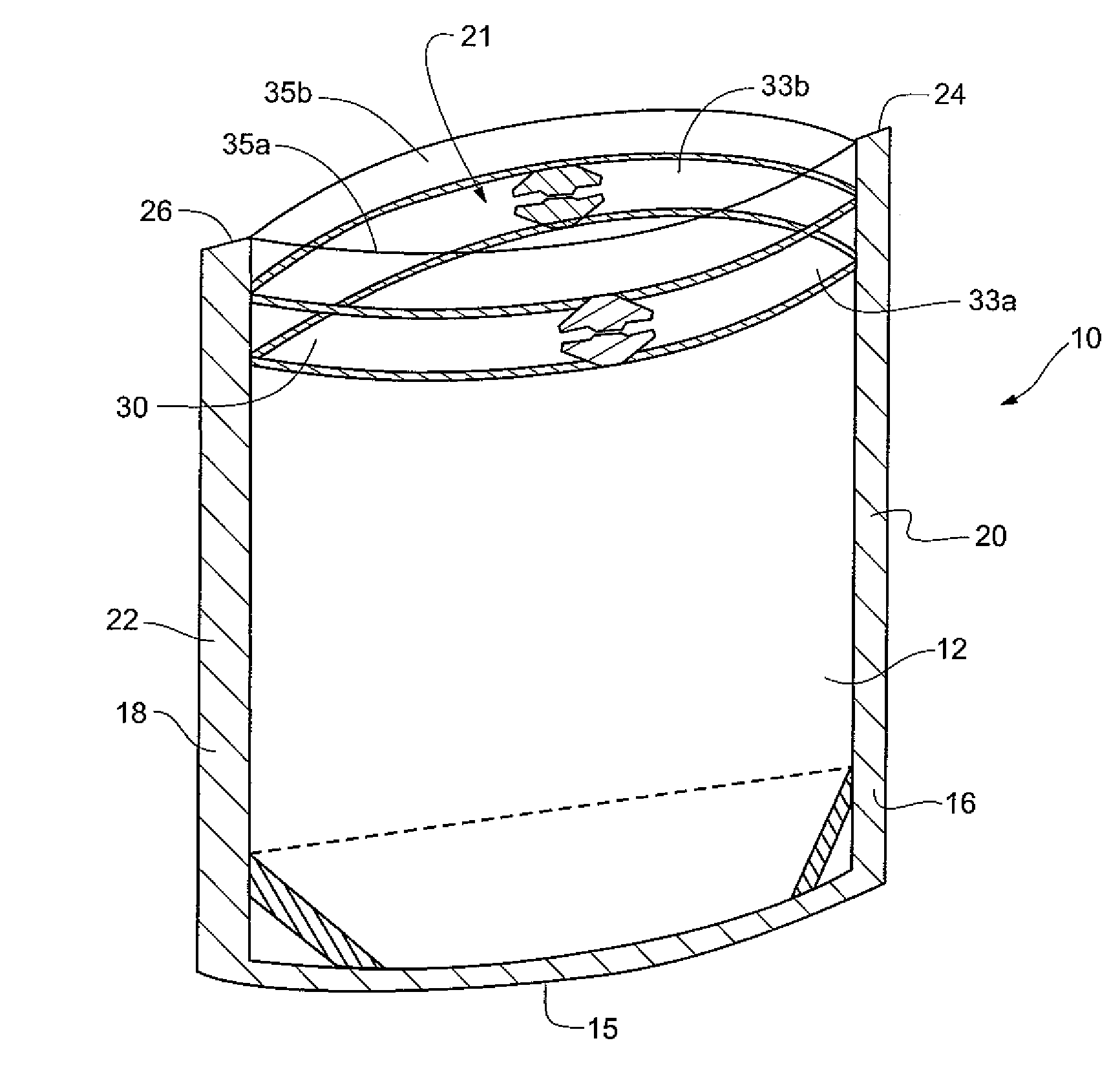

Sealed container for an article of personal use such as a razor cartridge

A sealed package for an article of personal use. The package includes a plastic container that defines a storage region and has a sealing surface around an entrance to the region. The package also includes a plastic, multi-layer laminate film sealed to the sealing surface of the container. The film is removable away from the sealing surface in one piece and has deadfold characteristics.

Owner:THE GILLETTE CO

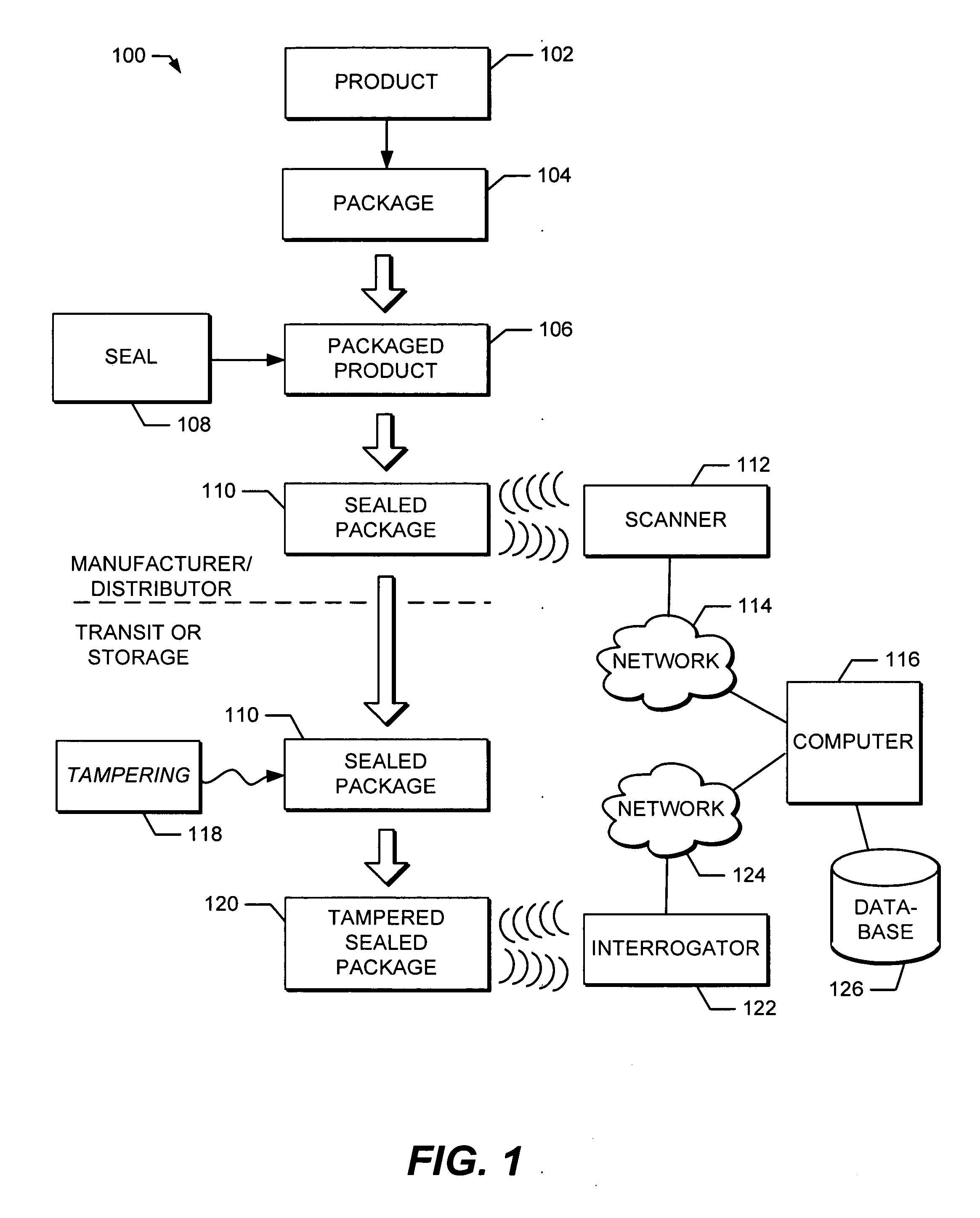

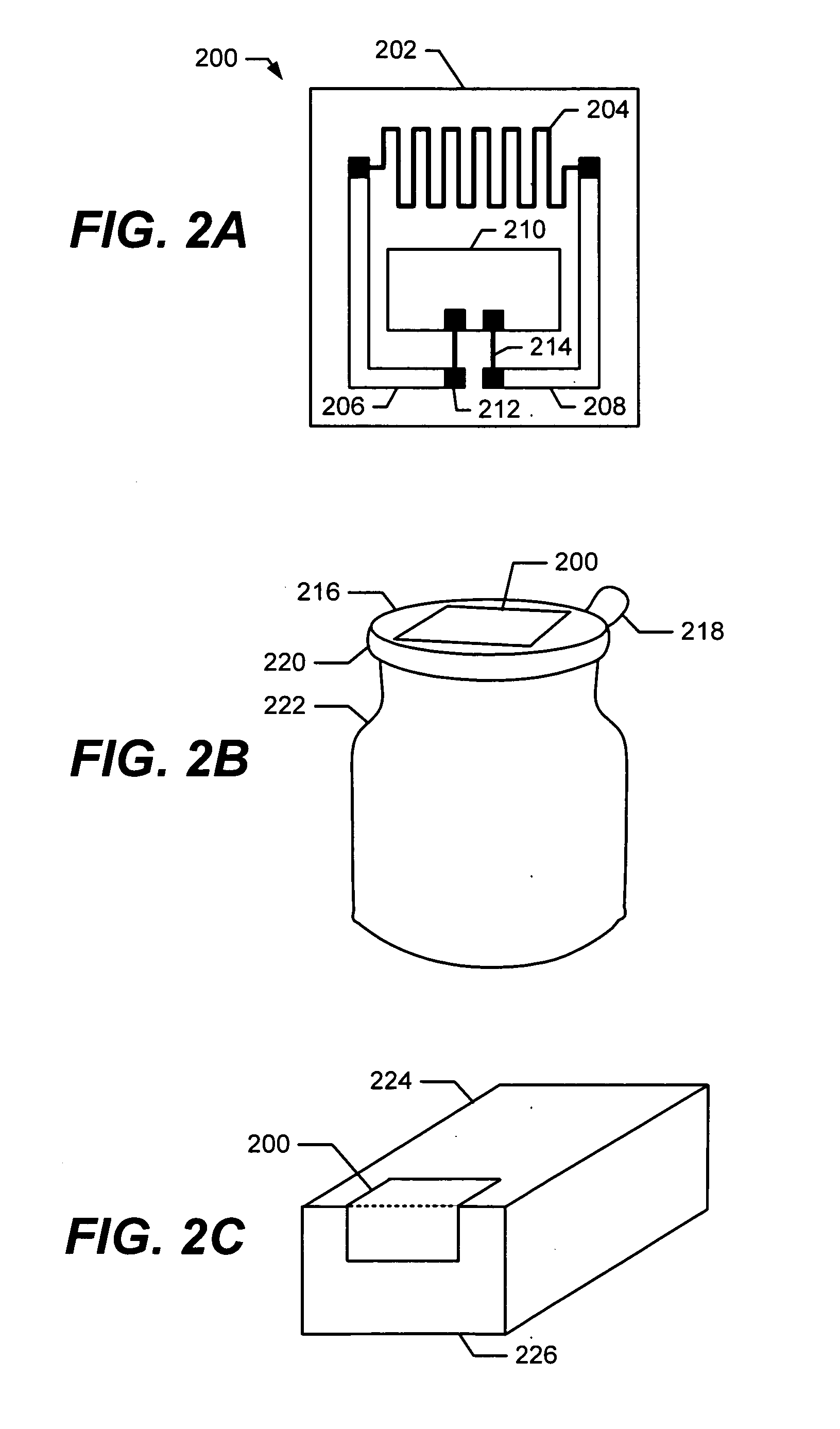

Seal method and system for packages

InactiveUS20060255953A1Detect such tamperingContainer decorationsLevel indicationsHermetic packagingElectrical and Electronics engineering

A seal for a package includes a circuit having electrical characteristics that change under mechanical deformation and an attaching material coupled to the circuit and for attaching the circuit to the package. The seal is attached to the package and processed prior to shipping to establish an untampered state for the seal. This includes identifying a circuit on the sealed package according to a seal type associated with the seal, recording one or more characteristics associated with the circuit from the seal and storing the seal type and one or more characteristics associated with the circuit from the seal for later comparison. To detect tampering to the package, the seal type and corresponding seal and circuit for the seal is identified, the characteristics associated with a circuit from the seal are determined and compared with the previous characteristics recorded when the seal was initially applied to the package. If the comparison indicates that a mechanical deformation of the seal occurred, it is possible the seal and package were tampered with during shipment or delivery.

Owner:HEWLETT PACKARD DEV CO LP

Resealable Laminate For Heat Sealed Packaging

A resealable and disposable package assembly is described. The assembly includes a container and a multilayer cover laminate that are bonded to one another to initially seal the contents of the package. The package can then be easily opened by at least partially separating the cover laminate along a predesignated interface. The package can be reliably and effectively sealed by recontacting the previously separated cover portions to one another.

Owner:AVERY DENNISON CORP

Method of handling, filling and sealing packaging containers

InactiveUS6256964B1Simplify handling and transportAvoid damage and dirt contaminationOpening closed containersPower operated devicesHermetic packagingProcessing plants

A method of handling, filling and sealing prefabricated packaging containers that are provided with a closure device is disclosed. The packaging containers are transported in the closed state to a processing plant in which the closure device is opened, the packaging container and closure device are sterilized, and thereafter the packaging container is filled with the desired liquid contents. The same closure device that was removed from the packaging container is then reapplied to seal the container.

Owner:TETRA LAVAL HLDG & FINANCE SA

Processes for hermetically packaging wafer level microscopic structures

InactiveUS20050189621A1AdaptableImprove integritySemiconductor/solid-state device detailsSolid-state devicesEtchingLithographic artist

A process for hermetically packaging a microscopic structure including a MEMS device is provided. The process for the present invention includes the steps of depositing a capping layer of sacrificial material patterned by lithography over the microscopic structure supported on a substrate, depositing a support layer of a dielectric material patterned by lithography over the capping layer, providing a plurality of vias through the support layer by lithography, removing the capping layer via wet etching to leave the support layer intact in the form of a shell having a cavity occupied by the microscopic structure, depositing a metal layer over the capping layer that is thick enough to provide a barrier against gas permeation, but thin enough to leave the vias open, and selectively applying under high vacuum a laser beam to the metal proximate each via for a sufficient period of time to melt the metal for sealing the via.

Owner:CHEUNG KIN P

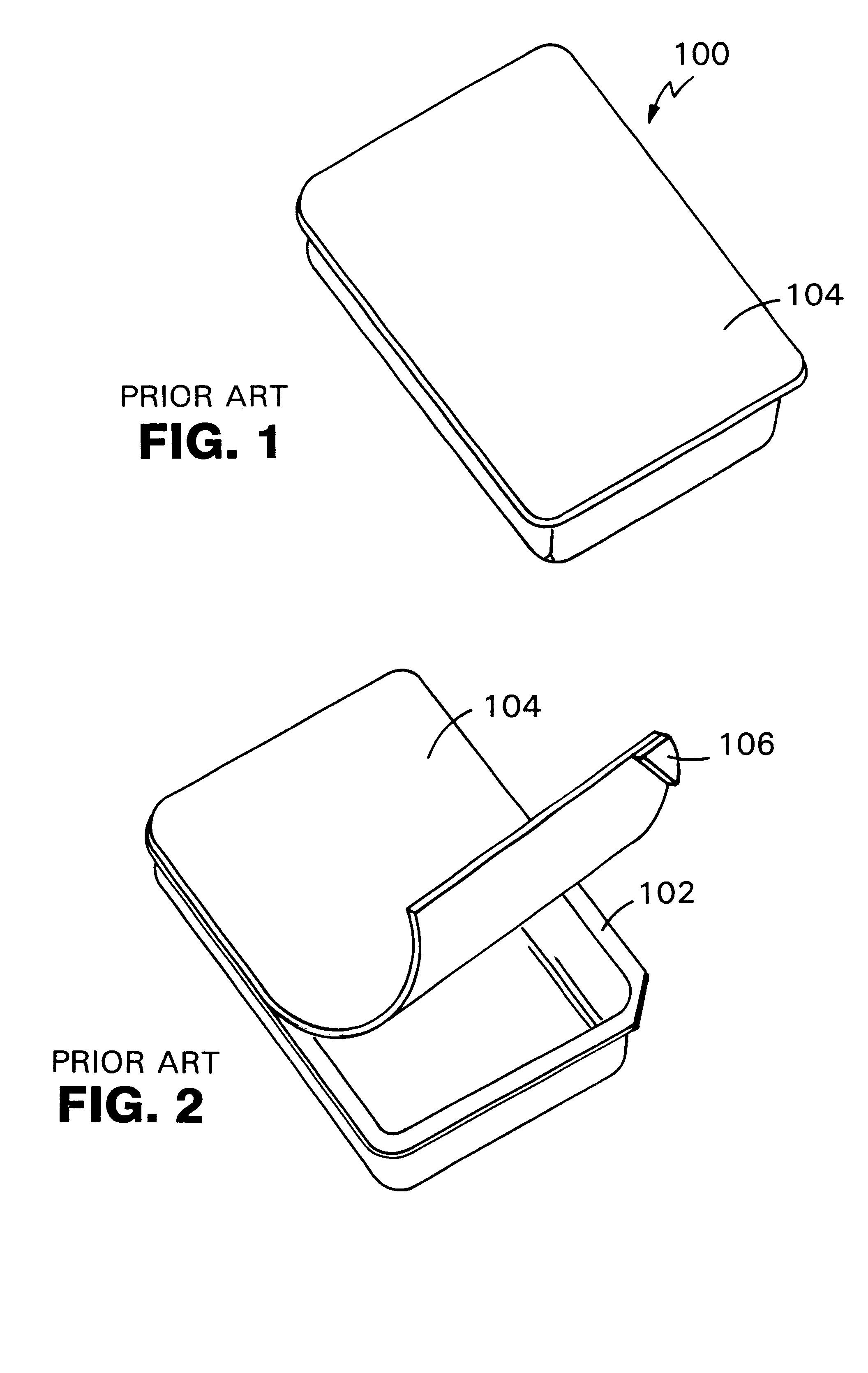

Thermoformed package with tamper evident seal

InactiveUS20120005994A1High bonding strengthReduce the possibilityCapsDecorative coversAdhesiveHermetic packaging

A thermoformed clamshell package with a pair of closing flanges and a double-sided adhesive for joining the closing flanges to seal the package. The package includes a carrier flange that carries the double-sided adhesive prior to sealing and a sealing flange that is brought into contact with the double-sided adhesive to seal the package. The package may include a frangible portion in the flange region for gaining access to the contents of the package after it has been sealed without breaking the adhesive seal created by the double-sided adhesive. The carrier flange may include a channel for seating the double-sided adhesive and for denesting adjacent packages when nested together for shipping and / or storage. The package may include one or more display strips disposed in the flange region. The present invention also provides a method for packaging articles in a package with a tamper-evident seal, and a method for manufacturing a package with a tamper-evident seal.

Owner:DISPLAY PACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com