Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1001 results about "Tube forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

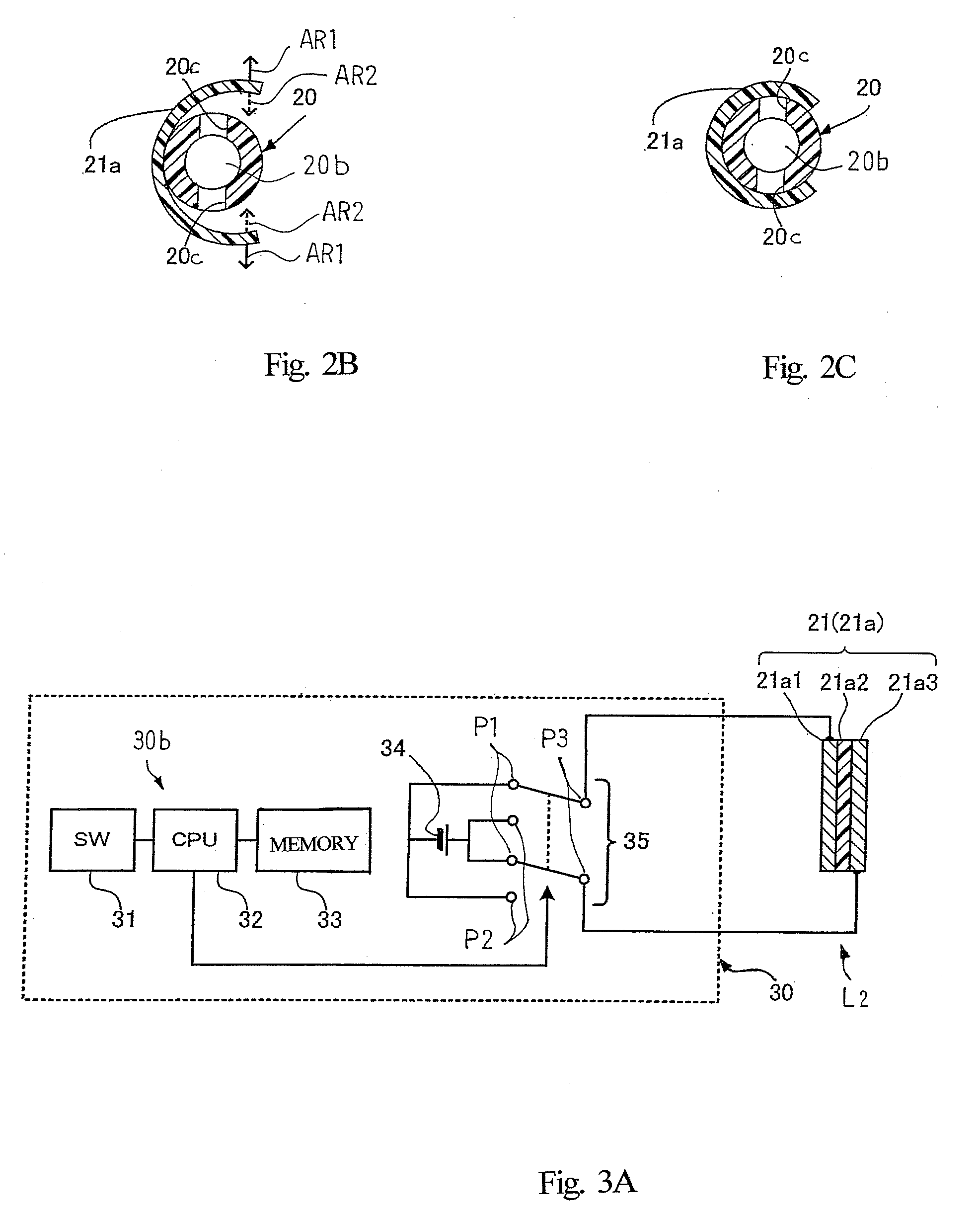

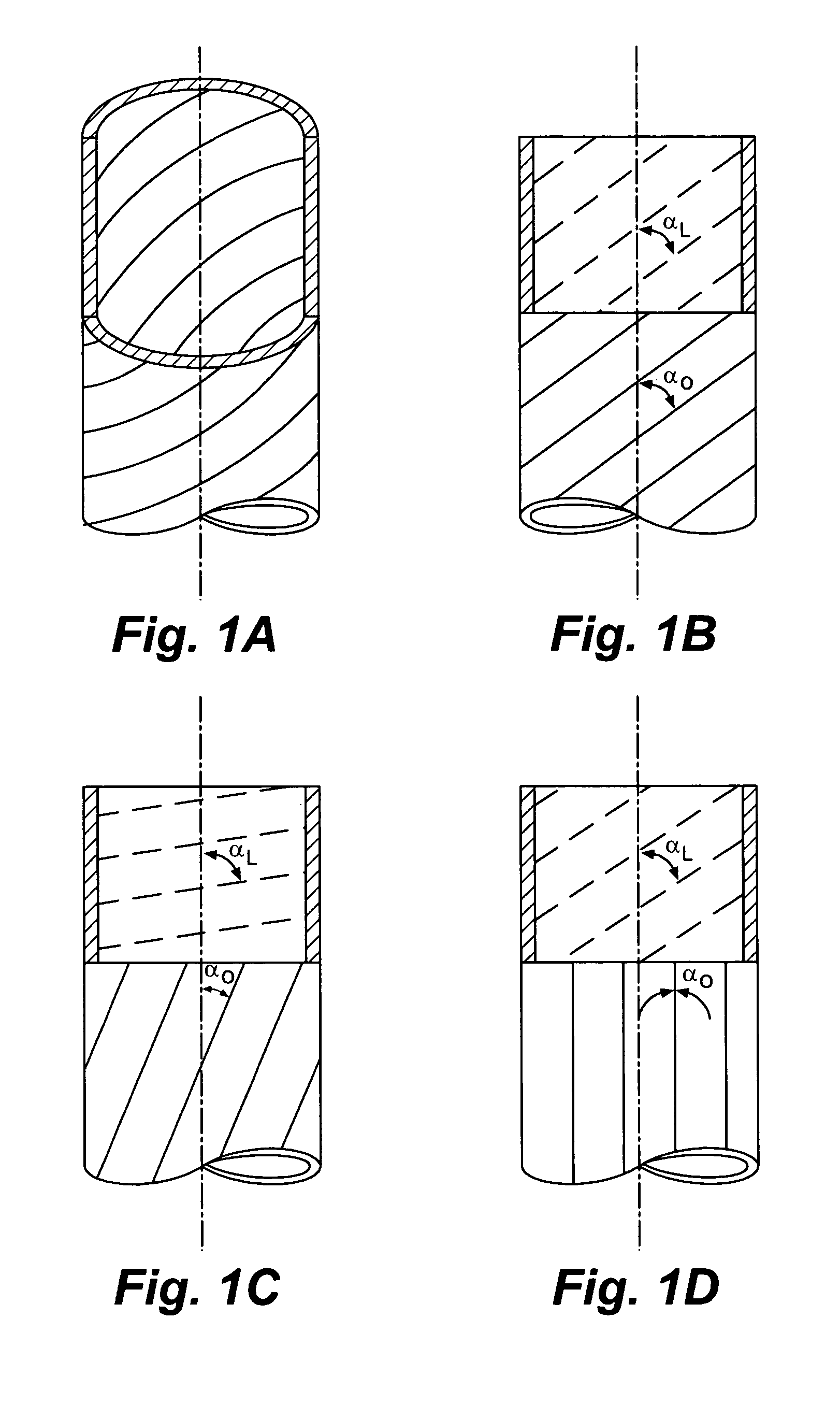

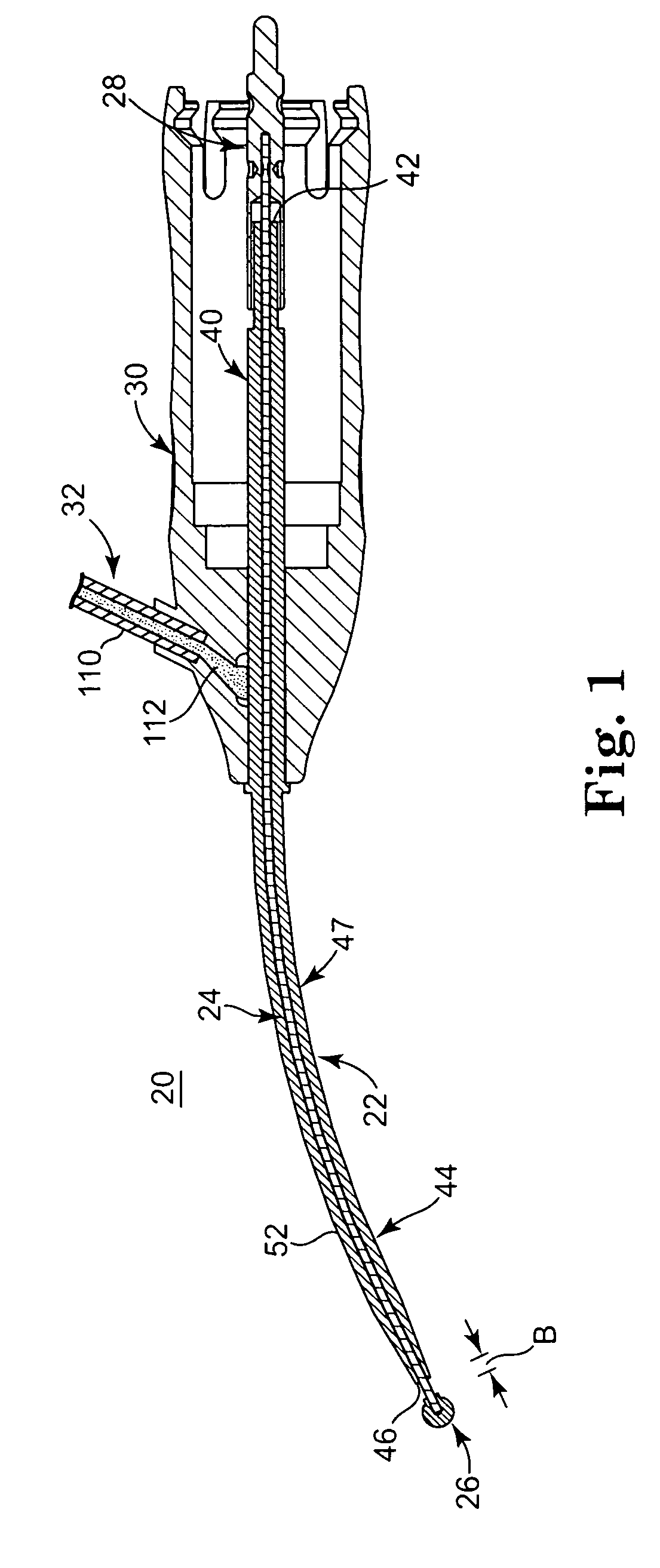

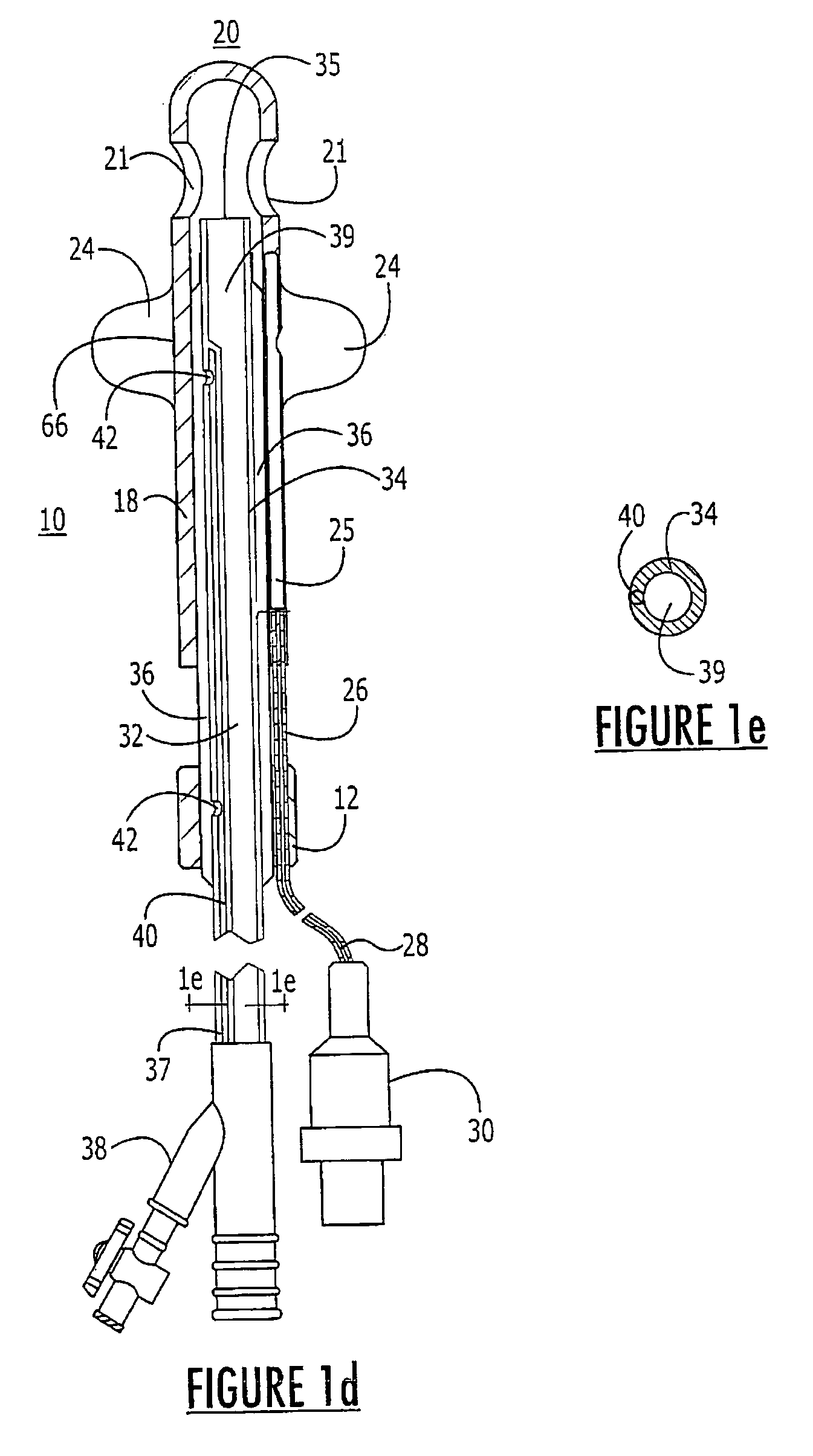

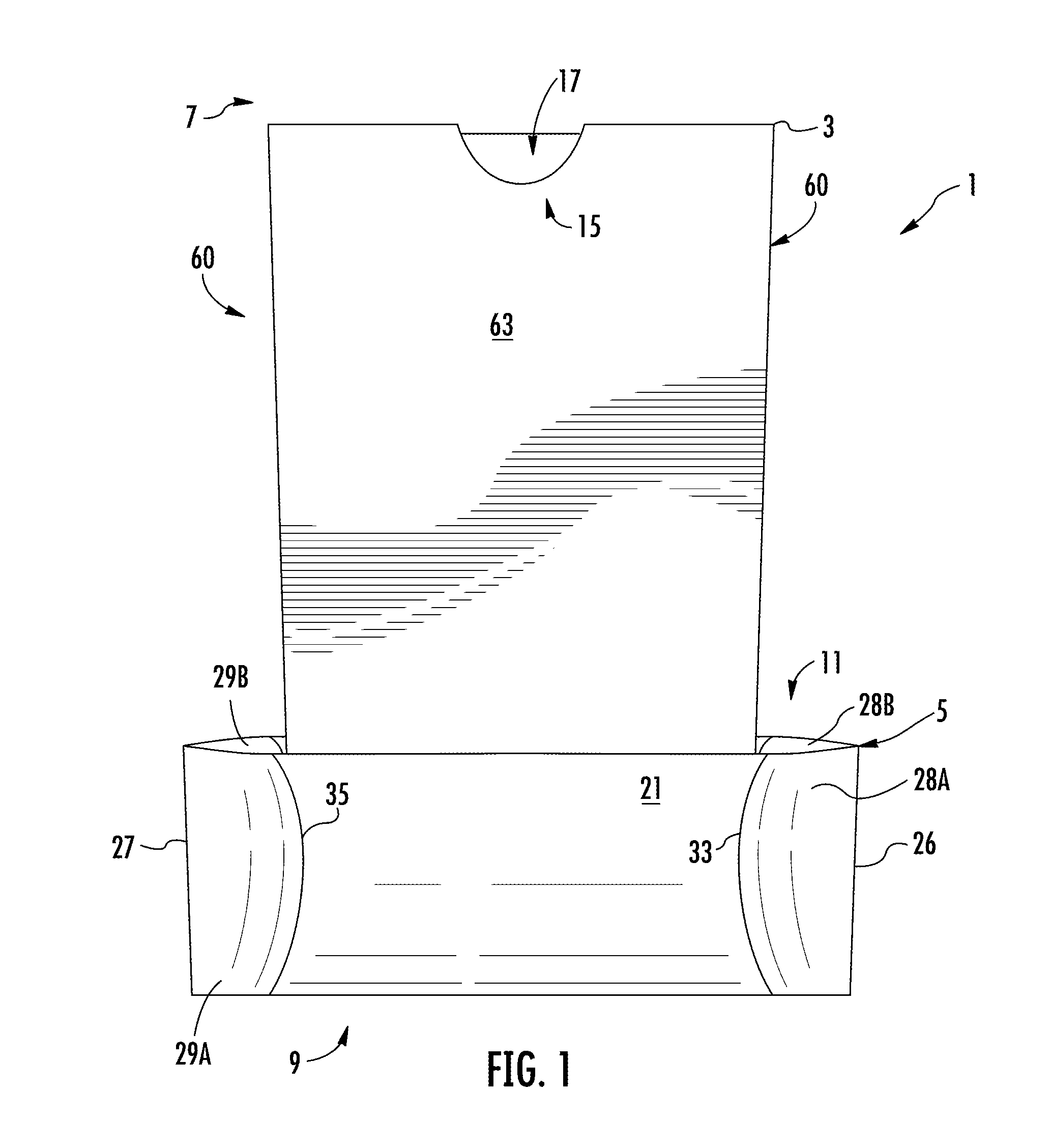

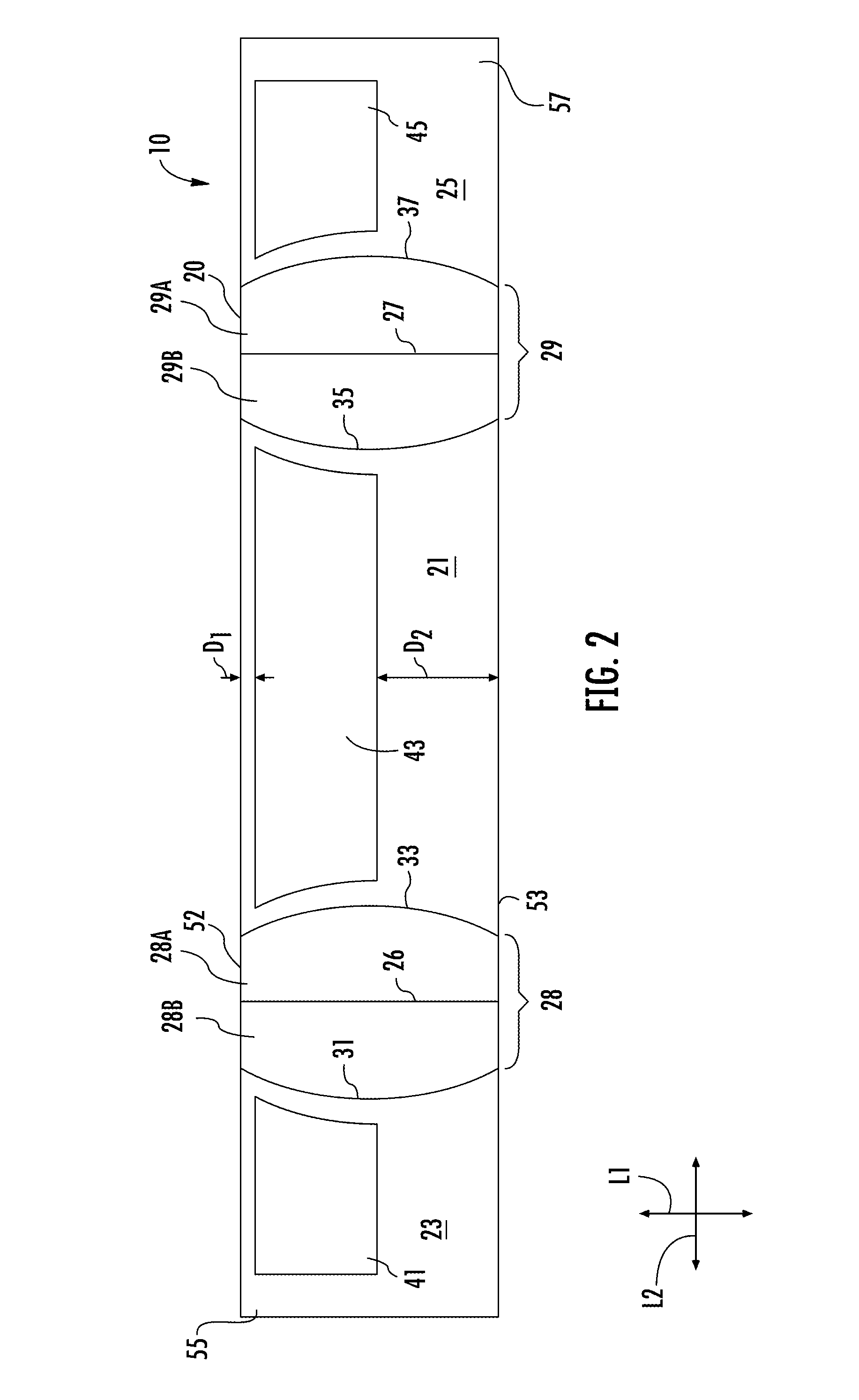

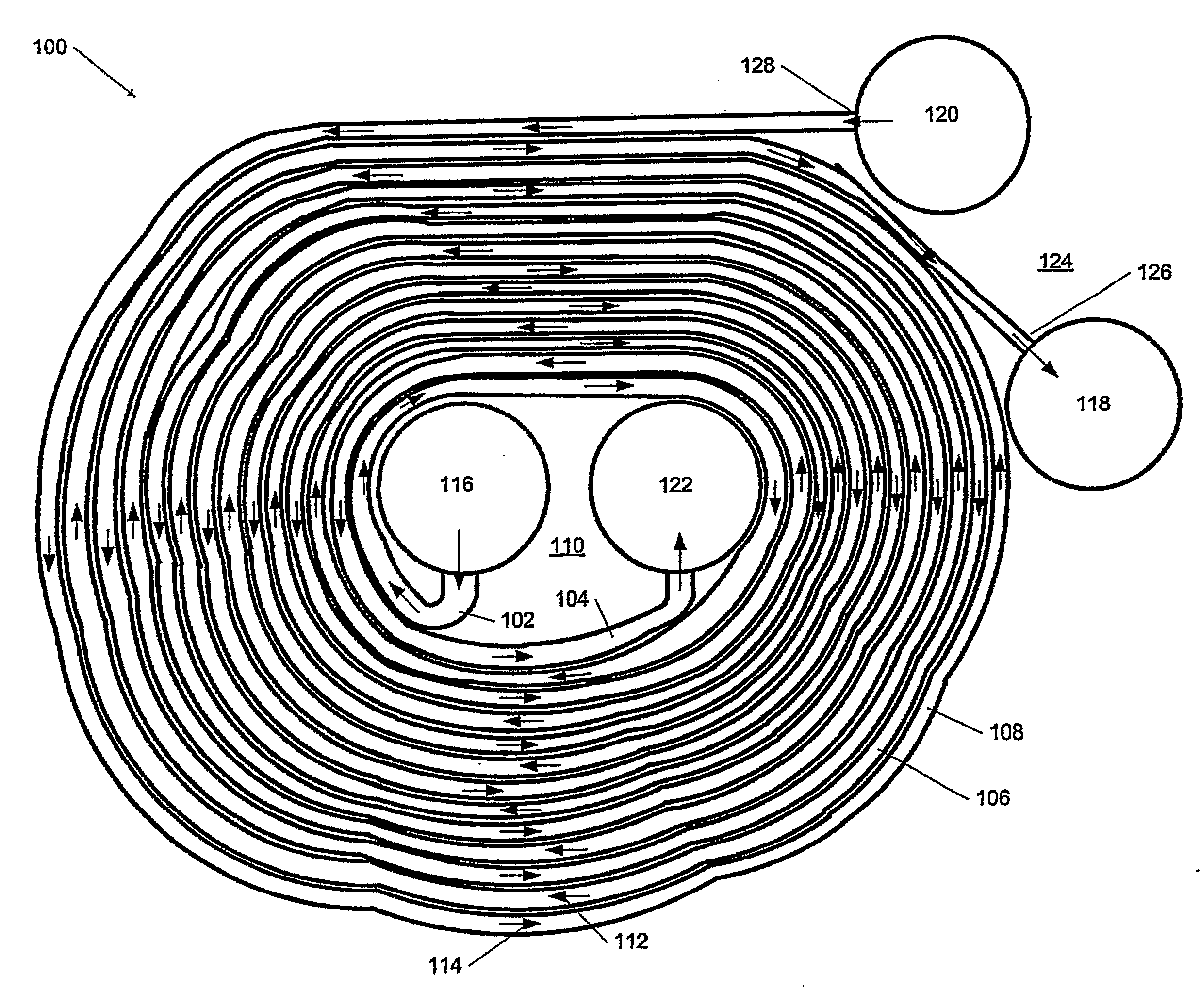

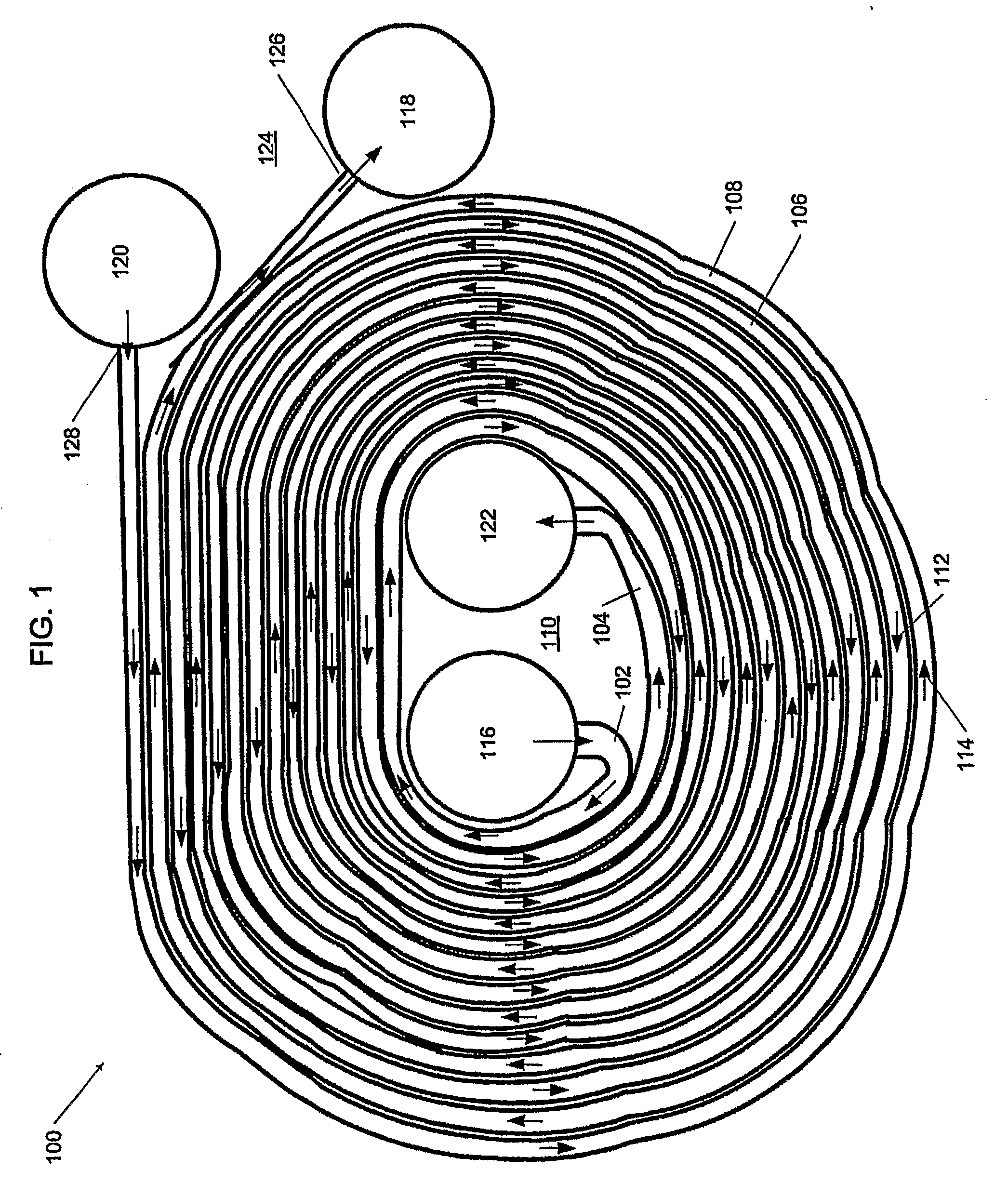

Tissue scaffold having aligned fibrils, apparatus and method for producing the same, and artificial tissue and methods of use thereof

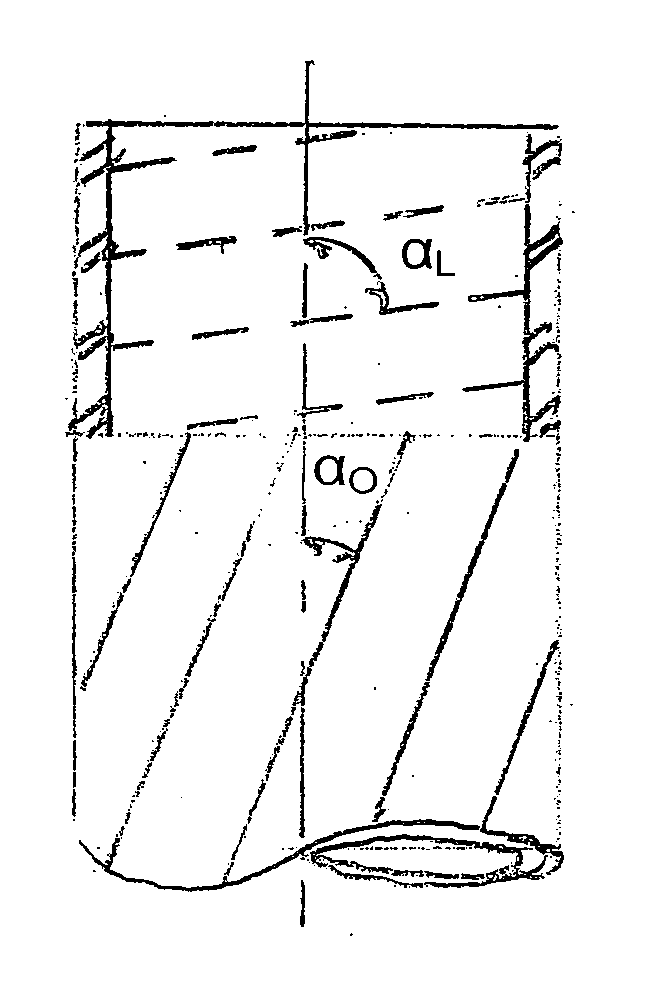

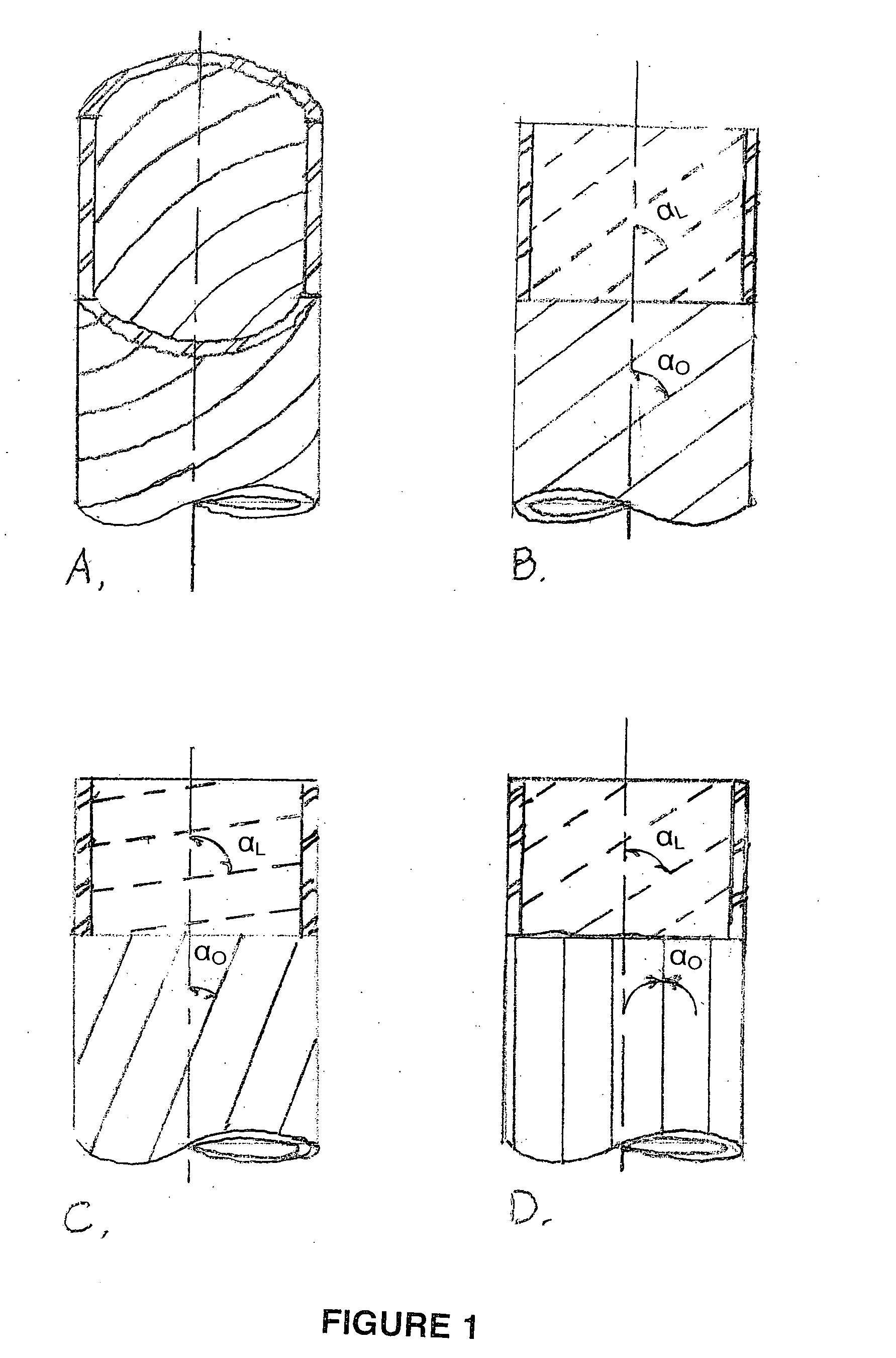

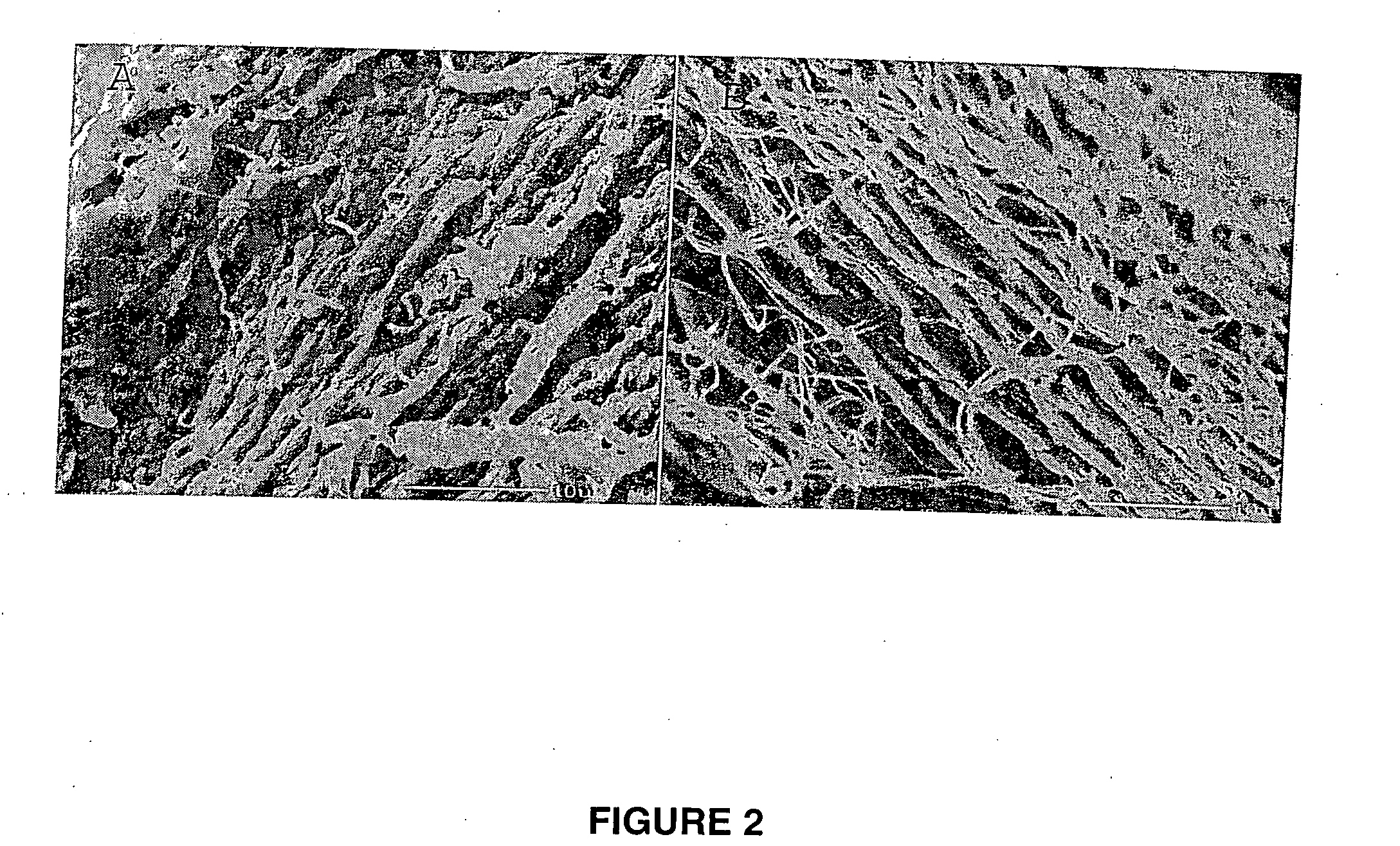

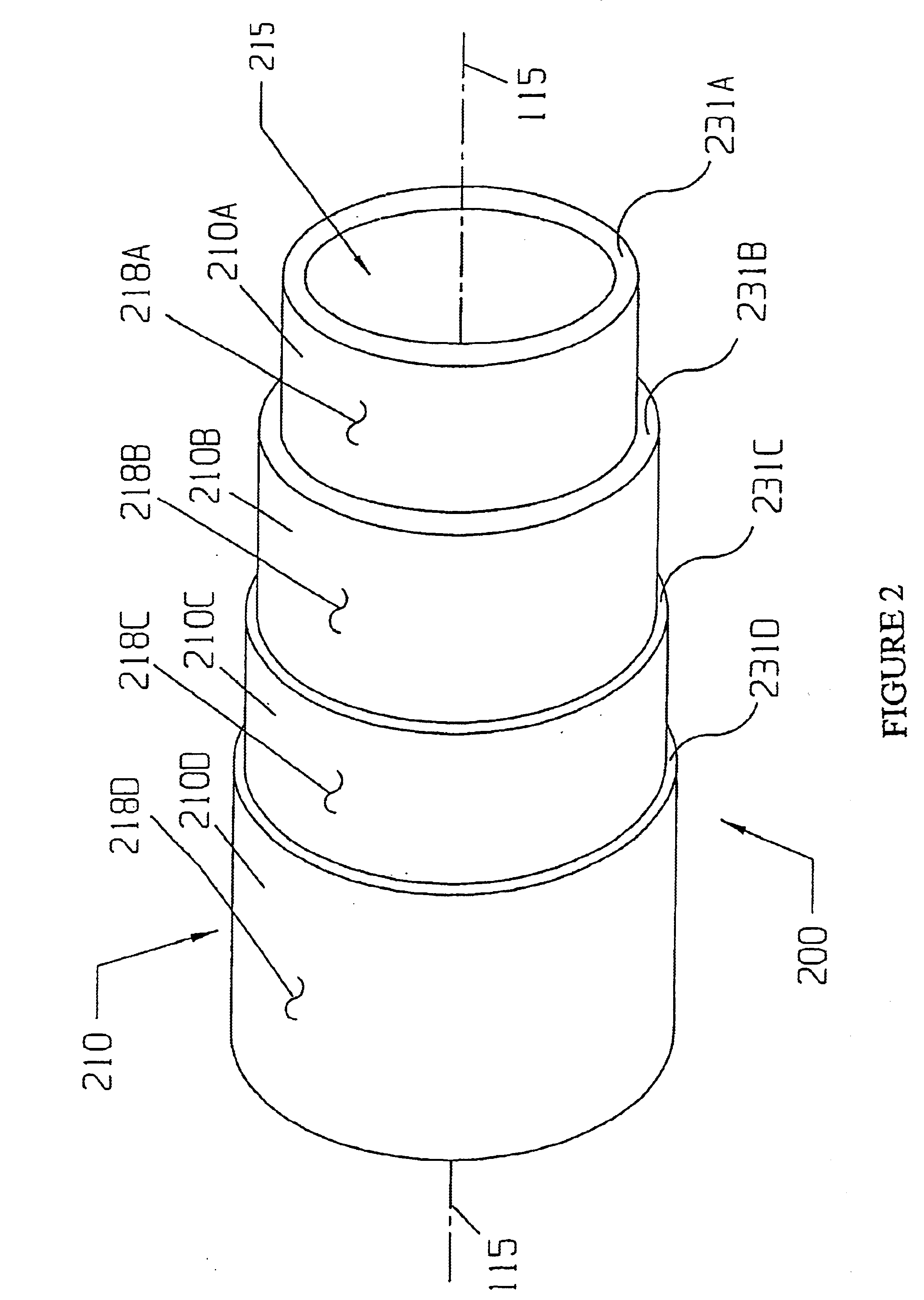

ActiveUS20050009178A1Improve structural strengthMinimal immunological responsePeptide/protein ingredientsHollow filament manufactureFiberRadial position

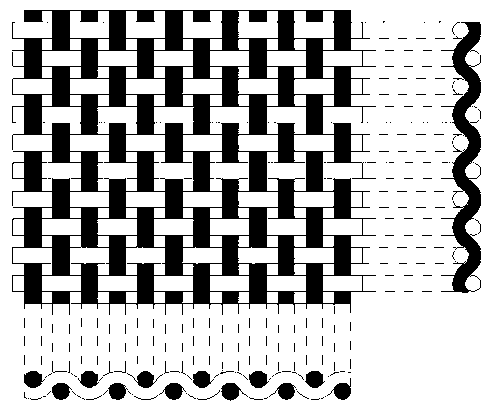

A tubular tissue scaffold is described which comprises a tube having a wall, wherein the wall includes biopolymer fibrils that are aligned in a helical pattern around the longitudinal axis of the tube where the pitch of the helical pattern changes with the radial position in the tube wall. The scaffold is capable of directing the morphological pattern of attached and growing cells to form a helical pattern around the tube walls. Additionally, an apparatus for producing such a tubular tissue scaffold is disclosed, the apparatus comprising a biopolymer gel dispersion feed pump that is operably connected to a tube-forming device having an exit port, where the tube-forming device is capable of producing a tube from the gel dispersion while providing an angular shear force across the wall of the tube, and a liquid bath located to receive the tubular tissue scaffold from the tube-forming device. A method for producing the tubular tissue scaffolds is also disclosed. Also, artificial tissue comprising living cells attached to a tubular tissue scaffold as described herein is disclosed. Methods for using the artificial tissue are also disclosed.

Owner:UNIVERSITY OF SOUTH CAROLINA

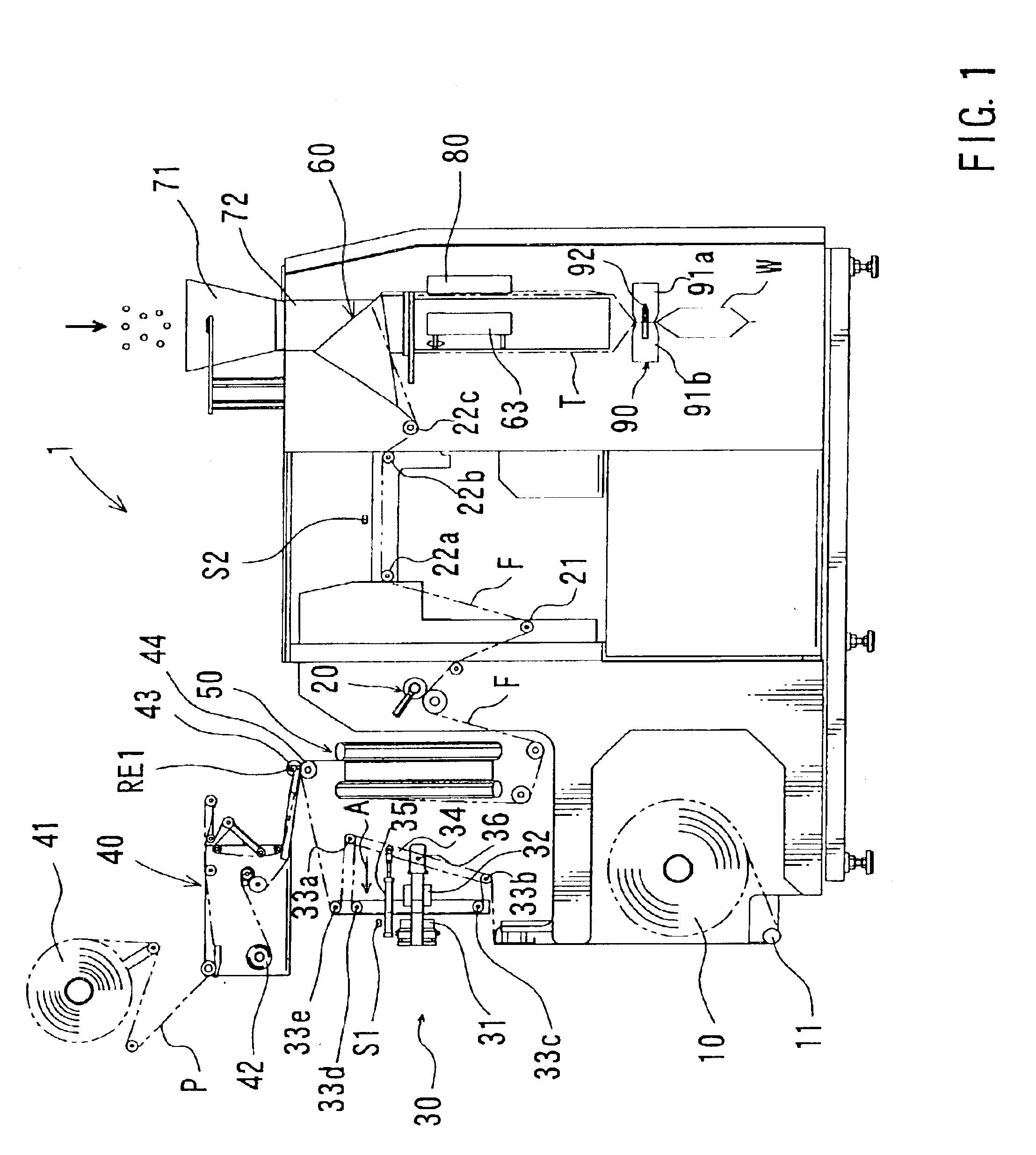

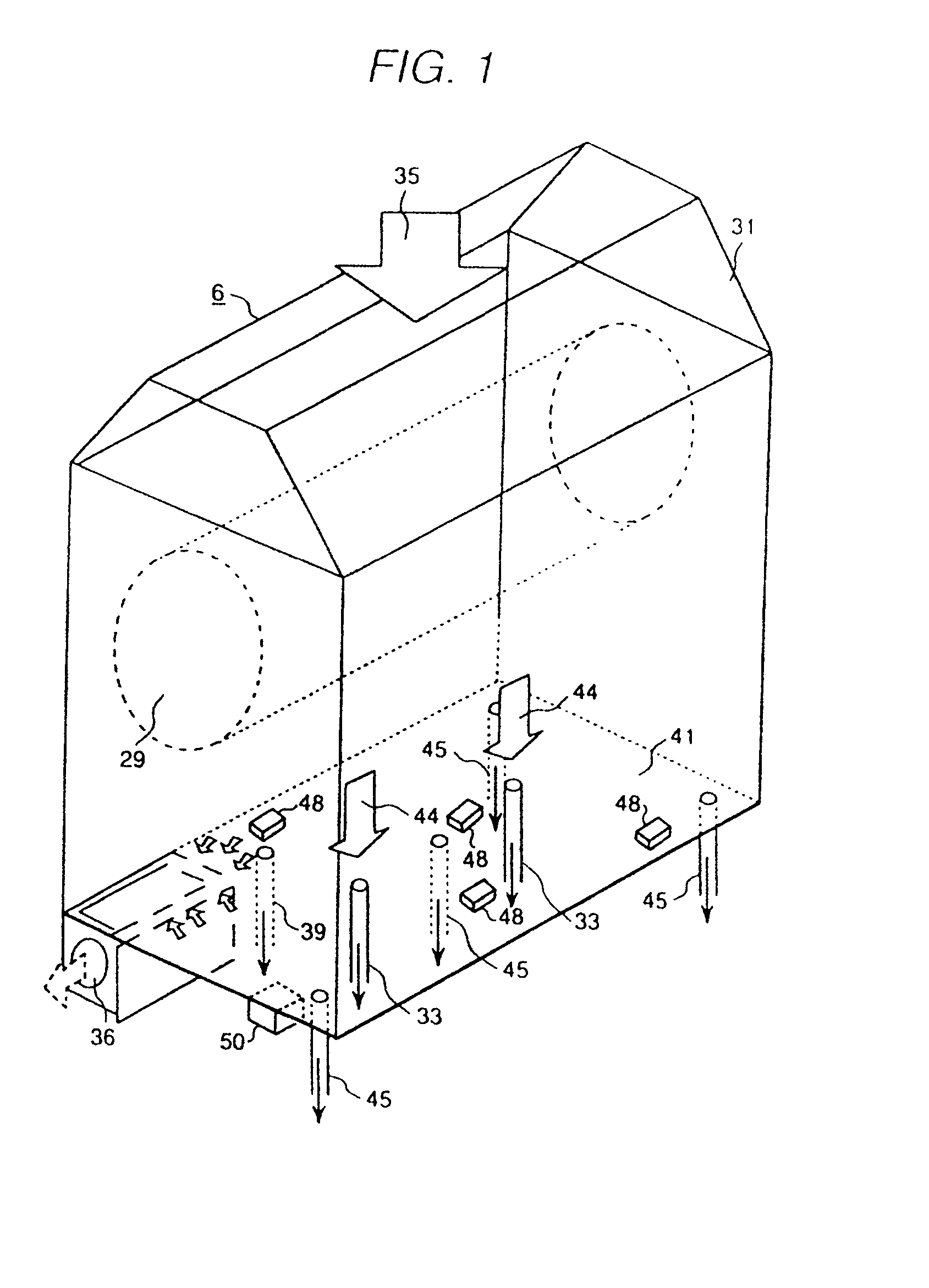

Form-fill sealing machines, resealable flexible packages and methods of manufacturing resealable flexible packages

InactiveUS6865860B2Hinders its propagationReliable stopWrapping material feeding apparatusBagsHermetic packagingEngineering

A form-fill sealing machine (1) for manufacturing resealable packages (W) includes a tearable line forming device (30) that serves to form tearable lines (104) in a film (F). A labeling device (40) serves to stick re-stickable labels (103) onto the film in positions to cover respective tearable lines. A tube forming device (60) serves to form the film into a tubular film (T). A first sealing device (80) serves to seal lapped edges of the tubular film so as to form a lengthwise sealed portion (111). A second sealing device (90) serves to seal the tubular film in a crosswise direction, so that crosswise sealed portions (109) are formed on the tubular film. Each tearable line is positioned between two adjacent crosswise sealed portions and adjacent to one of two adjacent crosswise sealed portions.

Owner:FUJI KIKAI KK

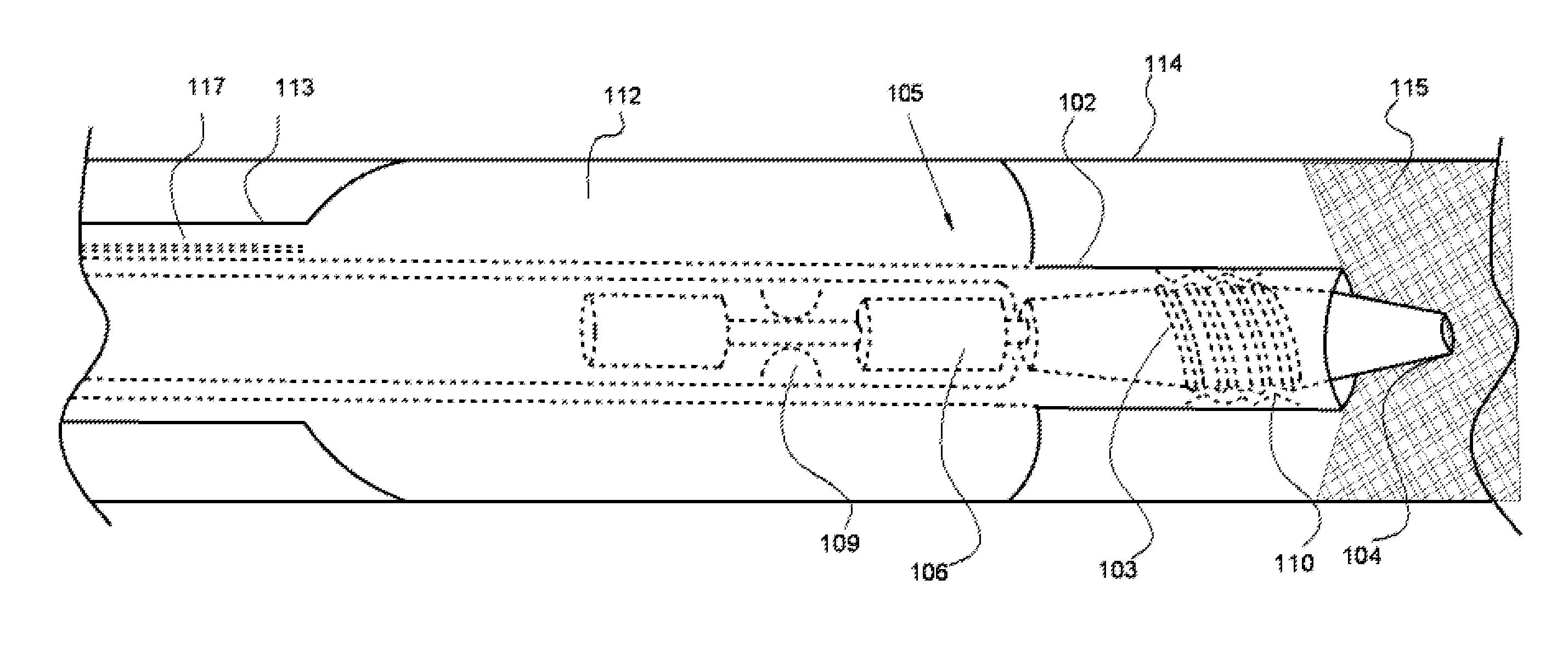

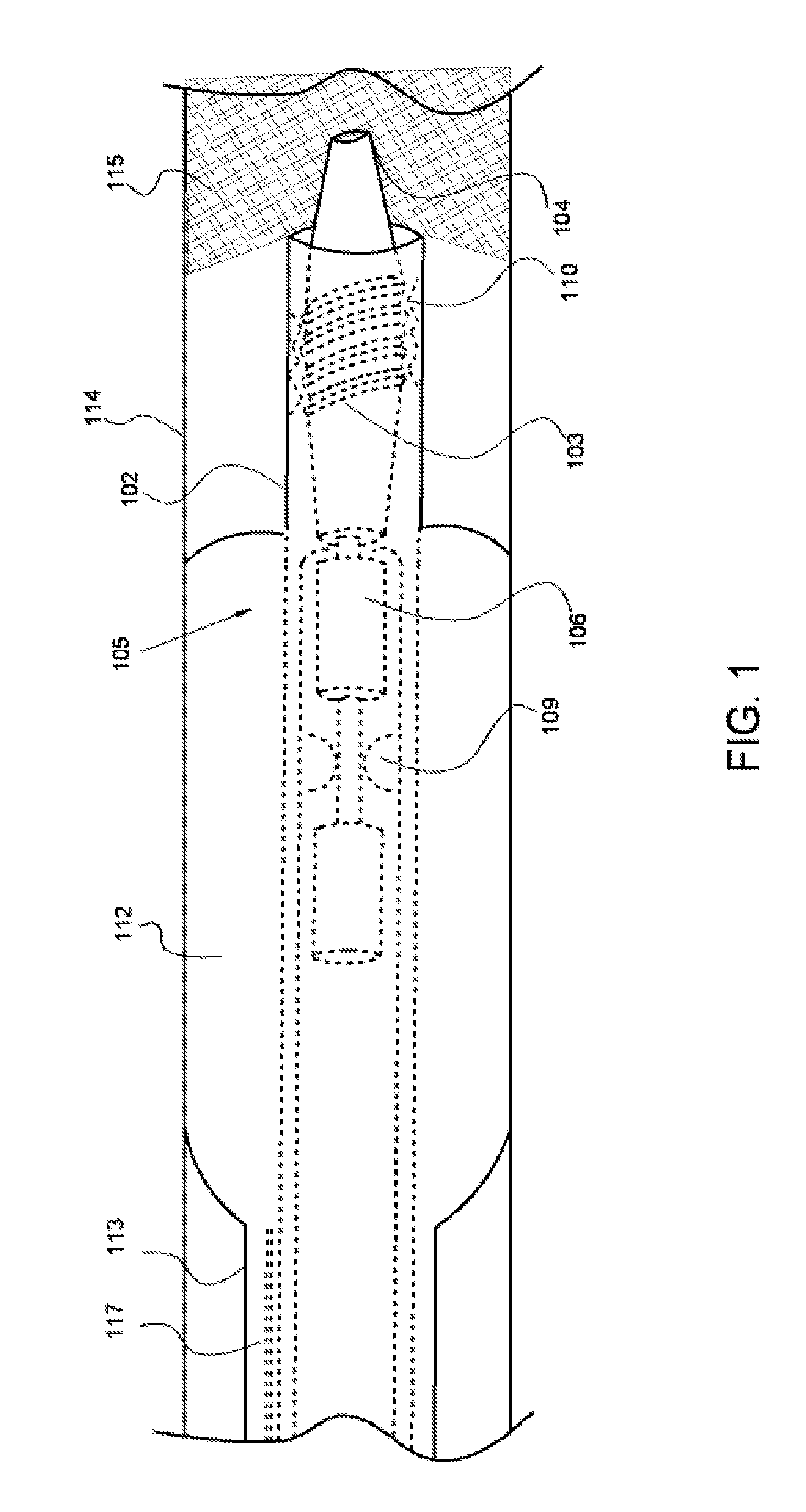

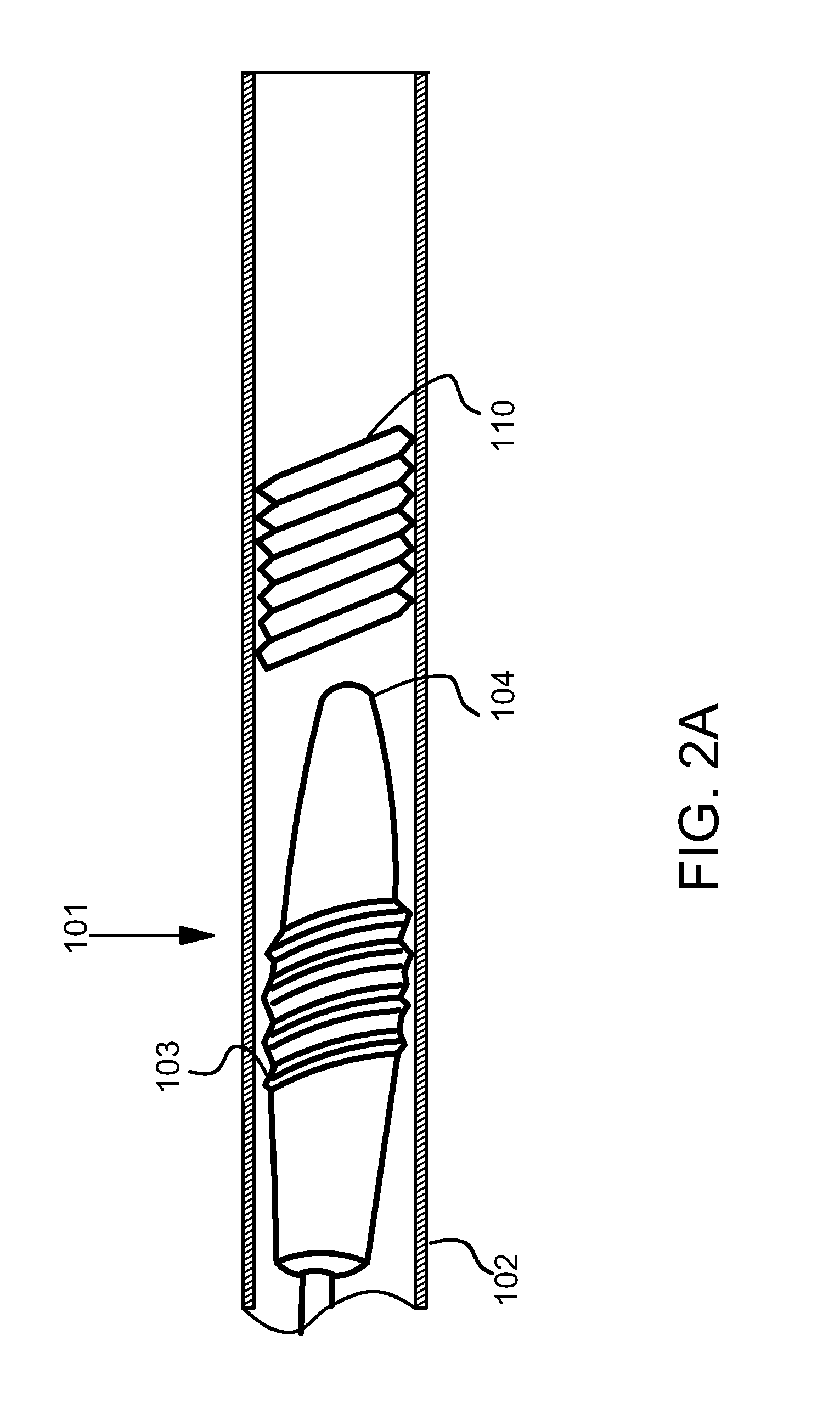

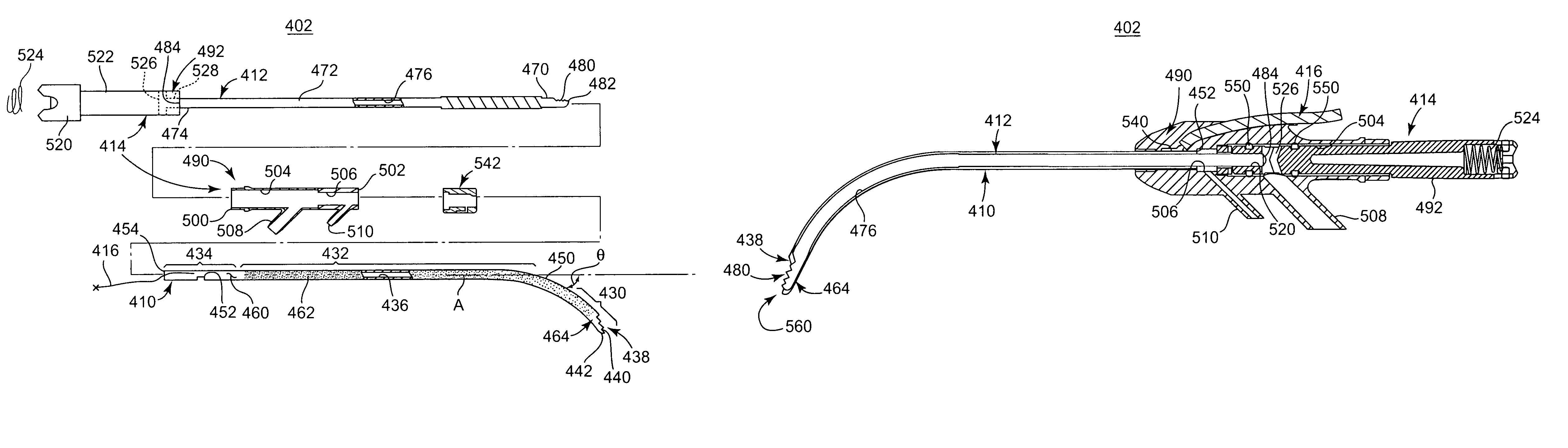

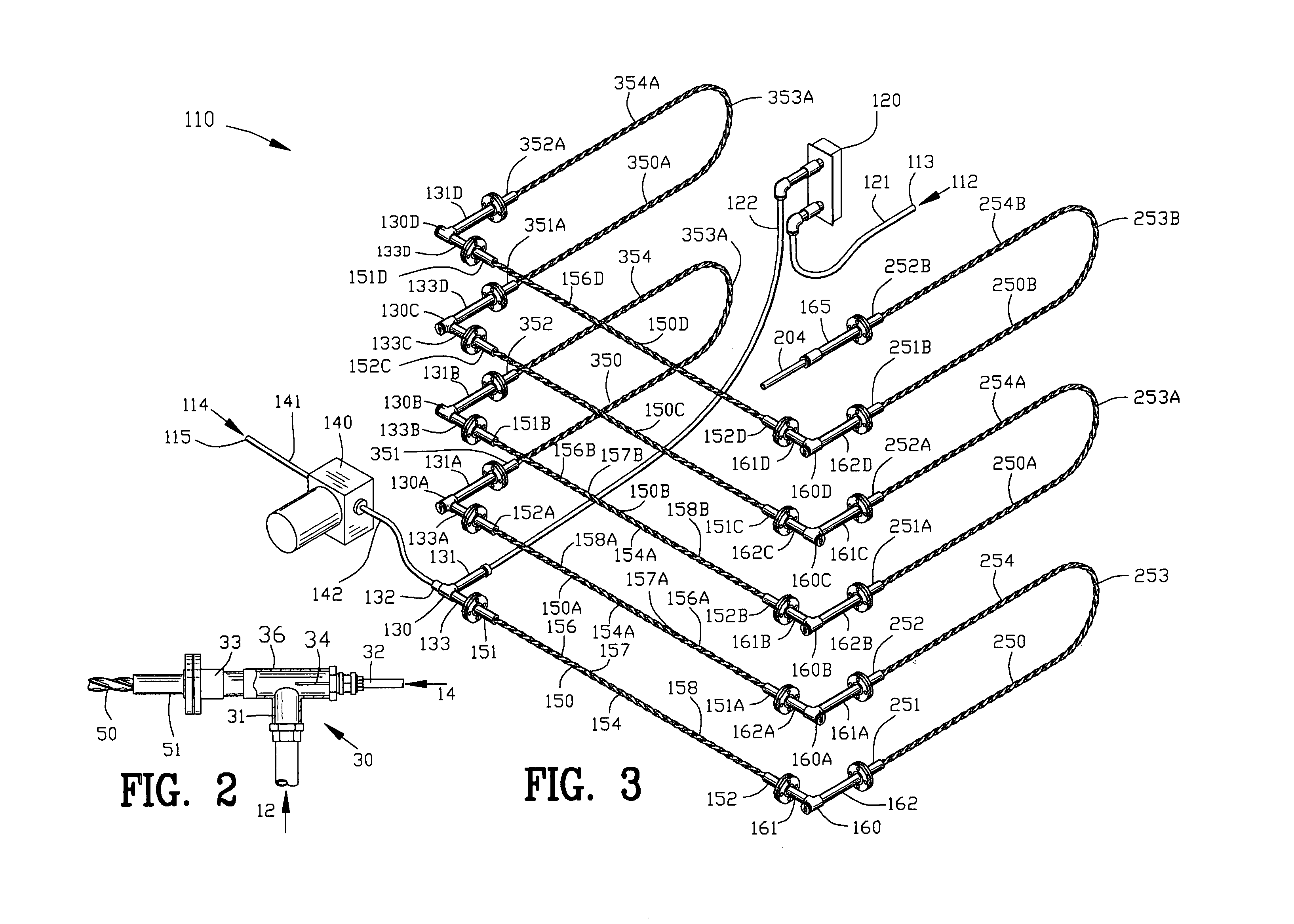

System and Method for the Treatment of Occluded Vessels

InactiveUS20110208222A1Prevent life threatening embolizationsIncrease successCannulasExcision instrumentsCatheterThree vessels

A system for treating an occlusive region of a blood vessel comprises: a catheter outer tube forming a lumen for inflation of a centering balloon; a catheter inner tube lined with either internal spiral threads or point slots to assist controlled guidewire movement; and a rotatable guidewire that may be solid or hollow. The guidewire comprises a rotatable body and a proximal shaft. The rotatable body has two components: a distal rotating head and a proximal rotating shaft, wherein these components are of equal length and the rotating shaft resides within the proximal shaft. Linear force applied to the proximal shaft will result in the rotational guidewire tip puncturing cutting through an occlusion. In an alternative embodiment, the guidewire rotatable body comprises two mechanical rings and a compression spring, wherein when the spring is released via depression of a button, the guidewire tip drills through an occlusion.

Owner:LJAHNICKY BORIS +1

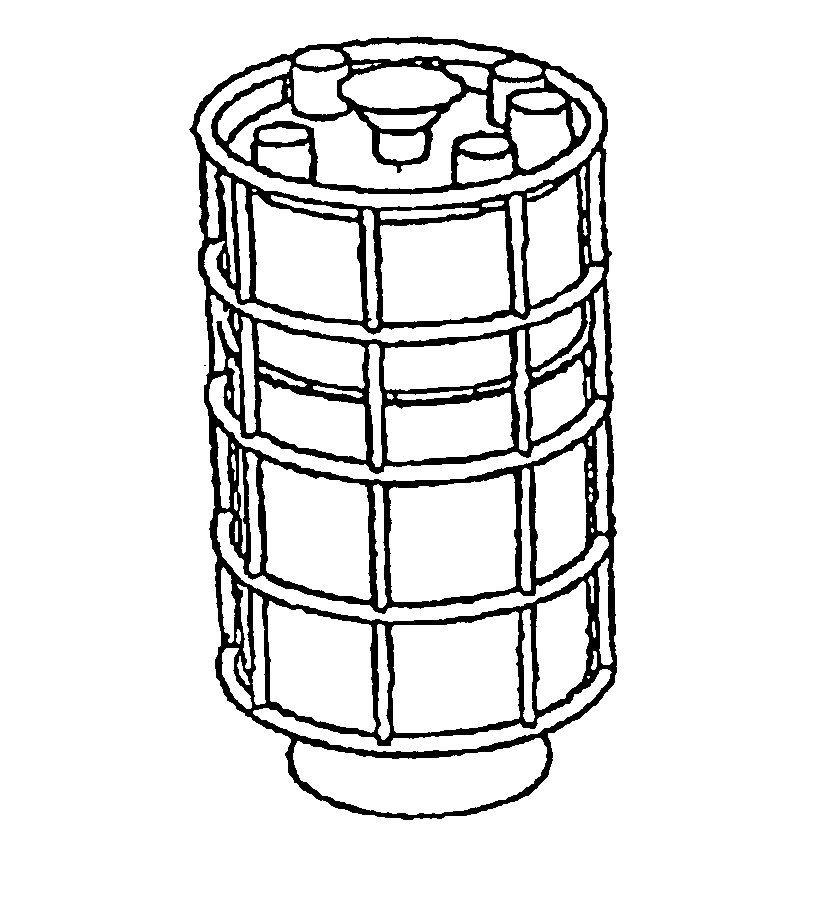

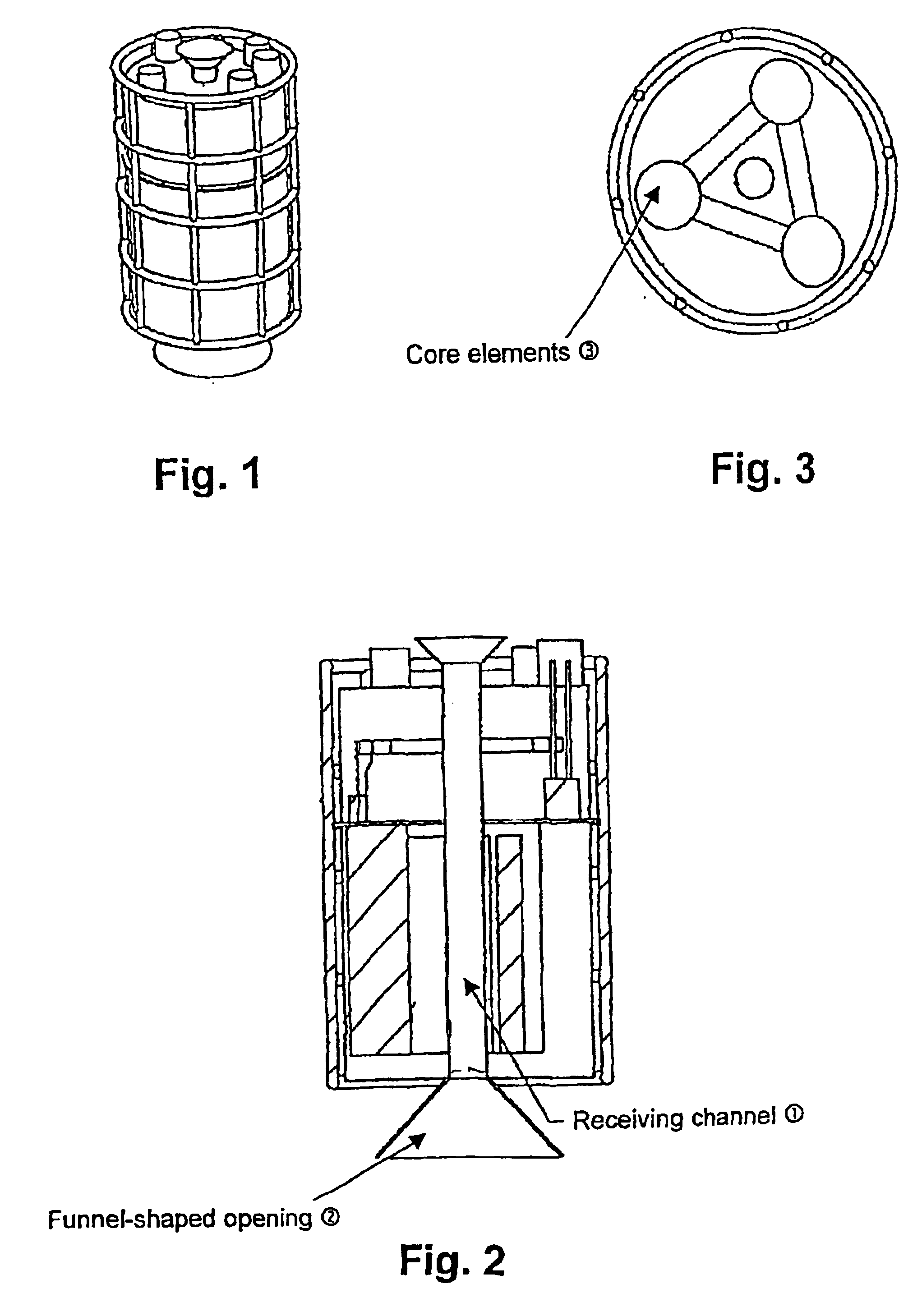

Arrangement and method for installing a subsea transformer

InactiveUS6985061B2Drawback can be obviatedSimplify the installation processTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerEngineering

An arrangement and a method for use in installation procedures for subsea transformers. A central, hole or tube is included in an encapsulation enclosing a transformer that is to be installed. Three core elements of the transformer are arranged symmetrically around the hole or tube forming a triangle or a delta. The transformer is lowered towards a a foundation placed on the sea floor wherein a guide pin is mounted. When the transformer has found its way to the foundation, the guide pin will enter the tube, and the transformer will slide down onto the guide line pin. The tube is terminated by a funnel shaped opening, thus making it easier not to miss the guide pin by the tube opening. The transformer is horizontally oriented by means of orientation keys localized within the tube.

Owner:VETCO GRAY SCANDINAVIA

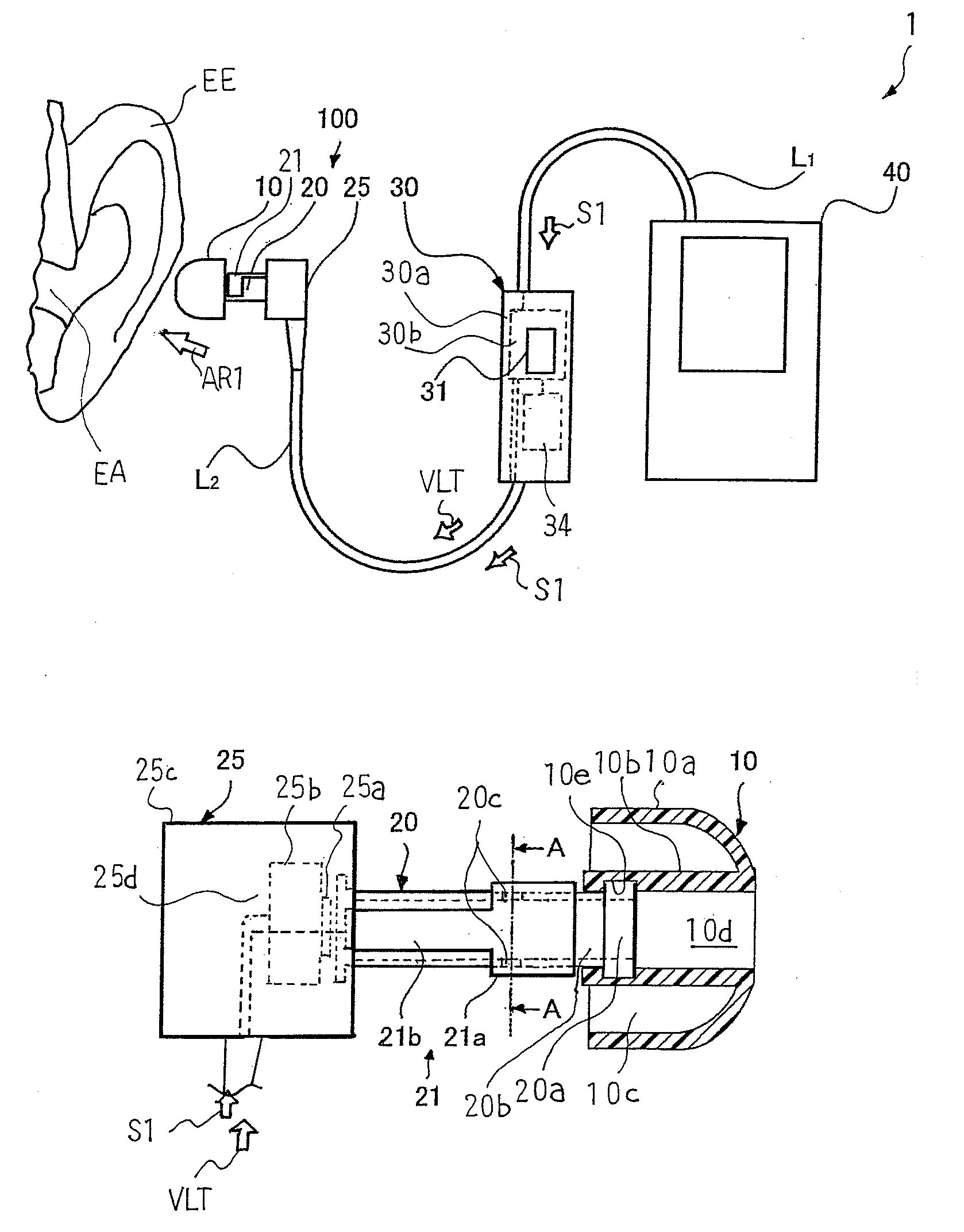

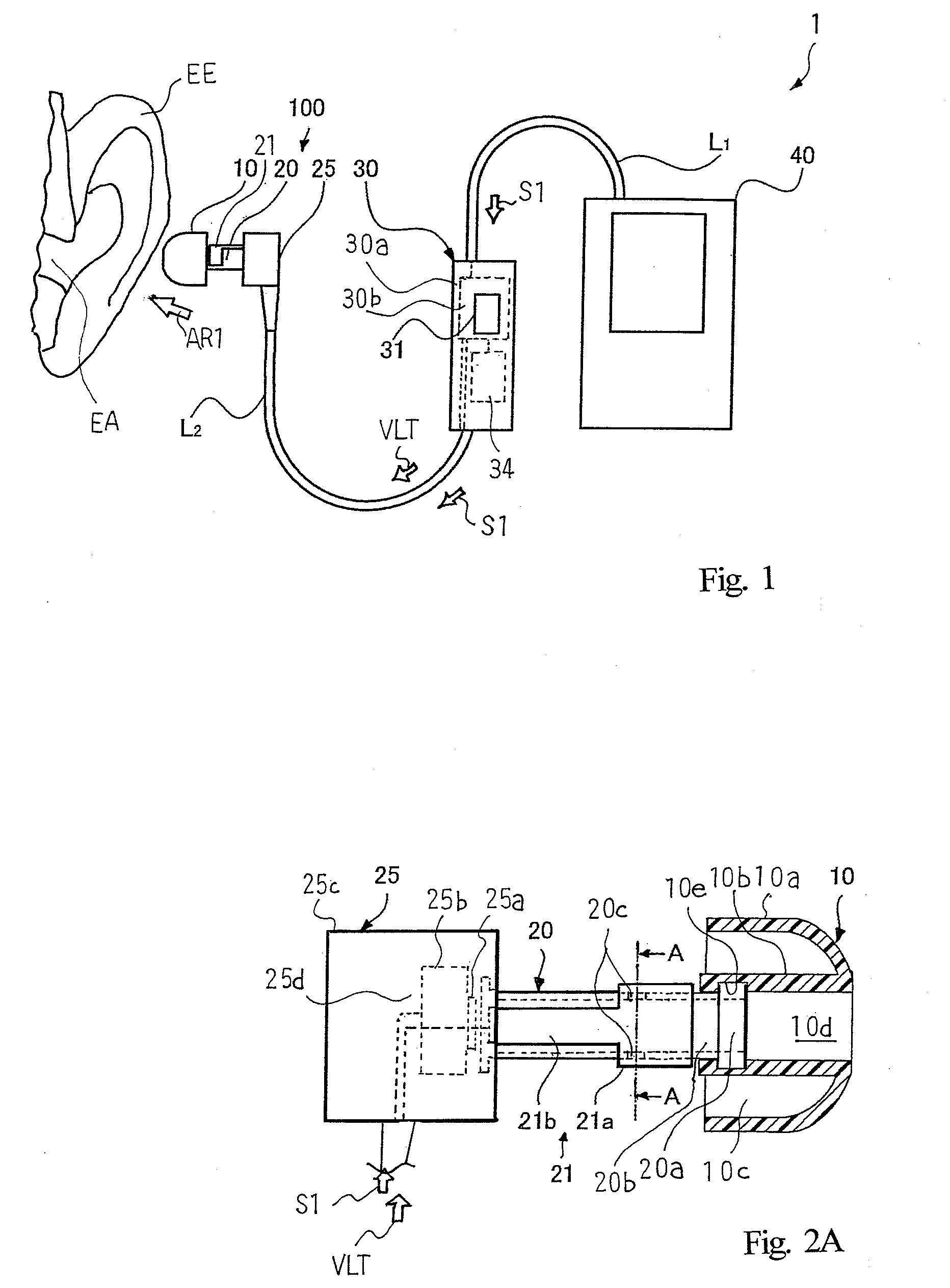

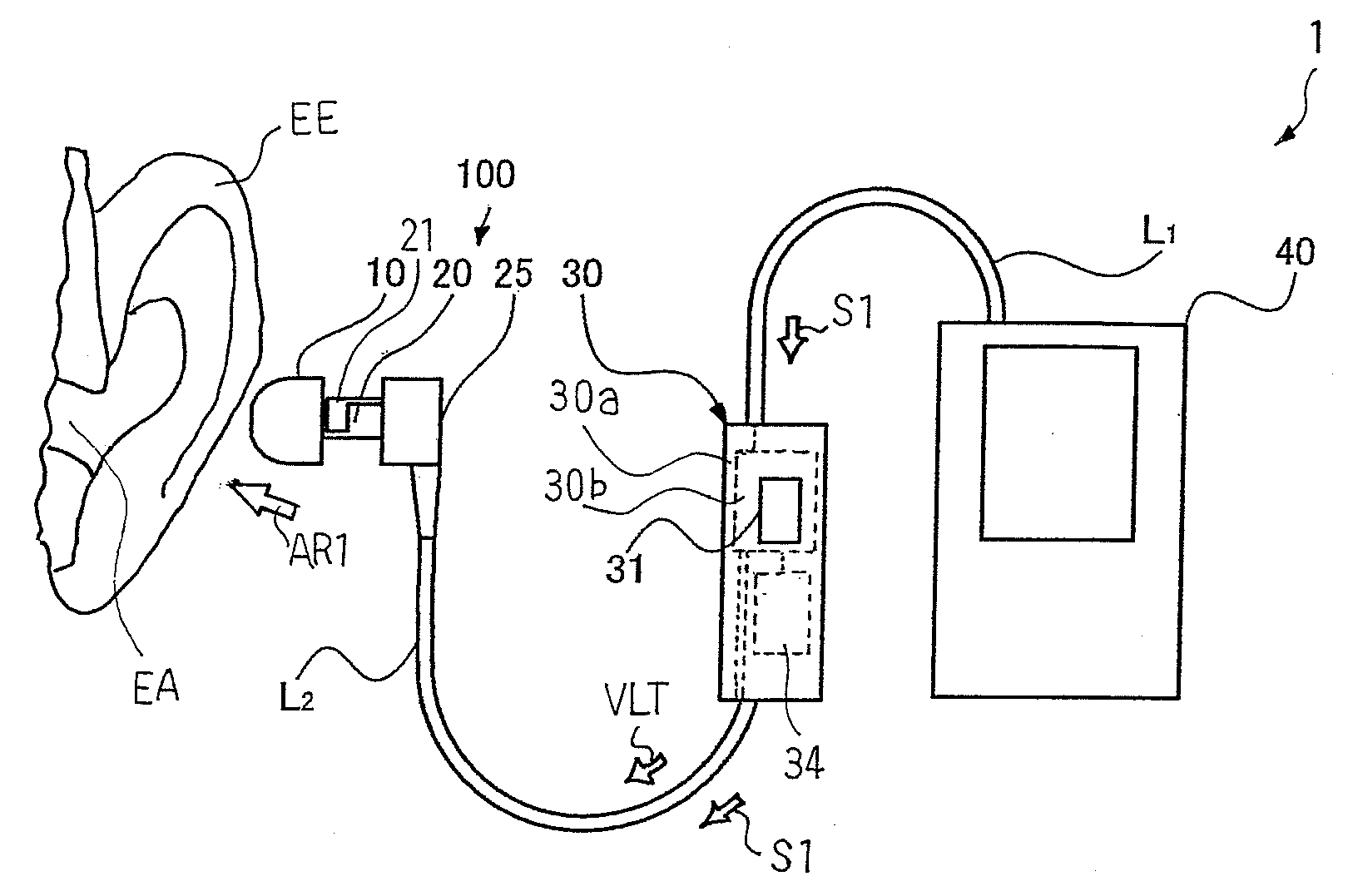

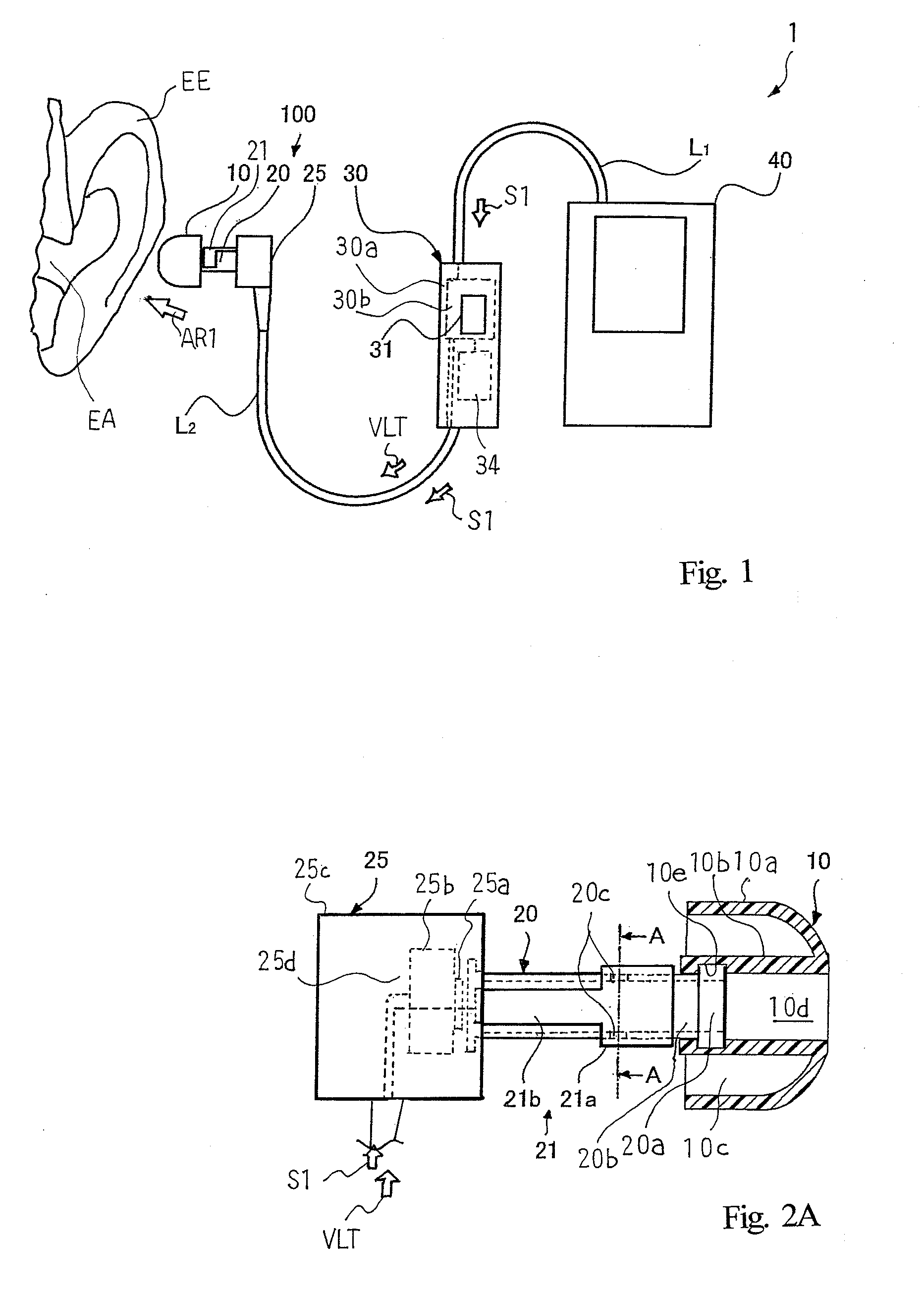

Earphone device, sound tube forming a part of earphone device and sound generating apparatus

InactiveUS8090134B2Intra aural earpiecesEarpiece/earphone mechanical/electrical switchesEngineeringHeadphones

An insert earphone device includes an electro-acoustic device, an inserting body, a sound tube connected between the electro-acoustic device and the inserting body and an active valve unit provided on the sound tube, the sound tube is formed with a sound propagation path open at both ends thereof to the electro-acoustic device and the inserting body and an external sound entrance open at both end thereof to environment and the sound propagation path, and the active valve unit is formed of electroactive polymer and responsive to voltage supplied through a cable so as to close and open the external sound entrance; when a user wishes to hear external sound, the user changes the polarity of voltage so that the active valve unit is deformed for conducting the environment to the sound propagation path, whereby the user hears the external sound without removing the earphone device from the ear.

Owner:YAMAHA CORP

Tissue scaffold having aligned fibrils and artificial tissue comprising the same

ActiveUS7338517B2Sufficient structural strength to withstand pressureMinimal immunological responsePeptide/protein ingredientsDough-sheeters/rolling-machines/rolling-pinsFiberFibril

Owner:UNIVERSITY OF SOUTH CAROLINA

Methods of producing high-strength metal tubular bars possessing improved cold formability

ActiveUS20070216126A1Maintain mechanical propertiesOvercome problemsTorsion springsInduction heatingAlloyHigh intensity

A method for producing a tubular bar, more particularly a stabilizer bar, is provided. The method comprises providing a tubular bar of desired size having an outer and inner surface, heating the bar to an elevated temperature, quenching the bar by application of a cooling fluid to the surfaces of the bar, and forming the tube to a desired shape without annealing. The method further provides for the composition of a high-strength, high formability carbon steel alloy to be used in conjunction with the method. Advantageously, the bar is formable without thermal processing subsequent to quenching. In this fashion, metal tubular bars, such as stabilizer bars, may be formed at reduced cost.

Owner:TENARIS CONNECTIONS

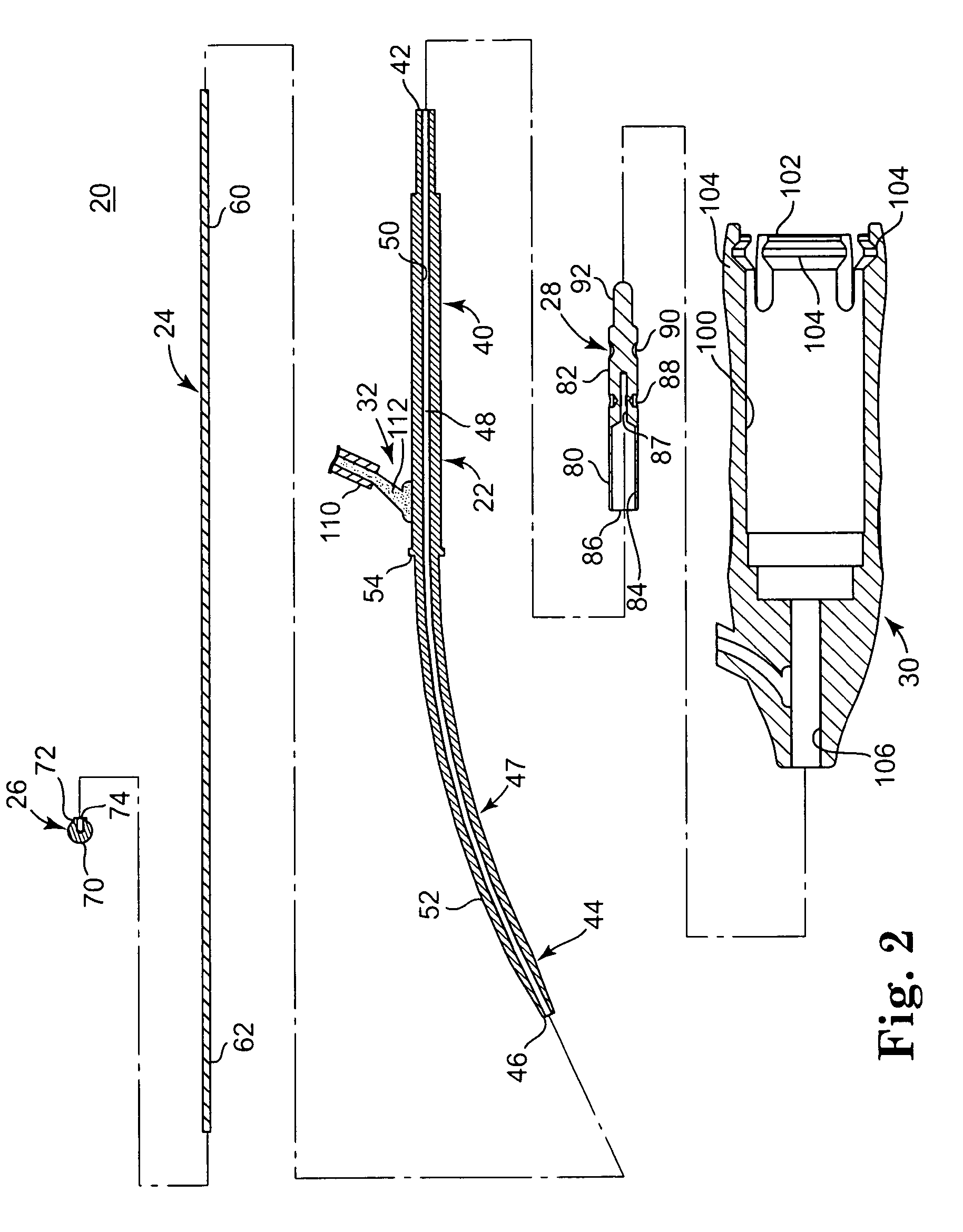

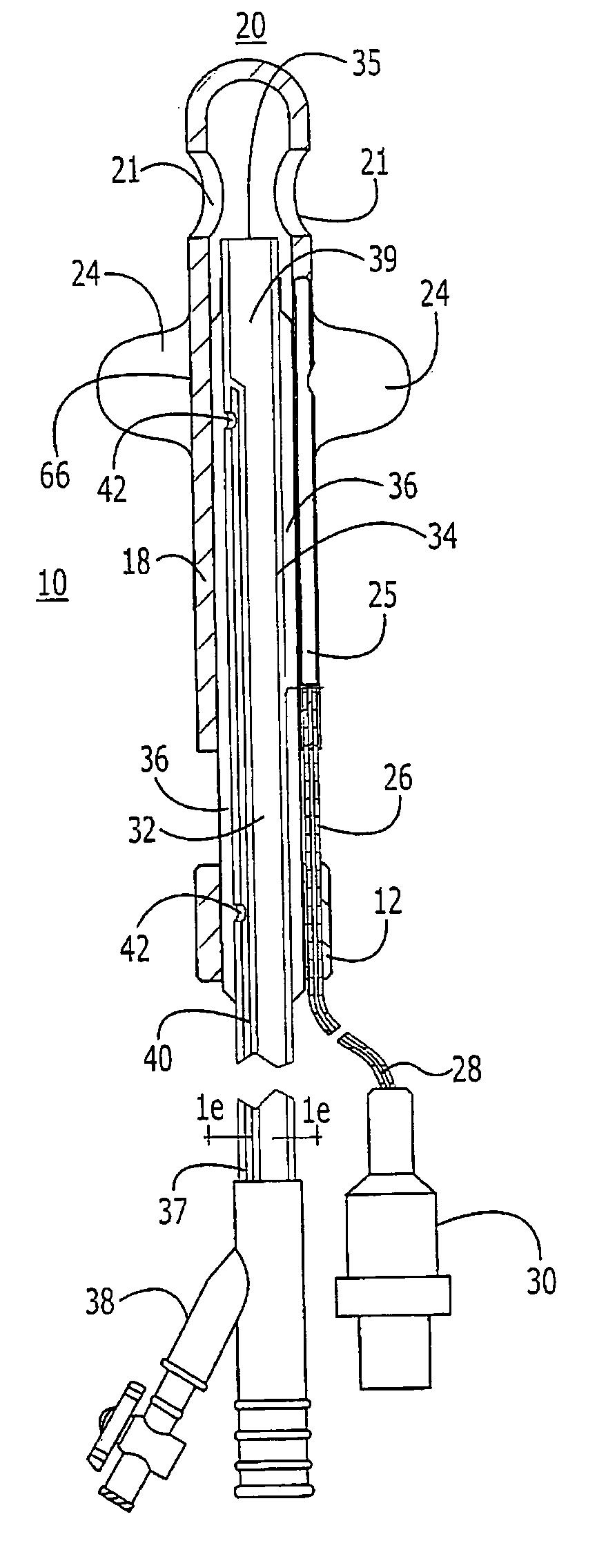

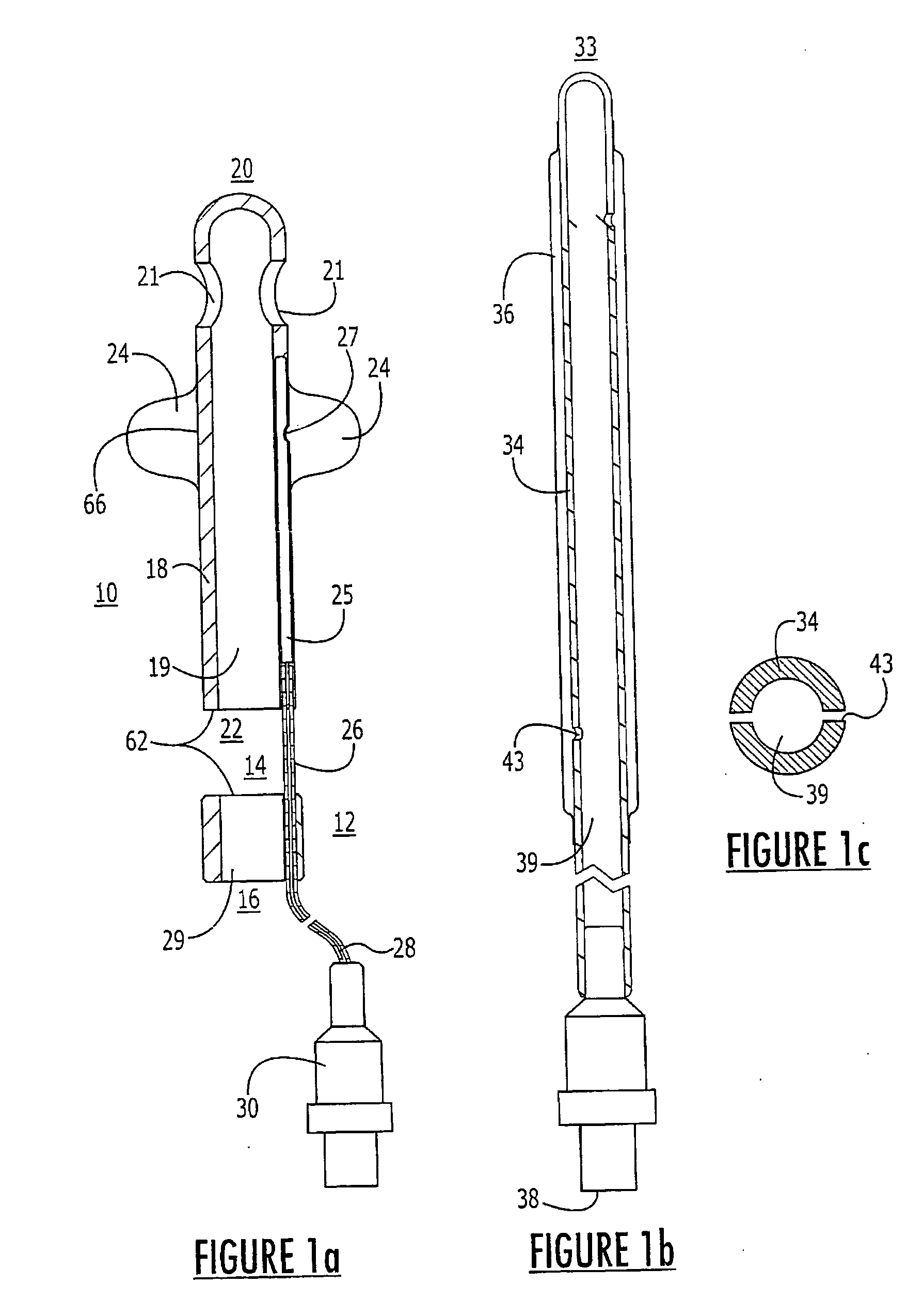

Micro-resecting and evoked potential monitoring system and method

ActiveUS8016846B2Computer-aided planning/modellingSurgical instruments for heatingMonitoring systemConductive materials

Surgical micro-resecting and evoked potential monitoring system and method. The system includes a micro-resecting instrument, handpiece, and evoked potential monitor. The instrument includes an outer tube forming a cutting window at which a cutting tip of an inner member is located. A hub assembly rotatably maintains the inner and outer members. An electrically non-conductive material covers a region of the outer tube, and wiring is connected to an exposed surface of the outer tube. The instrument defines a probe surface proximate the cutting window as part of an electrical pathway with the wiring. The hub assembly is powered by the handpiece, and the wiring is connected to the evoked potential monitor. Evoked potential monitoring is performed at the probe surface via stimulation energy delivered along the electrical pathway, and tissue / bone resection occurs with rotation of the cutting tip.

Owner:MEDTRONIC XOMED INC

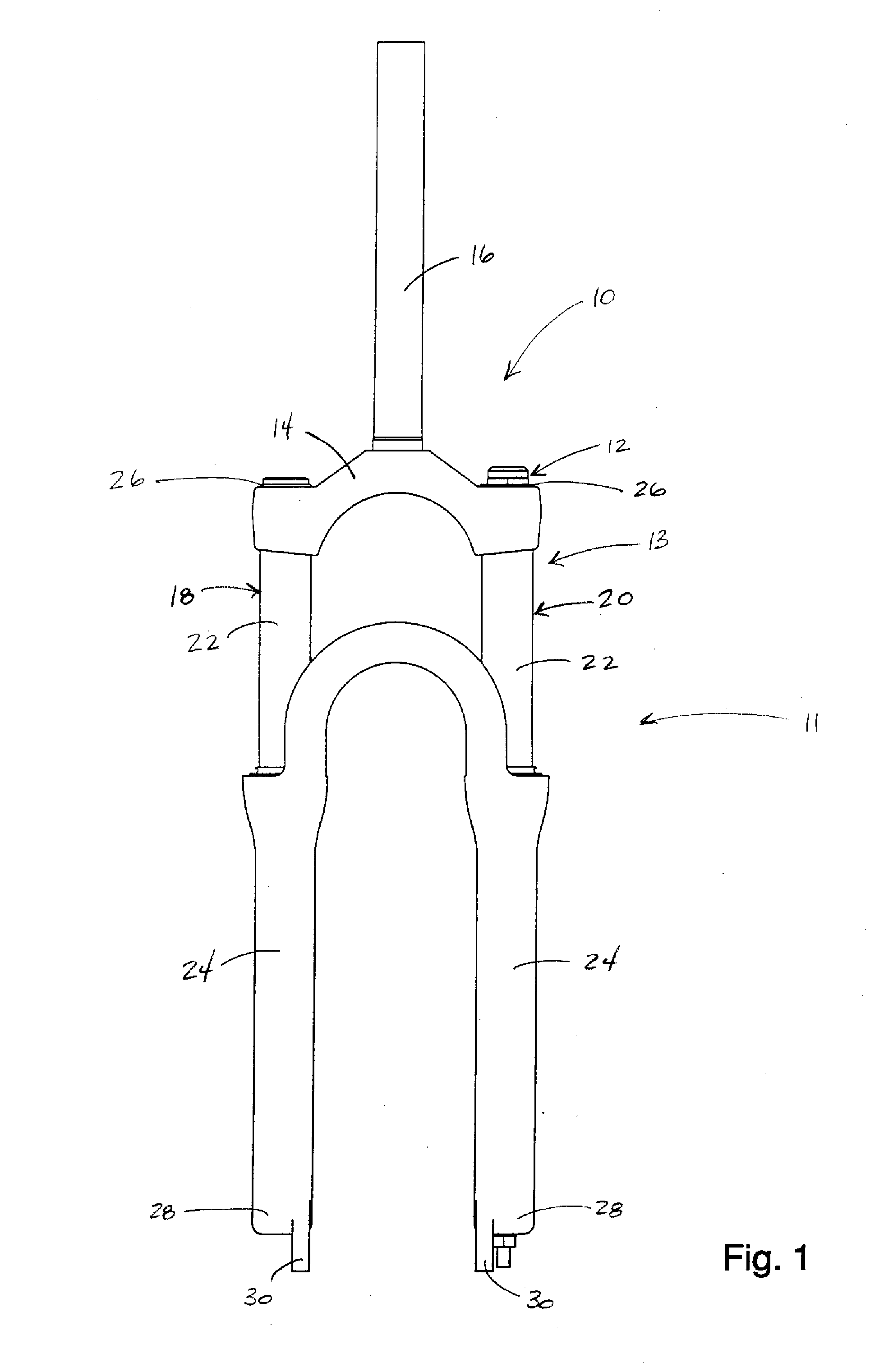

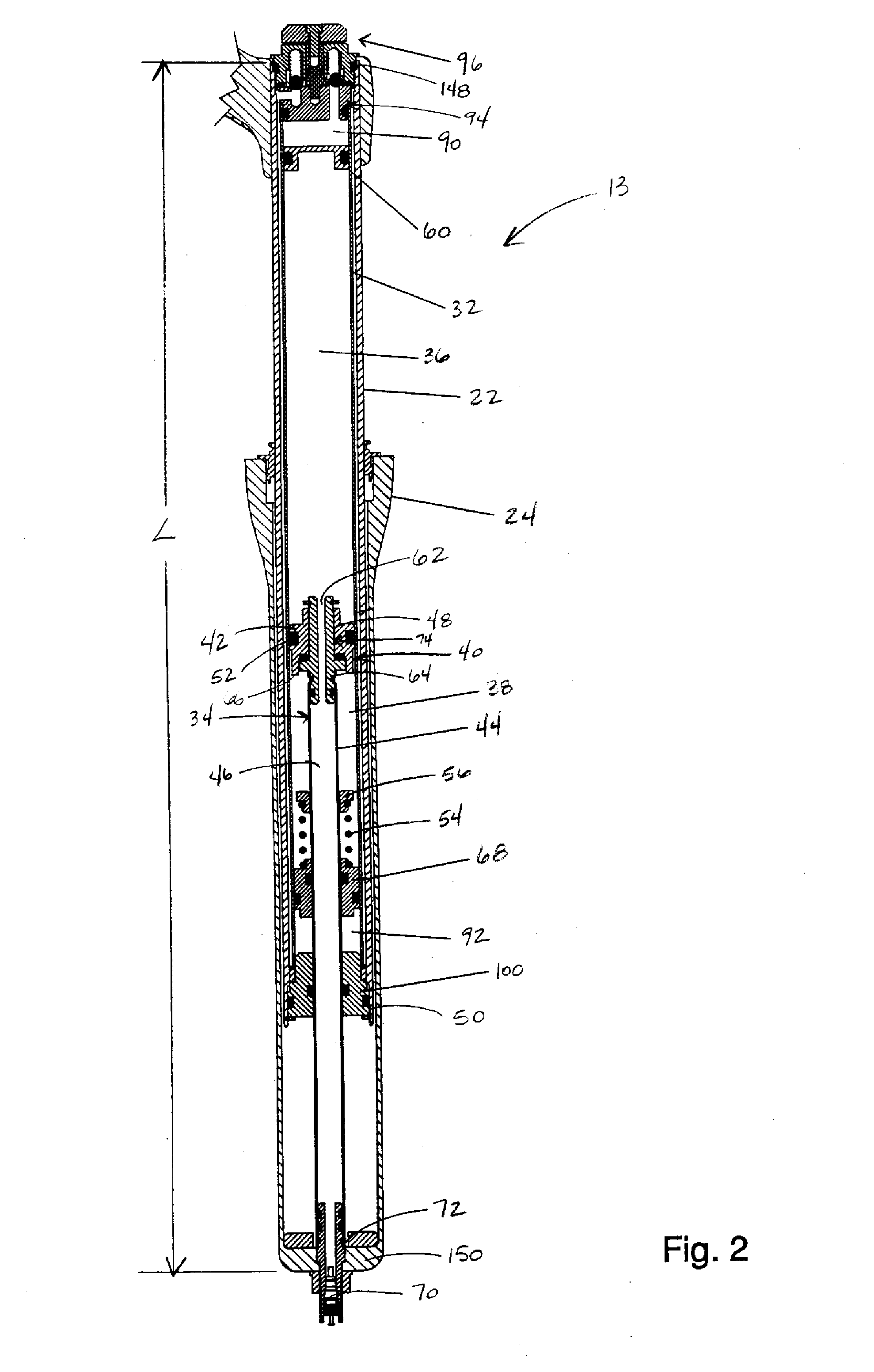

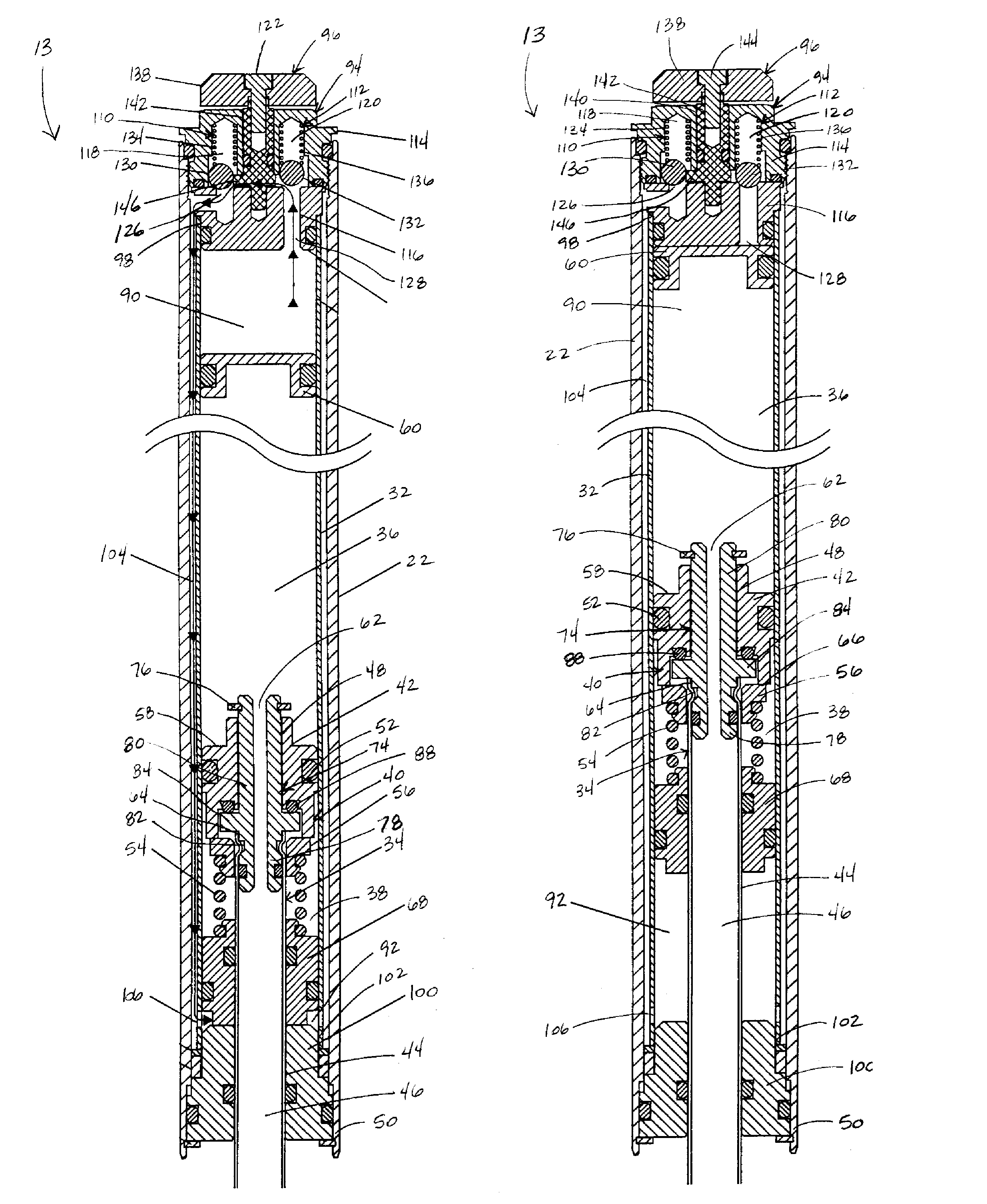

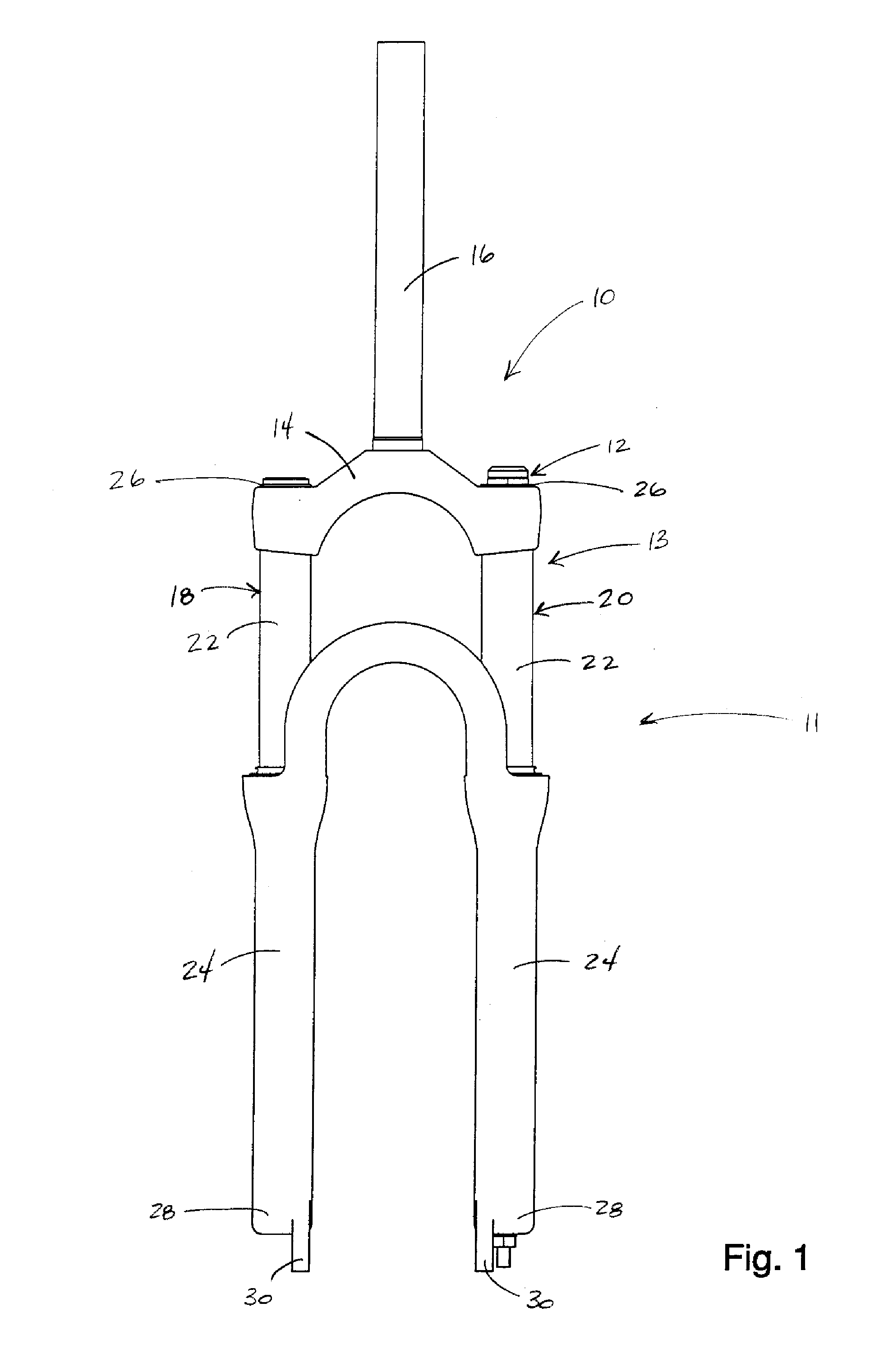

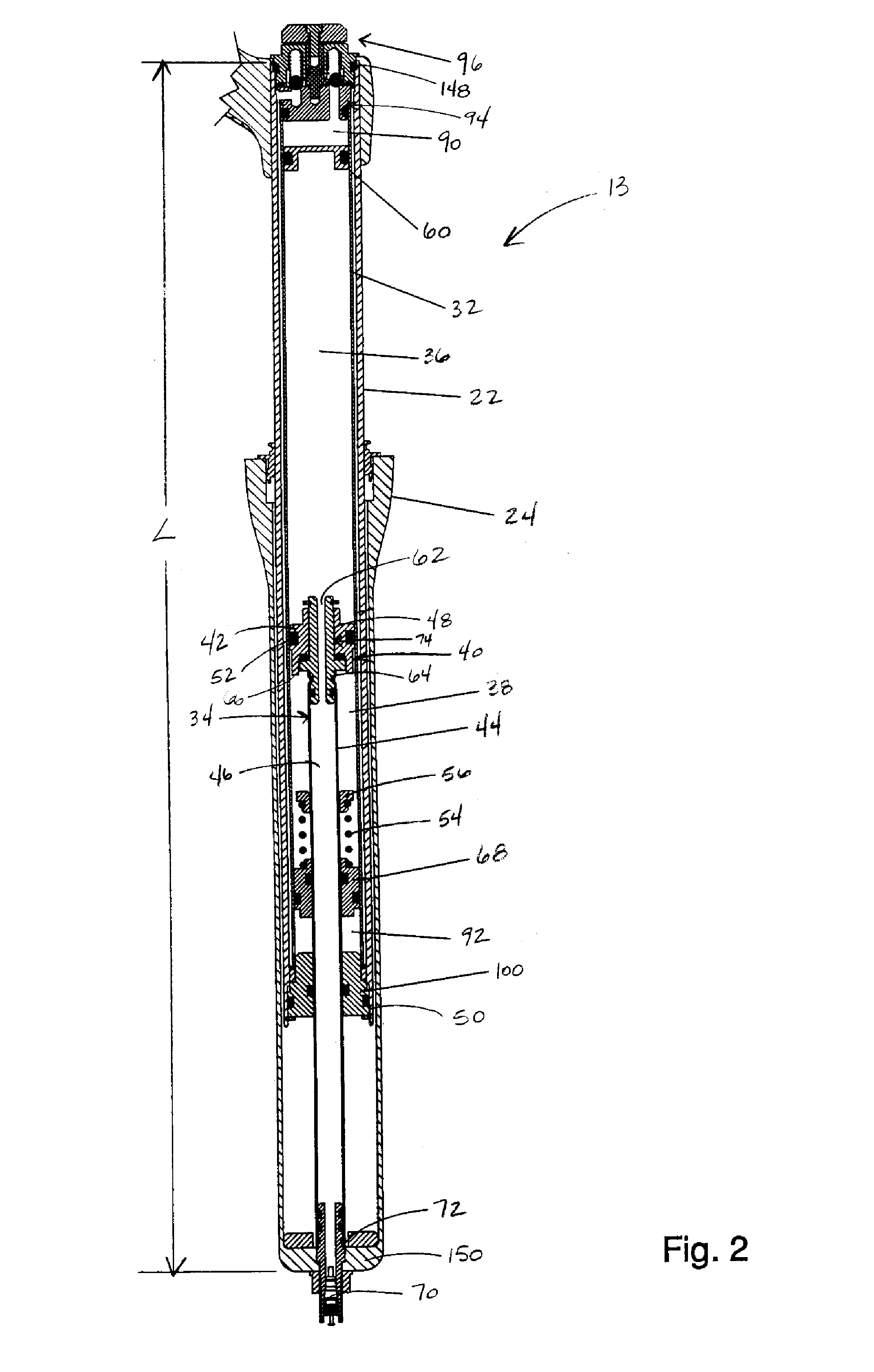

Bicycle suspension system

InactiveUS20080041681A1Wheel based transmissionFrictional rollers based transmissionEngineeringPiston

A bicycle suspension system including a travel adjustment apparatus. The bicycle suspension system includes a piston tube and a piston assembly slidably disposed in the piston tube forming a shock-absorbing mechanism. The piston assembly is in contact with the piston tube. The travel adjustment apparatus includes first and second fluid chambers, a fluid valve mechanism for controlling fluid flow between the first and second fluid chambers, and an actuating assembly operatively connected to the fluid valve mechanism operable between at least two rider-selectable travel settings to operate the fluid valve mechanism between at least two valve settings corresponding to the rider-selectable travel settings. The first and second fluid chamber are configured such that operation of the fluid valve mechanism between two of the at least two valve settings permits the piston assembly to be moved from a first initial position relative to the piston tube to a second initial position relative to the piston tube such that the suspension system changes from a first of the at least two amounts of travel to a second of the at least two amounts of travel.

Owner:SRAM CORPORATION

Earphone device, sound tube forming a part of earphone device and sound generating apparatus

InactiveUS20100061582A1Intra aural earpiecesEarpiece/earphone mechanical/electrical switchesEngineeringHeadphones

An insert earphone device includes an electro-acoustic device, an inserting body, a sound tube connected between the electro-acoustic device and the inserting body and an active valve unit provided on the sound tube, the sound tube is formed with a sound propagation path open at both ends thereof to the electro-acoustic device and the inserting body and an external sound entrance open at both end thereof to environment and the sound propagation path, and the active valve unit is formed of electroactive polymer and responsive to voltage supplied through a cable so as to close and open the external sound entrance; when a user wishes to hear external sound, the user changes the polarity of voltage so that the active valve unit is deformed for conducting the environment to the sound propagation path, whereby the user hears the external sound without removing the earphone device from the ear.

Owner:YAMAHA CORP

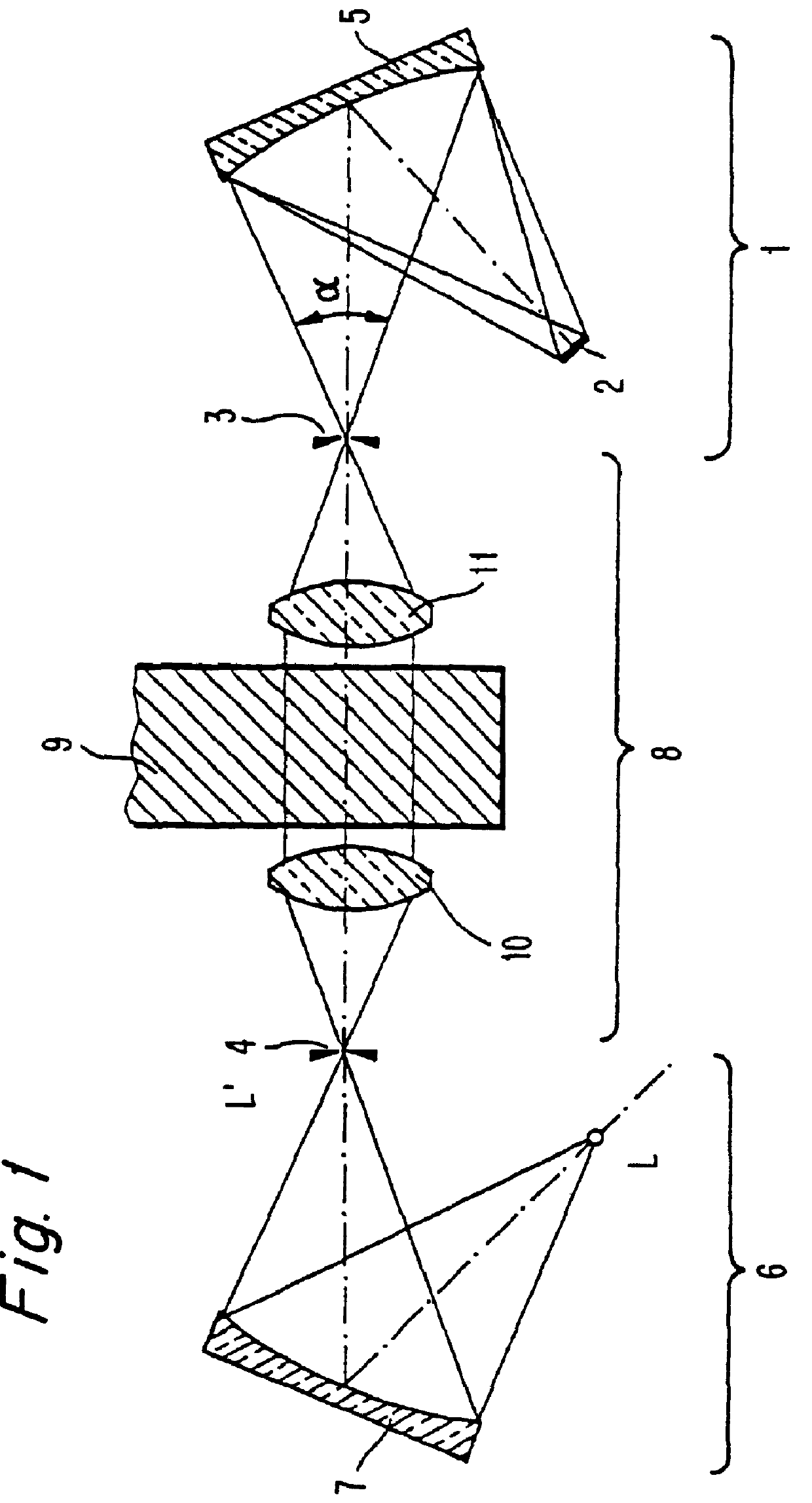

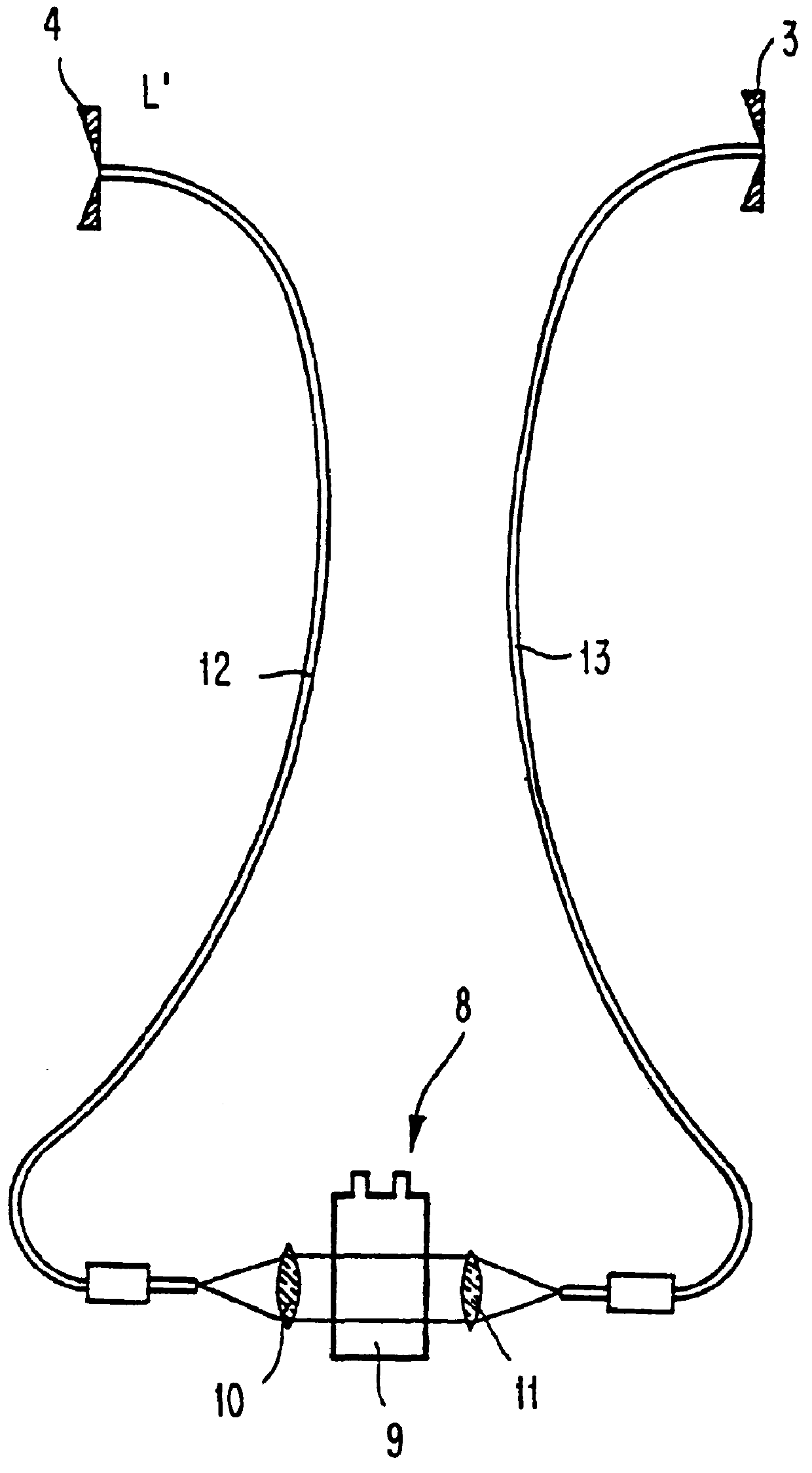

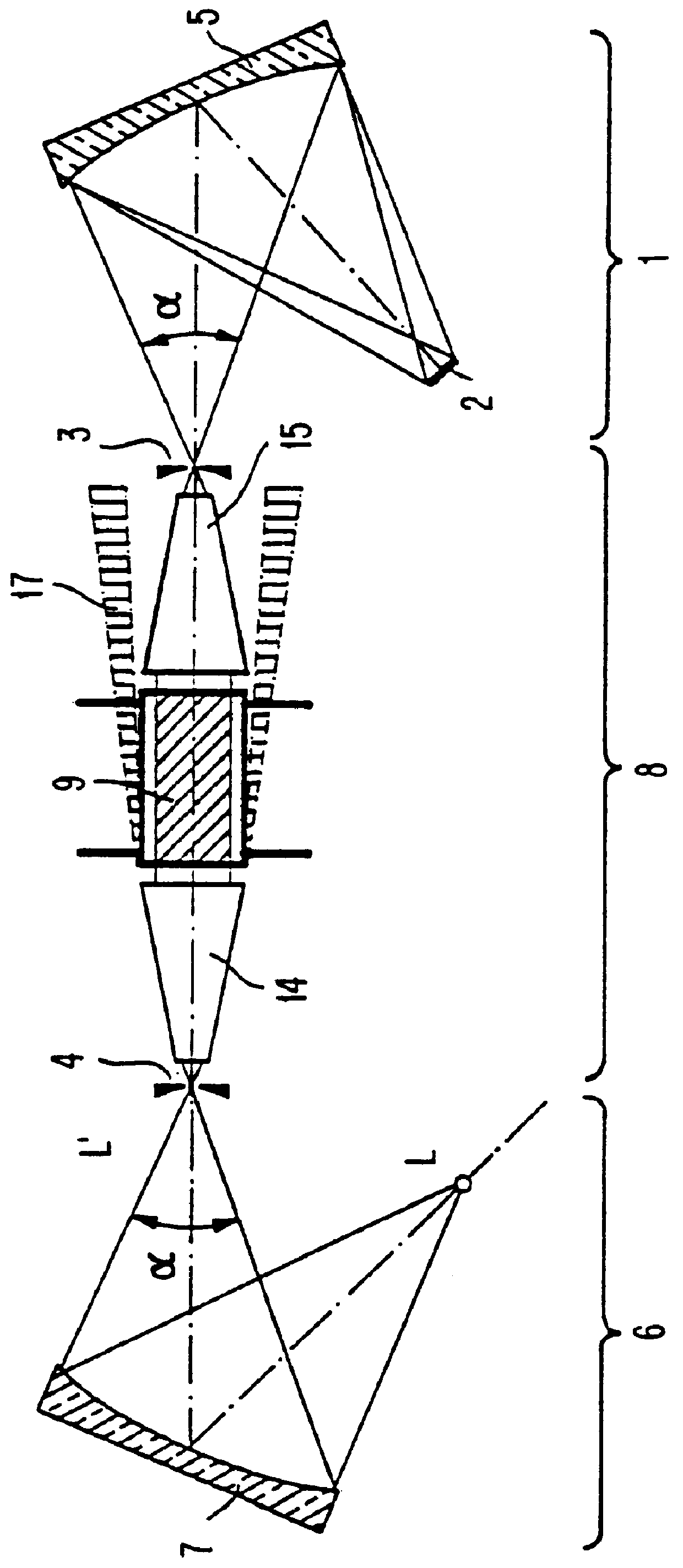

Spectroscopic systems for the analysis of small and very small quantities of substance

InactiveUS6108083AImprove radiation efficiencyLow costRadiation pyrometrySpectrum investigationEnergy transferRefractive index

A spectroscopic system for the analysis of small quantities of substances makes use for the purposes of energy transfer of cone-shaped aperture changers which are arranged in the object zone between the light source and the sample and, during absorption measurements, also between the sample and the inlet slot of a spectrometer. A microcell system is provided in the object space. The microcell system comprises a cylindrical cell tube with a hollow core for receiving a sample liquid. The cell tube and the sample liquid being adjustable with respect to the refractive index such that they act as a step waveguide for radiation, the sample liquid forming the core and the wall of the cell tube forming the sheath of the step waveguide.

Owner:AGILENT TECH INC

Fiber mesh tape-wound and reinforced composite pipe, preparation process and device

ActiveCN103016856AGuaranteed synchronicitySolve associativityRigid pipesMechanical propertyMaterials science

The invention relates to a fiber mesh tape-wound and reinforced composite pipe, a preparation process and a device, belonging to the technical field of forming processes of composite pipes. The composite pipe comprises an inner-layer core pipe and a post-coated layer, as well as a fiber mesh tape arranged between two layers, wherein the inner-layer core pipe is extruded by a core pipe extruding machine, the adhesive resin fiber mesh tape is heated through a post-heating box, and the composite pipe is finally obtained by traction through a post-traction machine, sizing through a vacuum spraying and sizing box and the like. According to the composite pipe disclosed by the invention, the technology is adopted, the preparation process is simple, the existing tape plastic covering treatment process and the composite pipe forming process are combined into a whole, the number of workers for production is reduced, and the degree of automation is improved; furthermore, the used device is a conventional device, and the cost is reduced; and in addition, adhesive resin is firstly coated on the outer surface of the core pipe, and the plain woven fiber mesh tape is further wounded, so that the interface problem in the pipe is effectively solved, the mechanical properties of the pipe are upgraded and the stability of the pipe during long-term use is also improved.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

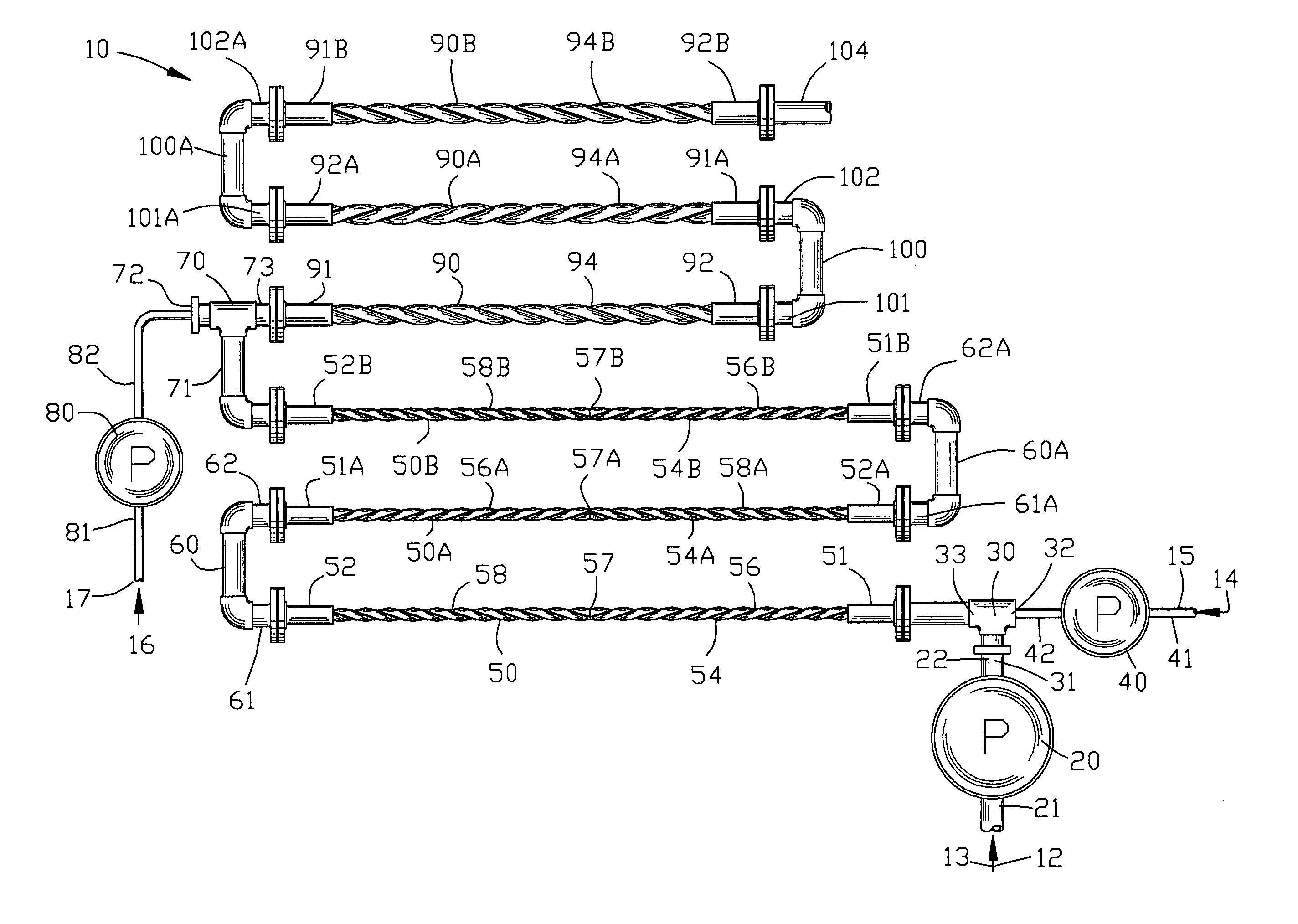

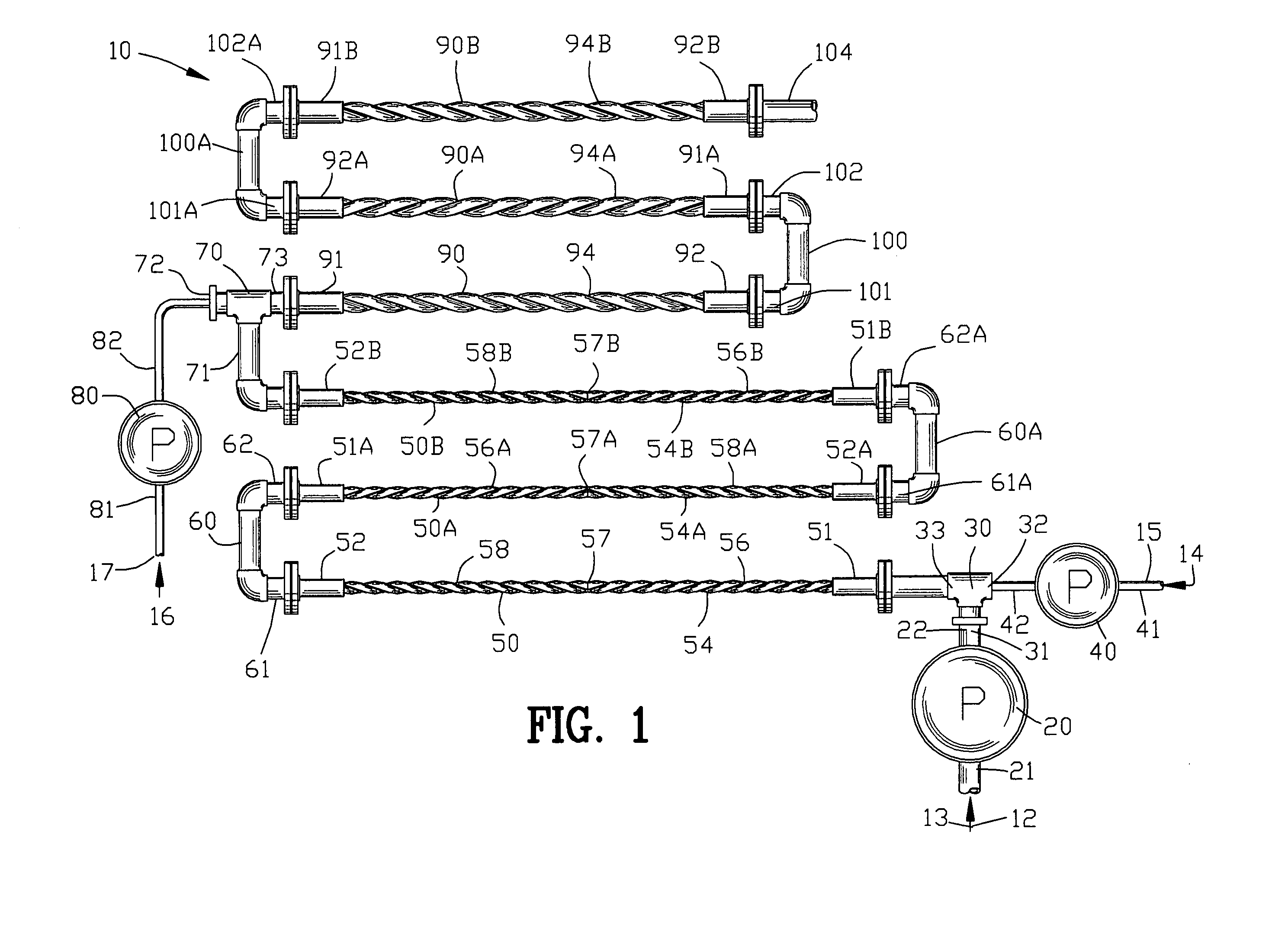

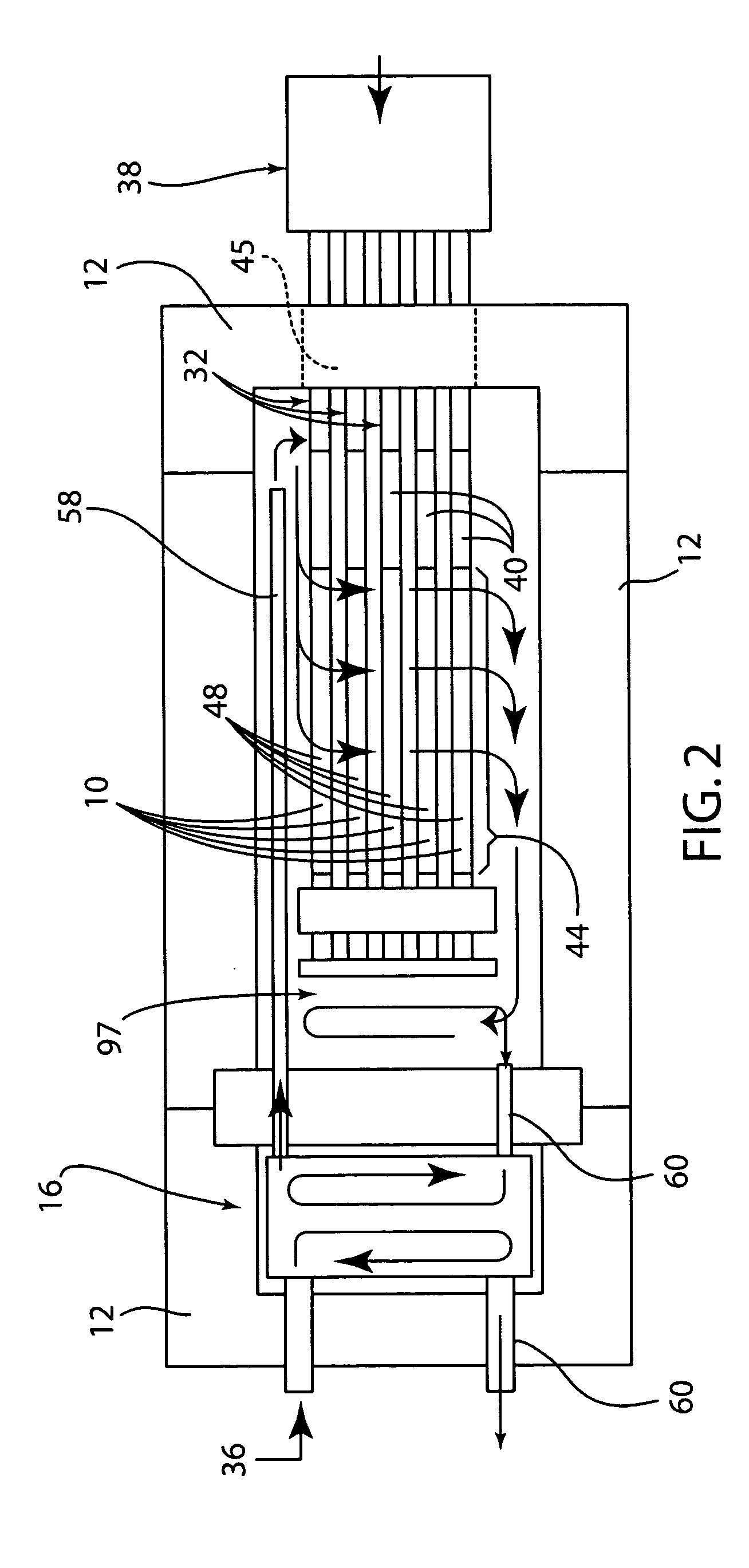

Apparatus and method for treating a liquid

An apparatus and method is disclosed for treating a liquid with a first and a second chemical. A liquid to be treated flows into a first inlet port of an intake manifold. A second inlet port of the intake manifold introduces a first chemical into the liquid. A first static mixing device comprising a spirally twisted tube forming a plurality of helixes and having an inlet port connected in fluid communication with an outlet port of the intake manifold is provided for mixing the first chemical with the liquid. The outlet port of the first static mixing device is connected to a first inlet port of an interconnecting manifold. A second inlet port of the interconnecting manifold introduces a second chemical into the liquid. A second static mixing device has an inlet in fluid communication with an outlet port of the interconnecting manifold for mixing the second chemical with the liquid and for eluting the treated liquid from an outlet port of the second static mixing device.

Owner:INFLOWSION

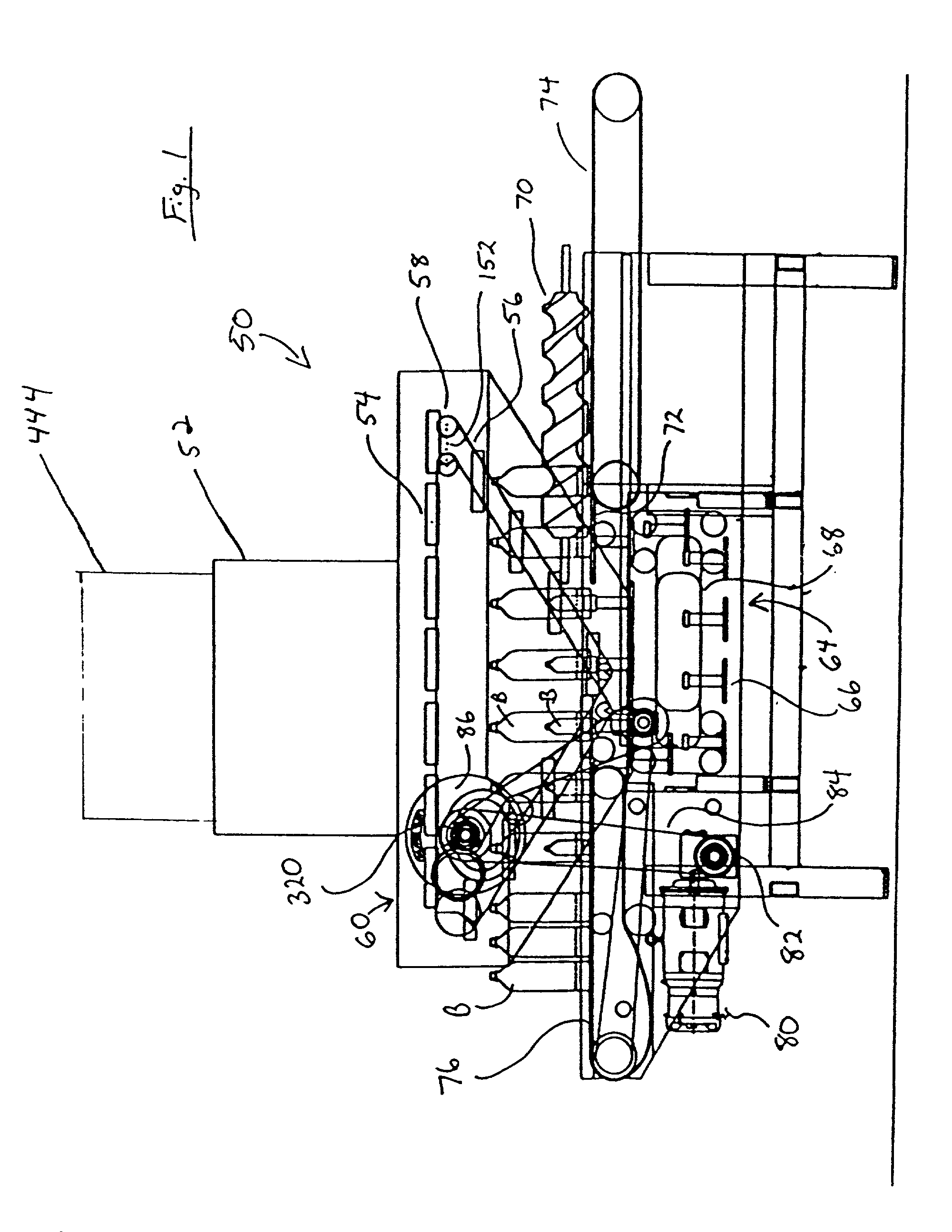

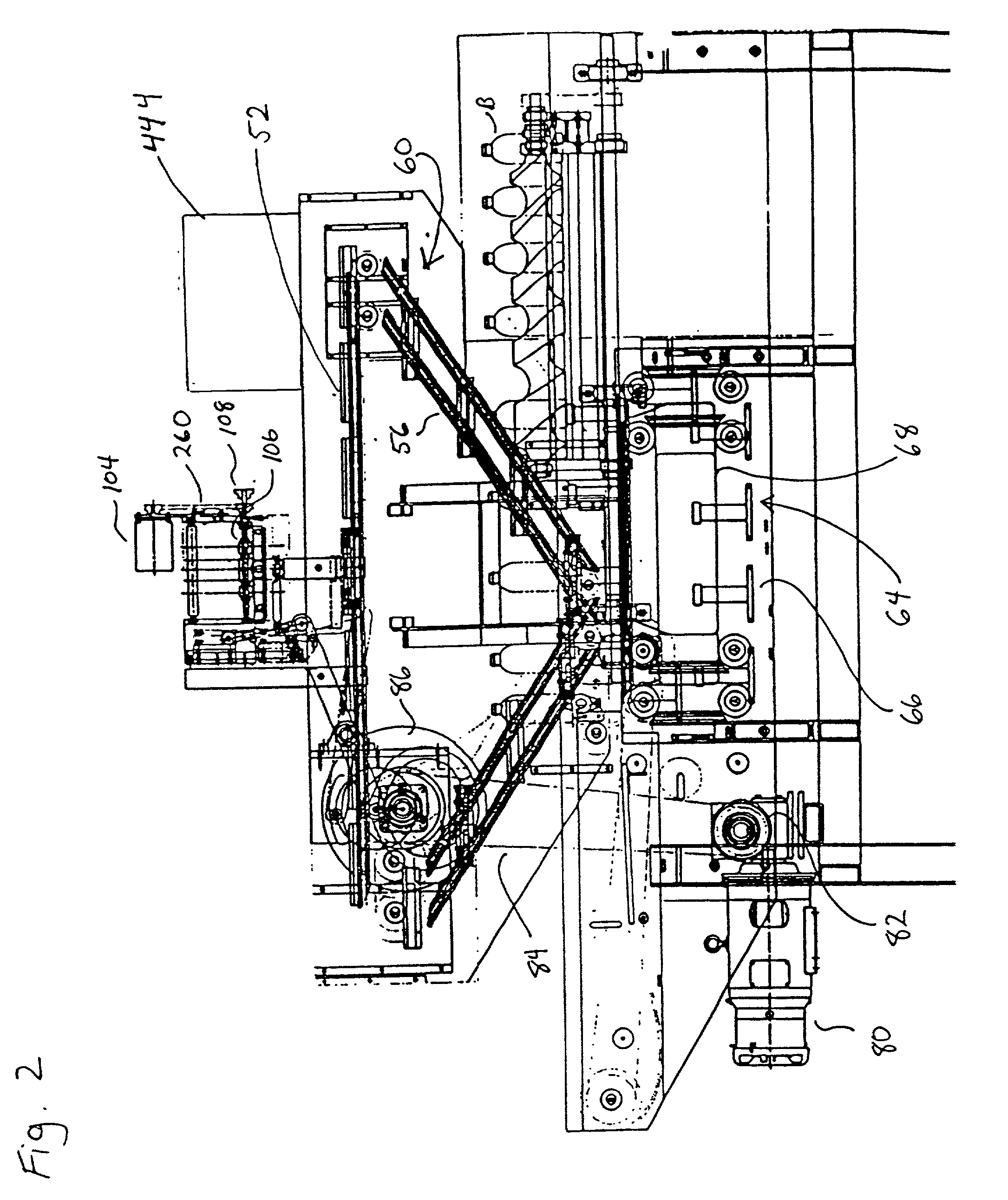

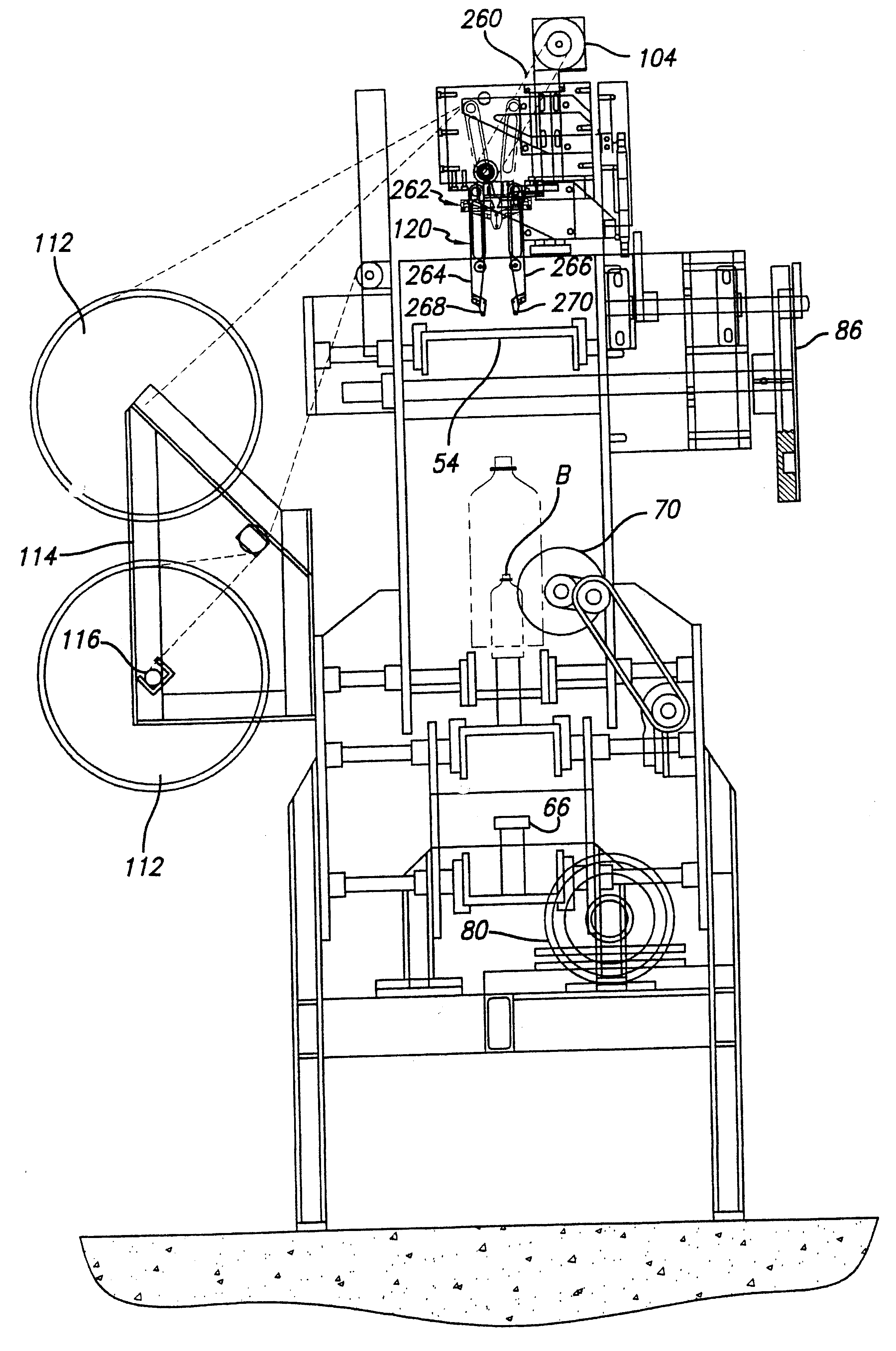

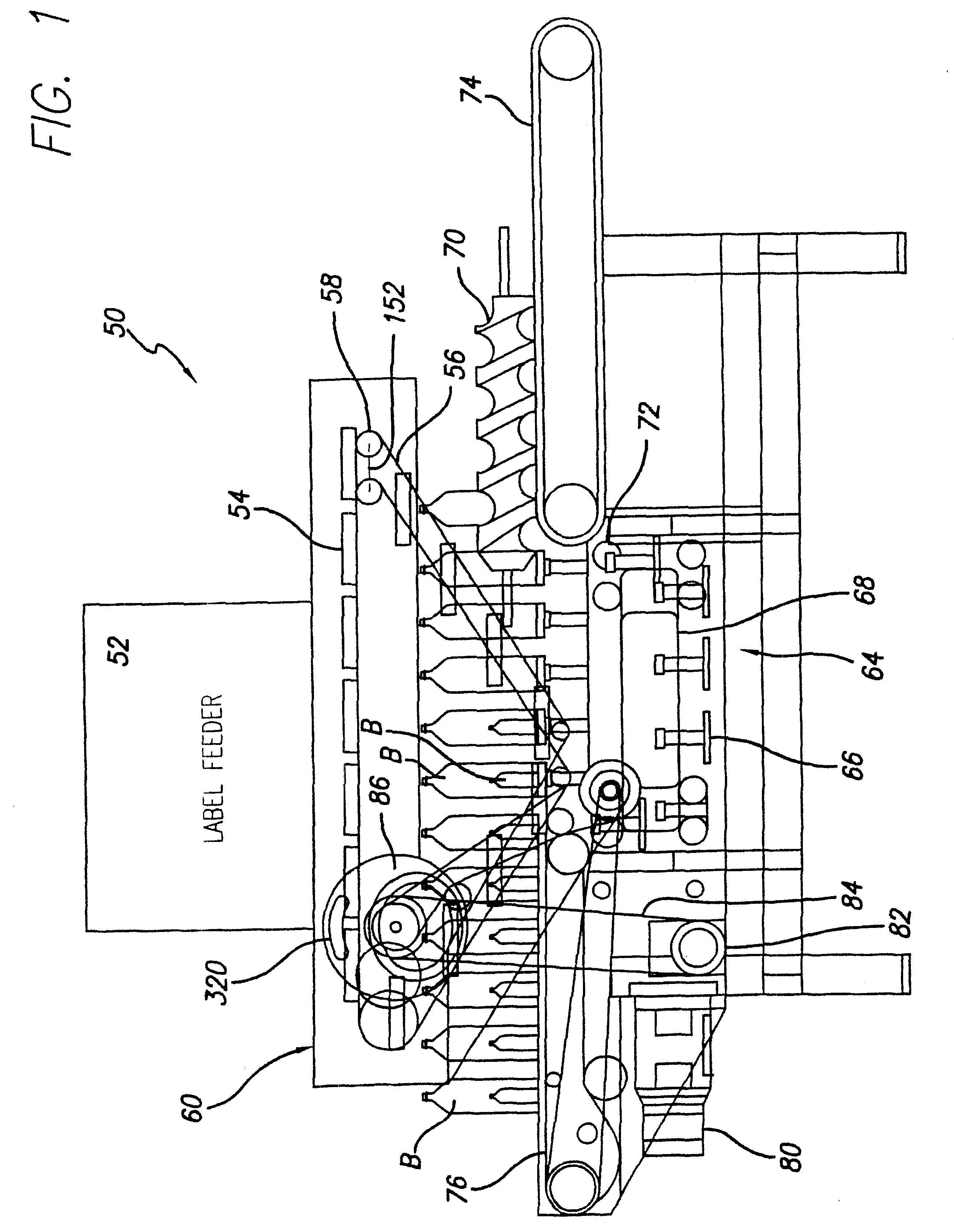

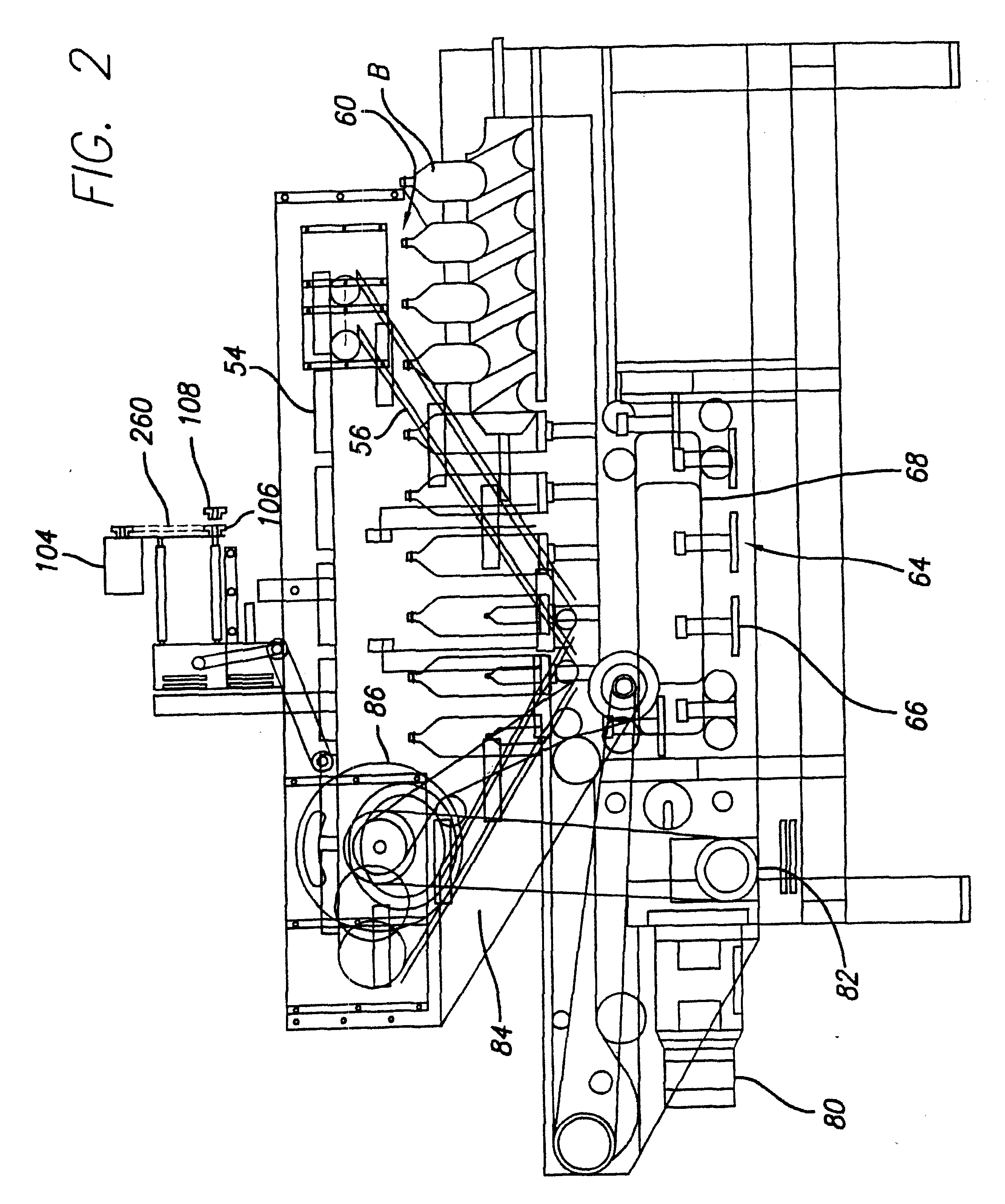

In-line continuous feed sleeve labeling machine and method

InactiveUS20010002614A1Wrappers shrinkageMechanical working/deformationUltrasonic weldingEngineering

An in-line continuous feed sleeve labeling machine labels containers, such as beverage containers, in an in-line fashion maintaining the elevation of the containers during their linear transport. The in-line continuous feed sleeve labeling machine of the present invention receives bottles in flood feeder or linear fashion. A timing screw or the like properly separates, and both spatially and temporally disposes, the containers for sleeving. The timing screw propels the containers onto a pedestal system. The pedestals of the pedestal system maintain their horizontal nature due to offset pivotable attachments to the track system upon which they travel. A sheet of film is unspooled from an unwind roll and passed through a tube forming apparatus that overlaps the edges of the film. The overlapping edges completing the tube enclosure are connected using ultrasonic welding or the like. The sleeve is then passed to an iris carrier. In coordinated fashion with the travel of the pedestal system, iris carriers carrying sleeves upon articulating radial arms descend upon the bottles. Once the label sleeve has reached the appropriate point (generally adjacent to the central portion of the bottle), the iris carrier allows the label sleeve to engage the central portion of the bottle. Frictional attachment or otherwise allows the finger rods of the iris carrier to pull away from the sleeve as the iris carrier continues to descend down towards the pedestal. The sleeve then becomes attached to or engaged by the bottle until the finger rods of the iris carrier free themselves from the sleeve label. A container stabilizer may provide lateral bottle support and aid the ensleevement process. The finger rods then dilate to better disengage the bottle as the iris carrier ascends up and away from the bottle. The bottle is then transported to an exit conveyor having been properly sleeved, while the iris carrier returns to transport another sleeve.

Owner:AXON LLC

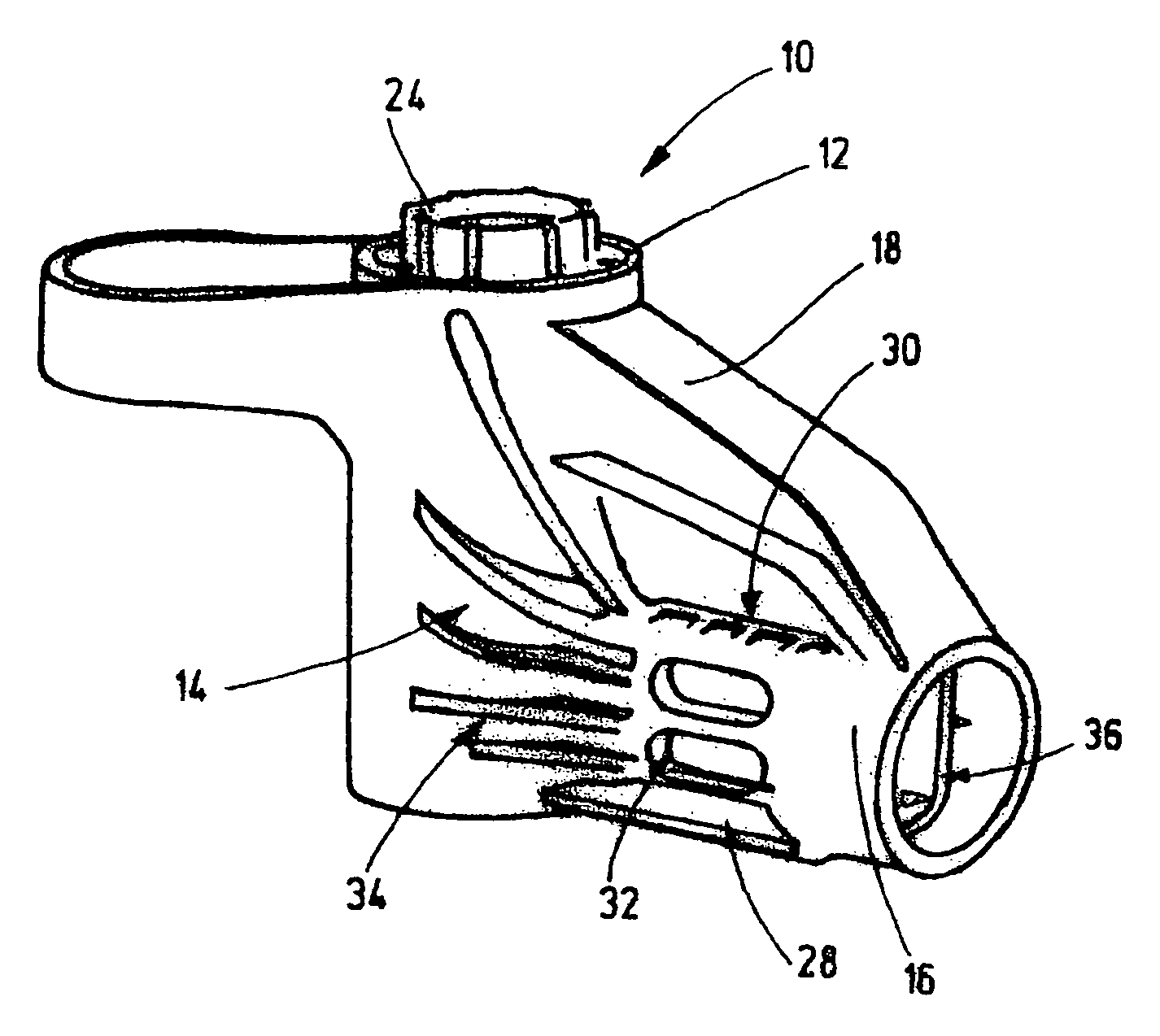

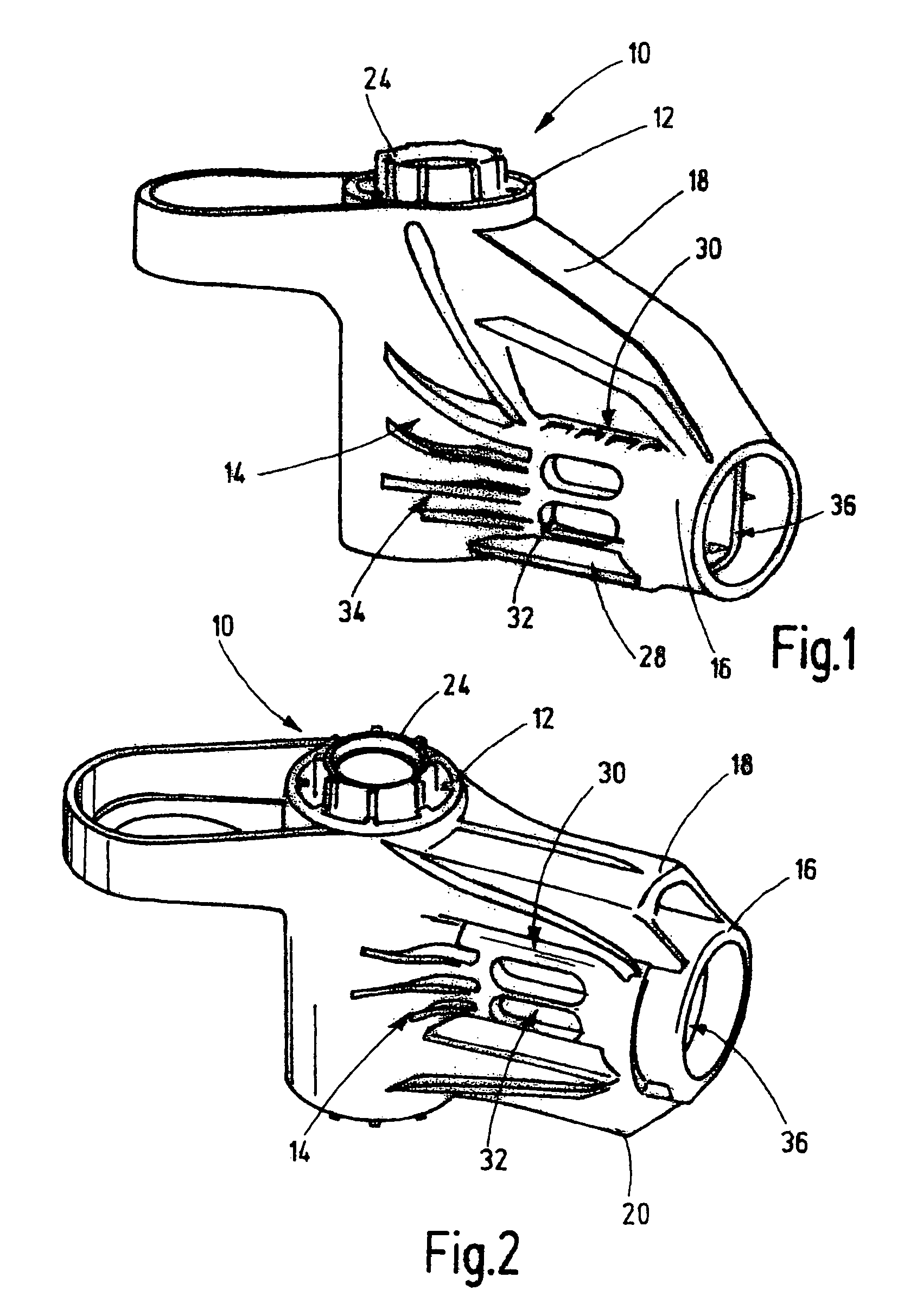

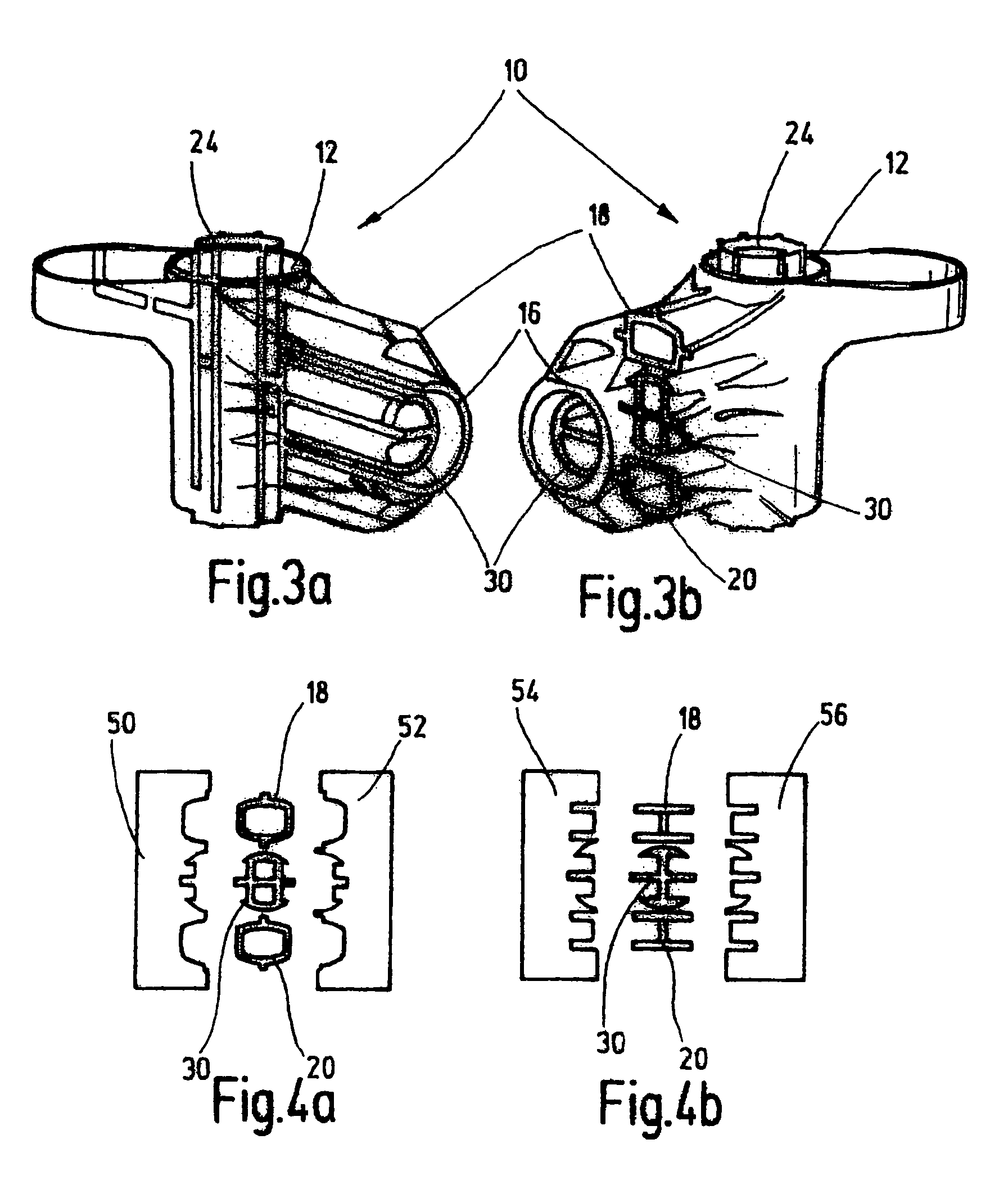

Wiper bearing

InactiveUS7581887B2Improve stabilityGuaranteed ease of connectionCrankshaftsCrossheadsEngineeringTube forming

The invention relates to a wiper bearing for a windshield wiper system comprising a bearing housing (12) provided with an outer tube forming the bearing housing (12) and an inner tube (24) arranged in a concentric manner in relation thereto and a journal (30) arranged on a bearing area (14) on the bearing housing (12) for receiving a tubular plate (40). It is proposed that an annular element (16), which is arranged in a coaxial manner on the journal (30), be provided outside the journal (30) in the region of the front side thereof (36).

Owner:ROBERT BOSCH GMBH

Urethral catheter and guide

An indwelling catheter for insertion into a patient's urinary tract is provided that includes first and second tubular members that enable drainage of physiological fluids. An inflatable balloon is attached to the second tubular member. The first and second tubular members are interconnected by a connecting tube forming a gap between the first and second tubular members. The connecting tube is in fluid communication with the balloon to enable the balloon to be inflated via the connecting tube. When the balloon is anchored within the urinary bladder the second tubular member is located within the prostatic urethra with one end in close proximity to the sphincter and the other end protruding into the urinary bladder. The first tubular member is located within the penile urethra with one end in close proximity to the sphincter so that the connecting tube traverses the sphincter permitting voluntary control of the sphincter.

Owner:ESHEL UZI +2

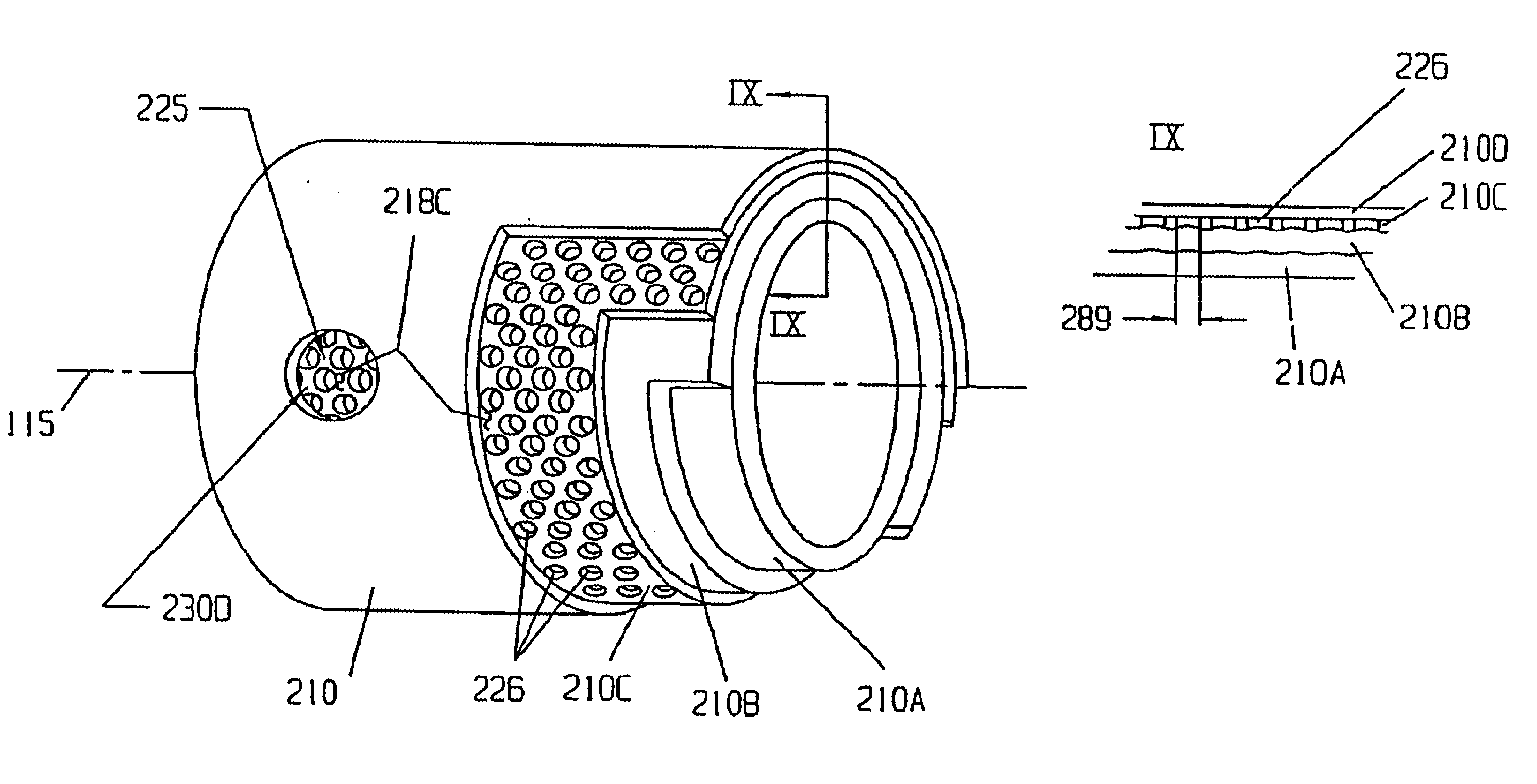

Method for making a well perforating gun

The invention relates to a method to make a perforating gun for use in oil and natural gas wells comprising the steps of: obtaining a length of a first tube; cutting scallop holes into the first tube forming an outer layer; placing the outer layer in a holder; cutting a second tube to the approximate length of the outer layer; pulling the second tube into the outer layer forming a laminate structure having a first and second end; repeating the process for a desired number of layers in the laminate structure; machining internal structures into the laminate structure; inserting the loading tube into the laminate structure; and forming thread protectors in the first end and the second end of the laminate structure.

Owner:KASH EDWARD CANNOY

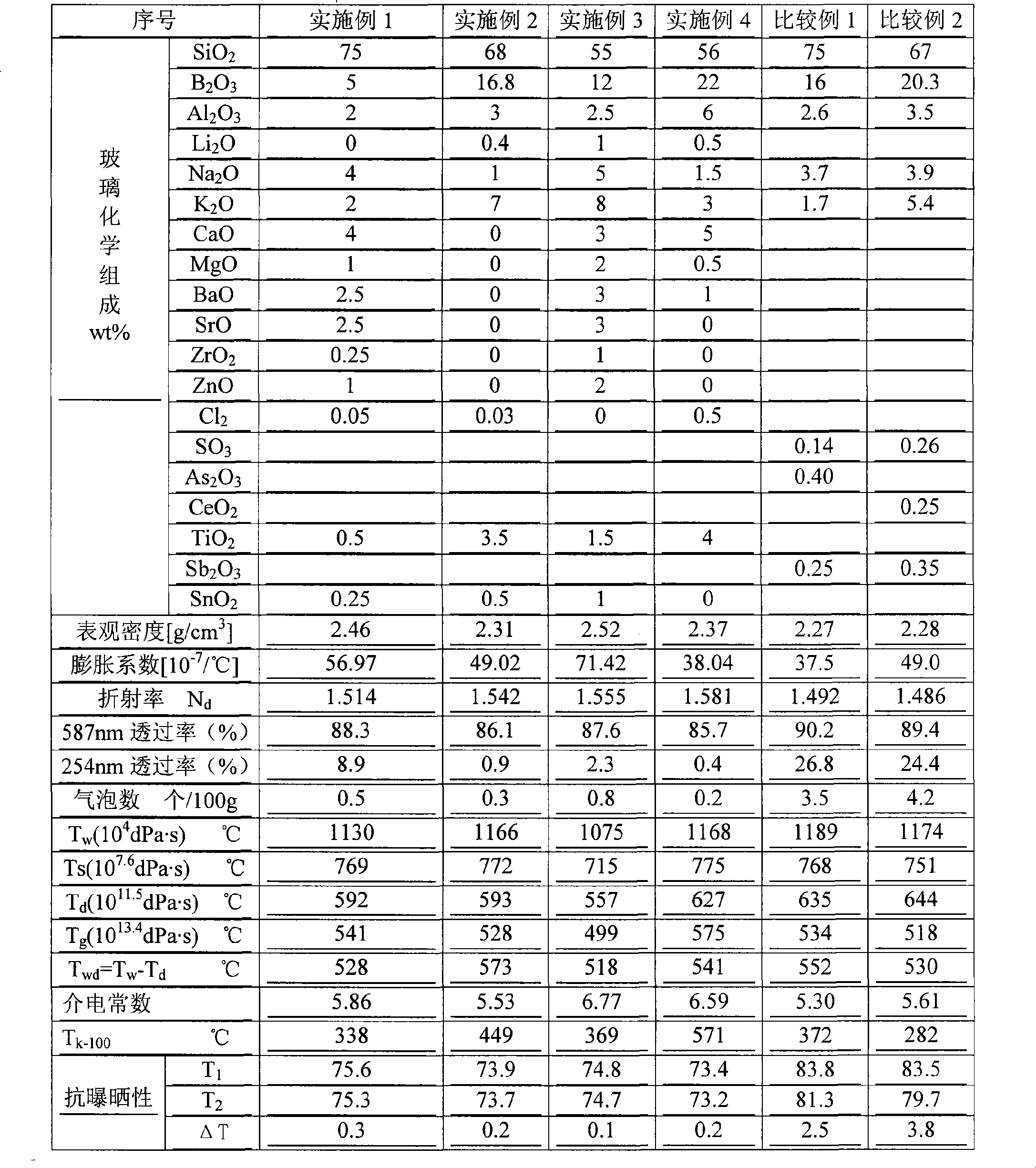

Borosilicate glass suitable for electric light source

The invention provides glass applicable to electric light source, which belongs to the field of borosilicate glass, in particular to a high-precision small-diameter glass tube through a public known pull tube forming process by using an environment-friendly fining agent to realize good melting quality, so as to meet the requirement of electric light source mechanical light manufacture. The swell factor of the glass is (38-76) multiplies 10<-7> / DEG C to fulfill sealing of tungsten, molybdenum and raft. The glass consists of the following chemical compositions in weight percentage: 55 to 75 percent of SiO2, 5 to 22 percent of B2O3, 2 to 6 percent of Al2O3, 0 to 8 percent of MgO, CaO, BaO and SrO, 5 to 12 percent of Li2O, Na2O and K2O, 0 to 1 percent of ZrO2, 0.5 to 4 percent of TiO2, 0 to 2 percent of ZnO, 0 to 1 percent of SnO 2, and 0 to 0.5 percent of Cl2. The glass is characterized by the borosilicate glass system. The glass product has the advantages of high transmission of visible light, ultraviolet resisting property and insolation resisting property without harmful elements.

Owner:BEIJING UNIV OF TECH

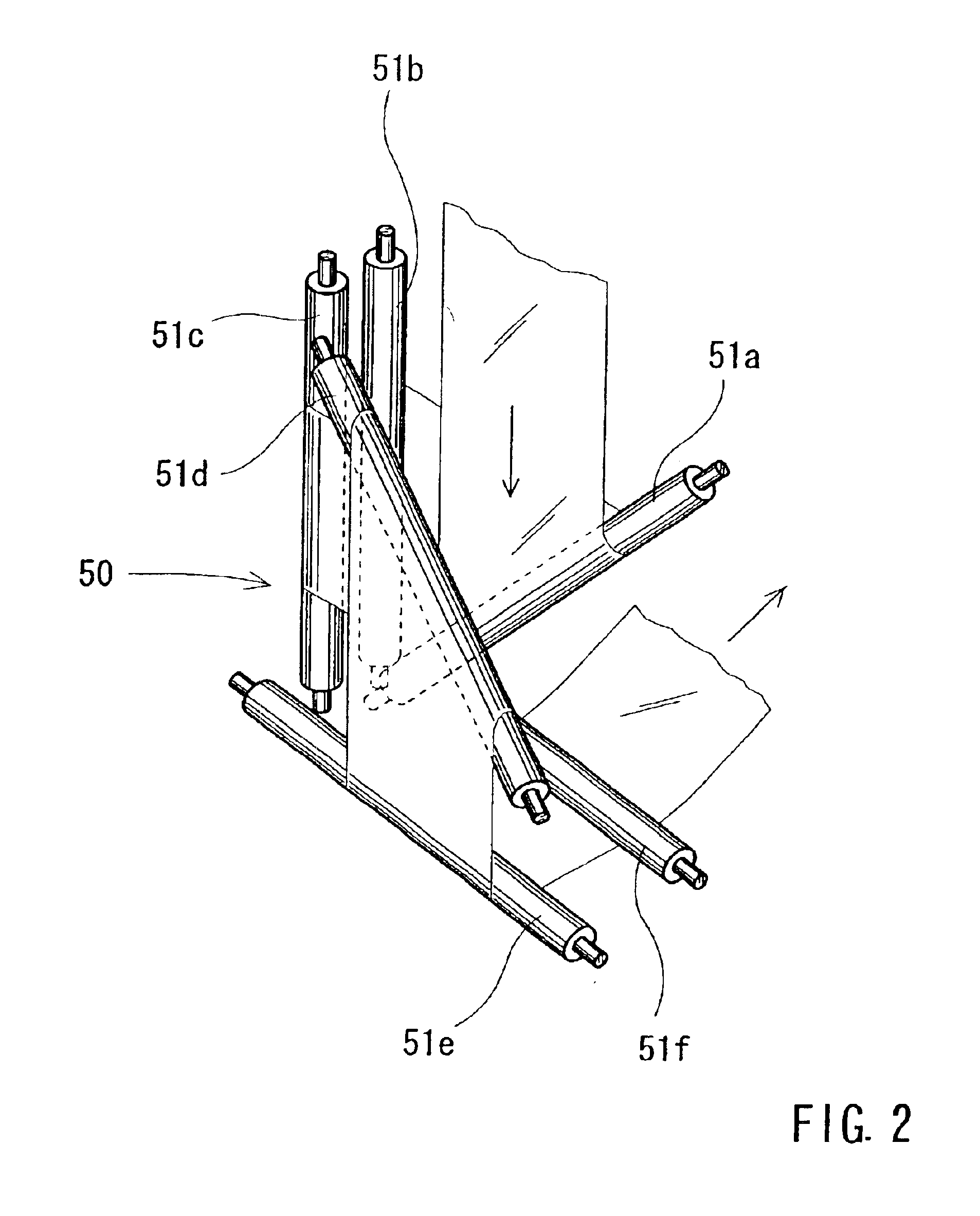

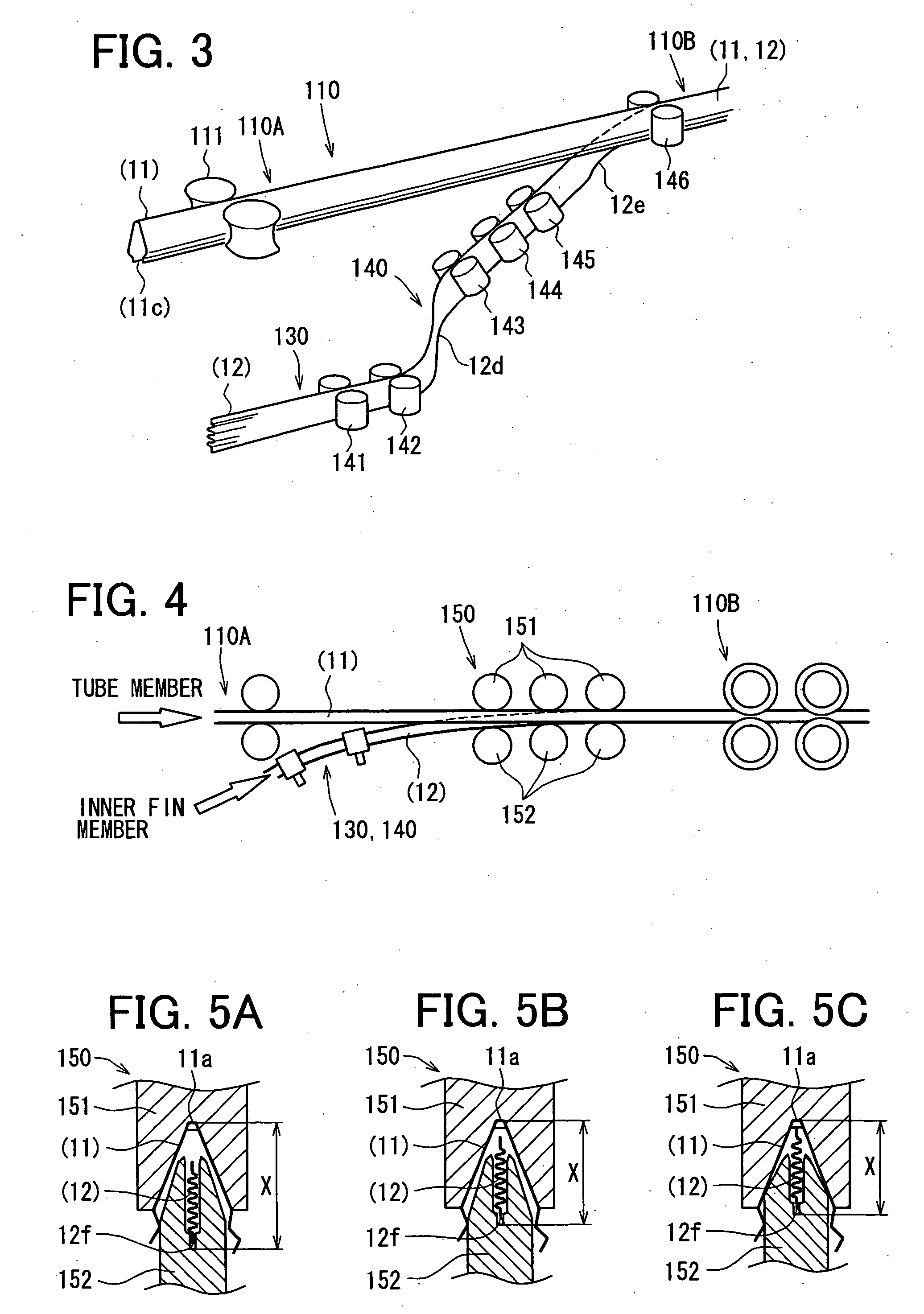

Manufacture method for inner-fin tube and manufacture device for the same

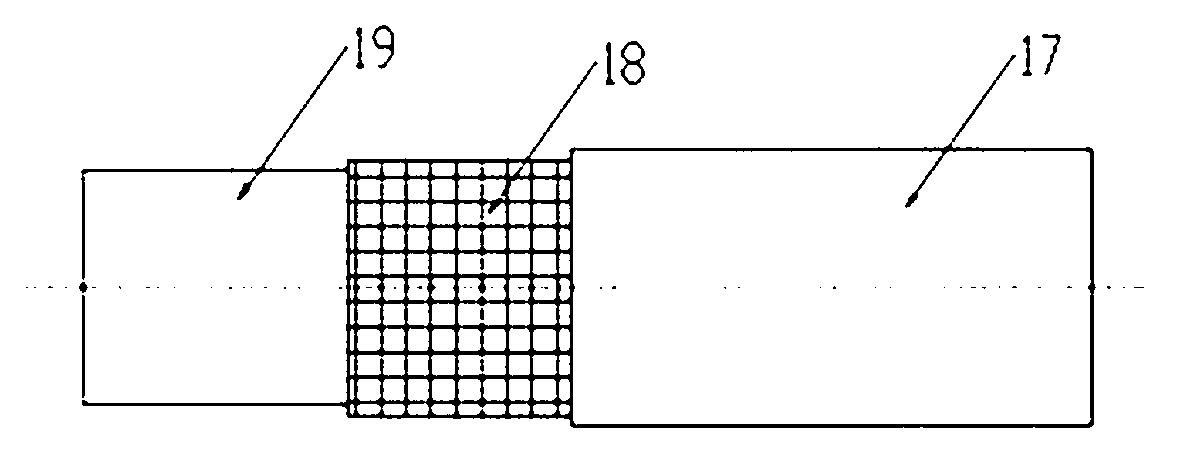

ActiveUS20060265874A1Easy to insertTransfer direction of the inner fin member can be readily alteredMetal-working apparatusStationary conduit assembliesLong axisEngineering

A manufacture method for an inner-fin tube includes a tube forming process for continuously forming a tube member joined at one end side thereof, an inner fin transferring process for continuously transferring an inner fin member, an inner fin twisting process for twisting the transferred inner fin member at at least two portions, and an inner fin inserting process for inserting the inner fin member into the tube member through the one end side thereof at the halfway stage of the tube forming process. At the inner fin twisting process, a transfer direction of the inner fin member is altered so that the inner fin member faces the one end side of the tube member and a longitudinal direction of a cross section (perpendicular to transfer direction thereof) of the inner fin member corresponds with a major axis direction of a flat cross section of the tube member.

Owner:DENSO CORP

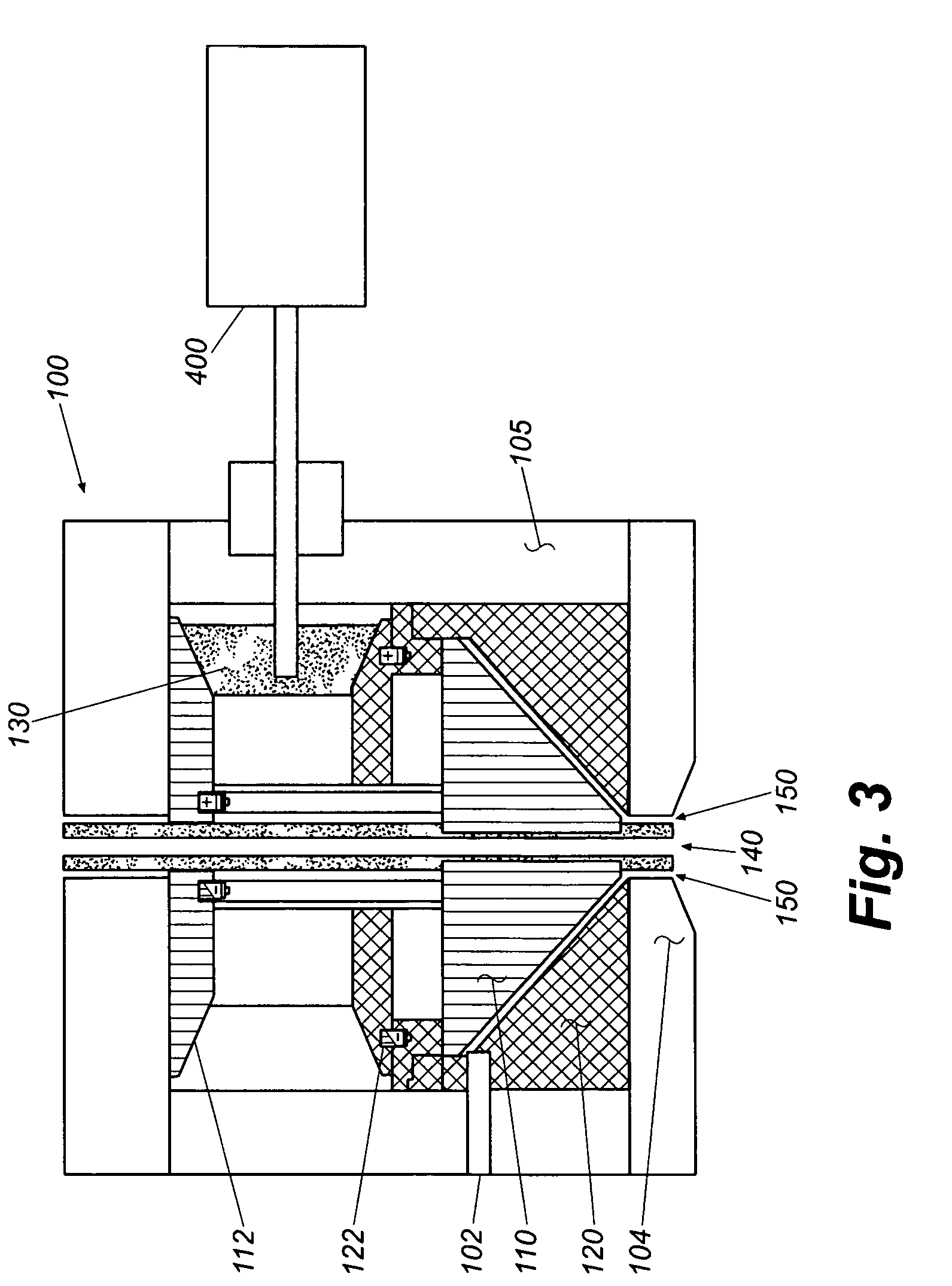

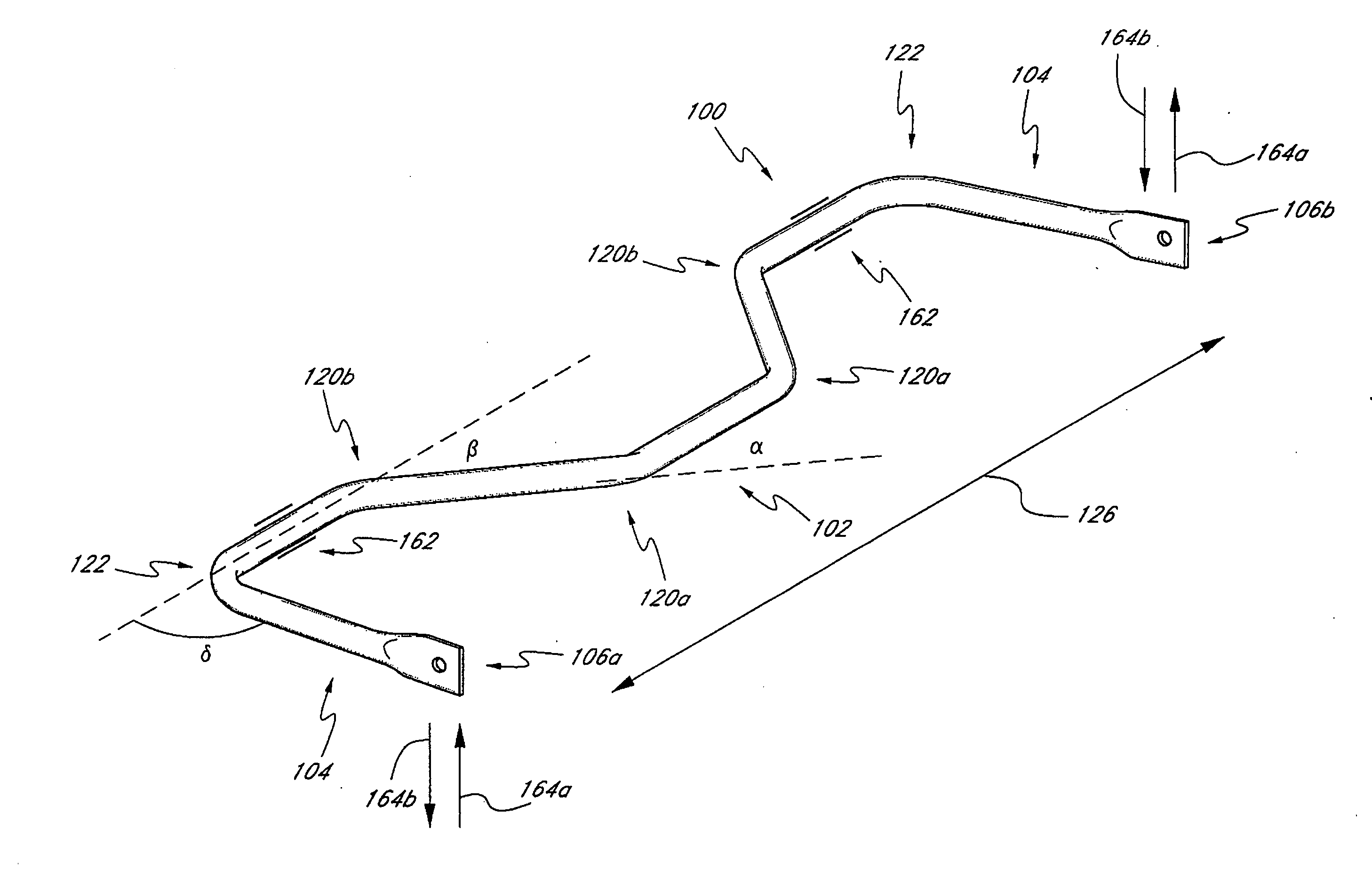

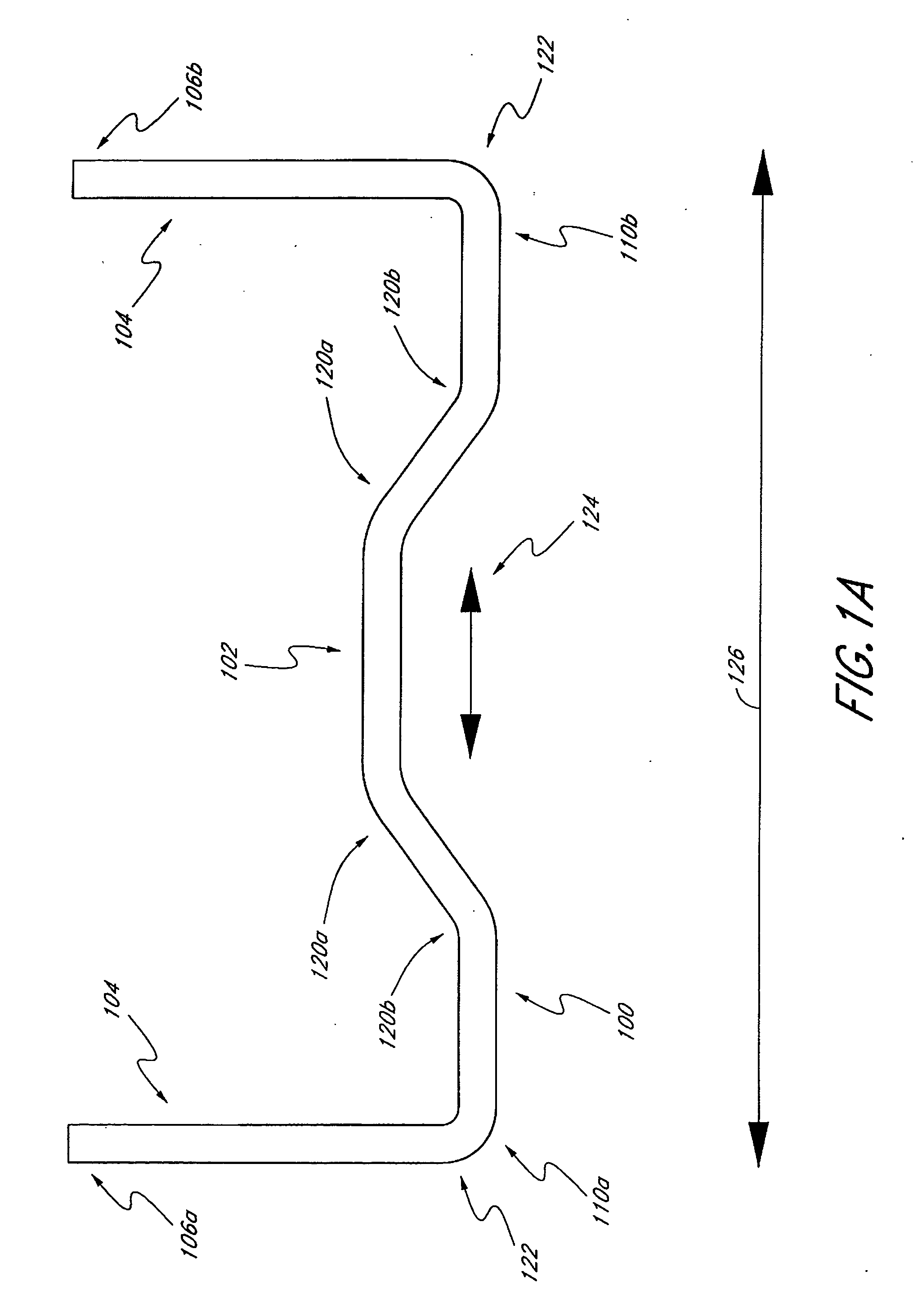

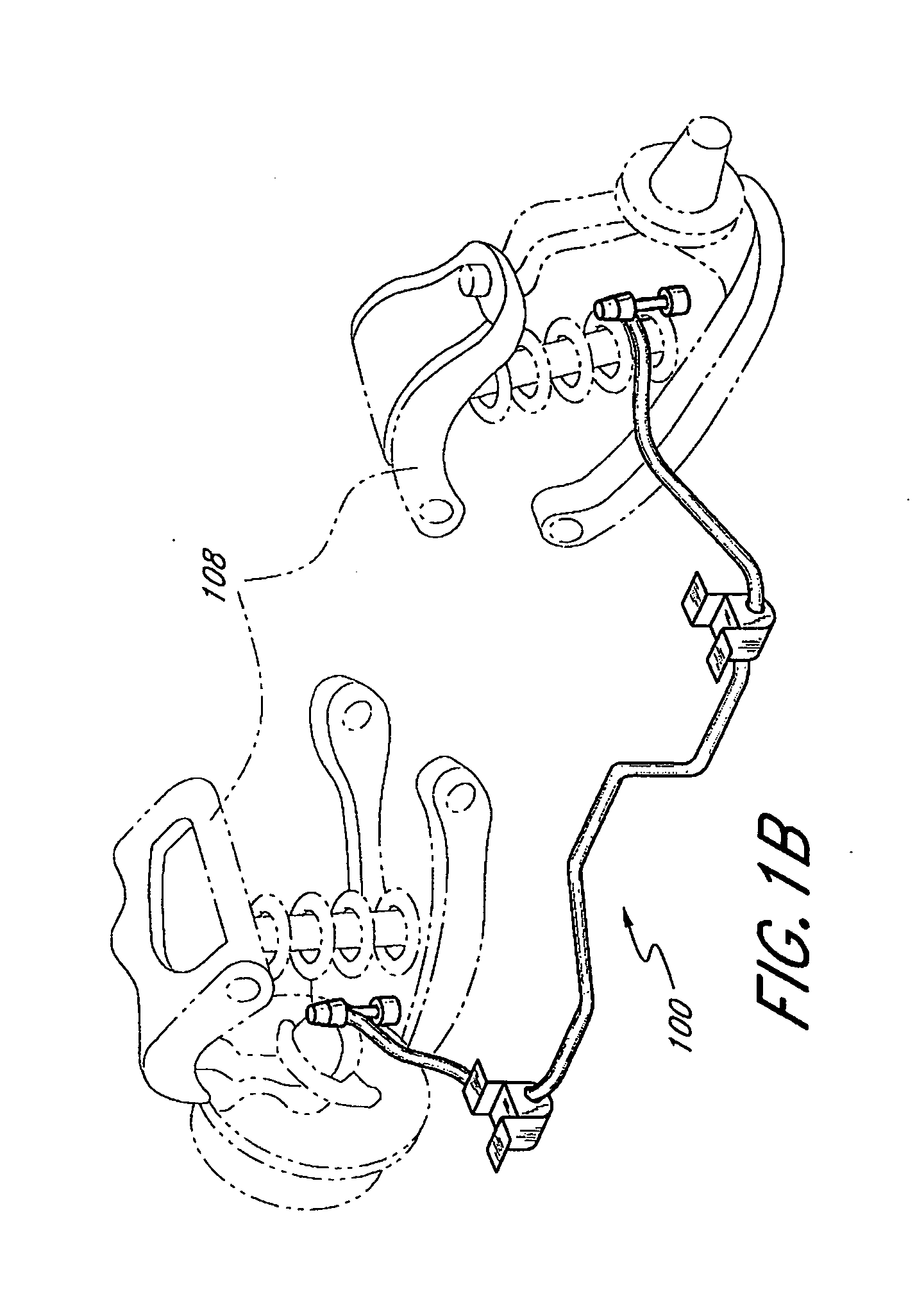

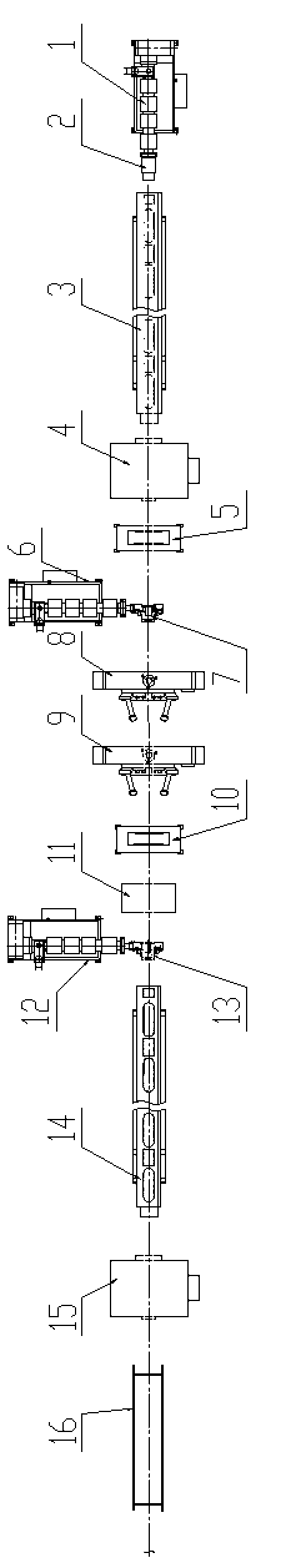

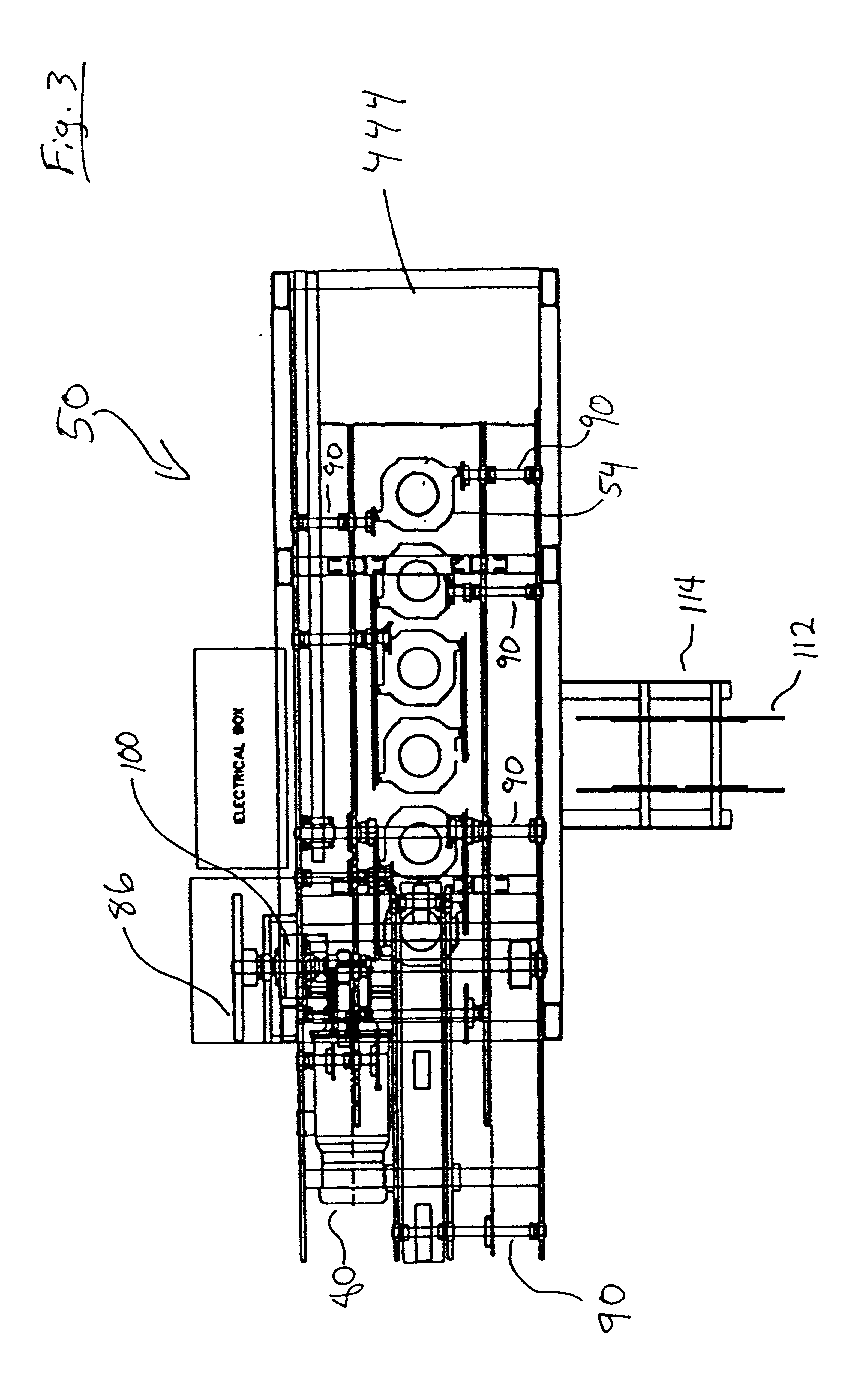

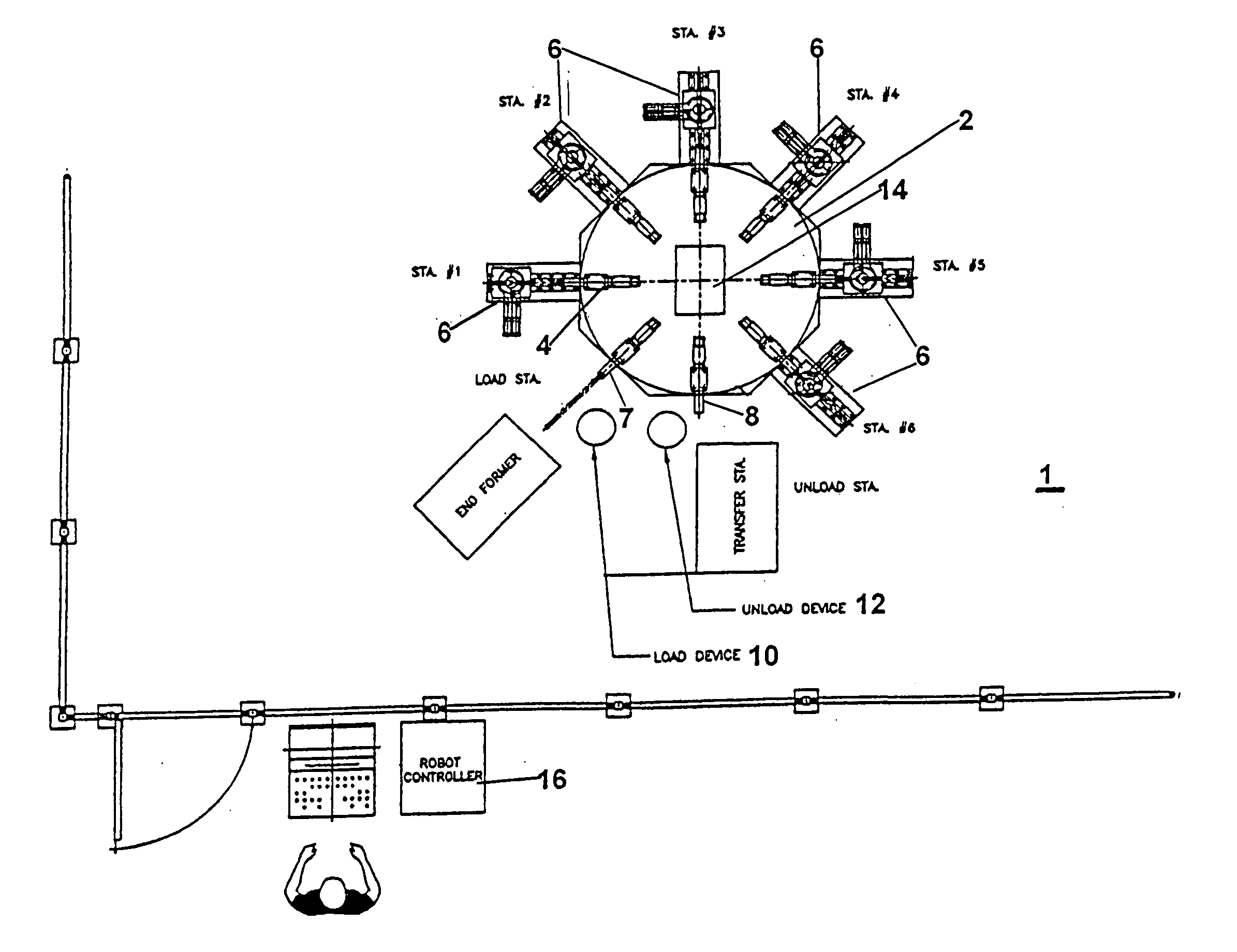

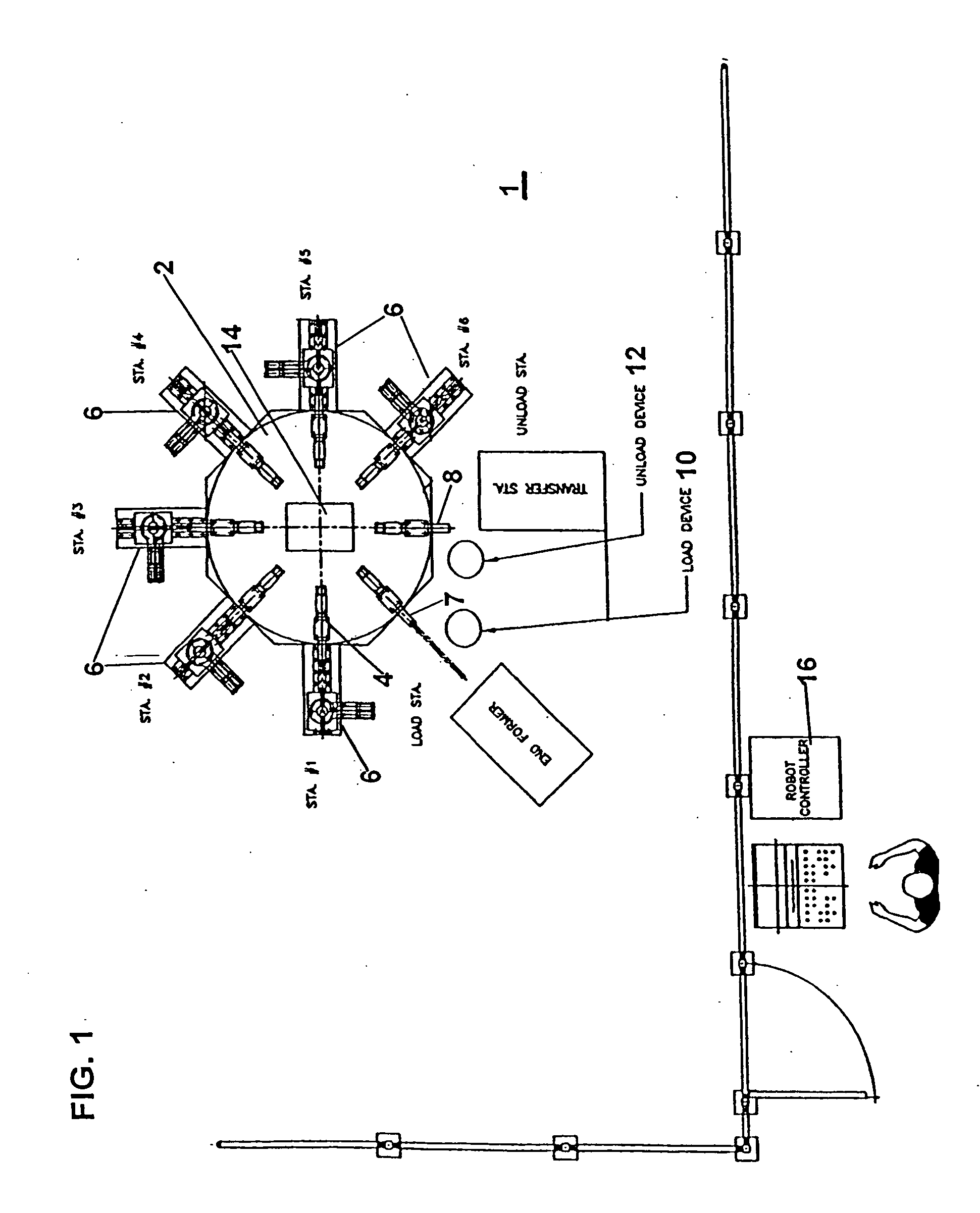

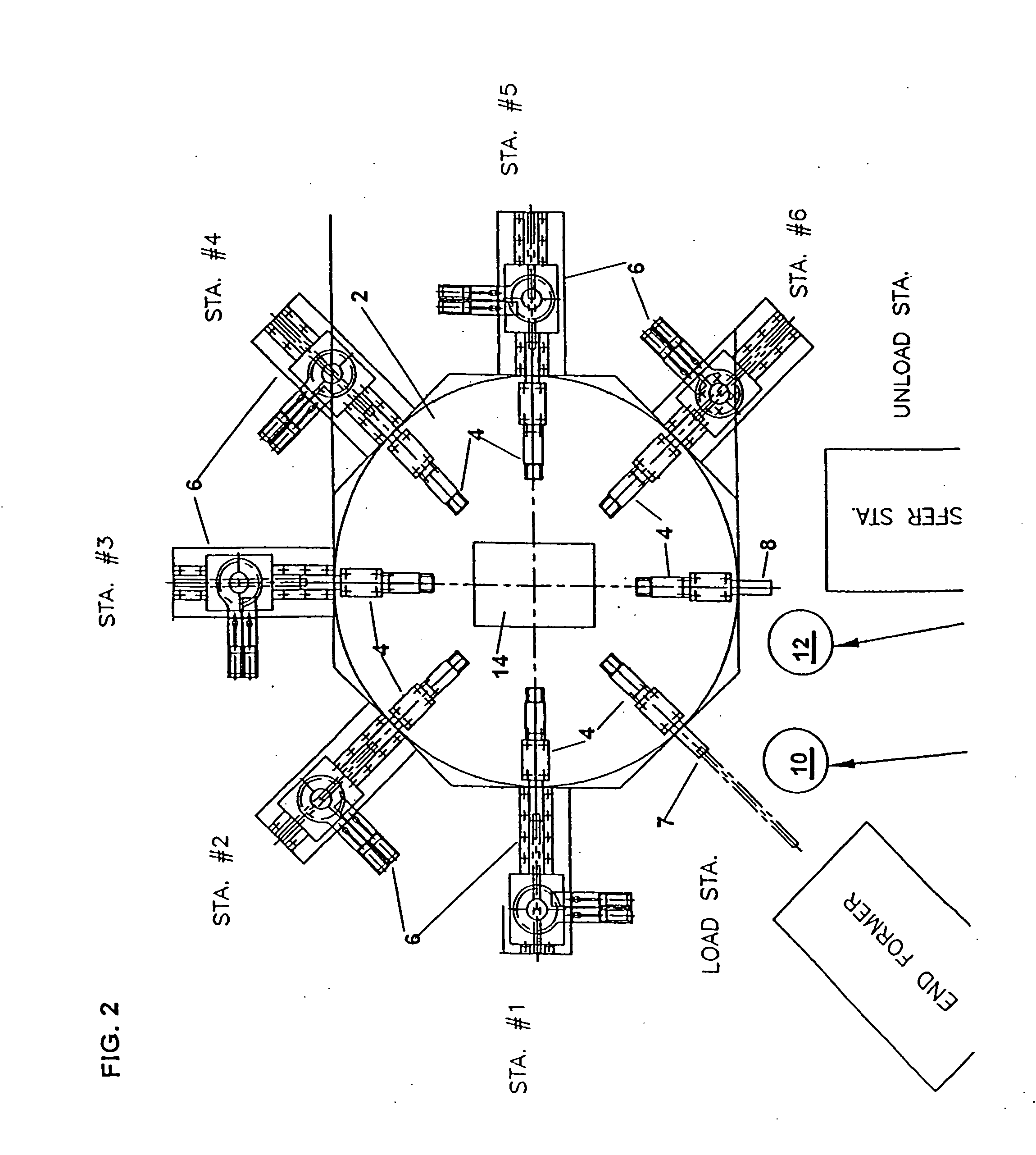

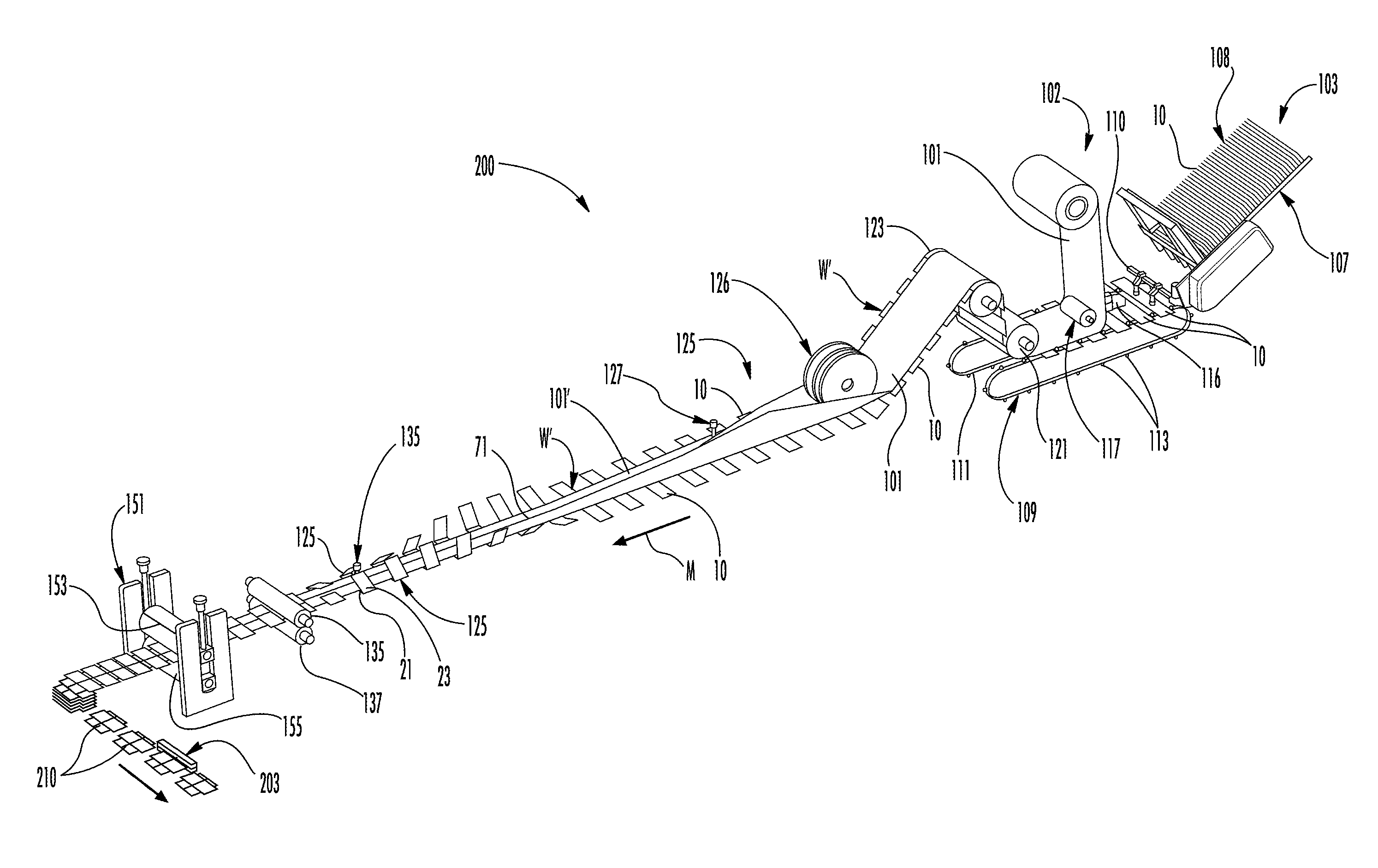

Automated continuous operation tube forming system

InactiveUS20070006447A1Easy to shapeMinimize the possibilityAutomatic control devicesAssembly machinesMovable typeEngineering

An automated, continuous tube forming system comprising: a plurality of workstations which respectively perform various operations on a workpiece; an indexing transfer carousel having a plurality of workpiece-holding collets provided in a spaced arrangement around the periphery-circumference of the of the carousel and which are adapted to support a plurality of workpieces, respectively, the multiple workstations are provided around the indexing transfer carousel and the carousel is selectively rotated to move the collet-supported workpieces such that the workpieces are associated with the workstations where various operations can be performed on the workpieces; a loading device which loads workpieces on the indexing transfer carousel; a transfer device which unloads the finished workpieces from the indexing transfer carousel after processed at the workstations; and a controller which controls operations of the indexing transfer carousel, the workstations, the loading device, and the transfer device. Electrical power may be provided to the indexing transfer carousel via a movable type power connector such as a slip-ring connector, operations of the indexing transfer carousel, the workstations, the loading device, and the transfer device are continuously monitored using appropriate sensors, and the sensors communicate with the controller via wireless communication signals such as RF signals.

Owner:WEBSTER M CRAIG

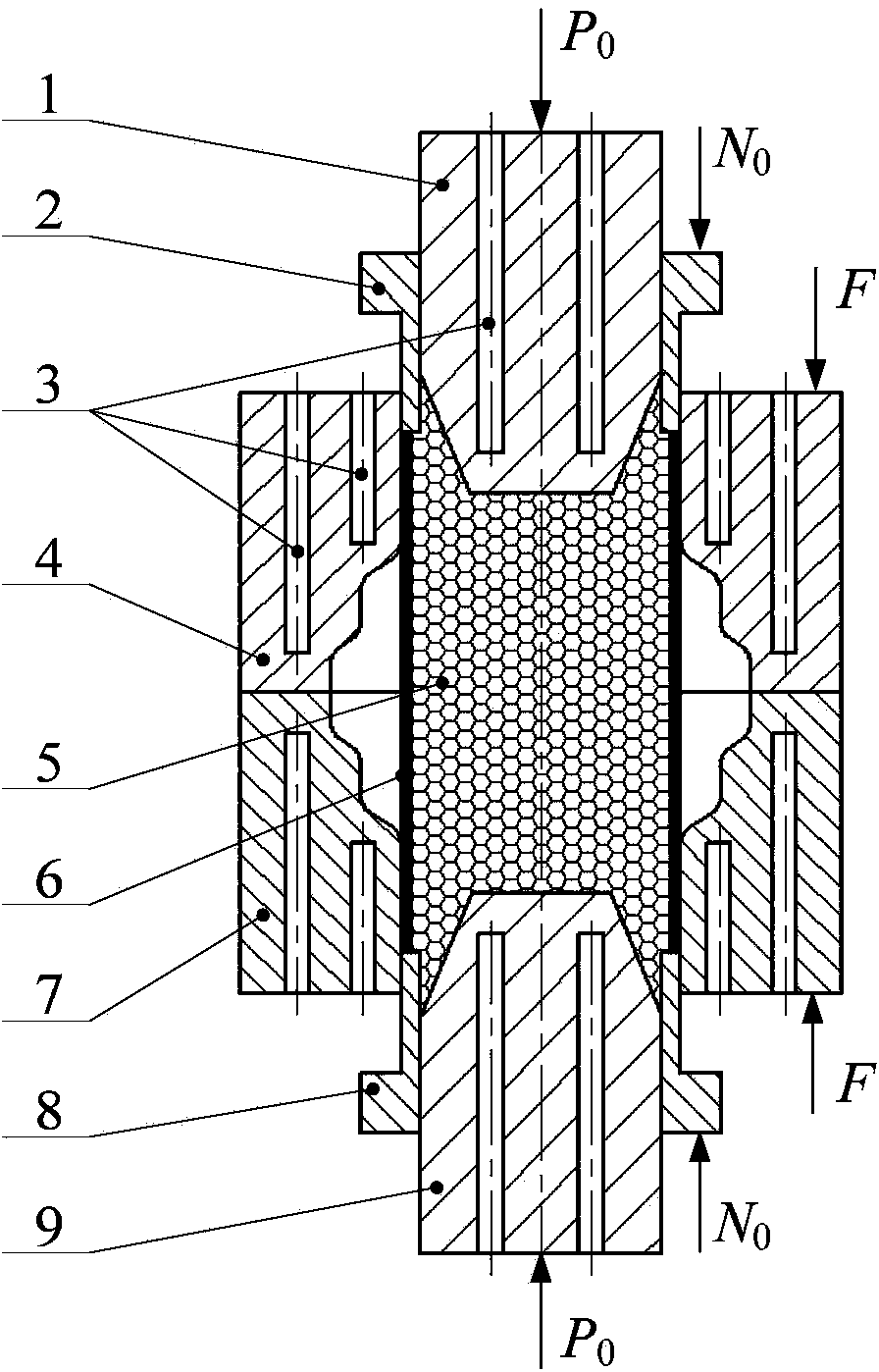

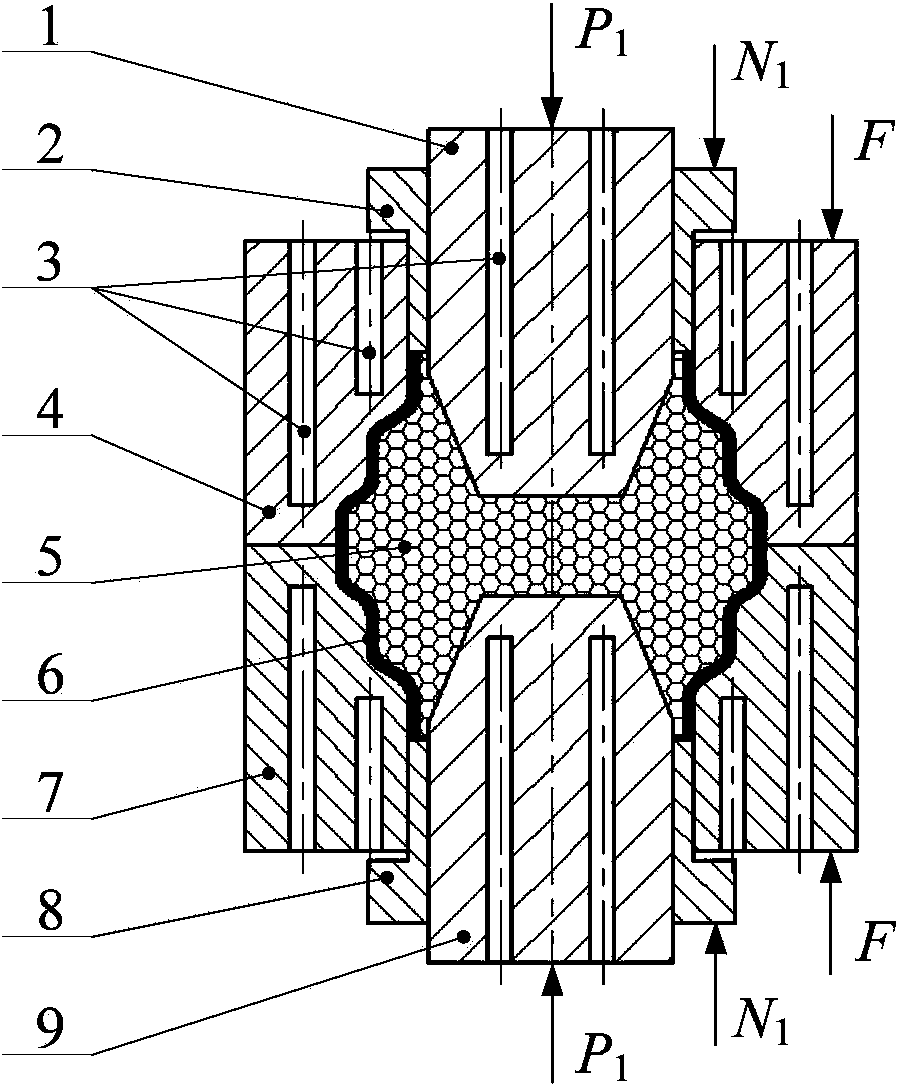

Solid particle medium thermal expansion forming method for light alloy tubular component

InactiveCN103894469ASimple process controlLow input costShaping toolsEnvironmental resistanceThermal expansion

Owner:YANSHAN UNIV

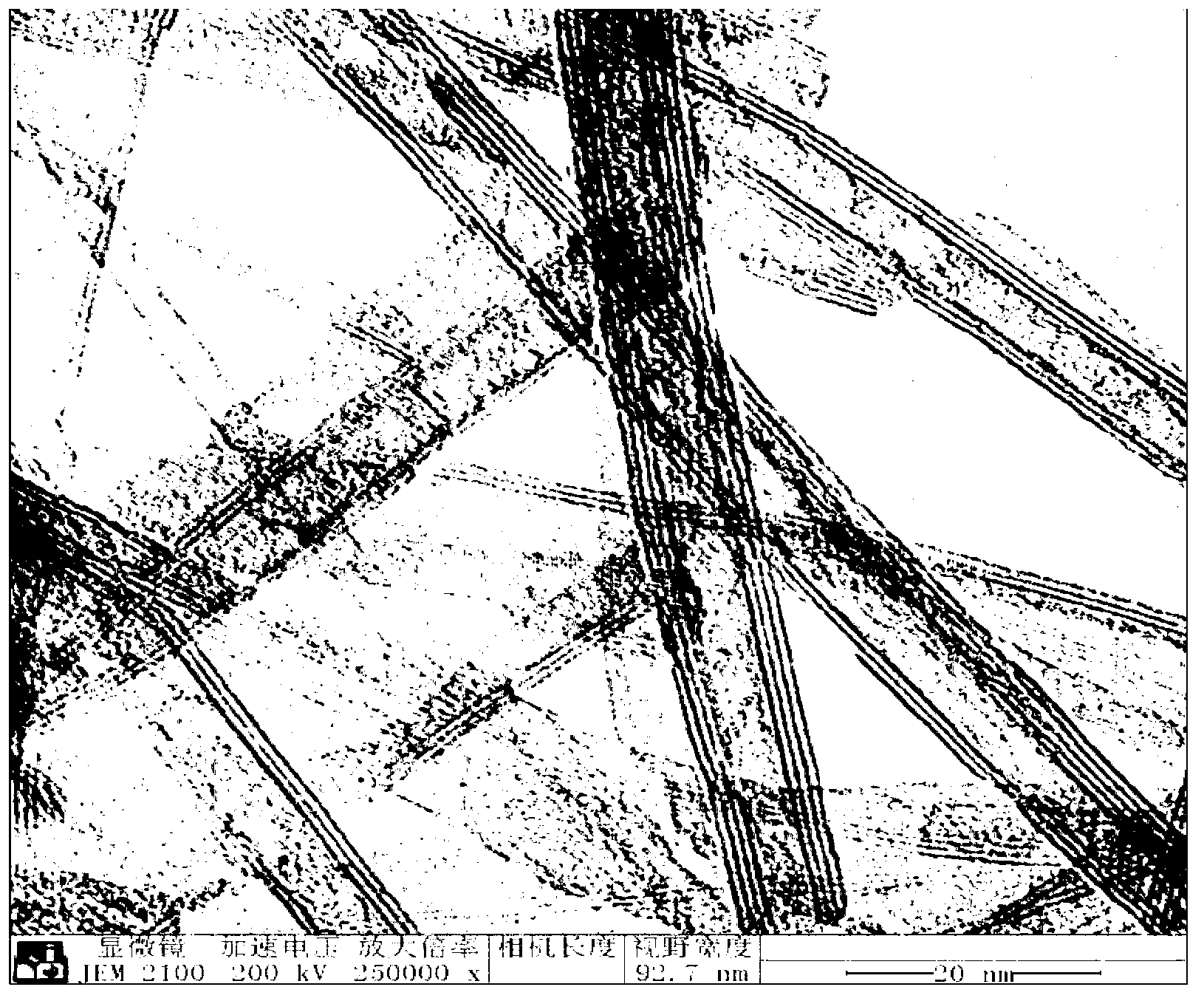

Method of preparing titanium dioxide nanotube with assistance of cationic surface active agent

InactiveCN103288126AHigh tube forming efficiencyUniform diameterNanotechnologyTitanium dioxideAdditive ingredientSurface-active agents

The invention discloses a method of preparing a titanium dioxide nanotube with assistance of a cationic surface active agent. The method comprises: adding titanium dioxide powder and hexadecyl trimethyl ammonium bromide into a polytetrafluoroethylene hydrothermal reaction kettle filled with a strong base solution according to a weight ratio of 1:1-1:5, uniformly mixing the ingredients, reacting at 100-200 DEG C for 15-30hours, performing acid treatment, washing, filtering, drying and burning the ingredients to obtain the titanium dioxide nanotube. The titanium dioxide nanotube is efficiently prepared by a soft template combining with a hydrothermal method. The length of the prepared titanium dioxide nanotube is hundreds of nanometers, the outside diameter is about 10nm, the inside diameter is about 5nm, the titanium dioxide nanotube contains 2-5 layers of tube walls and two open ends. Compared with the titanium dioxide nanotube prepared by a common hydrothermal method under the same condition, the tube length is obviously increased, the tube diameter is more uniform, the draw ratio is large, the tube forming efficiency is high and the aggregation condition is alleviated, thereby being very beneficial for application of the titanium dioxide nanotube in various fields.

Owner:HARBIN ENG UNIV

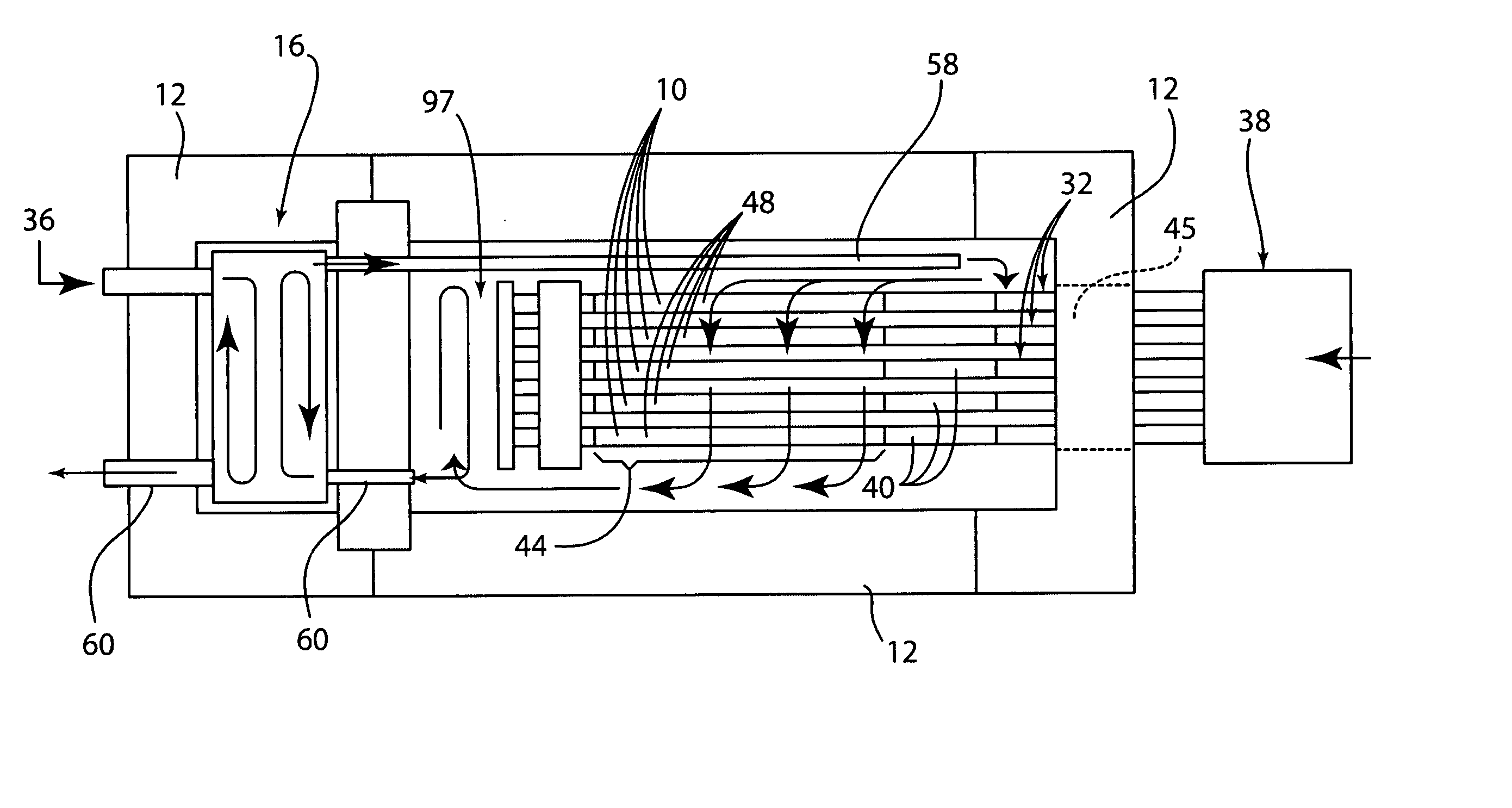

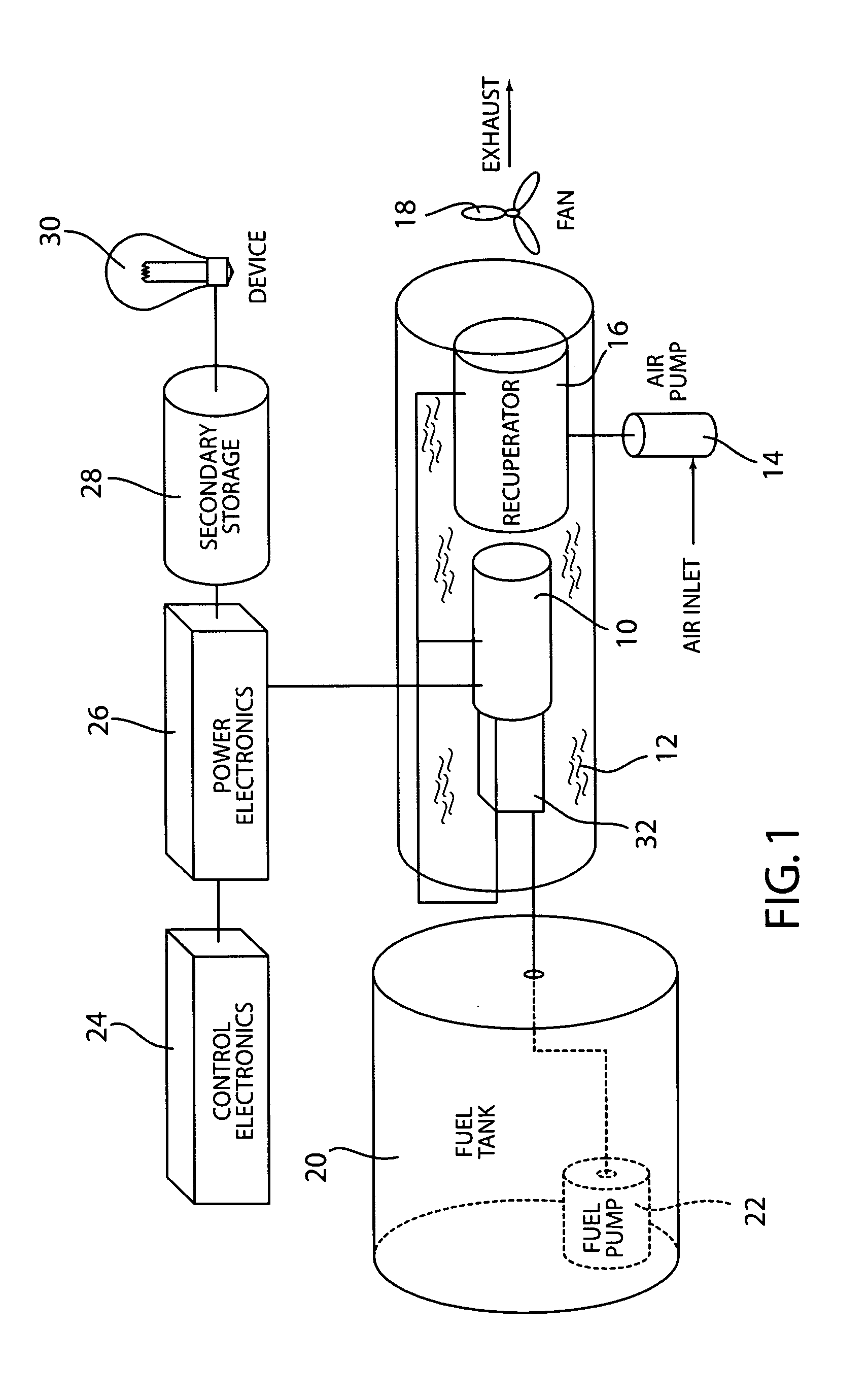

Solid oxide fuel cell tube with internal fuel processing

A solid oxide fuel cell comprises a tube forming an anode, electrolyte and cathode, and a catalytic substrate is positioned within the tube. Such solid oxide fuel cells are highly compact and lightweight, and can be used in portable applications.

Owner:ADAPTIVE MATERIALS

Method and system for forming packages

A method of forming reinforced packages. The method can comprise forming an attached web by adhering a blank to a web of material and moving the attached web in a downstream direction through at least a tube forming assembly and a carton forming assembly. The method also can comprise at least partially forming a tube by folding at least a portion of the web of material as the attached web moves through the tube forming assembly, forming a reinforcement sleeve by folding at least a portion of the blank so that the reinforcement sleeve extends at least partially around the tube as the attached web moves through the carton forming assembly, and forming a reinforced package comprising the reinforcement sleeve and a tube portion by separating the tube portion from a remainder of the tube, the reinforcement sleeve being adhered to the tube portion.

Owner:GRAPHIC PACKAGING INT

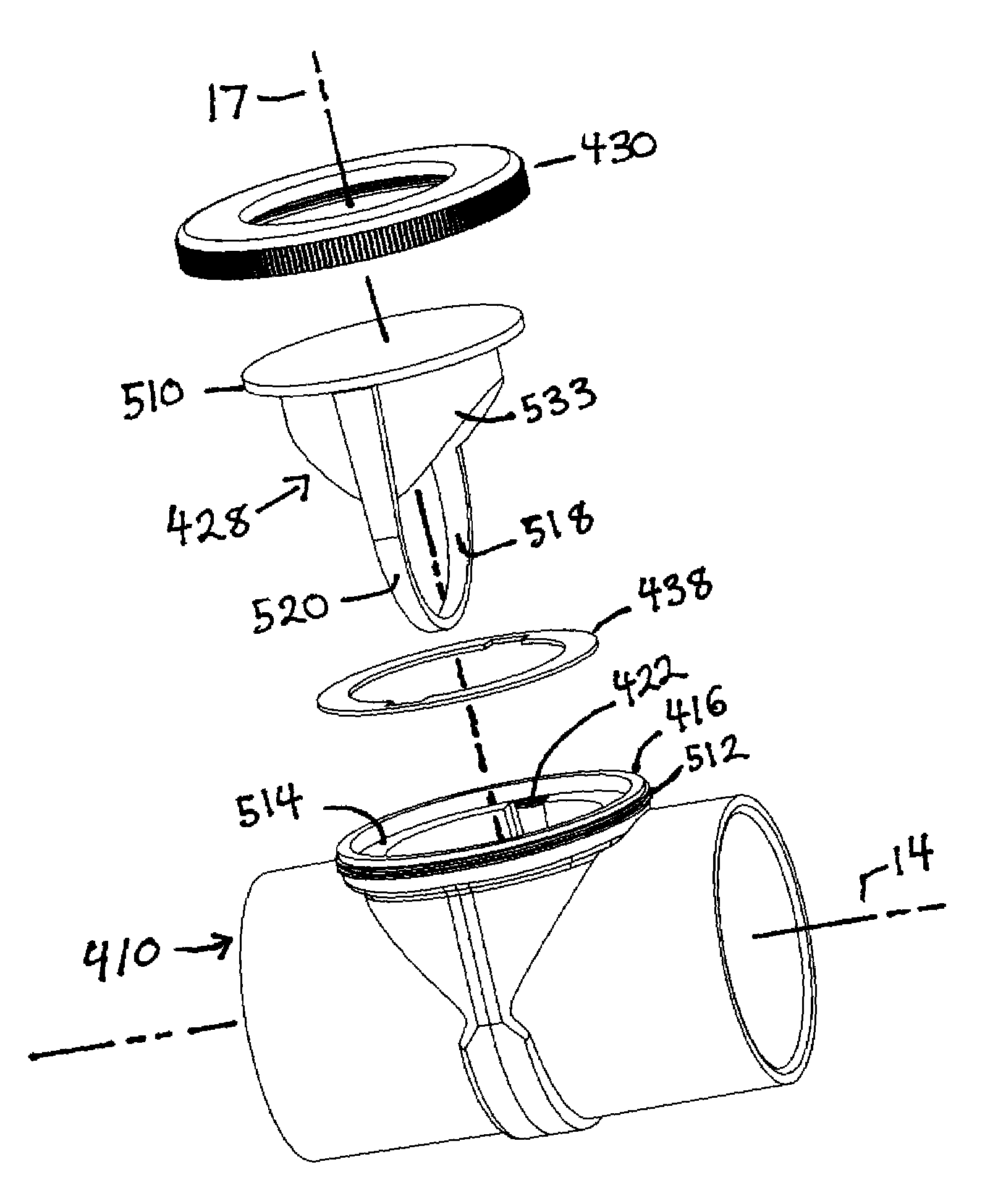

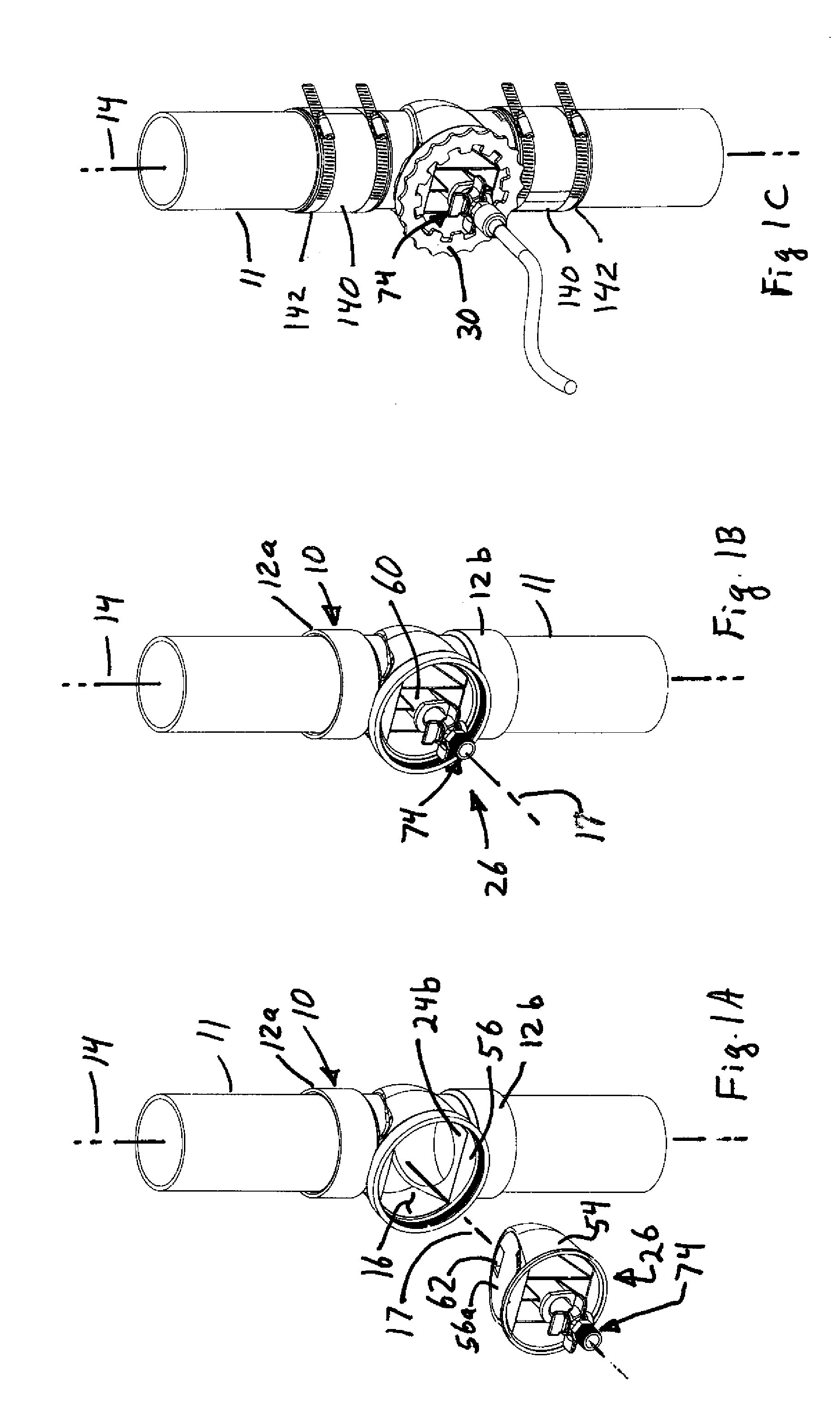

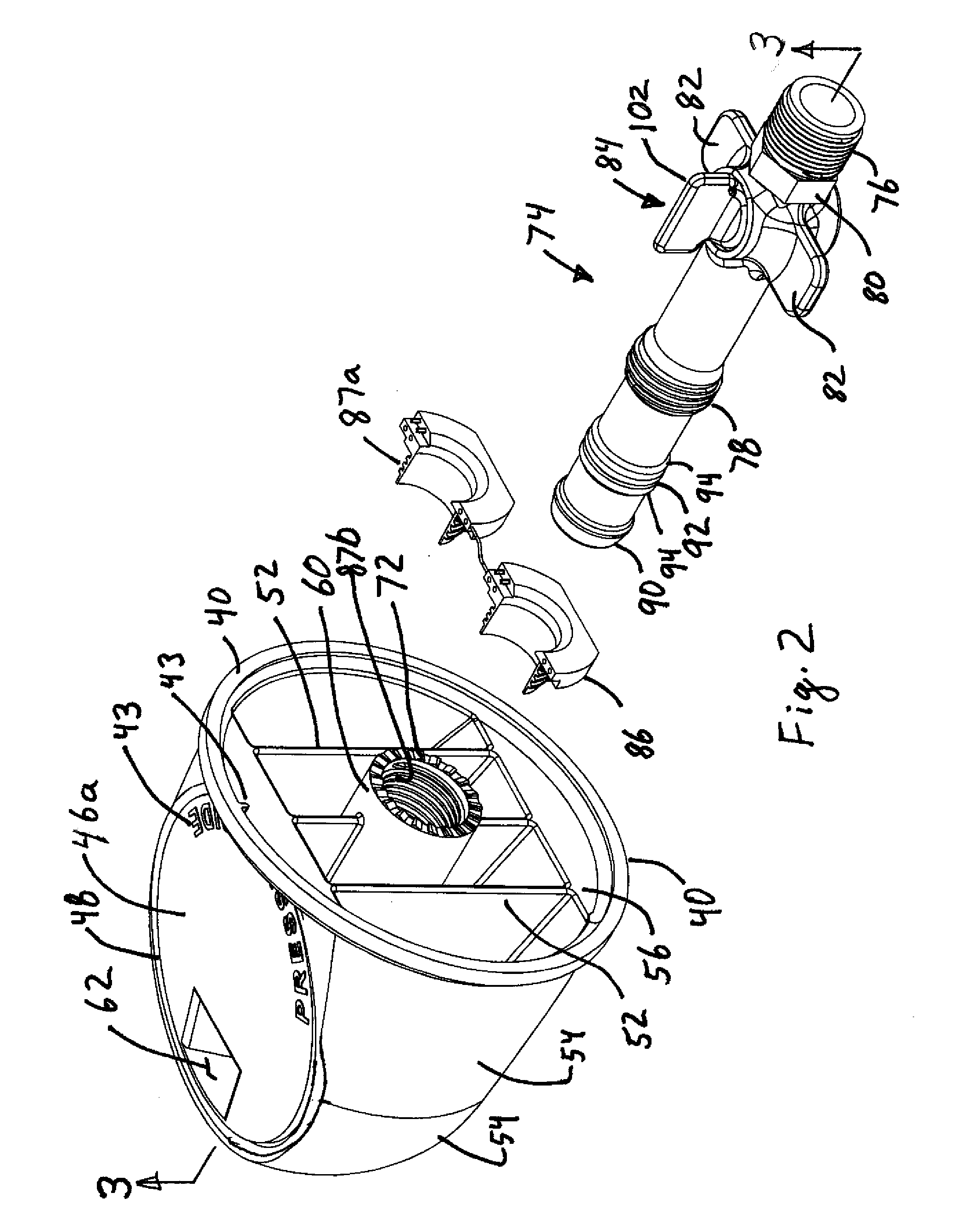

Pipe pressure testing method and apparatus

ActiveUS20100037681A1High strengthEasy accessDetection of fluid at leakage pointMeasurement of fluid loss/gain rateRotary valveValve stem

A pipeline pressure testing assembly has a fitting defining a flow path and having a port on a wall of the fitting into which a pressure testing device is removably inserted along a central axis of the port for pressure testing. The port is circular, larger than the interior diameter of the pipeline and located at or above the tube forming the flow path through the fitting. The fitting has a recess encircling at least part of the flow path and opening to the port to receive the testing and sealing devices. The recess is formed by two opposing walls inclined relative to the central axis of the recess. The recess walls at the top of the flow path by the port are spaced apart a distance as large as the pipe diameter for cleanout and inspection. A tubular valve stem screws into the testing device and has a rotary valve blocking flow through the tubular valve stem. Flow through the fitting is blocked with the rotary valve closed and the tubular valve stem in a first position. Flow through the testing device is allowed with the rotary valve closed and the tubular valve stem in an open position. With the rotary valve open, flow through the tubular valve stem is permitted when the tubular valve stem is in either the first or second position to provide multiple drain and fill options.

Owner:RELIANCE WORLDWIDE CORP

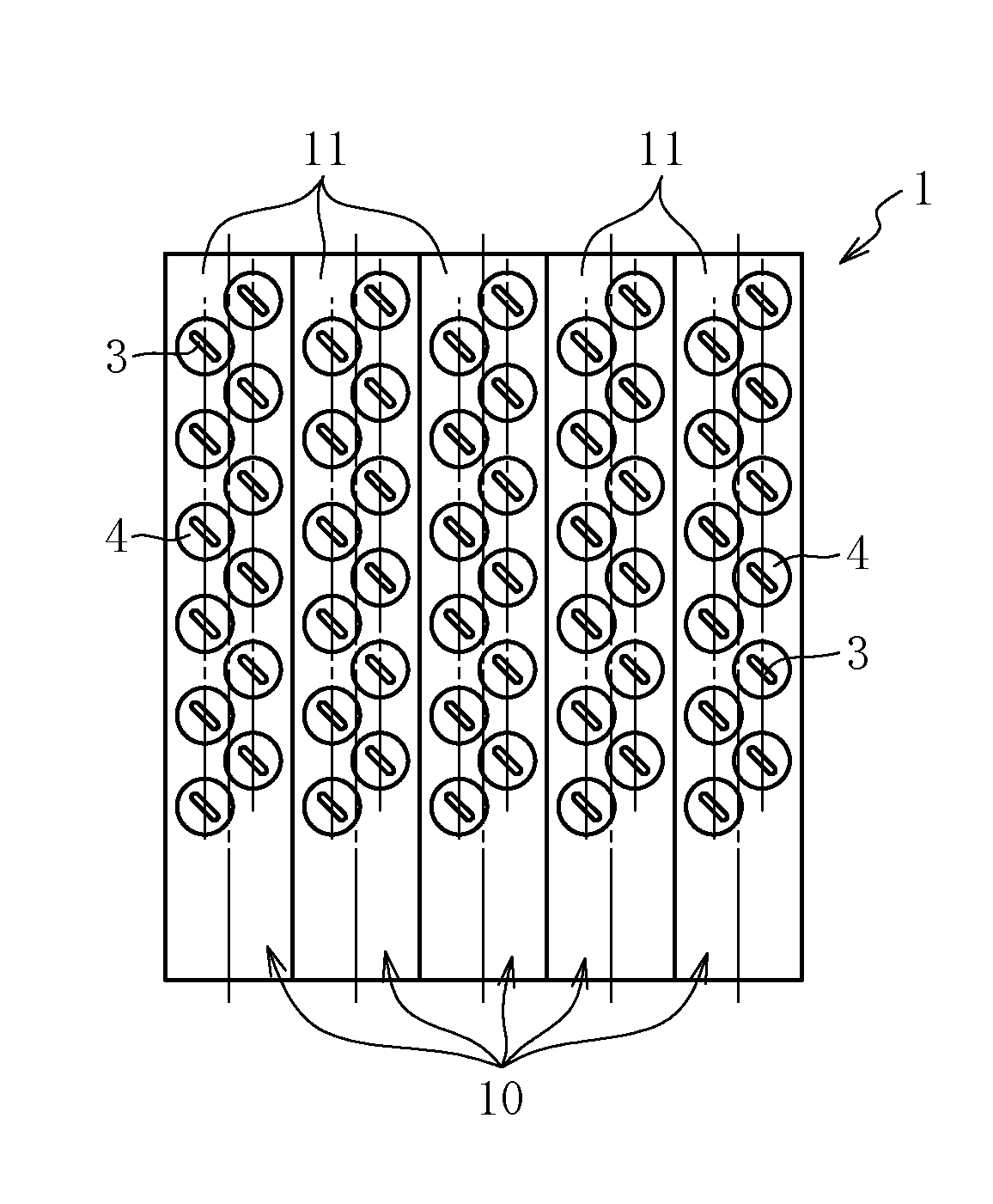

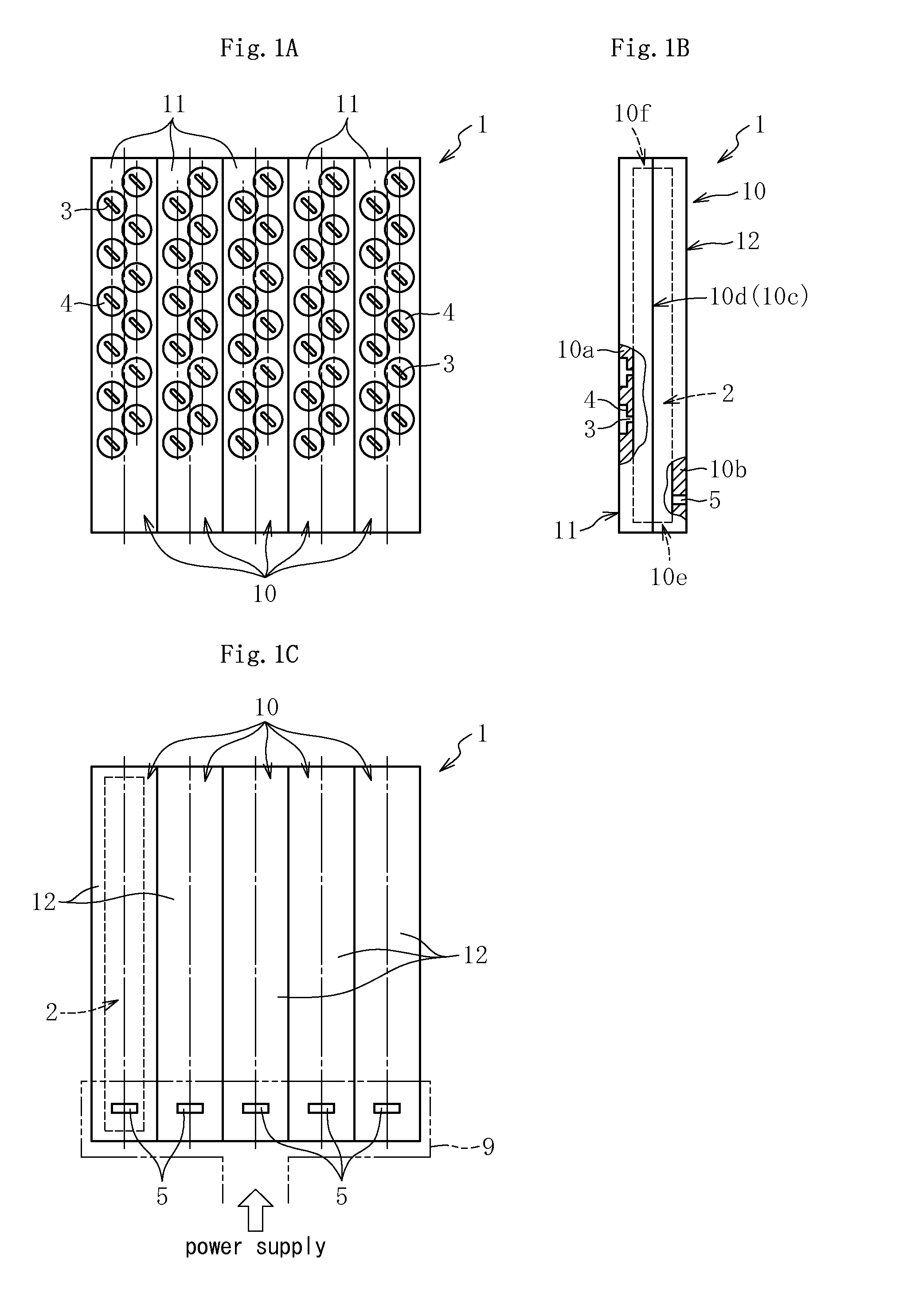

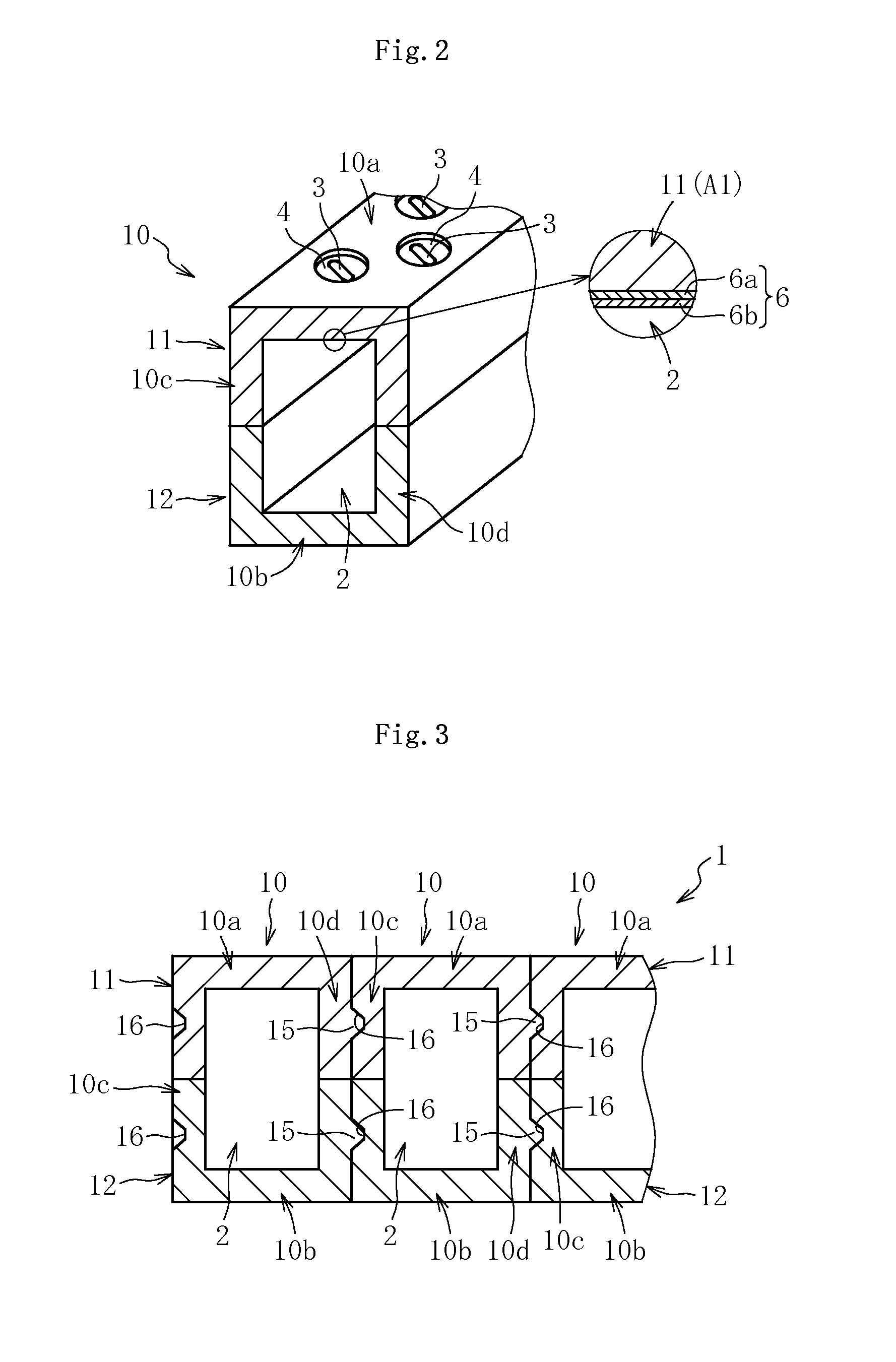

Waveguide tube slot antenna and wireless device provided therewith

ActiveUS20150229027A1Improve performanceIncrease freedomAntenna arrays manufactureIndividually energised antenna arraysEngineeringWaveguide

Provided is a waveguide tube slot antenna (1) including: a plurality of waveguides (2) arranged in parallel with each other; a plurality of radiating slots (3) formed along each of the plurality of waveguides (2); and a plurality of waveguide tubes (10) connected in parallel with each other, in which the plurality of waveguide tubes (10) each include a first waveguide tube forming member (11) and a second waveguide tube forming member (12) each having a transverse section having a shape with an end, the first waveguide tube forming member and the second waveguide tube forming member being configured to define one of the plurality of waveguides (2) by being connected to each other.

Owner:NTN CORP

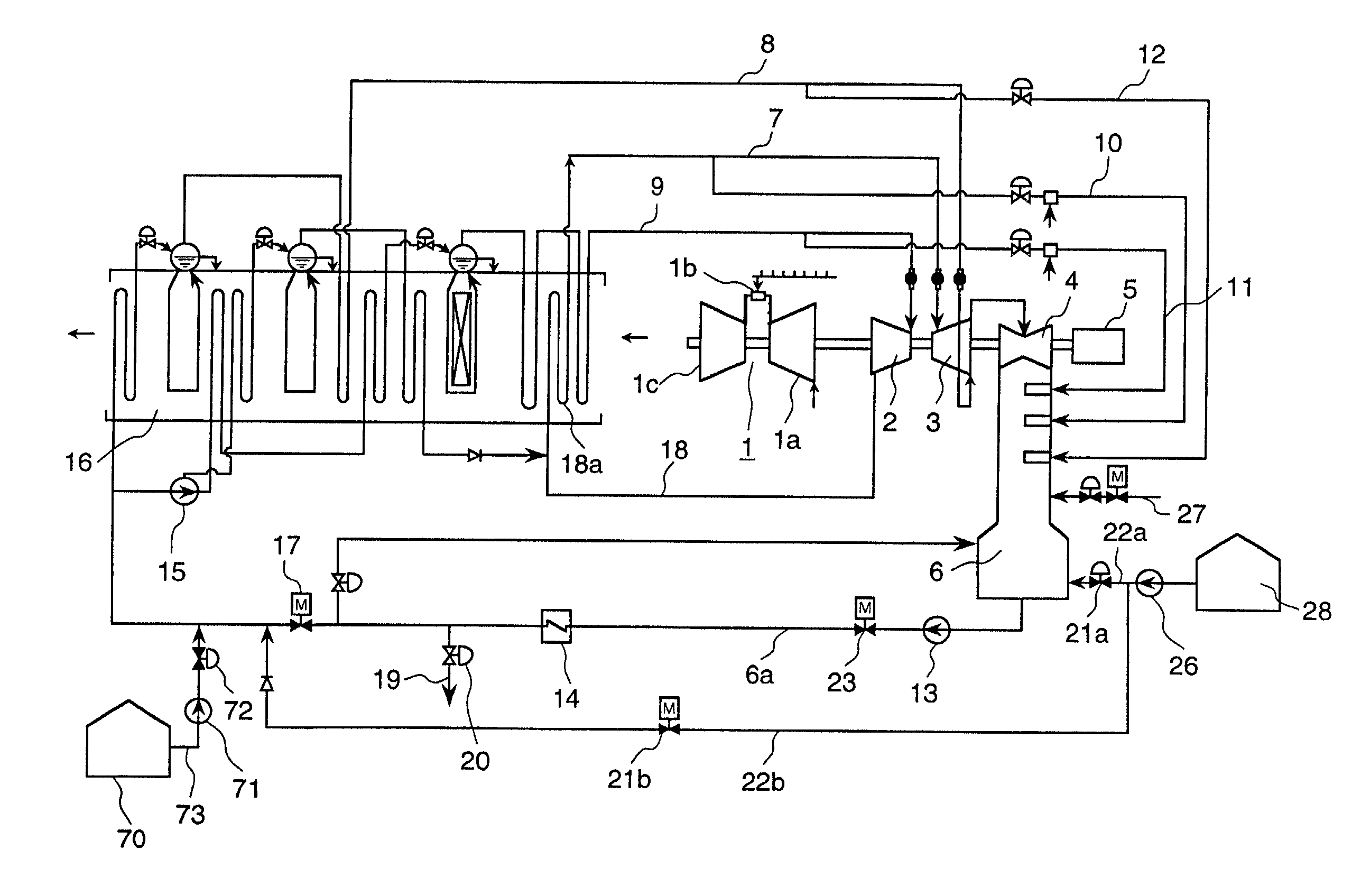

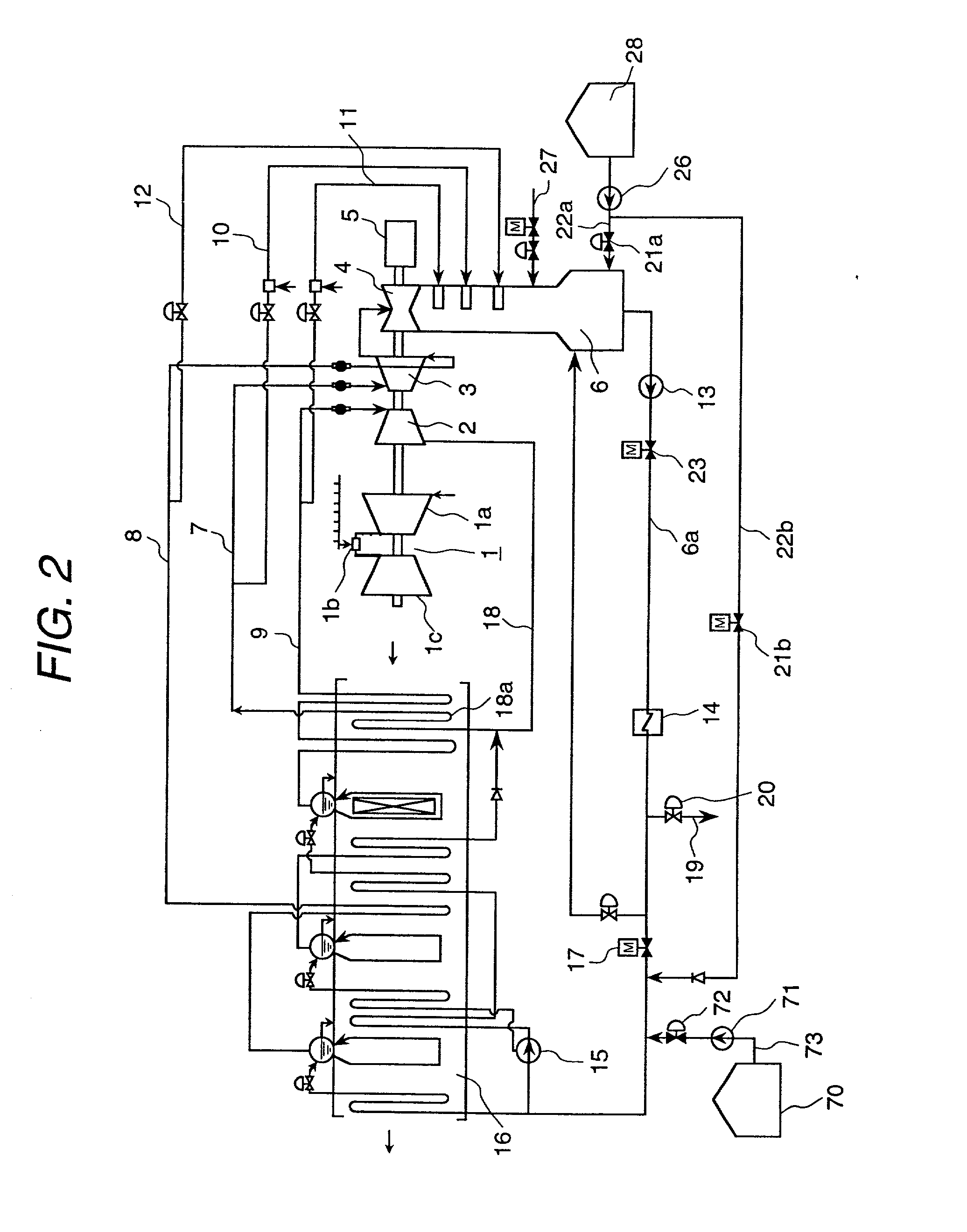

Condenser, power plant equipment and power plant operation method

InactiveUS20020029572A1Safety devices for heat exchange apparatusSteam useWater leakageWater quality

Water quality detecting points for detecting sea water leakage are provided at a portion in a hot well zone right under a tube bundle of heat exchange tube forming a steam condensing zone and at a condenser outlet allowing the condensate to be led out of the condenser or in the vicinity thereof, and a difference between detection values at both detecting points is monitored. Further, when leakage of sea water occurred, a feed water stop valve or a condensate stop valve is stopped for separating the system in which the sea water is mixed, and at same time, make-up water is supplied to a steam generator. Further, chemical or chemical dilution water is injected into the condensate mixed with sea water.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Bicycle suspension system

A bicycle suspension system including a travel adjustment apparatus. The bicycle suspension system includes a piston tube and a piston assembly slidably disposed in the piston tube forming a shock-absorbing mechanism. The piston assembly is in contact with the piston tube. The travel adjustment apparatus includes first and second fluid chambers, a fluid valve mechanism for controlling fluid flow between the first and second fluid chambers, and an actuating assembly operatively connected to the fluid valve mechanism operable between at least two rider-selectable travel settings to operate the fluid valve mechanism between at least two valve settings corresponding to the rider-selectable travel settings. The first and second fluid chamber are configured such that operation of the fluid valve mechanism between two of the at least two valve settings permits the piston assembly to be moved from a first initial position relative to the piston tube to a second initial position relative to the piston tube such that the suspension system changes from a first of the at least two amounts of travel to a second of the at least two amounts of travel.

Owner:SRAM CORPORATION

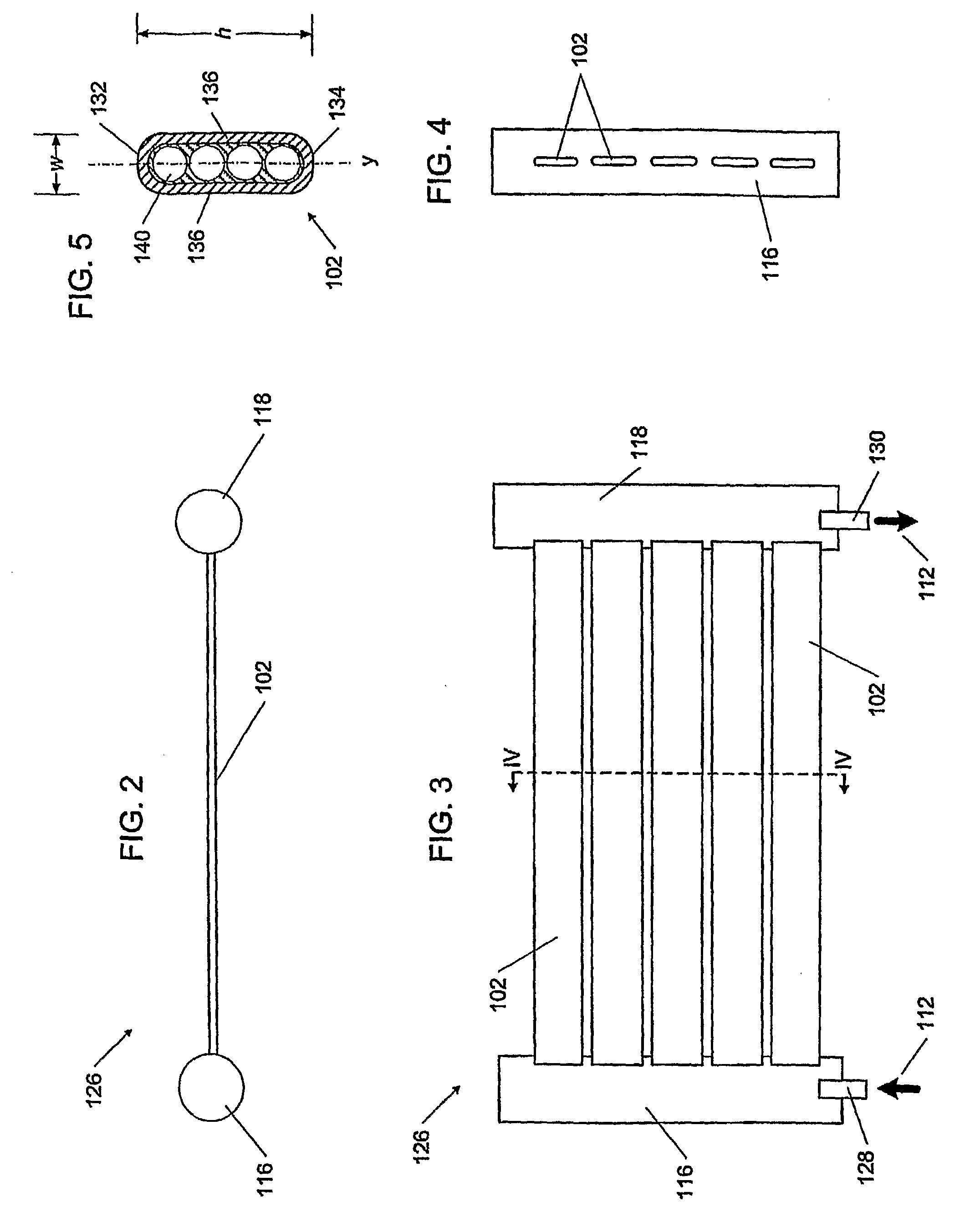

Spiral flat-tube heat exchanger

InactiveUS20090114380A1Good flexibilityMetal-working apparatusStationary tubular conduit assembliesPlate heat exchangerEngineering

A spiral flat tube heat exchanger comprising a first flat tube and a second flat tube thermally coupled to the first flat tube, the first flat tube and the second flat tube forming substantially concentric spirals. A first fluid flows through the first flat tube in a first flow direction, and second fluid flows through the second flat tube in a second flow direction. The flat tubes preferably contain microchannels to increase heat transfer efficiency.

Owner:CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com