Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4714results about "Wrapping material feeding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

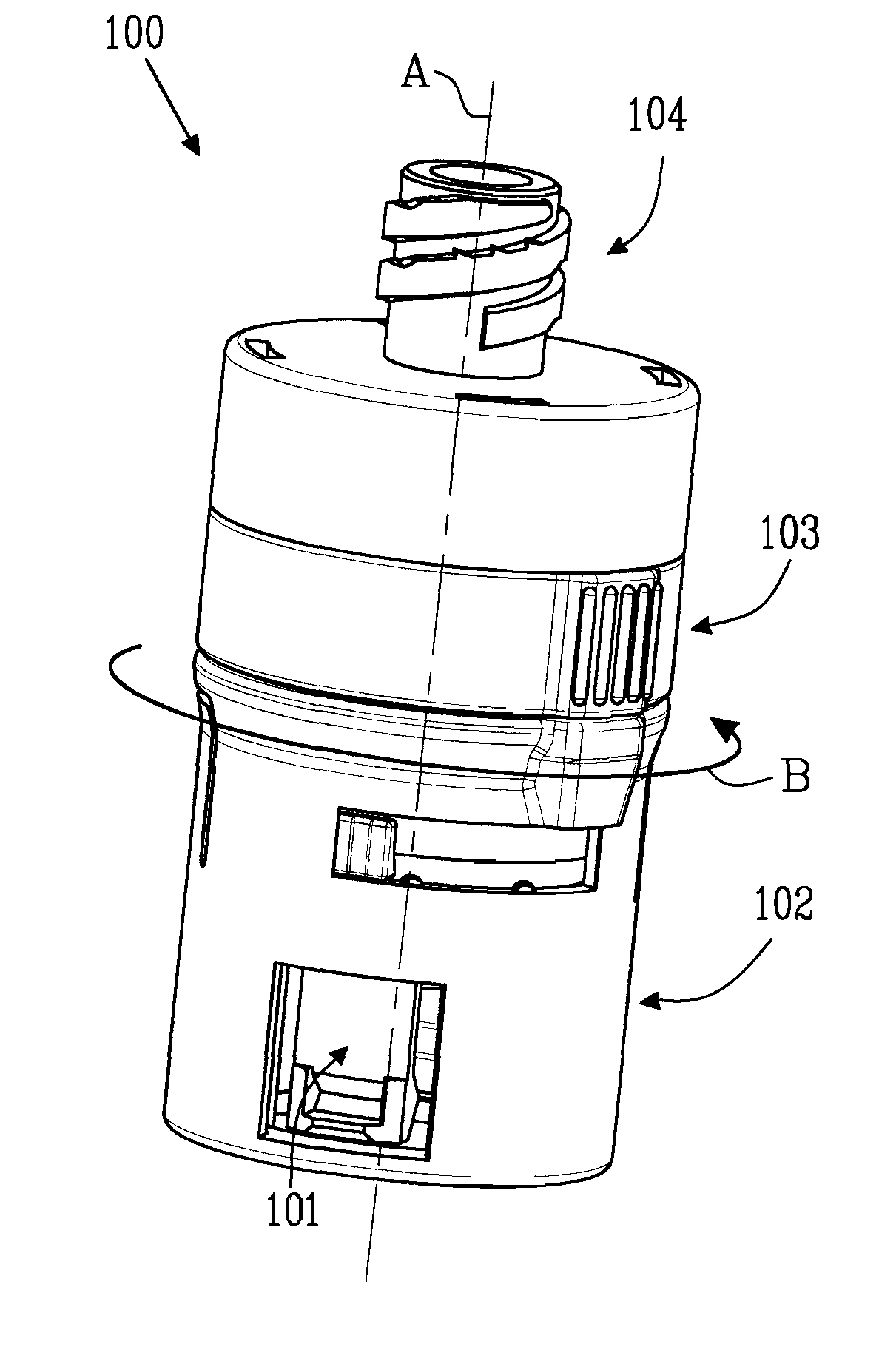

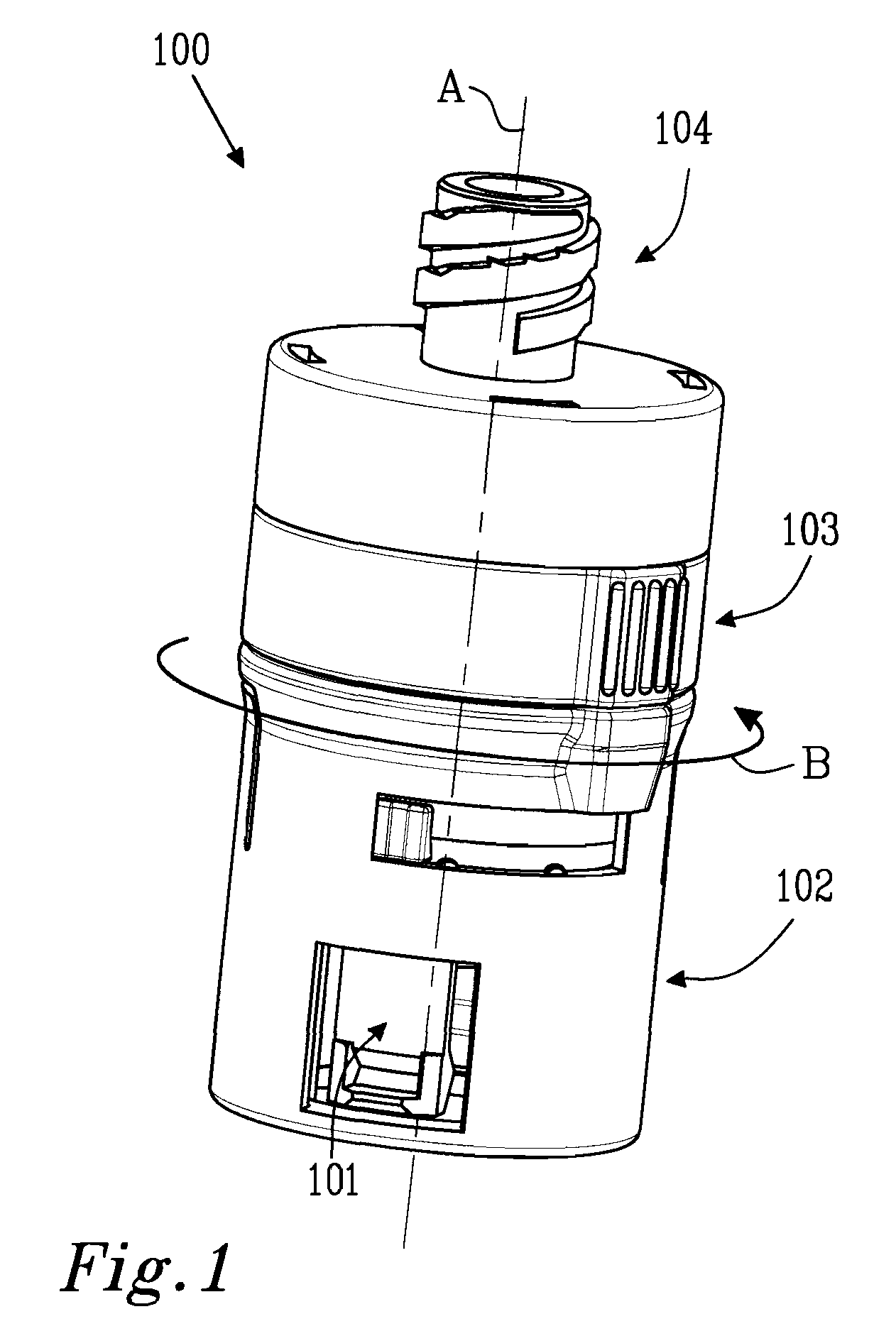

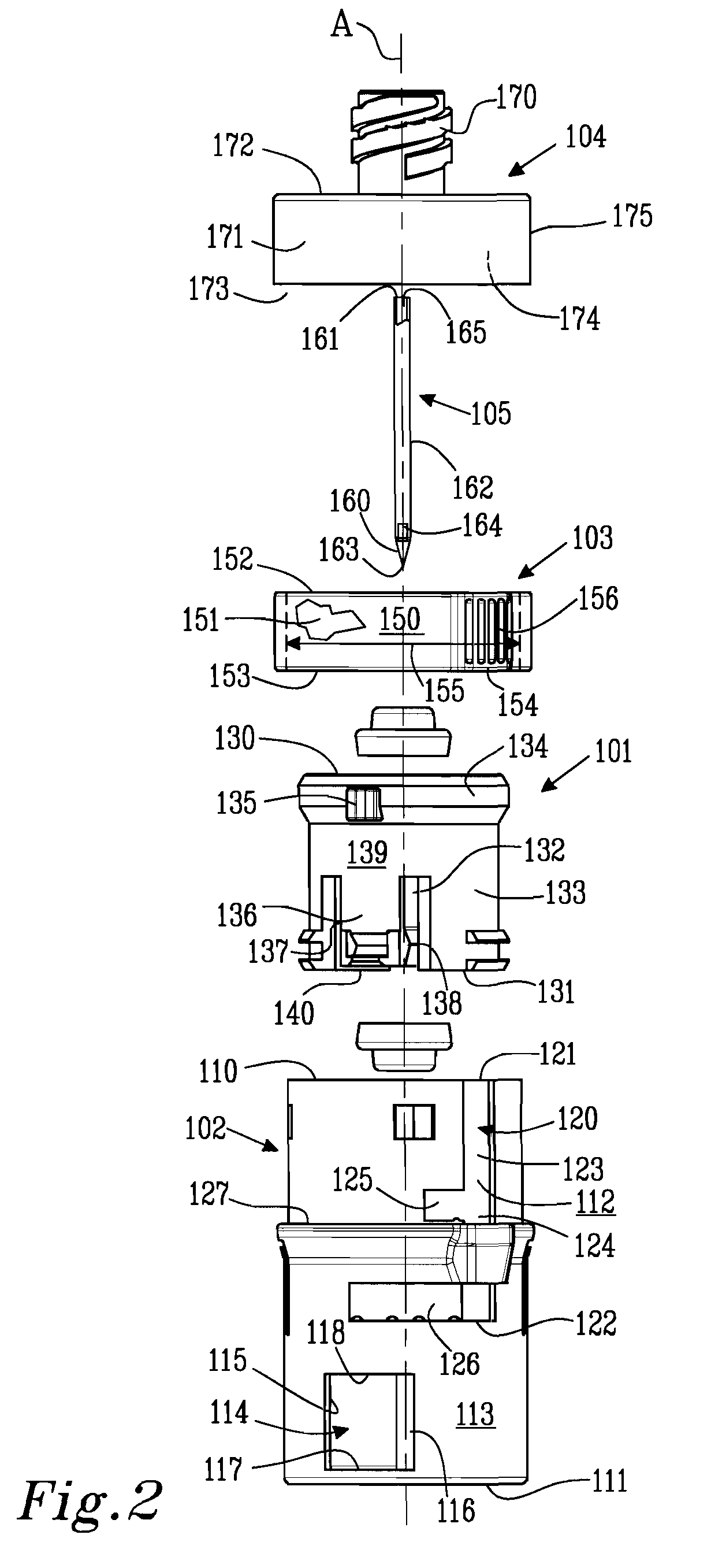

Piercing member protection device

ActiveUS8287513B2Avoid connectionPrevent disengagementCapsLiquid fillingEngineeringElectrical and Electronics engineering

Owner:CARMEL PHARMA

Inflation device for forming inflated containers

Owner:SEALED AIR U S

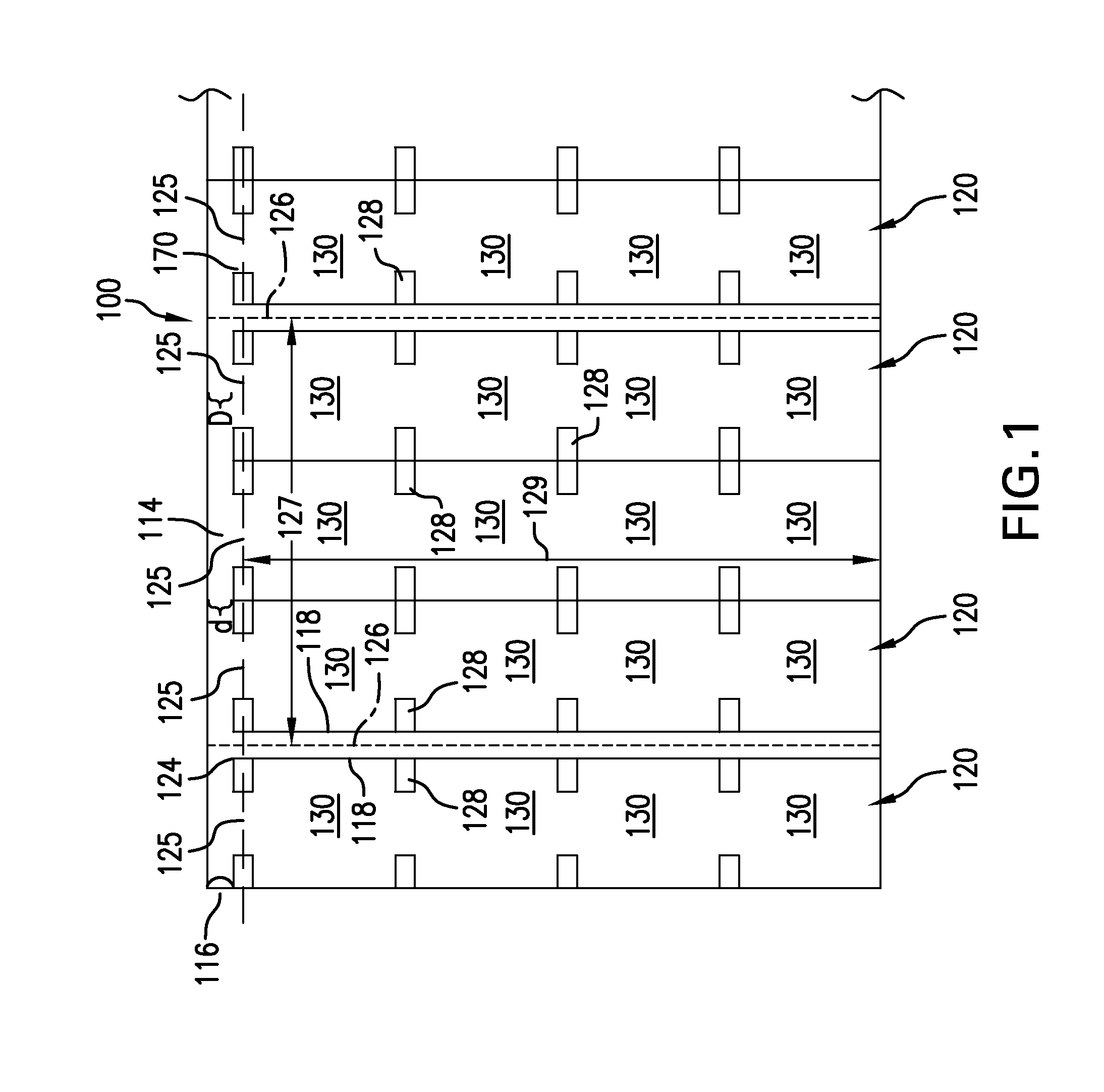

Form-fill sealing machines, resealable flexible packages and methods of manufacturing resealable flexible packages

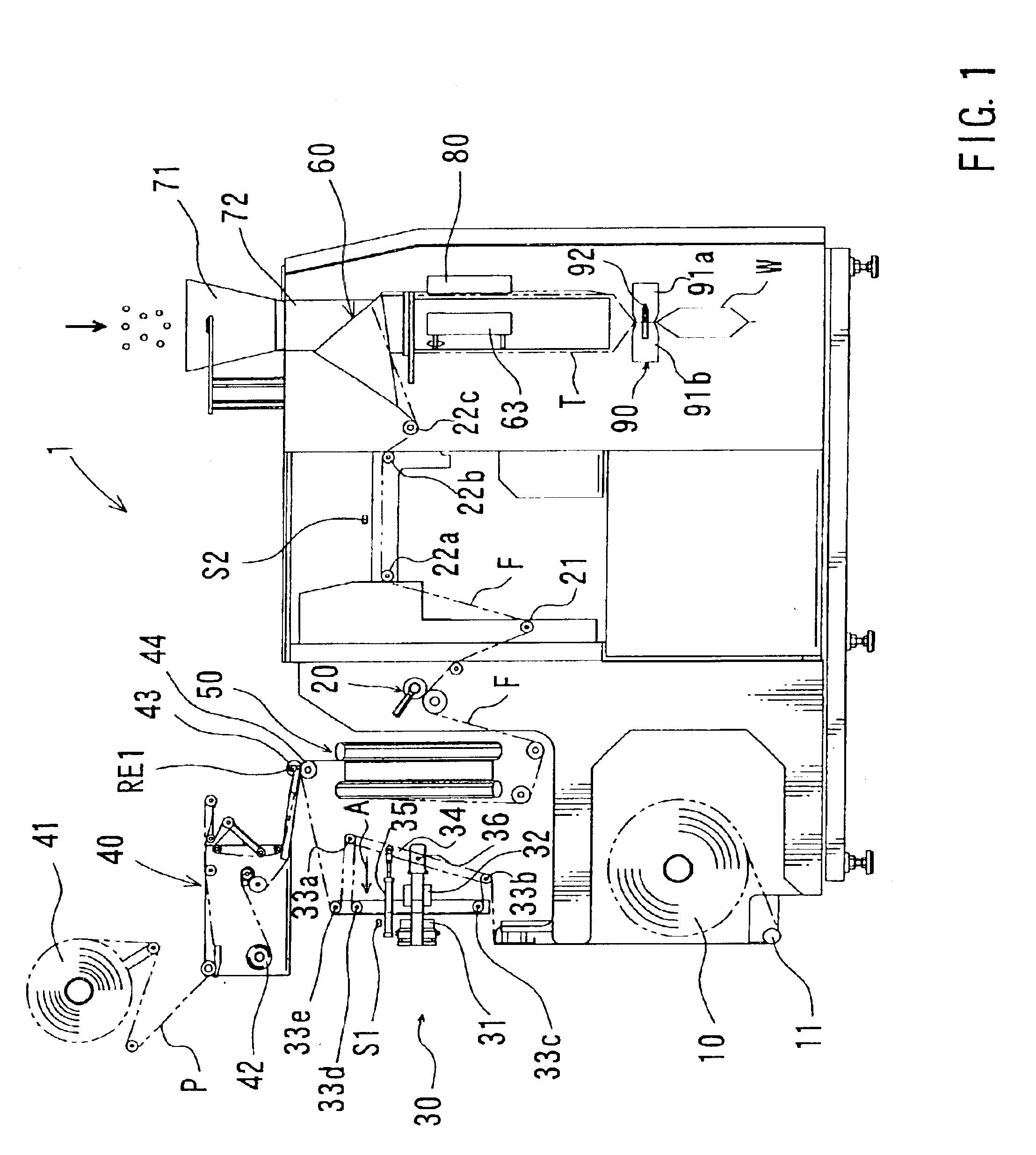

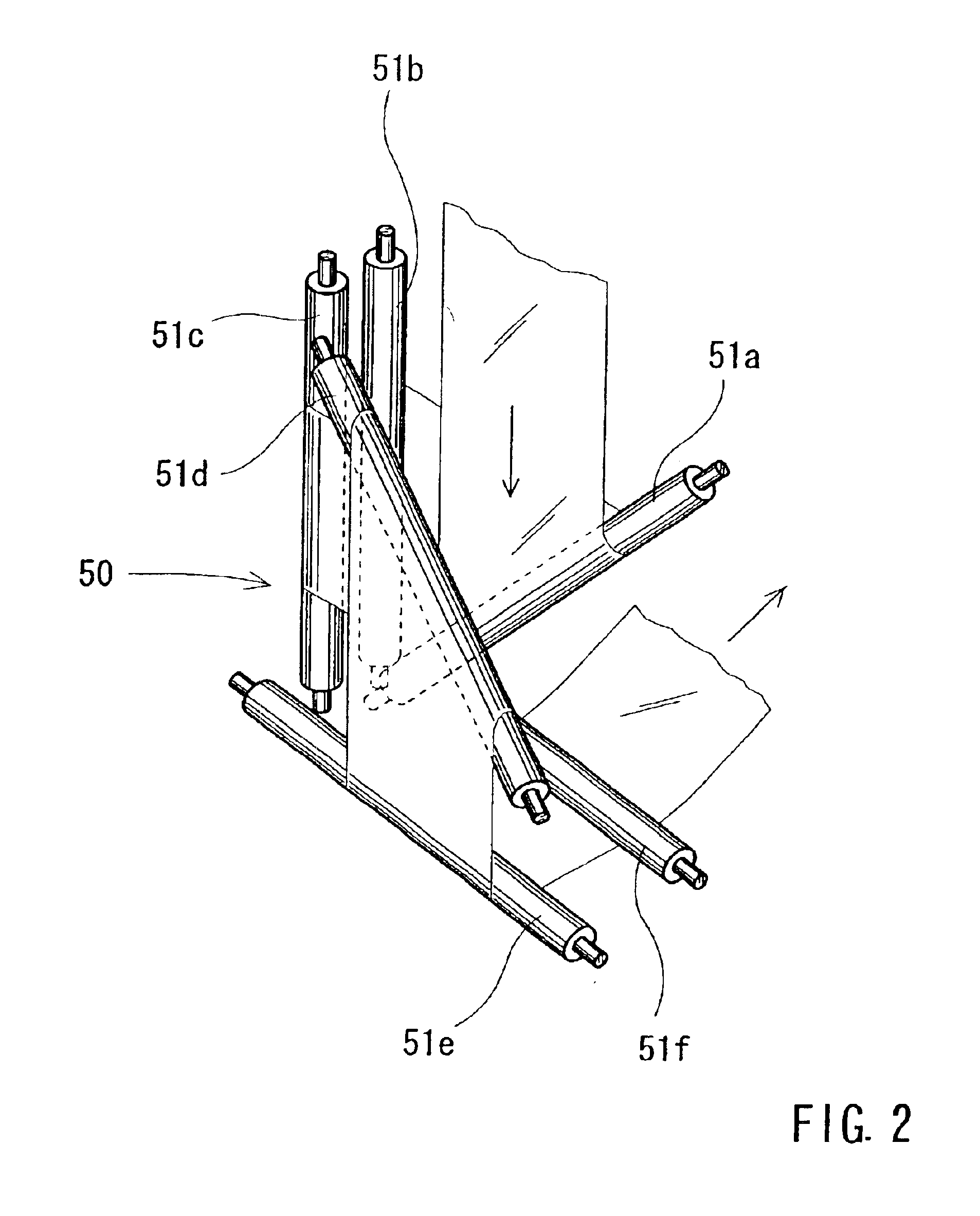

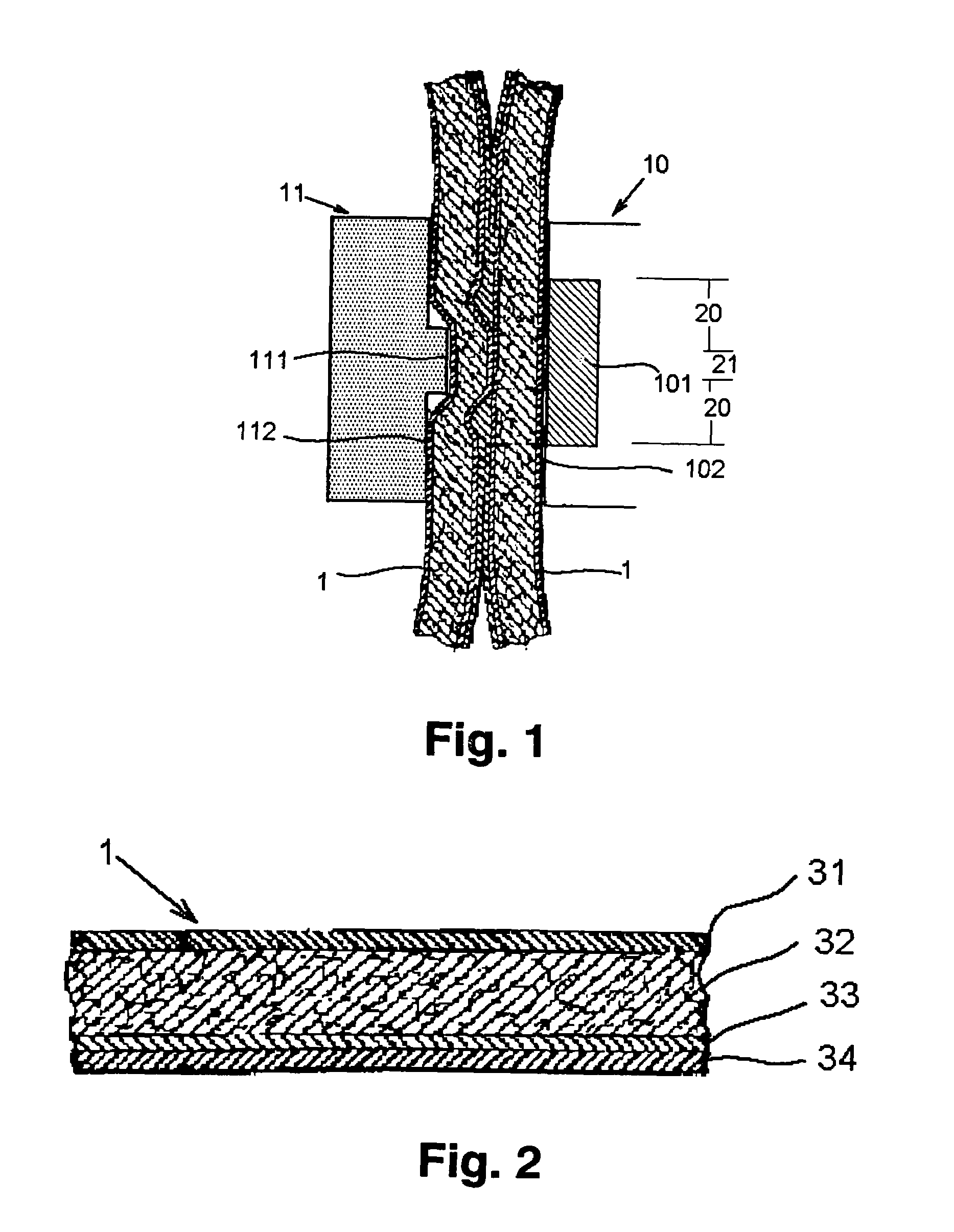

InactiveUS6865860B2Hinders its propagationReliable stopWrapping material feeding apparatusBagsHermetic packagingEngineering

A form-fill sealing machine (1) for manufacturing resealable packages (W) includes a tearable line forming device (30) that serves to form tearable lines (104) in a film (F). A labeling device (40) serves to stick re-stickable labels (103) onto the film in positions to cover respective tearable lines. A tube forming device (60) serves to form the film into a tubular film (T). A first sealing device (80) serves to seal lapped edges of the tubular film so as to form a lengthwise sealed portion (111). A second sealing device (90) serves to seal the tubular film in a crosswise direction, so that crosswise sealed portions (109) are formed on the tubular film. Each tearable line is positioned between two adjacent crosswise sealed portions and adjacent to one of two adjacent crosswise sealed portions.

Owner:FUJI KIKAI KK

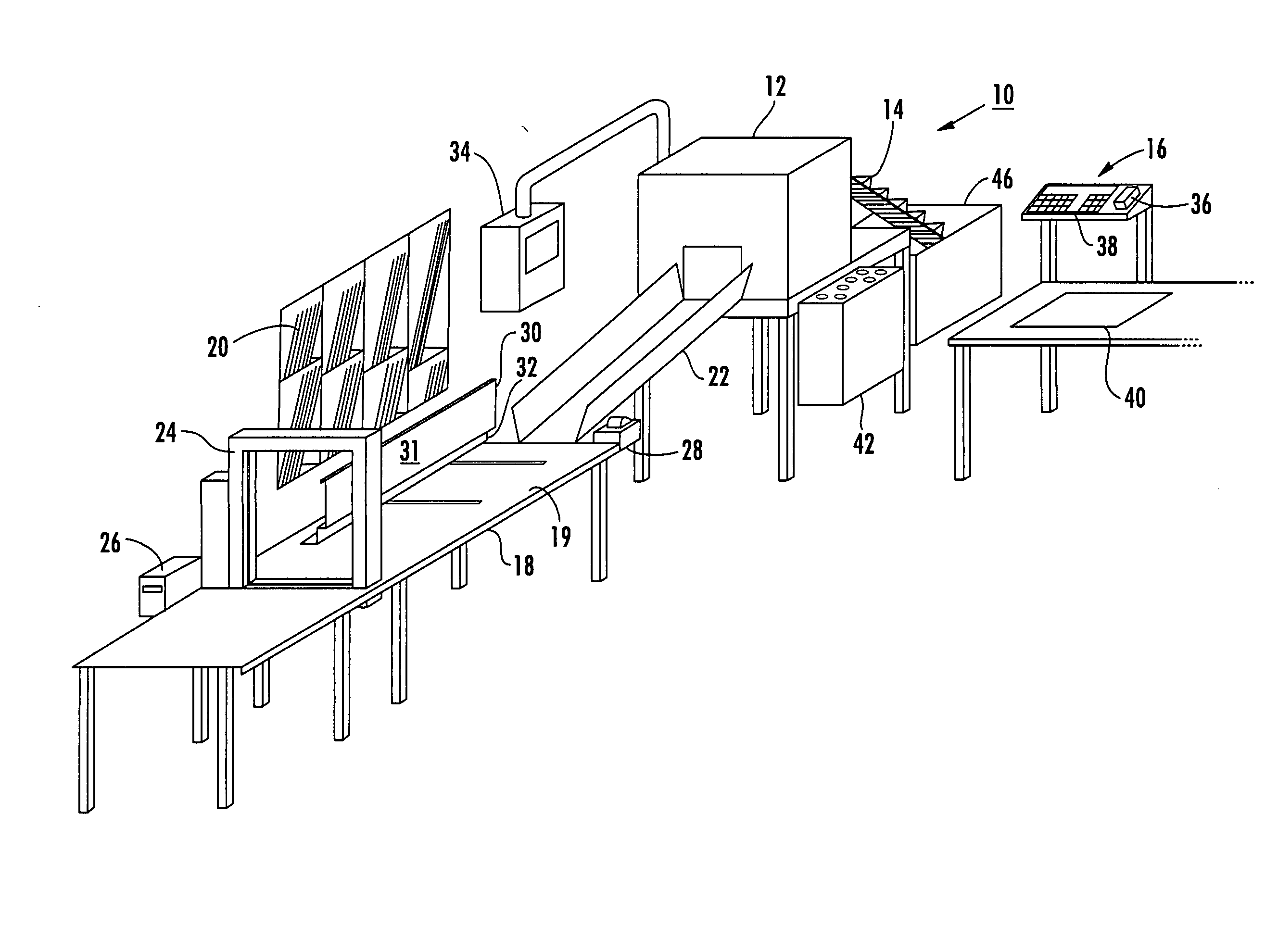

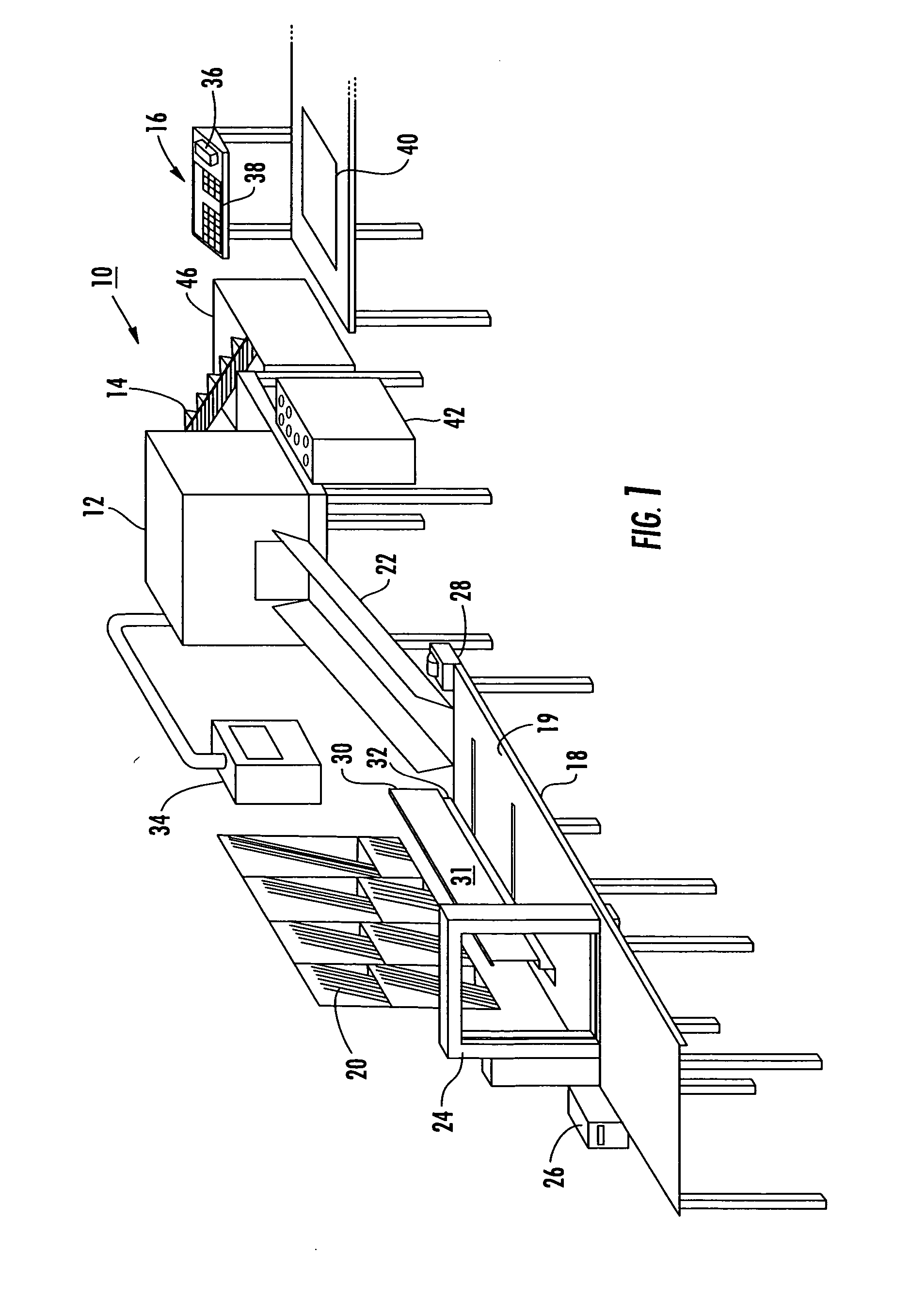

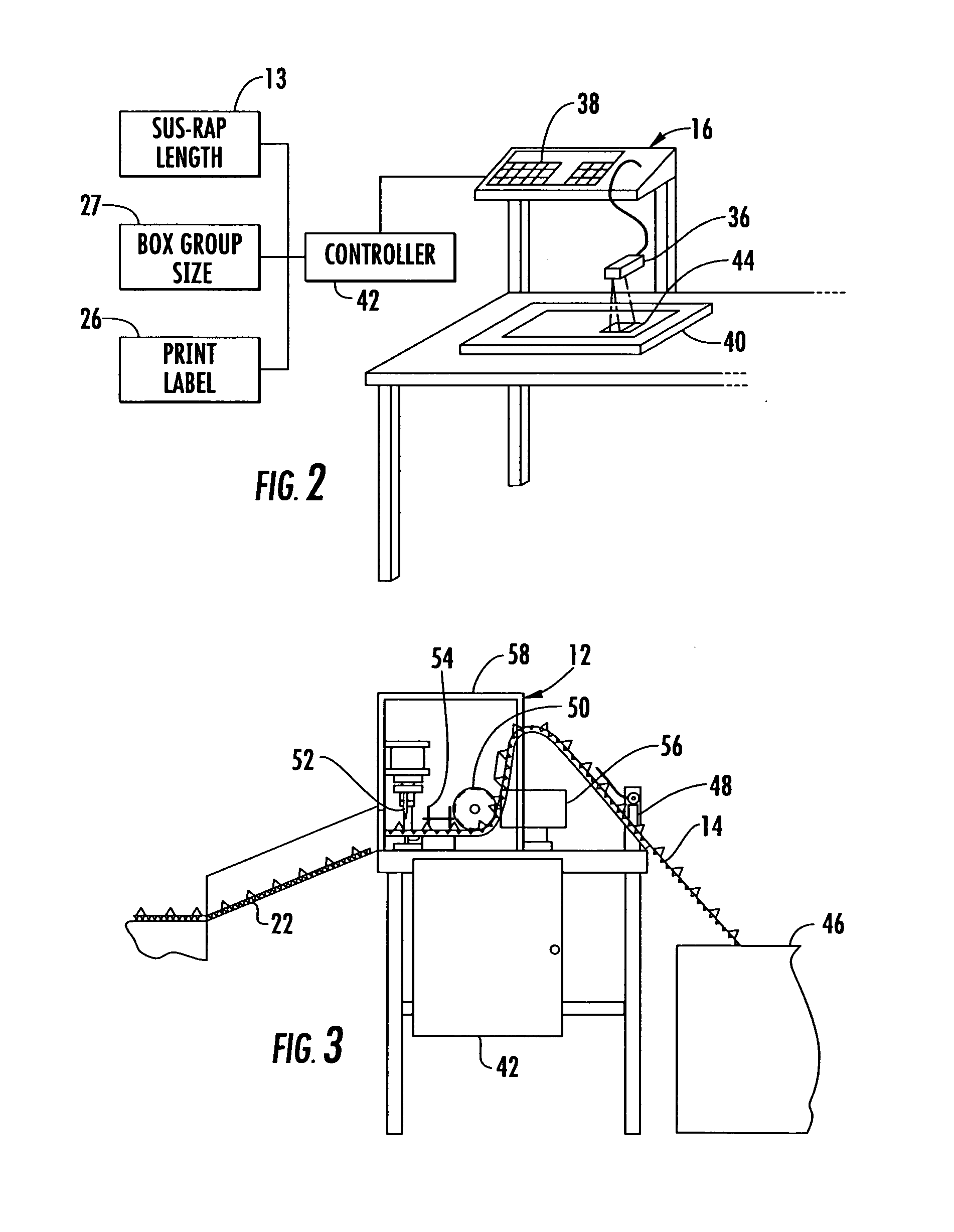

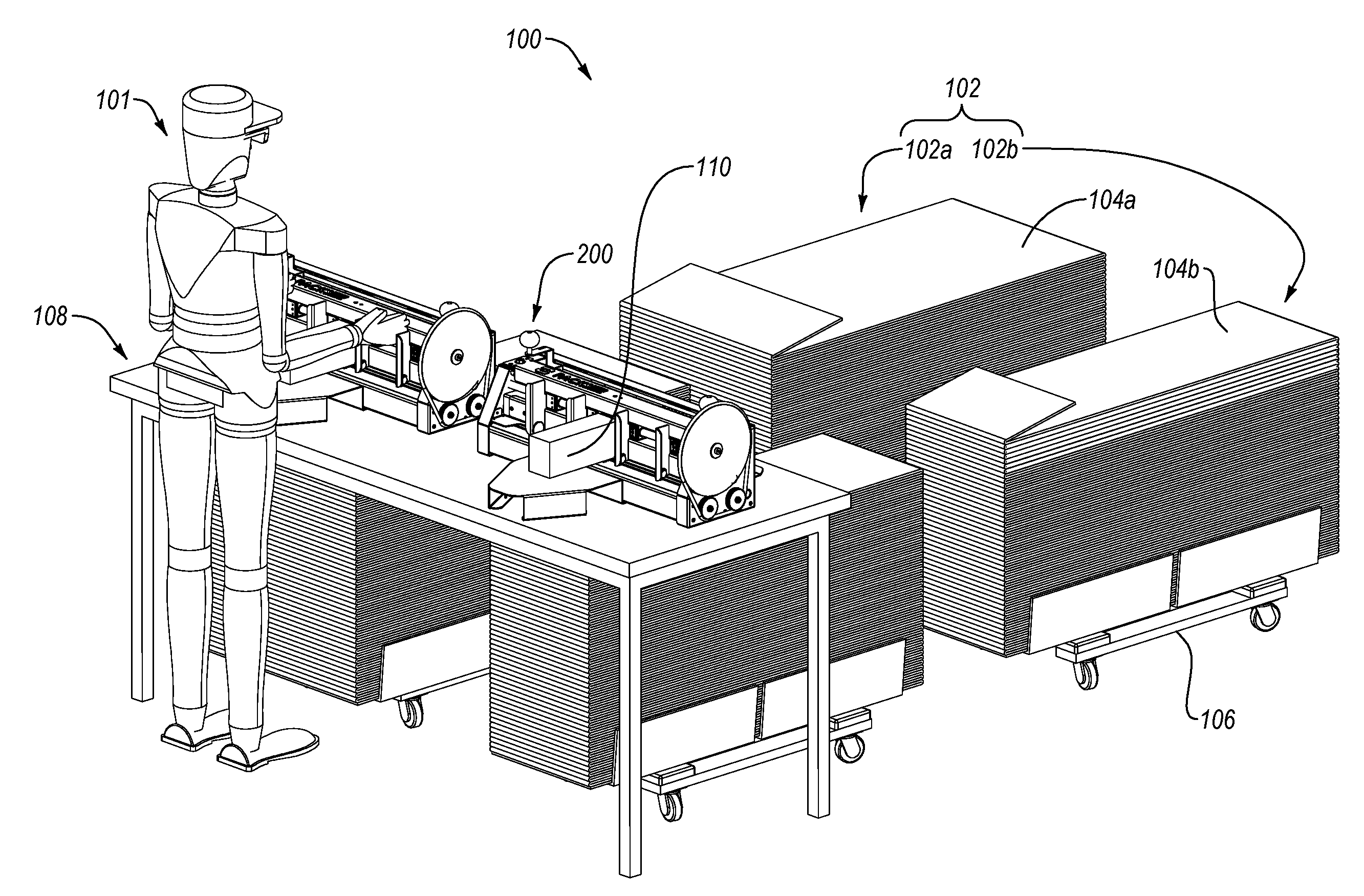

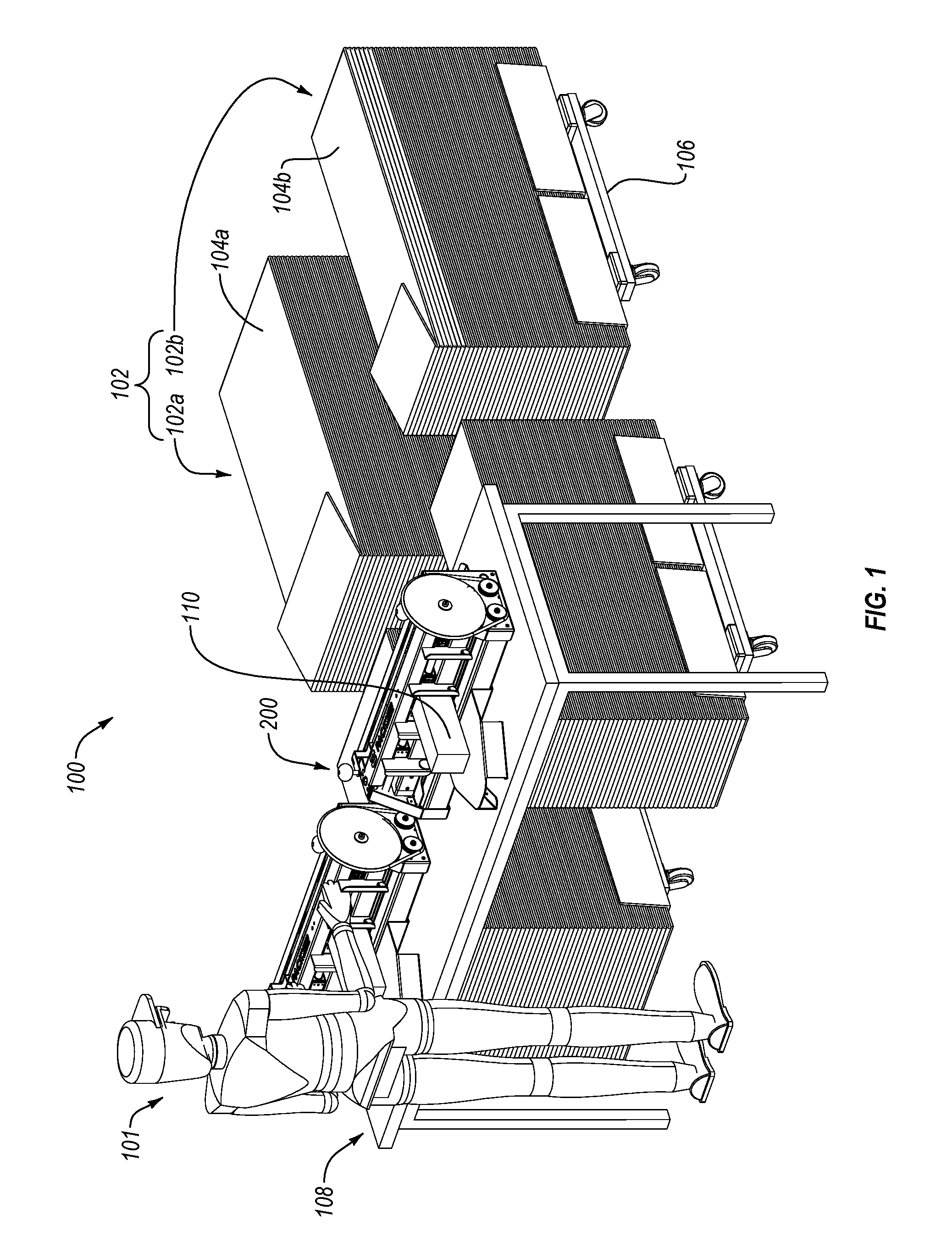

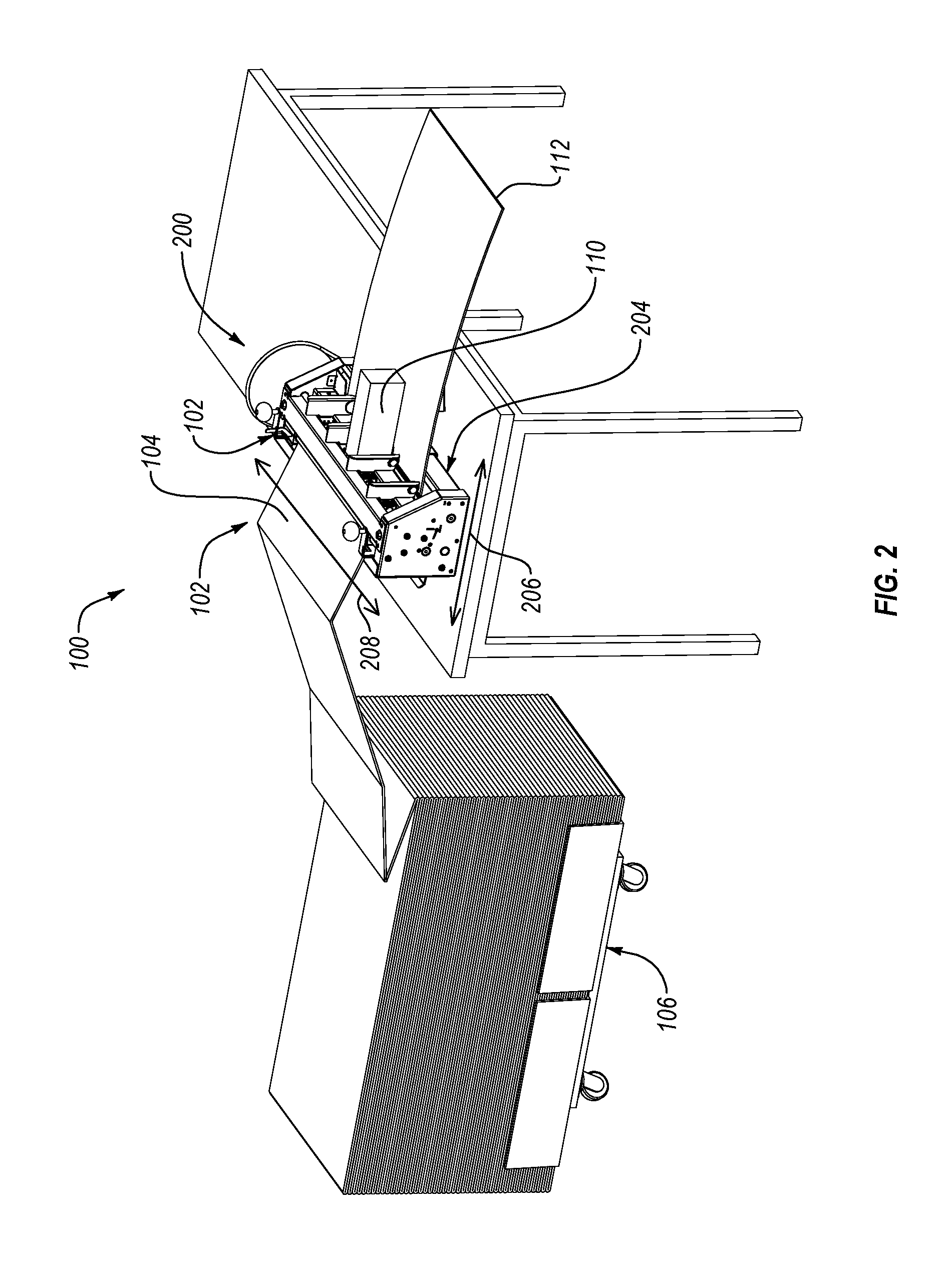

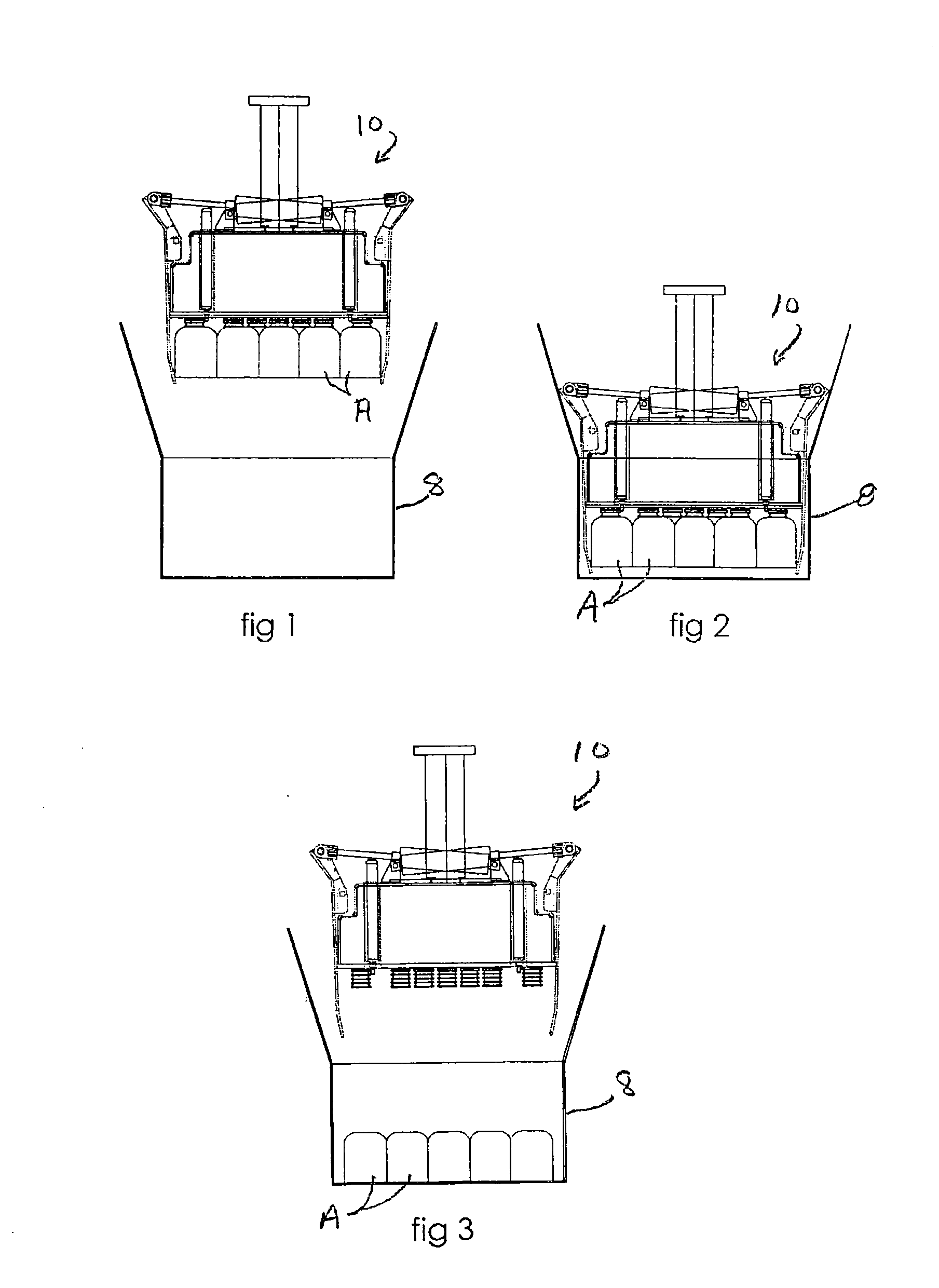

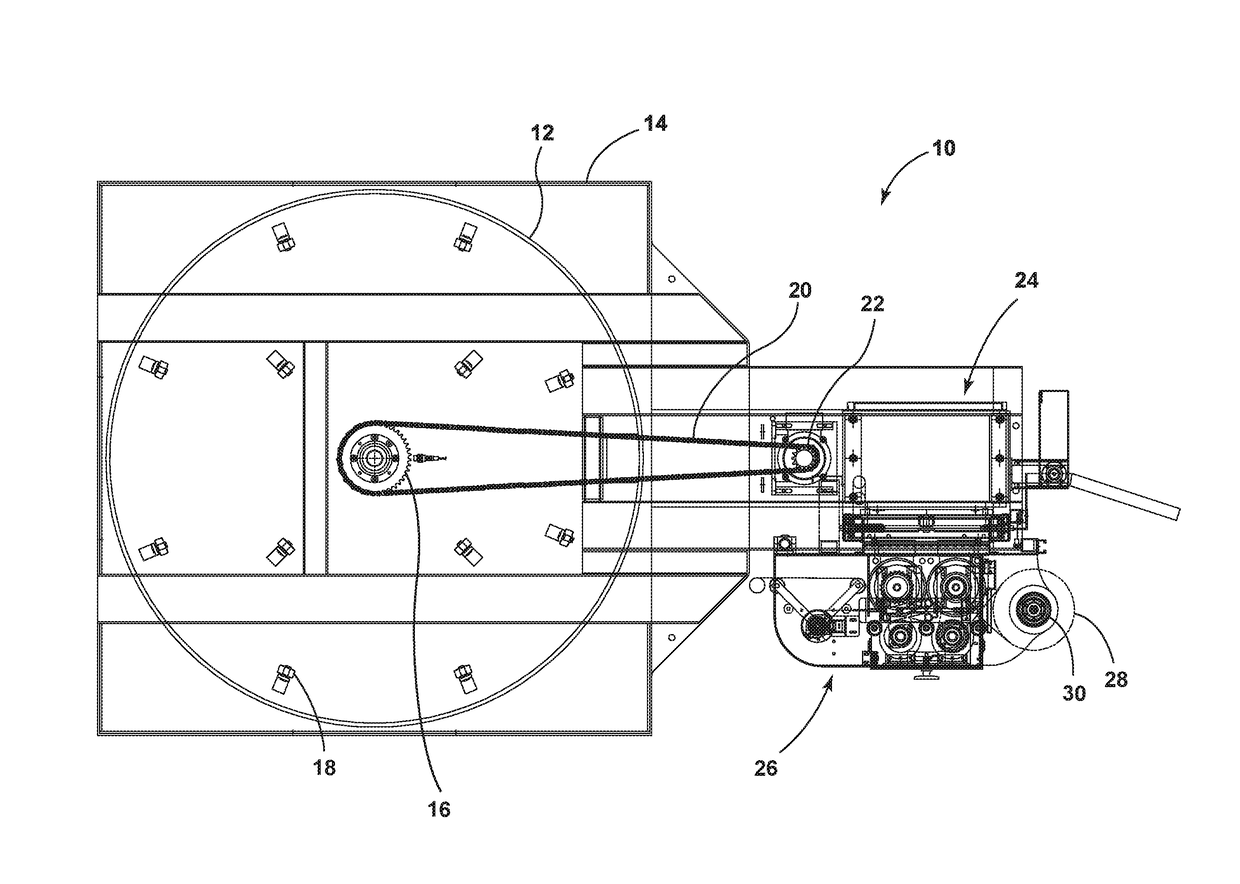

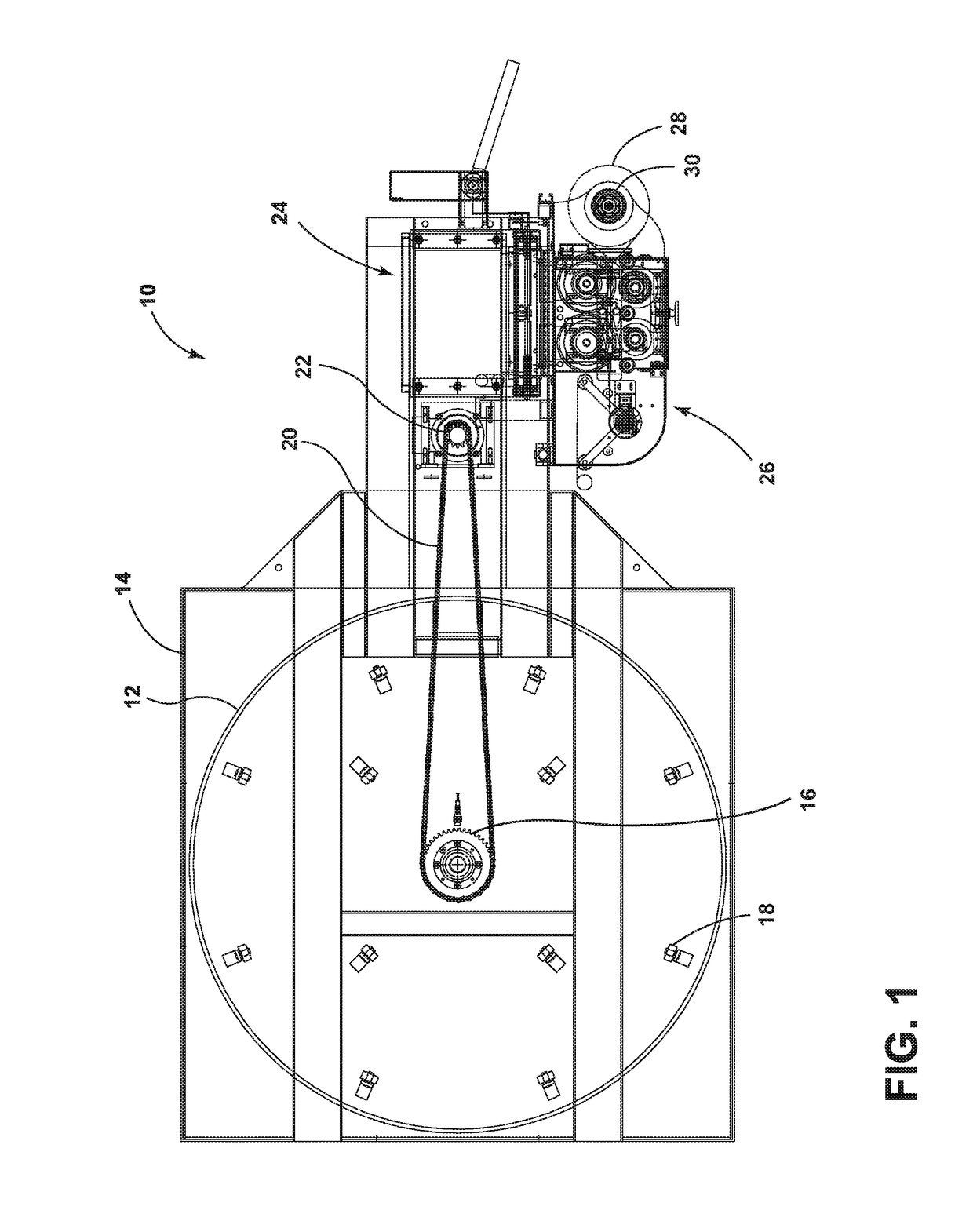

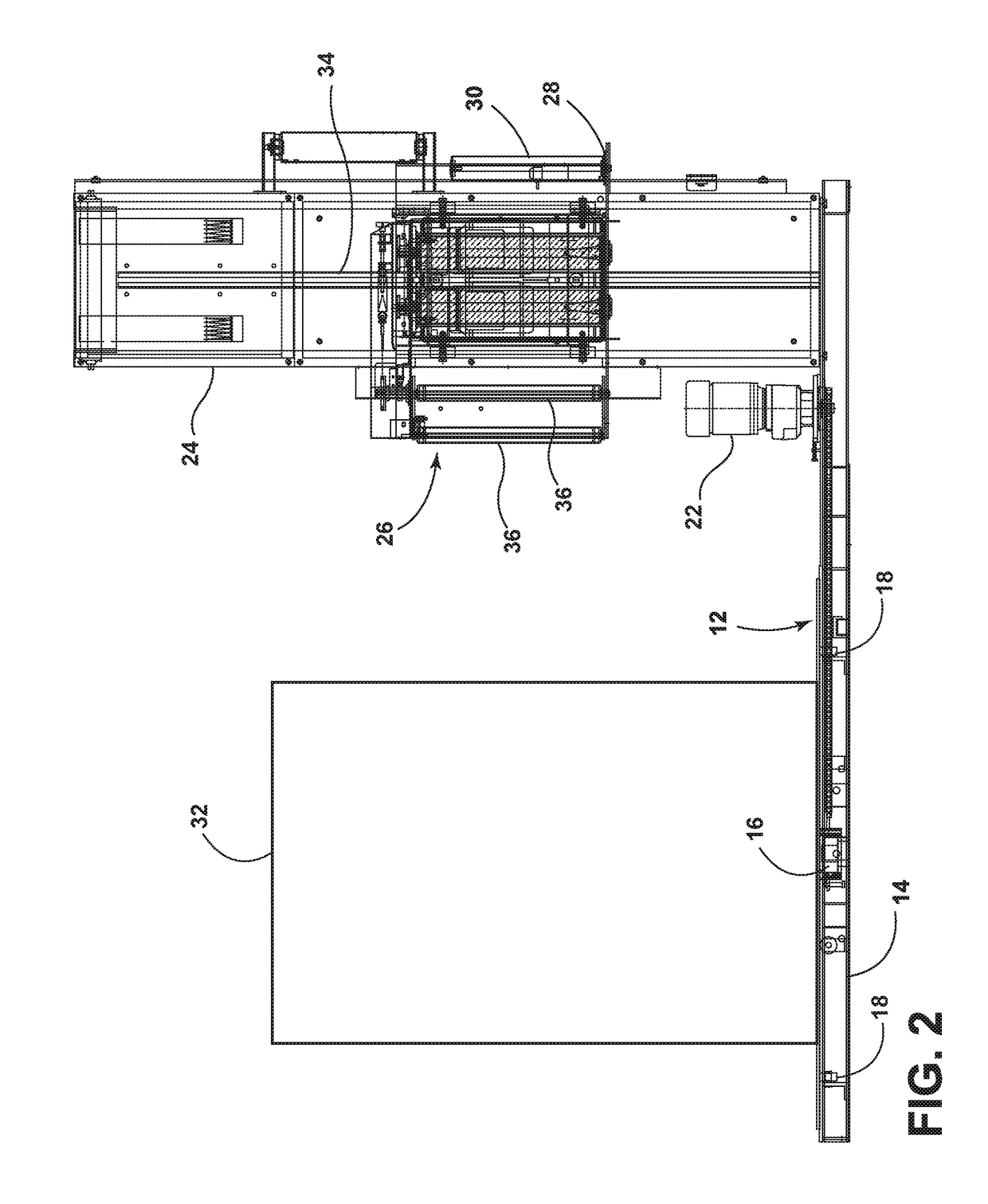

Method and apparatus for packaging panel products

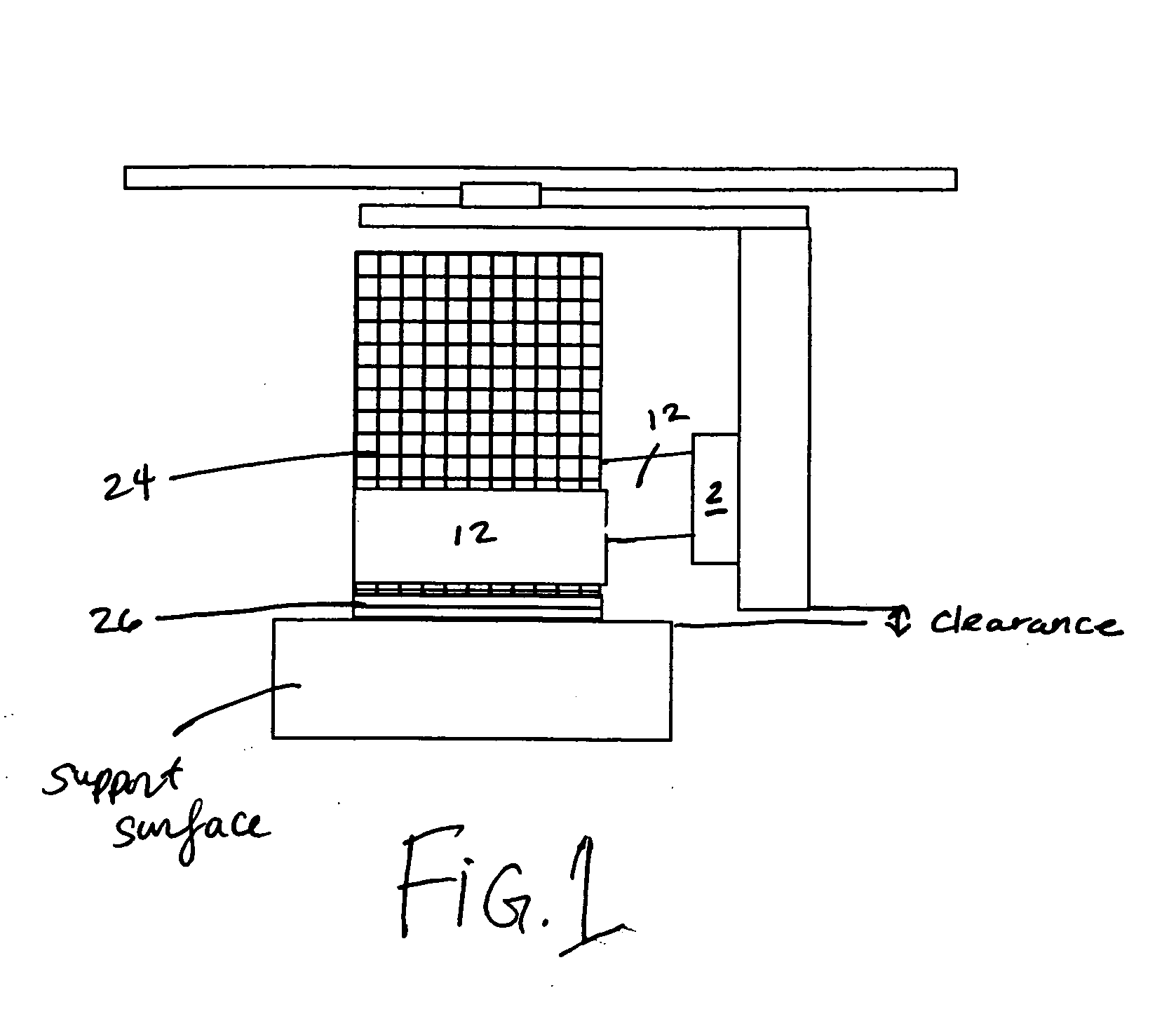

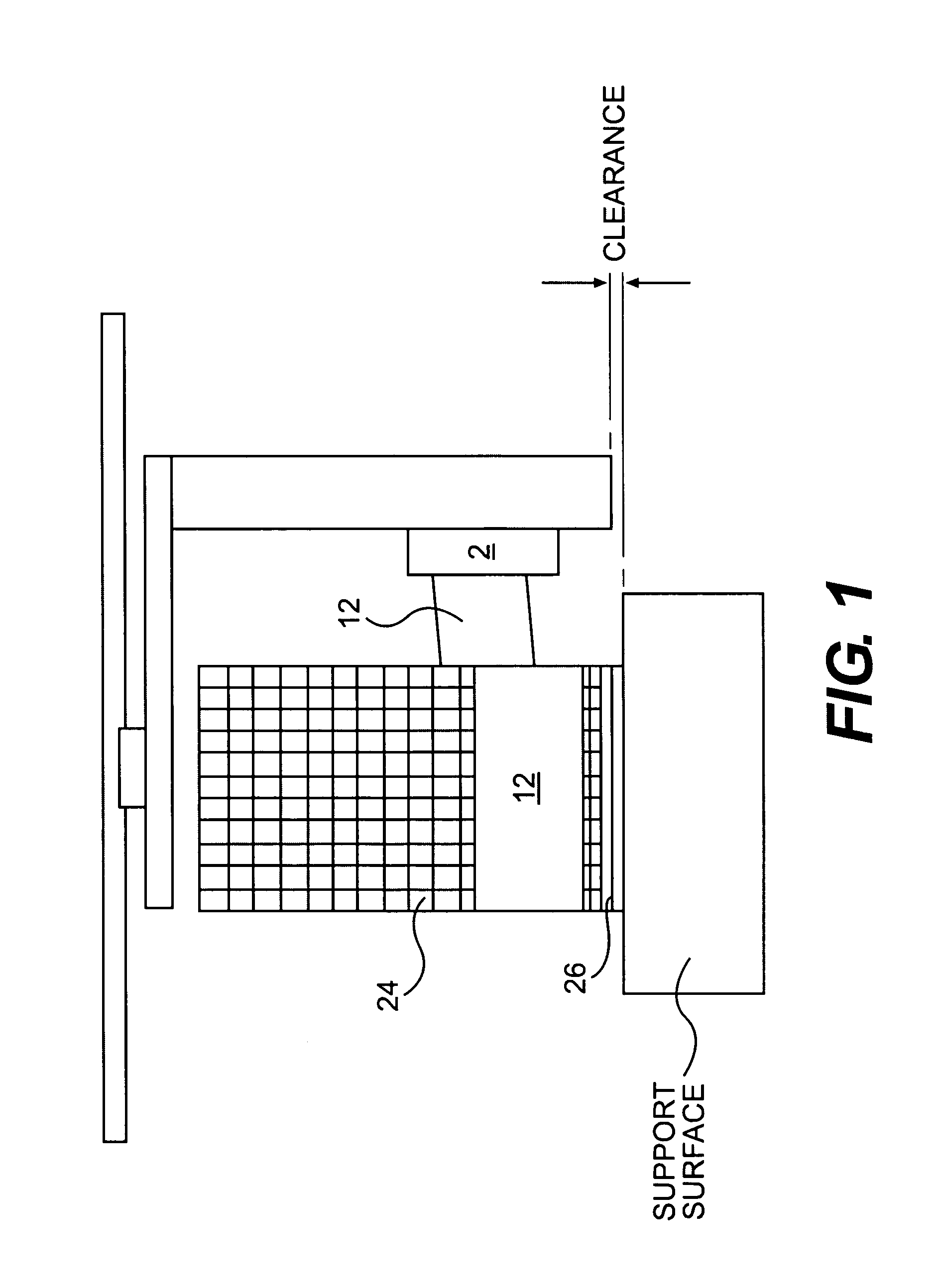

ActiveUS20050115202A1Easy to foldAdjustable sizeWrapping material feeding apparatusMultiple wrapper applicationBiomedical engineeringData entry

A system for packaging a flat panel product includes a dispensing device for dispensing a length of inner protective packaging material, a folding table for wrapping the inner protective packaging material around the product and folding an outer protective packaging material around the product, and a binding device for binding the outer packaging material, inner packaging material, and product together, suspending the product relative to at least one of the walls of the sidewall and supporting the product laterally. A data entry device provides data related to the length of inner protective packaging material required, and this data is fed to a controller, which controls the dispensing device to provide an appropriate length of material. The data entry device can also provide shipping information, fed to a printer for printing a shipping label.

Owner:SIGNODE IND GRP

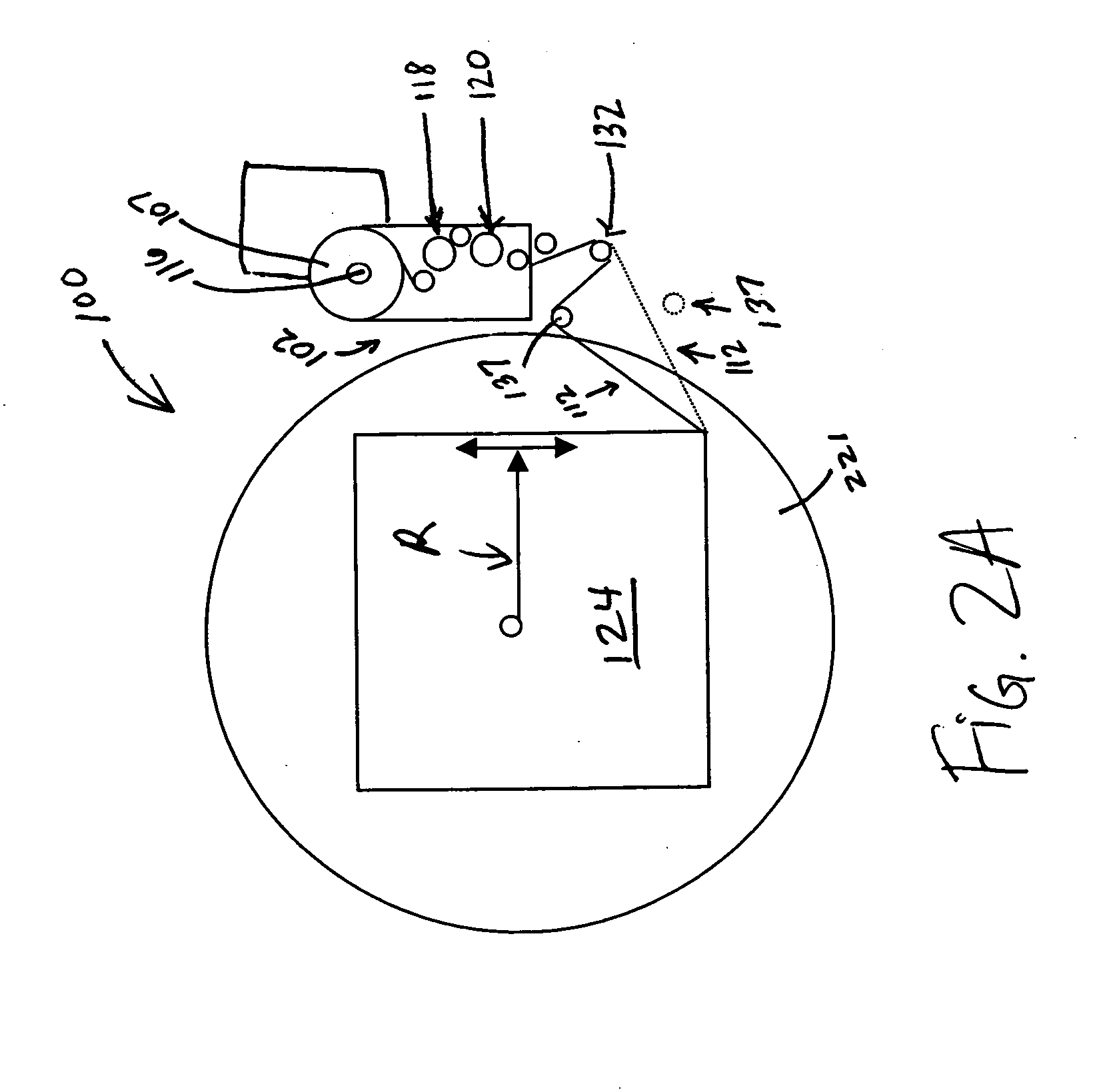

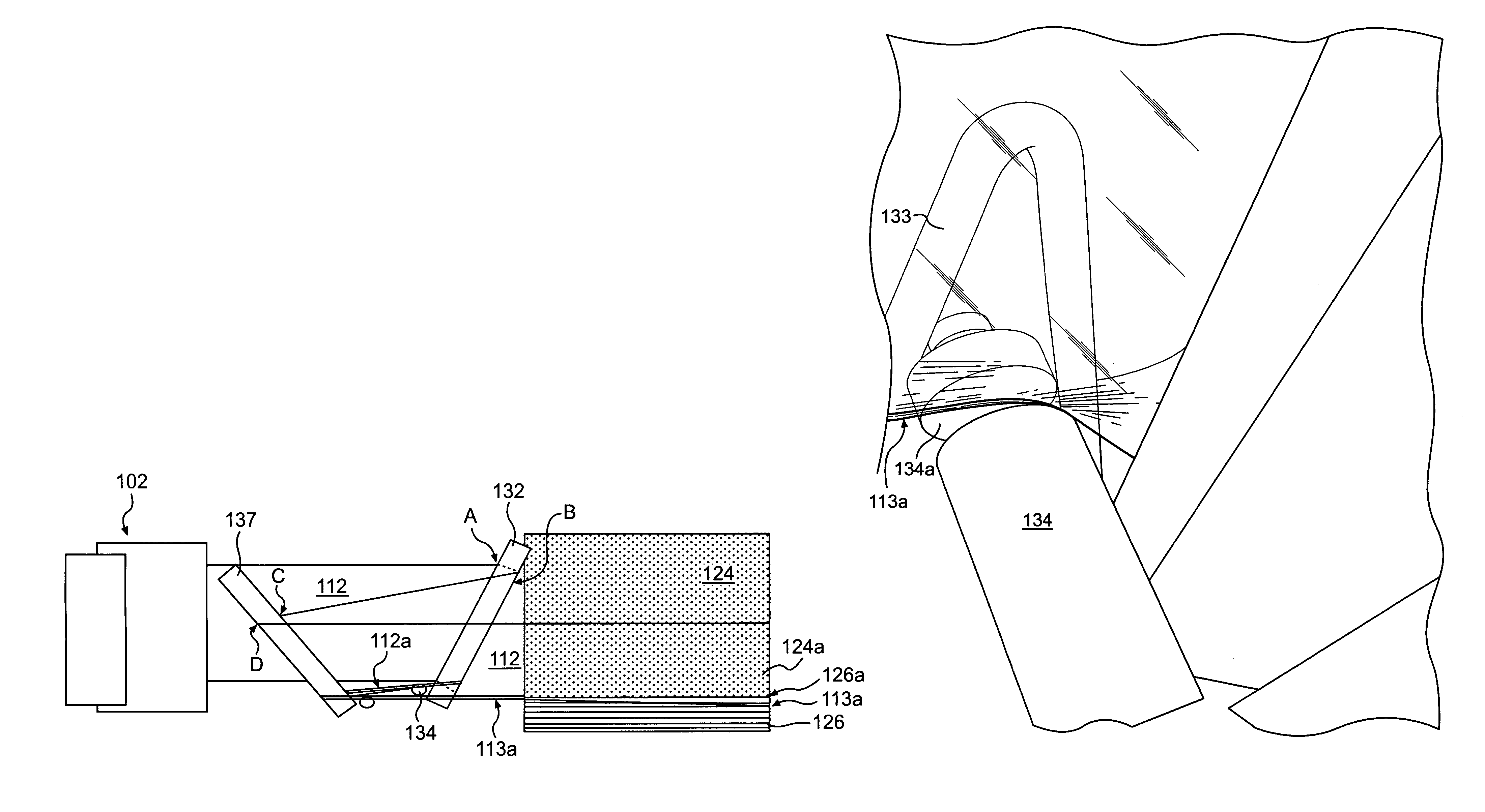

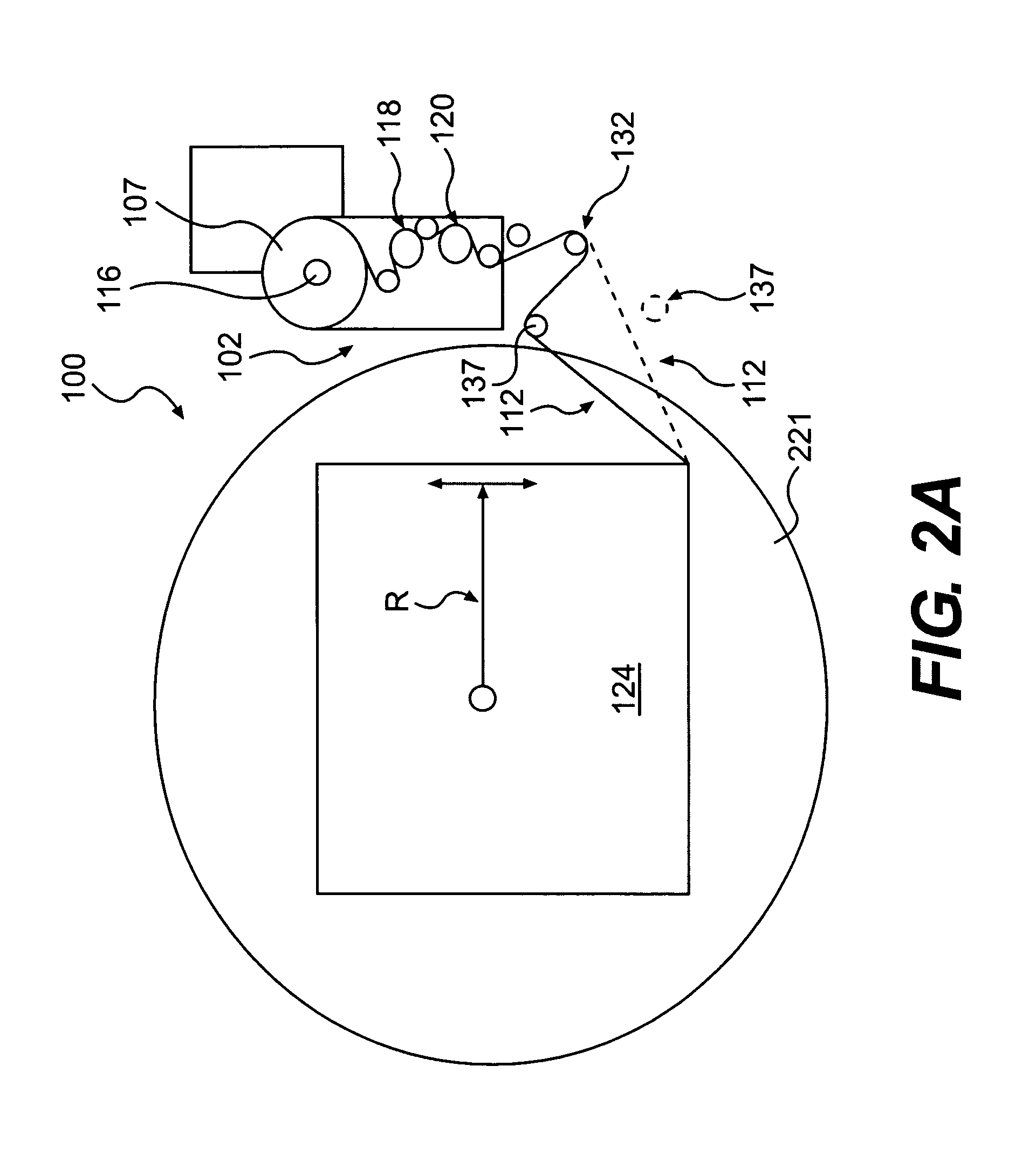

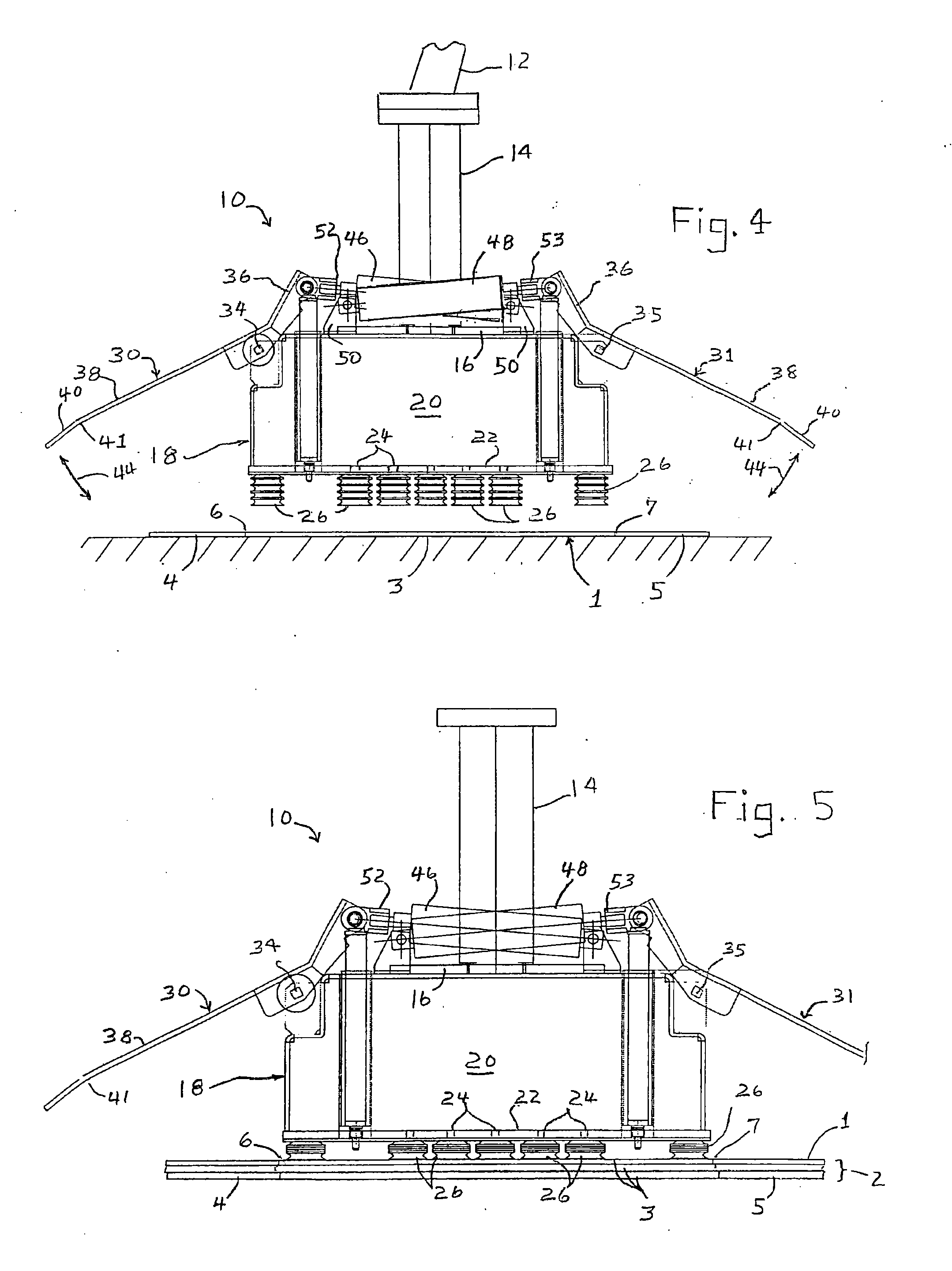

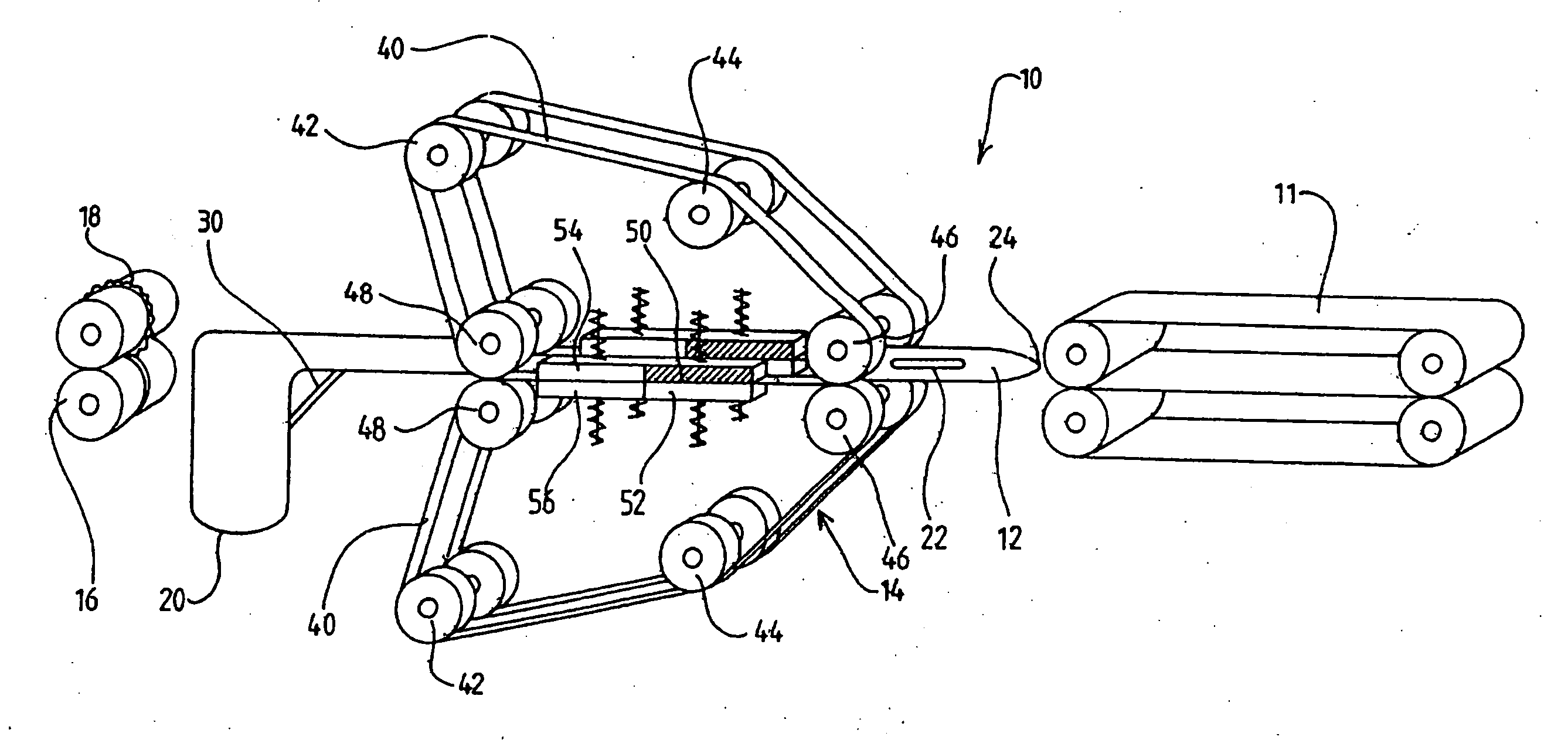

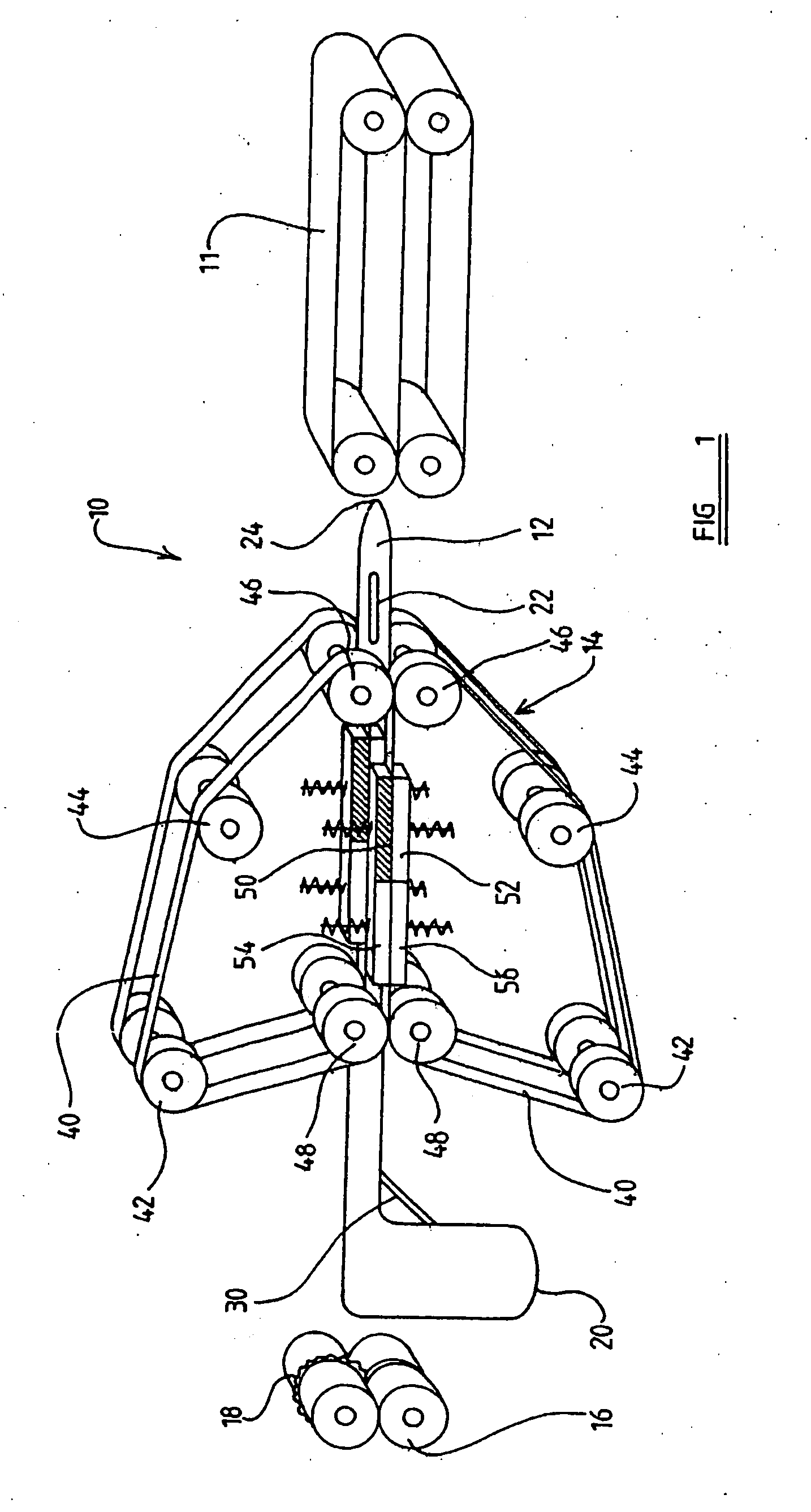

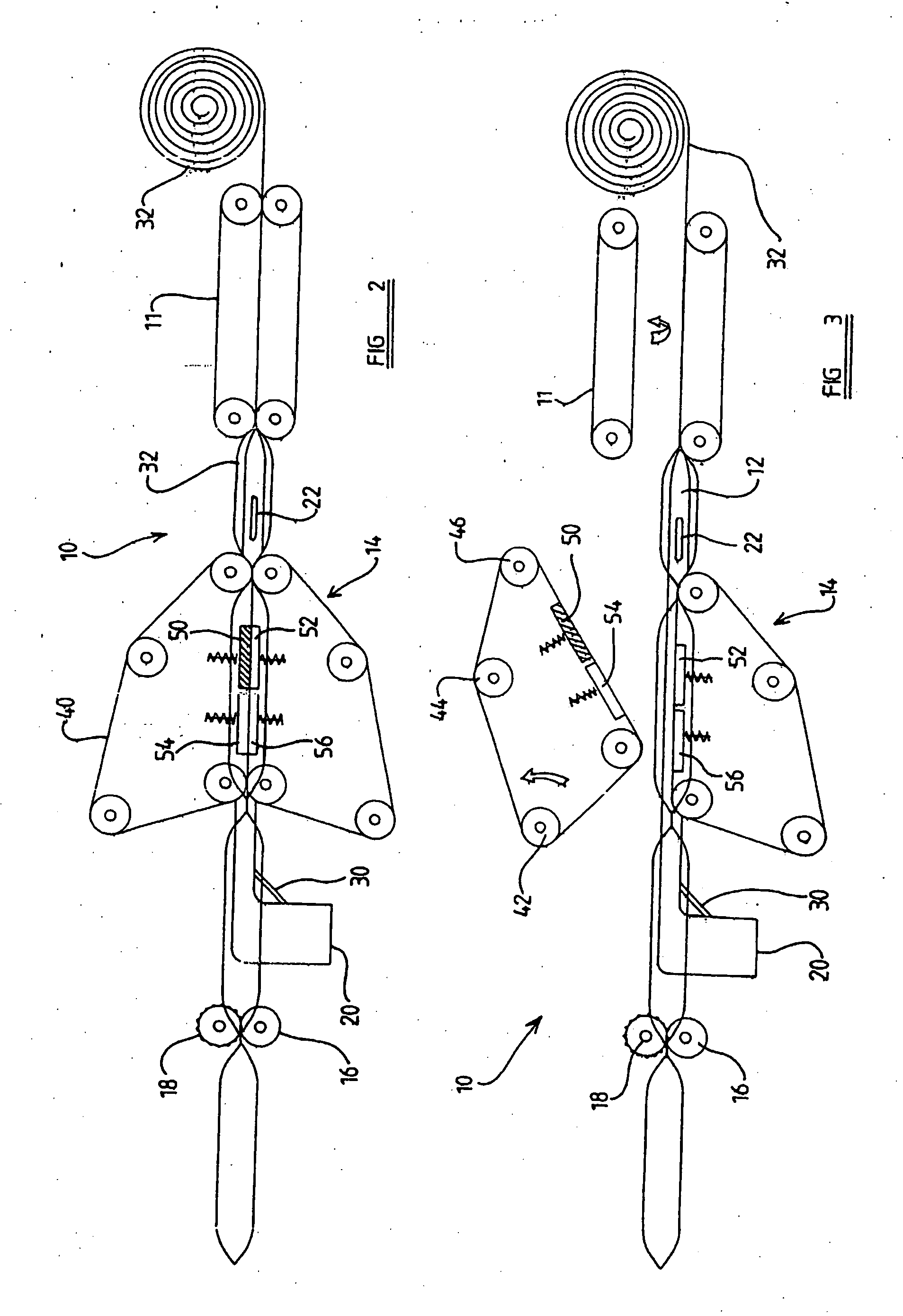

Method and apparatus for securing a load to a pallet with a roped film web

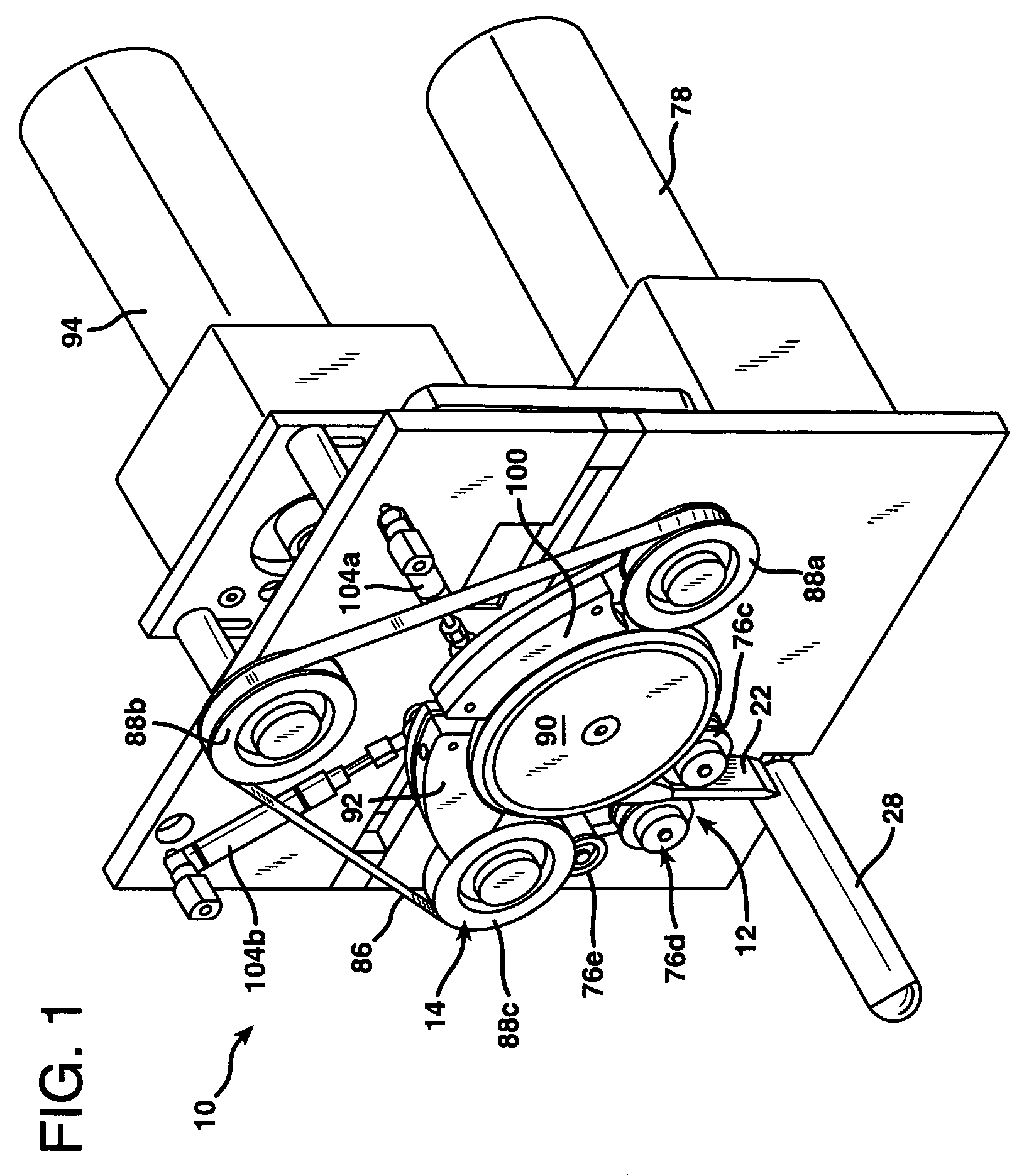

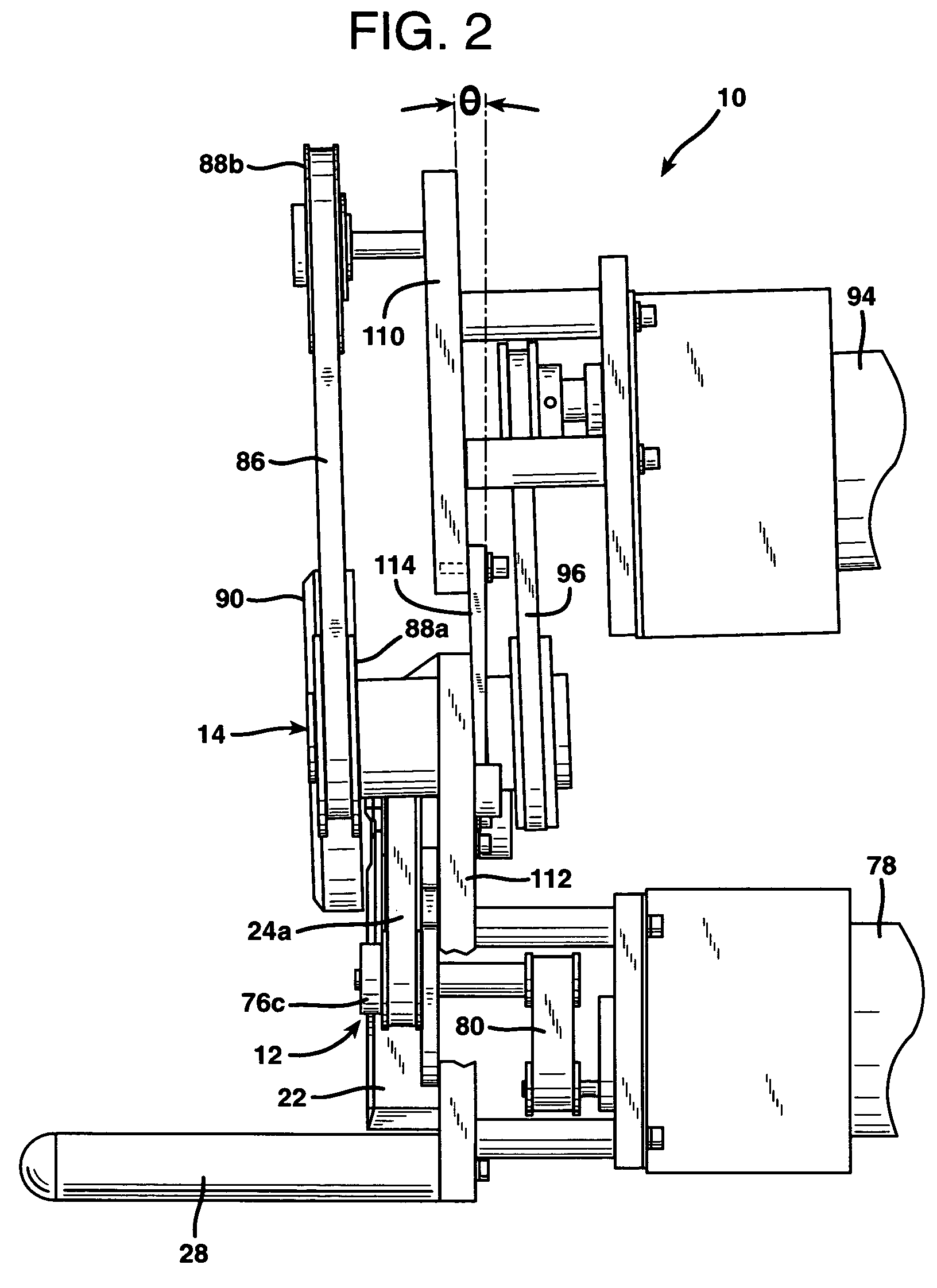

ActiveUS20050044812A1Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS7568327B2Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Process for making pouches

The present invention relates to a continuous, horizontal process for making water-reactive pouches, involving the steps of:a) continuously feeding a first water-soluble film onto a horizontal portion of an continuously and rotatably moving endless surface, which comprises a plurality of moulds, or onto a non-horizontal portion thereof and continuously moving the film to said horizontal portion;b) forming from the film on the horizontal portion of the continuously moving surface, and in the moulds on the surface, a continuously moving, horizontally positioned web of open pouches;c) filling the continuously moving, horizontally positioned web of open pouches with a product, to obtain a horizontally positioned web of open, filled pouches;d) closing the web of open pouches, to obtain closed pouches, preferably by feeding a closing material onto the horizontally positioned web of open, filed pouches, to obtain closed pouches; andpreferably sealing the closed pouches and whereby step d) and preferably step e) is also done in a continuous manner, preferably while the web of pouches is in horizontal position and continuously moving.The products introduced in the pouch are preferably cleaning compositions or fabric care compositions, in particular laundry or dish washing compositions.

Owner:THE PROCTER & GAMBLE COMPANY

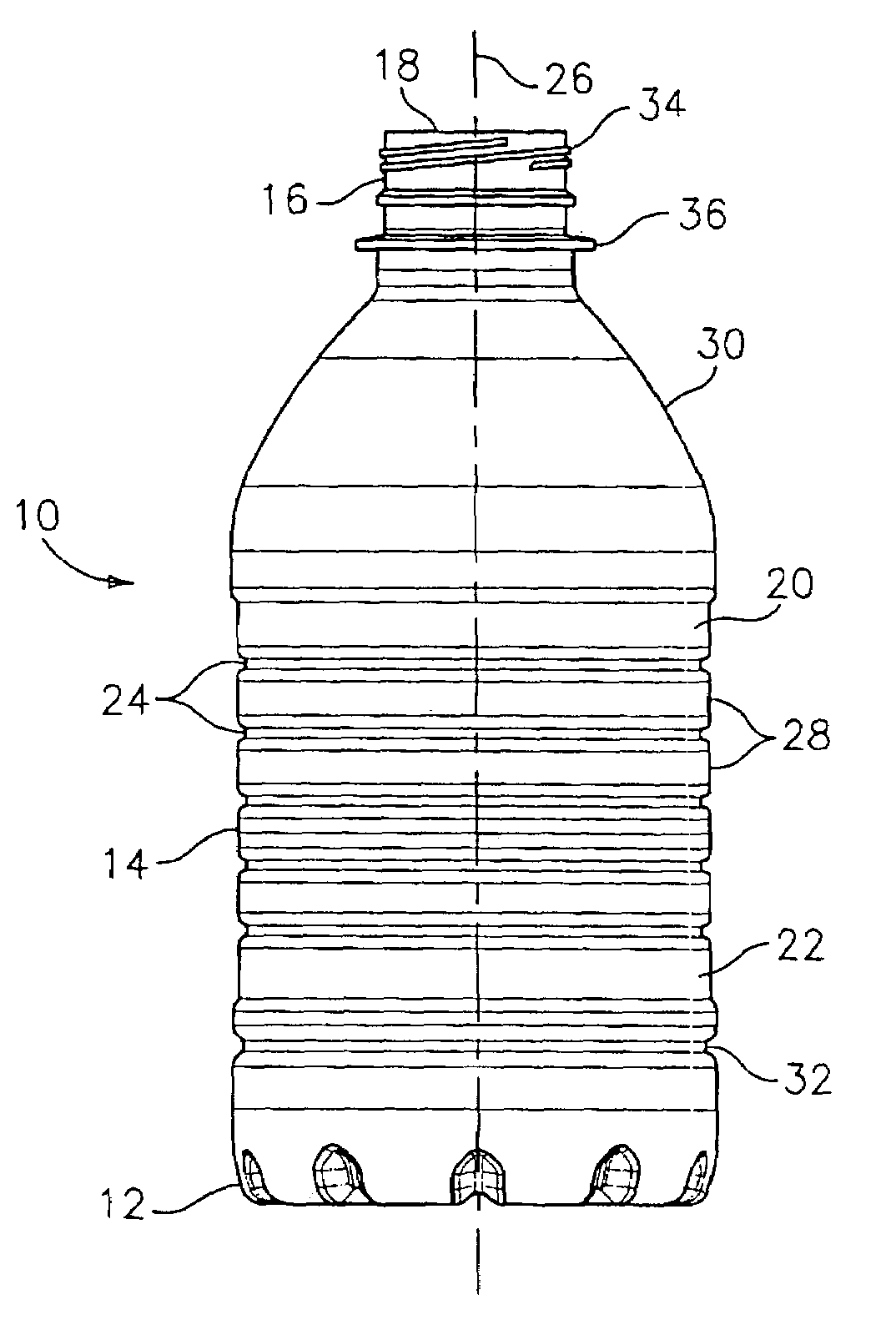

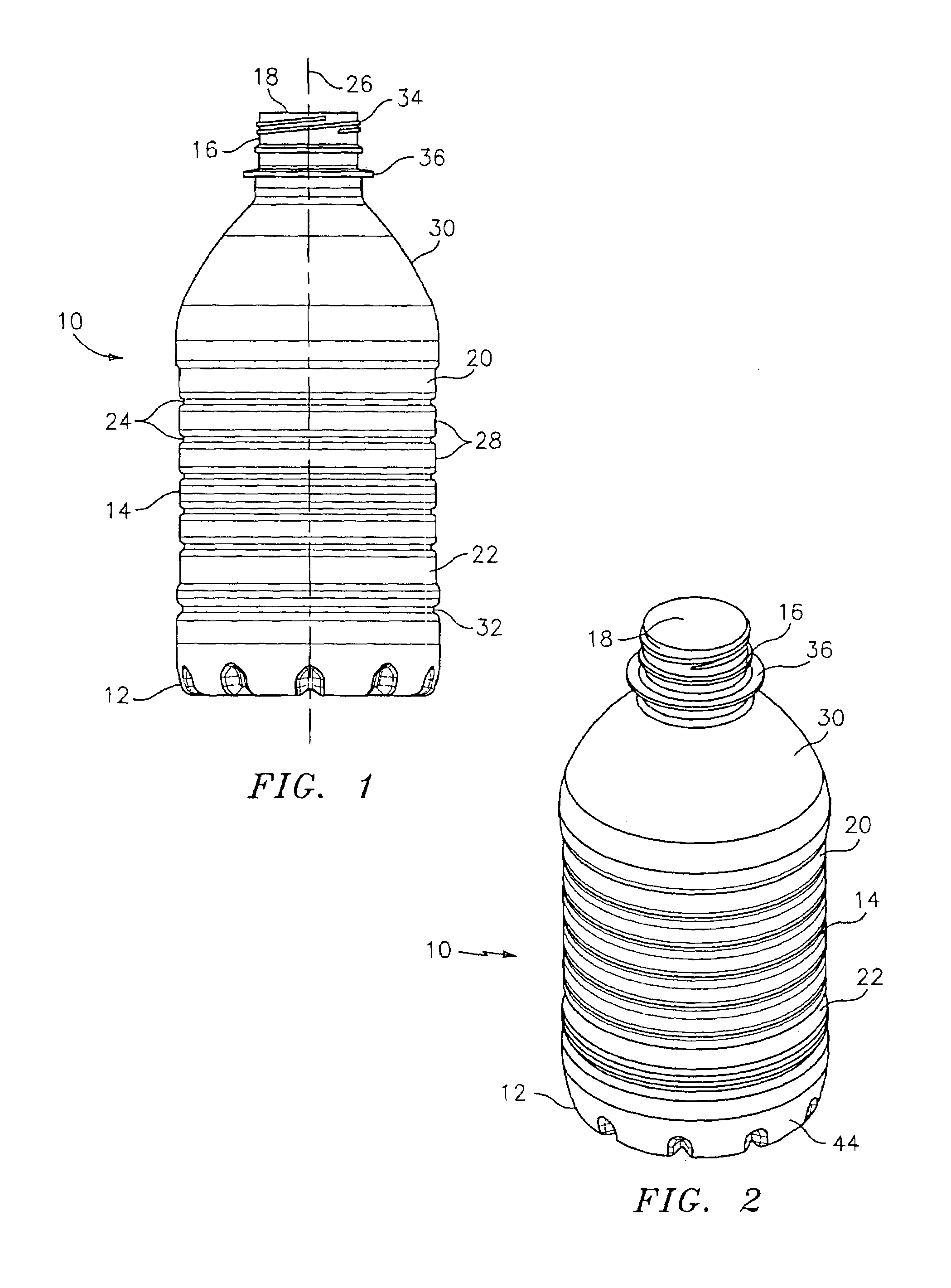

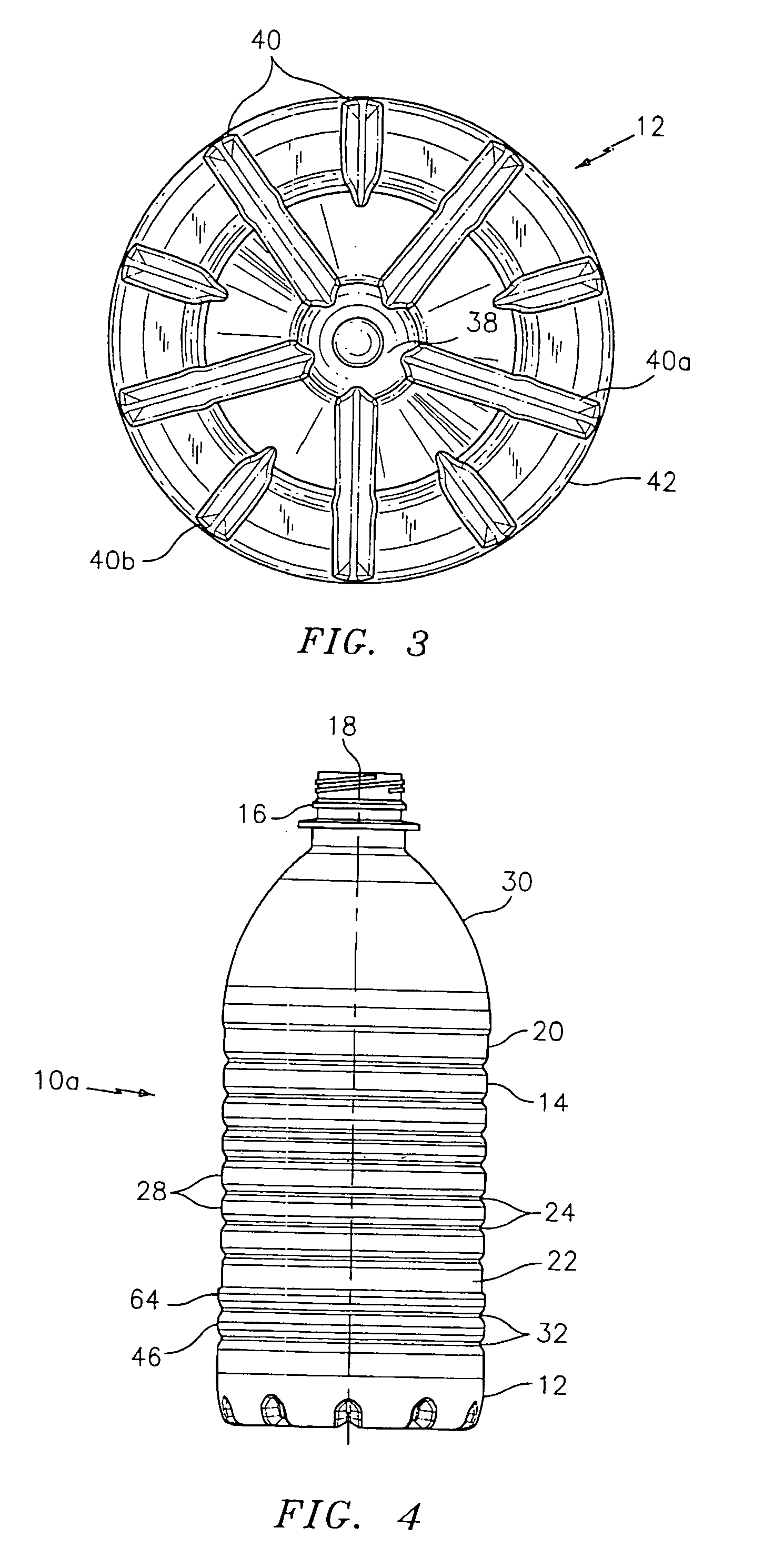

Plastic container with sidewall construction

Owner:PLASTIPAK PACKAGING

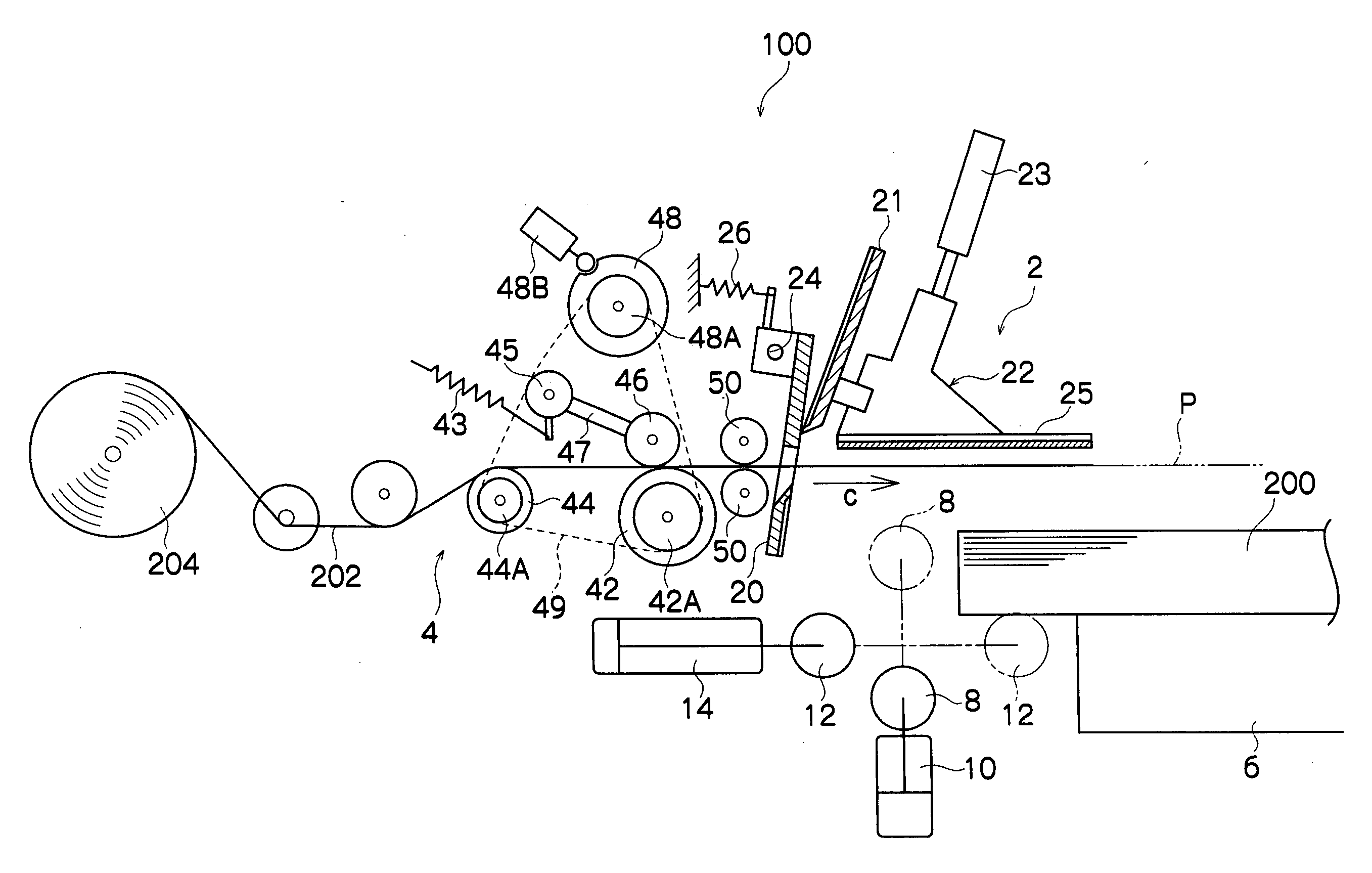

Converting machine

ActiveUS20160185475A1Mechanical working/deformationWrapping material feeding apparatusMachining systemSheet material

Systems, methods, and apparatus for converting a sheet material into packaging templates can include a converting machine that performs conversion functions, such as cutting, creasing, and scoring, on the sheet material. Items to be packed into boxes formed of the packaging templates can be used as the pattern for determining the location of performance of the conversion functions on the sheet material. Accordingly, no intermediate measuring of the items may be required prior to performance of the conversion functions. Instead, longheads can be positioned adjacent to opposing sides of the items and cross heads can be advanced inward to the positioned longheads.

Owner:PACKSIZE

Guillotine cutter and tape affixing apparatus

InactiveUS20060137827A1Lamination ancillary operationsWrapping material feeding apparatusEngineeringKnife blades

The guillotine cutter of the present invention has a fixed blade and a movable blade that moves back and forth along a straight line while contacting against the fixed blade, and the movable blade and the fixed blade cooperate to cut a tape-shaped object for cutting in a widthwise direction. In addition, a surface of the fixed blade at a side that contacts the movable blade and a surface of the movable blade at a side that contacts the fixed blade are provided with a recess portion which is a concave portion that is wider than the object for cutting.

Owner:FUJIFILM CORP +1

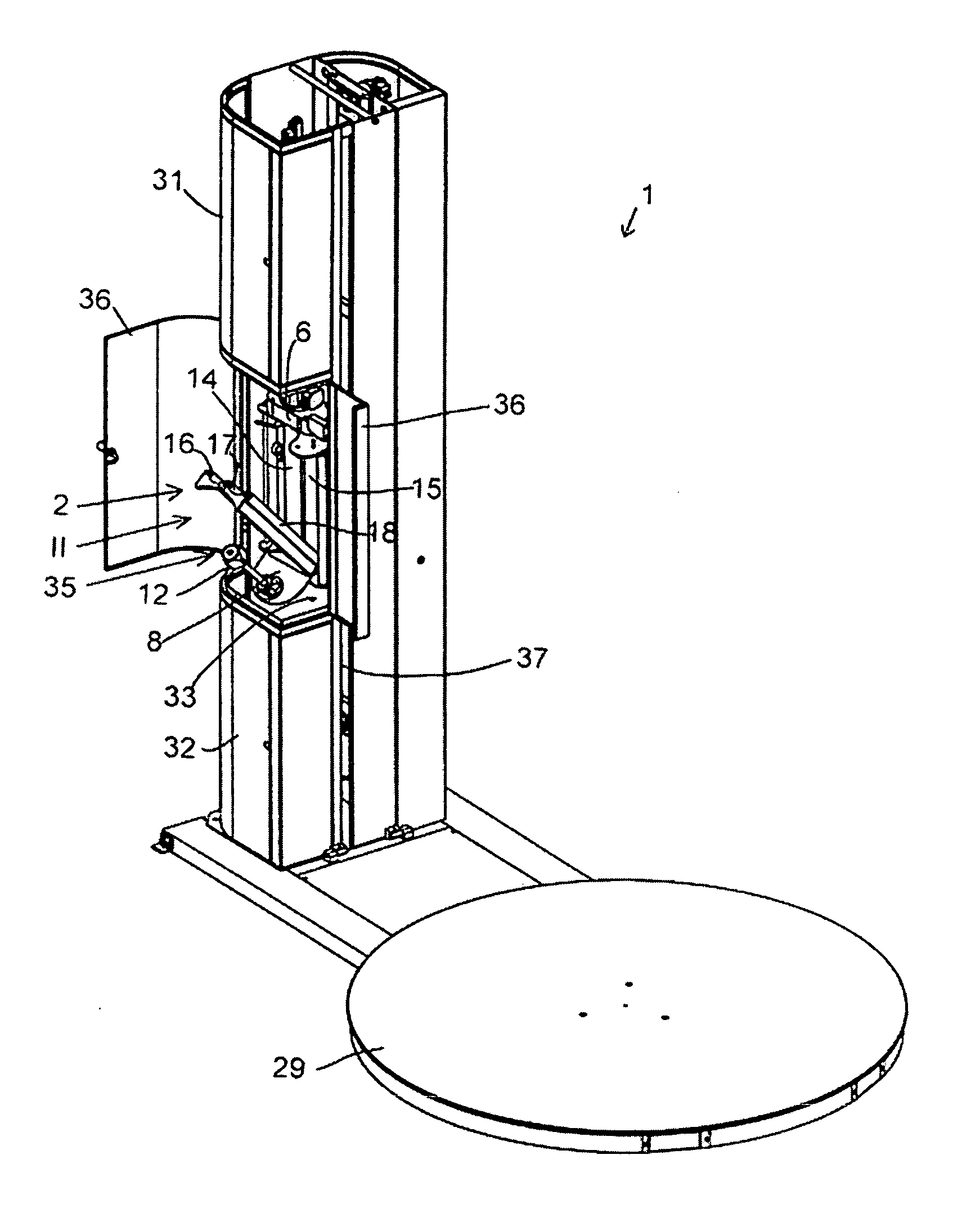

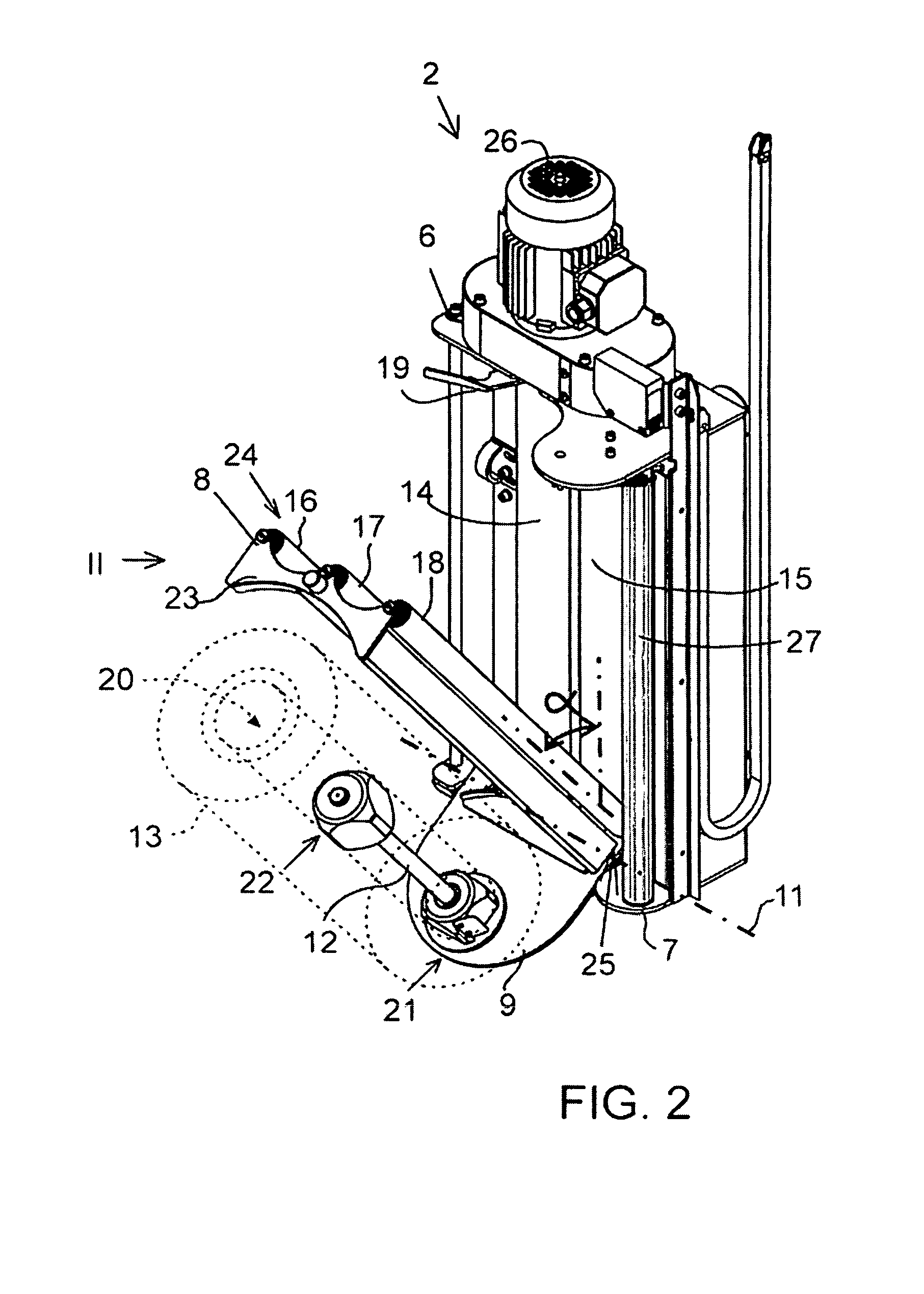

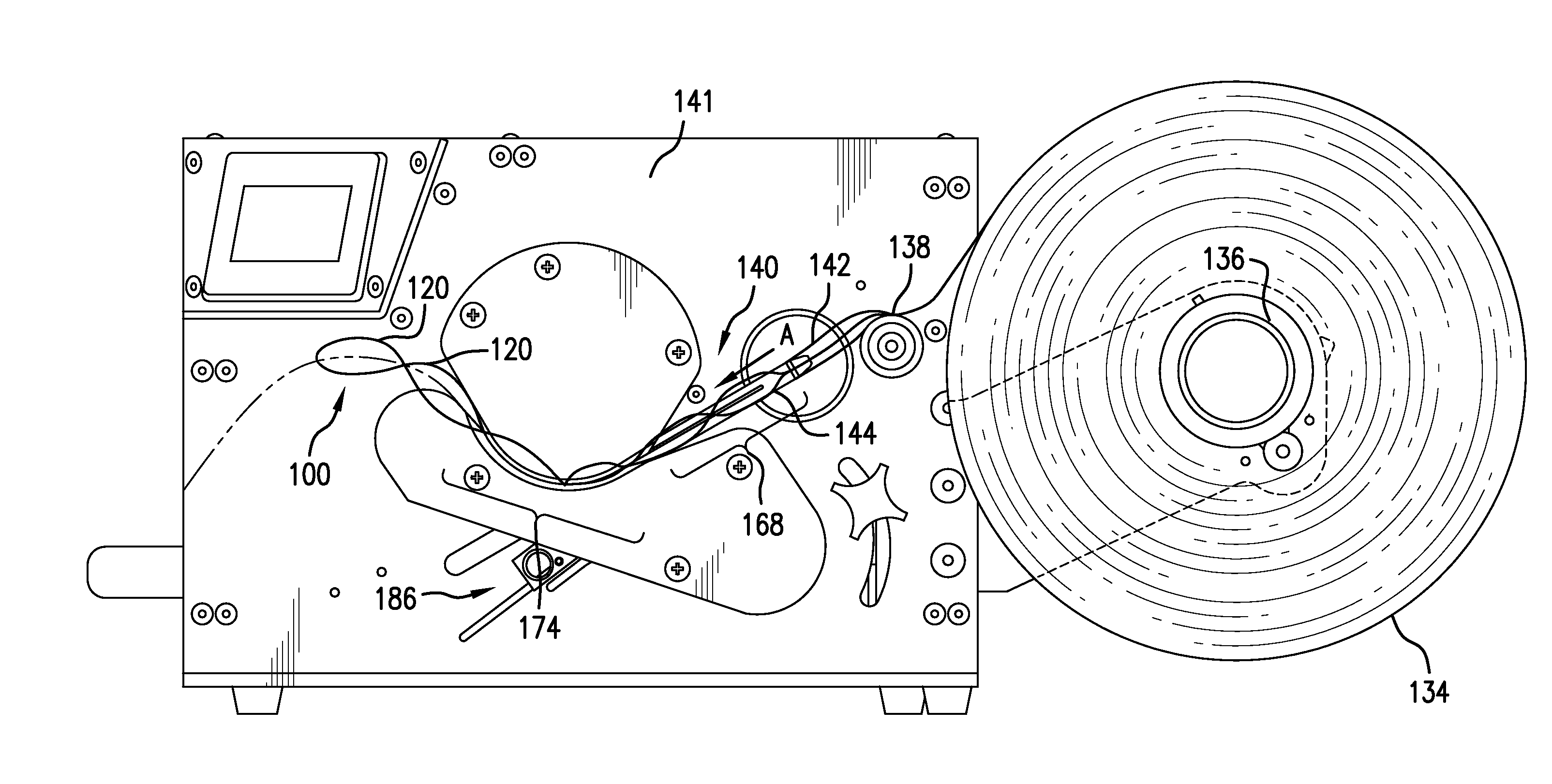

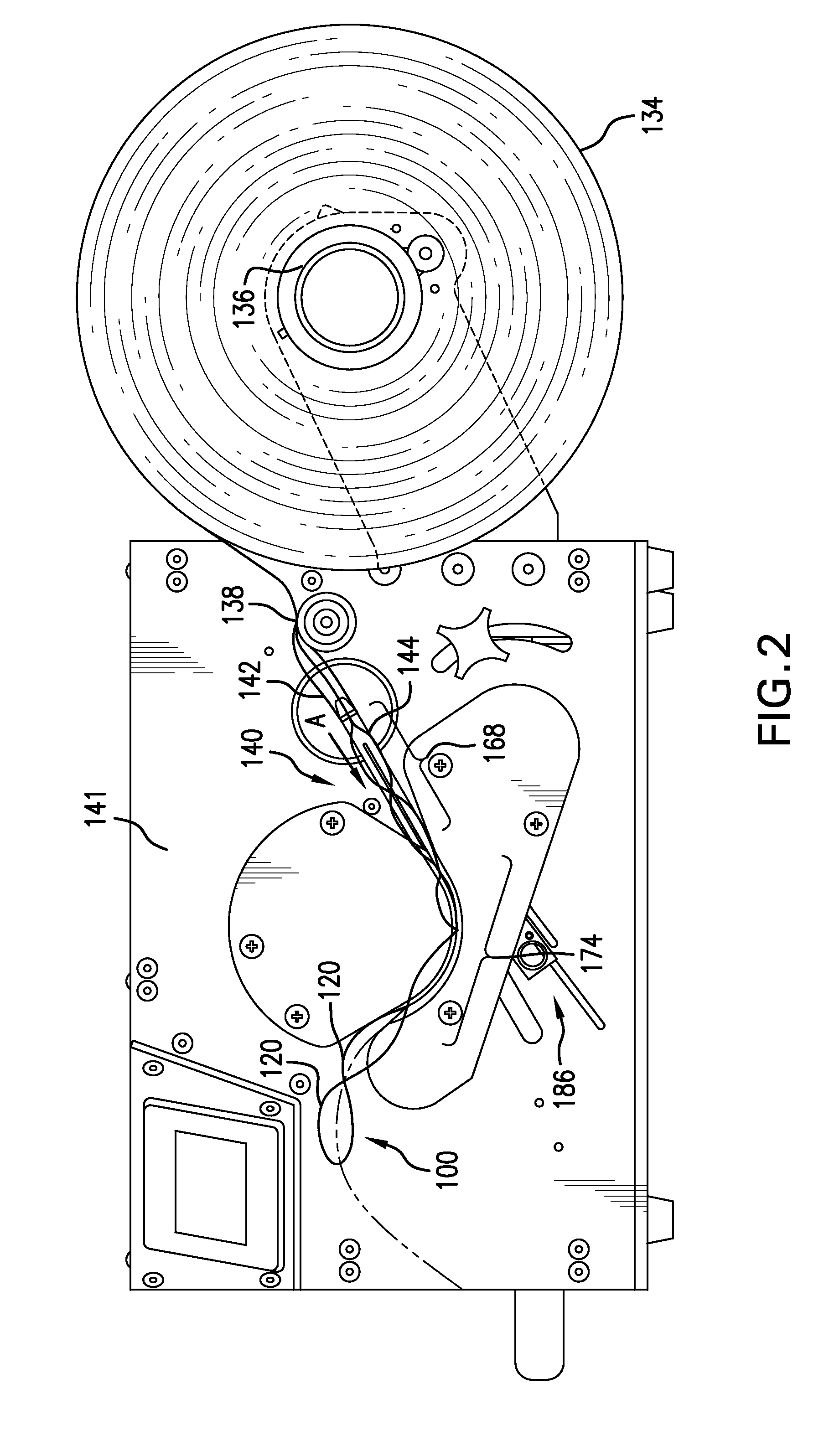

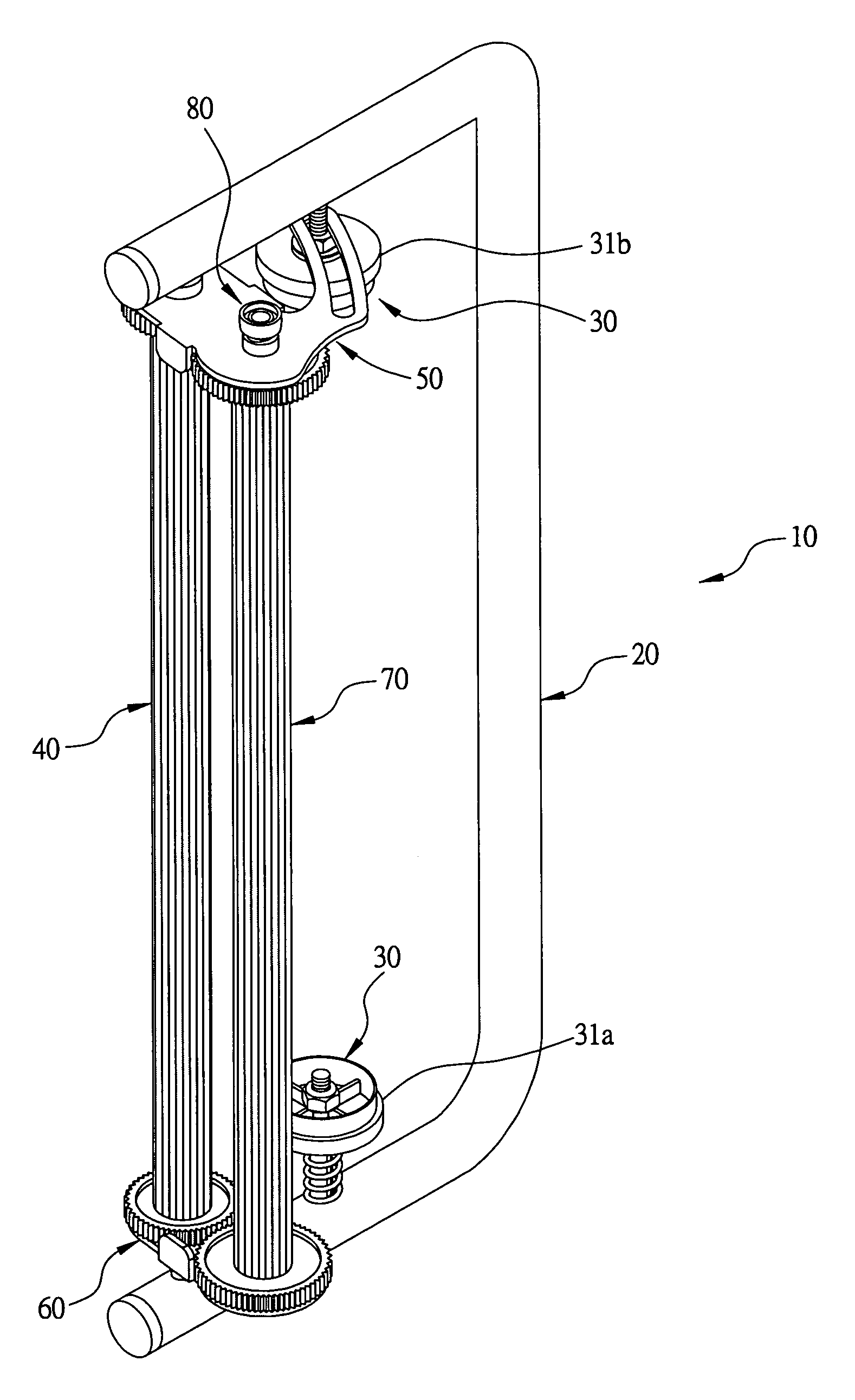

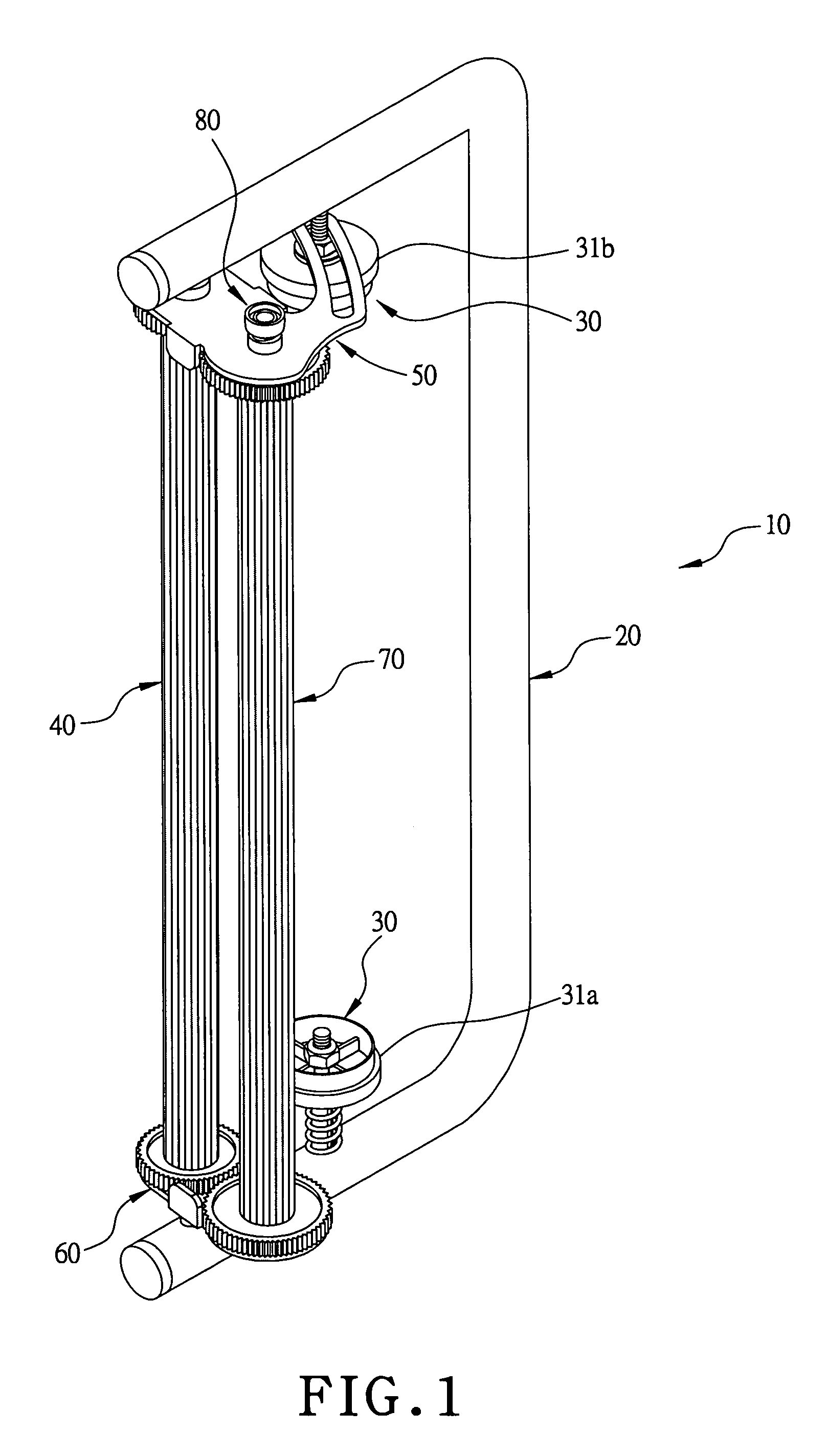

Wrapping apparatus comprising a dispenser for dispensing stretched wrap film

ActiveUS7178317B1Facilitate communicationPromote exchangeWrapping material feeding apparatusFilament handlingEngineeringMechanical engineering

Wrapping apparatus comprises a dispenser, for dispensing stretched wrap film, which includes a first frame assembly, and a second frame assembly pivotally mounted upon the first frame assembly between a first closed position and second open position. A film roll spindle is mounted upon the second frame assembly along with a plurality of guide rollers, while upstream and downstream prestretch rollers are mounted upon the first frame assembly. When the second frame assembly is disposed at the second open position, the film roll spindle and guide rollers project outwardly in a tilted orientation such that the exchange of film rolls, and the threading of the film between the guide rollers and the prestretch rollers, is facilitated.

Owner:M HALOILA

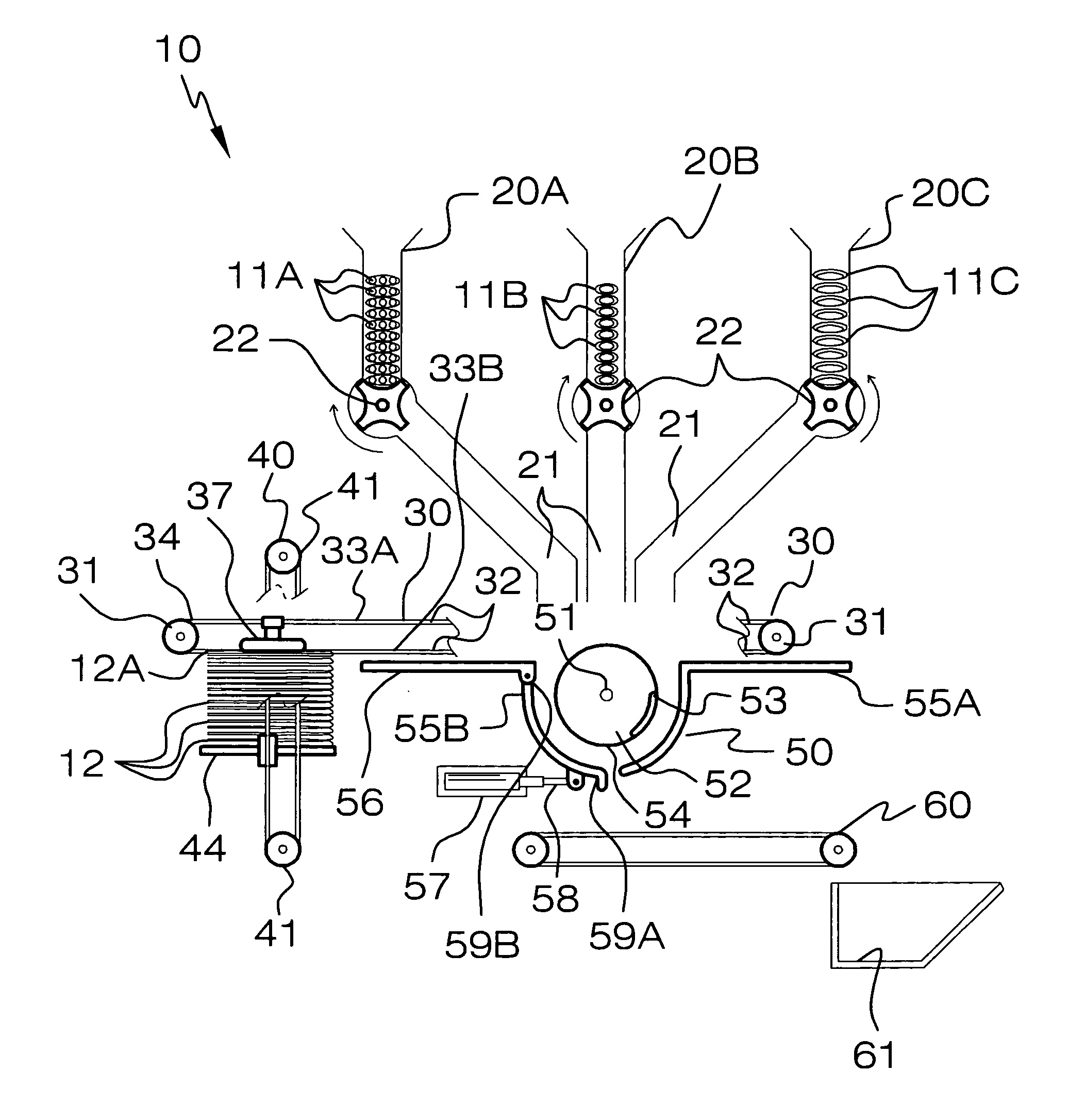

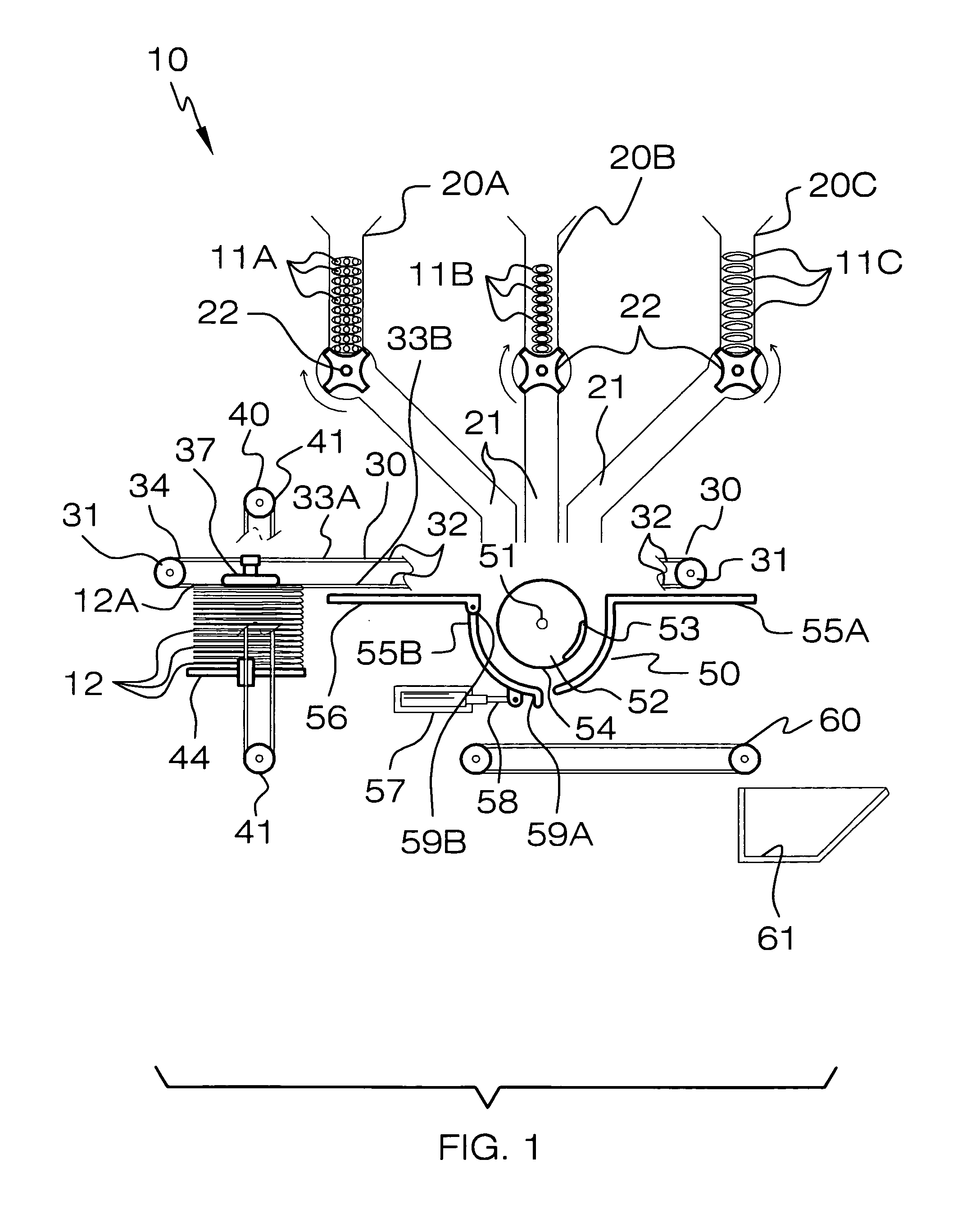

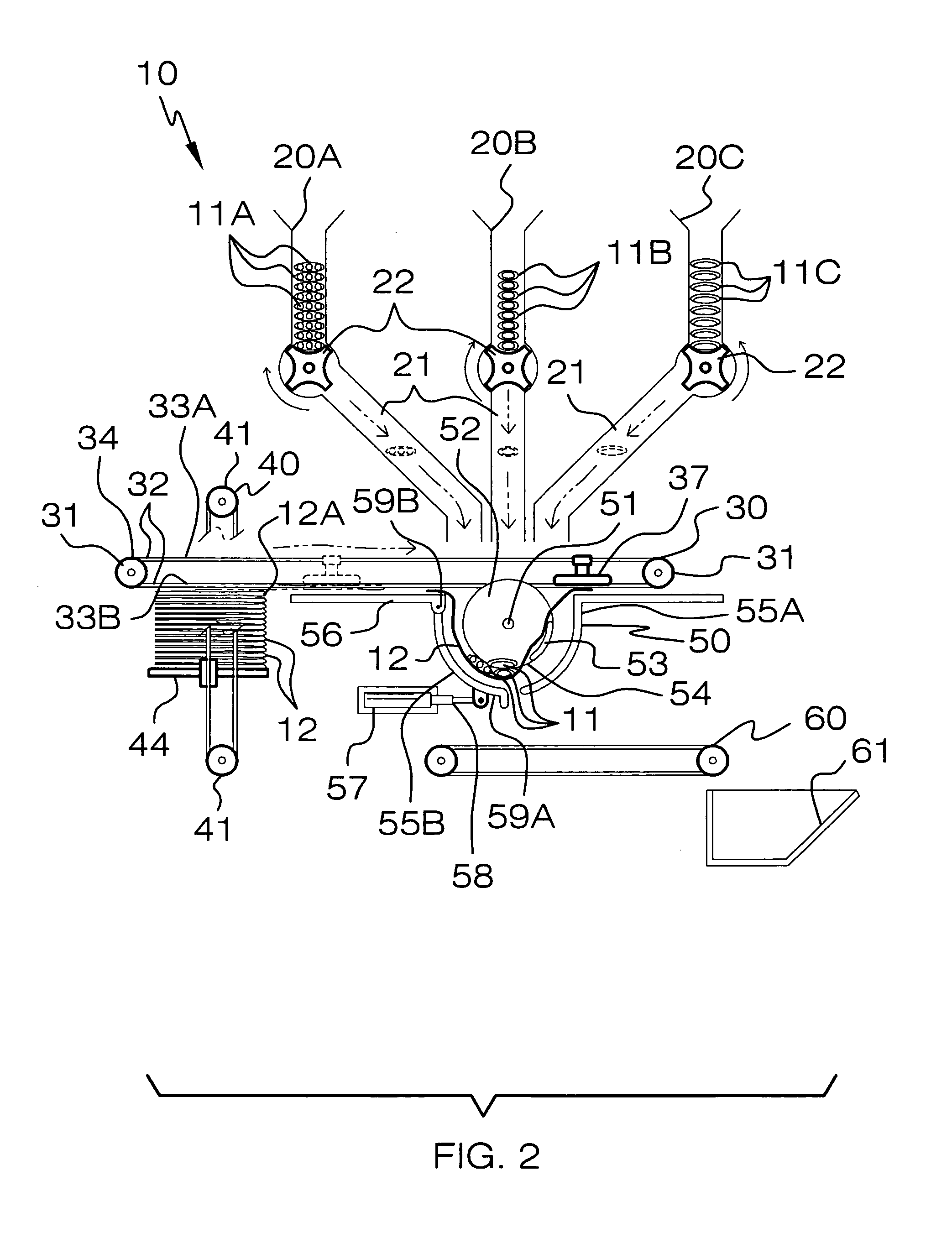

Device for wrapping a napkin about silverware and associated method

InactiveUS7210279B1Efficient extractionEfficient transferWrapping material feeding apparatusWrapper folding/bending apparatusEating UtensilsEngineering

A device includes isolated hoppers defining independent passageways converging downwardly towards a central and unitary area. A conveyor belt assembly is disposed subjacent to the hoppers, traverses the passageways, and travels along a linear path passing through the unitary area. A mechanism is included for depositing a napkin onto the conveyor belt. The napkin depositing mechanism is connected to the conveyor belt assembly and is spaced adjacent to one end portion thereof. A mechanism is included for simultaneously folding the napkin and horizontally stacking the eating utensils such that the napkin becomes folded about the eating utensils before being ejected from the simultaneous folding mechanism. A receiving conveyor belt assembly is disposed beneath the simultaneous folding mechanism for transporting the combined napkin and eating utensils. A storage bin is laid adjacent to the receiving conveyor belt and houses the combined napkin and eating utensils for transit.

Owner:AHMED IBRAHIM A +1

Replaceable blade

ActiveUS20140261752A1Wrapping material feeding apparatusPaper/cardboard articlesEngineeringBiomedical engineering

A flexible structure inflation device, comprising an inflation assembly configured for insertion between first and second overlapping film layers of a web of material, the inflation assembly having a fluid conduit configured directing a fluid in between the layers to inflate the web; and a cutting member held magnetically in an operative position adjacent the inflation assembly to cut the film passing over the inflation assembly.

Owner:PREGIS INNOVATIVE PACKAGING

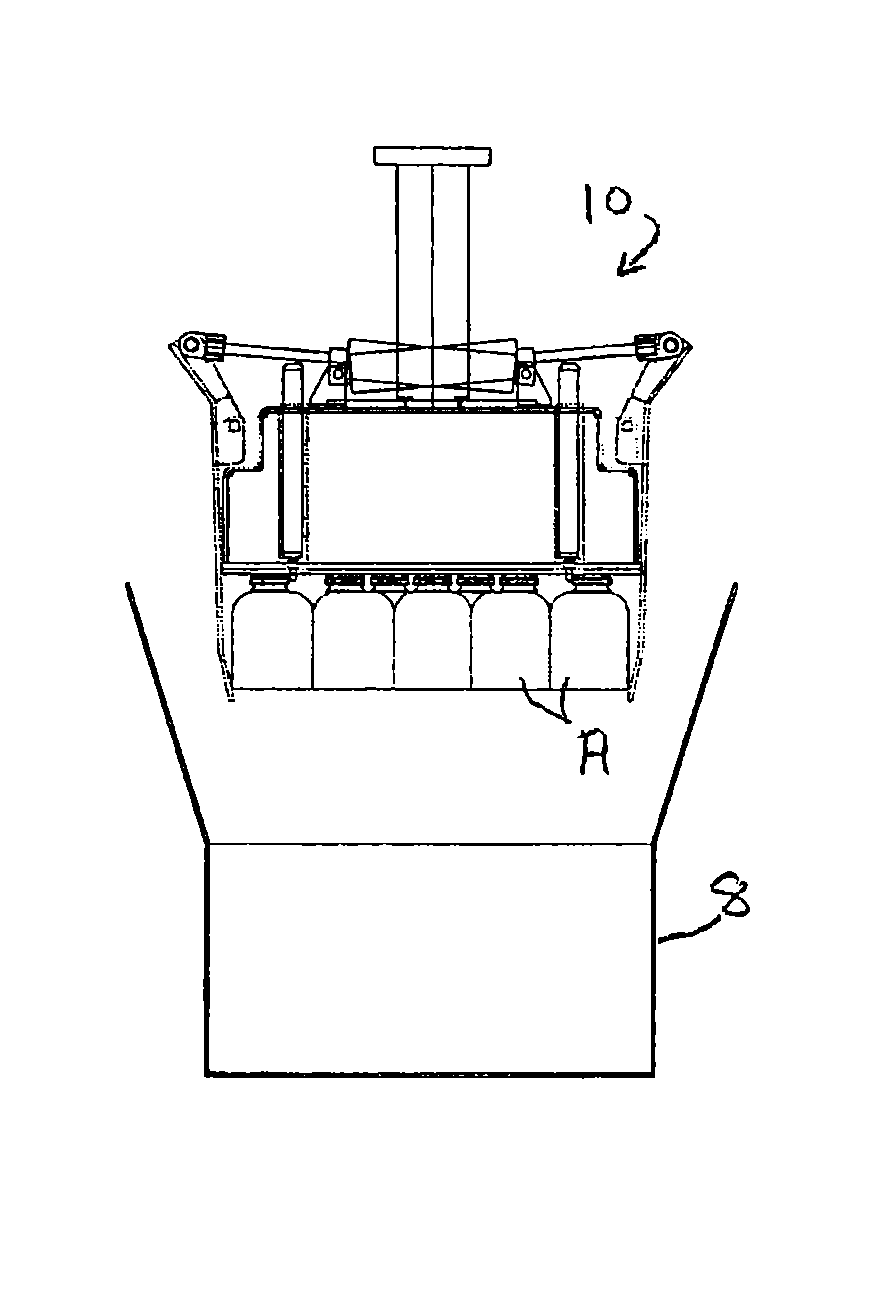

Method of Forming U-Shaped Insert and Inserting About Goods in Container

ActiveUS20130232918A1Wrapping material feeding apparatusGripping headsEngineeringMechanical engineering

End of arm tool (10) is used to load goods A and B in two layers in a packing container (8), with a packing insert positioned between the layers. The tool (10) also grasps a packing insert in the form of a flat sheet, bends the ends of the packing sheet downwardly to form an inverted U shape, and then inserts the packing insert in a straddling relationship about the lower layer of goods A, to protect the lower layer of goods from the weight applied by the upper layer of goods B.

Owner:AMF AUTOMATION TECH

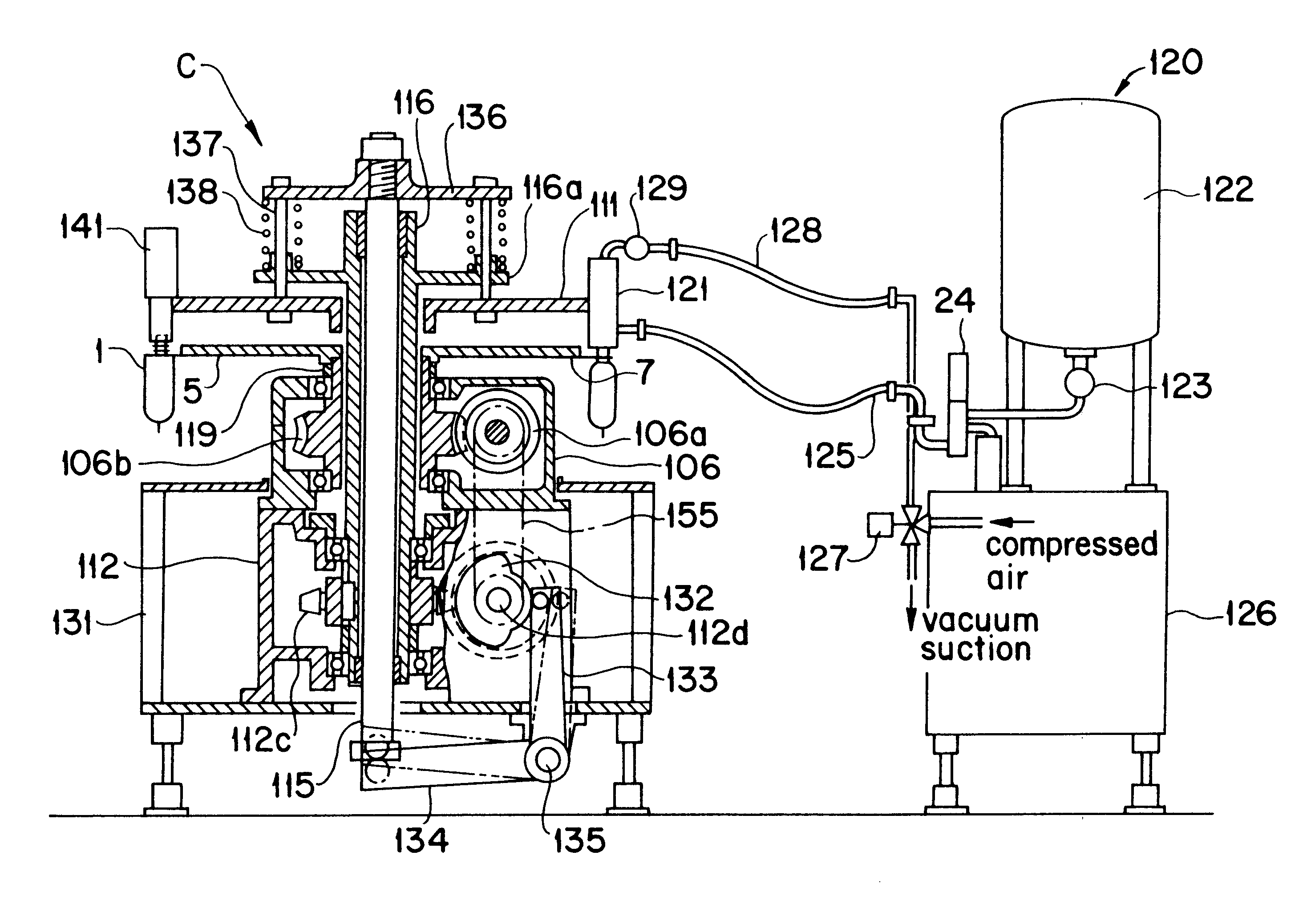

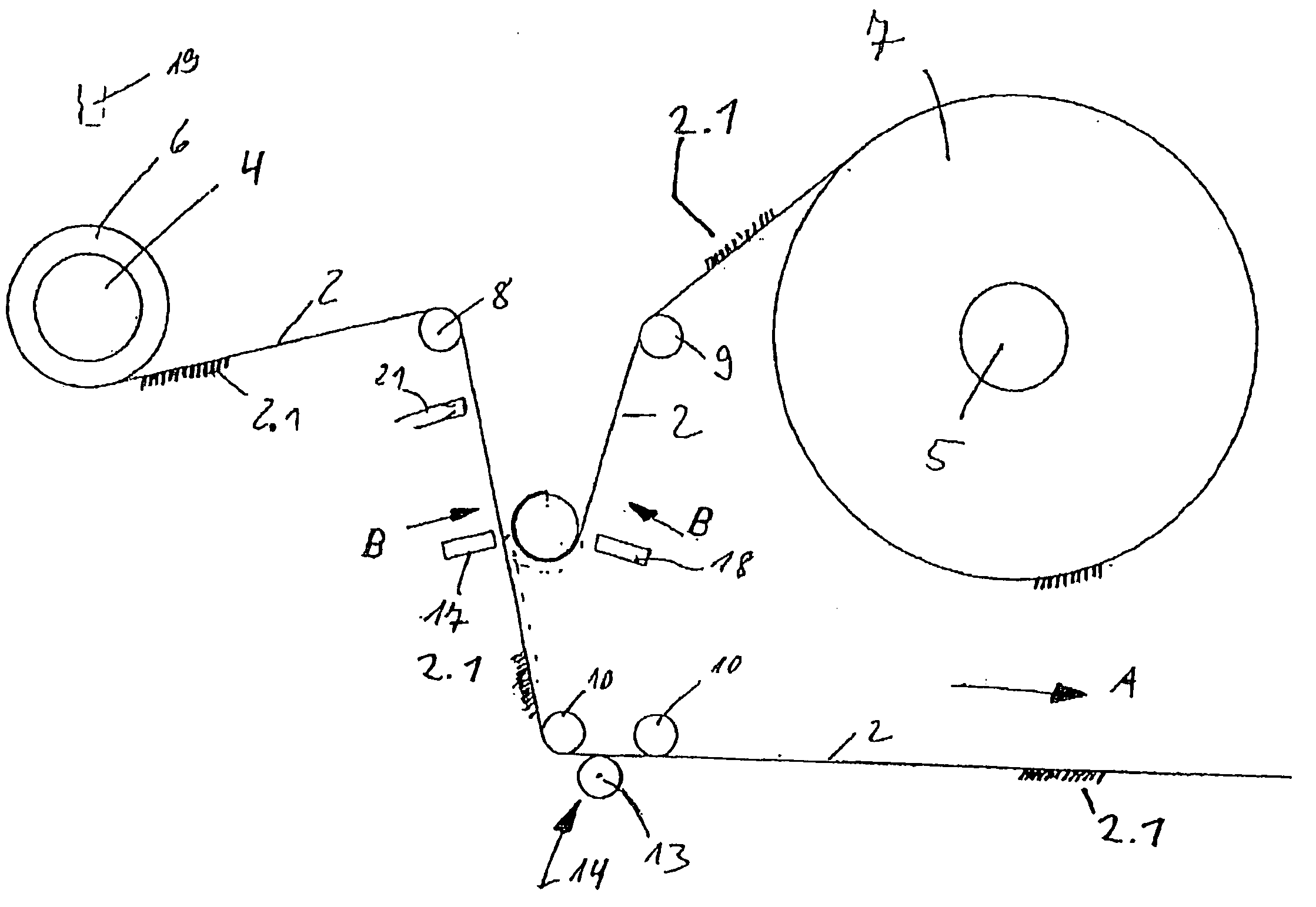

Apparatus for conveying, supplying, and filling unshaped containers, and method for conveying and supplying the same

InactiveUS6338371B1Reduce the numberEnvelopes/bags making machineryWrapping material feeding apparatusEngineeringContinuous rotation

A filling apparatus of irregular-formed vessels having an intermittent swinging table (111) disposed above a continuous rotation table (5) and having a plurality of filling nozzles (121) at a same pitch as the vessel holding pitch, filling means for pushing out the liquid from the filling nozzles (121), vertical moving means for vertically moving the filling nozzles (121), a continuously rotating outside hollow shaft (119) to which the continuous rotation table (5) is mounted, a hollow shaft (116) disposed concentrically with the outside hollow shaft (119) for reciprocally rotating the intermittent swinging table (111).

Owner:MITSUBISHI HEAVY IND LTD

Apparatus for cutting and/or welding flexible packaging

InactiveUS6207925B1Wrapping material feeding apparatusLaser beam welding apparatusPlastic materialsEngineering

This invention involves a method and apparatus for welding and / or cutting flexible packaging material (1) using lasers. The invention is specifically directed towards the use of lasers for cutting and / or welding plastics material (1) in motion, such as in association with high speed packaging machinery. The method and apparatus of the invention enables the cutting and / or welding of adjacent webs of plastics material (1) by scanning one or more processing laser beams (4), or sub-beams (5, 6) of the or each processing laser beam (4), across said moving layers (1) at a rate controlled in relation to the rate of motion of the layers (1) of substrate. The method and apparatus may produce straight or shaped cuts and / or welds.

Owner:KENDALL BRIAN ANDREW

Plastic container and preform

Owner:PLASTIPAK PACKAGING

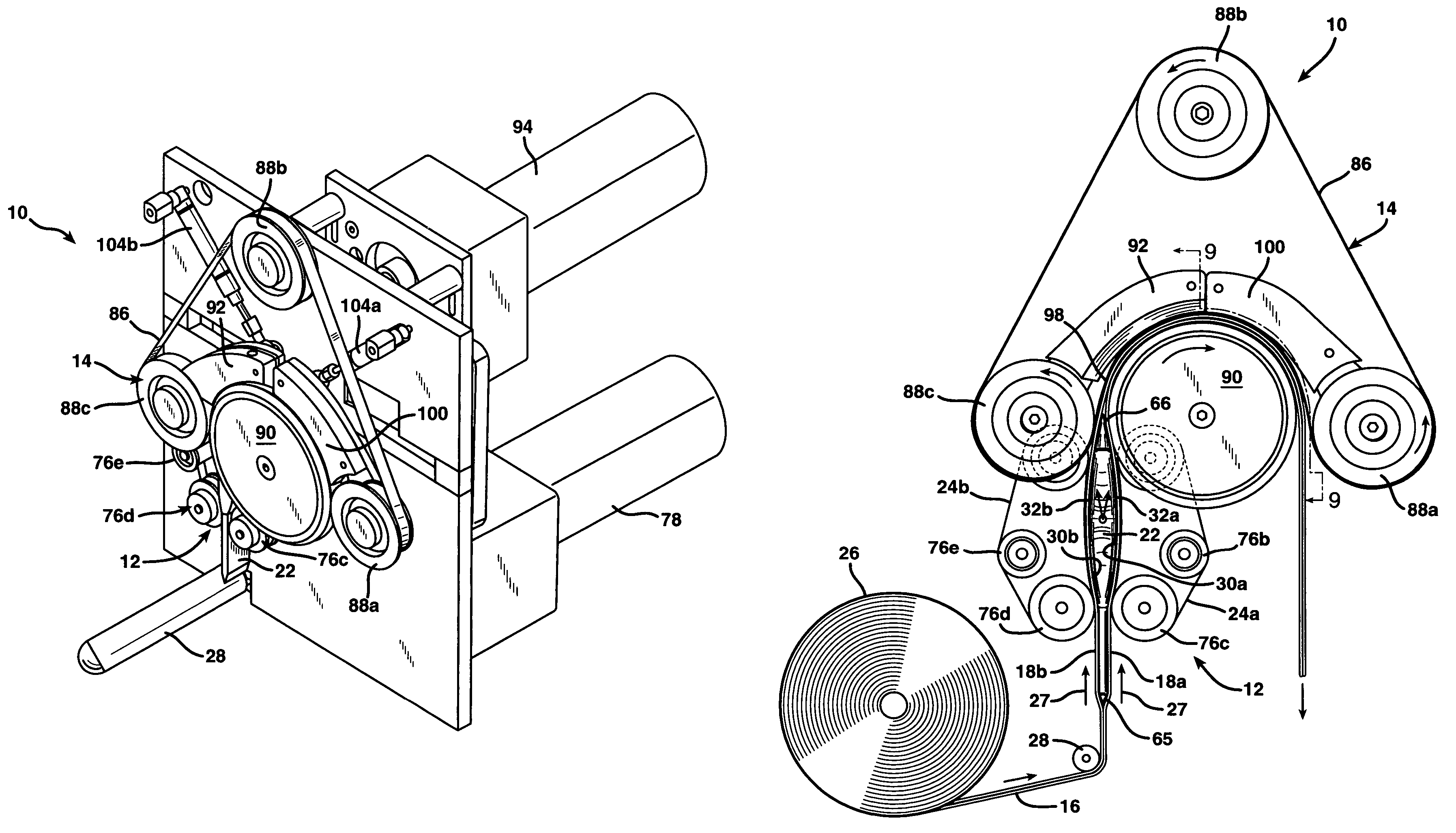

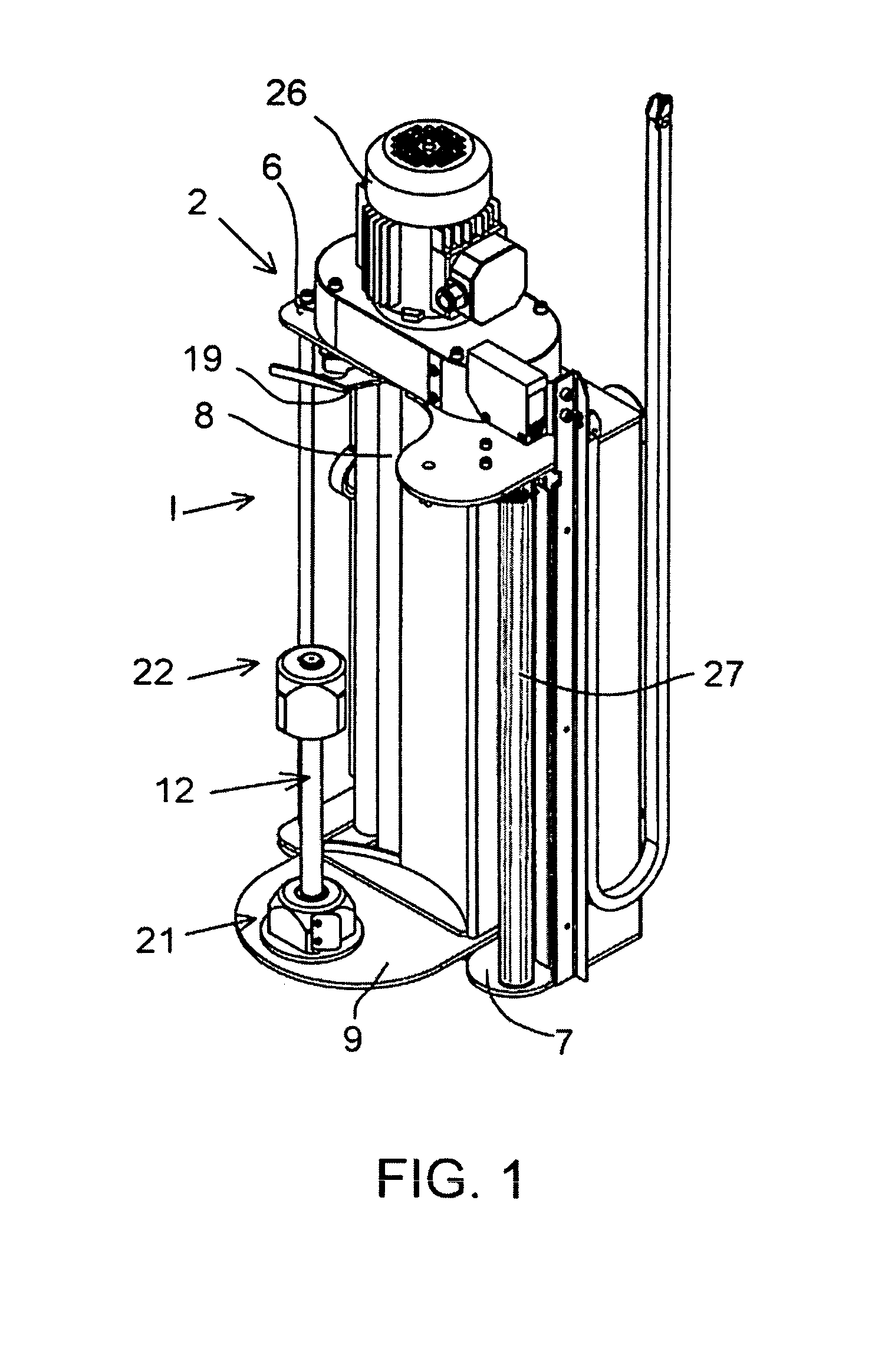

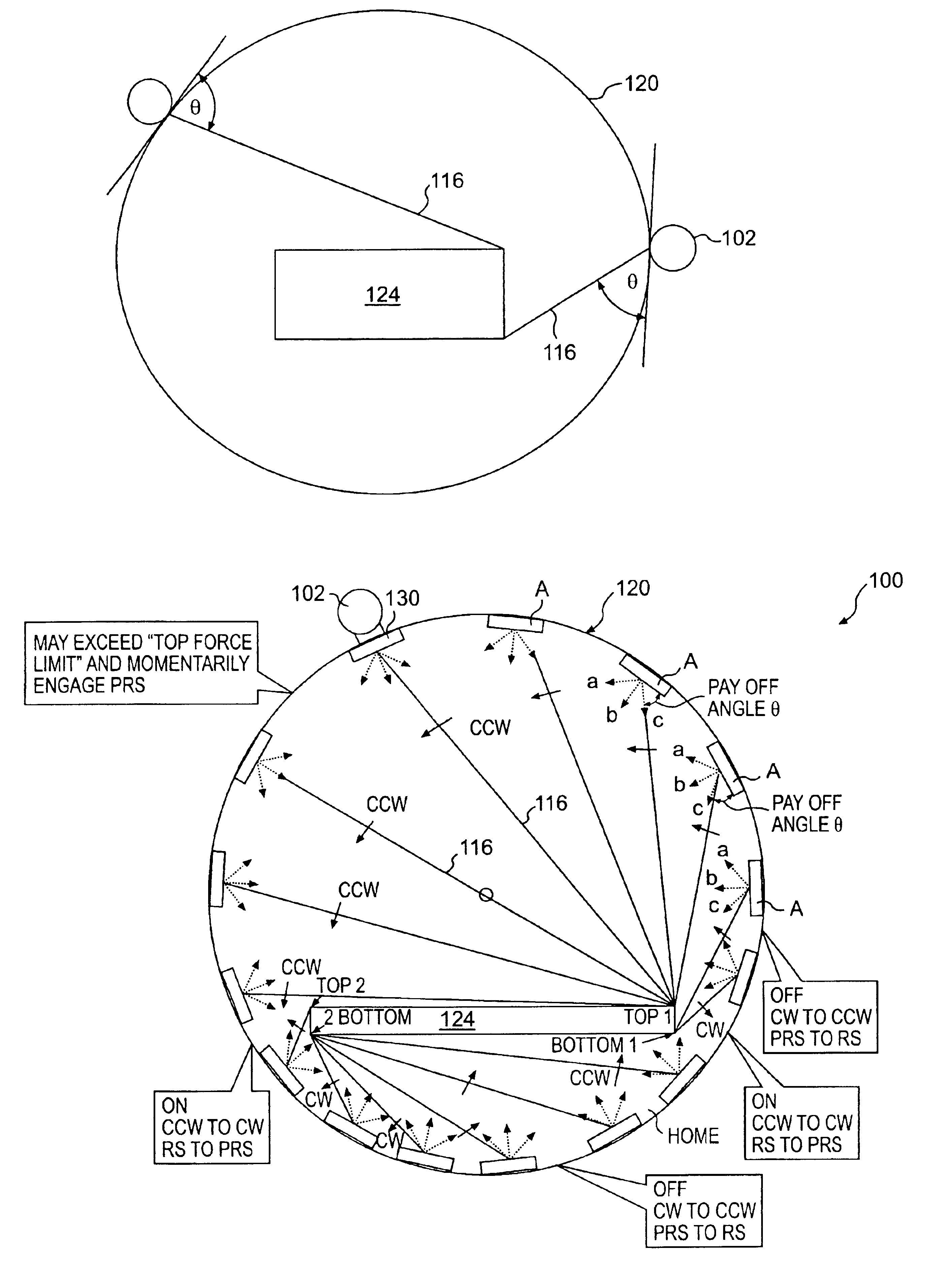

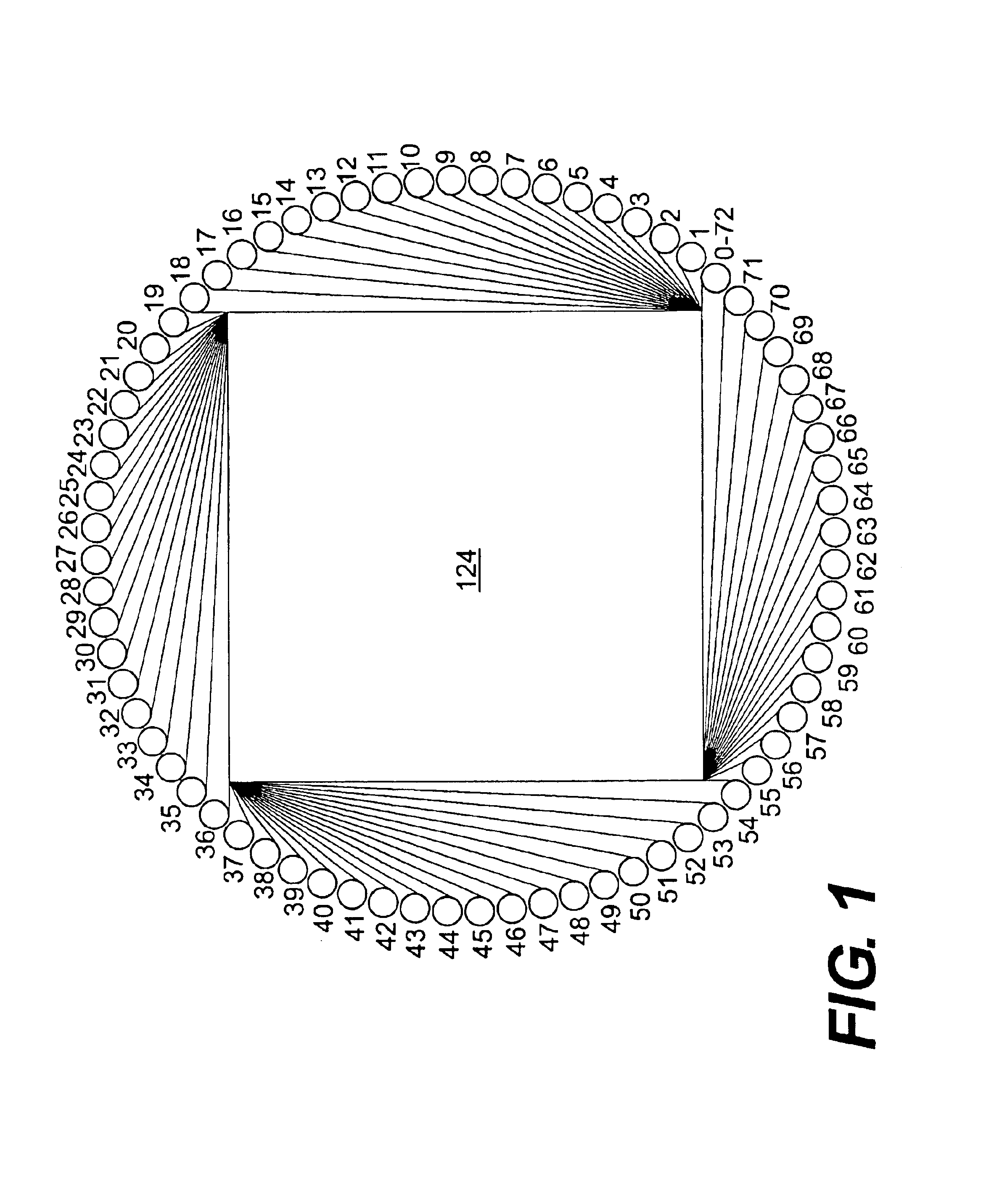

Method and apparatus for wrapping a load

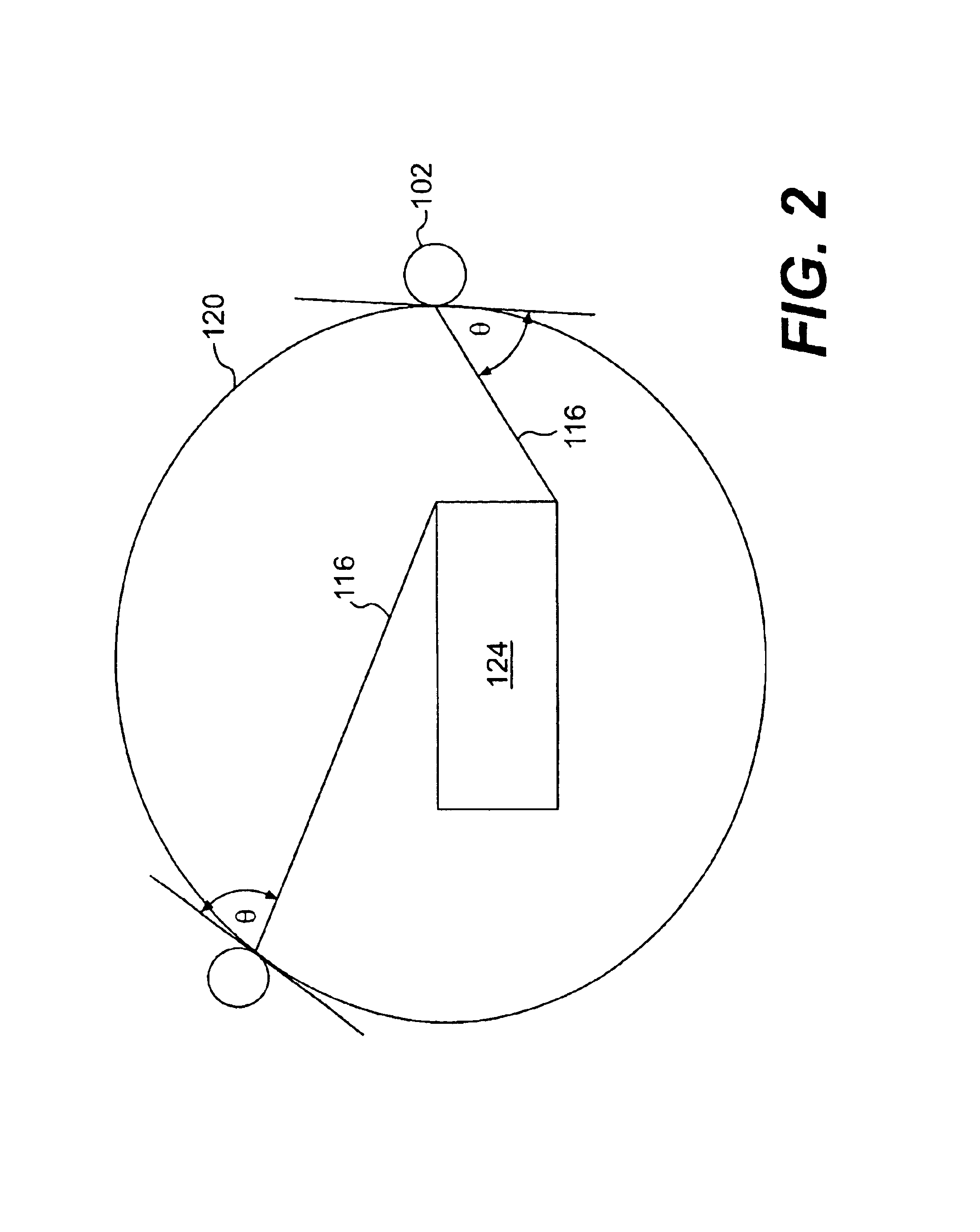

InactiveUS6918229B2Eliminate the problemWrappers shrinkageWrapping material feeding apparatusStretch wrapEngineering

The present invention relates to an apparatus and method for stretch wrapping a load in an efficient manner so as to tightly and securely wrap the load at a desired tension without rupturing the packaging material. The method and apparatus compensate for variation in demand rate as the load is wrapped so as to apply the wrapping material to a load at a desired force, maintain the desired containment tension on the wrapping material on the load after wrapping, and prevent the wrapping material from rupturing during wrapping. The apparatus combines two systems, power assisted roller stretch (“PRS”) and roller stretch (“RS”) to vary the supply rate of the packaging material as the demand rate varies. The apparatus automatically switches between the two types of prestretch to achieve “high” and “low” wrapping force dependent upon the demand rate. Changes in the demand rate are sensed by monitoring changes in the payoff angle of the packaging material extending between the dispenser and the load.

Owner:LANTECH COM

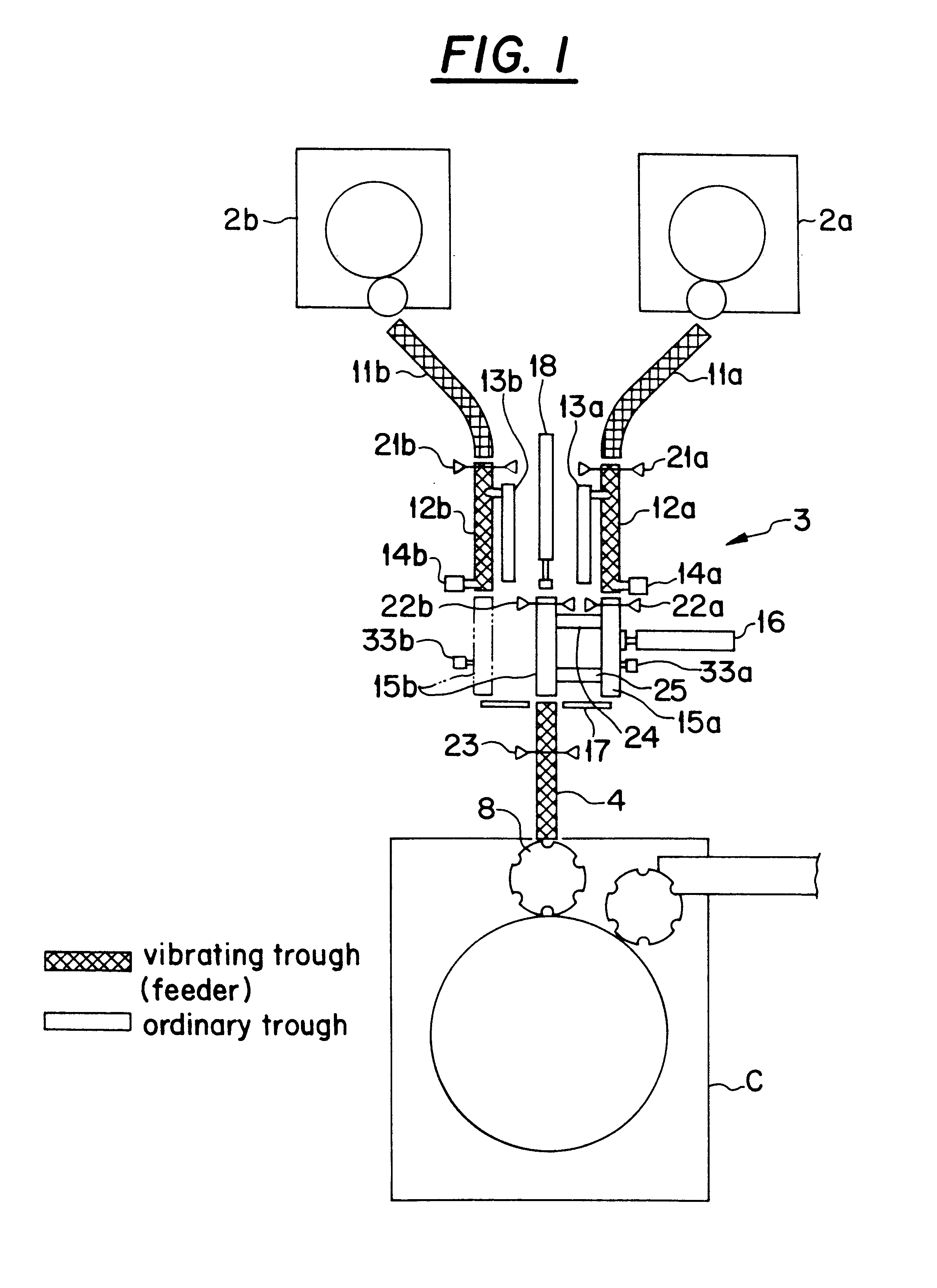

Packaging system

A packaging system is provided which supplies an item to be packaged and a bag covering the item to a pressure resistant chamber, for a heat sealing mechanism which arrives at a certain time interval, in accordance with the circulation timing of each sealing mechanism. The packaging system includes means for causing a beak-shaped hopper and a pair of opening and closing bars, to move back and forth in unison along a main travel path leading to a rotary vacuum packaging device, means for extending and supporting the opening section of an uppermost packaging bag, and conveying same into a pressure resistant chamber of the vacuum packaging device, means for causing a waiting station to move following the conveyance movement of the beak-shaped hopper into a pressure resistant chamber, and means for opening the opening and closing bars towards either side immediately after the bag has been conveyed into the pressure resistant chamber.

Owner:FURUKAWA MFG

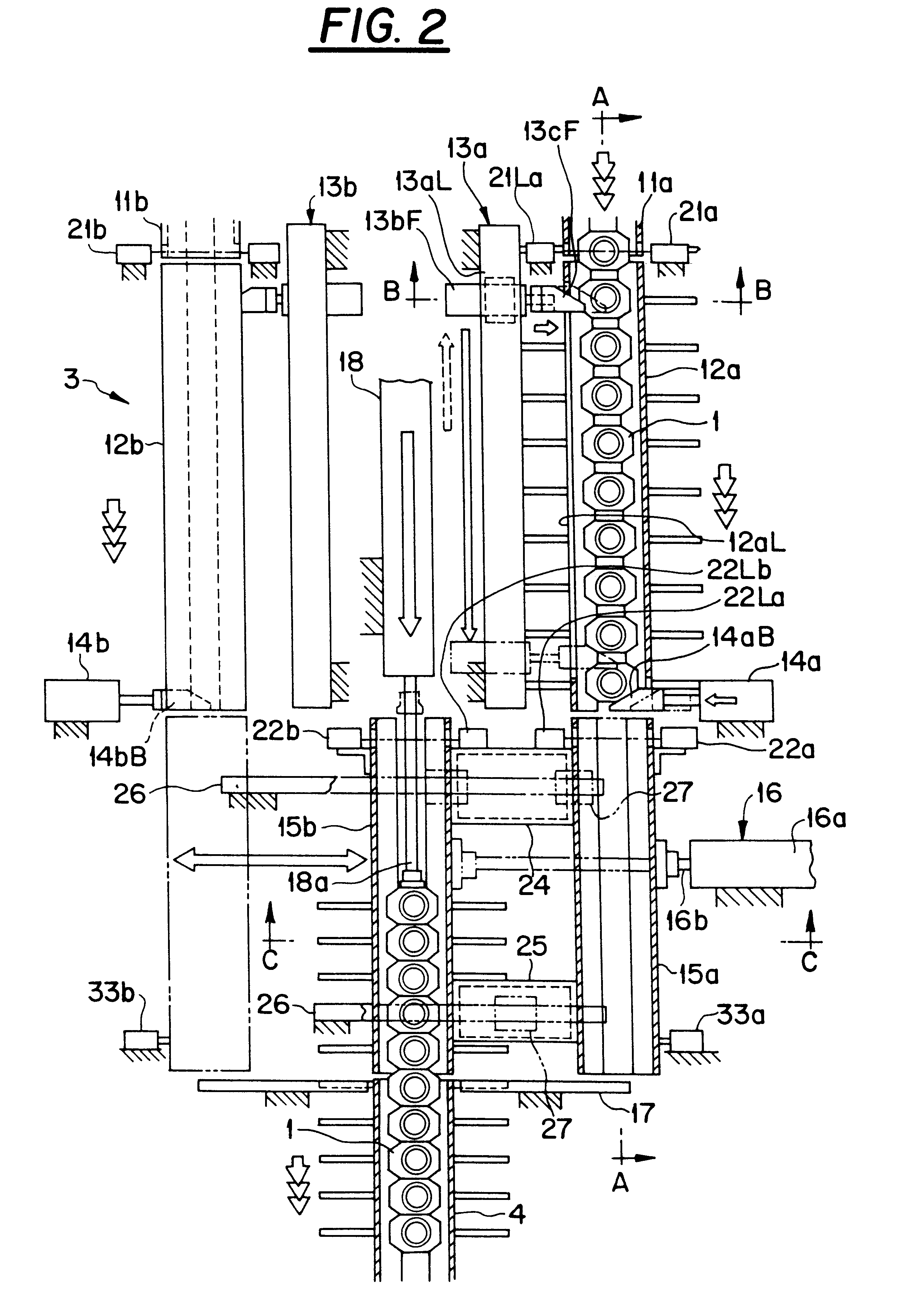

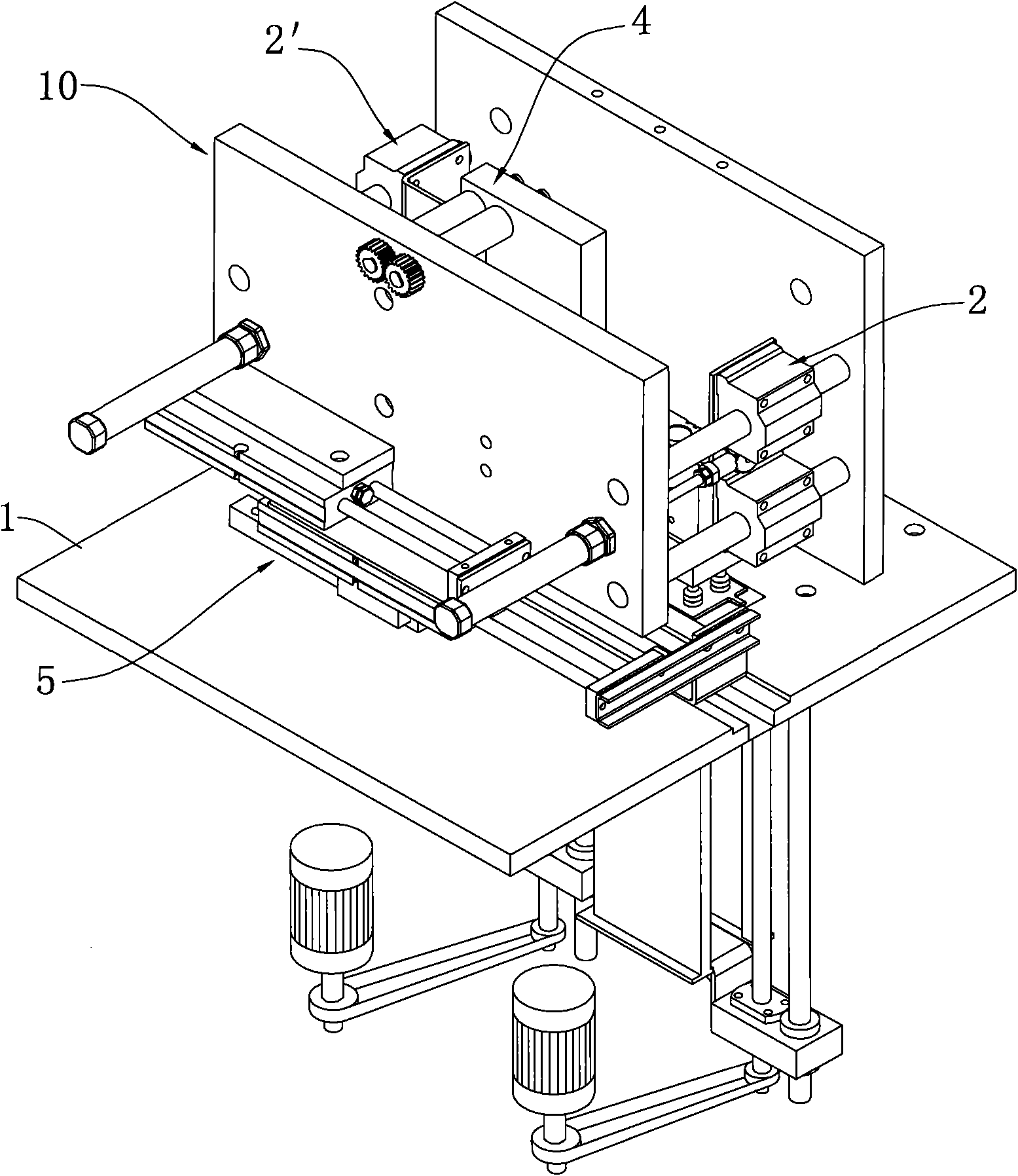

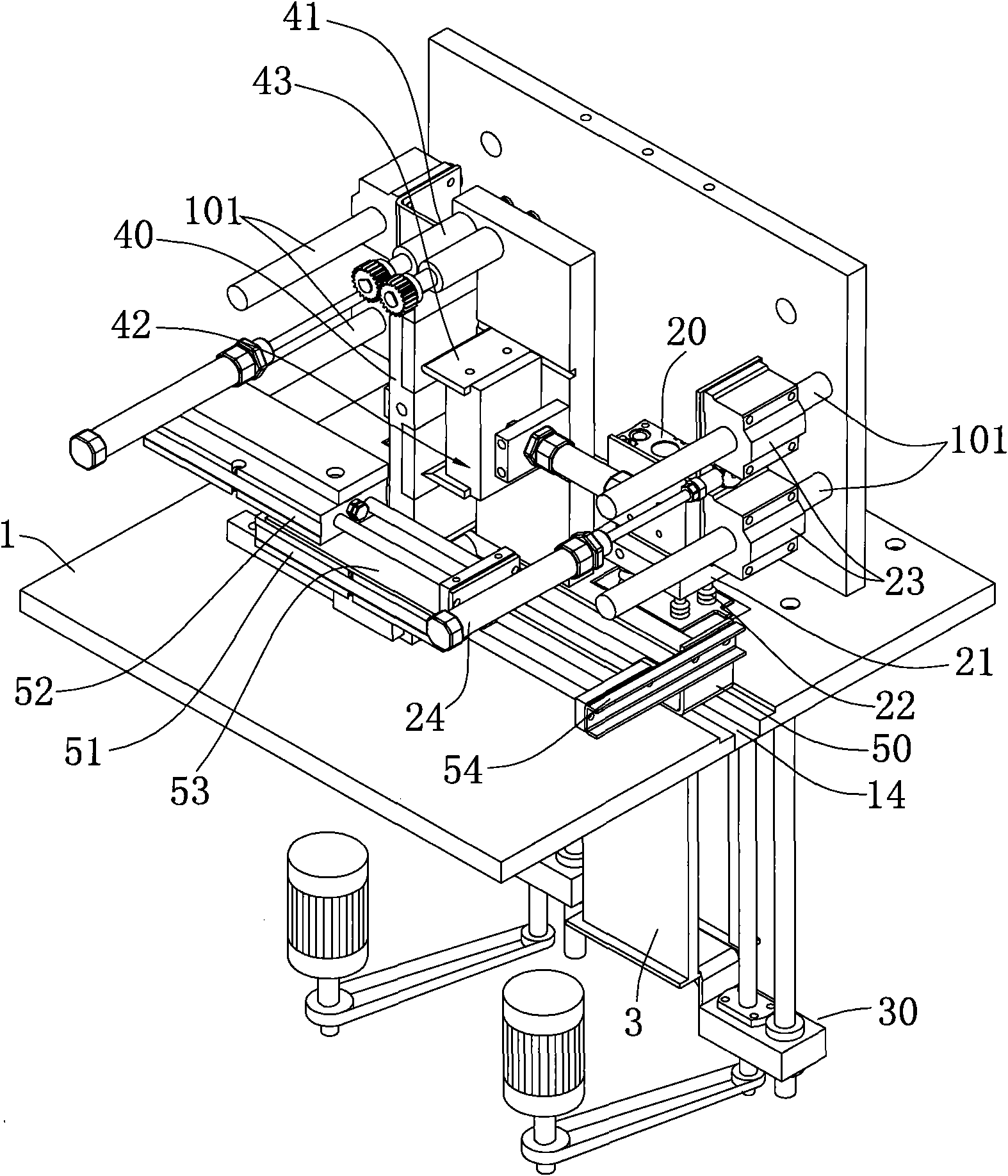

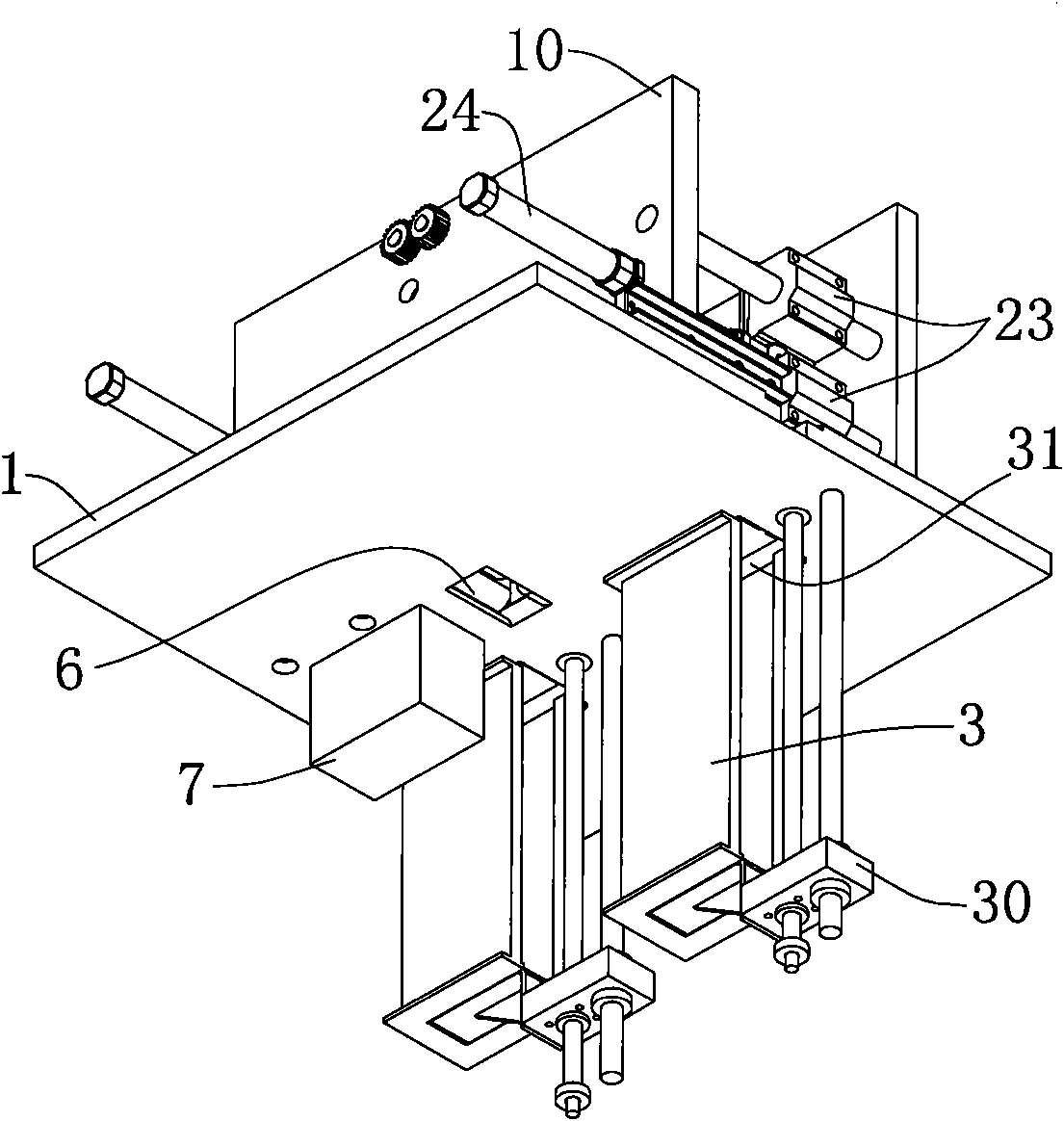

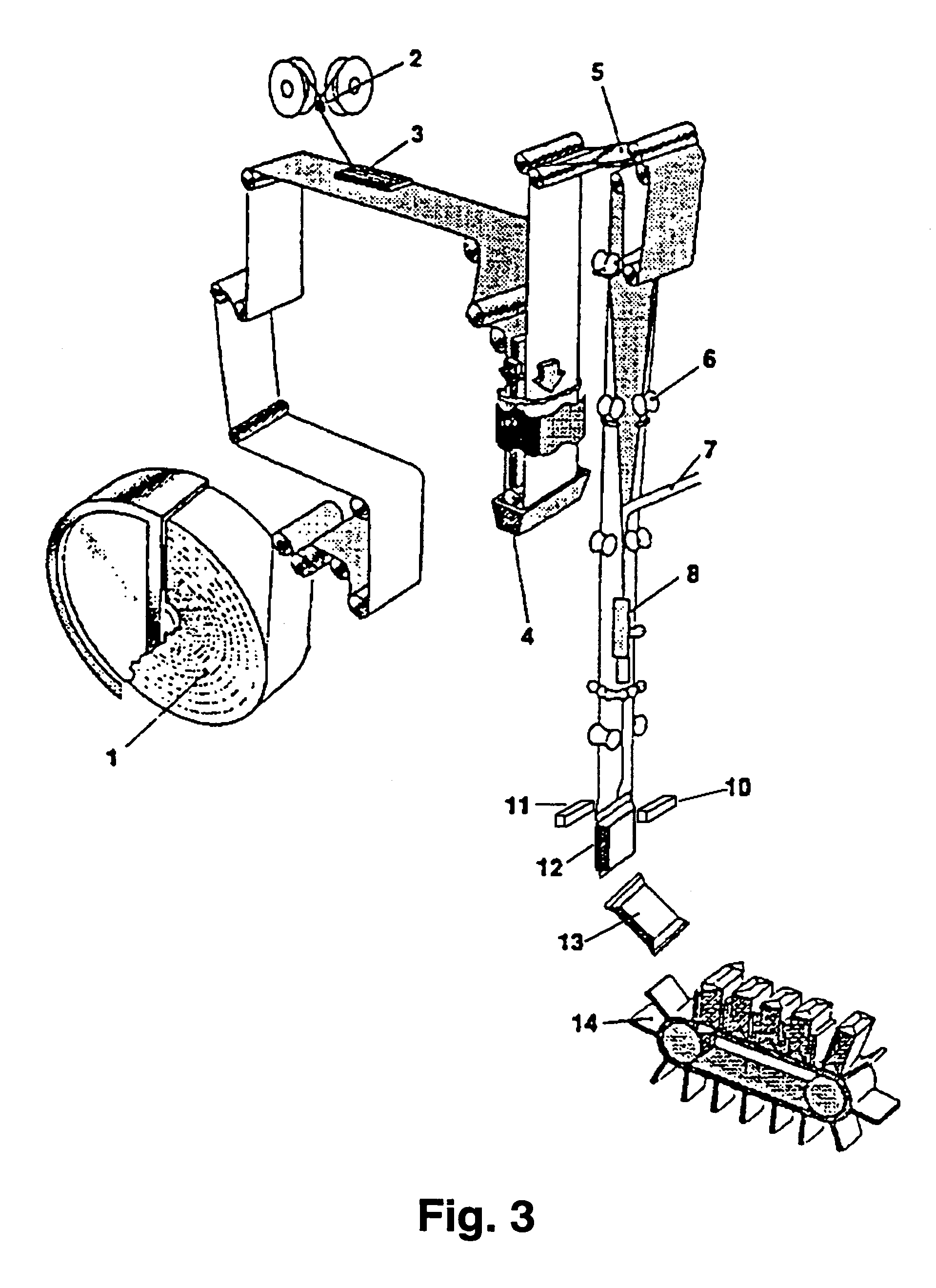

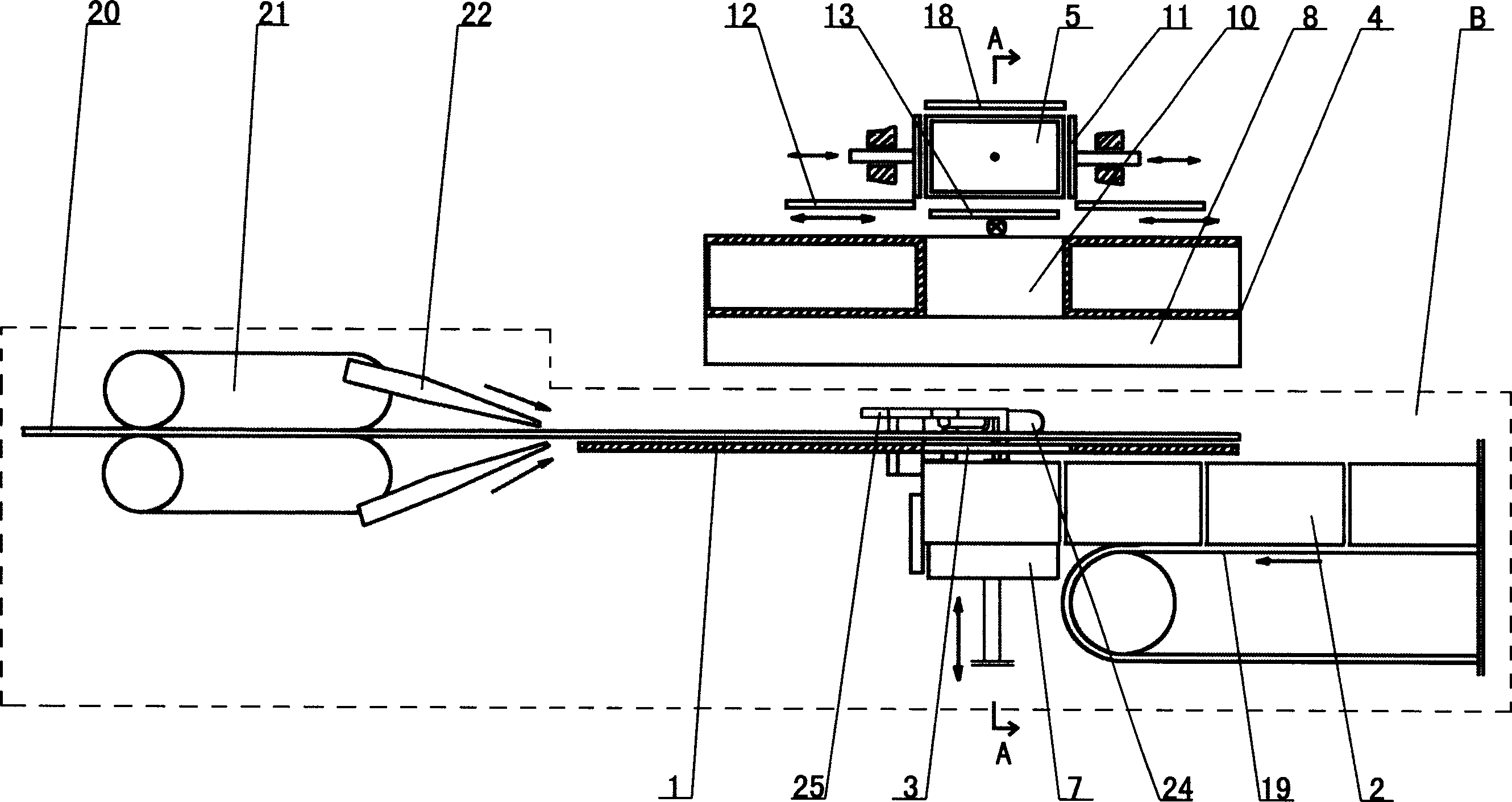

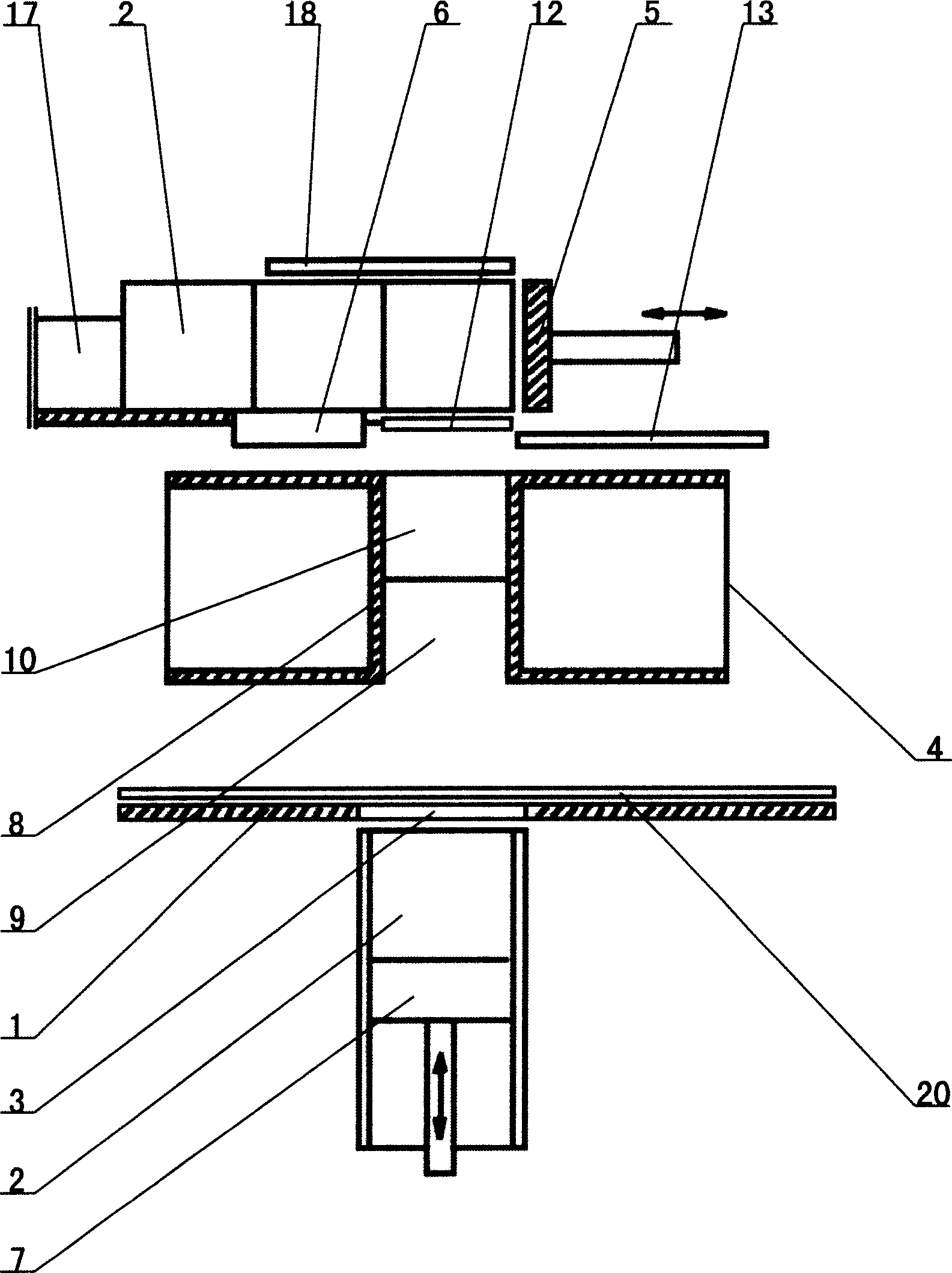

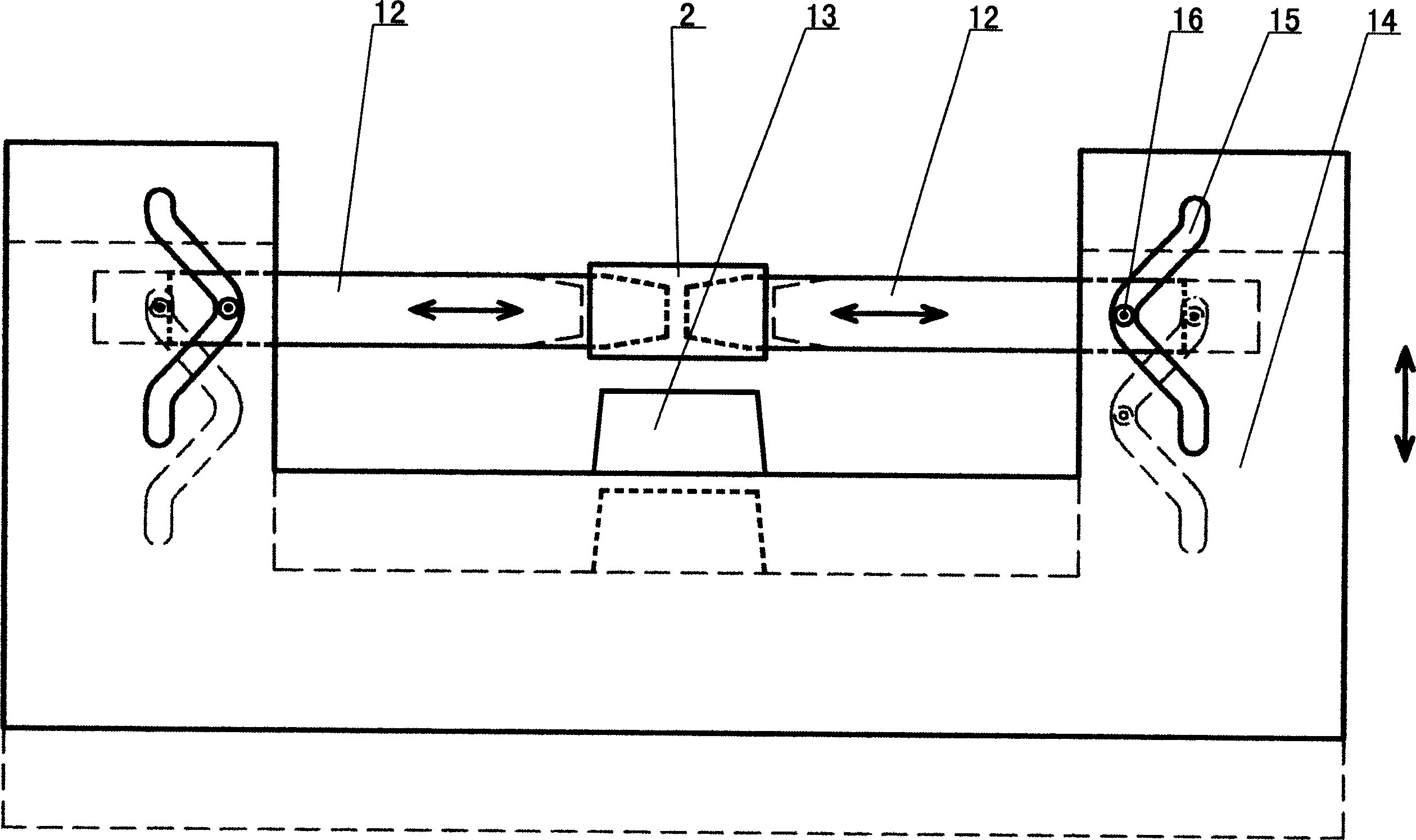

U-shaped automatic piece wrapping machine for pole pieces of storage batteries

InactiveCN101898646ARealize automatic feedingImprove efficiencyPaper article packagingWrapping material feeding apparatusPole pieceMechanical engineering

The invention discloses a U-shaped automatic piece wrapping machine for pole pieces of storage batteries, comprising a piece wrapping mechanism for wrapping a first pole piece, an assembly mechanism connected with the discharge end of the piece wrapping mechanism, a first piece supply mechanism for supplying the first pole piece to the piece wrapping mechanism and a second piece supply mechanism for supplying the second pole piece to the assembly mechanism, wherein the second pole piece and the wrapped first pole piece are piled up at intervals in the assembly mechanism to form a pole group. The machine realizes automatic feeding and automatic wrapping of the pole pieces and automatic assembly of the wrapped pole pieces, completes the whole operation process in a streamline manner in one step and improves the wrapping efficiency and quality of the pole pieces. Improvement of the degree of automation is conductive to correspondingly reducing the probability of manually contacting the pole pieces, thus greatly reducing the harm of lead dust to the operators.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

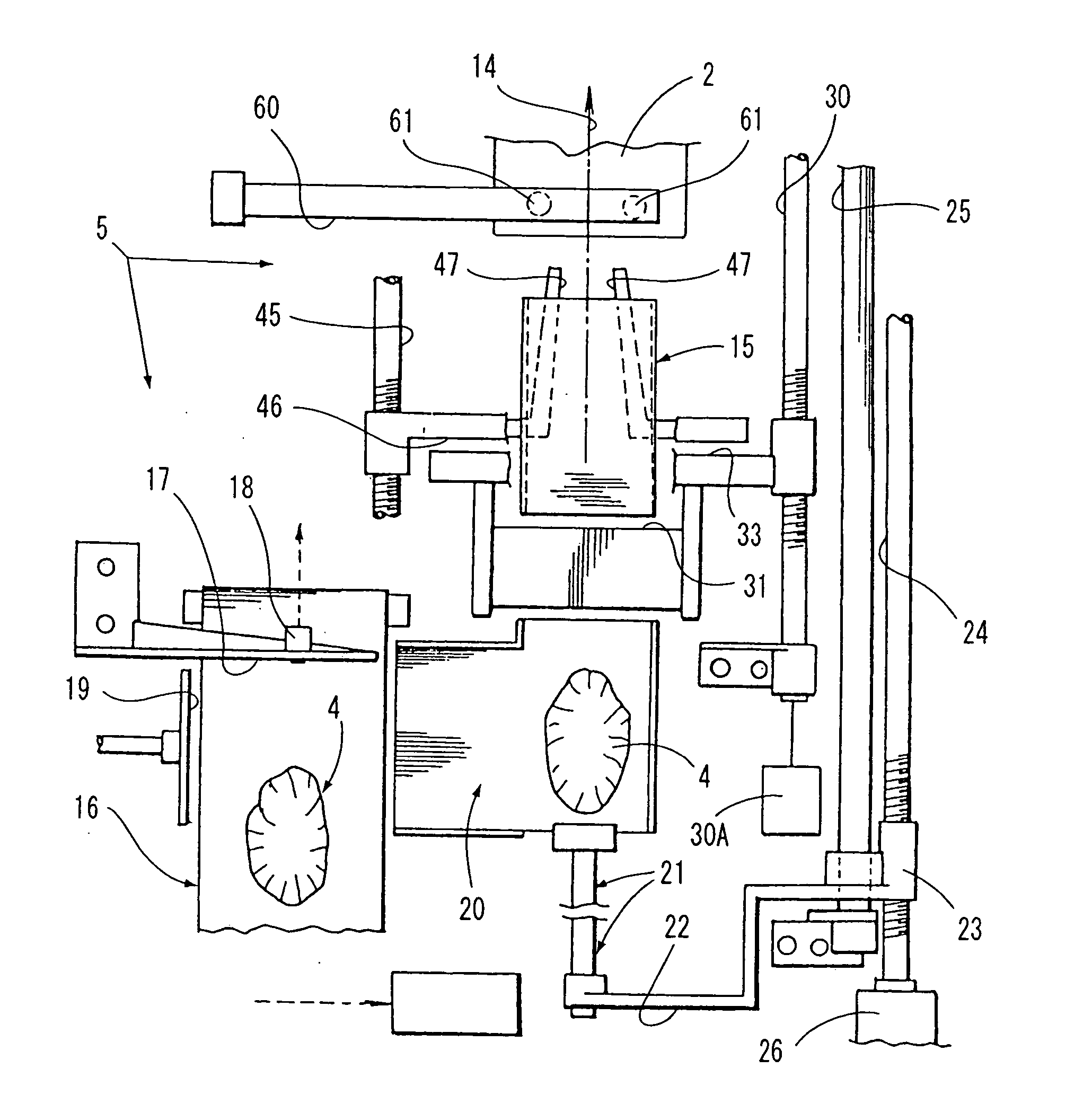

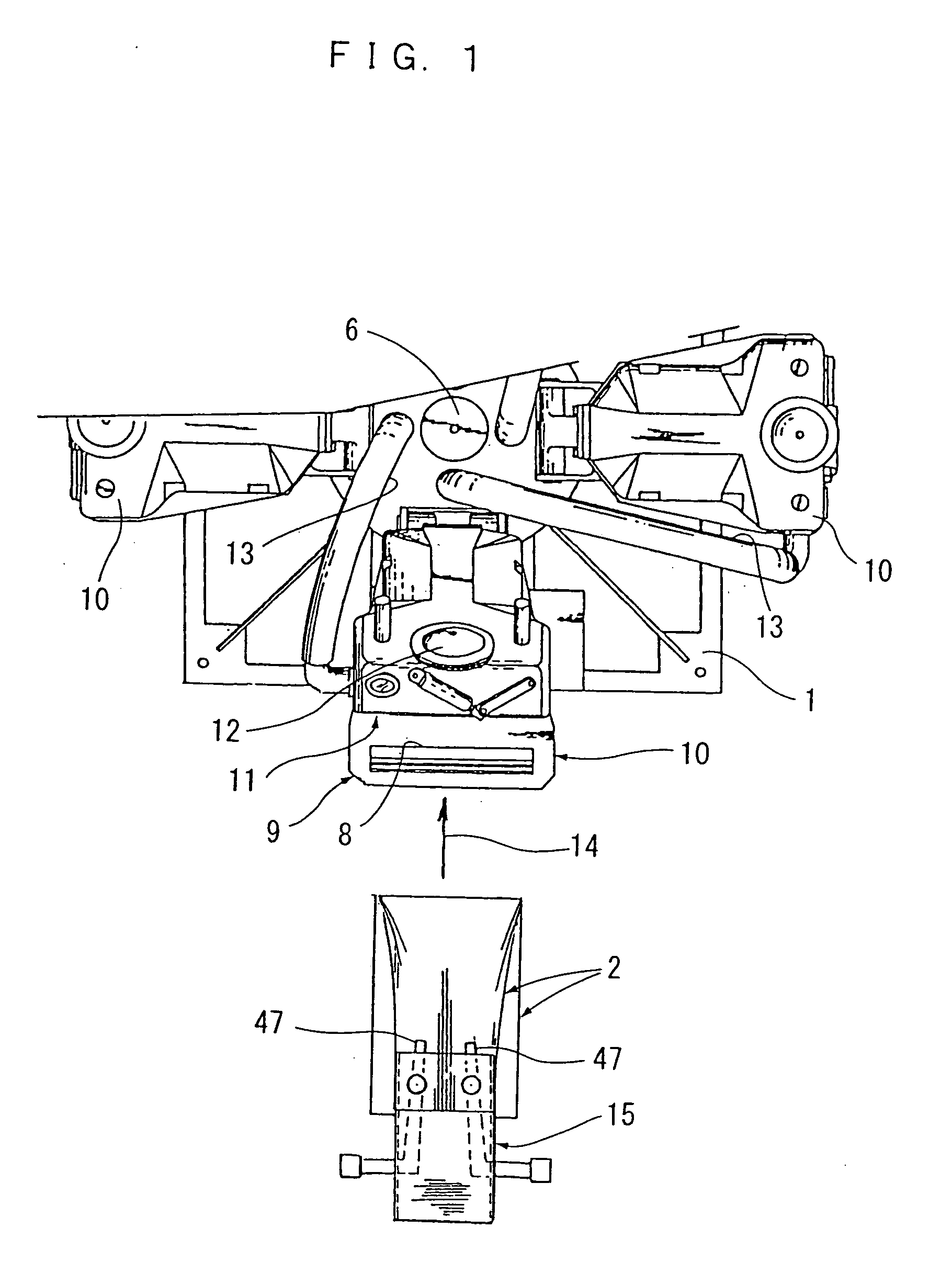

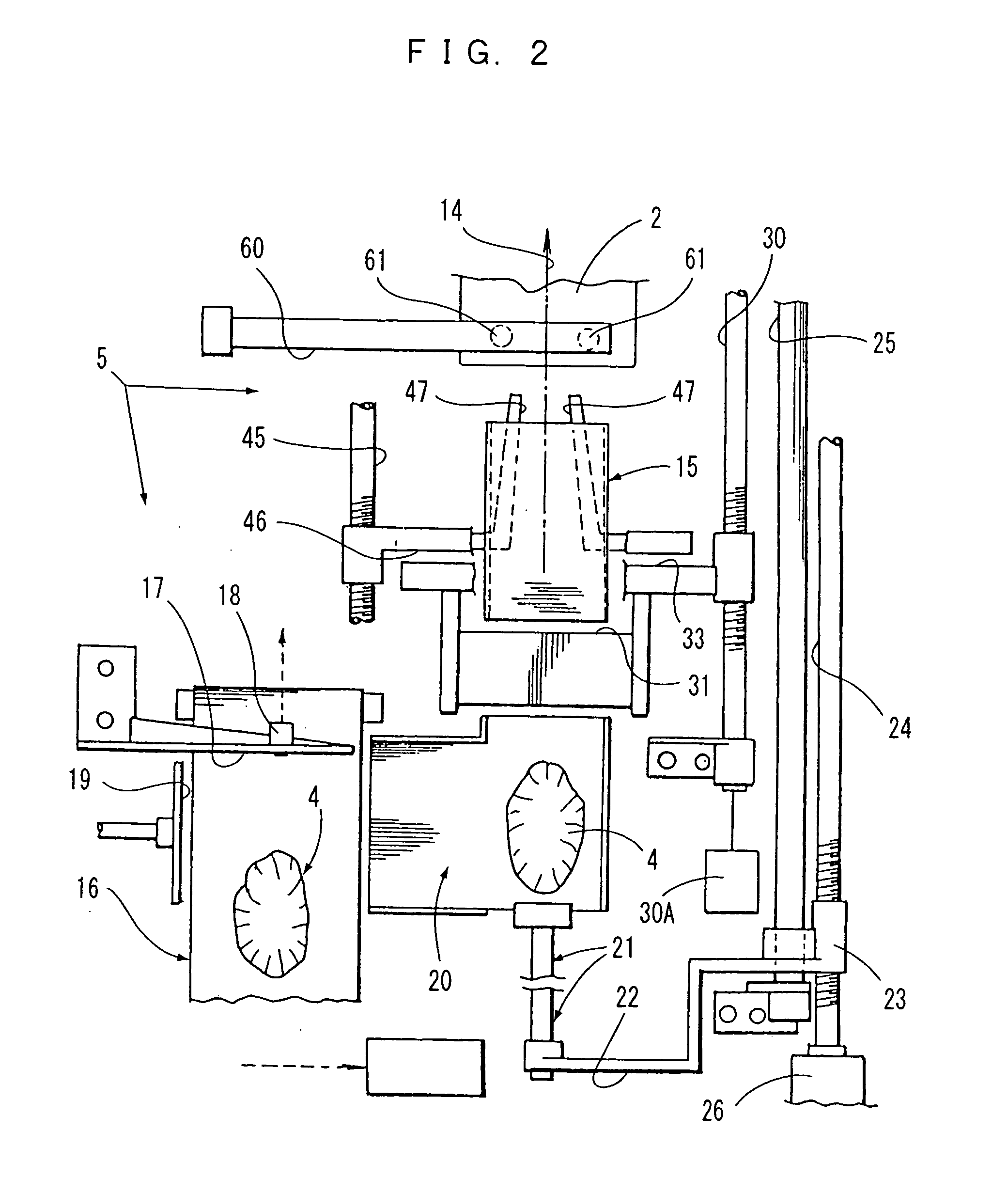

Heat seal device

InactiveUS7003934B1Improve sealingReduce adverse effectsWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringImpurity

A heat-sealing device moves a tube-shaped packaging material through operation of a seal jaw and counter jaw under the liquid surface of liquid food, and heat-seals a seal zone containing a cutting predetermined zone in the tube transverse direction. The tube-shaped packaging material is formed from the packaging material web, and is filled up with liquid food. The operation surface of the seal jaw facing the seal zone has a substantially flat surface. The heat-sealing device has a removal / mixture mechanism on the operation surface of the counter jaw. The removal / mixture mechanism removes seal prevention impurity from this seal zone and / or mixes the impurity with the melting / softening packaging material in this seal zone. Thus, even if the packaging laminated material is covered with an oxide, residual substances, or impurities, the heat-sealing device reduces the bad influence of the seal prevention impurity.

Owner:TETRA LAVAL HLDG & FINANCE SA

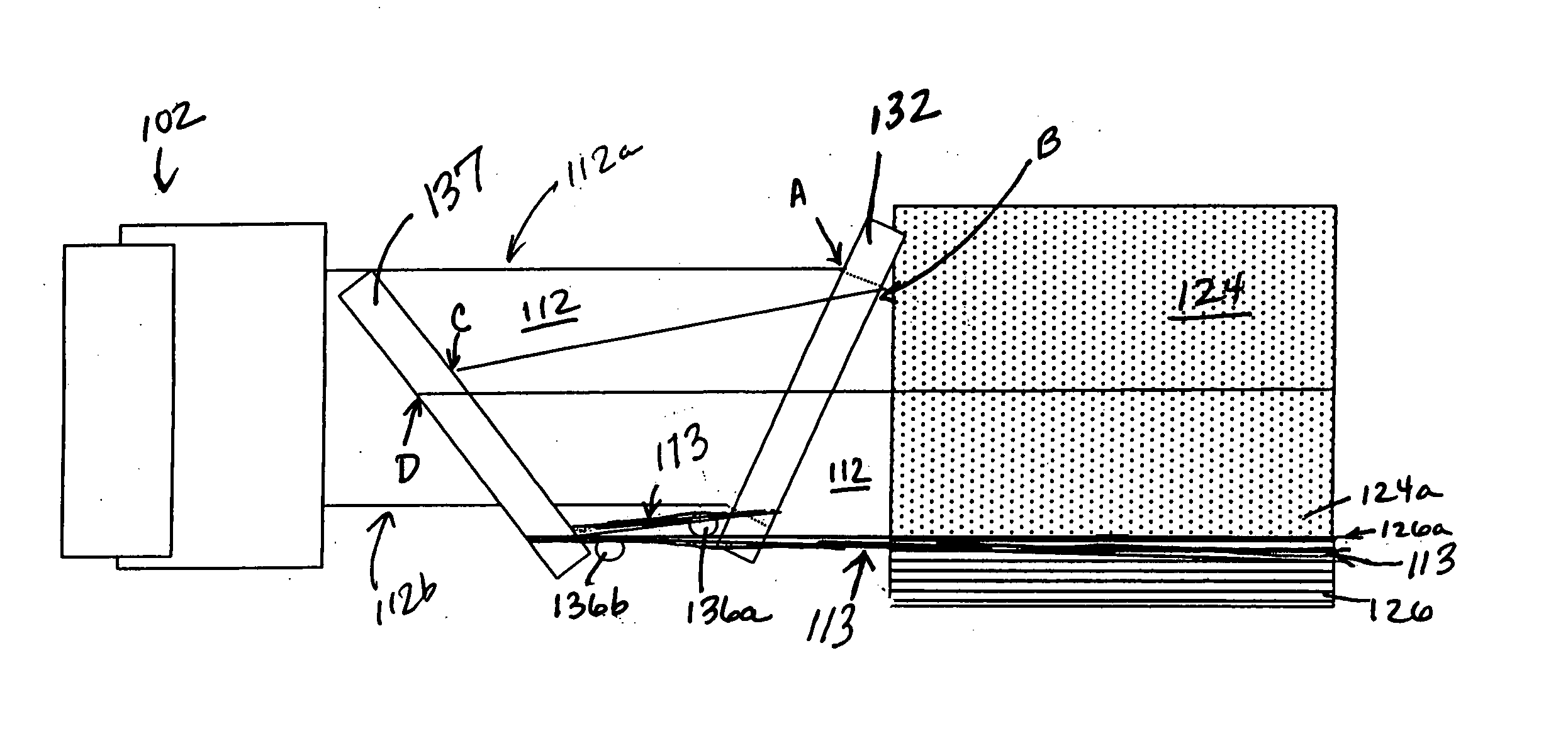

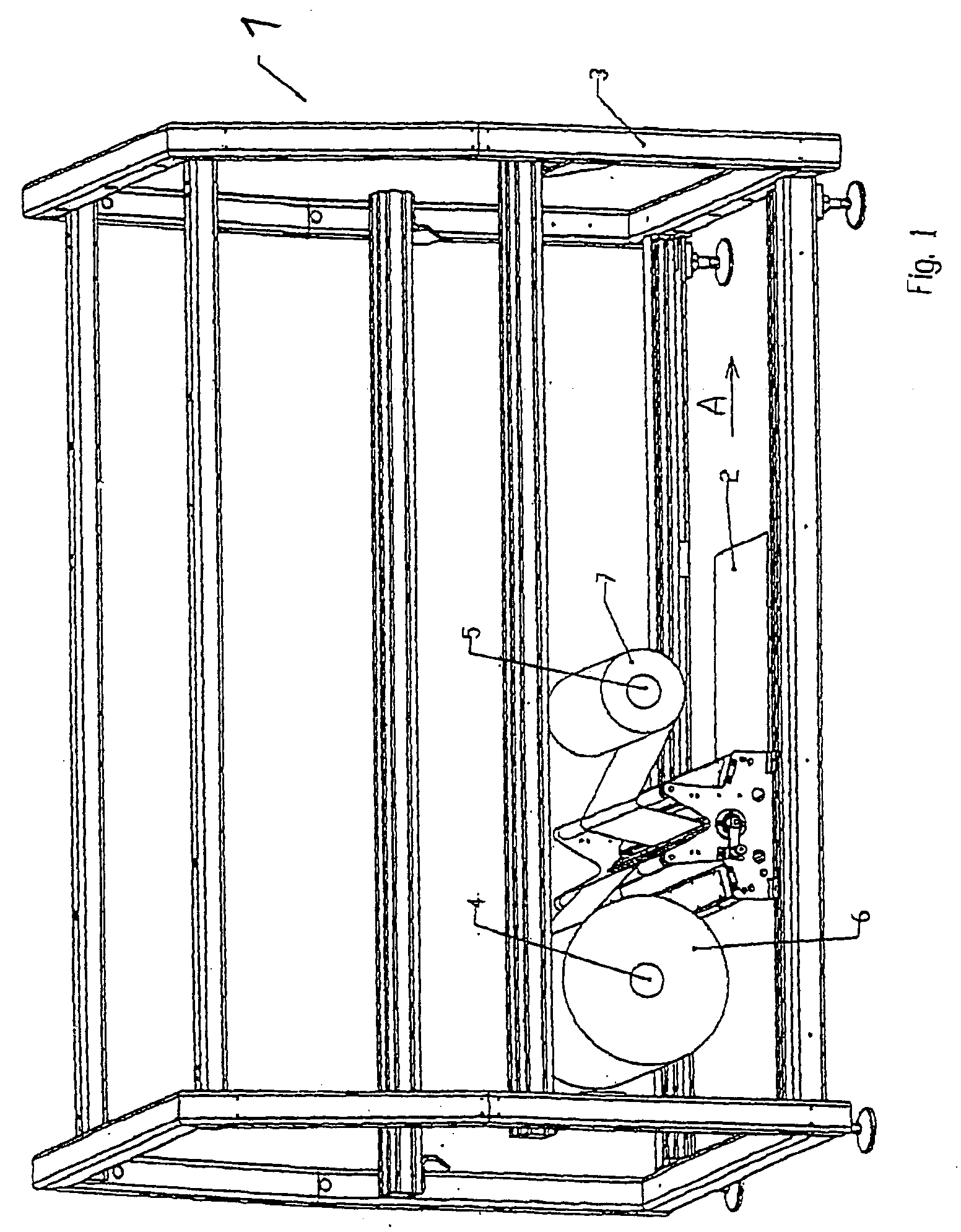

Machine and methods for the manufacture of air-filled cushions

ActiveUS20060292320A1Simpler air deliverySimple control systemEnvelopes/bags making machineryPaper/cardboard articlesContinuous flowGas-filled tube

A device and method are disclosed for forming air filled cushions. The device includes a drive mechanism to move inflatable tubing through the apparatus, and an injector, optionally including an outlet, located continuously within, or within a portion of, the tubing. This arrangement can permit the formation of air filled cushions in a continuous stream. Also disclosed is a roll of plastic tubing that is sealed transversely at a succession of intervals, with each pair of seals stopping just short of a longitudinal center line of the tubing. Such tubing might be used in conjunction with the apparatus, the central gap between the seals allowing passage of the injector.

Owner:PREGIS INNOVATIVE PACKAGING

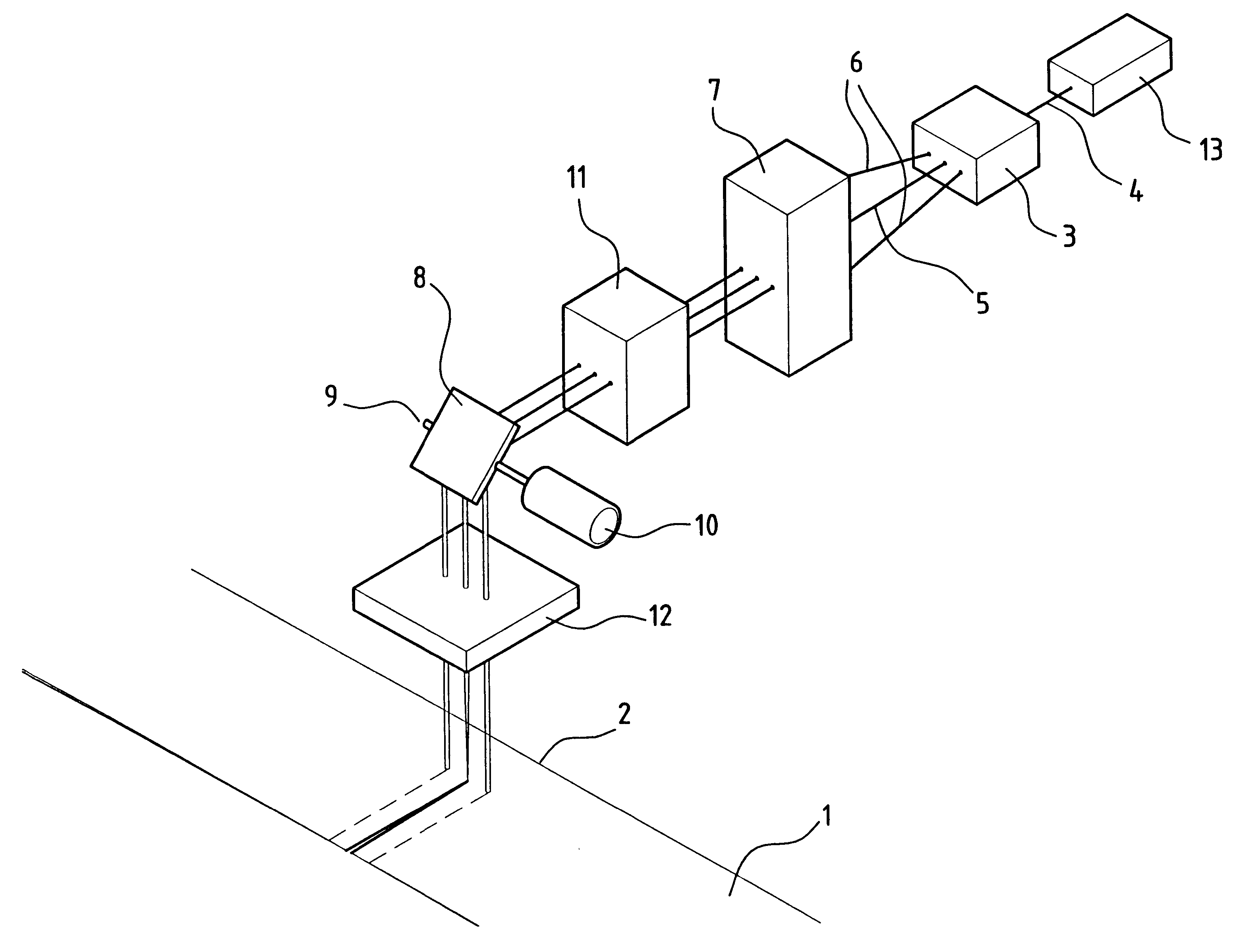

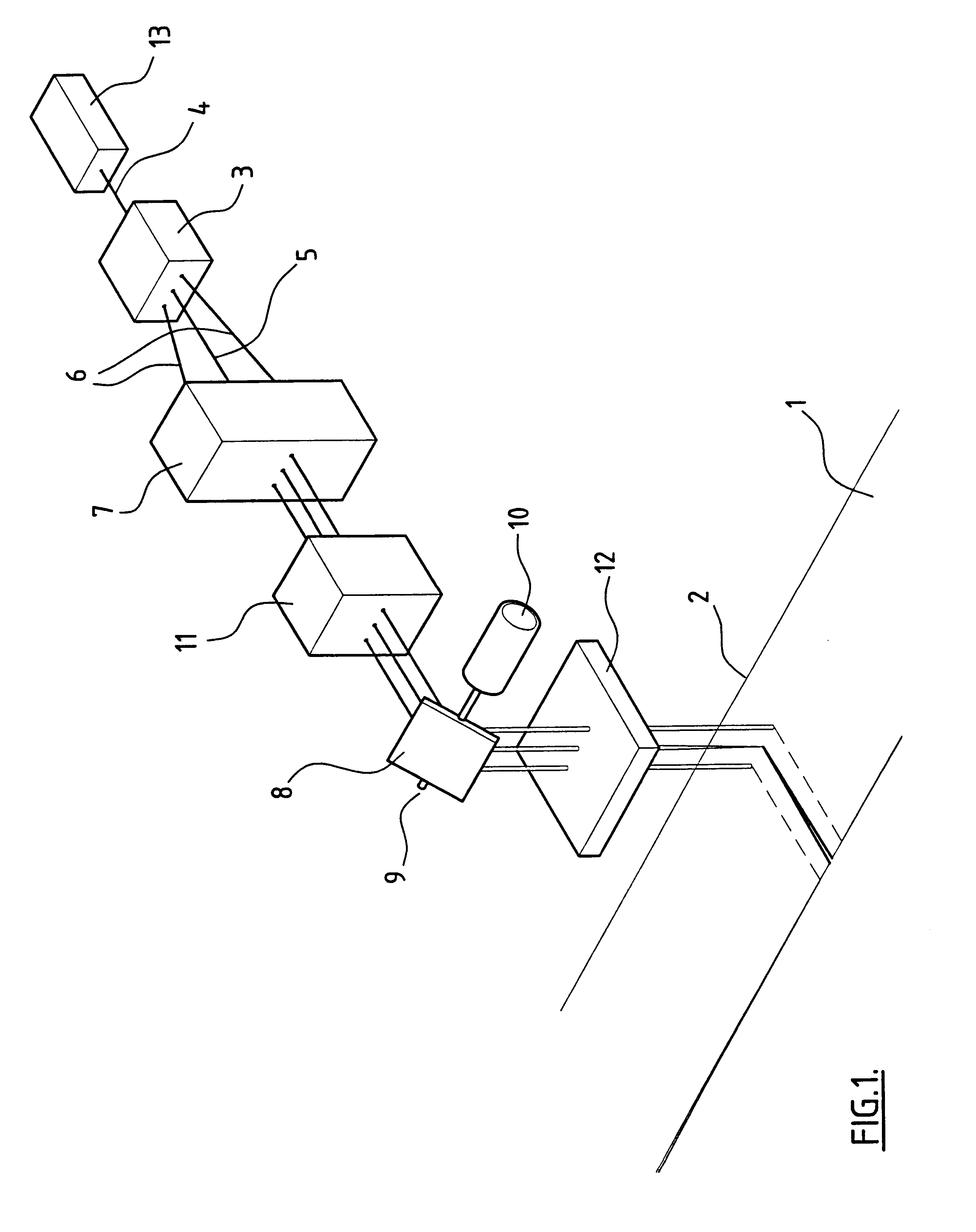

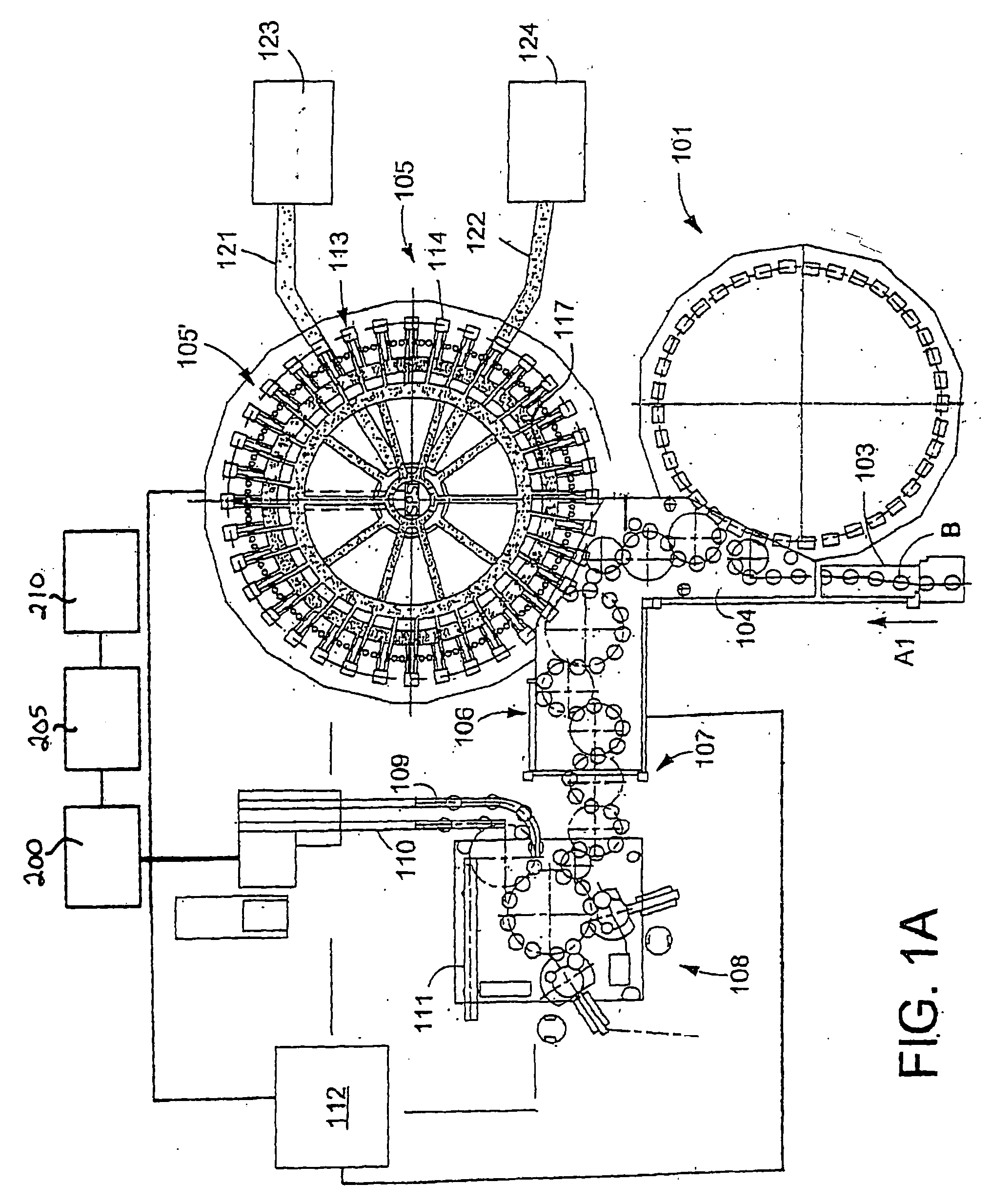

Beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles

InactiveUS20060026926A1Smooth and accurate connectionAccurate connectionMechanical working/deformationWrapping material feeding apparatusTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

System and method of applying stretch film to a load

ActiveUS20170088301A1Increase and decrease its speedIncrease and decrease tensionWrapping material feeding apparatusPackaging automatic controlAnalysis dataSystem controller

A method of wrapping a load with a stretch wrapping system utilizes a system for monitoring film properties, a module in the stretch wrapping systems controller to analyze the data or film properties and further utilize the data to determine, at least in part, appropriate machine settings and or wrapping pattern for the film and execute by providing appropriate machine settings such that effective wrapping of the load and proper use of the film are achieved. The film properties include film stiffness.

Owner:RIEMENSCHNEIDER PAUL KURT III

Materials packing machine

InactiveCN1736801AImprove packaging qualityImprove work efficiencyWrapping material feeding apparatusWrappingMaterials sciencePackaging machine

Disclosed is a material packing device, which contains a film feed device, a charging device and a packaging film forming enveloping device, and is characterized in that: said film feed device contains a film cutting mechanism; said packaging film forming enveloping device contains a packaging film supporting board fixed on the stand, the supporting board being equipped with material through-holes, all shapes and dimensions of which match with pre-packaging material; and the packaging film forming enveloping device contains a packaging film former above the material through-hole, a material fixing clamping part and material pushing part above the packaging film former, a group of material floor packaging hands and a scalding enveloping plate for enveloping packaging film of material floor between the packaging film former and the material clamping part, and a material lifting part which can send the material to material fixing clamping part from below the packaging film supporting board; the material fixing clamping part and material pushing part which moves vertically. The device can complete automatically the packaging of material, especially the rectangle material, the packaging quality perfect and stable, and the work efficiency high.

Owner:汕头市金海湾包装机械有限公司

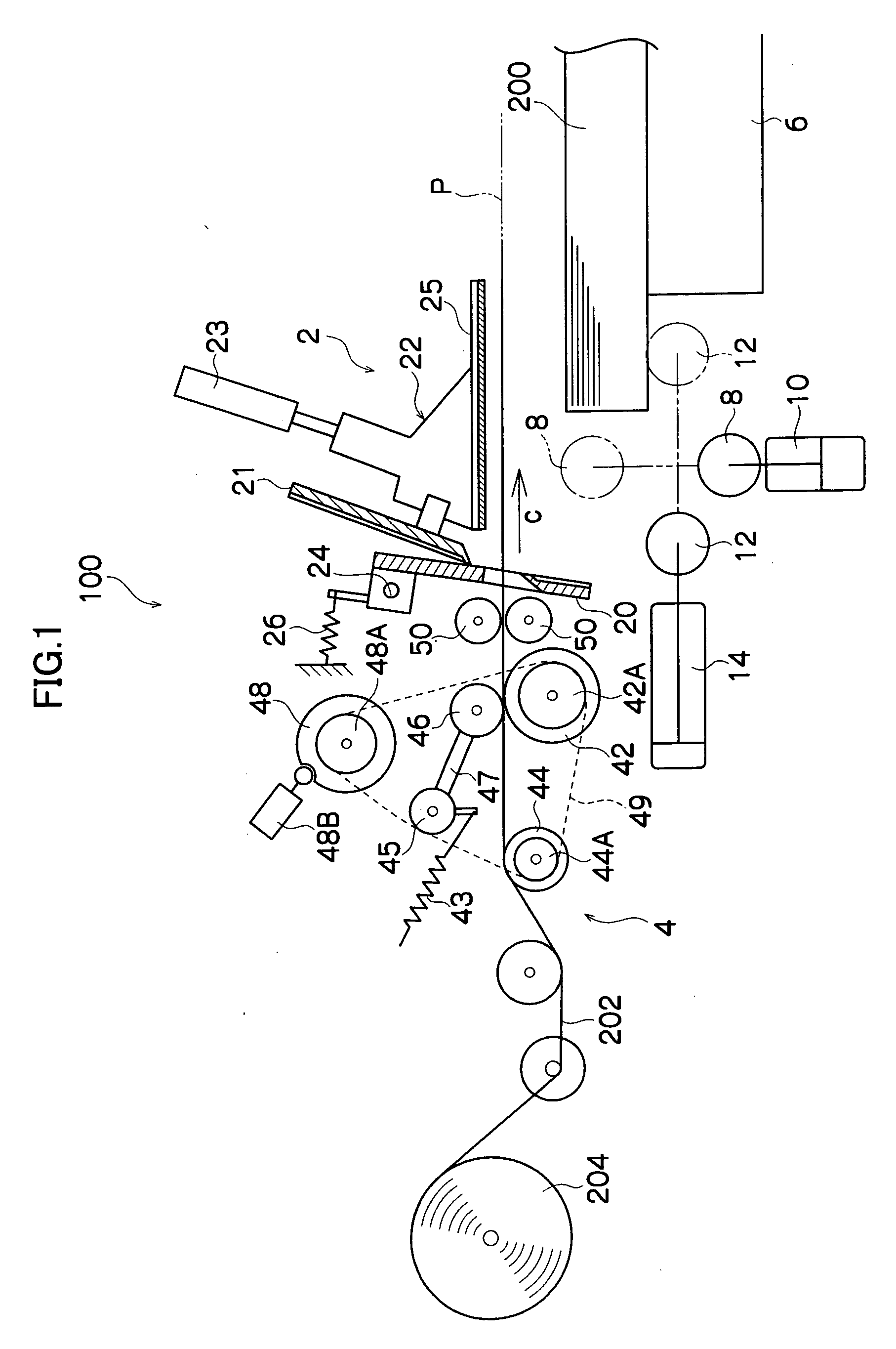

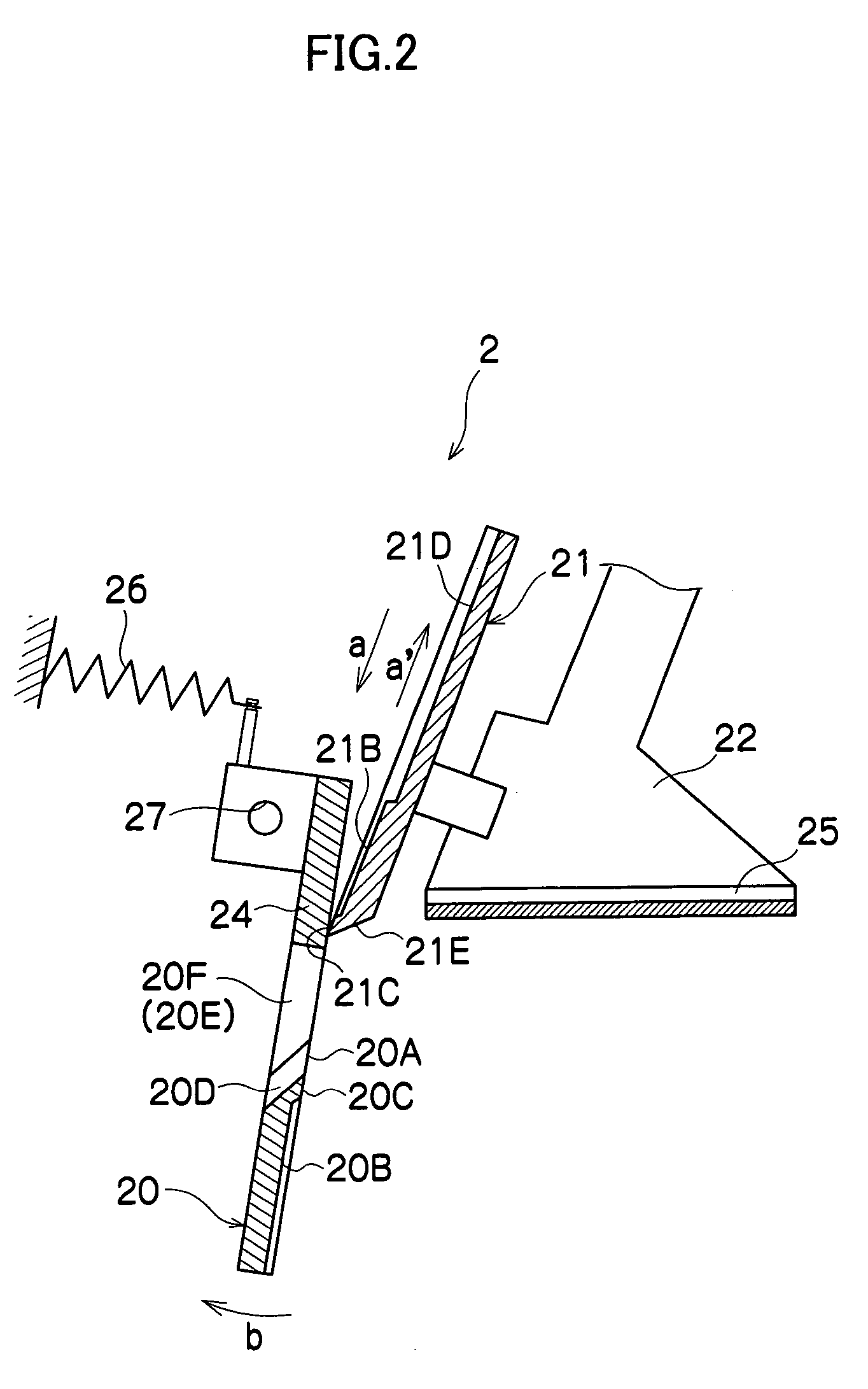

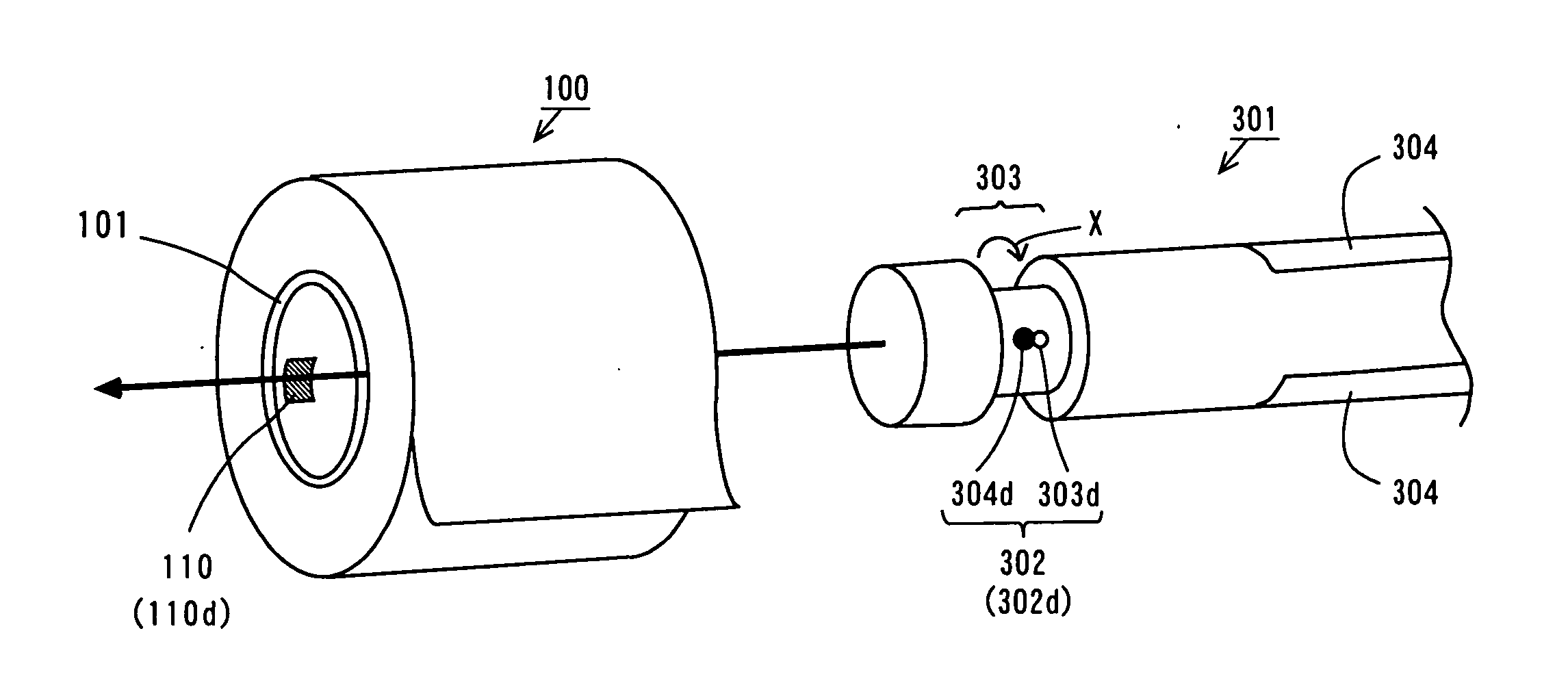

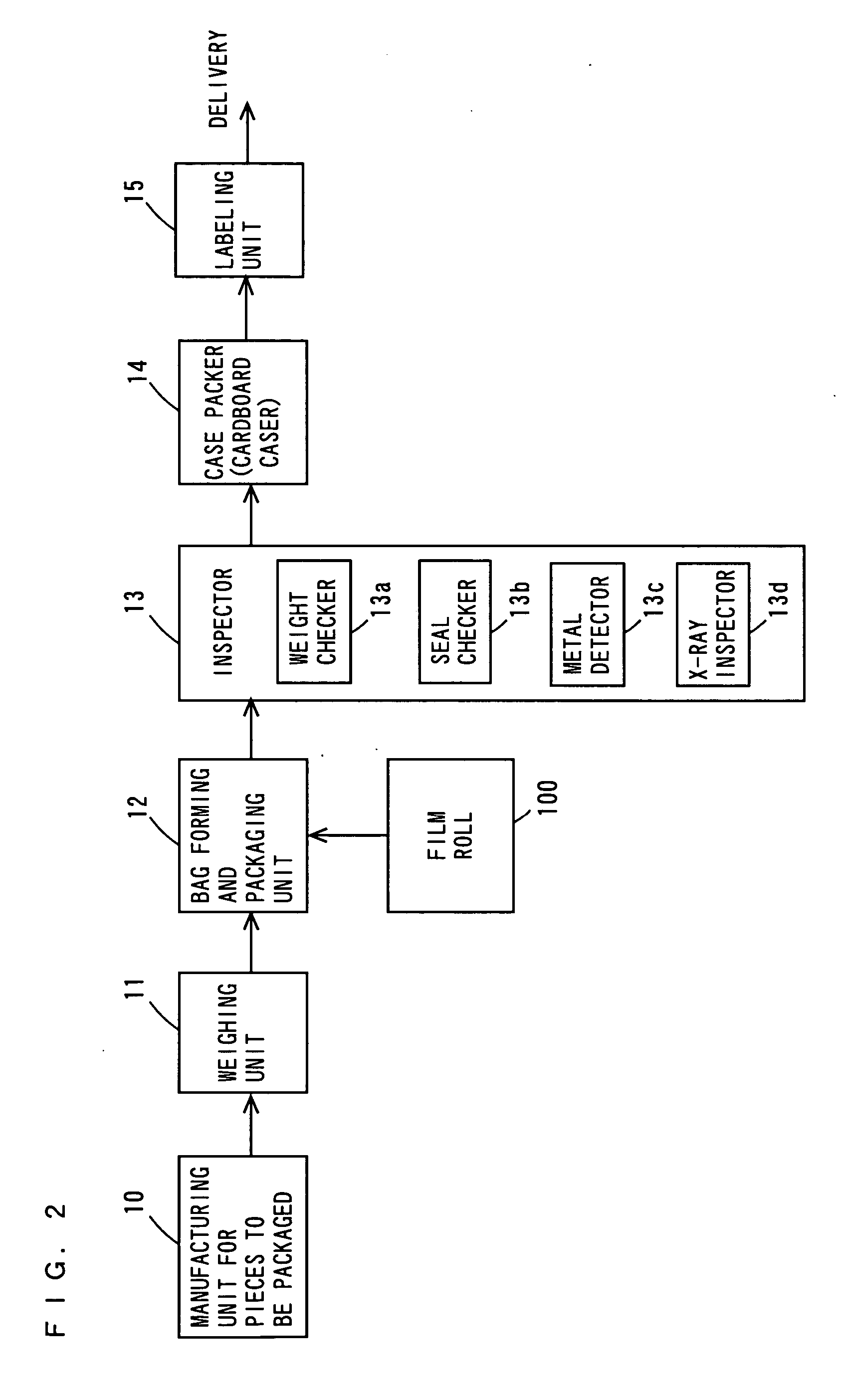

Packaging material roll, packing machine using the roll, and commercial goods processing system with the machine

InactiveUS20050198920A1Reduce downtimeReal-time managementWrapping material feeding apparatusOral administration deviceSkill setsEngineering

A packaging condition for packaging a product using a film roll is stored in a recording medium, and the packaging condition is read by a recording medium reading device in a rotator of a support shaft. In this case, an operator can set an optimum packaging condition at the time of exchange of packaging rolls regardless of his / her skill. Therefore, even an unskilled operator would not set an erroneous packaging condition which may result in additional time loss and film loss.

Owner:ISHIDA CO LTD

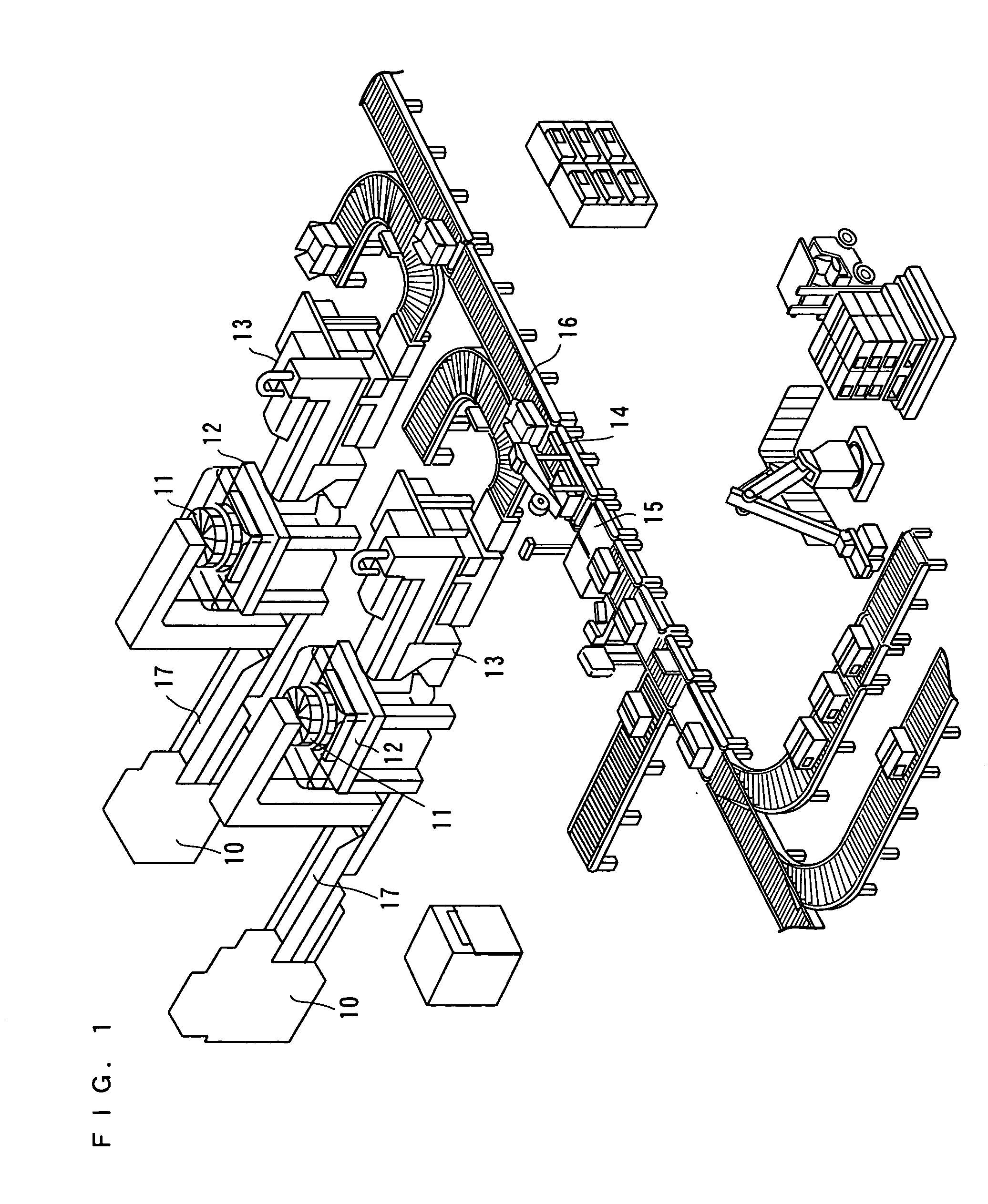

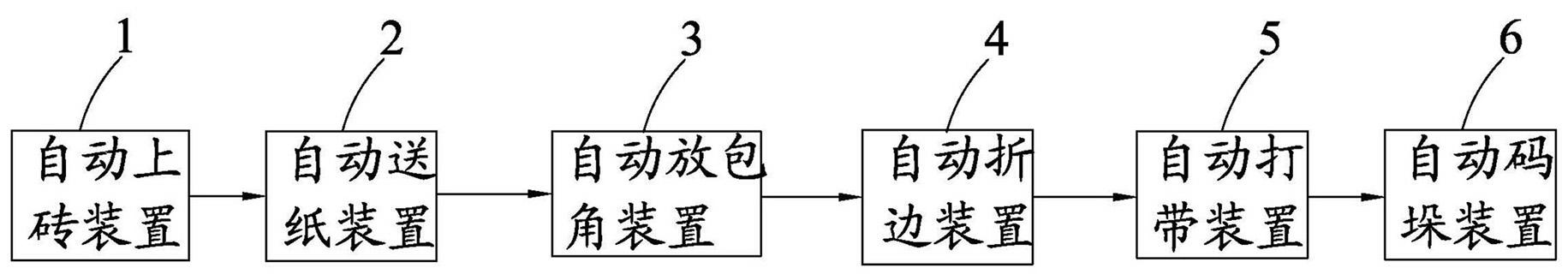

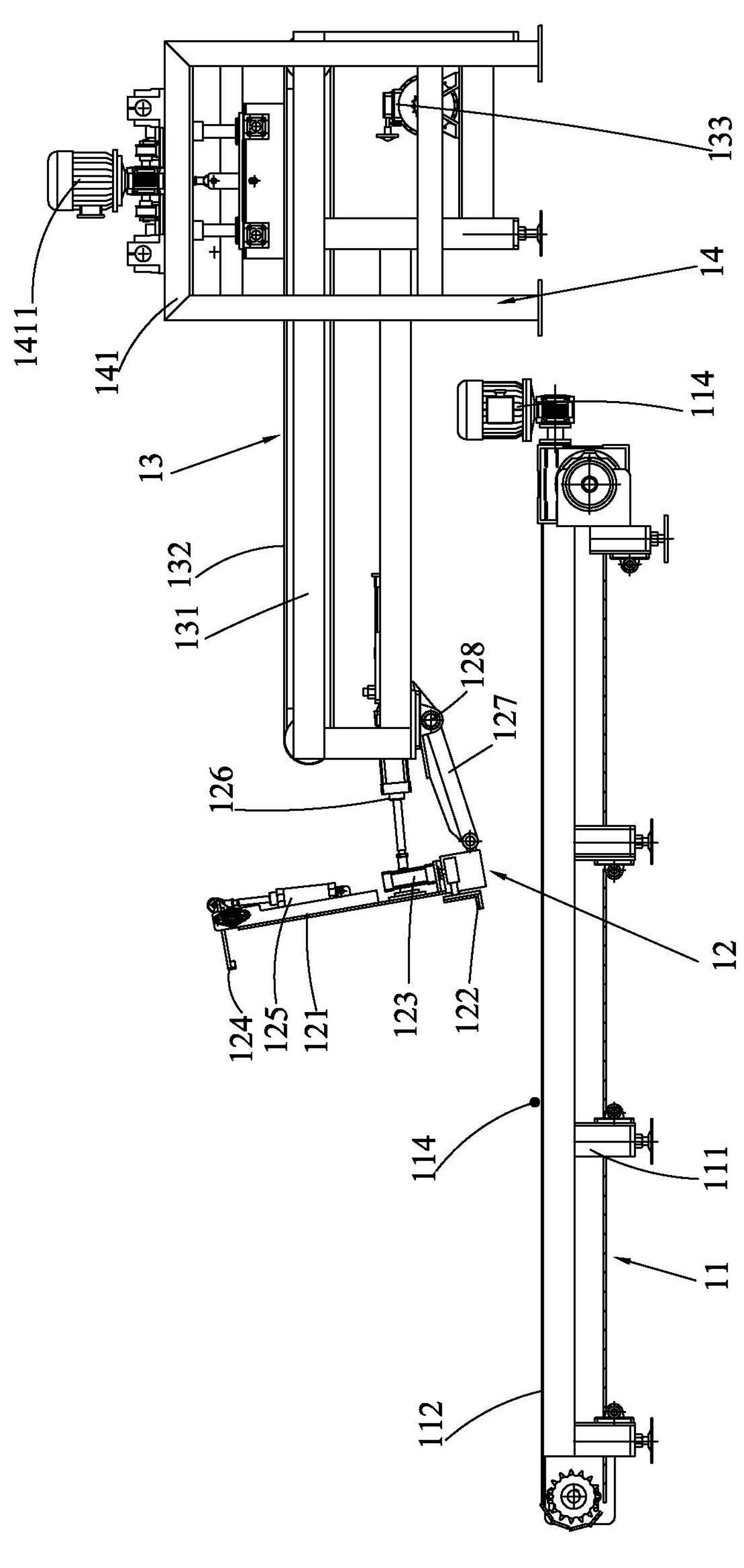

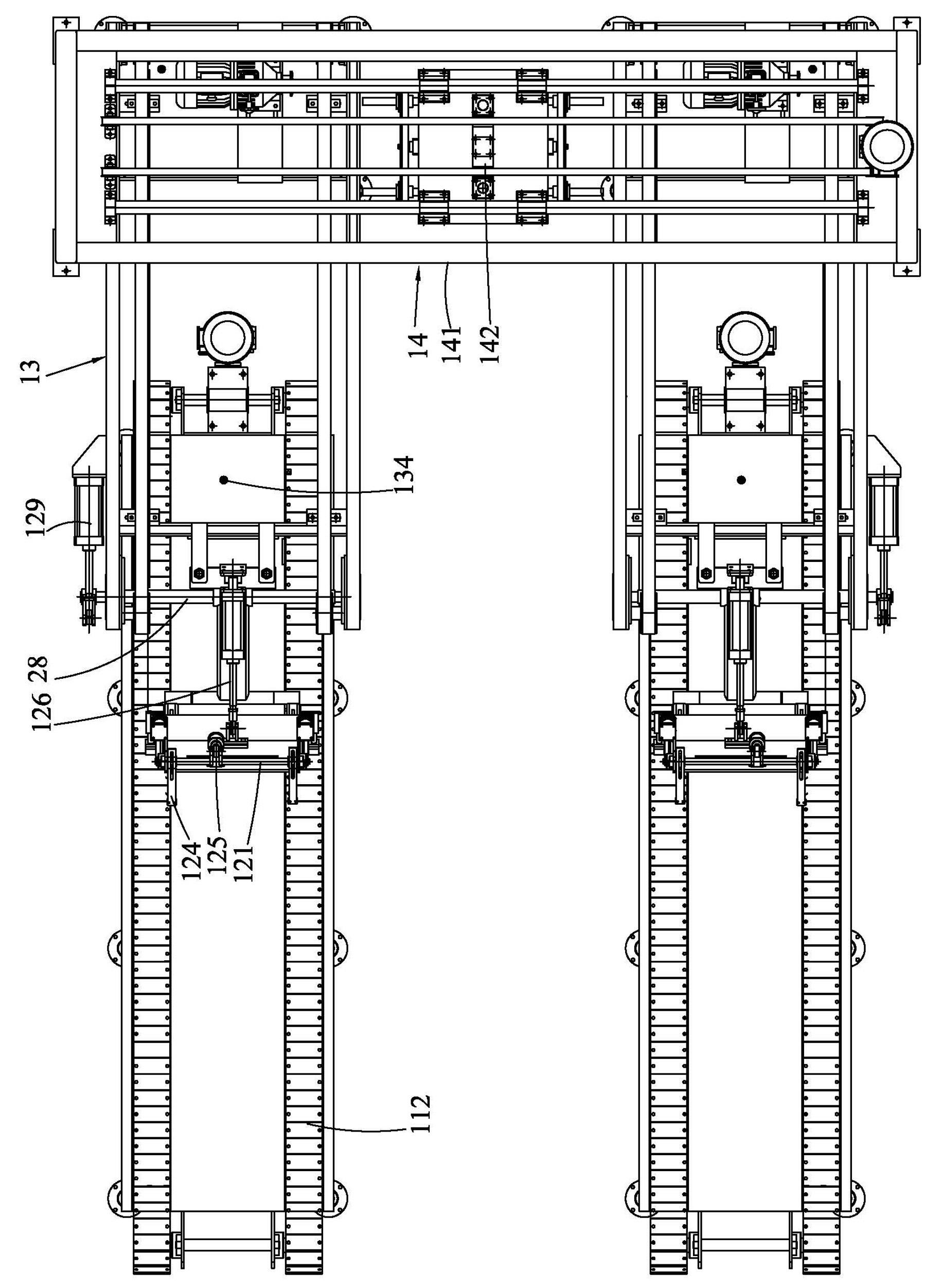

A ceramic tile automatic packaging production line

InactiveCN102275648AReduce labor intensityImprove efficiencyWrapping material feeding apparatusWrapper folding/bending apparatusProduction lineBrick

The invention discloses an automatic packing production line of ceramic tiles, and aims to provide an automatic packing production line of ceramic tiles with low labor intensity, high efficiency and low cost. The automatic packing production line of ceramic tiles sequentially comprises an automatic tile feeding device, an automatic paper feeding device, an automatic angle wrapping device, an automatic folding device, an automatic strapping device and an automatic stacking device. The automatic packing production line of ceramic tiles disclosed by the invention can be used for automatically packing ceramic tiles.

Owner:KING STRONG MATERIAL ENG LTD

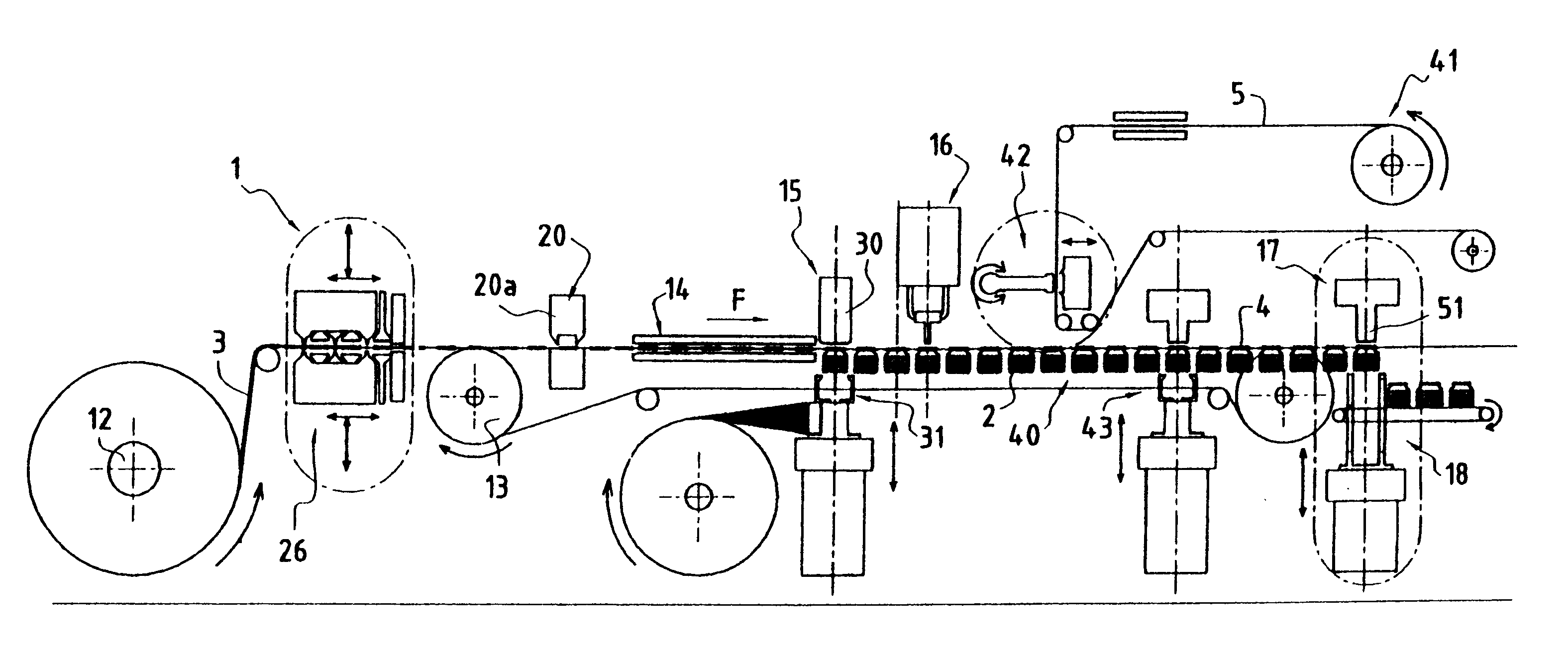

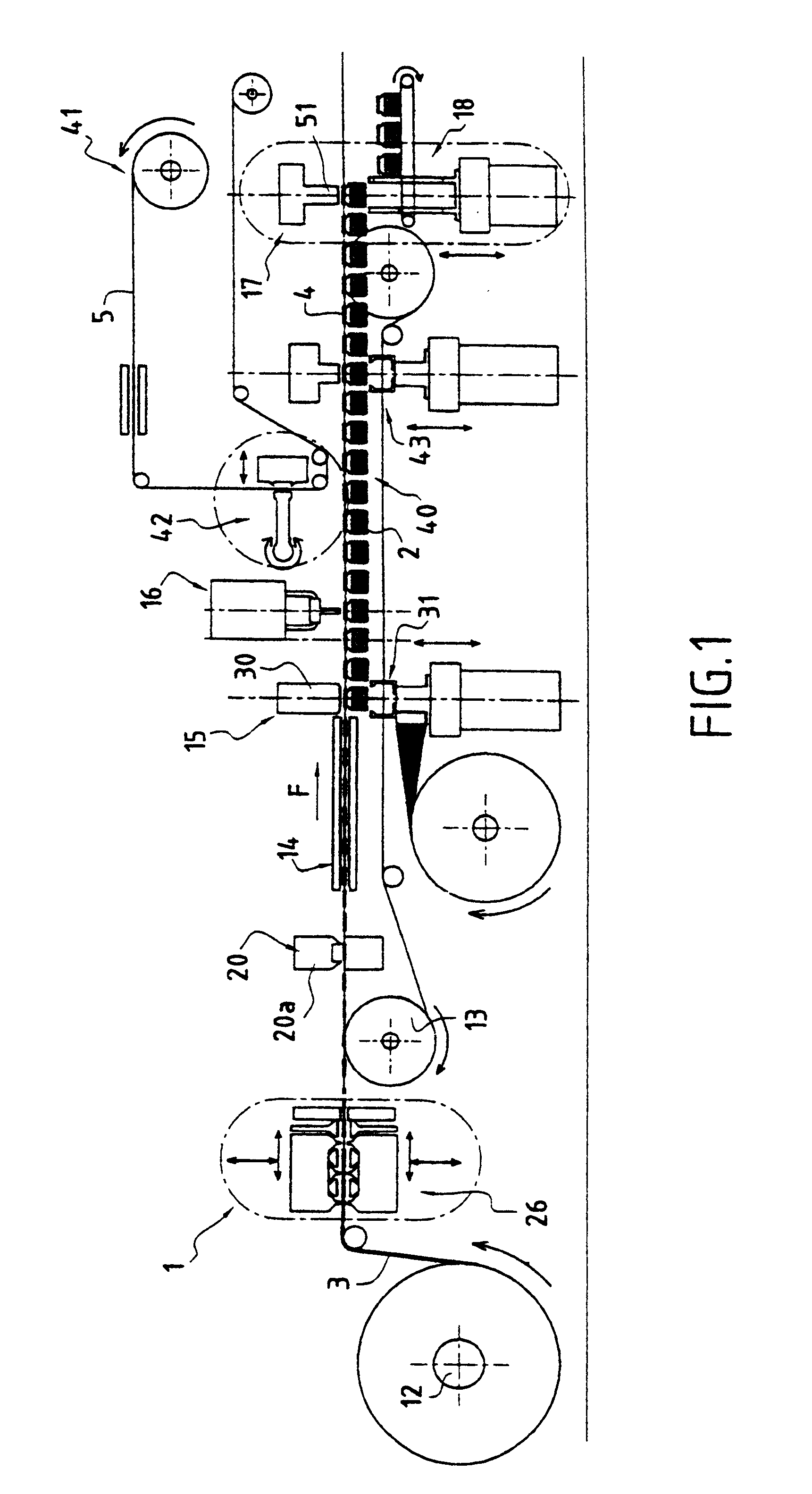

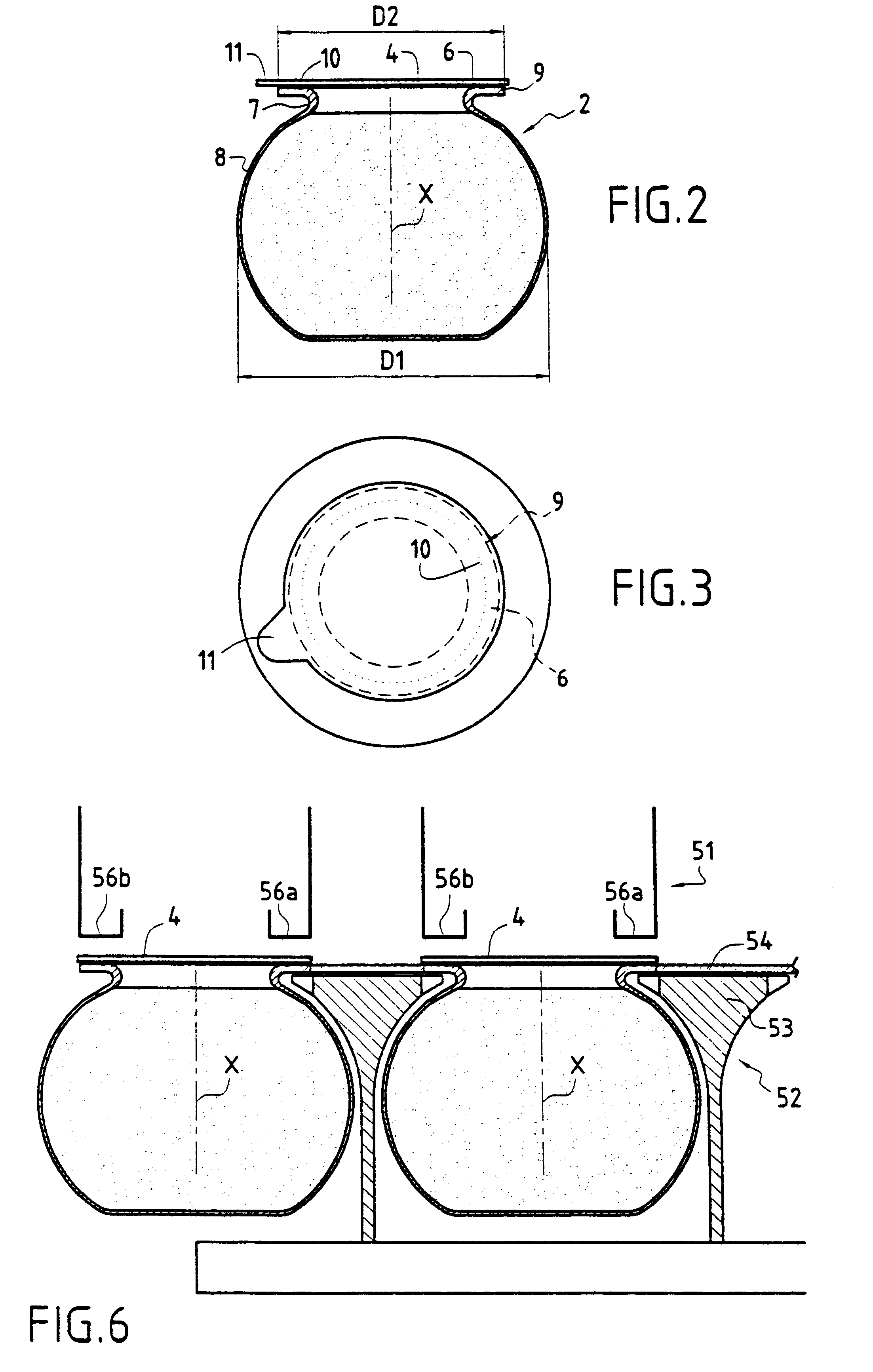

Method and an installation for thermoforming, filling, and closing re-entrant receptacles

The method and the installation of the invention enable re-entrant receptacles to be thermoformed, filled, and closed, the rim of each receptacle having a diameter that is smaller than the diameter of its body. Prior to thermoforming a row of receptacles, preliminary cuts separated by attachment points are made in a transverse stripe of the strip of the thermoplastic strip that is to be used for thermoforming in a subsequent cycle, and for each receptacle that is to be thermoformed, the cuts define practically the entire final periphery of the rim of said receptacle, the attachment points being broken when the receptacles are separated in a subsequent cycle after the filled receptacles have been closed.

Owner:ERCA FORMSEAL

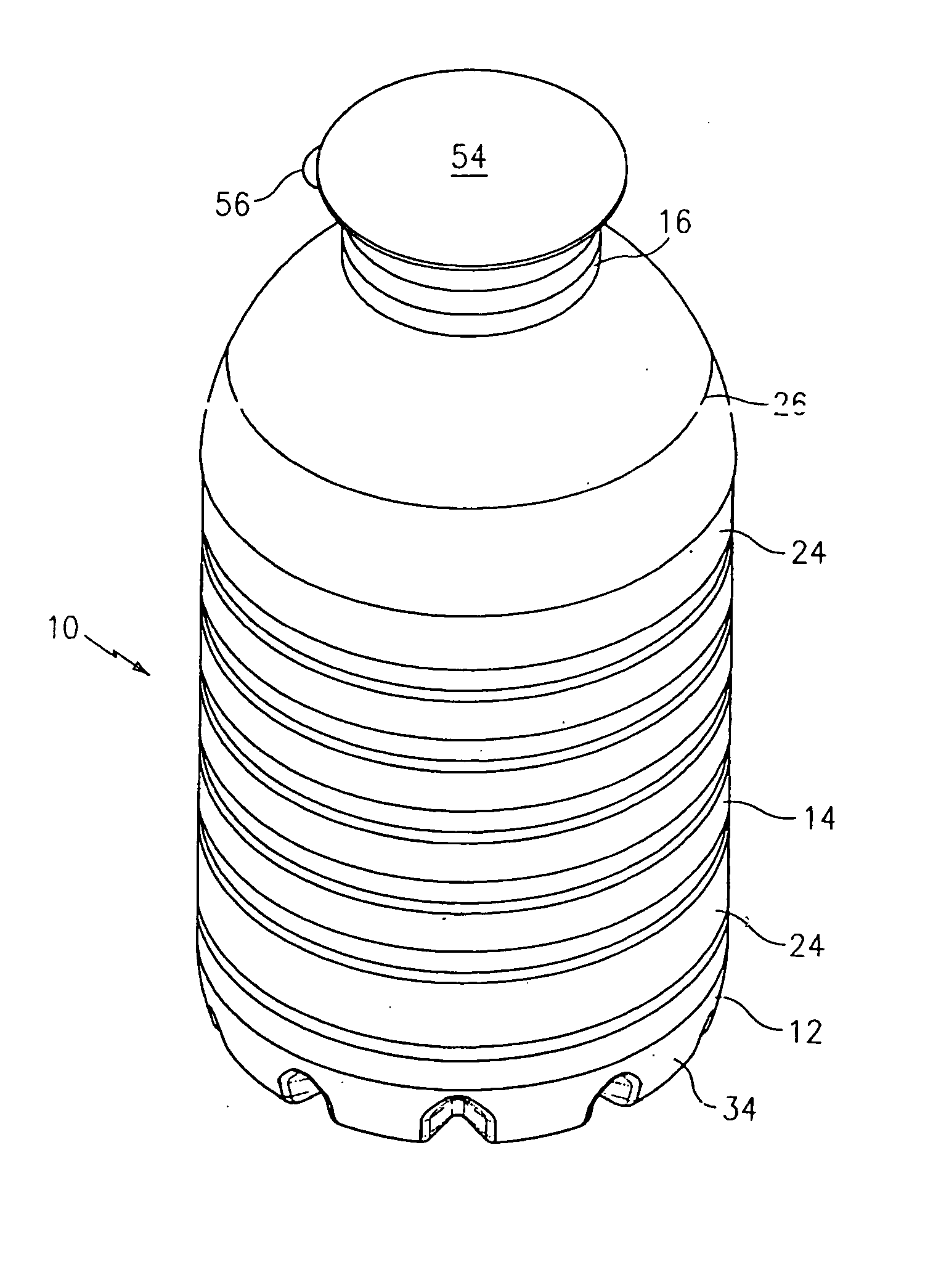

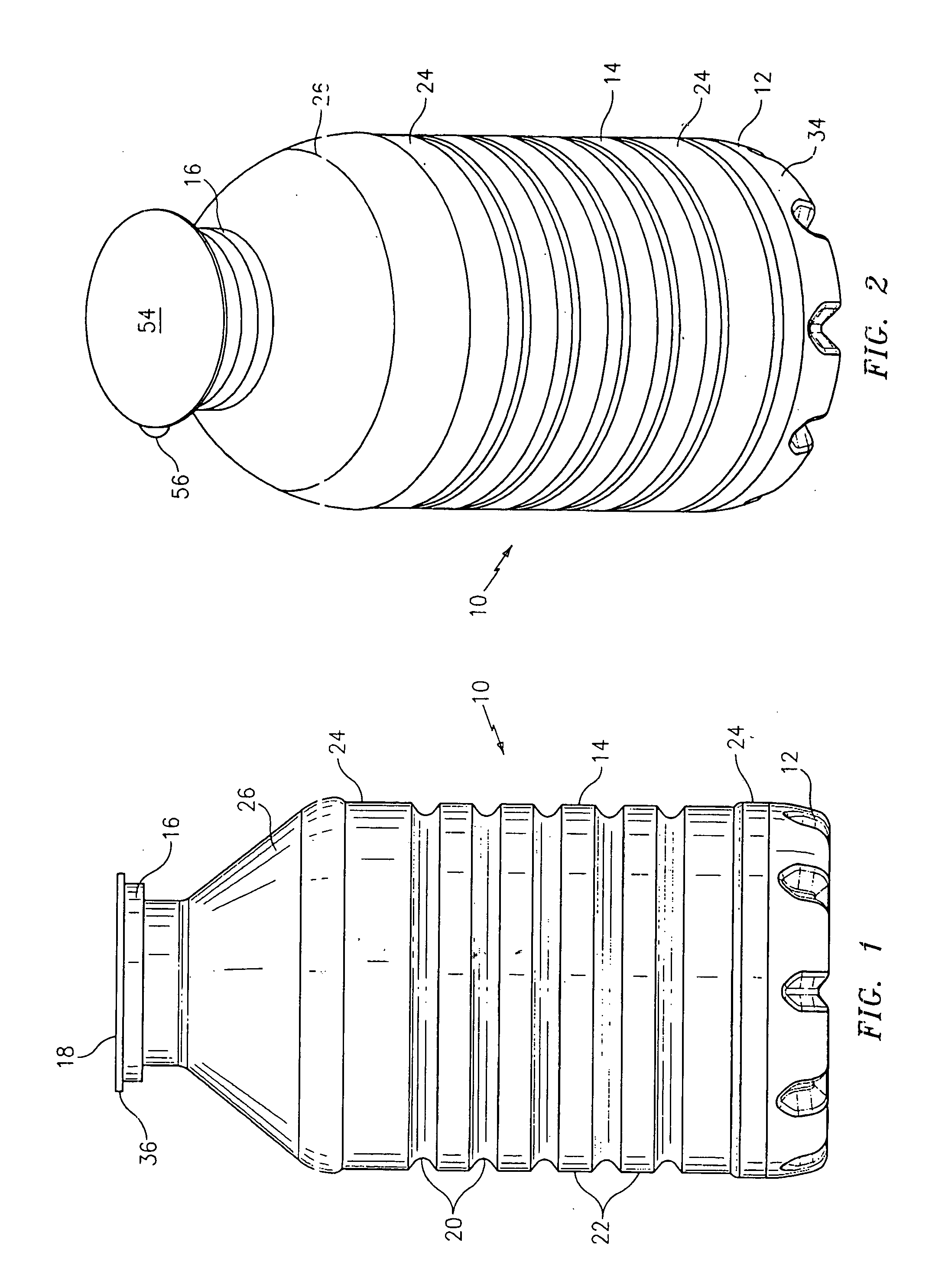

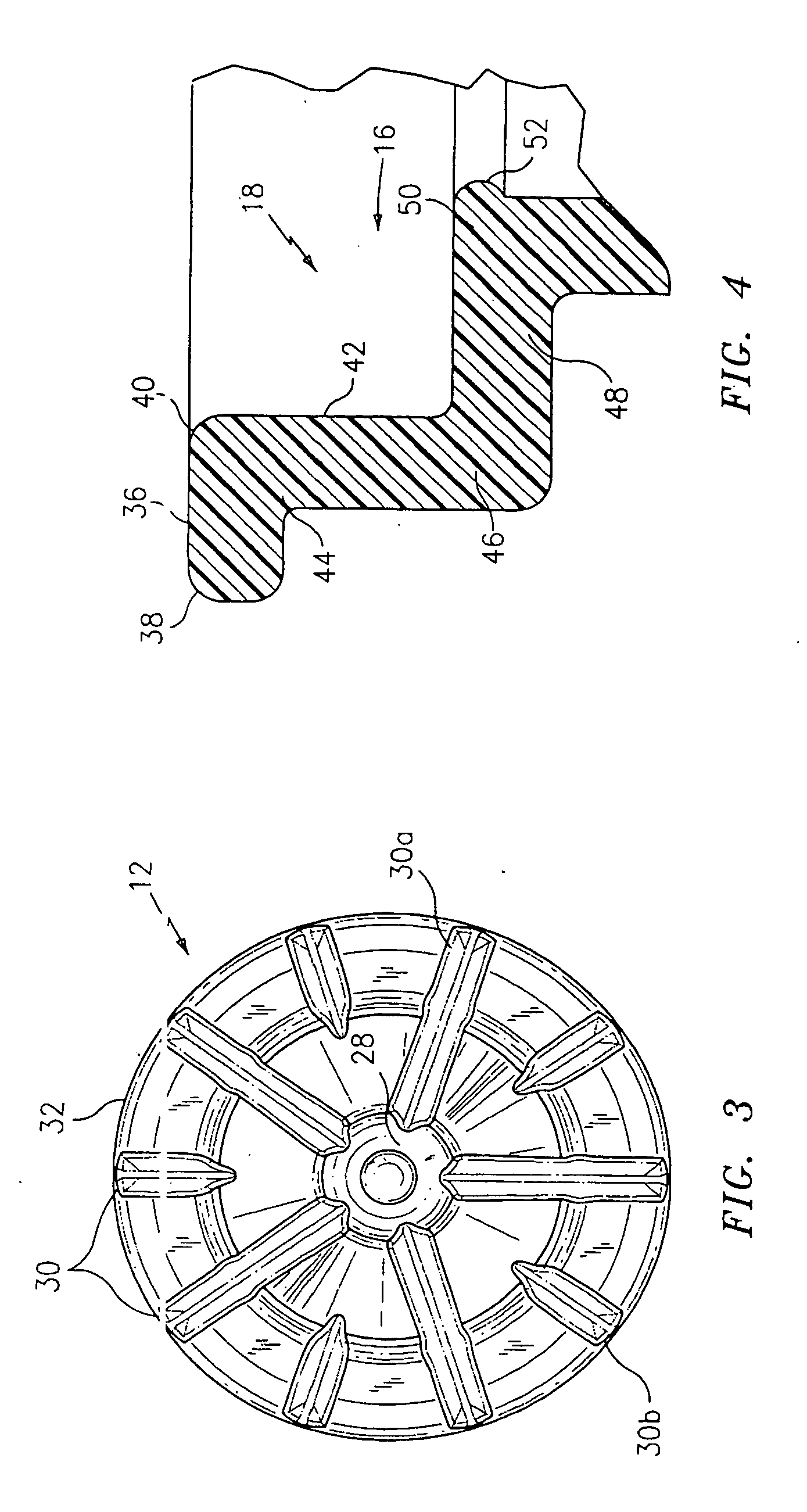

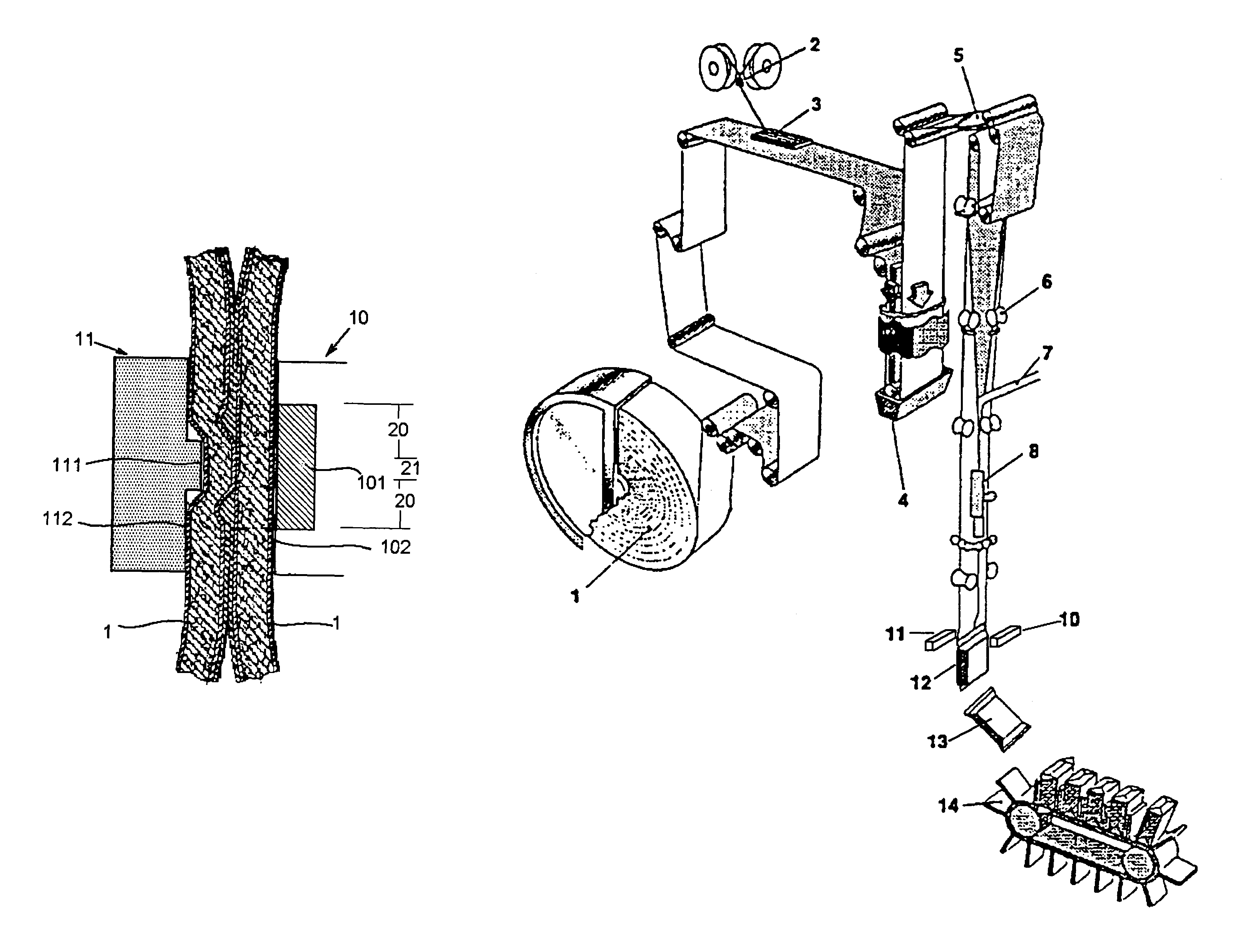

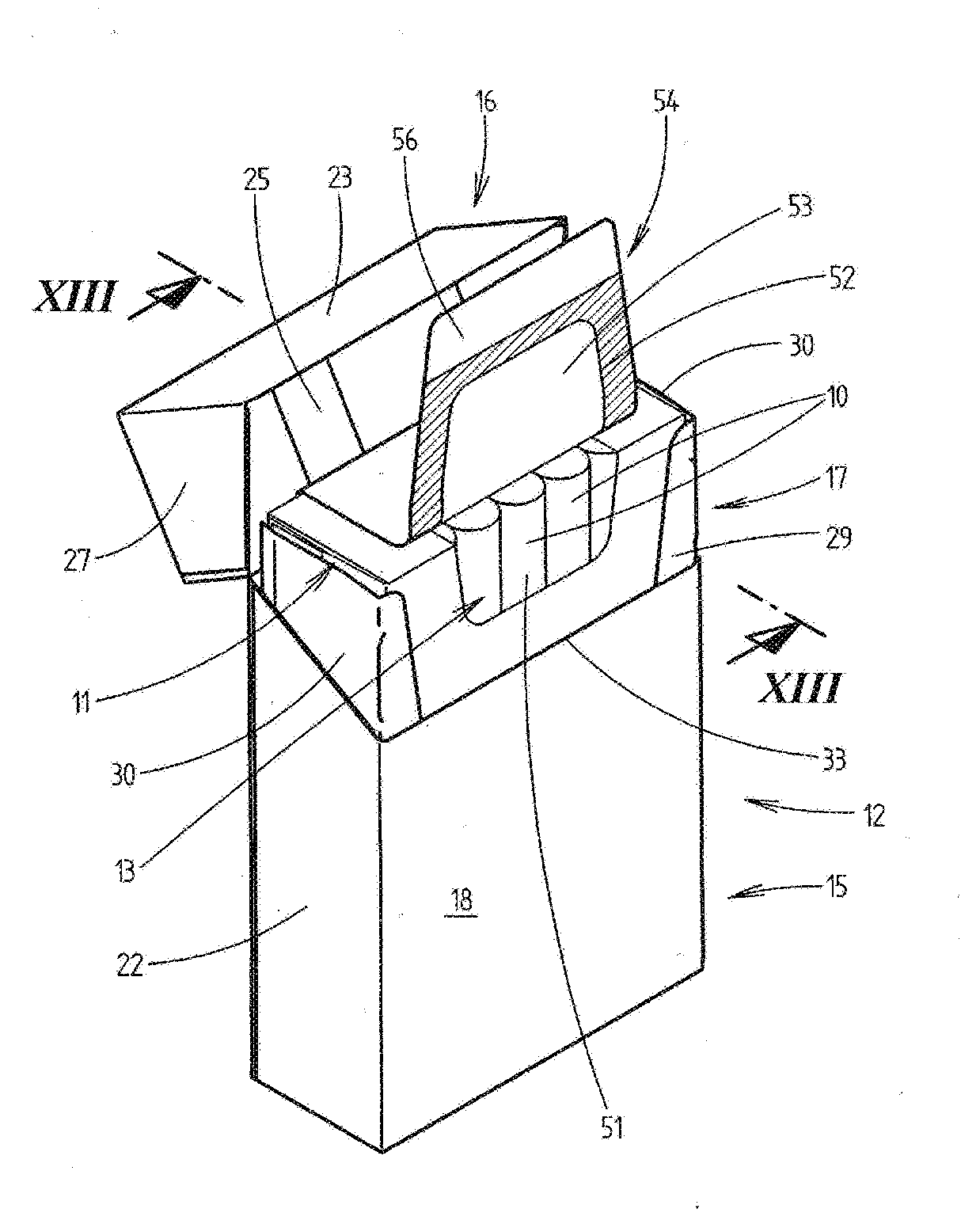

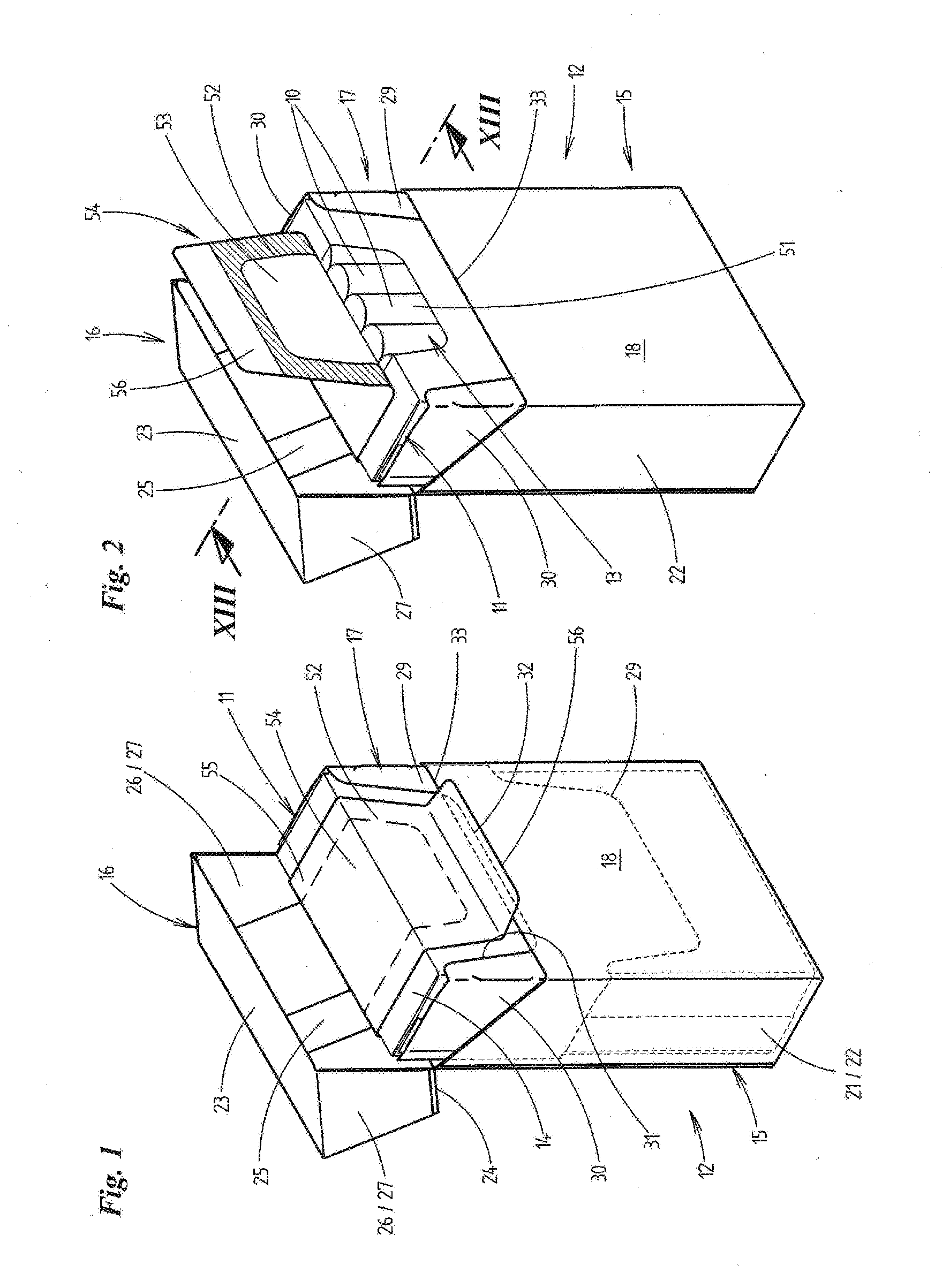

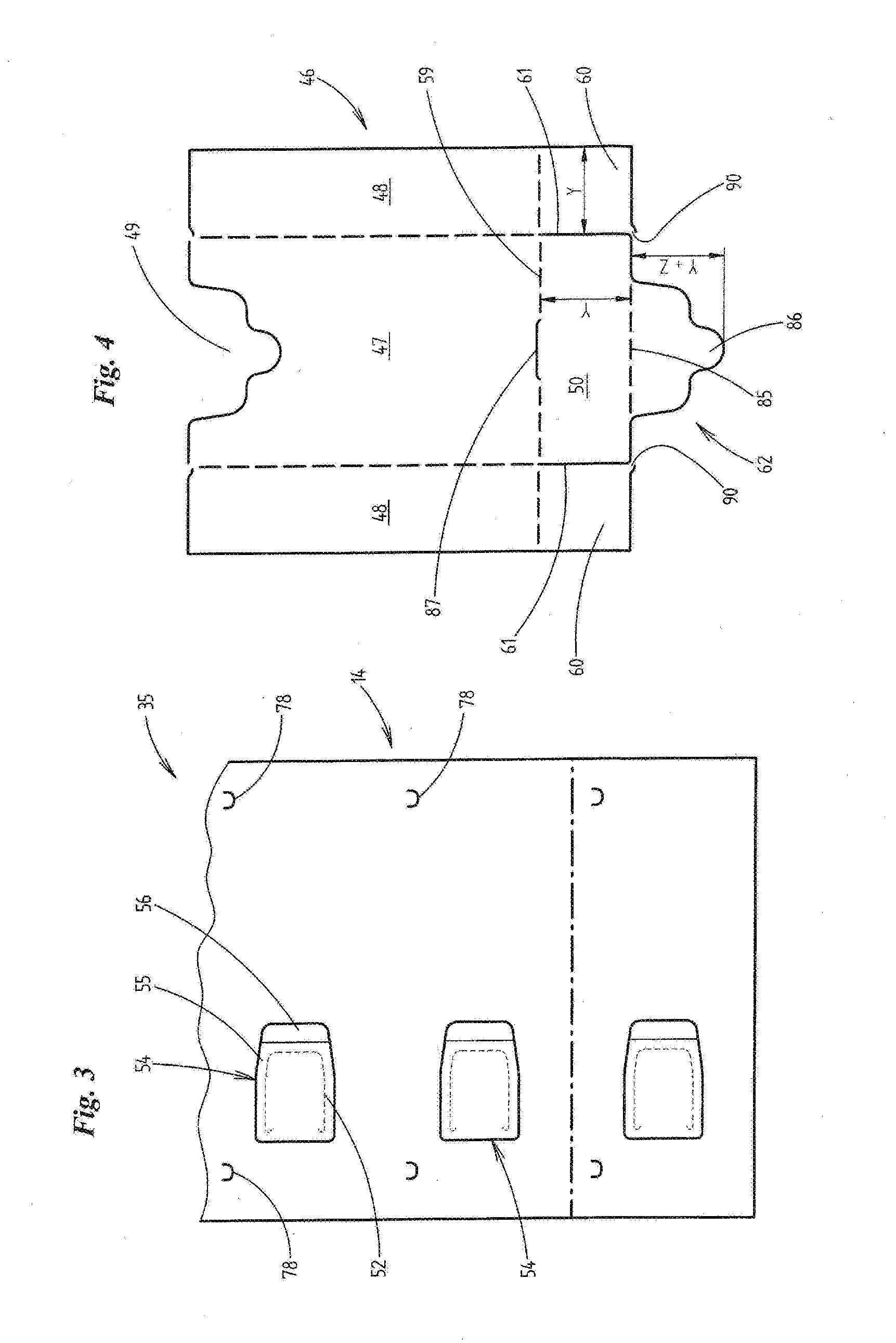

Method for producing a package for cigarettes

ActiveUS20160368645A1Easy to handleSimple production methodContainers for flexible articlesWrapping material feeding apparatusStructural engineeringIndustrial engineering

An aroma-tight cigarette pack with an outer pack (12) configured in the form of a hinge-lid box, and also with an inner pack (11) configured in the form of a sealed block with an opening aid which can be used a number of times. The opening aid has a removal opening (51) which extends in a sub-region of an inner front wall (39) and of an adjacent inner end wall (41) and is covered over by a closure label (54) with an adhesively bonding connecting periphery (55). The inner pack (11) has closure seams (37) which are designed in the form of fin seams.

Owner:FOCKE & CO (GMBH & CO KG)

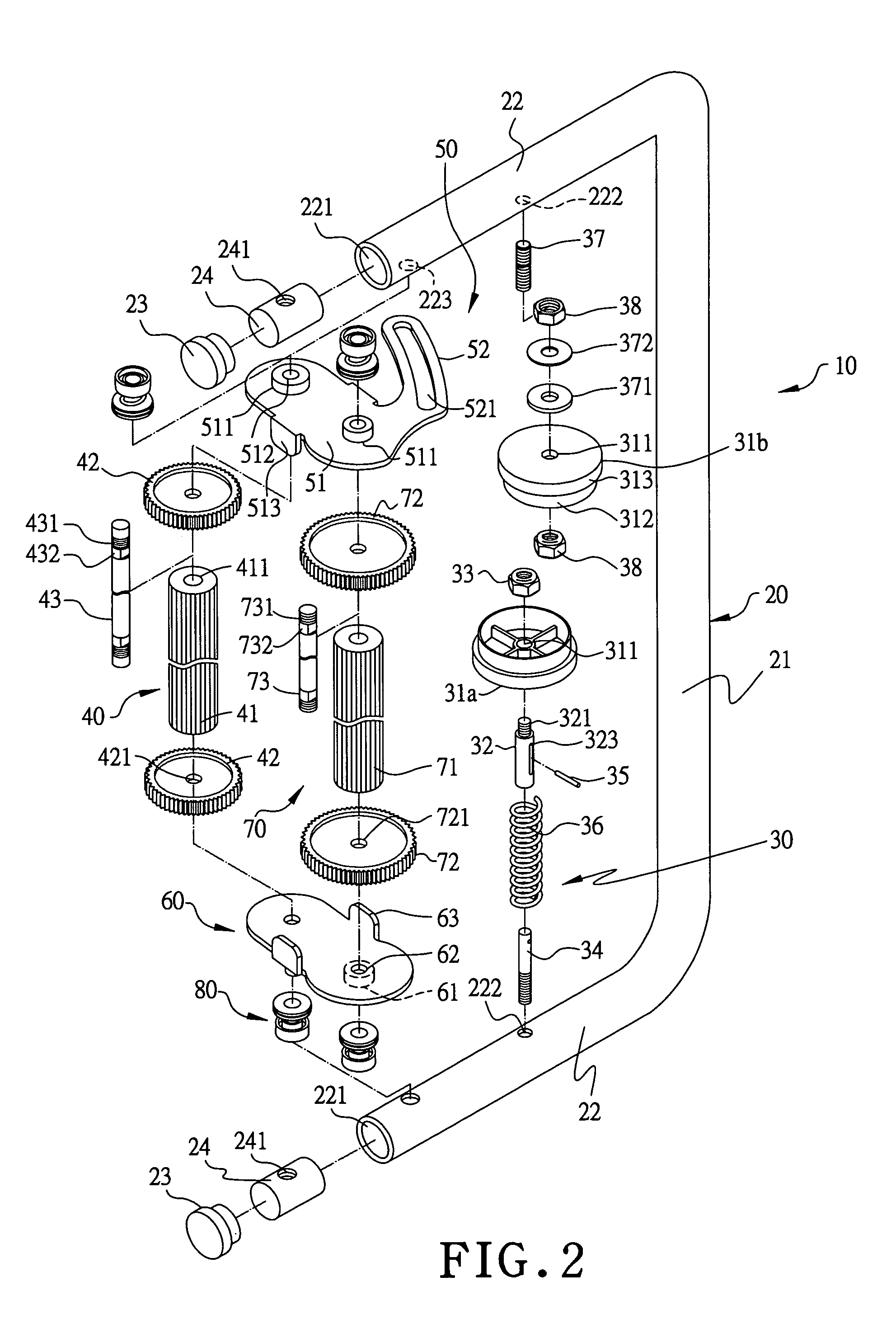

Portable membrane packing apparatus

InactiveUS6920742B1Containers for annular articlesWrapping material feeding apparatusEngineeringMechanical engineering

A portable membrane packing apparatus includes a holding-and-drawing rod, two reel connecting units, a first roller unit, a swaying plate, a connecting plate, a second roller unit, and four elastic compressing units. The first roller unit is axially assembled at the ends of the opposite combing rods, and the swaying plate and the connecting plate are respectively provided between the first roller unit and the combining rods, with the swaying plate restricted to sway biasly.

Owner:VAN GLABBEEK RENE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com