Materials packing machine

A technology of packaging machinery and materials, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult management, uneven packaging quality, low efficiency, etc., and achieve the effect of high work efficiency and excellent packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

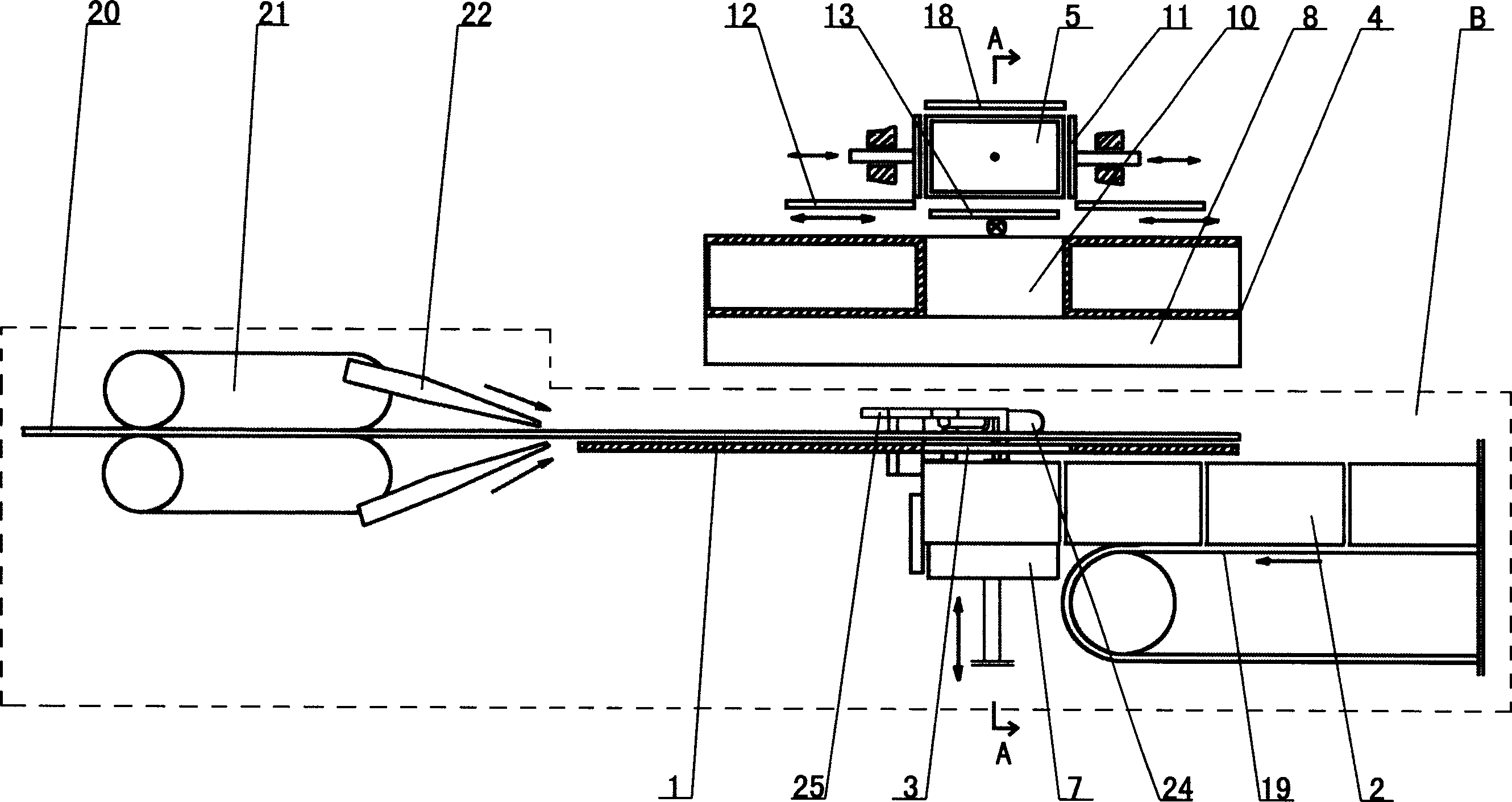

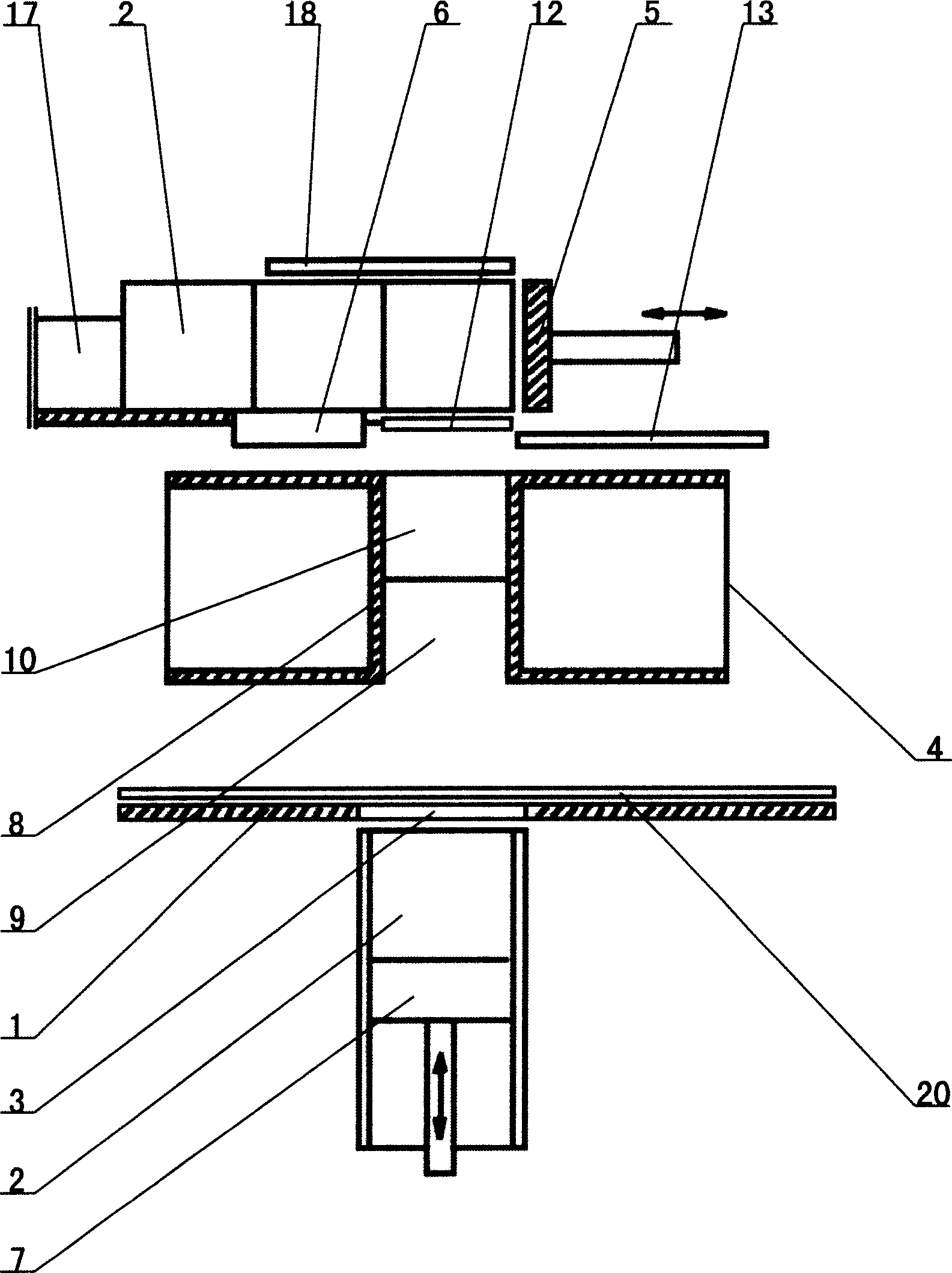

[0030] Such as figure 1 and figure 2 As shown, the material packaging machine includes a film feeding device, a feeding device 19 and a packaging film forming and sealing device, wherein the packaging film forming and sealing device includes a packaging film pallet 1 arranged on the machine base, and the pallet 1 is provided with There is a material through hole 3 whose shape and size match the material 2 to be packaged; and a packaging film former 4 arranged above the material through hole 3 of the packaging film pallet 1; and a material disposed above the packaging film former 4 The positioning clamping part and the material pushing part are perpendicular to the operating direction of the material positioning clamping part and the material pushing part; and a group of material bottom packing hands between the packaging film former 4 and the material clamping part and a set for ironing A hot-sealing plate 6 for sealing the packaging film on the bottom surface of the materia...

Embodiment 2

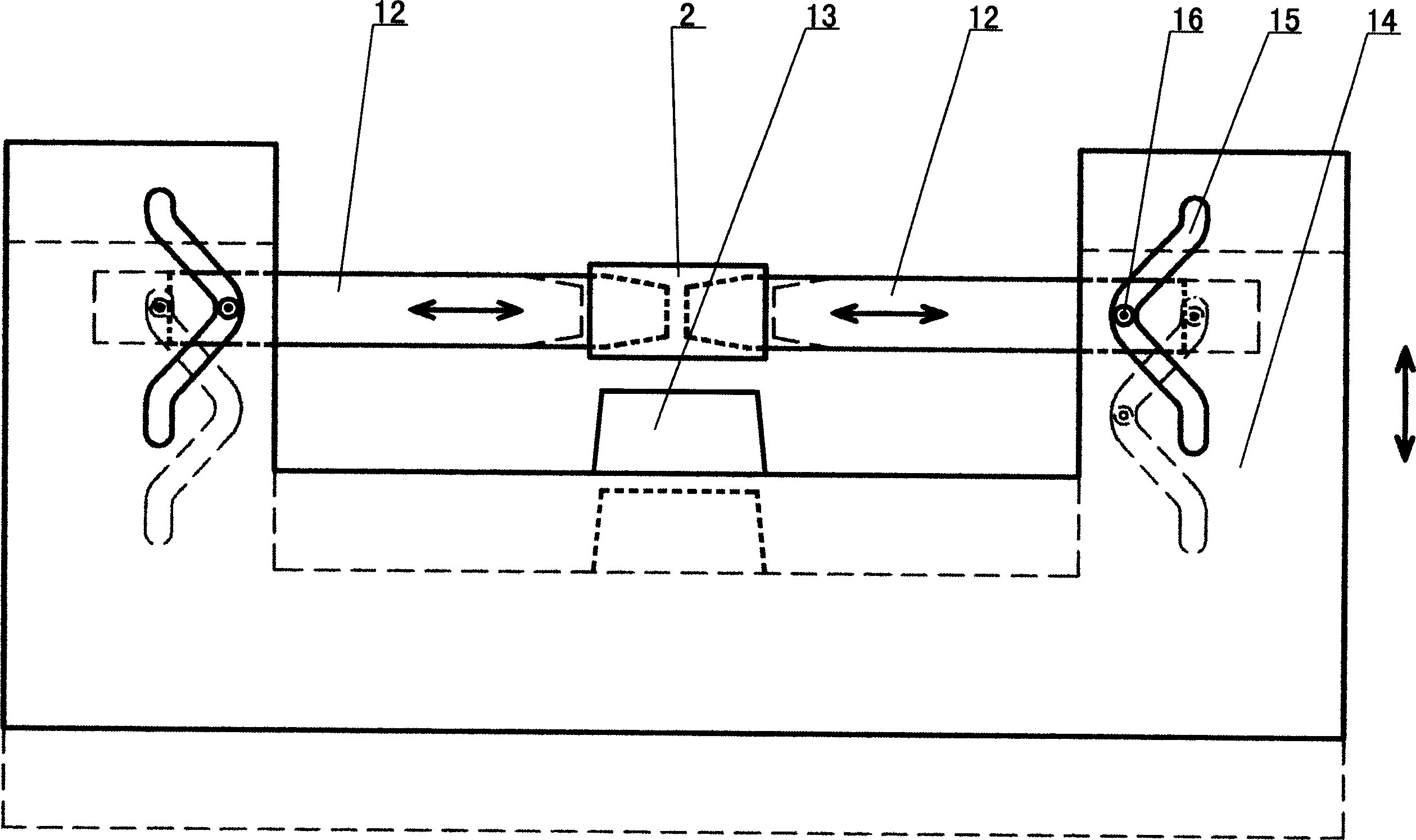

[0052] Such as Figure 5 and Figure 6 As shown, the packaging film forming device 4 of this material packaging machine is provided with a material passage 10, and the shape and size of the cross section of the upper half 31 of the material passage are all matched with the material through hole 3 on the supporting plate 1. Half part 31 is positioned at the top of material through hole 3; Material passage lower half 32 is the trumpet-shaped space that is surrounded by four planes 33, and its cross-section increases gradually from top to bottom, and its upper end 34 shape and size and material The cross-section of the upper half 31 of the channel is the same and aligned with the upper half 31 of the material channel. The lower half 32 of the material channel guides the packaging film blocks on the material 2, and the material channel 10 gradually becomes smaller from bottom to top, which can reduce the resistance of the packaging film blocks, and is more conducive to completing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com