Automatic thin film winding machine for packaging steel coils

A packaging and winding machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low production efficiency, waste of human resources, high production costs, etc., to improve packaging quality, reduce labor intensity, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

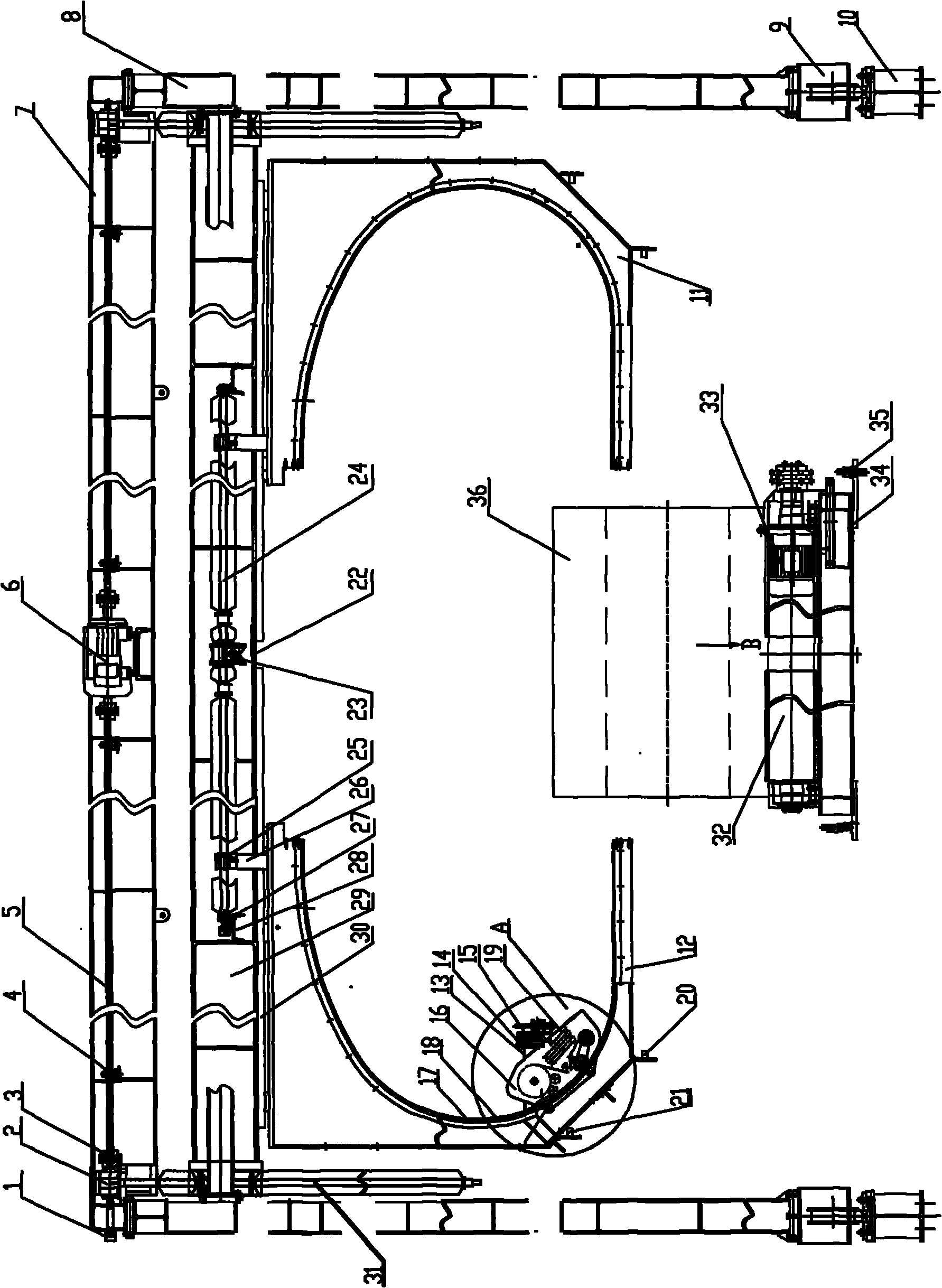

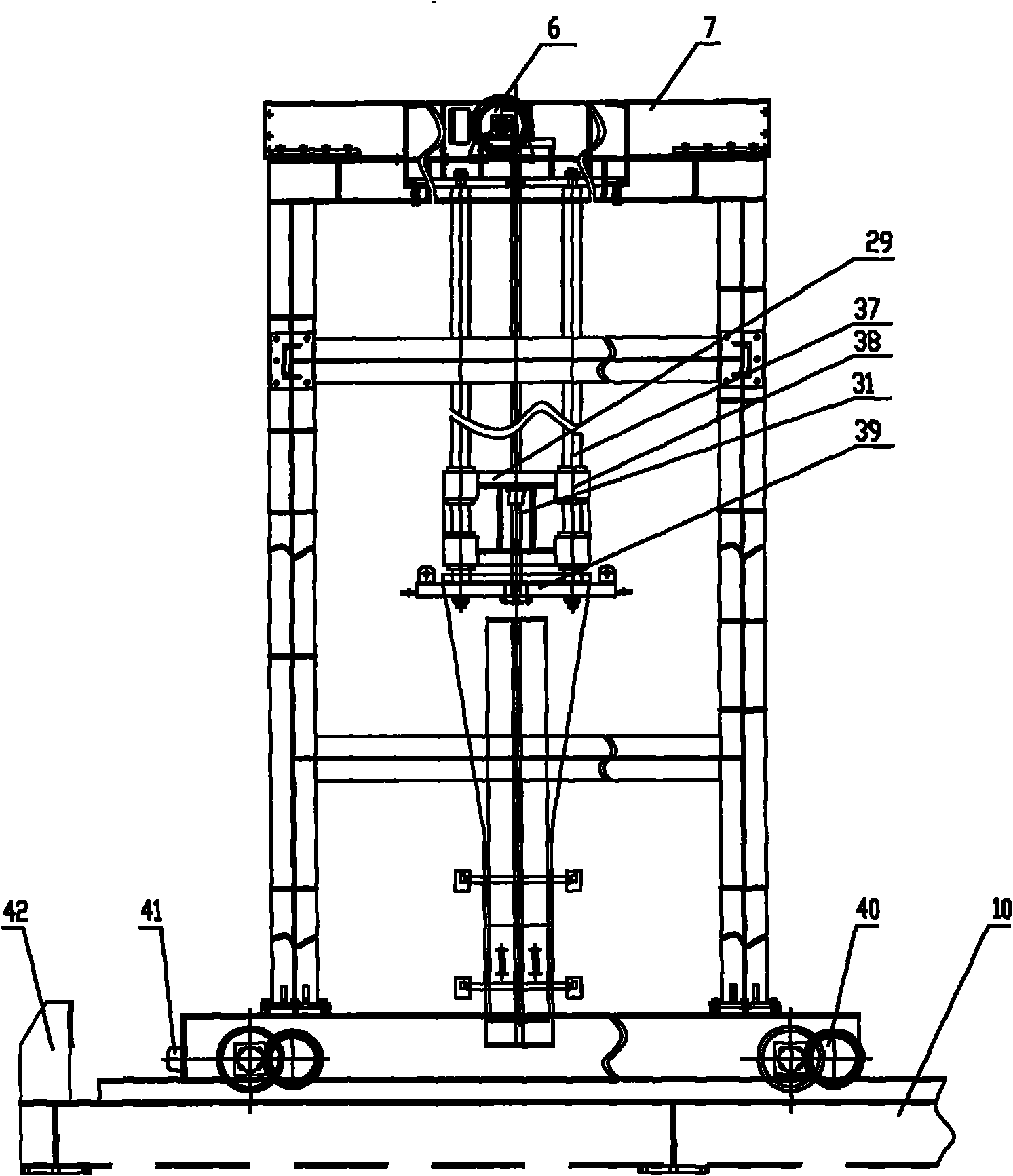

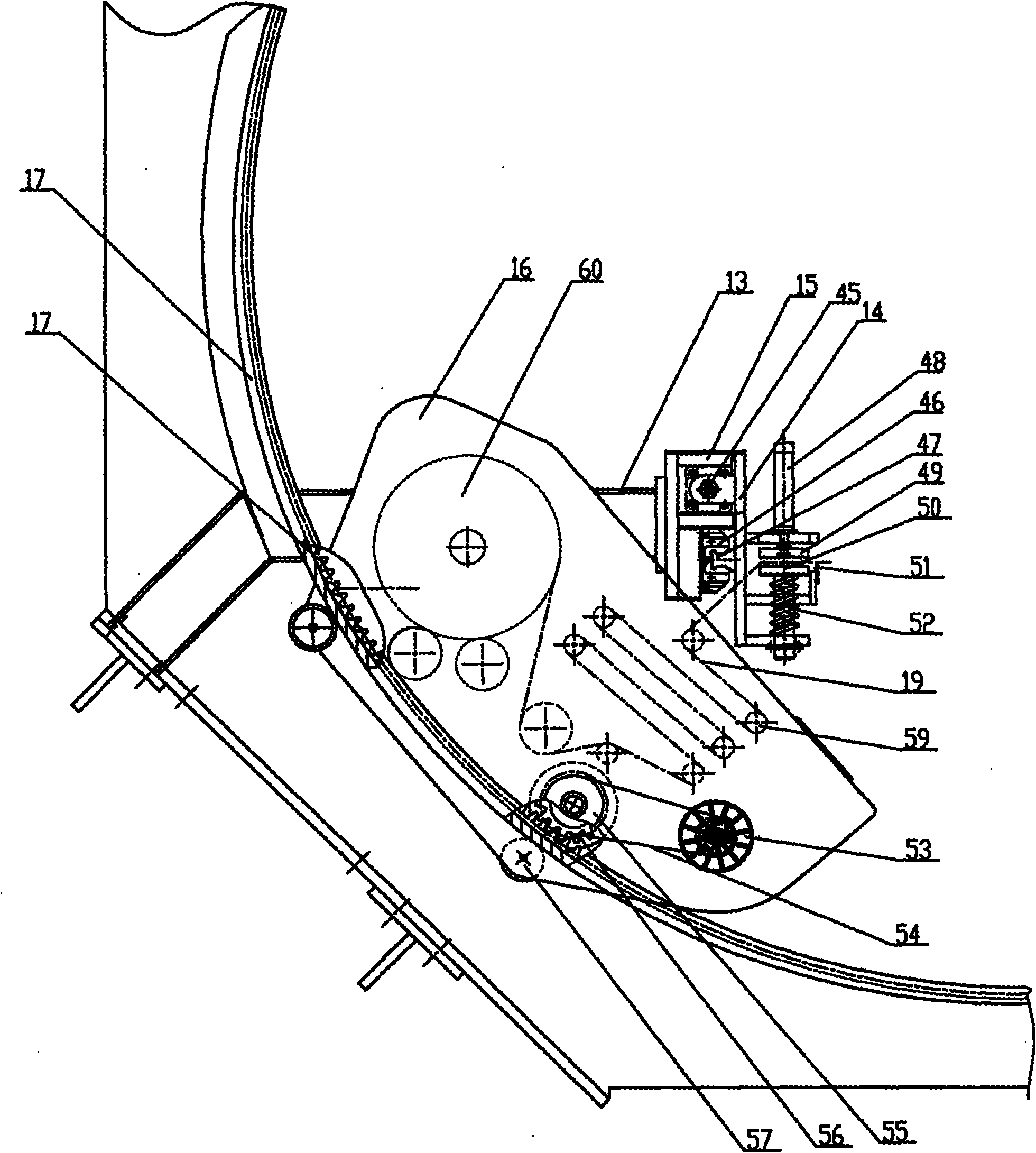

[0021] according to Figure 1-5 The specific structure of the present invention will be described in detail. The automatic film winding machine for steel coil packaging includes two main frames 8 walking on the track 10, the main frame connecting crossbeam 7 and a wrapping mechanism for automatic film packaging steel coils on the main frame connecting crossbeam 7, a film sports car 16 and Electrical control devices and other components with PLC programmable control modules as the core. Wherein the bottom of main frame 8 is assembled with main frame moving base 9 with rollers, the main frame moving motor 40 that is fixed on the main frame moving base 9 drives the rollers to rotate, so that main frame 8 and its main frame connect the package on crossbeam 7 The roll mechanism and the like travel along the track 10 together with the rollers. The main frame moving base buffer 41 arranged at one end of the main frame moving base 9 and the track limit stopper 42 arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com