Steel bar bounding, clamping and forming method and device thereof

A technology of clamping position and bar, applied in the parts, packaging and other directions of strapping machinery, which can solve the problems of large machine, complex device structure and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

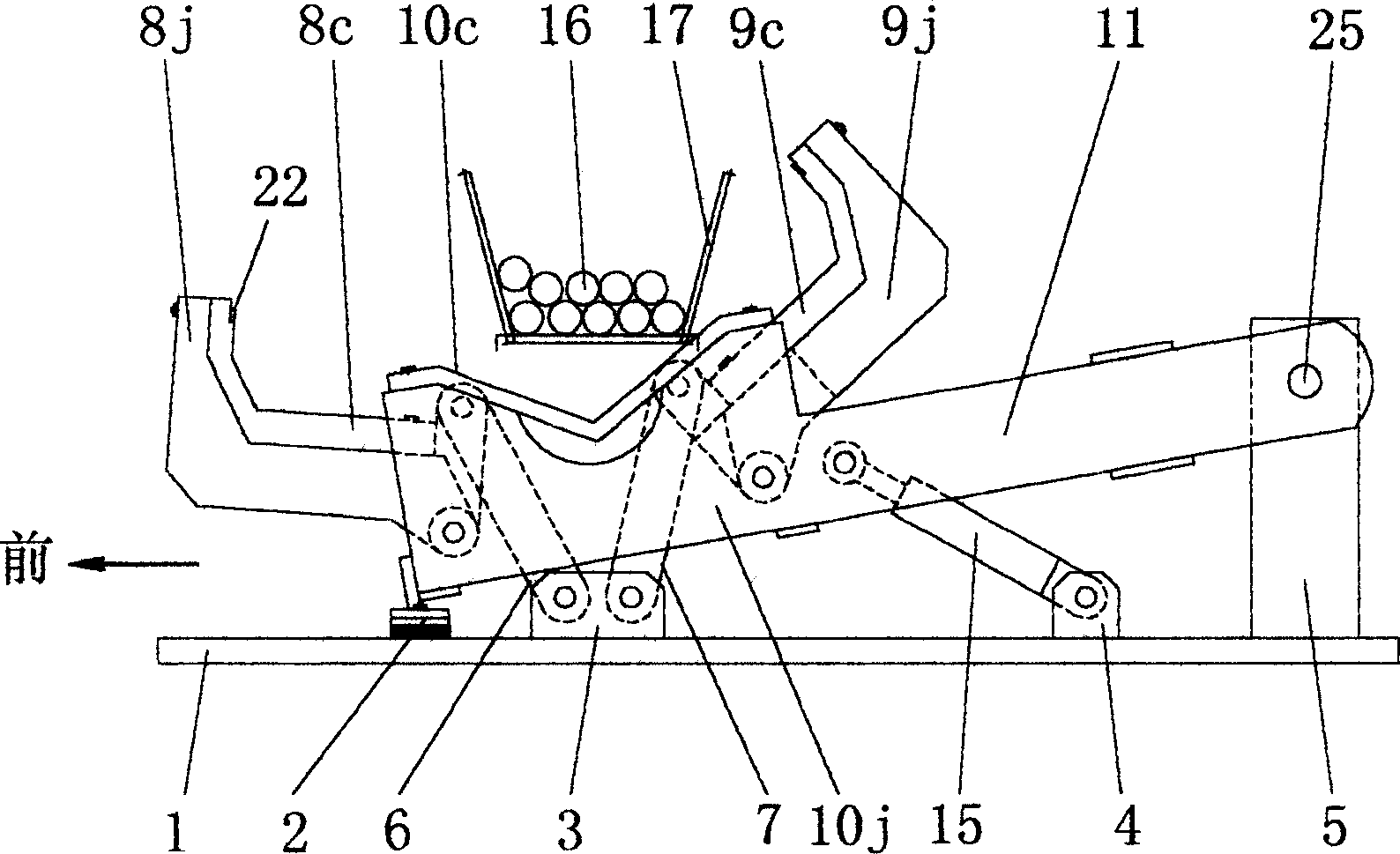

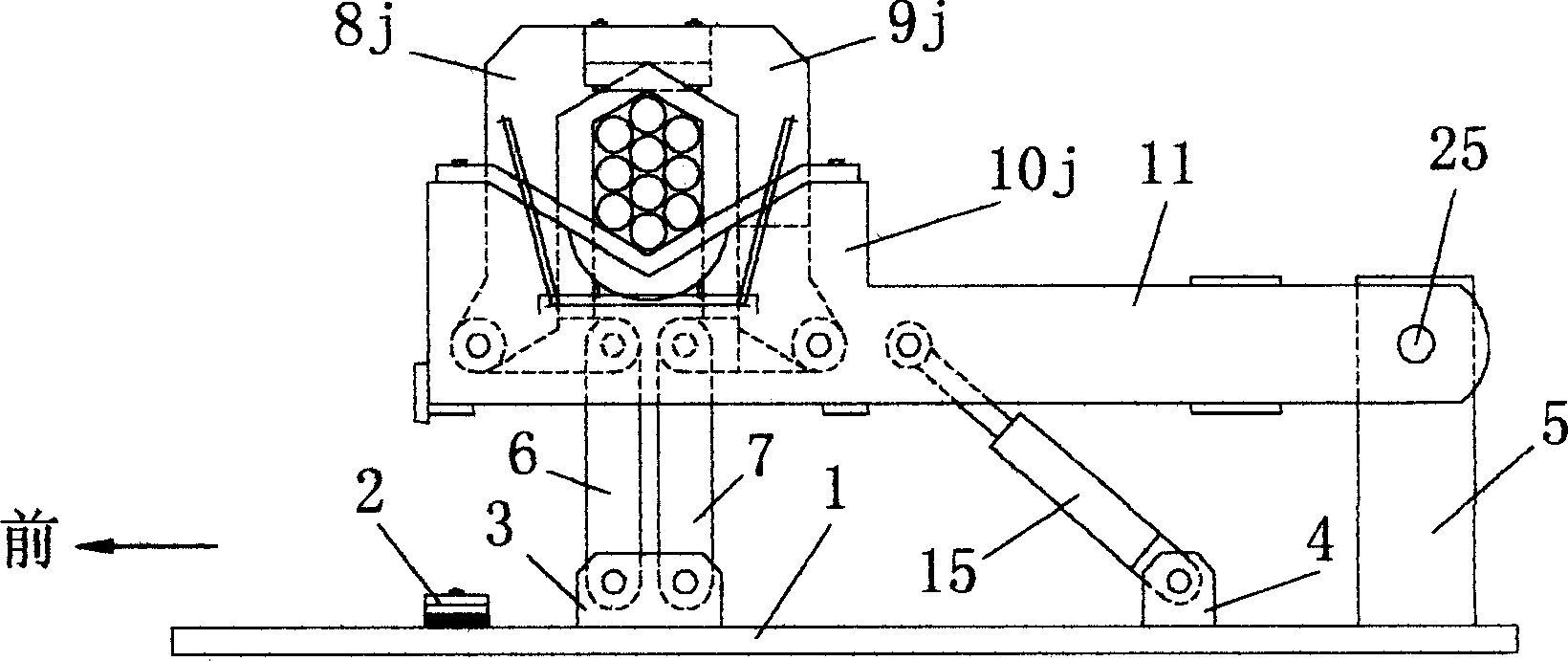

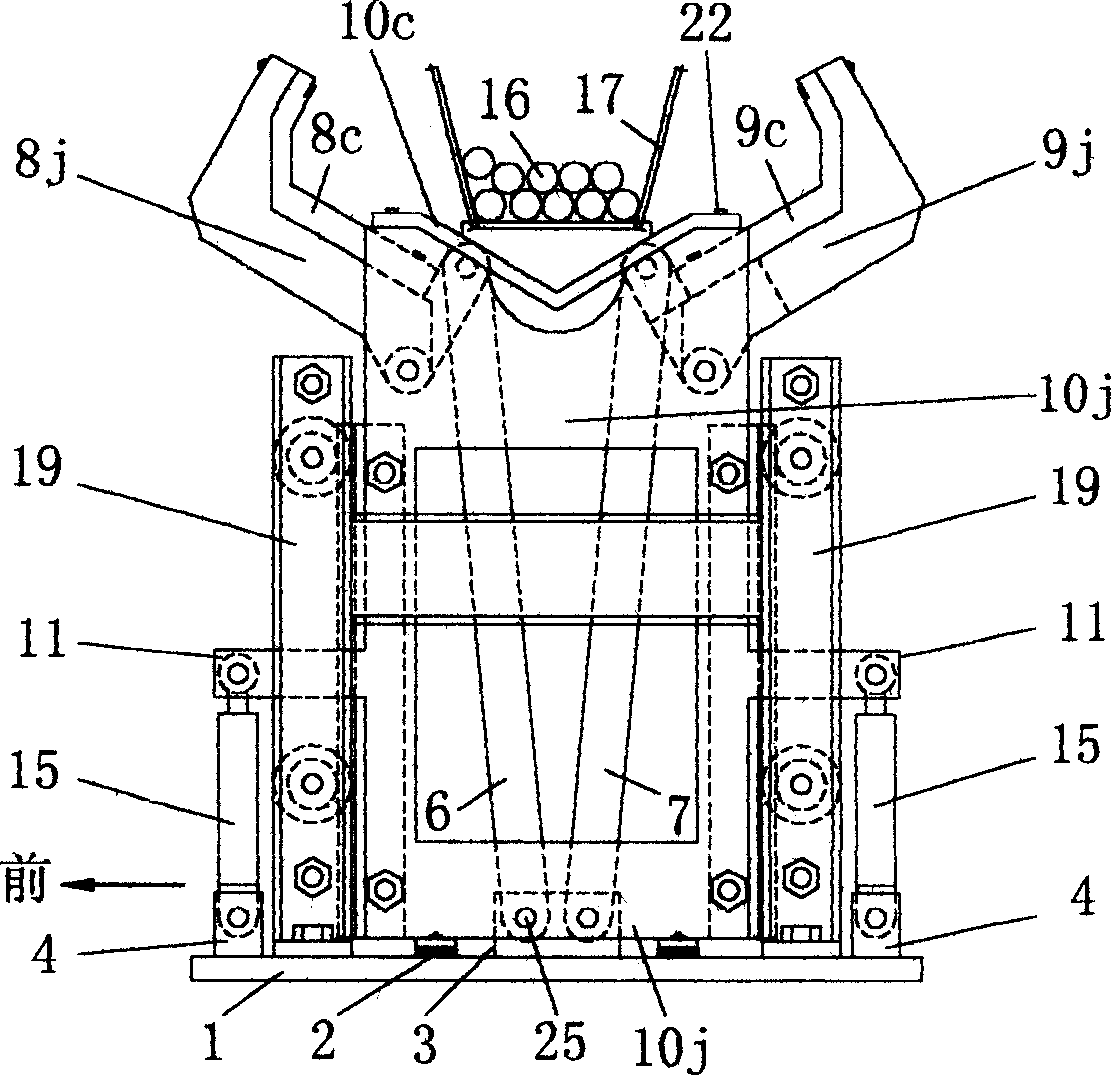

[0047] A method for forming bars by bundling and clamping them. refer to Figure 19 , including three rigid claws with front claws, rear claws, and supporting claws to clamp and form the bar group. The process of clamping and forming is divided into two steps:

[0048] The first step is to use the supporting claws 10 extending with guide slopes on both sides of the bundle-shaped part to hold up the rods 16 that are placed on the bottom of the rod conveying groove 17 and prepare to be bundled, so that the rods 16 on both sides of the bundle-shaped position are in the On the guide slope, the adjacent rods 16 are in mutually undulating and staggered positions in the direction in which the front paws 8 and the rear paws 9 move toward each other.

[0049] The second step is that the opposite-moving front claws 8 and rear claws 9 start to squeeze the rods 16 on the guide slope, so that the undulating and staggered rods 16 squeeze into the upper space through the sliding of the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com