A ceramic tile automatic packaging production line

An automatic packaging and production line technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost, low efficiency and high labor intensity, and achieve the effect of low cost, high efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

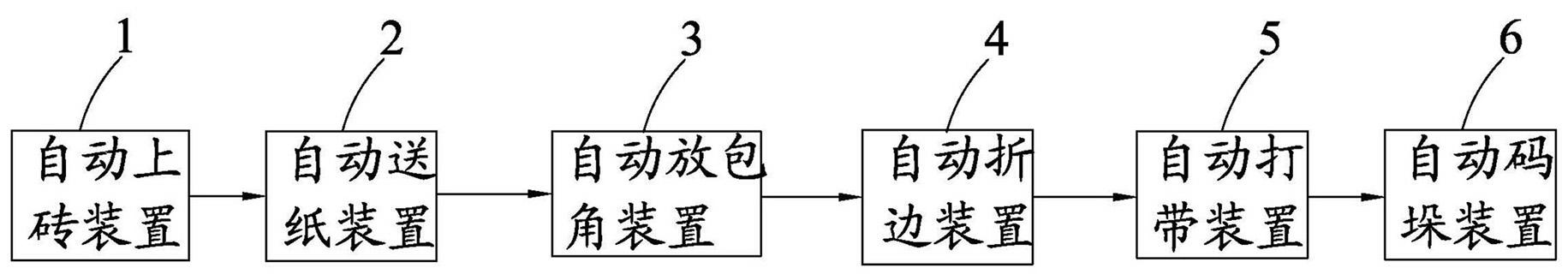

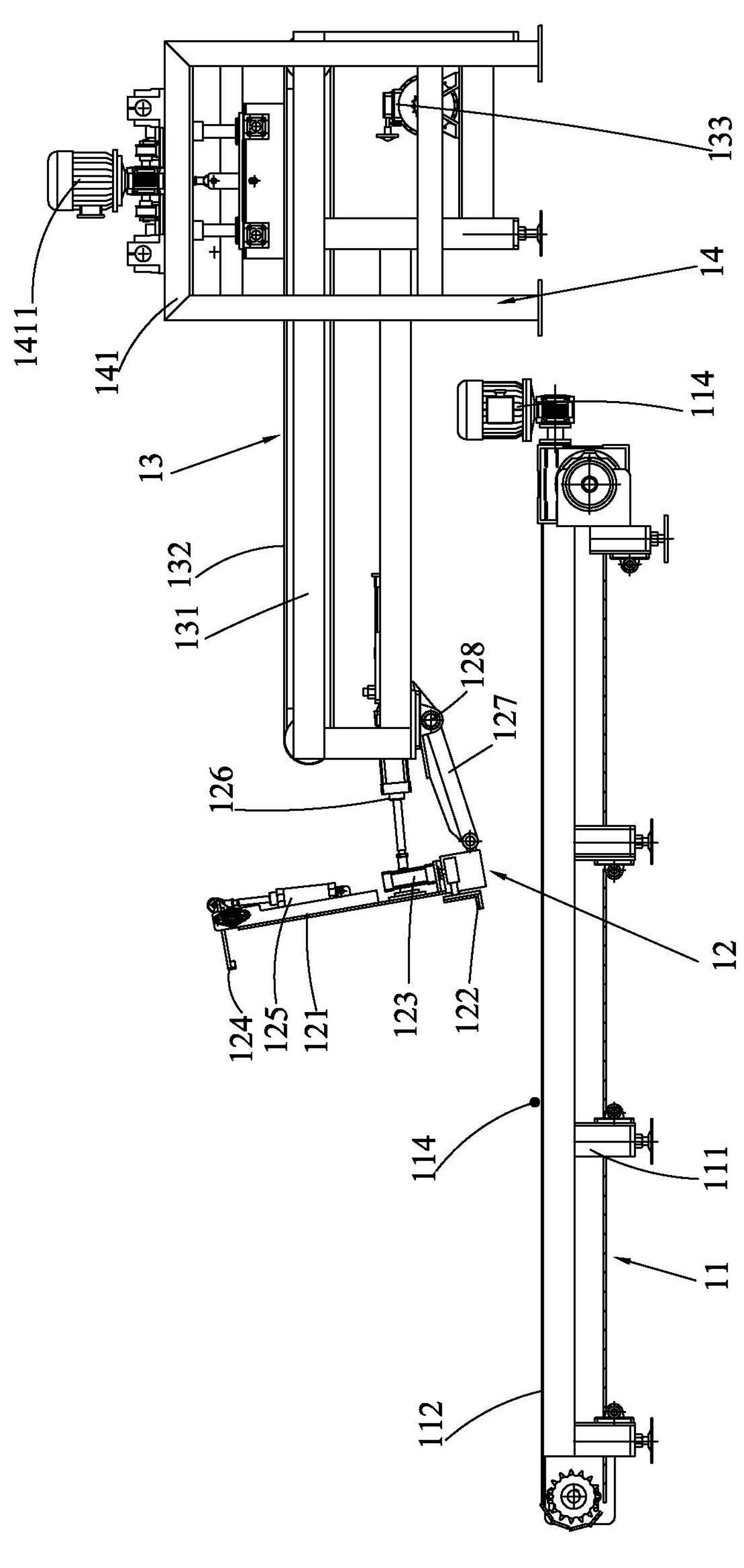

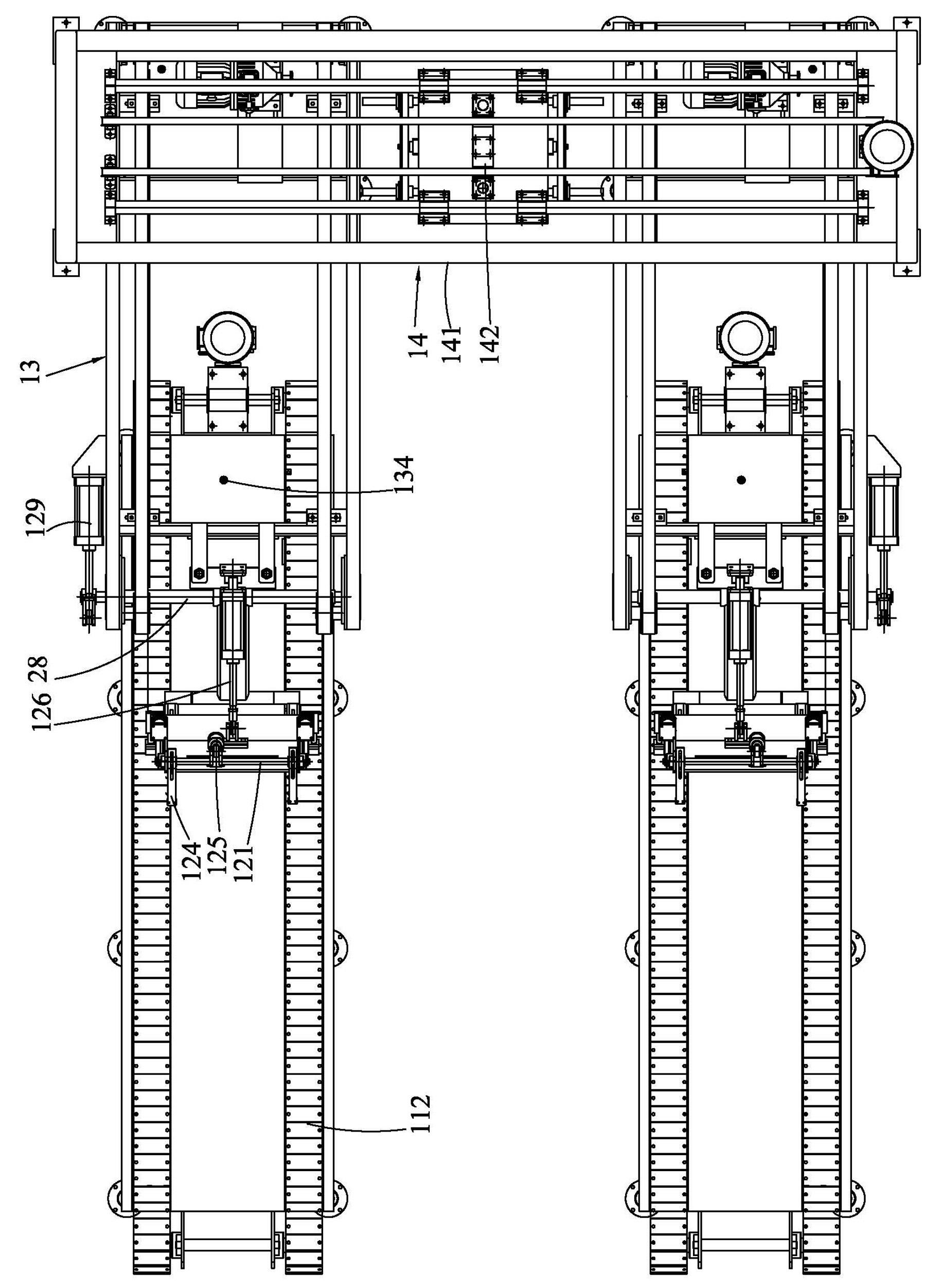

[0033] See figure 1 . The ceramic tile automatic packaging production line of the present invention includes an automatic brick loading device 1 , an automatic paper feeding device 2 , an automatic wrapping angle device 3 , an automatic edge folding device 4 , an automatic belting device 5 and an automatic stacking device 6 arranged in sequence.

[0034] Among them, the automatic brick loading device 1 is mainly used to automatically send the tiles from the brick rack to the production line, so as to facilitate subsequent processes such as automatic paper feeding. The automatic paper feeding device 2 is mainly used to receive the tiles sent by the automatic tile loading device and place the wrapping paper under the tiles for subsequent edge folding. The automatic wrapping corner device 3 is mainly used for automatically installing wrapping corners to the four corners of the tiles sent by the automatic paper feeding device. The automatic edge folding device 4 is mainly used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com