Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about "Packaging meat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

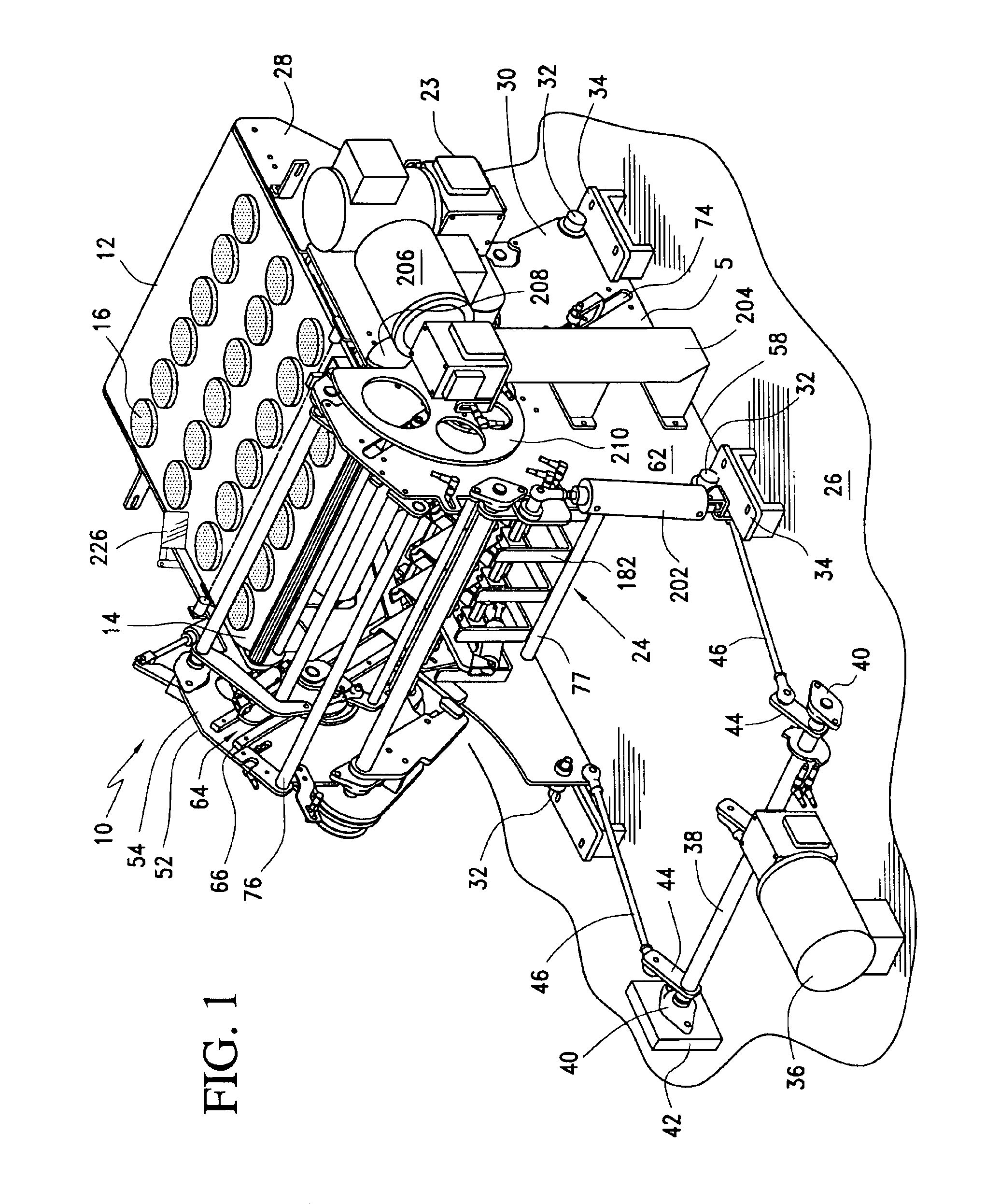

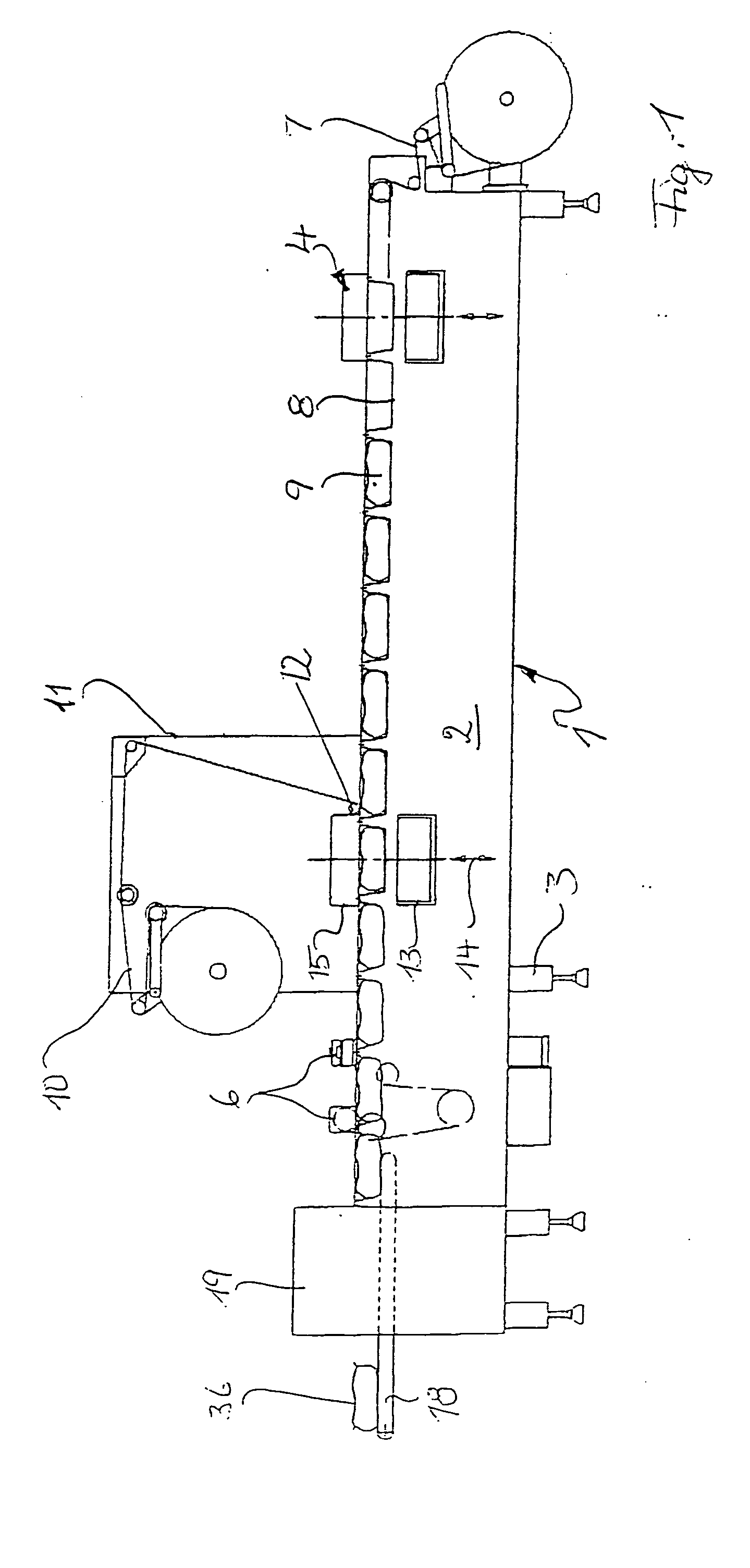

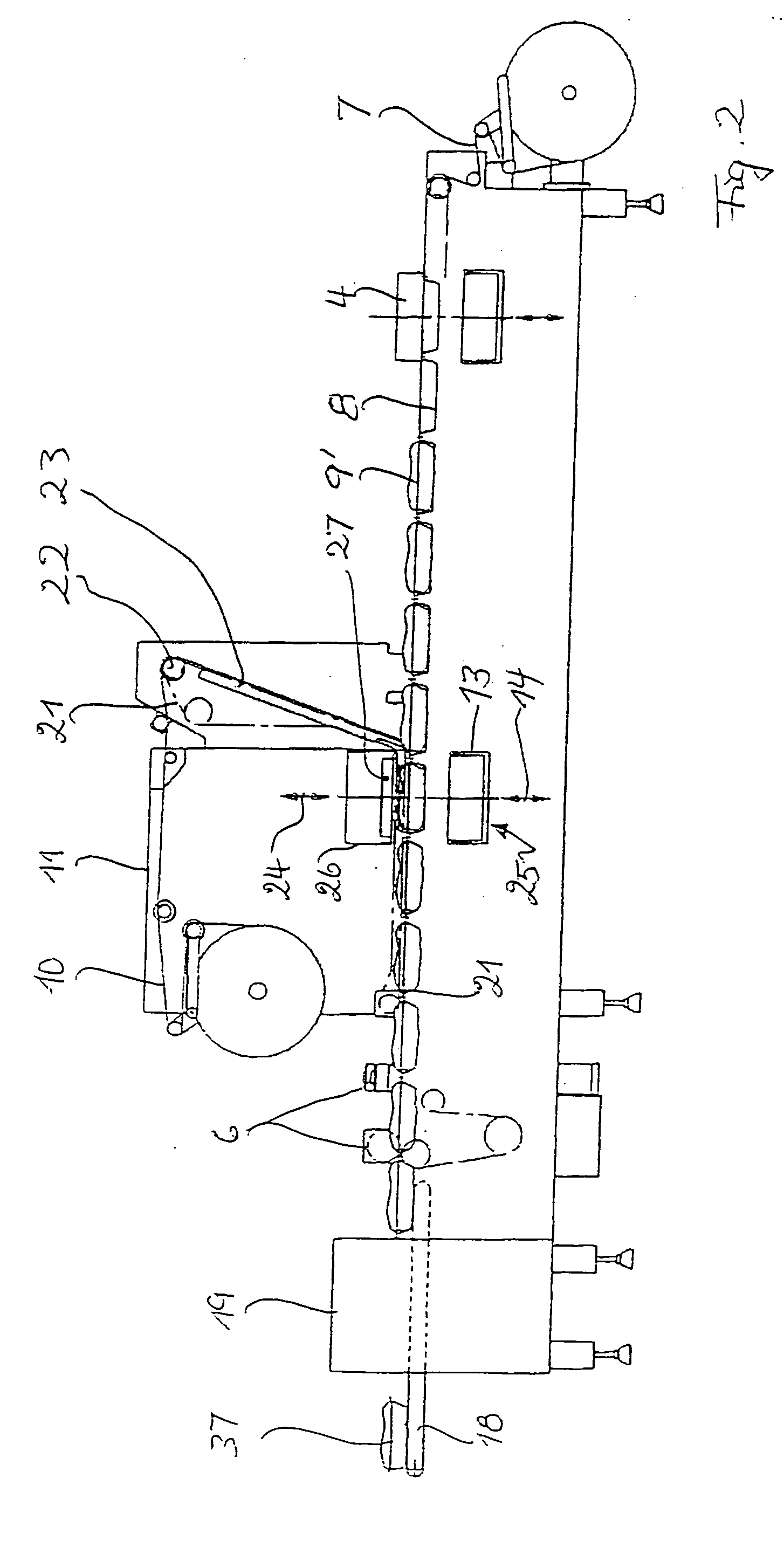

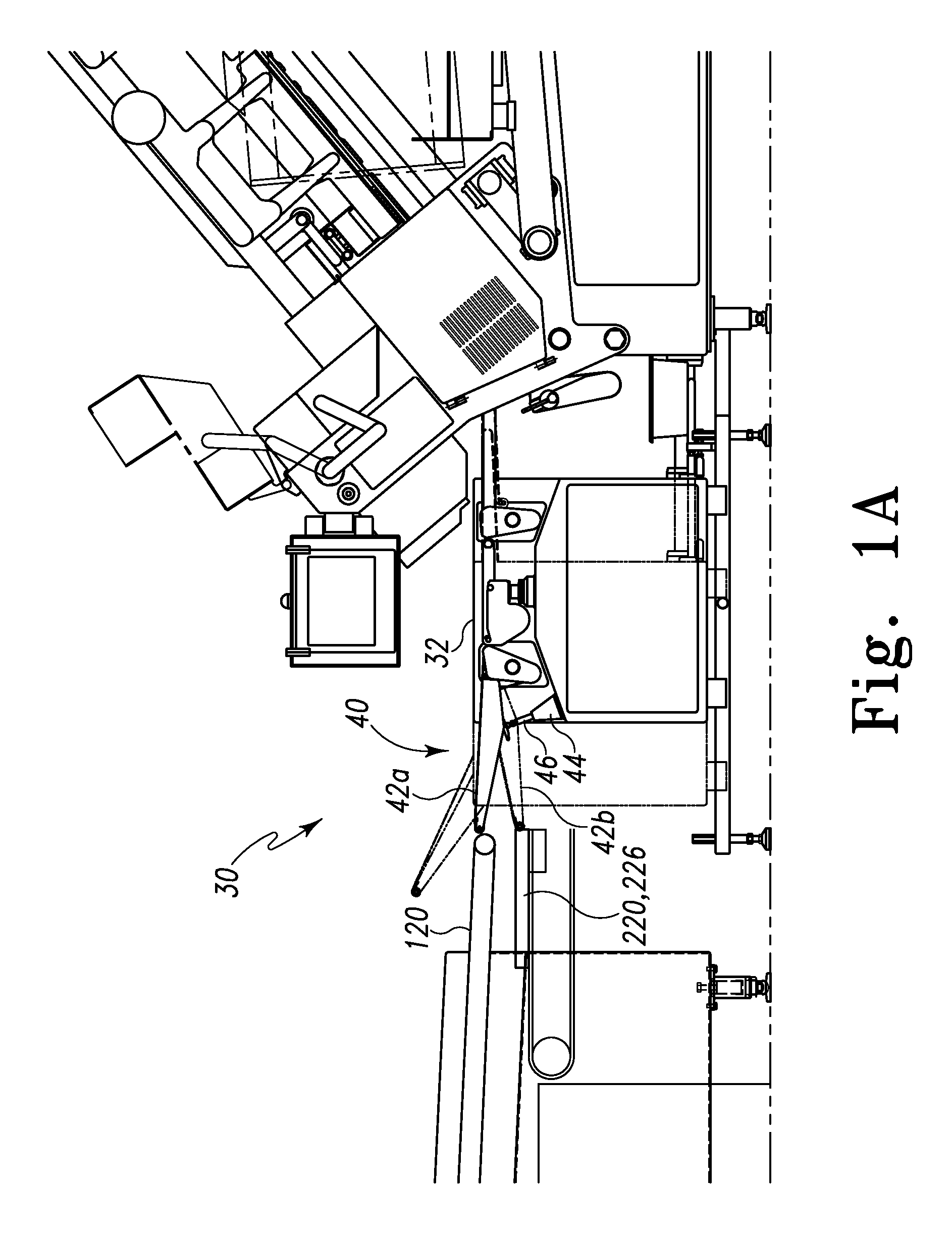

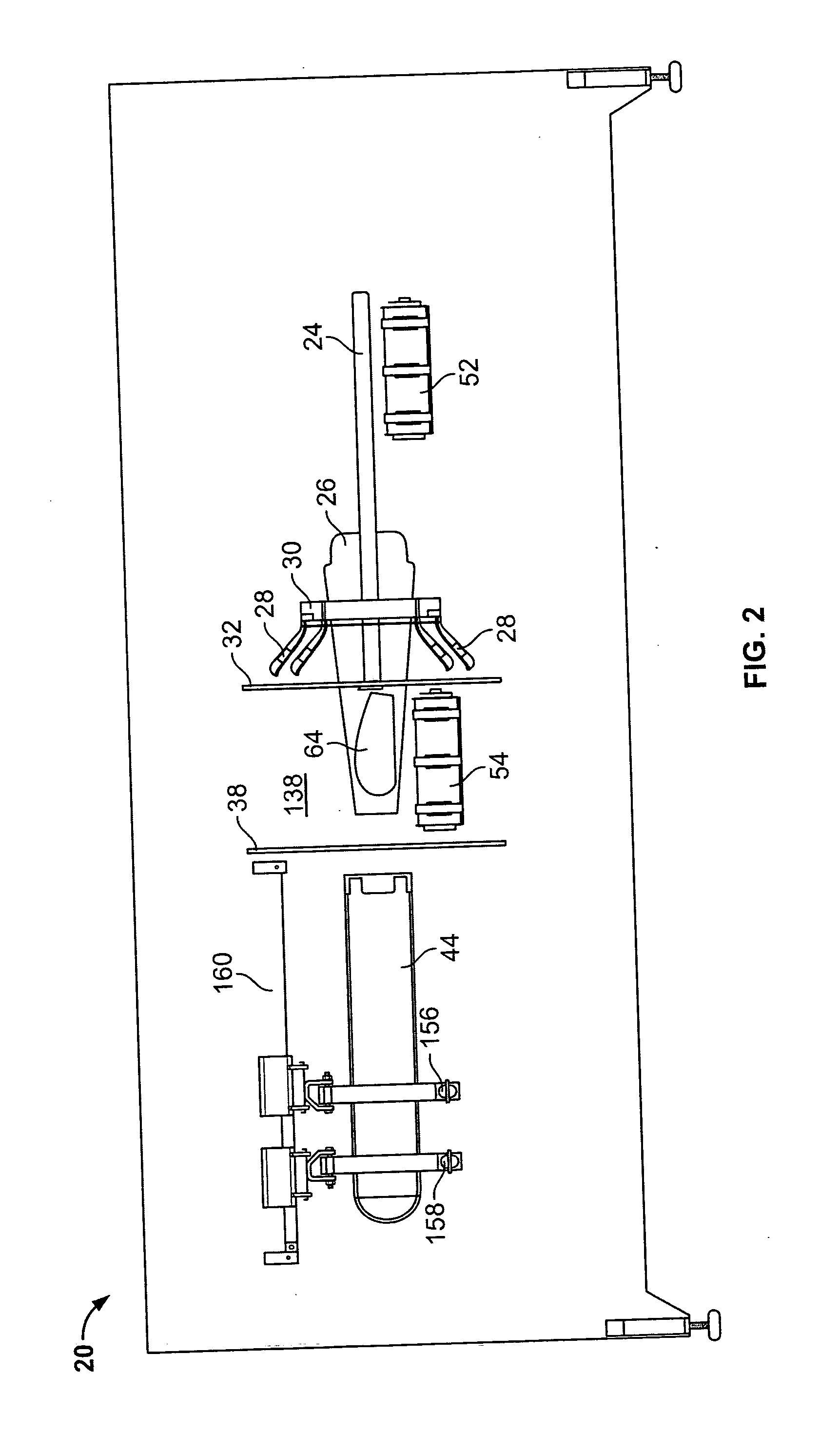

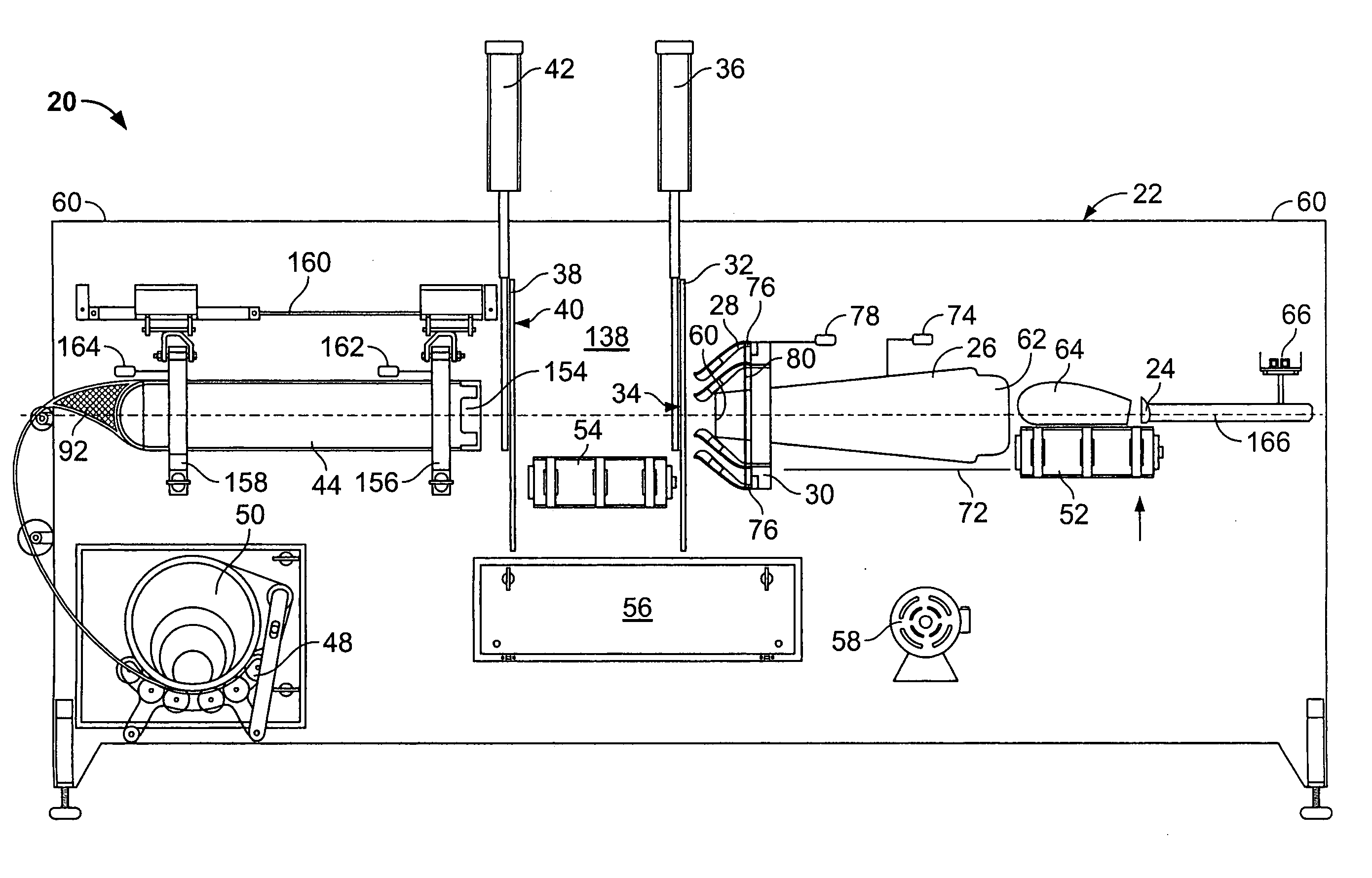

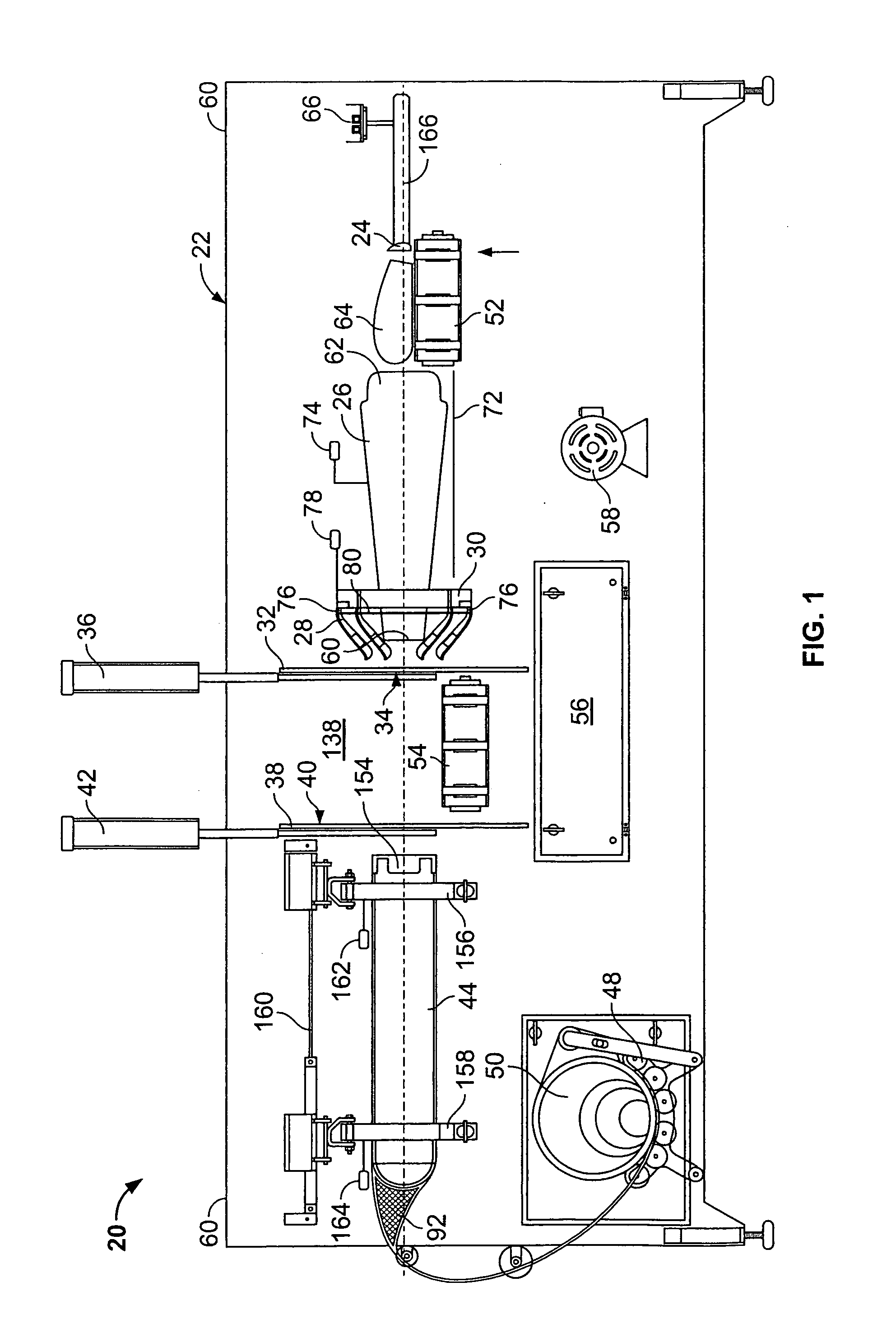

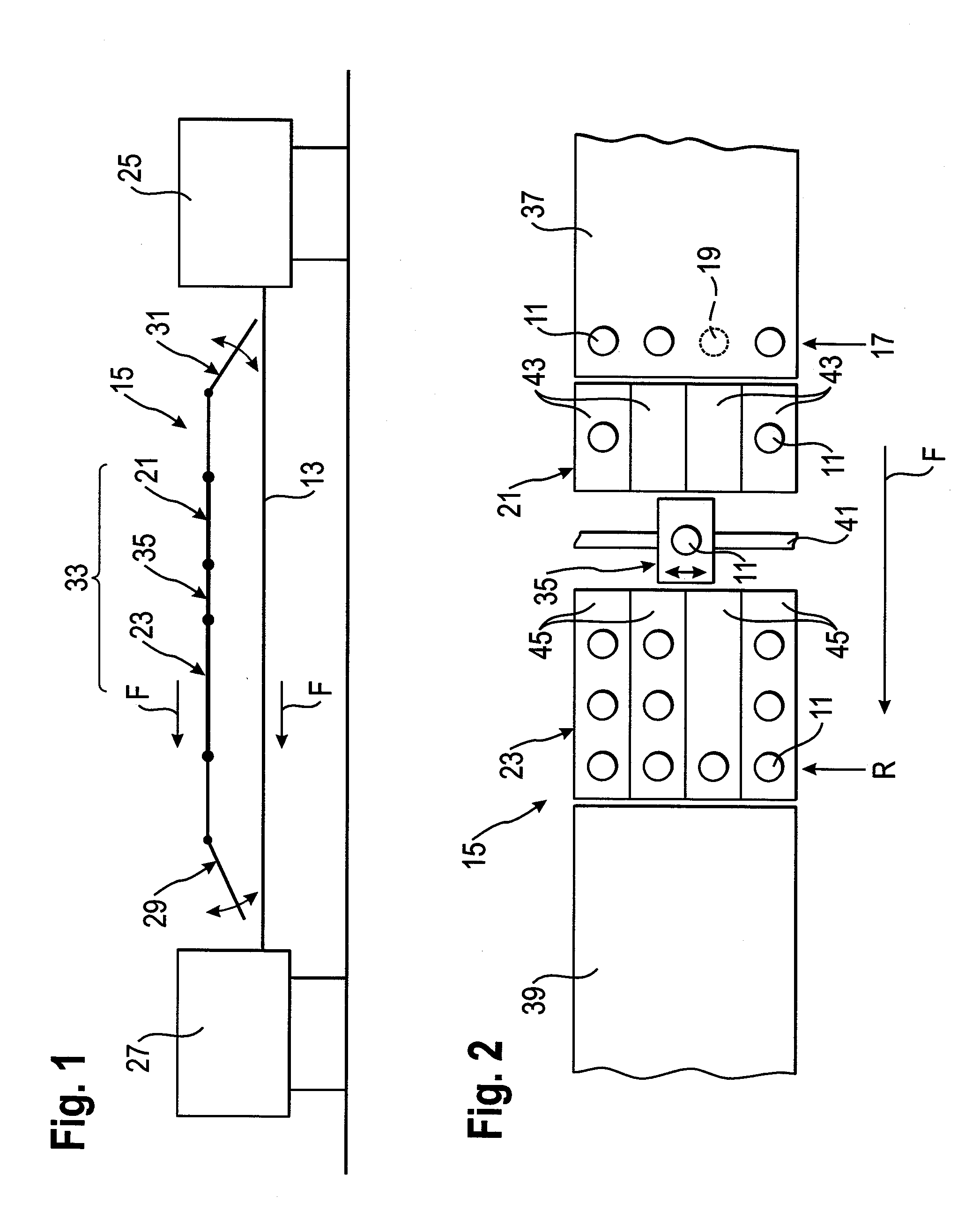

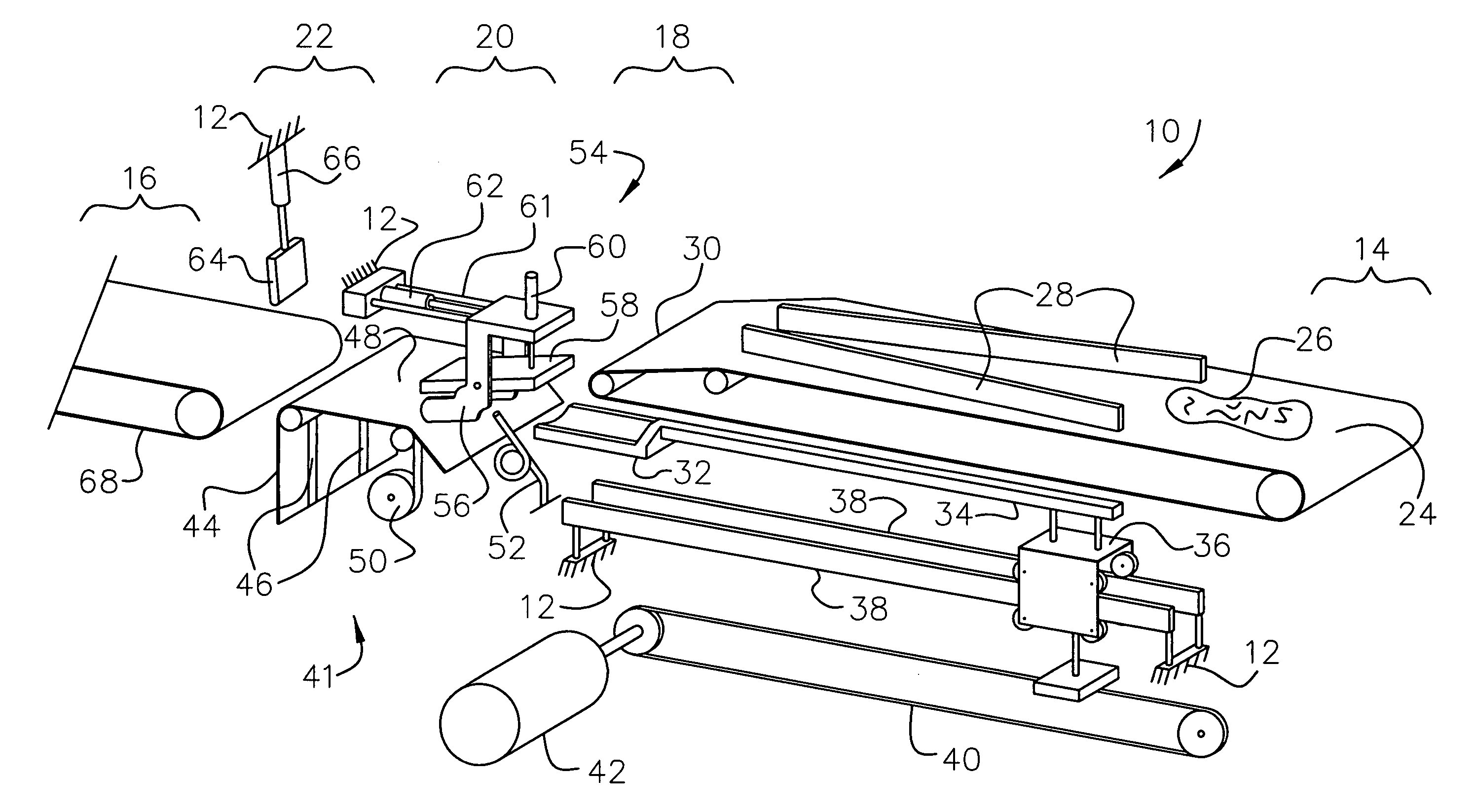

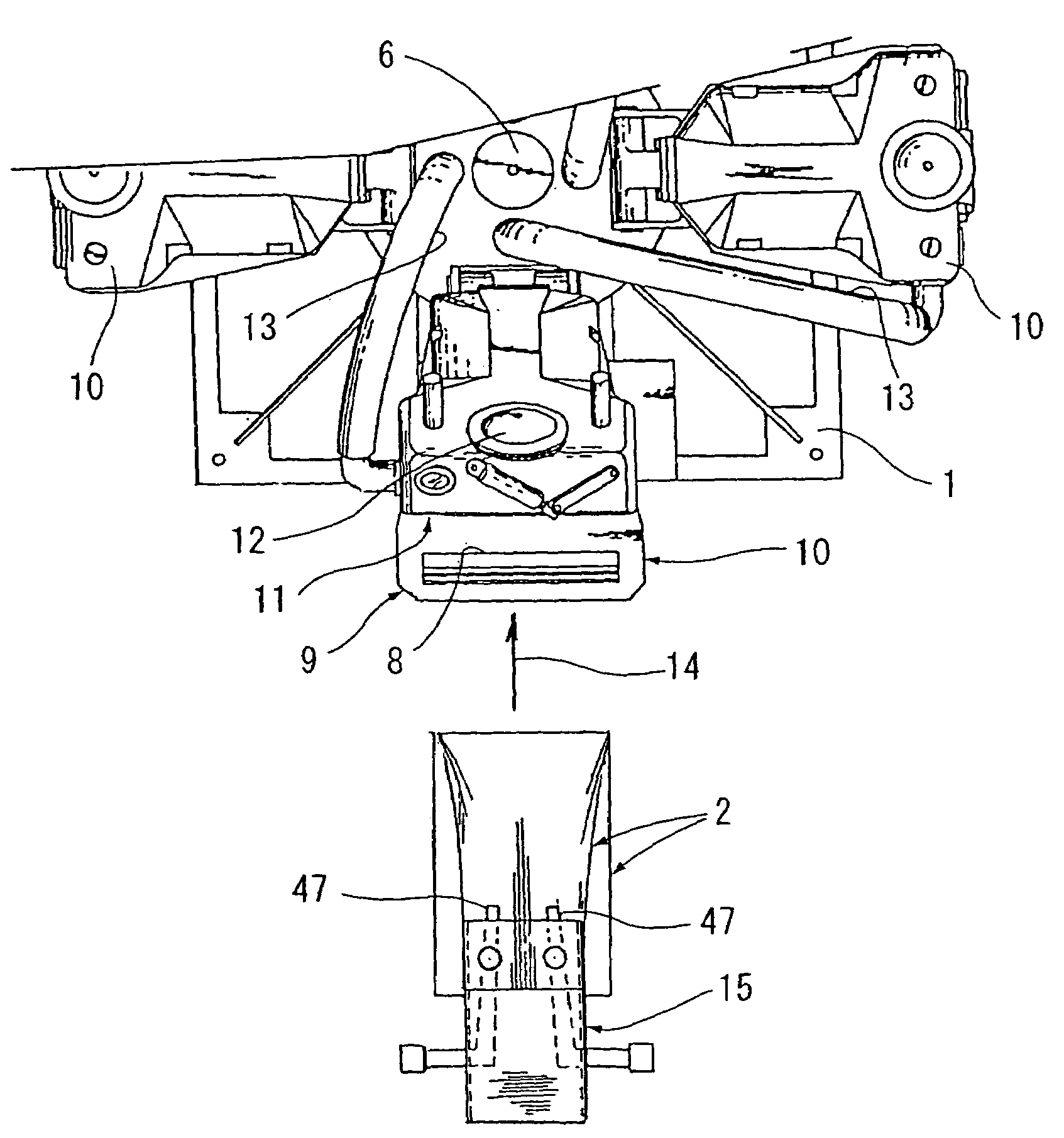

Method and apparatus for buffering a flow of objects

InactiveUS6957941B2Good flexibilityMinimize the numberPackaging meatCharge manipulationEngineeringPackaging machine

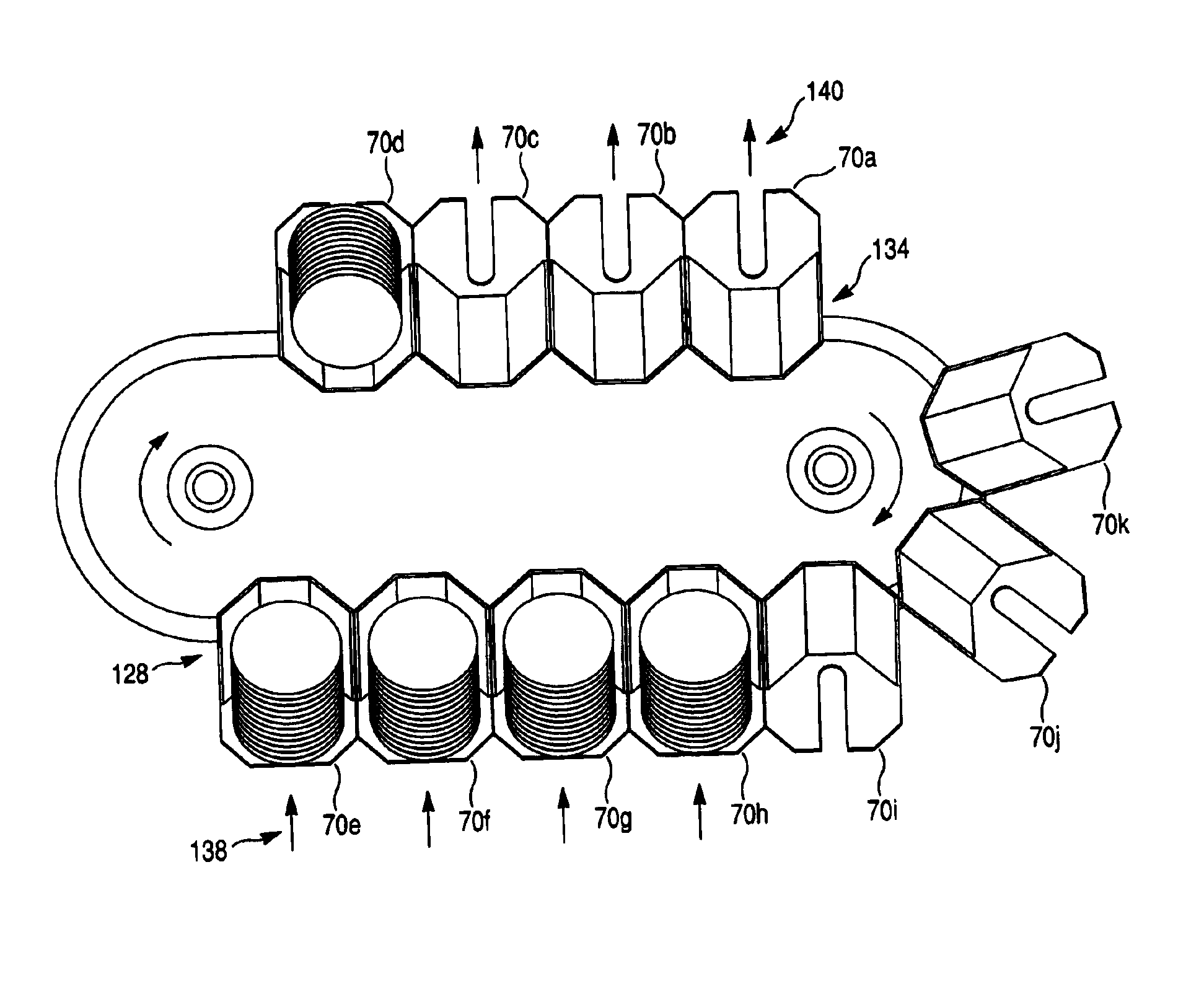

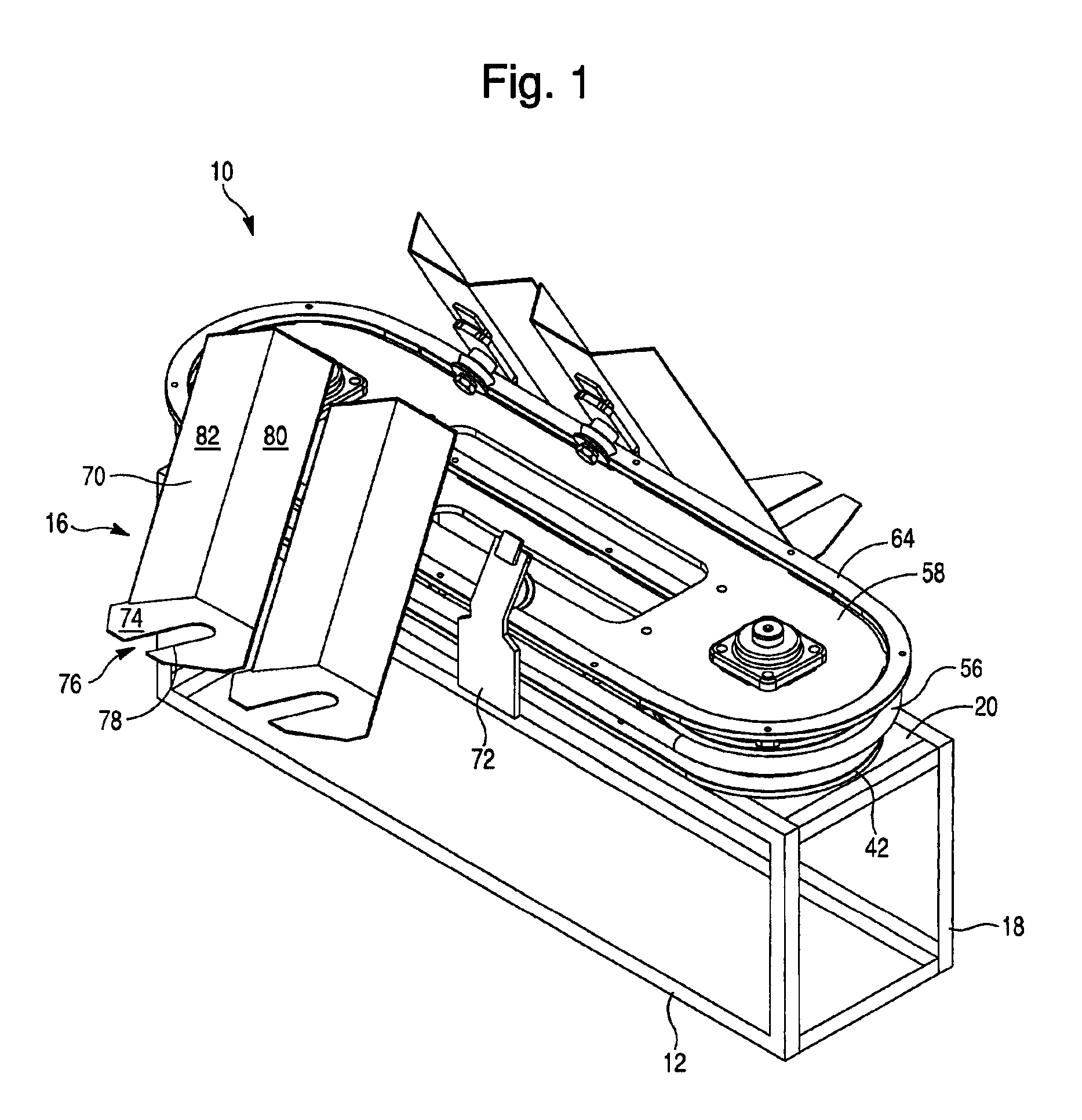

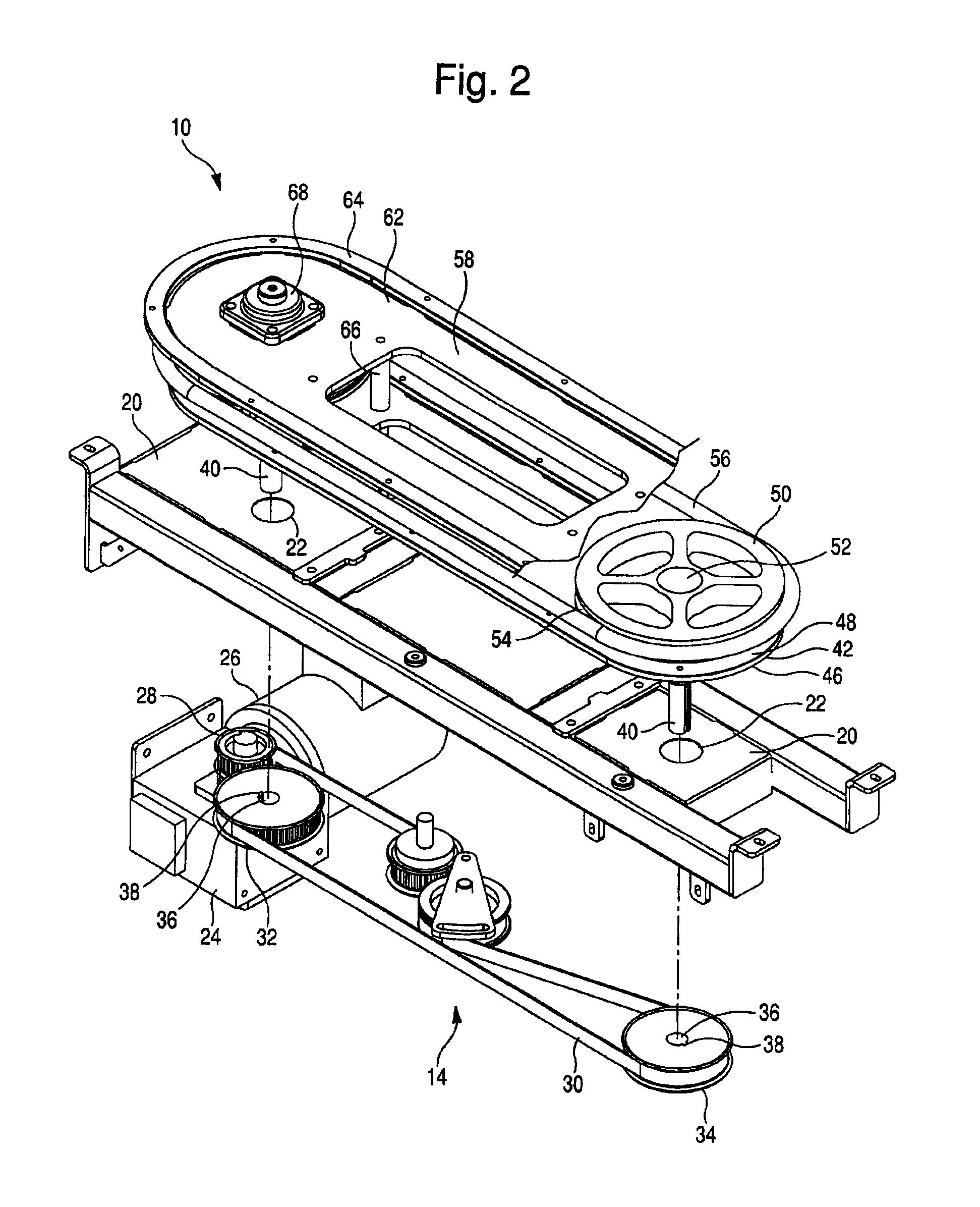

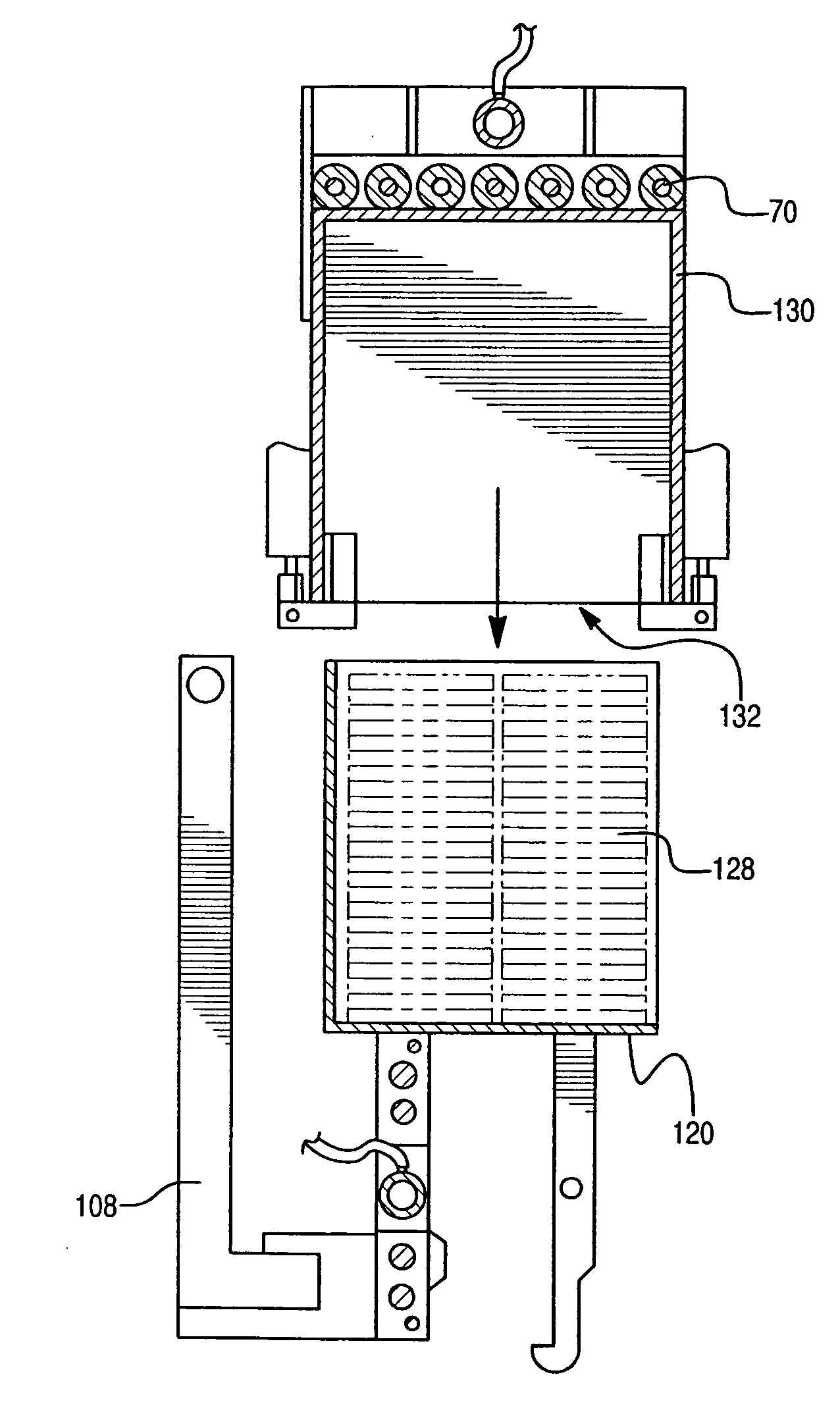

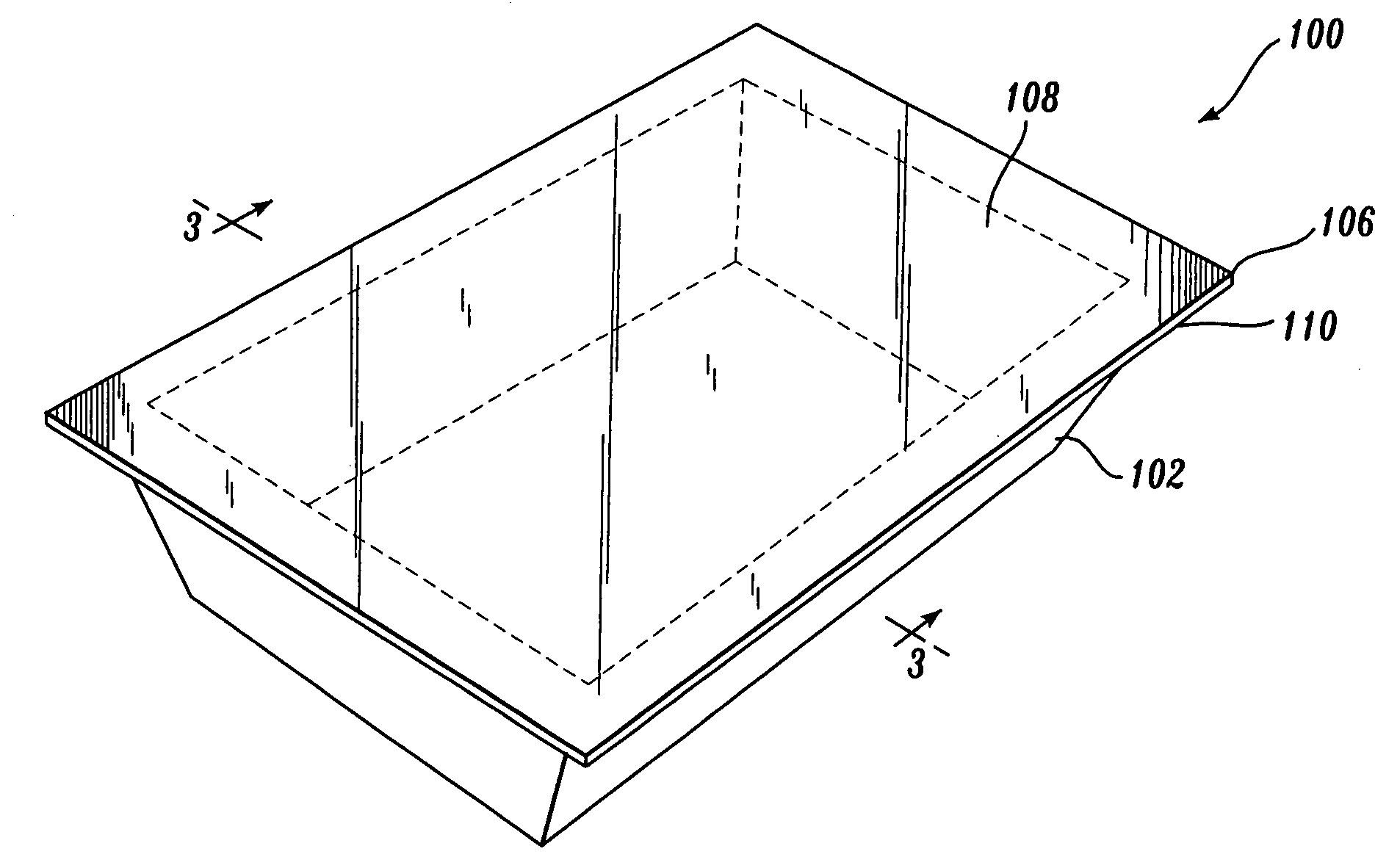

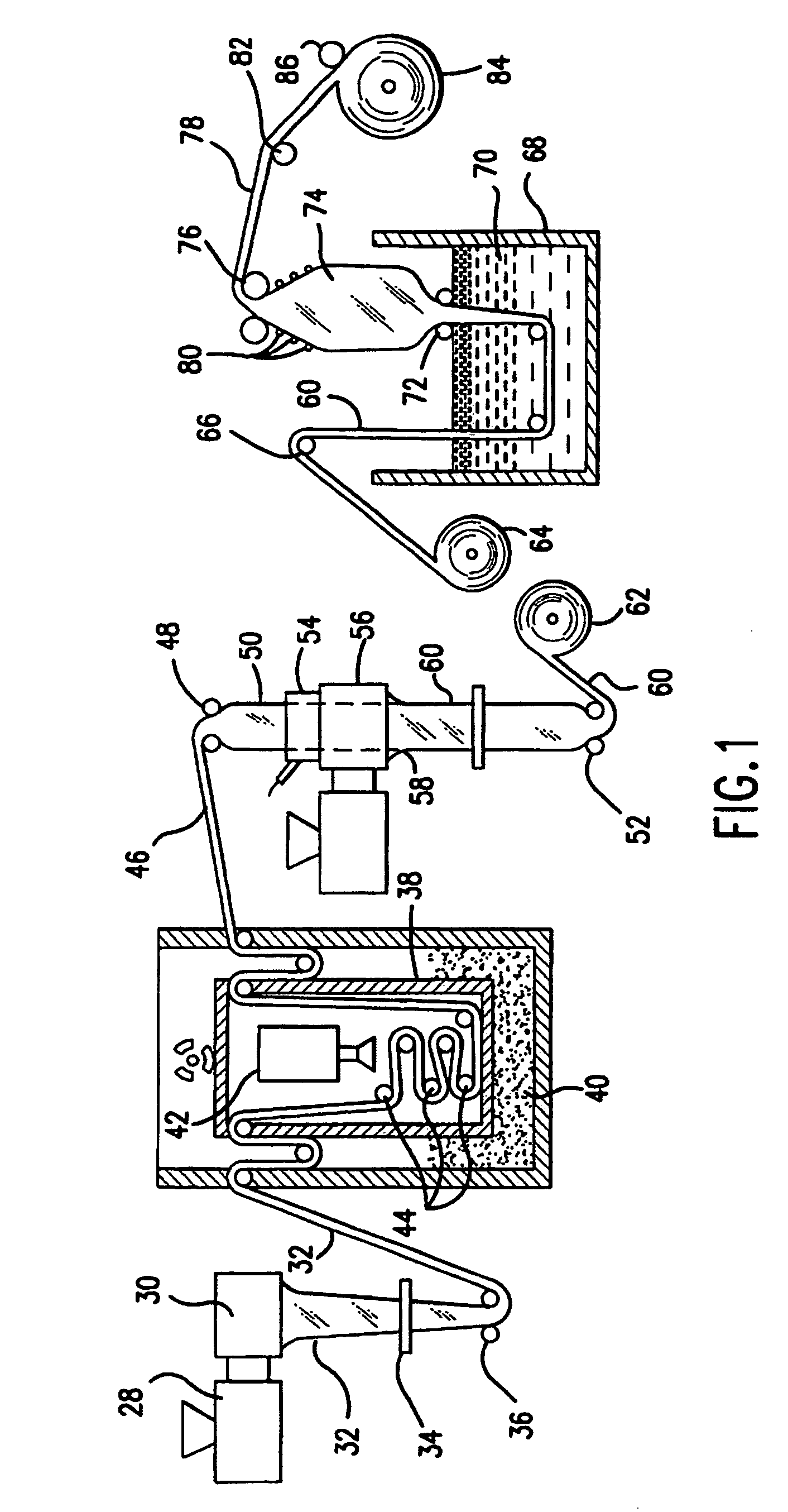

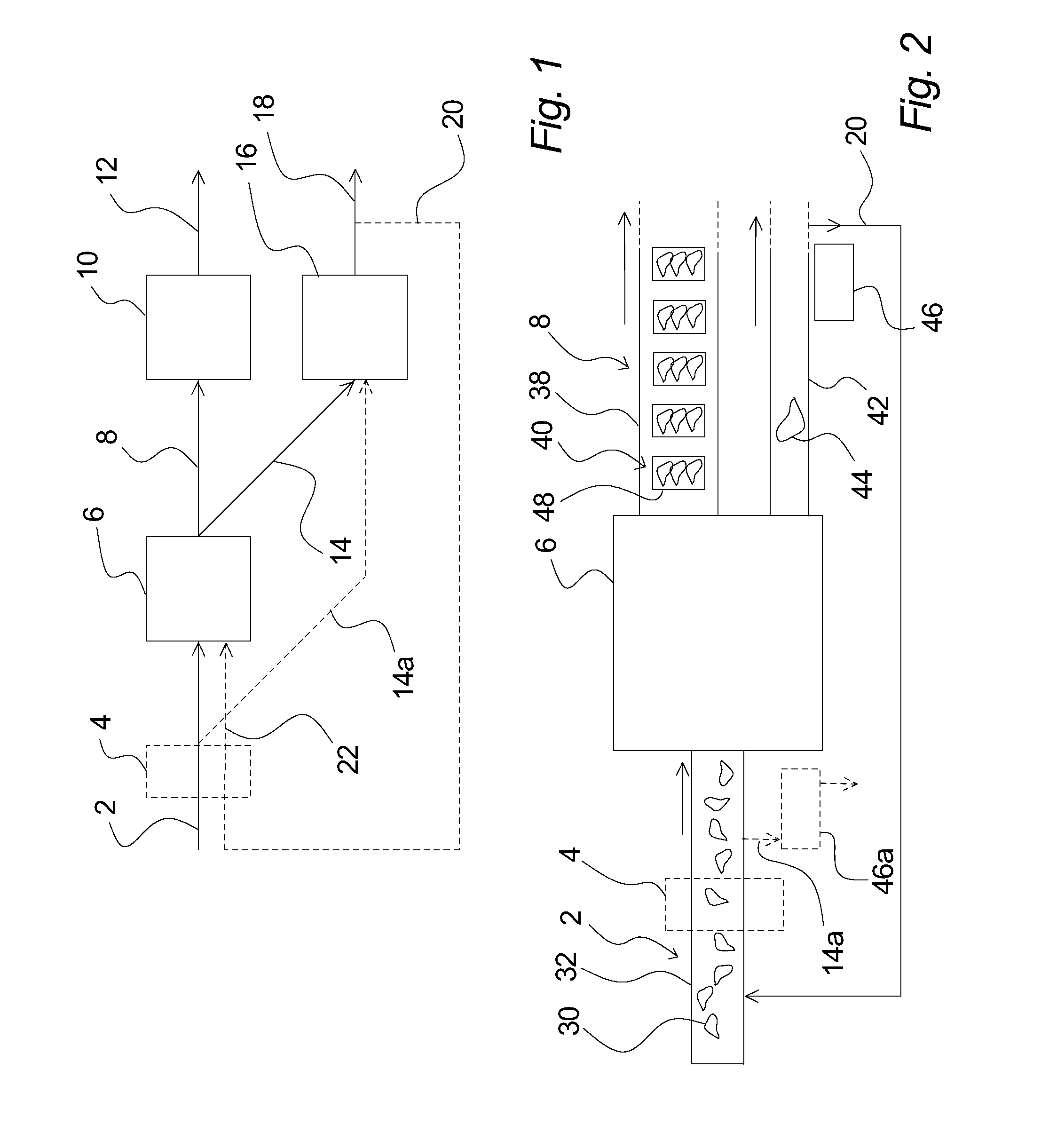

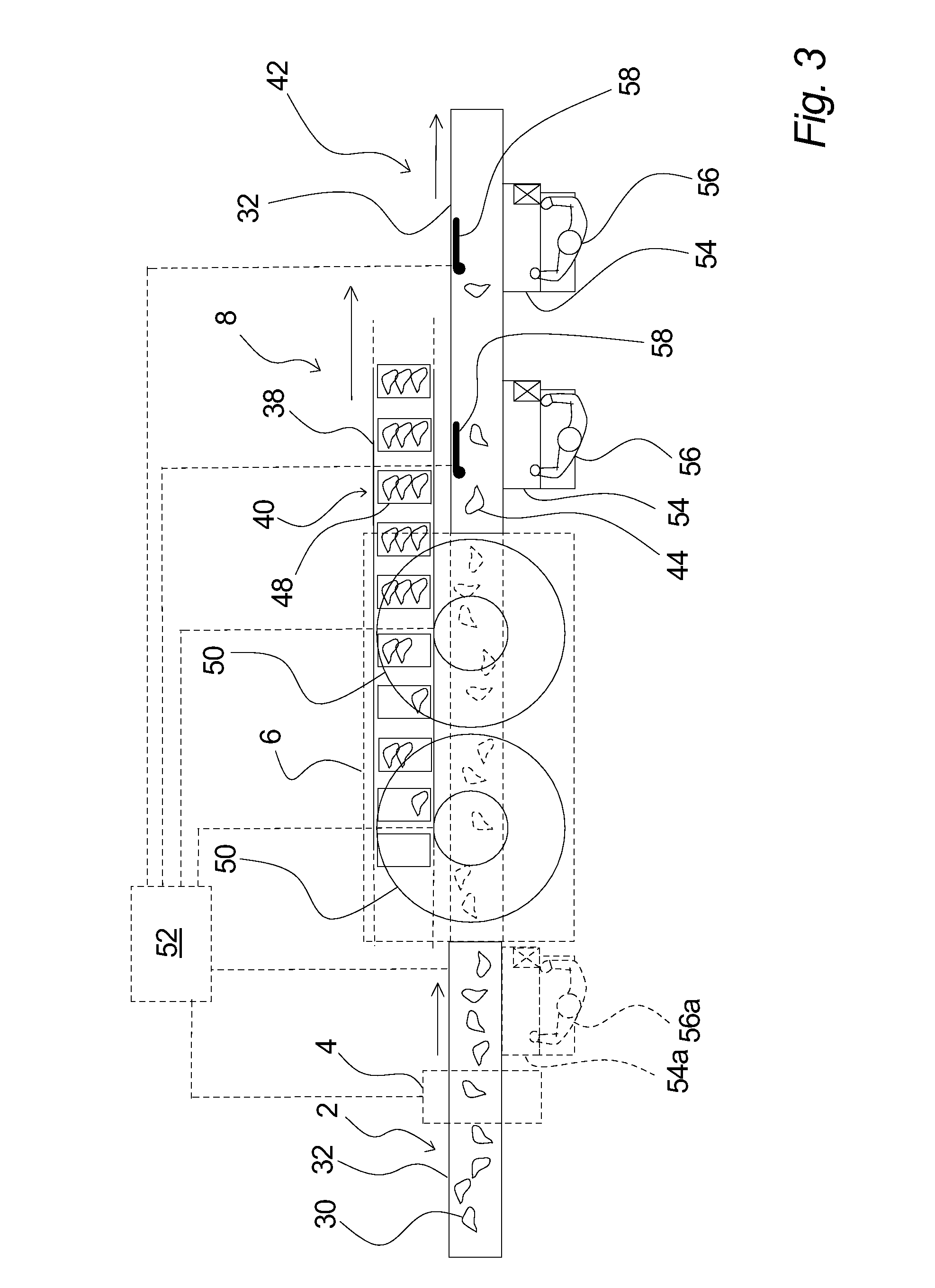

A buffer device for buffering a flow of stacks of discrete objects between a stacking machine and a packaging machine is disclosed which buffer includes a plurality of individual trays mounted on carriers which carriers are mounted on a frame and driven about the periphery of the frame by a drive. A first number of stacks of objects is placed on a first number of carriers on a first side of the frame and a second number of stacks are removed from a second number of carriers on a second side of the frame where the first number can be greater than, less than or equal to the first number. The carriers clamp onto a continuously moving drive belt in a manner that allow the drive belt to slip through the carrier clamps when motion of the carriers is obstructed. A method of using the buffer device is also disclosed.

Owner:F R DRAKE

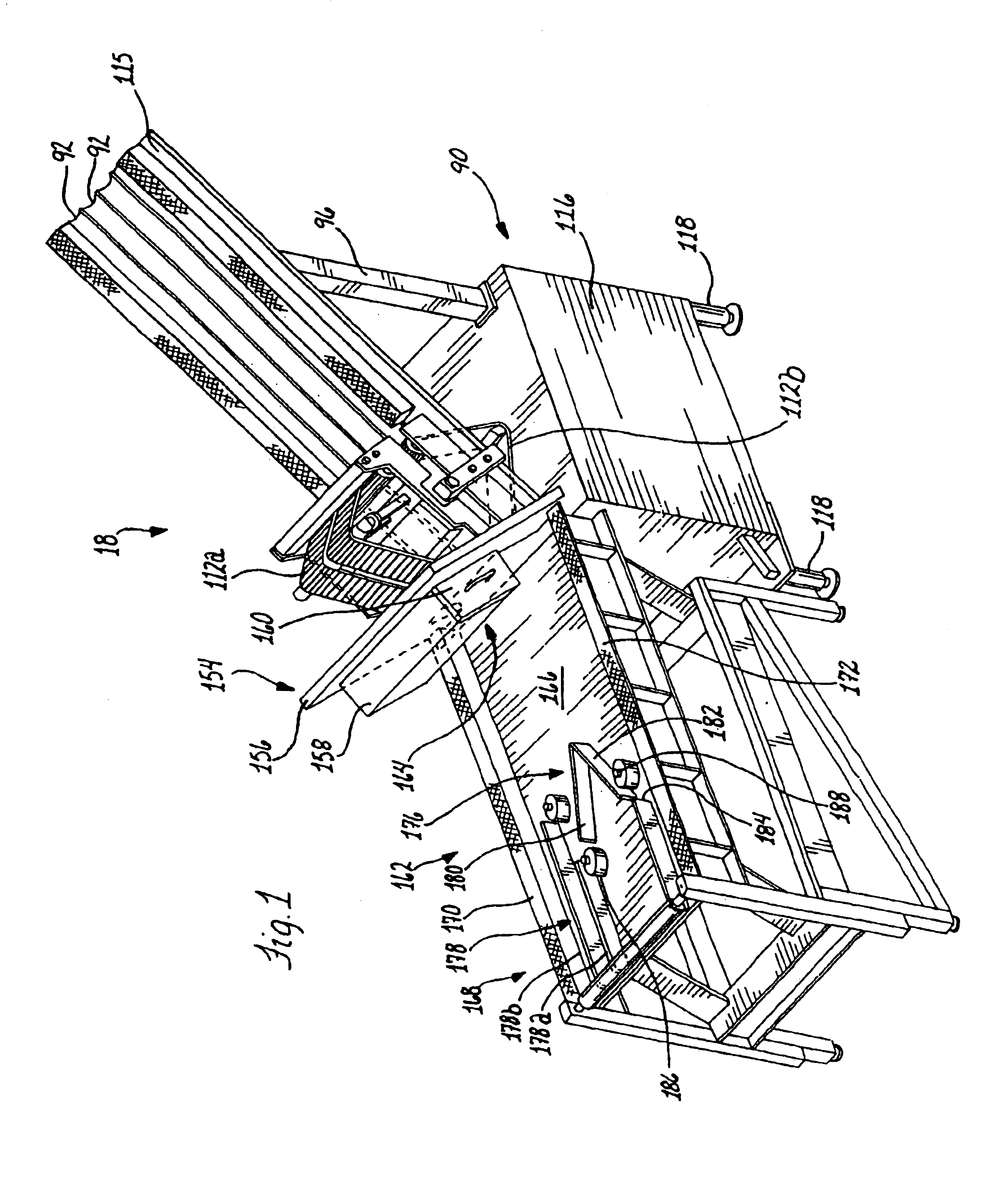

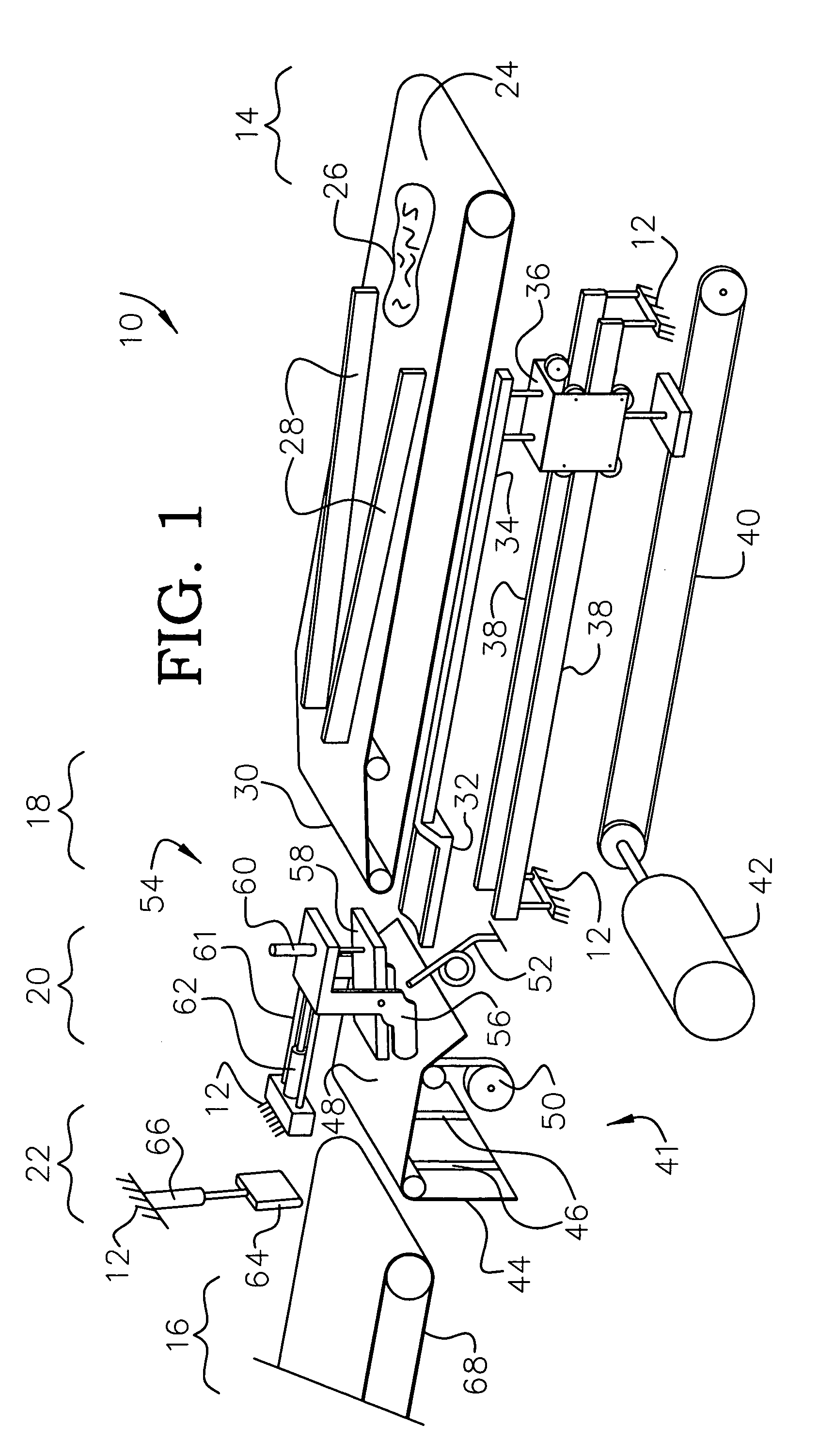

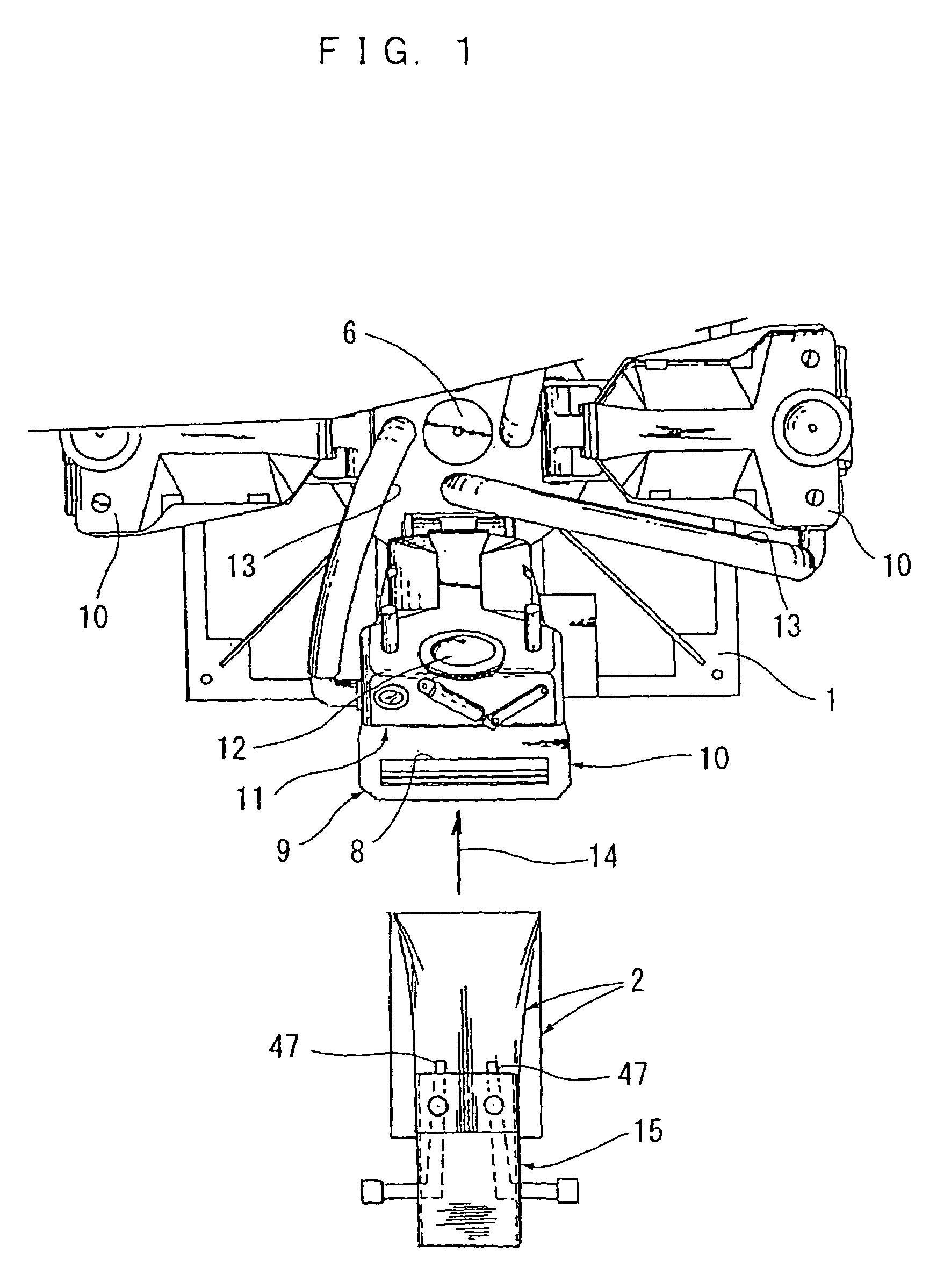

Method and apparatus for stacking discrete planar objects

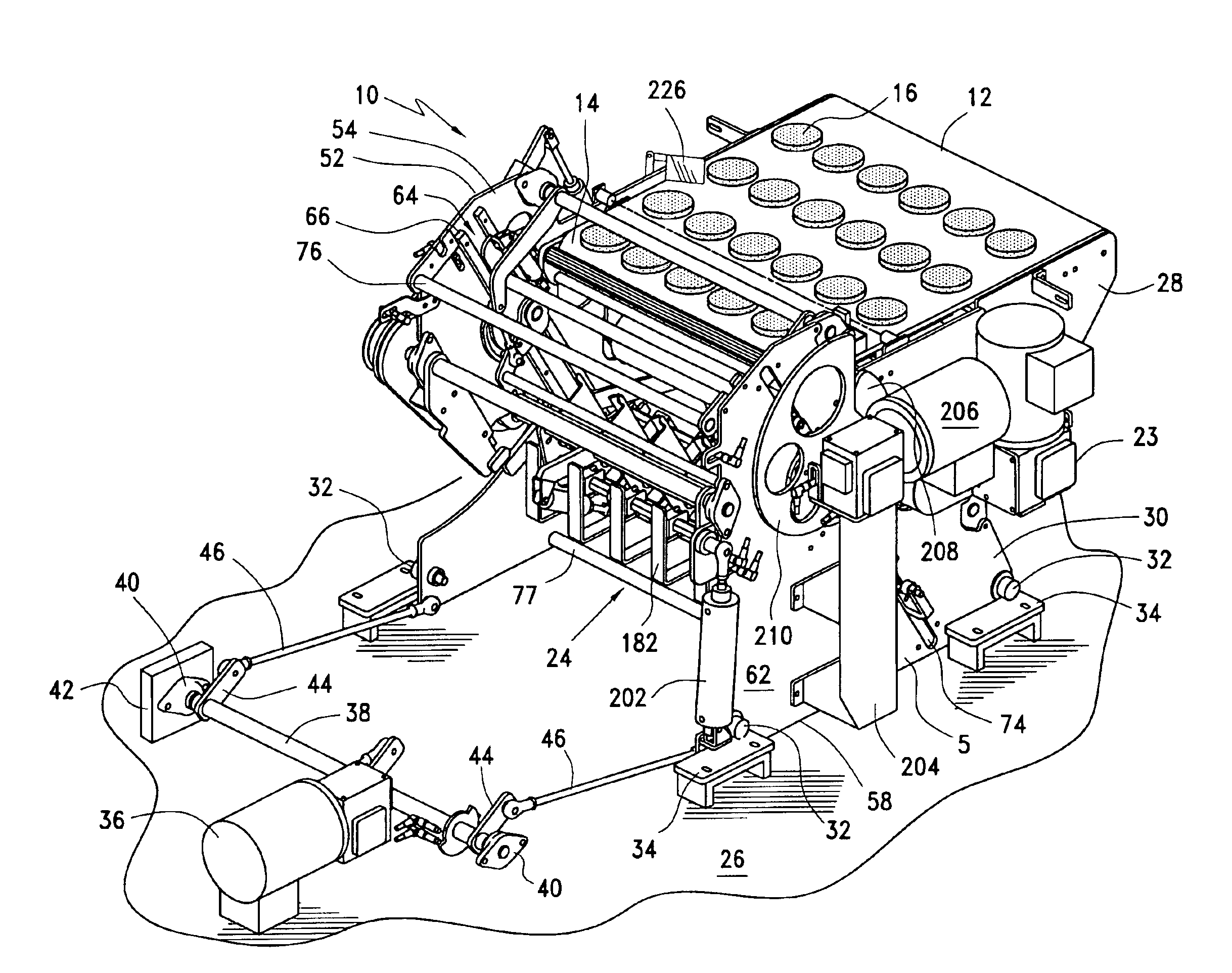

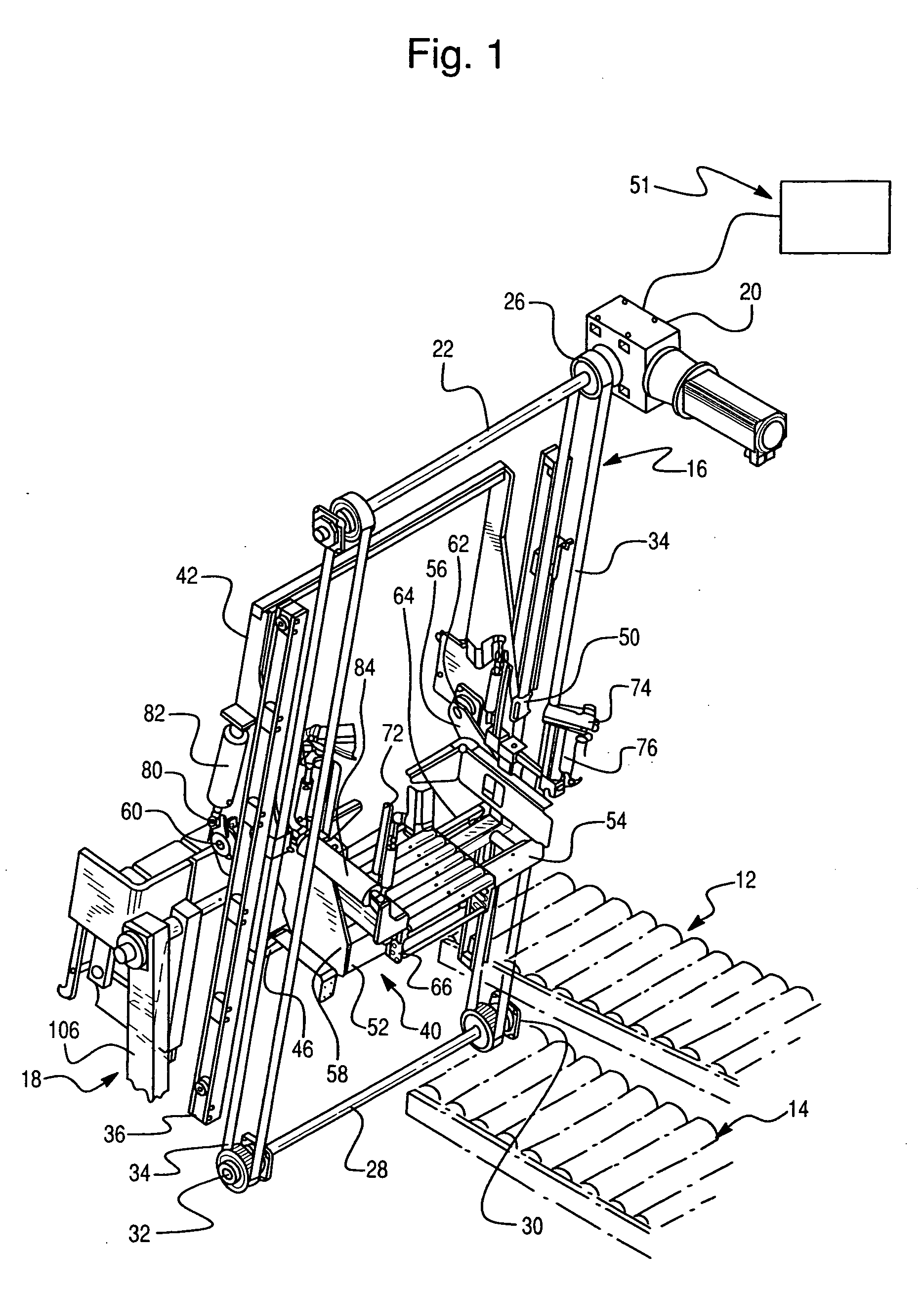

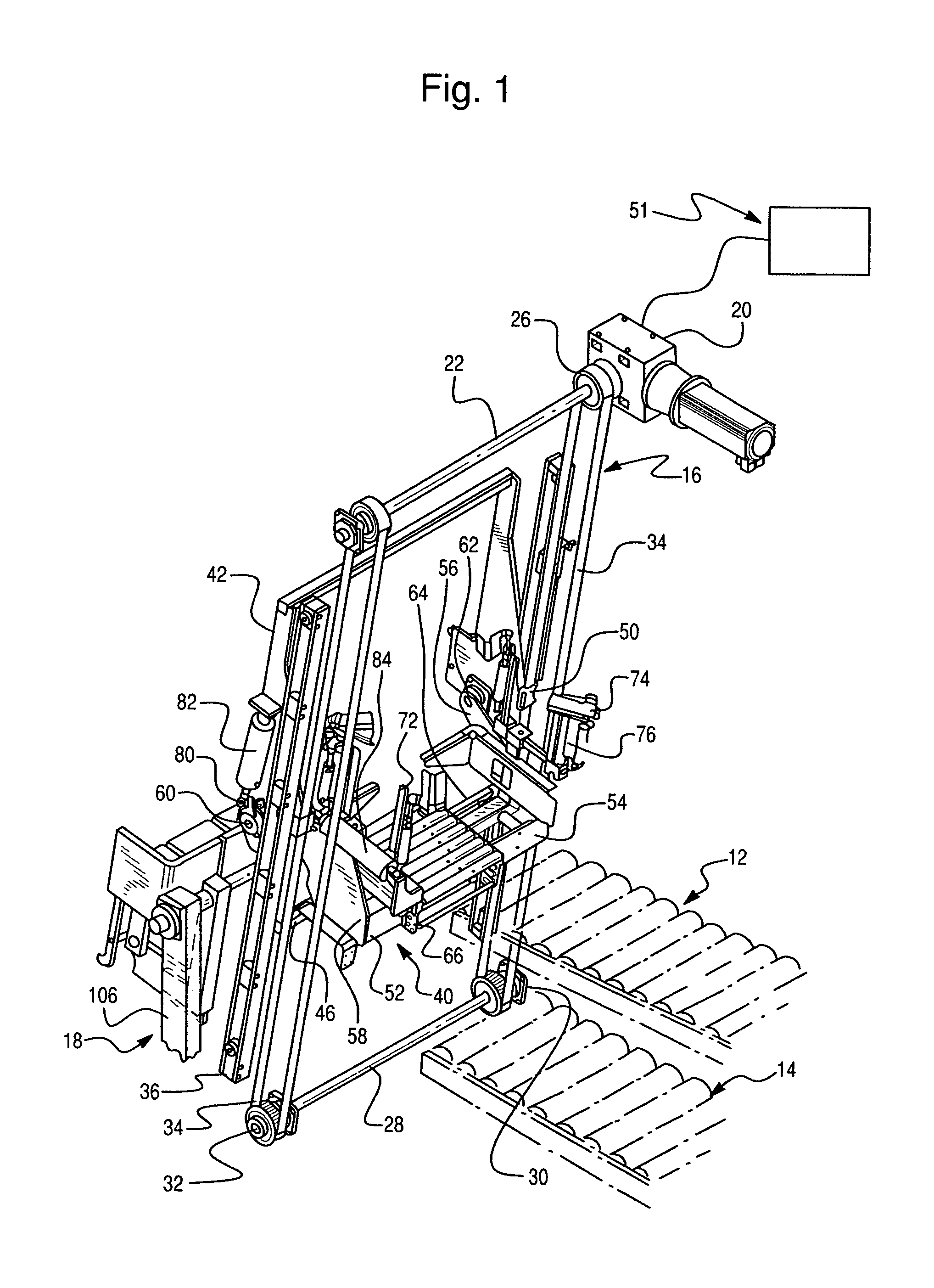

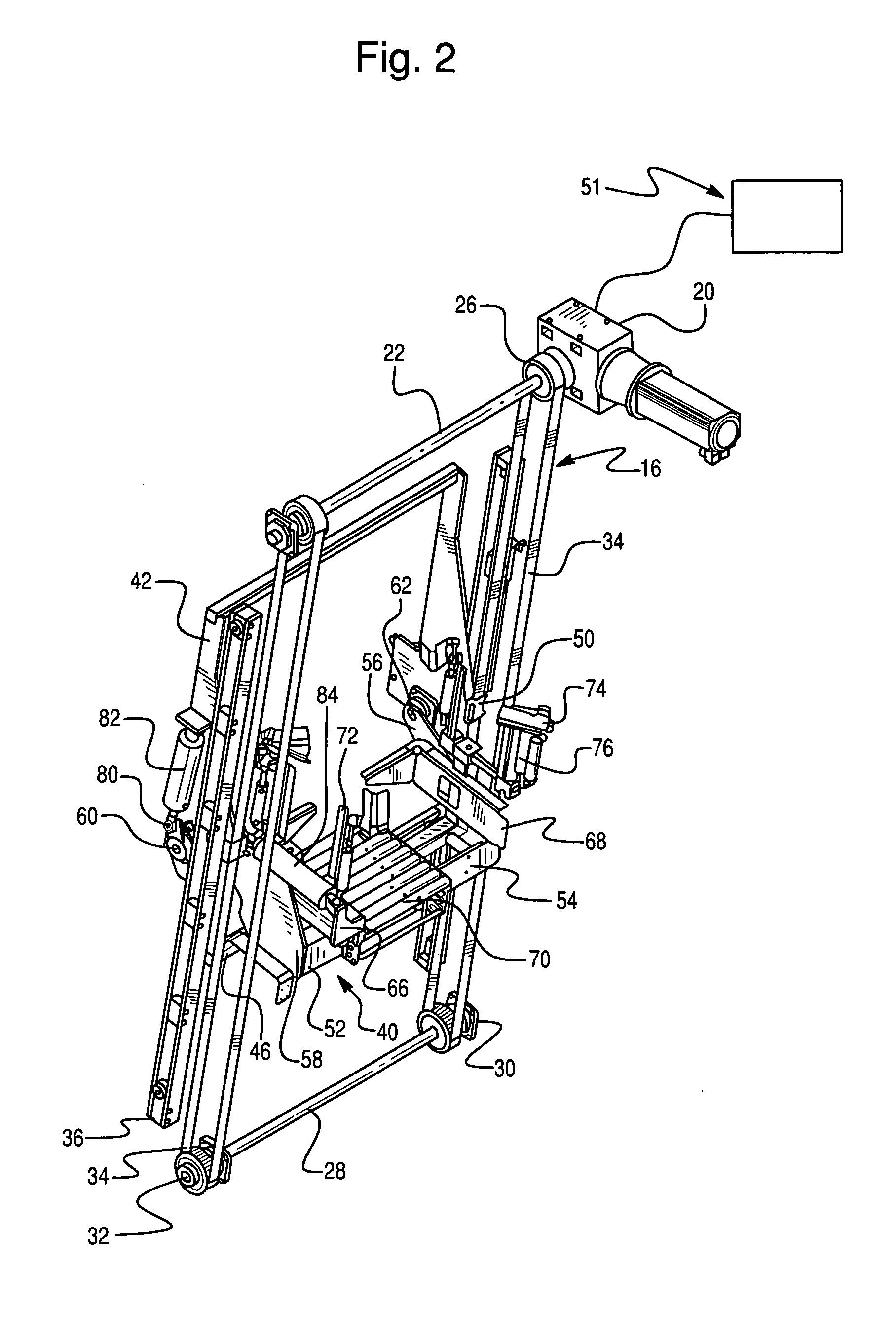

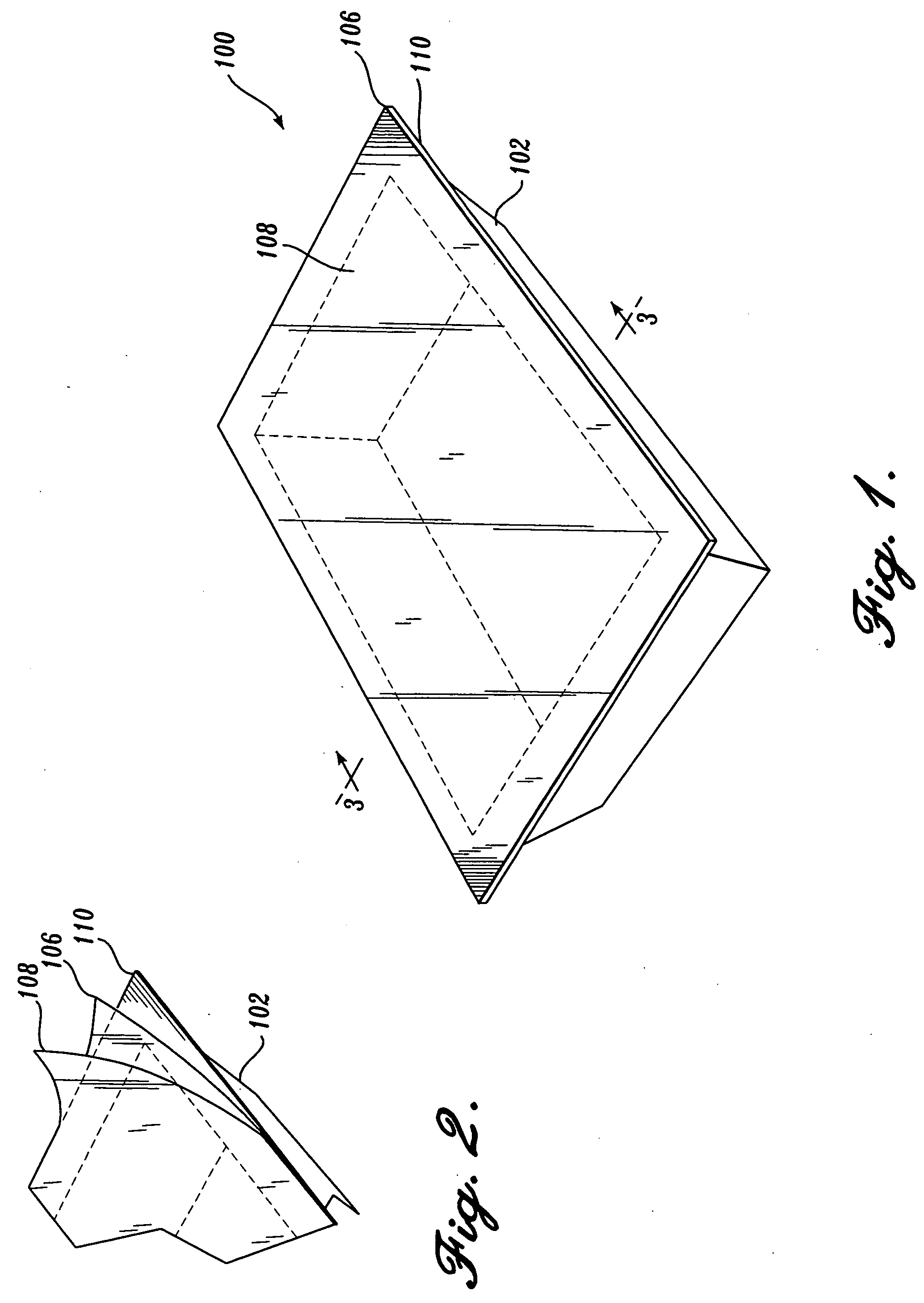

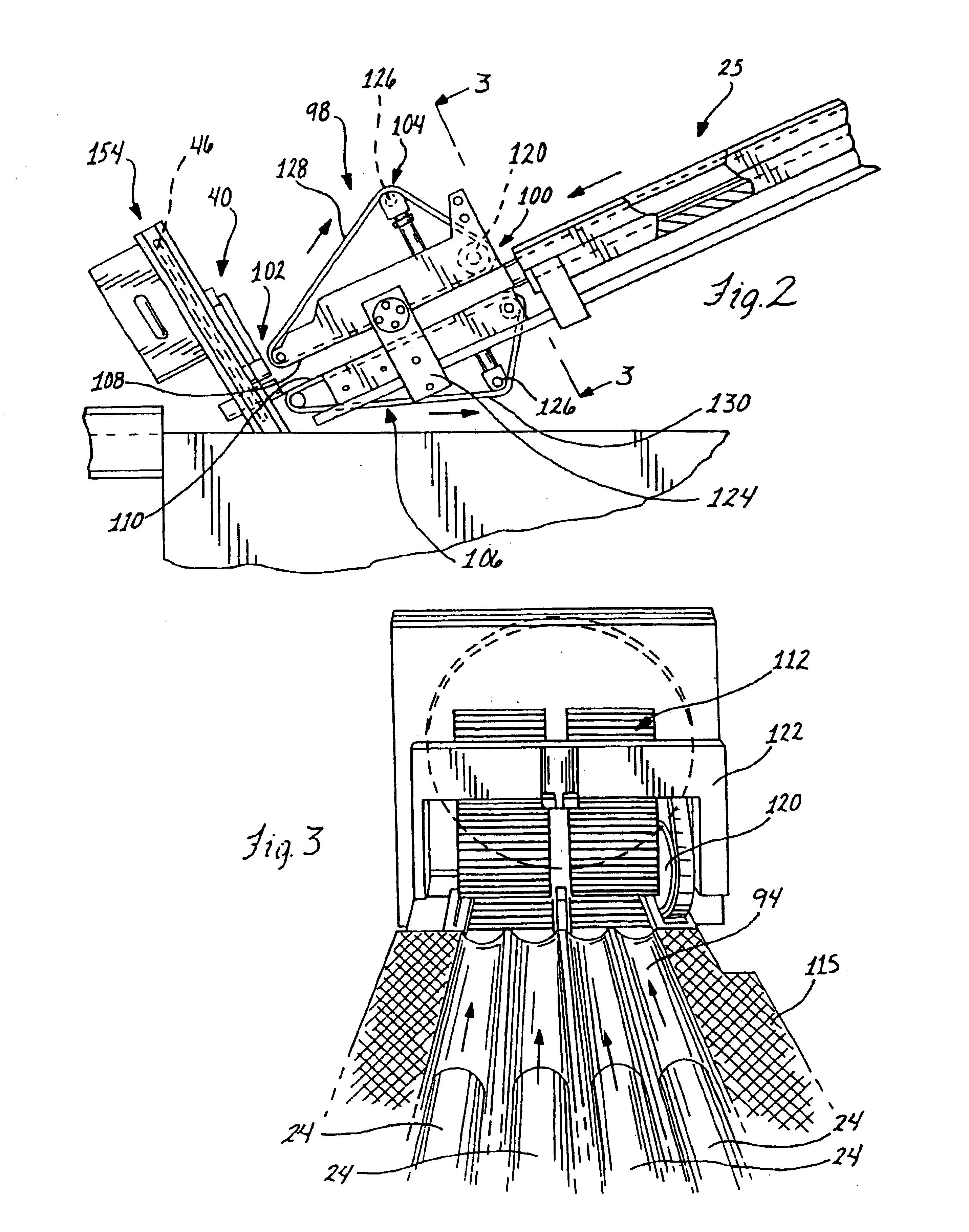

A system for forming a plurality of discrete objects into a stack is disclosed which system includes a frame having a top, a bottom and sides; a conveyor associated with the frame and having an end edge for dispensing discrete objects, a first support mounted on the frame near the end edge for receiving objects from the end edge and having an opening with a width smaller than the width of the objects, a first actuator operably connected to the first support for moving the first support between first and second positions relative to the end edge; a second actuator operably connected to the first support for moving the first support between upper and lower positions relative to the frame; a second support mounted on the frame beneath the first support having a width less than the width of the opening in the first support; a third actuator operatively connected to the second support for moving the second support between high and low positions, the second support high position being higher than the first support lower position; a third support mounted on the frame at a position higher than the second support low position and having an opening wider than the width of the second support; a fourth actuator operatively connected to the third support for moving the third support between a first position beneath the first support and a second position; a sensor for determining the number of discrete objects in a stack, the sensor being operatively coupled to the to the third actuator; and a controller for controlling the first, second, third and fourth actuators. A method of using the system is also disclosed.

Owner:F R DRAKE

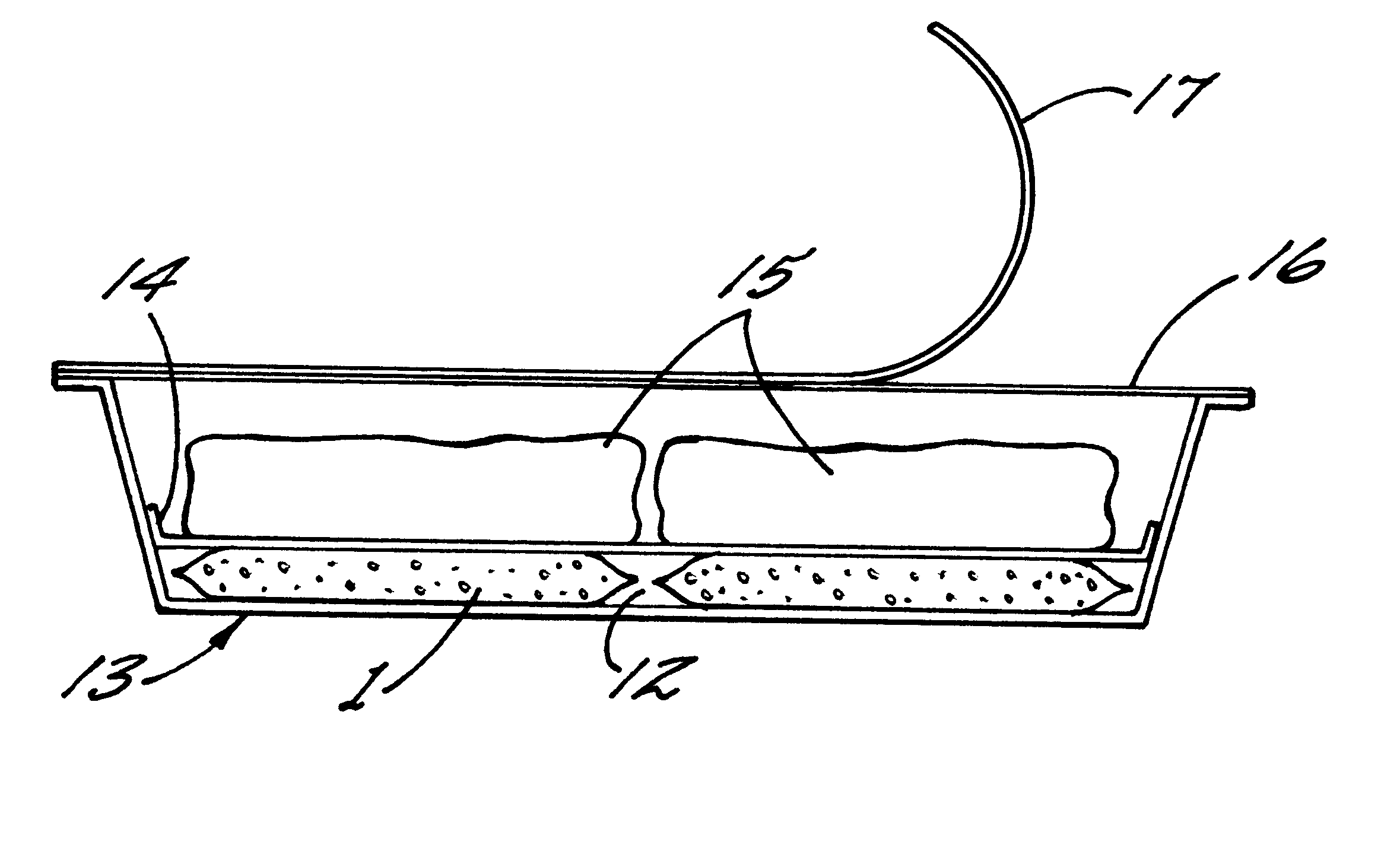

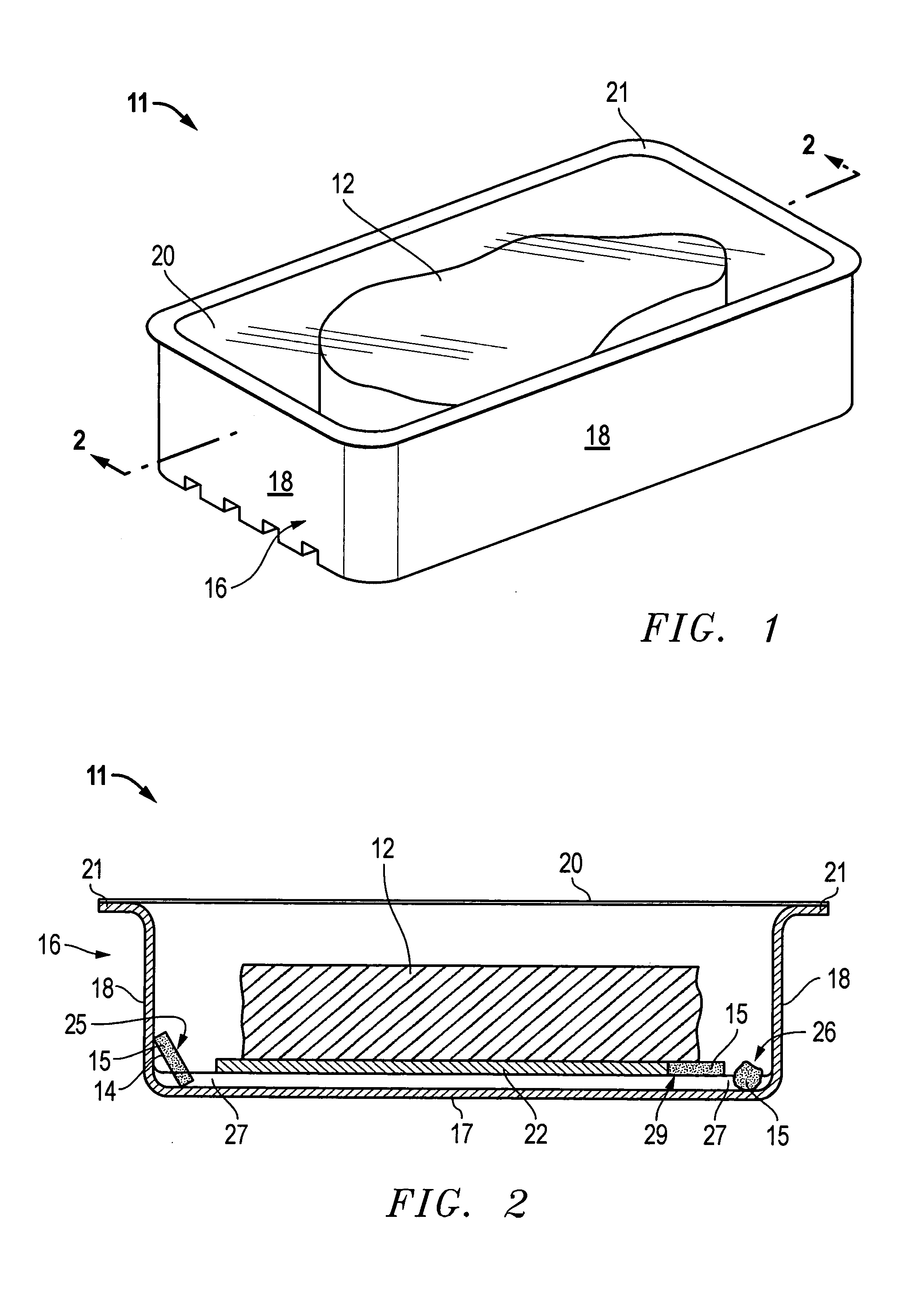

Packaging for meat and foodstuff

InactiveUS6447826B1Preventing inflationMaintain internal pressureReady-for-oven doughsFlexible coversFood packagingLow oxygen

Methodology for packaging and packages for meat or other foodstuffs in a carbon dioxide rich low oxygen environment by including without the packages carbon dioxide generating material and oxygen removing material where the production of carbon dioxide is not dependent upon removal of oxygen.

Owner:SEALED AIR NZ +1

Method and apparatus for packing

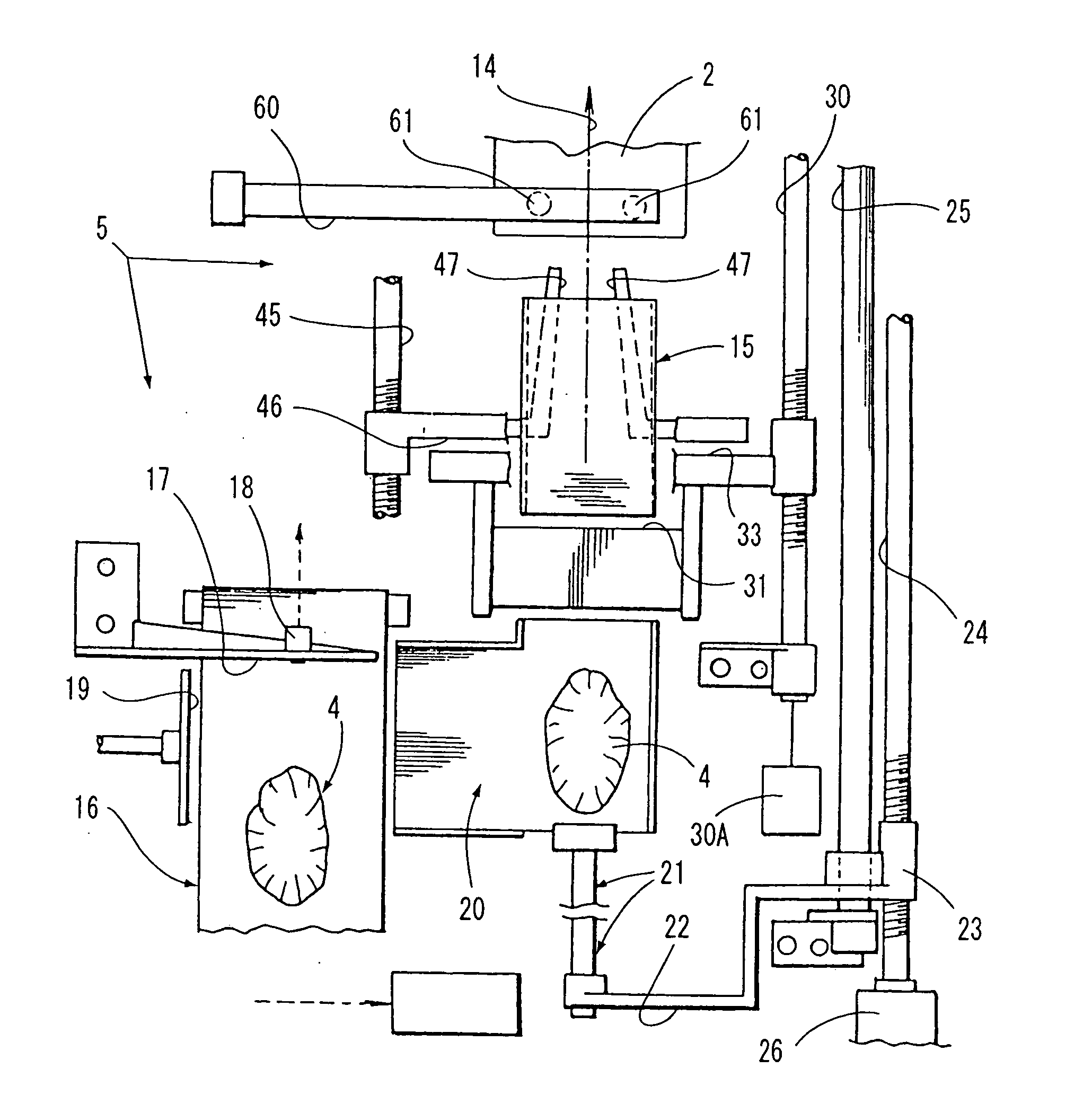

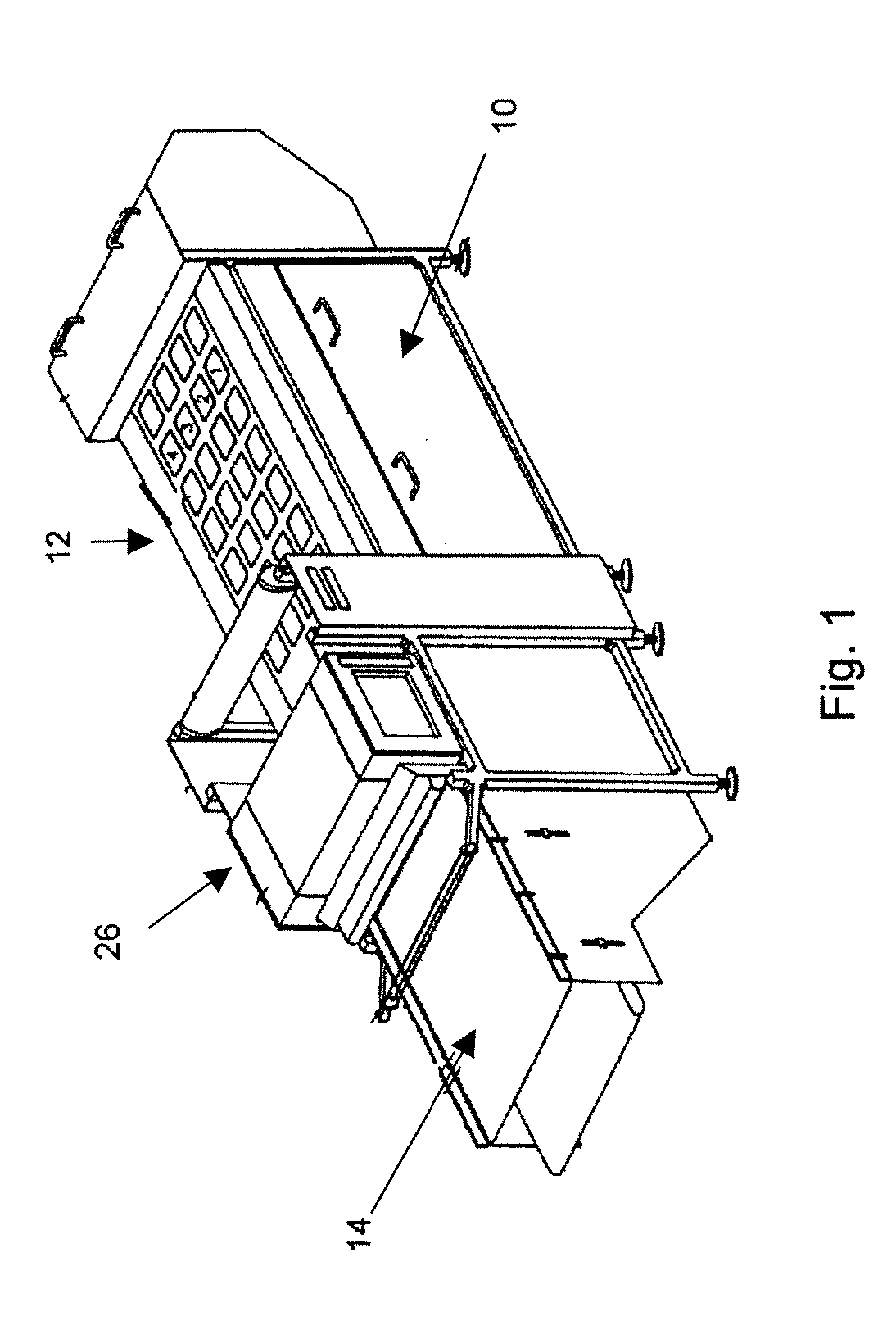

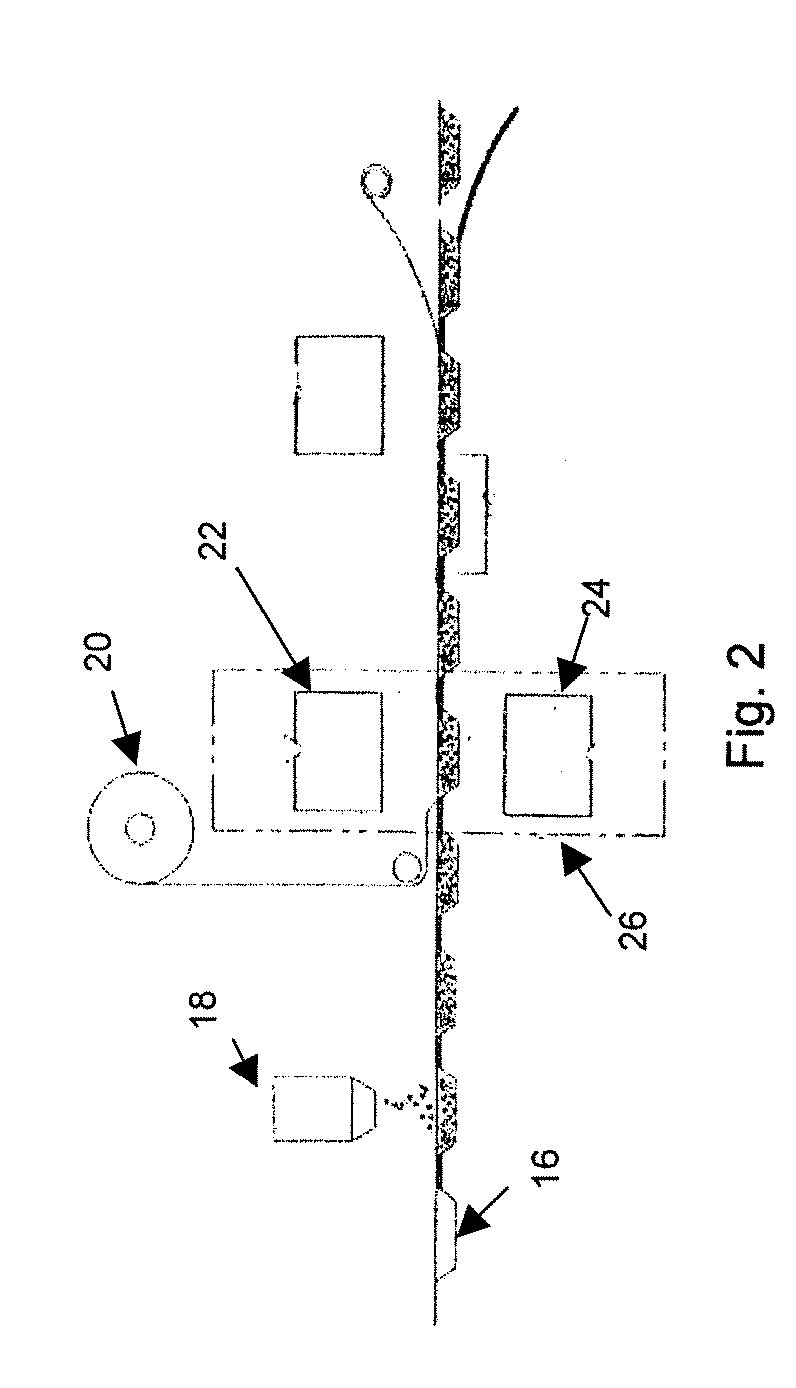

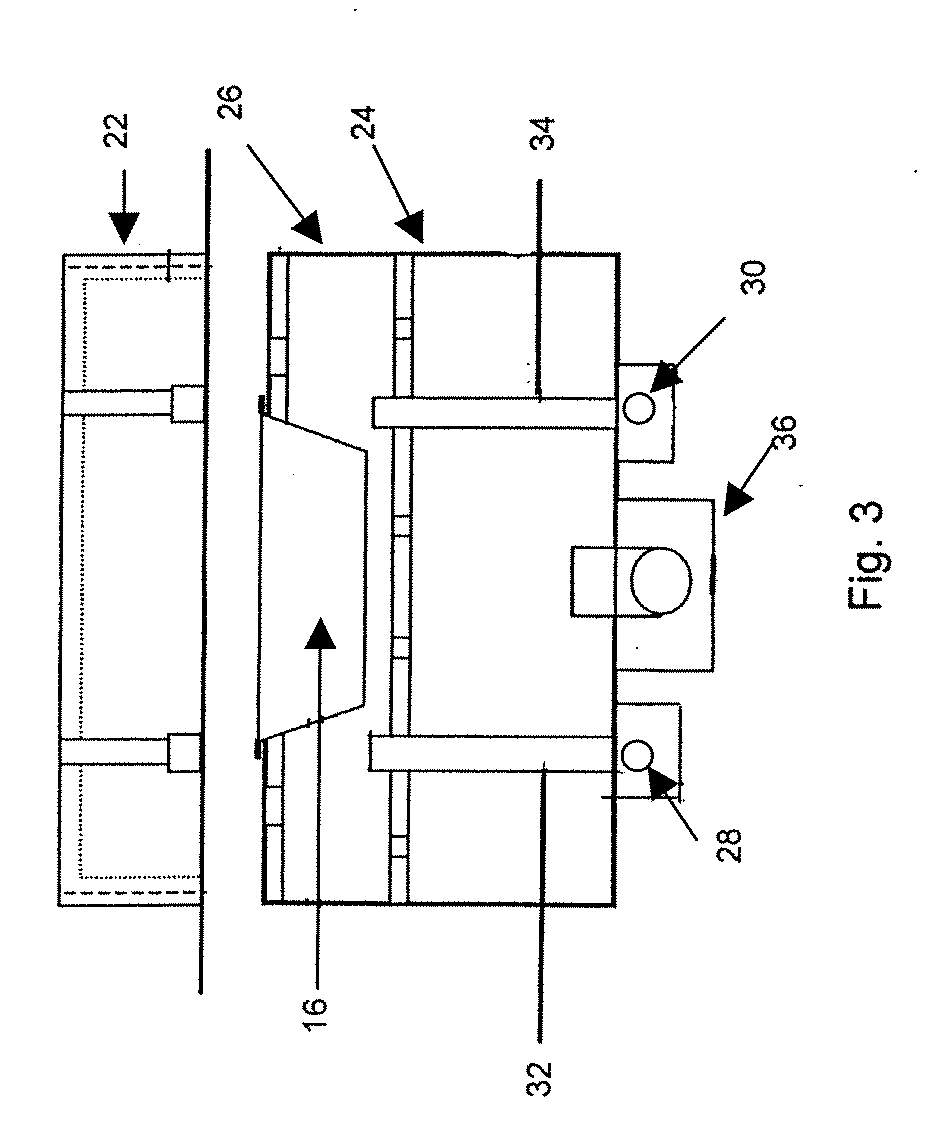

A packing method and system are disclosed which system includes a first platform having a product support surface for supporting a product and a second platform for supporting a box into which the product is to be packed. After a box is received on and secured to the second platform, the second platform is rotated so that the open top of the box faces the first platform and moved toward the first platform until the box substantially surrounds the product on the product support surface. The first and second platforms are then rotated simultaneously so that the product is transferred from the product support to the box, and the full box is discharged to a discharge conveyor.

Owner:WELBORN KENNETH M +4

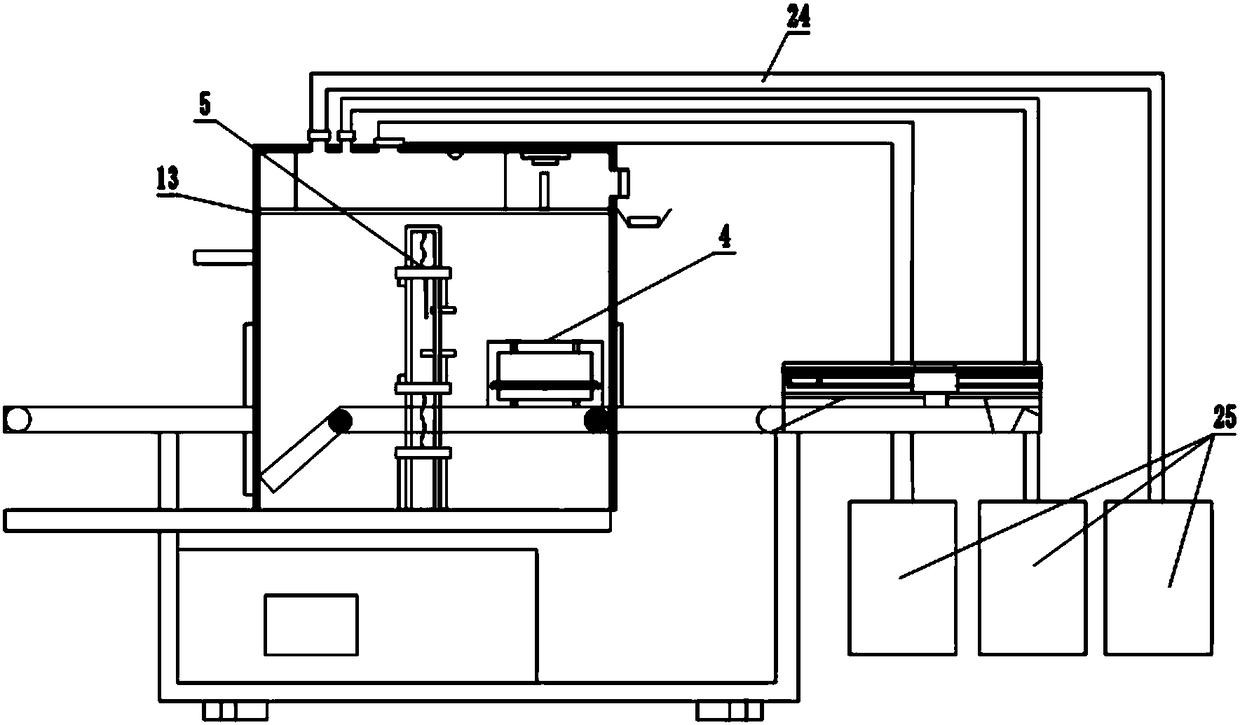

Apparatus for packing

A packing method and system are disclosed which system includes a first platform having a product support surface for supporting a product and a second platform for supporting a box into which the product is to be packed. After a box is received on and secured to the second platform, the second platform is rotated so that the open top of the box faces the first platform and moved toward the first platform until the box substantially surrounds the product on the product support surface. The first and second platforms are then rotated simultaneously so that the product is transferred from the product support to the box, and the full box is discharged to a discharge conveyor.

Owner:F R DRAKE

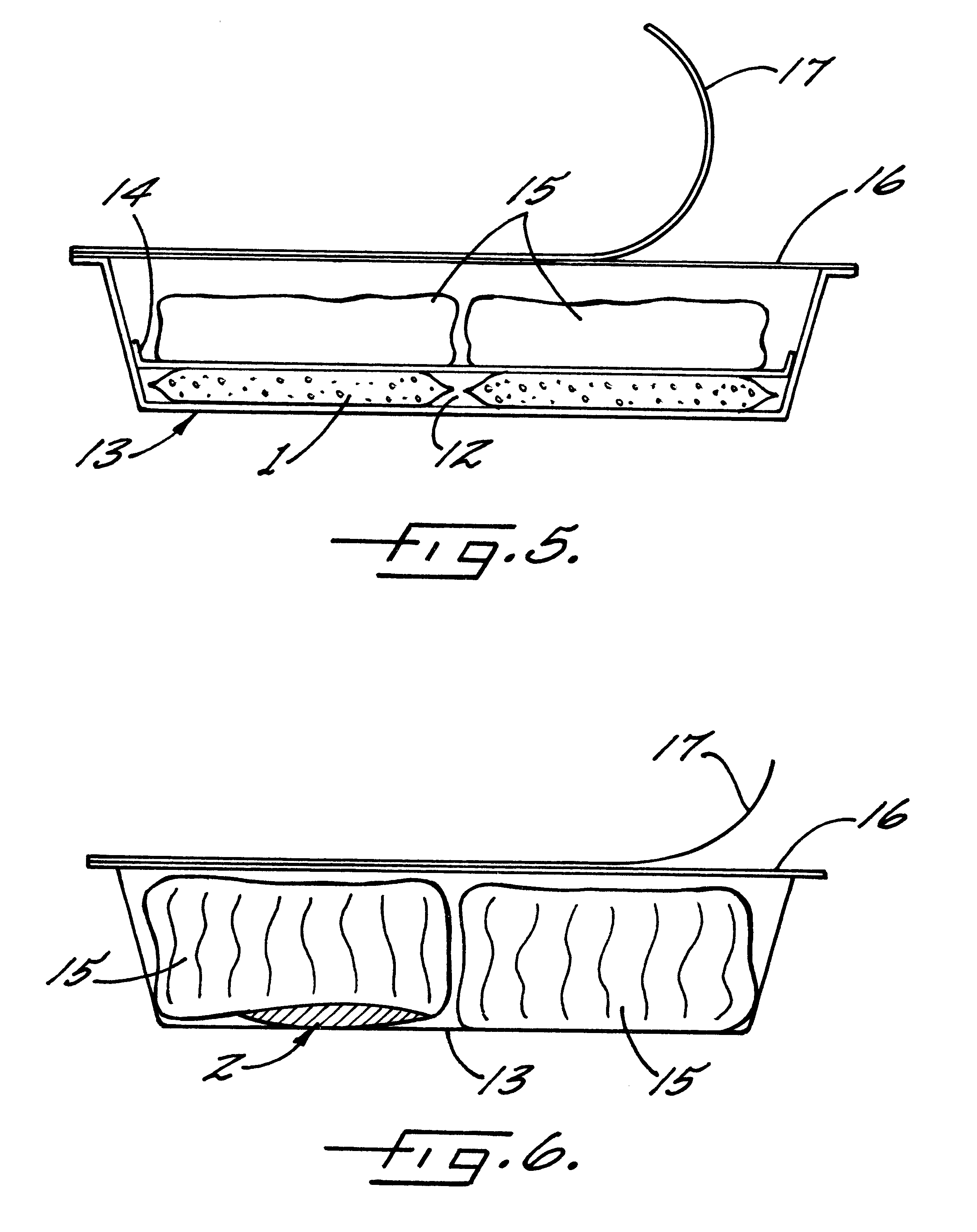

Products, methods and apparatus for fresh meat processing and packaging

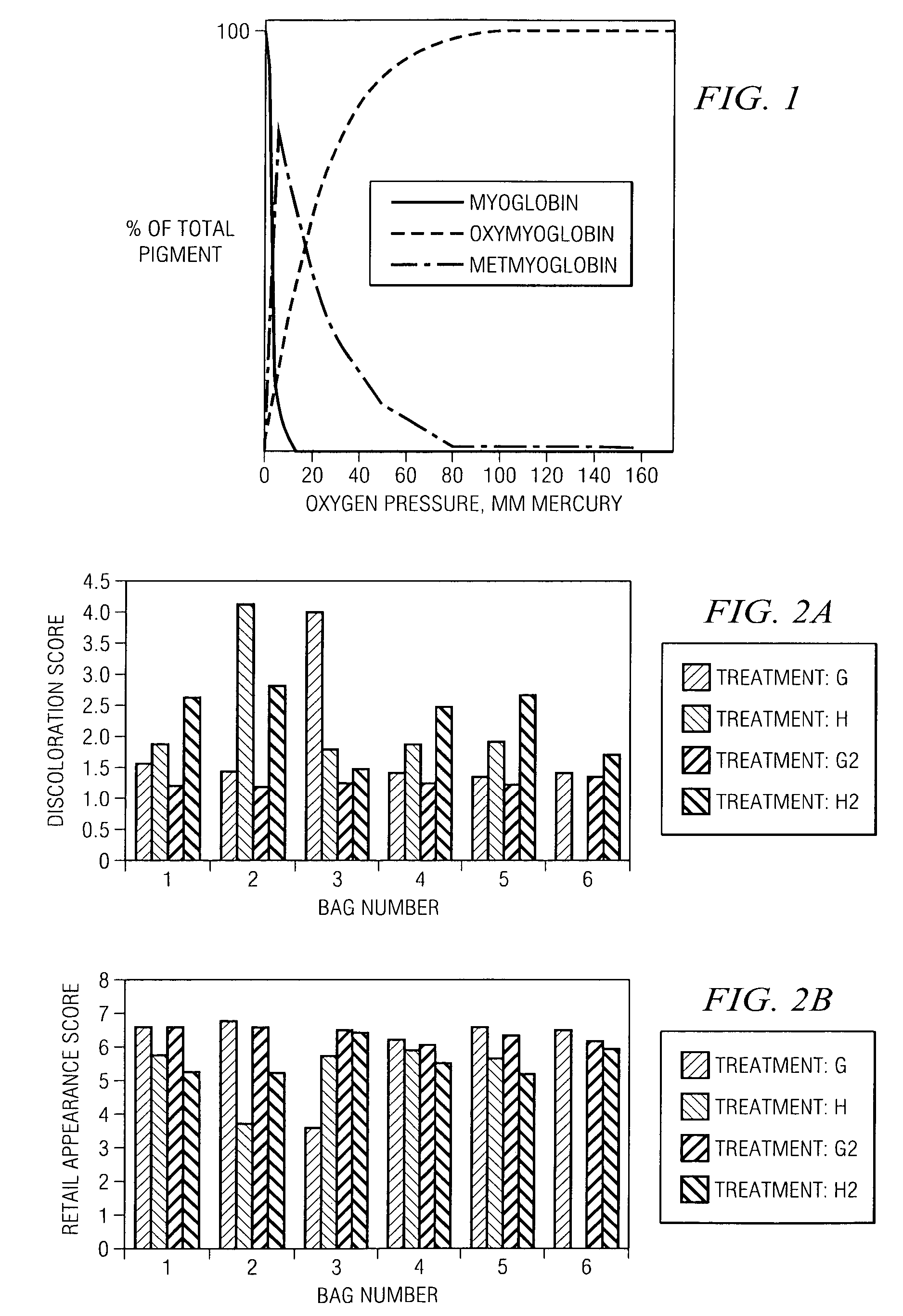

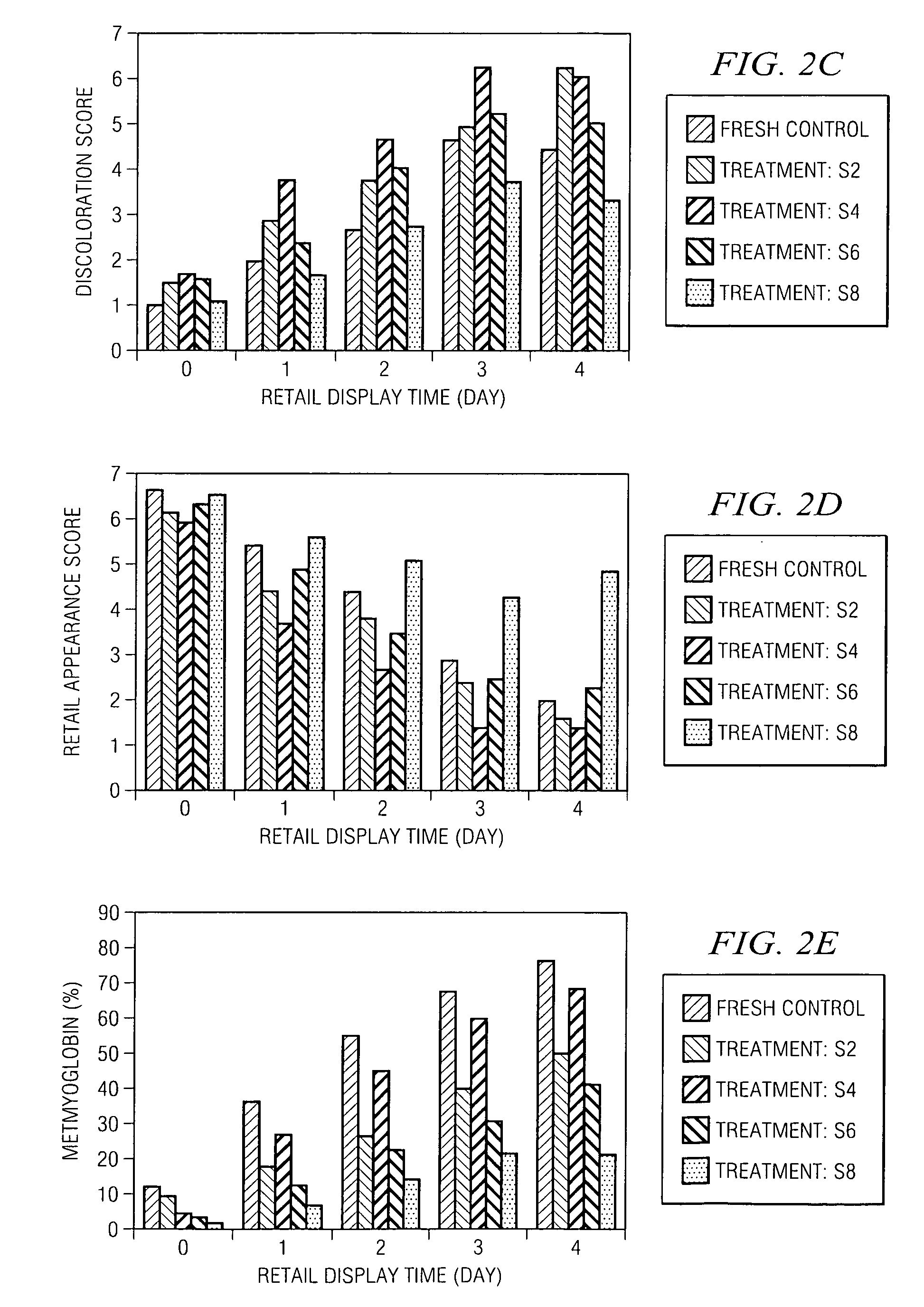

InactiveUS20060147588A1Lower display costsReduce packaging costsPackaging meatMeat/fish preservation using chemicalsAtmospheric oxygenRed meat

Improved processing and packaging for perishable goods such as red meats providing a processing system wherein ambient air is excluded and suitable gases such as carbon dioxide are provided at a suitable pressure and in such a manner as to increase the quantity of the gases dissolved in the perishable goods. Then providing a base and placing the perishable goods over the base. A flexible web of plastic wrapping material (second web) is then applied over the base and the goods and air or gas evacuated therefrom and replaced with a suitable gas. The base includes a cup-shaped tray with a recess (first web), of plastics or other suitable material, with side walls extending upwardly to connect to a narrow horizontally disposed flange. The first web, goods and second web are located inside a depression in a third web of gas barrier material and there together placed into an enclosed evacuation chamber. A suitable gas is provided in the chamber in such a manner as to displace substantially all other gas and particularly atmospheric oxygen that may be present with the enclosed goods and web materials. The third web is then sealed so as to enclose the goods with first and second webs. that the pressure of the gas may be increased to a level above atmospheric pressure. Most preferably the quantity of gas dissolved into the goods will be increased. Most preferably the gas introduced into the chamber and the space will enhance preservation of the packaging goods when contacting the goods. The first web, second web and third web are sealed together thereby producing a hermetically sealed package with the goods and a gas filled space contained therein to provide a sealed package. The sealed package can be stored for any convenient period of time after which the third web is can be removed so as to allow ambient air to contact the goods. The invention further includes the method and apparatus for producing the processed goods and packaging.

Owner:STONE MICHAEL

Packaging system

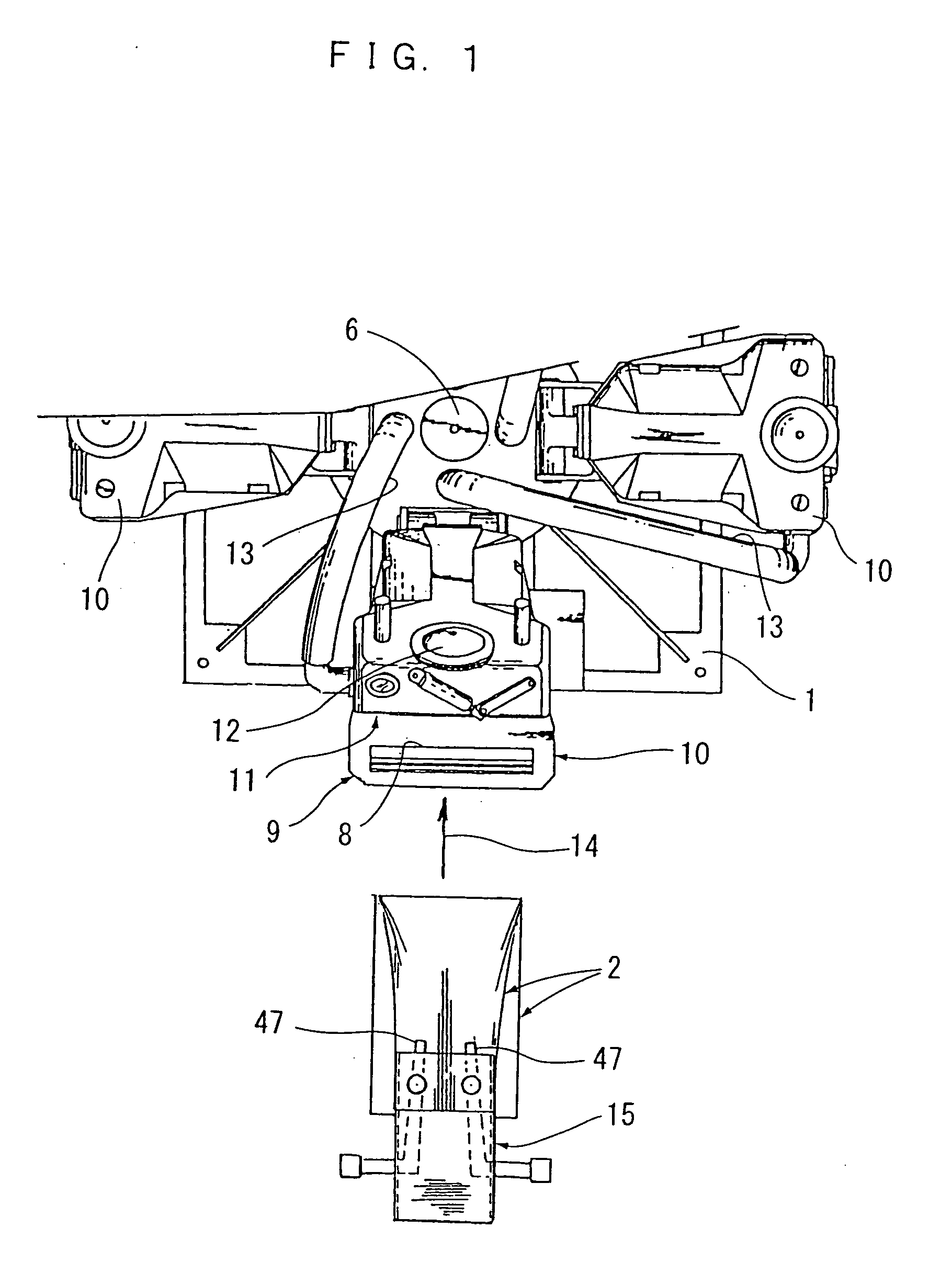

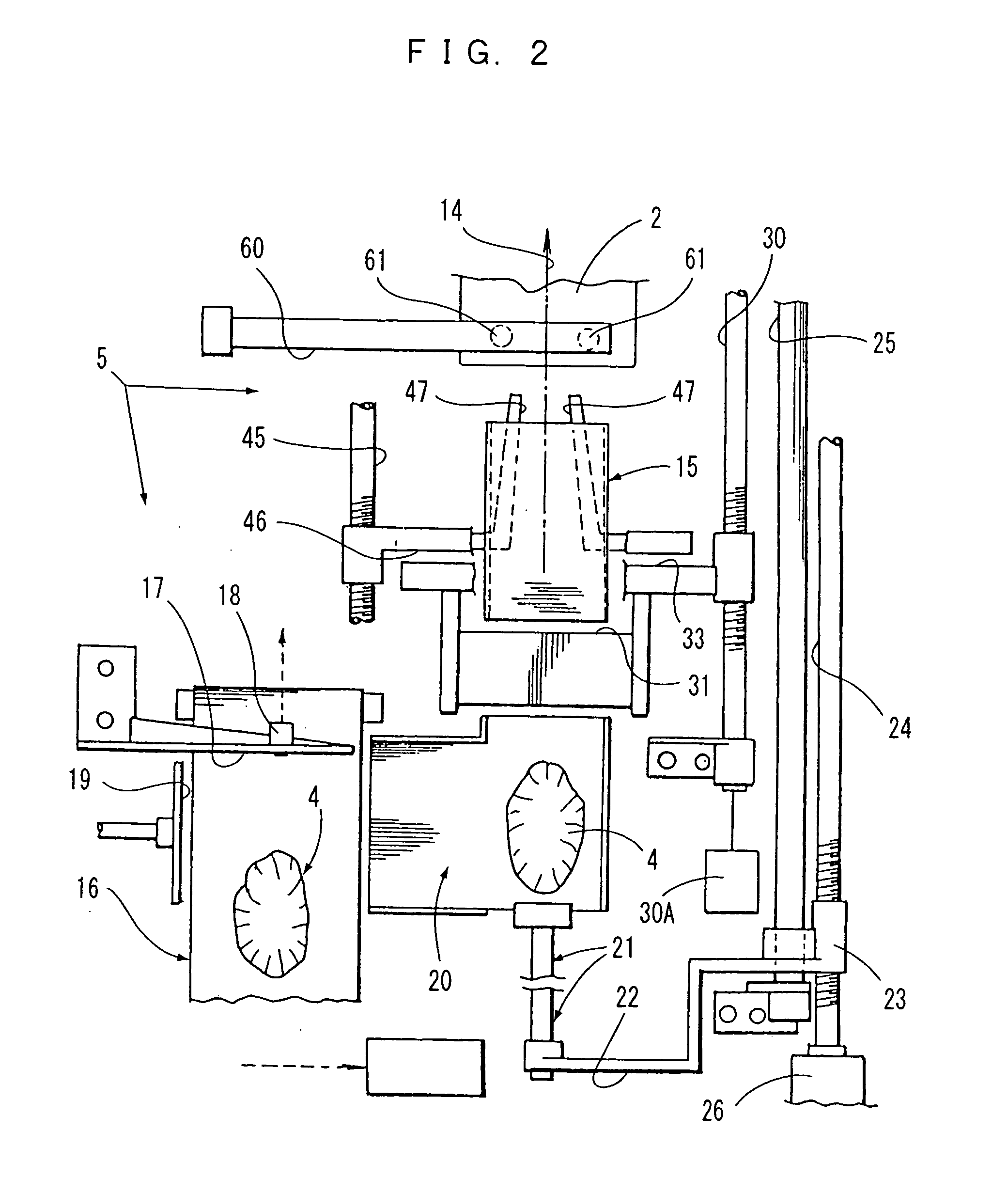

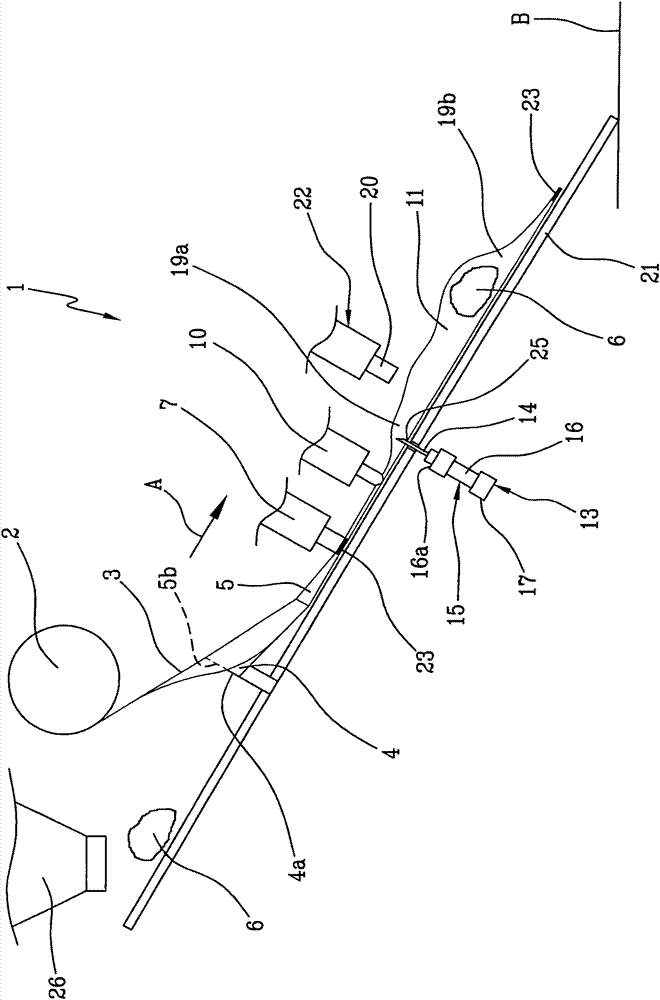

A packaging system is provided which supplies an item to be packaged and a bag covering the item to a pressure resistant chamber, for a heat sealing mechanism which arrives at a certain time interval, in accordance with the circulation timing of each sealing mechanism. The packaging system includes means for causing a beak-shaped hopper and a pair of opening and closing bars, to move back and forth in unison along a main travel path leading to a rotary vacuum packaging device, means for extending and supporting the opening section of an uppermost packaging bag, and conveying same into a pressure resistant chamber of the vacuum packaging device, means for causing a waiting station to move following the conveyance movement of the beak-shaped hopper into a pressure resistant chamber, and means for opening the opening and closing bars towards either side immediately after the bag has been conveyed into the pressure resistant chamber.

Owner:FURUKAWA MFG

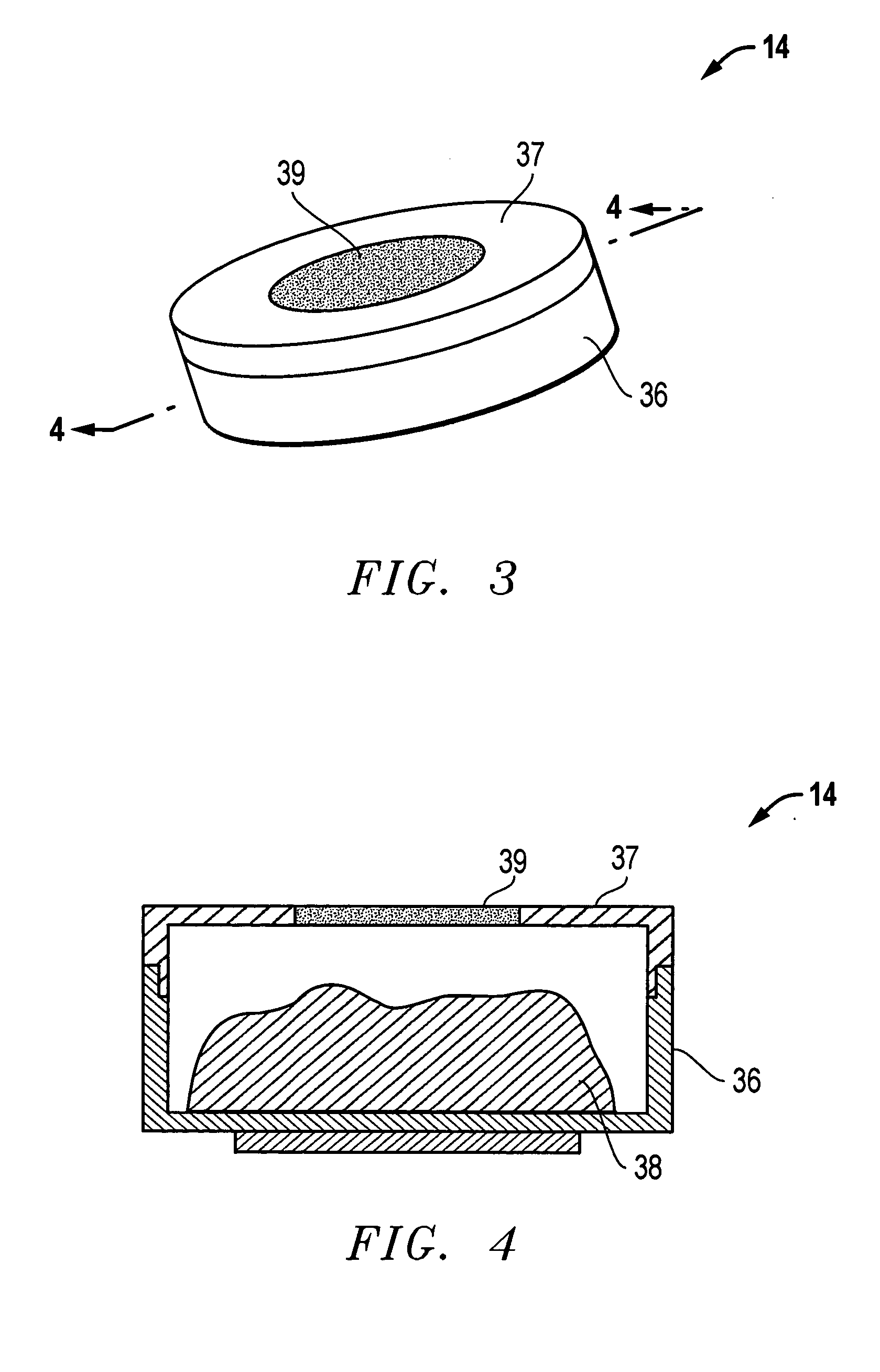

Method for imparting a food additive and package for same

A method for providing a package having a coated inner surface involves inverting a package having an inner surface defining an inner space, an outer surface, and a coating on the outer surface. The package can be inverted by application of a vacuum. The coating can be an additive such as a colorant, a flavorant, an antimicrobial agent, or the like.

Owner:CRYOVAC ILLC

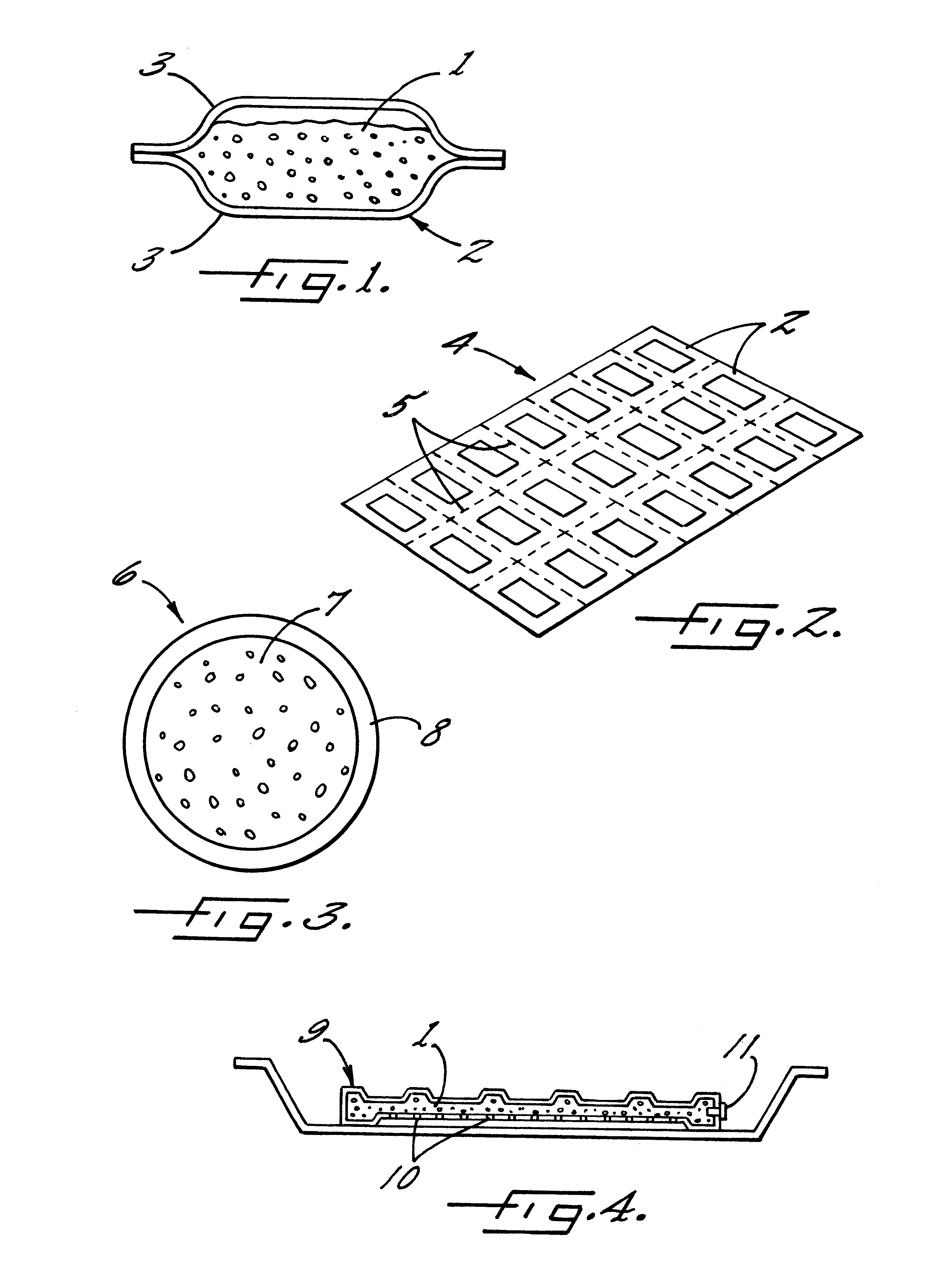

Vacuum packaging of a meat product using a film having a carbon dioxide scavenger

A package includes a vacuumized bag made from a film including an outer layer including an olefin polymer or copolymer, an inner layer including an olefin polymer or copolymer, an oxygen barrier layer, disposed between the outer and inner layer, including a polymer or copolymer having an oxygen permeability of less than 100 cm3 O2 / m2·day·atmosphere, and an intermediate layer, disposed between the oxygen barrier layer and inner layers, including a polymer or copolymer, wherein at least one of the inner and intermediate layers includes a carbon dioxide scavenger; and a meat product disposed in the bag. A method of packaging a meat product includes providing a bag made from the above film; putting a meat product into the bag through an open bag mouth; drawing a vacuum on the bag to provide a vacuumized bag; and heat sealing the open mouth of the bag.

Owner:CRYOVAC ILLC

Process for triggering, storing, and distributing an oxygen scavenger, and a stored oxygen scavenger

ActiveUS6942821B2Package sterilisationWater/sewage treatment by substance additionScavengerOxygen barrier

A method includes triggering an oxygen scavenger; and storing the scavenger in a container configured such that the oxygen scavenger exhibits no substantial oxygen scavenging activity while inside the container. The triggered oxygen scavenger can later be removed from the container, and used in packaging oxygen sensitive products. A stored oxygen scavenger, triggered, is also disclosed. A method of distributing an oxygen scavenger film includes providing a tubular film at a first location, the film having oxygen barrier and oxygen scavenger layers; triggering the oxygen scavenger; collapsing the film; rolling up the film; transporting the film to a second location; and triggering the oxygen scavenger. Another method of distributing an oxygen scavenger film includes providing an oxygen scavenger film at a first location; transporting the film to a second location; triggering the oxygen scavenger; storing the oxygen scavenger film in a container; and transporting the film to a third location.

Owner:CRYOVAC ILLC

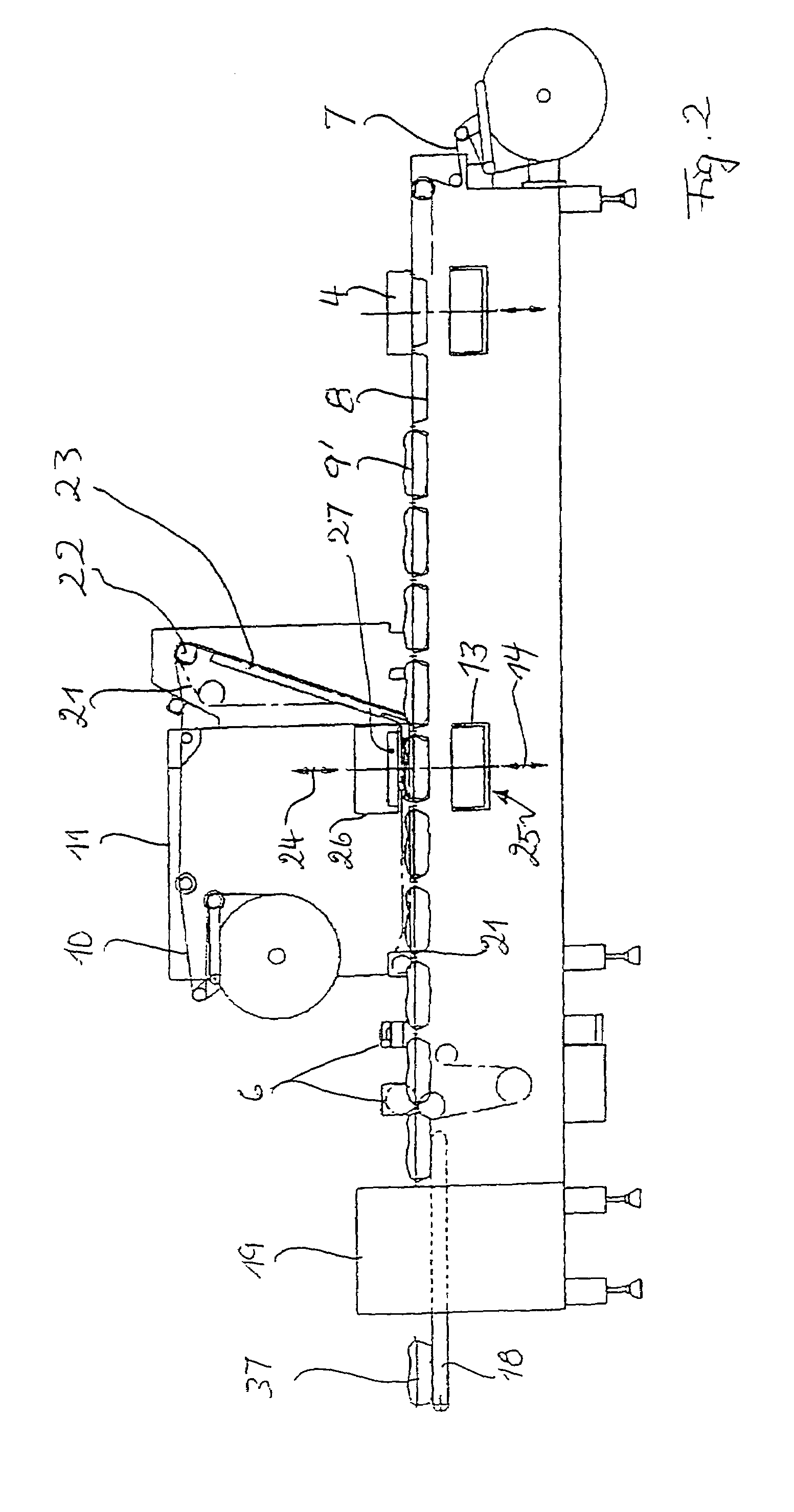

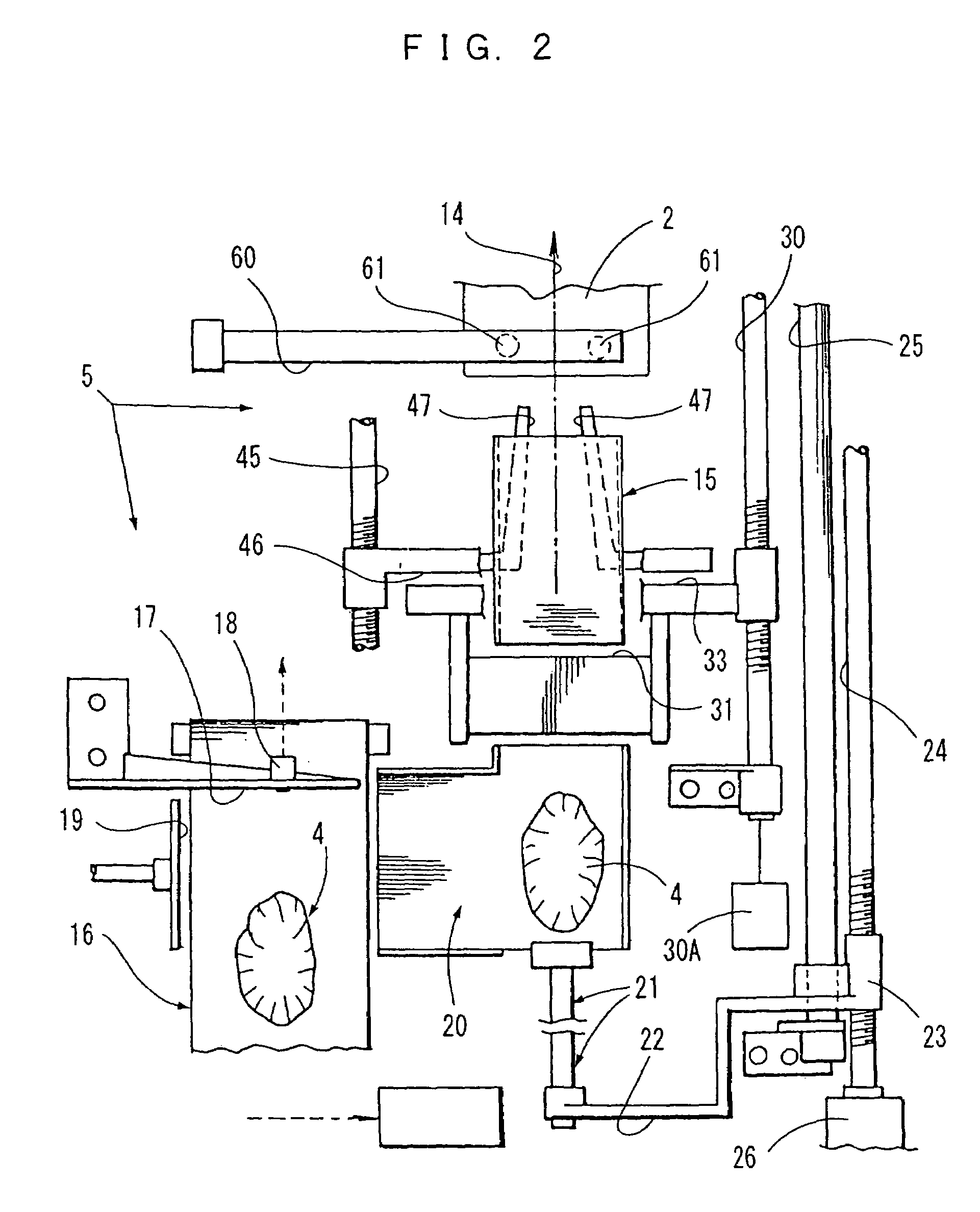

Packaging method and device

ActiveUS20050173289A1Appealing appearanceLong storage periodWrappers shrinkagePackaging meatEngineeringMechanical engineering

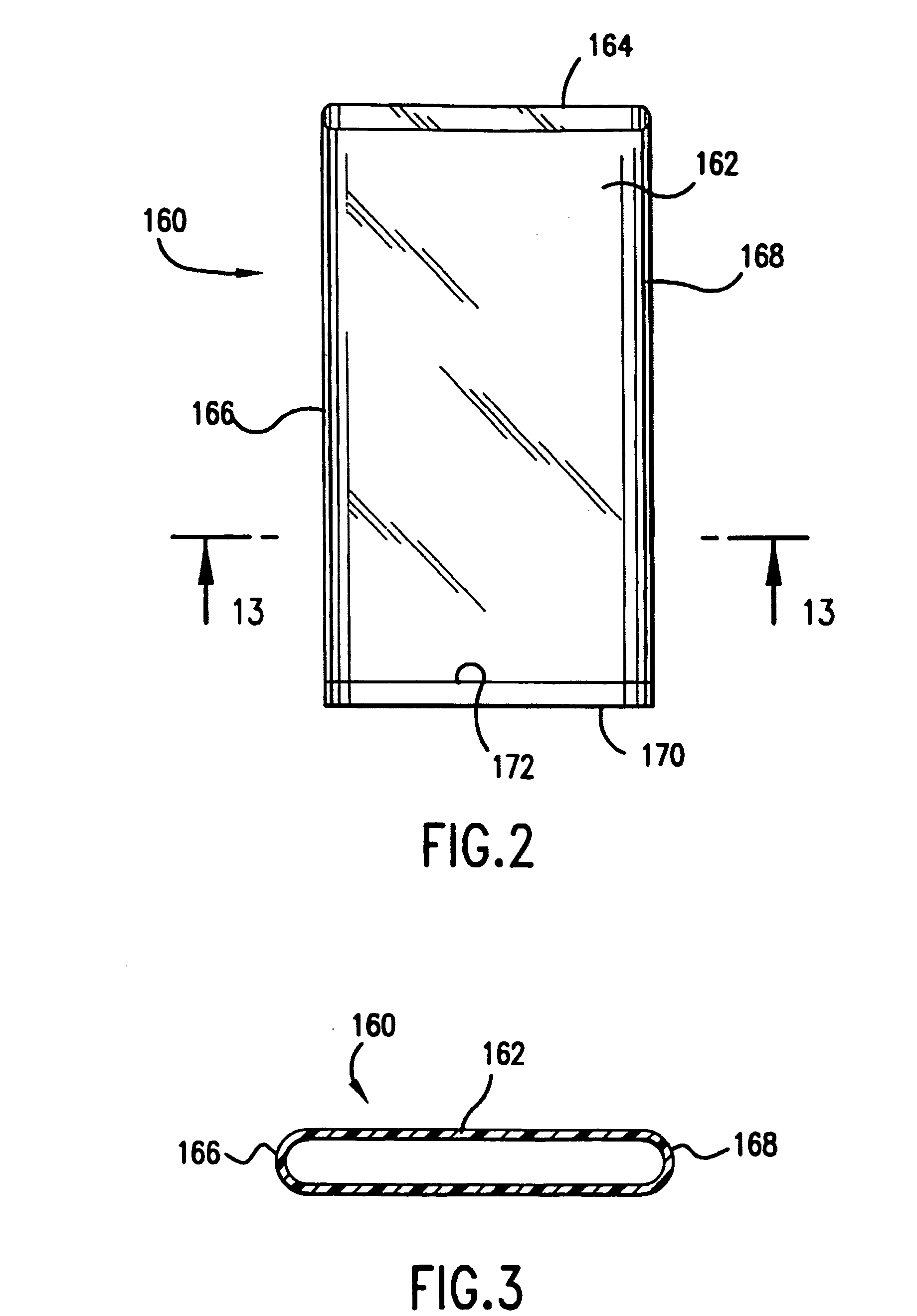

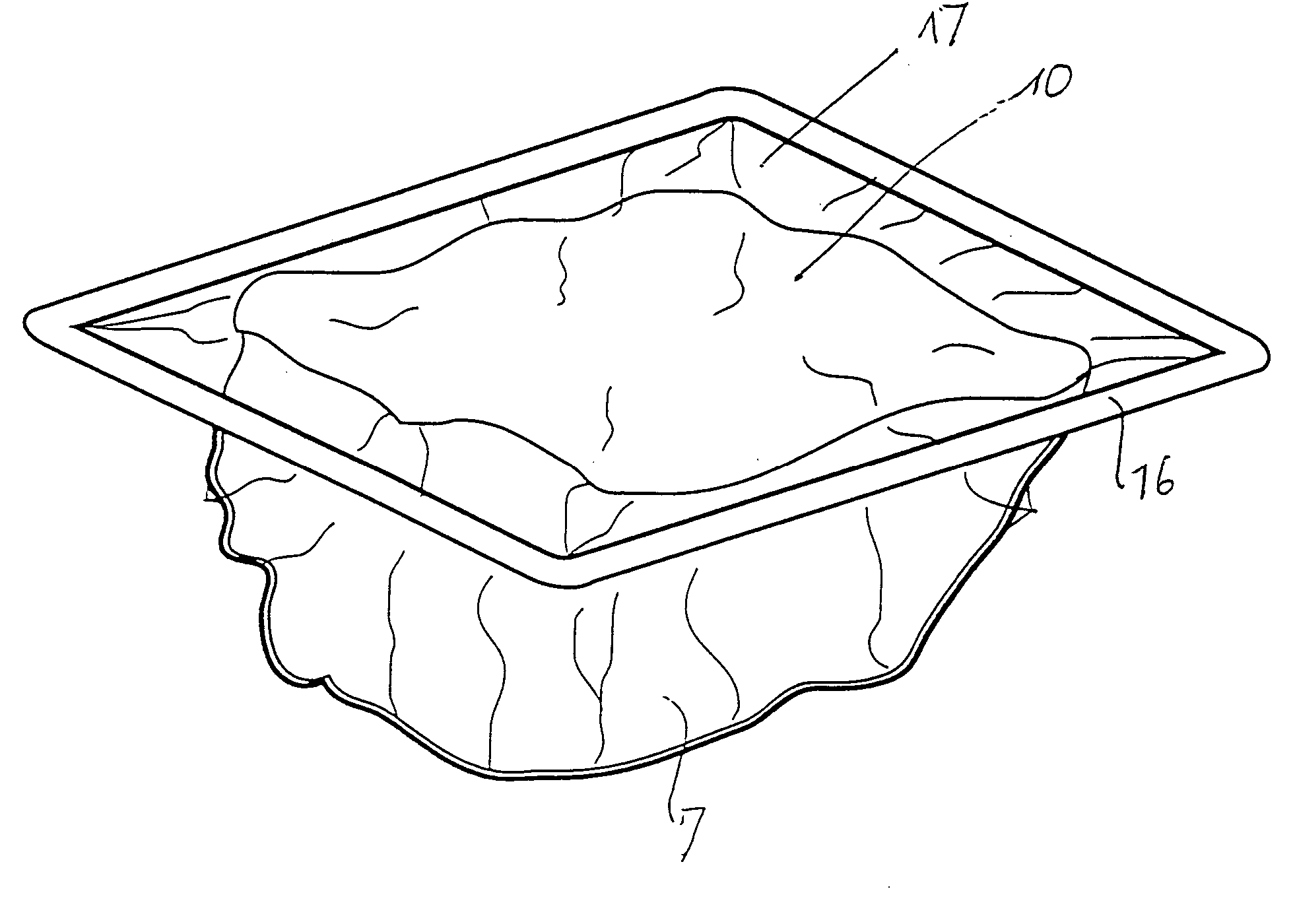

A method for packaging a good by means of a package formed of a shrinkable lower film 7 and an upper film 10 is provided. The lower film may be deep-drawn to form a container for accommodating the good, and after filling in the good, an upper film may be supplied for covering. The such-formed package is sealed and then may be subjected to shrinking in an evacuating and sealing station. Consecutively to the evacuating and sealing, an additional shrinking may be performed by subjecting the package to heat from all sides, so as to remove the film section having developed between the part of the lower and the upper film directly resting against the good and the sealing rim 16. A corresponding device for executing the method is indicated.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

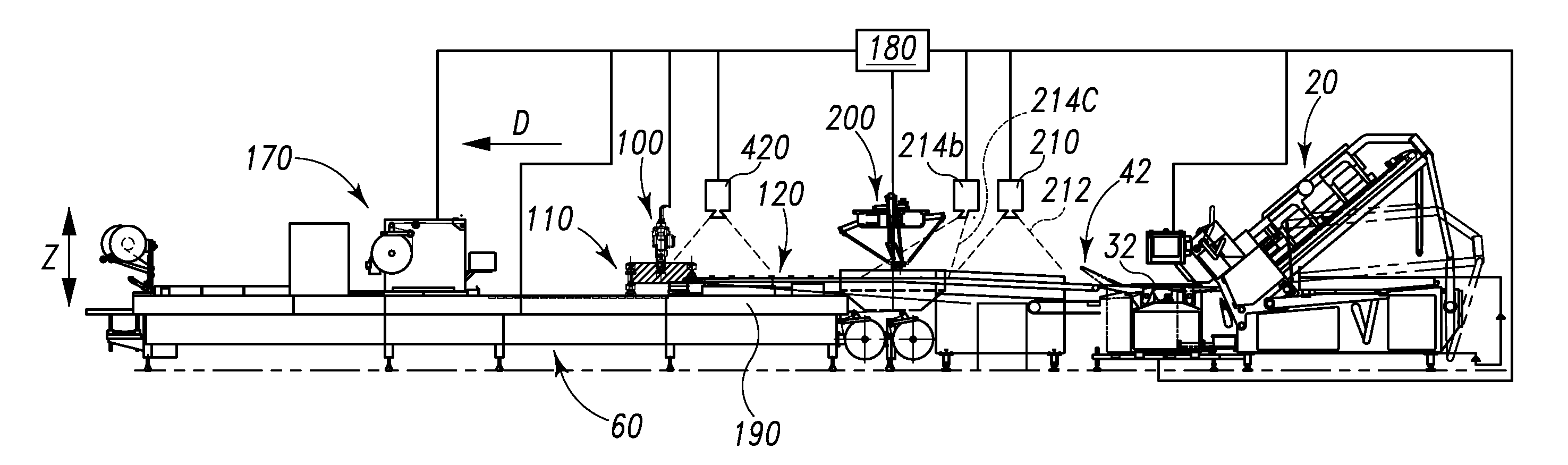

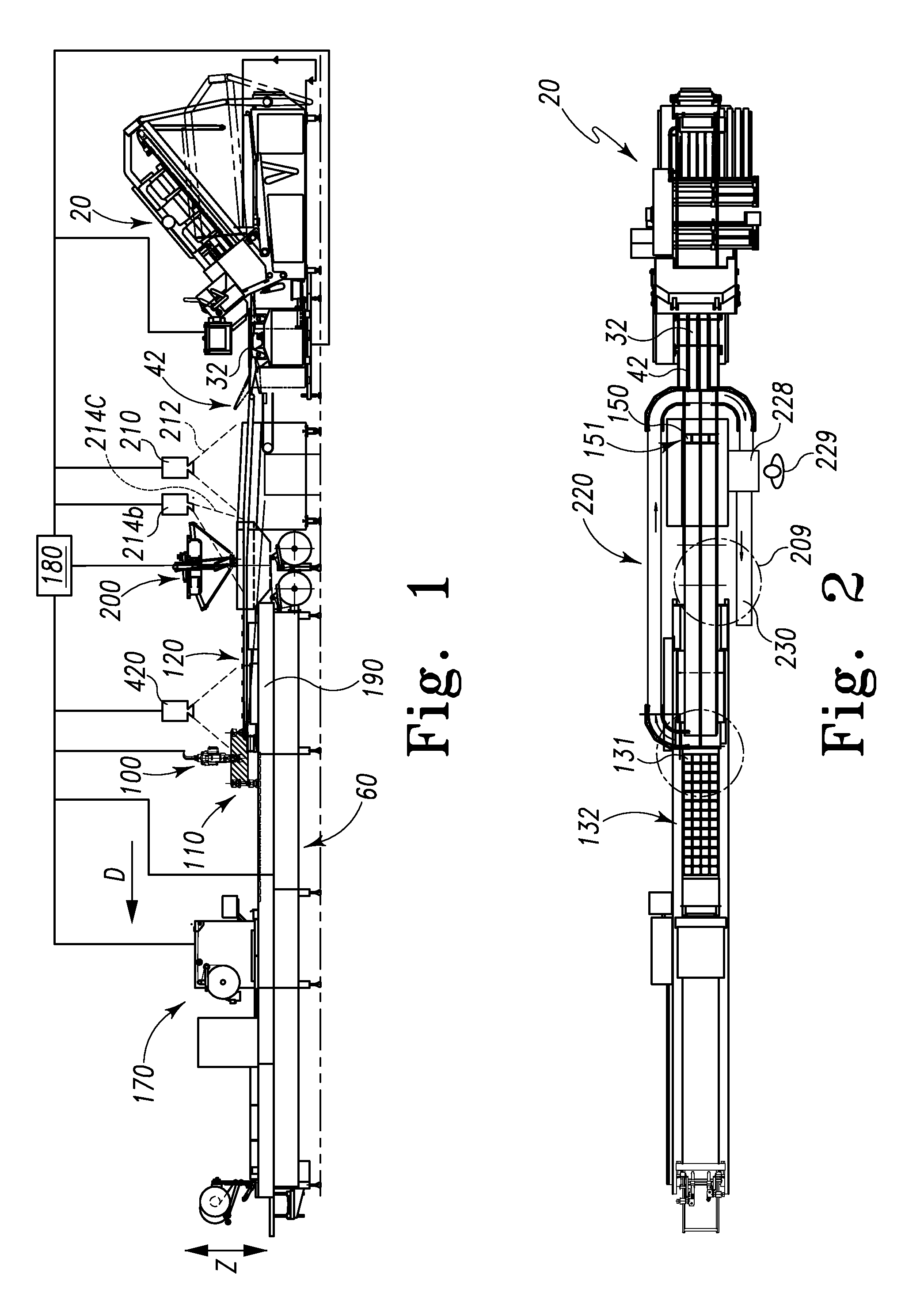

Food Product Vacancy Reduction System

A food handling system having a vacancy reduction system. The vacancy reduction system includes the main conveyor, a food product parking station, a vacancy detector, a robot, and a controller. The vacancy detector is configured to detect a vacant food product position on the main conveyor. The robot has a working range for moving between the parking station and the main conveyor. The controller is signal-connected to the vacancy detector. The controller is configured to receive a signal from the vacancy detector indicating a vacant food product position on the conveyor. The controller is signal-connected to the robot and has control instructions for instructing the robot to move the food product from the food product parking station to the vacant food product position on the main conveyor.

Owner:PROVISUR TECHNOLOGIES INC

Method and device for packaging

ActiveUS7487625B2Long storage periodAppealing appearanceWrappers shrinkagePackaging meatLower upperMechanical engineering

A method for packaging a good by means of a package formed of a shrinkable lower film 7 and an upper film 10 is provided. The lower film may be deep-drawn to form a container for accommodating the good, and after filling in the good, an upper film may be supplied for covering. The such-formed package is sealed and then may be subjected to shrinking in an evacuating and sealing station. Consecutively to the evacuating and sealing, an additional shrinking may be performed by subjecting the package to heat from all sides, so as to remove the film section having developed between the part of the lower and the upper film directly resting against the good and the sealing rim 16. A corresponding device for executing the method is indicated.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Method and system for processing of items

ActiveUS20100051513A1Operation efficiency can be improvedLittle mutual spacePackaging meatMeat packaging/handling/transportingIndividual itemSoftware engineering

A method and system for the processing of items that are supplied to a batching apparatus, where the batching apparatus comprises at least one handling means of the robotic type. By means of the batching apparatus a first process is performed, according to which items are selectively batched in consideration of measured, detected and / or estimated data for the individual items and in consideration of at least one predefined criterion. Particular items are identified and led to another process, the particular items being items that are deviant in relation to one or more predefined parameter(s) relating to the batching and / or items that have not been selected to be batched during the first process.

Owner:SCANVAEGT INT AS

Continuous roll stock netting machine

Owner:POLY CLIP SYST

Meat product package and packaging method with maintained atmosphere

InactiveUS20050244551A1Facilitated releaseDirect contact guaranteeReady-for-oven doughsPackaging meatPositive pressureProcess engineering

A method includes sealing a meat product into a container. The method then includes releasing carbon dioxide gas from a source contained inside the container to maintain a carbon dioxide gas presence in the atmosphere within the container. Sufficient carbon dioxide gas is preferably maintained in the package along or together with one or more gasses to maintain at least a slight positive pressure in the container or package, that is, a pressure slightly above atmospheric pressure.

Owner:FREEZING MACHINES

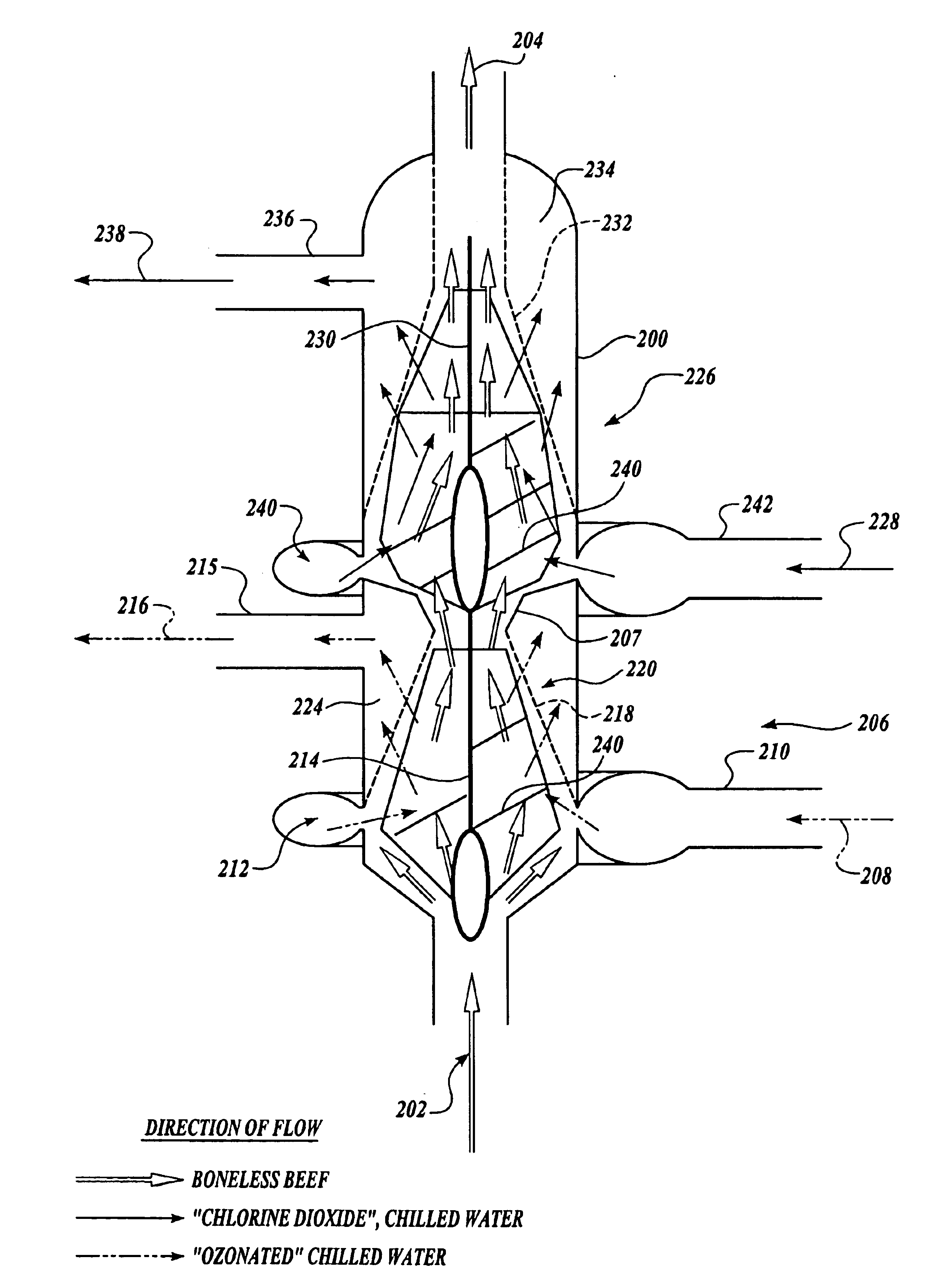

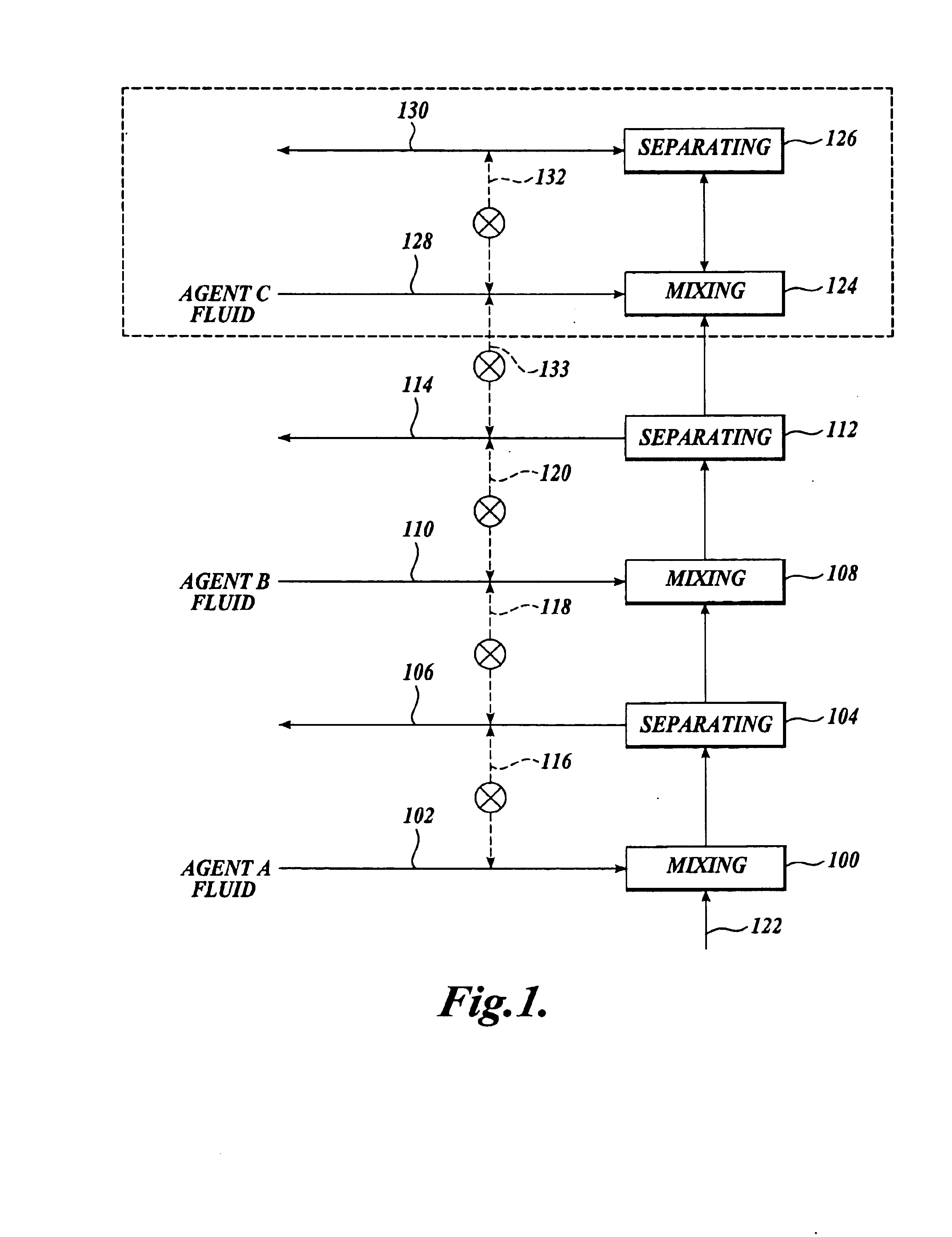

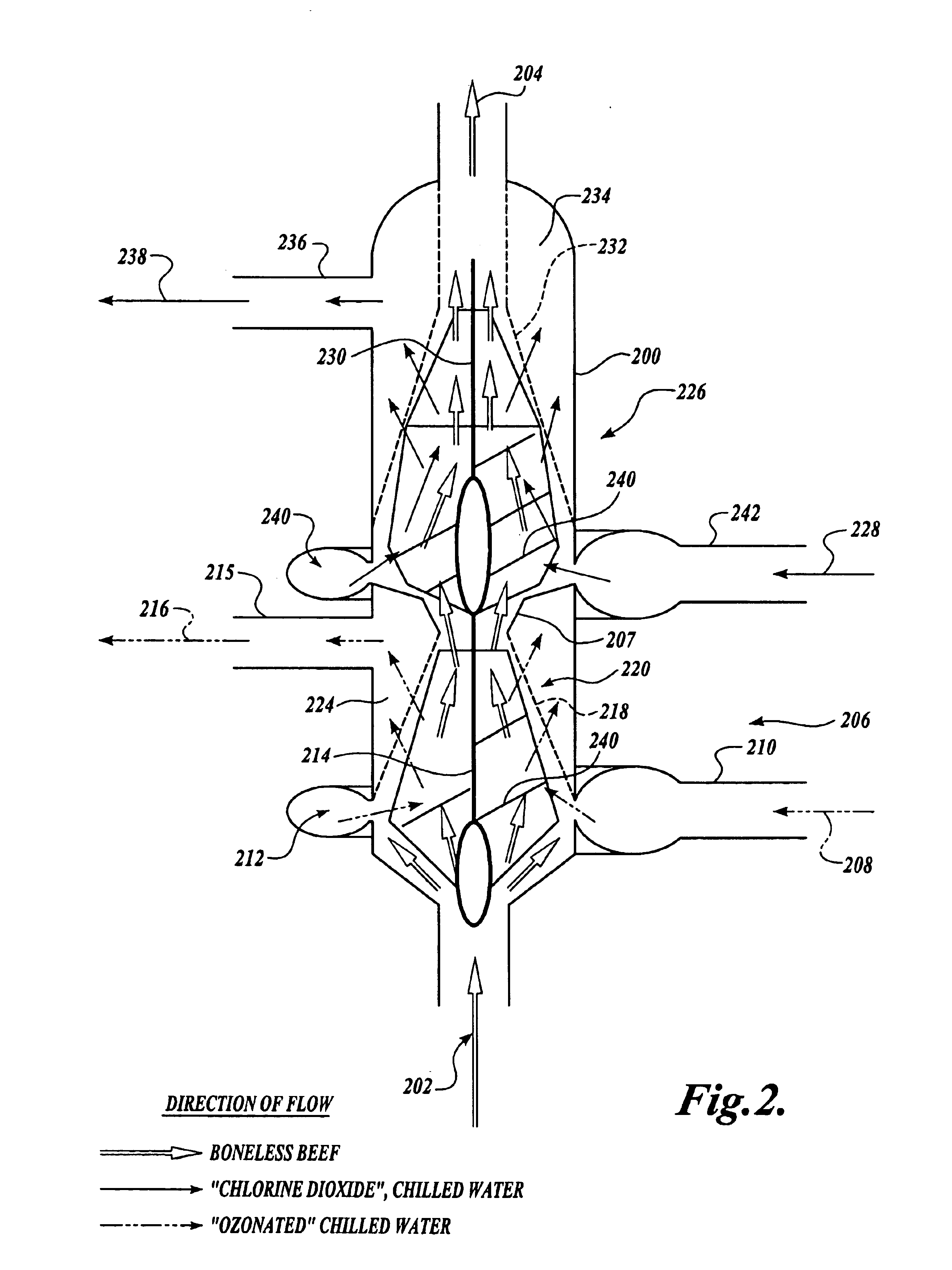

Method and apparatus for sanitizing perishable goods in enclosed conduits

InactiveUS6866832B2Minimized ozone concentrationReduce exposureSolid sorbent liquid separationLiquid displacementChemistryOzone

The invention is directed to a method and apparatus for sanitizing perishable goods by mixing the goods with sanitizing fluid for a suitable period of time followed by separating the fluid and substantially neutralizing any residual sanitizing agent left in the goods. In one instance, the sanitizing agent includes ozone and water, therefore separation of the ozonated water advantageously proceeds with a squeezing effect to more adequately remove the ozonated water from the goods.

Owner:SAFEFRESH TECH

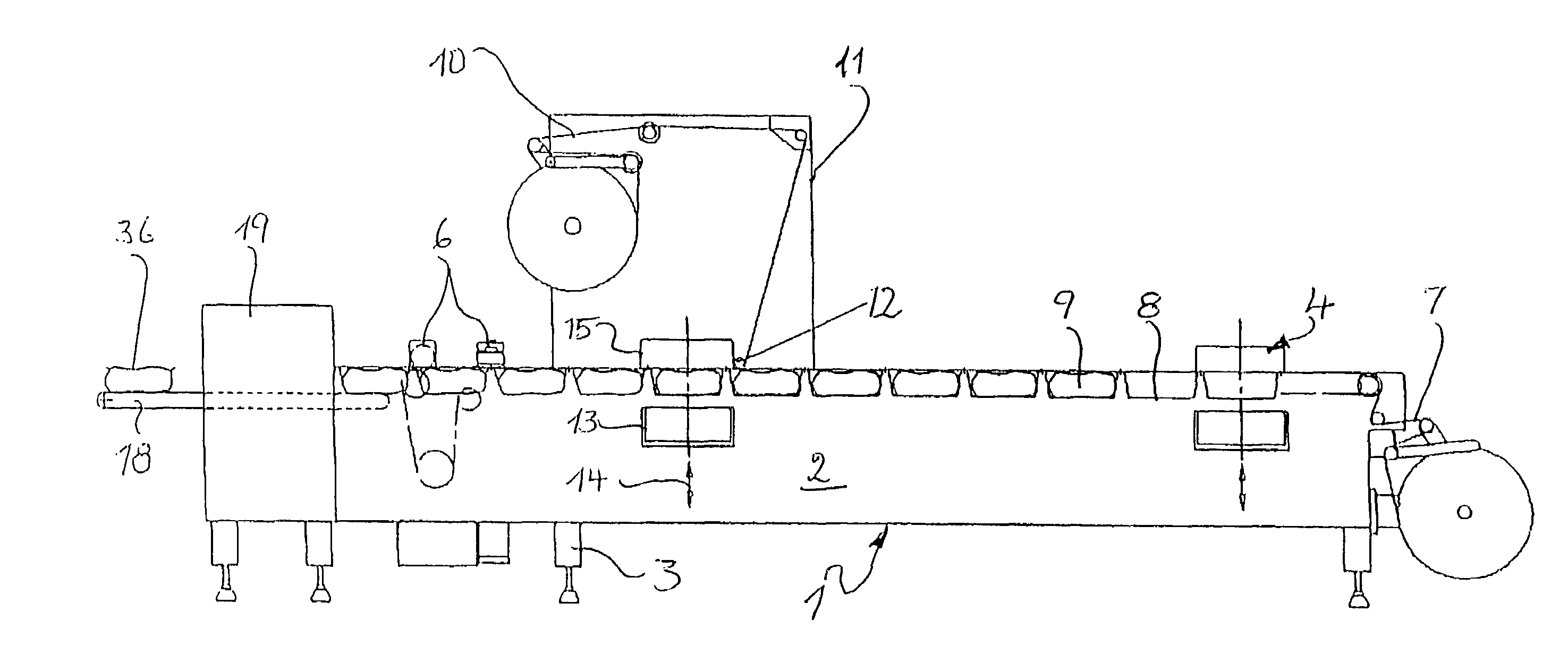

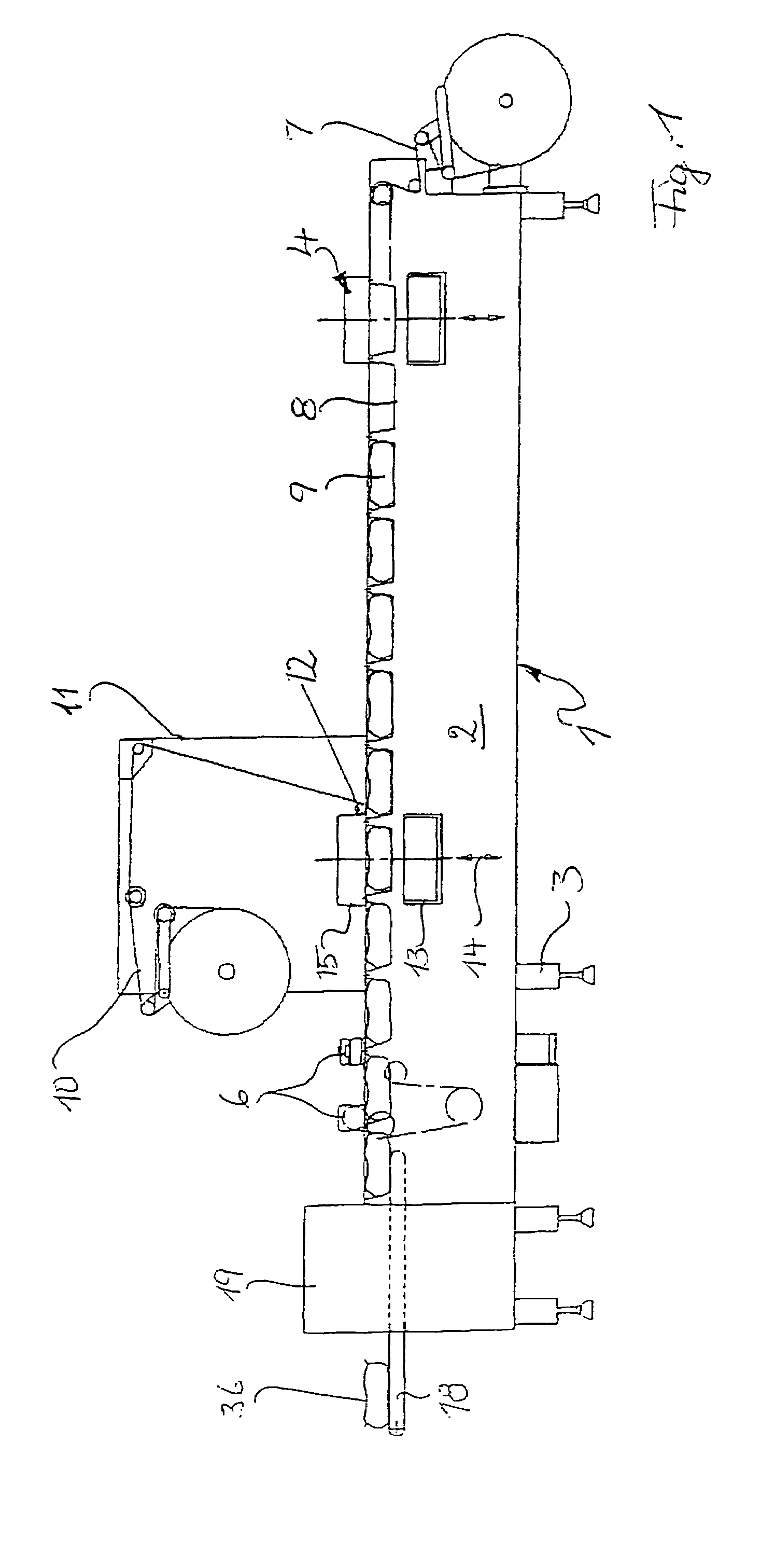

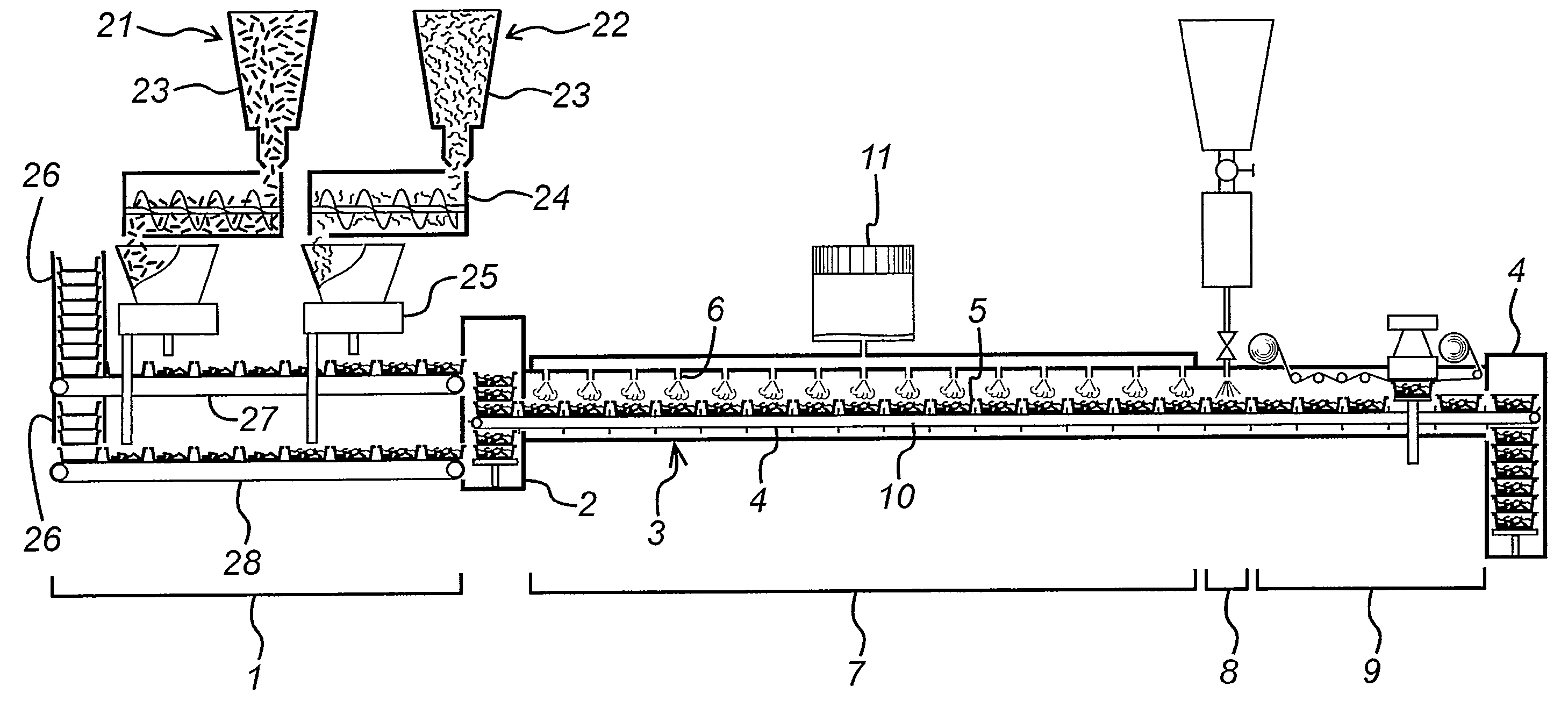

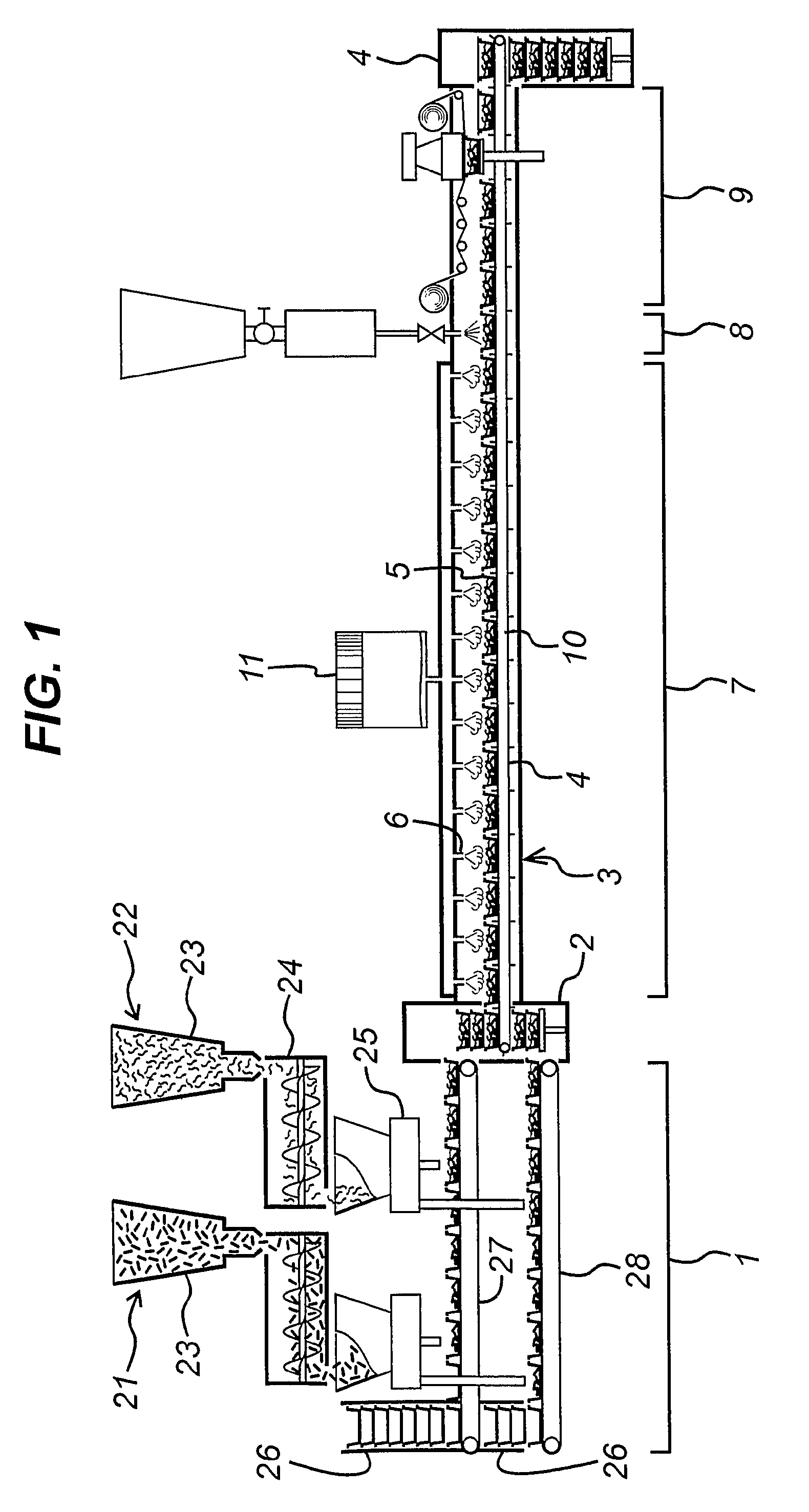

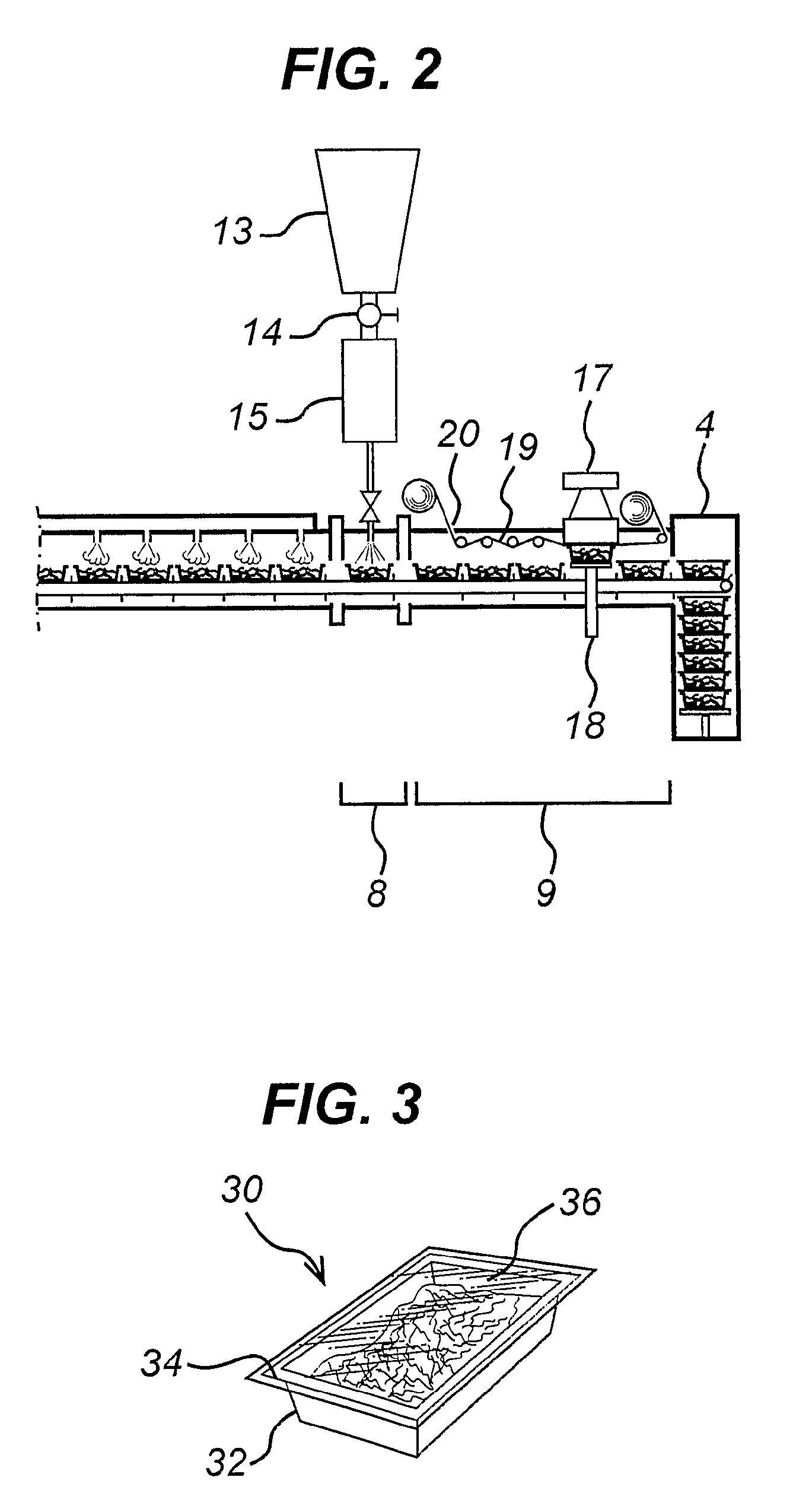

Automated method for placing sliced food stacks in packages

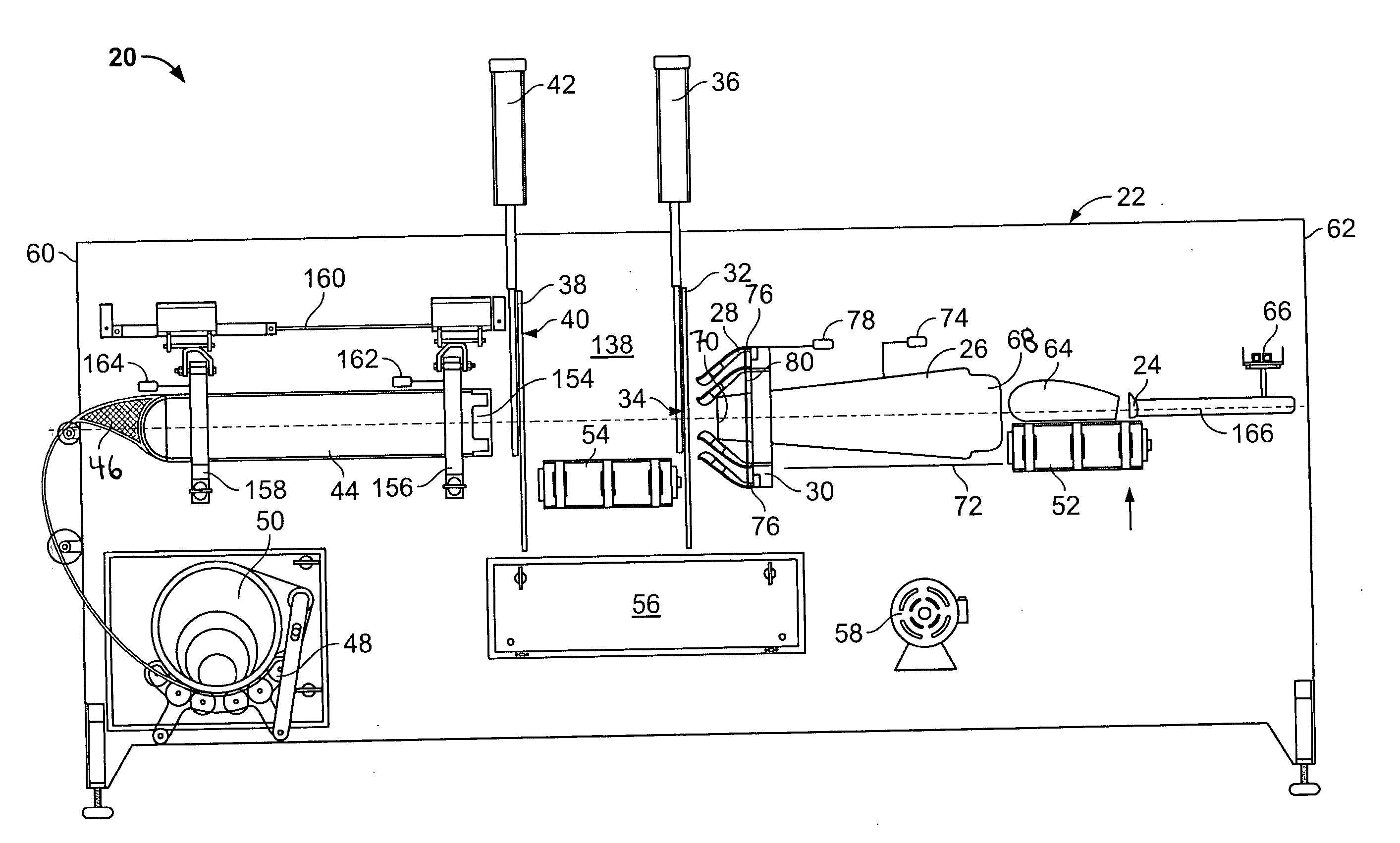

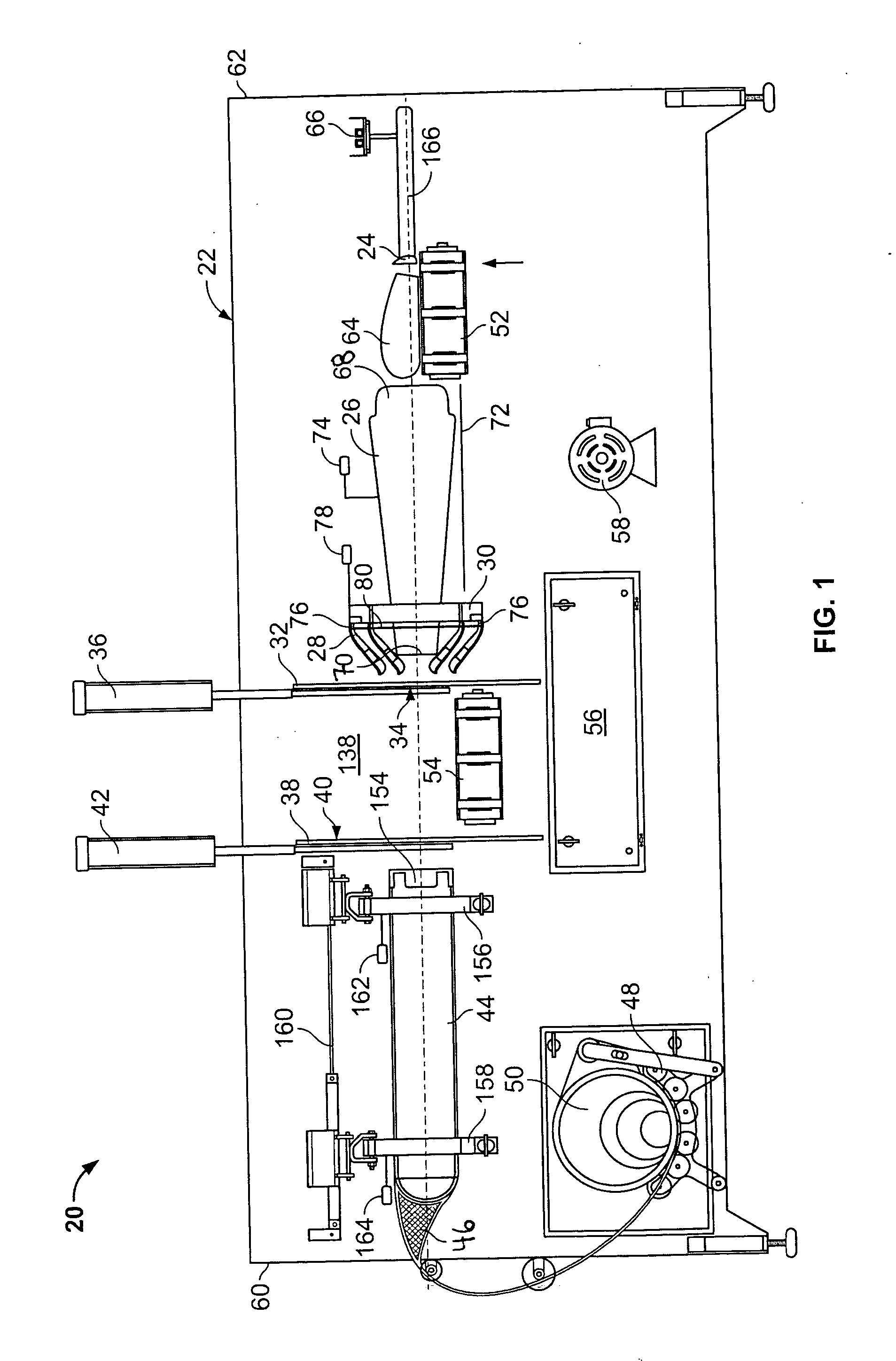

InactiveUS6837030B2Reduce the possibilityImprove productivityPackaging meatGang saw millsEngineeringWorkstation

A system and method are provided that allow meat logs to be manually loaded into a slicing station and thereafter be continuously automatically processed at the slicing station, a harping station, and an insertion station for automated packaging thereof without the need for handling of the meat stacks by workers. To this end, the slicing station is effective to form smaller sections or chubs from the meat logs and to do so such that the chubs are provided with substantially parallel flat end-faces to ensure that high quality meat slices are generated therefrom. The chubs are then transported to the harping station where each of the chubs undergoes a single cutting operation, thus simultaneously forming the meat slices therefrom and substantially maintaining the slices in the configuration of the chubs for generating well-formed stacks of the slices. Thereafter, the stacks are received at the insertion station where they are transferred to their packages, on an automated basis without the need for manual handling thereof. This is enabled due to the well-formed stacks generated by the harping station which allows the stacks to be dropped into the packages aligned therebelow.

Owner:KRAFT FOODS GRP BRANDS LLC

Packaging of foodstuffs

The present invention relates generally to a system for packaging foodstuffs such as beef, pork, seafood and poultry products wherein the system provides an apparatus and various methods for exposing the food products to one or more gases, or a blend of gases, in a series of steps controlling the pressure of the chamber during one or more flushing operations wherein at least some of the gas or gases associated with at least one flush are allowed to at least partially penetrate the structure of the food product, and thereafter sealing the food product in a container.

Owner:TYSON FRESH MEATS

Continuous roll stock netting machine

Owner:POLY CLIP SYST

Packaged food products

InactiveUS20100178401A1Minimize damageReduce heat lossCapsDecorative coversSterile foodSterile environment

A method for the production of a stabilized packaged food product includes the steps of: filling a tray with a predetermined quantity of a food starting material; introducing the tray into a pressure vessel and conveying the tray through the pressure vessel while performing the following steps in sequence inside the pressure vessel: (i) treating the food starting material with high-temperature pressurized steam to sterilize the material, (ii) dosing the sterile food material inside the tray with a predetermined amount of sterile water; and (iii) applying a lid to the tray to seal the food product inside the tray while maintaining the tray in a sterile environment. Also provided are an apparatus for performing the method and packaged stabilized full moisture food products obtainable by the process.

Owner:MARS INC

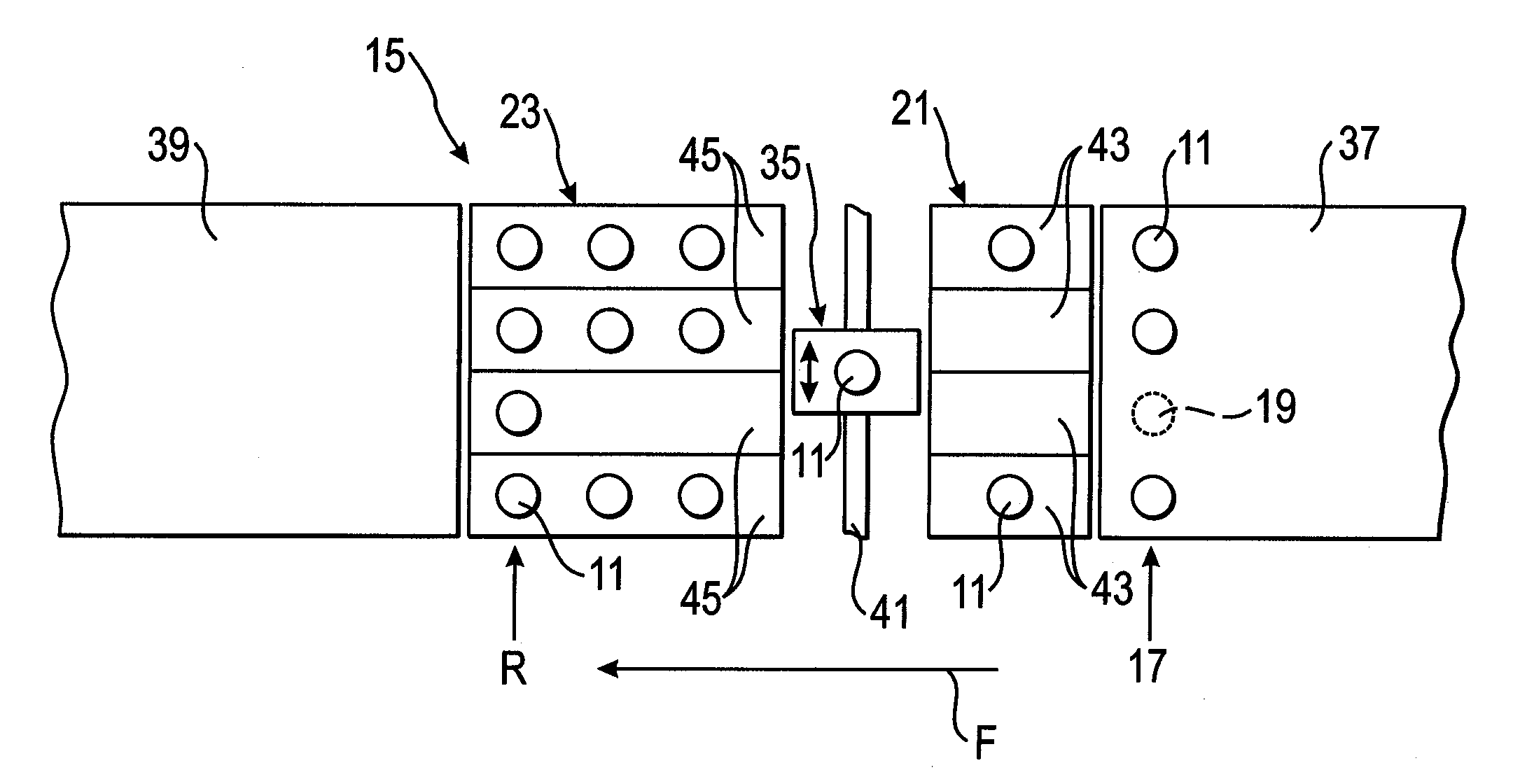

Conveying of articles

InactiveUS20120042612A1Simple processAvoid impairmentPackaging meatPackaging automatic controlEngineeringMechanical engineering

The invention relates to a method for conveying articles, in particular product slices produced by simultaneous slicing of a plurality of food products or respective portions including a plurality of product slices, wherein the articles are conveyed in a conveying direction on a main conveying path in multitracks in desired arrangements formed by articles from different tracks, in particular in rows extending transverse to the conveying direction, incomplete arrangements of articles having at least one deficient point are expelled onto a secondary conveying path and desired arrangements are formed from the articles forming the incomplete arrangements.

Owner:WEBER MASCHENBAU

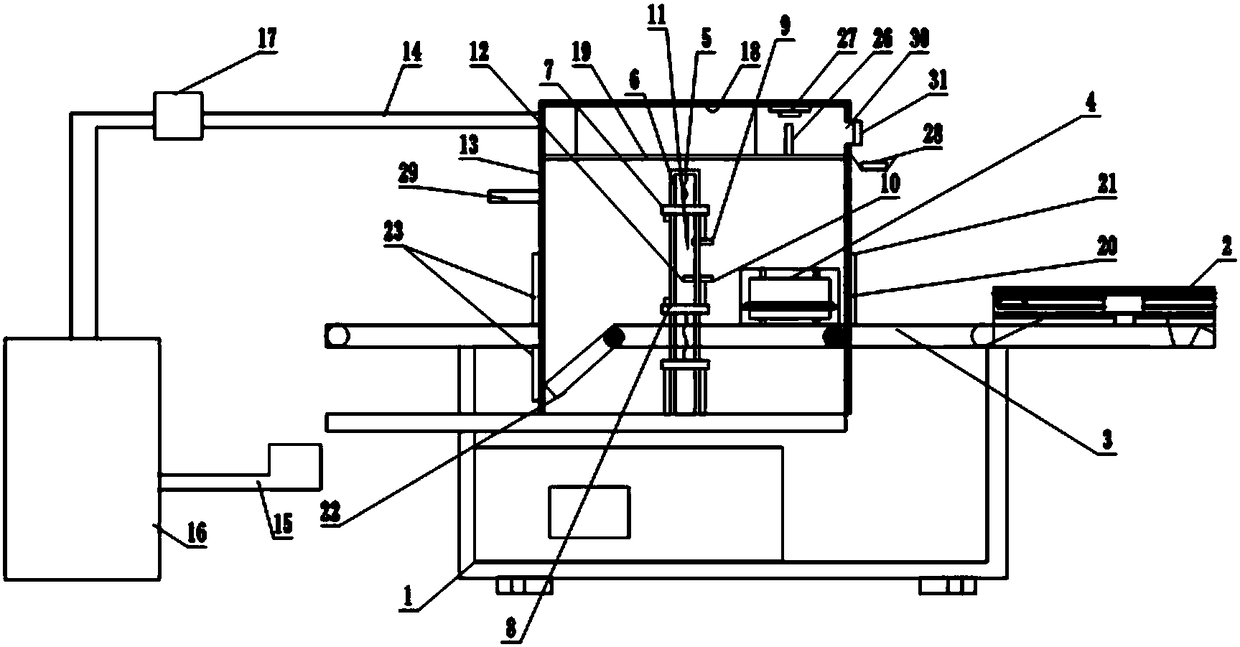

Food packing device provided with detector

ActiveCN108438371AAvoid mildew and spoilageKeep the color and fragrancePackaging meatPackaging under vacuum/special atmosphereFine lineExhaust valve

The invention belongs to the technical field of food packing, and specifically discloses a food packing device provided with a detector. The device comprises a rack, a feeding mechanism, a bagging mechanism, a bag sealing mechanism, an opening sealing device and a vacuum box, wherein the bag sealing mechanism and the opening sealing device are arranged in the vacuum box; the vacuum box further comprises an infrared sensor and a degraded product distributing device; a box discharging door is in sliding connection with a box discharging port; an electromagnet is arranged in the sliding directionof the box discharging door; a distribution switch for controlling a distribution plate to rotate is arranged on the top part of the vacuum box; a floating plate which is hoisted on the top part of the vacuum box through a fine line is arranged below the distribution switch; a propping pressing rod for propping and pressing the distribution switch to turn on is arranged on the floating plate; a water outlet is formed in the wall, at one side above the floating plate, of the box; an one-way air exhausting valve is arranged on the water outlet; a control switch for electrifying the electromagnet is arranged on the outer wall, under the water outlet, of the vacuum box; water overflowing from the water outlet downwards flows and triggers the control switch to start the electromagnet.

Owner:重庆晨极商贸有限公司

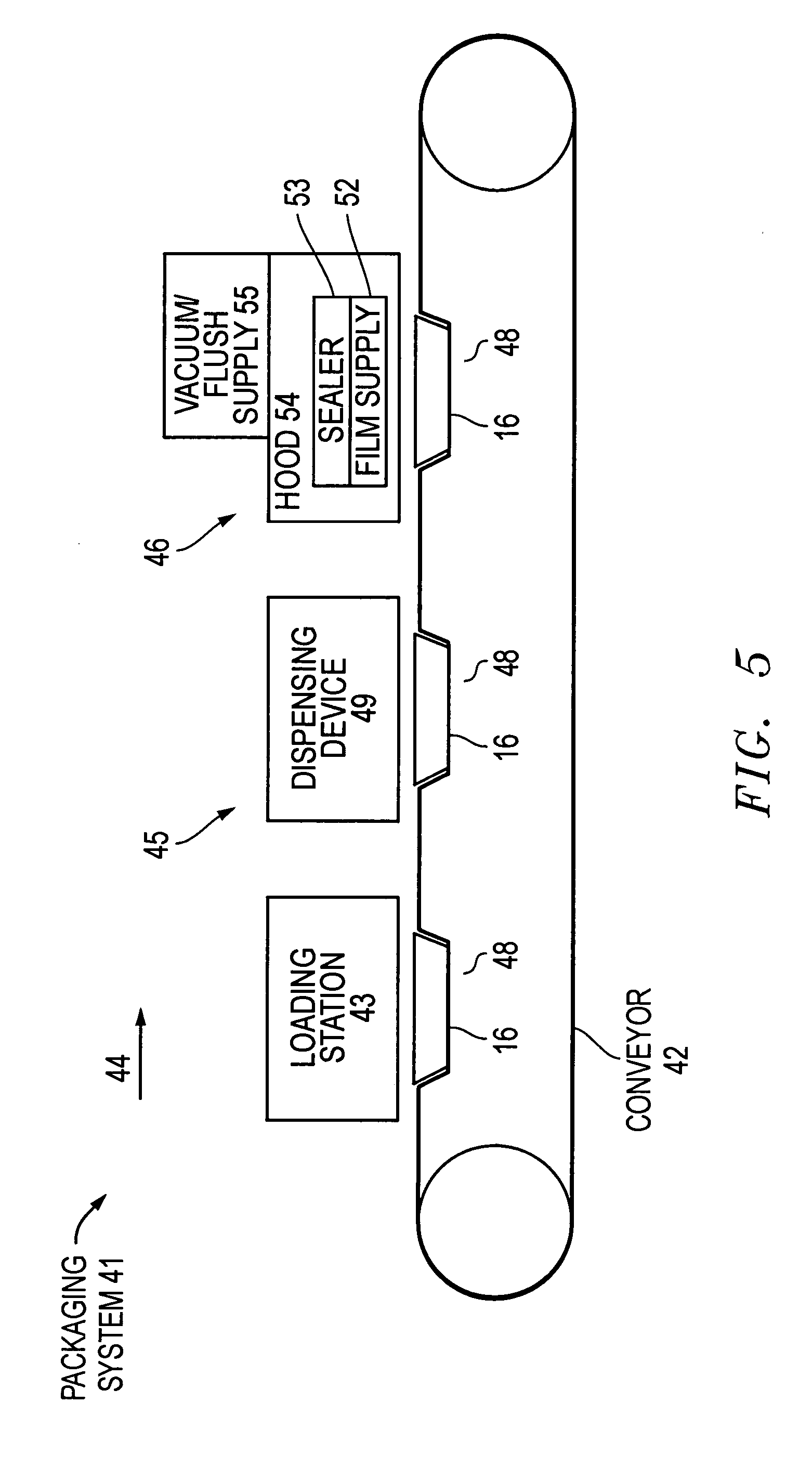

Food article packaging apparatus and method

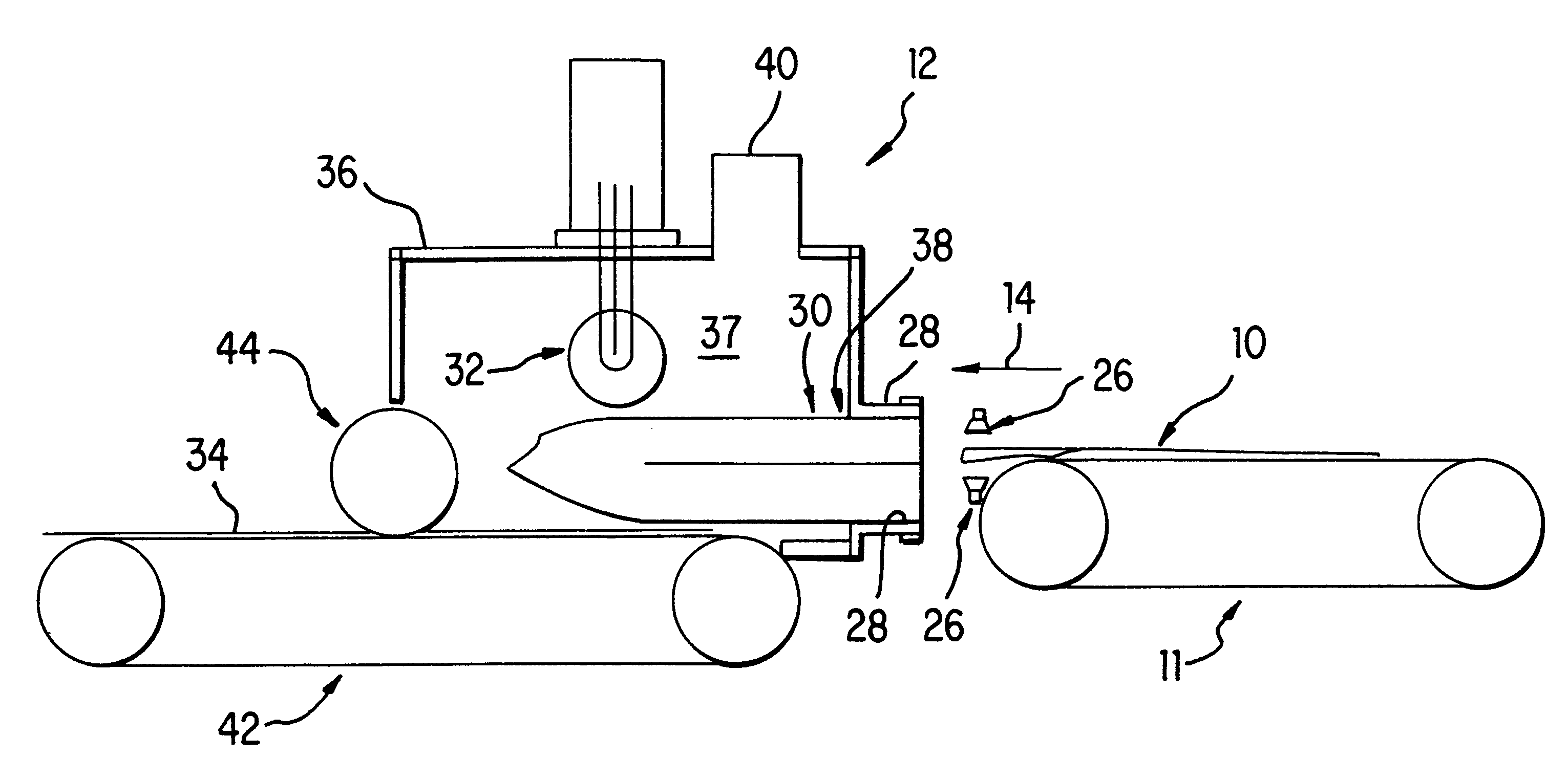

InactiveUS20070193229A1Improve productivityReduce the possibilityPackaging meatMultiple wrapper applicationComparable sizeEngineering

Packaging apparatus and method for inserting food articles into a bag of comparable size. The apparatus has a conveyor that orients the product along a longitudinal axis and delivers the food article to a tray disposed below the conveyor so the product drops from the conveyor and onto the tray. The tray and conveyor move at speeds selected so the product maintains its longitudinal orientation as it drops from the conveyor into the product tray. A bag scoop holds the bag mouth open while the tray carrying the product advances into the bag. A product stripper moves into a position behind the bagged product after passage of the tray so that when the tray returns to its start position, the stripper butts against the end of the product and holds the product while the tray slides out of the bag.

Owner:CURWOOD INC

Packaging machine and method of packaging products

A packaging machine (1) comprises a device for the formation of a tube (5) of wrap material into which a succession of products (6) can be inserted; a sealing device (7) being active on said tube (5) to make a succession of seals (23) transverse to the direction of advancement "A" of tube (5) and to define a corresponding succession of pockets (11) for holding the products (6); an air-removing device (13) being active on each pocket (11) in correspondence of a respective aperture (25) to produce a vacuum inside each pocket (11); and an additional sealing device (22) operatively located at least in correspondence of the air-removing device (13) for isolating said aperture (25) and hermetically sealing the pocket (11).

Owner:弗朗西斯科·迪纳尔多

Packaging system

The present invention provides a packaging system that includes a beak-shaped hopper, a pair of opening and closing bars, and a sensor for sensing a limitless opening and closing movement of the opening and closing bars. The beak-shaped hopper and the pair of opening and closing bars are operable to move in unison back and forth along a main travel path. The main travel path leads to a rotary vacuum packaging device having a pressure resistant chamber. The beak-shaped hopper is dimensioned to convey packaging bags into the pressure resistant chamber. The opening and closing bars are dimensioned to detect a bag on the hopper by opening towards both sides immediately after a bag has been conveyed into the pressure resistant chamber. A pushing bar is dimensioned to convey an item to be packaged into the bag when the bag is detected on the hopper by the opening and closing bars. The opening and closing bars contact a sensor for detecting movement of the opening and closing bars when a bag is not on the hopper.

Owner:FURUKAWA MFG

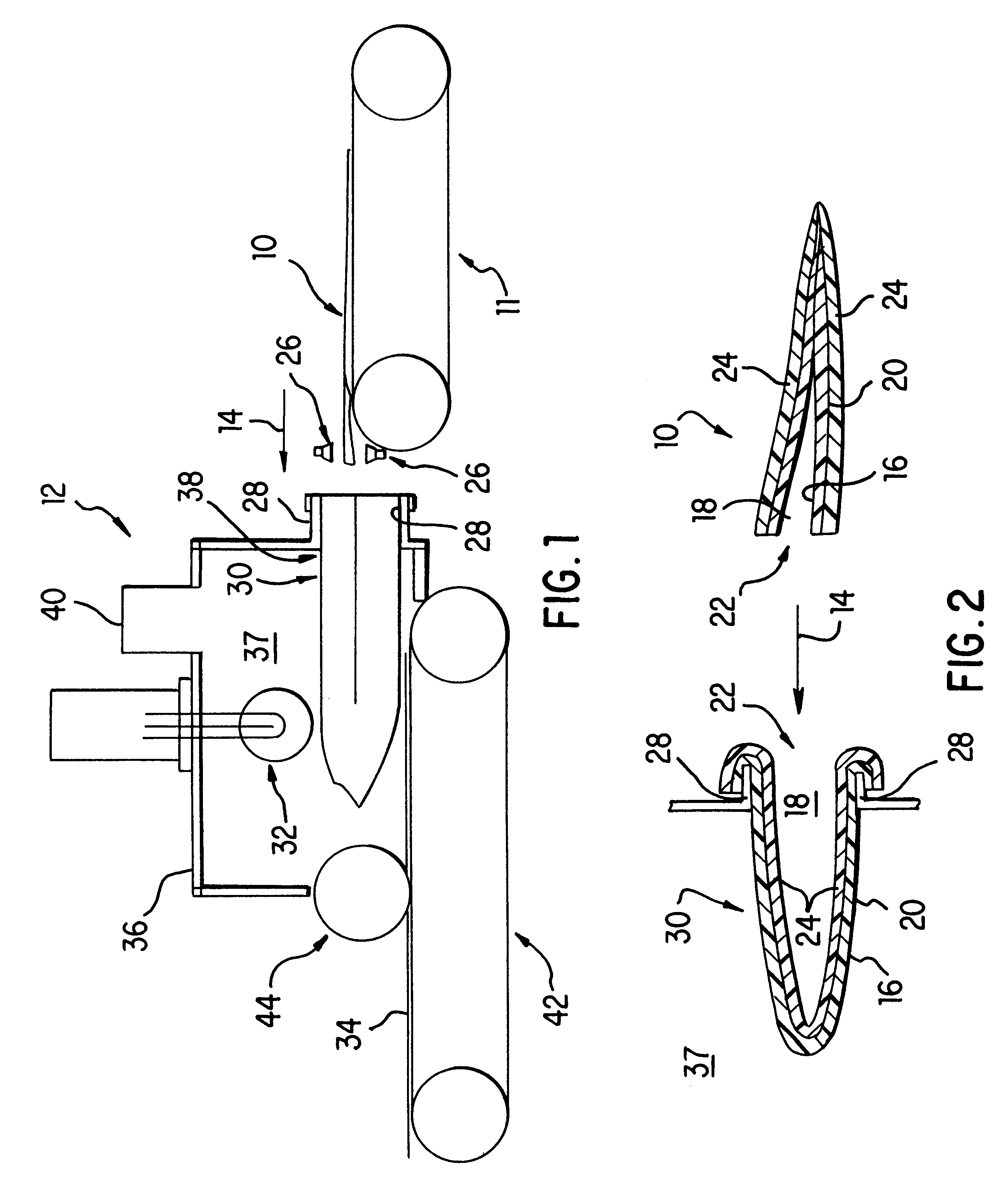

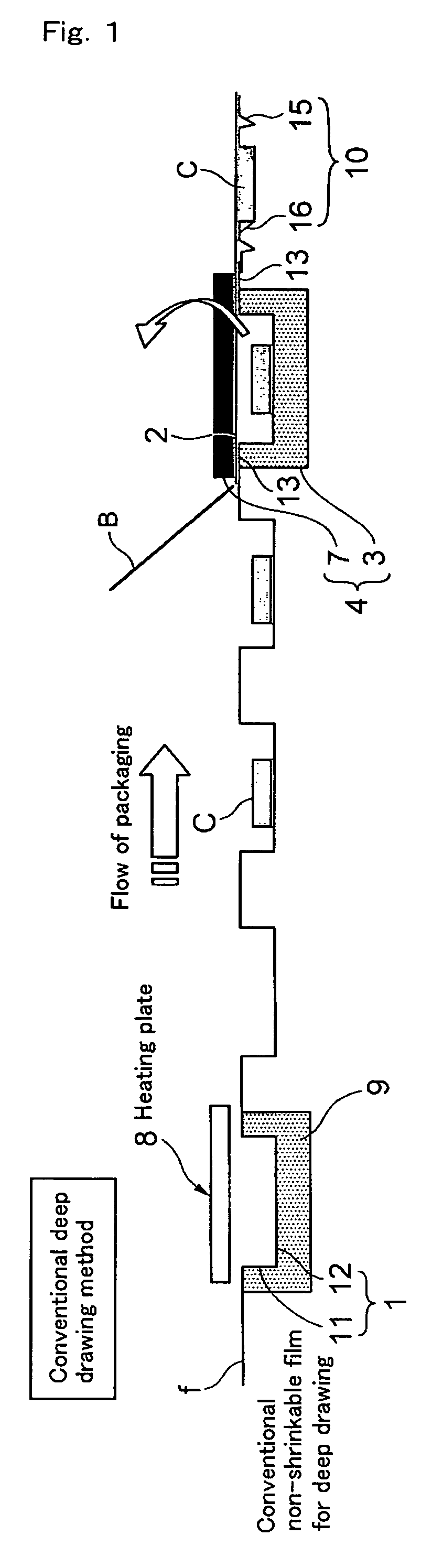

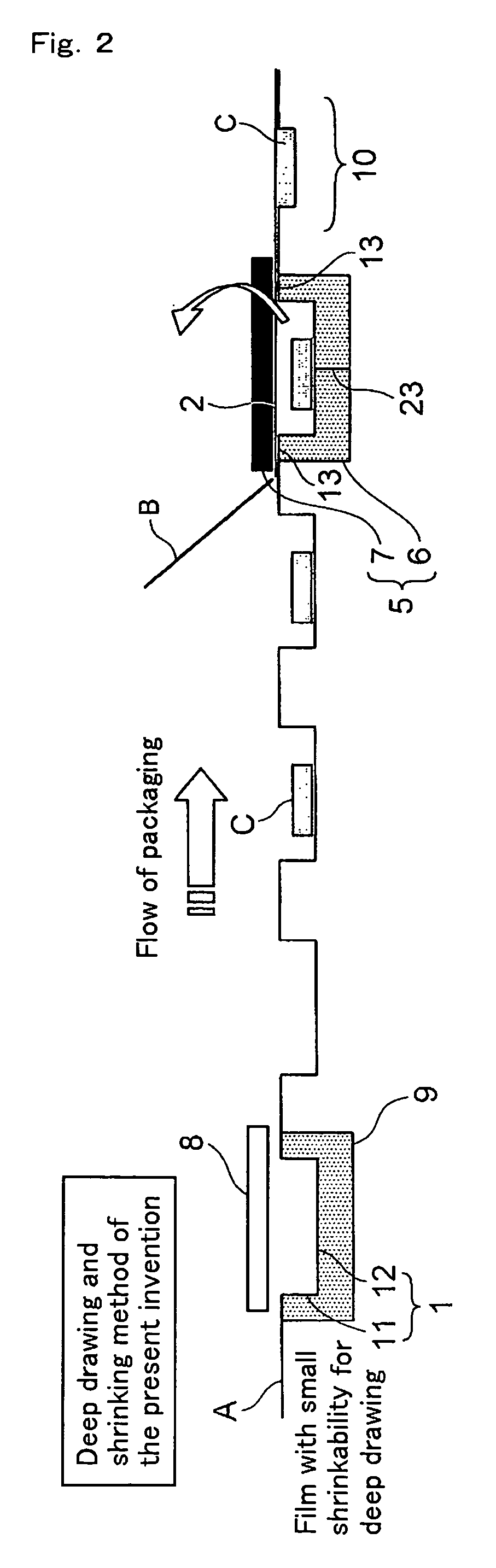

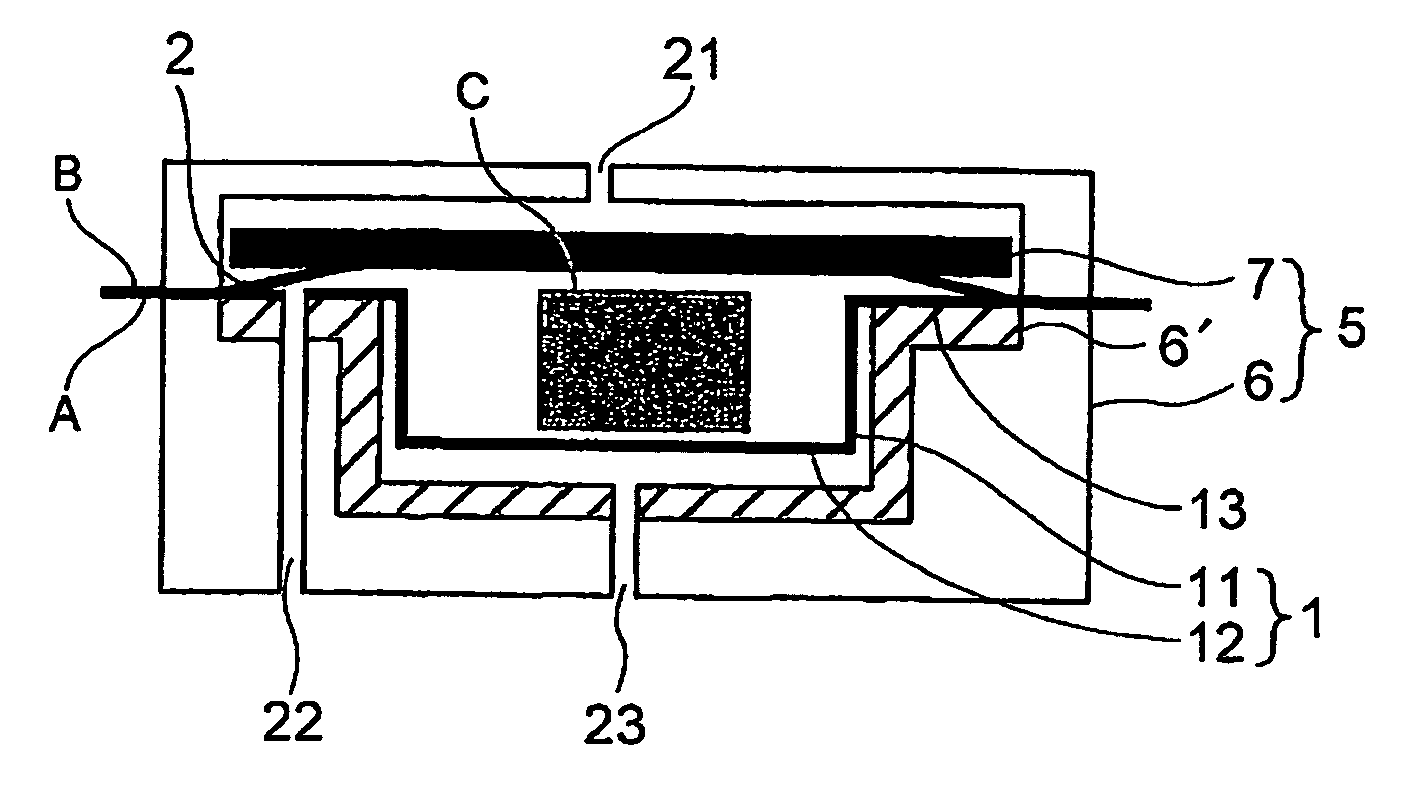

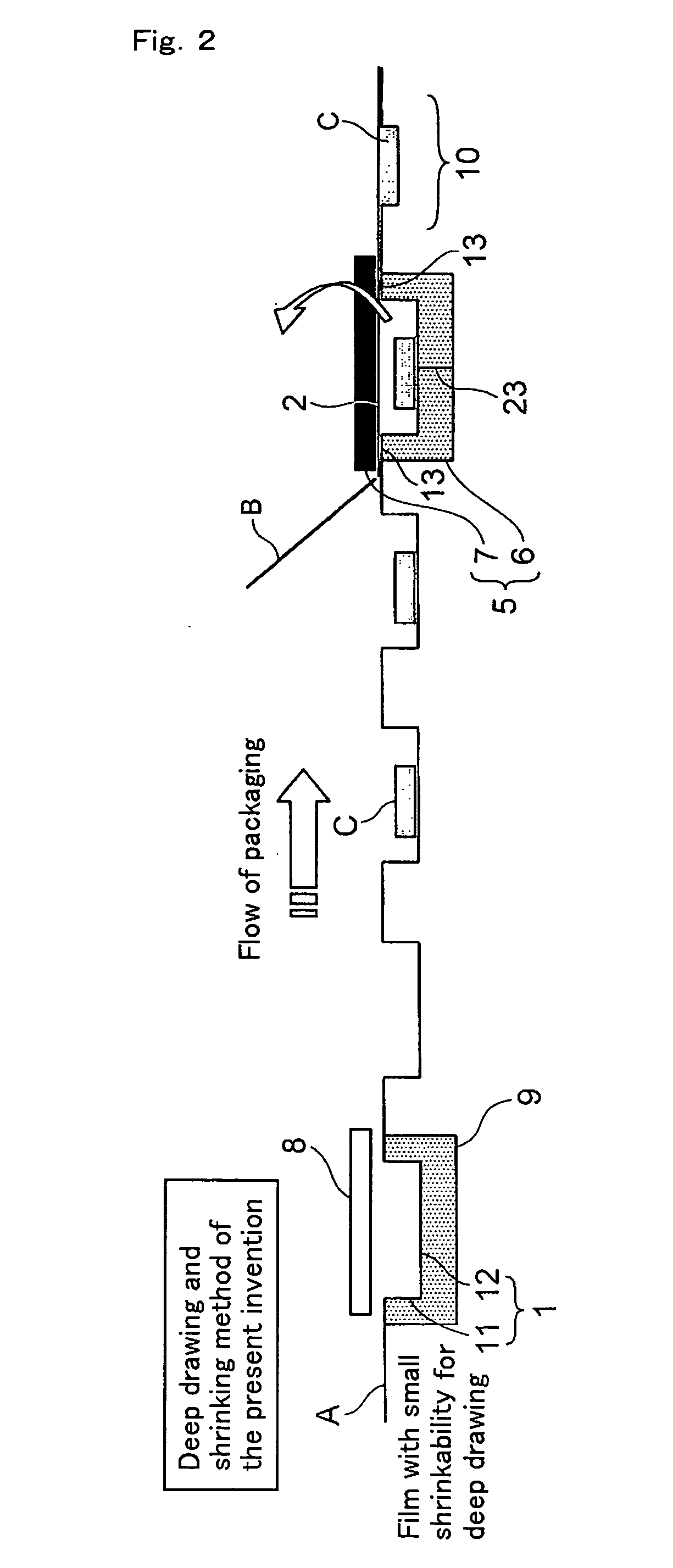

Deep draw packing method and film with small shrinkability for deep draw packing

Deep draw packaging includes placing an object (C) in a concave container portion (1) formed by molding a film with small shrinkability (A), that is a film having a residual thermal shrinkage rate at 100° C. of 1 to 15 %. The film (A) is formed by stretching a film having deep draw moldability and then thermally relaxing the film. The film has a surface which is formed of a heat sealable material which becomes the inner wall of the container portion. The concave container portion (1) is thereafter transferred to to a vacuum packaging apparatus (5) where it is covered by a cover portion (2) formed of a film (B) which can be heat welded to the film (A). A side face portion (11) and a bottom face portion (12) of the concave container portion (1) are thermally shrunk into close contact with the object (C). Less curling is exhibited when an upper peripheral portion (13) of the concave container portion (1) is sealed with the film (B).

Owner:KUREHA KAGAKU KOGYO KK

Deep draw packing method and film with small shrinkability for deep draw packing

The present invention provides a deep draw packaging method including placing an object (C) in a concave container portion (1) formed through molding of a film with small shrinkability (A) having a residual thermal shrinkage rate at 100° C. of more than 0 and 15% or less, the film (A) being formed by stretching a film having deep draw moldability and then thermally relaxing the film, the film having a surface which is formed of a heat sealable material and to become the inner wall of the container portion; transferring the concave container portion (1) to a vacuum packaging apparatus (5); placing, on the concave container portion (1), a cover portion (2) formed of a film (B) which can be heat welded to the film with small shrinkability (A); thermally shrinking a side face portion (11) and a bottom face portion (12) of the concave container portion (1) by use of a concave portion heating / shrinking mold (6) such that the side face portion (11) and the bottom face portion (12) come into close contact with the object (C); and sealing an upper peripheral portion (13) of the concave container portion (1) with the film (B) through heating / sealing means (7). The method of the invention attains a close contact between the film and an object to be packed, preventing generation of wrinkles or vacant gaps. Moreover, less curling is generated at the seal portion.

Owner:KUREHA KAGAKU KOGYO KK

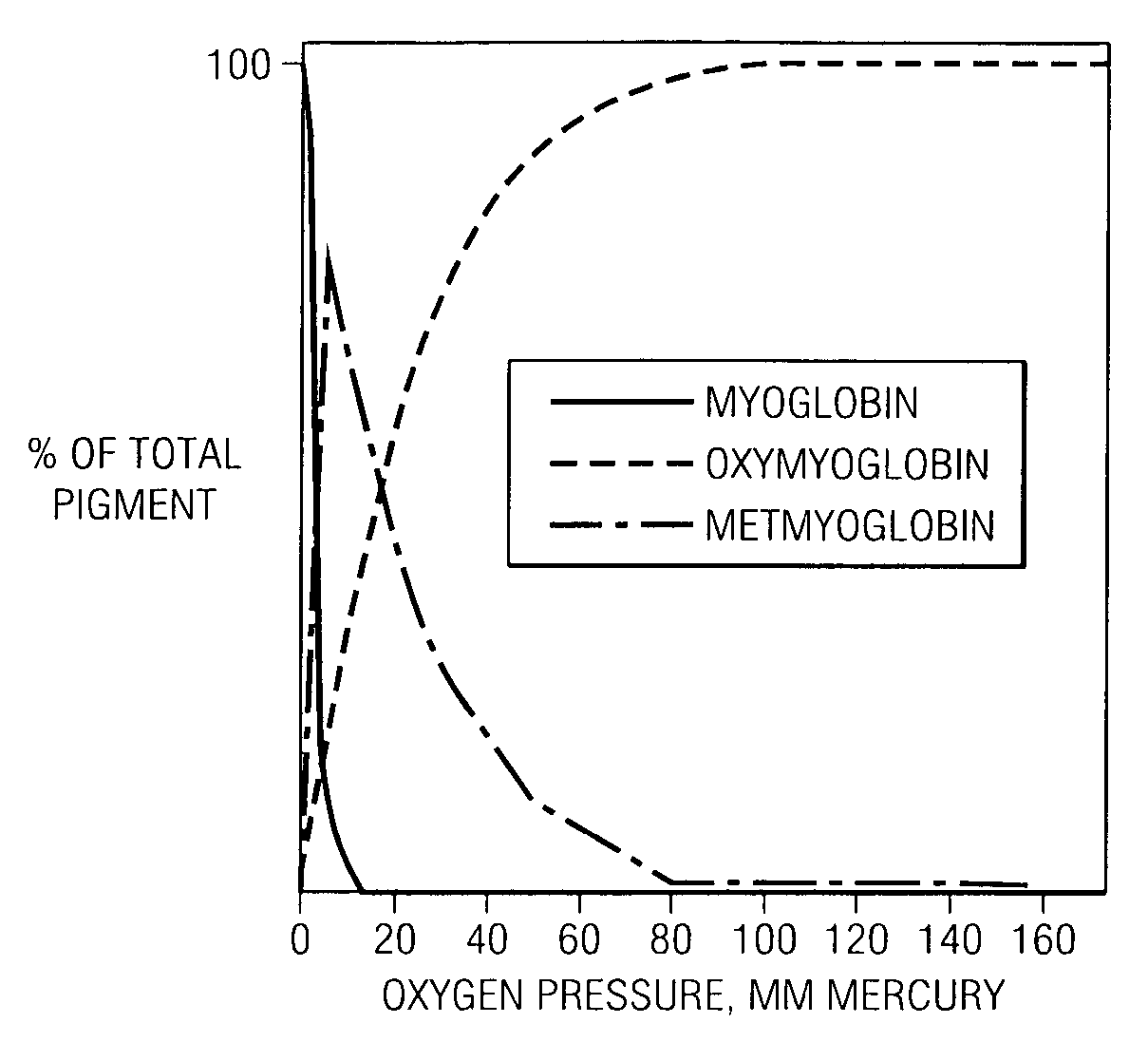

Apparatus and method for extending shelf-life and prevention of discoloration of meat

InactiveUS20060228449A1Zero shrinkageReduce Shrinkage ProblemsReady-for-oven doughsPackaging meatNitrogen richGas exchange

The current invention covers an improved meat-packaging procedure and machine for packaging meat cuts for long-term storage at temperatures of between 28° and 32° F. The process includes sealing meat cuts within a master bag containing oxygen scavenger materials capable of reducing the residual oxygen content of the atmosphere within the bag to 0 ppm within 24 hours of sealing. Gas is injected into the master bag to form a nitrogen-rich storage environment of at least 50% nitrogen. A small amount of carbon monoxide gas (0.1% to 5%) is preferred for the storage environment, as this helps to preserve the red coloration of meat under long-term storage conditions. The over-wrap of the meat trays can be perforated so that gas exchange occurs within the master bag between the interior and exterior of the meat tray to absorb the residual oxygen inside the meat trays. For meat trays containing meat with poor color stability, oxygen scavengers are preferably placed within the meat trays. For cuts with good color stability, the oxygen scavengers may be placed outside the meat trays. Meat can be stored by this system for up to 15 weeks and up to nine days of retail display life.

Owner:TEXAS MEAT PACKAGING SYST

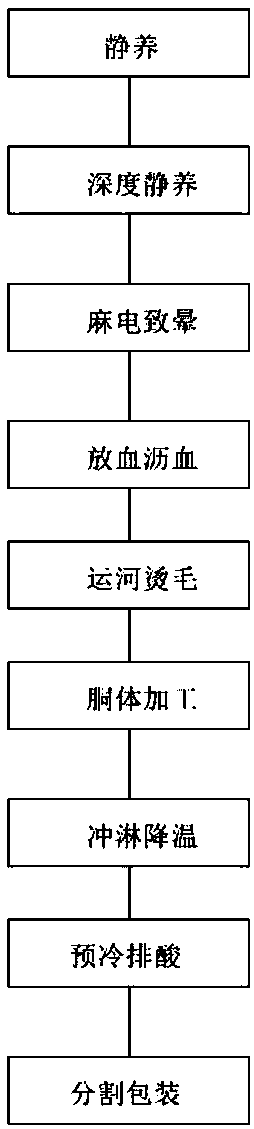

Slaughtering and producing technology of safety pigs

InactiveCN107668151AReduce formationBright colorPackaging meatElectric current slaughtering/stunningElectricityLean meat

The invention discloses a slaughtering and producing technology of safety pigs. The slaughtering and producing technology comprises the following steps of: a. performing relaxation; b. performing deeprelaxation: after the pigs to be slaughtered are in relaxation, showering the pigs with water for 3-5 minutes, wherein when the season for deep relaxation is summer, the water temperature is 20 DEG C, and when the season for deep relaxation is winter, the water temperature is 38 DEG C; c. performing electric-shock for stunning; d. performing bloodletting and bleeding; e. performing transferring and scalding; f. performing carcass processing; g. performing showering for cooling; h. performing pre-cooling and acid discharge; and i. performing segmentation and packaging: wherein in the whole segmentation process of chilled meat, the temperature of a segmentation workshop is less than or equal to 12 DEG C, the temperature of a packaging workshop is less than or equal to 10 DEG C, and the segmented chilled meat is safety pork, putting the safety pork on a tray with absorbent paper being spread, then transferring the safety pork into a packaging machine, performing overlay film packaging, and in the packaging process, charging mixed gas consisting of oxygen and carbon dioxide in the ratio of the oxygen to the carbon dioxide being 1 to 4 into an overlay film. According to the slaughtering and producing technology disclosed by the invention, the residual heat inside the product is reduced by water gradient, the product loss is smaller, and the lean meat of the product in the market isbrighter in color.

Owner:成都春源食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com