Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

728results about How to "Continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

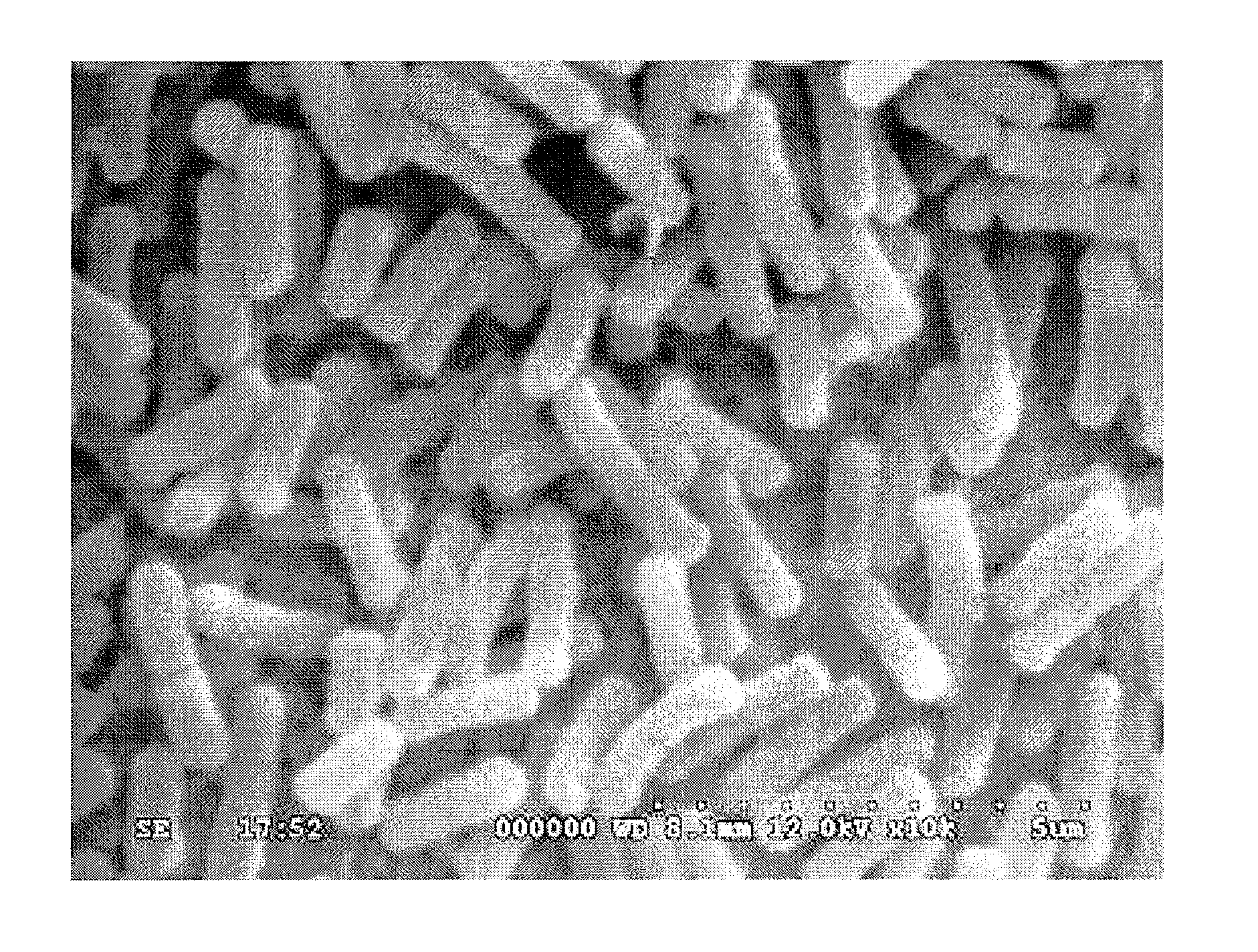

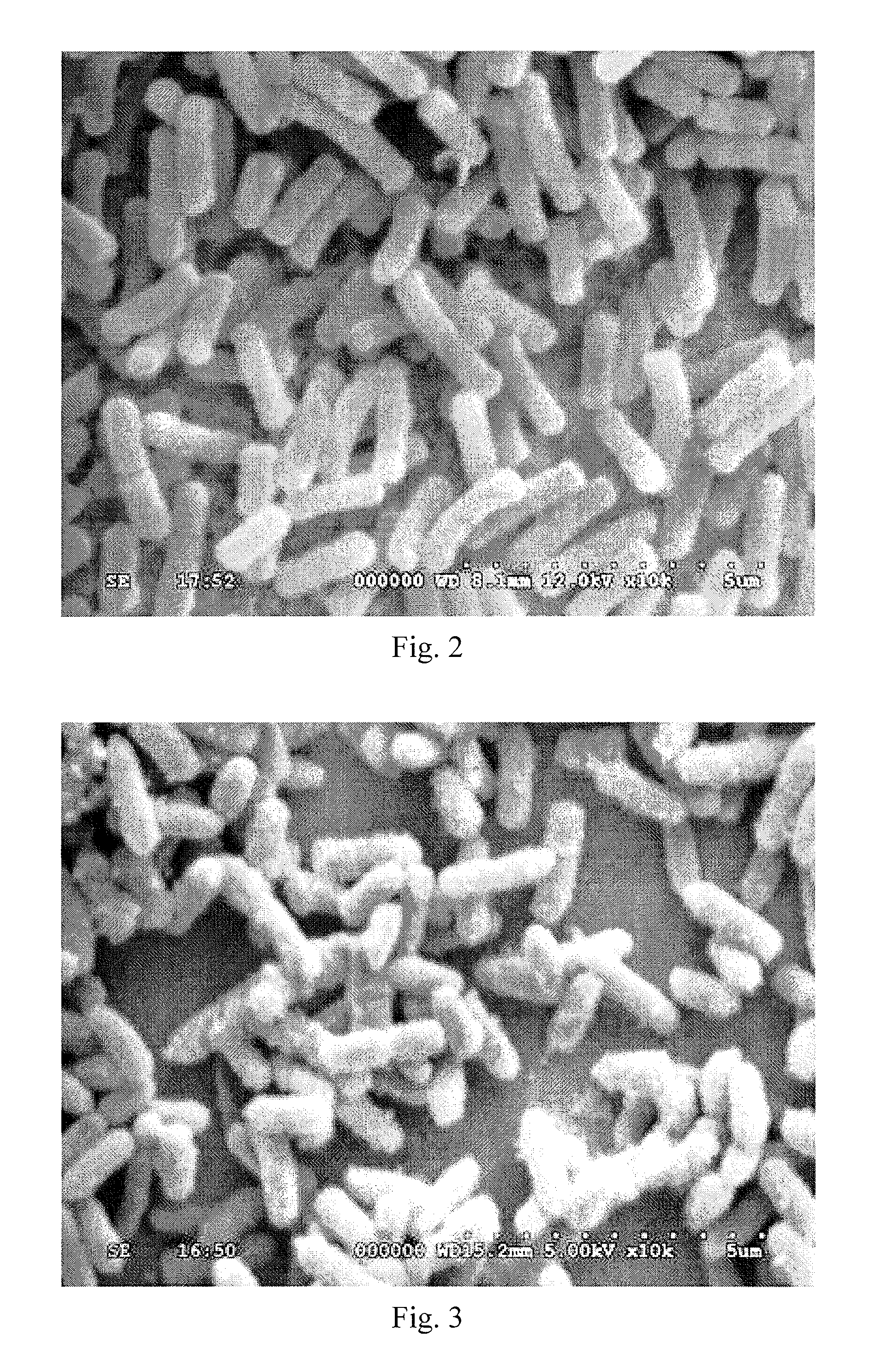

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

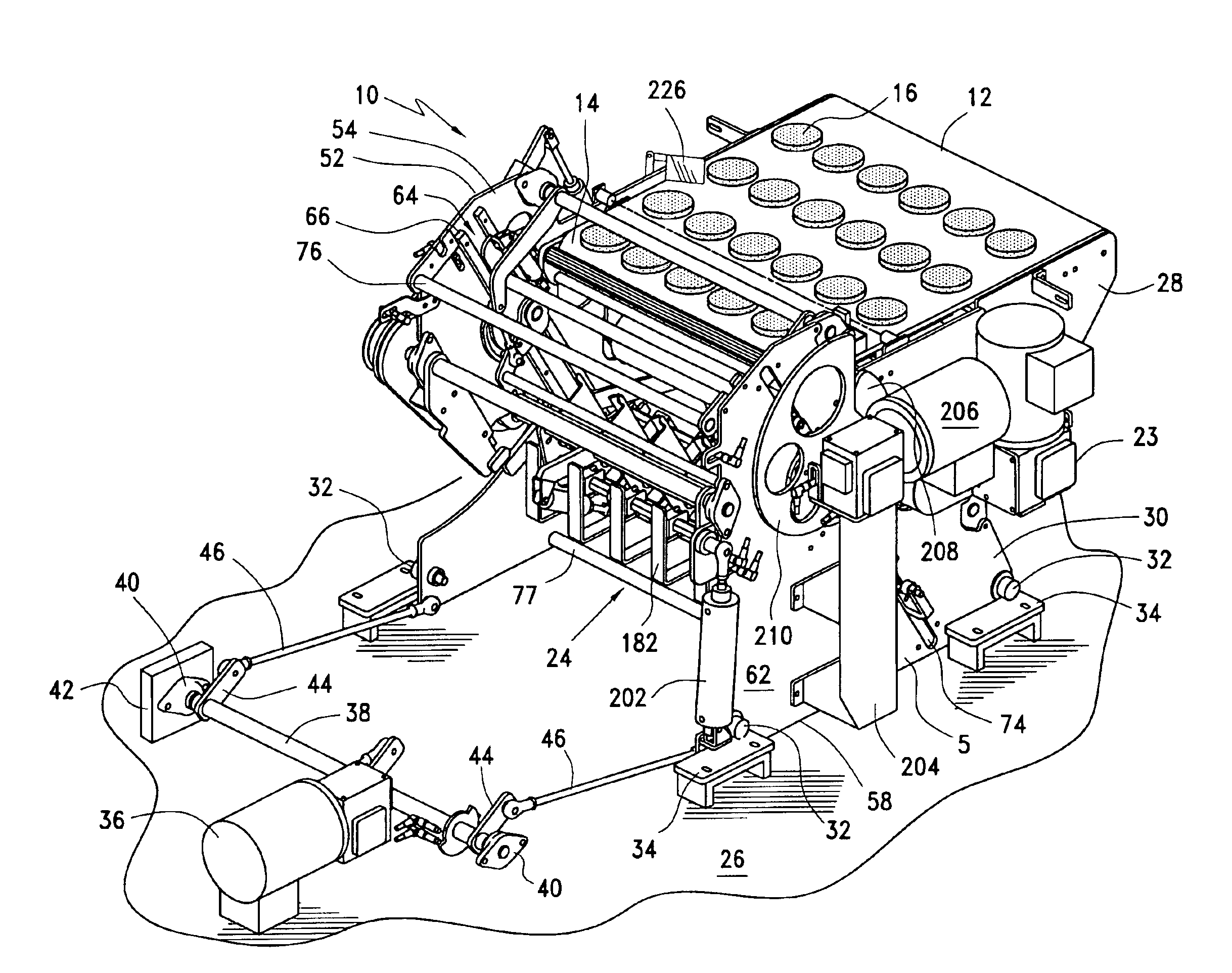

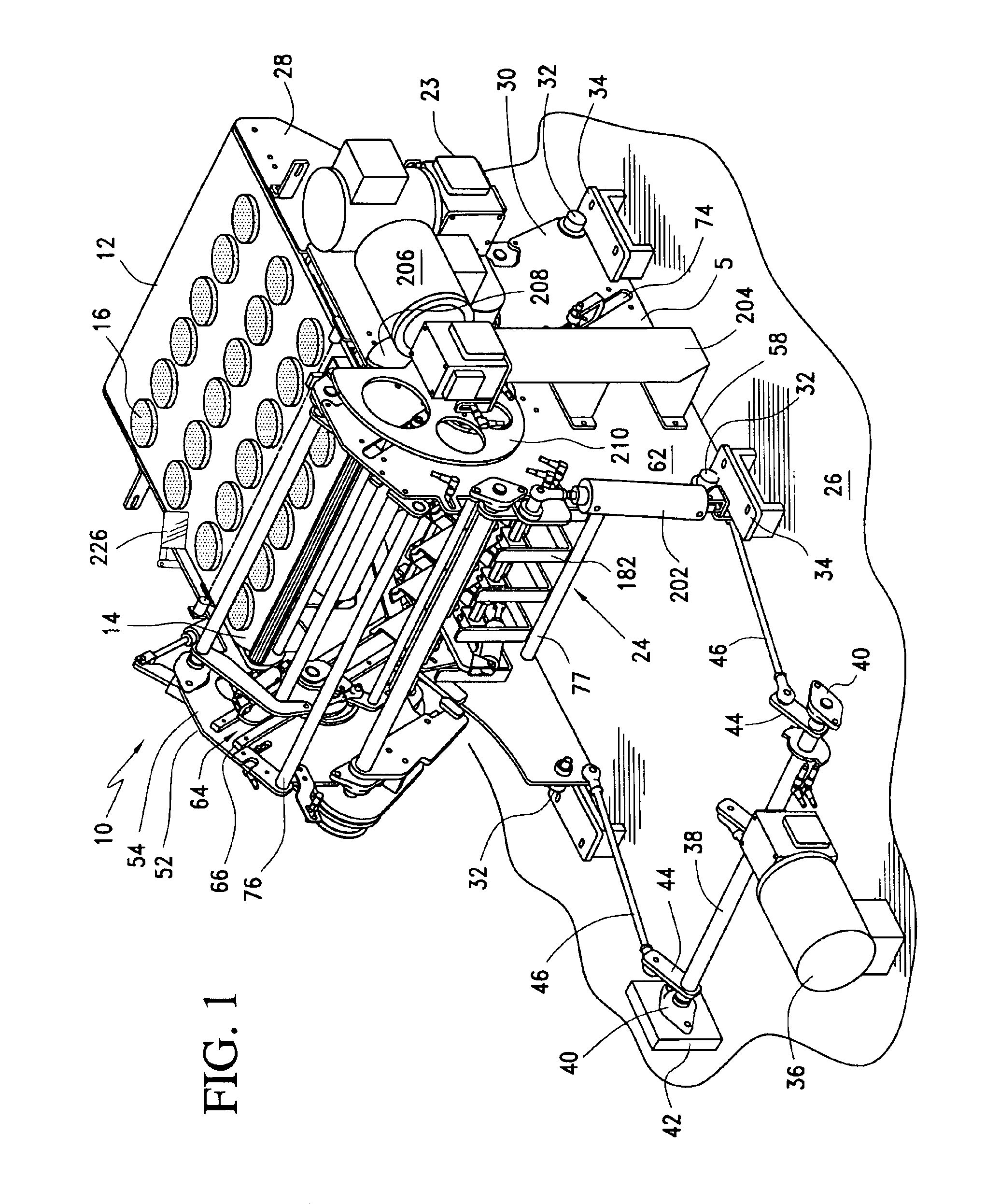

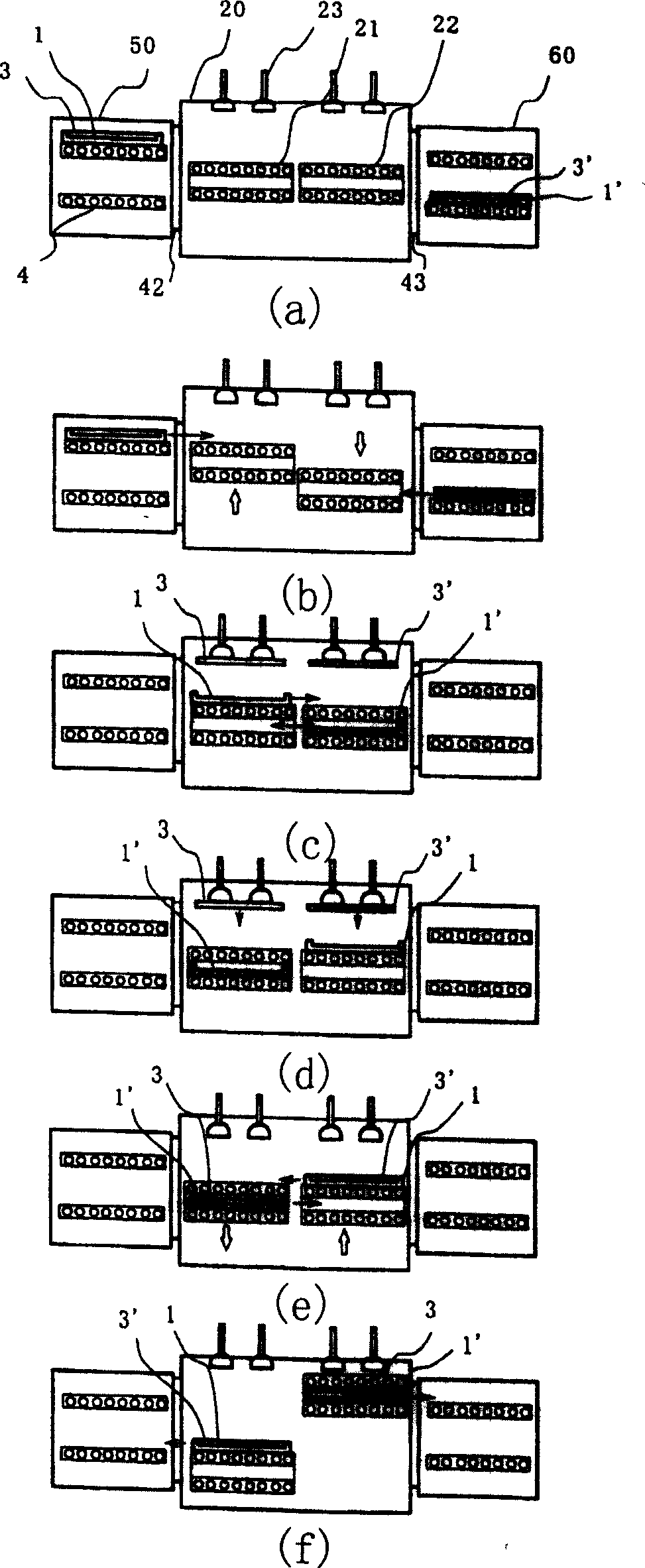

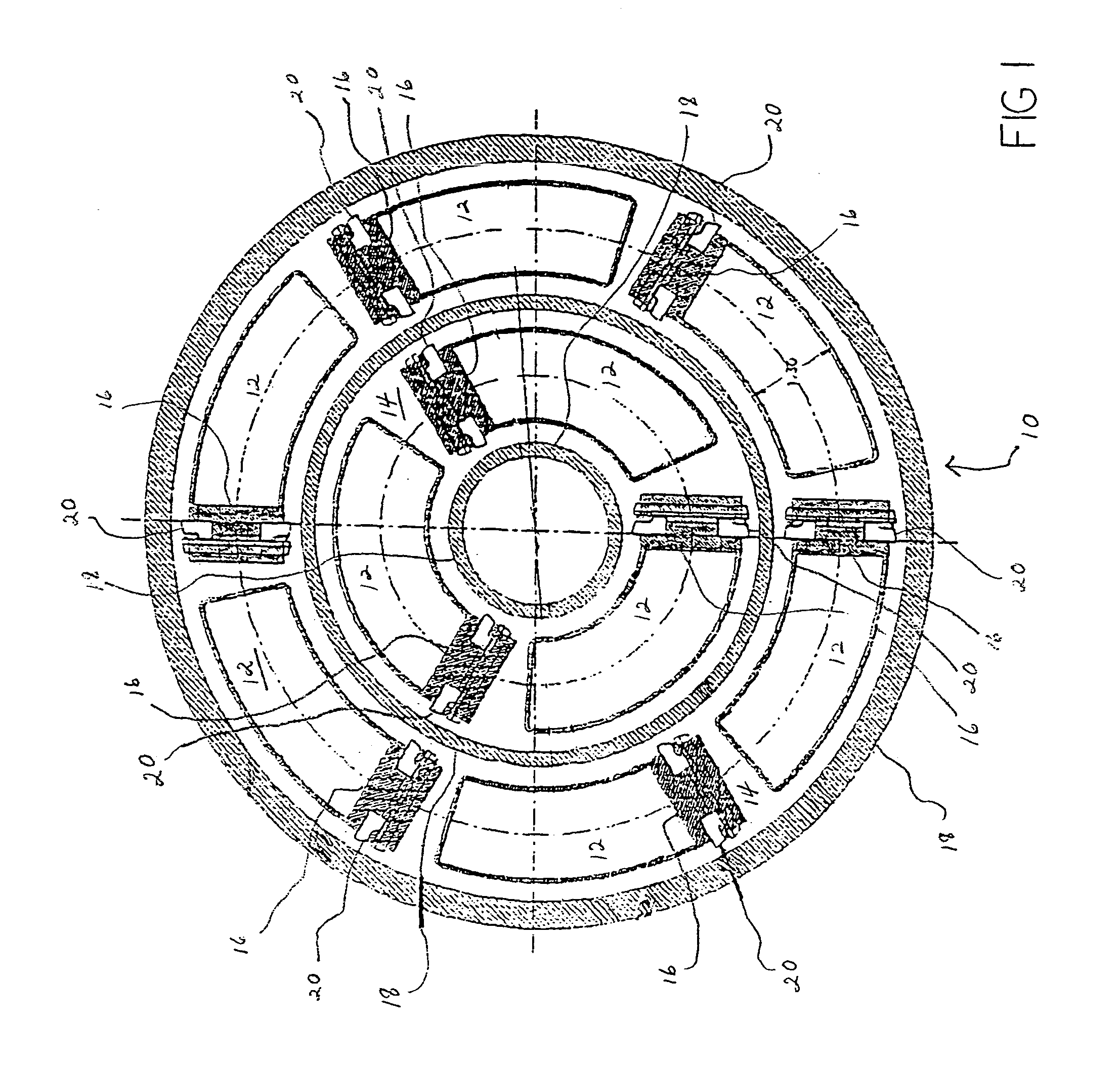

Method and apparatus for stacking discrete planar objects

A system for forming a plurality of discrete objects into a stack is disclosed which system includes a frame having a top, a bottom and sides; a conveyor associated with the frame and having an end edge for dispensing discrete objects, a first support mounted on the frame near the end edge for receiving objects from the end edge and having an opening with a width smaller than the width of the objects, a first actuator operably connected to the first support for moving the first support between first and second positions relative to the end edge; a second actuator operably connected to the first support for moving the first support between upper and lower positions relative to the frame; a second support mounted on the frame beneath the first support having a width less than the width of the opening in the first support; a third actuator operatively connected to the second support for moving the second support between high and low positions, the second support high position being higher than the first support lower position; a third support mounted on the frame at a position higher than the second support low position and having an opening wider than the width of the second support; a fourth actuator operatively connected to the third support for moving the third support between a first position beneath the first support and a second position; a sensor for determining the number of discrete objects in a stack, the sensor being operatively coupled to the to the third actuator; and a controller for controlling the first, second, third and fourth actuators. A method of using the system is also disclosed.

Owner:F R DRAKE

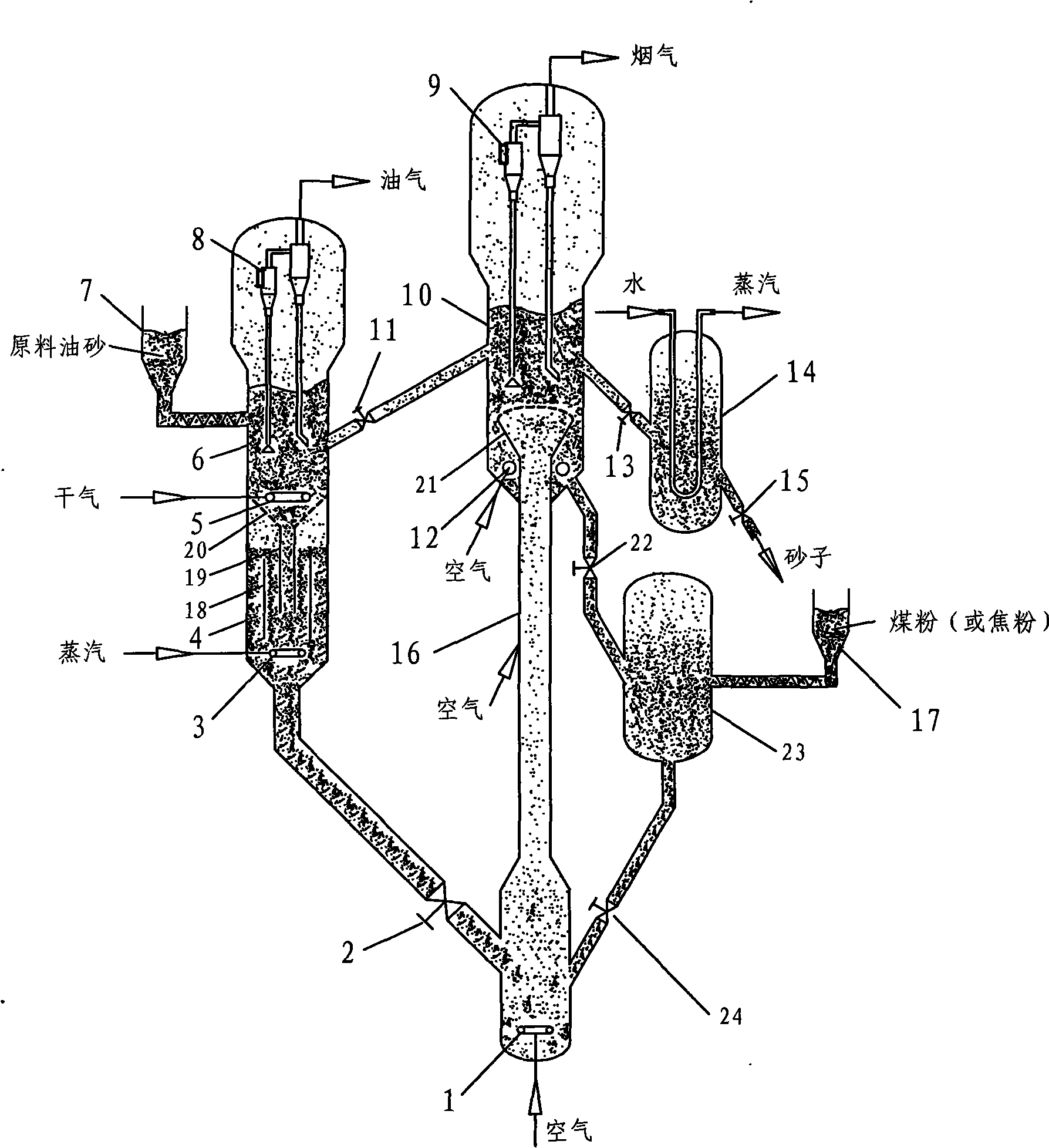

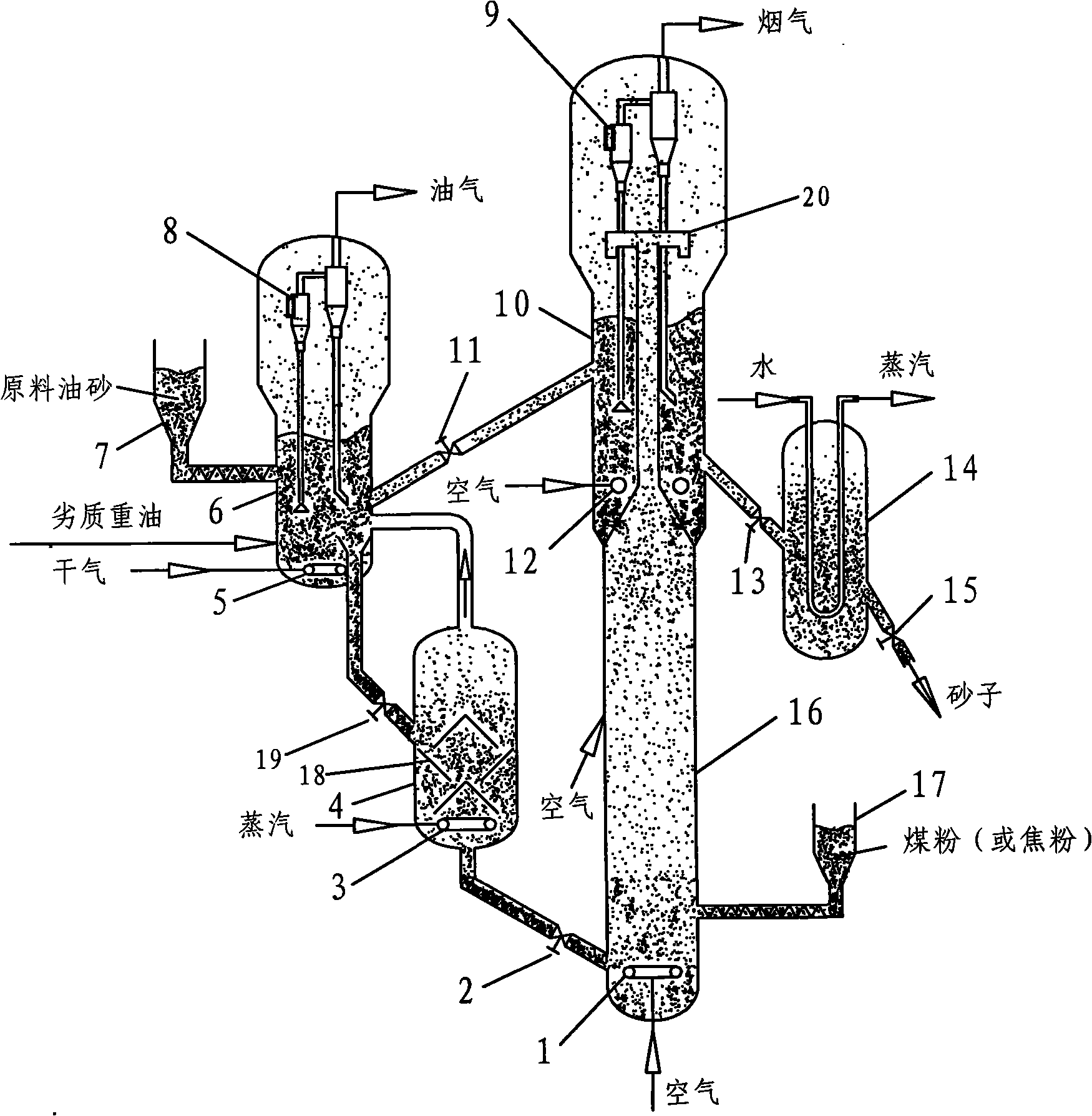

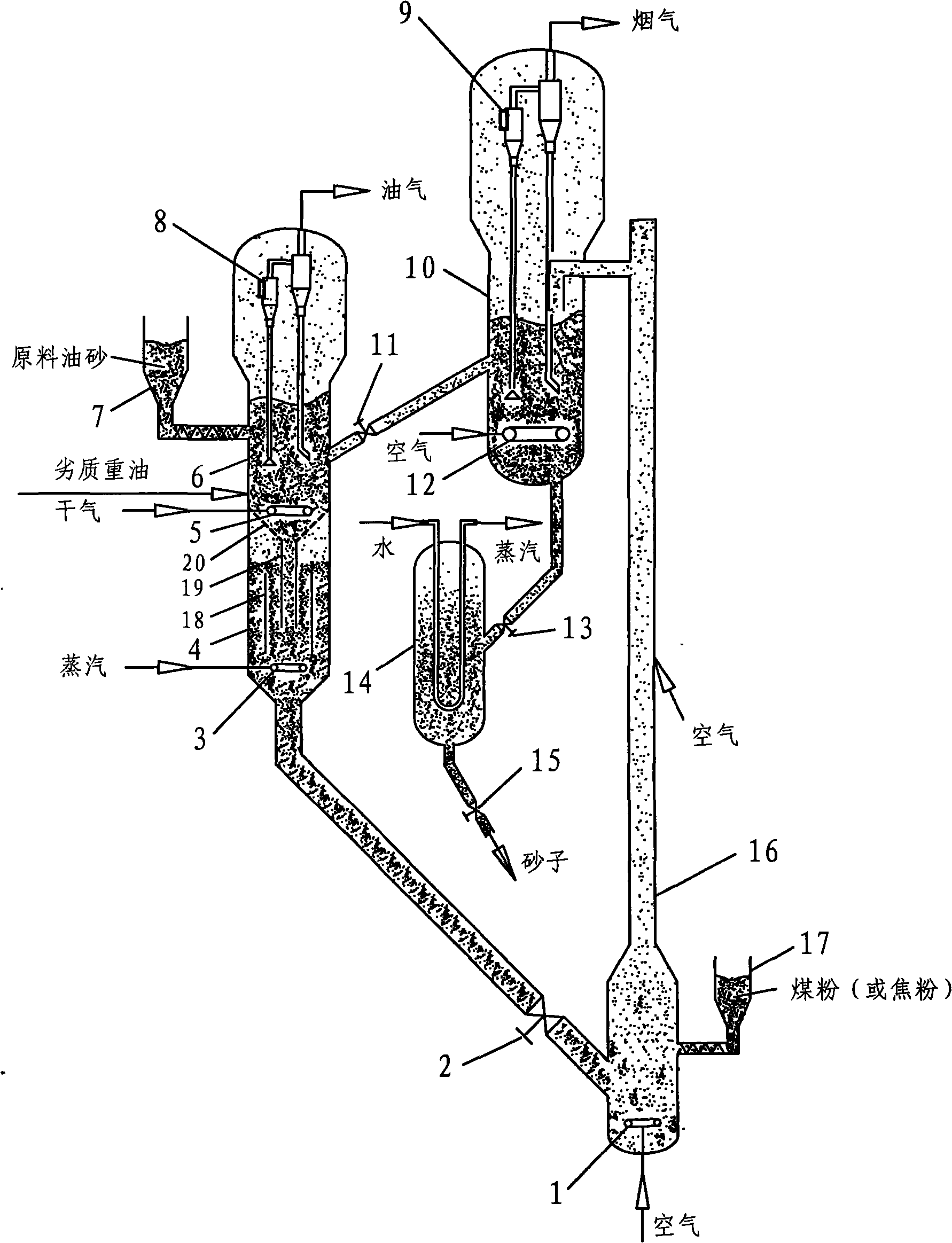

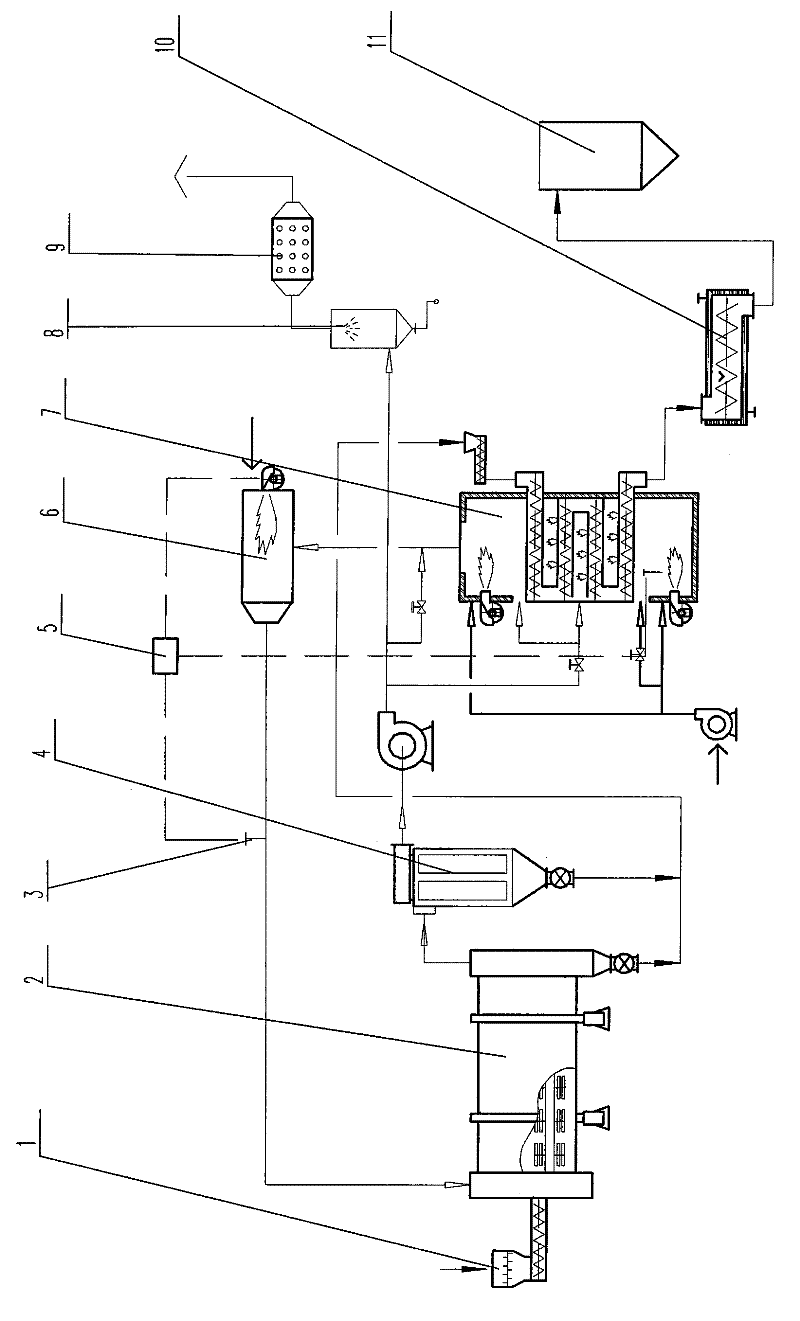

Method for directly fluid coking oil sand and apparatus

ActiveCN101358136ANo pollution in the processContinuous processingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The present invention provides a method and a device which are used for the direct coking of oil sand on a fluidized bed. The method is as follows: after being mixed with and exchanging heat with the high-temperature sand from a dense-phase coking-burning reactor, the oil sand material in a coking reactor undergoes coking reaction; the dedusted oil gas enters into a fractionation and absorption stabilization system; after being stripped by a stripper, tar sand is led into a dilute-phase coking-burning riser to be burnt in the dilute-phase coking-burning riser and the dense-phase coking-burning reactor above the dilute-phase coking-burning riser; and one flow of the burnt hot sand serving as a heat carrier is led into the coking reactor, and the other flow is led into an external heat collector for heat exchange. If the coke yield is low and the coke-burning heat is insufficient, burning oil, coal dust or coke powder can be added into the coking-burning riser in order to maintain the heat balance of the system. The device at least comprises a material feeder, the coking reactor, the stripper, the dilute-phase coking-burning riser, the dense-phase coking-burning reactor, the external heat collector and a cyclone separator. The device, which is characterized by strong continuous operability and high flexibility, can directly process unconventional petroleum resources such as oil sand and oil shales and does not pollute the environment, and the comprehensive energy utilization rate of the system is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

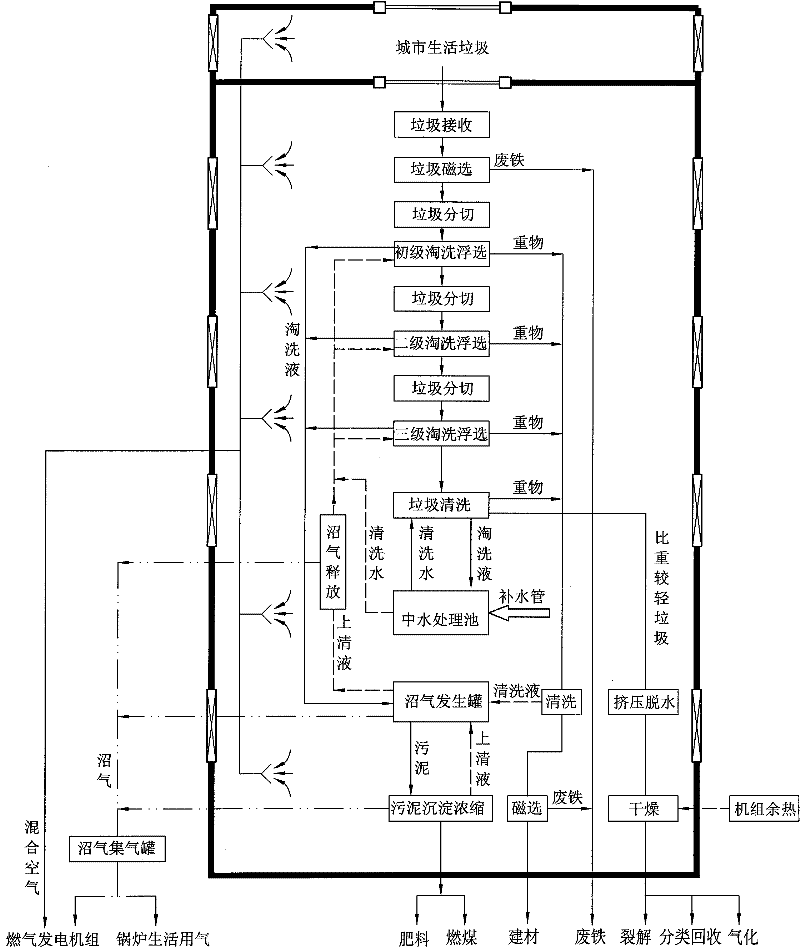

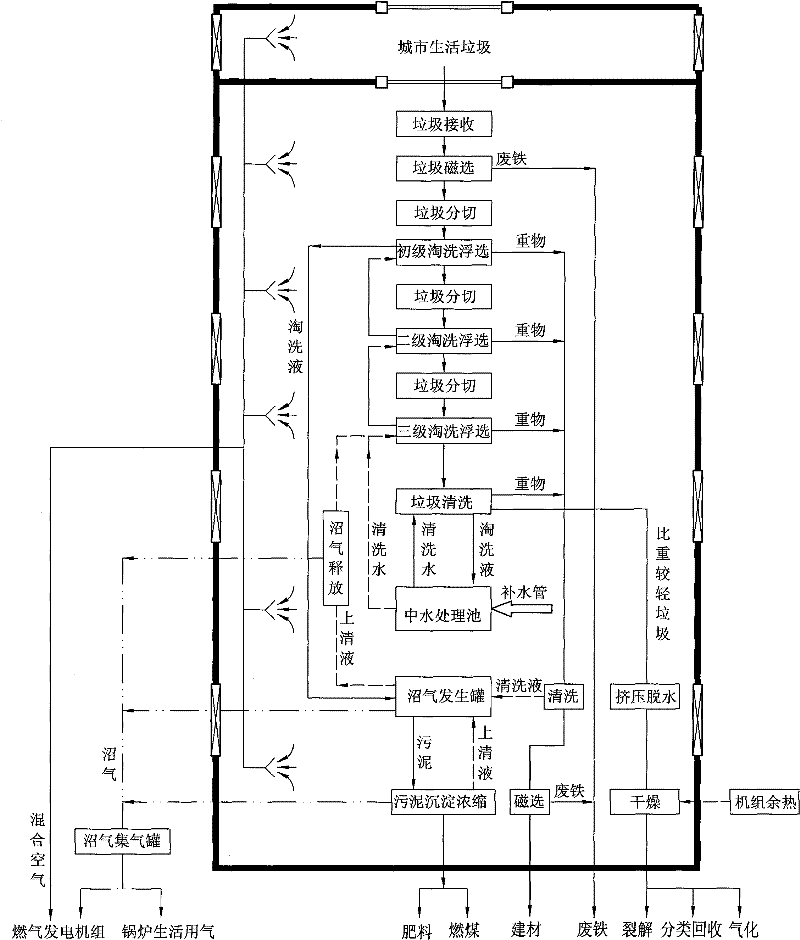

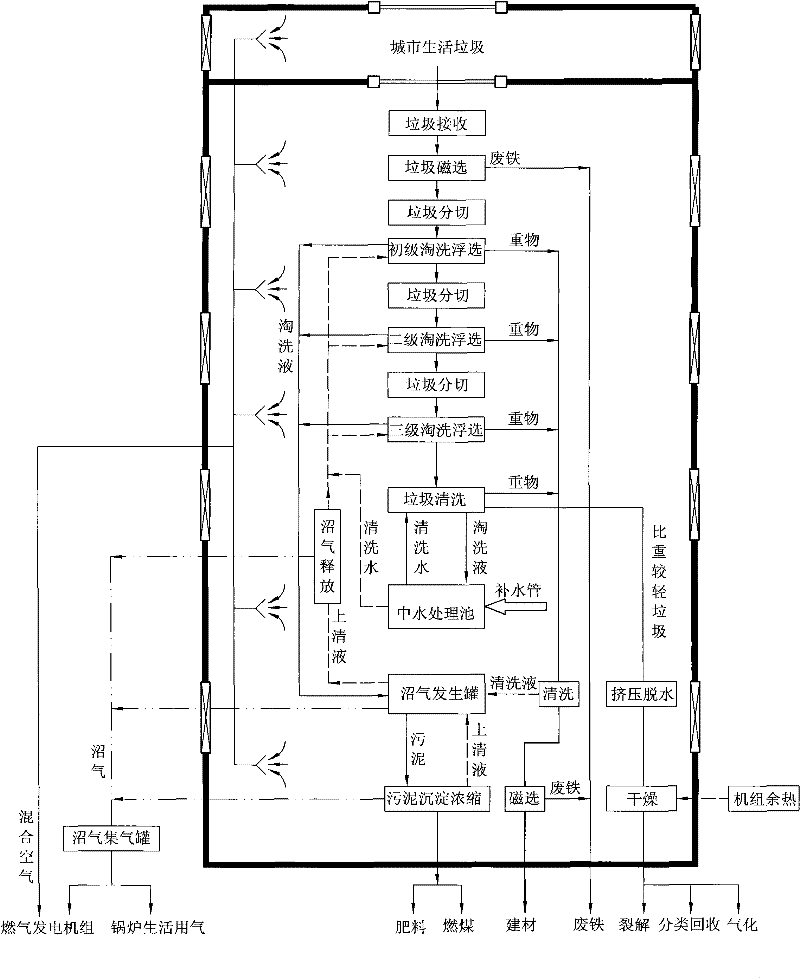

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

Compositions and methods for preparing multiple-component composite materials

InactiveUS20020130434A1Improve the preparation effectLow costAdditive manufacturing apparatusTailstocks/centresMaterials scienceMultiple component

Owner:ADVANCED CERAMICS

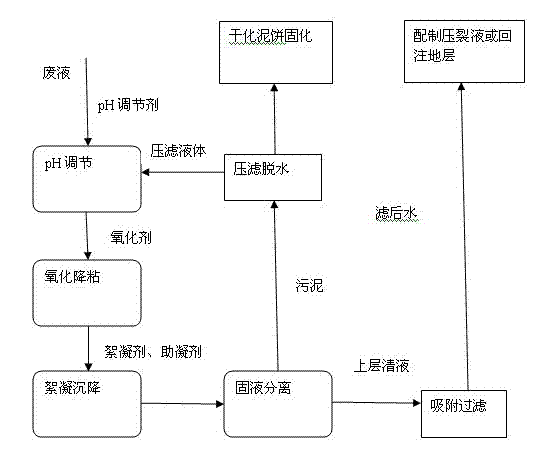

Treatment method of continental shale gas well fracturing operation waste liquid

ActiveCN103043831AProtectSimple processWaste water treatment from quariesMultistage water/sewage treatmentLiquid wasteWater resources

The invention relates to the technical field of waste liquid treatment, relates to wastewater treatment of development of continental shale gas and especially relates to a treatment method of a continental shale gas well fracturing operation waste liquid. The treatment method of continental shale gas well fracturing operation waste liquid is characterized in that the treatment method is carried out by five steps of: adjusting pH, oxidizing and reducing viscosity, flocculating and settling, separating solid and liquid, absorbing and filtering. The method provided by the invention has the characteristics of simple process, low cost, continuous treatment, safe production, stable treatment effect and no limit of environment condition; the treated water can be recycled; the fracturing liquid or reinjection formation is configured, so that the water resource is saved; and the method provided by the invention is beneficial to environmental conservation.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

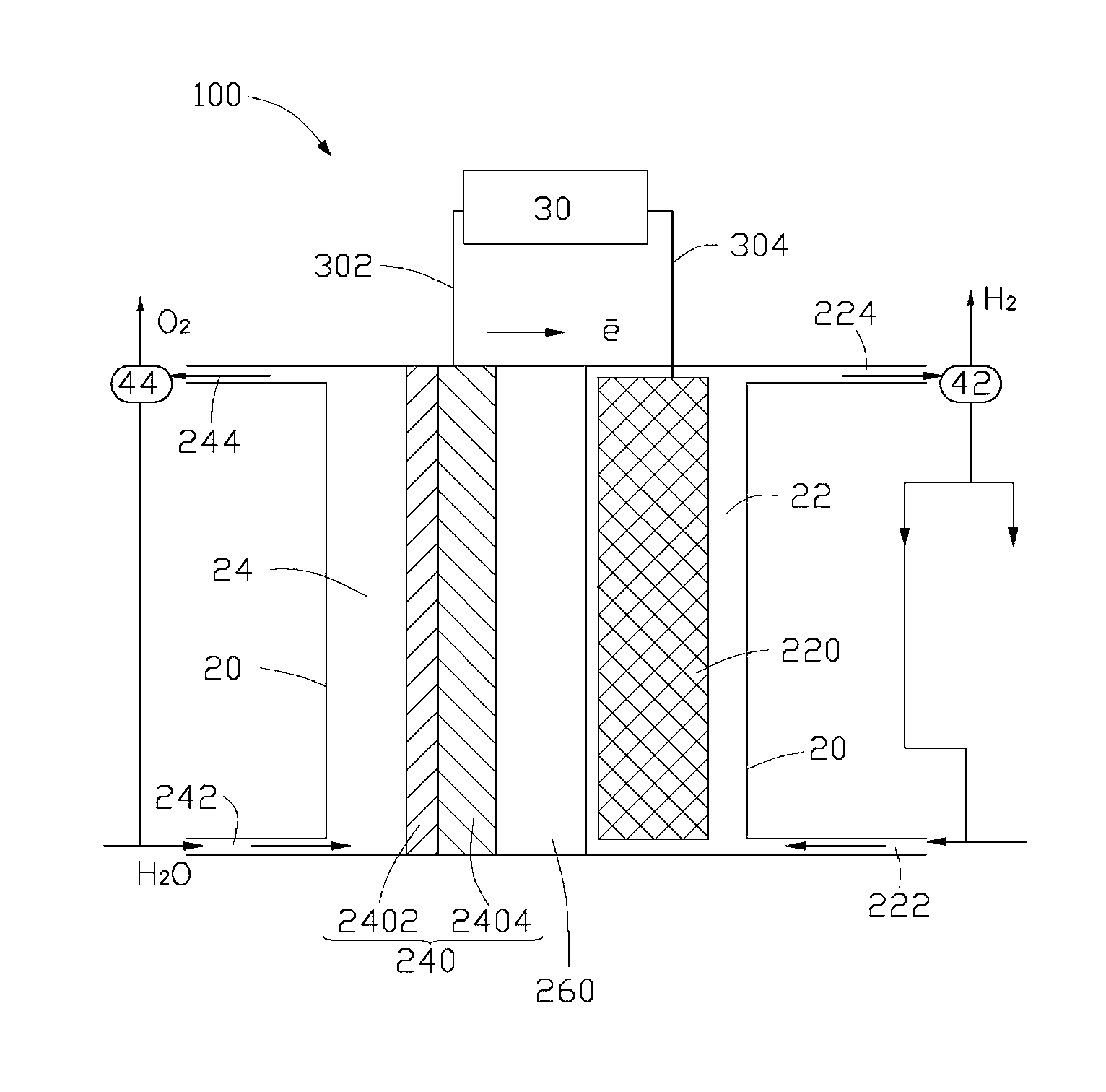

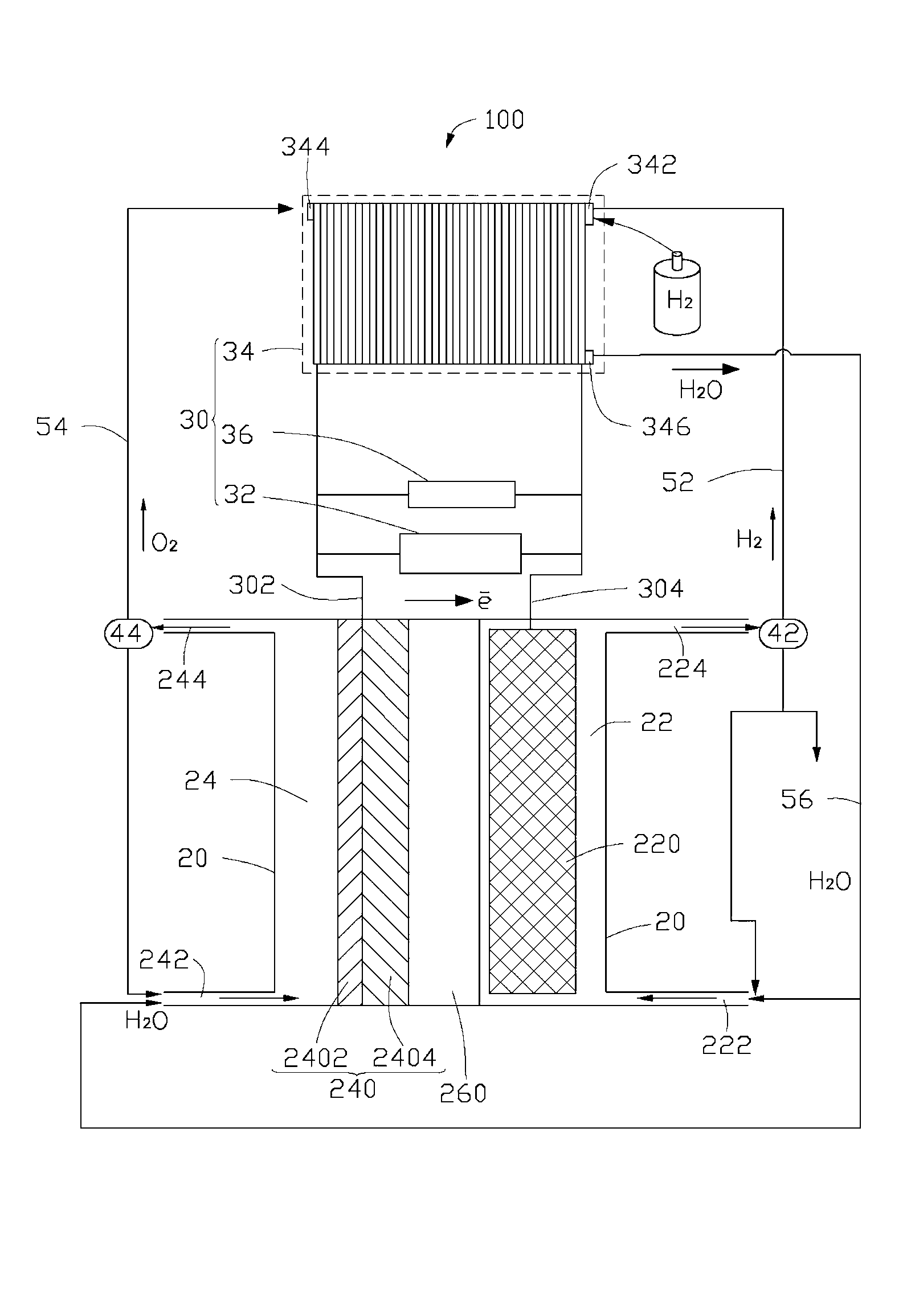

Carbon dioxide electrochemical reduction conversion utilization method

ActiveCN103160849AContinuous processingImprove recycling ratesCellsElectrochemical generatorsElectrolysisFuel cells

The invention relates to a carbon dioxide electrochemical reduction conversion utilization method comprising the steps that: a membrane reactor is provided, wherein the membrane reactor comprises a fuel cell and a cavity; an electrolyte separation membrane is arranged in the cavity, and divides the cavity into a cathode chamber and an anode chamber; an anode is arranged in the anode chamber, and a cathode is arranged in the cathode chamber; a cathode electrolyte and carbon dioxide are continuously and concurrently delivered into the cathode chamber of the membrane reactor, and an anode electrolyte and an anode active substance are continuously delivered into the anode chamber of the membrane reactor; electrolysis voltage is provided between the cathode and anode of the membrane reactor by using the fuel cell, such that carbon dioxide is decomposed, and expected products including hydrogen and oxygen are obtained; and hydrogen and oxygen are delivered into the fuel cell as fuels of the fuel cell, such that electric power can be obtained. The method provides good carbon dioxide conversion rate and energy circulation utilization rate.

Owner:TSINGHUA UNIV +1

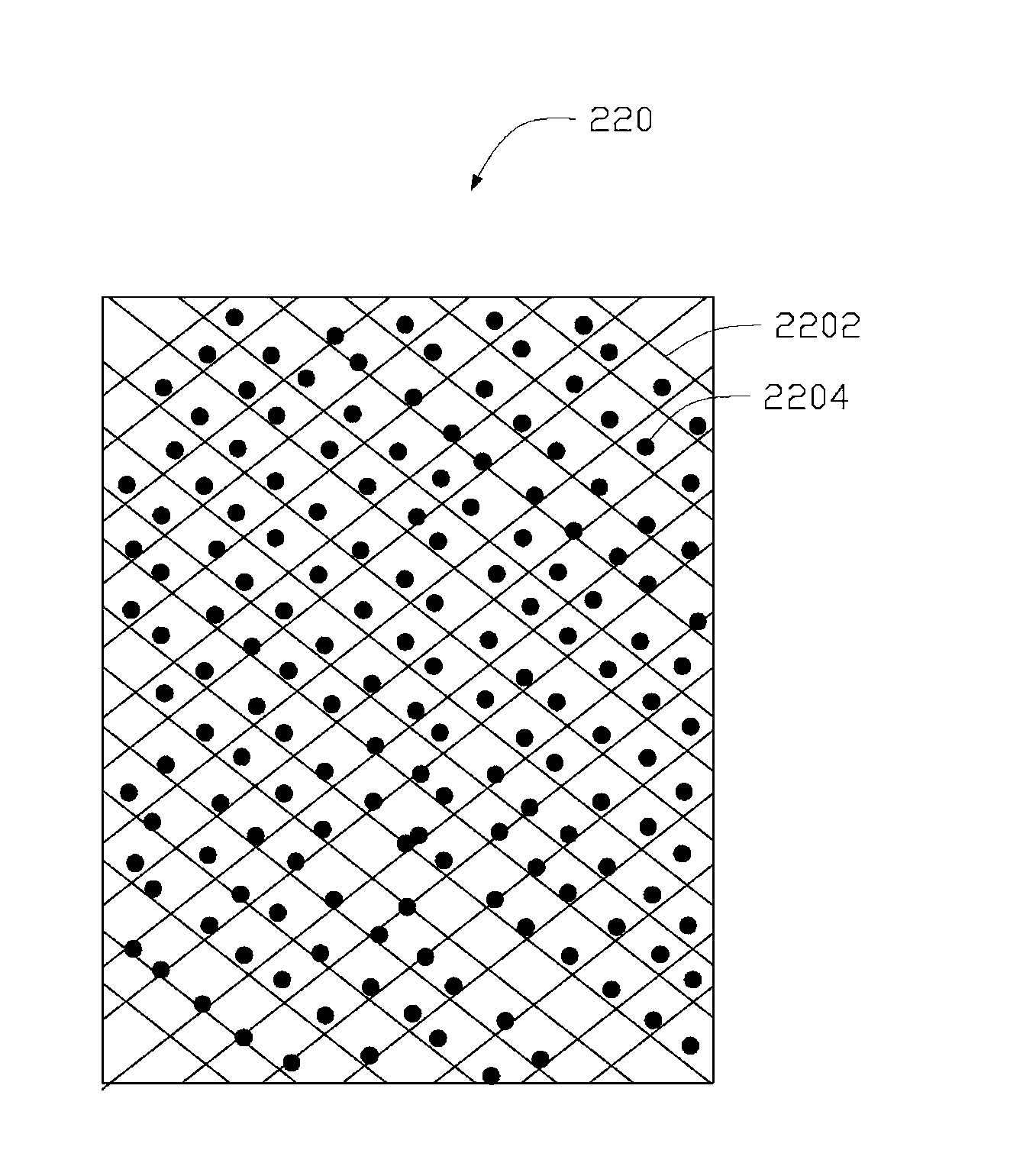

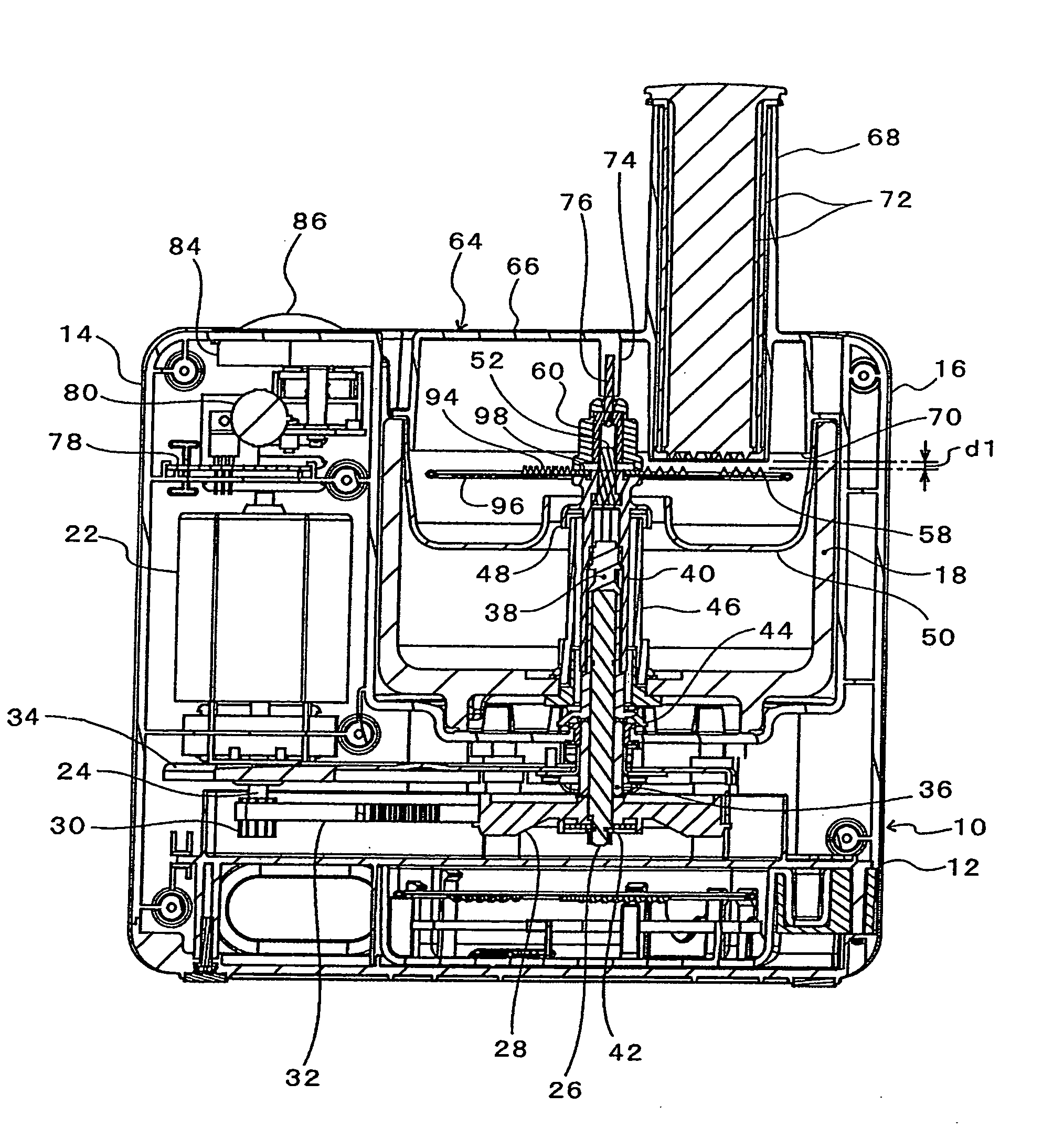

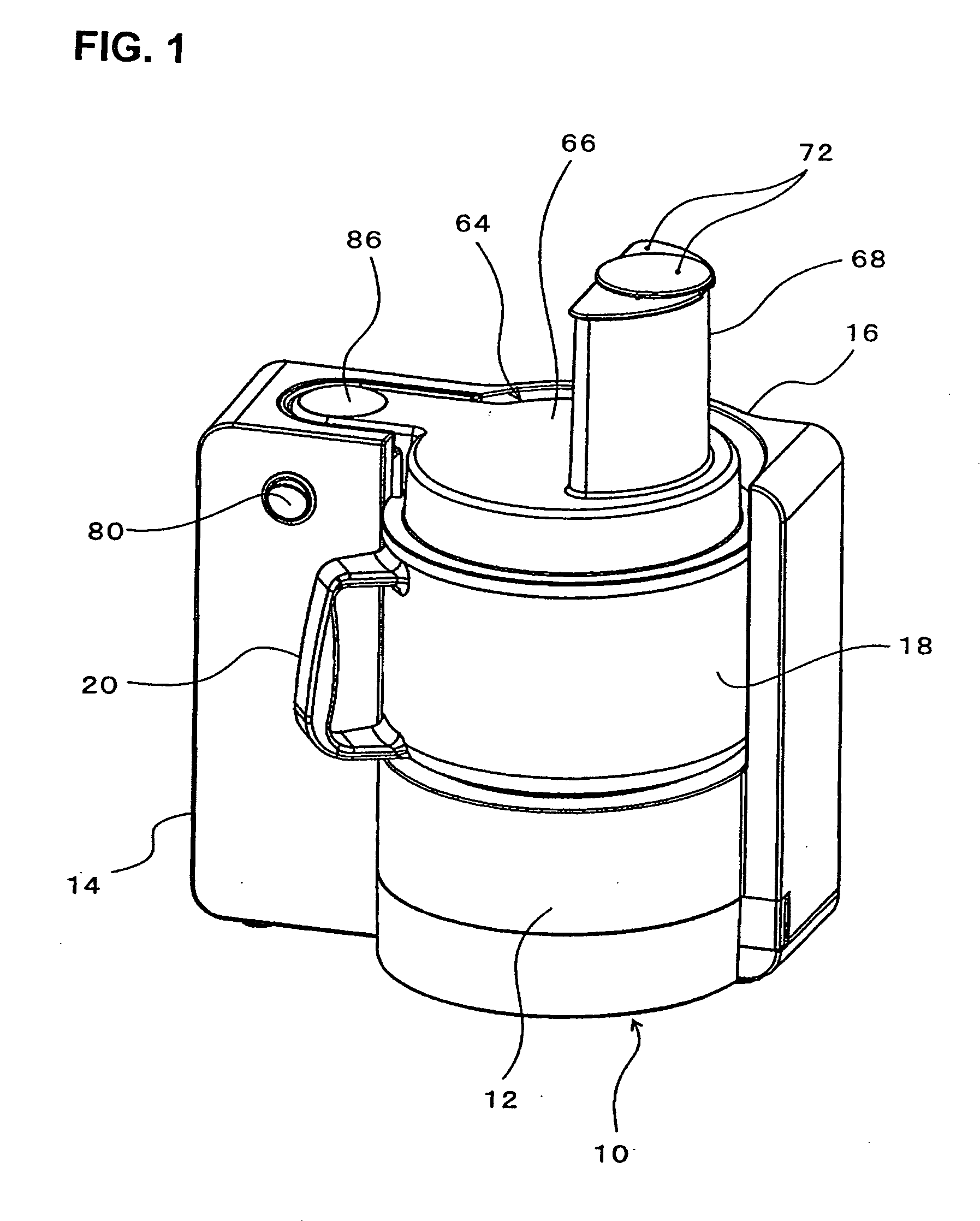

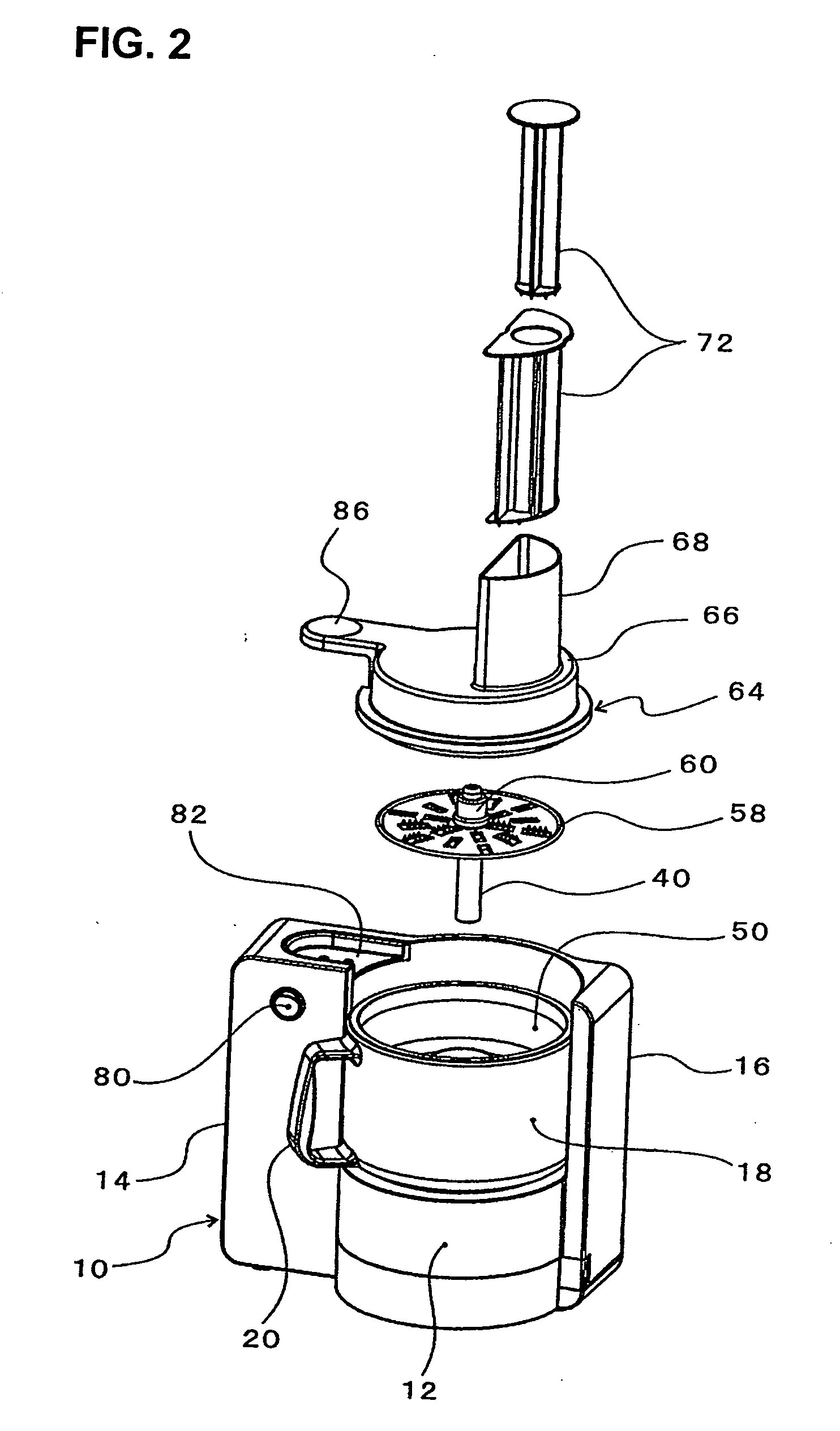

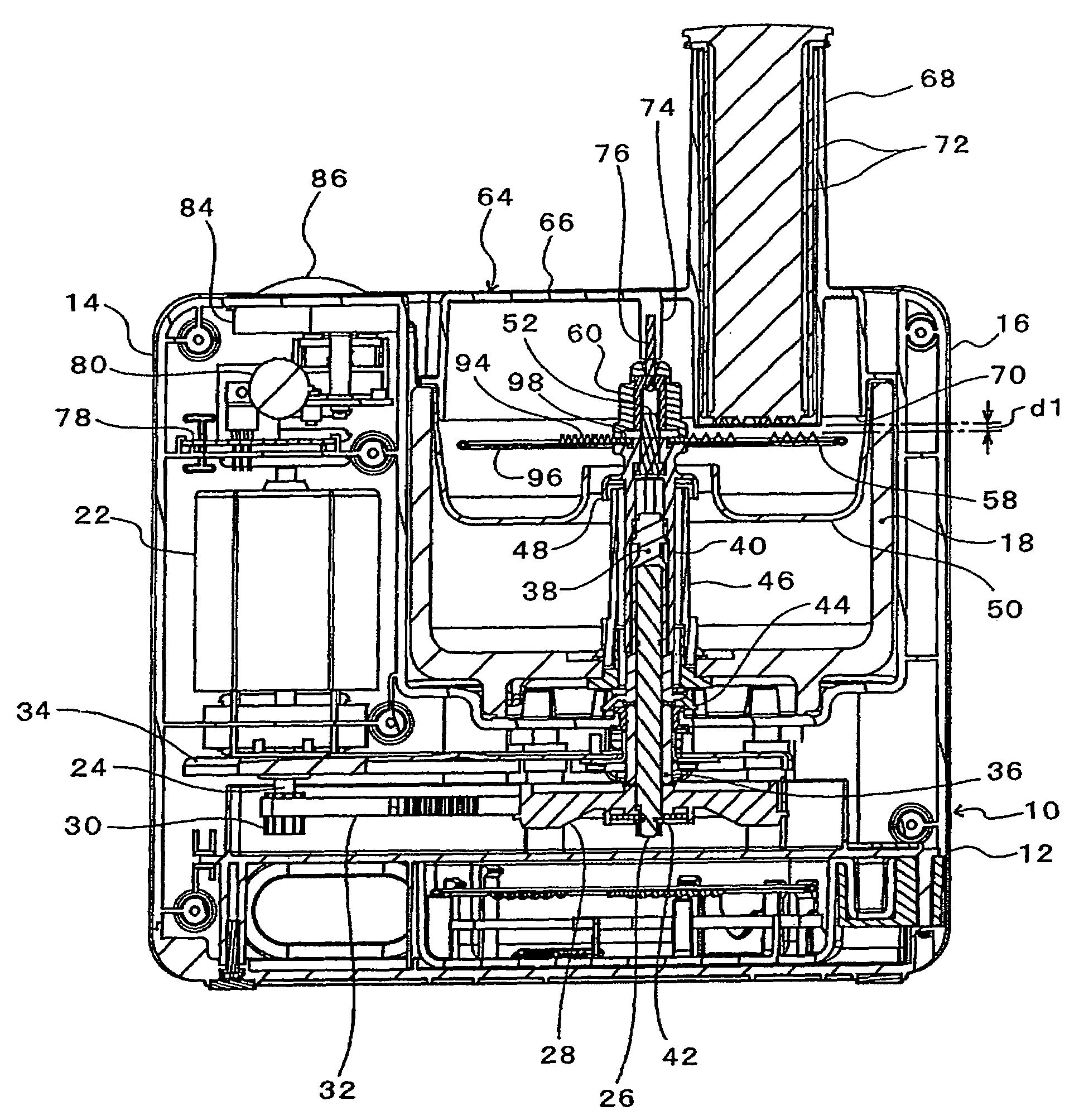

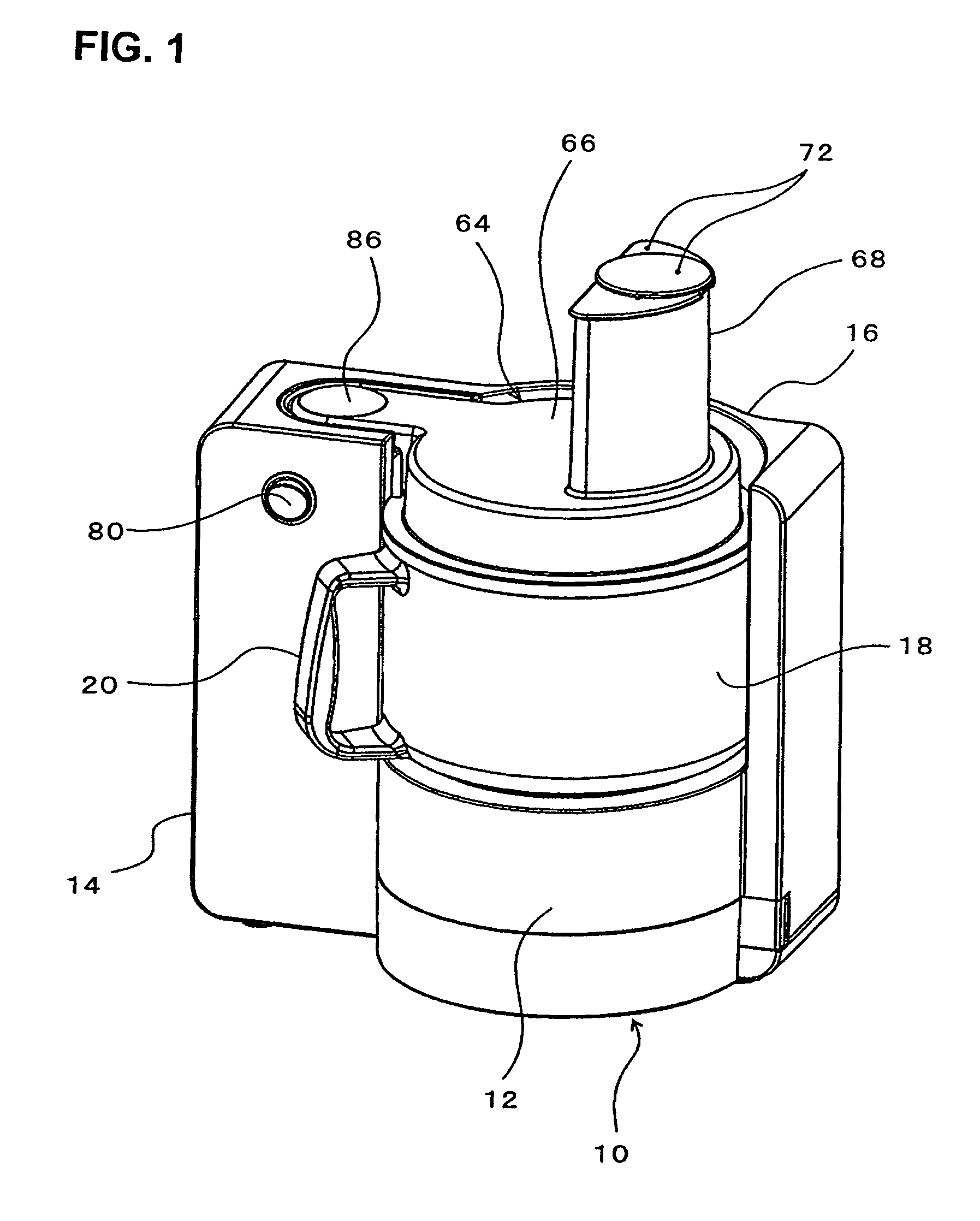

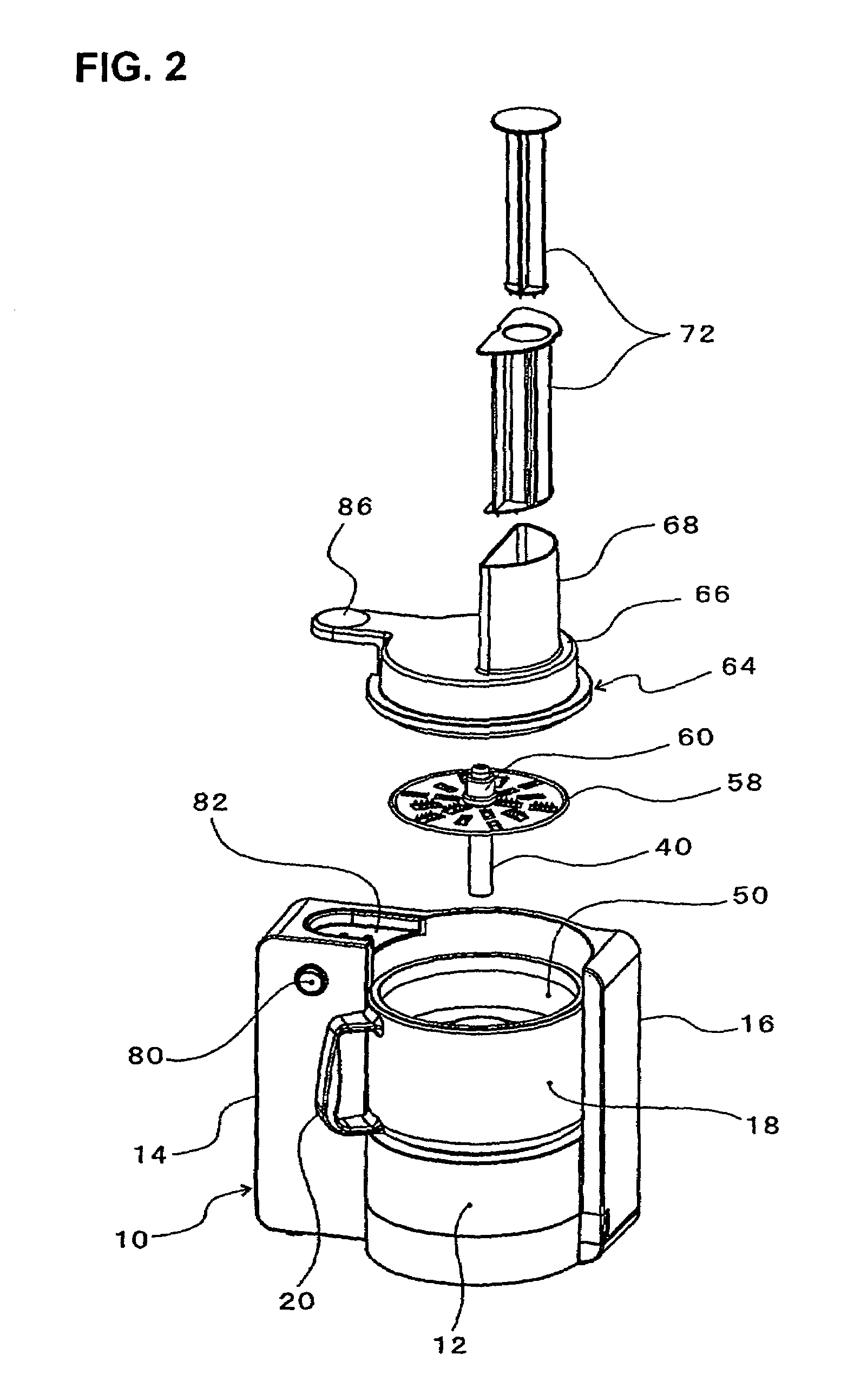

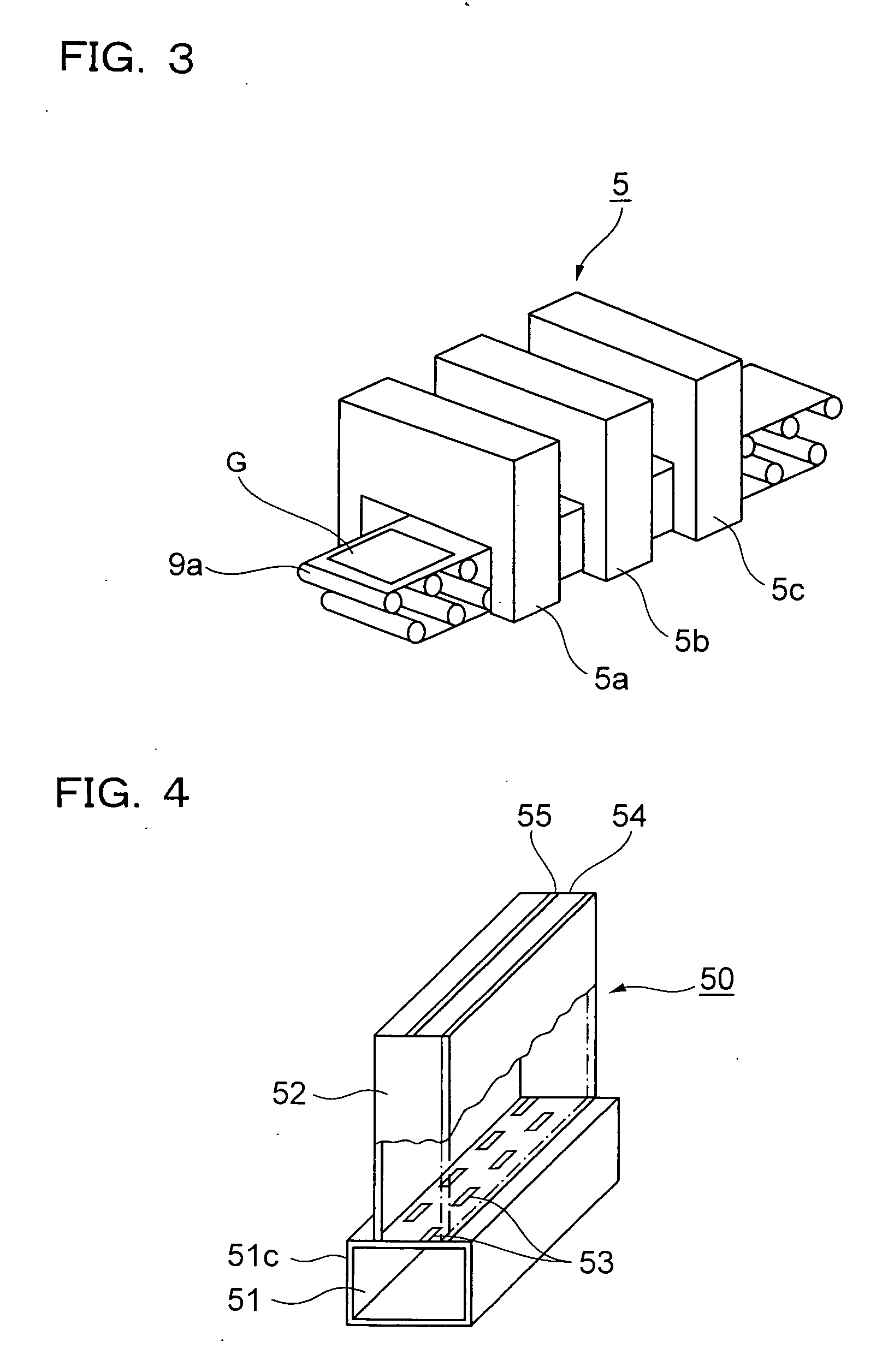

Electric grating food processor and grater plate

InactiveUS20070095959A1Uniform processing qualityUniform qualityKitchen equipmentGrain treatmentsGratingReciprocating motion

An electric grating food processor including a food material receiving section 18 that has an opening in its upper part and receives processed food materials therein, a cylindrical food material charging section 68 that has a lower end opening at its lower end, a grater plate 58 that is rotated or linearly reciprocated under the lower end opening of the food material charging section, and a drive unit for operating (rotating or linearly reciprocating) the grater plate; and the grater plate is formed with larger grating blades on one surface side thereof and lower grating blades on another surface side thereof, and the grater plate is further provided thereon with a gap adjuster 98 that adjusts the gap between the tip ends of the grating blades and the lower end opening of the food material charging section.

Owner:IZUMI PROD CO

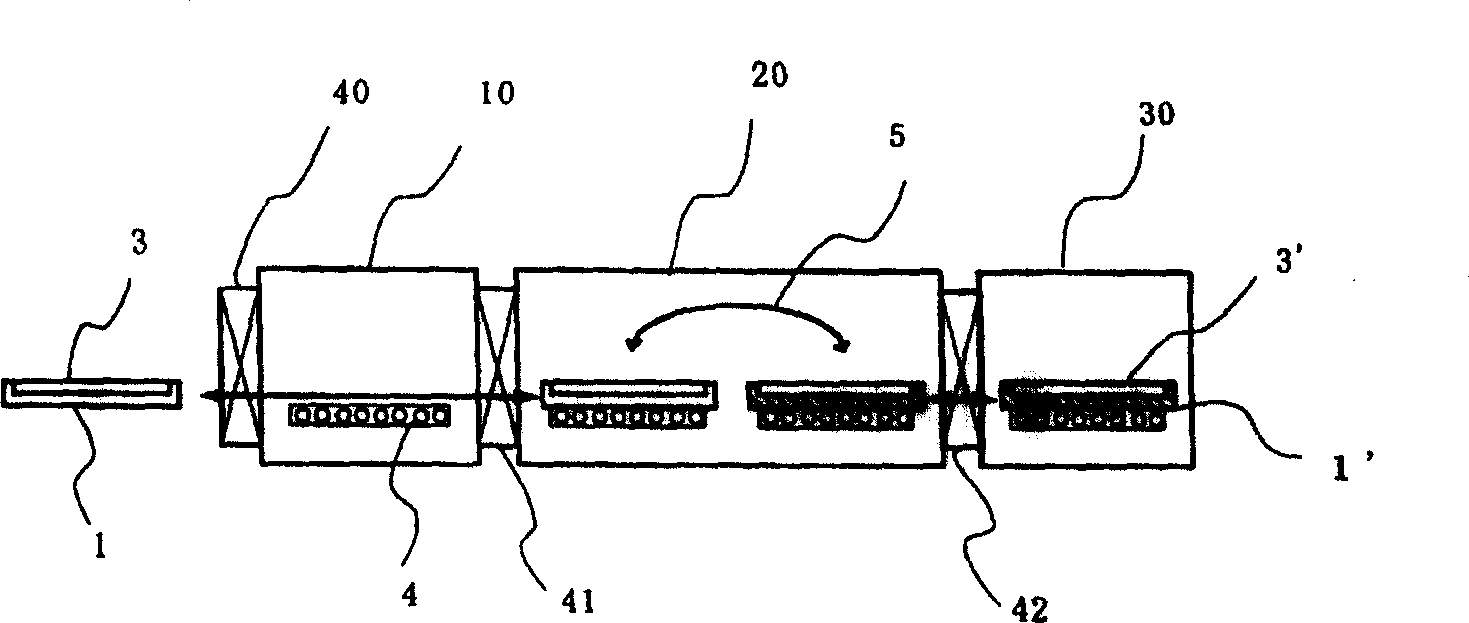

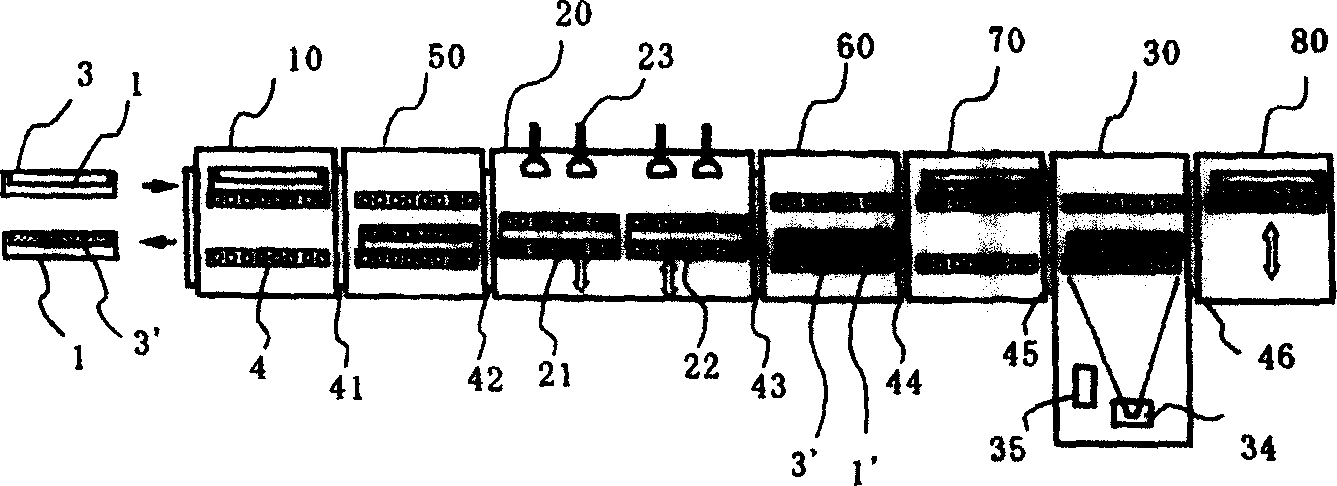

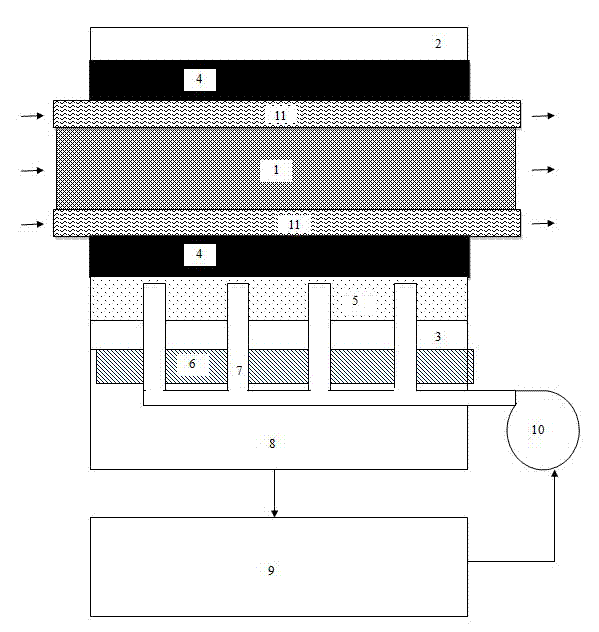

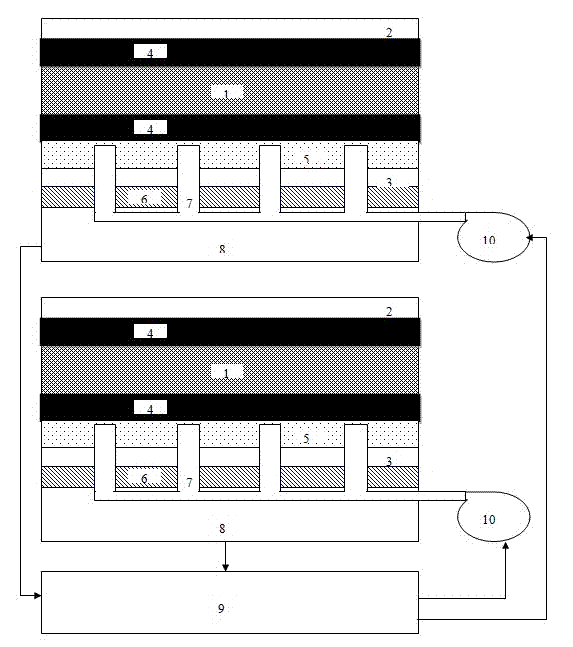

Substrate processing device and substrate processing method

ActiveCN1650416AReduced film peelingContinuous processingVacuum evaporation coatingSemiconductor/solid-state device manufacturingTransfer mechanismEngineering

A substrate processing device and a substrate processing method for general purpose capable of suppressing the contamination of atmosphere in a processing chamber through carriers, continuously performing a stable conveyance and a high quality substrate processing, and coping with further upsizing substrates and various substrate dimensions, the device comprising a load lock chamber allowing the carriers having the substrate mounted thereon to be carried therein, a substrate transfer chamber having a transfer mechanism for transferring the substrate between the carriers, and a substrate processing chamber for applying a specified processing to the substrate, characterized in that the first carrier moves between the load lock chamber and the substrate transfer chamber and the second carrier moves between the substrate transfer chamber and the substrate processing chamber, and the substrate is transferred between the first carrier and the second carrier by the transfer mechanism.

Owner:ANELVA CORP

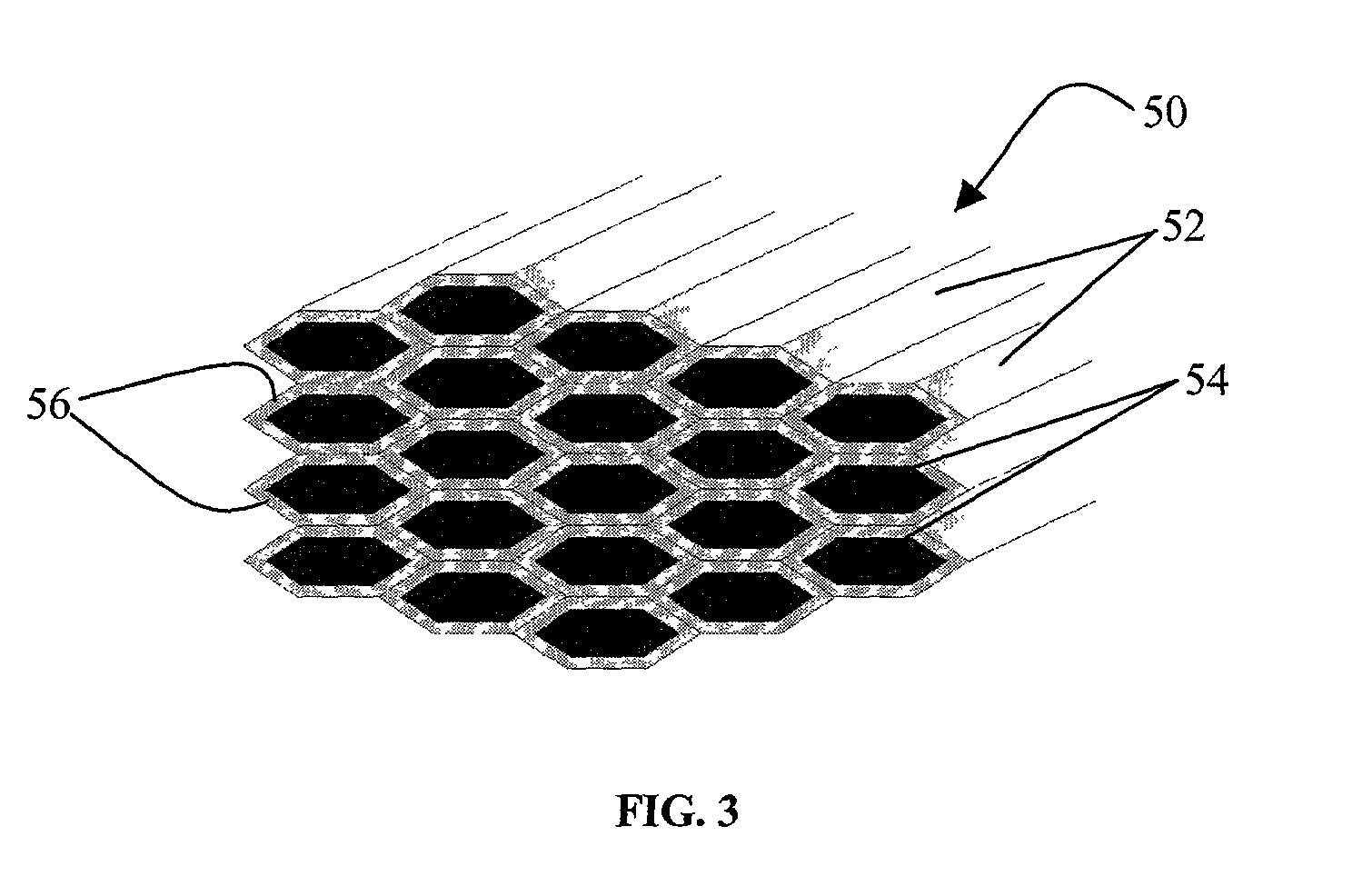

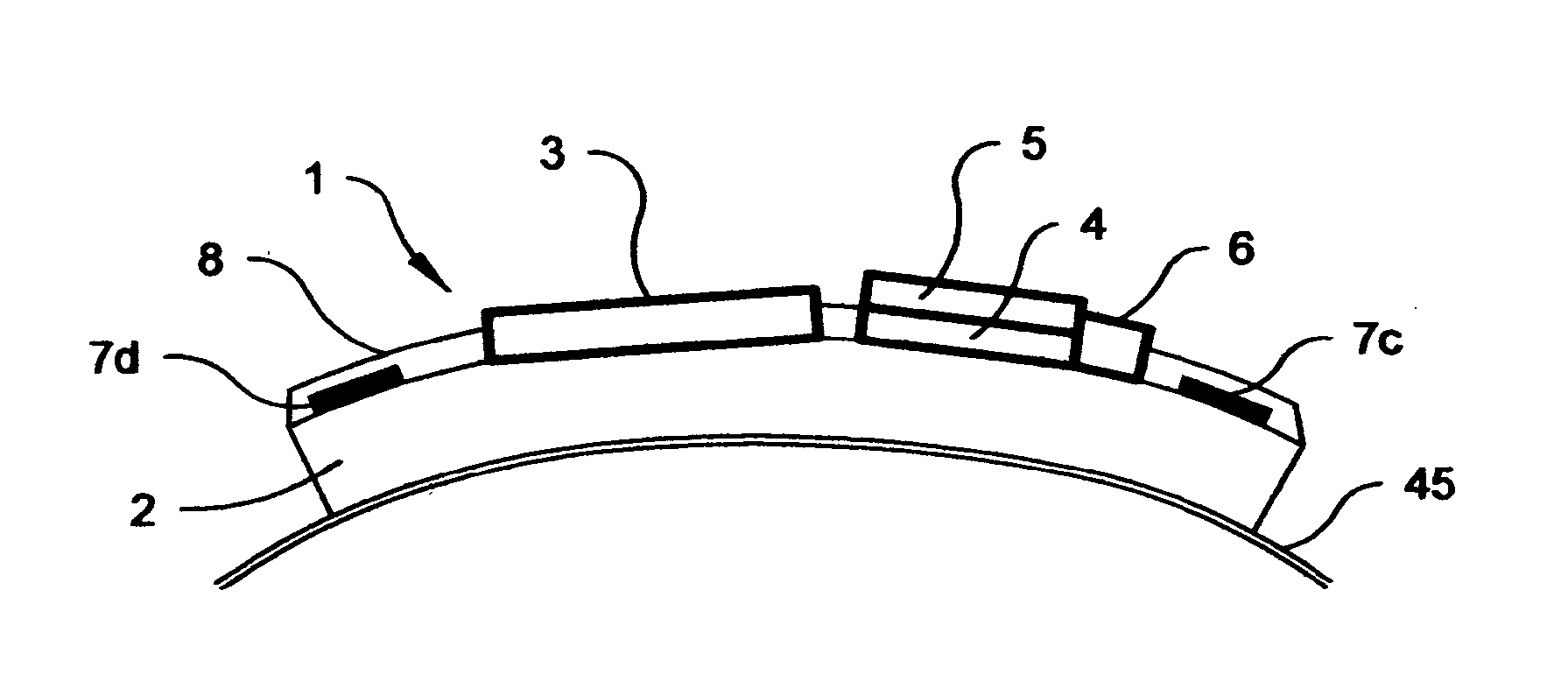

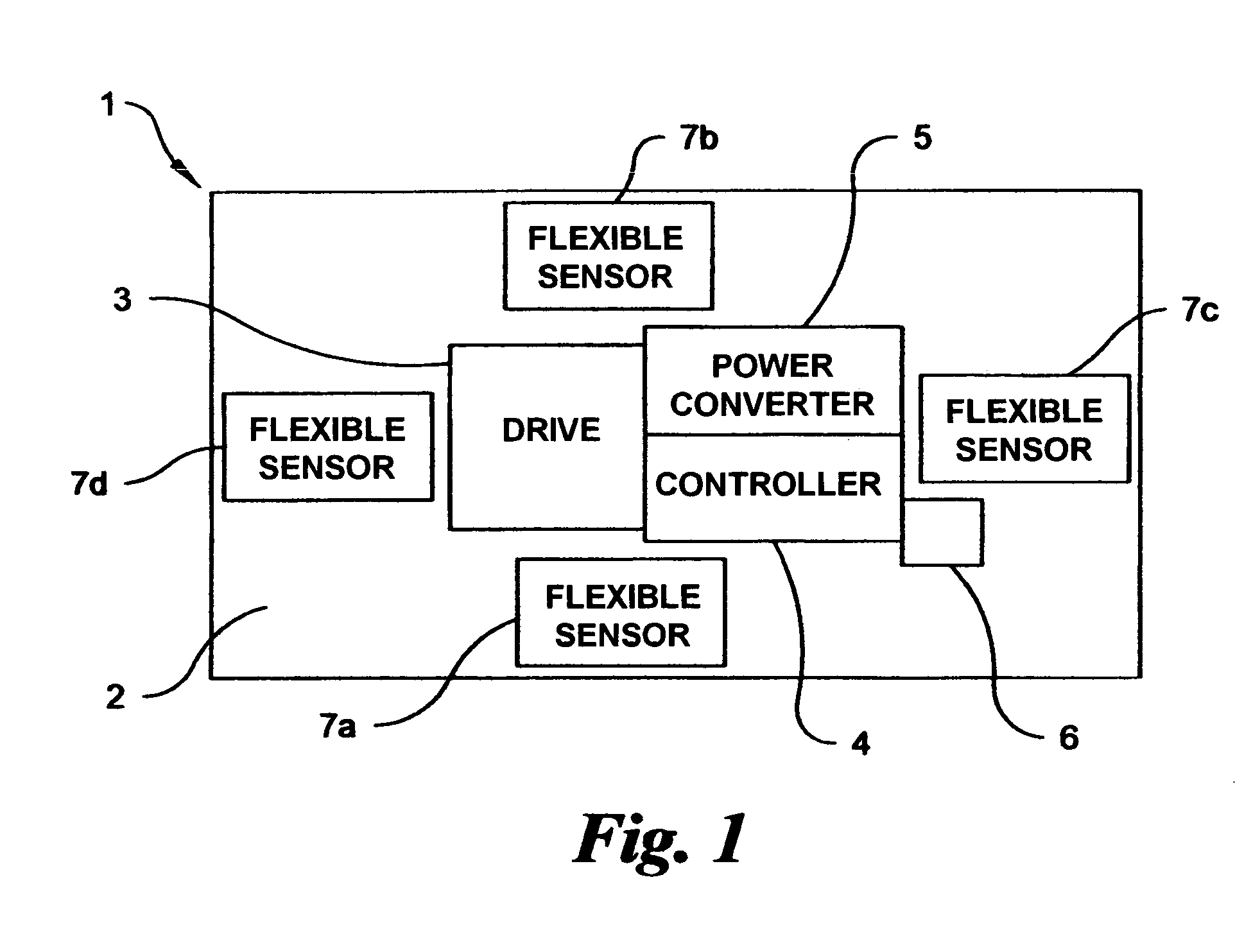

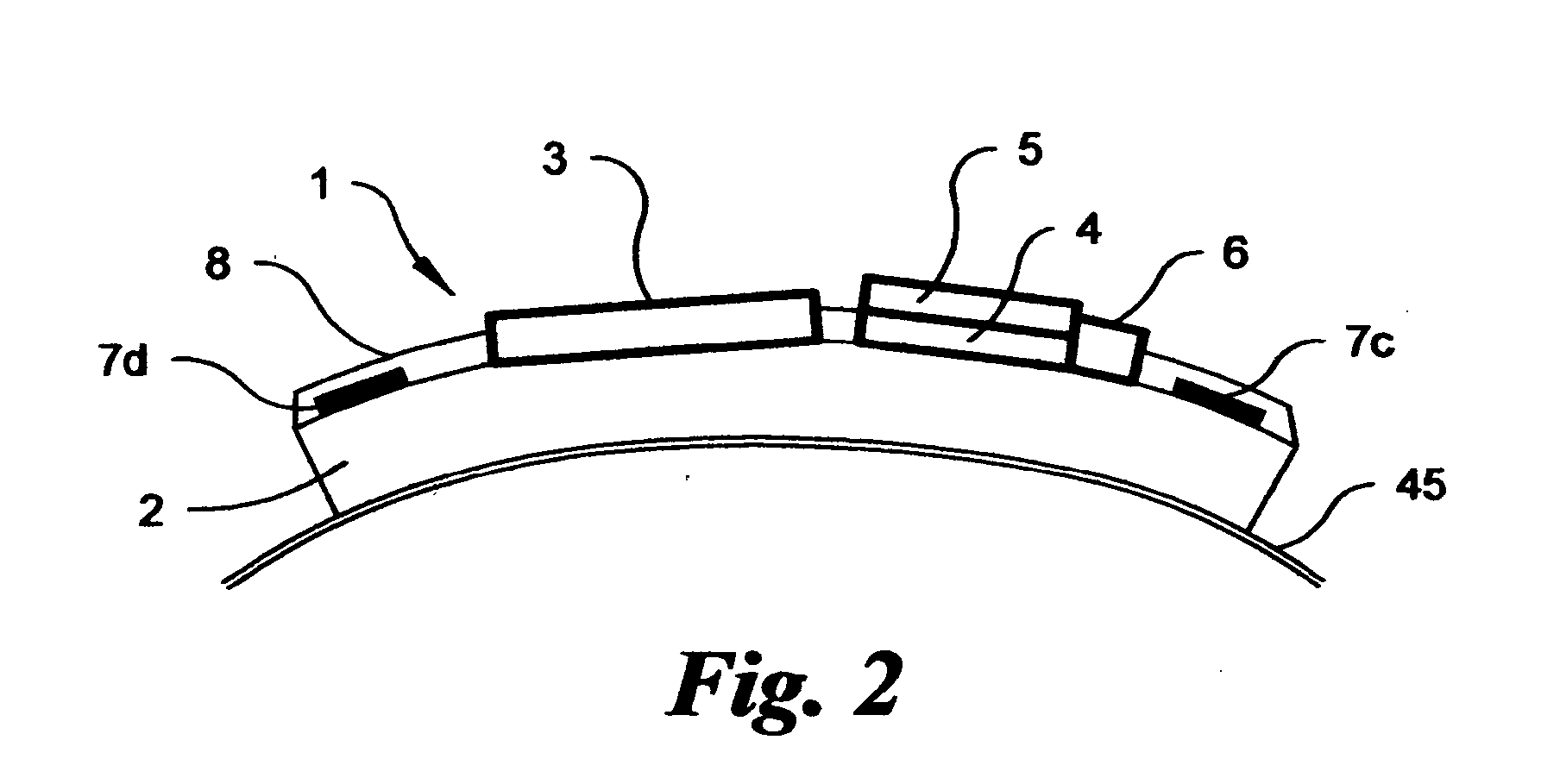

Flexible actuator with integral control circuitry and sensors

InactiveUS20060169837A1Fit closelyLow-profileAircraft stabilisationWing adjustmentsShear stressSpatial function

A low-profile, actively-controllable flexible piezo-composite actuator with flexibly mated drive, control, and power circuit architecture is presented. The low-profile, functionally-integrated actuator package retains the flexible nature of the actuator while not increasing the overall footprint of the device. The functionally integrated package incorporates flexible structural sensors and embedded control as to enable either active or autonomous control of a unified flexible package that can be installed conformally to non-planar structures. Integral flexible sensors include strain, normal stress, shear stress, pressure, velocity, and acceleration. The invention has immediate applicability to vibration and noise abatement, strain-based compensation, shape control, and structural damping within a variety of aircraft, ships and ground vehicles.

Owner:BIRD ROSS W +1

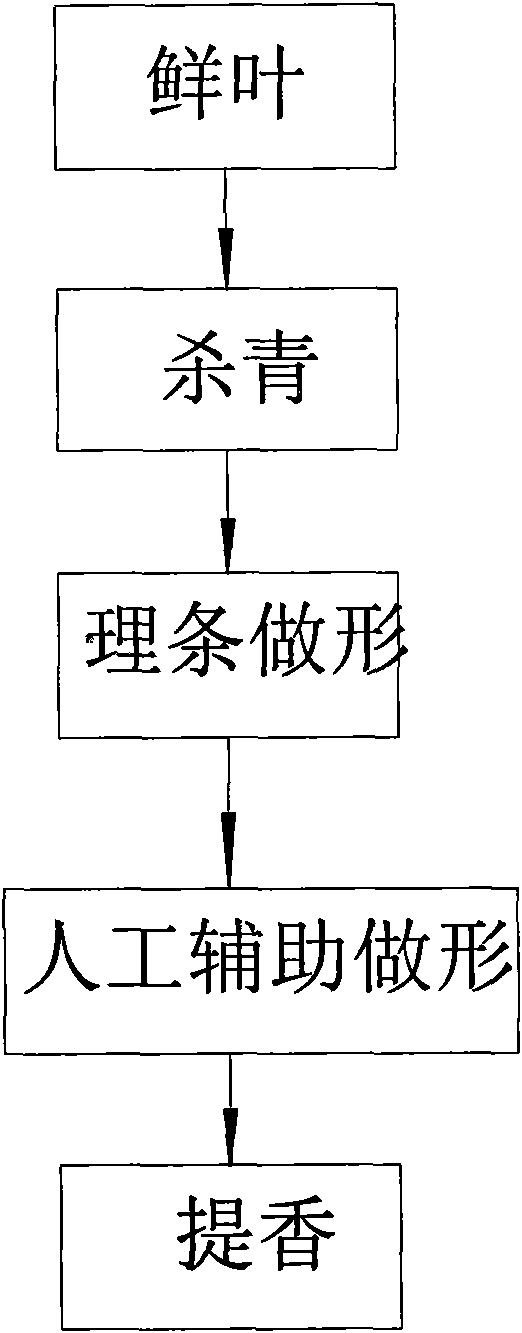

Processing method of tea-leaf like sparrow tongue

InactiveCN101606556AContinuous productionFully convertedPre-extraction tea treatmentEngineeringTea leaf

The invention relates to a processing method of tea-leaf like sparrow tongue, including main steps of water-removing, wire tidying and shaping, artificial assist shaping and deoiling. The tea leaves like sparrow tongue prepared by adopting the invention have flat, tall and graceful and smooth tea wires, like a sparrow tongue in appearance, are green You Run in colour, are dark green, clear and bright in soup colour, and possess of strong long-lasting fragrance, fresh, pure, daintily and unforgettable taste, light green, uniform and bright colour and complete leaves. Green ingredients in the tea leaves are fixed through water removing by a microwave water removing machine, and alcoholization sterilization is carried out on the tea leaves, thus achieving 'three greens' of product and safety and sanitation; a microwave dryer and a far infrared deoiling machine are used and intermediate temperature intermediate speed alcoholization fragrance improving technology is adopted to promote full inversion and polymerization of inclusion and fragrance ingredients, thus the tea leaves are fragrant in smell and rich and pure in taste. In addition, owing to addition of the microwave water removing machine, the microwave dryer and the far infrared deoiling machine, influence caused by man-induced factor is reduced in production of the tea leaves like sparrow tongue, continuous and clean processing is realized, and product quality and yield are ensured.

Owner:SICHUAN WENG TEA IND

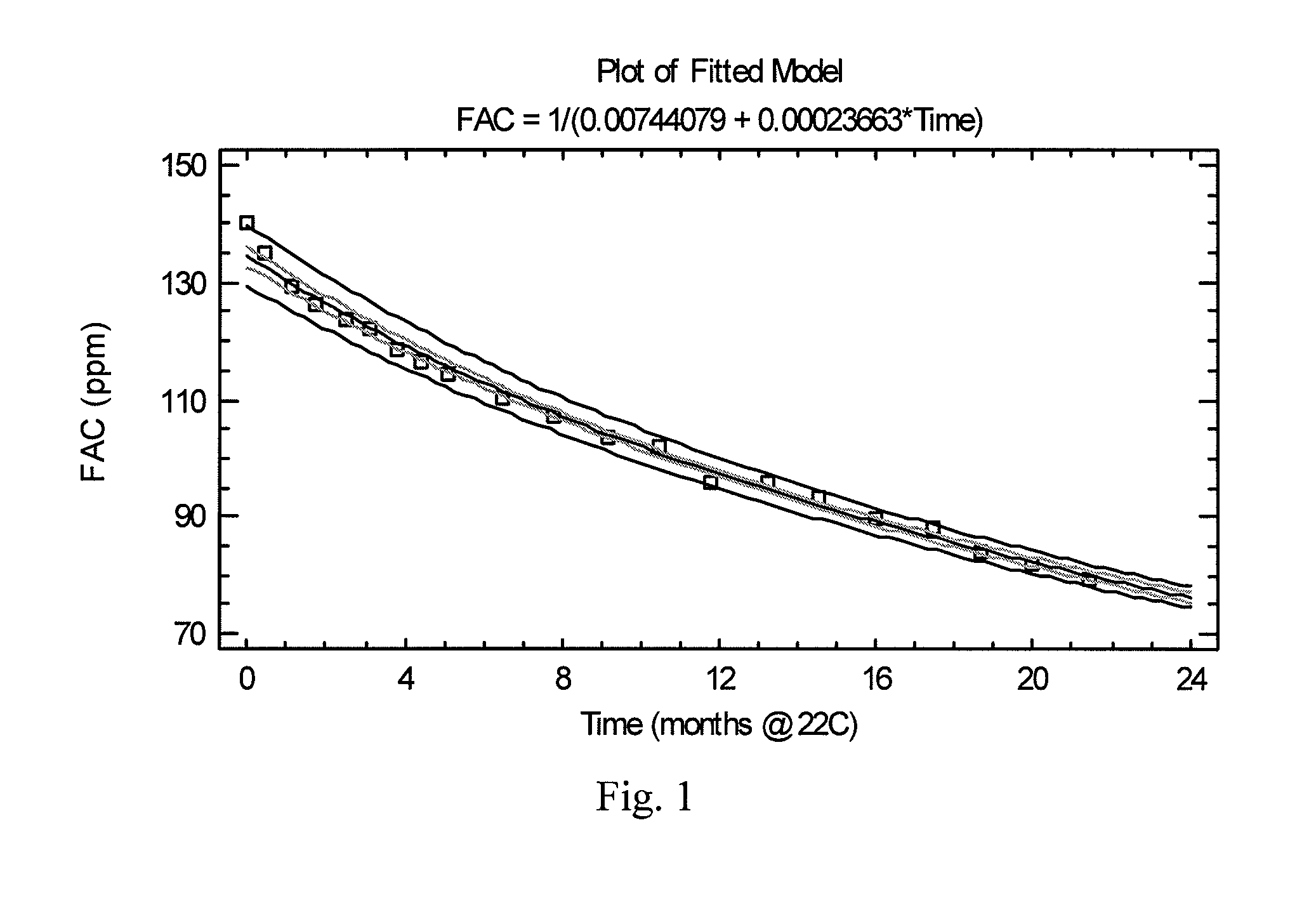

Solution containing hypochlorous acid and methods of using same

The present invention relates to low pH antimicrobial solutions comprising hypochlorous acid, water, and, optionally, a buffer. The inventive low pH antimicrobial solutions have a pH from about 4 to about 6 and are useful for treating impaired or damaged tissue and for disinfecting surfaces. Chemical processes for the production of the low pH antimicrobial solutions are also provided wherein chlorine gas is added to a buffer solution containing a buffering agent and water. The present invention also provides an electrochemical process for the production of the low pH antimicrobial solutions.

Owner:SONOMA PHARMA INC

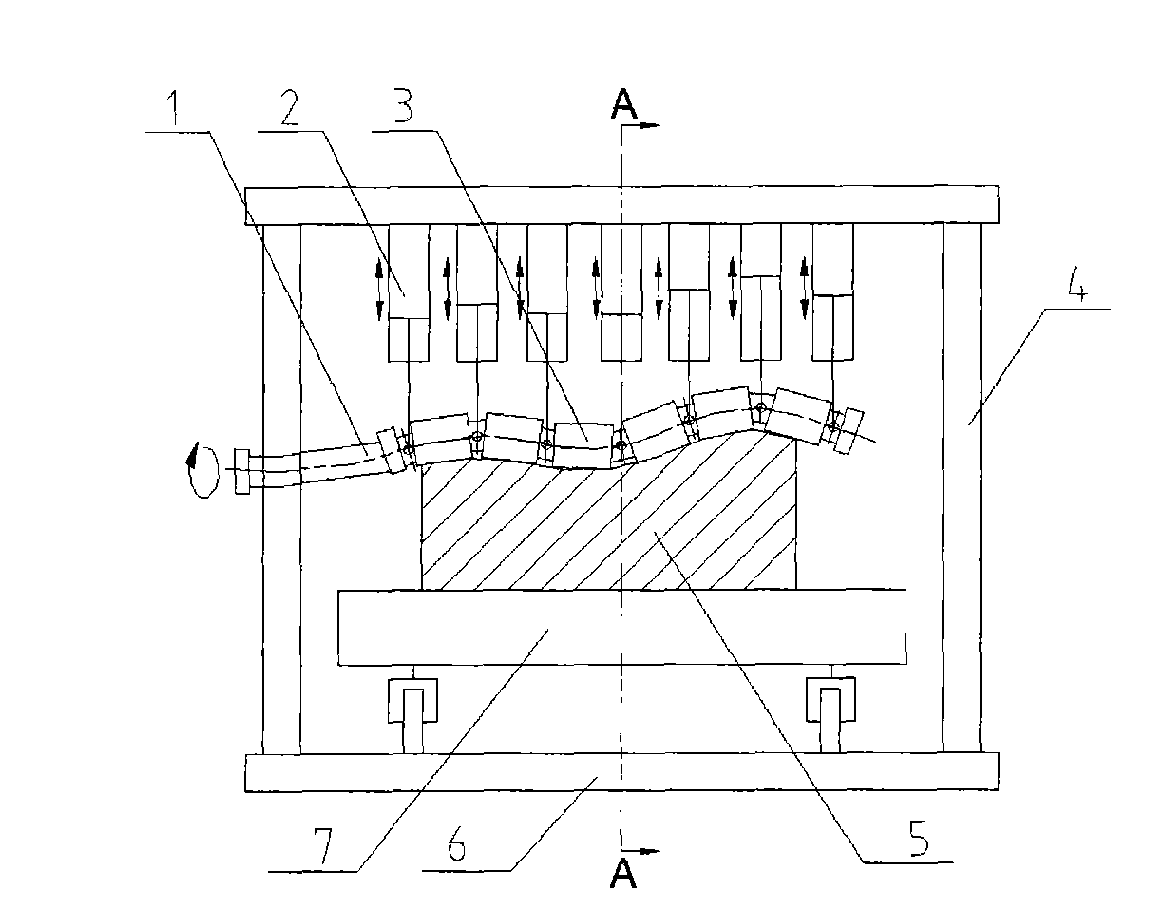

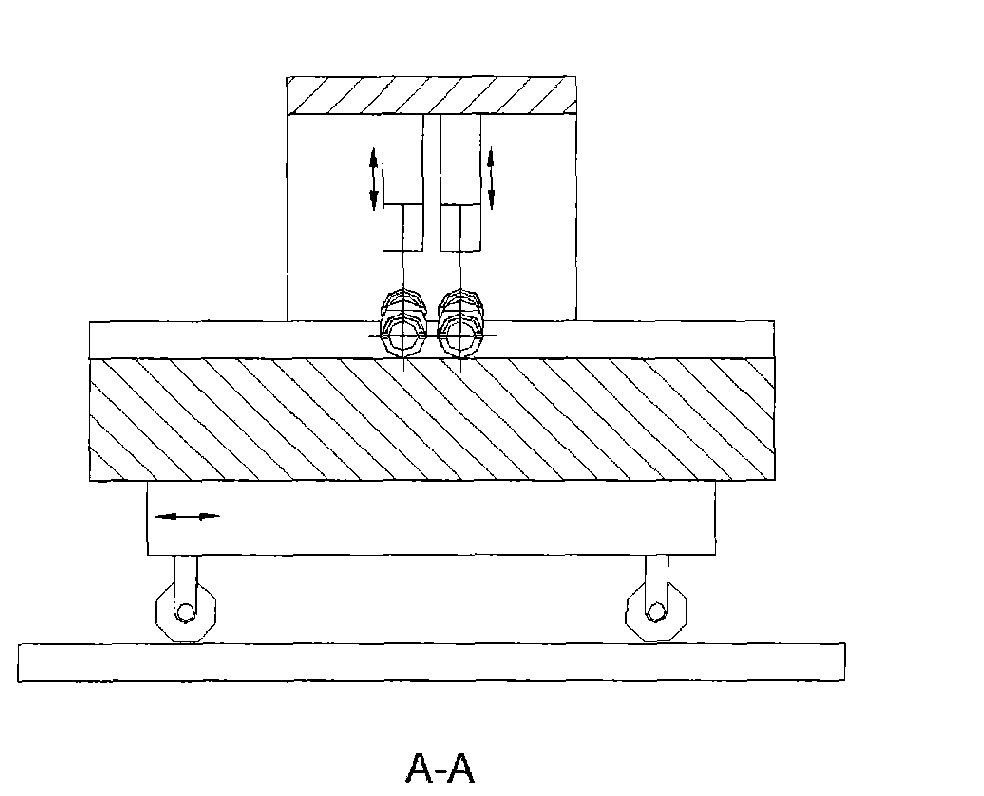

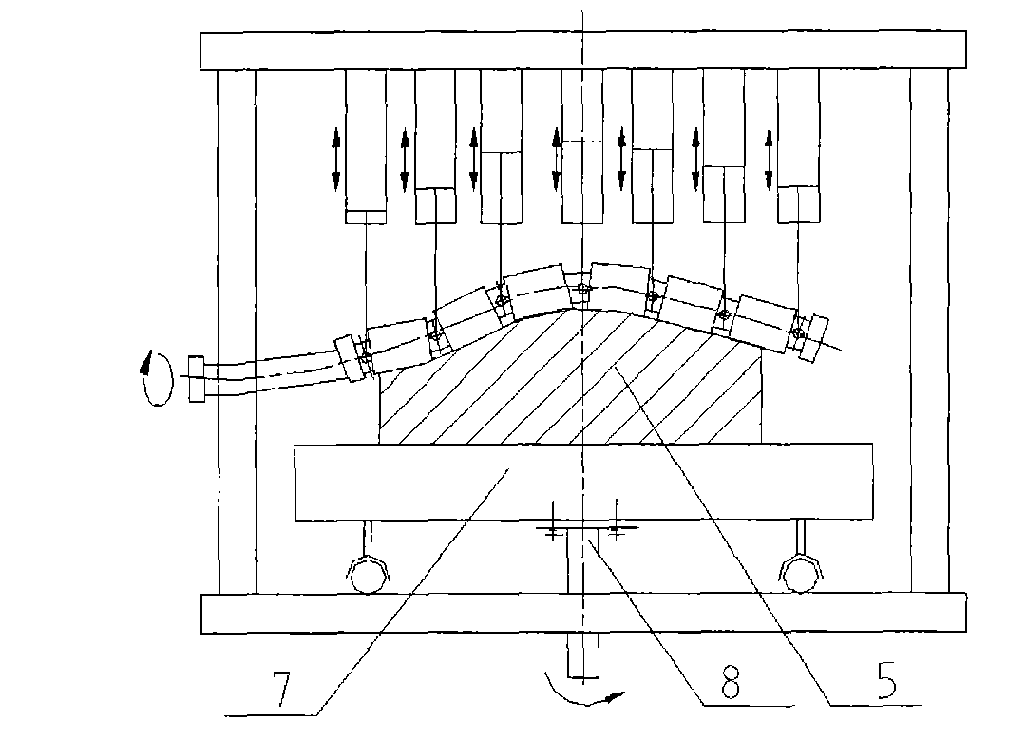

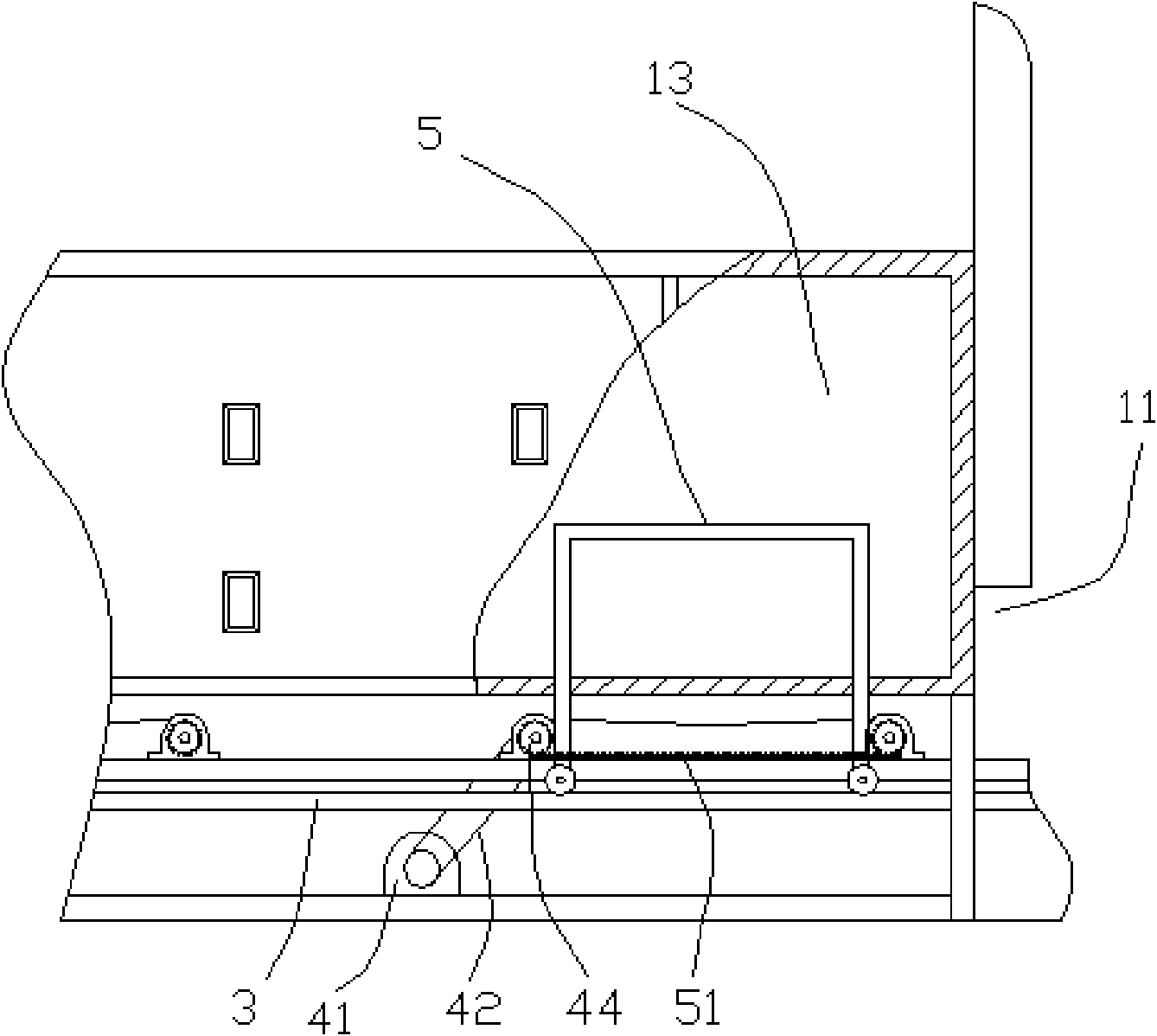

Curved surface finishing processing device

InactiveCN101648358AWide adaptabilityContinuous processingBelt grinding machinesShaft for rotary movementSurface finishEngineering

The invention relates to a curved surface finishing processing device which is equipment for surface processing, in particular to a processing device using flexible shafts and surface processing toolsto finish or smoothen a processed three-dimensional curved surface, belonging to the field of mechanical engineering and aiming at changing the traditional processing way finishing the surface of a plane workpiece by driving the tool by a rigid shaft and providing a solving scheme for the finishing processing of the three-dimensional surface of the workpiece. The curved surface finishing processing device comprises flexible shafts, flexible shaft support mechanisms, the surface processing tools, a support frame, a base and a work table and is characterized in that the flexible shafts (1) areone group or a plurality of groups, each group of flexible shafts (1) are provided with a plurality of the surface processing tools (3), the flexible shafts (1) are arranged on the support frame (4) through a popularity of the flexible shaft support mechanisms (2), and axes of the flexible shafts (1) are passively bent following the surfaces of workpieces (5) to be processed.

Owner:JILIN UNIV

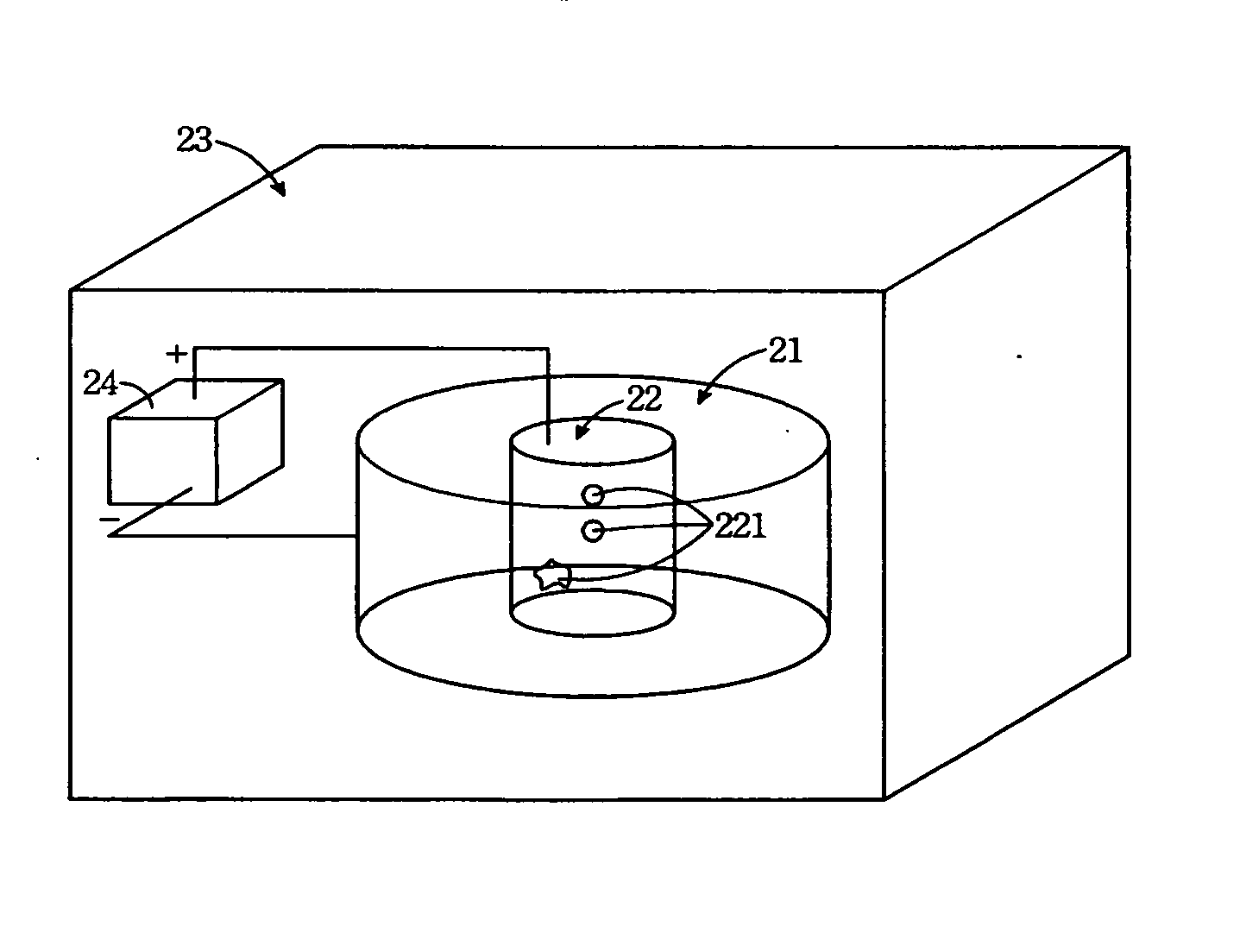

Contaminated soil ex-situ electrokinetic remediation device and method thereof

InactiveCN102806228AContinuous processingIncrease moisture contentContaminated soil reclamationSpray nozzleContaminated soils

The invention provides a contaminated soil ex-situ electrokinetic remediation device and a method of the contaminated soil ex-situ electrokinetic remediation device, and aims to avoid the occurrence of the pollutant aggregation phenomenon and shorten the electrokinetic remediation time, so as to improve the electrokinetic remediation effect and reduce the electrokinetic remediation expense. In order to realize the aim of the invention, the adopted technical shame is as follows: the contaminated soil ex-situ electrokinetic remediation device comprises a soil bearing system, an electrode system and an electrode working solution spray system, wherein the bottom of the soil bearing system is a porous layer I; the electrode system comprises an upper electrode and a lower electrode which are arranged above and below the soil bearing system respectively, and in working, the charges carried by the upper electrode and the charges carried by the lower electrode are opposite; and the electrode working solution spray system comprises a plurality of spray nozzles which are arranged below the soil bearing system, and in working, the spray nozzles spray upwards working solution.

Owner:CHONGQING UNIV

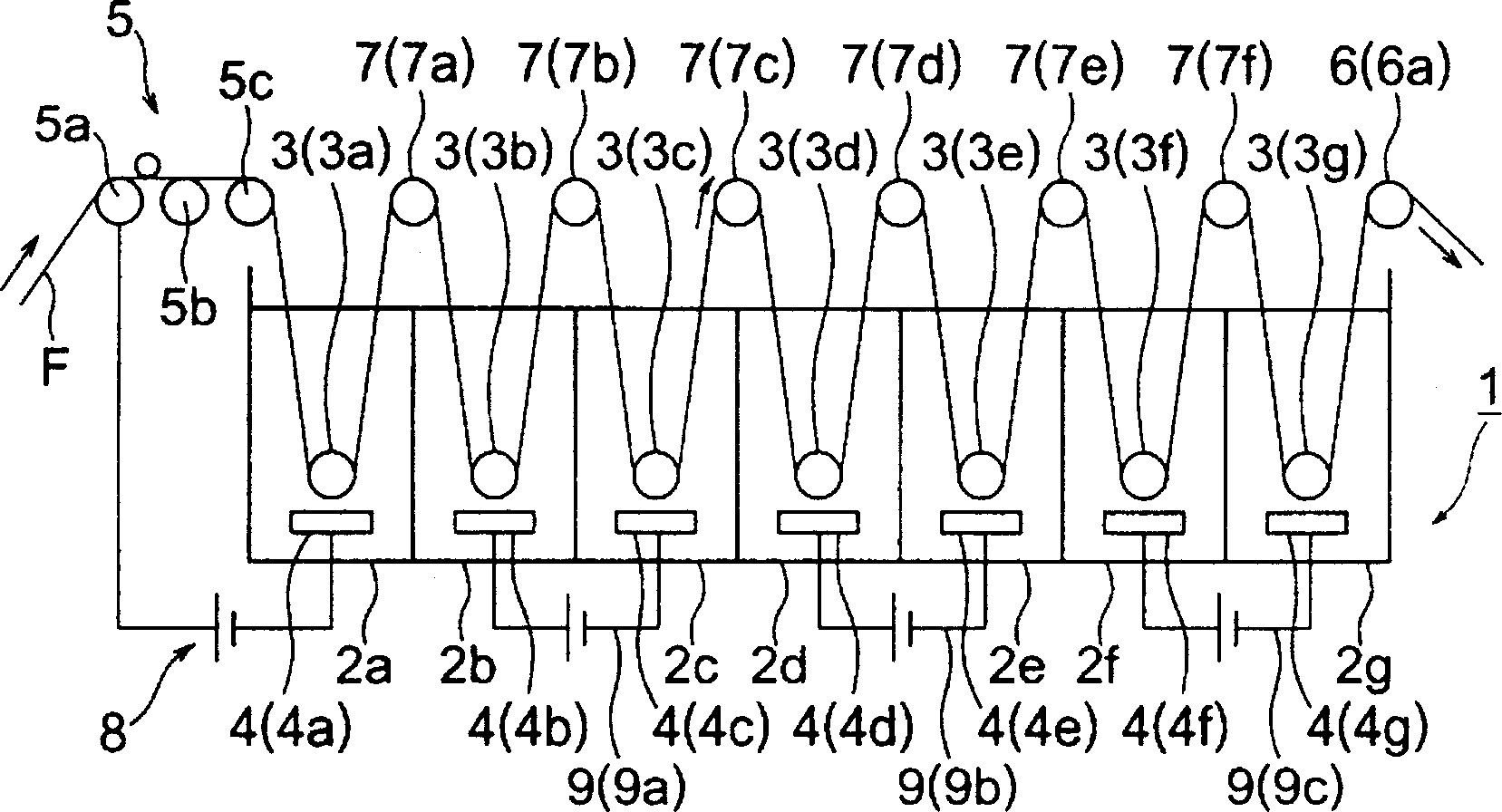

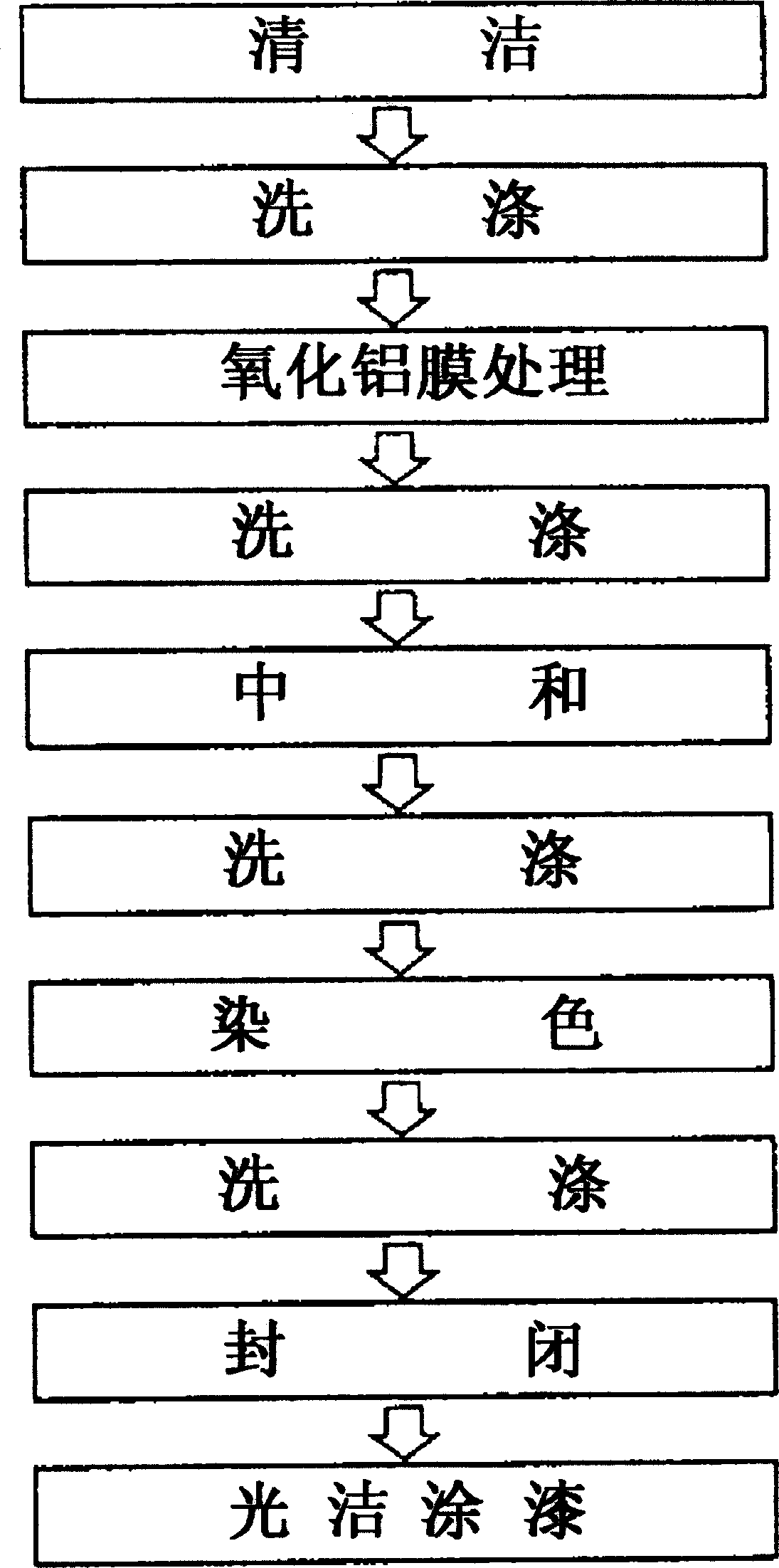

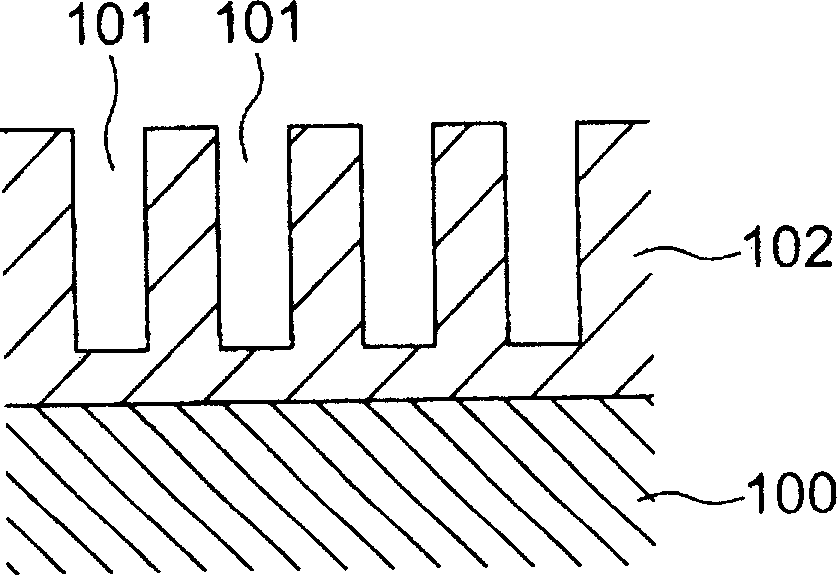

Forming method of anode oxidation film on chain tooth row and its forming equipment

PROBLEM TO BE SOLVED: To form the anodically oxidized films of the row of zip teeth of a fastener chain to arbitrary thicknesses while preventing the defects of energization and contact.SOLUTION: The forming apparatus 1 has an external energizing section 8 for electrically and directly energizing an electrode plate 4a disposed in an electrolyte of a first electrolytic cell 2a and a chain introducing section 5 to each other and a plurality of energizing sections 9 for energizing two sets a pair of adjacent electrode plates 4 within the second and subsequent electrolytic cells 2 to each other across the electrolyte and the fastener chain F. While the fastener chain is successively wrapped around a plurality of rollers 3 and 7 and is transferred zigzag, the tooth trains of the fastener chain are directly energized through the energizing yarn of the fastener chain by the external energizing section. The two sets a pair of the second and subsequent electrode plates are energized to each other in the bath by the energizing sections. The anodically oxidized films having the arbitrary film thicknesses are formed by changing the number of the passage stages to the second and subsequent electrolytic cells, the energizing quantity in the arbitrary electrolytic cells, etc.

Owner:YKK CORP

Electric grating food processor and grater plate

InactiveUS7328864B2Uniform processing qualityUniform qualityKitchen equipmentGrain treatmentsGratingReciprocating motion

An electric grating food processor including a food material receiving section 18 that has an opening in its upper part and receives processed food materials therein, a cylindrical food material charging section 68 that has a lower end opening at its lower end, a grater plate 58 that is rotated or linearly reciprocated under the lower end opening of the food material charging section, and a drive unit for operating (rotating or linearly reciprocating) the grater plate; and the grater plate is formed with larger grating blades on one surface side thereof and lower grating blades on another surface side thereof, and the grater plate is further provided thereon with a gap adjuster 98 that adjusts the gap between the tip ends of the grating blades and the lower end opening of the food material charging section.

Owner:IZUMI PROD CO

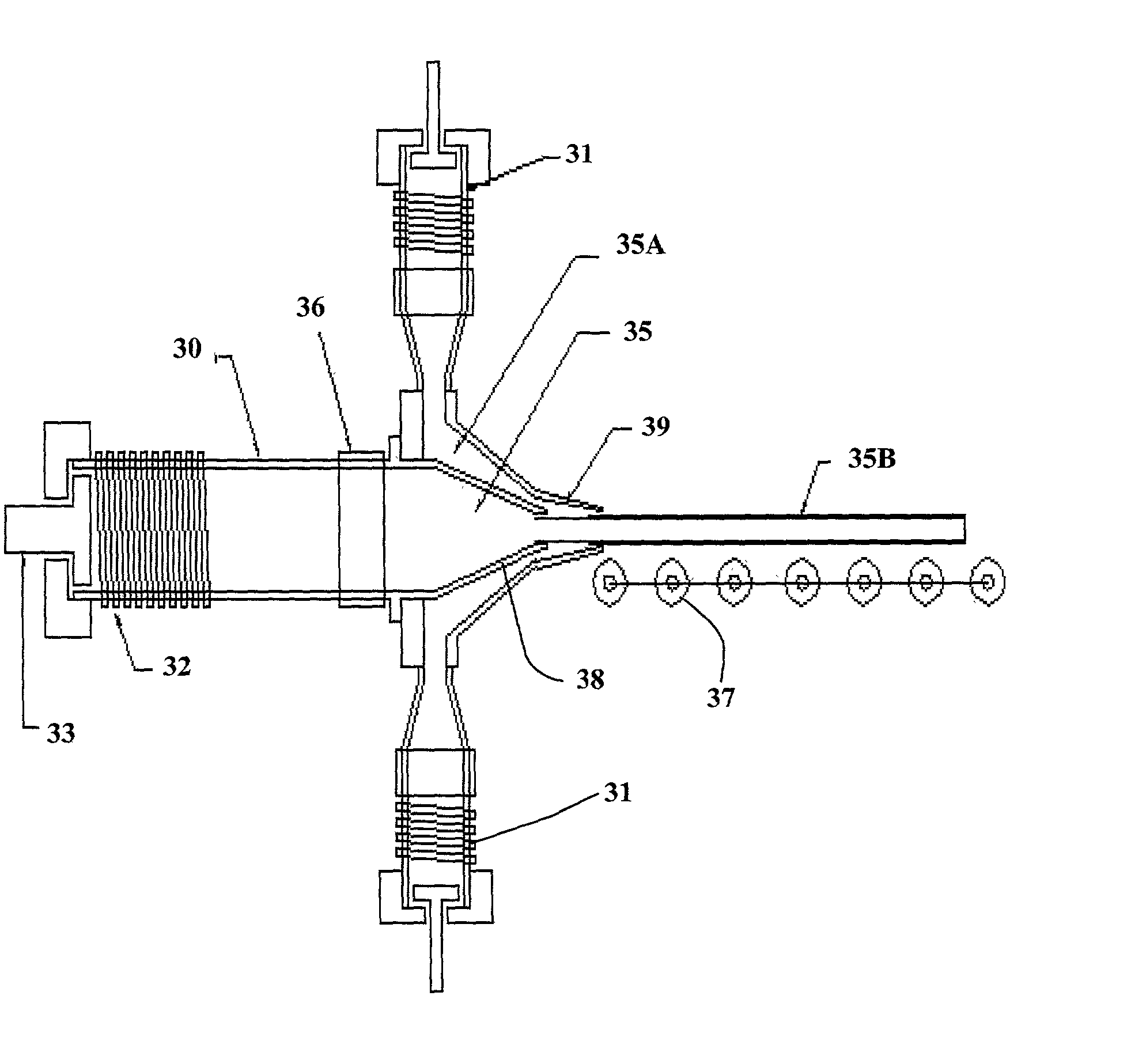

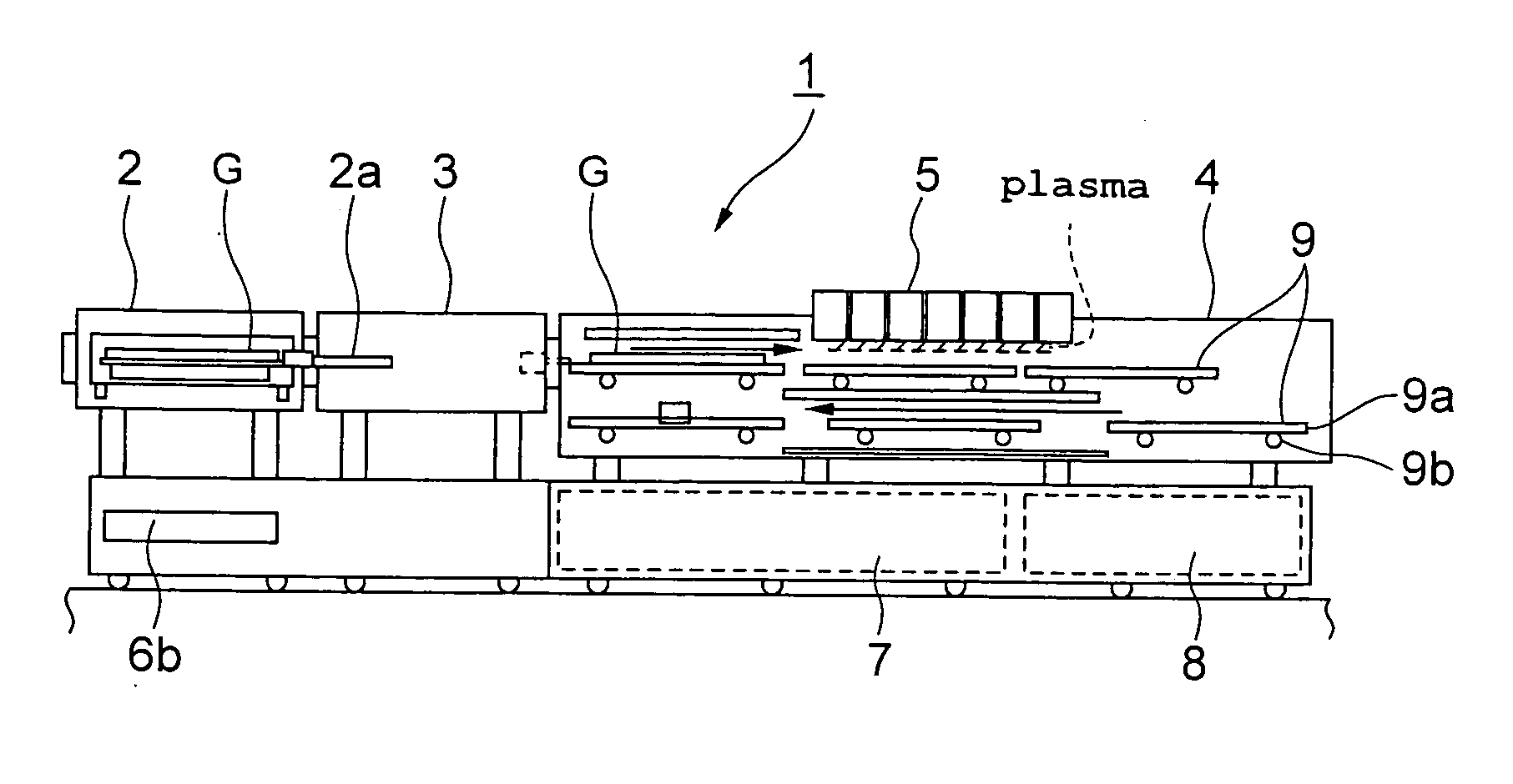

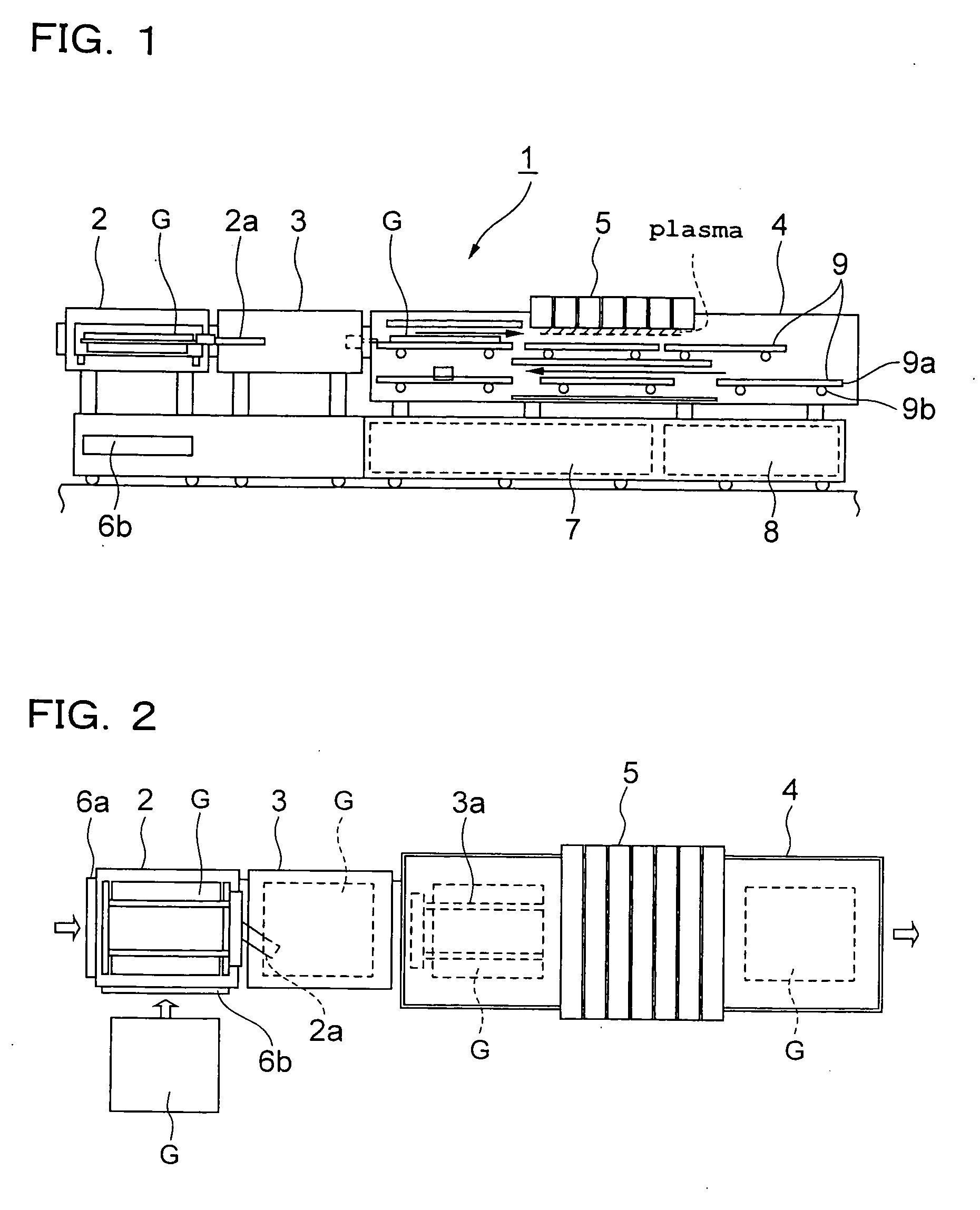

Microwave plasma processing method, microwave plasma processing apparatus, and its plasma head

InactiveUS20070054064A1Prevent gas leakageImprove accuracySemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric pressureLength wave

A microwave plasma processing method and, in which a linear plasma is produced by means of a microwave, and an object to be processed is subjected to processing under atmospheric pressure or under a pressure near atmospheric pressure when the object is moved, while a surface of the object is maintained at a horizontal position with respect to the linear plasma. A plasma head has an H-plane slot antenna, and slots are arranged alternately on both sides of a centerline of a waveguide at a pitch of λg / 2 (λg: wavelength of the microwave with the waveguide). A uniforming line having a distance of n·λg / 2 from the slots to an emission end of the plasma head is provided (n: an integral number).

Owner:FUTURE VISION +1

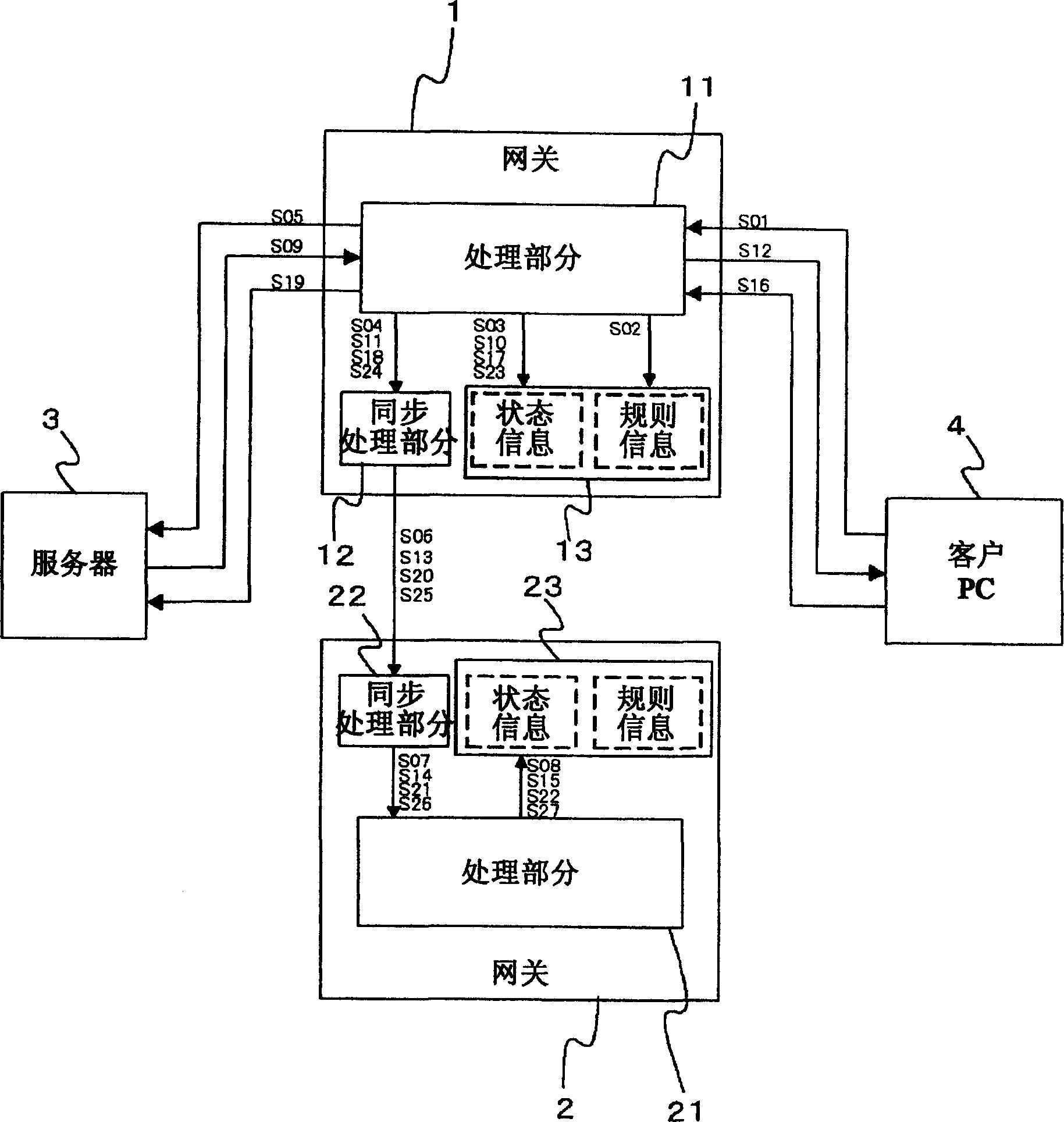

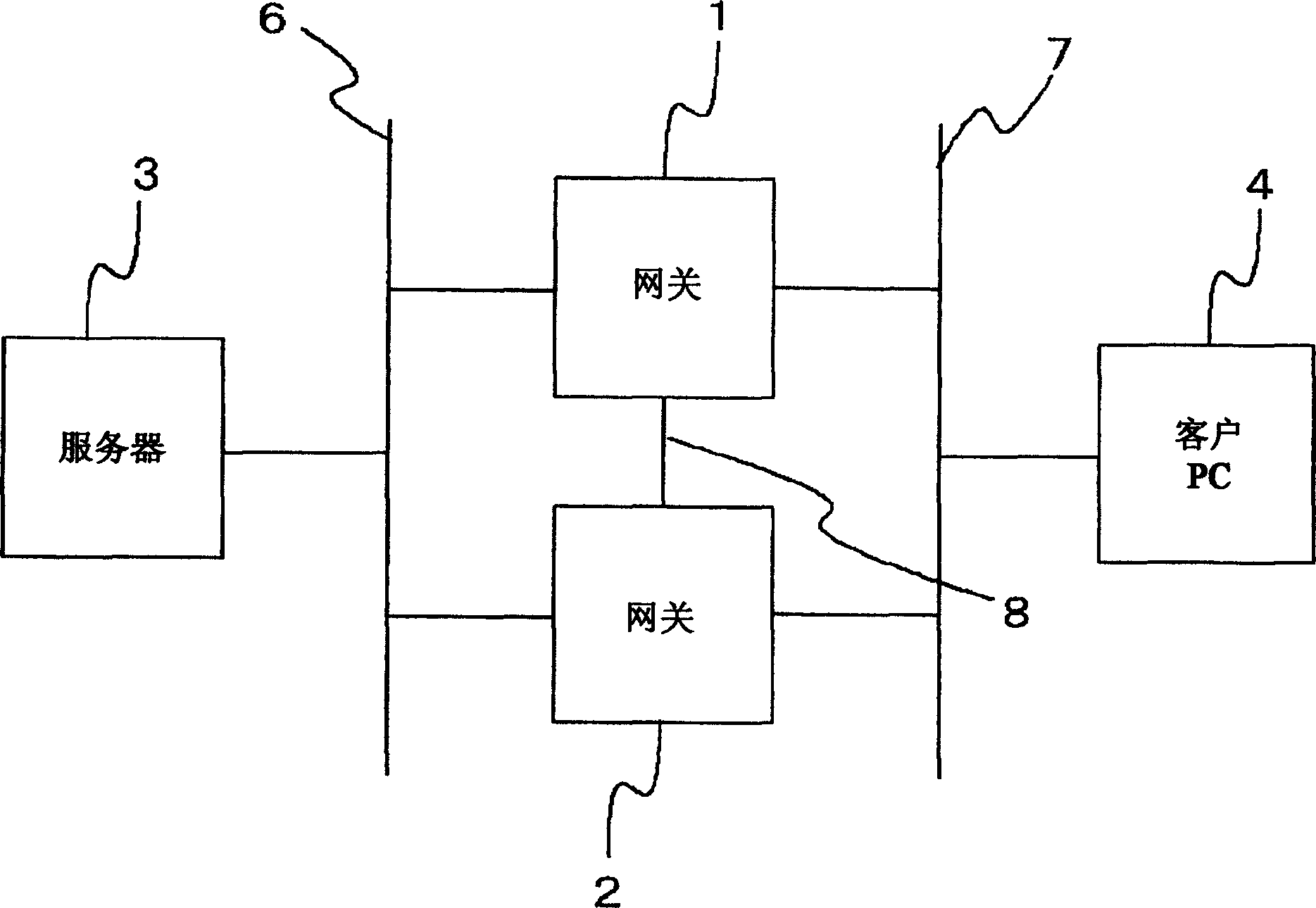

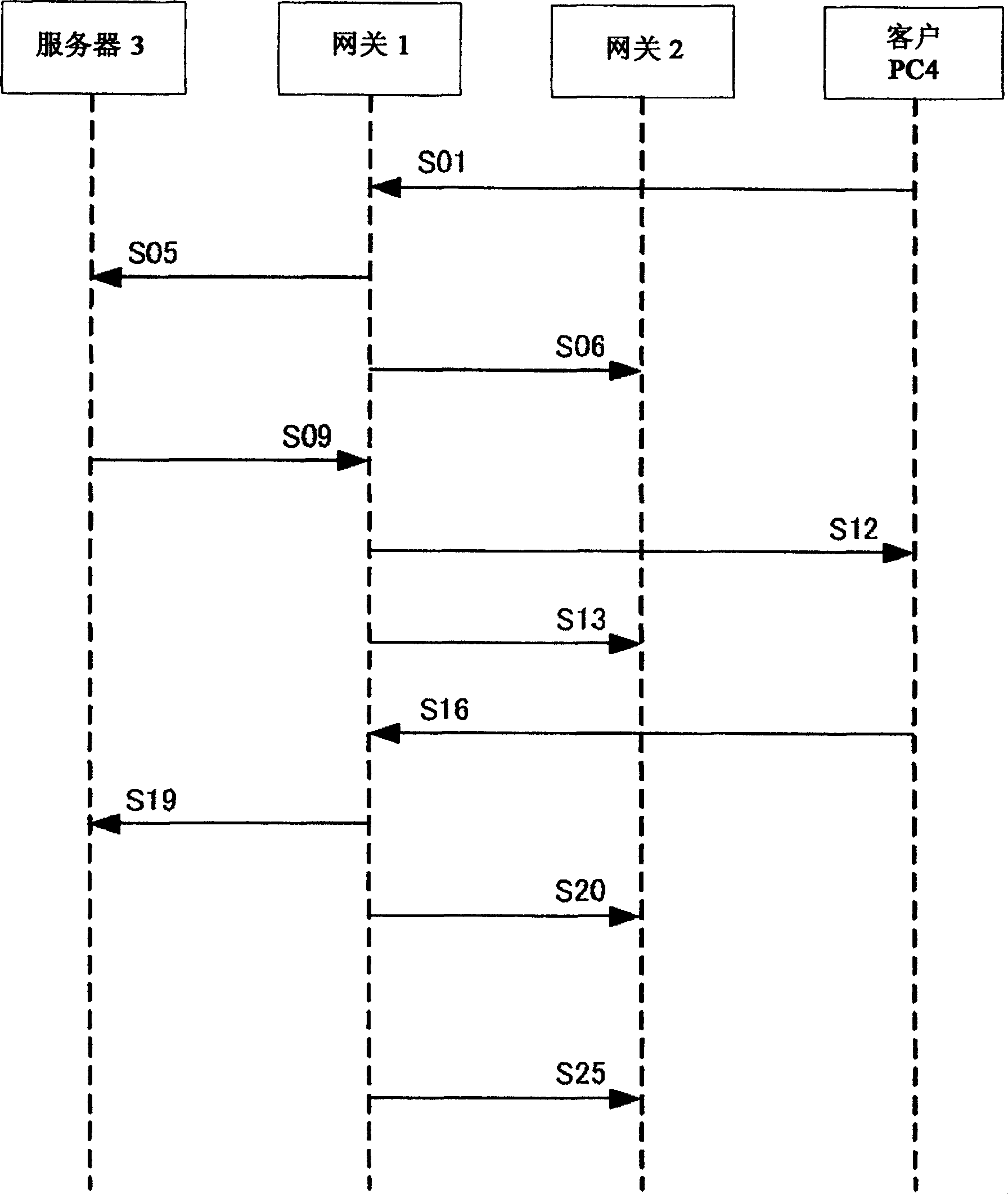

Gateway system

InactiveCN1855900AContinuous processingFlexible designNetworks interconnectionNetwork connectionsNetwork packetComputer science

A gateway system for transiting communications at the boundary between networks includes a master gateway and at least one slave gateway. The master gateway processes a communication packet, updates state information based on the processing of the communication packet, and transmits the updated state information. The slave gateway receives state information transmitted from the master gateway, and stores the received state information as state information of the slave gateway. The slave gateway operates instead of the master gateway based on the stored state information.

Owner:YOKOGAWA ELECTRIC CORP

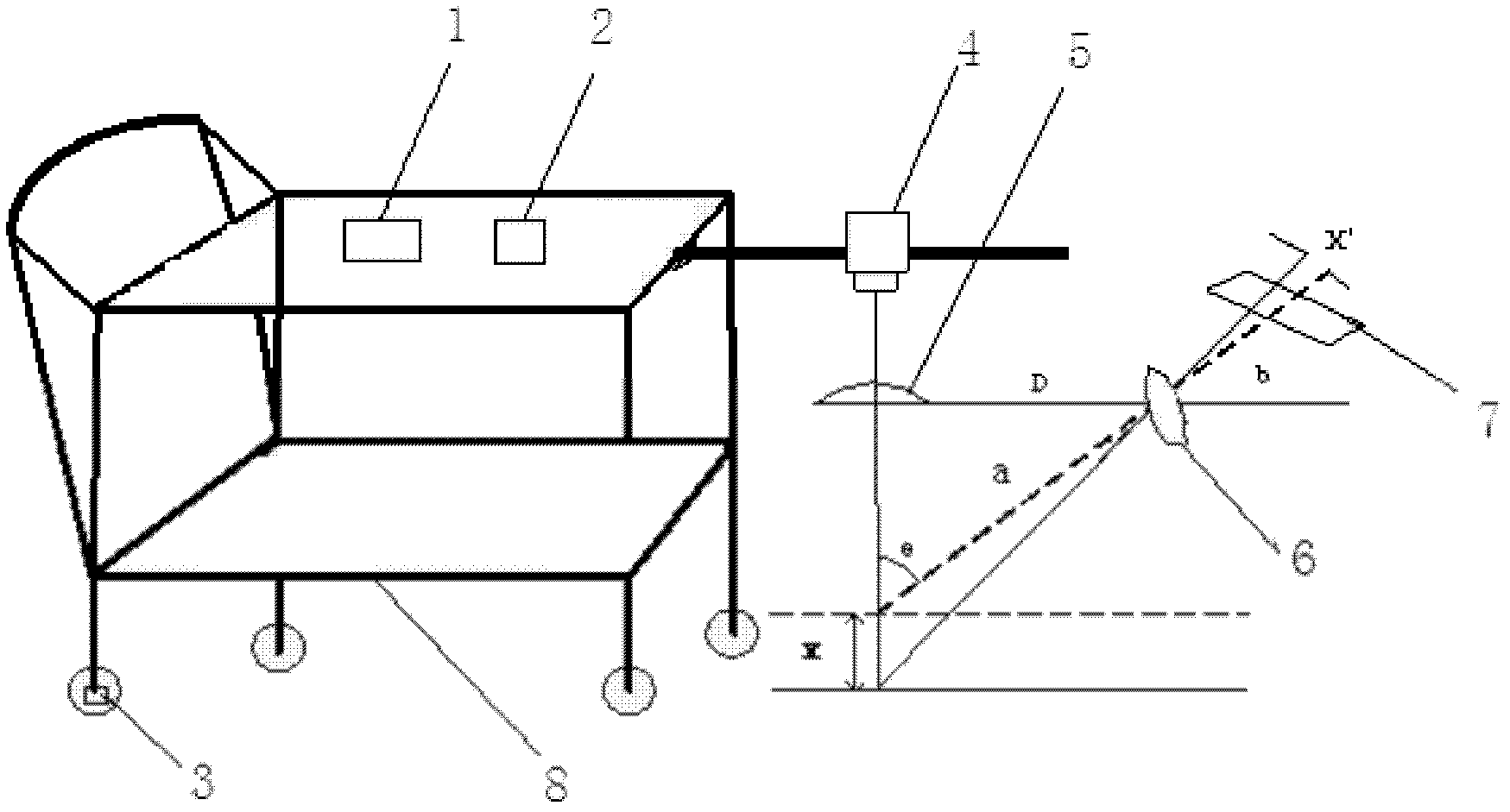

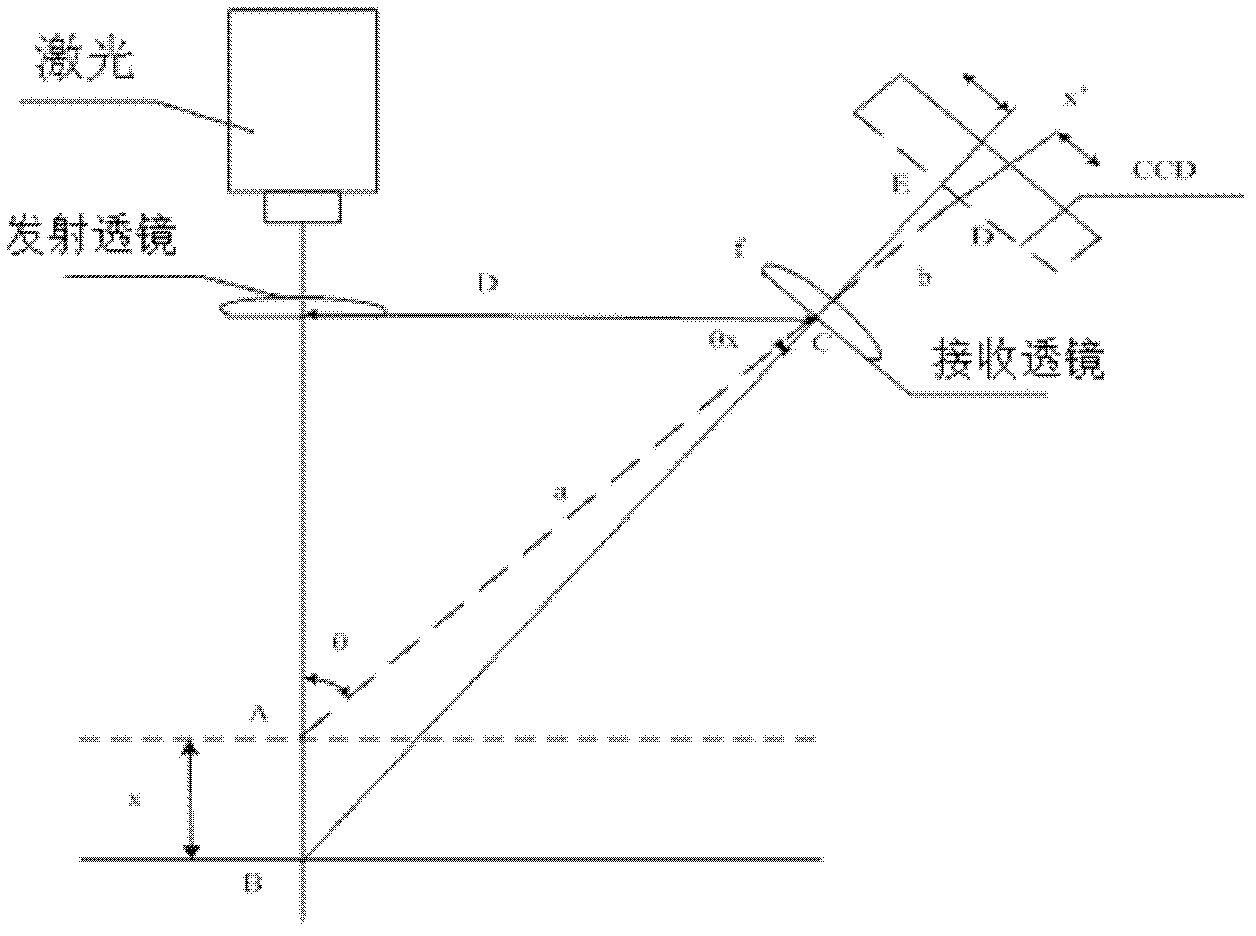

Measuring method for construction depth of asphalt road surface

InactiveCN102635056AIntegrity guaranteedGuaranteed non-superpositionUsing optical meansRoads maintainenceRoad surfaceGravity center

The invention discloses a measuring method for the construction depth of an asphalt road surface, comprising the following steps of: starting a computer, a UPS (Uninterrupted Power Supply), a laser device, an encoder and a camera; calibrating the camera; pushing a handcart to move forwards on a road surface to be detected; sending a pulse signal to the computer by the encoder; emitting laser beams by the laser device; receiving a triggering signal sent by the computer, collecting images and sending the images to the computer; sequentially carrying out image de-noising on each image received by the computer and carrying out mass center extraction row by row through a threshold value gravity center method; subtracting a coordinate value of a mass center of each row by a height coordinate value corresponding to a reference standard surface corresponding to the image to obtain a difference value; and calculating a height value of each row in each image by a formula 1 and calculating an arithmetic mean value of all the obtained height values to obtain the construction depth of the asphalt road surface. The measuring method improves the measuring precision of the construction depth and has the advantages of simplicity and flexibility in operation and convenience for calculation.

Owner:CHANGAN UNIV

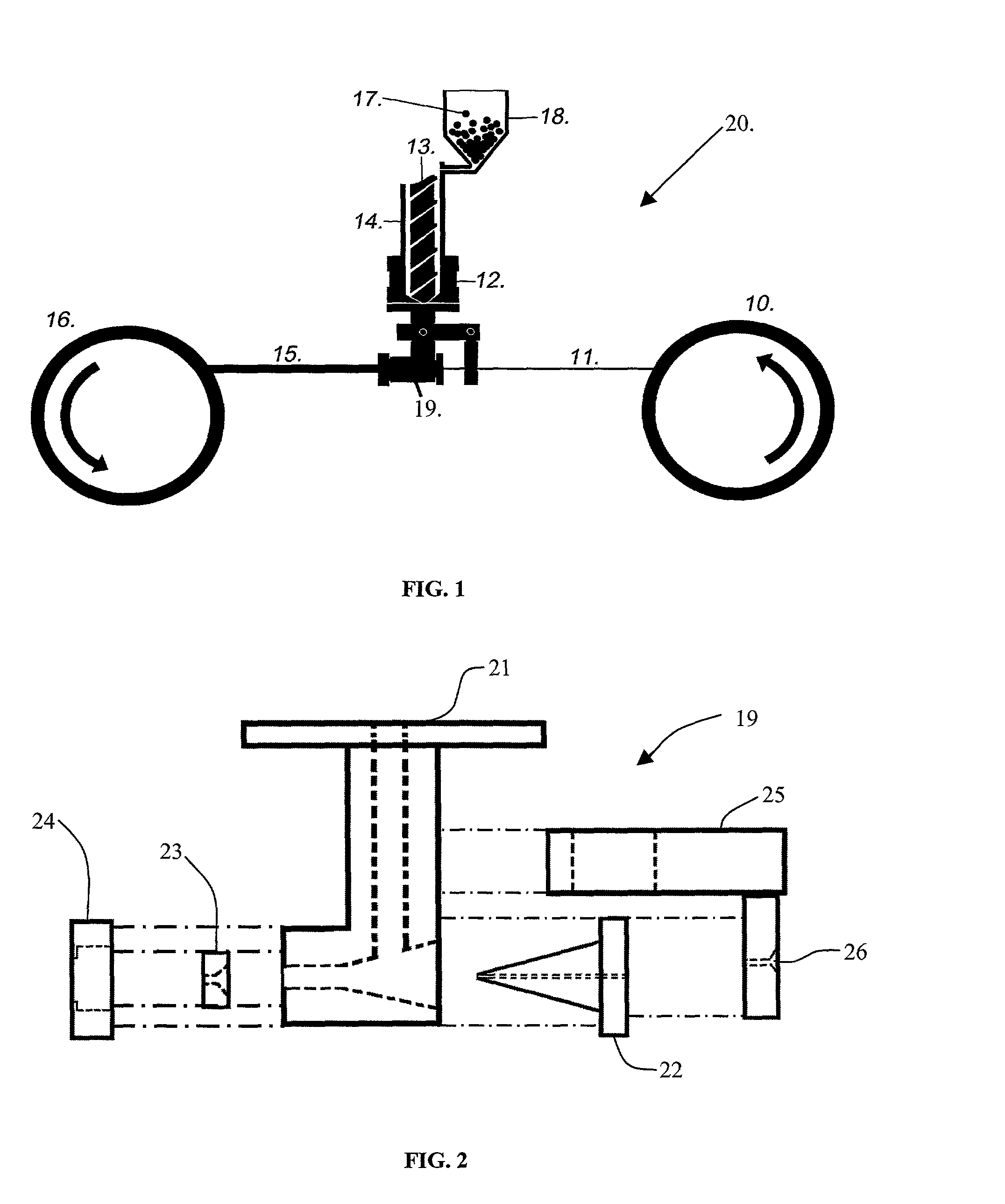

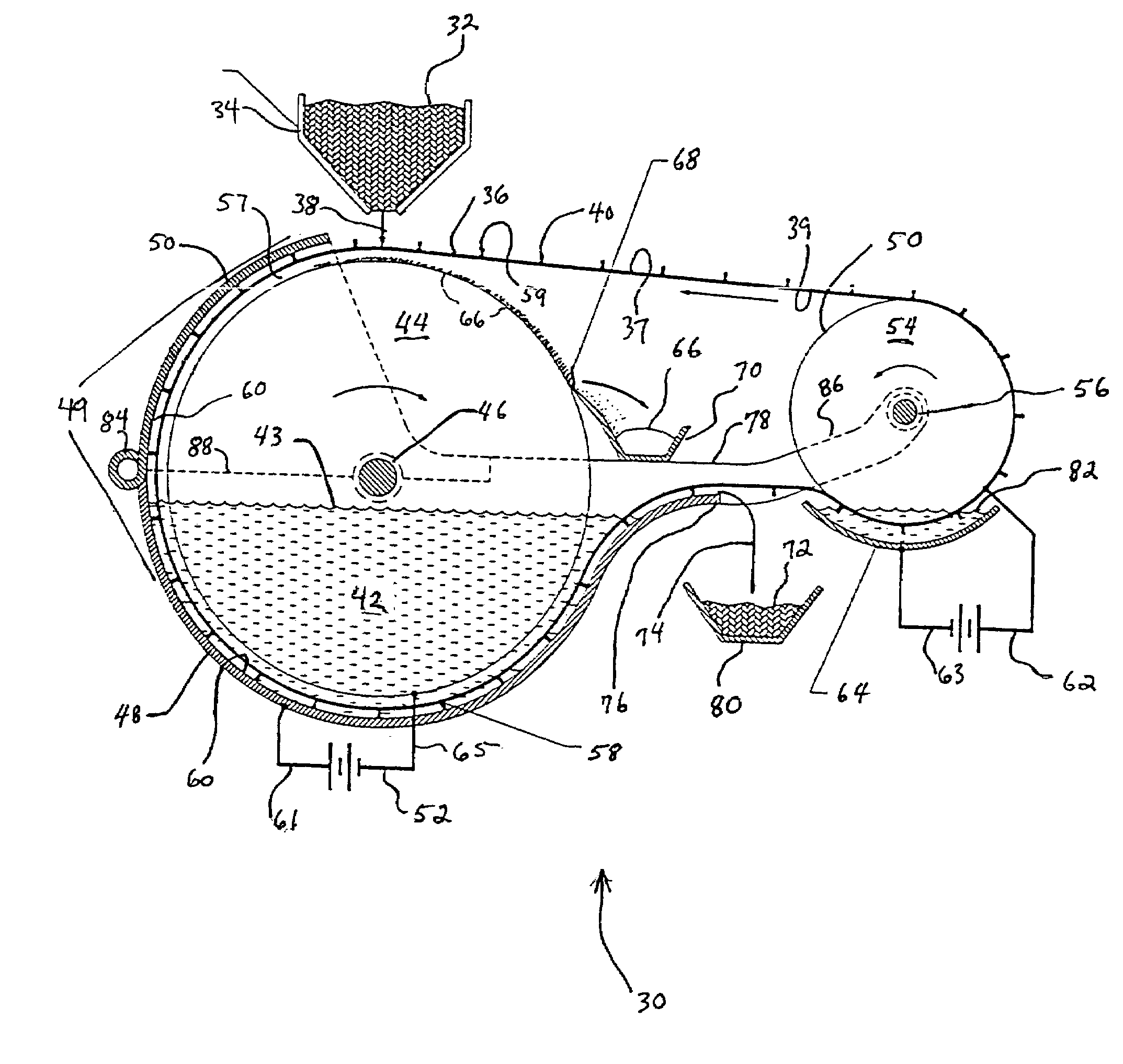

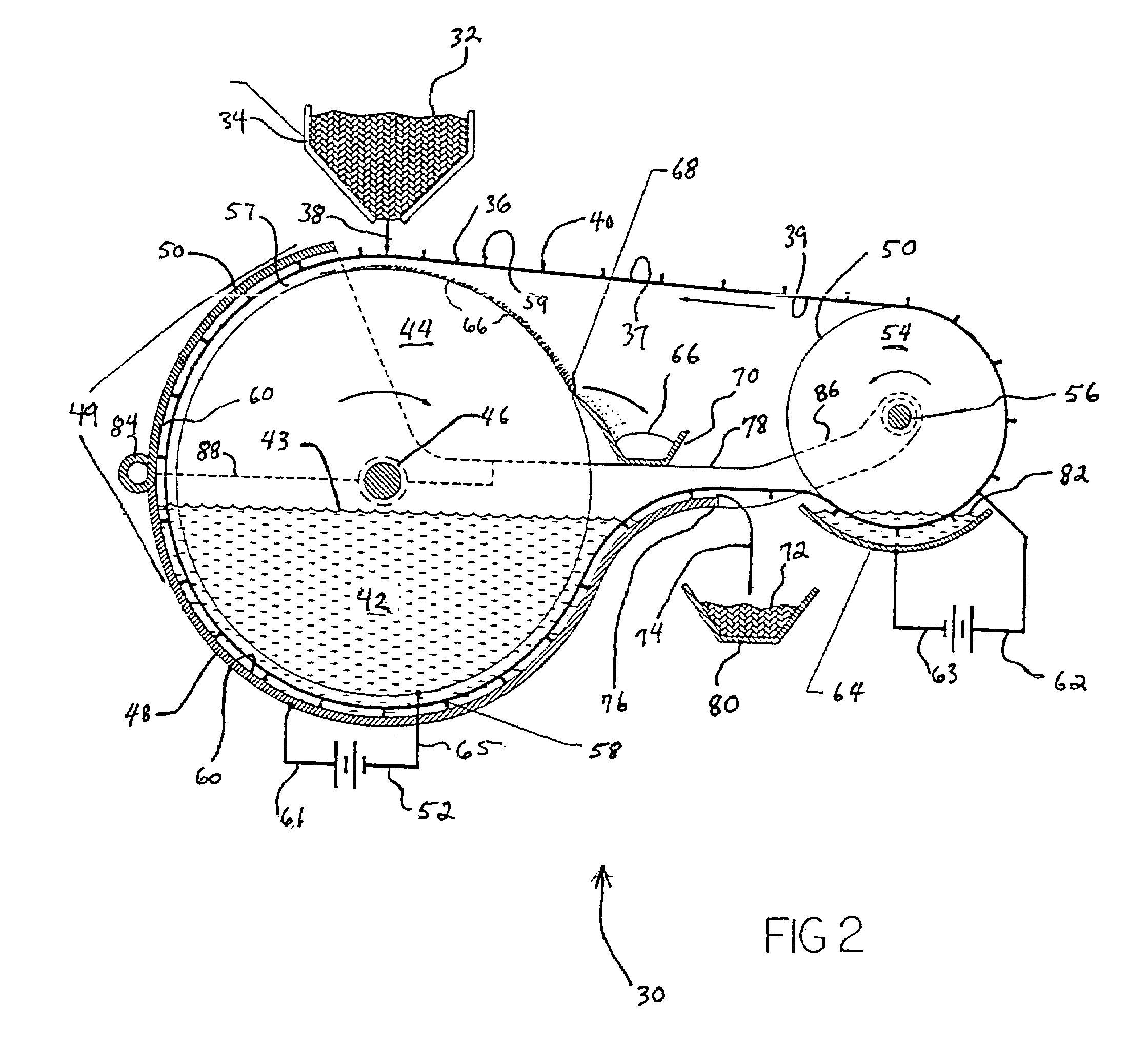

Continuous process electrorefiner

A new device is provided for the electrorefining of uranium in spent metallic nuclear fuels by the separation of unreacted zirconium, noble metal fission products, transuranic elements, and uranium from spent fuel rods. The process comprises an electrorefiner cell. The cell includes a drum-shaped cathode horizontally immersed about half-way into an electrolyte salt bath. A conveyor belt comprising segmented perforated metal plates transports spent fuel into the salt bath. The anode comprises the conveyor belt, the containment vessel, and the spent fuel. Uranium and transuranic elements such as plutonium (Pu) are oxidized at the anode, and, subsequently, the uranium is reduced to uranium metal at the cathode. A mechanical cutter above the surface of the salt bath removes the deposited uranium metal from the cathode.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

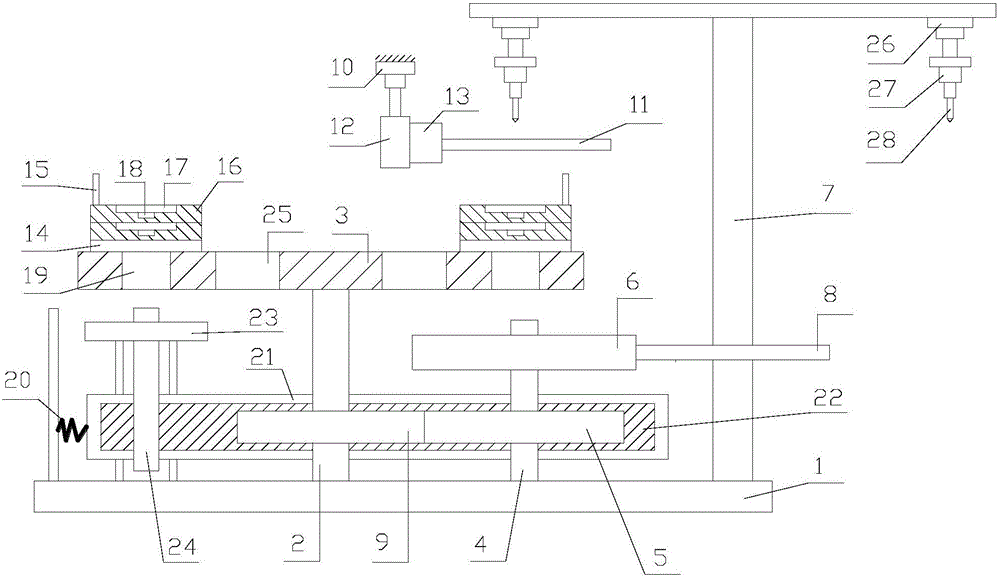

Machine tool for processing workpieces

InactiveCN105710730ACooperate skillfullyConvenient and flexible processingMetal working apparatusPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool for workpiece processing, which comprises a base, a rotating shaft, a wheel disc, a plurality of clamps, a rotating shaft, a first rotating wheel, a second rotating wheel, a supporting shaft, a driven gear, and M actuators . Drive mechanism, wherein, M is an integer greater than or equal to 2; the rotating shaft is installed on the base in rotation, the center line of the rotating shaft is vertically arranged, and the circumferential surface of the rotating shaft is provided with first gear teeth; the wheel disc is installed on on the rotating shaft; multiple fixtures are installed on the wheel, and the multiple fixtures are evenly distributed on the circumference centered on the center of rotation of the wheel; the rotating shaft is installed vertically on the base, and the rotating shaft is connected to the base in rotation on one side of the wheel. The invention has high processing precision and good processing effect.

Owner:芜湖中驰机床制造有限公司

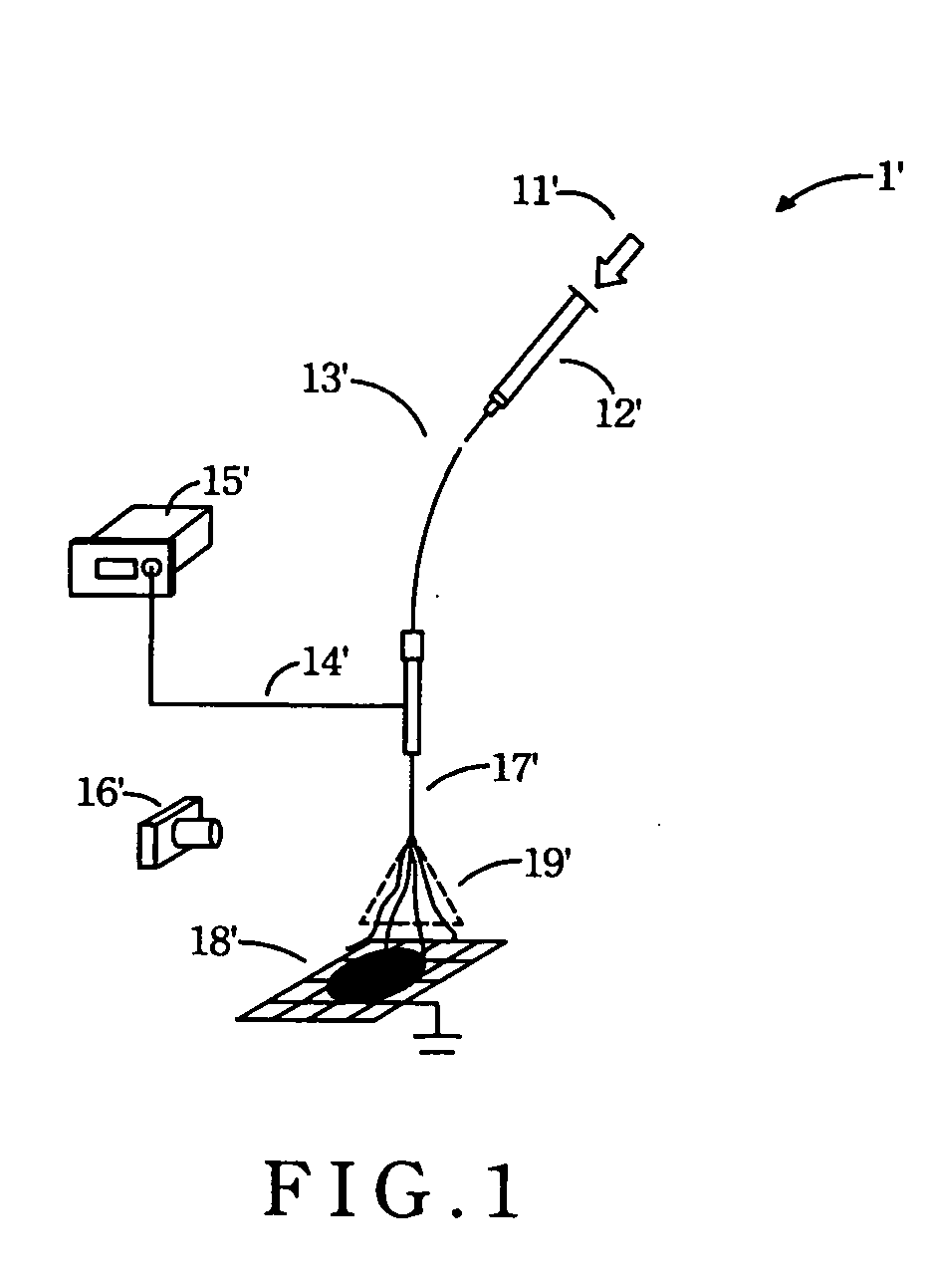

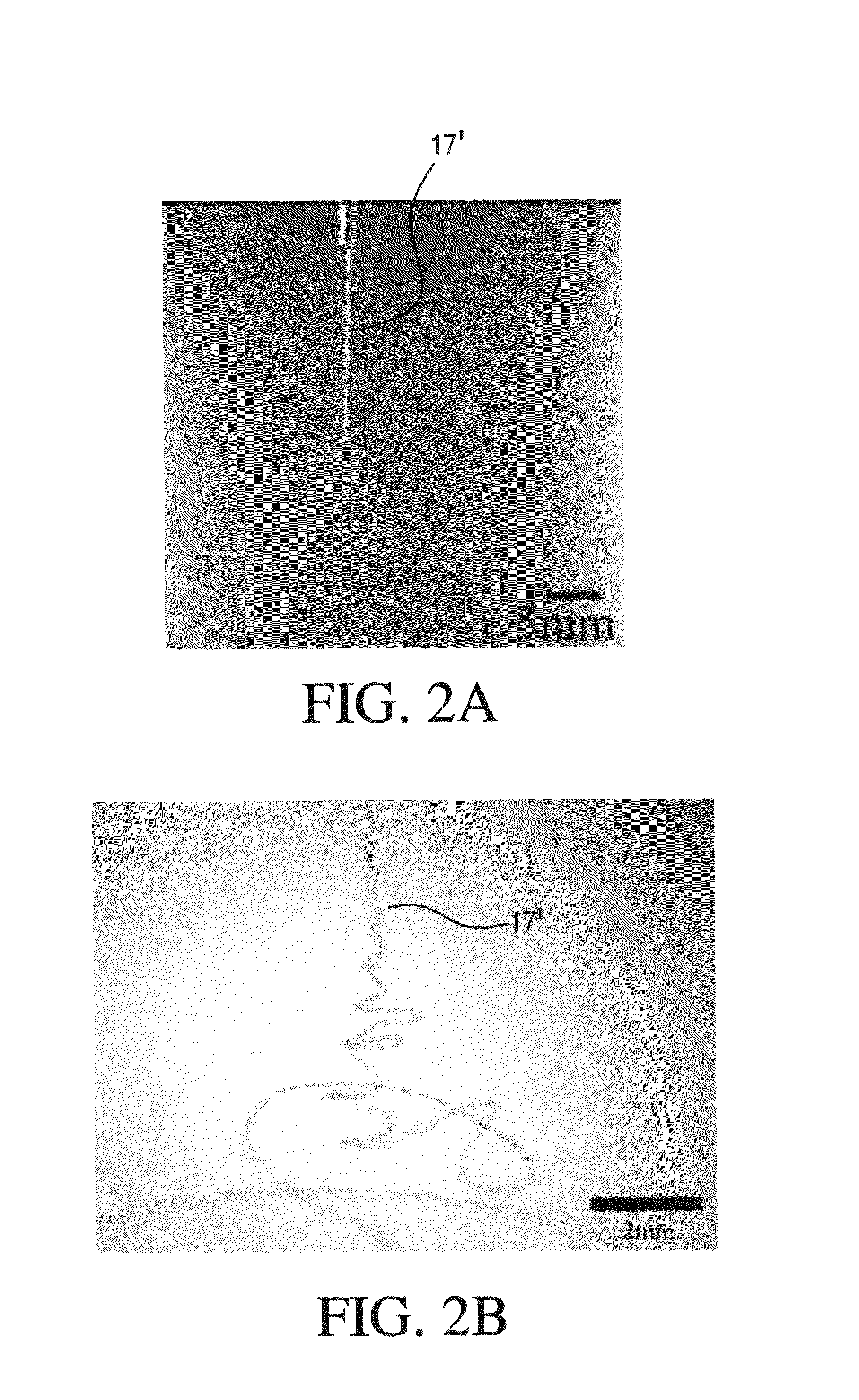

Device for manufacturing fabrils and method thereof

InactiveUS20080211121A1Save spaceContinuous processingFilament/thread formingAuxillary shaping apparatusBiomedical engineeringConductive materials

The present invention discloses a device for manufacturing fibrils comprising: a rotating device with at least one opening being made of an electric conduction material and hollow for containing polymer or biopolymer; and an outer barrier being made of electric conduction materials and around the rotating device; wherein while revolving the rotating device results in that the polymer or biopolymer is out of the rotating device through the opening so as to gain the fibrils in between the rotating device and the outer barrier.

Owner:BODY ORGAN BIOMEDICAL CORP

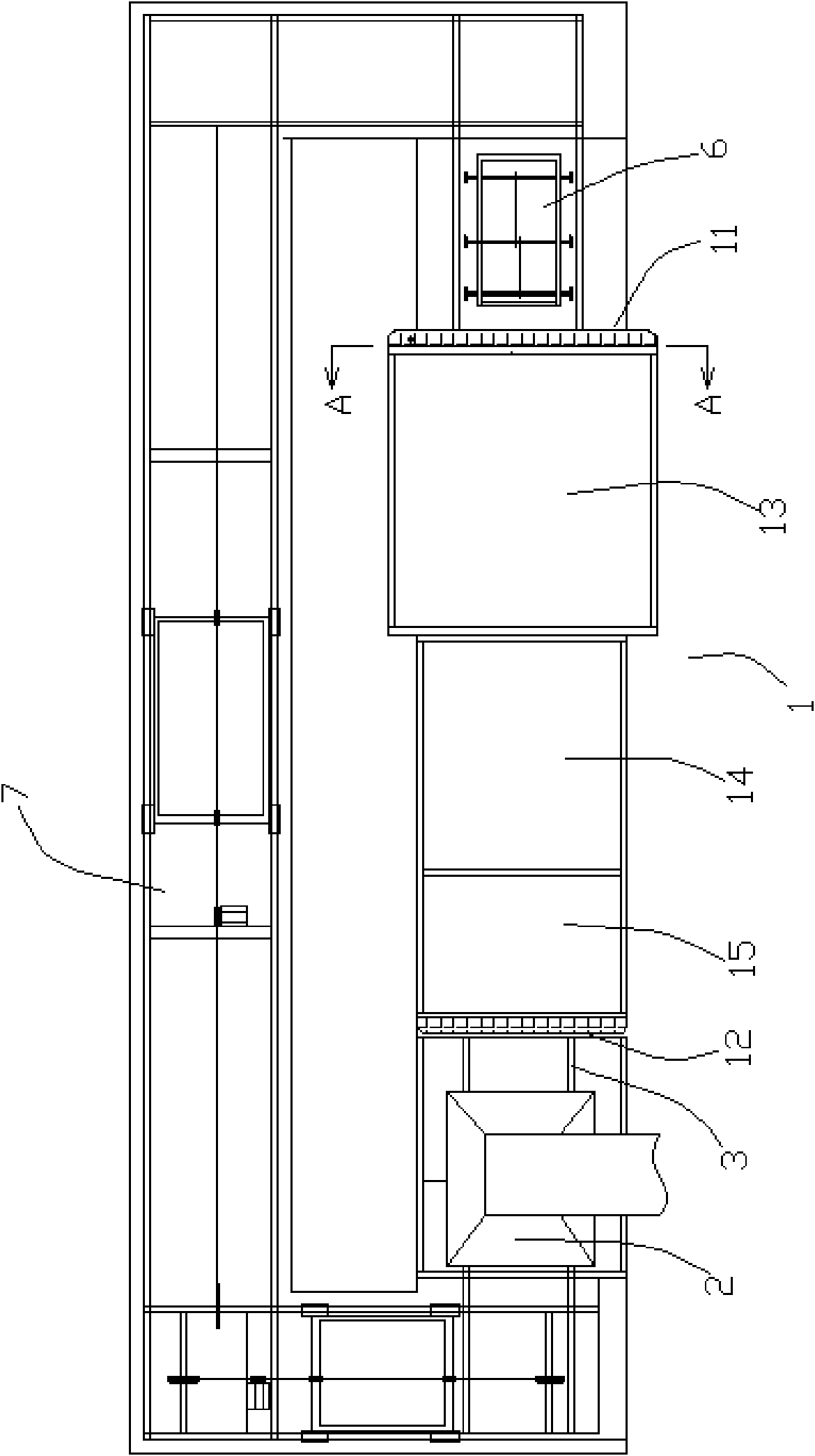

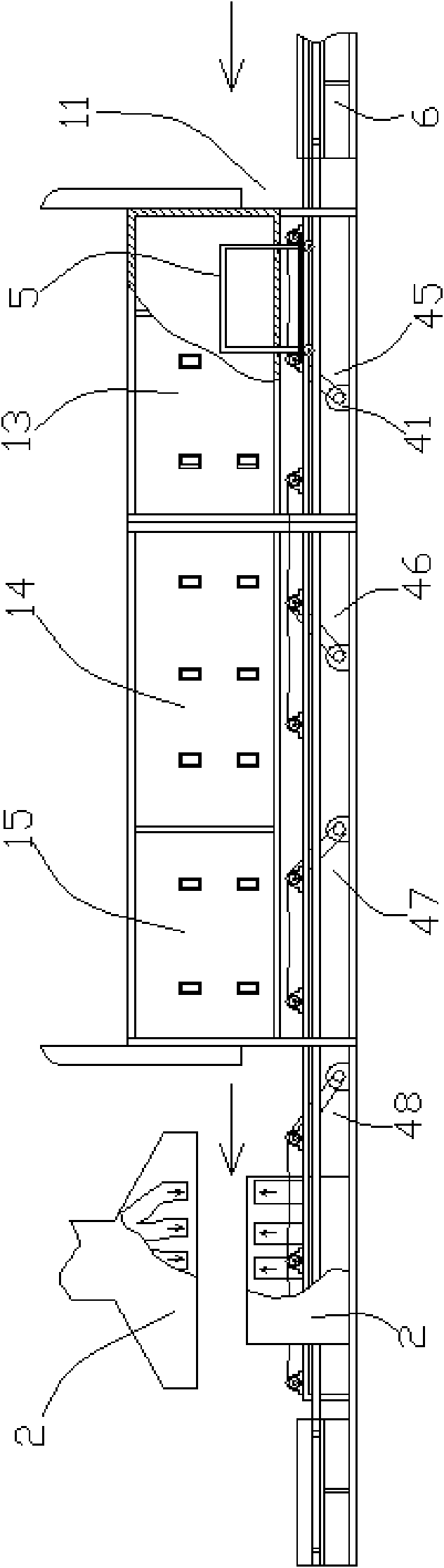

Continuous tempering furnace and processing technique of bent tempered glass

InactiveCN101628783AQuality improvementLower skill requirementsGlass tempering apparatusGlass productionHigh energyHeating furnace

The invention relates to a continuous tempering furnace used for processing bent tempered glass, comprising a heating furnace and a quenching air duct. The front end and the rear end of the heating furnace are respectively provided with a feed port and a discharge port, respectively. The heating furnace consists of a hot forming region, a glass balanced heat-preservation region and a fast heating region which are arranged sequentially. A track and a driving device are arranged at the bottom of the heating furnace and the quenching air duct. A plurality of mobile trolleys running through the heating furnace and the quenching air duct run on the track, and the mobile trolleys are driven to run by the driving device. The invention further discloses a processing technique of bent tempered glass utilizing the tempering furnace. The tempering furnace has reasonable structure, high production efficiency, convenient operation and high energy utilization rate.

Owner:陈永乐

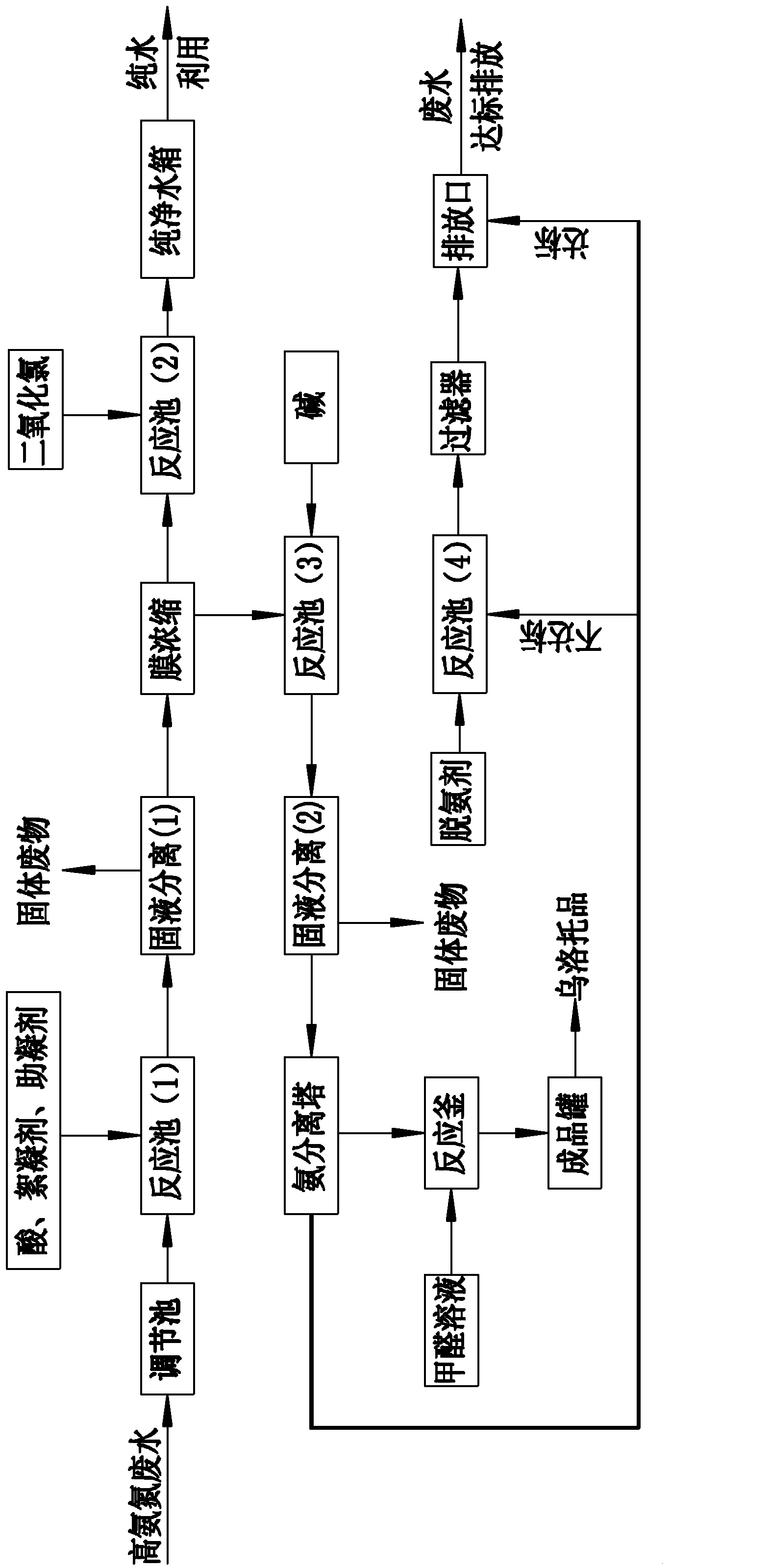

High-ammonia-nitrogen waste water resource recovery technology

InactiveCN102491562AHigh ammonia nitrogen contentReduce volumeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChlorine dioxideImpurity

The invention discloses a high-ammonia-nitrogen waste water resource recovery technology. A method used in the technology comprises the following steps of: removing solid impurities from waste water by performing flocculation and solid-liquid separation, treating with a membrane concentrating system to obtain two parts, and performing ammonium-nitrogen oxidation on one part, i.e., purified water through chlorine dioxide for recycling; and adding an alkali into the other part, i.e., a concentrated solution for regulating, performing solid-liquid separation for removing solids, feeding into an ammonia separating tower for removing ammonia, reacting ammonia gas extracted from the ammonia separating tower with formaldehyde in a reaction kettle to generate urotropine serving as a medical intermediate with a high added value, and directly discharging ammonia-removed tower bottom water or discharging after feeding chemicals, removing ammonia and filtering. The method is suitable for ammonia-nitrogen waste water of which the ammonia-nitrogen concentration is over 300 mg / L; treated discharged water can reach a national first class discharge standard; and the ammonia-nitrogen concentration in waste water is higher, the waste water treatment profit is higher.

Owner:CHONGQING RUIZHI ENVIRONMENTAL TECH

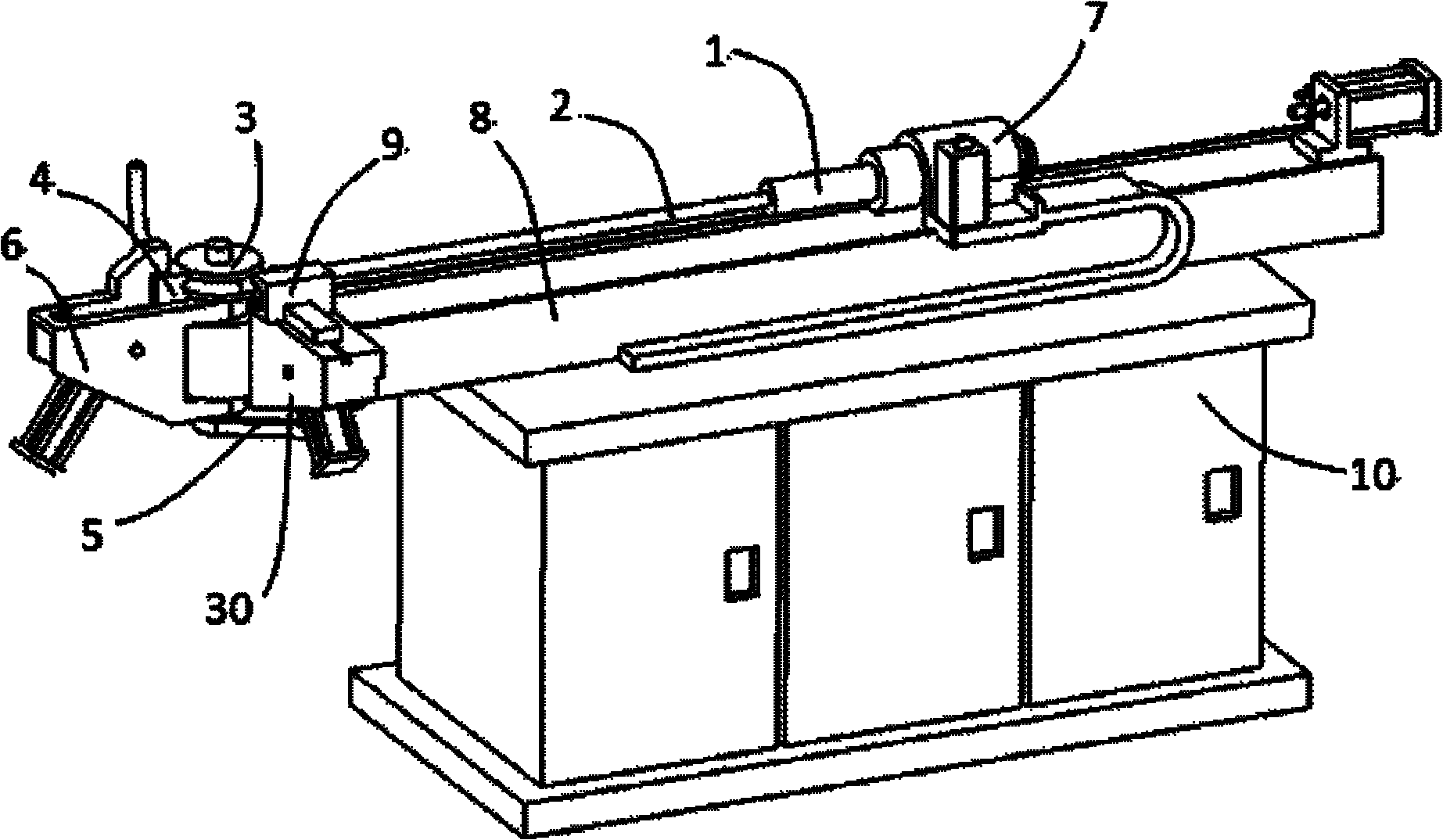

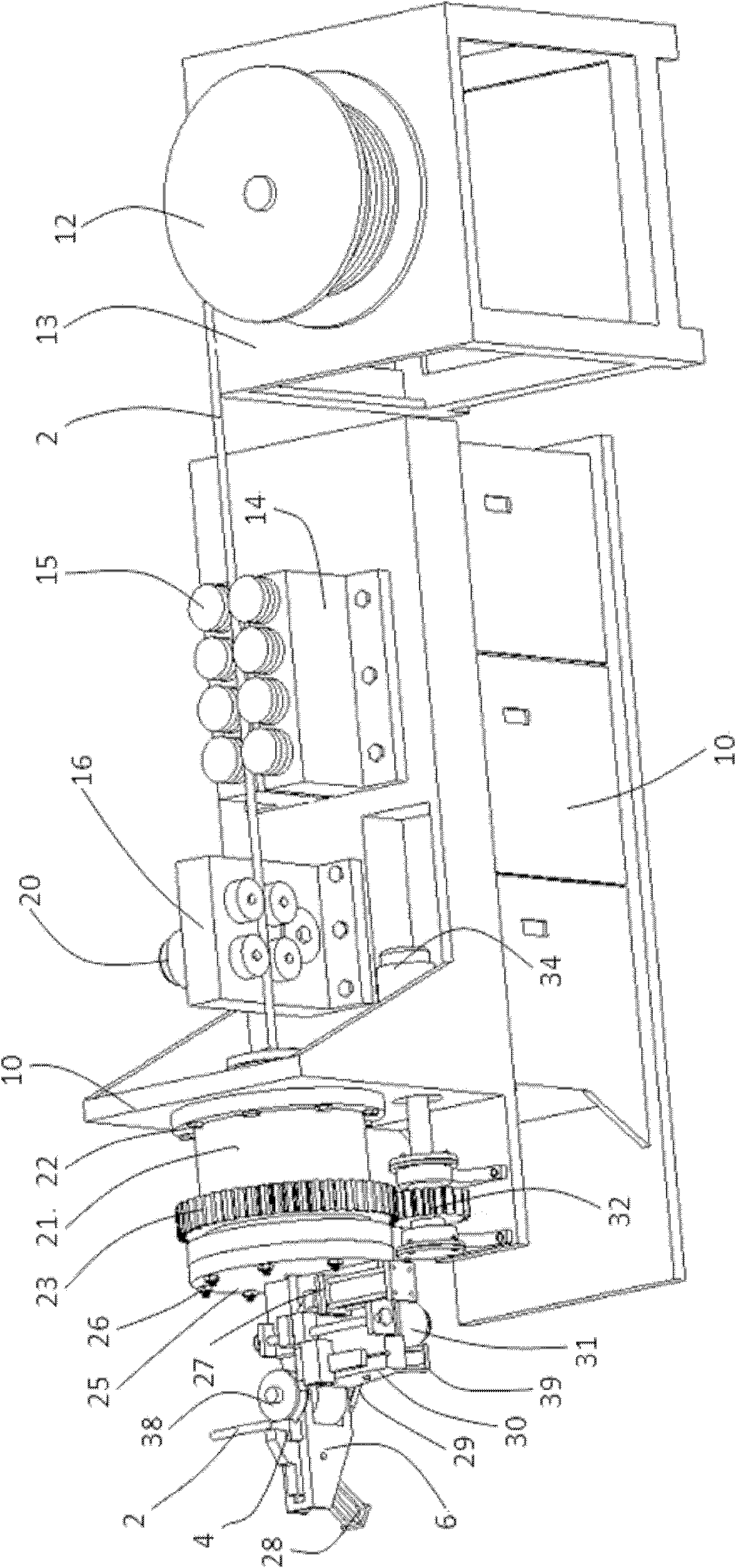

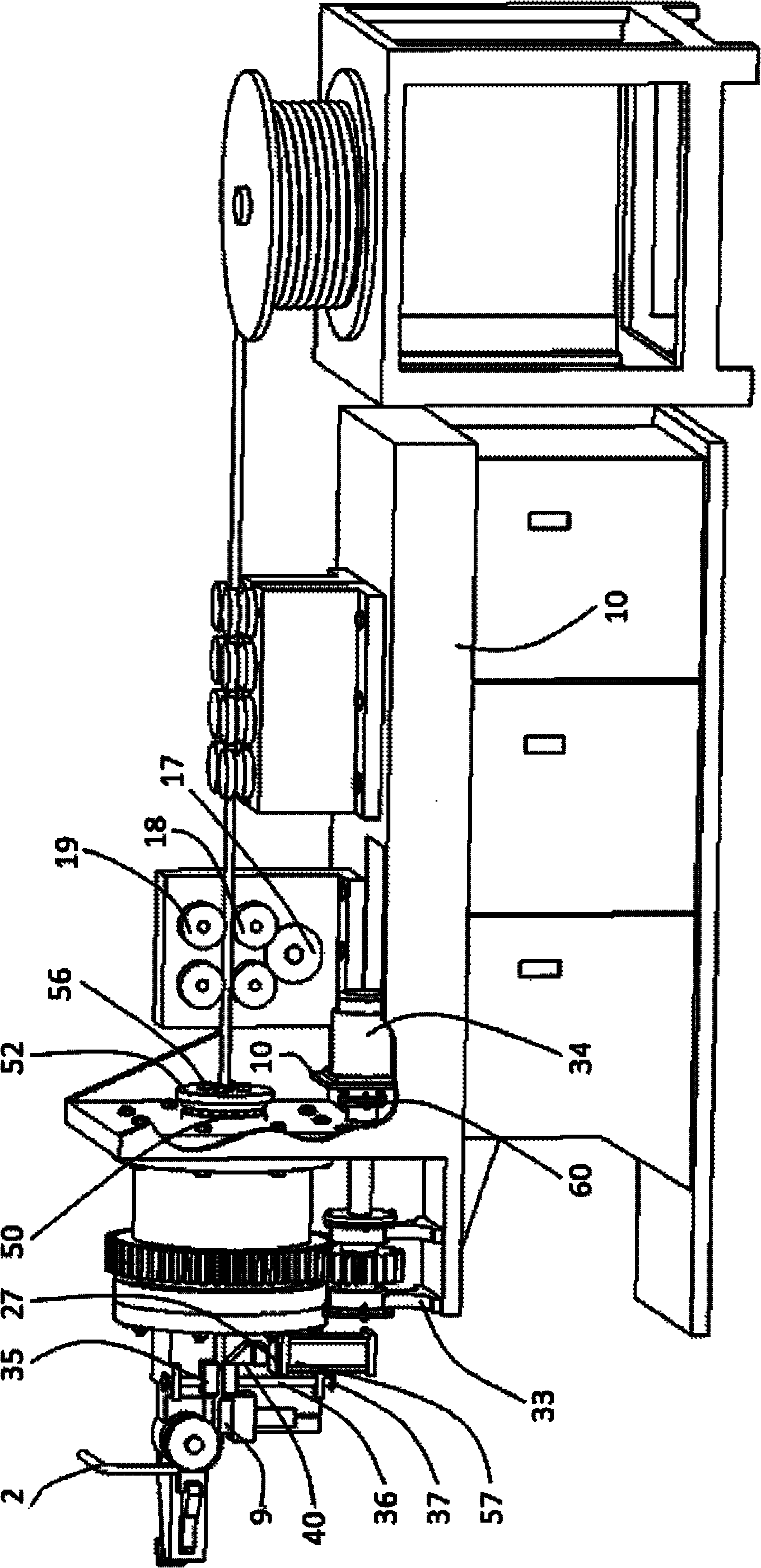

Rotary machine head type wire bending equipment

InactiveCN101862800AContinuous processingHigh equipment flexibilityMetal-working feeding devicesPositioning devicesRotary machineElectric machinery

The invention discloses rotary machine head type wire bending equipment, which comprises a machine frame, a material feeding mechanism, a fixed mold seat and a bending hand mechanism, wherein the material feeding mechanism, and the fixed mold seat and the bending hand mechanism are arranged on the machine frame and are used for wire bending on wire materials. The invention is characterized in that a straightening device and a feeding device are arranged on the machine frame, the conveying end of the feeding device is connected with a rotating device, a driven gearwheel arranged on the rotating device is engaged with a driving pinion connected on the machine frame, a wheel shaft of the driving pinion is connected with a motor output shaft fixed on the machine frame for realizing motive power transmission, in addition, the end surface of the rotating device is connected with a machine head frame, the bending hand mechanism, a shearing device and a support mold are arranged on the machine head frame, the bending hand mechanism and the shearing device are matched with the support mold for realizing the bending and the shearing on the wire materials, the wire bending equipment uses a motor to output the motive power, the driving pinion drives the driven gearwheel, a rotary joint and the machine head frame to rotate, the rotation movement of the machine head frame correspondingly to the wire materials is realized, the rotary machine head type wire bending equipment is matched with the feeding mechanism to realize the continuous processing, and the equipment flexibility is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

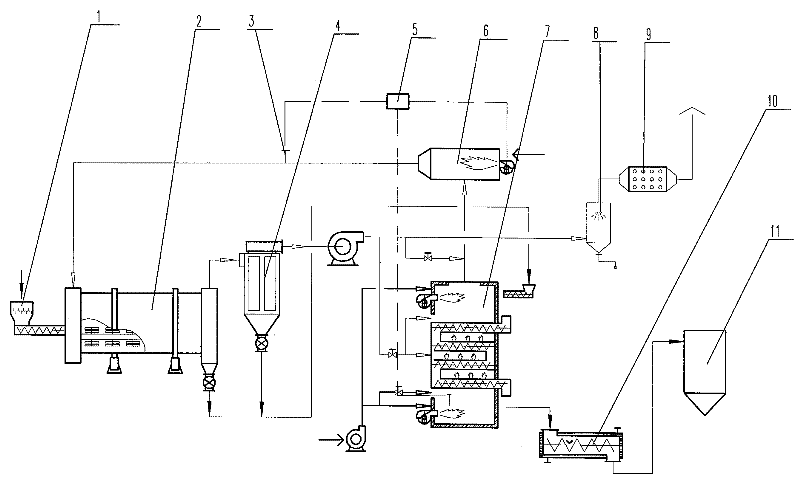

Equipment and method of high-efficiency high-speed environmentally-friendly energy-saving sludge treatment system

ActiveCN102476907AReduce weightReduce volumeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAutomatic controlCombustion

The invention discloses a technique of sludge drying and carbonization, particularly a technique of a high-efficiency high-speed environmentally-friendly energy-saving sludge treatment system. The equipment mainly comprises a feeding unit, a sludge drier, a standby furnace, a sludge carbonization furnace, a temperature controller, a temperature sensor I, a temperature sensor II, a duster, a hydroscrubber, an photochemical deodorizer, a cooling humidifier, a storage bin, an induced draught fan, an air blower, a valve, and the like. The method is characterized in that the sludge is dried in the drier, then the dried sludge is put in the carbonization furnace for carbonization, wherein the temperatures of drying and carbonization are automatically controlled by the temperature controllers; the waste heat moisture discharged from the sludge drier is discharged safely after being subject to dedusting, recycling, photochemical deodorizing; the carbonized sludge particles are put into the storage bin after being subject to cooling and humidification. According to the invention, various germs can be killed; by using the combustion of the sludge to dry and carbonize the sludge, the carbonized product can be used as a soil amendment, an organic fertilizer, a snow-melting agent and the like, the advantages of energy saving, environmental protection, and continuous high speed operation are achieved, thus the invention deserves to be broadened.

Owner:溧阳正昌干燥设备有限公司 +1

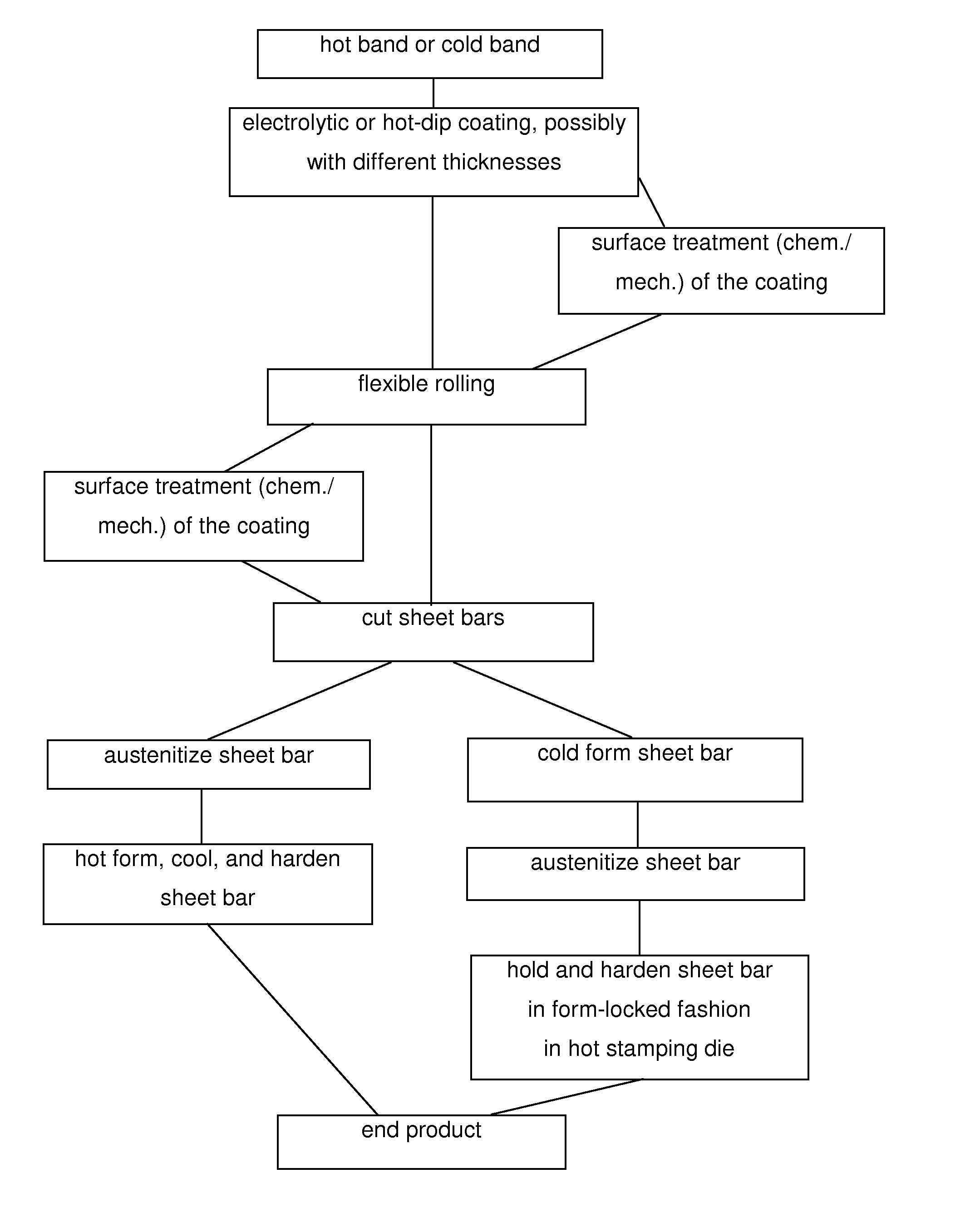

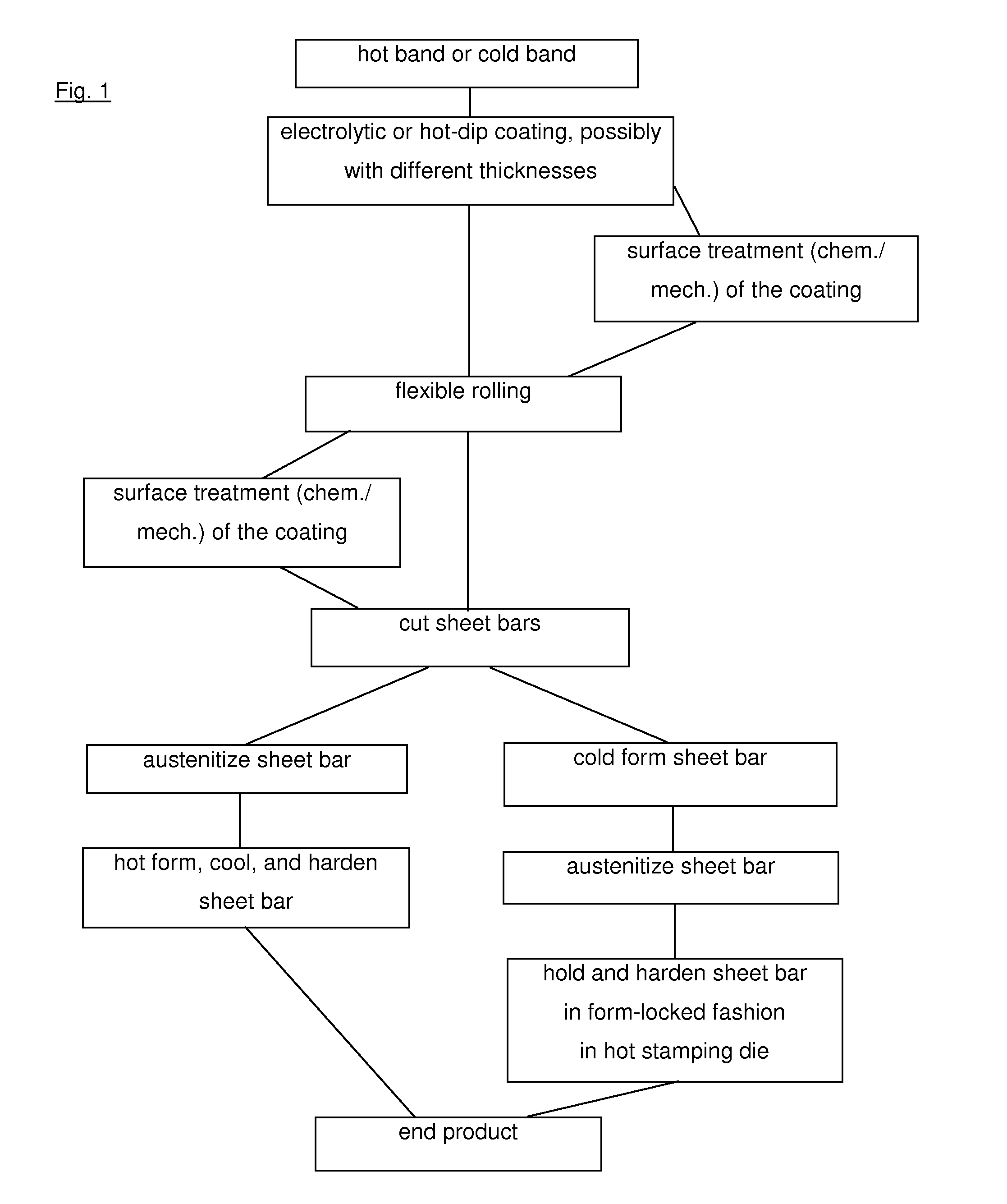

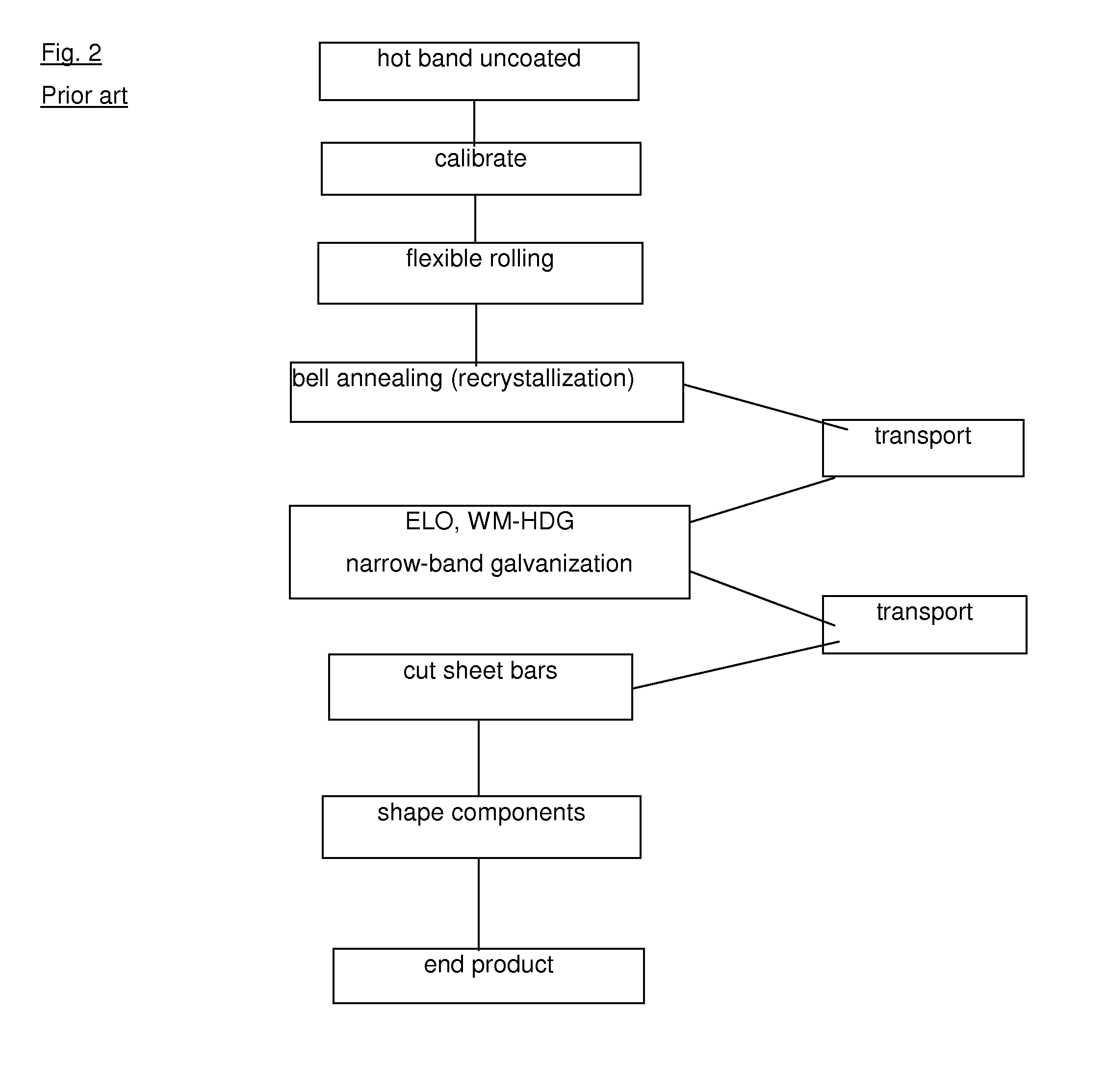

Method for flexibly rolling coated steel strips

ActiveUS20110132052A1Cost efficient to manufactureContinuous processingHot-dipping/immersion processesRoll mill control devicesElectrolysisMolten bath

The invention relates to a method for producing a sheet metal component. A hot or cold strip is electrolytically coated or coated in a smelting bath and the thus coated hot or cold strip is subjected to a flexible rolling process. During said process, sheet metal having various thicknesses of the flexibly rolled steel strips are produced due to various rolling pressures. Said invention is characterized in that in accordance with the thickness of the sheet metal after being rolled in a flexible manner or in accordance with the rolling pressure during flexible rolling, either the coating whilst being coated has various thicknesses, and in accordance with the rolling pressure with increasing rolling pressure that is expected, the thickness of the coating is thicker and / or the coating prior to or after the flexible rolling is subjected to a mechanical or chemical surface treatment for adjusting the desired emissivity or heat absorption capacity.

Owner:VOESTALPINE STAHL GMBH

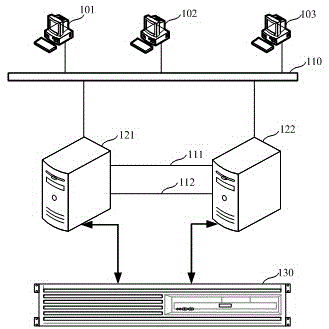

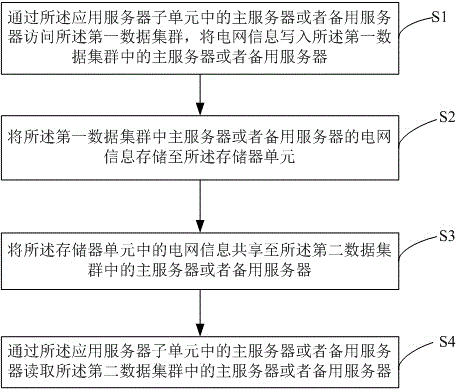

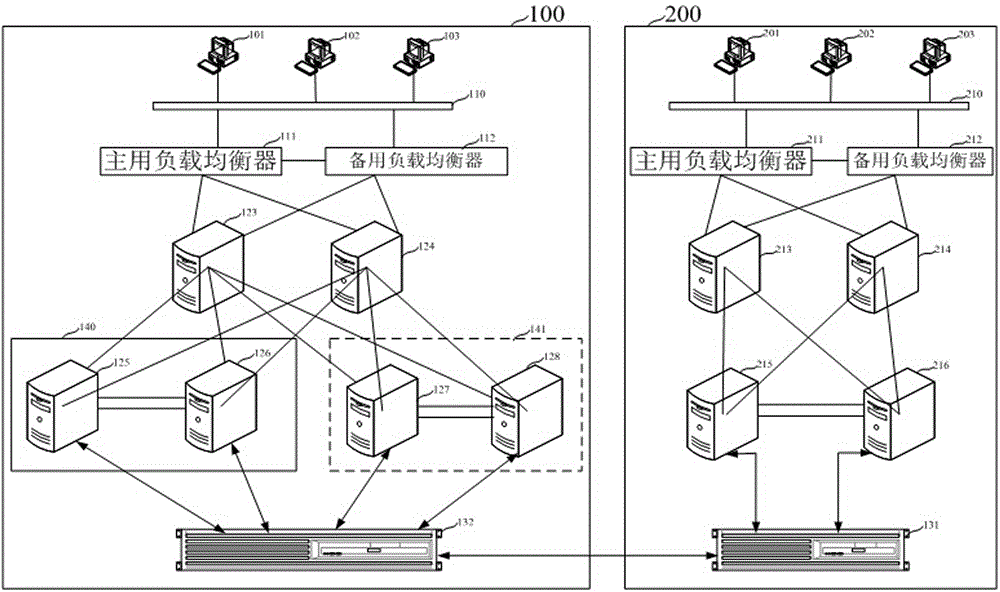

Distribution network adjustment and control system and control method thereof

InactiveCN105553701AReliable distribution network control systemProcessing speedData switching networksPower gridFully automatic

The invention provides a distribution network adjustment and control system and a control method thereof. The distribution network adjustment and control system comprises a terminal for querying and inputting power grid information, a server unit used for storing related applications and data of a distribution network, a memory unit which is connected with a main server and a backup server; the server unit is connected with the terminal through a network; the server unit is provided with the main server and the backup server; the main server and the backup server can exchange heartbeat signals between each other. As for a user, a work process is fully automatic and can be completed in a very short period, and therefore, business will not be impacted; since a shared storage device is adopted, the two servers actually use the same data; and thus, the distribution network adjustment and control system is more reliable.

Owner:STATE GRID QINGHAI ELECTRIC POWER +2

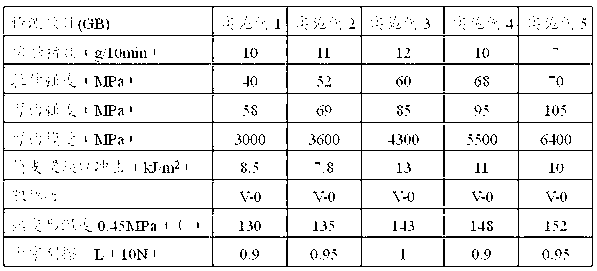

Kitchen flame-retardant and scrapping-resistant polypropylene materials and preparation method of the same

The invention discloses kitchen flame-retardant and scrapping-resistant polypropylene materials, and further discloses a preparation method of the kitchen flame-retardant and scrapping-resistant polypropylene materials. The kitchen flame-retardant and scrapping-resistant polypropylene materials are prepared from the following components: by weight, 29-55.5 parts of polypropylene, 5-20 parts of continuous glass fiber, 5-10 parts of compatilizer, 19-27 parts of compound flame retardant and 1.5-3 parts of scrapping-resistant agent. The kitchen flame-retardant and scrapping-resistant polypropylene materials have the advantages of being flame-retardant, scrapping-resistant, environment-friendly, non-poisonous, free of sucking water, mould-proof, anticorrosion, acid-alkali resistant, anti-aging, heat-resisting, recoverable, capable of conducting injection molding, convenient to process, capable of having different color custom-made according to requirements and being made into different styles and patterns in an injection molding mode according to requirements and the like, simple in production flow, continuous in production process, high in production efficiency and stable in production quality, and satisfies requirements for energy conservation, emission reduction, environmental-friendly residence, comfort and beauty, and are ideal kitchen materials.

Owner:HEFEI GENIUS NEW MATERIALS

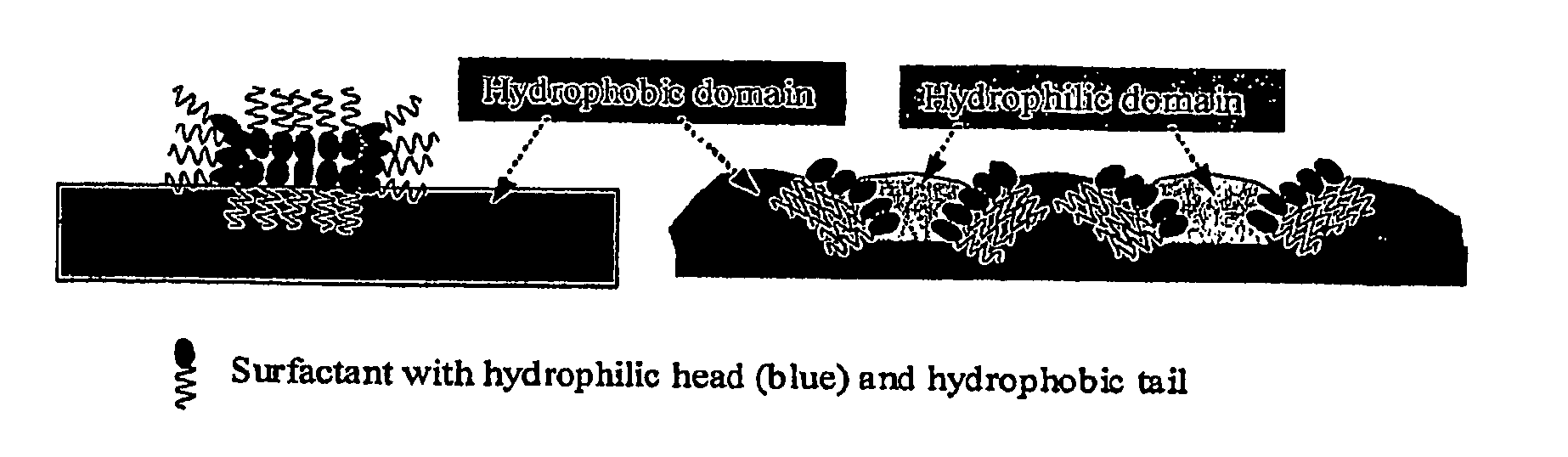

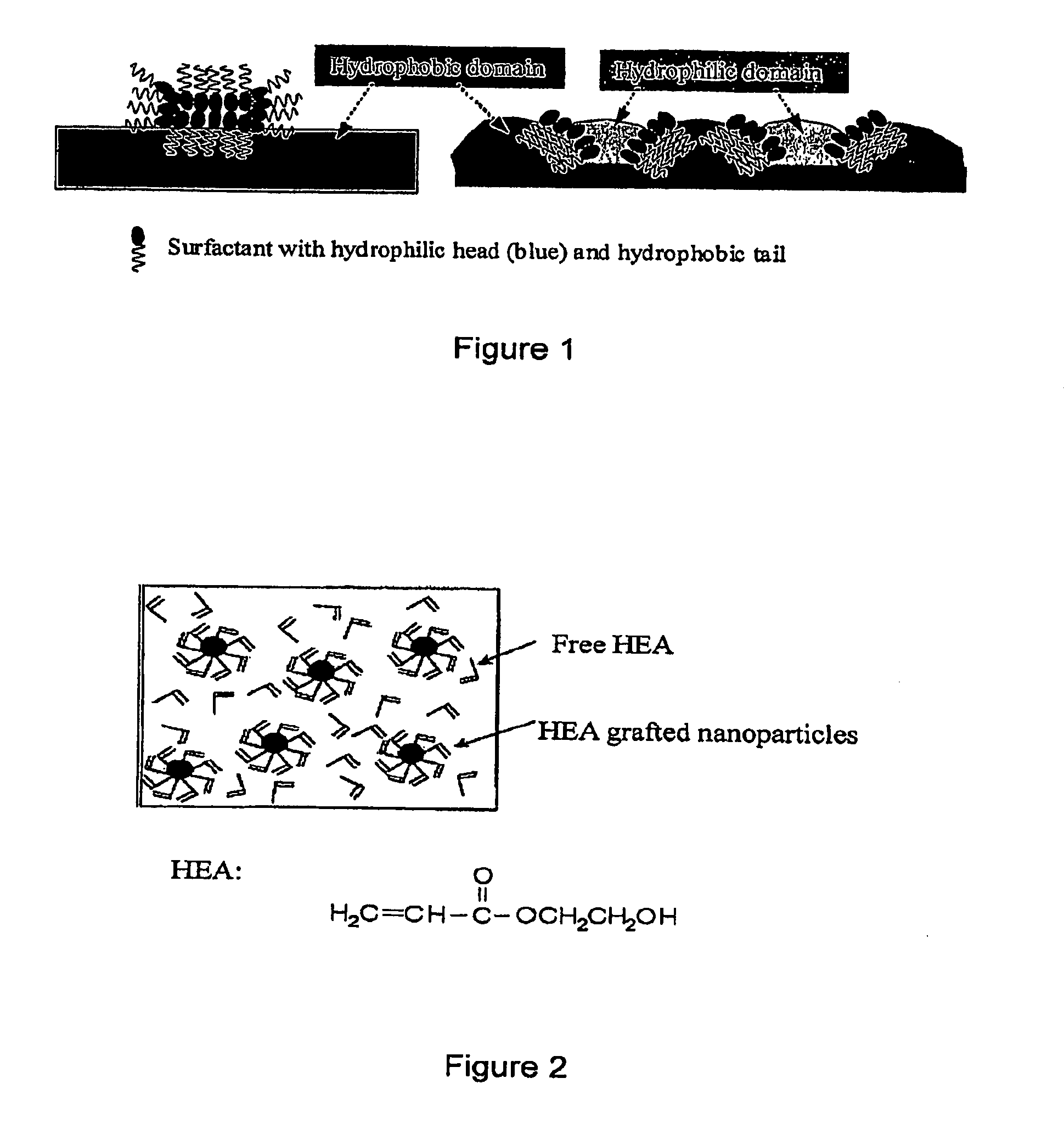

Nanoengineered composite defog coating

ActiveUS20100028694A1Minimizing light scatteringHigh transparencyOrganic chemistrySynthetic resin layered productsNanometreChemistry

An engineered nano-composite coating may include hydrophobic an hydrophilic domains, may be applied to transparent and non-transparent substrates using a continuous process, may be UV curable and may impart antifogging characteristics to the substrate.

Owner:VENTURA BIOSCIENCE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com