Kitchen flame-retardant and scrapping-resistant polypropylene materials and preparation method of the same

A polypropylene material and scratch-resistant technology, which is applied in the field of flame-retardant and scratch-resistant polypropylene materials for cabinets and its preparation, can solve the problems of formaldehyde, non-recyclability, and easy to mold, and achieves simple production process and product quality. Stable, continuous production process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

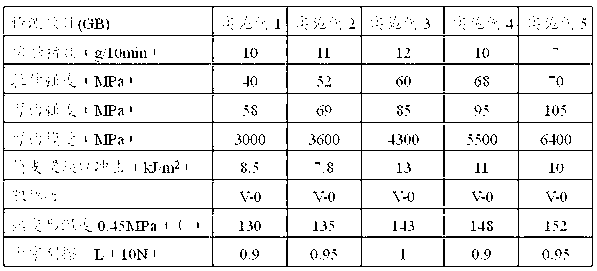

Examples

Embodiment 1

[0027] (1) 55.5 parts (parts by weight, the same below) of homopolypropylene PP S700, 5 parts of maleic anhydride grafted polypropylene PP-G, 27 parts of decabromodiphenylethane and antimony trioxide in mass ratio 3:1 compound flame retardant, 2.5 parts of anti-scratch agent organically modified silicone masterbatch AS100, 0.1 part of primary antioxidant 1010, 0.2 part of auxiliary antioxidant 168, add to high-speed mixer and mix 3 minutes;

[0028] (2) Add the mixture in step (1) into the lower hopper of the twin-screw extruder, and at the same time, add 10 parts of continuous glass fiber through the side feeding port by controlling the feeding and the speed of the main machine, and co-extrude to granulate, twin-screw extruder The temperature of each zone is set at 170°C-210°C-195°C-200°C-205°C-210°C-215°C (machine head).

Embodiment 2

[0030] (1) 46 parts of homopolypropylene PP S700, 10 parts of talc powder 2500 mesh, 6 parts of maleic anhydride grafted polypropylene PP-G, 25 parts of decabromodiphenylethane and antimony trioxide in mass ratio 3:1 compound flame retardant, 3 parts of scratch resistance organic modified silicone masterbatch AS100, 0.2 part of processing aid calcium stearate, 0.1 part of primary antioxidant 1010, 0.1 part of antioxidant Agent DSTDP, 0.1 part of auxiliary antioxidant 168, 0.1 part of green toner, added to a high-speed mixer and mixed for 5 minutes;

[0031] (2) Add the mixture in step (1) into the lower hopper of the extruder, and at the same time, add 10 parts of continuous glass fiber through the side feeding port by controlling the feeding and the speed of the main machine, and jointly extrude and granulate. The temperature in each zone of the twin-screw The setting is 170°C-210°C-195°C-200°C-205°C-210°C-215°C (machine head).

Embodiment 3

[0033] (1) 47.5 parts of copolymerized polypropylene PP K7926, 8 parts of maleic anhydride grafted polypropylene PP-G, 23 parts of decabromodiphenylethane and antimony trioxide compounded at a mass ratio of 3:1 With flame retardant, 1.5 parts of anti-scratch agent organically modified silicone masterbatch AS100, 0.1 part of processing aid calcium stearate, 0.15 part of primary antioxidant 1010, 0.3 part of antioxidant DSTDP, 0.1 part of red toner , added to a high-speed mixer and mixed for 4 minutes;

[0034] (2) Add the mixture in step (1) into the lower hopper of the extruder, and at the same time, add 20 parts of continuous glass fiber through the side feeding port by controlling the feeding and the speed of the main machine, and jointly extrude and granulate. The temperature in each zone of the twin-screw The setting is 170°C-210°C-195°C-200°C-205°C-210°C-215°C (machine head).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com