Vegetable insulating oil and preparation method thereof

A technology of plant insulating oil and vegetable oil, which is applied in the direction of insulators, organic insulators, organic liquid insulators, etc., can solve the problems of insulating oil resistance to oxidation, low temperature performance and stability, and achieve high natural decomposition performance, strong overload capacity, Good security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

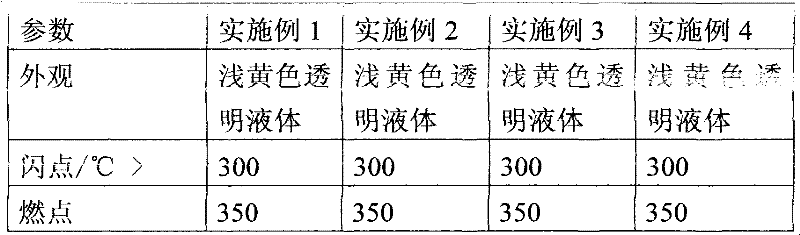

Embodiment 1

[0049] Vegetable insulating oil of the present invention is mainly made of the following raw materials in weight percentage:

[0050] Vegetable oil 95%; antioxidant 2.5%; anticoagulant 2.5%; vegetable oil is rapeseed oil.

[0051] The preparation method of described vegetable insulating oil, comprises the following steps:

[0052] 1. The filter cloth filters the vegetable oil.

[0053] 2. Add an equal volume of 0.5% NaOH to neutralize the free fatty acid, add distilled water to extract the sodium fatty acid, separate the oil-water phase, and dry in vacuum.

[0054] 3. Add 2% activated carbon to the oil, decolorize at 60°C for 30 minutes, and filter to remove the activated carbon.

[0055] 4. Repeat steps 3 and 4 until the vegetable oil is transparent and clear.

[0056] 5. Add 2.5% of the antioxidant tert-butyl hydroquinone and 2.5% of the pour point depressant polyalphaolefin to the vegetable oil, and vibrate until transparent.

Embodiment 2

[0058] Vegetable insulating oil of the present invention is mainly made of the following raw materials in weight percentage:

[0059] Vegetable oil 98%; antioxidant 1.5%; anticoagulant 0.5%; vegetable oil is olive oil.

[0060] The preparation method of described vegetable insulating oil, comprises the following steps:

[0061] 1. The filter cloth filters the vegetable oil.

[0062] 2. Add an equal volume of 0.8% NaOH to neutralize the free fatty acid, add distilled water to extract the sodium fatty acid, separate the oil from water, and dry in vacuum.

[0063] 3. Add 1.5% activated carbon to the oil, decolorize at 60°C for 30 minutes, and filter to remove the activated carbon.

[0064] 4. Repeat steps 3 and 4 until the vegetable oil is transparent and clear.

[0065] 5. Add 1.5% of the antioxidant tert-butyl hydroquinone and 0.5% of the pour point depressant polyalphaolefin to the vegetable oil, and vibrate until transparent.

Embodiment 3

[0067] Vegetable insulating oil of the present invention is mainly made of the following raw materials in weight percentage:

[0068] Vegetable oil 96%; antioxidant 2%; pour point depressant 2%; vegetable oil is sunflower oil.

[0069] The preparation method of described vegetable insulating oil, comprises the following steps:

[0070] 1. The filter cloth filters the vegetable oil.

[0071] 2. Add an equal volume of 0.5% NaOH to neutralize the free fatty acid, add distilled water to extract the sodium fatty acid, separate the oil from water, and dry in vacuum.

[0072] 3. Add 1% activated carbon to the oil, decolorize at 60°C for 30 minutes, and filter to remove the activated carbon.

[0073] 4. Repeat steps 3 and 4 until the vegetable oil is transparent and clear.

[0074] 5. Add 2% of the antioxidant tert-butyl hydroquinone and 2% of the pour point depressant polyalphaolefin to the vegetable oil, and vibrate until transparent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com